Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce bendability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Windmill

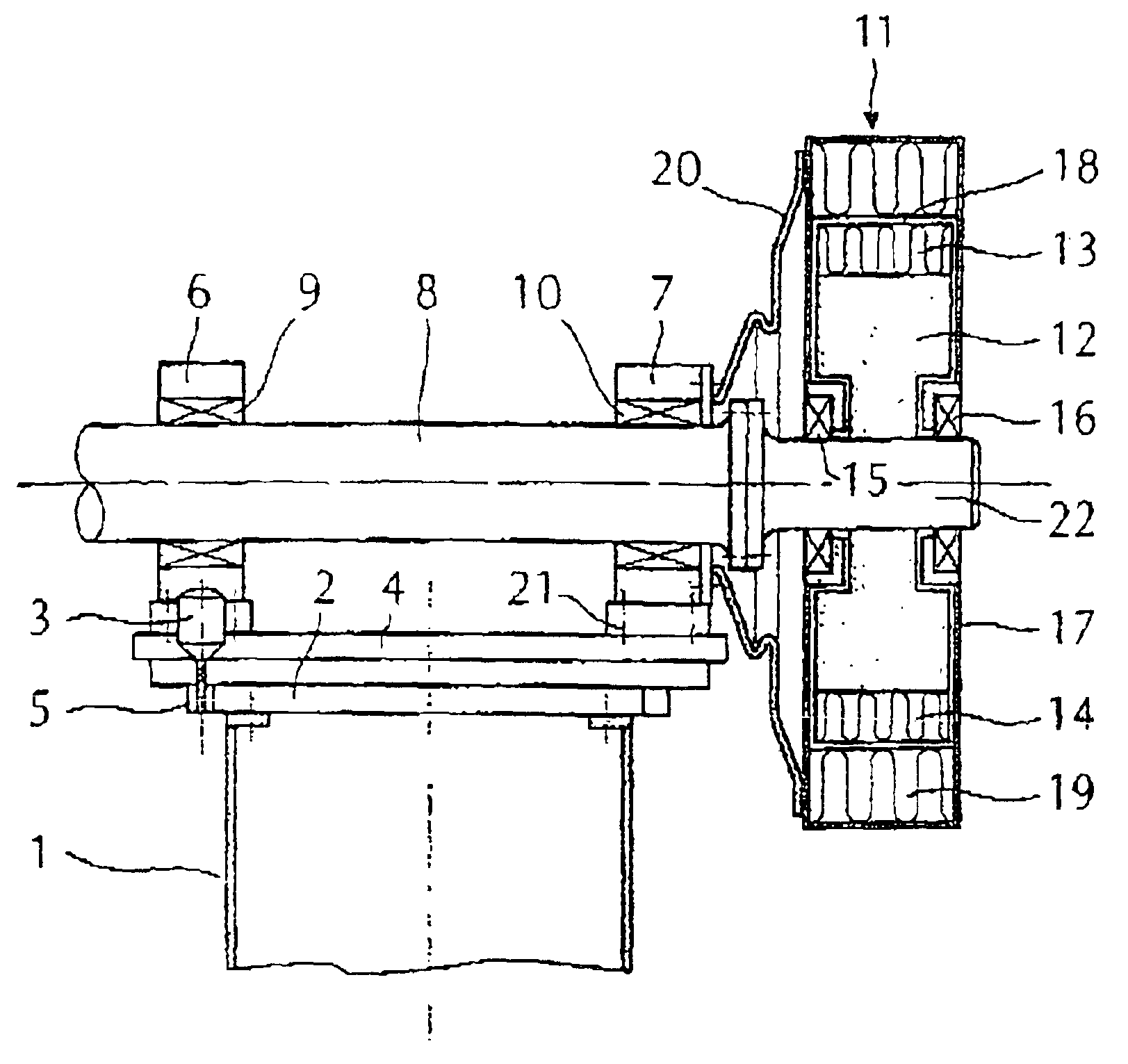

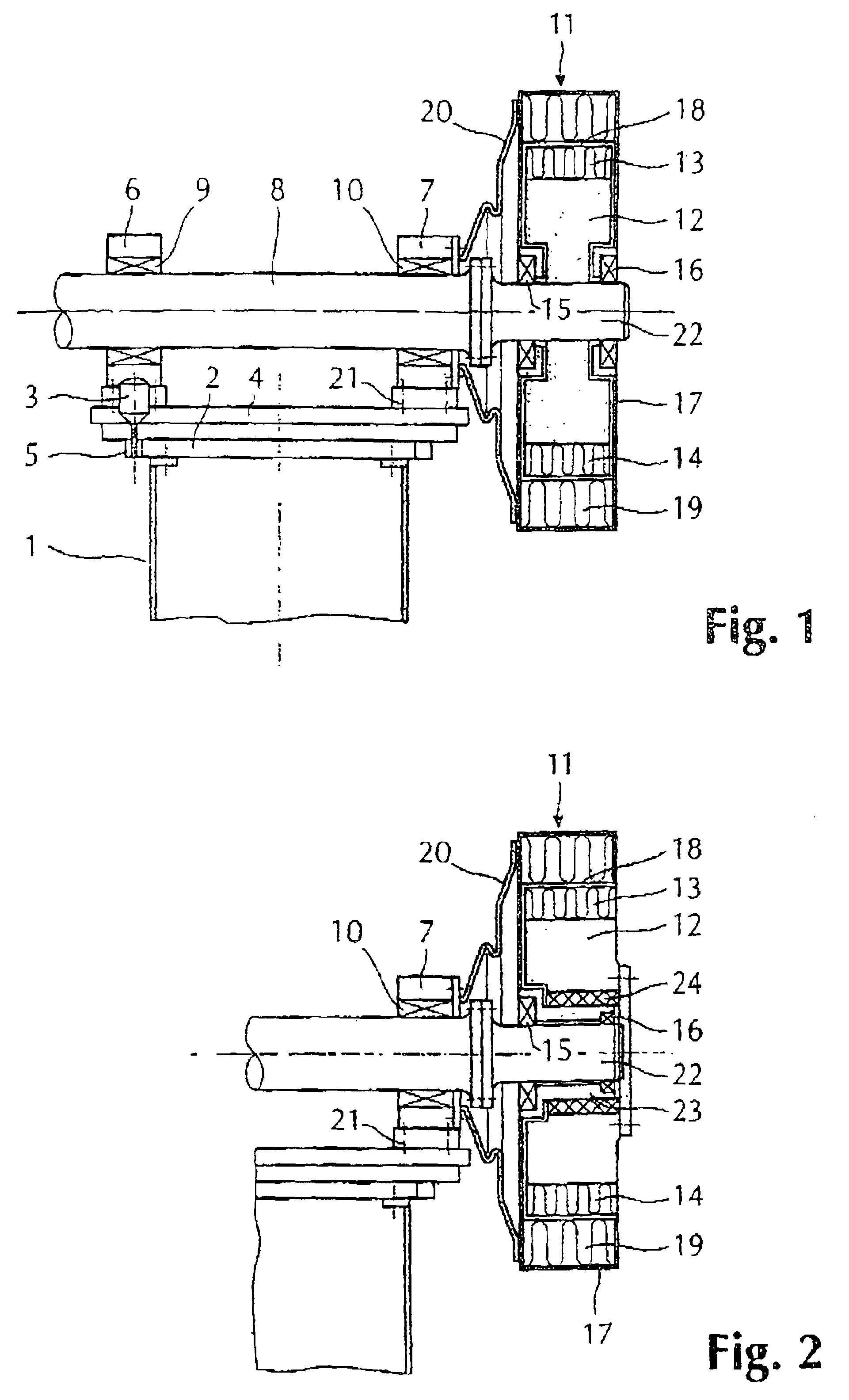

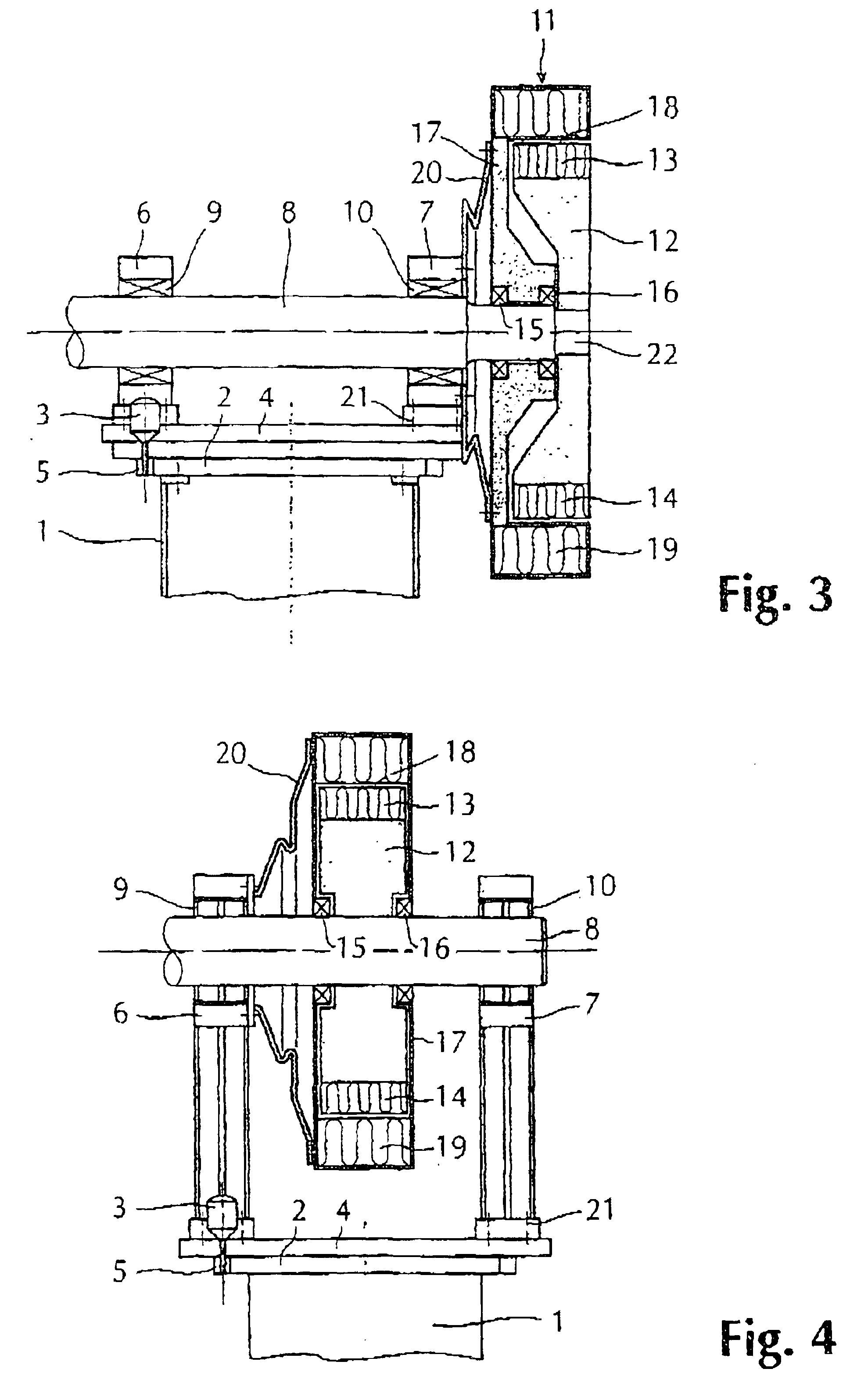

InactiveUS6911741B2Reduce bendabilityImprove bearing capacityEnergy storageWind motor combinationsVertical axisElectric generator

Wind power plant with a wind turbine with a turbine shaft with which a generator shaft, which can be an extension of the turbine shaft, is connected to the rotor (12) of an electric generator. The rotor is radially surrounded by a stator, the turbine shaft is journalled in two bearing housings with bearings arranged on a base at the top of a tower, the base is pivotable around a vertical axis, and a motor is provided to effect the pivoting. The generator shaft is integrated with or rigidly connected to a flexing turbine shaft, the stator and rotor are carried by the generator shaft, to allow the generator to follow the flexing movement of the turbine shaft and the stator is locked against turning by a non-rotatable coupling which transfers substantially no bending moment or axial force acting against the flexing of the turbine shaft due to the bending moment acting on the turbine shaft from its hub, the bearings being provided to allow flexing of the turbine shaft.

Owner:SCAN WIND GROUP

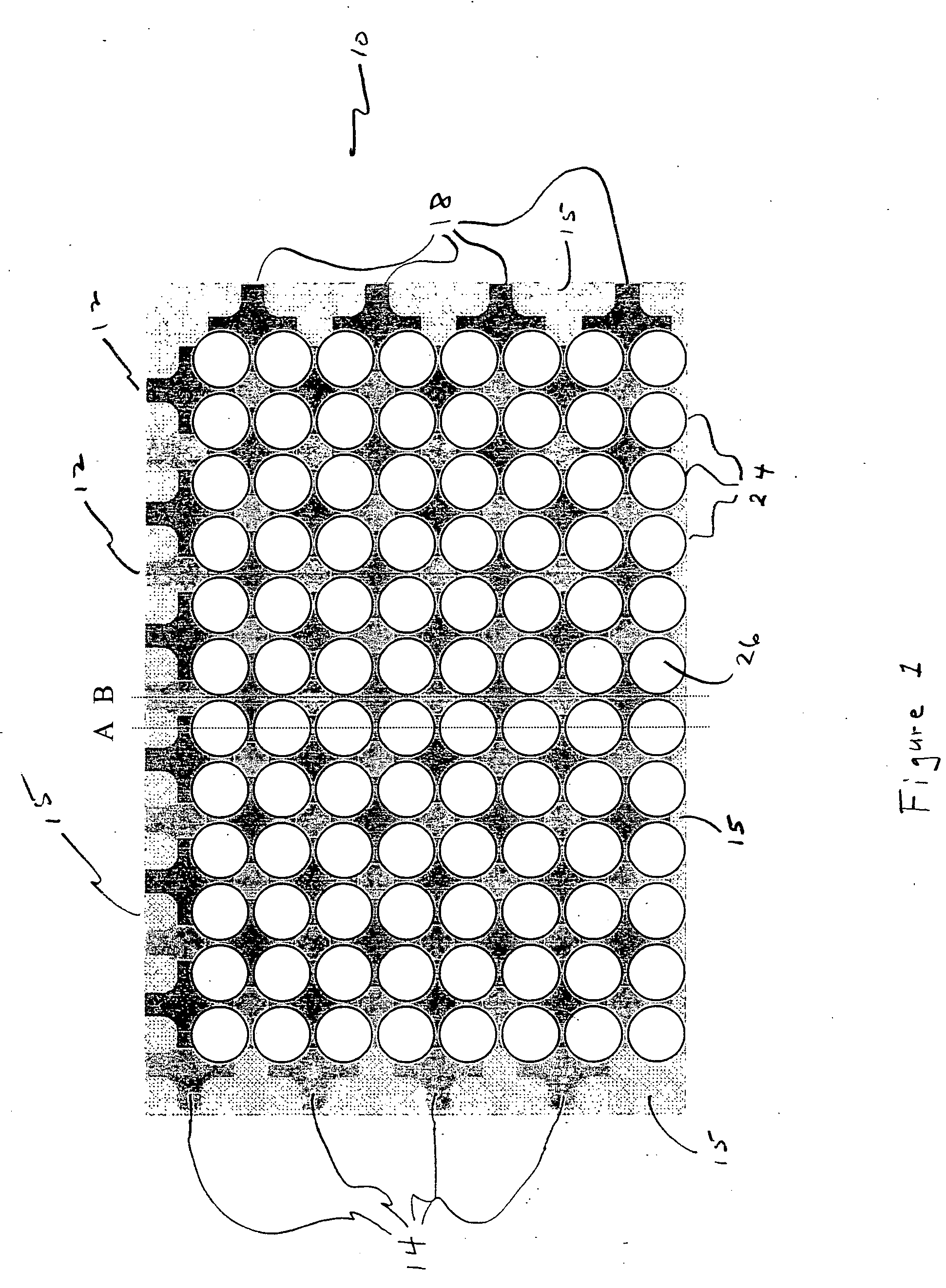

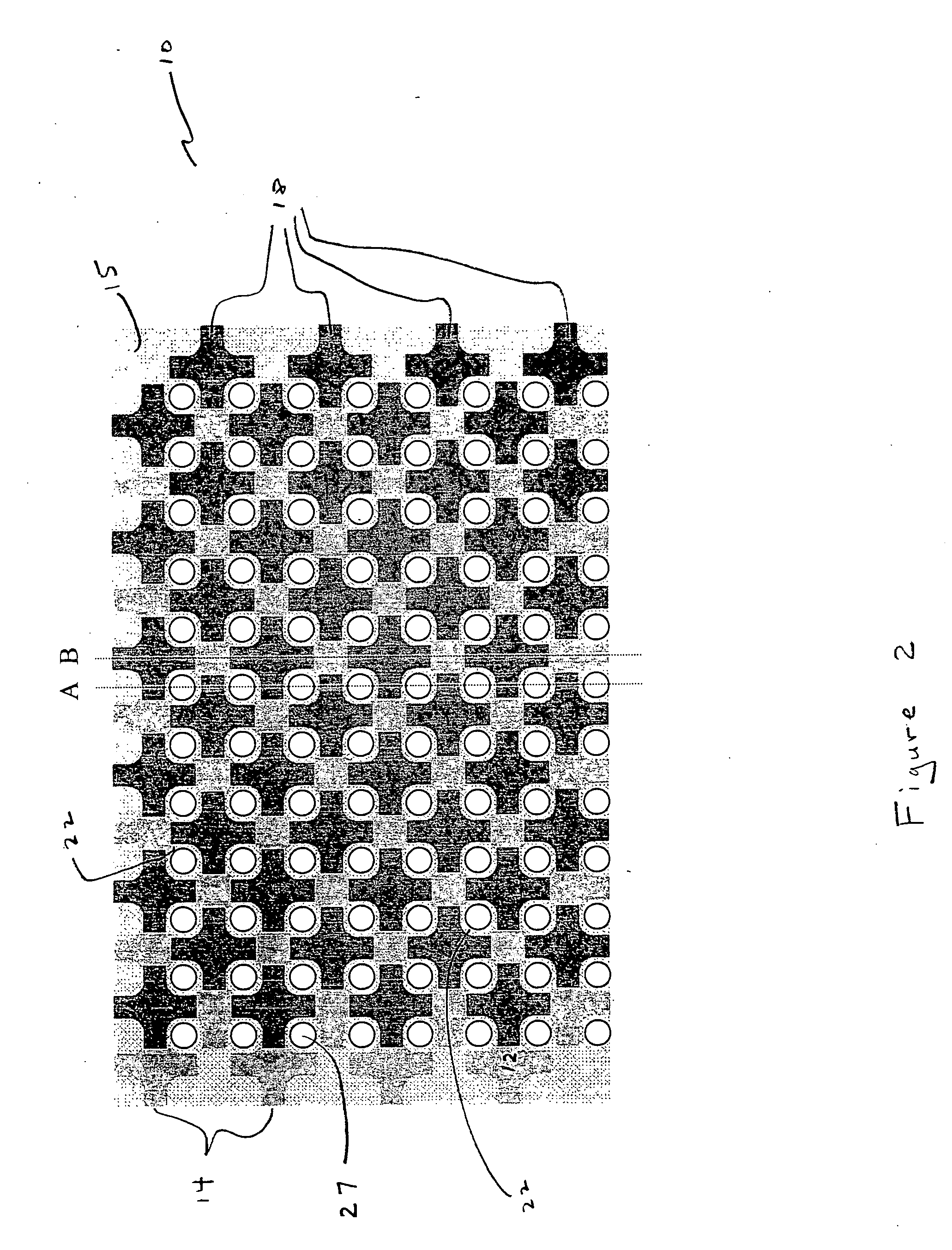

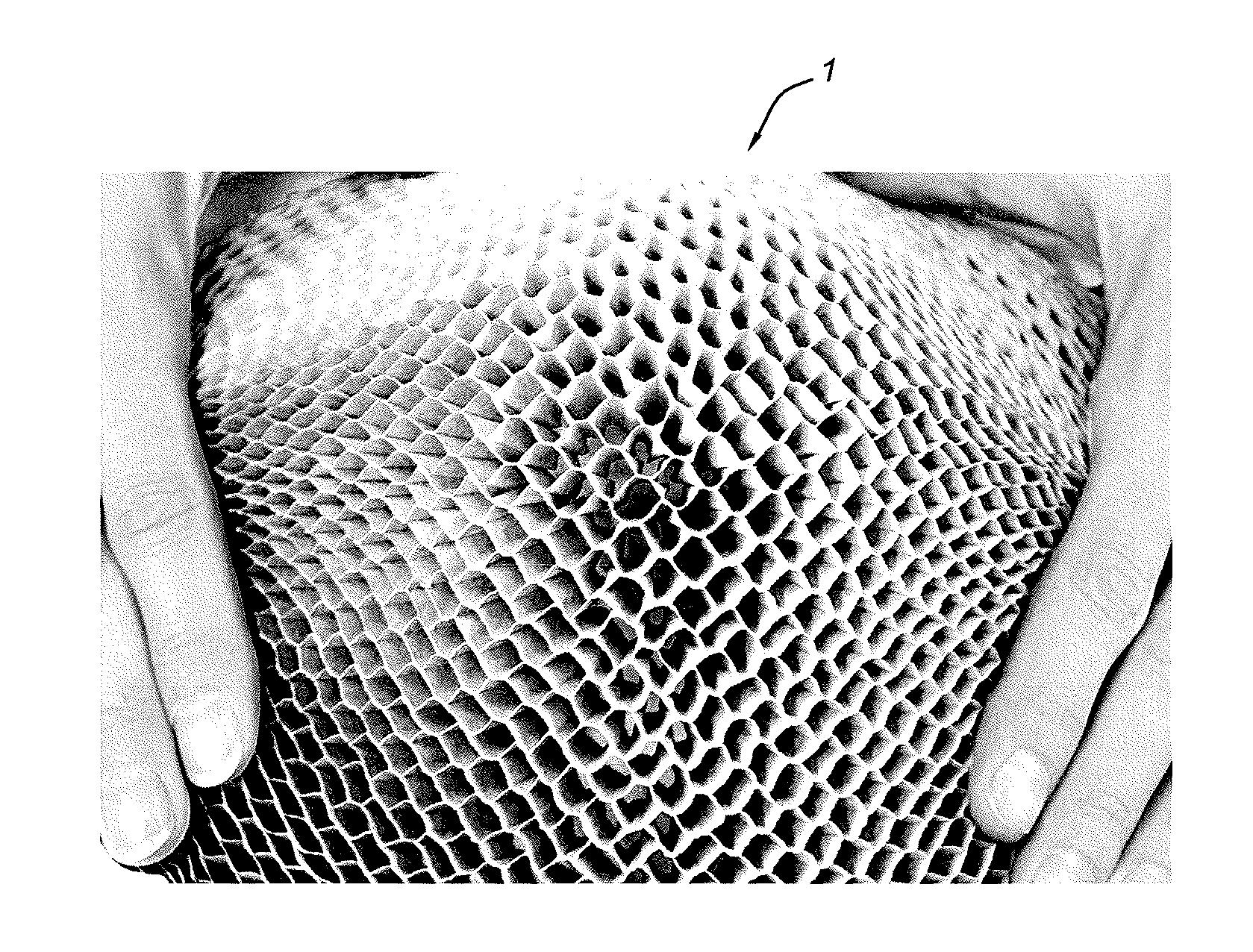

Supple penetration resistant fabric and method of making

InactiveUS6962739B1High fabric strengthStrong materialGlovesSynthetic resin layered productsBiomedical engineeringMedical treatment

Owner:HIGHER DIMENSION MATERIALS INC (US)

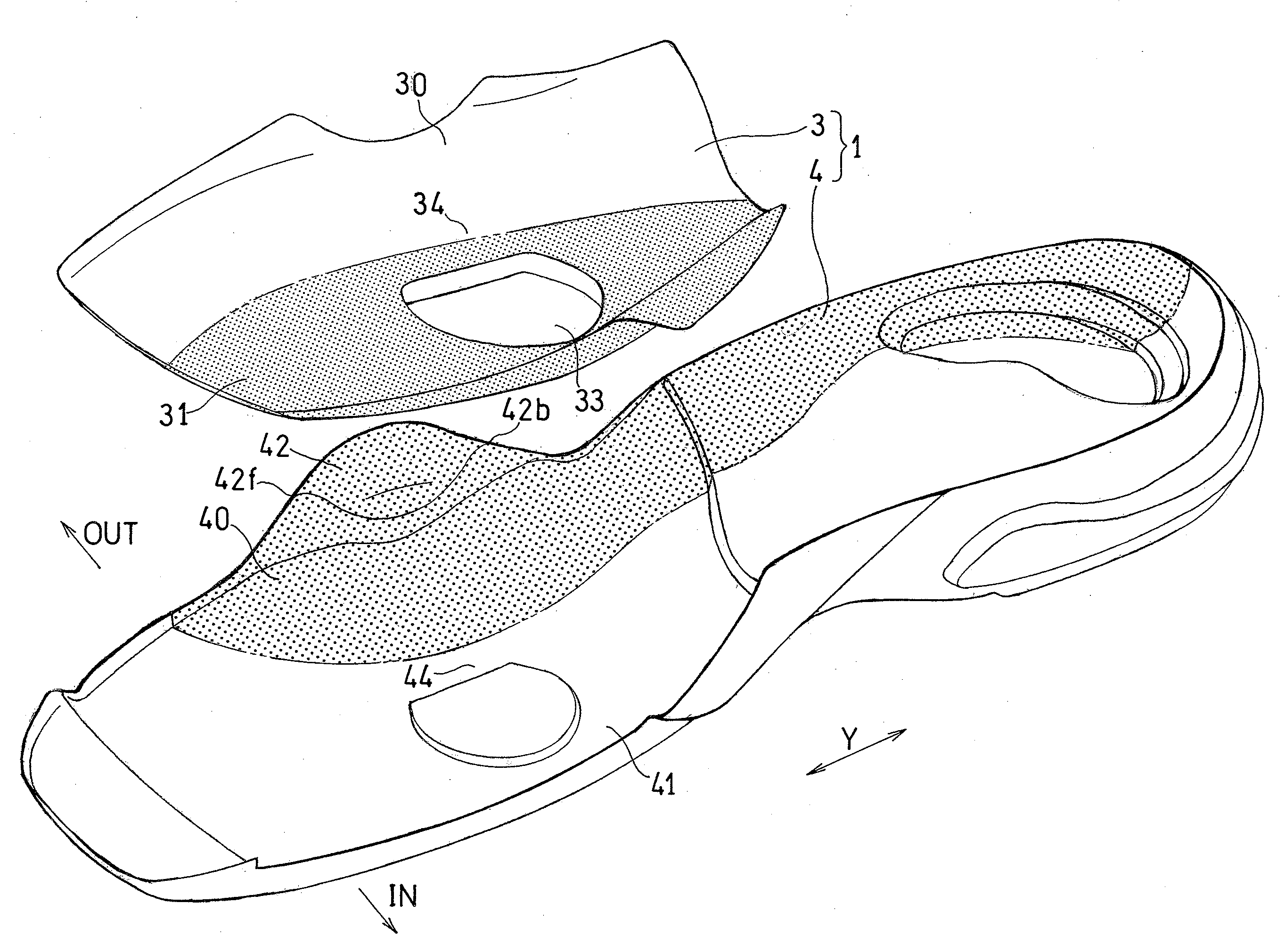

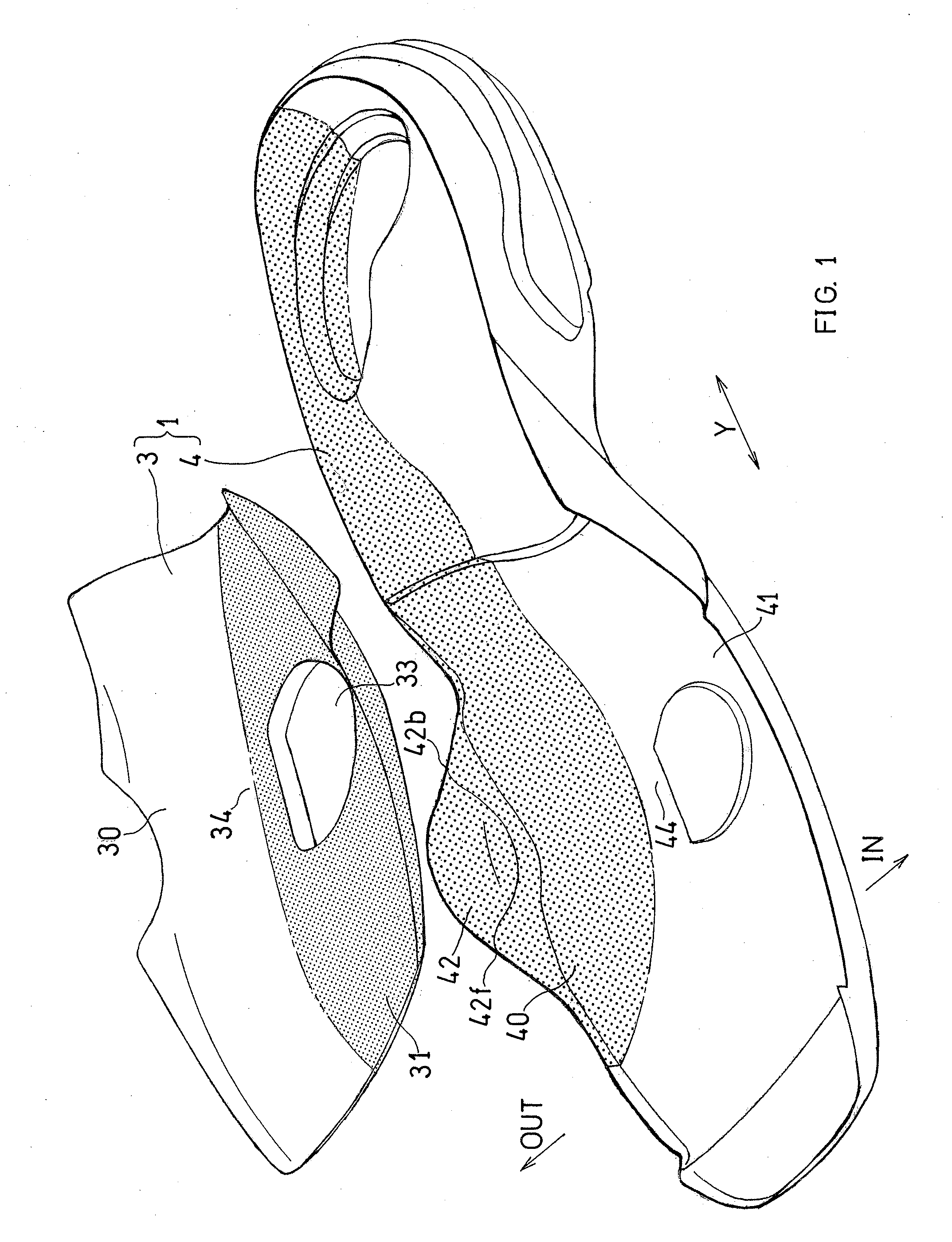

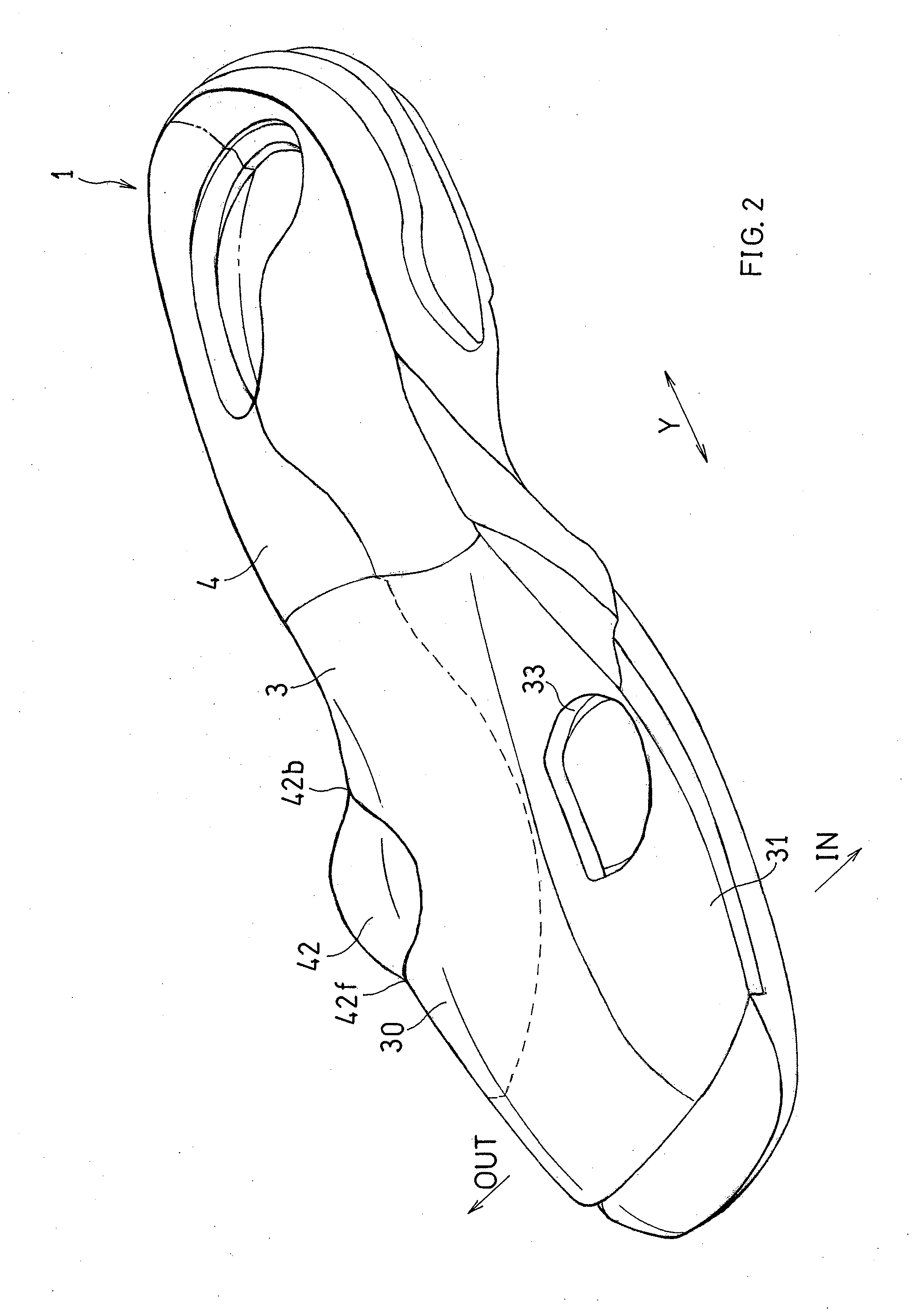

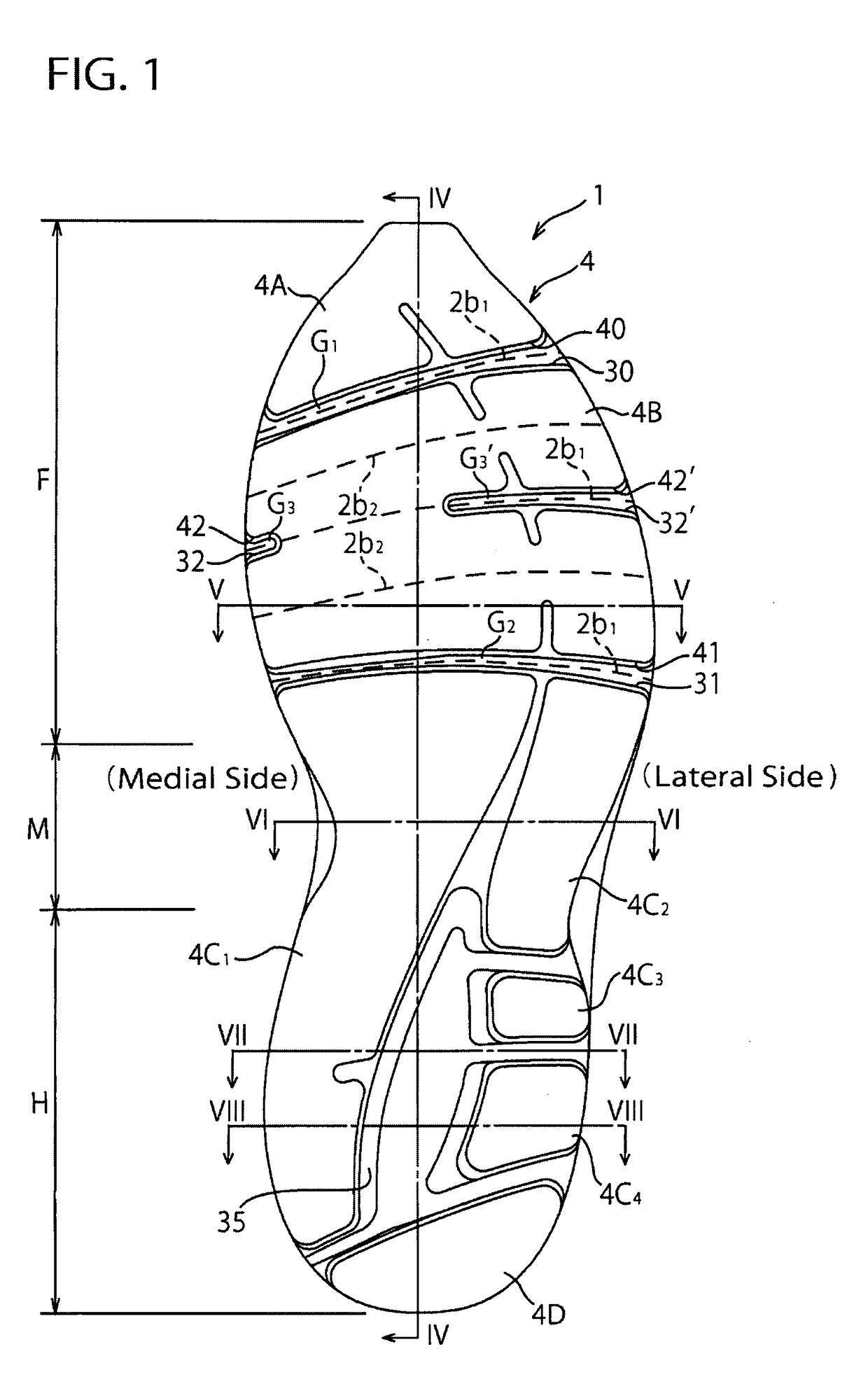

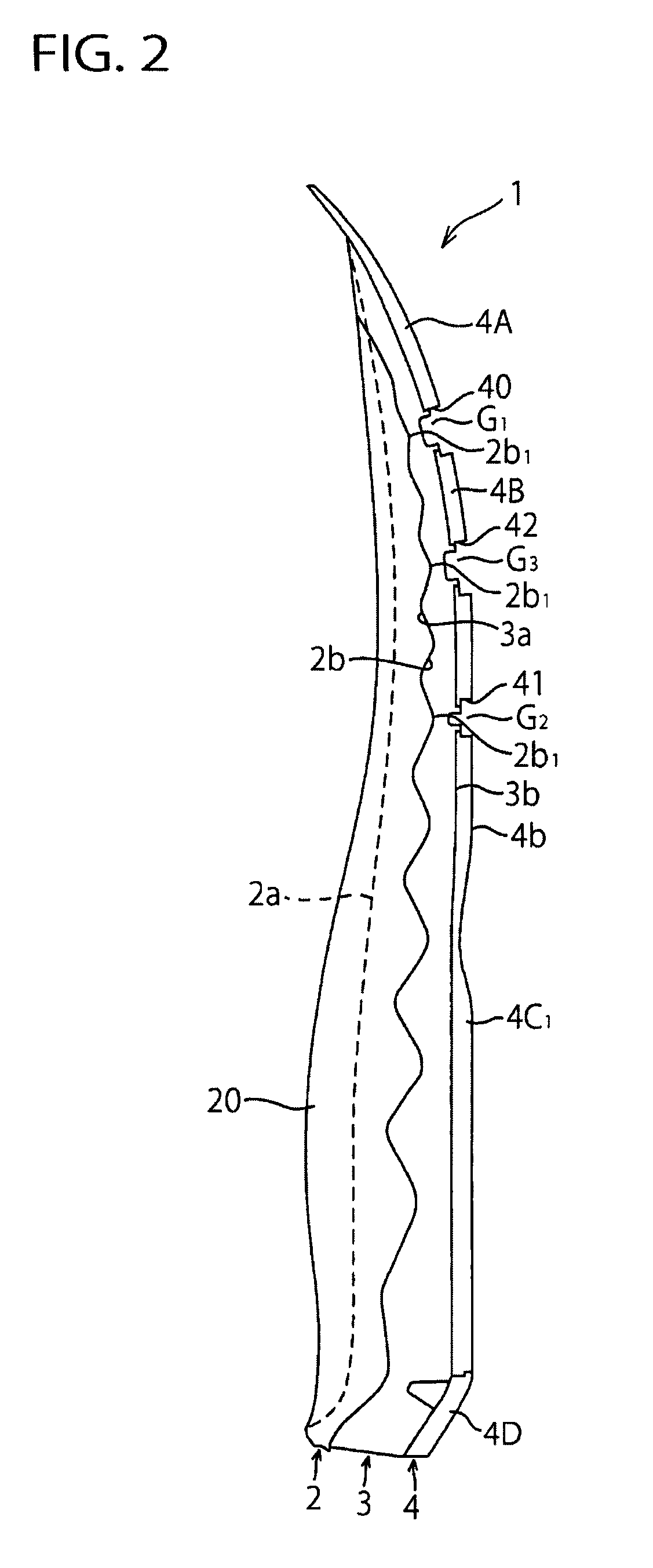

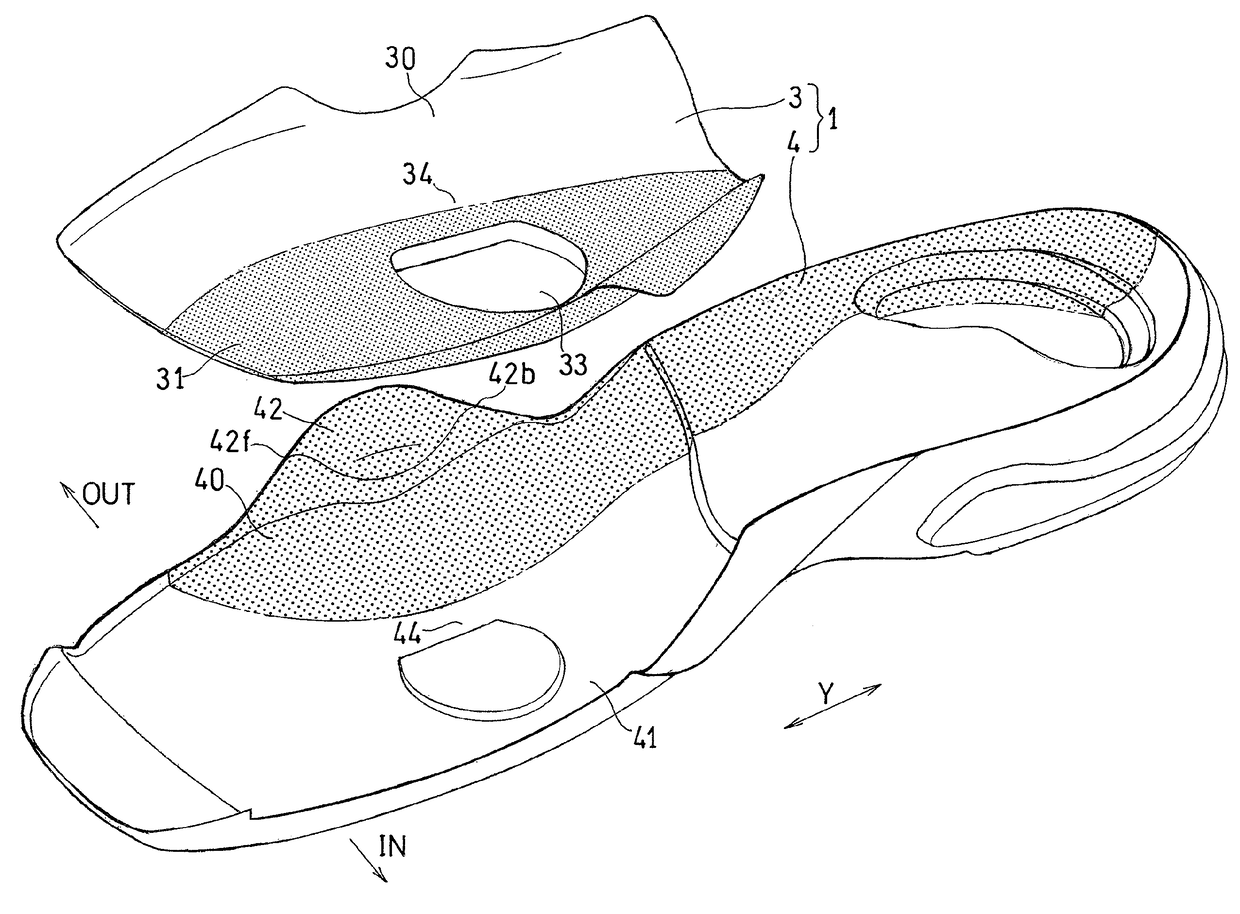

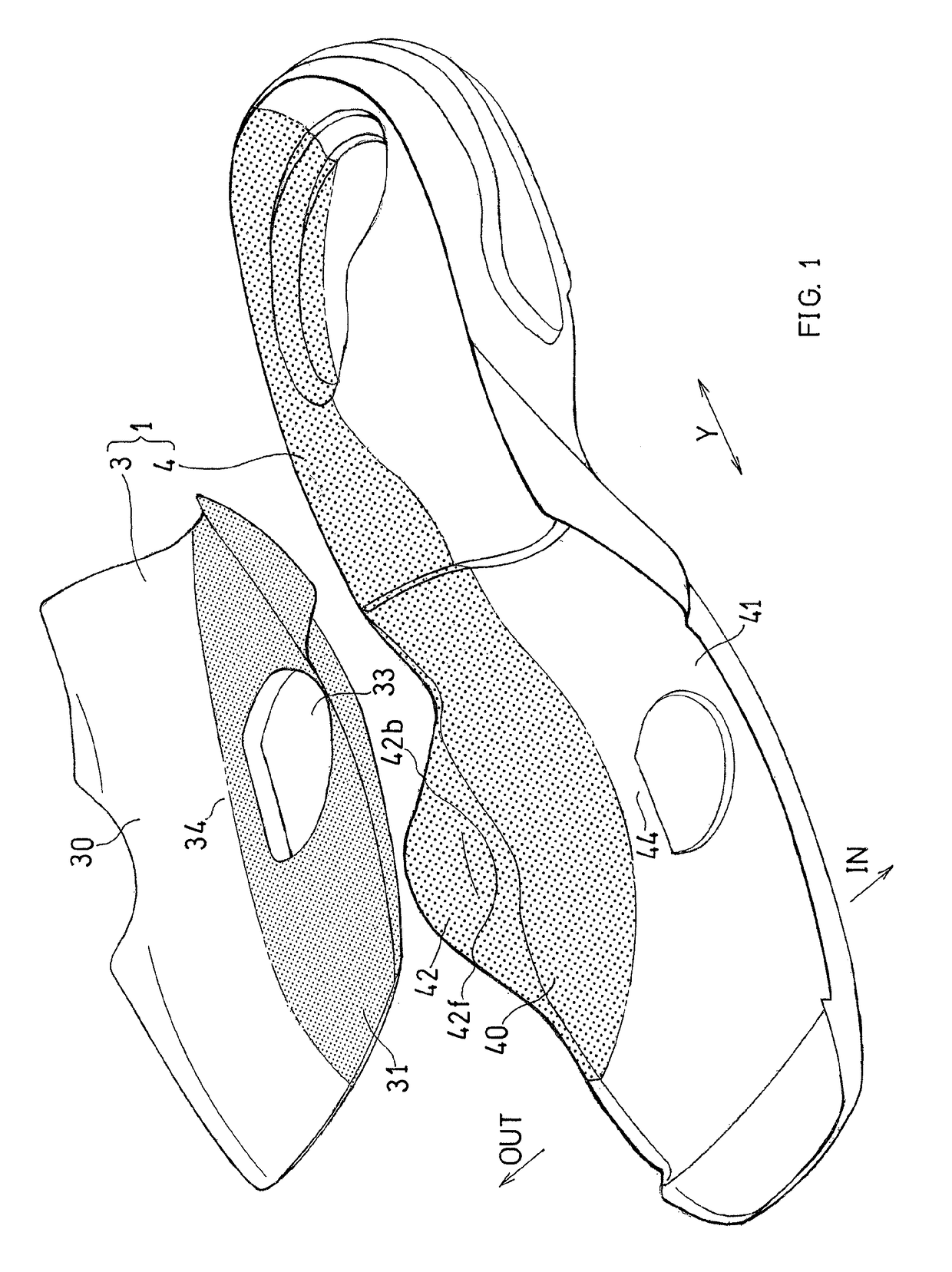

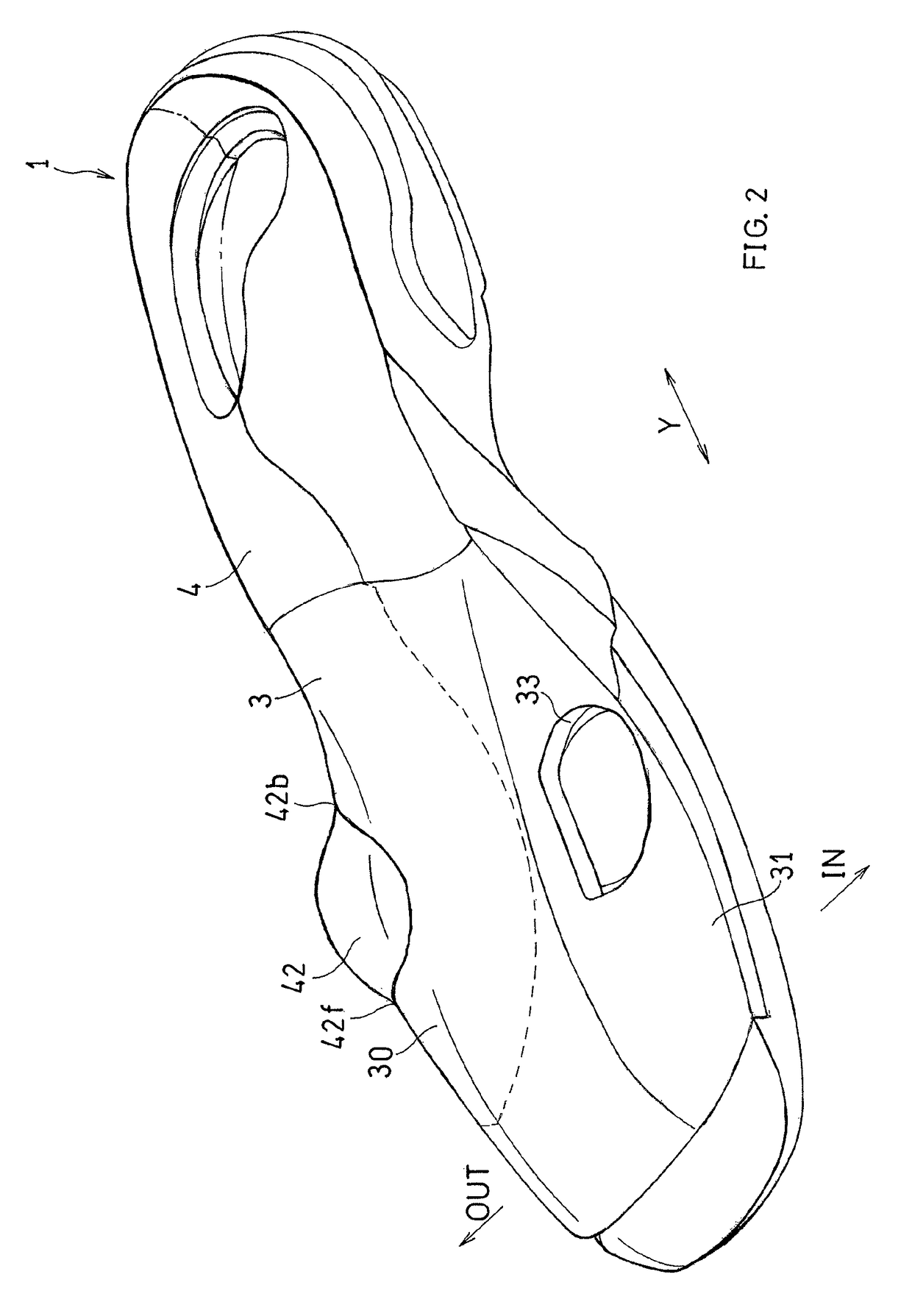

Shoe Sole Having Outsole and Midsole

A shoe sole including an outsole 2 and a midsole 1, wherein: the midsole 1 includes a lower midsole 4 of a lower layer formed by a foamed body of a resin, and an upper midsole 3 of an upper layer formed by a foamed body of a resin and arranged on the lower midsole 4; a lateral roll-up portion 42 for supporting a lateral side of a foot from a side of the foot is formed integrally with the lower midsole 4; a hardness of a lateral portion 40 of the lower midsole 4 including the lateral roll-up portion 42 is a first hardness; a hardness of a medial portion 41 of the lower midsole 4 is a second hardness lower than the first hardness; a hardness of a lateral portion 30 of the upper midsole 3 is a third hardness lower than the first hardness; and a part or a whole of the high-hardness lateral roll-up portion 42 is protruding in an upward direction past the upper midsole 3 on a lateral side of the upper midsole 3 so that the lateral side of the foot is supported by the lateral roll-up portion 42 from the side of the foot without being supported by the upper midsole 3 from the side of the foot.

Owner:ASICS CORP

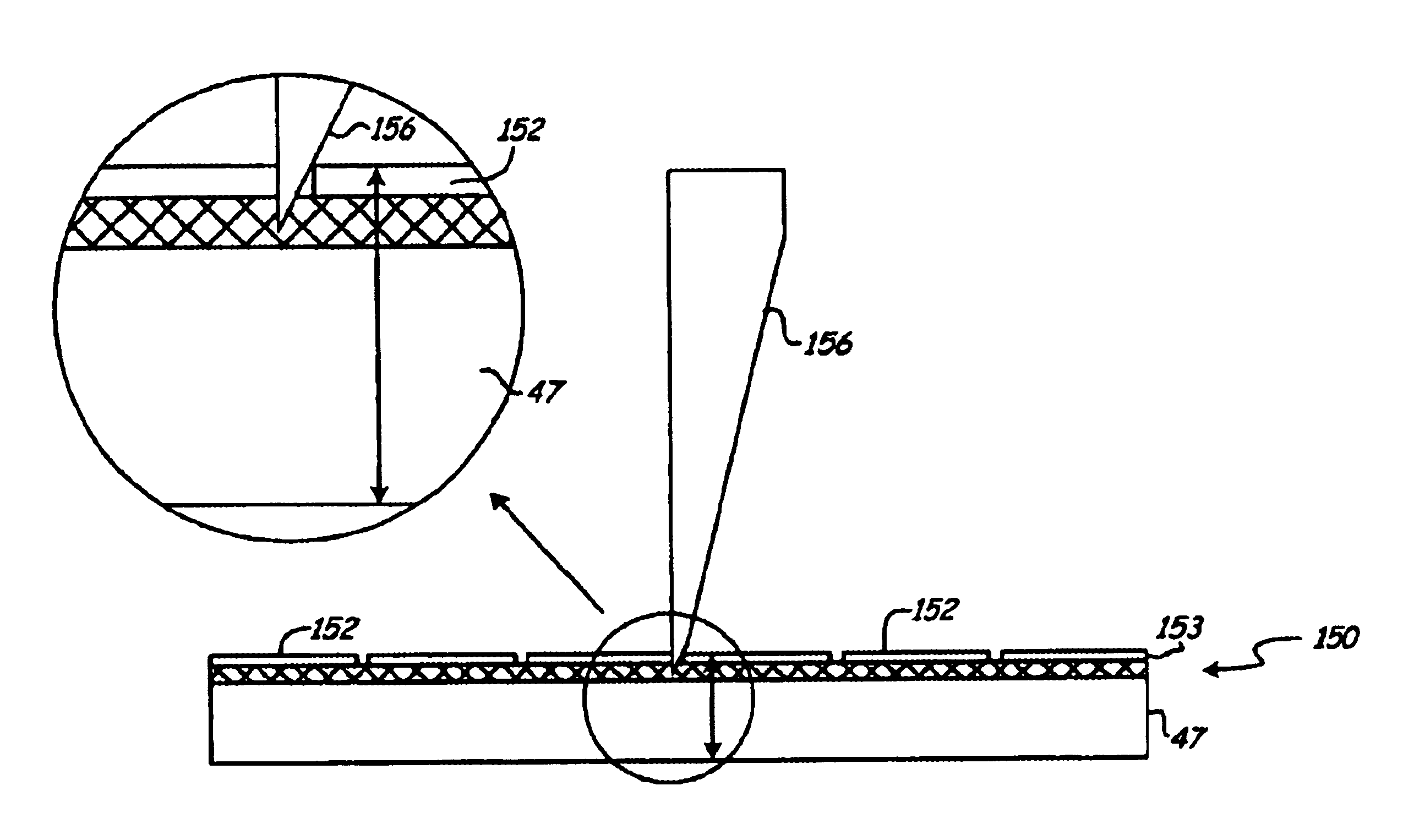

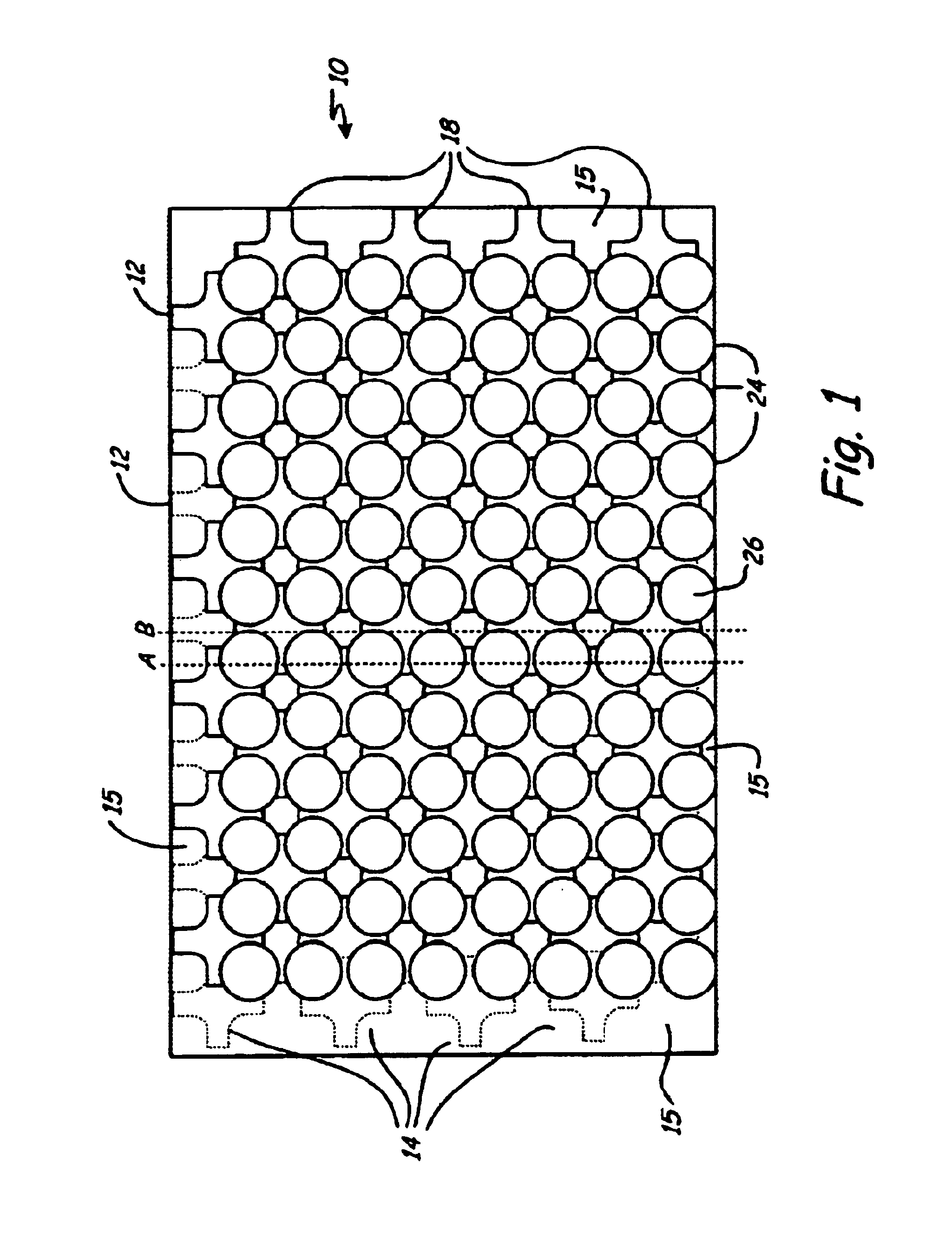

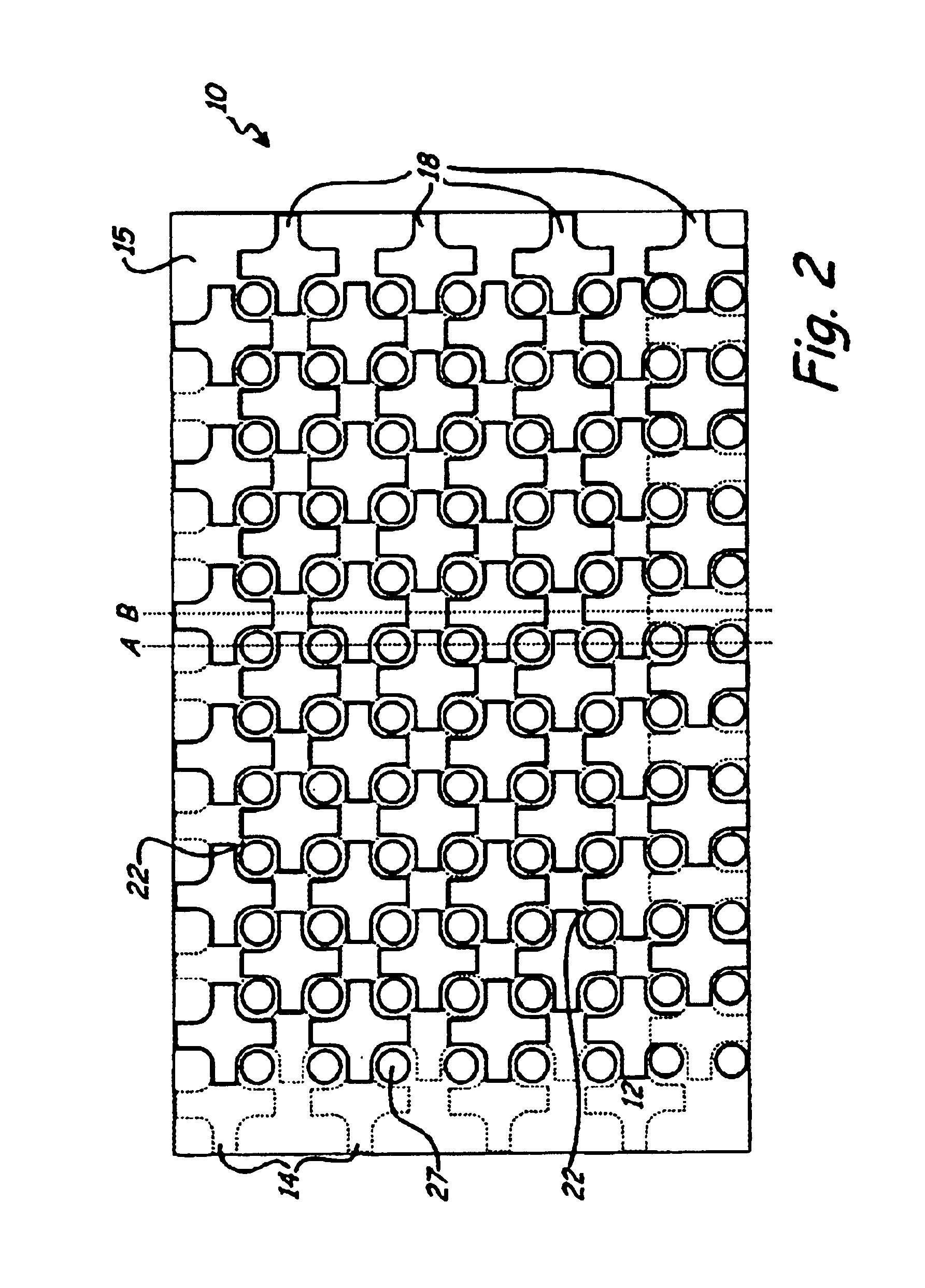

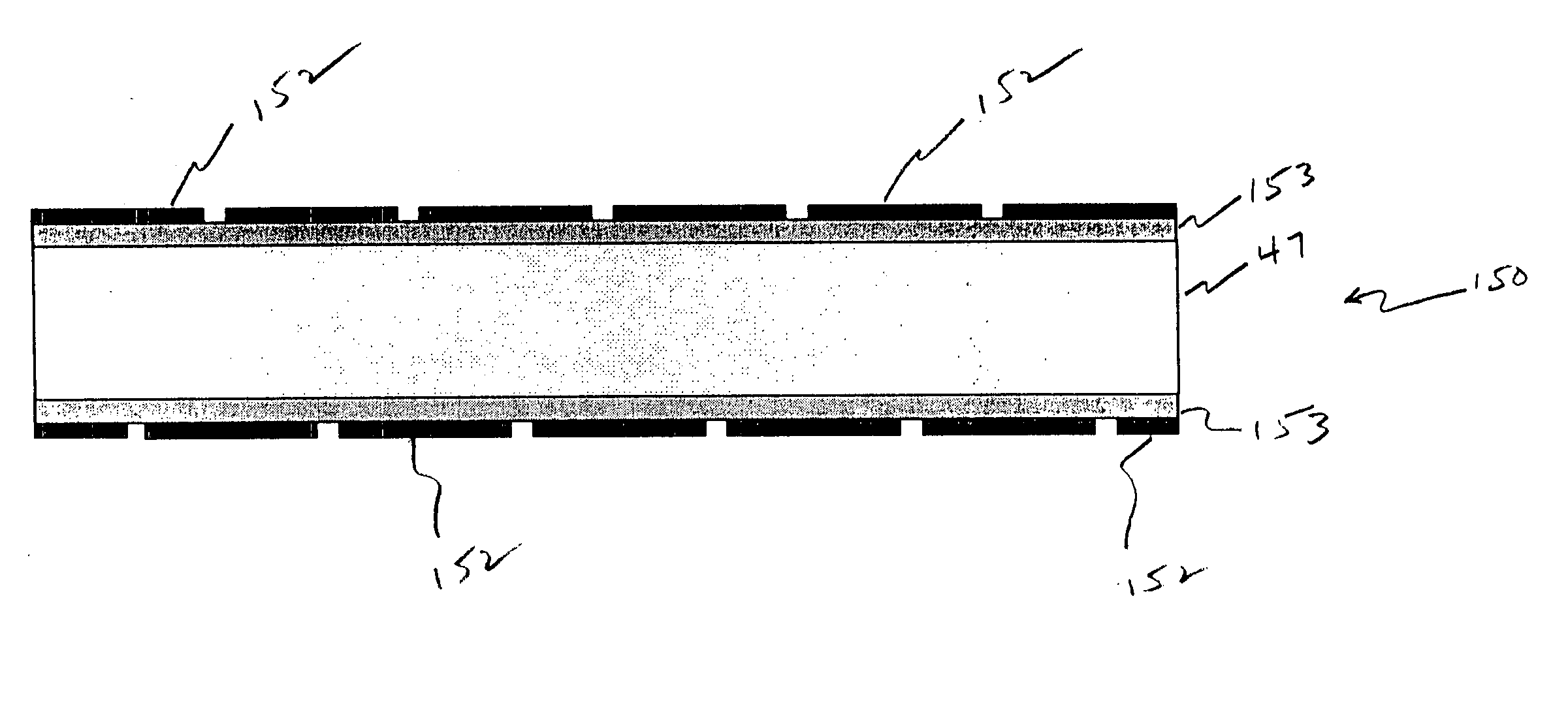

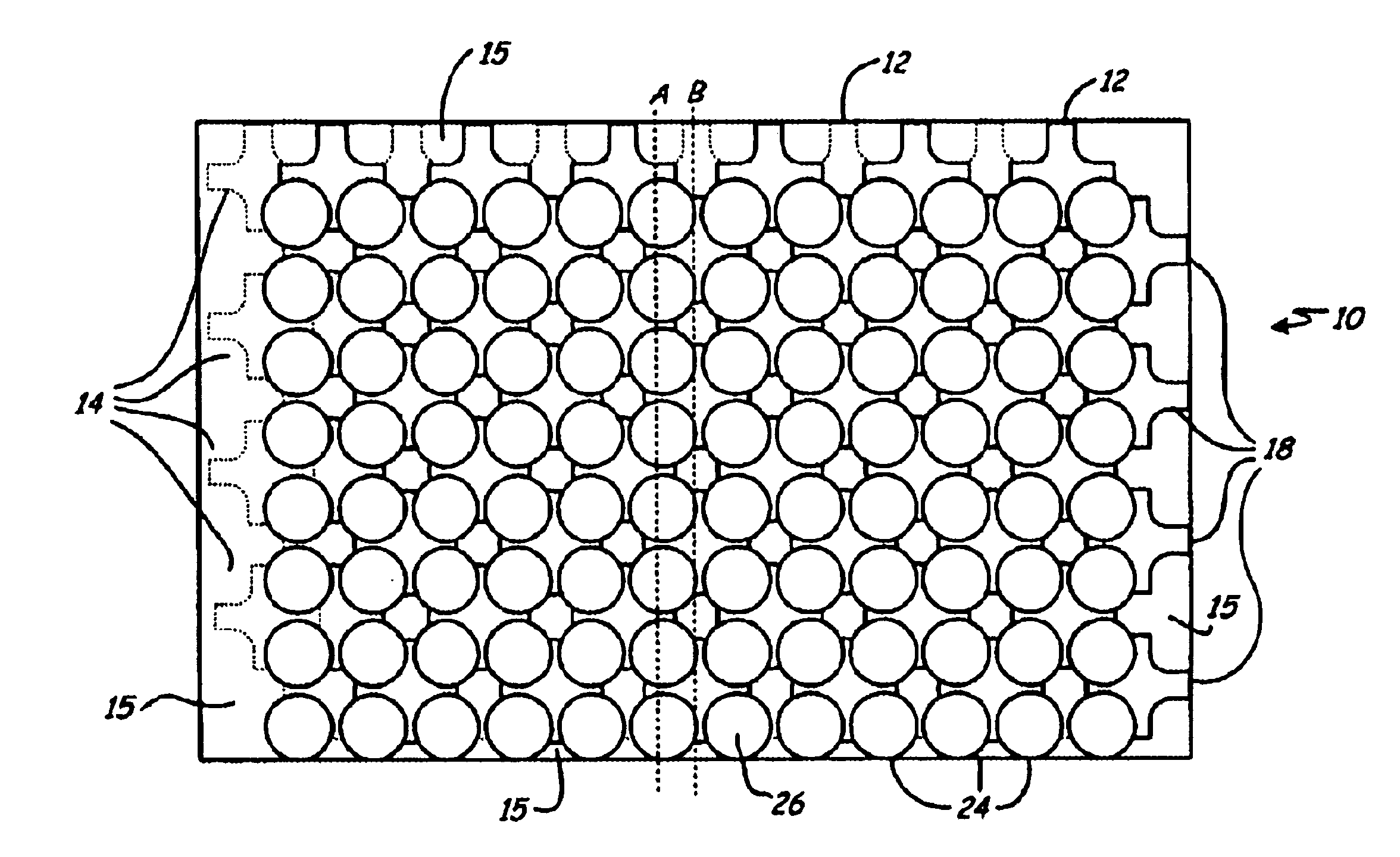

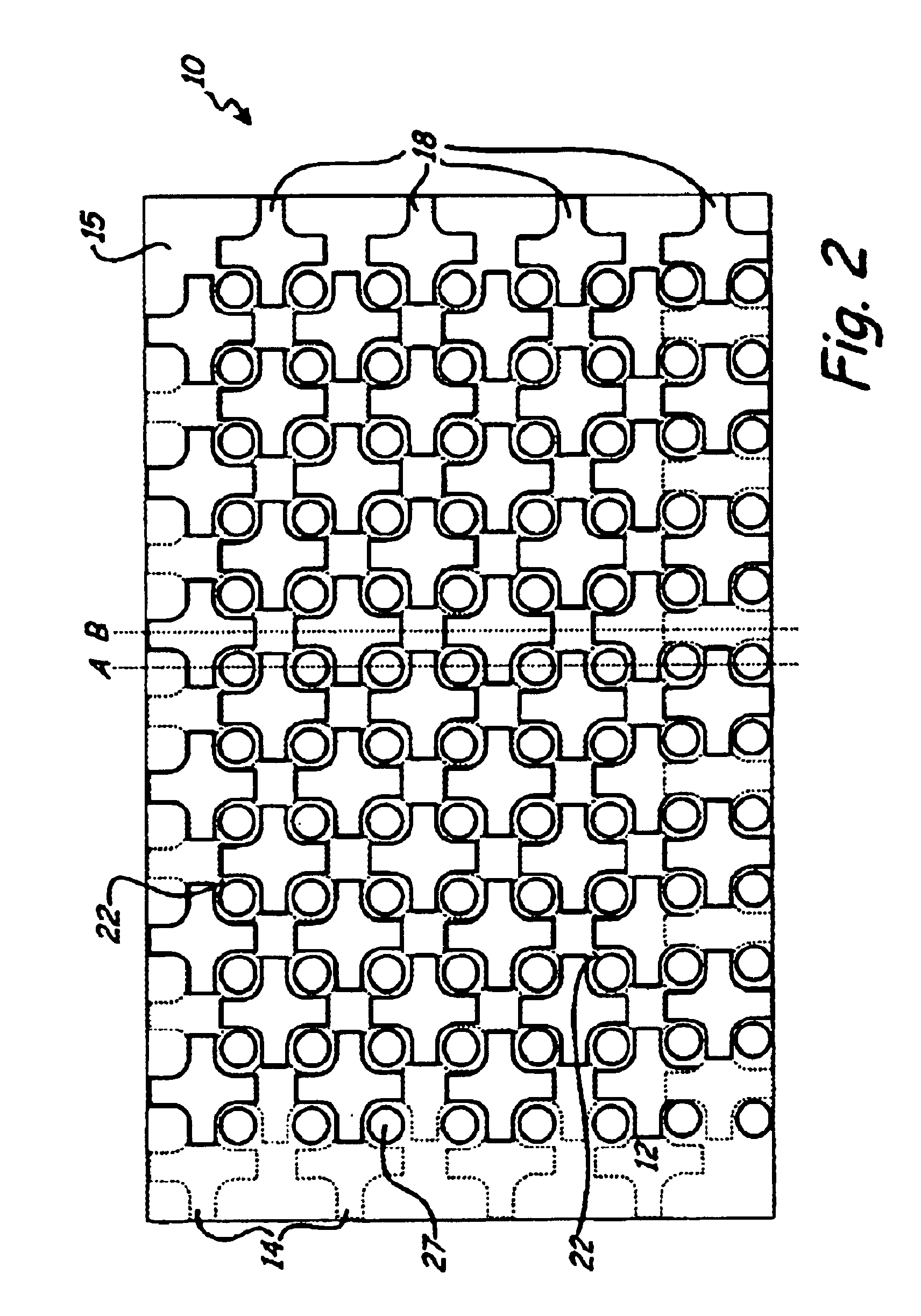

Supple penetration resistant fabric and method of making

InactiveUS20050170221A1Sustain damageGlobal supplenessGlovesSynthetic resin layered productsMedical treatmentCivil engineering

A puncture, pierce, and cut resistant fabric comprised of a plurality of sheets of plates arranged in a repeating pattern. A material interconnects the plates. The fabric is twistable, bendable, and flexible. It is constructed of substances that will withstand cutting, puncture, and piercing forces encountered in medical or other environments.

Owner:HIGHER DIMENSION MATERIALS INC (US)

Copper alloy having bendability and stress relaxation property

InactiveUS20060137773A1Improve bendabilityImprove stress relaxation propertyMetallic pattern materialsStress relaxationMaterials science

A copper alloy contains 0.01% to 1.0% of Fe, 0.01% to 0.4% of P, and 0.1% to 1.0% of Mg with the remainder being copper and inevitable impurities and has a volume fraction of dispersoids having a particle diameter exceeding 200 nm of 5% or less, in which dispersoids having a particle diameter of 200 nm or less and containing Mg and P have an average particle diameter of 5 nm or more and 50 nm or less. The copper alloy preferably has an average particle diameter of dispersoids containing Fe and P of 20 nm or less. The copper alloy has improved bendability and stress relaxation property.

Owner:KOBE STEEL LTD

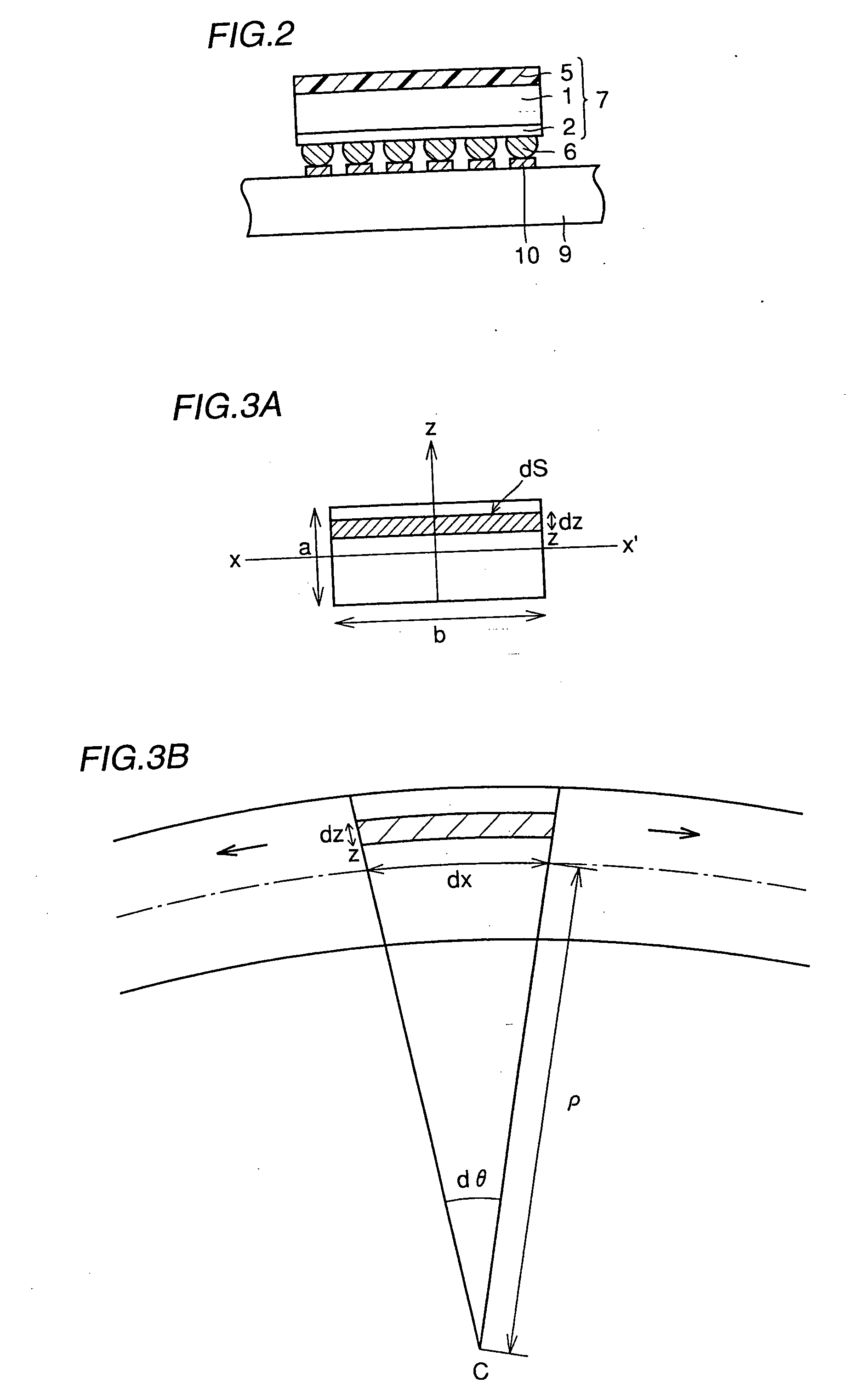

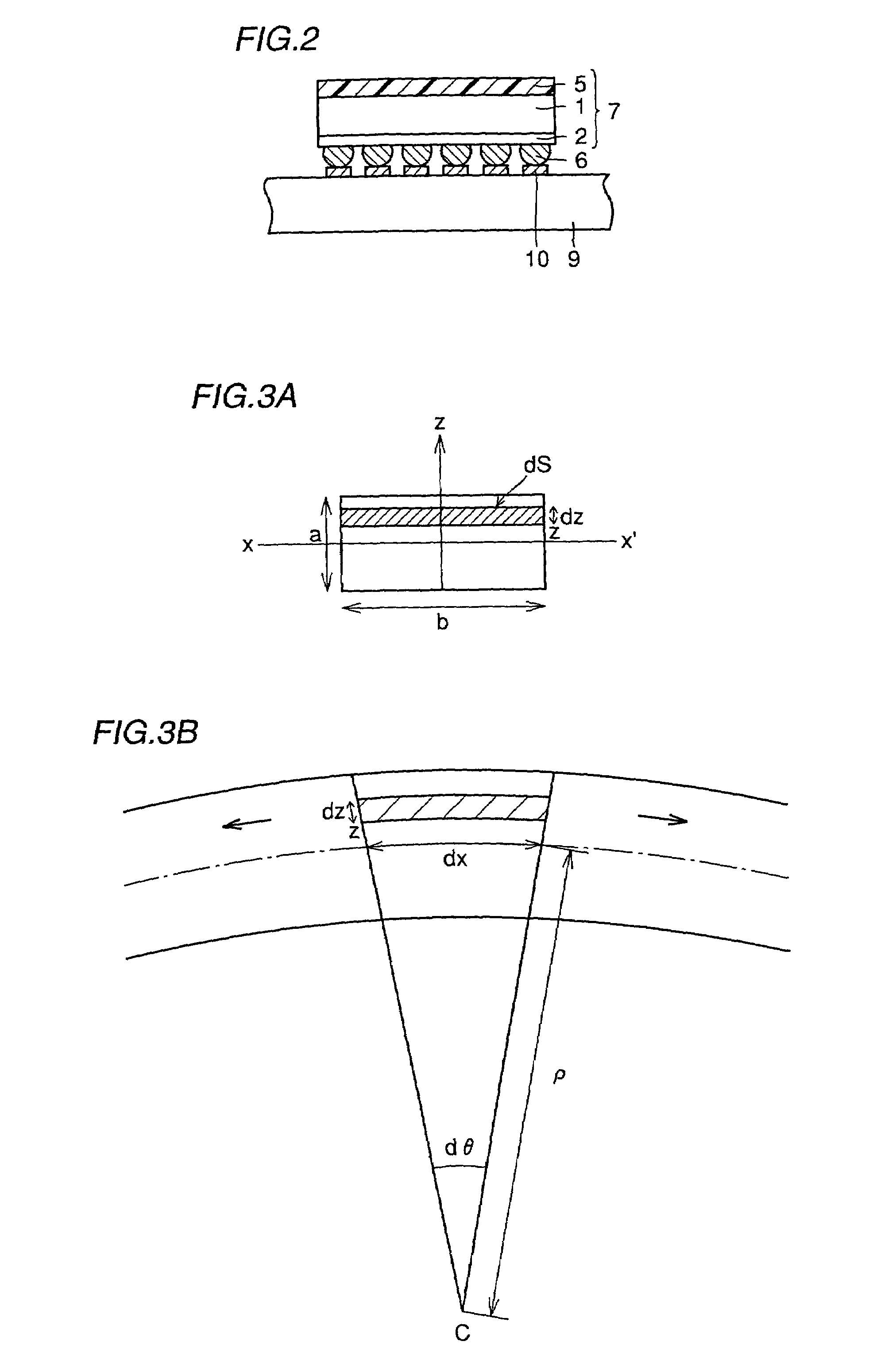

Liquid crystal display device and manufacturing method thereof

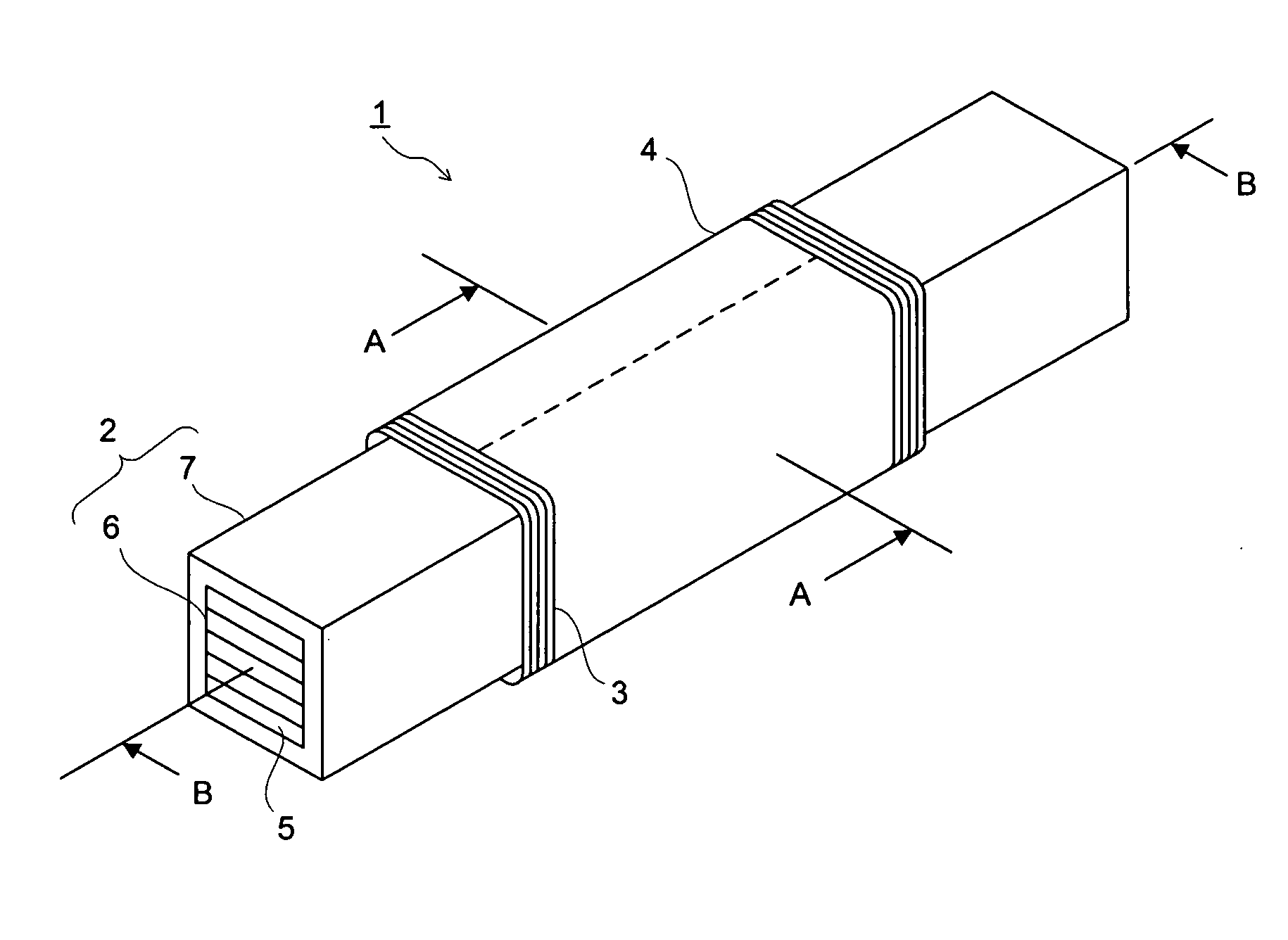

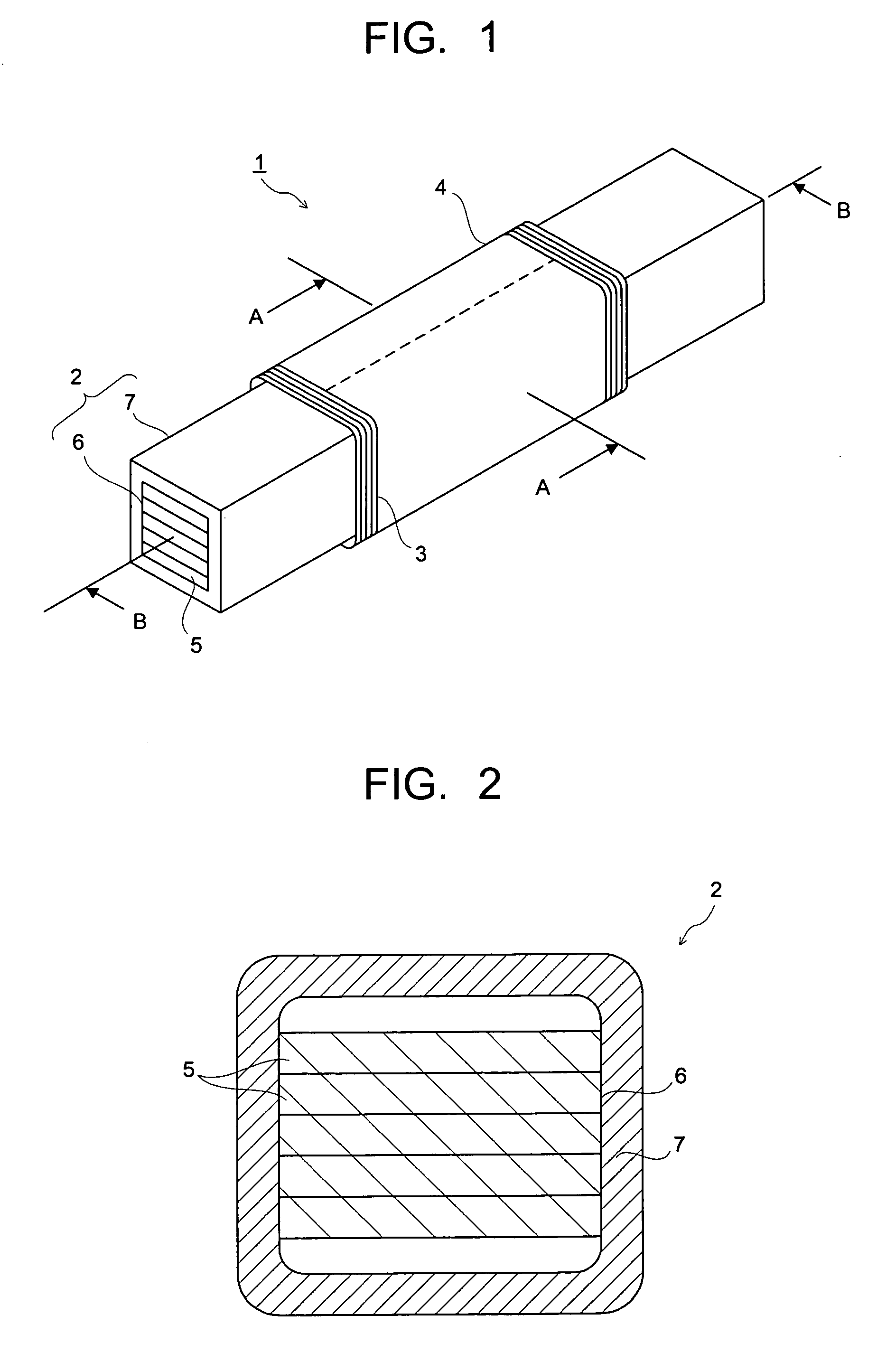

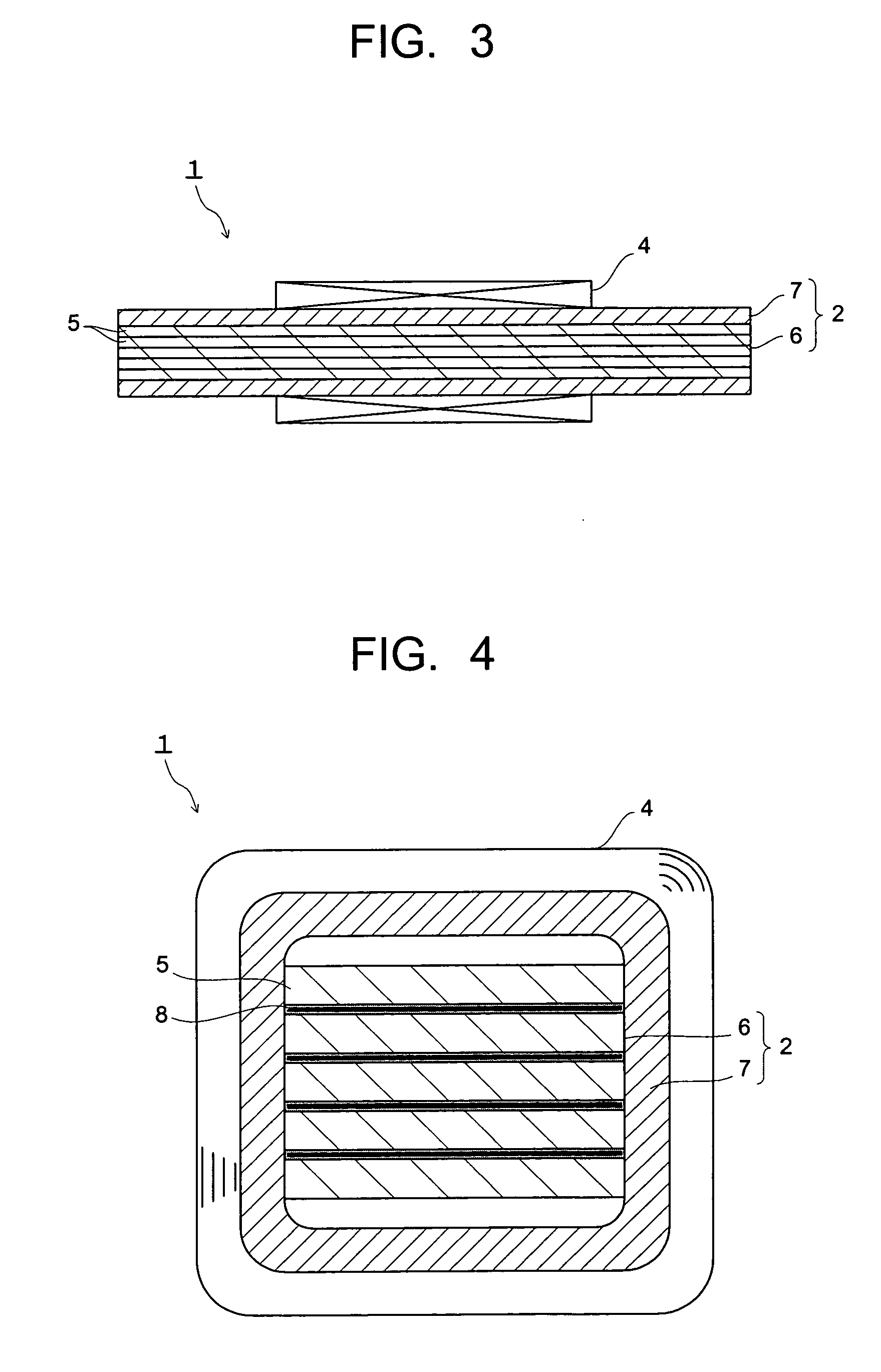

ActiveUS20070040643A1Improve featuresReduce bendabilityLoop antennas with ferromagnetic coreTransformers/inductances coils/windings/connectionsLiquid-crystal displayInductance

An inductance element (1) comprises a core (2) having a multilayer body (6) composed of magnetic alloy thin ribbons (5) and an insulating coating layer (7) which covers the peripheral surface of the multilayer body without being bonded thereto, and a coil (4) wound around the core (2). The magnetic alloy thin ribbons (5) are stacked in a non-adhered state or with a flexible insulating adhesive layer therebetween. Having such a structure, the inductance element can stably attain good characteristics even when it is small-sized or made short.

Owner:KK TOSHIBA +1

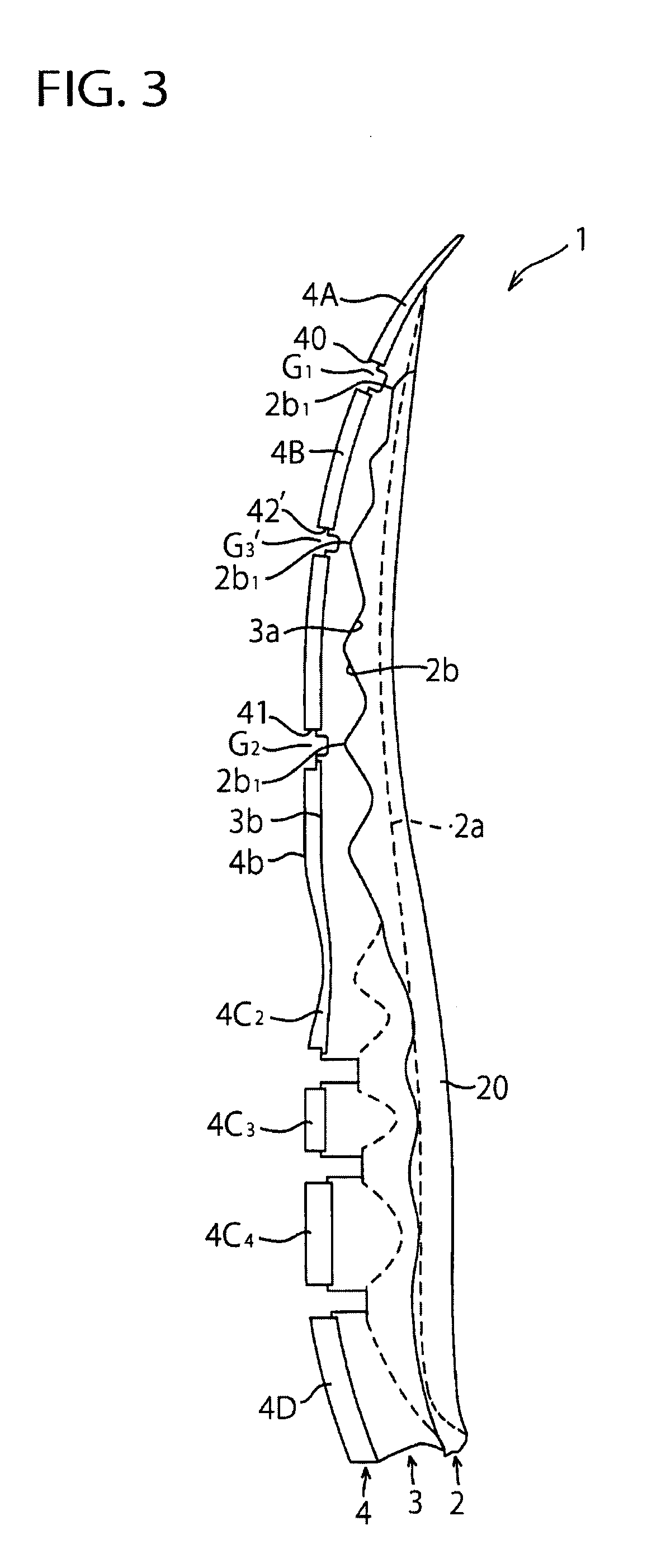

Sole Structure for a Sports Shoe

InactiveUS20190082781A1Improve bending resistancePrevents an excessive bendingSolesEngineeringForefoot

A sole structure for a sports shoe that controls bendability of a forefoot region of the sole structure. The sole structure includes an upper midsole disposed on an upper side of the forefoot region of the sports shoe and formed of a soft elastic material, a lower midsole disposed under the upper midsole and formed of a soft elastic material, and an outsole that is disposed on a lower surface of the lower midsole and that has sole bent grooves extending substantially in a sole width direction. Both the lower surface of the upper midsole and the upper surface of the lower midsole have corrugated mating surfaces that are formed of wavy shapes extending substantially in a sole longitudinal direction. Ridge lines and trough lines of the wavy shapes of the upper midsole extend substantially in the sole width direction. The ridge lines of the wavy shapes of the upper midsole of a relatively higher hardness are overlapped with the sole bent grooves of the outsole in a vertical direction.

Owner:MIZUNO CORPORATION

Supple penetration resistant fabric and method of making

InactiveUS20090142535A1High fabric strengthStrong materialGlovesSynthetic resin layered productsBiomedical engineeringMedical treatment

A puncture, pierce, and cut resistant fabric comprised of a plurality of sheets of plates arranged in a repeating pattern. A material interconnects the plates. The fabric is twistable, bendable, and flexible. It is constructed of substances that will withstand cutting, puncture, and piercing forces encountered in medical or other environments.

Owner:HIGHER DIMENSION MATERIALS INC

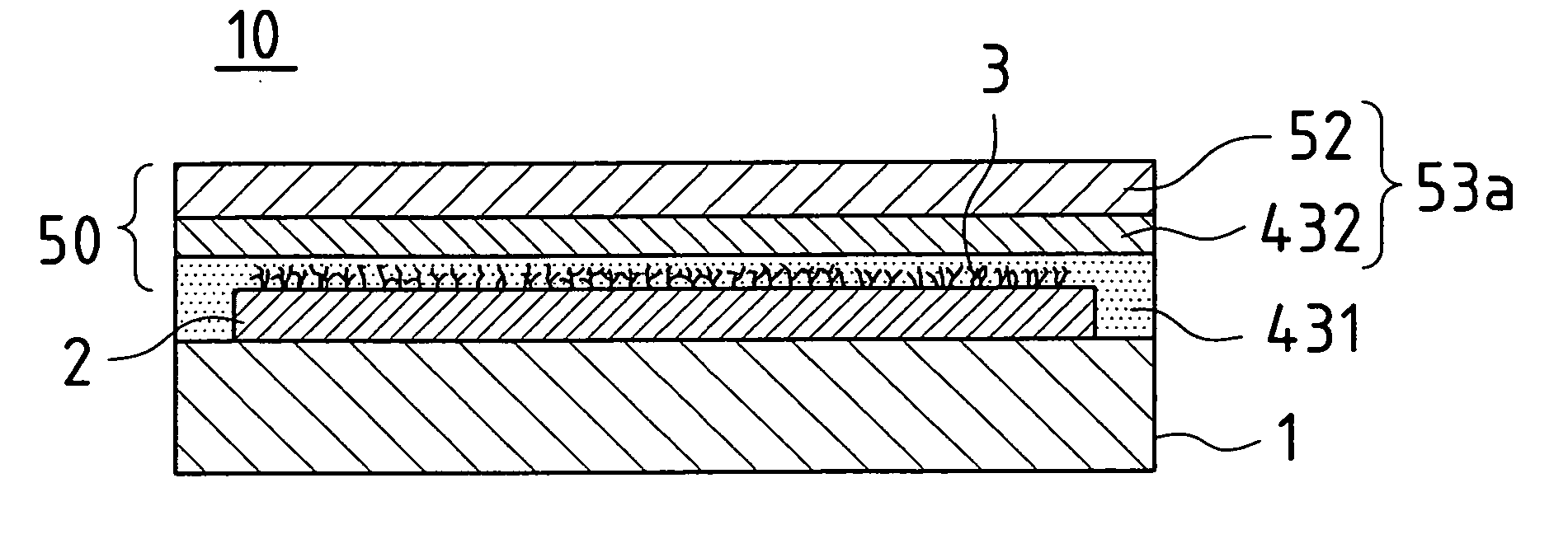

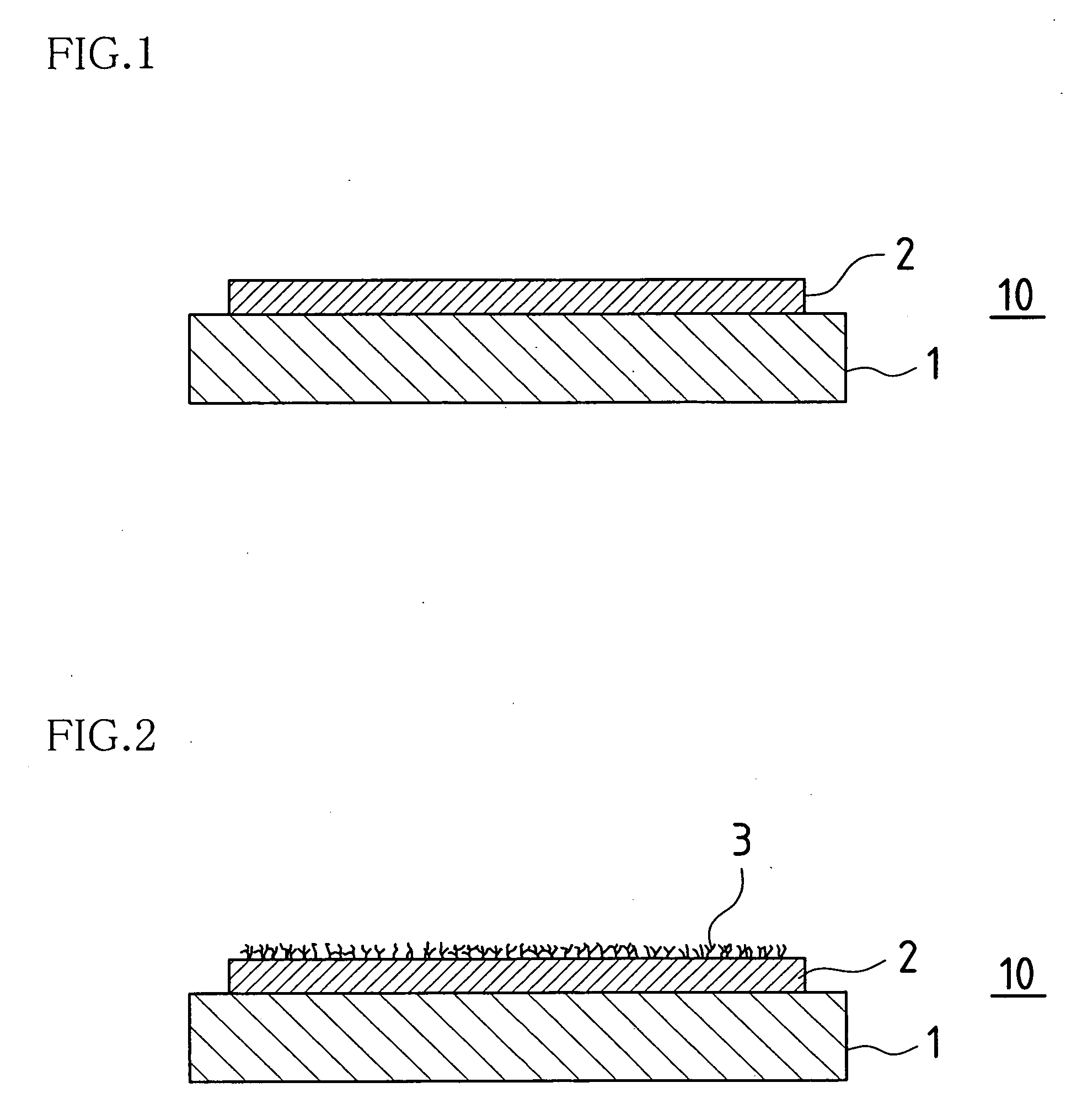

Shoe sole having outsole and midsole

A shoe sole including an outsole 2 and a midsole 1, wherein: the midsole 1 includes a lower midsole 4 of a lower layer formed by a foamed body of a resin, and an upper midsole 3 of an upper layer formed by a foamed body of a resin and arranged on the lower midsole 4; a lateral roll-up portion 42 for supporting a lateral side of a foot from a side of the foot is formed integrally with the lower midsole 4; a hardness of a lateral portion 40 of the lower midsole 4 including the lateral roll-up portion 42 is a first hardness; a hardness of a medial portion 41 of the lower midsole 4 is a second hardness lower than the first hardness; a hardness of a lateral portion 30 of the upper midsole 3 is a third hardness lower than the first hardness; and a part or a whole of the high-hardness lateral roll-up portion 42 is protruding in an upward direction past the upper midsole 3 on a lateral side of the upper midsole 3 so that the lateral side of the foot is supported by the lateral roll-up portion 42 from the side of the foot without being supported by the upper midsole 3 from the side of the foot.

Owner:ASICS CORP

Copper alloy

InactiveUS20140193293A1Reduce intensityHigh yield strengthConductive materialMetal/alloy conductorsUltimate tensile strengthImpurity

Disclosed is a copper alloy containing 1.0% to 3.6% of Ni, 0.2% to 1.0% of Si, 0.05% to 3.0% of Sn, 0.05% to 3.0% of Zn, with the remainder including copper and inevitable impurities. The copper alloy has an average grain size of 25 pm or less and has a texture having an average area percentage of cube orientation of 20% to 60% and an average total area percentage of brass orientation, S orientation and copper orientation of 20% to 50%. The copper alloy has a KAM value of 0.8 to 3.0 and does not suffer from cracking even when subjected to U-bending. The copper alloy has excellent balance between strengths (particularly yield strength in a direction perpendicular to the rolling direction) and bending workability.

Owner:KOBE STEEL LTD

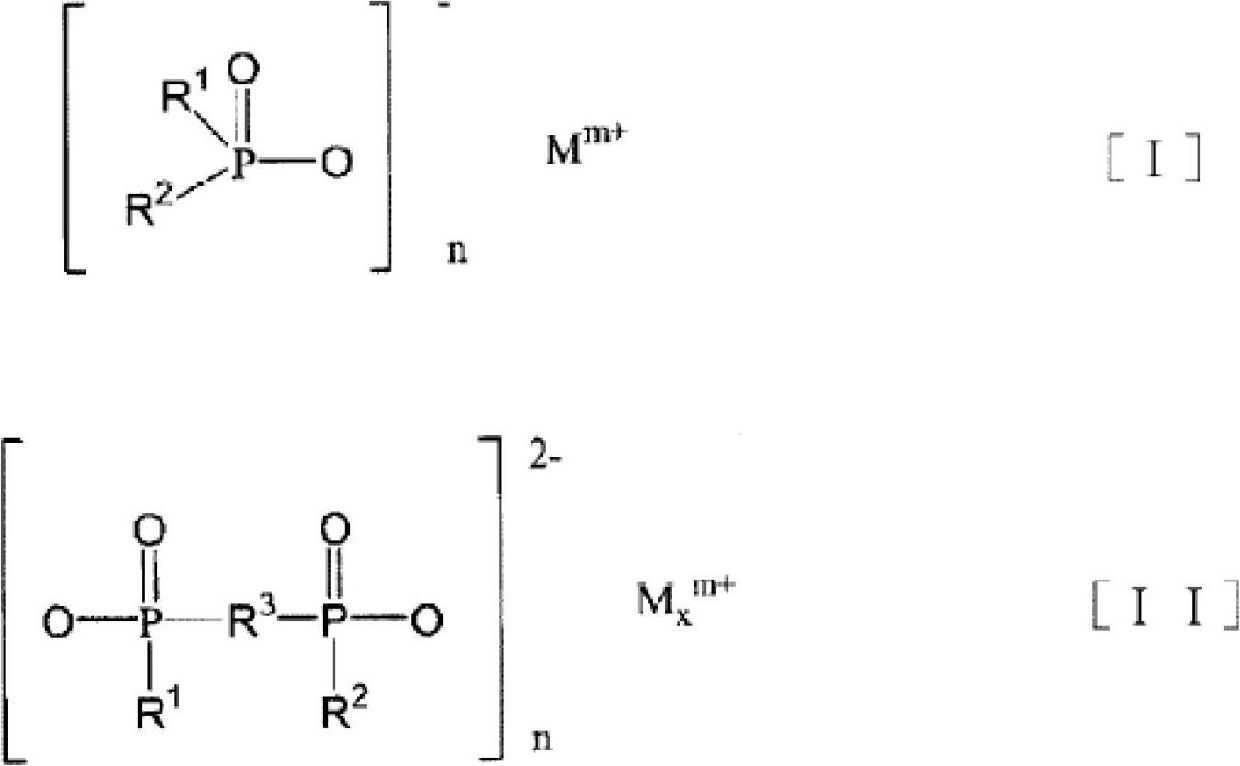

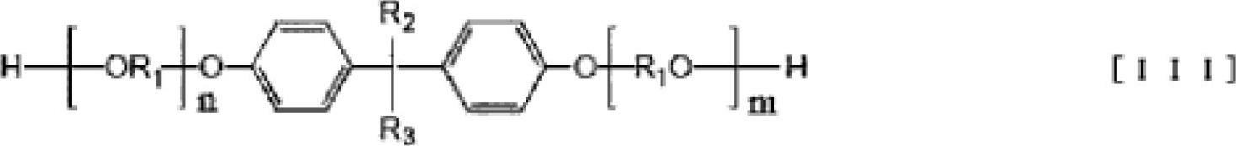

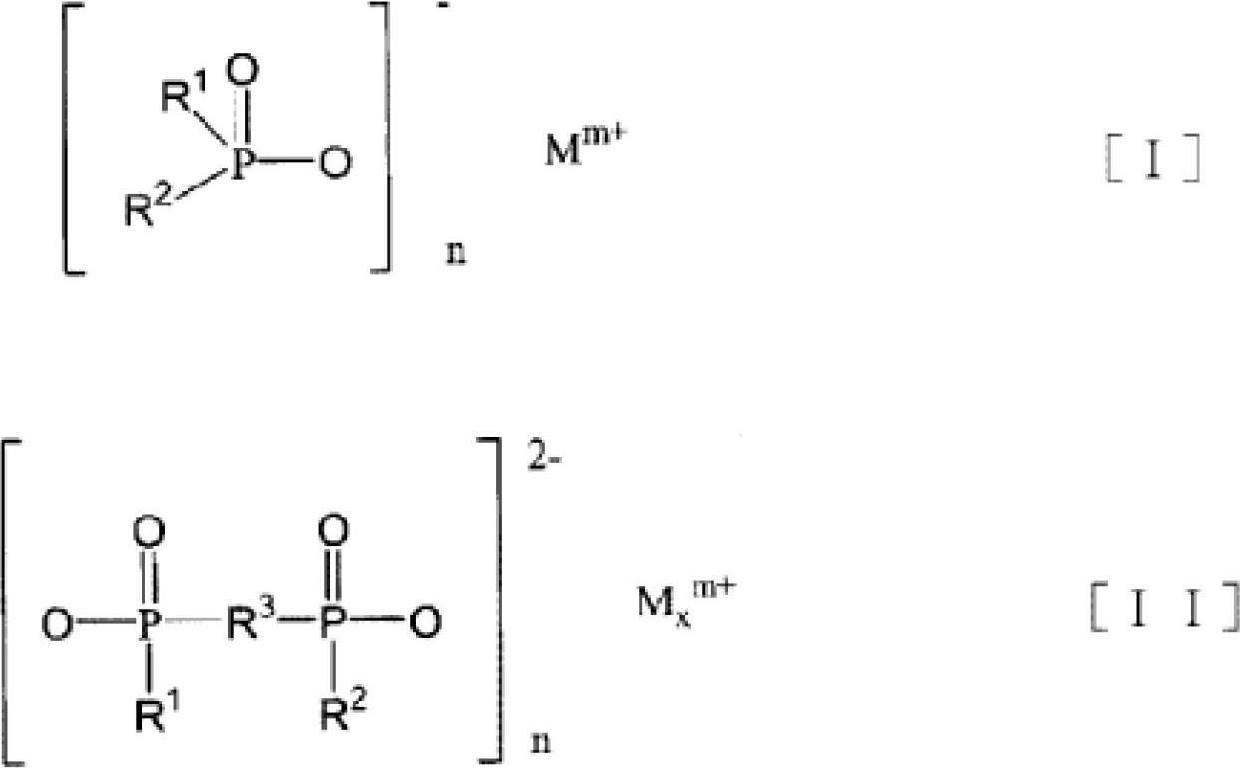

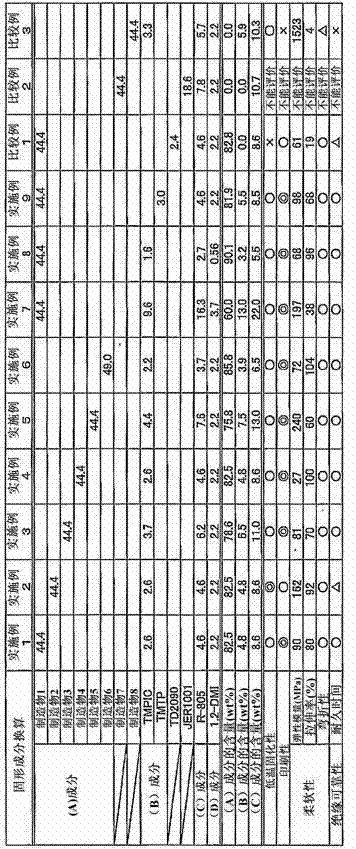

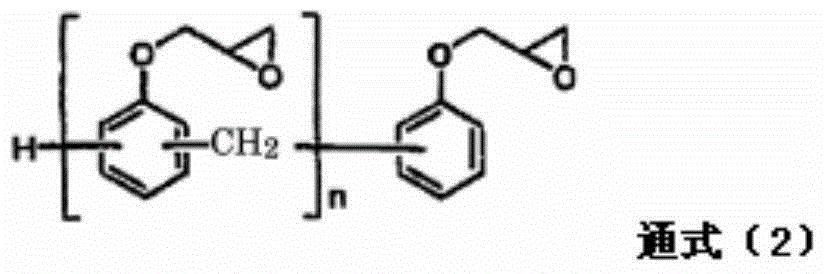

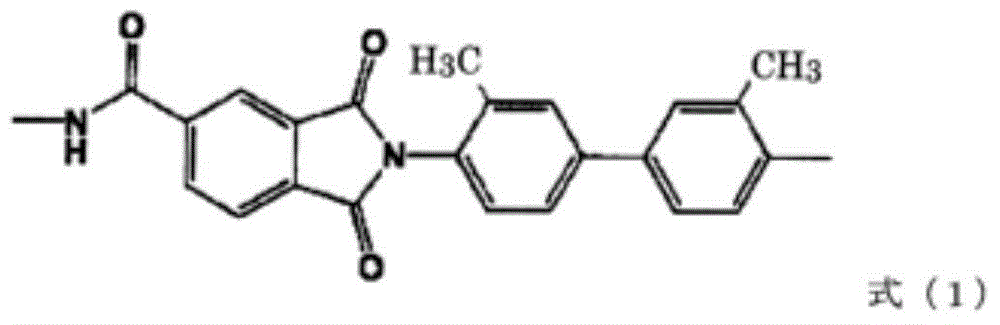

Urethane modified polyimide based flame retardant resin composition

Disclosed is a urethane modified polyimide based flame retardant resin composition having excellent solubility in non-nitrogenous solvents, varnish stability, low temperature drying / curing, low warpage, flexibility, printability, and flame resistance, and also having excellent heat resistance, chemical resistance, electrical properties, and operability, and is low-cost. The urethane modified polyimide based flame retardant resin composition is characterized by containing: (A) a urethane modified polyimide based resin having urethane bonds and generated having as essential components (a) trivalent and / or 4-valent polycarboxylic acid derivatives having an acid anhydride group, (b) diol compounds, and (c) aliphatic polyamine residue derivatives and / or aromatic polyamine residue derivatives; (B) an epoxy resin having two or more epoxy groups per molecule; (C) an organic or inorganic filler; and, (D) a non-halogen-based flame retardant, wherein the non-halogen-based flame retardant (D) contains two essential components (D-1 and D-2), wherein, in an air atmosphere at 350 DEG C, the rate of weight reduction of one component (D-1) is greater than or equal to 50% and less than or equal to 90%, and that of the other component (D-2) is greater than or equal to 0% and less than or equal to 20%.

Owner:TOYOBO CO LTD

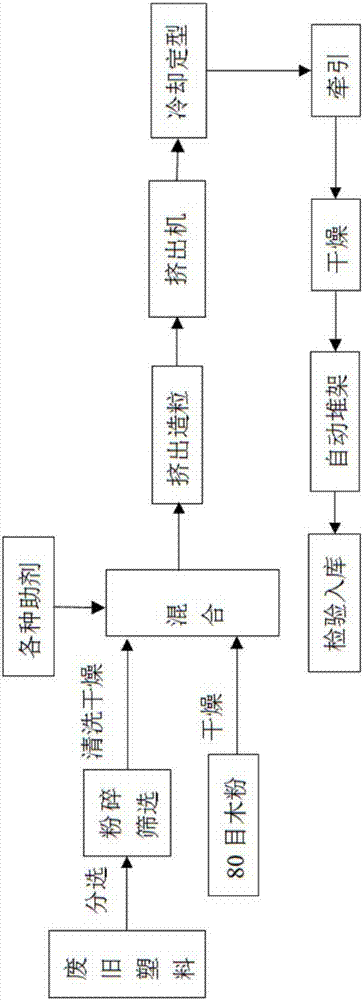

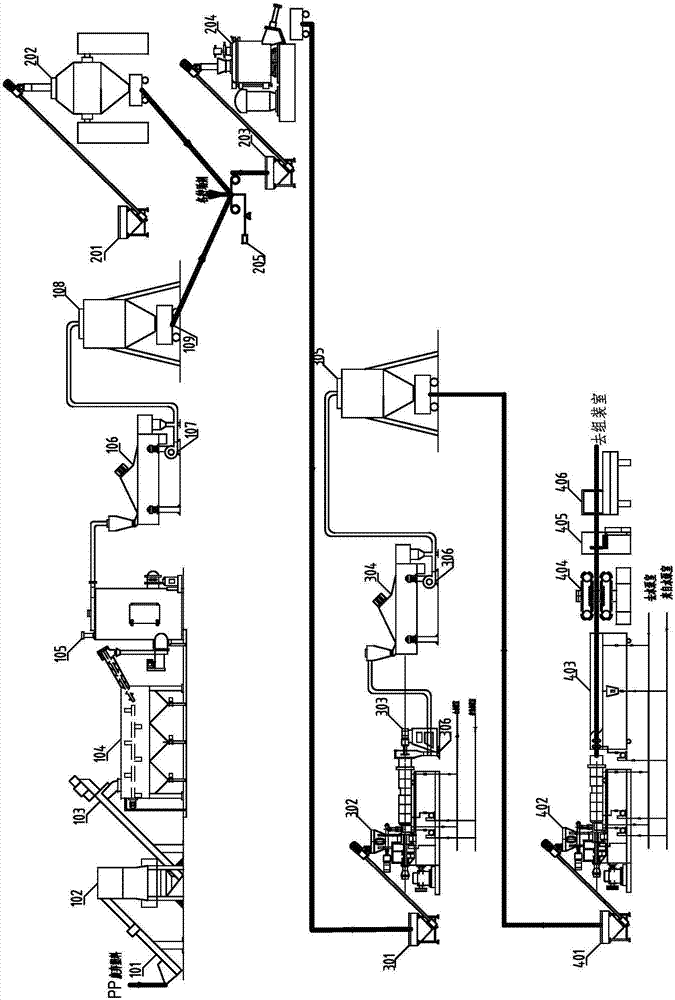

Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

InactiveCN107189216AImprove impact performance at room temperatureHigh low temperature impact resistanceHeat resistanceAntioxidant

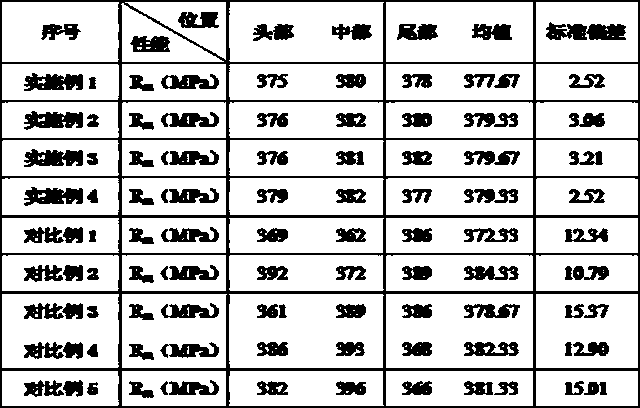

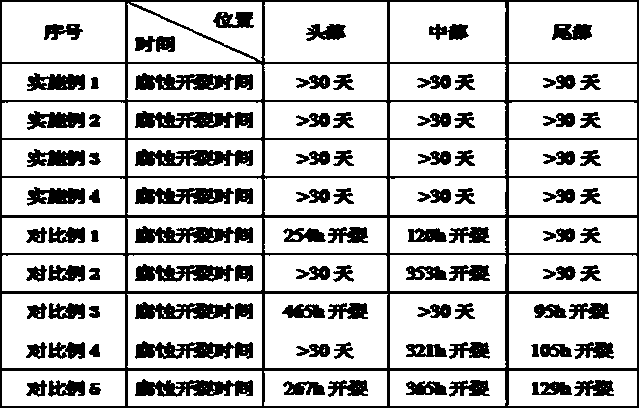

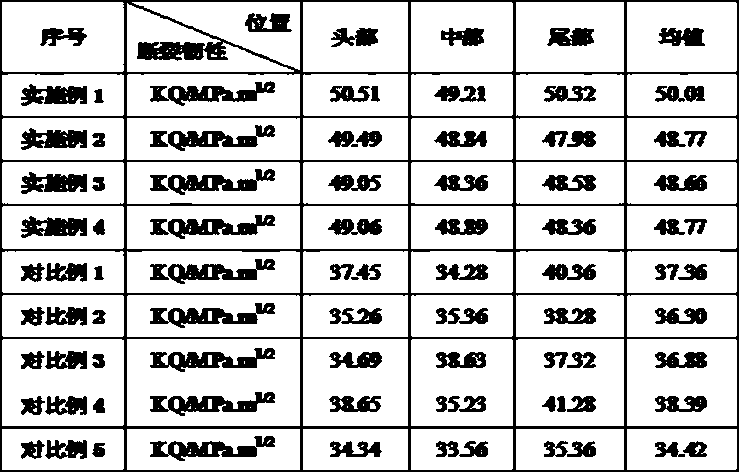

The invention particularly relates to a formulation of wood-plastic profile as well as a preparation method and a manufacturing device thereof. The formula is characterized by being prepared from the following raw materials in parts: 100 parts of PP waste plastic with good mobility, 20 to 75 parts of wood powder, 5 to 15 parts of flexibilizer; 2 to 10 parts of compatibilizer; 1 to 10 parts of lubricant; 0.1 to 1 part of main antioxidant; 0.1 to 0.5 part of auxiliary antioxidant; 0.02 to 0.5 part of light stabilizer and 0.1 to 4 parts of antibacterial agents; the preparation method is characterized by comprising the following steps:(1) recycling the PP waste plastic with good mobility; (2) cleaning, crushing and drying; 3) drying the wood powder; 4) extruding and granulating; and 5) extruding and molding; and the manufacturing device is characterized by comprising a plastic cleaning device, a wood powder drying device, a weighing device, a mixing device, an extrusion granulation device and an extrusion molding device. The invention has the advantages of low cost, durability, long life, good heat resistance, good resistance to ultraviolet rays, high hardness and high load capacity.

Owner:YANTAI UNIV

Al-Zn-Mn alloy profile for rail transit vehicle body and preparation method thereof

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

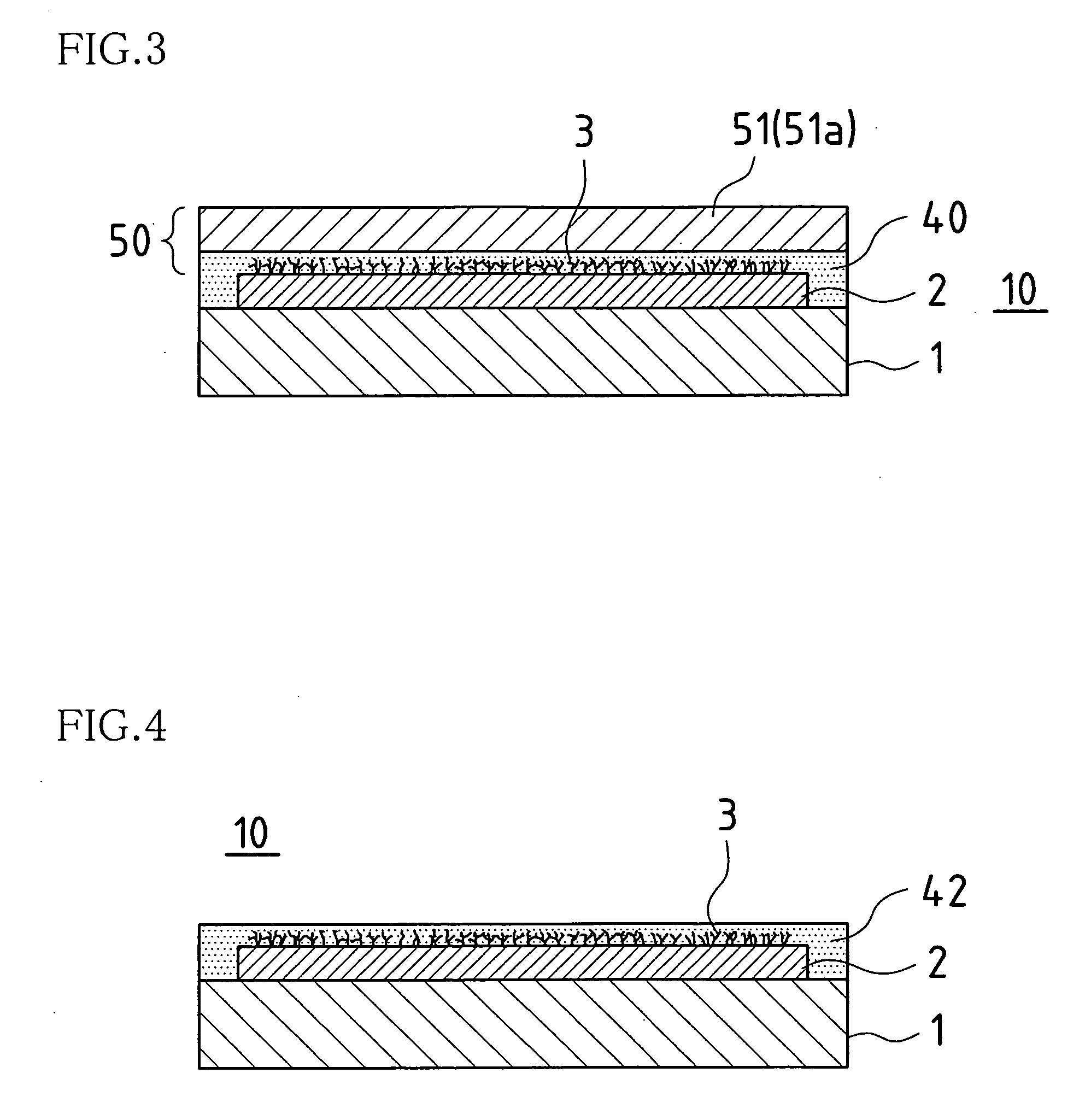

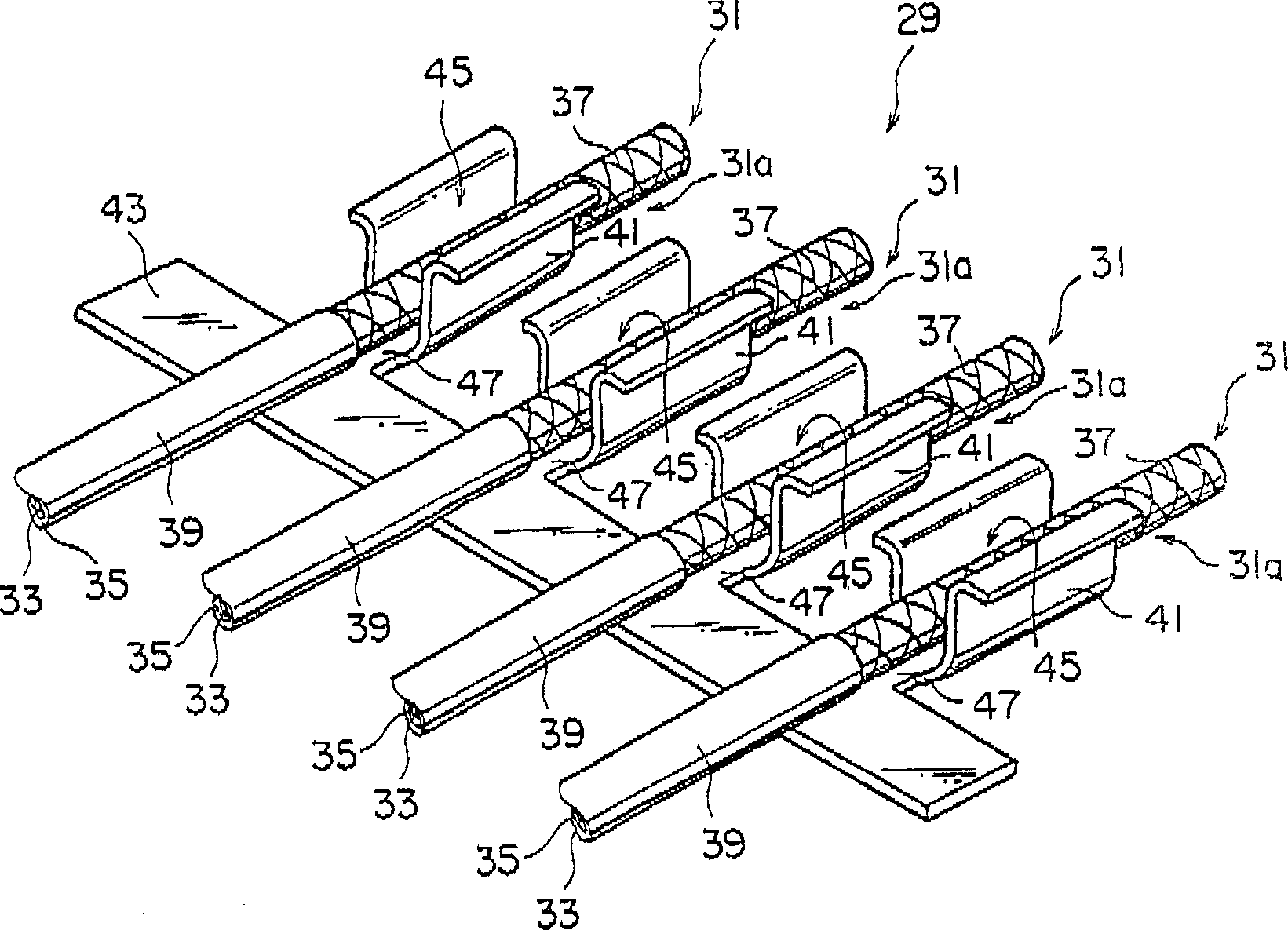

Method for producing printed wiring board

InactiveUS20060108145A1Improve performanceHigh strengthPrinted circuit aspectsPrinted circuit manufactureChemical platingElectrical conductor

An insulating resin layer 50 is formed on a surface of a conductor portion 2 by performing a plating pretreatment to the conductor portion 2 that has been formed on a surface of a wiring board substrate 1, and forming numerous dendrites 3 on the surface of the conductor portion 2 using an electroplating or chemical plating method. The insulating resin layer 50 is then formed by stacking an insulating resin plate 50 that has a semi-cured adhesive layer 40 formed thereon in advance on the conductor portion 2 and the dendrites 3, and then applying pressure and raising temperature for laminate bonding.

Owner:SHARP KK

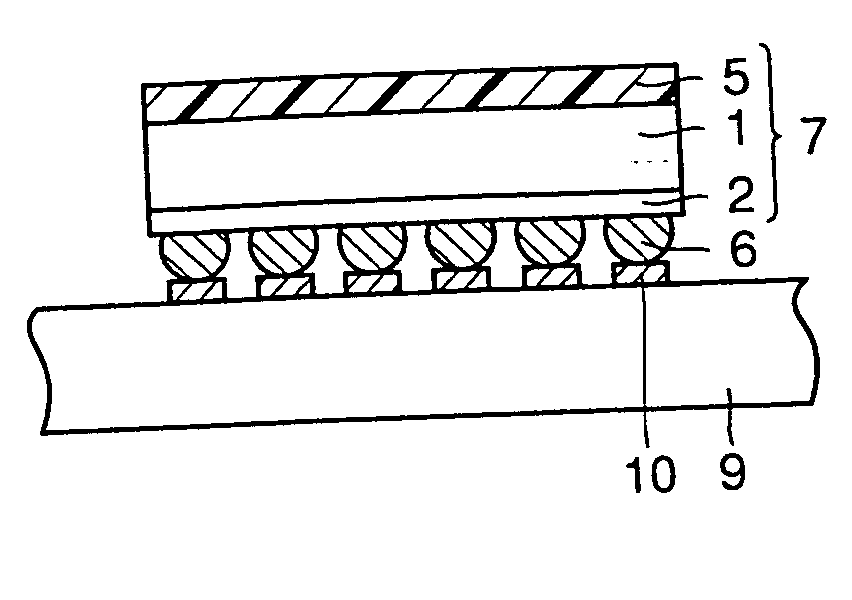

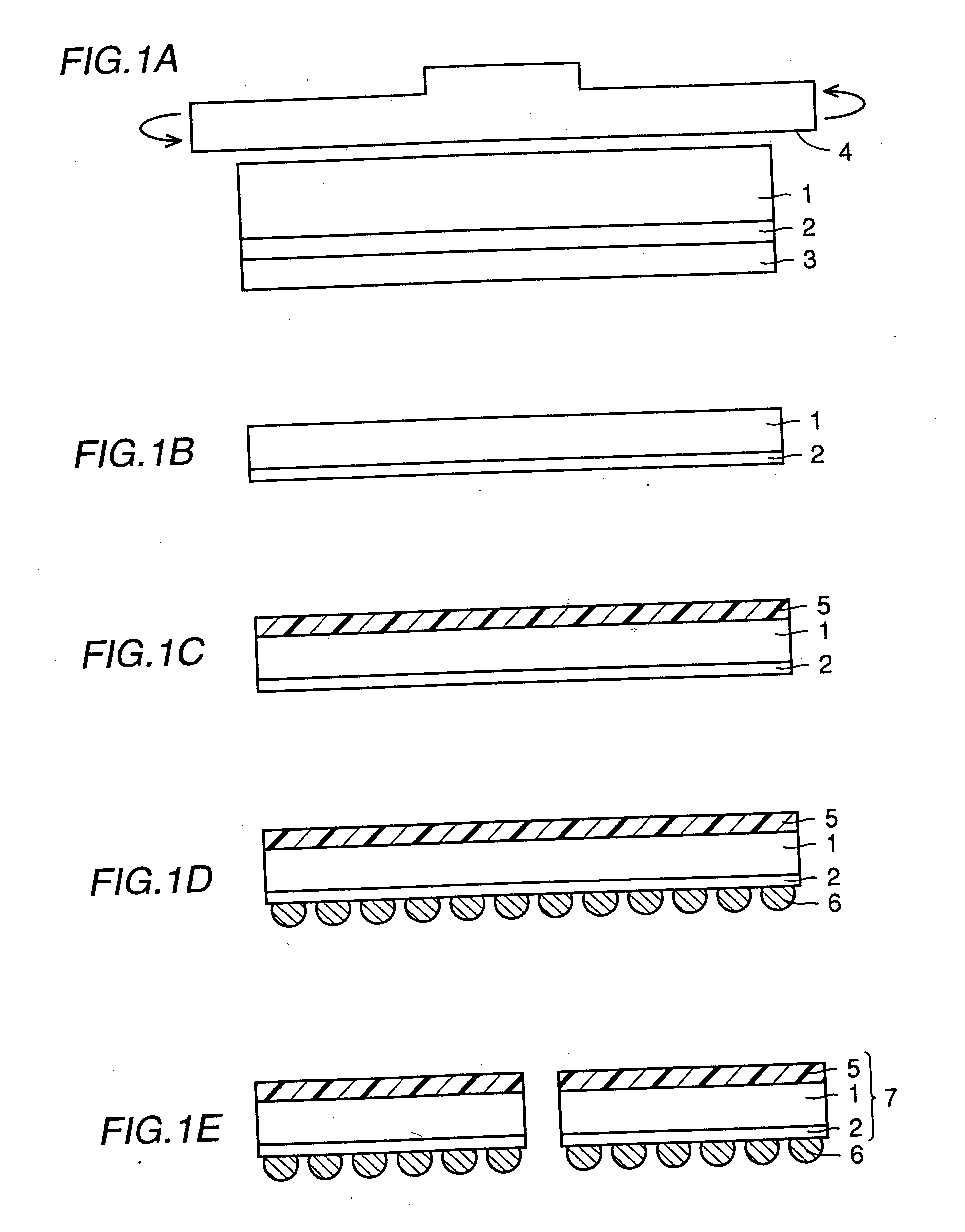

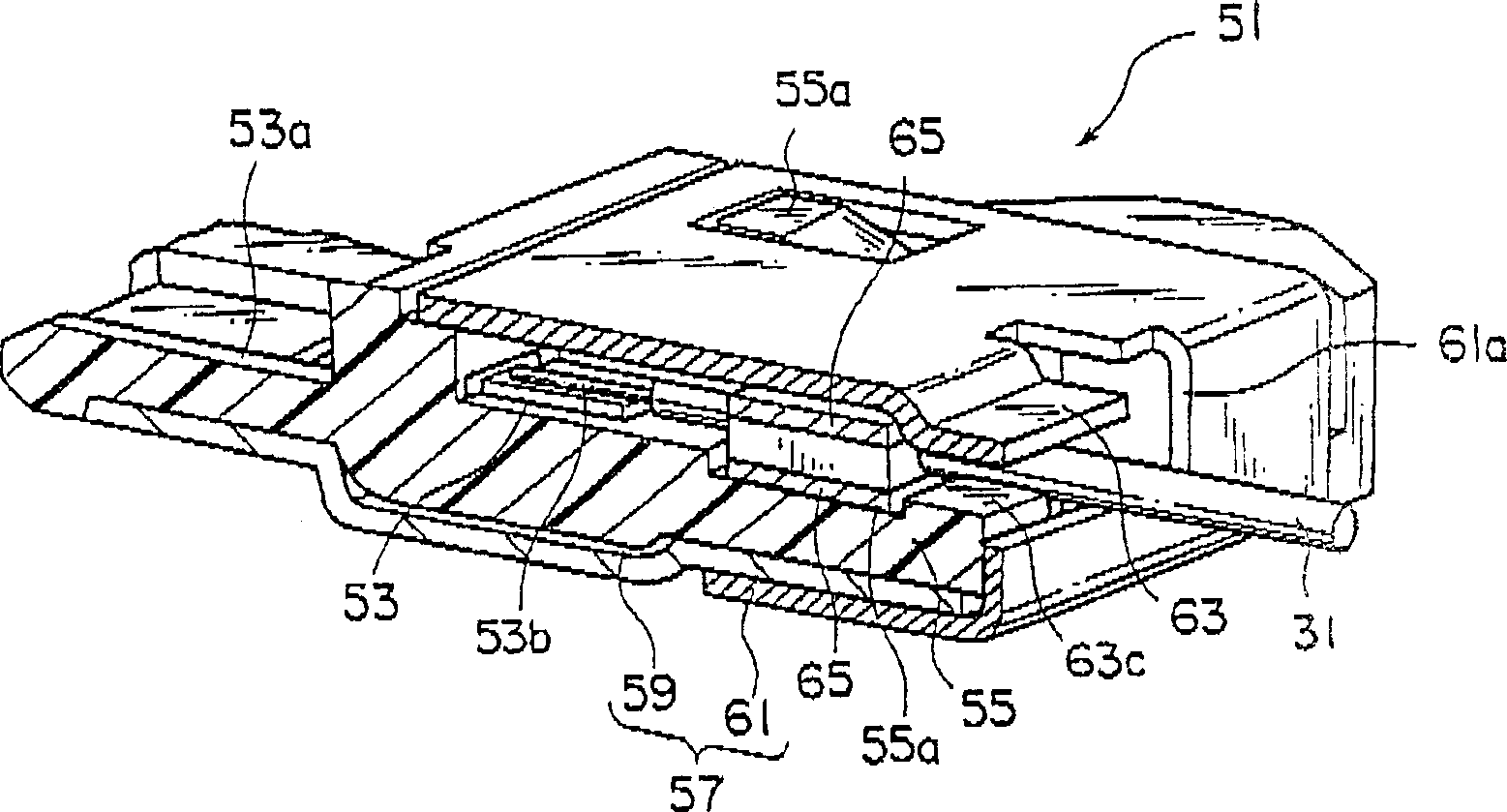

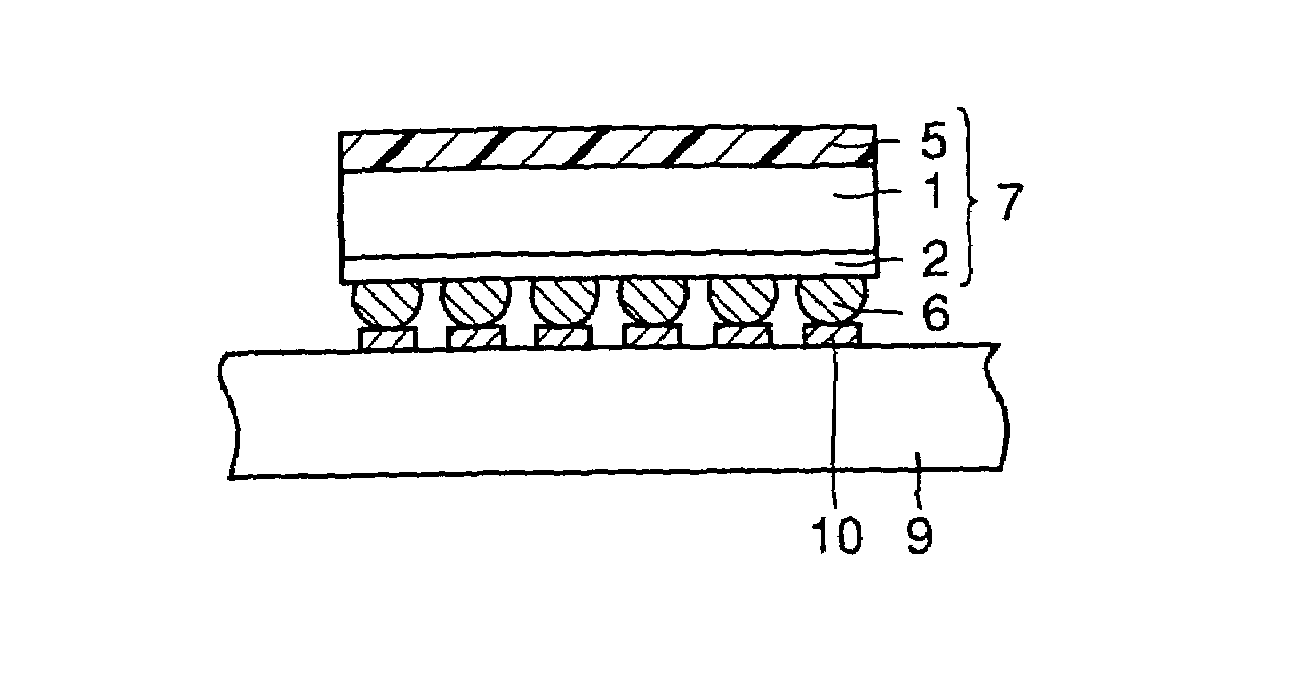

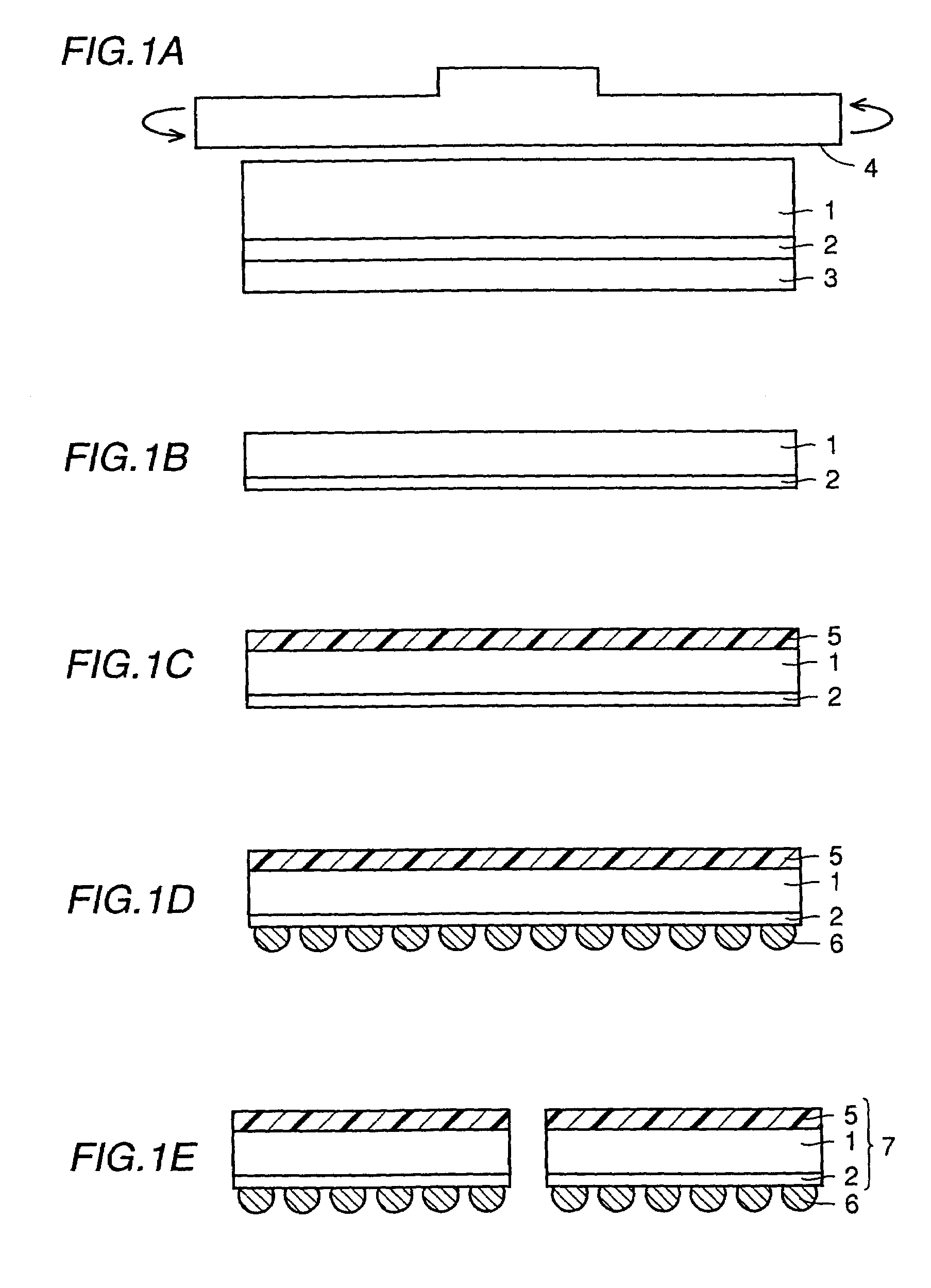

Semiconductor device and method of manufacturing the same

InactiveUS20060249853A1Reduce thicknessLevel of rigiditySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor package

A semiconductor package providing with a printed circuit board and a semiconductor device, including a semiconductor substrate having a surface provided with an external connection electrode and mounted on the printed circuit board, and, a surface opposite that with said external connection electrode, abrased with a mirror finish and reinforced with a back-surface reinforcement.

Owner:SHARP KK

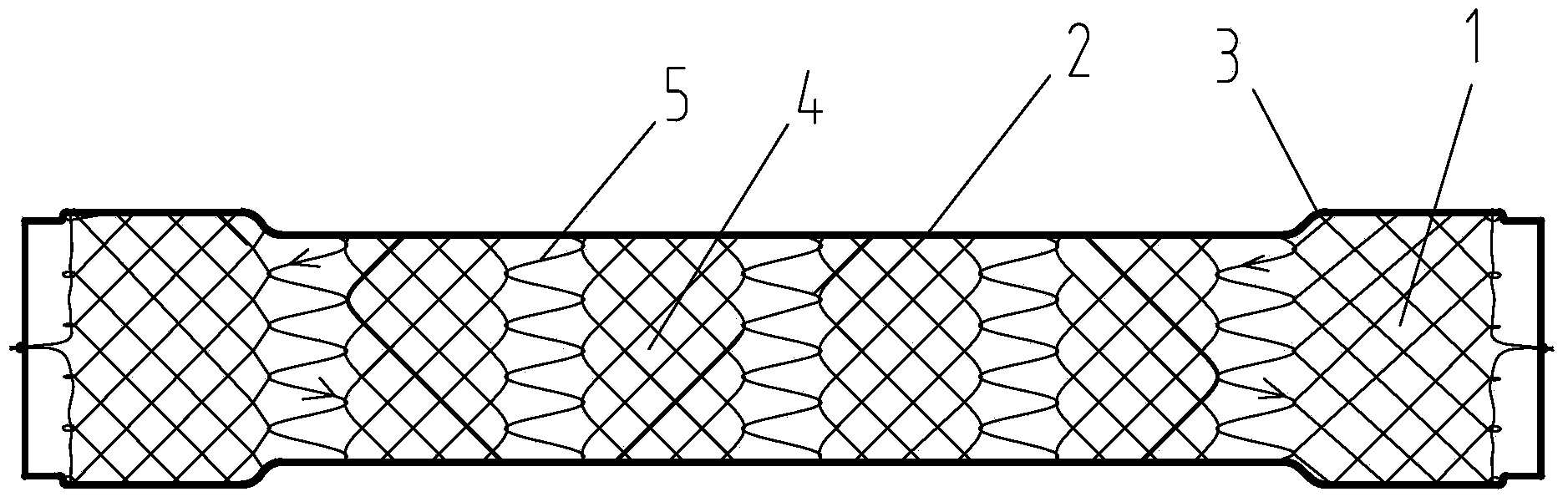

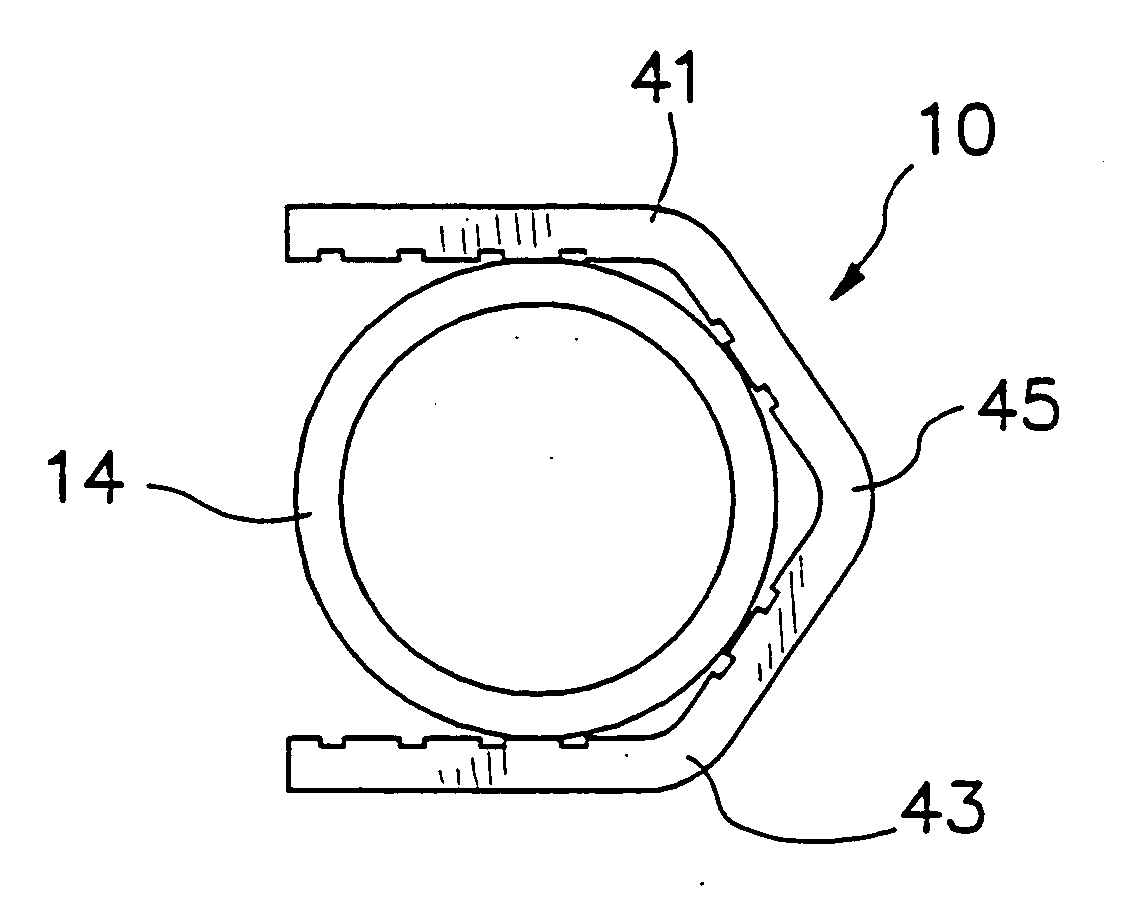

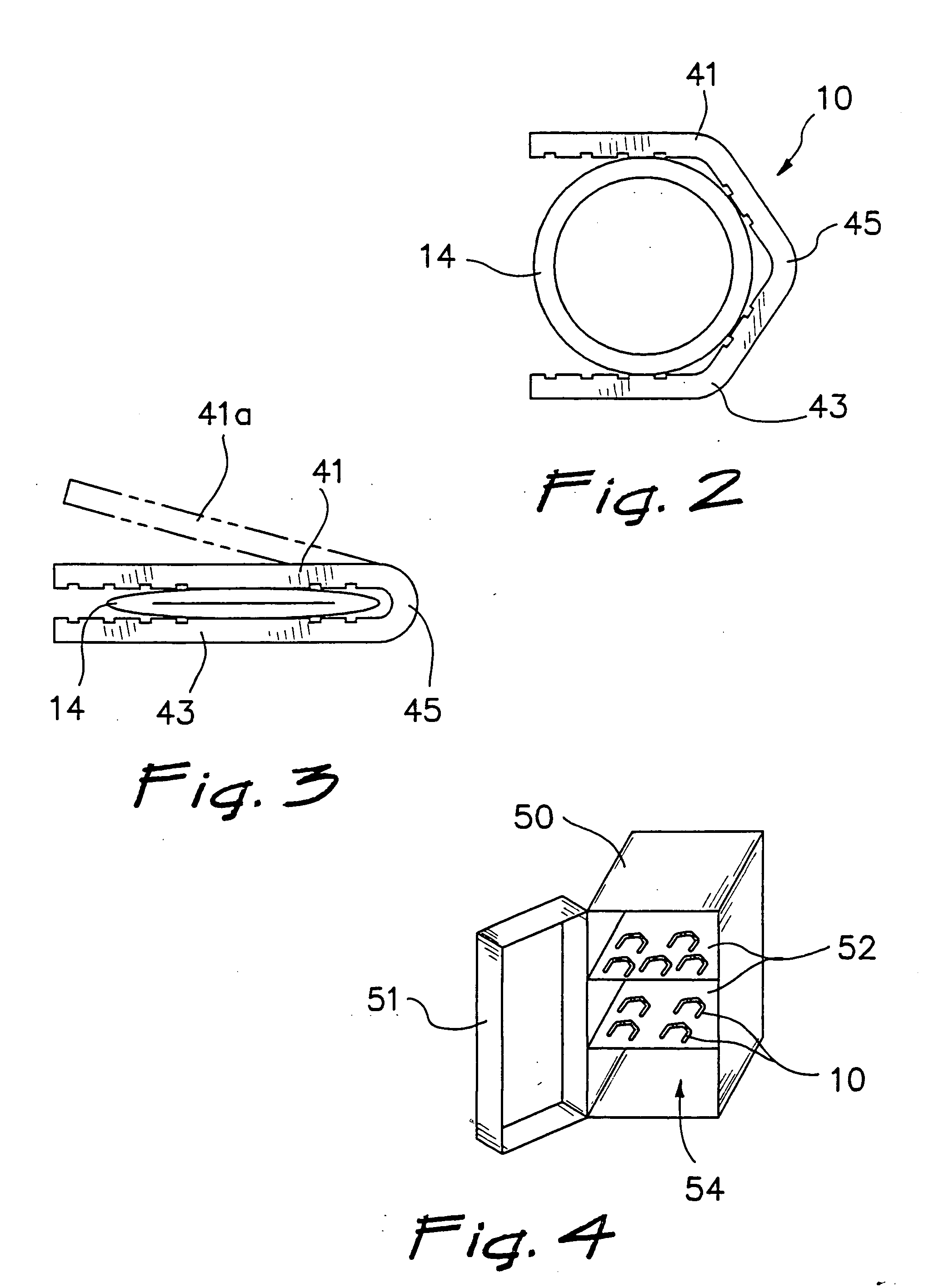

Super compliable recyclable film-covered subsection support and manufacturing method thereof

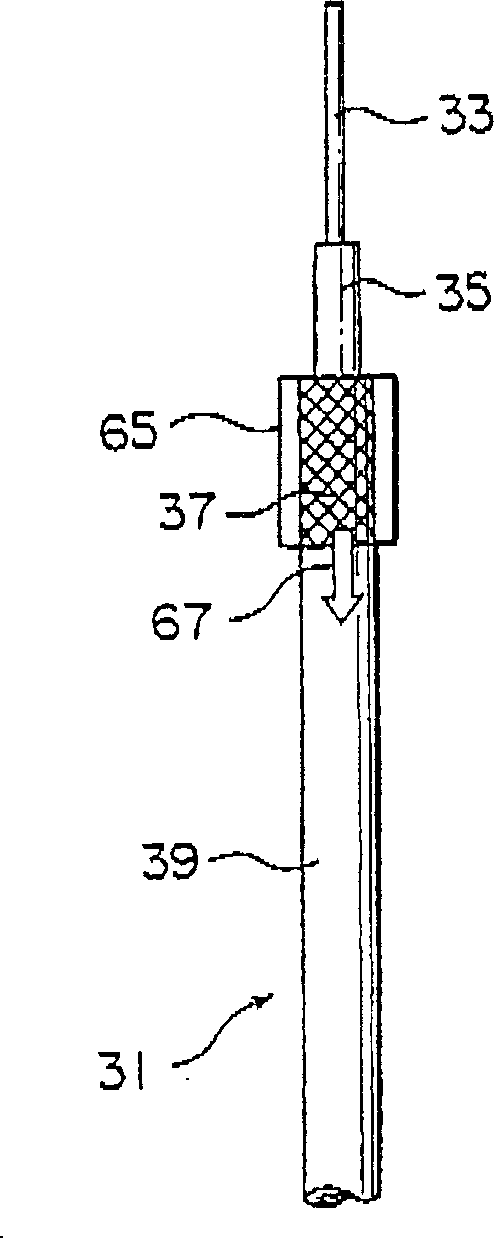

ActiveCN104367399ASolve technical problems with poor complianceEasy to bend angleStentsBlood vesselsVulcanizationEngineering

The invention discloses a super compliable recyclable film-covered subsection support which comprises support cup rim portions at the two ends and a support body. The support body is connected with the support cup rim portions at the two ends and is composed of two or more subsection portions. The inner diameter of each cup rim portion is larger than that of each subsection portion. A layer of independent outer sleeving film is arranged on the exterior of the support body in a nested mode, and a mutual motion gap exists between the subsection portions and the outer sleeving film. The subsection portions are connected through an operation line. The invention further discloses a manufacturing method of the super compliable recyclable film-covered subsection support. The manufacturing method comprises the steps that the cup rim portions at the two ends of the support body are embedded into the corresponding positions of the outer sleeving film; a high temperature vulcanization way is adopted to fix the outer sleeving film and the cup rim portions at the two ends of the support body; the connected subsection portions are placed into the outer sleeving film; the operation line is adopted for connecting the subsection portions with the cup rim portions at the two ends of the support body.

Owner:MICRO TECH (NANJING) CO LTD

Resin composition

ActiveCN103374219ANo thermal deteriorationReduce thermal degradationSolid-state devicesPolyurea/polyurethane coatingsEpoxyCarbamate

The invention relates to a resin composition, comprising (A) polybutadiene resin with epoxy and carbamate and (B) a mercaptan curing agent. The resin composition is characterized in that the content of polybutadiene resin with epoxy and carbamate is 50-95 mass% of the resin composition.

Owner:AJINOMOTO CO INC

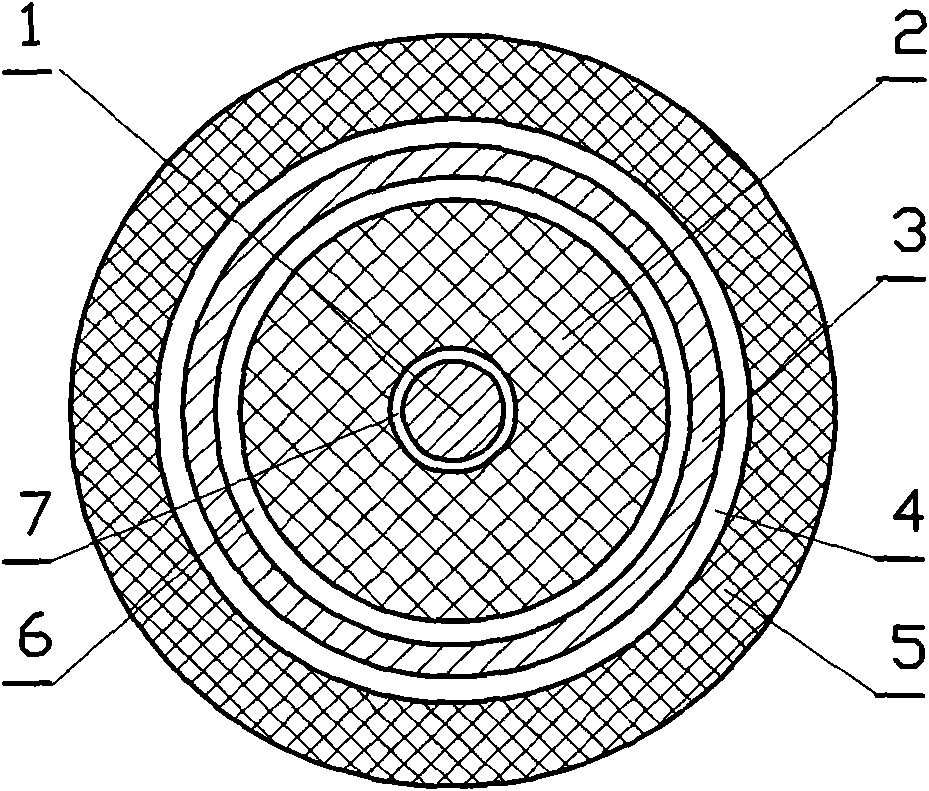

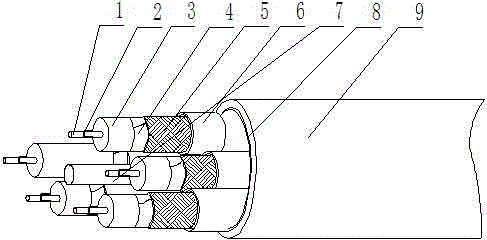

High-performance radiant leaky coaxial cable

InactiveCN101651245APrevent mutual slippageLow dielectric constantInsulated cablesWaveguidesSurface layerElectrical conductor

The invention discloses a high-performance radiant leaky coaxial cable which comprises an inner conductor, an insulating layer, an outer conductor and an outer jacket, wherein the inner conductor is embedded in the outer conductor through the insulating layer, and the inner conductor and the outer conductor are positioned at the position of a concentric circle; the outer conductor is provided witha plurality of rabbets along the longitudinal direction; the insulating layer sequentially comprises an inner insulating surface layer, an insulating foaming layer and an outer insulating surface layer from the inside out; and a bonding layer which is a natural adhesive coating or a synthetic adhesive coating is arranged between the outer conductor and the outer jacket. The coaxial cable not onlyhas excellent bending mechanical property and waterproof and anti-corrosion property, but also has excellent information transmission performance. Meanwhile, the coaxial cable also has the characteristics of simple structure and convenient mounting and construction.

Owner:JIANGSU DONGQIANG

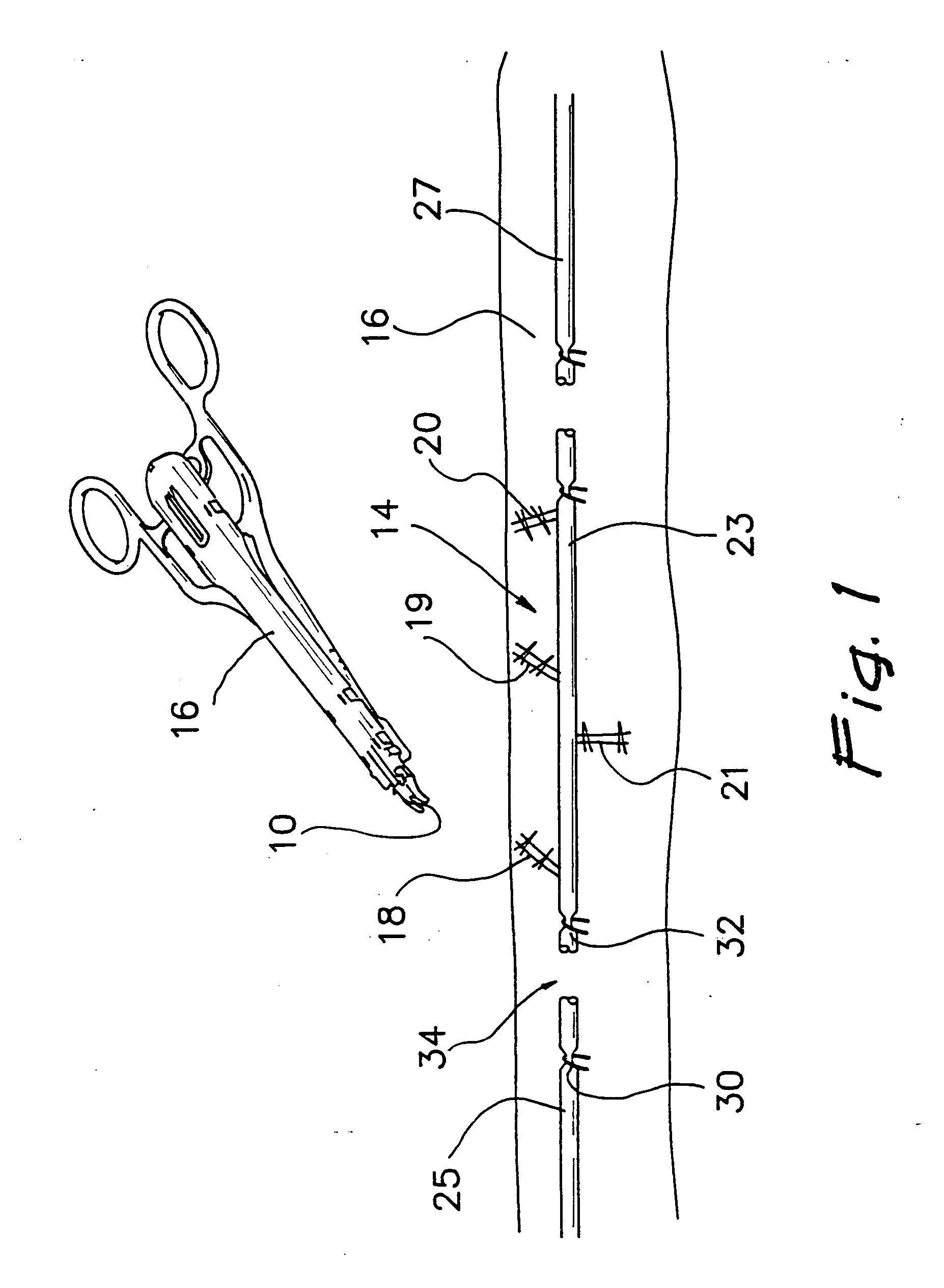

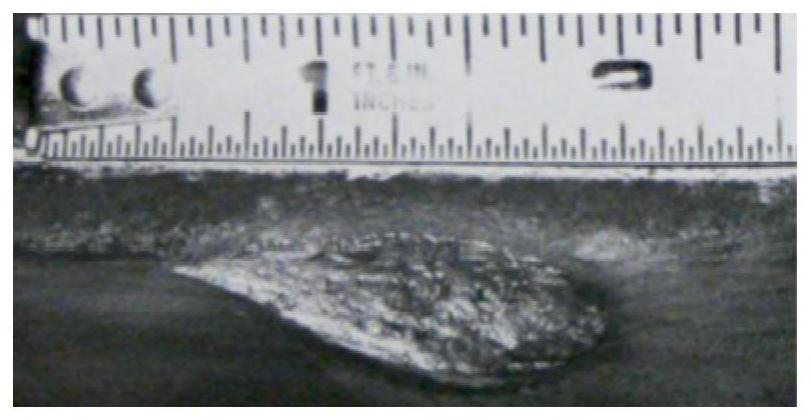

Surgicals metals with improved hardness and methods for making same

InactiveUS20050065537A1High strengthDecrease in bendabilityInternal osteosythesisSurgical needlesConcentration gradientEngineering

A surgical device includes a structural portion which is formed of a first element, such as titanium, which has an outer surface and an inner core. A second element, such as oxygen, is combined with the first element without creating a shear plane, to create a concentration of the second element in the first element which varies from the outer surface to the inner core. In an associated method, the second element is driven into the first element under other than ambient conditions to develop a concentration gradient of the second element between the outer surface and the inner core of the first element.

Owner:APPL MEDICAL RESOURCES CORP

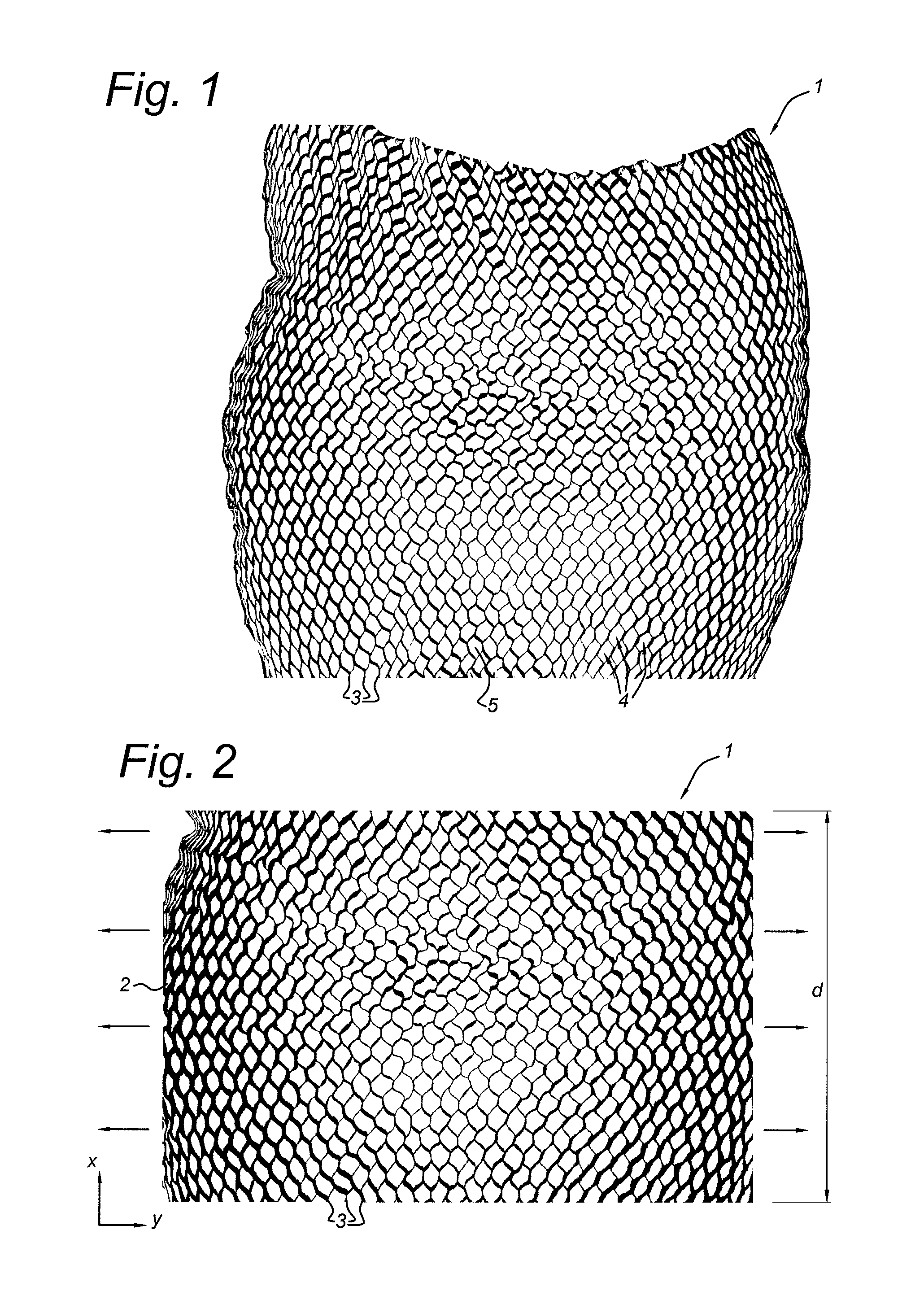

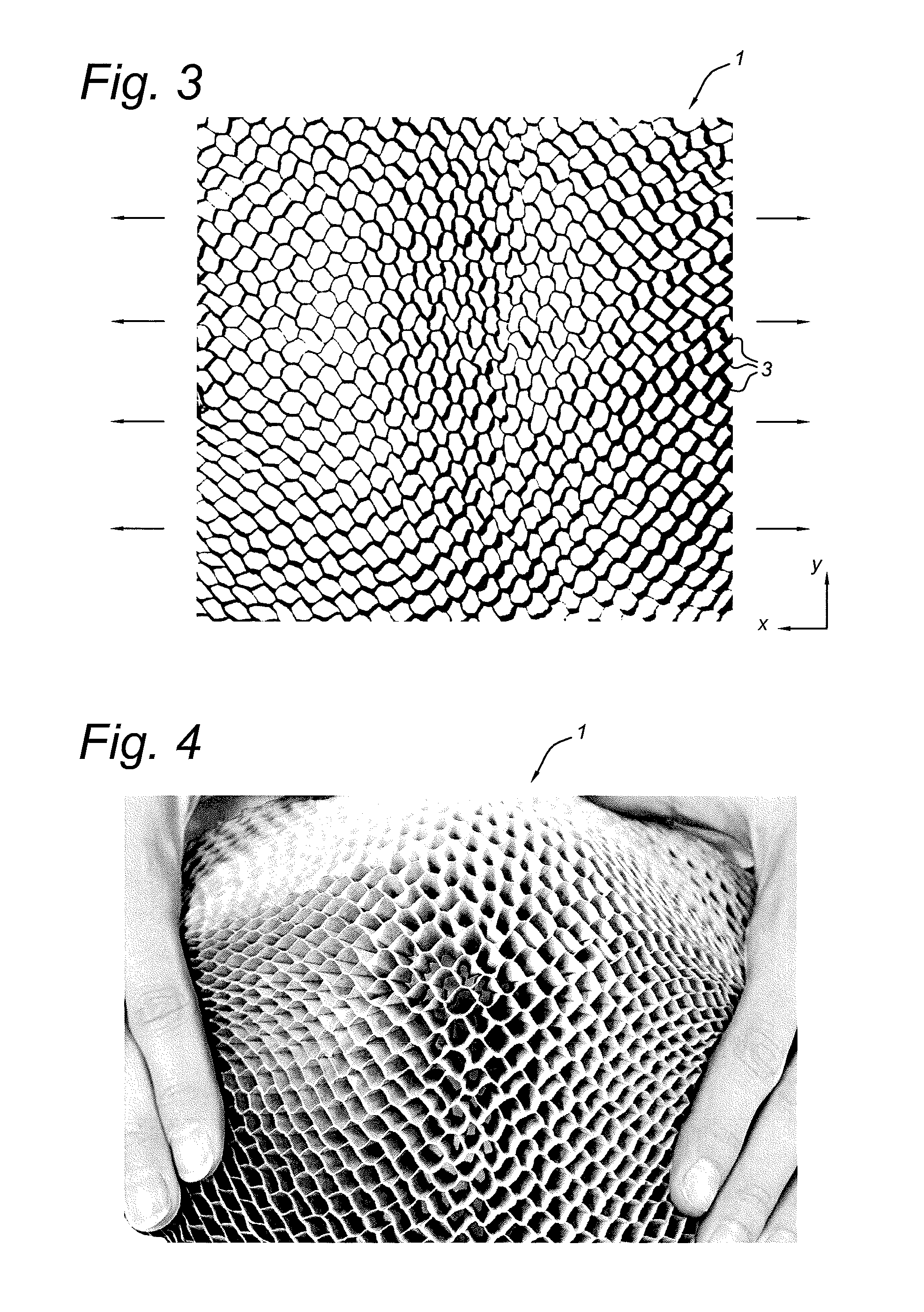

Cellular structure for double curvature panel

InactiveUS20140004299A1Stable supportEasy to handlePaper/cardboard articlesLayered productsClassical mechanicsEngineering

The present invention relates to a cellular core having, in an expanded state, a bonding surface area suitable for sandwich type construction, wherein the cellular core comprises a plurality of elongate planar rectangular wall elements which define the depth and height of said core and extend in a core plane in a wall element direction, and wherein, in the expanded state of the cellular core, arrays of closed cells are formed between two adjacent wall elements, and wherein a respective cell is formed by wall element sections and bonded wall element sections of the two adjacent wall elements. The bonded wall elements have with this folding facility of the wall elements, the freedom to take a position of being almost or exact rectangular to the skin line which means that with this core we have on almost all positions the best skin support as it is the closest to rectangular support. An advantage is that the core can be formed with a double curvature.

Owner:AXXION TECH

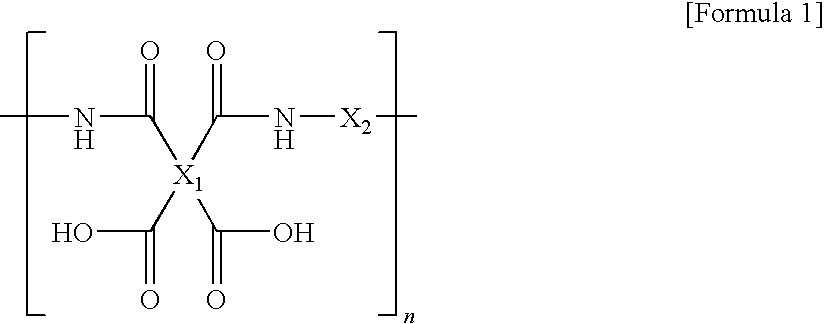

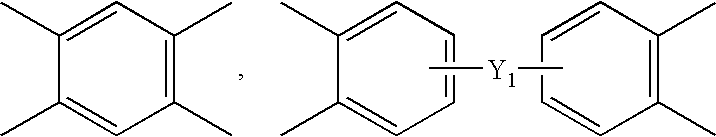

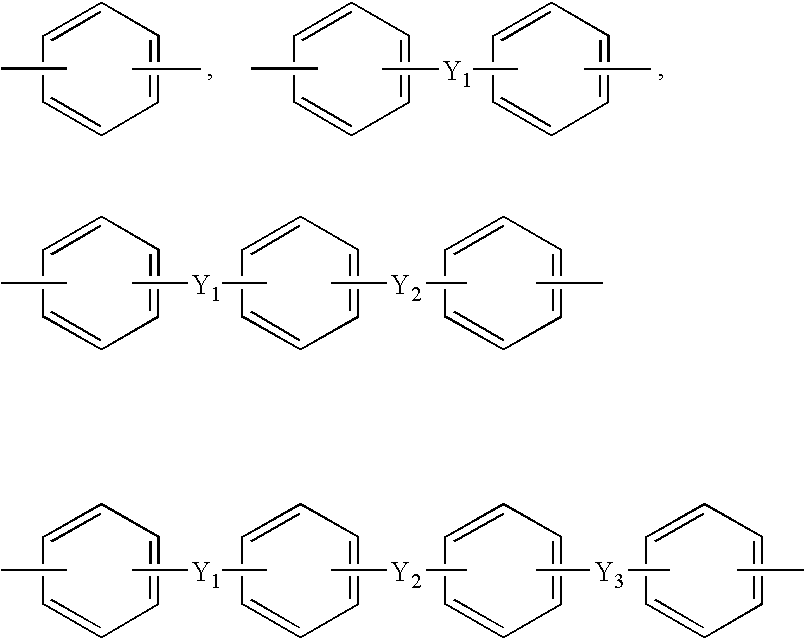

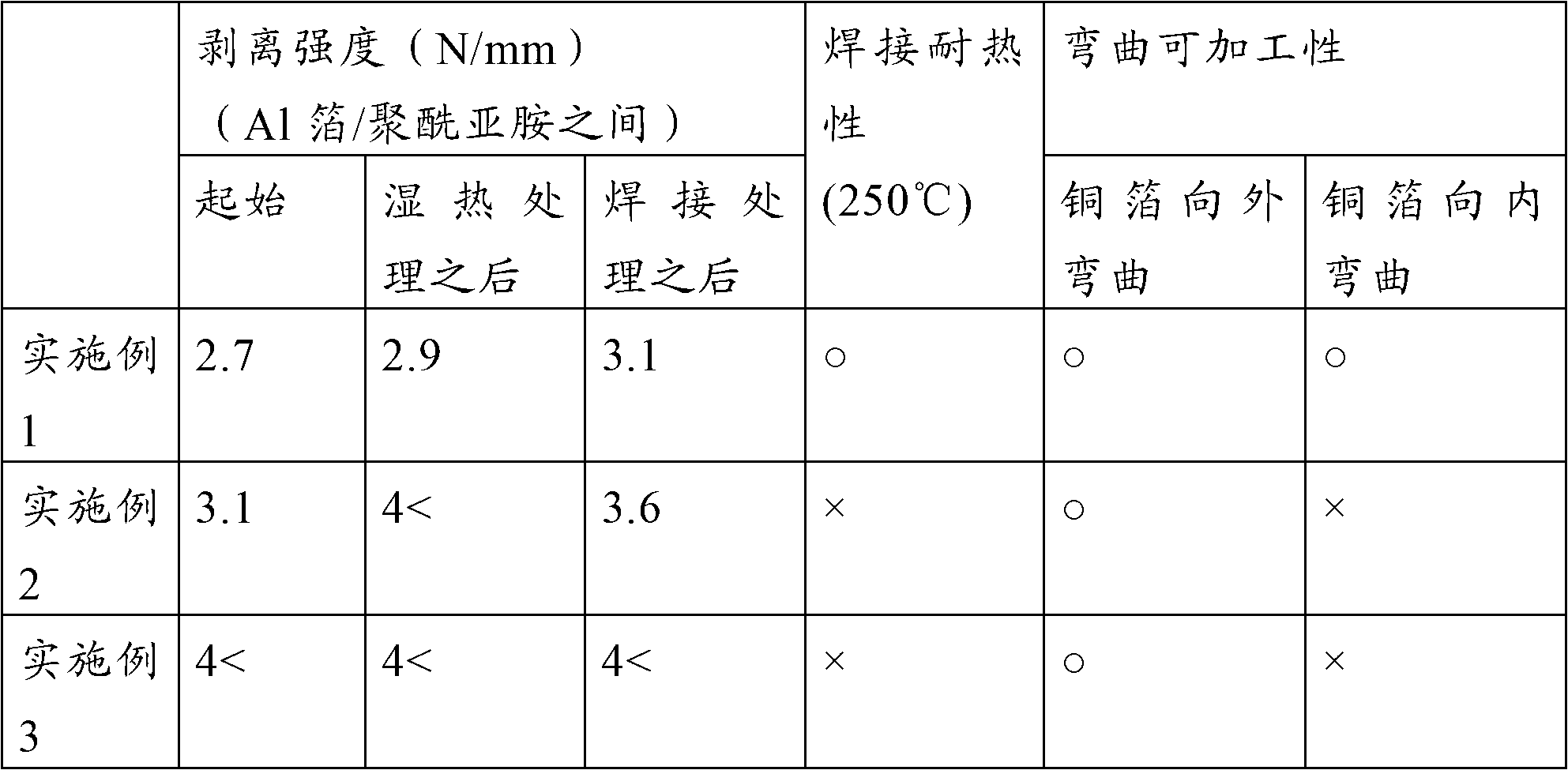

Metal foil laminate

ActiveCN105102221ACheap manufacturingAvoid dentsPrinted circuit aspectsSynthetic resin layered productsEpoxyFolding endurance

To attain simultaneously the prevention of a tip from sinking into a substrate film layer in bonding the tip to metal wiring (namely mountability) and properties which have a trade-off relationship therewith, namely, flex resistance, folding endurance, pliability, and reduction in spring back which is seen as a problem in mounting a circuit board in a bent state or the like. A metal foil laminate composed of a metal foil and a substrate film which is made of a heat-resistant resin composition that comprises a polyimide-based resin crosslinked with an epoxy resin and which is laminated on at least one surface of the metal foil, characterized by satisfying the requirements (a) and (b): (a) when the total amount of the polyimide-based resin and the epoxy resin is taken as 100 mass%, the amount of the epoxy resin is 0.1 to 10 mass%; and (b) the insoluble matter rate of a base film which has been prepared by removing the metal foil from the metal foil laminate is 40% or more as determined by adding N-methyl-2-pyrrolidone to the base film in such an amount as to adjust the base film concentration to 0.5 mass% and heating the resulting mixture at 100ºC for 2 hours.

Owner:TOYOBO CO LTD

Connector

InactiveCN1707863AReduce bendabilityEasy to bendRelieving strain on wire connectionEngineeringMechanical engineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

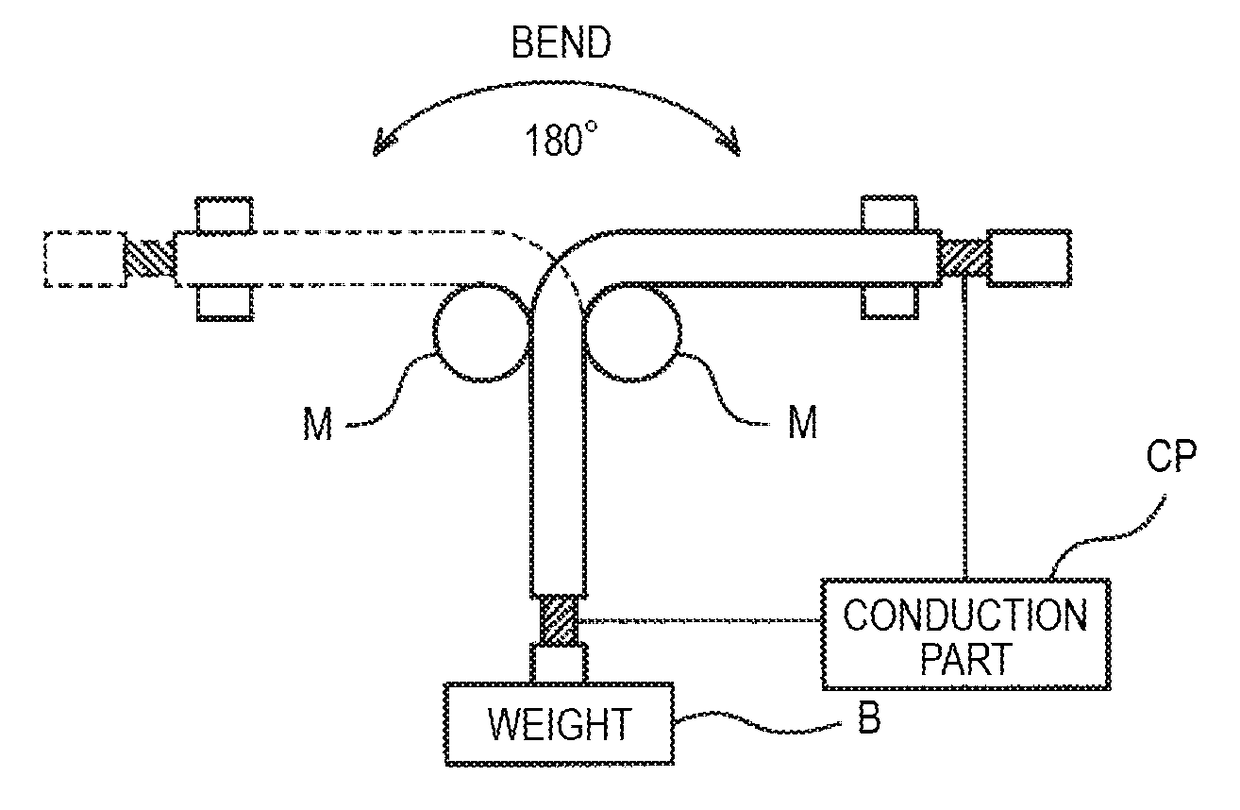

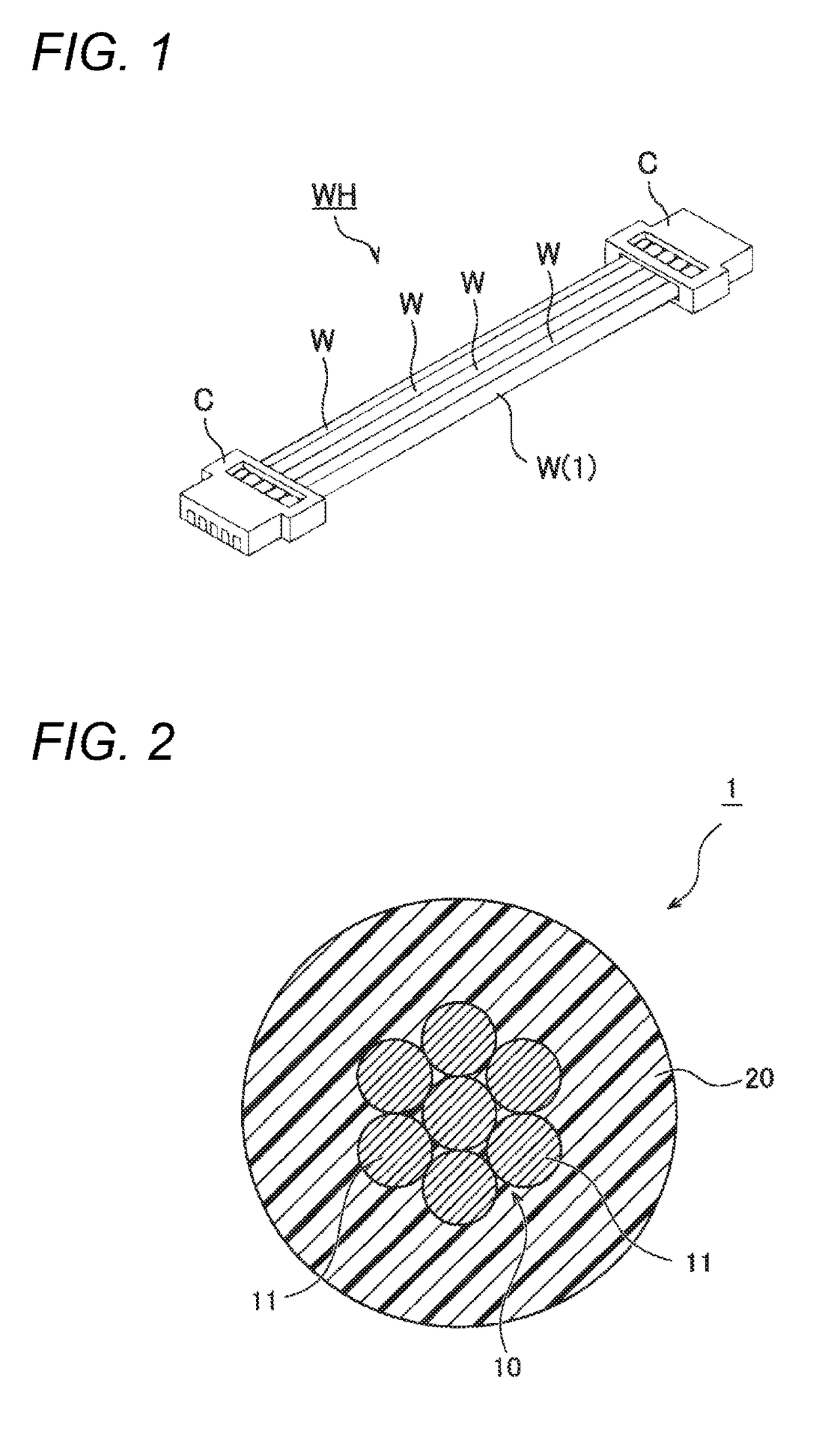

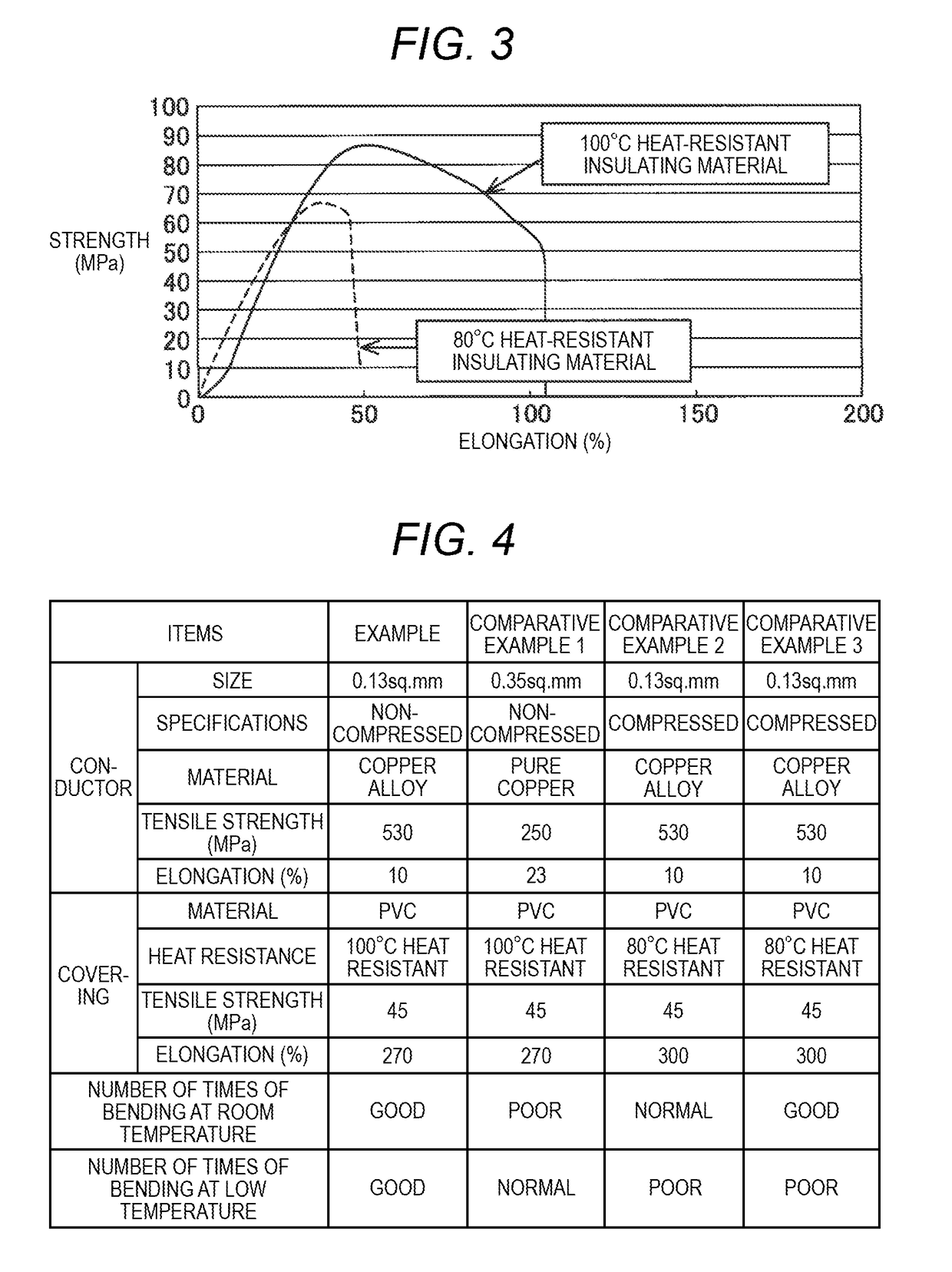

Highly bendable insulated electric wire and wire harness

ActiveUS20170309369A1Reduce electricity costsRaise room temperatureConductive materialDetails of conductive coresElectrical conductorPolyvinyl chloride

A highly bendable insulated electric wire includes a conductor part that has a plurality of non-compressed strands made of a copper alloy, each of the non-compressed strands having a cross-sectional area of 0.13 sq. mm, and a covering part that is provided on the conductor part, wherein the conductor part has an elongation of 7% or more and a tensile strength of 500 MPa or more, and the covering part is made of 100 degree Celsius heat-resistant polyvinyl chloride and has an elongation of 100% or more at a temperature of −40 degree Celsius.

Owner:YAZAKI CORP

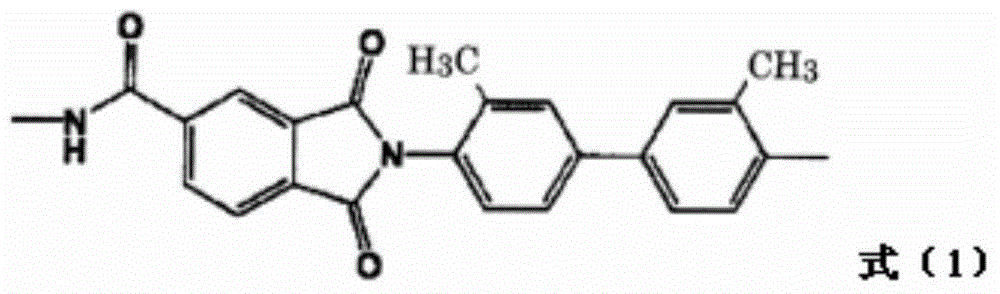

Alkali developable photosensitive resin composition and dry film manufactured by the same

ActiveUS20100113640A1Good resolutionExcellent heat resistance and dielectric propertiesImpression capsOrganic chemistryDouble bondAqueous solution

The present invention relates to a polyimide photosensitive resin composition that is capable of being developed by an alkali aqueous solution, and a dry film that is produced by the same, and more particularly to a photosensitive resin composition which comprises a) a polyamic acid, b) two or more (meth)acrylate-based compounds that include one or more double bonds between carbons, c) a photopolymerization initiator, d) a phosphorus-based flame retardant, and e) an organic solvent, and a dry film that is produced by the same.

Owner:LG CHEM LTD

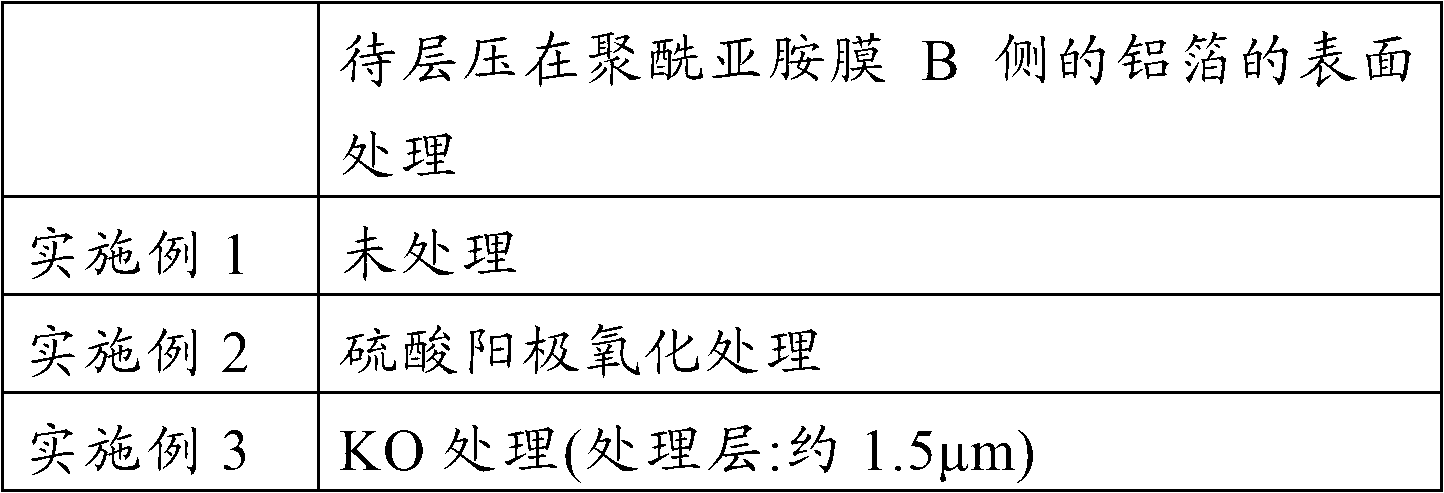

Heat dissipation substrate for led

InactiveCN102939671AImprove flexibilityImprove cooling effectPrinted circuit aspectsHeat exchange apparatusCopper foilPolyimide membrane

A heat dissipation substrate for an LED has copper foil or copper alloy foil layered on one side of a polyimide film and also has aluminum foil or aluminum alloy foil layered on the other side thereof. The thermal resistance between the surface of the copper foil or the copper alloy foil and the surface of the aluminum foil or the aluminum alloy foil is 1.8 DEG C / W or less.

Owner:UBE IND LTD

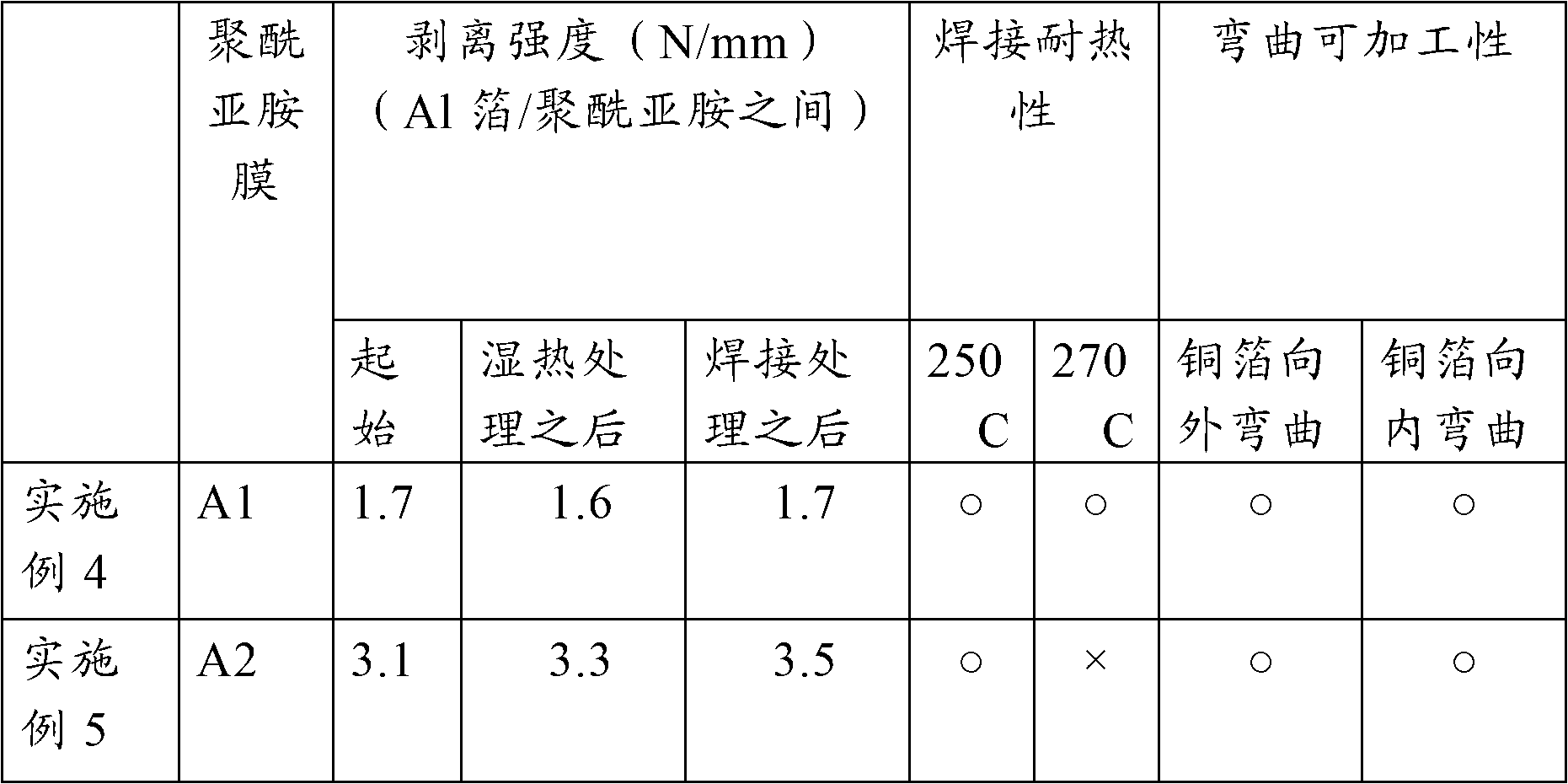

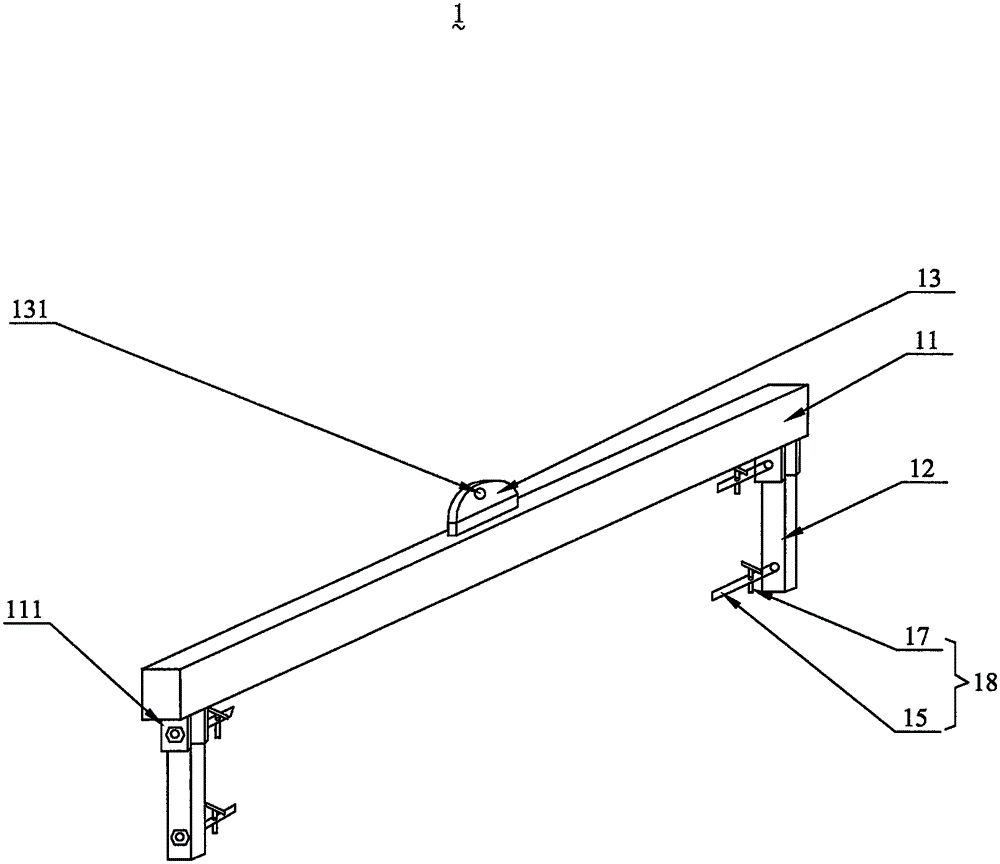

Lifting sling for prefabricated component

InactiveCN105384057AGood finishSmall amount of workLoad-engaging elementsMechanical engineeringEngineering

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Five-core coaxial cable

InactiveCN103606412AUniform structureStable qualityCables with twisted pairs/quadsCoaxial lineAluminum composites

The invention provides a technical scheme of a five-core coaxial cable. The five-core coaxial cable comprises five coaxial lines; the coaxial lines are wired to form an integrated cable core layer; the integrated cable core layer is wrapped by a bonding type plastic-aluminum composite tape; and the bonding type plastic-aluminum composite tape is wrapped by an outer sheath layer. The five-core coaxial cable provided by the scheme has the advantages of excellent shielding performance, quite high transmission rate, super high resolution, good signal transmission quality, low attenuation, wide transmission frequency scope, large information transmission capacity, high echo loss, good bendability, stable performance, simultaneous transmission of multipath super high resolution radiofrequency signals, and the like.

Owner:SICHUAN JIUZHOU WIRE & CABLE

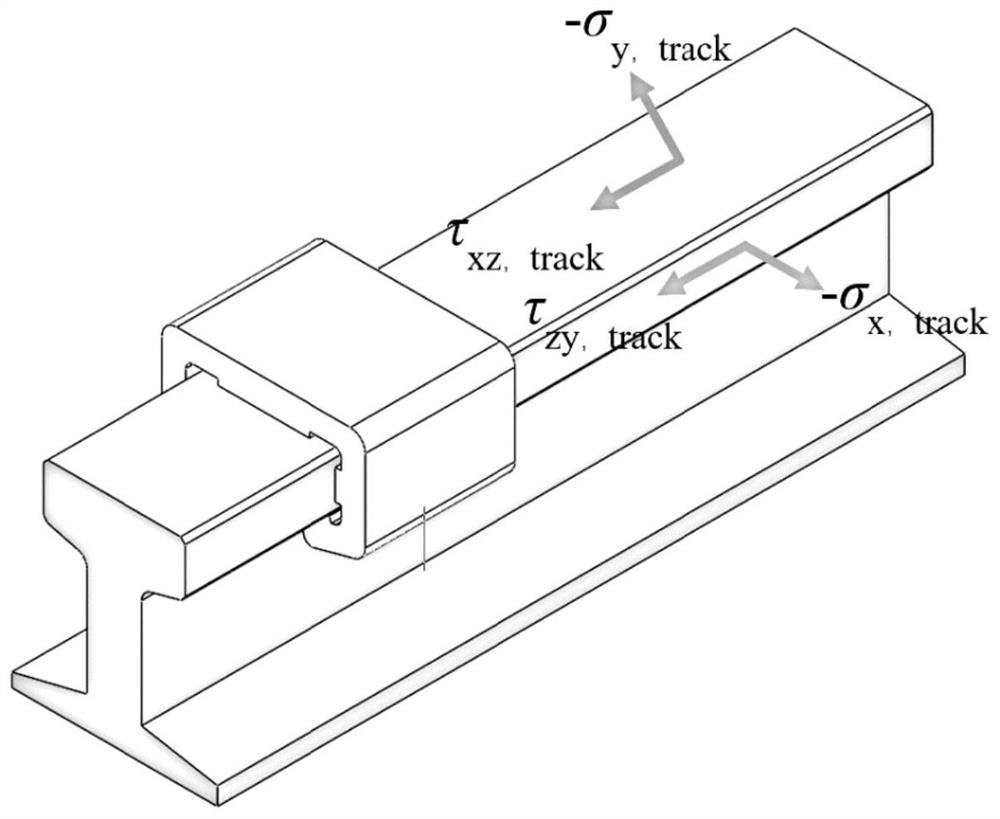

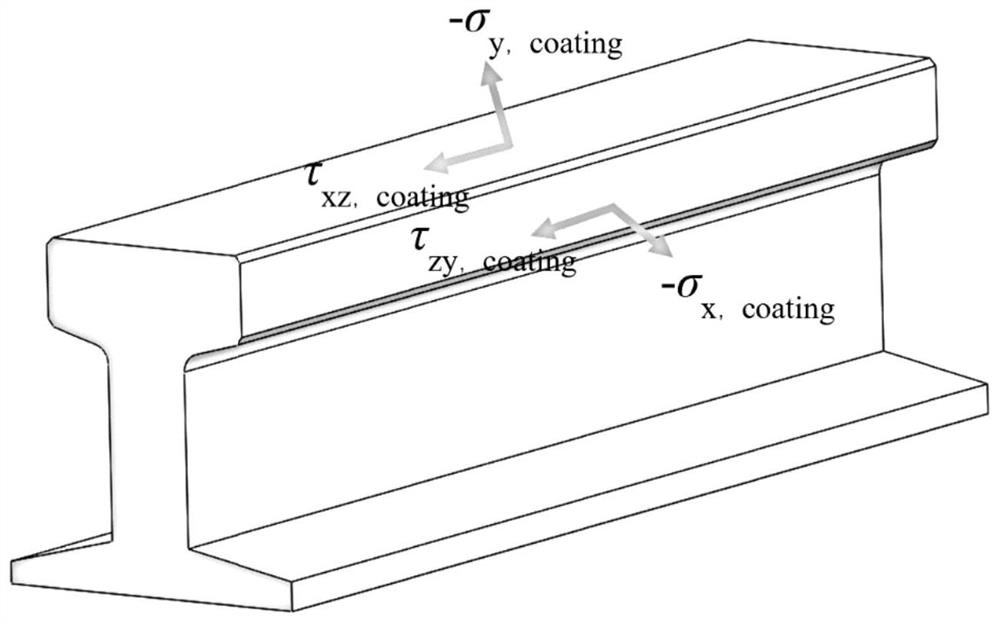

Surface chiseling protective coating for hypersonic rocket sled slide rail and preparation method thereof

InactiveCN112646454AHigh bonding strengthDestabilizingPretreated surfacesEpoxy resin coatingsChemistryPolyamide

The invention discloses a surface chiseling protective coating for a hypersonic rocket sled slide rail and a preparation method thereof. The preparation method comprises the following steps: 1, pretreating the surface of a matrix; 2, preparing a PES / E51 / polyamide system in proportion; and 3, directionally and uniformly spraying the powder onto a metal matrix by adopting a directional spraying technology. The bonding strength of the coating and a metal matrix is high, the impact resistance is good, and the chiseling phenomenon on the sliding rail can be effectively relieved.

Owner:XI AN JIAOTONG UNIV

Steel sheet for hot press formed product having superior bendability and ultra-high strength, hot press formed product using same, and method for manufacturing same

ActiveUS10253388B2High strengthImprove bending performanceHot-dipping/immersion processesFurnace typesSheet steelThermal compression

The present invention provides: a steel sheet capable of manufacturing a formed product having superior bendability and ultra-high strength when compared with conventional steel sheets for manufacturing a hot press formed product; the formed product having superior bendability and ultra-high strength by using the same; and a method for manufacturing the same.

Owner:POHANG IRON & STEEL CO LTD

Semiconductor device having reinforcement member and method of manufacturing the same

InactiveUS7692312B2Reduce thicknessLevel of rigiditySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package providing with a printed circuit board and a semiconductor device, including a semiconductor substrate having a surface provided with an external connection electrode and mounted on the printed circuit board, and, a surface opposite that with said external connection electrode, abrased with a mirror finish and reinforced with a back-surface reinforcement.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com