Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25605results about "Epoxy resin coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

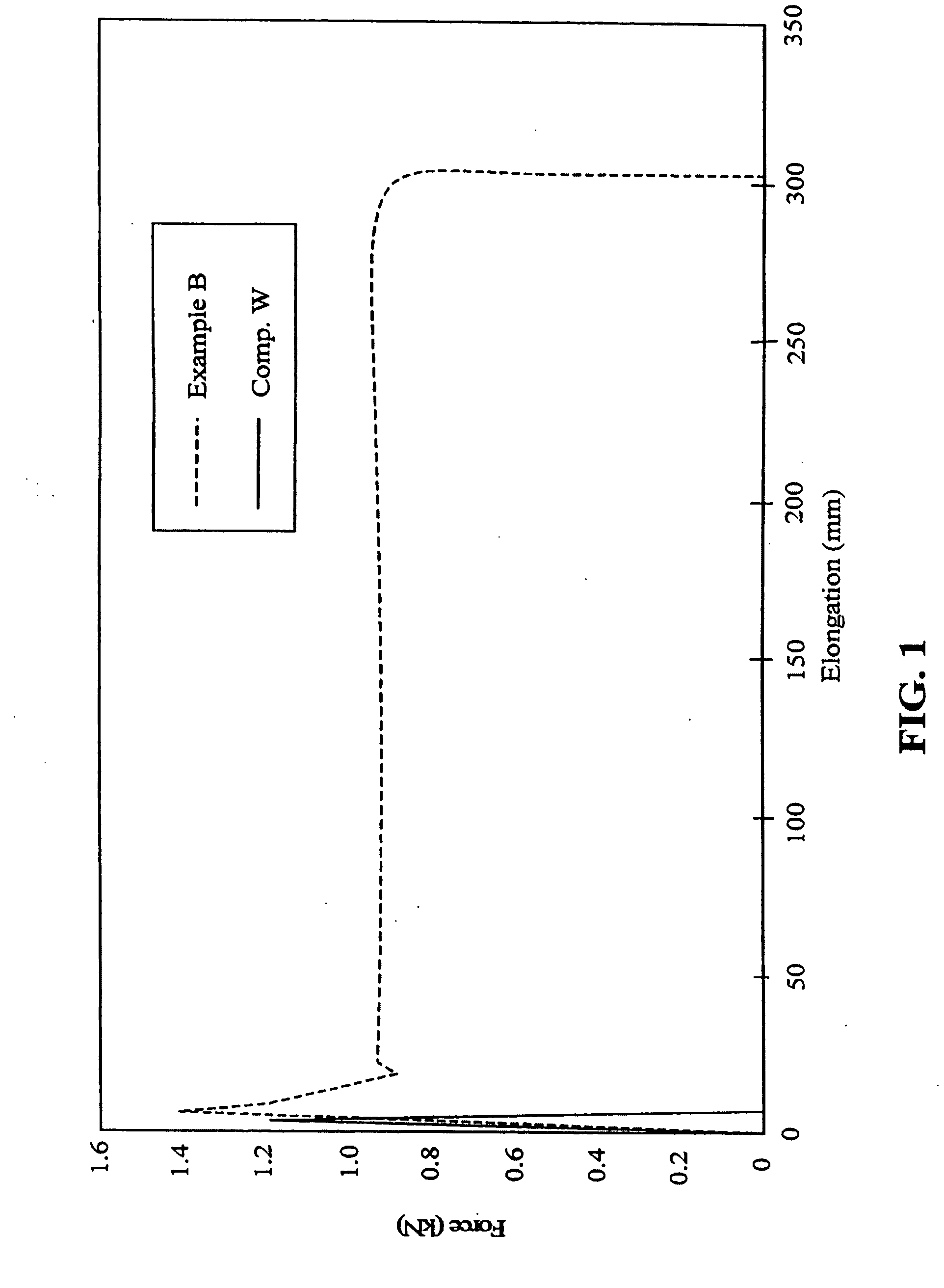

Oxygen scavenging condensation copolymers for bottles and packaging articles

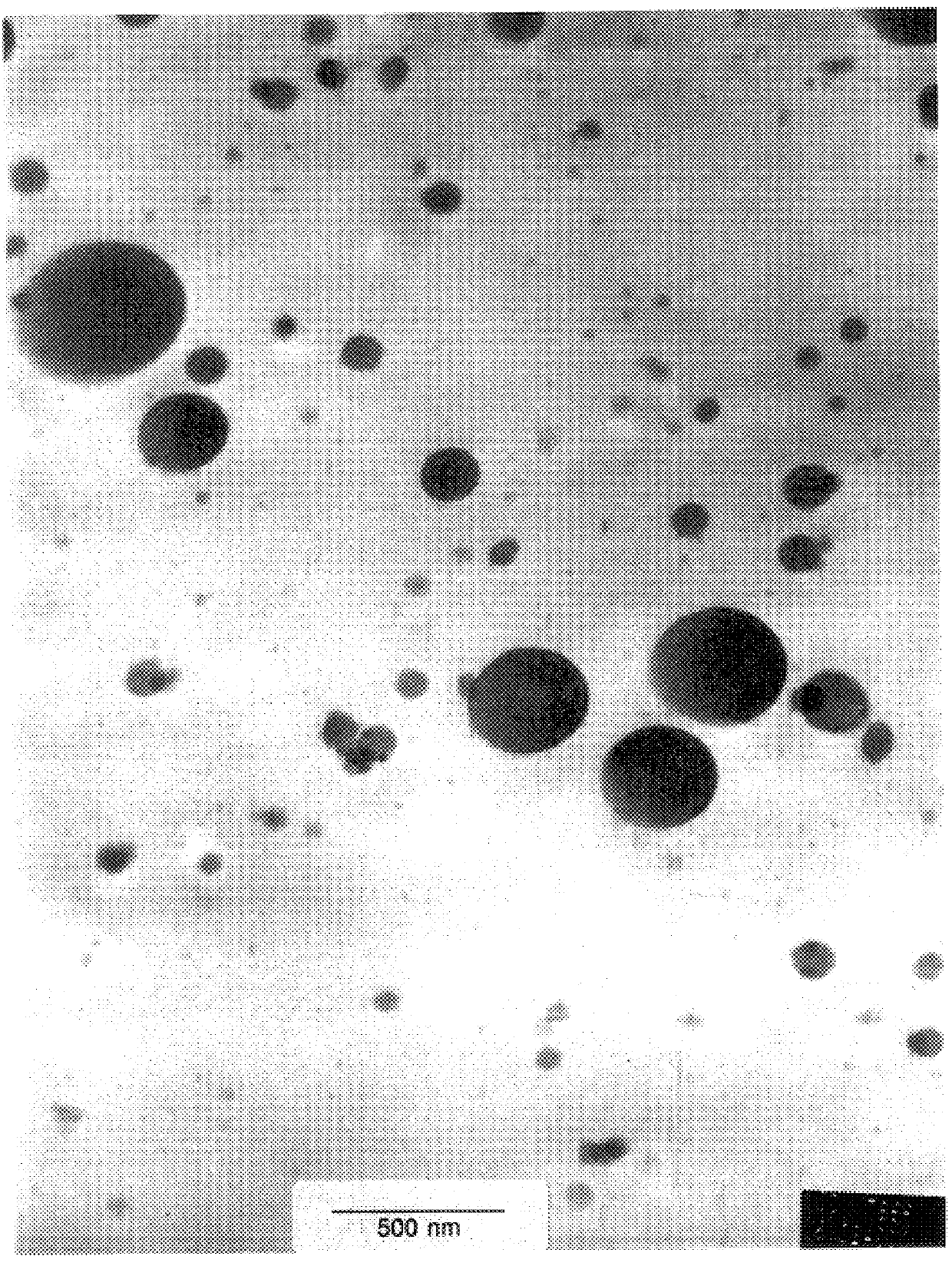

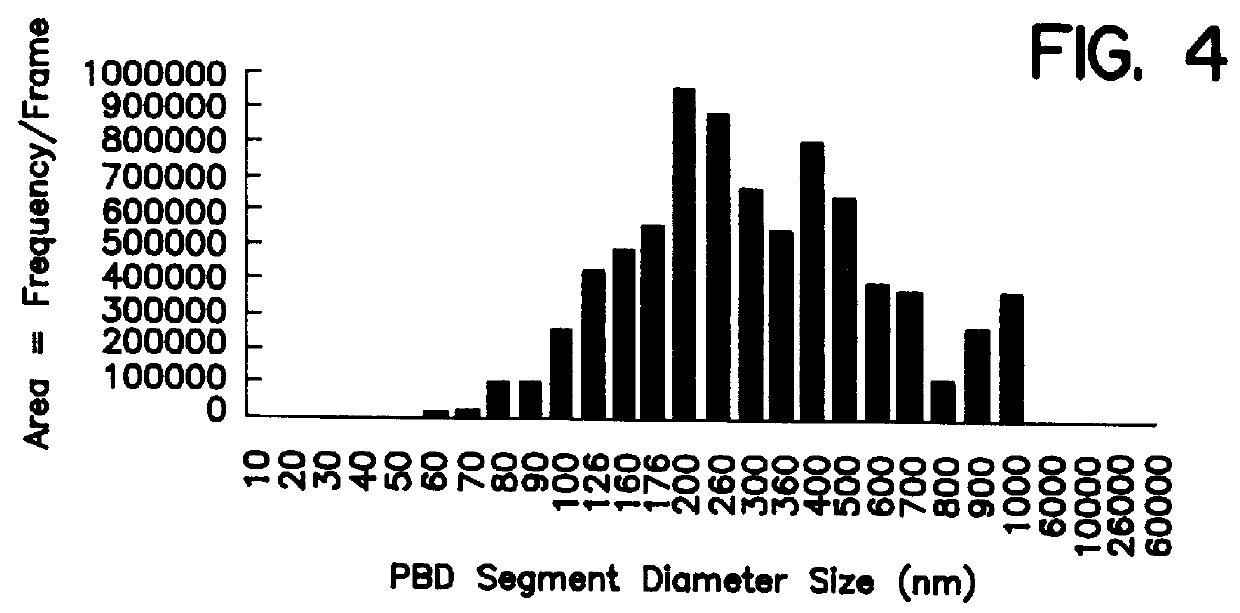

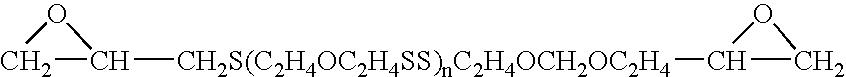

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Epoxy coating

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

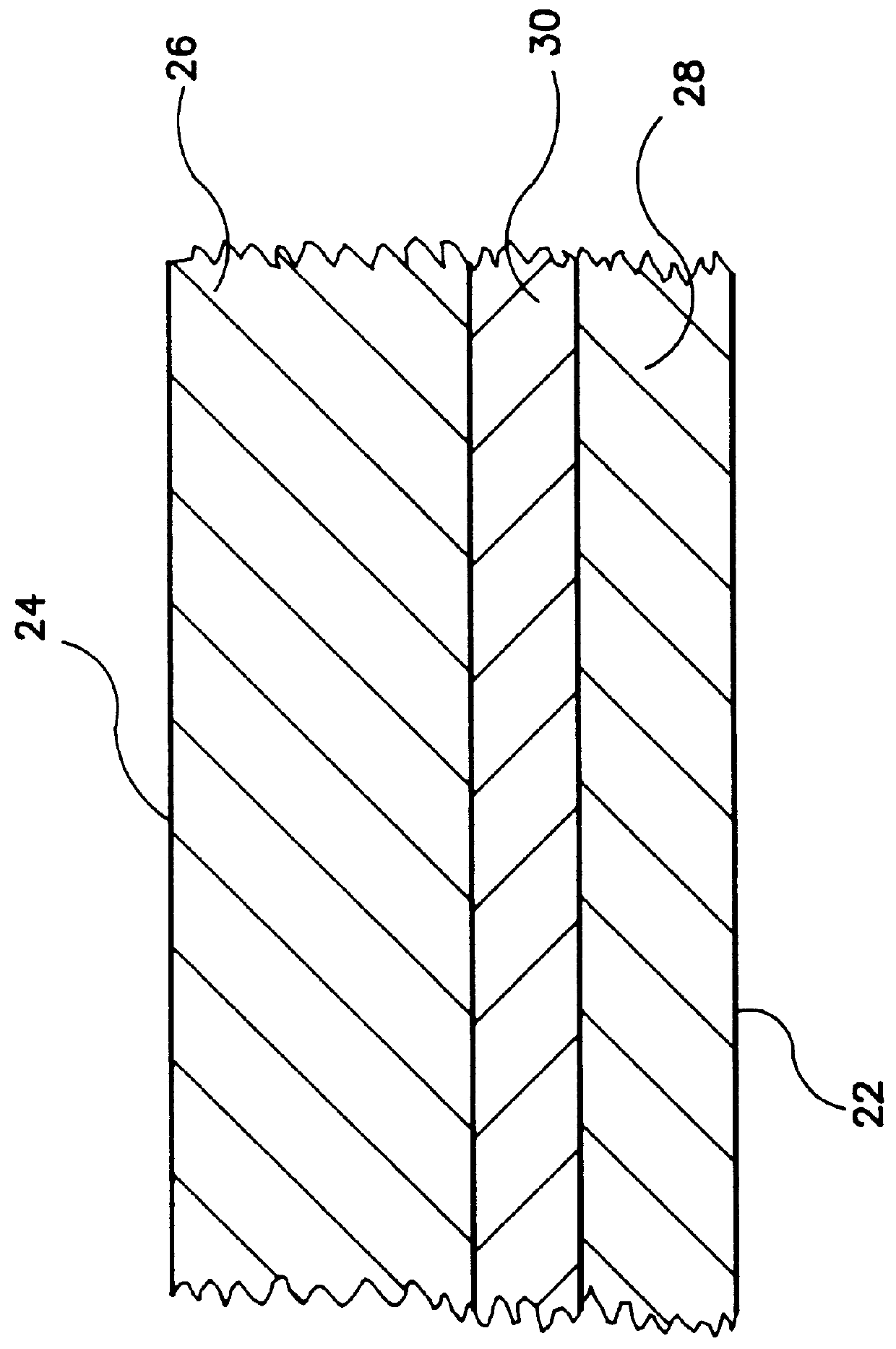

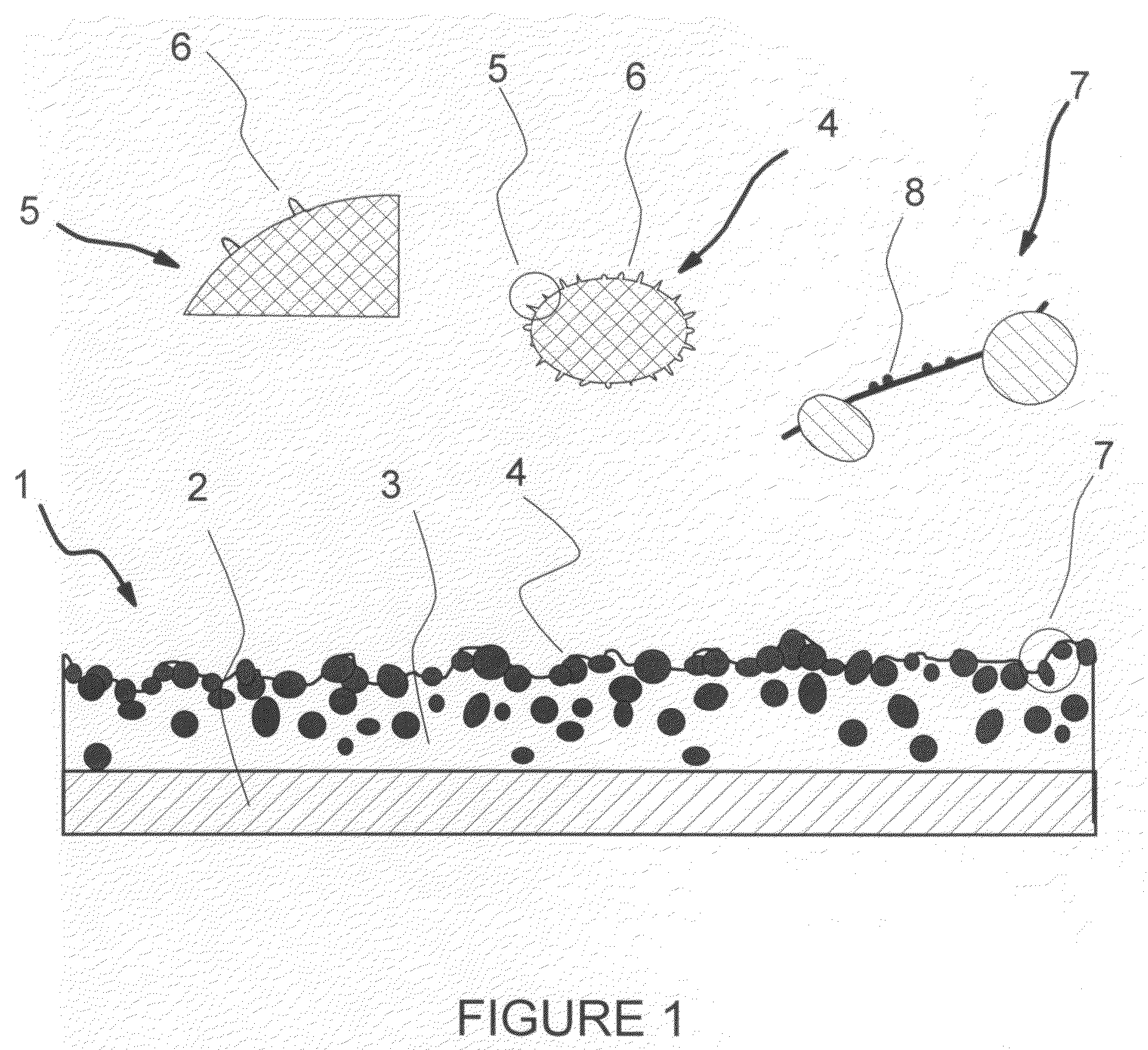

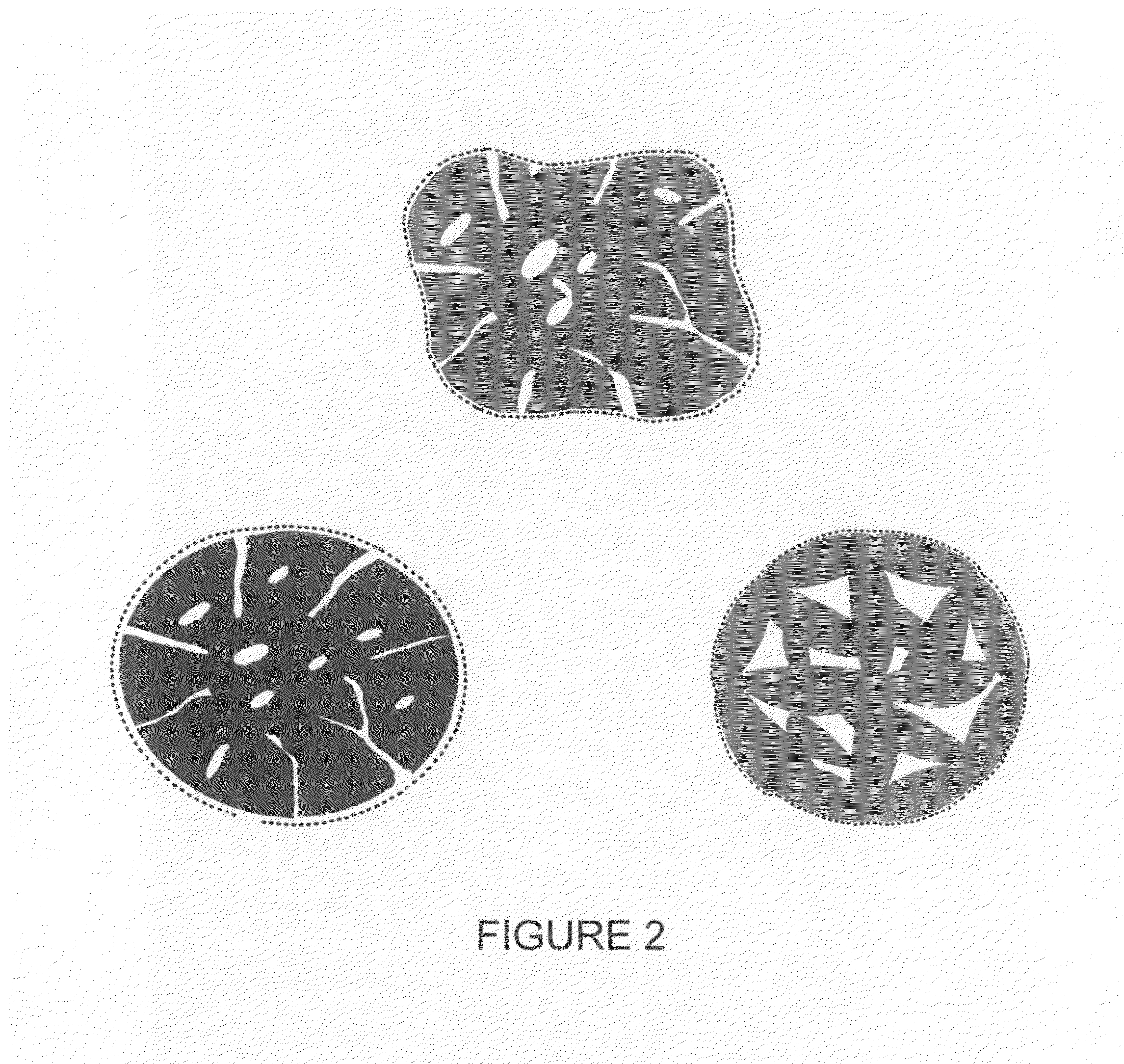

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

Lightweight particles and compositions containing them

Disclosed are particles that have an exterior surface coated with a thin polymeric coating, such as a coating that includes a sulfur-containing polymer. Also disclosed are compositions, such as fuel-resistant sealant and coating compositions, which include such particles. Aerospace vehicles having an aperture at least partially sealed with a sealant deposited from such a sealant composition are also disclosed.

Owner:PPG IND OHIO INC

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

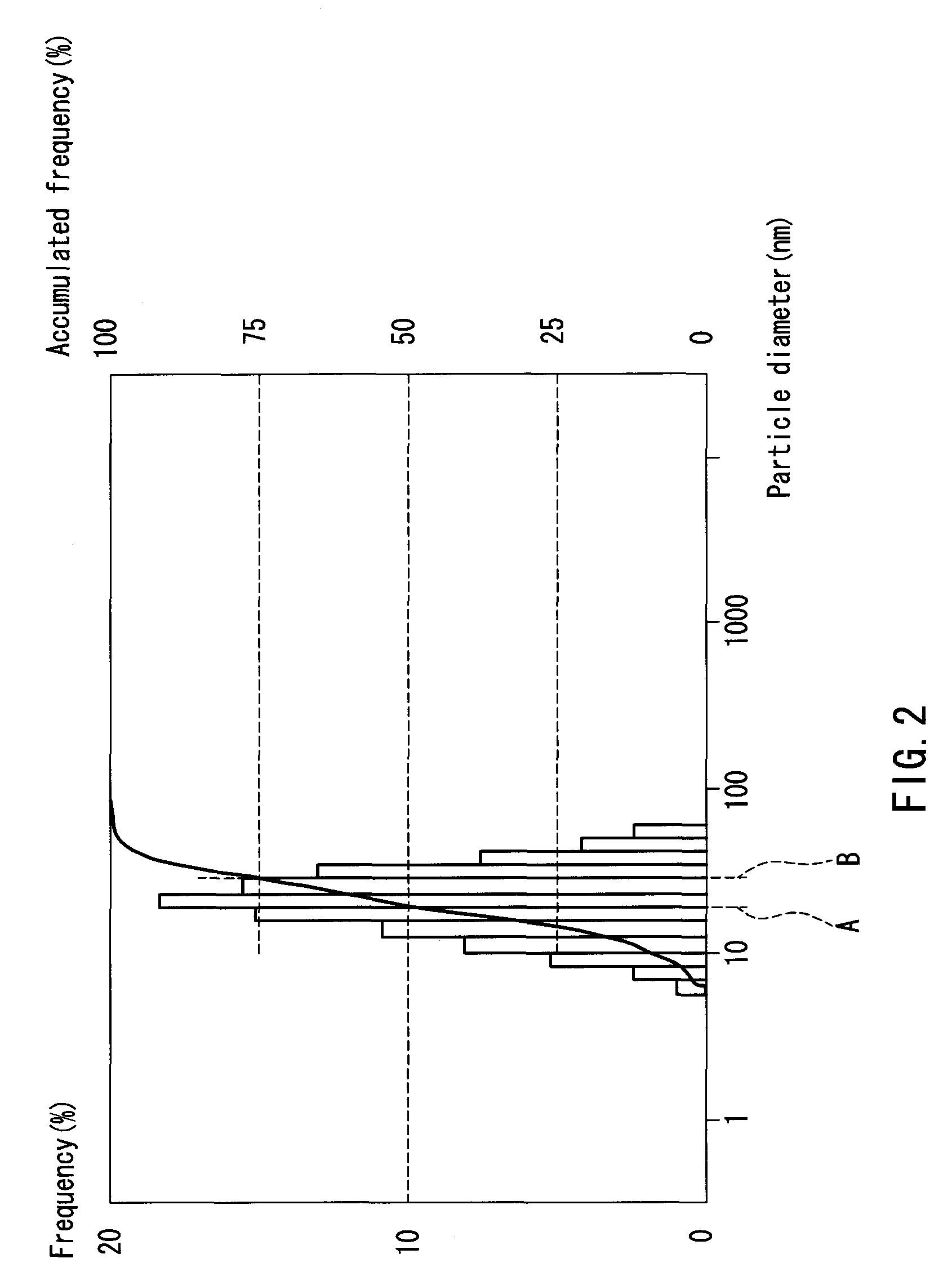

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

Adhesive bonding composition and method of use

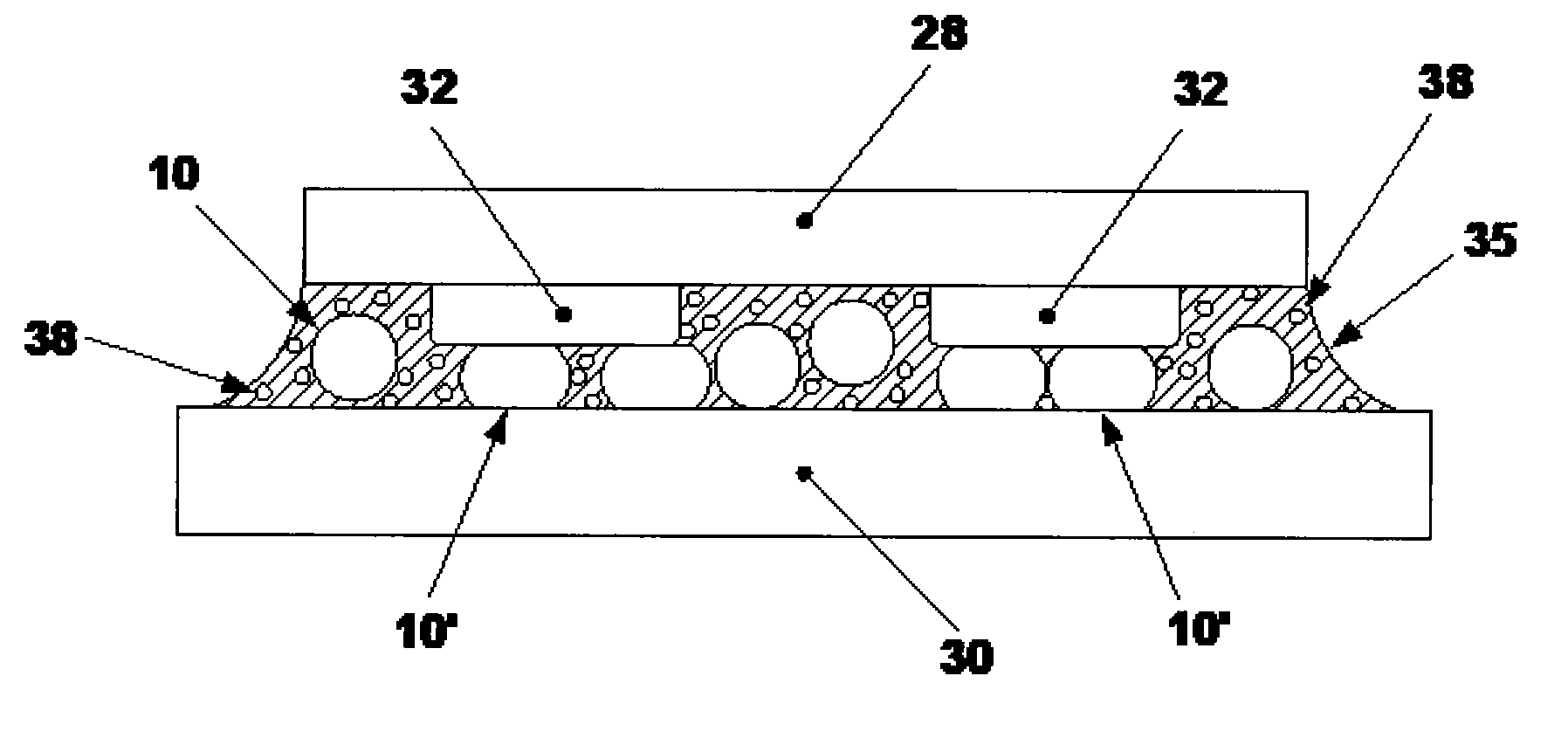

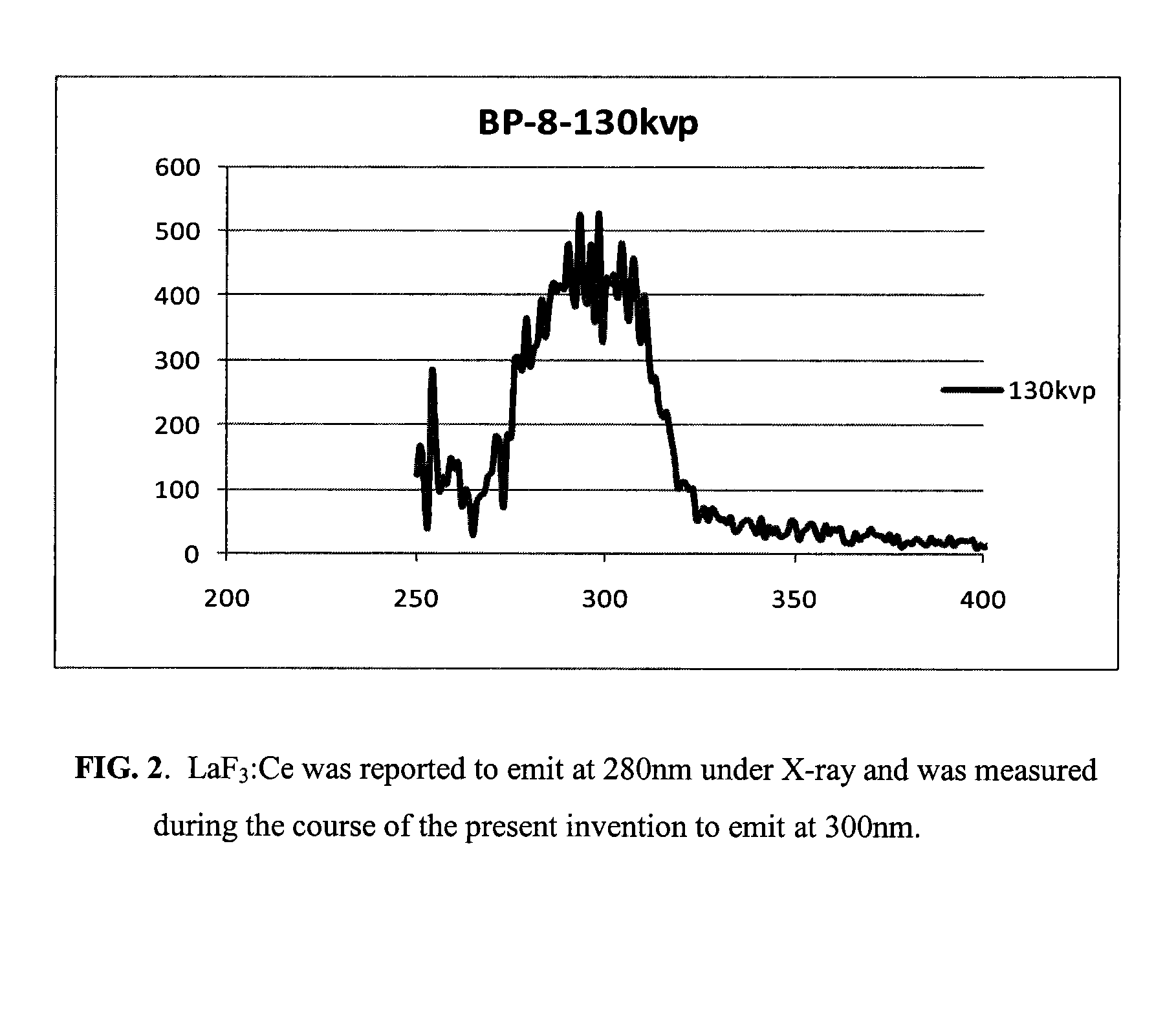

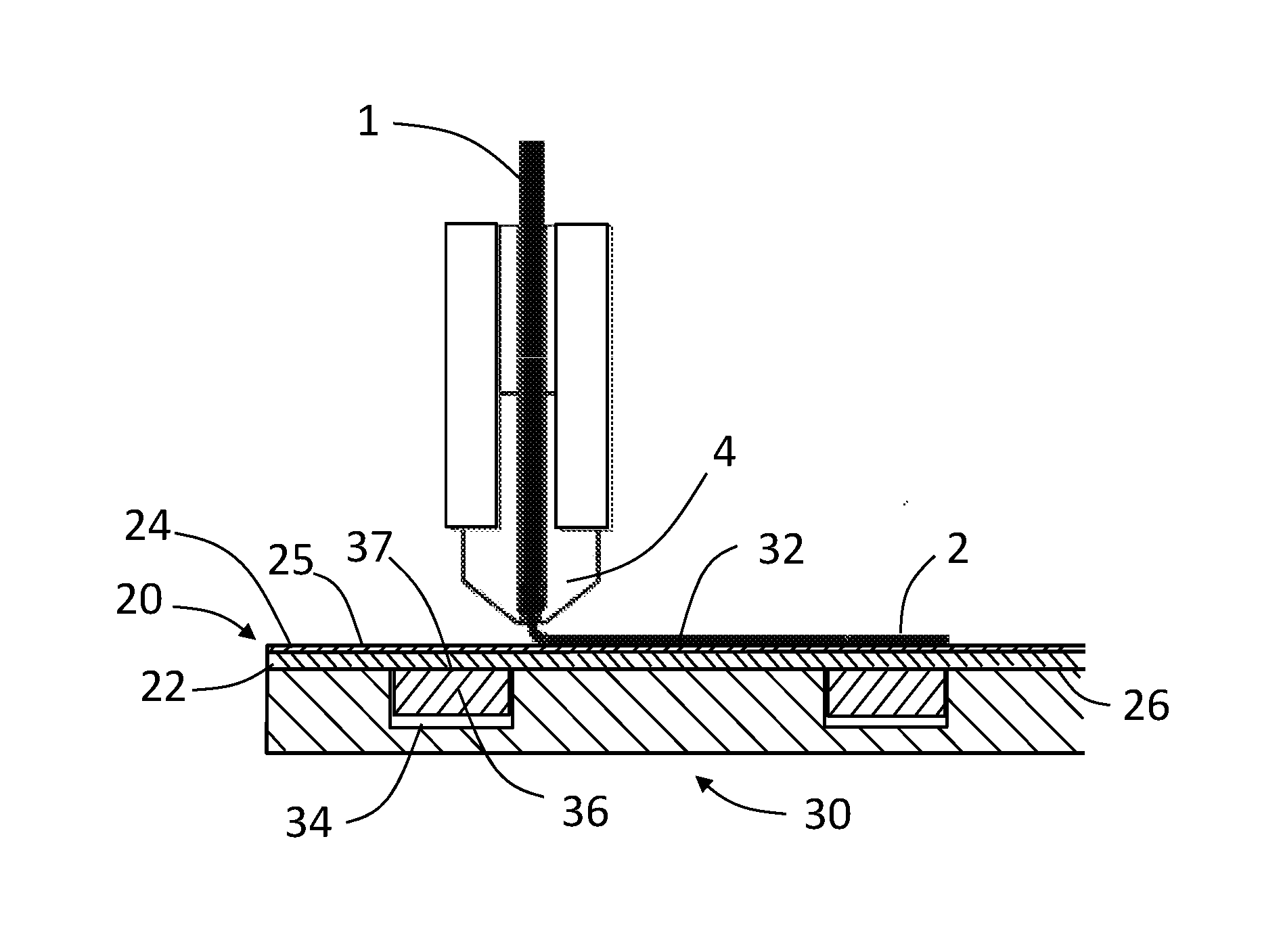

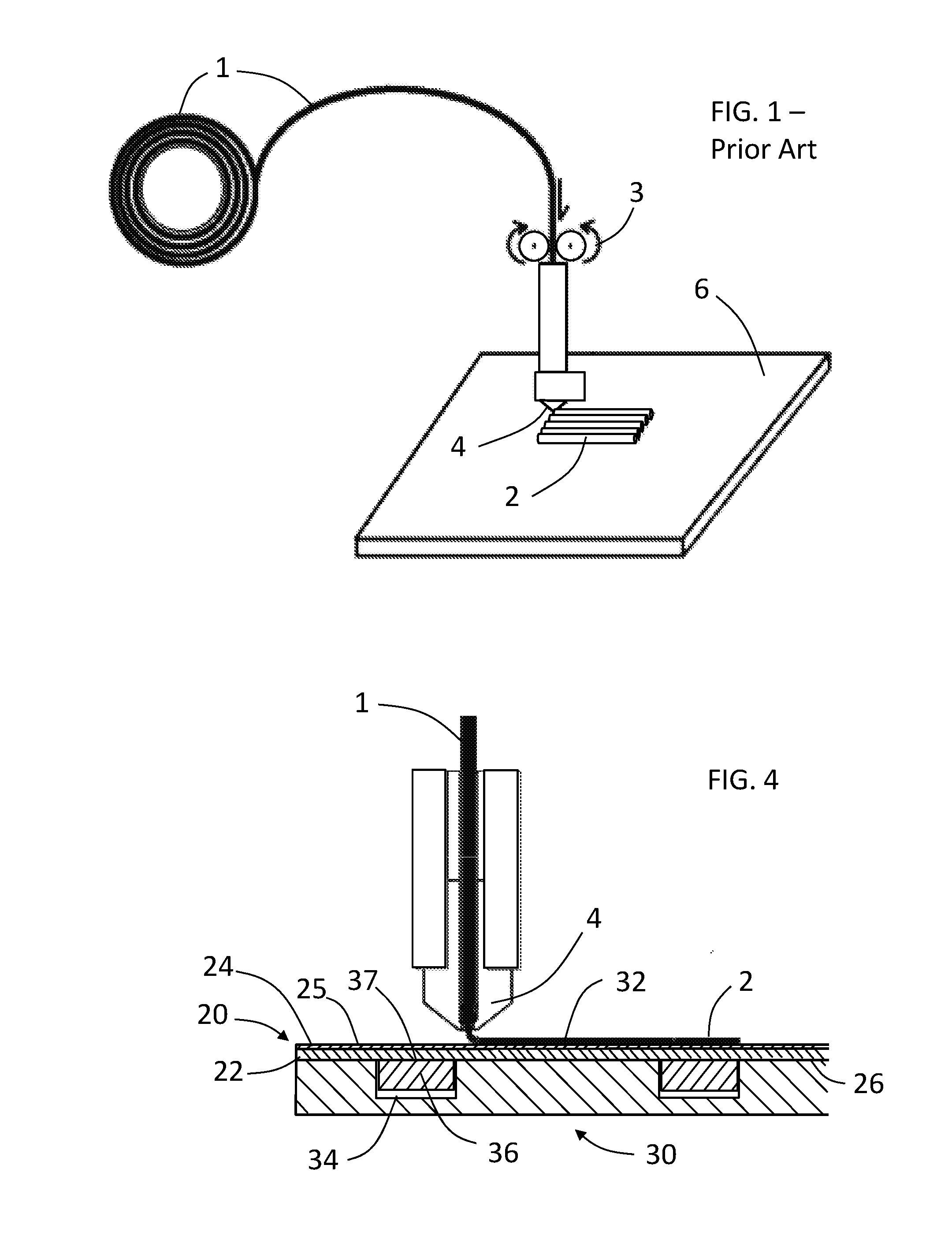

A polymerizable composition includes at least one monomer, a photoinitiator capable of initiating polymerization of the monomer when exposed to light, and a phosphor capable of producing light when exposed to radiation (typically X-rays). The material is particularly suitable for bonding components at ambient temperature in situations where the bond joint is not accessible to an external light source. An associated method includes: placing a polymerizable adhesive composition, including a photoinitiator and energy converting material, such as a down-converting phosphor, in contact with at least two components to be bonded to form an assembly; and, irradiating the assembly with radiation at a first wavelength, capable of conversion (down-conversion by the phosphor) to a second wavelength capable of activating the photoinitiator, to prepare items such as inkjet cartridges, wafer-to-wafer assemblies, semiconductors, integrated circuits, and the like.

Owner:IMMUNOLIGTHT LLC +1

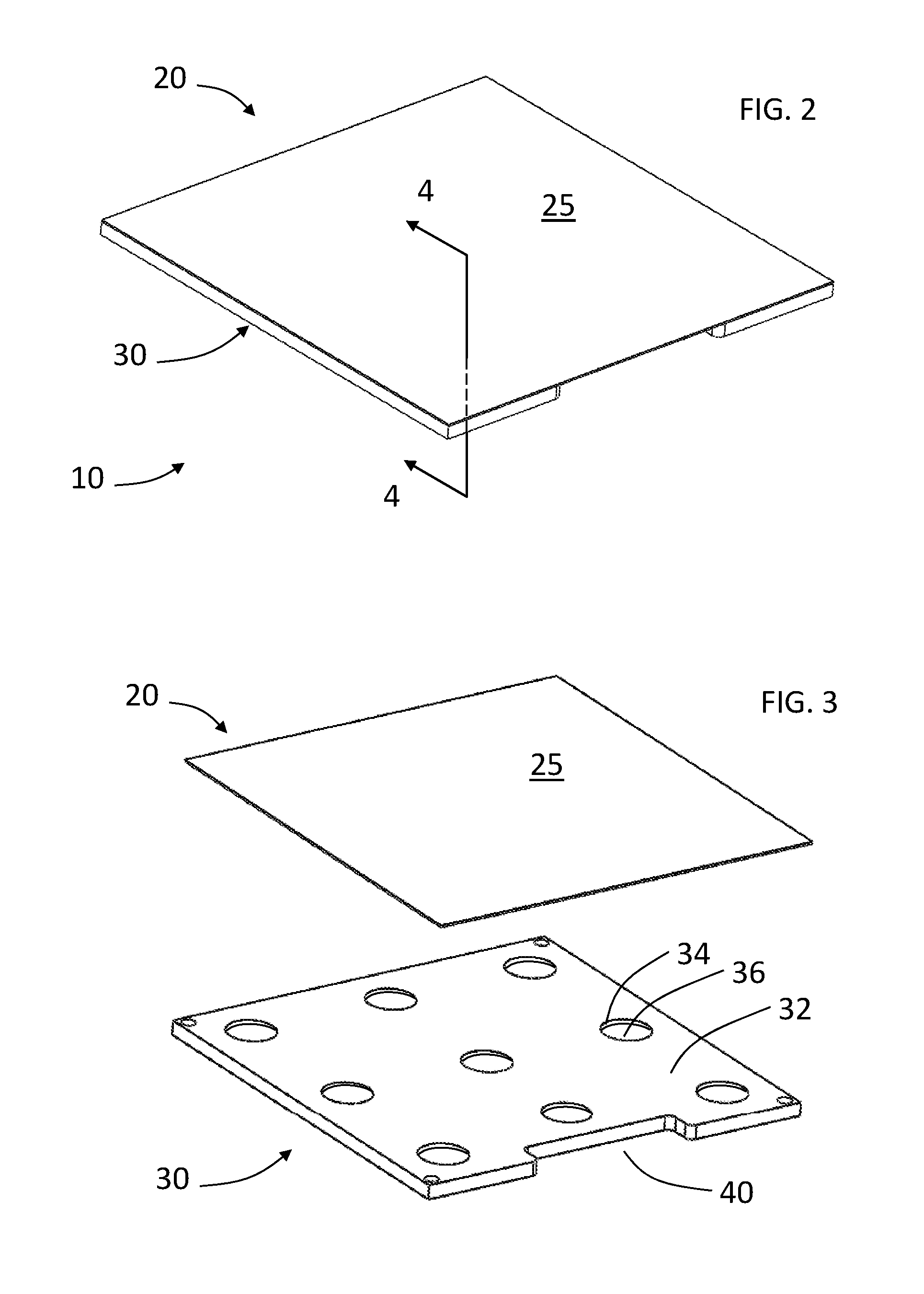

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

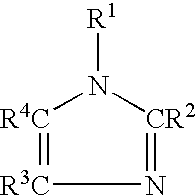

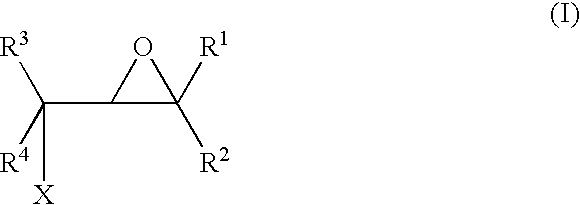

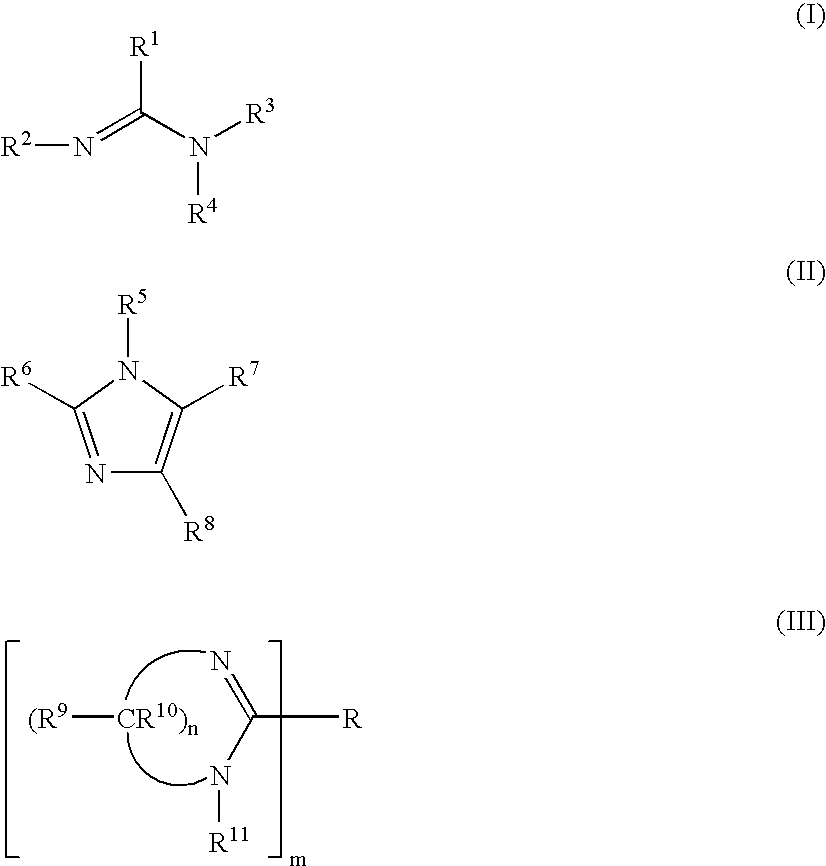

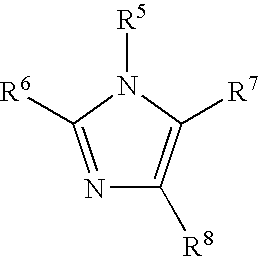

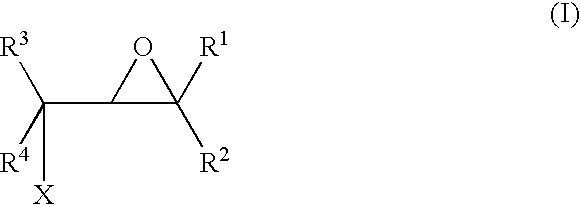

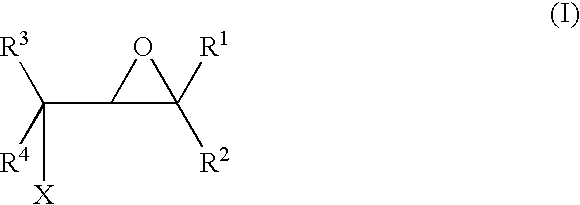

Cross-linkable polyionic coatings for medical devices

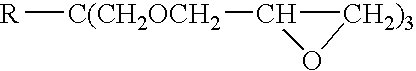

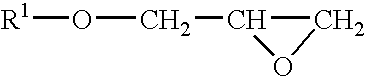

A method for making an article comprising a core material and a coating thereon, the method comprising the steps of:(a) providing the core material;(b) applying one or more layers of a crosslinkable polycationic material, wherein the polycationic material is a reaction product of:(i) an epoxide of formula (I)wherein X equals bromo, chloro, iodo, or cyano, and R1, R2, R3, R4, independently of one another, are selected from the group consisting of hydrogen, linear or branched C1-C6-alkyl, and linear or branched C1-C6-alkyl which is substituted with halogen, and(ii) a polymer having repeating units comprising one or more secondary or tertiary amine group(s);(c) applying one or more layers of a polyanionic material; and(d) cross-linking the layers of polyelectrolytes formed by steps (b) and (c).The articles obtainable by the method of the invention have desirable characteristics regarding adherence to the core material, durability, hydrophilicity, and wettability and are thus useful for the manufacture of medical articles such as ophthalmic devices.

Owner:ALCON INC

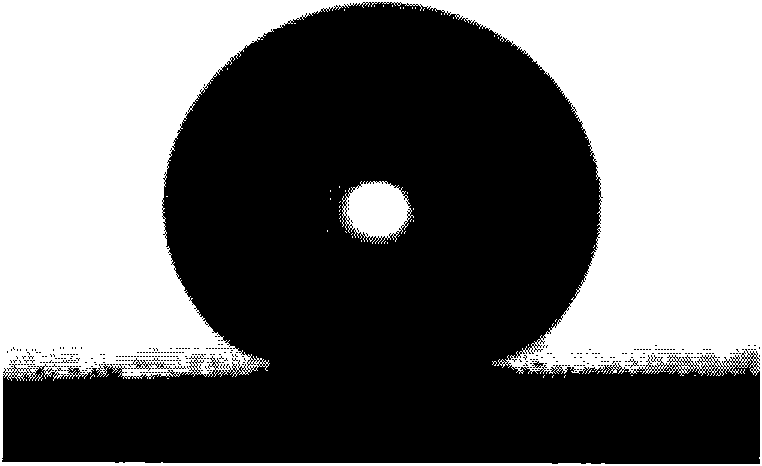

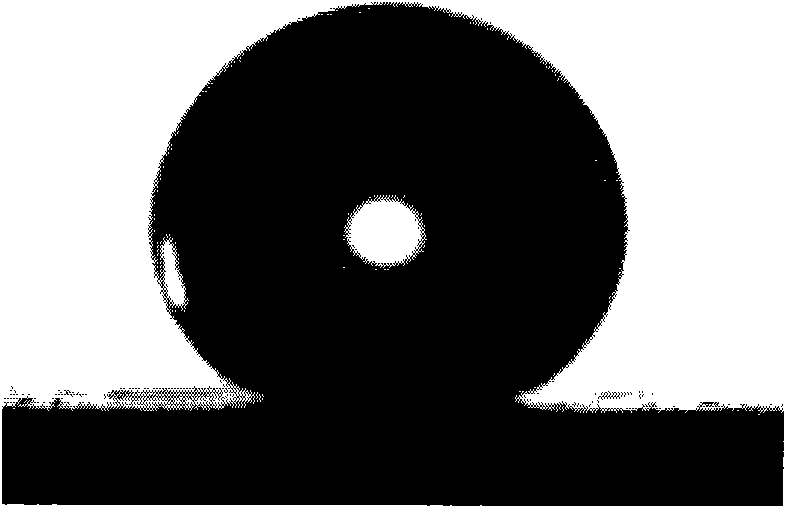

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Polymeric nanocomposites

InactiveUS20050191490A1Increase heightEnhanced interactionMaterial nanotechnologySynthetic resin layered productsEpoxyPolyolefin

Disclosed is a nanocomposite comprising a nano-reinforcing material (e.g., layered clay), a polymer matrix (e.g., a polyolefin), and, an epoxy-functionalized graft polymer compatible with the polymer matrix (e.g., epoxy-grafted polyolefin). Such nanocomposites are useful in the fabrication of a variety of materials including parts for the transportation and packaging industries, electronics, business equipment, building and construction materials.

Owner:NAT RES COUNCIL OF CANADA

Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

InactiveCN102516852AImprove thermal conductivityMeet service life requirementsPolyureas/polyurethane adhesivesPhotovoltaicsWeather resistanceConductive coating

The invention discloses a weather-resistant and high thermal conductive coating, a radiating solar rear panel and an efficient solar cell panel. The weather-resistant and high thermal conductive coating consists of 10 to 50 parts of weather-resistant resin, 5 to 30 parts of curing agent, 0.1 to 5 parts of organic filler, 30 to 80 parts of inorganic filler, and 30 to 100 parts of solvent. The radiating solar rear panel comprises a base layer, and the weather-resistant and high thermal conductive coating is arranged on at least one surface of the base layer or arranged between the base layers. The efficient solar cell panel comprises a solar front panel and the radiating solar rear panel, a solar cell circuit is arranged between the solar front panel and the radiating solar rear panel, and an encapsulation material is arranged on one side or two sides of the solar cell circuit. The weather-resistant and high thermal conductive coating can be directly coated on a base material and has high binding power and an excellent thermal conductive effect, and the weather resistance of the coating meets the requirement of a solar module for the service life of over 25 years.

Owner:ALLSTAE TECH ZHONGSHAN

Modified epoxy resin composition, production process for the same and solvent-free coating comprising the same

InactiveUS6677426B2Satisfactory curabilityImprove mechanical propertiesEpoxy resin coatingsAcetoacetatesEpoxy

There is provided a modified epoxy resin composition including a reaction product of an epoxy resin and an alkyl-substituted acetoacetate and a reaction product of an alcohol having at least one hydroxyl group in one molecule and an alkyl-substituted acetoacetate; a production process for the same; and a solvent-free coating using the same. The composition provides a solvent-free epoxy resin composition which has a low viscosity and excellent low-temperature curability.

Owner:WESTLAKE EPOXY INC

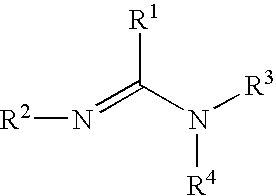

Organometallic compositions and coating compositions

InactiveUS20060247341A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsCarbamateZinc

The present invention is directed to novel organometallic complexes as catalysts for the reaction of compounds with isocyanate and hydroxyl functional groups to form urethane and / or polyurethane and the process employing such catalysts. More particularly, the present invention is directed to novel complexes of zinc(II) with substituted amidines. These novel catalysts are useful for the production of urethanes and polyurethanes which are important in many industrial applications.

Owner:KING INDUSTRIES INC

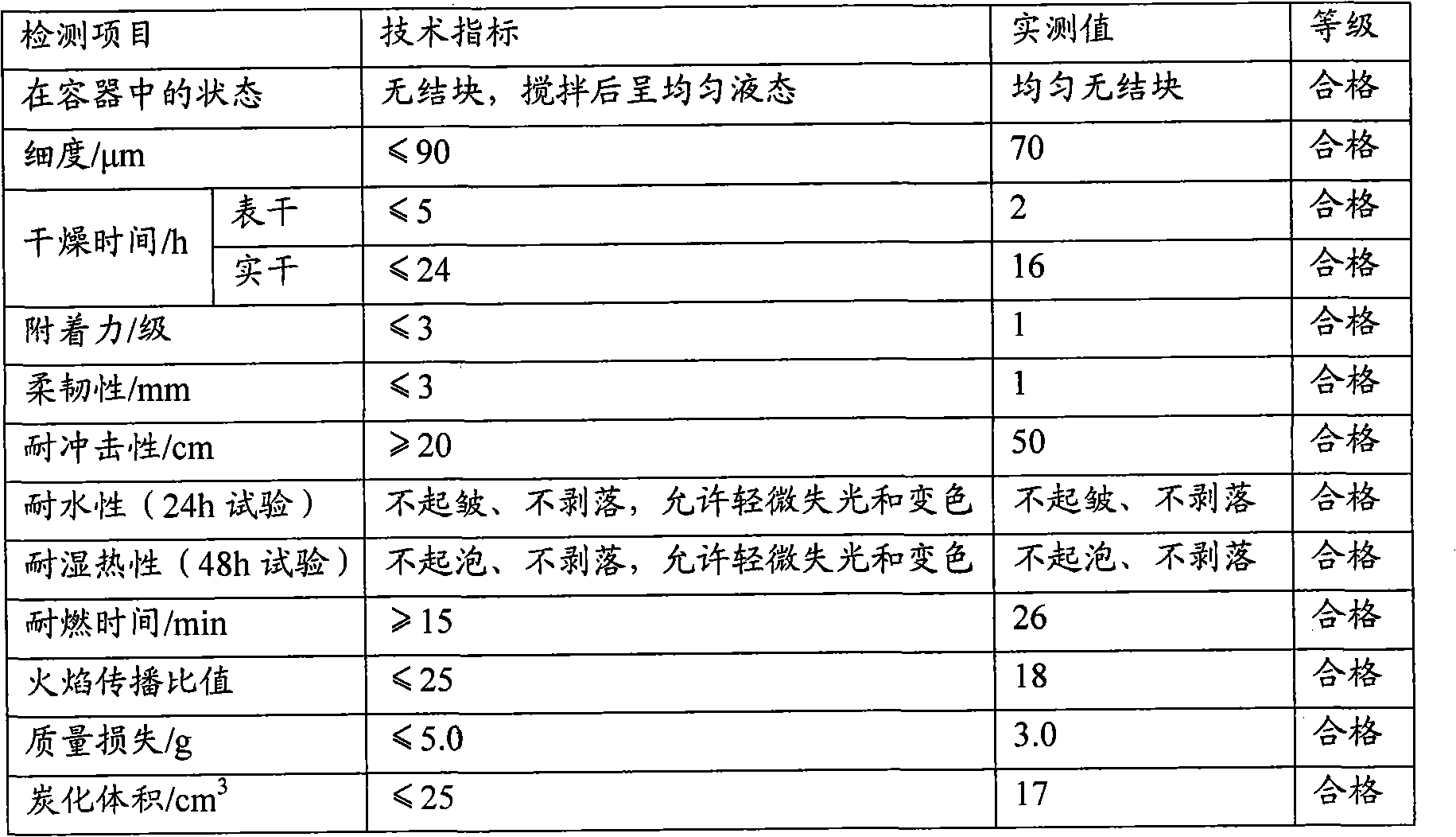

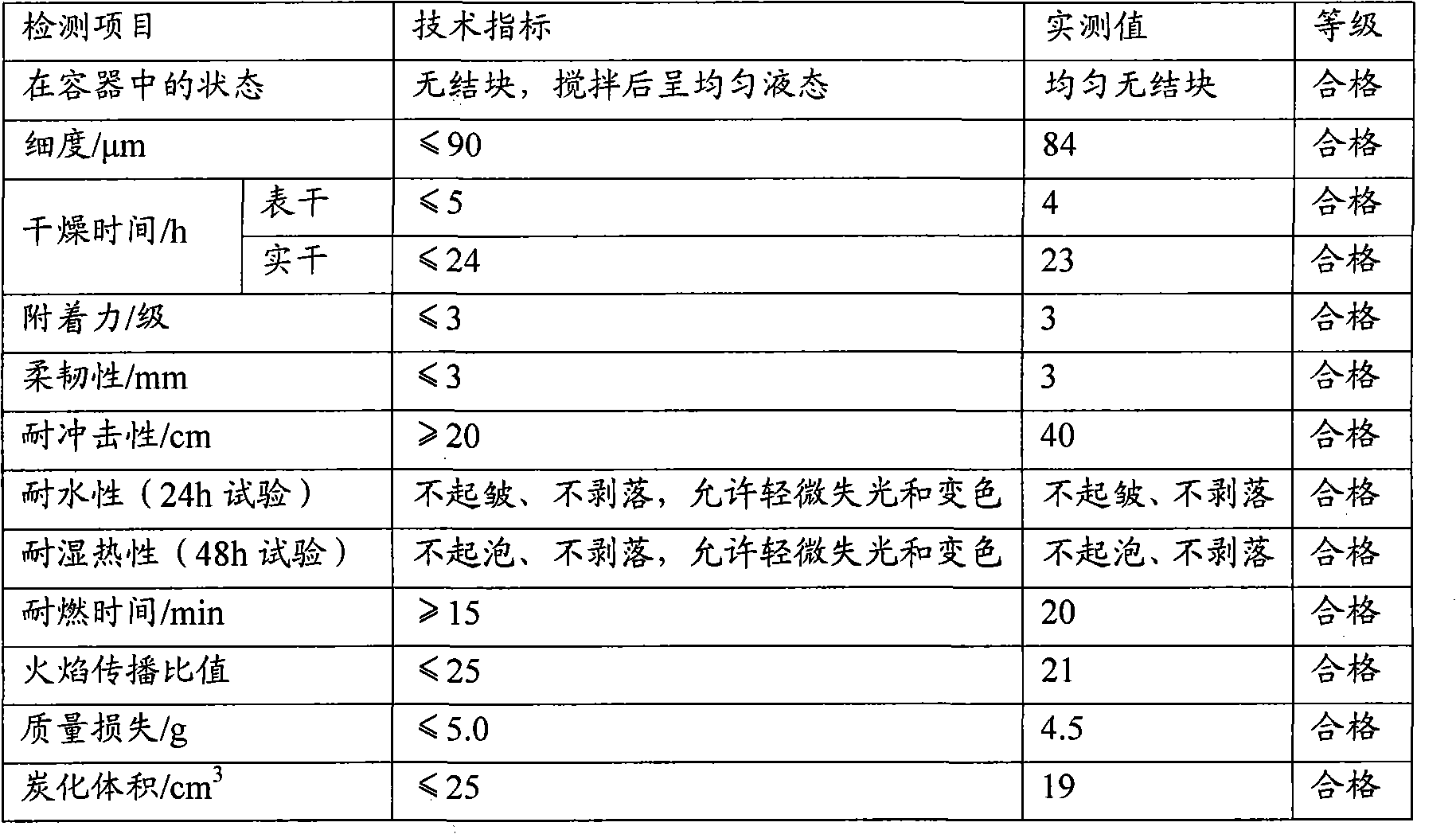

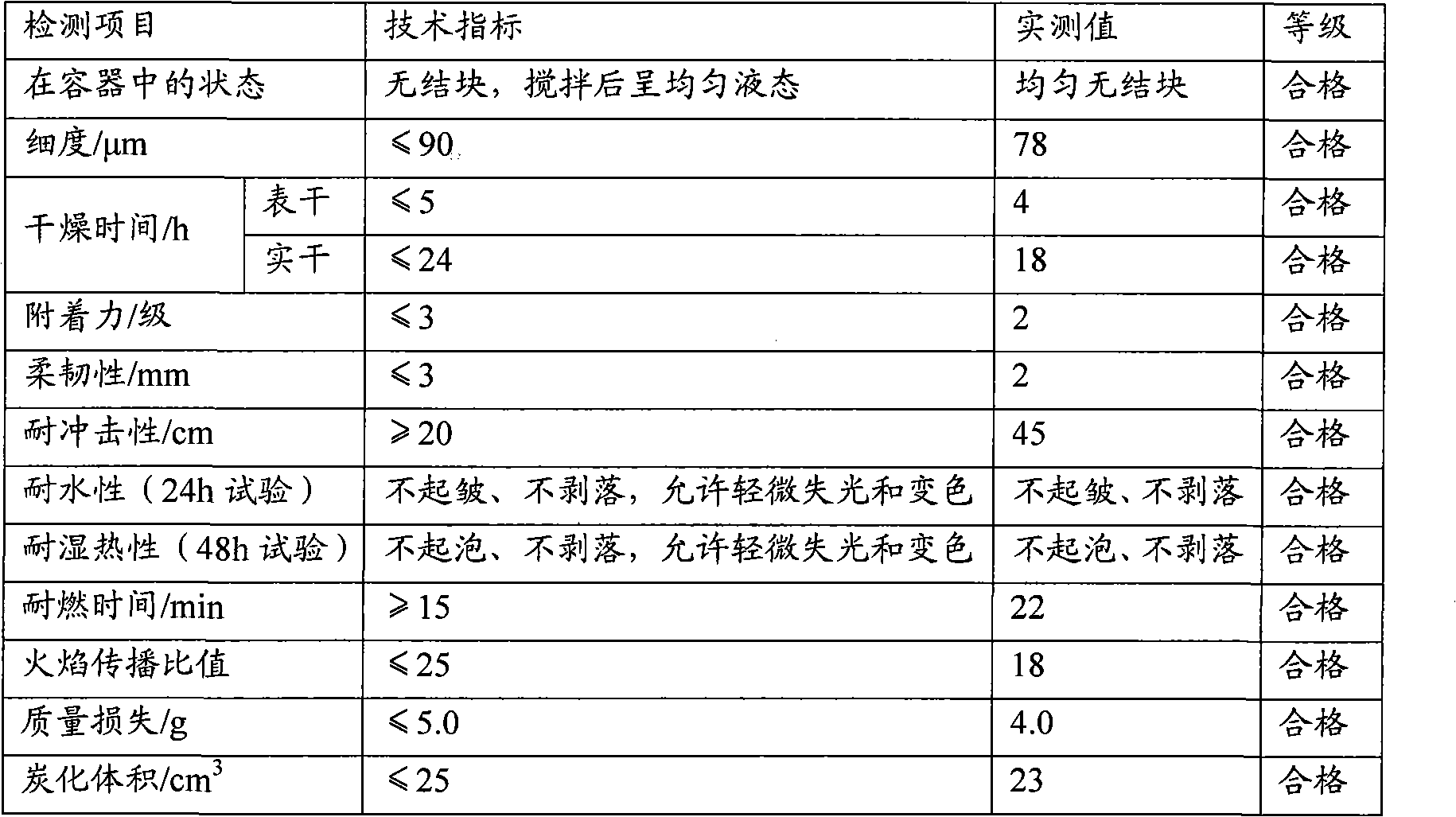

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

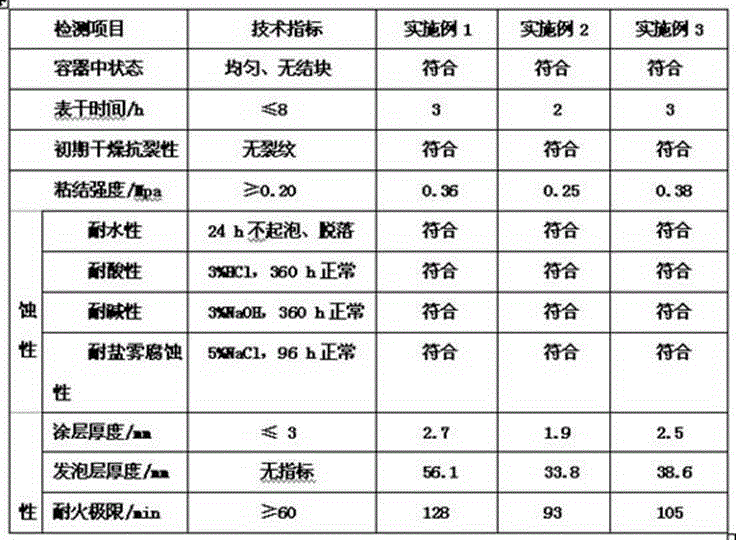

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

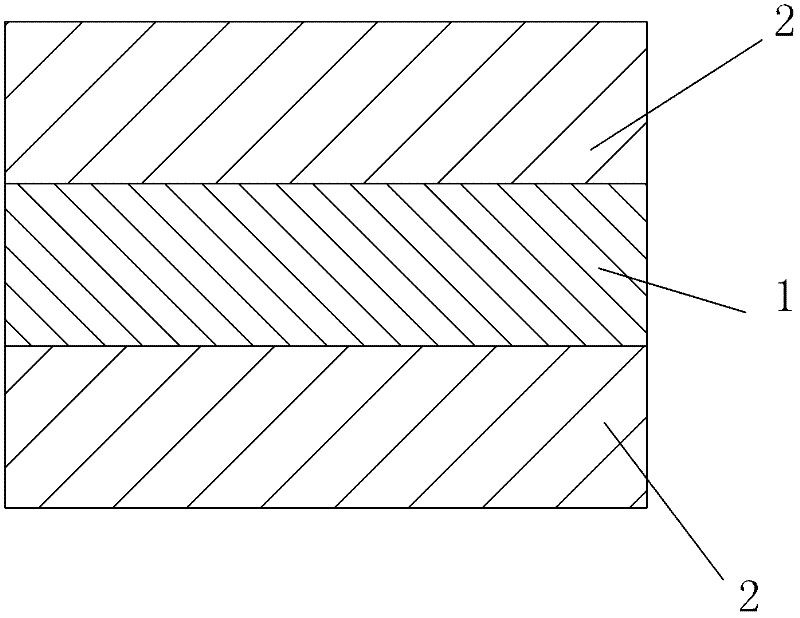

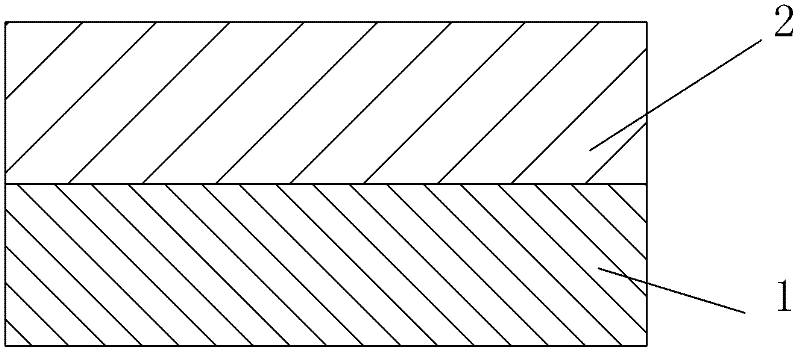

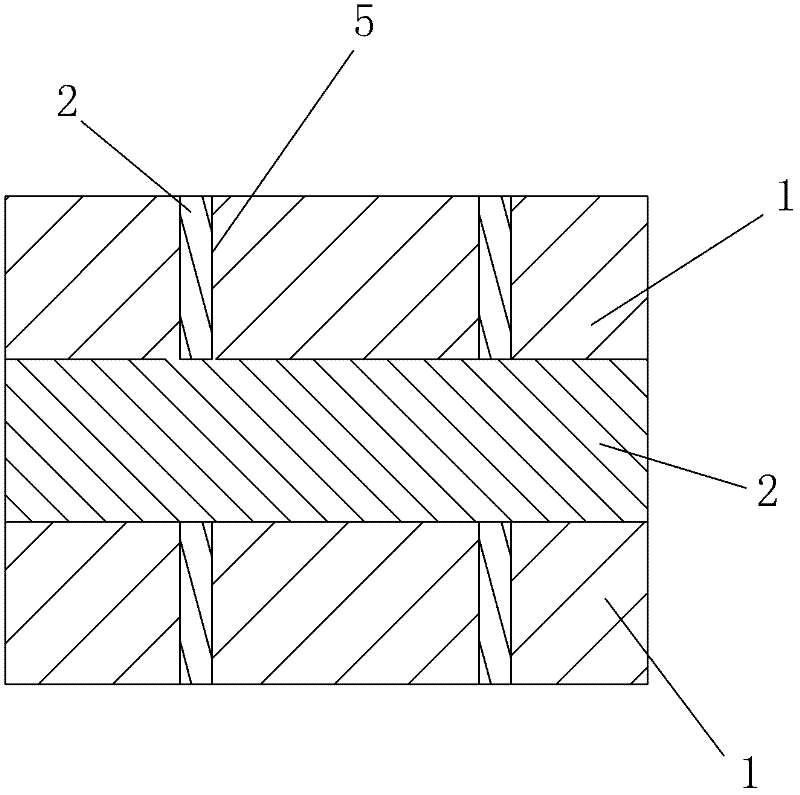

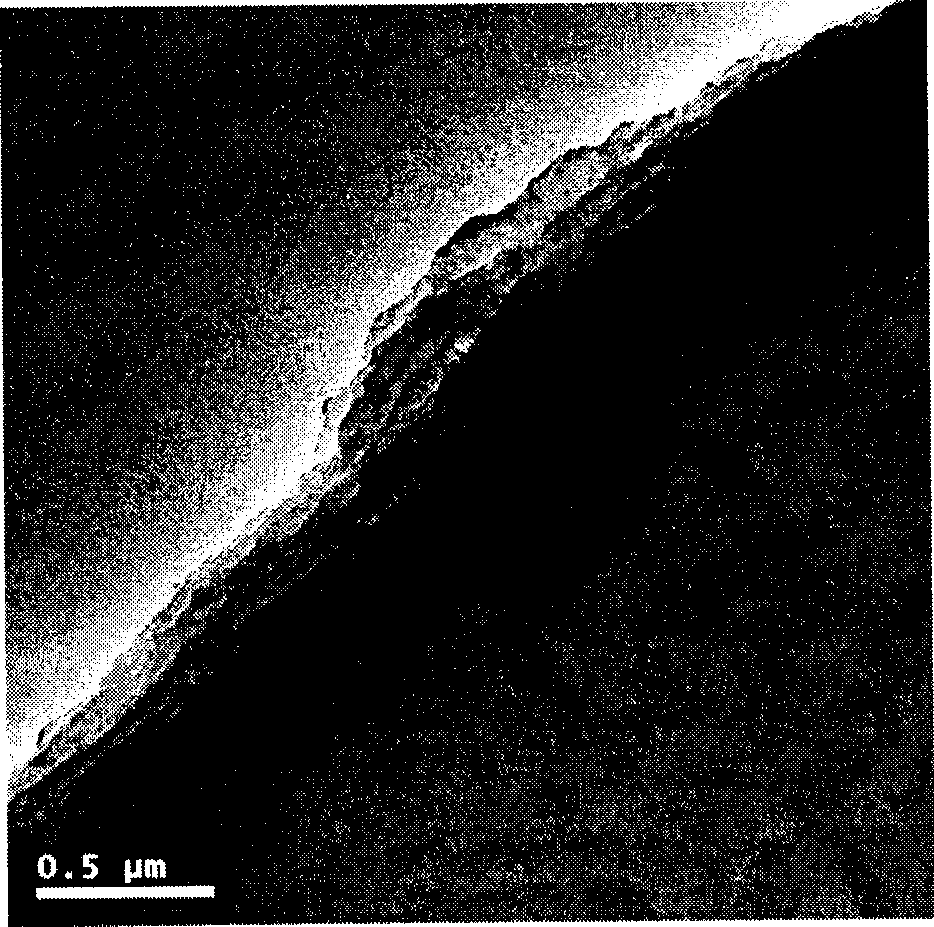

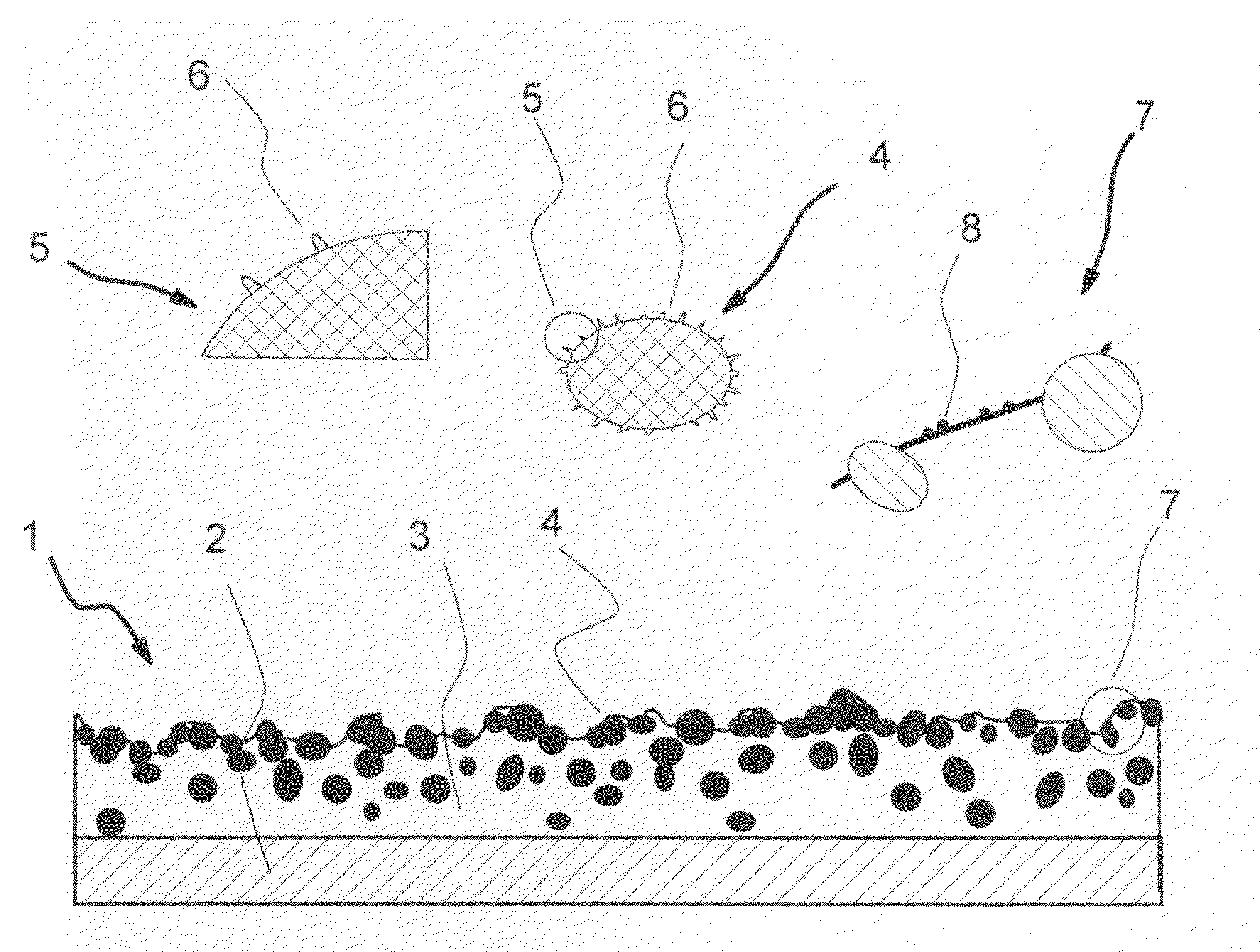

Grapheme-organic material layered assembling film and preparation method thereof

InactiveCN101474897ALow priceLight in massLayered productsPretreated surfacesChemical industryElectromagnetic shielding

The invention relates to a graphene-organic material layered assembly film and a preparation method thereof. The preparation method comprises: using a graphene material and an organic material as raw materials, utilizing interaction of static electricity, hydrogen bonds, coordinate bonds or charge transfer and the like between the graphene and the organic material, and superposing films layer by layer through the film preparation methods such as spin coating, spraying, dipping, lifting and pulling and the like to prepare the film, wherein the thickness of each layer of the film can be controlled between 10 nanometers and 2 millimeters according to requirement. The layered assembly film and the preparation method have the characteristics that multilayer film materials with different functions are prepared by utilizing unique electric, magnetic, mechanical and chemical properties of the grapheme, and can be used as biomaterials, conductive materials, electromagnetic shielding and wave absorbing materials, photovoltaic materials, electrode materials, film filtering and separating materials, and the like to be applied to chemistry and chemical industry, biology and precision instruments, and manufacture of micro electrons, machinery and aviation and aerospace devices according to the selected different organic materials.

Owner:NANKAI UNIV

Cross-linkable polyionic coatings for medical devices

A method for making an article comprising a core material and a coating thereon, the method comprising the steps of:(a) providing the core material;(b) applying one or more layers of a crosslinkable polycationic material, wherein the polycationic material is a reaction product of:(i) an epoxide of formula (I)wherein X equals bromo, chloro, iodo, or cyano, and R1, R2, R3, R4, independently of one another, are selected from the group consisting of hydrogen, linear or branched C1-C6-alkyl, and linear or branched C1-C6-alkyl which is substituted with halogen, and(ii) a polymer having repeating units comprising one or more secondary or tertiary amine group(s);(c) applying one or more layers of a polyanionic material; and(d) cross-linking the layers of polyelectrolytes formed by steps (b) and (c).The articles obtainable by the method of the invention have desirable characteristics regarding adherence to the core material, durability, hydrophilicity, and wettability and are thus useful for the manufacture of medical articles such as ophthalmic devices.

Owner:ALCON INC

Screw thread adhesion abrasion resisting self-lubricating coating and preparation method thereof

InactiveCN101125995APrevent Adhesive WearReduce coefficient of frictionPolyurea/polyurethane coatingsEpoxy resin coatingsWear resistantSolvent

The invention relates to a self-greasing paint which can prevent screw thread from sticking and wearing and a preparation method thereof. The self-greasing paint which can prevent screw thread from sticking and wearing is a two-component self-greasing paint that consists of a component A and a component B. Component A consists of raw materials with weight proportion of 40-90 percent of film-forming material, 5-60 percent of solid greasing material, 0-10 percent of additive, 0-50 percent of solvent, 0-10 percent of color paint and 0-10 percent of filling while component B consists of raw materials with weight proportion of 50-100 percent of curing agent and 0-50 percent of solvent. The weight ratio of component A and component B is 1 to 0.1-5. The friction coefficient of the coat formed by the paint is low and the paint has self greasing function, anti-sticking and wearing resistant performances; the invention reduces and even avoids the use of grease and solves pollution problem caused by grease. The self-greasing paint is applicable to various mechanical parts such as bolt, screw, etc., in particular to screw threads of oil pipe, cashing and drill rod, etc. that are special for oil industry.

Owner:王新虎

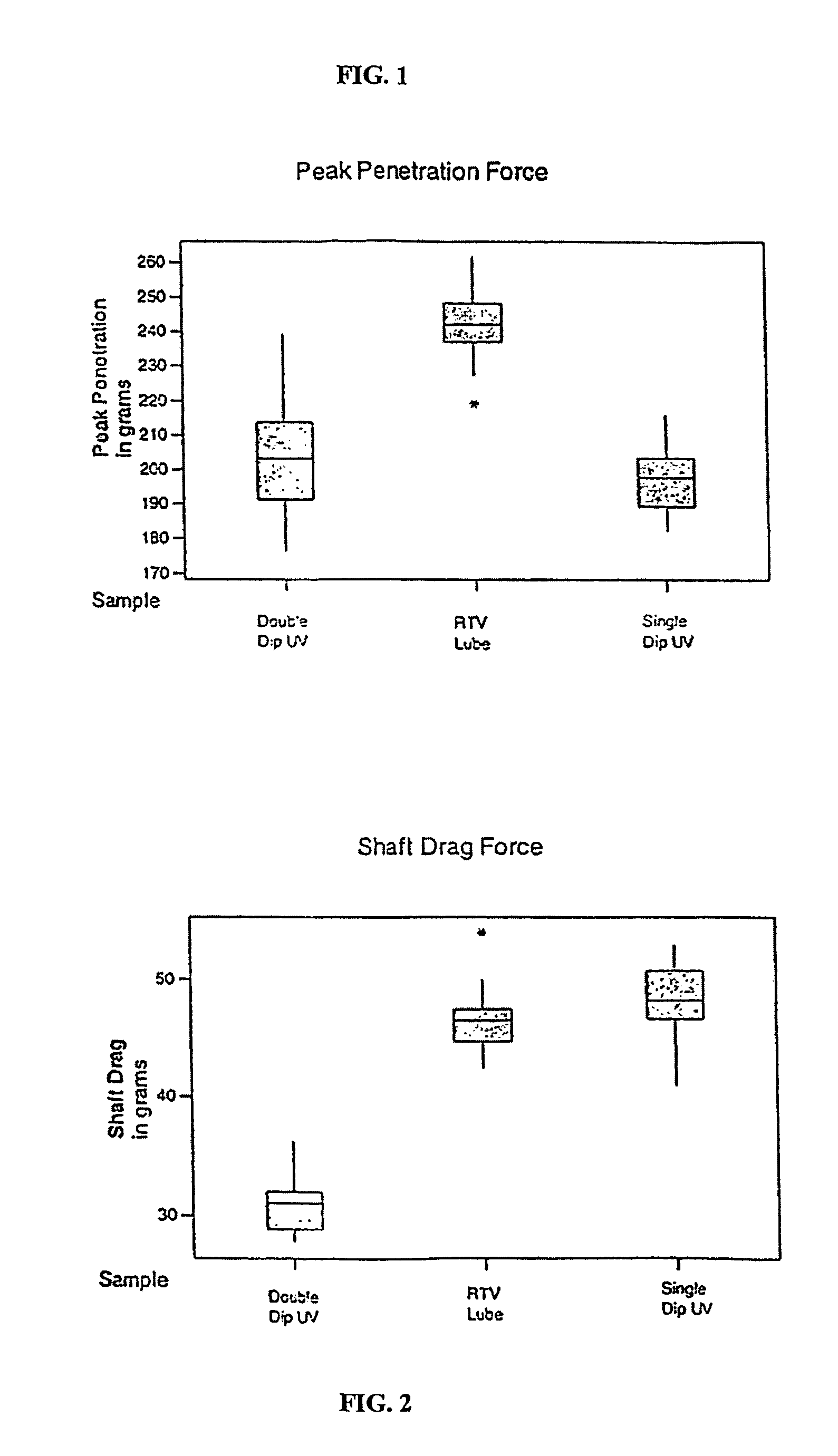

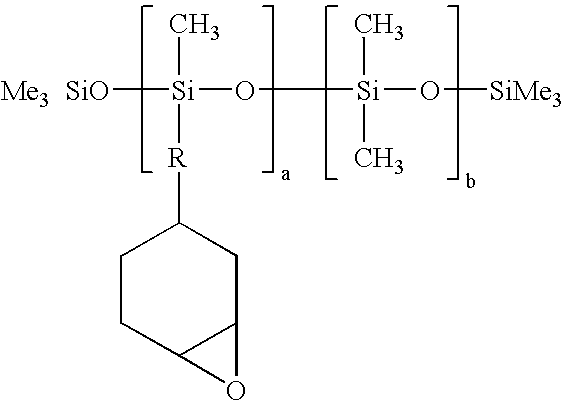

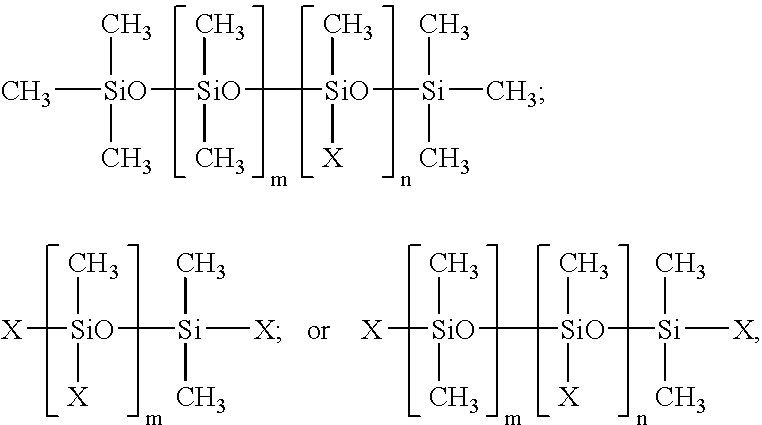

Medical device lubricant comprising radiation curable silicon material

ActiveUS7354628B2Improve performanceEliminate delaysIncision instrumentsSurgical needlesEpoxyVinyl ether

Owner:CARDINAL HEALTH IRELAND UNLTD

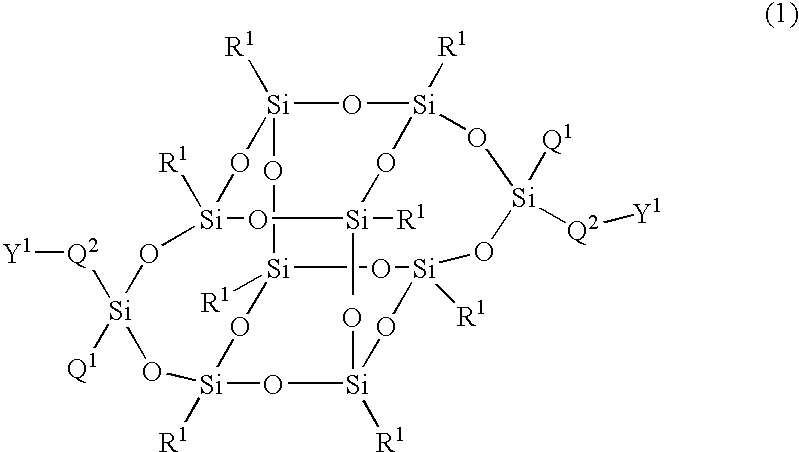

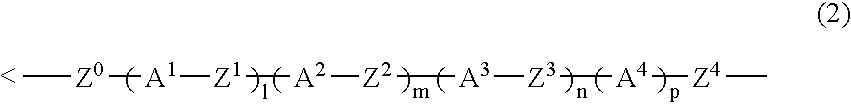

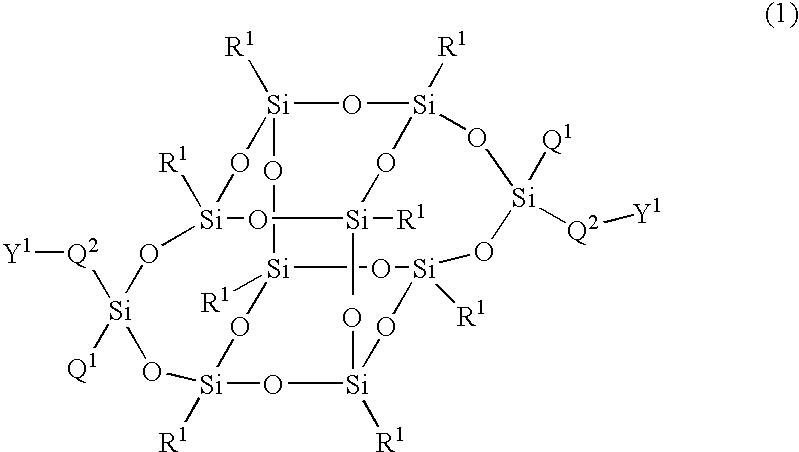

Compound having silsesquioxane skeleton and its polymer

The present invention relates to a compound represented by Formula (1) and a polymer obtained using the compound: wherein R1 is phenyl which may have substituents, Q1 is hydrogen, halogen, alkyl having 1 to 10 carbon atoms, cyclopropyl, cyclobutyl, cyclopentyl, cyclohexyl, cyclohexenyl or phenyl in which optional hydrogen may be replaced by halogen or alkyl having 1 to 5 carbon atoms, and Q2 is a group represented by Formula (2) wherein the code < represents a bonding point with silicon, l, m, n and p are independently 0, 1, 2 or 3, A1 to A4 are independently a single bond, 1,4-cyclohexylene, 1,4-cyclohexenylene, a condensed ring group having 6 to 10 carbon atoms which is a divalent group, or 1,4-phenylene, Z0 to Z3 are independently a single bond, —CH═CR—, —C≡C—, —COO—, —OCO—, or alkylene having 1 to 20 carbon atoms, and Z4 is a single bond, —CH═CH—, —C≡C—, —COO—, —OCO—, or alkylene having 1 to 20 carbon atoms. And Y1 in Formula (1) is the group defined in Claim 1.

Owner:JNC PETROCHEM CORP +1

Chip resistant, vibration damping coatings for vehicles

A formulation for covering vehicle panels, such as the inner fenders or floor boards of an automobile, with a chip resistant, vibration damping coating. The formulation includes a blocked polyurethane prepolymer (or a blocked polyisocyanate and a polyol), an epoxy resin, a filler and a plasticizer. A method for forming a chip resistant, vibration damping coating on such a panel including the steps of applying a coating mixture to the panel, the coating mixture including a blocked polyurethane prepolymer (or a blocked polyisocyanate and a polyol) and an epoxy resin, and then heating the panel to form the coating. An improved vehicle panel, wherein the improvement is a polyurethane modified epoxy coating (or a coating which is an interpenetrating network of polyurethane resin and epoxy resin) on the panel.

Owner:ESSEX SPECIALITY PROD INC

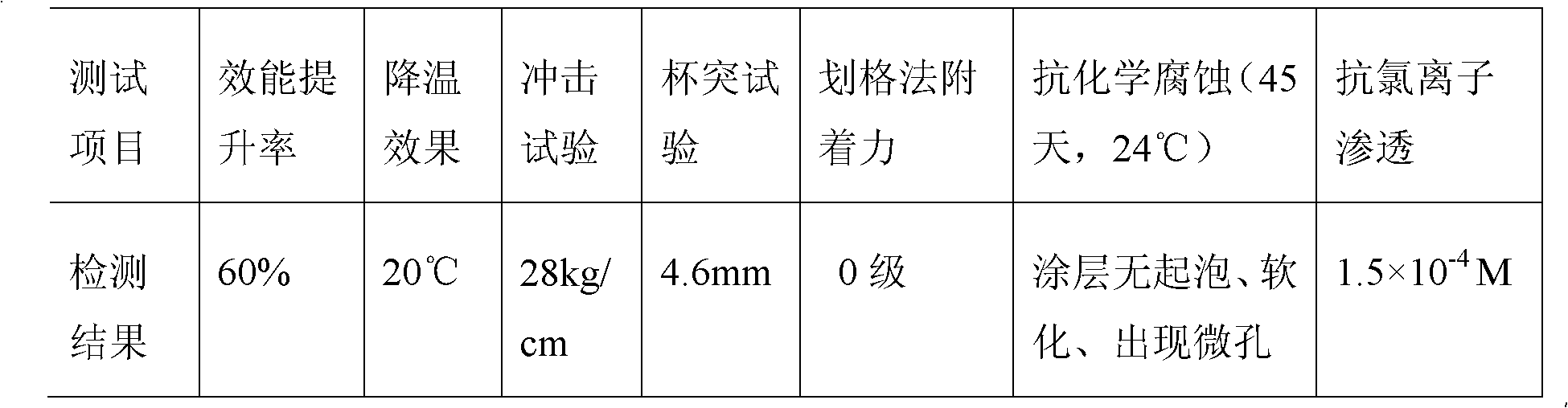

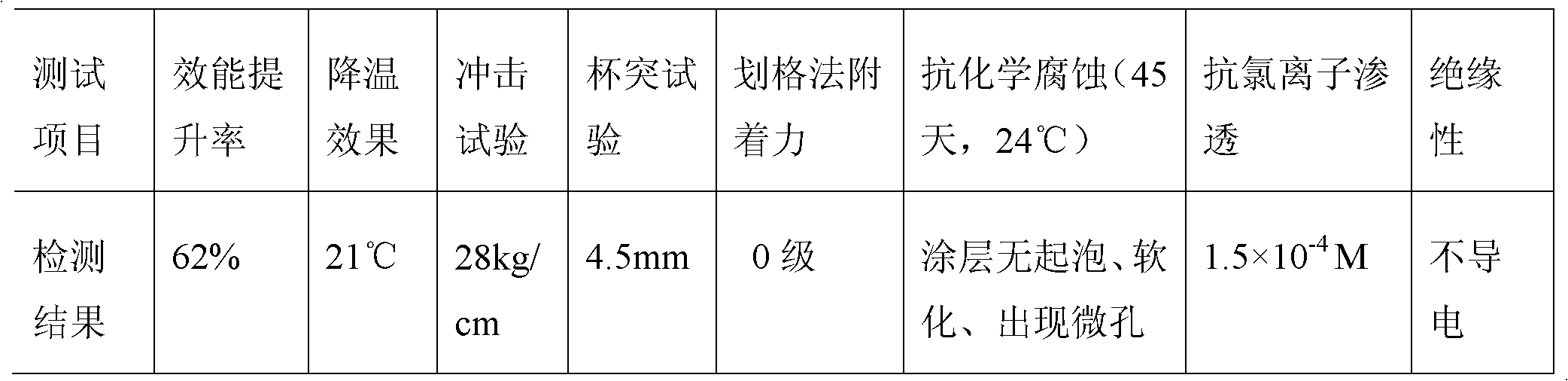

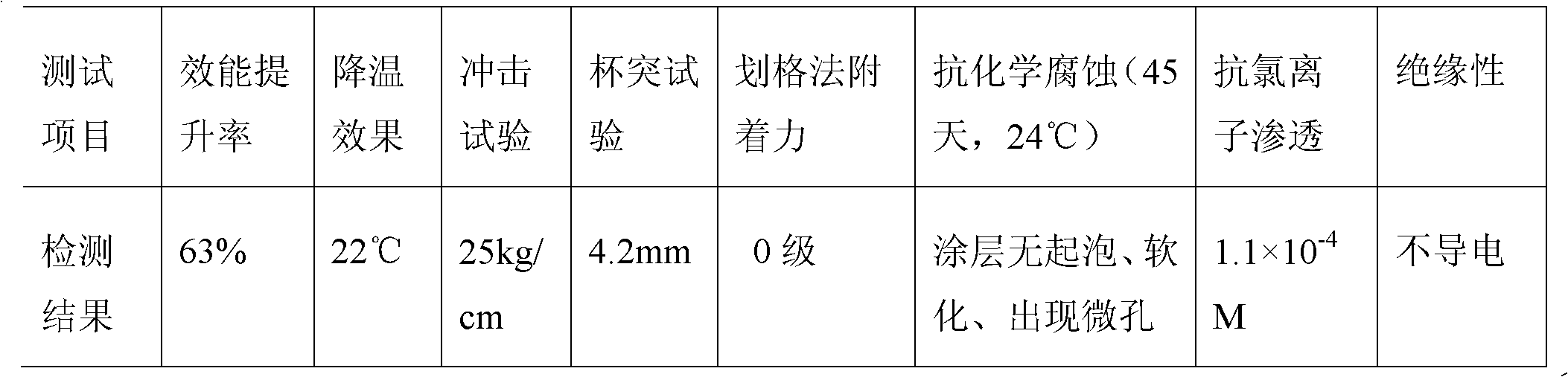

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

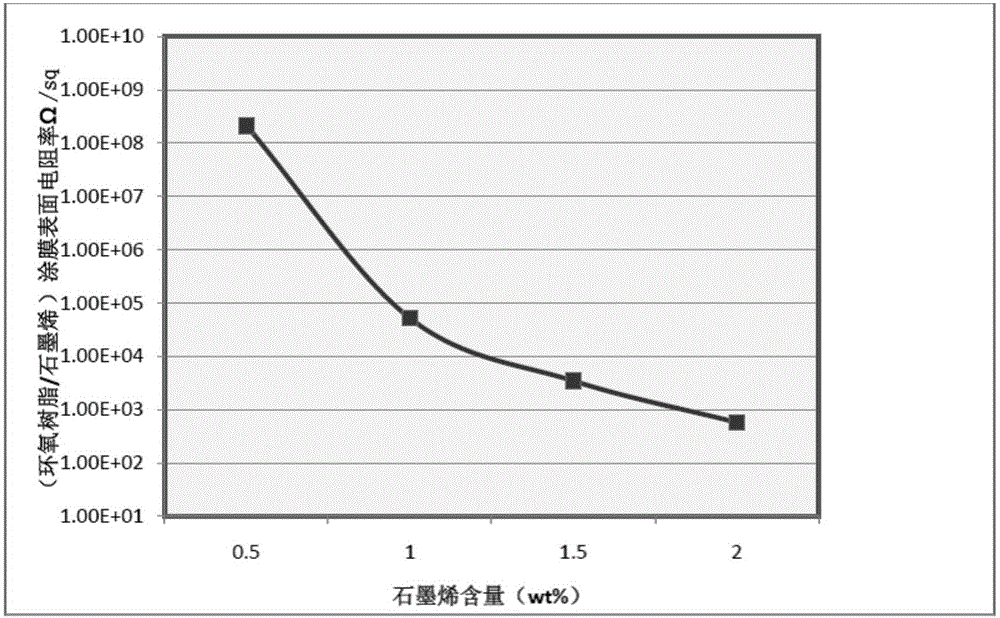

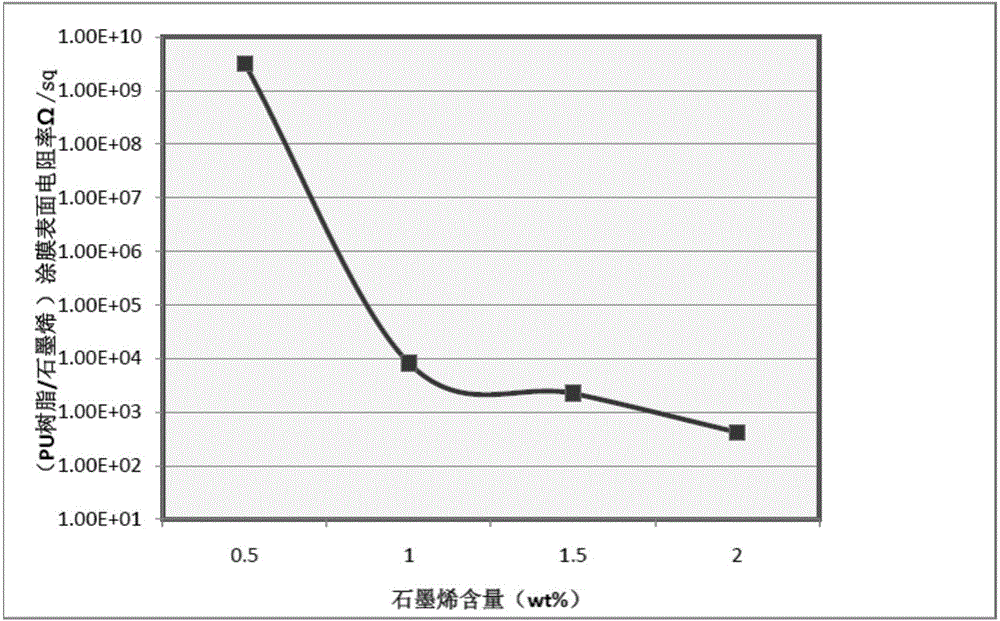

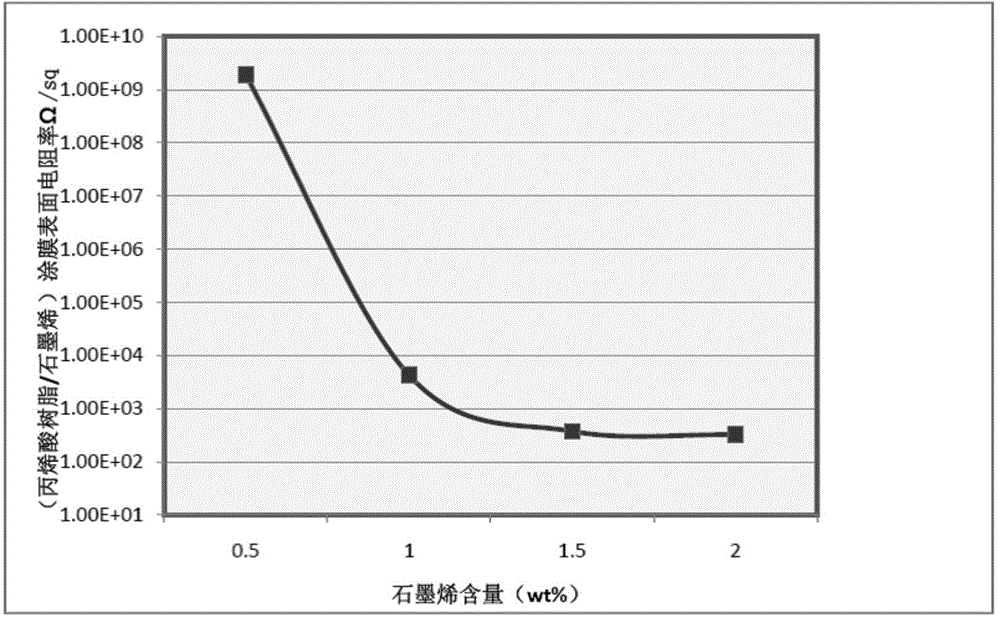

Conductive heat-conductive graphene slurry and coating

InactiveCN104163928AAdd lessReduce pollutionPolyurea/polyurethane coatingsEpoxy resin coatingsHeat conductingConductive materials

The invention relates to a conductive heat-conductive graphene slurry and a coating. The conductive heat-conductive graphene slurry comprises the following raw materials: 0.1-90wt% of conductive heat-conductive graphene slurry ( consisting of 3-20wt% of less graphene, 0-80wt% of base solvent, 0-80wt% of base resin), 0-60wt% of filler, 0-10% of dispersing agent, 10-60wt% of resin, 10-60wt% of curing agent, and 30-70wt% of solvent, wherein not only can the graphene slurry be antistatic, conductive and heat-conducting despite of less addition amount, but also the surface of a coated article is smoother and finer, firmer and more durable; compared with the addition amount of the existing conductive material, the conductive heat-conductive graphene slurry is lower in addition amount and can also reach lower resistivity.

Owner:SUPERCDONGGUAN TECH

Compositions and processes for producing durable hydrophobic and/or olephobic surfaces

InactiveUS20100004373A1Reduce contact areaProtection is in progressGroup 4/14 element organic compoundsSpecial tyresPowder coatingMaterials science

Coating compositions for producing hydrophobic or super-hydrophobic surfaces and olephobic or super-olephobic surfaces, and to processes for producing such surfaces. In particular, the present invention relates to hydrophobic or olephobic powder coatings and their use for transforming surfaces of articles into hard-to-wet and self-cleaning surfaces.

Owner:UNIV OF WESTERN ONTARIO

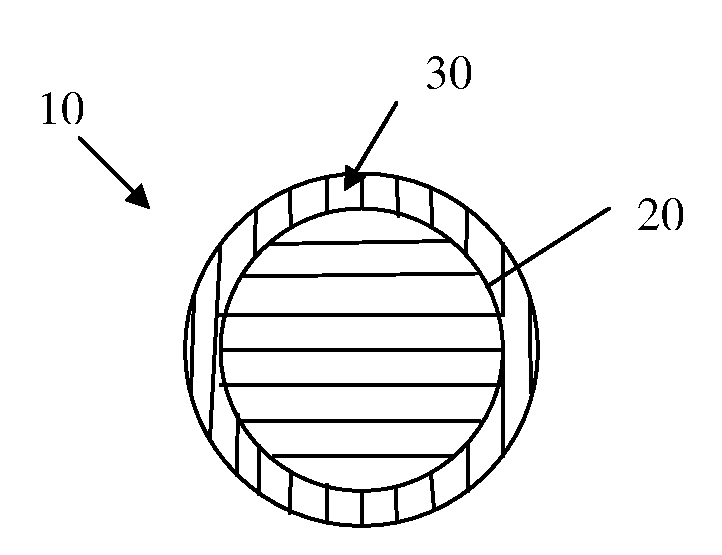

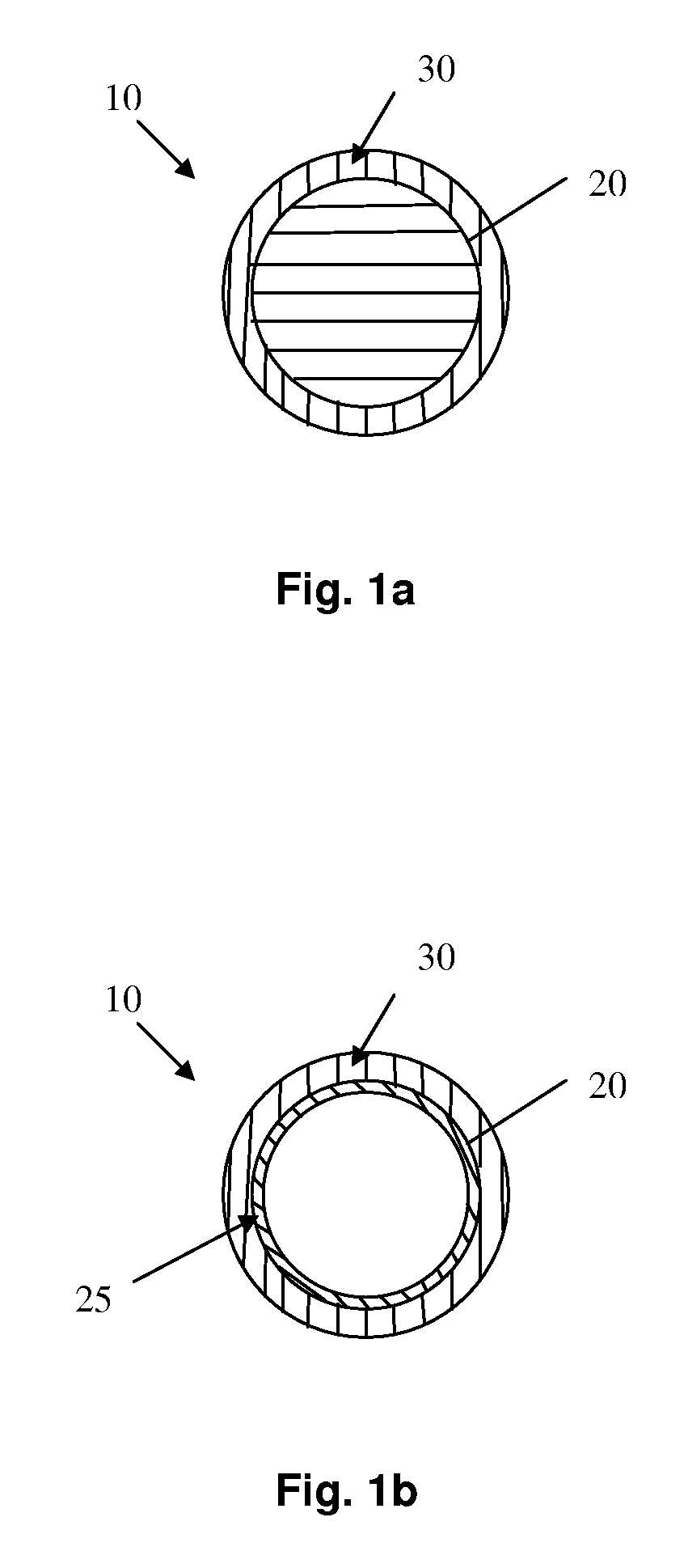

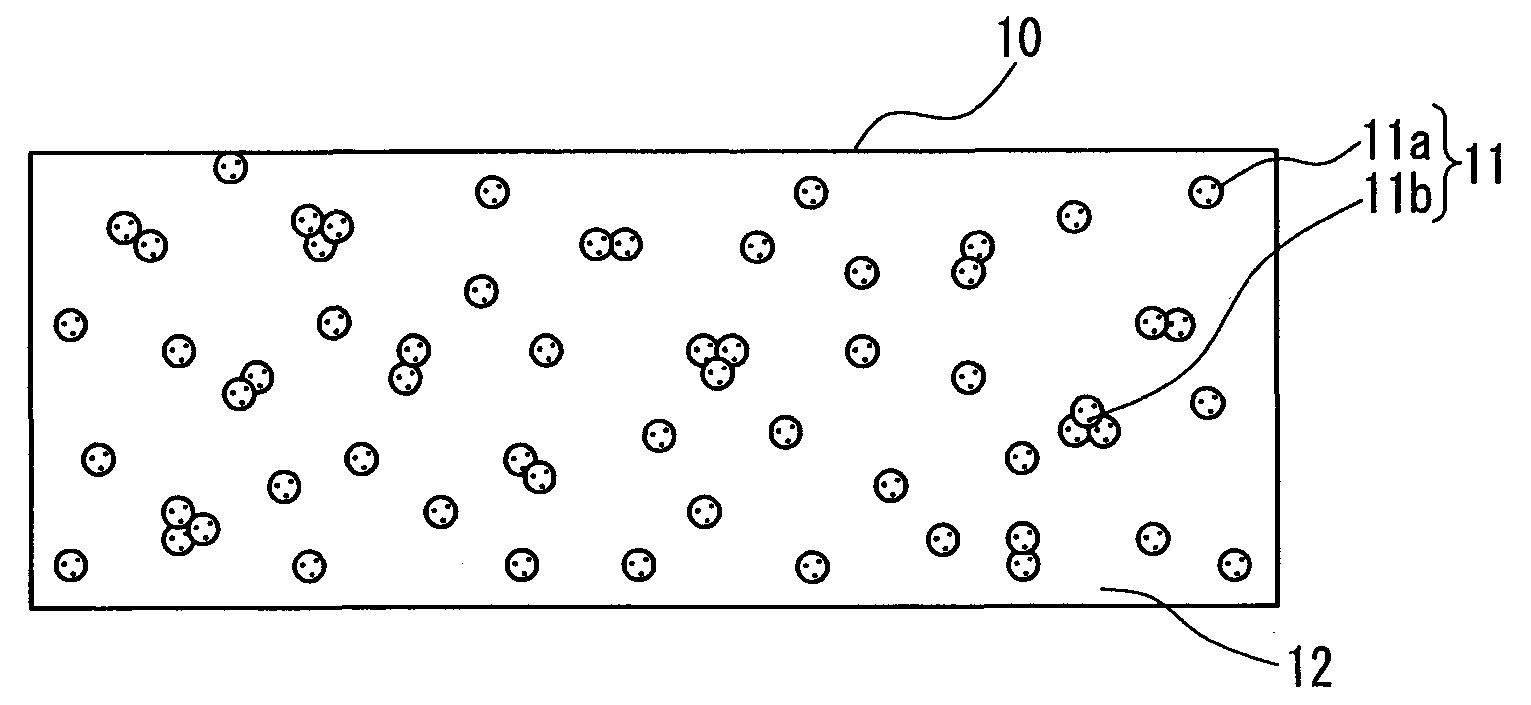

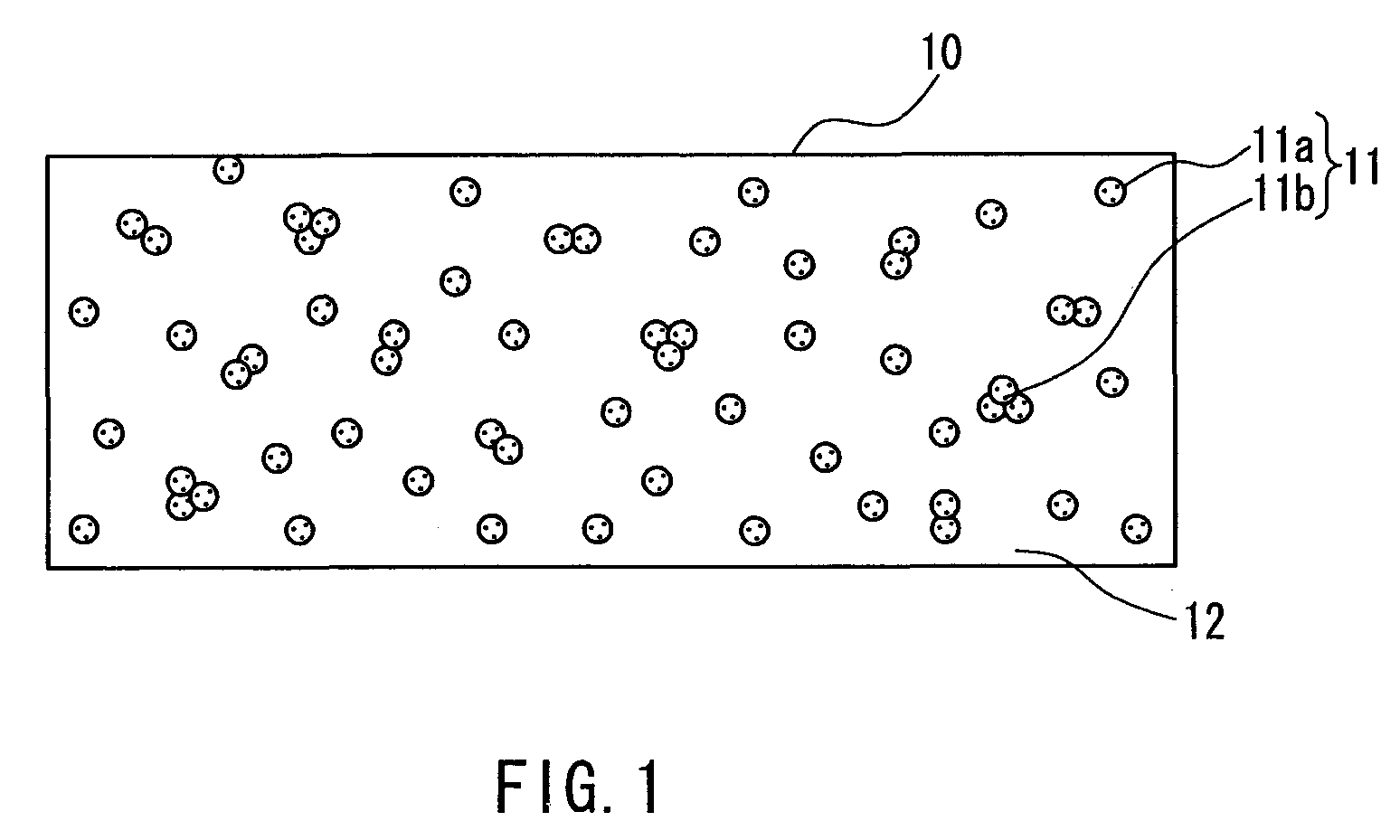

Composite material and optical component using the same

ActiveUS20090128912A1Good dispersionHigh refractive indexDiffraction gratingsEpoxy resin coatingsInorganic particleRefractive index

A composite material (10) includes a resin (12), and first inorganic particles (11) dispersed in the resin and containing at least zirconium oxide. The composite material has a refractive index at the d line nCOMd of not less than 1.60 and an Abbe's number νCOM of not less than 20, and satisfies a relationship nCOMd≧1.8−0.005 νCOM. This composite material exhibits both a high refractive index and low dispersion in good balance, and has excellent workability. Accordingly, using this composite material makes it possible to realize a small optical component having favorable wavelength characteristics.

Owner:PANASONIC CORP

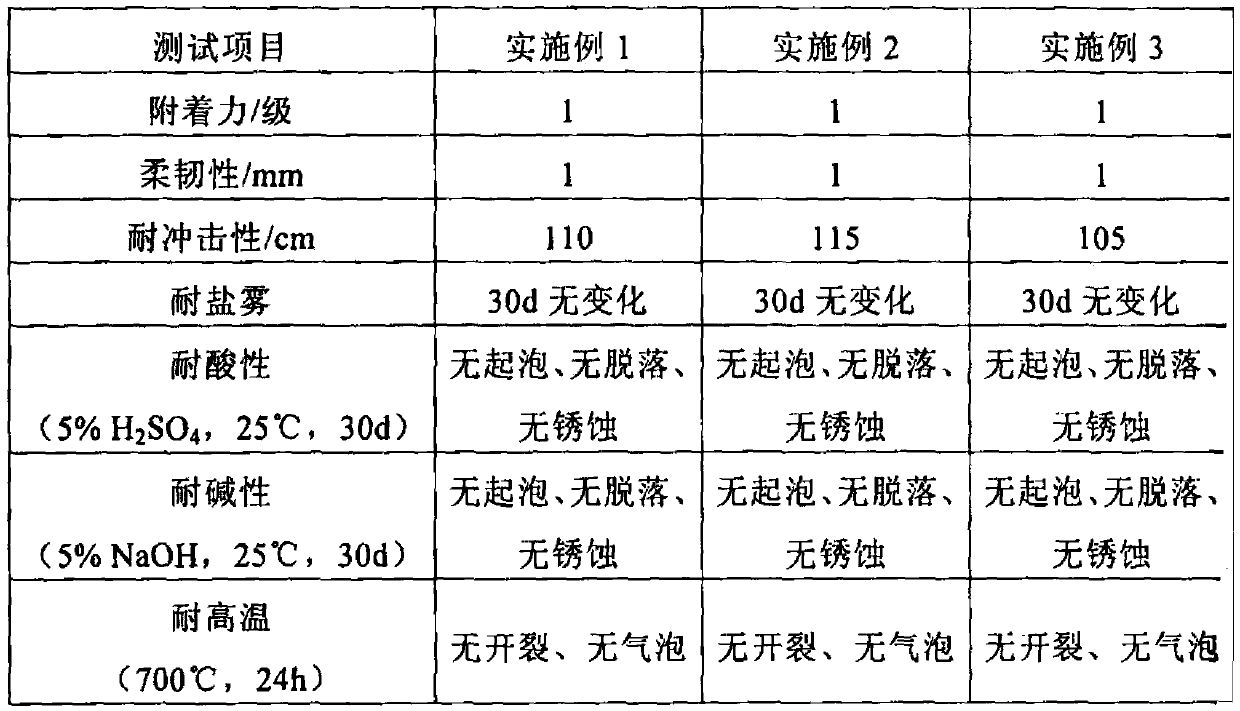

Fiber-reinforced high-temperature-resistant thermal insulation and heat preserving ceramic coating and preparation method thereof

InactiveCN102464933ADelivery barrierHigh surface strength of the coatingEpoxy resin coatingsCeramic coatingThermal insulation

The invention relates to a high-temperature-resistant thermal insulation and heat preserving ceramic coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by weight: 30-50 percent of film forming substance, 30-40 percent of high-temperature-resistant filler, 10-15 percent of hollow micro beads, 2-5 percent of thermal insulation fiber and 2-8 percent of aid and solvent. The coating has the toughness of an organic coating and the rigidity and hardness of an inorganic coating, has high adhesion, can be used at the high temperature of 400-1,200 DEG C for a long time, and is resistant to chemical reagents, acids, alkalis and oil. A coating film has high surface intensity, and can bear strong shear force without being damaged when a high-temperature pipeline is required to be connected mechanically. The coating has excellent heat preserving performance, and the surface temperature of a pipeline of 350 DEG C can be lowered to be below 100 DEG C by coating the coating outside the pipeline in the thickness of 4-6 millimeters. The coating can be widely applied to heat-resistant protection of the inner and outer surfaces of equipment such as high-temperature steam pipelines, metallurgy high-temperature furnaces, high-temperature valves, high-temperature containers and the like.

Owner:SHENYANG LIGONG UNIV

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

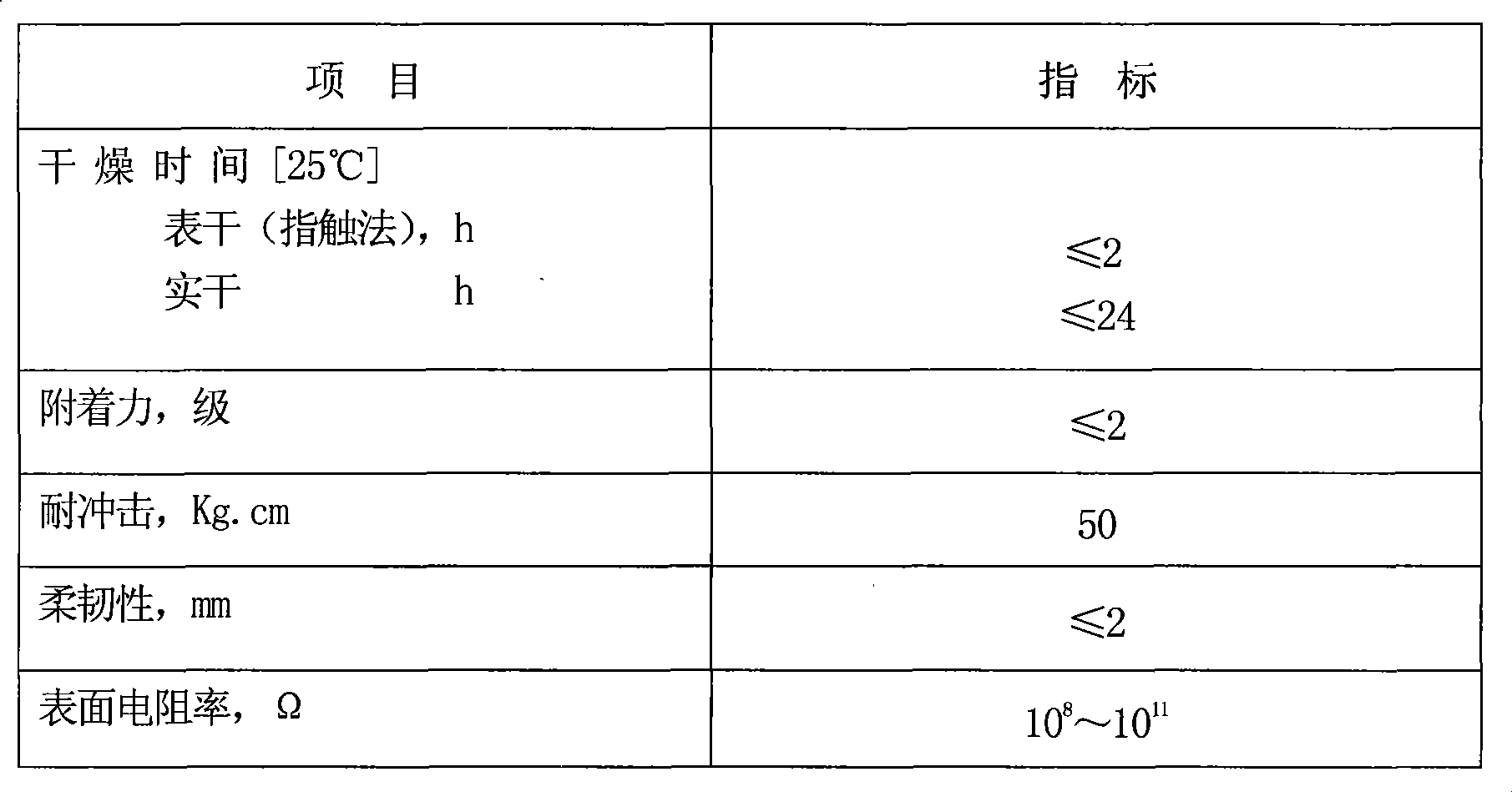

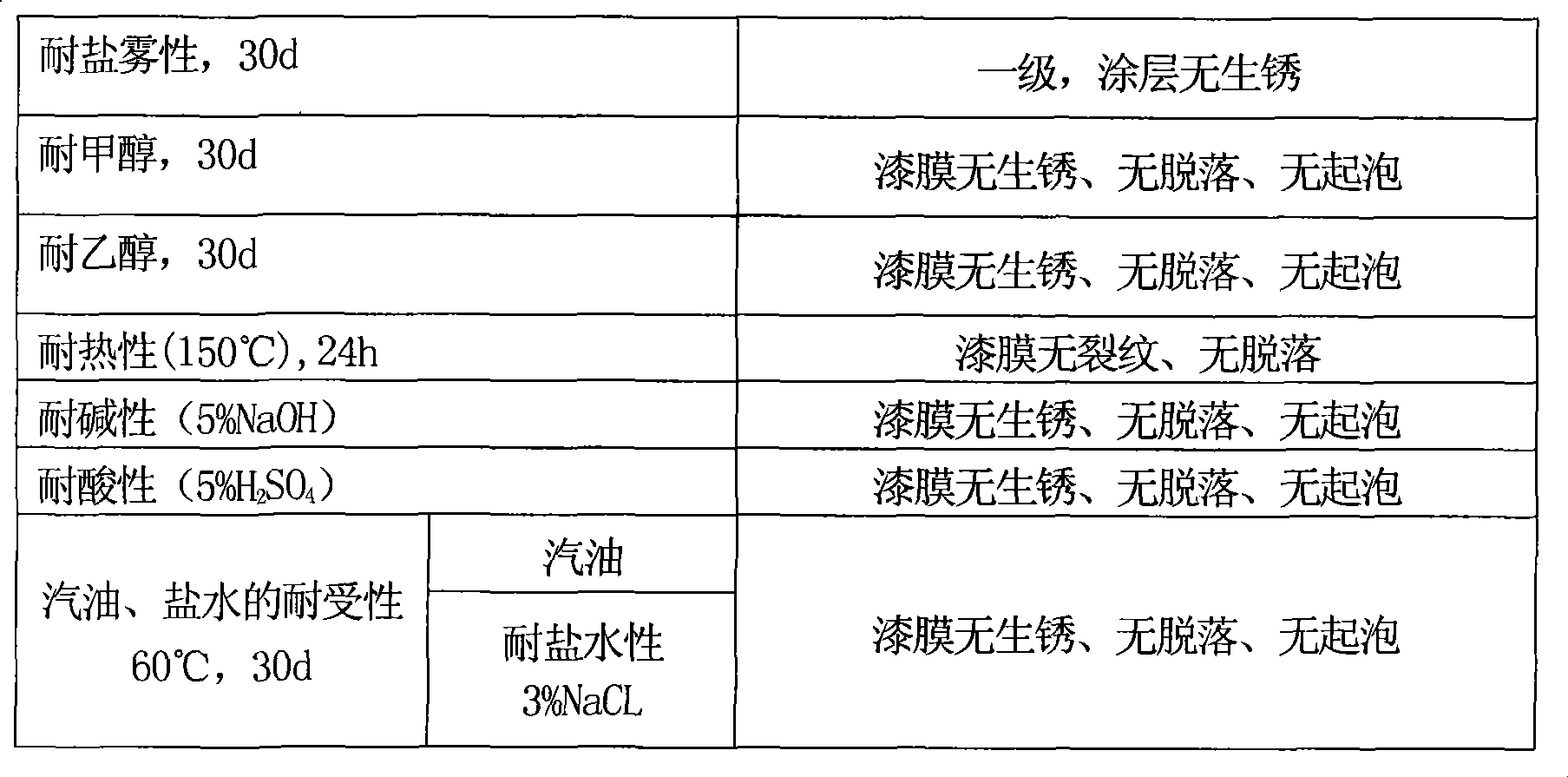

Oil resistant (solvent), heatproof static conducting anti-corrosive paint and preparation thereof

InactiveCN101372601AHigh solid contentReduce the number of coatsAnti-corrosive paintsPolyurea/polyurethane coatingsPlasticizerSolvent

The invention belongs to the corrosion protective coating technique field and provides an oil resistance (solvent) and temperature resistance electrostatic conducting corrosion protective coating and a preparation method thereof. The coating is mainly made by raw components by weight percentage of 20-35 percent of resinI which is used as basic material, 0-15 percent of modified resin II, 15-30 percent of conductive fillers, 1-3 percent of coupling agent, 8-20 percent of fillers, 10-15 percent of solvent, 2-10 percent of plasticizer, 0.5-1 percent of defoamer, 0.5-1 percent of flatting agent and 6-15 percent of curing agent. The coating is prepared according to the following steps: the resin I, the modified resin II, the coupling agent, the plasticizer, the flatting agent and the defoamer are put in a distributing tank. And part of mixed solvent is added to be stirred and distributed uniformly. The fillers are added proportionally and are put in a sand mill for sand milling after being dispersed and stirred uniformly at high speed, so as to obtain upper grinding pigment paste. The conductive fillers and the rest mixed solvent are added at low stirring speed. The conductive fillers are totally blended into the upper grinding pigment paste and stirring is carried out at middle speed, the viscosity is adjusted to be qualified and the fillers are filtered to obtain a qualified component A product. The curing agent is carried out subpackage according to proportion.

Owner:洛阳双瑞防腐工程技术有限公司

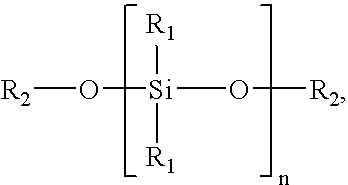

Silicone resin containing coating compositions, related coated substrates and methods

Disclosed are coating compositions that include both (a) an alkoxy-functional and / or silanol-functional silicone; and (b) an epoxy-functional silicone. Also disclosed are substrates at least partially coated with a coating deposited from such a composition and methods for coating substrates with such compositions.

Owner:PPG IND OHIO INC

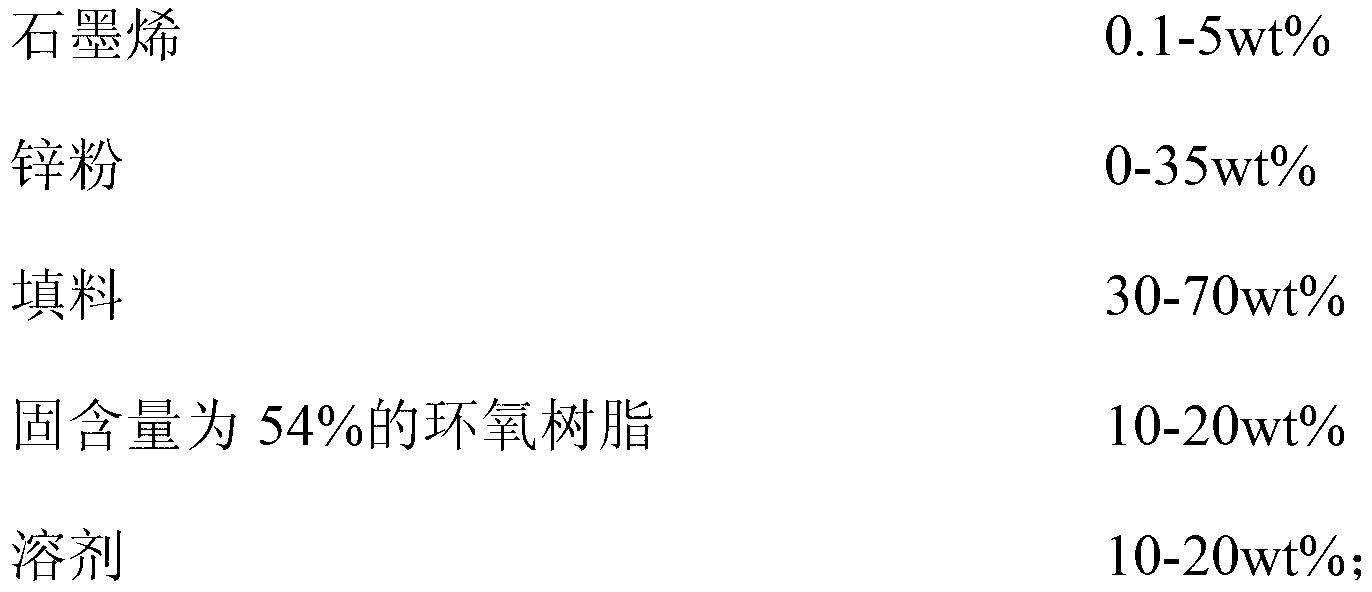

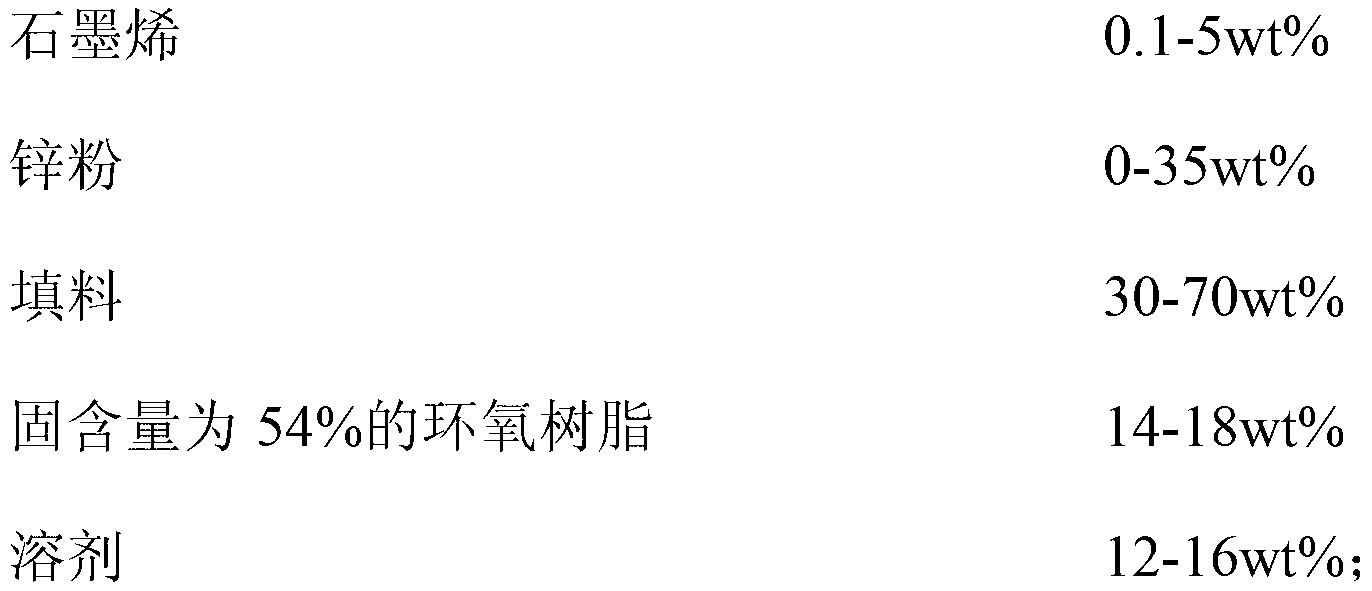

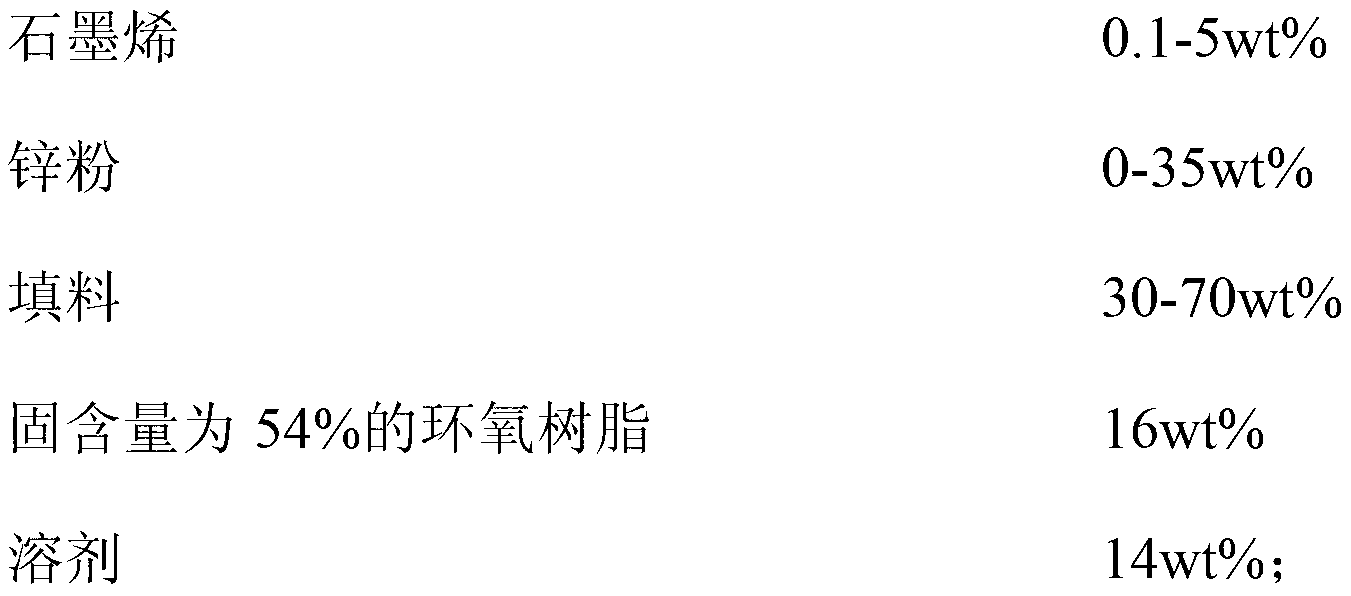

Zinc-rich epoxy anticorrosion paint and preparation method thereof

ActiveCN103173095AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

The invention relates to a zinc-rich epoxy anticorrosion paint. The paint comprises a component A which can be cured into a film and a component B comprising a curing agent. The component A comprises the components of, by mass, 0.1-5wt% of graphene, 0-35wt% of zinc powder, 30-70wt% of a filling material, 10-20wt% of epoxy resin with a solid content of 54%, and 10-20wt% of a solvent, wherein a total mass percentage of graphene, zinc powder, and the filling material is 60-80wt%, and a total mass content of the component A is 100wt%. According to the invention, graphene is added into the anticorrosion paint, such that paint film thickness is greatly reduced. Through the selection of the components, the anticorrosion effect is improved, and zinc powder content is greatly reduced. Therefore, a zinc-rich paint anticorrosion manner with the cost of sacrifice of zinc powder is overcome, and zinc oxide mist produced during welding is greatly reduced. The paint is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com