Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1077results about "Artificial filament chemical after-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

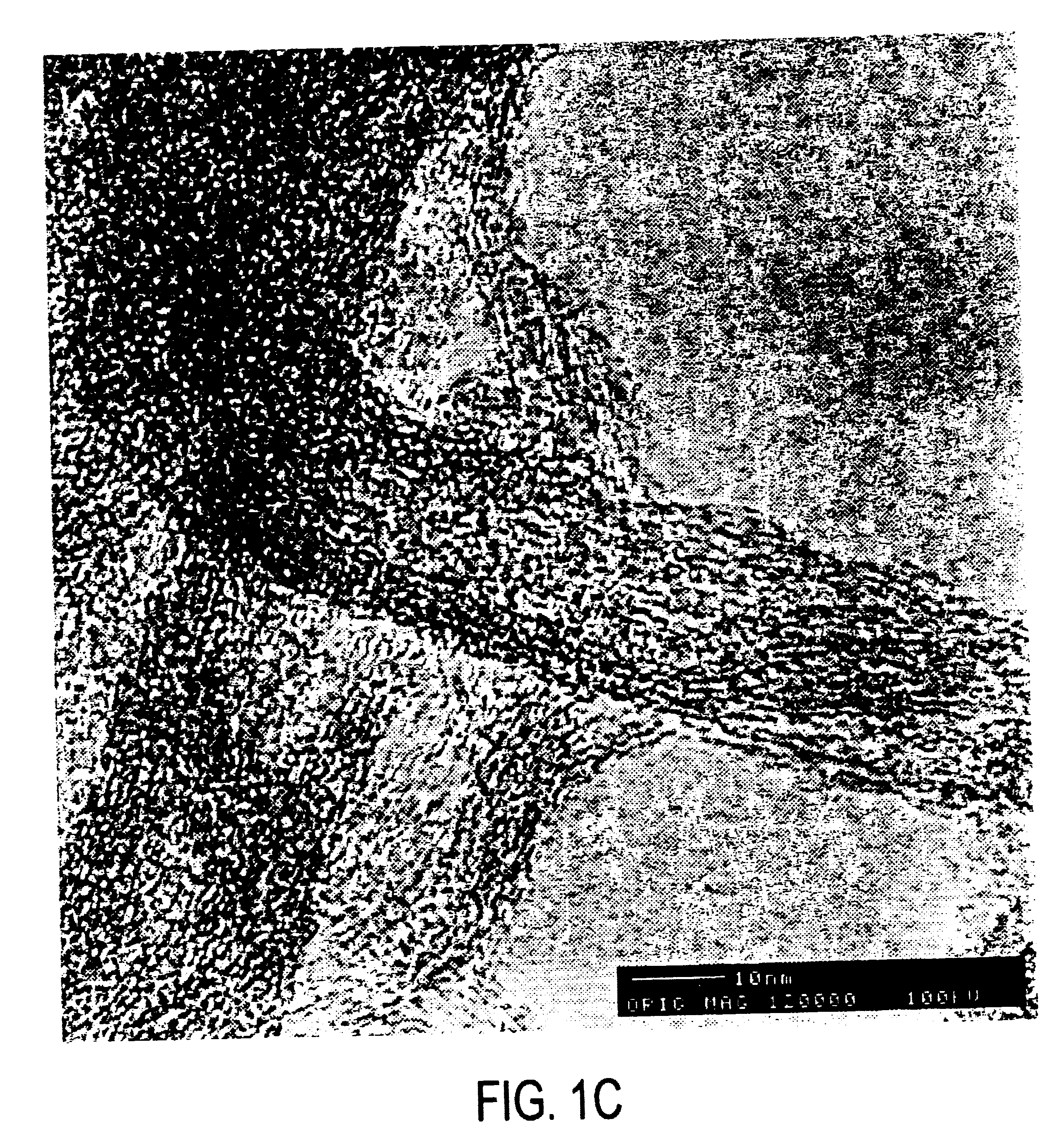

Method of making functionalized nanotubes

InactiveUS6203814B1Good dispersionImprove adhesionMaterial nanotechnologyCarbon compoundsChemical MoietyFiber

Owner:HYPERION CATALYSIS INT

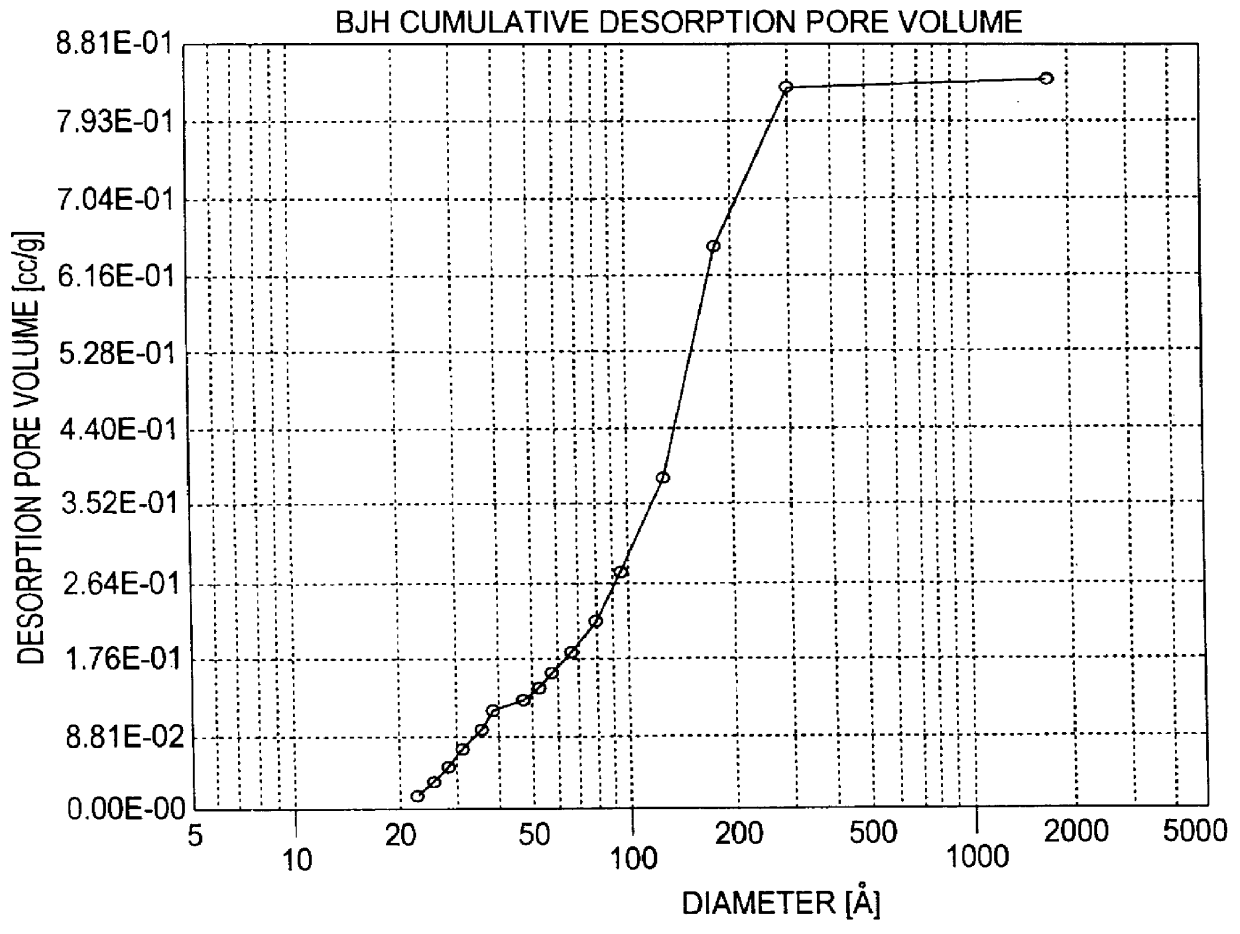

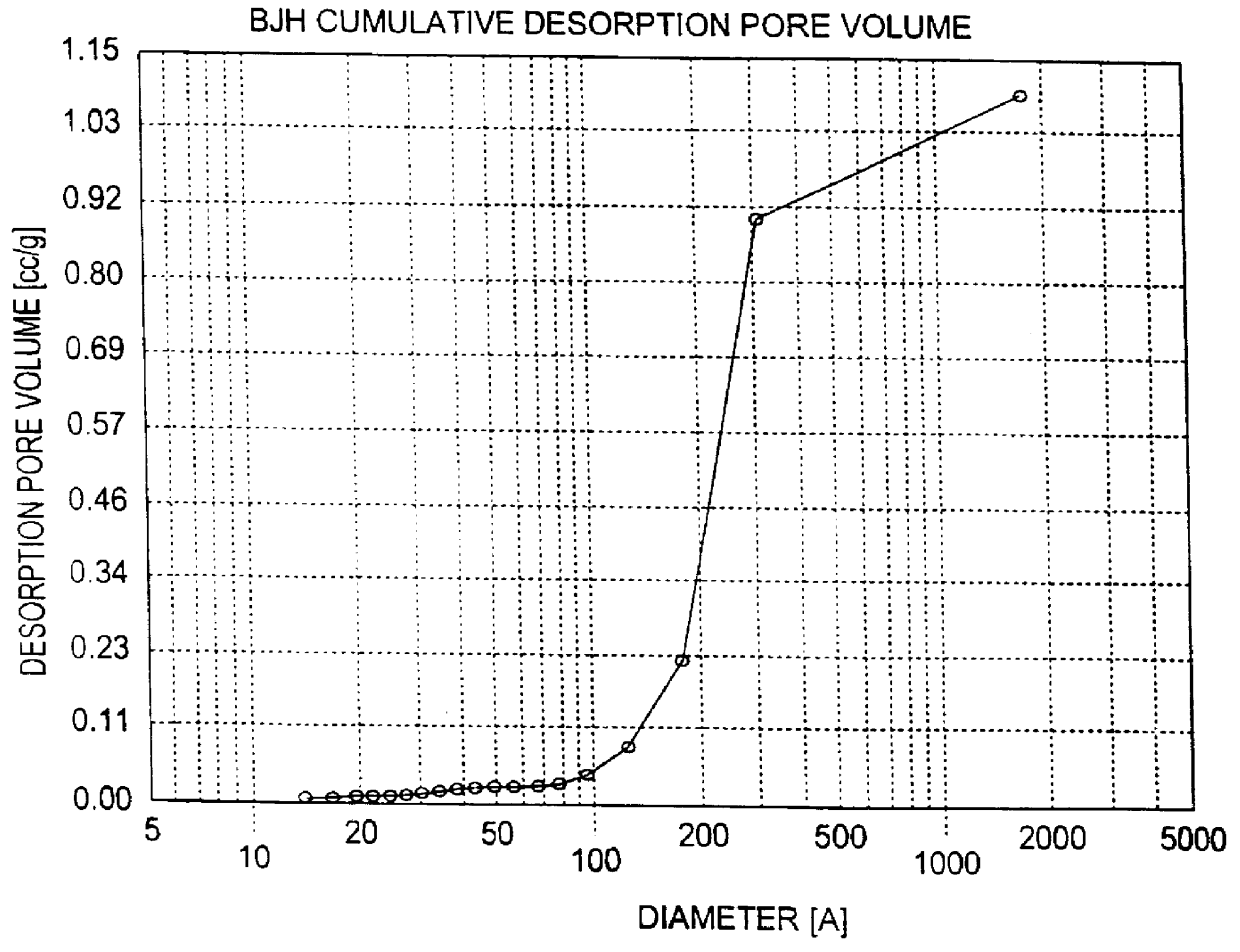

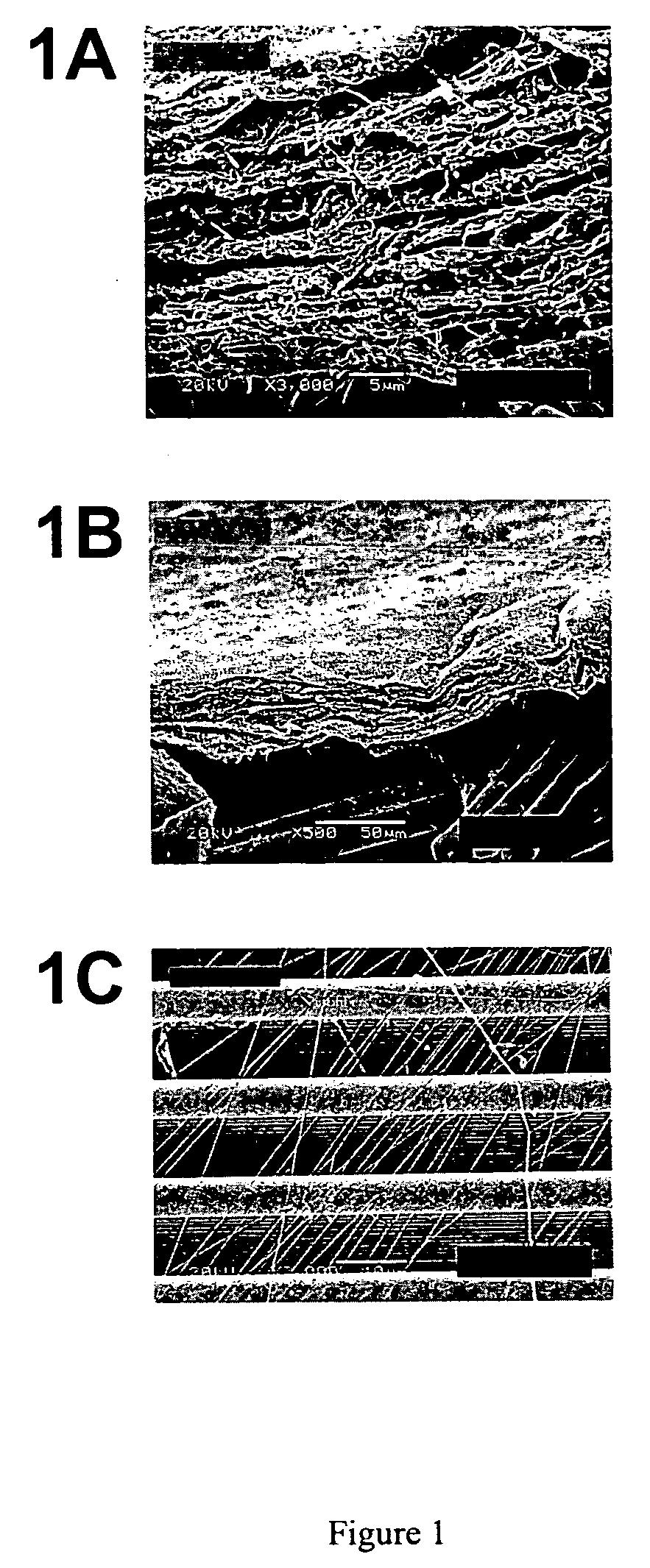

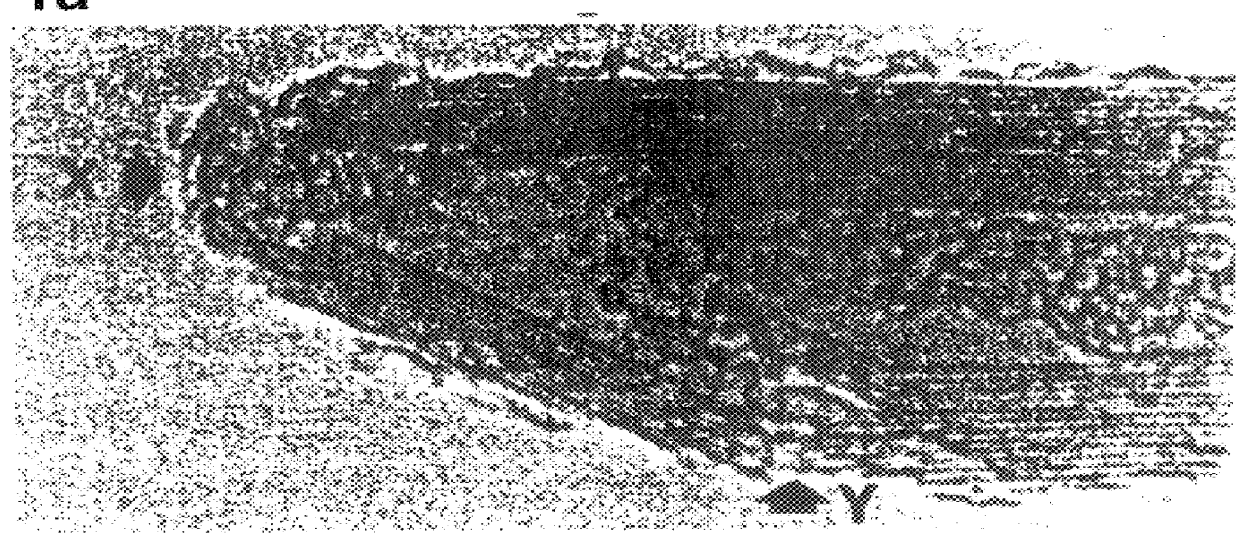

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

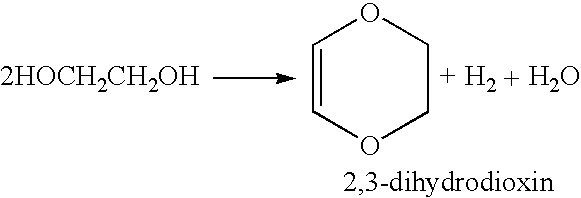

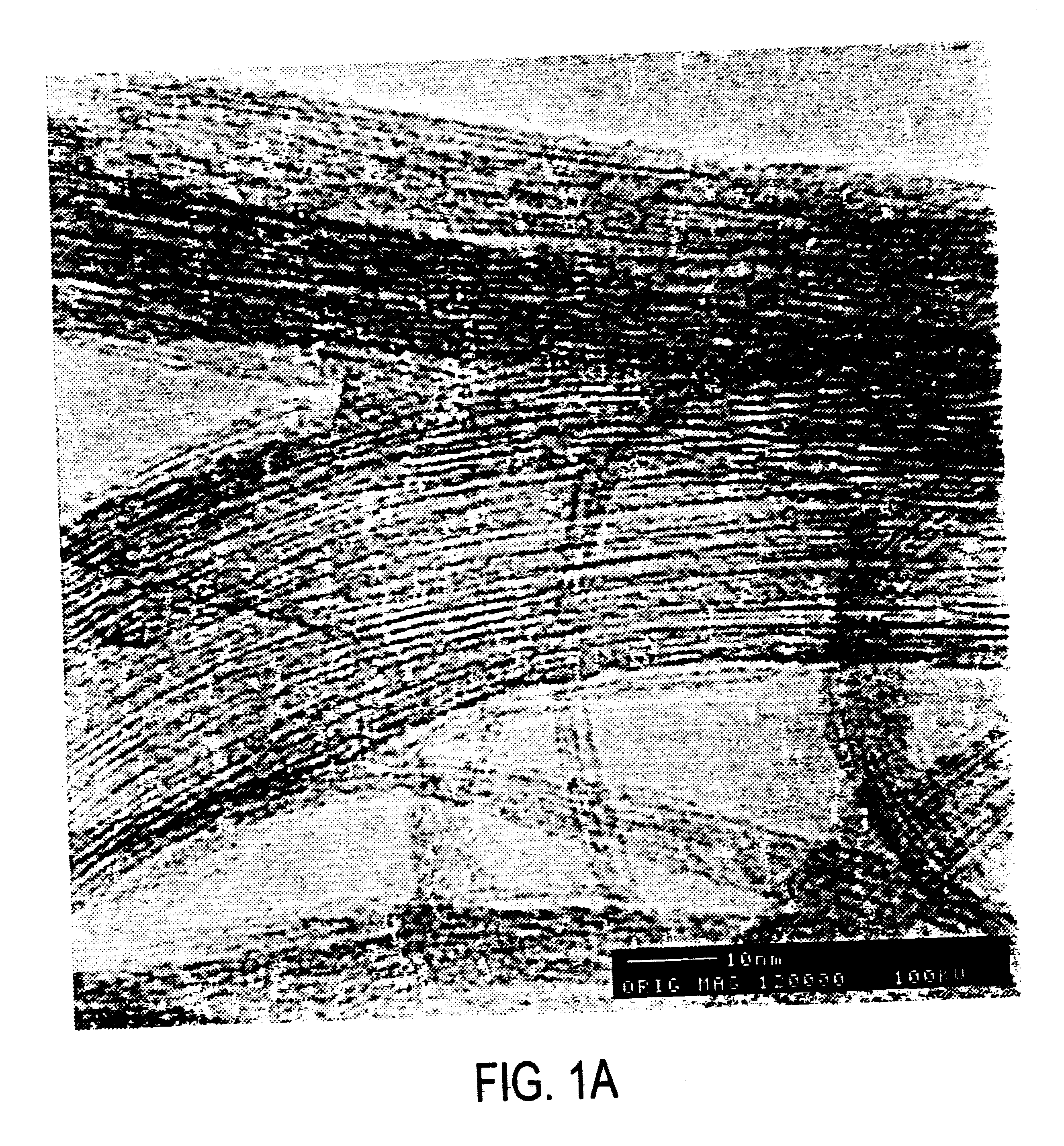

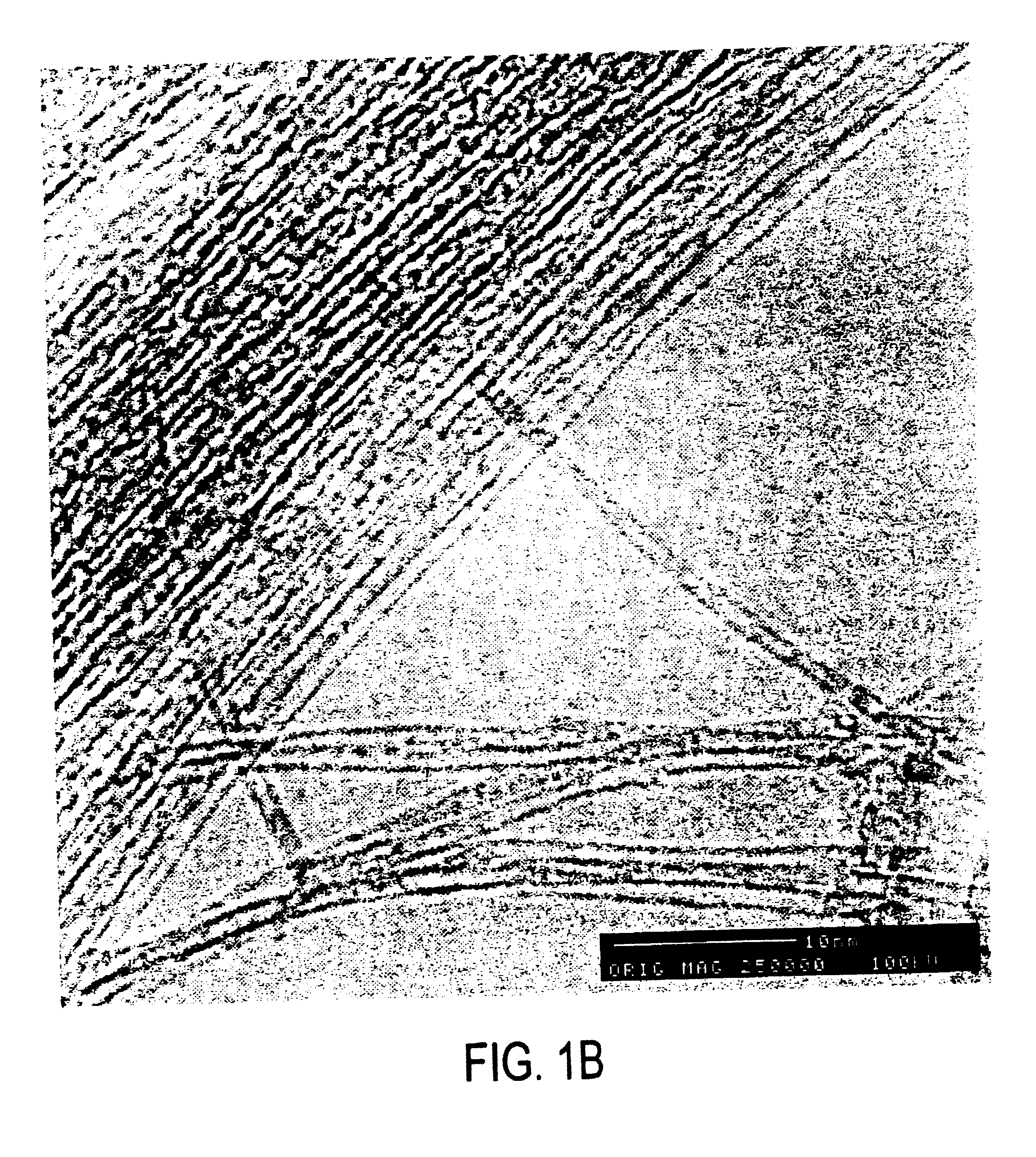

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

Graphitic nanotubes in luminescence assays

Graphitic nanotubes, which include tubular fullerenes (commonly called "buckytubes") and fibrils, which are functionalized by chemical substitution, are used as solid supports in electrogenerated chemiluminescence assays. The graphitic nanotubes are chemically modified with functional group biomolecules prior to use in an assay. Association of electrochemiluminescent ruthenium complexes with the functional group biomolecule-modified nanotubes permits detection of molecules including nucleic acids, antigens, enzymes, and enzyme substrates by multiple formats.

Owner:MESO SCALE TECH LLC

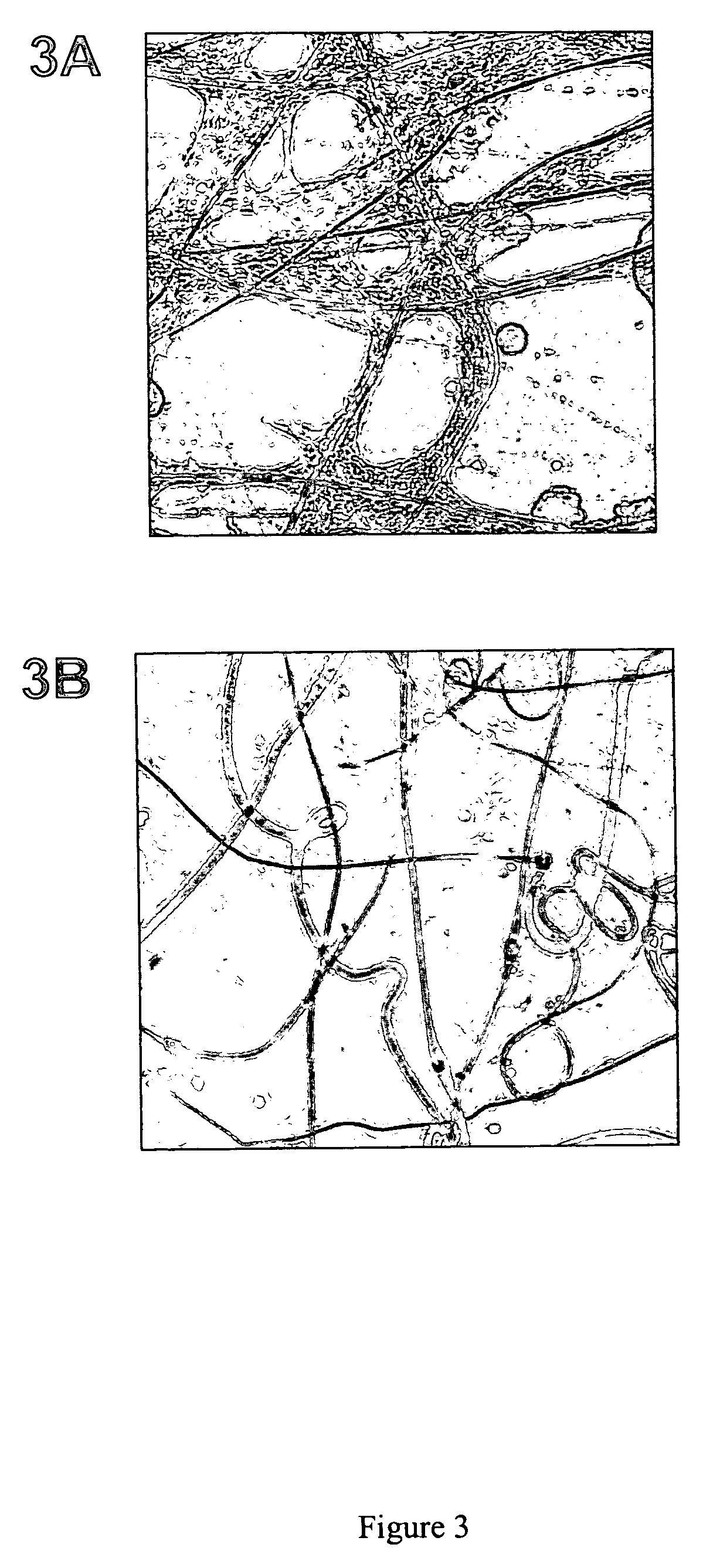

Nanofibrillar structure and applications including cell and tissue culture

ActiveUS20050095695A1Reduce usageBioreactor/fermenter combinationsNanostructure manufactureLipid formationNanofiber

A nanofibrillar structure for cell culture and tissue engineering is disclosed. The nanofibrillar structure can be used in a variety of applications including methods for proliferating and / or differentiating cells and manufacturing a tissue. Also disclosed is an improved nanofiber comprising a lipid, lipophilic molecule, or chemically modified surface. The nanofibers can be used in a variety of applications including the formation of nanofibrillar structures for cell culture and tissue engineering.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

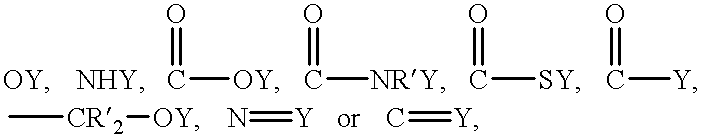

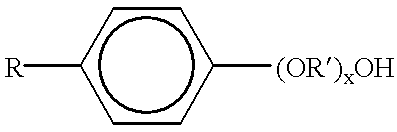

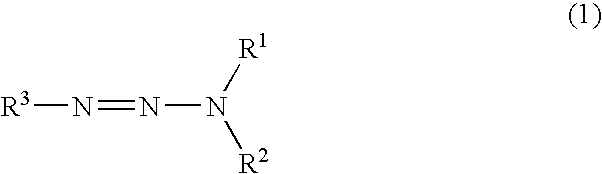

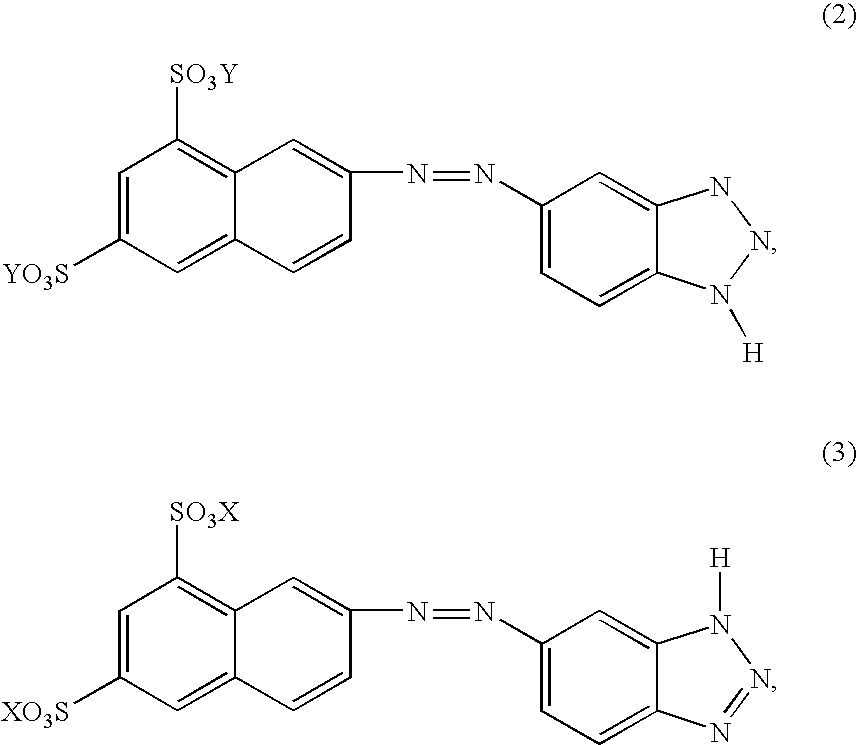

Carbon-containing material

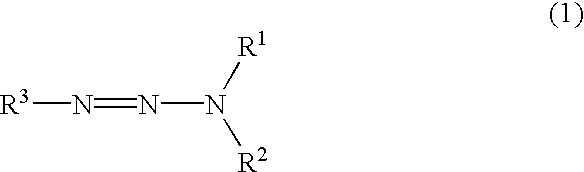

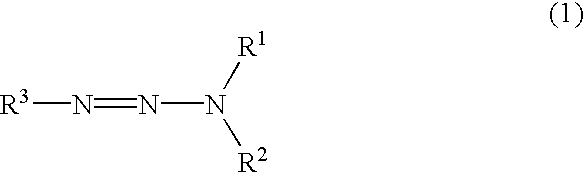

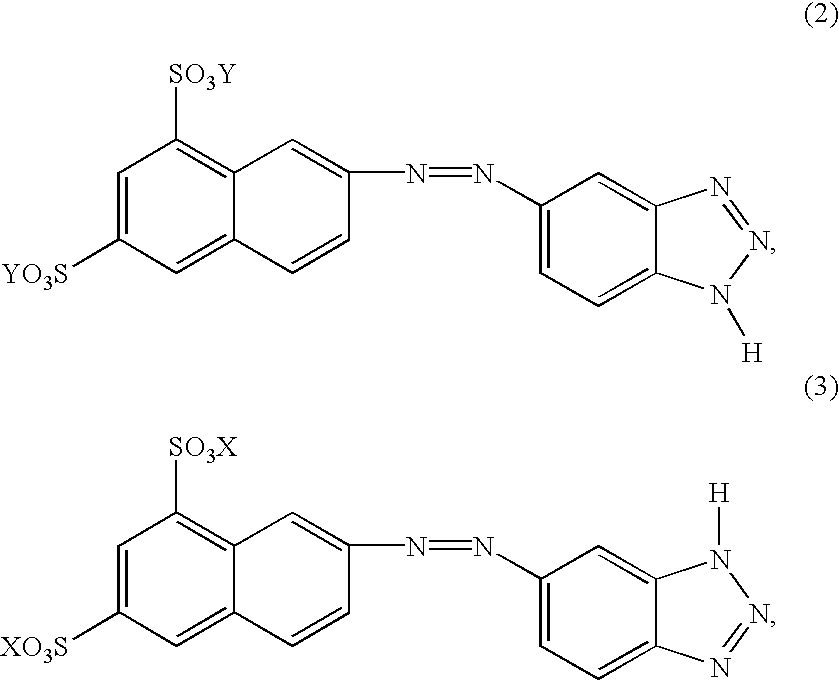

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1 A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilisers, conductivity carbon blacks or pigments.

Owner:UBS AG

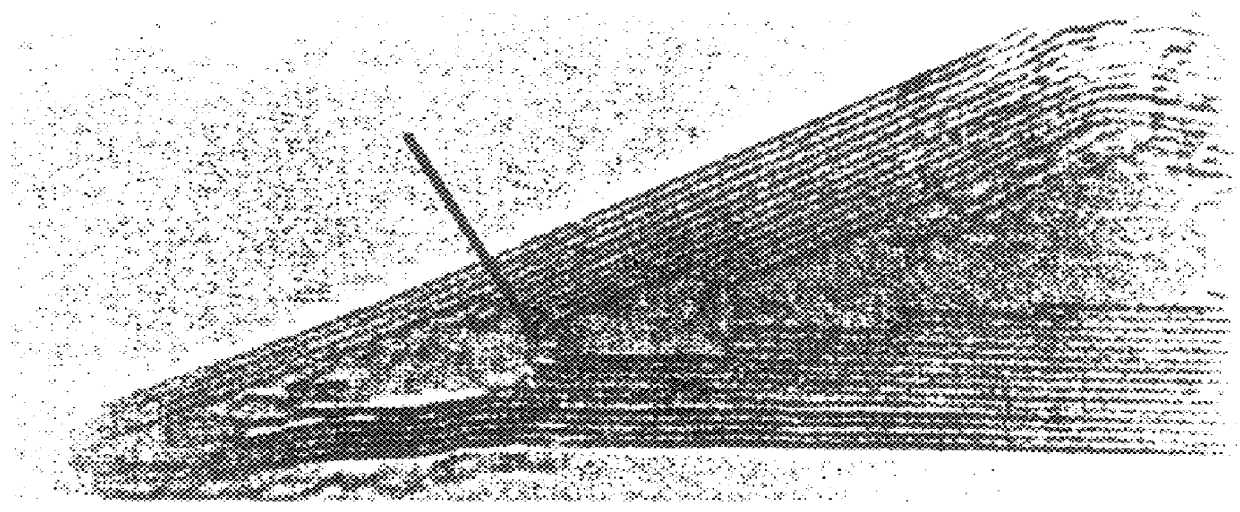

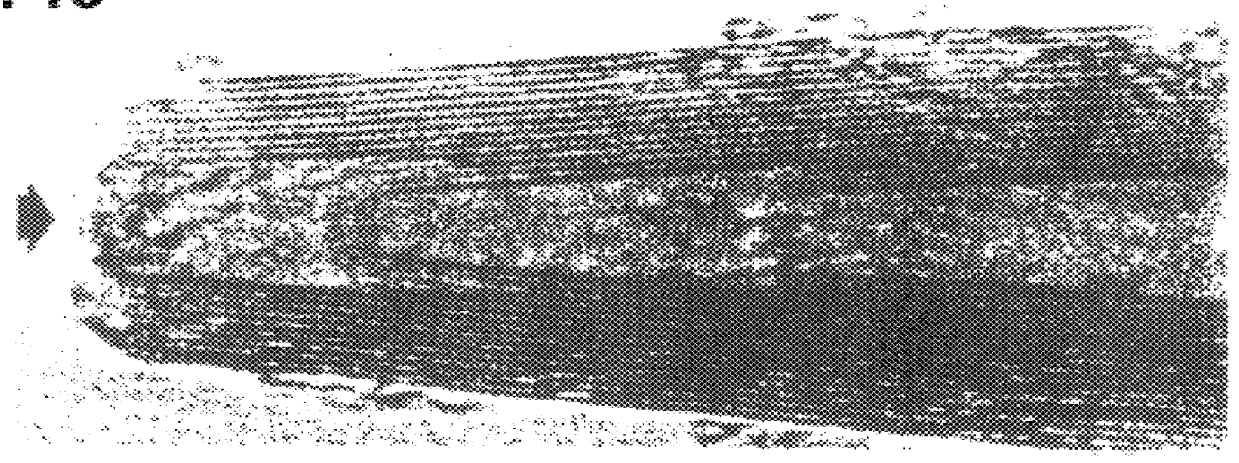

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6432866B1High accessible surface areaHigh activityMaterial nanotechnologyLayered productsFiberPorous carbon

Owner:HYPERION CATALYSIS INT

Methods of chemically derivatizing single-wall carbon nanotubes

InactiveUS6841139B2Increase resistanceHigh yieldMaterial nanotechnologyPigmenting treatmentFiberLithium

This invention is directed to making chemical derivatives of carbon nanotubes and to uses for the derivatized nanotubes, including making arrays as a basis for synthesis of carbon fibers. In one embodiment, this invention also provides a method for preparing single wall carbon nanotubes having substituents attached to the side wall of the nanotube by reacting single wall carbon nanotubes with fluorine gas and recovering fluorine derivatized carbon nanotubes, then reacting fluorine derivatized carbon nanotubes with a nucleophile. Some of the fluorine substituents are replaced by nucleophilic substitution. If desired, the remaining fluorine can be completely or partially eliminated to produce single wall carbon nanotubes having substituents attached to the side wall of the nanotube. The substituents will, of course, be dependent on the nucleophile, and preferred nucleophiles include alkyl lithium species such as methyl lithium. Alternatively, fluorine may be fully or partially removed from fluorine derivatized carbon nanotubes by reacting the fluorine derivatized carbon nanotubes with various amounts of hydrazine, substituted hydrazine or alkyl amine. The present invention also provides seed materials for growth of single wall carbon nanotubes comprising a plurality of single wall carbon nanotubes or short tubular molecules having a catalyst precursor moiety covalently bound or physisorbed on the outer surface of the sidewall to provide the optimum metal cluster size under conditions that result in migration of the metal moiety to the tube end.

Owner:RICE UNIV

Method of opening and filling carbon nanotubes

PCT No. PCT / GB95 / 02235 Sec. 371 Date Apr. 10, 1997 Sec. 102(e) Date Apr. 10, 1997 PCT Filed Sep. 20, 1995 PCT Pub. No. WO96 / 09246 PCT Pub. Date Mar. 28, 1996Method of making carbon nanotubes open on at least one end wherein capped nanotubes are treated with an oxidizing acid such as nitric acid. The treatment is effective to open at least 50% of the nanotubes on at least one end.

Owner:ISIS INNOVATION LTD

Chemically modifying single wall carbon nanotubes to facilitate dispersal in solvents

InactiveUS6875412B2High yieldIncrease resistanceMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

Owner:RICE UNIV

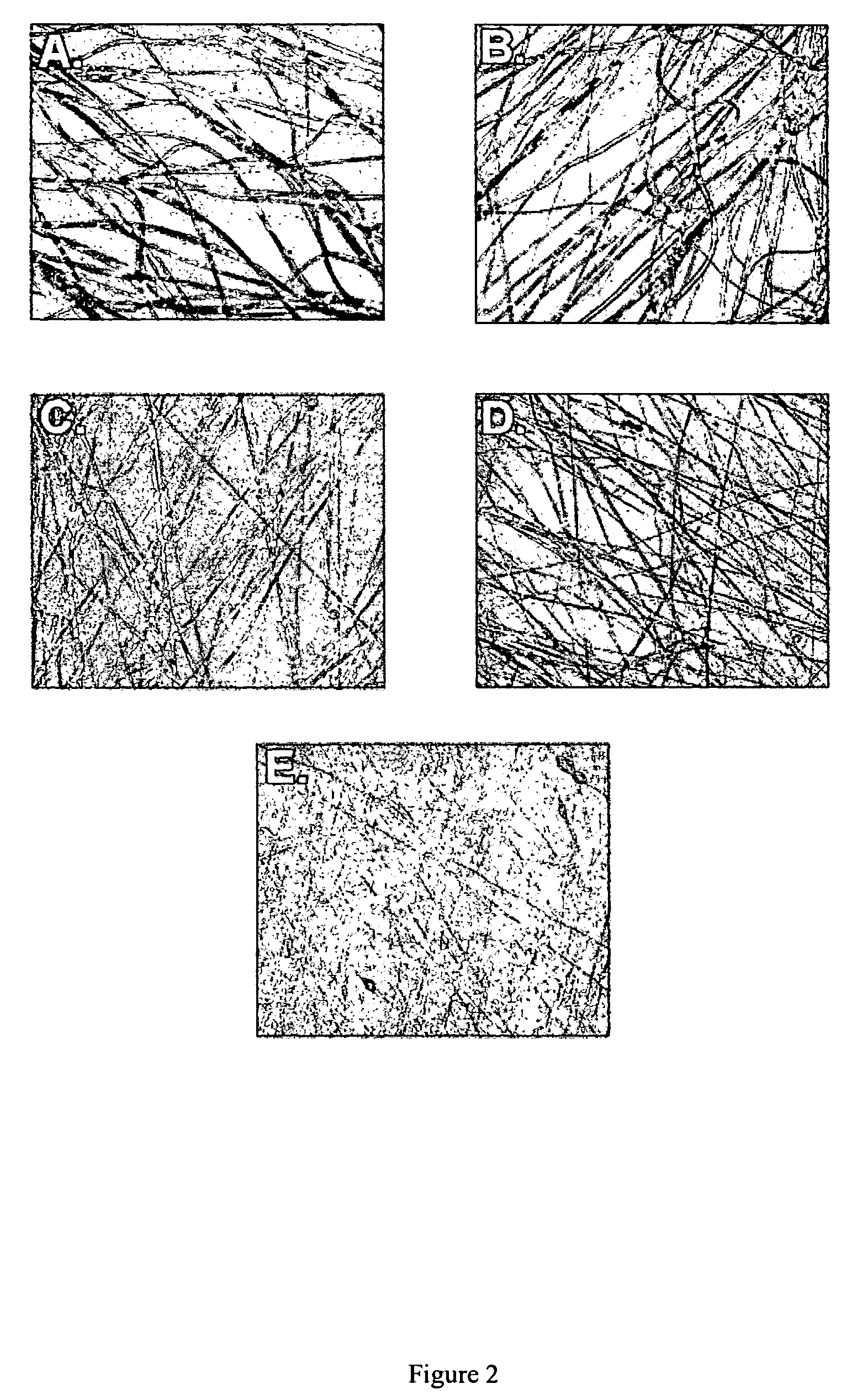

Spatial localization of dispersed single walled carbon nanotubes into useful structures

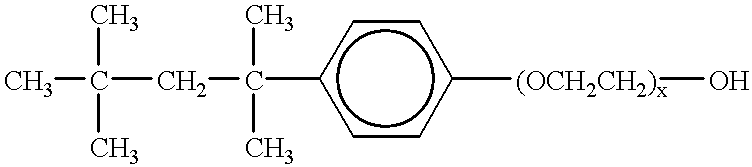

InactiveUS6896864B2Improve structural performanceMaterial nanotechnologyNanostructure manufactureBinding siteAqueous solution

Methods of aligning single walled carbon nanotube structures into selected orientations for a variety of different applications are achieved by initially dispersing the nanotube structures in aqueous solutions utilizing a suitable dispersal agent. The dispersal agent coats each individual nanotube structure in solution. The dispersal agent may be substituted with a suitable functional group that reacts with a corresponding binding site. Dispersed nanotube structures coated with substituted dispersal agents are exposed to a selected array of binding sites such that the nanotubes align with the binding sites due to the binding of the substituted functional groups with such binding sites. Alternatively, crystalline nanotube material is formed upon deposition of dispersed nanotube structures within solution into channels disposed on the surface of the substrate. Combining dispersal agent chemical modification techniques with deposition of the nanotubes into substrate channels is also utilized to produce useful structures.

Owner:BATTELLE MEMORIAL INST

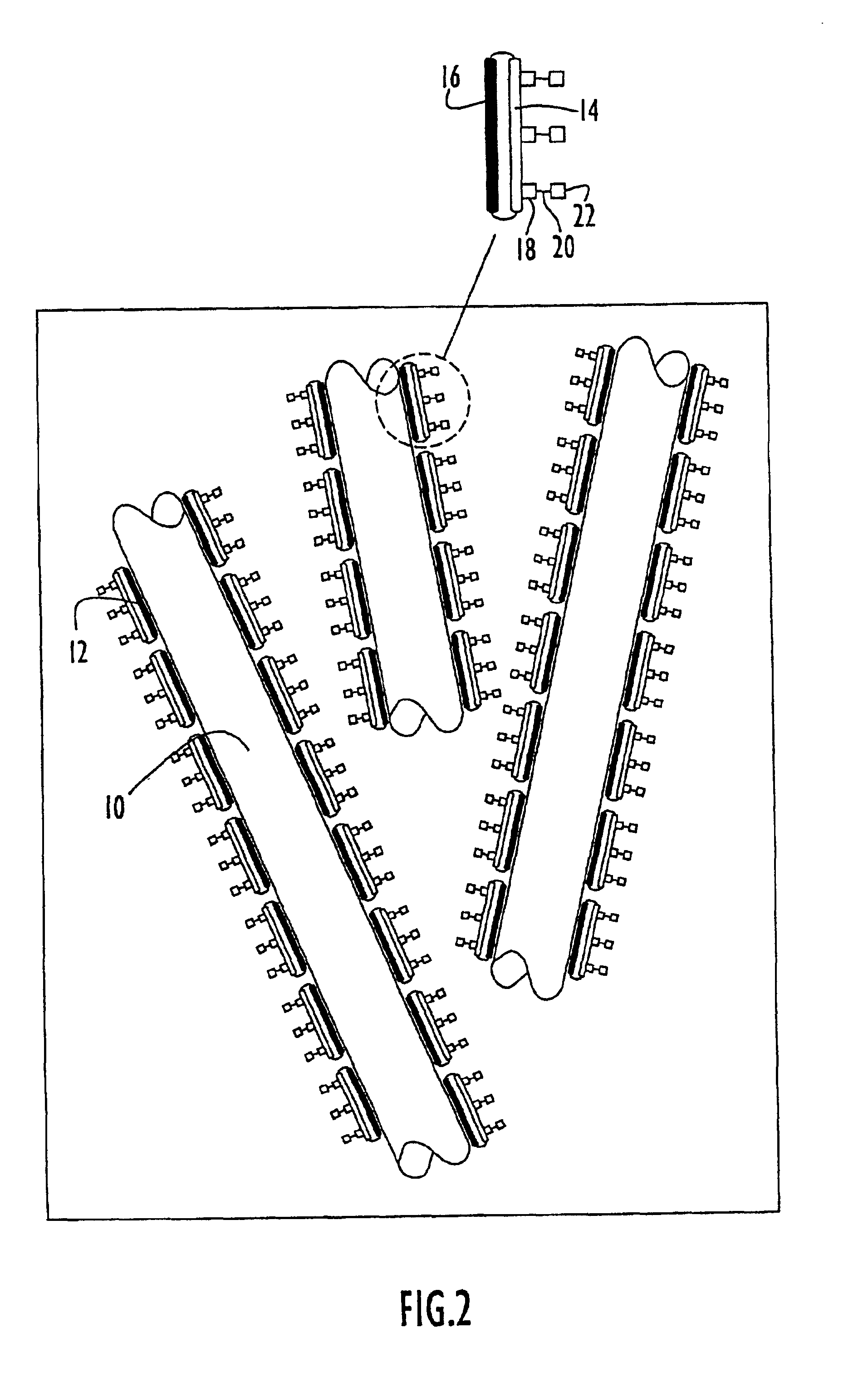

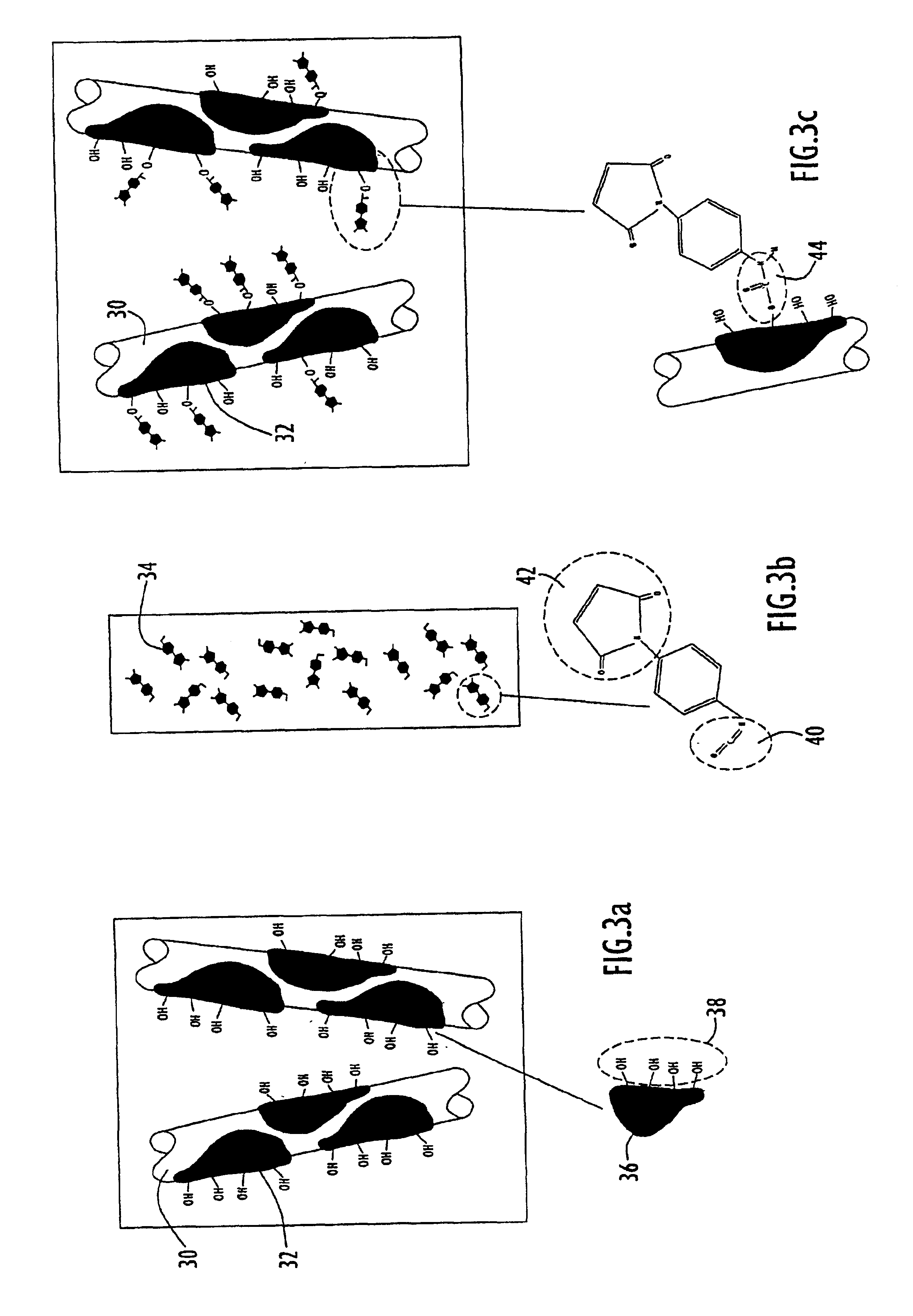

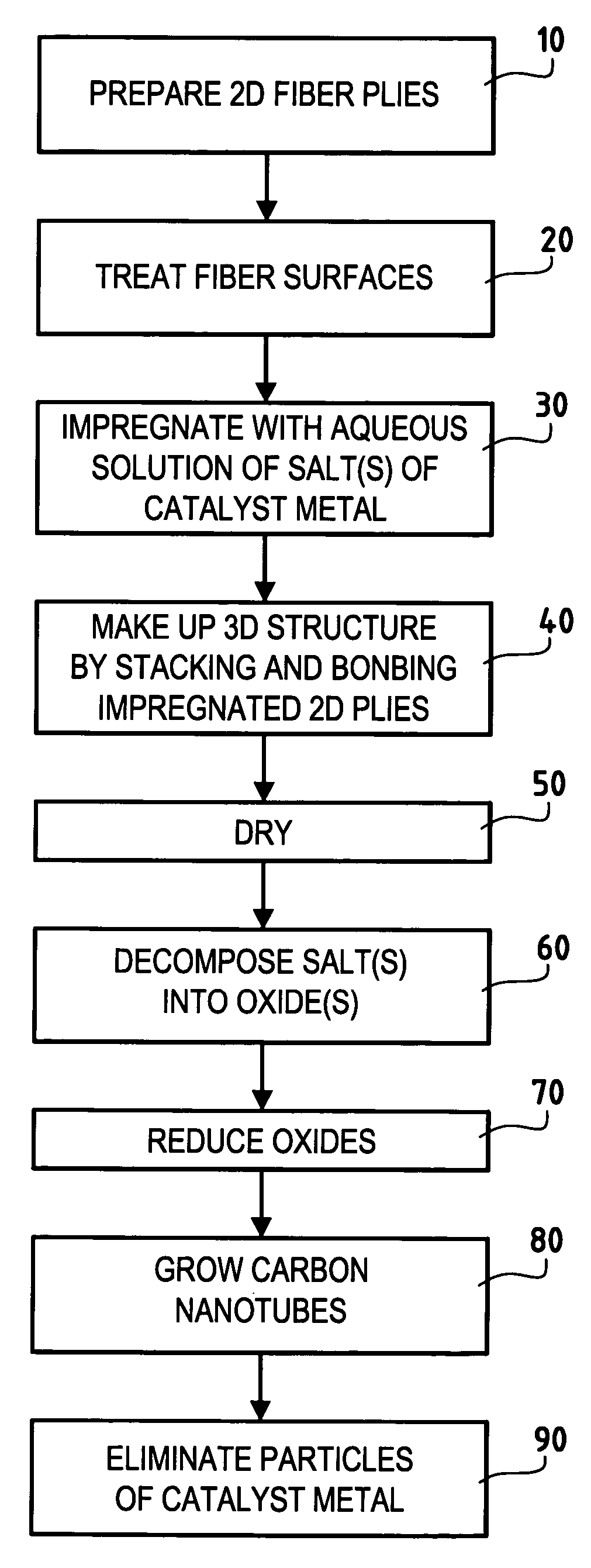

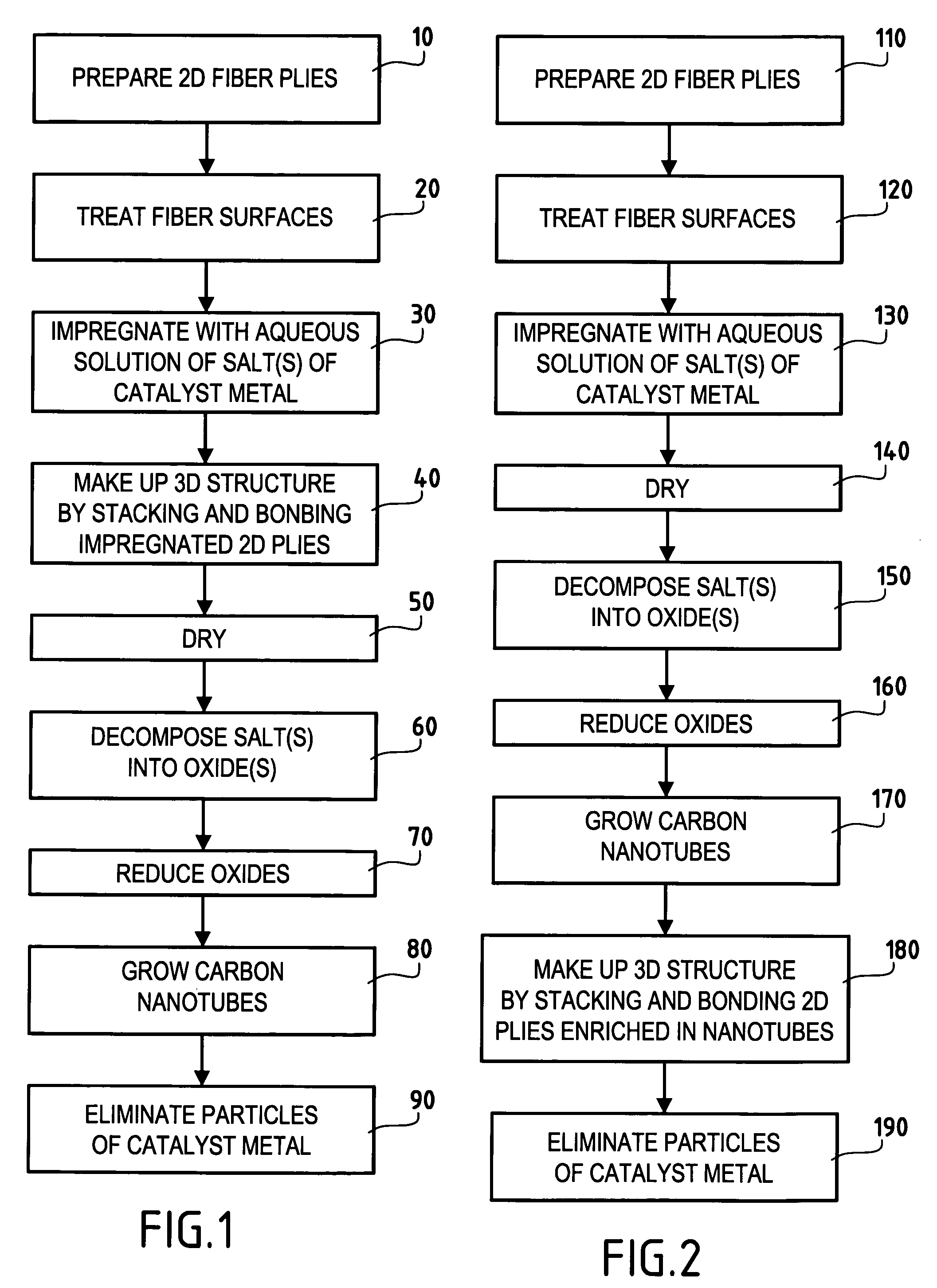

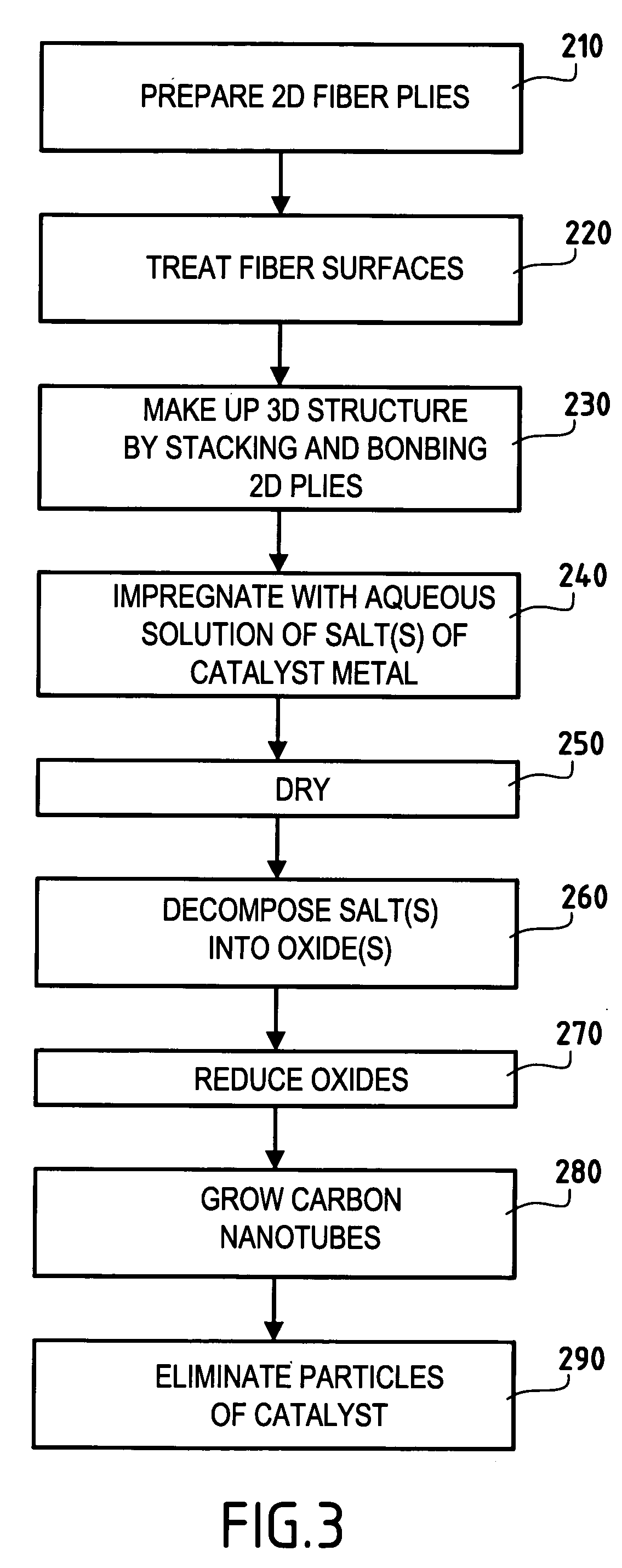

Three-dimensional fiber structure of refractory fibers, a method of making it, and thermostructural composite materials, in particular friction parts, made therefrom

ActiveUS20050176329A1Improve propertiesEasy to prepareMaterial nanotechnologyCarbon fibresMetallurgyCarbon nanotube

Carbon nanotubes are incorporated in the fiber structure by growing them on the refractory fibers of the substrate so as to obtain a three-dimensional substrate made of refractory fibers and enriched in carbon nanotubes. The substrate is densified with a matrix to form a part of composite material such as a friction part of C / C composite material.

Owner:CENT NAT DE LA RECHERCHE SCI

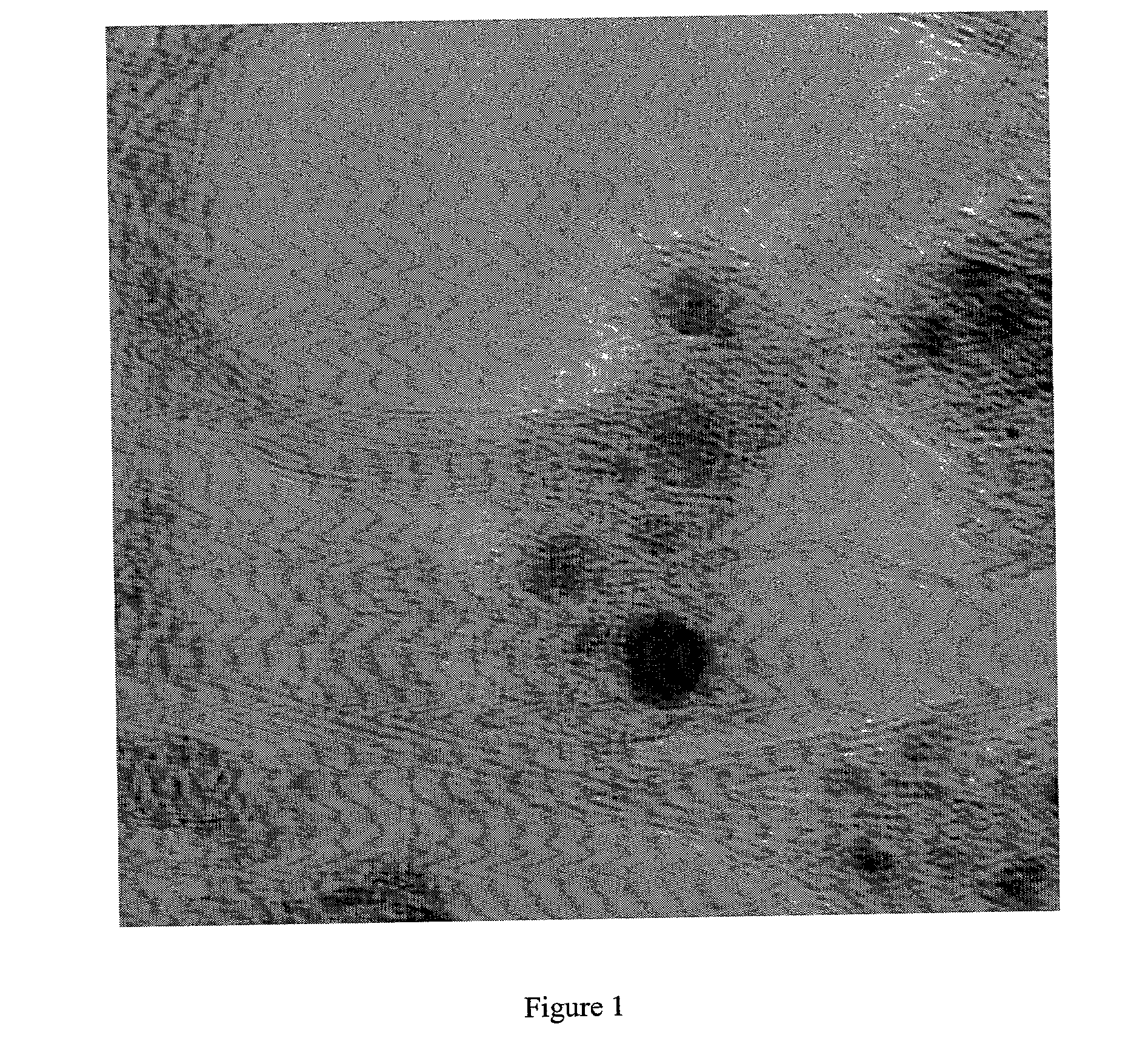

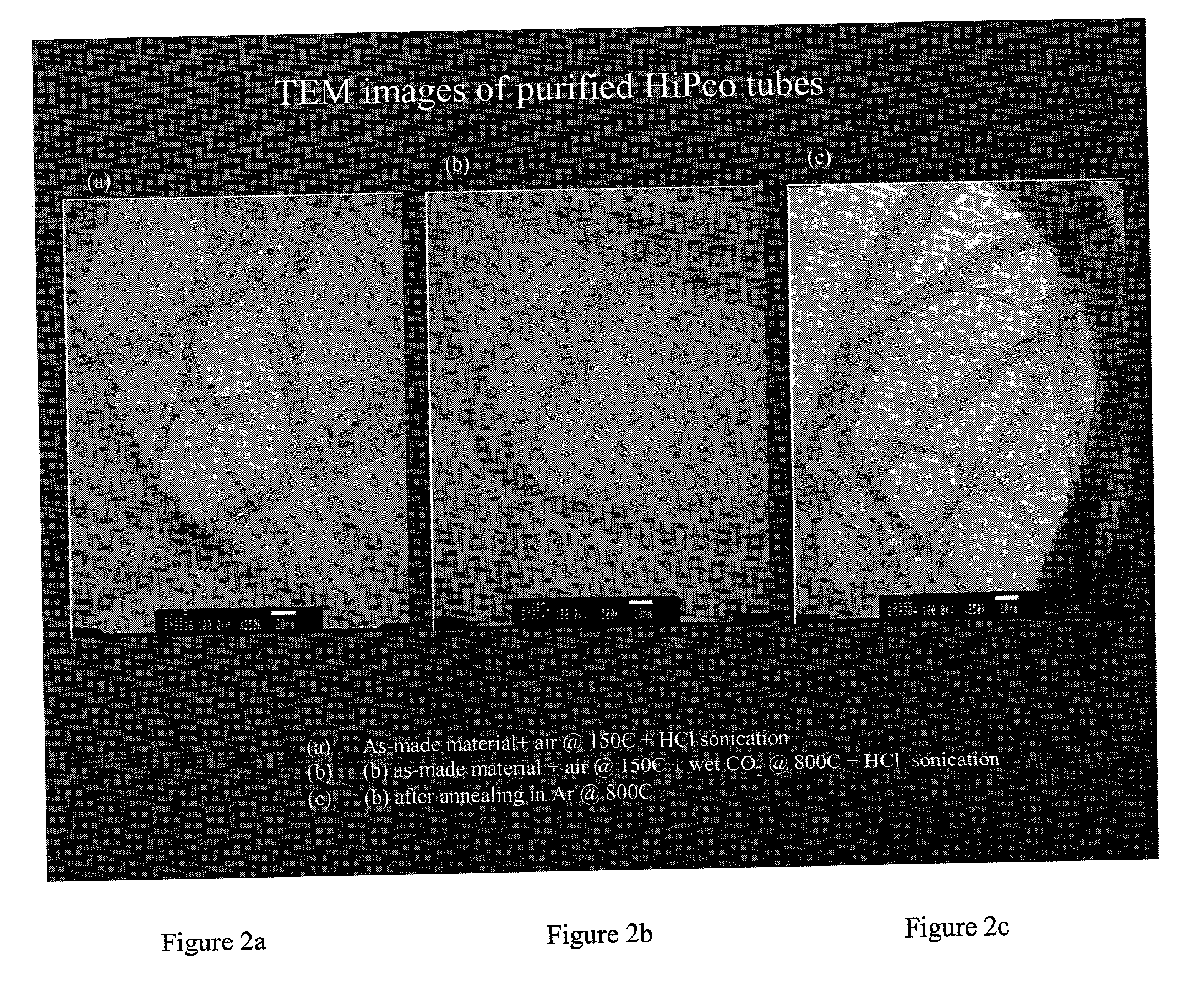

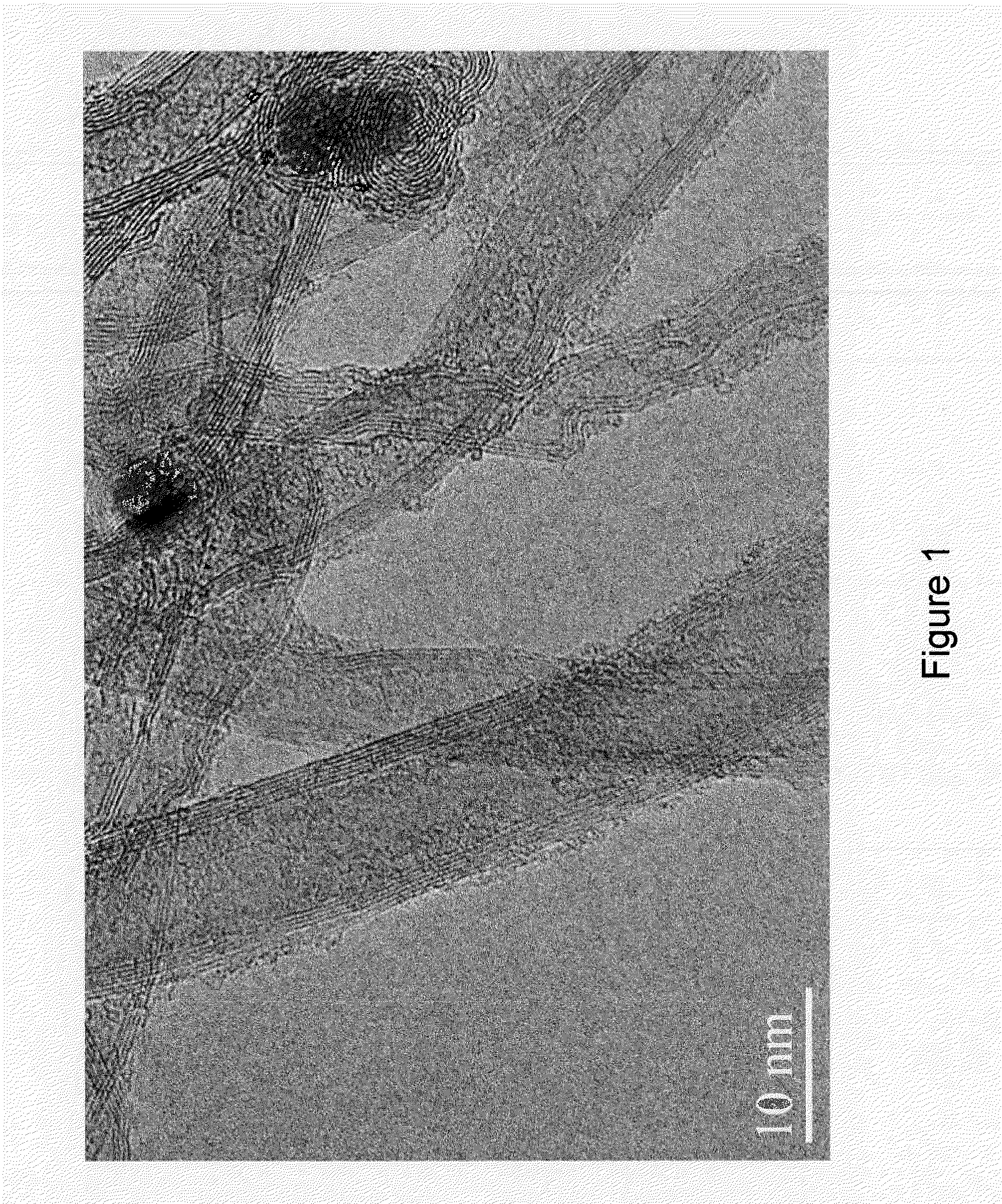

Process for purifying single-wall carbon nanotubes and compositions thereof

The present invention relates to a process for the purification of single-wall carbon nanotubes and the purified single-wall carbon nanotube material. Known methods of single-wall carbon nanotube production result in a single-wall carbon nanotube product that contains single-wall carbon nanotubes in addition to impurities including residual metal catalyst particles and amounts of small amorphous carbon sheets that surround the catalyst particles and appear on the sides of the single-wall carbon nanotubes and "ropes" of single-wall carbon nanotubes. The purification process removes the extraneous carbon as well as metal-containing residual catalyst particles. The process employs steps including a gas-phase oxidation of the amorphous carbon and subsequent liquid-phase reaction of a halogen-containing acid with the metal-containing species. Optionally, the single-wall carbon nanotube material may be annealed dry or in the presence of moisture. The present invention provides a scalable means for producing high-purity single-wall carbon nanotube material.

Owner:RICE UNIV

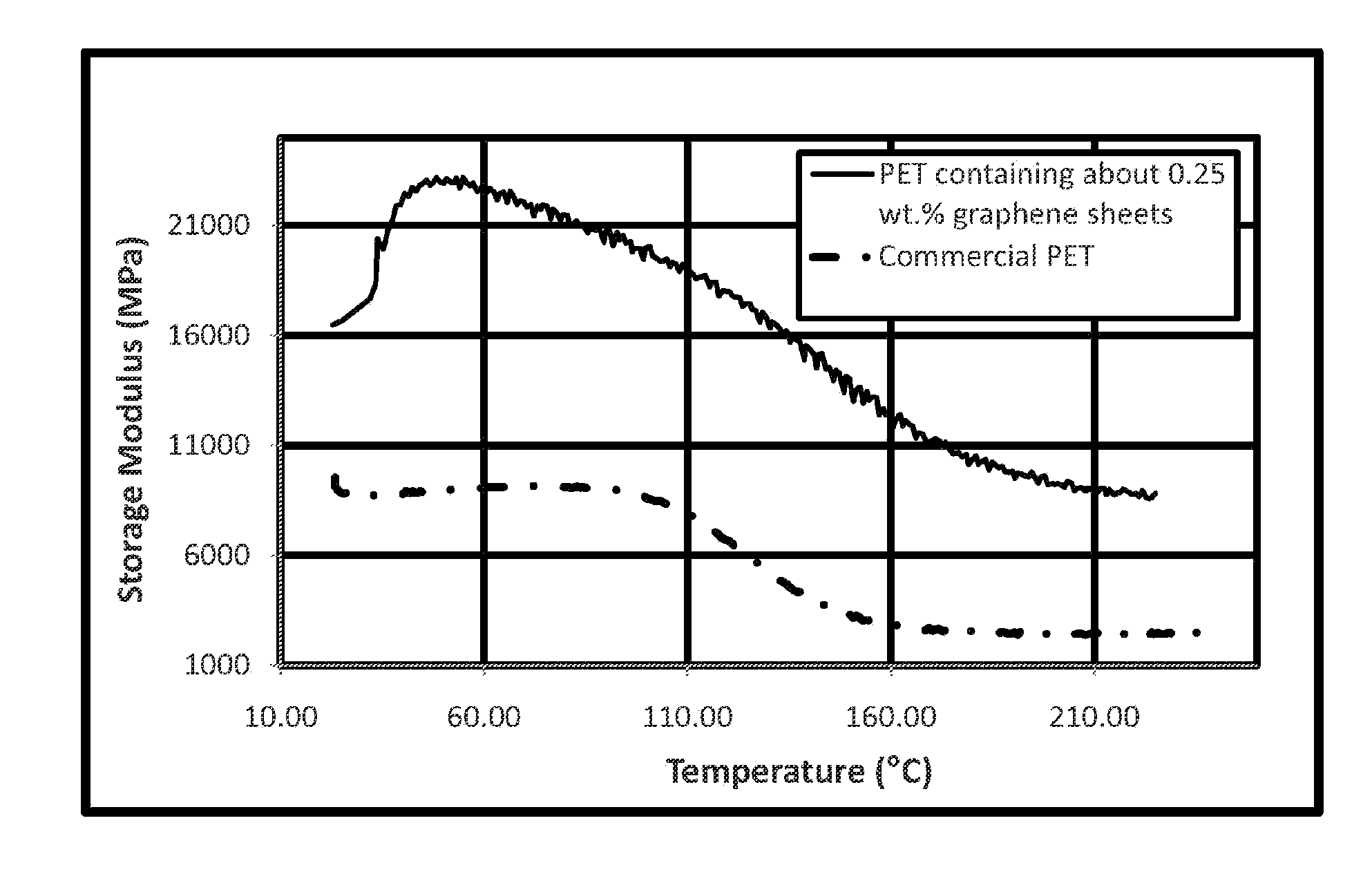

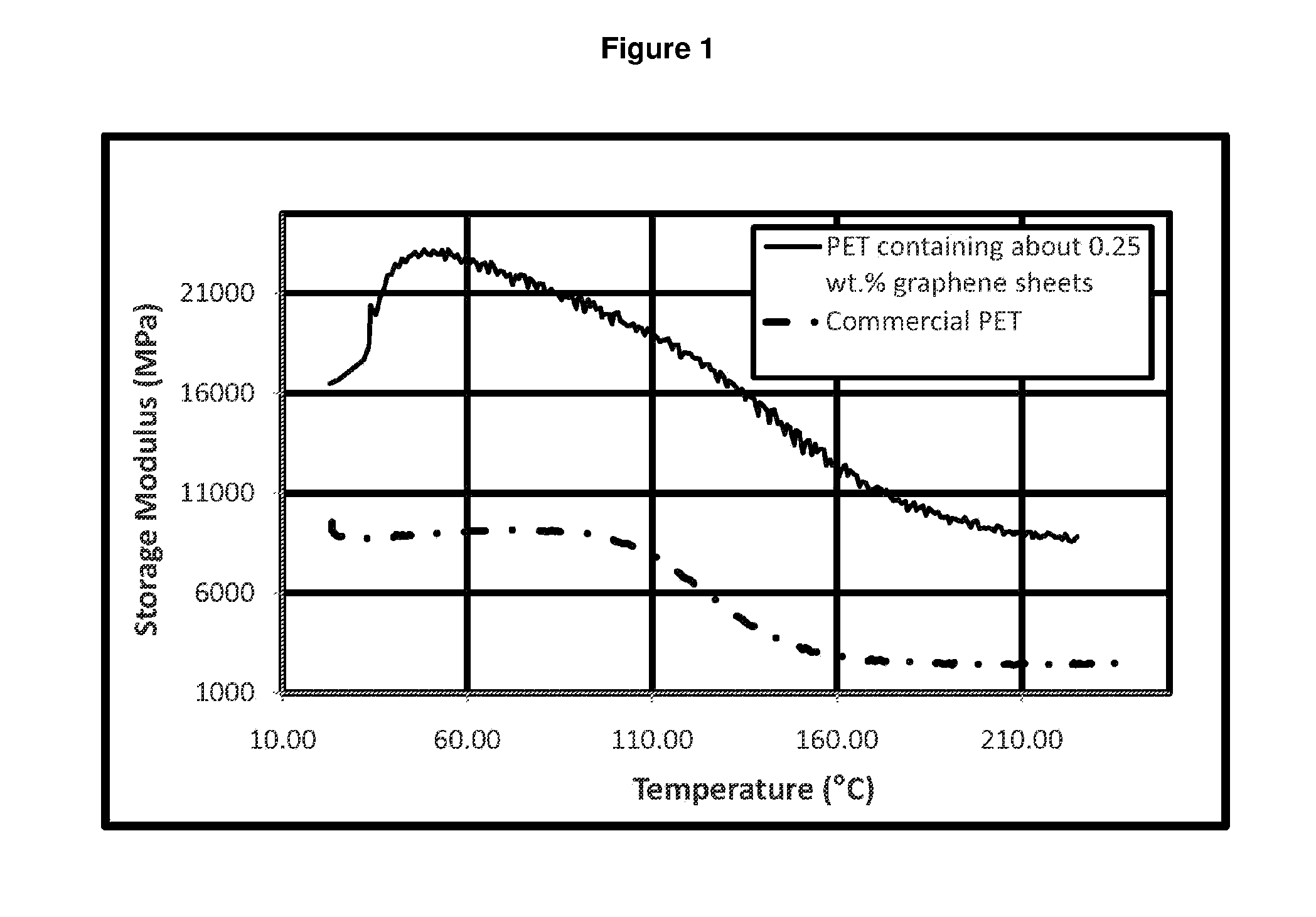

Polymeric fibers and articles made therefrom

InactiveUS20120244333A1Electric discharge heatingMonocomponent cellulose artificial filamentPolyesterYarn

Fibers described herein comprise a composition including a polymer and graphene sheets. The fibers can be further formed into yarns, cords, and fabrics. The fibers can be in the form of polyamide, polyester, acrylic, acetate, modacrylic, spandex, lyocell fibers, and the like. Such fibers can take on a variety of forms, including, staple fibers, spun fibers, monofilaments, multifilaments, and the like.

Owner:VORBECK MATERIALS CORP +1

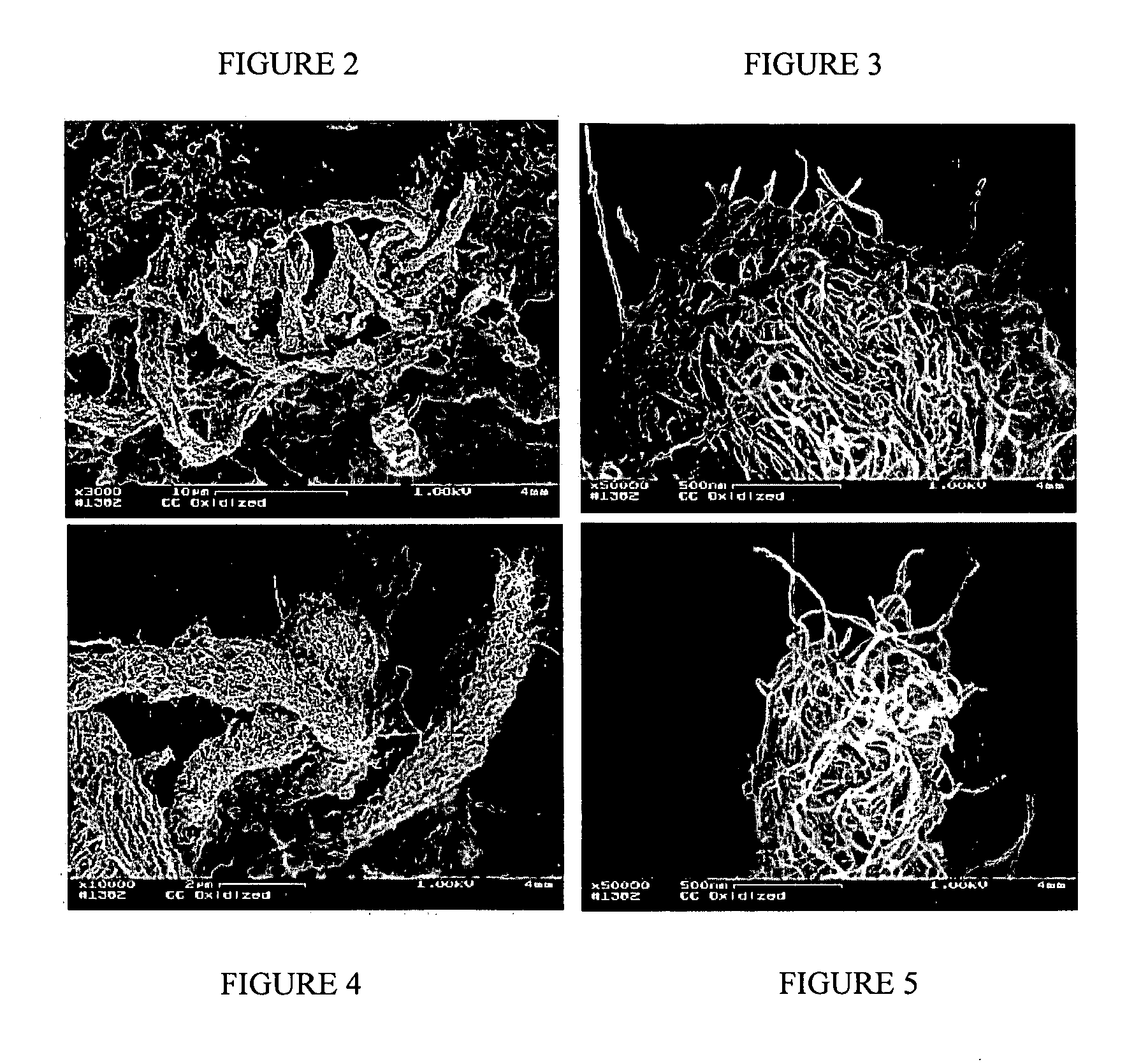

Methods of oxidizing multiwalled carbon nanotubes

InactiveUS20060239891A1Good electrochemical propertiesMaterial nanotechnologyHybrid capacitor electrodesMultiwalled carbonElectrochemistry

Methods of oxidizing multiwalled carbon nanotubes are provided. The multiwalled carbon nanotubes are oxidized by contacting the carbon nanotubes with gas-phase oxidizing agents such as CO2, O2, steam, N2O, NO, NO2, O3, and ClO2. Near critical and supercritical water can also be used as oxidizing agents. The multiwalled carbon nanotubes oxidized according to methods of the invention can be used to prepare rigid porous structures which can be utilized to form electrodes for fabrication of improved electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, triglyceride, and optionally acid. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, triglyceride, and optionally acid, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

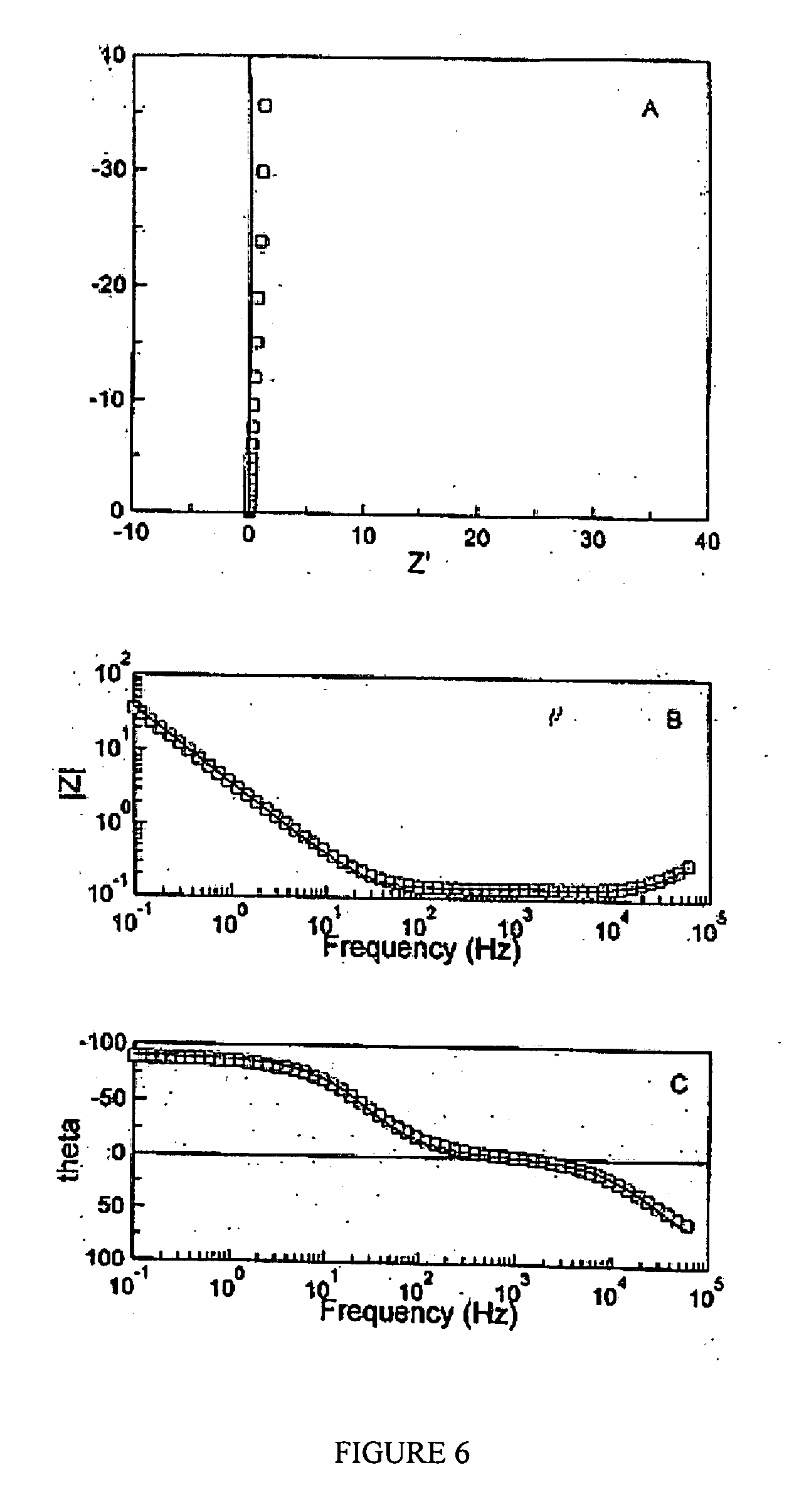

Modification of nanotubes oxidation with peroxygen compounds

InactiveUS20030039604A1Easy to shapeEasy to measureMaterial nanotechnologyNanostructure manufactureCompound aNanotube

A method of chemically modifying carbon nanotubes having a diameter less than one micron comprising: contacting the nanotubes with a peroxygen compound selected from the group consisting of organic peroxyacids, inorganic peroxoacids and organic hydroperoxides, or a salt thereof, under oxidation conditions and thereby producing modified carbon nanotubes. Oxidation of the nanotubes increases the degree of dispersion of aggregates of nanotubes and aids in the disassembling of such aggregates. The dispersed nanotubes are used to prepare rigid structures and can be used in electrodes and capacitors.

Owner:HYPERION CATALYSIS INT

Carbon-containing material

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilizers, conductivity carbon blacks or pigments.

Owner:UBS AG

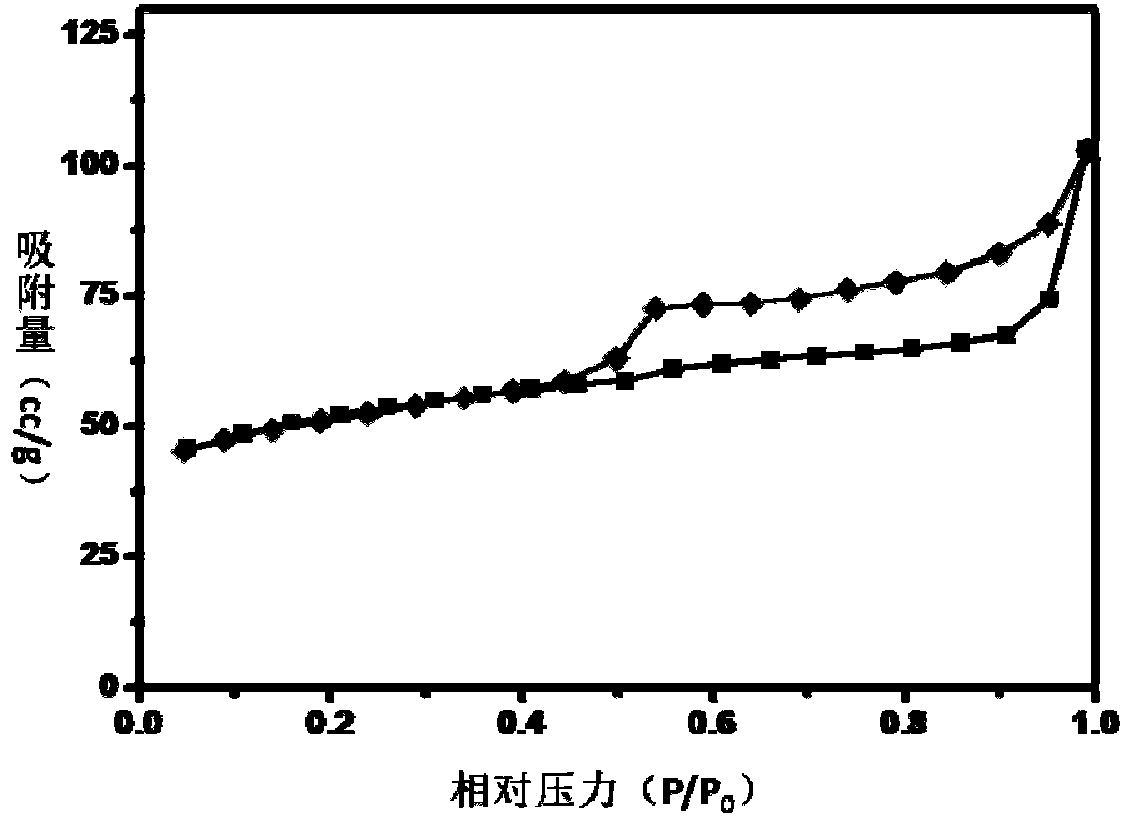

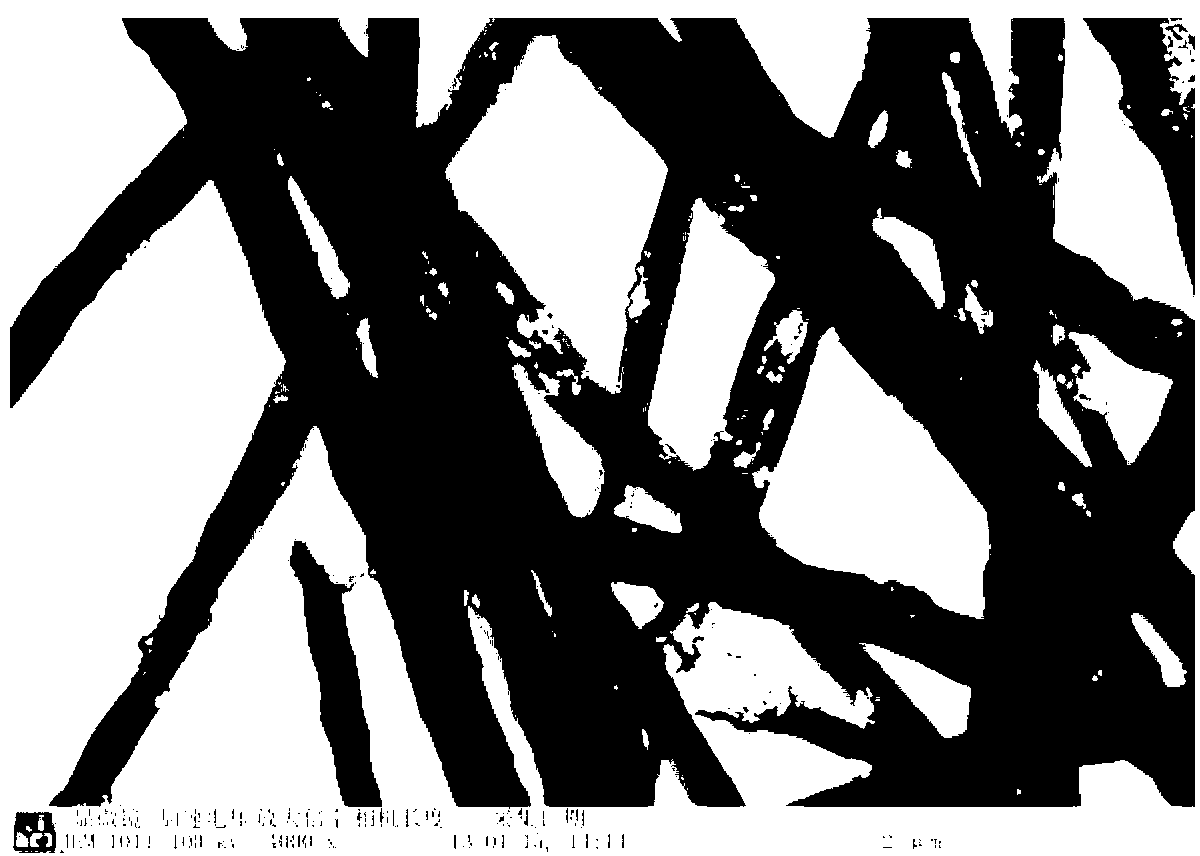

Porous carbon fiber, and preparation method and application thereof

ActiveCN103225135AEasy to makeLow costFilament/thread formingArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a porous carbon fiber and a preparation method thereof. The method comprises the following steps: spinning a spinning liquid composed of a pore forming agent, a high polymer and an organic solvent, carbonizing, and pickling to obtain the porous carbon fiber. The method has the advantages of simple preparation, high output and low cost, and allows the porous carbon fiber simultaneously having micro-pores, meso-pores and macro-pores to be prepared; and the carbon fiber prepared in the invention is more flexible than that of carbon fibers prepared through other methods.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing graphene oxide films and fibers

ActiveUS20150111449A1Improve conductivityHigh densityCarbon compoundsFilament/thread formingFiberSolid content

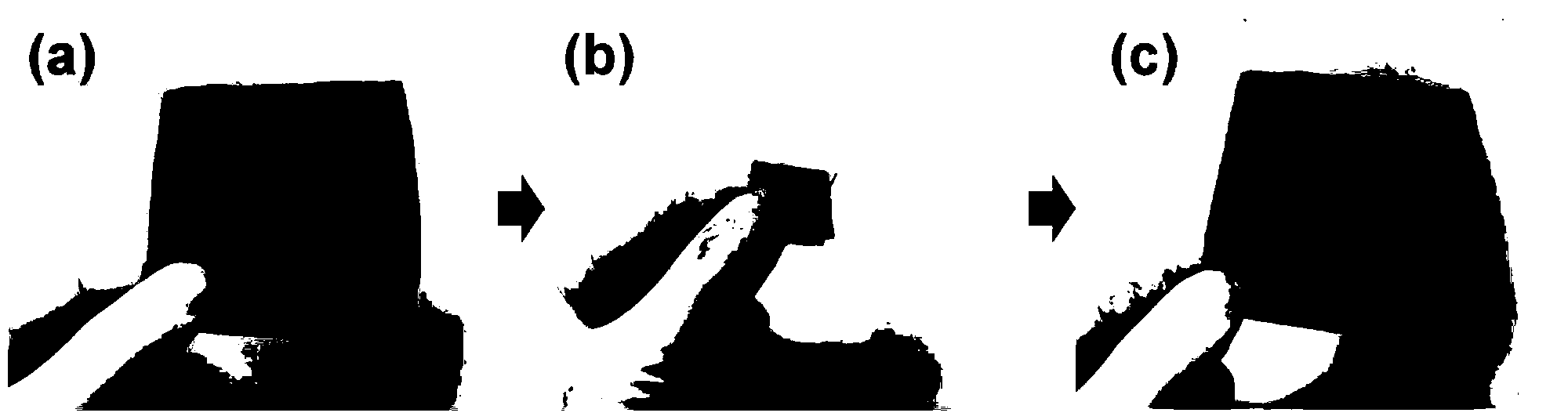

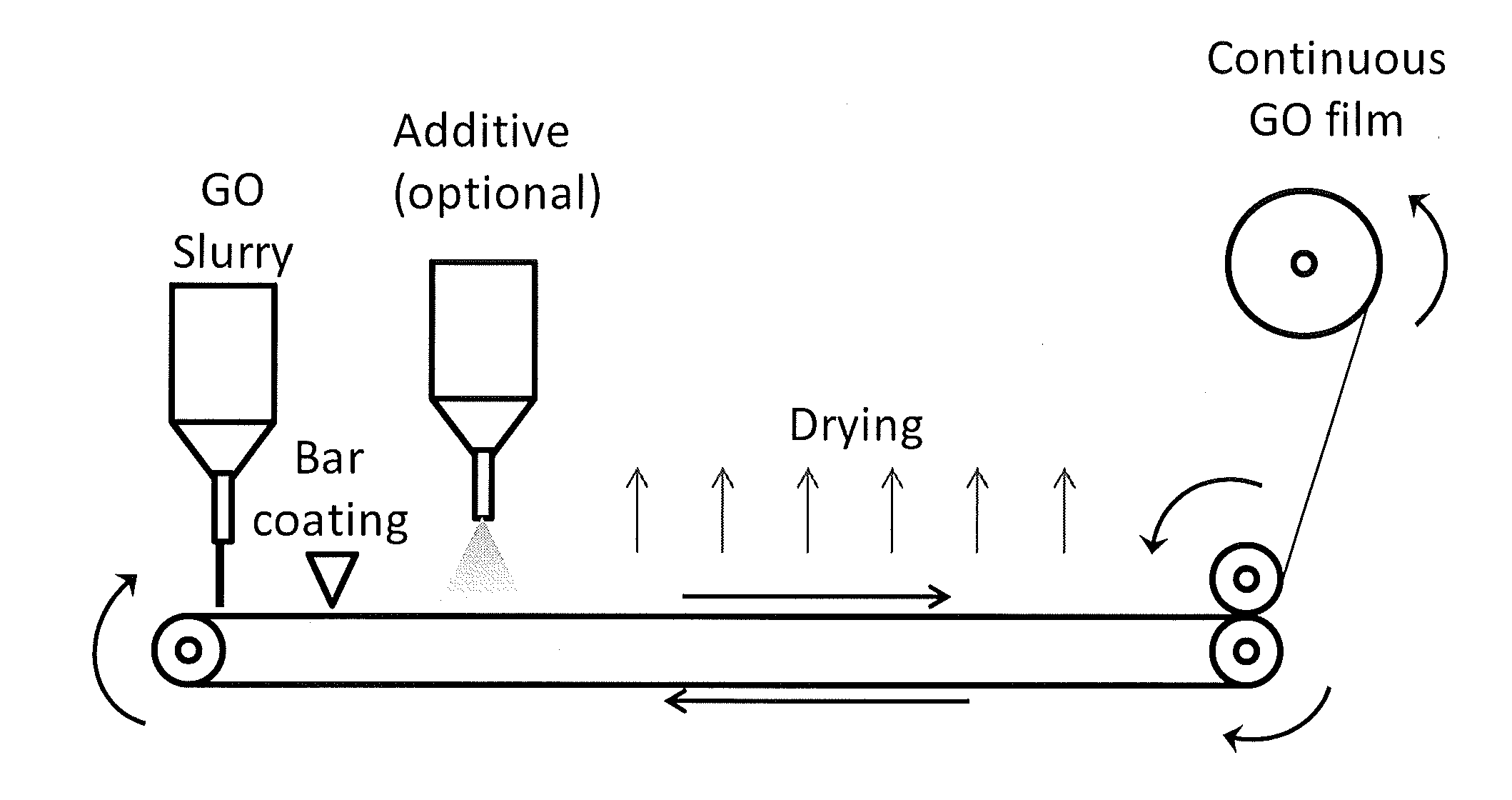

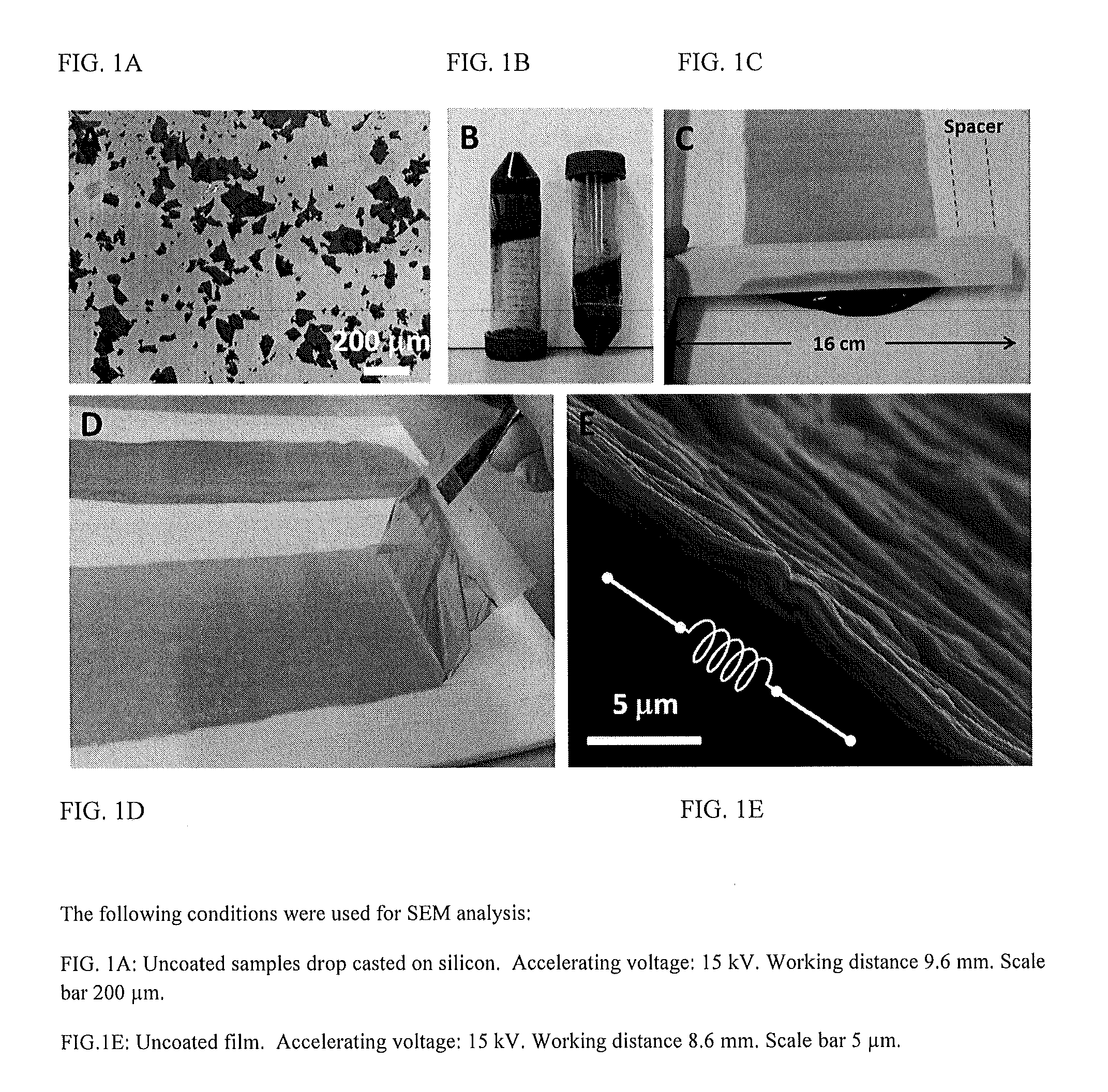

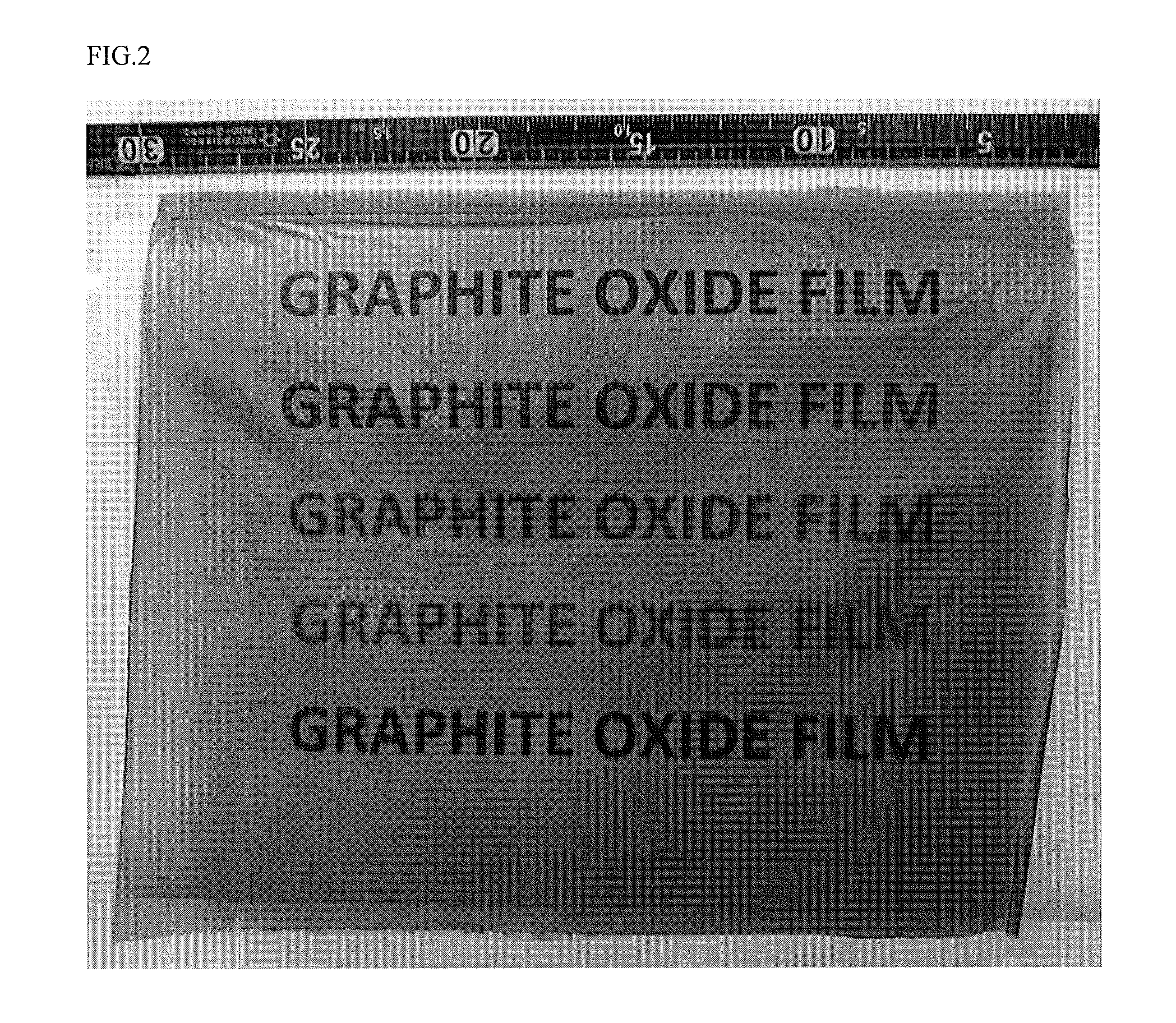

We report a method of preparation of highly elastic graphene oxide films, and their transformation into graphene oxide fibers and electrically conductive graphene fibers by spinning. Methods typically include: 1) oxidation of graphite to graphene oxide, 2) preparation of graphene oxide slurry with high solid contents and residues of sulfuric acid impurities. 3) preparation of large area films by bar-coating or dropcasting the graphene oxide dispersion and drying at low temperature. 4) spinning the graphene oxide film into a fiber, and 5) thermal or chemical reduction of the graphene oxide fiber into an electrically conductive graphene fiber. The resulting films and fiber have excellent mechanical properties, improved morphology as compared with current graphene oxide fibers, high electrical conductivity upon thermal reduction, and improved field emission properties.

Owner:PENN STATE RES FOUND +1

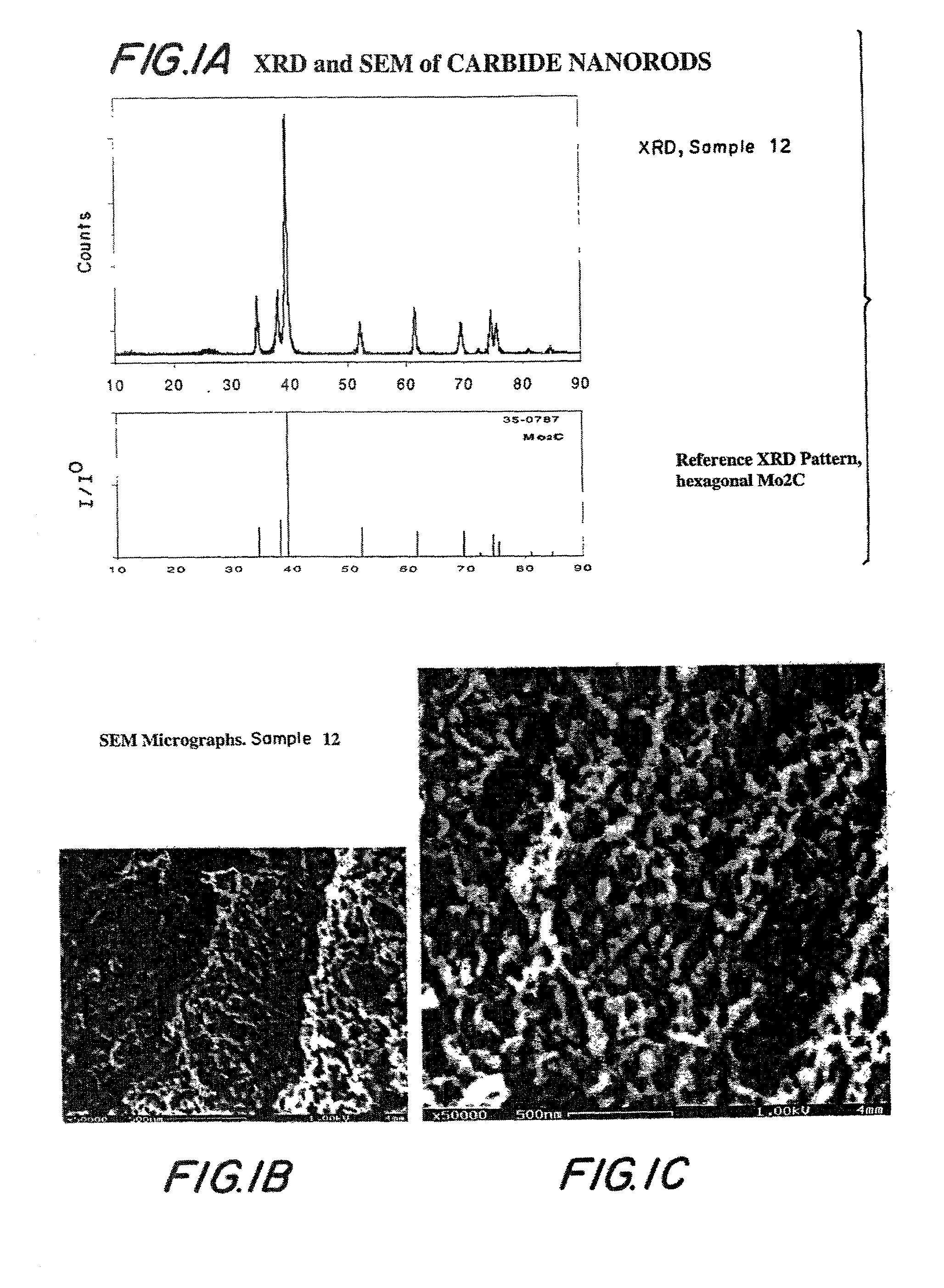

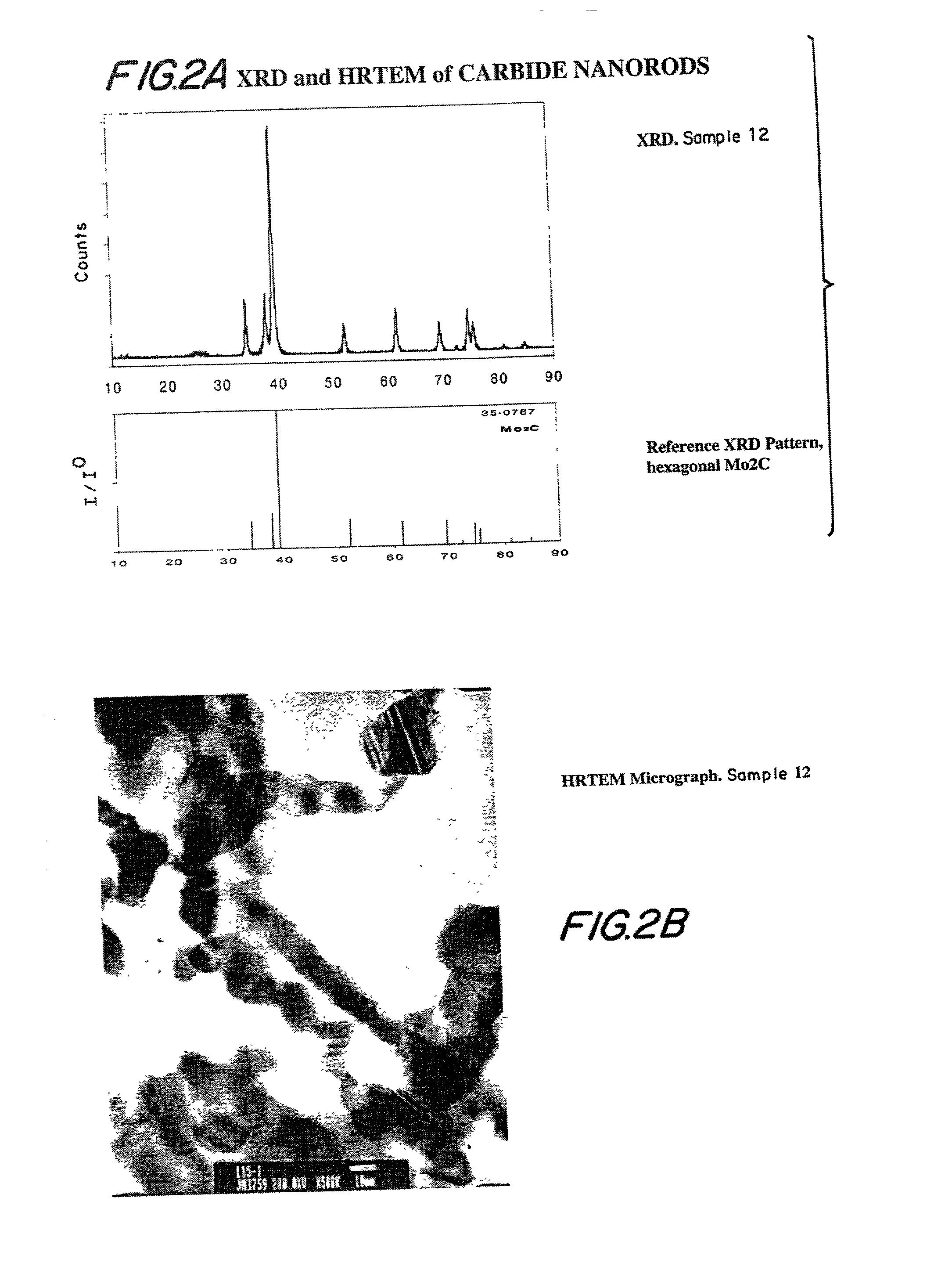

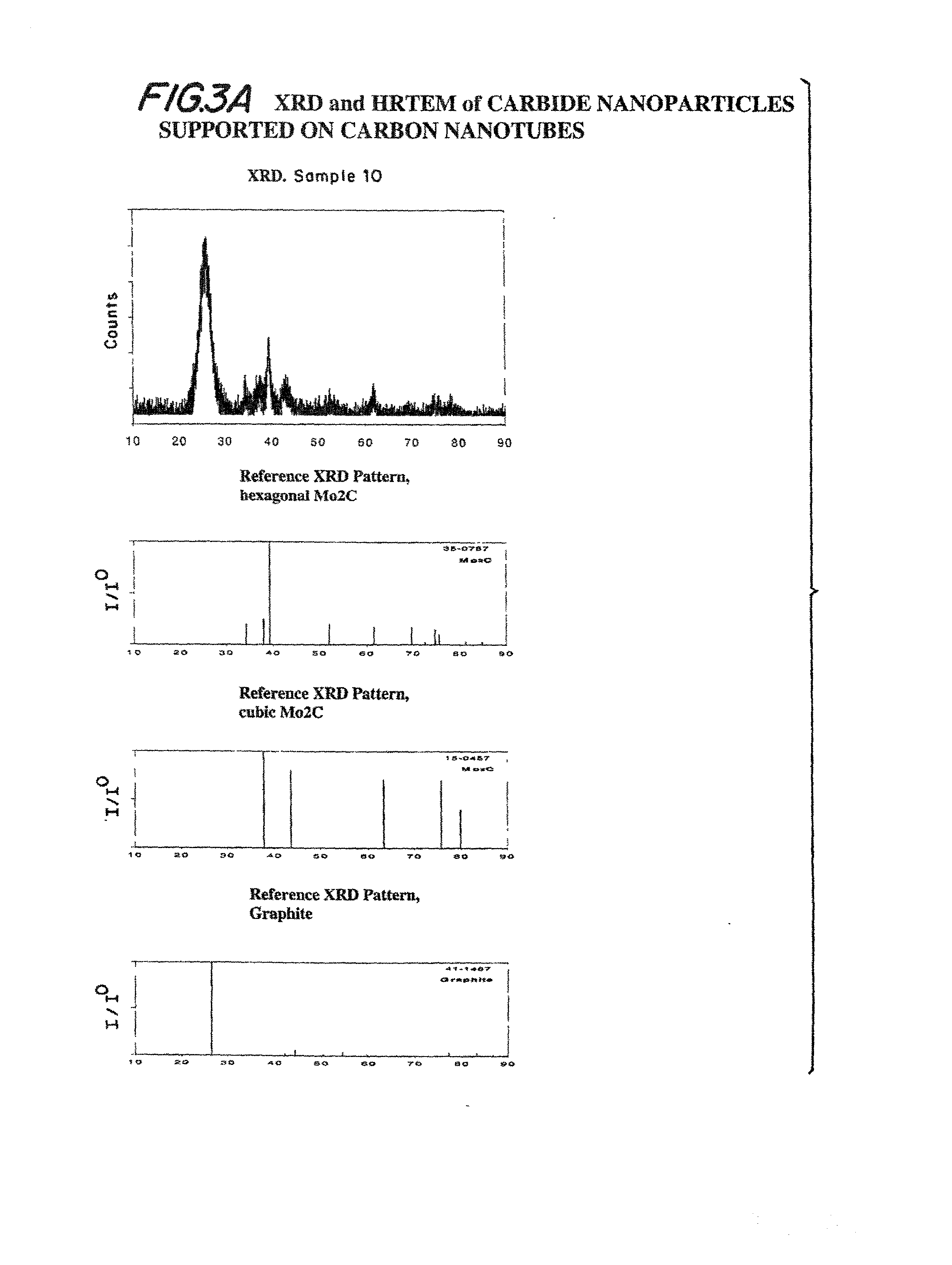

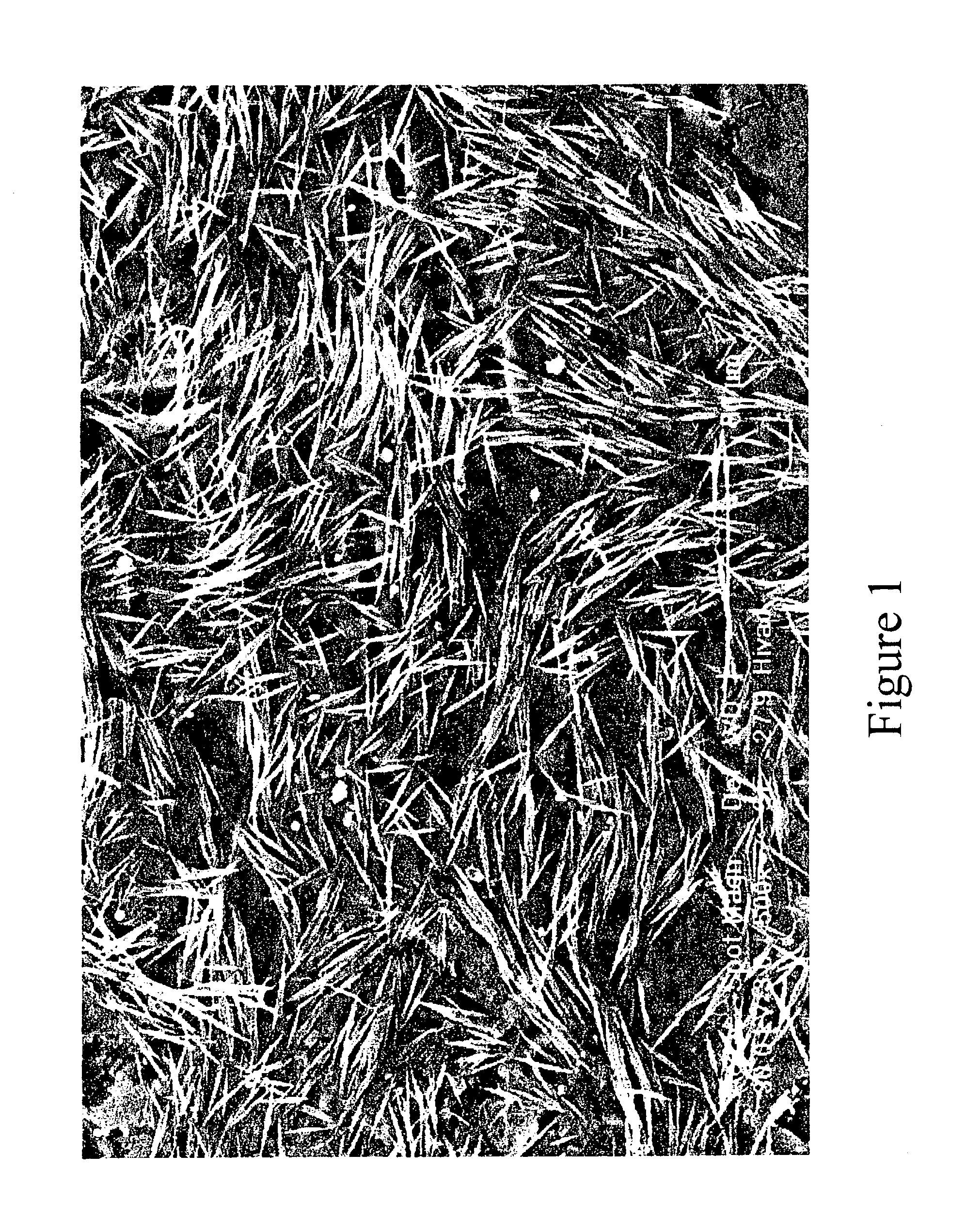

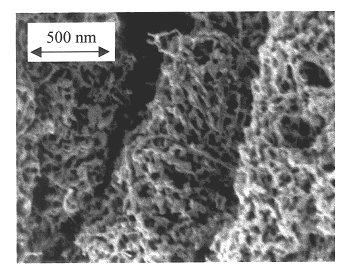

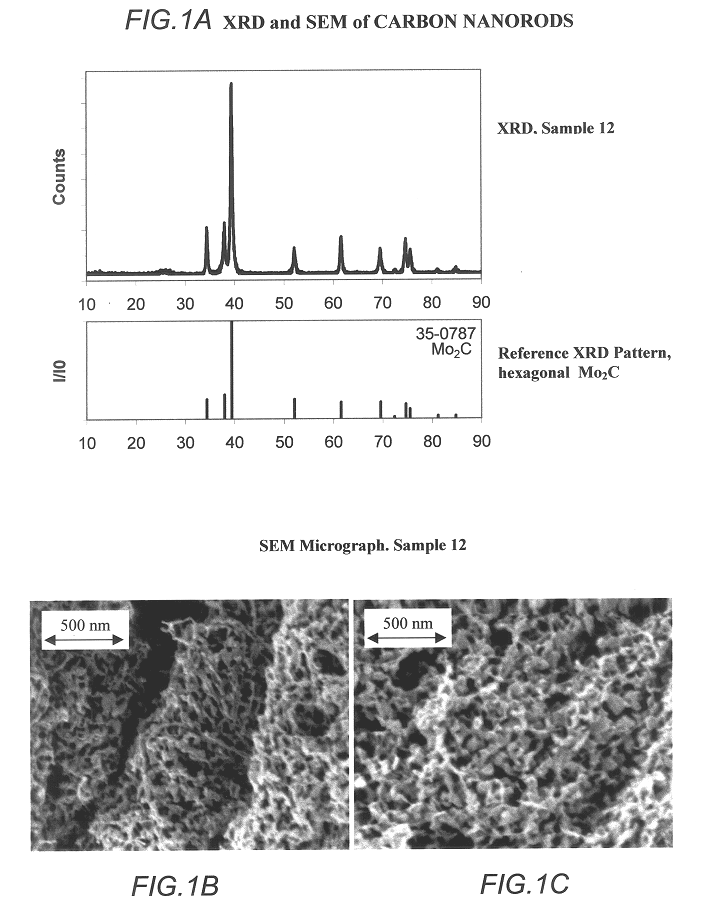

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

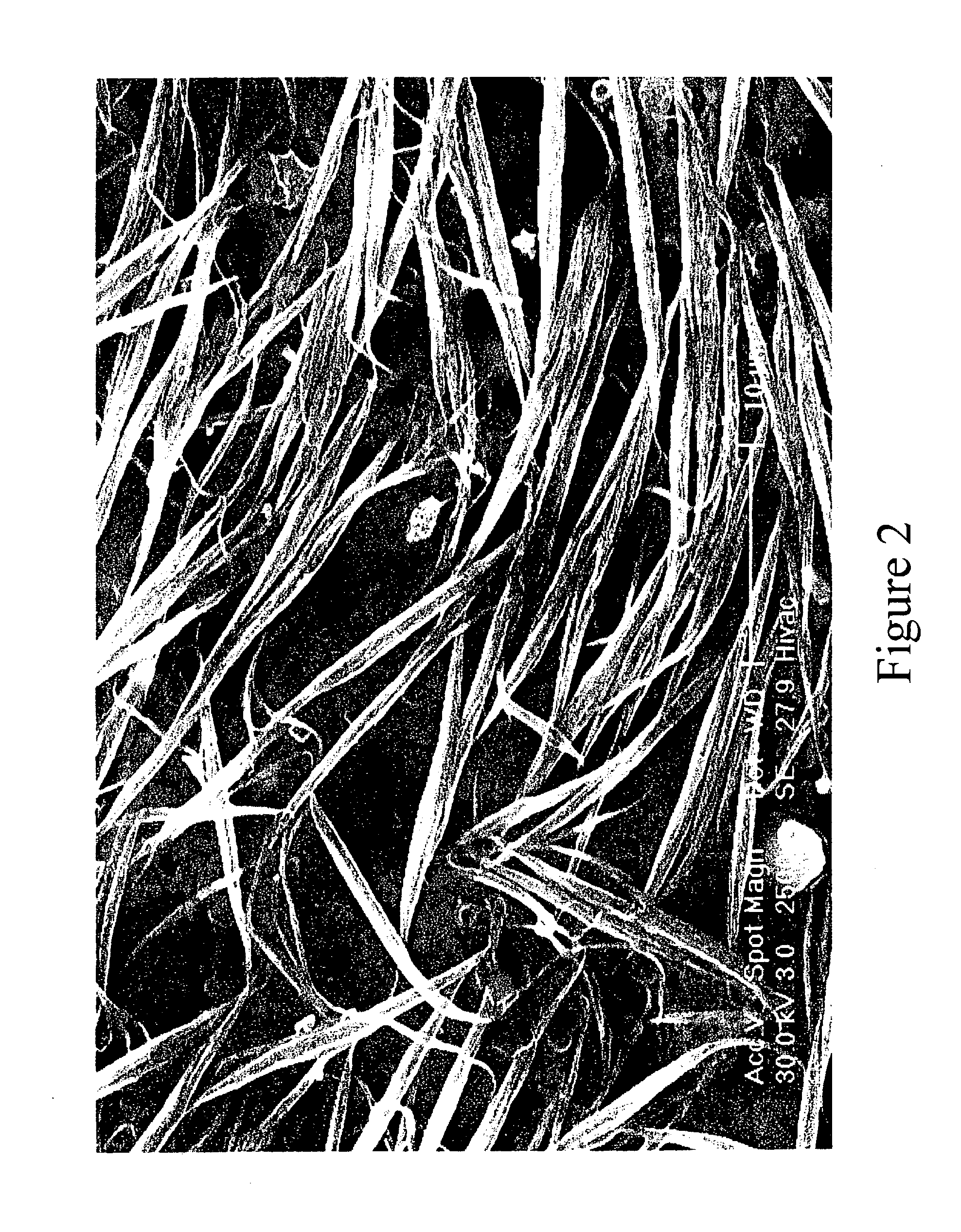

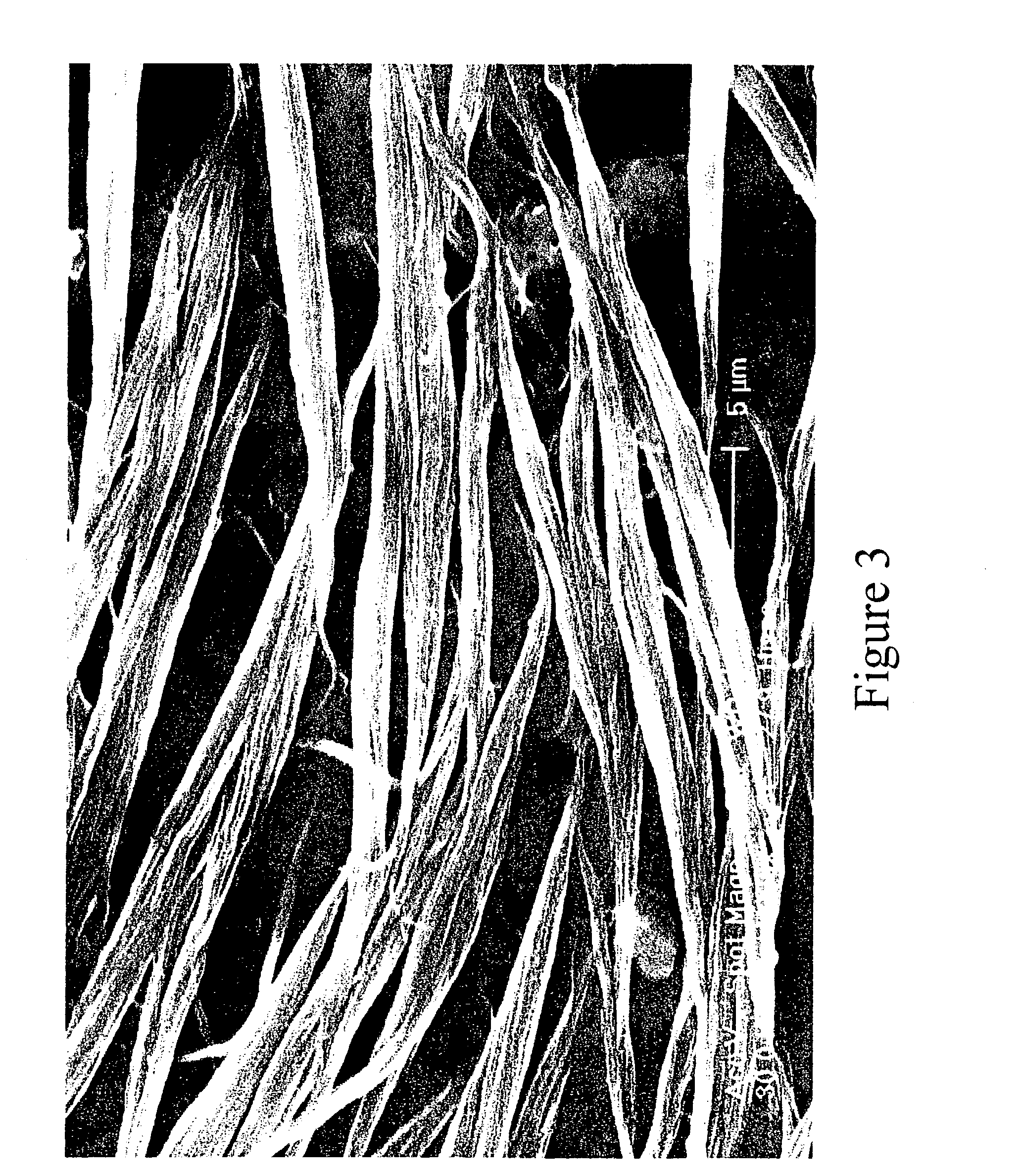

Fibers of aligned single-wall carbon nanotubes and process for making the same

ActiveUS7125502B2Good dispersionEasy to incorporatePigmenting treatmentNanosensorsFiberCarbon nanotube

The present invention involves fibers of highly aligned single-wall carbon nanotubes and a process for making the same. The present invention provides a method for effectively dispersing single-wall carbon nanotubes. The process for dispersing the single-wall carbon nanotubes comprises mixing single-wall carbon nanotubes with 100% sulfuric acid or a superacid, heating and stirring under an inert, oxygen-free environment. The single-wall carbon nanotube / acid mixture is wet spun into a coagulant to form the single-wall carbon nanotube fibers. The fibers are recovered, washed and dried. The single-wall carbon nanotubes were highly aligned in the fibers, as determined by Raman spectroscopy analysis.

Owner:DEXMAT INC

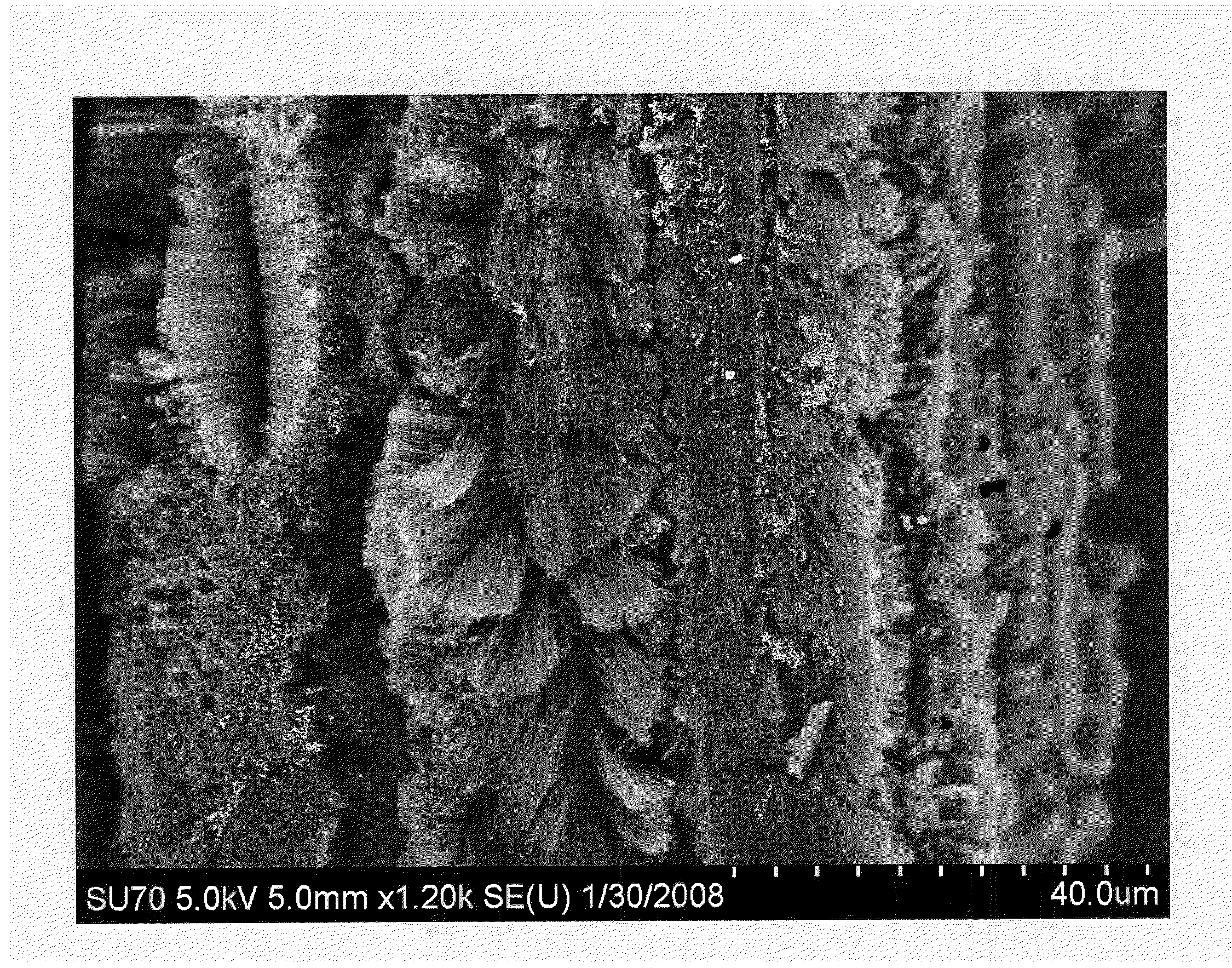

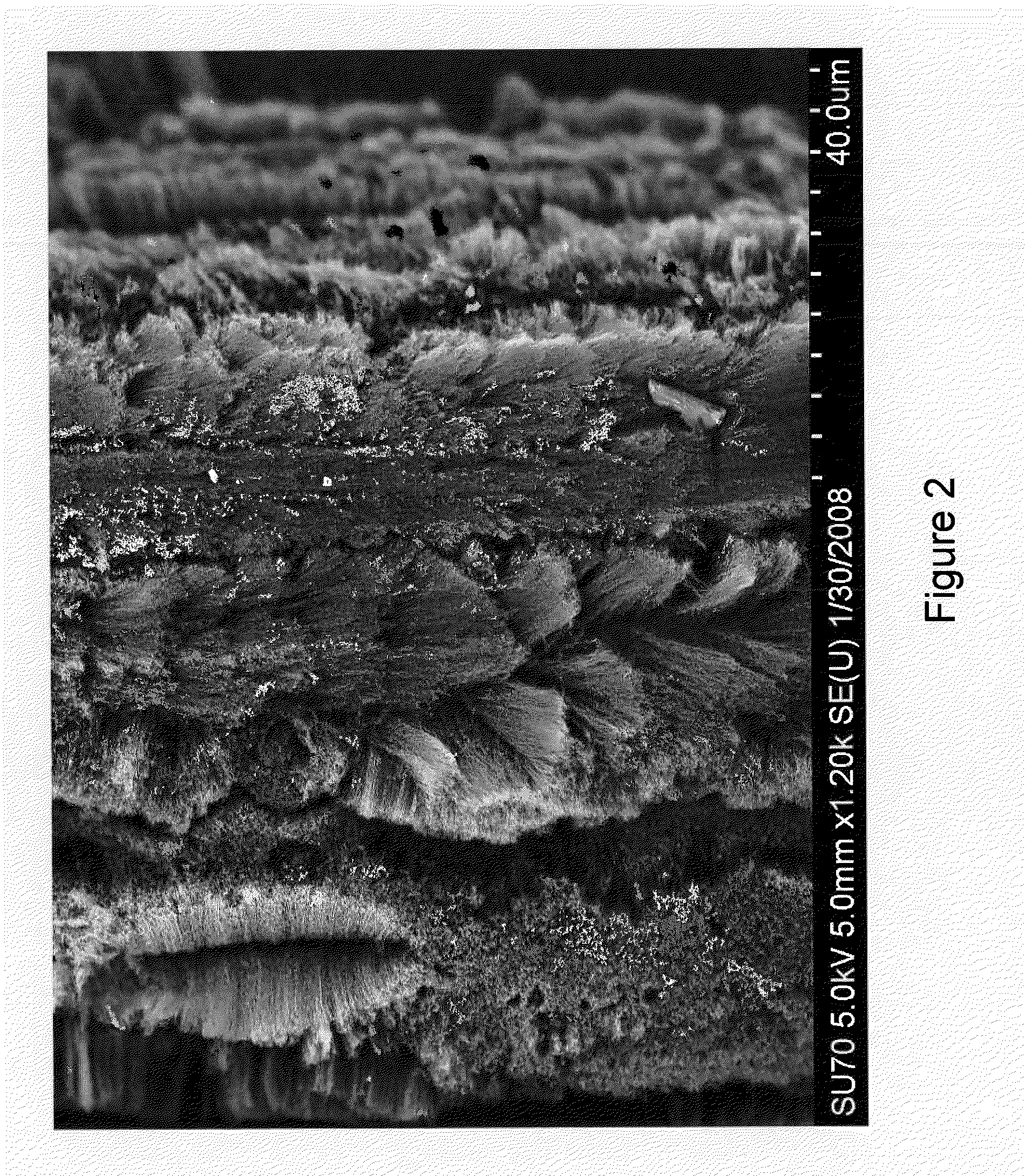

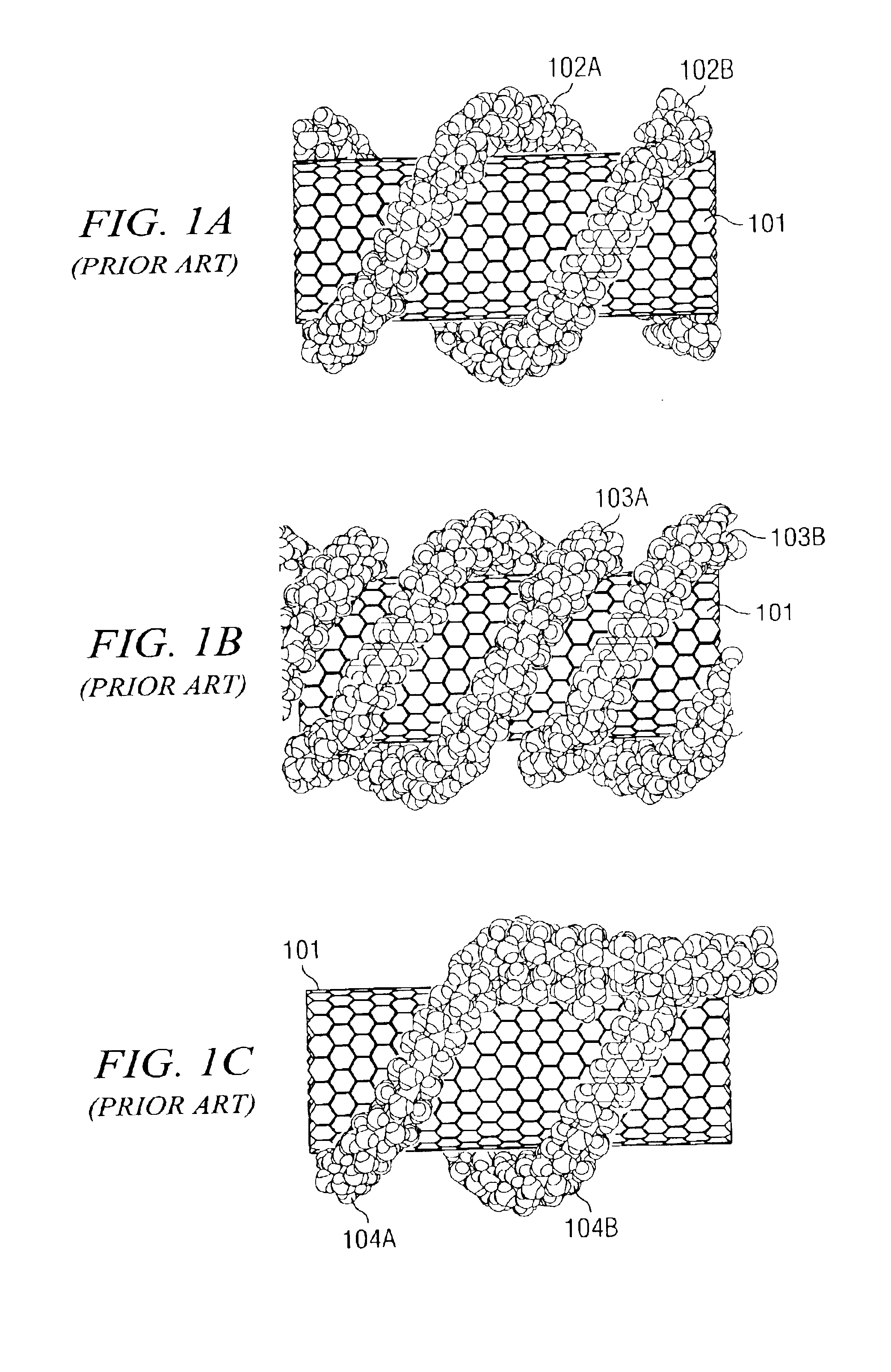

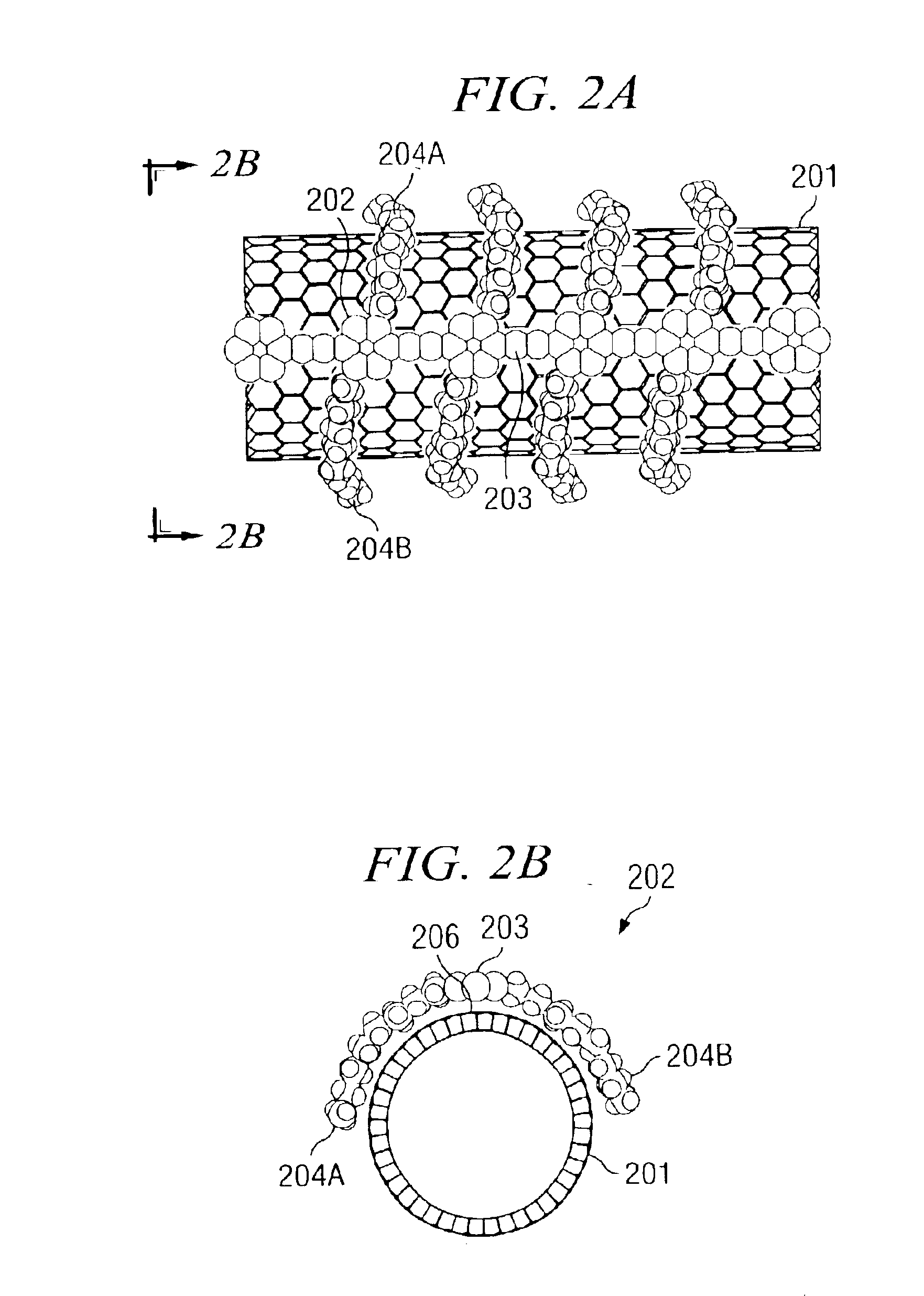

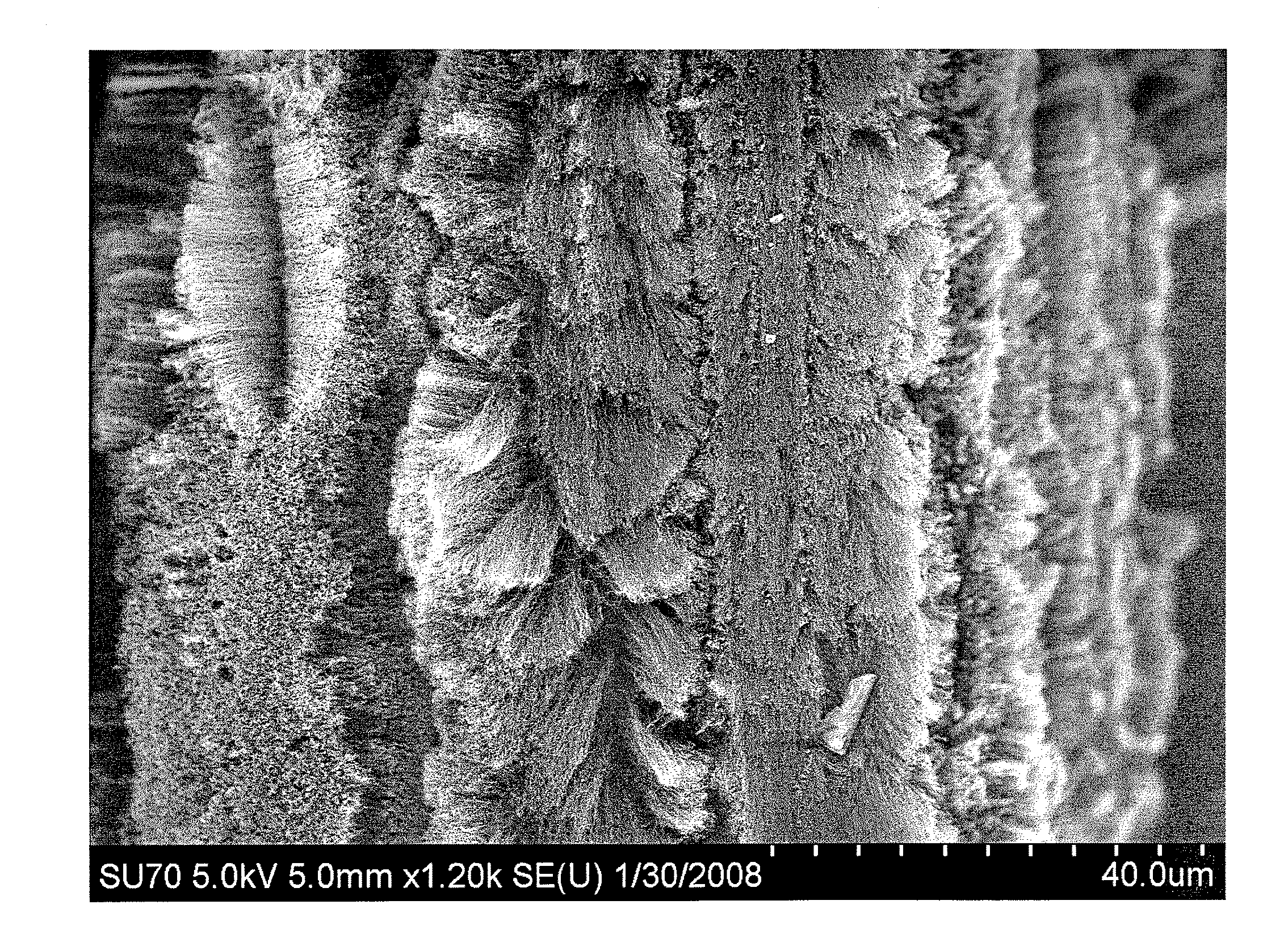

Cnt-infused glass fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused glass fiber material, which includes a glass fiber material of spoolable dimensions and carbon nanotubes (CNTs) bonded to it. The CNTs are uniform in length and distribution. A continuous CNT infusion process includes: (a) disposing a carbon-nanotube forming catalyst on a surface of a glass fiber material of spoolable dimensions; and (b) synthesizing carbon nanotubes on the glass fiber material, thereby forming a carbon nanotube-infused glass fiber material. The continuous CNT infusion process optionally includes extruding a glass fiber material from a glass melt or removing sizing material from a pre-fabricated glass fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

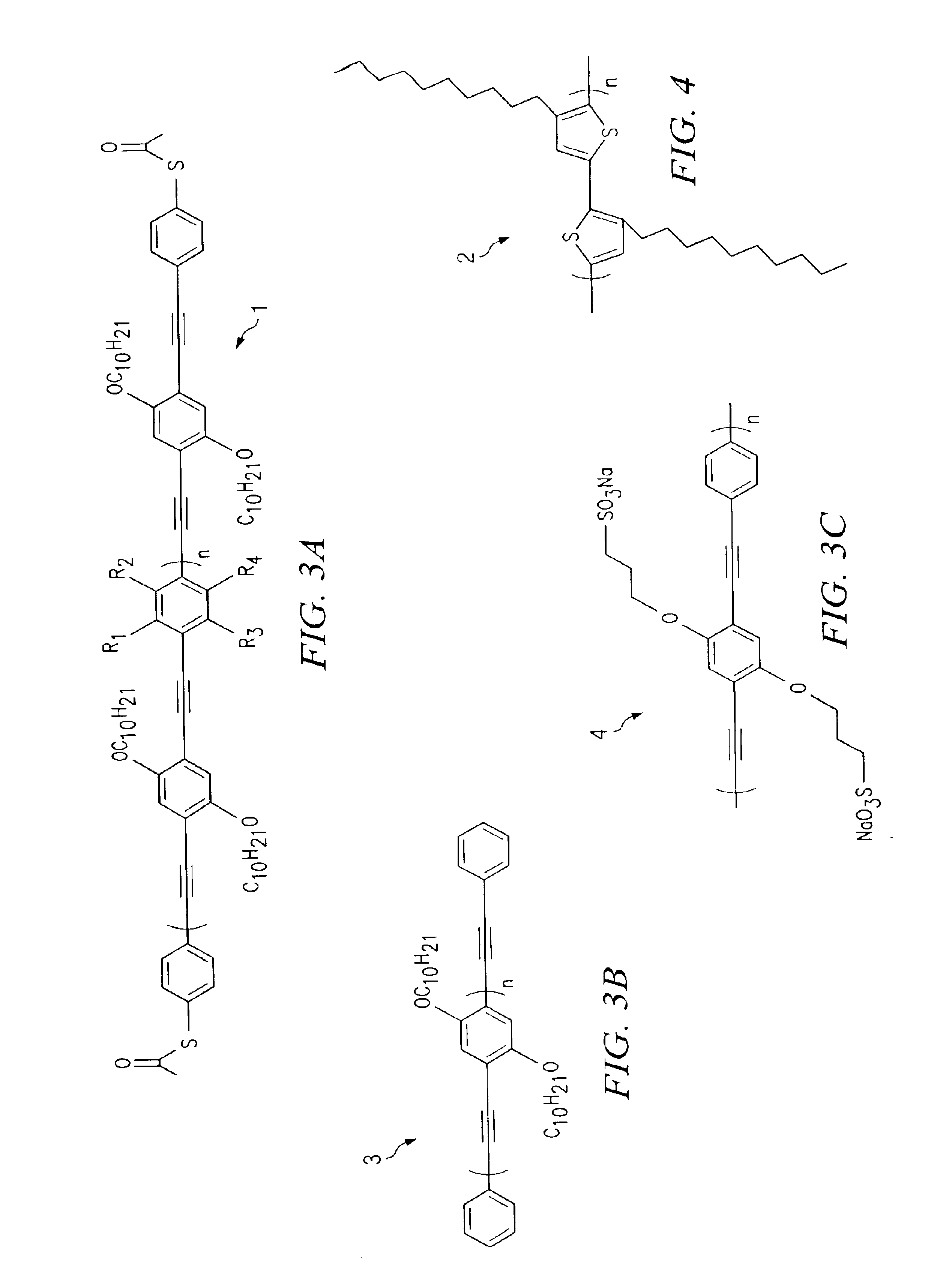

Polymer and method for using the polymer for noncovalently functionalizing nanotubes

A new, non-wrapping approach to functionalizing nanotubes, such as carbon nanotubes, in organic and inorganic solvents is provided. In accordance with certain embodiments, carbon nanotube surfaces are functionalized in a non-wrapping fashion by functional conjugated polymers that include functional groups. Various embodiments provide polymers that noncovalently bond with carbon nanotubes in a non-wrapping fashion. For example, various embodiments of polymers are provided that comprise a relatively rigid backbone that is suitable for noncovalently bonding with a carbon nanotube substantially along the nanotube's length, as opposed to about its diameter. In preferred polymers, the major interaction between the polymer backbone and the nanotube surface is parallel π-stacking. In certain implementations, the polymers further comprise at least one functional extension from the backbone that are any of various desired functional groups for functionalizing a carbon nanotube.

Owner:UNIV OF PITTSBURGH THE +1

Preparation method for high strength macro graphene conductive fiber

ActiveCN102534868AEasy to manufactureImprove solubilityArtificial filament chemical after-treatmentFiberCarbon fibers

The invention discloses a preparation method for high strength macro graphene conductive fiber. According to the method, graphite is oxidized to obtain a graphene oxide; the graphene oxide is dispersed in water or a polar organic solvent to prepare a spinning liquid sol with the mass concentration of 1-20%; the spinning liquid sol is transferred to a spinning device; the spinning liquid is continuously extruded from a spinning head capillary at a uniform speed; the extruded spinning liquid enters a solidification liquid; the solidified primary fiber is collected by using a polytetrafluoroethylene roller; a drying treatment is performed to obtain the graphene oxide fiber; the graphene oxide fiber is subjected to chemical reduction to obtain the graphene fiber. According to the present invention, the spinning process is simple; the operation is performed at the room temperature; no strong corrosive reagent is used; the process has the characteristics of green environmental protection; the prepared graphene fiber has characteristics of good conductivity, excellent mechanical property and good toughness, can be woven into the pure graphene fiber cloth, can further be woven into various fabrics with other fibers, and can further be added to the polymer as the conduction enhancing additive and the like; the prepared graphene fiber can replace the carbon fiber to use in a plurality of fields.

Owner:杭州德烯科技集团有限公司

Sidewall-functionalized carbon nanotubes, and methods for making the same

ActiveUS20050147553A1Broaden applicationPigmenting treatmentMaterial nanotechnologyCarbon nanotubeOxygen mixture

The invention provides a method of functionalizing the sidewalls of a plurality of carbon nanotubes with oxygen moieties, the method comprising: exposing a carbon nanotube dispersion to an ozone / oxygen mixture to form a plurality of ozonized carbon nanotubes; and contacting the plurality of ozonized carbon nanotubes with a cleaving agent to form a plurality of sidewall-functionalized carbon nanotubes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

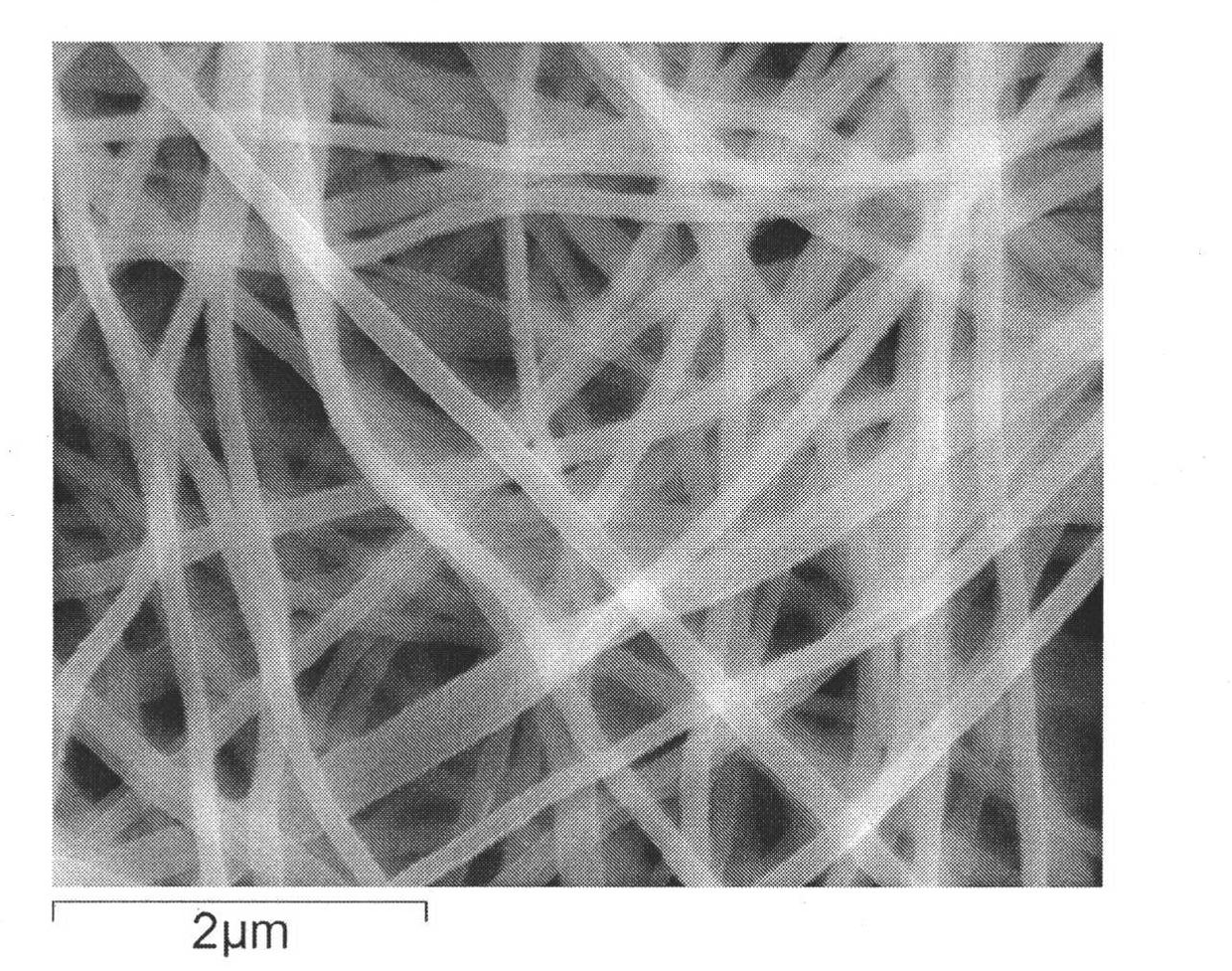

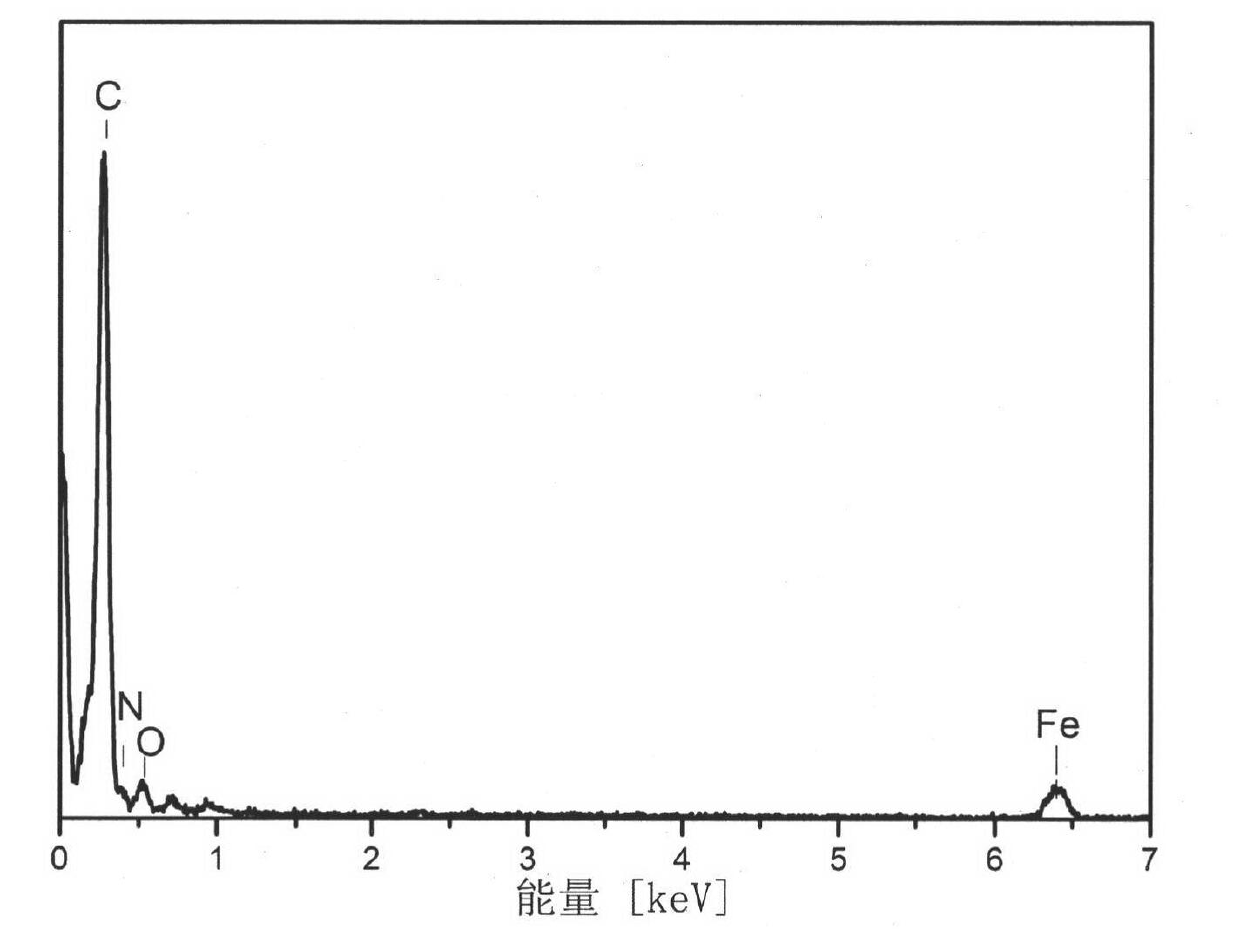

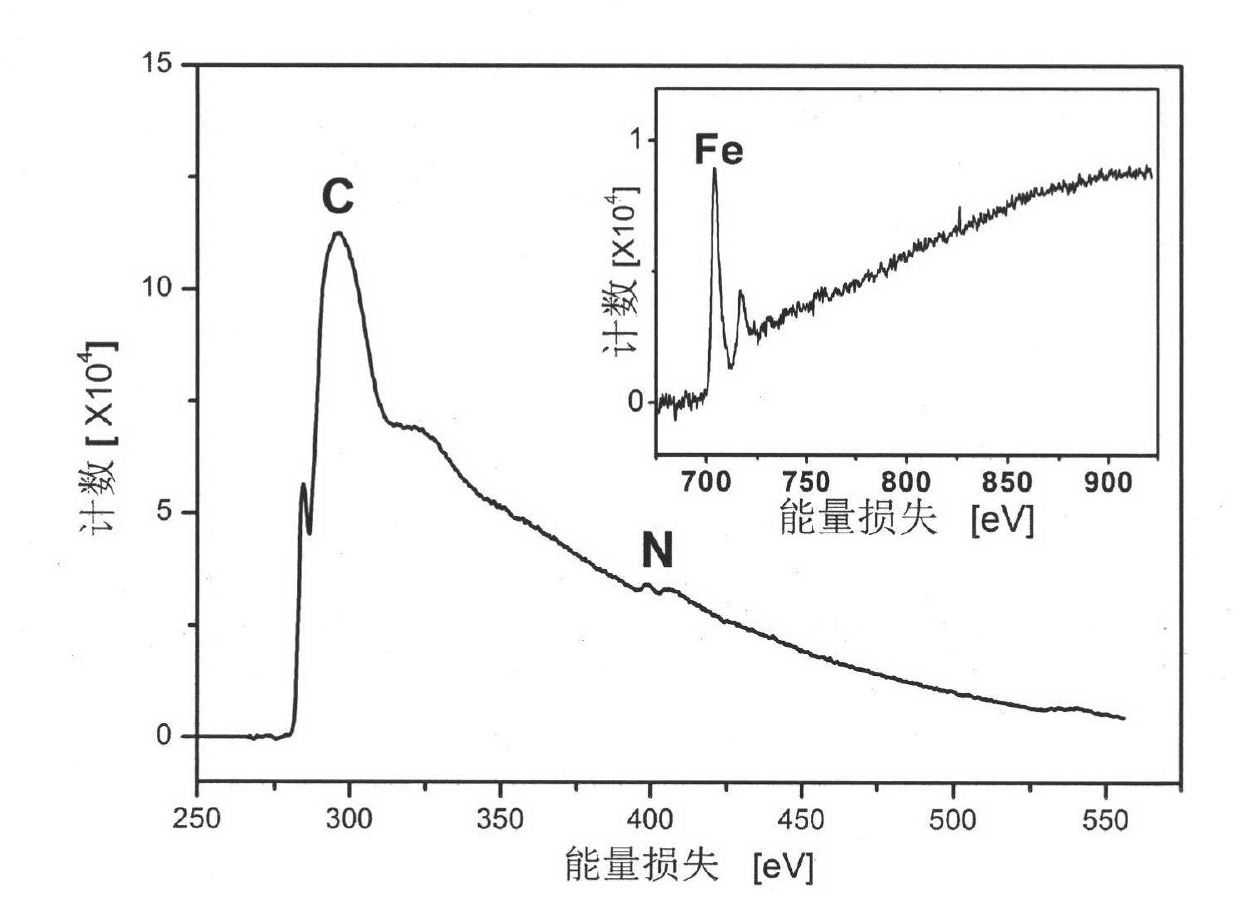

Preparation method for carbon nanofiber containing transition metal and nitrogen element and application of carbon nanofiber in fuel-cell catalysts

InactiveCN102021677ASimple structureSimple manufacturing processCell electrodesFilament/thread formingPtru catalystFuel cells

The invention discloses a preparation method for a carbon nanofiber containing transition metal and a nitrogen element and application of the carbon nanofiber in fuel-cell catalysts, belonging to the technical field of carbon nanofibers and the fuel-cell catalysts. The preparation method comprises the following steps of: dissolving at least one transition metal salt and at least one nitrogenous polymer into a solvent to form a precursor solution; carrying out electrostatic spinning on the precursor solution to obtain an organic nanofiber; and heating to carbonize the organic nanofiber in a basic inert atmosphere to obtain the carbon nanofiber containing the transition metal and the nitrogen element. A nanofiber self-supporting membrane is directly used as a fuel cell electrode after dipped in the solution, or the carbon nanofiber is coated on the electrode to be used as a fuel cell catalysis electrode after formed into powder and then mixed with the solution. The method is simple and is easy to operate; and the prepared carbon nanofiber containing the transition metal and the nitrogen element performs good catalytic activity on oxygen reduction reaction.

Owner:TSINGHUA UNIV

Cnt-infused glass fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused glass fiber material, which includes a glass fiber material of spoolable dimensions and carbon nanotubes (CNTs) bonded to it. The CNTs are uniform in length and distribution. A continuous CNT infusion process includes: (a) disposing a carbon-nanotube forming catalyst on a surface of a glass fiber material of spoolable dimensions; and (b) synthesizing carbon nanotubes on the glass fiber material, thereby forming a carbon nanotube-infused glass fiber material. The continuous CNT infusion process optionally includes extruding a glass fiber material from a glass melt or removing sizing material from a pre-fabricated glass fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

High tensile strength carbon nanotube film and process for making the same

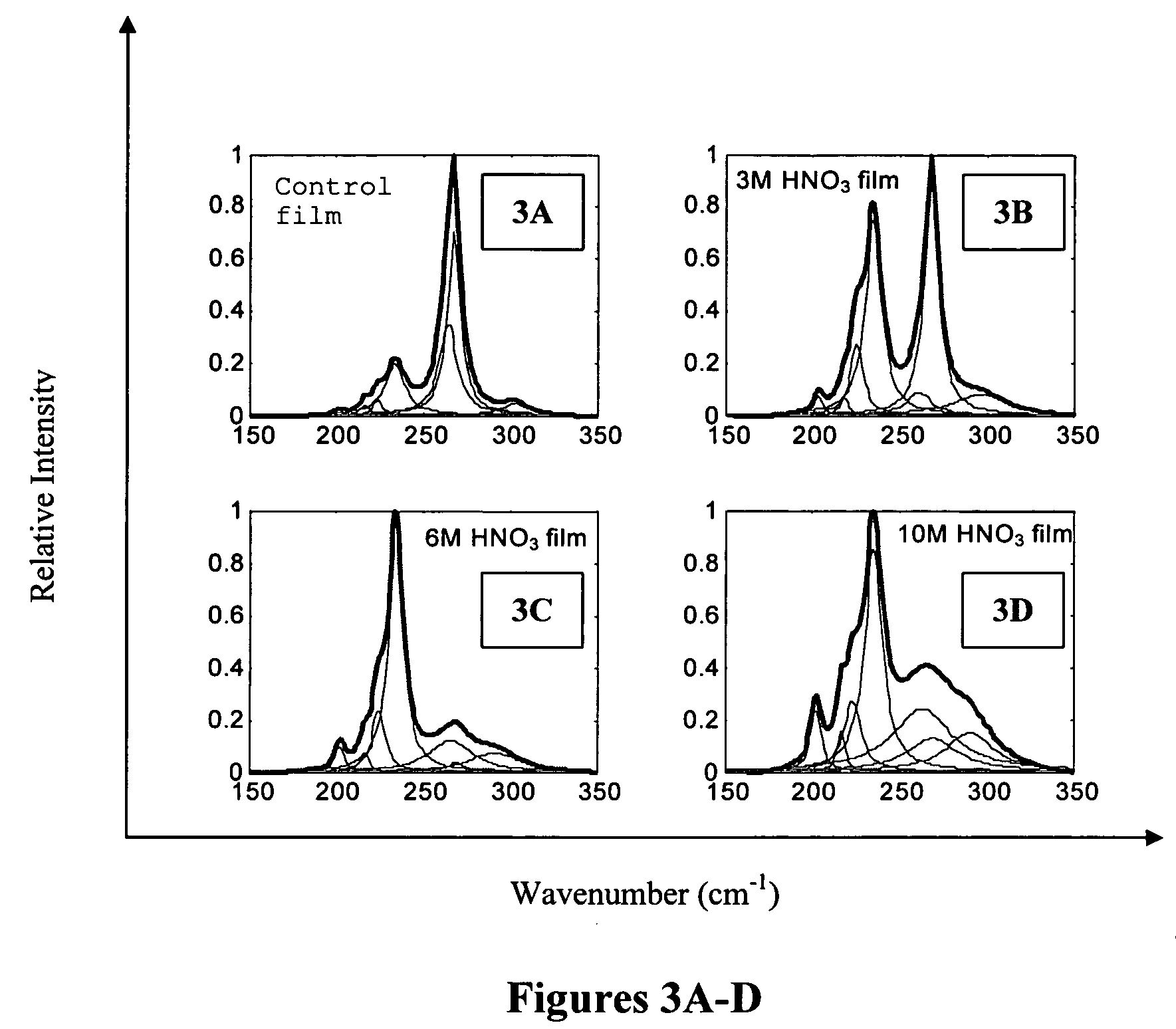

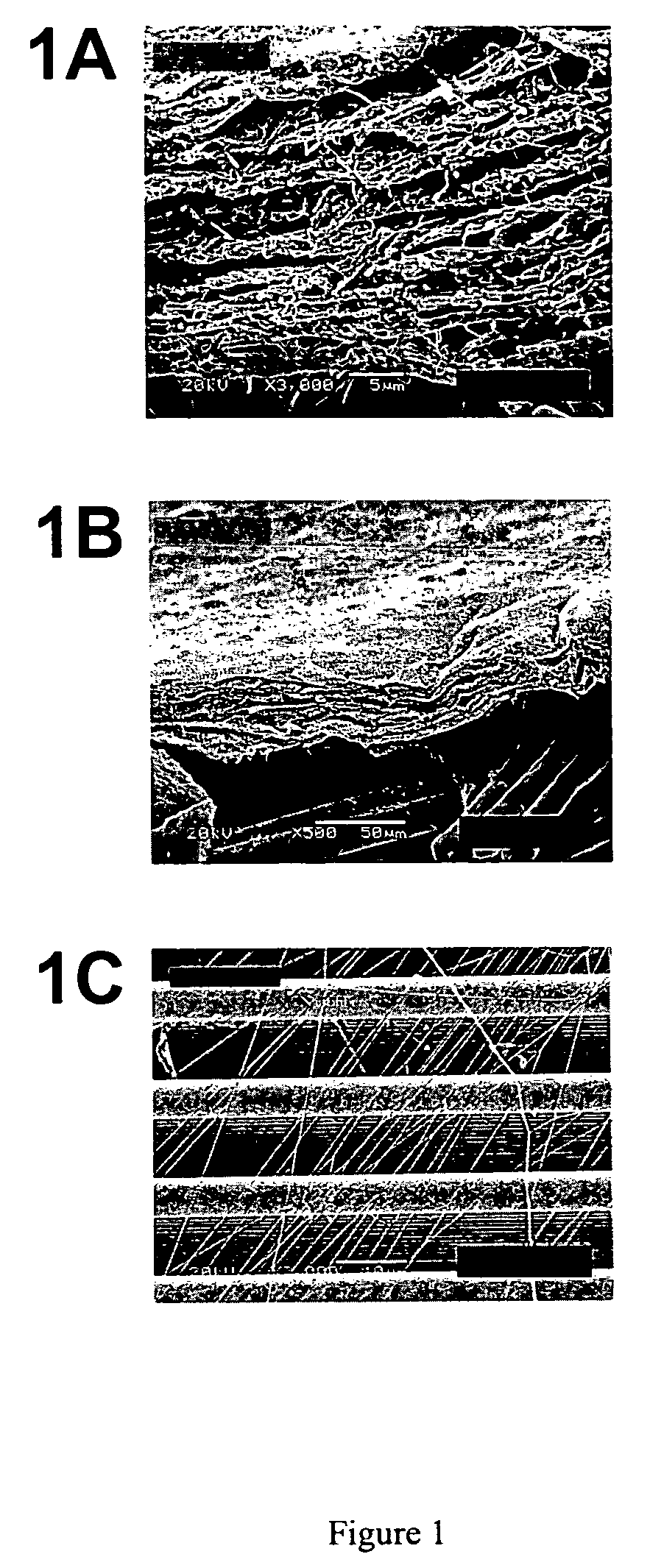

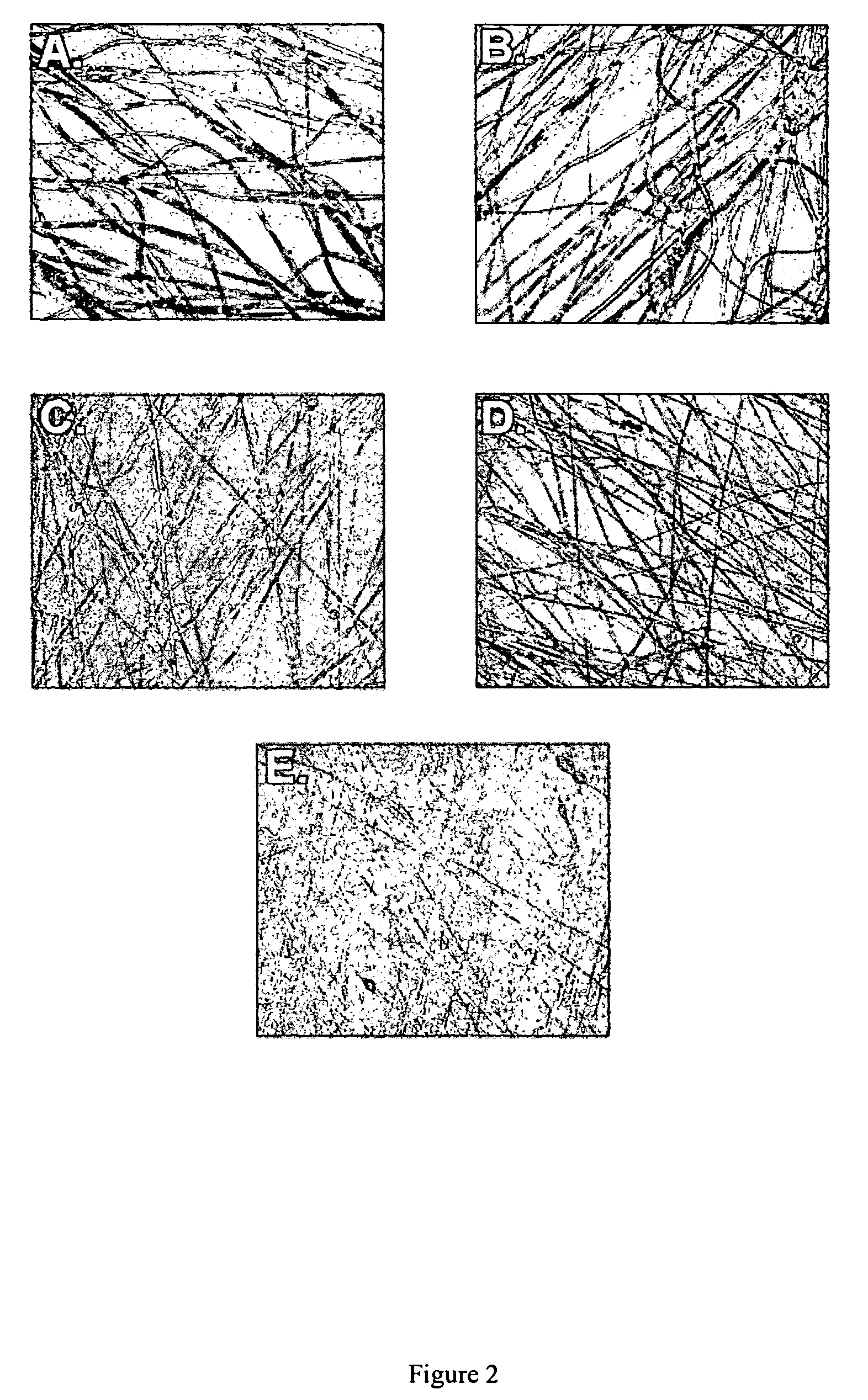

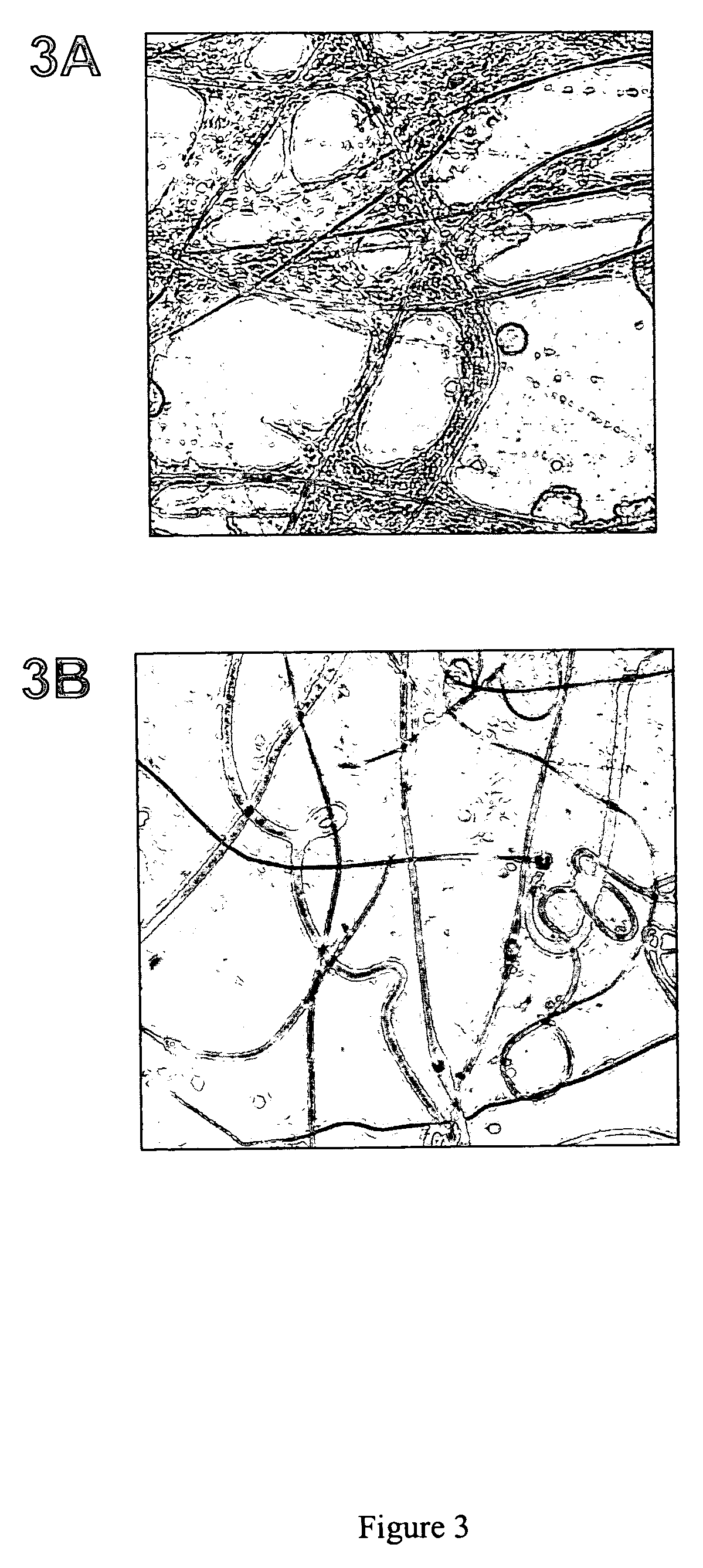

InactiveUS20060029537A1Material nanotechnologyArtificial filament chemical after-treatmentOxidizing agentNanotube

A conductive carbon nanotube film having high tensile strength and initial tensile modulus comprises primarily oxidized small-diameter carbon nanotubes wherein the diameter of the small-diameter carbon nanotubes are at most about 3 nm. A method for making the film comprises refluxing an aqueous mixture comprising carbon nanotubes and an oxidizing agent to form a refluxed nanotube dispersion; forming a carbon nanotube film from the refluxed carbon nanotube dispersion; optionally removing nitric acid or other oxidizing agent from the carbon nanotube film; drying the carbon nanotube film; and heat-treating the carbon nanotube film to form a heat-treated carbon nanotube film. The method can also comprise sonicating the nanotubes prior to or after refluxing. A heat-treated small-diameter carbon nanotube film can have a tensile strength of over 70 MPa and an initial tensile modulus of about 5 GPa.

Owner:GEORGIA TECH RES CORP

Nanofibrillar structure and applications including cell and tissue culture

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com