Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35221 results about "Steel tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

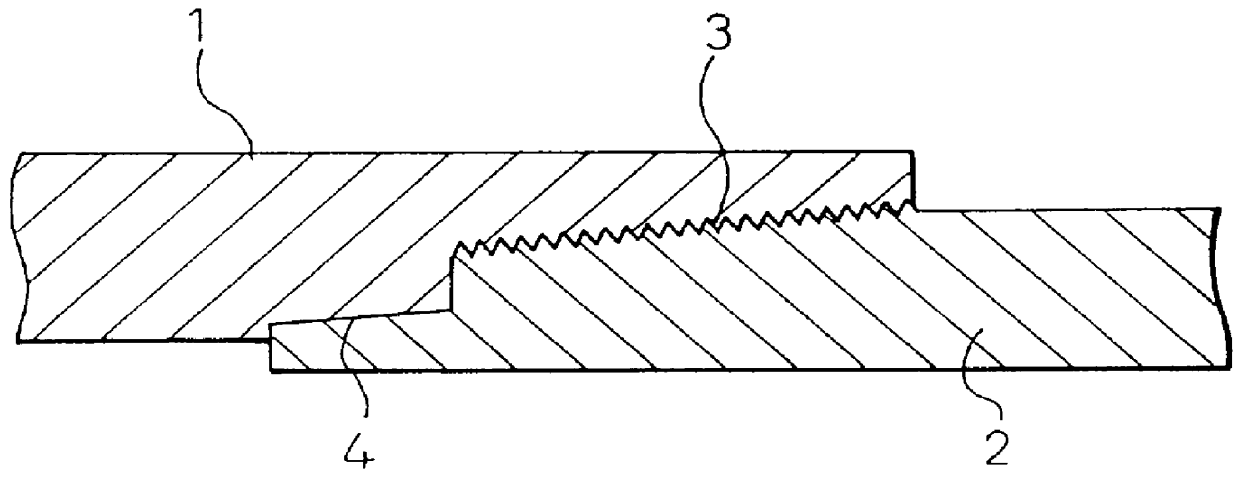

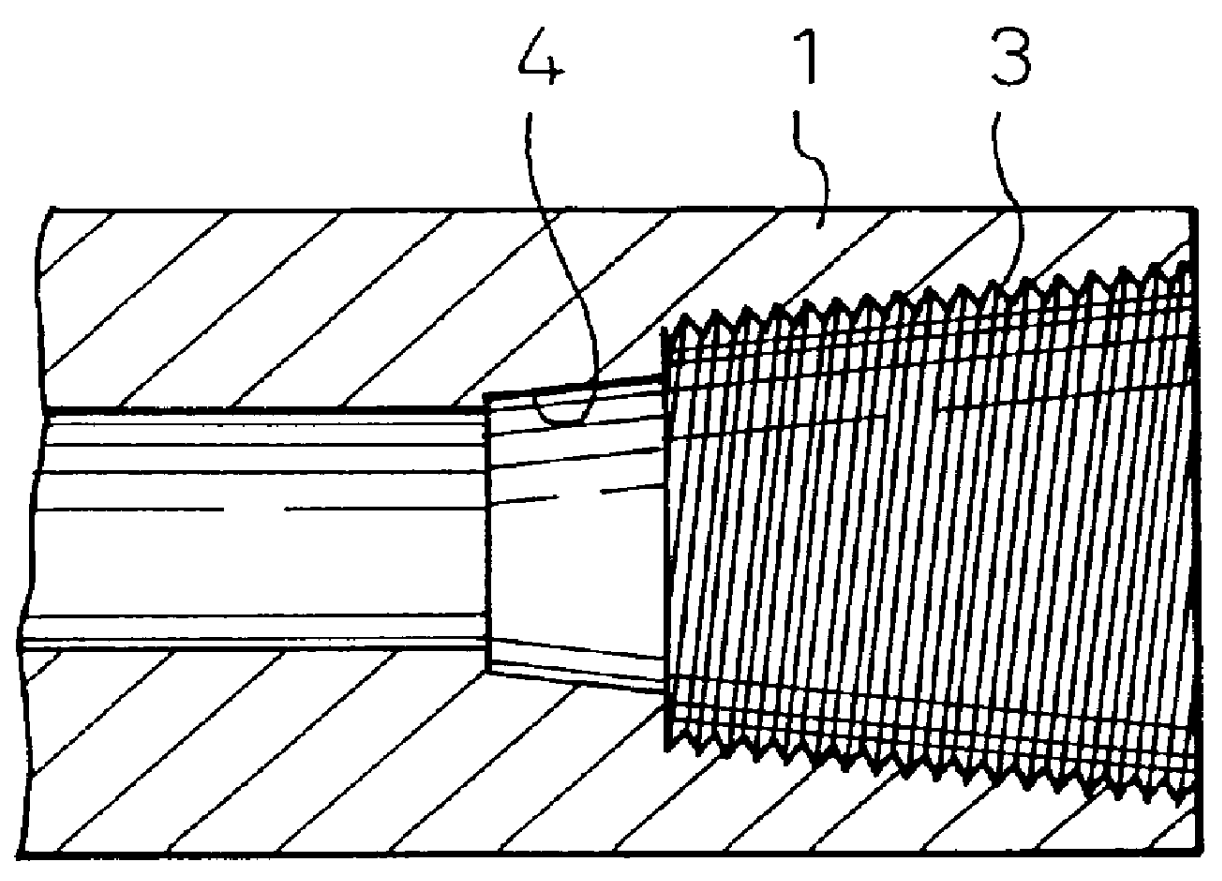

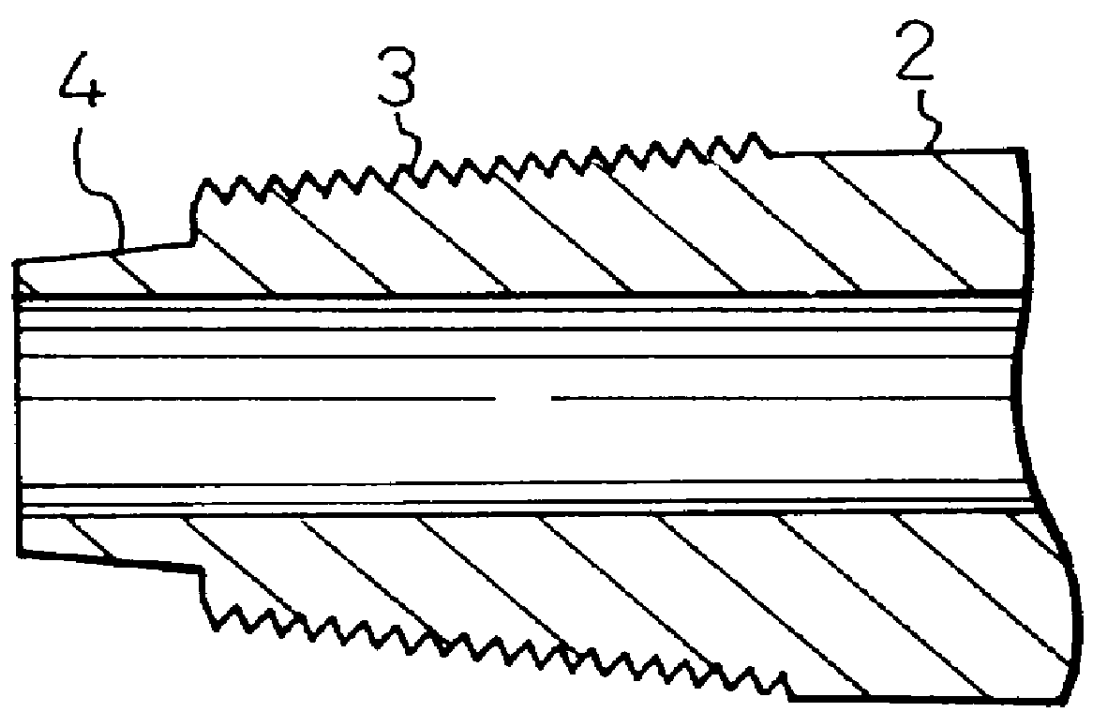

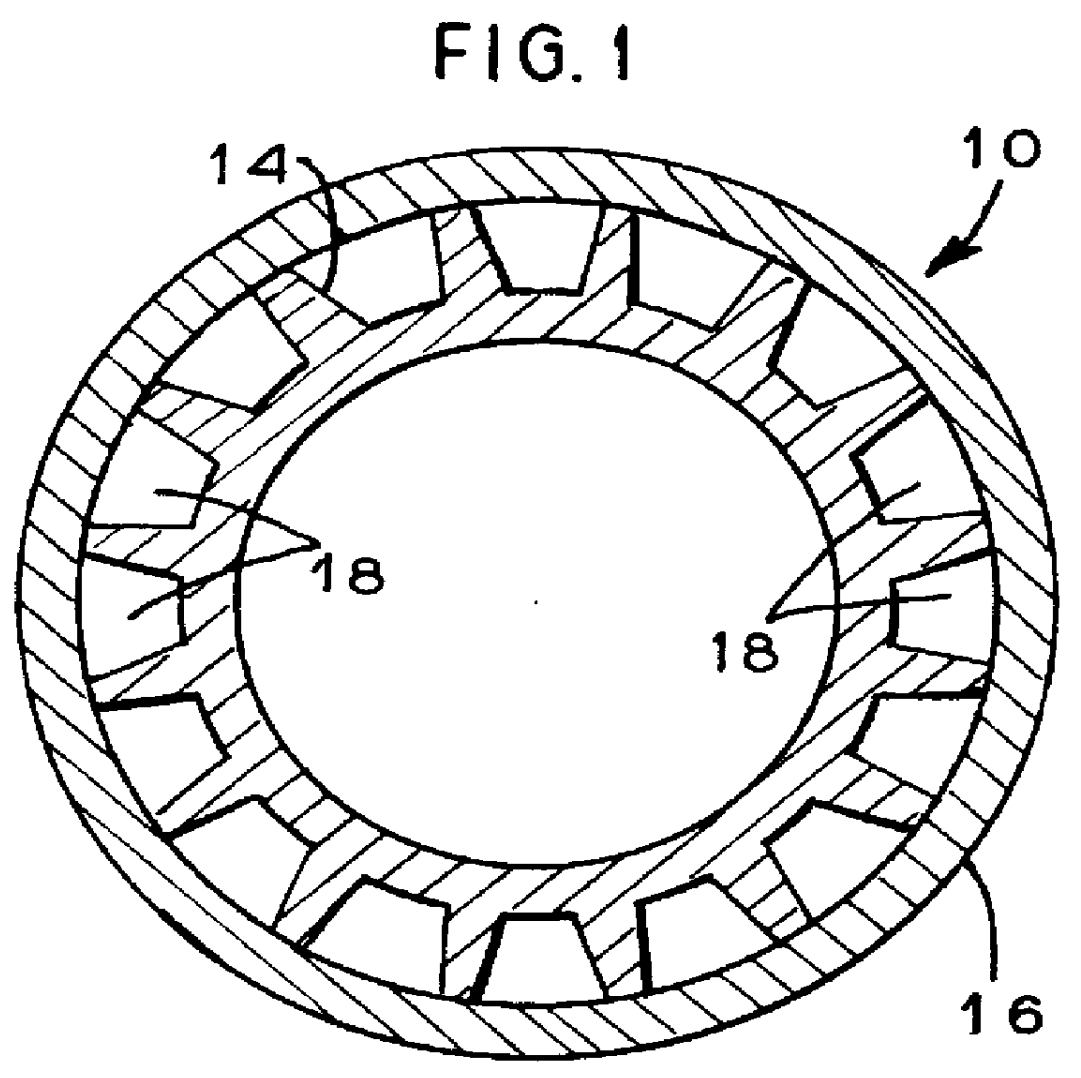

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

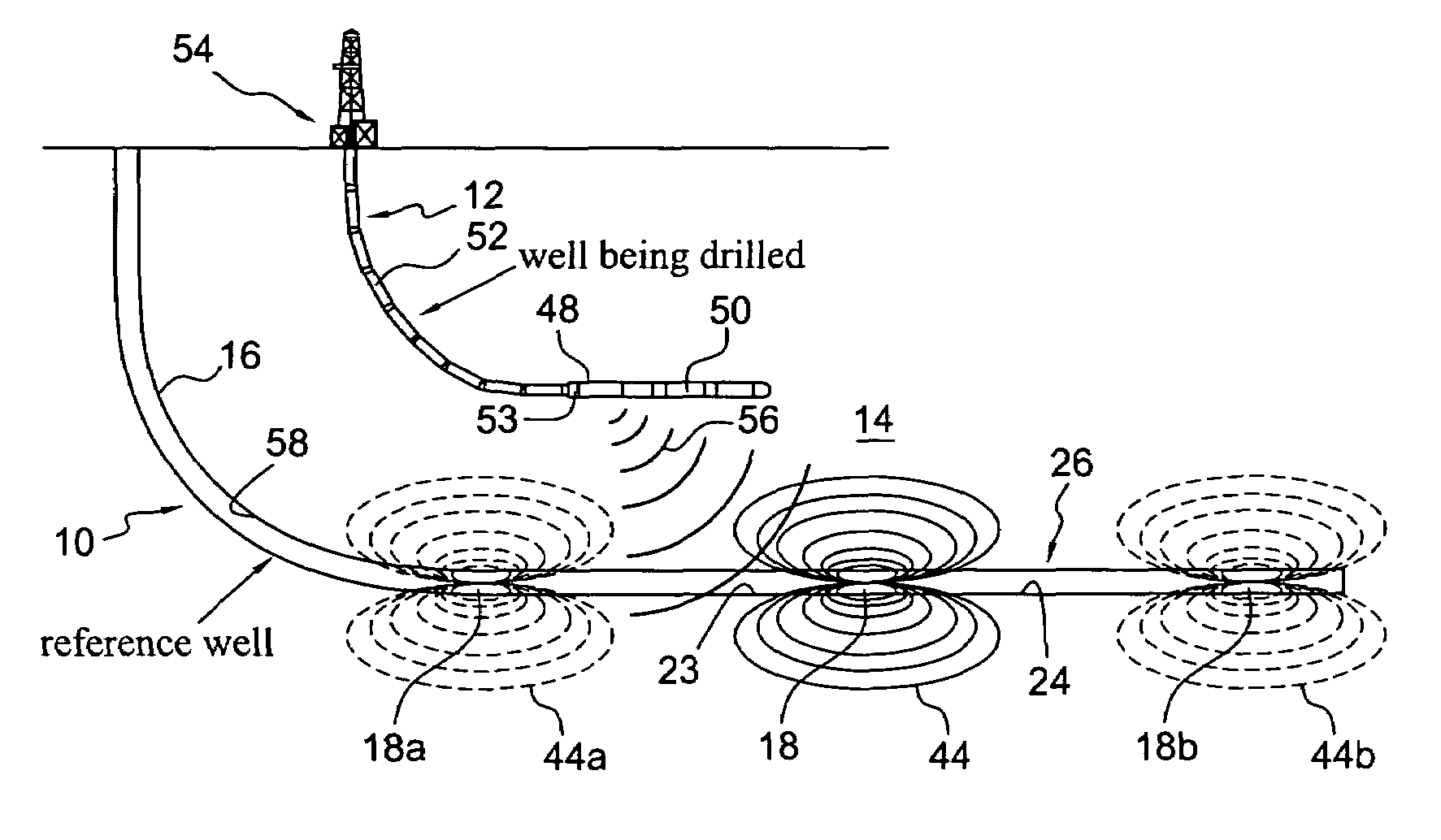

Electromagnetically determining the relative location of a drill bit using a solenoid source installed on a steel casing

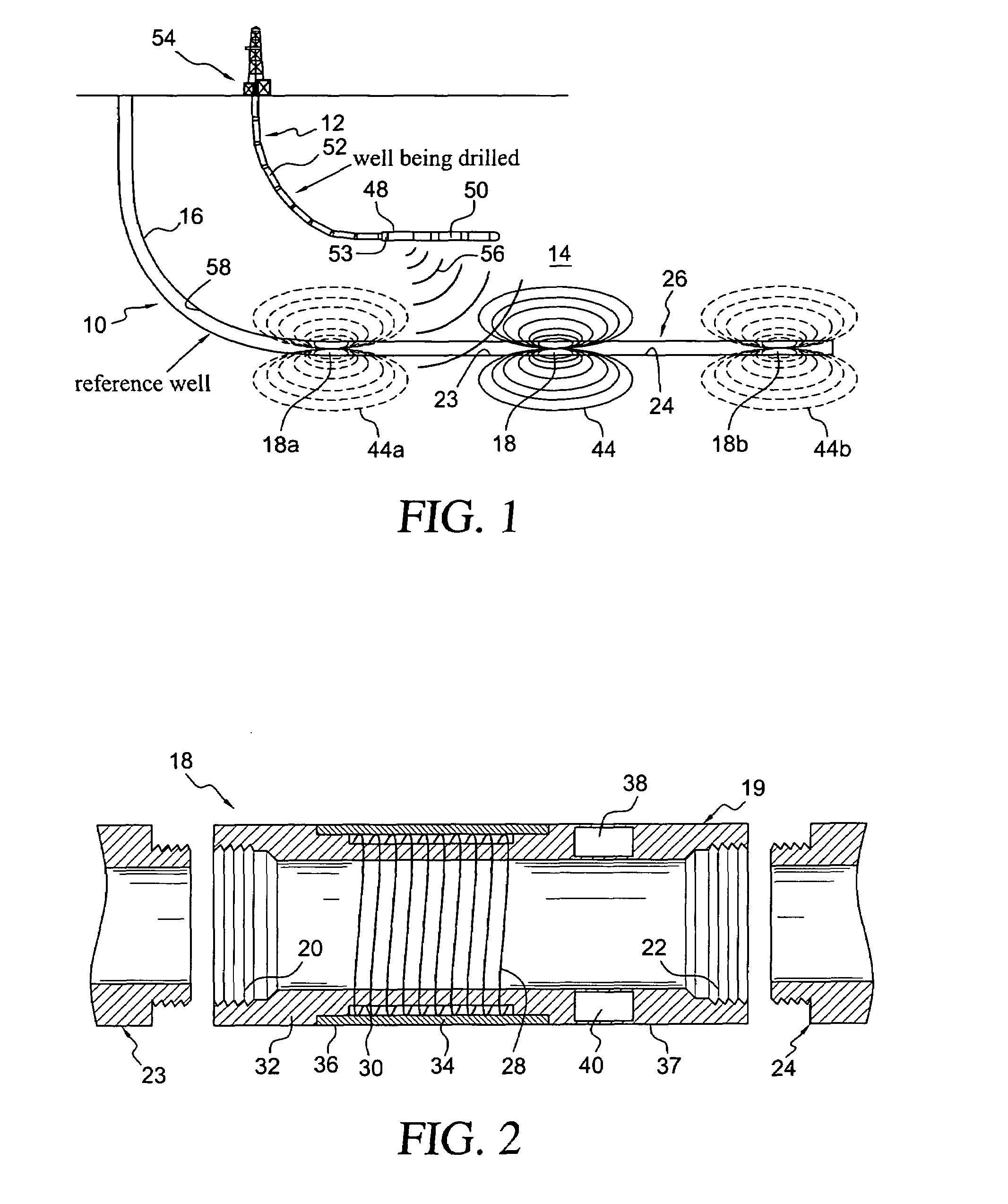

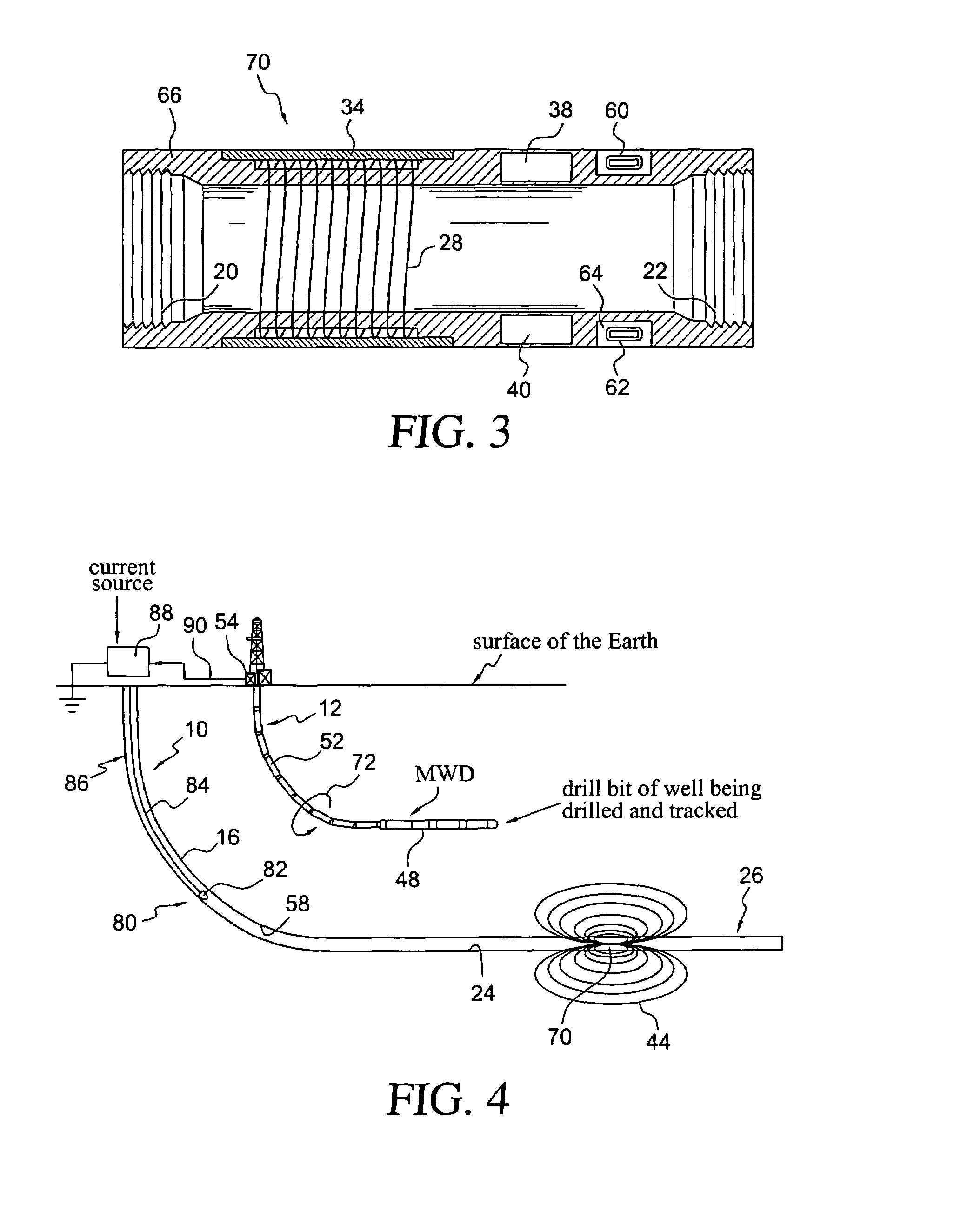

Electrically powered electromagnetic field source beacons installed in a reference well in combination with a down-hole measurement while drilling (MWD) electronic survey instrument near the drill bit in the borehole being drilled permit distance and direction measurements for drilling guidance. Each magnetic field source beacon consists of a coil of wire wound on a steel coupling between two lengths of steel tubing in the reference well, and powered by an electronic package. Control circuitry in the electronic package continuously “listens” for, and recognizes, a “start” signal that is initiated by the driller. After a “start” signal has been received, the beacon is energized for a short time interval during which an electromagnetic field is generated, which is measured by the MWD apparatus. The generated magnetic field may be an AC field, or switching circuitry can periodically reverse the direction of a generated DC electromagnetic field, and the measured vector components of the electromagnetic field are used to determine the relative location coordinates of the drilling bit and the beacon using well-known mathematical methods. The magnetic field source and powering electronic packages may be integral parts of the reference well casing or may be part of a temporary work string installed therein. Generally, numerous beacons will be installed along the length of the reference well, particularly in the important oil field application of drilling steam assisted gravity drainage (SAGD) well pairs.

Owner:HALLIBURTON ENERGY SERVICES INC

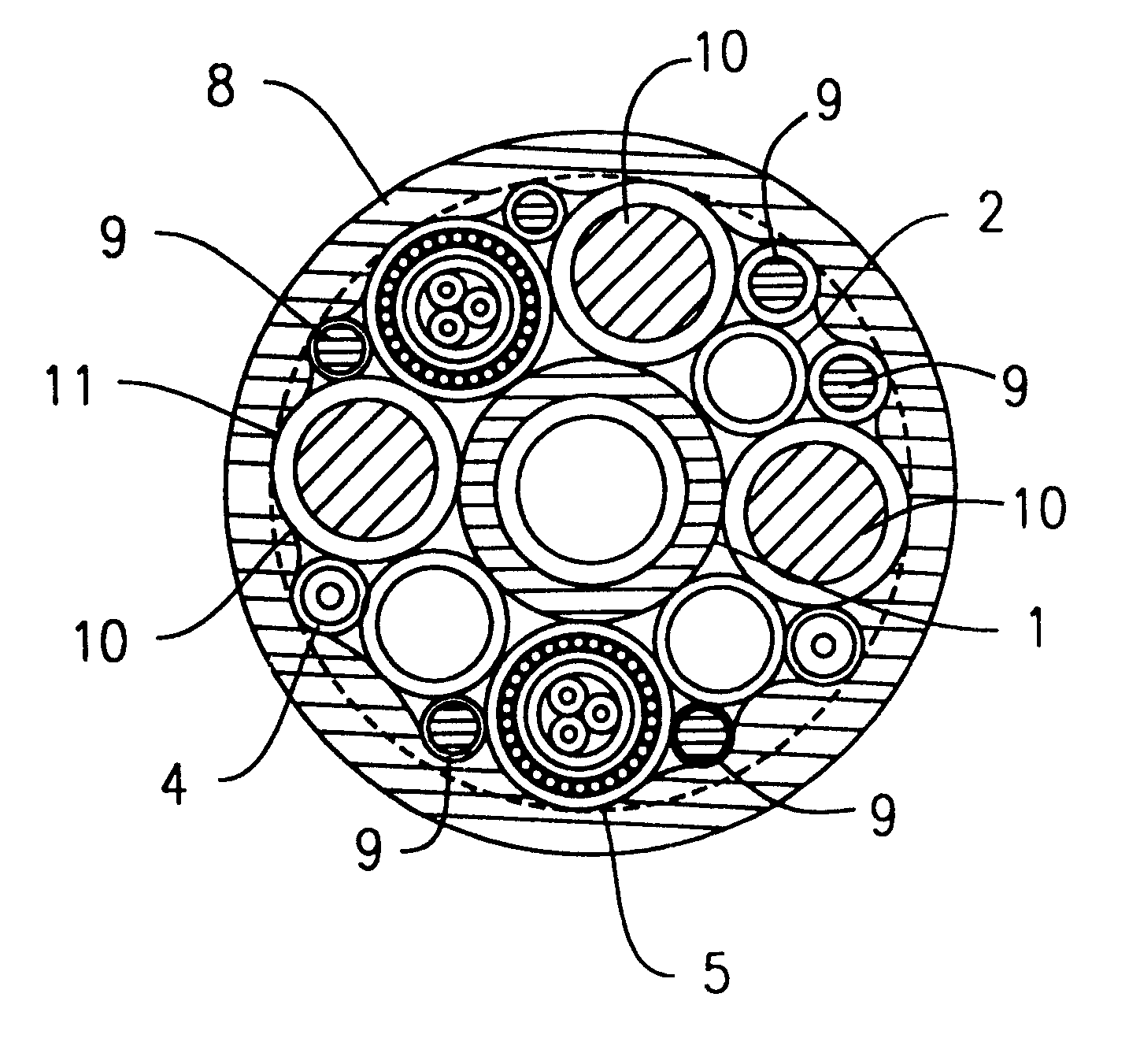

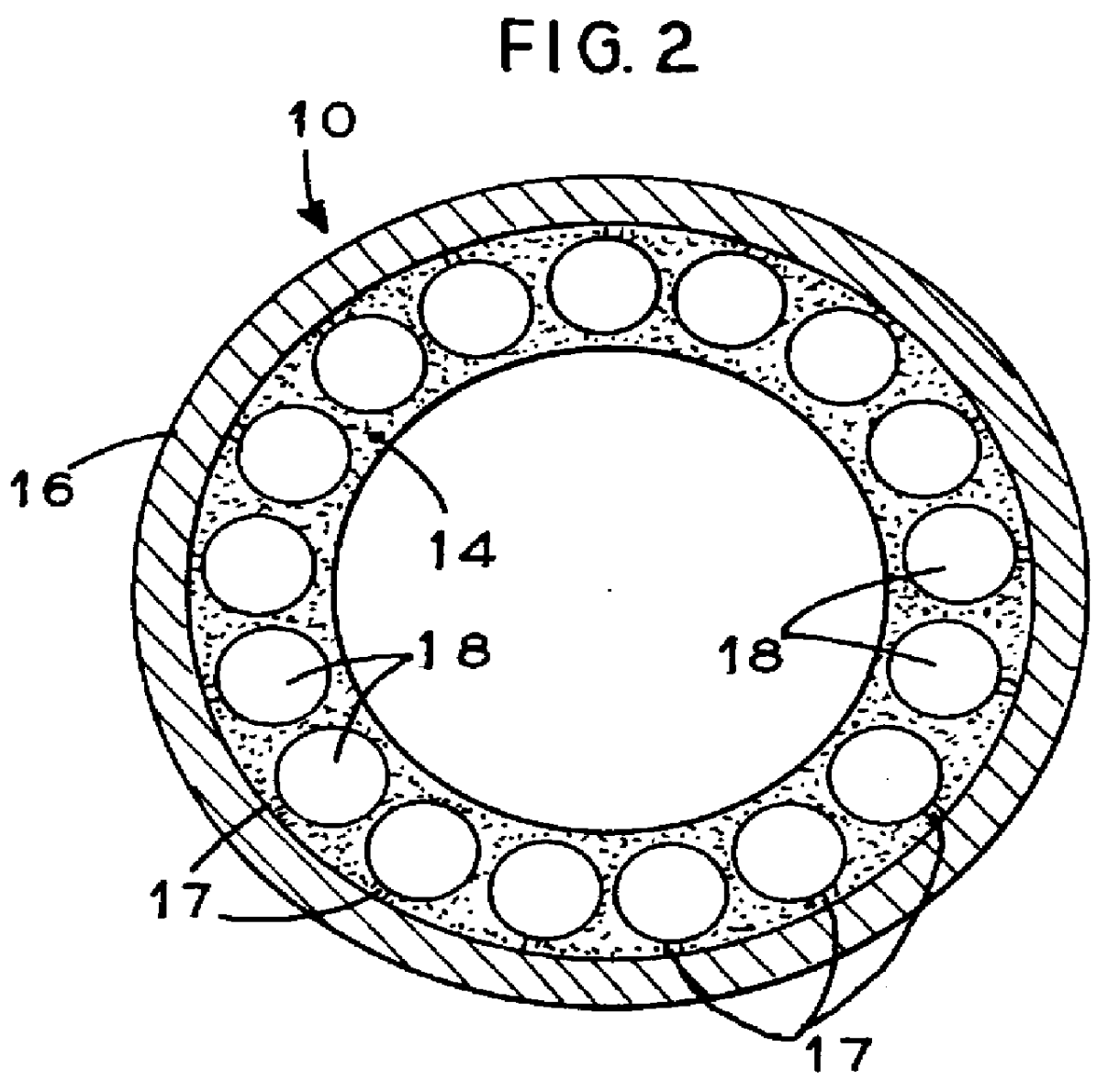

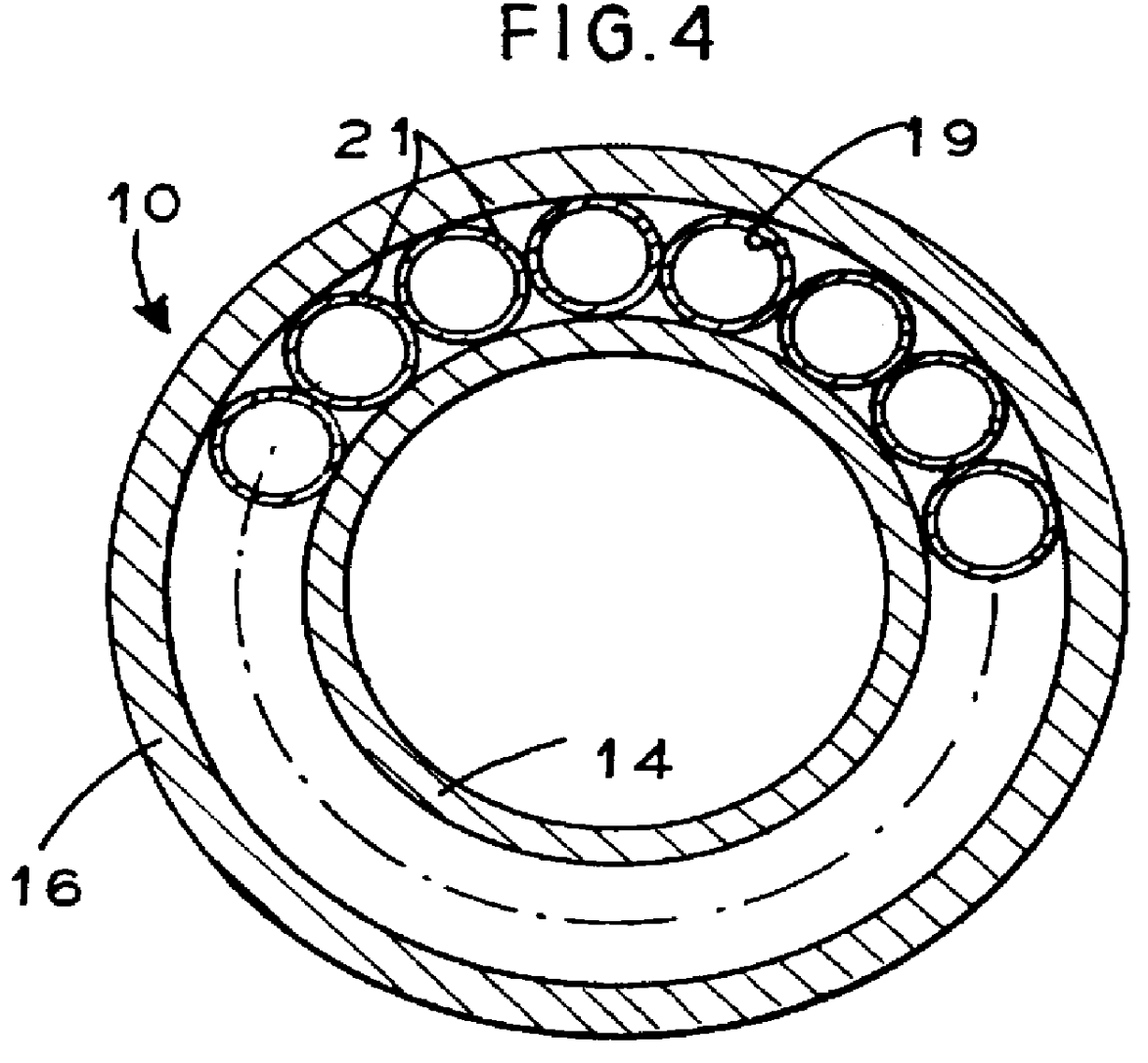

Dynamic umbilicals with internal steel rods

InactiveUS6472614B1Power cables including communication wiresPower cables including electrical controlUltimate tensile strengthBallast

In an umbilical, one or more steel rods, which provide strength and ballast, are wound helically within the umbilical along with the steel tubes and / or elongated active umbilical elements. These steel rods replace some or all of the thermoplastic filler elements that would otherwise be included within the umbilical. An umbilical according to an embodiment of the invention may include a plurality of steel tubes helically wound around a core, and at least one substantially solid steel rod helically wound around the core, the steel rod being arranged in a void between the steel tubes. Thus, the invention avoids the need to apply additional armoring layers to the outside of the umbilical for strength and ballast.

Owner:TECH FRANCE SA

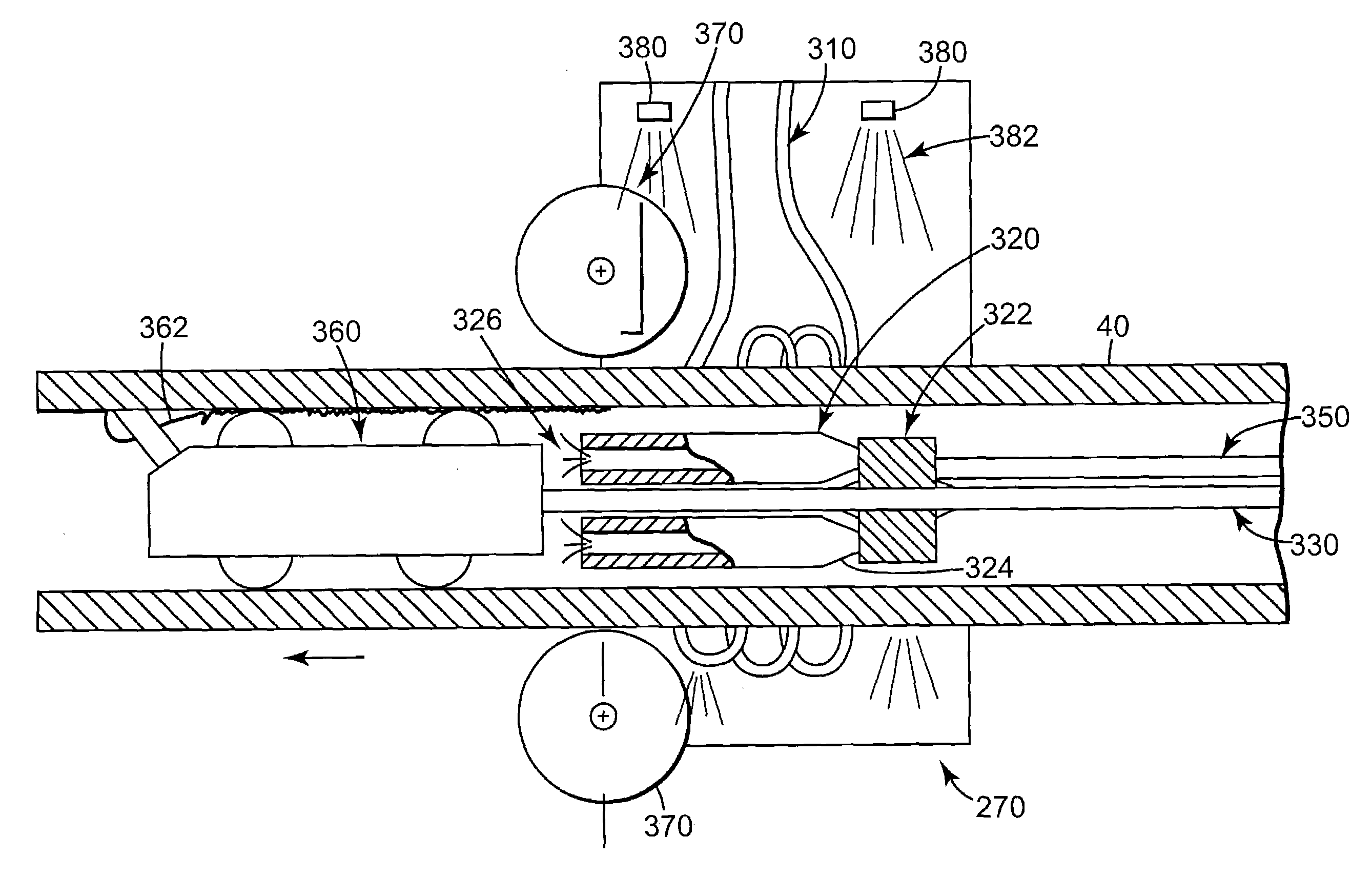

Seam-welded metal pipe and method of making the same without seam anneal

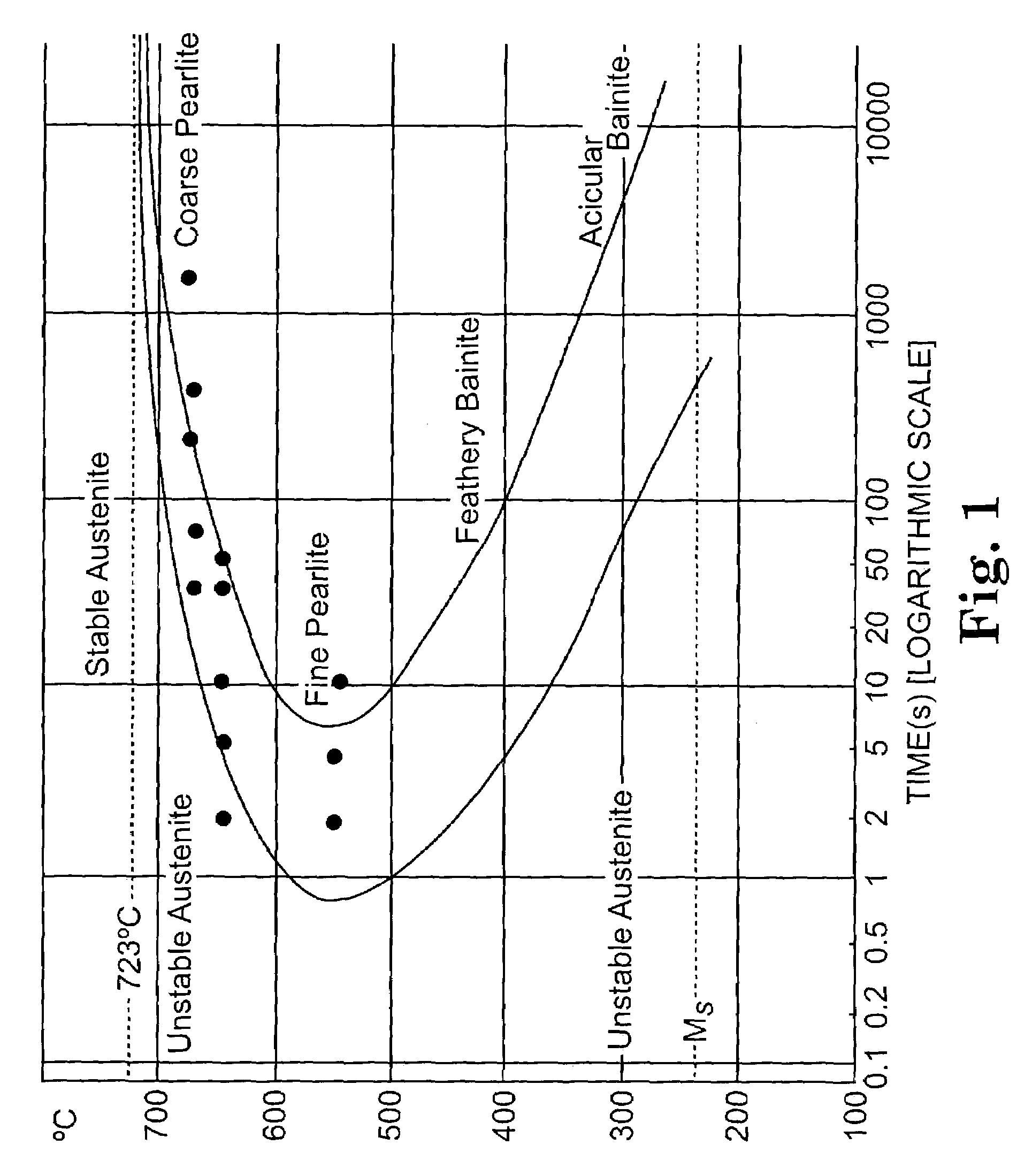

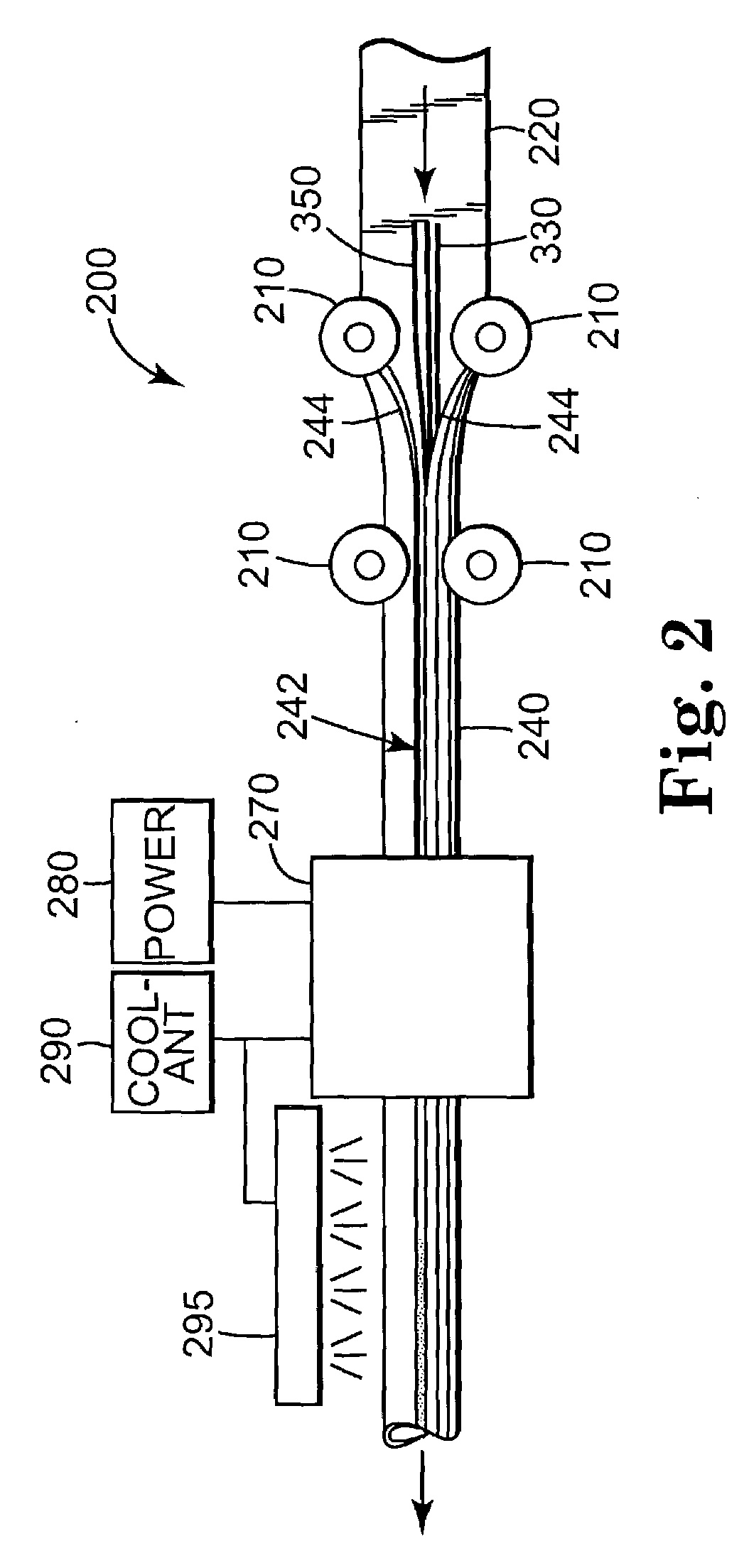

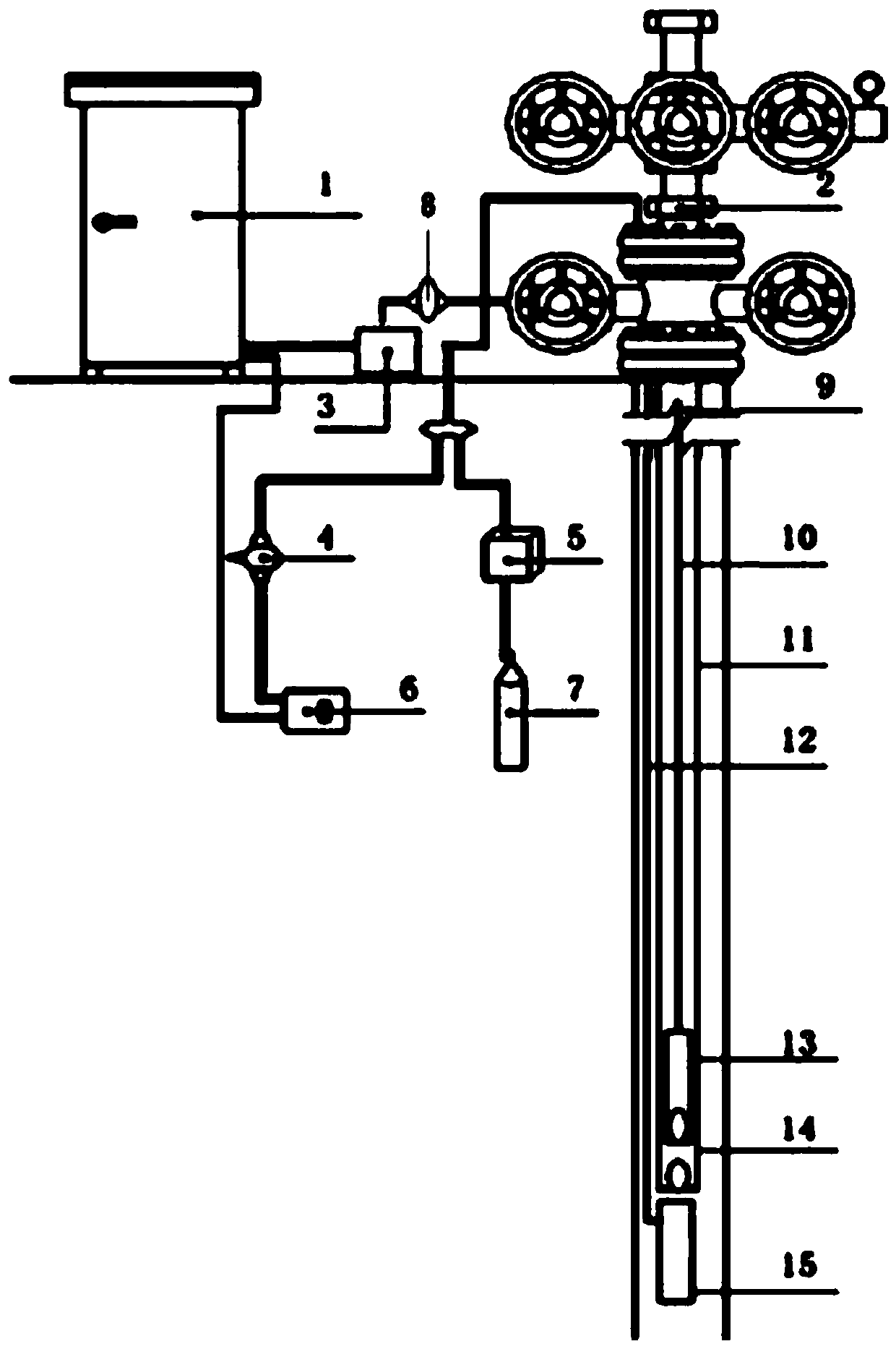

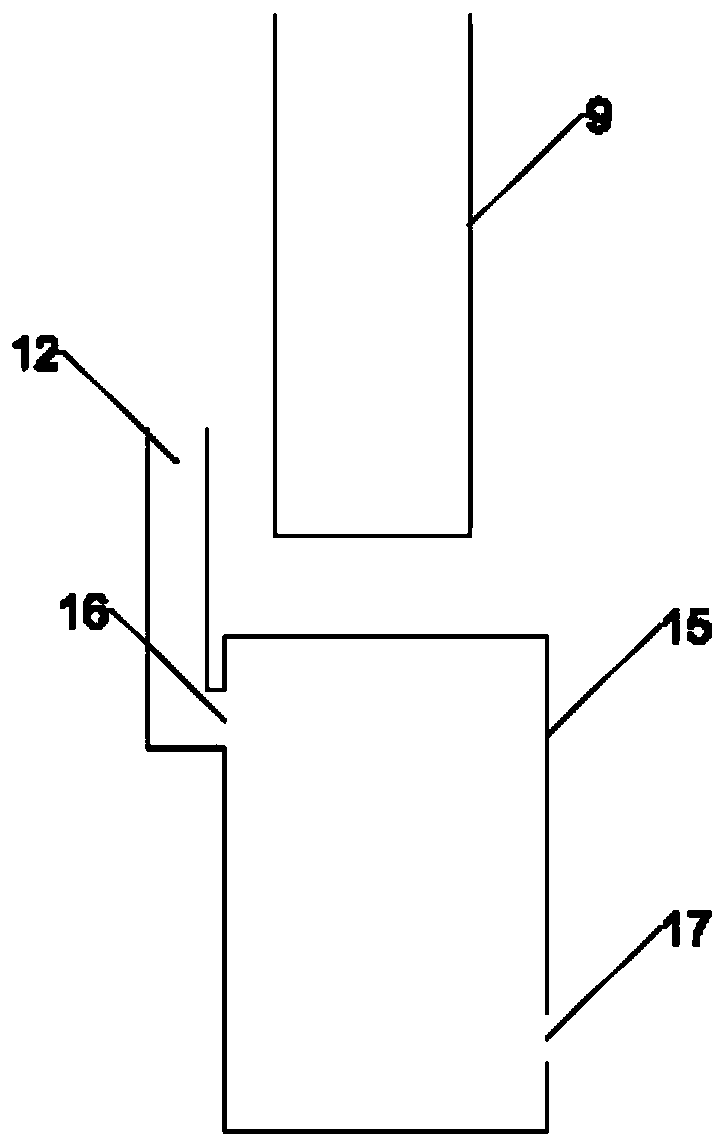

InactiveUS7032809B1Efficient processingEliminates annealing stepArc welding apparatusFurnace typesSufficient timeWeld seam

An apparatus and method for making a seam-welded steel pipe free of untempered martensite without seam anneal. The method includes selecting a steel containing a carbon concentration below a predetermined level, for example, 0.14% or 0.12% by weight. The method also includes flooding both outside and inside of the strip with a coolant while the weld seam is being formed, and continuing to immerse the welded strip for a sufficient time after the weld seam is formed to prevent the formation of untempered martensite. The apparatus includes a heater capable of heating the strip to a temperature sufficient to form a welded seam, a cooling module configured to supply a coolant to the welded seam both inside and outside of the strip as the weld seam is being formed, and another cooling module configured to immerse the welded strip in a coolant after the weld seam is formed for a sufficient length of time to prevent the formation of untempered martensite.

Owner:STEEL VENTURES

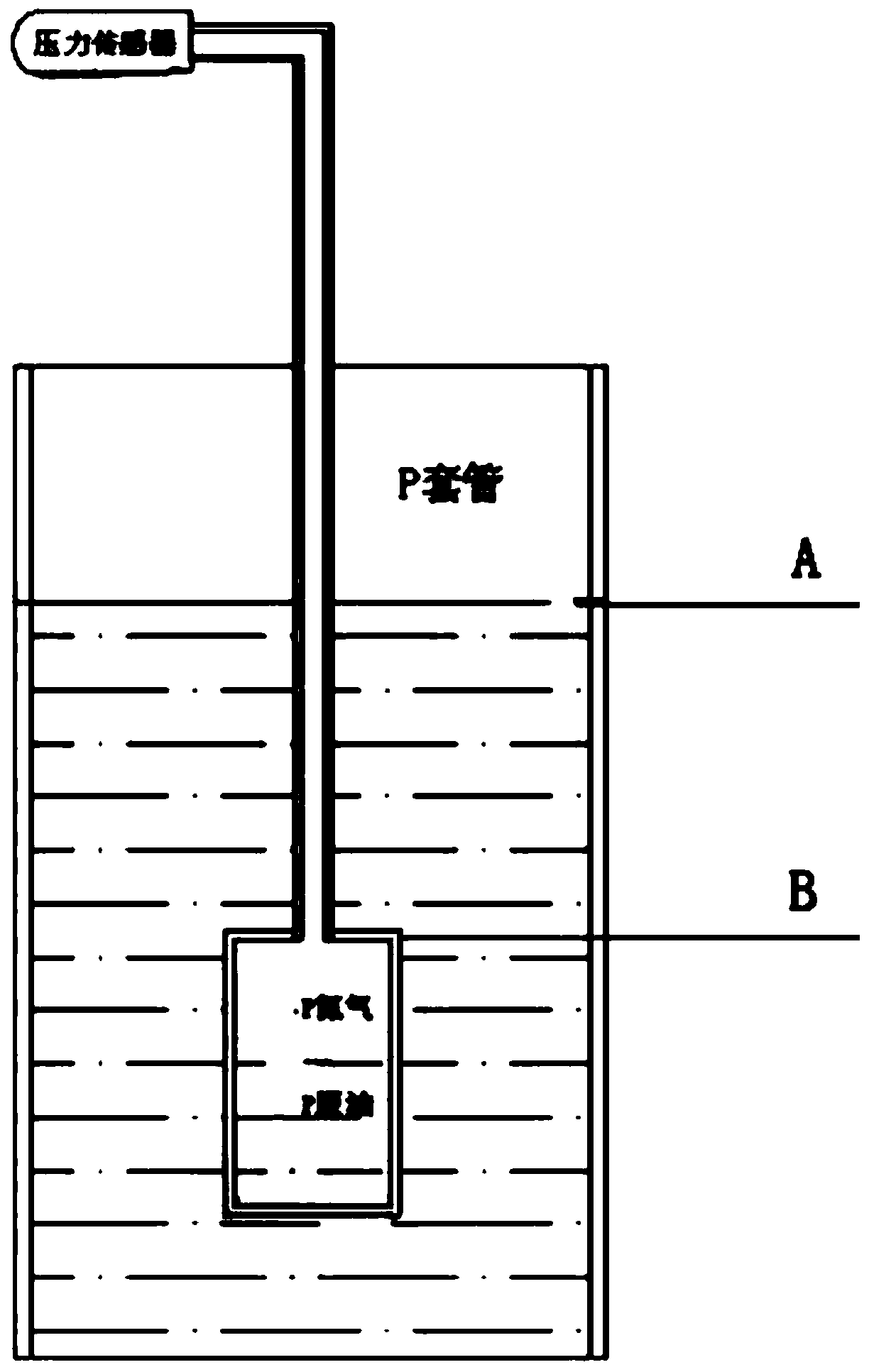

Gas-conducting pressure measuring intermittent producing oil exploitation device

The invention discloses a gas-conducting pressure measuring intermittent producing oil exploitation device. The gas-conducting pressure measuring intermittent producing oil exploitation device makes contact with well liquid during working, the gas-conducting pressure measuring intermittent producing oil exploitation device comprises gas conducting and pressure measuring equipment used for measuring the hydrostatic fluid column pressure, controlling equipment used for receiving data of the gas conducting and pressure measuring equipment so as to control oil pumping equipment to realize intermittent oil production, and the oil pumping equipment making direct contact with the well liquid, wherein the gas conducting and pressure measuring equipment comprises tubular billet pressure measuring equipment and sleeving pressure measuring equipment, the tubular billet pressure measuring device comprises a nitrogen cylinder, a nitrogen booster pump, a capillary steel pipe used for conducting nitrogen, a pressure transmitting cylinder used for bearing the nitrogen and tubular billet pressure sensors connected to an outlet of the nitrogen booster pump and an inlet of the capillary steel pipe which are sequentially connected, and the sleeving pressure measuring device comprises a sleeving pressure sensor connected with the oil pumping equipment. Controller equipment receives data of a data collector to control the working frequency of oil extraction equipment or start and stop of the oil extraction equipment, so that the intermittent production is realized to achieve the effect of reducing the production cost.

Owner:JEREH ENERGY SERVICES

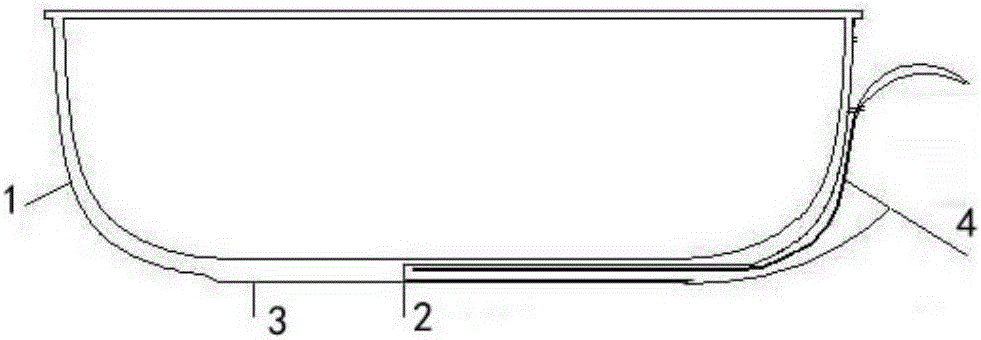

Internally insulated, corrosion resistant pipeline

An internally insulated, corrosion resistant pipeline. An inner fluid barrier is formed preferably by a polymer liner. The outer pipe may be a steel pipe. The liner is provided with a plurality of passages or an open annulus. The passages in the liner or annulus between the pipe and liner are filled with an insulation material.

Owner:J RAY MCCDERMOTT SA

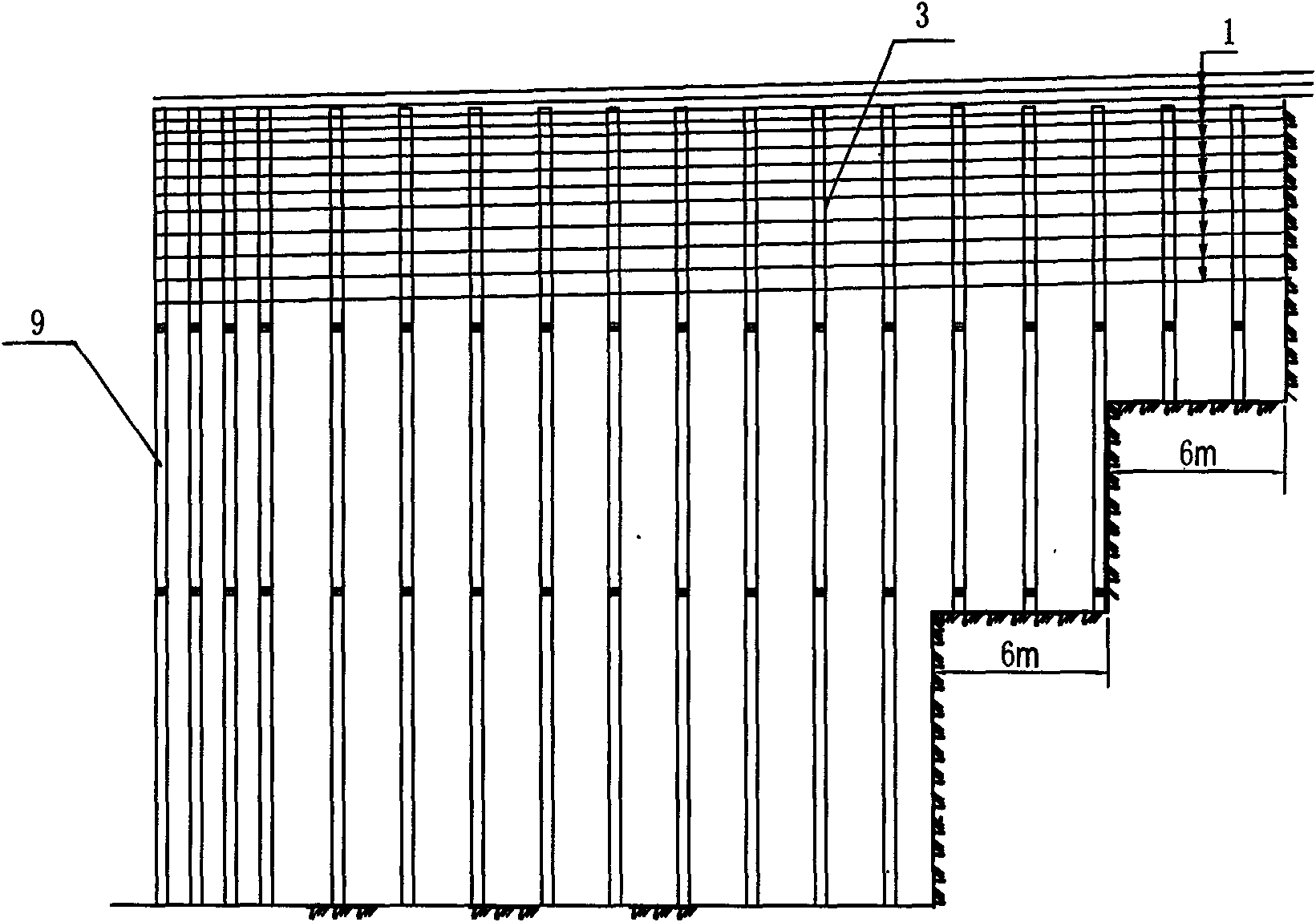

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

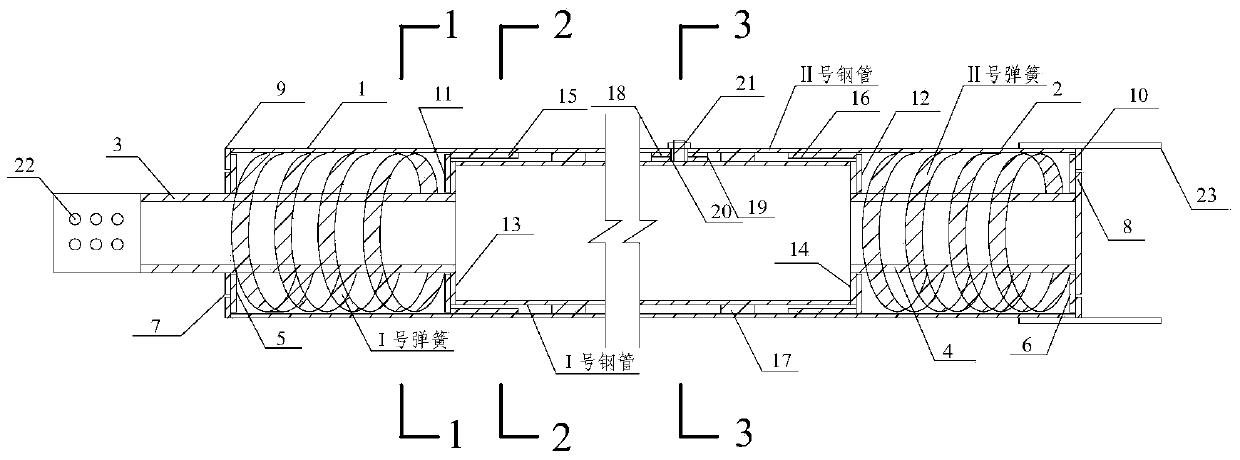

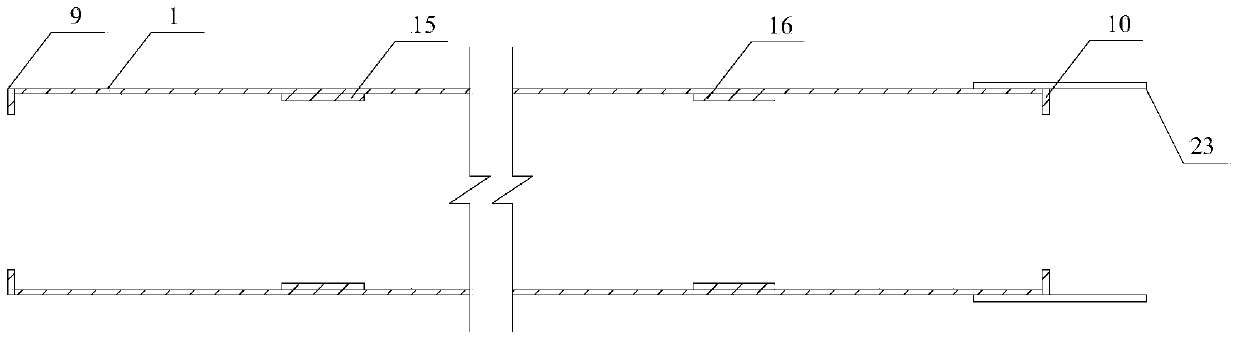

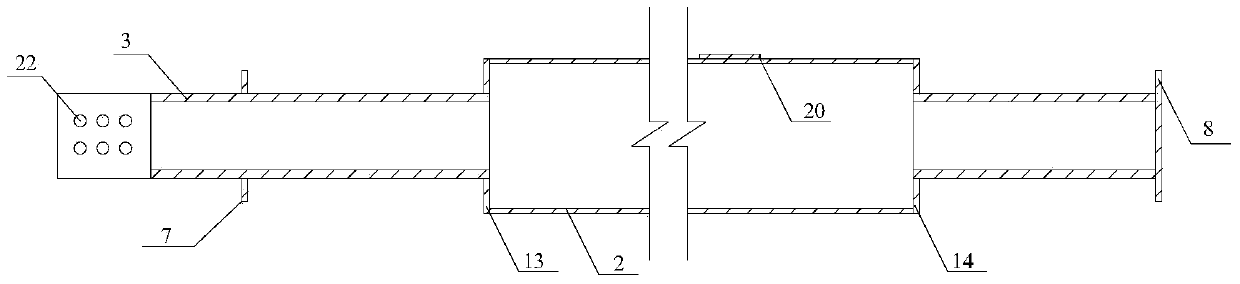

Setup spring self-recovery energy dissipation brace

ActiveCN103469921AReduce residual deformationEasy constructionShock proofingResidual deformationPipe

The invention discloses a setup spring self-recovery energy dissipation brace in the technical field of self-recovery energy dissipation braces. The brace comprises an inner pipe, an outer pipe, a spring, a spring baffle and a guide block; the inner pipe comprises a left inner pipe, a right inner pipe, a first steel pipe, a first steel pipe left baffle, a first steel pipe right baffle, an inner pipe left stopper, an inner pipe right stopper, an inner pipe outer friction plate, a high-strength bolt and an inner pipe connecting plate; the outer pipe comprises a left outer pipe, a right outer pipe, a second steel pipe, an outer pipe left baffle, an outer pipe right baffle, an outer pipe internal left stopper, an outer pipe internal right stopper, an outer pipe inner friction plate and an outer pipe connecting plate; the spring comprises a first spring and a second spring, wherein the first spring is sleeved outside the left inner pipe, and the second spring is sleeved outside the right inner pipe; two ends of the spring are connected with the spring baffle. The brace has the advantages that residual deformation of a structure is decreased, the brace is convenient to construct and easy to maintain and replace after earthquake action, and normal usage state affecting time is shortened.

Owner:BEIJING JIAOTONG UNIV

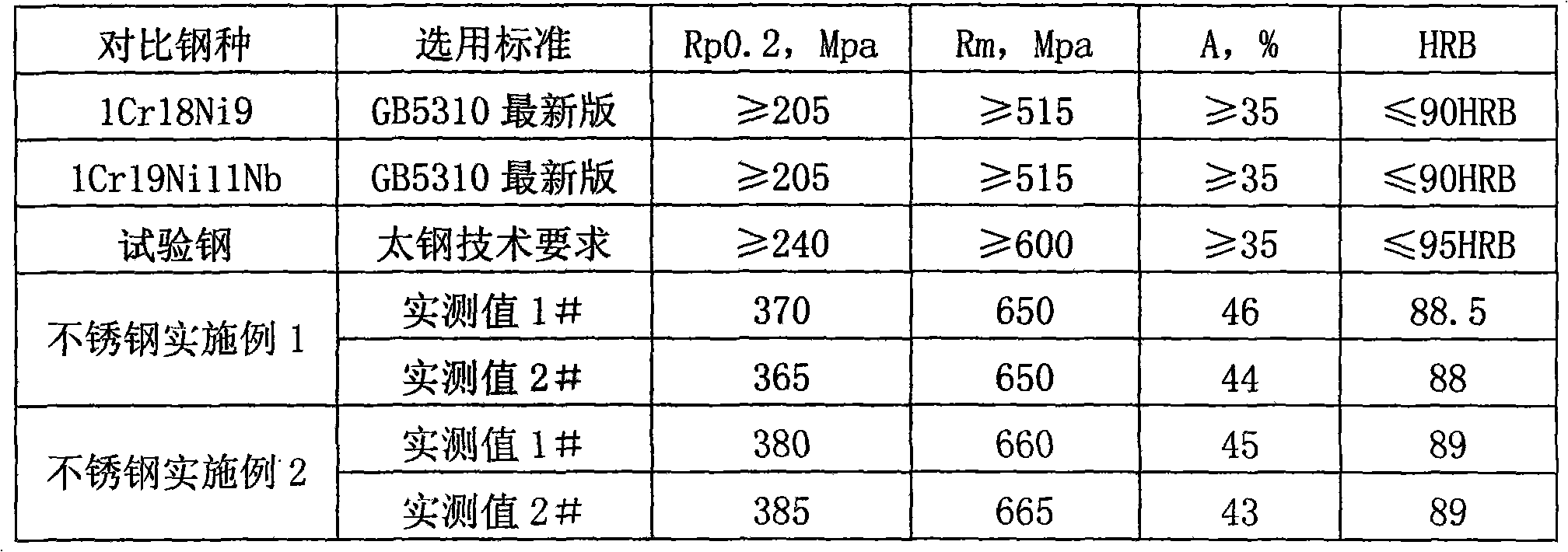

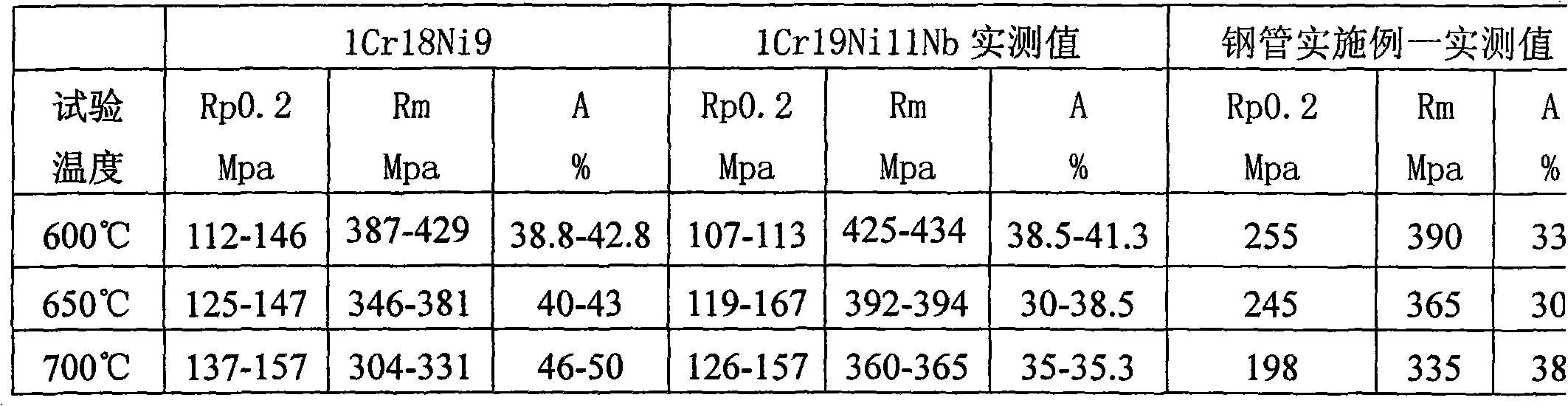

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

Oil country tubular goods excellent in collapse characteristics after expansion and method of production thereof

InactiveUS20050217768A1Excellent in collapse characteristicSmall rate of dropFurnace typesHeat treatment furnacesMethods of productionSteel belt

The present invention provides a method of production of oil country tubular goods having a small drop in collapse pressure after expansion and having a collapse pressure recovering by low temperature ageing at about 100° C. and oil country tubular goods obtained by this method of production. This method of production comprises hot rolling a steel slab having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities and shaping the steel strip coiled at a temperature of not more than 300° C. as it is into a tube. Alternatively, it comprises heating steel pipe having amounts of addition of C, Mn, P, S, Nb, Ti, Al, and N in specific ranges and having a balance of iron and unavoidable impurities to a temperature of the Ac3 [° C.] to 1150° C., then cooling it in a range of 400 to 800° C. at a rate of 5 to 50° C. / second.

Owner:NIPPON STEEL CORP

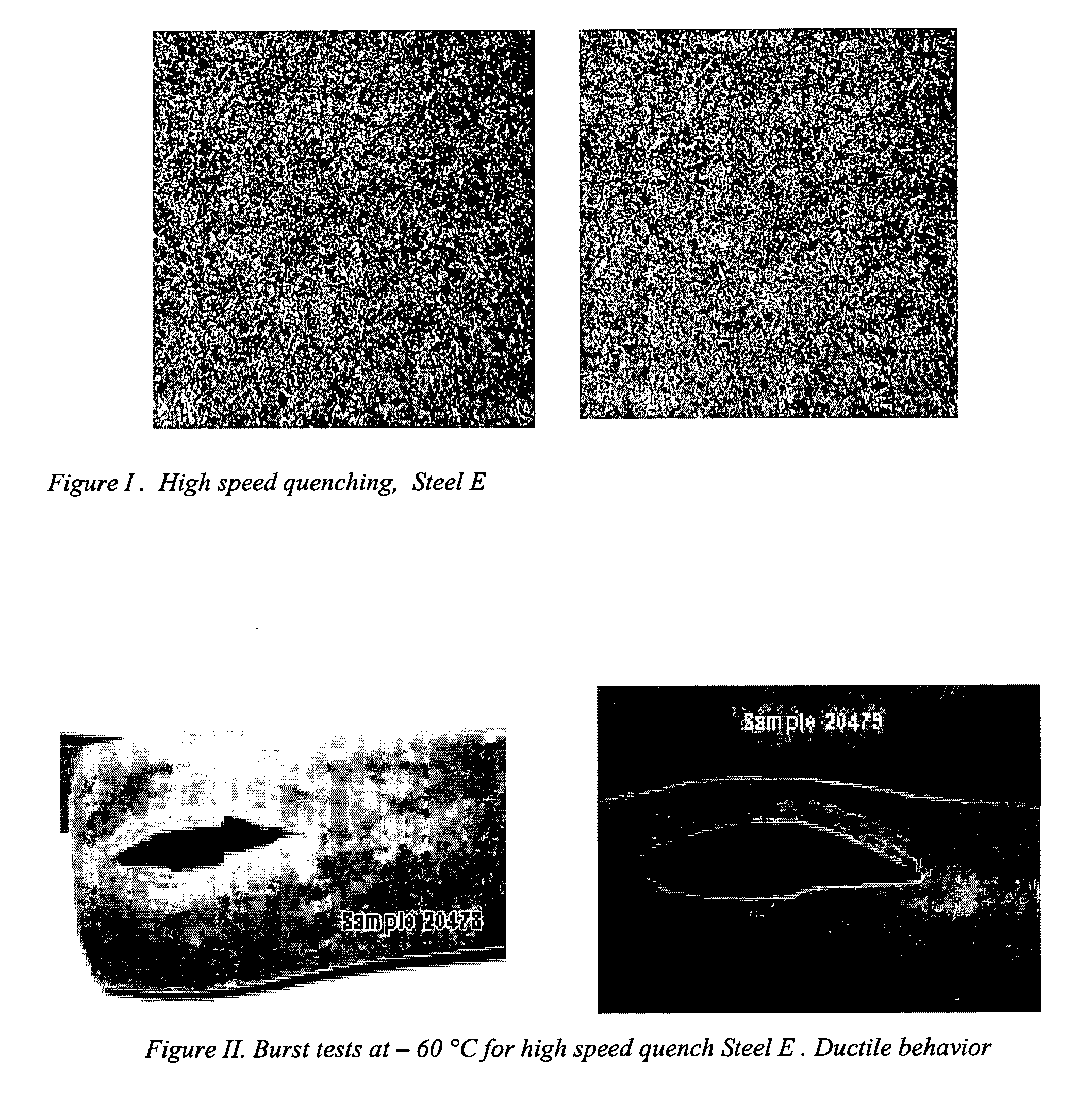

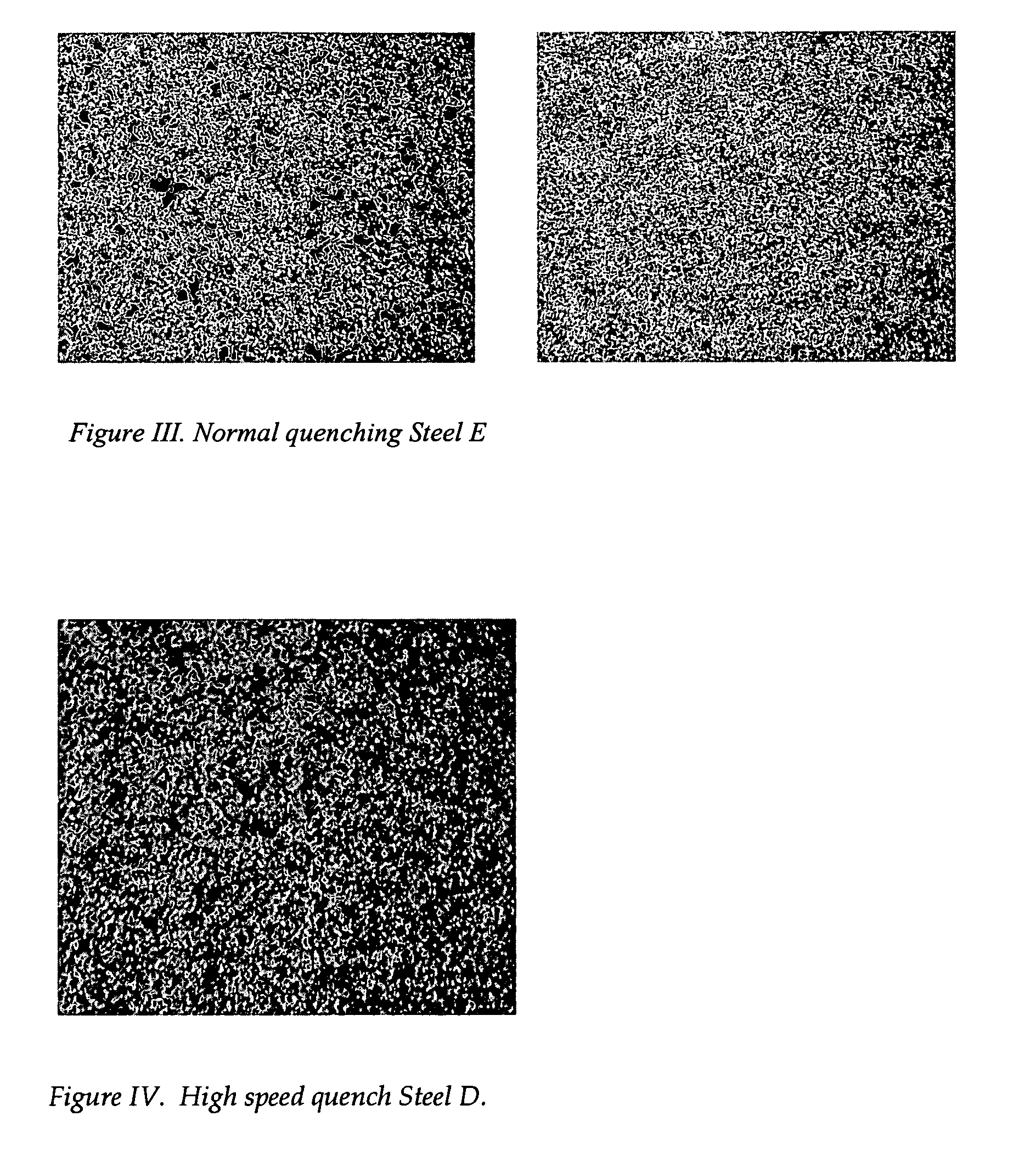

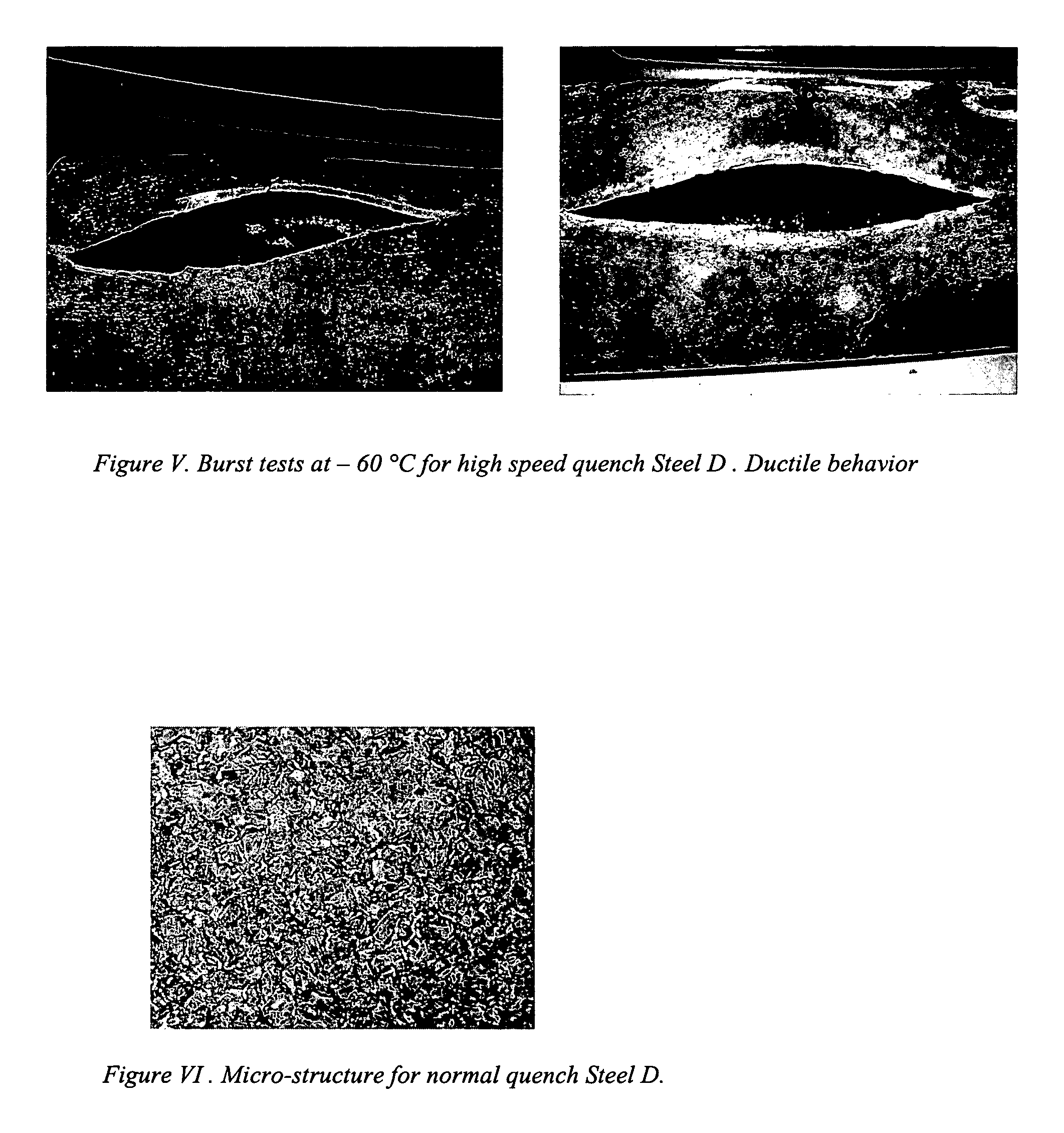

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20050076975A1High strengthImprove toughnessFurnace typesHeat treatment furnacesNiobiumManganese

A low carbon alloy steel tube and a method of manufacturing the same, in which the steel tube consists essentially of, by weight: about 0.06% to about 0.18% carbon; about 0.5% to about 1.5% manganese; about 0.1% to about 0.5% silicon; up to about 0.015% sulfur; up to about 0.025% phosphorous; up to about 0.50% nickel; about 0.1% to about 1.0% chromium; about 0.1% to about 1.0% molybdenum; about 0.01% to about 0.10% vanadium; about 0.01% to about 0.10% titanium; about 0.05% to about 0.35% copper; about 0.010% to about 0.050% aluminum; up to about 0.05% niobium; up to about 0.15% residual elements; and the balance iron and incidental impurities. The steel has a tensile strength of at least about 145 ksi and exhibits ductile behavior at temperatures as low as −60° C.

Owner:TENARIS CONNECTIONS

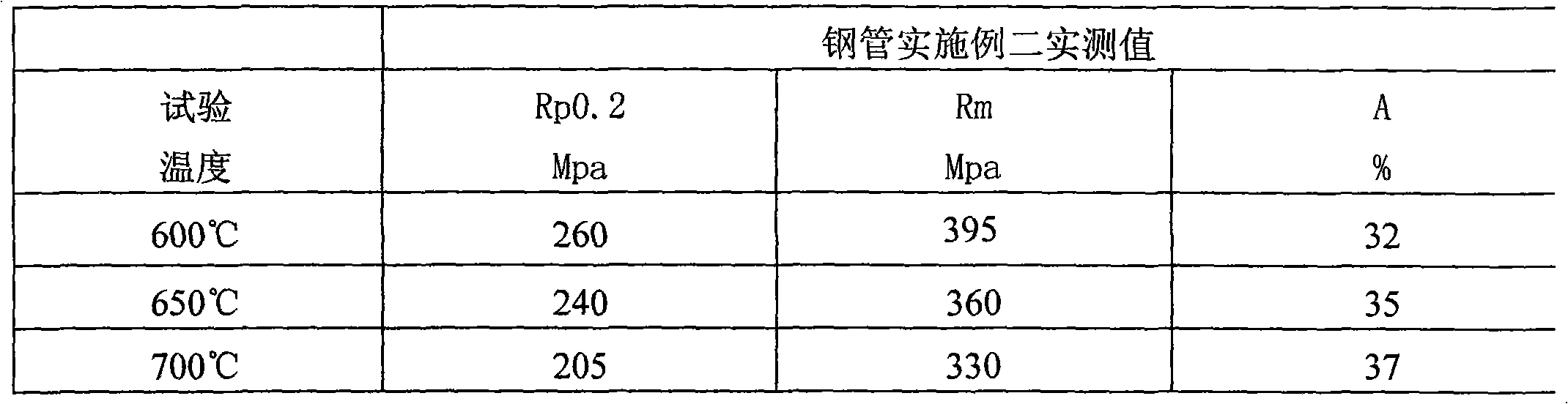

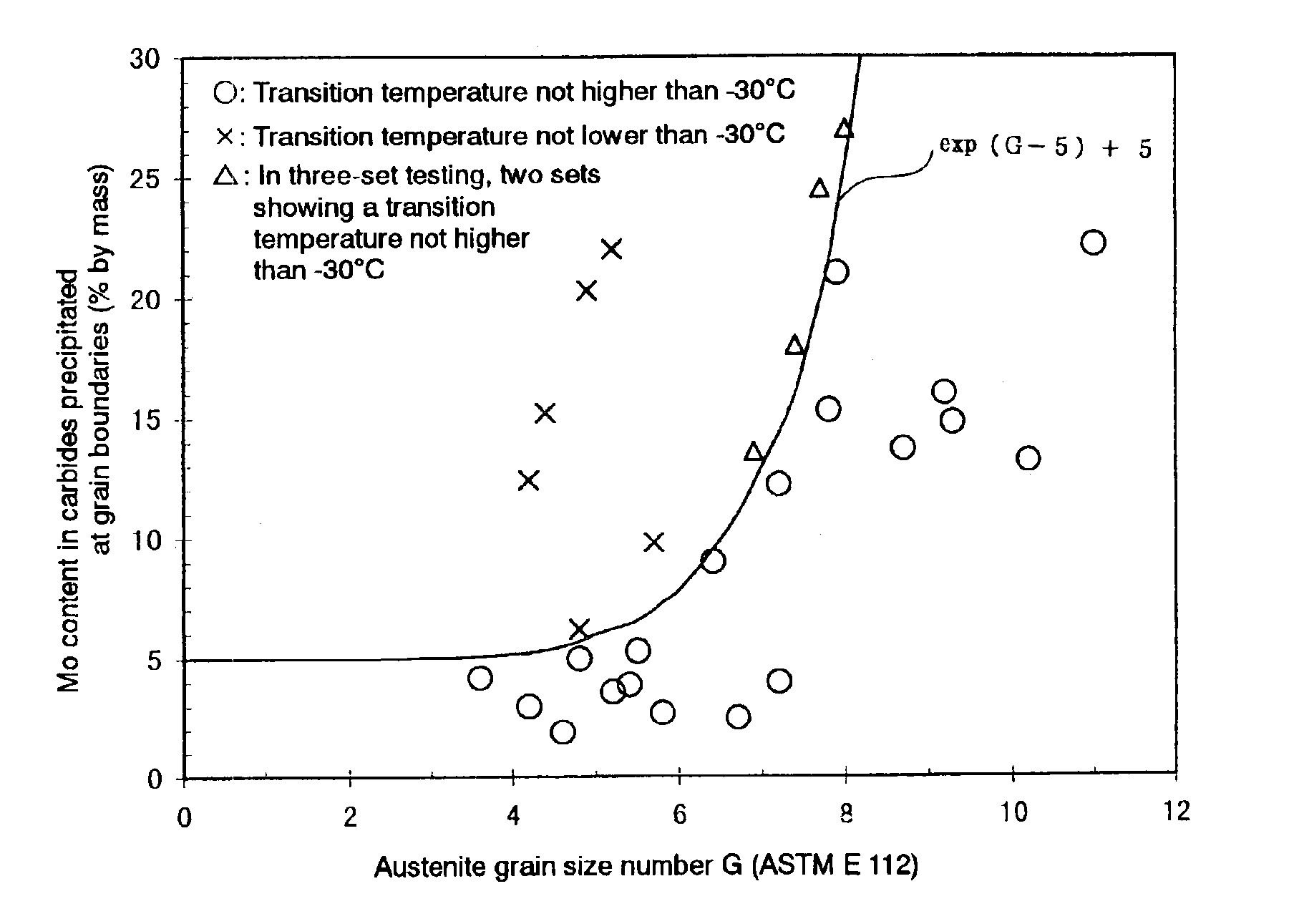

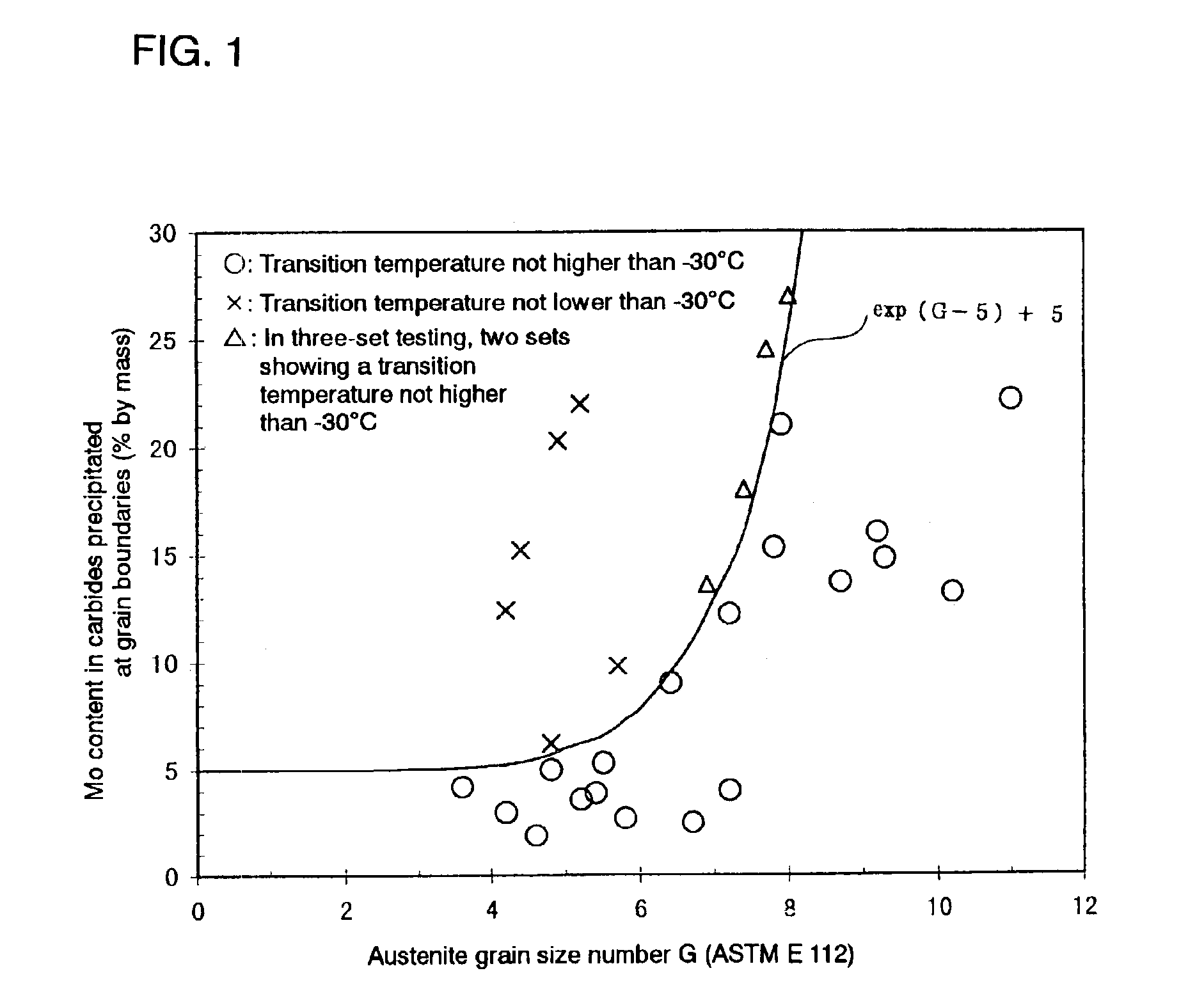

High toughness steel material and method of producing steel pipes using same

InactiveUS6958099B2Improve toughnessReduce hardenabilityFurnace typesHeat treatment furnacesProduction rateAustenite grain

A steel material and a steel pipe made by using the same are provided which are to be used in severe oil well environments. Such a highly tough oil well steel pipe can be produced by rolling the base material, quenching the rolling product from the austenite region and tempering the same so that the relationship between the content of Mo [Mo] in the carbides precipitated at austenite grain boundaries and the austenite grain size (according to ASTM E 112) can be defined by the formula (a) given below. In this manner, steel pipes suited for use even under oil well environments becoming more and more severe can be produced while satisfying the requirements that the cost should be rationalized, the productivity improved and energy saved.[Mo]≦exp(G−5)+5 (a)

Owner:NIPPON STEEL CORP

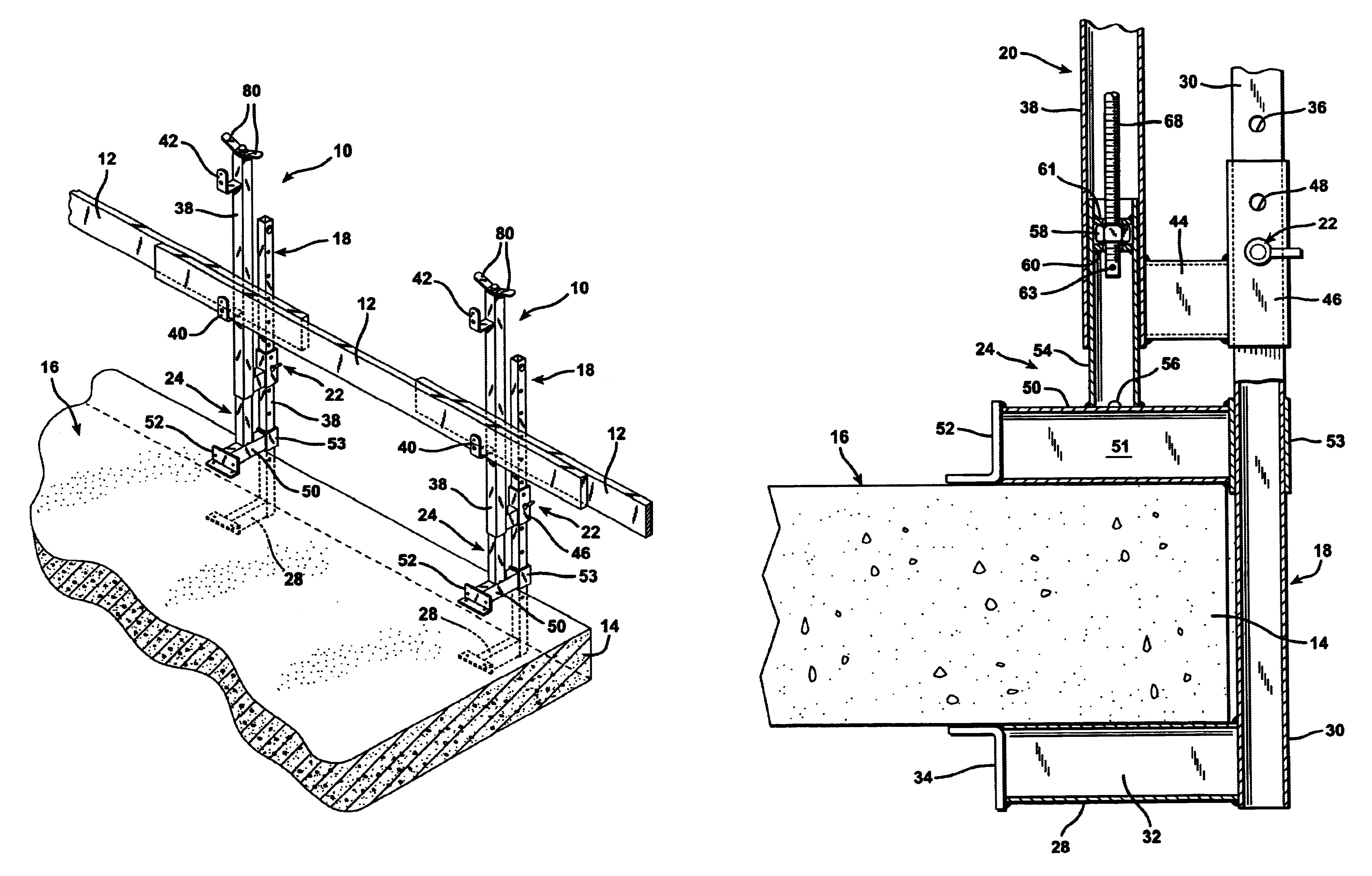

Construction perimeter guard

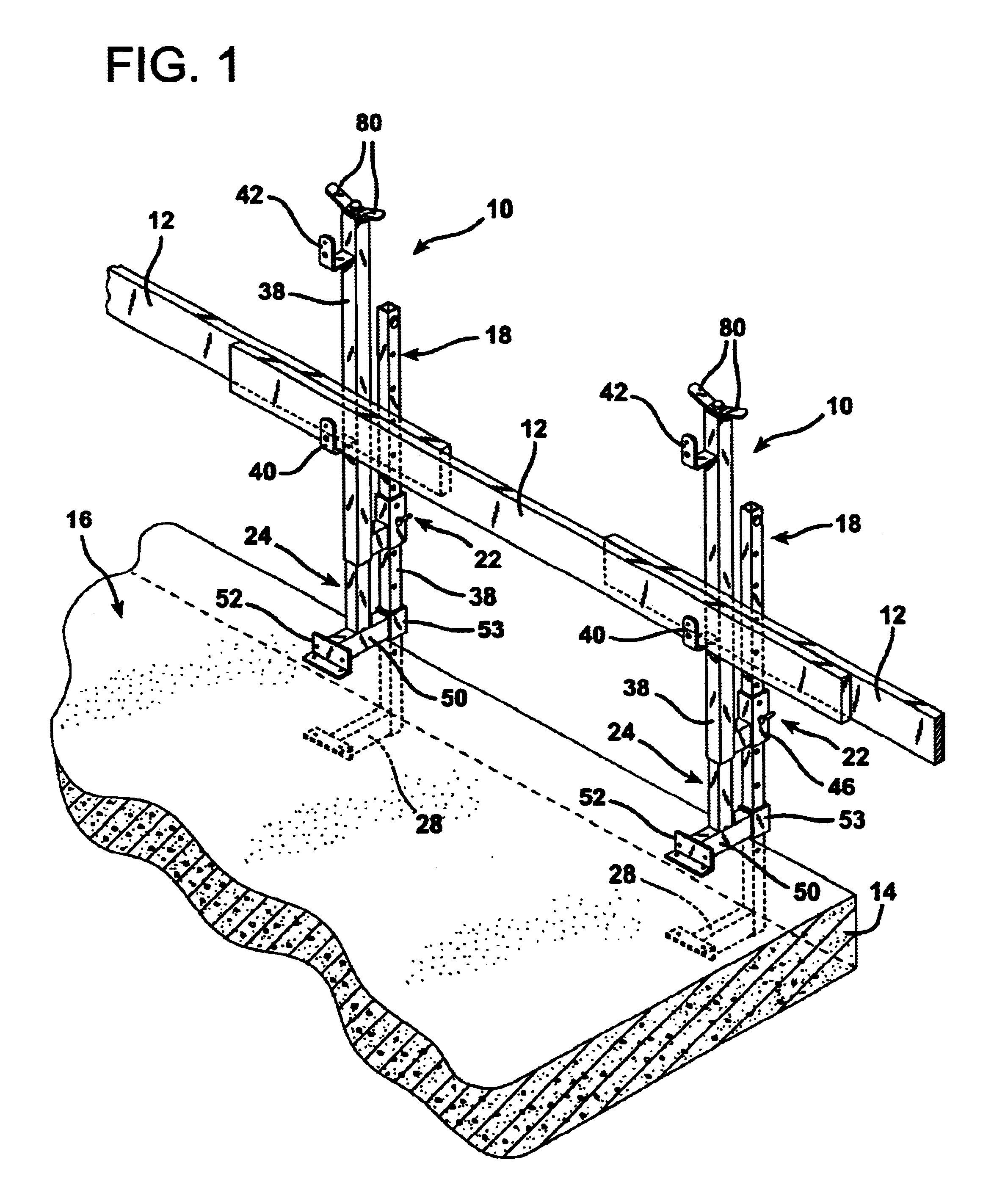

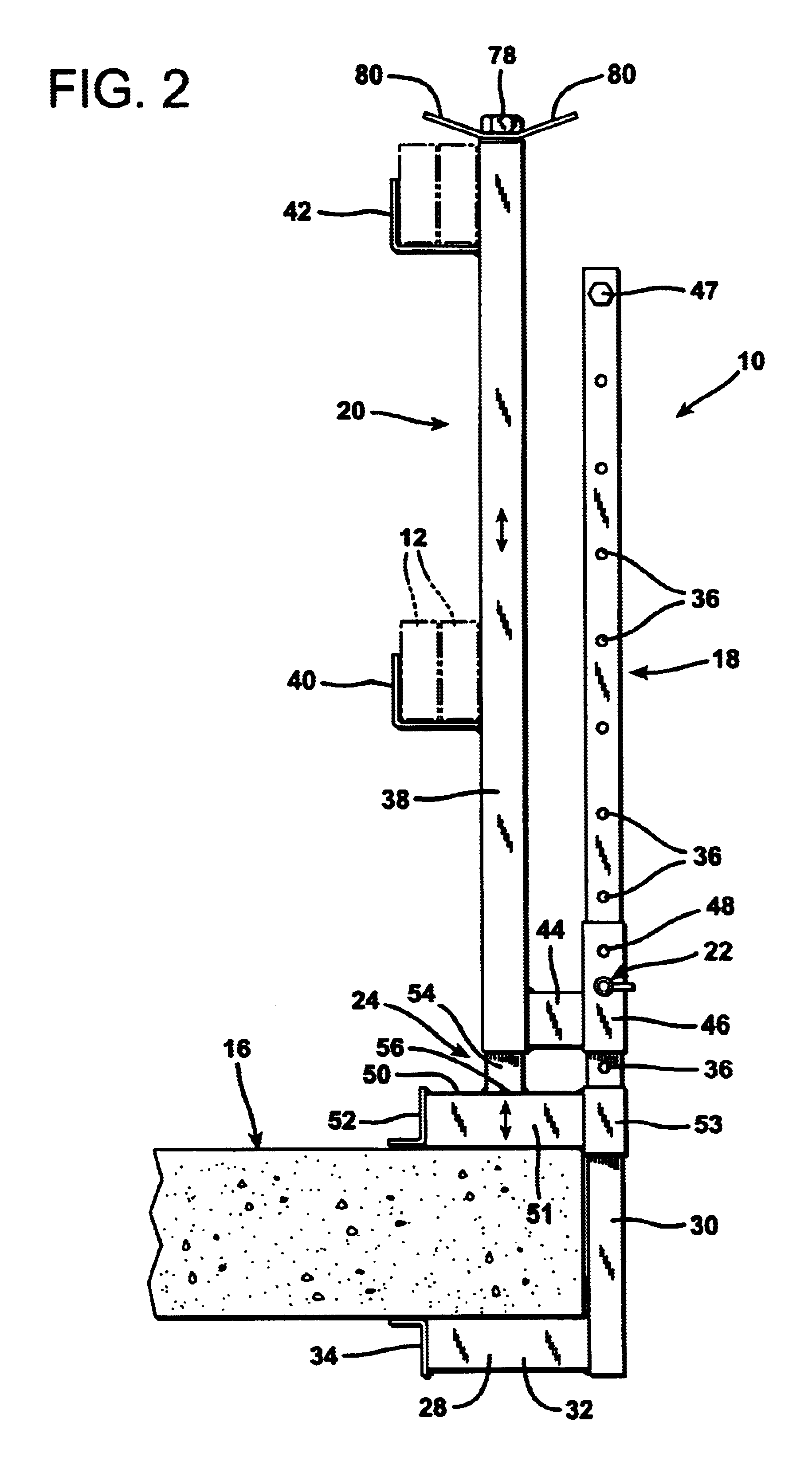

The present invention is an improved construction perimeter guard stanchion. A dual adjustment system performs both coarse and fine adjustments to tightly clamp a pair of jaws at the lower end of the stanchion upon the edge of a floor slab in an elevated, unfinished building structure. A coarse jaw adjustment sleeve formed of a short section of hollow steel tubing is coaxially disposed about an outboard support member in sliding engagement therewith. The coarse adjustment sleeve has one or more perforations therethrough so that a locking pin can be passed through it and through aligned openings in the outboard support member. A fine adjustment screw member is disposed coaxially within a vertical rail support tube and may be rotated by lever arms to move the upper jaw closer to or further from the lower jaw. Adjustment of the fine positioning mechanism is performed by manipulating handles at the top of the vertical rail support tube. A workman installing the stanchion thereby does not have to stoop over to operate a clamp located down near the concrete slab.

Owner:A 1 PLANK & SCAFFOLD MFG

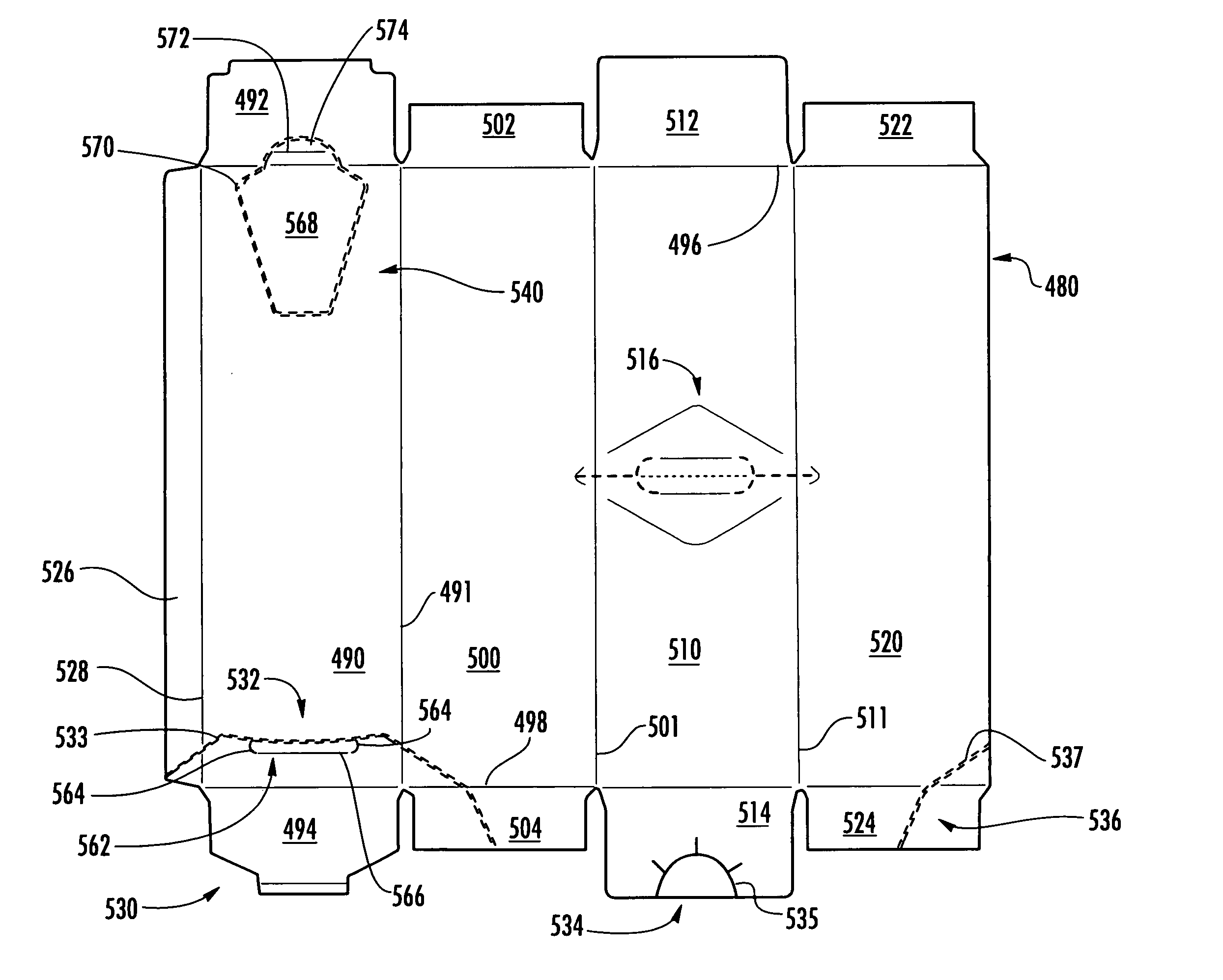

Bag-in-a-box

A package includes a carton having an access opening that is for providing access to the interior of the carton. The package further includes a flexible bag that is positioned in the interior of the carton, and a spigot that is operatively connected to the bag for selectively dispensing flowable material from the bag. A holder is cooperatively associated with the spigot and the carton for holding the spigot so that the spigot is simultaneously proximate the access opening of the carton and disposed at least partially within the interior of the carton, so that access to the spigot is at least temporarily restricted in a manner that at least temporarily restricts any dispensing of flowable material from the bag by way of the spigot.

Owner:GRAPHIC PACKAGING INT

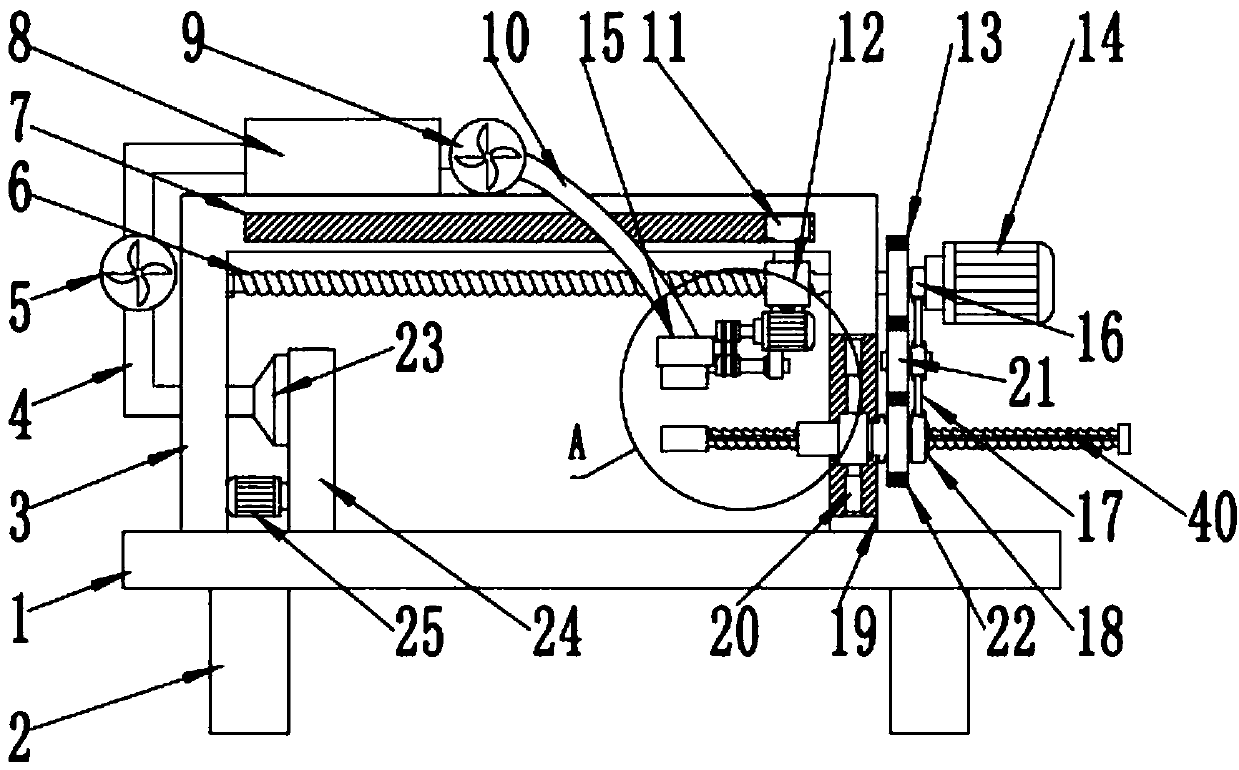

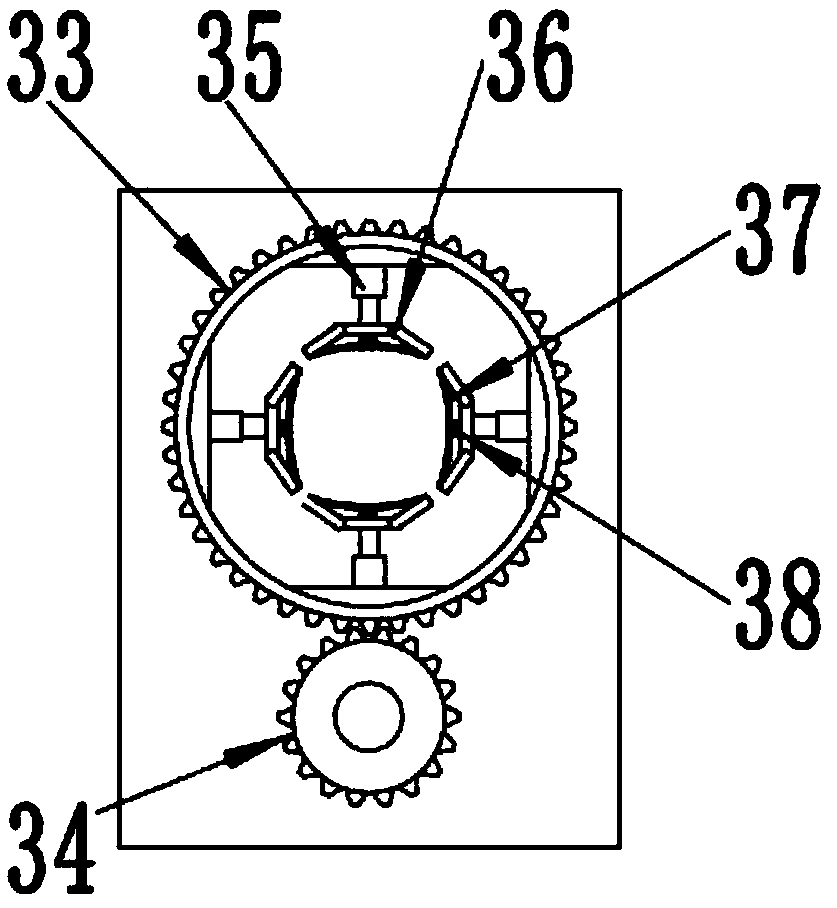

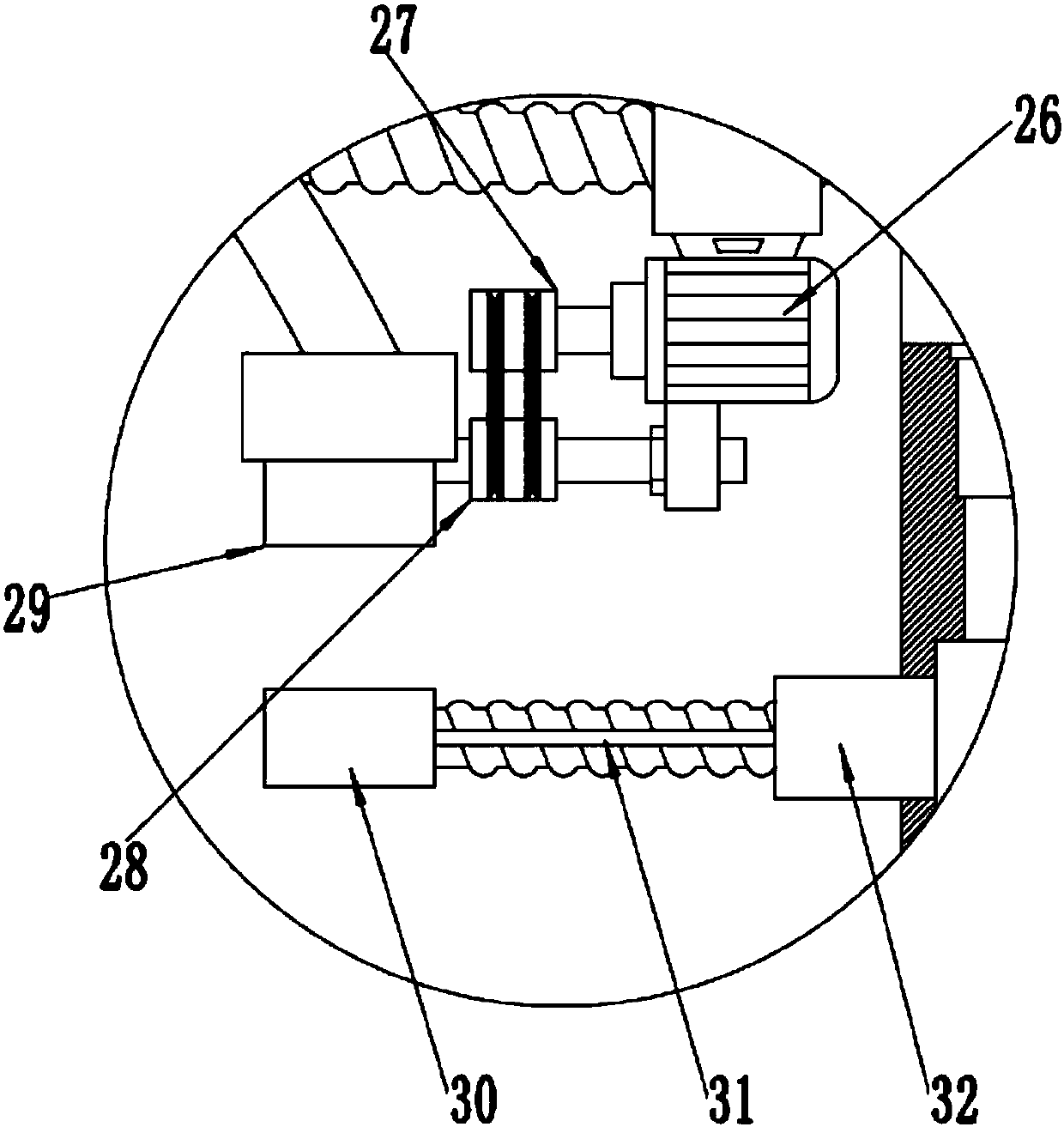

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

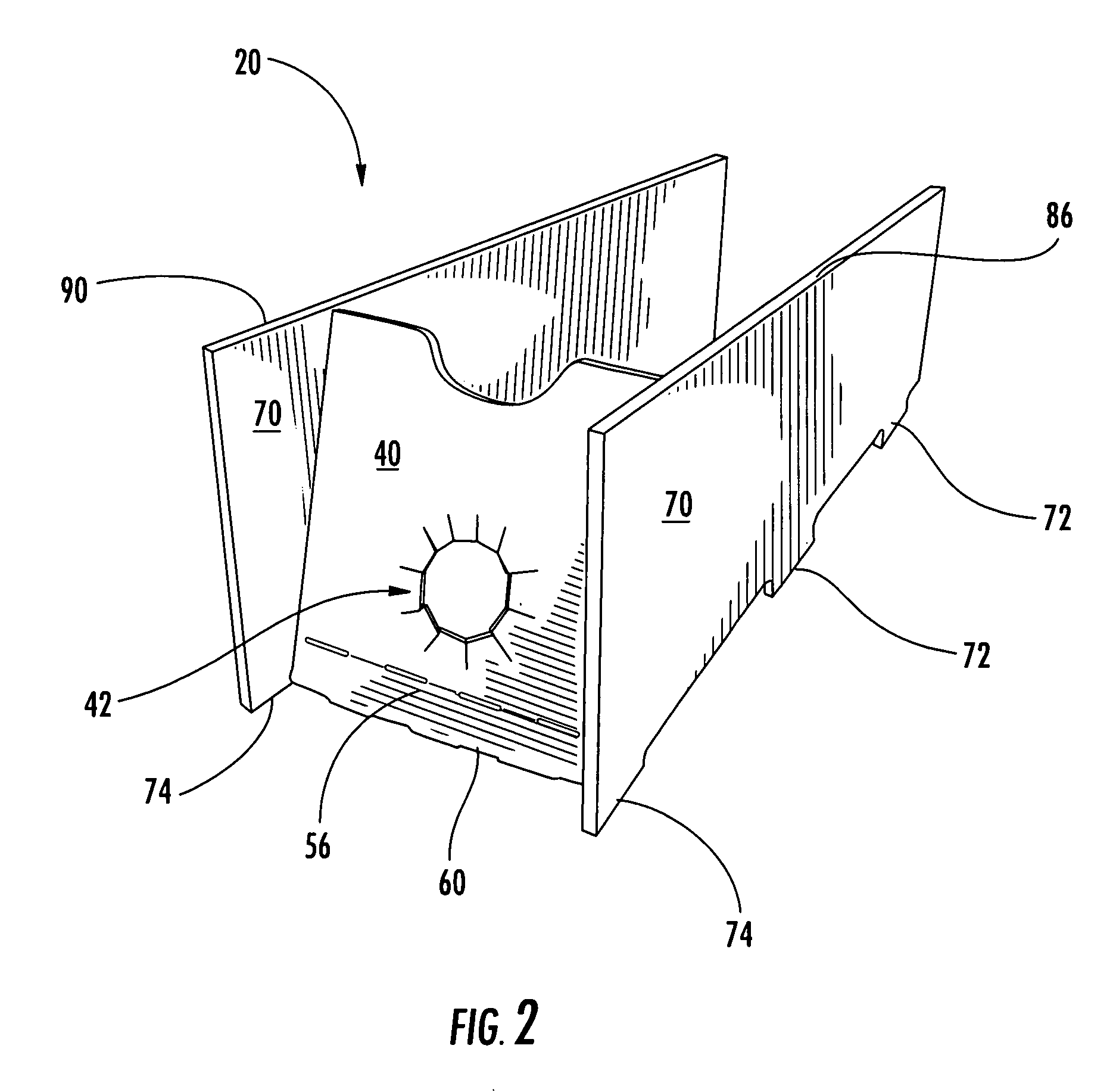

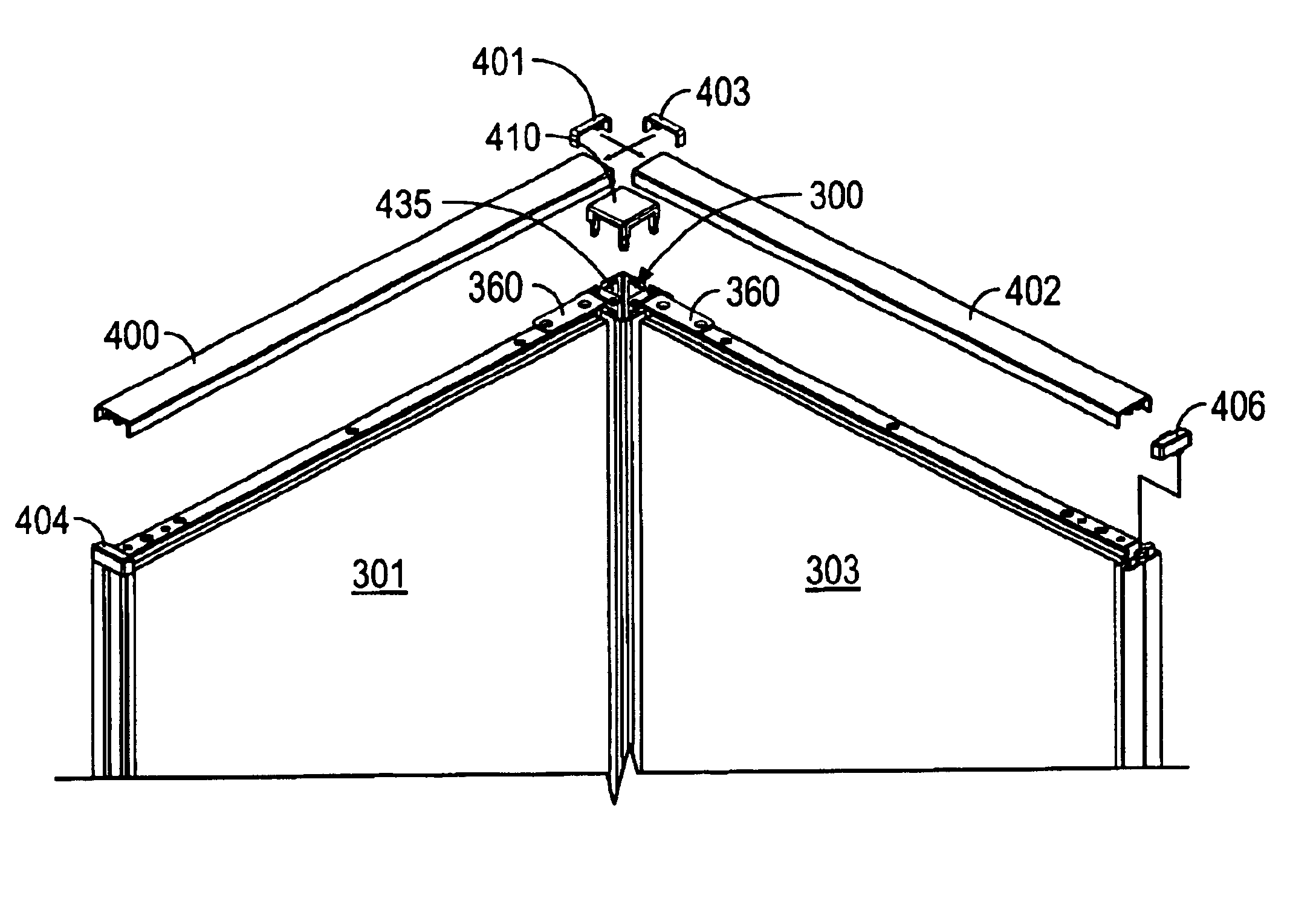

Wall panel system

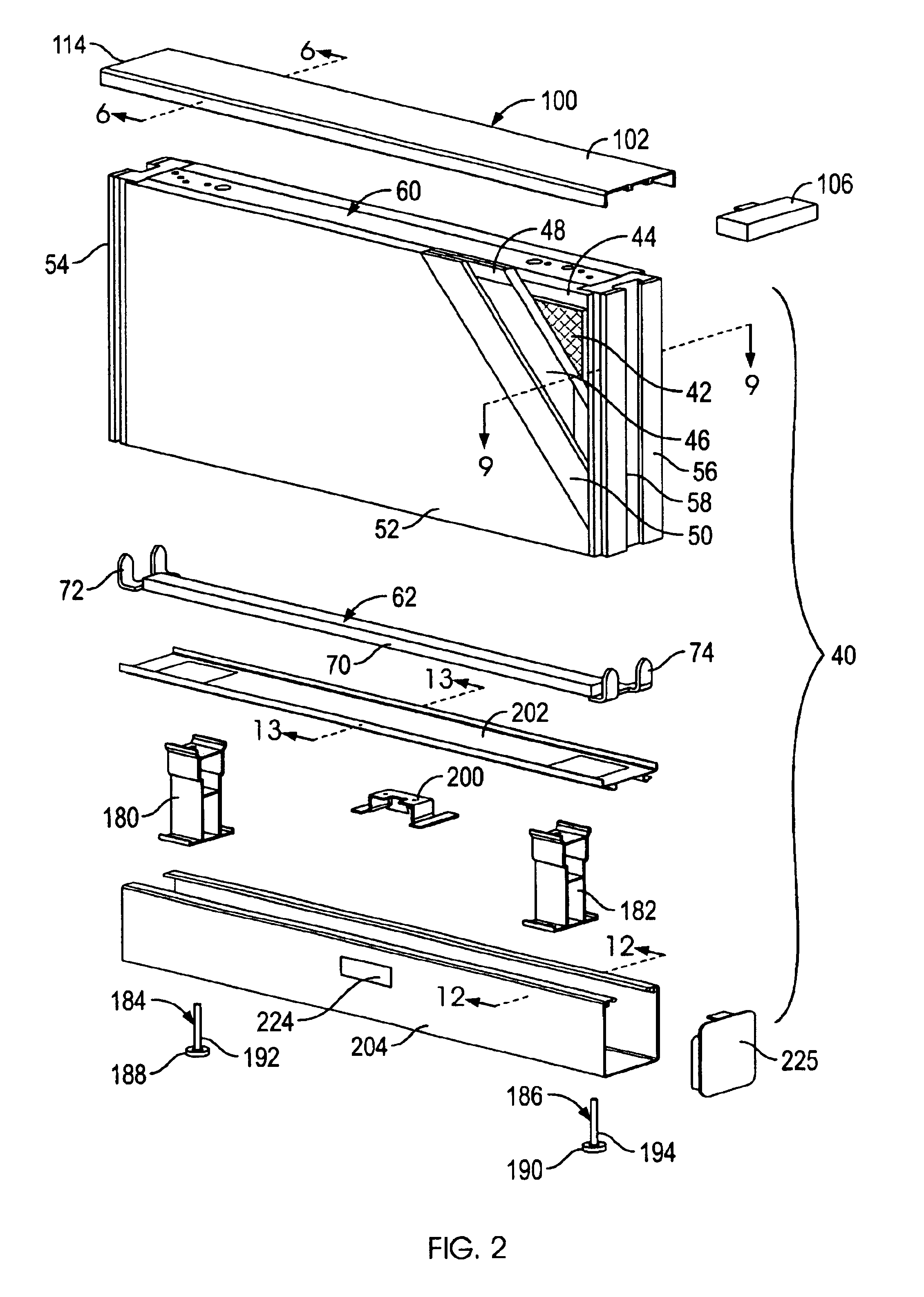

InactiveUS6964138B2Simple structureEasily and quickly assembled and disassembledWallsPublic buildingsEngineeringMechanical engineering

An improved wall panel system is disclosed. The system includes wall panel assemblies, each assembly having a pair of side frame members having slotted channels, top and bottom steel tubes and fork connectors for attachment to the side frame members, a top cap, lower metal supports and a plastic base rail channel and cover. The system also includes a universal connector post, a universal I-beam shaped connector, a universal bracket, a variable height bracket and adjustable corner and end caps. The corner and end caps are scored to allow removal of cap walls resulting in an inventory of fewer parts and system versatility. A removal tool is also disclosed.

Owner:HNI TECH INC

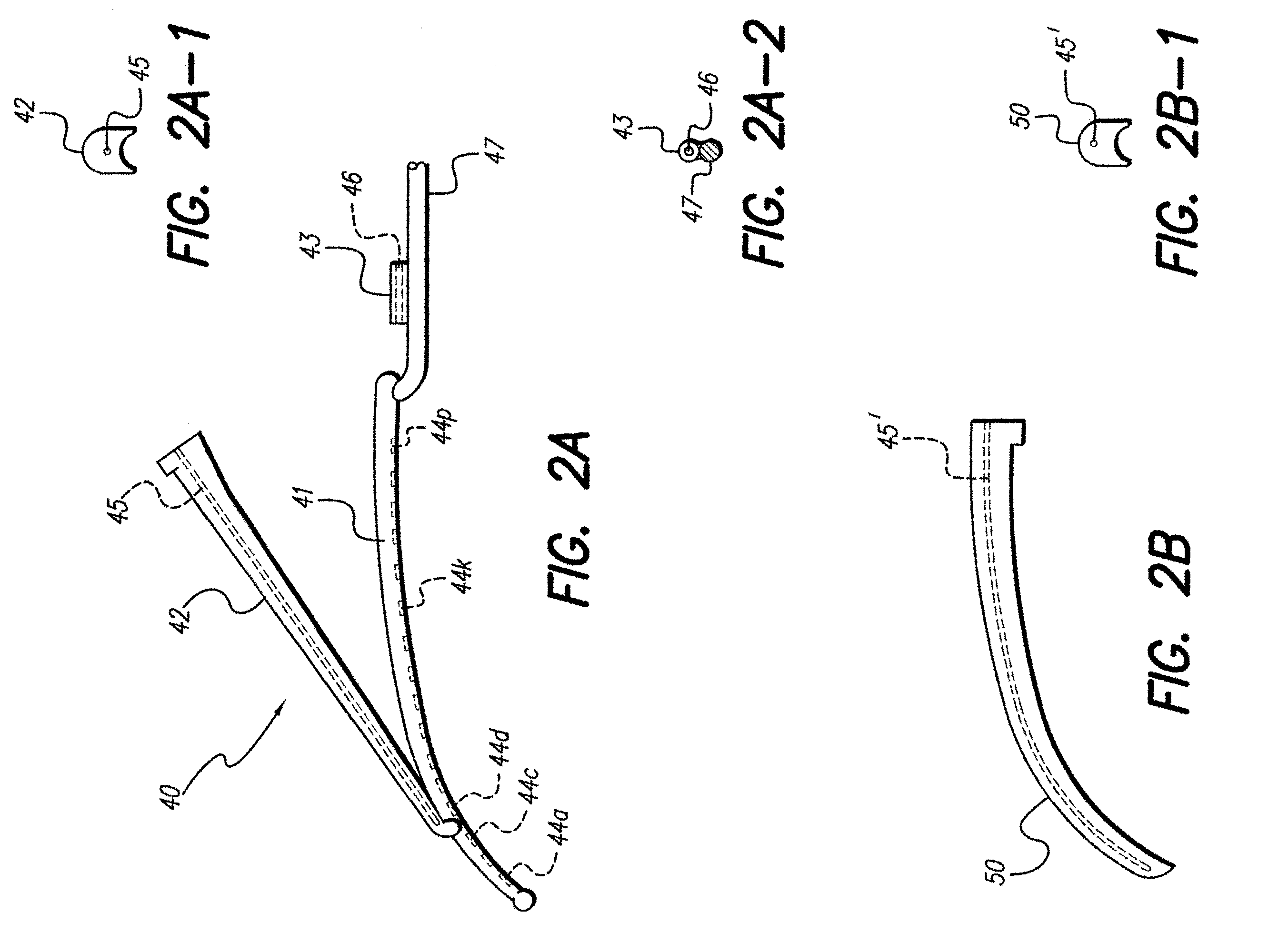

Insertion tool for placement of electrode system inside the cochlear lumen

An insertion tool uses a stylet wire to help guide an electrode system into a cochlea. The insertion tool includes three main elements or parts: a handle, a guide and a slider. The handle is made from light stainless steel tube flattened in front with a machined slot. The guide consists of a plurality of metal tubes, fixed to each other within a holding bracket. In one embodiment, the slider includes a stabilizer wire, a long stylet wire, and a short stylet wire. During the assembly process, the stabilizer and stylet wires are inserted into respective tubes of the guide and the end of the stabilizer wire is bent to form an offset. The electrode system is loaded onto the tool by inserting the short stylet wire into a holder that supports the electrode lead.

Owner:ADVANCED BIONICS AG

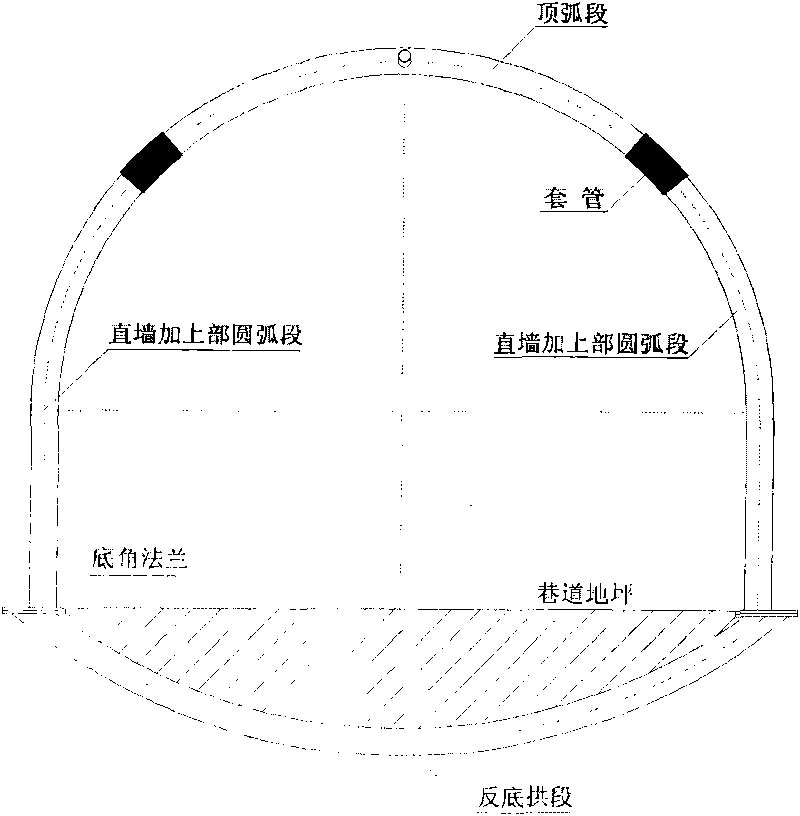

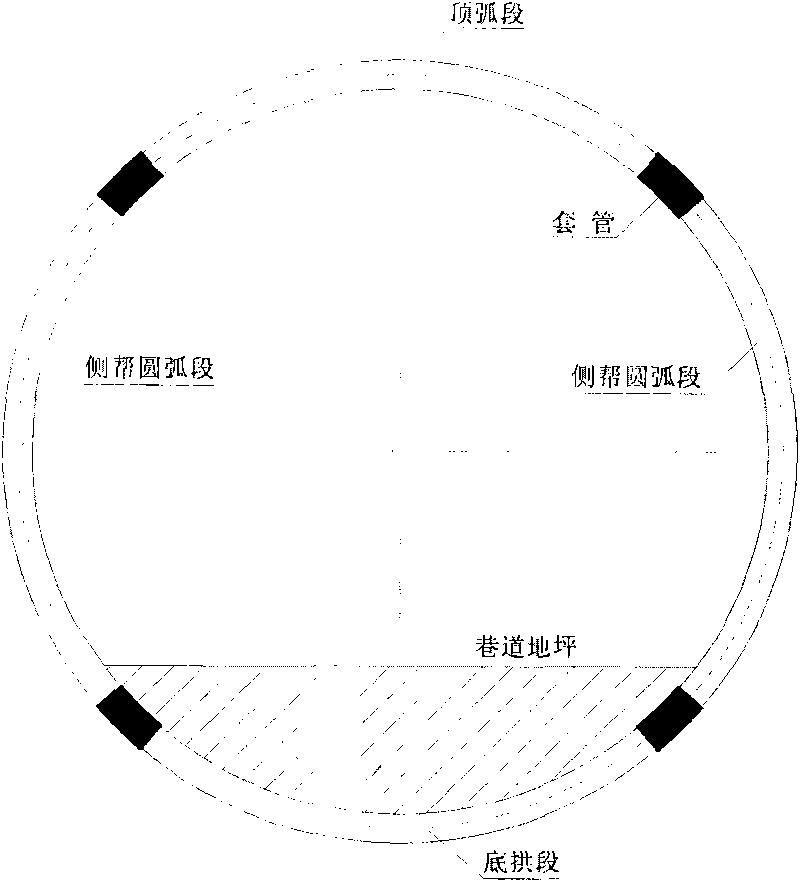

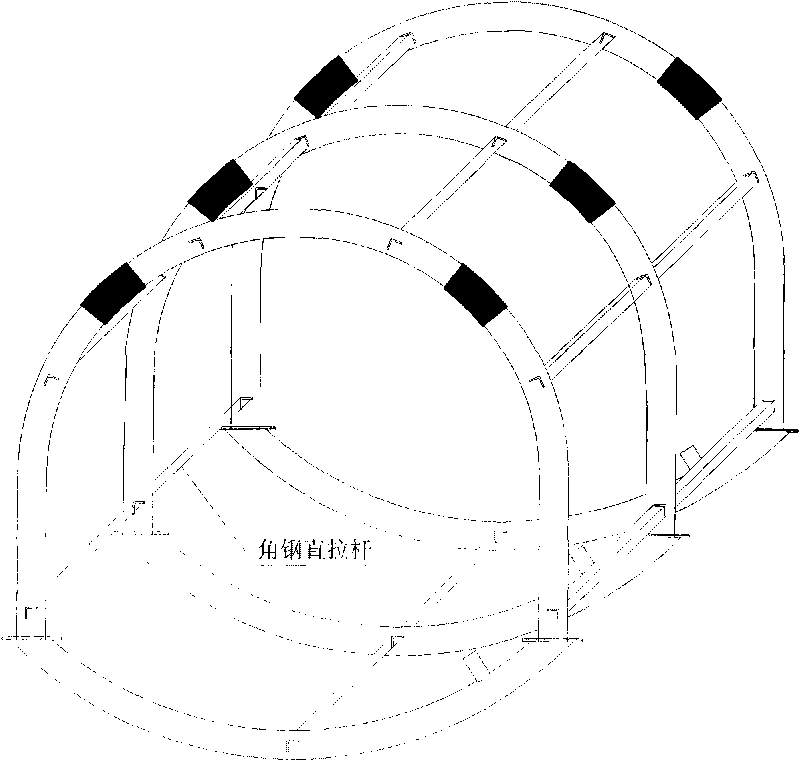

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

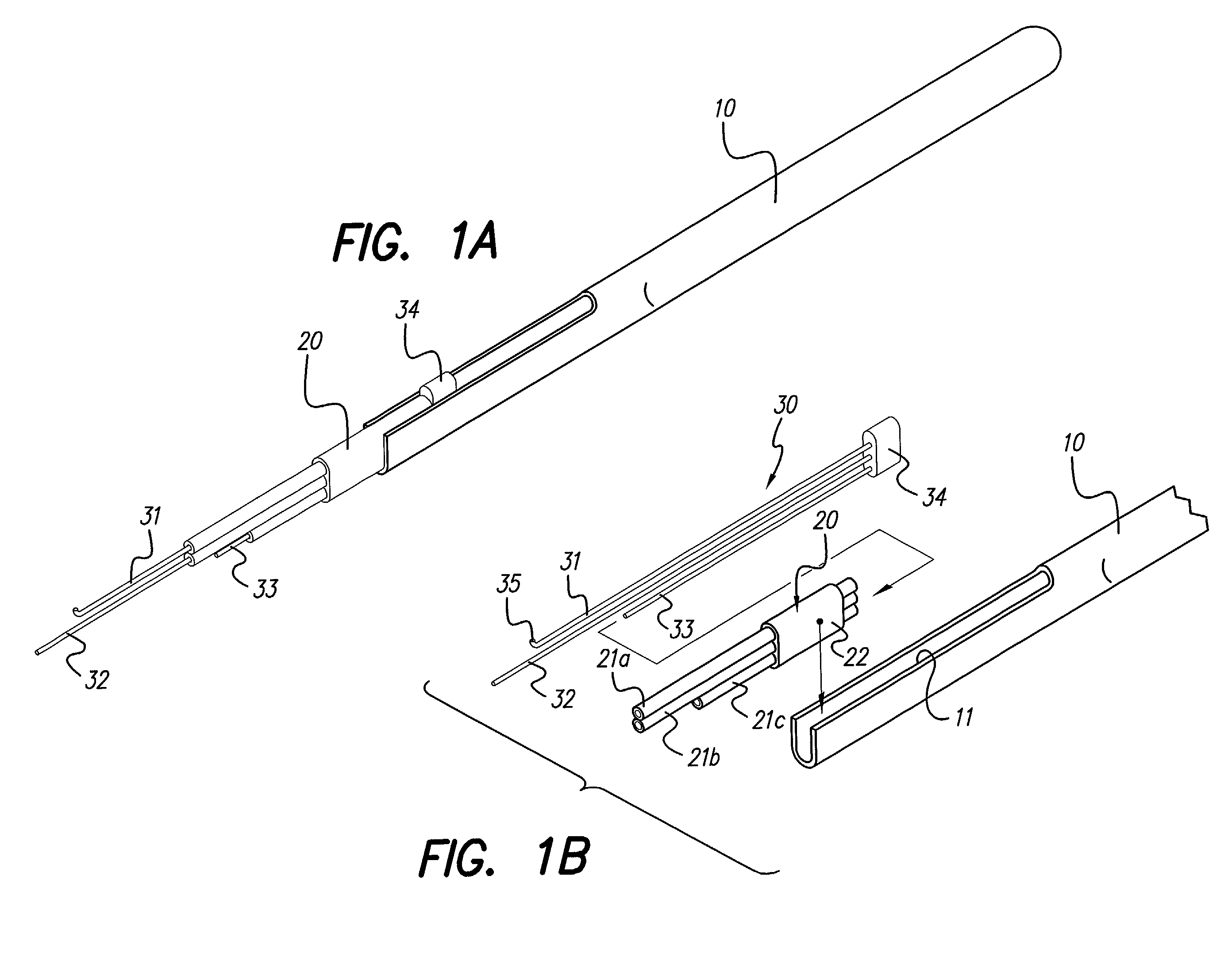

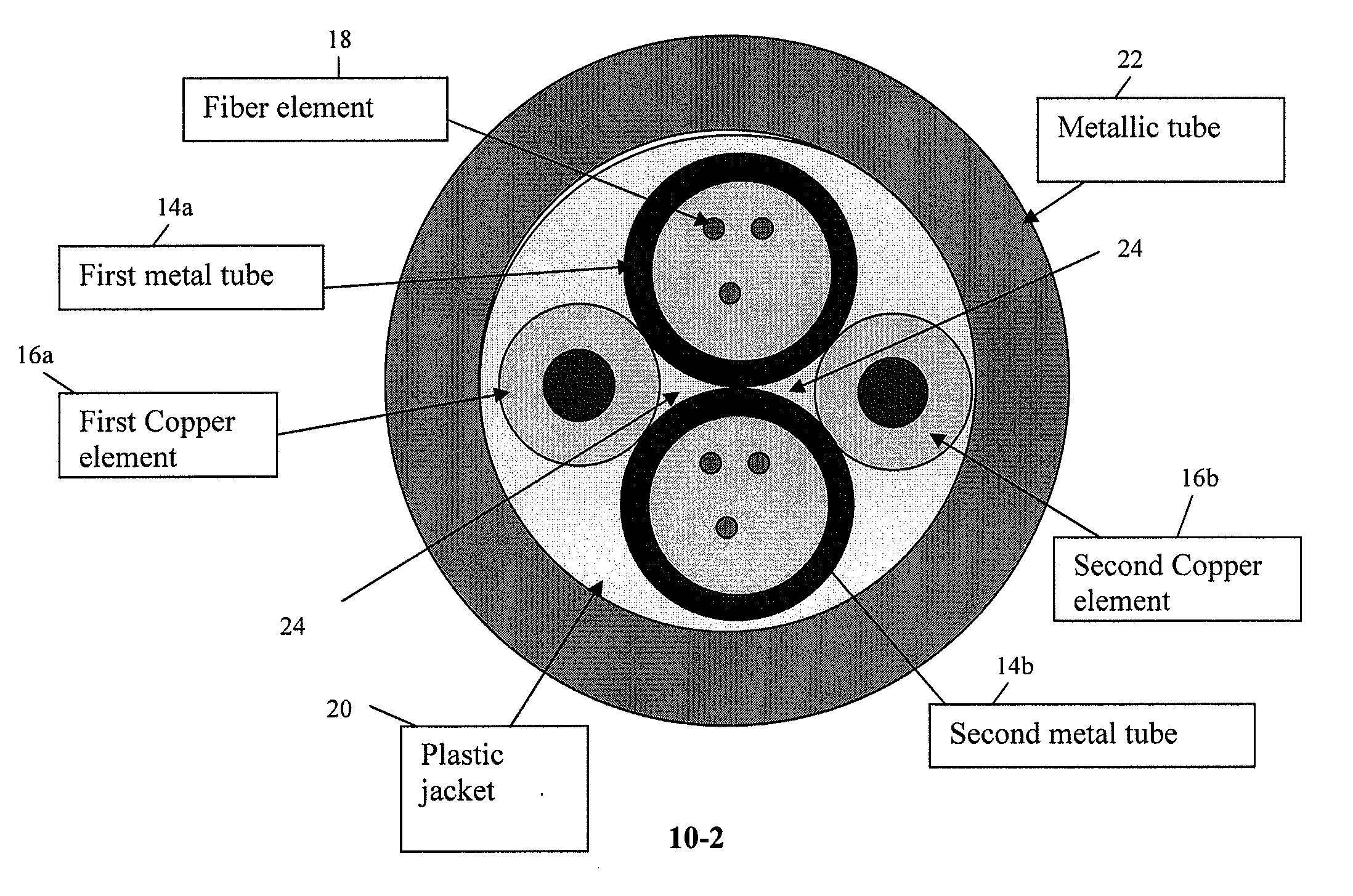

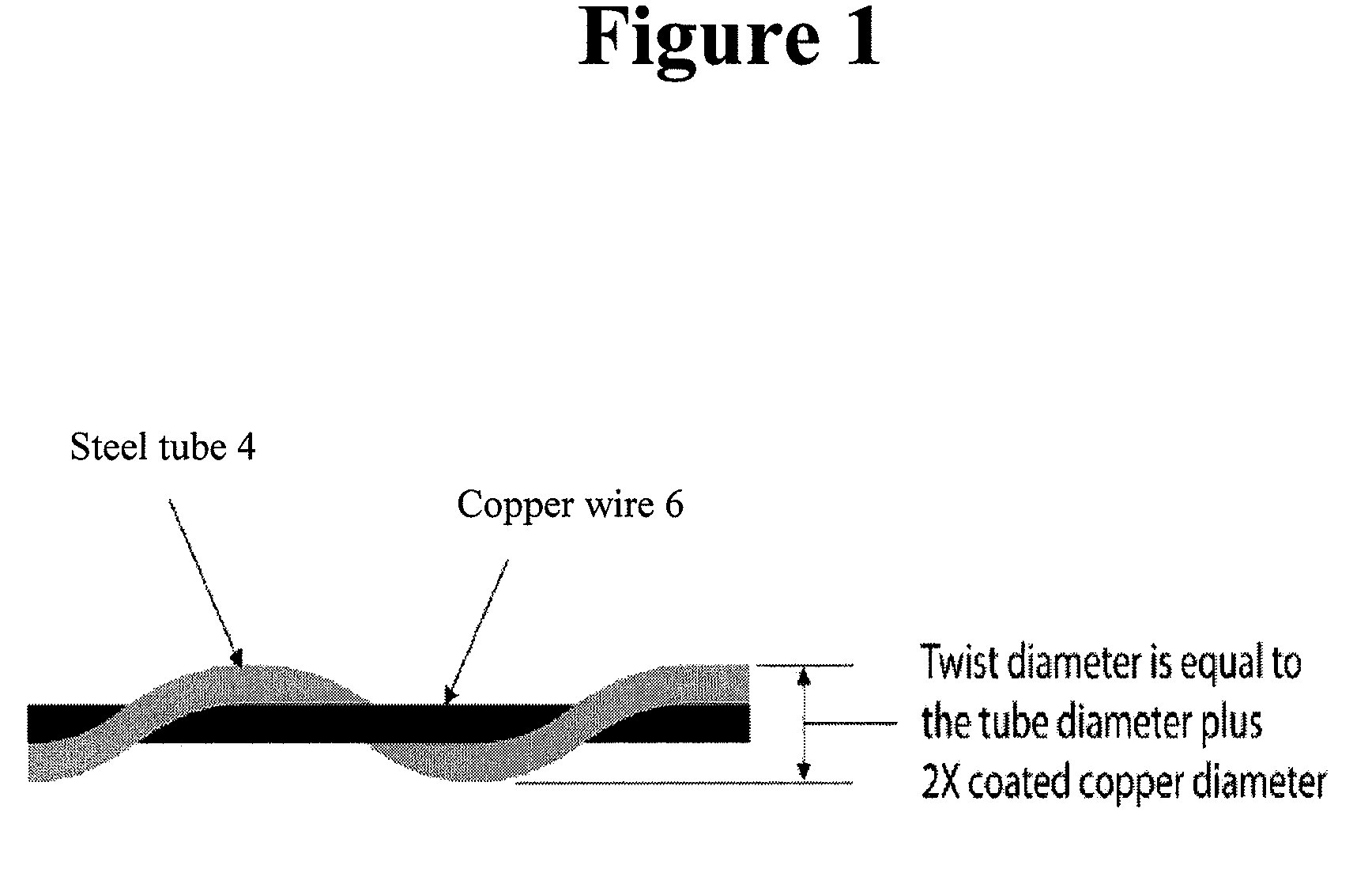

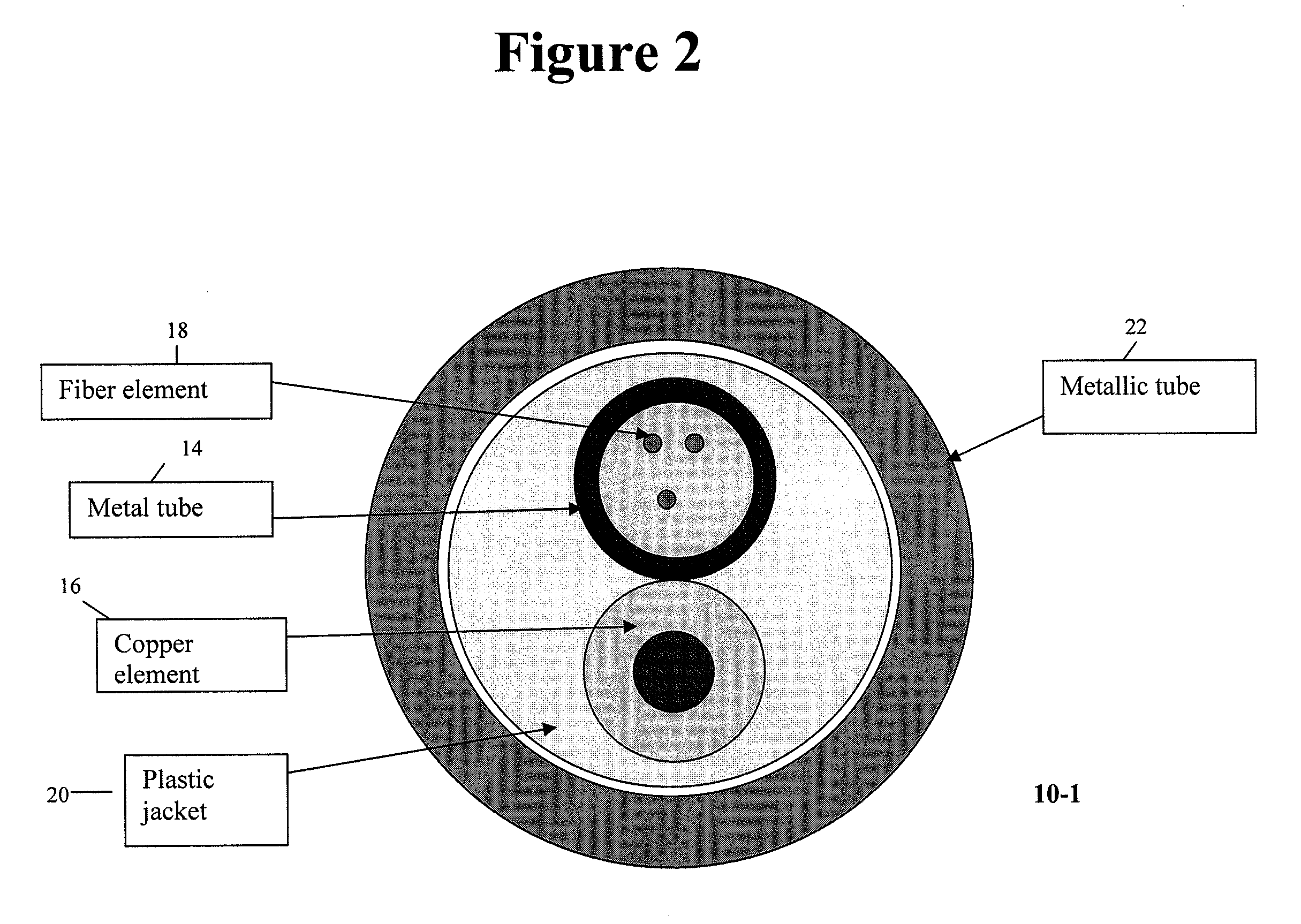

Downhole cables with both fiber and copper elements

ActiveUS20100008631A1Increase strainExcessively strainingLine/current collector detailsConductive materialFiberDouble tube

Provided is a method of manufacturing a downhole cable, the method including, forming a helical shape in an outer circumferential surface of a metal tube, the metal tube having a fiber element housed therein, and stranding a copper element in a helical space formed by the metallic tube. Also provided is a downhole cable including, a metallic tube having a helical space in an outer circumferential surface thereof, wherein the metallic tube has a fiber element housed therein, and a copper element disposed in a helical space formed by the steel tube. Double-tube and multi-tube configurations of the downhole cable are also provided.

Owner:AFL COMM LLC

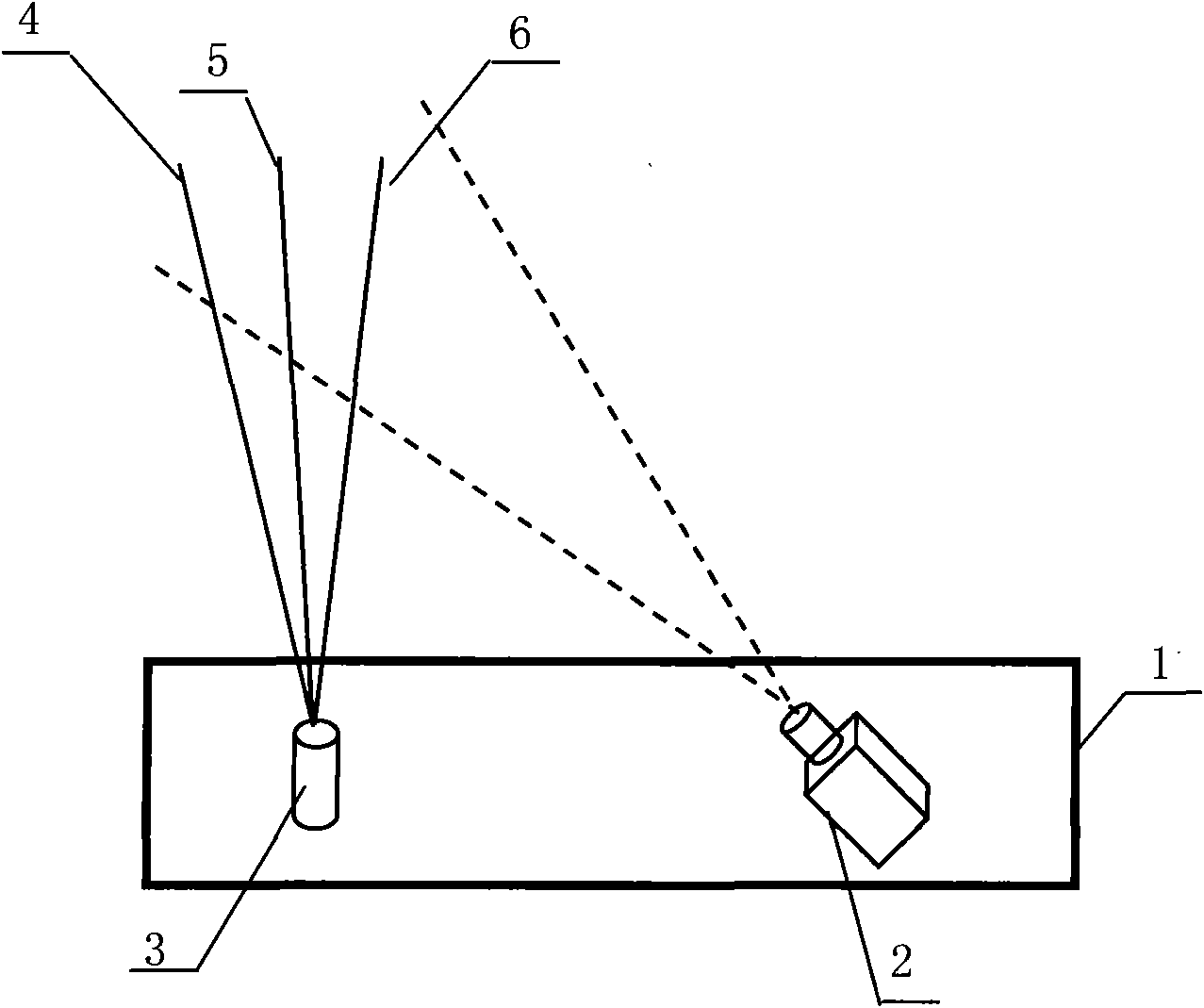

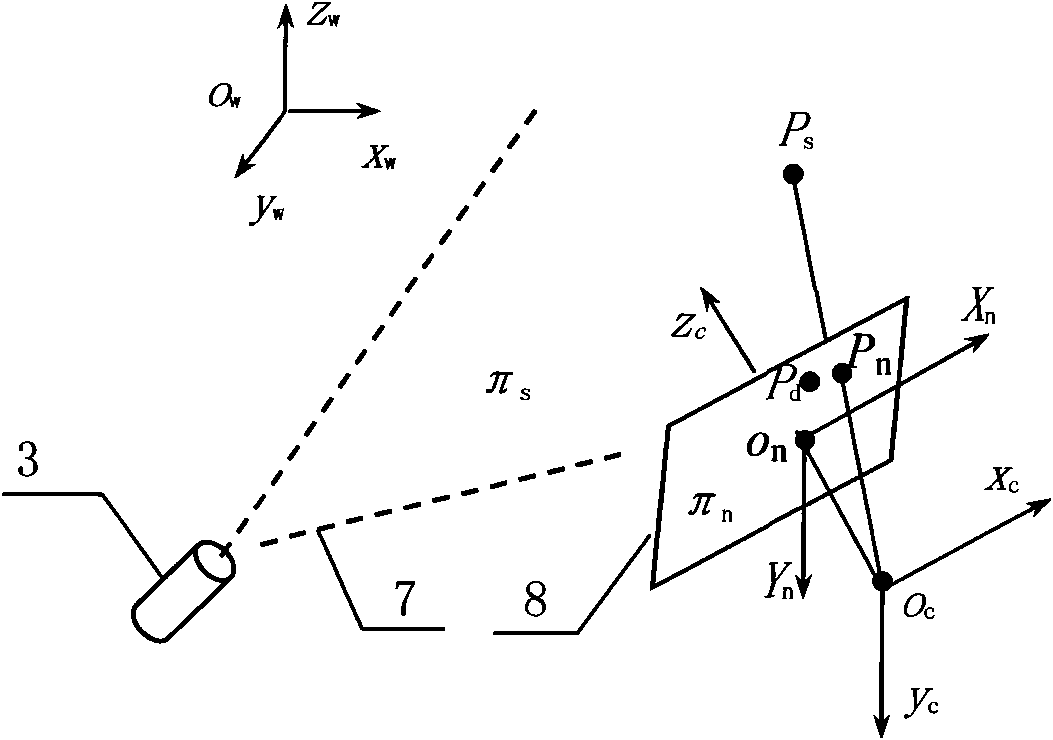

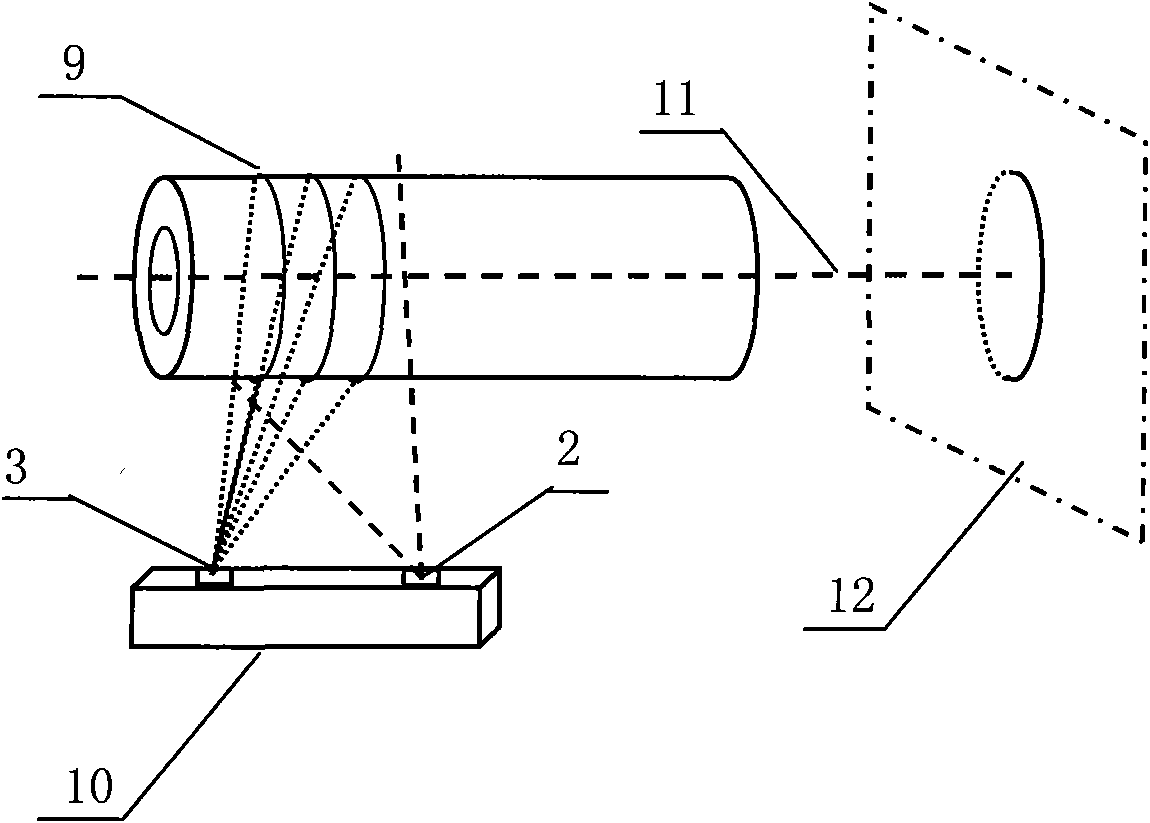

Method for measuring diameter and straightness accuracy parameters of seamless round steel pipe

InactiveCN101571379ARealize onlineRealize non-contact measurementUsing optical meansEllipseEngineering

The invention relates to a method for measuring the diameter and the straightness accuracy parameters of a seamless round steel pipe. The method includes the steps as follows: accomplishing the calibration of parameters of a multi-linear structured light vision sensor formed by one video camera and multi-line laser projectors; distributing the multi-linear structured light vision sensors on the periphery of the seamless round steel pipe to be tested; respectively controlling the laser projectors to project structured light plane onto the measured section of the seamless round steel pipe by a computer, collecting the images of laser stripes on the surface of the seamless round steel pipe and processing the images of the laser strip by a video camera, and calculating the three-dimensional coordinates of different sections according to a measurement model; determining the elliptical center of each section of the space, realizing the measurement of the straightness accuracy of the seamless round steel pipe and establishing the dynamic and virtual central axis of the seamless round steel pipe; establishing the reference plane of the dynamic and virtual projection of ellipse of the section of the space; and front projecting the ellipse of the section of the space onto the reference plane of the dynamic and virtual projection, and carrying out the operation of circle fitting on the reference plane, thereby obtaining the section circle of the steel pipe. The method can realize the on-line, real-time, automatic and noncontact measurement of the diameter and the straightness accuracy parameters of the seamless round steel pipe.

Owner:TIANJIN UNIV

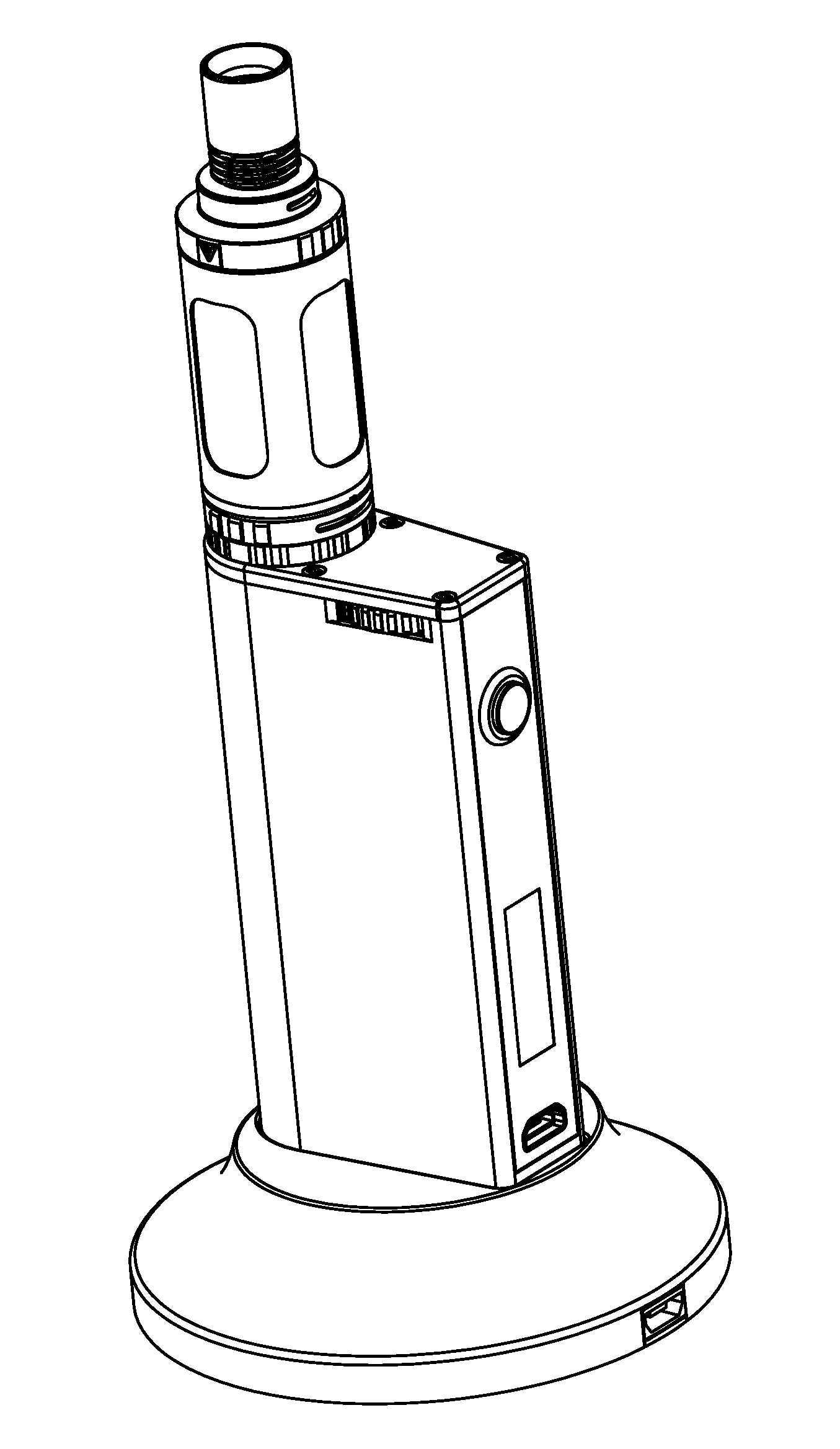

Electronic cigarette

ActiveUS20170042228A1Easy to useEfficient use ofEngine sealsBatteries circuit arrangementsElectricityTemperature control

An electronic cigarette, including: an atomizer assembly, a battery assembly, and a charger assembly. The atomizer assembly includes: a temperature sensing wire, a first steel tube configured to receive the temperature sensing wire, and a temperature sensing base. The battery assembly includes an adjustment wheel. The charger assembly includes two elastic contact pins. The atomizer assembly is in threaded connection with the battery assembly. The battery assembly is disposed on the charger assembly. The charger assembly is electrically connected to the battery assembly via the two elastic contact pins so as to charge the battery assembly. The temperature sensing wire transmits temperature parameters to the battery assembly, and a power output is adjusted by the adjustment wheel thereby realizing temperature control.

Owner:LIU TUANFANG

High intensity metallic core type seamless flux-cored wire

InactiveCN101323057AImprove impact toughnessReduce the ductile-brittle transition temperatureWelding/cutting media/materialsSoldering mediaManufacturing technologyHigh intensity

The invention discloses a high strength metal core type seamless flux-cored welding wire relating to the technical field of welding materials; the invention can be manufactured by adopting the existing steel tube drawing or in-service welding seamless flux-cored welding wire manufacturing technology; the diameter of a steel tube is reduced to the extent that the filling diameter of a specified filling rate can be acquired; by using the vibration filling pattern, filler is filled from one end of the steel tube; wire drawing processing is performed by using a roller group or a wire drawing die group, and during the period intermediate annealing is carried out (under 650 DEG C for two hours). The high strength metal core type seamless flux-cored welding wire of the invention has the advantage that yield strength is larger than 785MPa, and the requirements of high strength structure steel welding can be satisfied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

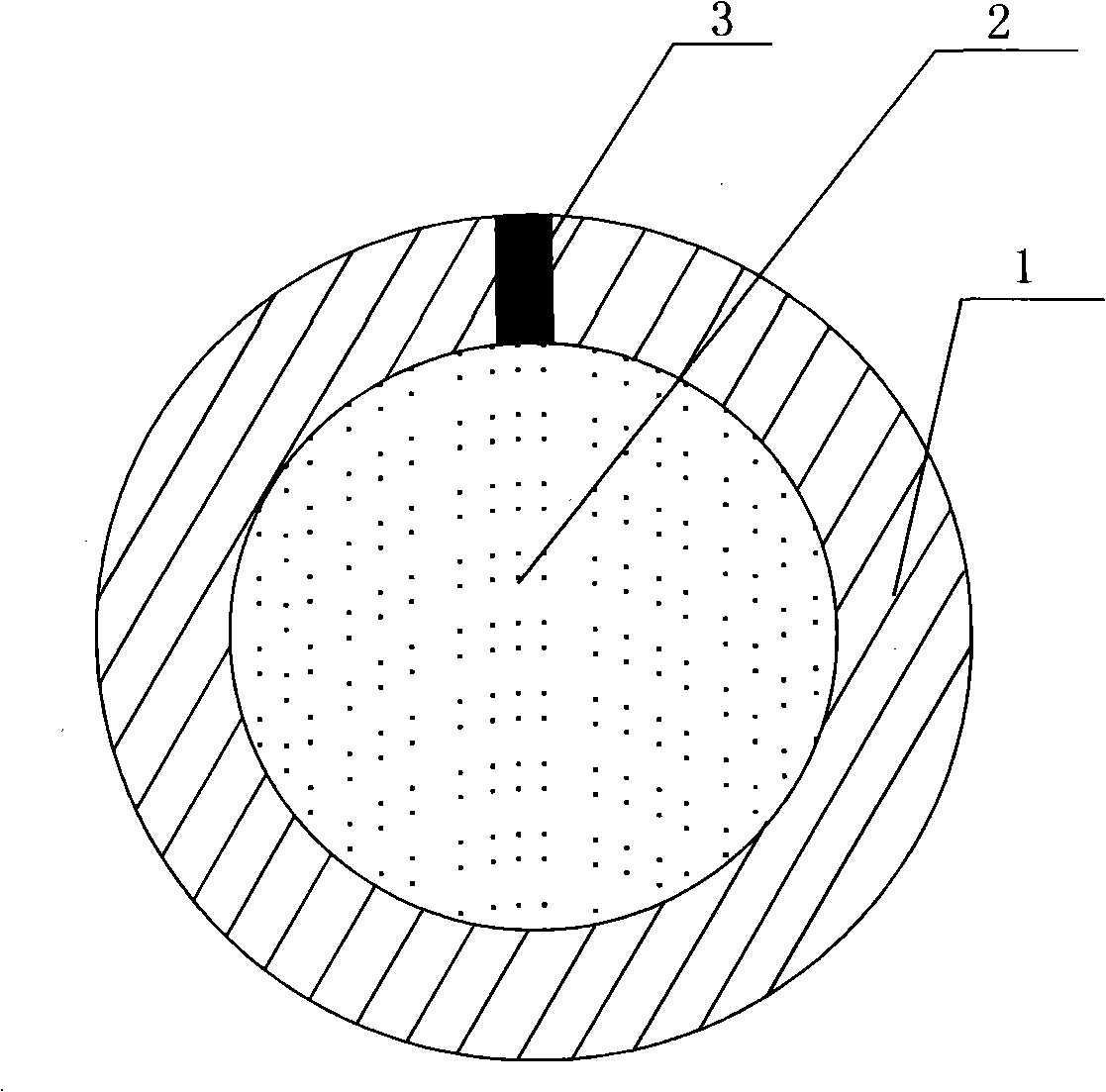

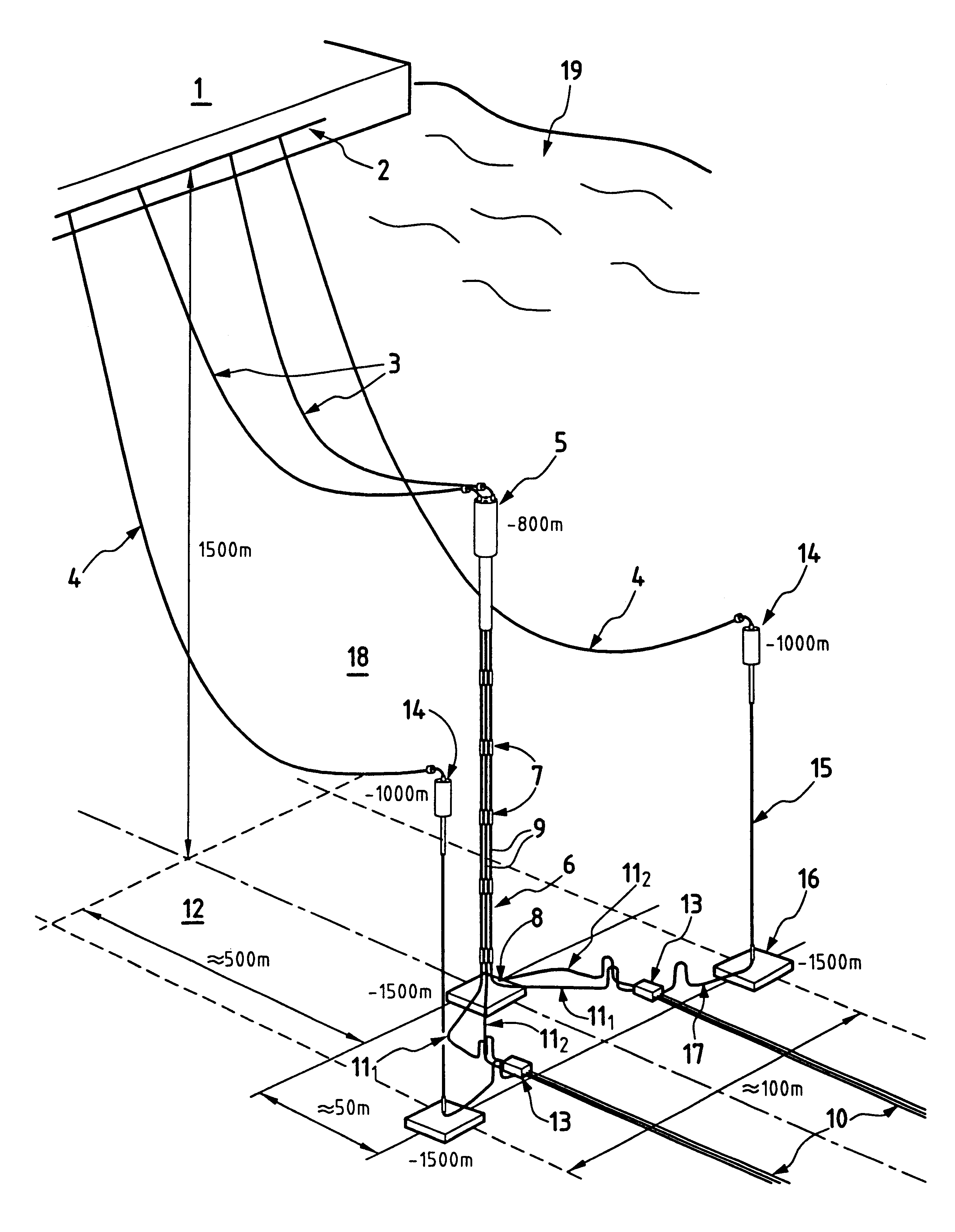

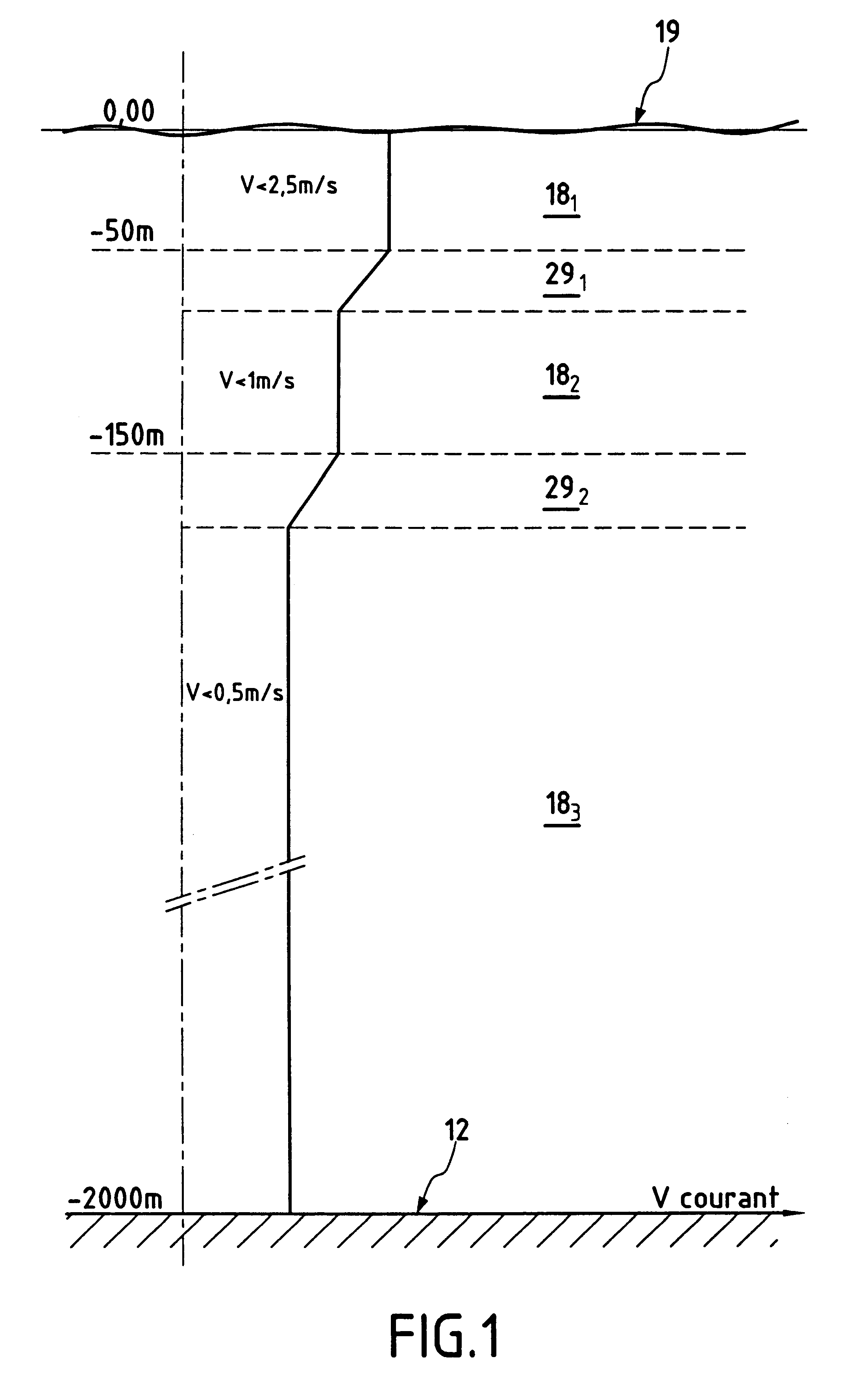

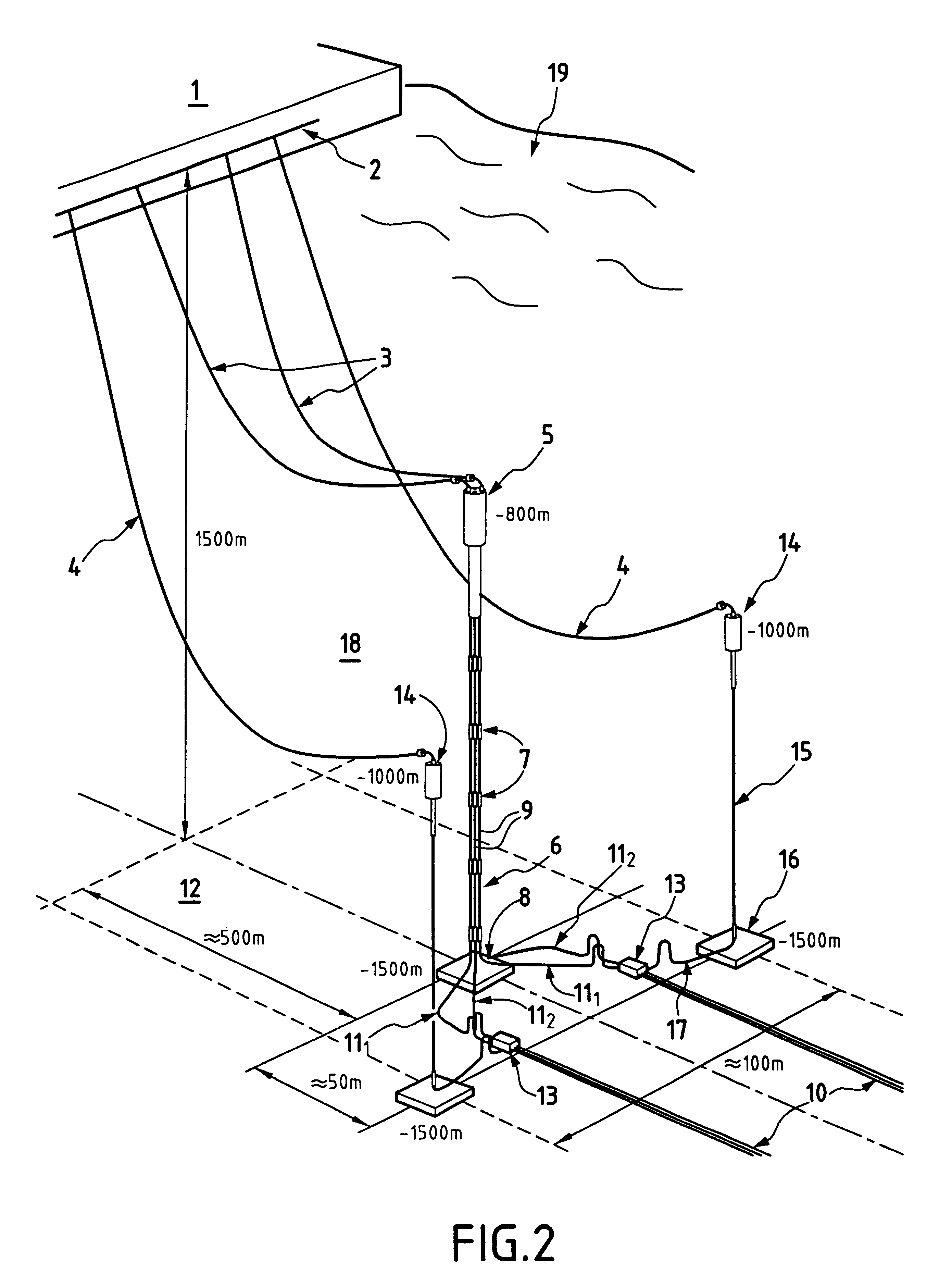

Method and device for linking surface to the seabed for a submarine pipeline installed at great depth

The present invention relates to a bottom-to-surface link system for an underwater pipe installed at great depth, the system comprising:firstly a vertical tower constituted by at least one float (5, 14) associated with an anchor system (6, 8, 16) and carrying at least one vertical riser (9, 15) suitable for going down to the sea bed (18); andsecondly at least one link pipe (4, 3) extending from said float (5, 14) to a surface support (1). According to the invention, said link pipe is a riser whose wall is constituted by a rigid steel tube, and said float (5, 14) is installed at a depth situated below the last thermocline (29).

Owner:BOUYGUESS OFFSHORE +1

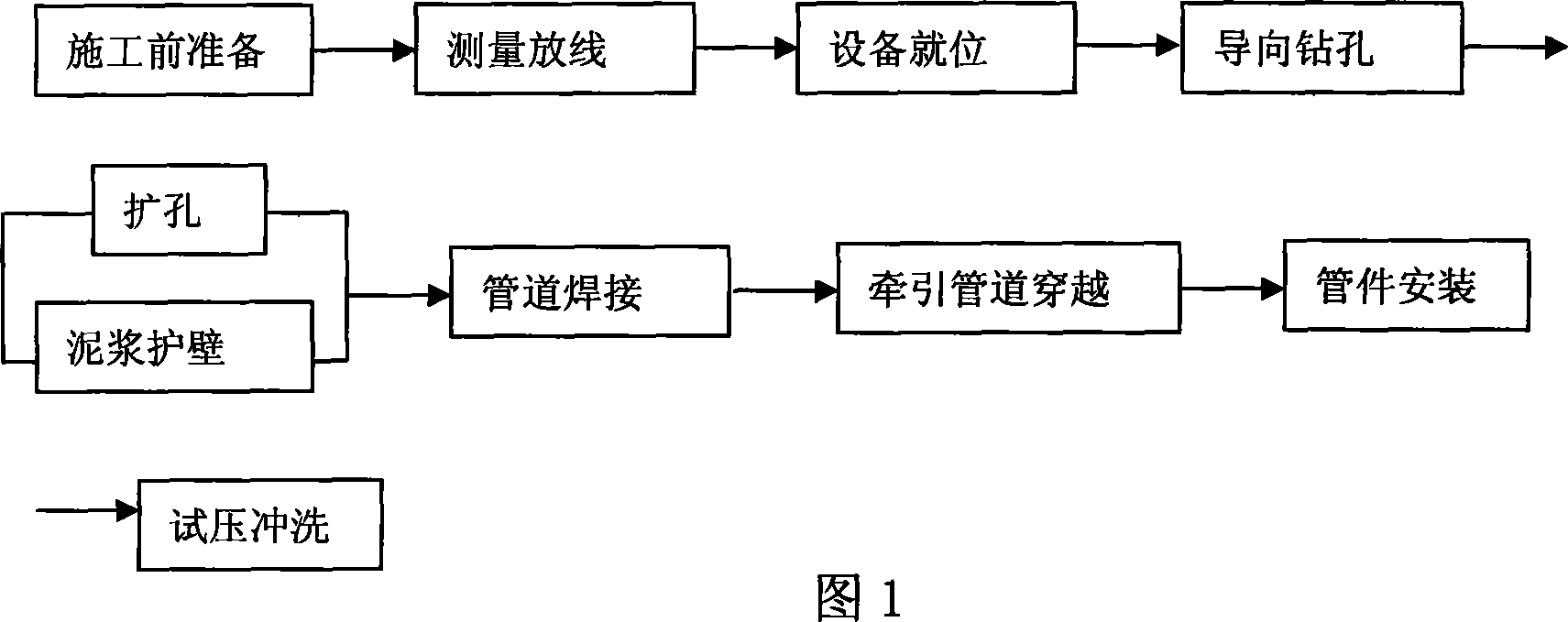

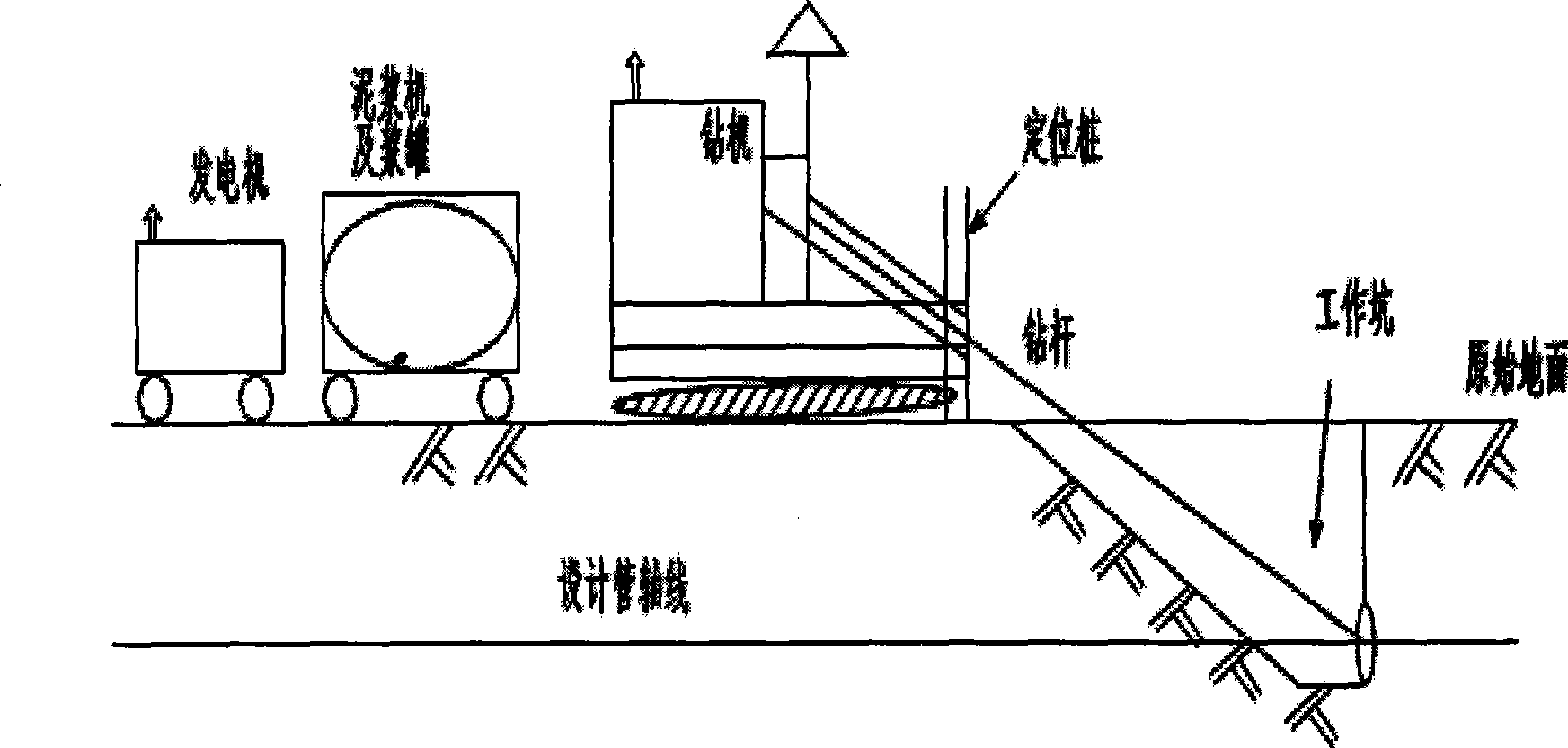

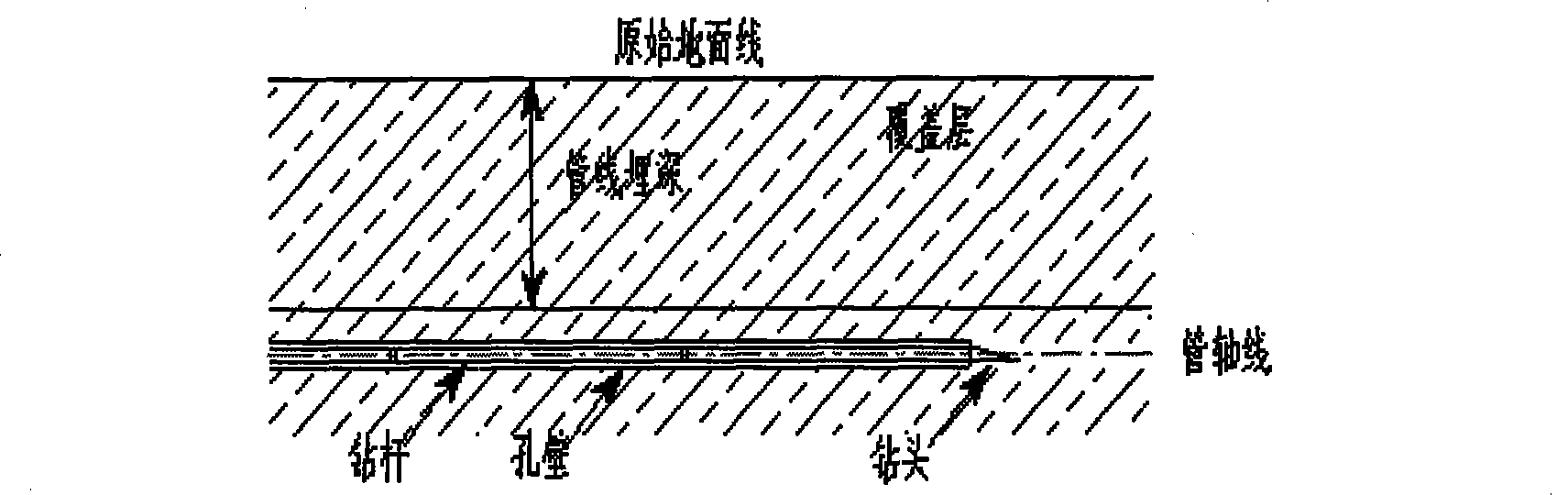

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

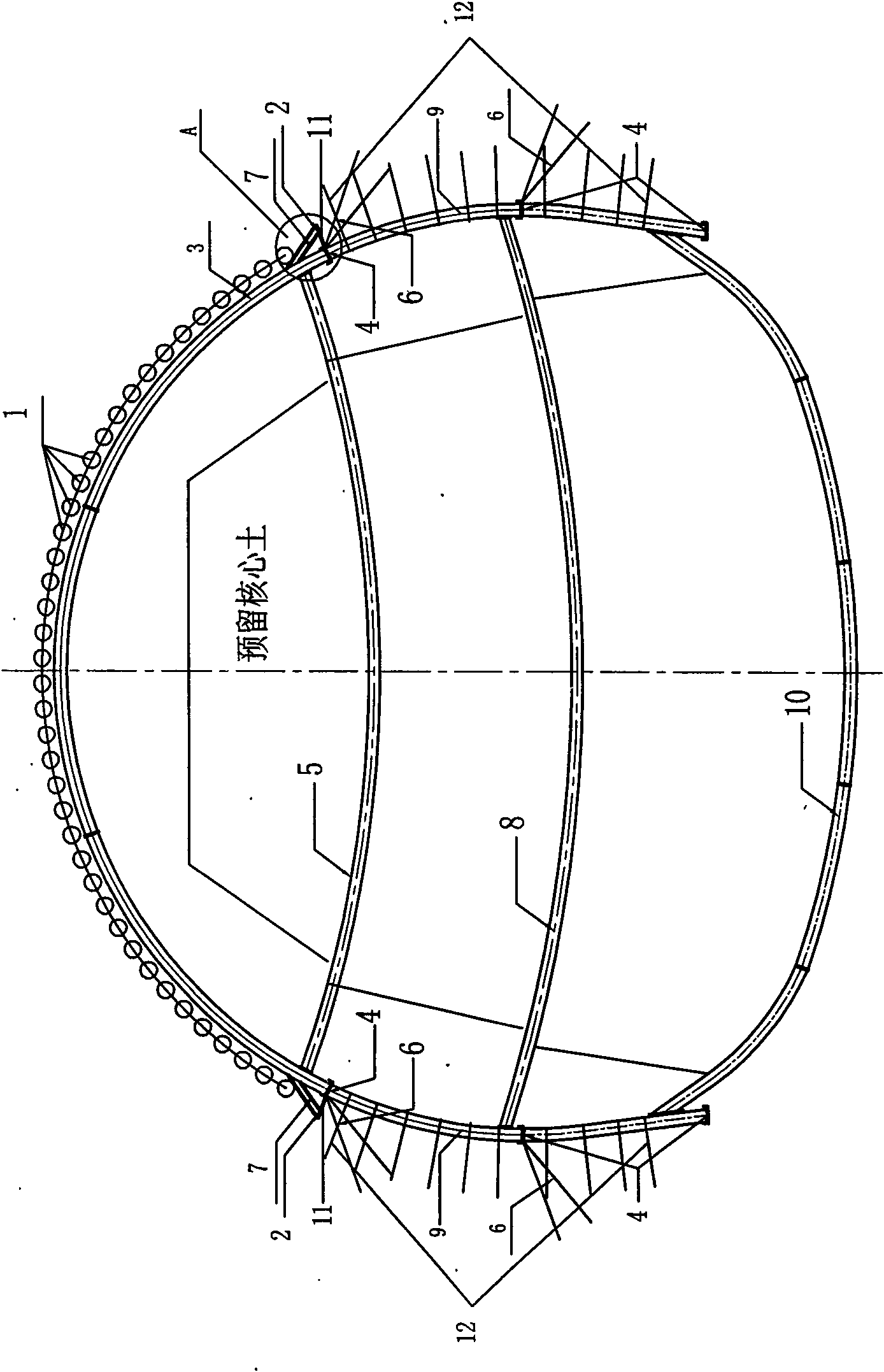

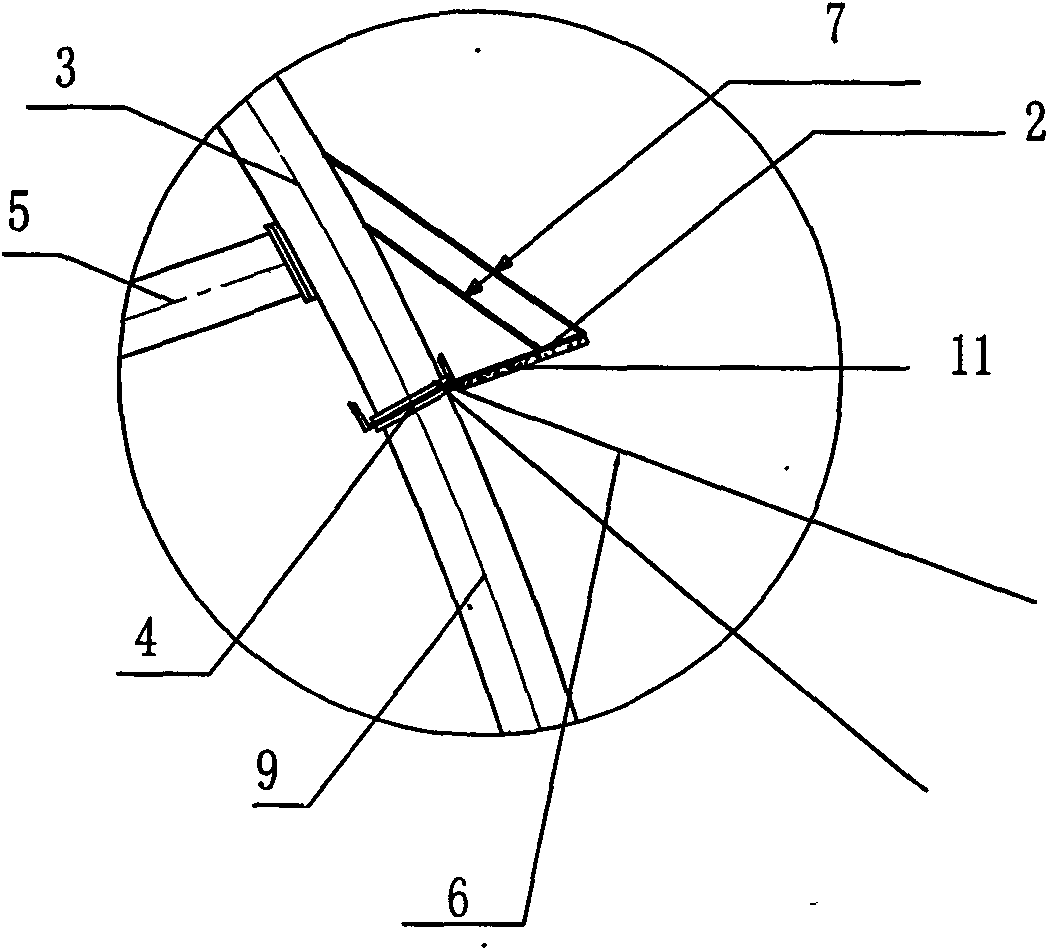

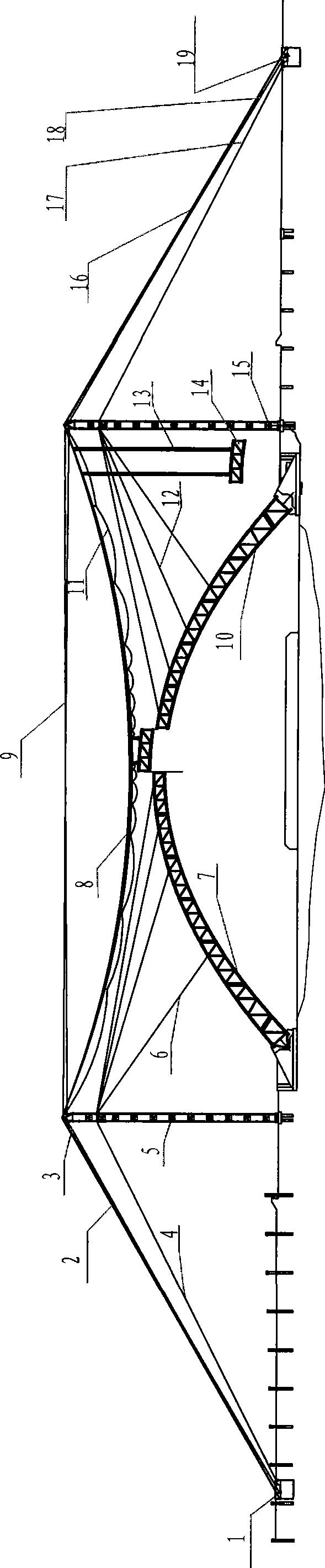

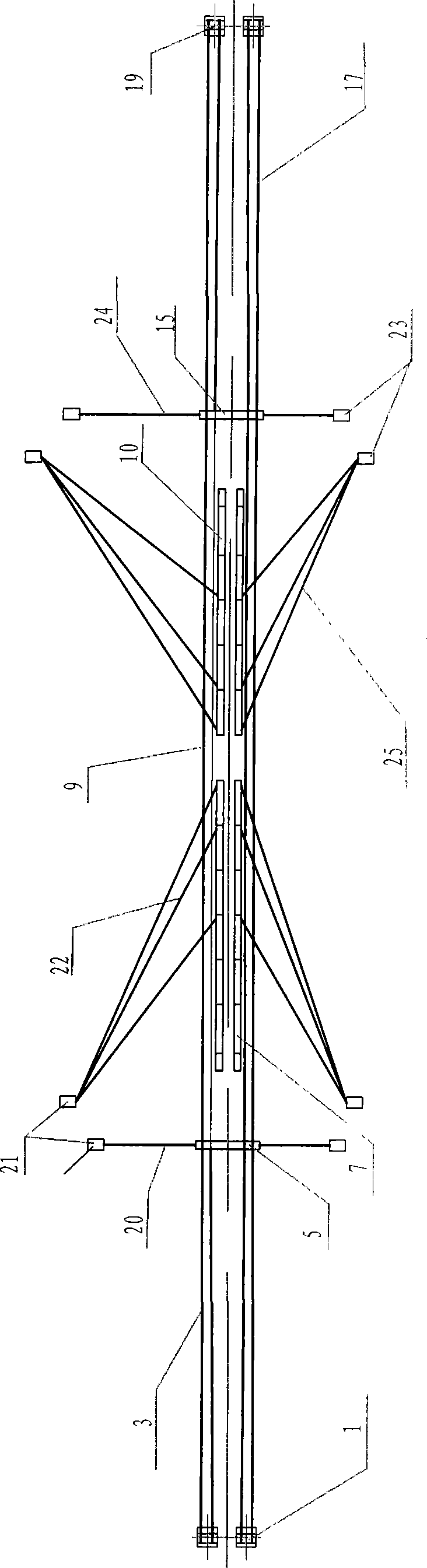

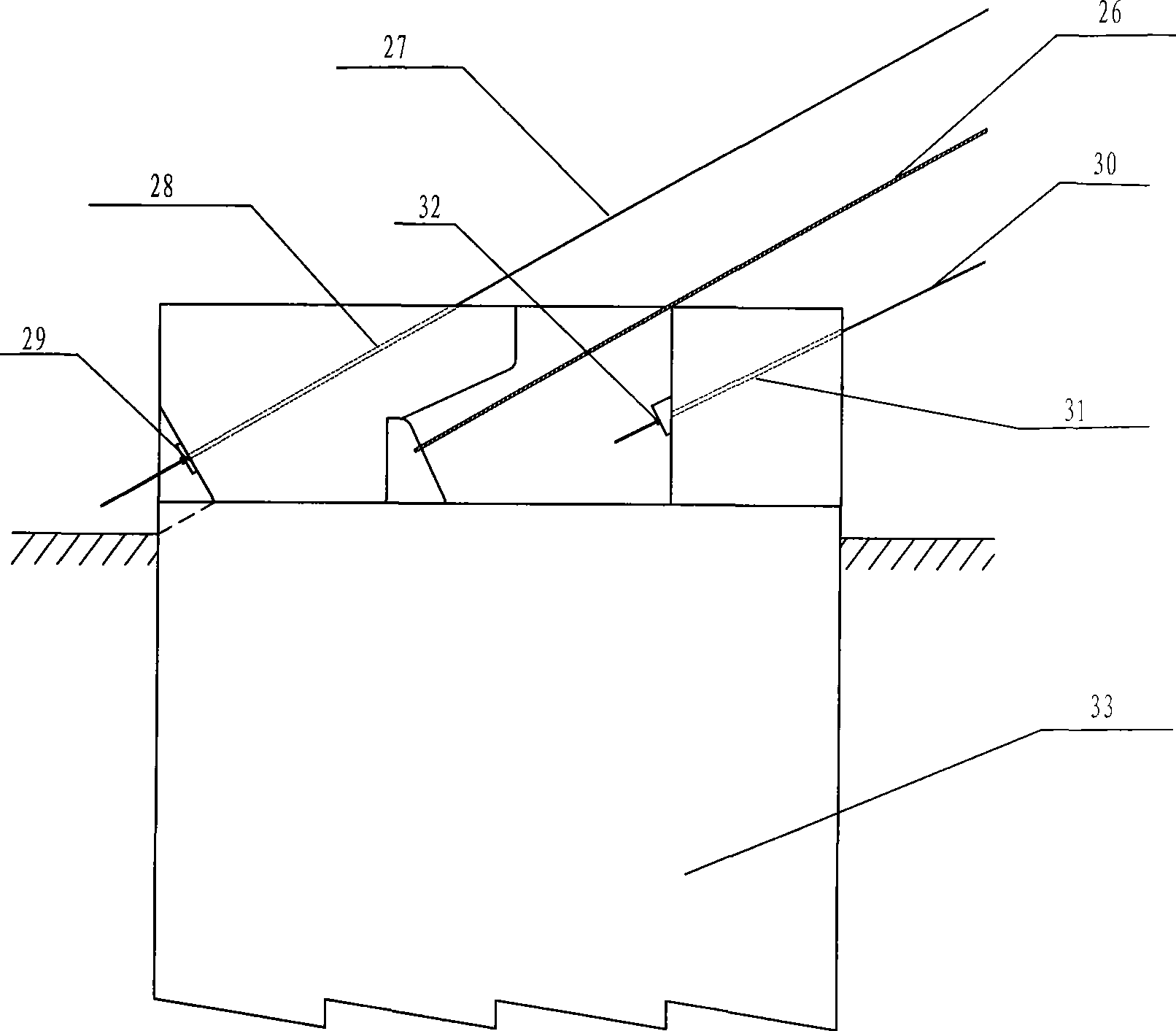

Non-stand construction method for large bridge arch rib

InactiveCN101476293AReduce constructionSave spaceCable-stayed bridgeBridge erection/assemblyPipe supportSteel tube

The invention relates to a large-scale bridge (steel pipe concrete arch bridge) arch rib non-support construction method, which is characterized in that: the fastening tower process and hanging tower process are combined; the fastening anchor process and hanging anchor process are combined; rubber support is applied in the tower articulation (steel structure); steel twisted wire is used as the fastening-hanging tower -anti-wind rope (tower pressing cable); centralized working surfaces and steel twisted wires are adopted in the fastening-hanging process; steel pipe support are used in tower; and less fastening cables are used in the fastening-hanging process. The construction method reduces arch rib assembling places and mounting supports, accelerates the construction progress; the stayed-fastening cable construction uses the masts type tower hung by the cable to mount arch rib, reduces construction of a group of tower and anchor; by adopting less cable construction method, the invention reduces the anchor box segment positions on the tower and reduces anchor cable quantity; and by adopting one-time forming, monitoring and measuring method, the invention simplifies the arch rib mounting construction process and the cable adjusting construction engineering, increases production efficiency, accelerates construction progress and ensures arch rib mounting quality.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

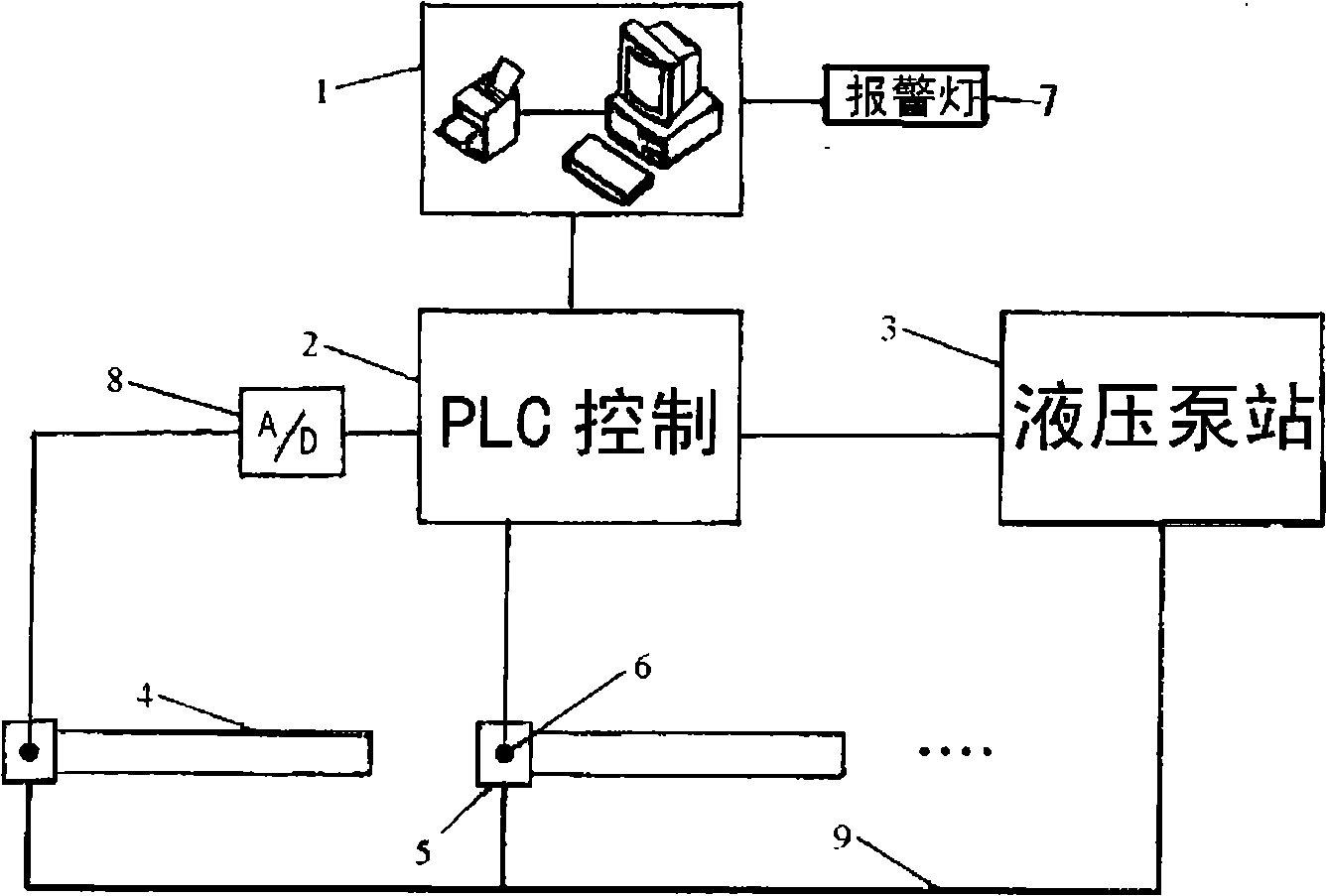

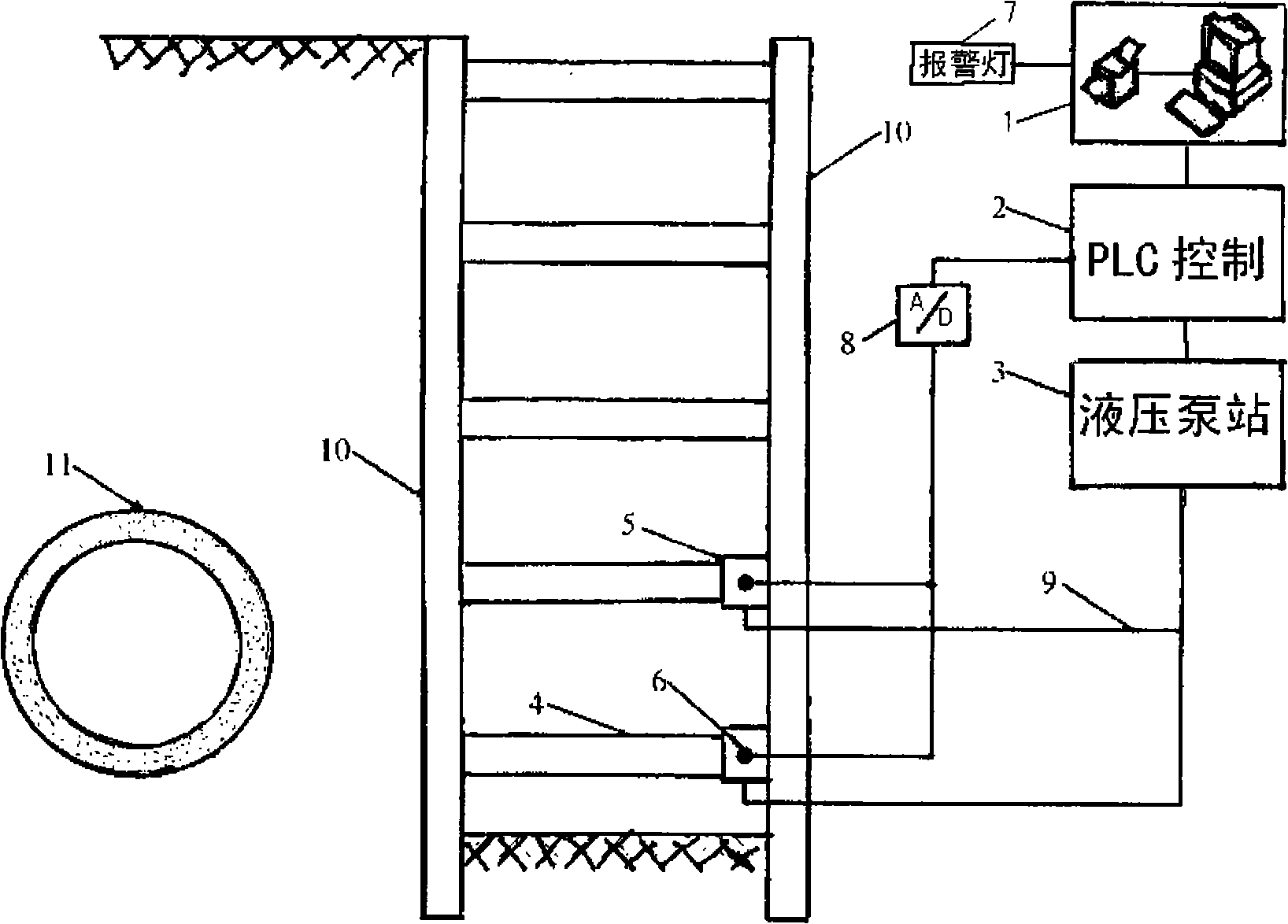

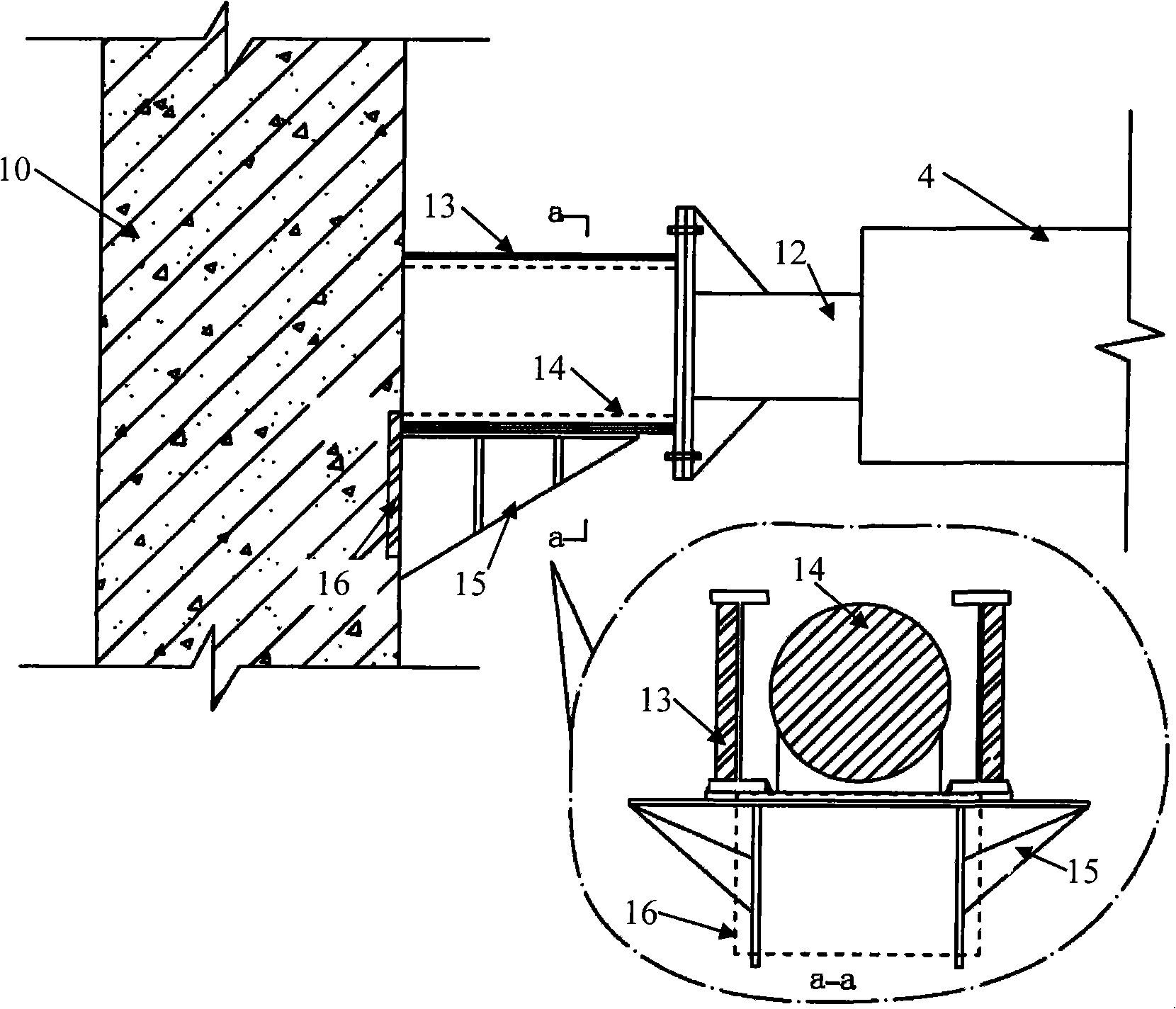

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20060169368A1Increase burst pressureImprove toughnessFurnace typesHeat treatment furnacesWater basedNiobium

A low carbon alloy steel tube and a method of manufacturing the same, especially for a stored gas inflator pressure vessel, in which the steel tube consists essentially of, by weight: about 0.06% to about 0.18% carbon, about 0.3% to about 1.5% manganese, about 0.05% to about 0.5% silicon, up to about 0.015% sulfur, up to about 0.025% phosphorous, and at least one of the following elements: up to about 0.30% vanadium, upto t about 0.10% aluminum, up to about 0.06% niobium, up to about 1% chromium, up to about 0.70% nickel, up to about 0.70% molybdenum, up to about 0.35% copper, up to about 0.15% residual elements, and the balance iron and incidental impurities. After a high heating rate of about 100° C. per second; rapidly and fully quenching the steel tubing in a water-based quenching solution at a cooling rate of about 100° C. per second. The steel has a tensile strength of at least about 145 ksi and as high as 220 ksi and exhibits ductile behavior at temperatures as low as -100° C.

Owner:TENARIS CONNECTIONS LIECHTENSTEIN CORP

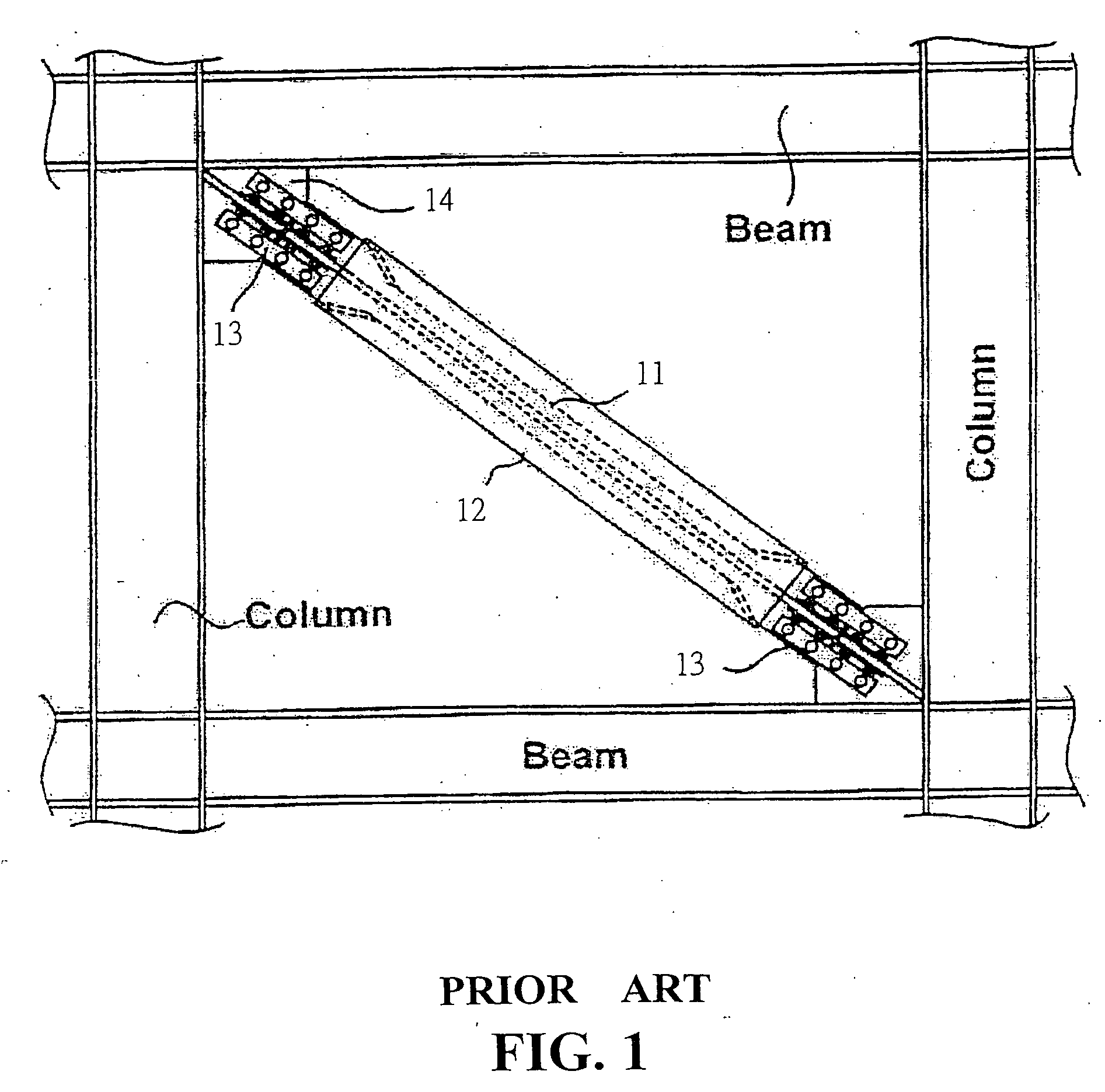

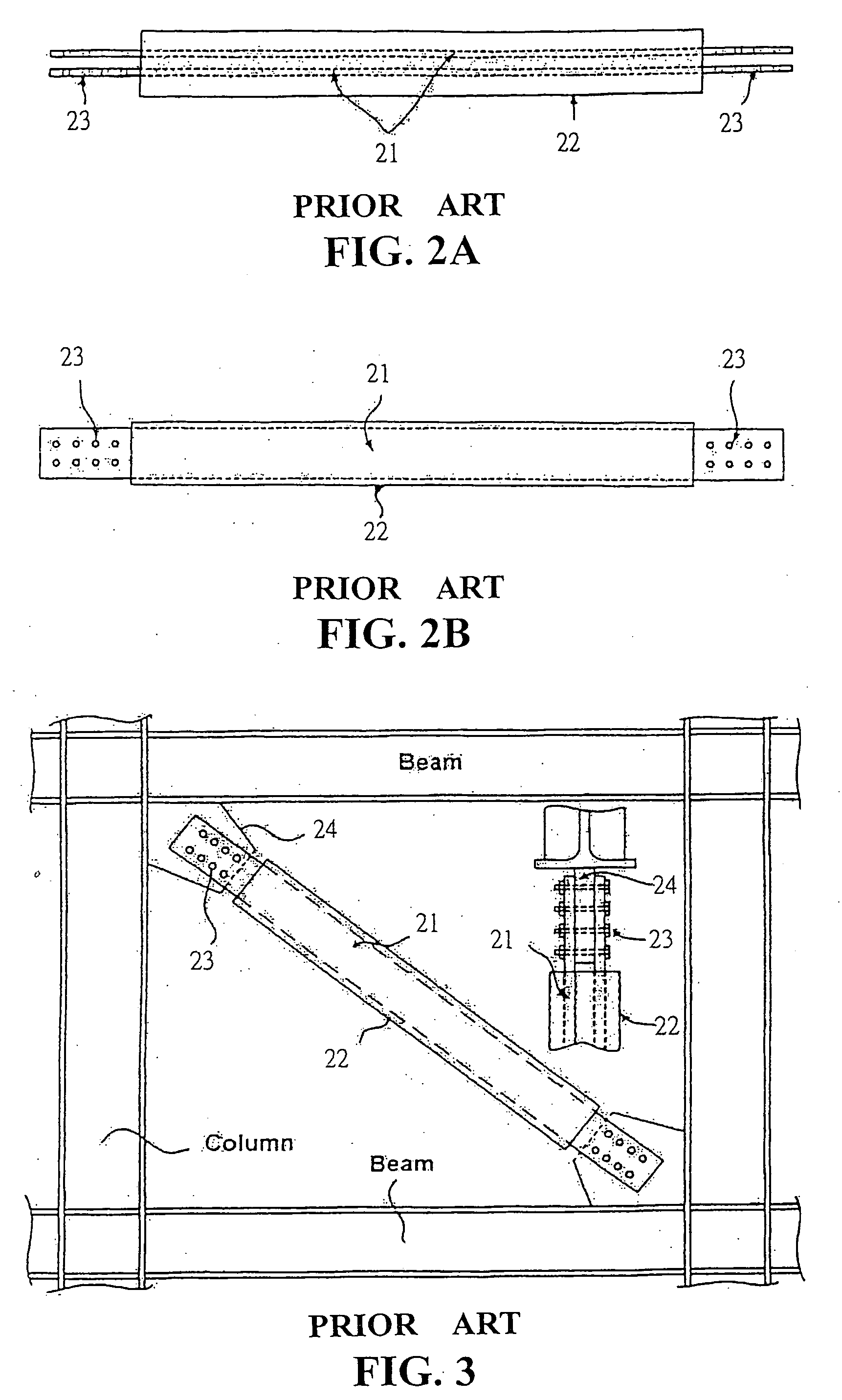

Buckling-restrained diagonal brace using lapping and improved plugging connection

InactiveUS20060101733A1Efficient and economical and convenientProtective buildings/sheltersShock proofingSteel tubeDuctility

A buckling-restrained diagonal brace is provided. The buckling-restrained diagonal brace mainly contains a core element and a restraining element. The core element is an assembly of a specific number of steel members having a specific shape whose cross-sectional dimension is determined based on the load requirement. The core element has a larger cross-section at the ends than at its medial section. The core element is encased in the restraining element. The restraining element manly contains a single or multiple steel tubes filled with concrete, mortar, or reinforcing members. The restraining element is to protect the core element so that it wouldn't be buckled and destructed under load. By using a lapping or an improved plugging type of connection to a structure frame, the buckling-restrained diagonal brace is able to yield steadily when loaded in both tension and compression and the buckling-restrained diagonal brace would have a full hysteretic curve. The buckling-restrained diagonal brace has a significantly enhanced ductility and energy dissipation capability, and is able to reduce vibration and to lower seismic impact.

Owner:JEN CHIAO YU +1

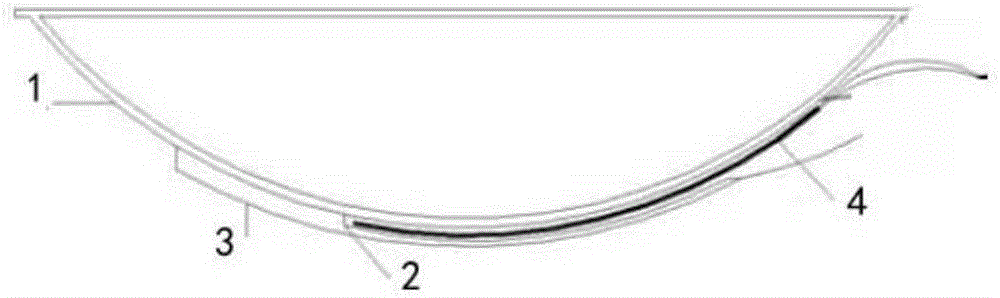

Pot with hidden temperature measurement structure

InactiveCN106419486AExpand the temperature measurement rangeHigh temperature range and high efficiencyCooking vessel constructionsEngineeringThermocouple

The invention relates to a pot with a hidden temperature measurement structure. The pot with the hidden temperature measurement structure comprises a pot body. The pot body is characterized in that an attached bottom is arranged on the bottom surface of the pot body, a thermocouple is provided with the connecting part of the pot body and the attached bottom, a detecting end of the thermocouple is hidden near the center position of the bottom surface of the pot body and in contact with the bottom surface of the pot body, so as to form a temperature measurement structure to directly detect the center position and the periphery of the pot body; the attached bottom is tightly united with the pot body, the detecting end of the thermocouple is inserted into a capillary steel tube and extends straightly into the bottom of the pot, a signal outputting end of the thermocouple is a real-time temperature outputting end of the pot body; a hidden temperature measurement structure is formed on the bottom surface of the pot body. According to the pot with a hidden temperature measurement structure, a temperature measurement structure capable of directly detecting the center position and the periphery of the pot body is formed, and the pot has the advantages of evenly distributed temperature measurement points, good concealing, and being solid and durable, safe in use, precise in temperature measurement, large in temperature measurement range, high in temperature measurement efficiency and simple in workmanship.

Owner:深圳酷平方科技有限公司

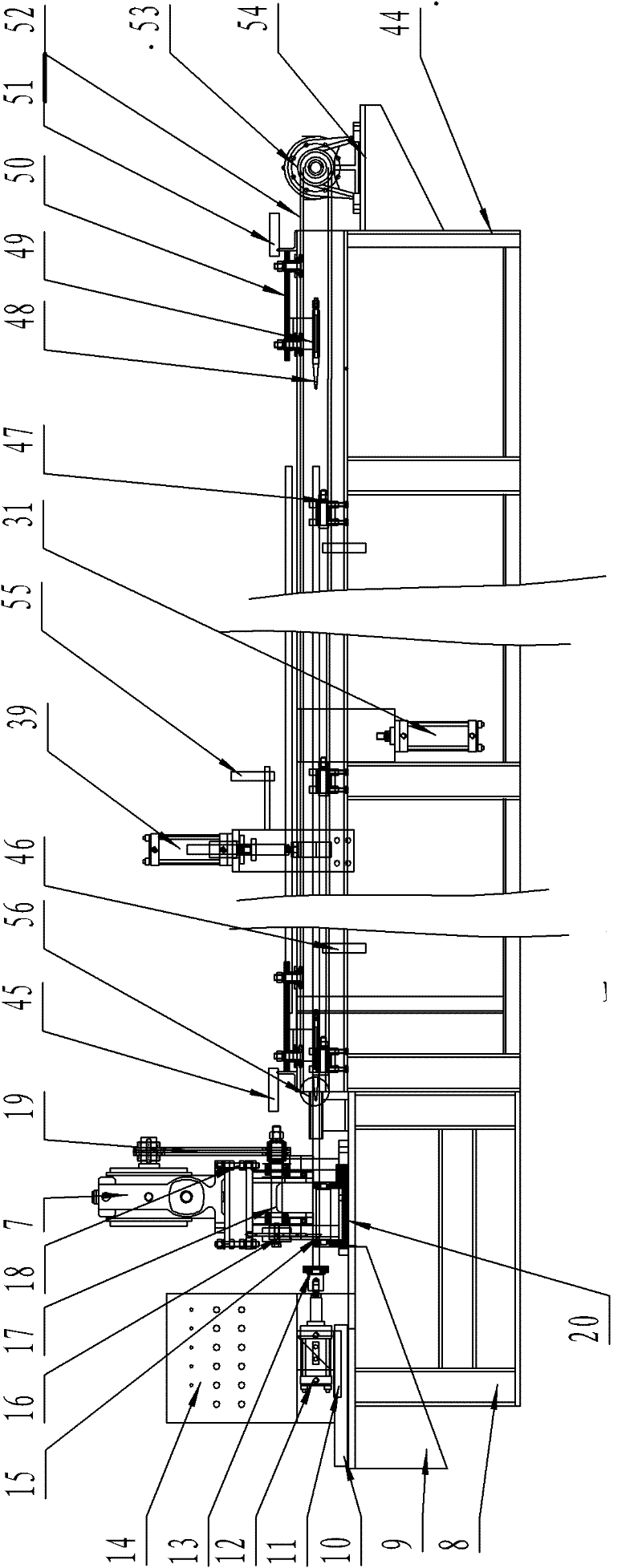

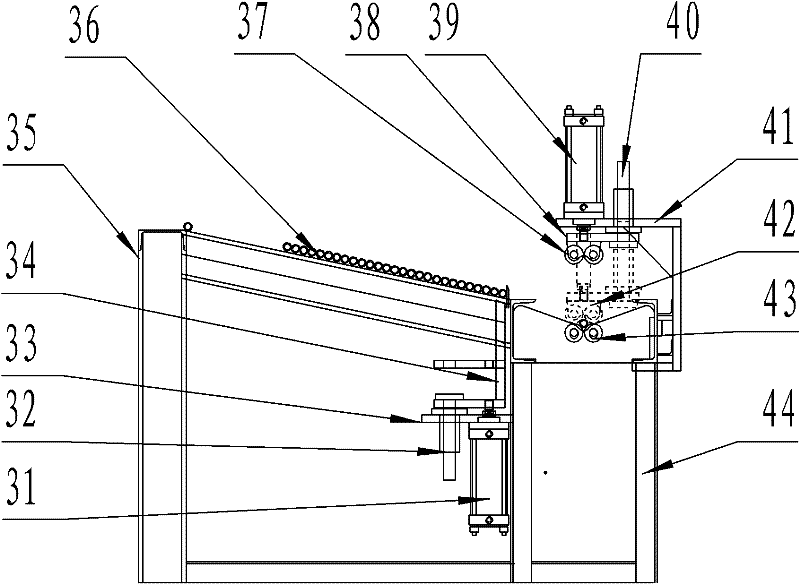

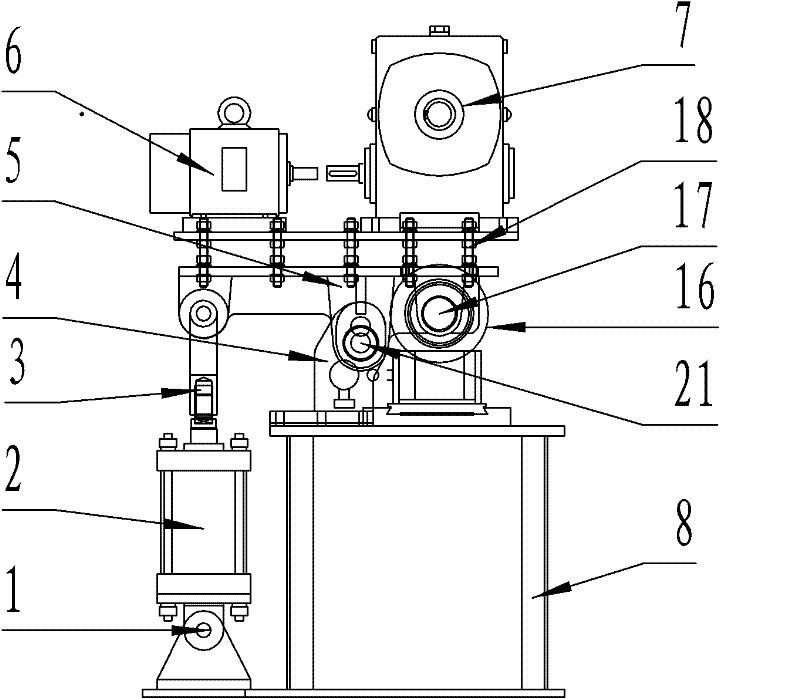

Automatic blanking machine for steel pipes

ActiveCN102126045AExact lengthFully automatedTube shearing machinesShearing machine accessoriesElectrical controlSlide plate

The invention discloses an automatic blanking machine for steel pipes, belongs to the field of cutting-off equipment of the steel pipes and particularly relates a steel pipe cutting-off device with a mechanical automatic material supply device and a cutting-off device. The automatic blanking machine for the steel pipes is characterized by mainly comprising a fixed scale cutting-off system, a steel pipe conveying system and an electrical control system, wherein the steel pipe conveying system and the electrical control system are connected with the fixed scale cutting-off system, wherein the fixed scale cutting-off system comprises a steel pipe fixed scale device mounted on a transverse sliding track at the left end of a lathe bed and the cutting-off device mounted on the lathe bed, a front positioning sliding plate is mounted on a front positioning sliding plate seat fixed on the transverse sliding track of the steel pipe fixed scale device, a steel pipe fixed scale cylinder is arranged on the sliding plate, a steel pipe fixed scale detection switch is arranged at the front end of the cylinder, and the steel pipe conveying pipe comprises a steel pipe storage device and a steel pipe feed device. The automatic blanking machine for the steel pipes has the beneficial effects of realizing automation of supply, compression and fixed scale cutting-off of the steel pipes, not only improving the working efficiency and reducing the labor intensity, but also ensuring the precise length of the steel pipes which are cut off, and being suitable for being used in occasions which need to cut the steel pipes into steel pipe sections with equal length.

Owner:济南玛钢钢管制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com