Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1014 results about "Double phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

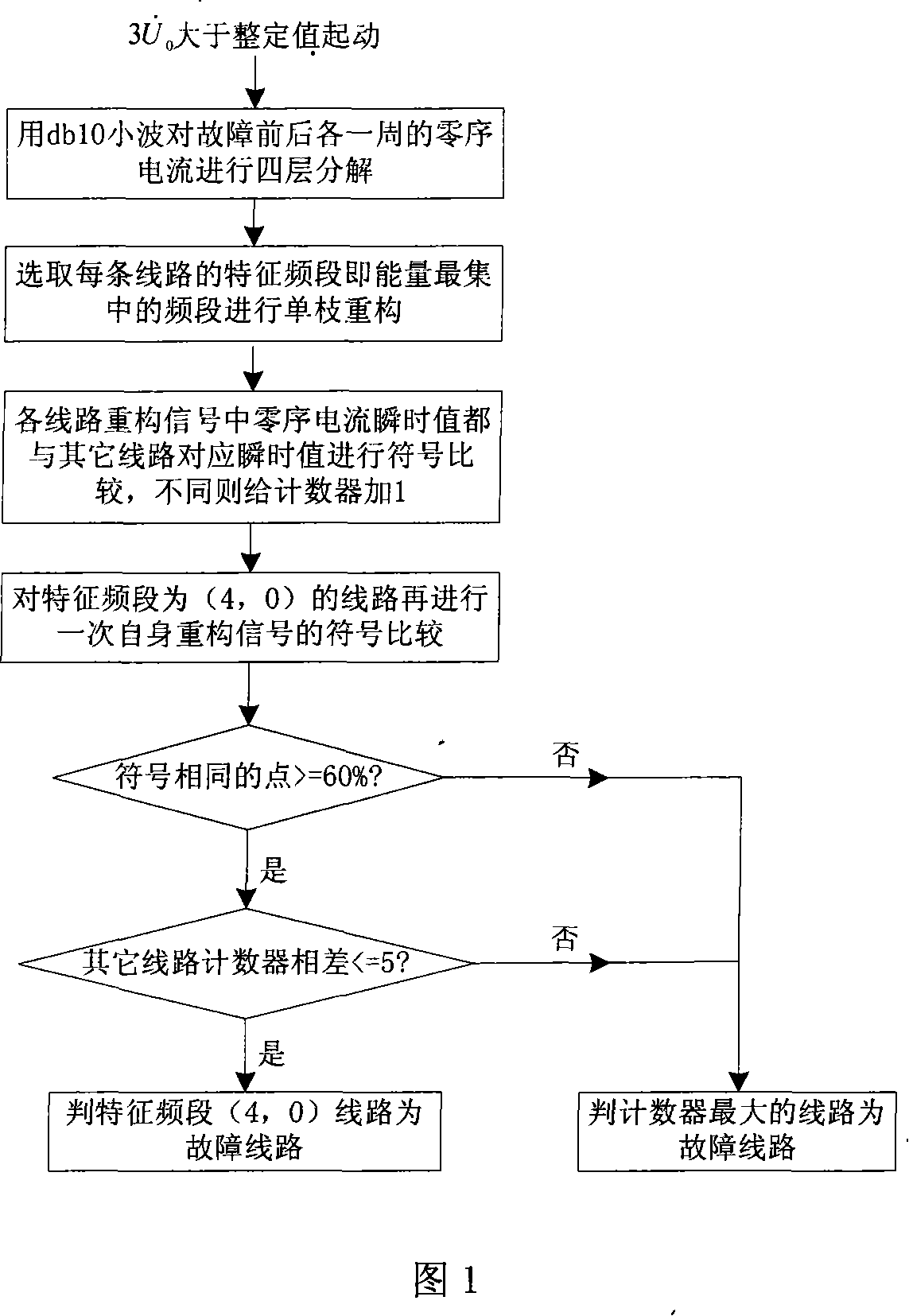

Self-adaption route selection method for single-phase ground fault of power distribution network based on transient zero sequence current

ActiveCN101154807AEfficient use ofImprove reliabilityEmergency protective circuit arrangementsTransient stateDouble phase

The invention relates to the relay protection field of a distribution network, in particular to a single-phase earth fault self-adapting selection method of a double-phase TA distribution network based on transient state zero sequence current frequency distribution. The invention is characterized in that: firstly zero sequence currents before and after failure are decomposed into wavelets and character frequency ranges of each line are reconstructed by single branches; then zero sequence current instantaneous values in reconstructed signals of each line are compared with corresponding instantaneous values of other lines through symbols; if the symbols of the zero sequence current instantaneous values are different from that of other lines, 1 is added to a counter; after all the sampling points are compared, a line with largest counter value is obtained; symbol comparison of respective reconstructed data is performed again to lines with the character frequency range of (4,0), and if points with uniform symbols account for over 60 percent and the values of the points are larger than counter values of other lines by five, then the line is estimated as a fault line; otherwise the line with largest counter value verified is estimated as a fault line. The invention can effectively utilize information included in the fault transient state process and greatly improve the reliability of fault selection.

Owner:NANTONG UNIVERSAL MACHINERY

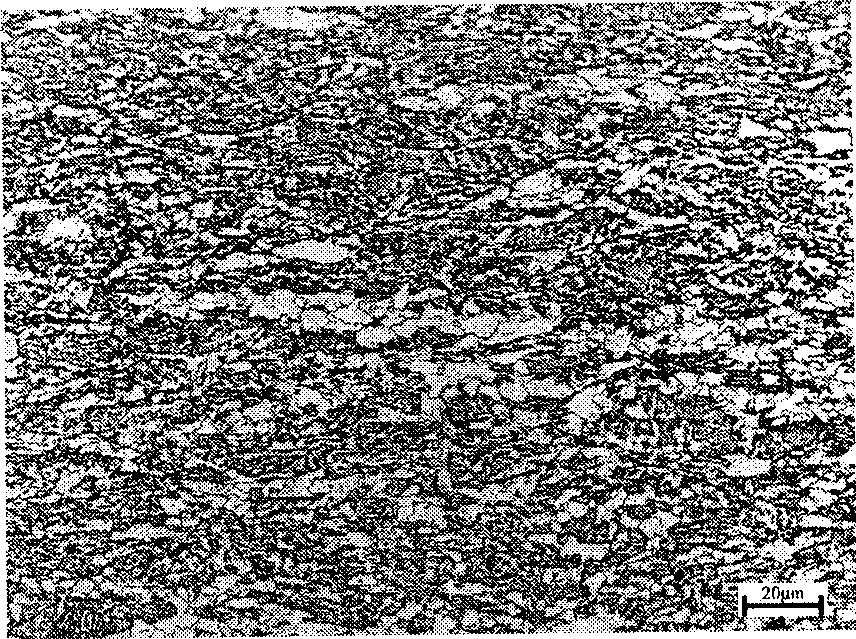

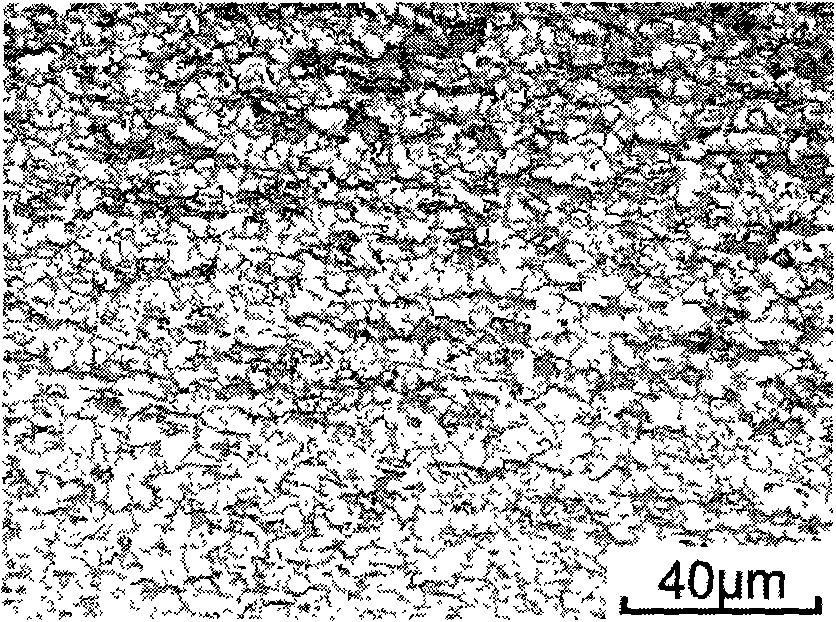

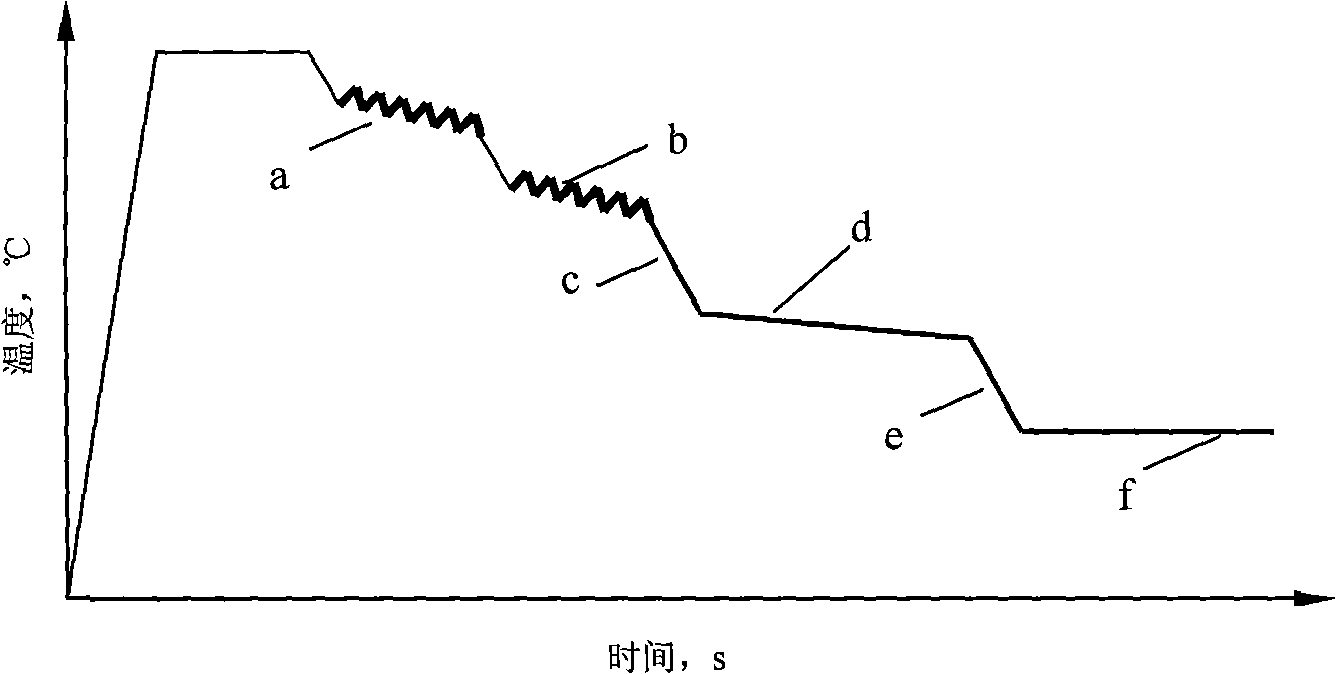

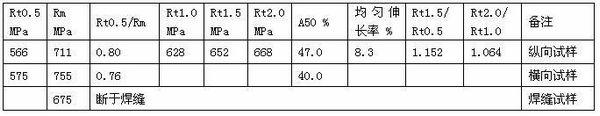

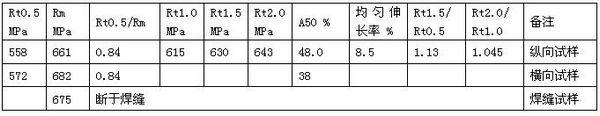

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Phase change cold storage material with double phase change points and preparation method thereof

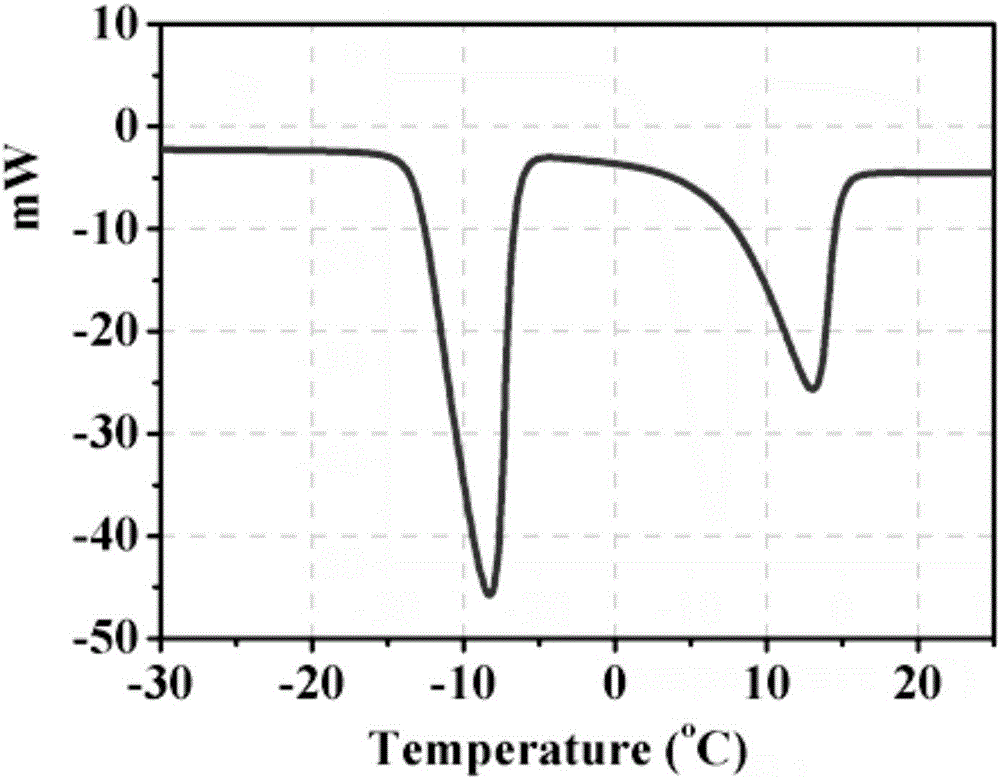

InactiveCN106675525AHigh latent enthalpy of phase changeThe role of proper thawingHeat-exchange elementsDouble phaseCold storage

The invention discloses a phase change cold storage material with double phase change points and a preparation method thereof. The phase change cold storage material with double phase change points is prepared from the following raw materials in percentage by weight: 0 to 60 percent of inorganic salts, 5 to 60 percent of organic phase change materials, 20 to 95 percent of de-ionized water, 0.1 to 2 percent of surfactants, 1 to 5 percent of thickening agents and 1 to 5 percent of nucleating agents. The phase change cold storage material provided by the invention has double phase change points; the temperature can be controlled between the double phase change point temperatures in the material distribution process; the freezing and cold storage effect is achieved; the proper unfreezing effect can also be achieved; in addition, the material has high phrase change latent heat enthalpy value (greater than 220kJ / kg); the more efficient and faster temperature reduction effect is achieved; in addition, the temperature can be permanently maintained in a specific temperature range.

Owner:贺迈新能源科技(上海)有限公司

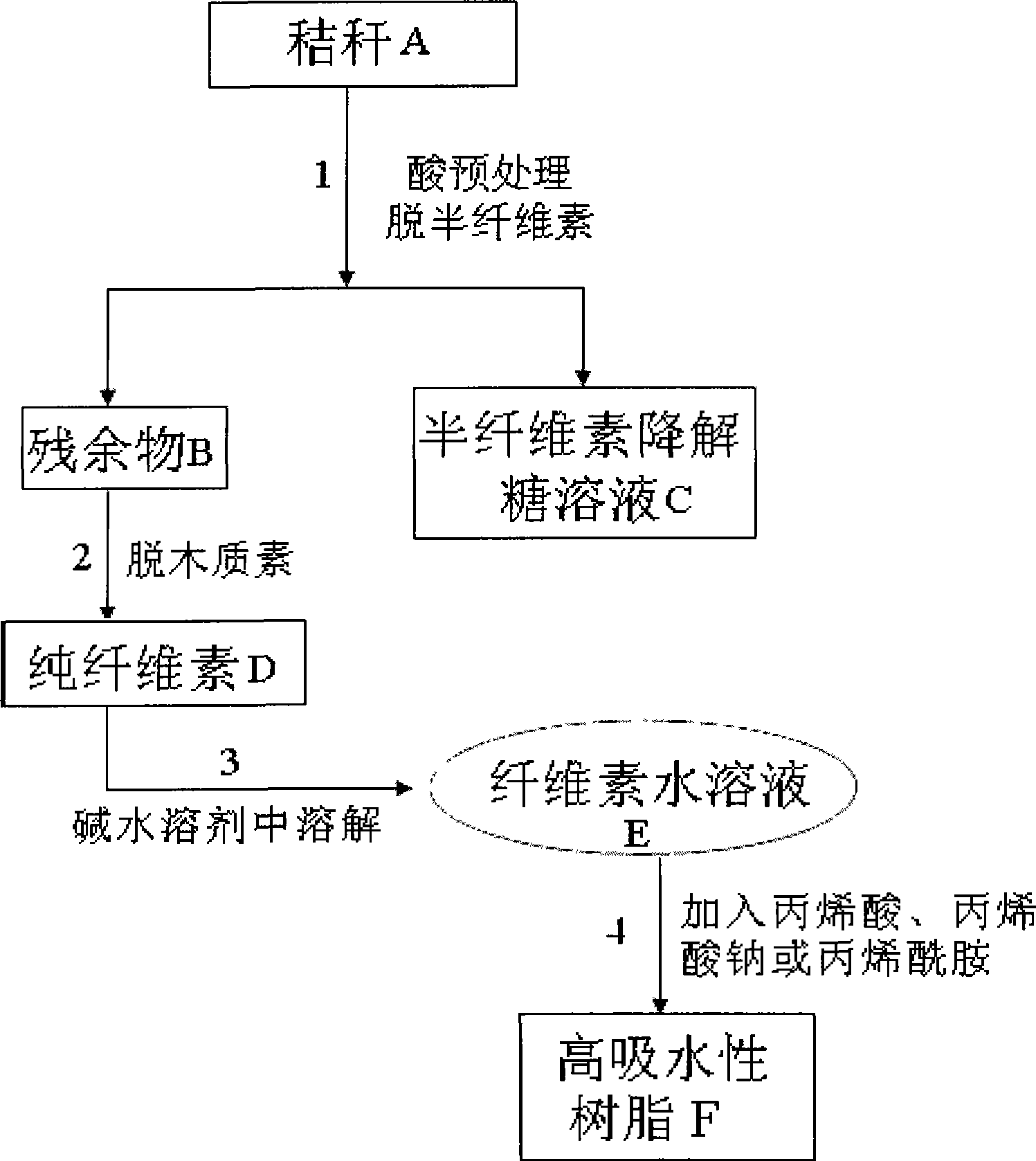

Method for preparing high-hydroscopicity resin in homogeneous aqueous medium by using straw as raw material

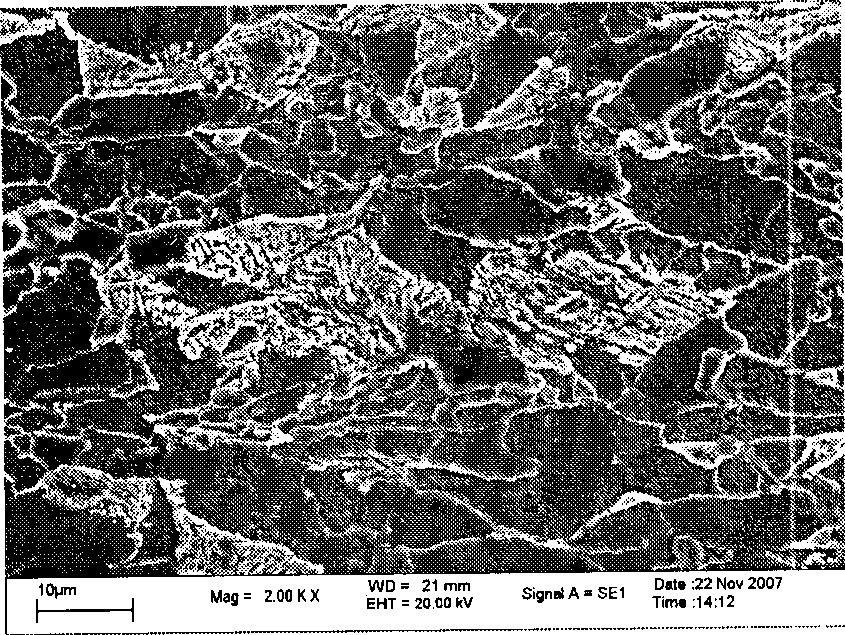

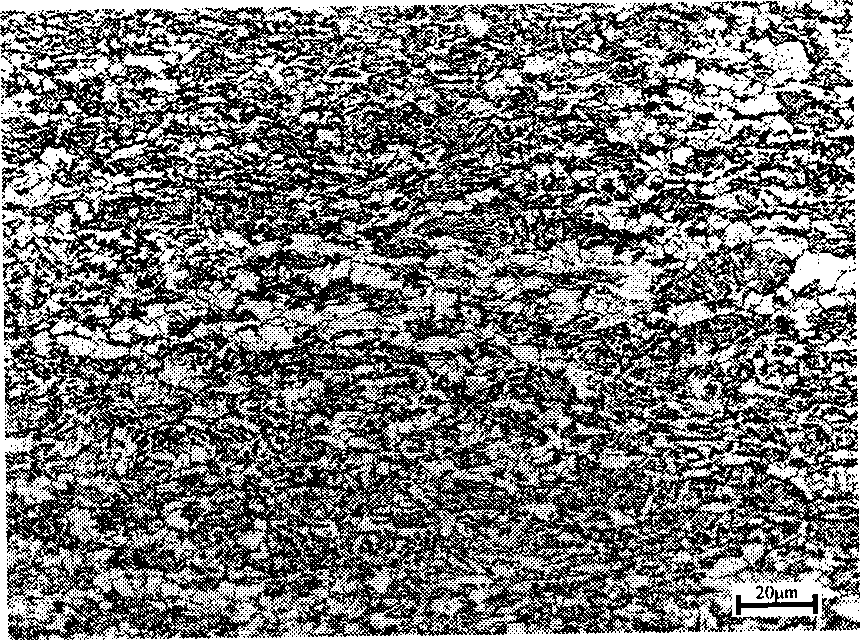

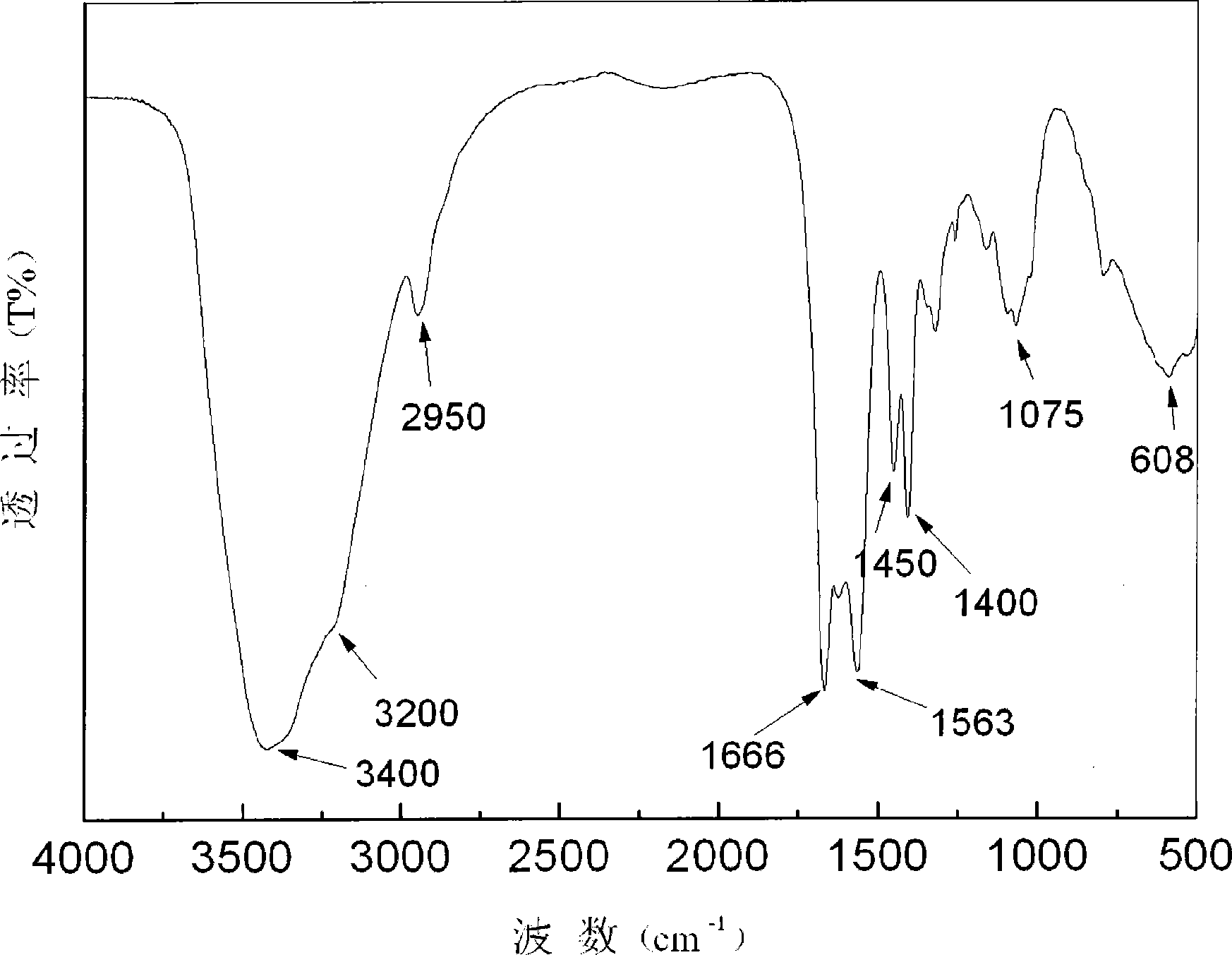

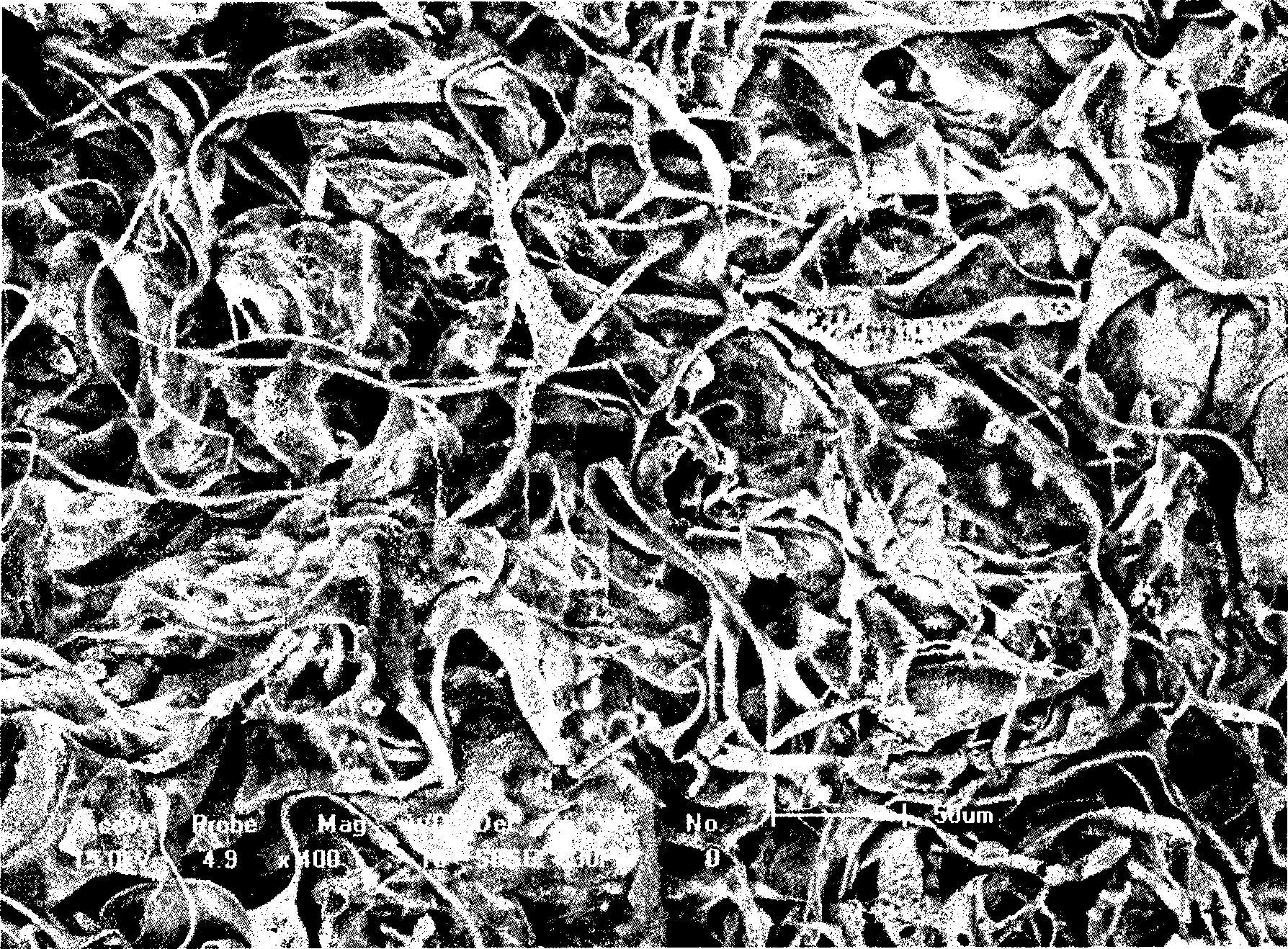

InactiveCN101519476AAvoid the disadvantages of microscopic heterogeneous phase separationHas biodegradable propertiesPaper material treatmentCelluloseDouble phase

The invention relates to a method for preparing high-hydroscopicity resin in uniform-phase aqueous medium by using straw as a raw material. The method comprises the following steps: adopting a double-phase saline aqueous solution system of inorganic acid and polyethylene glycol to sequentially process the straw to obtain cellulose; then, adding the cellulose to a pre-prepared sodium hydroxide-urea aqueous solution or a lithium hydroxide-urea aqueous solution; putting the solution in a refrigerator to be cooled, taking out the solution for mechanically stirring to obtain a uniform cellulose solution; afterwards, adding propenyl monomer to the obtained cellulose aqueous solution and carrying out homogeneous glycerol polymerization to obtain the high-hydroscopicity resin. The hydroscopicity resin has the advantages of low cost, high hydroscopicity and potential biodegradable characteristic and has wide application space in the fields, such as agriculture, forestry, sanitary health products, building materials, perfume emission, and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Manufactring method for smelting stainless steel containing N biphase

InactiveCN1563463AGood decarburization effectCarbon content is not limitedElectric arc furnaceDouble phase

A method for smelting double-phase with N stain less steel characterizes 1. carrying out the primary smelting according to the return oxygen blowing wethod 2. smelting qualified double stainless steel with N in composition and purity (1) blown temperature is higher than or equal to 1540deg,c (2) carbon elimination: blowing N2, O2 mixed gas for decarbonization and increasing N2 and process the increased temperature O2 / N2=4, sampling to regulated the components: when c=0.10%, stop blowing O2 but Ar instead, adding prerecovered stags for 7min, total sample analysis including all stags and adding recovery stags (3) recovery: blowing Ar and forcing to eliminate O, blowing N to increase N, sample analysis, fine adjustment to the composition to get the cast ingot.

Owner:宝钢特钢有限公司

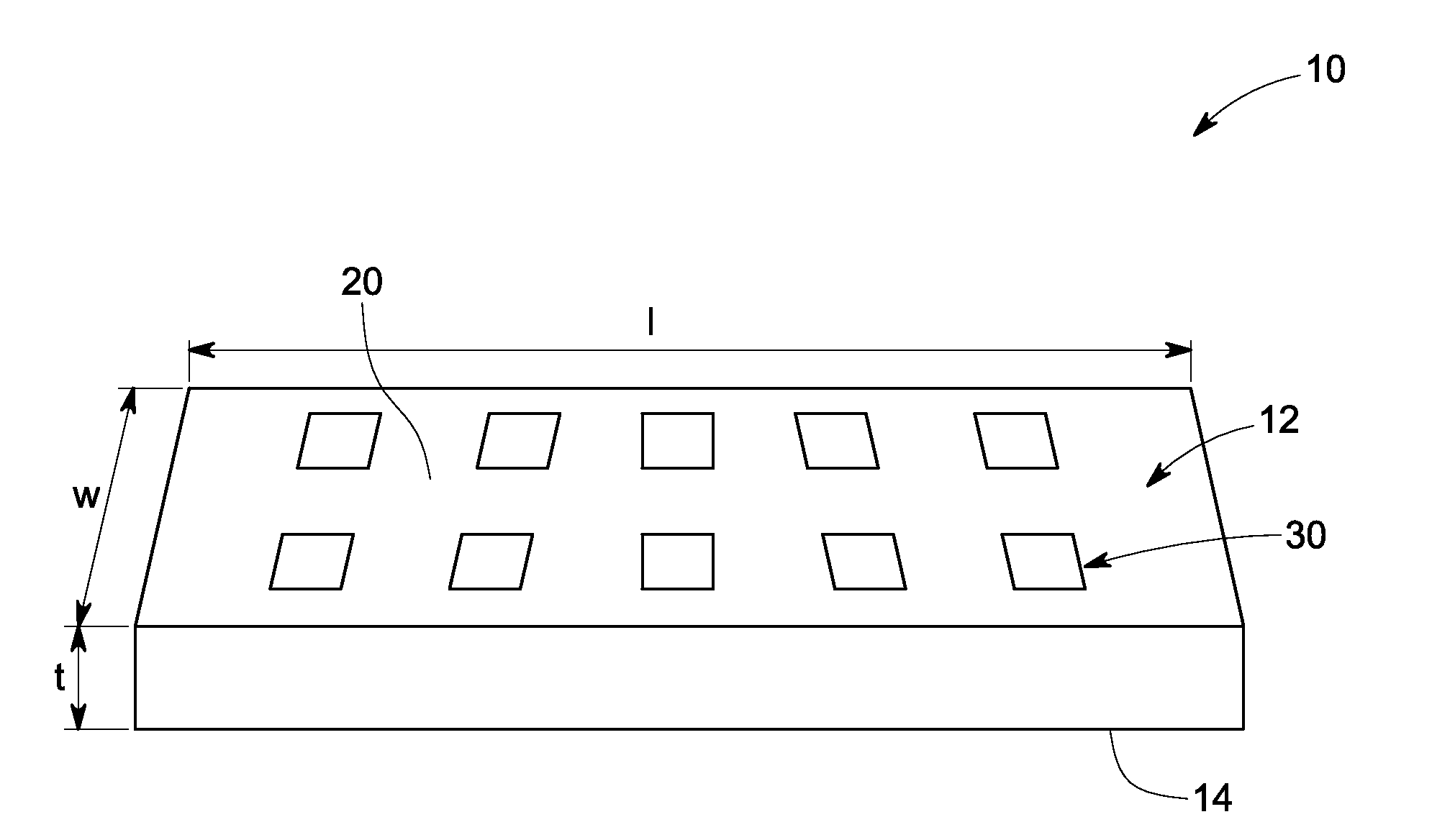

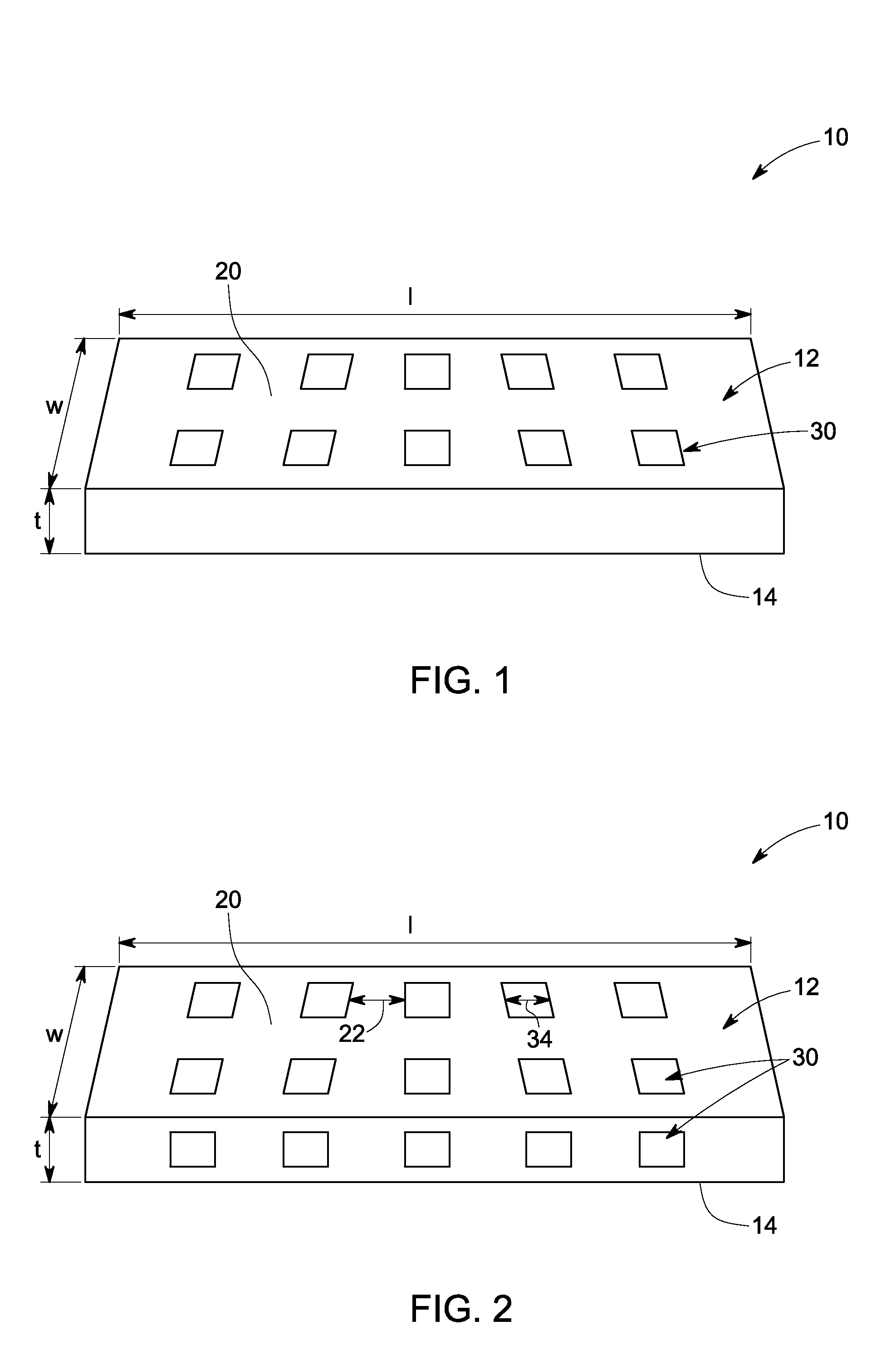

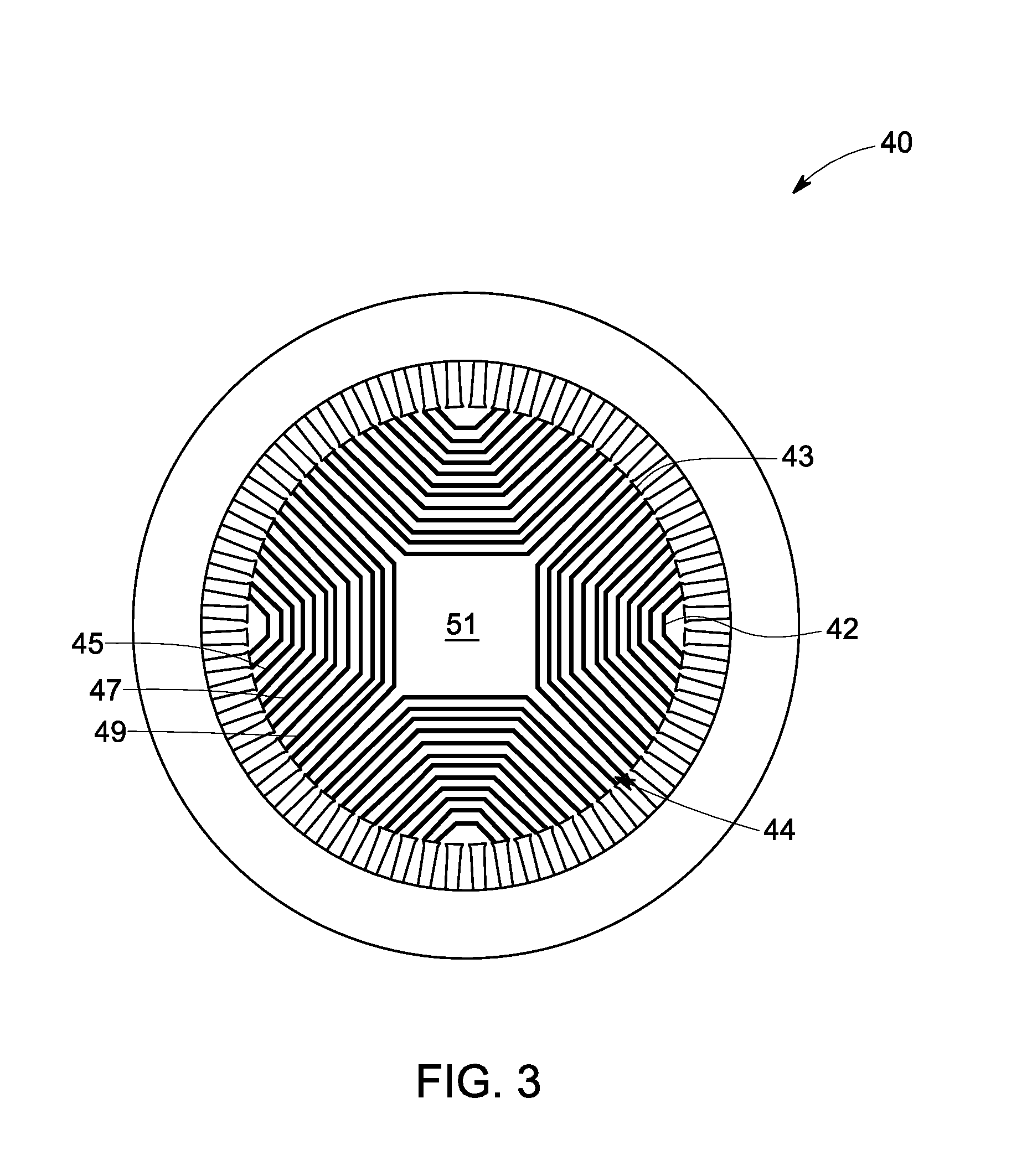

Dual phase magnetic material component and method of forming

A magnetic component having intermixed first and second regions, and a method of preparing that magnetic component are disclosed. The first region includes a magnetic phase and the second region includes a non-magnetic phase. The method includes mechanically masking pre-selected sections of a surface portion of the component by using a nitrogen stop-off material and heat-treating the component in a nitrogen-rich atmosphere at a temperature greater than about 900° C. Both the first and second regions are substantially free of carbon, or contain only limited amounts of carbon; and the second region includes greater than about 0.1 weight % of nitrogen.

Owner:GENERAL ELECTRIC CO

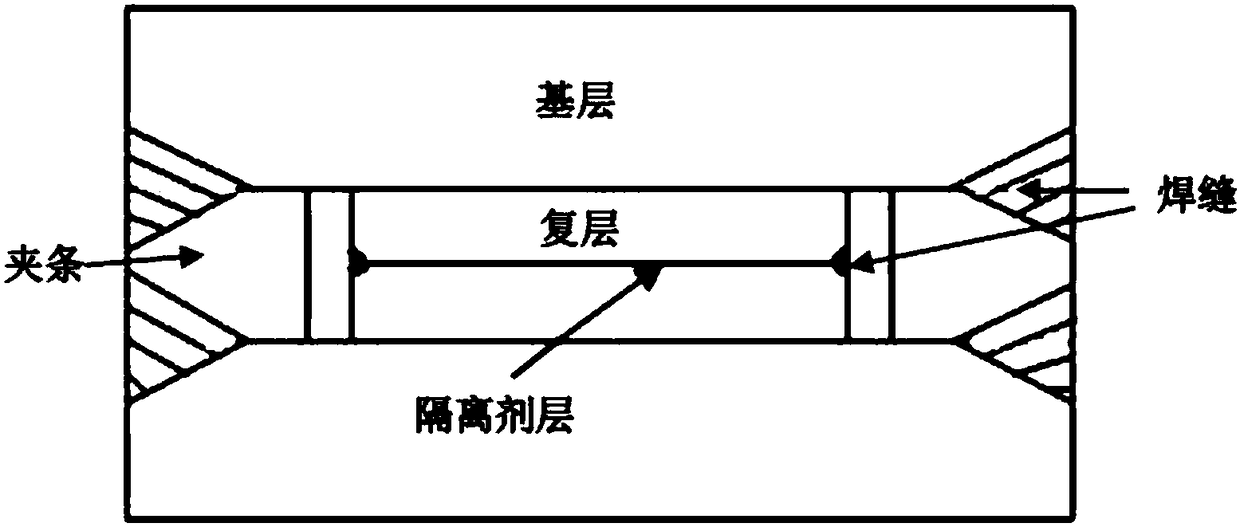

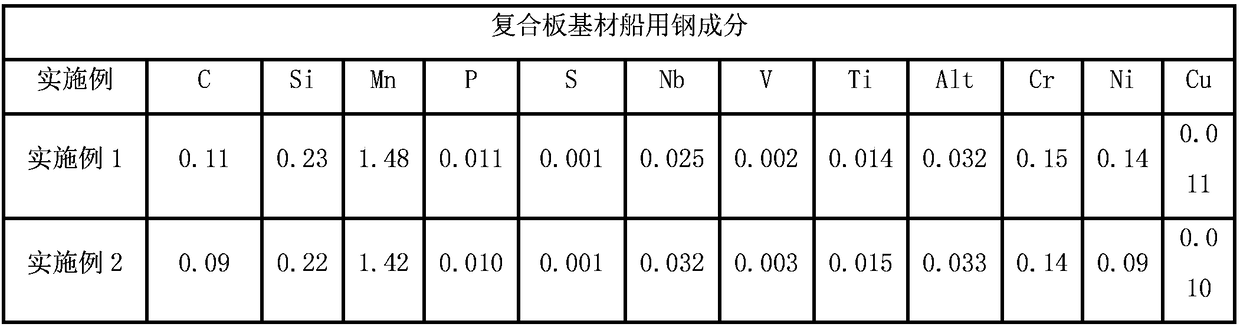

Preparation method of TMCP double phase stainless steel composite board for ship

InactiveCN108246825AGuaranteed toughnessPerformance with toughnessNon-electric welding apparatusDouble phaseComposite plate

The invention relates to a preparation method of a TMCP double phase stainless steel composite board for a ship. The double phase stainless steel composite board for the ship good in metallurgical bonding and excellent in corrosion resistance and structural strength is prepared by the following steps: blank selection, surface treatment, separant brushing, assembling, electron beam sealing, heating, rolling, online quenching, straightening, cutting and board dividing and the like. By adopting electronic beams to seal directly in a vacuum environment, the conventional drilling, vacuumizing stepsand the like are canceled, so that the vacuum degree is further guaranteed. Through a TMCP process, a good mechanical property of a substrate ship board is guaranteed, the substrate ship board whichis rolled is quickly quenched and cooled on line, and a disadvantageous precipitated phase of a composite material is controlled to be separated out, and meanwhile, the composite material is good corrosion resistance as the method is replaced by an online process; the substrate is a low-carbon designed blank, and the prepared composite board is low in carbon equivalent of the substrate, good in welding property and convenient for field construction. In addition, the composite board needs not to be thermally treated, so that a good comprehensive performance can be obtained.

Owner:NANJING IRON & STEEL CO LTD

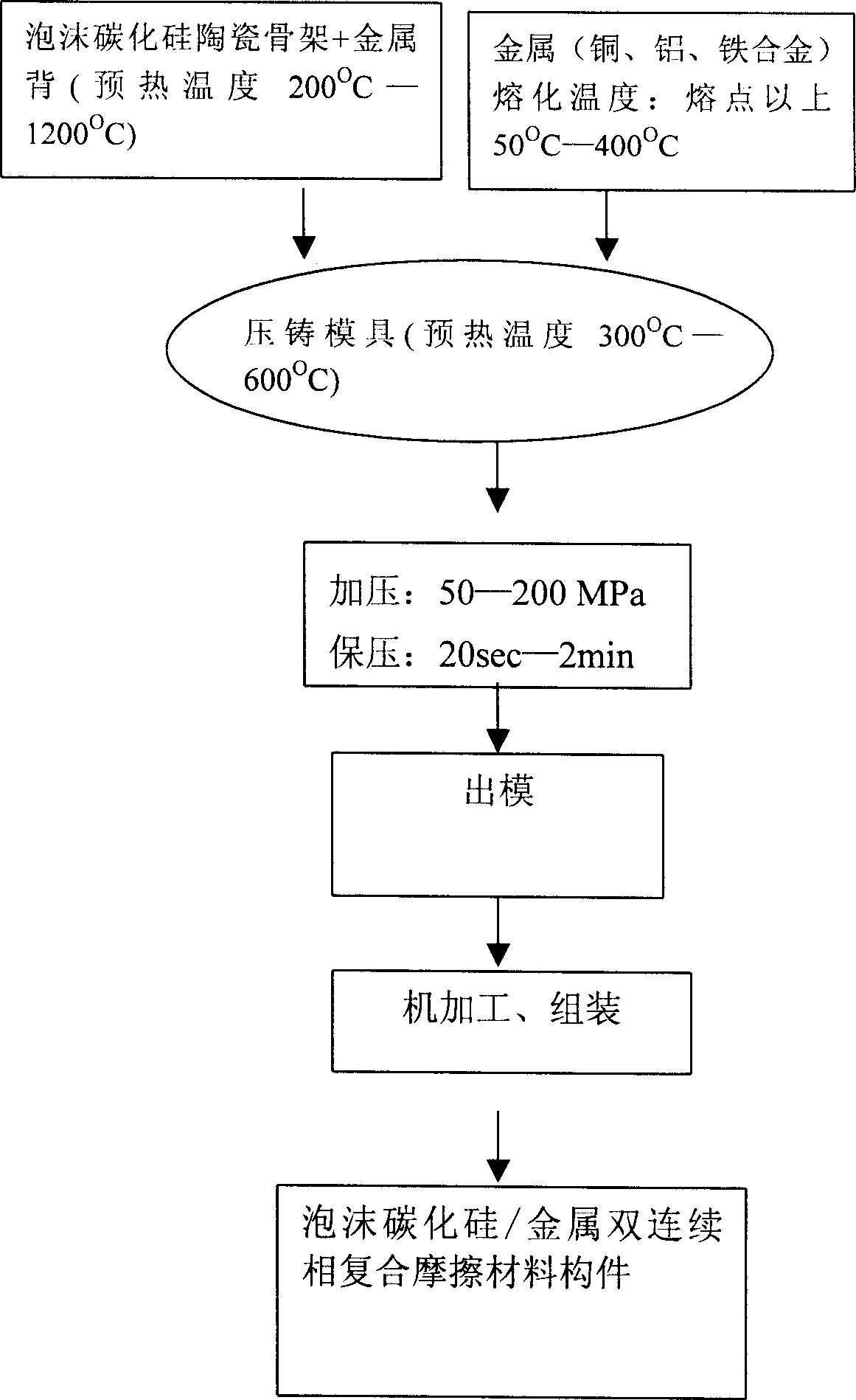

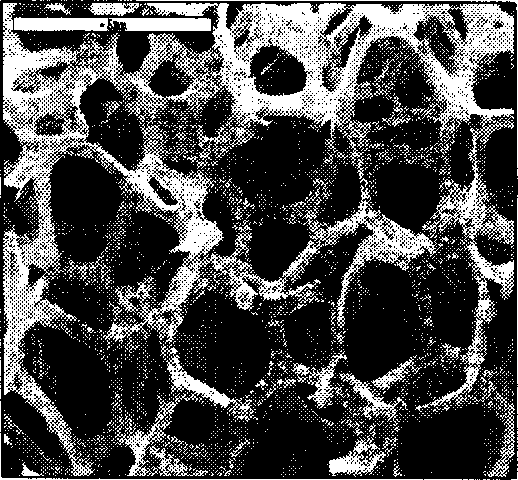

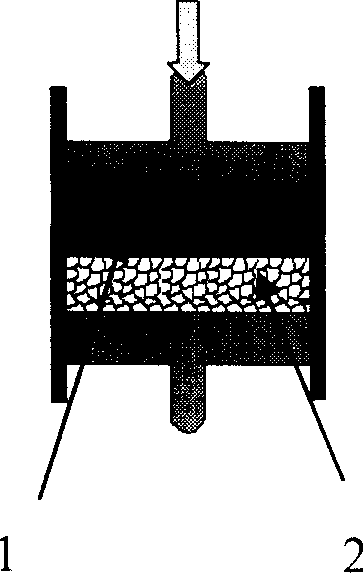

Bi-continuous-phase composite friction material of foaming silicon carbide/metal, its member and preparation

A foaming silicon carbide / metal double-phase continuous composite friction material, its member and production are disclosed. The composite friction material consists of 15-60% foaming silicon carbide ceramic and 40-85% metal matrix. The procedure is carried out by synthesizing foaming silicon carbide ceramic with metal matrix and combing friction layer with metal layer. It can fulfill friction and bearing functions. It can be used for plane, track train, caterpillar vehicles, wheeled vehicles and ship.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

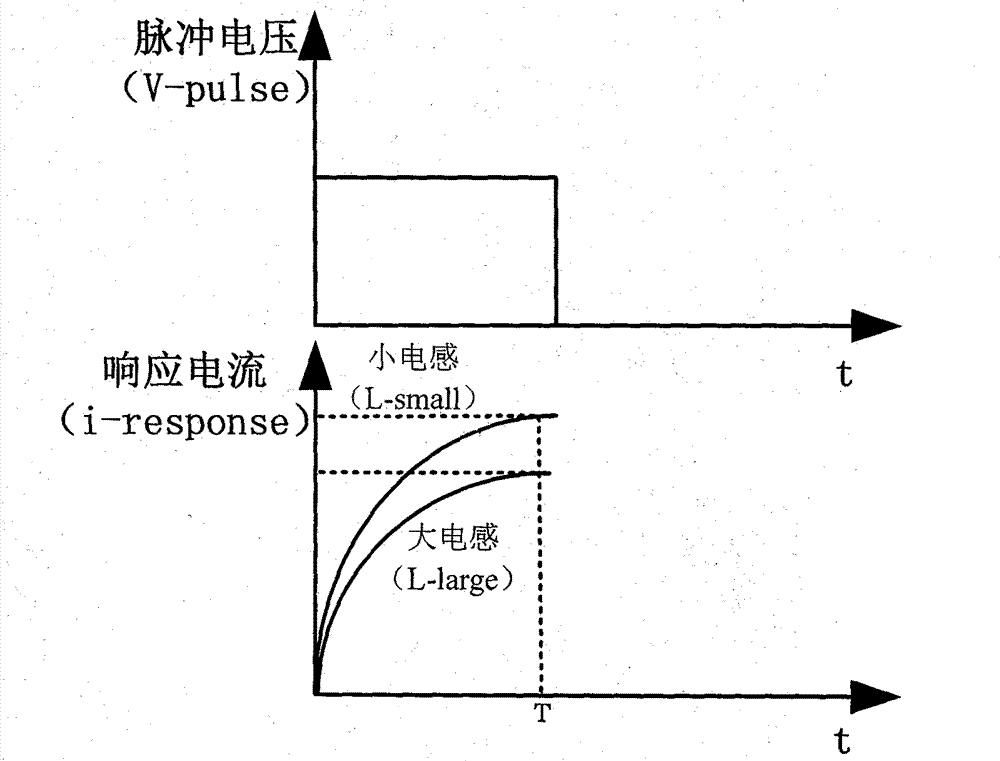

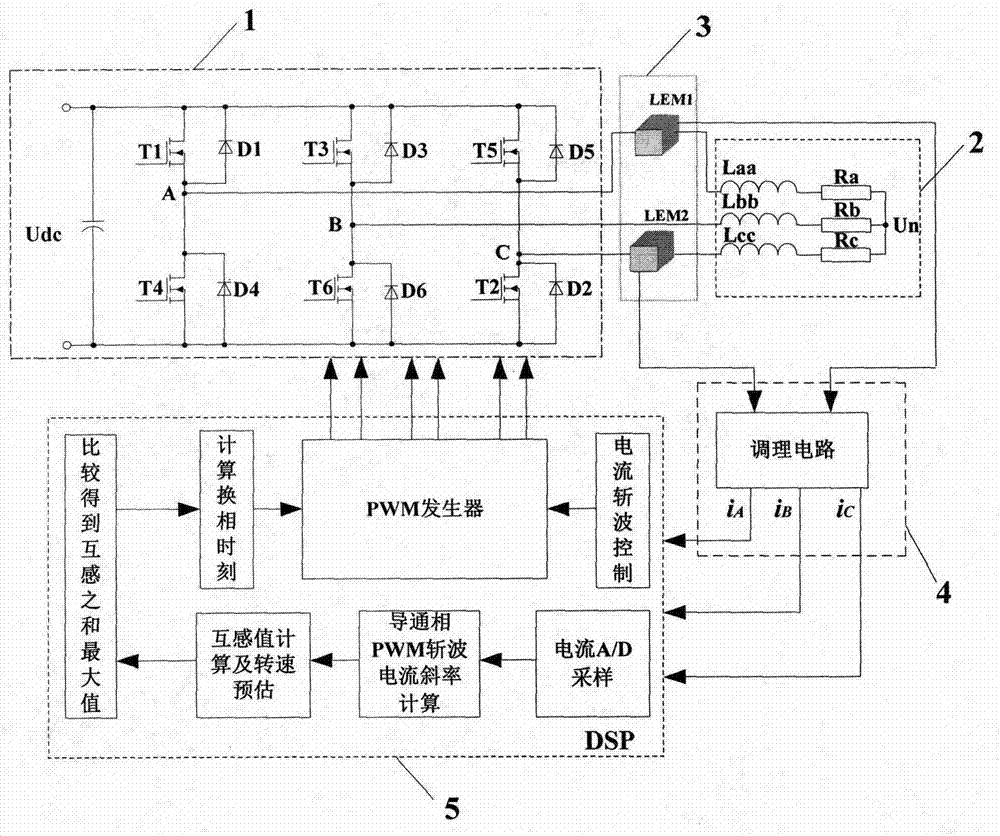

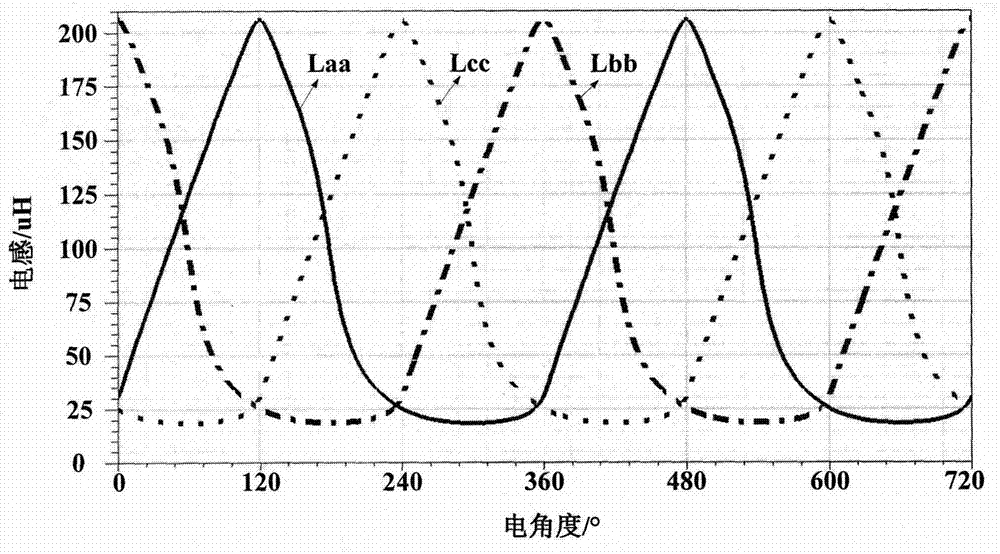

Non-location technology for three-phase electro-magnetic double-salient pole machine starting and accelerating based on induction method

InactiveCN103078586APrecise positioningPrecise location sectorMotor parameters estimation/adaptationPhase currentsLow speed

The invention discloses a non-location sensor technology for three-phase electro-magnetic double-salient pole machine starting and low-speed accelerating processes. According to the characteristics of an electro-magnetic double-salient pole machine, exciting current is not applied in a static state, but fixed-cycle low voltage pulse signal judging phase current is applied on armature windings, double-phase series connection self inductance is then calculated, and a rotor position is estimated. During a low-speed accelerating process, the mutual inductance sum of two phases of series connection windings and an excitation winding is calculated according to the armature current gradient when chopped waves are acquired in real time, so that the non-location low-speed accelerating technology for accelerating a motor is carried out. By utilizing the method, the initial rotor position can be accurately positioned, a rotor sector can be identified and fed back in real time during the low-speed accelerating, the maximum inductance is obtained through comparison, and the phase shifting time is determined after time delay. Consequently, the rotor positions can be fed back during the whole starting and accelerating processes, so that the motor cannot be out of step during the starting process and has strong antijamming capability. By utilizing the technology, the three-phase electro-magnetic double-salient pole machine can be enabled to start and accelerate stably and reliably.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

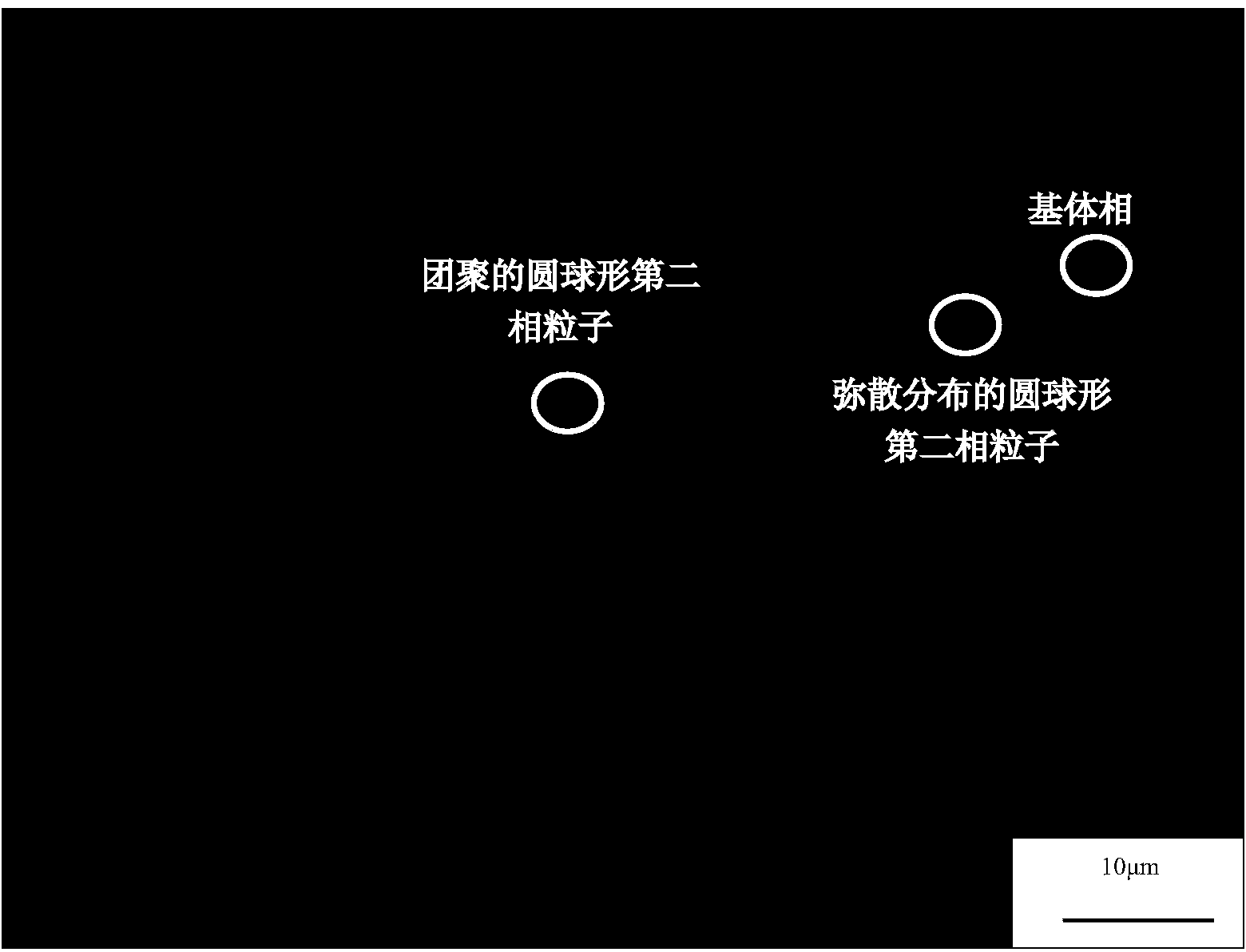

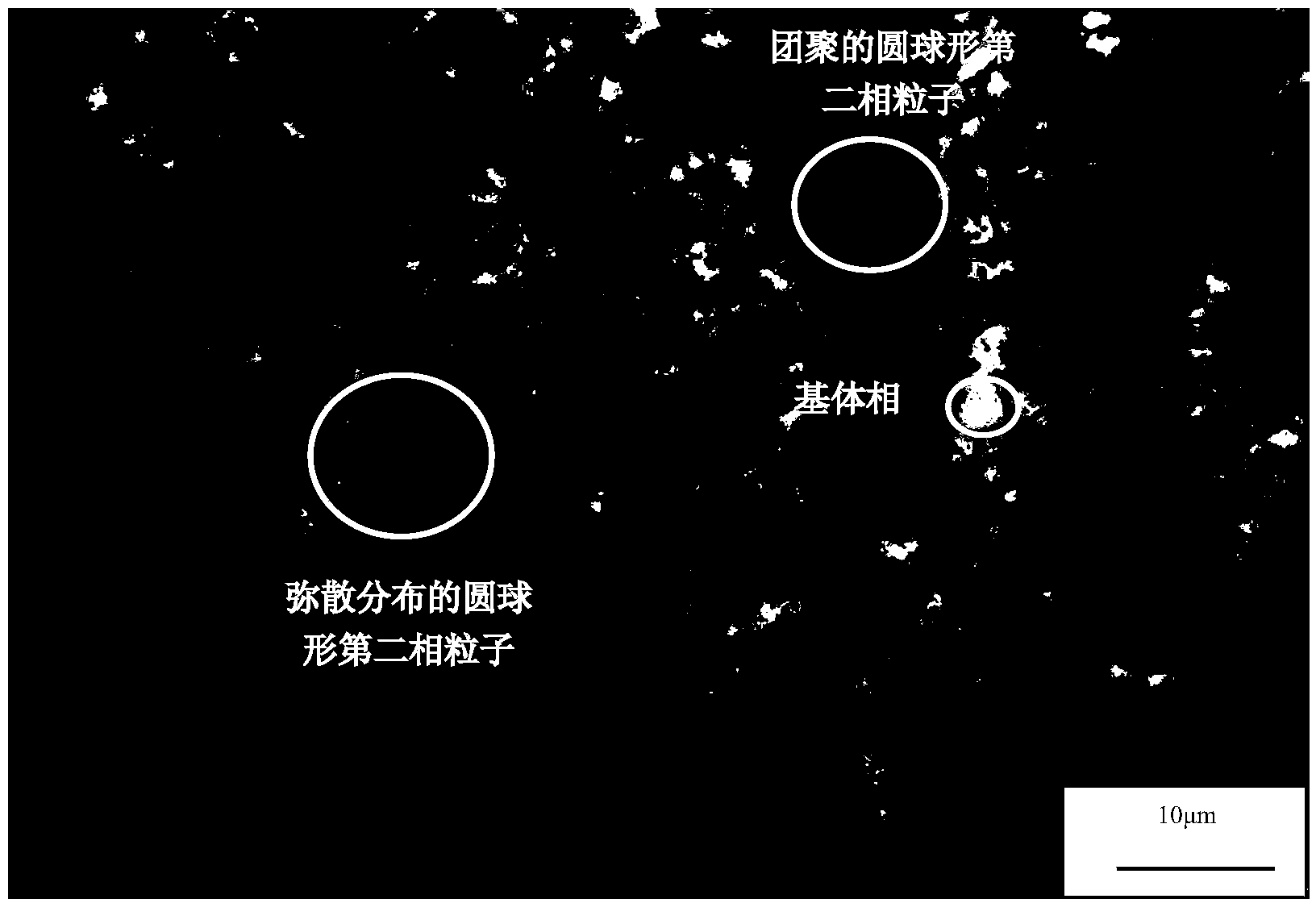

Preparation method of high-performance magnesium alloy plate with double-phase structure

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

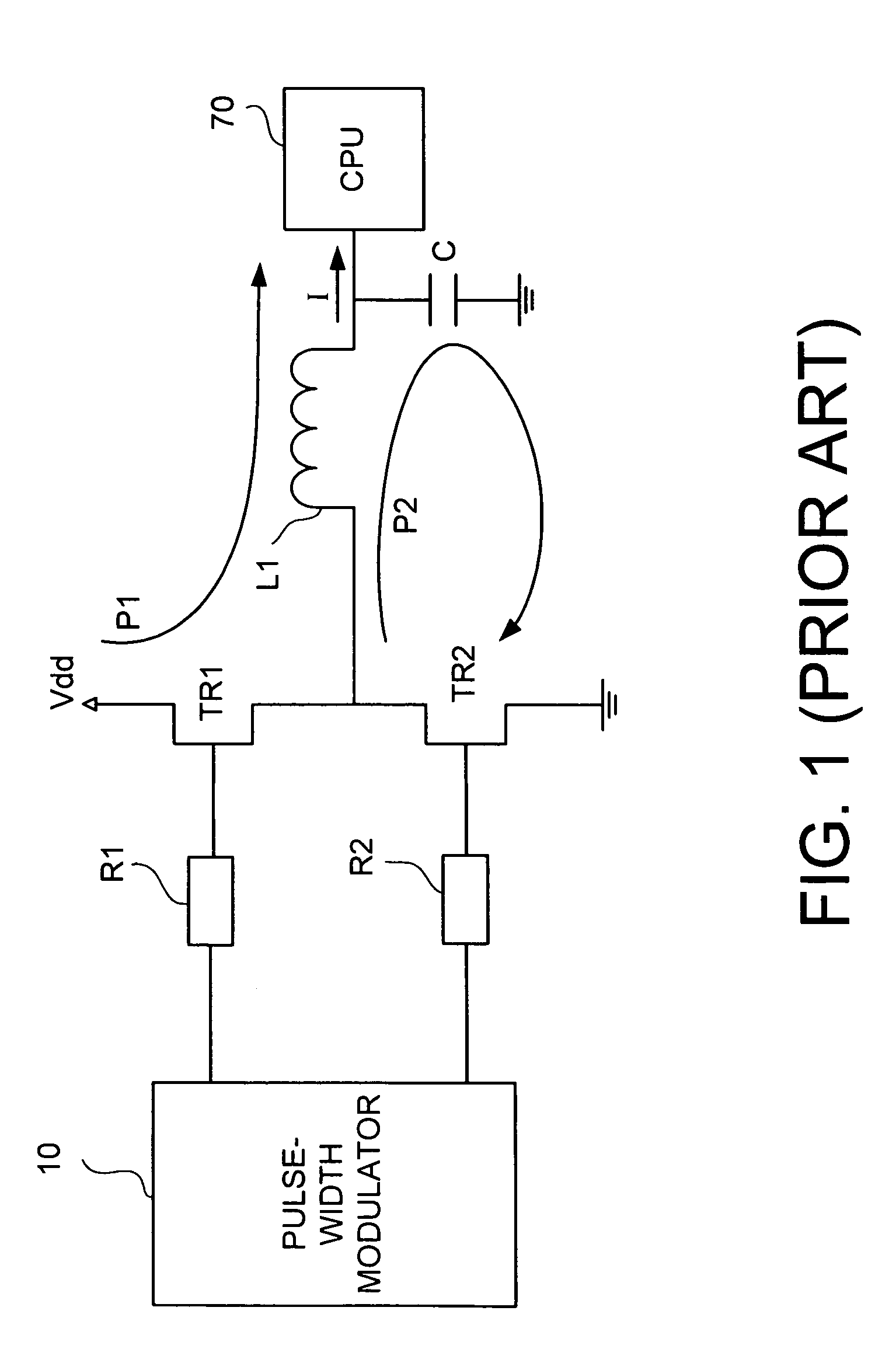

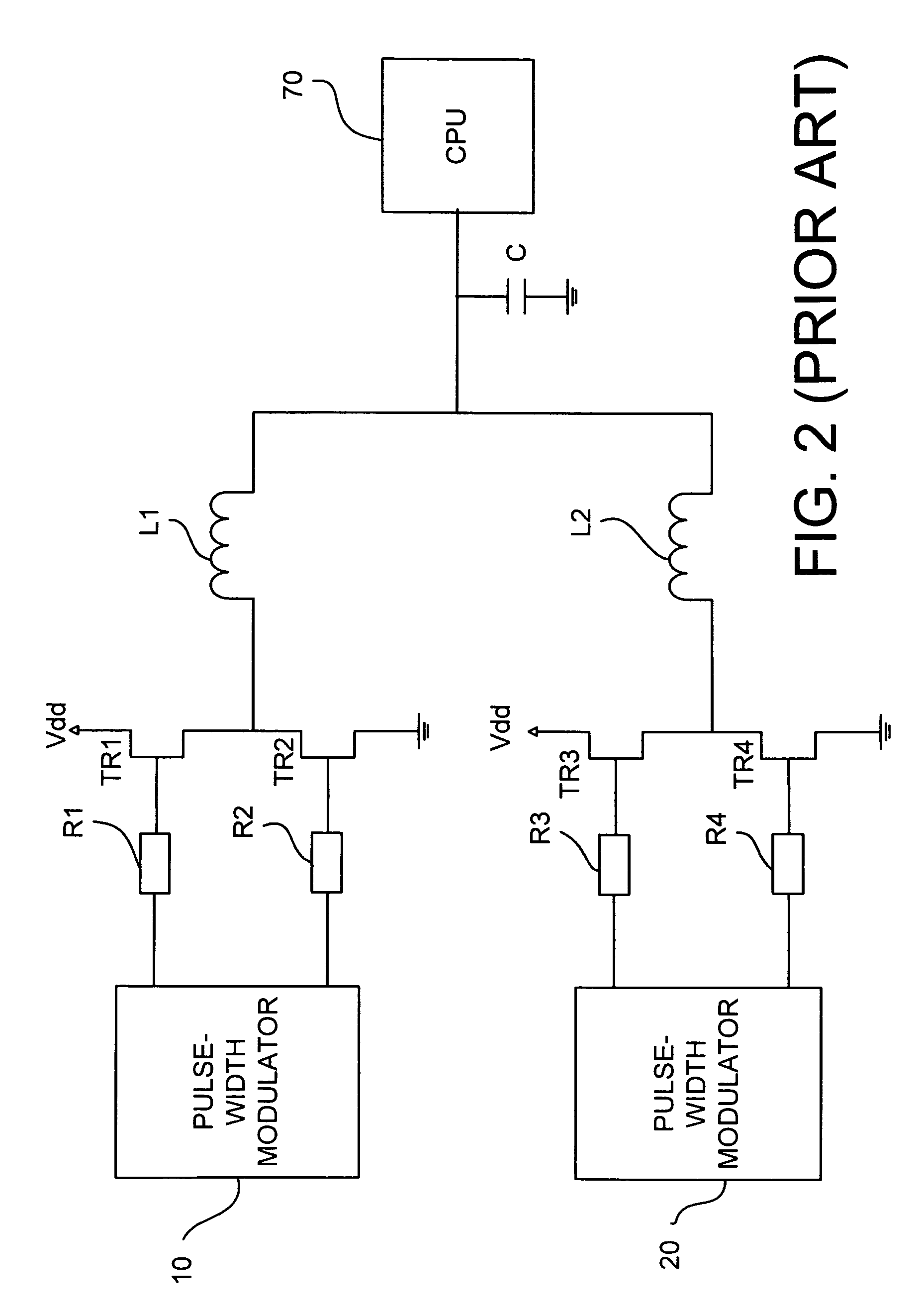

Synchronized parallel running power converter

In prior arts, additional pulse-width modulators and more costs are needed for increasing the current output. The invention provides a synchronized parallel running power converter. The power converter includes multiple power converters controlled by single-phase or double-phase pulse-width modulators. Each power converter includes a first pulse input port, a second pulse input port and a current output port. Each first pulse input ports are coupled, and each second pulse input ports are coupled also, so that each power converter is controlled by the same pulse signal and provide a same output current to be added as several times of current output.

Owner:MICRO-STAR INTERNATIONAL

Low-expansion antioxidative Ni-Fe-Cr-based high temperature alloy and preparation method thereof

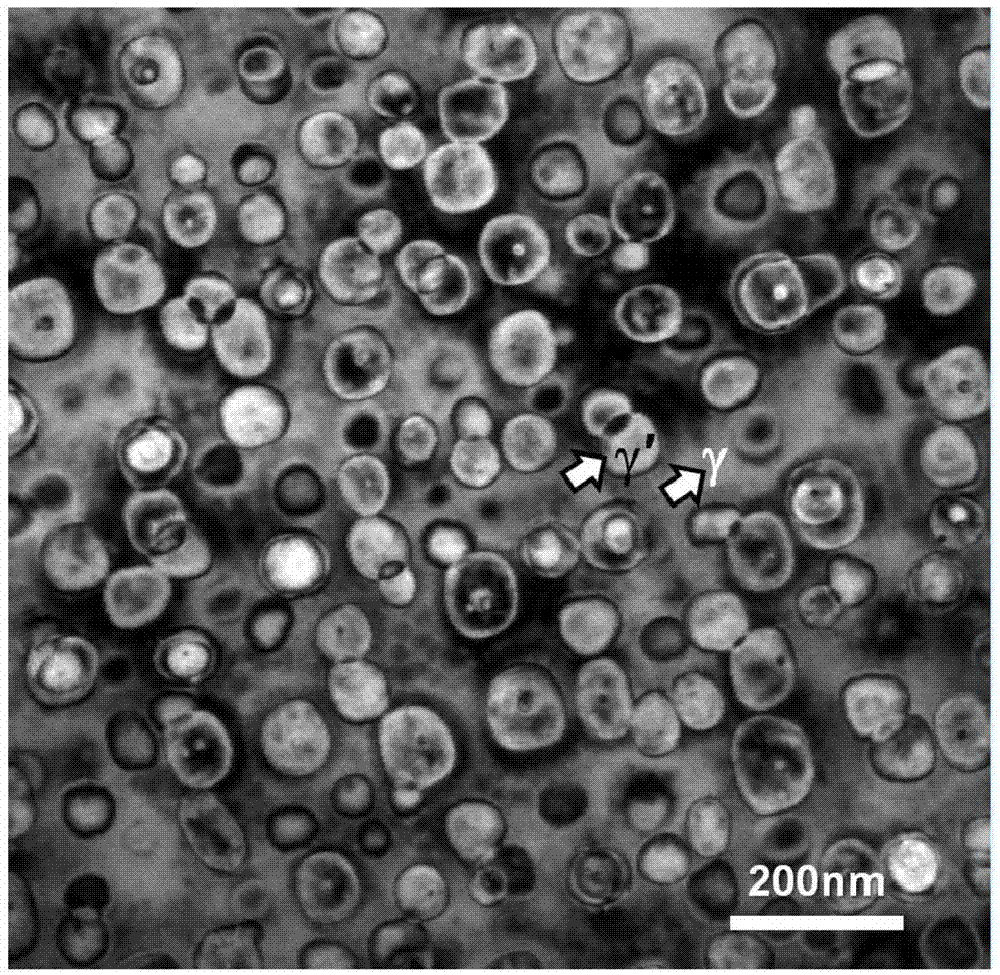

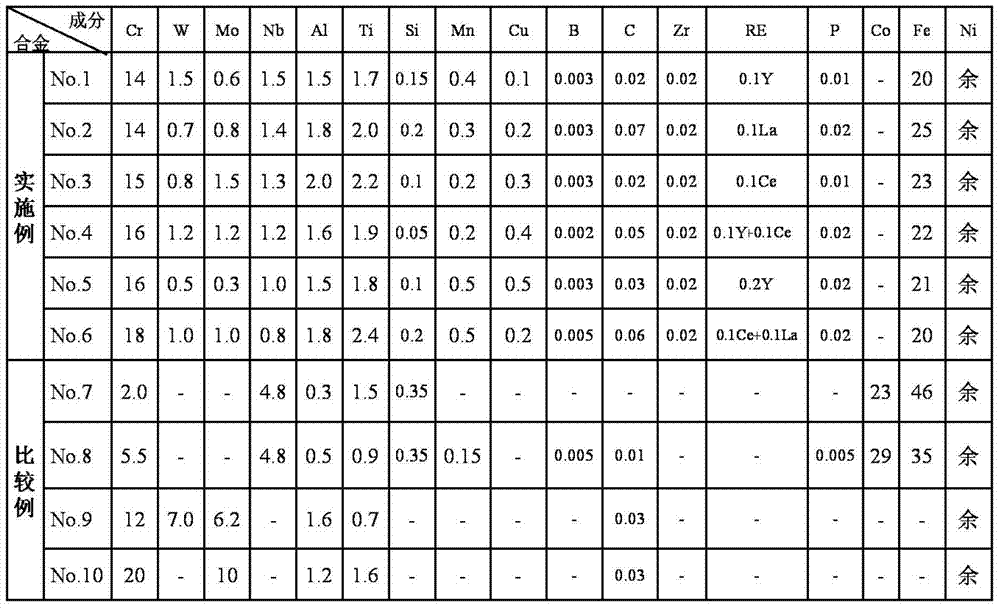

The invention provides a low-expansion antioxidative Ni-Fe-Cr-based high temperature alloy and a preparation method thereof. The alloy comprises 20 to 25% of Fe, 14 to 18% of Cr, 1.5 to 2.0% of Al, 1.5 to 2.5% of Ti, 0.5 to 2.0% of Nb, 0.3 to 2.0% of Mo, 0.5 to 2.0% of W, no more than 1.0% of Si, no more than 1.0% of Mn, no more than 0.5% of Cu, no more than 0.1% of C, no more than 0.01% of B, no more than 0.05% of Zr, no more than 0.05% of P and no more than 0.20% of a rare earth element, with the balance being Ni. The alloy is of a double-phase structure, wherein a substrate is an austenite (gamma) phase with a disordered face-centered structure, and a gamma' [Ni3(Al,Ti)] phase with an ordered structure is dispersed in the austenite. According to the invention, on the basis that structural stability, corrosion resistance and high temperature strength of the alloy are not influenced, the content of Fe is increased as much as possible to improve hot workability of the alloy and reduce cost. Compared with the prior art, the alloy provided by the invention has the advantages of low material cost, a low thermal expansion coefficient, excellent high temperature strength, hot-working performance and anti-oxidation corrosion and in particular, better cost performance when used under the conditions of high temperature, high pressure and supercritical water vapor.

Owner:XIAN THERMAL POWER RES INST CO LTD

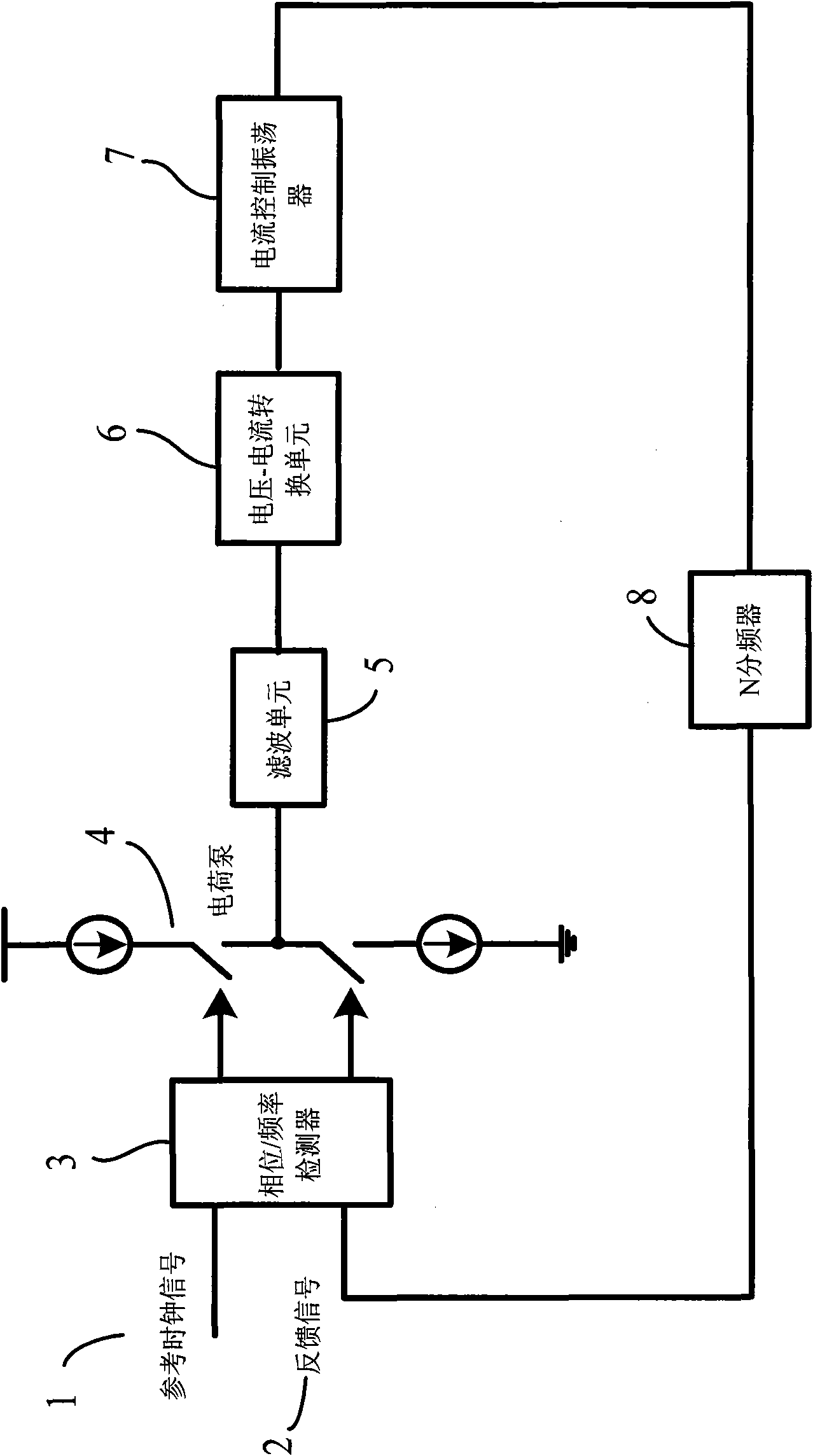

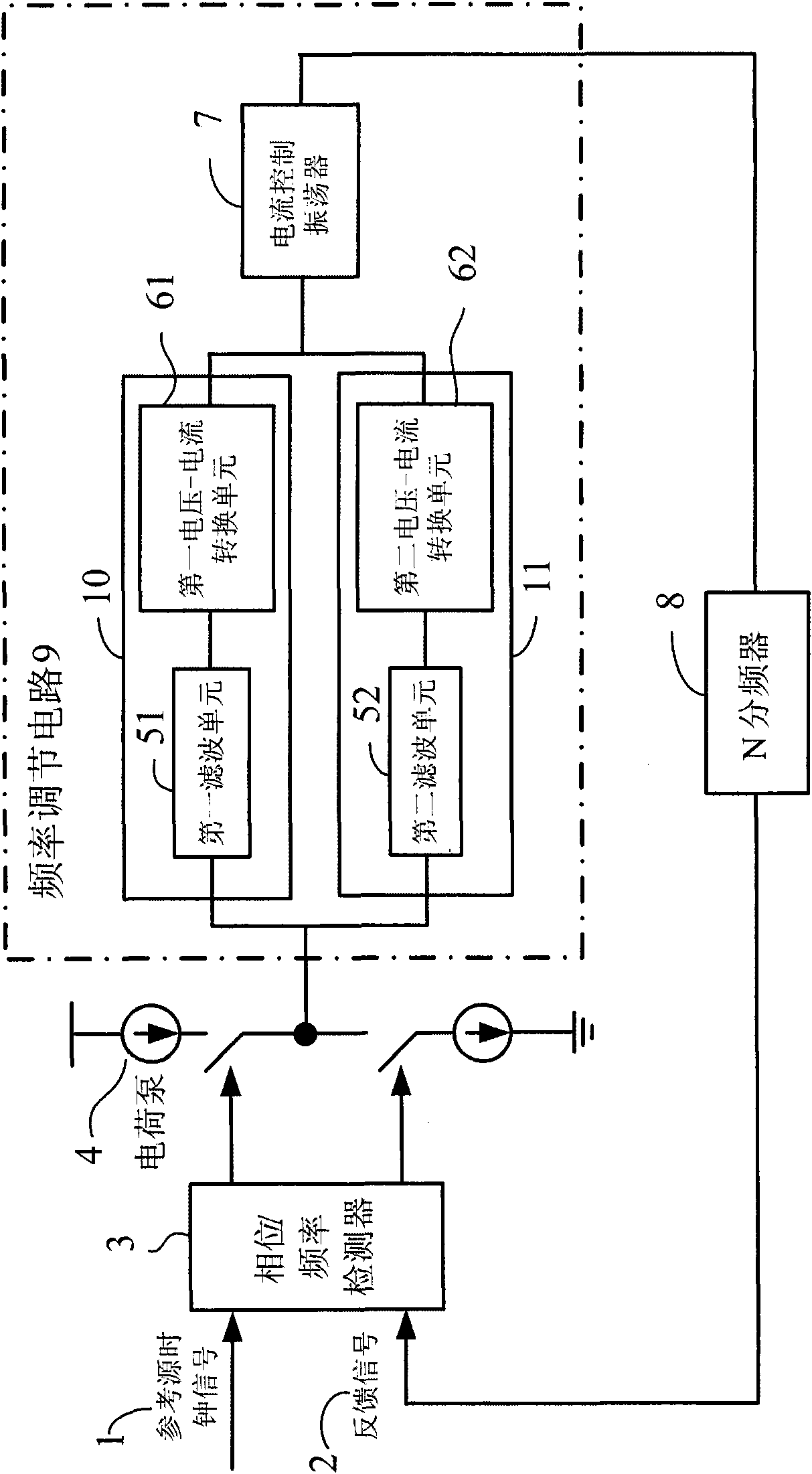

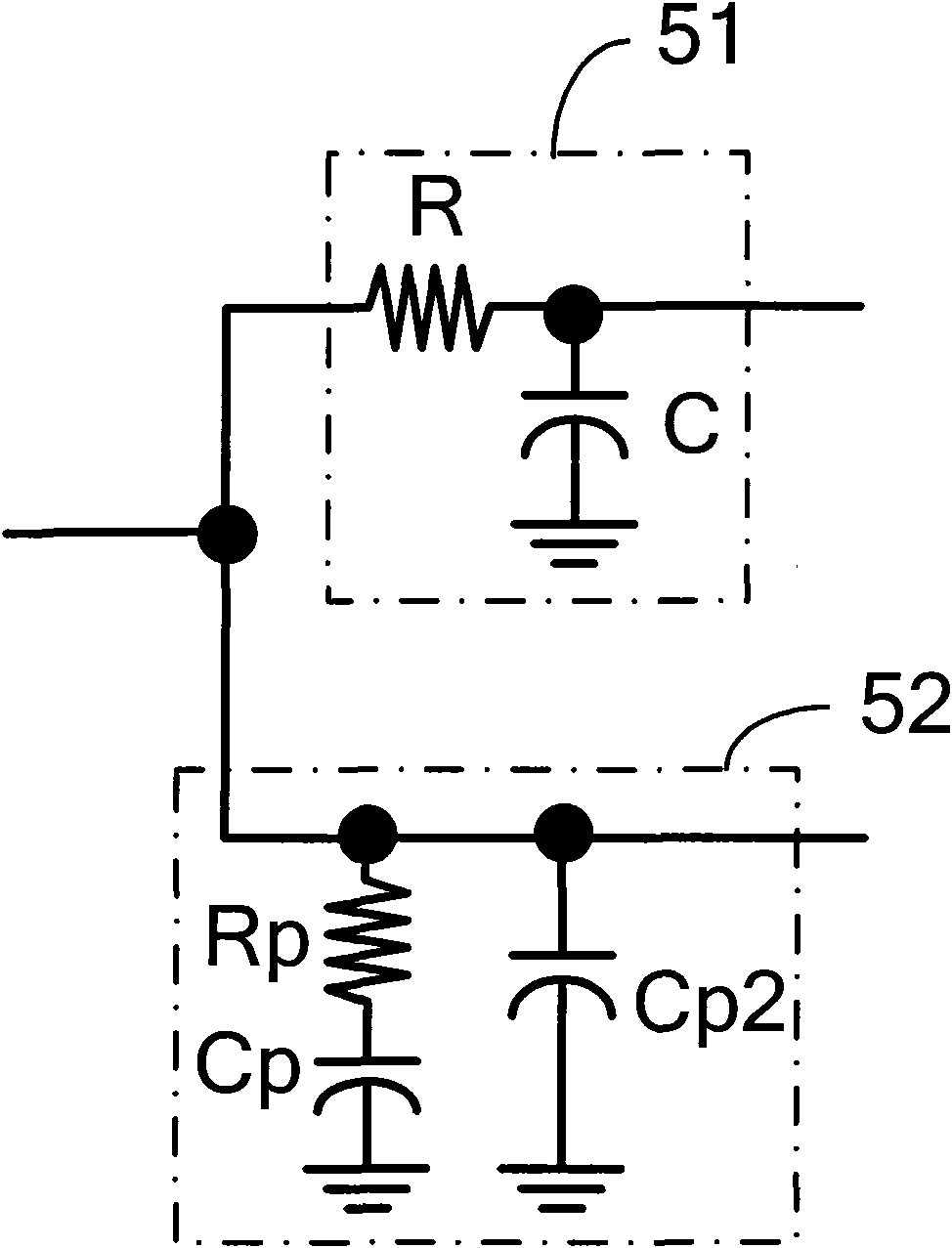

Double-phase-locked loop circuit and control method thereof

ActiveCN101944910AReduce Design ComplexityImprove performancePulse automatic controlPhase locked loop circuitDouble phase

The invention discloses a double-phase-locked loop circuit and a control method thereof. The double-phase-locked loop circuit comprises a phase / frequency detector, a charge pump, a frequency adjustment circuit and an N frequency divider. The frequency adjustment circuit comprises a coarse adjustment circuit, a fine adjustment circuit and a current-controlled oscillator, wherein the coarse adjustment circuit is used for coarse adjustment of frequency of output signals of phase-locked loops till approaching a target frequency; the fine adjustment circuit is used for fine adjustment of the frequency of the output signals of the phase-locked loops till the target frequency; and the current-controlled oscillator is coupled with the coarse adjustment circuit and the fine adjustment circuit and used for producing the output signals of the phase-locked loops, wherein the frequency of the output signals is the target frequency. The double-phase-locked loop circuit can effectively achieve the purpose of expanding the frequency adjustment range under the situation of keeping the loop bandwidth of the phase-locked loops smaller, realize the on-chip integration and further reduce the cost and the design complexity of the circuit.

Owner:MEDIATEK INC

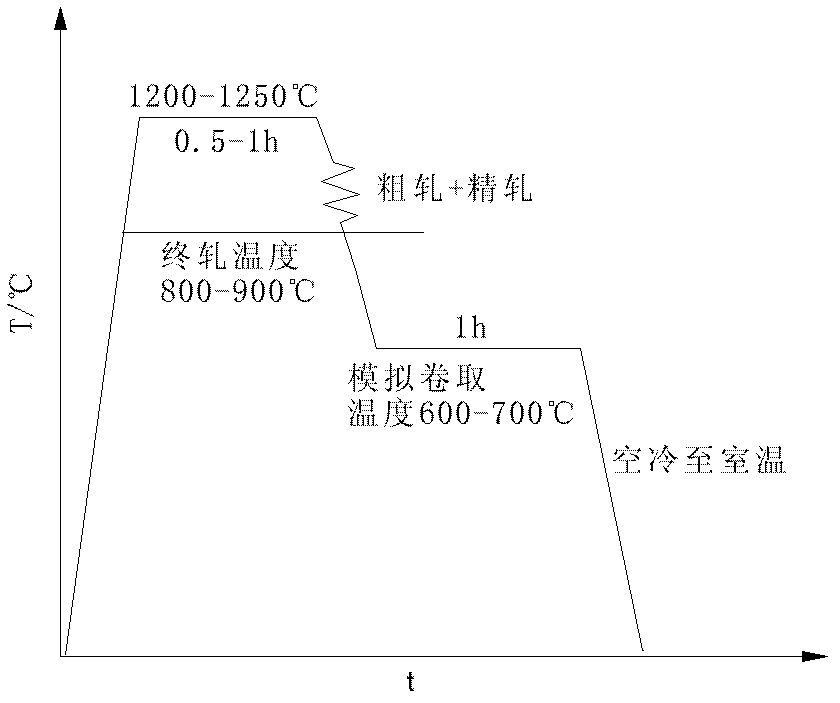

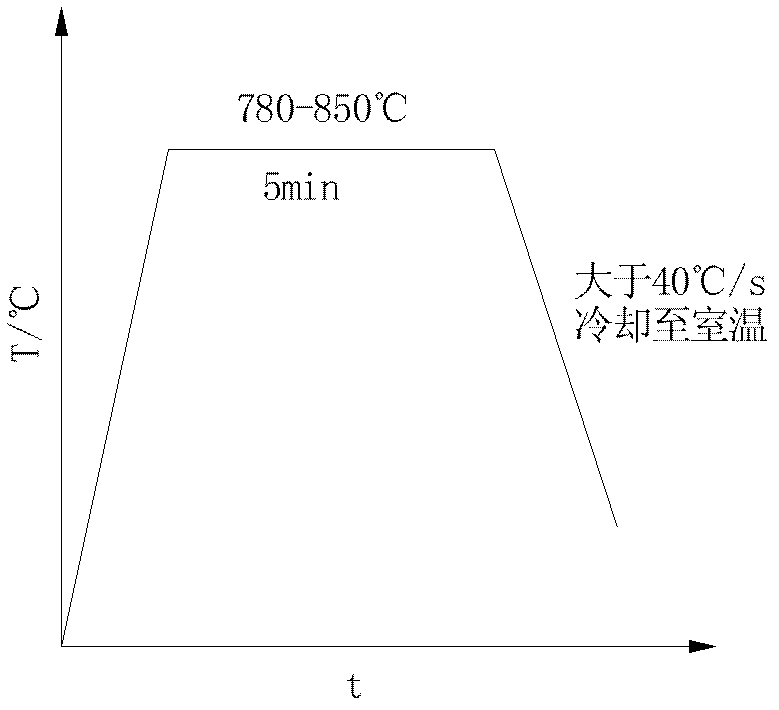

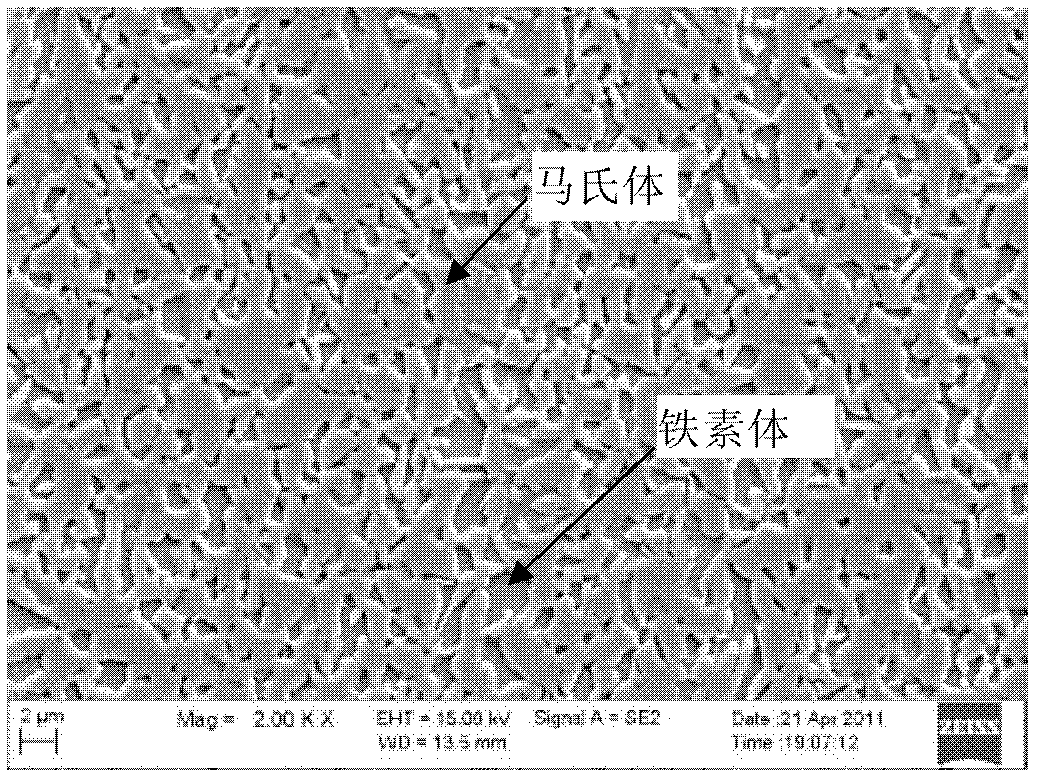

A kind of preparation method of dual-phase hot forming steel

The invention provides a preparation method for double-phase forming steel, which belongs to the technical field of high-intensity steel for automobiles. The steel comprises the following ingredients by mass percent: 0.1 to 0.5 percent of C, 0.3 to 2.5 percent of Si, 1.0 to 3.0 percent of Mn, 1.0 to 3.0 percent of Al, at most 0.02 percent of P, at most 0.01 percent of S, at most 0.01 percent of Nand the balance iron and unavoidable impurities. A production process comprises the following steps of: smelting, hot rolling and hot forming process simulation after the hot rolling. The controlled process parameters are as follows: hot rolling plate blanks are heated to 1200 to 1250 DEG C, the heat insulation is carried out for 0.5 to 1 hour, the final rolling temperature is 800 to 900 DEG C, and the coiling temperature is 600 to 700 DEG C. The hot forming process comprises the following steps of: carrying out heat insulation for 5min at the heating temperature being 750 to 850 DEG C and cooling the materials to the room temperature at the speed greater than 40 DEG C / s. The preparation method adopts the Al micro alloying treatment. Compared with the traditional thermal forming manganeseboron steel, the double-phase forming steel has the advantages that: 1, the hot forming heating temperature is low, and the surface oxidation is reduced; and 2, tissues after the hot forming are ferrite and martensite double-phase tissues.

Owner:UNIV OF SCI & TECH BEIJING

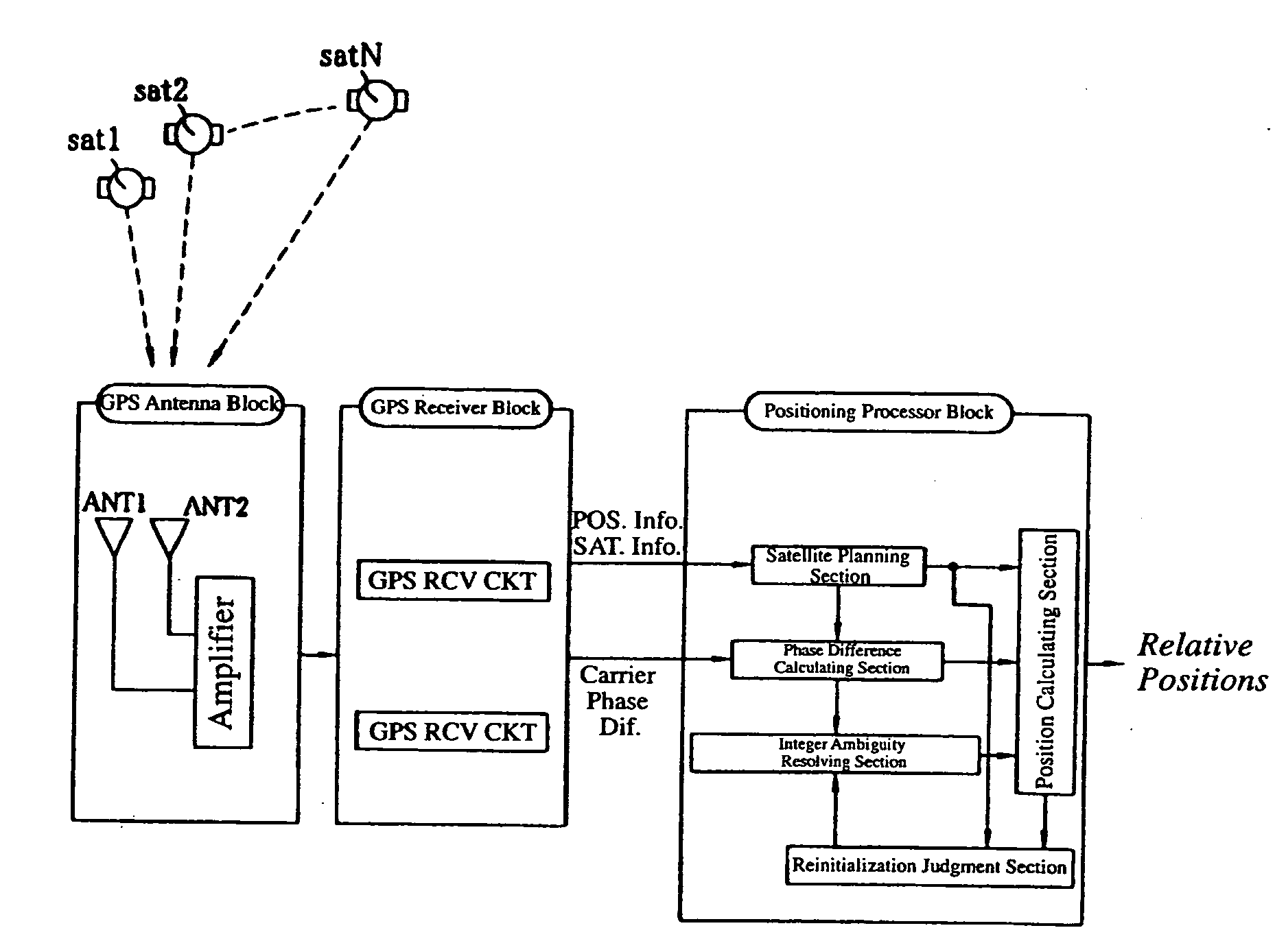

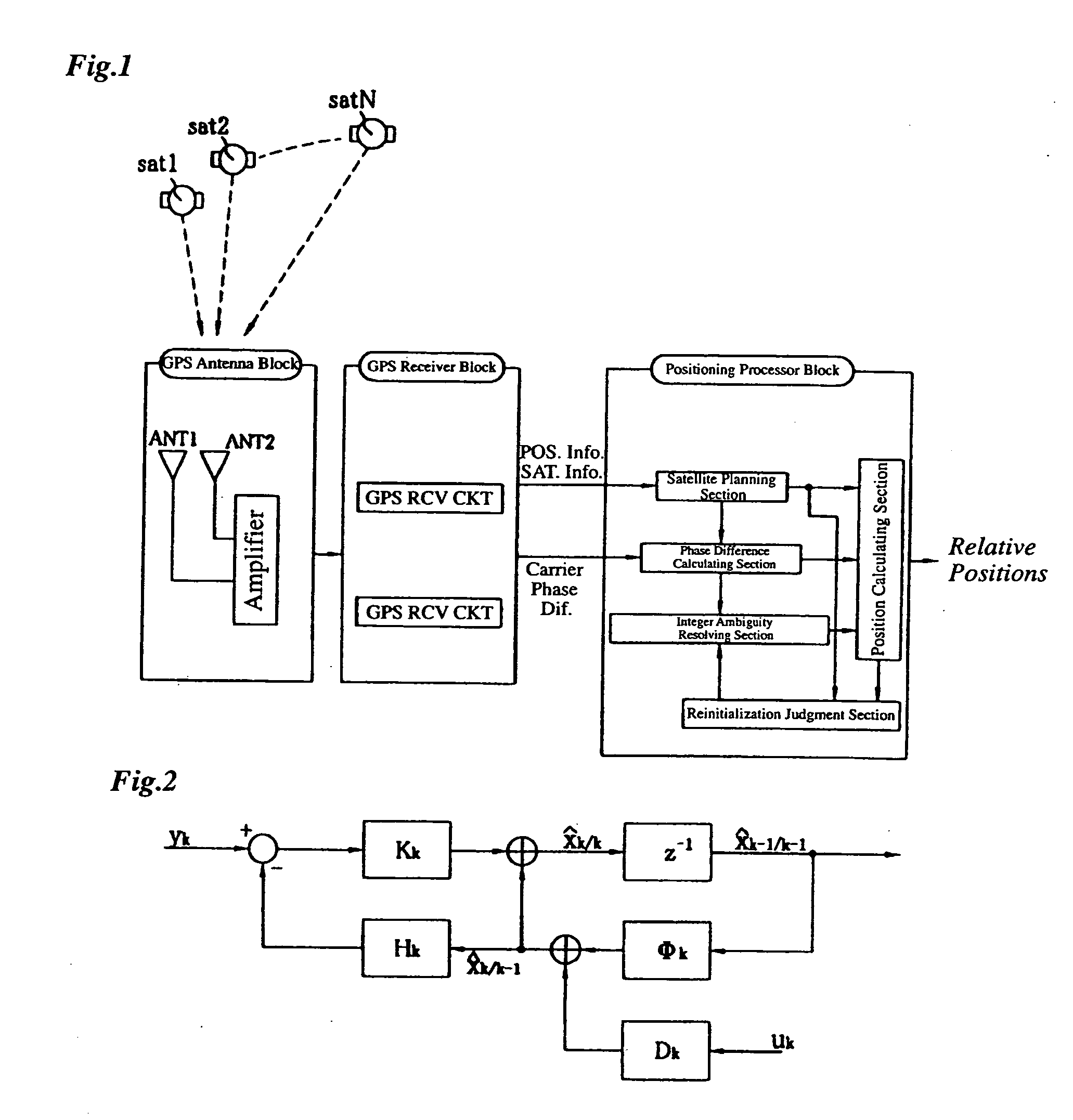

Carrier-phase-based relative positioning device

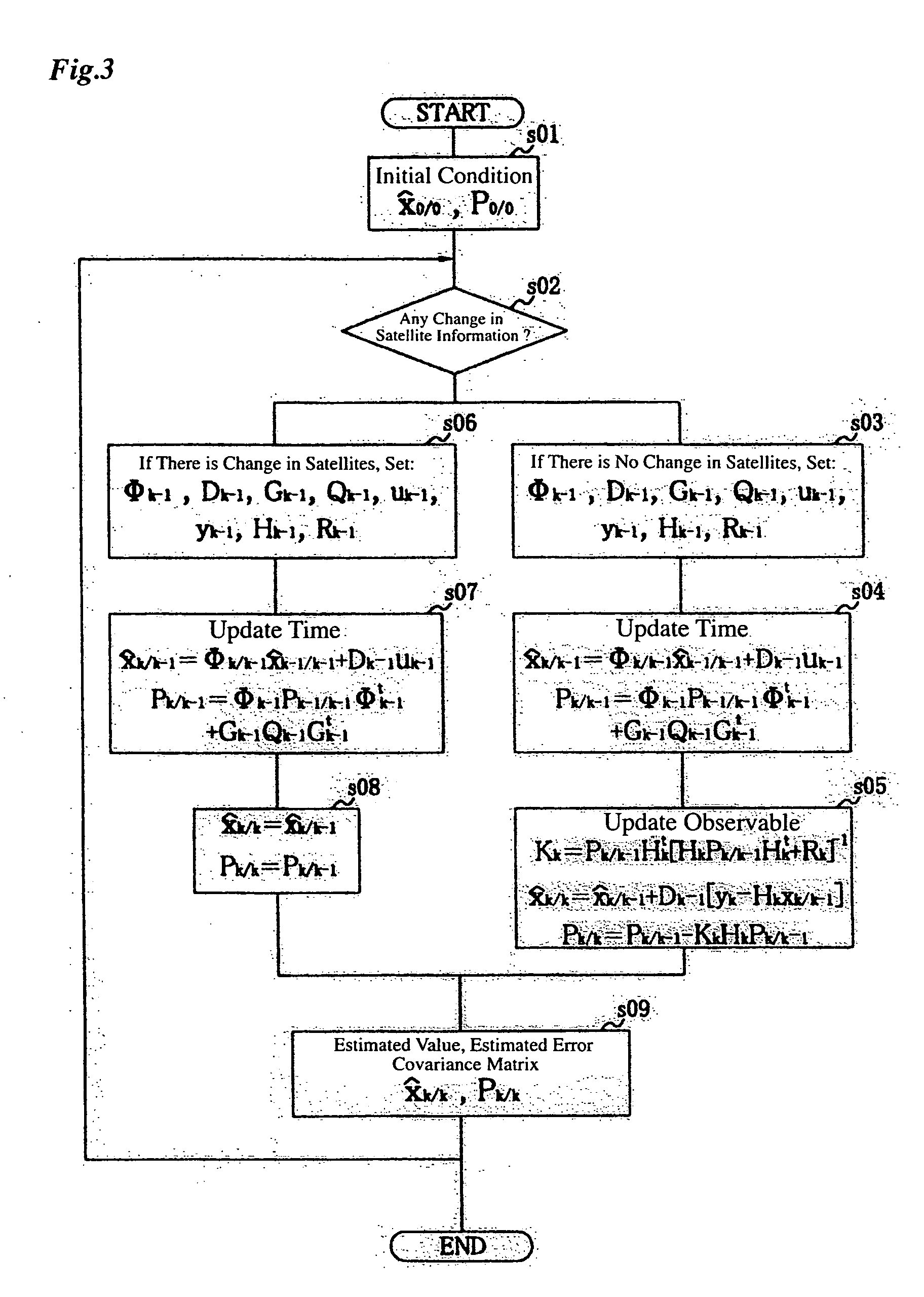

InactiveUS20040145518A1Quick fixEasily and uninterruptedly estimate integer ambiguityPosition fixationSatellite radio beaconingKaiman filterDouble phase

A carrier-phase-based relative positioning device employs a signal processing method which makes it possible to continue estimation of integer ambiguity values even when the number of positioning satellites has changed, determine an integer ambiguity value by efficiently verifying the integer ambiguities in a short time, and calculate a baseline vector. The positioning device includes an integer ambiguity resolving section which determines integer ambiguities of single or double phase differences using a Kalman filter and lambda notation. The Kalman filter is used to calculate estimated values of floating ambiguities and the lambda notation is used to calculate estimated values of the integer ambiguities based on the floating ambiguities. A candidate of a potentially true integer ambiguity that is considered most reliable is determined through various verification processes. When the number of positioning satellites has increased or decreased, or when a reference satellite has been switched, a floating ambiguity after the change in satellite information is estimated from a baseline vector estimated before the change.

Owner:FURUNO ELECTRIC CO LTD

Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

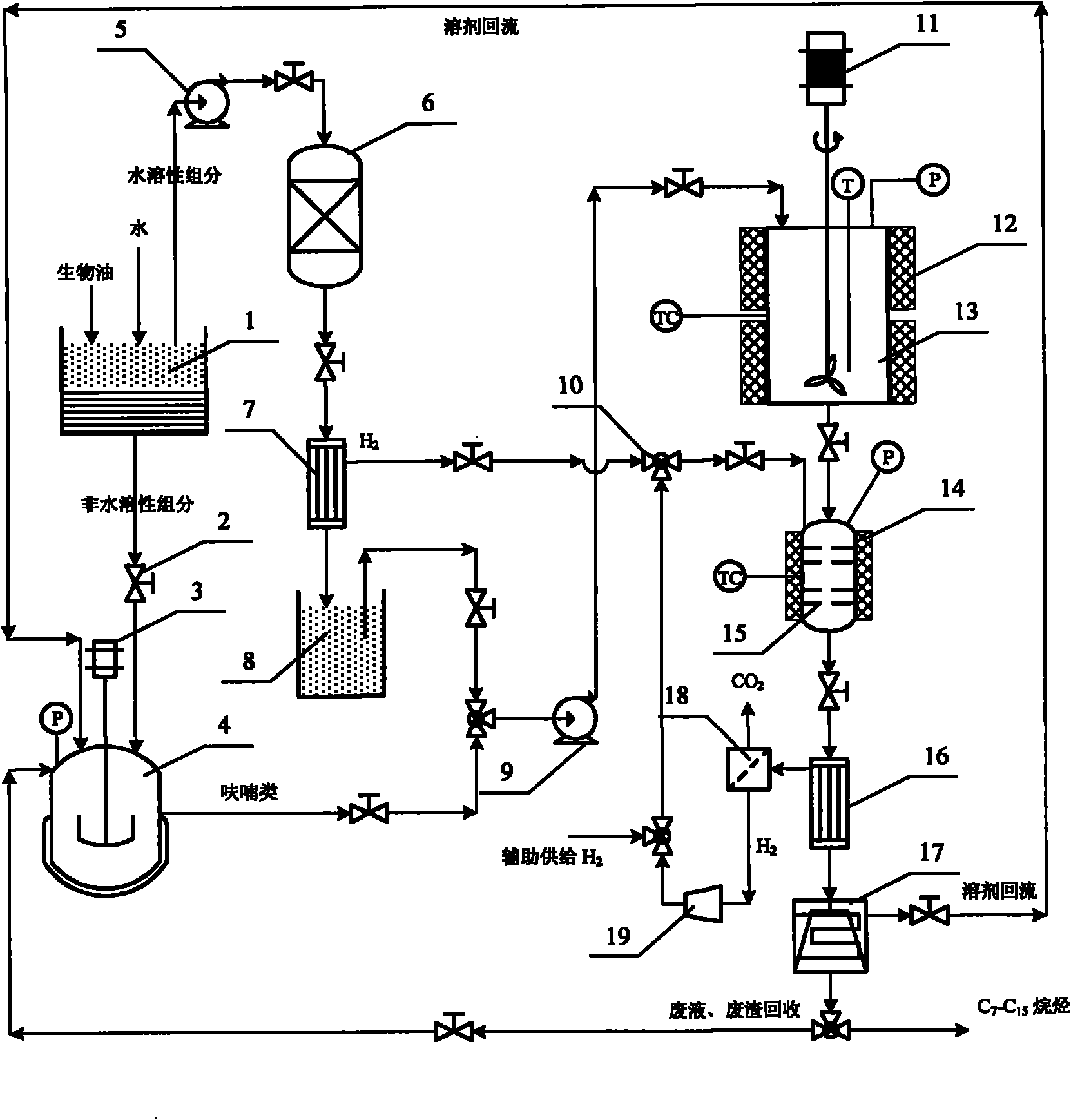

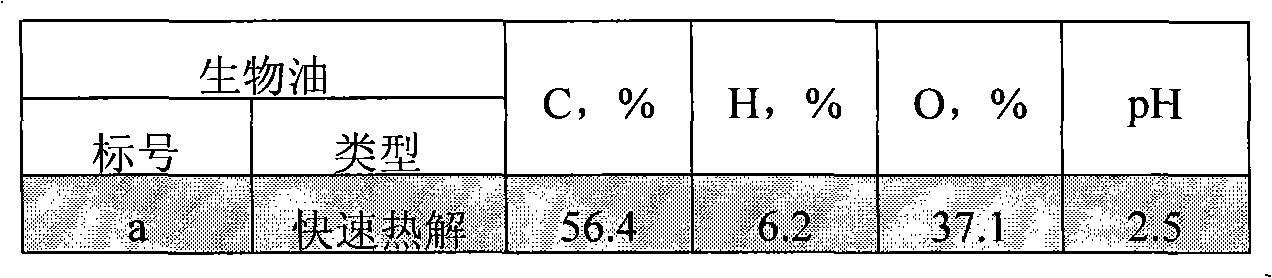

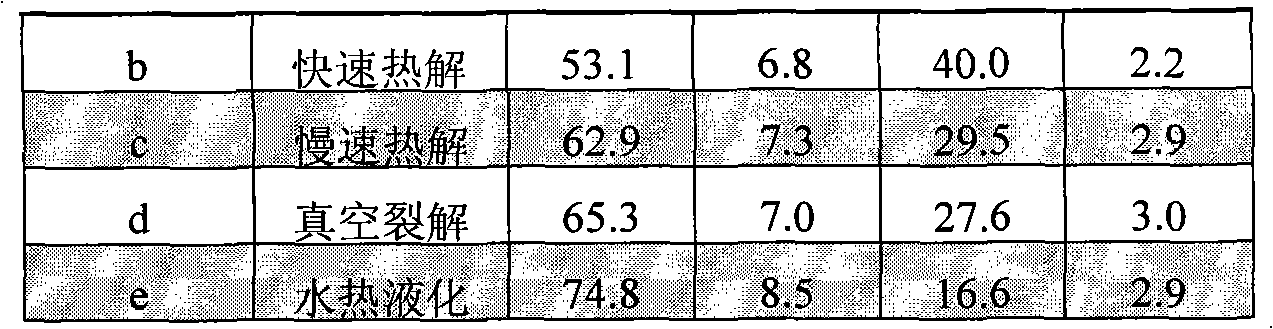

ActiveCN101870881AHigh recovery rateReduce latent heat loss of vaporizationLiquid hydrocarbon mixture productionBio-feedstockAlkaneDesorption

The invention provides a method for preparing liquid alkane fuel by upgrading bio-oil in an aqueous phase catalytic mode. The method comprises the following steps of: 1) pretreating the bio-oil to obtain a water-soluble component and a water-insoluble component; 2) performing a pressurized acid hydrolysis process on a furan compound of the water-insoluble component to prepare the furan compound; 3) performing a reforming and hydrogen production reaction on the water-soluble component; 4) mixing the furan compound with a liquid-phase product separated from the step 3) to perform an aldol condensation reaction to increase carbon chains; and 5) performing a hydrogenation and dehydration reaction on an aldol condensation product to obtain liquid linear alkane. The method has the advantages that: an upgrading process, which is performed in a double-phase system, can effectively contribute to the desorption of an intermediate product from the surface of a catalyst and the mass transfer of an upgraded product, and can reduce the risk of carbon deposition on the surface of the catalyst; the quality of oil obtained by the method is high; the energy density and the energy grade of the bio-oil are improved greatly; and the liquid alkane fuel can be obtained from all kinds of bio-oil so as to partially substitute for the conventional widely-used fossil gasoline and diesel oil fuel.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

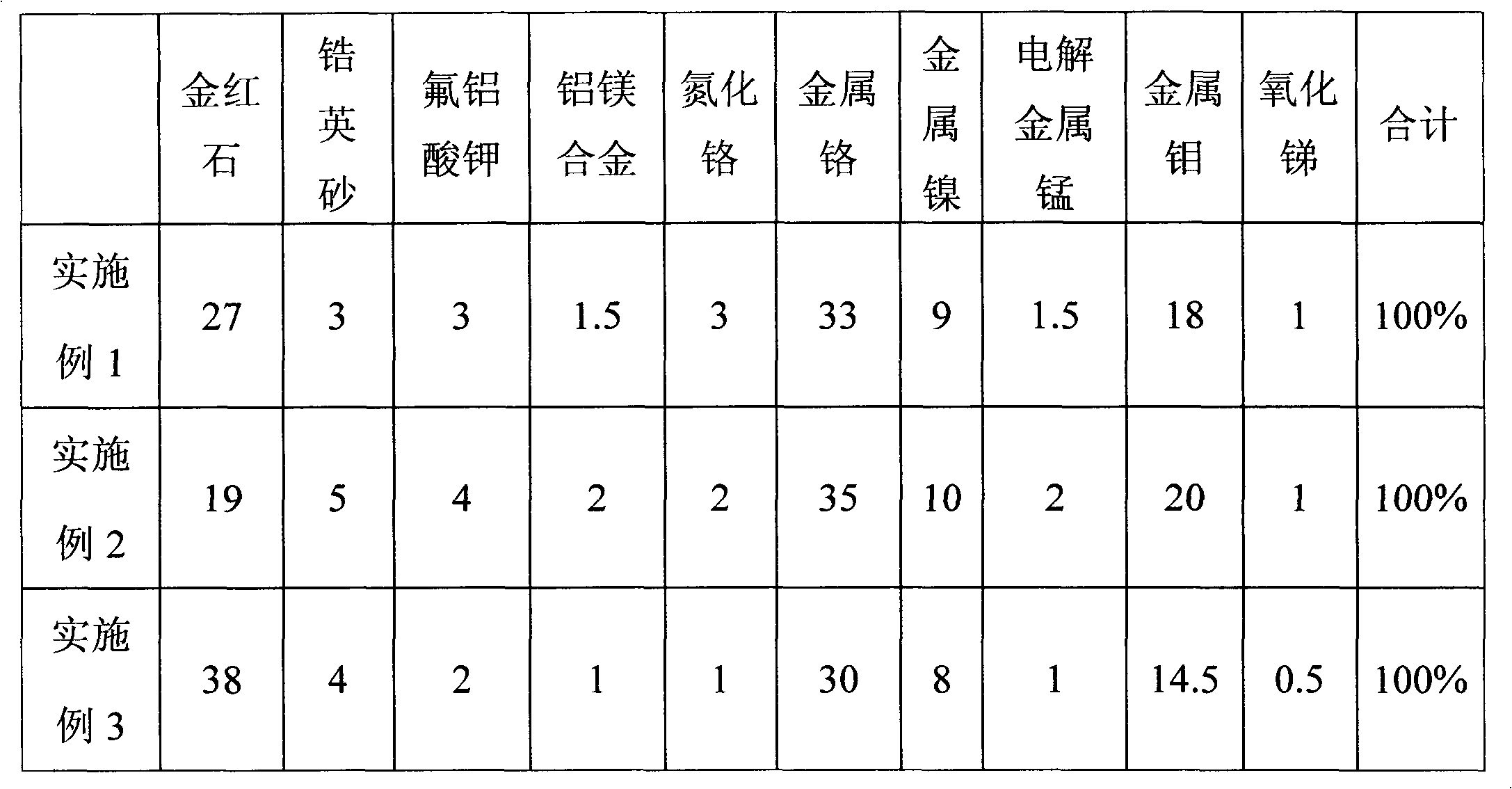

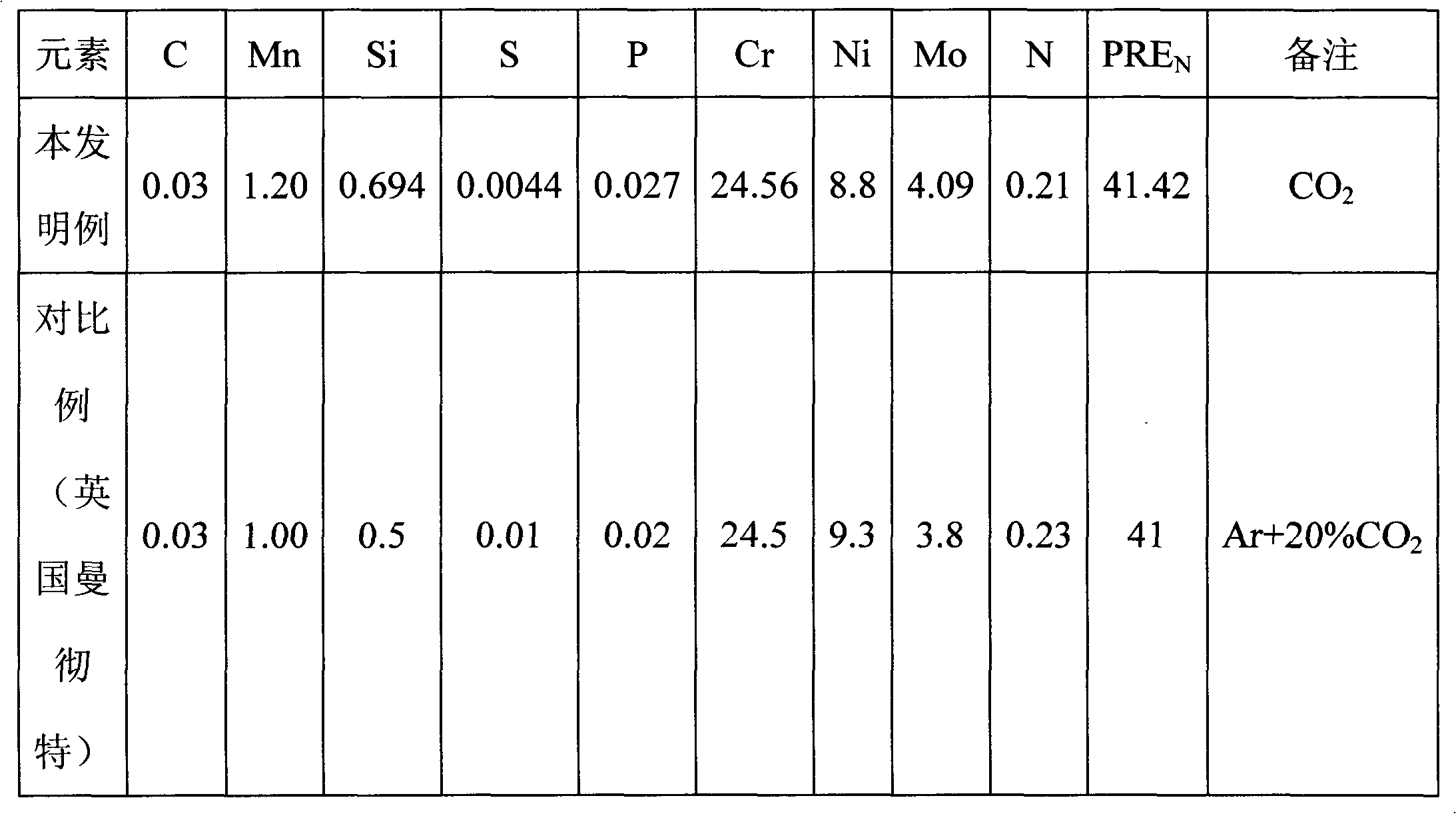

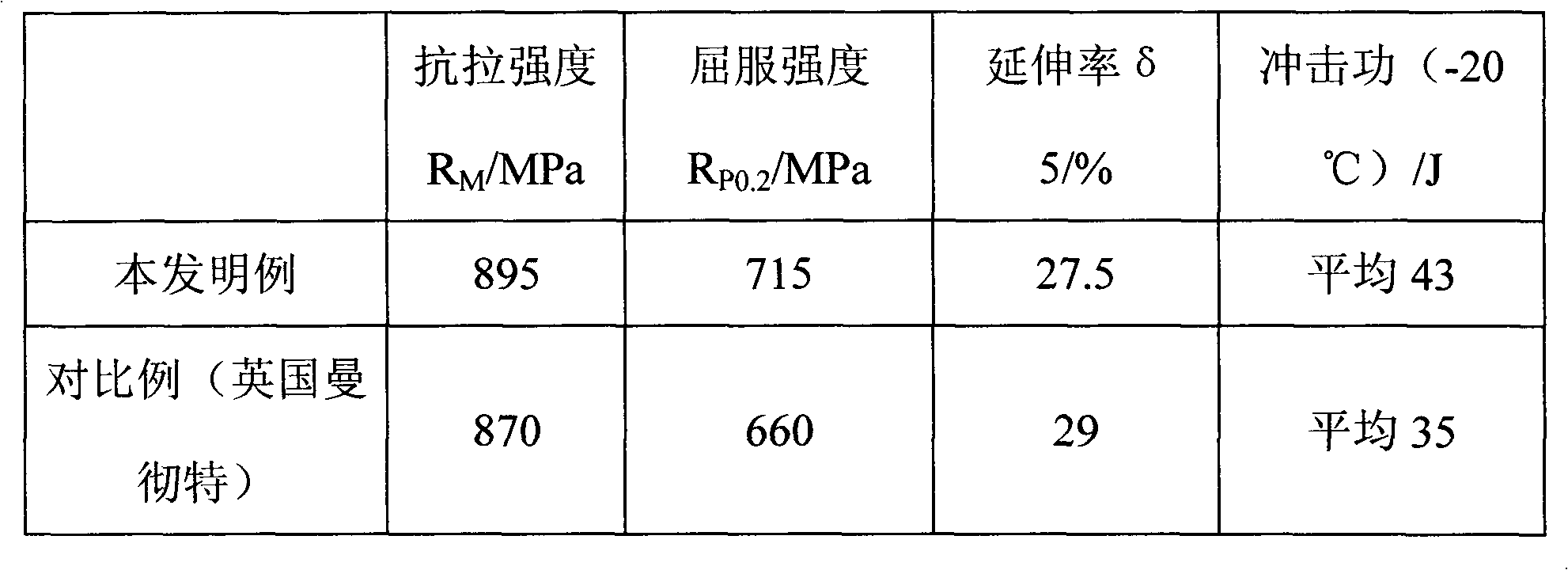

Chemical powder components of 2507 type super double-phase stainless steel flux-cored wire

InactiveCN101966628AGood performance in welding operationBeautiful weld shapeWelding/cutting media/materialsSoldering mediaElectrolysisDouble phase

The invention belongs to the field of welding materials and discloses chemical powder components of a 2507 type super double-phase stainless steel flux-cored wire. A common 304L stainless steel metal strip is used as an outer skin; the chemical powder components are filled inside the common 304L stainless steel metal strip to be rolled into a flux-cored wire. The chemical powder components of the 2507 type super double-phase stainless steel flux-cored wire are characterized by comprising the following components in percent by mass: 19 percent-38 percent of rutile, 3 percent-5 percent of zircon sand, 2 percent-4 percent of potassium fluoroaluminate, 1 percent-2 percent of aluminium magnesium alloy, 1 percent-3 percent of chromium nitride, 30 percent-35 percent of metallic chrome, 8 percent-10 percent of metallic nickel, 1 percent-2 percent of electrolytic manganese metal, 14.5 percent-20 percent of metallic molybdenum and 0.5 percent-1 percent of antimony oxide. In the invention, the steel pipe made from the 304L stainless steel strip (with the specification of 10*0.4mm) filled with the chemical powder is manufactured into the super double-phase stainless steel flux-cored wire according to the general production process. CO2 is used as welding protection gas for the flux-cored wire, and the flux-cored wire has the characteristics of good welding operation process performance, attractive welding line moulding, excellent welding process performance, favorable balance of welding tissue austenite and ferrite and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

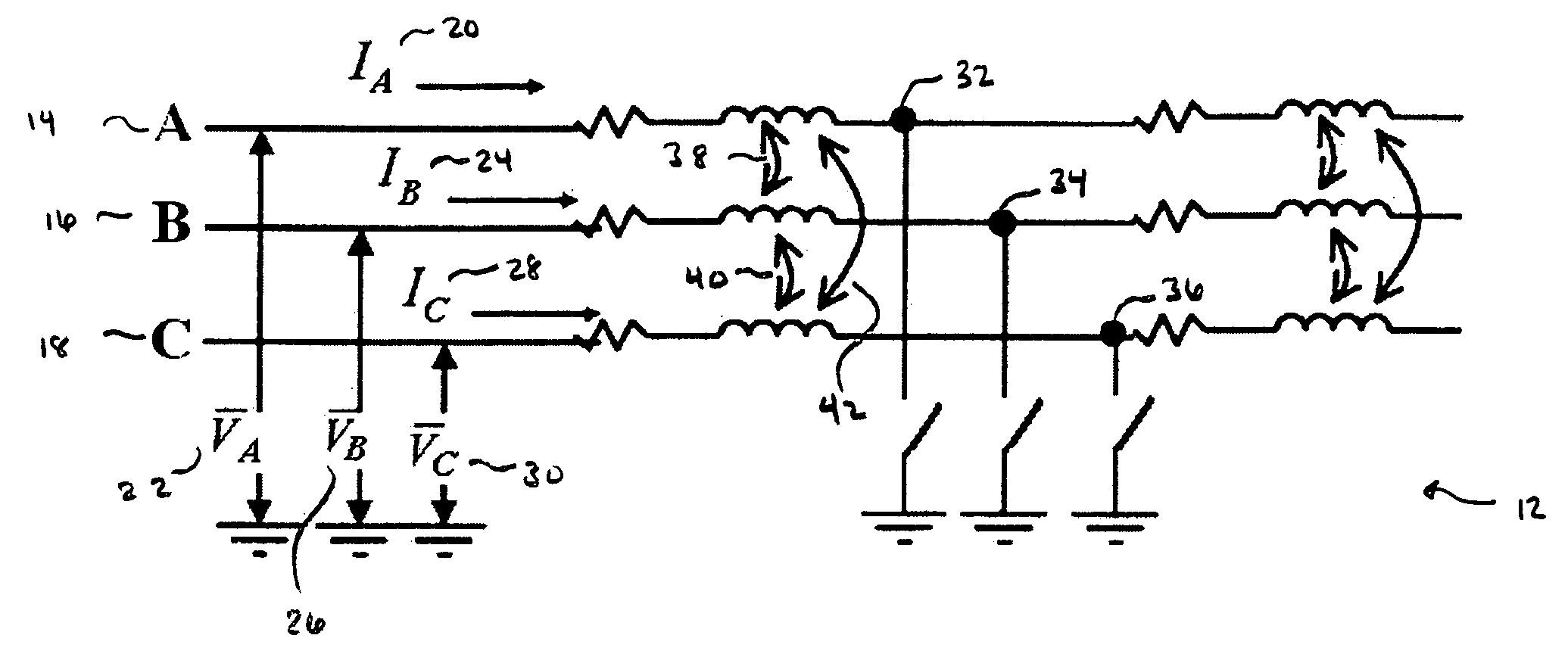

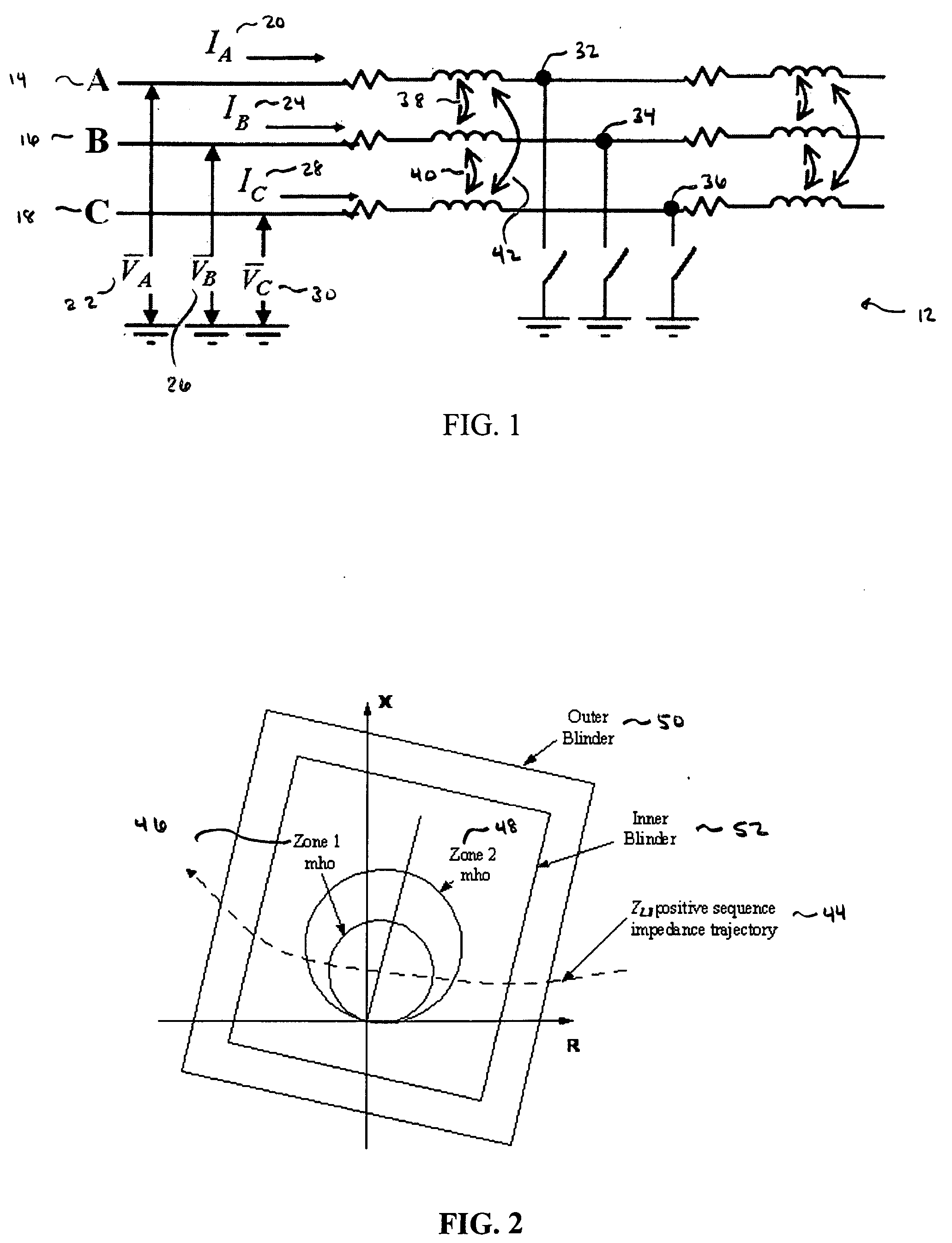

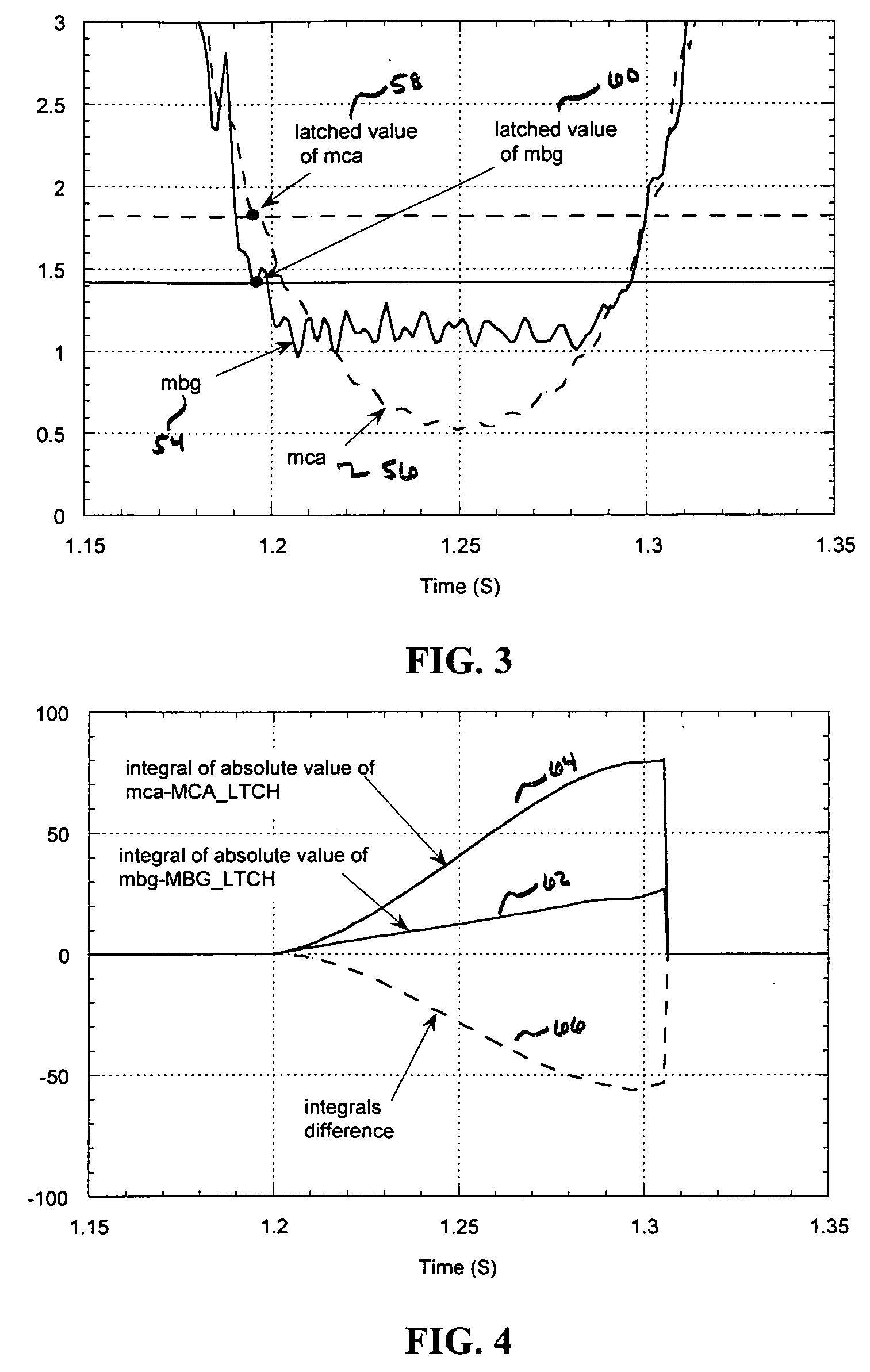

System for maintaining fault-type selection during an out-of-step condition

InactiveUS20060152866A1Emergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentDouble phaseStep detection

A system for maintaining fault-type selection during an out-of-step condition is provided comprising an element for calculating the element reach M; an element for fault type selection; an element for out-of-step detection and blocking; and an element for distinguishing between single-phase-to-ground faults and double-phase-to-ground faults. Single-phase-to-ground faults are distinguished from double-phase-to-ground faults through either a derivative or integration element.

Owner:SCHWEITZER ENGINEERING LABORATORIES

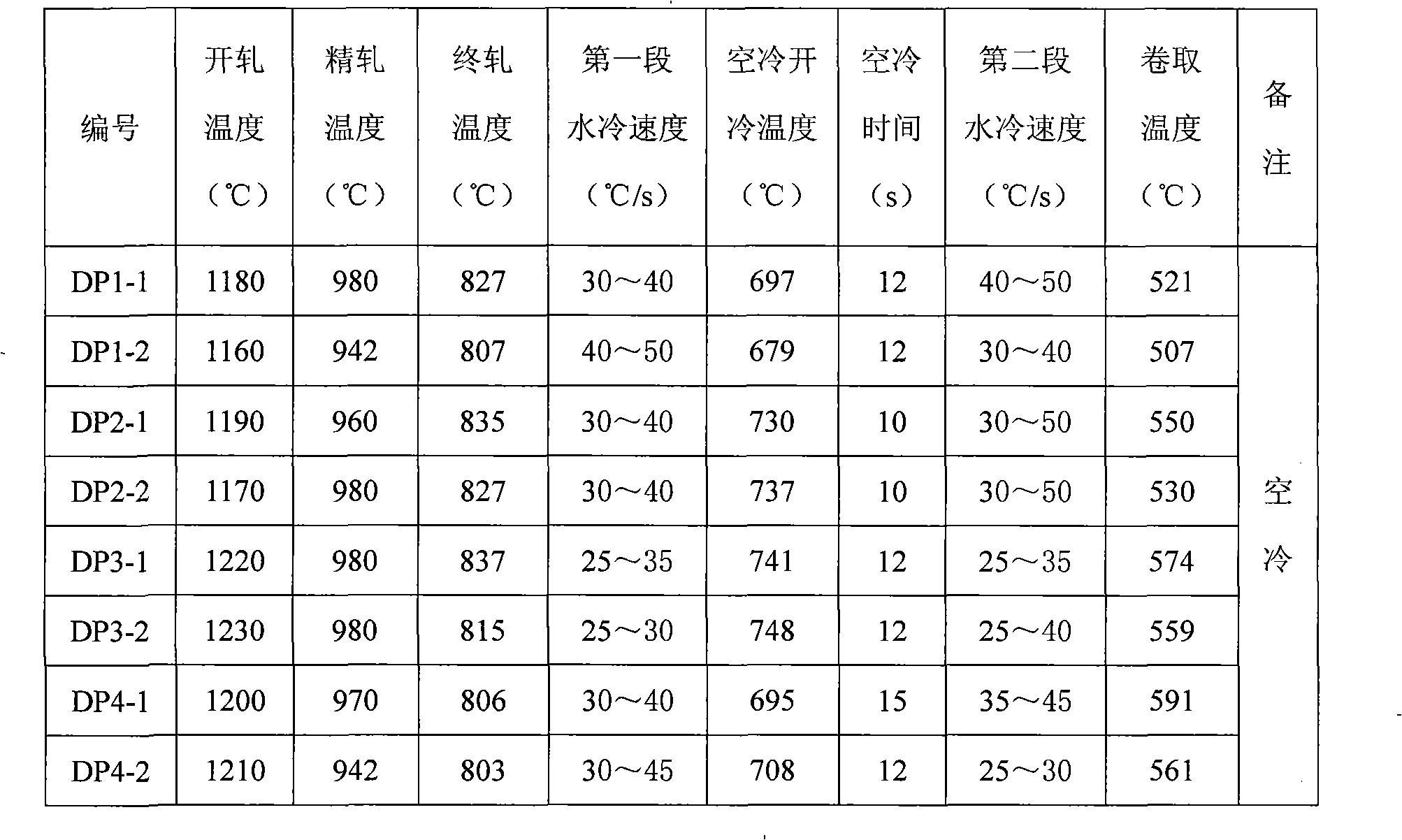

Method for producing hot rolling two-phase steel plate at 700MPa level of tensile strength

InactiveCN101279330AImprove mechanical propertiesLow costTemperature control deviceFurnace typesSheet steelChemical composition

The invention relates to a manufacture method for a thermal rolling double-phase steel plate with 700MPa of anti-tension intensity; the main chemical components of the invention calculated by weight percentage include: 0.03 to 0.08 percent of C, 0.50 to 0.70 percent of Si, 1.00 to 1.60 percent of Mn, 0 to 0.60 percent of Cr, 0 to 0.40 percent of Mo, and 0.02 to 0.05 percent of Nb, and the rest is Fe; the thickness specification of the invention is 3.0 to 4.0mm; the invention is provided with a polygonal ferrite and a martensite double-phase tissue; a few amount of grain bainites appear; wherein, the volume percent of the ferrite is 70 to 90 percent; the volume percent of the martensite is 30 to 10 percent; the average crystal grain dimension of the ferrite is 5Mum. The invention is rolled by a controlled rolling and controlled cooling technology; a beginning rolling temperature is controlled between 1250 to 1150 DEG C; the stopping rolling temperature is controlled between 800 to 850 DEG C; the cooling speed for a first section is controlled between 25 to 50 DEG C / s; after cooling the temperature is 680 to 750 DEG C; a second section controllable cooling is carried out after cooling the temperature between 670 to 700 DEG C by air; the cooling speed for a second section is controlled between 25 to 50 DEG C / s; the stopping cooling temperature, namely the coiling temperature is between 500 and 600 DEG C; then the steel plate is cooled to the room temperature by air.

Owner:UNIV OF SCI & TECH BEIJING

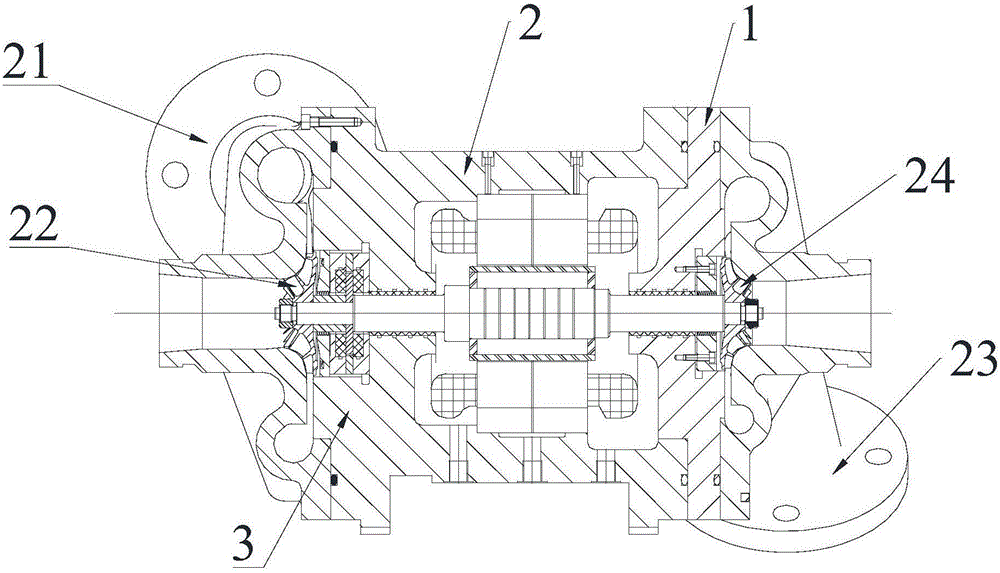

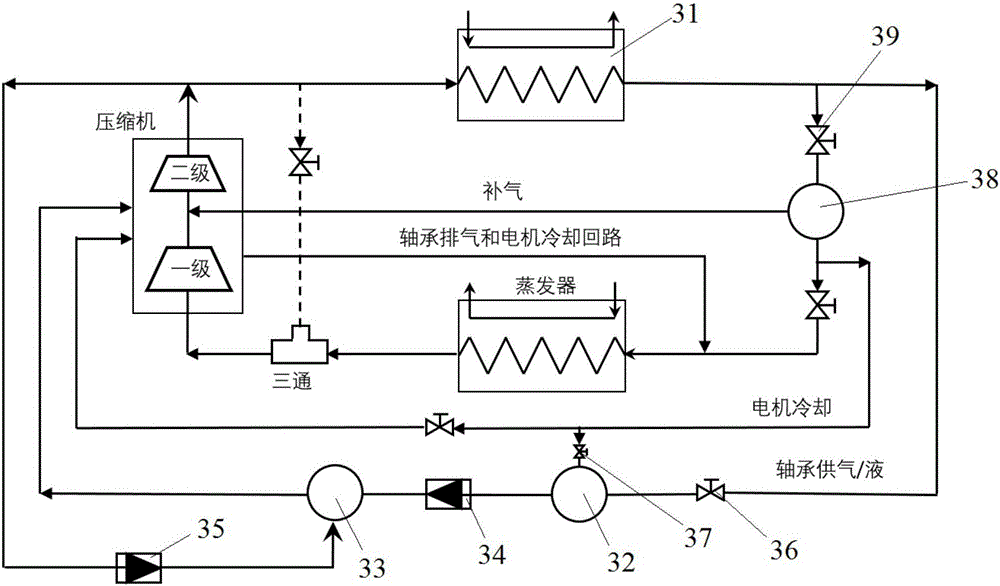

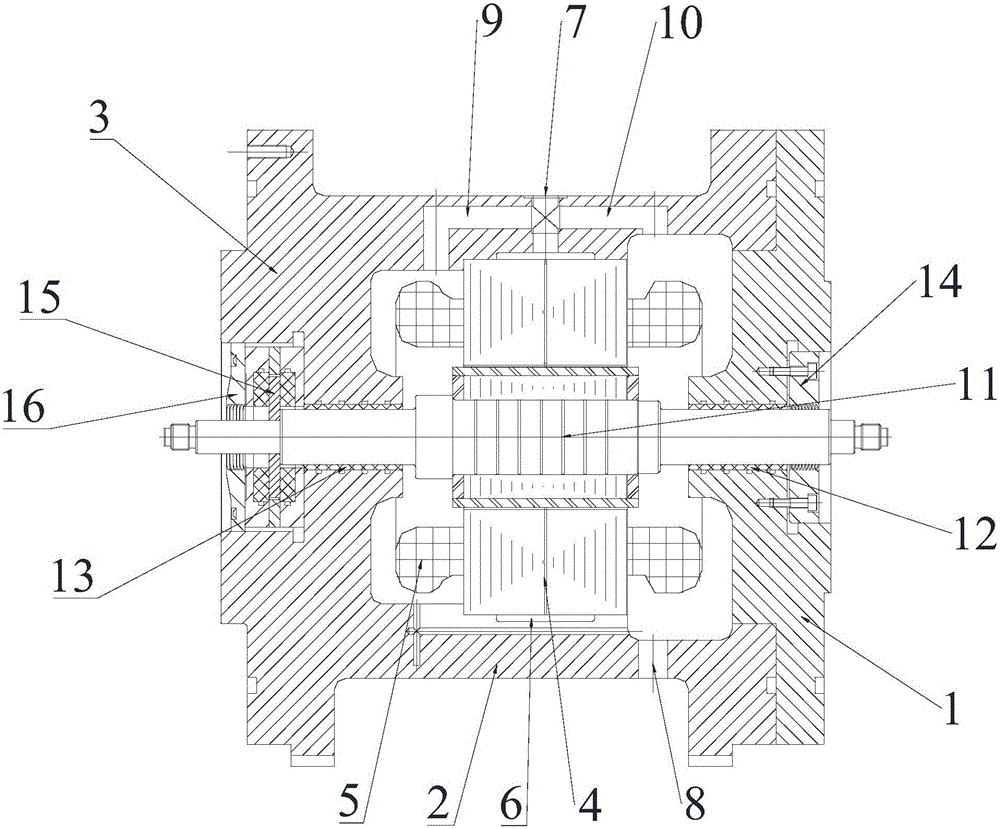

Centrifugal compressor

The invention discloses a centrifugal compressor. The centrifugal compressor comprises a motor and a first-level compressor body. The motor drives the first-level compressor body to run. A motor rotor of the motor is supported by a radial hydrostatic bearing to rotate, and the axial force of the motor rotor is balanced through an axial hydrostatic bearing. Gas and liquid double-phase low-viscosity fluid is adopted as lubrication media for the radial hydrostatic bearing and the axial hydrostatic bearing. According to the centrifugal compressor, low-velocity liquid and gas double-phase refrigerant porous material hydrostatic air bearings are adopted as the radial hydrostatic bearing and the axial hydrostatic bearing supporting the motor rotor, the radial and axial waggling of the rotor is reduced, and therefore gaps and sealing gaps between the tops of blades of impellers and volutes are allowed to be reduced by a half, and accordingly the efficiency of the centrifugal compressor can be improved by 10% or above.

Owner:ZHEJIANG FUTENG FLUID TECH CO LTD

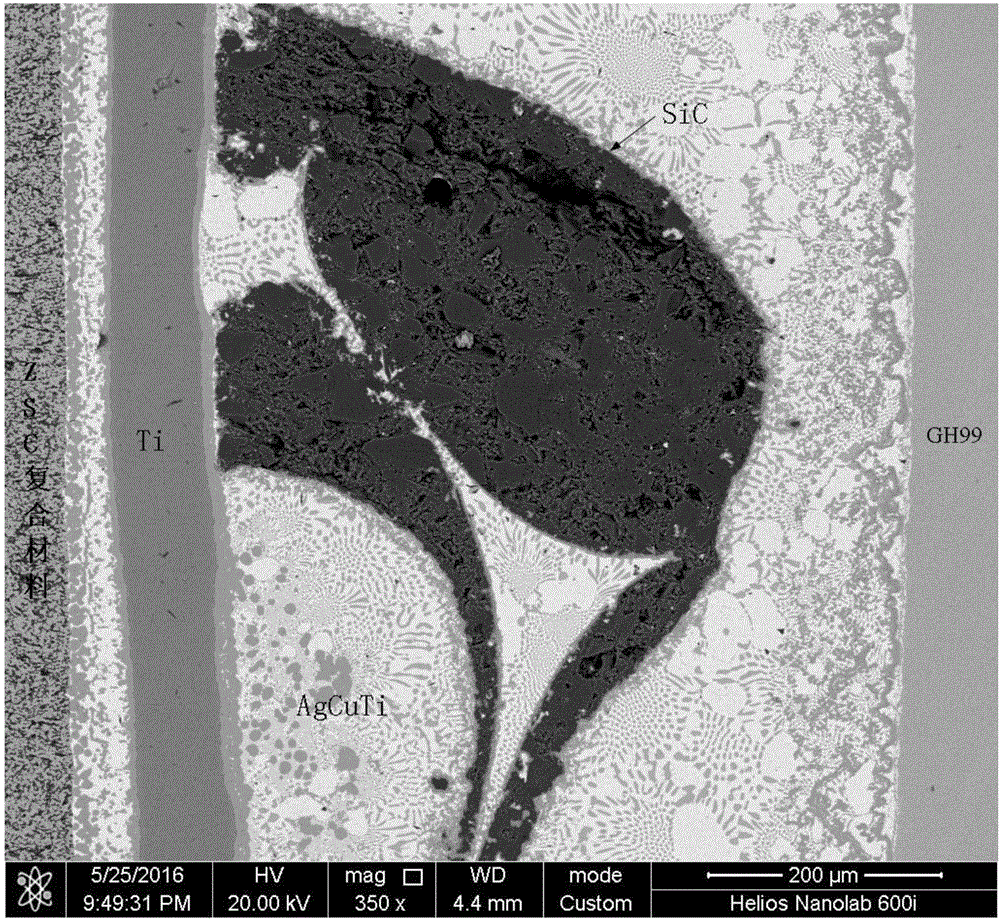

Braze-welding method for ceramic or ceramic-based composite material and metal through composite interlayer

ActiveCN106493443AFlexible adjustment of elastic modulusFlexible adjustment of thermal expansion coefficientWelding/cutting media/materialsSoldering mediaDouble phaseLiquid state

The invention discloses a braze-welding method for a ceramic or ceramic-based composite material and metal through a composite interlayer. The braze-welding method for the ceramic or ceramic-based composite material and metal solves the problems that an existing braze-welding joint for the ceramic or ceramic-based composite material and metal is relatively high in residual stress and is relatively low in reliability. The braze-welding method comprises the following steps of: I, grinding braze-welding materials such as to-be-welded ceramic and a to-be-welded metal material; II, coating porous ceramic with AgCuTi powder brazing filler metal to form an interlayer, and heating and melting the interlayer, and cooling the heated and molten interlayer to obtain a ceramic-dual-phase continuous interlayer; III, superposing the to-be-welded material, AgCuTi foil-shaped brazing filler metal, the double-phase continuous interlayer, a Ti foil, AgCuTi foil-shaped brazing filler metal and to-be-welded ceramic from bottom to top in sequence; and IV, carrying out vacuum braze-welding on a to-be-welded part. According to the braze-welding method, a pressureless infiltration method is adopted to fill porous ceramic with liquid-state AgCuTi brazing filler metal, and AgCuTi foil, the double-phase interlayer, the Ti foil and the AgCuTi foil are superposed for being subjected to braze-welding, so that joint strength is improved.

Owner:HARBIN INST OF TECH

Method for continuous pickling of double-phase stainless steel coil

The invention relates to a method for continuous pickling of a double-phase stainless steel coil, which comprises the following steps: connecting a high-Cr and high-Ni austenitic stainless steel coil at the front end and the rear end of the double-phase stainless steel coil after hot-roll annealing; performing shot blasting on the steel coil at a low rotational speed before pickling; passing the annealed steel coil through a chemical pretreatment stage, wherein a medium is H2SO4, the concentration of H2SO4 is between 300 and 400 g / l and a pickling temperature is between 88 and 90 DEG C. and pickling catalysts of NaCl and hydrogen peroxide are added into the annealed steel coil; passing the steel coil through No.1 and No.2 chemical mixed pickling stages, wherein a medium is HNO3 and HF, the concentration of HNO3 is between 180 and 270 g / l, the concentration of HF is between 45 and 80 g / l and the pickling temperature is between 45 and 60 DEG C; passing the steel coil through No.1 and No.2 troughs, wherein a temperature is between 45 and 60 DEG C; and cutting the austenitic stainless steel at the front end and the rear end of the double-phase stainless steel. After the method for the continuous pickling of the double-phase stainless steel coil is adopted, the iron scale of the double-phase stainless steel coil is removed, the surface of the steel coil is bright and has high lustrousness, and the steel coil meets the using requirements of No.1 in GB4237.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

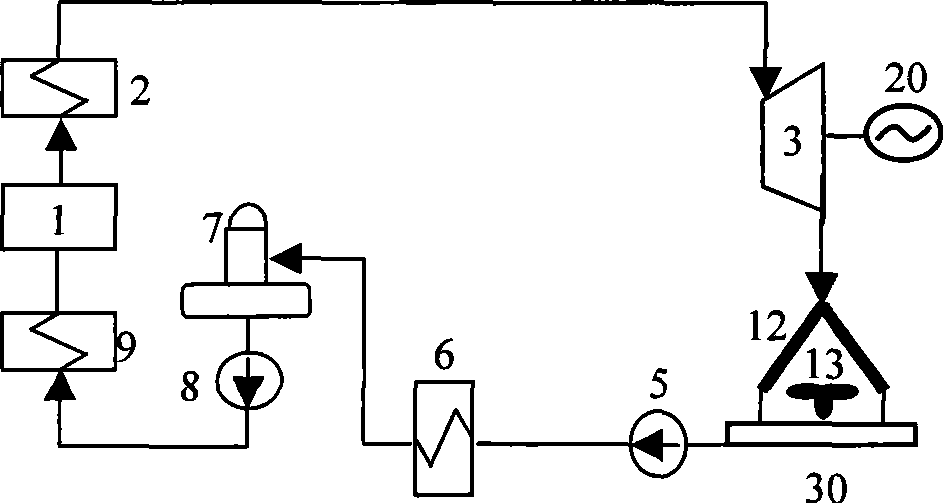

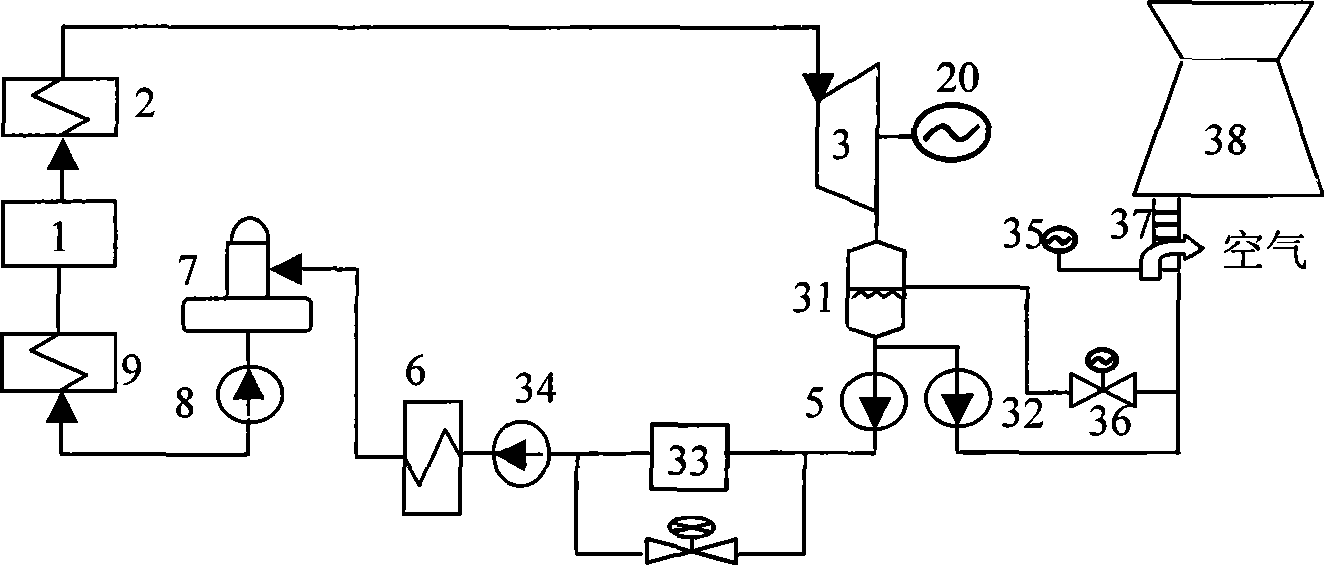

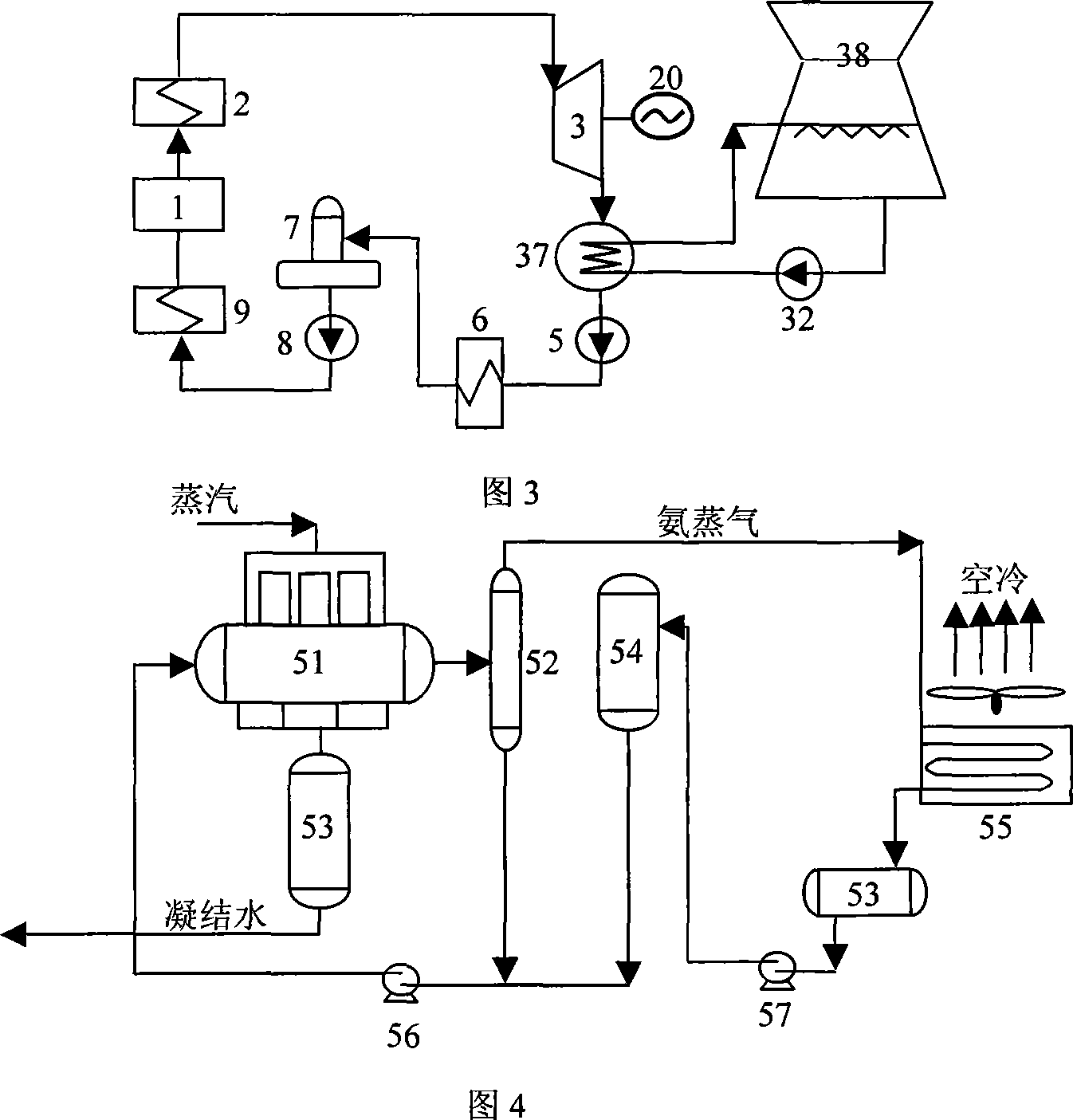

Indirect air cooling method and system for working medium adopting parallel-connection positive and reverse refrigeration cycle

InactiveCN101368767AEasy to implementNovel ideaCompression machines with reversible cycleWorking fluidNuclear power

The invention discloses an indirect air cooling method and a system with the working fluid of parallel-connected obverse and inverse refrigeration cycles. Based on the phase transition in the working fluid cooling process, a double-phase transition heat exchanger and a single-phase transition heat exchanger are respectively coupled with an obverse refrigeration cycle and an inverse refrigeration cycle which are connected in parallel; the saturated gaseous refrigerant from the phase-transition heat exchangers is compressed, boosted and then sent to an air-cooled radiator for exothermic condensation, then the condensed refrigerant enters a liquid storage tank and is decompressed through a throttle valve and sent to the phase-transition heat exchangers so as to complete the obverse refrigeration cycle; or the saturated gaseous refrigerant from the phase-transition heat exchangers is throttled and decompressed through a thermal expansion valve and then sent to the air-cooled radiator and the liquid storage tank, pressurized by a booster pump and finally sent back to the phase-transition heat exchangers so as to complete the inverse refrigeration cycle. The method and the system can be widely applied to the cooling systems of the condensers in thermal power, nuclear power and other turbine-generator units or the cooling systems of the intercoolers in petroleum, chemical and other industries to reduce energy consumption, save investments, as well as improve water-saving rate and the adaptability of the cooling system to the environment; therefore, the method and the system are provided with promotional values and can produce larger social environmental benefits and economic benefits after implementation.

Owner:NORTHEAST DIANLI UNIVERSITY

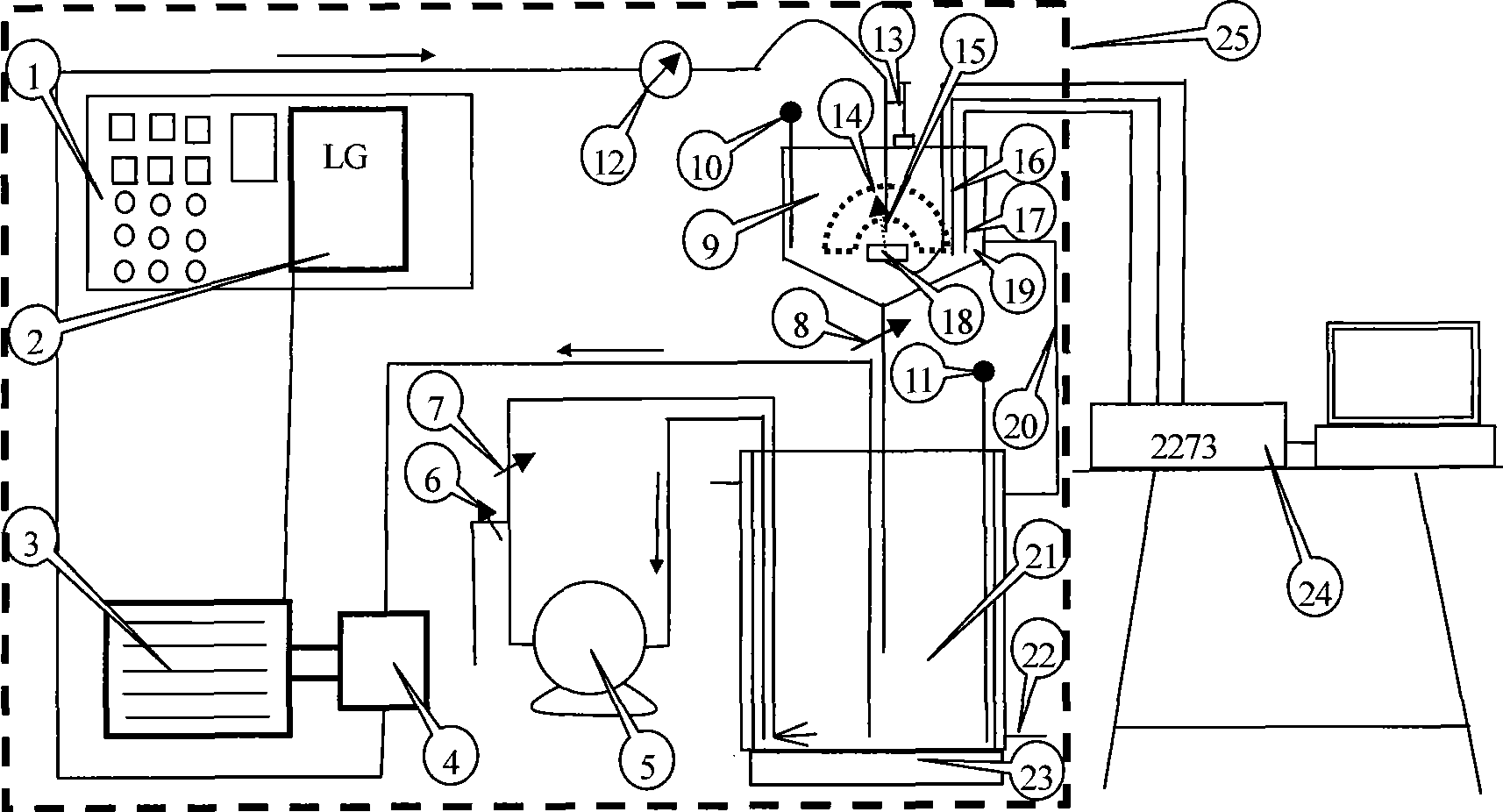

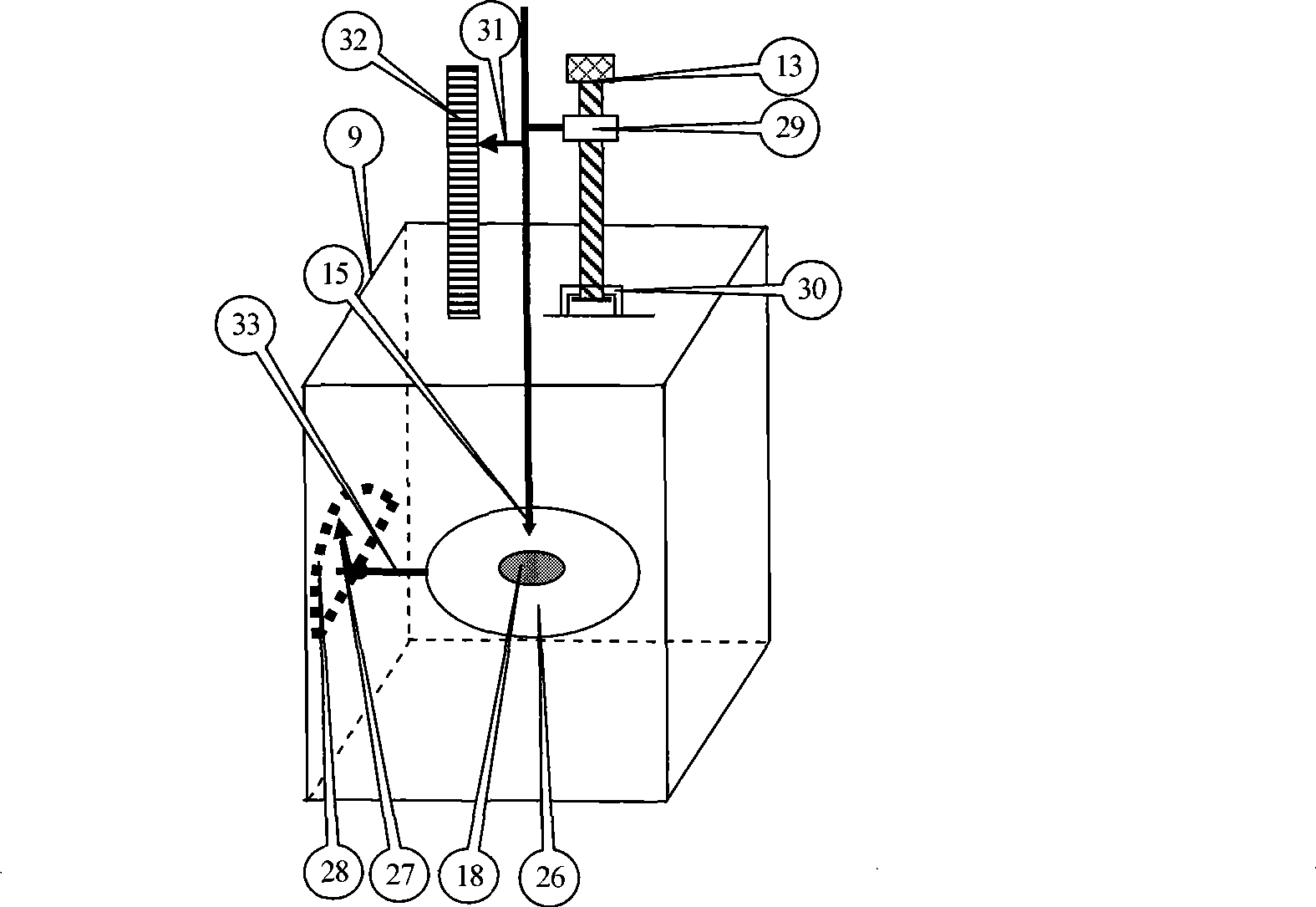

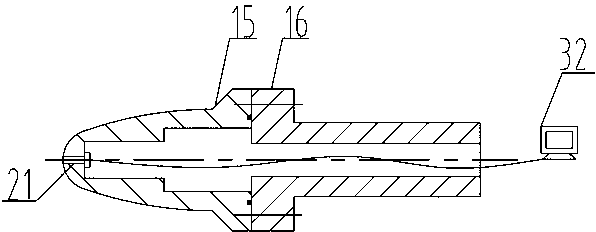

Jetting type liquid-solid double-phase scouring corrosion experiment apparatus

InactiveCN101382477AReduce pulsationWith angle of attackWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFrequency changerDouble phase

The invention relates to an erosion-corrosion device, in particular to a jet type liquid-solid dual-phase fluid erosion-corrosion experimental device which solves the problems in the prior art that the adjustment of an attack angle is relatively difficult and the experimental period is long as well as the problem of real-time measurement of electrochemical parameters and the like. The experimental apparatus is provided with an ejector pump, a nozzle, a nozzle chamber and an electrochemical test system, and adopts the cam pump of a motor drive provided with a transducer as the ejector pump, wherein, an attack angle adjustment device used for adjusting the attack angle of samples is arranged in the nozzle chamber, the pipeline where the nozzle locates is connected with a jet distance adjustment device. The device adopts the cam pump as the ejector pump to realize the smooth conveying of media containing bigger solid phase particles, utilizes the cam pump of the motor drive provided with the transducer to control the flow speed; and the nozzle chamber is provided with the samples which can control the attack angle and the jet distance, the samples can fulfill the electrochemical measurement. The device can control the flow speed, attack angle and the temperature of the media, and fulfill the electrochemical measurement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

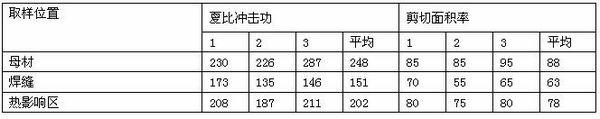

Method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipe

The invention discloses a method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipes, which is applied to the manufacture of special welding pipes for oil and gas transmission. In the method, a controllable rolled steel plate is used, wherein the controllable rolled steel plate has a ferrite-bainite double-phase metallurgical microstructure and contains the following chemical components: 0.04 to 0.07 percent of C, 1.60 to 1.85 percent of Mn, 0.15 to 0.30 percent of Si, not more than 0.003 percent of S, not more than 0.010 percent of P, 0.15 to 0.30 percent of Ni, not more than 0.020 percent of Ti, 0.015 to 0.040 percent of Al, 0.010 to 0.065 percent of Nb, not more than 0.006 percent of N, not more than 0.30 percent of Cu, 0.10 to 0.25 percent of Cr, and not more than 0.0005 percent of B. The method comprises the following steps: (1) milling edges of the steel plate; (2) pre-bending bended edges; (3) performing JCO forming; (4) pre-welding joint seams; and (5) performing finish-welding on the inner and the outer sides of the joint seams. The method is applied to the manufacture of large-deformation-resistant welding pipes which are used in seismic belts, frozen soil areas, landslide area and other areas with high risk of deformation. The method has the advantages as follows: in the JCO forming process, the local deformation amounts and straight edge sizes of the steel plate in different rolling passes are analytically acquired according to the width, thickness and strength of the steel plate and the size of a die so as to determine the rolling passes and ensure uniform deformation at all parts of the steel plate after forming; and in the diameter expansion process, the minimum diameter expansion amount is determined according to the size and shape of the formed steel pipe, so as to ensure the size, shape and physiochemical properties of the steel pipe after diameter expansion.

Owner:CNPC BOHAI EQUIP MFG +2

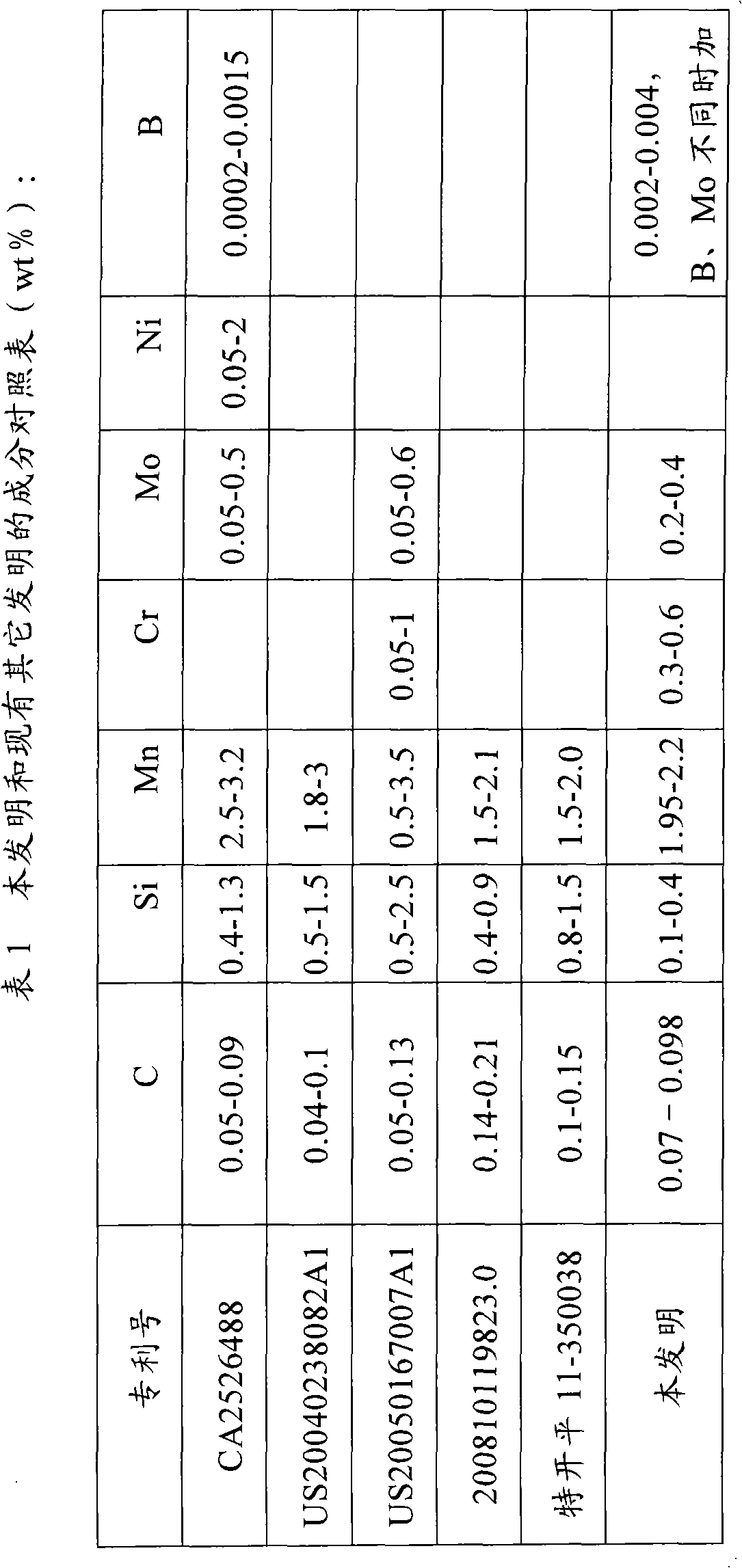

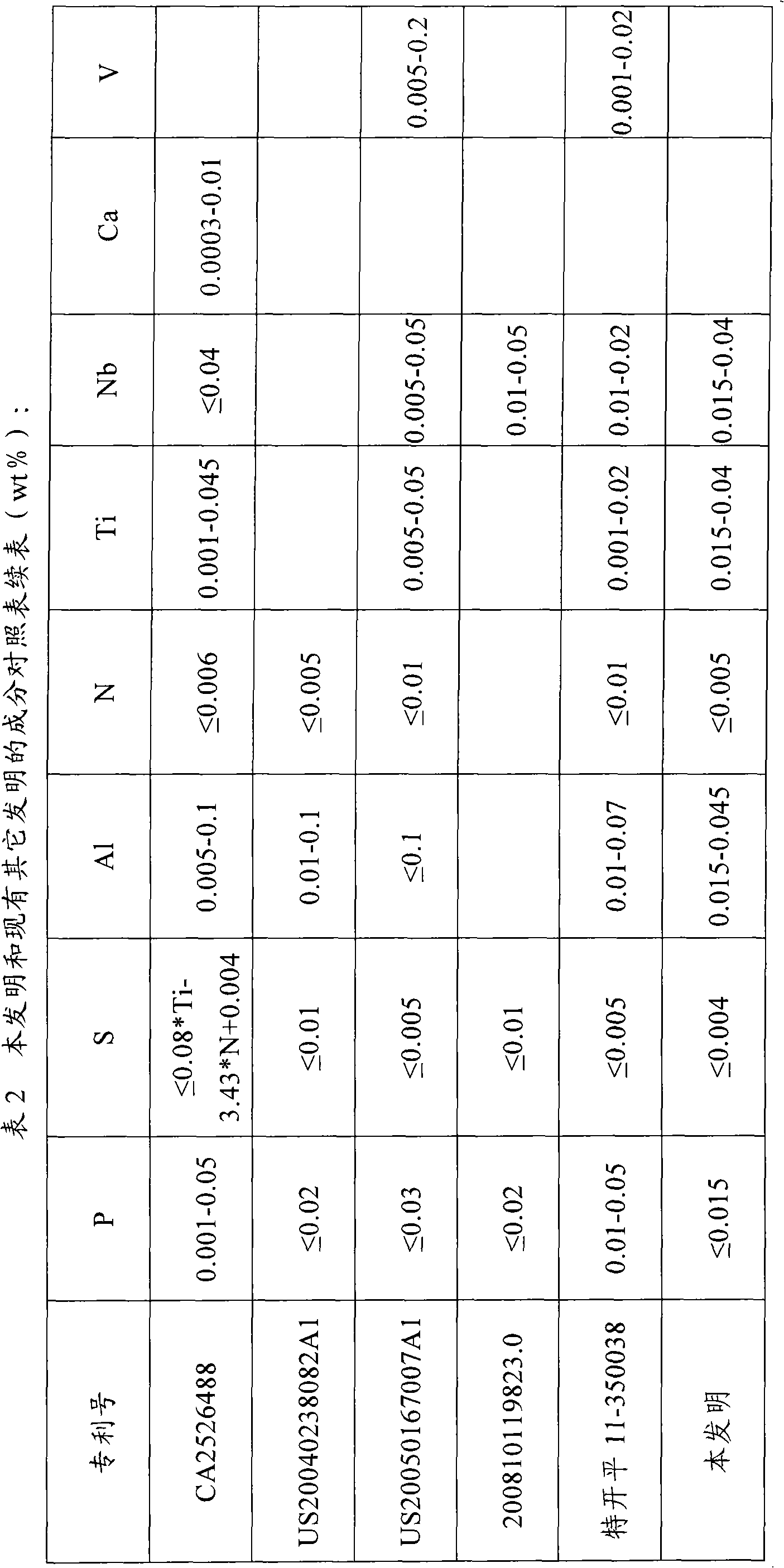

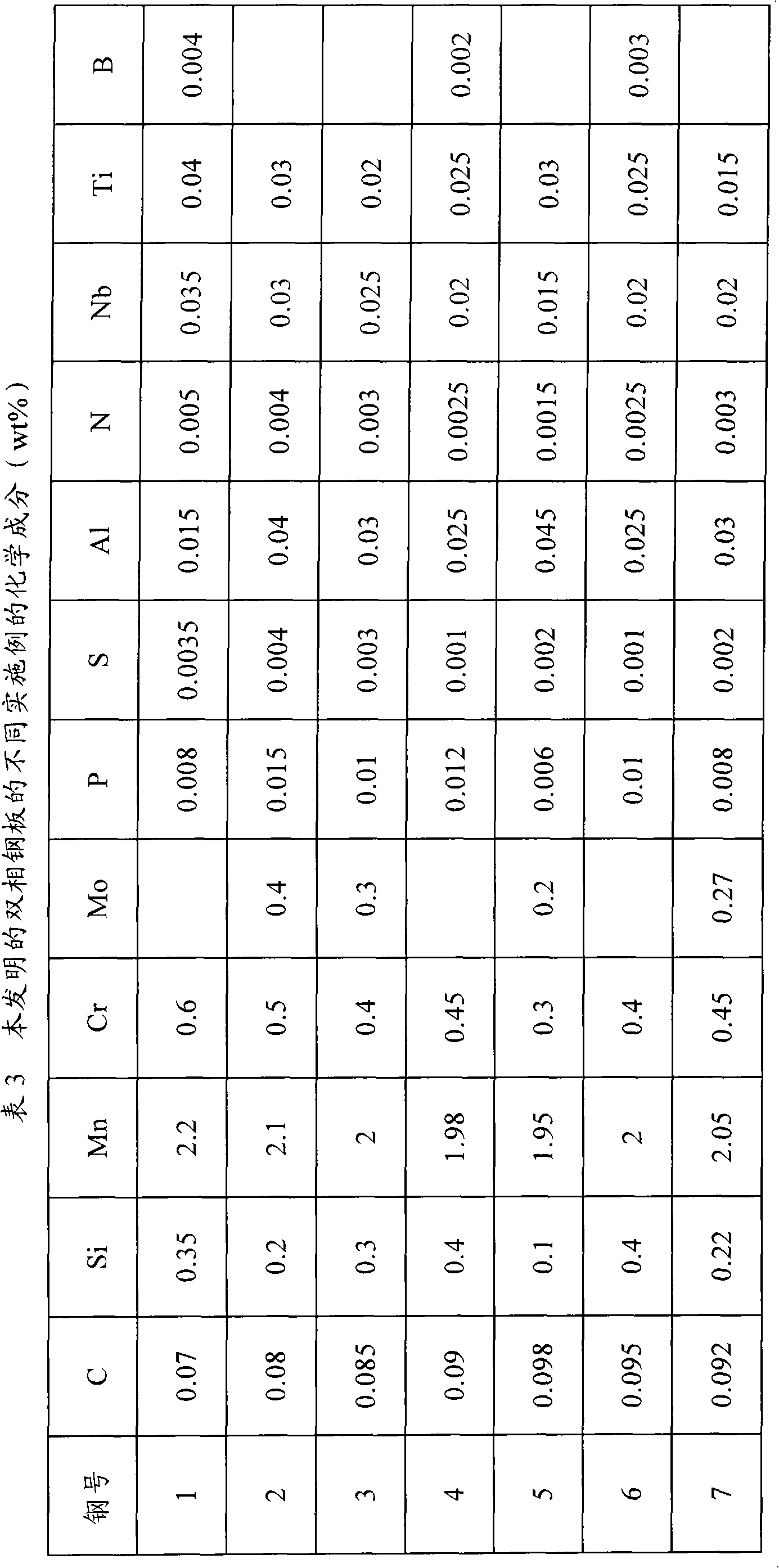

Double-phase steel plate and manufacturing method thereof

ActiveCN102586688AReduce the degree of enrichmentReduce defects such as red rustManufacturing technologyDouble phase

The invention provides a double-phase steel plate which comprises 0.07-0.098 of C, 0.1-0.4 of Si, 1.95-2.2 of Mn, 0.3-0.6 of Cr, less than or equal to 0.015 of P, less than or equal to 0.004 of S, less than or equal to 0.005 of N, 0.015-0.04 of Nb, 0.015-0.04 of Ti, 0.015-0.045 of Al, and 0.002-0.004 of B or 0.2-0.4 or Mo, wherein Pcm equals to C+Si / 30+Mn / 20+2P+4S which is less than or equals to 0.24; and the double-phase steel plate also comprises the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the double-phase steel plate. The high-strength uniform-performance double-phase steel plate can be obtained by the proper composition design and manufacturing technology, and the manufacturing requirements on parts of a high-strength automobile body can be better met.

Owner:BAOSHAN IRON & STEEL CO LTD

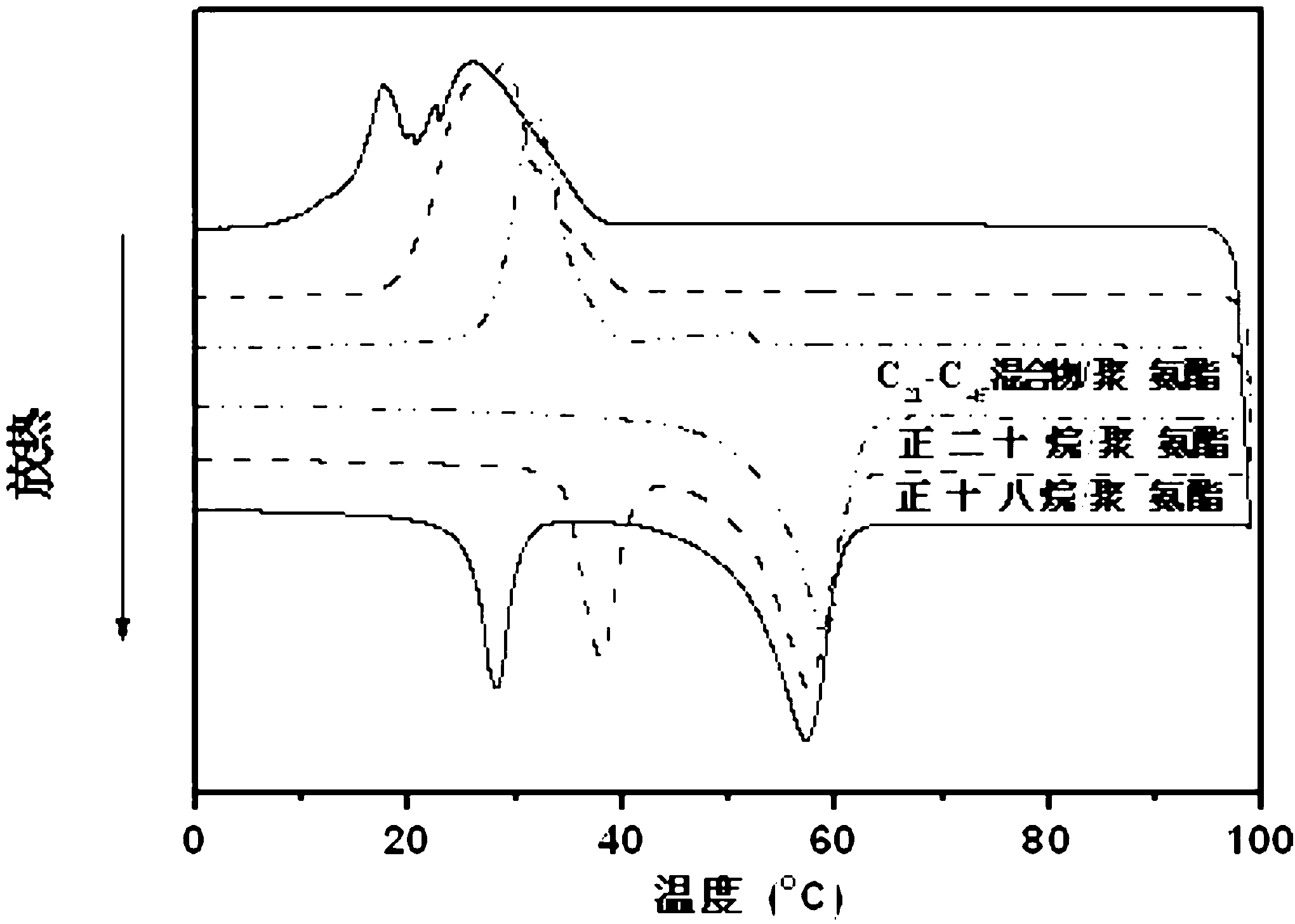

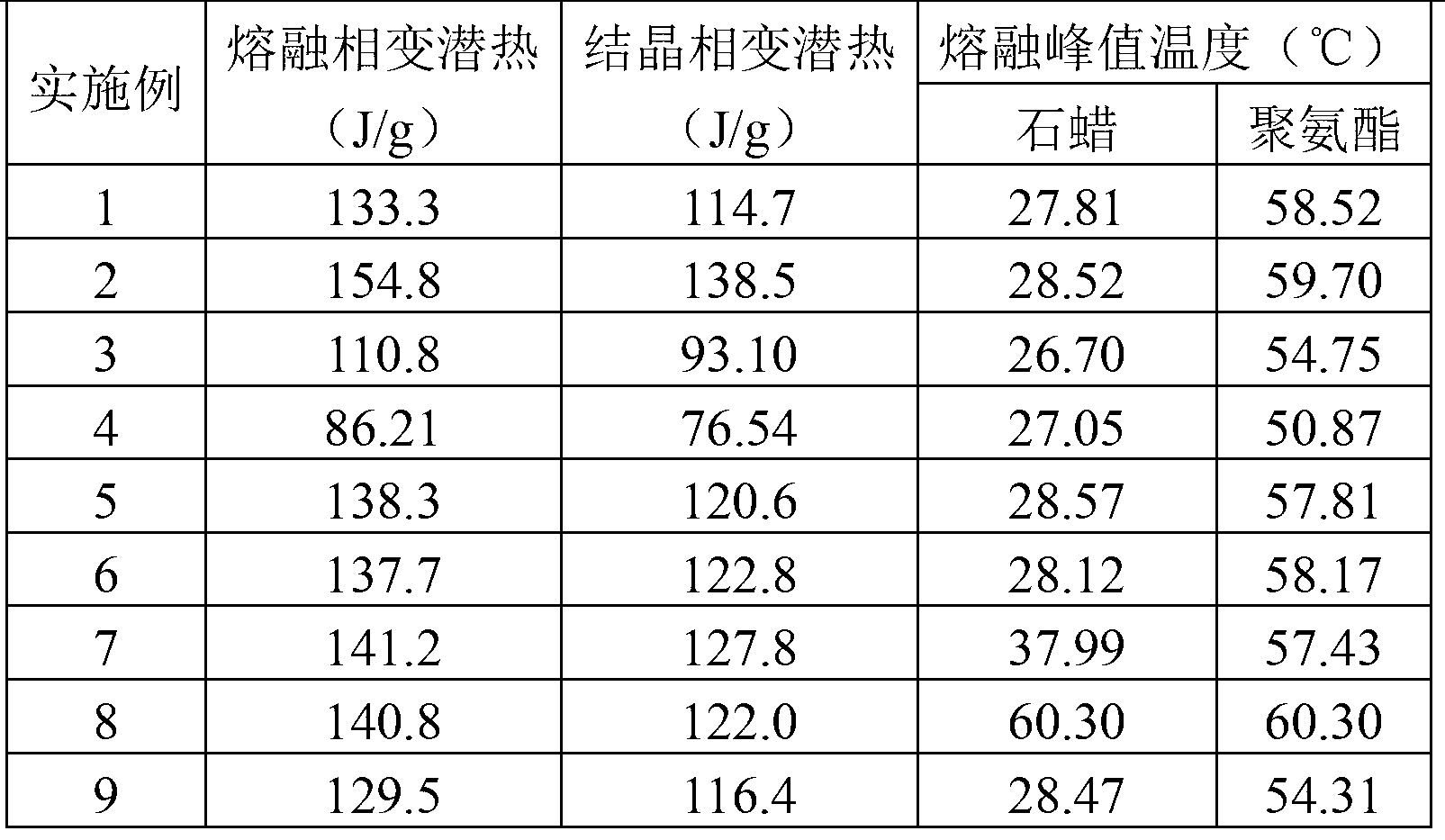

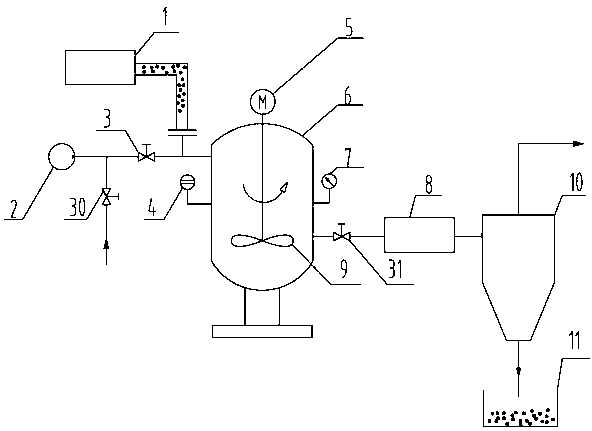

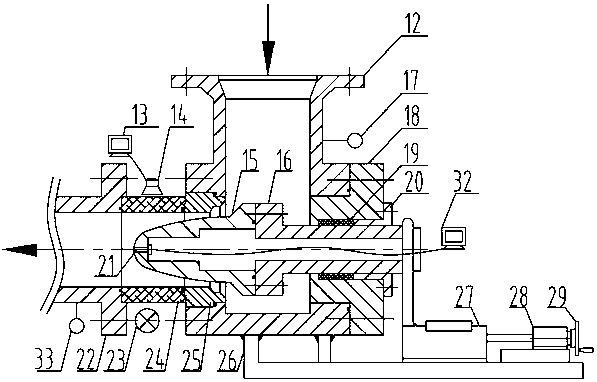

Preparation method of paraffin/polyurethane solid-solid composite double-phase change energy storage material

ActiveCN103224601AHigh latent heat of phase changeWide phase transition temperature rangeHeat-exchange elementsParaffin waxDouble phase

The invention discloses a preparation method of a paraffin / polyurethane solid-solid composite double-phase change energy storage material, comprising the following steps: selecting raw materials which comprises the following components: by weight, 40-90 parts of polyethylene glycol, 4-20 parts of isocyanate, 0-10 parts of a chain extender, 0-50 parts of paraffin, 0-5 parts of a surfactant and 0-1 part of a catalyst; melting glycol and carrying out vacuum-pumping processing, mixing the molten glycol with the surfactant and paraffin, adding isocyanate, the chain extender and the catalyst to react at a temperature of 60-90 DEG C to obtain a performed polymer, carrying out deaeration on the performed polymer, injecting the deaerated performed polymer into a mould, solidifying, cooling and demoulding. According to the composite double-phase change energy storage material provided by the invention, a paraffin hydrocarbon compound with large latent heat of phase change is used as a filling material, and a polyurethane material with a phase change function is used as a matrix. Latent heat of phase change of the prepared paraffin / polyurethane solid-solid composite double-phase change energy storage material reaches 154J / g, phase-change temperature ranges from 15 DEG C to 70 DEG C, and the material is a composite phase change material having a double-phase change character.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Cavitation erosion-erosion wearing cooperative test device

ActiveCN103323356AReduce or avoid unplanned downtime accidentsExtend the safe and stable operation periodInvestigating abrasion/wear resistanceGas phaseDouble phase

The invention discloses a cavitation erosion-erosion wearing cooperative test device. A slurry tank inlet is formed by a convergence of three branches which are a gas inlet, a water inlet, and a solid particle inlet. A transmission shaft of a motor extends into the slurry tank, and drives stirring blades to rotate. The outlet of the slurry tank is connected to an inlet of a separator through a stop valve and a cavitation erosion-erosion wearing test valve, and a pipeline. A gas phase outlet is provided on the top of the separator. A solid-liquid double-phase outflow port on the bottom of the separator communicates with a recovery tank. A liquid level gauge and pressure gauge are arranged on the side of the slurry tank. With the device provided by the invention, the flow state of a multiphase flow medium can be observed, and particle motion trajectory can be observed. With a valve core pressure sensor on the top of the test valve core, the determination of flow cavitation number is realized. The device is suitable to be used for researching cavitation erosion and erosion wearing, and weight loss law of a metal material under the cooperative effect of cavitation erosion-erosion under different influencing facts. With the device, a functional relationship between a corresponding failure mode and weight loss can be established. The relationship can be used in guiding design of pipes, valves, and pipe fittings, and in optimization operations of operation conditions.

Owner:ZHEJIANG SCI-TECH UNIV

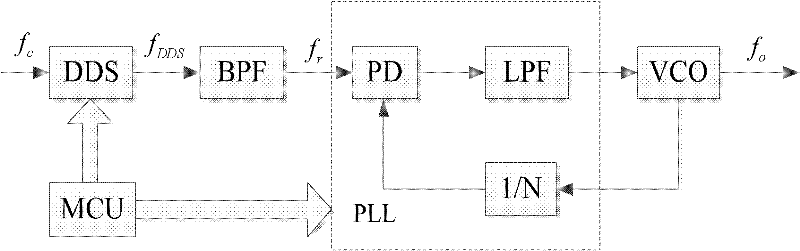

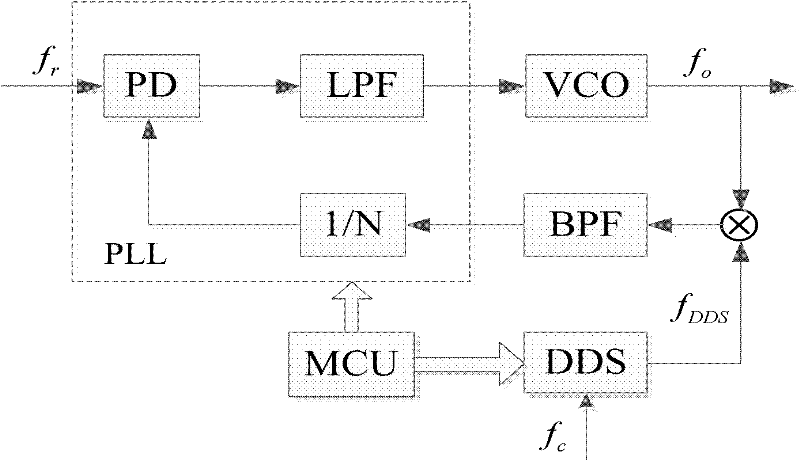

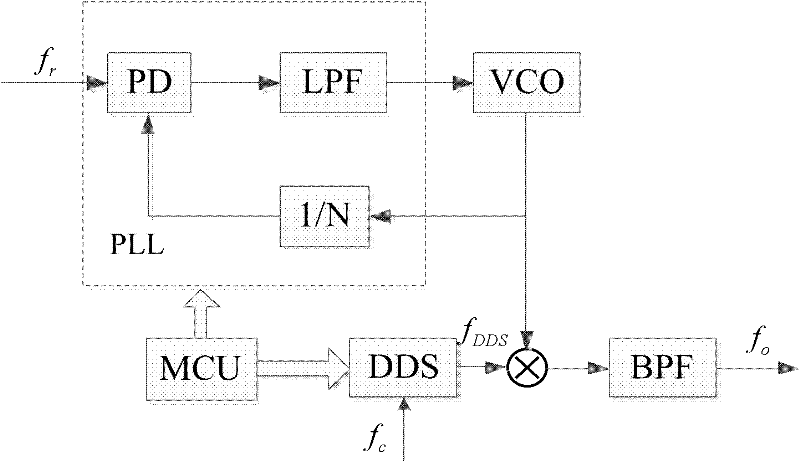

Design method of low-phase-noise microwave wideband frequency combiner

ActiveCN102651649AGuaranteed normal outputLow spuriousPulse automatic controlMicrocontrollerPhase noise

The invention relates to a design method of a microwave wideband frequency combiner applied to the field of signal interference. According to the method, a DDS (Direct Digital Synthesis) + PLL (Phase Locked Loop) + DAFS (Direct Analog Frequency Synthesis) hybrid frequency synthesis mode is utilized to synthesize a 0.1-18GHz ultra wide band microwave frequency, wherein the frequency band comprises working frequencies of most of microwave signals, can meet the frequency requirement for interfering with most of the microwave signals and especially can be applied to the field of satellite interference; in a DDS+PLL link, a 4-10GHz waveband is synthesized, a double phase locked loop internal mixing synthesis mode is adopted, a secondary phase locked loop adopts a mode of stimulating PLL by DDS, and a main phase locked loop is inserted into an output frequency so as to be mixed with the output frequency; in a DAFS link, DDS+PLL output is utilized as input and expanded to a 0.1-18GHz band width by virtue of a frequency multiplication, frequency demultiplication and down frequency conversion mode so as to be output; and in the whole frequency synthesis process, through carrying out frequency control by virtue of a singlechip and an FPGA (Field Programmable Gate Array) and reasonably selecting the output frequency, frequency multiplication times and mixing frequency of each link, the final output frequency has the characteristics of low phase noise and wide band, and simultaneously the output of strays and harmonic waves can be well restrained.

Owner:BEIHANG UNIV

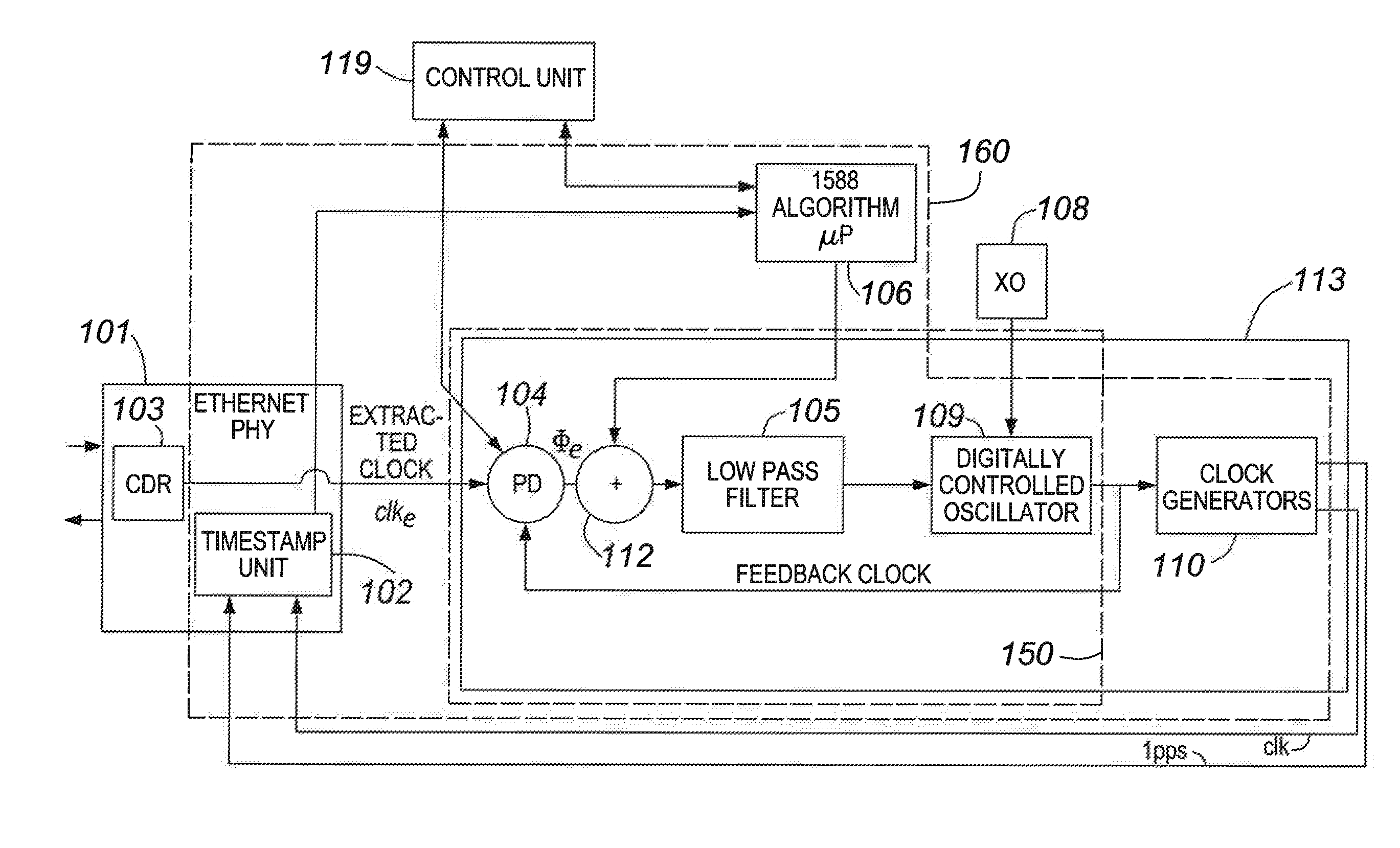

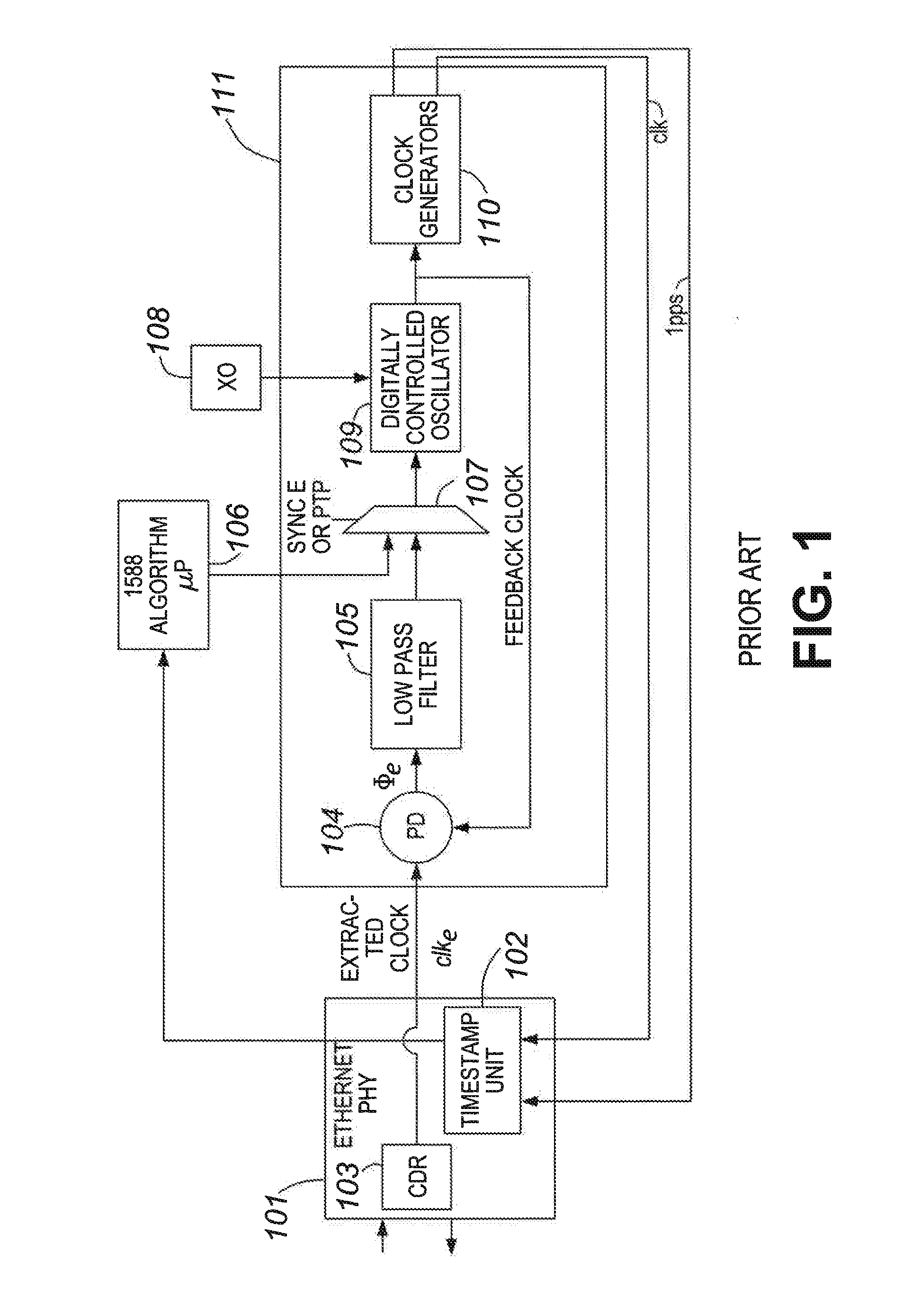

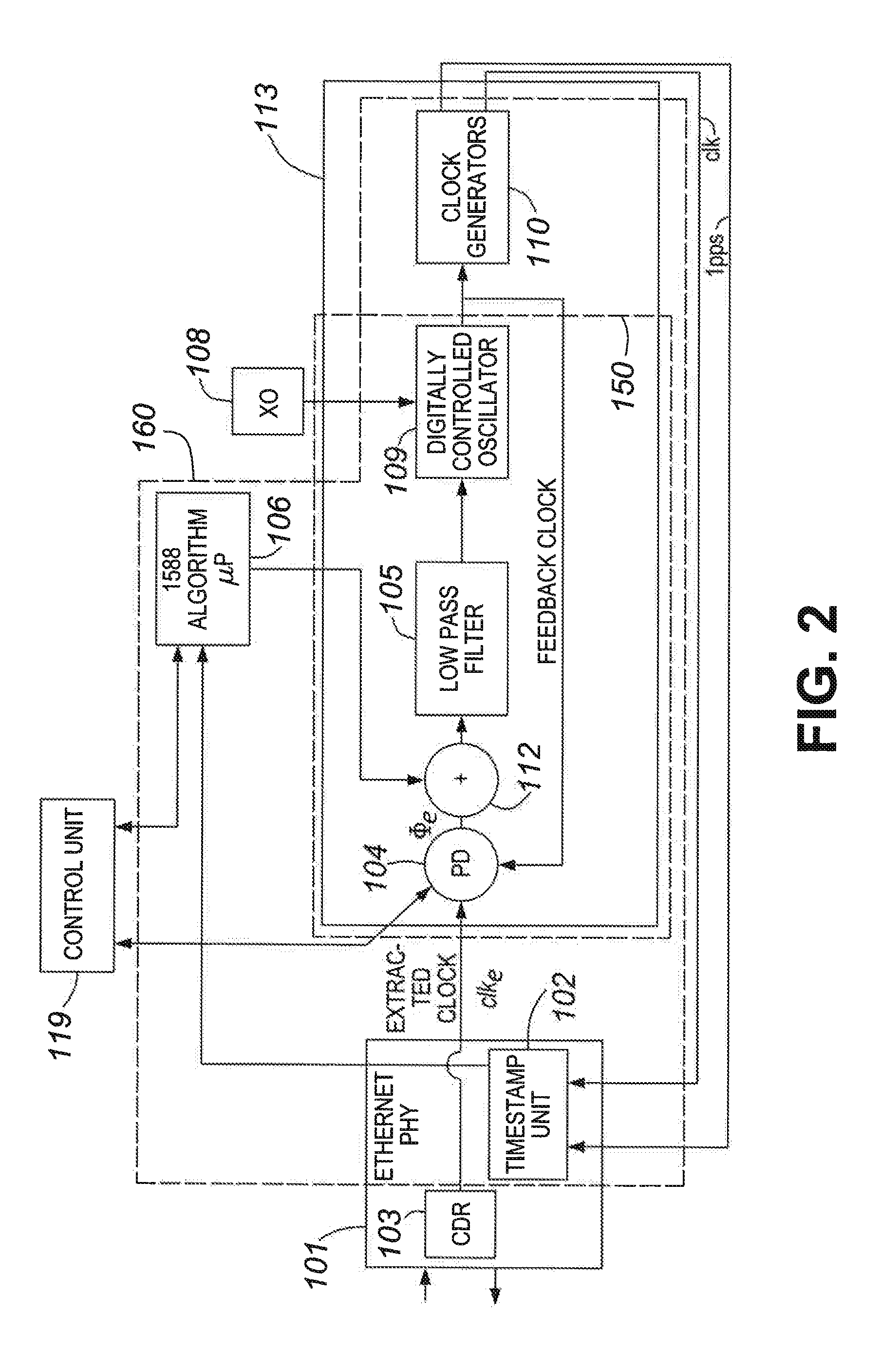

Double phase-locked loop with frequency stabilization

ActiveUS20150222276A1Without loss of stabilityEliminate wanderPulse automatic controlLoop filterFrequency stabilization

Owner:MICROSEMI SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com