Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3335results about "Work treatment devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

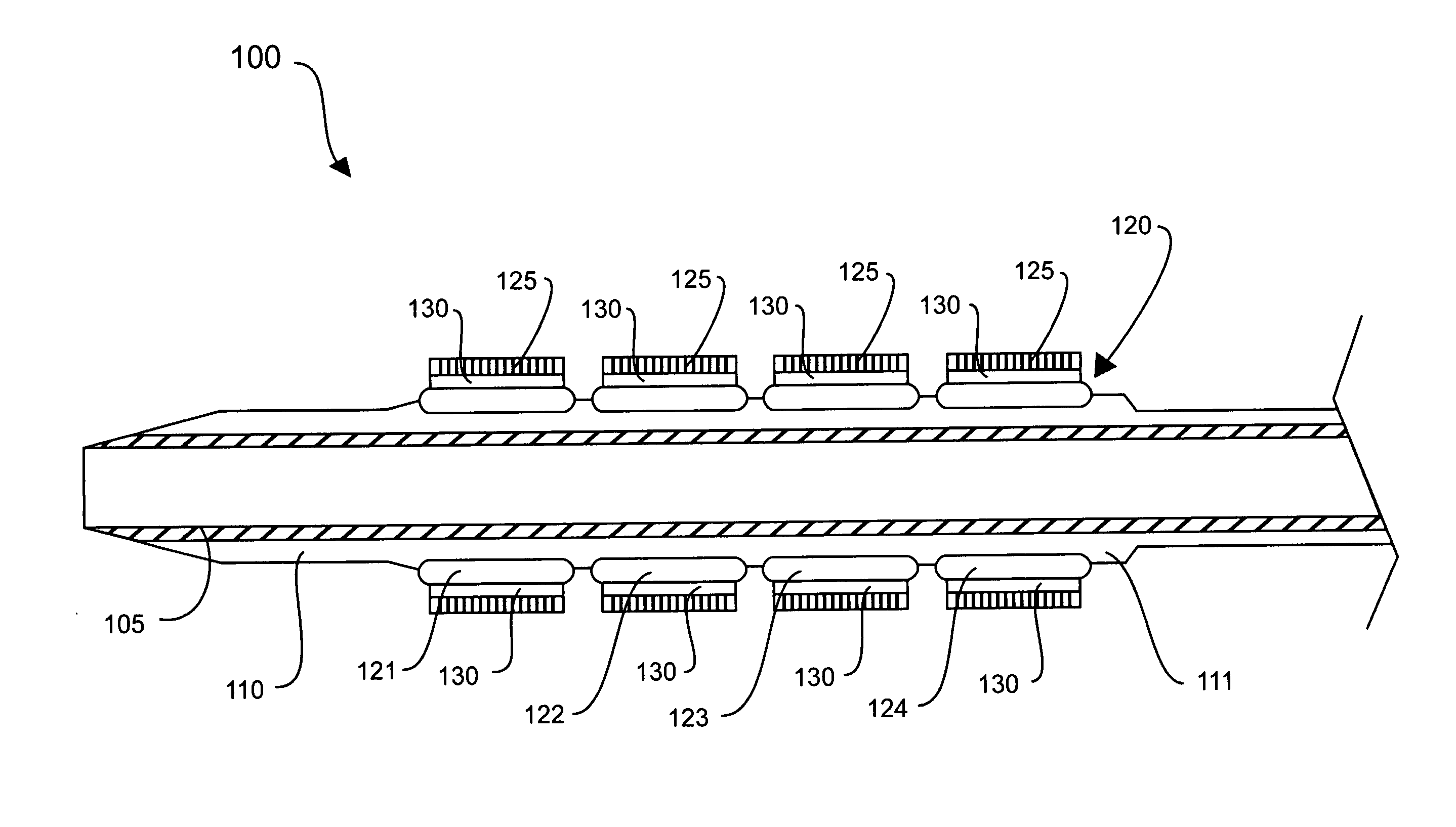

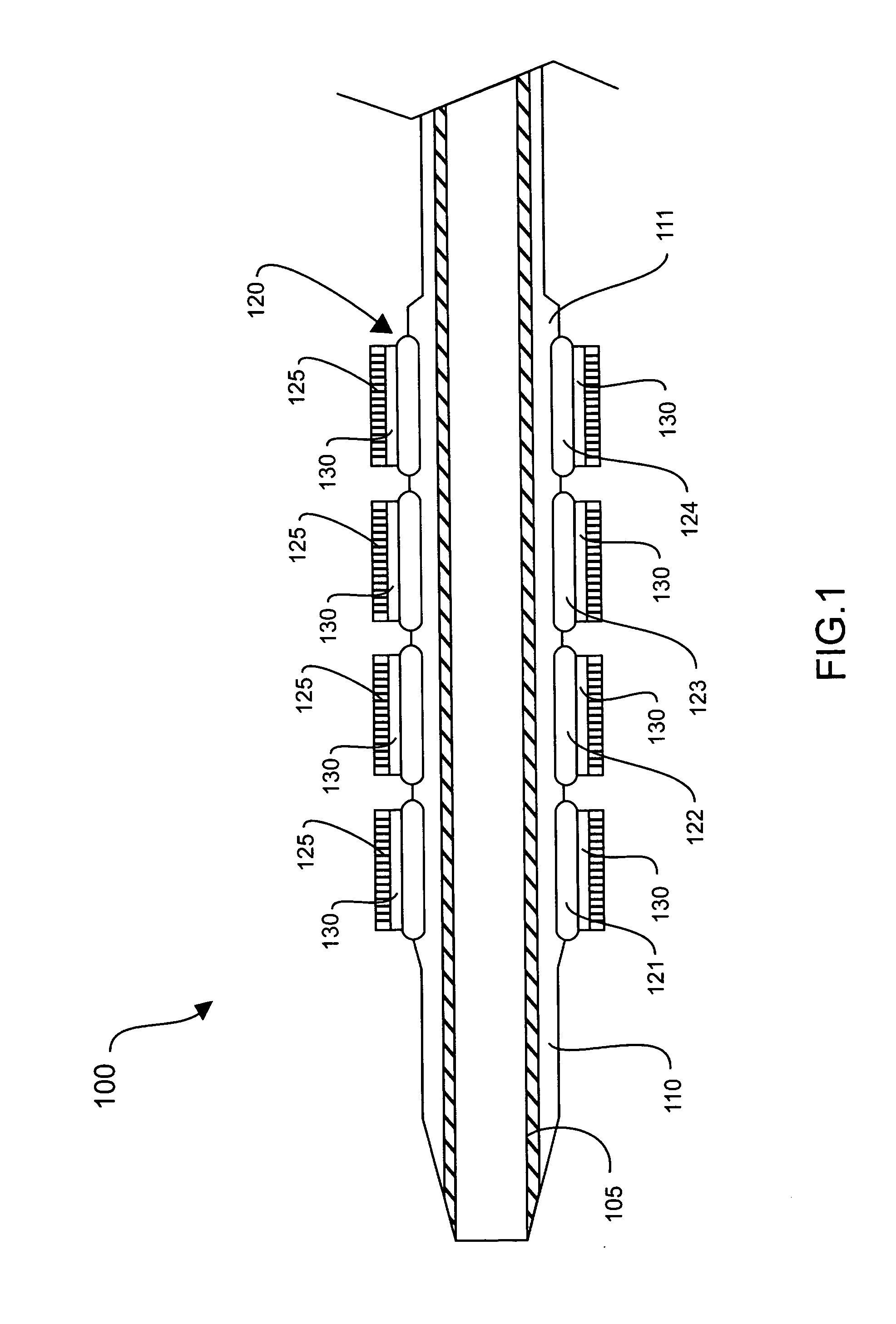

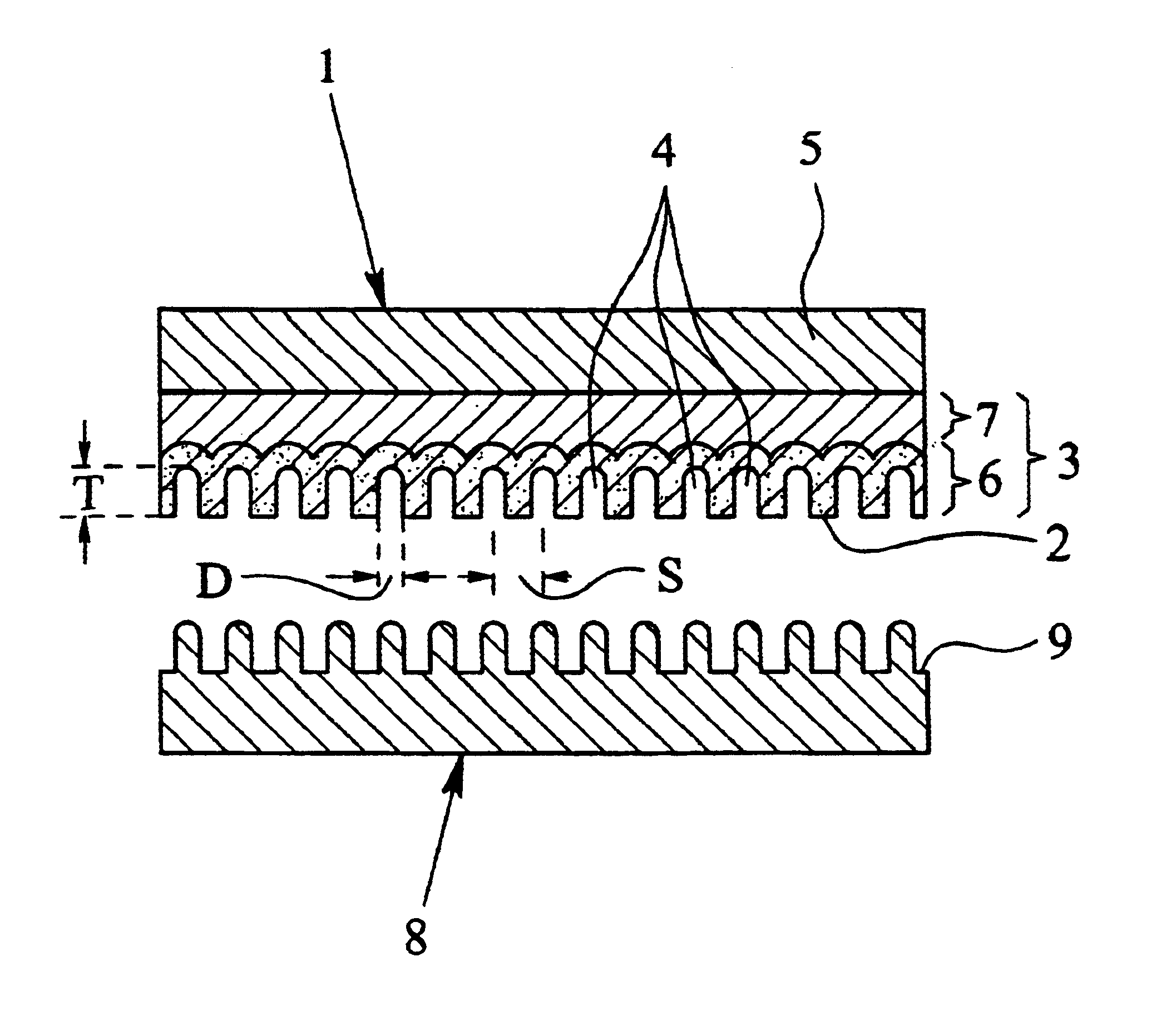

Stent with improved drug loading capacity

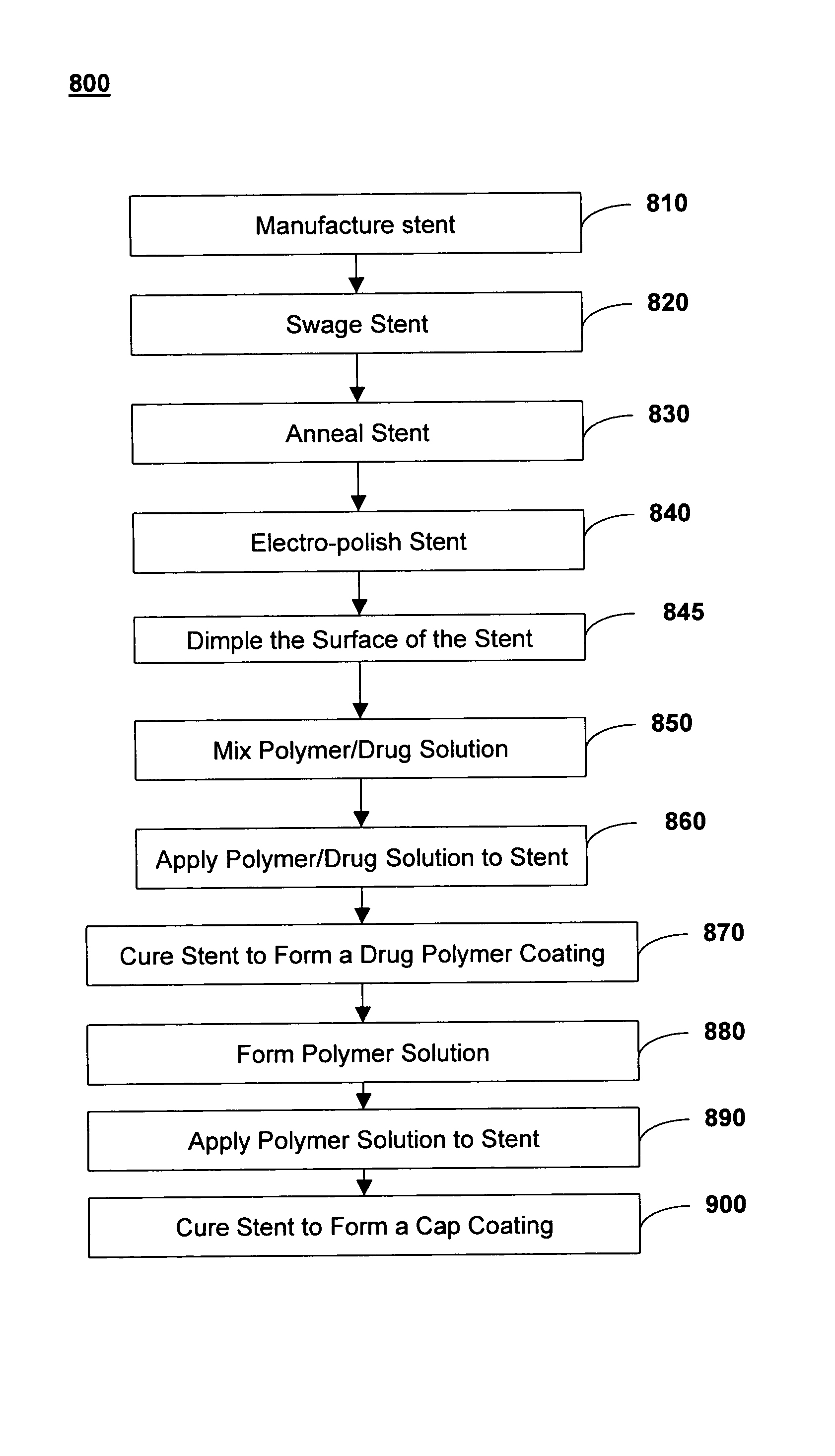

The present invention provides a method of forming a drug eluting stent, the method comprising coupling a stent framework to a mandrel, inserting the mandrel with stent framework into an open die, the die including a forming surface including a plurality of raised indention forming portions; closing the die against the stent framework; pressing the raised indention portions into the stent framework to form indentions in the stent framework; and inserting at least one drug polymer into the indentions formed in the stent framework.

Owner:MEDTRONIC VASCULAR INC

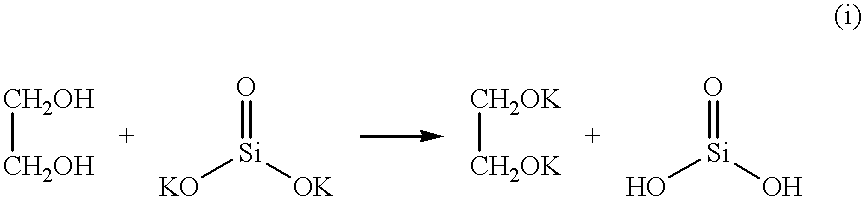

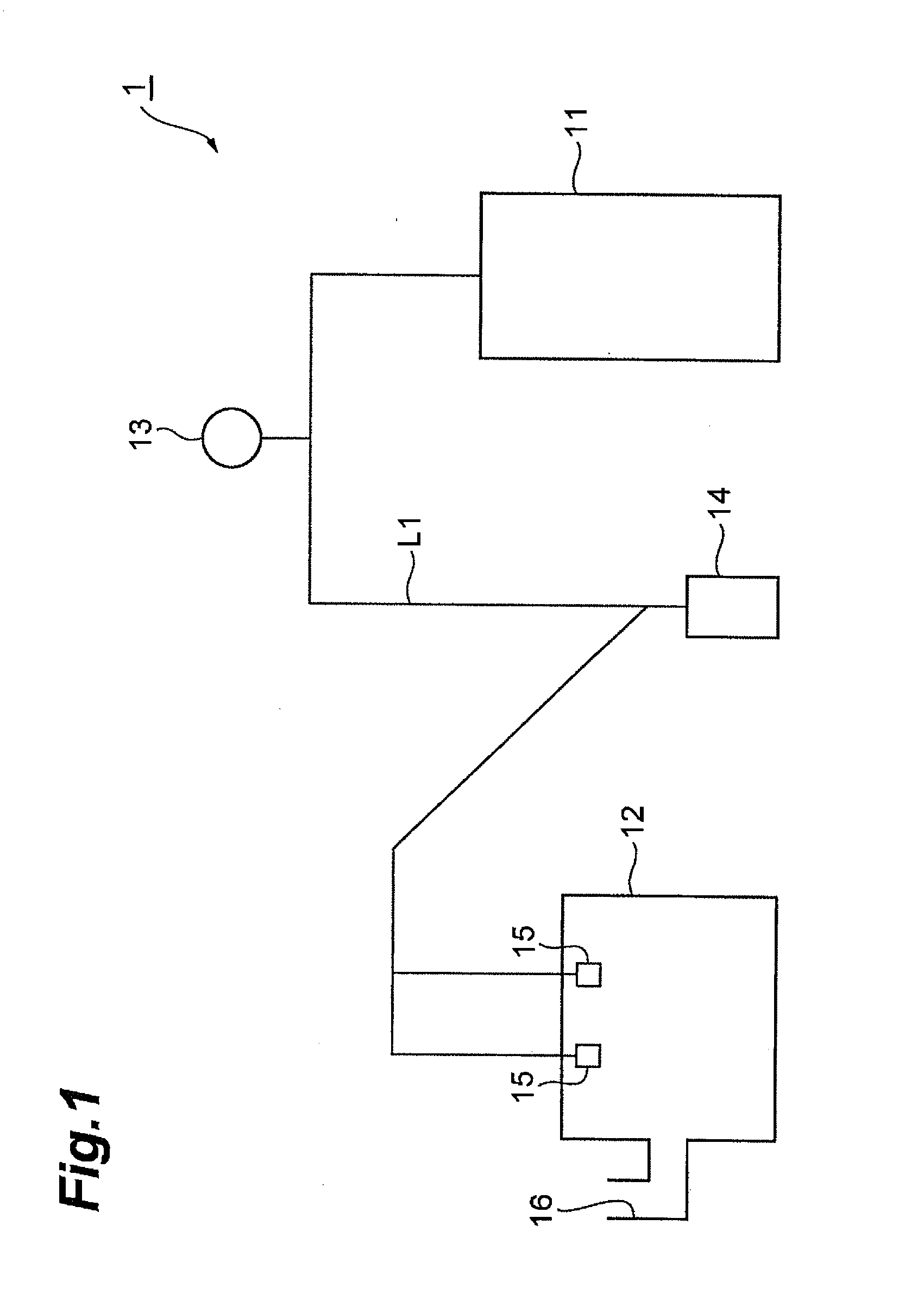

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

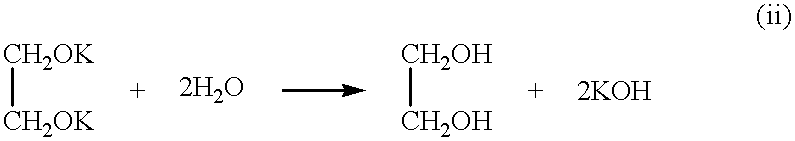

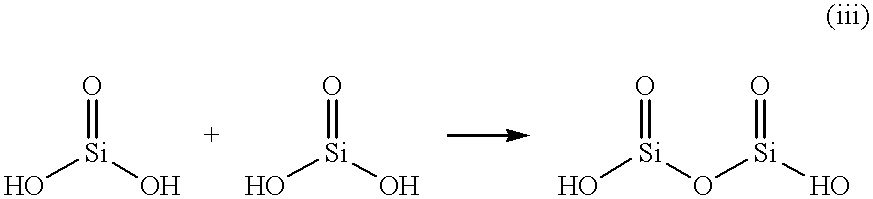

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

Composition and process for lubricated plastic working of metals

InactiveUS6455476B1Work treatment devicesMetallic material coating processesInorganic saltsPhosphate

A lubricant composition for the plastic working of metals that does not require a phosphate undercoating, is waterborne, requires only a simple application process of immersion or spraying followed by drying, and provides an excellent lubricating performance comprises synthetic resin, water-soluble inorganic salt, and water. The weight ratio of the content of salt to that of synthetic resin is from 0.25:1 to 9: 1. This composition can also contain liquid and / or solid lubricating agent(s) and an extreme pressure additive.

Owner:HENKEL KGAA

Warming and nonirritating lubricant compositions and method of comparing irritation

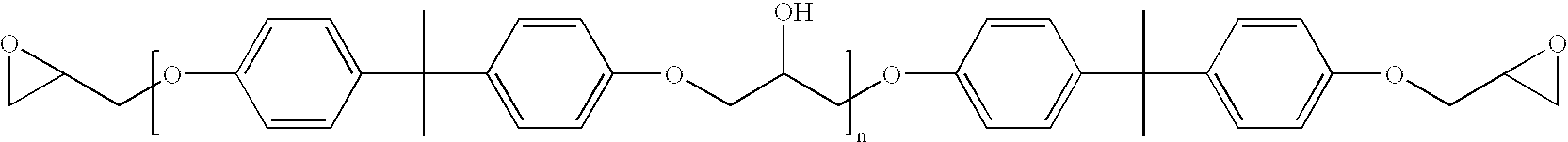

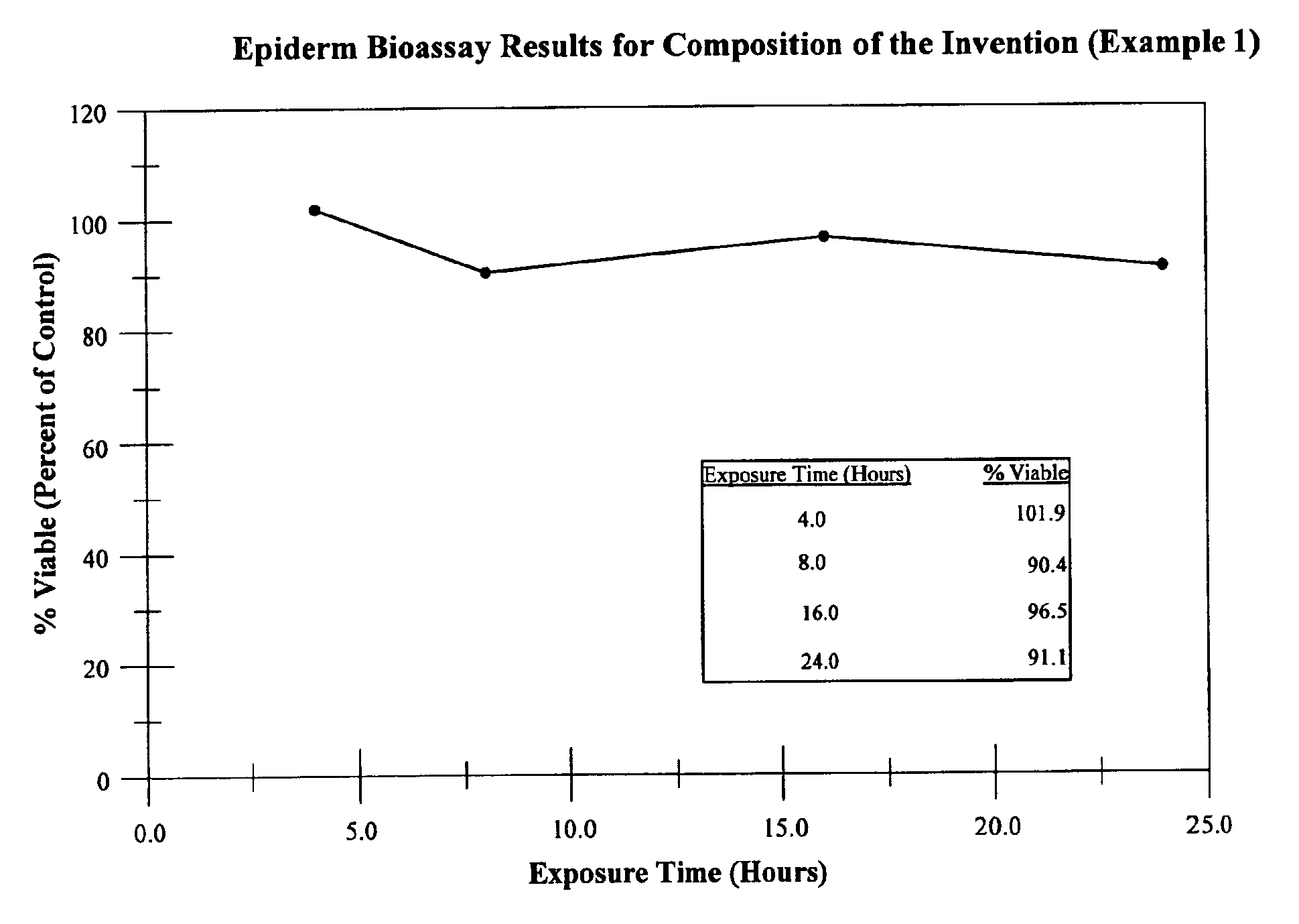

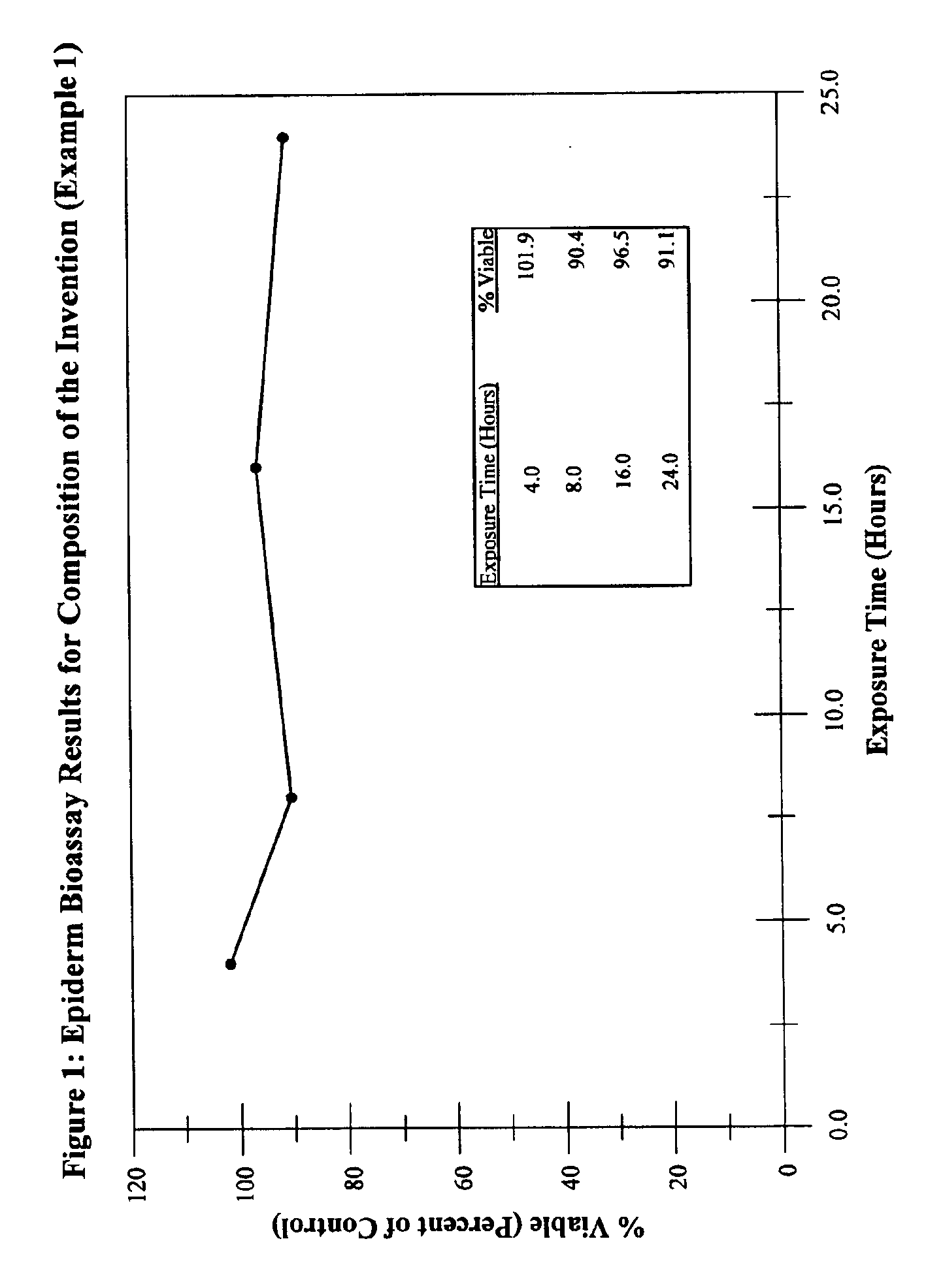

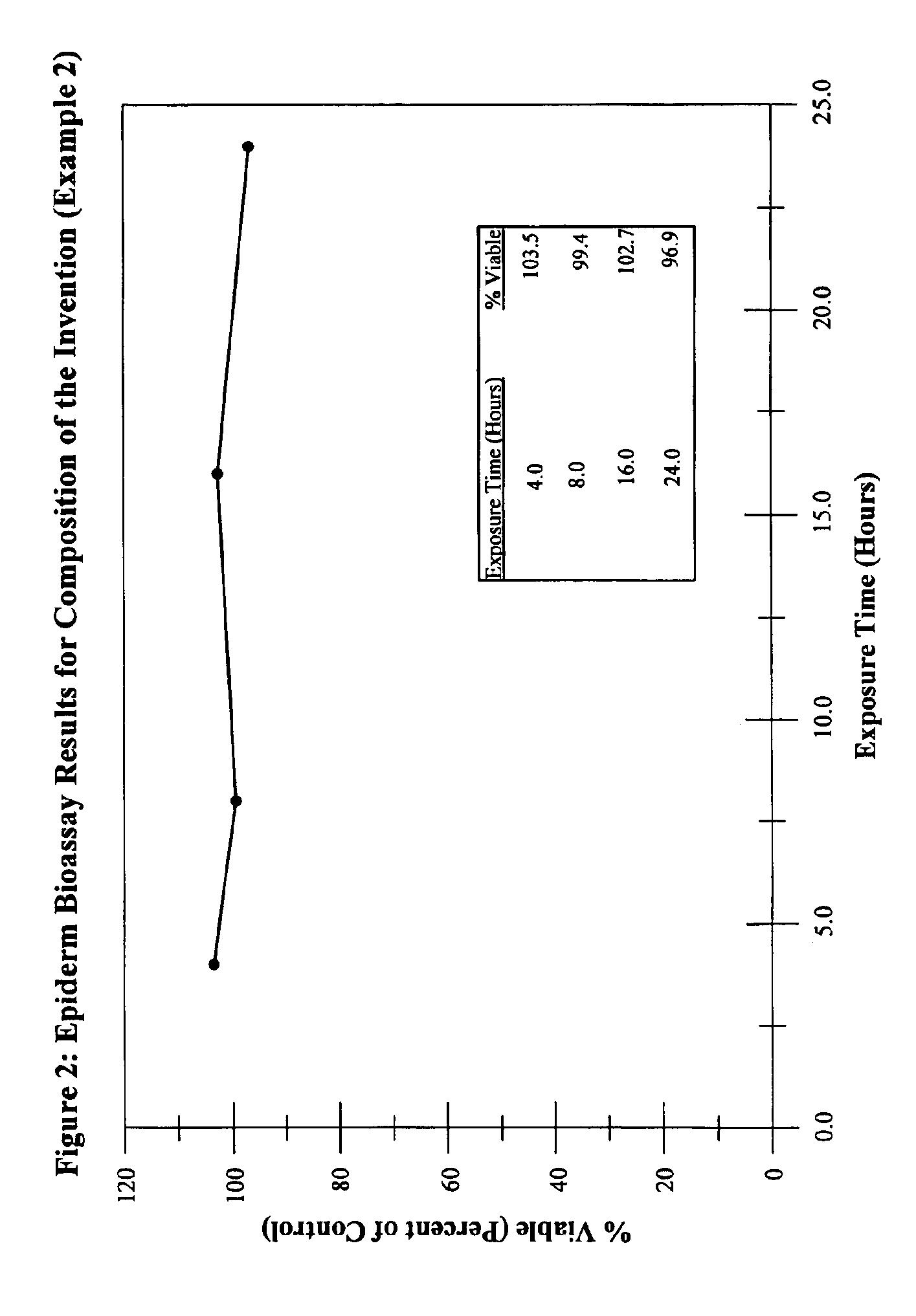

InactiveUS7005408B2Capacitive effectIncrease temperatureAntibacterial agentsOrganic active ingredientsPolyolAlcohol

This invention relates to substantially anhydrous warming, non-toxic and nonirritating lubricating compositions containing polyhydric alcohols and an insulating agent. The invention also relates to methods of using such compositions for lubrication, administration of active ingredients and for preventing or treating dysmenorrhea.

Owner:RECKITT BENCKISER HEALTH LTD

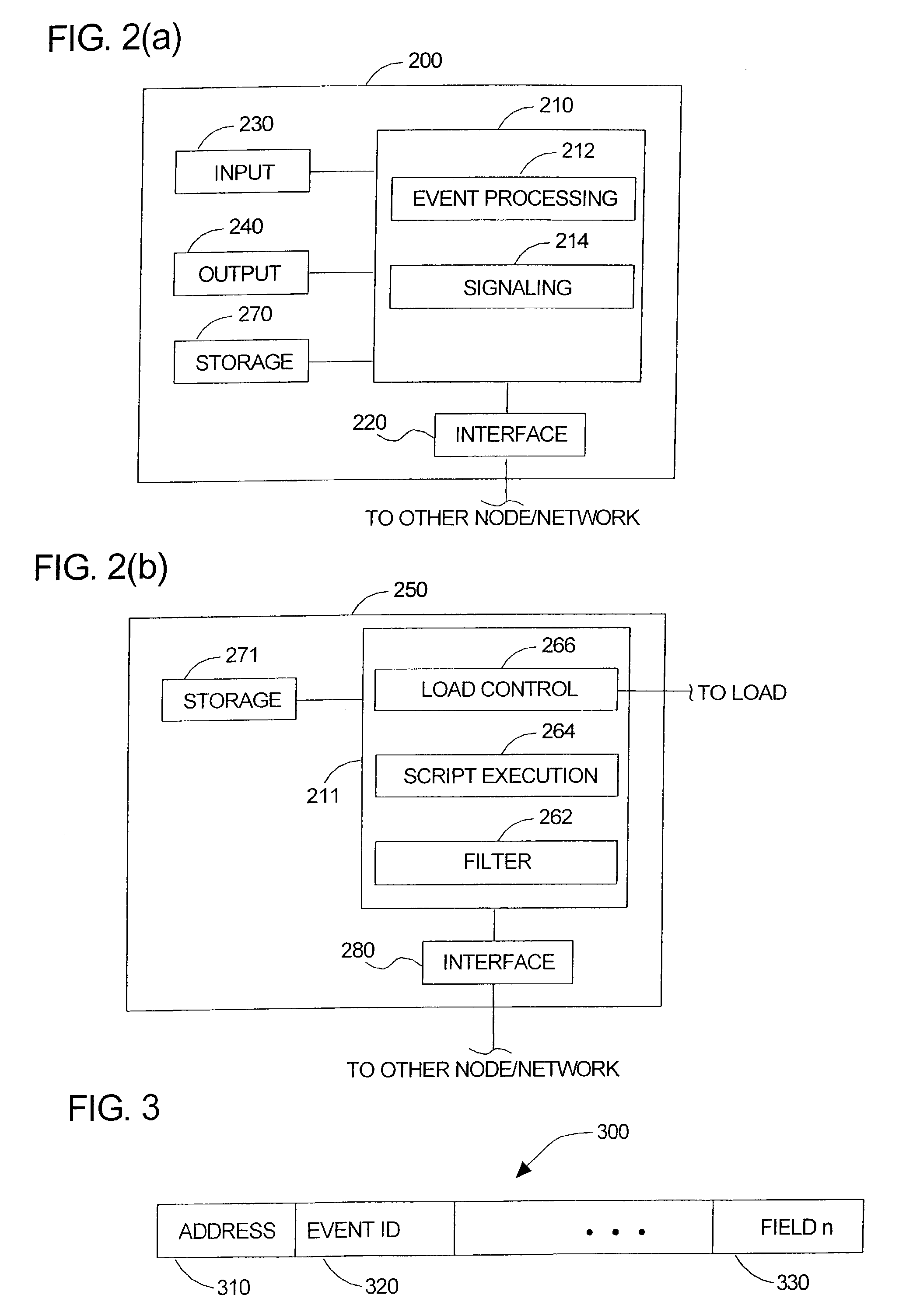

Distributed control systems and methods

ActiveUS7089066B2Level controlHeating and refrigeration combinationsDistributed control systemComputer science

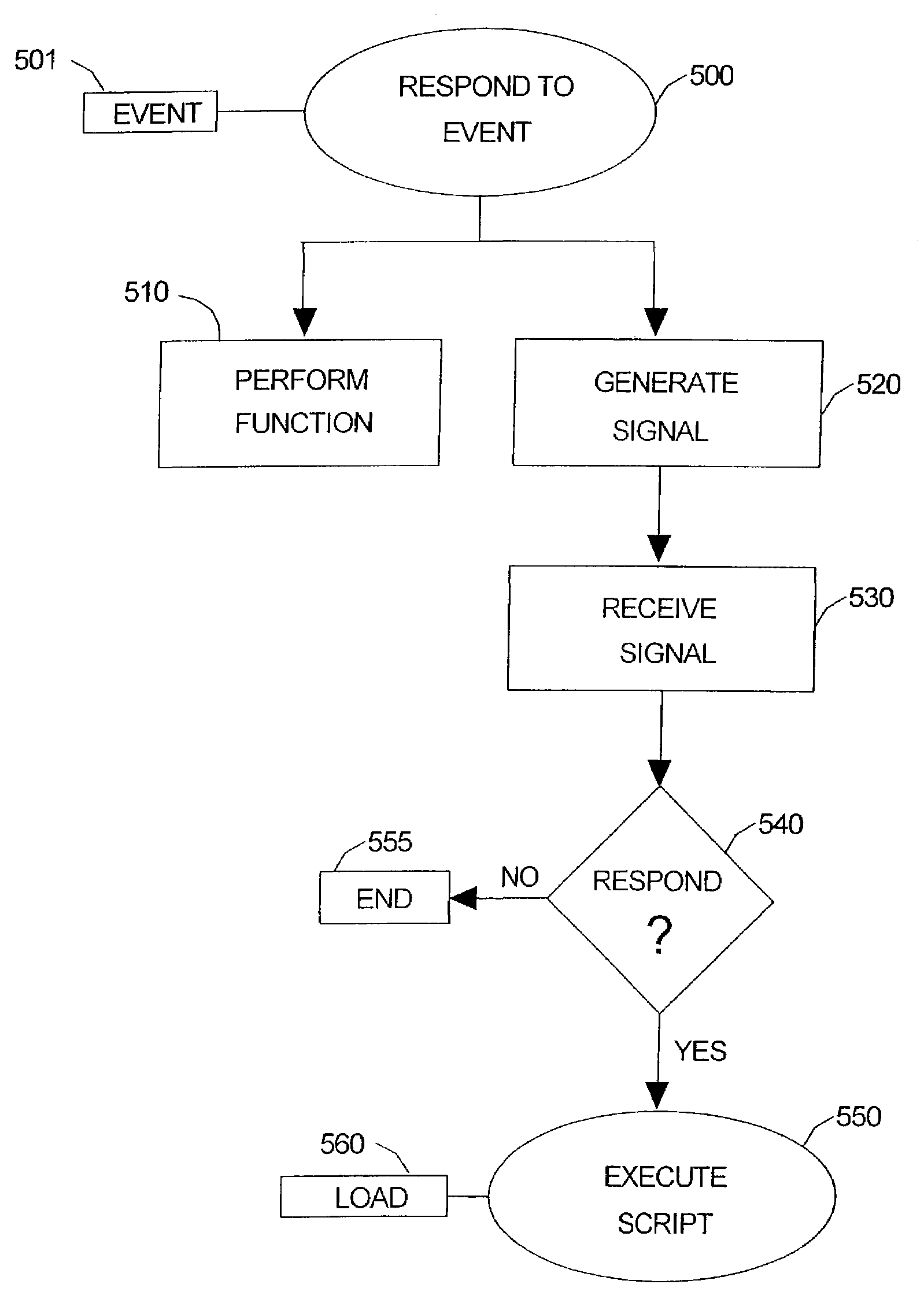

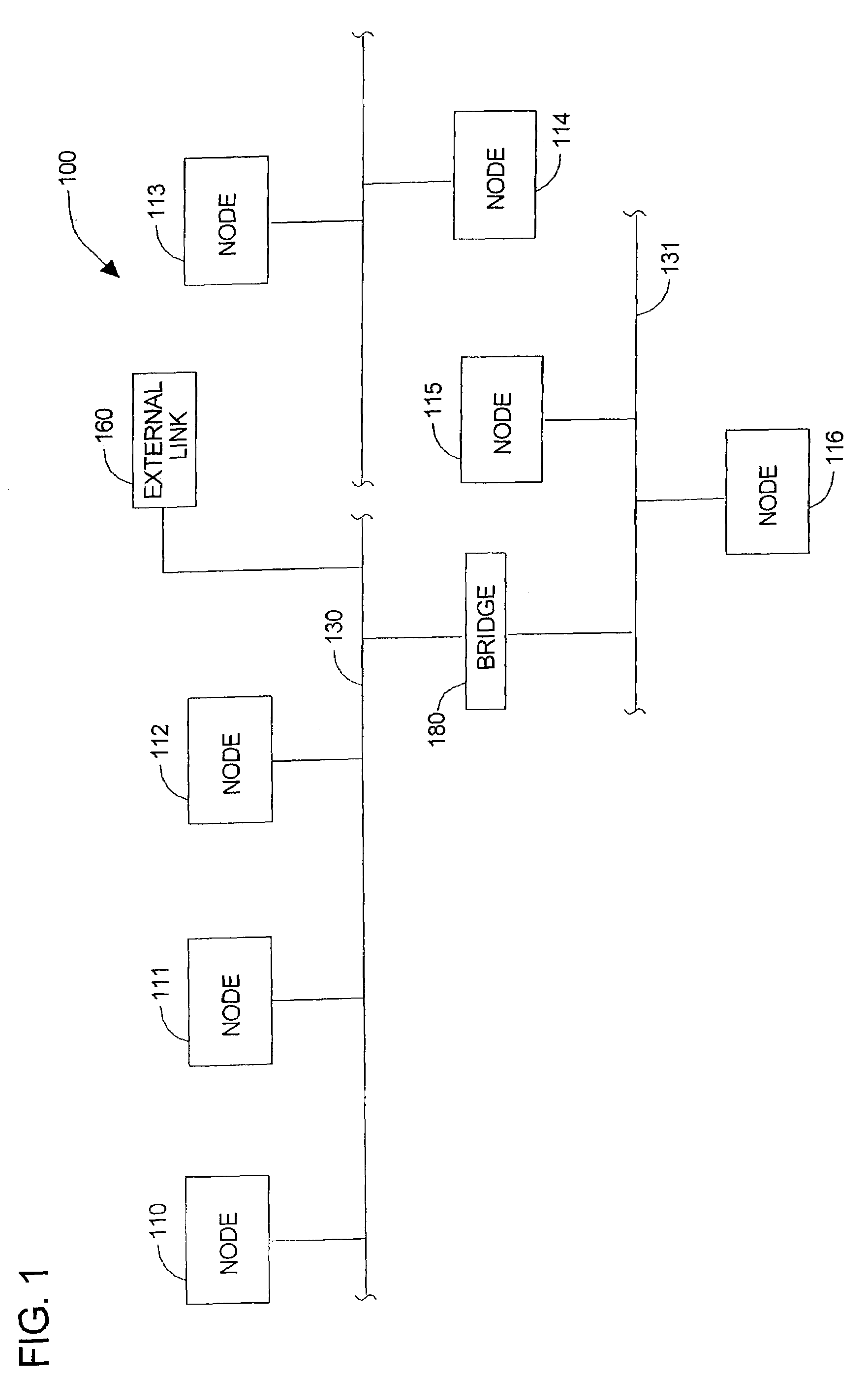

Distributed control systems and methods. An embodiment of distributed control system may comprise at least first and second nodes operatively associated with one another, the first node issuing a signal to at least the second node in response to an event. A load controlled by the second node, and a distributed controller provided at the second node. The distributed controller executing at least one script corresponding to the signal to control the load.

Owner:GOOGLE LLC

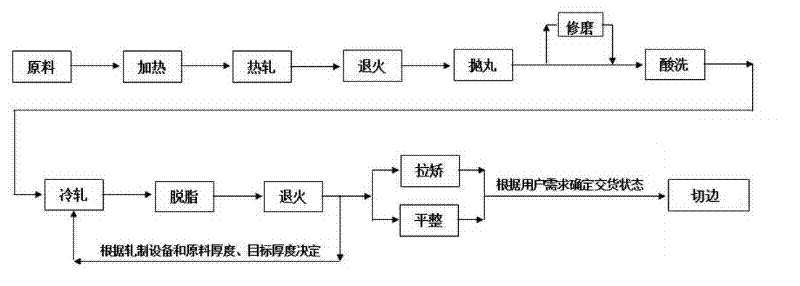

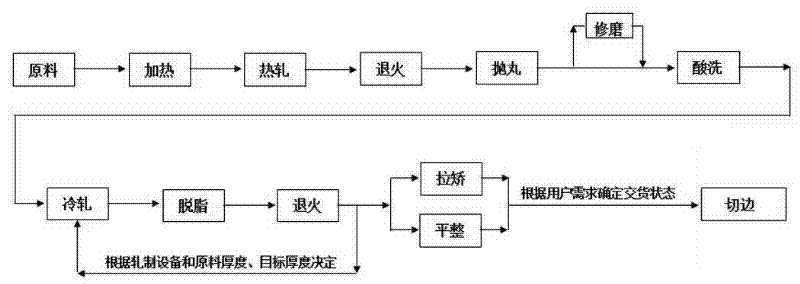

Processing method of titanium and titanium alloy strip coils

ActiveCN102310314ASolve the shortage of titanium-free surface processing technologyImprove processing efficiencyWork treatment devicesMetal rolling arrangementsSingle plateTitanium

The invention provides a processing method of titanium and titanium alloy strip coils, which comprises the steps of raw material preparation, heating, rolling, annealing, shot blasting treatment, coping, pickling, cold rolling, derosination, annealing, straightening or flattening, edge scraping, and product obtaining. According to the method, existing large steel rolling equipment of various types in the steel processing industry is fully utilized, the defect that no titanium material surface processing and treatment technology exists in the steel processing industry is overcome, the advantages of the steel processing industry are combined with the uniqueness of the titanium material processing industry, and the essential leap of titanium material processing from single plate rolling to long strip rolling plus collection and coiling is completed. By using the method, goods can be delivered in a coiled state as well as a flat plate state, the titanium material processing efficiency is improved, the titanium material processing yield is increased, and conditions are created and high quality raw materials are provided for the processing of titanium welded pipes with various diametersand longer lengths, so high efficiency, energy conservation and economization of titanium material processing are realized.

Owner:YUNNAN TITANIUM IND

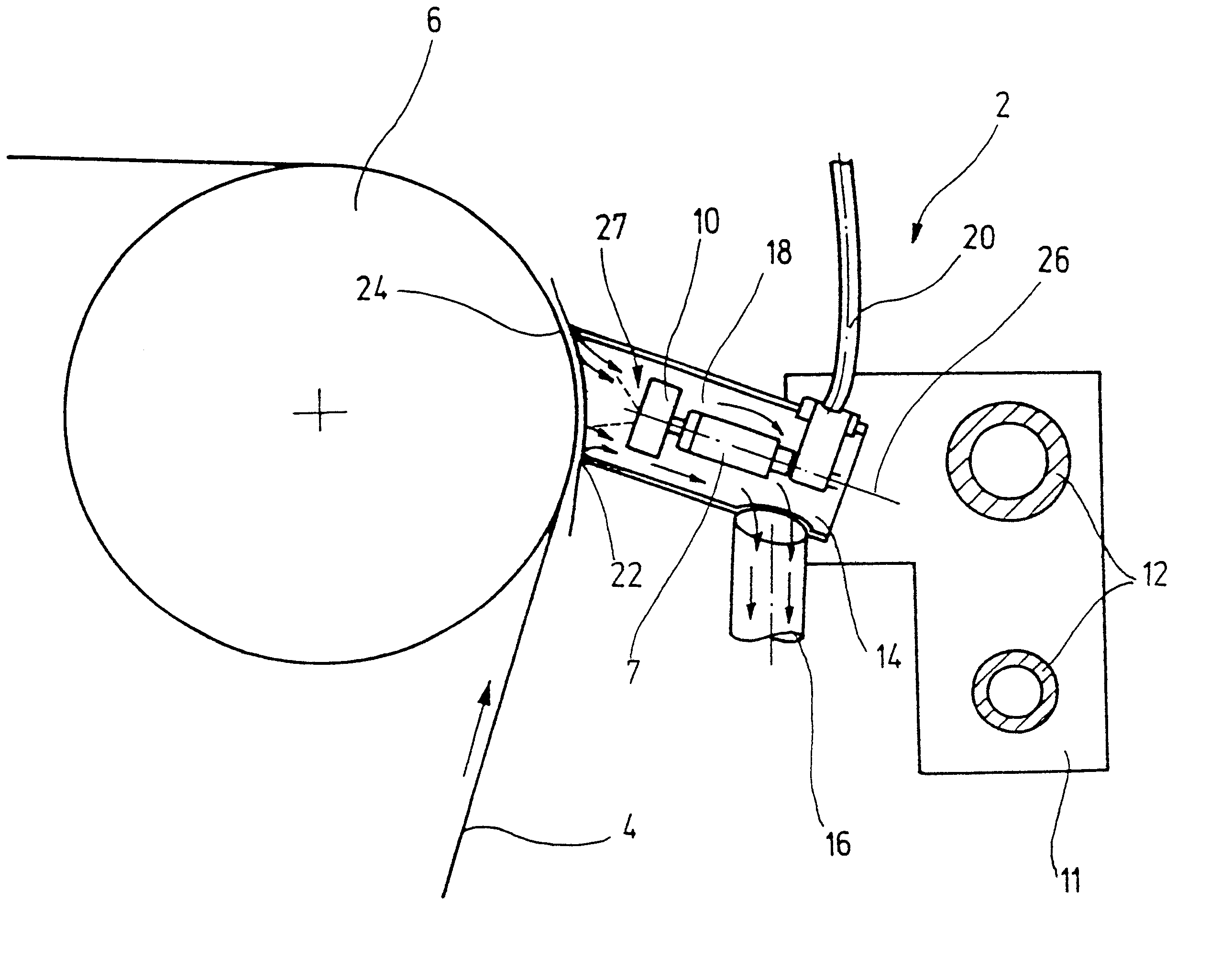

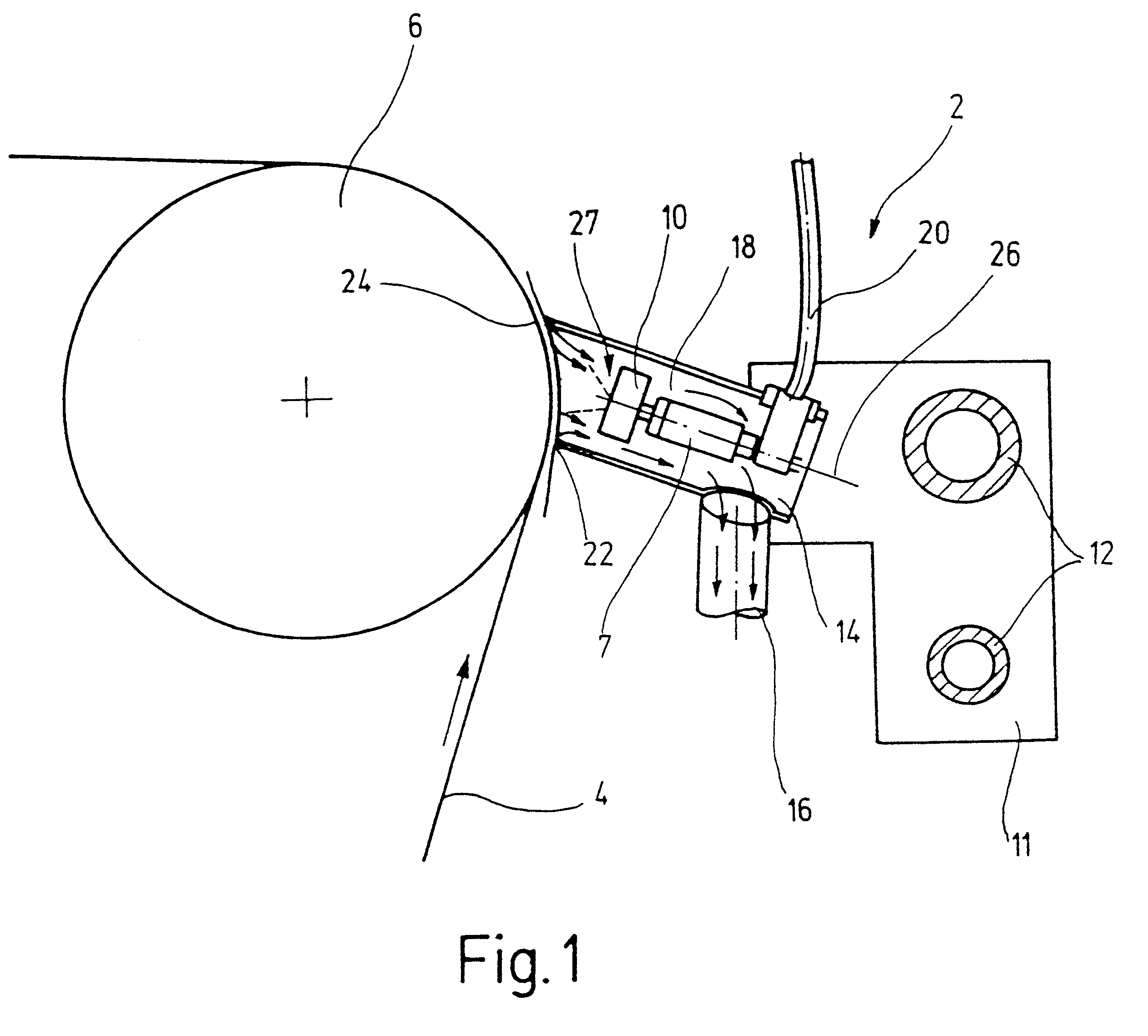

Cable covered in solid lubricant

The invention relates to apparatus for depositing a lubricant coating on a cable, the cable including a sheath made by means of an extruder followed by a cooling vessel. Downstream from the cooling vessel, the apparatus includes a heater member followed by a deposition chamber for depositing a lubricant material.

Owner:ALCATEL LUCENT SAS

Method of removing contaminants from an epidermal surface using an oscillating fluidic spray

Owner:FLUIDIC TECH

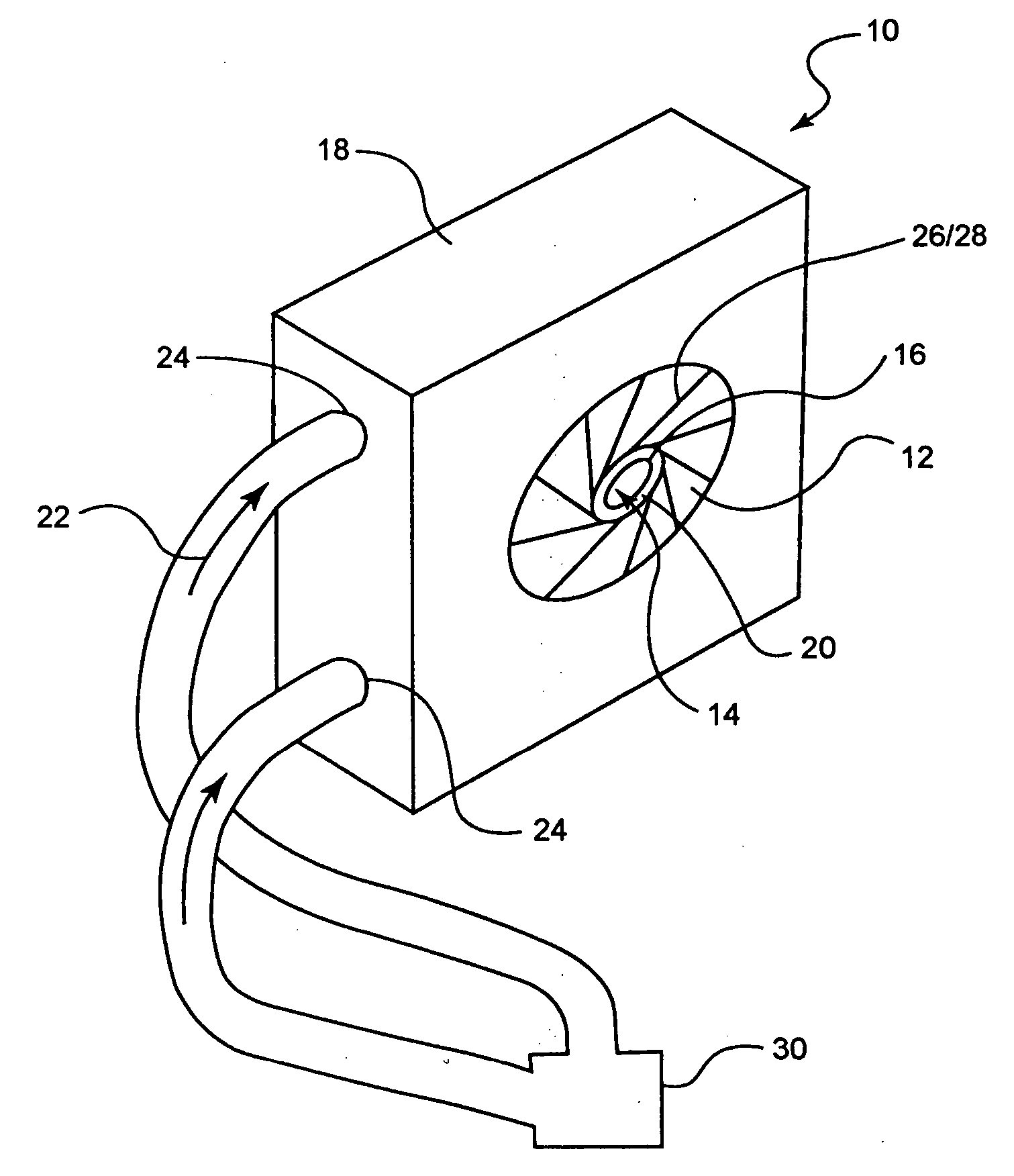

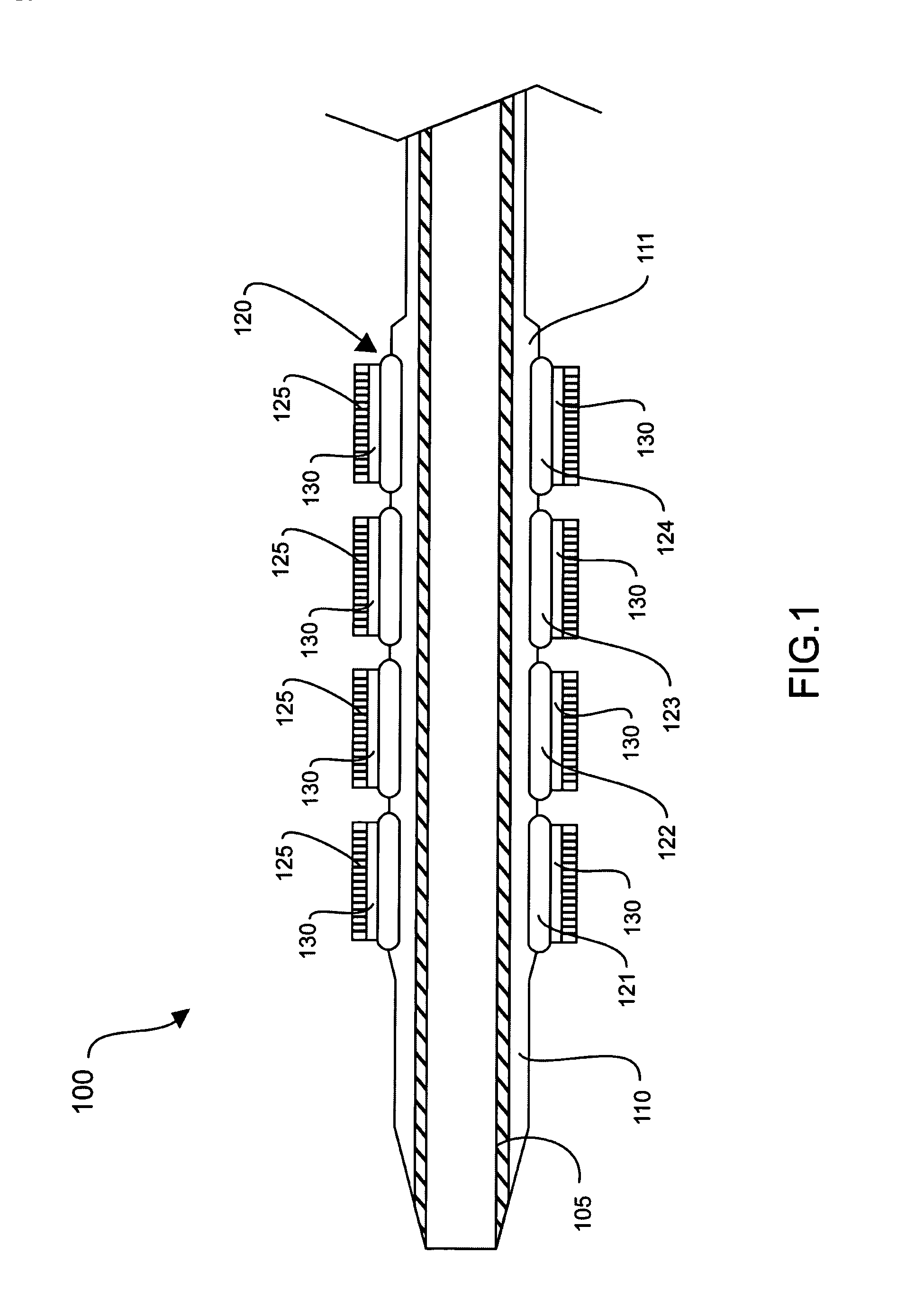

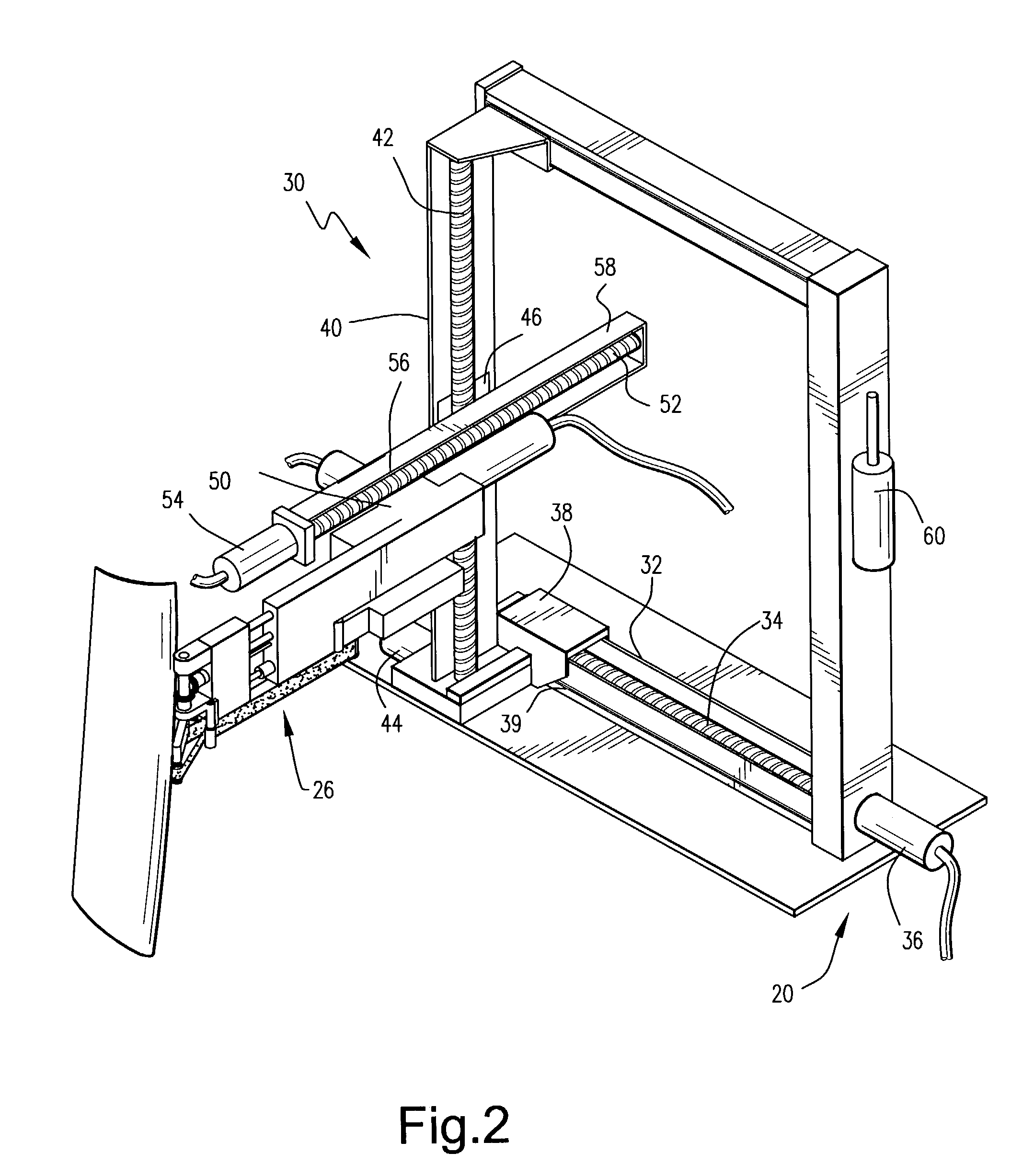

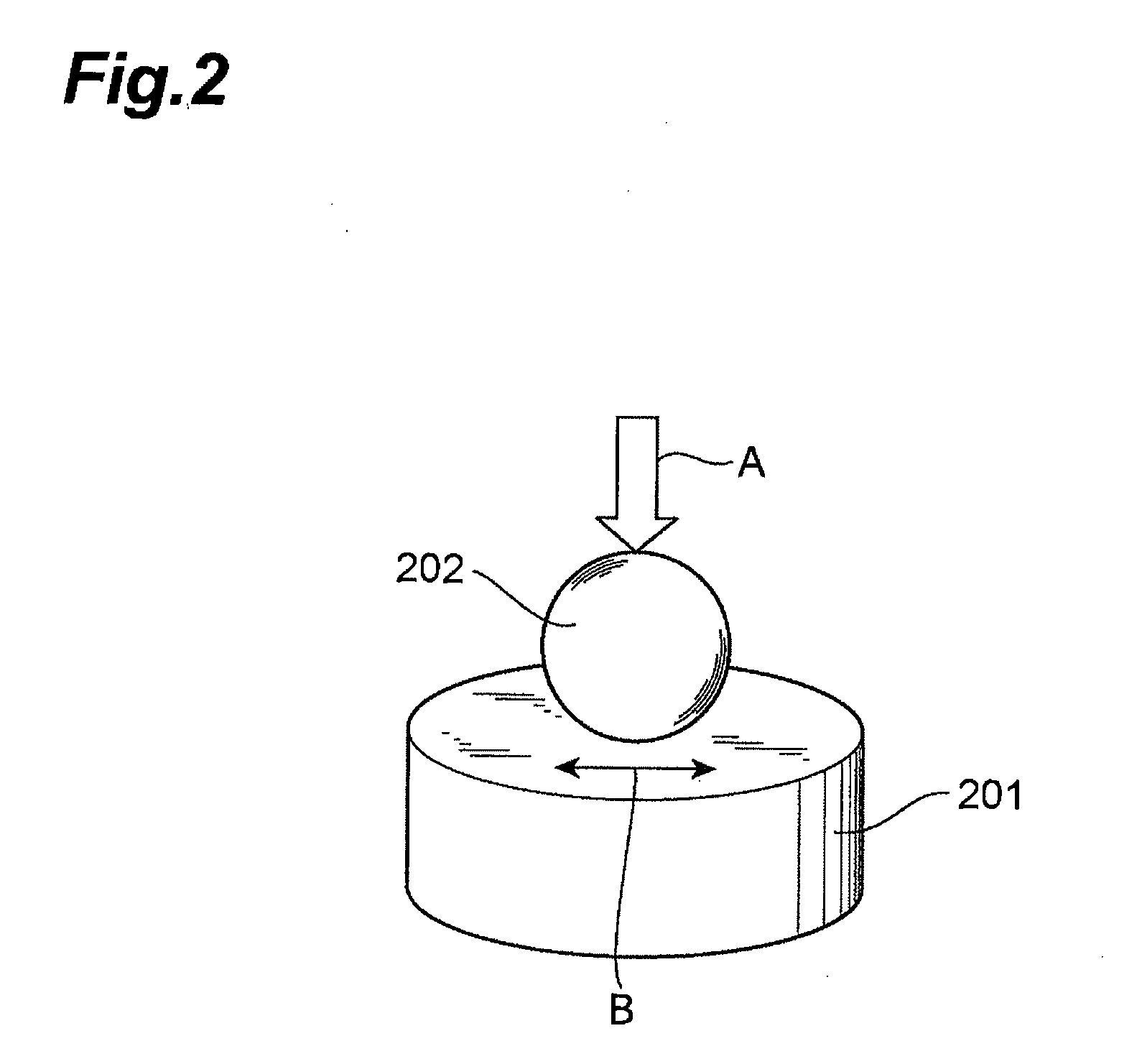

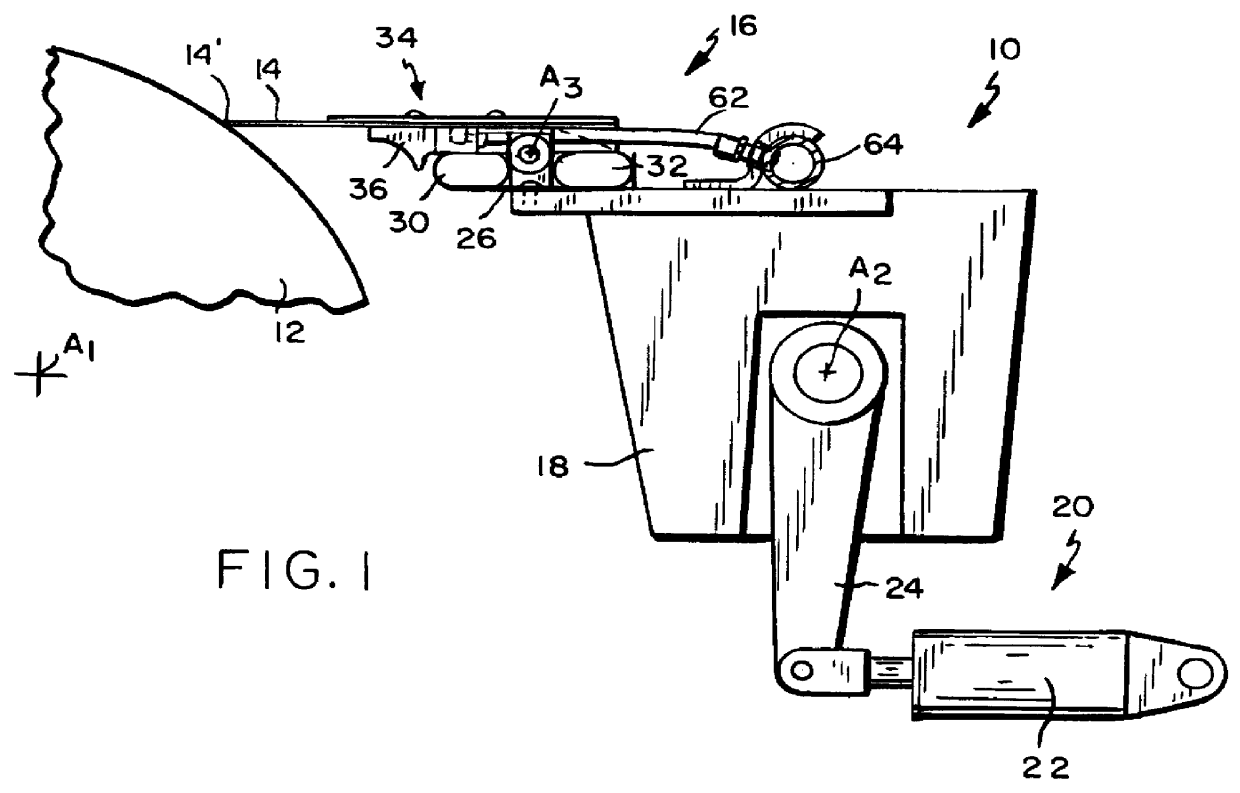

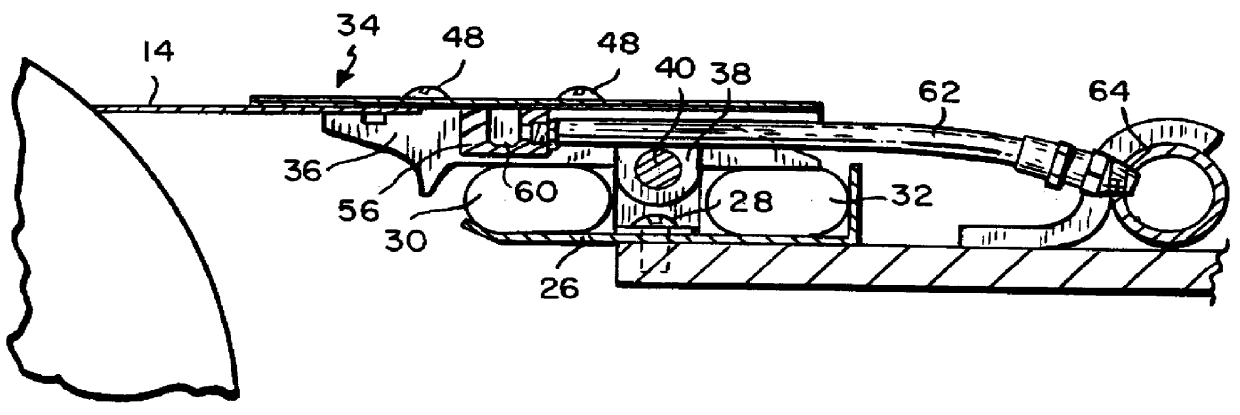

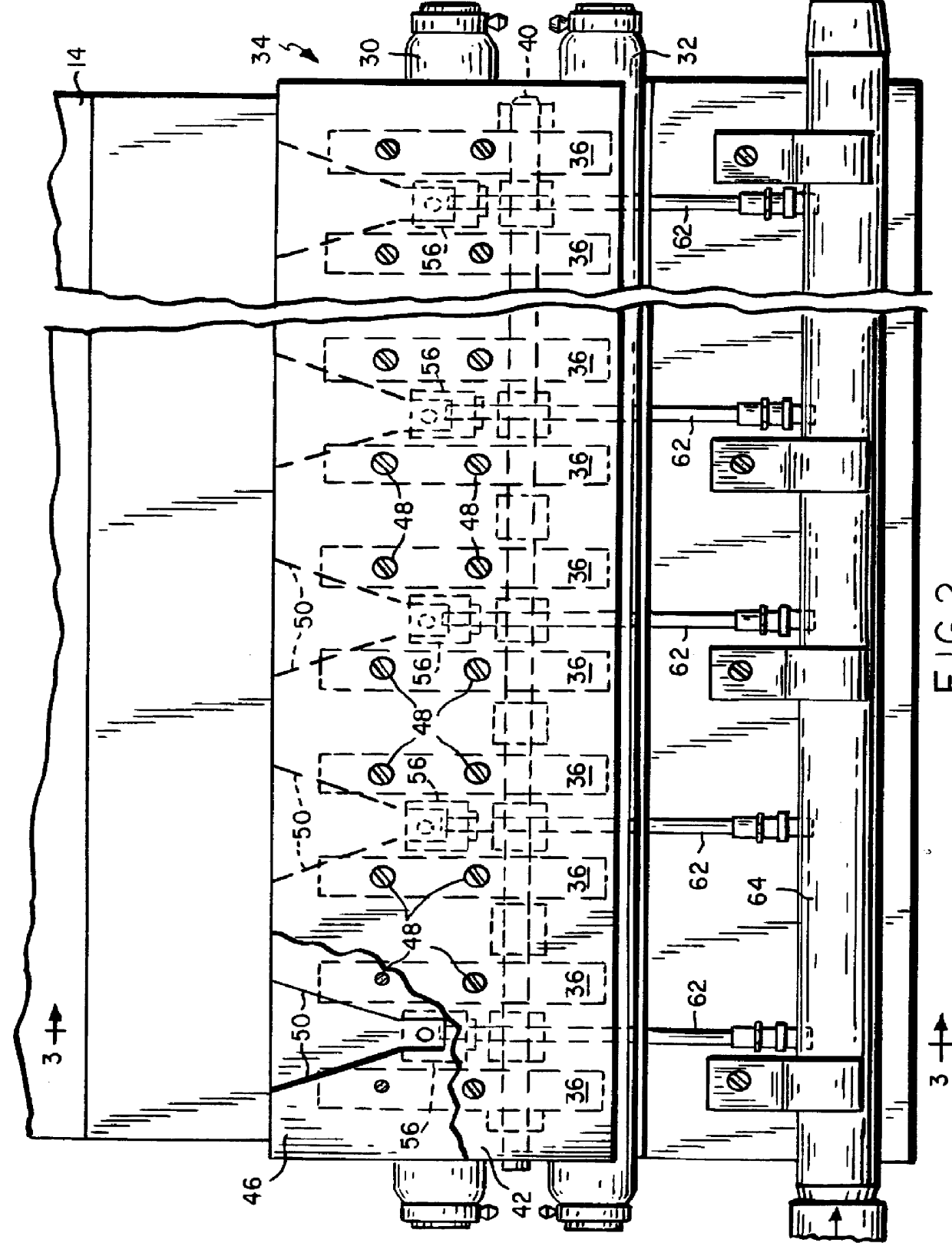

Stent reducing system and device

ActiveUS20050154450A1Reduce frictionMinimize adhesionStentsForging hammersInsertion stent% diameter reduction

A system for reducing the diameter of a stent comprises a stent contracting assembly and a fluid source. The assembly comprises a plurality of contracting members that define a diameter reduction chamber for receiving a stent. When the chamber is in a pre-reduction configuration the stent has a first diameter and when the chamber is in a reduced configuration the stent has a second diameter. The second diameter is less than the first diameter. The fluid source is in fluid communication with the chamber and is constructed and arranged to inject a fluid therein. The fluid forms a fluid bearing between the contracting members and the stent which prevents the contracting members from contacting the stent in the reduced diameter configuration.

Owner:BOSTON SCI SCIMED INC

Solar panel cleaning system and method

ActiveUS8500918B1Water freeMake the solar panel cleaning process automatic and economicalSolar heating energyBrush bodiesEngineeringControl unit

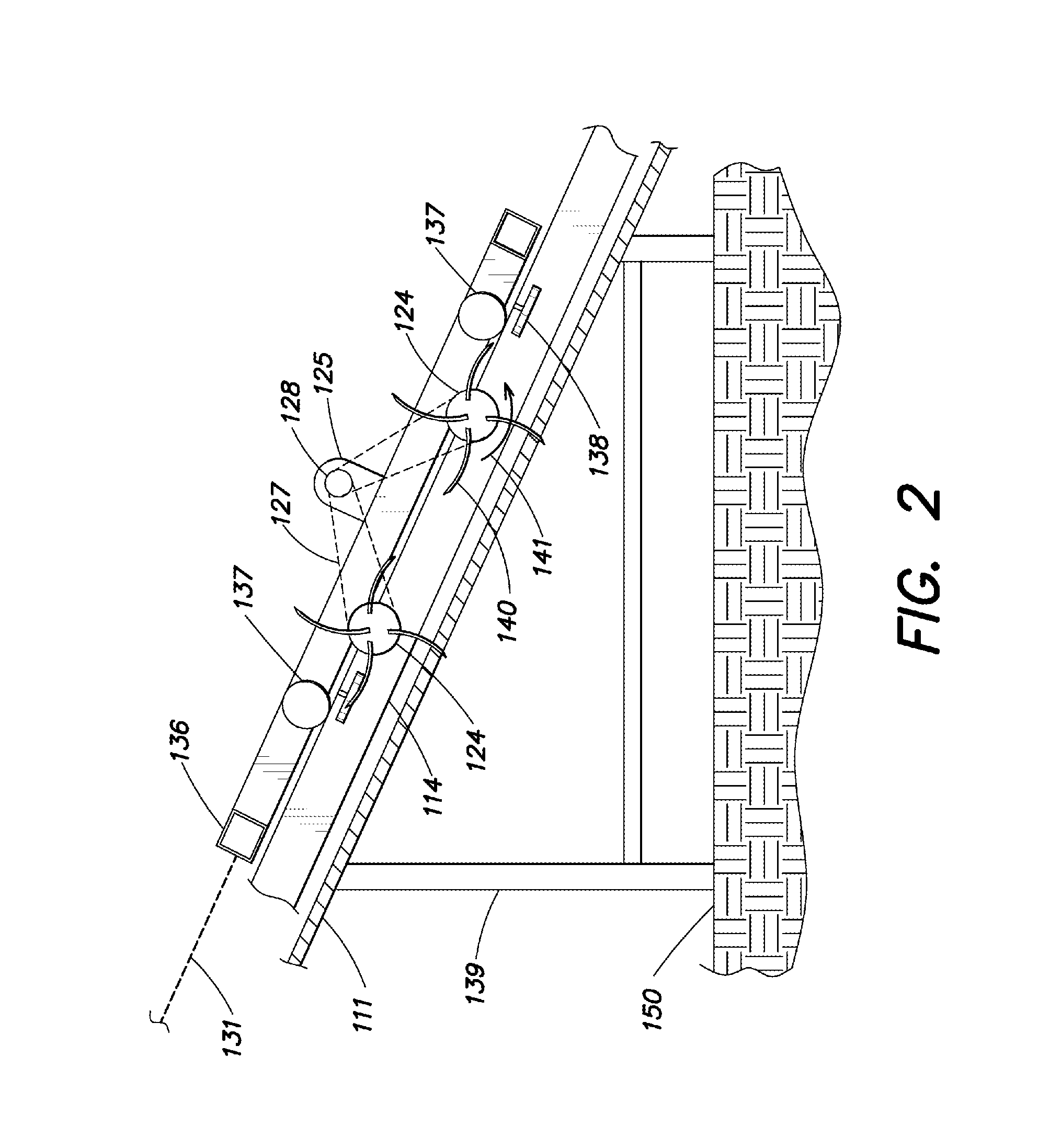

System and method for cleaning a solar row of solar panels. The solar row has an upper edge elevated from ground level more than a lower edge to provide an inclination of the solar row. A cleaning assembly operates to clean a surface of the solar panels. A support frame supports the cleaning assembly and enables the cleaning assembly to move (1) upwardly and downwardly in the width direction of the solar row, and (2) in the length direction of the solar row. Operation and movement of the cleaning assembly is controlled by a control unit to cause the cleaning assembly to clean a surface of the solar panels during downward movement of the cleaning assembly. The cleaning assembly is preferably not operative during its upward vertical movement. During the downward movement, the cleaning assembly removes dirt, debris and dust from the surface of the solar panels and generates an air stream to blow off the dirt, debris, and dust.

Owner:ECOPPIA SCI

Method of forming a drug eluting stent

The present invention provides a method of forming a drug eluting stent, the method comprising coupling a stent framework to a mandrel, inserting the mandrel with stent framework into an open die, the die including a forming surface including a plurality of raised indention forming portions; closing the die against the stent framework; pressing the raised indention portions into the stent framework to form indentions in the stent framework; and inserting at least one drug polymer into the indentions formed in the stent framework.

Owner:MEDTRONIC VASCULAR INC

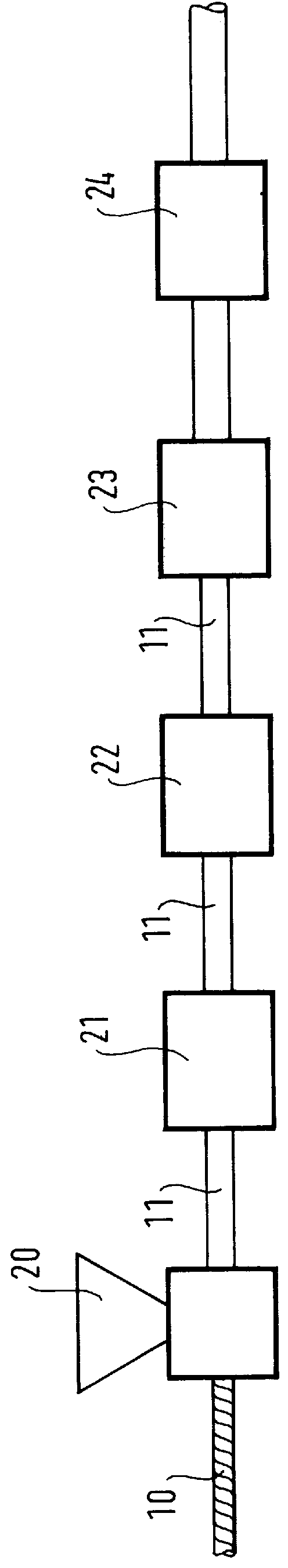

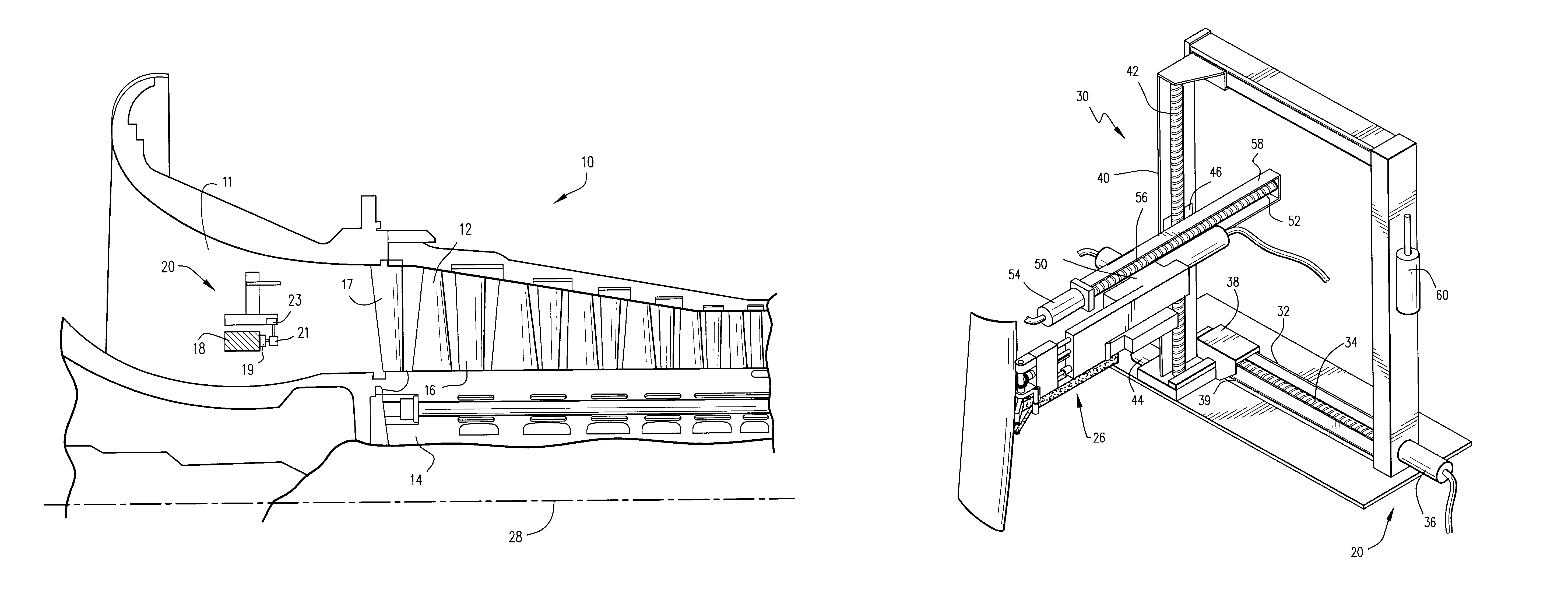

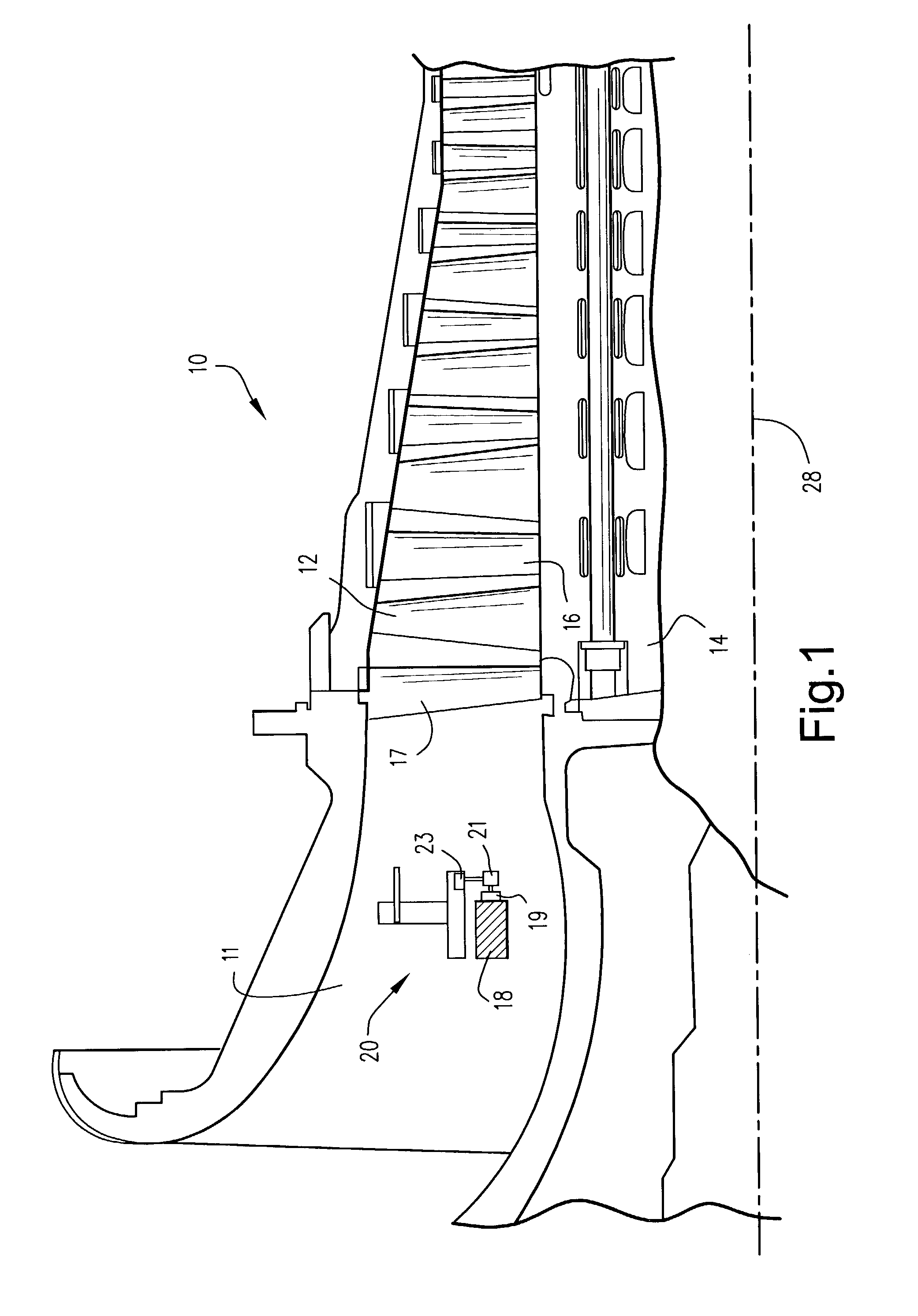

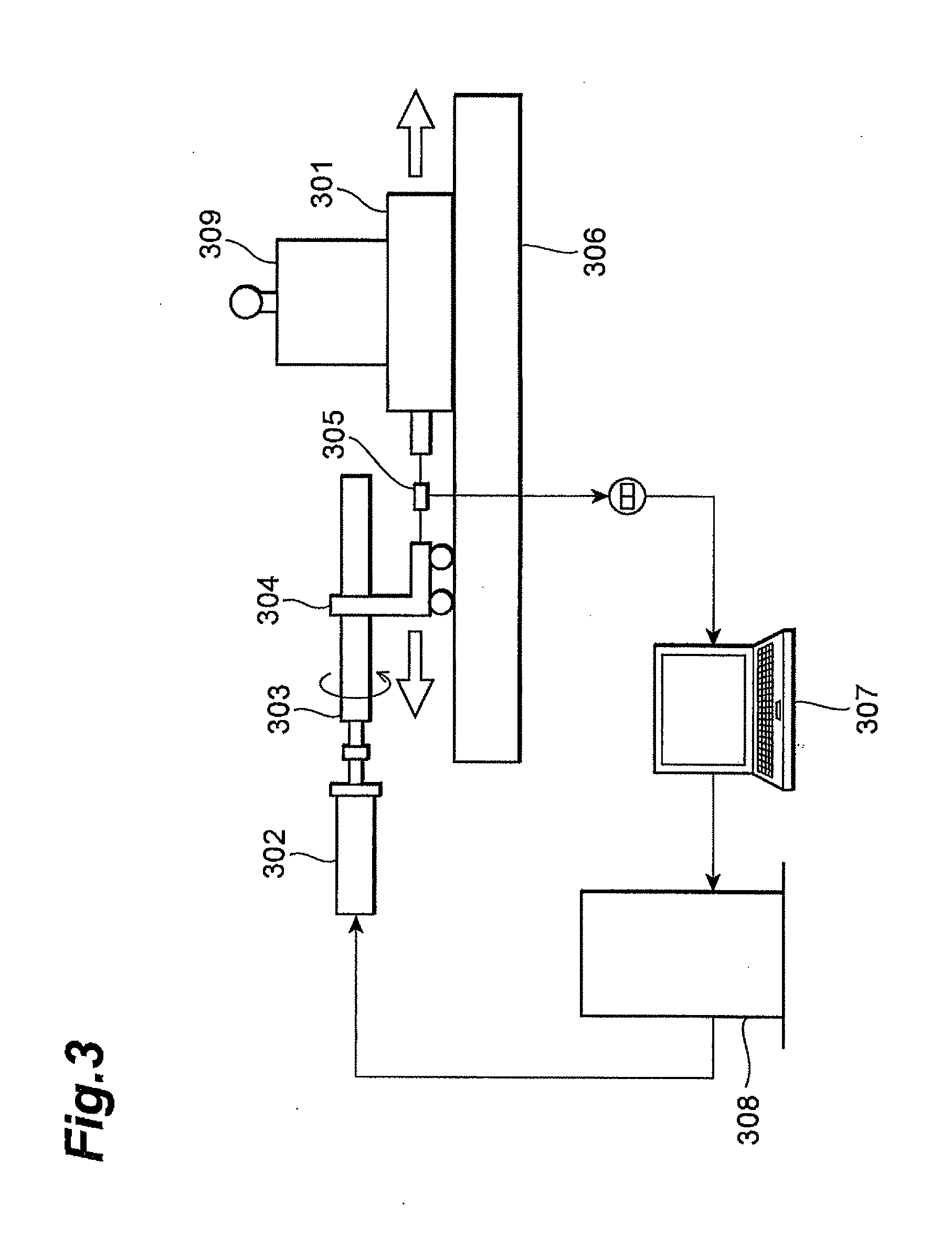

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

Lubricant composition

Use of a liquid composition for lubricating conveyor belts is provided, said liquid composition being suitable for producing a “dry” lubricant film on a surface by discontinuous application thereof, wherein the liquid composition can also be used for continuous application to a conveyor belt surface, with or without further dilution with water, to remove incidental spillages of extraneous material from the conveyor belt surface without loss of the required lubricity.This liquid composition was found to exhibit remarkably good durability.

Owner:JOHNSONDIVERSEY INC

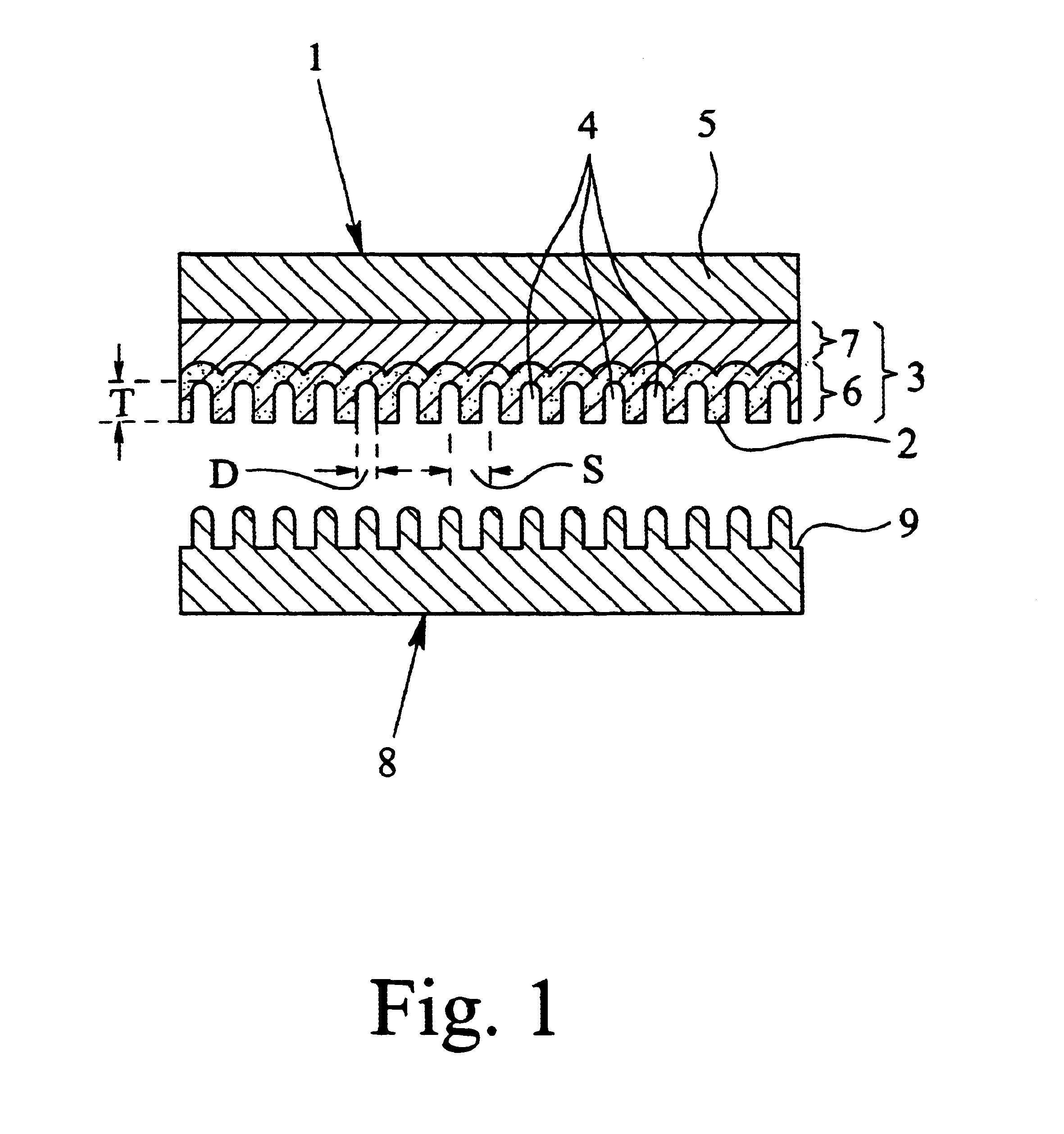

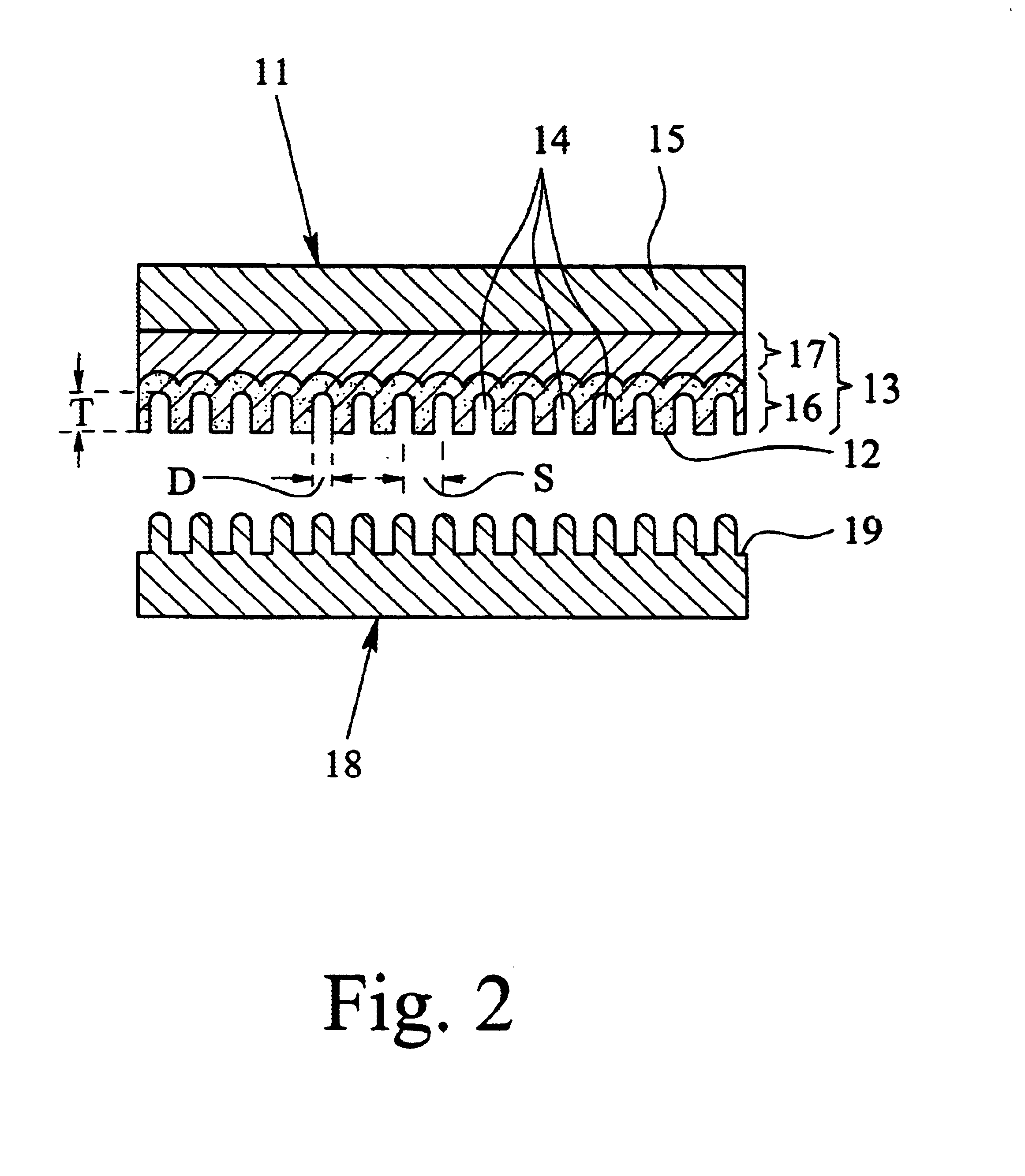

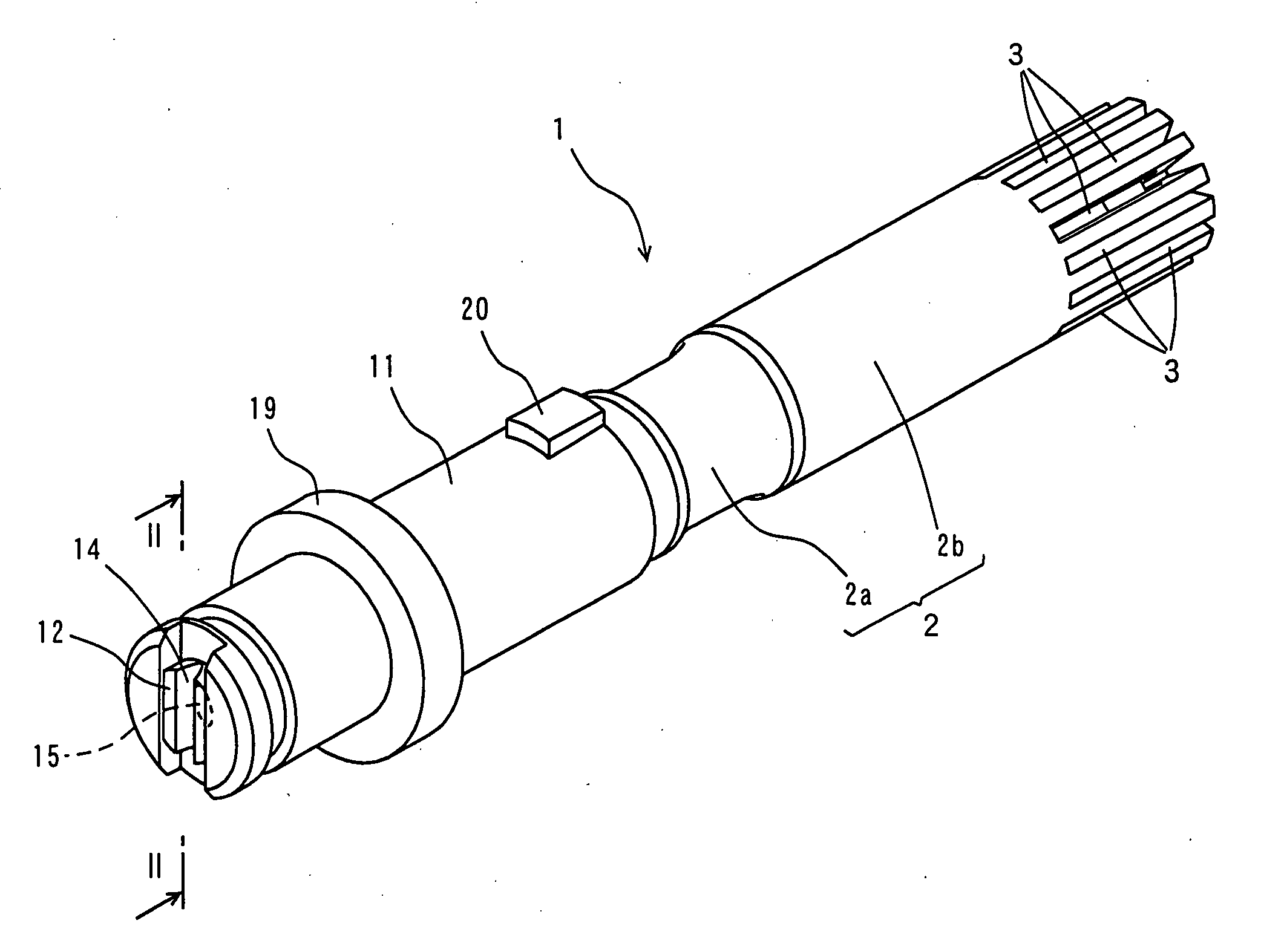

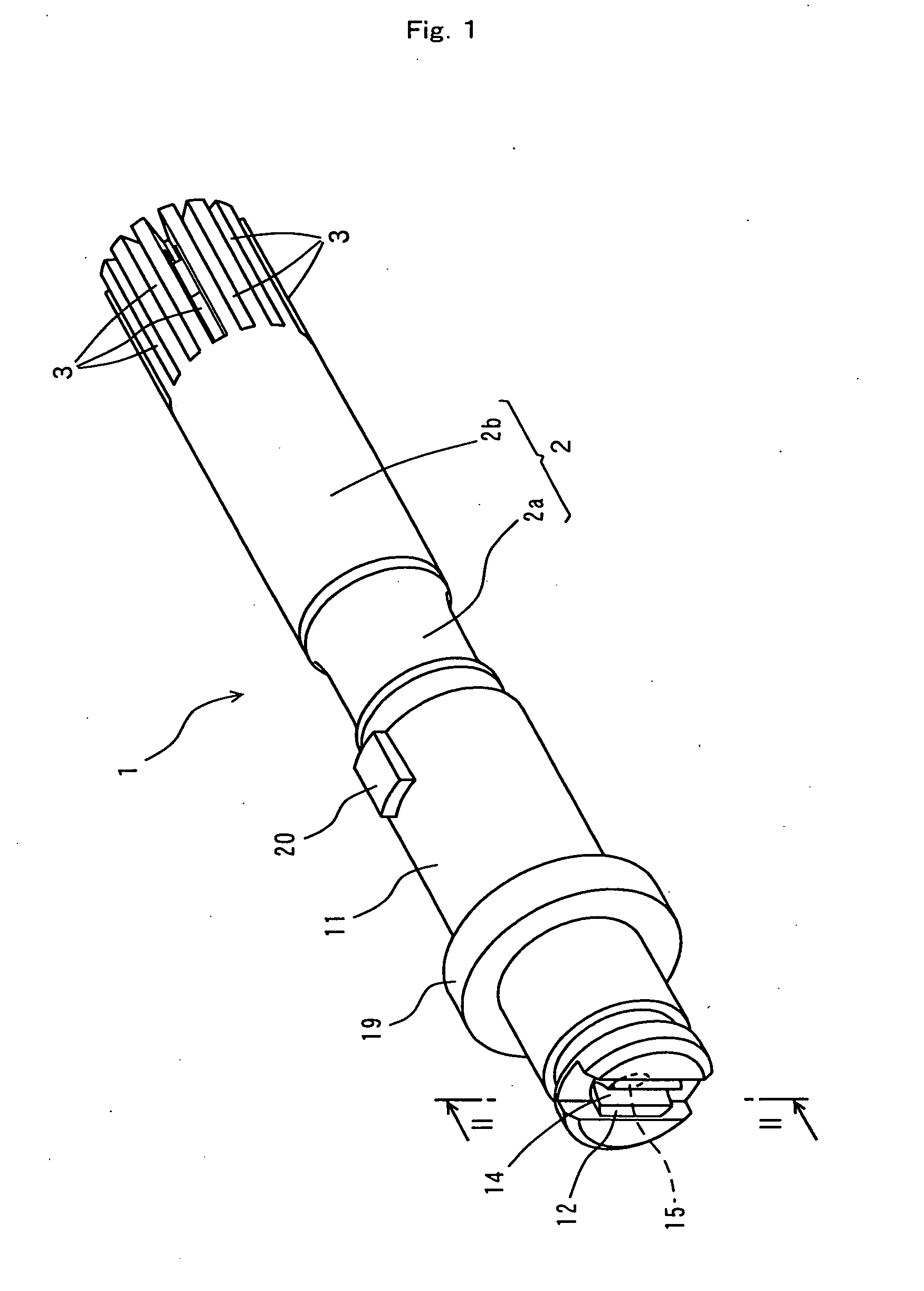

Stamping tool, casting mold and methods for structuring a surface of a work piece

InactiveUS7066234B2Simple and cost-effectiveProlong lifeAnodisationMoulding toolsSurface layerCasting mold

A simple, cost-effective stamping or molding in the nanometer range is enabled using a stamping surface or molding face with a surface layer having hollow chambers that have been formed by anodic oxidation.

Owner:SHARP KK

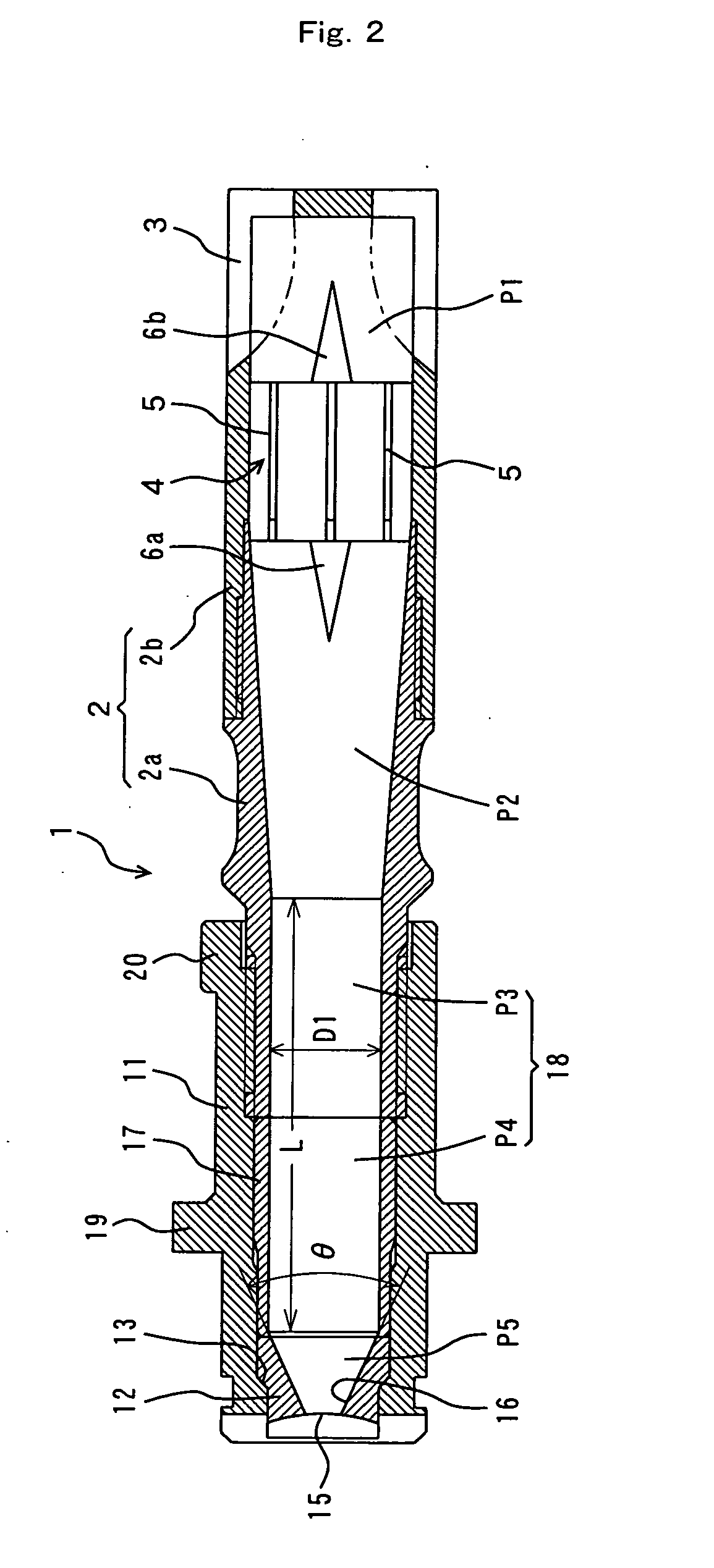

Descaling nozzle

ActiveUS20050156064A1Improve descaling efficiencyIncrease forceSpray nozzlesWork treatment devicesEngineeringErosion

A nozzle orifice of a nozzle 1 comprises a tapered segment 16 extending from an elliptical discharge orifice 15 and having a taper angle θ of 30 to 80°, and a large-diameter segment 18 continuing with the tapered segment, and scale on a steel plate is removed by discharging water from the nozzle at a distance between discharge orifice 15 and the steel plate of not more than 600 mm, a pressure of 5 to 30 MPa, and a discharge flow rate of 40 to 200 l / minute. The ratio of the inner diameter of large-diameter segment 18 relative to the minor diameter of the discharge orifice 15 is not less than 3 and less than 7. Also, the discharge flow from the nozzle spreads in a single direction (width direction) within a plane perpendicular to the central axis of the nozzle and the erosion thickness angle is 1.5 to 30 in the direction (thickness direction) perpendicular to the width direction. Such a descaling nozzle enables that scale is removed efficiently at low pressure and / or low flow rate while restraining the cooling of a steel plate.

Owner:KYORITSU GOKIN +1

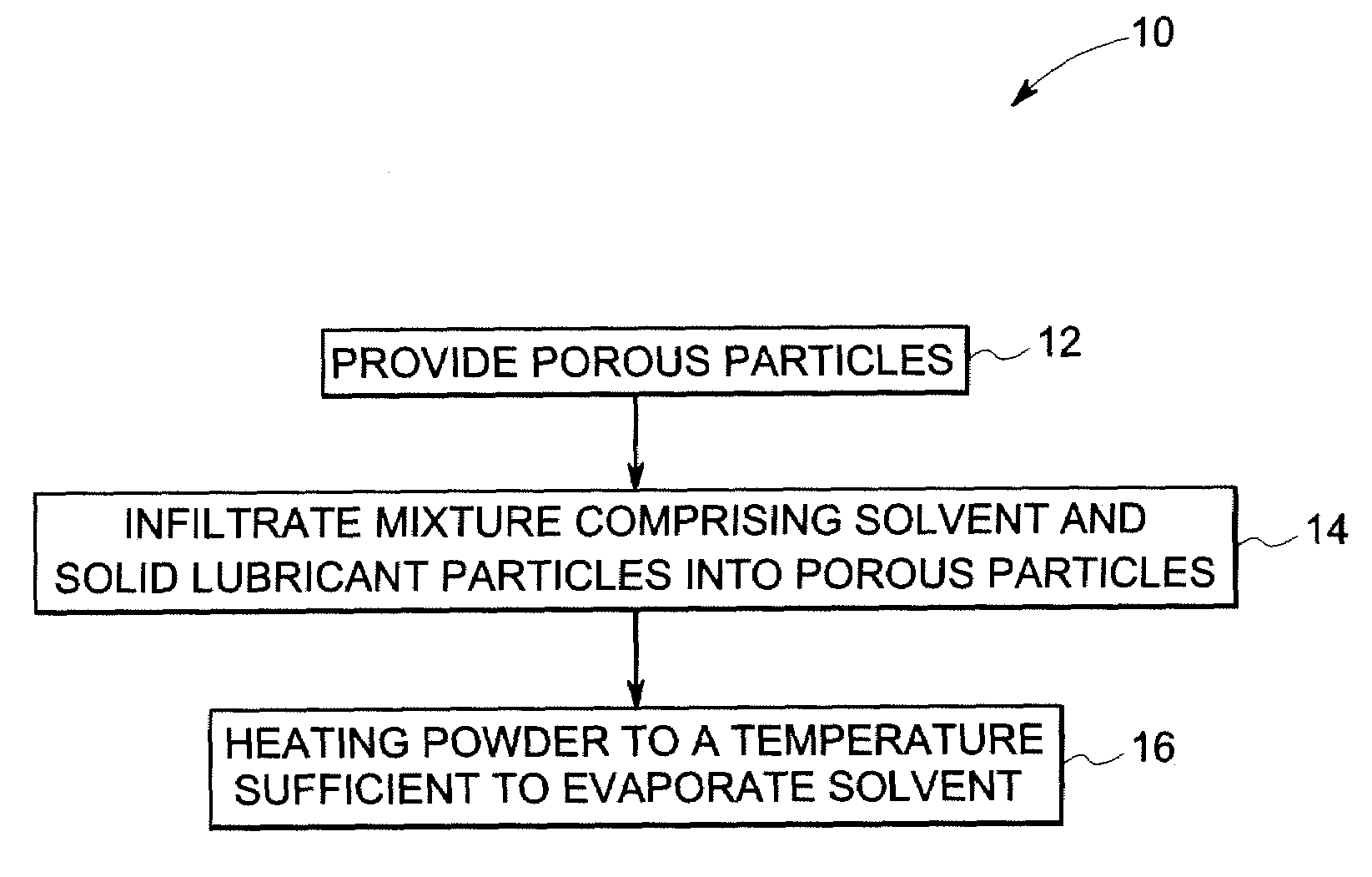

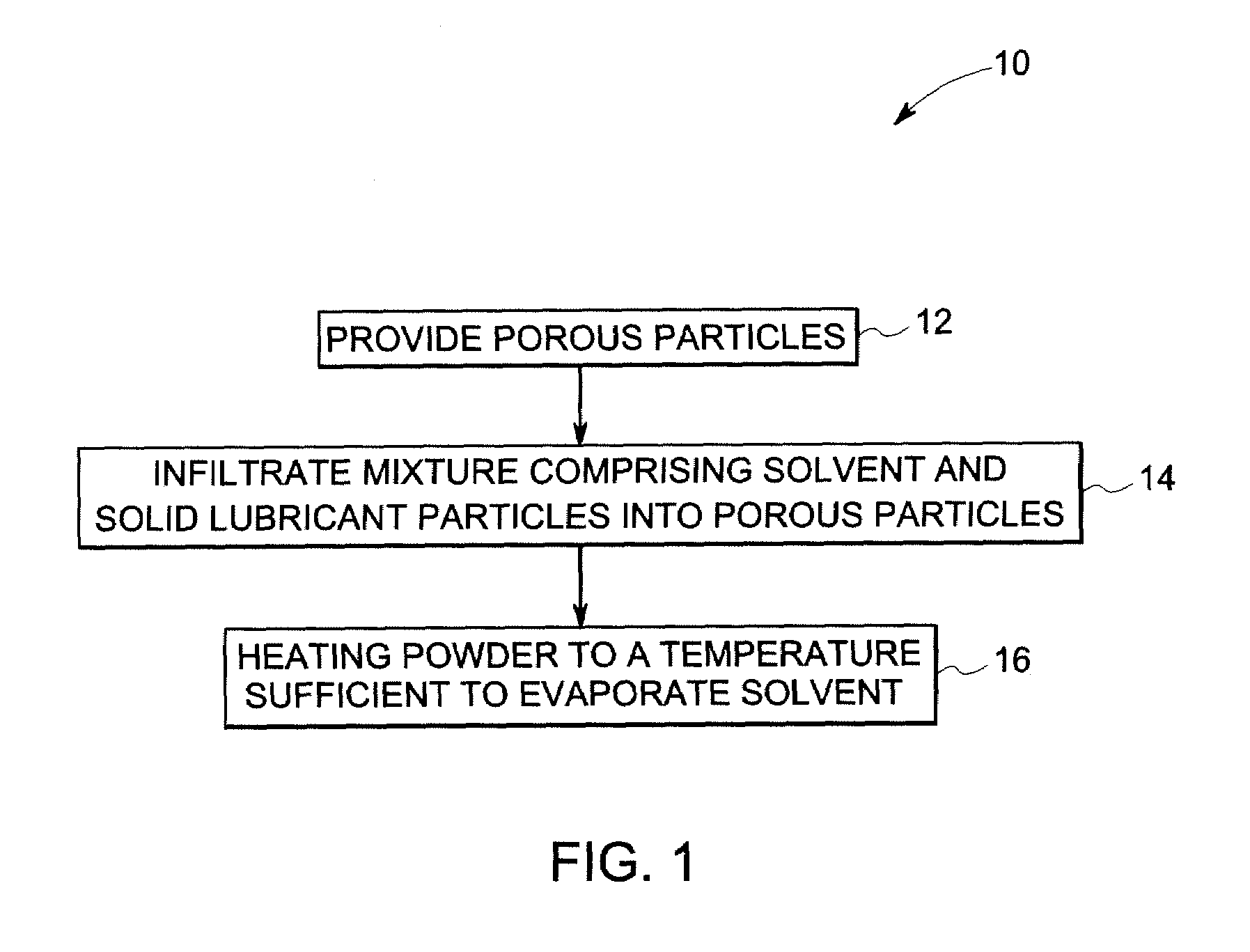

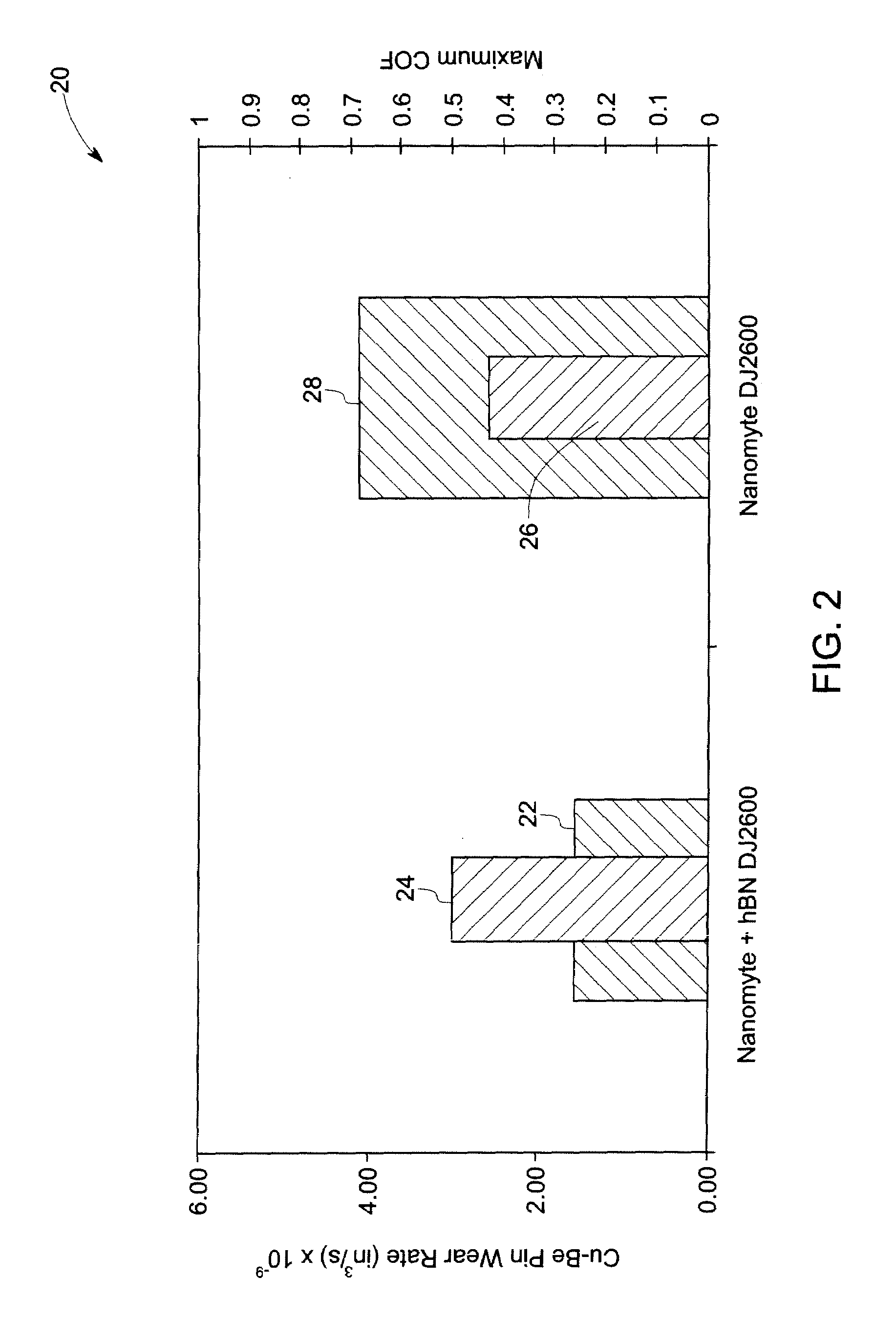

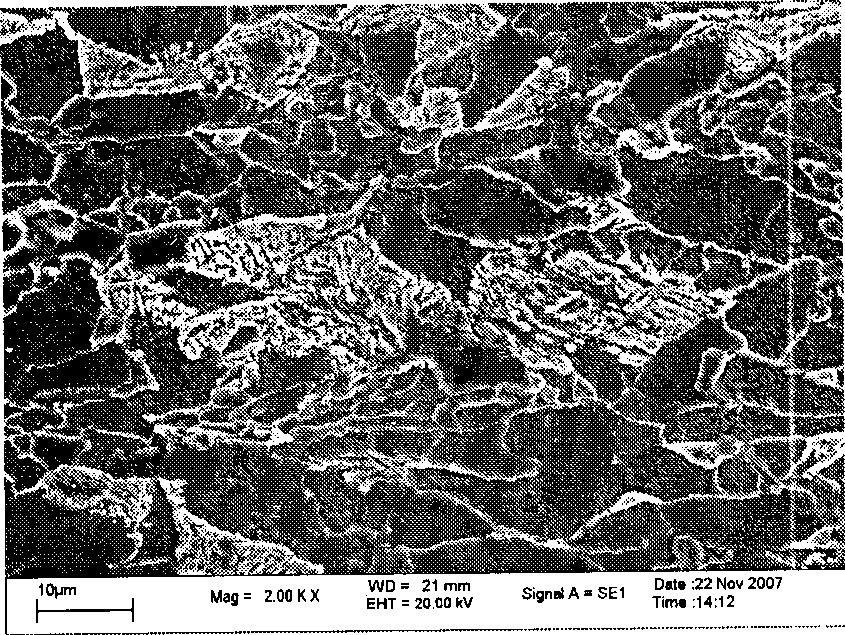

Thermal spray powders for wear-resistant coatings, and related methods

InactiveUS20080145554A1High solid lubricant loadingUniform solid lubricant dispersionLiquid surface applicatorsMolten spray coatingThermal sprayingWear resistant

A method of making a thermal spray powder is provided. The method comprises: providing a powder comprising a plurality of porous particles; infiltrating a mixture comprising a solvent and a plurality of solid lubricant particles into the porous particles; and heating the powder to a temperature sufficient to evaporate the solvent. The method of forming a wear-resistant coating is provided. The method comprises: providing a thermal spray powder; heating the thermal spray powder; and accelerating the thermal spray powder from a thermal spray gun onto the substrate, to form a deposit. Yet another embodiment provides a wear resistant coating. The wear resistant coating is formed by thermally spraying the thermal spray powder.

Owner:GENERAL ELECTRIC CO

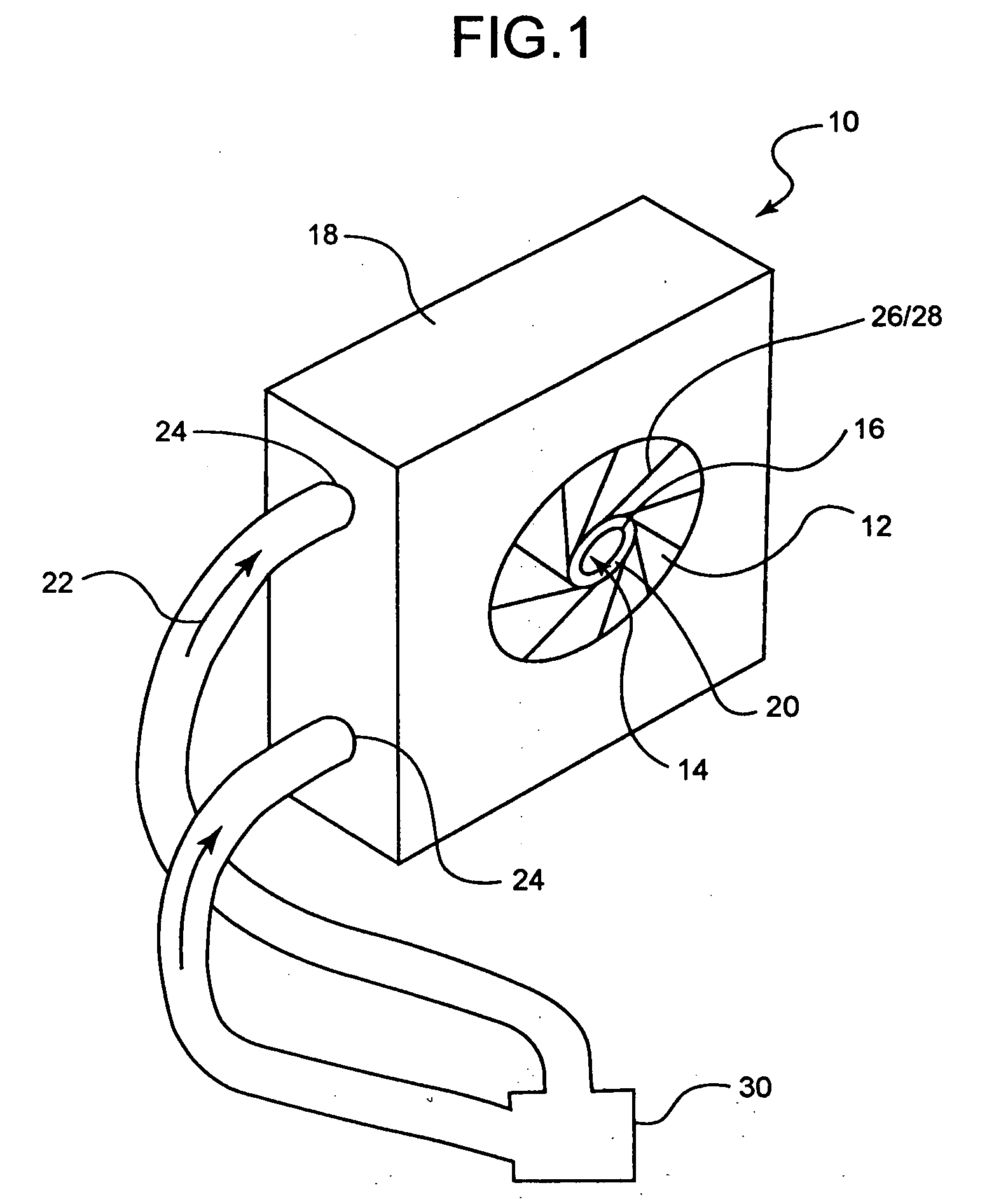

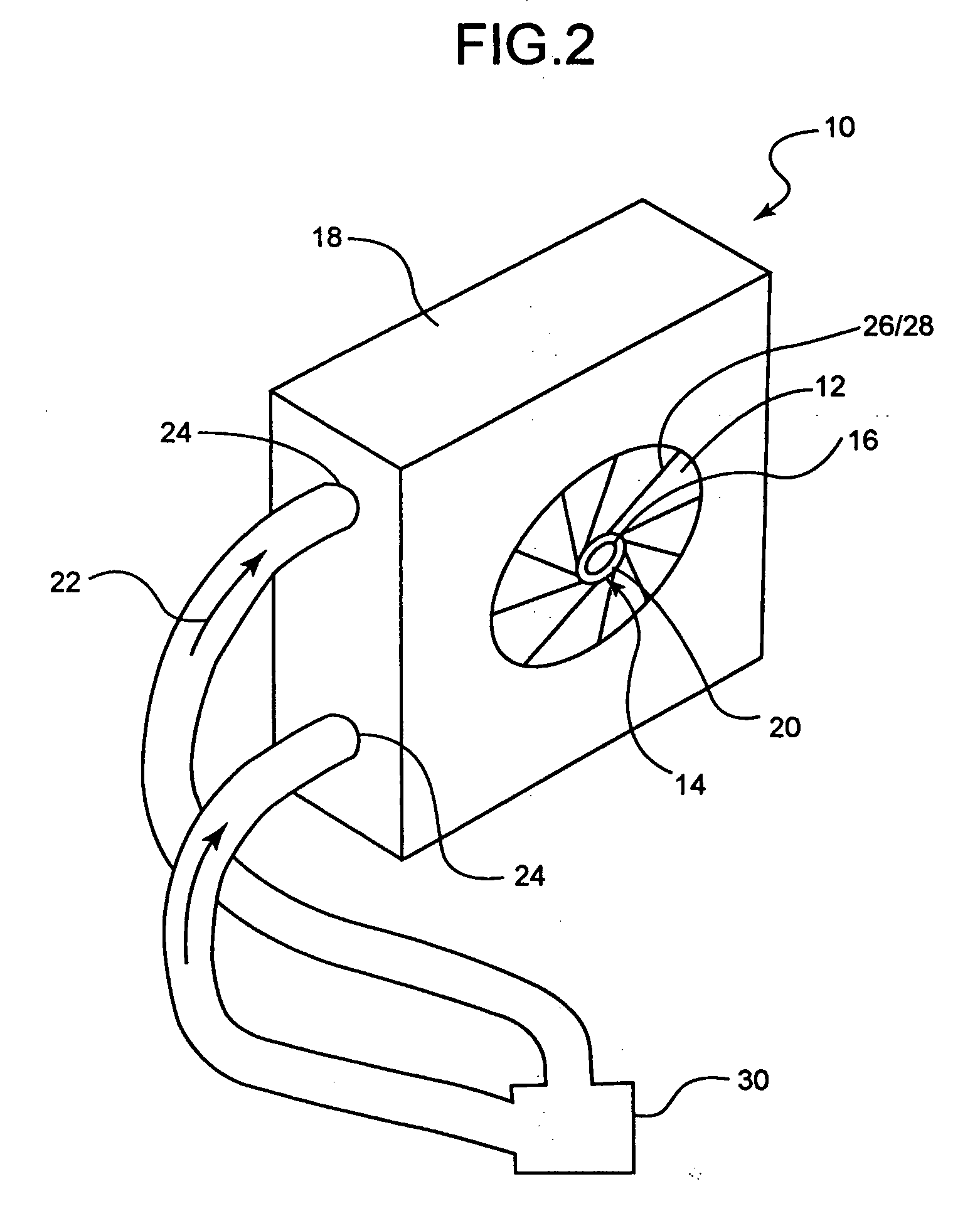

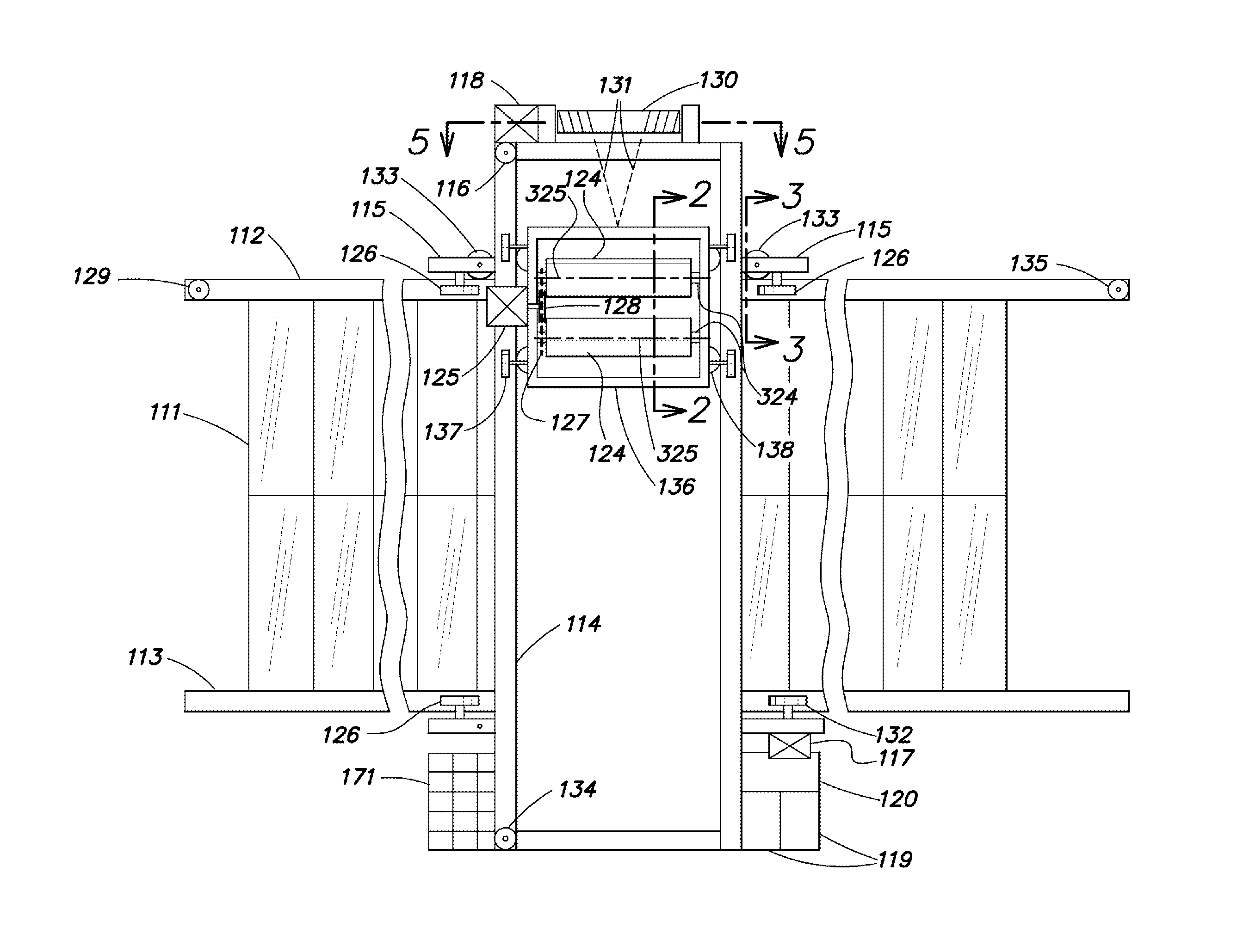

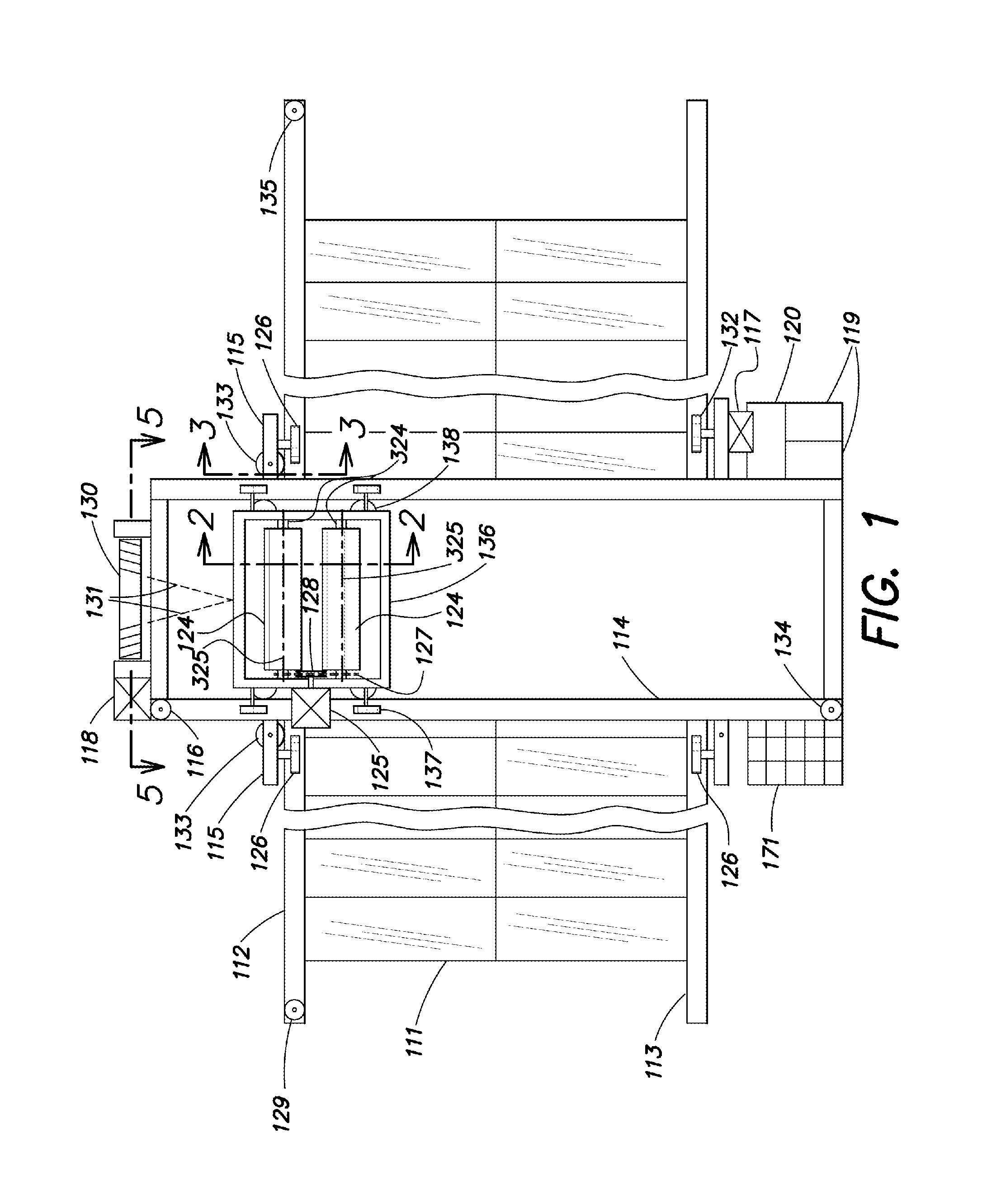

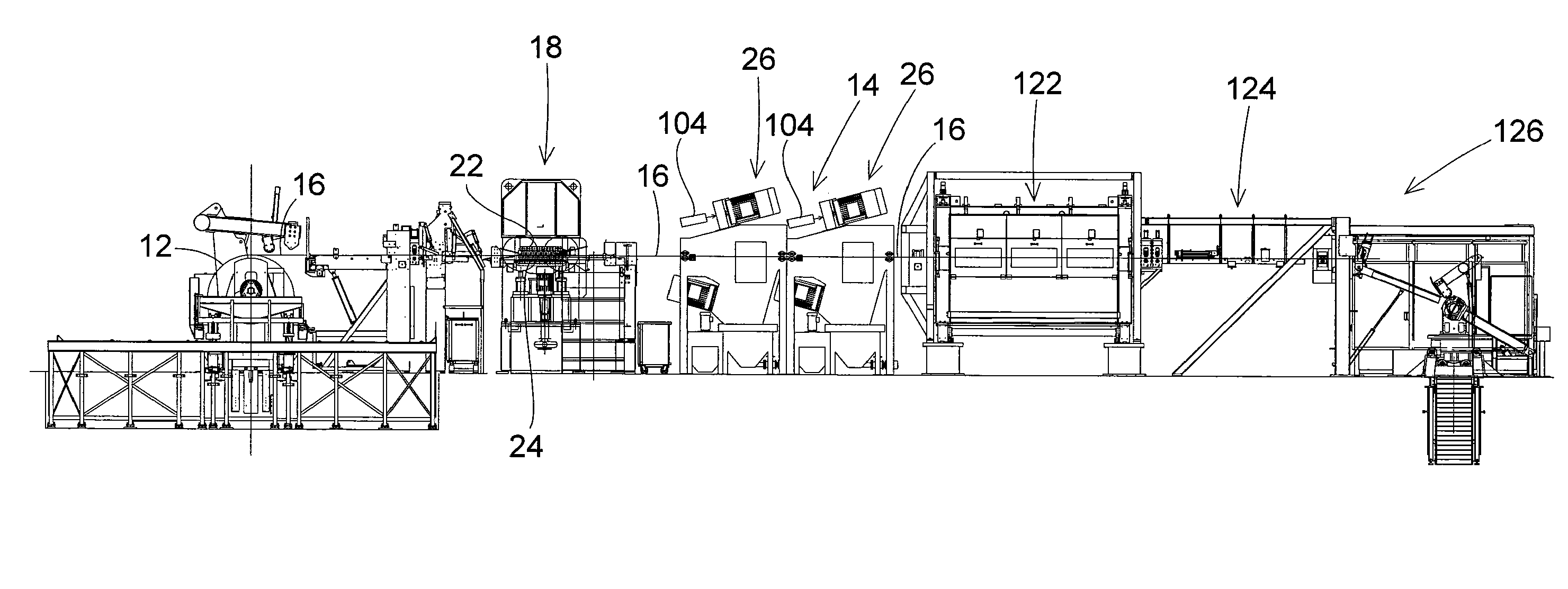

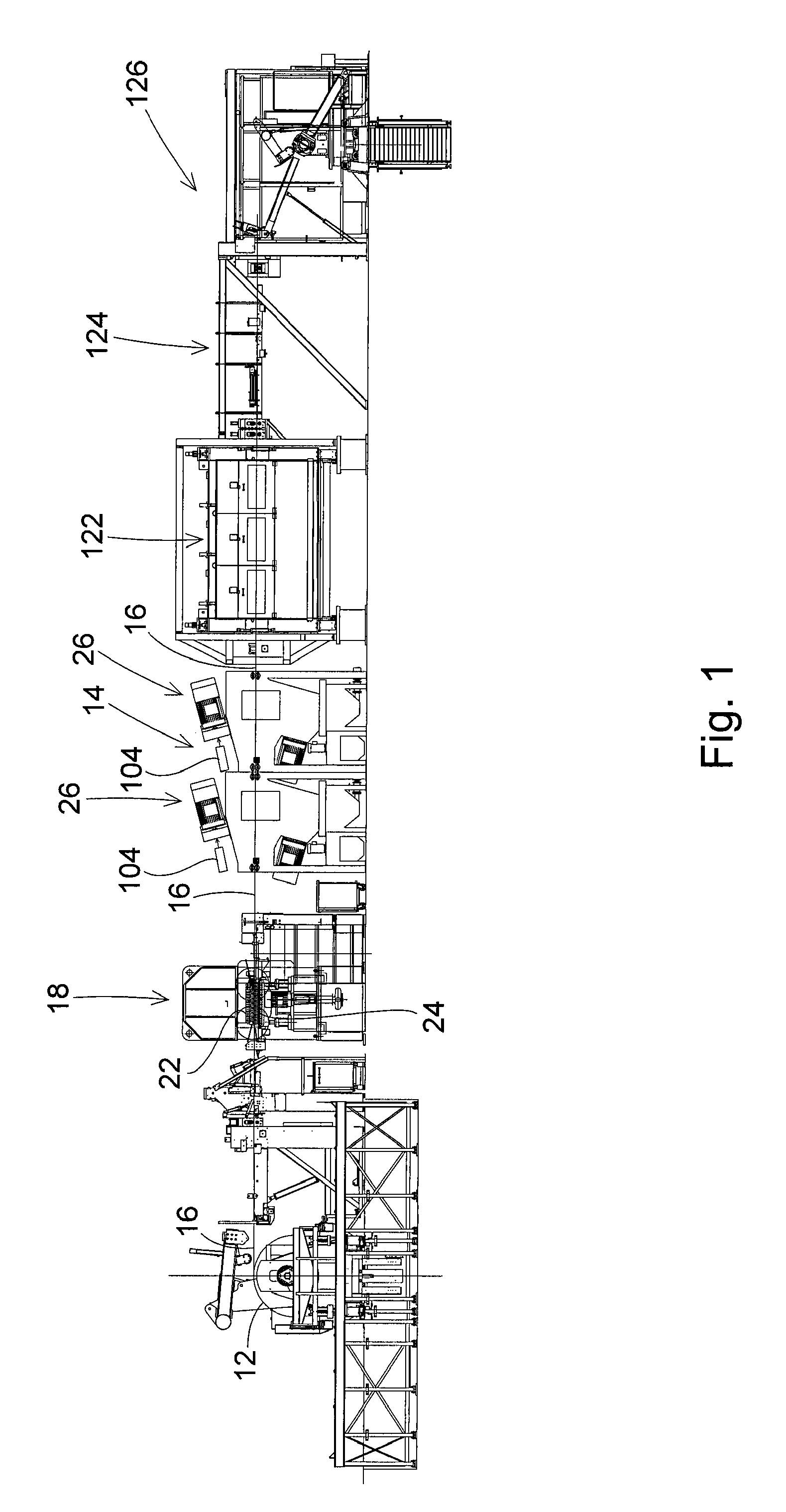

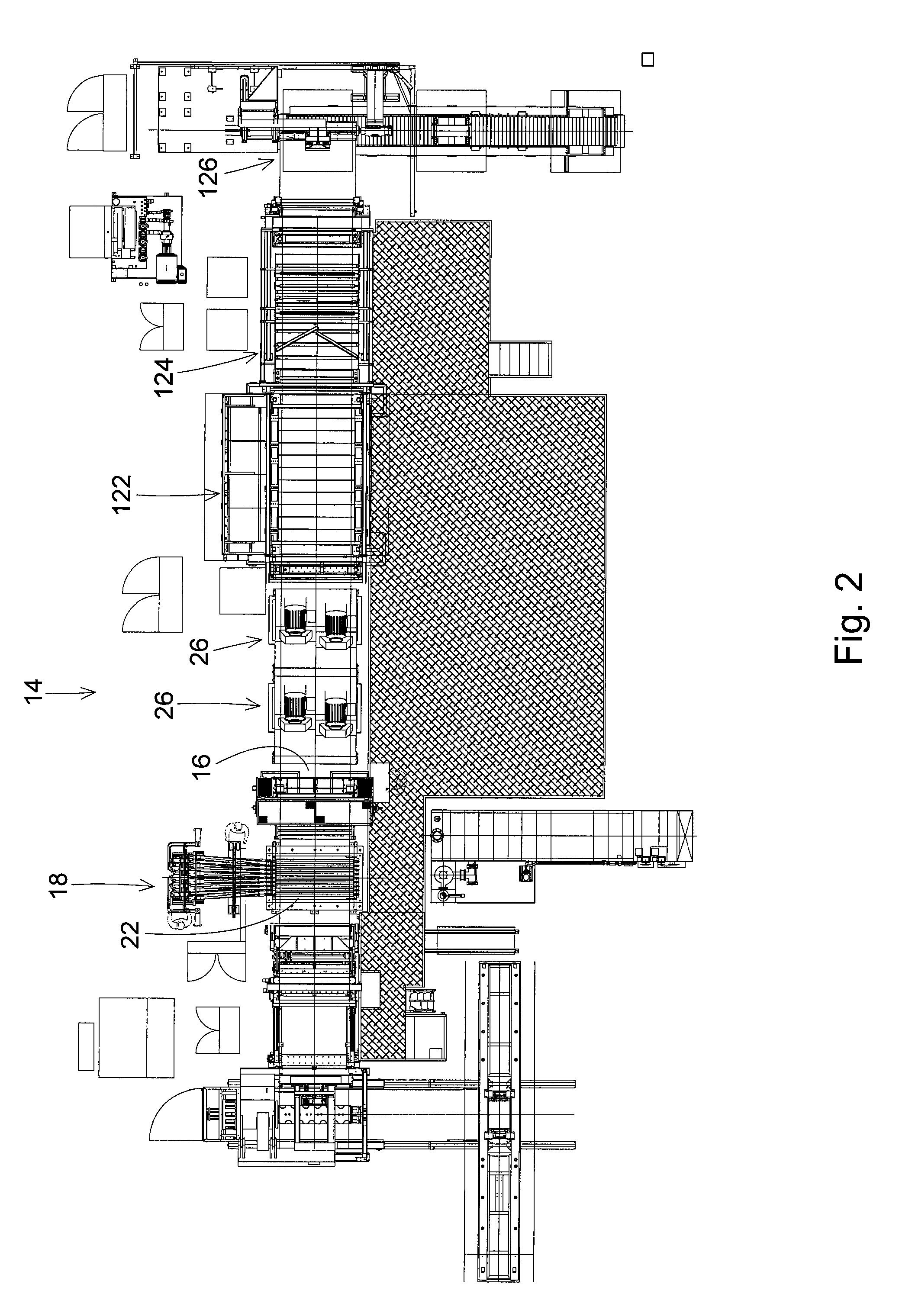

Slurry Blasting Apparatus for Removing Scale From Sheet Metal

ActiveUS20080182486A1Prevent reoxidationAvoid contact damageImpeller wheelsRotor bladesEngineeringMetal

Owner:THE MATERIAL WORKS

Lubricant composition for refrigerator and compressor using the same

ActiveUS20100175421A1Low global warming potentialImprove stabilityWork treatment devicesHeat-exchange elementsAir conditioningBase oil

Provided is a lubricant composition for a refrigerator, which is characterized by using a substance mainly containing a polyoxyalkylene glycol derivative and having a hydroxyl number of 5 mgKOH / g or less, as a base oil. Also provided is a compressor using such the lubricant composition for a refrigerator. The lubricant composition for a refrigerator is used for a refrigerator which uses a refrigerant having a specific structure such as an unsaturated fluorohydrocarbon and being usable in current air-conditioning systems for cars or the like. The lubricant composition for a refrigerator exhibits excellent compatibility with the refrigerant, while having excellent stability. The compressor uses such the lubricant composition for a refrigerator.

Owner:IDEMITSU KOSAN CO LTD +2

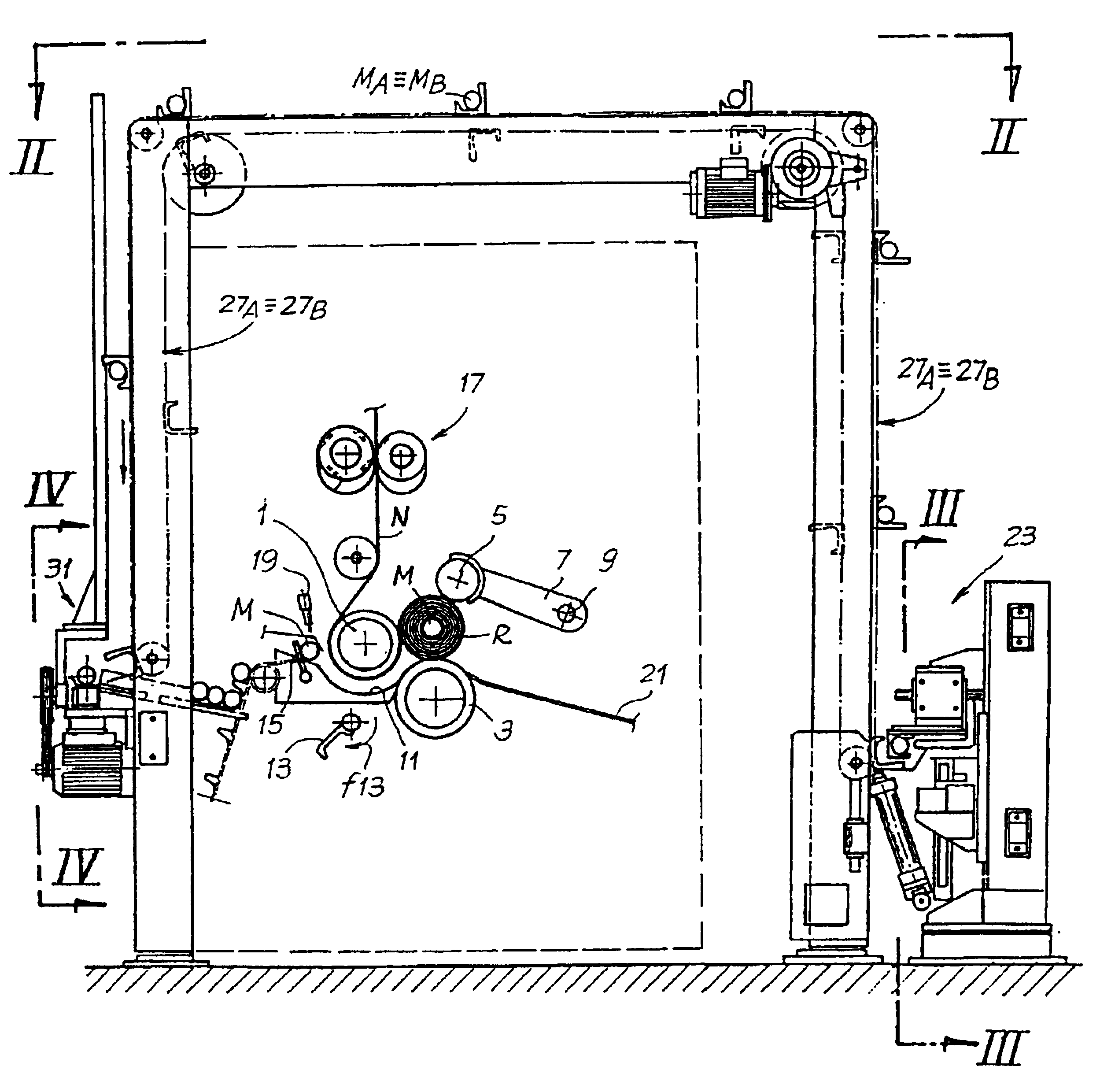

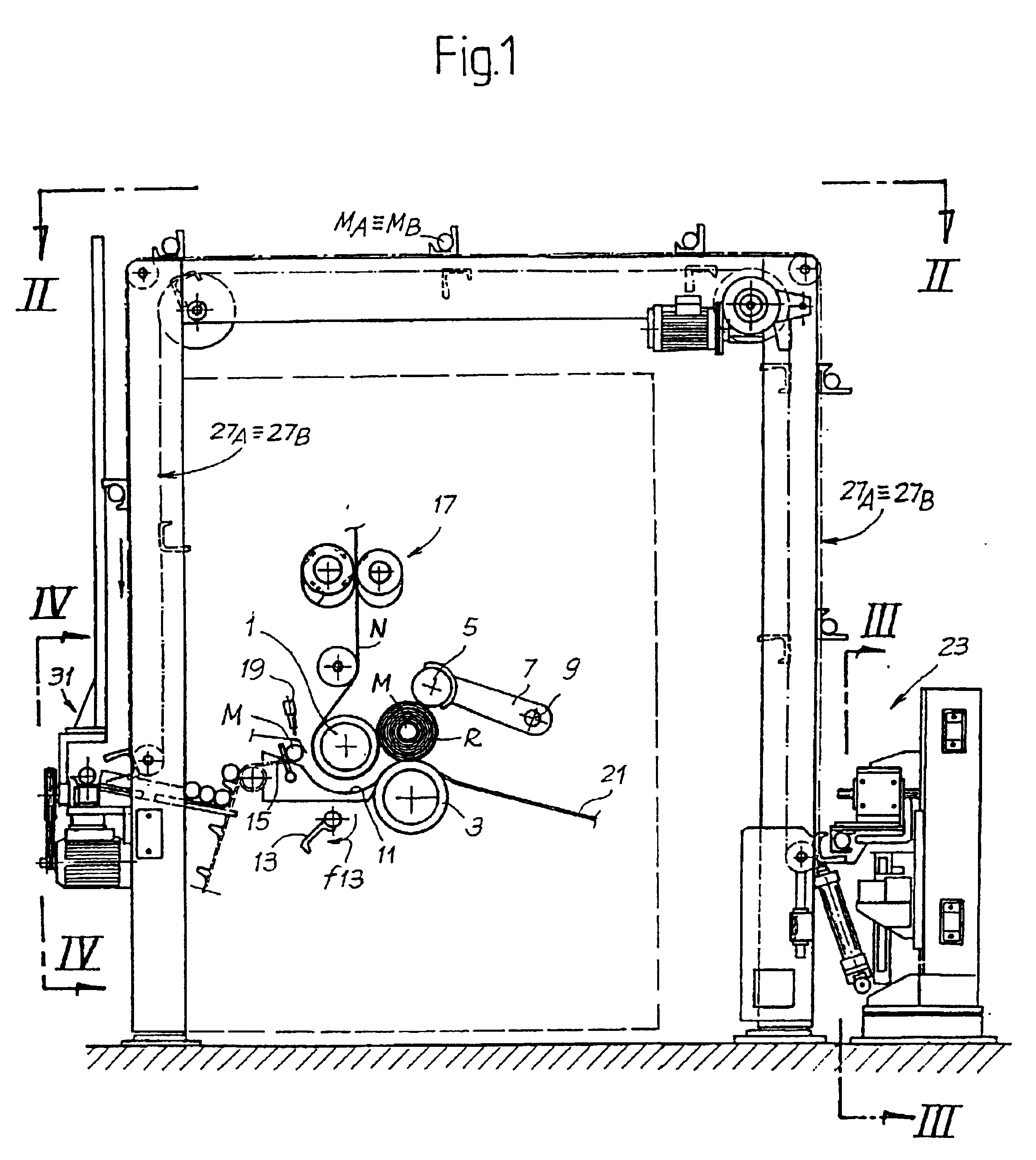

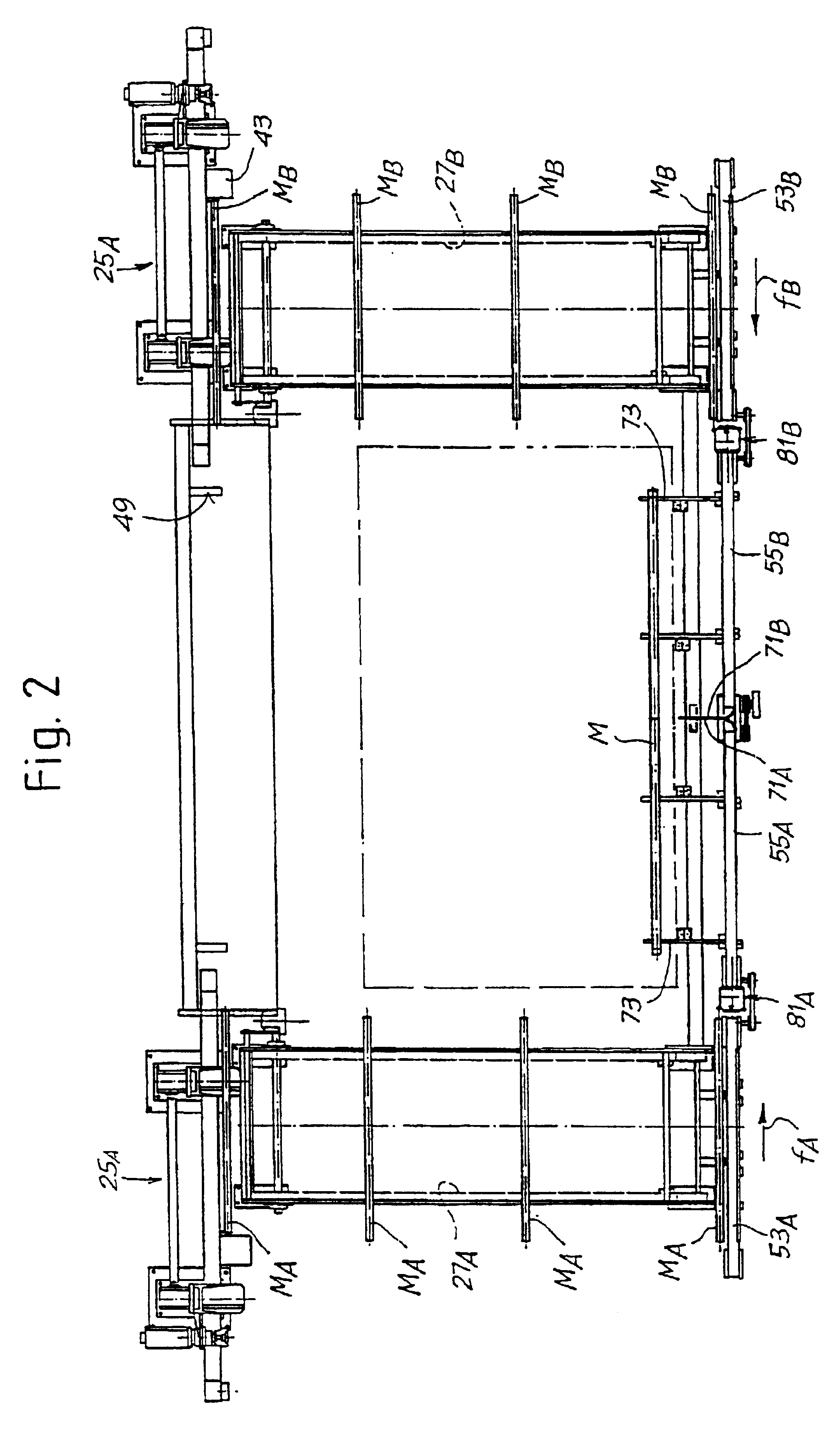

Rewinding machine and method for winding up rolls of weblike material on extractable mandrels

InactiveUS6752345B2Effective and reliable anchoring of free lengthFilament handlingHollow article cleaningEngineeringConductor Coil

The rewinding machine for the production of rolls of weblike material comprises: a winding-up system (1, 3, 5) for winding up the weblike material on winding-up mandrels (M), and an extractor (23) for separating the mandrels from the respective rolls formed thereon. A device for washing the mandrels is also provided.

Owner:FABIO PERINI SPA

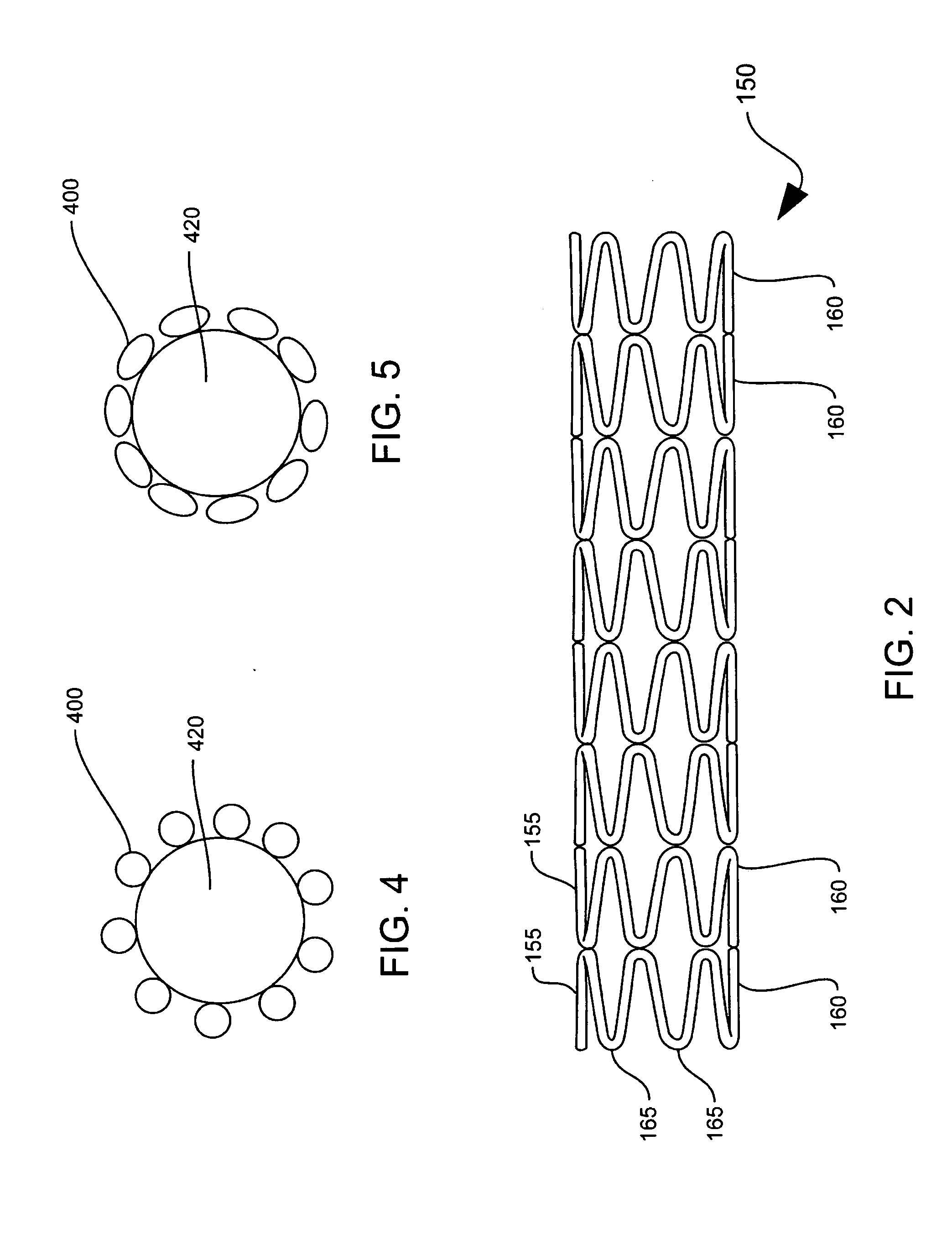

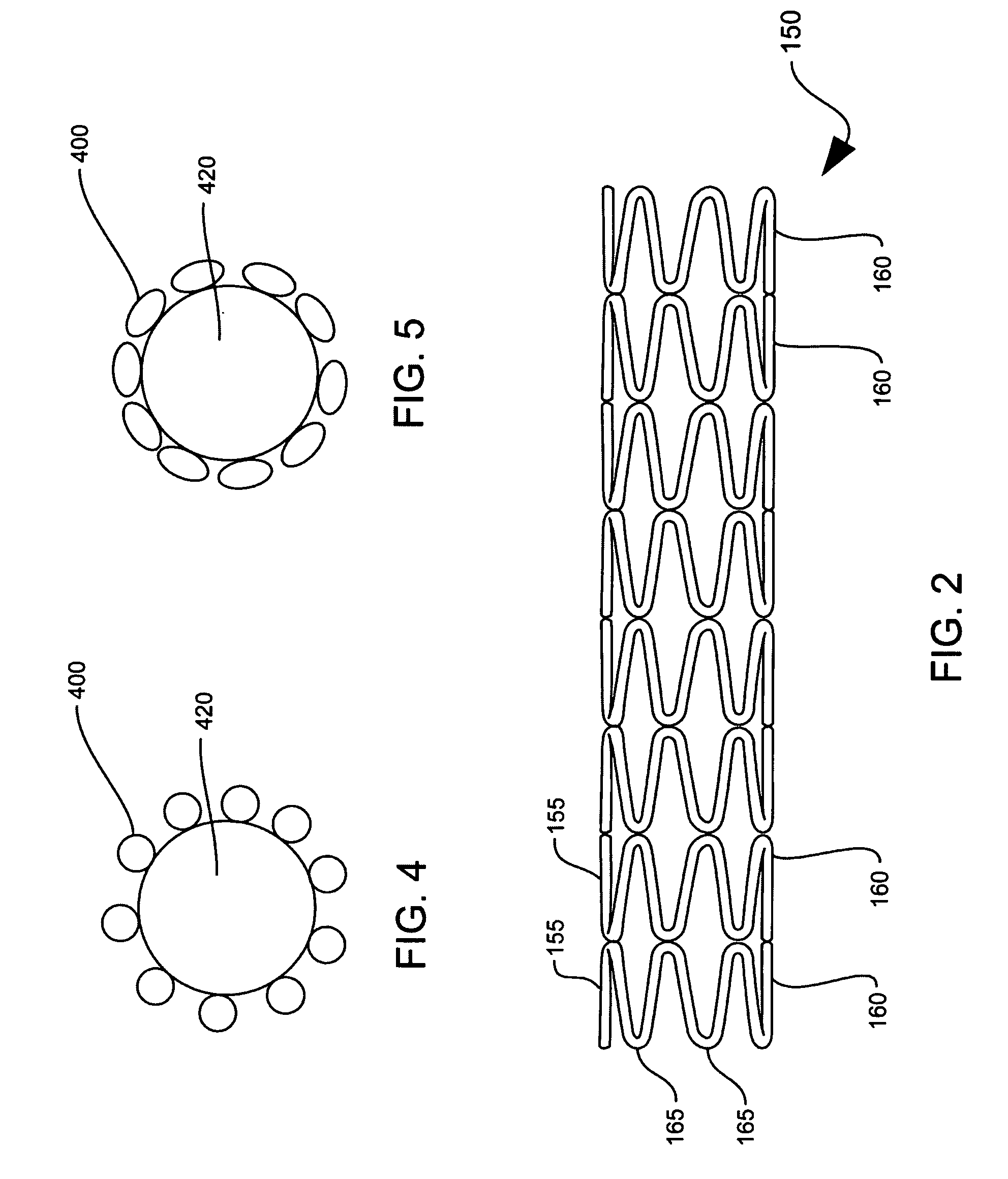

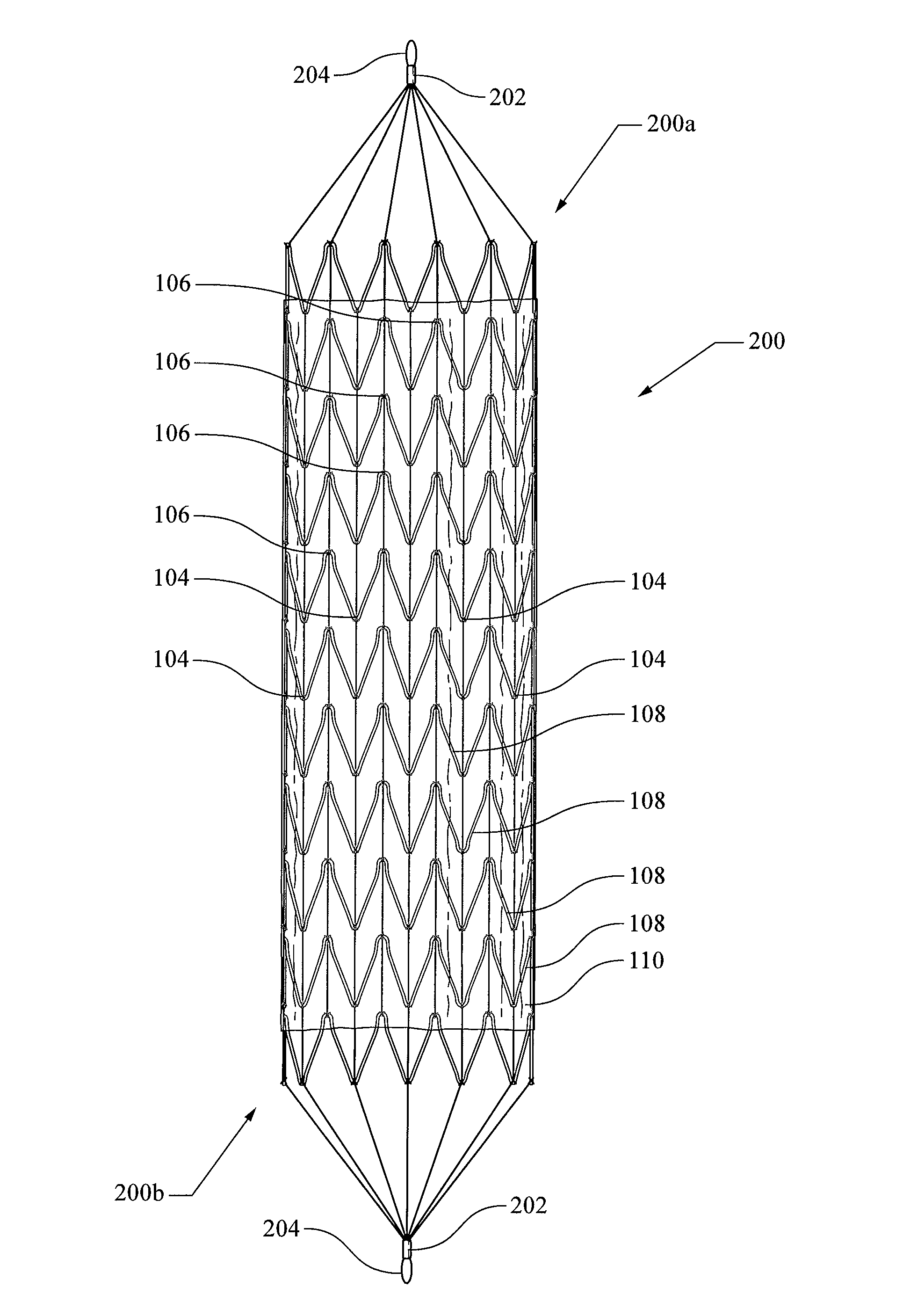

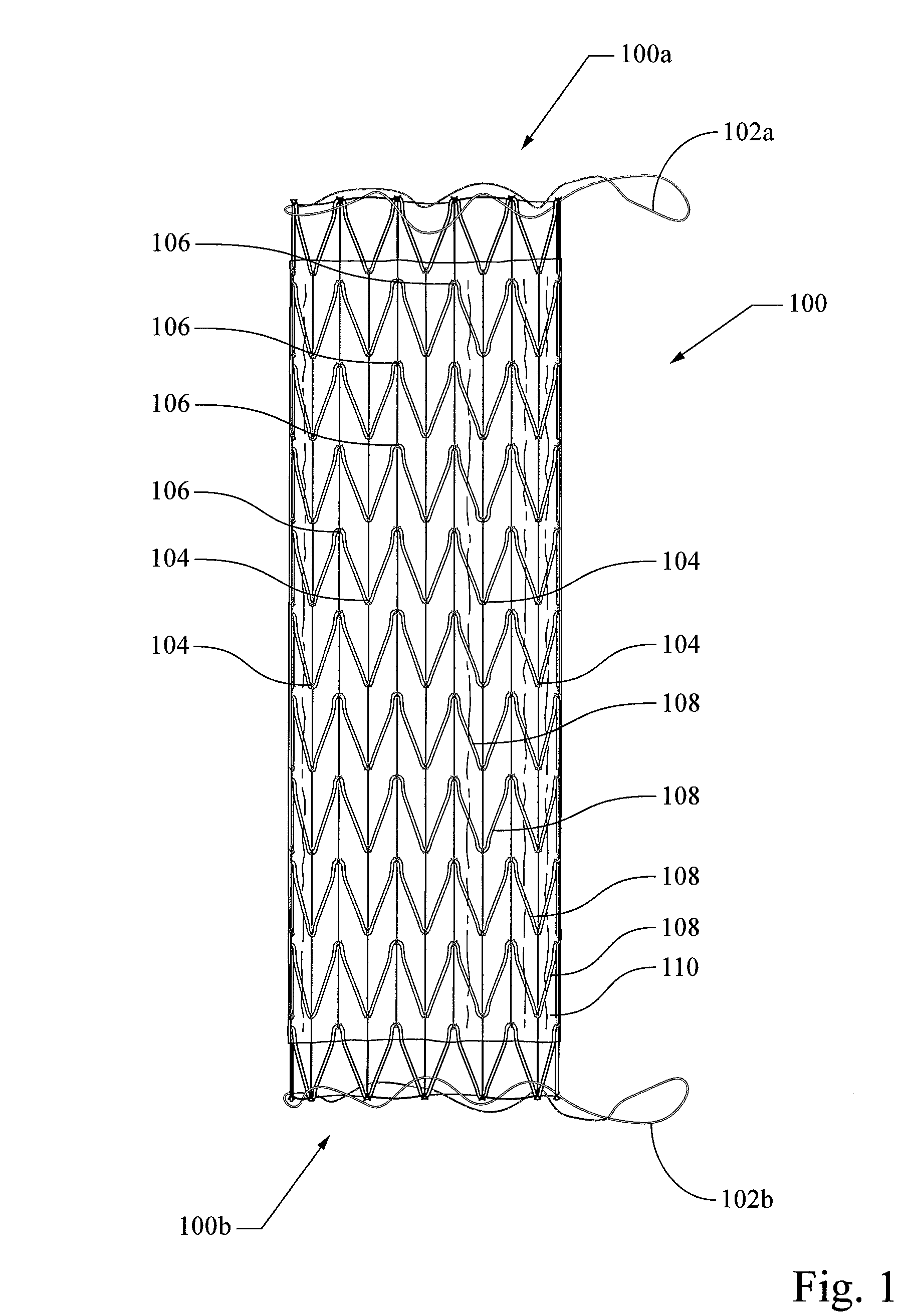

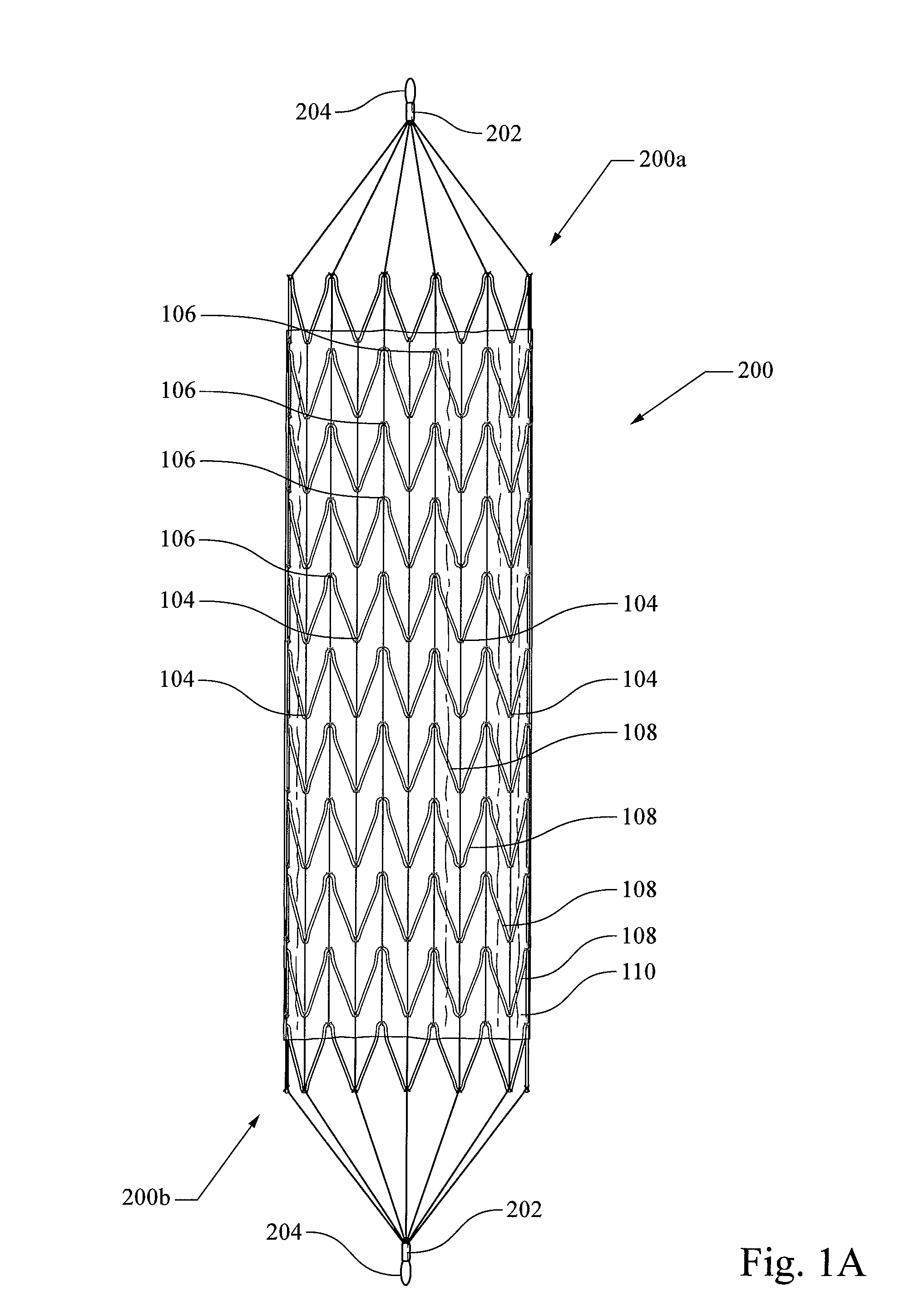

Non-foreshortening, axial tension constrainable stent

Methods and devices for a non-foreshortening, axial tension constrainable stent are illustrated such that a length of the stent in a collapsed state is about equal to the length of the stent in an expanded state which provides for better stent placement, easier repositioning and removal, and reduced stent migration.

Owner:COOK MEDICAL TECH LLC

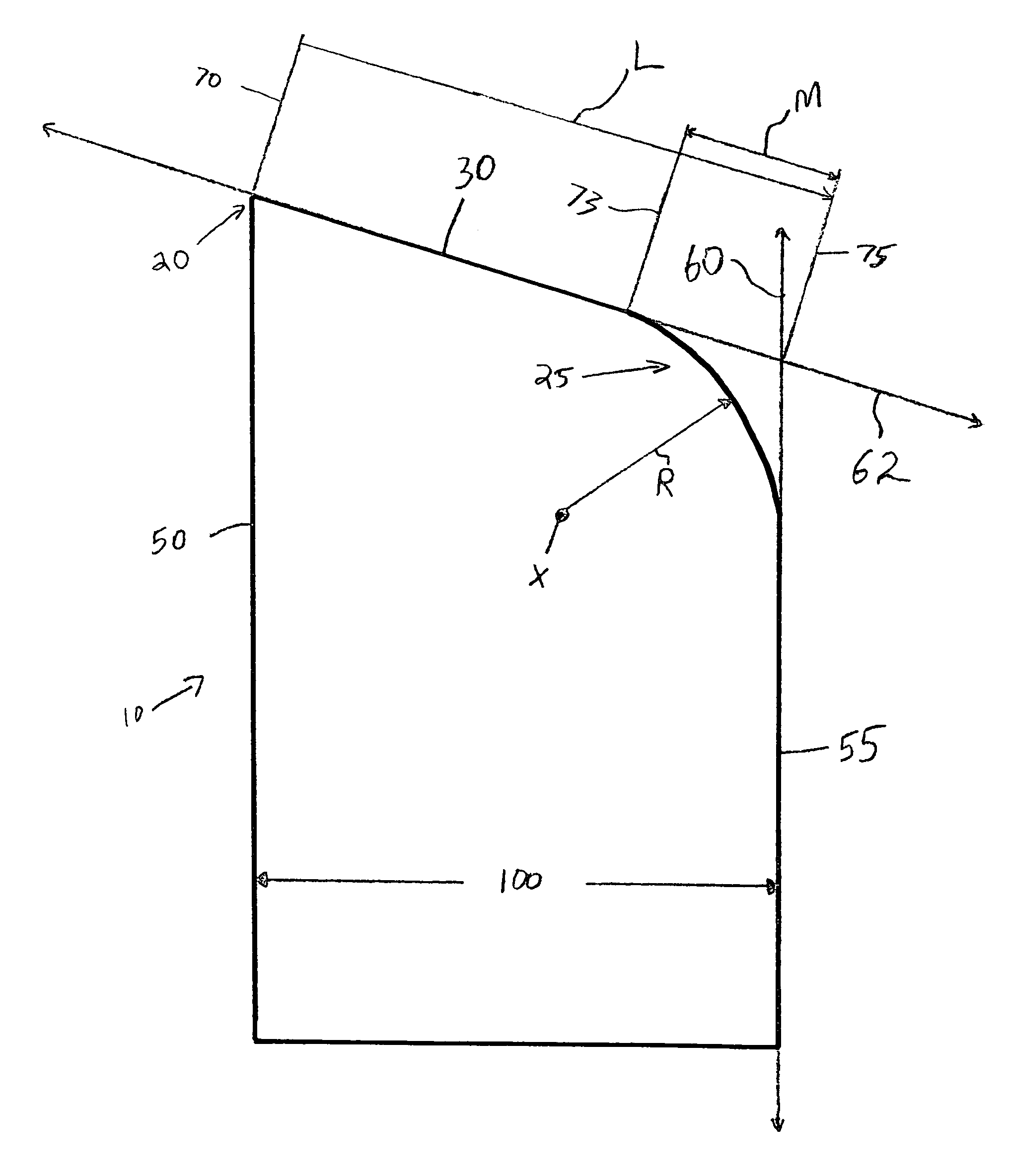

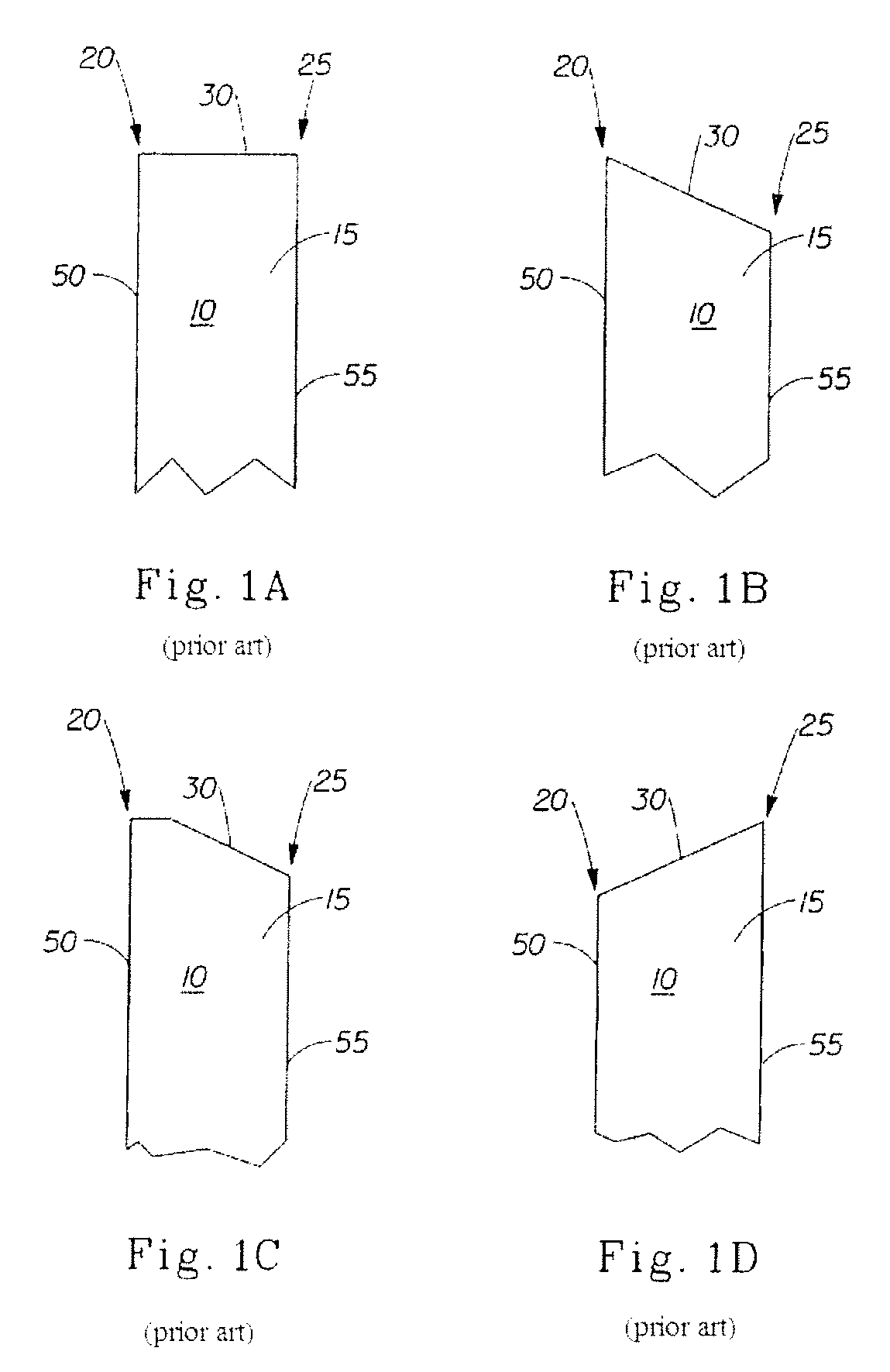

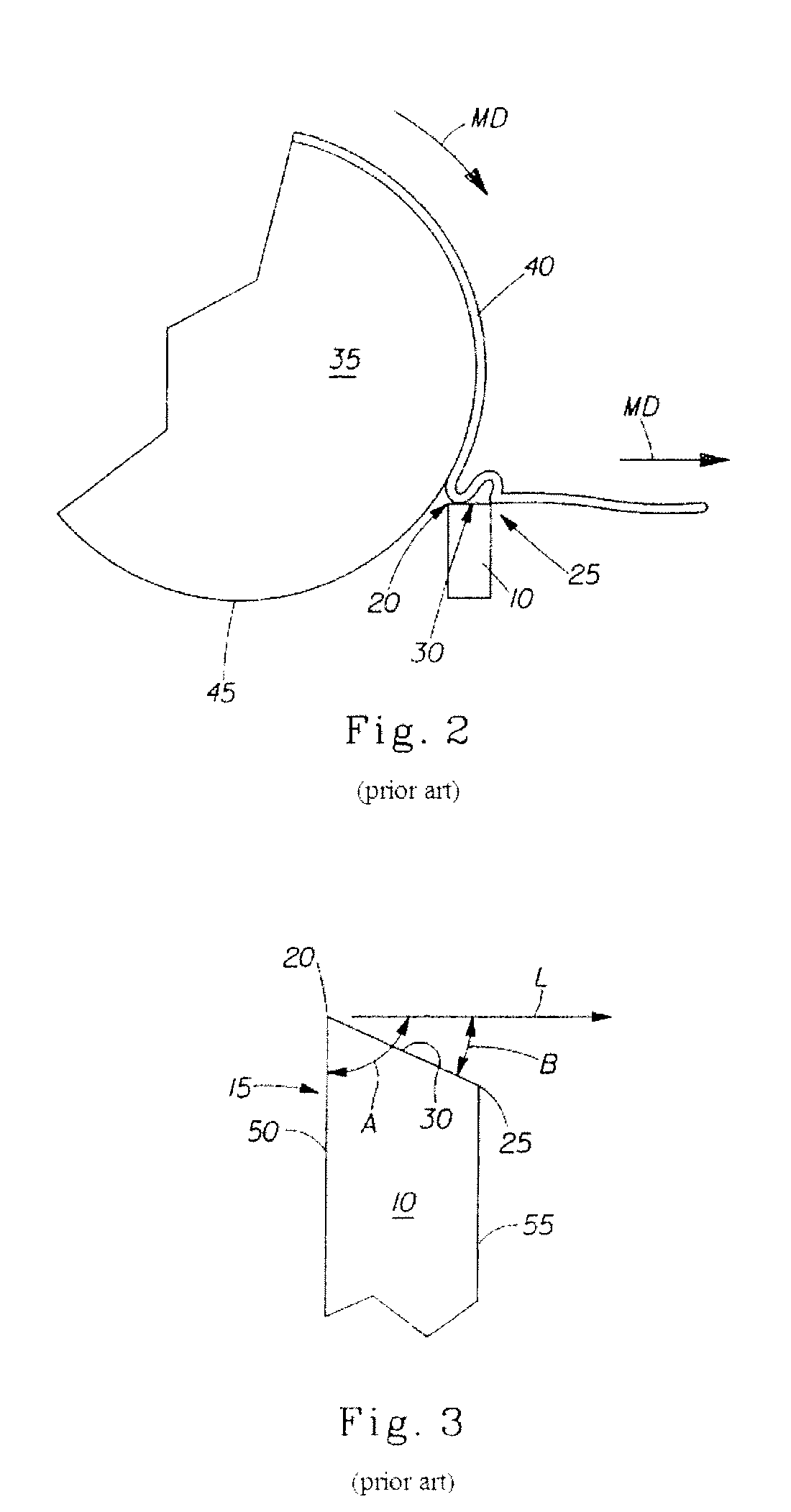

Creping blade

A creping blade including a body having a leading side, a trailing side, and working end including a bevel surface. The bevel surface is defined by a leading edge and a trailing edge, wherein the trailing edge of the creping blade has a trailing edge radius of greater than about 0.001 inches (about 0.0254 mm).

Owner:PROCTER & GAMBLE CO

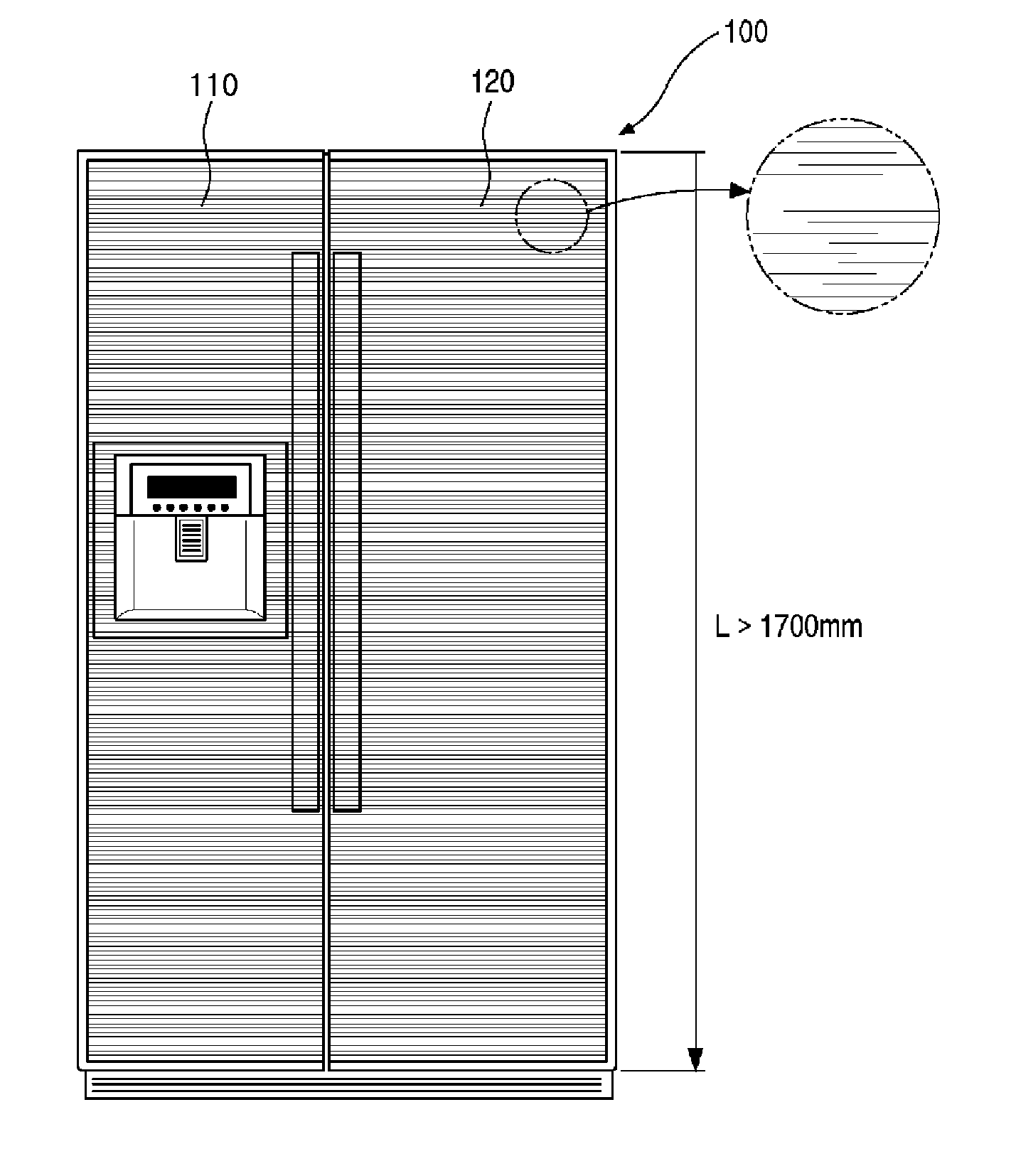

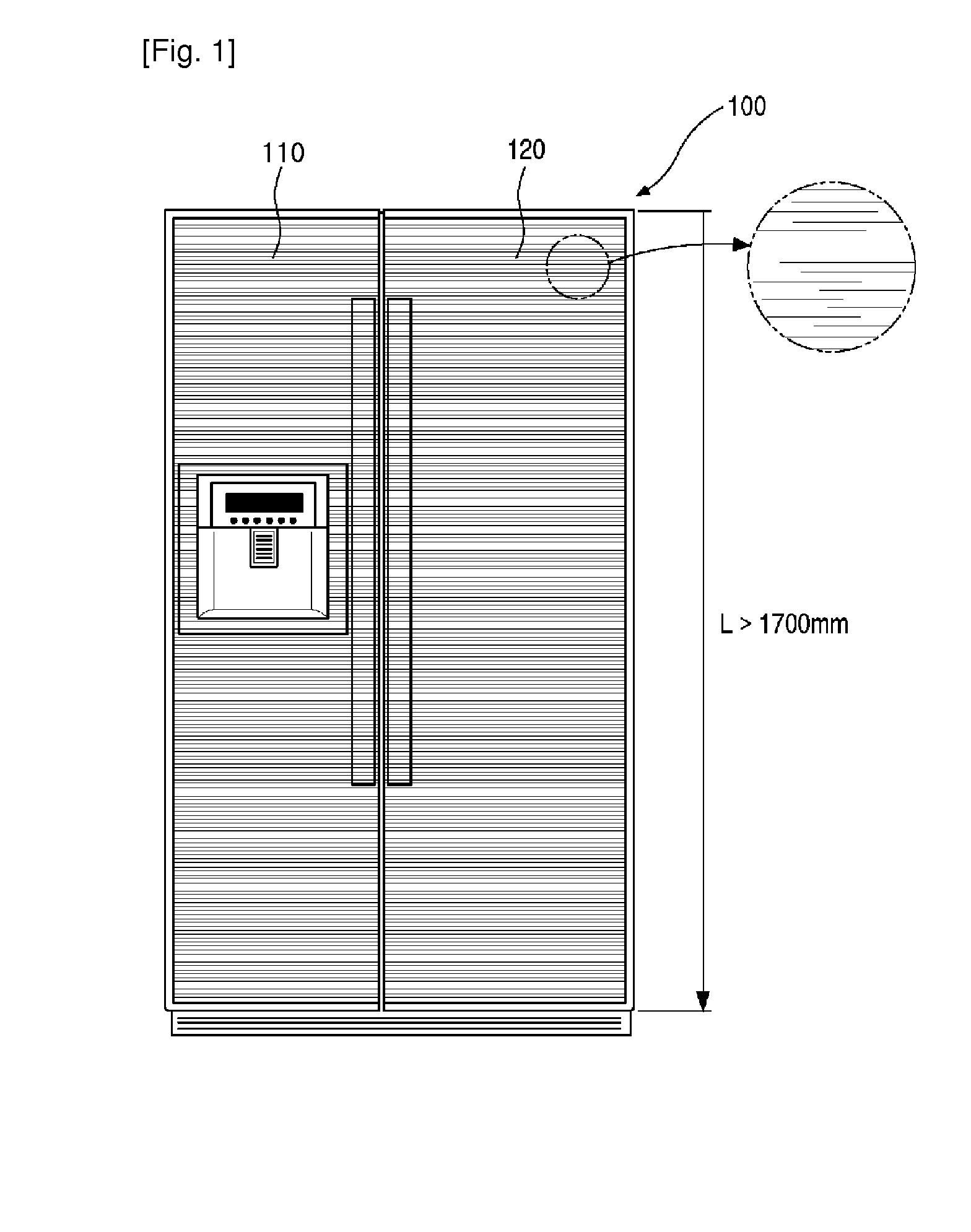

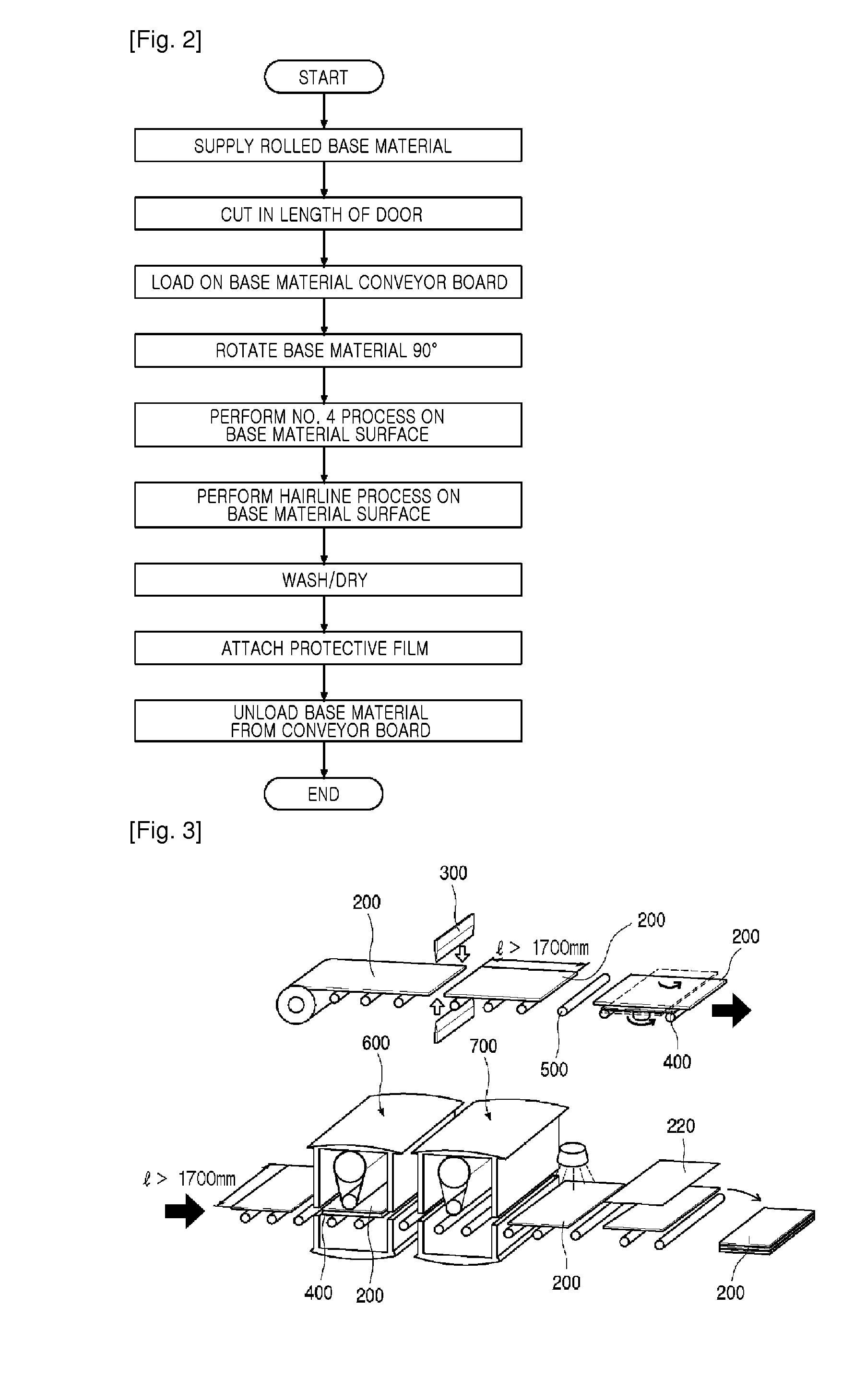

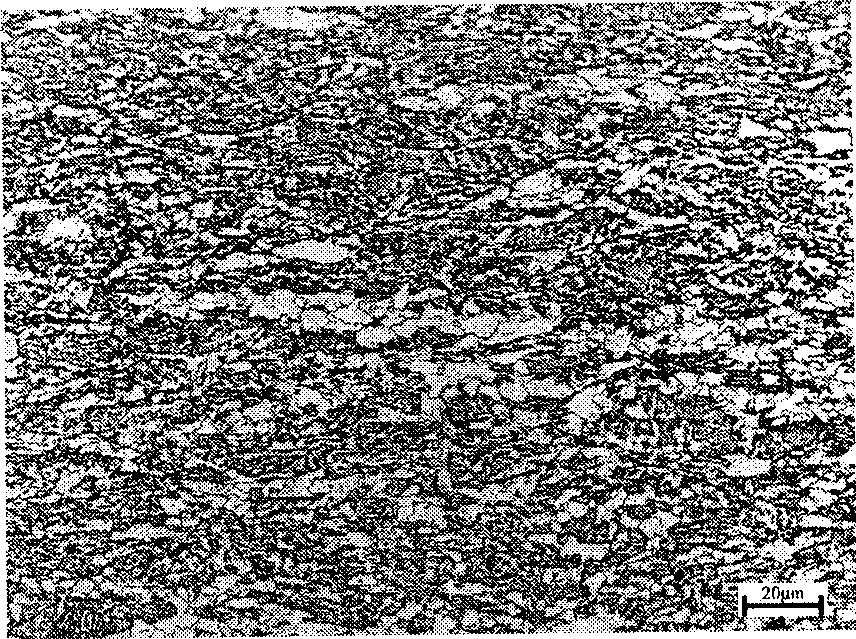

Steel plate for refrigerator door and manufacturing method thereof

InactiveUS20100206464A1Increase brightnessReduce reflectivityLamination ancillary operationsLighting and heating apparatusRefrigerator carSheet steel

Provided are a steel plate for a refrigerator door and a method for manufacturing the steel plate. The steel plate includes a stainless steel plate provided on and forming an exterior of a refrigerator door with a vertical length of 1250 mm or more. The stainless steel plate surface is processed to form a finished texture oriented in a horizontal direction with respect to the refrigerator door. The method includes cutting a section from a rolled stainless steel plate base material corresponding in length to a length of a refrigerator door, rotating the cut section by a 90° angle, and surface processing through grinding a surface of the cut section in a direction perpendicular to a rolled direction thereof.

Owner:LG ELECTRONICS INC

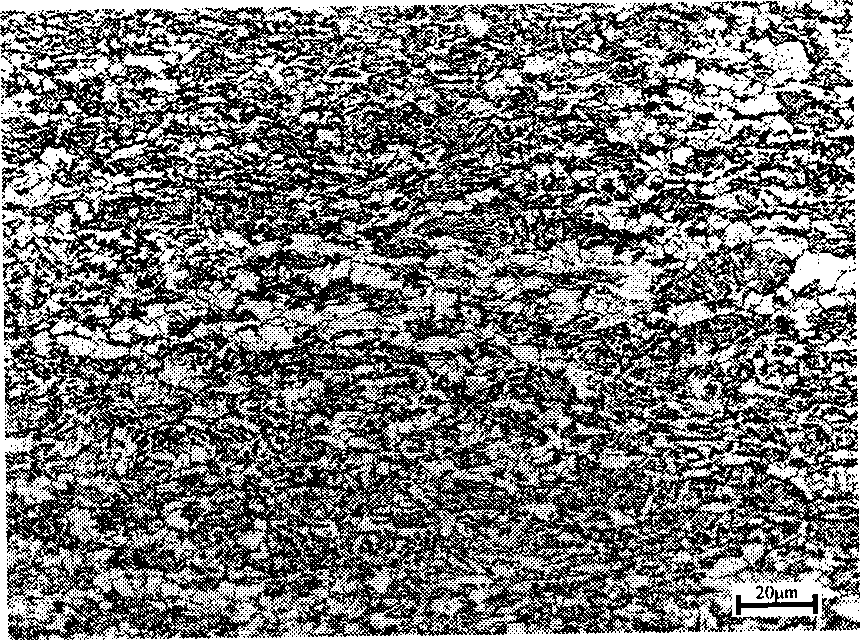

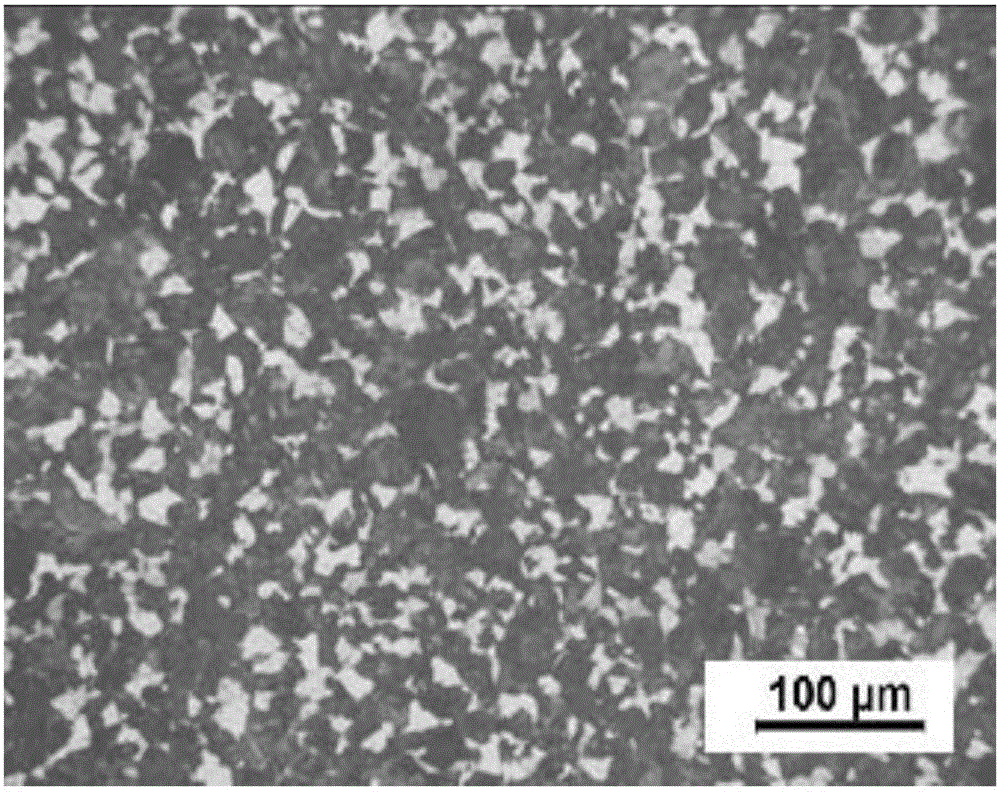

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

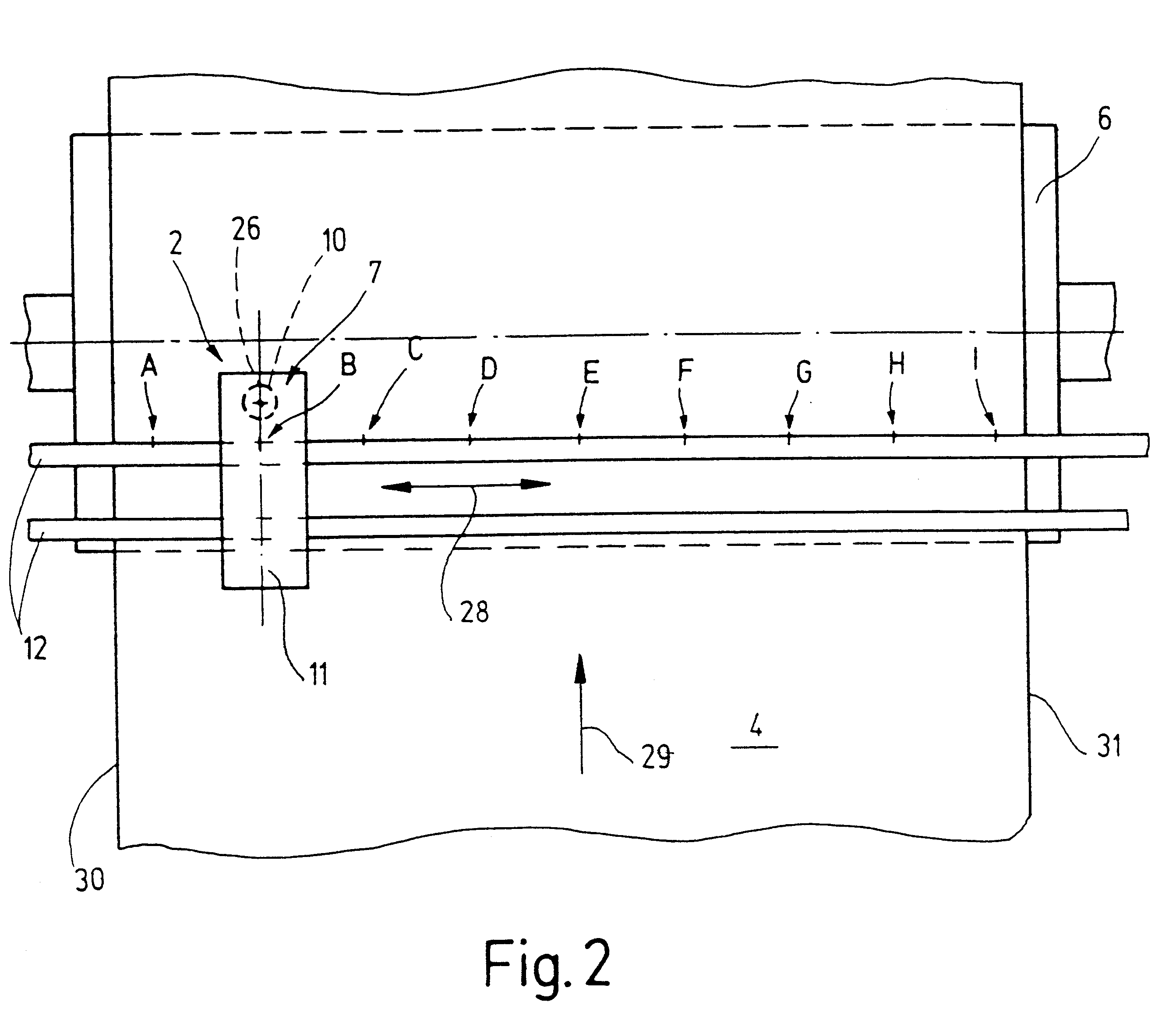

Process for cleaning a transport belt

InactiveUS6364959B1Reduce movement speedUniform and intense and cleaningCleaningWork treatment devicesEngineeringNozzle

A process and apparatus for cleaning a transport belt of a machine for the production or processing a web. The apparatus includes at least one nozzle device composed of a rotatable nozzle head having at least one cleaning nozzle, a transport device including a crosspiece extending substantially crosswise to a transport belt travel direction, in which the at least one nozzle device is coupled to the transport device and adapted for displacement along the crosspiece. A traversing speed of the nozzle device is very low and falls within a range of between approximately 1 mm / min and 10 mm / min. Alternatively, the at least one nozzle is positionable in a plurality of cleaning positions that are successively arranged crosswise to the transport belt, and the at least one nozzle is held stationary in each respective cleaning position for a predefined time period. The process includes displacing the at least one cleaning nozzle at a very slow traversing speed within a range of between approximately 1 mm / min and 10 mm / min. Alternatively, the process includes discontinuously moving the at least one cleaning nozzle to a plurality of cleaning positions successively arranged in a transport belt travel direction, positioning the at least one nozzle to remain in the cleaning positions for a predefined period of time, and rapidly displacing the at least one nozzle between adjacent cleaning positions.

Owner:VOITH PATENT GMBH

Refrigerator oil, compressor oil composition, hydraulic fluid composition, metalworking fluid composition, heat treatment oil composition, lubricant composition for machine tool and lubricant composition

ActiveUS20100093568A1Improve the level ofImprove balanceGroup 4/14 element organic compoundsOrganic compound preparationChemical compositionMetalworking fluid

The present invention provides a refrigerating machine oil, a compressor oil composition, a hydraulic oil composition, a metalworking oil composition, a heat treating oil composition, a lubricating oil composition for machine tools and a lubricating oil composition which comprise a lubricating oil base oil having % CA of not more than 2, % CP / % CN of not less than 6 and an iodine value of not more than 2.5.

Owner:NIPPON OIL CORP

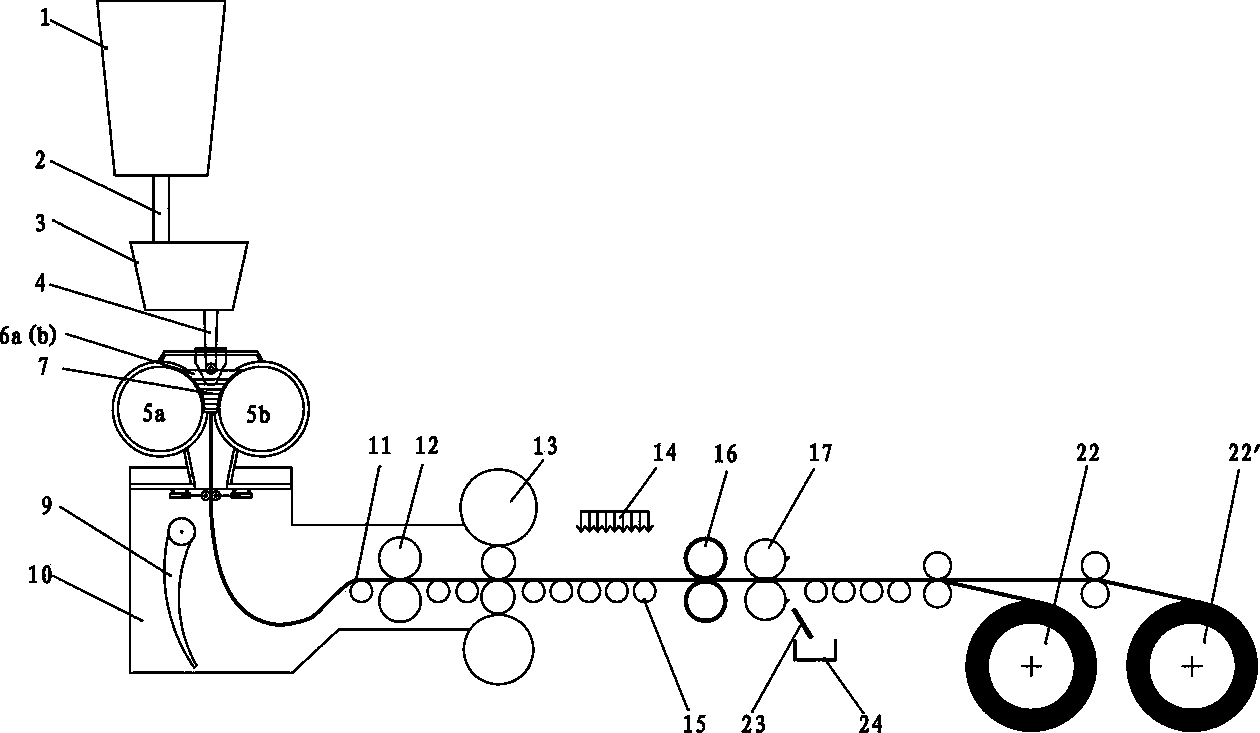

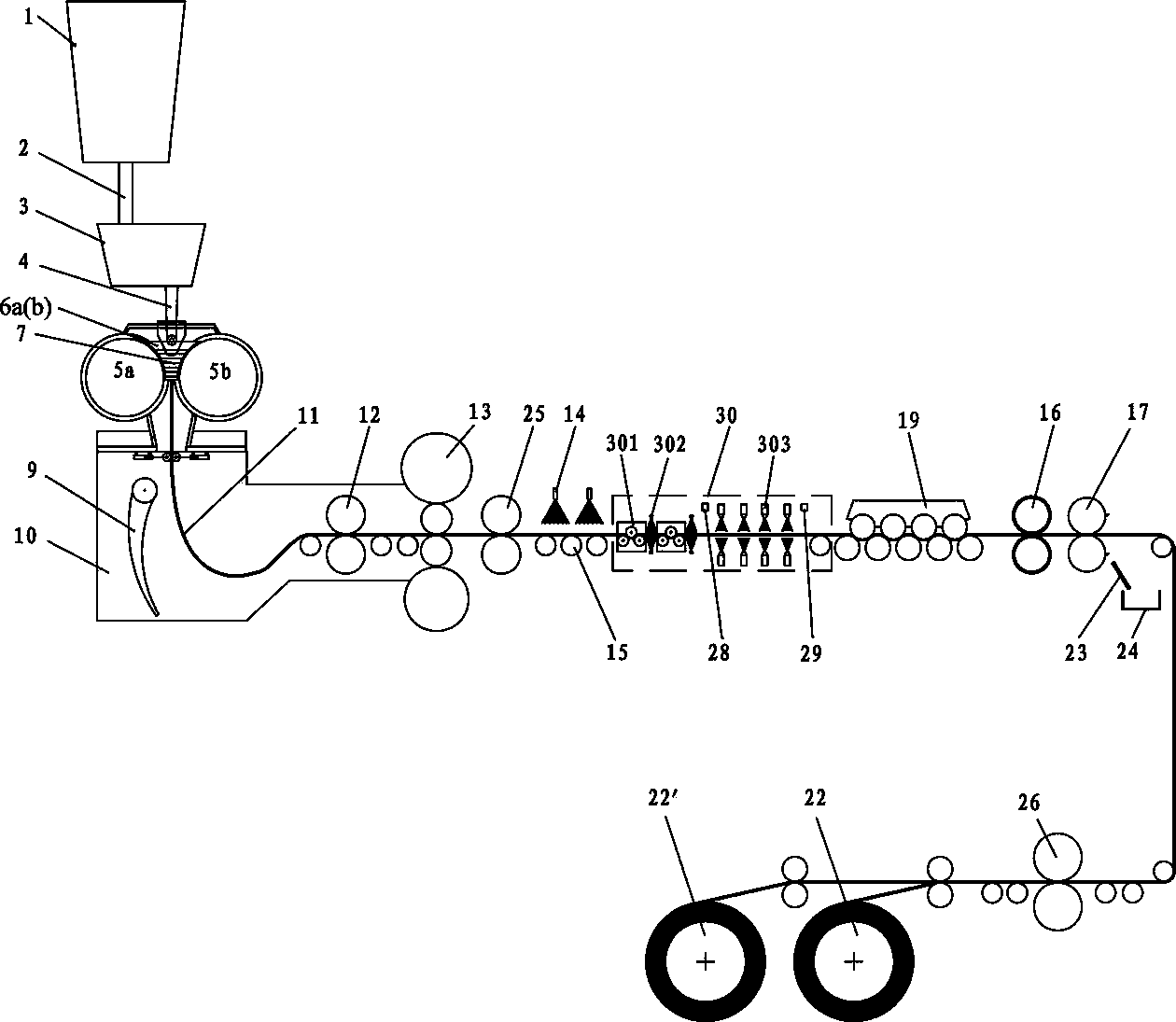

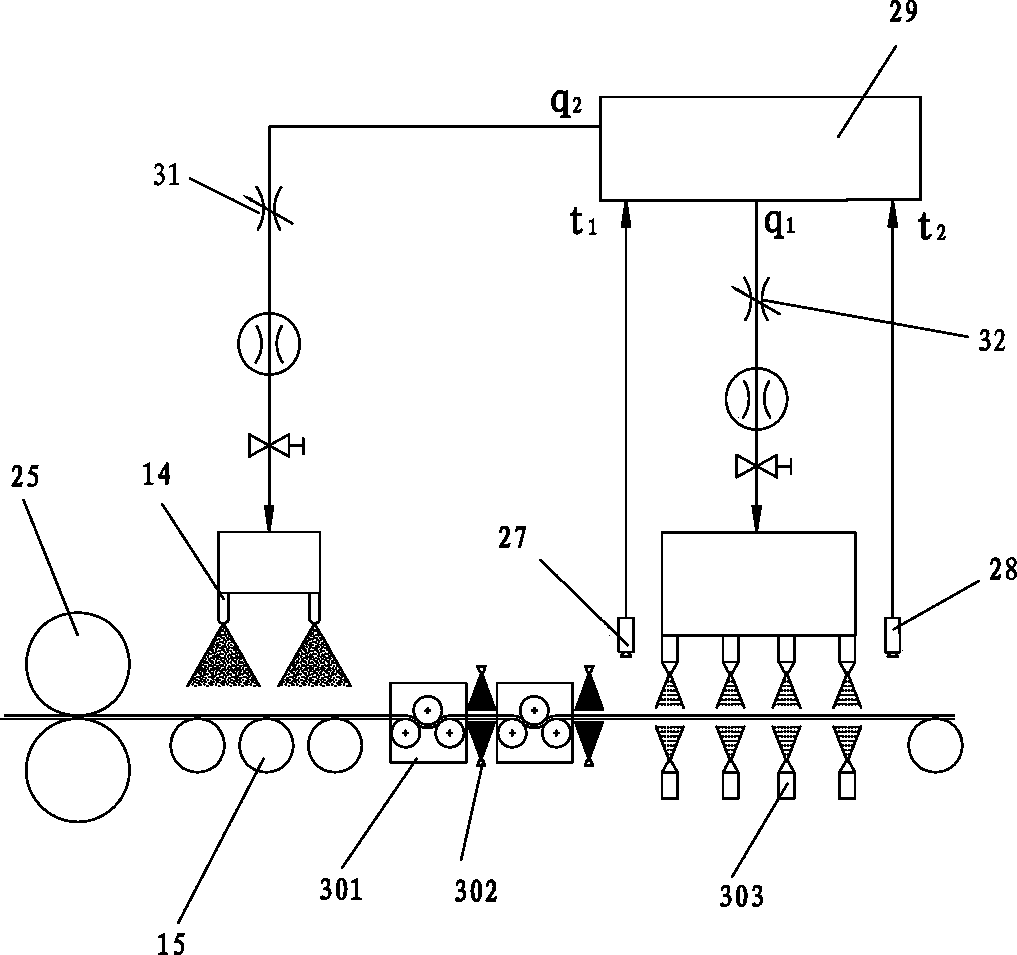

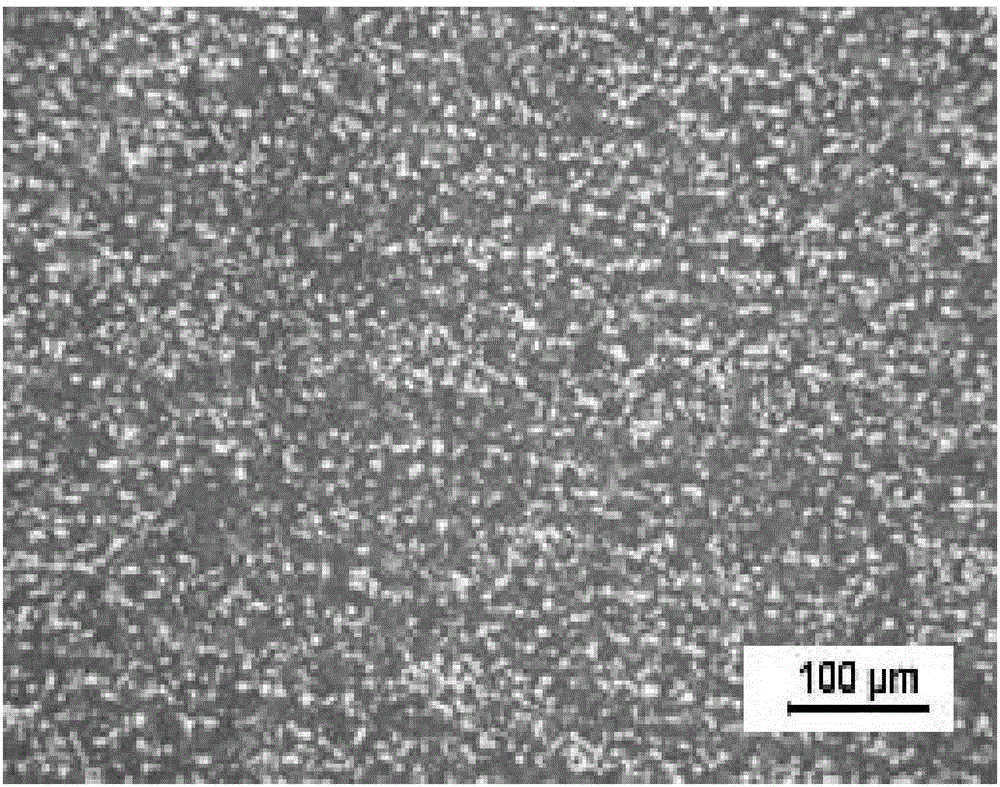

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

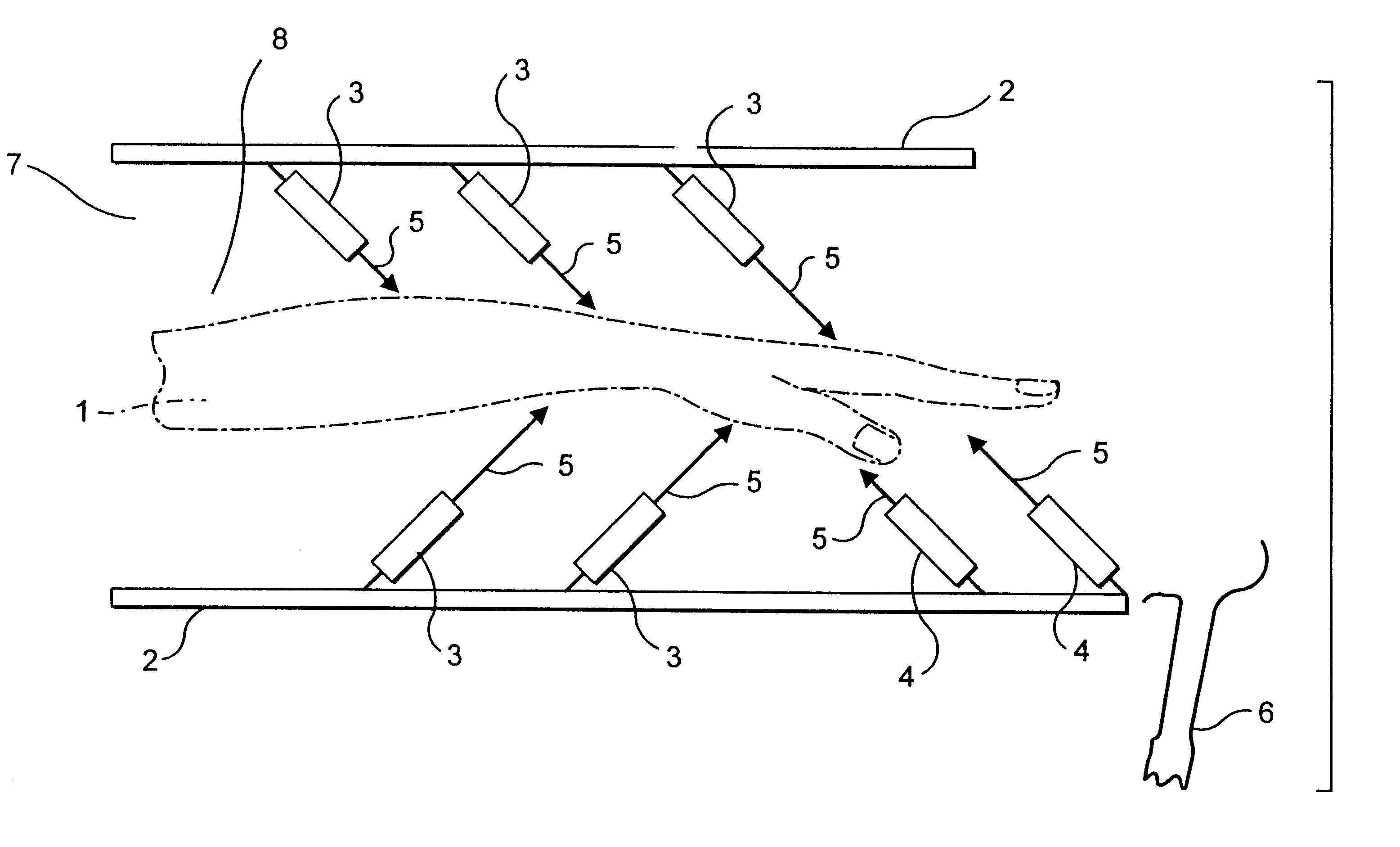

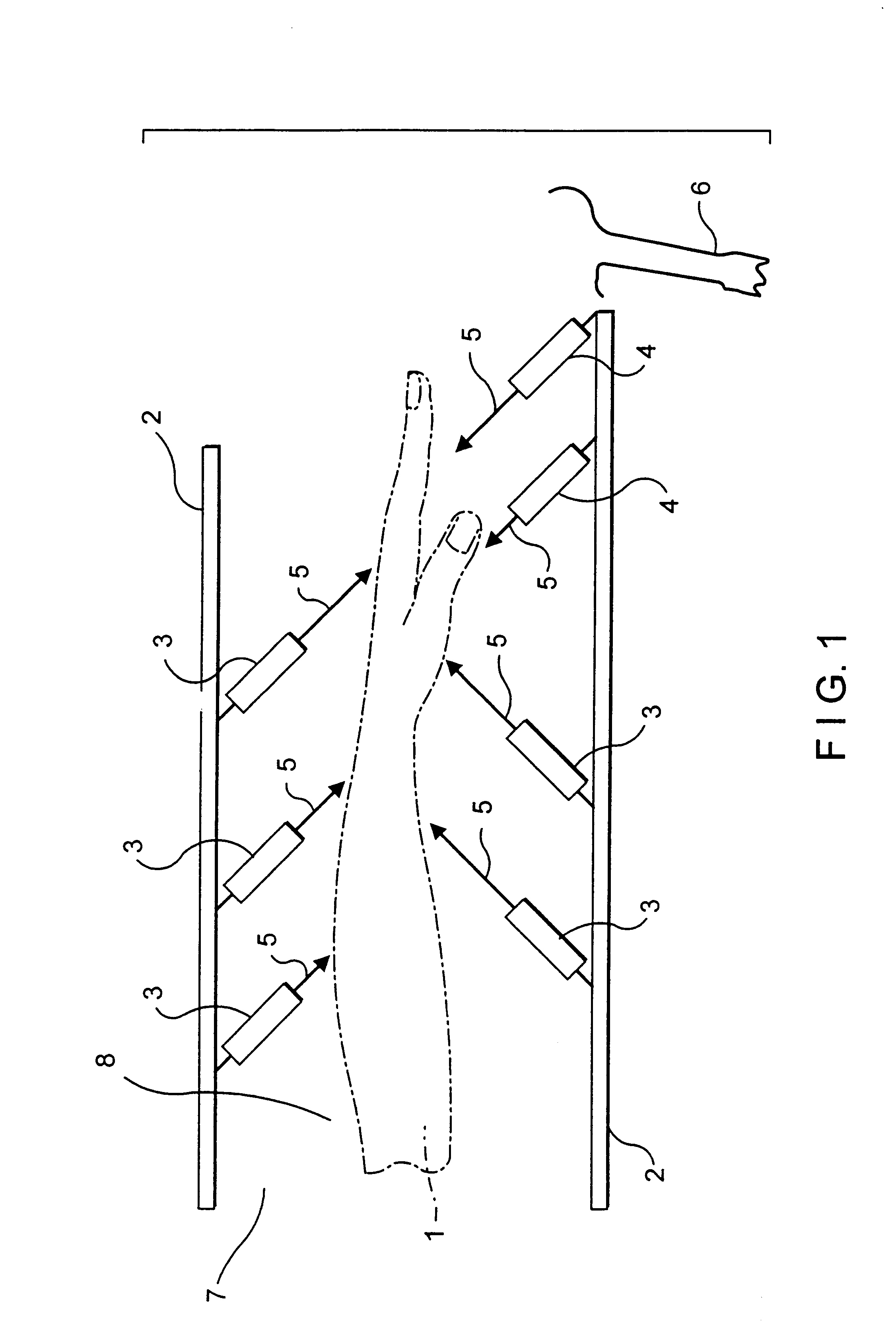

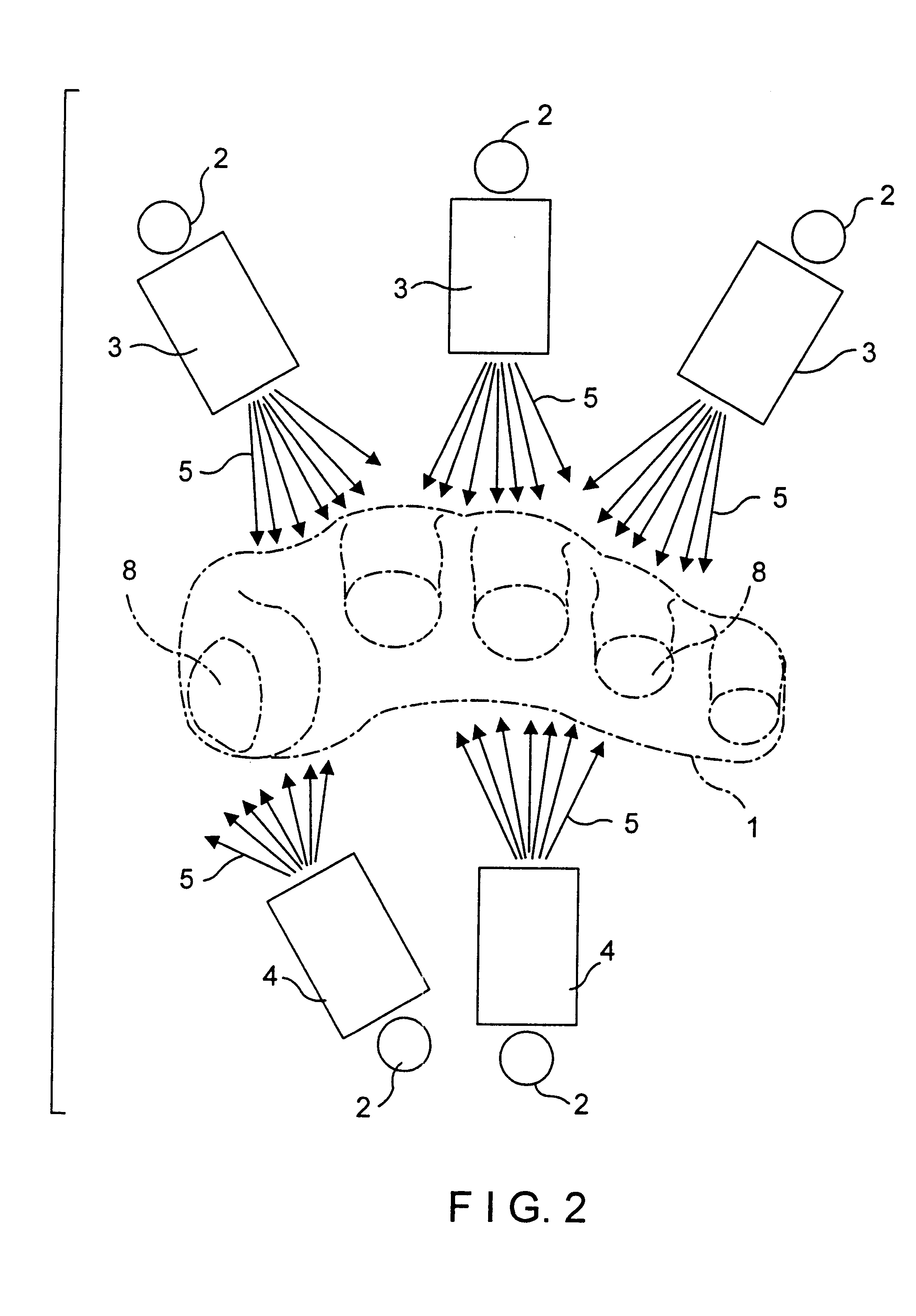

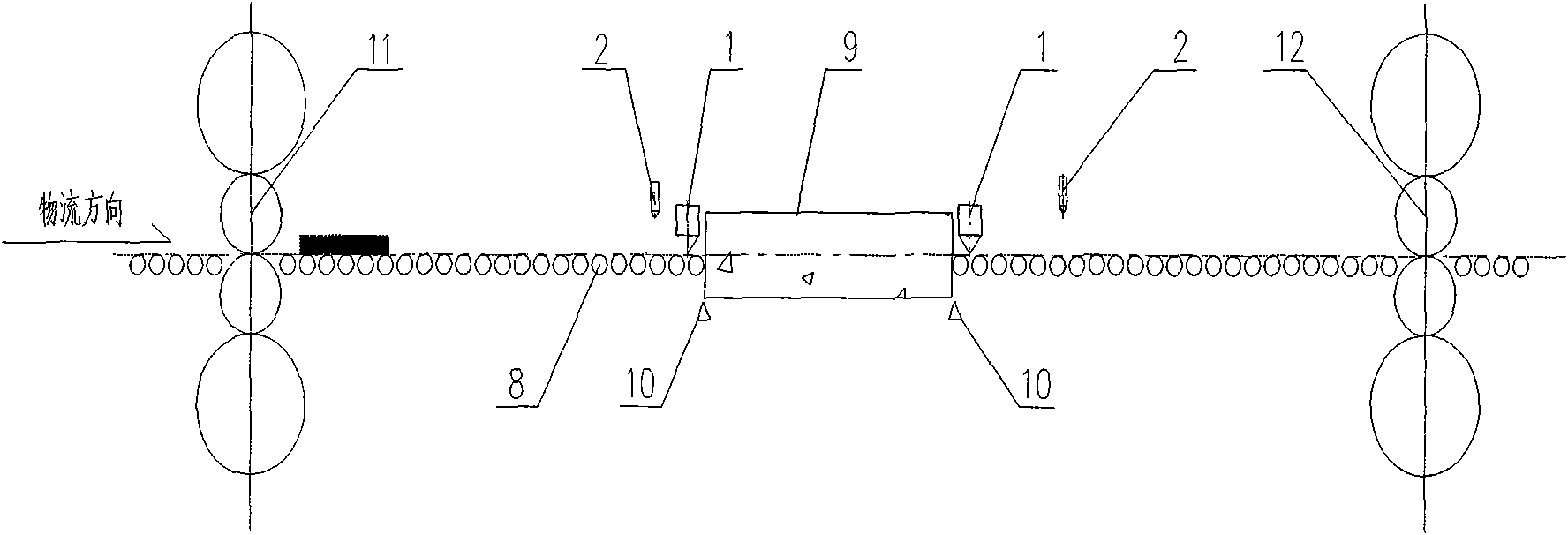

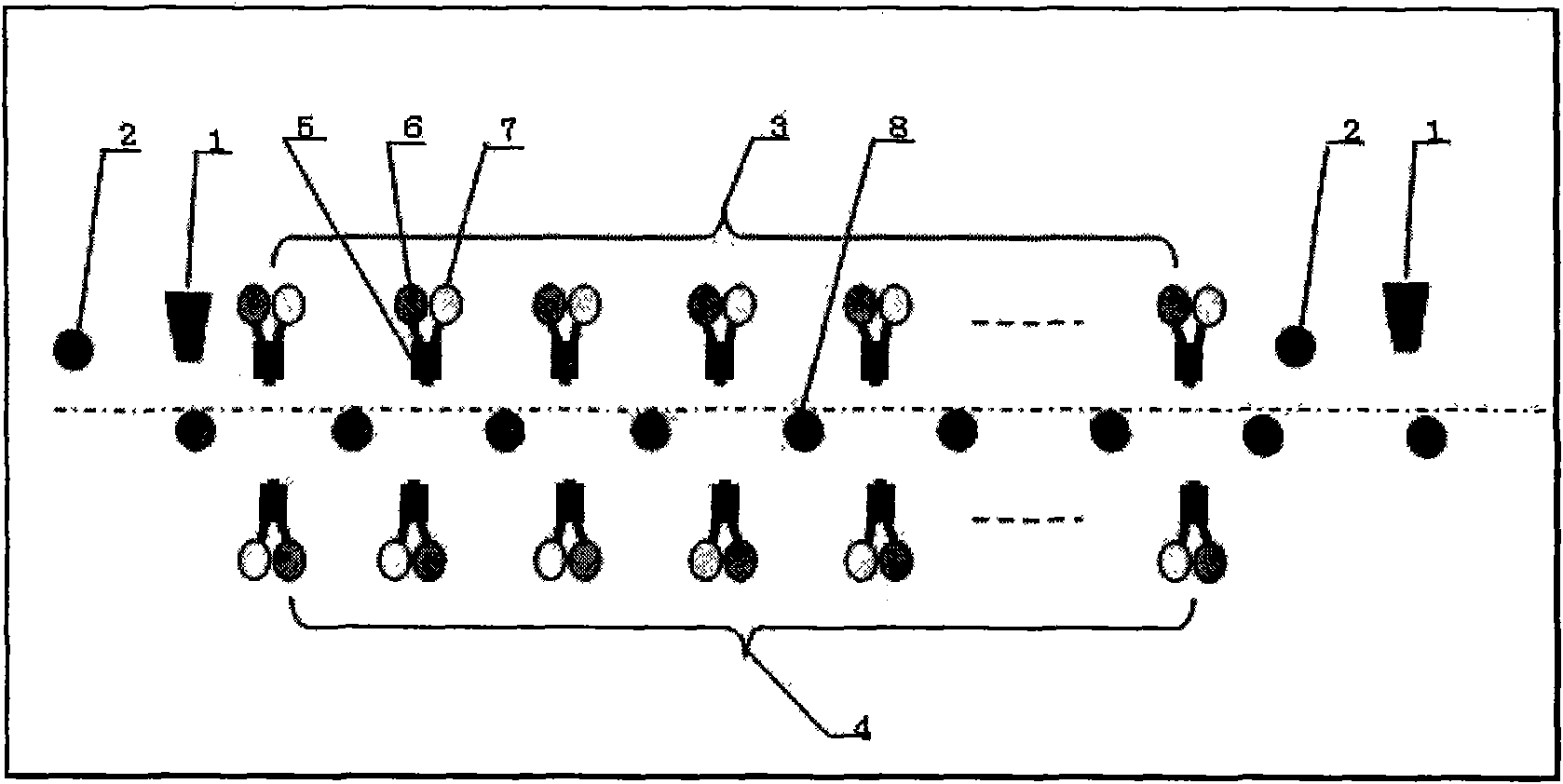

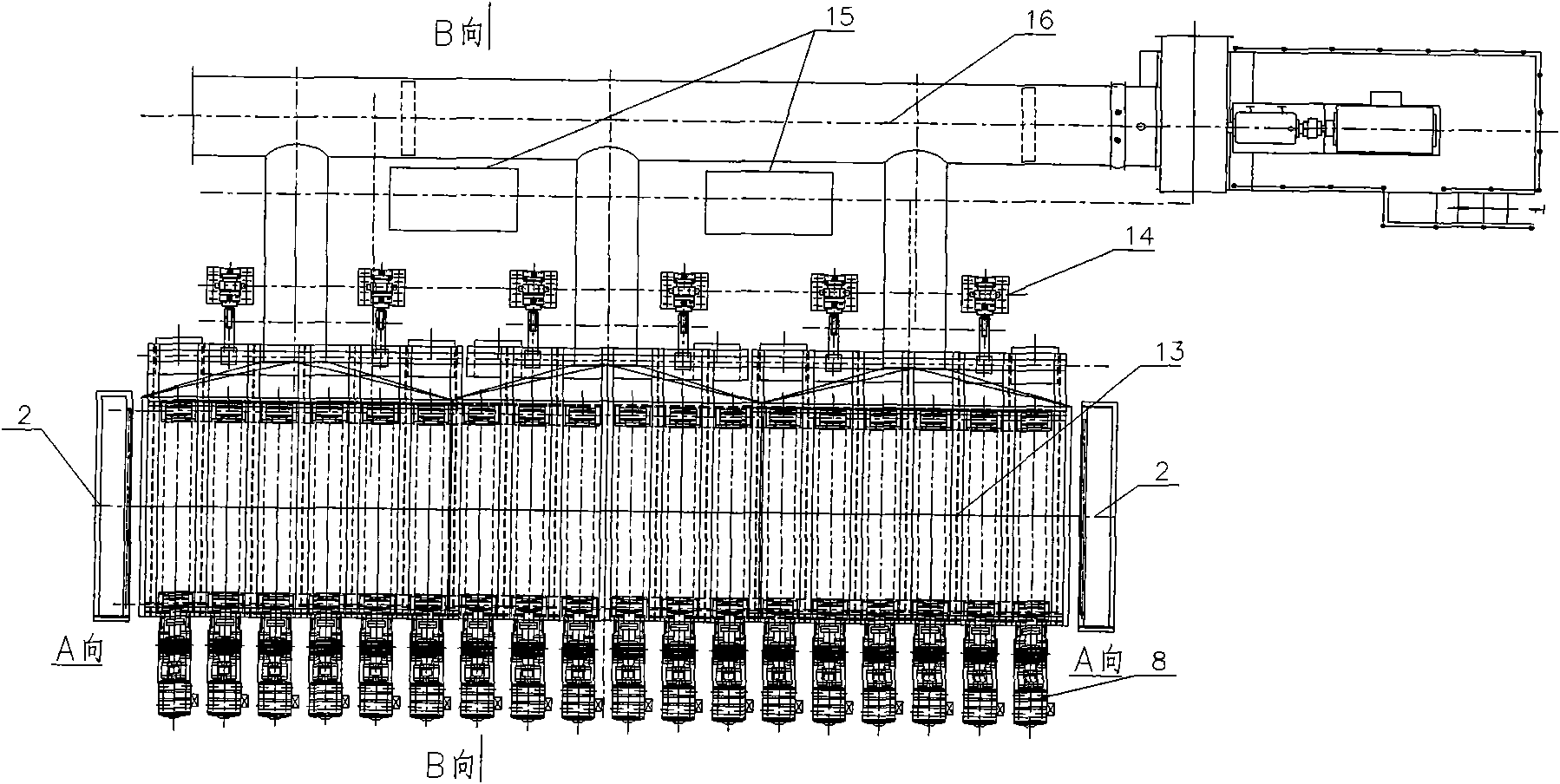

Intermediate blank cooling system and cooling control technology

ActiveCN101642780ADoes not change metal propertiesReduce difficultyTemperature control deviceWork treatment devicesProduction lineEngineering

The invention belongs to the metallurgy technical field and in particular relates to an intermediate blank cooling system and cooling control technology. The intermediate blank cooling system is characterized in that an aerial fog cooling device body is arranged between a rough mill and a finishing mill. The aerial fog cooling device body is composed of an upper cooling header and a lower coolingheader, and an aerial fog nozzle and a compression air pipe are arranged on the cooling water pipe of the upper cooling header and the lower cooling header; and the on / off control valve and flow control valve of the cooling water pipe and the compression air pipe are connected with a control valve station. The intermediate blank aerial fog cooling technology is controlled by the aerial fog controltechnology sprayed on the cooling header arranged near roller ways at the front and rear of the mills. The invention has fast cooling speed without changing metal performance, water yield regulatingrange is wide and the water yield can be regulated continuously, the cooling speed of the intermediate blank can be precisely controlled, and the invention can be widely applicable to middle and thickplate production line.

Owner:CISDI ENG CO LTD

Rolling production method capable of reducing hardness of 42CrMo

ActiveCN106216391AMeet the national standardMeet user needsTemperature control deviceWork treatment devicesAutomatic controlContinuous rolling

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

Fluid assisted doctor

InactiveUS6139638ALiquid surface applicatorsMechanical working/deformationMechanical engineeringEngineering

Owner:KADANT WEB SYSTEMS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com