Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3429 results about "Bainite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

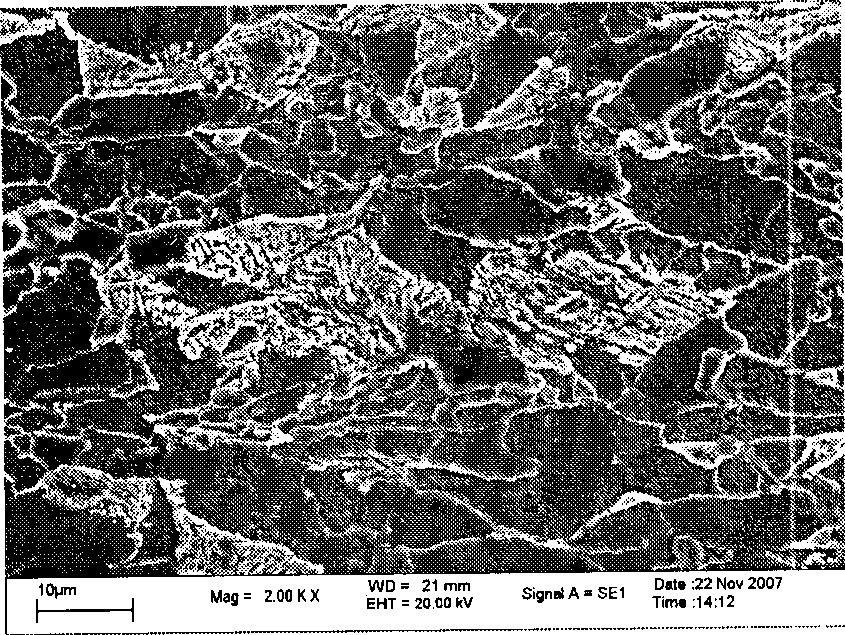

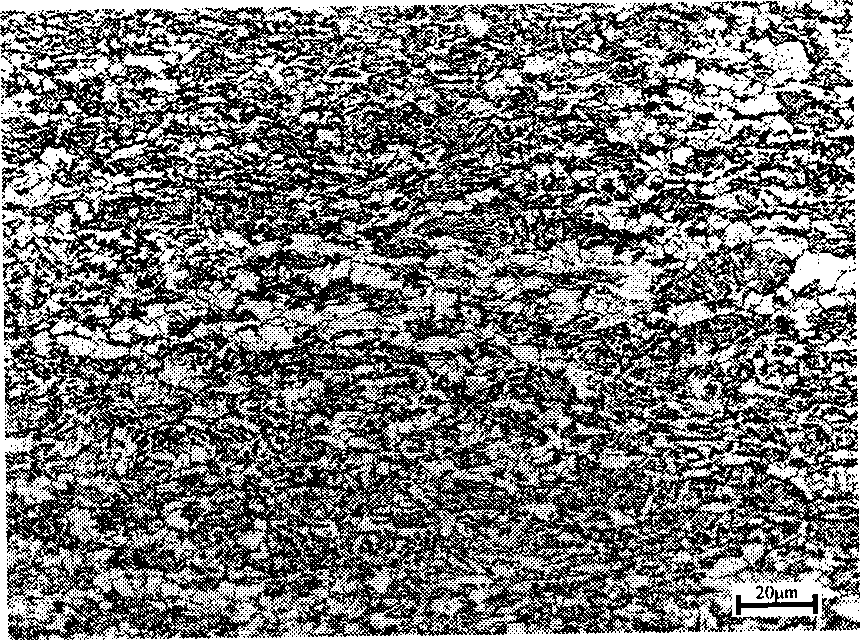

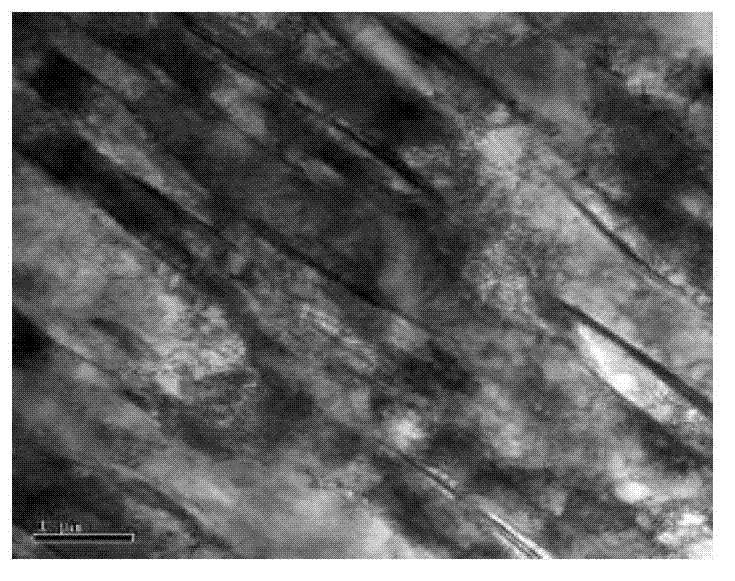

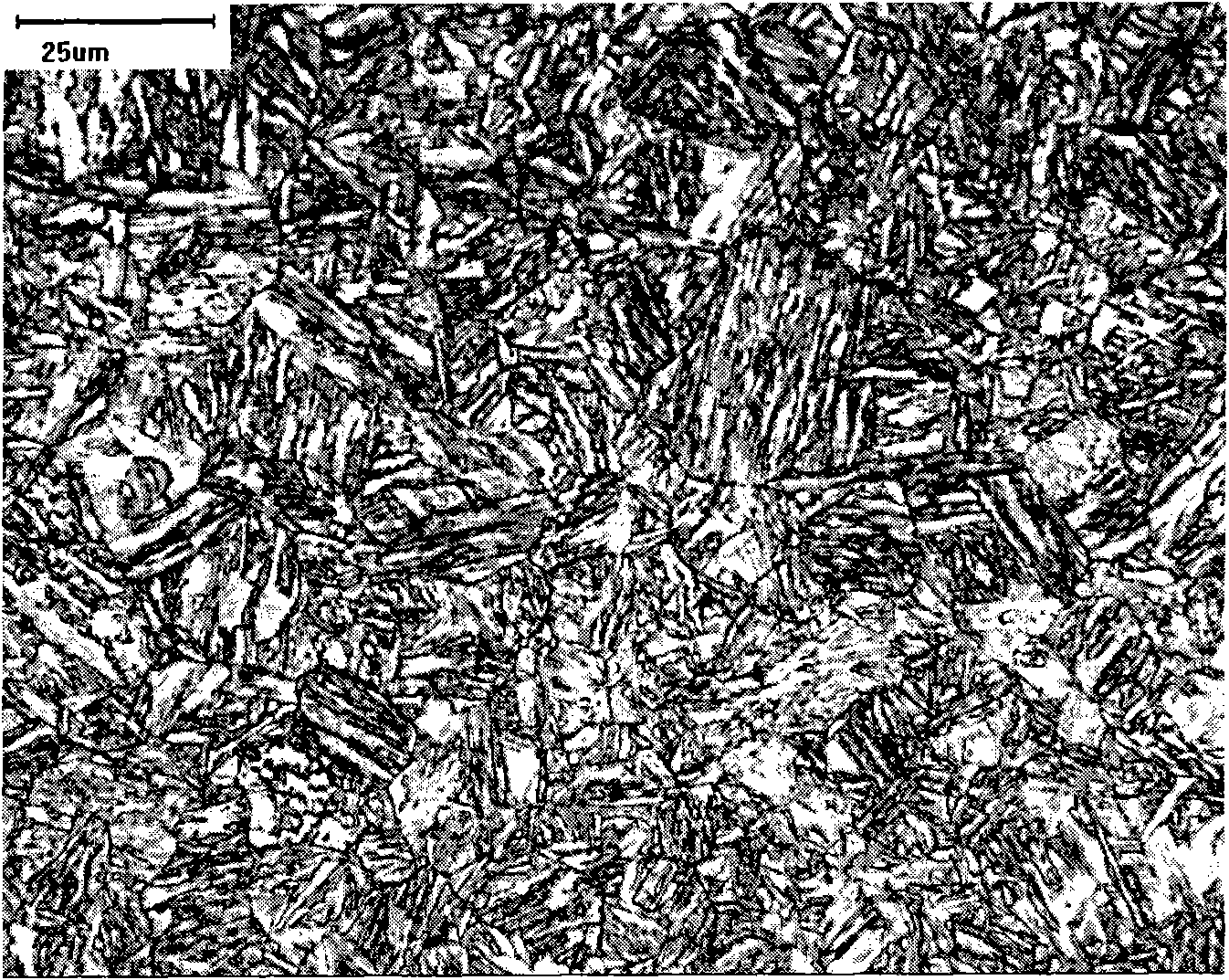

Bainite is a plate-like microstructure that forms in steels at temperatures of 125–550 °C (depending on alloy content). First described by E. S. Davenport and Edgar Bain, it is one of the products that may form when austenite (the face centered cubic crystal structure of iron) is cooled past a temperature where it no longer is thermodynamically stable with respect to ferrite, cementite, or ferrite and cementite. Davenport and Bain originally described the microstructure as being similar in appearance to tempered martensite.

High-strength hot-rolled steel sheet having excellent stretch flangeability, and method of producing the same

InactiveUS6364968B1Easy to stretchImprove uniformityFurnace typesHeat treatment furnacesHigh intensityMechanical property

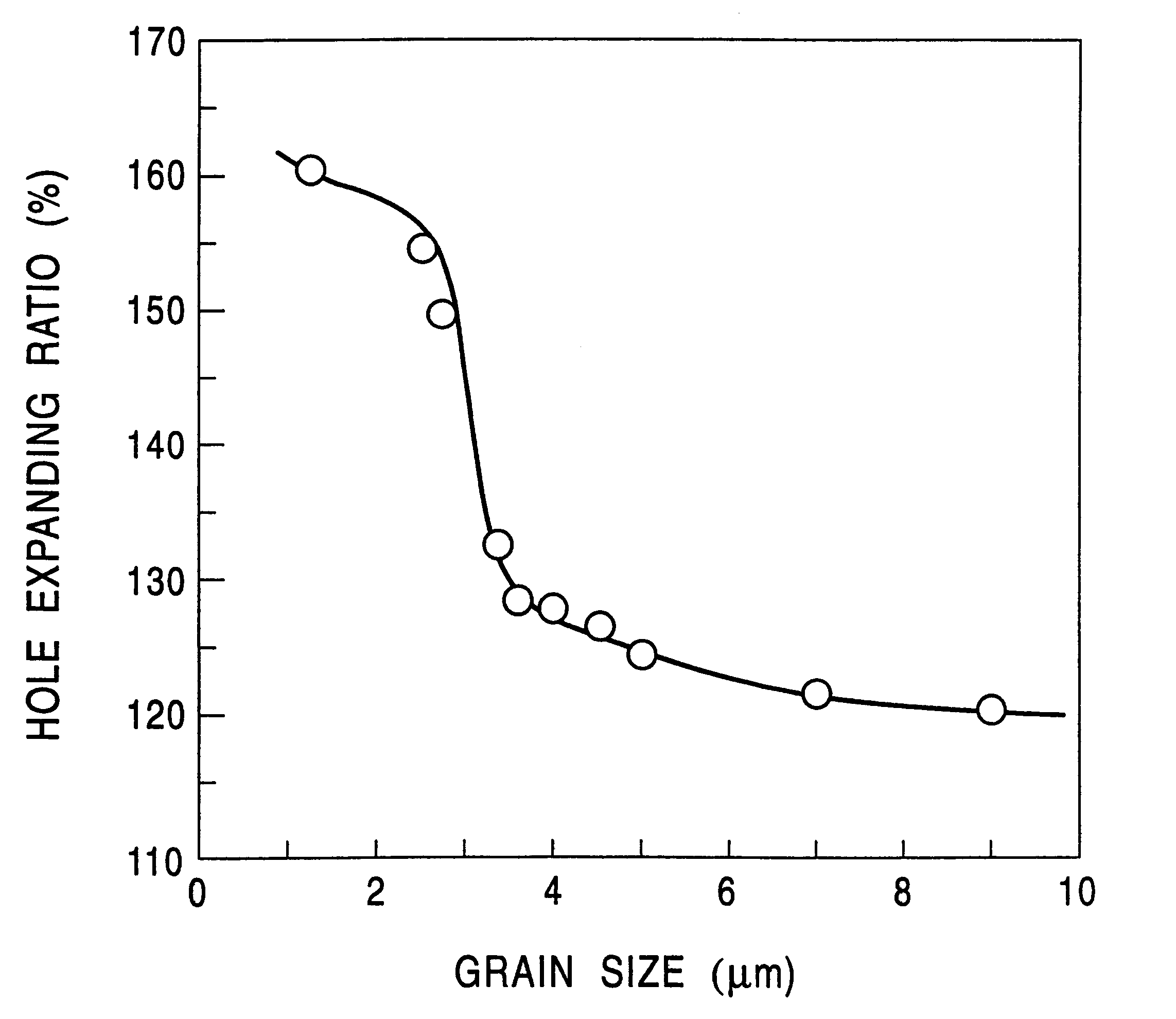

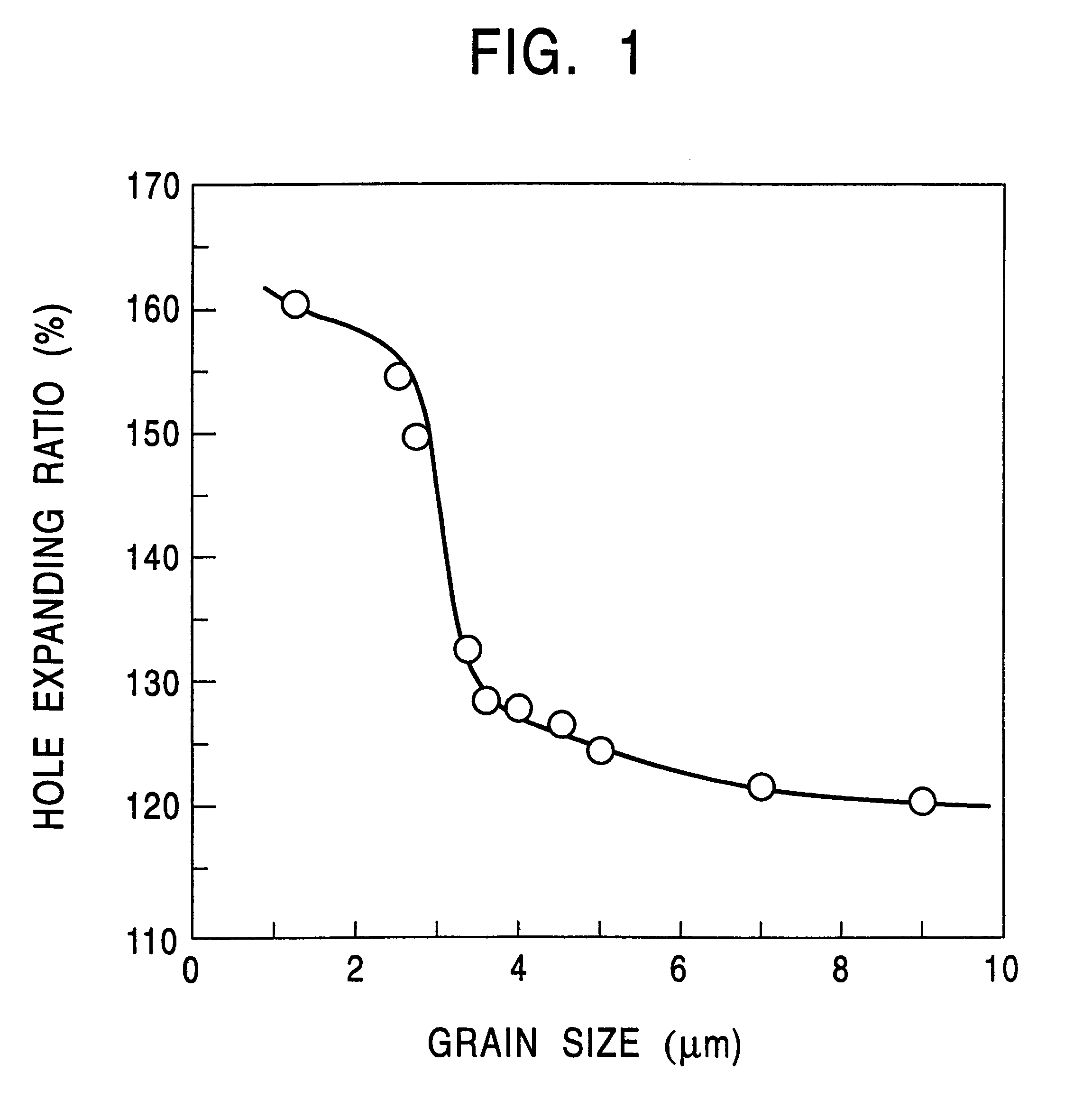

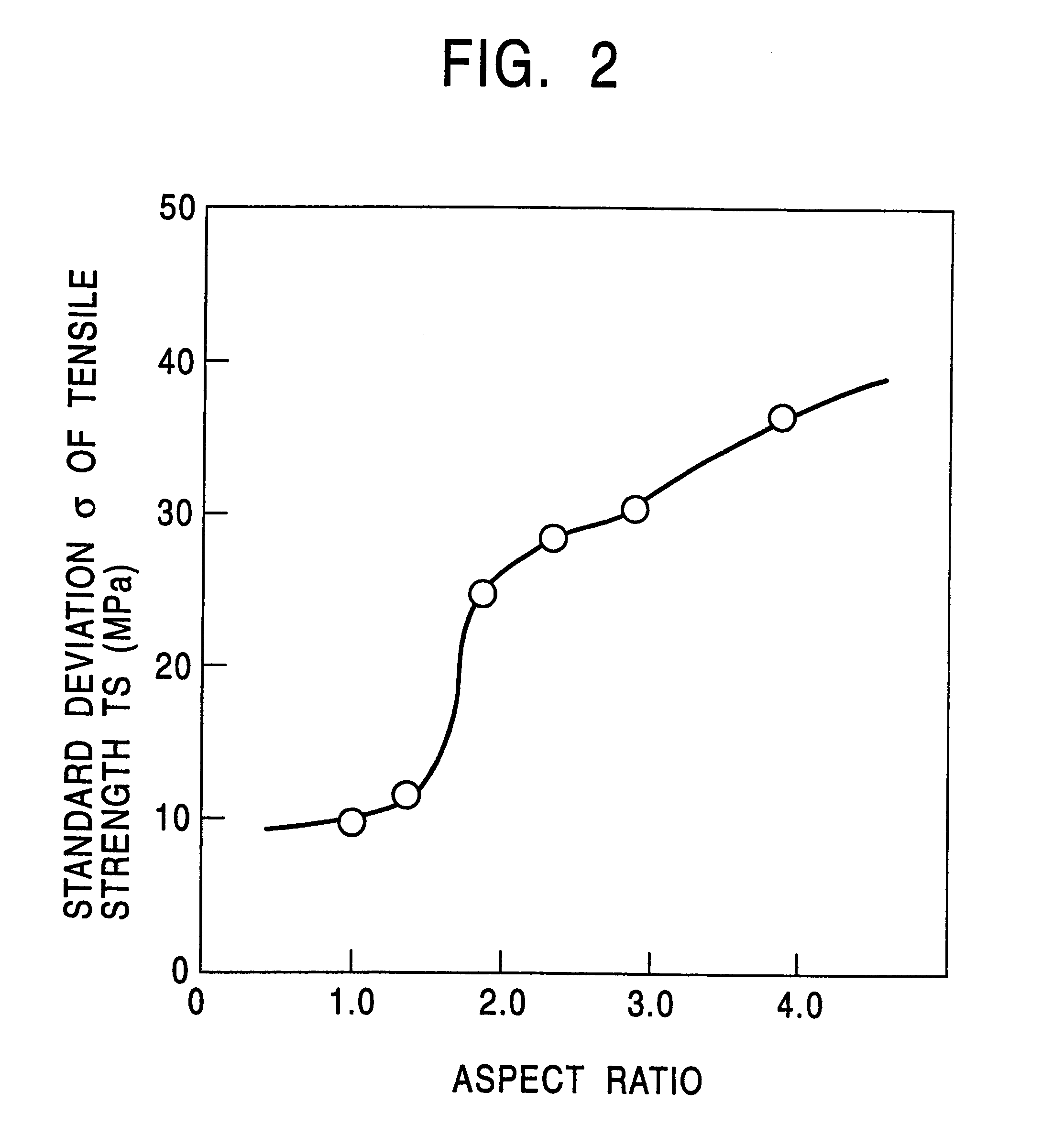

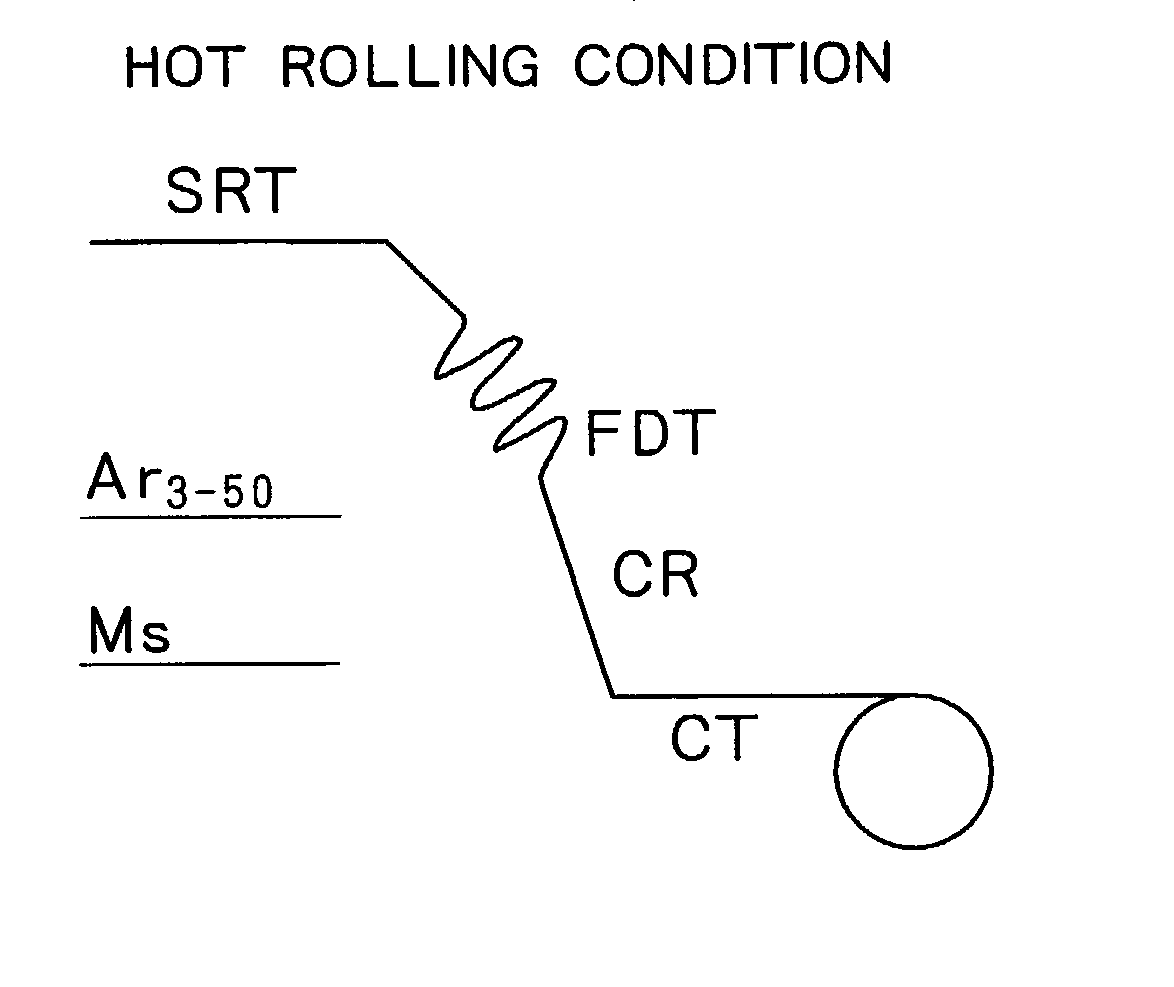

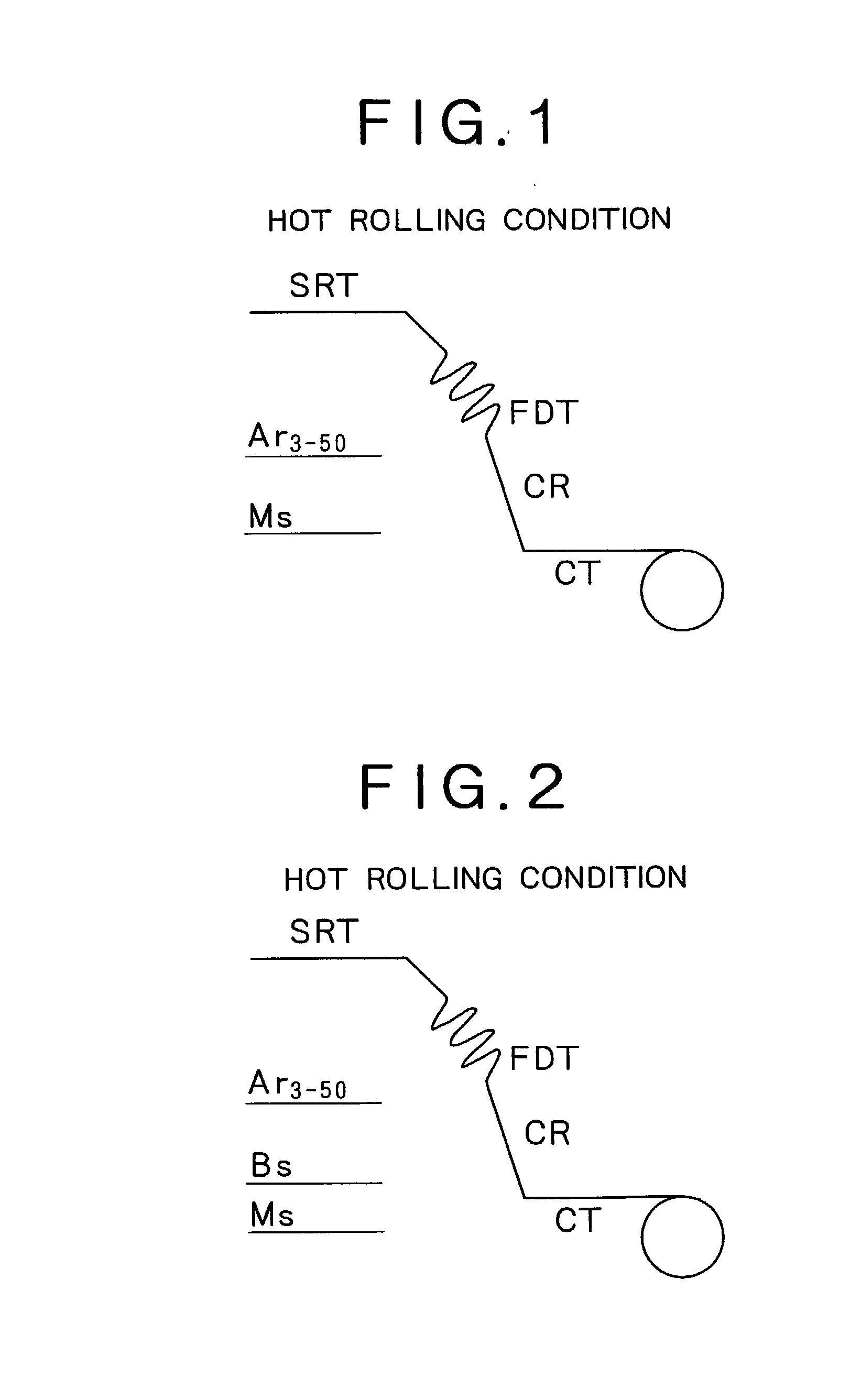

The invention provides a thin high-strength hot-rolled steel sheet with a thickness of not more than 3.5 mm which has excellent stretch flangeability and high uniformity in both shape and mechanical properties of the steel sheet, as well as a method of producing the hot-rolled steel sheet. A slab containing C: 0.05-0.30 wt %, Si: 0.03-1.0 wt %, Mn: 1.5-3.5 wt %, P: not more than 0.02 wt %, S: not more than 0.005 wt %, Al: not more than 0.150 wt %, N: not more than 0.0200 wt %, and one or two of Nb: 0.003-0.20 wt % and Ti: 0.005-0.20 wt % is heated at a temperature of not higher than 1200° C. The slab is hot-rolled at a finish rolling end temperature of not lower than 800° C., preferably at a finish rolling start temperature of 950-1050° C. A hot-rolled sheet is started to be cooled within two seconds after the end of the rolling, and then continuously cooled down to a coiling temperature at a cooling rate of 20-150° C. / sec. The hot-rolled sheet is coiled at a temperature of 300-550° C., preferably in excess of 400° C. A fine bainite structure is obtained in which the mean grain size is not greater than 3.0 mum, the aspect ratio is not more than 1.5, and preferably the maximum size of the major axis is not greater than 10 mum.

Owner:KAWASAKI STEEL CORP

High strength steel sheet having excellent formability and method for production thereof

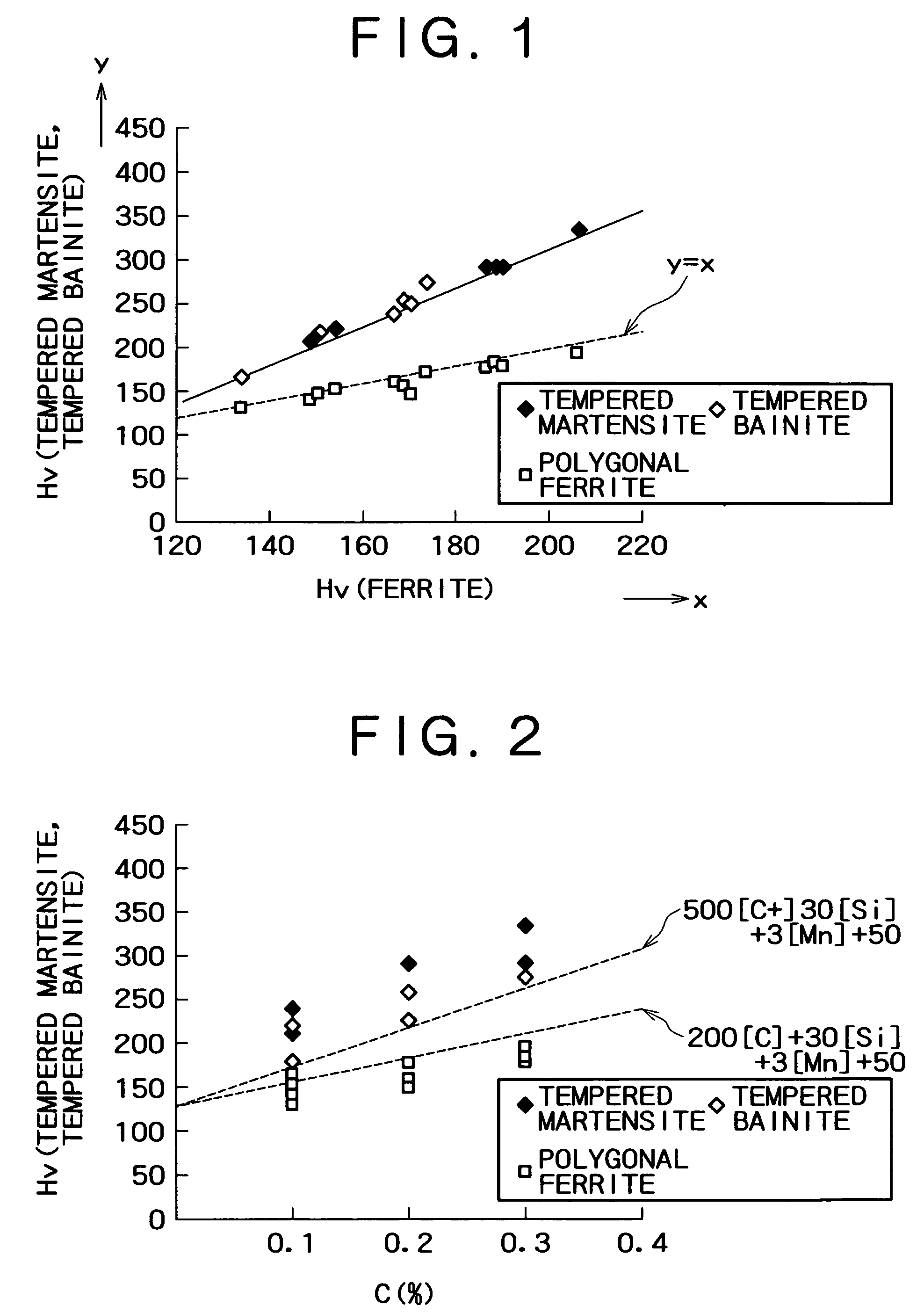

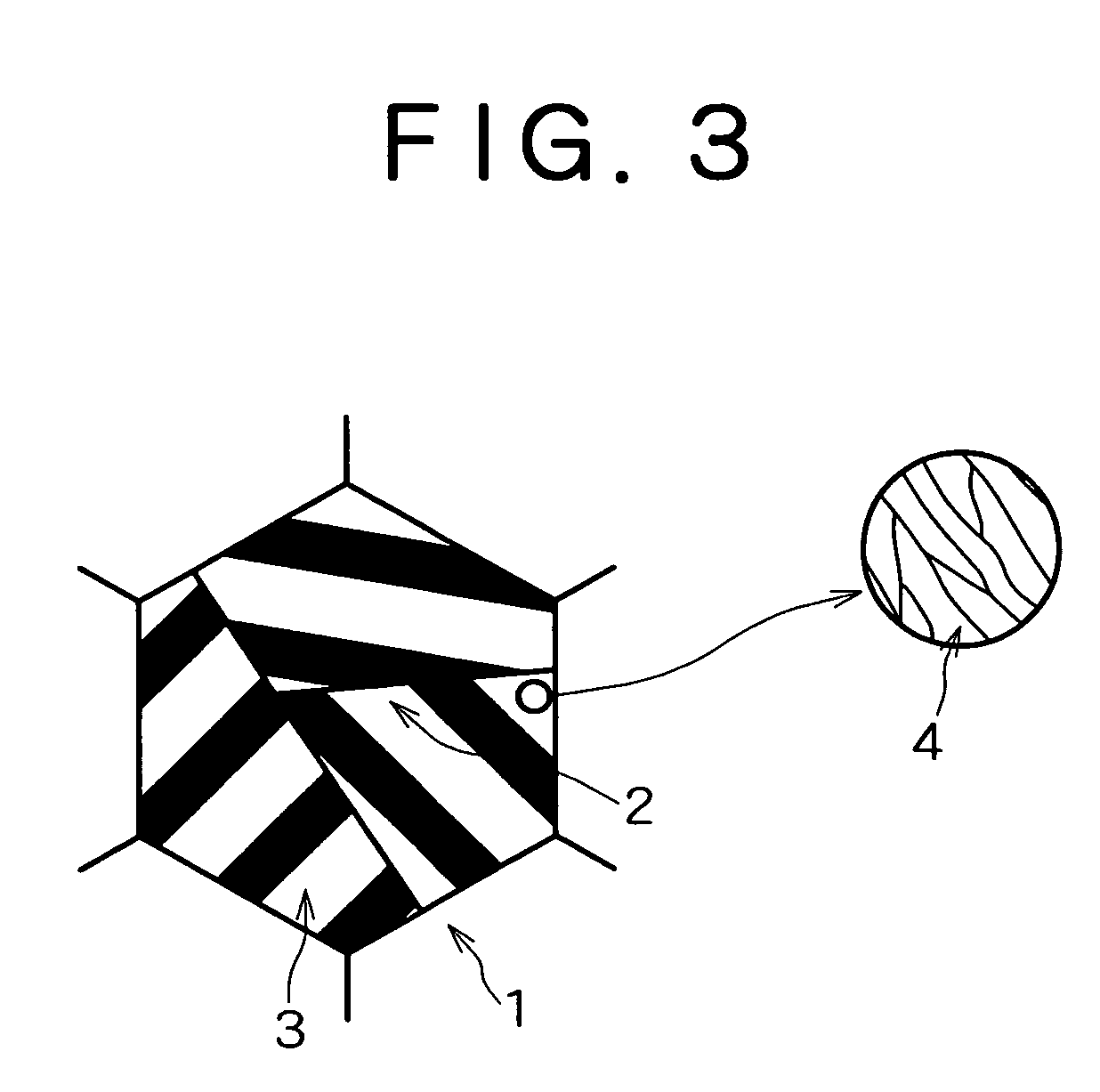

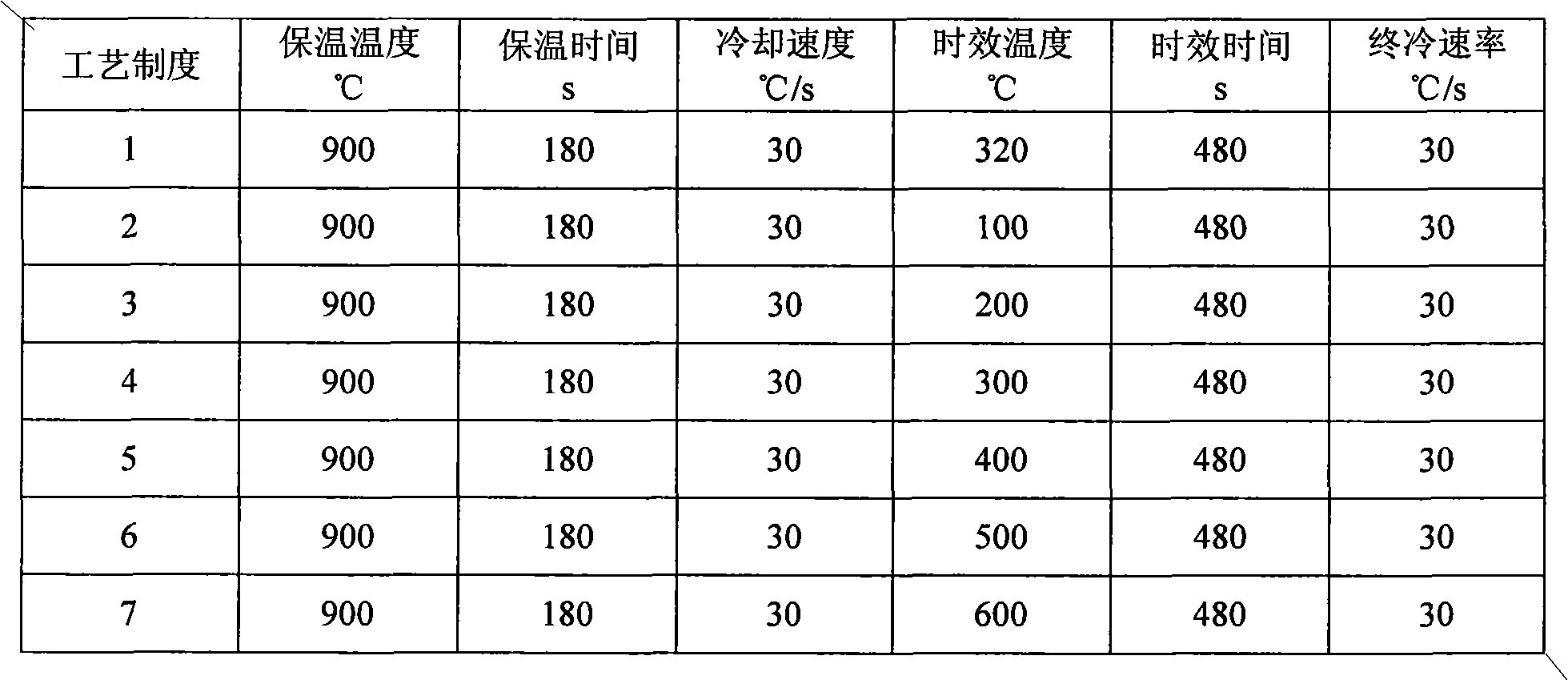

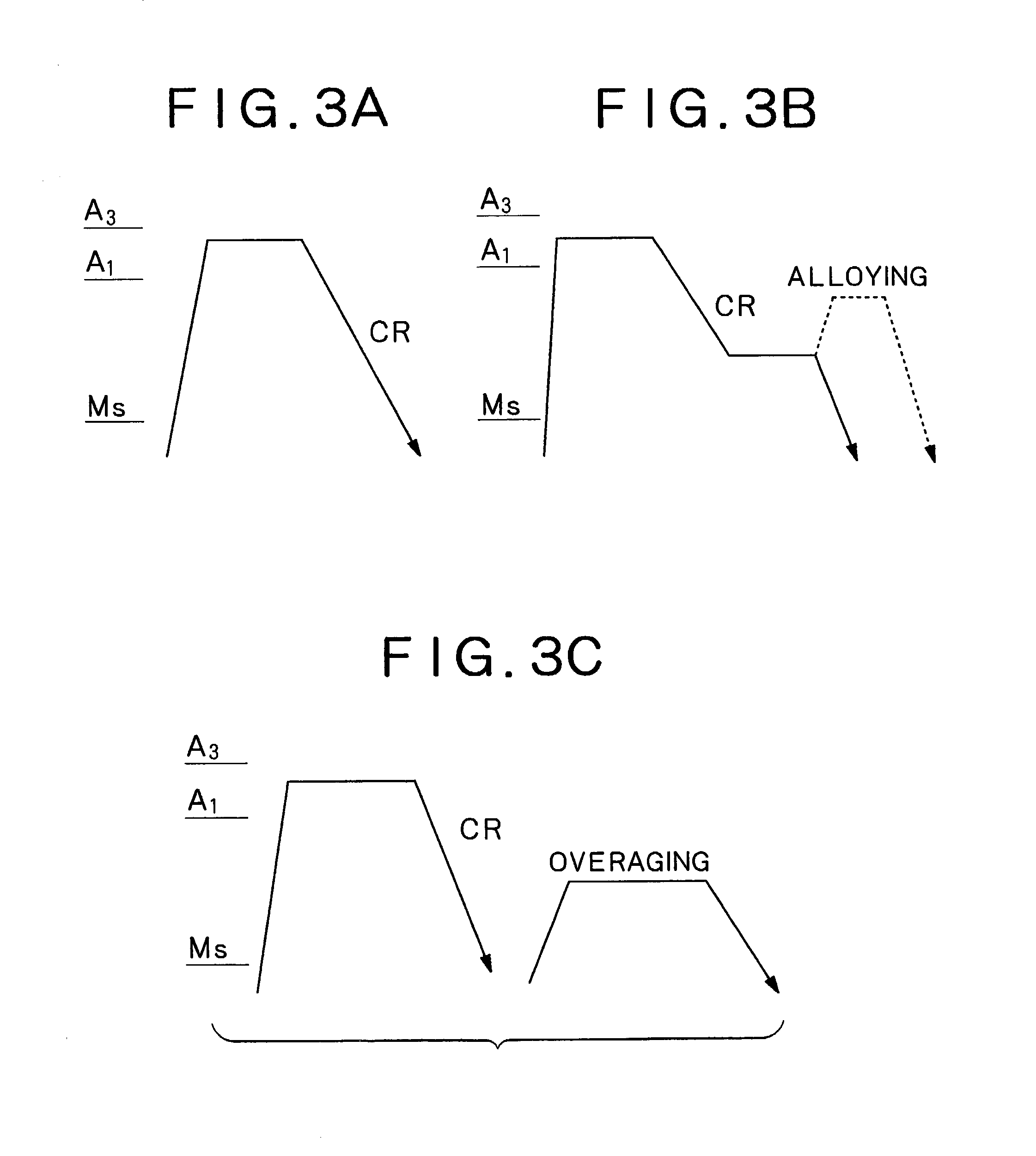

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

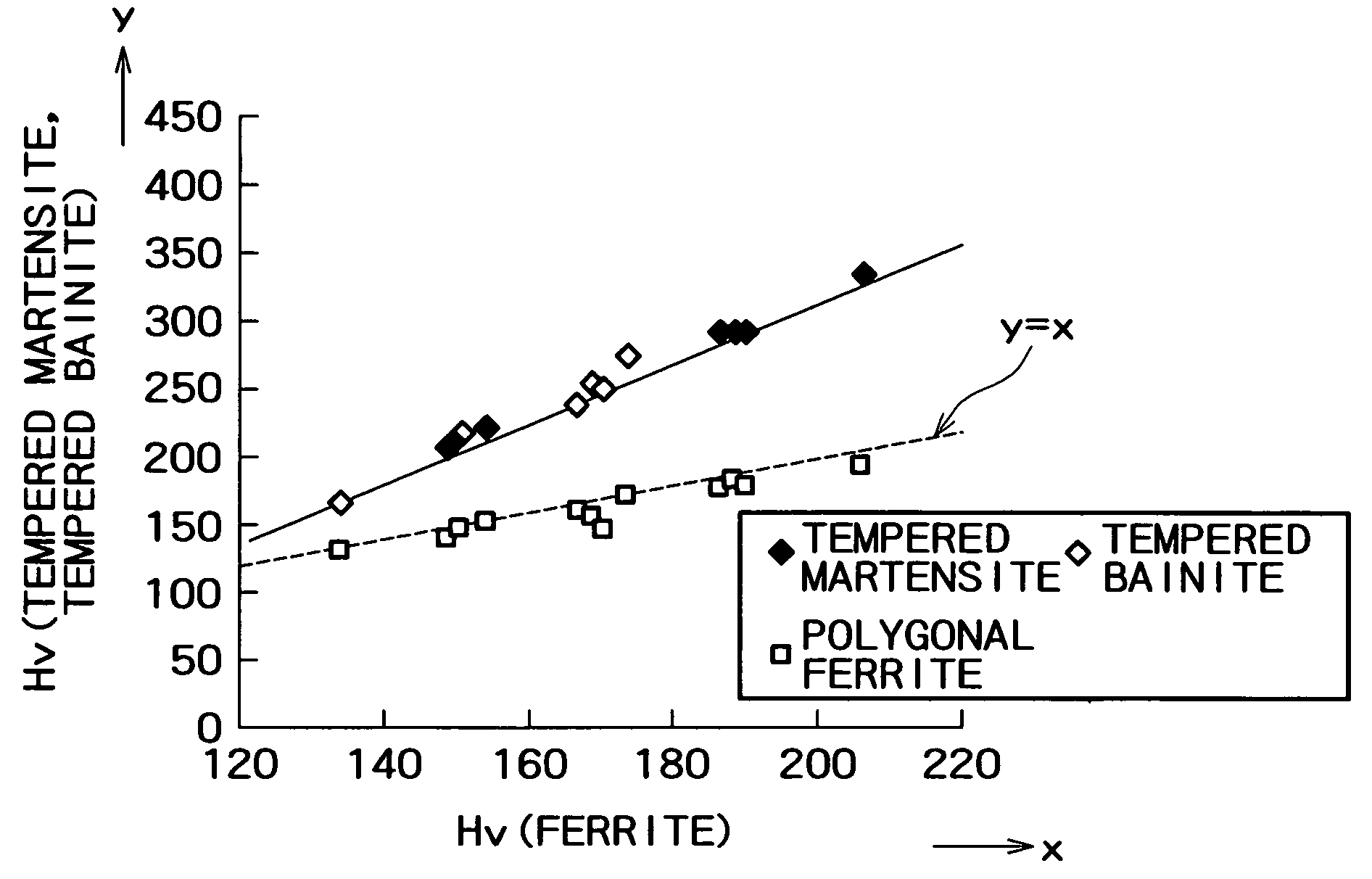

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

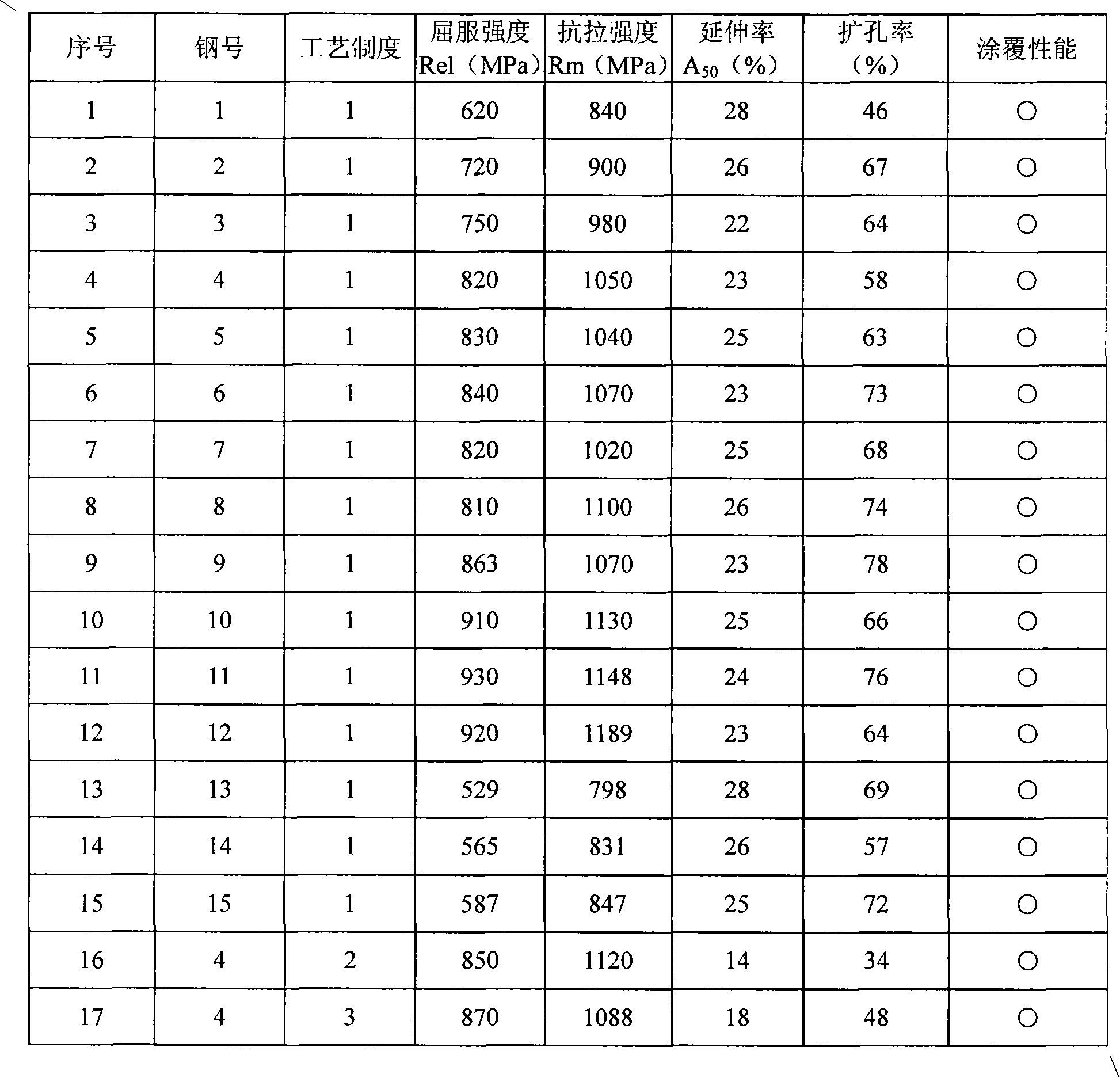

High-strength cold-rolled plate with favorable forming property and preparation method thereof

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

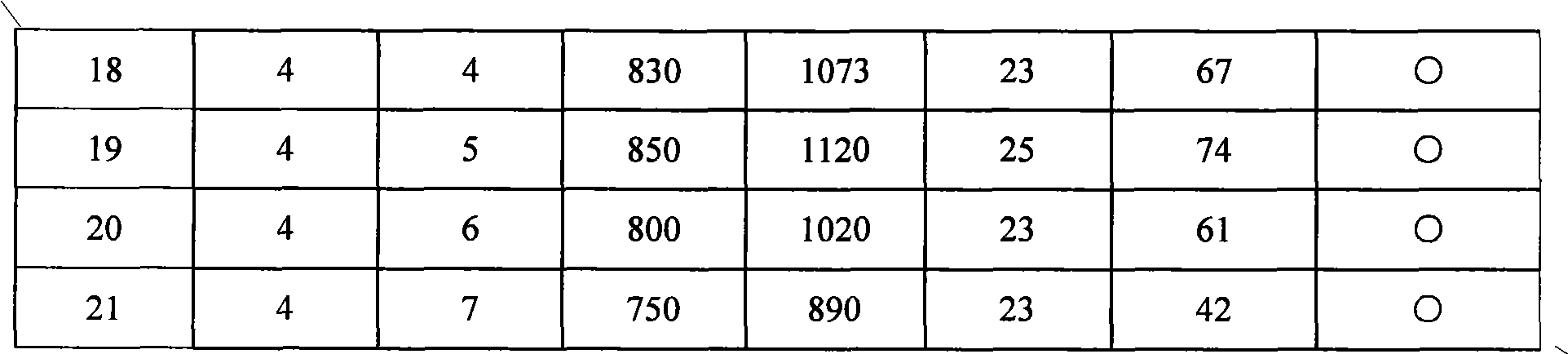

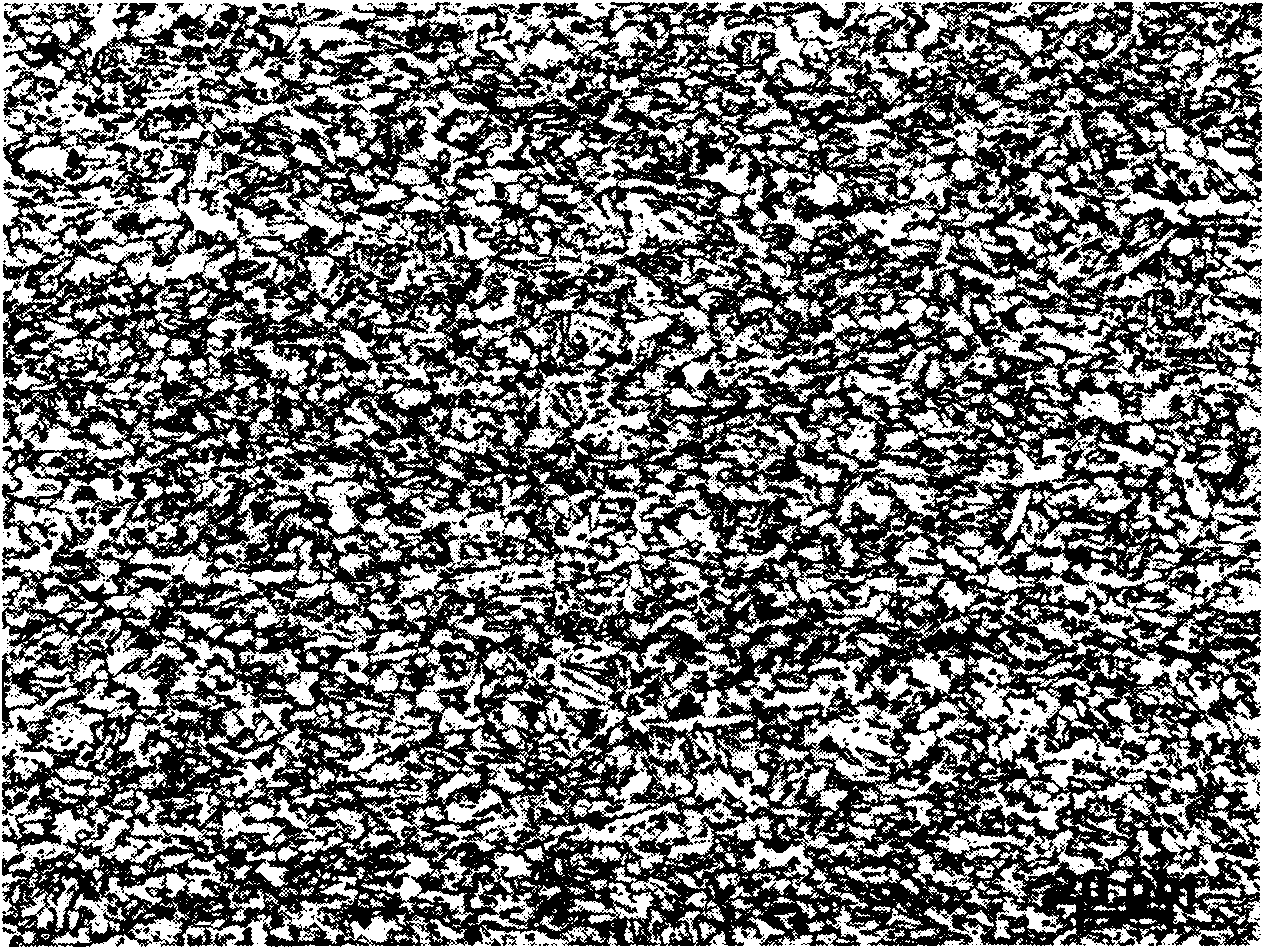

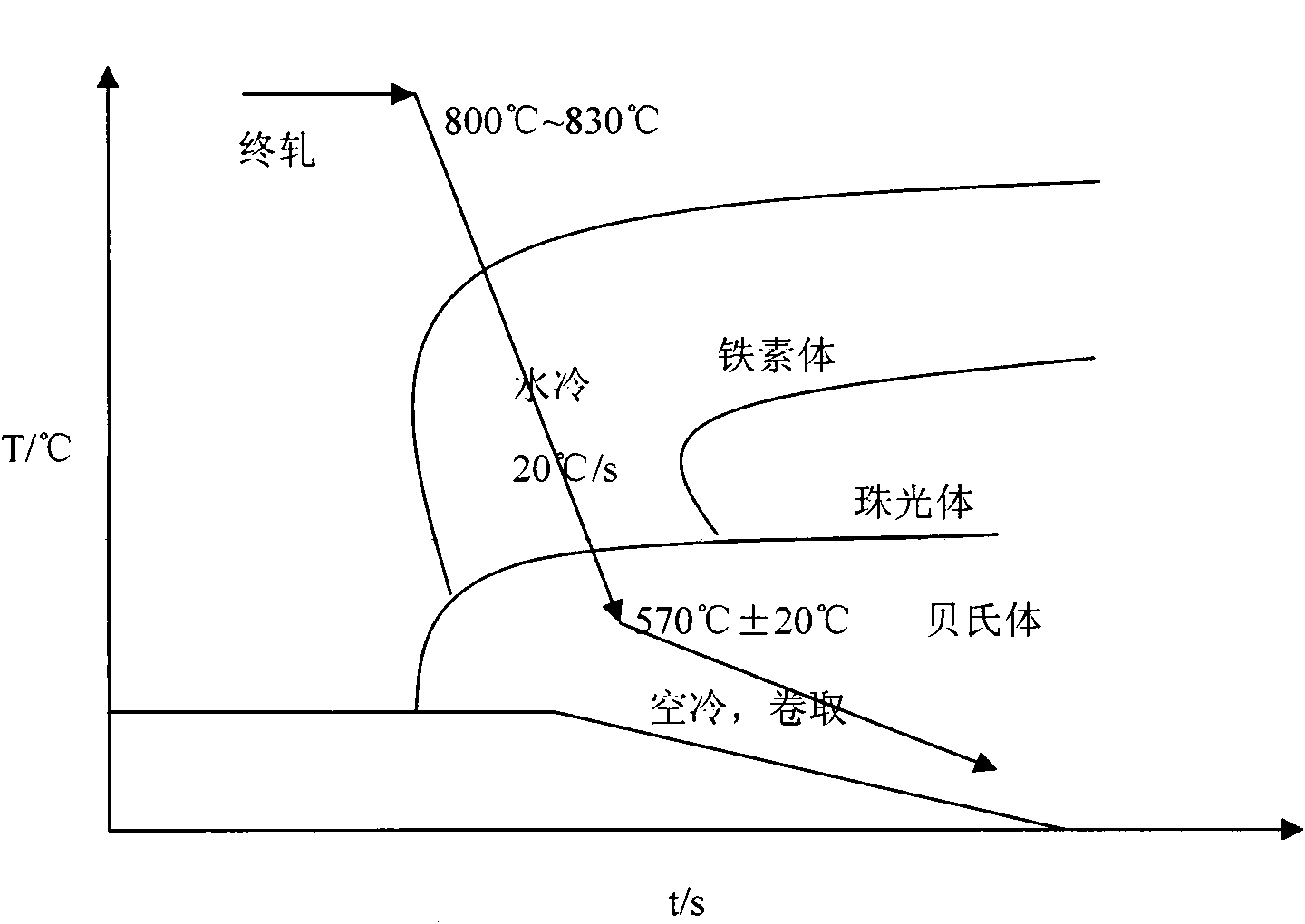

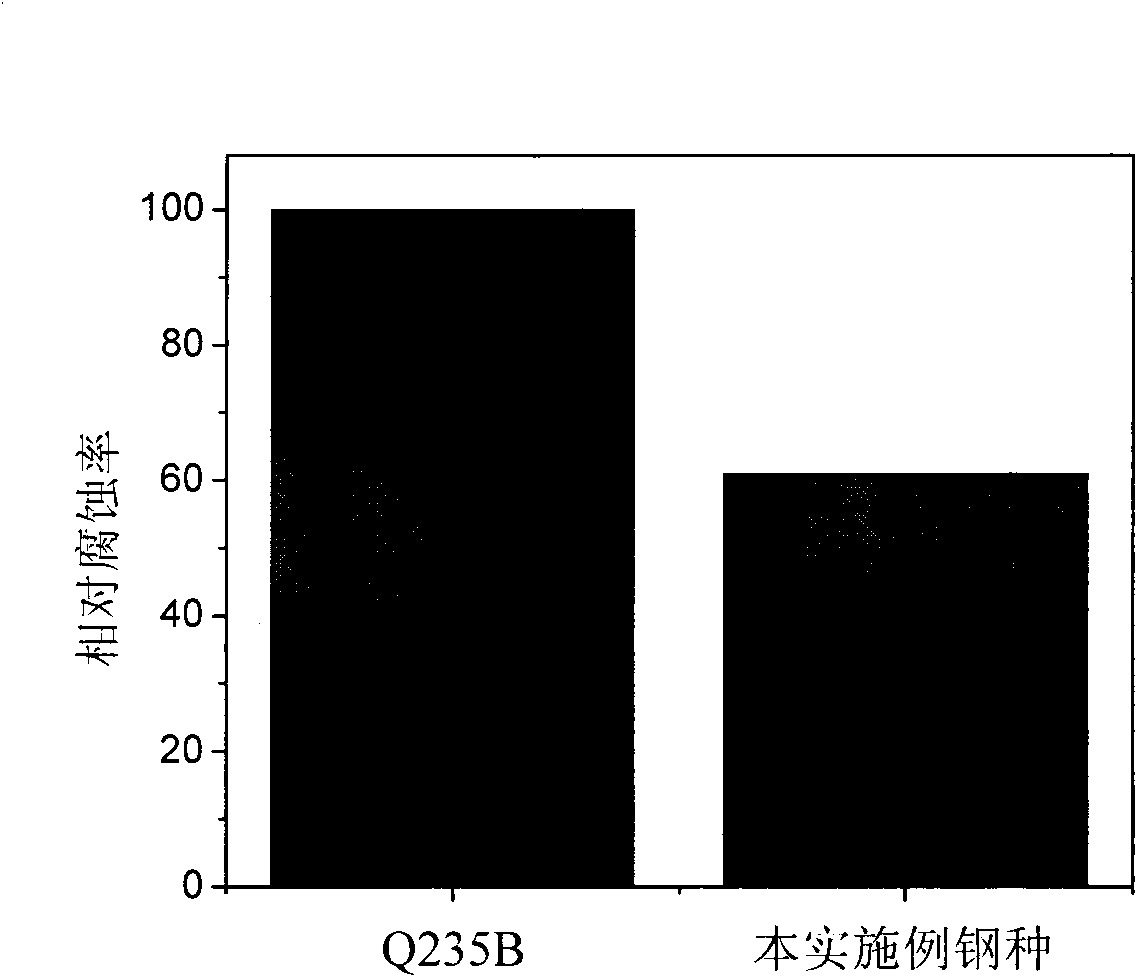

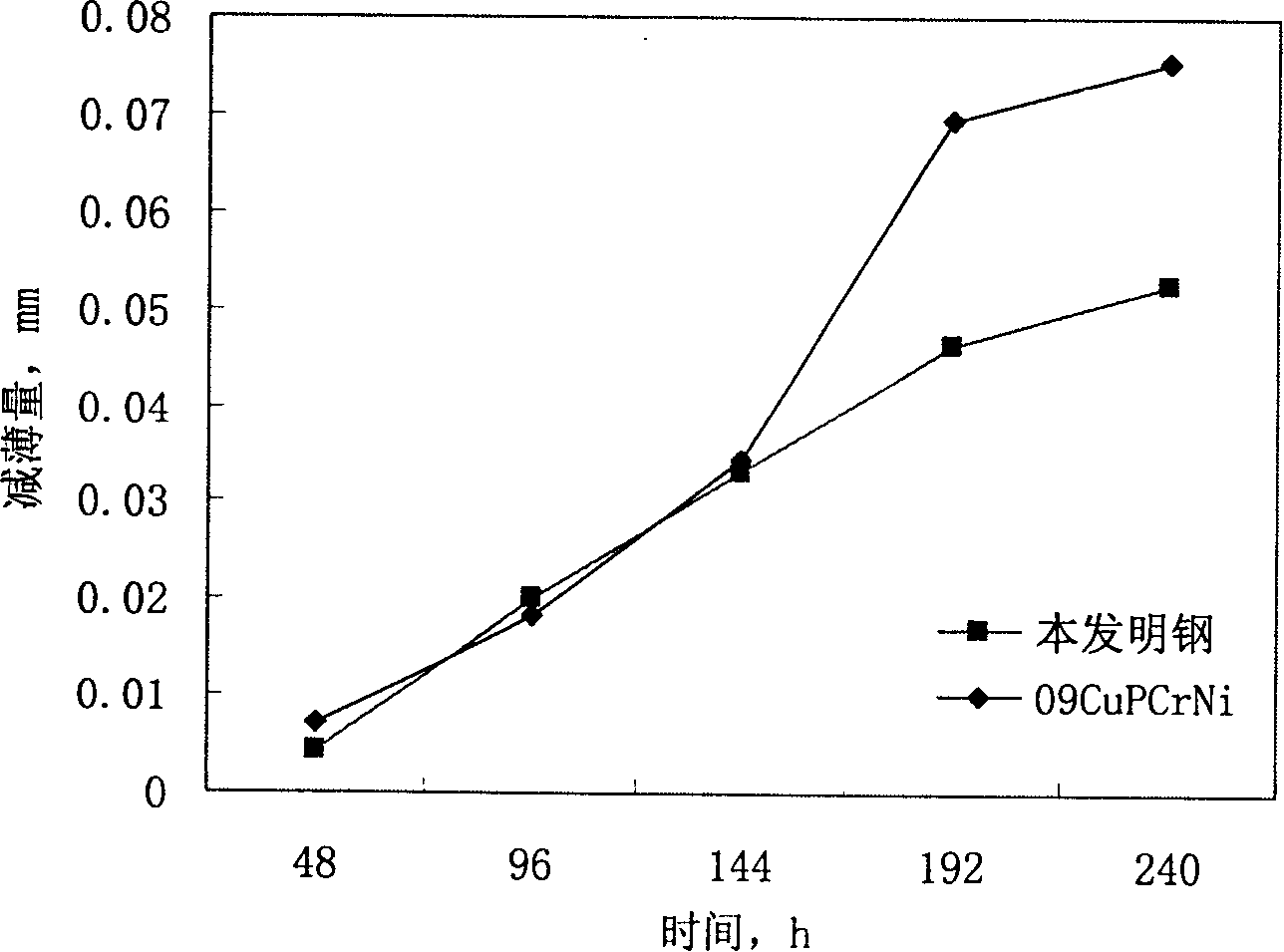

High strength low alloy hot rolling ferrite bainite weathering resistant steel and production method thereof

ActiveCN101660099AHigh strengthImprove toughnessTemperature control deviceManufacturing convertersNiobiumManganese

The invention relates to a high strength low alloy hot rolling ferrite bainite weathering resistant steel and a production method thereof. The steel comprises the components by weight percent: 0.05-0.10% of C, 0.30-0.45% of Si, 1.00-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.50-0.70% of Cr, 0.20-0.30% of Ni, 0.20-0.40% of Cu, less than or equal to 0.05% ofAl, 0.01-0.025% of Ti, 0.03-0.05% of Nb and the rest of Fe and impurities; and the yield strength is more than or equal to 450MPa, and the welding cold crack susceptibility coefficient is less than orequal to 0.2. The invention has the advantages of low cost, high strength, low yield ratio, high weatherability, excellent weldability and low temperature toughness, simple process flow of the preparation technique and easy operation. Therefore, the invention can be widely applied to the fields such as bridges, buildings, containers, railway coaches, etc.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

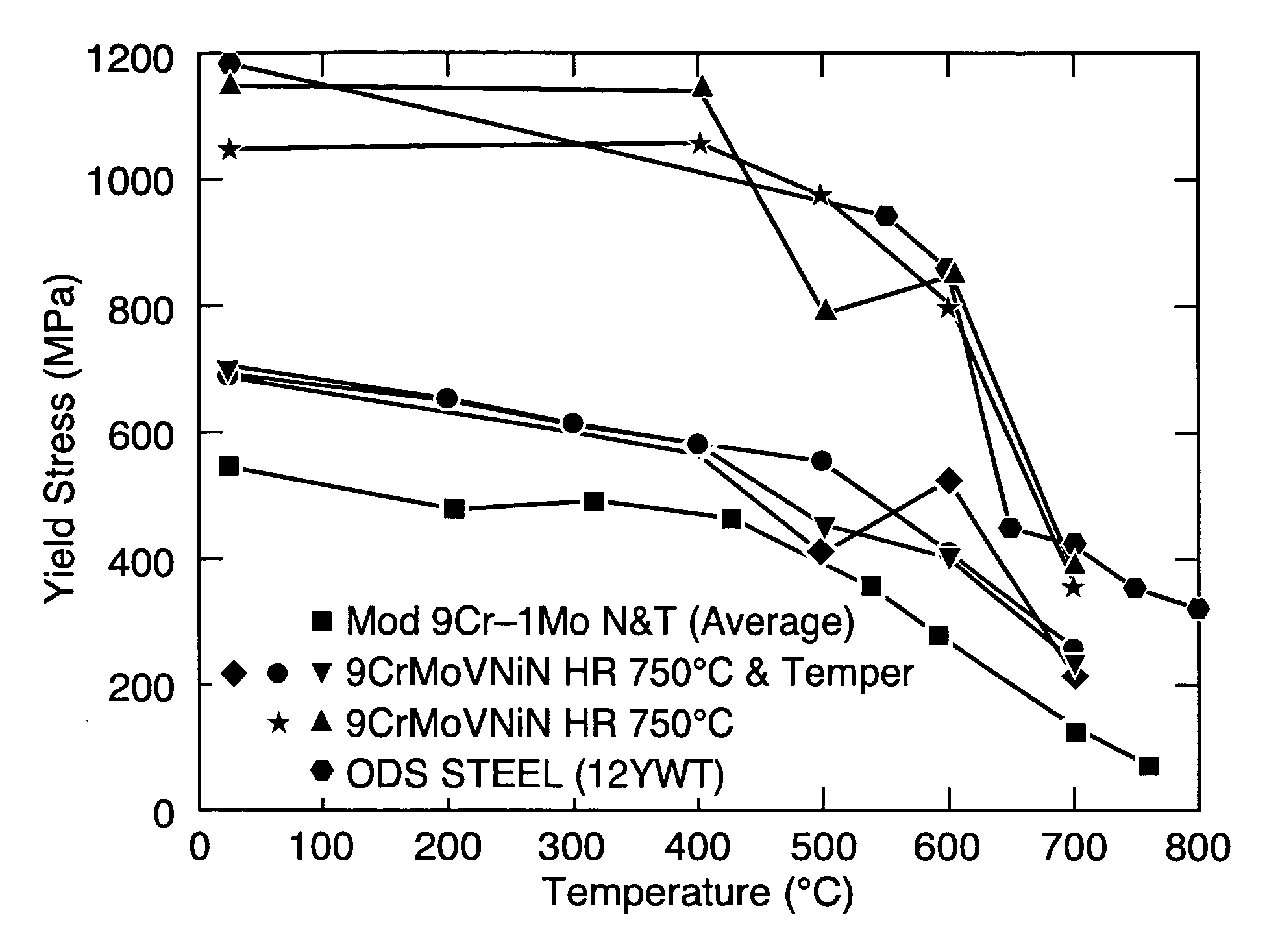

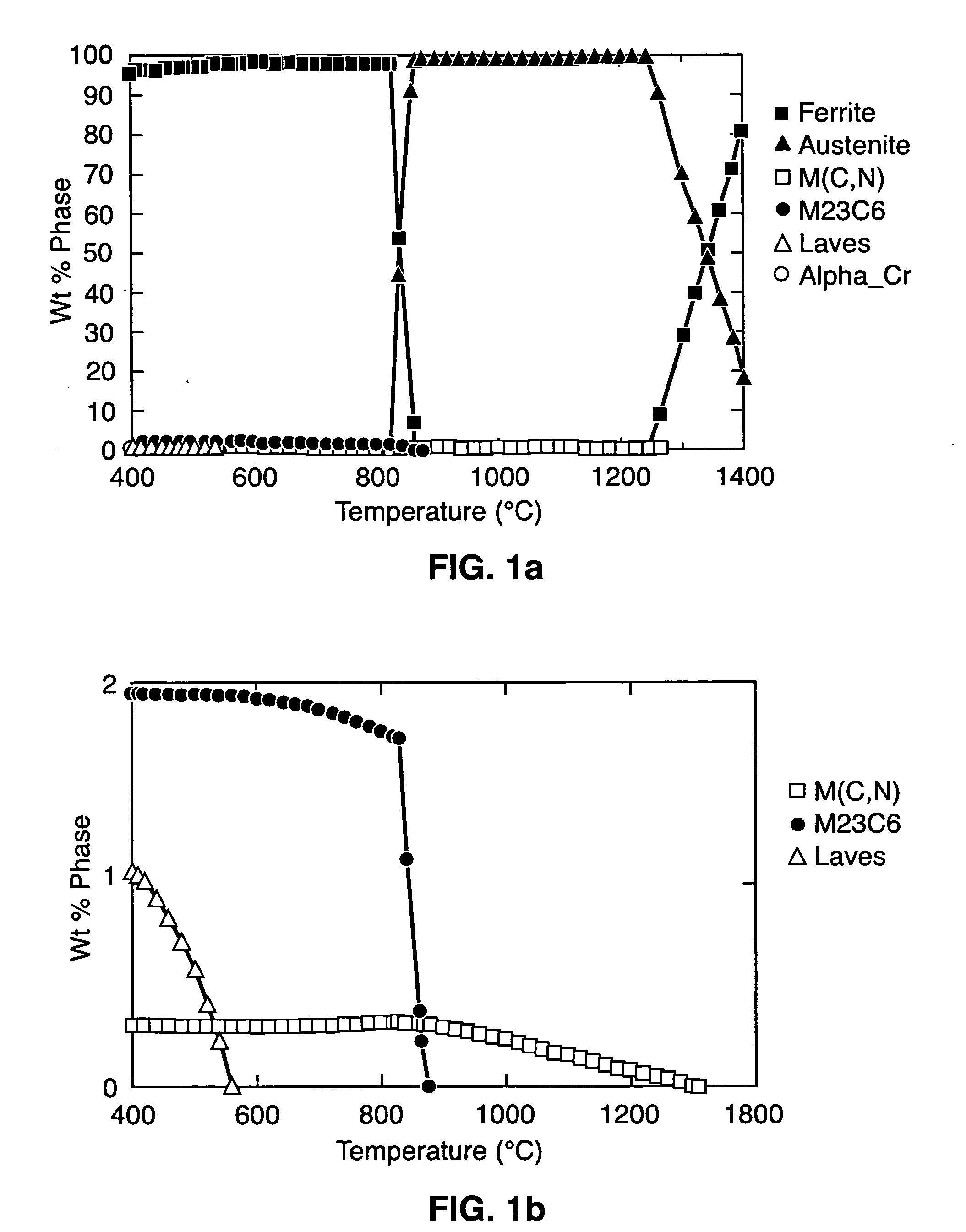

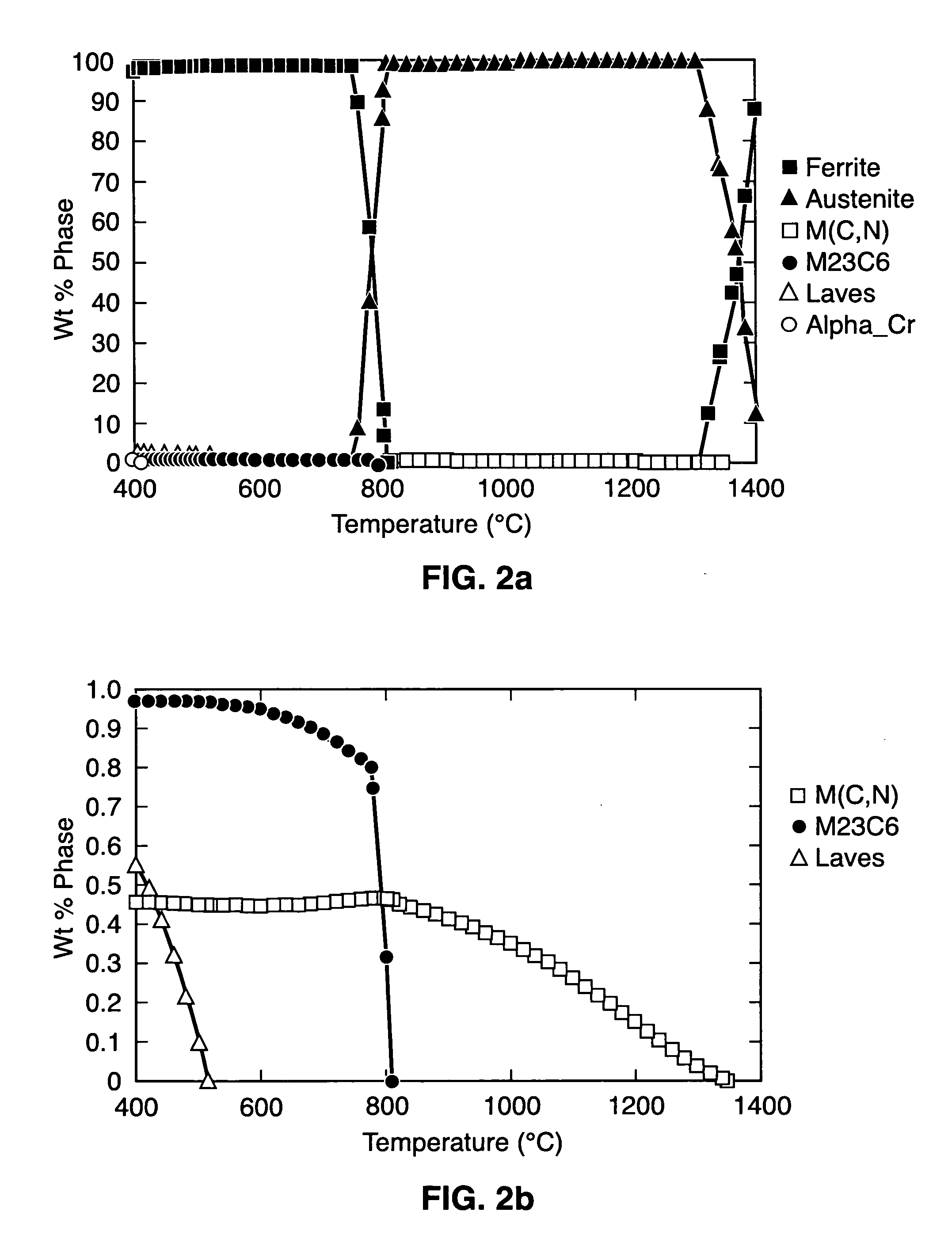

Nano-scale nitride-particle-strengthened high-temperature wrought ferritic and martensitic steels

InactiveUS20060060270A1Improved elevated-temperature strength propertyImprove strength propertiesFurnace typesHeat treatment furnacesHot workingNitride

A method of making a steel composition includes the steps of: a. providing a steel composition that includes up to 15% Cr, up to 3% Mo, up to 4% W, 0.05-1% V, up to 2% Si, up to 3% Mn, up to 10% Co, up to 3% Cu, up to 5% Ni, up to 0.3% C, 0.02-0.3% N, balance iron, wherein the percentages are by total weight of the composition; b. austenitizing the composition at a temperature in the range of 1000° C. to 1400° C.; c. cooling the composition of steel to a selected hot-working temperature in the range 500° C. to 1000° C.; d. hot-working the composition at the selected hot-working temperature; e. annealing the composition for a time period of up to 10 hours at a temperature in the range of 500° C. to 1000° C.; and f. cooling the composition to ambient temperature to transform the steel composition to martensite, bainite, ferrite, or a combination of those microstructures.

Owner:UT BATTELLE LLC

High-strength weathering steel and method of manufacturing same

InactiveCN1970818AReduce control requirementsUniform microstructureRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

High-strength steel sheet and process for production thereof

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

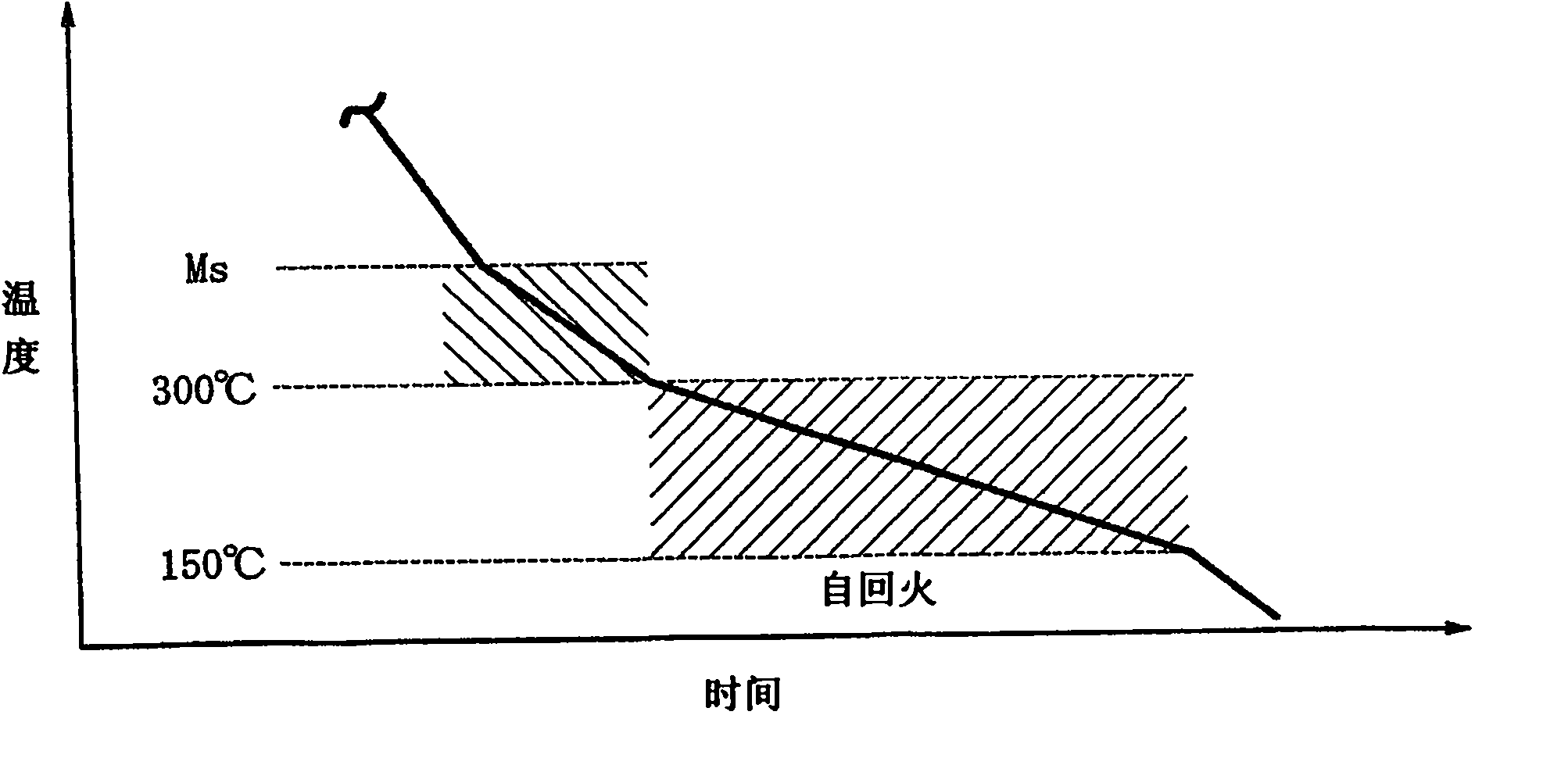

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

High Strength Thin-Gauge Steel Sheet Excellent in Elongation and Hole Expandability and Method of Production of Same

InactiveUS20080000555A1High strengthHigh elongationFurnace typesMetal rolling arrangementsSectilityHigh intensity

The present invention provides high strength thin-gauge steel sheet with excellent elongation and hole expandability having a tensile strength of 500 MPa or more and a method of production of high strength thin-gauge steel sheet with excellent elongation and hole expandability enabling production of this on an industrial scale, that is, high strength thin-gauge steel sheet comprised of, by mass %, C: 0.03 to 0.25%, Si: 0.4 to 2.0%, Mn: 0.8 to 3.1%, P≦0.02%, S≦0.02%, Al≦2.0%, N≦0.01%, and a balance of Fe and unavoidable impurities and having a microstructure comprised of ferrite with an area fraction of 10 to 85% and residual austenite with a volume fraction of 1 to 10%, an area fraction of 10% to 60% of tempered martensite, and a balance of bainite.

Owner:NIPPON STEEL CORP

980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and manufacturing method thereof

The invention provides 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel and a manufacturing method thereof. The 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel comprises, by weight, 0.05%-0.10% of C, 0.1%-0.8% of Si, 1.5% -2.5% of Mn, 0-0.015% of P, 0-0.005% of S, 0-0.003% of O, 0.02%-0.08% of Al, 0-0.005% of N, 0.05%-0.15% of Ti, 0.02%-0.06% of Nb, 0.1%-1.0% of Cr, 0.01%-0.10% of V, and the balance Fe and inevitable impurities, wherein the chemical components meet the relations that 0.15%<=Nb+Ti+V<=0.25%, and 0.01%<=(Ti-3.42N) / 4+V / 4.24<=0.06%. The microstructure of the steel is made of granular bainite and martensite; the yield strength of the steel is equal to or higher than 900 MPa, the tensile strength of the steel is equal to or higher than 980 MPa, the ductility of the steel is equal to or higher than 15%, and the hole expansion ratio of the steel is equal or higher than 50%; and the 980 MPa-grade hot-rolled high-strength high-hole-expansion-ratio steel has excellent strength, ductility and hole expansion matching and can be widely applied to thinned high-strength complexly-formed components such as an automobile chassis, a crossbeam and a wheel.

Owner:BAOSHAN IRON & STEEL CO LTD

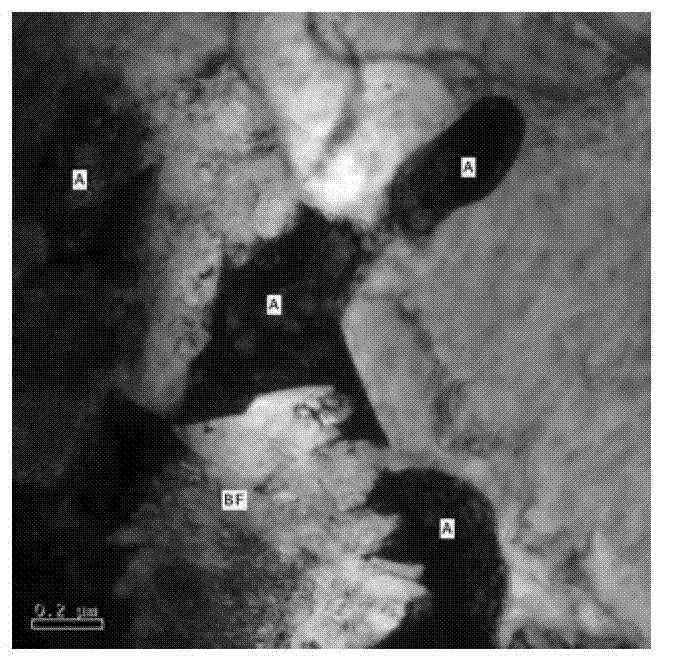

Ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, and method for manufacturing the same

InactiveUS20050150580A1High strengthImprove hydrogen embrittlement resistanceManganeseUltimate tensile strength

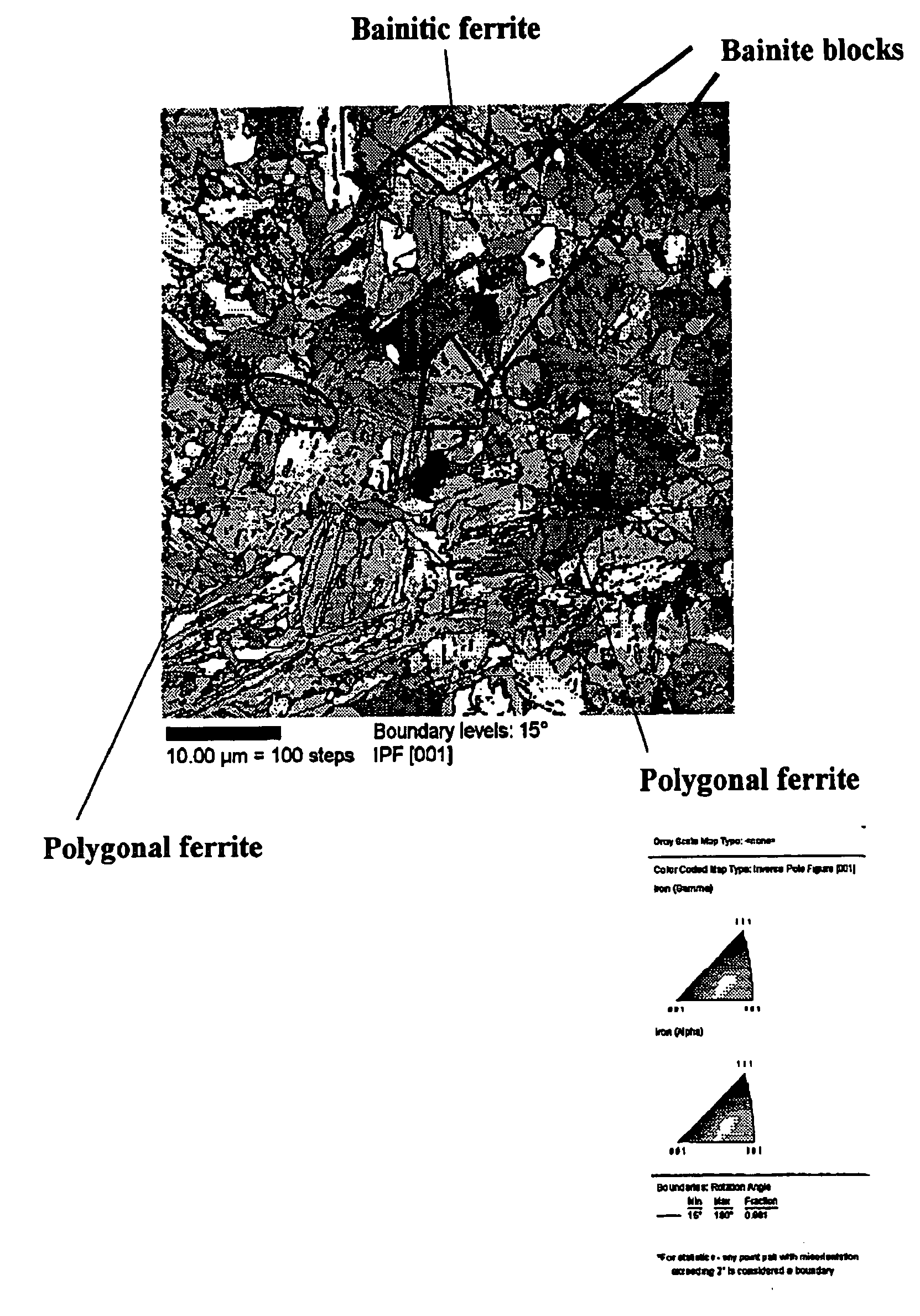

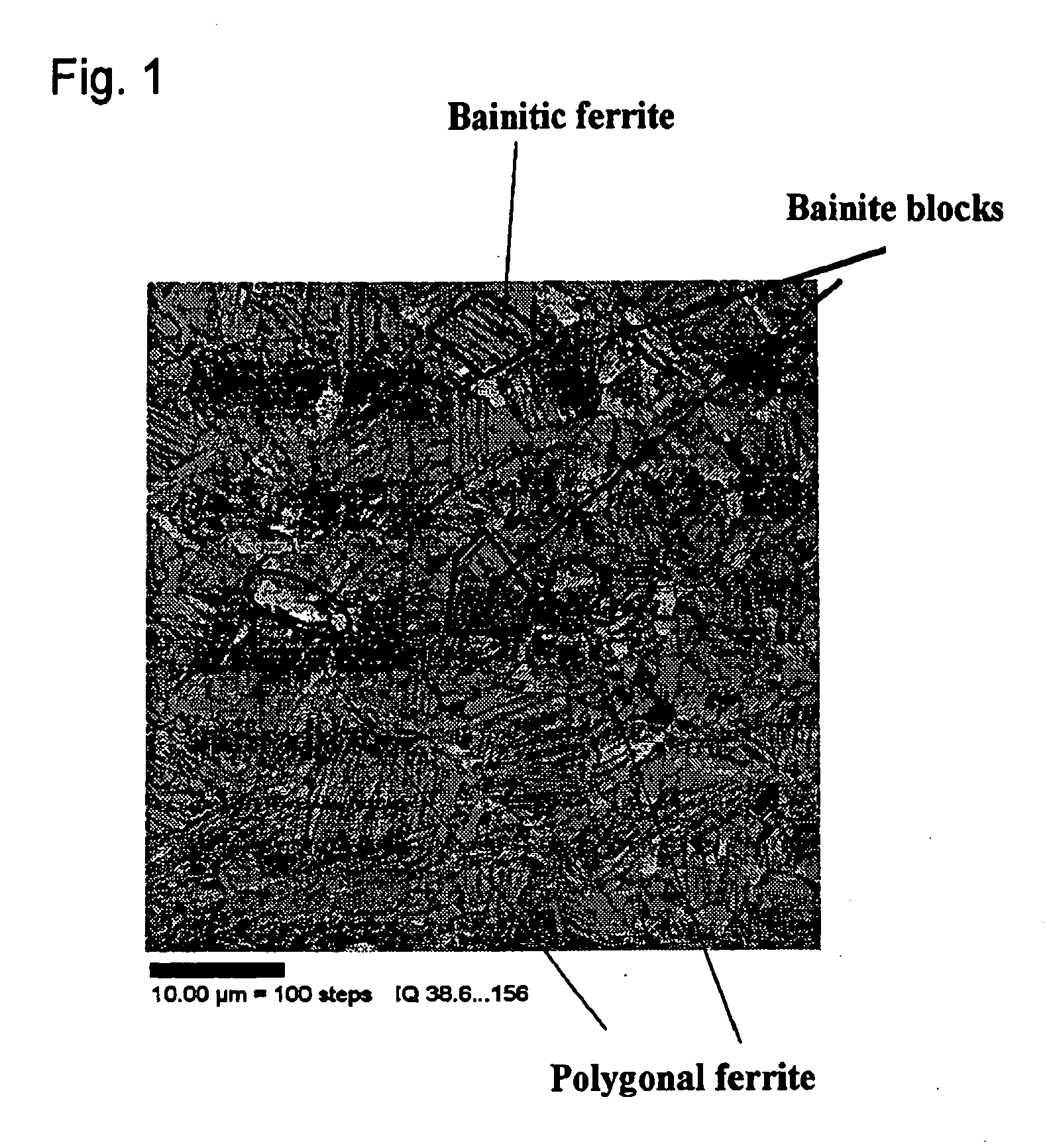

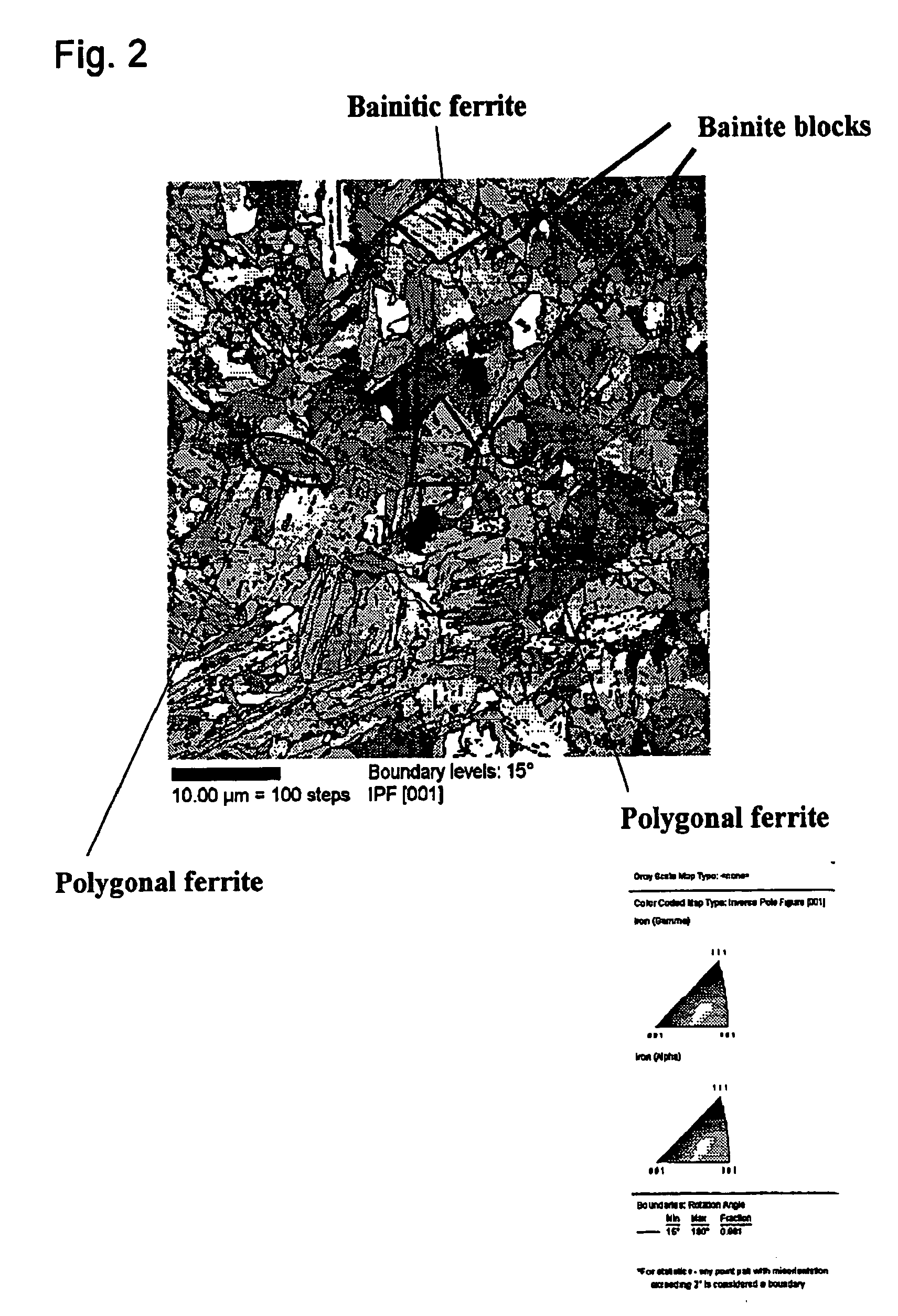

The present invention provides an ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, which includes: 0.06 to 0.6% of C; 0.5 to 3% of Si+Al; 0.5 to 3% of Mn; 0.15% or lower of P; and 0.02% or lower of S in terms of mass percentage, and also includes 3% or higher of residual austenite structure, 30% or higher of bainitic ferrite structure, and preferably 50% or lower of polygonal ferrite in terms of an areal ratio to the entire structure, wherein a mean grain size of bainite blocks is smaller than 20 μm as determined by comparing observations of the same region of the bainitic ferrite structure by EBSP (electron back scatter diffraction pattern) and SEM.

Owner:KOBE STEEL LTD

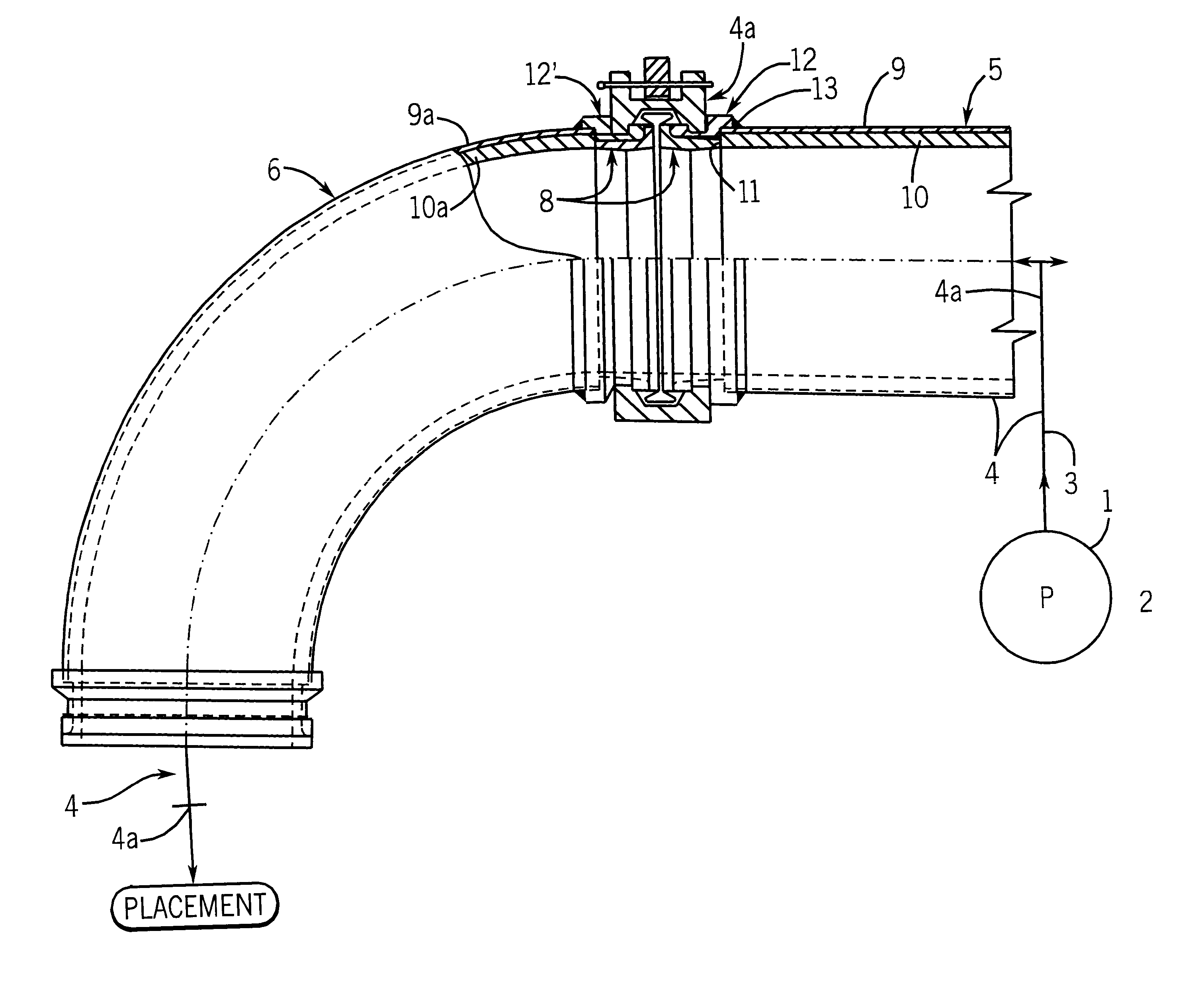

Pipe having replaceable wear resistant lined coupler

InactiveUS6467812B1Rapid and cost-effective formationQuick inexpensive replacementFlanged jointsThermal insulationWear resistantEngineering

A pipe section for concrete includes an end coupler interconnecting to another pipe section in a flow line. The coupler has an outer clamp secured extended from the pipe end with a coupling groove. An encircling clamp has sides located in the grooves of adjacent pipe sections to lock the pipe section together. The body and pipe end form an inner recess extending from the pipe end. An insert liner has a tubular portion matching the recess, with the outer surface of the tubular portion tapered to form a gap within the recess. The insert liner has an outer flange matching the outer diameter of the body and abuts the body. The inner wall of the liner has a central transition point from which the wall tapers inwardly in opposite directions to the outer end. The body member is formed of a high strength ductile steel. The insert liner is formed of a wear resistant material having a Rockwell hardness of 80 to 90. A carbide alloy consisting essentially of carbides, martensite, bainite and austenite, and 12-15% chromium, 2-3% carbon and traces nickel, molybdenum and austenite. A toughened ceramic is disclosed. The liner is adhesively bonded to the body using an epoxy adhesive which is responsive to heat for release of the liner. The liner is inserted by applying adhesive on the tubular portion and then pushing the liner into the recess.

Owner:CONSTR FORMS

Ultra-low-carbon bainite steel and producing method thereof

InactiveCN1521285AImprove low temperature toughnessImprove cold resistanceChemical compositionUltimate tensile strength

The present invention is super-low carbon bainite steel and its production process. The chemical components include C0.01-0.05 wt%, Si 0.05-0.5 wt%, Mn 1.0-2.2 wt%, Nb 0.015-0.070 wt%, Ti 0.005-0.03 wt%, B 0.0005-0.005 wt%, Al 0.015-0.07 wt%, Mo 0.0-0.5 wt%, Cu 0.0-1.8 wt%, Ni 0.0-1.0 wt% and Cr 0.0-0.70 wt% except Fe and evitable impurity. The super-low carbon bainite steel is produced in controlled rolling and controlled cooling process. It has toughness-to-brittleness conversion temperature below -80 deg.c, excellent cold bending formation performance, simple production process, low cost and serial strength, and may be used widely in engineering machinery, mining and excavating machine, heavy truck, pipeline, container, bridge, ship, cargo transporter, marine facility, etc.

Owner:ANGANG STEEL CO LTD

High-strength steel sheet, hot-dipped steel sheet, and alloy hot-dipped steel sheet that have excellent fatigue, elongation, and collision characteristics, and manufacturing method for said steel sheets

ActiveUS20120031528A1Improve crash performanceHigh yield stressHot-dipping/immersion processesFurnace typesUltimate tensile strengthImpurity

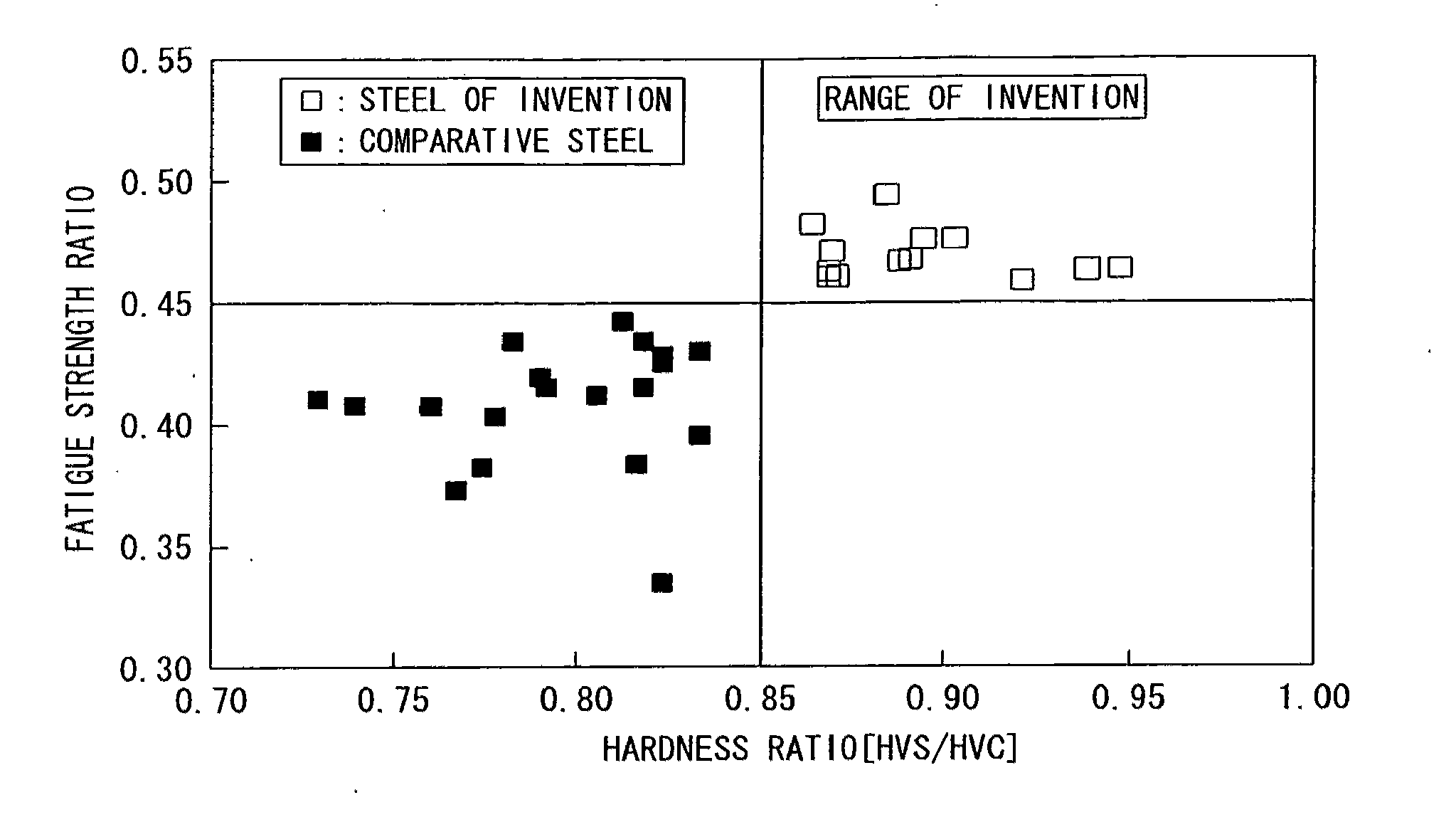

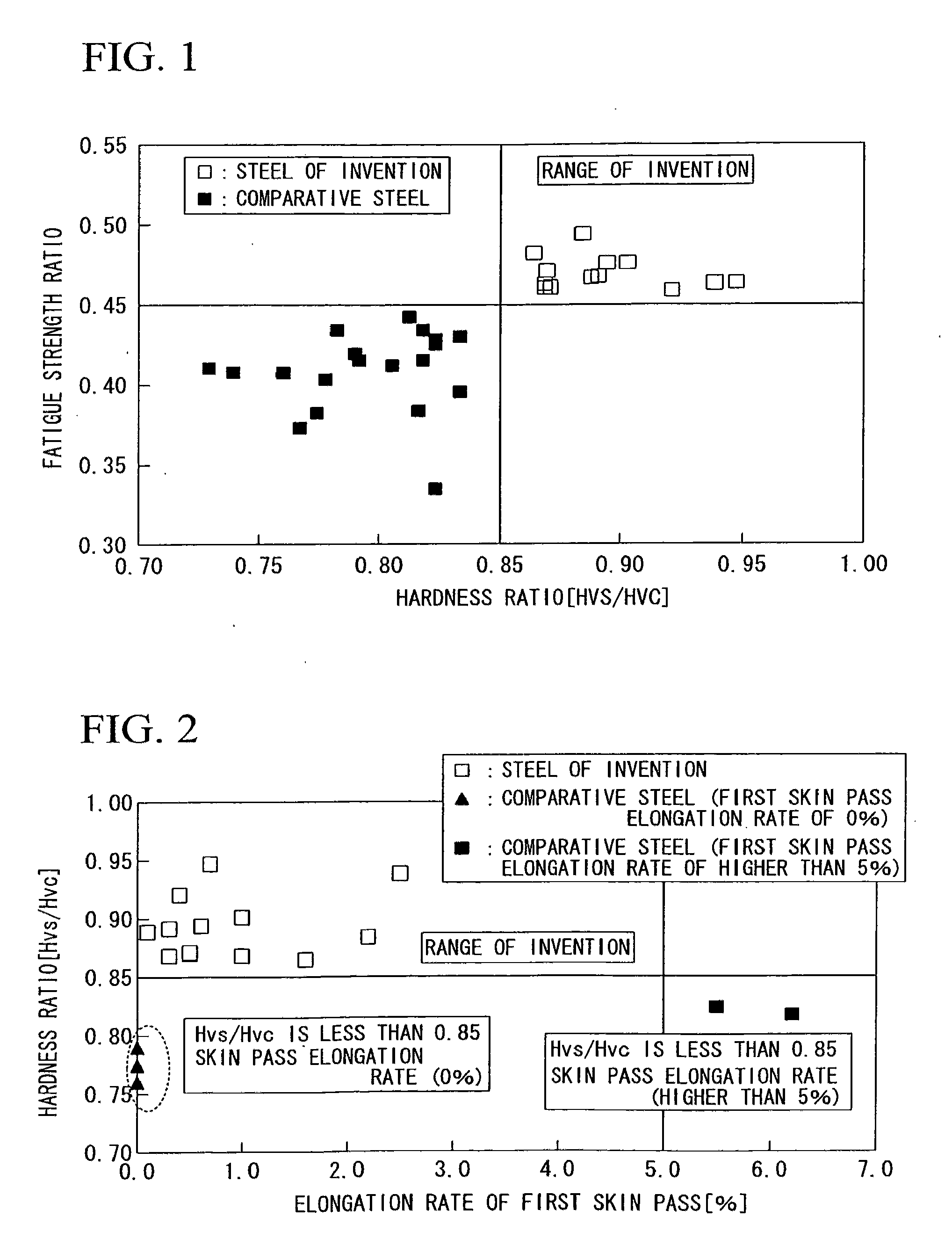

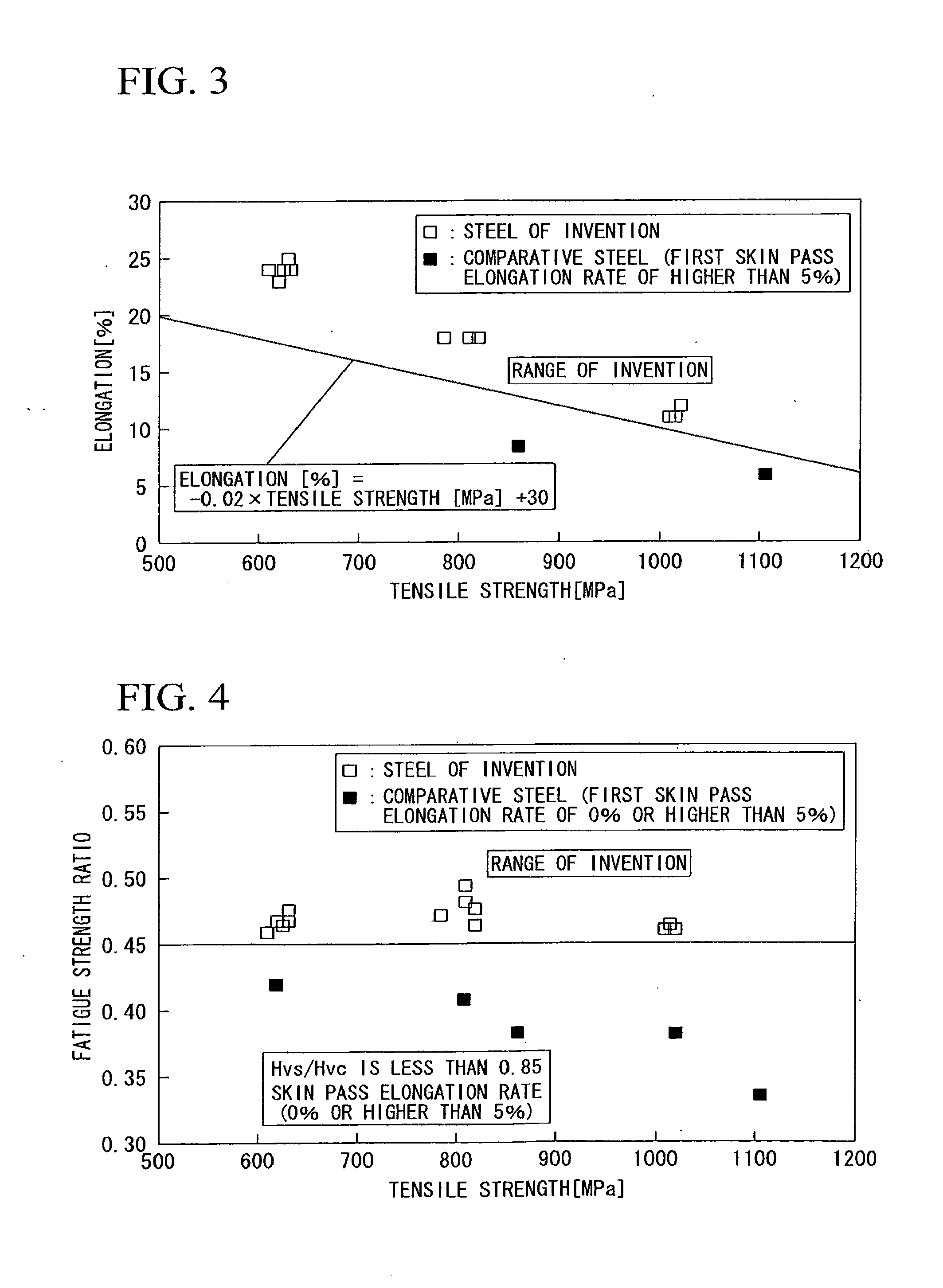

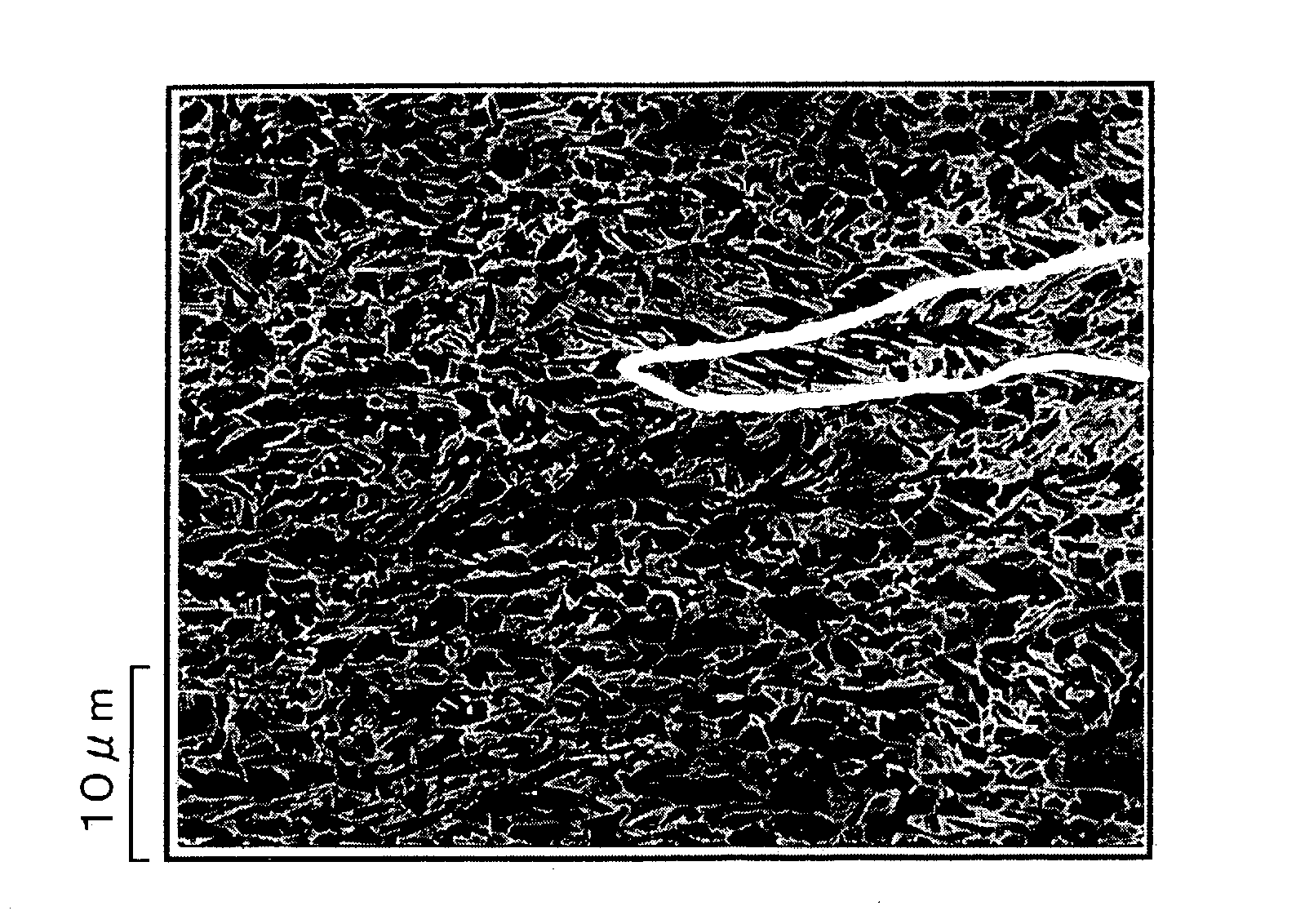

This high-strength steel sheet includes: in terms of percent by mass, 0.03 to 0.10% of C; 0.01 to 1.5% of Si; 1.0 to 2.5% of Mn; 0.1% or less of P; 0.02% or less of S; 0.01 to 1.2% of Al; 0.06 to 0.15% of Ti; and 0.01% or less of N; and contains as the balance, iron and inevitable impurities, wherein a tensile strength is in a range of 590 MPa or more, and a ratio between the tensile strength and a yield strength is in a range of 0.80 or more, a microstructure includes bainite at an area ratio of 40% or more and the balance being either one or both of ferrite and martensite, a density of Ti(C,N) precipitates having sizes of 10 nm or smaller is in a range of 1010 precipitates / mm3 or more, and a ratio (Hvs / Hvc) of a hardness (Hvs) at a depth of 10 μm from a surface to a hardness (Hvc) at a center of a sheet thickness is in a range of 0.85 or more.

Owner:NIPPON STEEL CORP

High-strength steel sheet and high-strength steel pipe excellent in deformability and method for producing the same

The present invention provides a line pipe of, e.g., the API standard X60 to X100 class. The line pipe has an excellent deformability, as well as excellent low temperature toughness and high productivity, a steel plate used as the material of the steel pipe. Methods for producing the steel pipe and the steel plate are also provided. In particular, a high-strength steel plate excellent in the deformability has a ferrite phase is dispersed finely, and accounts for 5% to 40% in area percentage in a low temperature transformation structure mainly composed of a bainite phase. For example, most grain sizes of the ferrite phase are smaller than the average grain size of the bainite phase. A high-strength steel pipe excellent in deformability is also provided, in which a large diameter steel pipe is produced through forming the steel plate into a pipe shape. The steel pipe has the above-referenced structure, and satisfies the conditions that YS / TS is 0.95 or less and YSxuEL is 5,000 or more. Methods for producing such steel plate and steel pipe are also provided.

Owner:NIPPON STEEL CORP

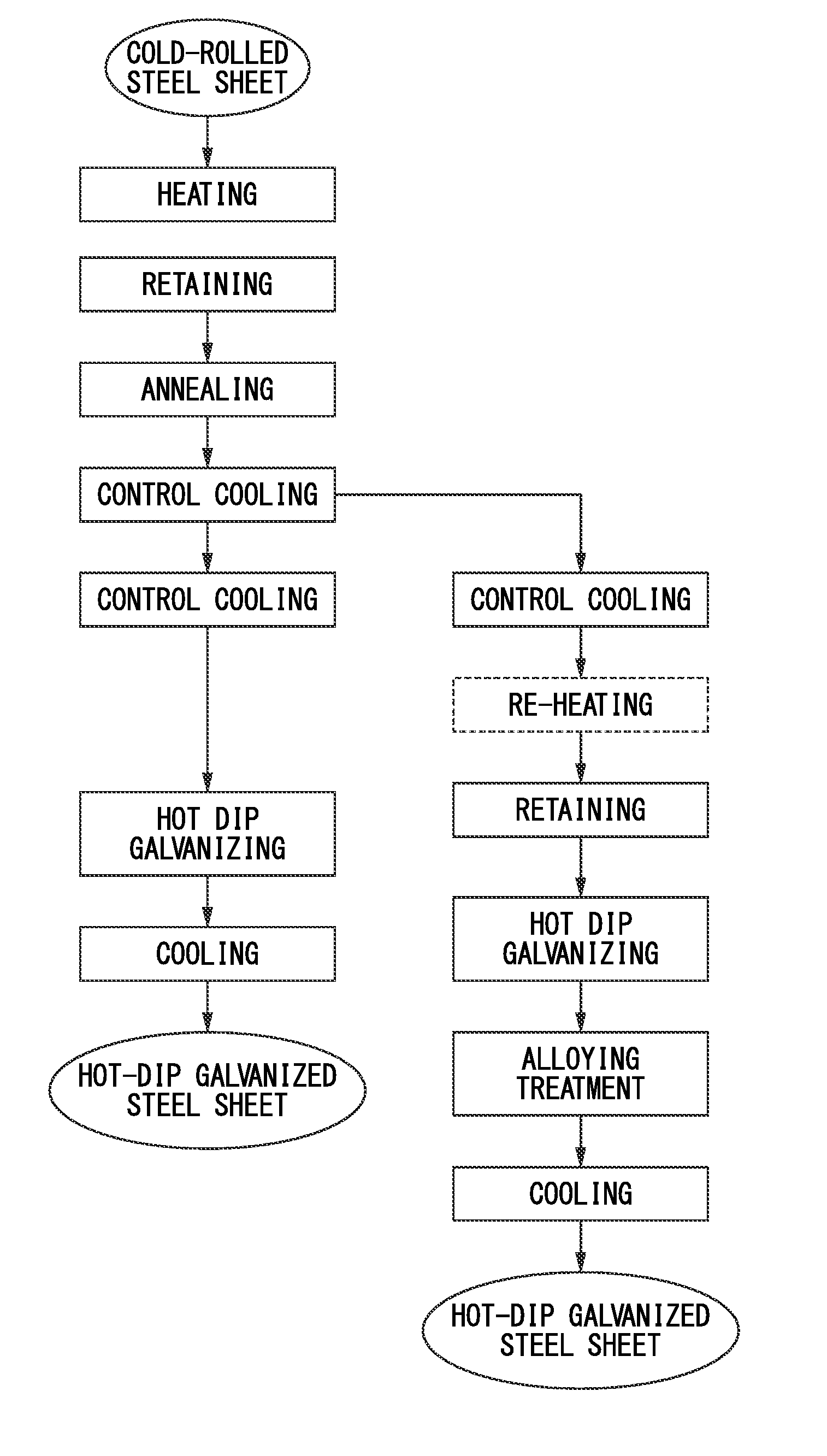

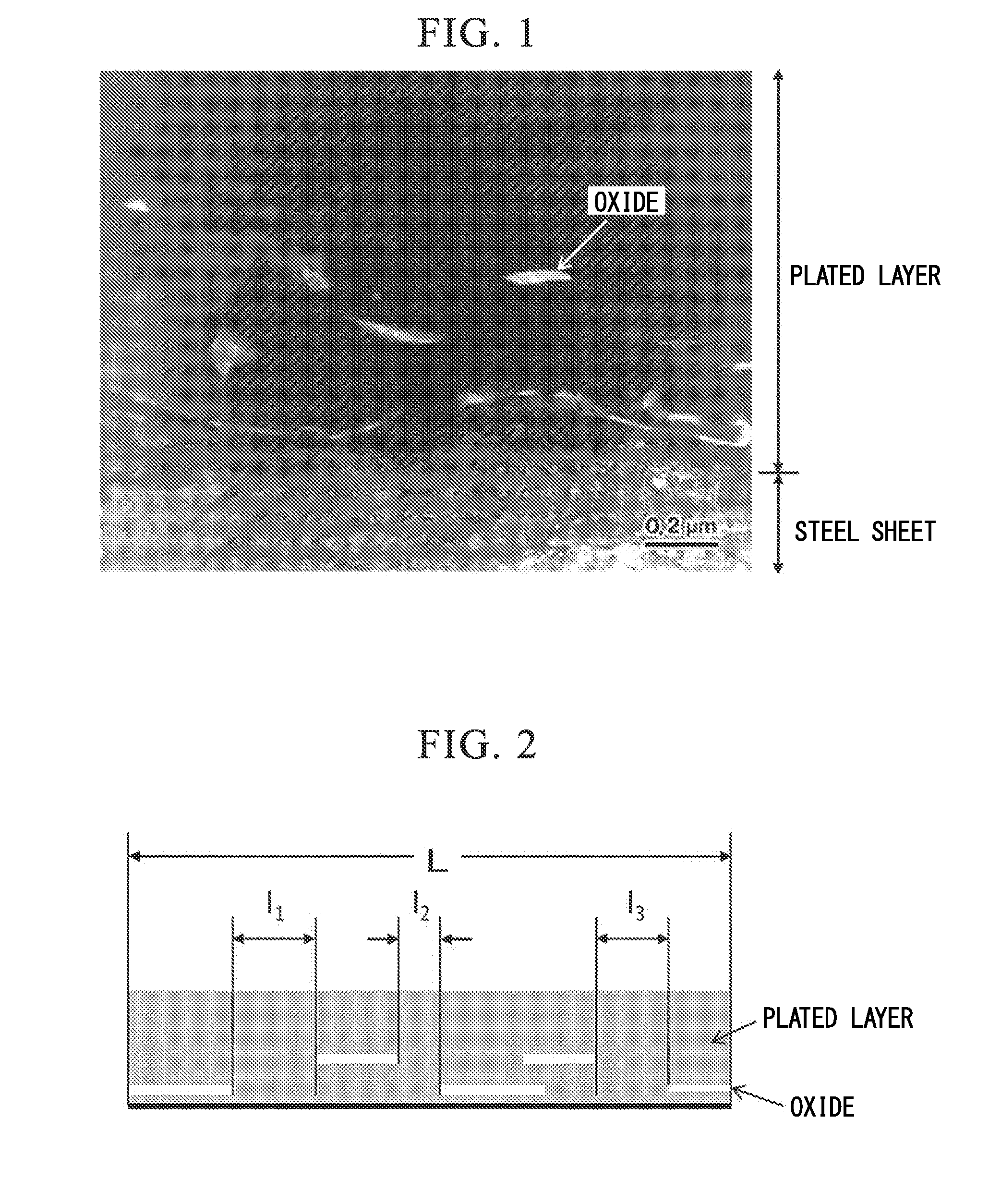

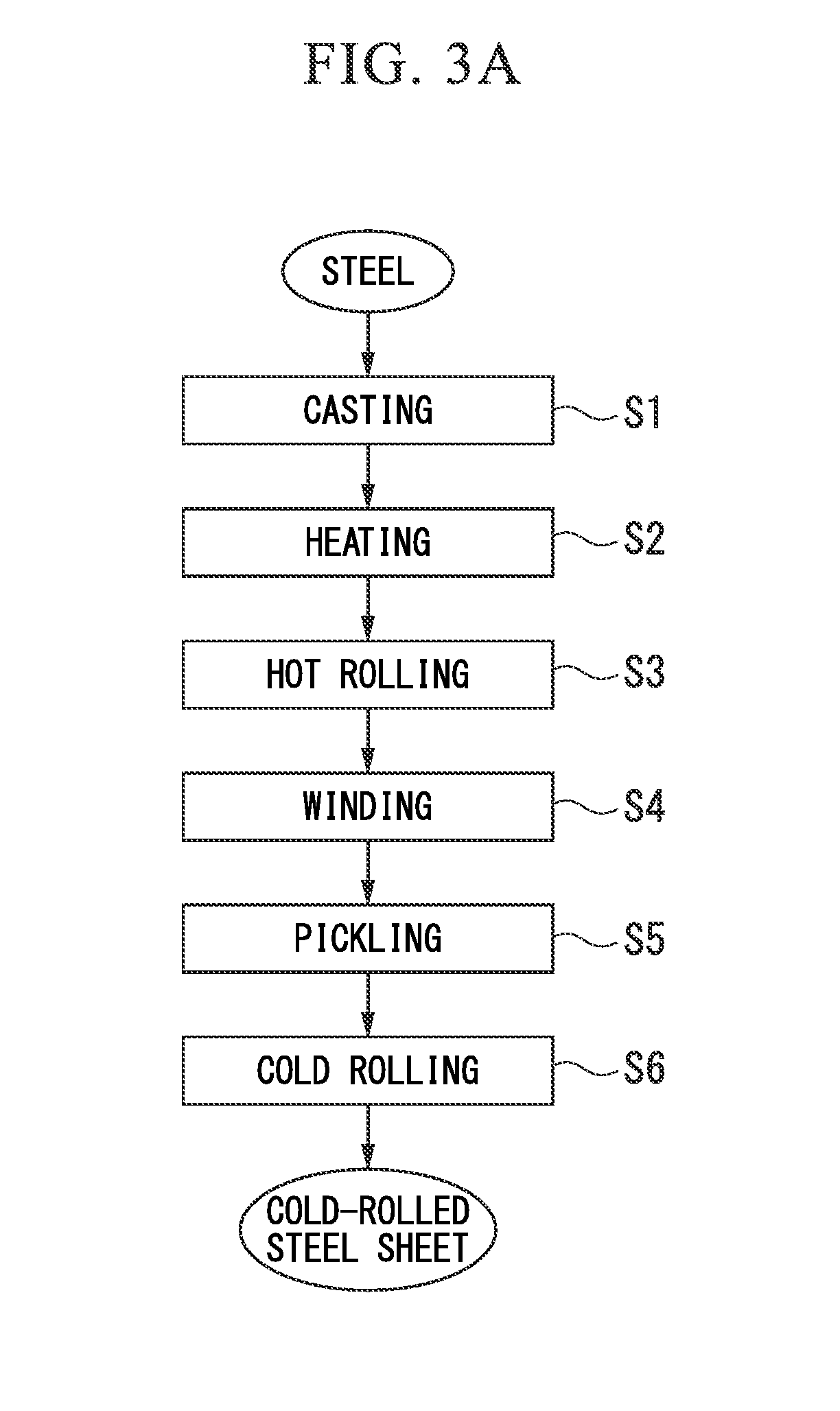

Hot-dip galvanized steel sheet and manufacturing method thereof

ActiveUS20140234657A1Low costImprove adhesionHot-dipping/immersion processesFurnace typesPearliteBainite

A hot-dip galvanized steel sheet includes: a steel sheet; and a plated layer on a surface of the steel sheet, a microstructure contains, by volume fraction, equal to or more than 20% and equal to or less than 99% in total of one or two of martensite and bainite, a residual structure contains one or two of ferrite, residual austenite of less than 8% by volume fraction, and pearlite of equal to or less than 10% by volume fraction, tensile strength is equal to or greater than 980 MPa, the plated layer is a hot-dip galvanized layer which contains oxides including one or two or more of Si, Mn, and Al, contains equal to or less than 15 mass % of Fe, and a remainder including Zn, Al, and unavoidable impurities, and when a cross section including the steel sheet and the hot-dip galvanized layer is seen in a sheet thickness direction, a projected area ratio is equal to or more than 10% and equal to or less than 90%.

Owner:NIPPON STEEL CORP

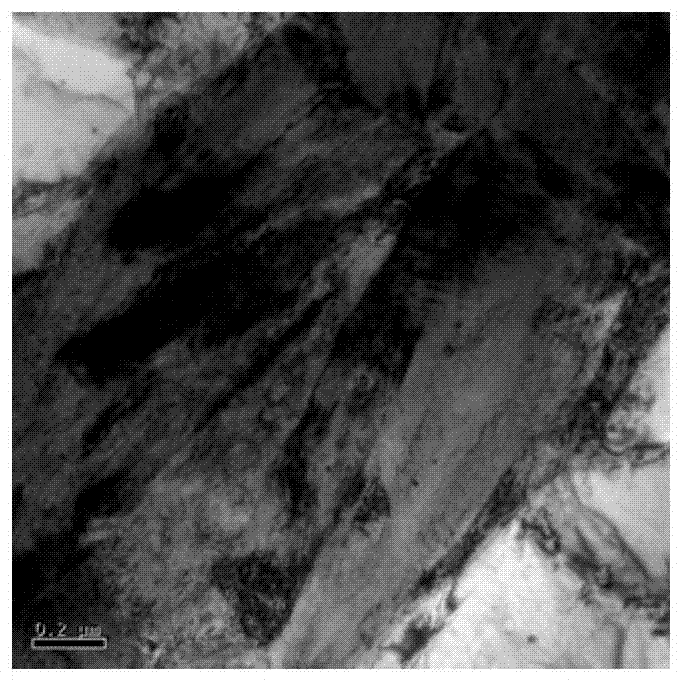

Nano-composite martensitic steels

Carbon steels of high performance are disclosed that contain dislocated lath structures in which laths of martensite alternate with thin films of austenite, but in which each grain of the dislocated lath structure is limited to a single microstructure variant by orienting all austenite thin films in the same direction. This is achieved by careful control of the grain size to less than ten microns. Further improvement in the performance of the steel is achieved by processing the steel in such a way that the formation of bainite, pearlite, and interphase precipitation is avoided.

Owner:MMFX STEEL CORP OF AMERICA +1

Super-thick non-hardening plastic mold steel and method for manufacturing the same

ActiveCN101096743ARealize non-temperedEliminate quenching and temperingHeat treatment process controlHardnessImpurity

The invention discloses a hyper-thick non-modified plastic die steel, which comprises the following parts: 0.20-0.32% C , 0.20-0.80% Si , 1.80-2.50% Mn, 0.80-1.50% Cr, 0.20-0.60% Mo, 0.08-0.20% V, 0.0010-0.0030% B, 0.02-0.06% Ti , not more than 0.035% P, not more than 0.035% S, ferric and inevitable impurity, wherein the structure condition is bainite. The invention ensures the hardness HRC30-36 of bainite structure and pre-hardening plastic die steel, which controls the cooling speed after forging with thickness over 300mm.

Owner:宝武特种冶金有限公司

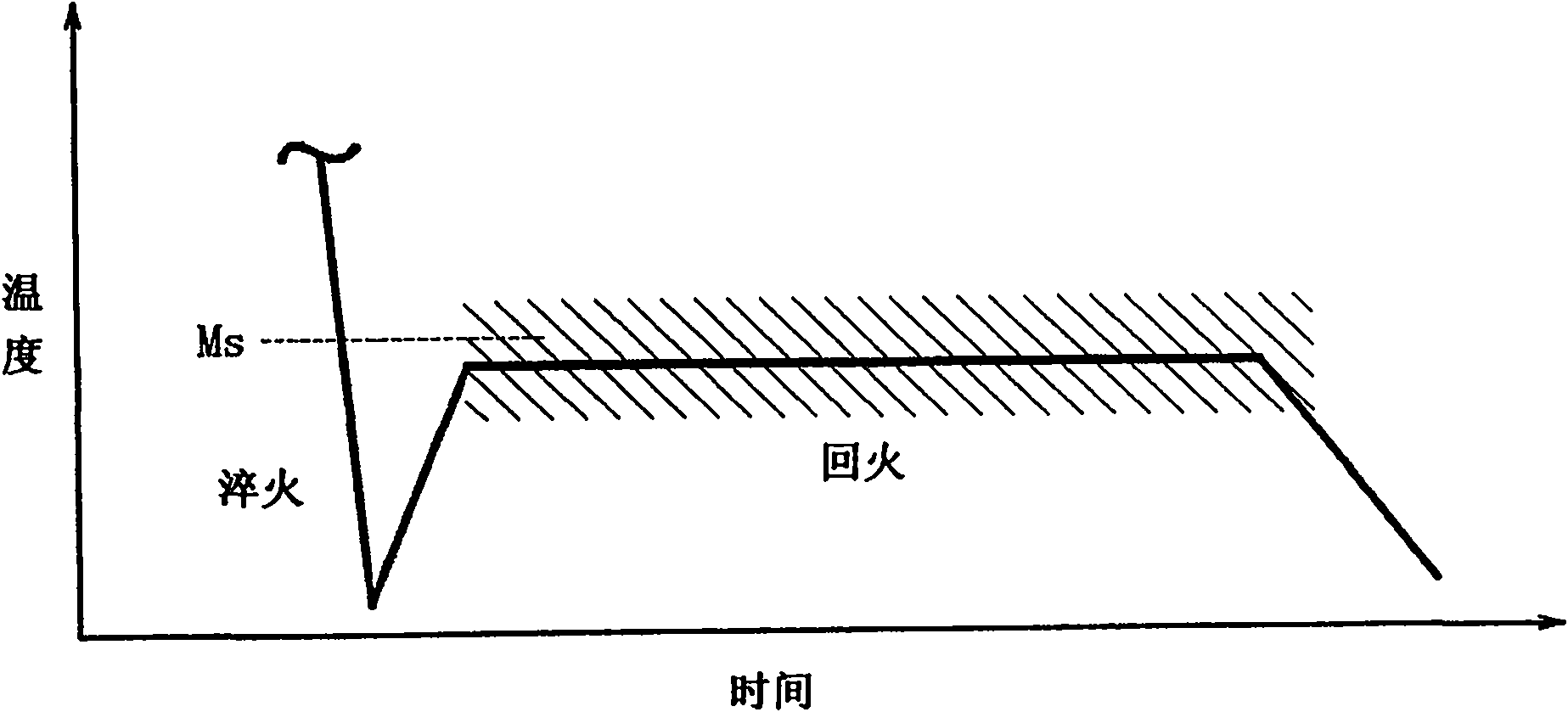

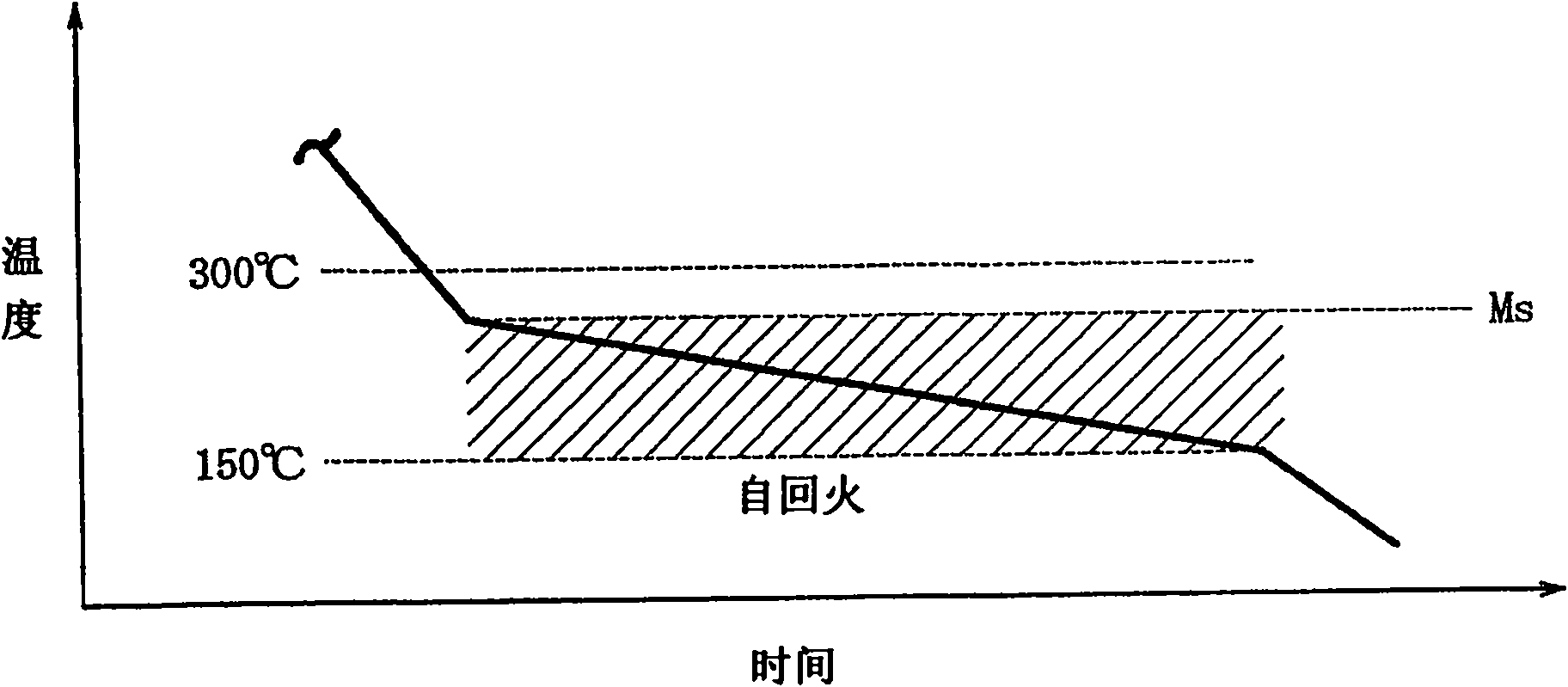

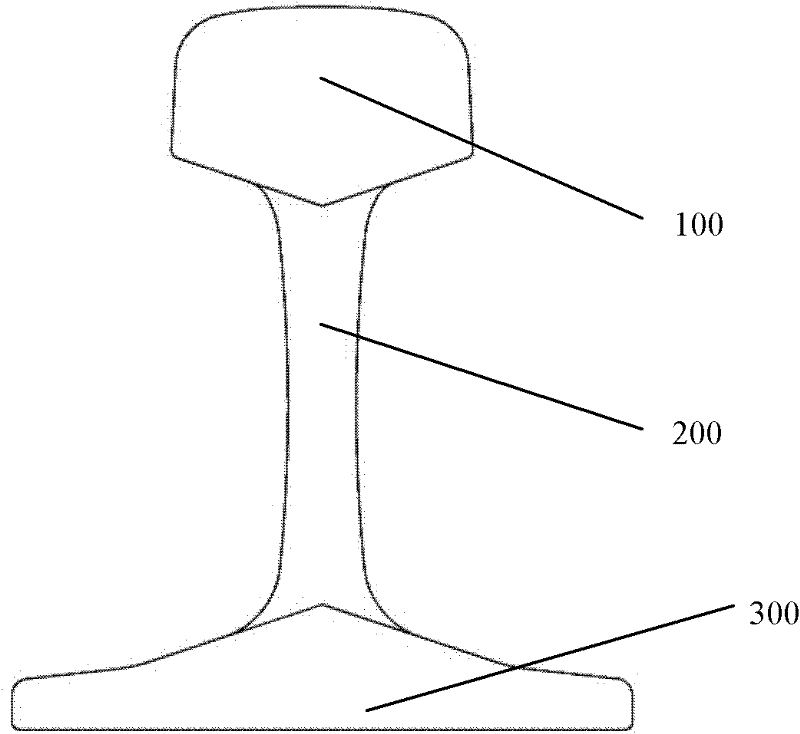

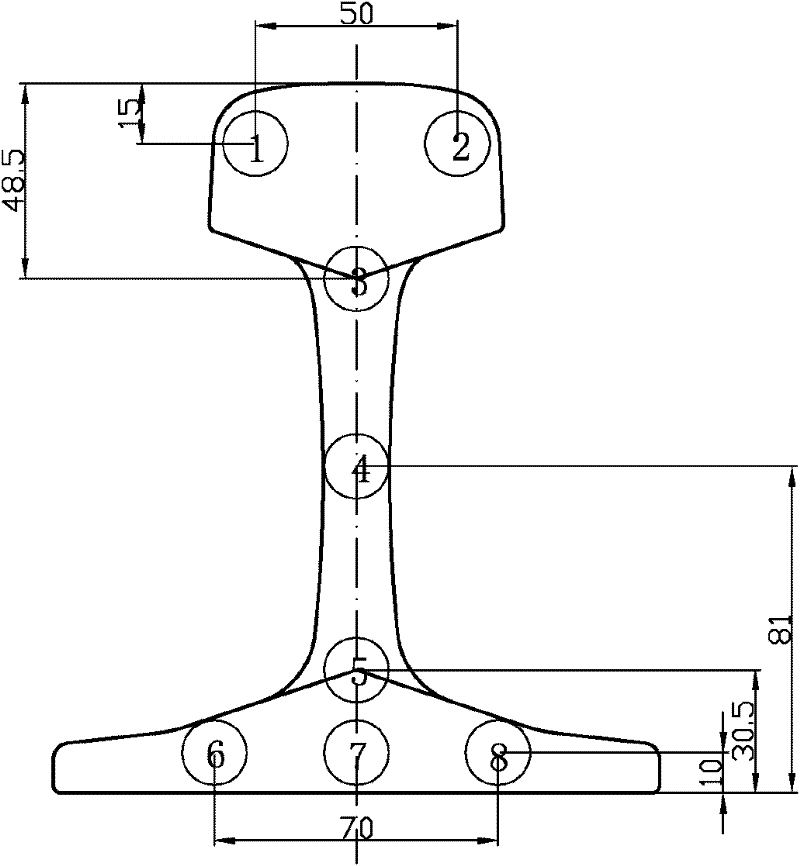

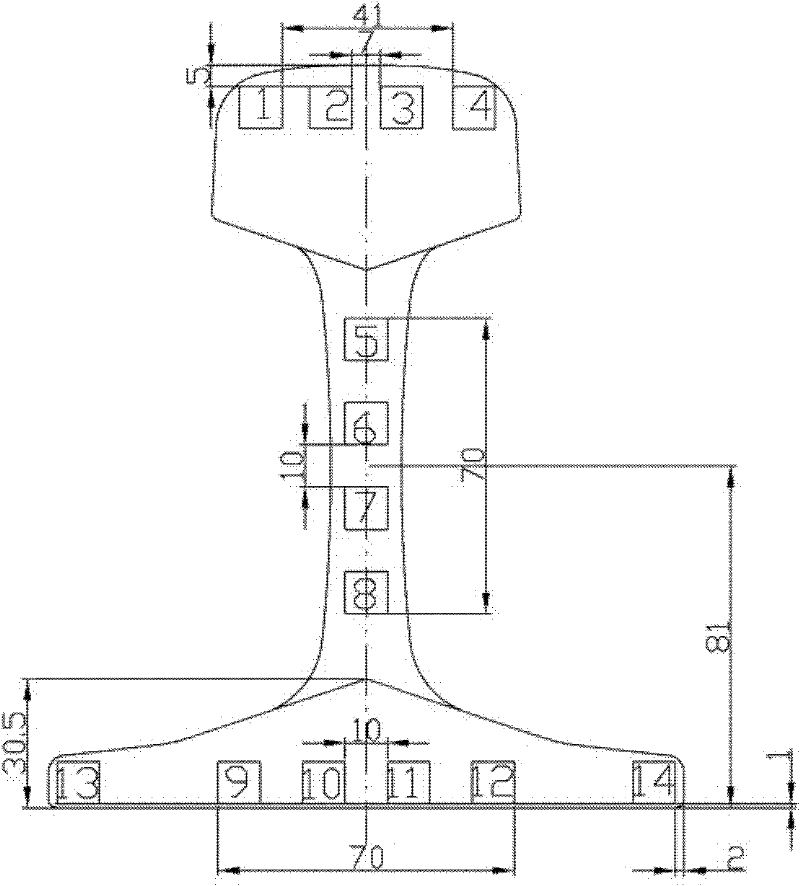

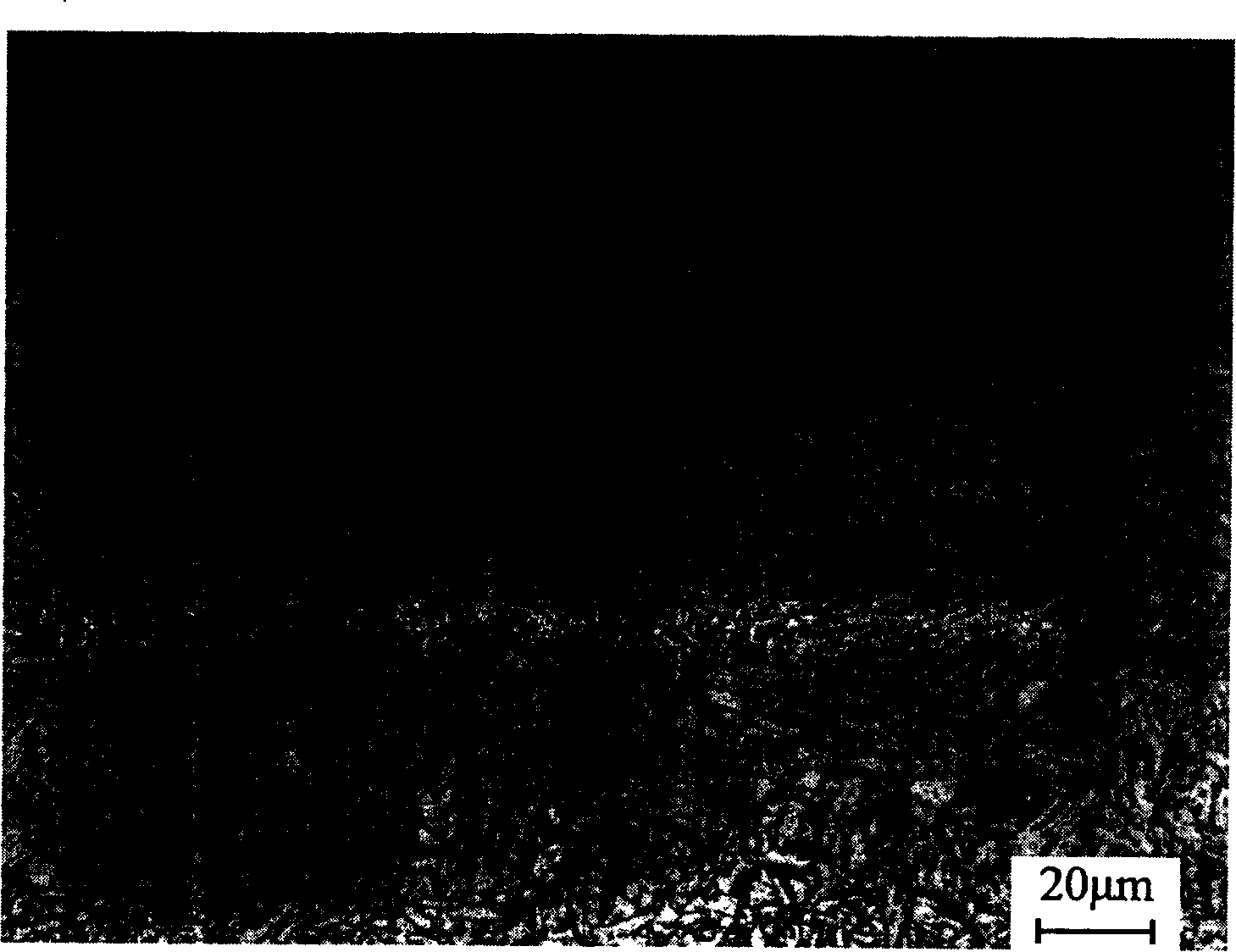

High strength bainitic steel rail and heat treatment process thereof

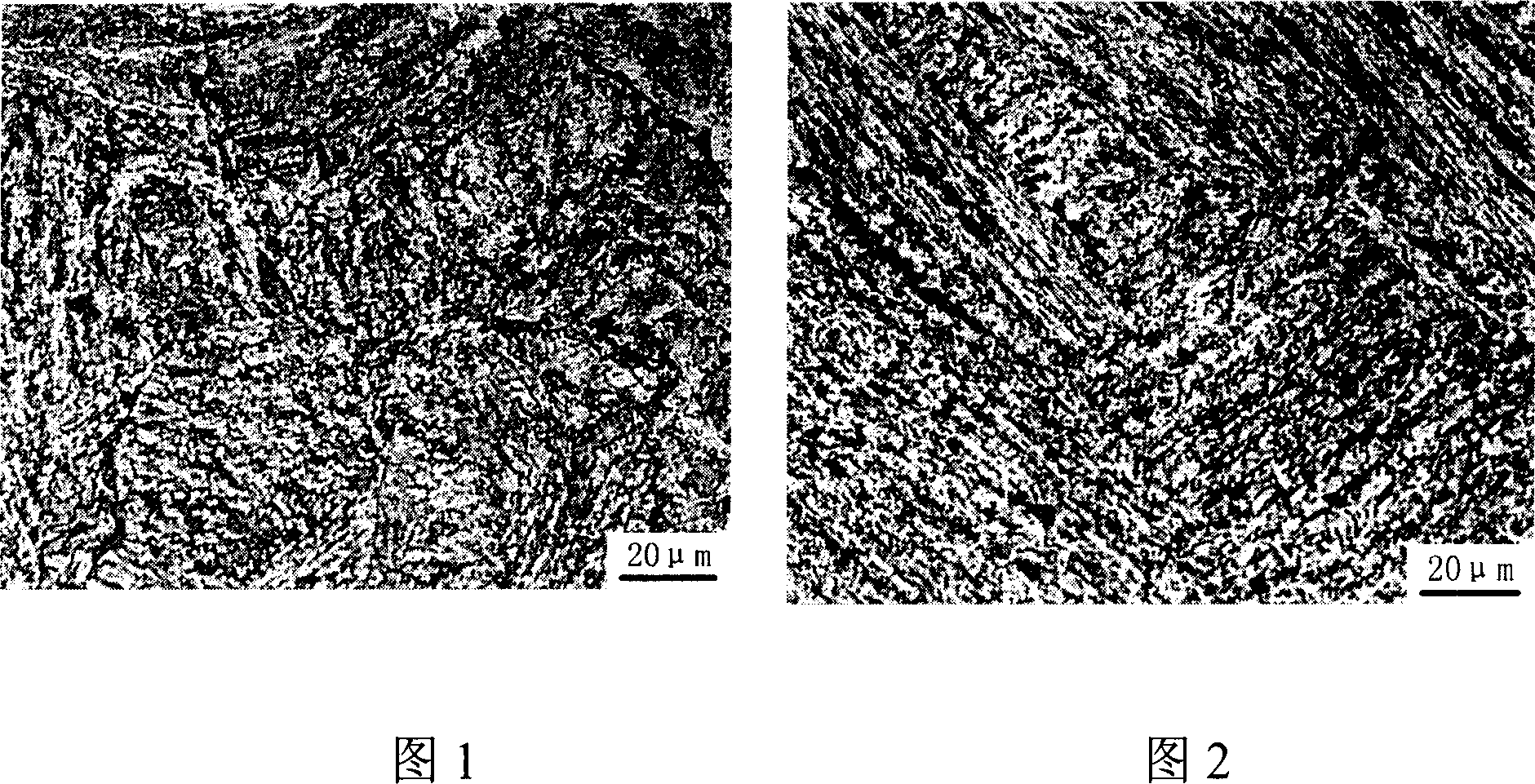

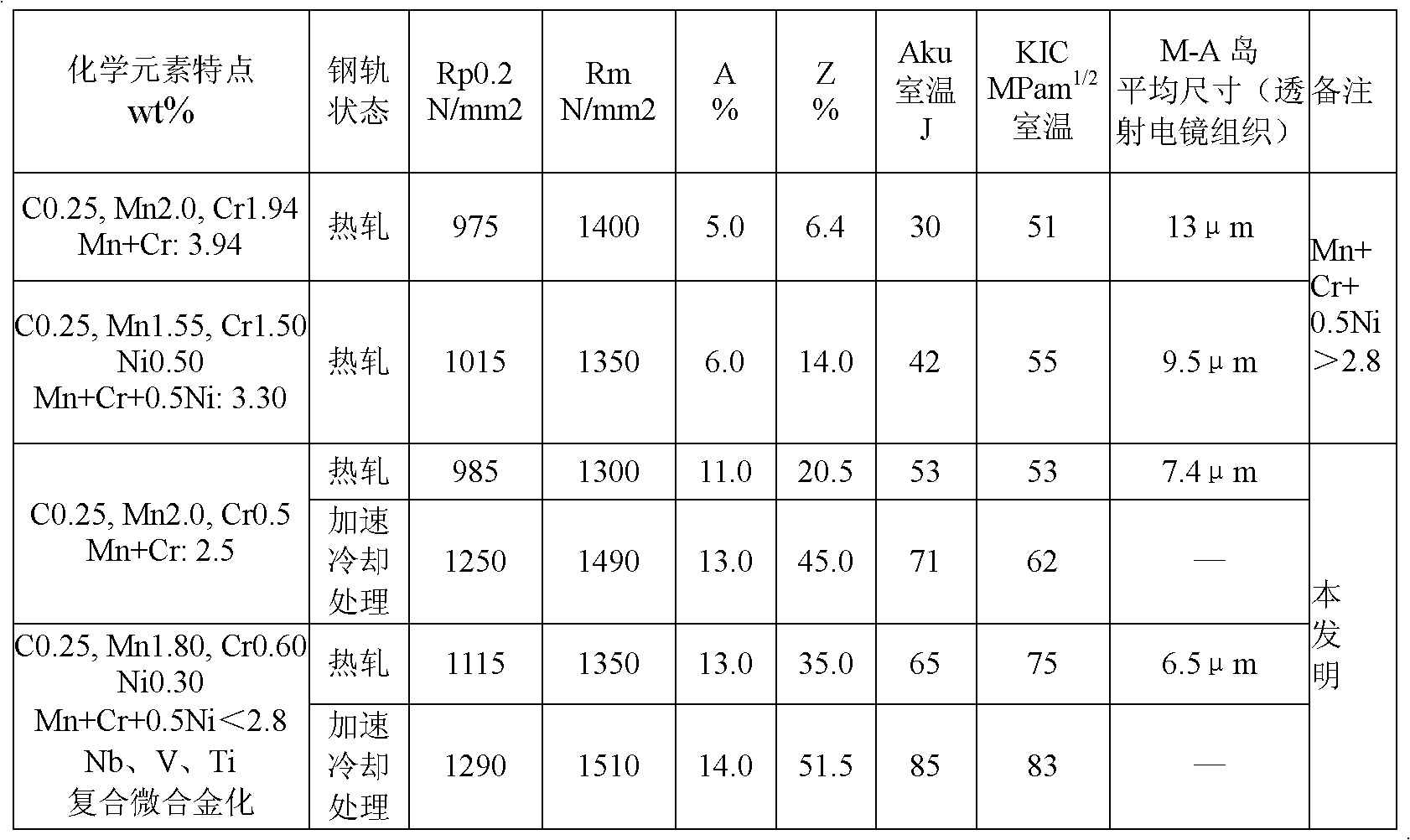

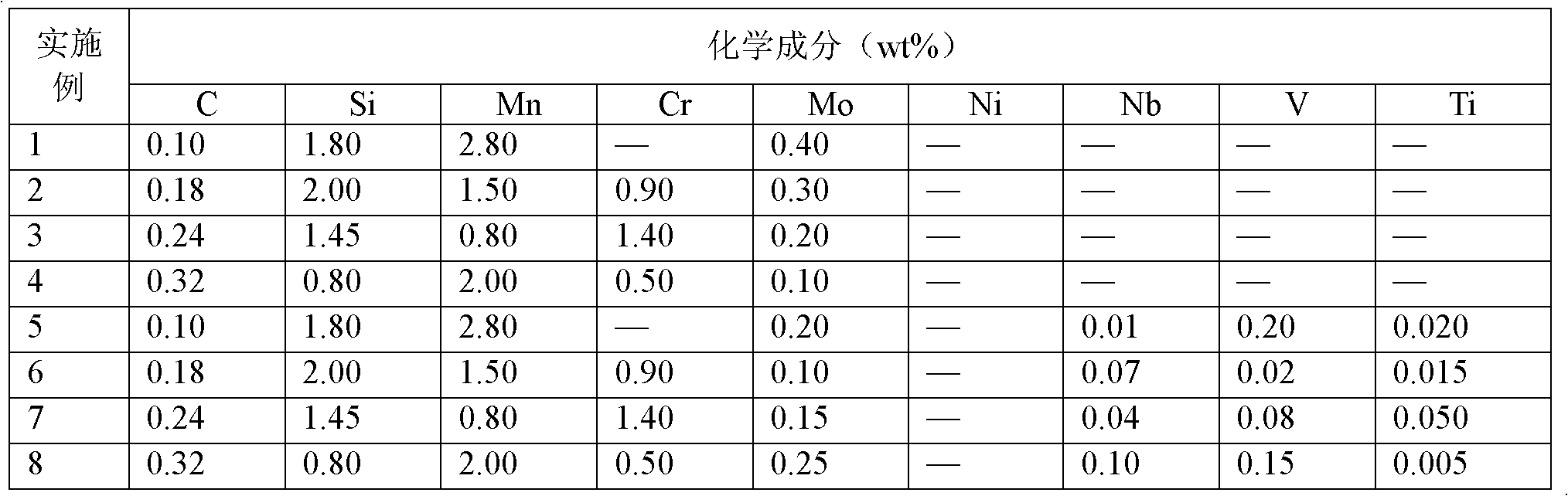

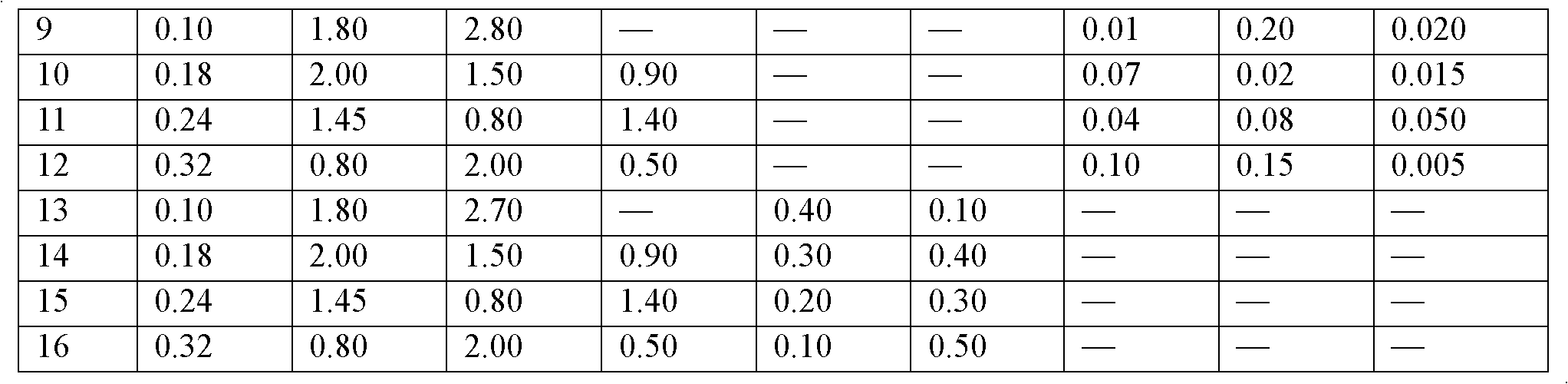

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

High-strength cold-rolled steel sheet excellent in workability and method for manufacturing the same

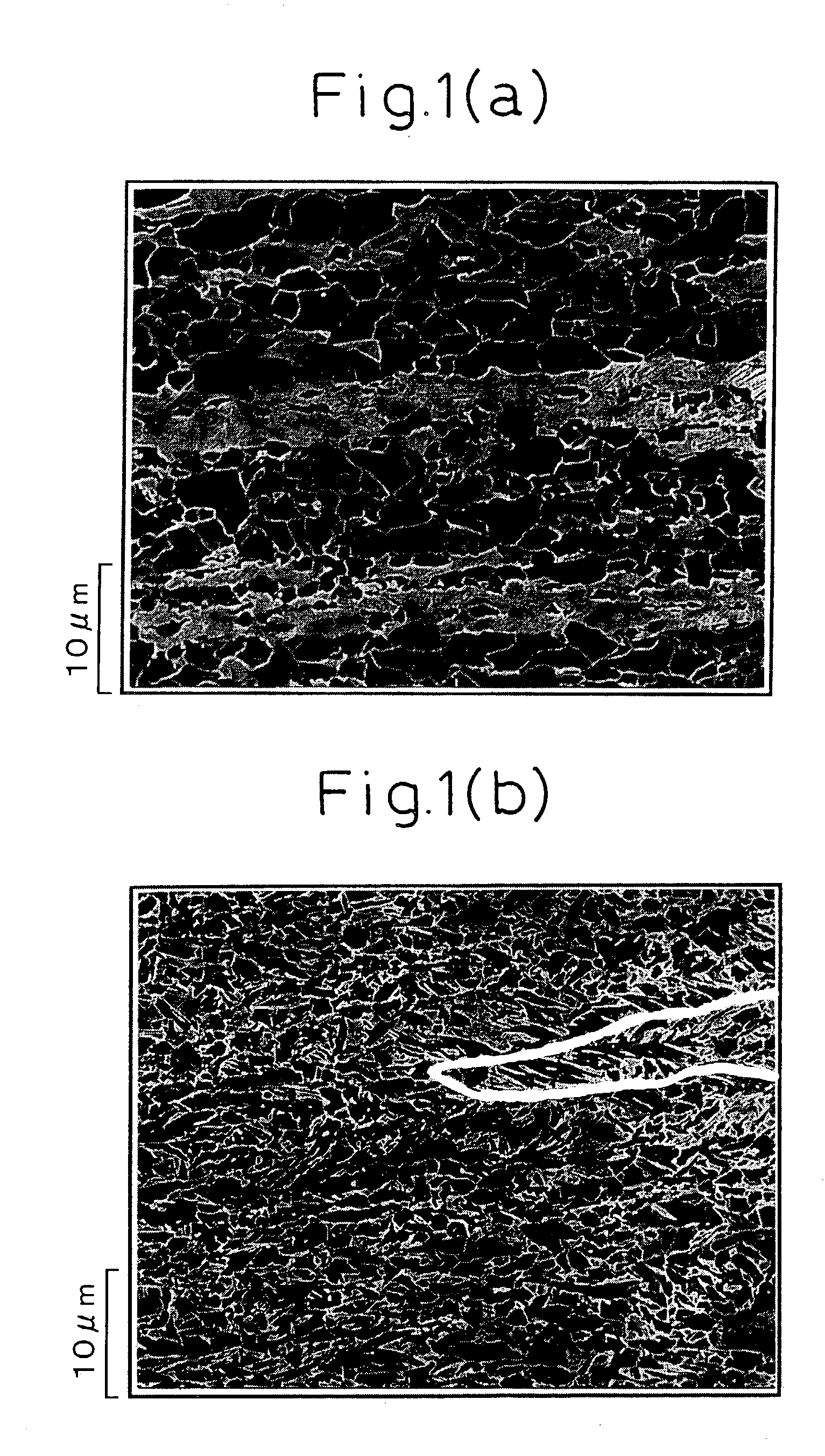

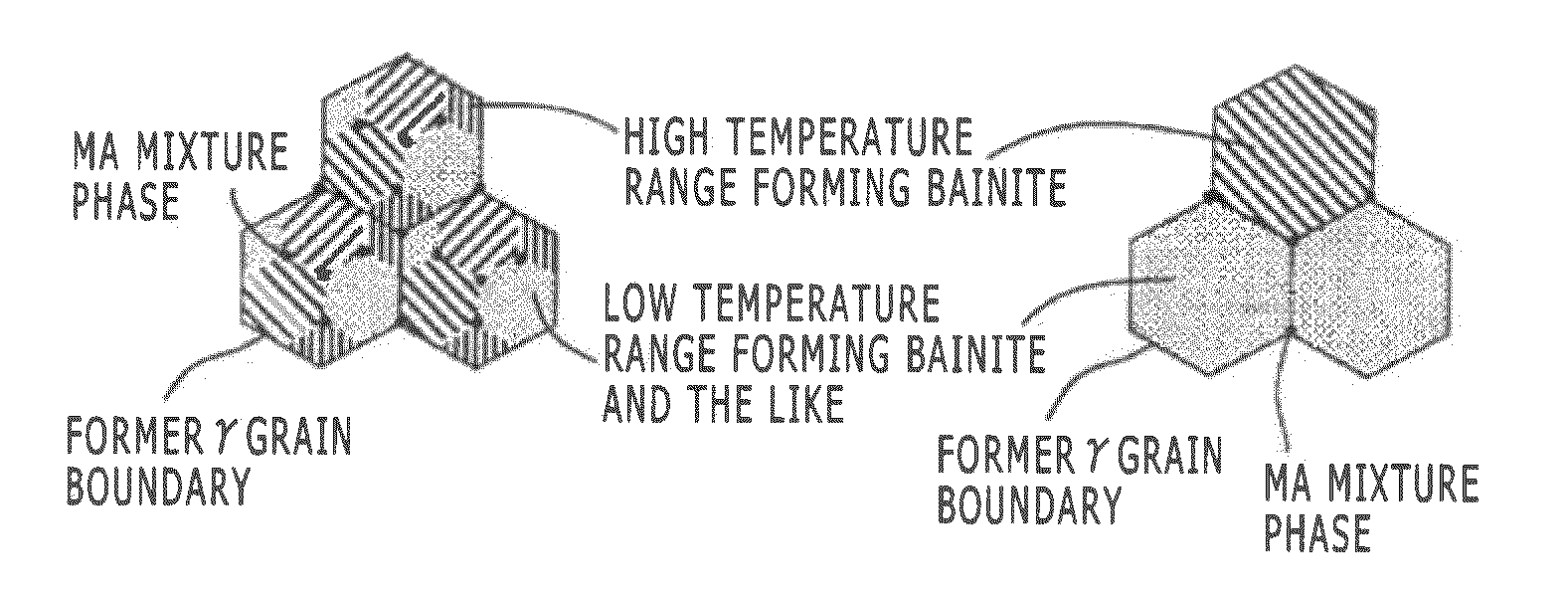

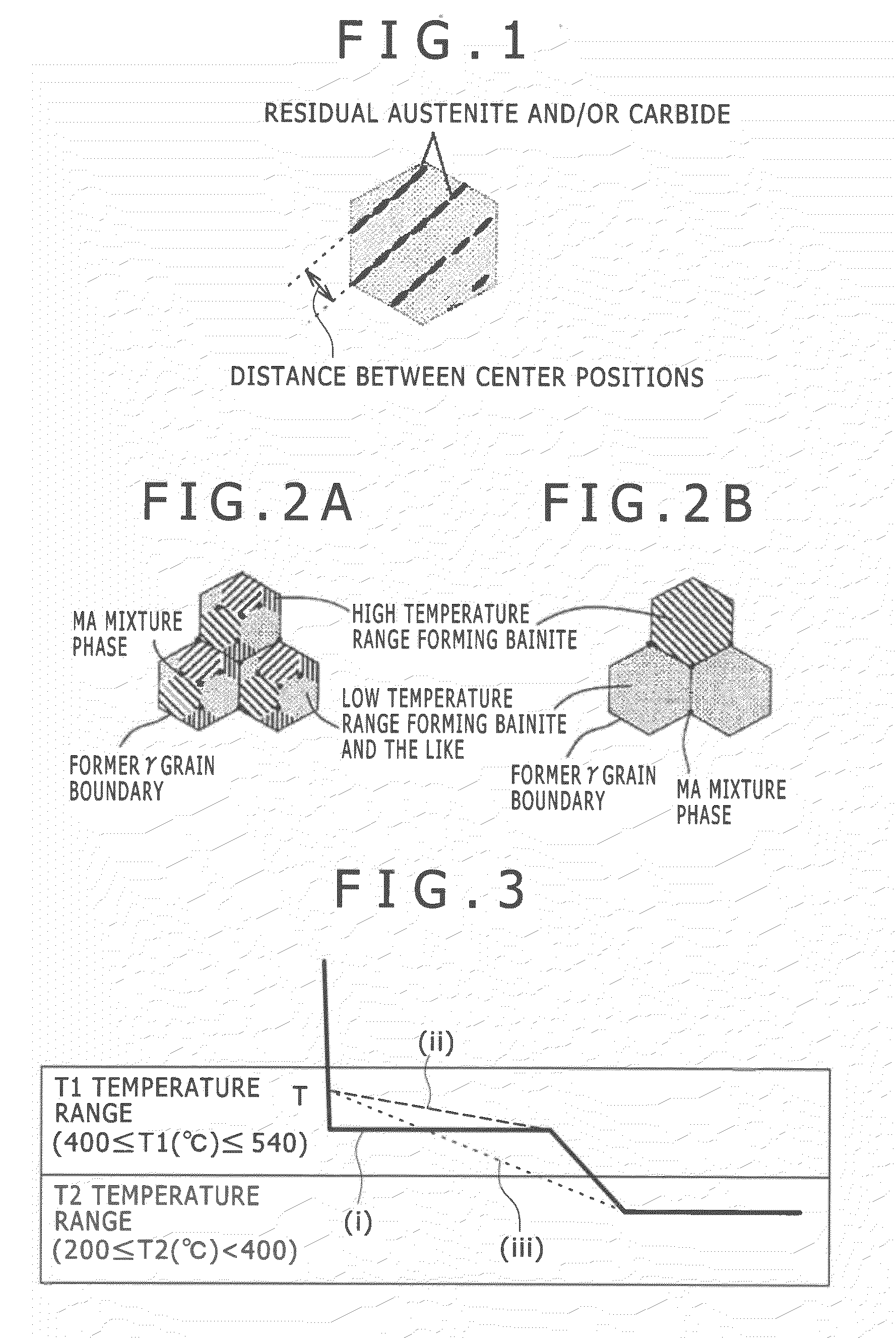

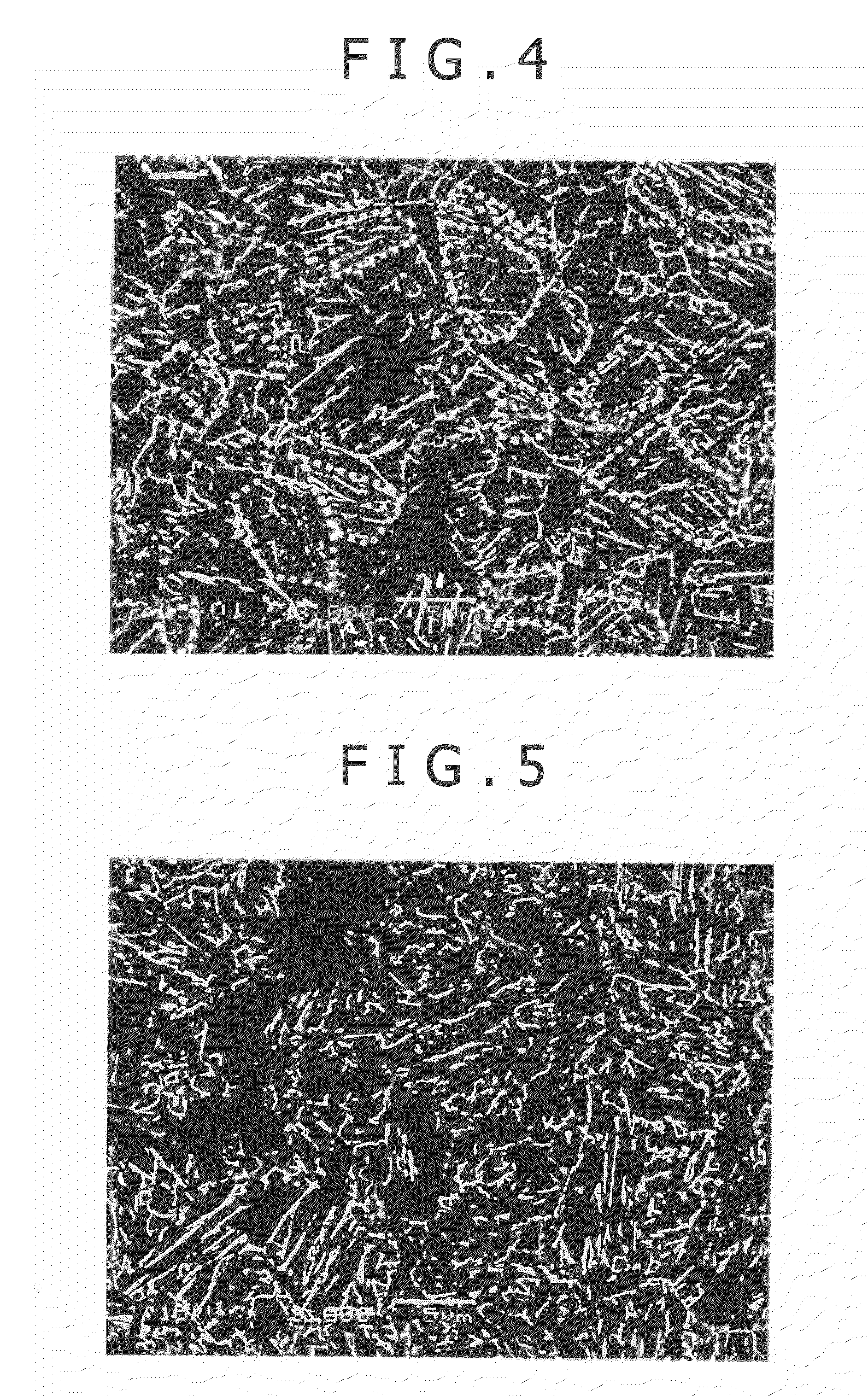

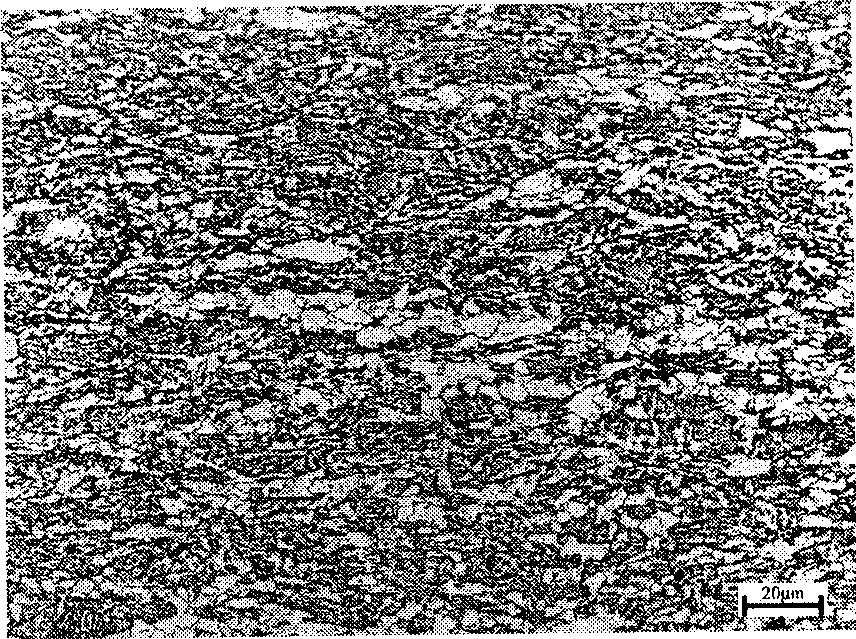

ActiveUS20110186189A1Improve machinabilityHigh strengthHot-dipping/immersion processesFurnace typesCarbideScanning electron microscope

In a cold-rolled steel sheet in relation with the present invention, metallurgical structure of the steel sheet is made a mixture structure including bainite, residual austenite and tempered martensite, particularly, when the metallurgical structure is observed with a scanning electron microscope, bainite is constituted of composite structure of high temperature range forming bainite with 1 μm or above average distance between neighboring residual austenite and / or carbide and low temperature range forming bainite with below 1 μm average distance between neighboring residual austenite and / or carbide, and when the area ratio of the high temperature range forming bainite with respect to total metallurgical structure is made a and the total area ratio of the low temperature range forming bainite and the tempered martensite with respect to the total metallurgical structure is made b, a: 20-80%, b: 20-80%, and a+b: 70% or above are satisfied. The cold-rolled steel sheet in relation with the present invention is improved in all of the elongation (EL), stretch flange formability (A), and bending properties (R) with a good balance, is excellent in the overall workability, and has 980 MPa or above tensile strength.

Owner:KOBE STEEL LTD

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

High-elongation cold-rolled TRIP (Transformation-Induced Plasticity) steel plate and preparation method thereof

InactiveCN102952996AHigh elongationLow costProcess efficiency improvementRoom temperatureHeating temperature

The invention discloses a high-elongation cold-rolled TRIP (Transformation-Induced Plasticity) steel plate, comprising 0.15-0.25% of C, 0.4-1.5% of Si, 0.5-2.5% of Mn, 0.04-0.10% of P, less than or equal to 0.02% of S, 0.02-0.5% of Al, less than or equal to 0.01% of N, 0-0.5% of Nb, 0-0.5% of V, 0-0.5% of Ti, 0-2% of Cr, 0-1% of Mo, and the balance of Fe and inevitable impurities, wherein in the microscopic structure, the area ratio of ferrite is 10-80%, while the area ratio of residual austenite is 3-20% and the area ratio of martensite is 0-20%, and the rest part is bainite; the hot rolling heating temperature is 1100-1250 DEG C, the heat preservation time is greater than or equal to 2 h, the rolling starting temperature is equal to or higher than 1100 DEG C, the final rolling temperature ranges from 850 to 950 DEG C, and the coiling temperature is lower than 720 DEG C; the hot-rolled plate is 2-4 mm thick; accumulated compression quantity of cold rolling is 40-80%; the annealing temperature is 700-(Ac3+50) DEG C, the heat preservation time is 30-360 s, the cooling rate is 10-150 DEG C / s, the aging temperature is 300-600 DEG C, the aging time is 30-1200 s and the cooling rate is 5-100 DEG C / s; and finally, cooling is performed until the temperature reaches the room temperature.

Owner:ANGANG STEEL CO LTD

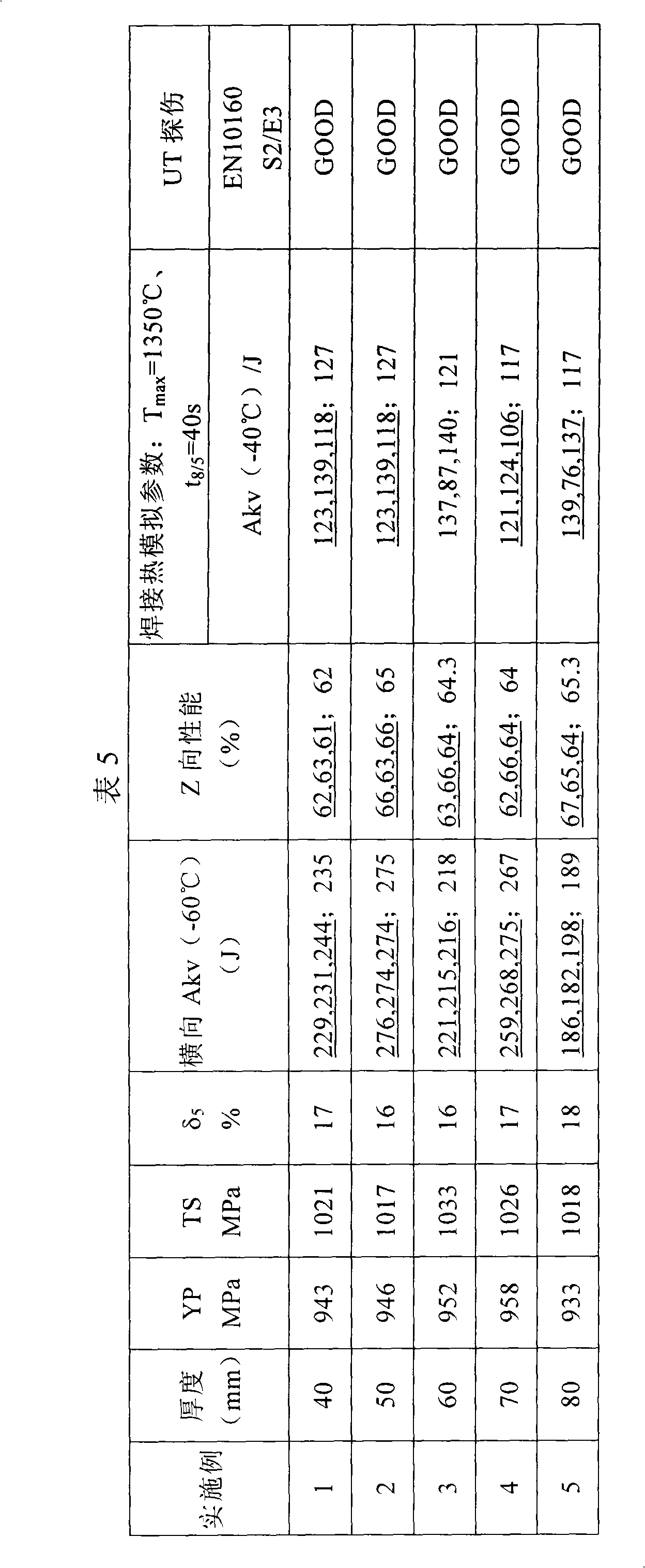

Excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity, and manufacturing method thereof

ActiveCN102337478ASimple welding processImprove stability and securityUltimate tensile strengthQuenching

The invention discloses an excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity, and a manufacturing method thereof. The excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity comprises: by weight, 0.09 to 0.15% of C, less than or equal to 0.10% of Si, 0.70 to 1.10% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0030% of S, 0.20 to 0.45% of Cu, 1.30 to 2.00% of Ni, 0.45 to 0.85% of Cr, 0.45 to 0.75% of Mo, 0.045 to 0.070% of Als, 0.008 to 0.025% of Nb, 0.030 to 0.060% of V, 0.004 to 0.010% of Ti, less than or equal to 0.0060% of N, 0.001 to 0.005% of Ca, 0.0006 to 0.0014% of B, and the balance Fe and unavoidable impurities. Through a technology (RQ+RQ+T) combining optimally controlled rolling and offline special conditioning, the excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity forms a microstructure composed of a fine tempered lower bainite and a tempered martensite, wherein an average size of druses is below 20 micrometers; tensile strength is great than or equal to 980MPa; yield strength is great than or equal to 890MPa; and single transverse Charpy impact energy (-60 DEG C) is great than or equal to 47J. Therefore, the excellent 100 kg-grade quenched and tempered steel plate with strong toughness and plasticity has excellent weldability and can solve the problem of over-quenching of a surface of a steel plate with ultra-high strength.

Owner:BAOSHAN IRON & STEEL CO LTD

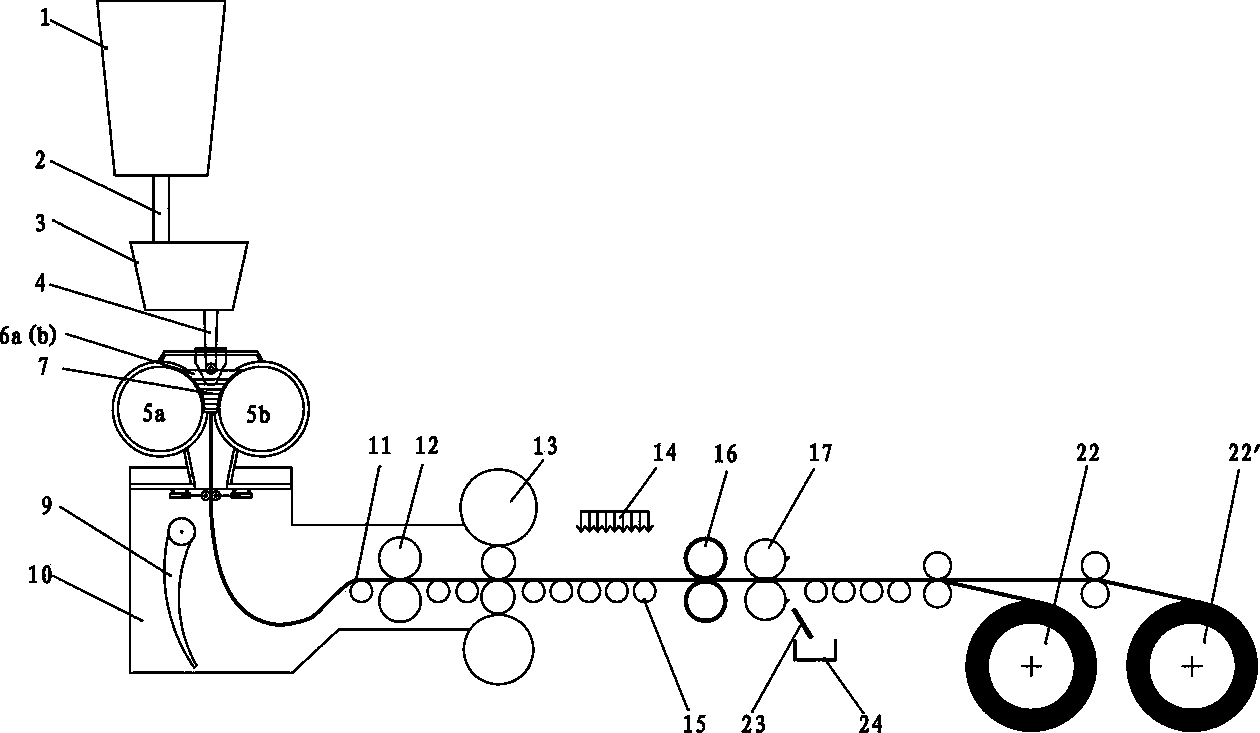

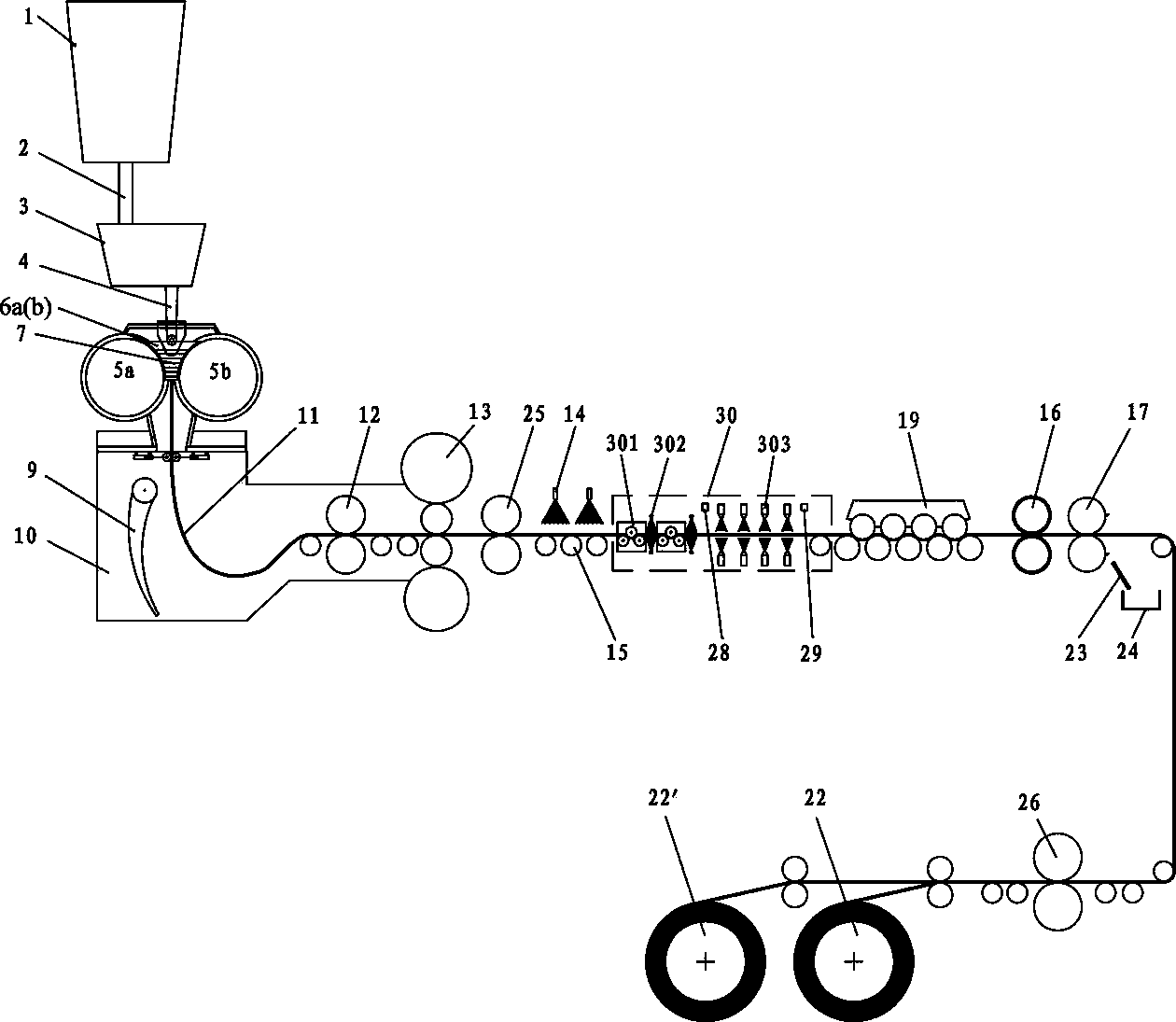

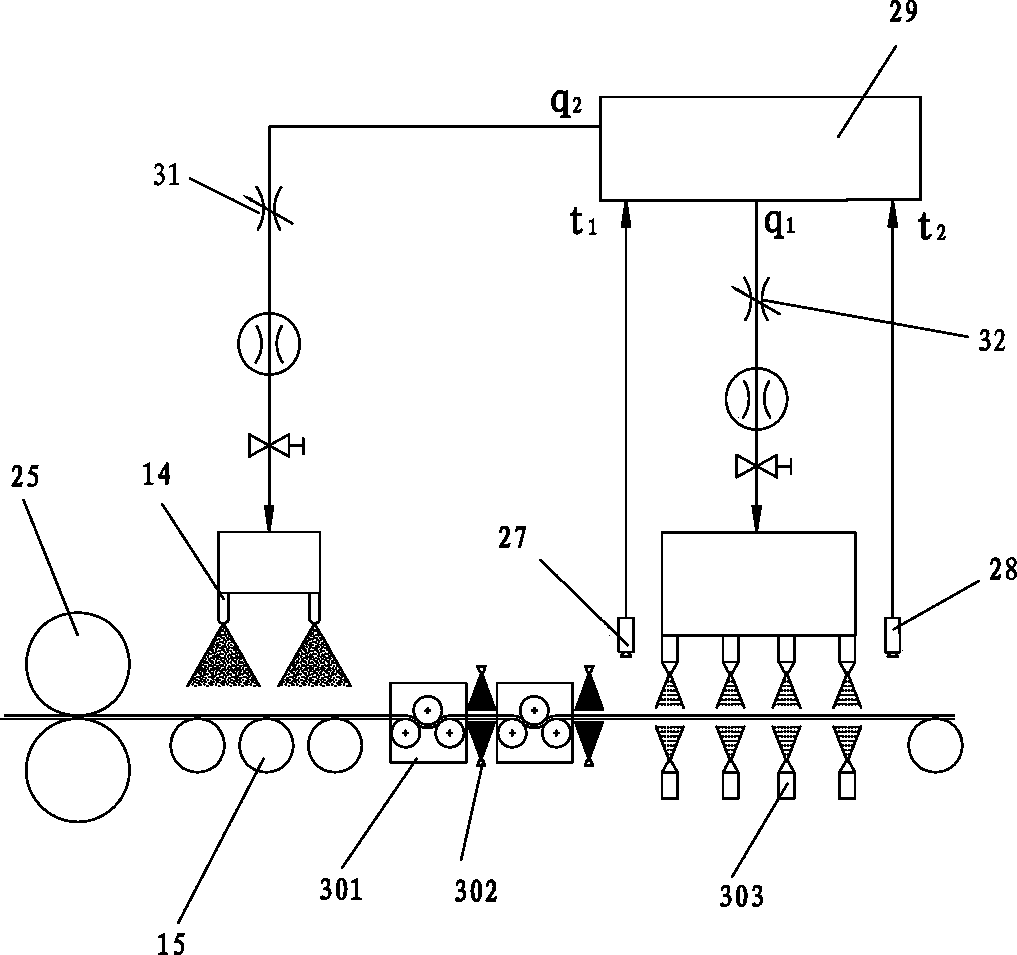

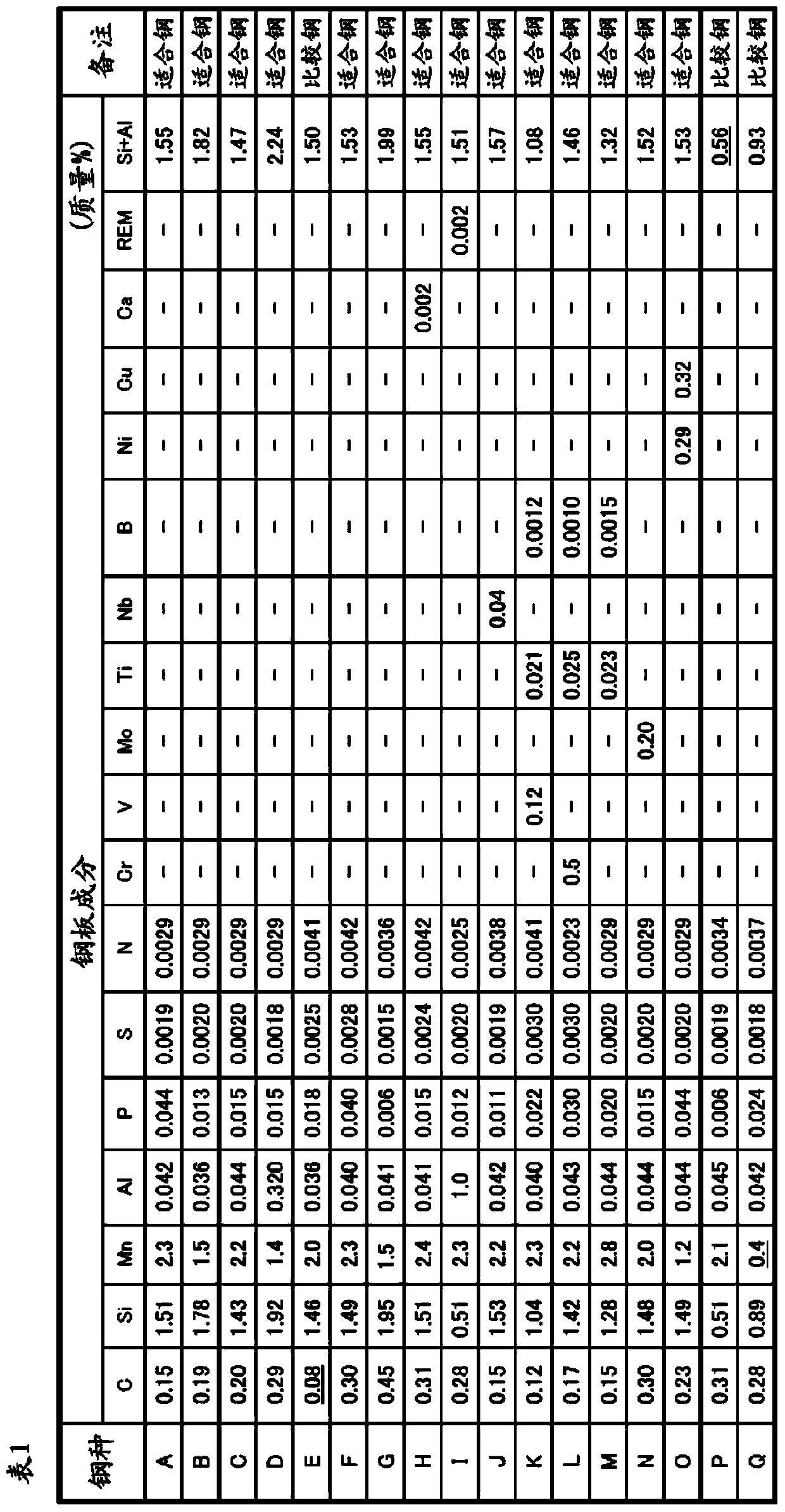

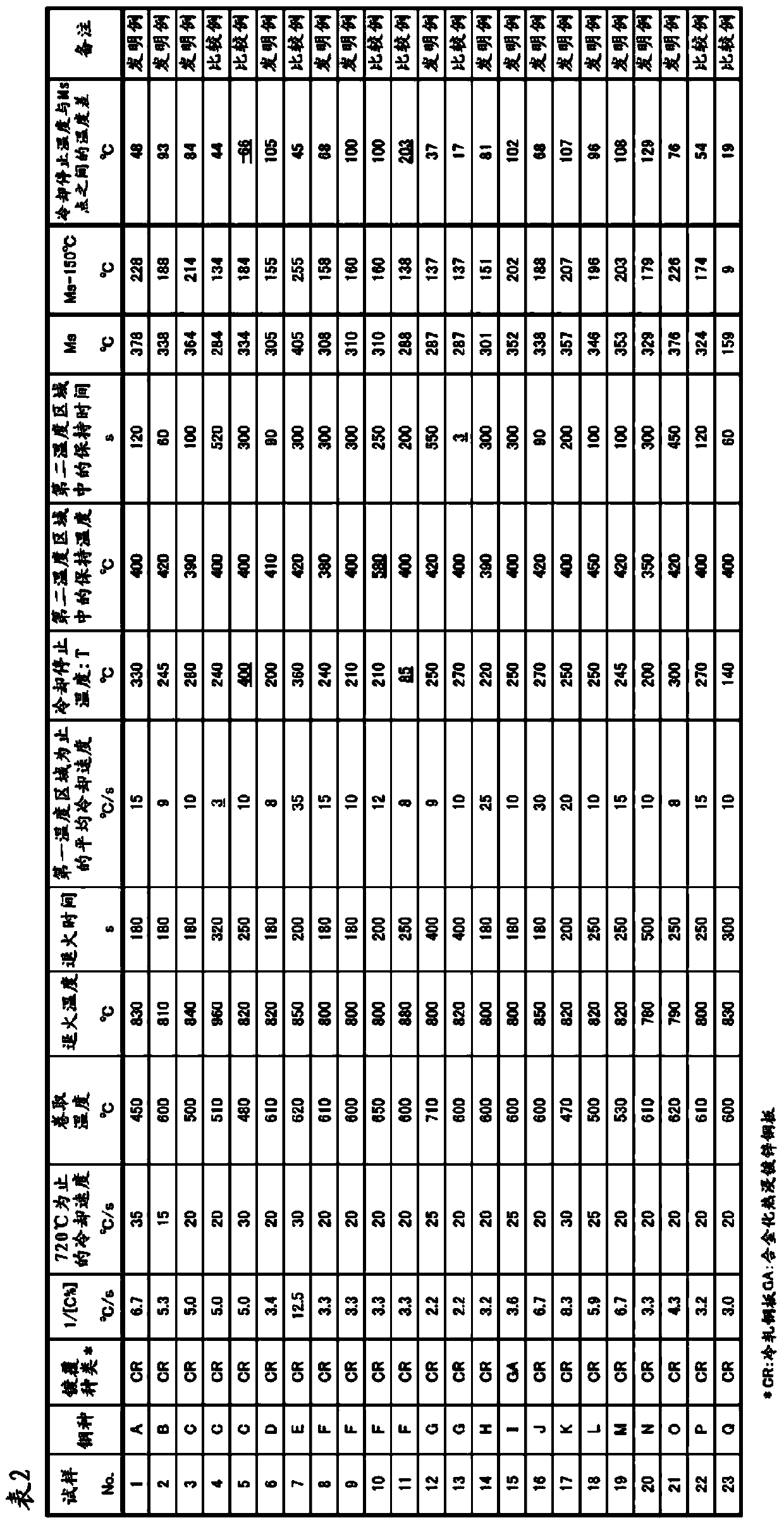

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength steel sheet and method for manufacturing same

ActiveCN103857819ALightweight is usefulImprove ductilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

According to the present invention, a predetermined steel component is included; a steel plate composition is made to have 5-70% of a martensite, 5-40% of a residual austenite, and 5% or more of a bainitic ferrite in an upper bainite, by area in relation to the entire steel plate composition; the total area of the martensite, the residual austenite, and the bainitic ferrite is made to be 40% or more; 25% or more of the martensite is made to be tempered martensite; the area of a polygonal ferrite in relation to the entire steel plate composition is more than 10% and less than 50%, and the average grain size thereof is made to be 8 mum or less; and when a group of ferrite grains comprising adjacent polygonal ferrite grains is made to be a polygonal ferrite grain group, the average diameter thereof is 15 mum or less, the average amount of C in the residual austenite is made to be 0.70 mass% or more, and the tensile strength is made to be 780 MPa or more; whereby it is possible to obtain a high-strength press member having excellent ductility and stretch flangeability, as well as a tensile strength of 780-1400 MPa.

Owner:JFE STEEL CORP

Method for displaying and quantitatively determining retained austenite or island martensite- austenite in TRIP steel

InactiveCN101382494AEasy extractionImprove accuracyMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationObject structureTRIP steel

The invention relates to a display and quantitative detection method of residual austenite or island martensite-austenite (MA island for short) in TRIP steel. The method comprises the steps: (1) a TRIP tapping sample is prepared into a metallographic specimen; (2) after grinding and polishing, the metallographic specimen is light etched for 5 to 8 seconds in Nital of 1 to 3 percent by weight, and water is sprinkled on a flannel polishing disk for 1 to 2 seconds; sodium pyrosulfite water solution of 1 to 3 percent by weight and picral of 2 to 6 percent by weight are mixed by volume ratio of 1:1 to prepare corrosive liquid, then the metallographic specimen is put into the corrosive liquid for etching of 55 to 65 seconds; (3) the structure of the TRIP steel is observed under a metallurgical microscopy: the delta ferrite is minus blue, the residual austenite or MA island is white, and bainite is brownish-black; and (4) each phase in the structure is carried out quantitative analysis. The method presents different colors, each phase of structure has distinct layers which are easy to distinguish; and a quantitative image analysis method is utilized to fix amount of the feature object structure, which is objective and accurate and has good repeatability.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Bainite/martensite steel rail with 1,500 Mpa level of high toughness and manufacturing method thereof

The invention provides a bainite / martensite steel rail and a manufacturing method thereof. The steel rail is formed by performing steel hot rolling on the following components in percentage by weight: 0.10 to 0.40 percent of C, 0.80 to 2.00 percent of Si, 1.20 to 2.40 percent of Mn, 0.50 to 1.20 percent of Cr, 0.20 to 0.60 percent of Mo, and the balance of Fe and inevitable impurities. The steel rail comprises a rail head, a rail waist and a rail bottom, wherein the rail head is subjected to accelerated cooling at a cooling speed of higher than 1 DEG C / s and lower than and equal to 5 DEG C / s to an accelerated cooling stop temperature of lower than 300 DEG C and higher than 200 DEG C.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

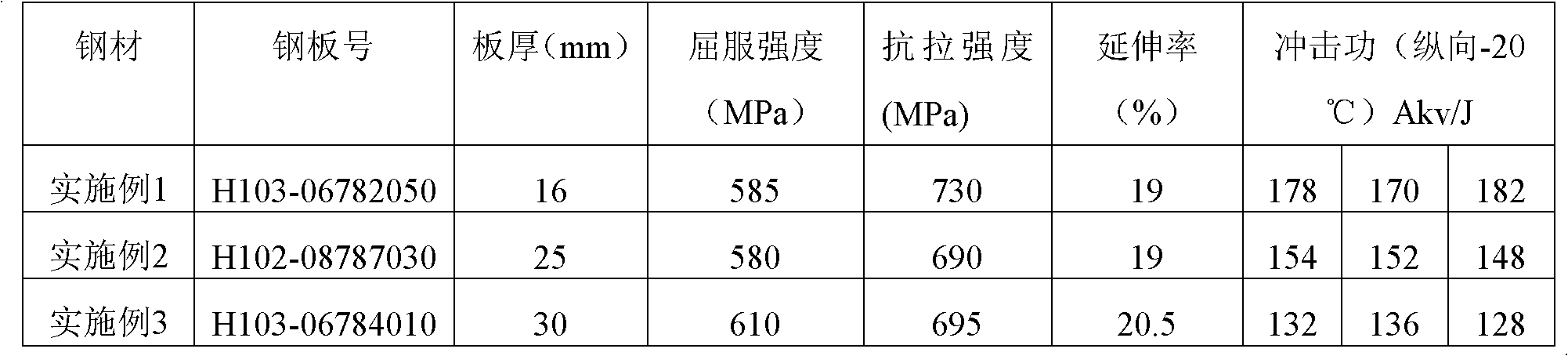

High-performance low-carbon bainite construction steel and producing method thereof

InactiveCN101168826AHigh strengthImprove toughnessTemperature control deviceHeat treatment process controlTemperature controlWeather resistance

The invention provides a high-performance low-carbon bainitic structural steel, the chemical composition of which is: C: 0.04% to 0.07%, Si: 0.20% to 0.50%, Mn: 1.50% to 1.80%, Nb: 0.03% to 0.06% %, Ti: 0.005% to 0.030%, Cr: 0.25% to 0.50%, Cu: 0.30% to 0.60%, Ni: 0.20% to 0.50%, Als: 0.010% to 0.070%, and the balance is Fe and unavoidable Impurities. The rolling process adopts TMCP+RPC process, the heating temperature before rolling is 1050-1220°C, two-stage controlled rolling is adopted, the rolling temperature in the recrystallization zone is controlled at ≥1000°C, and the rolling temperature in the non-recrystallization zone is controlled at 950°C~ (Ar3+0°C~100°C), the cumulative rolling deformation in the non-recrystallized area is greater than 50%, relax for 10-120s after rolling, and then accelerate cooling, the end cooling temperature is 380-530°C, and then air-cooled. The invention has low cost, does not need complex heat treatment, can obtain bainite structure without quenching and tempering, has high strength, high toughness, and good welding and weather resistance.

Owner:ANGANG STEEL CO LTD +1

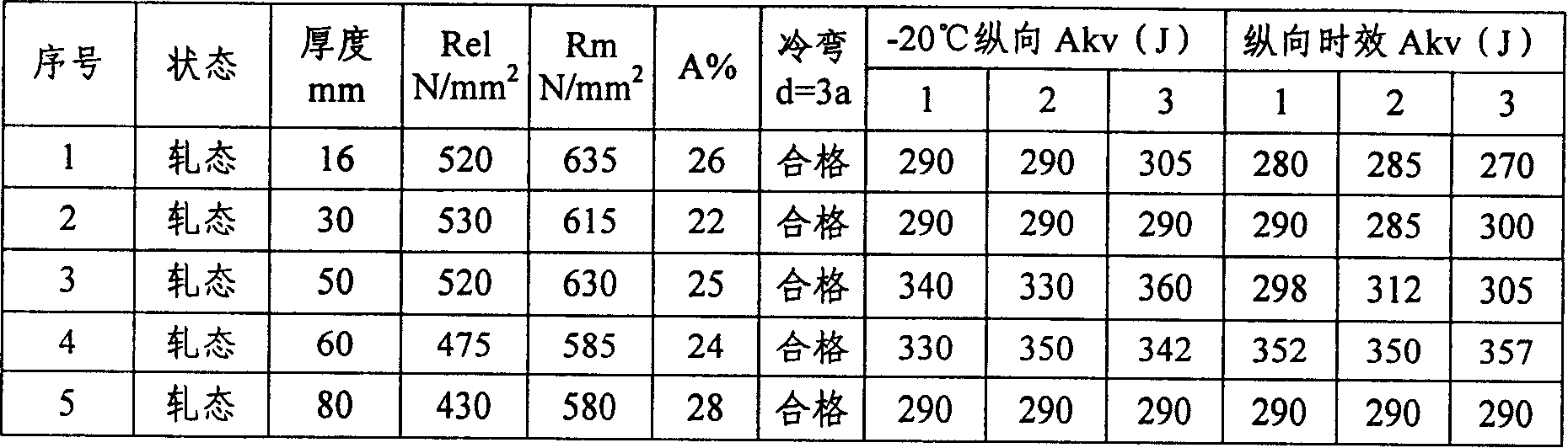

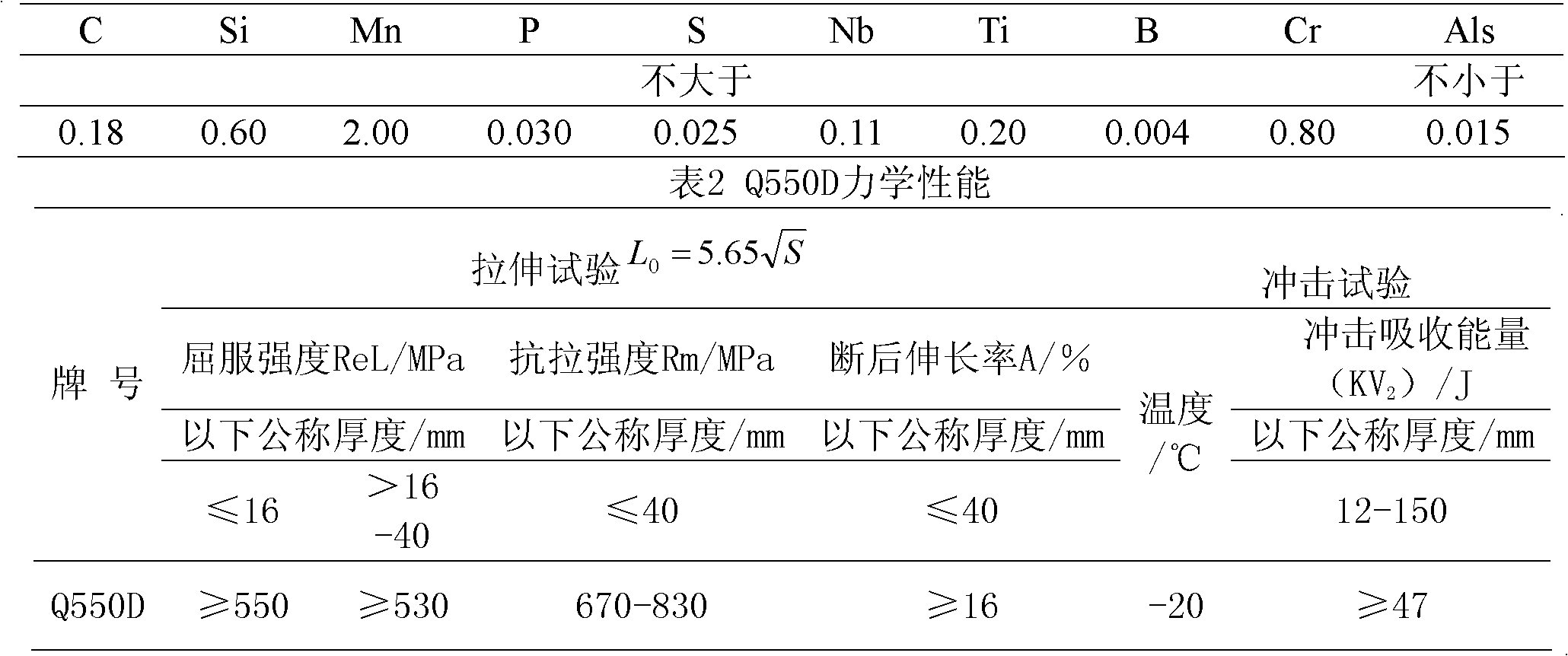

550Mpa yield-strength low-carbon bainitic steel for engineering machinery and preparation method thereof

The invention relates to a low-carbon bainitic steel for engineering machinery, which is prepared from the following chemical components in percentage by weight: 0.05-0.10% of C, 0.20-0.50% of Si, 1.50-1.80% of Mn, at most 0.010% of S, at most 0.018% of P, at most 0.10% of Nb, at most 0.10% of Mo, 0.010-0.040% of Ti, 0.0010-0.0030% of B, 0.20-0.50% of Cr, 0.015-0.050% of Al and the balance of Fe and trace impurity. The existing equipment is utilized; molten iron pretreatment, reblowing converter smelting, LF (ladle furnace) refining, RH refining, and plate blank continuous casting are carried out; and the contents of part of elements are adjusted, microalloying treatment, TMCP (thermomechanical rolling process) production, controlled rolling and water cooling are carried out, and no heat treatment is required, thereby obtaining the bainitic steel for engineering machinery, which has the advantages of high strength and favorable low-temperature toughness. The bainitic steel for engineering machinery is widely used in the fields of engineering machinery manufacturing and the like, such as large-size load-bearing steel structures, large-size earth mover, autocranes, excavators, mining machines, hydraulic supports, electric wheel dump trucks, mine cars and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com