Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6438 results about "Axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An axial force is any force that directly acts on the center axis of an object. These forces are typically stretching force or compression force, depending on direction. In addition, when the force load is even across the form’s geometric center, it is concentric, and when it is uneven, it is eccentric.

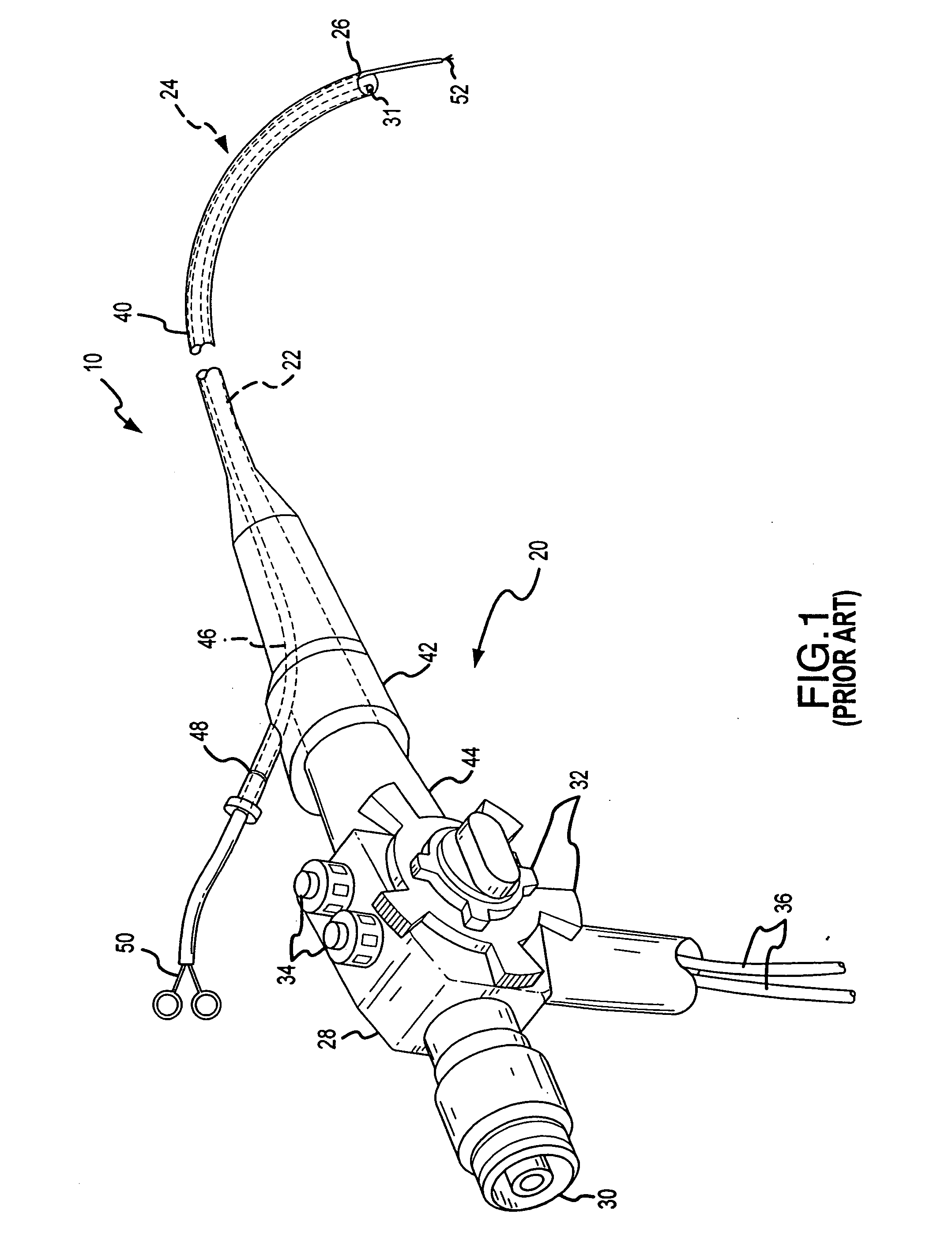

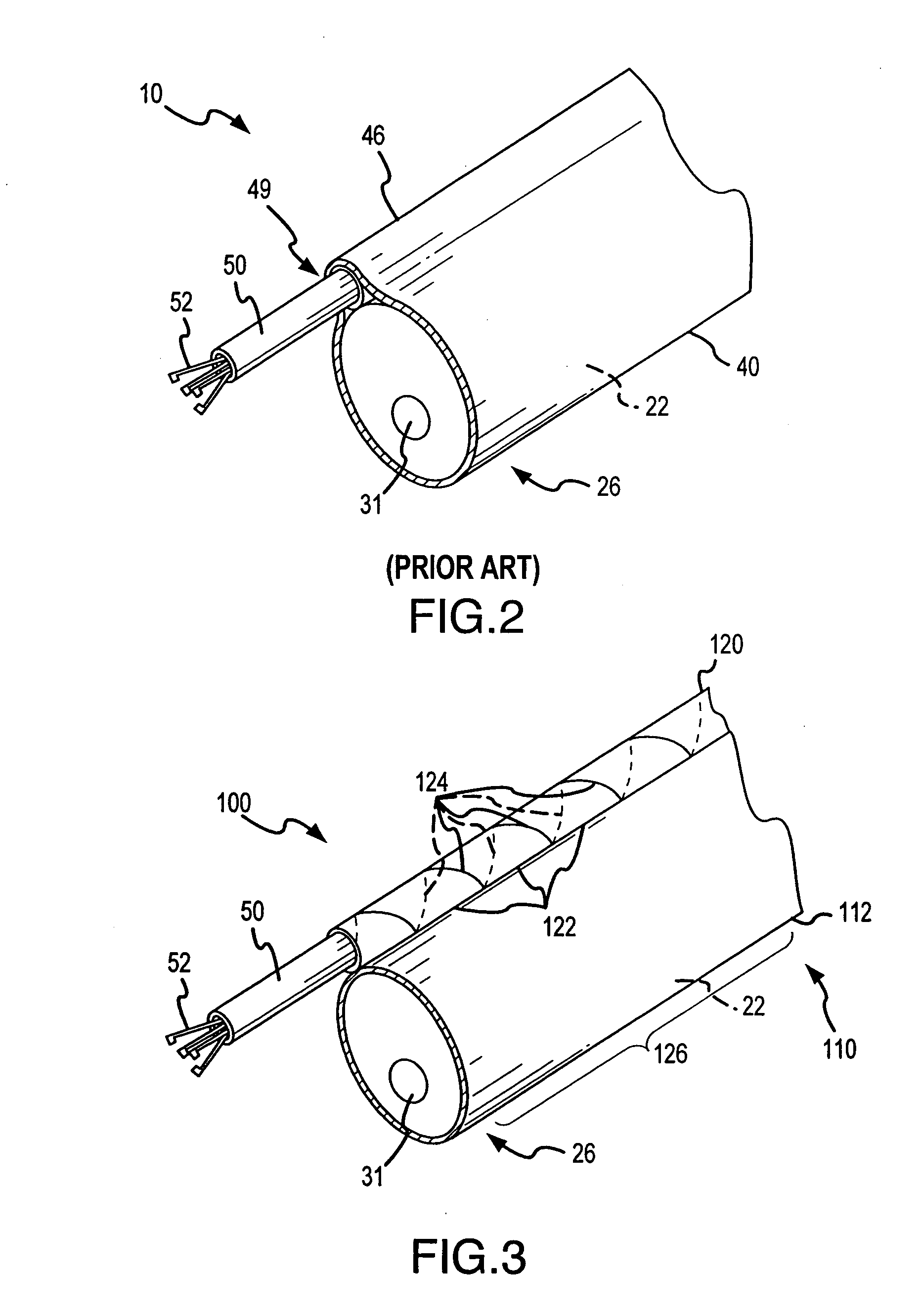

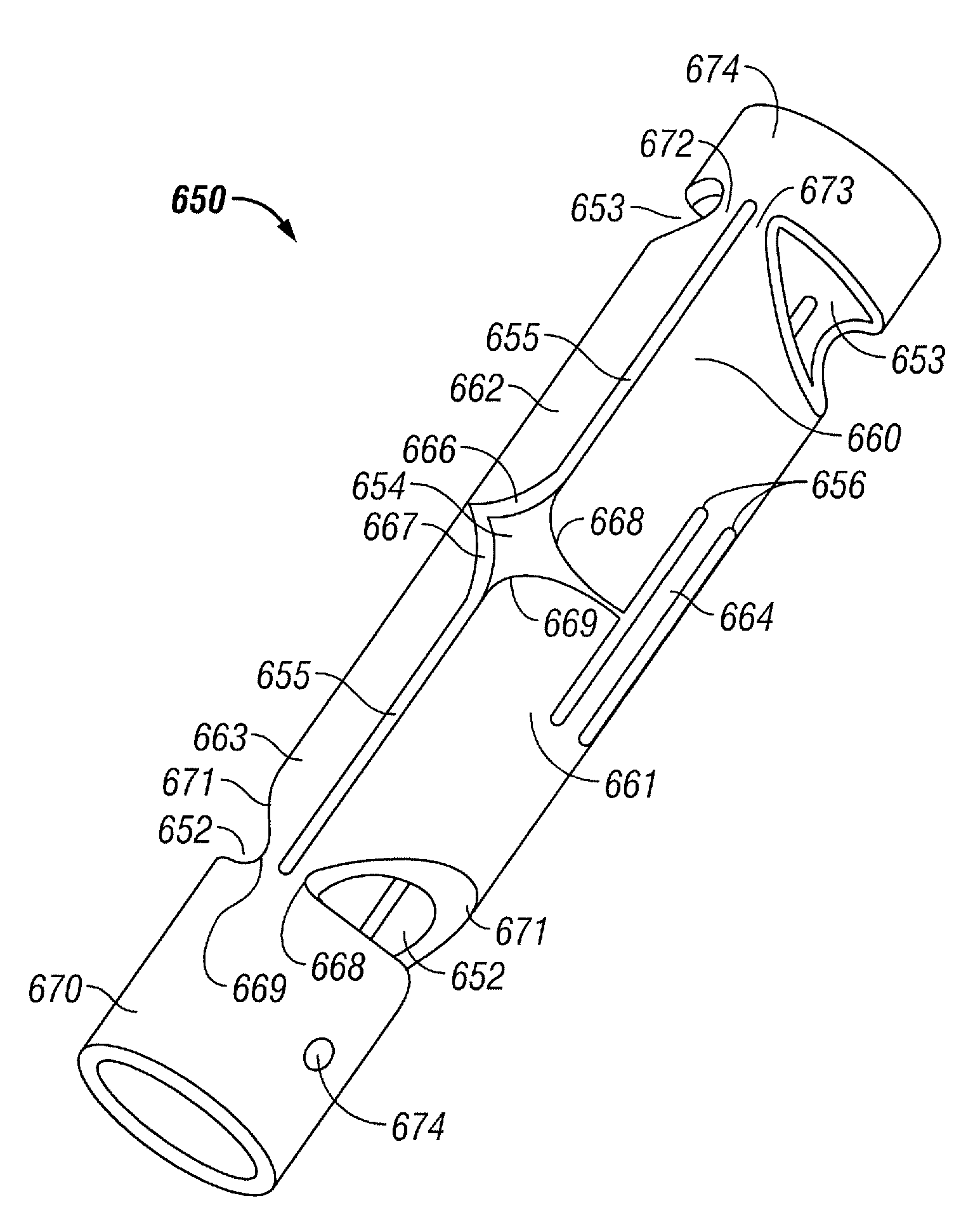

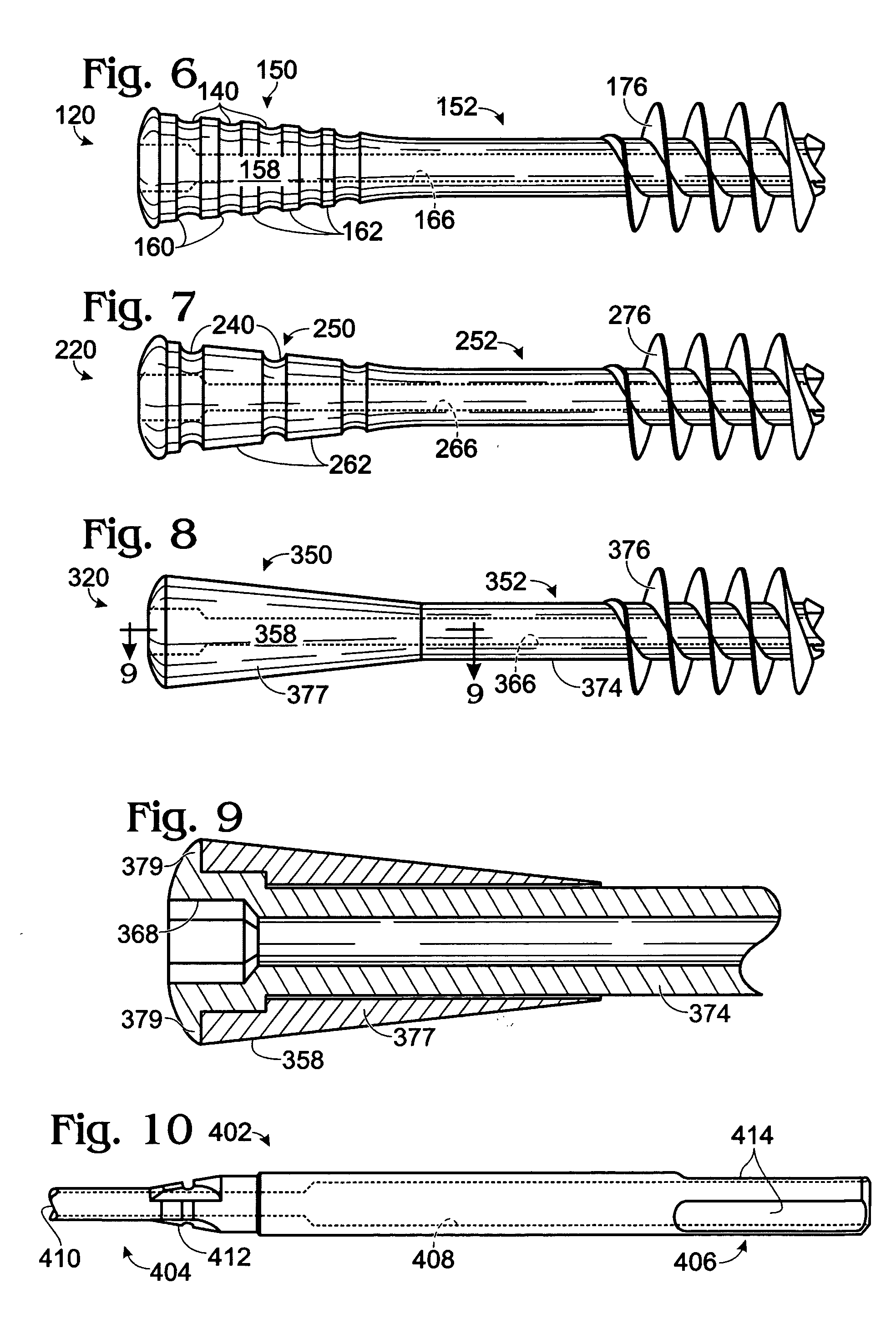

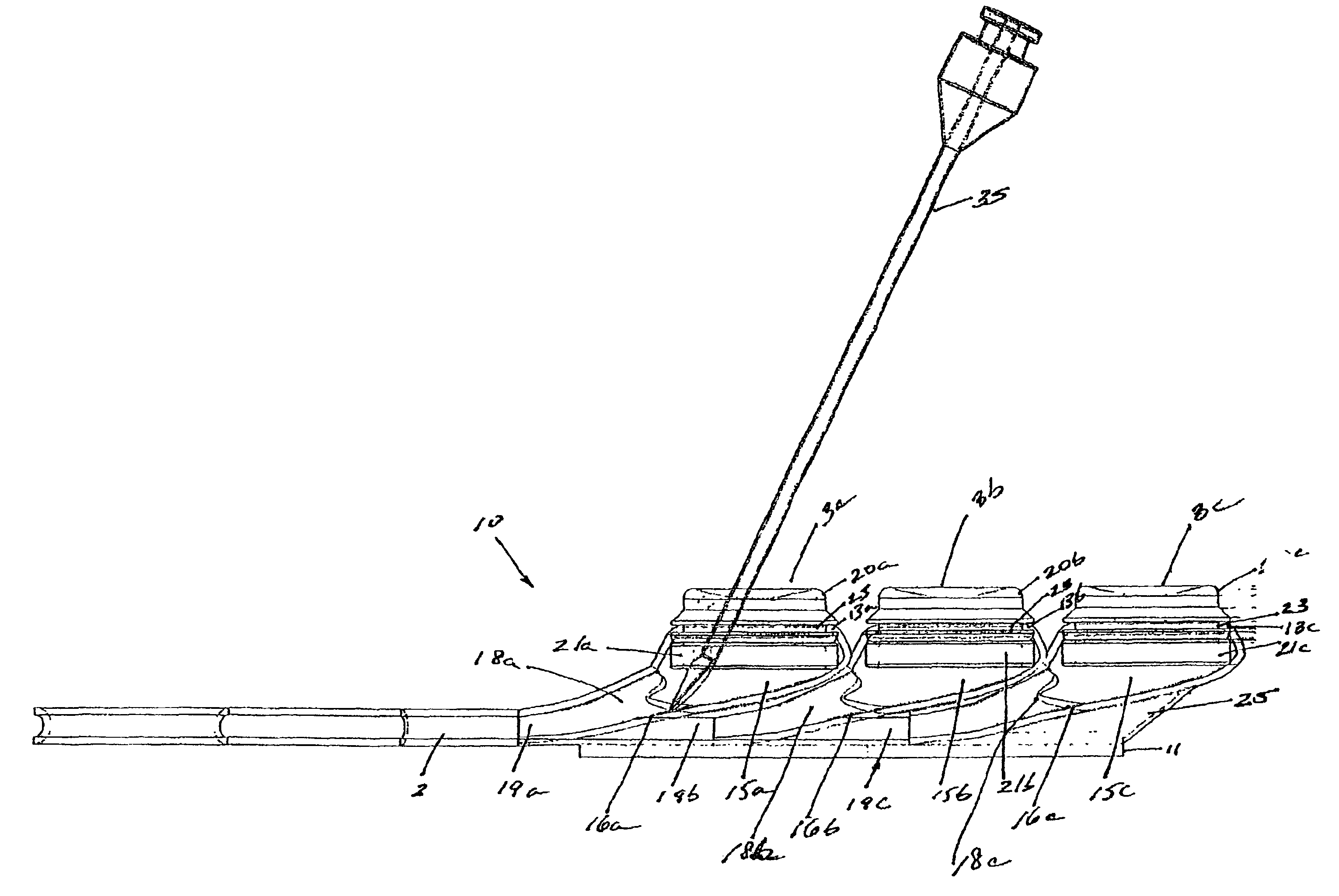

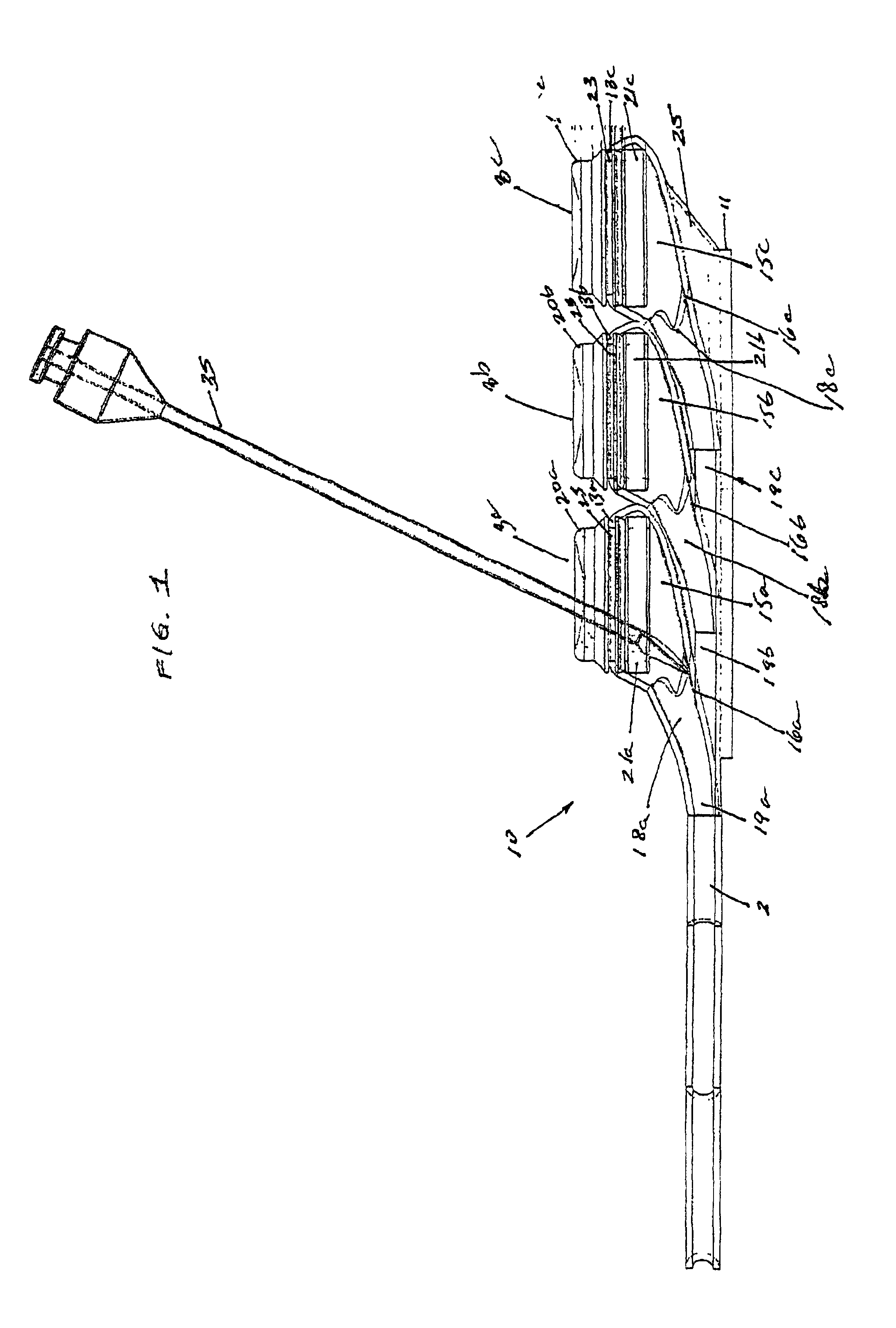

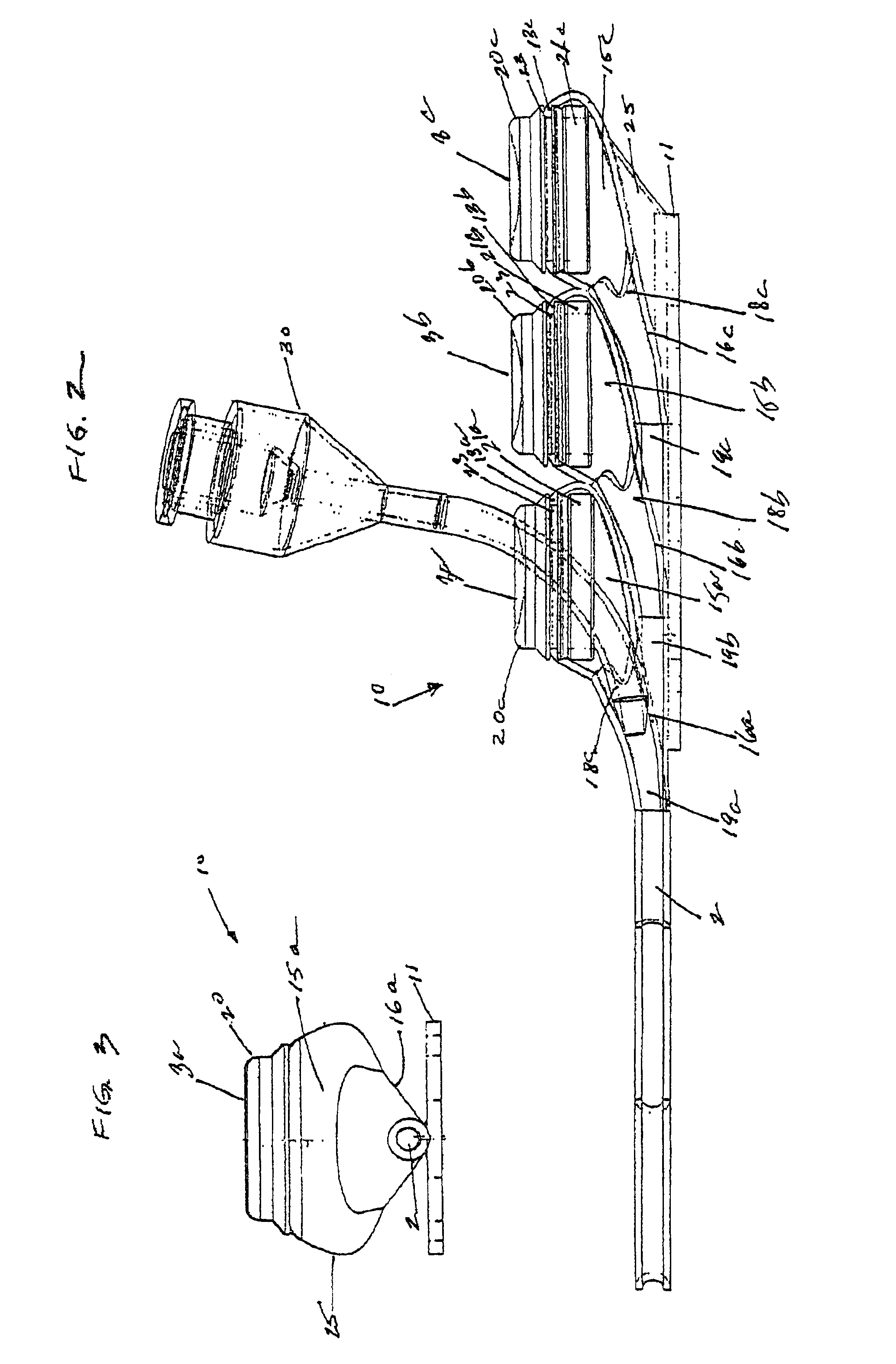

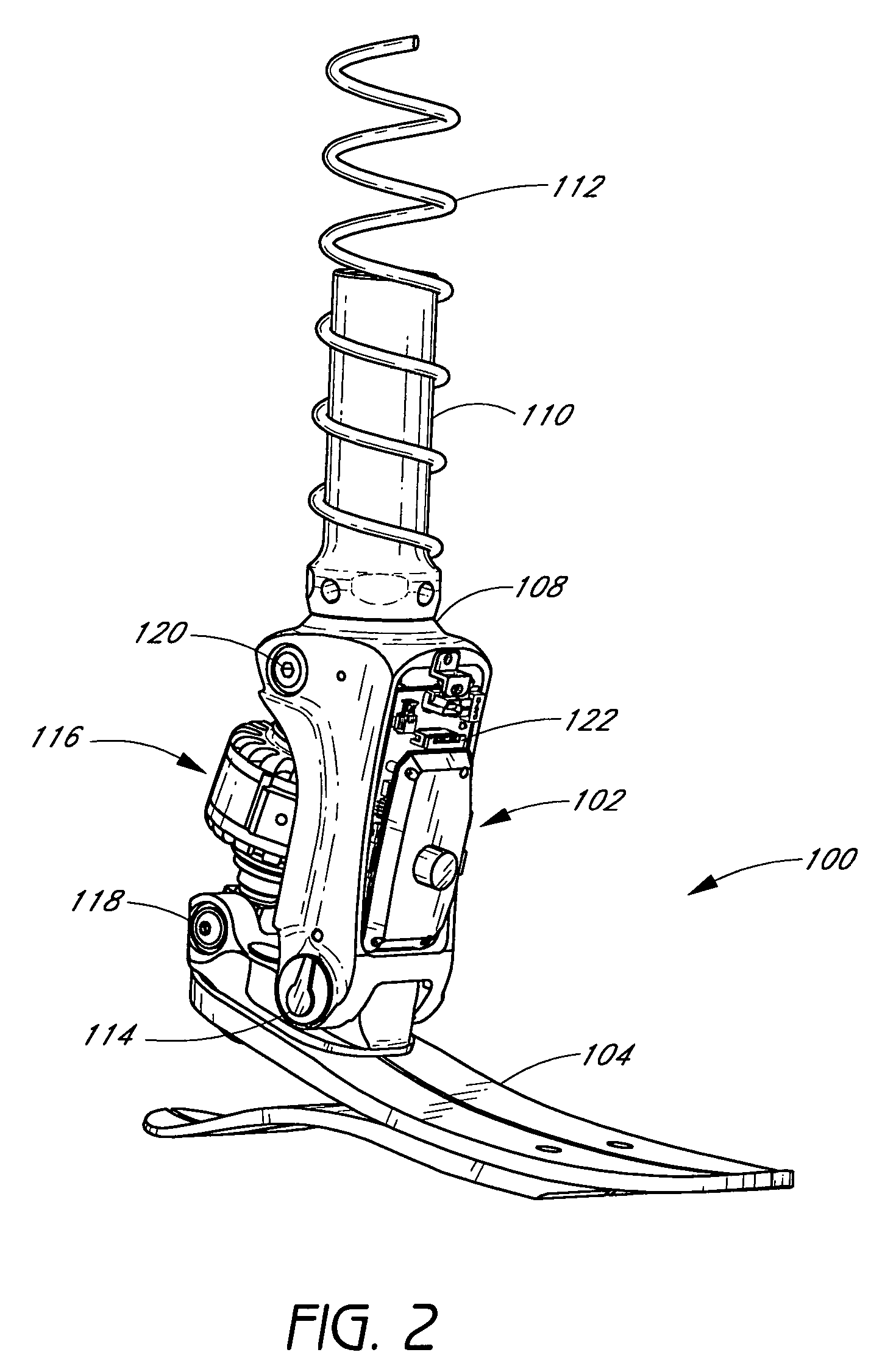

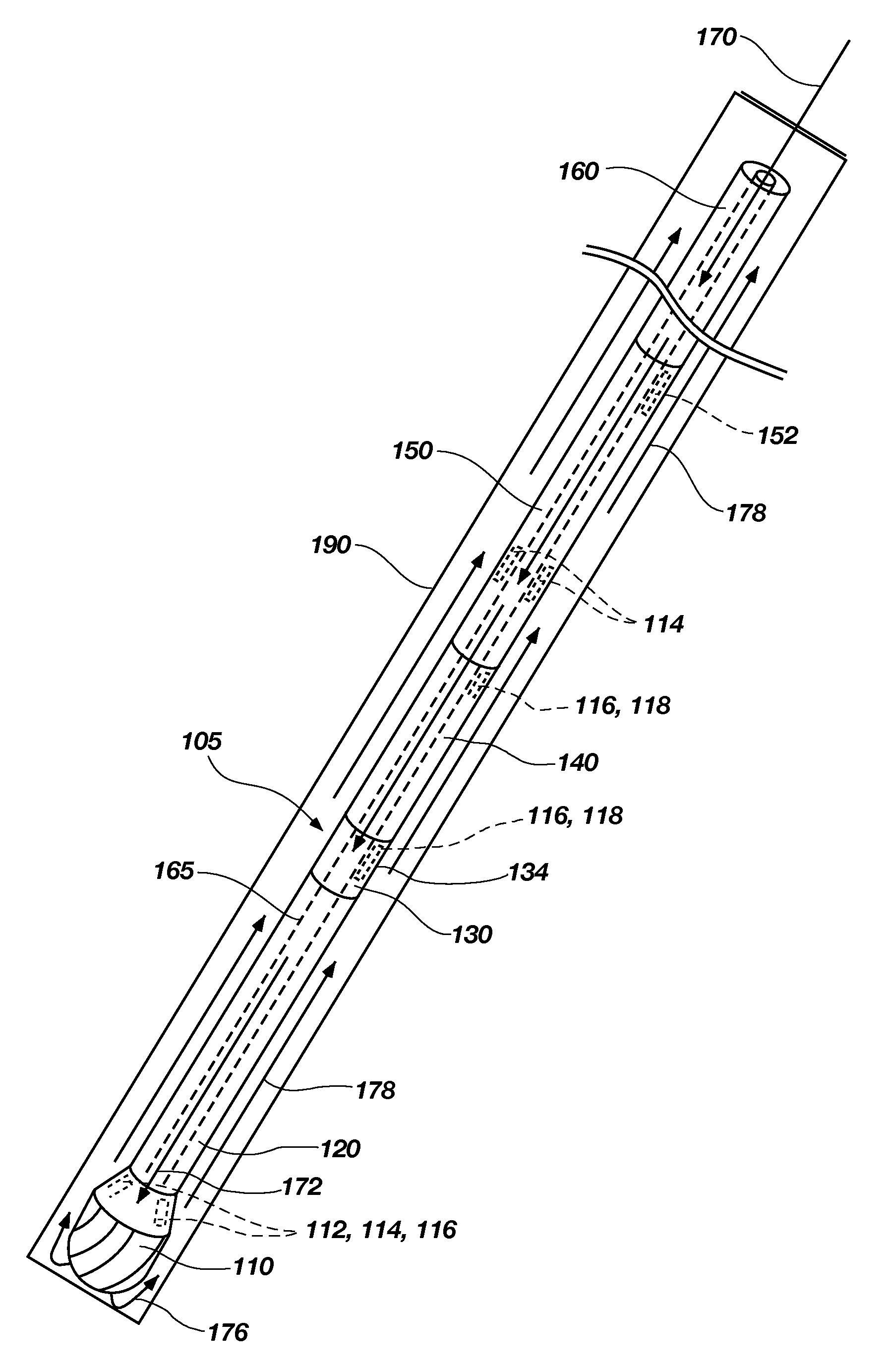

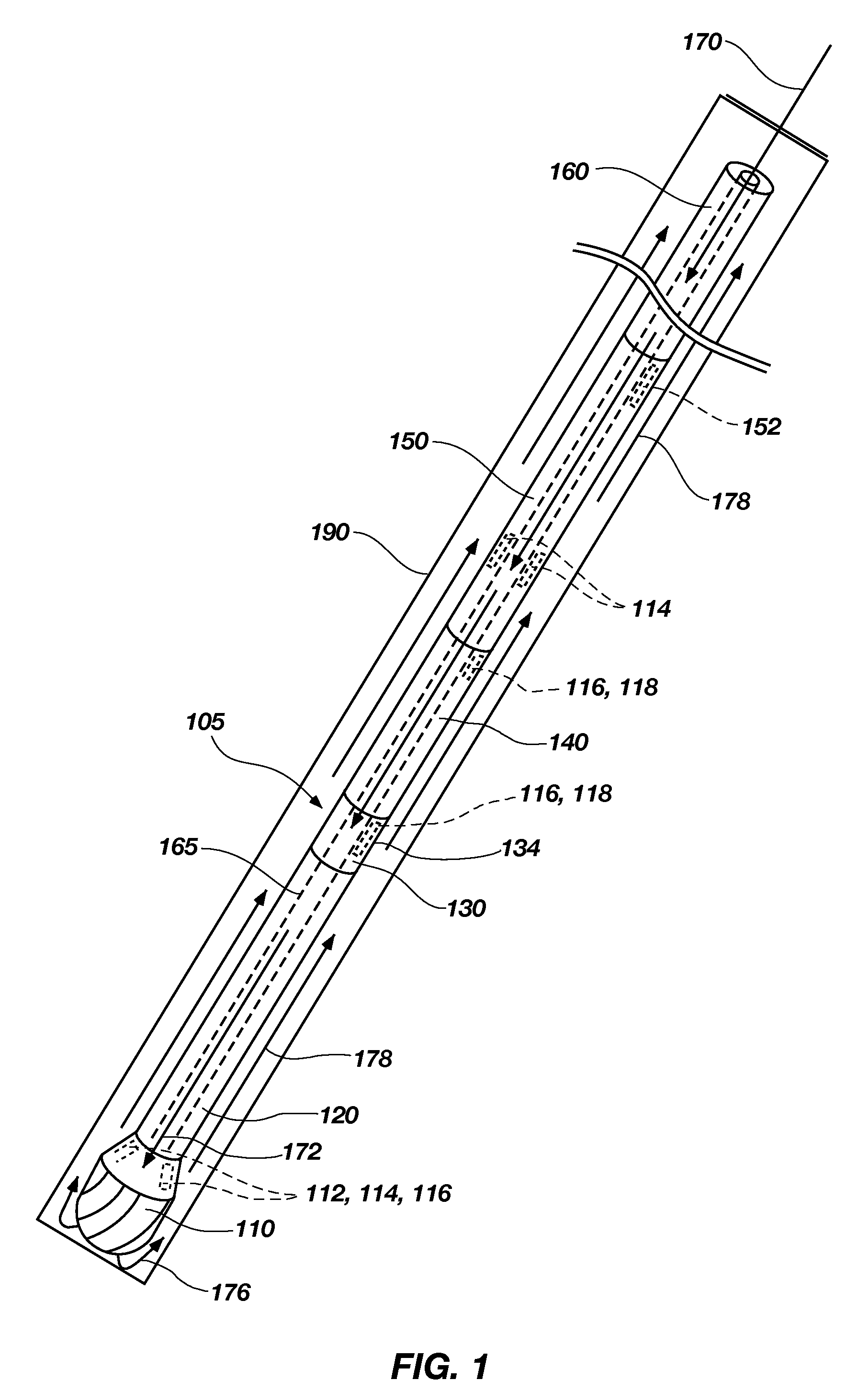

Endoscope assemblies having working channels with reduced bending and stretching resistance

InactiveUS7056284B2Reduce bending and stretching resistanceReduce tensionSurgeryVaccination/ovulation diagnosticsAxial forceEngineering

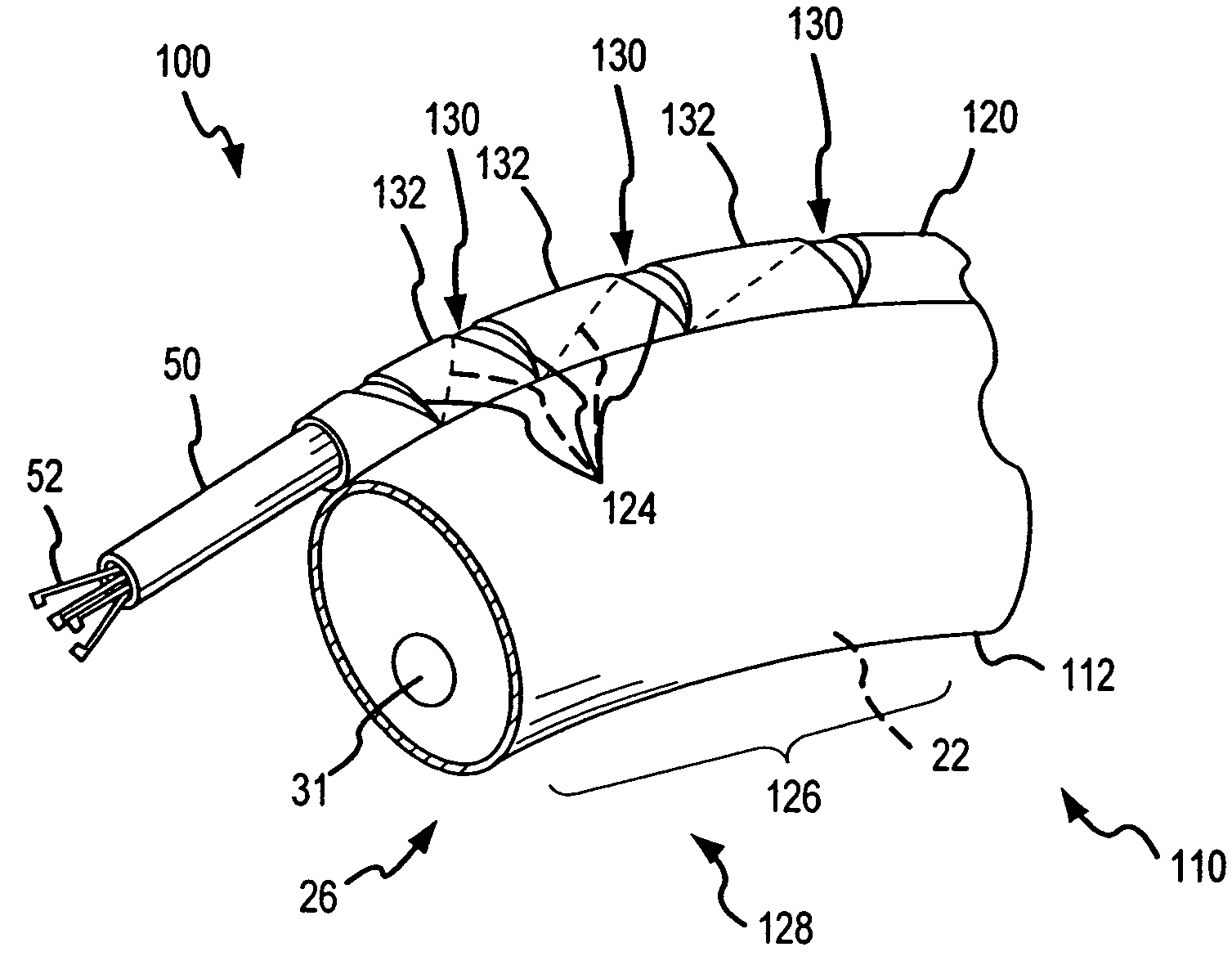

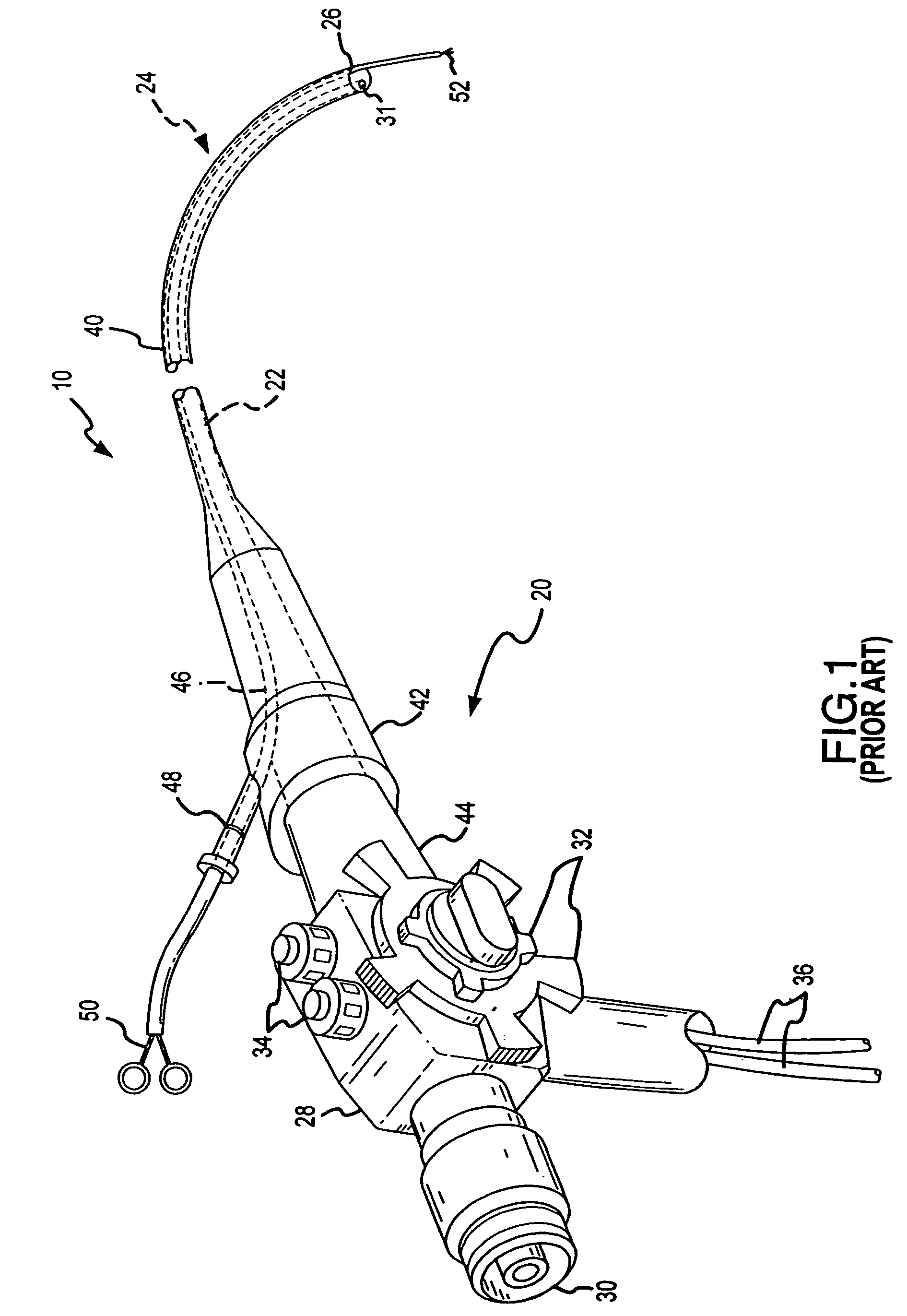

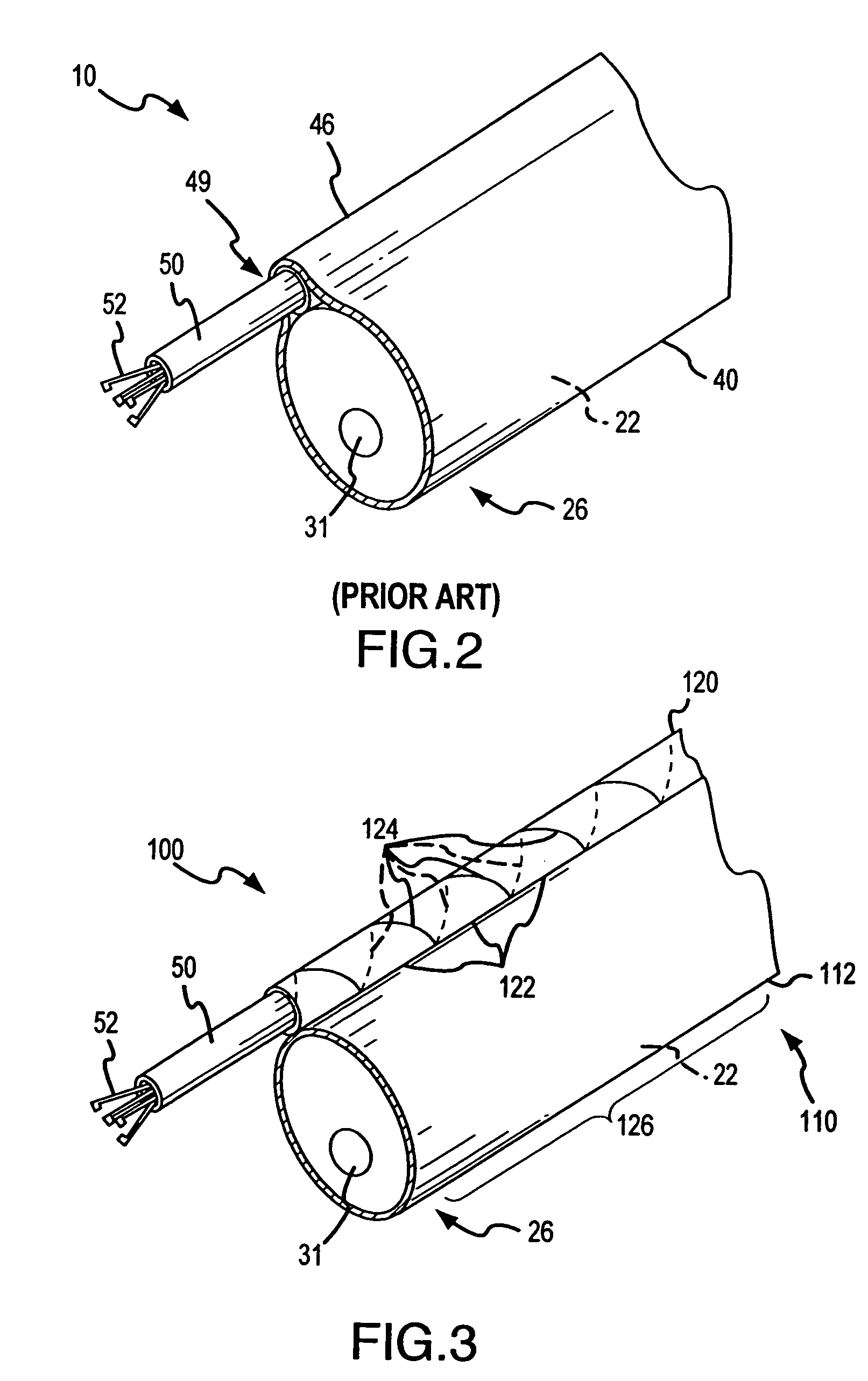

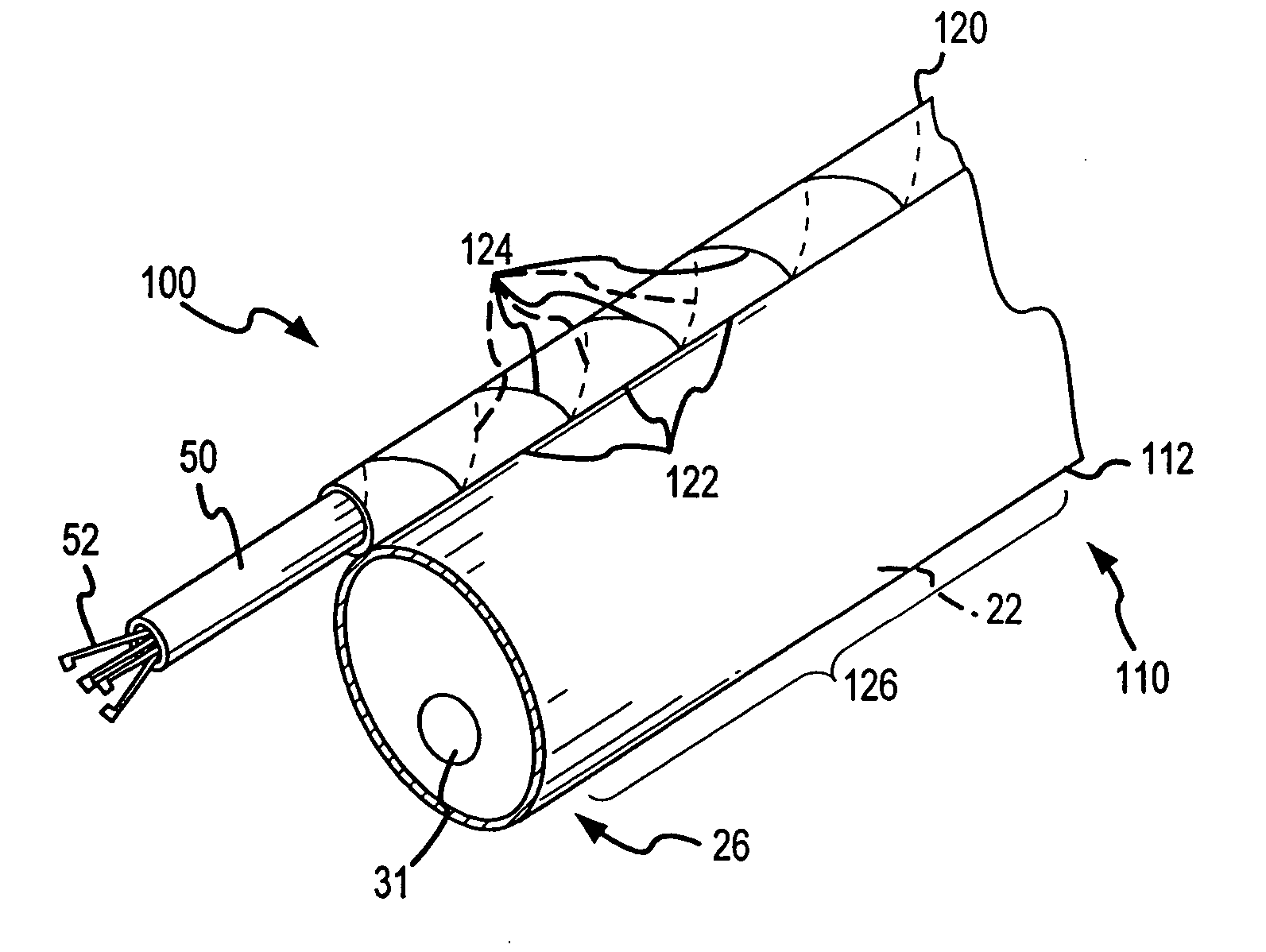

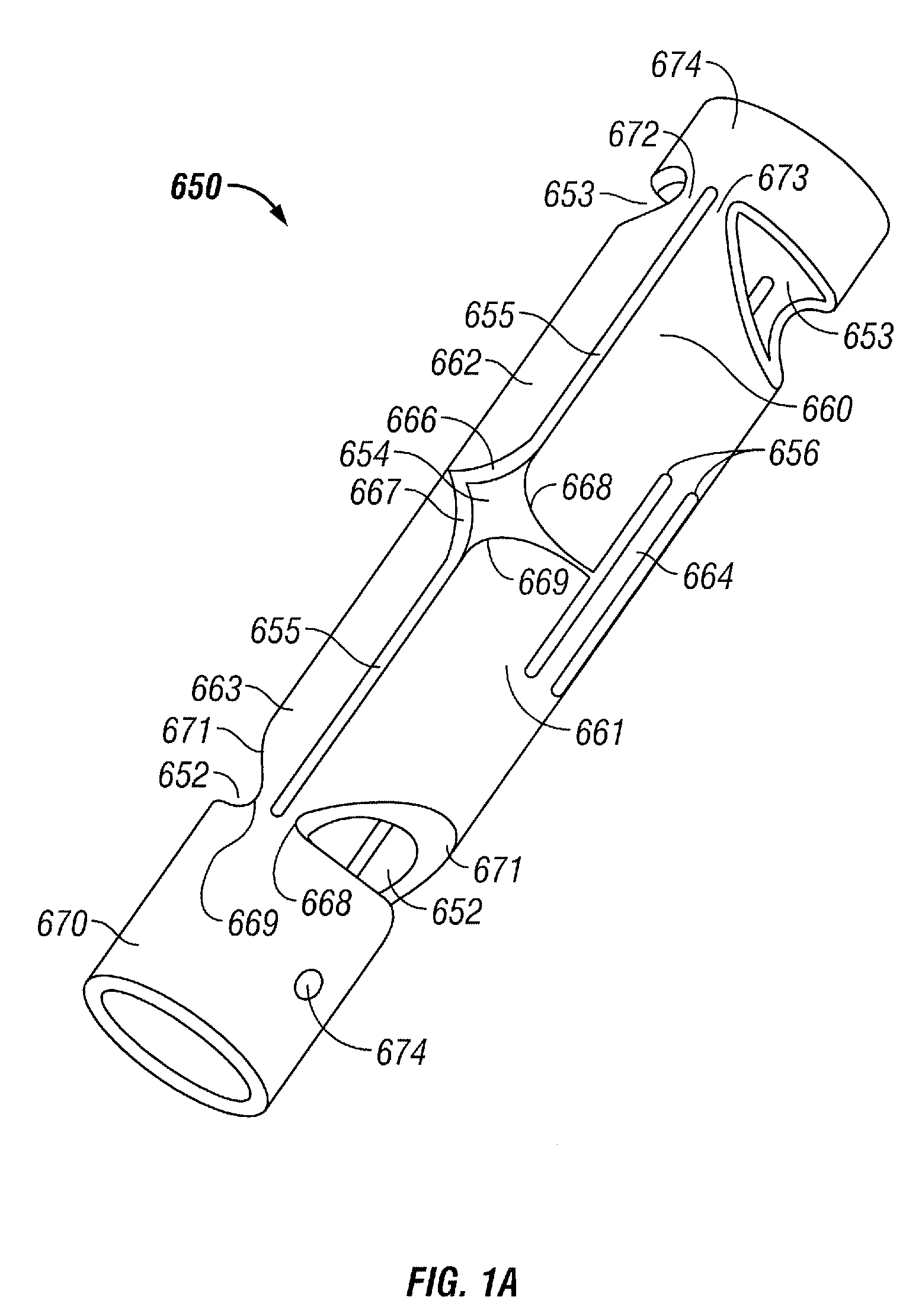

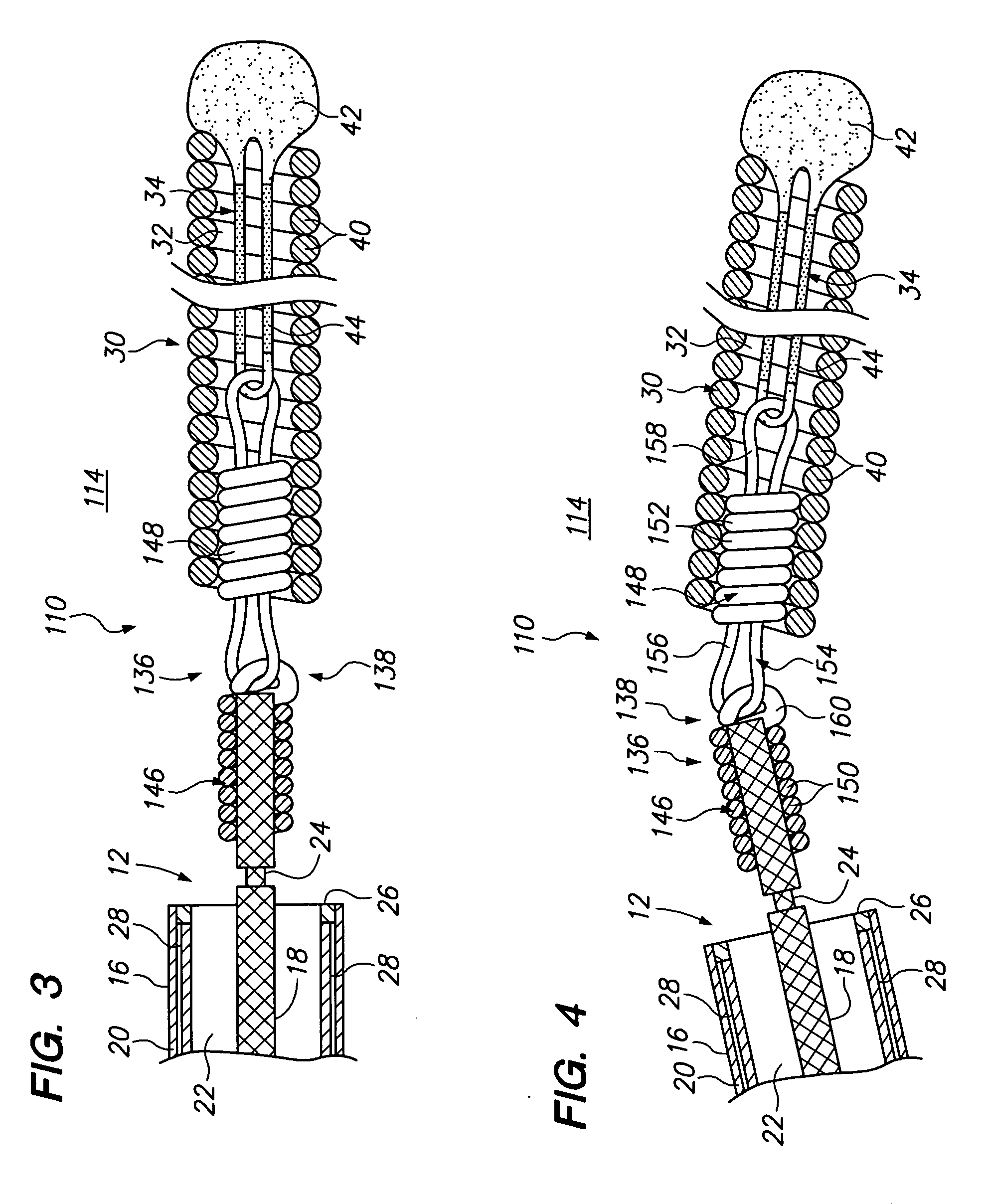

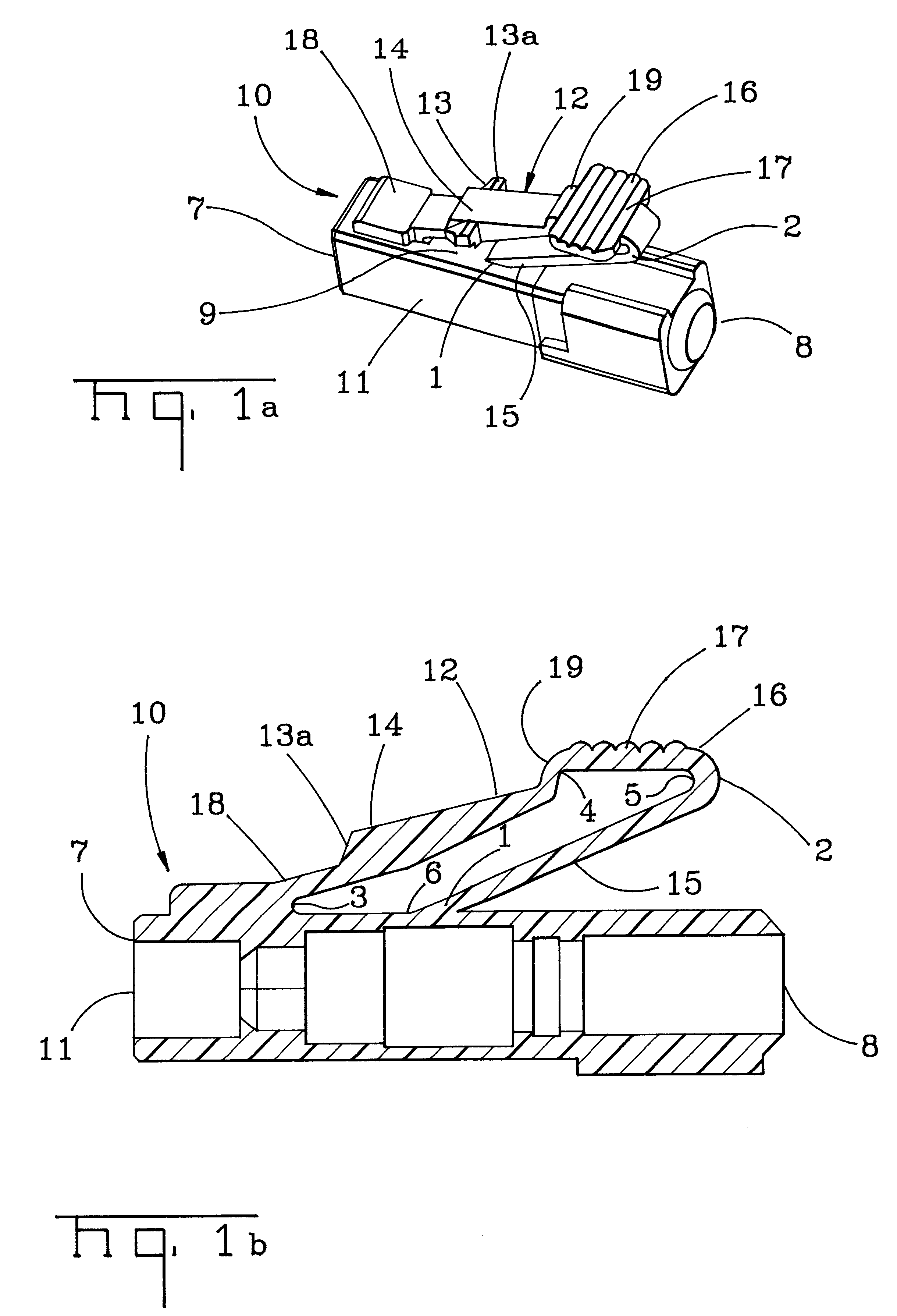

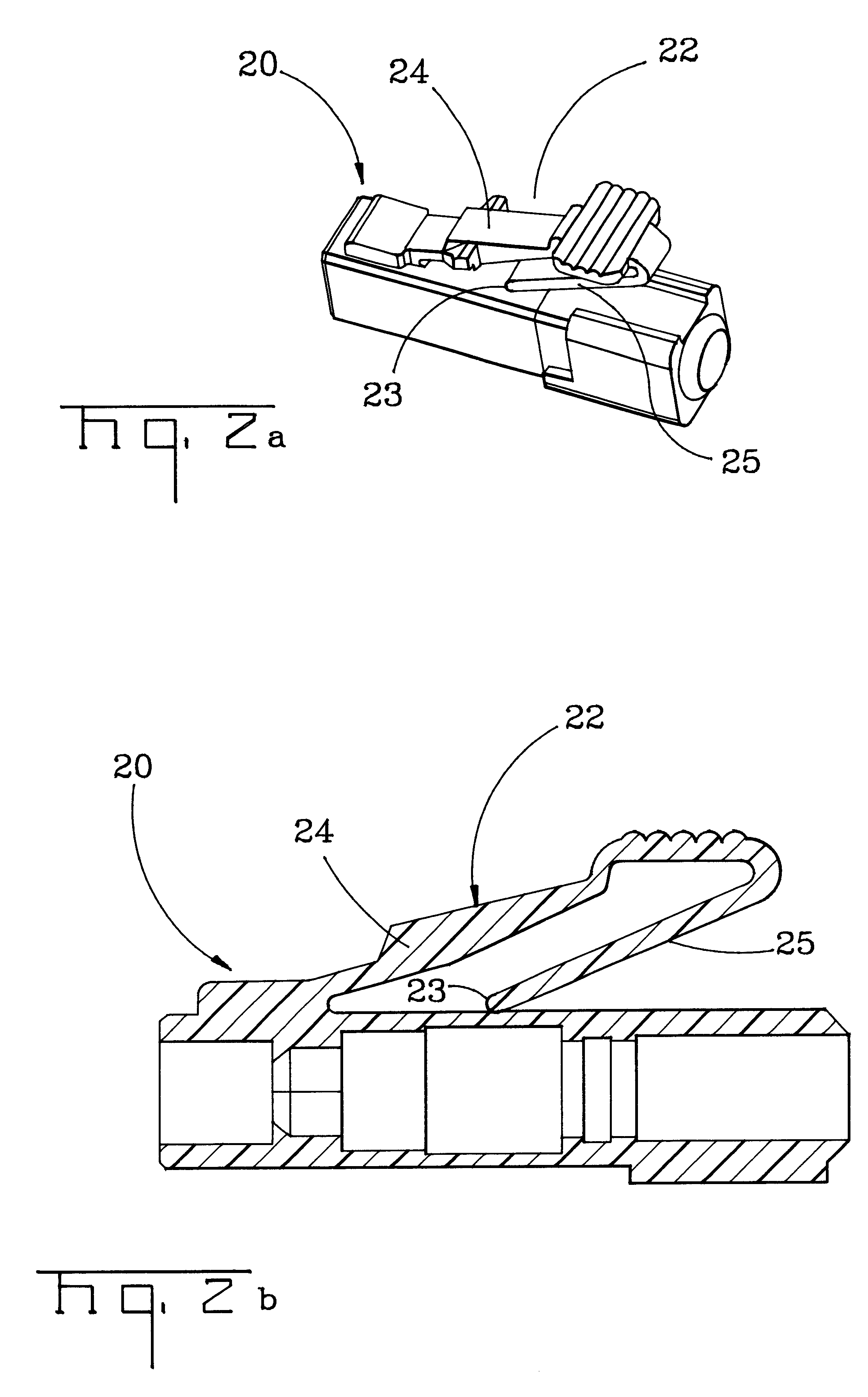

Apparatus and methods for endoscope assemblies having working channels with reduced bending and stretching resistance are disclosed. In one embodiment, an endoscope assembly includes a sheath having a body portion adapted to at least partially encapsulate an endoscopic insertion tube, and a working channel attached to the body portion and extending along at least a portion of the body portion. The working channel includes a component for reducing the resistance of the assembly to bending and stretching. In alternate aspects, the working channel may include a cut, a gap, a sliding portion, or an expansion section. Endoscope assemblies having a working channel in accordance with the invention advantageously reduce the articulation and stretching resistance of the assembly during articulation of the endoscope assembly. Also, because the axial forces (tension and compression) within the working channel are reduced, the working channel can be fabricated out of a relatively hard, inelastic material, thereby reducing the friction within the working channel and improving the physician's ability to perform a medical procedure.

Owner:COGENTIX MEDICAL

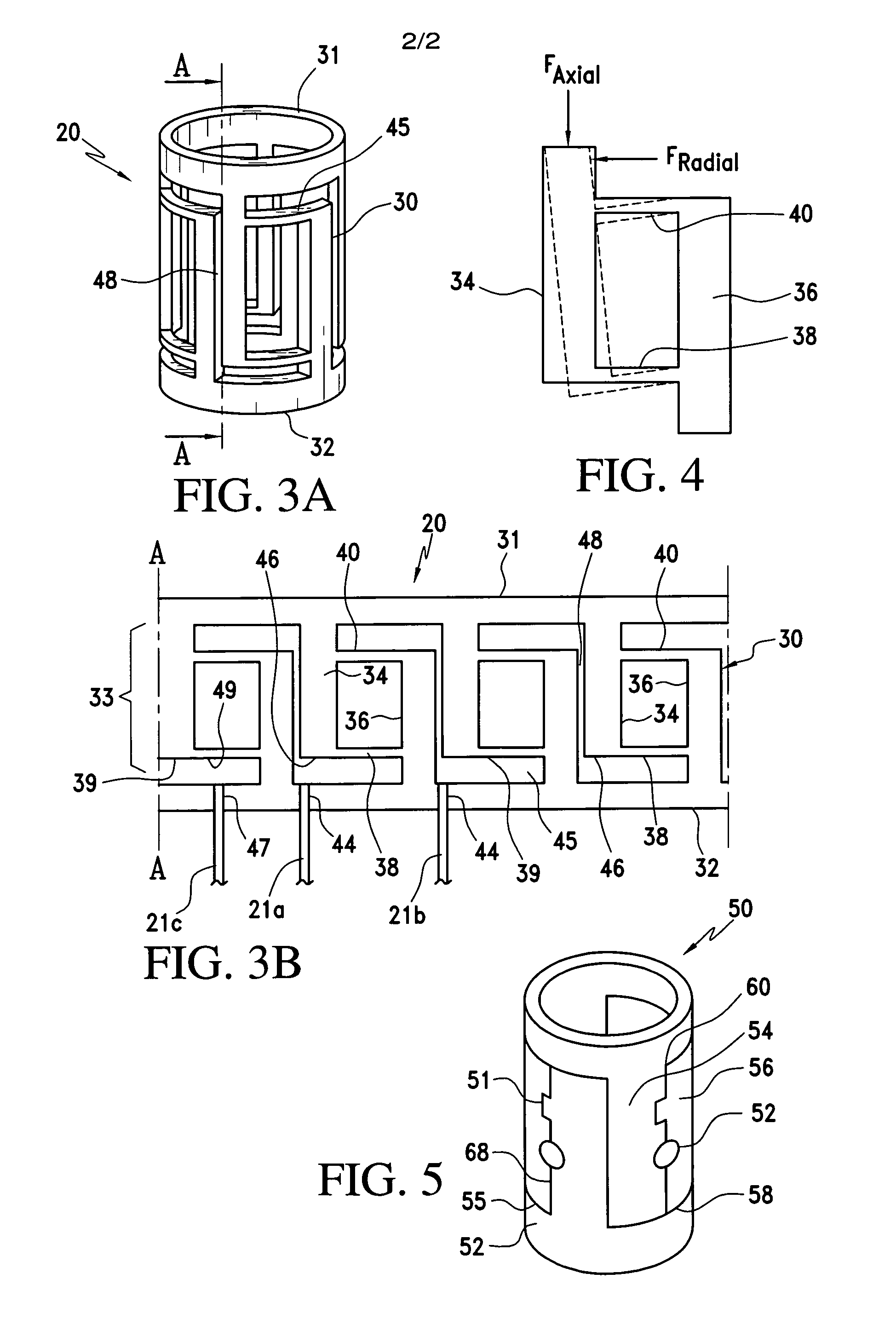

Endoscope assemblies having working channels with reduced bending and stretching resistance

InactiveUS20060079735A1Reduce bendingReduce stretch resistanceSurgeryVaccination/ovulation diagnosticsElectrical resistance and conductanceAxial force

Apparatus and methods for endoscope assemblies having working channels with reduced bending and stretching resistance are disclosed. In one embodiment, an endoscope assembly includes a sheath having a body portion adapted to at least partially encapsulate an endoscopic insertion tube, and a working channel attached to the body portion and extending along at least a portion of the body portion. The working channel includes a component for reducing the resistance of the assembly to bending and stretching. In alternate aspects, the working channel may include a cut, a gap, a sliding portion, or an expansion section. Endoscope assemblies having a working channel in accordance with the invention advantageously reduce the articulation and stretching resistance of the assembly during articulation of the endoscope assembly. Also, because the axial forces (tension and compression) within the working channel are reduced, the working channel can be fabricated out of a relatively hard, inelastic material, thereby reducing the friction within the working channel and improving the physician's ability to perform a medical procedure.

Owner:MARTONE STEPHEN +1

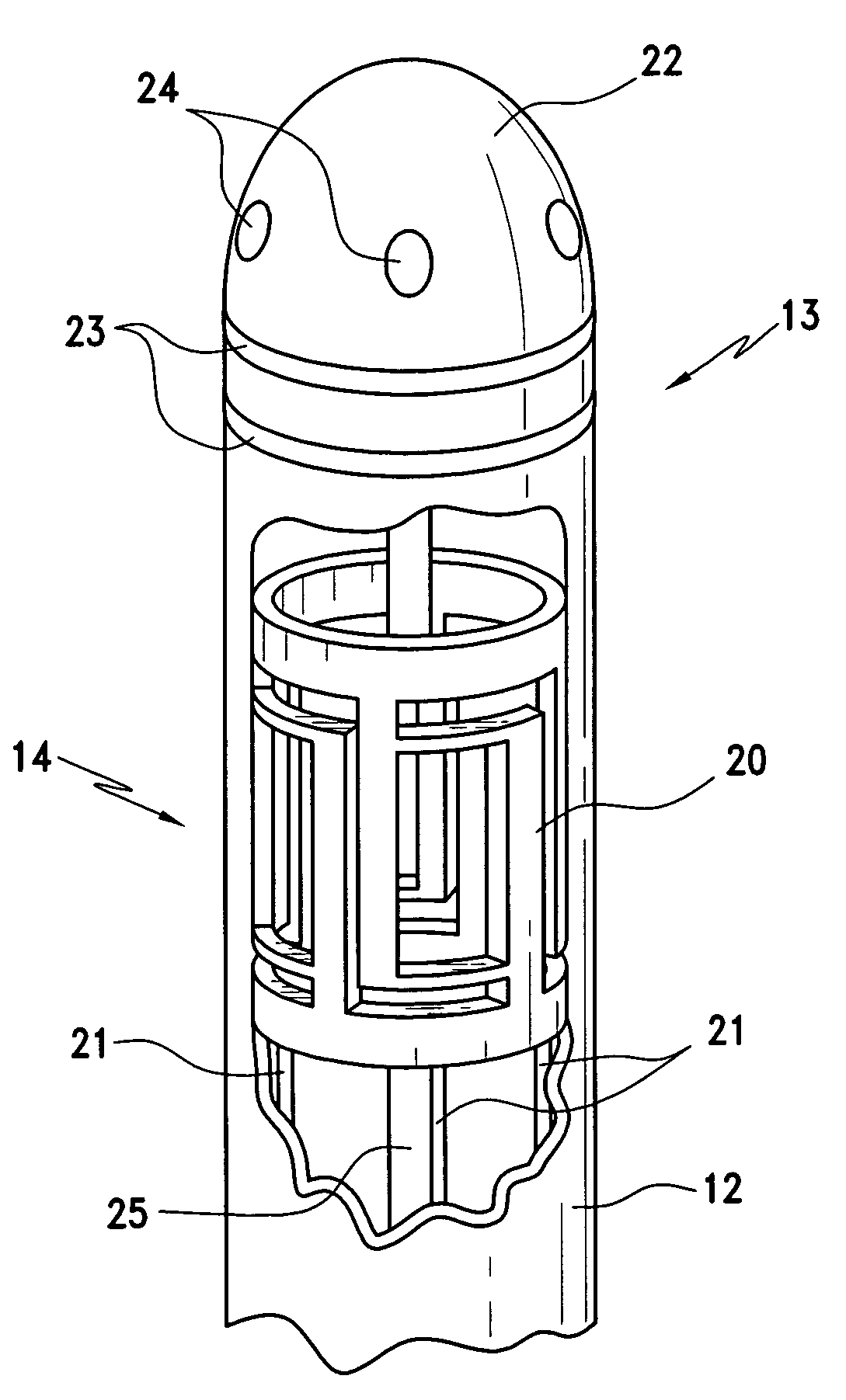

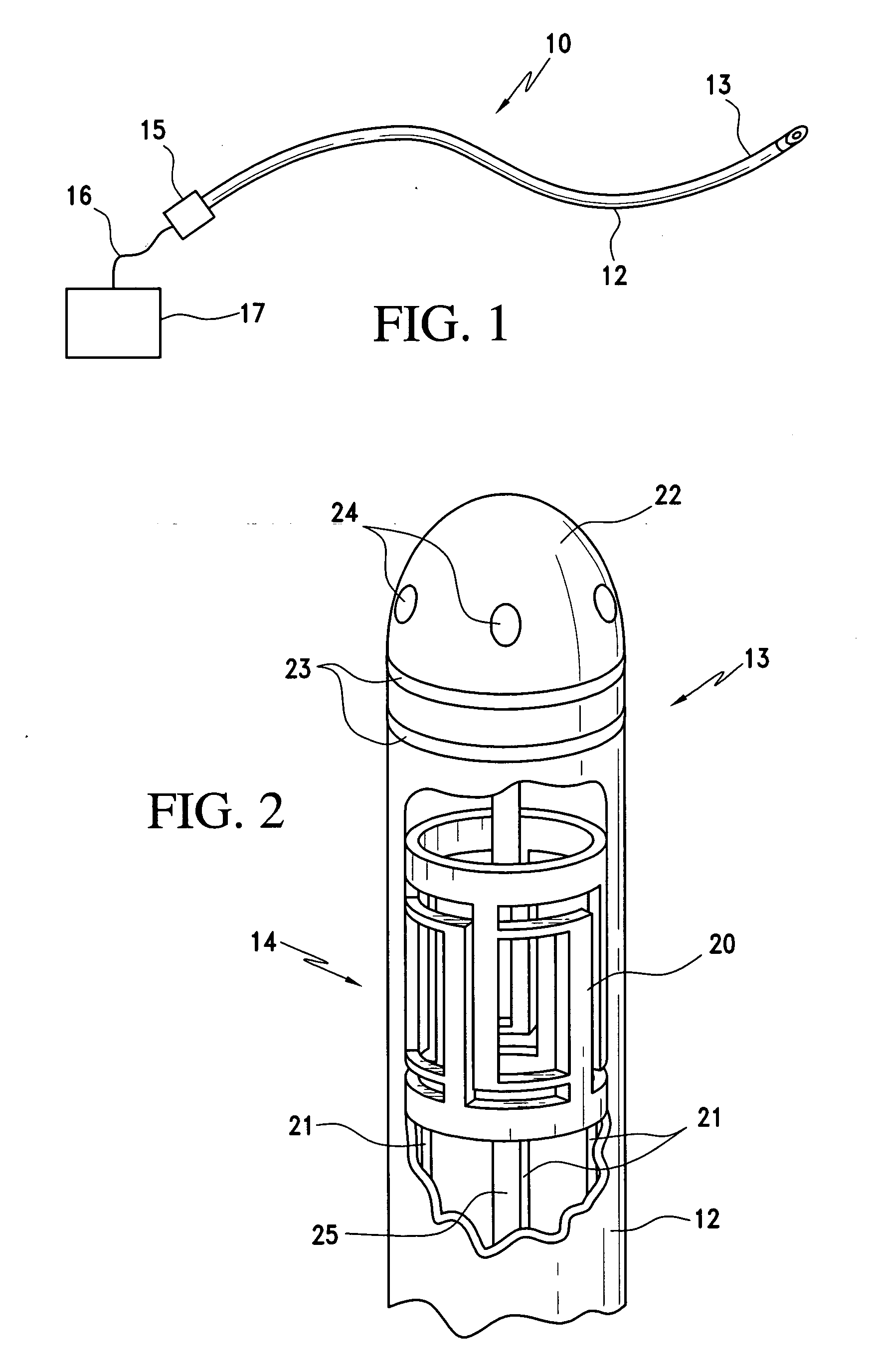

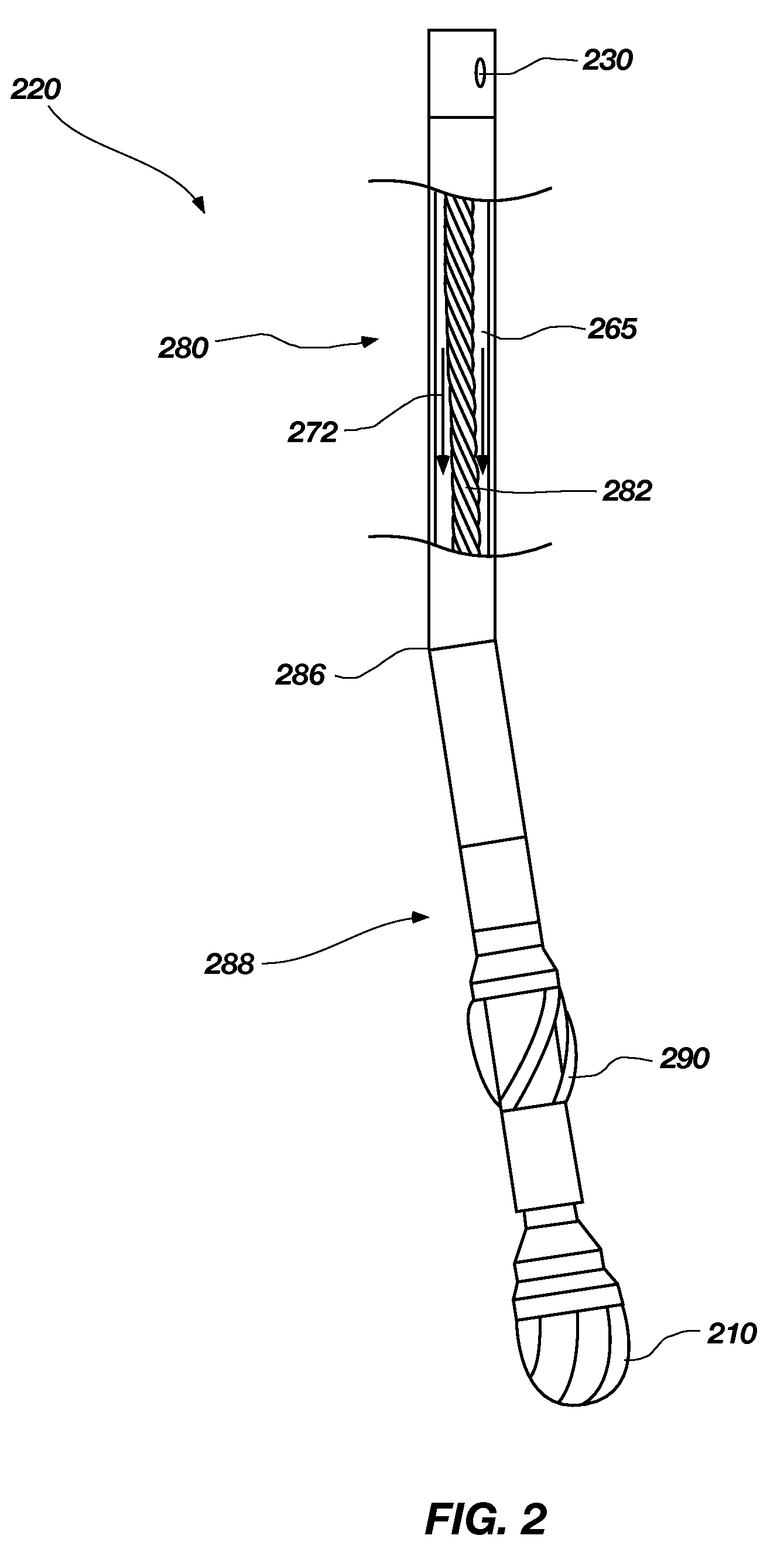

Catheter having tri-axial force sensor

ActiveUS20080009750A1Plenty of spaceFacilitate speedElectrocardiographySurgical instrument detailsAxial forceContact force

A catheter for diagnosis or treatment of a vessel or organ is provided in which a flexible elongated body includes a tri-axial force sensor formed of a housing and a plurality of optical fibers associated with the housing that measure changes in the intensity of light reflected from the lateral surfaces of the housing resulting from deformation caused by forces applied to a distal extremity of the housing. A controller receives an output of the optical fibers and computes a multi-dimensional force vector corresponding to the contact force.

Owner:ST JUDE MEDICAL INT HLDG SARL

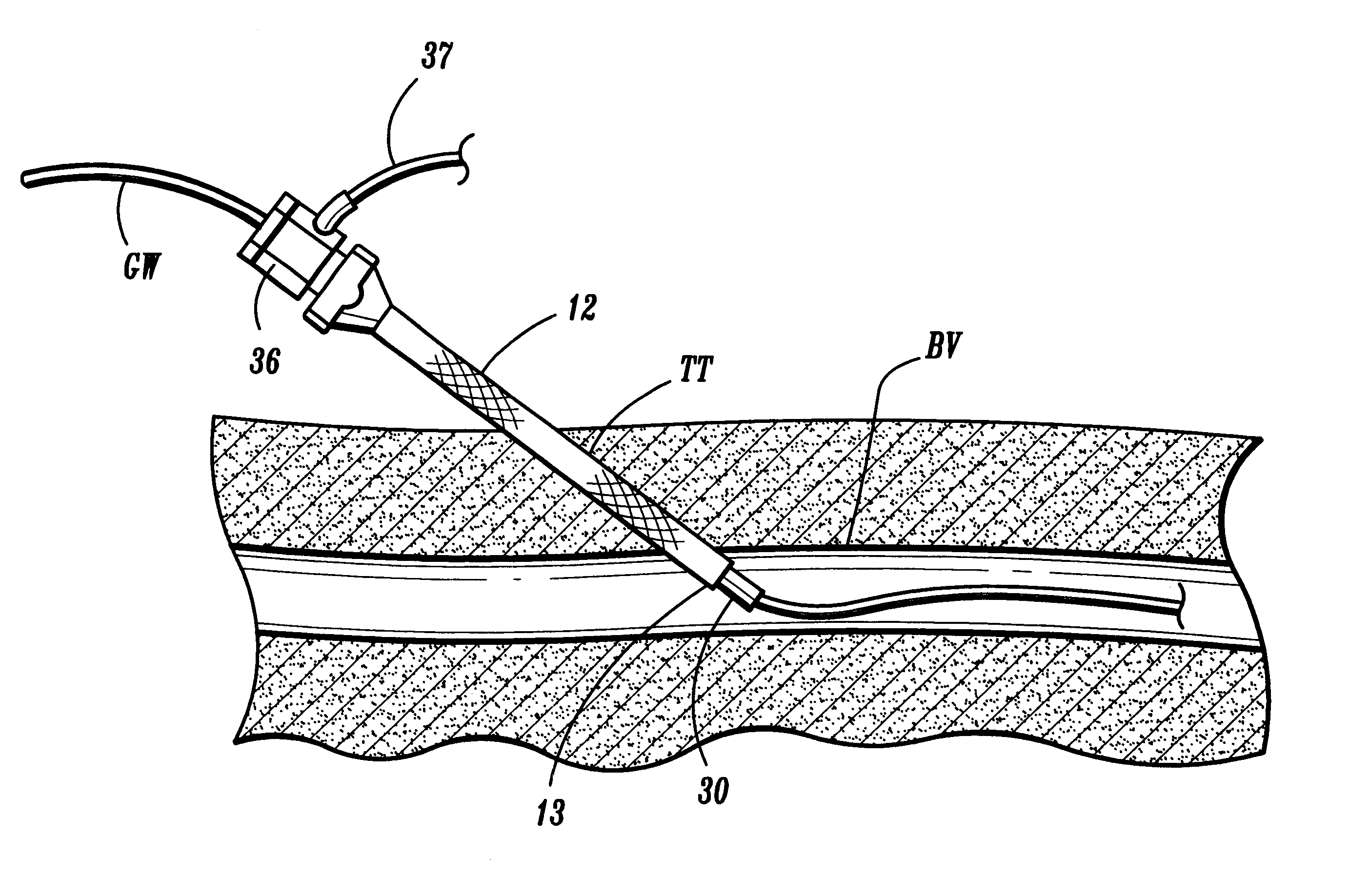

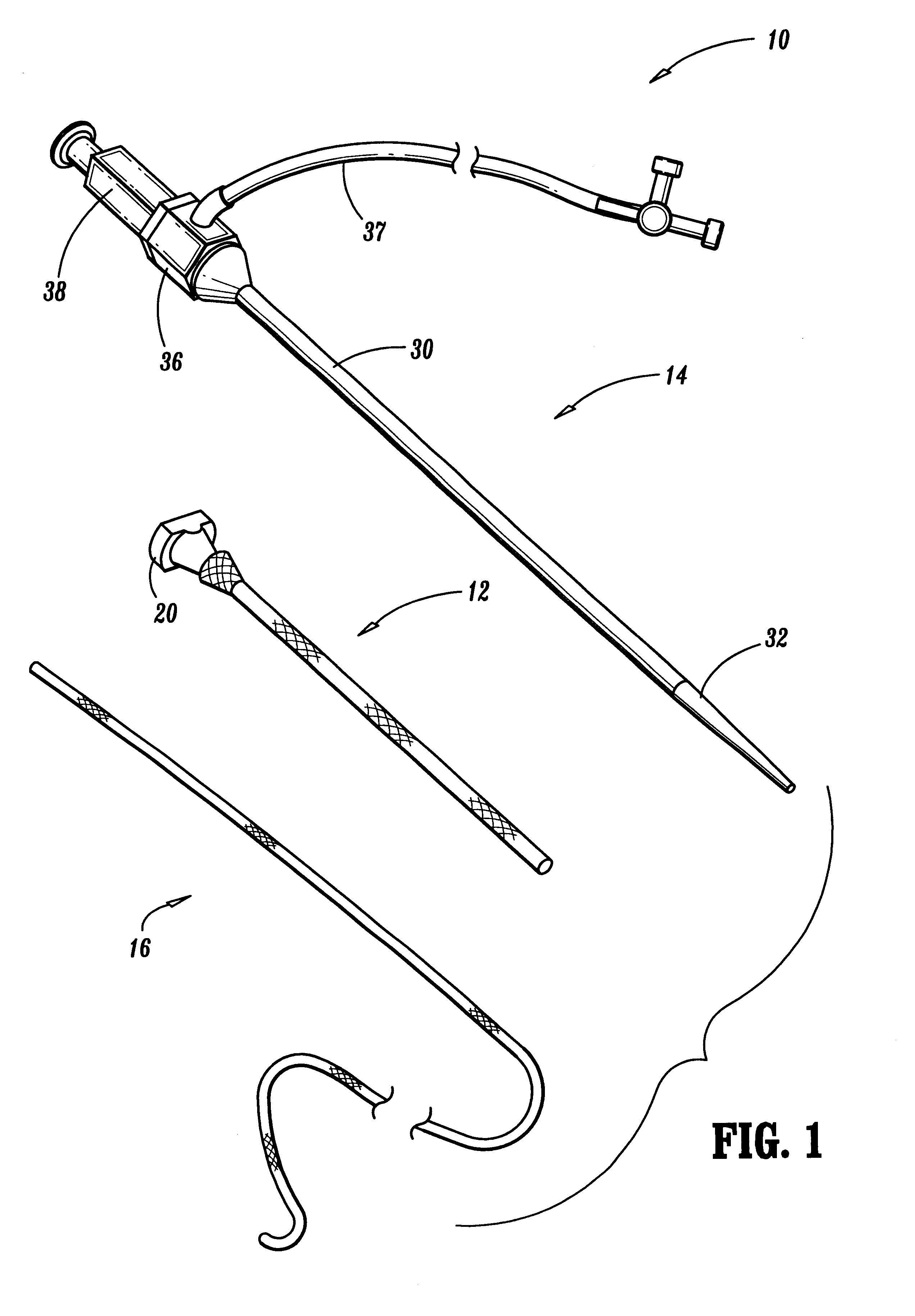

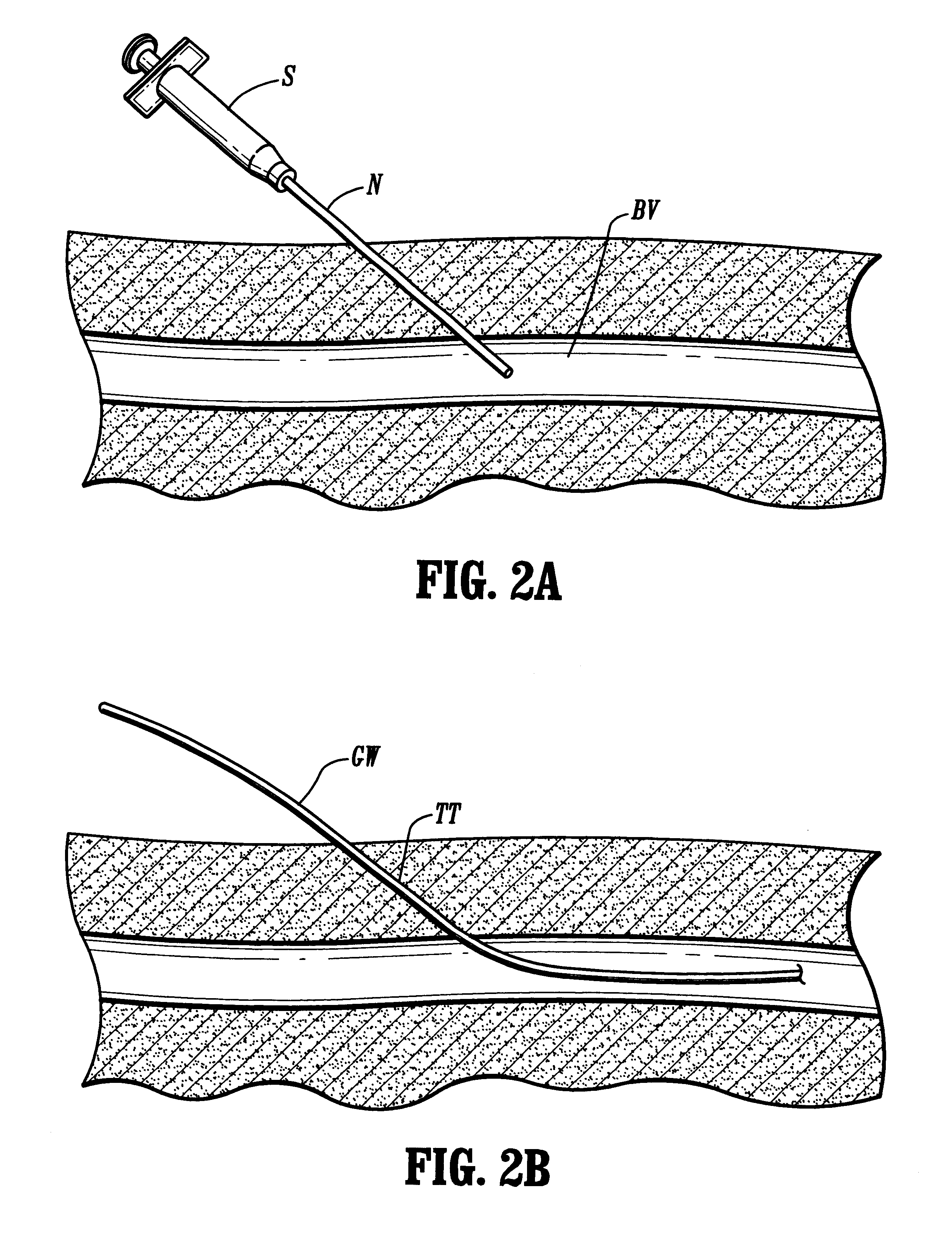

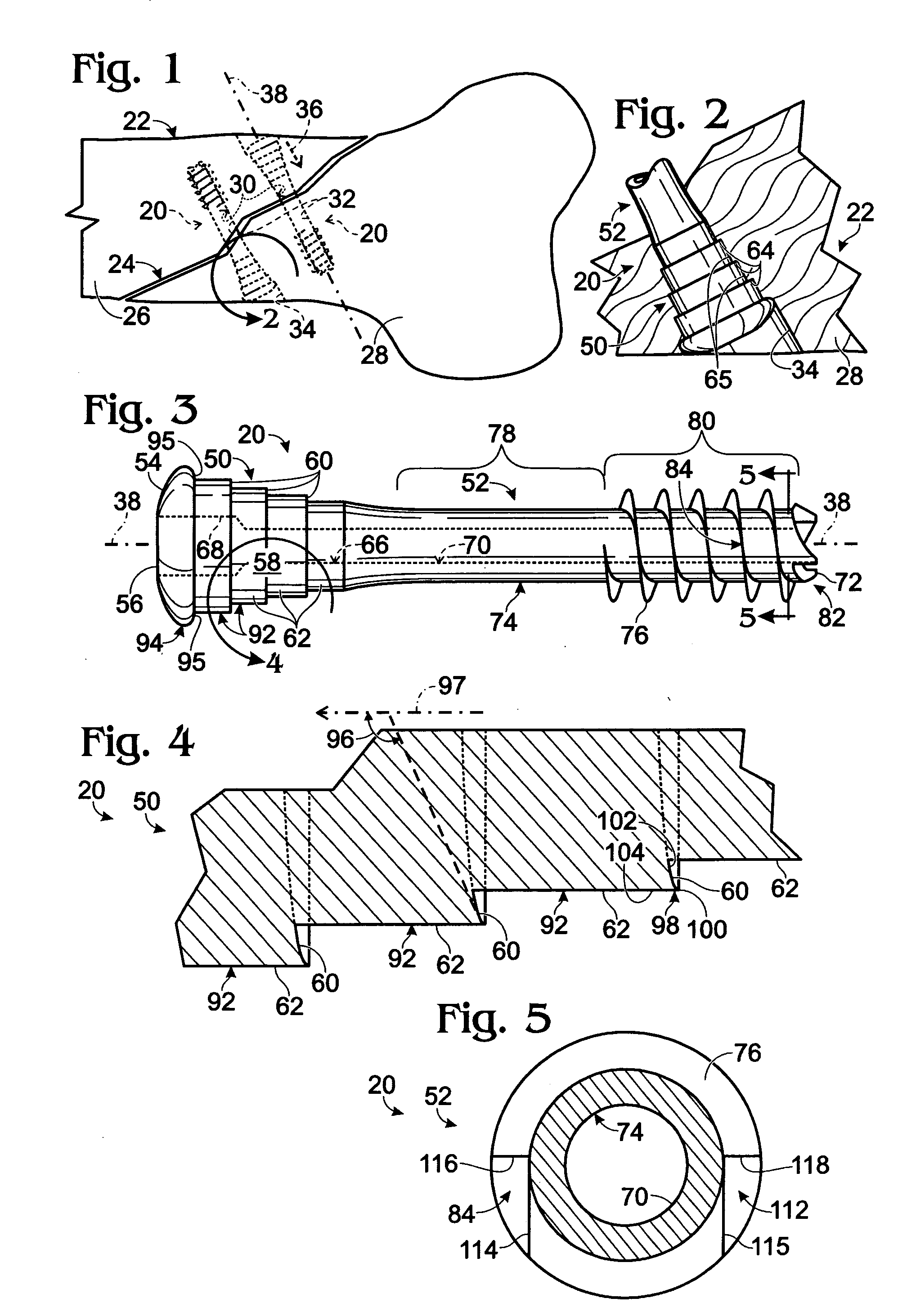

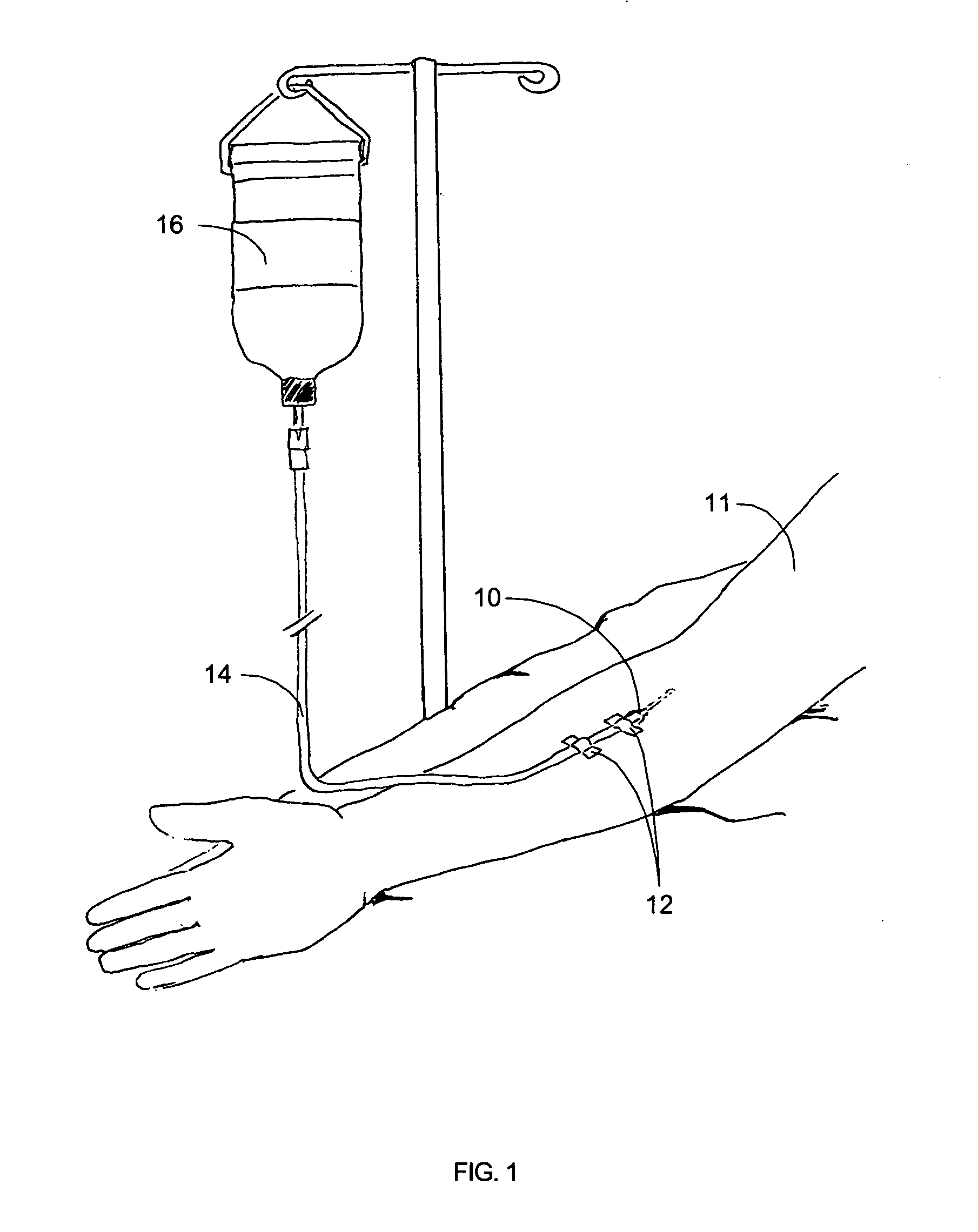

System and method for establishing vascular access

Systems, kits, and methods for establishing vascular access are described. A system may include a needle, a radially expandable sleeve and a dilator. The methods include creating an initial tissue tract to a target blood vessel with a radially expandable sleeve mounted on a needle. Upon removal of the needle, the dilator is then passed through the radially expandable sleeve to effect radial expansion of the sleeve. Use of the sleeve reduces the risk of injuring tissue surrounding the tissue tract by lessening the axial forces imparted to the tissue. Kits comprise at least the radially expandable sleeve together with instructions for use.

Owner:TYCO HEALTHCARE GRP LP

Ultrasonic lead screw motor

InactiveUS6940209B2Piezoelectric/electrostriction/magnetostriction machinesPressure infusionUltrasonic vibrationAxial force

An apparatus for driving a threaded shaft assembly that contains a threaded shaft with an axis of rotation and, engaged therewith, a threaded nut. Subjecting the threaded nut to ultrasonic vibrations causes the threaded shaft to simultaneously rotate and translate in the axial direction. The threaded shaft is connected to a load that applies an axial force to the threaded shaft.

Owner:NEW SCALE TECH

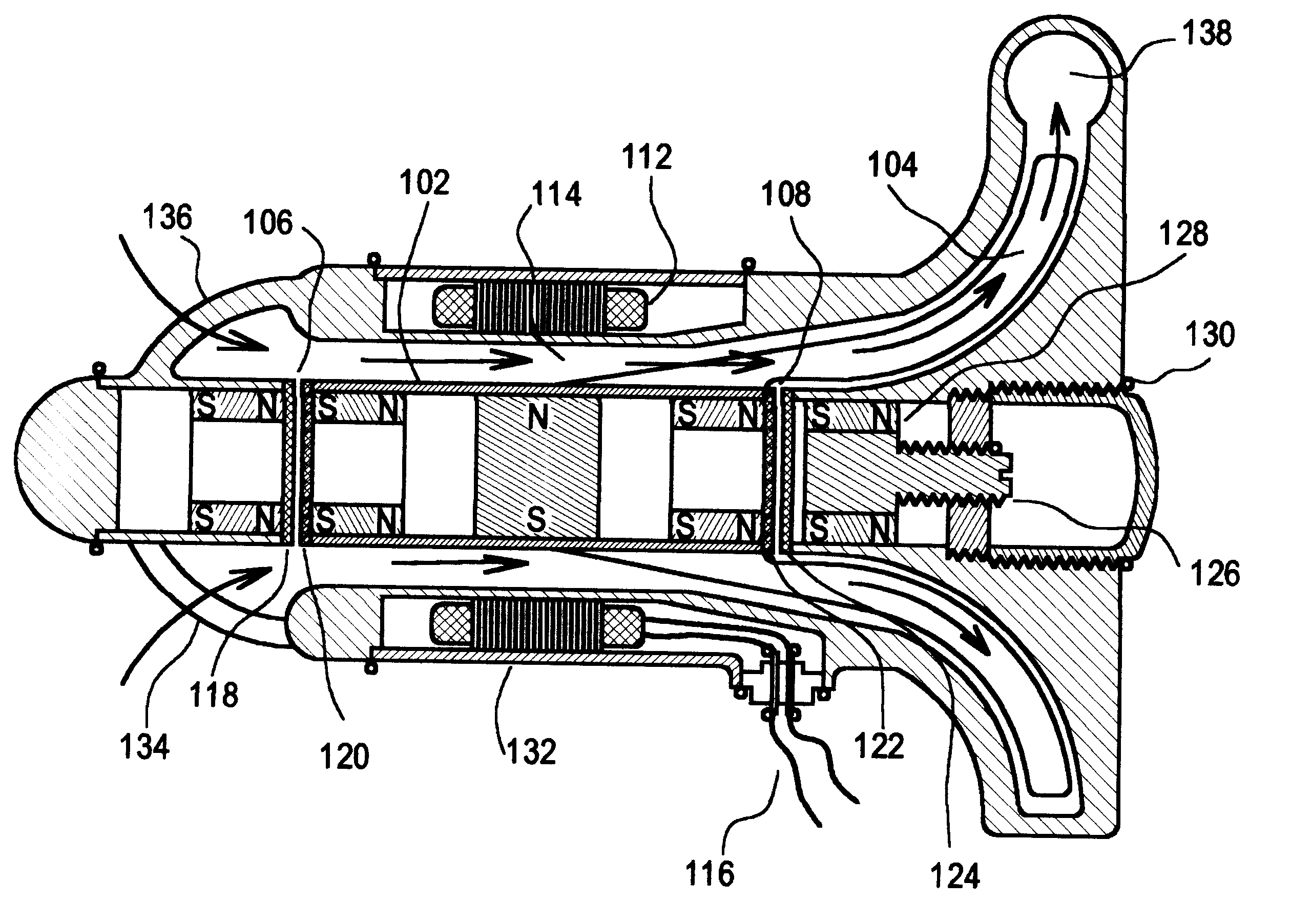

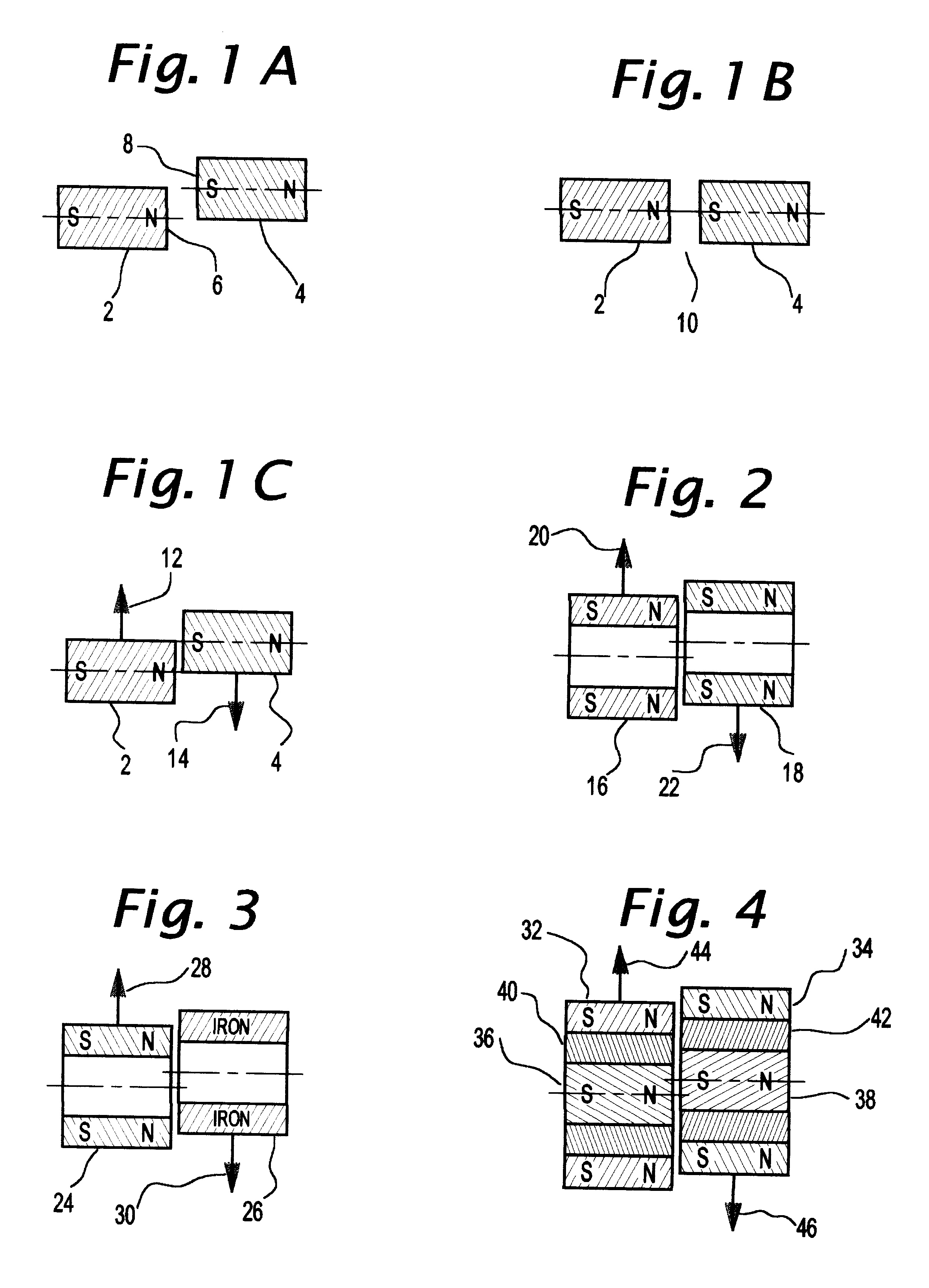

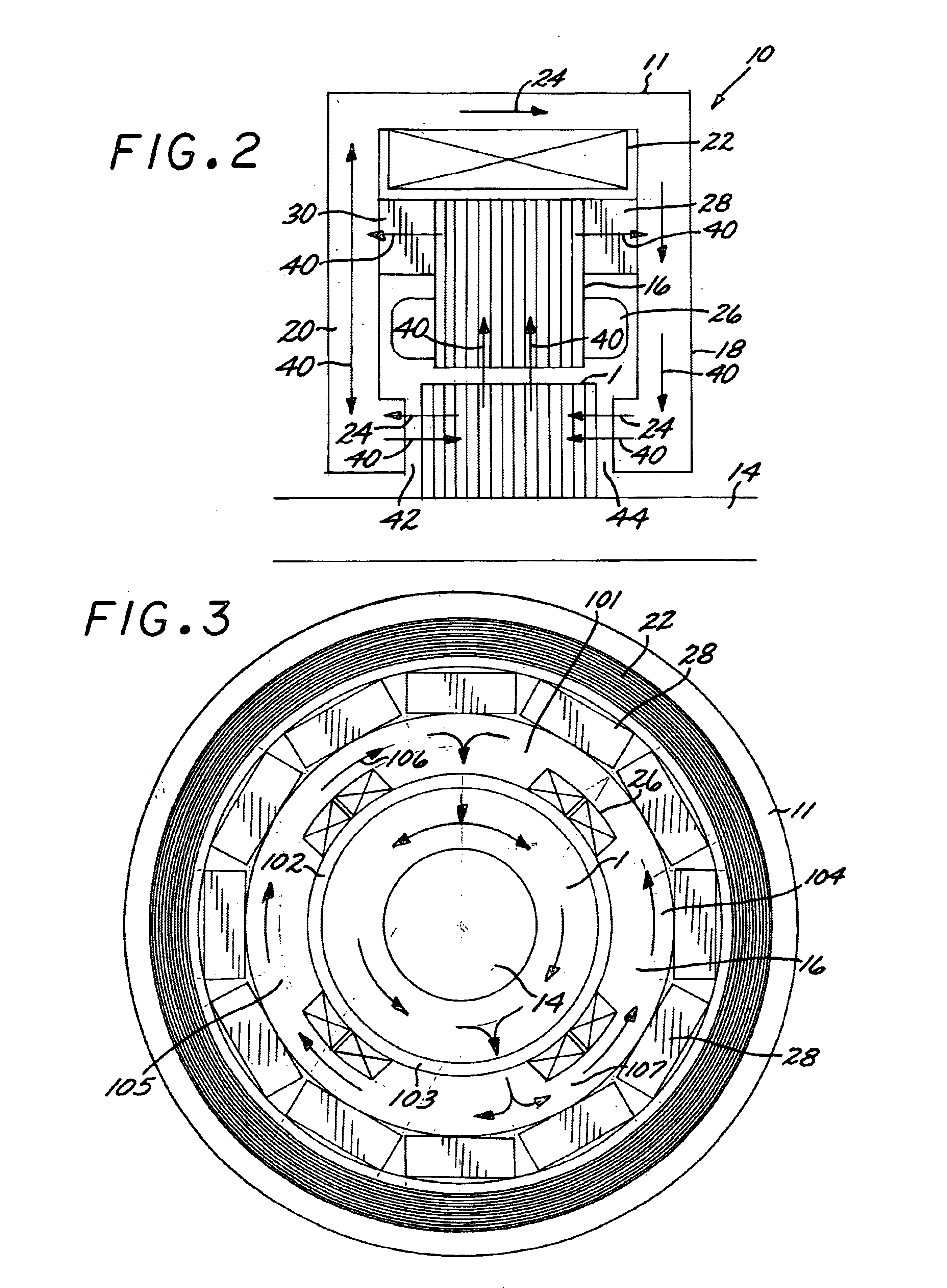

Axial force null position magnetic bearing and rotary blood pumps which use them

InactiveUS6227820B1Improve radial stiffnessSimple designPump componentsSurgeryAxial-flow pumpMagnetic tension force

A generally cylindrical rotor very closely confined between two rigid thrust bearing surfaces is radially suspended by an array of attracting or repelling magnets or by a combination of permanent magnets and ring shaped members composed of ferromagnetic material. The geometry permits very small spacing between magnetic components to achieve high radial stiffness. High magnetic axial forces exerted between the rotor and stationary component on one end of the rotor are counter-balanced by equal and opposite forces at the other end of the rotor. Precise positioning of the rotor in the location where the opposing axial magnetic forces counterballance each other yields a net magnetic axial force on the rotor of near zero, hence the reference to this as the null position. Wear resistant mechanical thrust bearings confine the rotor axially to maintain this position during rotatioin. Precisely balance the magnetic axial forces in the proper geometry with relation to the mechanical thrust bearings. Blood pumps utilizing this type of bearing are disclosed, including both axial flow pump and centrifugal flow pump configurations with high flow washing of the junction of the rotating and stationary parts to prevent thrombus accumulation.

Owner:JARVIK ROBERT

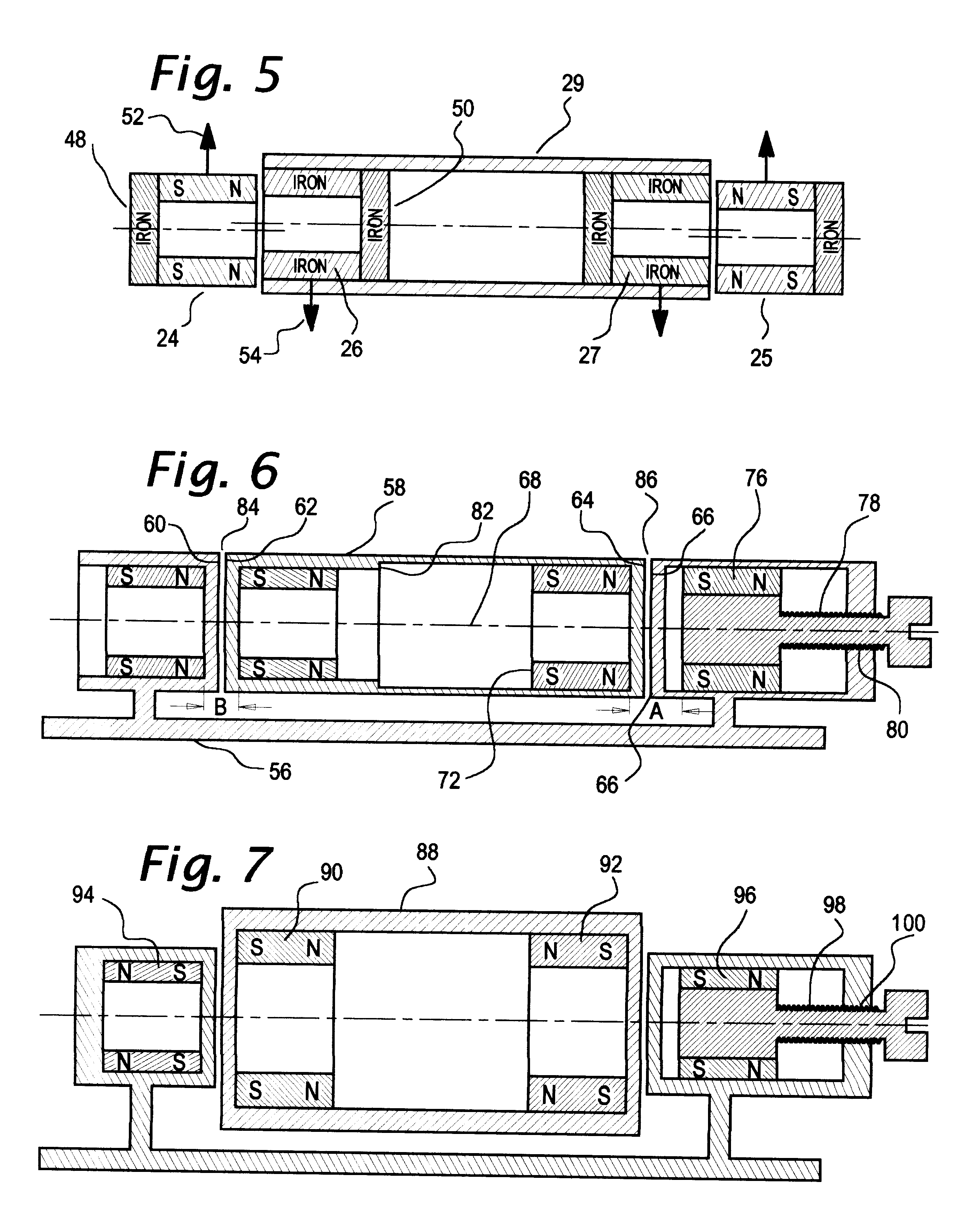

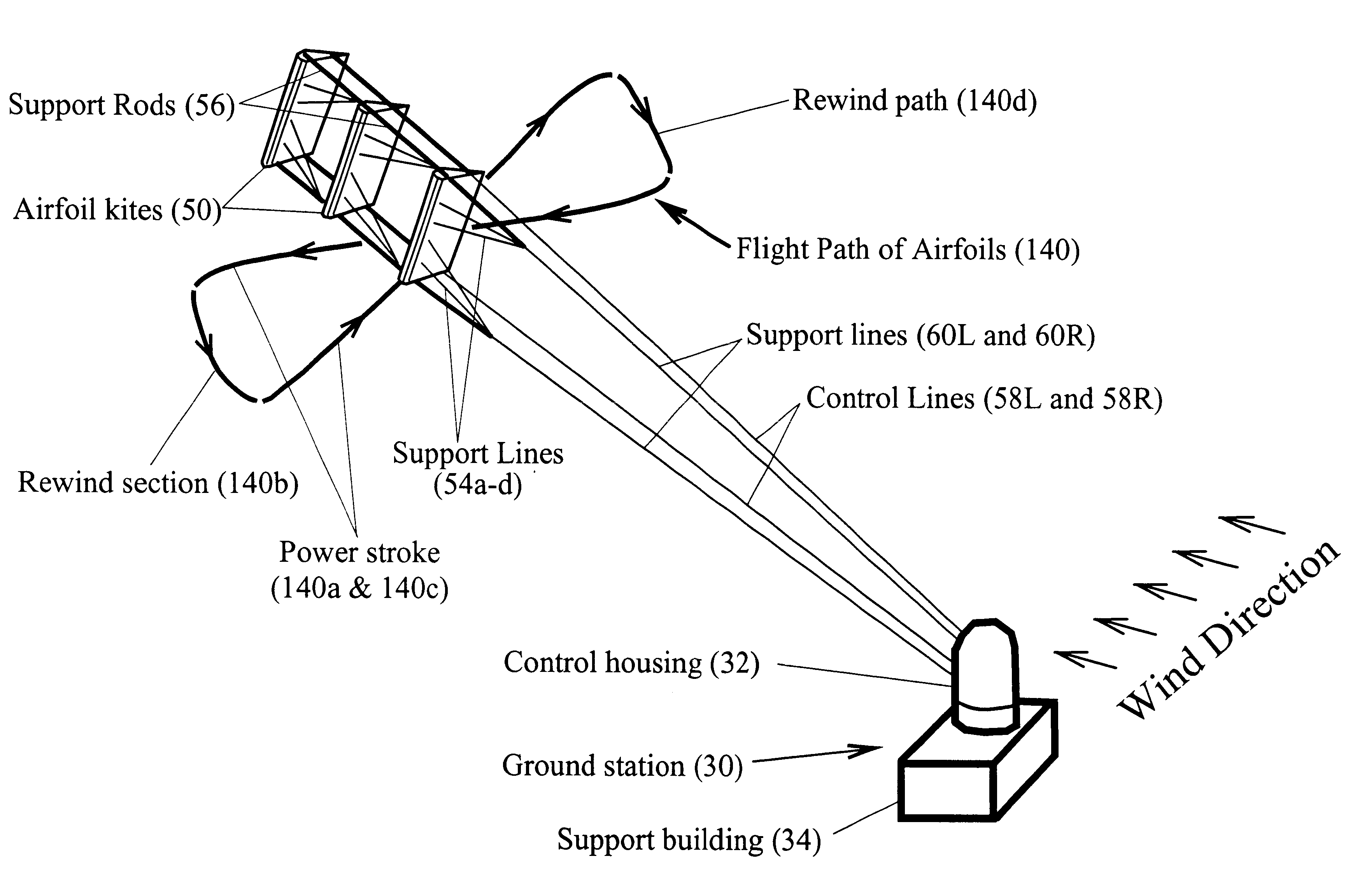

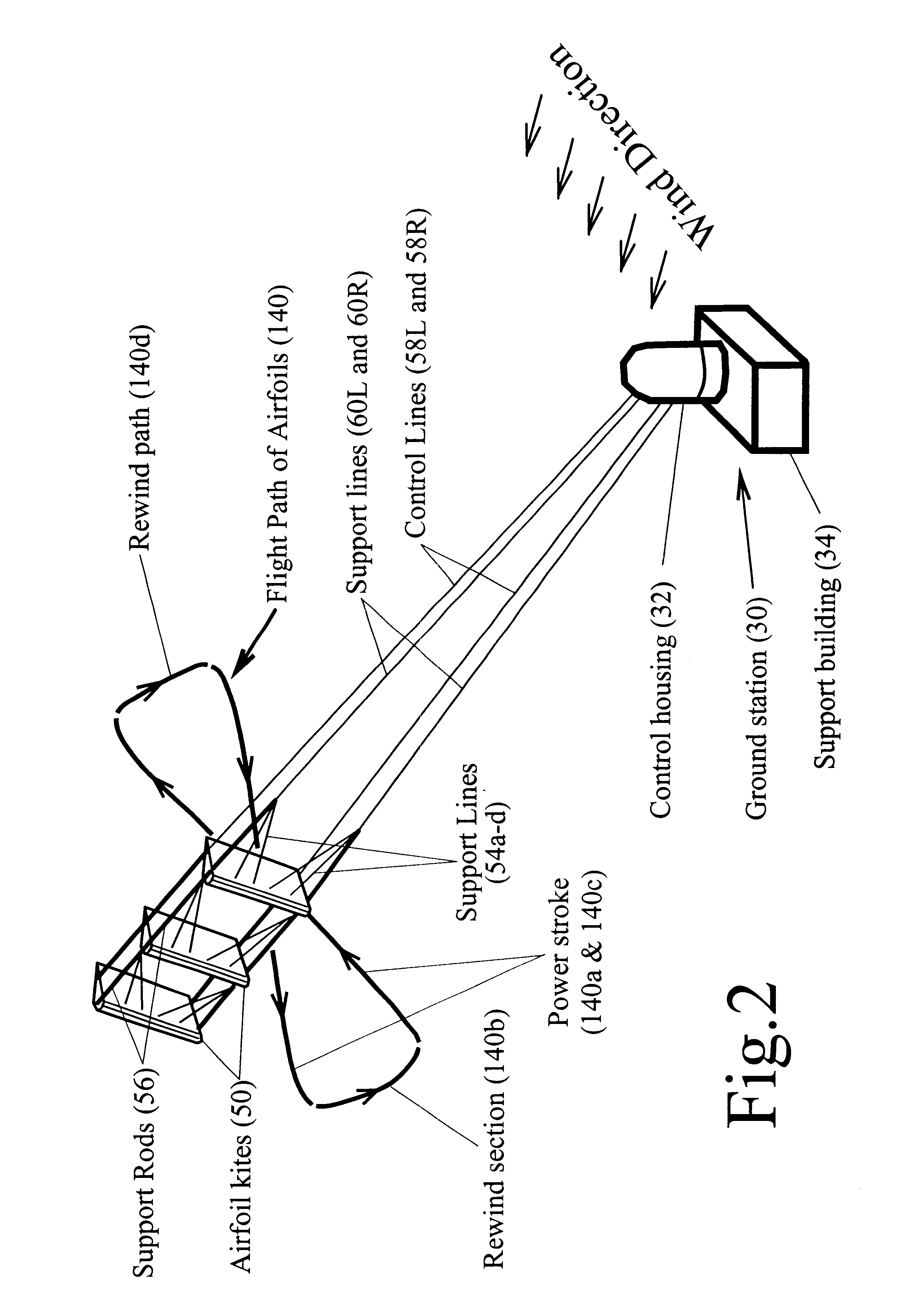

Axial-mode linear wind-turbine

A wind harnessing system using a plurality of self supporting airfoil kites 50 for production of useful power. The system comprising multiple airfoil kites 50 in tandem attached to a pivotal control housing 32 by control lines 58L and 58R and support lines 60L and 60R. Control lines 58L and 58R can change length with respect to the length of support lines 60L and 60R to control the airfoil kites' 50 angle-of-attack, pitch angle, direction of flight, and flight speed. The length of control lines 58L and 58R are controlled from ground station 30 by a movable pulley system in control housing 32 to adjust the airfoils' direction to follow a specific flight path 140. Control lines 58R and 58L and support lines 60R and 60L are also wound on a power shaft and pulley system in control housing 32. As the airfoil kites are propelled by the wind at very-high speed, the airfoils generate a powerful AXIAL force. The control lines 58L and 58R and support lines 60L and 60R are then reeled-out under this AXIAL tension causing the power shaft and pulley system in control housing 32 to turn a generator to generate electricity. After airfoil kites 50 have finished their reel-out power stroke 140a, the airfoil's pitch angle is made negative so they can be reeled-in by their control and support lines using a minimum of force along path 140b. Once the airfoils have been rewound to the proper distance, the airfoils are again angled for high-speed operation to generate powerful AXIAL force and reeled-out along 140c to provide another power stroke. The airfoil kites are then reeled-in again along path 140d and the entire process repeats starting with power stroke 140a. Since the force to rewind the airfoils is much less than the force generated during reel-out, there is net power generated.

Owner:RAGNER GARY DEAN

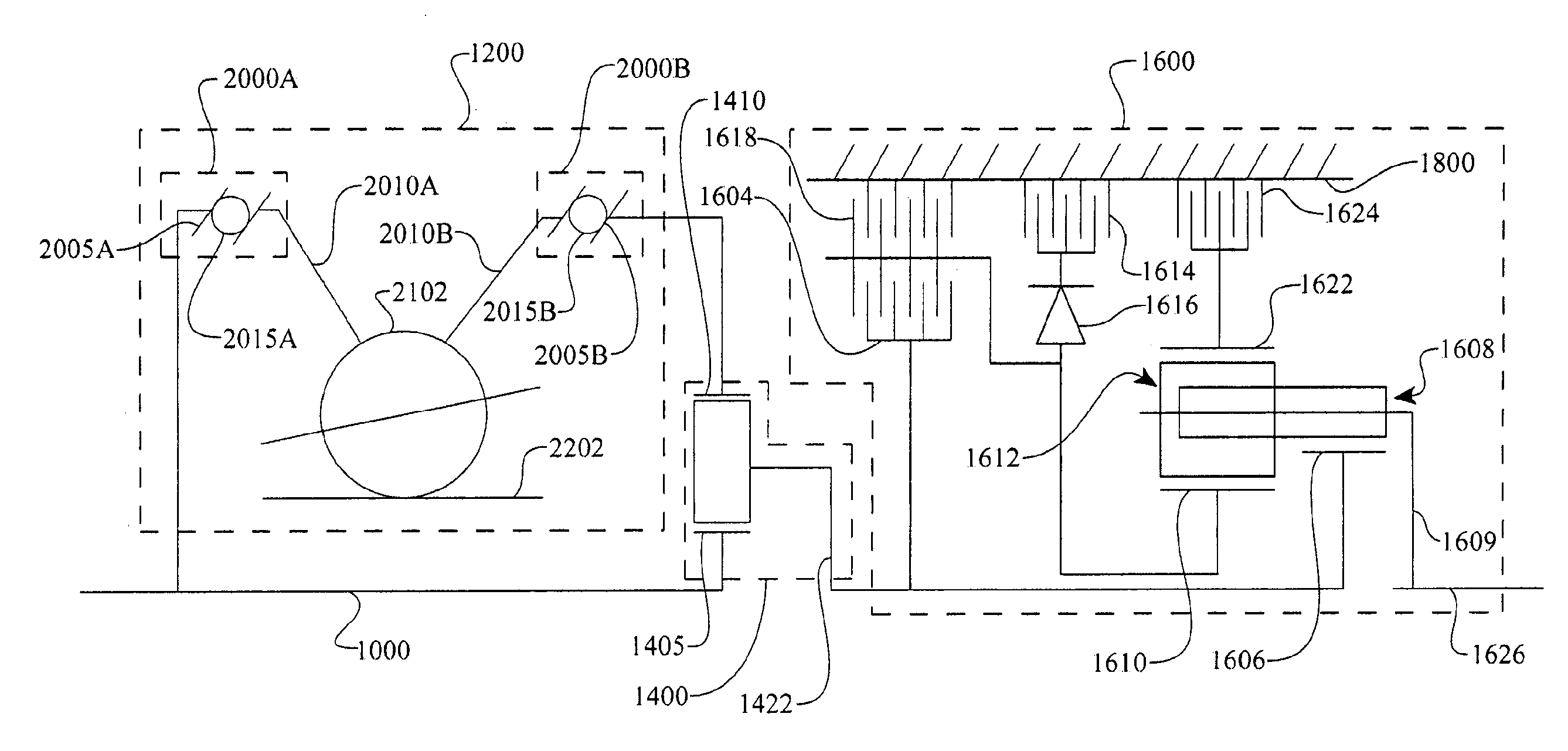

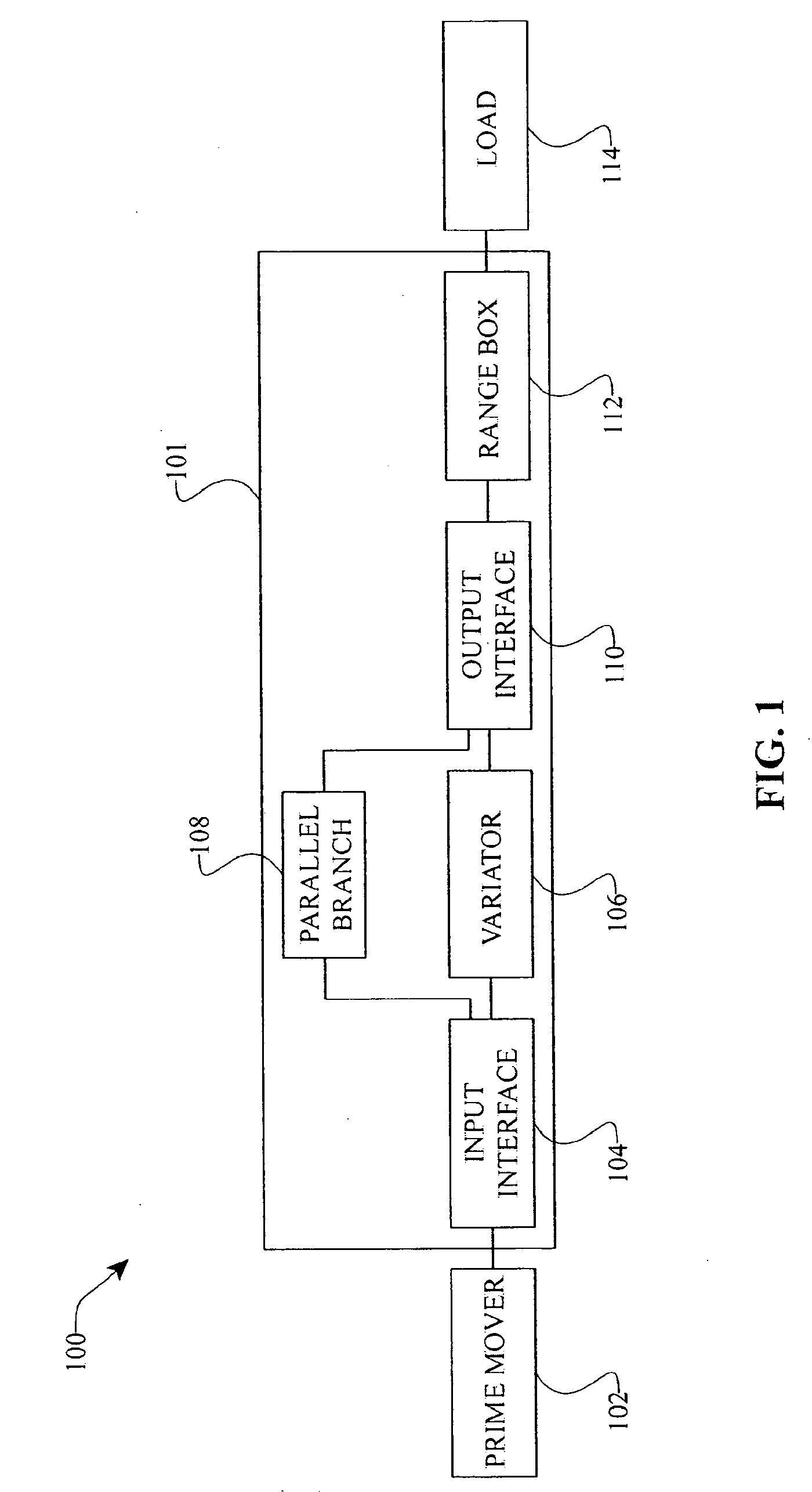

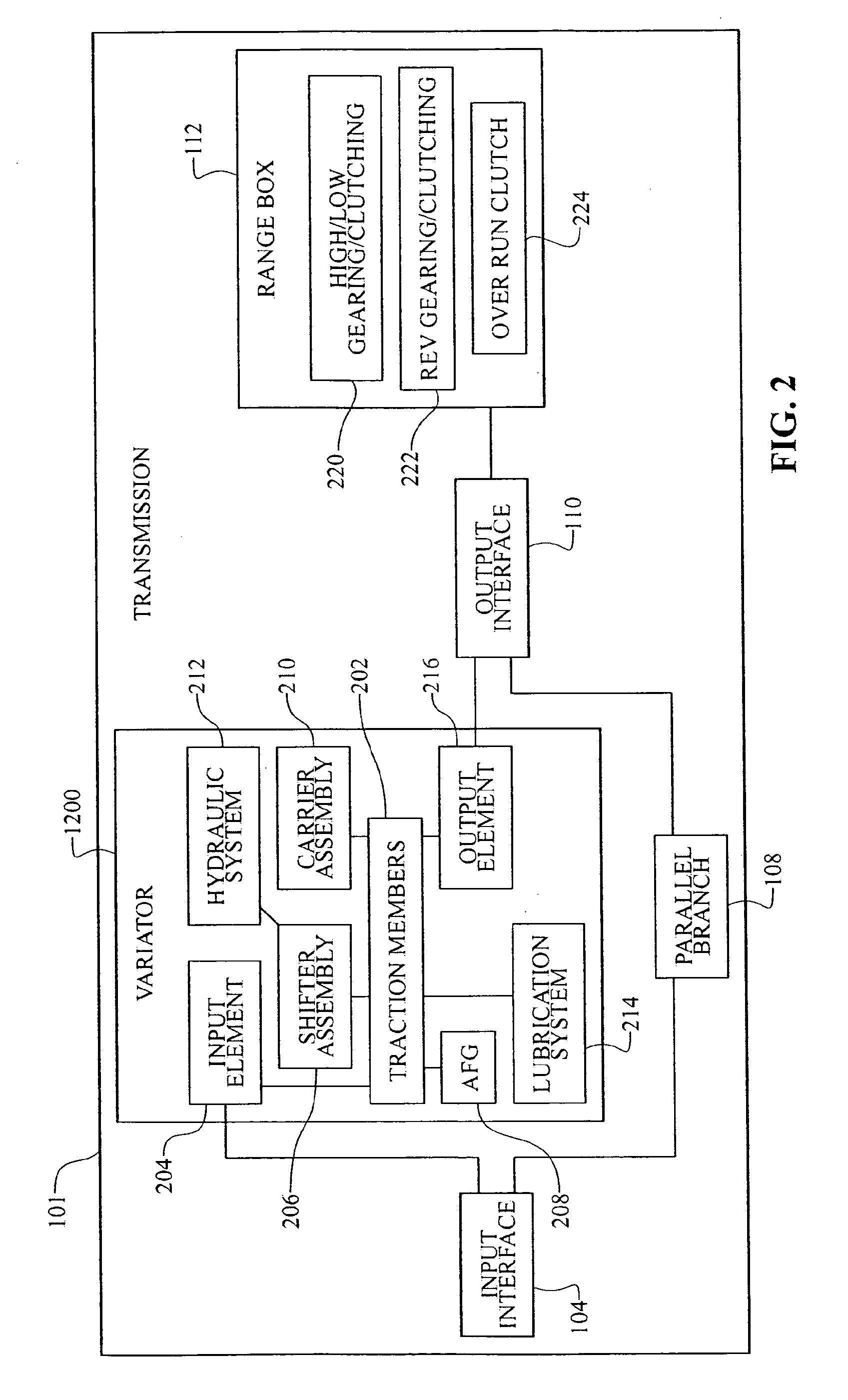

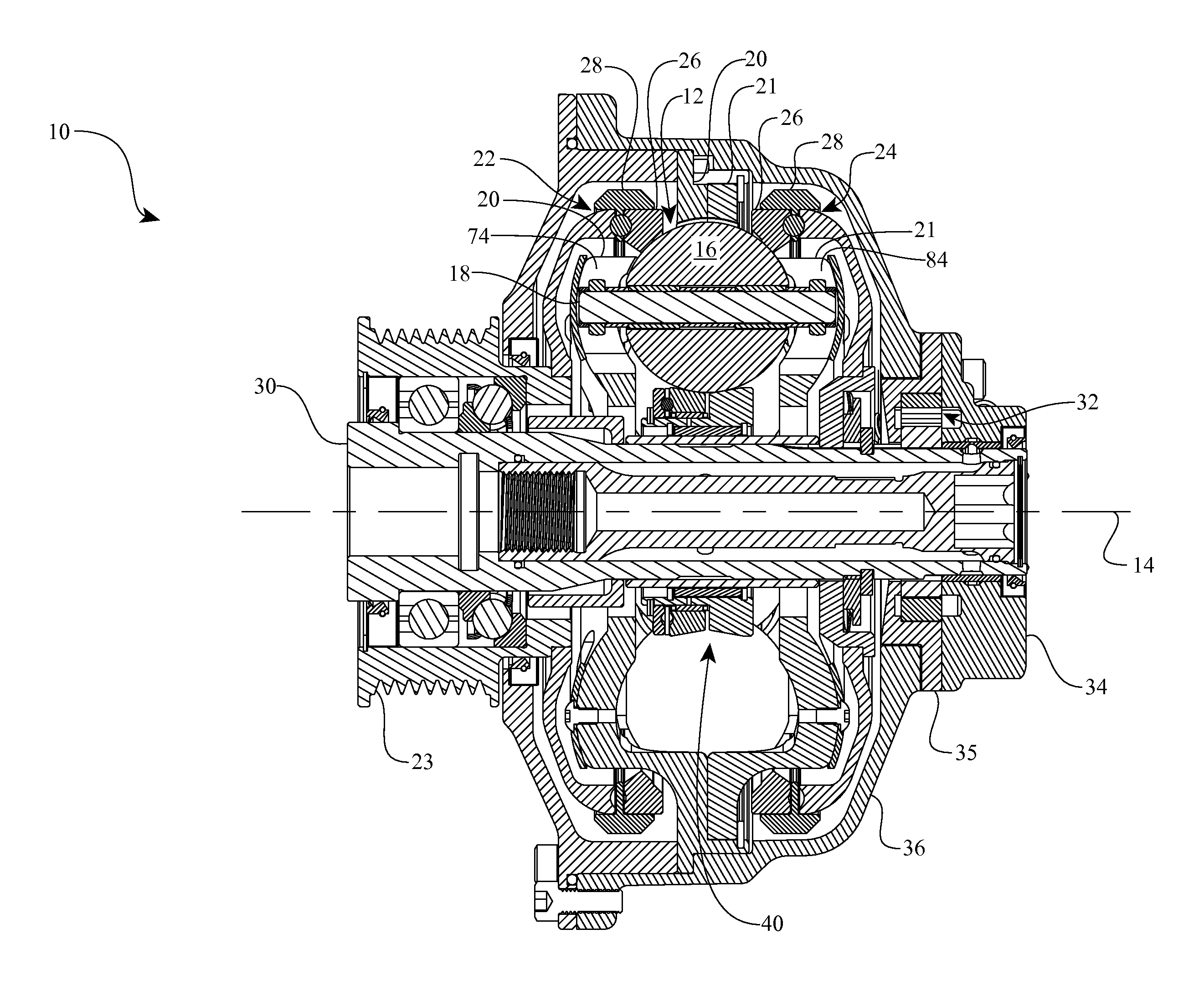

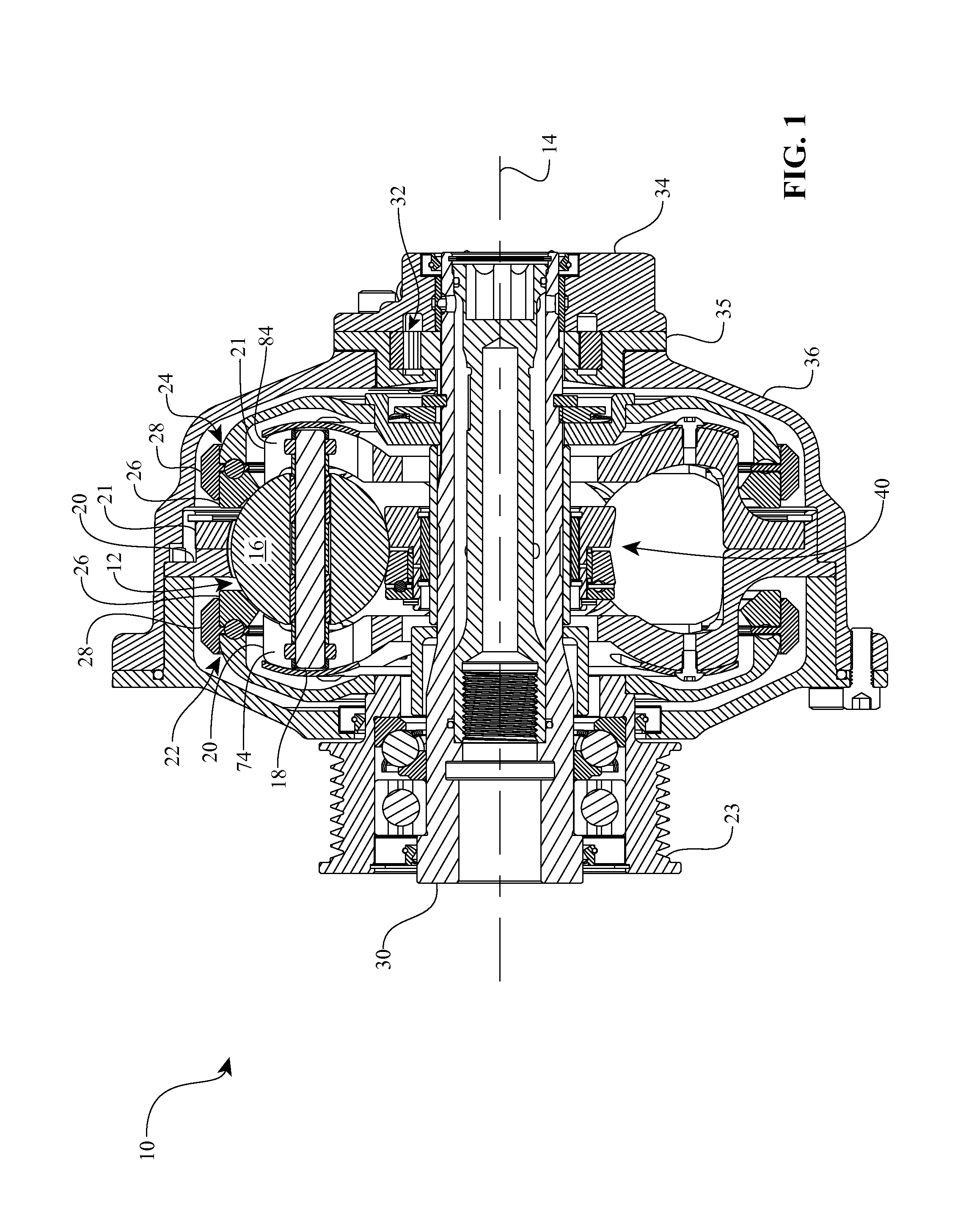

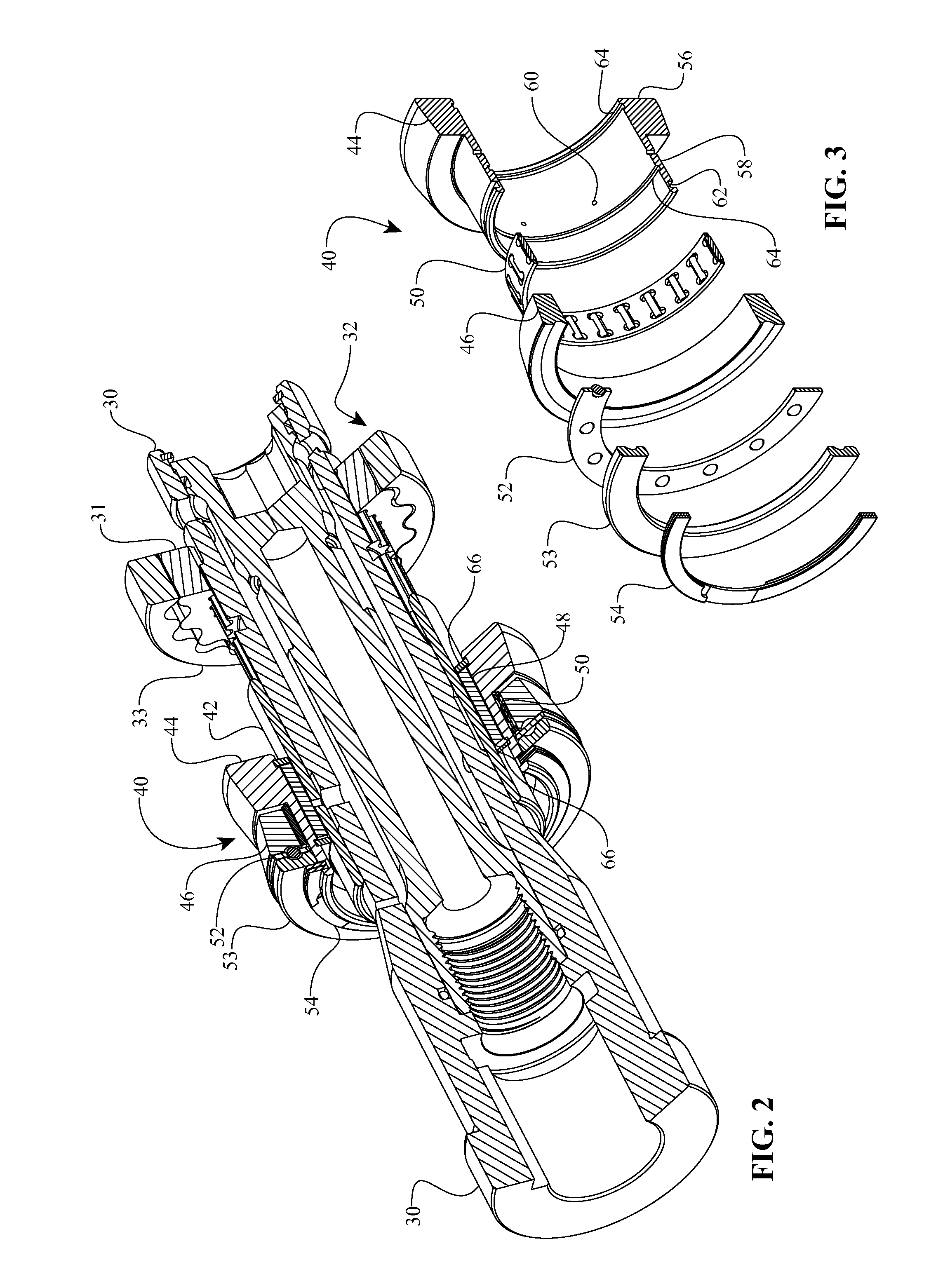

Continuously variable transmissions and methods therefor

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Various inventive shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. Embodiments of a transmission housing and bell housing are adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Various related devices include embodiments of, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies. FIG. 72 shows a torque-split ball-type rolling traction CVT with a ball-type rolling traction variator (1200) and planetary gearset (1400) which is followed by a rangebox (1600).

Owner:FALLBROOK INTPROP COMPANY

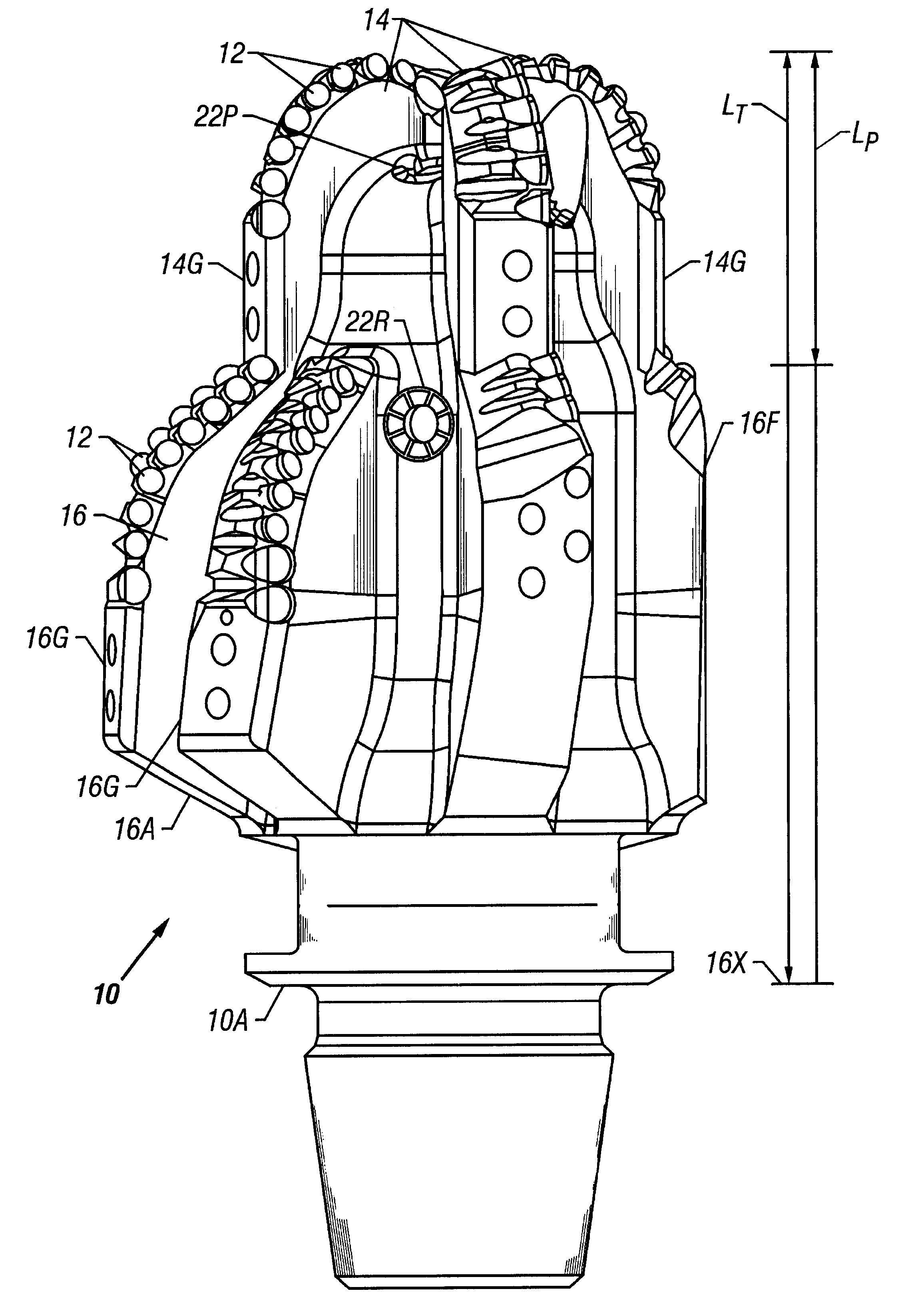

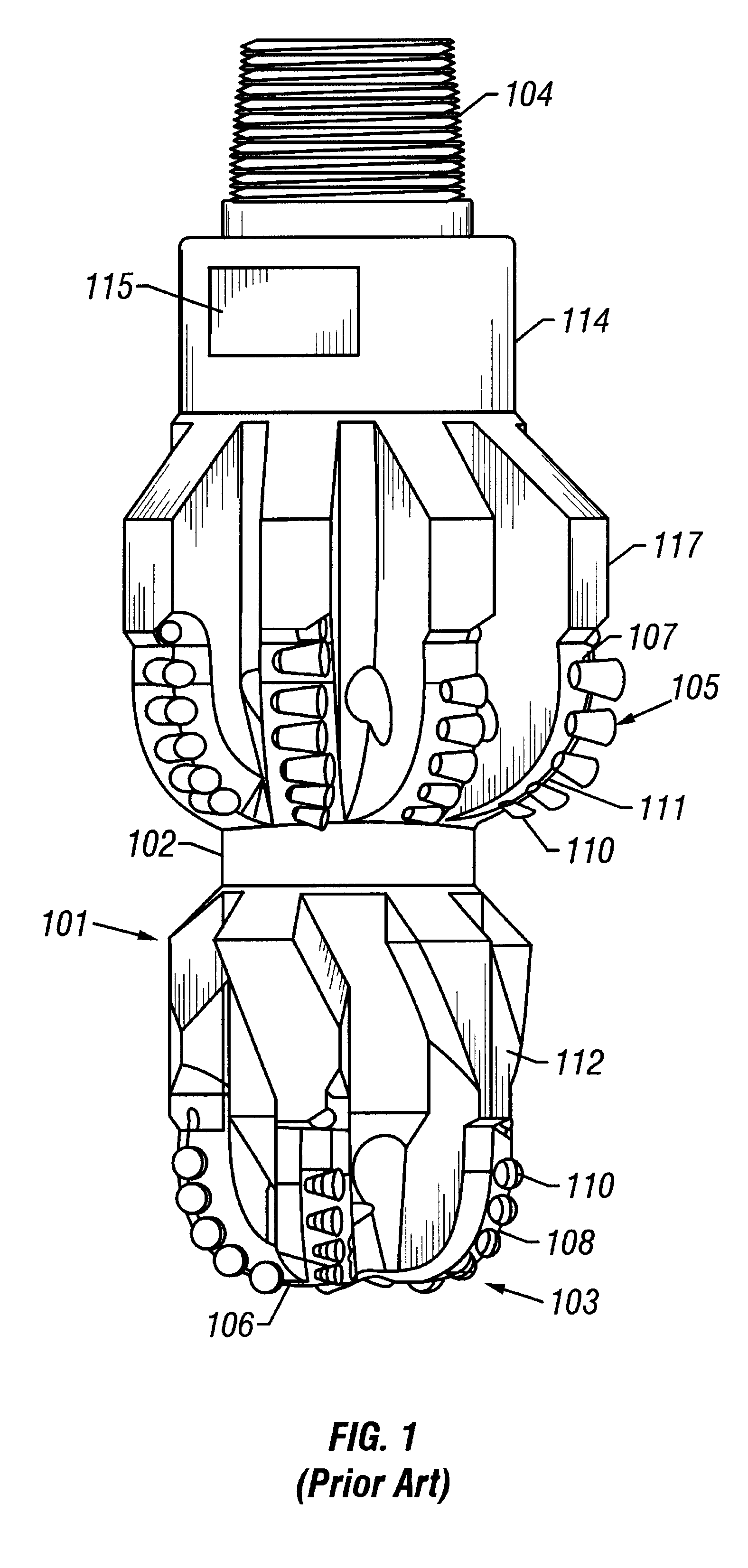

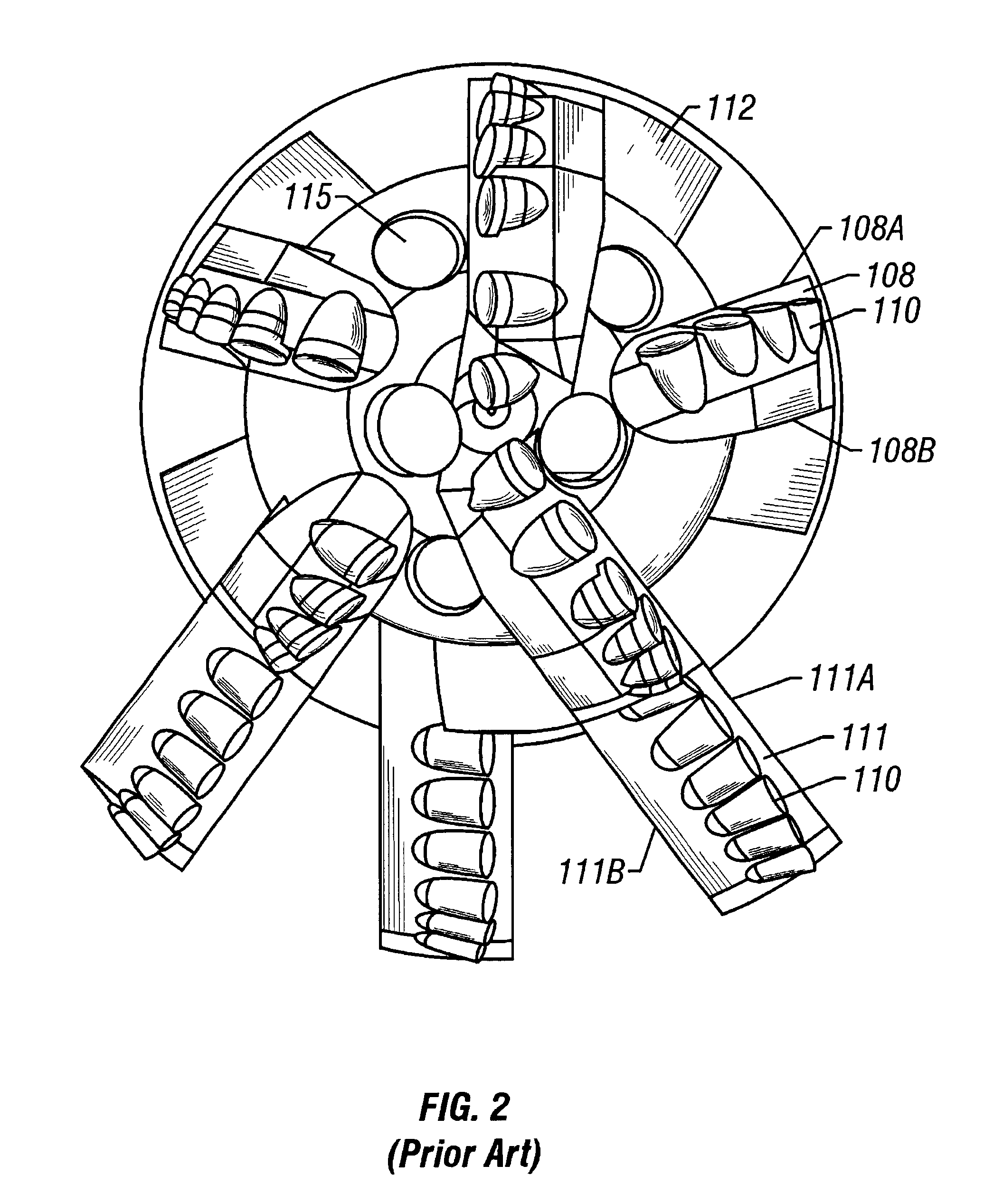

Bi-centered drill bit having improved drilling stability mud hydraulics and resistance to cutter damage

A bi-center drill bit includes pilot and reaming blades affixed to a body at azimuthally spaced locations. The blades have PDC cutters attached at selected positions. In one aspect, the pilot blades form a section having length along the bit axis less than about 80 percent of a diameter of the section. In another aspect, selected pilot blades and corresponding reaming blades are formed into single spiral structures. In another aspect, shapes and positions of the blades and inserts are selected so that lateral forces exerted by the reaming and the pilot sections are balanced as a single structure. Lateral forces are preferably balanced to within 10 percent of the total axial force on the bit. In another aspect, the center of mass of the bit is located less than about 2.5 percent of the diameter of the bit from the axis of rotation. In another aspect, jets are disposed in the reaming section oriented so that their axes are within about 30 degrees of normal to the axis of the bit. In another aspect, the reaming blades are shaped to conform to the radially least extensive, from the longitudinal axis, of a pass-through circle or a drill circle, so the cutters on the reaming blades drill at the drill diameter, without contact to the cutters on the reaming blades when the bit passes through an opening having about the pass-through diameter.

Owner:SMITH INT INC

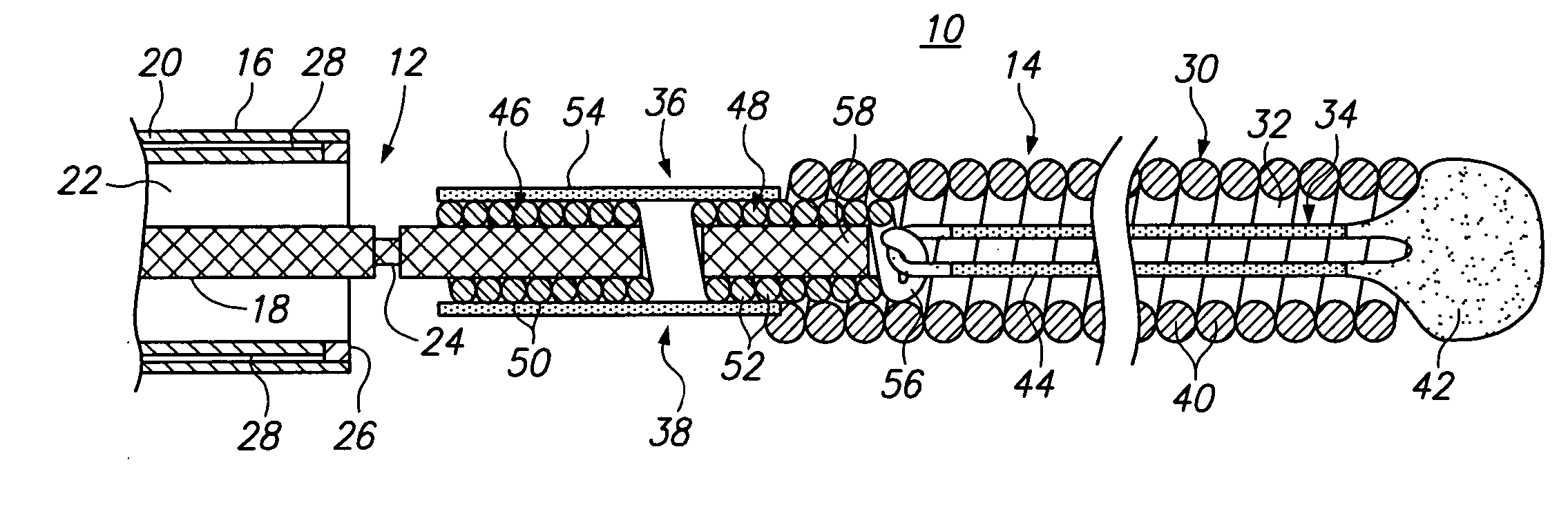

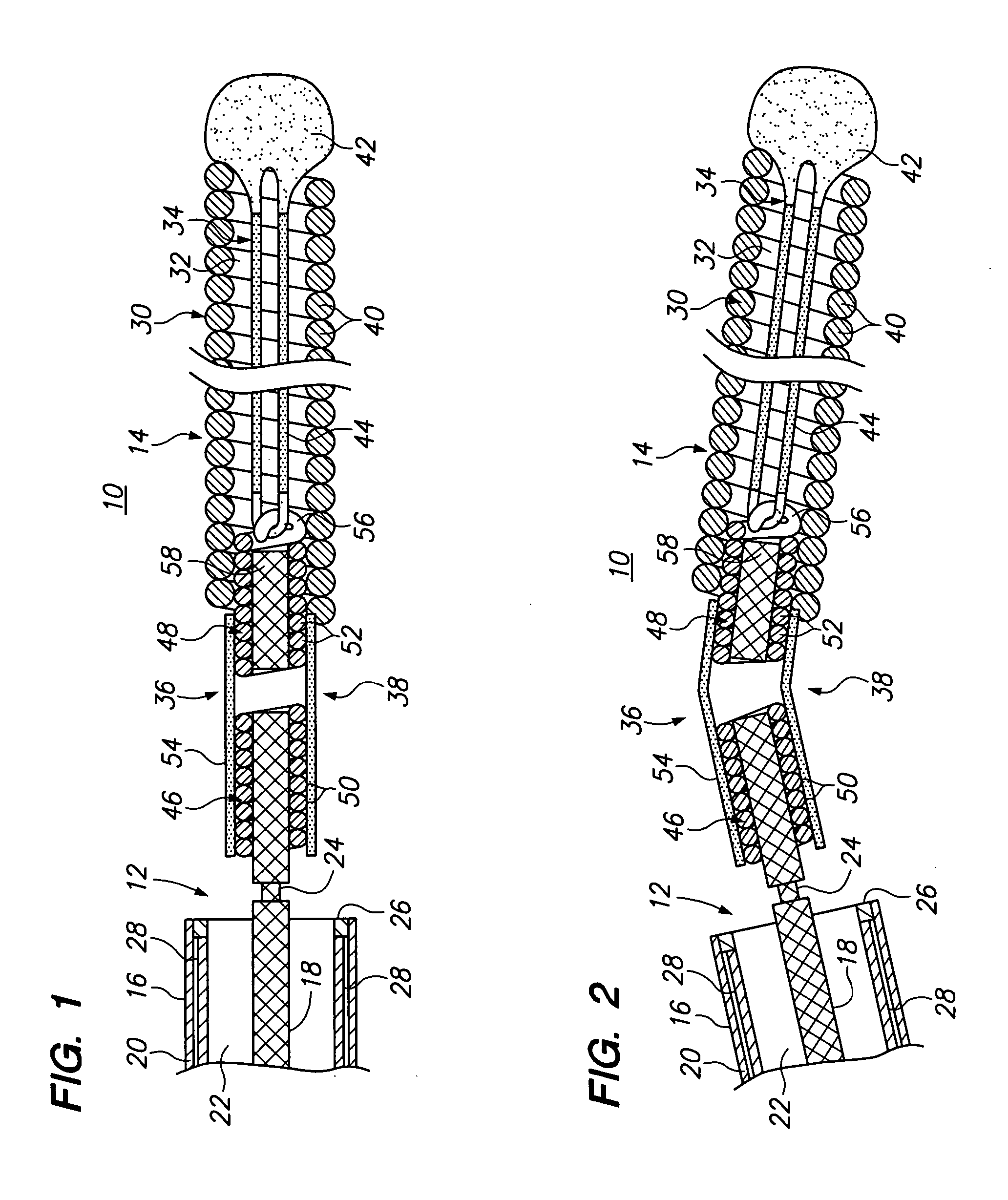

Suture anchor

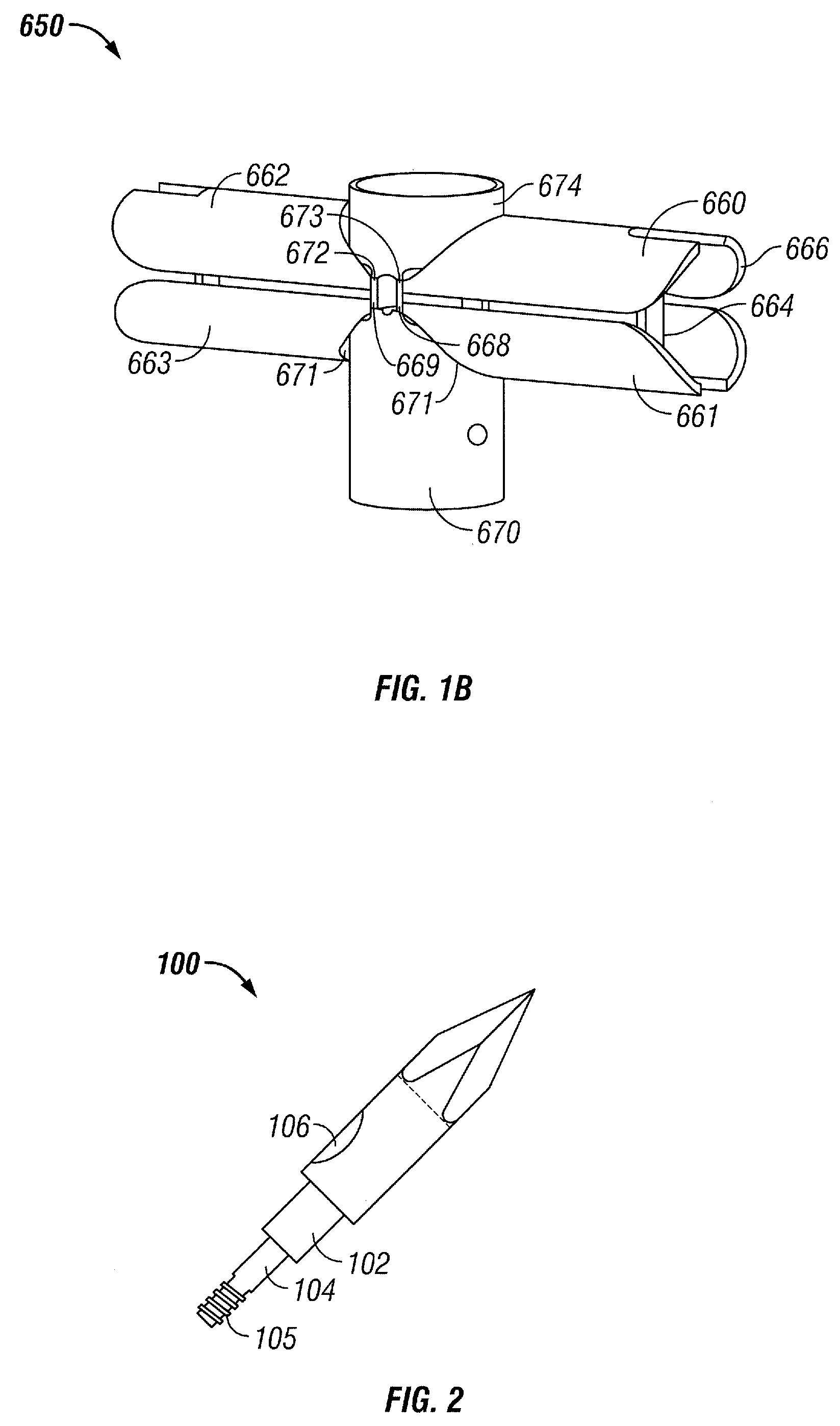

A bone anchor is described having pre-attached suture material. After insertion, lateral wings can be deployed on the bone anchor to prevent anchor pull-out. The suture may be attached at the tip of the anchor by tying it to a wire hook secured in a cavity in the anchor tip. The anchor may be inserted and deployed using an anchor inserter that is configured to apply an axial force to the anchor, thereby deforming the anchor to form the lateral wings.

Owner:SCOTT W TATE

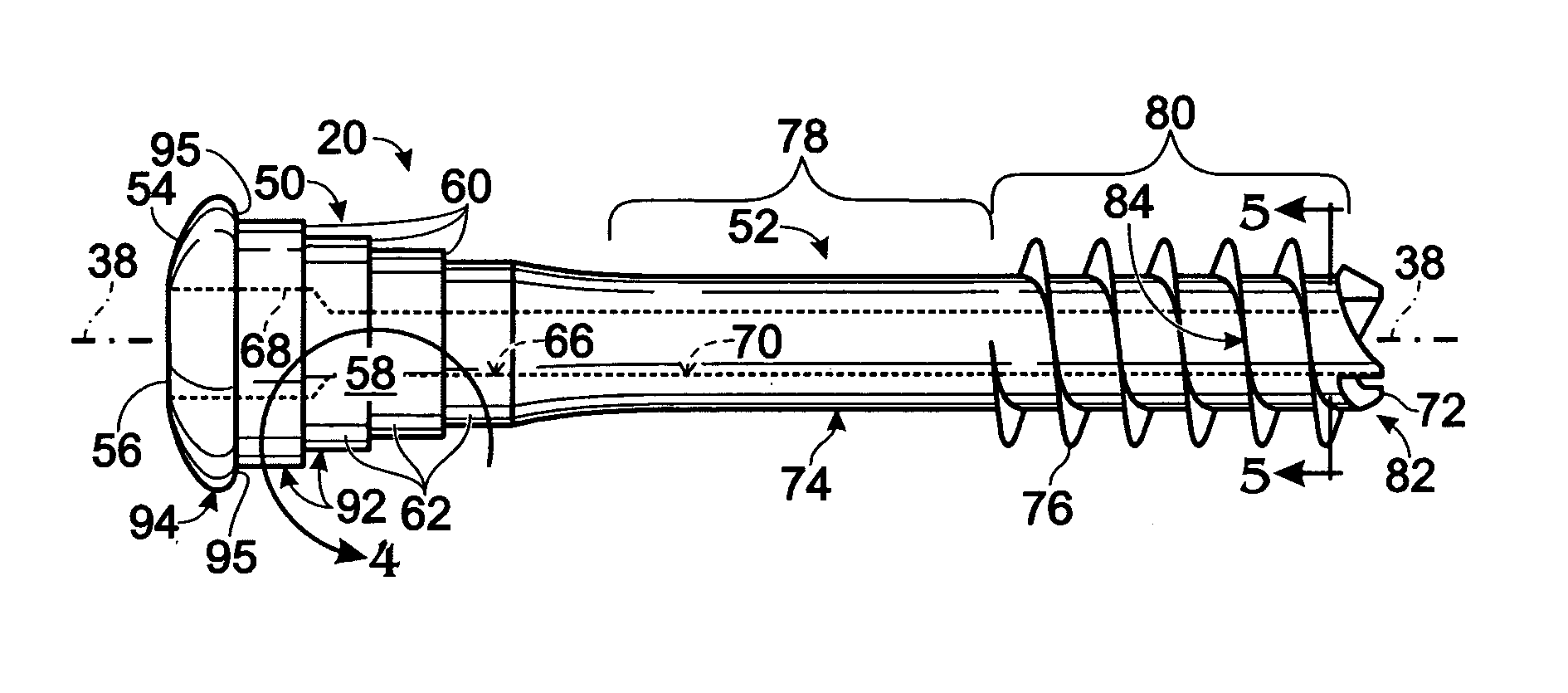

Bone screws

Bone screws, and methods of using bone screws, for compression of a bone. The bone screw may include a head configured to exert an axial force selectively on spaced regions of the bone. The head may be fixed, rotatable, and / or slidable relative to a distal, shank portion of the bone screw.

Owner:ACUMED

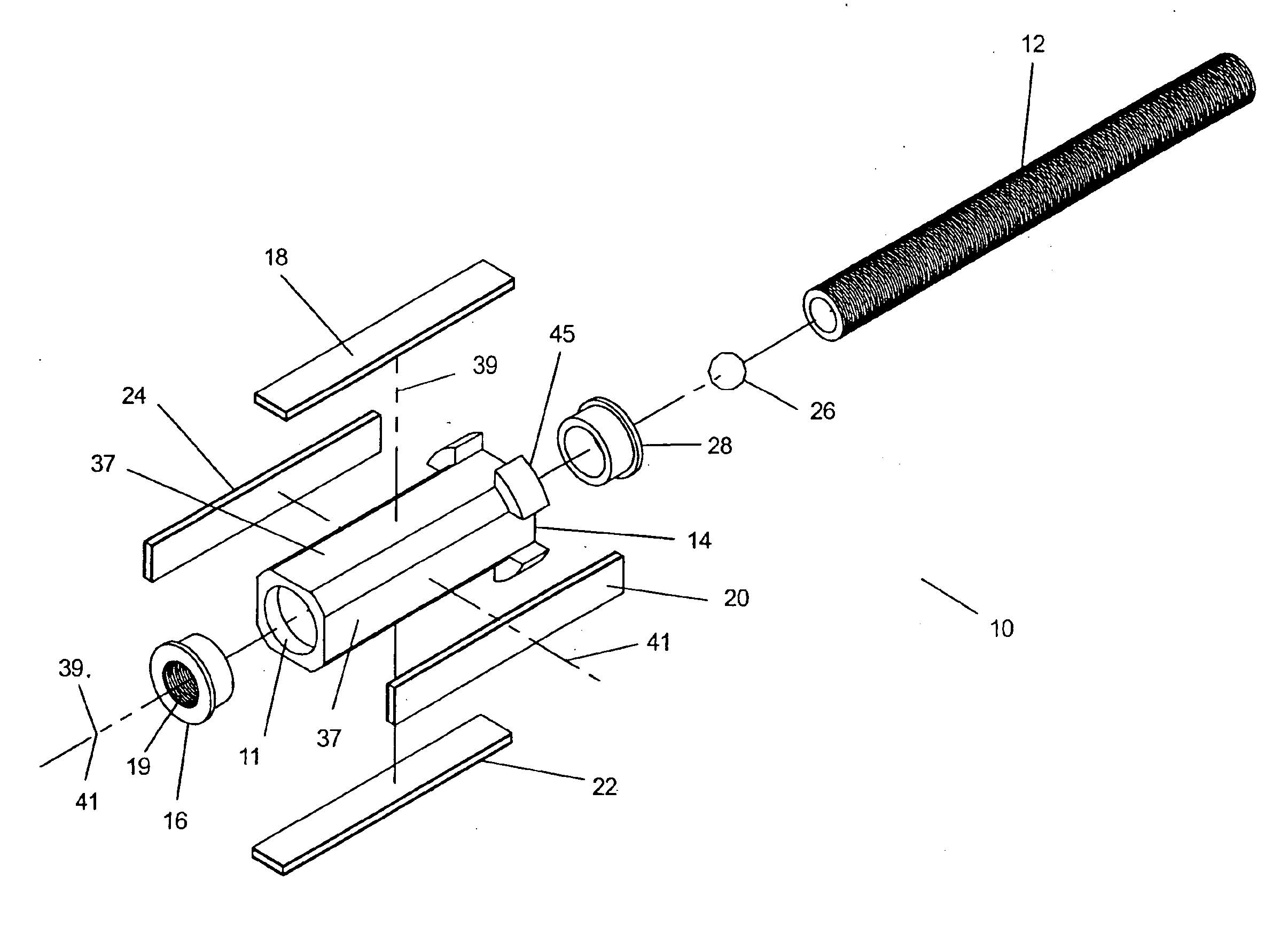

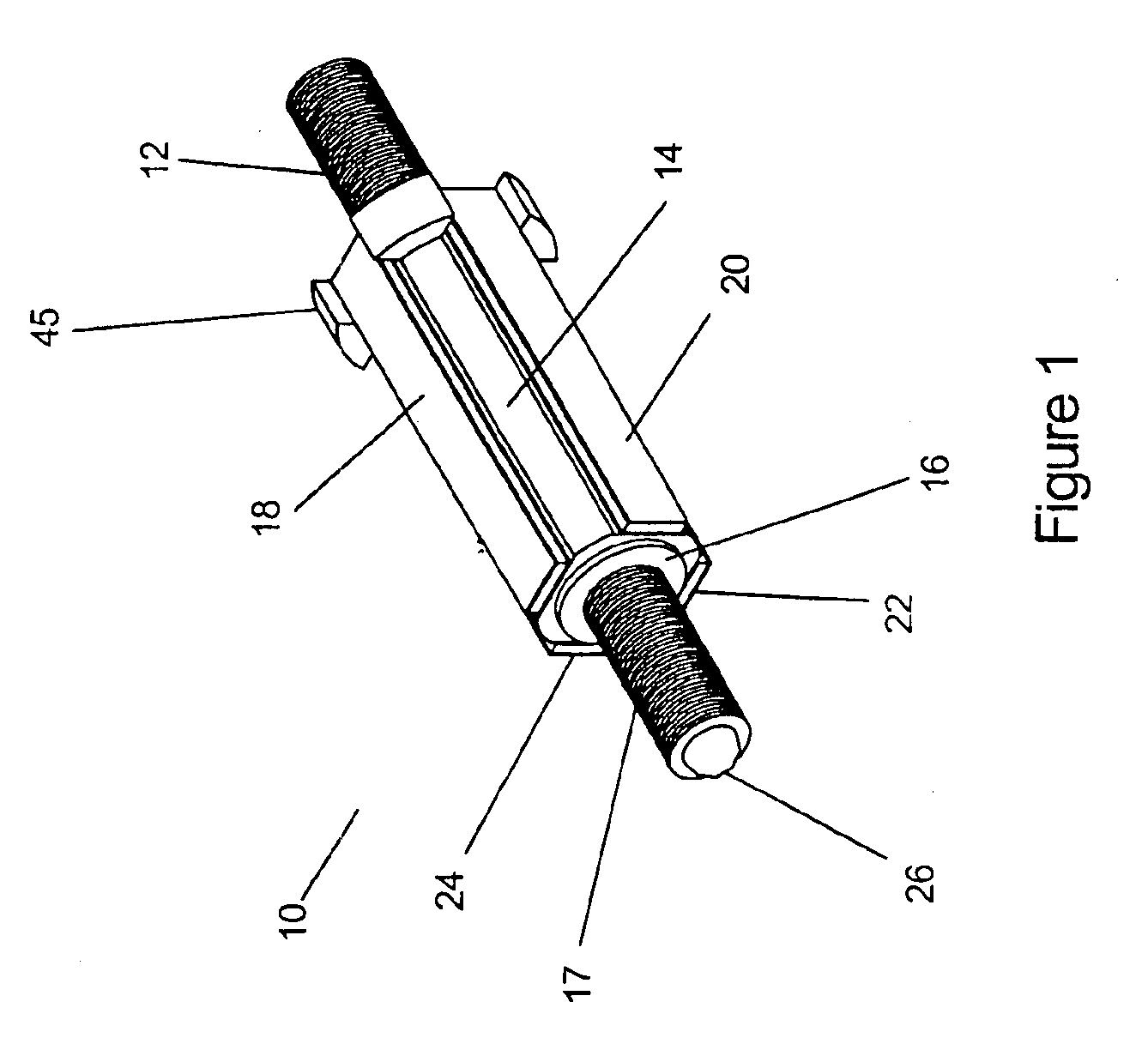

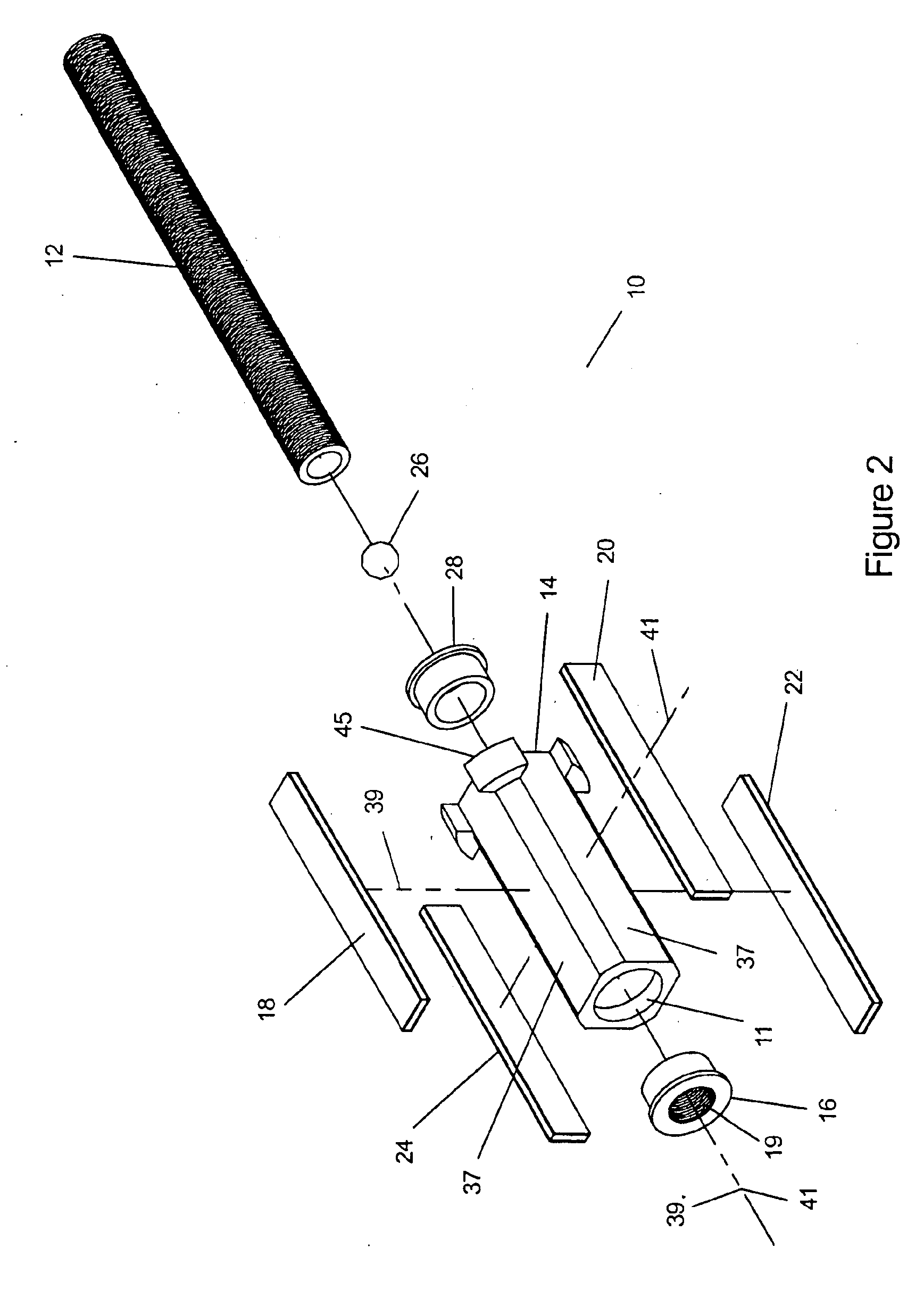

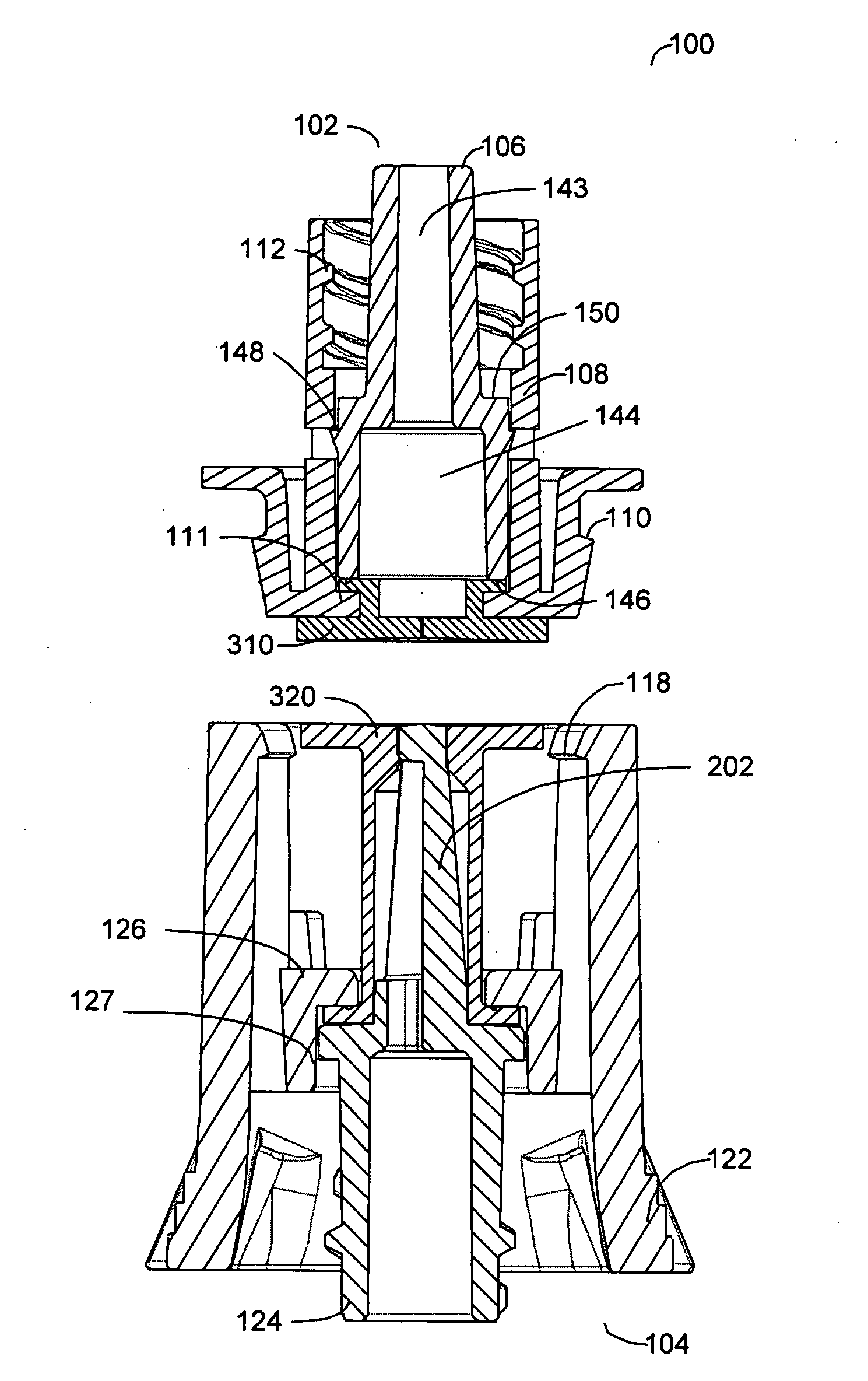

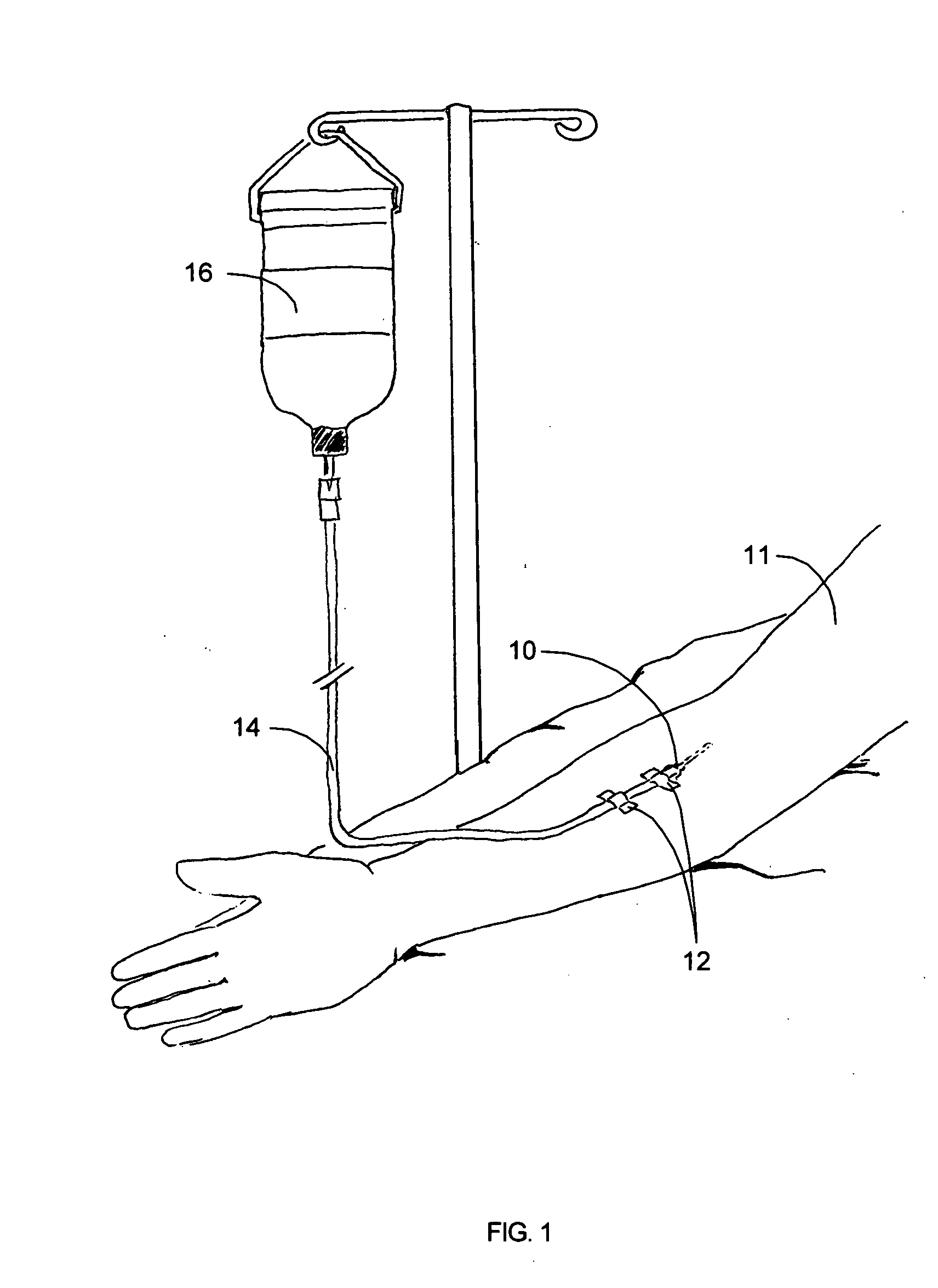

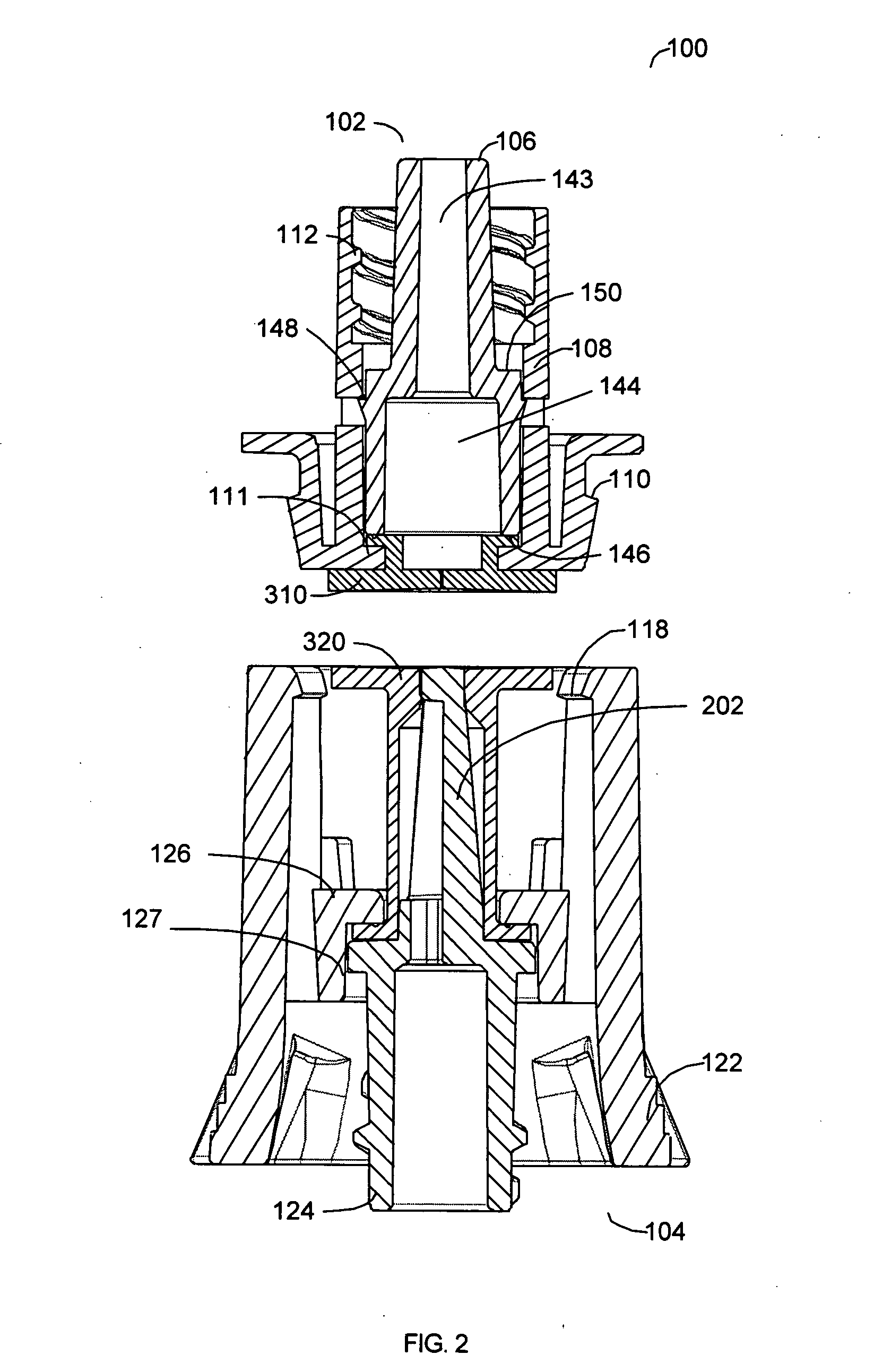

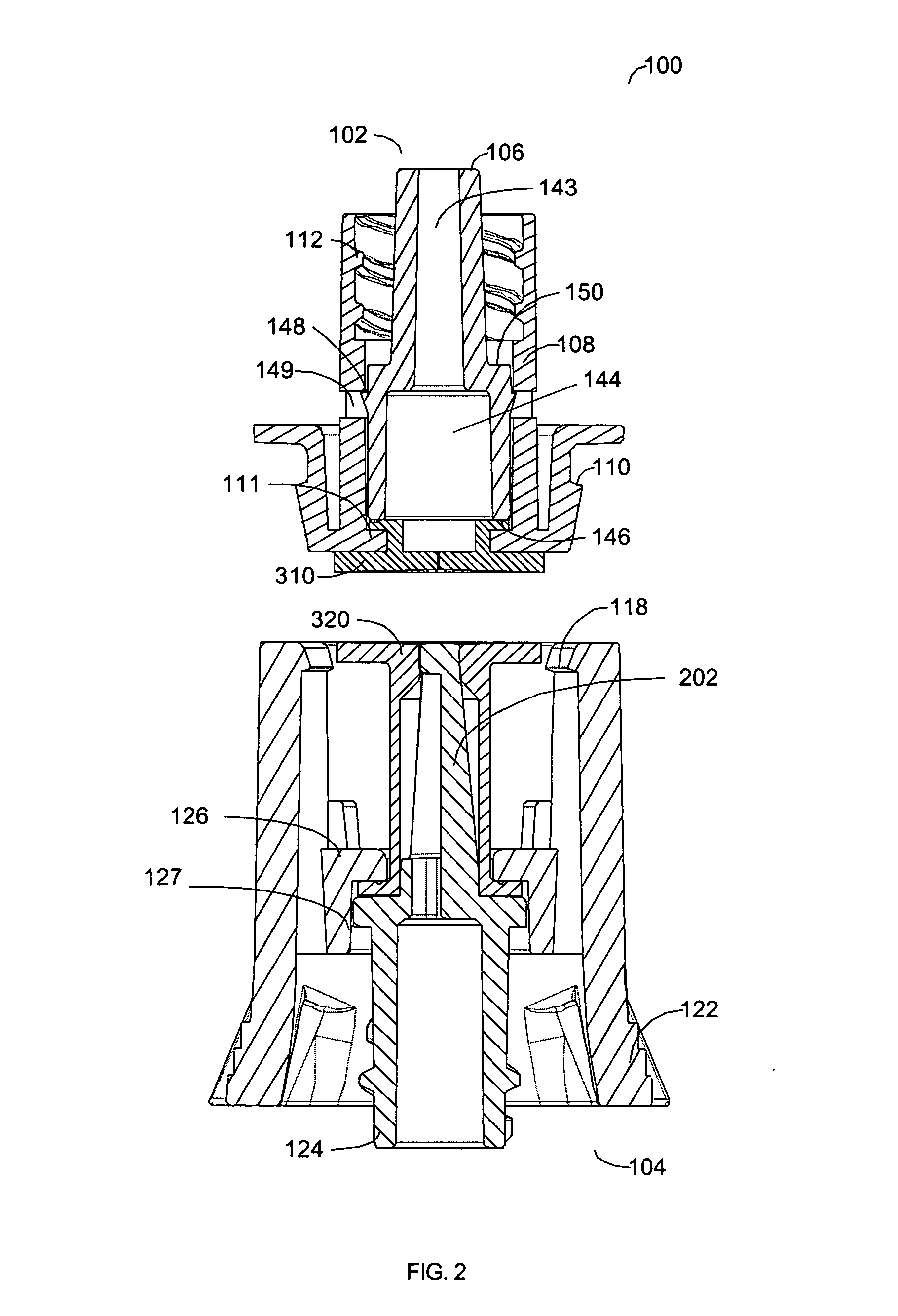

Reconnectable disconnect device for fluid transfer line

InactiveUS20060129109A1Avoid injuryEasy to disinfectIntravenous devicesValvesMedical productAxial force

An improved disconnect device suitable for use with an IV tube or other medical tubing device which can be either manually disconnected or automatically disconnected by the application of an axial force sufficiently low to prevent patient injury; which can be sterilely reattached after disconnection; which allows fluid flow in either direction; which shuts off fluid flow from both directions when disconnected; and which can be simply and inexpensively manufactured and assembled with techniques common to the injection molding, and medical products manufacturing industry.

Owner:SHAW SCOTT RANDALL +1

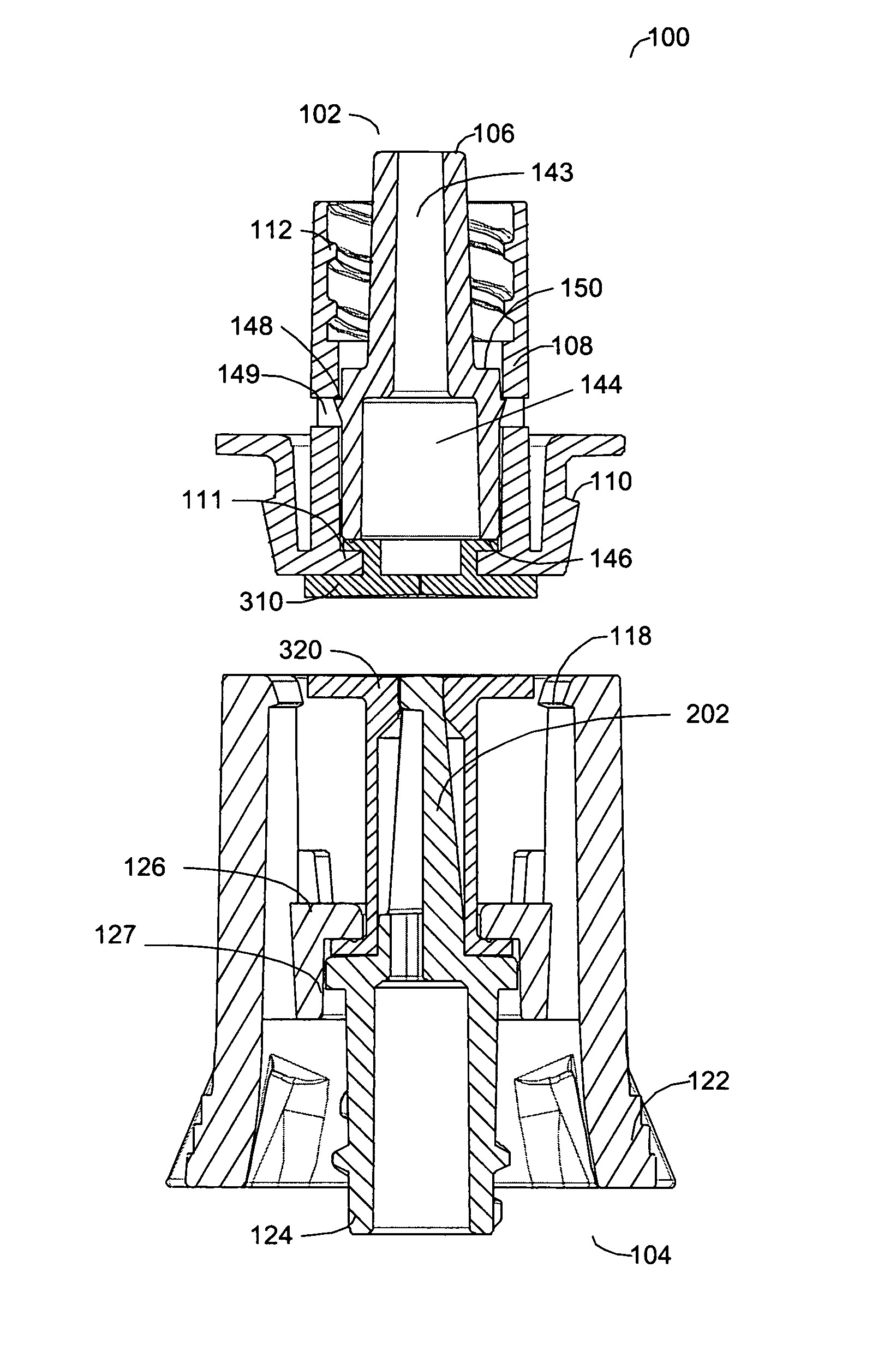

Implantable hemodialysis access device

InactiveUS6962577B2Extend equipment lifeLess traumaPharmaceutical delivery mechanismMedical devicesHaemodialysis machineDilator

A hemodialysis port comprising a flexible housing member defining one or more ports. Each port has a selectively-permeable septum member disposed thereon to permit medical devices, for example, Huber needles, sheath and / or dilators to be inserted therein. At the interface between the housing and the septum, a spring member is provided to provide an axial force on the septum which seals the puncture created by the aforementioned medical devices. In one exemplary embodiment, the hemodialysis access port of the present invention is comprised of a plurality of ports designed for multiple hemodialysis treatments over the life of the port. In other exemplary embodiments, the bottom of each port may comprise a needle stop insert formed of, for example, metal, titanium, stainless steel or ceramic.

Owner:VERSAGO VASCULAR ACCESS

Reconnectable disconnect device for fluid transfer line

InactiveUS20050090805A1Simply and inexpensively manufacturedSimply and inexpensively and assembledCatheterTube connectorsMedical productAxial force

An improved disconnect device suitable for use with an IV tube or other medical tubing device which can be either manually disconnected or automatically disconnected by the application of an axial force sufficiently low to prevent patient injury; which can be sterilely reattached after disconnection; which allows fluid flow in either direction; which shuts off fluid flow from both directions when disconnected; and which can be simply and inexpensively manufactured and assembled with techniques common to the injection molding, and medical products manufacturing industry.

Owner:SHAW SCOTT RANDALL +1

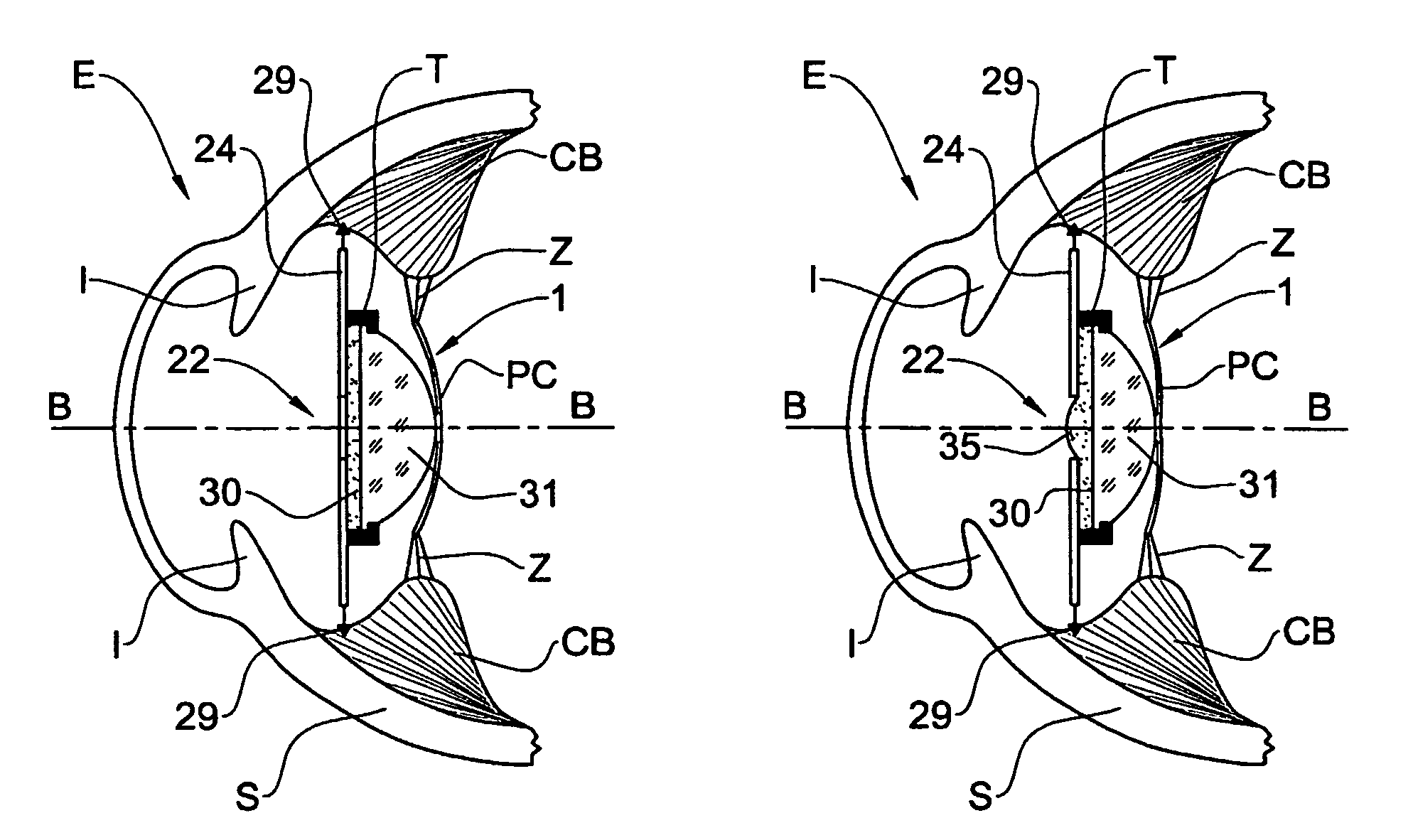

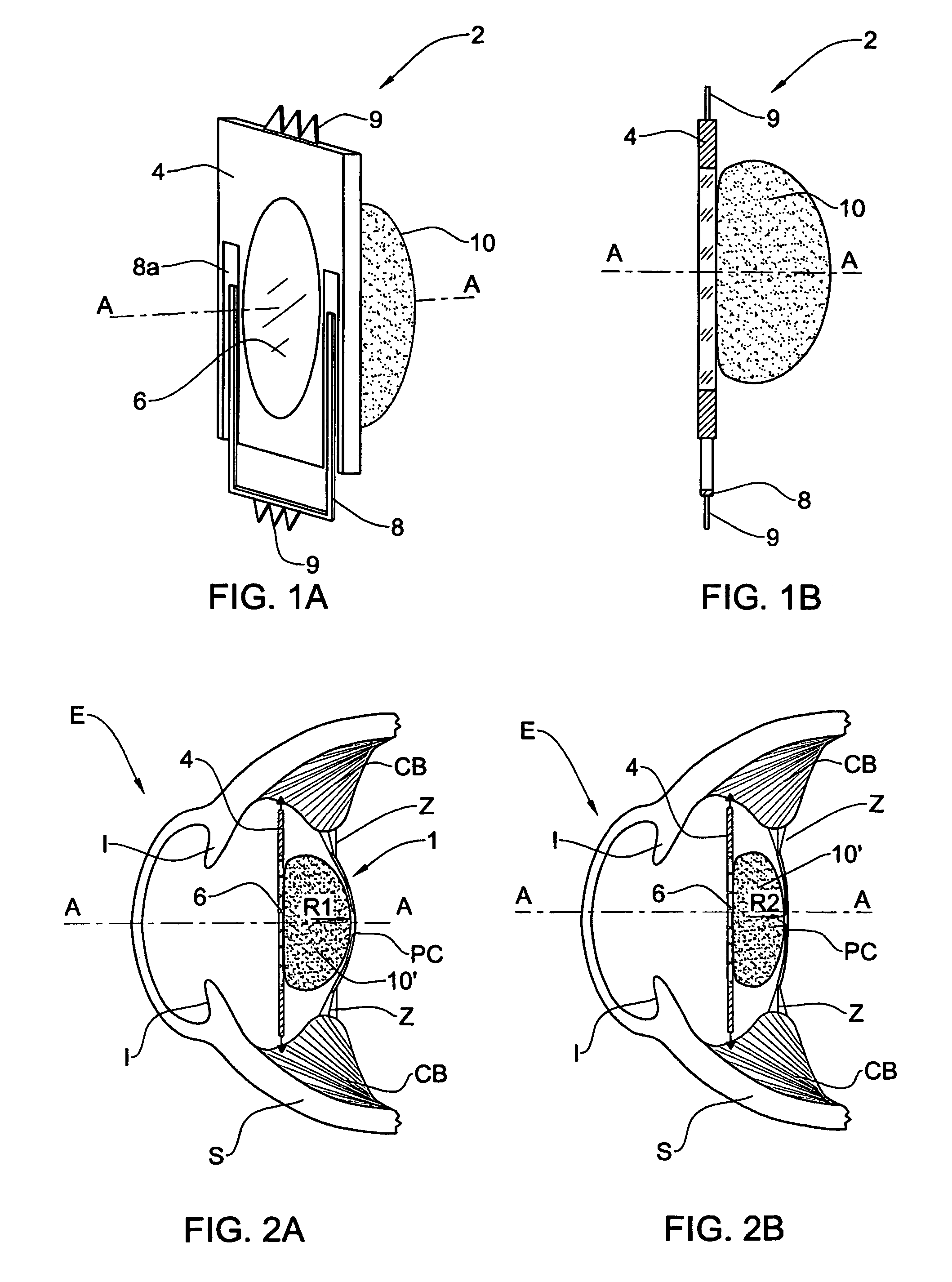

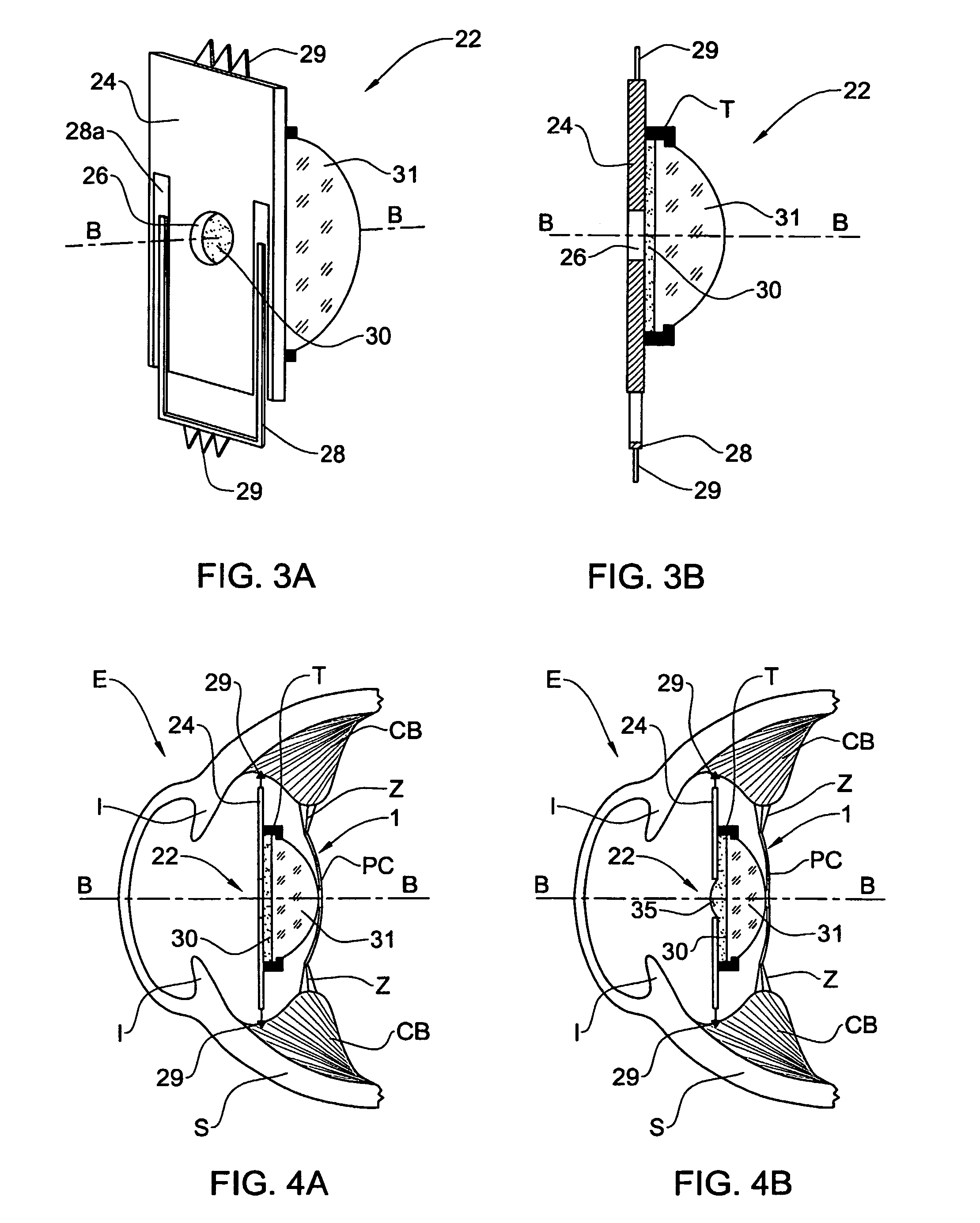

Accommodating lens assembly

InactiveUS7220279B2Large variety of designSimple and inexpensive constructionIntraocular lensCamera lensOptical axis

An accommodating lens assembly having an optical axis and being adapted to be implanted in a posterior chamber of an eye having a capsular unit located therein. The assembly includes a rigid haptics element adapted to secure the assembly within the posterior chamber outside said capsular unit. The element is transparent at least in a region around the axis. The assembly further includes a resilient body adapted to operate as a lens having a curved surface when pressed up against the region of the haptics element by an axial force applied thereto by the capsular unit. A change in this force causes a change in a radius of curvature for the curved surface.

Owner:FORSIGHT VISION5 INC

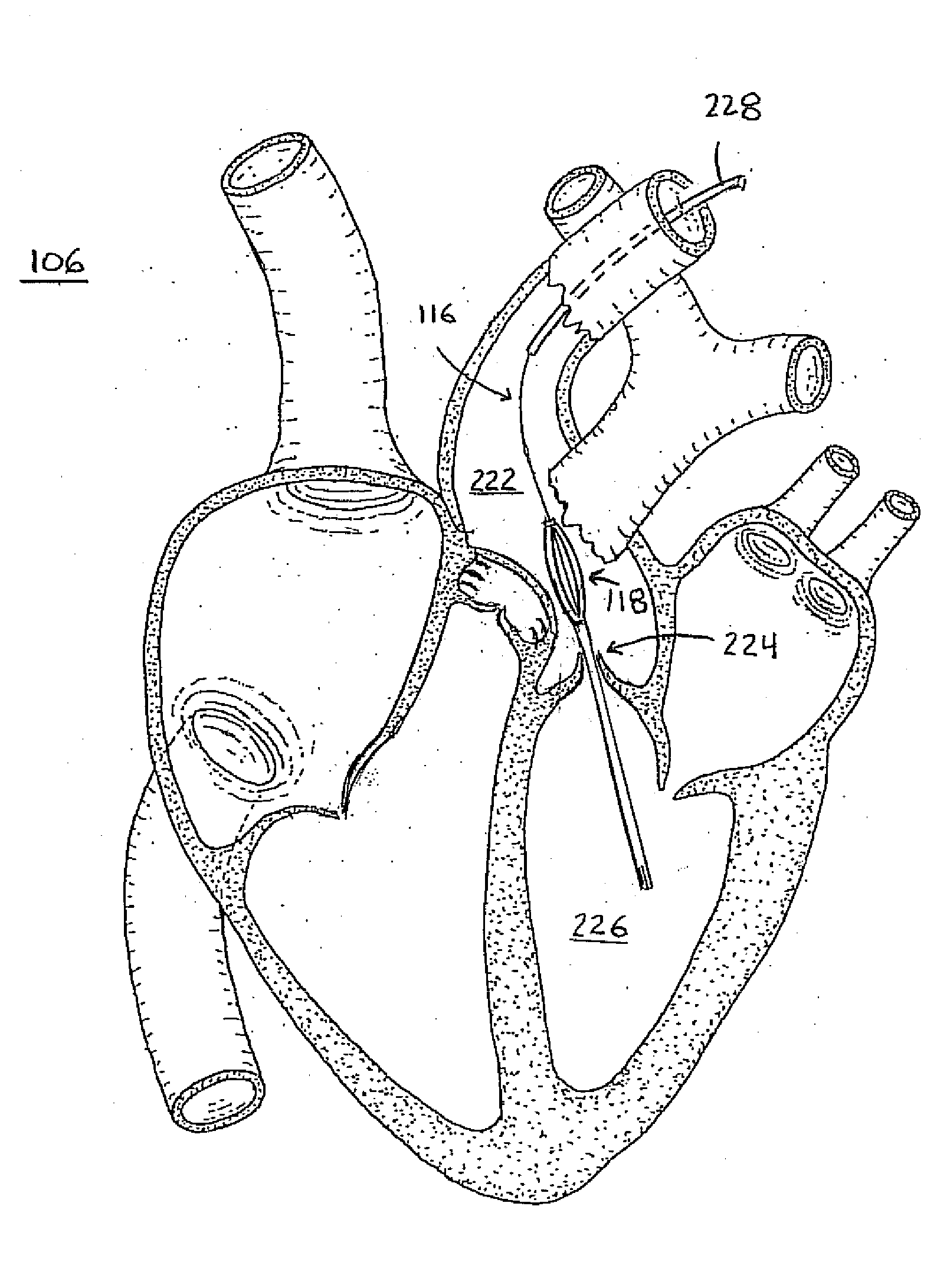

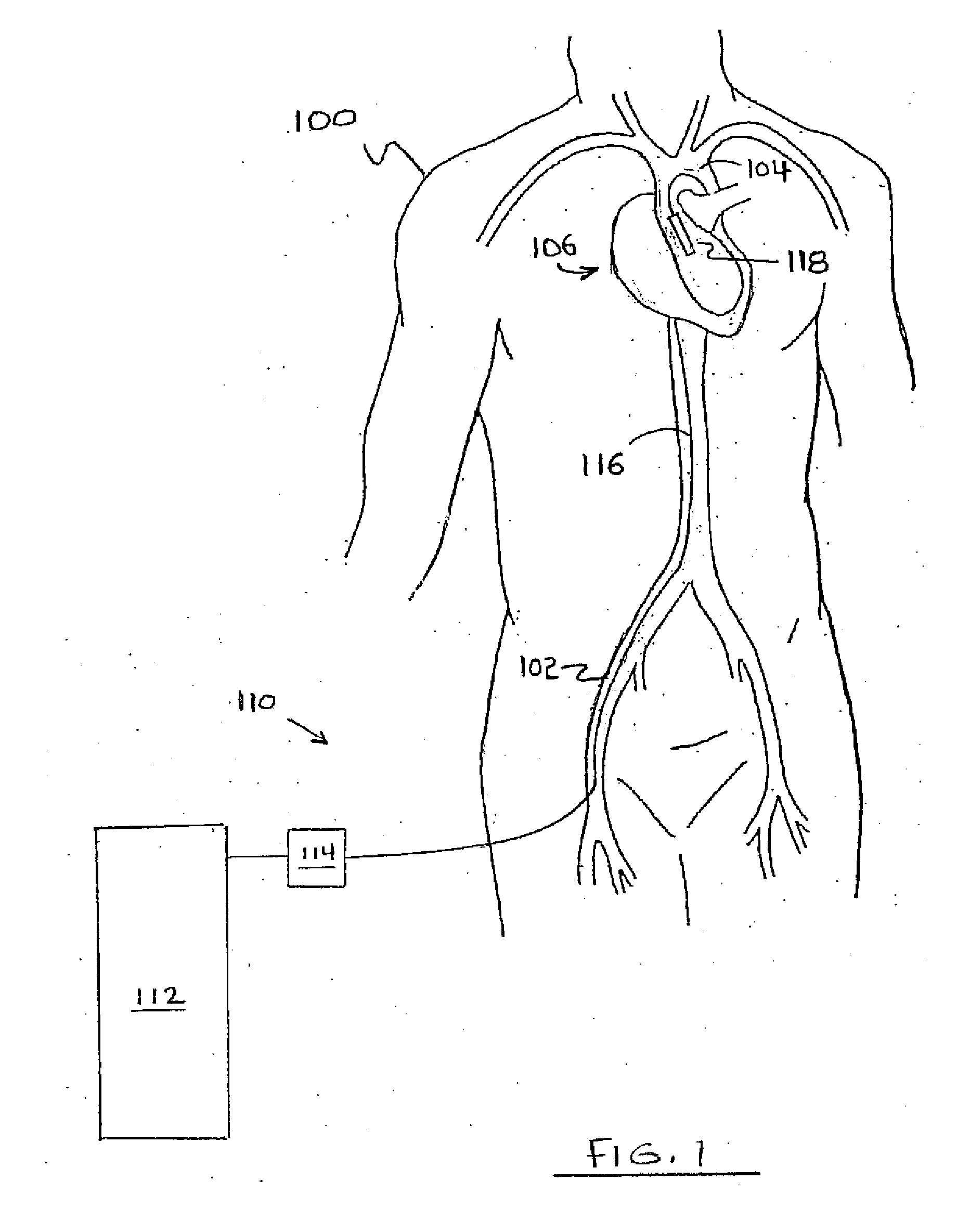

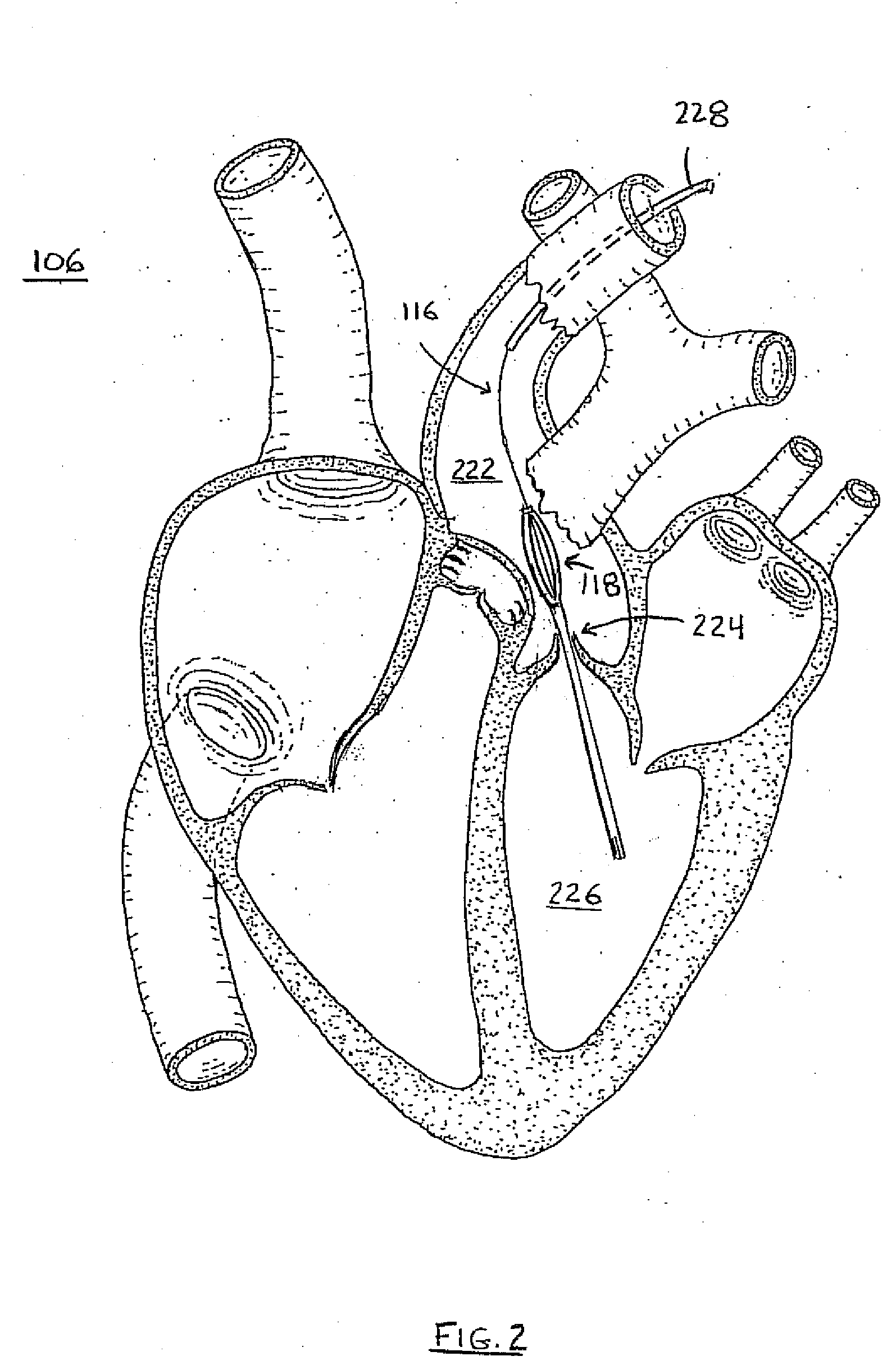

Medical Device

ActiveUS20080132747A1Reduce bending loadMinimizing contact pressureBlood pumpsIntravenous devicesAscending aortaImpeller

A temporary cardiac-assist device is disclosed. The device includes a pump assembly that is deployed in the ascending aorta or the heart. A torque transmission line couples the pump assembly to an external motor for driving impeller blades within the pump assembly. The pump assembly expands in size at its destination site for operation. In operation, neither the torque transmission line nor elements that support the impeller blades are under axial forces.

Owner:FBR MEDICAL INC

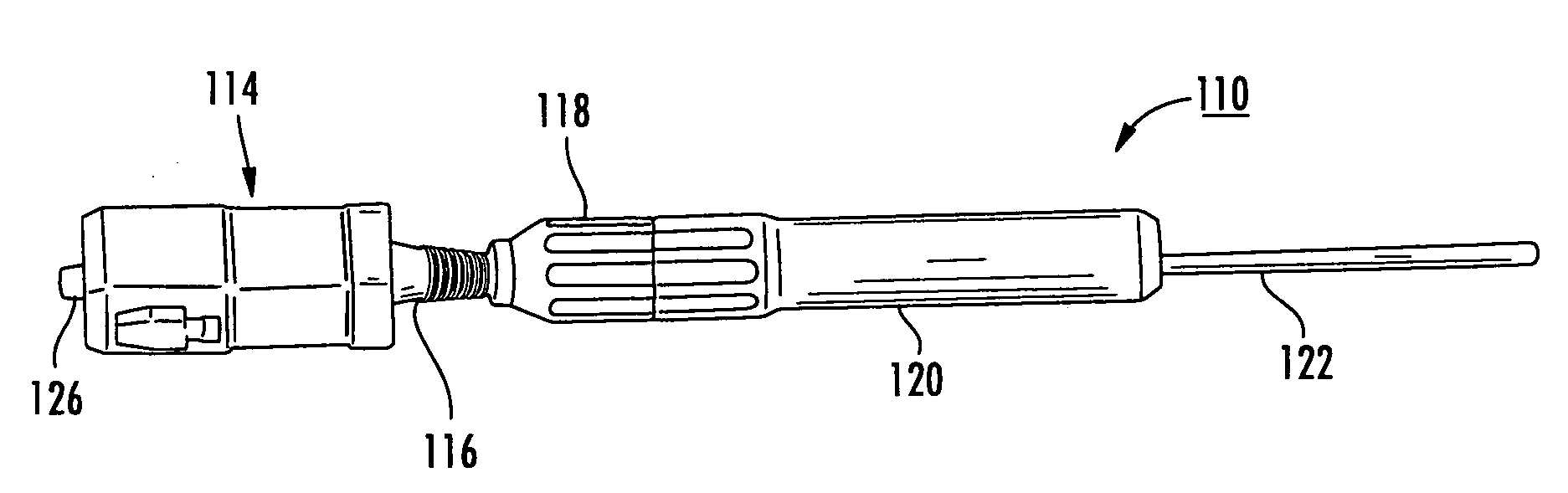

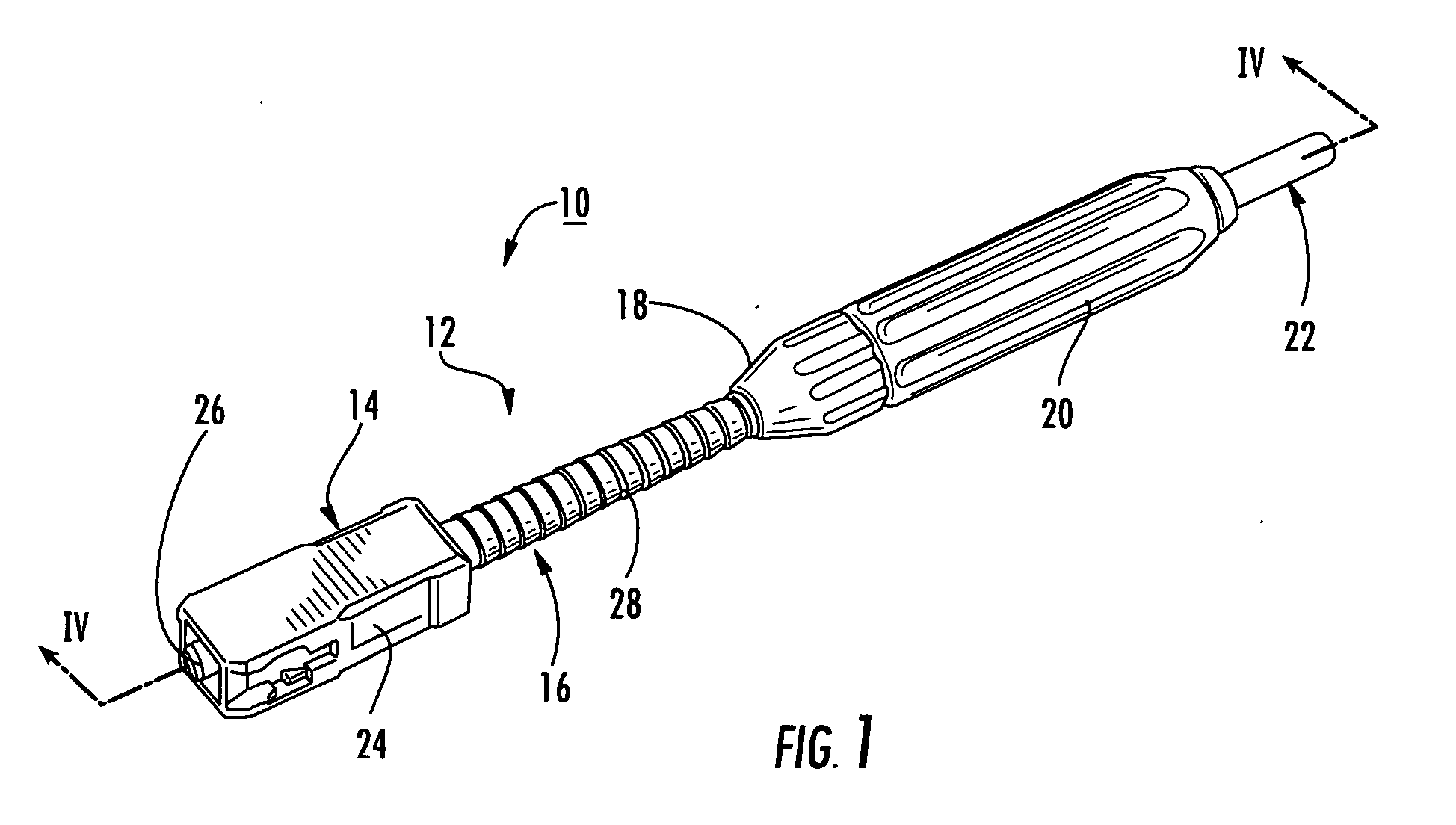

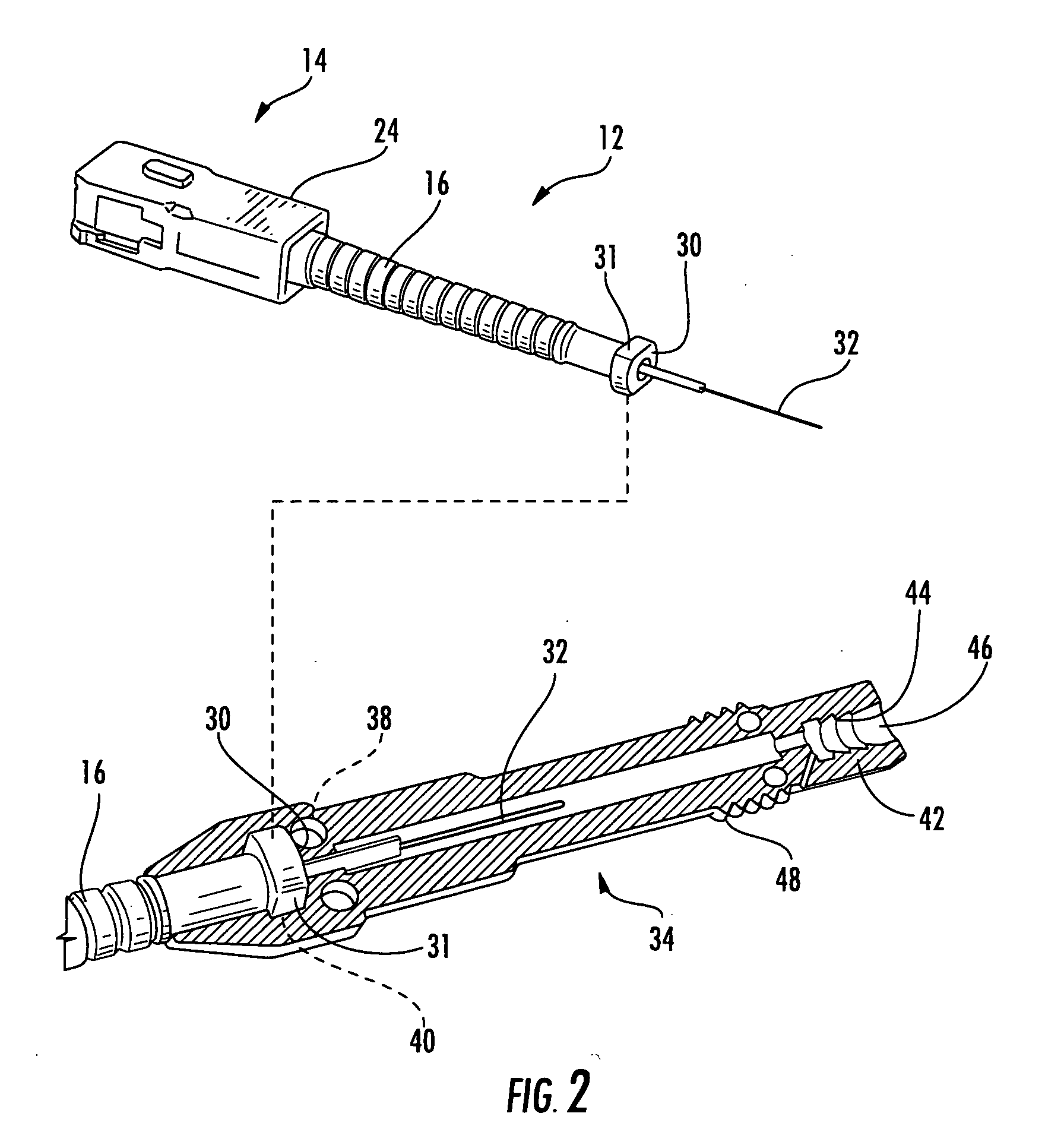

Fusion-splice fiber optic connectors and related tools

Fiber optic connectors having an optical fiber stub that is fusion-spliced for optical connection and related tools for the fiber optic connectors are disclosed. Specifically, the connector assembly for fusion-splicing includes a fiber optic connector having an optic fiber stub and a boot attachable to the fiber optic connector. The boot is configured to transfer the majority of the axial force from the fiber optic cable to the fiber optic connector. Specifically, a splice housing for housing the fusion splice is configured for attachment to an end of the boot for transferring forces from the fiber optic cable to the boot. Consequently, the boot preferably has an extensibility of less than about 2 millimeters under an axial load of about fifteen pounds to inhibit excess forces from acting on the optical fiber stub.

Owner:CORNING OPTICAL COMM LLC

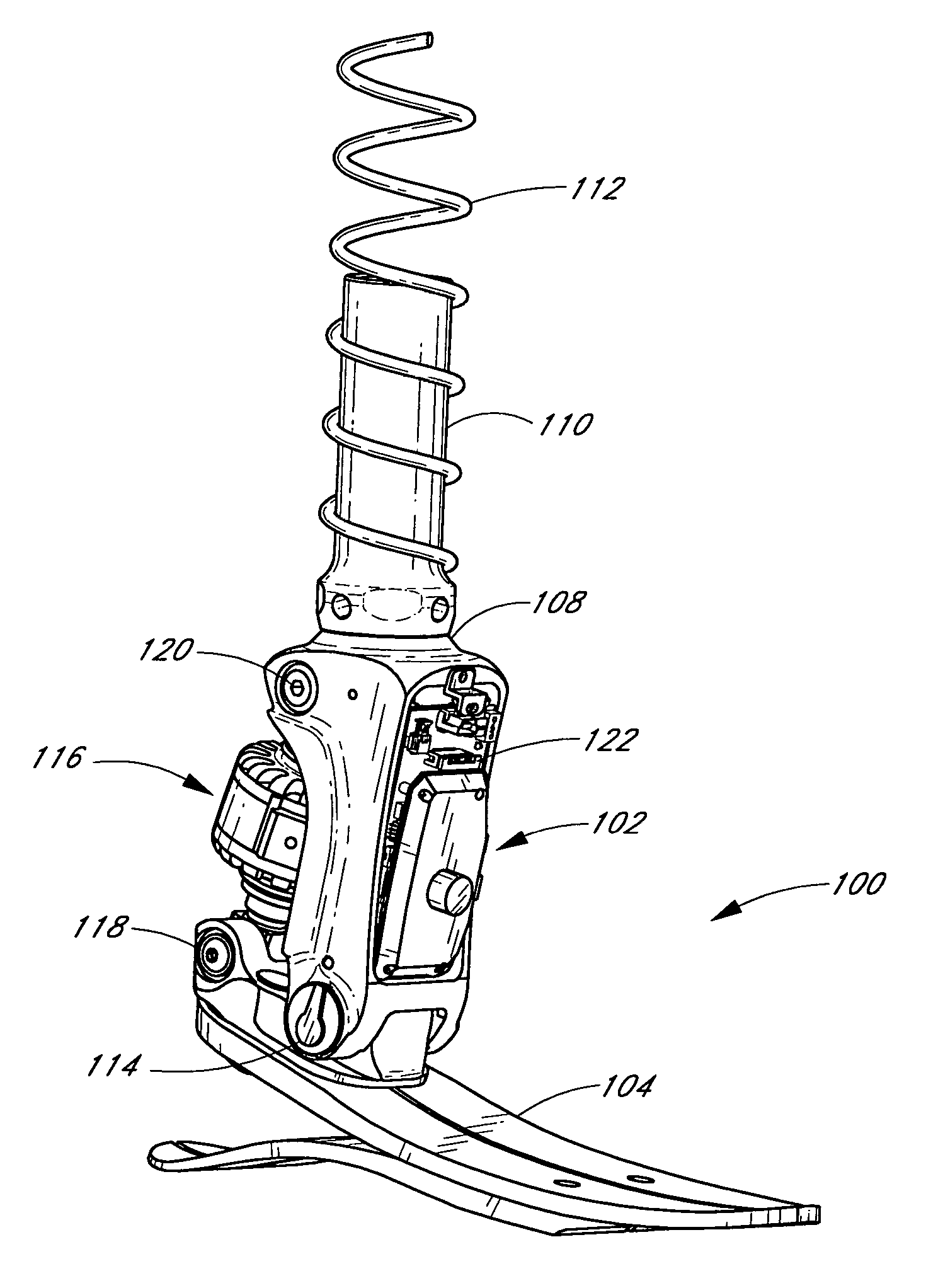

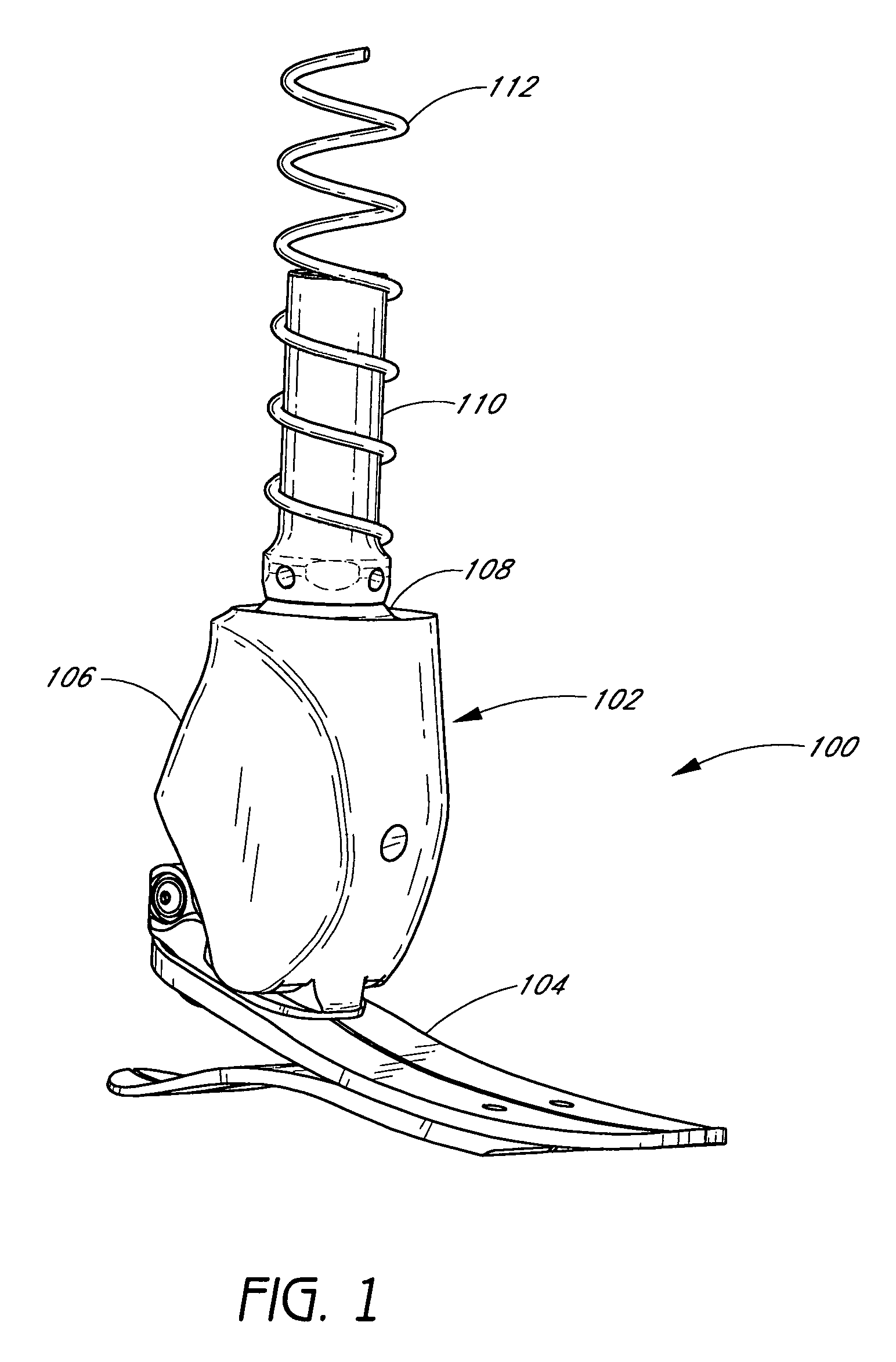

Sensing system and method for motion-controlled foot unit

ActiveUS7531006B2Enhanced couplingNon-surgical orthopedic devicesArtificial legsAxial forceEngineering

A system and method for sensing movement of a device associated with a limb. In one example, a prosthetic or orthotic system includes a sensor assembly configured to measure movement of a component of the system in a single direction while substantially isolating negative effects of forces and / or loads in other directions. For instance, the sensor assembly may be advantageously coupled to a pivot assembly configured to substantially mimic a natural ankle joint. The sensor assembly may monitor rotation of a foot unit about an axis of a pivot pin of the pivot assembly and disregard other movements and / or forces. For example, the sensor assembly may include a potentiometer that detects rotation of an associated elongated bellow portion about the axis, wherein the bellow portion includes a plurality of ridges configured to substantially eliminate effects of radial and / or axial forces.

Owner:OSSUR HF

Vaso-occlusive device having pivotable coupling

An assembly for occluding a vascular site (e.g., an aneurysm) of a human or veterinary patient includes a vaso-occlusive member, a pusher member having a distal end and a severable junction located proximal to the distal end, and a pivotable coupling that couples the pusher member to the occlusive member. A delivery catheter can be used to deliver the vaso-occlusive member to the vascular site. A method of using the assembly to occlude an aneurysm having an aneurysmal sac and an aneurysmal neck, comprises locating the catheter within the aneurysmal neck, and manipulating the pusher member to place the vaso-occlusive member within the aneurysmal sac. The method further comprises severing the severable junction to detach the vaso-occlusive member from the pusher member. As a result, an axial force is applied by the vaso-occlusive member in a proximal direction, which buckles the pivotable coupling to laterally deflect the axial force. The lateral deflection of the axial force caused by the buckling of the pivotable coupling prevents the catheter from being displaced from the aneurysmal neck by the axial force.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

Automatic injection device with delay mechanism including dual functioning biasing member

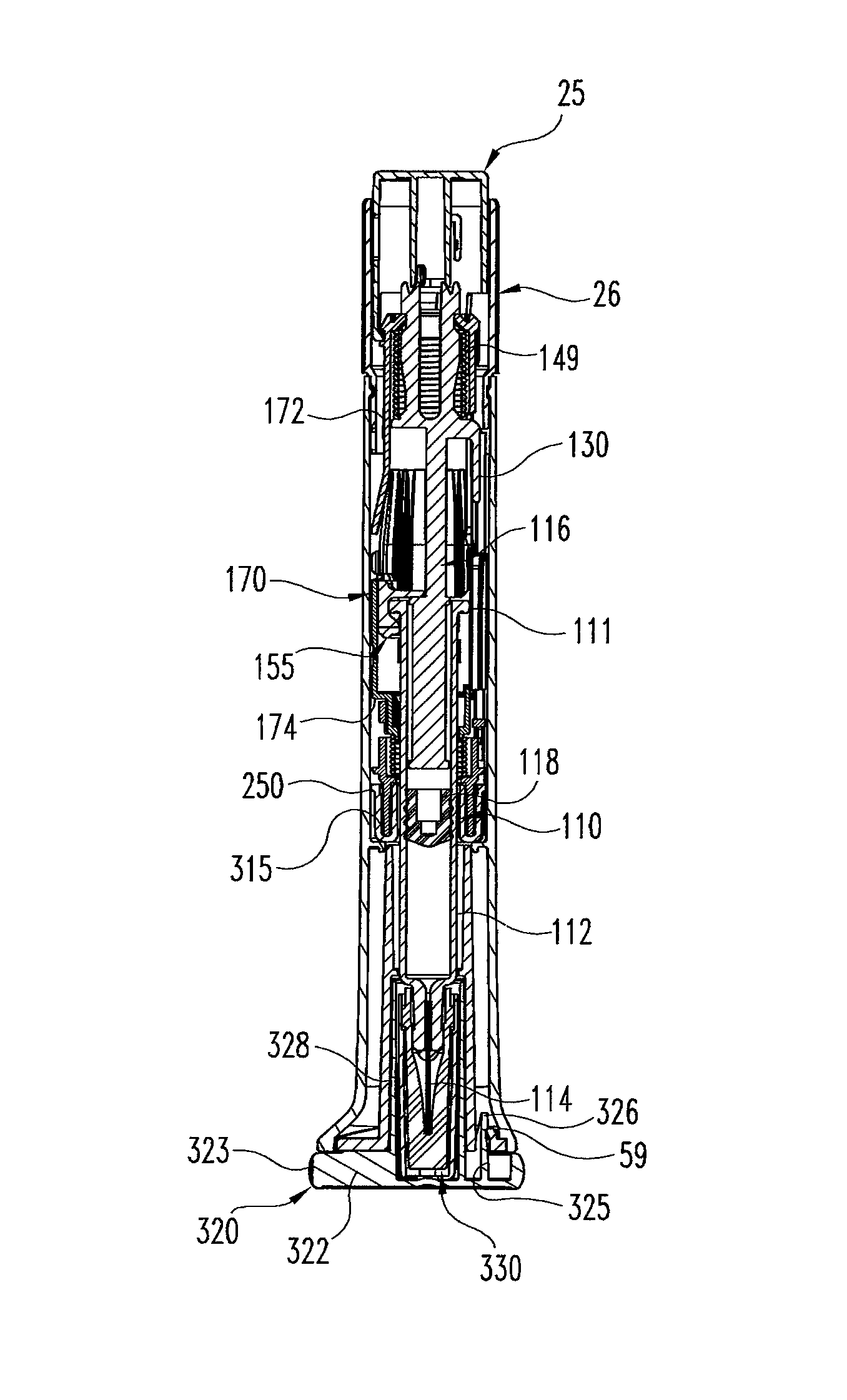

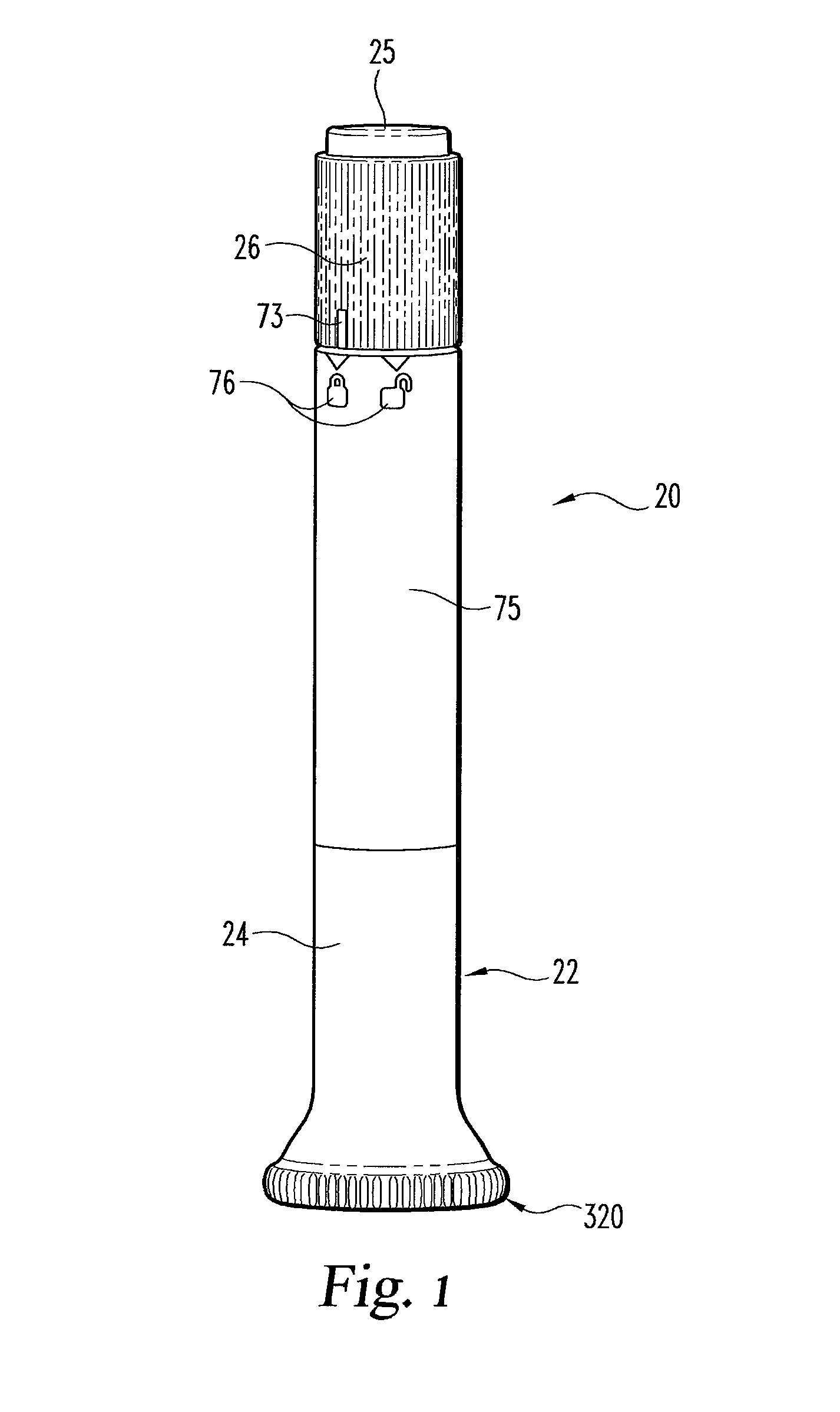

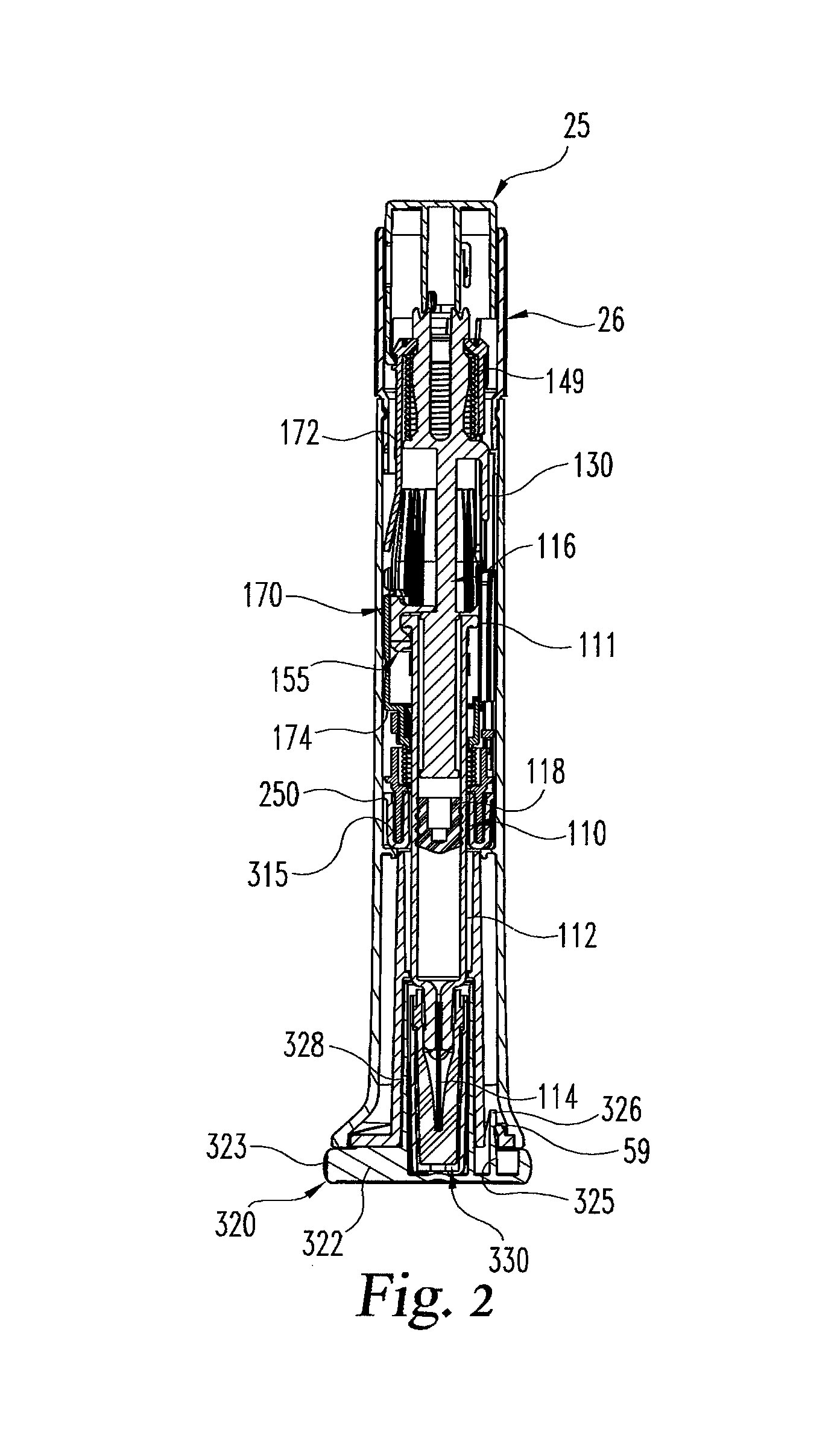

ActiveUS8734394B2Thin profileReduce in quantityAutomatic syringesMedical devicesAxial forceEngineering

An automatic injection apparatus including a delay mechanism for properly delivering medication prior to the needled syringe of the apparatus being retracted. In one form, the delay mechanism includes a shuttle (170) for the syringe, a follower (250), a locking member, a damping compound between the follower and a supporting surface (308) to dampen rotation of the follower relative to the shuttle, and a dual functioning biasing member (290) acting between the shuttle and the follower. When the locking member moves to a release position during an injection, the dual functioning biasing member first provides a torsional force to force the follower to rotate relative to the shuttle from a latching position to an unlatching position, and then the dual functioning biasing member provides an axial force to force the shuttle axially relative to the follower to move the shuttle for retracting the syringe needle into the housing of the apparatus after injection.

Owner:ELI LILLY & CO

Vented, layered-wall deepwater conduit and method

A flexible conduit constructed of overlapping layers of sealing and strengthening materials designed to resist tensile, compressive, and axial forces is employed as a submerged flow line carrying pressurized fluid. Sealing material layers disposed radially on either side of the strengthening layers isolate the strengthening layers from the liquids that contact the internal and external conduit walls. The innermost seal layer is positioned within a burst layer that protects the external strengthening layers from pressure-induced damage. The annular area between the strengthening layers is continuously vented to the atmosphere to prevent pressure damage to the strengthening layers caused by gases leaking or permeating into the annular area through the seal layers. End connectors join sections of the conduit together and connect the vents of the sections to each other to form a continuous vent passage that vents the annulus gas at the water surface.

Owner:GE OIL & GAS UK LTD

Drilling components and systems to dynamically control drilling dysfunctions and methods of drilling a well with same

Drilling tools that may detect and dynamically adjust drilling parameters to enhance the drilling performance of a drilling system used to drill a well. The tools may include sensors, such as RPM, axial force for measuring the weight on a drill bit, torque, vibration, and other sensors known in the art. A processor may compare the data measured by the sensors against various drilling models to determine whether a drilling dysfunction is occurring and what remedial actions, if any, ought to be taken. The processor may command various tools within the bottom hole assembly (BHA), including a bypass valve assembly and / or a hydraulic thruster to take actions that may eliminate drilling dysfunctions or improve overall drilling performance. The processor may communicate with a measurement while drilling (MWD) assembly, which may transmit the data measured by the sensors, the present status of the tools, and any remedial actions taken to the surface.

Owner:BAKER HUGHES INC

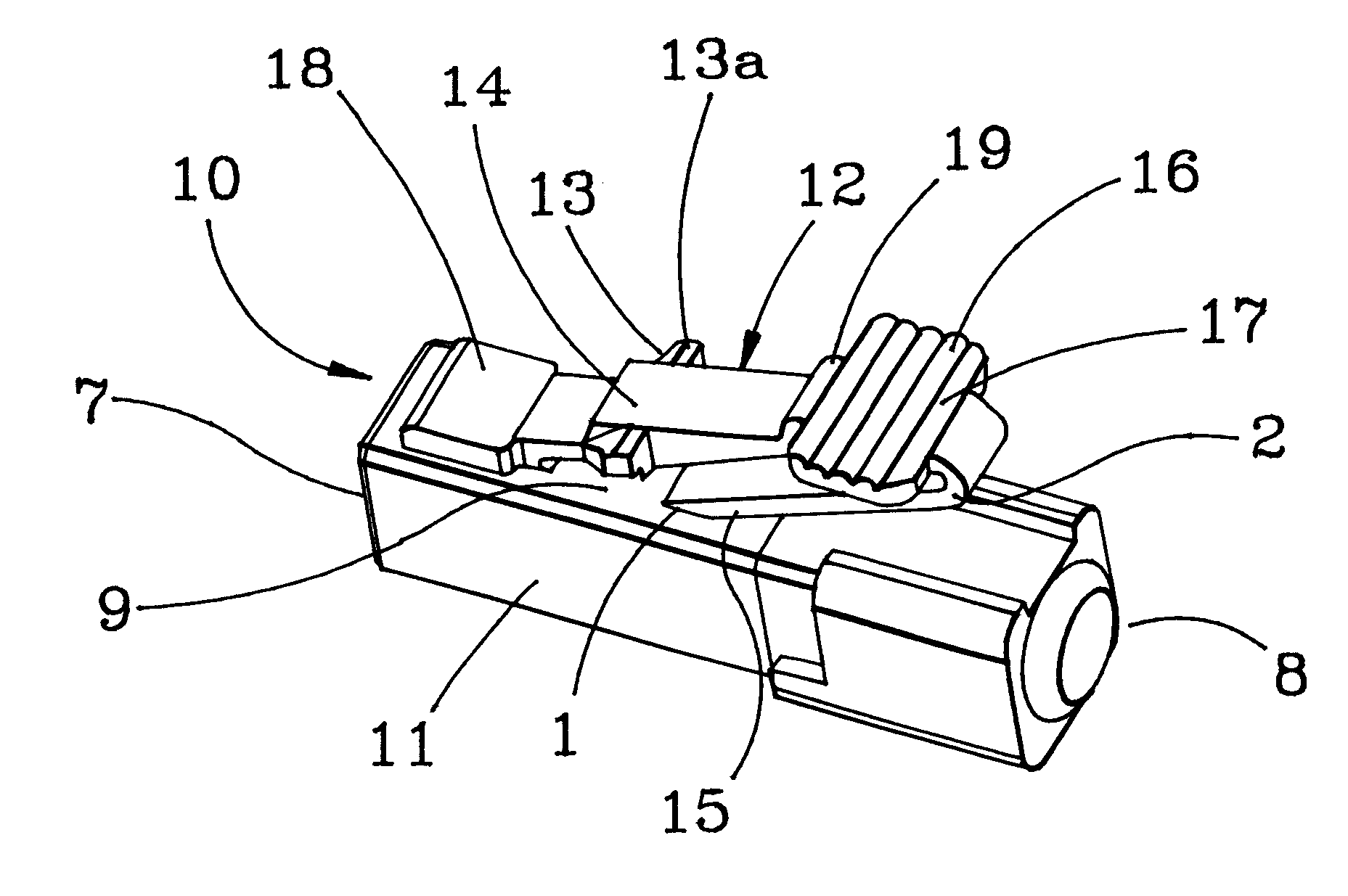

Connector with articulated latch

InactiveUS6364685B1Reduce axial forceMinimize rotationCoupling device detailsCoupling light guidesMating connectionEngineering

A connector for engaging a mating connector comprising: (a) a housing having a longitudinal axis and a front and back orientation and being adapted for receiving a signal carrying medium; and (b) an articulated latch connected to the housing at one or more primary joints and having a plurality of sections, wherein at least one of the sections has an engagement structure which is adapted to engage a corresponding structure on the mating connector such that the connector and the mating connector cannot be separated without actuating the latch, and wherein at least two sections are connected at a secondary joint, the primary and secondary joints being configured such that, when an actuating force is applied to the articulated latch, a moment on one side of the actuation point is reduced by an opposing moment on the opposite side of the actuation point, thereby reducing the axial force on the connector.

Owner:COMMSCOPE TECH LLC

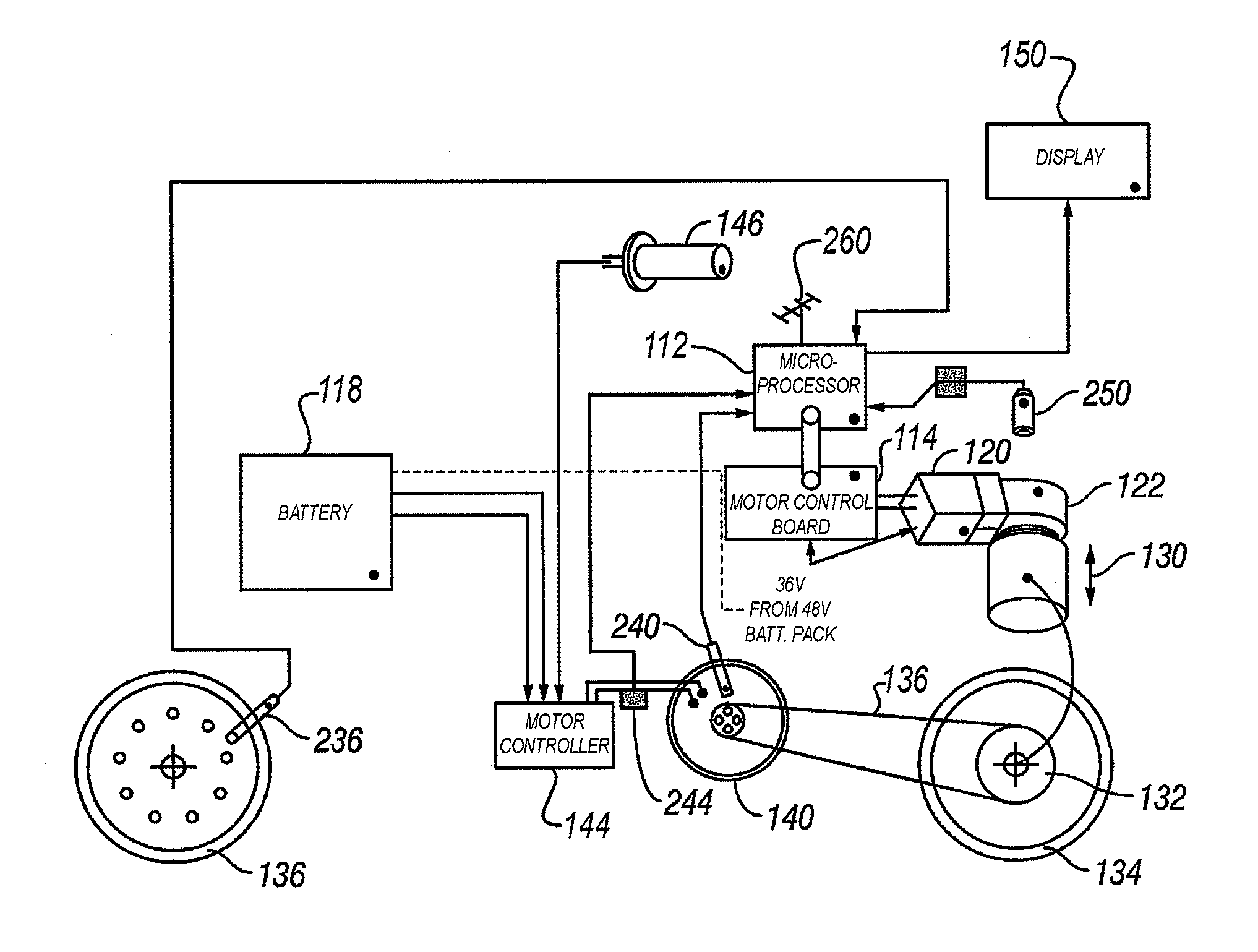

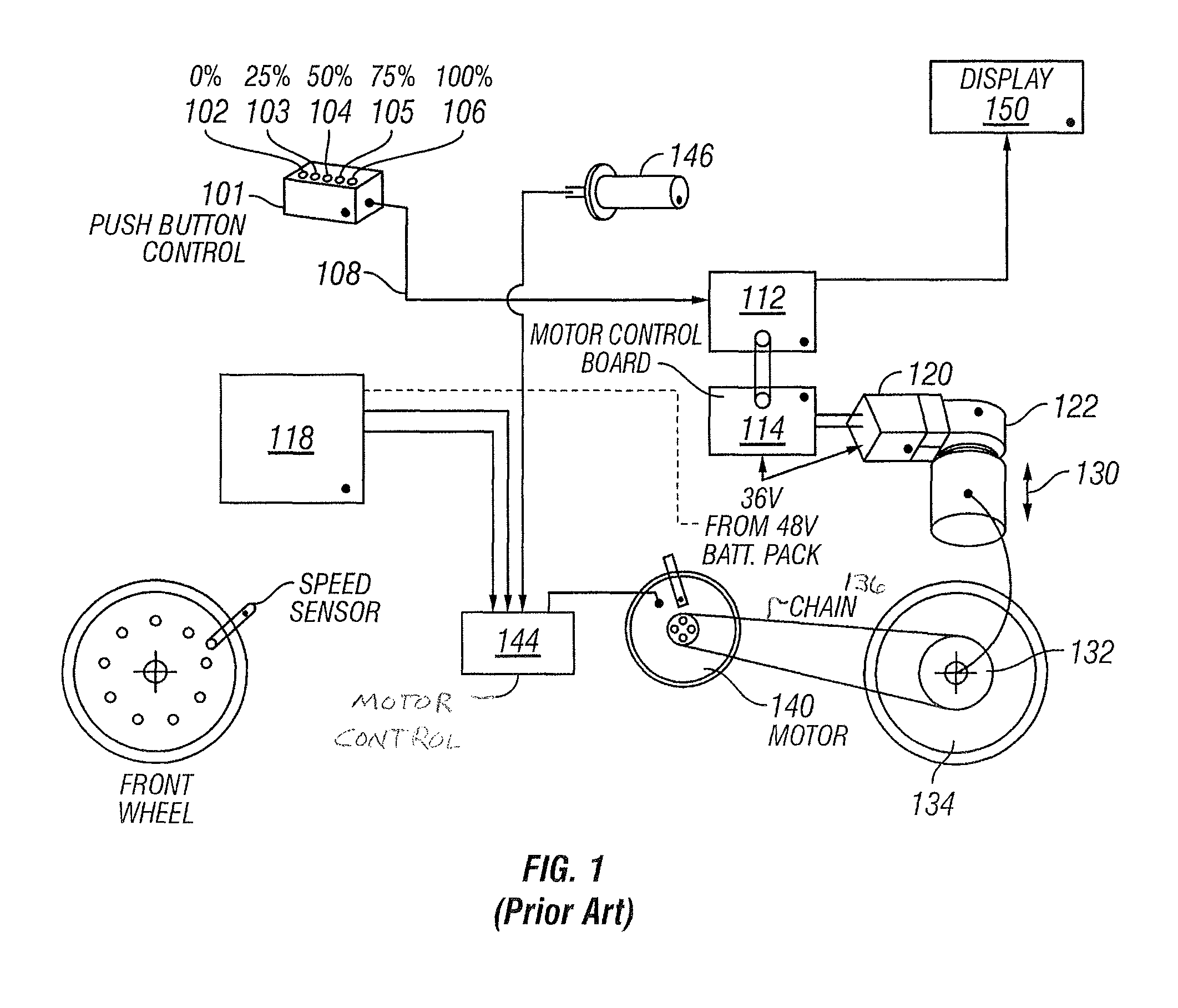

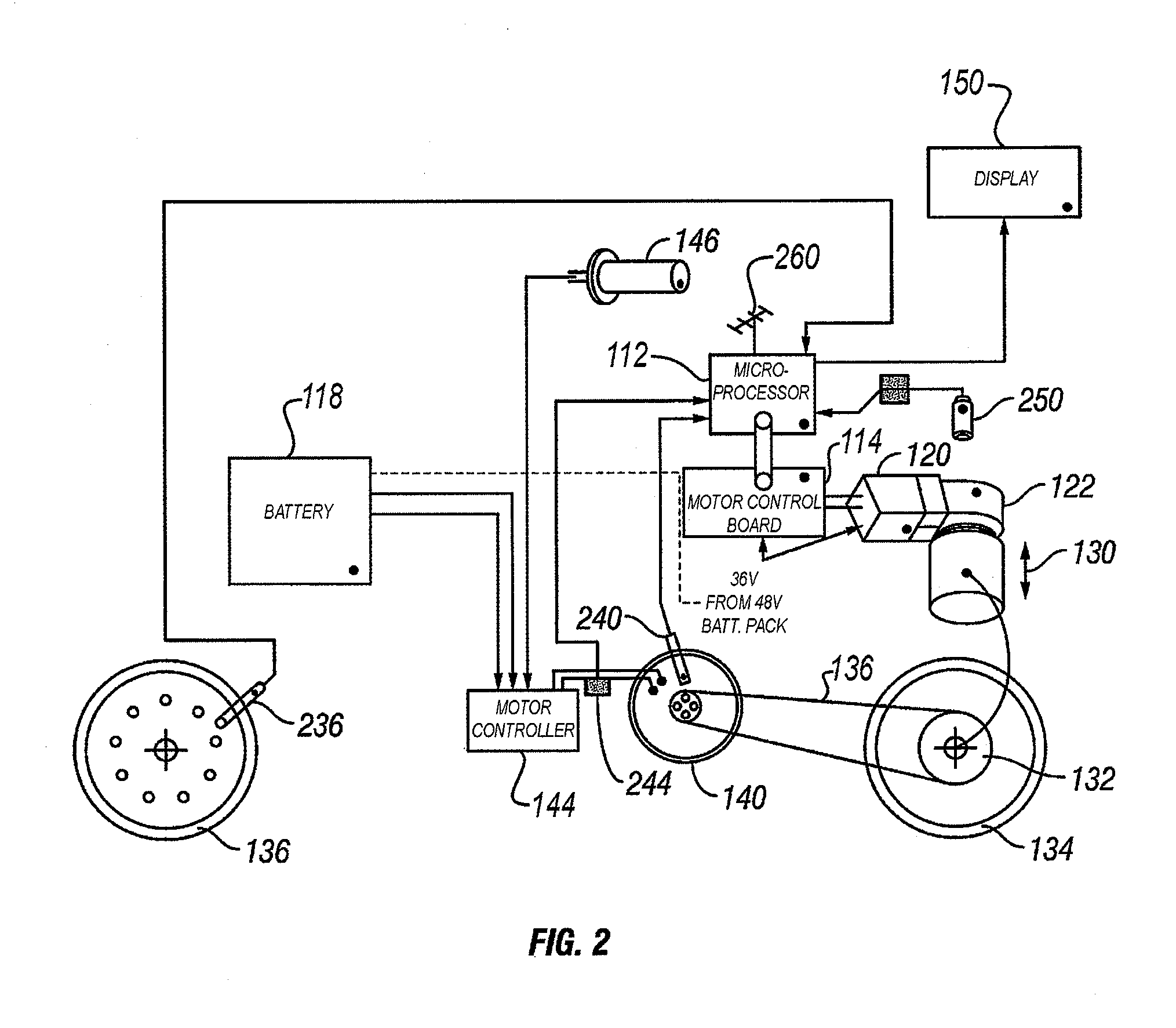

Scooter shifter

The present invention provides a system and method for automatically adjusting a continuously variable transmission (CVT) in a motorized vehicle. A microprocessor processor in the vehicle receives data about the operating status of the vehicle from a plurality. Examples of vehicle data include vehicle speed, motor speed, throttle position, current draw from a battery, and battery level. A servo motor is in mechanical communication with the CVT and provides an axial force to adjust the CVT. The microprocessor uses lookup tables of optimal set points for vehicle data to instruct the servo motor to adjust the transmission ratio of the CVT according to the vehicle data provided by the sensors.

Owner:FALLBROOK INTPROP COMPANY

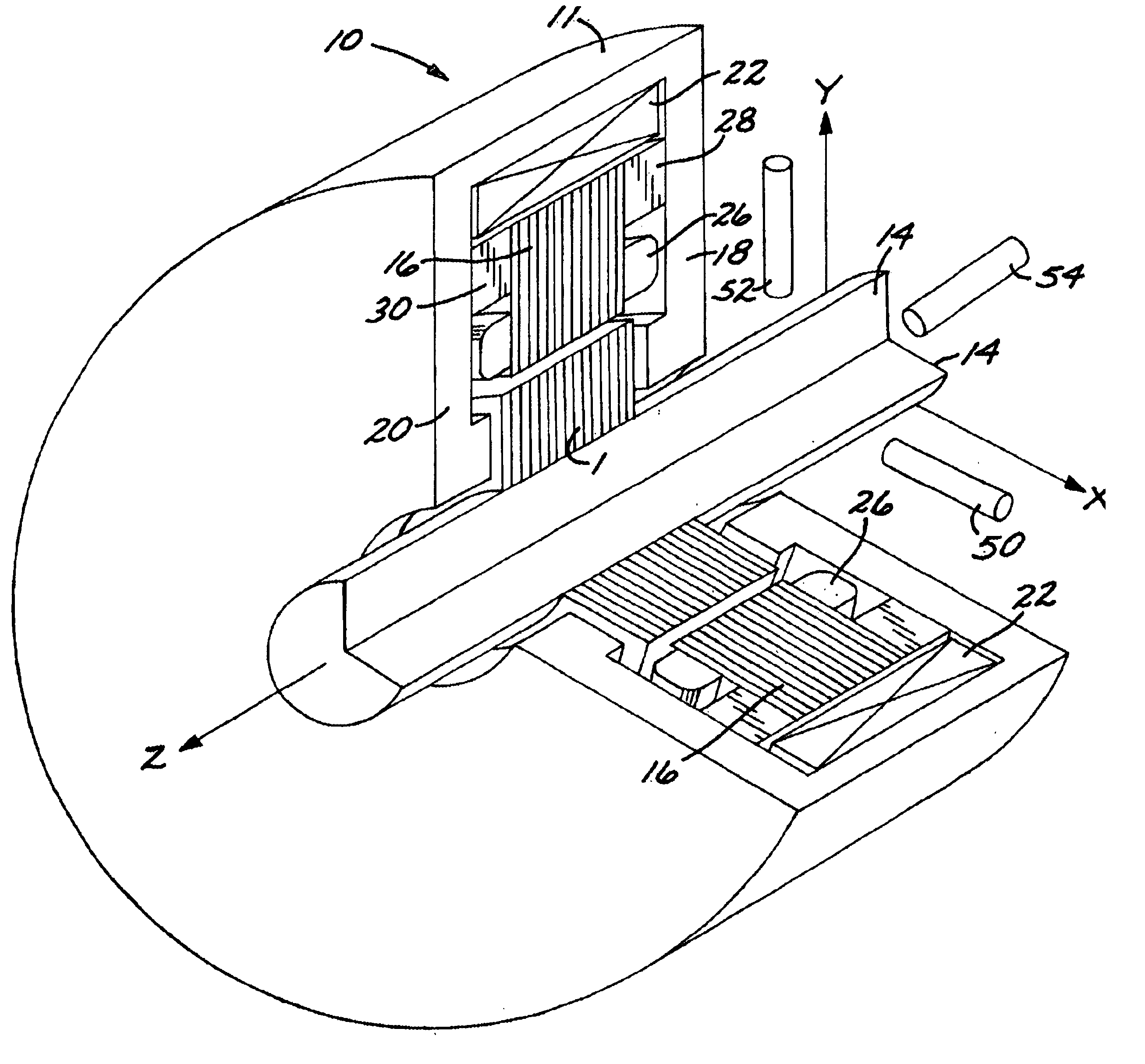

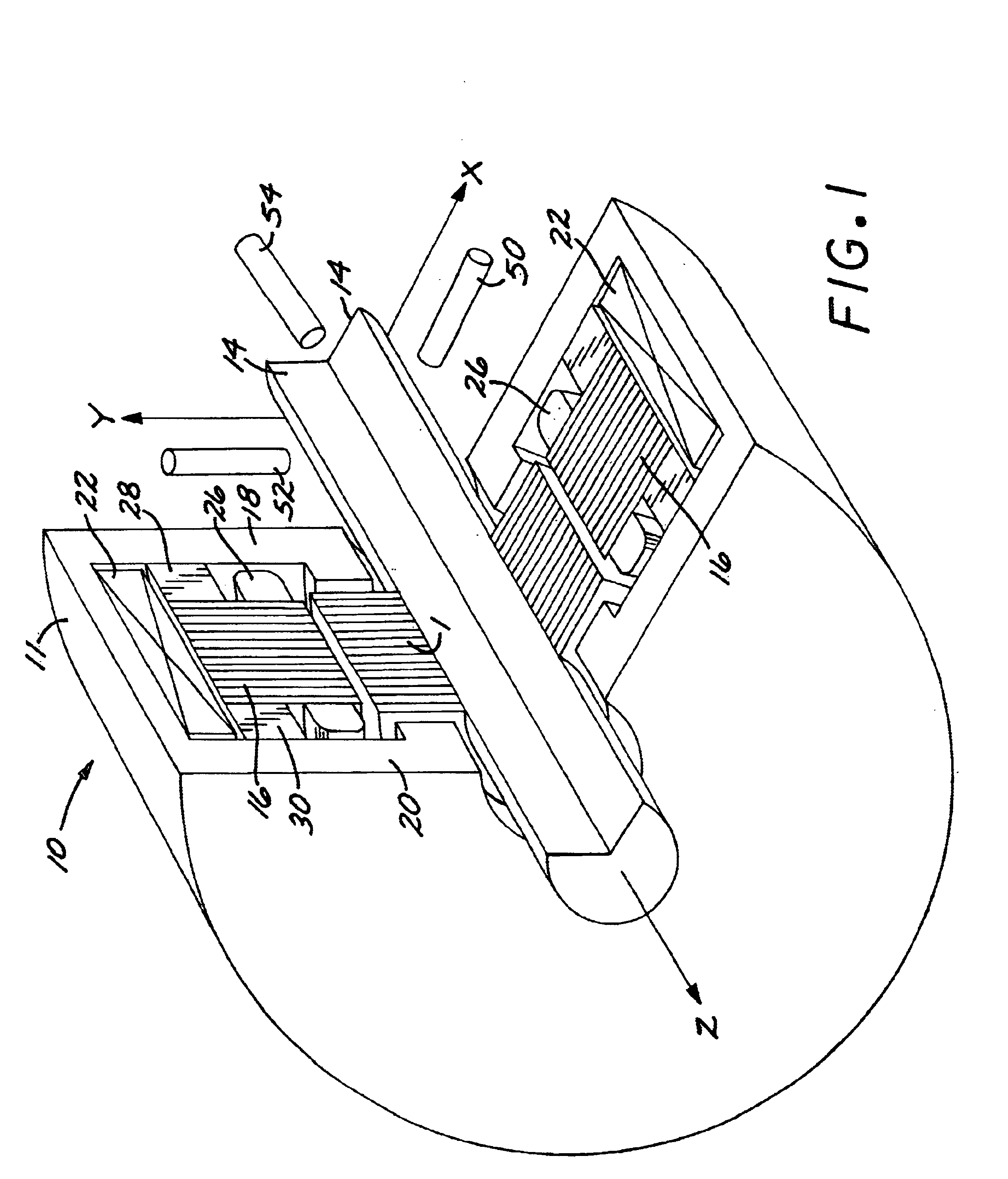

Method and apparatus for providing three axis magnetic bearing having permanent magnets mounted on radial pole stack

InactiveUS6727617B2Effective and inexpensive techniqueHighly linear magnetic biasMechanical energy handlingBearingsAxial displacementAudio power amplifier

An improved magnetic bearing that uses permanent magnets to provide the bias flux. The magnetic circuits generating the control flux and bias fluxes are substantially non-coincident but share the same path over some portions that include radial and axial airgaps allowing for a low reluctance and an efficient path for the electromagnetic flux. The flux paths of the permanent magnets are completely defined with minimized airgaps for achieving higher forces and efficiency and very low control currents that produce extremely large forces. A single coil and amplifier for the axial force control and two coils with one associated amplifier for each radial axis of control provides simplicity and cost effectiveness. A single thrust disk is provided that is reacted against for both radial and the axial displacement. The permanent magnets used in the present invention are first fabricated and axially magnetized as segments or as continuous rings prior to being mounted on the sides of the rotor pole, providing an effective and inexpensive technique of manufacturing magnetic bearings.

Owner:CALNETIX TECH +1

Field serviceable electronic display

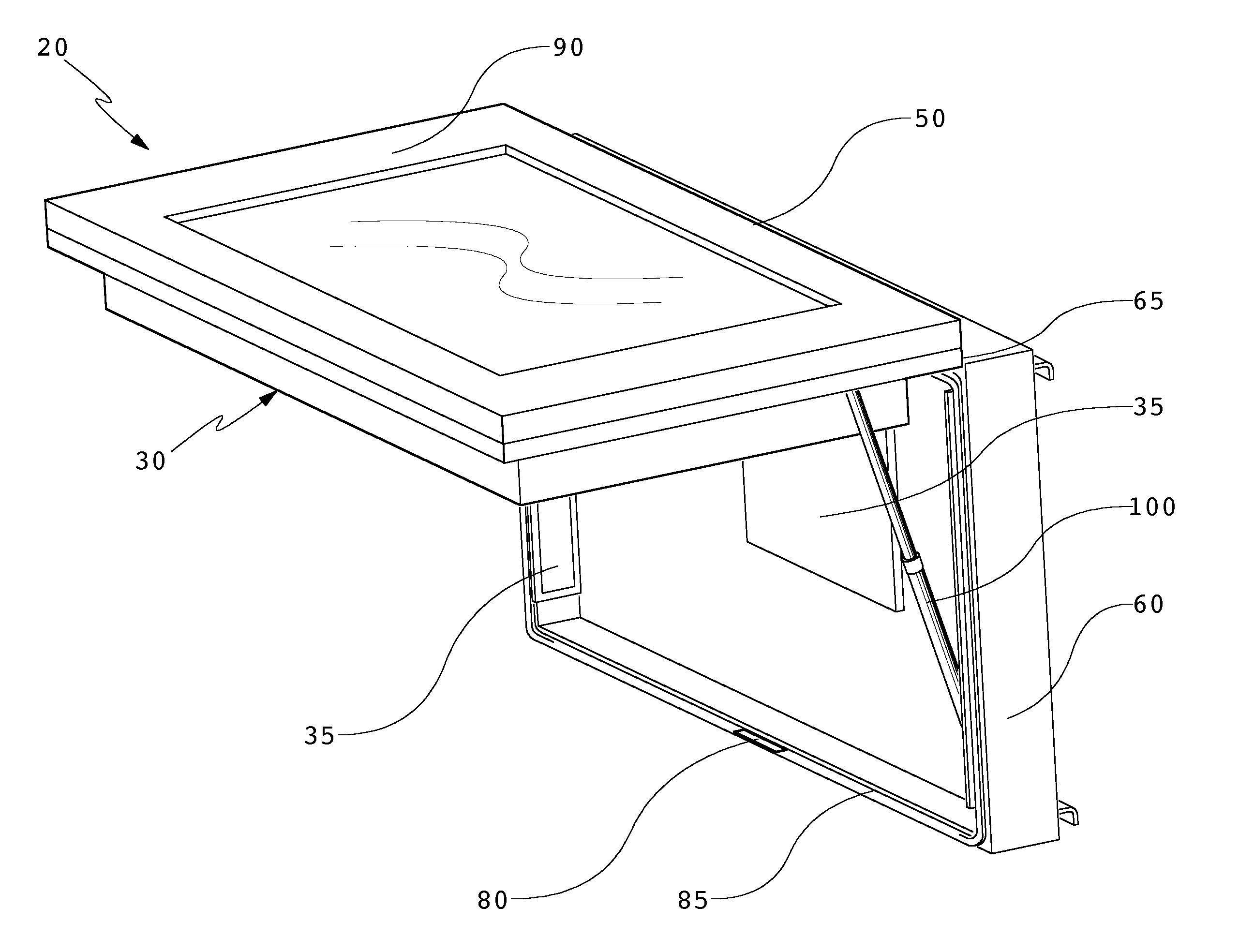

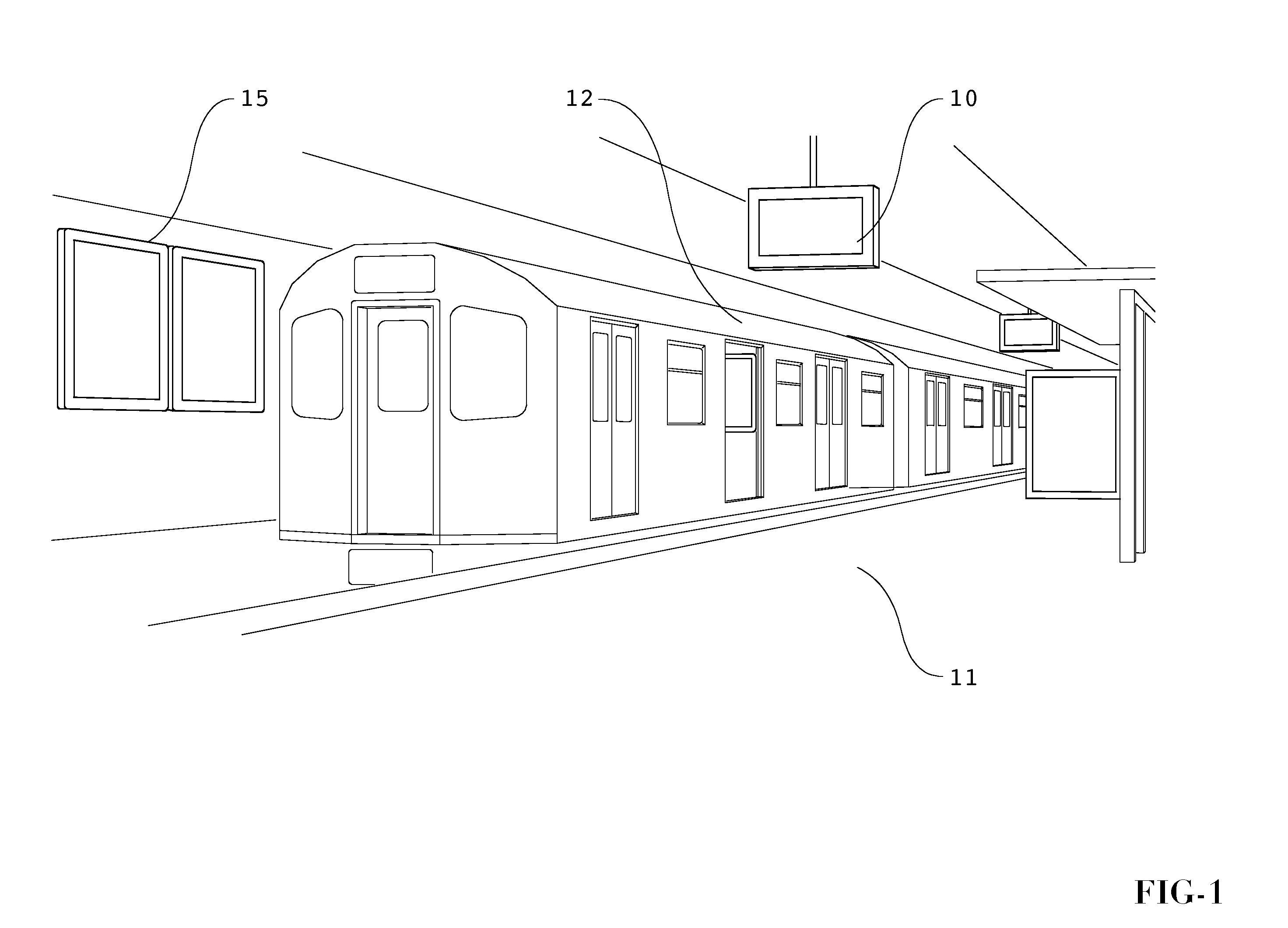

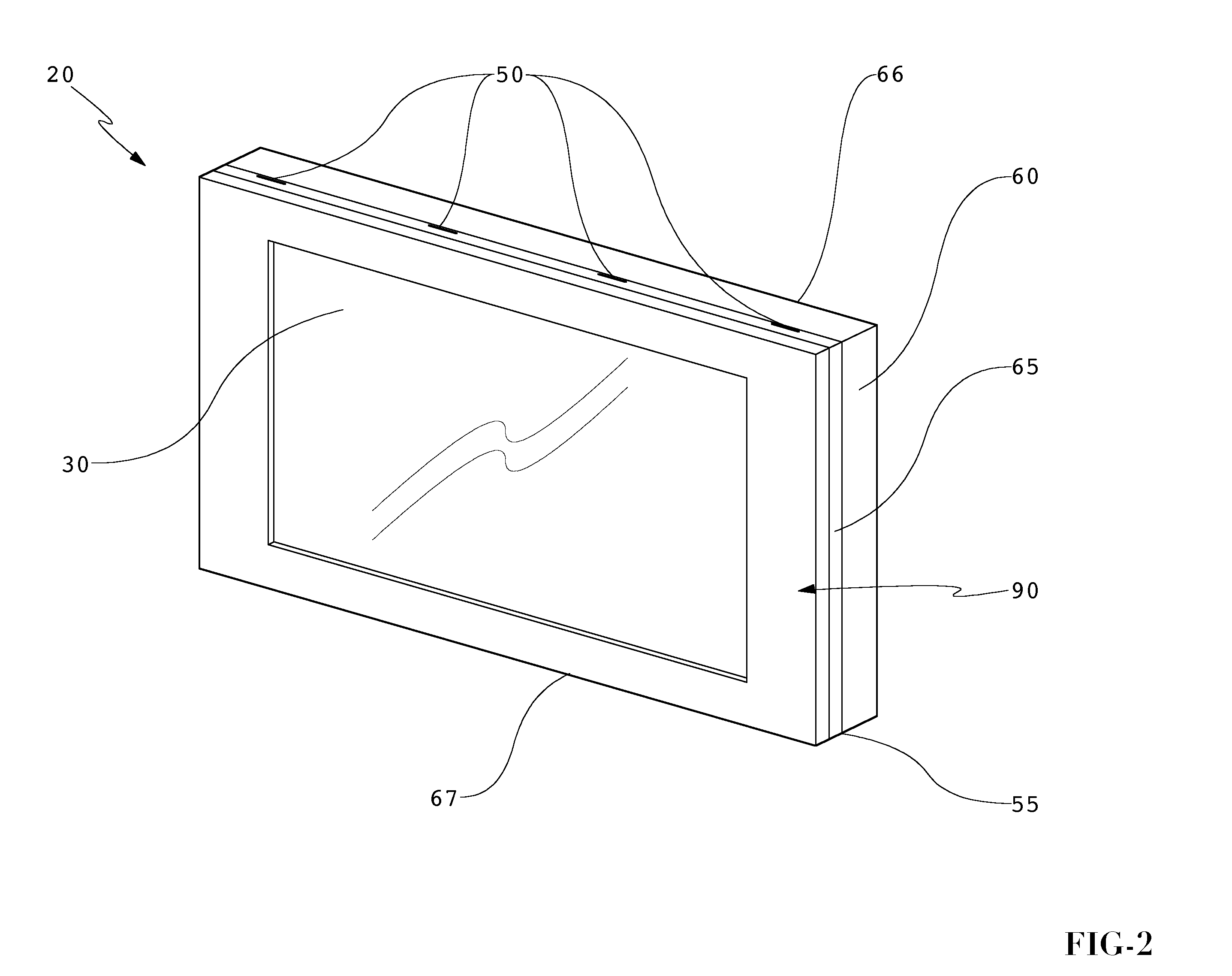

ActiveUS20110116231A1Amount of timeValuable advertising revenueTelevision system detailsDigital data processing detailsDisplay deviceAxial force

An electronic display which can be serviced without having to remove the display from its mounted position. A front housing and a rear housing are hingedly attached so that the front housing can rotate and allow access to the interior of the display. An axial force mechanism can be used to aid in rotating the front housing to an open position. A locking collar, support member, or axial locking member may be used to ensure that the front housing remains open. A removable front glass assembly or removable glass panel may be used with an exemplary embodiment. The front glass assembly or glass panel can be easily replaced if it becomes damaged by minimally-trained personnel. Gutters may be used between the front and rear housing as well as the front housing and front glass assembly to ensure an adequate seal against contaminates.

Owner:MFG RESOURCES INT INC

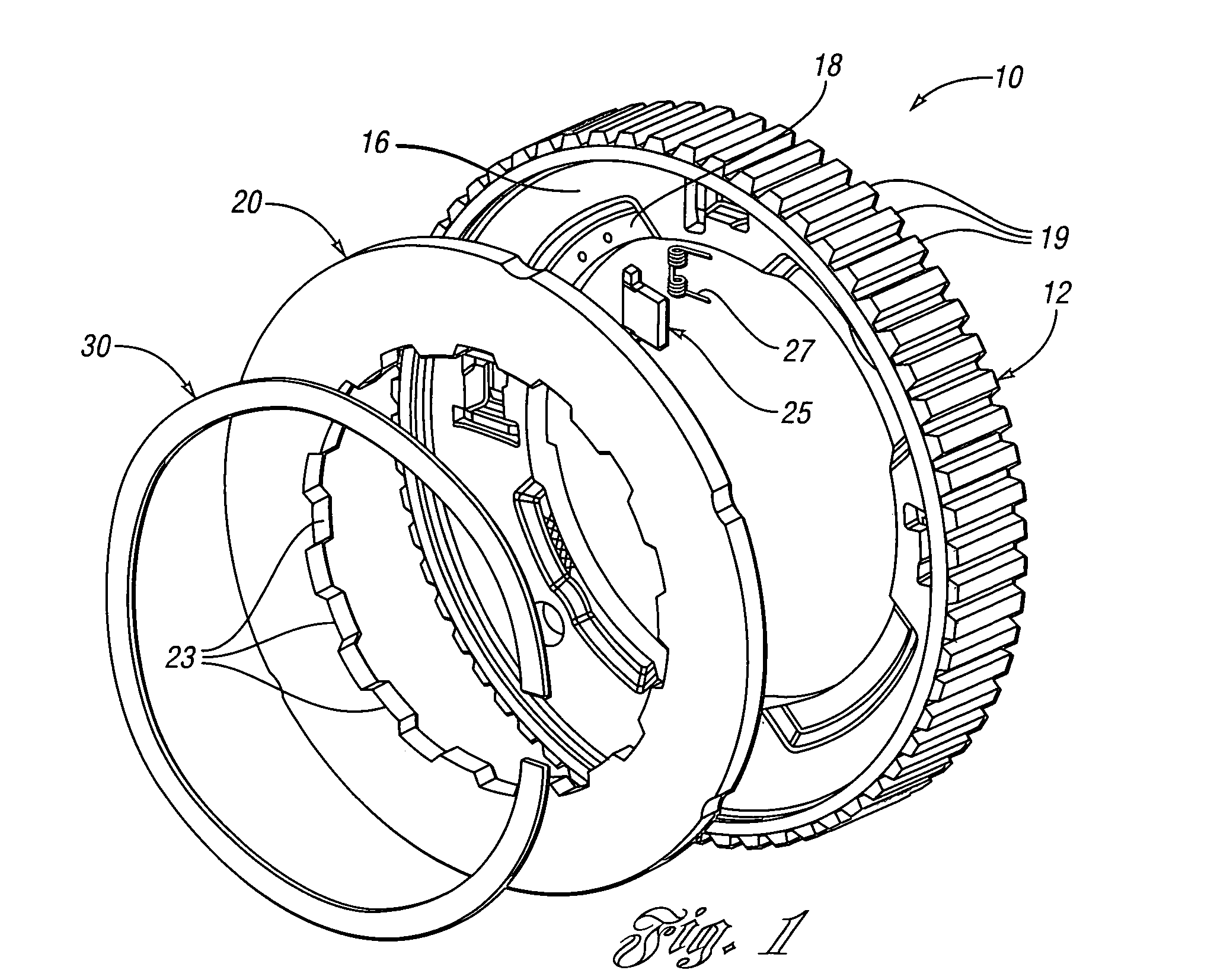

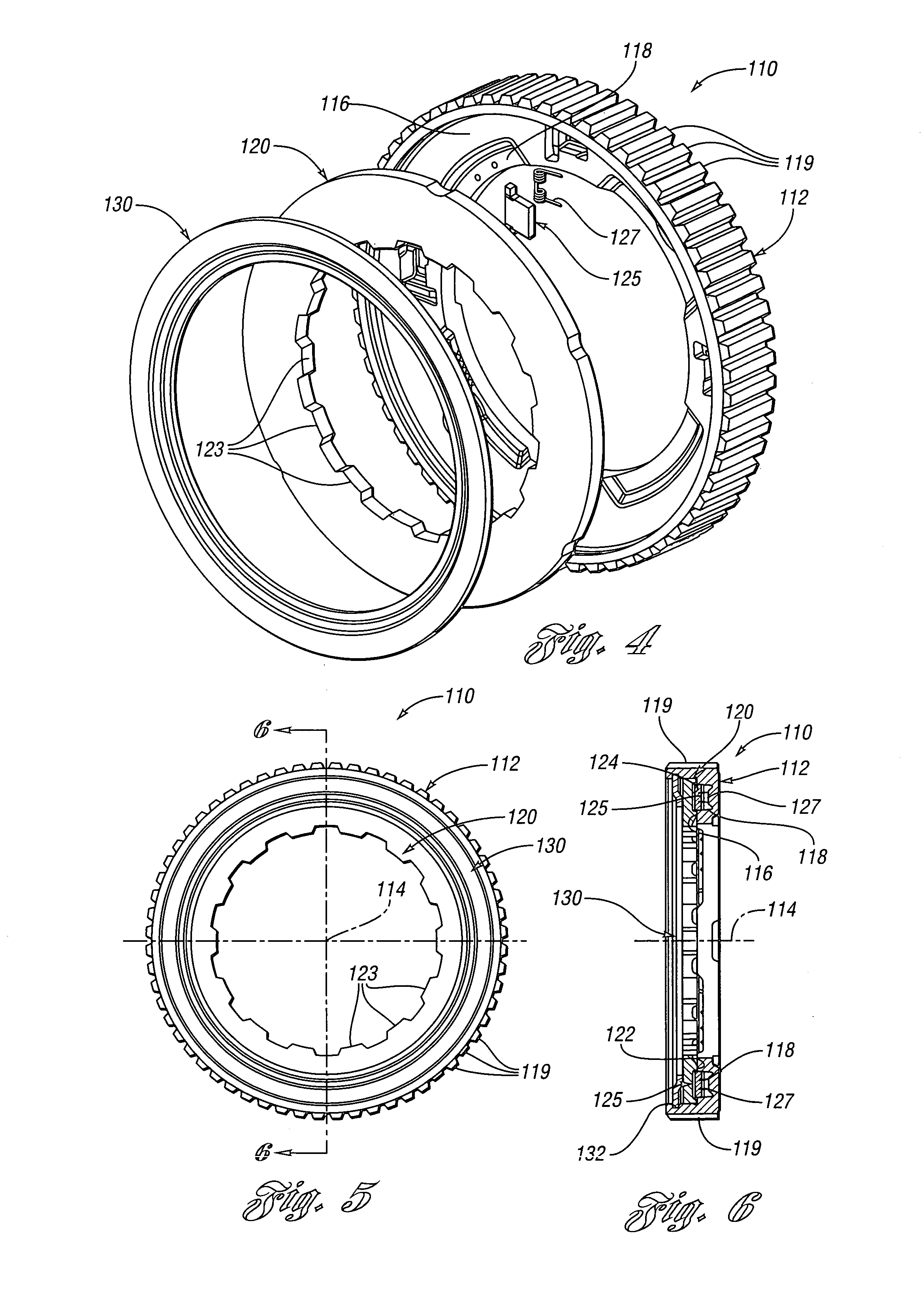

Overrunning coupling assembly having improved shift feel and/or noise reduction

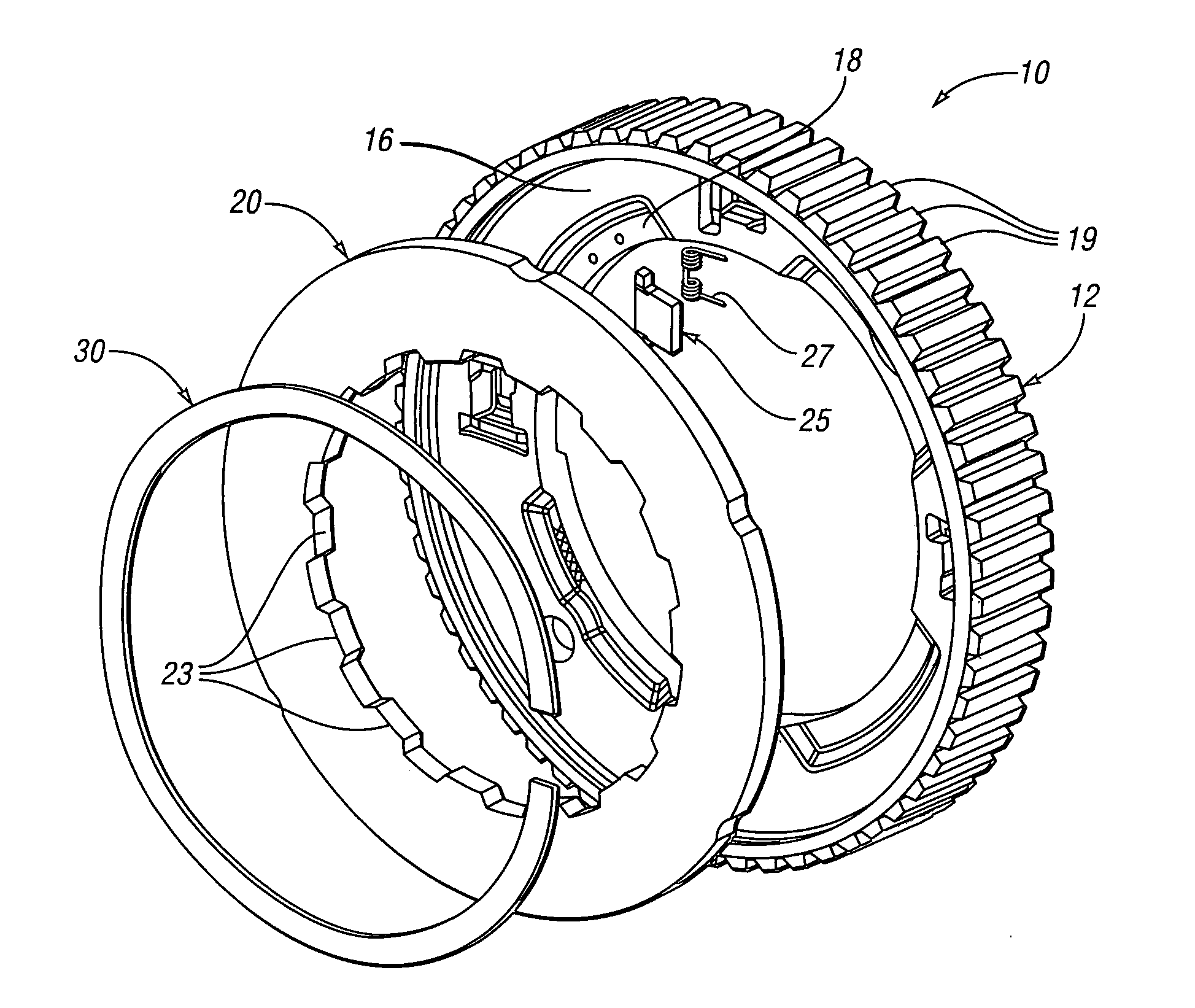

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

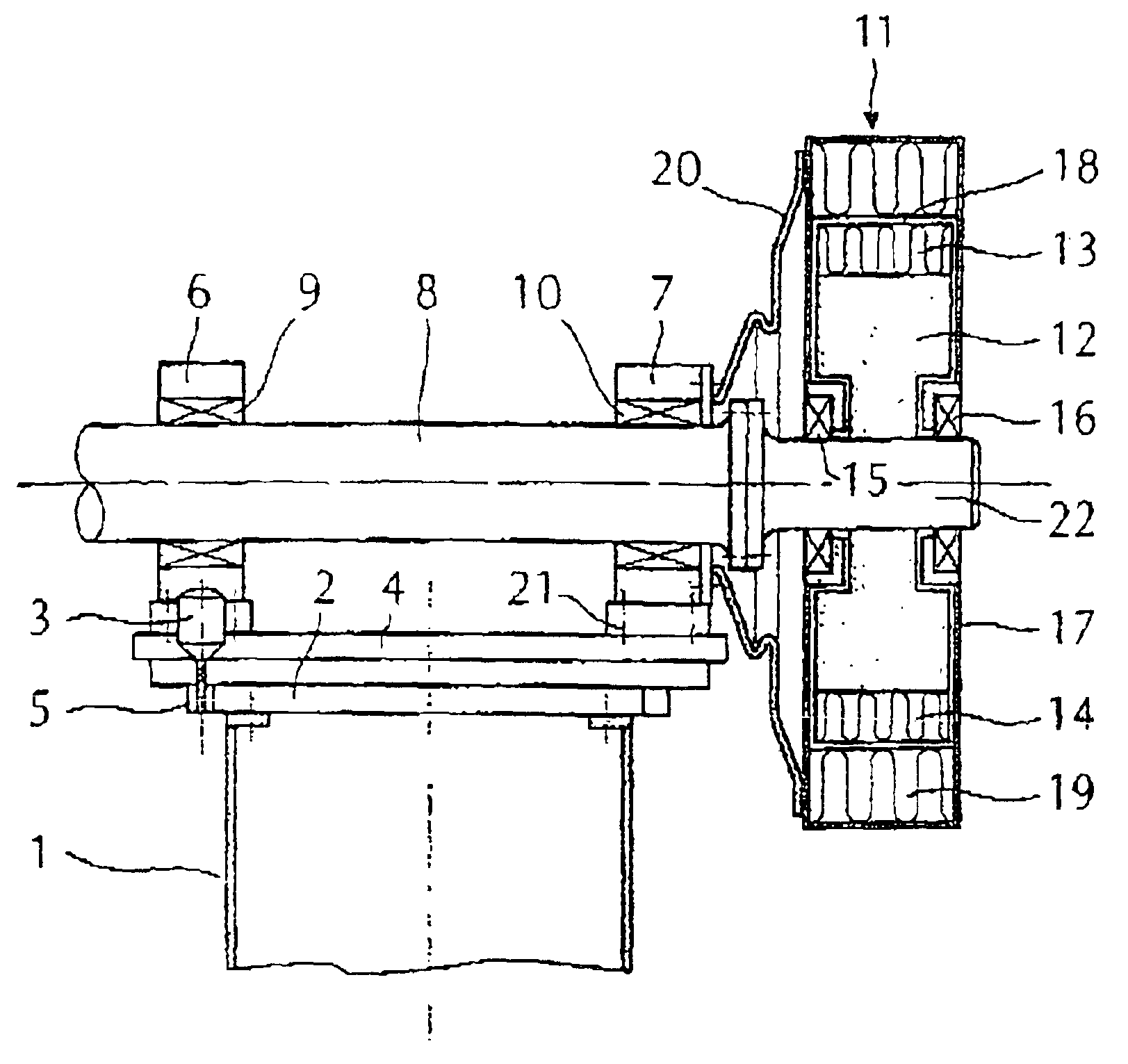

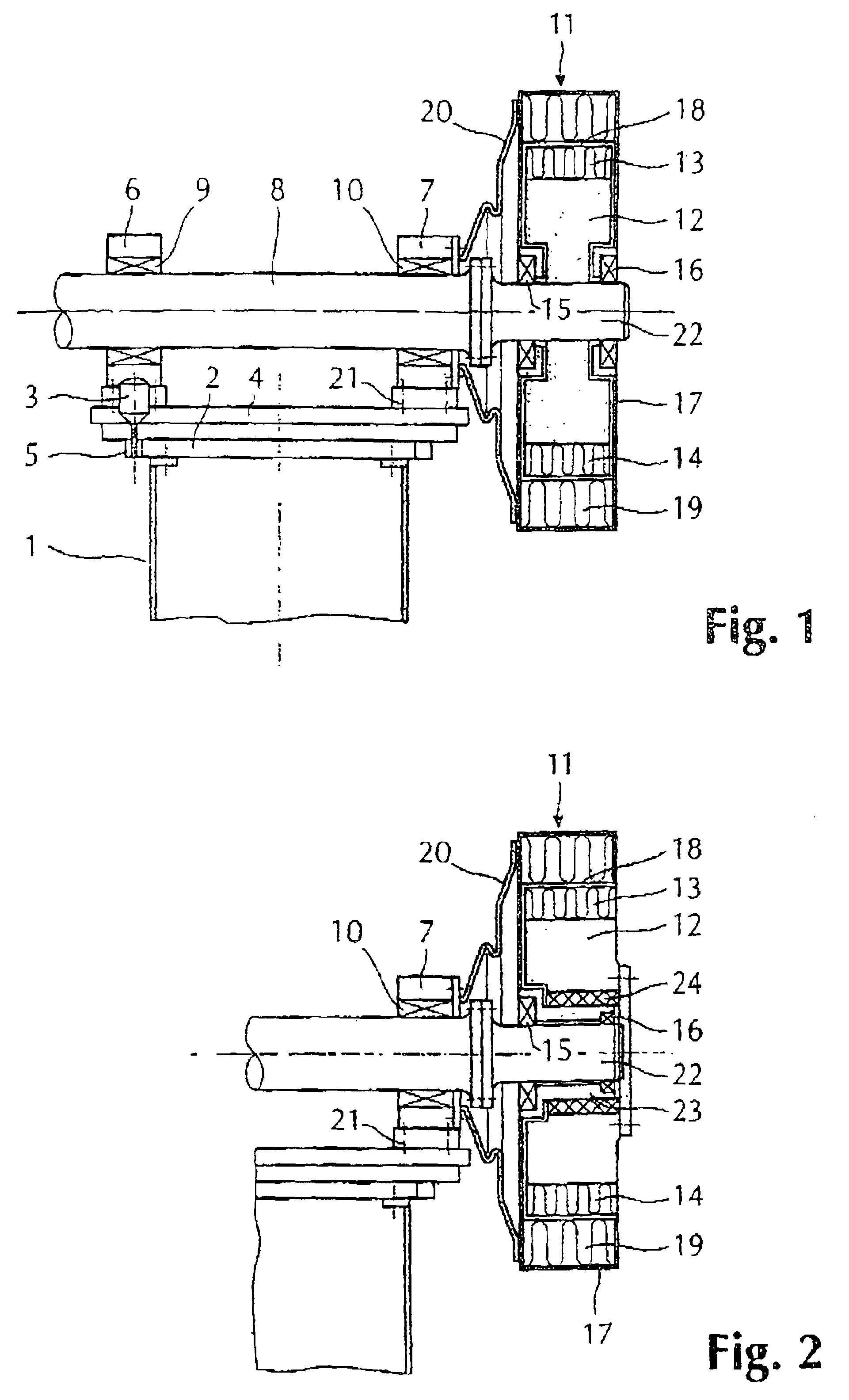

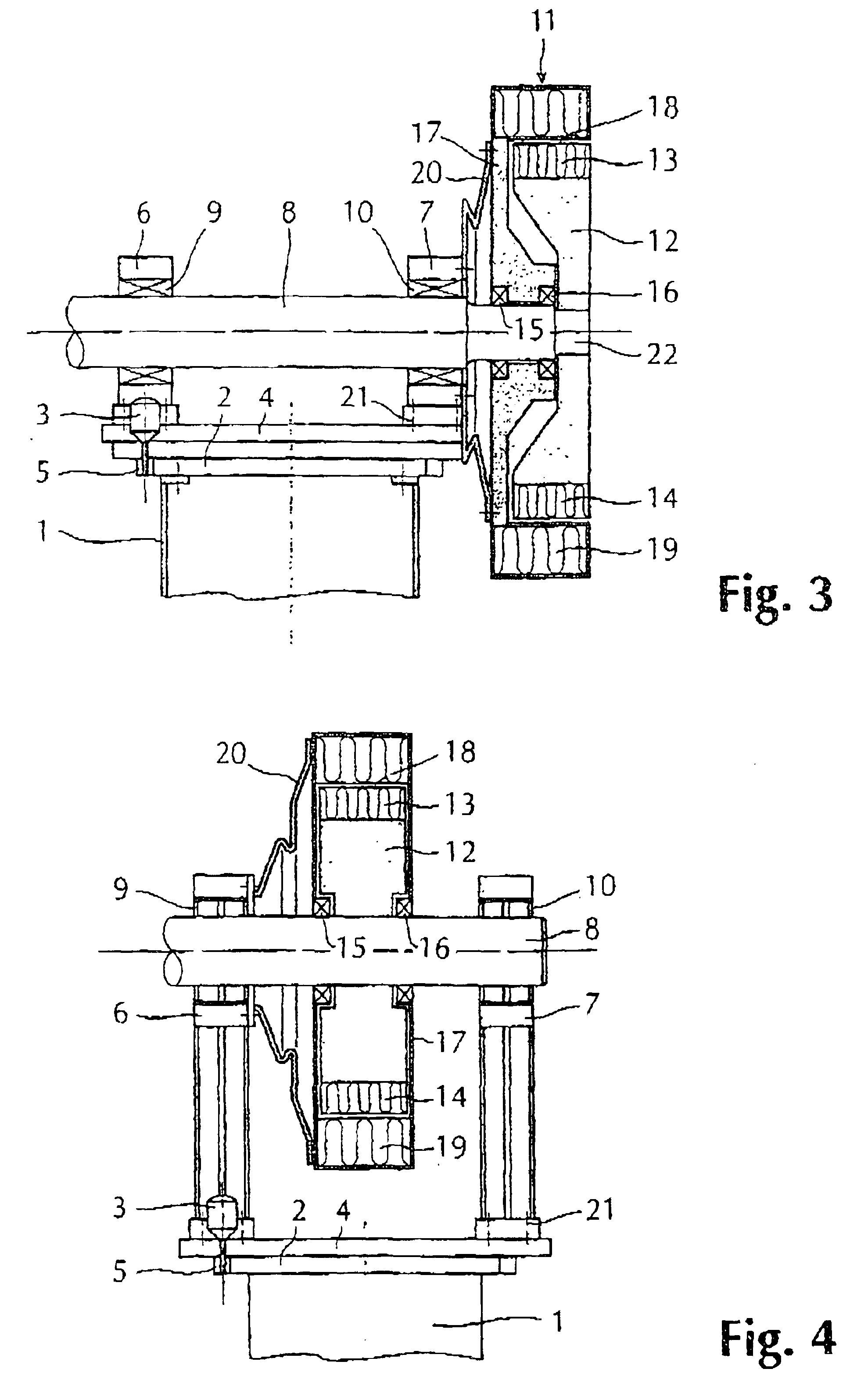

Windmill

InactiveUS6911741B2Reduce bendabilityImprove bearing capacityEnergy storageWind motor combinationsVertical axisElectric generator

Wind power plant with a wind turbine with a turbine shaft with which a generator shaft, which can be an extension of the turbine shaft, is connected to the rotor (12) of an electric generator. The rotor is radially surrounded by a stator, the turbine shaft is journalled in two bearing housings with bearings arranged on a base at the top of a tower, the base is pivotable around a vertical axis, and a motor is provided to effect the pivoting. The generator shaft is integrated with or rigidly connected to a flexing turbine shaft, the stator and rotor are carried by the generator shaft, to allow the generator to follow the flexing movement of the turbine shaft and the stator is locked against turning by a non-rotatable coupling which transfers substantially no bending moment or axial force acting against the flexing of the turbine shaft due to the bending moment acting on the turbine shaft from its hub, the bearings being provided to allow flexing of the turbine shaft.

Owner:SCAN WIND GROUP

Continuously variable transmission

Owner:FALLBROOK INTPROP COMPANY

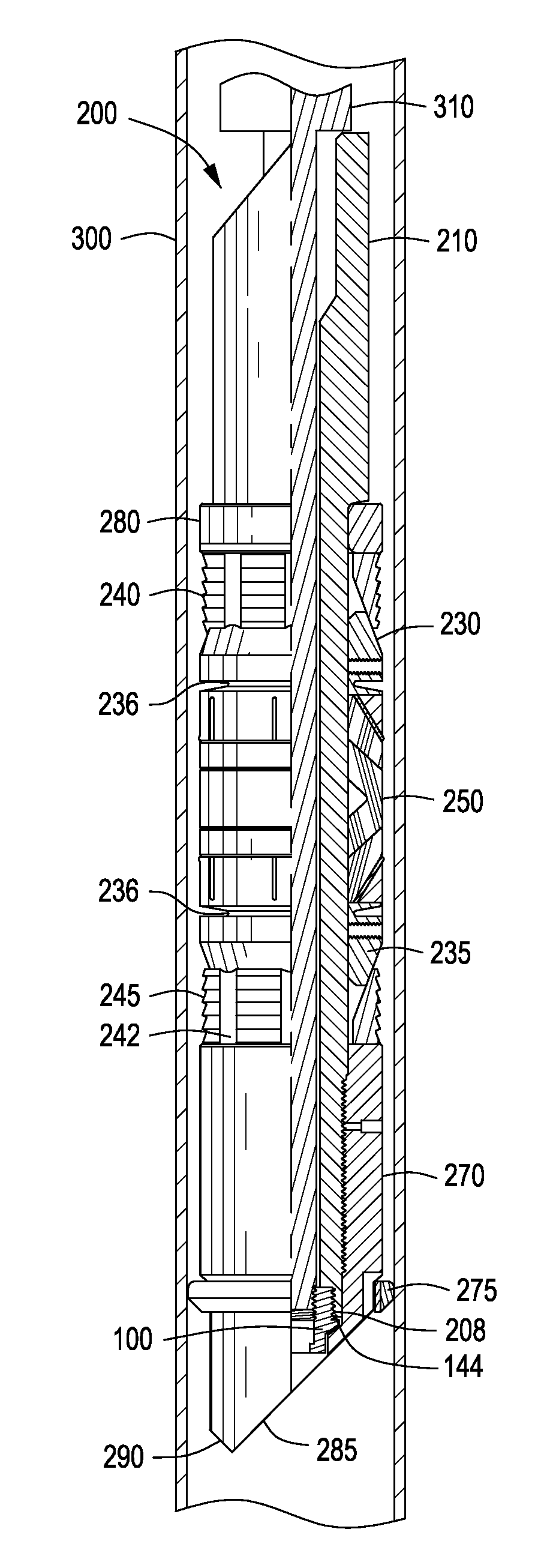

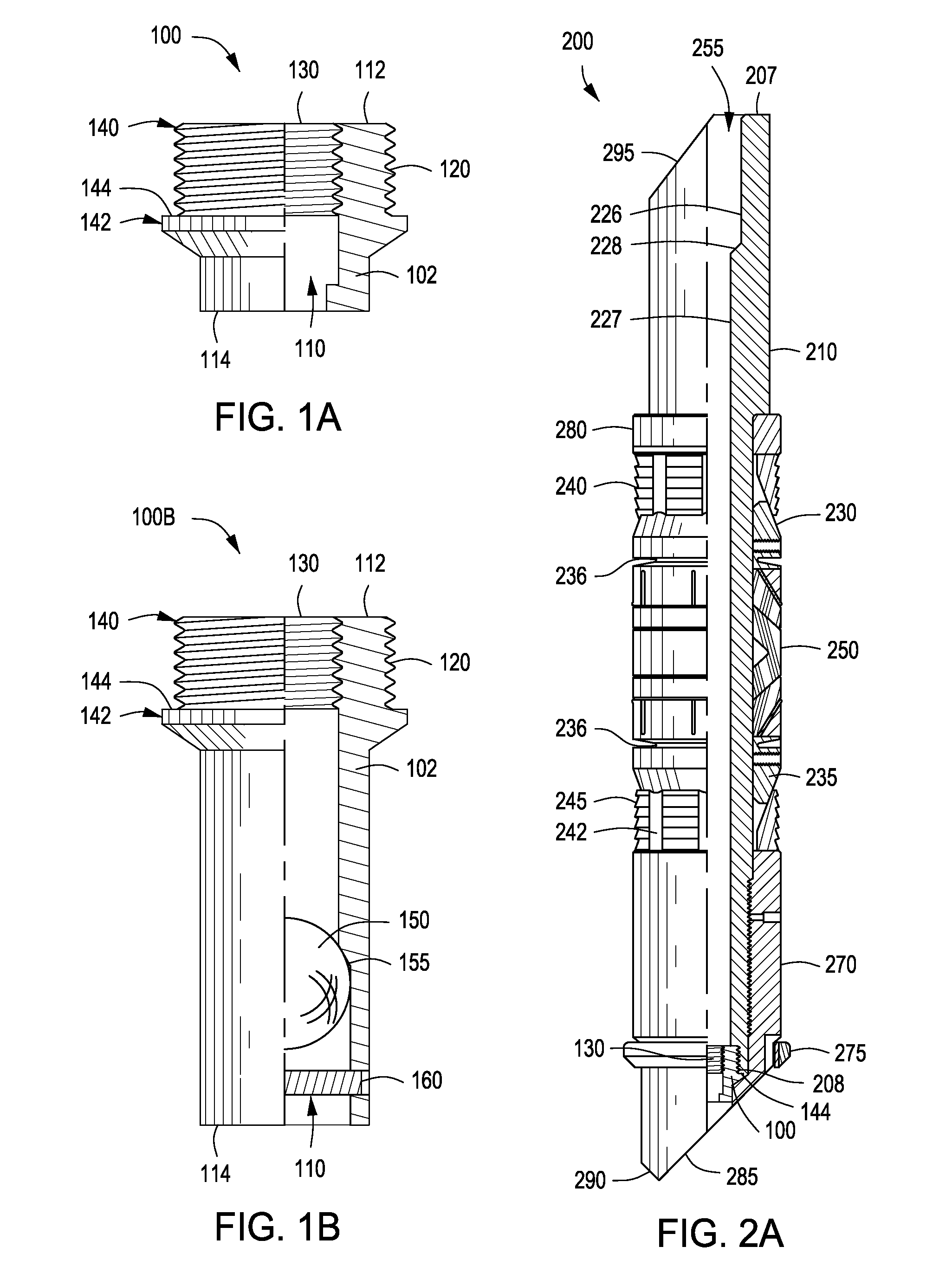

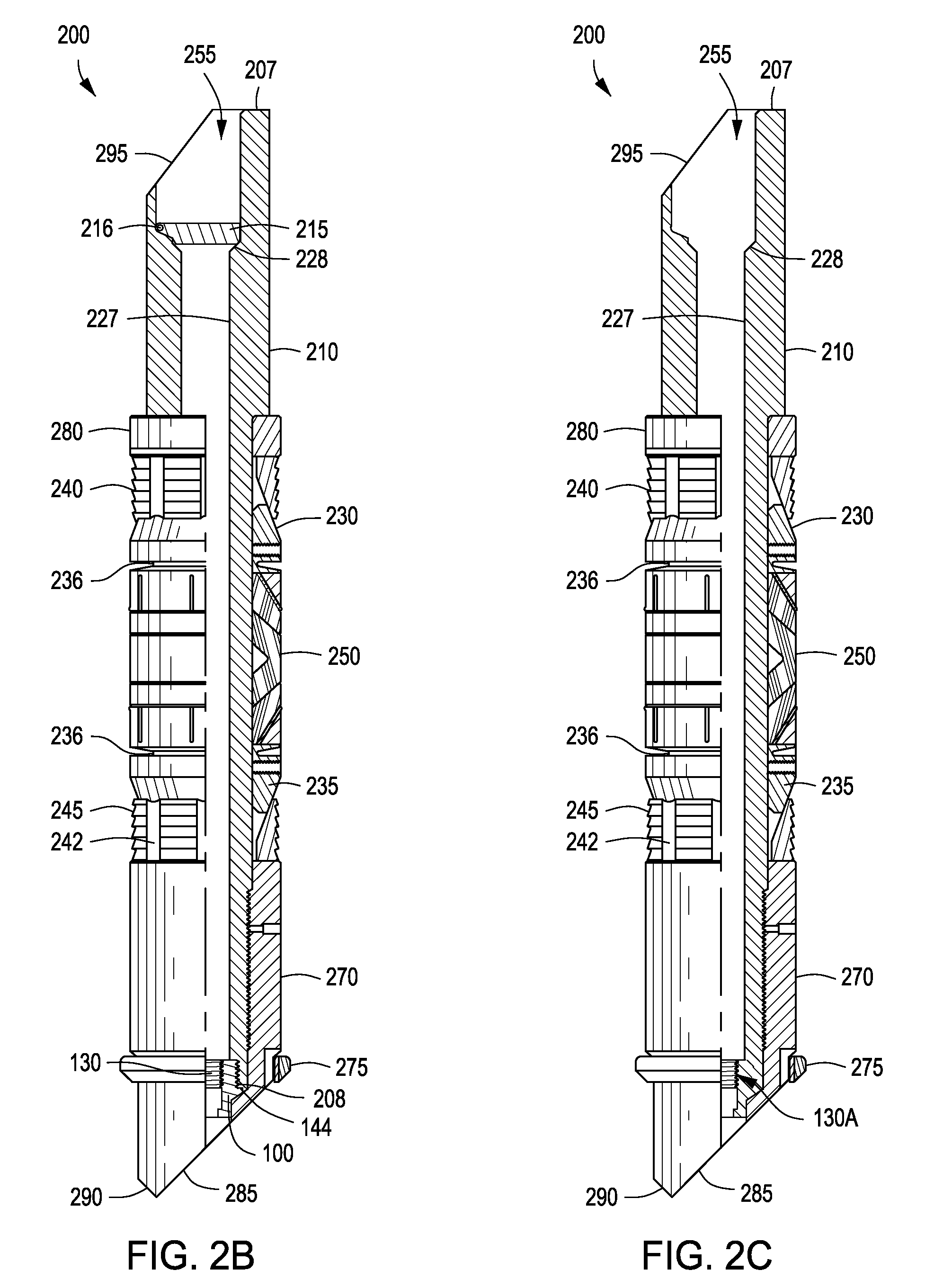

Bottom set downhole plug

A plug for isolating a wellbore. The plug can include a body having a first end and a second end, wherein the body is formed from one or more composite materials and adapted to receive a setting tool through the first end thereof, at least one malleable element disposed about the body, at least one slip disposed about the body, at least one conical member disposed about the body, and one or more shearable threads disposed on an inner surface of the body, adjacent the second end thereof, wherein the one or more shearable threads are adapted to receive at least a portion of a setting tool that enters the body through the first end thereof, and wherein the one or more shearable threads are adapted to engage the setting tool when disposed through the body and adapted to release the setting tool when exposed to a predetermined axial force.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com