Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391 results about "Precursor polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

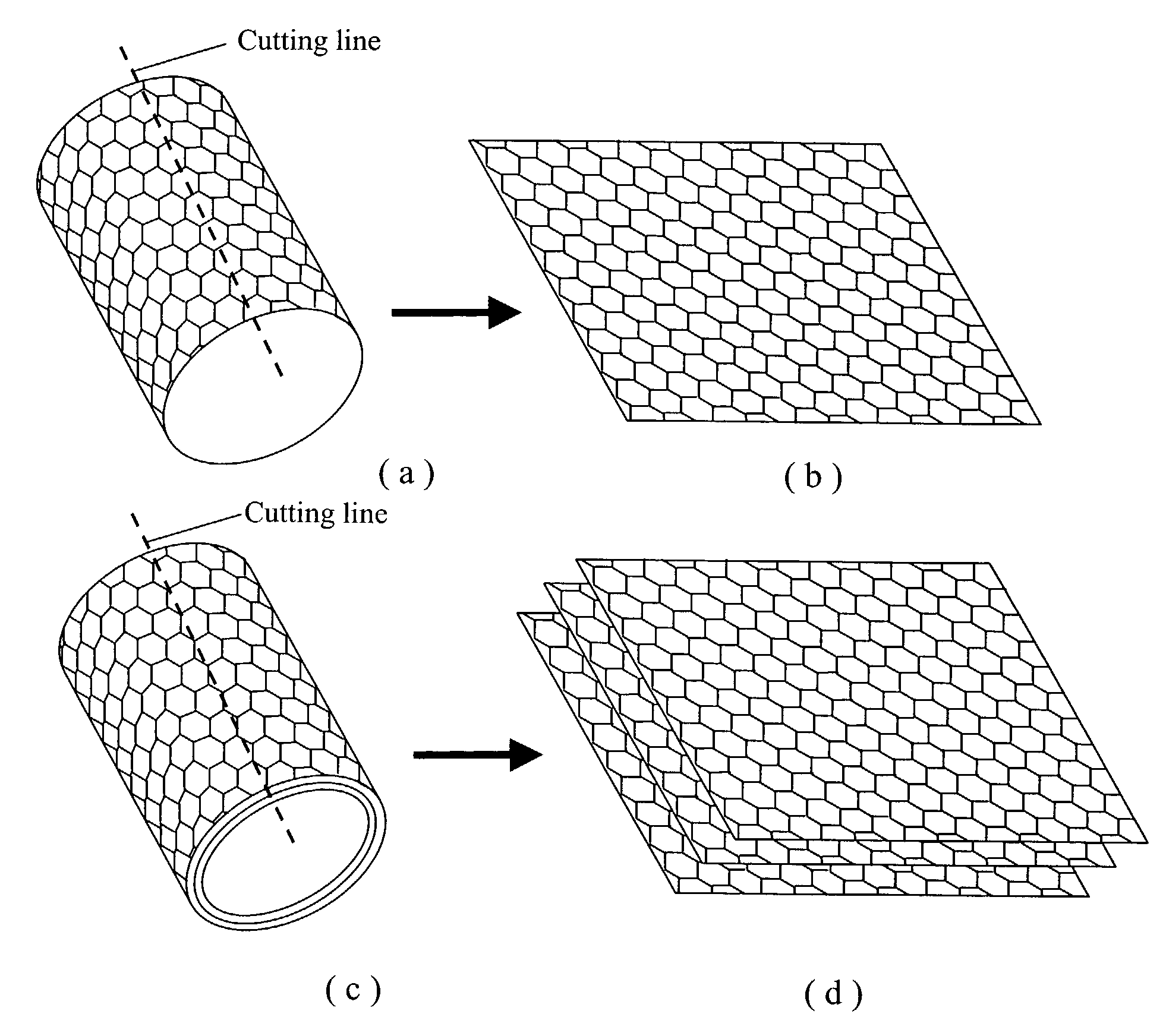

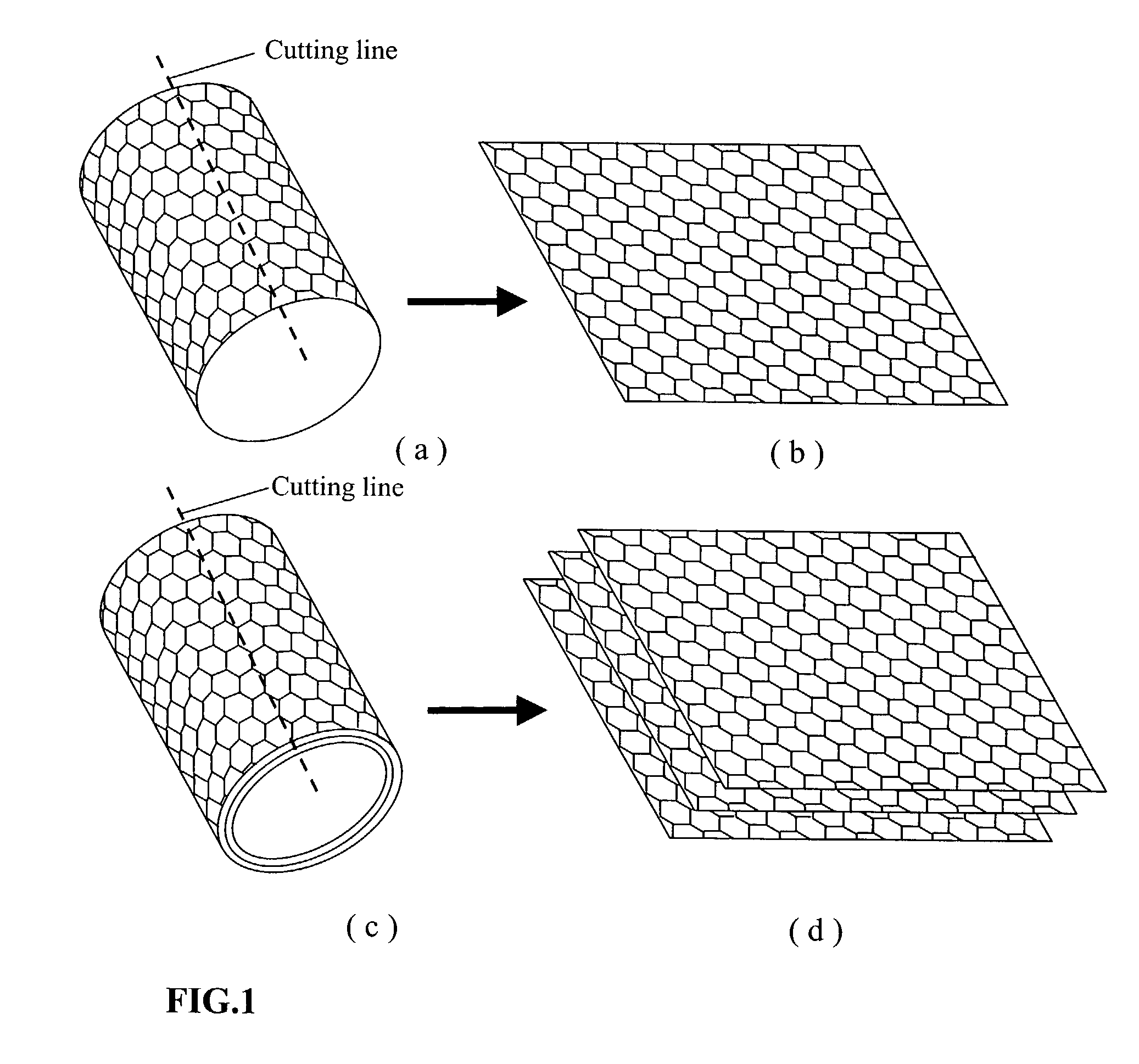

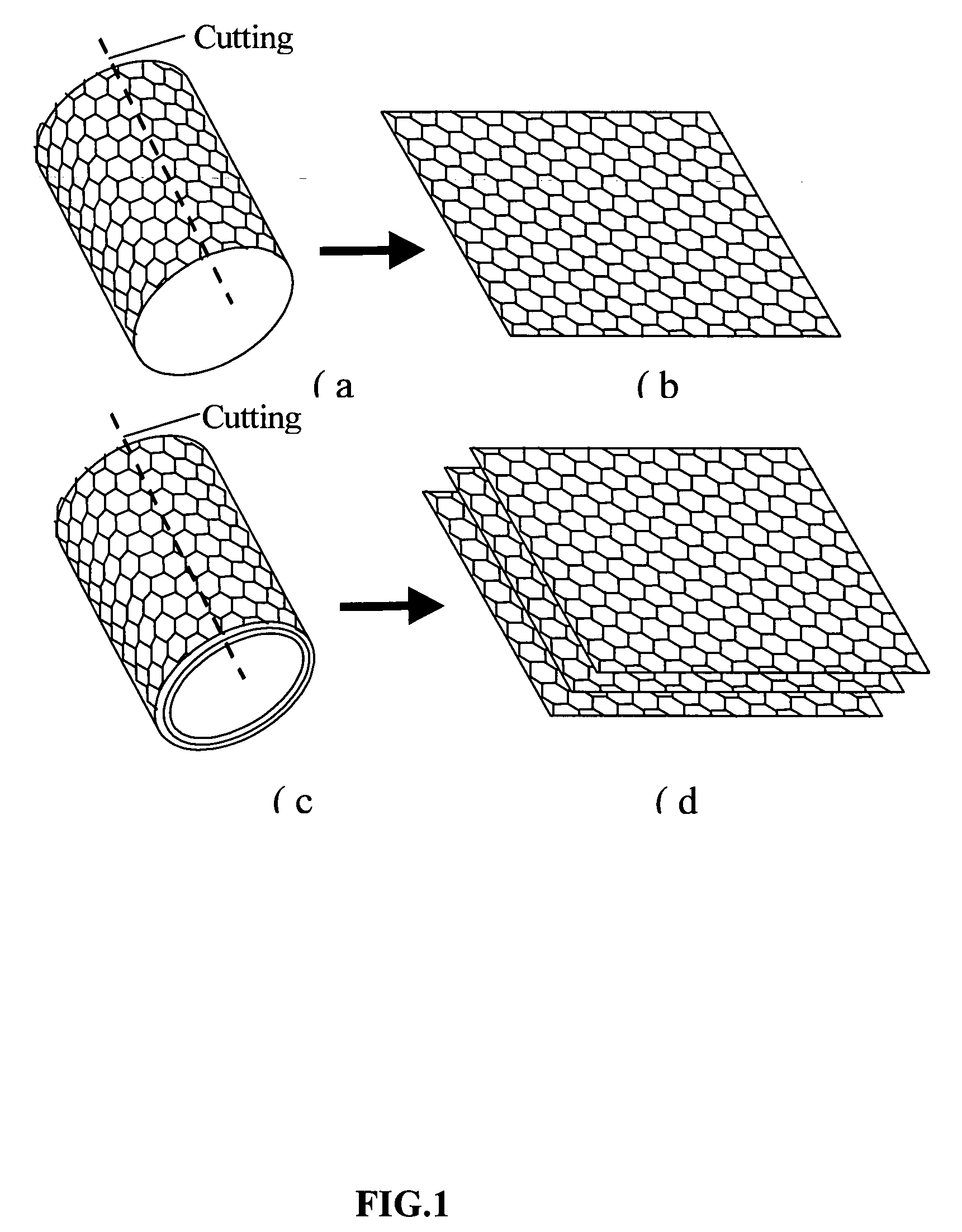

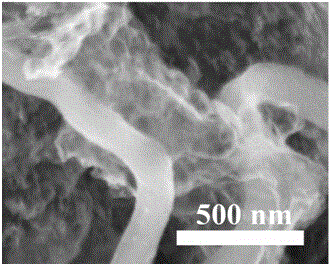

Nano-scaled graphene plates

A nano-scaled graphene plate material and a process for producing this material. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:GLOBAL GRAPHENE GRP INC

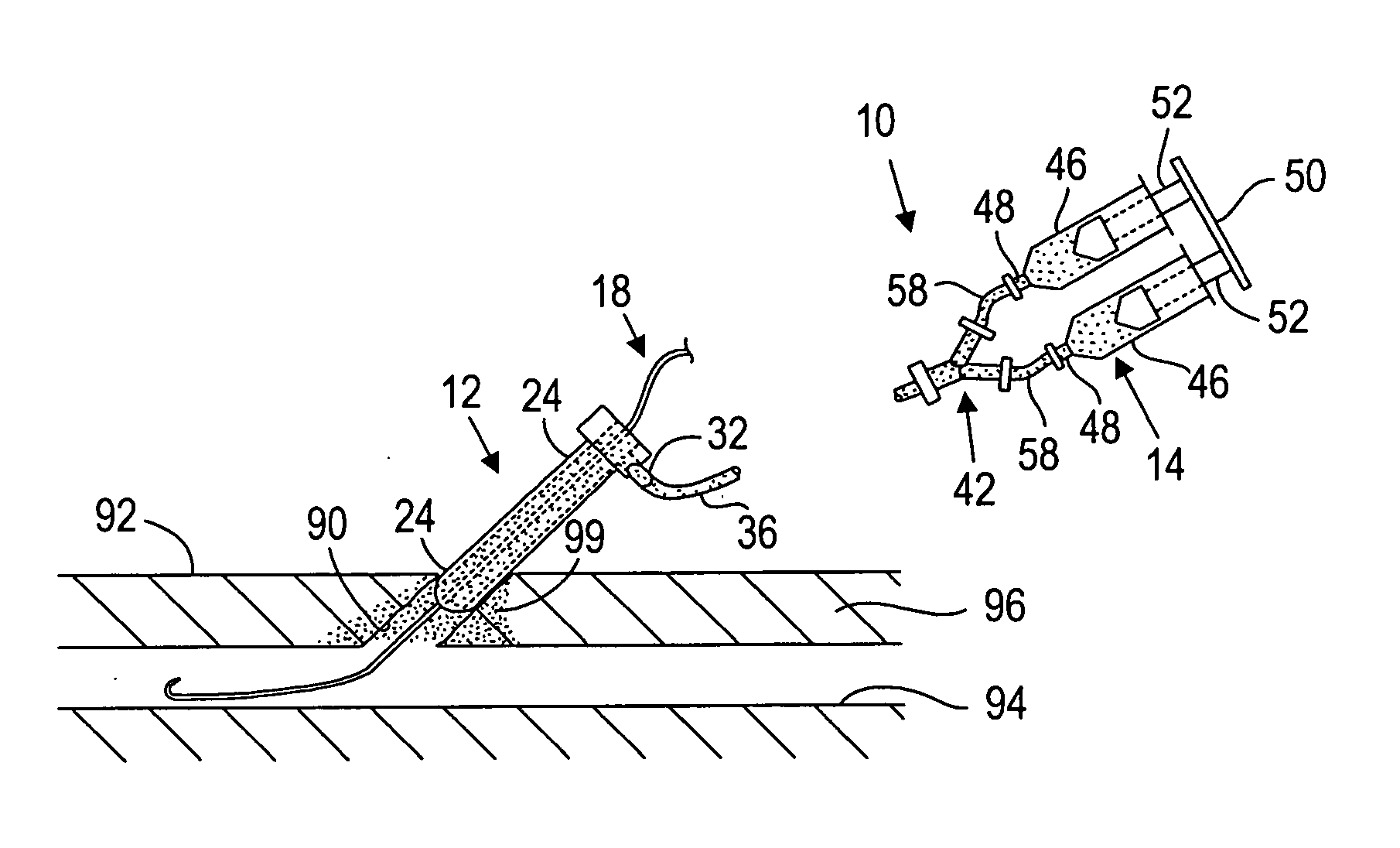

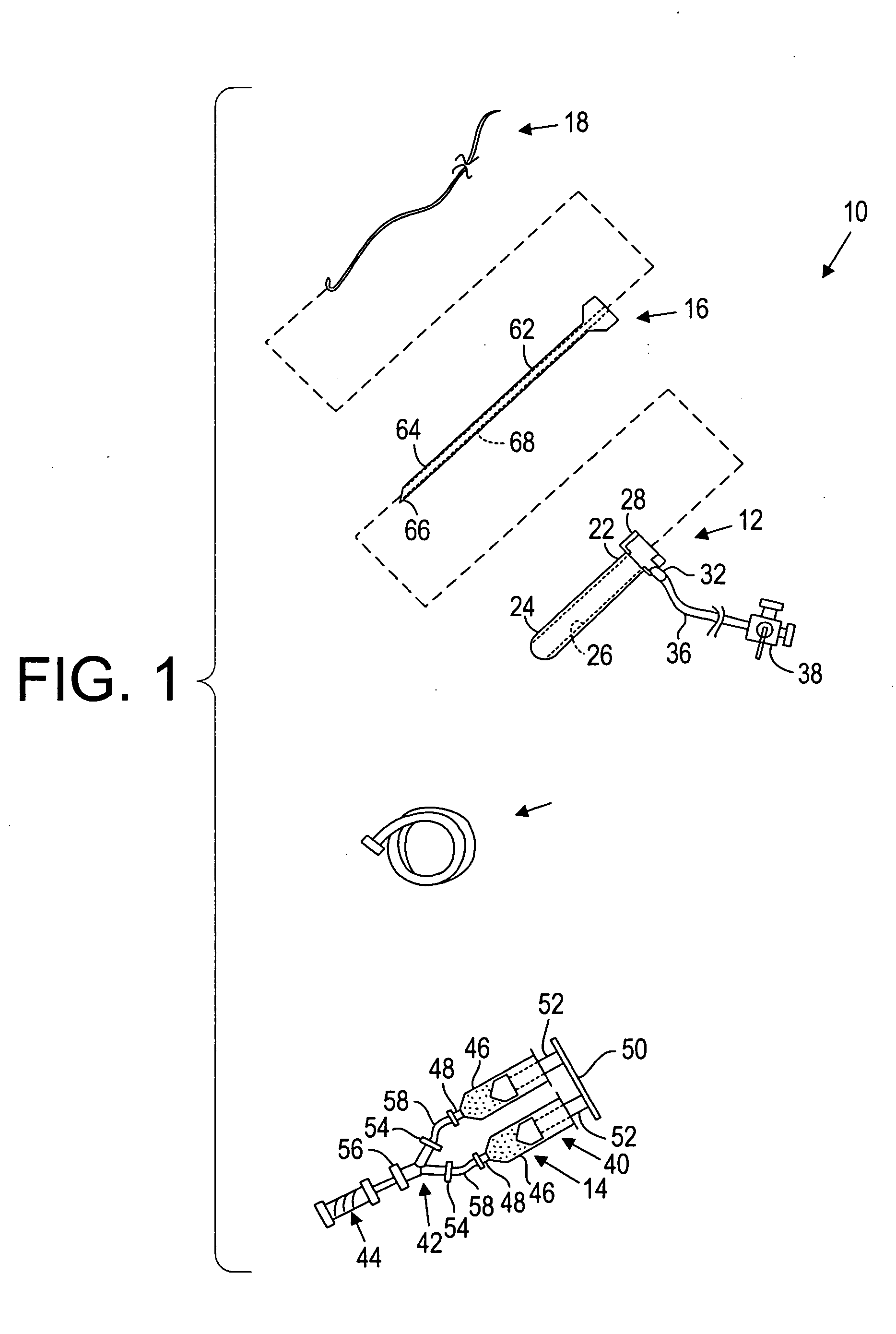

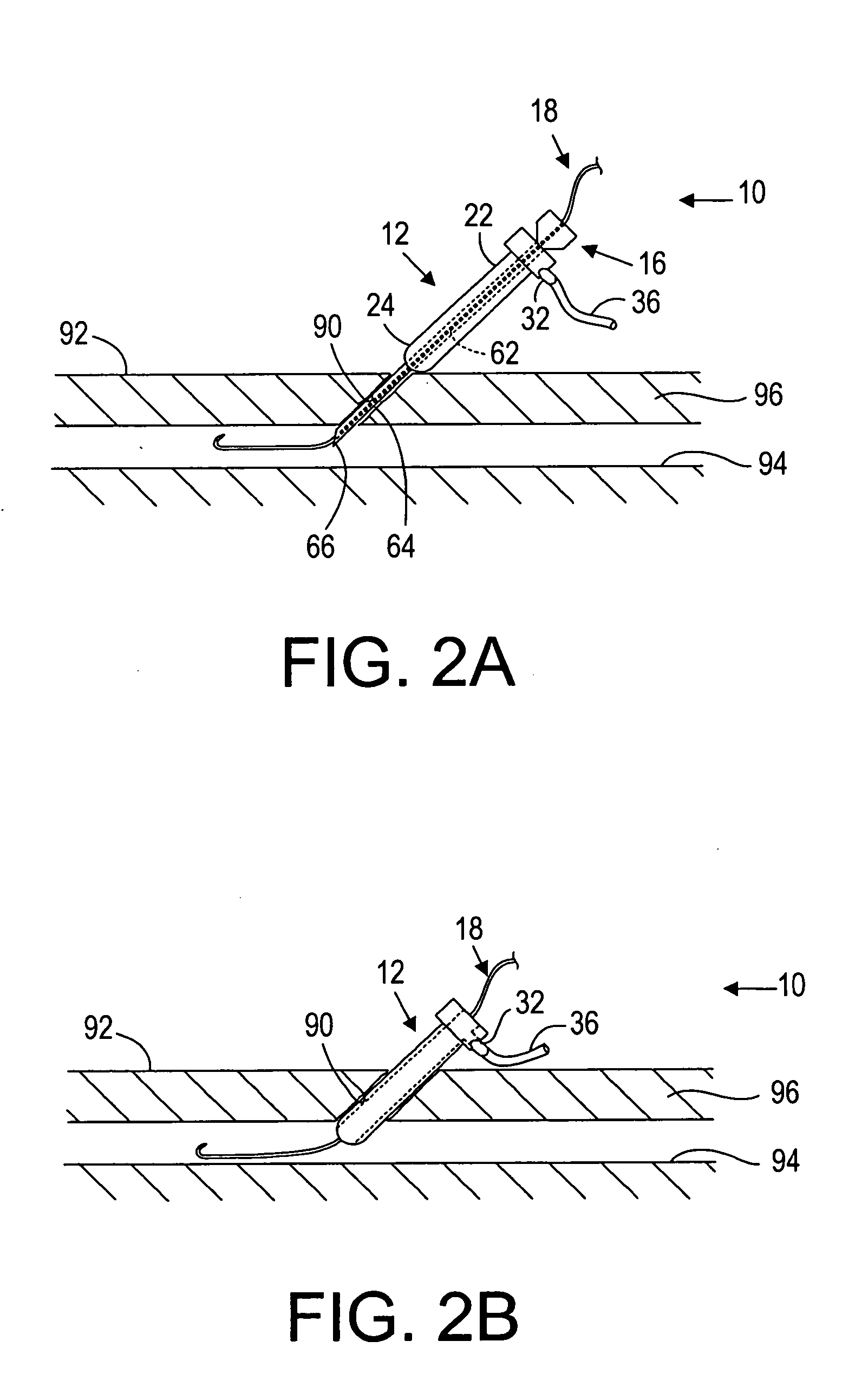

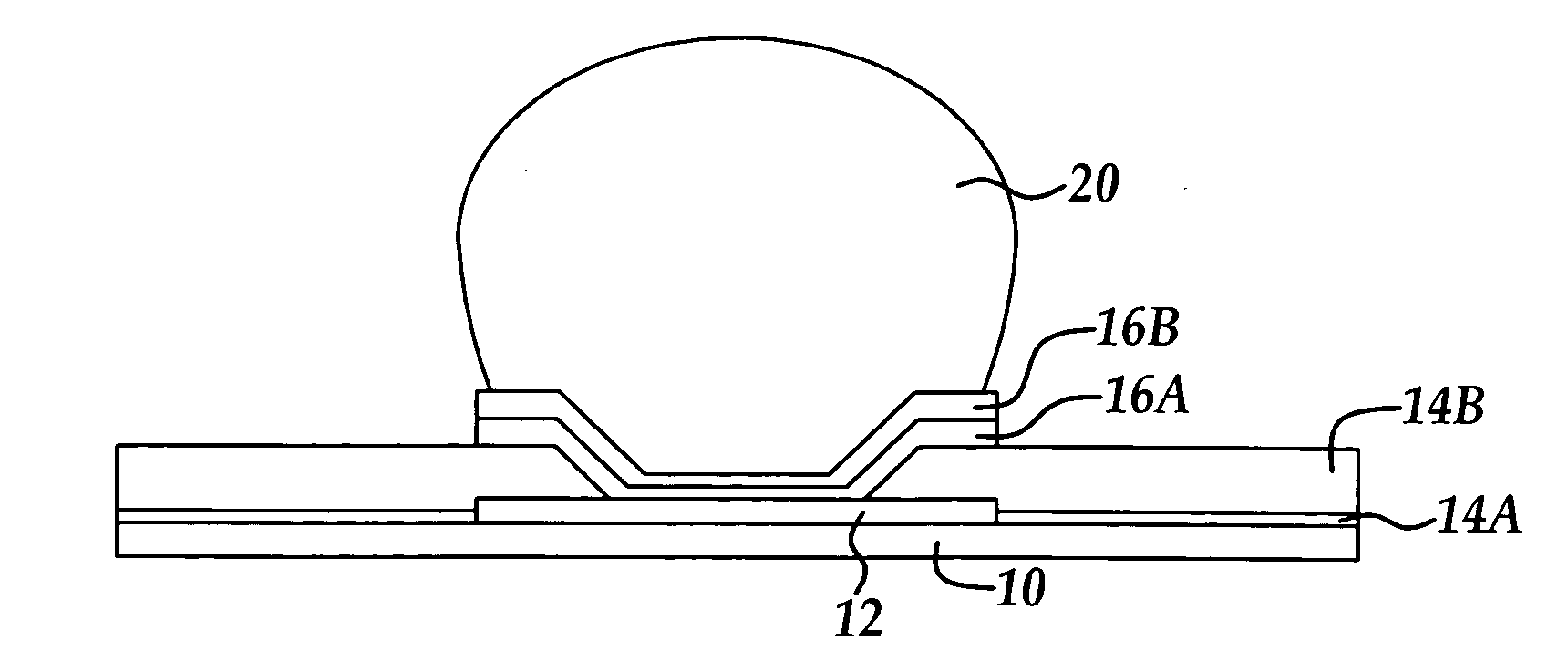

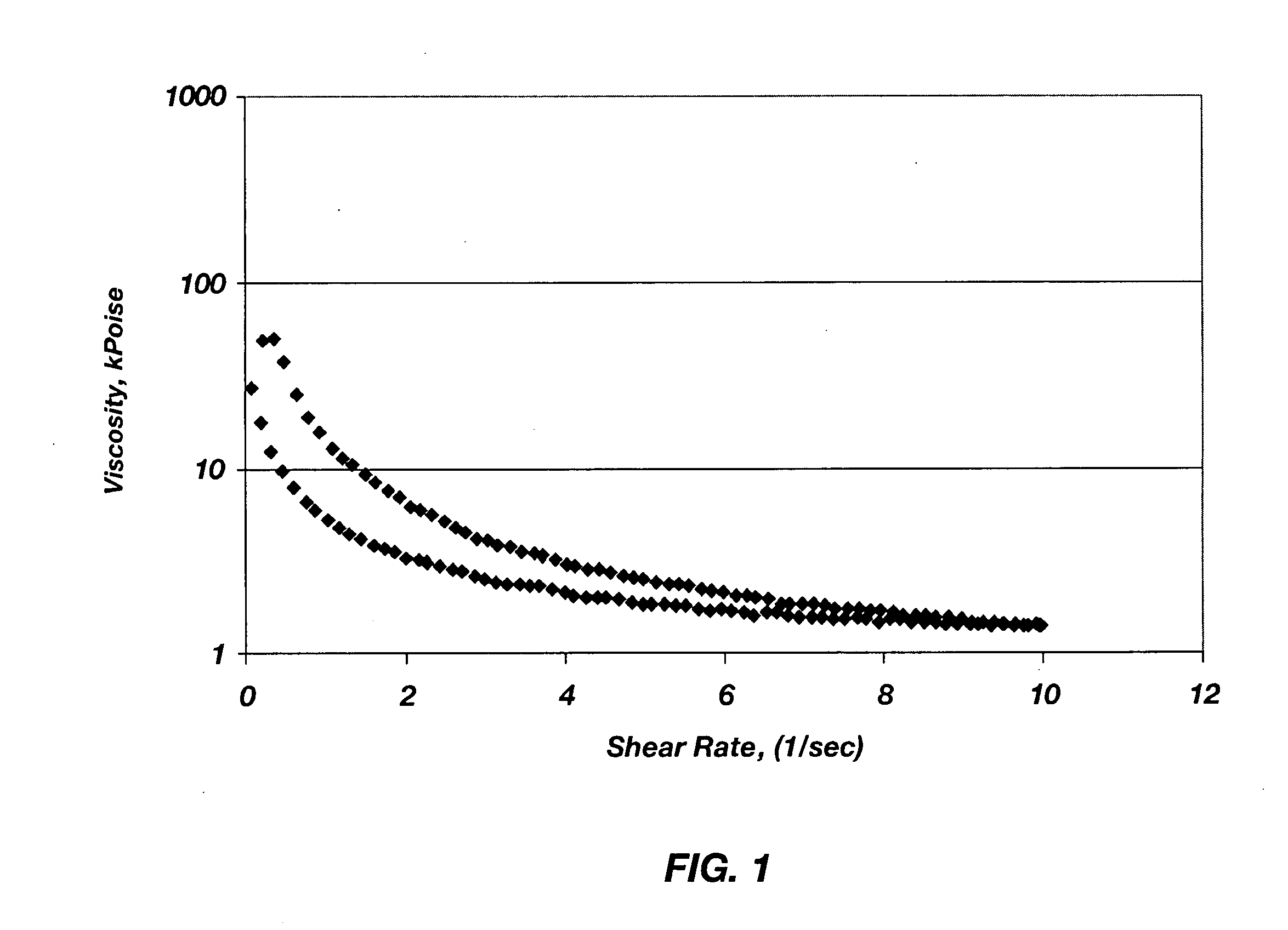

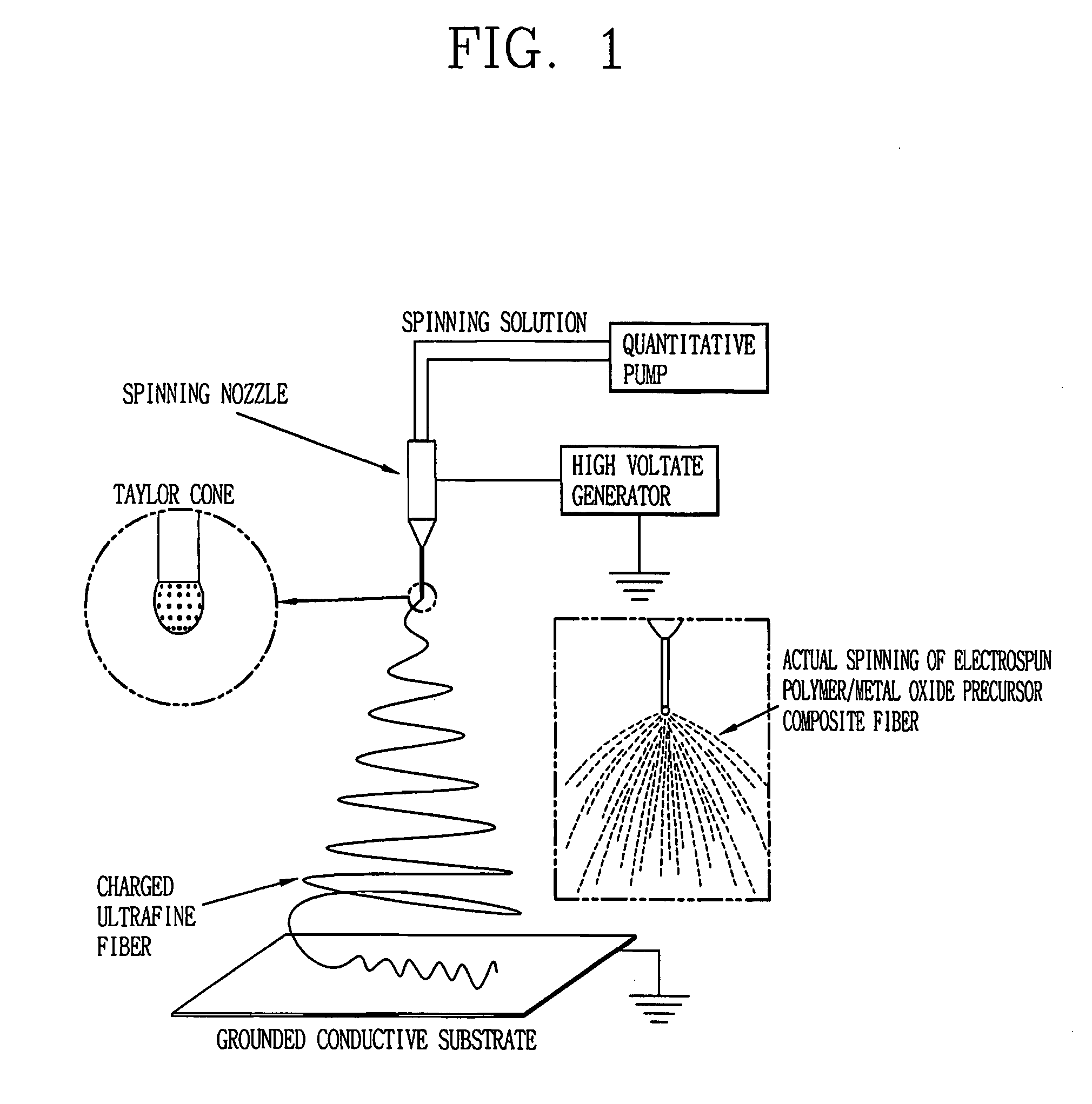

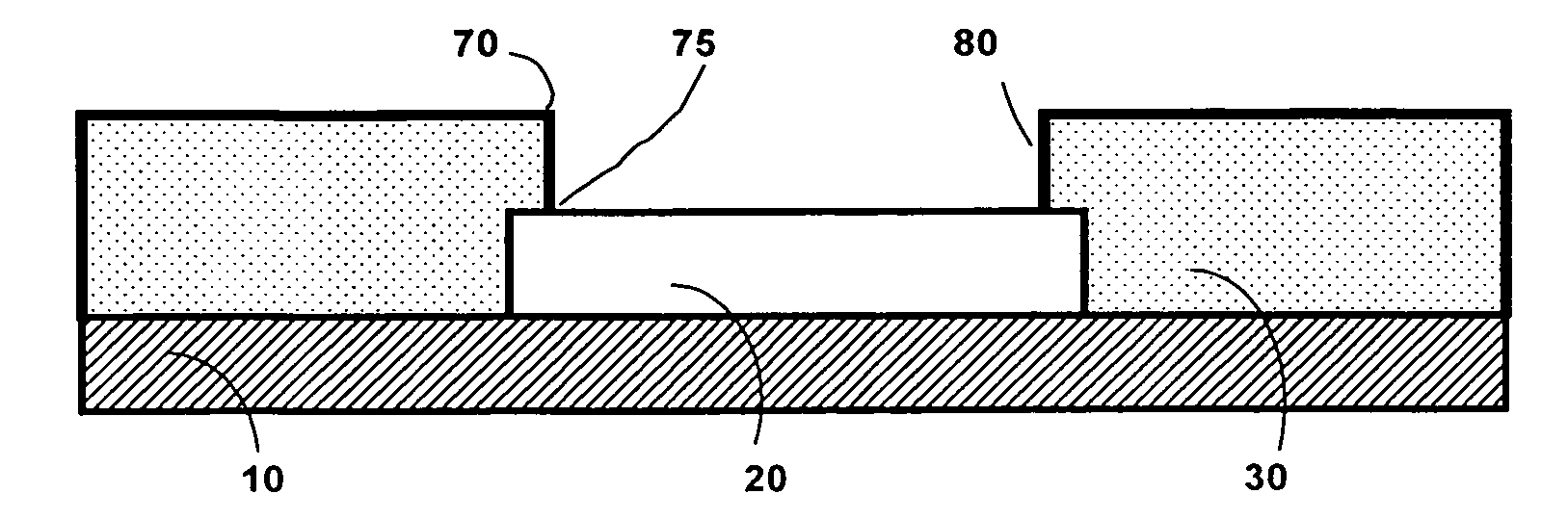

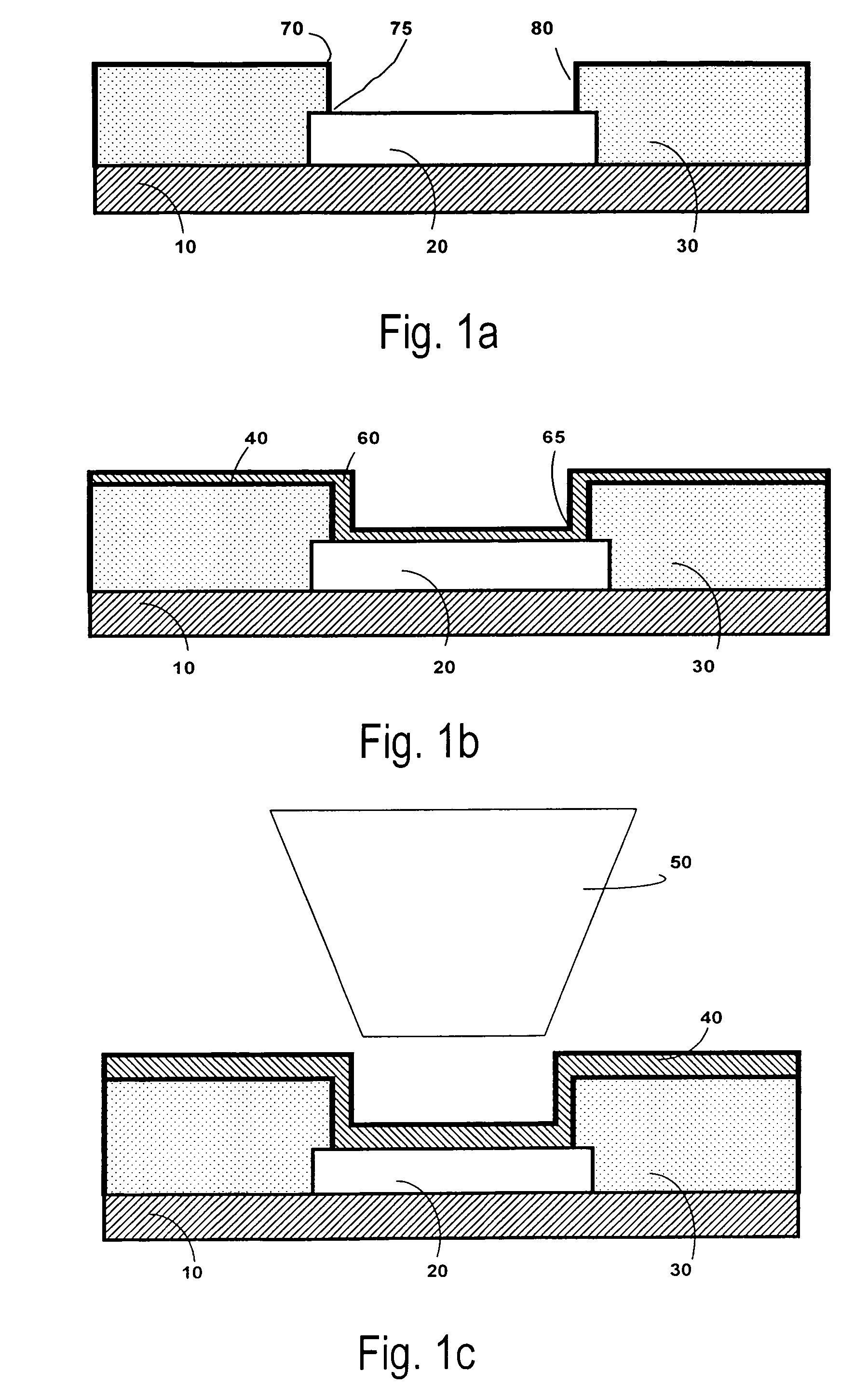

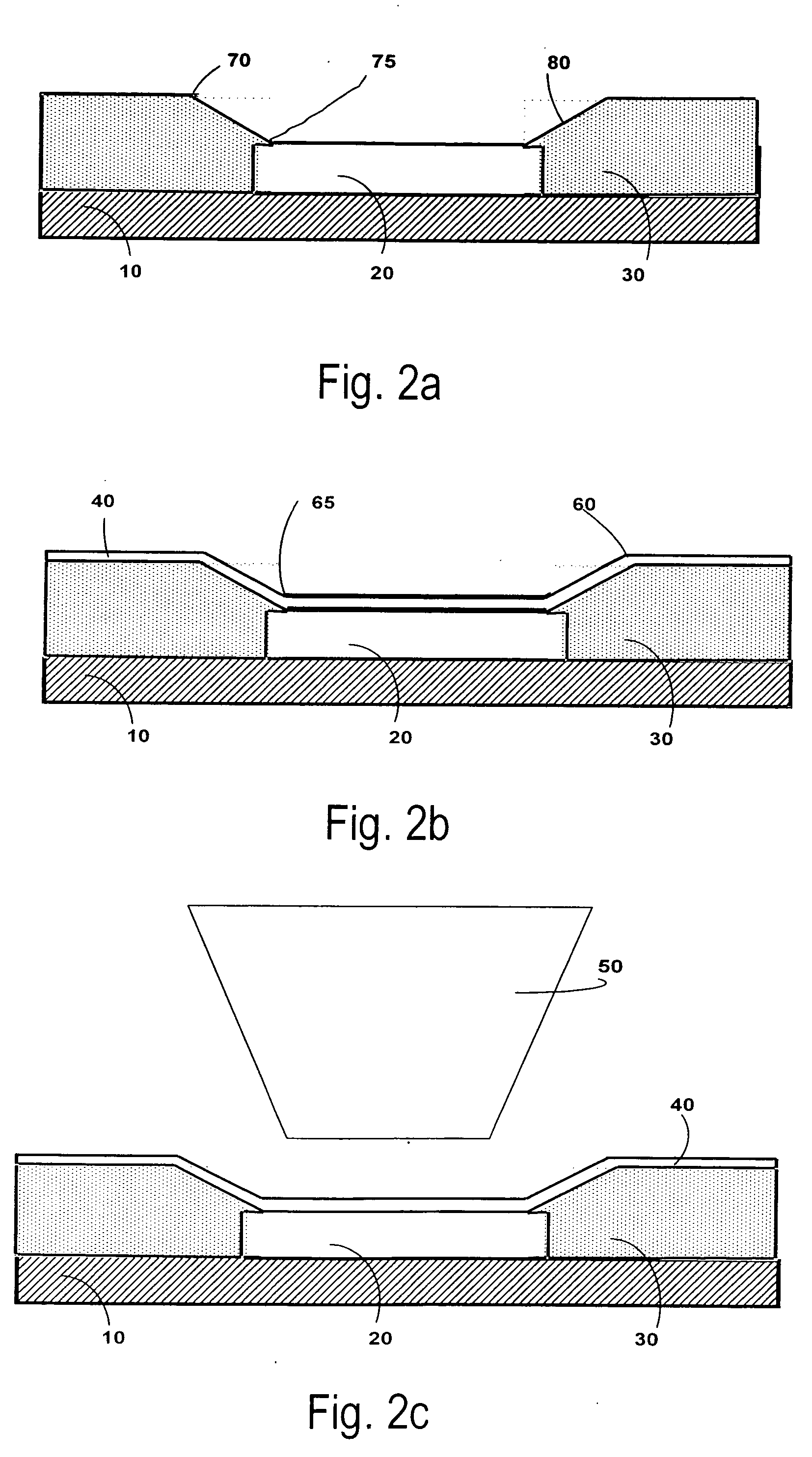

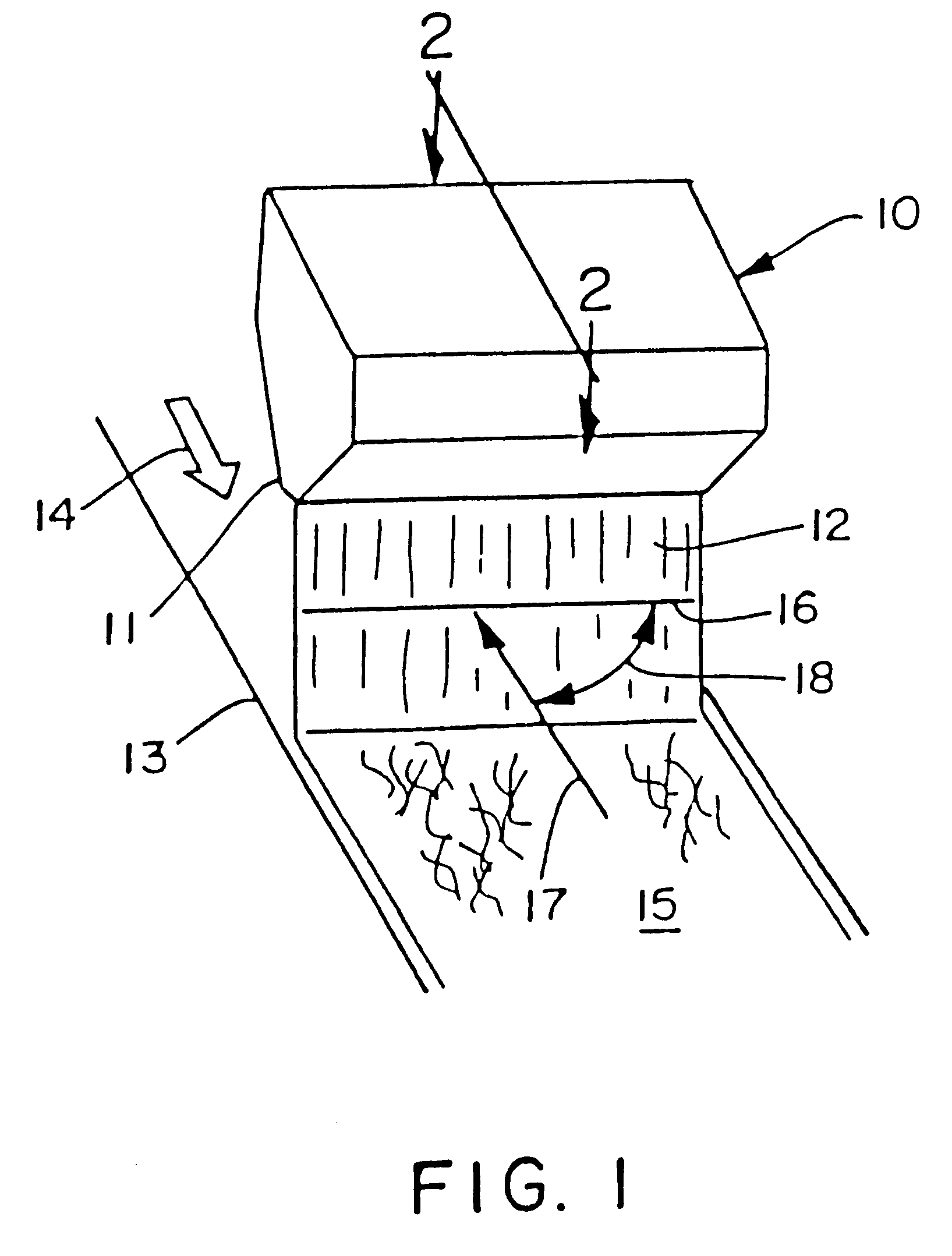

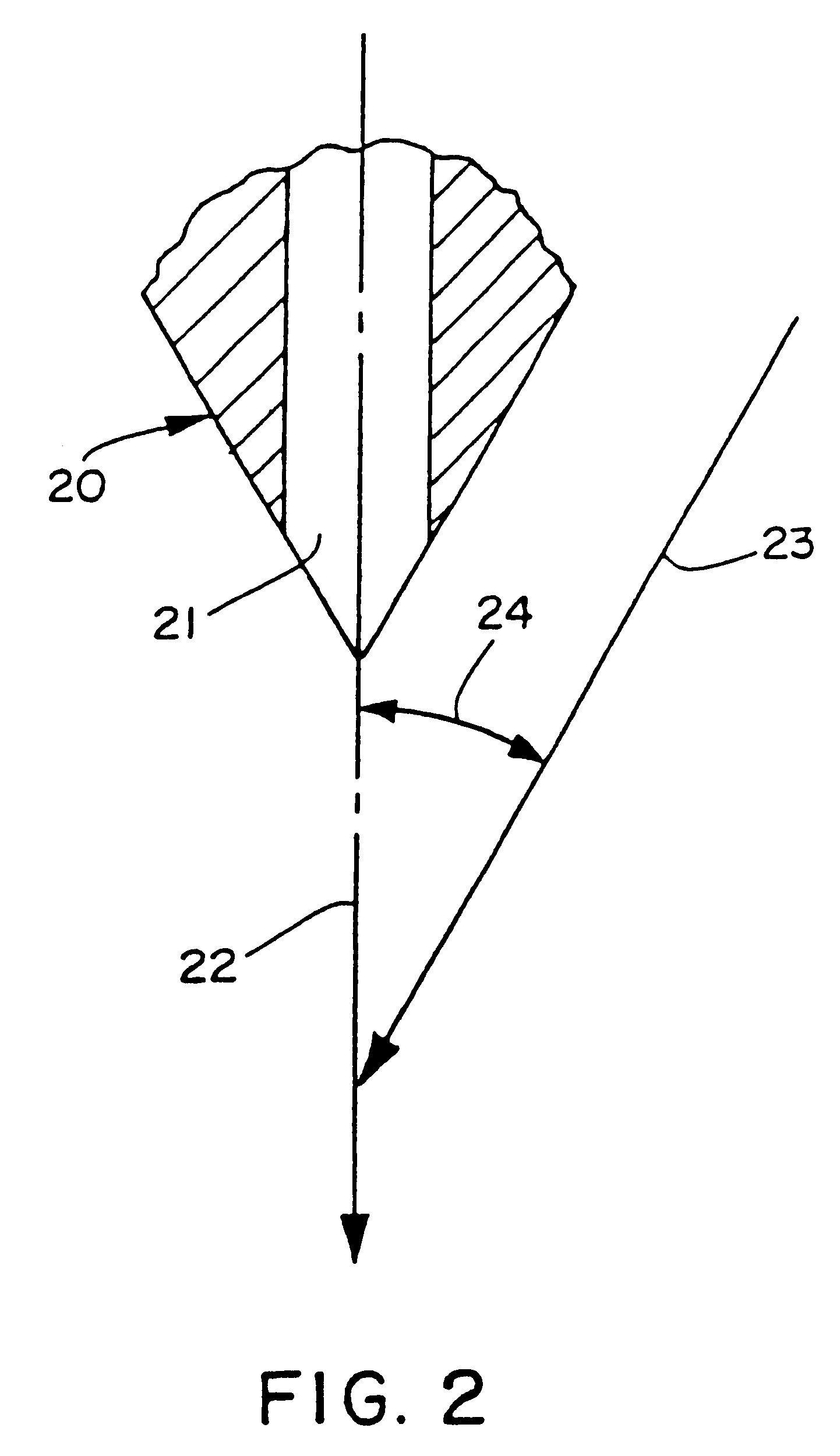

Apparatus and methods for delivering sealing materials during a percutaneous procedure to facilitate hemostasis

InactiveUS20050149117A1Good hemostasisImprove sealingInfusion syringesSurgical veterinaryIntroducer sheathPrecursor polymer

Apparatus and methods are provided for sealing a puncture extending through tissue to a blood vessel. A delivery sheath is introduced-into the puncture, and a sealing compound, e.g., precursor polymers that mix to create a hydrogel, is introduced through the delivery sheath into the puncture. The delivery sheath is then removed, an introducer sheath is advanced through the puncture into the vessel, and instruments are introduced through the introducer sheath into the vessel to perform a medical procedure. After completing the procedure, the introducer sheath is withdrawn. The sealing compound may expand into the puncture and / or tissue recoil of the surrounding tissue may cause the sealing compound to at least partially occlude the puncture to facilitate sealing and / or hemostasis.

Owner:ACCESSCLOSURE

Process for nano-scaled graphene plates

A process for producing a nano-scaled graphene plate. The material comprises a sheet of graphite plane or a multiplicity of sheets of graphite plane. The graphite plane is composed of a two-dimensional hexagonal lattice of carbon atoms and the plate has a length and a width parallel to the graphite plane and a thickness orthogonal to the graphite plane with at least one of the length, width, and thickness values being 100 nanometers or smaller. The process for producing nano-scaled graphene plate material comprises the steps of: a). partially or fully carbonizing a precursor polymer or heat-treating petroleum or coal tar pitch to produce a polymeric carbon containing micron- and / or nanometer-scaled graphite crystallites with each crystallite comprising one sheet or a multiplicity of sheets of graphite plane; b). exfoliating the graphite crystallites in the polymeric carbon; and c). subjecting the polymeric carbon containing exfoliated graphite crystallites to a mechanical attrition treatment to produce the nano-scaled graphene plate material.

Owner:JANG BOR Z

Negative-working radiation-sensitive compositions and imageable materials

InactiveUS7332253B1Good solvent resistanceEasy to attachPhotosensitive materialsRadiation applicationsRadiation sensitivitySolvent

A radiation-sensitive composition and negative-working imageable element includes a polymeric binder comprising pendant allyl ester groups to provide solvent resistance, excellent digital speed (sensitivity) and can be imaged and developed without a preheat step to provide lithographic printing plates. The polymeric binder can be prepared with a precursor polymer having pendant carboxy groups that are converted to allyl ester groups using an allyl-containing halide in the presence of a base in order to avoid gelation.

Owner:EASTMAN KODAK CO

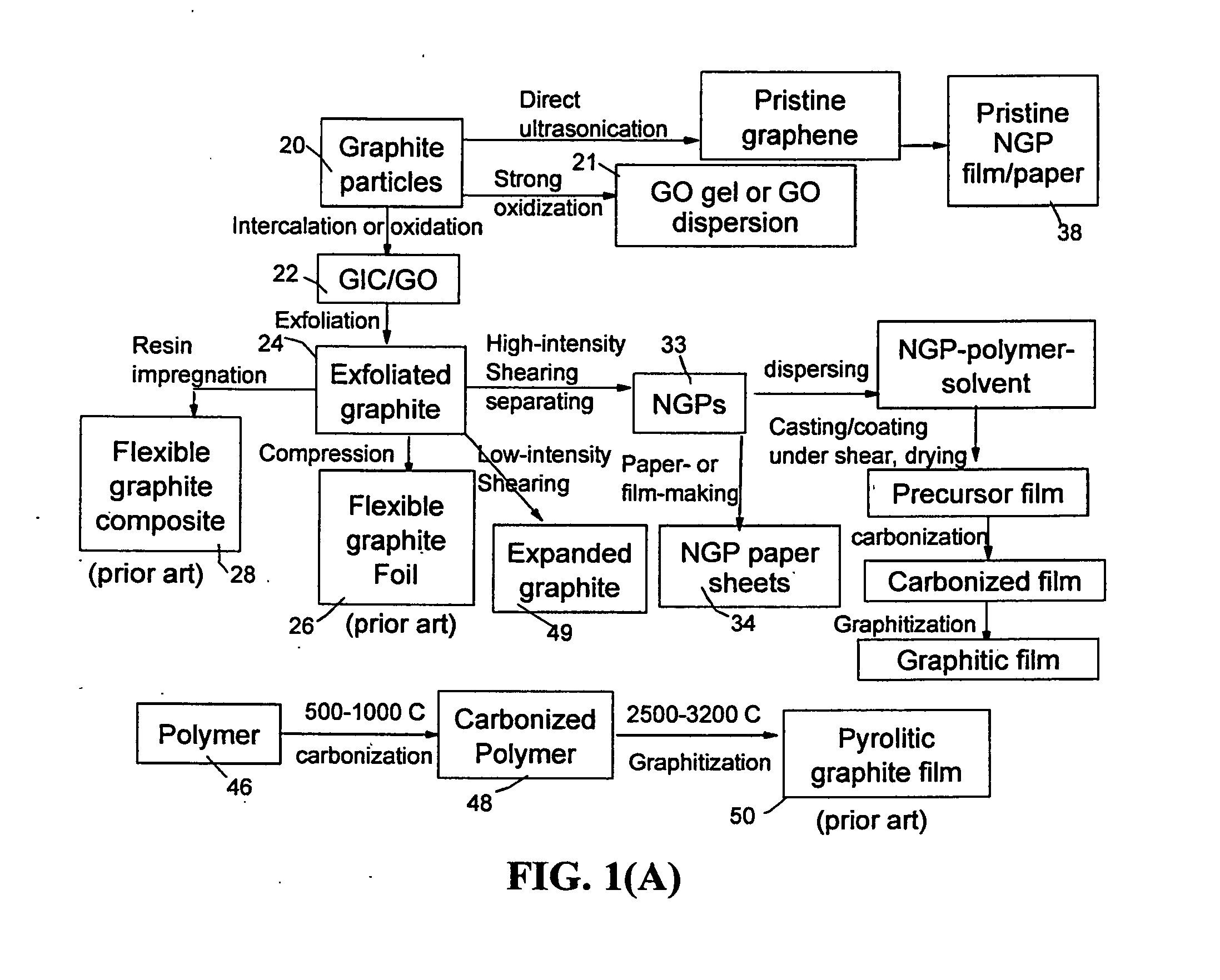

Production process for highly conductive graphitic films

ActiveUS20150266739A1Reduce thicknessImprove in-plane property of filmShielding materialsGraphiteComposite filmCarbonization

A process for producing a graphitic film comprising the steps of (a) mixing graphene platelets with a carbon precursor polymer and a liquid to form a slurry and forming the slurry into a wet film under the influence of an orientation-inducing stress field to align the graphene platelets on a solid substrate; (b) removing the liquid to form a precursor polymer composite film wherein the graphene platelets occupy a weight fraction of 1% to 99%; (c) carbonizing the precursor polymer composite film at a carbonization temperature of at least 300° C. to obtain a carbonized composite film; and (d) thermally treating the carbonized composite film at a final graphitization temperature higher than 1,500° C. to obtain the graphitic film. Preferably, the carbon precursor polymer is selected from the group consisting of polyimide, polyamide, polyoxadiazole, polybenzoxazole, polybenzobisoxazole, polythiazole, polybenzothiazole, polybenzobisthiazole, poly(p-phenylene vinylene), polybenzimidazole, polybenzobisimidazole, and combinations thereof.

Owner:GLOBAL GRAPHENE GRP INC

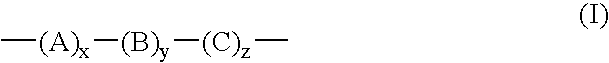

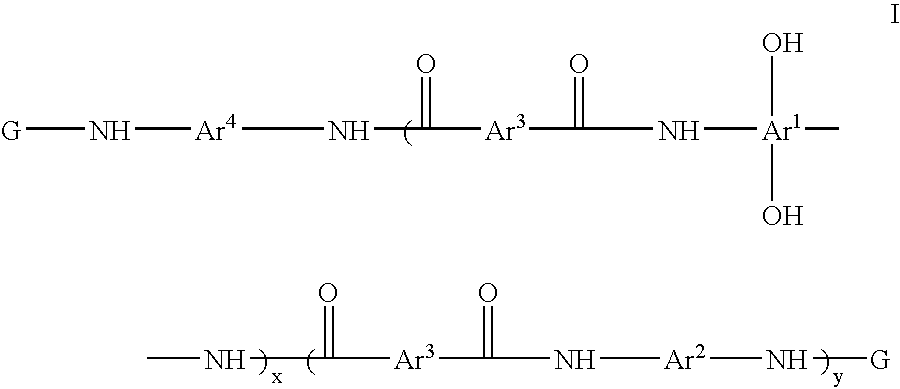

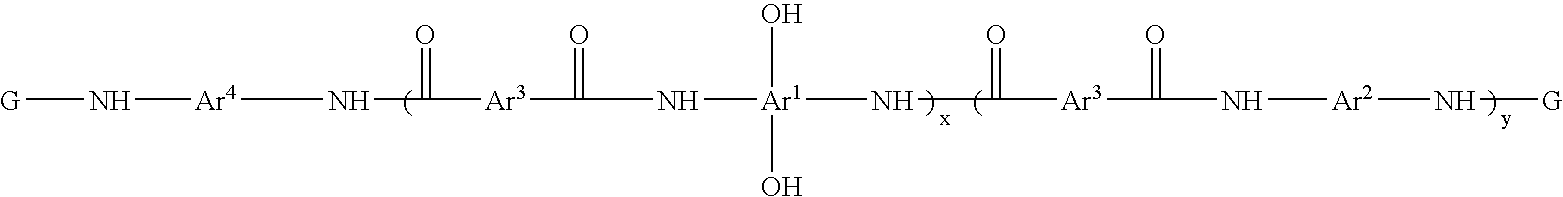

Photosensitive resin compositions

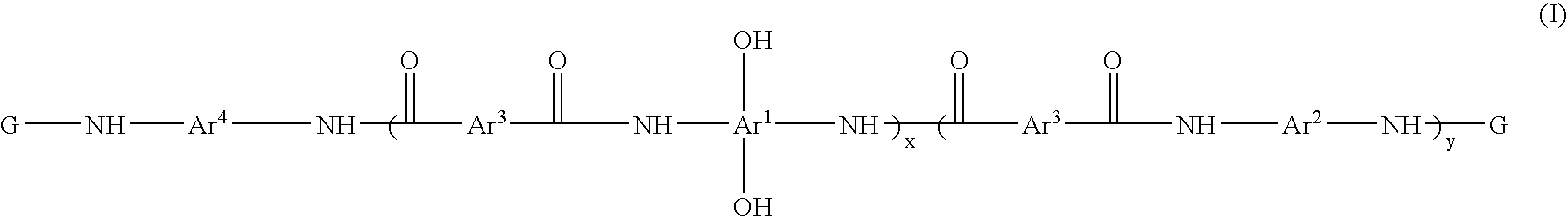

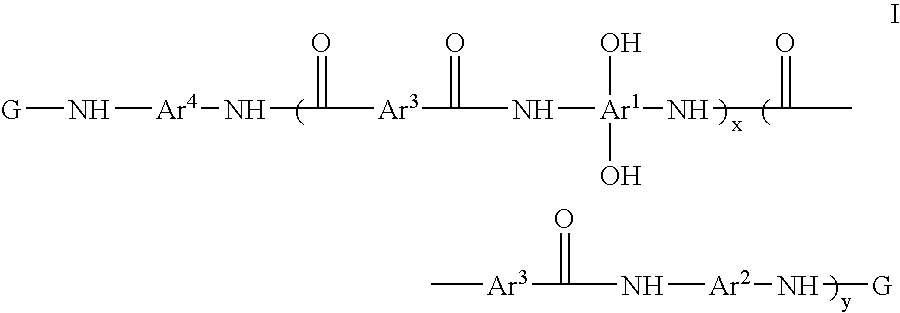

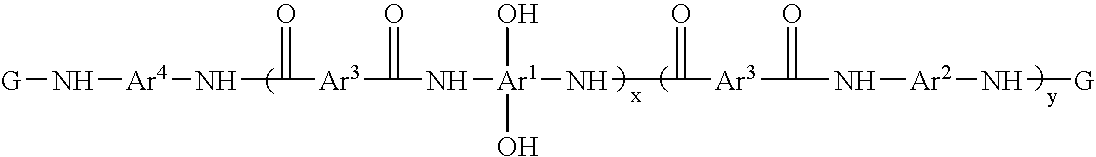

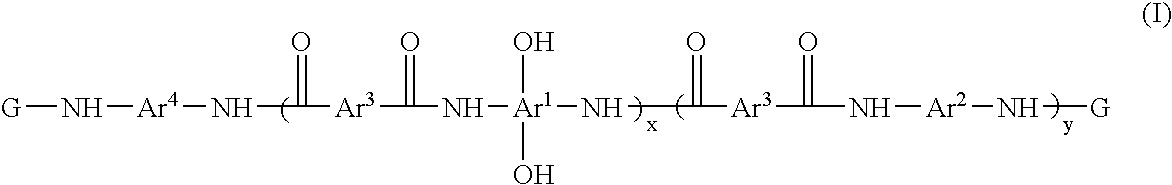

A heat resistant negative working photosensitive composition that comprises(a) one or more polybenzoxazole precursor polymers (I): wherein x is an integer from about 10 to about 1000, y is an integer from 0 to about 900 and (x+y) is about less then 1000; Ar1 is selected from the group consisting of a tetravalent aromatic group, a tetravalent heterocyclic group, or mixtures thereof; Ar2 is selected from the group consisting a divalent aromatic, a divalent heterocyclic, a divalent alicyclic, a divalent aliphatic group that may contain silicon, or mixtures thereof; Ar3 is selected from the group consisting a divalent aromatic group, a divalent aliphatic group, a divalent heterocyclic group, or mixtures thereof; Ar4 is selected from the group consisting Ar1 (OH)2 or Ar2; G is an organic group selected from the group consisting groups having a carbonyl, carbonyloxy or sulfonyl group attached directly to the terminal NH group of the polymer;(b) one or more photo-active compounds which release acid upon irradiation (PAGs);(c) a latent crosslinker which contains at least two ˜N—(CH2OR)n units wherein n=1 or 2 and R is a linear or branched C1-C8 alkyl group, with the proviso that when a glycoluril is employed as the latent crosslinker, the G group in the polybenzoxazole precursor polymer is produced from the reaction of a cyclic anhydride; and(d) at least one solvent that is not NMP.

Owner:FUJIFILM ELECTRONICS MATERIALS US

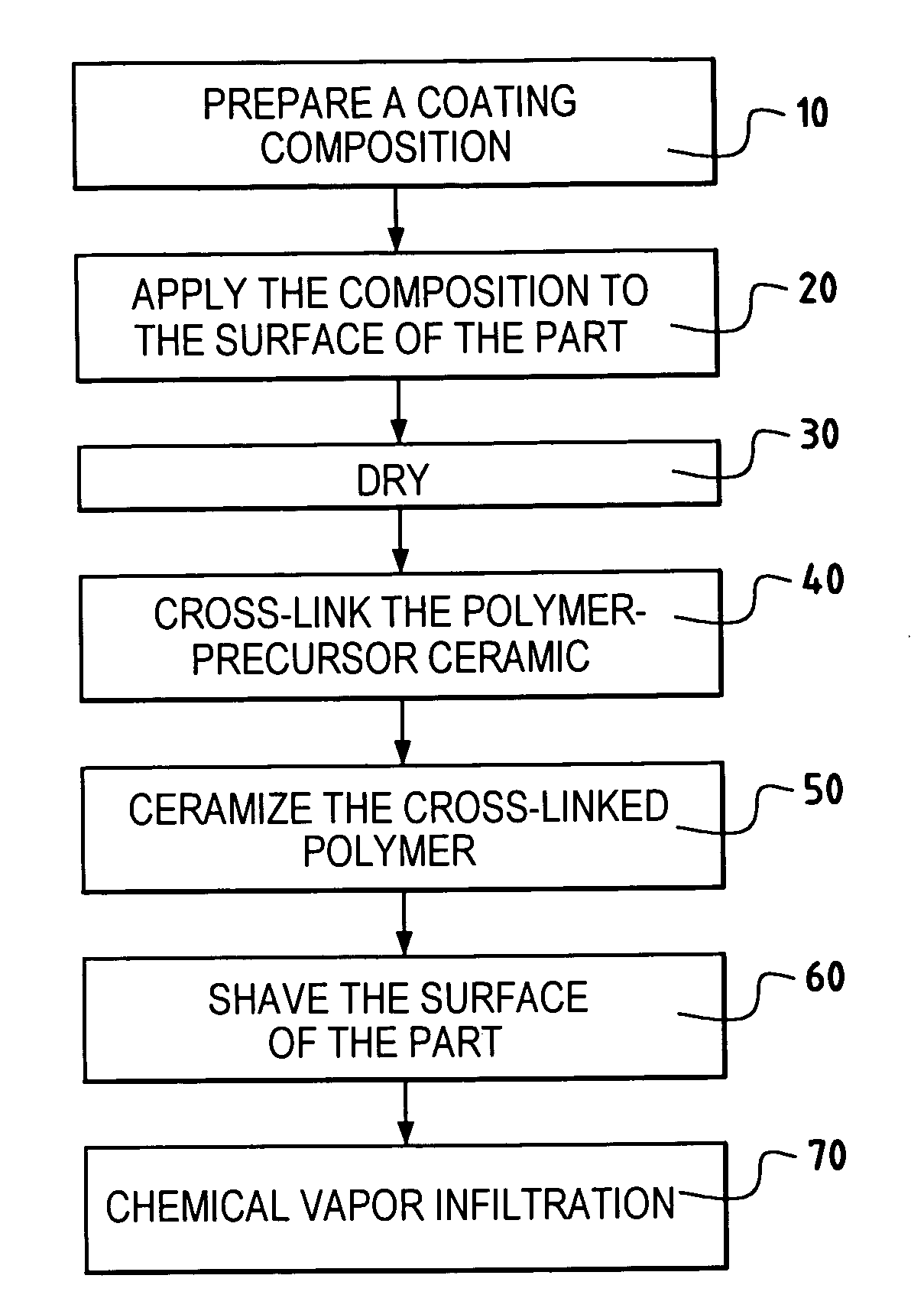

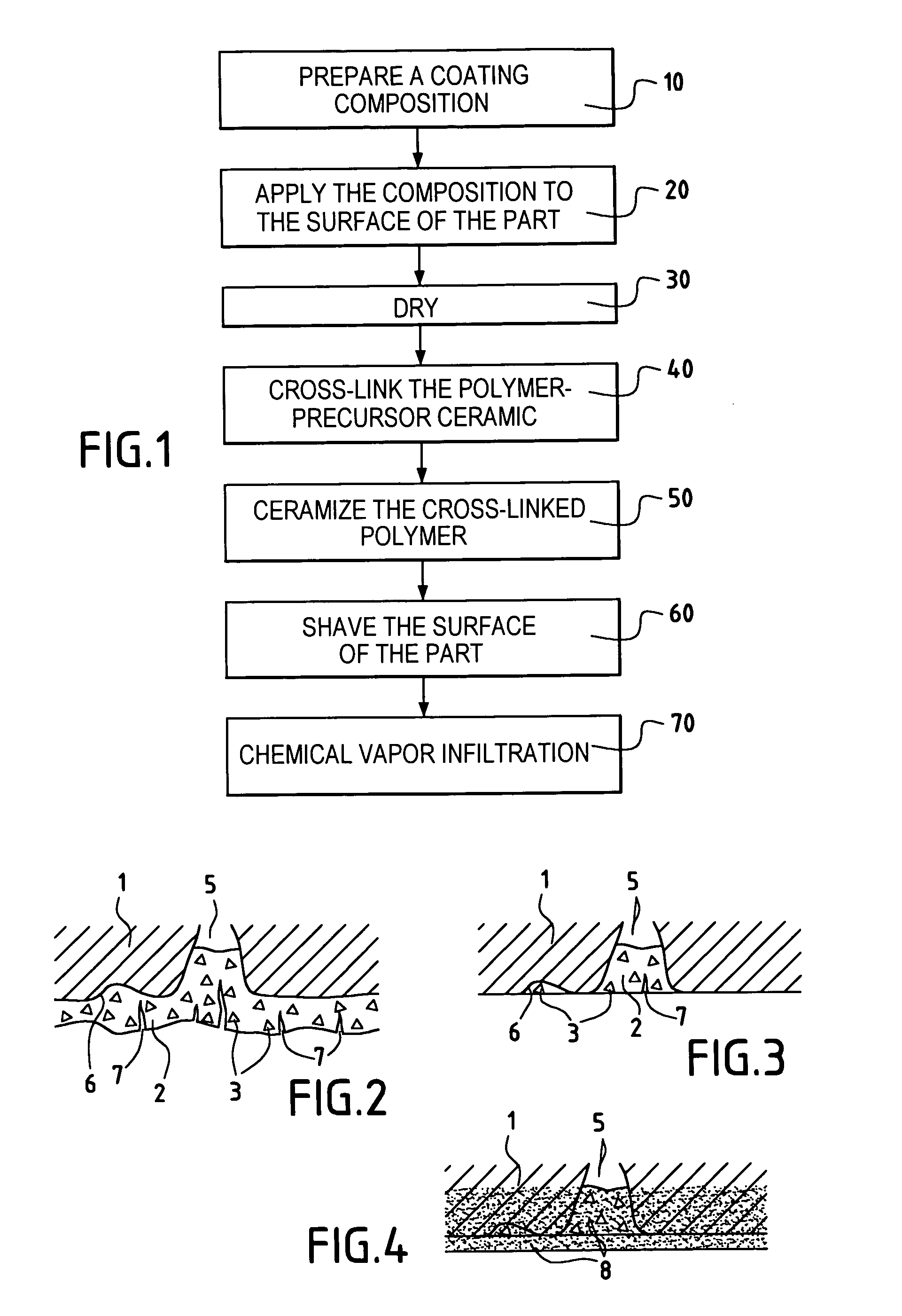

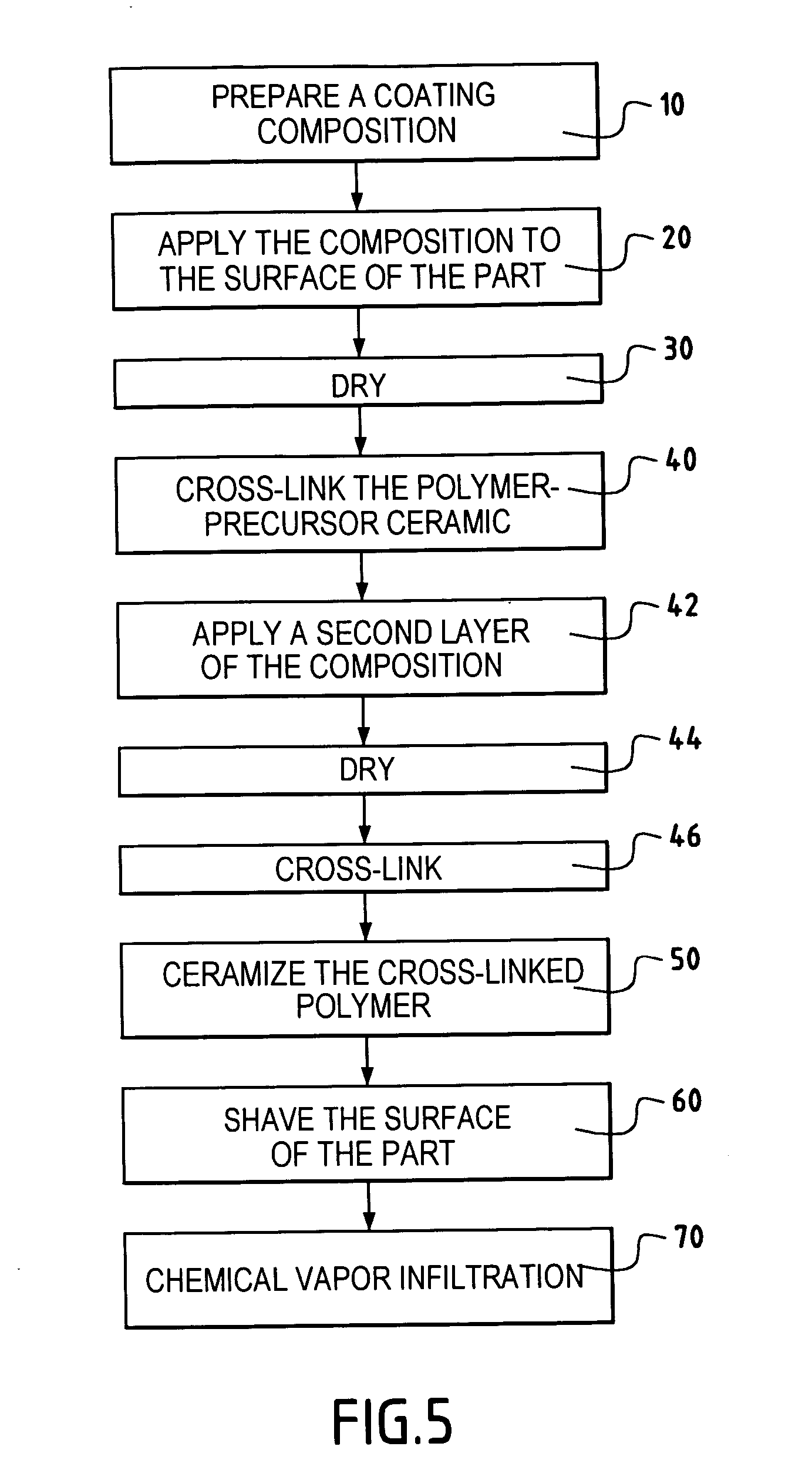

Method for treating the surface of a part made of a heat-structured composite material and use thereof in brazing parts made of a heat-structured composite material

InactiveUS20060141154A1Satisfies dimensional requirementMeet size requirementsChemical vapor deposition coatingGas phasePrecursor polymer

A liquid composition is applied onto the surface of the part to be treated, the composition containing a ceramic precursor polymer and a refractory solid filler. After cross-linking, the polymer is transformed into ceramic by heat treatment, and subsequently ceramic is deposited by chemical vapor infiltration. Before the chemical vapor infiltration step, the surface of the part is shaved so as to return the composite part to its initial shape so that the chemical vapor infiltration forms a deposit that fills in the residual micropores in the shaved surface of the part.

Owner:SNECMA PROPULSION SOLIDE

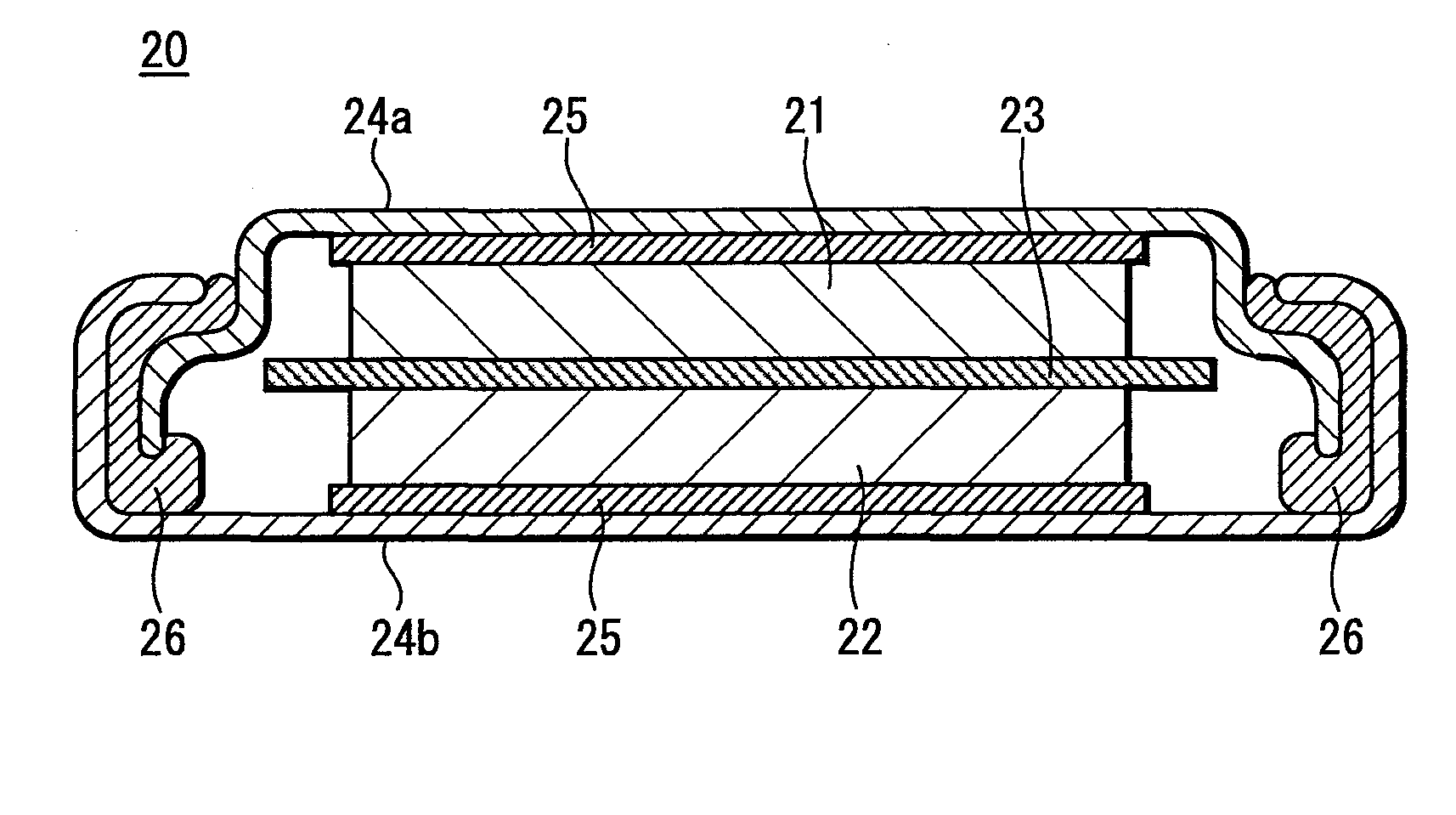

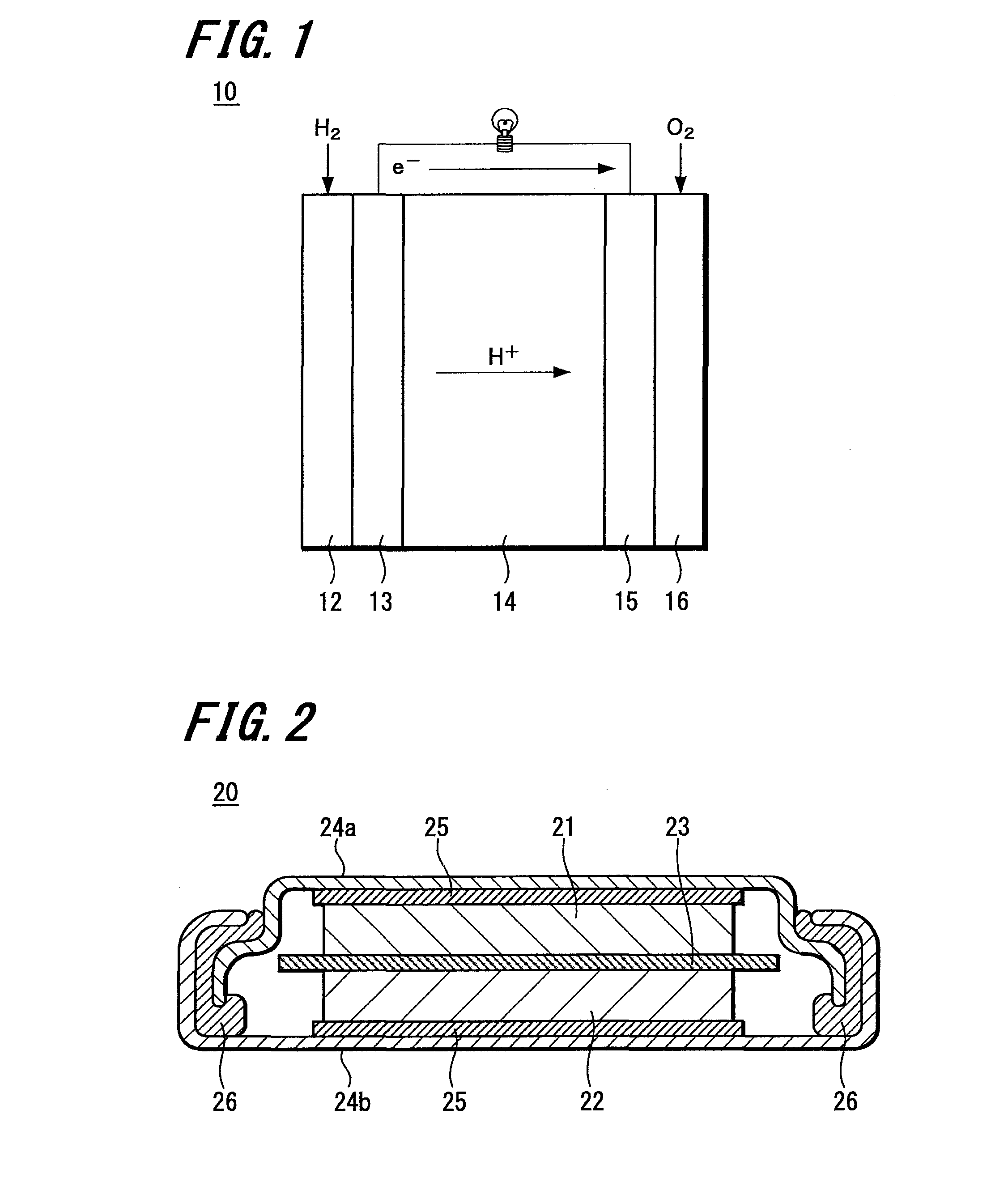

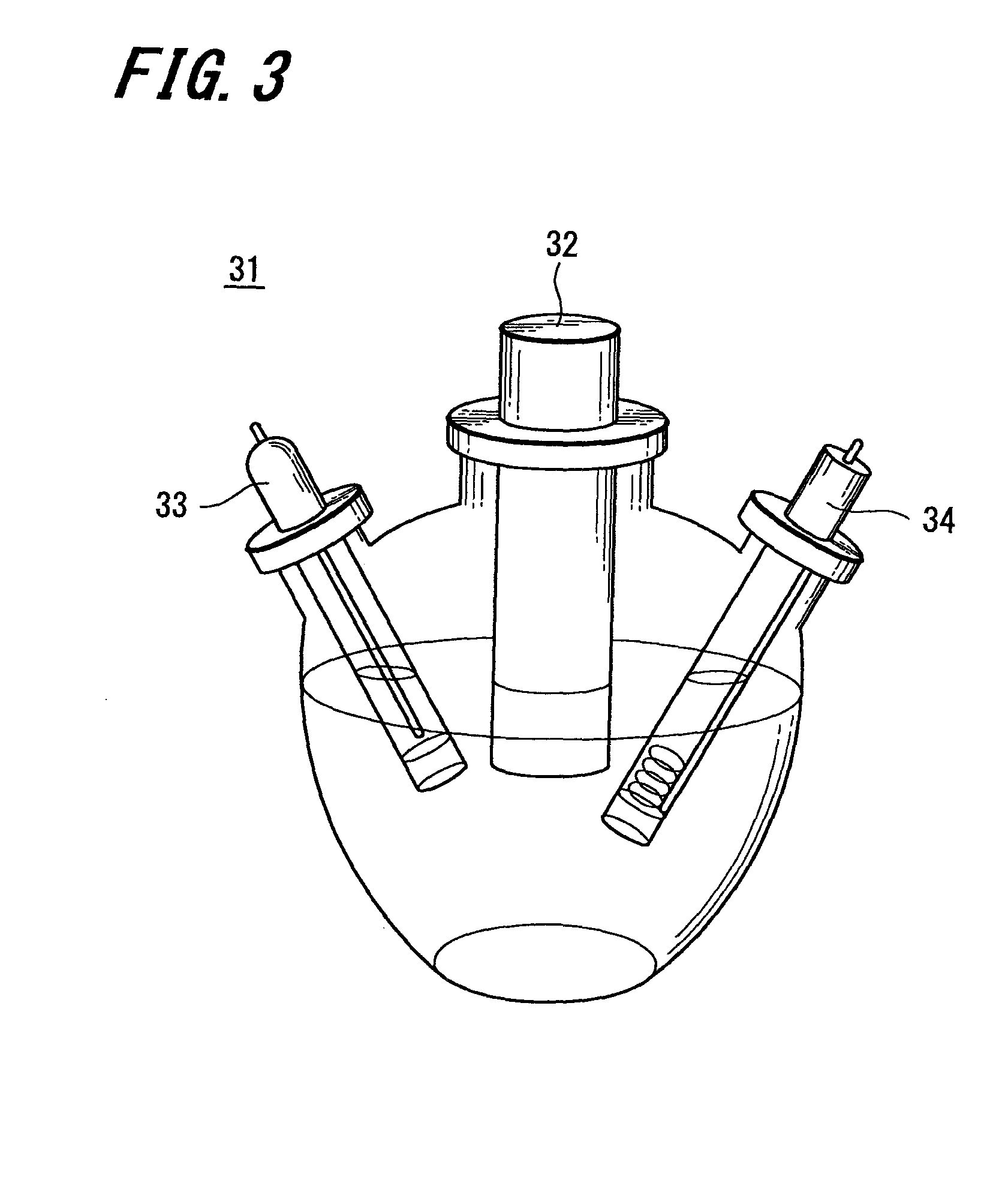

Carbon catalyst, slurry containing the carbon catalyst, process for producing carbon catalyst, and fuel cell, storage device, and environmental catalyst each employing carbon catalyst

InactiveUS20100323272A1Reduced responseImprove responseMaterial nanotechnologyCyanogen compoundsFiberFuel cells

The present invention is made to provide a carbon catalyst capable of preventing the coarsening of particles of nanoshell structure of carbon which causes reduction in activity for oxygen reduction reaction. The carbon catalyst is produced by the steps of: preparing a carbon precursor polymer; mixing a transition metal or a compound of the transition metal into the carbon precursor polymer; spinning the mixture of the carbon precursor polymer and the transition metal or the compound of the transition metal into fibers; and carbonizing the fibers.

Owner:GUNMA UNIVERSITY +1

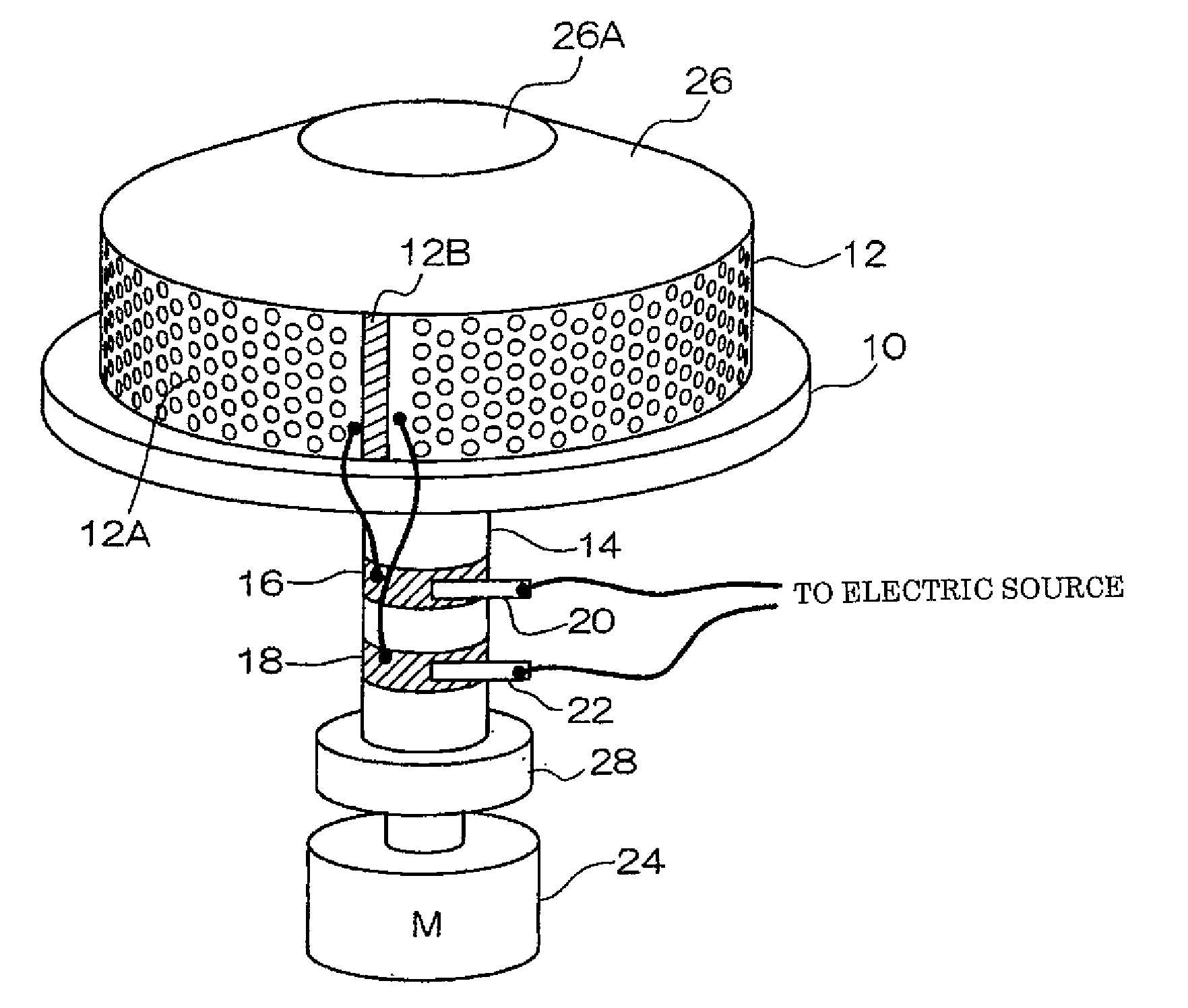

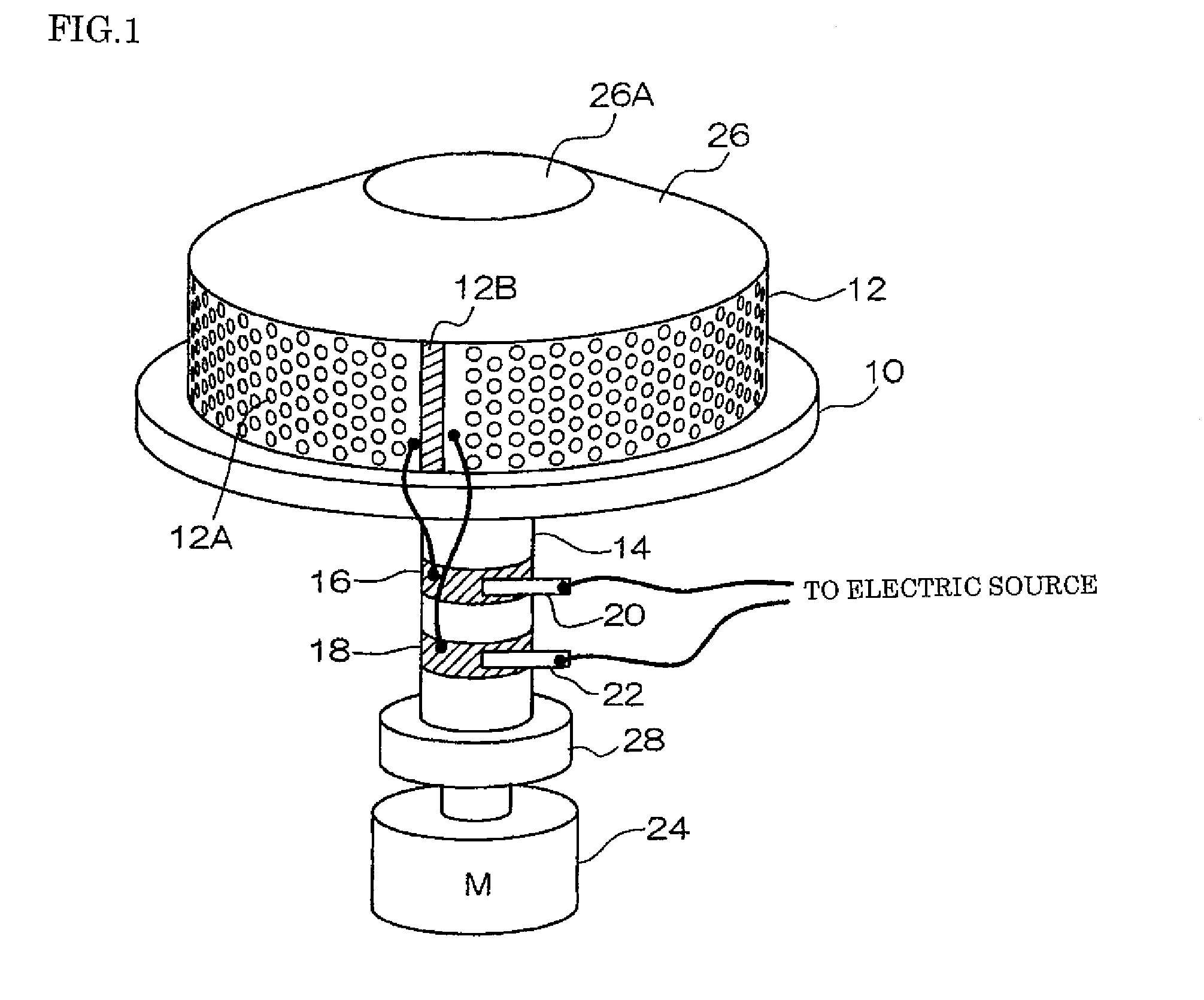

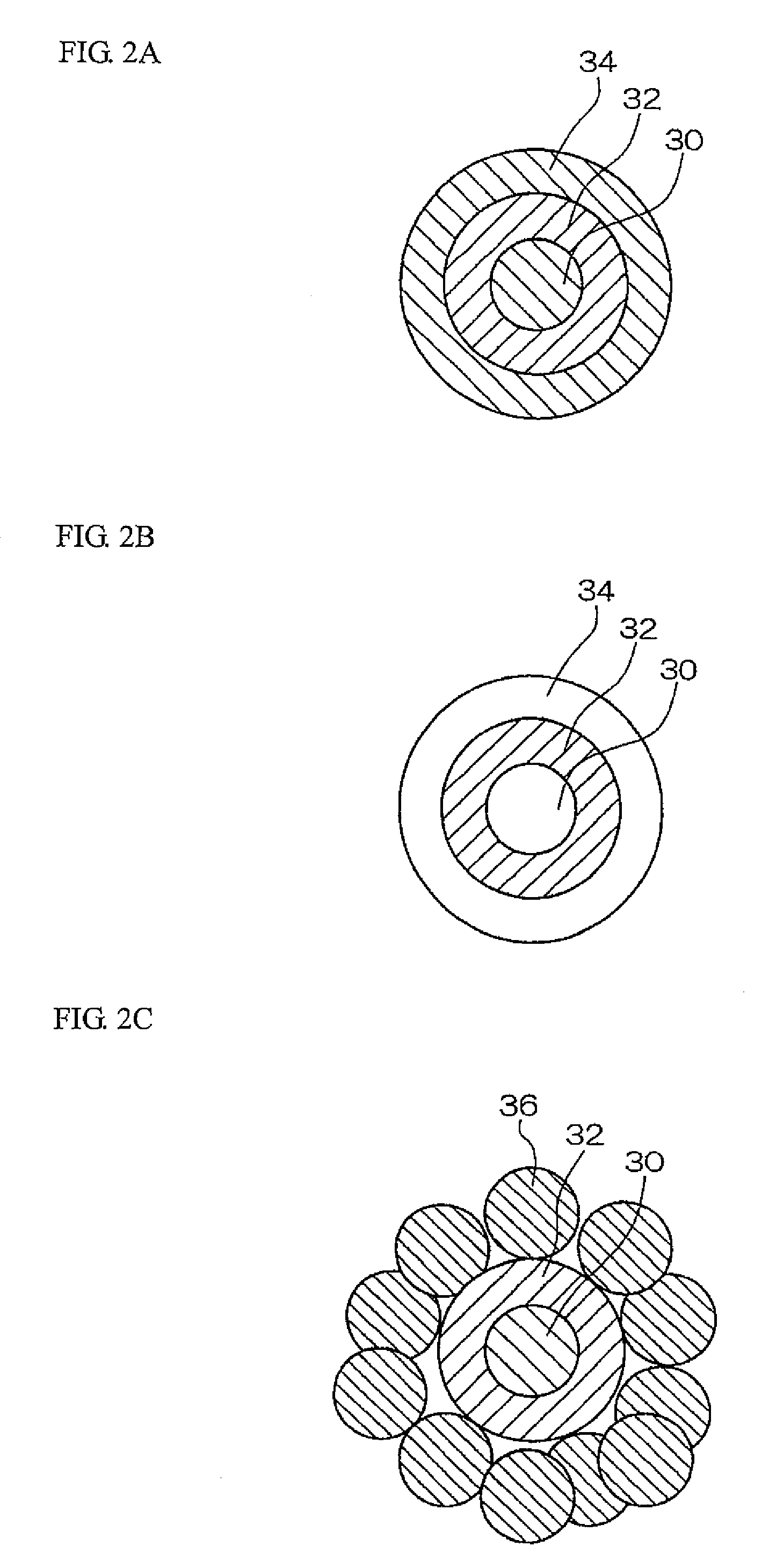

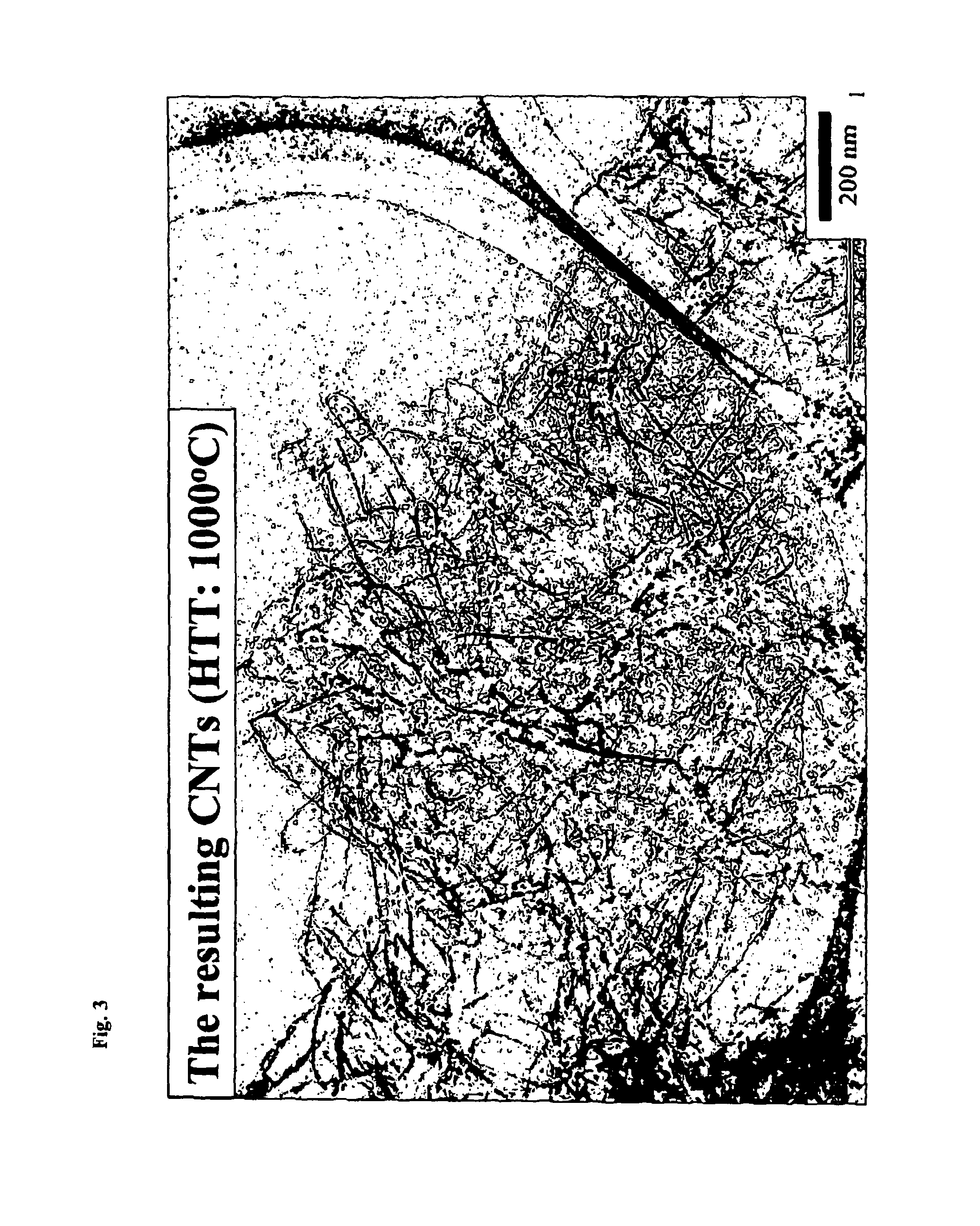

Method of Producing Carbon Nanomaterials and Centrifugal Melt Spinning Apparatus

InactiveUS20080050304A1Producing a carbon nanomaterialImprove efficiencyMaterial nanotechnologyFilament/thread formingPolymer scienceCarbonization

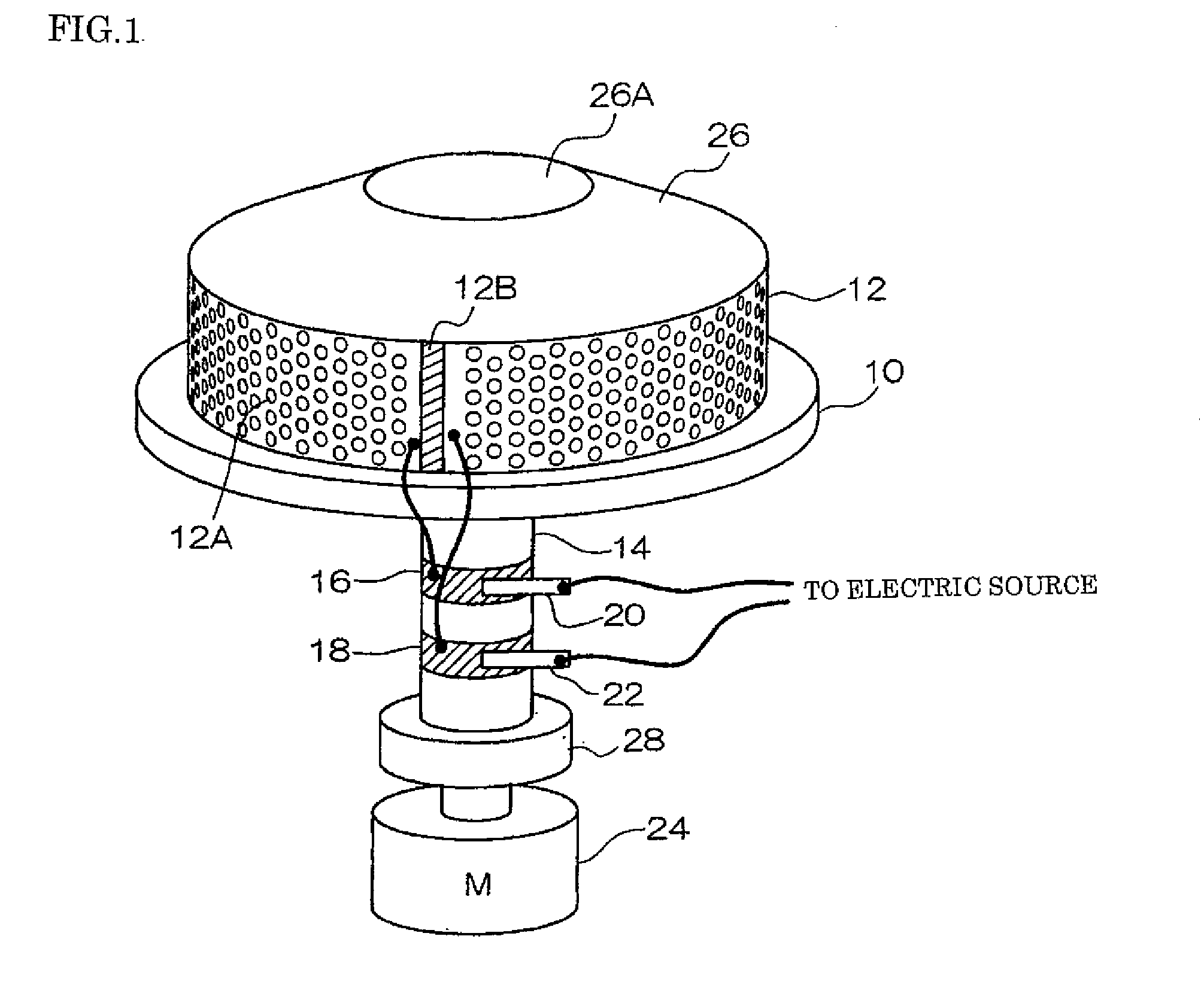

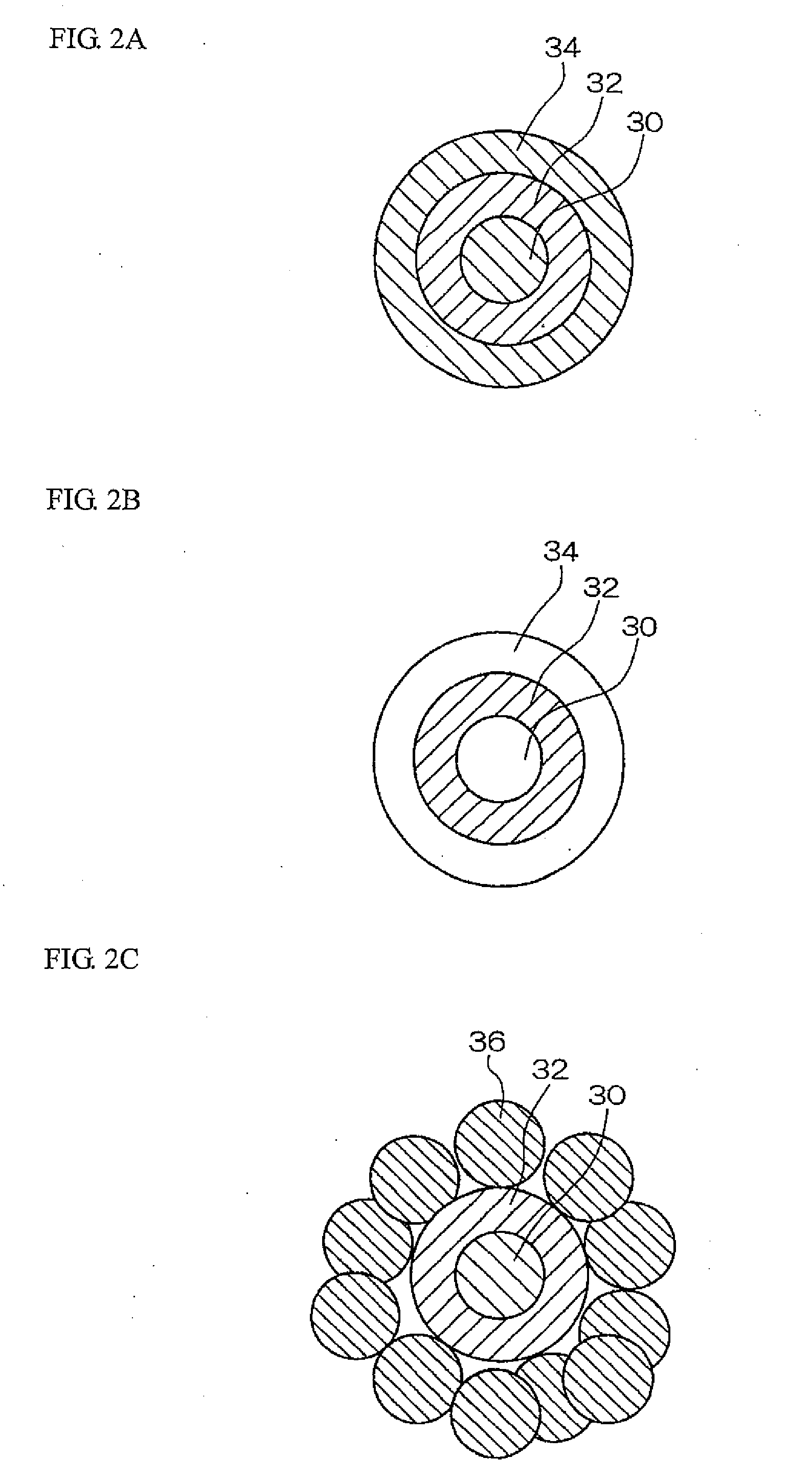

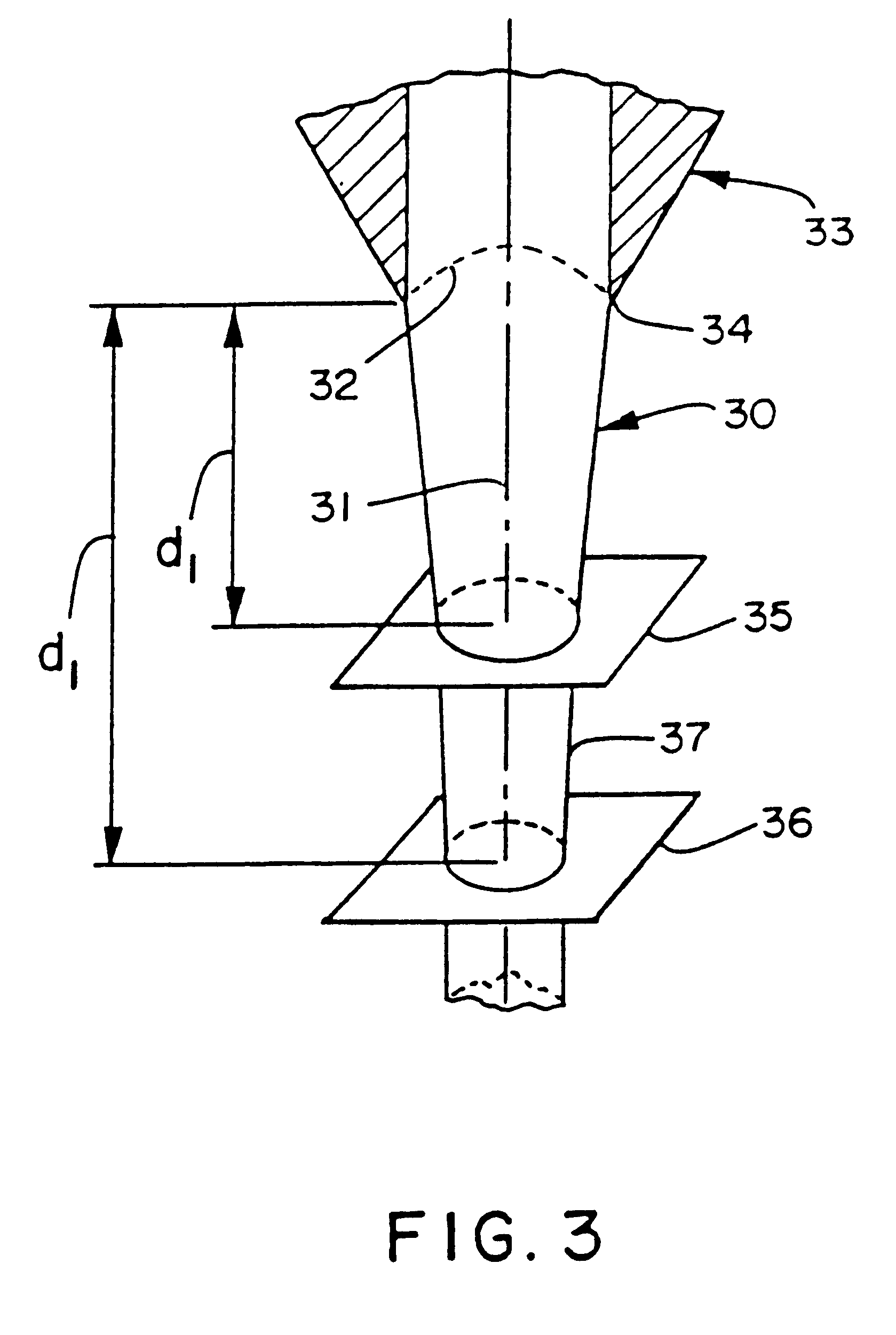

A carbon nanomaterial produced by: performing centrifugal melt spinning of core-shell particles that are prepared by using fine particles containing a carbon precursor polymer and a thermally decomposable polymer that disappears as a result of heat treatment, wherein the core-shell particles are heated up to a temperature at which phase separation thereof is not caused, and pressed against a plate-like heater 12 having a large number of pores 12A that penetrate therethrough in a thickness direction of the plate-like heater using centrifugal force; making the fiber obtained by the centrifugal melt spinning infusible; and performing carbonization thereof. According to this method, a carbon nanomaterial such as a carbon nanotube or a carbon nanofiber can be produced with high efficiency.

Owner:GUNMA UNIVERSITY

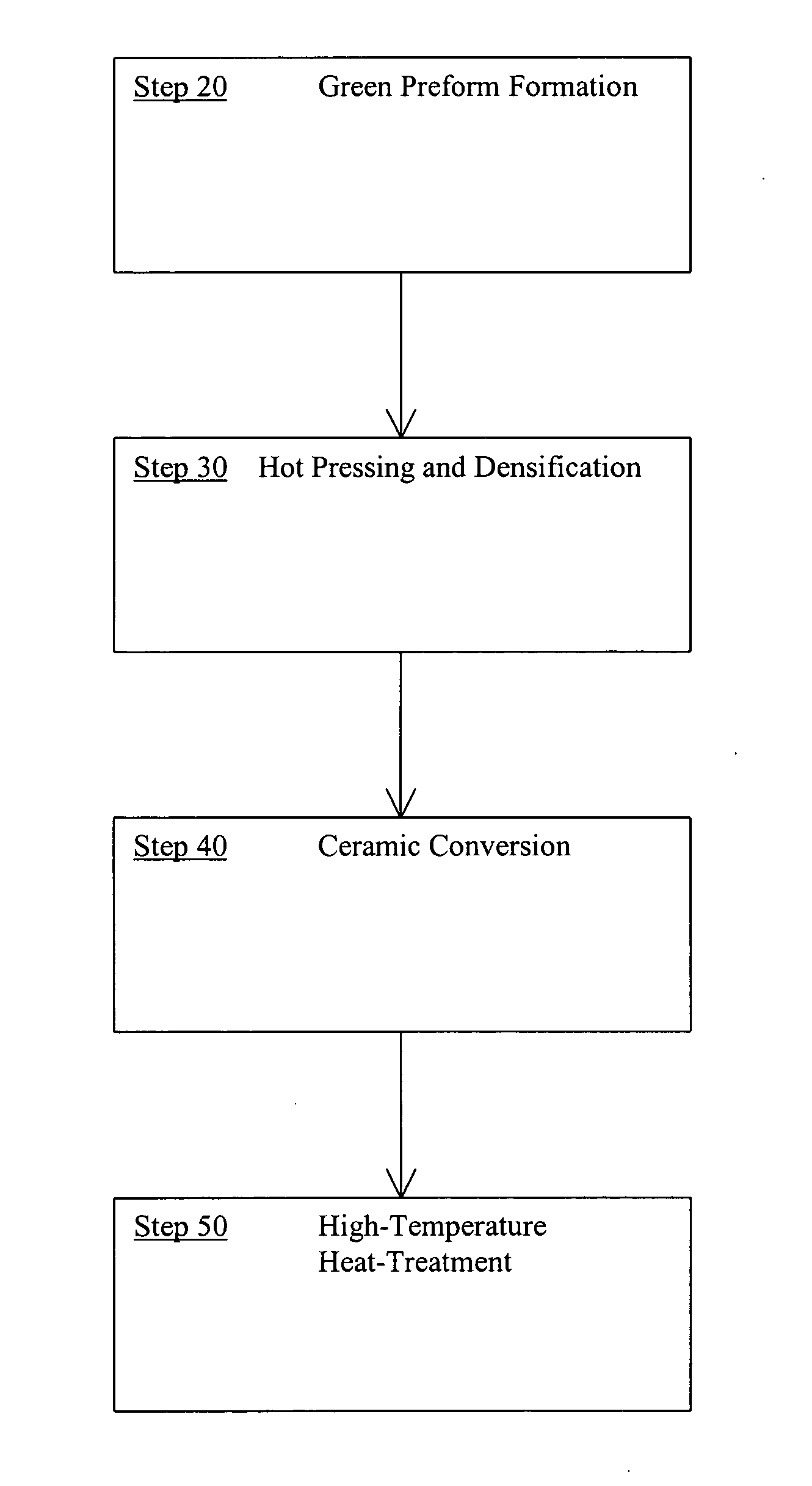

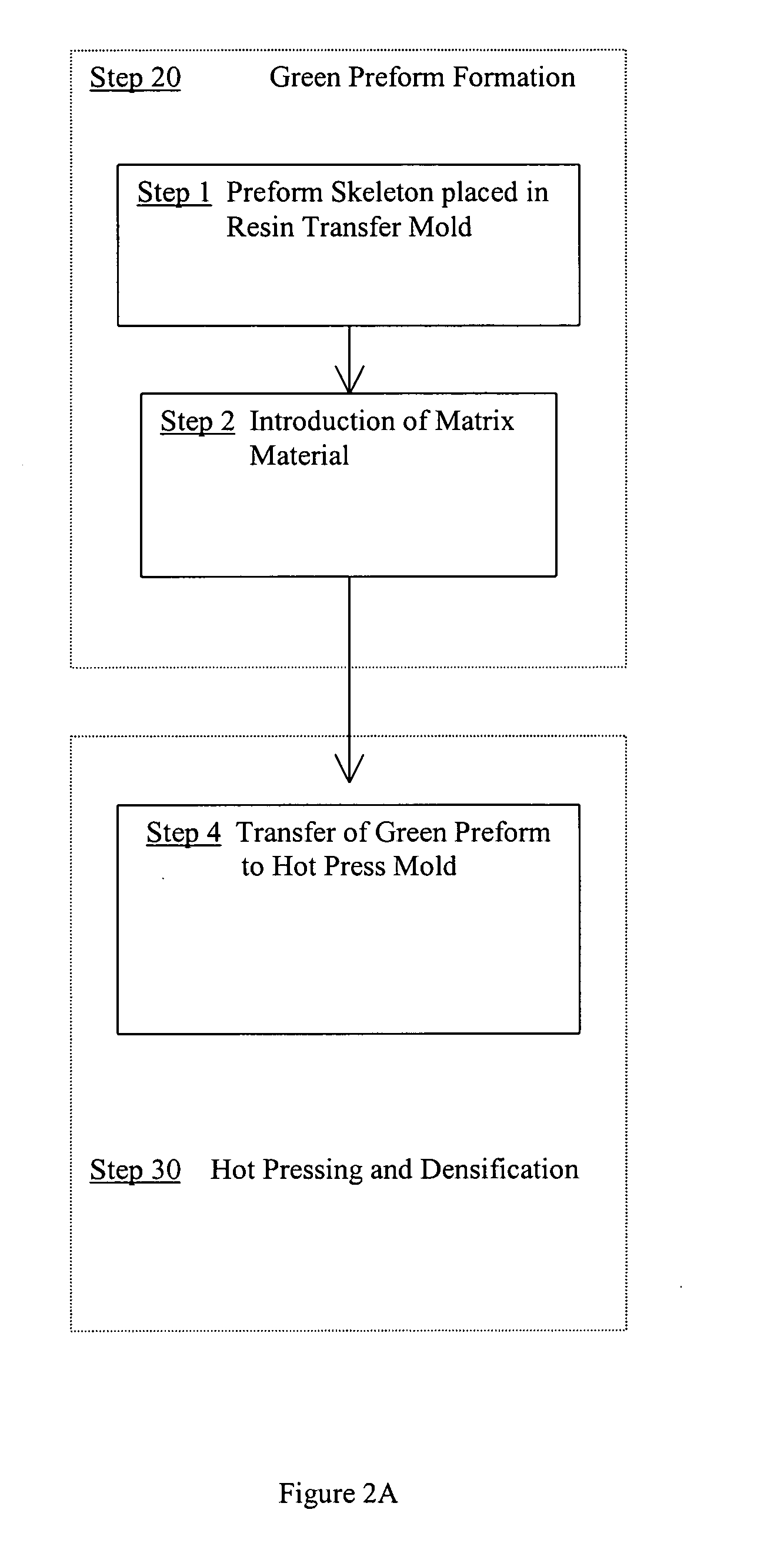

Manufacturing carbon fiber reinforced ceramics as brake discs

InactiveUS20060244165A1Short timeGreat degreeFriction liningActuatorsCooking & bakingCarbon composites

A carbon fiber reinforced ceramic brake disc or pad is formed from a rapidly hot-pressed carbon / carbon composite material. First, a reinforcement material, preferably including carbon fibers, is combined with a carbonizable matrix material to form a green preform. The green preform is heated and a portion of the matrix material is at least partially carbonized so as to form a carbon / carbon composite. Optionally, a carbonizable material is introduced into voids in the carbon / carbon composite. The product is then heated to carbonize the carbonizable material. The carbonizable material infiltration and baking steps are optionally repeated to increase the density of the composite. A pre-ceramic polymer material is introduced into voids of the carbon / carbon composite and heat-treated so as to pyrolytically decompose the pre-ceramic polymer. Finally, the carbon / ceramic composite is then high-temperature heat treated so as to form a carbon fiber reinforced ceramic material.

Owner:GRAFTECH INT HLDG INC

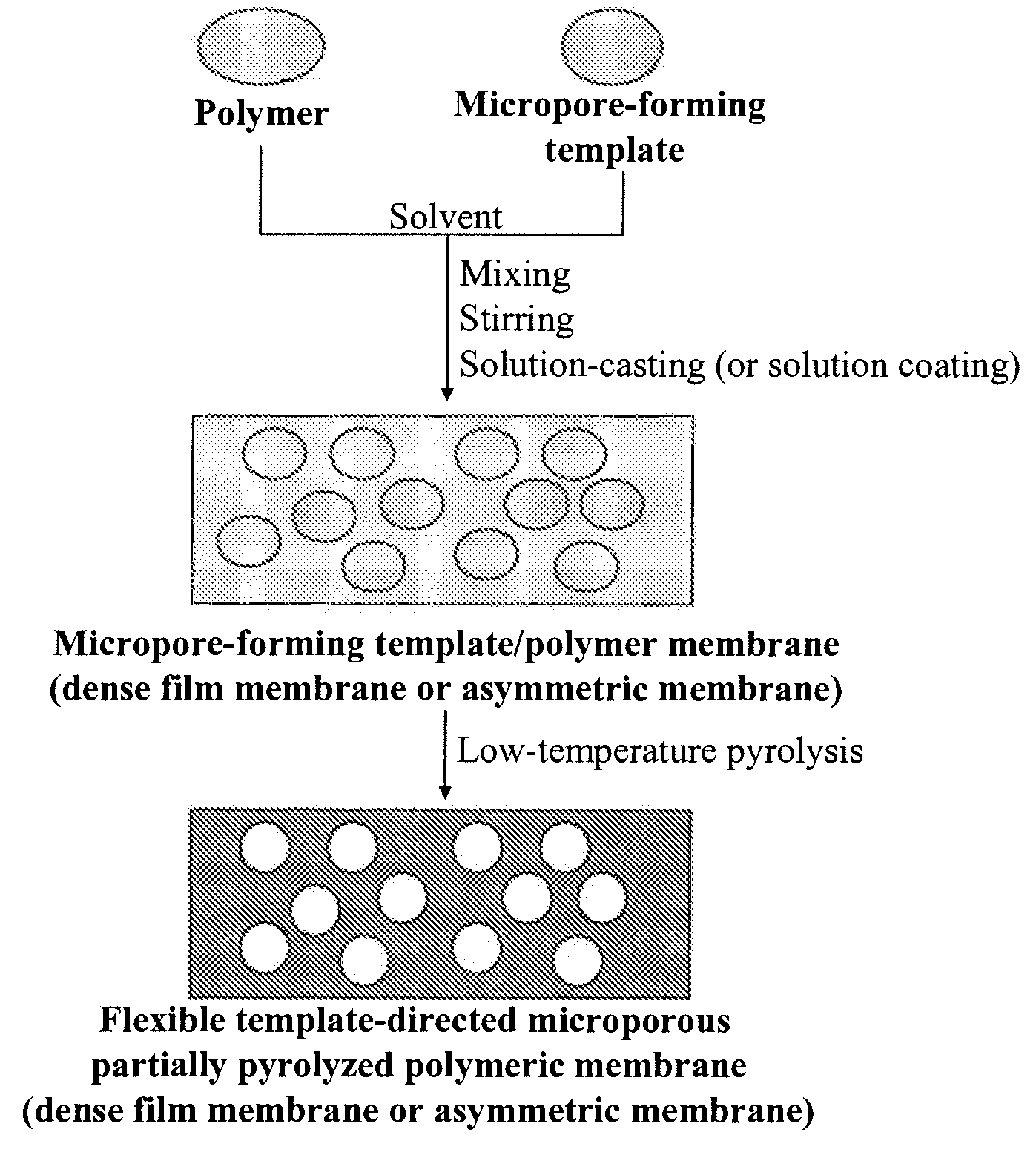

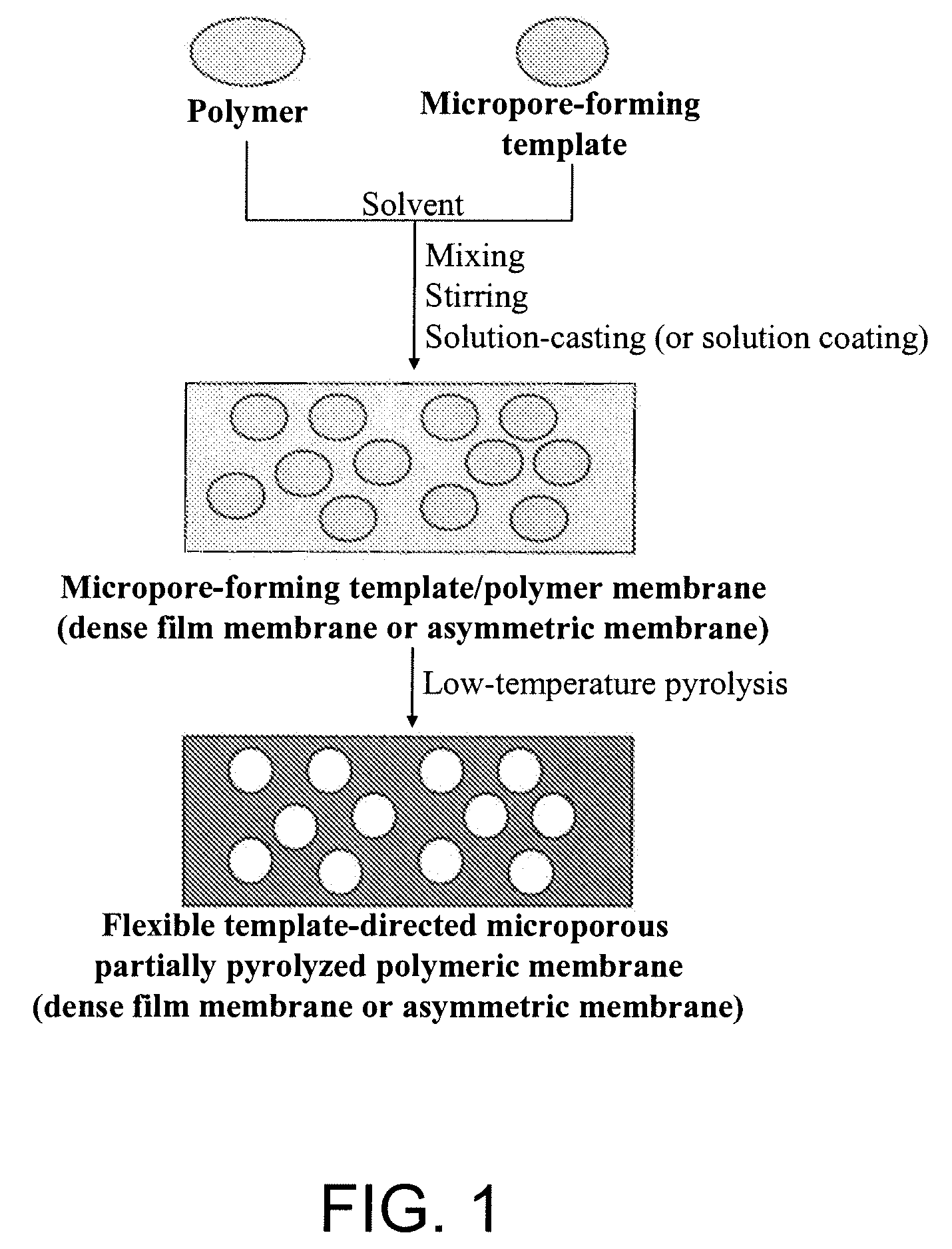

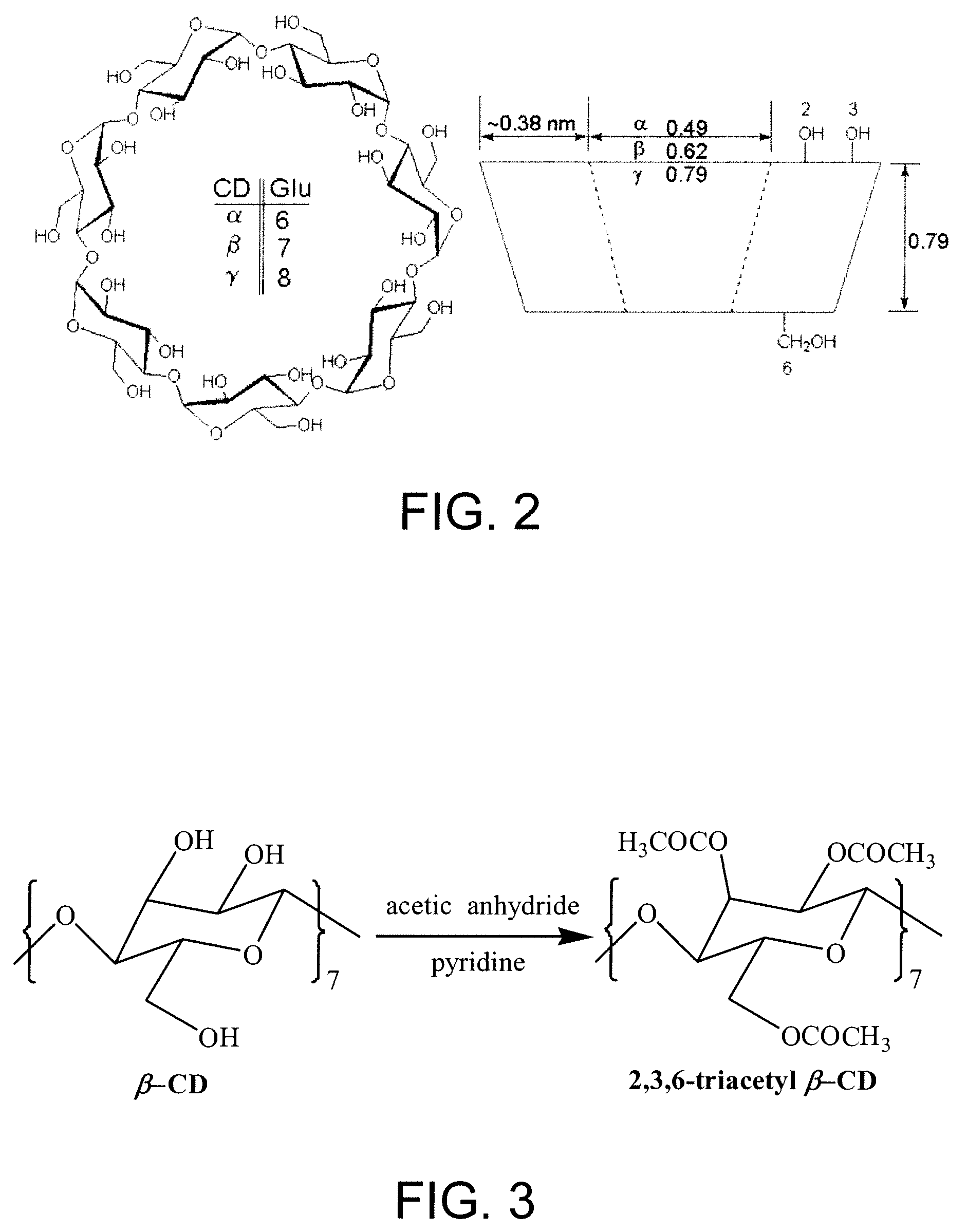

Flexible Template-Directed Microporous Partially Pyrolyzed Polymeric Membranes

InactiveUS20070209506A1High selectivityGood anti-plasticizing performanceMembranesSemi-permeable membranesCyclodextrinSolvent

This invention describes a new concept of flexible template-directed microporous partially pyrolyzed polymeric membranes which have greatly improved performance in separation of gas pairs compared to their precursor polymeric membranes. Organic hosts, such as crown ethers, cyclodextrins (CDs), calixarenes (CXs), and spherands, or polymeric additives, such as poly(ethylene glycol) (PEG) and polyvinylpyrrolidone (PVP) were used as the micropore-forming templates. Micropore-forming template / polymer blend membranes comprising organic micropore-forming templates embedded in a polymer matrix were prepared by dissolving the organic micropore-forming templates in the polymer solution followed by solution-casting and solvent evaporation or solvent exchange. Low-temperature selectively pyrolyzing micropore-forming templates in the micropore-forming template / polymer blend membranes at a nitrogen flow resulted in the formation of flexible microporous partially pyrolyzed polymeric membranes.

Owner:UOP LLC

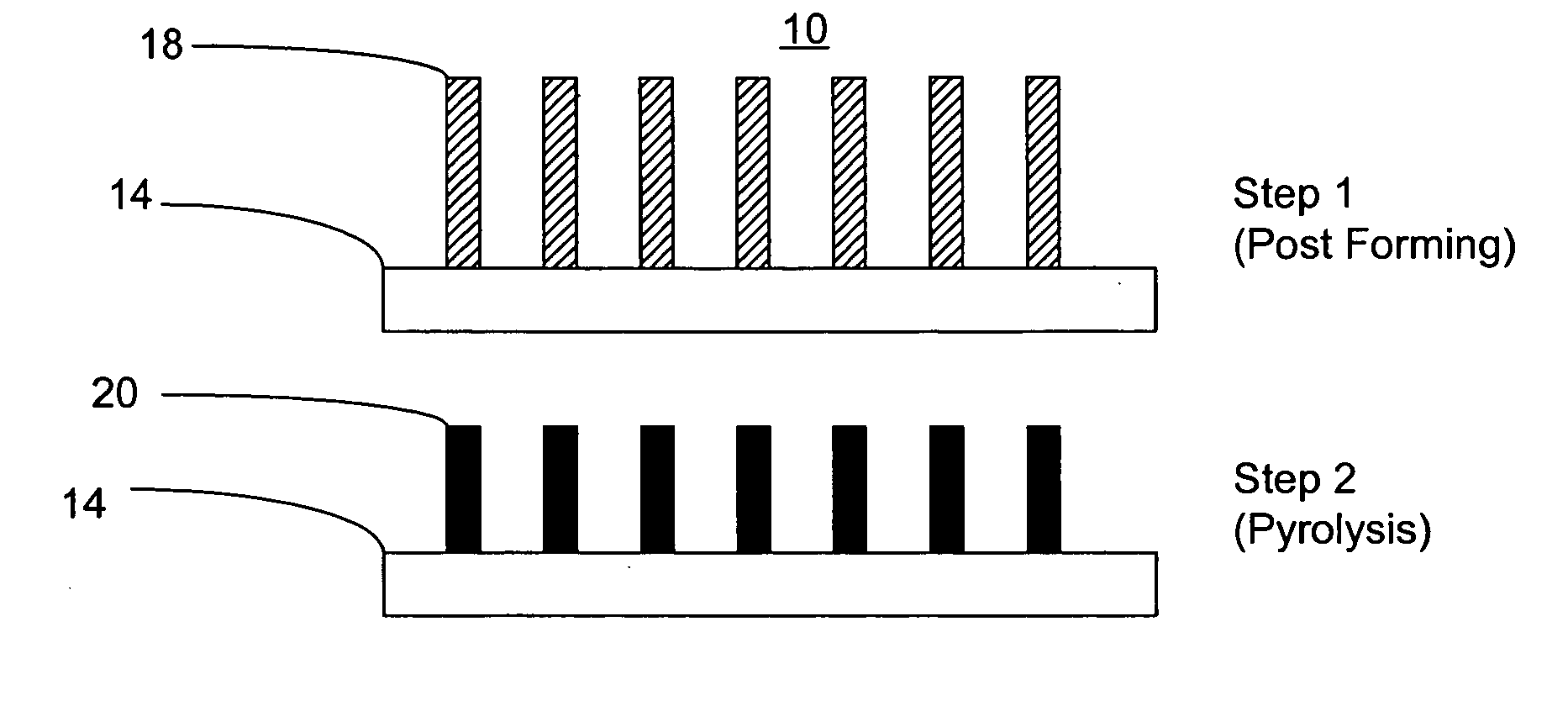

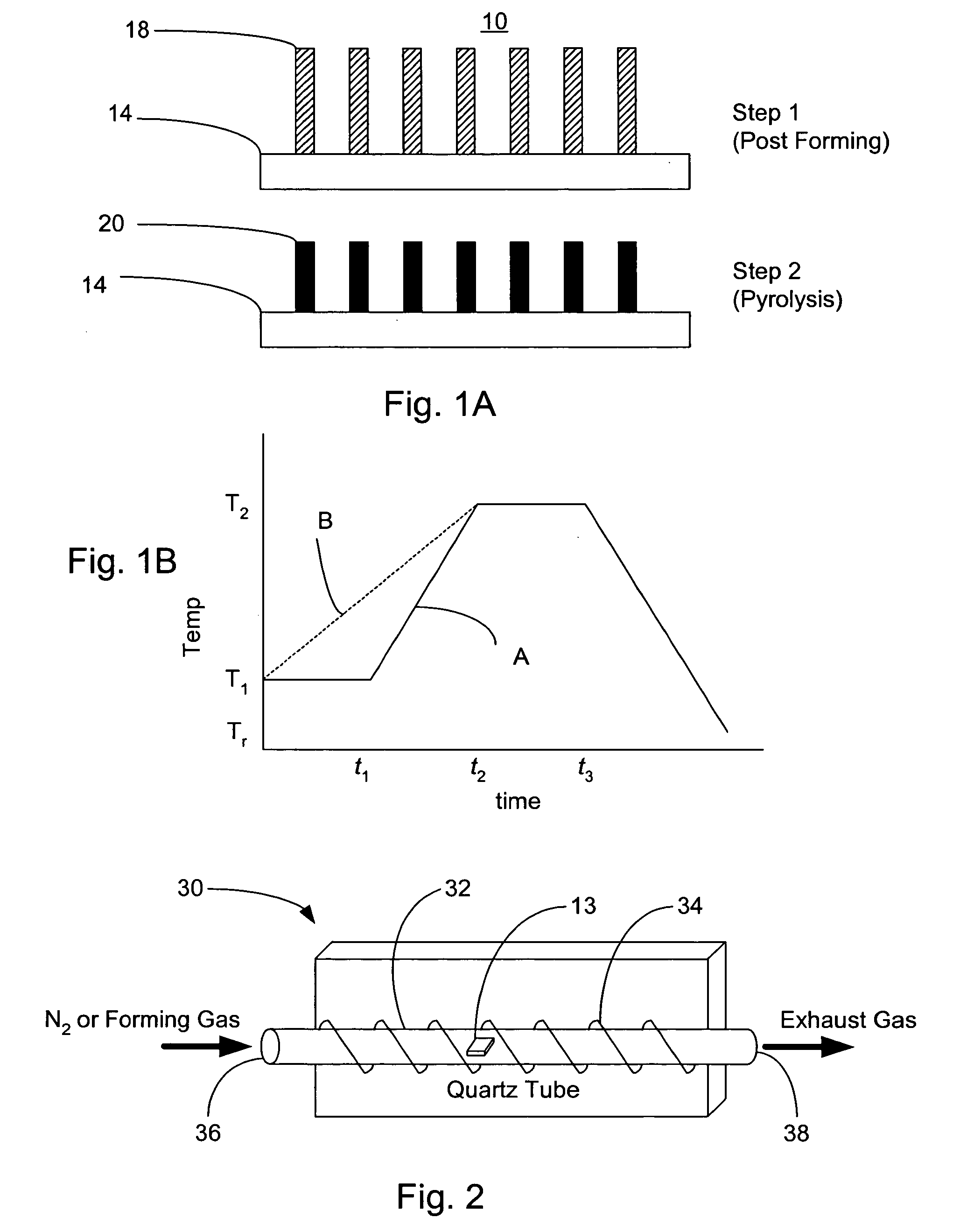

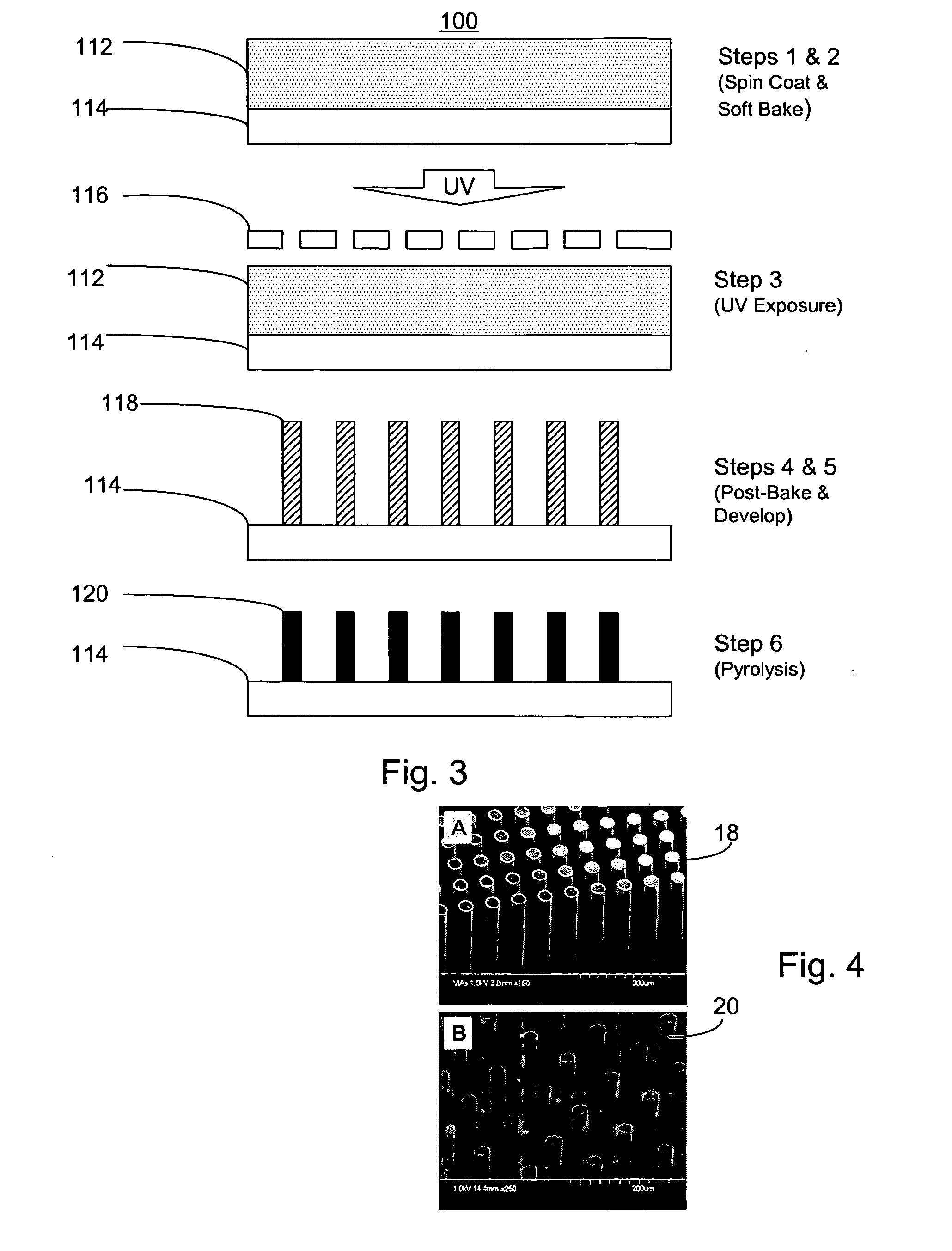

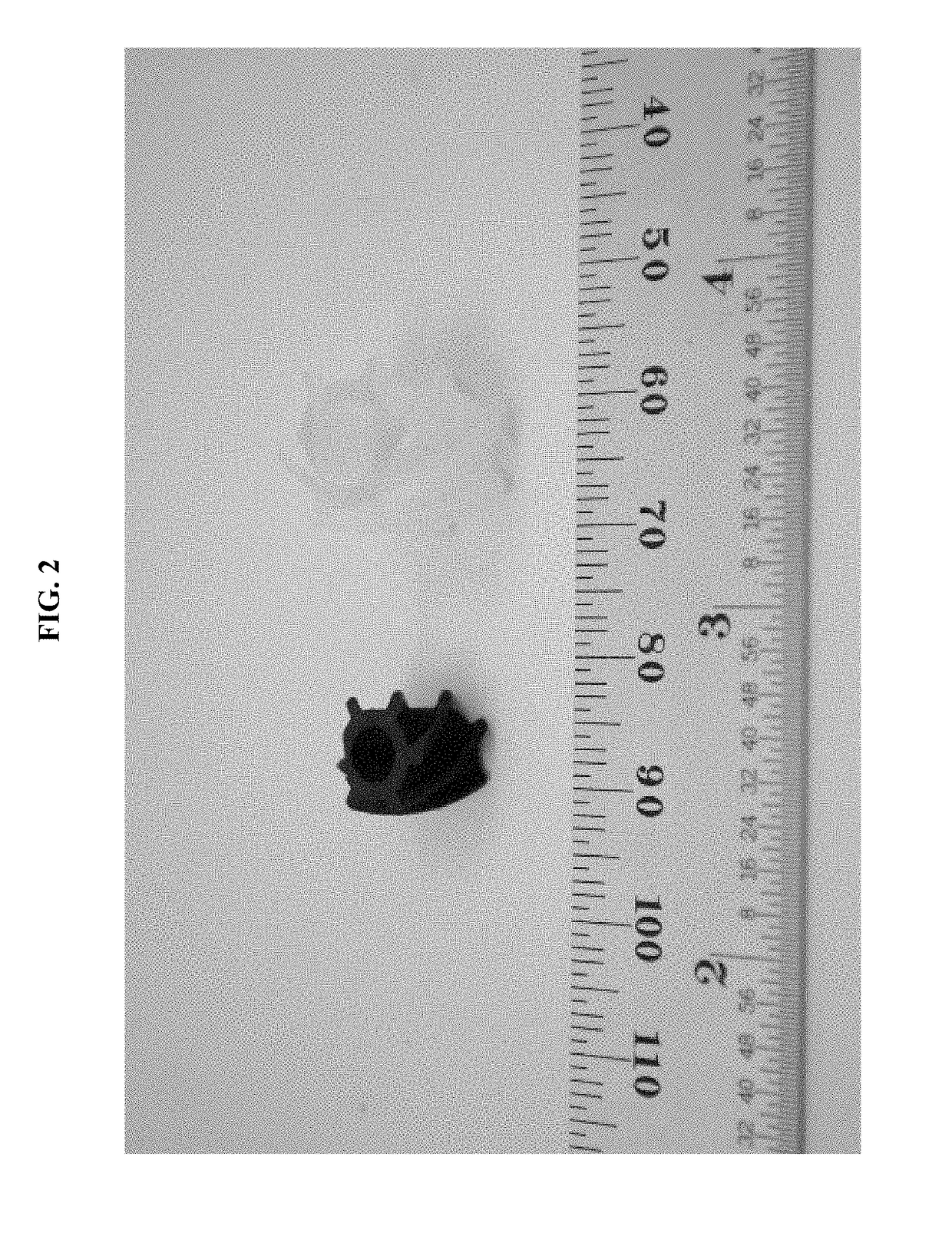

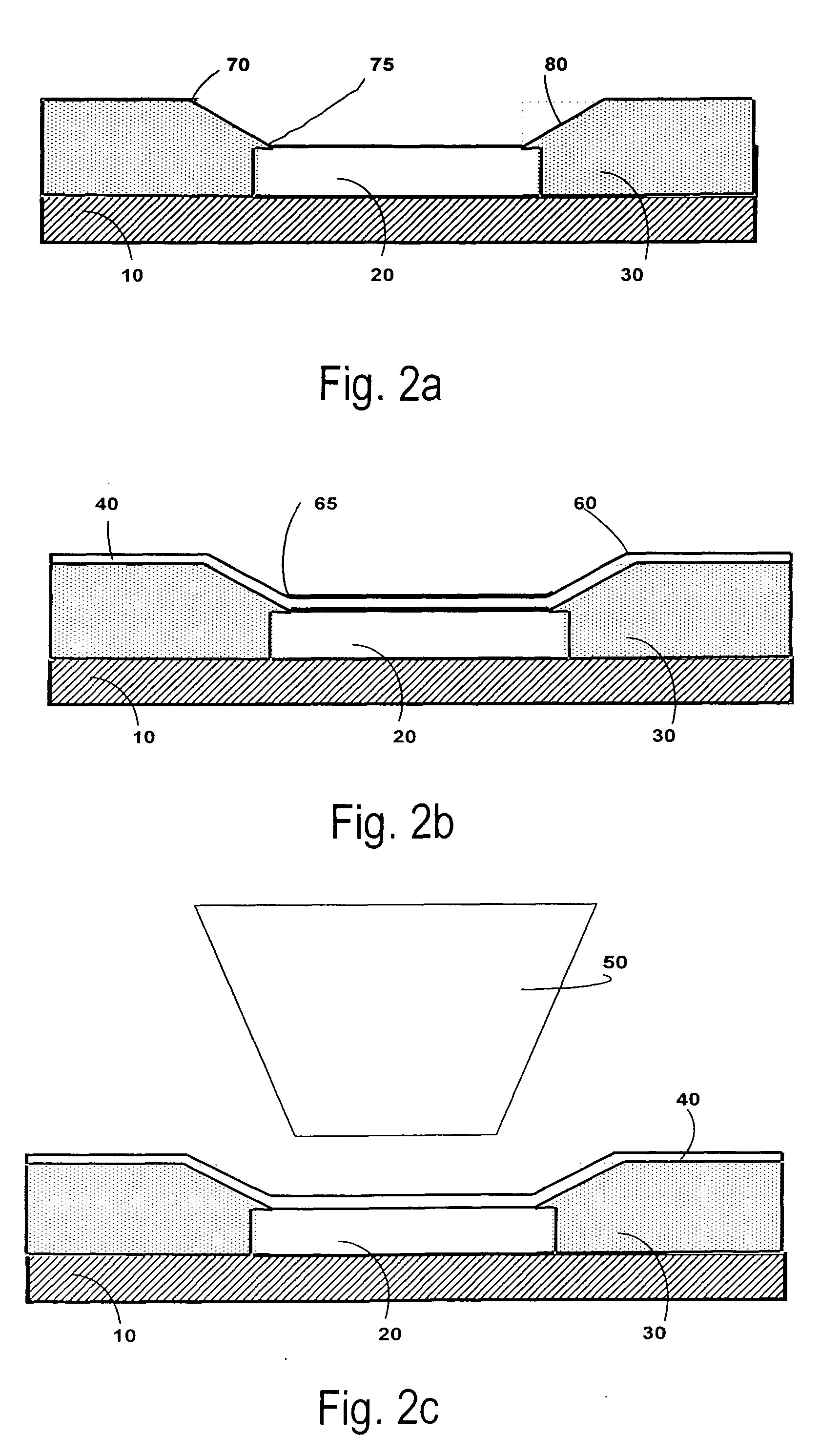

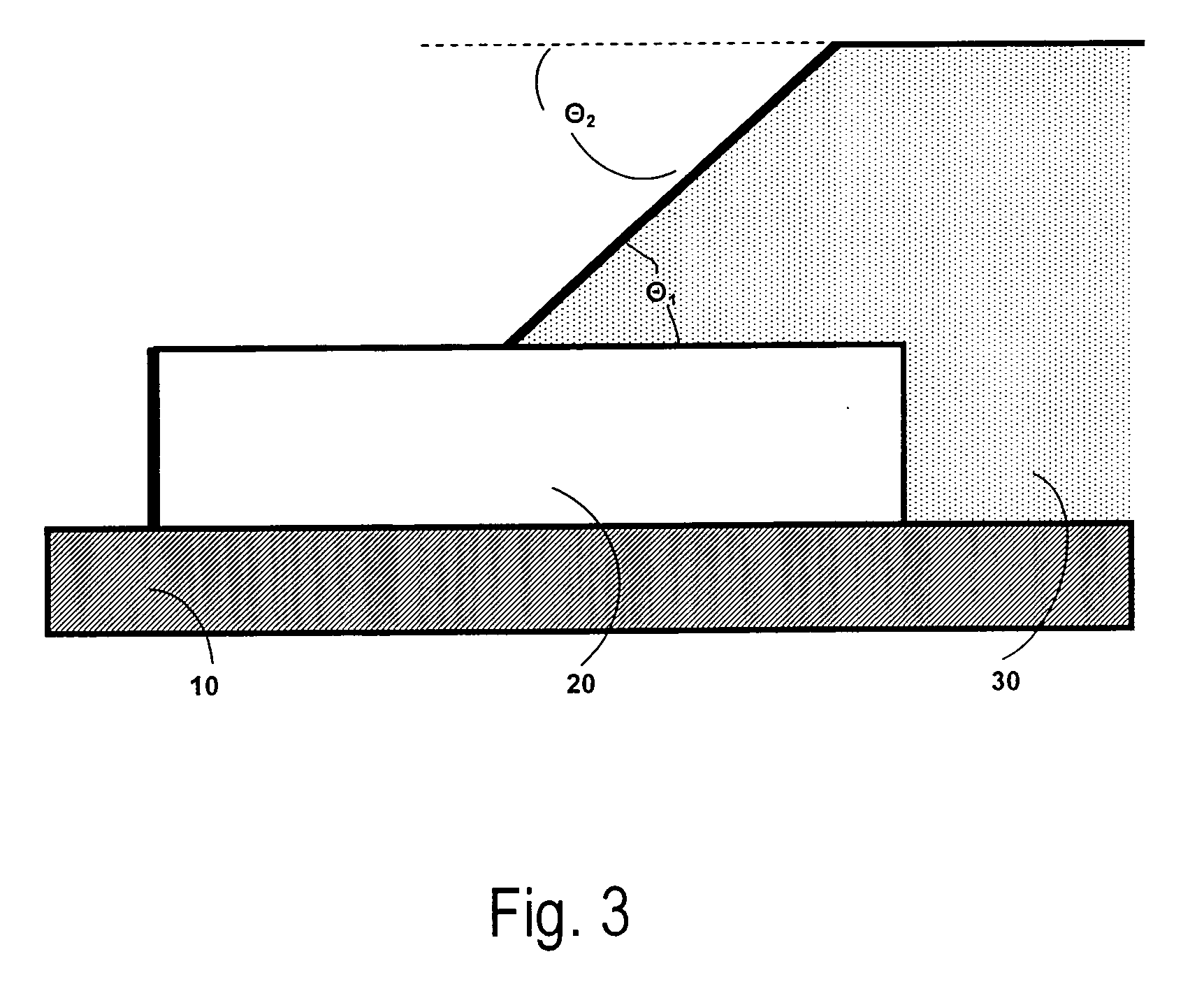

Surface and composition enhancements to high aspect ratio C-MEMS

ActiveUS20060068107A1Increase surface areaHigh aspect ratioMaterial nanotechnologyChemical vapor deposition coatingForming gasOxygen plasma

C-MEMS architecture having carbon structures with high surface areas due to high aspect ratios and nanoscale surface enhancements, and improved systems and methods for producing such structures are provided. Specifically, high aspect ratio carbon structures are microfabricated by pyrolyzing a patterned carbon precursor polymer. Pyrolysing the polymer preferably comprises a multi-step process in an atmosphere of inert and forming gas at high temperatures that trail the glass transition temperature (Tg) for the polymer. The surface area of the carbon microstructures is increases by nanotexturing the surface through oxygen plasma exposure, and by integrating nanoscale structures with the carbon microstructures by exposing the carbon microstructures and a catalyst to hydrocarbon gas. In a preferred embodiment, the carbon microstructures are the source of carbon gas.

Owner:RGT UNIV OF CALIFORNIA

Latex compositions having improved drying speed

Disclosed are modified latexes having improved drying speed, comprising a polymer having one or more pendant side chains, such side chain comprising the product of the reaction between a mono- or poly-functional group capable of reacting with an acid or hydroxyl unit, and such units present on the precursor polymer. Such modified latexes are storage-stable one-pack compositions useful alone or in combination in coating applications, or as adhesives, sizing agents, composites, impregnants, castings, caulks, and non-woven binders. Also disclosed is a method for providing a crosslinked protective coating on a substrate, comprising the steps of: applying a coating of the composition of the present invention to the substrate; and allowing the composition to cure at ambient temperature or greater, or applying radiation to the composition to effect curing.

Owner:ROHM & HAAS CO

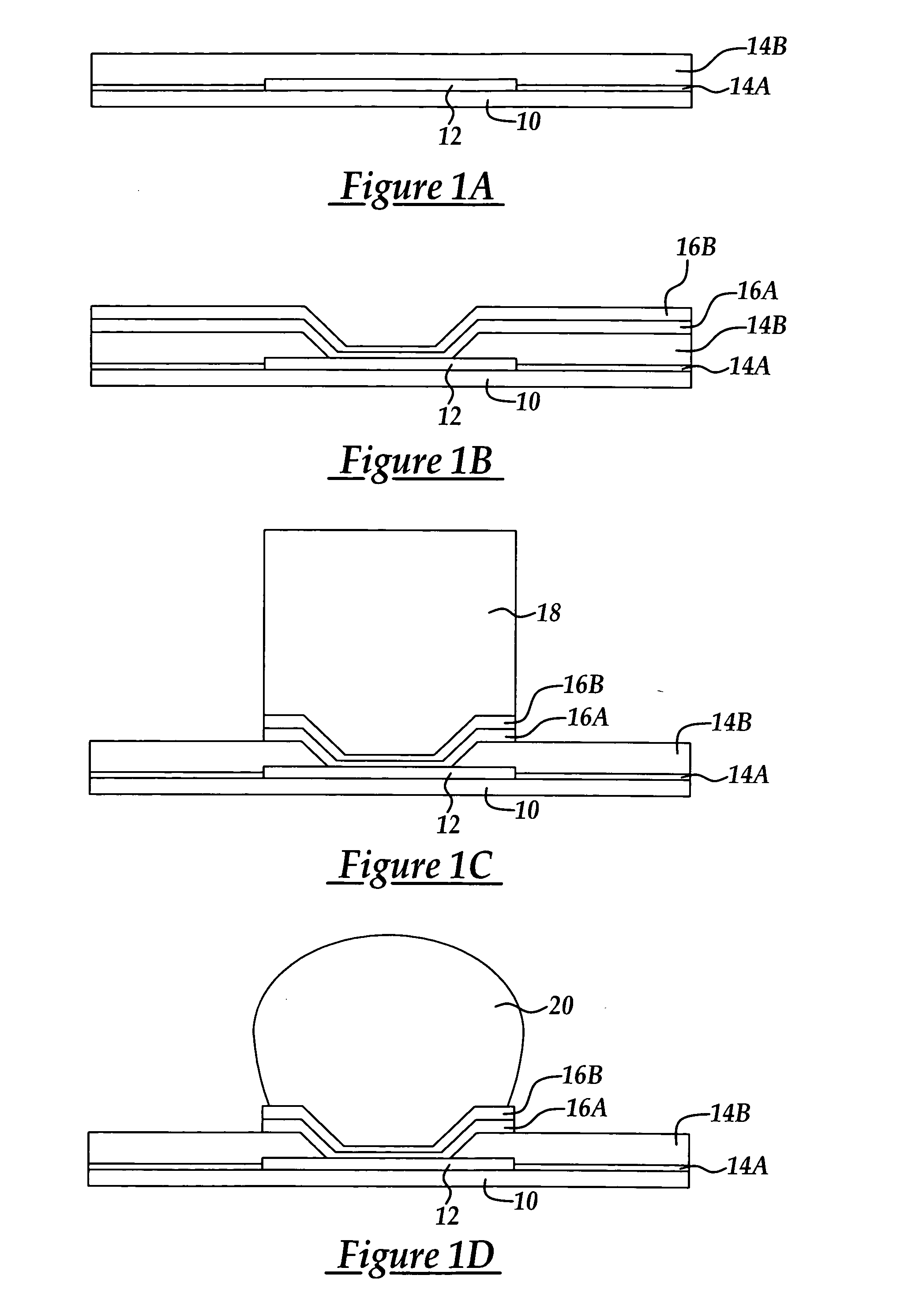

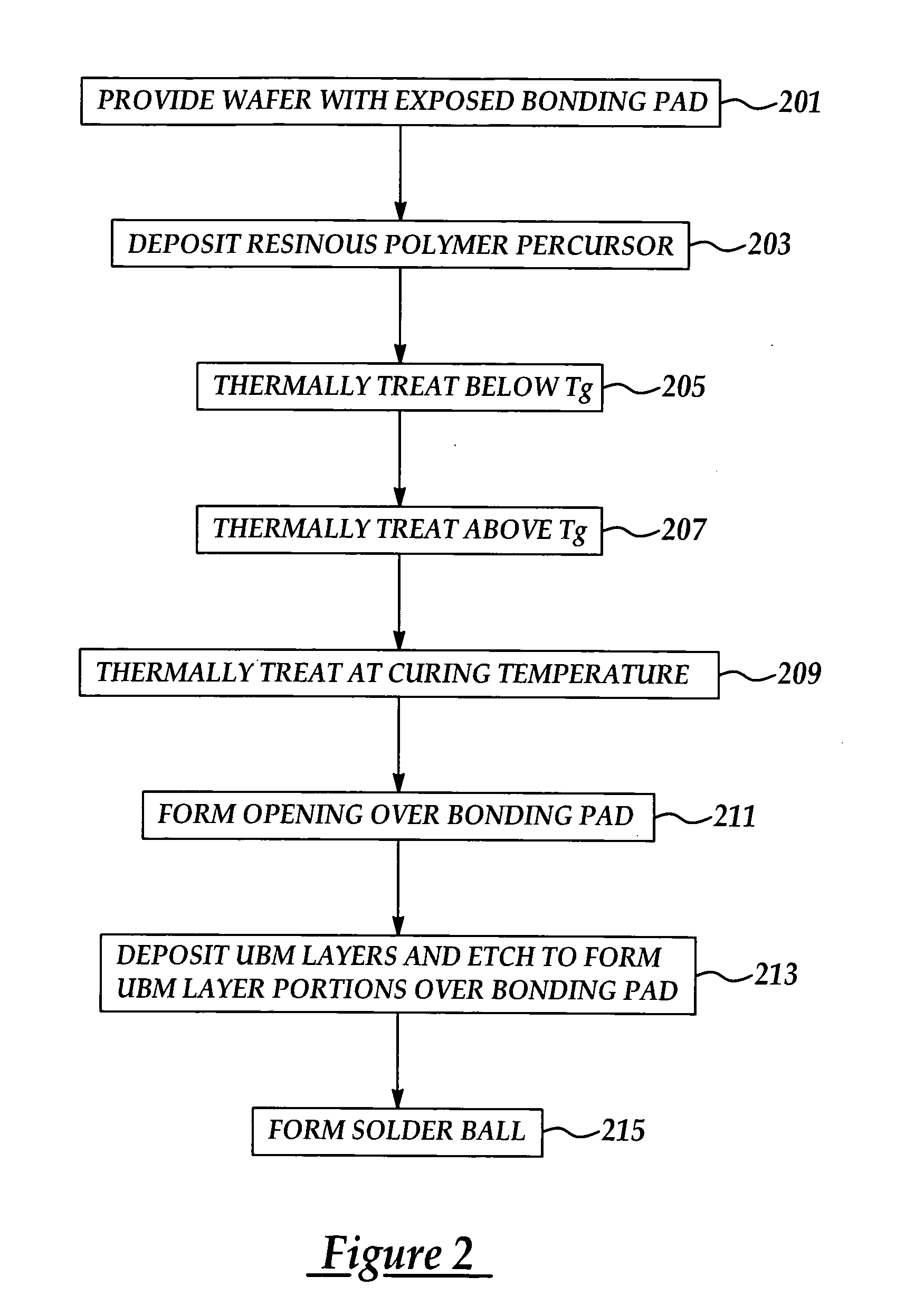

Method to prevent passivation layer peeling in a solder bump formation process

InactiveUS20050191836A1Improve Wafer YieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCross-linkVitrification

A method for reducing peeling of a cross-linked polymer passivation layer in a solder bump formation process including providing a multi-level semiconductor device formed on a semiconductor process wafer having an uppermost surface comprising a metal bonding pad in electrical communication with underlying device levels; forming a layer of resinous pre-cursor polymeric material over the process surface said resinous polymeric material having a glass transition temperature (Tg) upon curing; subjecting the semiconductor process wafer to a pre-curing thermal treatment temperature below Tg for a period of time; and, subjecting the semiconductor process wafer to at least one subsequent thermal treatment temperature above Tg for a period of time to form an uppermost passivation layer.

Owner:TAIWAN SEMICON MFG CO LTD

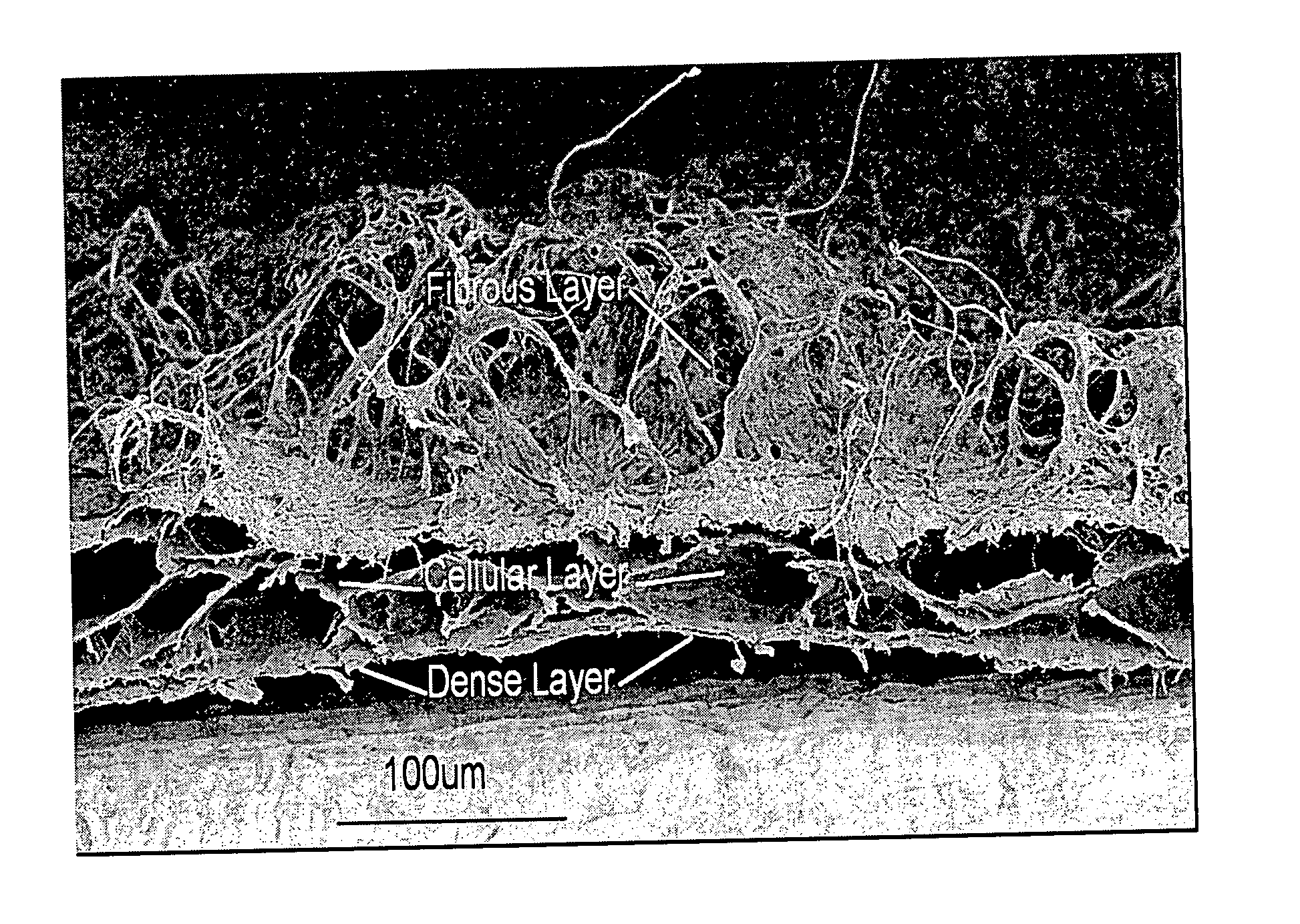

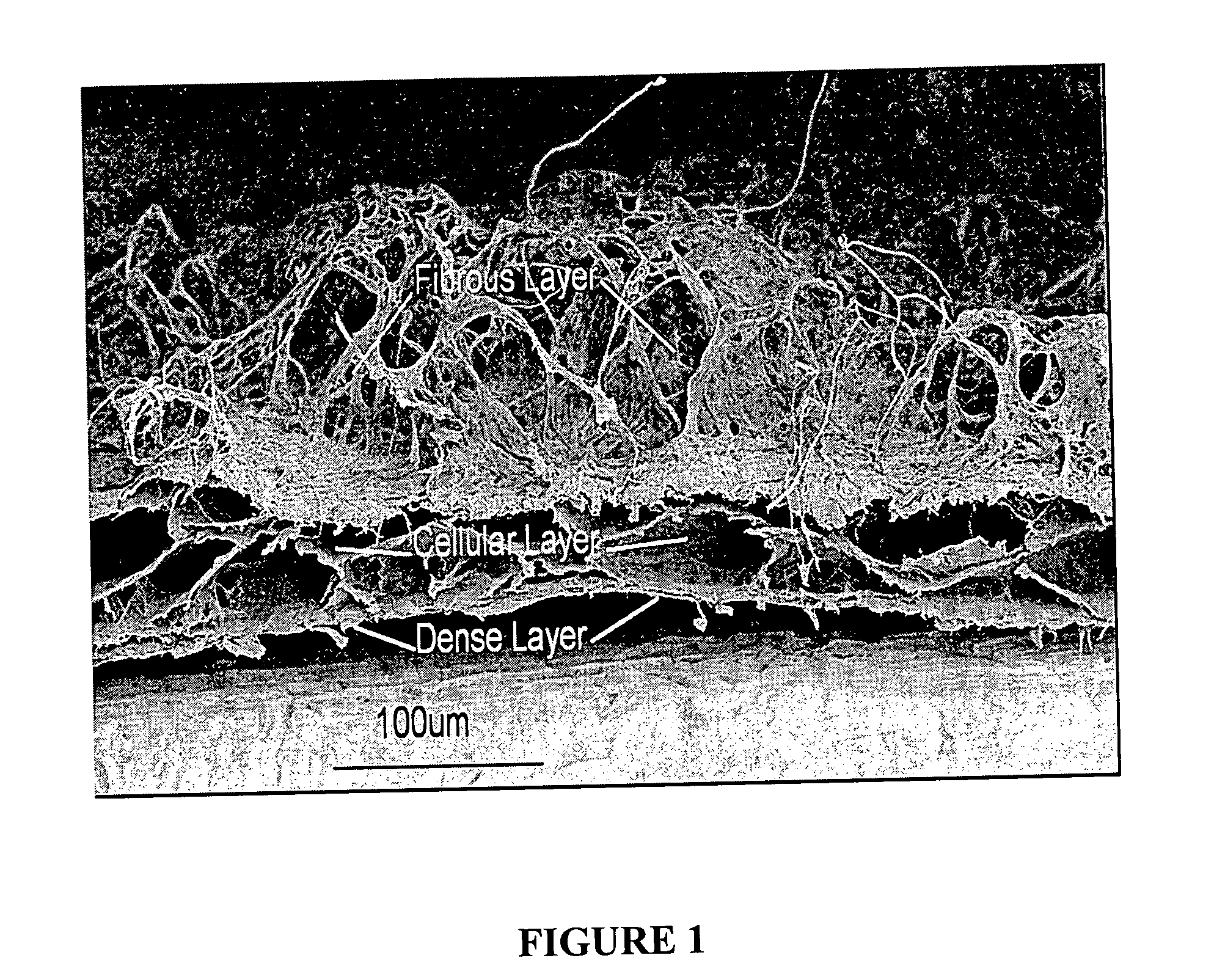

Three dimensional-BIO-mimicking active scaffolds

InactiveUS20070275458A1Easy to useLow costBioreactor/fermenter combinationsBiological substance pretreatmentsNano structuringCell-Extracellular Matrix

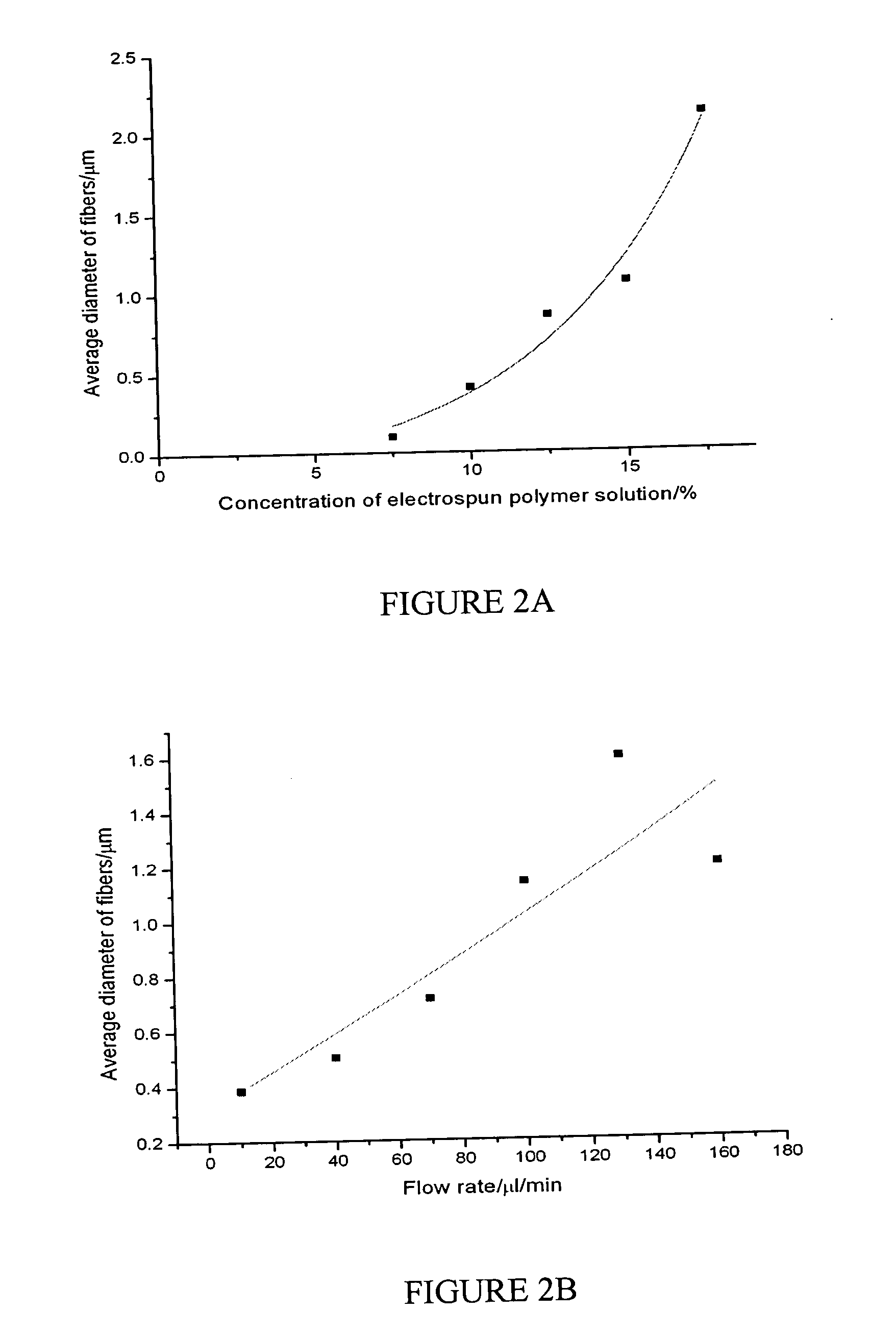

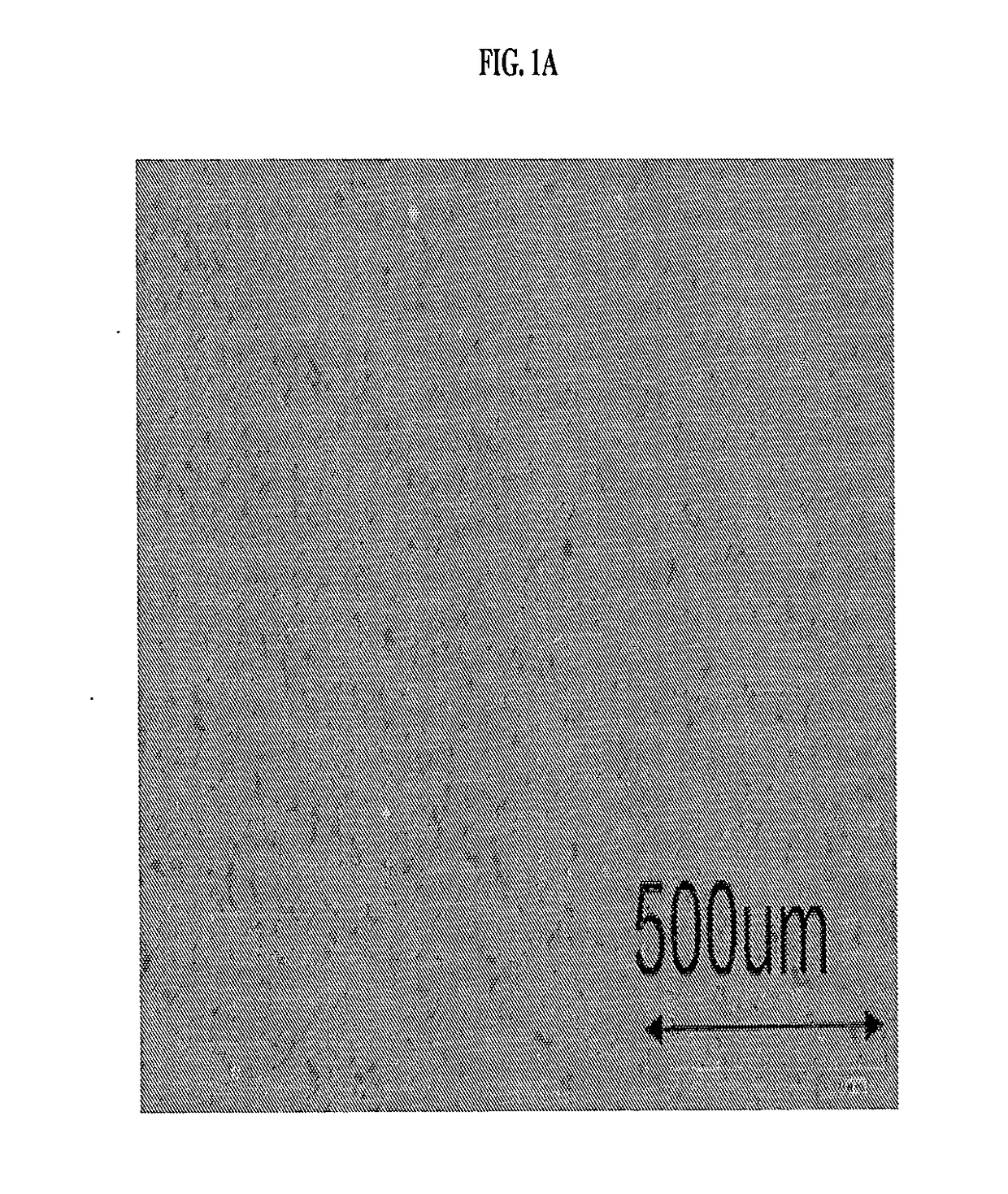

The invention provides a Cellulose acetate (CA) thin, porous membranes produced by electrospinning precursor polymer solutions in acetone at room temperature and a process for manufacturing the same. The invention also provides a Cellulose acetate (CA) thin, porous membranes produced by electrospinning precursor polymer solutions in acetone at room temperature further comprising ceramic nano-structured component (carbon nanotubes) in the polymer membranes to provide additional strength and porosity and a process for manufacturing the same. The fabricated CA-CT membranes specifically mimic the topography and porosity of natural Extracellular Matrix (ECM) and can be used as scaffolding for cell growth.

Owner:GOUMA PELAGIA IRENE

Monomer formulations and methods for 3D printing of preceramic polymers

ActiveUS20180148380A1Prevent degradationGood compatibilityAdditive manufacturing apparatusInks3d shapesFree form

This invention provides resin formulations which may be used for 3D printing and pyrolyzing to produce a ceramic matrix composite. The resin formulations contain a solid-phase filler, to provide high thermal stability and mechanical strength (e.g., fracture toughness) in the final ceramic material. The invention provides direct, free-form 3D printing of a preceramic polymer loaded with a solid-phase filler, followed by converting the preceramic polymer to a 3D-printed ceramic matrix composite with potentially complex 3D shapes or in the form of large parts. Other variations provide active solid-phase functional additives as solid-phase fillers, to perform or enhance at least one chemical, physical, mechanical, or electrical function within the ceramic structure as it is being formed as well as in the final structure. Solid-phase functional additives actively improve the final ceramic structure through one or more changes actively induced by the additives during pyrolysis or other thermal treatment.

Owner:HRL LAB

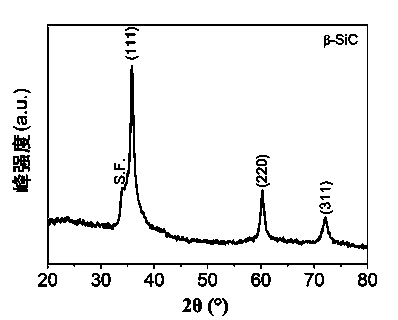

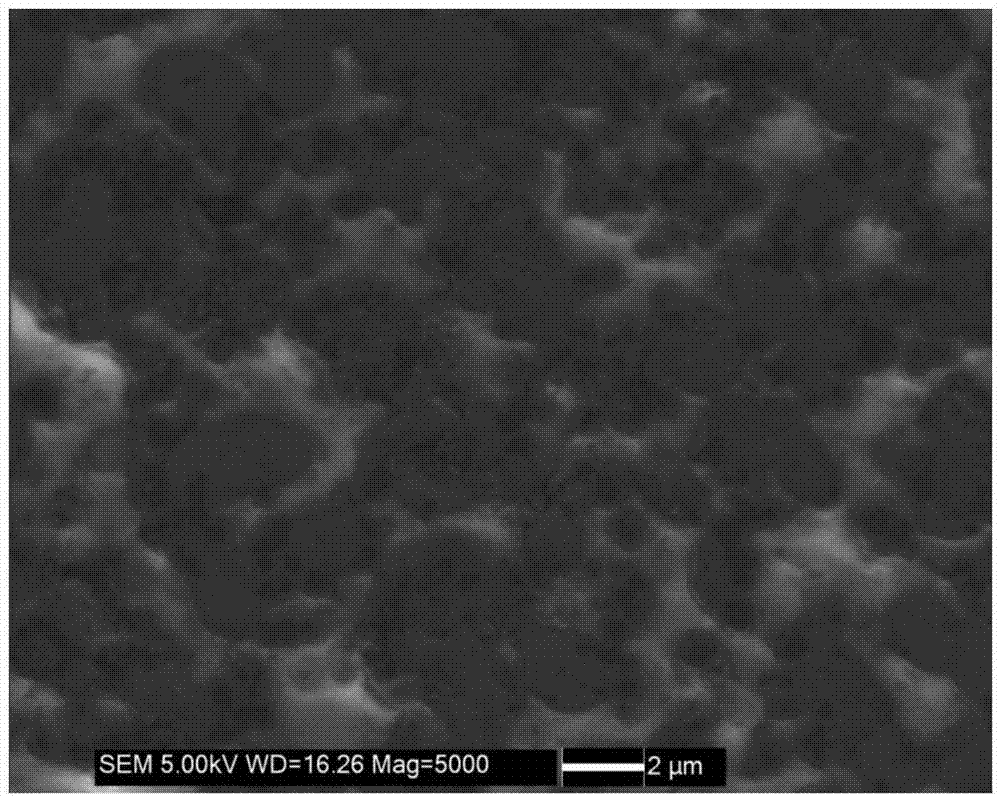

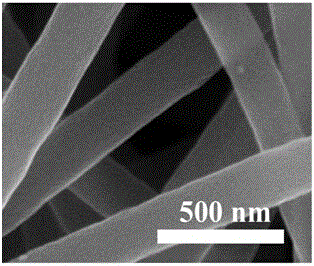

Preparation method of porous silicon carbide nanofiber

ActiveCN103966701AUniform diameterLarge specific surface areaArtificial filament chemical after-treatmentFiltrationElectrospinning

The invention discloses a preparation method of a porous silicon carbide nanofiber. The preparation method comprises the following steps of: (1) preparing a carbon nanofiber precursor polymer spinning solution; (2) performing electrostatic spinning to prepare a polymer nanofiber; (3) carrying out pre-oxidization crosslinking on the polymer nanofiber; (4) carrying out high-temperature firing on the pre-oxidized polymer nanofiber to prepare a carbon nanofiber; and (5) carrying out carbon thermal reduction on the carbon nanofiber and silicon powder to obtain the porous silicon carbide nanofiber. According to the preparation method, the morphology, the diameter and the ordering of the obtained silicon carbide nanofiber can be effectively regulated and controlled through simple means; the production cycle is relatively short so that expanded production can be conveniently realized and the preparation process is simple so that the industrial production can be conveniently realized; the porous silicon carbide nanofiber has wide application prospect in the fields of high-temperature filtration, high-temperature catalysis, catalyst carriers, heat insulation and sound insulation, gas separation, chemical sensors and the like.

Owner:NAT UNIV OF DEFENSE TECH

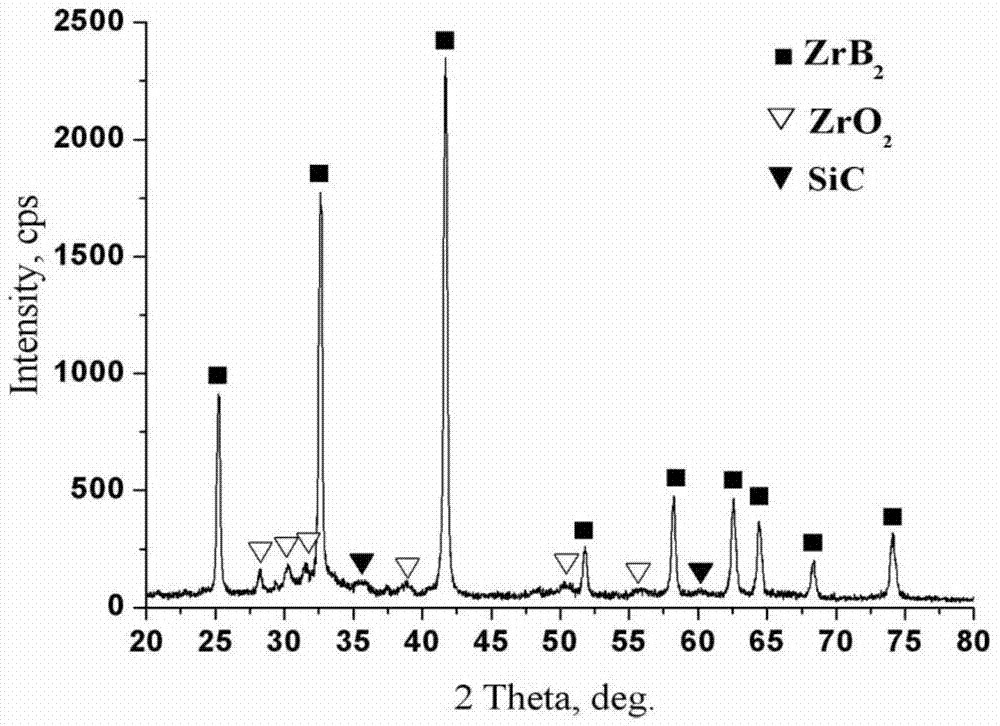

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

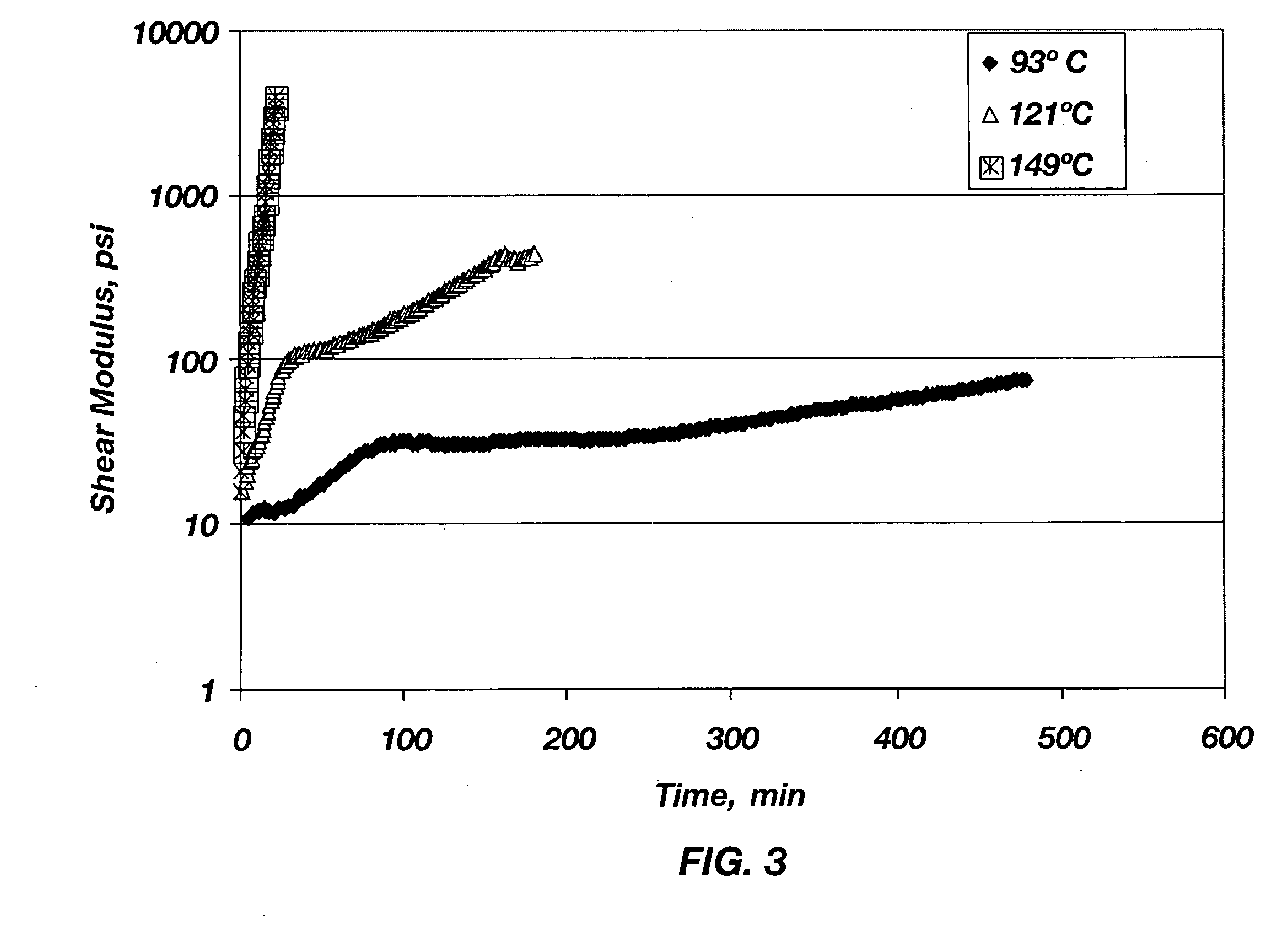

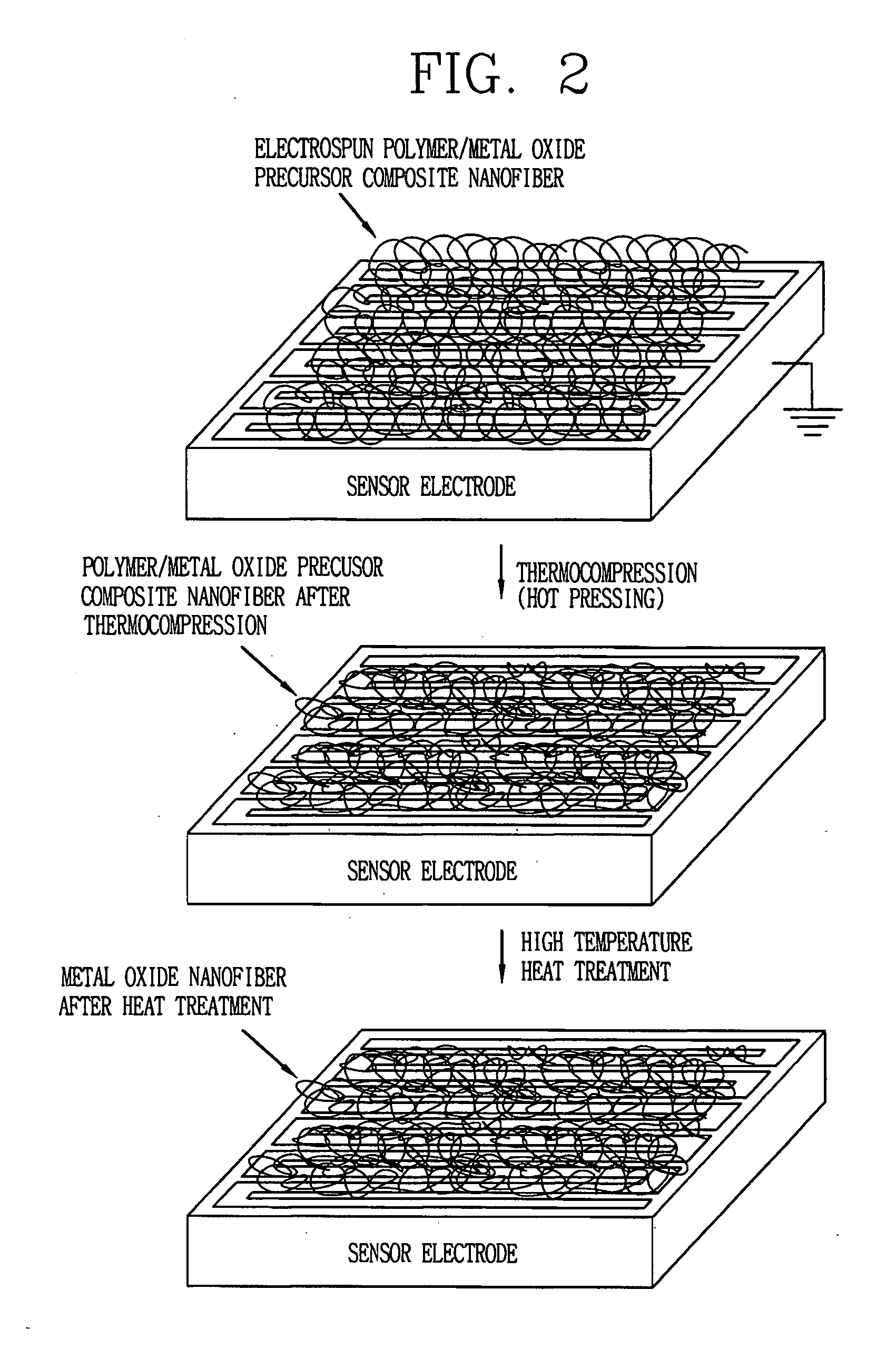

Ultra-sensitive metal oxide gas sensor and fabrication method thereof

InactiveUS20070261959A1Improve gas diffusivityLarge specific surface areaPretreated surfacesNanosensorsFiberUltra sensitive

A method for fabricating an ultra-sensitive metal oxide gas sensor is disclosed, which comprises the steps of spinning a mixture solution including a metal oxide precursor and a polymer onto a sensor electrode to form a metal oxide precursor-polymer composite fiber; thermally compressing or thermally pressurizing the composite fiber; and thermally treating the thermally compressed or thermally pressurized composite fiber to remove the polymer from the composite fiber. Since the gas sensor includes a macro pore between nanofibers and a meso pore between nano-rods and / or nano-grains, gas diffusion and surface area can be maximized. Also, the ultra-sensitive sensor having high stability in view of mechanical, thermal, and electrical aspects can be obtained through rapid increase of adhesion between the metal oxide thin layer and the sensor electrode.

Owner:KOREA INST OF SCI & TECH

Novel positive photosensitive polybenzoxazole precursor compositions

ActiveUS20070099111A1Reduce sidewall angleAvoid stress failurePhotomechanical apparatusDiazo compound compositionsPolymer sciencePlasticizer

A heat resistant positive-working photosensitive PBO precursor composition comprising: (a) at least one polybenzoxazole precursor polymer; (a) at least one plasticizer compound; (b) at least one solvent; wherein the amount of the plasticizer present in the composition is an amount effective to reduce the sidewall angle of imaged and cured features in the coated film on the substrate to prevent stress failures in subsequent metallization of the substrate due to steep angles of the imaged features, and with the proviso that if the polybenzoxazole precursor polymer solely consists of polybenzoxazole precursor polymers that do not contain a photoactive moiety on the polymer, then (c) at least one photoactive compound is also present in the composition.

Owner:FUJIFILM ELECTRONICS MATERIALS US

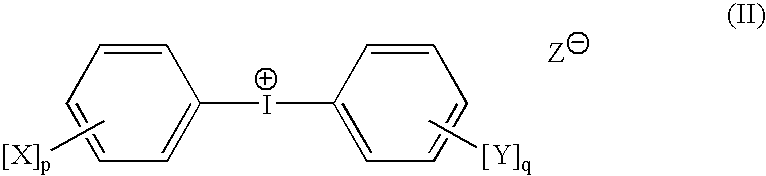

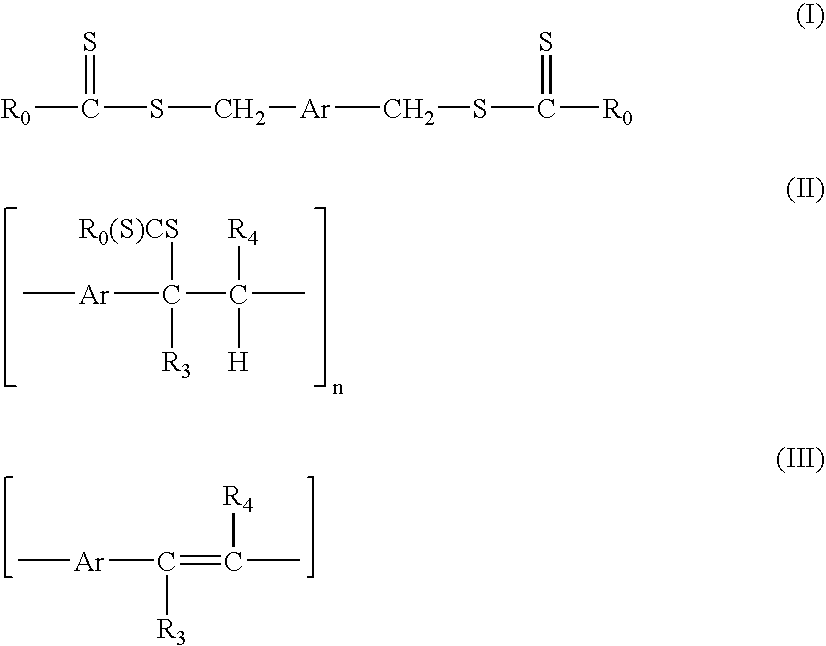

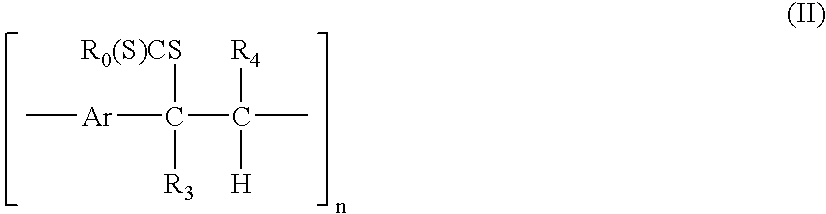

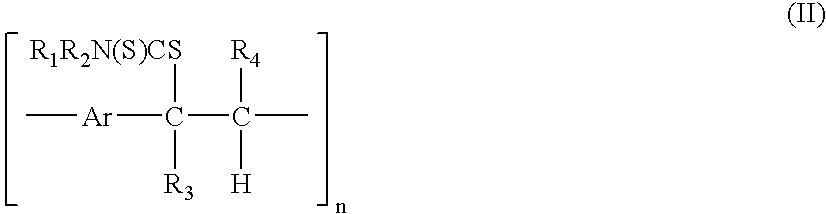

Method of preparing derivatives of polyarylene vinylene and method of preparing an electronic device including same

InactiveUS20050159581A1High yieldHigh molecular weightSolid-state devicesDomestic articlesPolymer scienceLeaving group

A technique is described for the preparation of polymers according to a process in which the starting compound of formula (I) is polymerized in the presence of a base in an organic solvent. No end chain controlling agents are required during the polymerisation to obtain soluble precursor polymers. The precursor polymer such obtained comprises structural units of the formula (II). In a next step, the precursor polymer (II) is subjected to a conversion reaction towards a soluble or insoluble conjugated polymer by thermal treatment. The arylene or heteroarylene polymer comprises structural units of the formula III. In this process the dithiocarbamate group acts as a leaving group and permits the formation of a precursor polymer of structural formula (II), which has an average molecular weight from 5000 to 1000000 Dalton and is soluble in common organic solvents. The precursor polymer with structural units of formula (II) is thermally converted to the conjugated polymer with structural formula (III).

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Continuous, carbon-nanotube-reinforced polymer precursors and carbon fibers

ActiveUS20100120969A1Satisfies needGroup 4/14 element organic compoundsNanotechPrecursor polymerPolyacrylonitrile

The present invention relates to a continuous, carbon fiber with nanoscale features comprising carbon and carbon nanotubes, wherein the nanotubes are substantially aligned along a longitudinal axis of the fiber. Also provided is a polyacrylonitrile (PAN) precursor including about 50% to about 99.9% by weight of a melt-spinnable PAN and about 0.01% to about 10% of carbon nanotubes. Other precursor materials such as polyphenylene sulfide, pitch and solution-spinnable PAN are also provided. The precursor can also include a fugitive polymer which is dissociable from the precursor polymer.

Owner:THE BOEING CO

Positive photosensitive polybenzoxazole precursor compositions

ActiveUS7803510B2Reduce sidewall angleAvoid stress failureDiazo compound compositionsPhotosensitive material processingBenzoxazolePlasticizer

A heat resistant positive-working photosensitive PBO precursor composition comprising:(a) at least one polybenzoxazole precursor polymer;(a) at least one plasticizer compound;(b) at least one solvent;wherein the amount of the plasticizer present in the composition is an amount effective to reduce the sidewall angle of imaged and cured features in the coated film on the substrate to prevent stress failures in subsequent metallization of the substrate due to steep angles of the imaged features, and with the proviso that if the polybenzoxazole precursor polymer solely consists of polybenzoxazole precursor polymers that do not contain a photoactive moiety on the polymer, then(c) at least one photoactive compound is also present in the composition.

Owner:FUJIFILM ELECTRONICS MATERIALS US

Photosensitive resin compositions

A heat resistant negative working photosensitive composition that comprises(a) one or more polybenzoxazole precursor polymers (I): wherein x is an integer from about 10 to about 1000, y is an integer from 0 to about 900 and (x+y) is about less then 1000; Ar1 is a tetravalent aromatic group, a tetravalent heterocyclic group, or mixtures thereof; Ar2 is a divalent aromatic, a divalent heterocyclic, a divalent alicyclic, or a divalent aliphatic group that may contain silicon; Ar3 is a divalent aromatic group, a divalent aliphatic group, a divalent heterocyclic group, or mixtures thereof; Ar4 is Ar1 (OH)2 or Ar2; G is a monovalent organic group a carbonyl, carbonyloxy or sulfonyl group;(b) one or more photo-active compounds which release acid upon irradiation (PAGs);(c) one or more latent crosslinkers each of which contains at least two ˜N—(CH2OR)n units (n=1 or 2, wherein R is a linear or branched C1–C8 alkyl group);(d) at least one solvent, and(e) at least one dissolution rate modifier,with the proviso that when the latent crosslinker is highly reactive, the dissolution rate modifier does not contain carboxylic acid groups.

Owner:FUJIFILM ELECTRONICS MATERIALS US

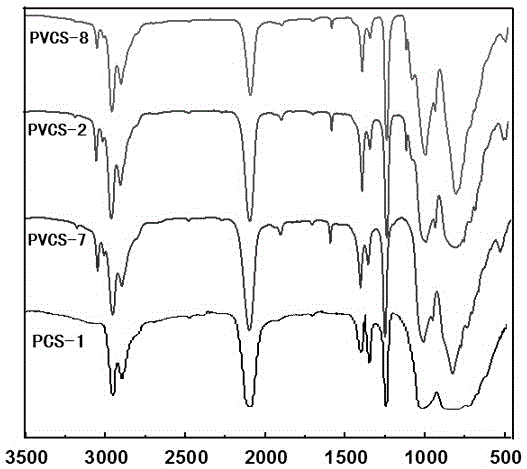

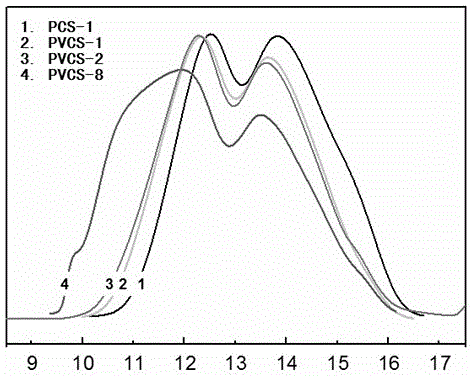

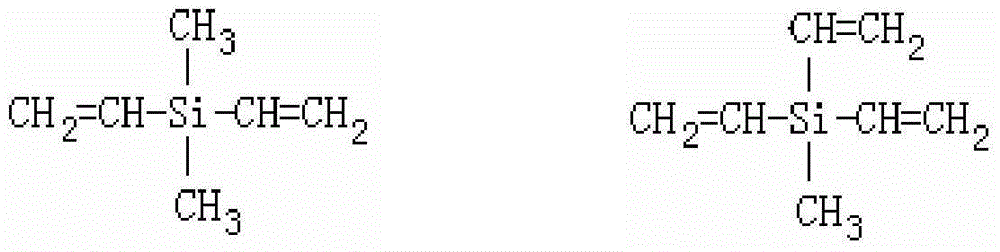

Synthesis method of polycarbosilane capable of being used for thermosetting crosslinking

A synthesis method of polycarbosilane capable of being used for thermosetting crosslinking comprises the following steps: taking polycarbosilane used for preparing a composite material as a raw material; placing the polycarbosilane used for preparing the composite material and an organosilan compound containing 2 to 3 -C=C- groups into a reaction vessel; adding dimethyl benzene; mixing uniformly for dissolving; adding a Si-H additive reaction catalyst; vacuumizing; carrying out replacing with high-purity nitrogen; carrying out an Si-H additive reaction under a normal-pressure or high-pressure heating condition and the protection of the high-purity nitrogen. The synthesis method is simple and convenient, and easy to implement; the product PVCS can be used for self-setting crosslinking under an inert atmosphere after being treated at 400 DEG C; the smelting outflow of PCS during heat treatment can be avoided; the ceramic yield can be improved remarkably; the polycarbosilane synthesized according to the synthesize method can be used as a precursor polymer of ceramic-based composite materials such as Cf / SiC, and SiCf / SiC.

Owner:NAT UNIV OF DEFENSE TECH

Method of producing carbon nanomaterials and centrifugal melt spinning apparatus

InactiveUS7763228B2Producing a carbon nanomaterialImprove efficiencyMaterial nanotechnologyFilament/thread formingPolymer scienceCarbonization

A carbon nanomaterial produced by: performing centrifugal melt spinning of core-shell particles that are prepared by using fine particles containing a carbon precursor polymer and a thermally decomposable polymer that disappears as a result of heat treatment, wherein the core-shell particles are heated up to a temperature at which phase separation thereof is not caused, and pressed against a plate-like heater 12 having a large number of pores 12A that penetrate therethrough in a thickness direction of the plate-like heater using centrifugal force; making the fiber obtained by the centrifugal melt spinning infusible; and performing carbonization thereof. According to this method, a carbon nanomaterial such as a carbon nanotube or a carbon nanofiber can be produced with high efficiency.

Owner:GUNMA UNIVERSITY

Method for preparing composite ceramic material through utilizing ceramic and precursor

The invention provides a method for preparing a composite ceramic material through utilizing ceramic and a precursor. The method comprises the steps that (1) ceramic powder and the precursor are mixed uniformly; (2) the mixture material is solidified, wherein the solidifying temperature is between 120 and 500 DEG C, and the thermal insulation time is between 0.5 and 10 hours; (3) the solidified product is subjected to die pressing so as to preform a body, and then, the body is further densified through isostatic pressing; (4) the body is subjected to net final dimension processing through adopting a mechanical processing mode; and (5) the processed product is sintered in a sintering furnace, so that the composite ceramic product is finally obtained, wherein the sintering pressure is between 100 pascals and 10 mega pascals, the sintering temperature is between 1600 and 2200 DEG C, and the sintering time is between 0.5 and 10 hours. A precursor polymer has plasticity and plays a role of a 'plasticizer' during the body forming process; and moreover, the 'plasticizer' can be directly converted into a component which is required by composite ceramic through cracking during the subsequent high-temperature processes, other impurities cannot be brought in, and the dispersion of all the components can be effectively improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

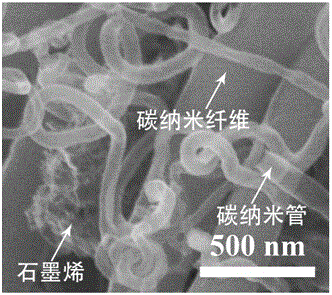

Graphene/carbon nano tube/carbon nanofiber electrocatalyst and preparation method thereof

ActiveCN105148892AImprove reducibilityReduce transmission resistancePhysical/chemical process catalystsCell electrodesFiberSpinning

The invention provides a graphene / carbon nano tube / carbon nanofiber electrocatalyst and a preparation method thereof. The electrocatalyst is prepared with the method comprising steps as follows: (1), spinning solution preparation: transition metal salt, a carbon nanofiber precursor polymer and a solvent are mixed uniformly, and a homogeneous spinning solution is obtained; (2), electrospinning: the homogeneous spinning solution is used for electrospinning, fibril felt is obtained; (3), pre-oxidation: the fibril felt is pre-oxidized in an air atmosphere, and pre-oxidized fiber felt is obtained; (4), pyrolysis: the pre-oxidized fiber felt is mixed uniformly with a graphite-phase carbon nitride precursor and graphite-phase carbon nitride and pyrolyzed in an inert atmosphere, and the graphene / carbon nano tube / carbon nanofiber electrocatalyst is obtained. The electrocatalyst has high electrical conductivity, many favorable active sites, good oxygen reduction electrocatalysis performance and better electrocatalysis performance, can be widely applied to the fields of super capacitors, cathode catalysis of fuel cells and the like; the preparation method is simple and large-scale production can be realized.

Owner:NAT UNIV OF DEFENSE TECH

Synthetic fiber nonwoven web and method

InactiveUS6469130B1Mechanical strengthHigh fluid absorbencySynthetic resin layered productsPaper/cardboard layered productsUltrasound attenuationFiber diameter

A nonwoven web and method of preparing a novel nonwoven web of synthetic fiber are disclosed. An aqueous solution amide crosslinked synthetic precursor polymer is extruded under defined conditions through a plurality of die orifices to form a plurality of threadlines. The threadlines are attenuated with a defined primary gaseous source to form fiber under conditions of controlled macro scale turbulence and under conditions sufficient to permit the viscosity of each threadline, as it leaves a die orifice and for a distance of no more than about 8 cm, to increase incrementally with increasing distance from the die, while substantially maintaining uniformity of viscosity in the radial direction, at a rate sufficient to provide fiber having,the desired attenuation and mean fiber diameter without significant fiber breakage. The attenuated threadlines are dried with a defined secondary gaseous source. The resulting fibers are deposited randomly on a moving foraminous surface to form a substantially uniform web. The moving foraminous surface is positioned about 10 to about 100 cm from the last gaseous source to contact the threadlines. The fibers have a mean fiber diameter in the range of about 0.1 to 30 mum and are substantially free of shot. The attenuating and drying steps are carried out under conditions of controlled macro scale turbulence.

Owner:KIMBERLY-CLARK WORLDWIDE INC

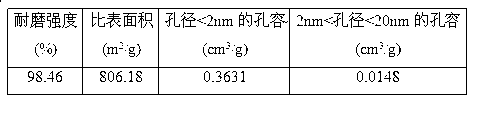

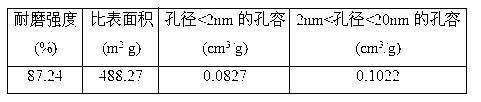

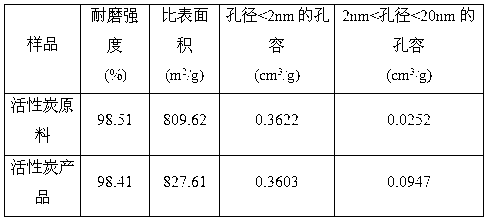

Method for preparing activated carbon

ActiveCN103253664AImprove wear resistanceIncrease microporosityCarbon compoundsPorosityPolyvinyl butyral

The invention relates to a method for preparing activated carbon. The method comprises the following steps of: weighing one of soluble phenolic resin, furfuryl alcohol resin, polyacrylonitrile and soluble starch, a carbon precursor polymer and one pore-forming agent of polyethylene glycol, polyvinyl alcohol and polyvinyl butyral, mixing, and adding one of methanol, ethanol and deionized water as a solvent for dissolution; and weighing the activated carbon raw material, adding into the solution for dipping, then drying, and carbonizing in a microwave high-temperature sintering furnace at the temperature of 500-1100 DEG C in a nitrogen atmosphere for 0.5-24h. According to the method for preparing activated carbon, provided by the invention, an activated carbon product prepared by the method has abrasion resistance and micropore porosity which are equivalent to those of the raw material activated carbon; and furthermore, the mesopore porosity is further increased in comparison with the raw material activated carbon, and the activated carbon has the advantages of double aperture distribution, large specific surface area and high abrasion resistance, and can meet the application requirements under specific conditions.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com