Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12773results about "Special tyres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

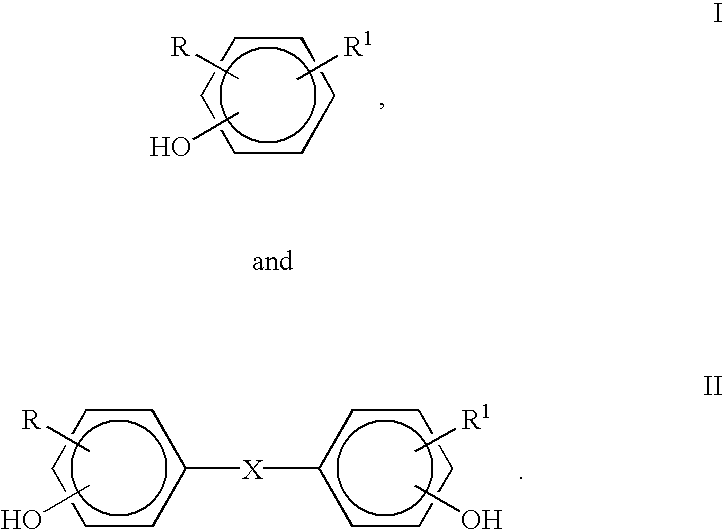

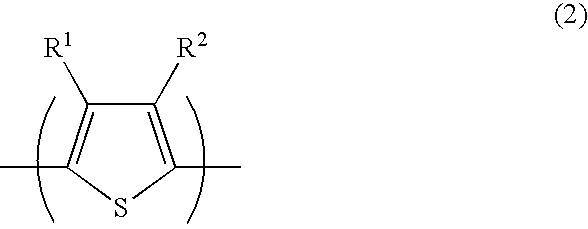

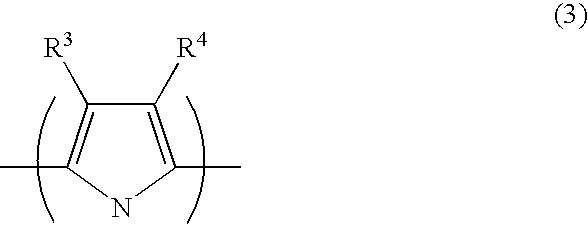

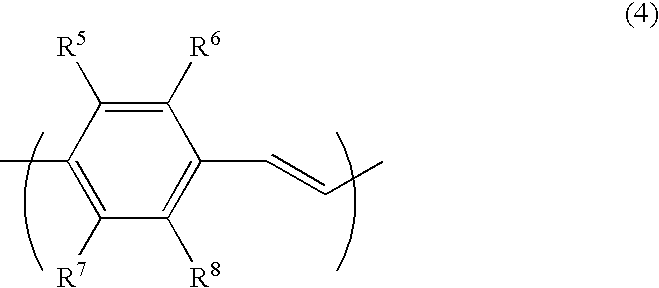

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

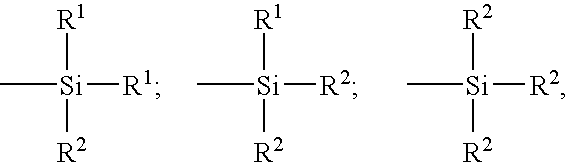

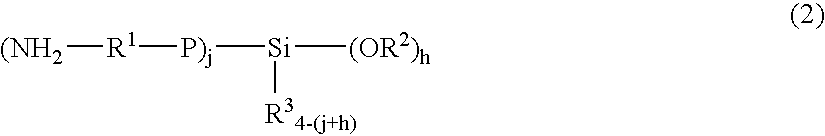

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

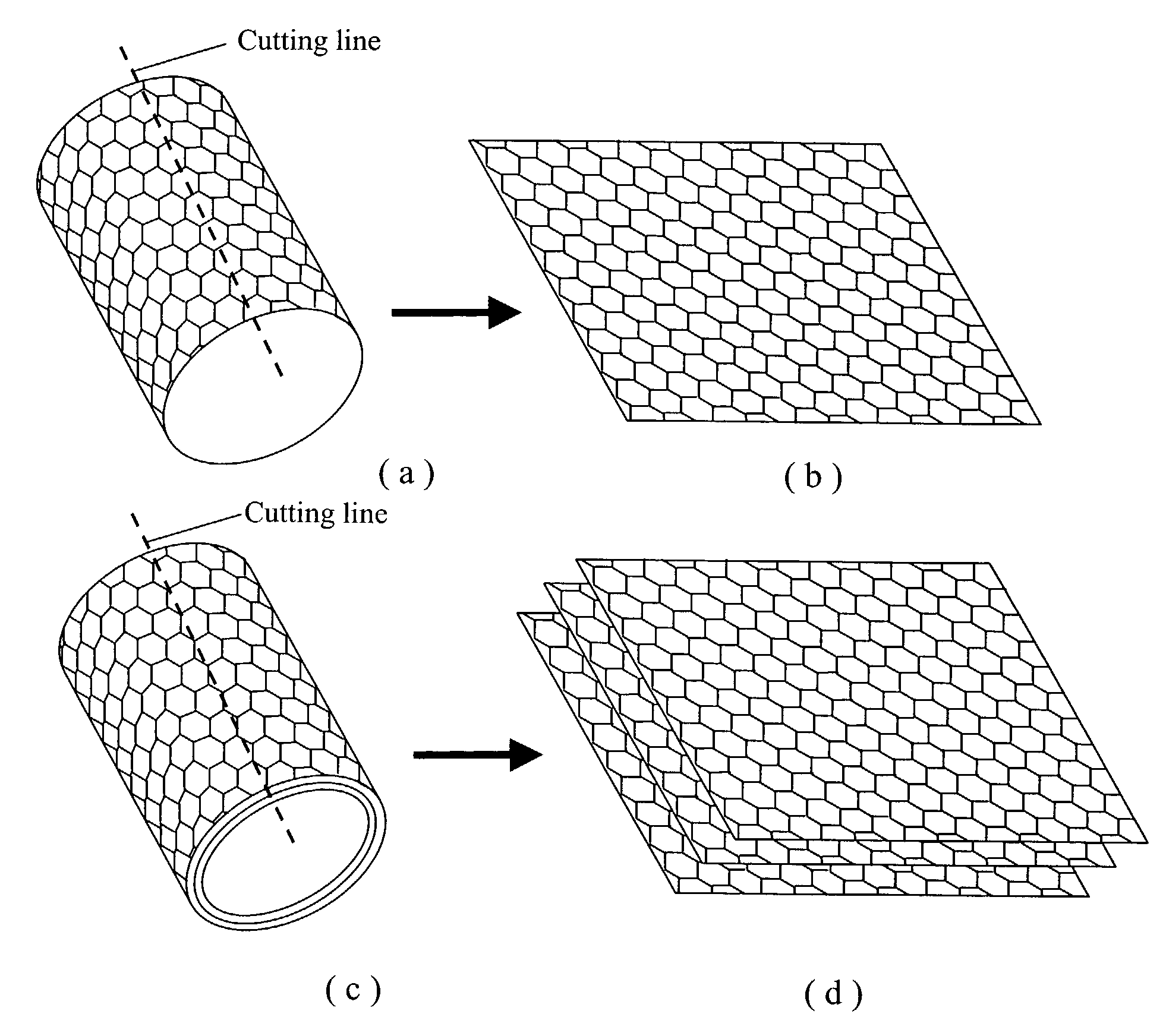

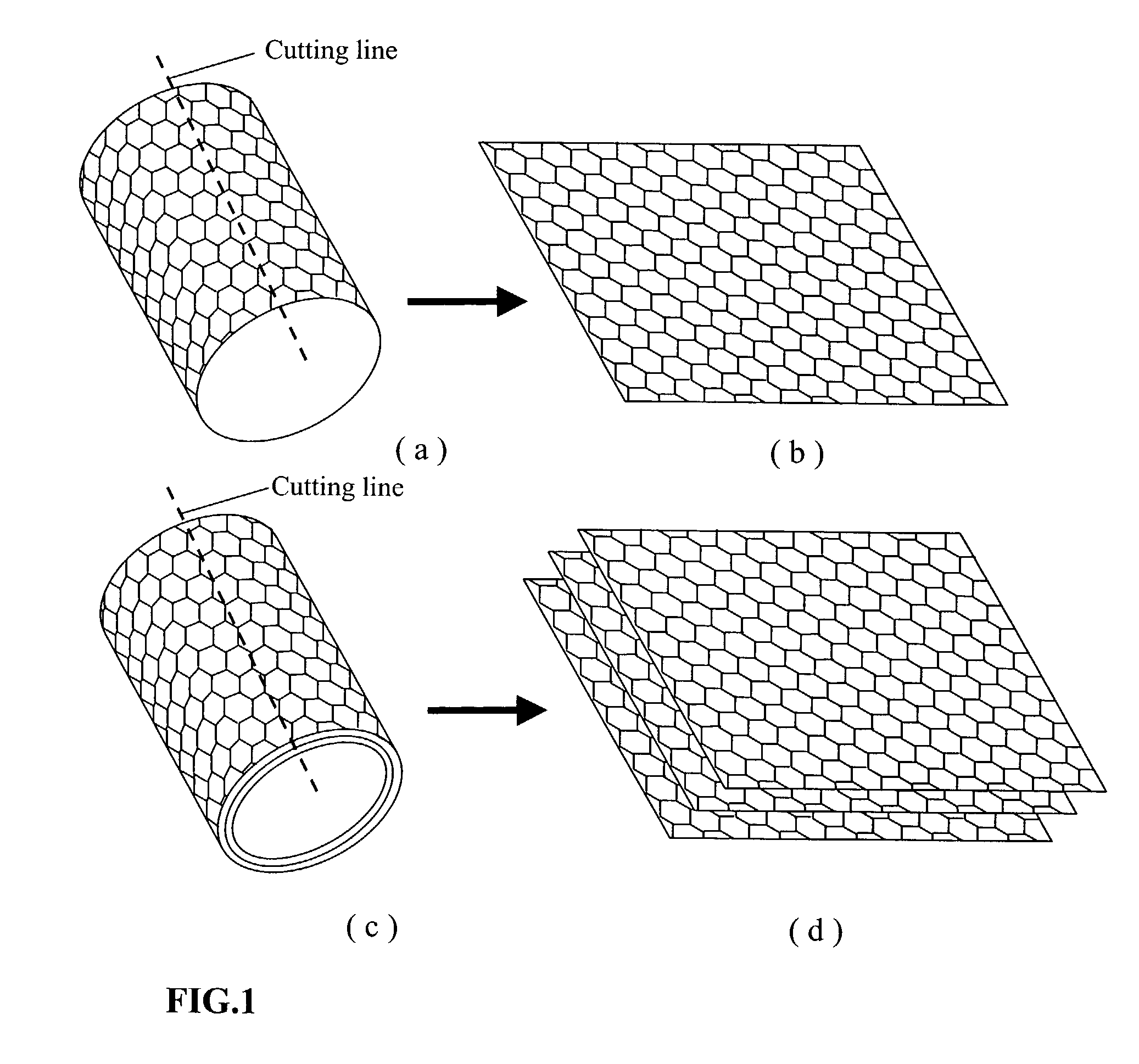

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

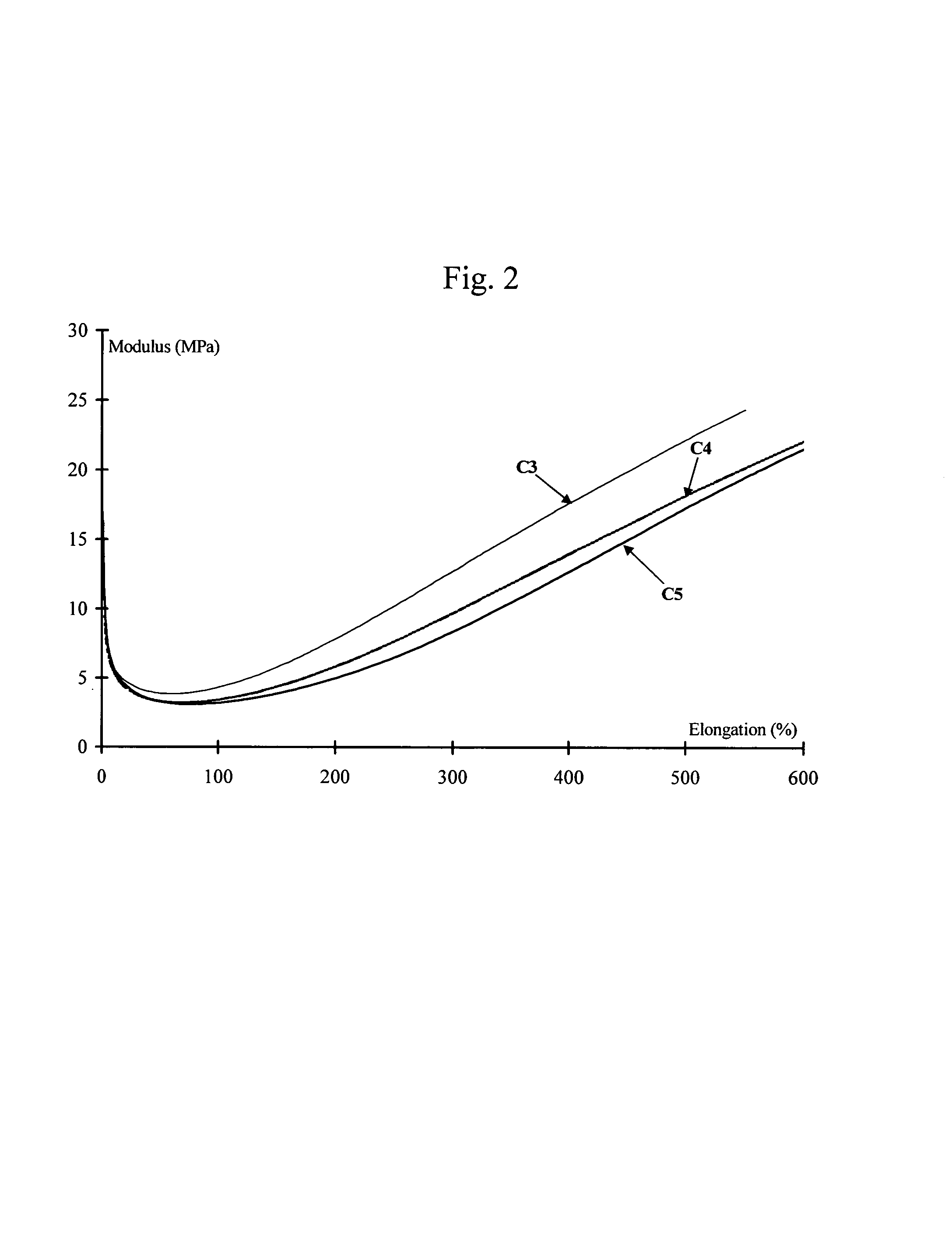

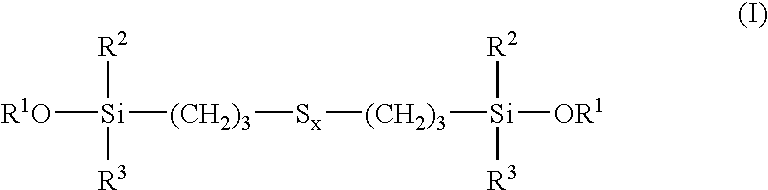

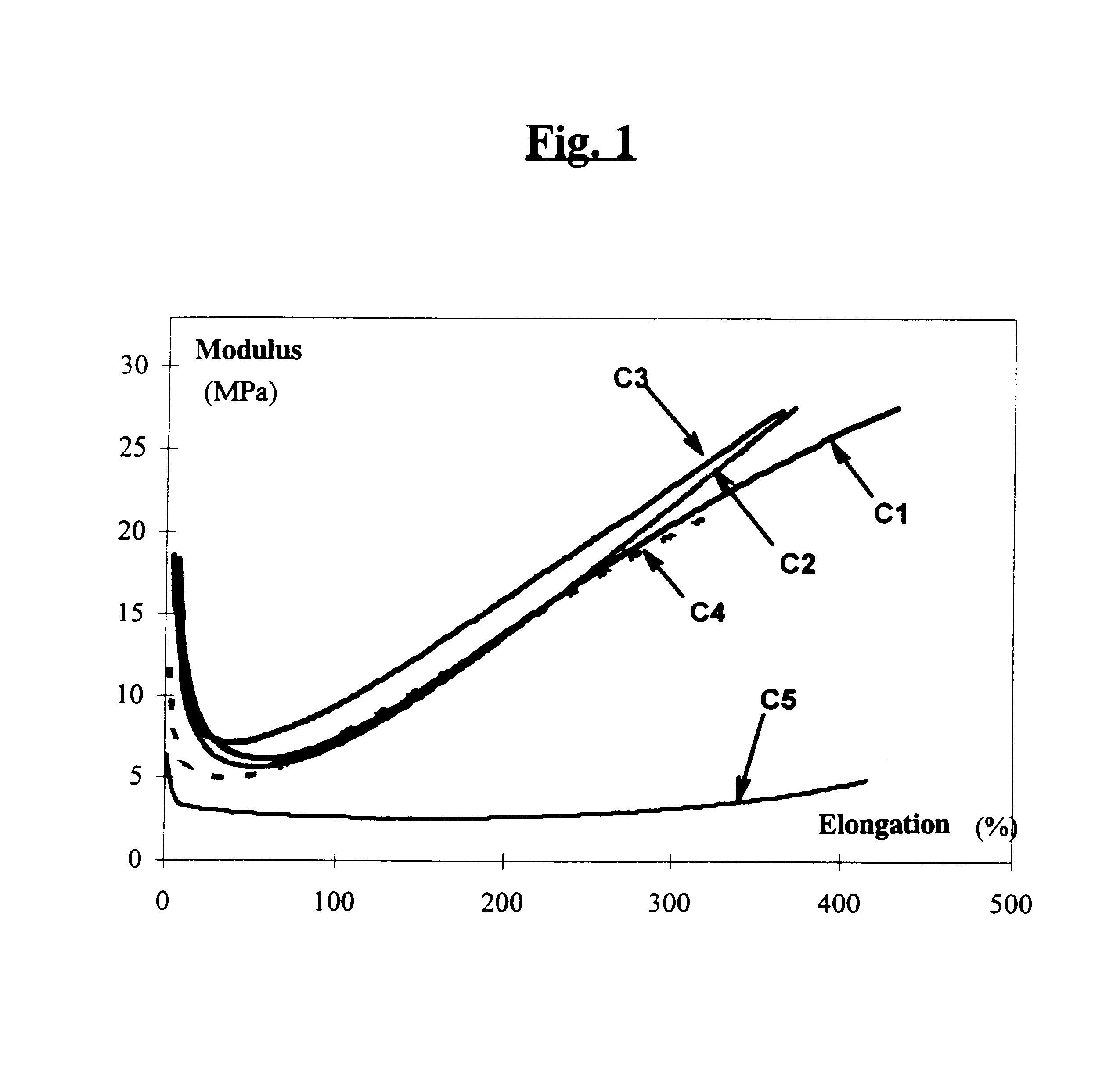

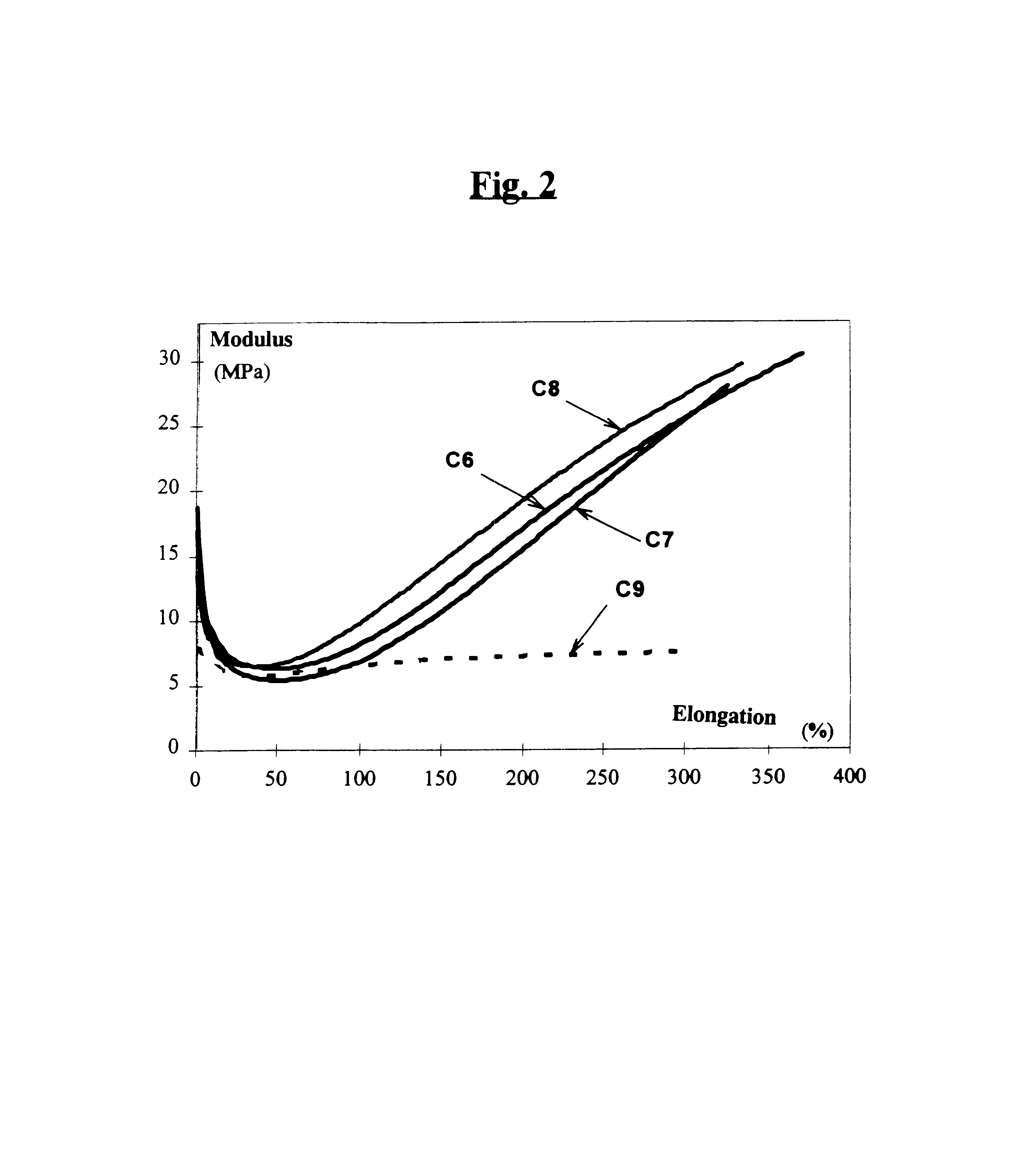

Tire and tread comprising a bis-alkoxysilane tetrasulfide as coupling agent

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Electrically conductive polymer composition

InactiveUS6184280B1Sufficient electrical conductivityImprove polymer propertiesOther chemical processesConductive materialPolymer scienceCarbon fibers

An electrically conductive polymer composition comprises a moldable organic polymer having hollow carbon microfibers and an electrically conductive white powder uniformly dispersed therein, the carbon fibers being present in an amount of 0.01 wt. % to less than 2 wt. % and the electrically conductive white powder being present in an amount of 2.5-40 wt. %, each percent range based on the total weight of the composition, the amounts of carbon microfibers and white powder being sufficient to simultaneously impart the desired electrical conductivity to the composition and white pigmentation to the composition.

Owner:MITSUBISHI MATERIALS CORP +1

Reinforcing aluminum-based filler and rubber composition comprising such a filter

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers):the specific BET surface area of which is between 30 and 400 m2 / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10-3 mum-1 / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

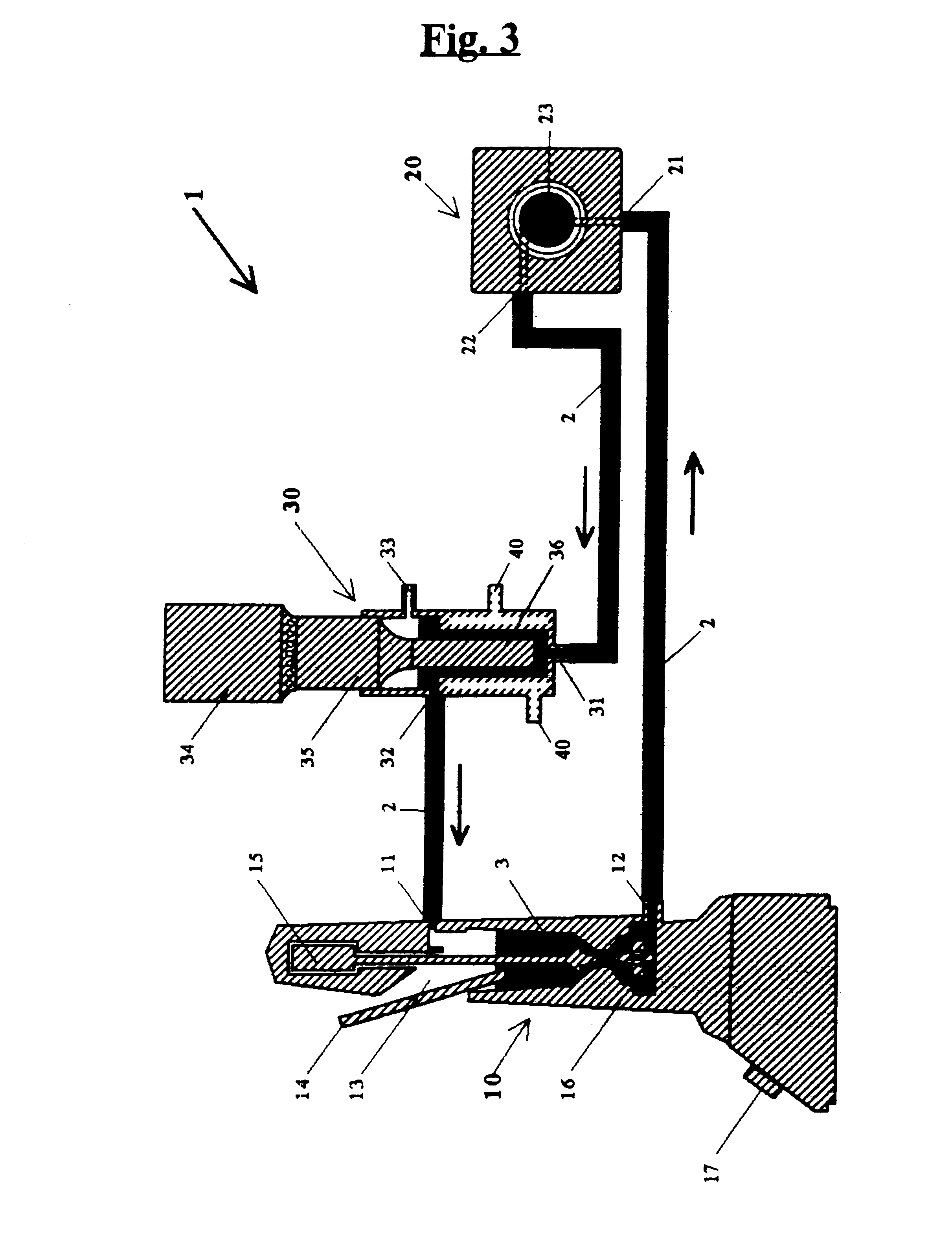

PVC nanocomposite manufacturing technology and applications

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

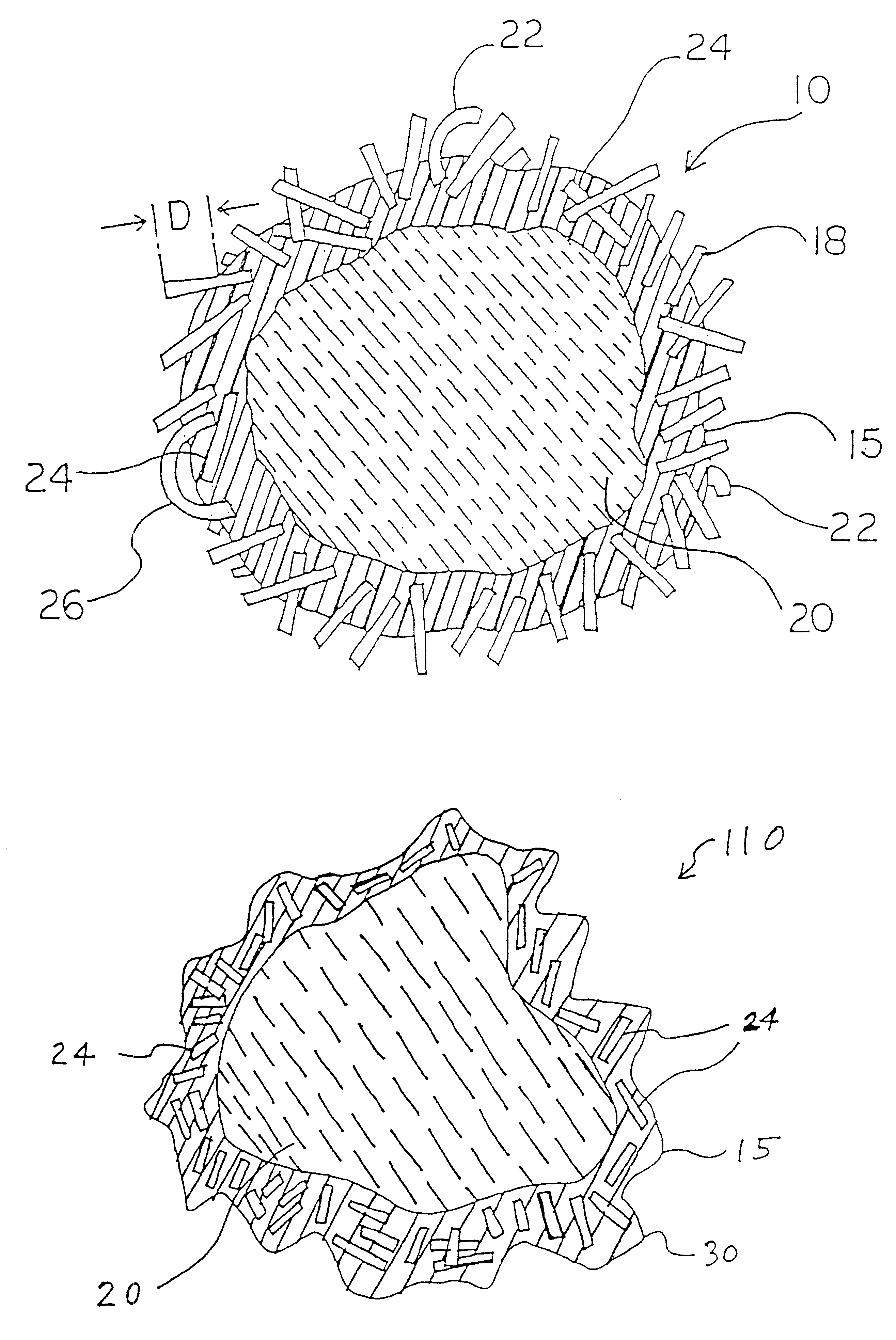

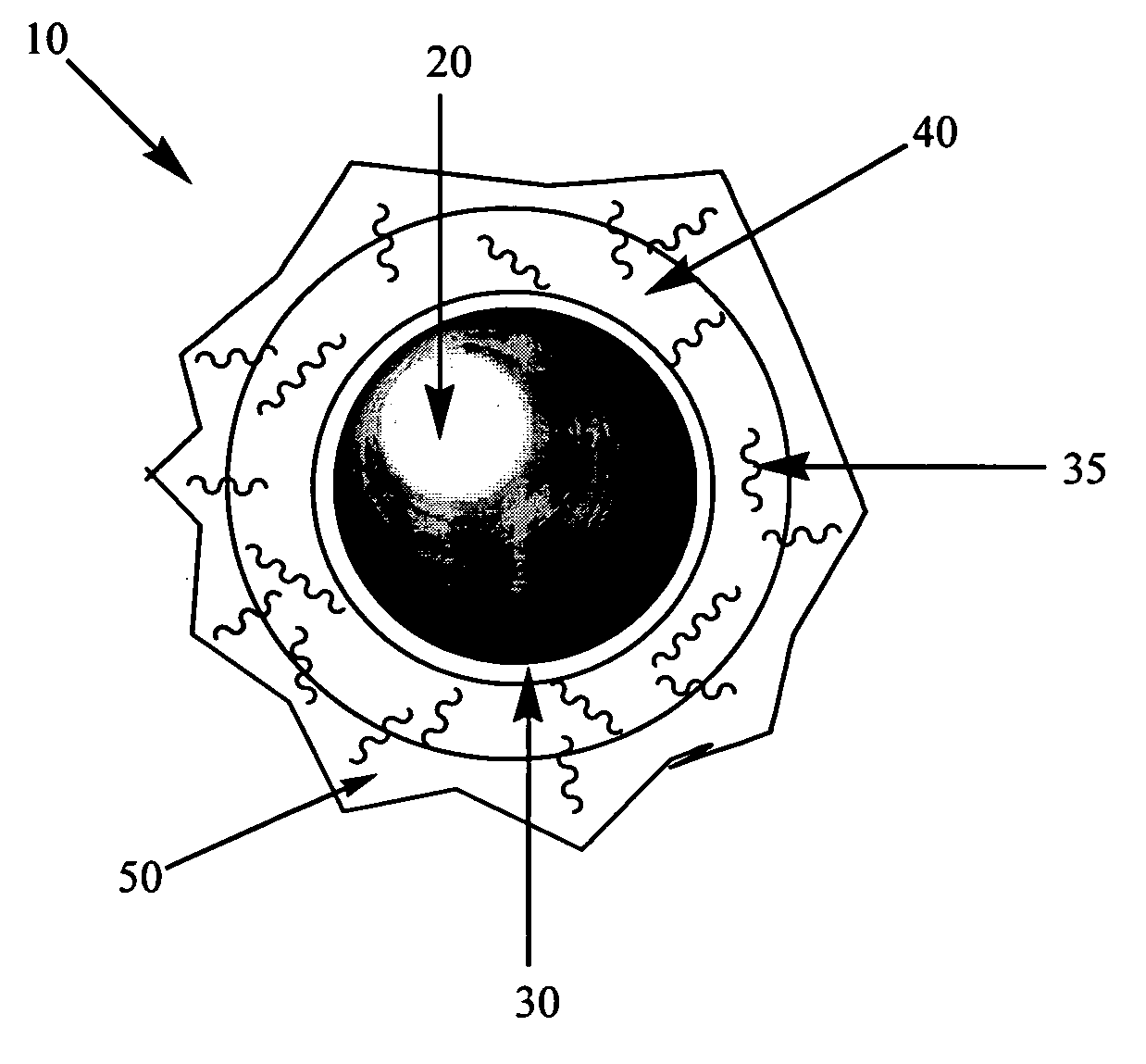

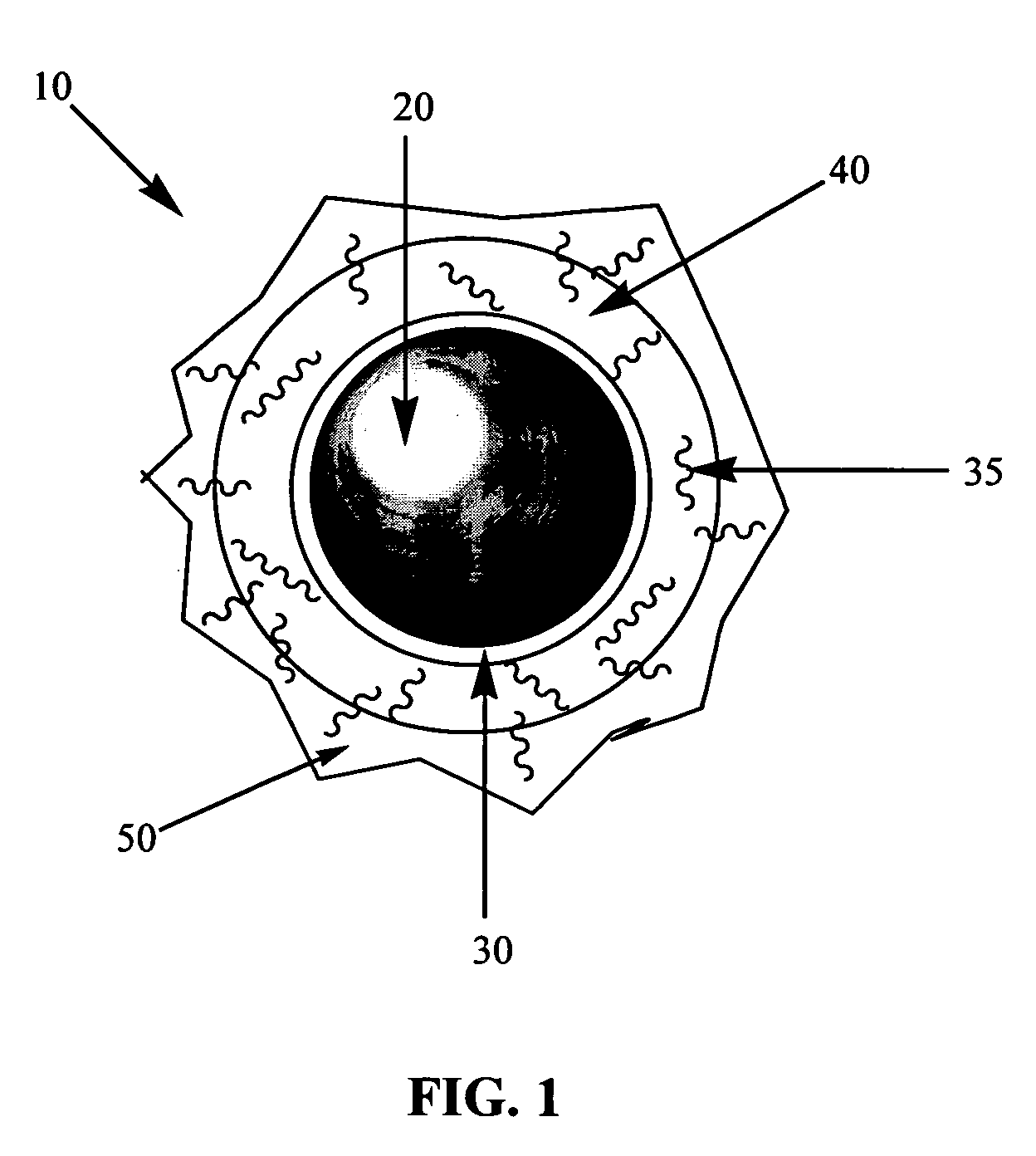

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

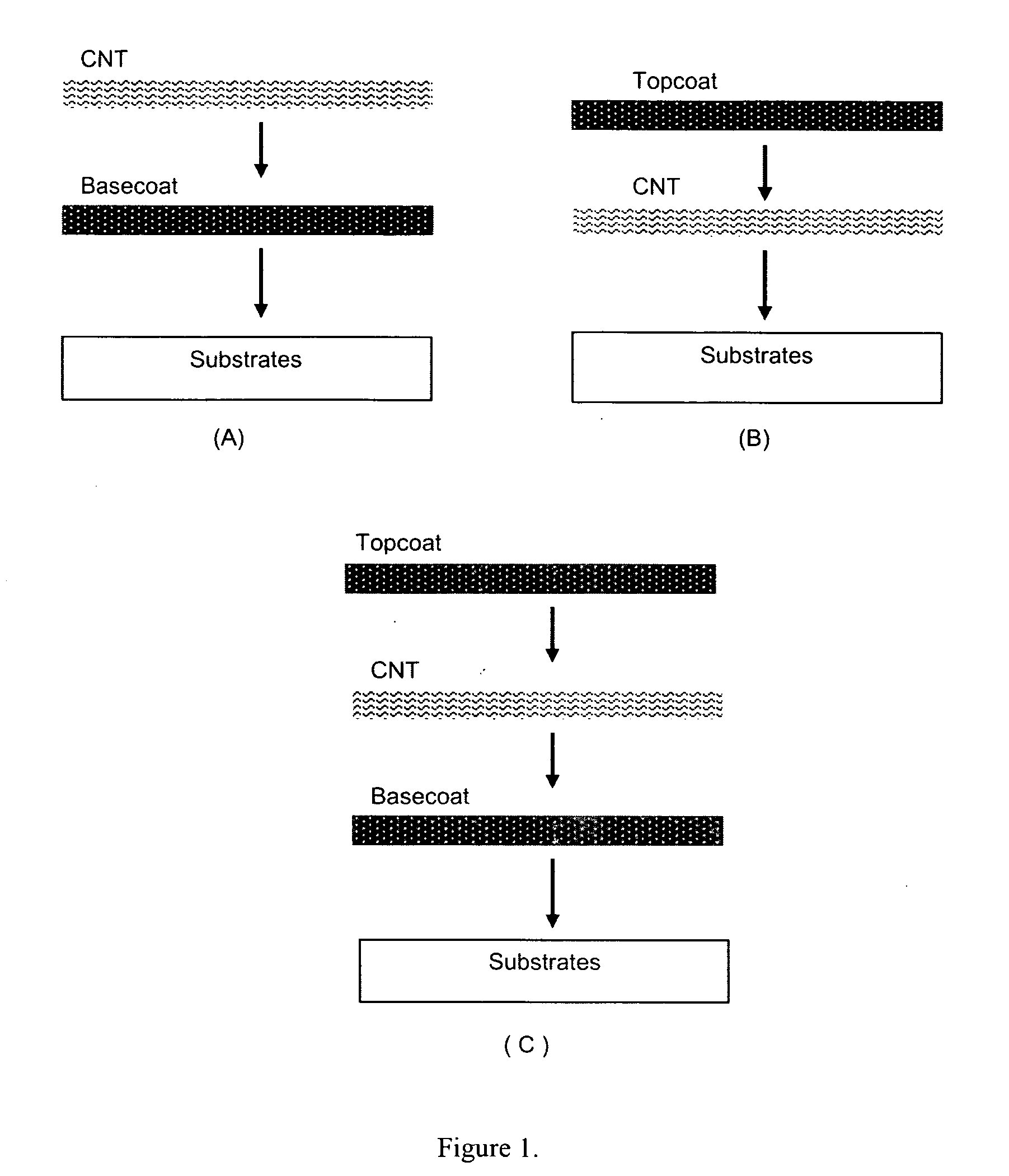

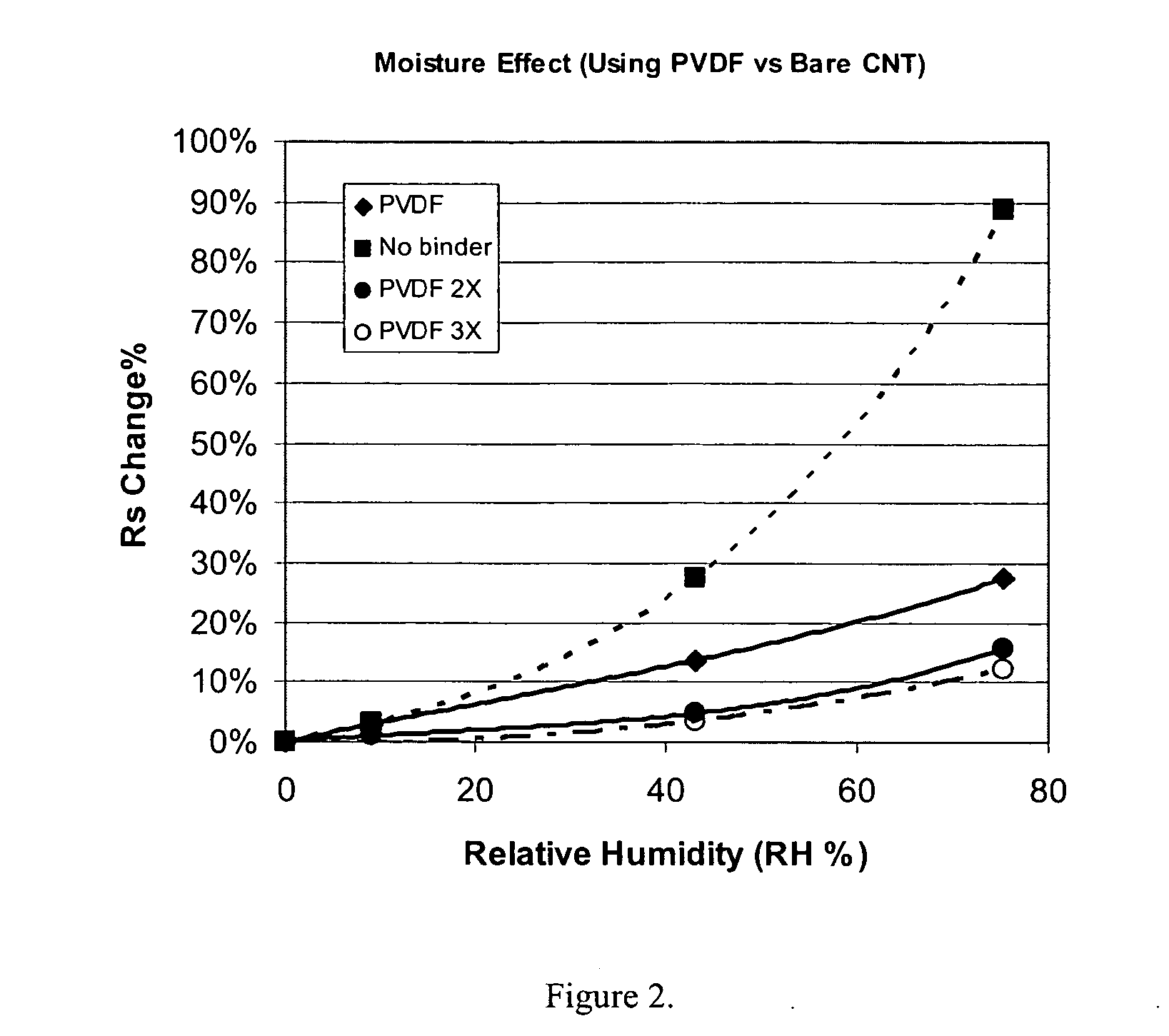

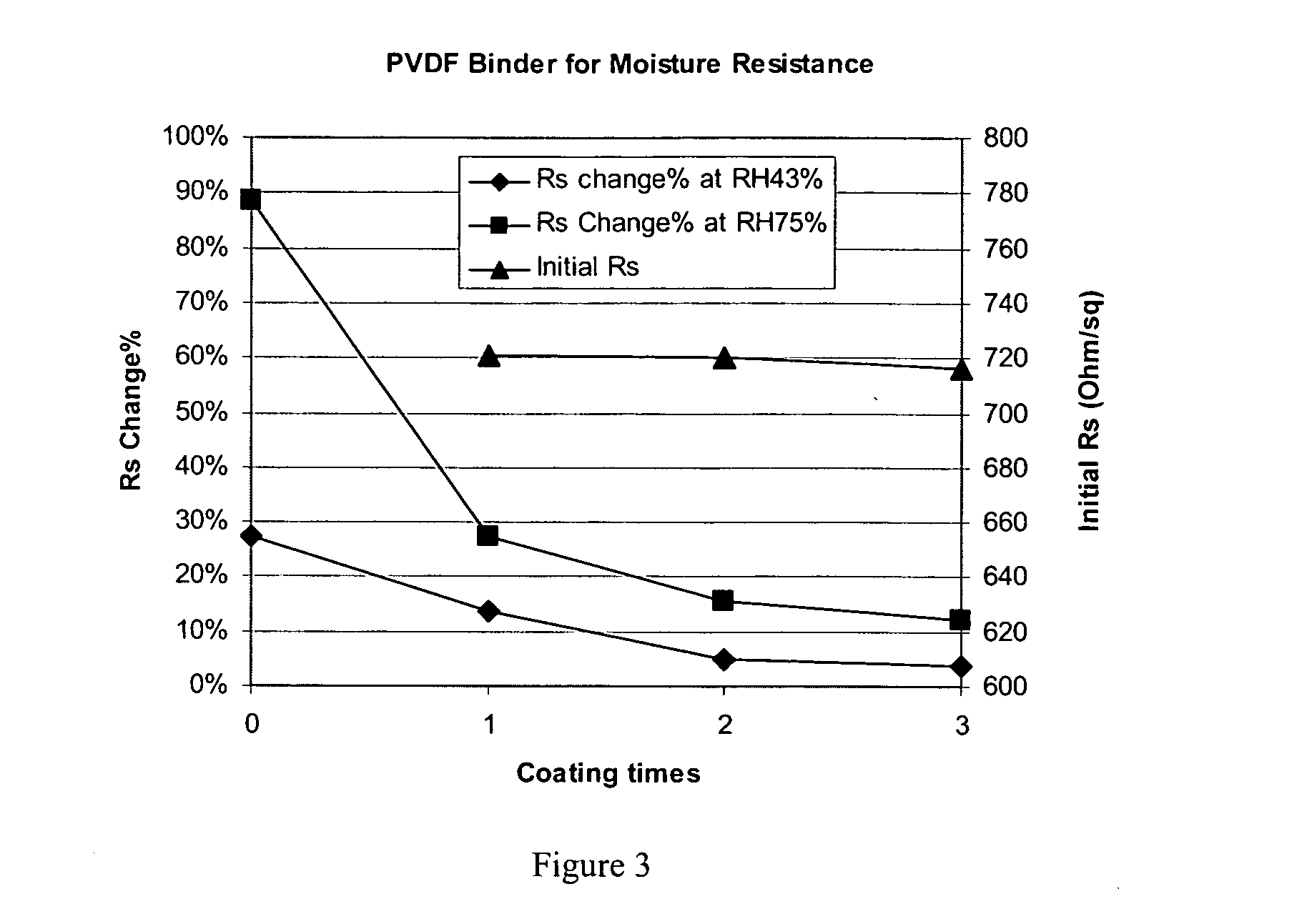

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

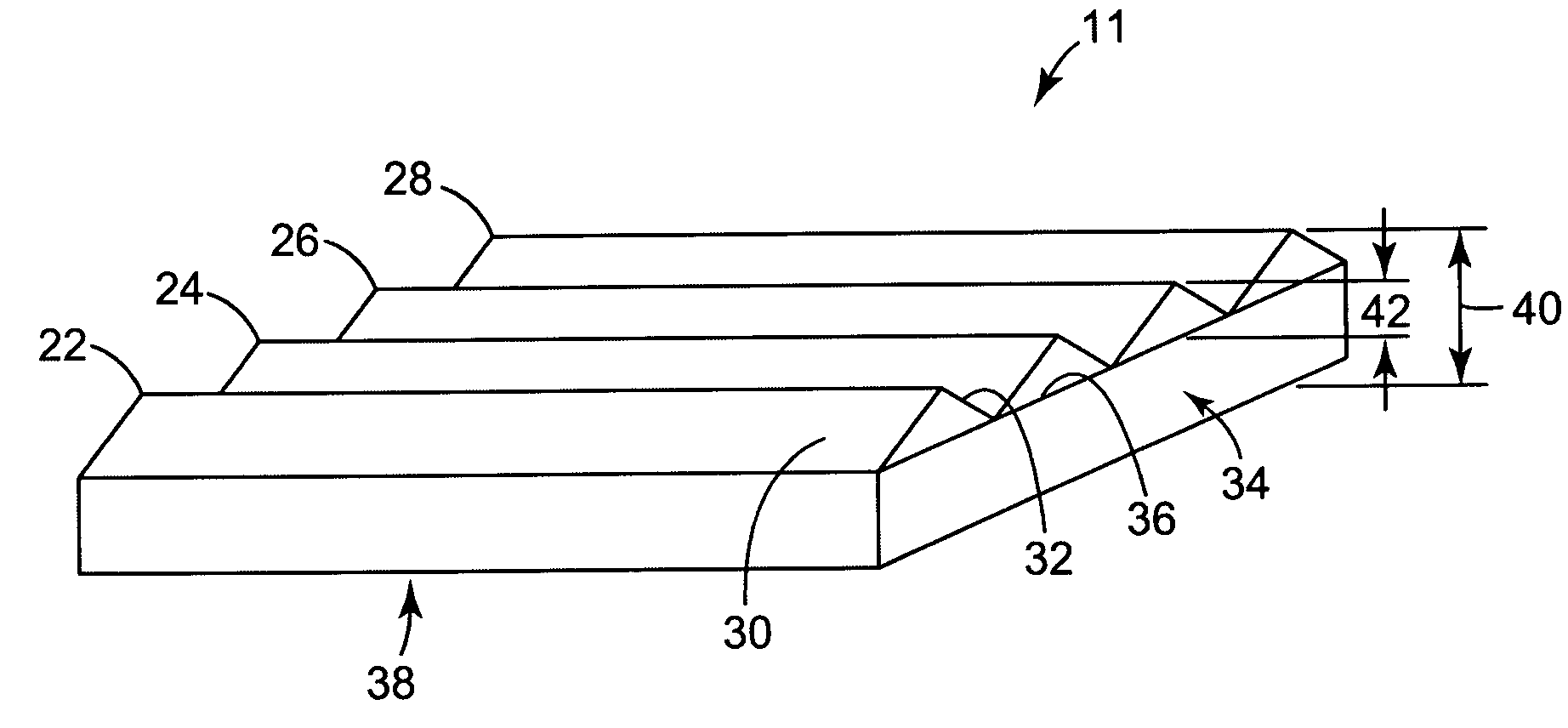

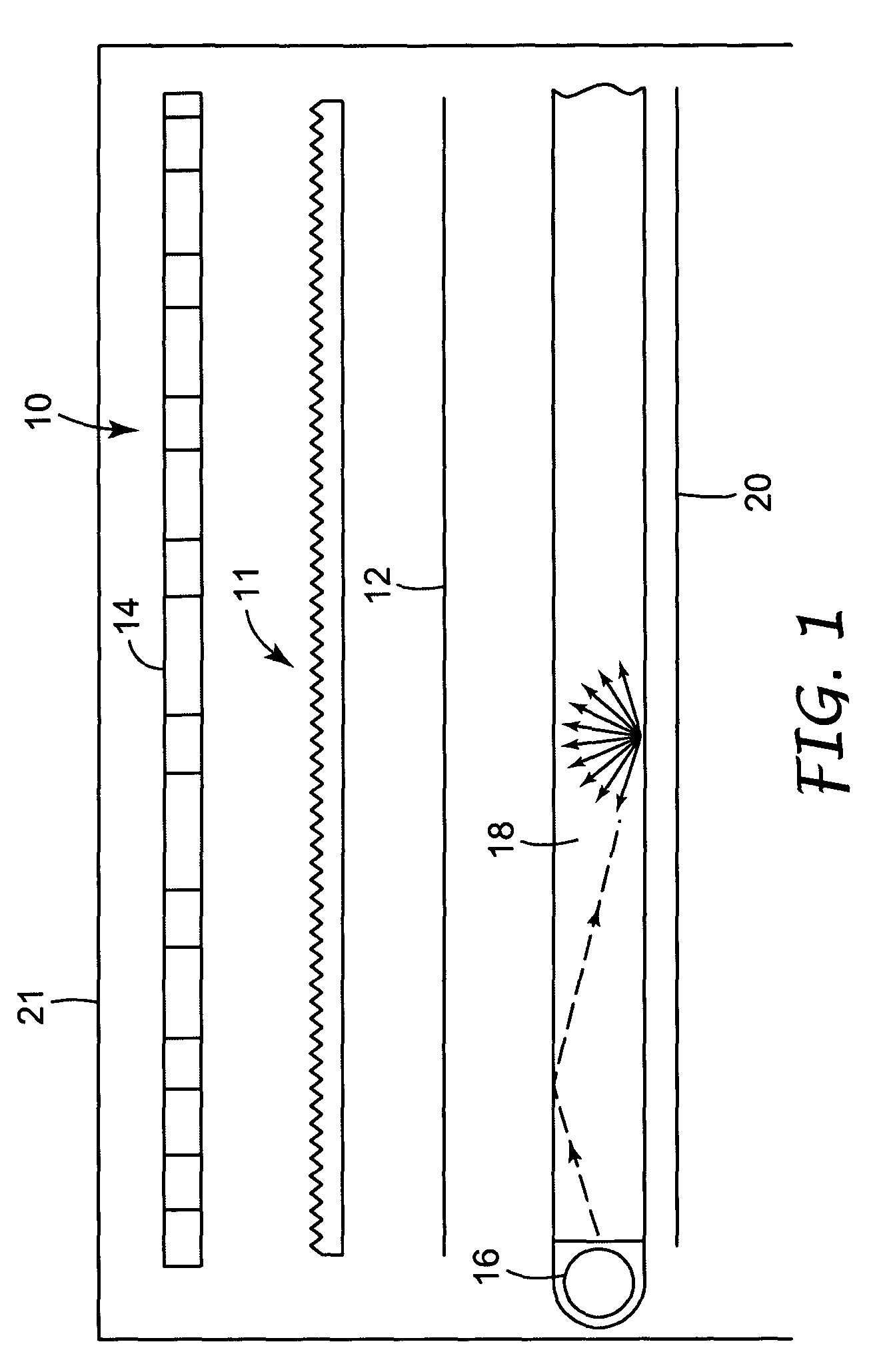

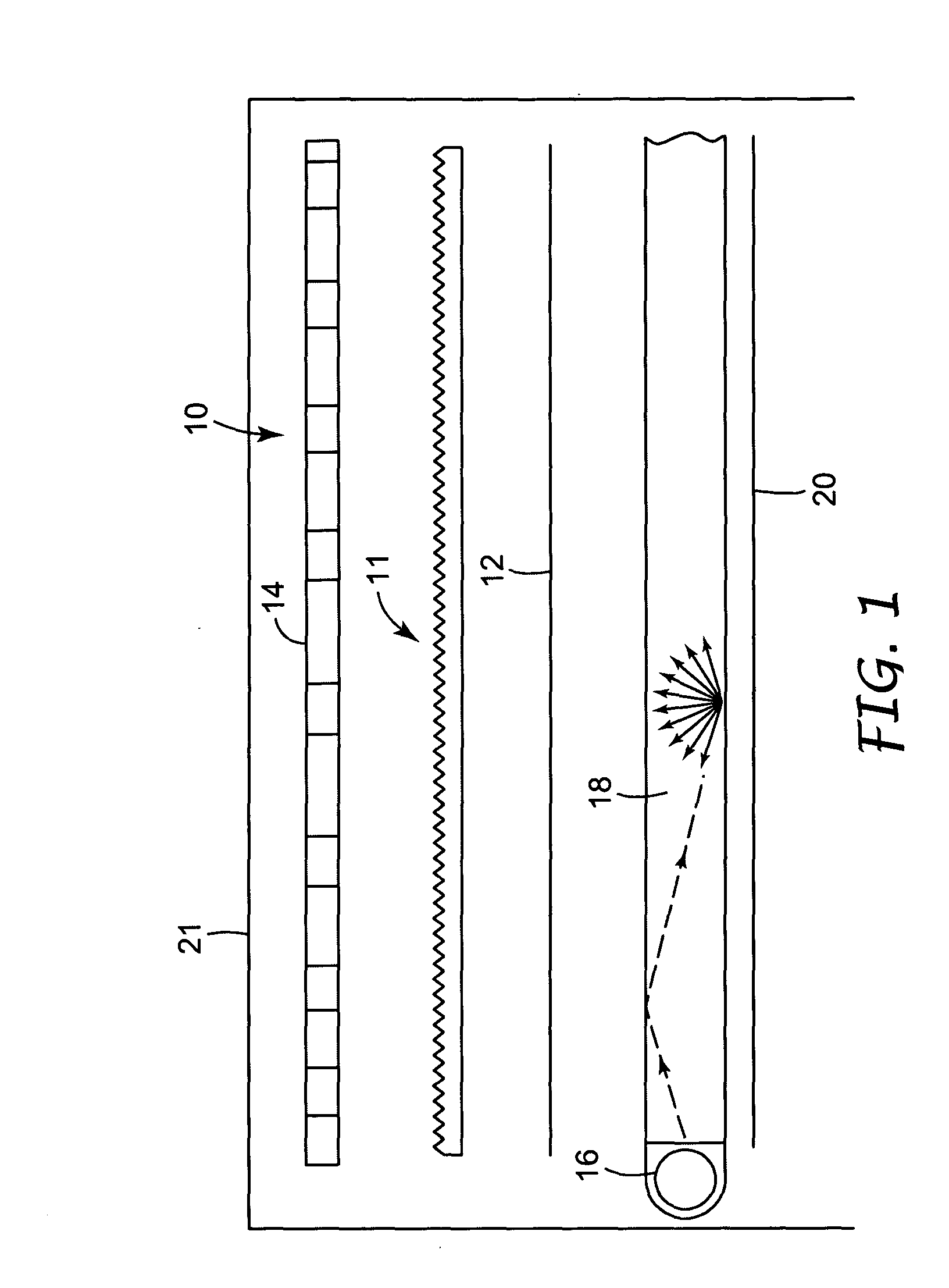

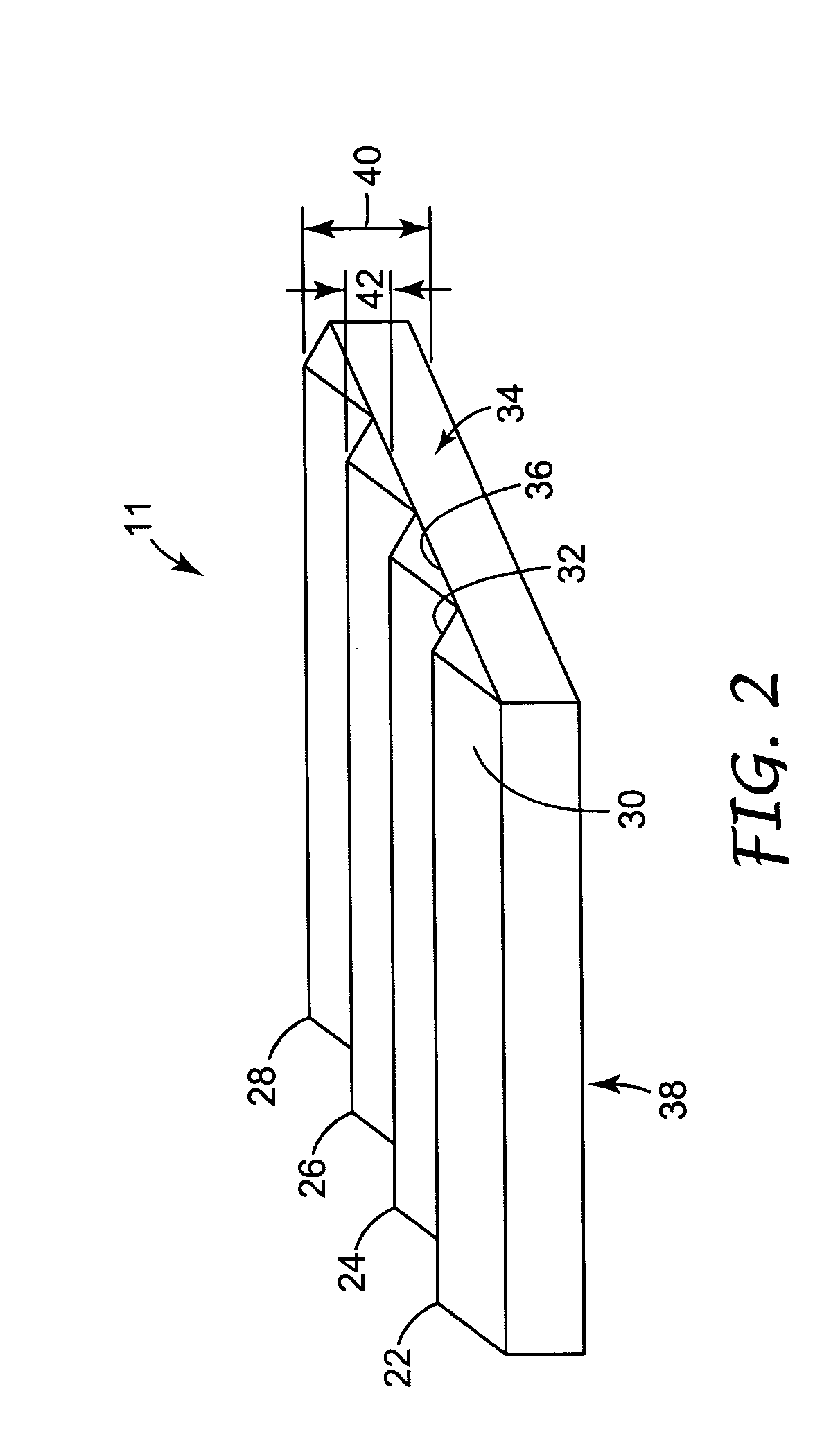

Durable optical element

ActiveUS7074463B2Liquid crystal compositionsTelevision system detailsDisplay deviceColloidal nanoparticles

A durable optical film or element includes a polymerized structure having a microstructured surface and a plurality of surface modified colloidal nanoparticles of silica, zirconia, or mixtures thereof. Display devices including the durable microstructured film are also described.

Owner:3M INNOVATIVE PROPERTIES CO

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

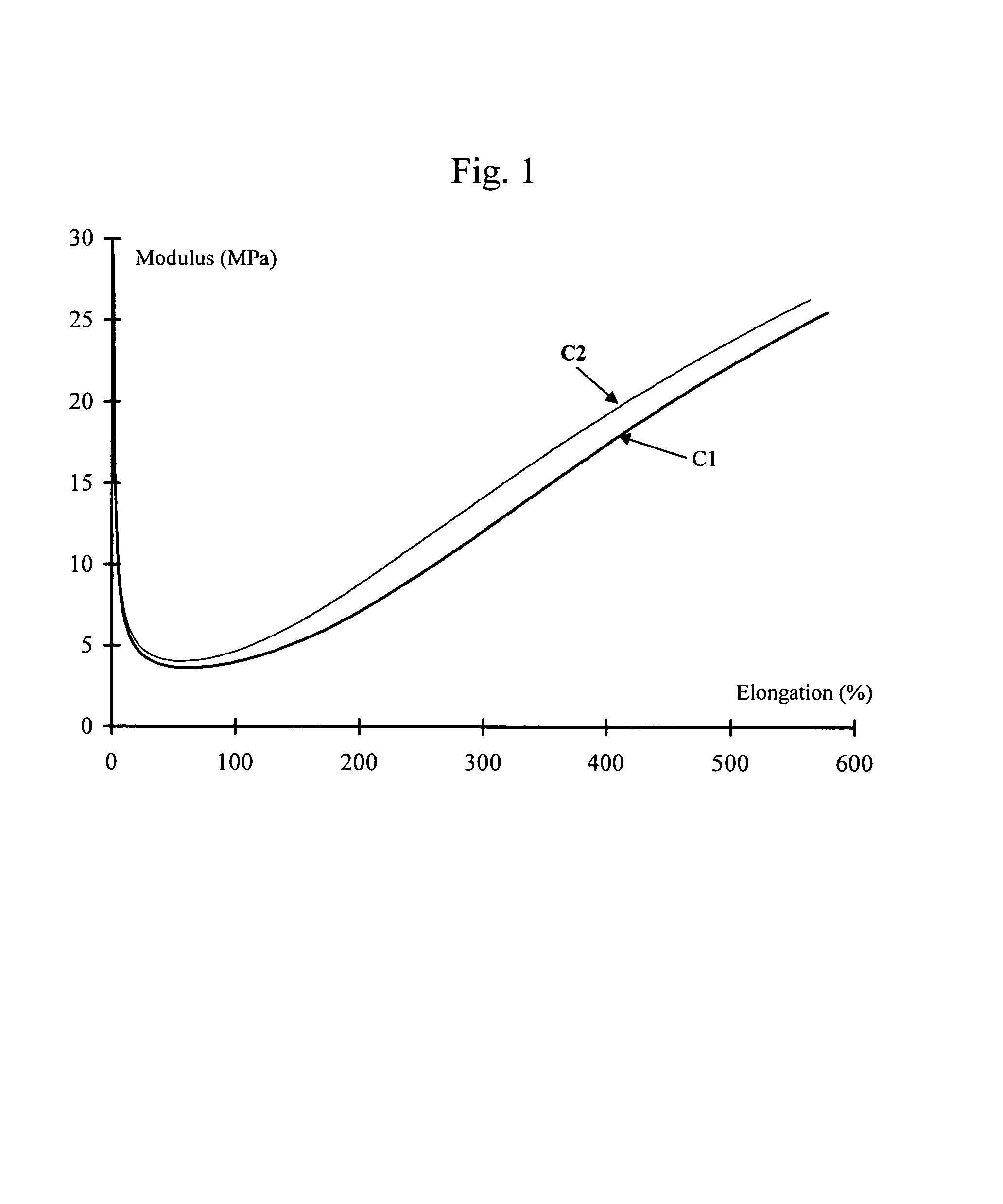

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

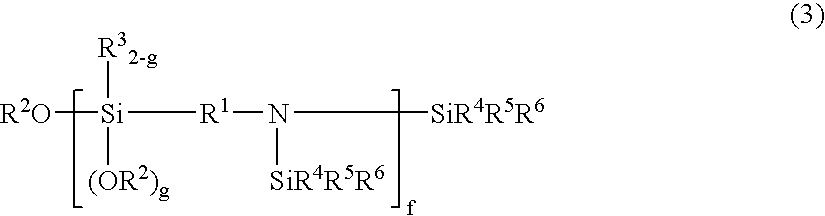

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

Image making medium

InactiveUS8921473B1Improve aestheticsEnhance and enable bondingDuplicating/marking methodsSpecial tyresEngineeringSmart material

The invention relates to an image support medium for creation of an aesthetic image that is a work or object for display. This support medium is made from a smart or intelligent material so that the medium provides or enables formation of an image having at least one aesthetic element that can be responsive, interactive, controlled, changed, programmed, and / or modulated. The support medium can further comprise stimuli, triggers or influences that cause the smart or intelligent material to respond to change shape, size, volume, density, light properties, color, appearance, and / or another physical property of the aesthetic element. In a preferred embodiment, the smart or intelligent material is reversibly responsive to the stimuli, triggers or influences.

Owner:HYMAN SYDNEY

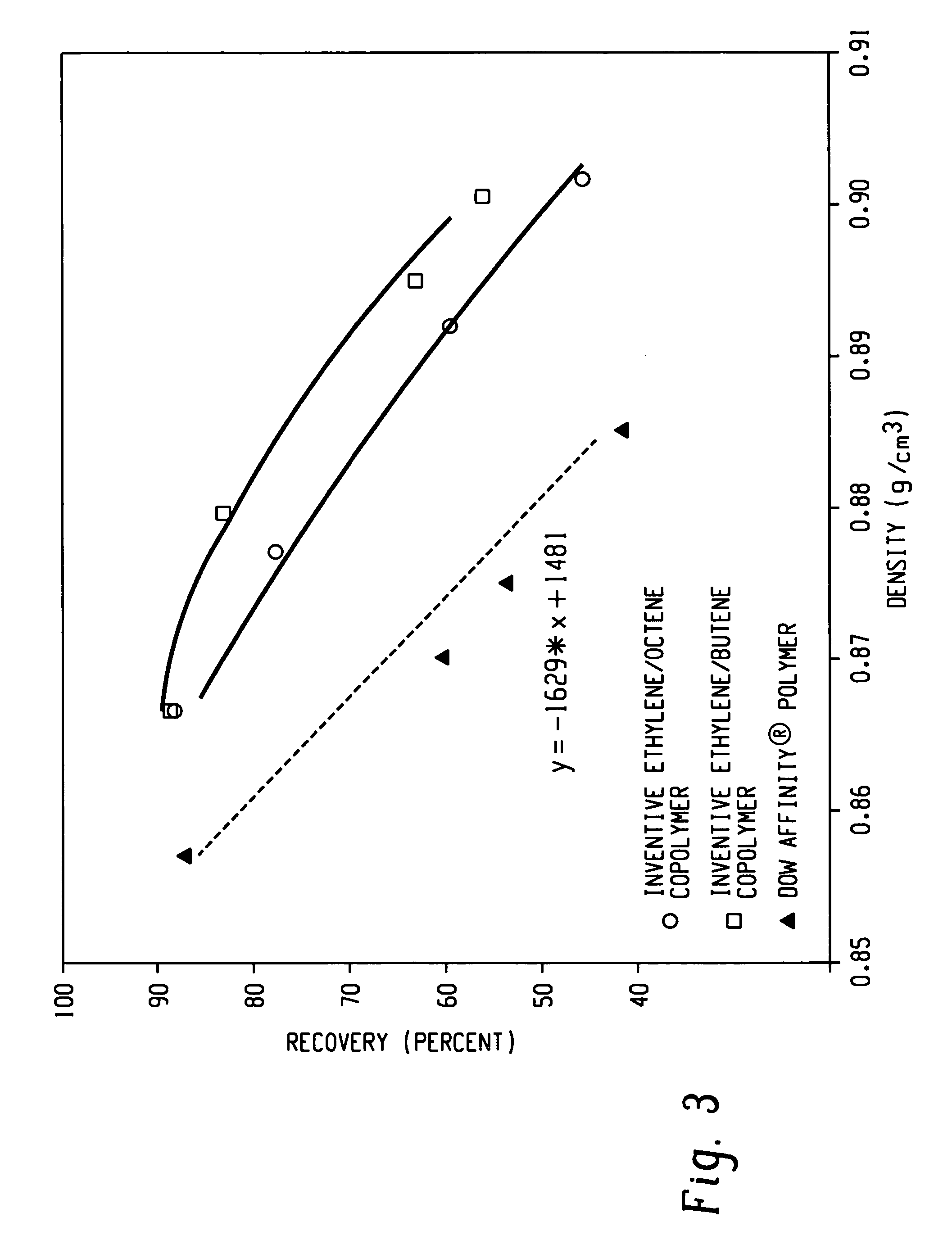

Filled polymer compositions made from interpolymers of ethylene/a-olefins and uses thereof

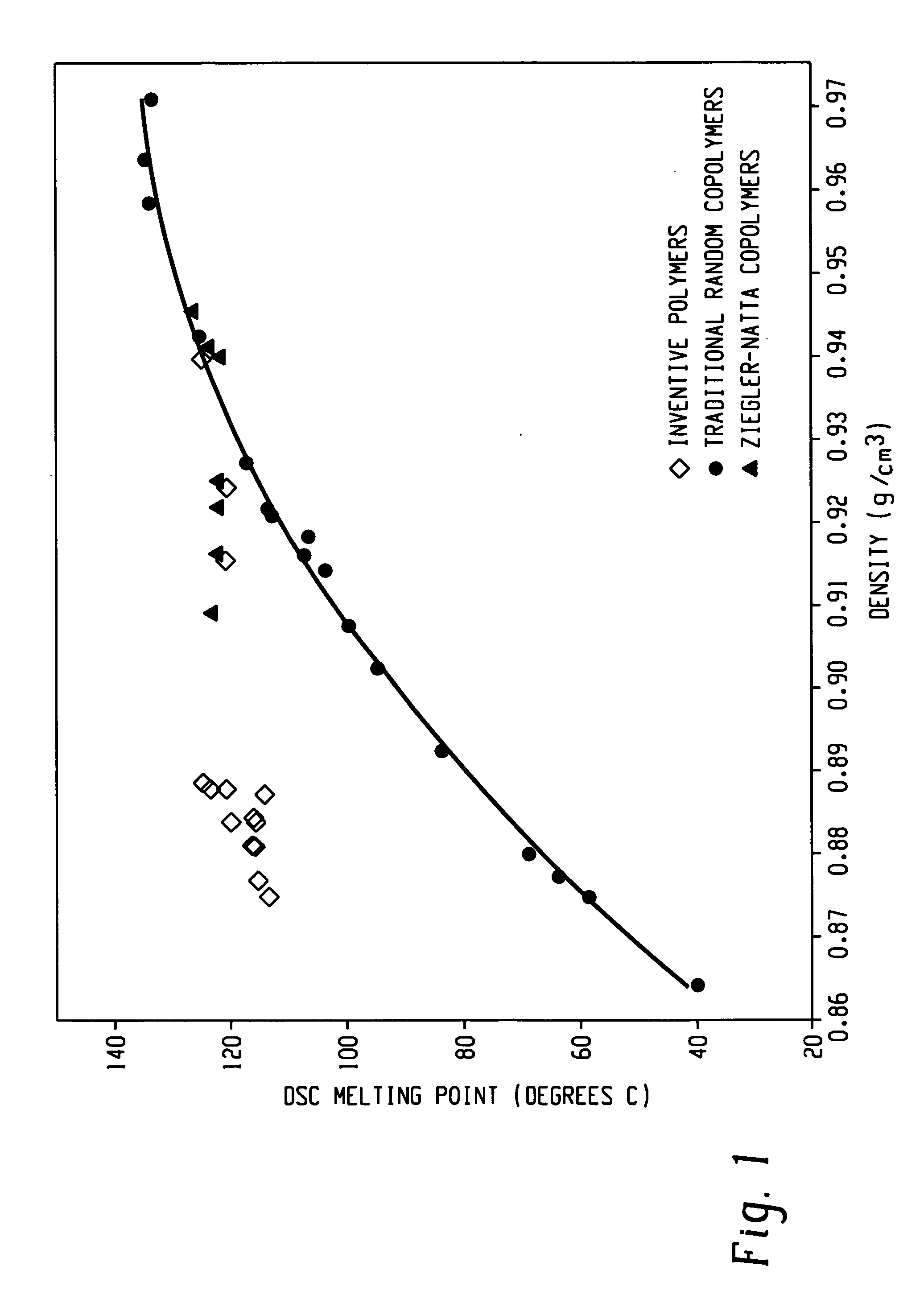

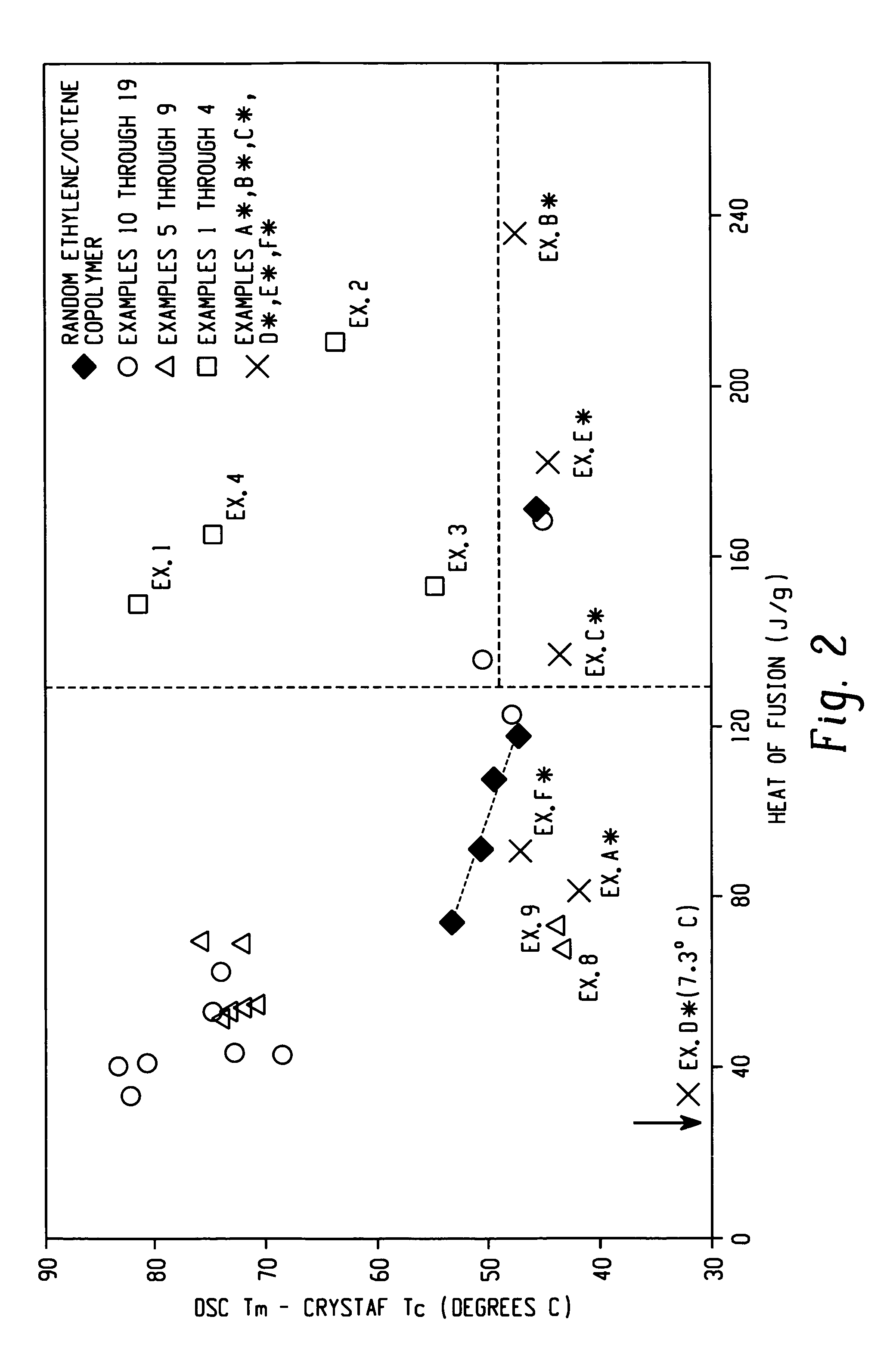

A filled polymer composition comprises (i) an ethylene / α-olefin interpolymer, and (ii) a filler. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. The filled polymer compositions provided herein, in certain embodiments, have relatively higher heat resistance and improved noise, vibration and harshness properties and can be used in automotive floorings, roofings, wire and cable coating applications.

Owner:DOW GLOBAL TECH LLC

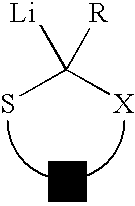

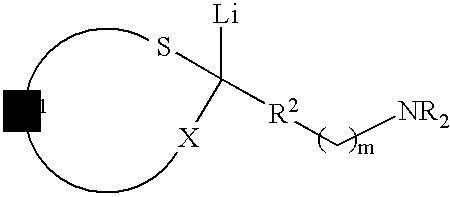

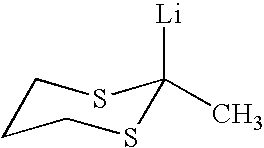

Use of sulfur containing initiators for anionic polymerization of monomers

InactiveUS7153919B2Reduced hysteresis lossSilicon organic compoundsLithium organic compoundsElastomerRolling resistance

An initiator is presented for anionically polymerizing monomers, to provide a functional head group on the polymer. A polymer having a functional head group derived from a sulfur containing anionic initiator, and optionally as additional functional group resulting from the use of a functional terminating reagent, coupling agent or linking agent is also provided. A method is presented for anionically polymerizing monomers comprising the step of polymerizing the monomers with a sulfur containing anionic initiator to provide a functional head group on the polymer. An elastomeric compound, comprising a functional polymer and filler is also described. Also provided is a tire having decreased rolling resistance resulting from a tire component containing a vulcanizable elastomeric compound.

Owner:BRIDGESTONE CORP

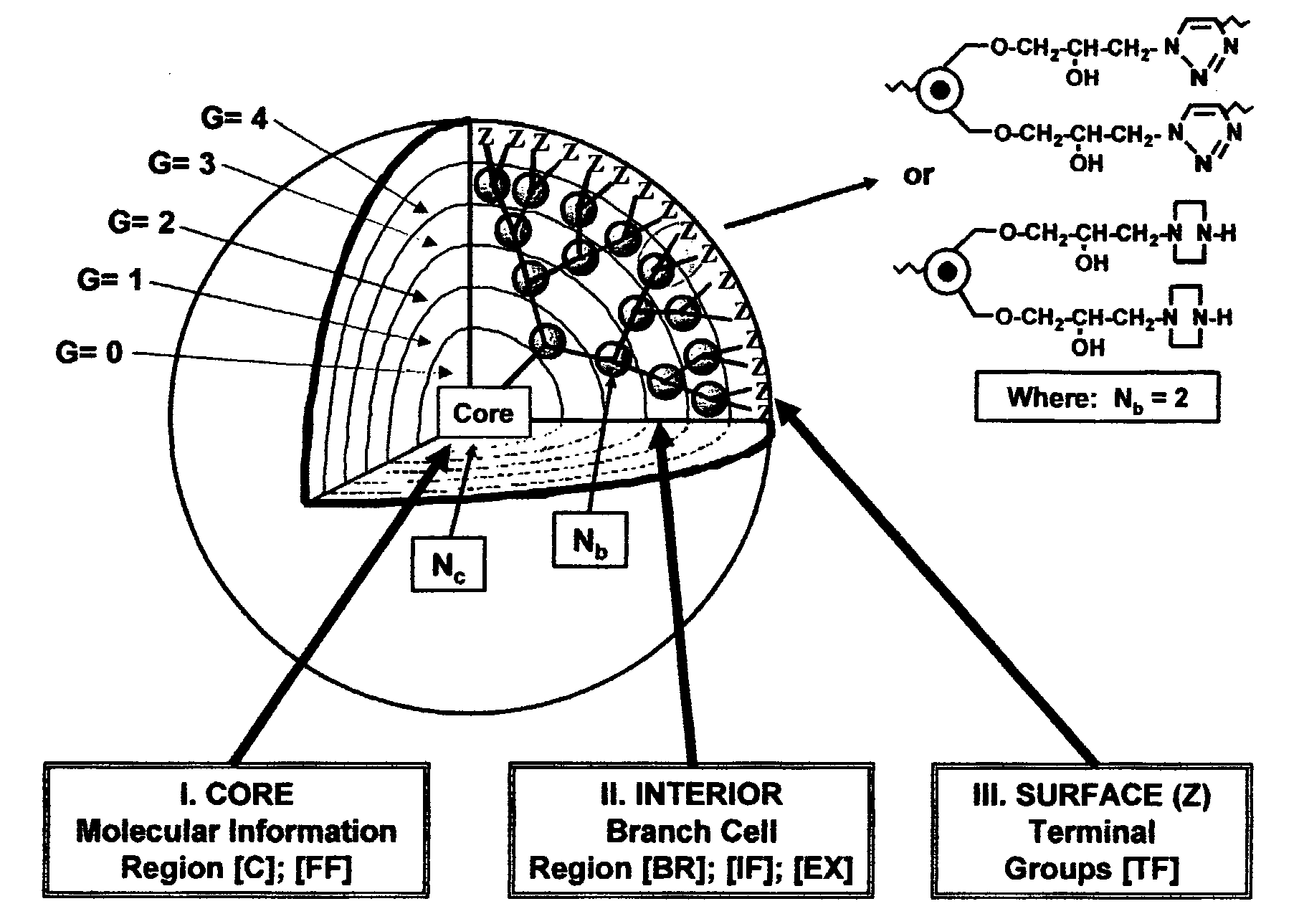

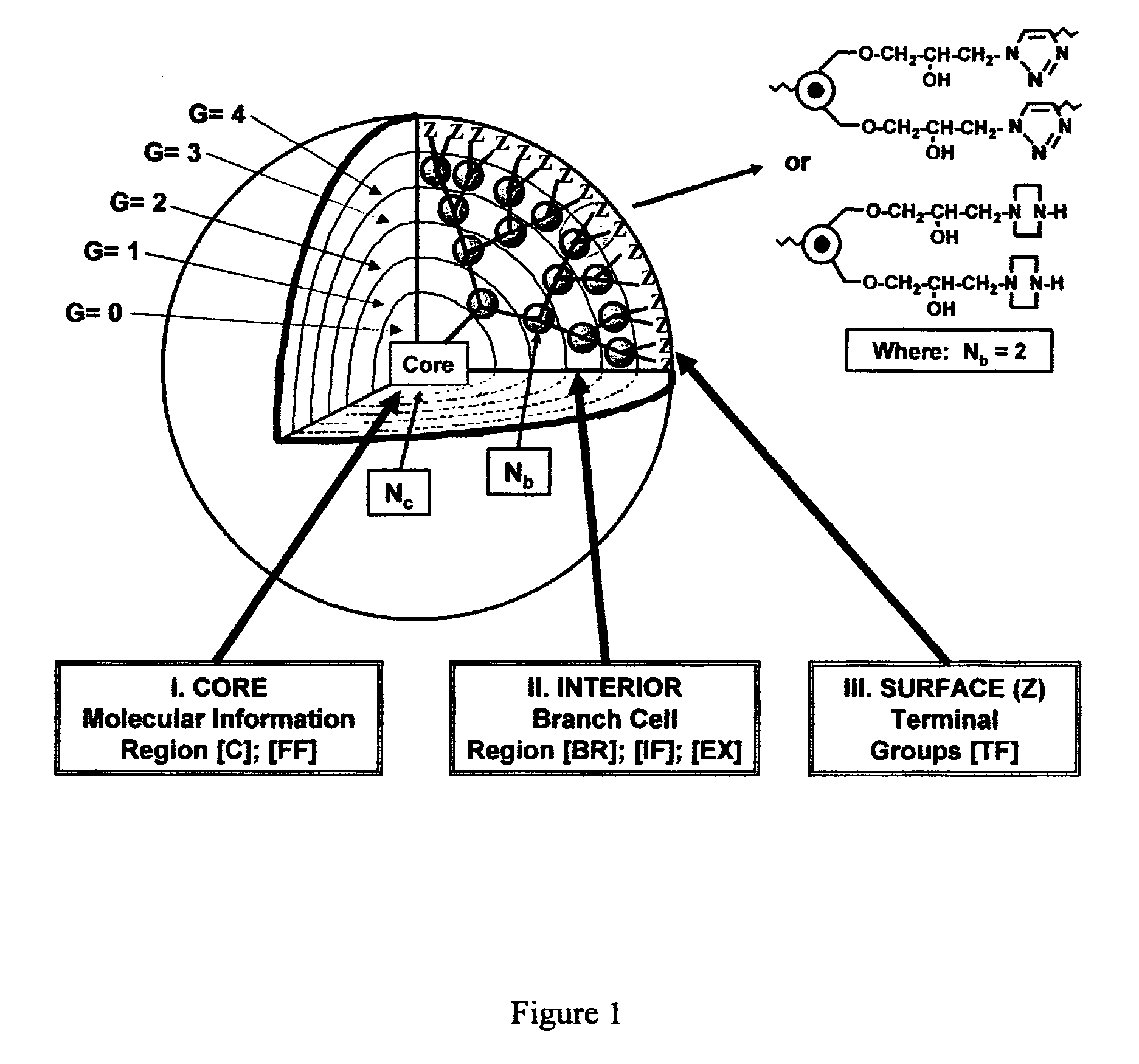

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

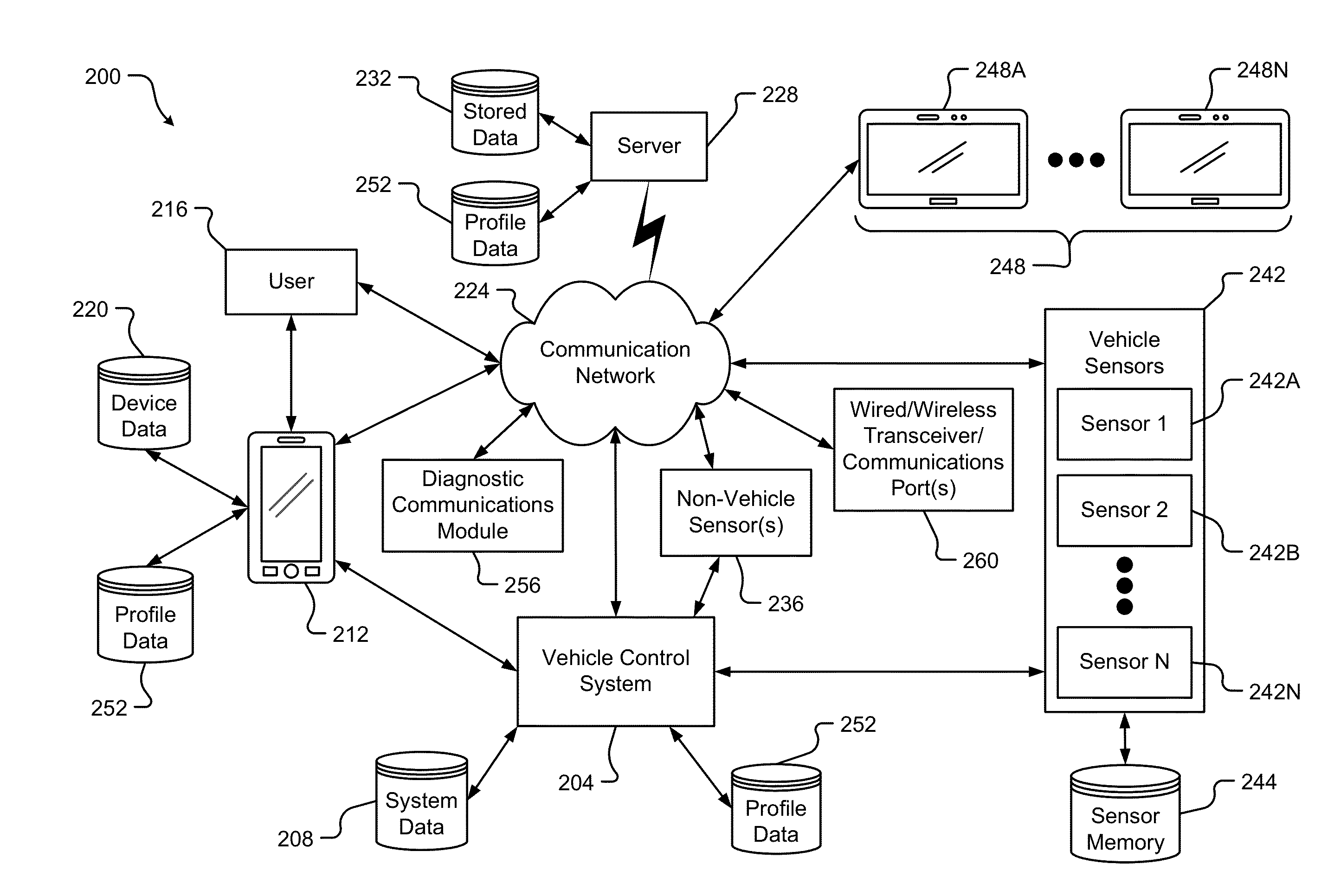

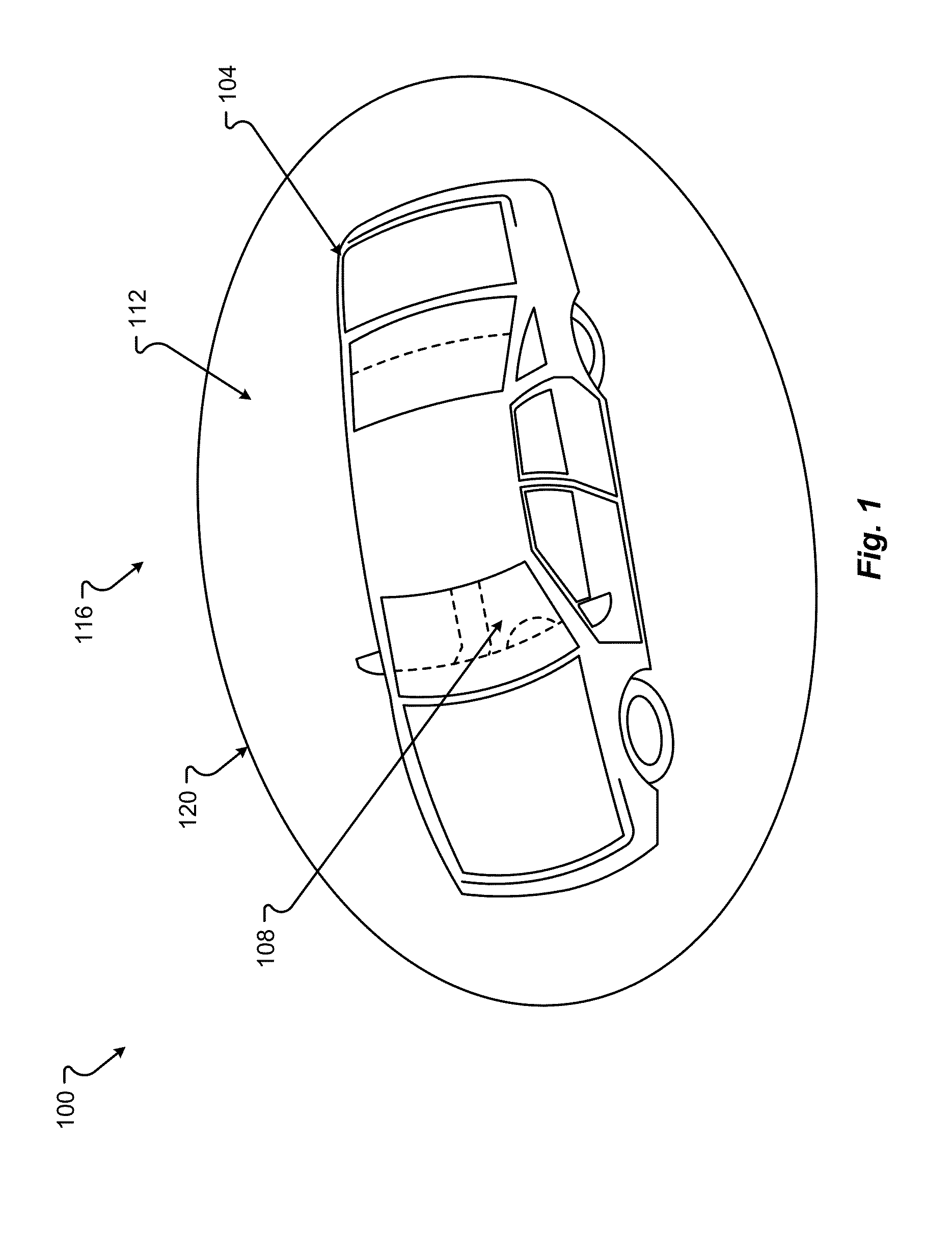

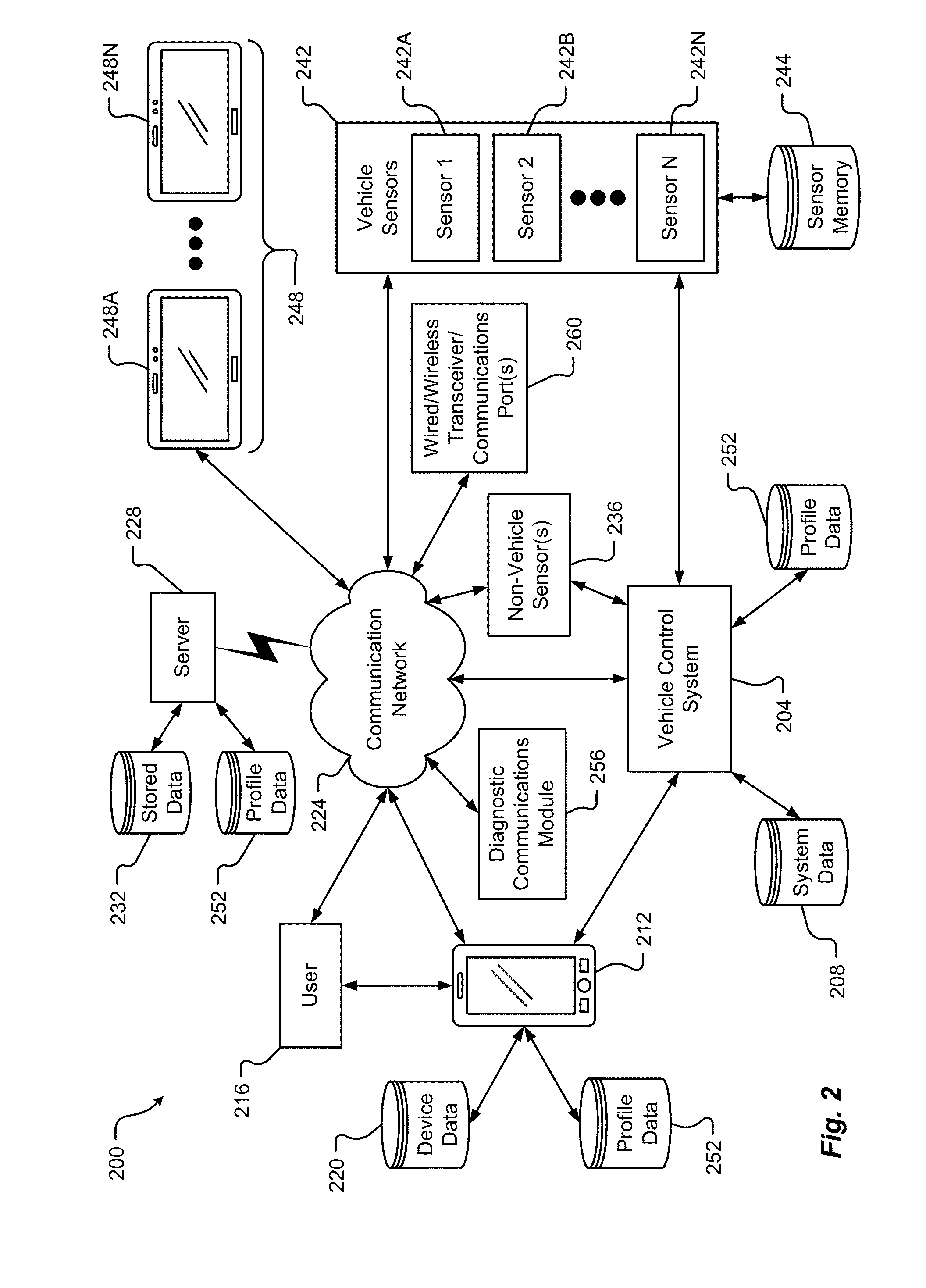

Vehicle-based multimode discovery

ActiveUS20150232065A1Improve reliabilityUnnecessary removalControlling traffic signalsVehicle seatsTelecommunicationsOn board

Methods and systems for a device discovery daemon that bases access of a communication device to an on board vehicle network on device location are provided.

Owner:AUTOCONNECT HLDG

Soluble fibers for use in resin coated proppant

Coated particle substrates having a coating of resin and / or water soluble polymers and soluble, fibrous material are provided for use in subterranean formations. The coated particle substrate particles are typically proppants used to prop open subterranean hydrocarbon formations during recovery processes, such as after a hydraulic fracture, and provide both improved settling characteristics and improved hydrocarbon flow characteristics due to the conductive channels formed by the soluble fibers downhole. Methods of making the coated particles are also described.

Owner:FAIRMOUNT SANTROL

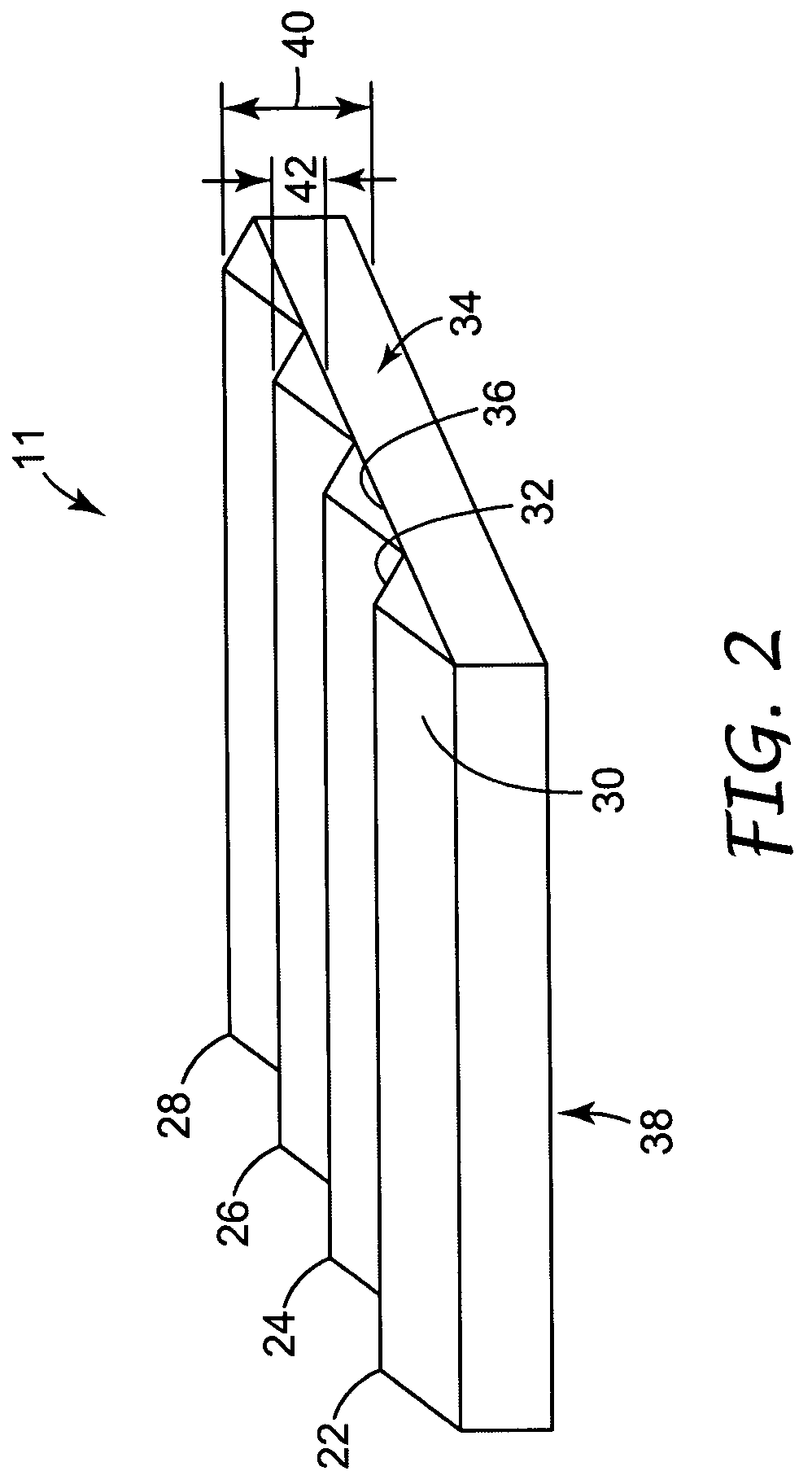

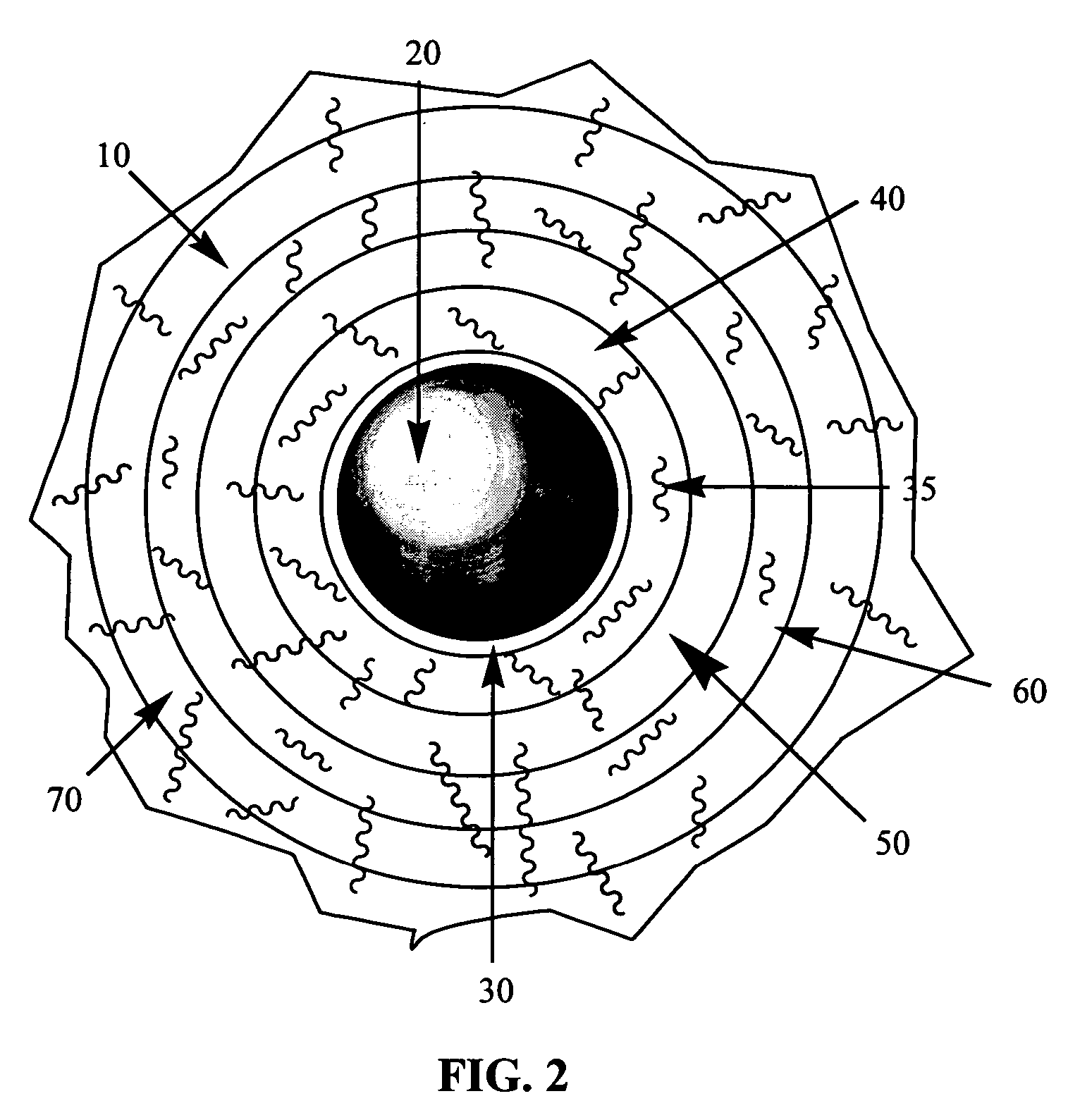

Structurally supported resilient tire and materials

The invention comprises an improved non-pneumatic tire, and particularly a shear layer for a non-pneumatic tire wherein the shear layer comprises an elastomeric composition that includes a metal salt of a carboxylic acid. The shear layer preferably comprises a dienic elastomeric composition that includes a metal salt of a carboxylic acid. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate, and a peroxide curative agent is employed.

Owner:MICHELIN RECH & TECH SA

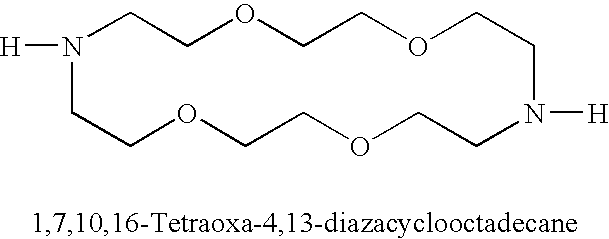

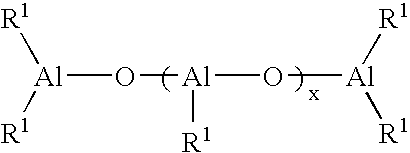

Cure catalyst, composition, electronic device and associated method

InactiveUS20060293172A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSimple Organic CompoundsNitrogen

A cure catalyst is provided. The cure catalyst may include a Lewis acid and one or both of a nitrogen-containing molecule or a non-tertiary phosphine. The nitrogen-containing molecule may include a mono amine or a heterocyclic aromatic organic compound. A curable composition may include the cure catalyst. An electronic device may include the curable composition. Methods associated with the foregoing are provided also.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

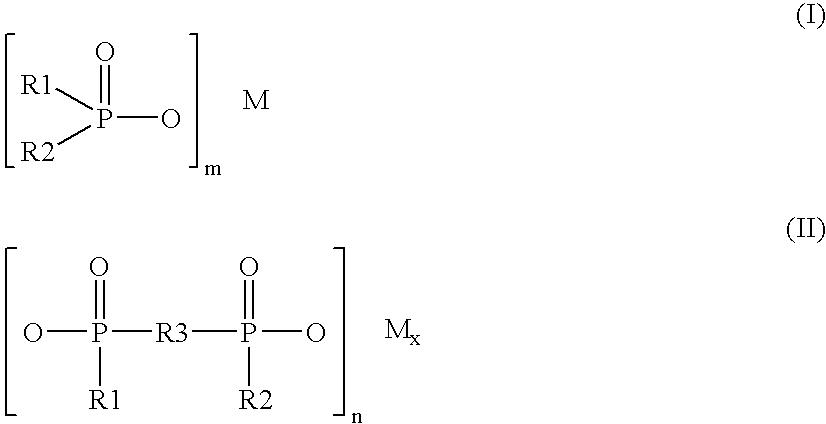

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

Durable optical element

A durable optical film or element includes a polymerized structure having a microstructured surface and a plurality of surface modified colloidal nanoparticles of silica, zirconia, or mixtures thereof. Display devices including the durable microstructured film are also described.

Owner:3M INNOVATIVE PROPERTIES CO

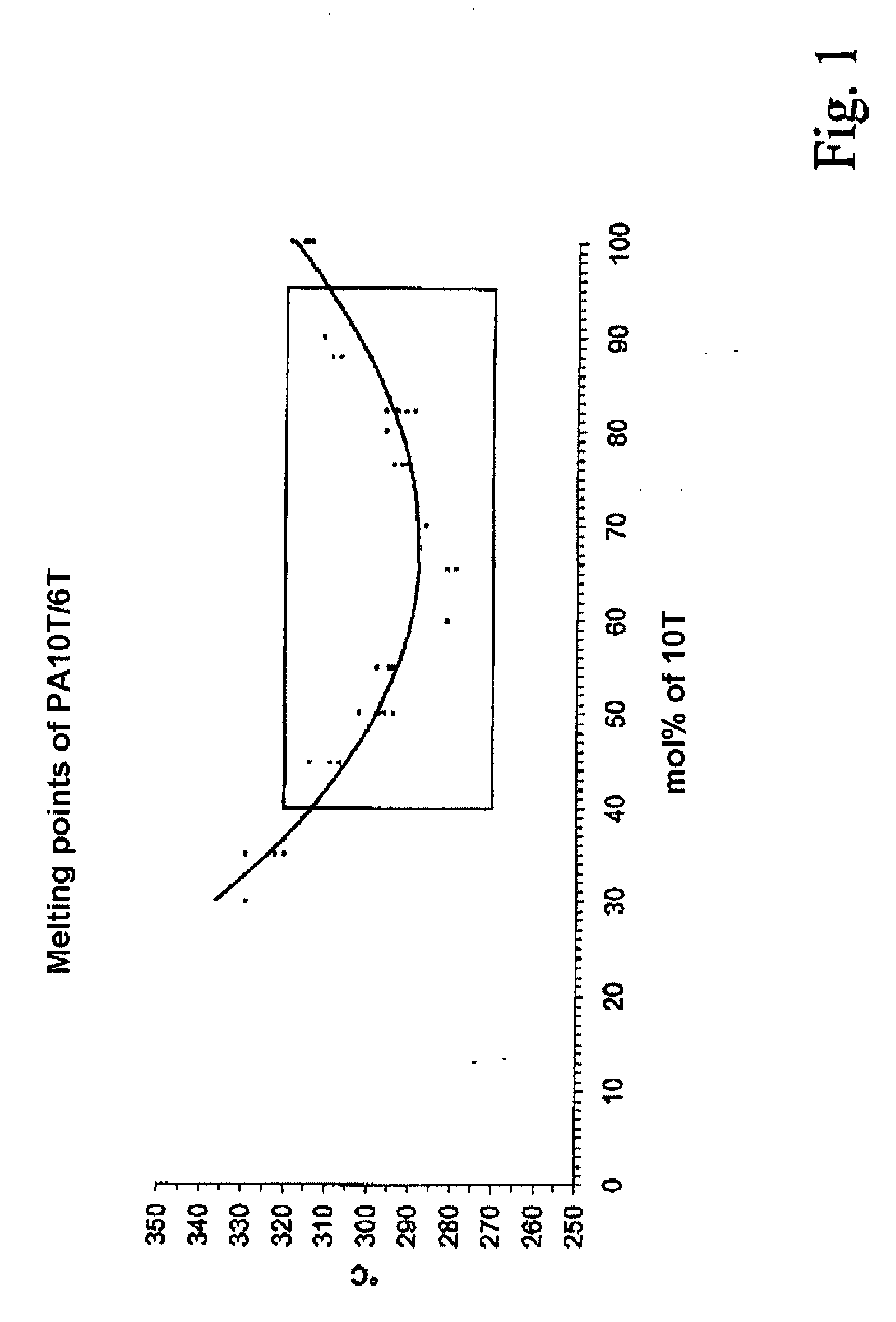

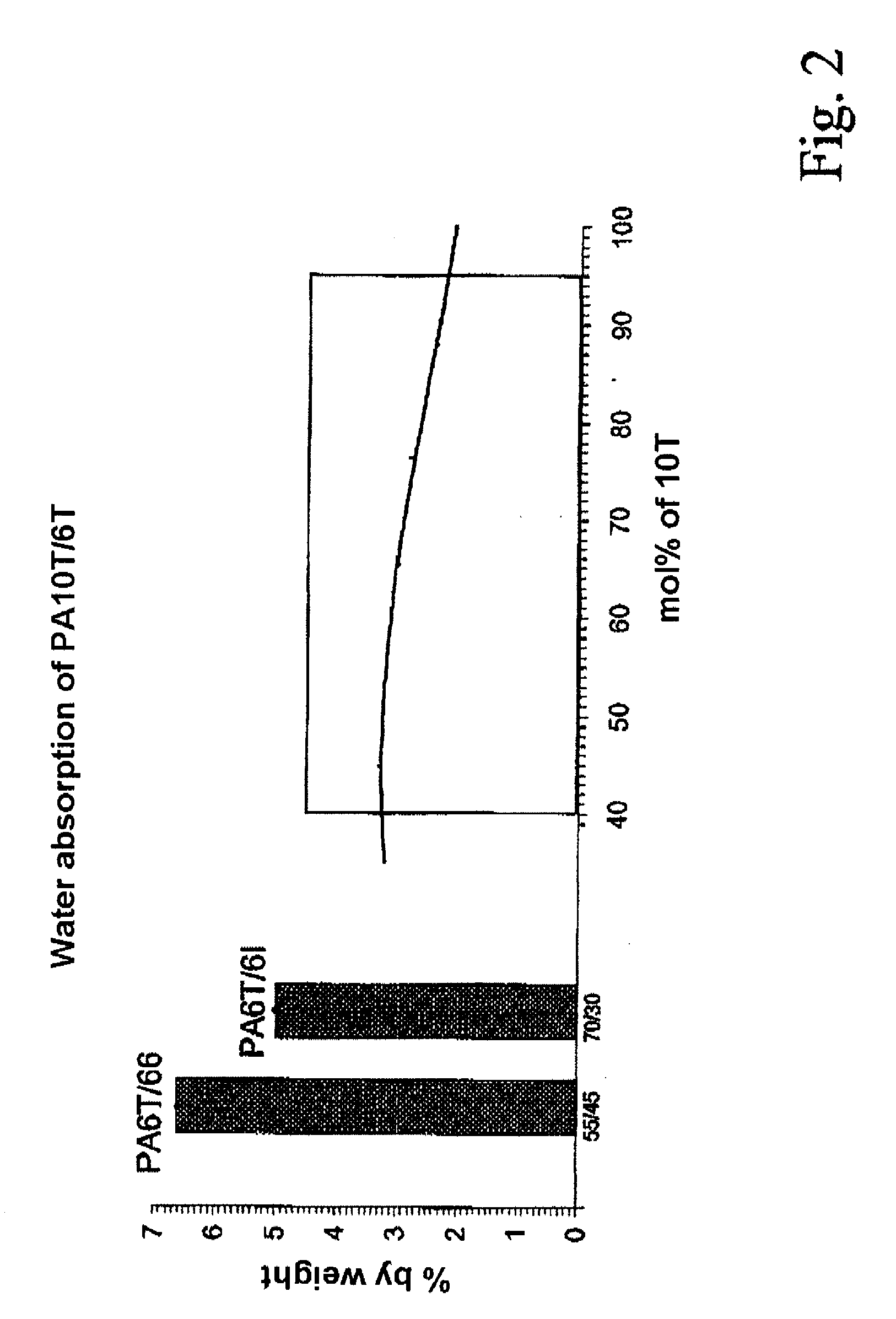

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

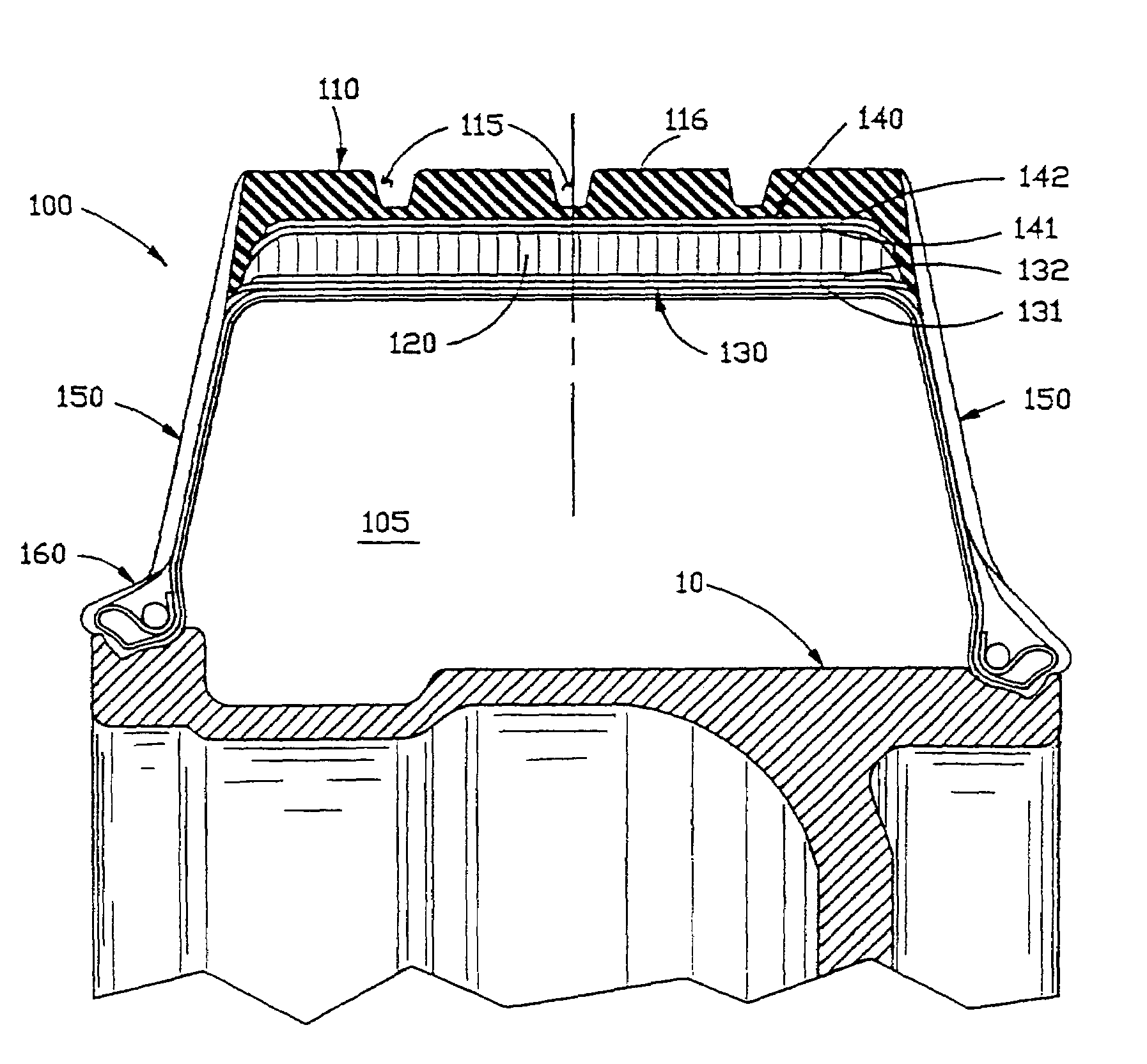

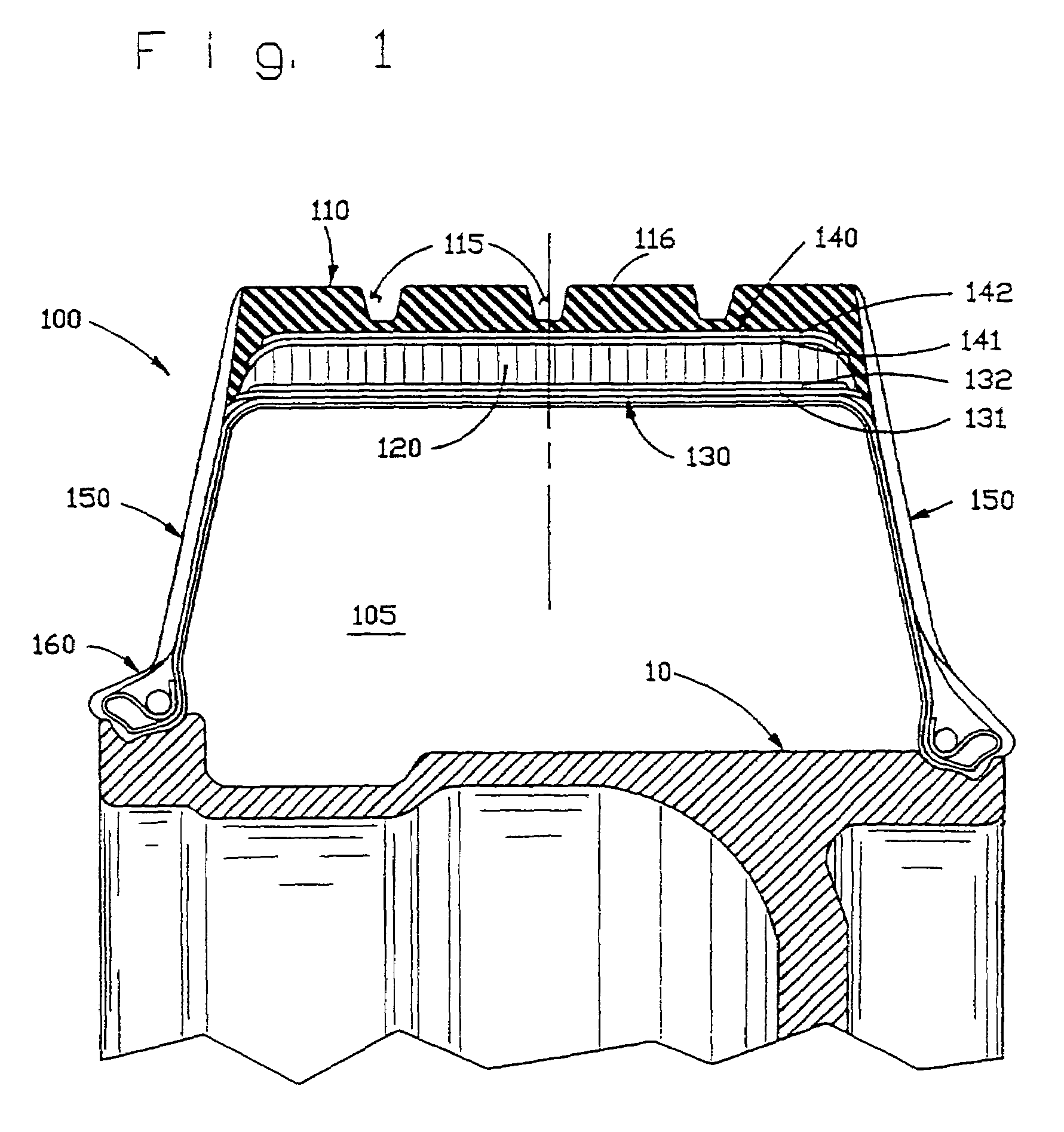

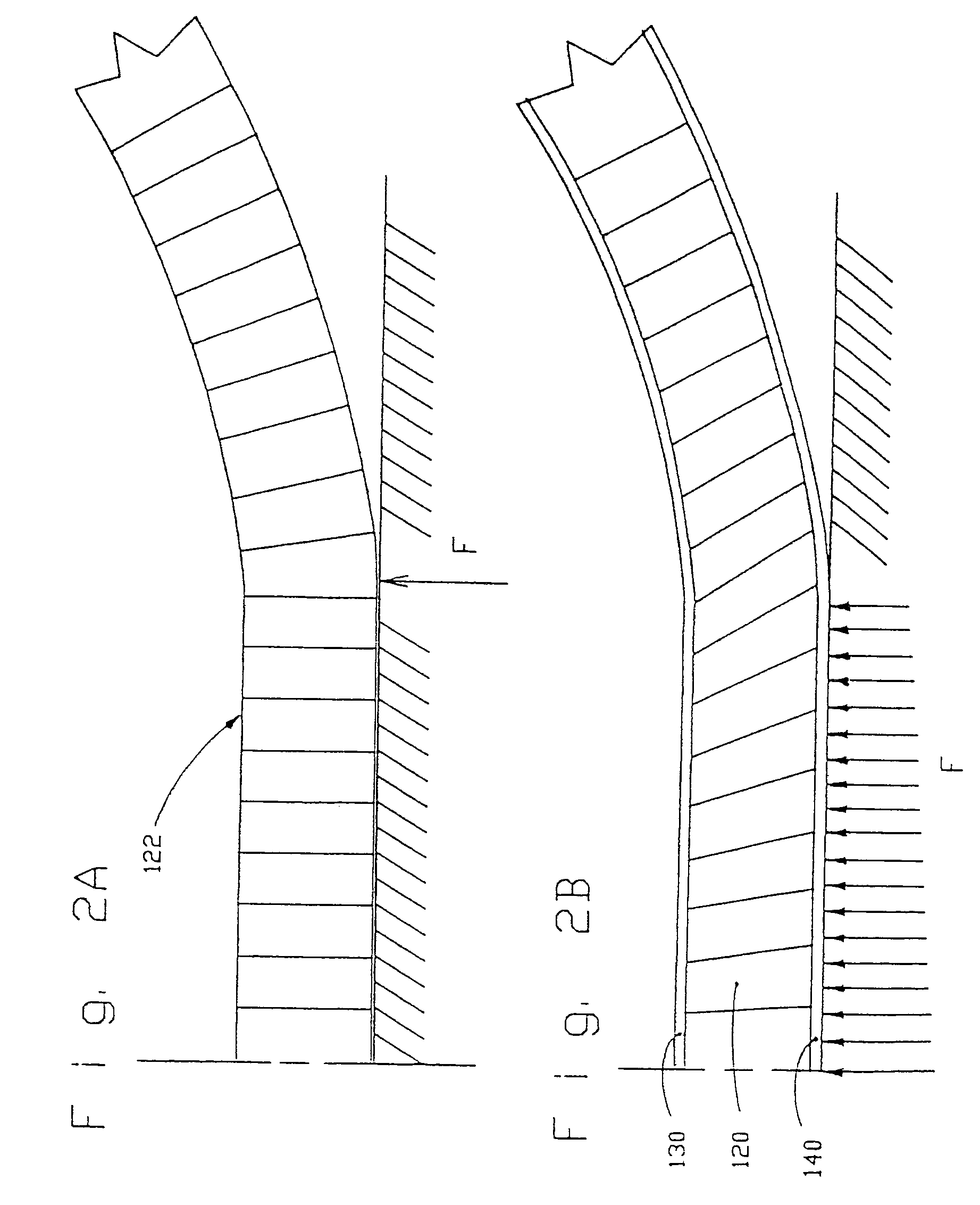

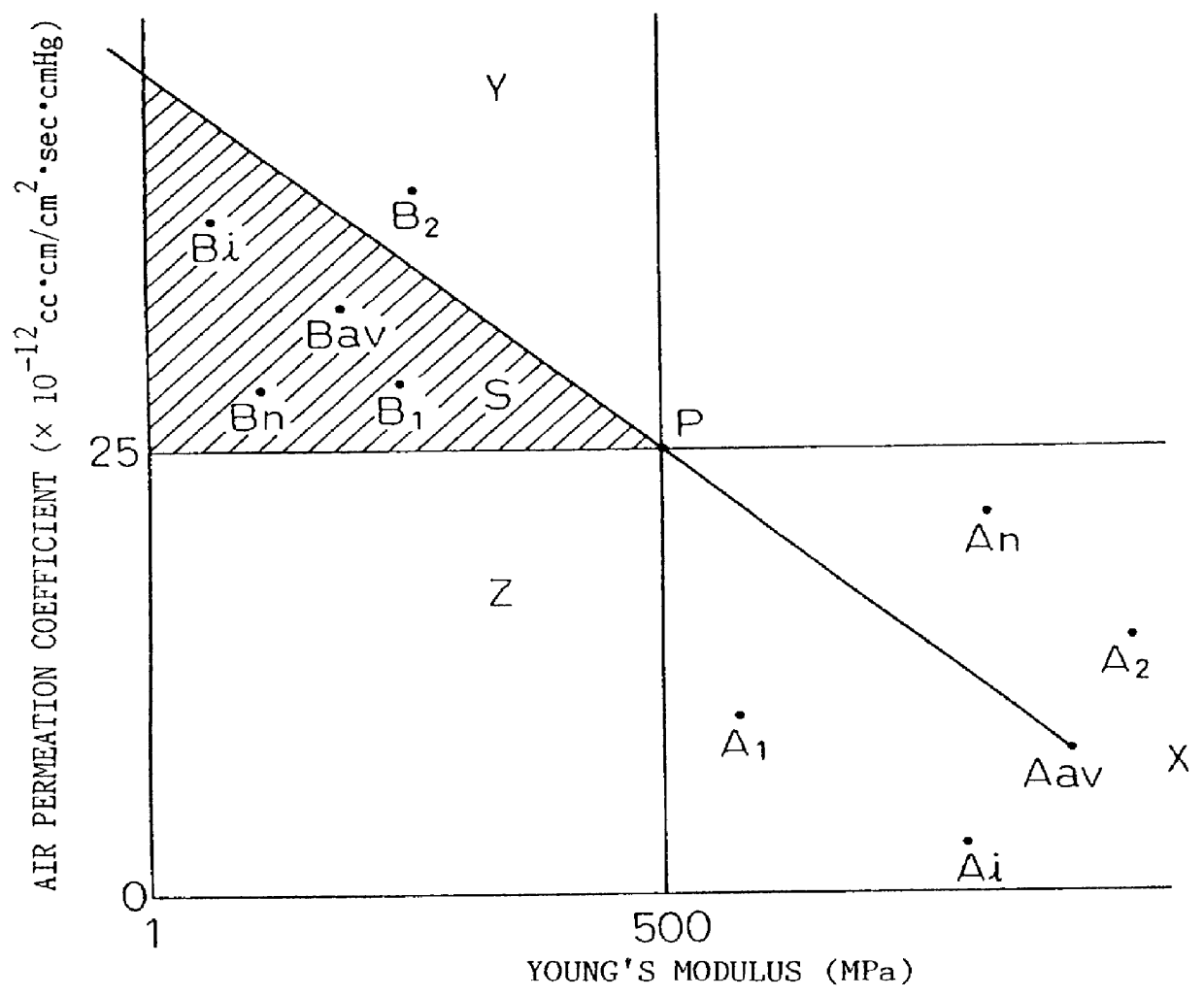

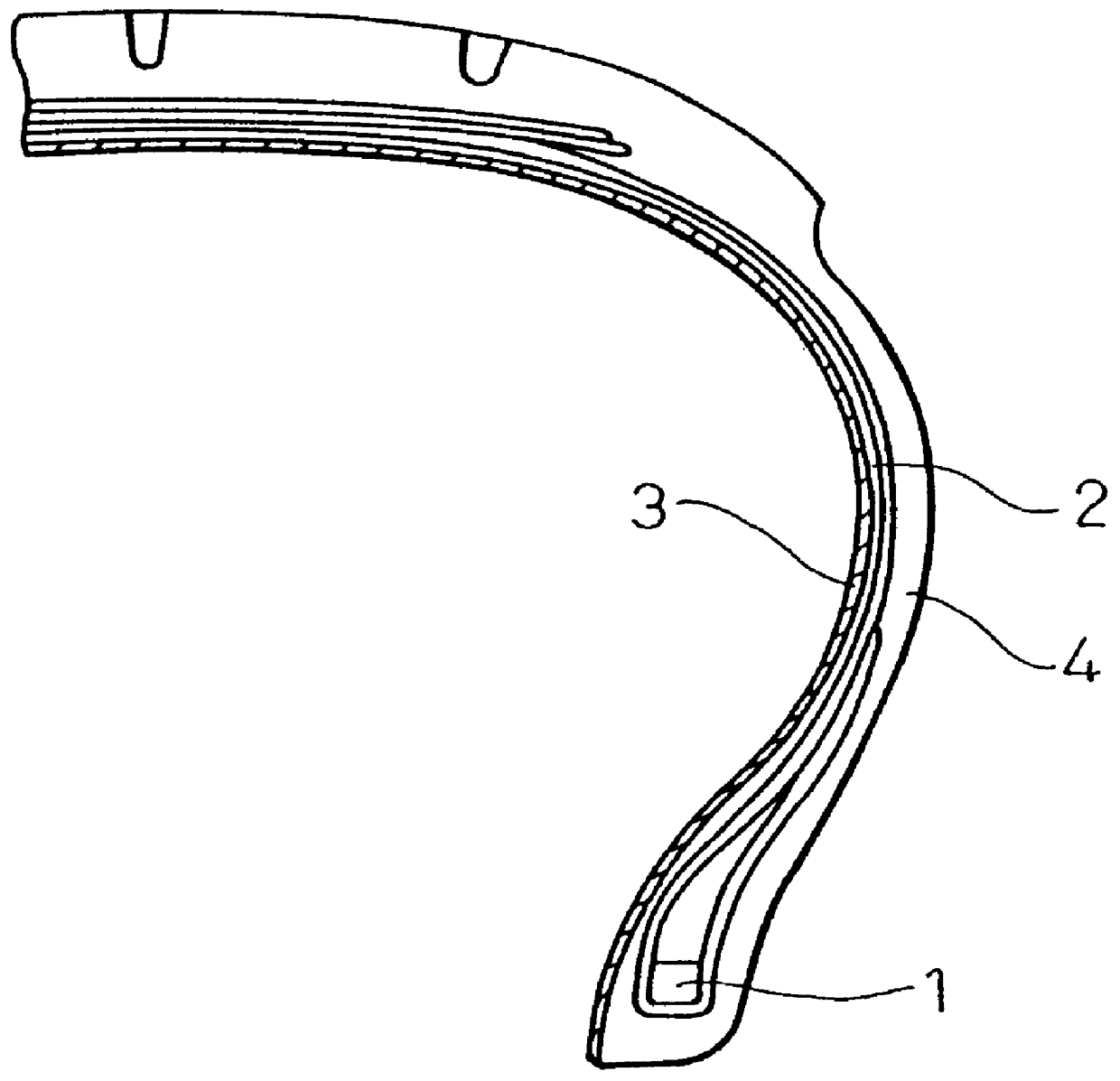

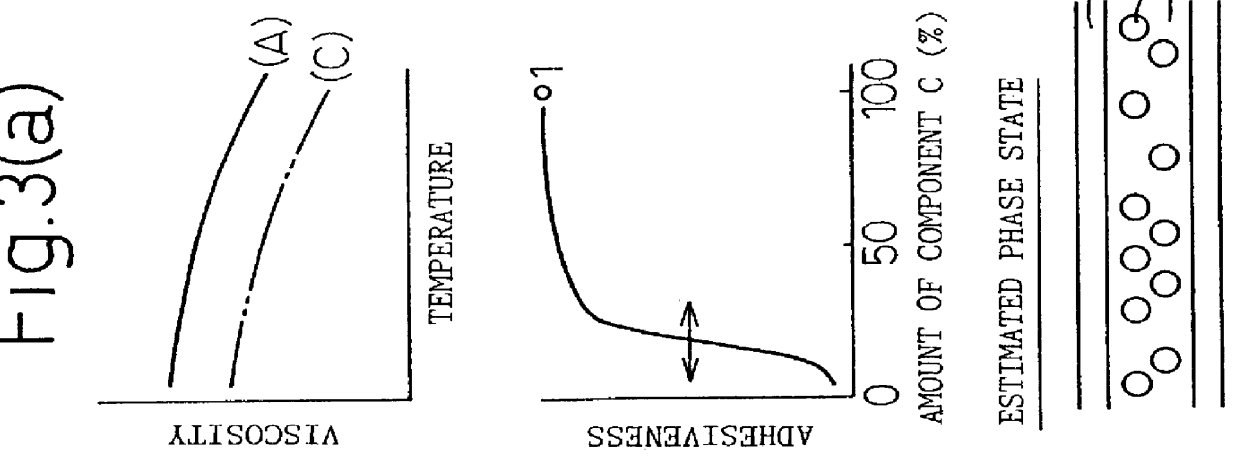

Pneumatic tire made by using lowly permeable thermoplastic elastomer composition in gas-barrier layer and thermoplastic elastomer composition for use therein

InactiveUS6062283AHigh elastomer ratioAbundant flexibilityWithout separate inflatable insertsWith separate inflatable insertsElastomerThermoplastic elastomer

PCT No. PCT / JP97 / 01514 Sec. 371 Date Jan. 28, 1998 Sec. 102(e) Date Jan. 28, 1998 PCT Filed May 2, 1997 PCT Pub. No. WO97 / 45489 PCT Pub. Date Dec. 4, 1997A pneumatic tire having an air permeation preventive layer comprising a low permeability thermoplastic elastomer composition comprising a thermoplastic elastomer having a thermoplastic resin composition as a continuous phase and a rubber composition as a dispersed phase, in which a barrier resin composition is contained, which low permeability thermoplastic elastomer composition has a phase structure in which the barrier resin composition is dispersed in the form of a flat state in the thermoplastic elastomer, is abundant in flexibility, is superior in gas permeation preventive property, and enables the tire to be reduced in weight.

Owner:YOKOHAMA RUBBER CO LTD

Hydrophilic polysiloxane compositions

The instant invention provides a method for improving the miscibility of the lower molecular weight unsaturated siloxane-polyether copolymers with the alpha , omega -divinylpolysiloxanes without loss of storage stability, or delay of cure at the vulcanization temperature, or loss of permanent hydrophilicity or other desirable features of the cured polysiloxane. The compositions of the present invention comprise one or more alpha , omega -divinylpolysiloxanes, unsaturated polysiloxane-polyether copolymers having from 2 to 5 silicon atoms per molecule which are preferably trisiloxanes, and a compatibilizing additive. The permanently hydrophilic, rapidly wettable polysiloxane compositions yield static water contact angles <50 DEG dynamic advancing contact angles of less than about 100.

Owner:GENERAL ELECTRIC CO

Gelatinous elastomer

An improved gelatinous elastomer is disclosed which uses an A-B-A triblock copolymer having a molecular weight in the range of 125,000 to 175,000, or about 150,000, and a plasticizer.

Owner:PURPLE INNOVATION LLC

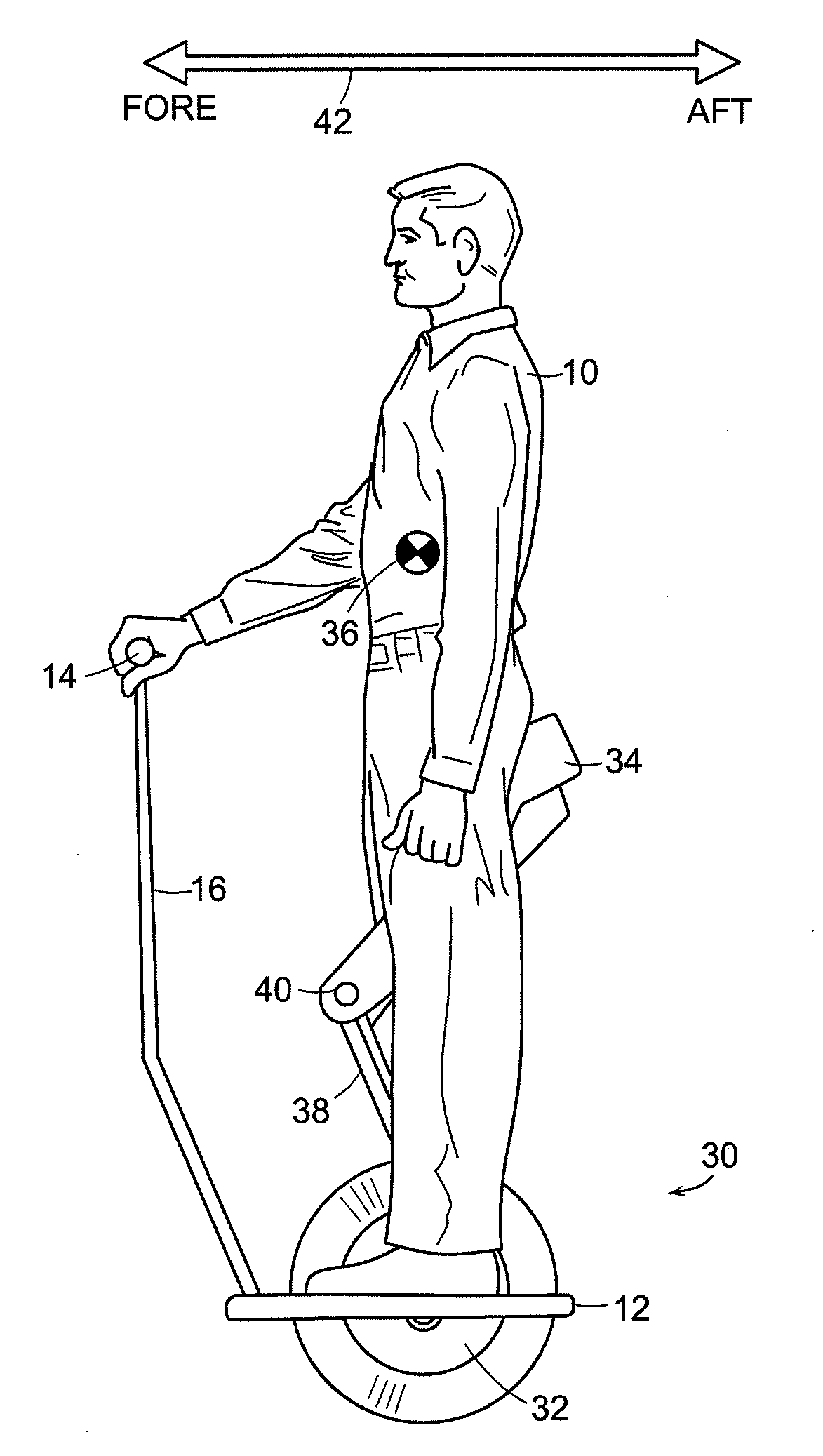

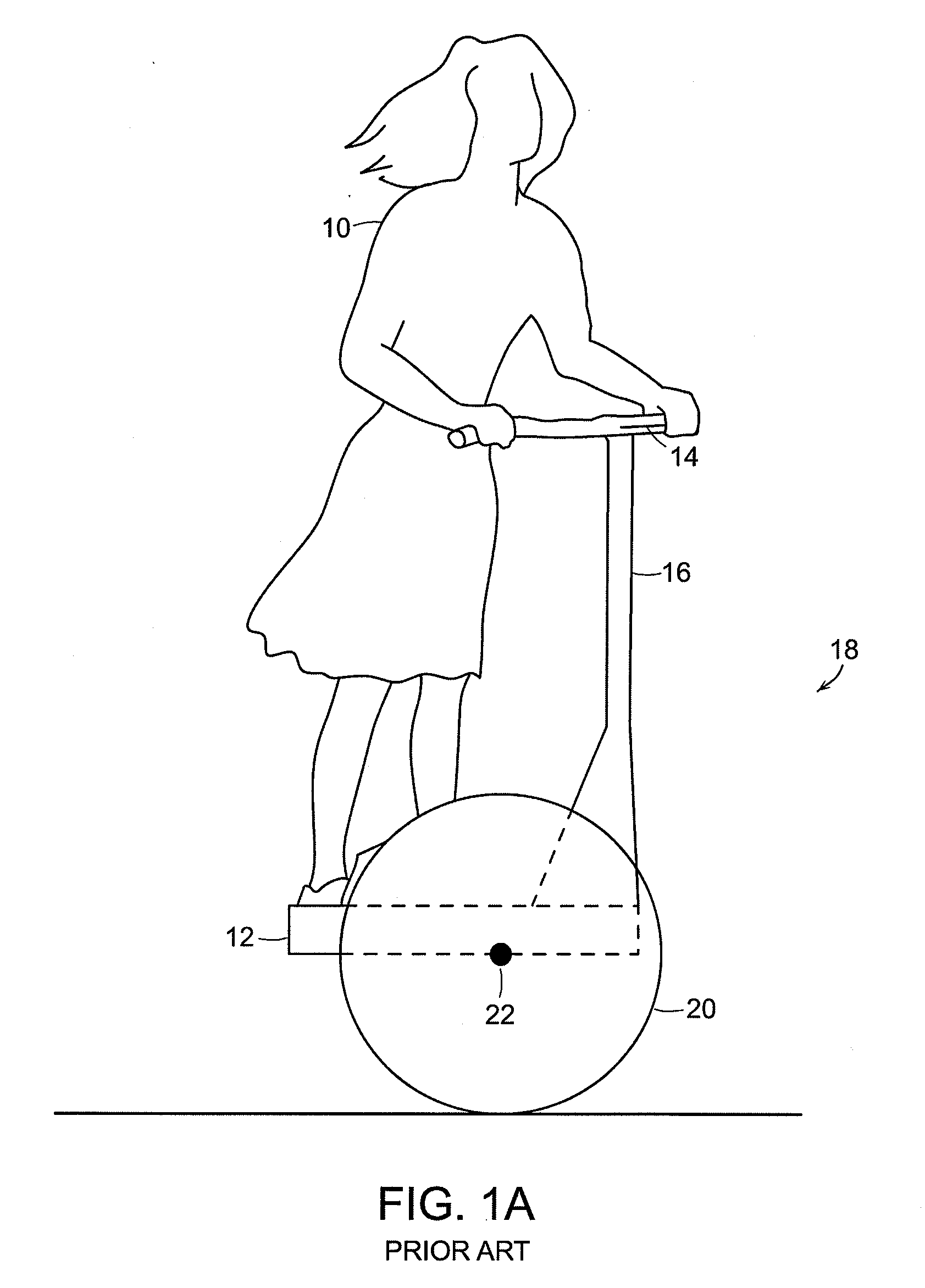

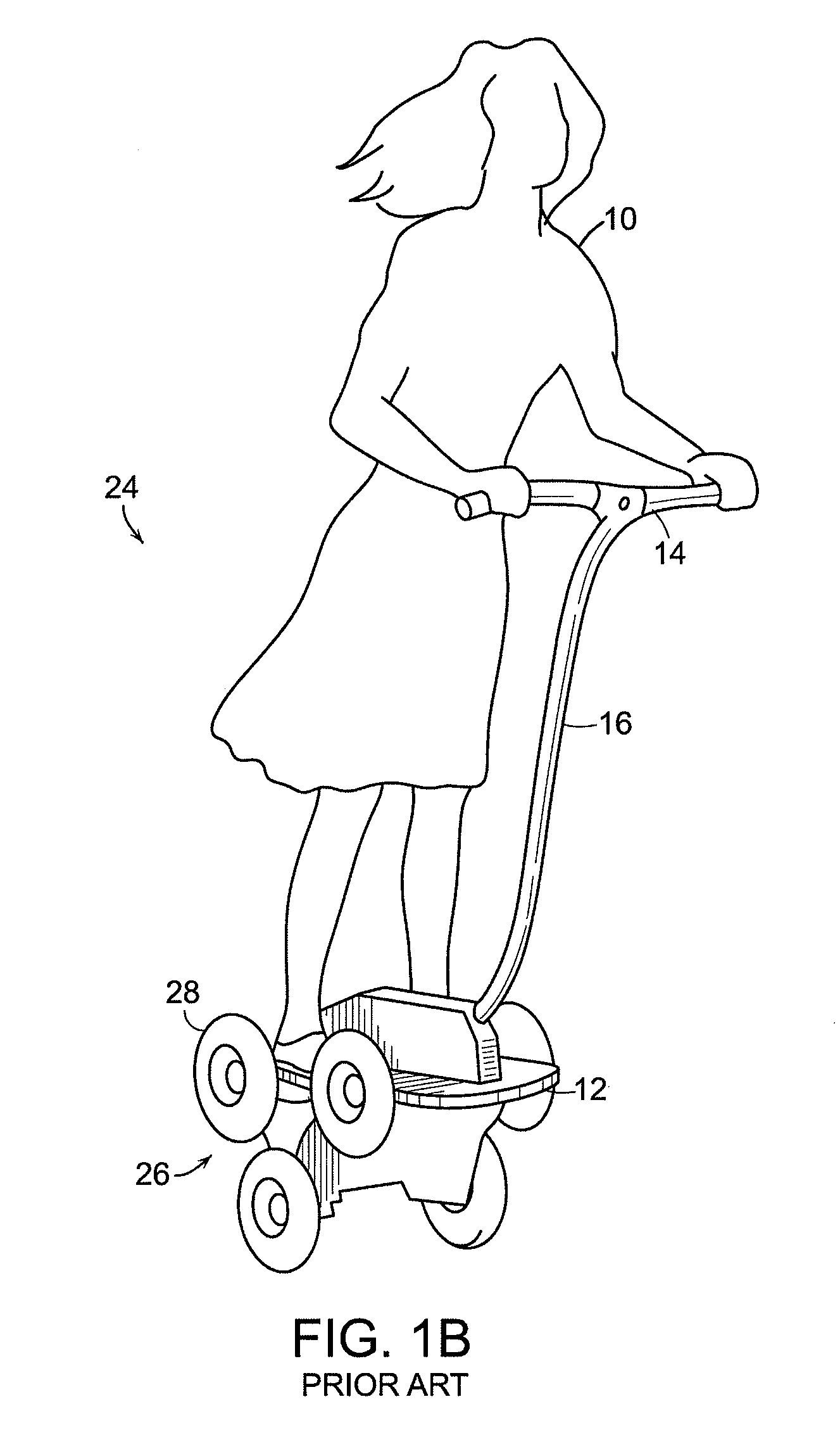

Apparatus and method for control of a vehicle

An apparatus and method for transporting a payload over a surface is provided. A vehicle supports a payload with a support partially enclosed by an enclosure. Two laterally disposed ground-contacting elements are coupled to at least one of the enclosure or support. A motorized drive is coupled to the ground-contacting elements. A controller coupled to the drive governs the operation of the drive at least in response to the position of the center of gravity of the vehicle to dynamically control balancing of the vehicle.

Owner:SEGWAY INC

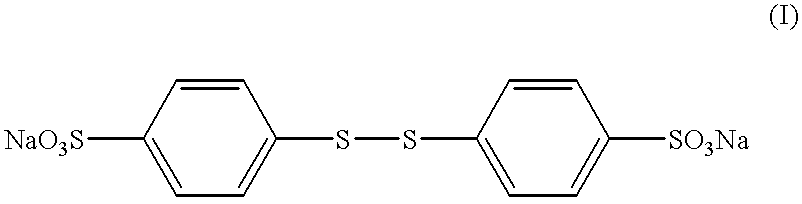

Carbon black

A carbon black with organic groups in which the organic groups are linked to the black via a sulfide- and / or polysulfide bridge. Furthermore, a method of producing the black of the invention is described in which carbon black and compounds of the general formula R-Sy-R are reacted. The carbon blacks of the invention can be used as filler, UV stabilizer, conductivity black and pigment.

Owner:DEGUSSA AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com