Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52809 results about "Polyester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

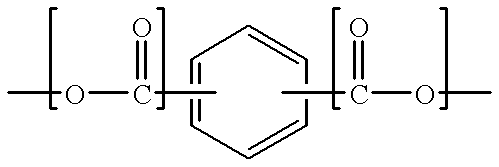

Polyester is a category of polymers that contain the ester functional group in their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in the cutin of plant cuticles, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. The material is used extensively in clothing.

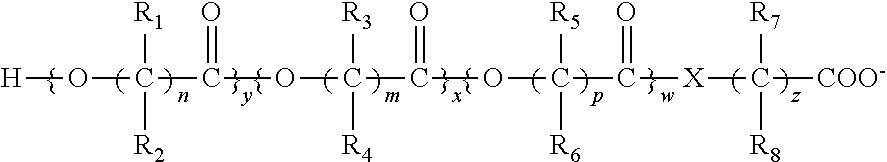

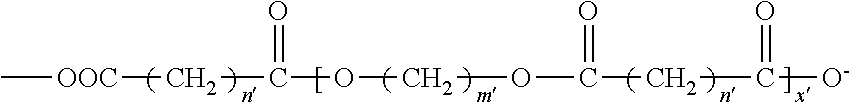

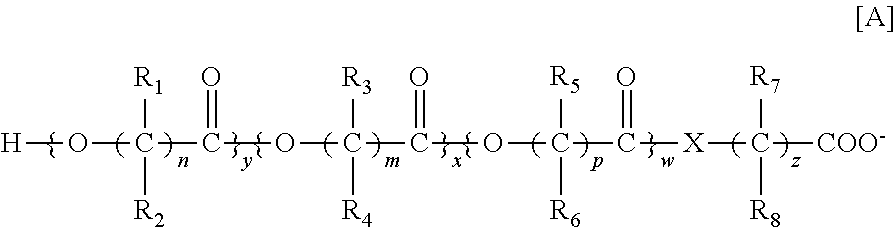

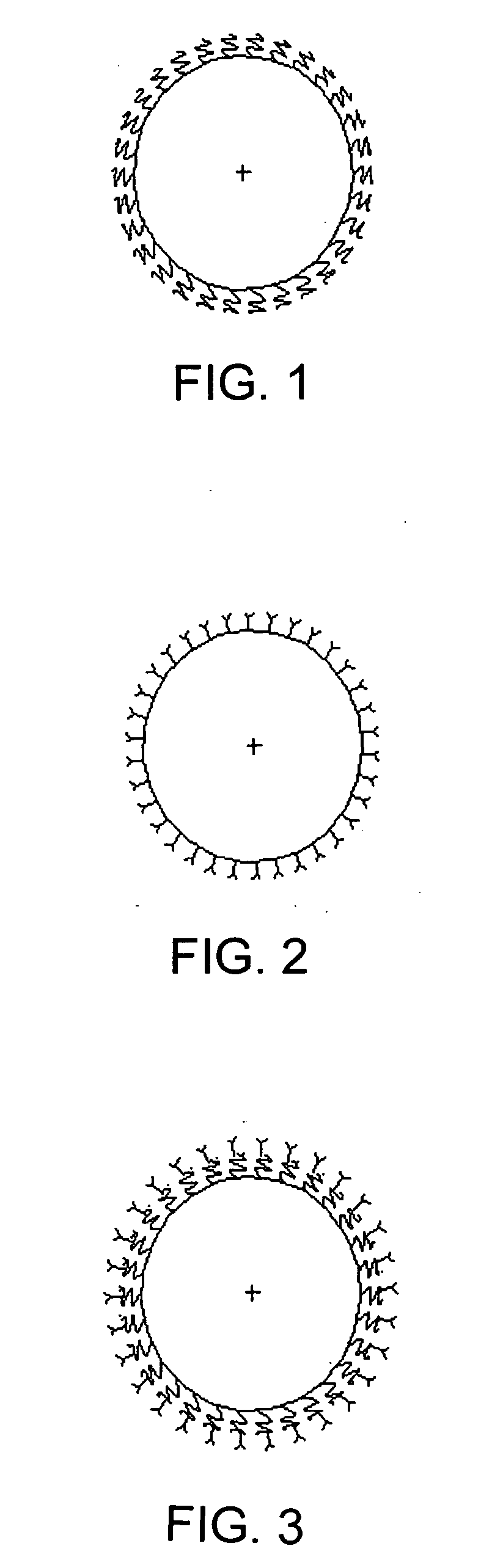

Antimicrobial polymer compositions and the use thereof

An antimicrobial composition comprising: a complex of an anionic polyester with an antimicrobial cationic surfactant, wherein the anionic polyester has at least one carboxylic group. A medical device having an antimicrobial composition comprising: a complex of an anionic polyester with an antimicrobial cationic surfactant wherein the anionic polyester has at least one carboxylic group.

Owner:ETHICON INC

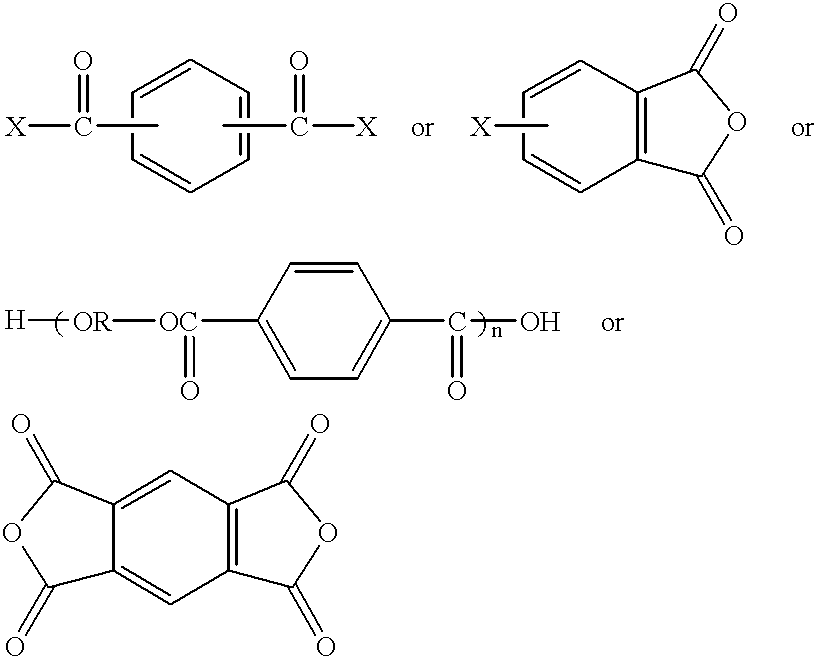

Polyester process

A process for the preparation of an unsaturated polyester which comprises (i) reacting an organic diol with a cyclic akylene carbonate in the presence of a first catalyst to thereby form a polyalkoxy diol, and (ii) optionally adding thereto a further amount of cyclic alkylene carbonate in the presence of a second catalyst, and (iii) subsequently polycondensing the resulting mixture with a dicarboxylic acid.

Owner:XEROX CORP

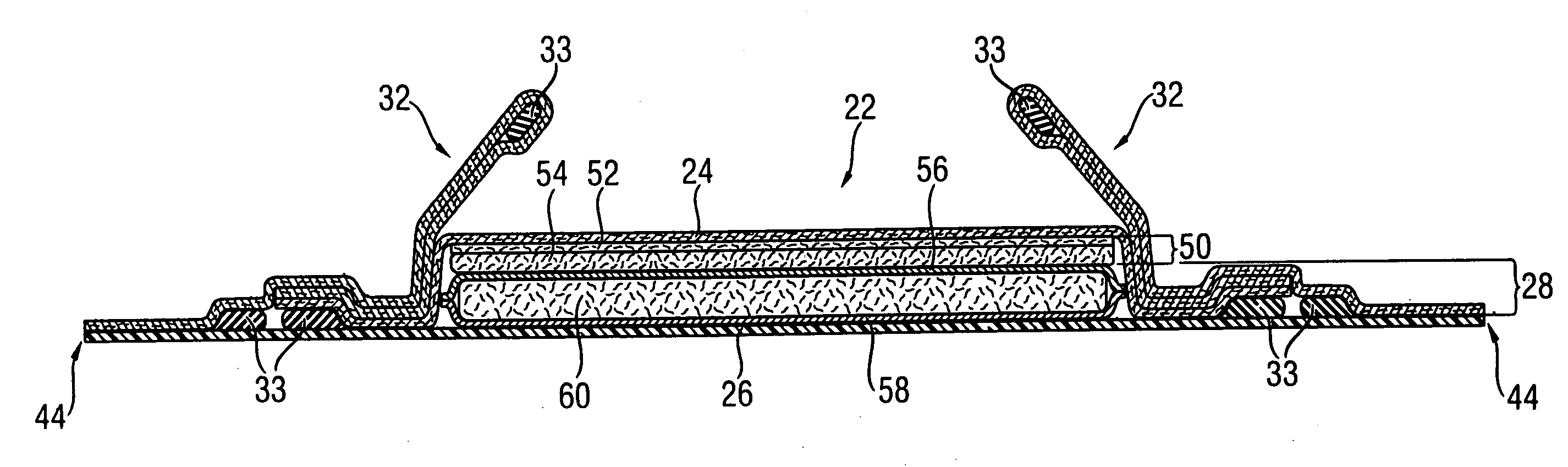

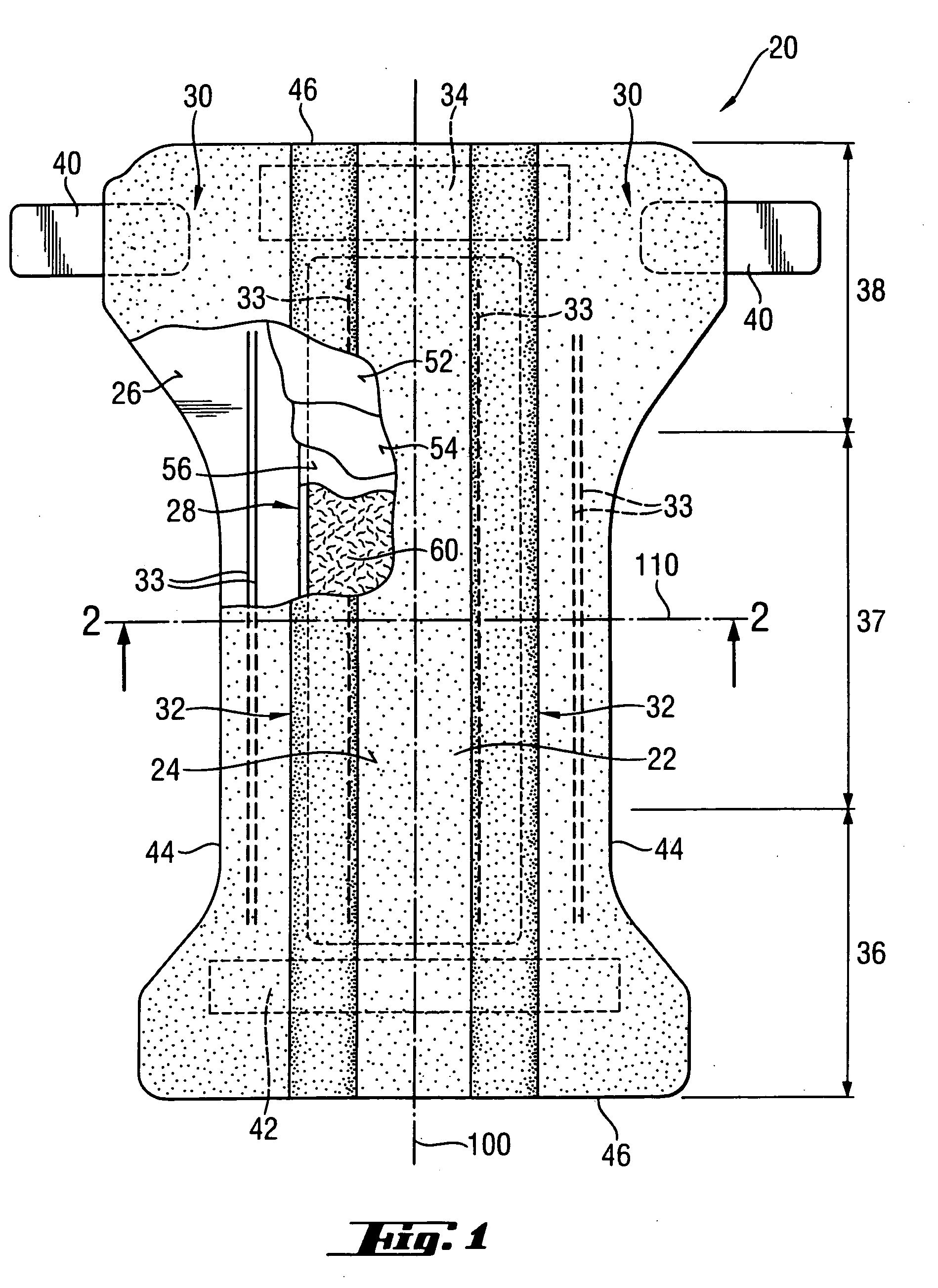

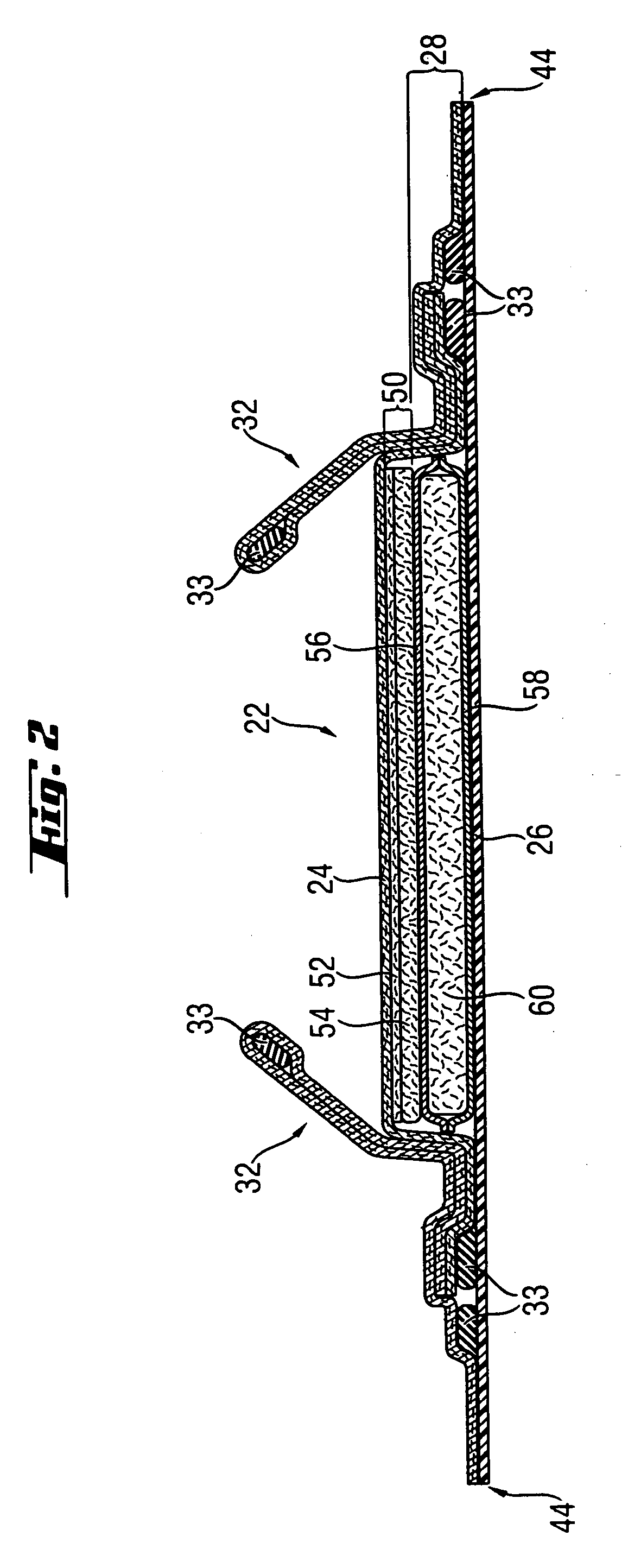

Fluid acquisition layer

A liquid acquisition material for use in an absorbent article. The liquid acquisition material having first fibers and second fibers. The first fibers are chemically cross-linked cellulose fibers and the second fibers are selected from the group consisting of: polyethylene, polypropylene, polyester, rayon, lyocell, and mixtures thereof. The liquid acquisition material has a total dry weight, the first fibers have a first dry weight, and the second fibers have a second dry weight. The first dry weight is from 30 to 95 percent of the total dry weight and the second dry weight is from 5 to 70 percent of the total dry weight.

Owner:THE PROCTER & GAMBLE COMPANY

Isosorbide containing polyesters and methods for making same

InactiveUS6063464AHigher inherent viscosityInherent viscosityBottlesSynthetic resin layered productsPolyesterDiol

A polyester polymer and method for making the polyester, wherein the polyester is prepared by (1) combining in a reactor a monomer containing a diacid moiety; a monomer comprising a diol moiety; and a monomer containing an isosorbide moiety; with a condensation catalyst suitable for condensing aromatic diacids and diols; and (2) heating the monomers and catalyst to polymerize the monomers to yield a polyester having an inherent viscosity of at least about 0.15 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

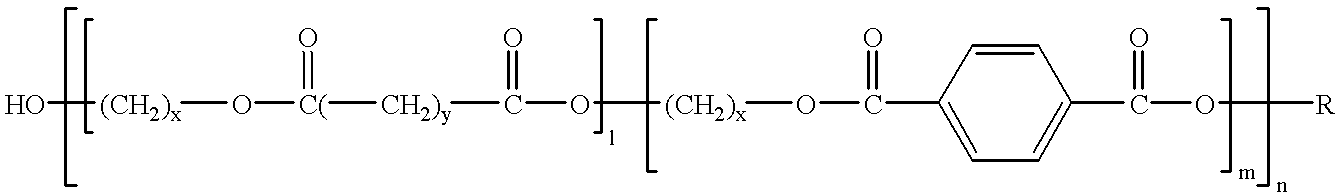

Methods and compositions for reducing or eliminating post-surgical adhesion formation

The present invention relates to a method for reducing adhesions associated with post-operative surgery. The present method comprises administering or affixing a polymeric composition preferably comprising chain extended, coupled or crosslinked polyester / poly(oxyalkylene) ABA triblocks or AB diblocks having favorable EO / LA ratios to a site in the body which has been subjected to trauma, e.g. by surgery, excision or inflammatory disease. In the present invention, the polymeric material provides a barrier to prevent or reduce the extent of adhesions forming.

Owner:YISSUM RES DEV CO OF THE HEBREW UNIV OF JERUSALEM LTD

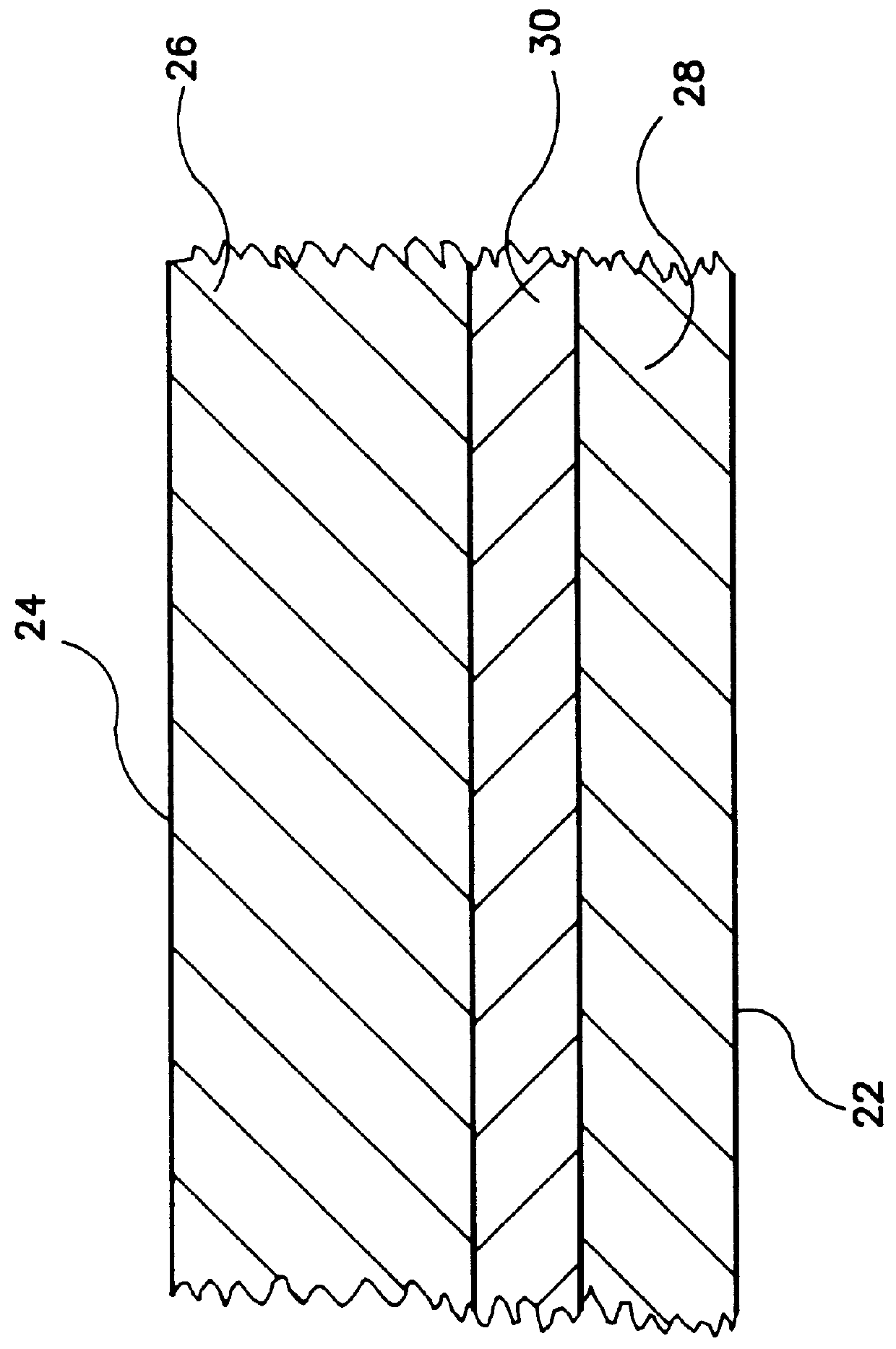

Polyester polyether block copolymers

The present invention relates to novel bioabsorbable polymeric compositions based upon AB polyester polyether or related diblocks and triblocks. Compositions according to the present invention may be used in medical applications, for example, for reducing or preventing adhesion formation subsequent to medical procedures such as surgery, for producing surgical articles including stents and grafts, as coatings, sealants, lubricants, as transient barriers in the body, for materials which control the release of bioactive agents in the body, for wound and bum dressings and producing biodegradable articles, among numerous others.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Oxygen scavenging condensation copolymers for bottles and packaging articles

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

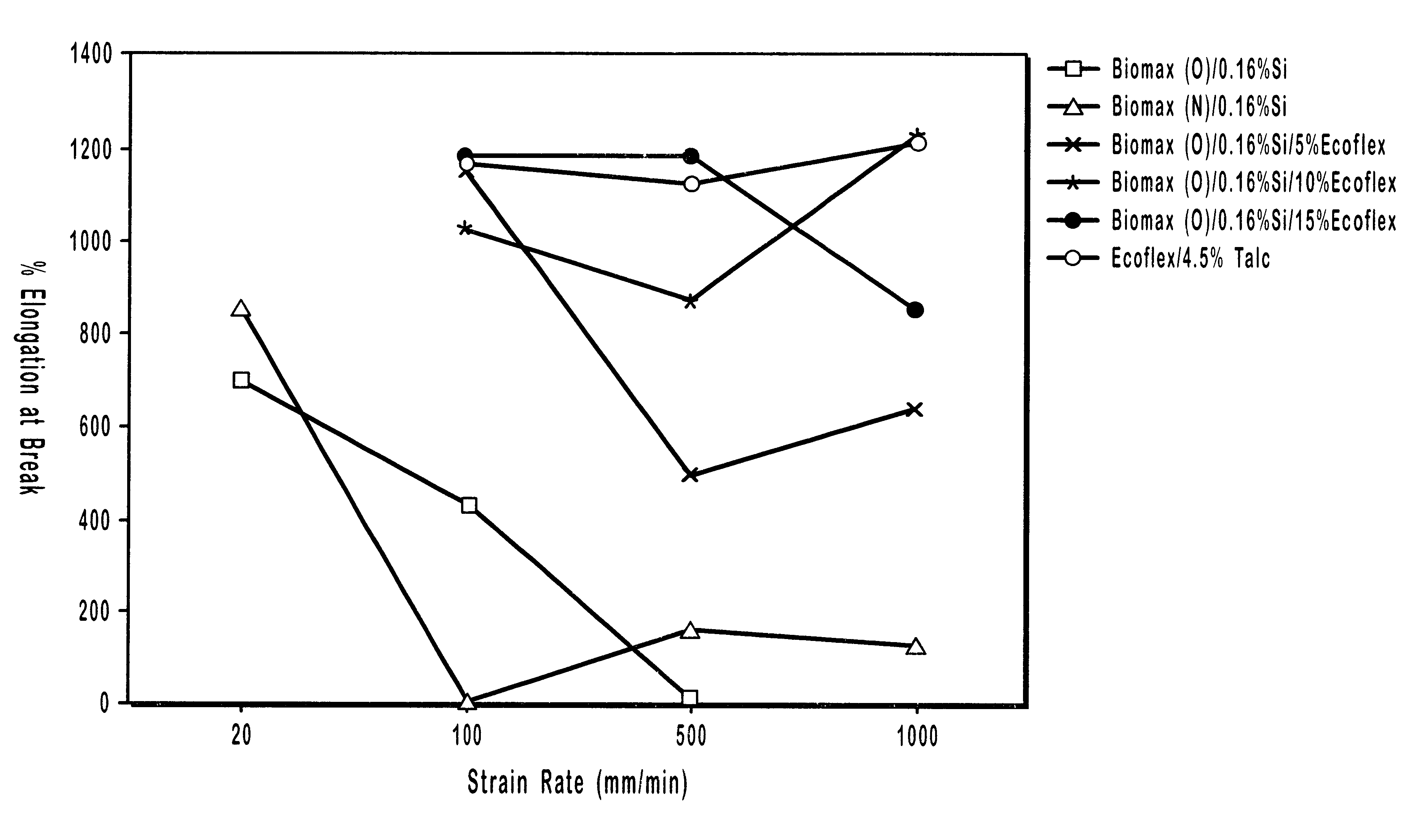

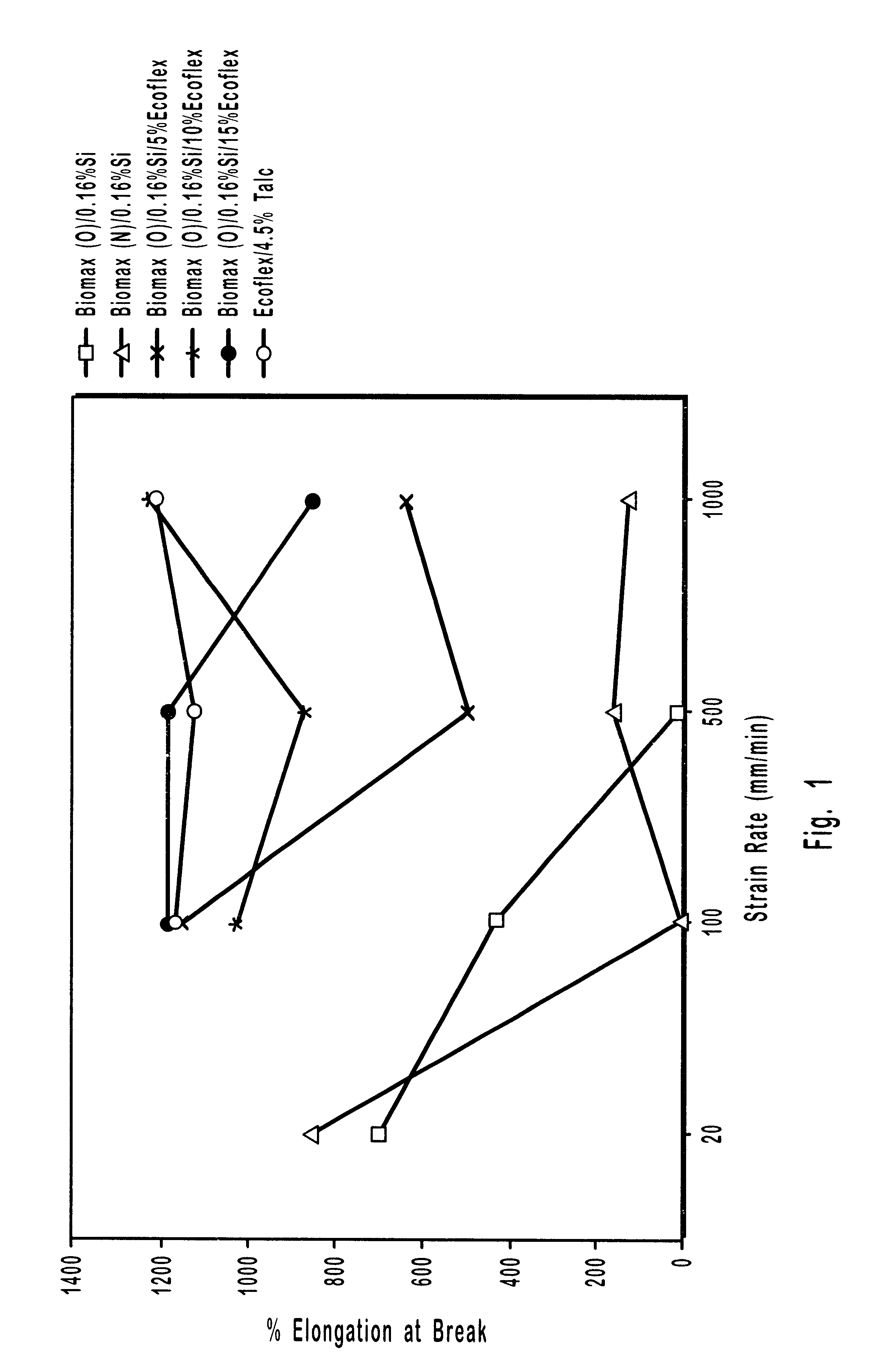

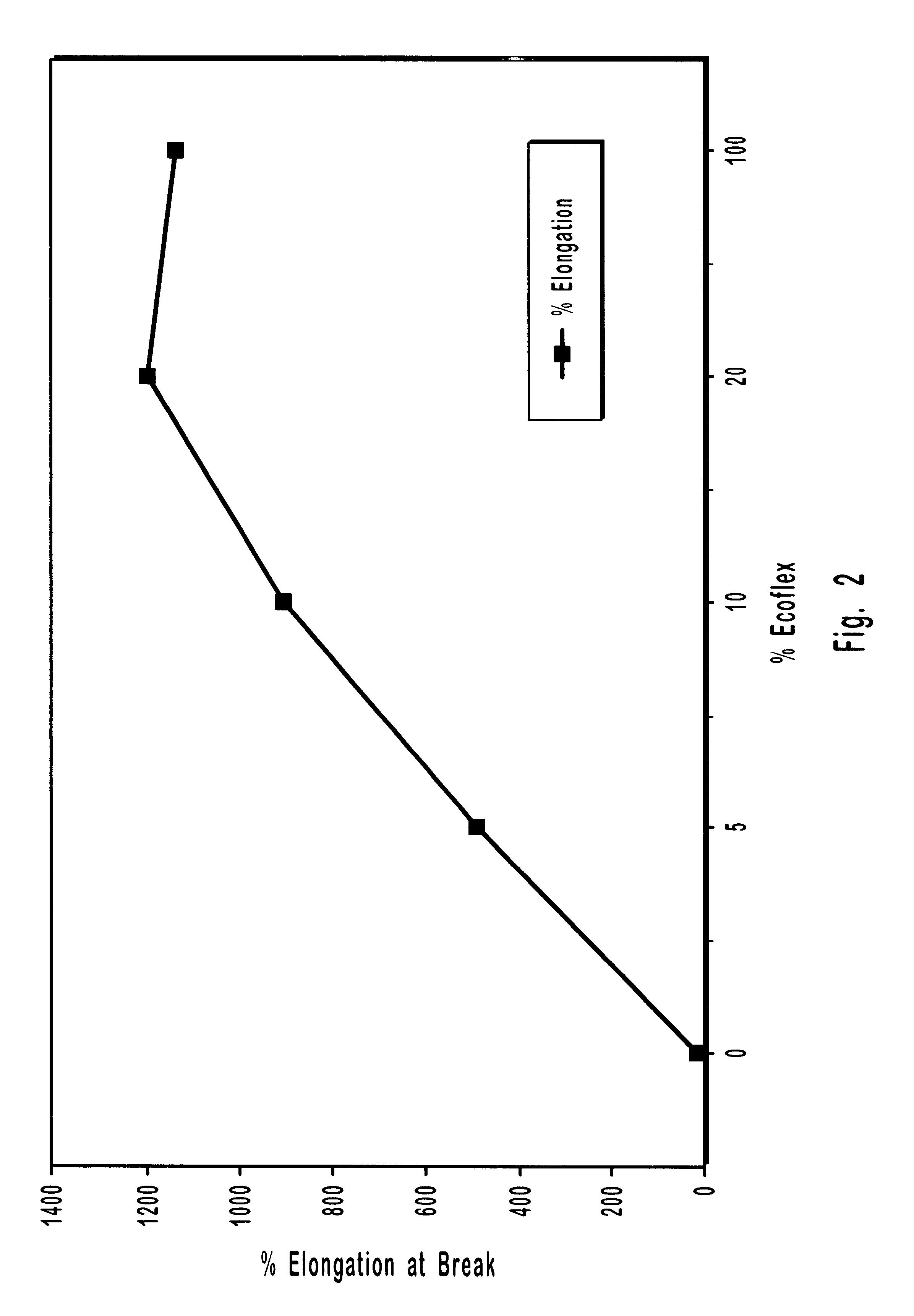

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

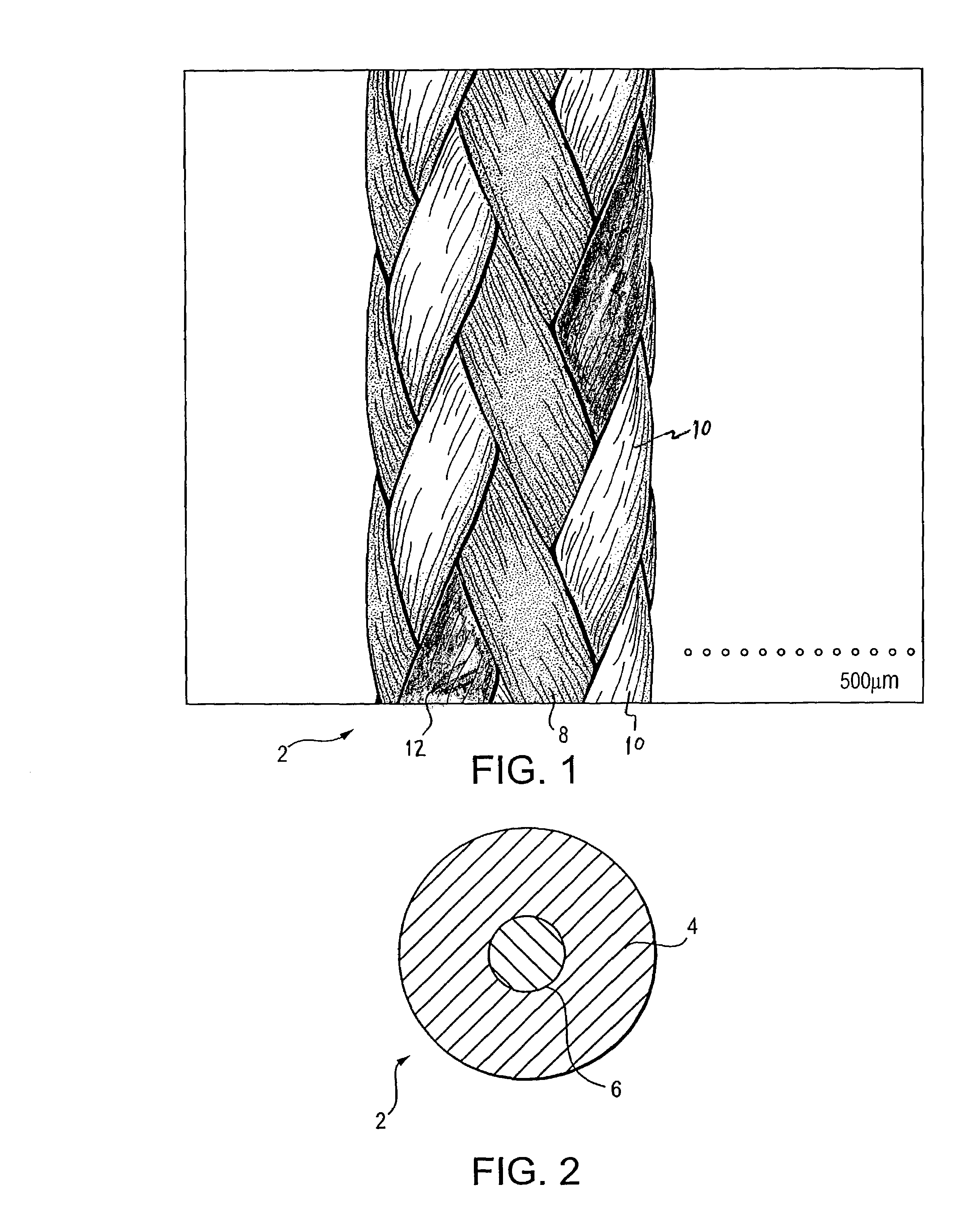

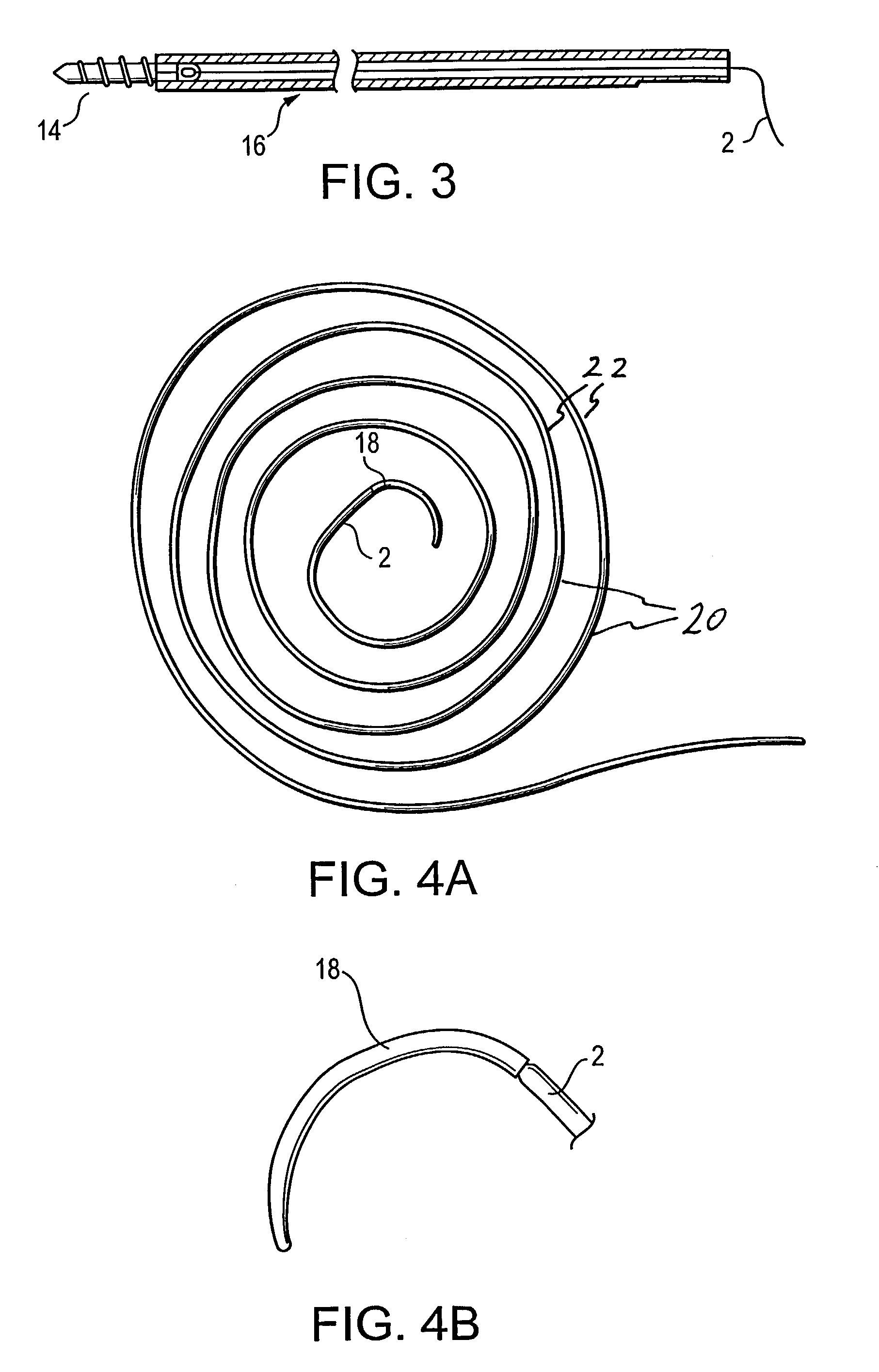

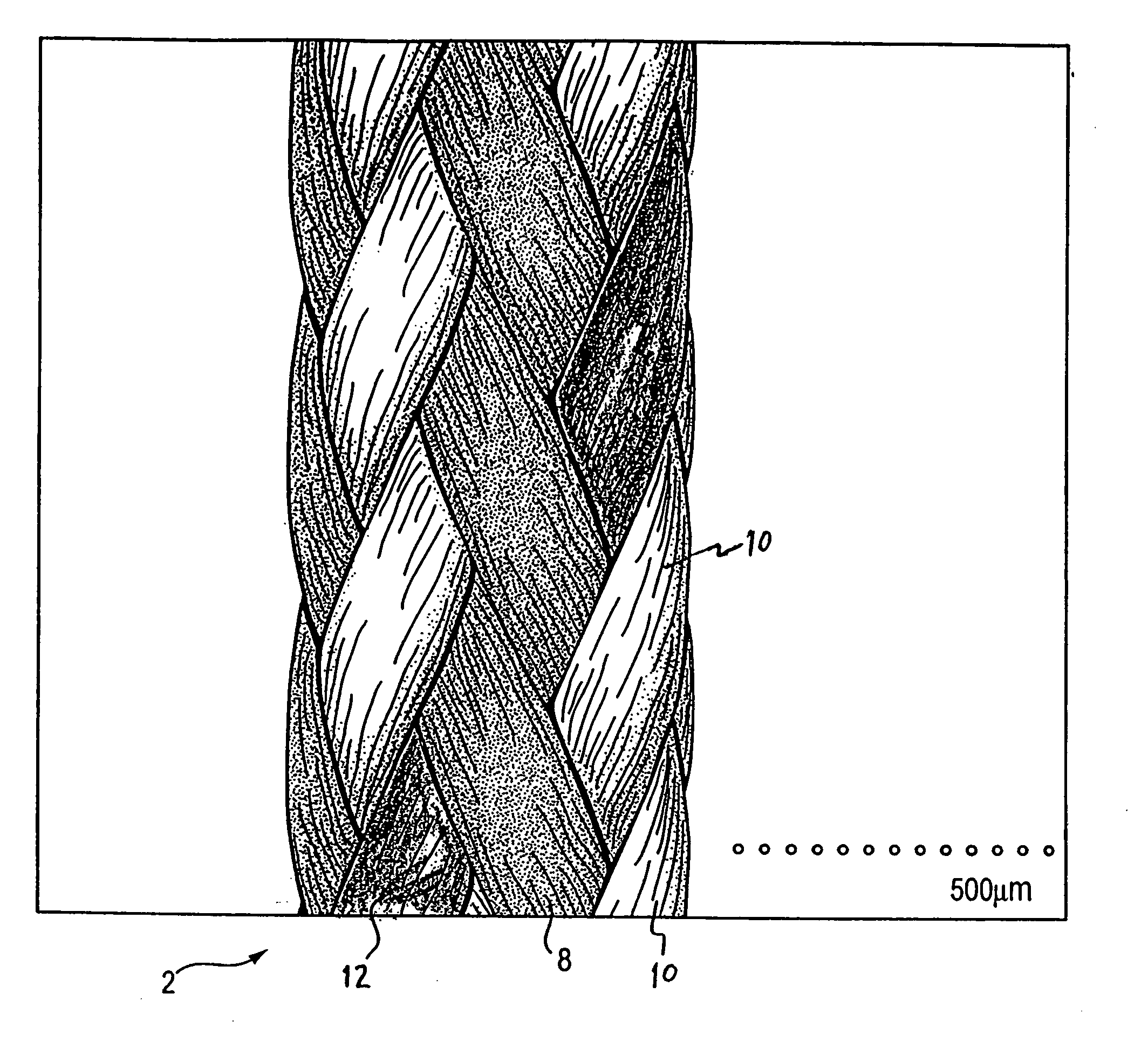

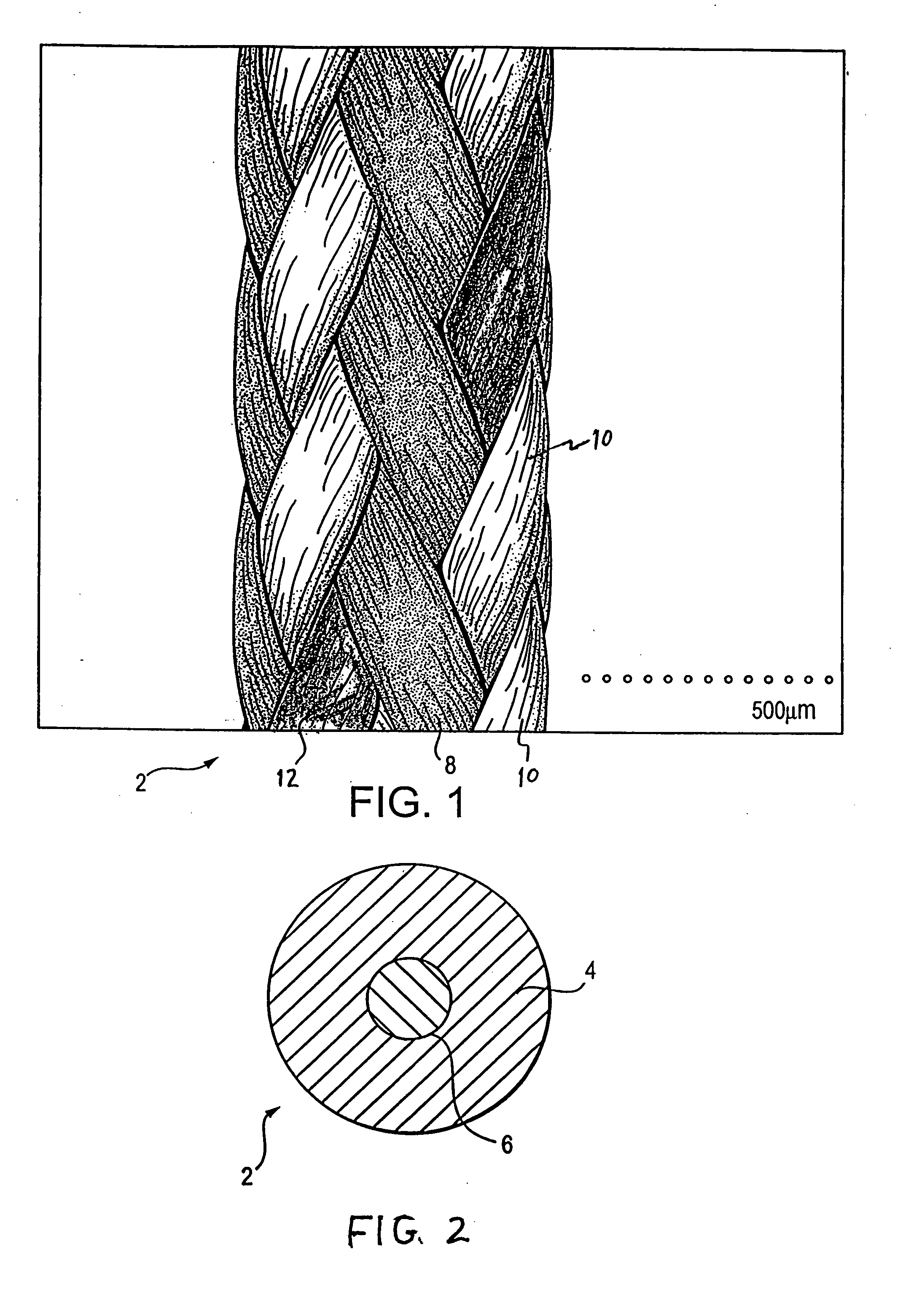

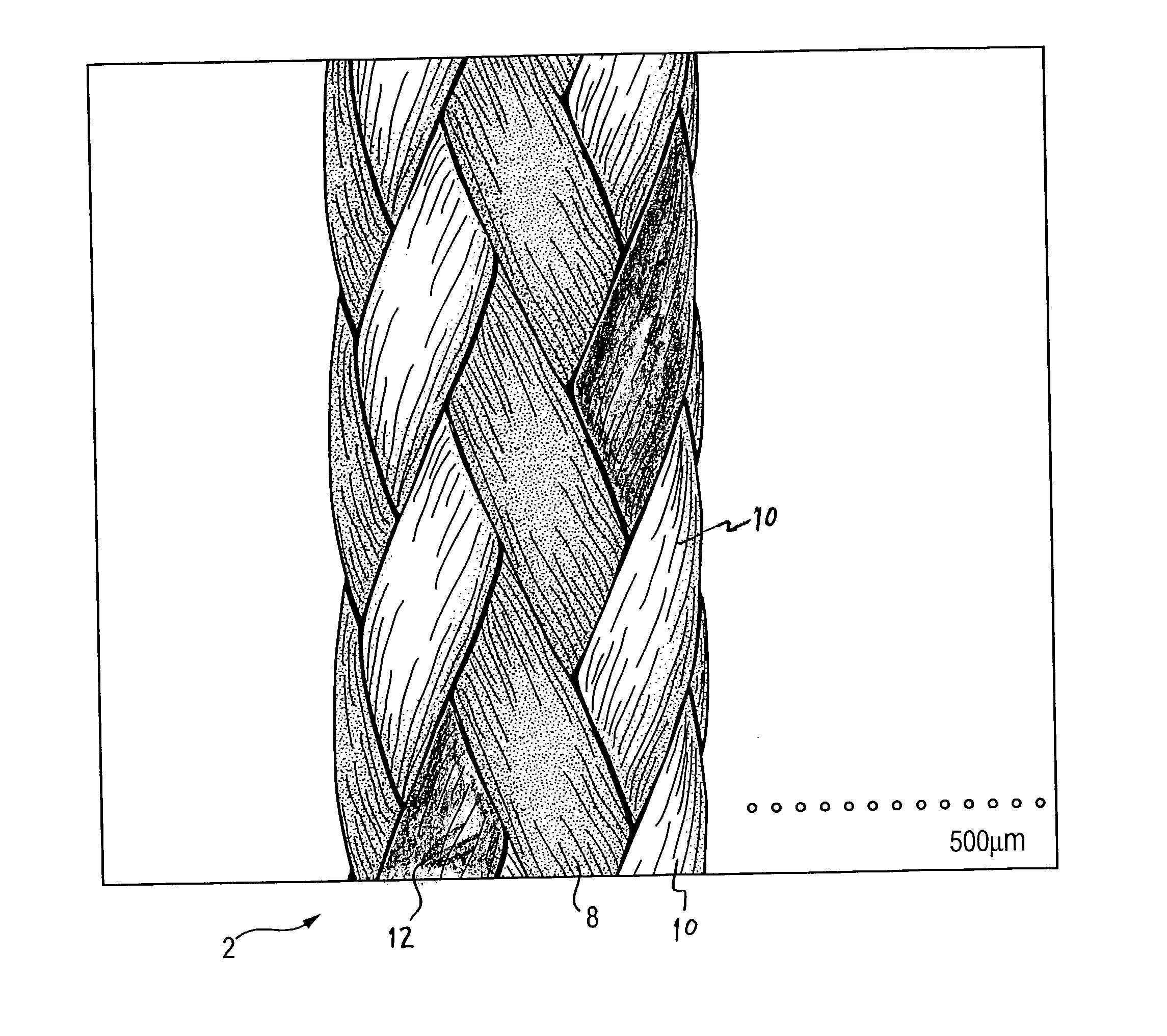

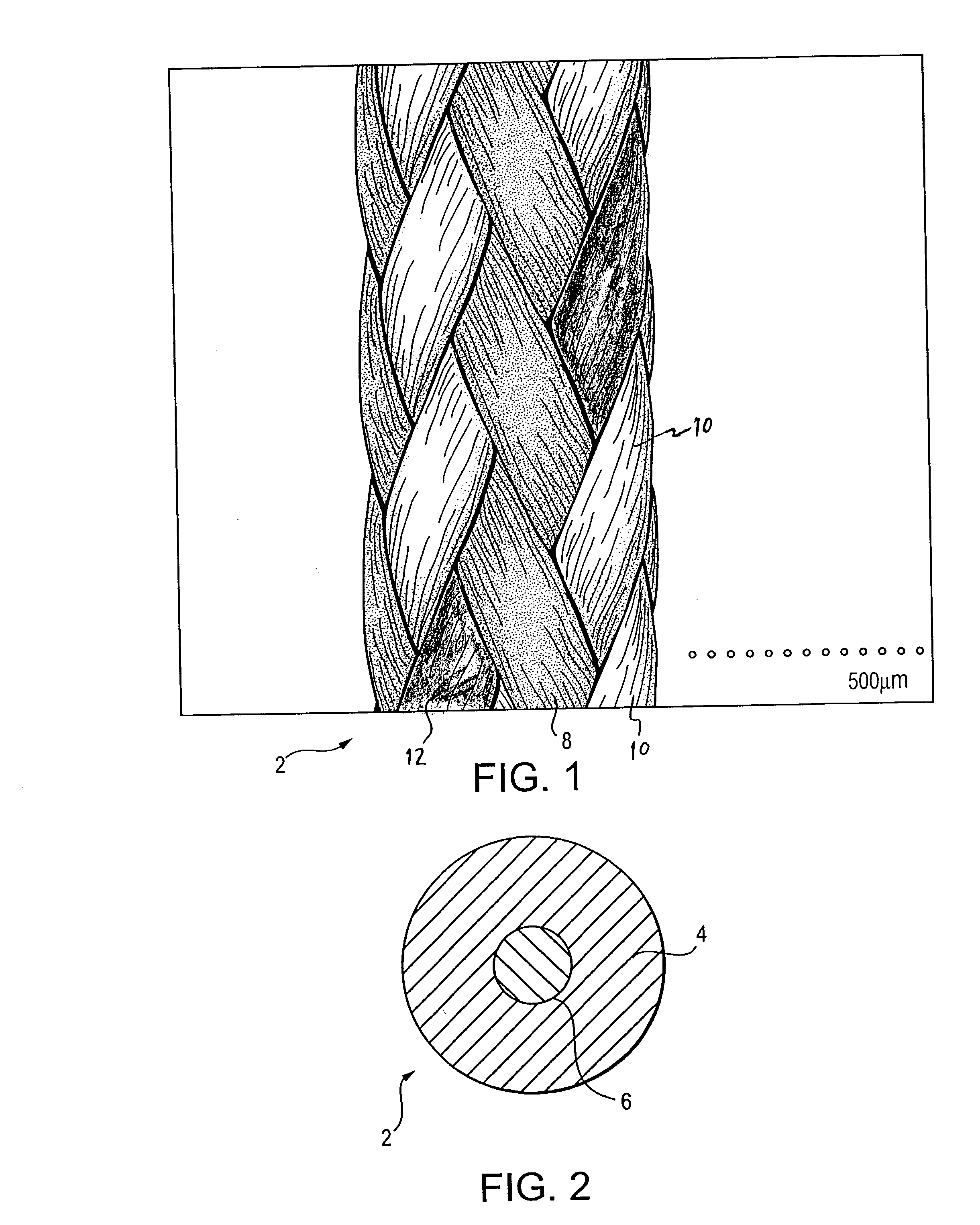

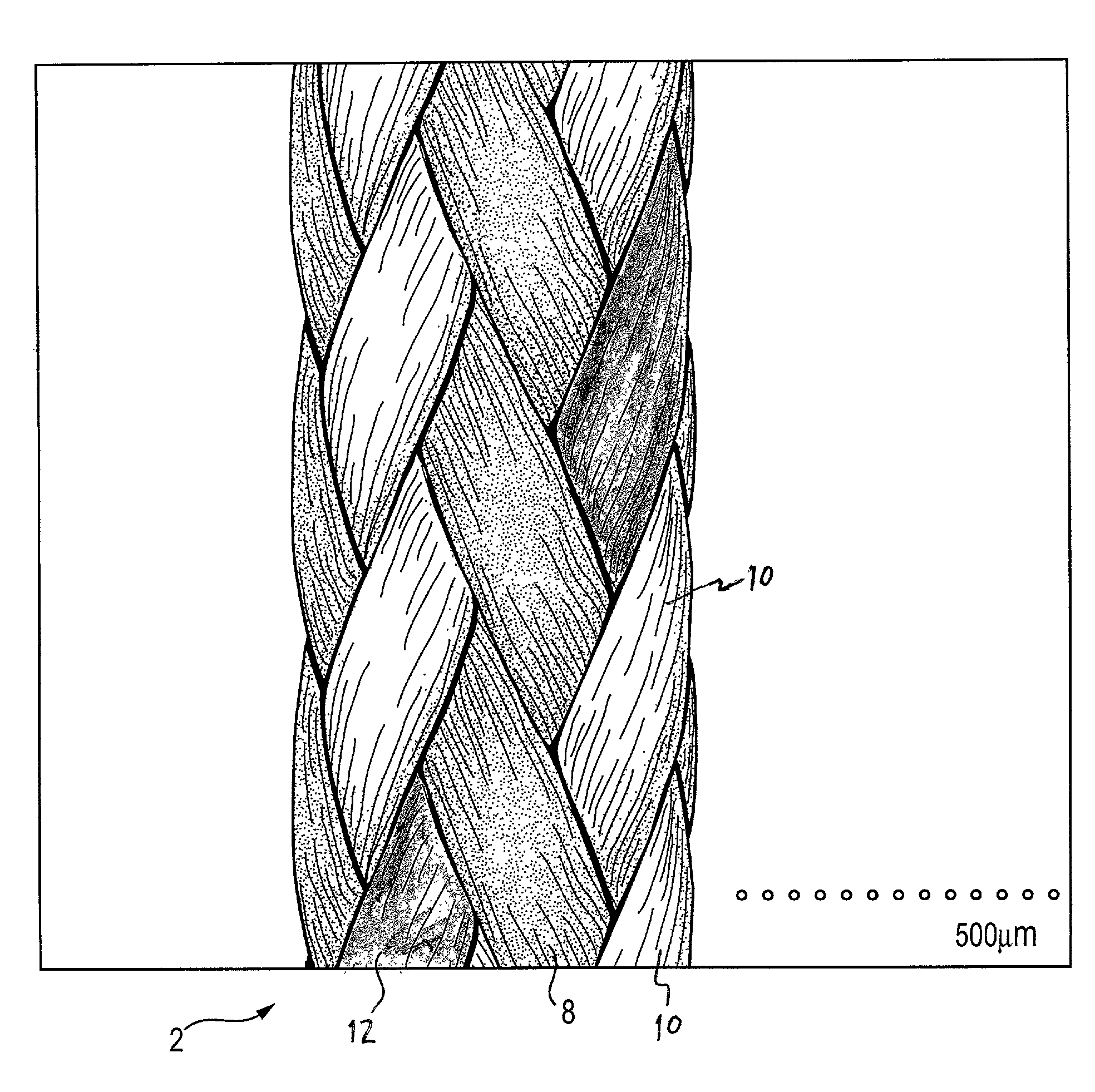

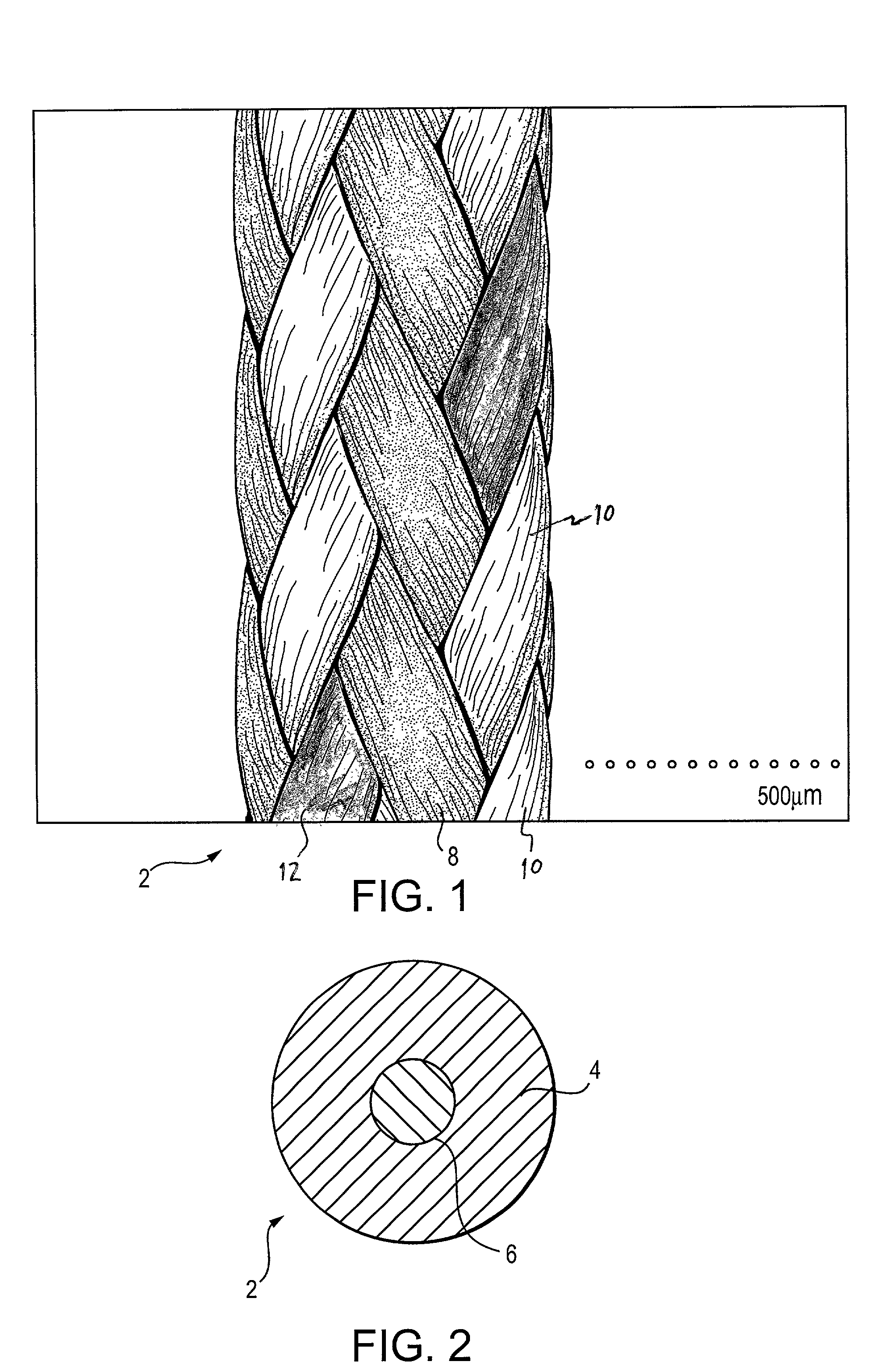

High strength suture with colored trace at one end

InactiveUS6994719B2High strengthImproved tie down characteristicSuture equipmentsDiagnosticsPolyesterEngineering

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable trace preferably is provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily identified.

Owner:ARTHREX INC

Sheets formed from polyesters including isosorbide

InactiveUS6025061AImprove low temperature impact strengthIncrease the maximum use temperatureLayered productsAnimal housingPolyesterInherent viscosity

A sheet made of a polyester which includes monomer units of terephthaloyl moieties, ethylene glycol moieties and isosorbide moieties is described. The polyester has an inherent viscosity of at least about 0.35 dL / g when measured as a 1% (weight / volume) solution of said polyester in o-chlorophenol at a temperature of 25 DEG C. The present invention also relates to a method of making the polyester sheet described above and a method of thermoforming the sheet into articles.

Owner:EI DU PONT DE NEMOURS & CO

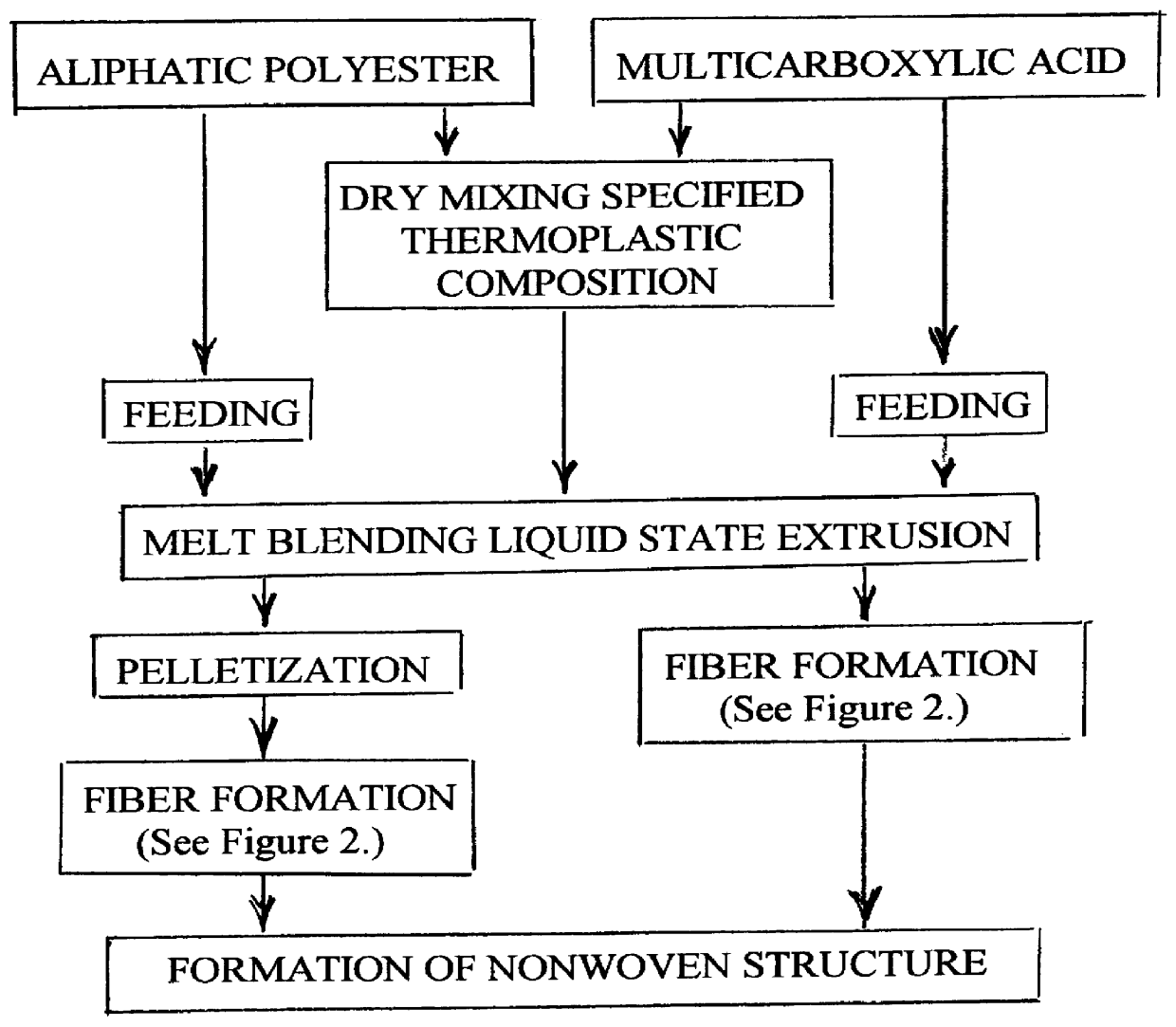

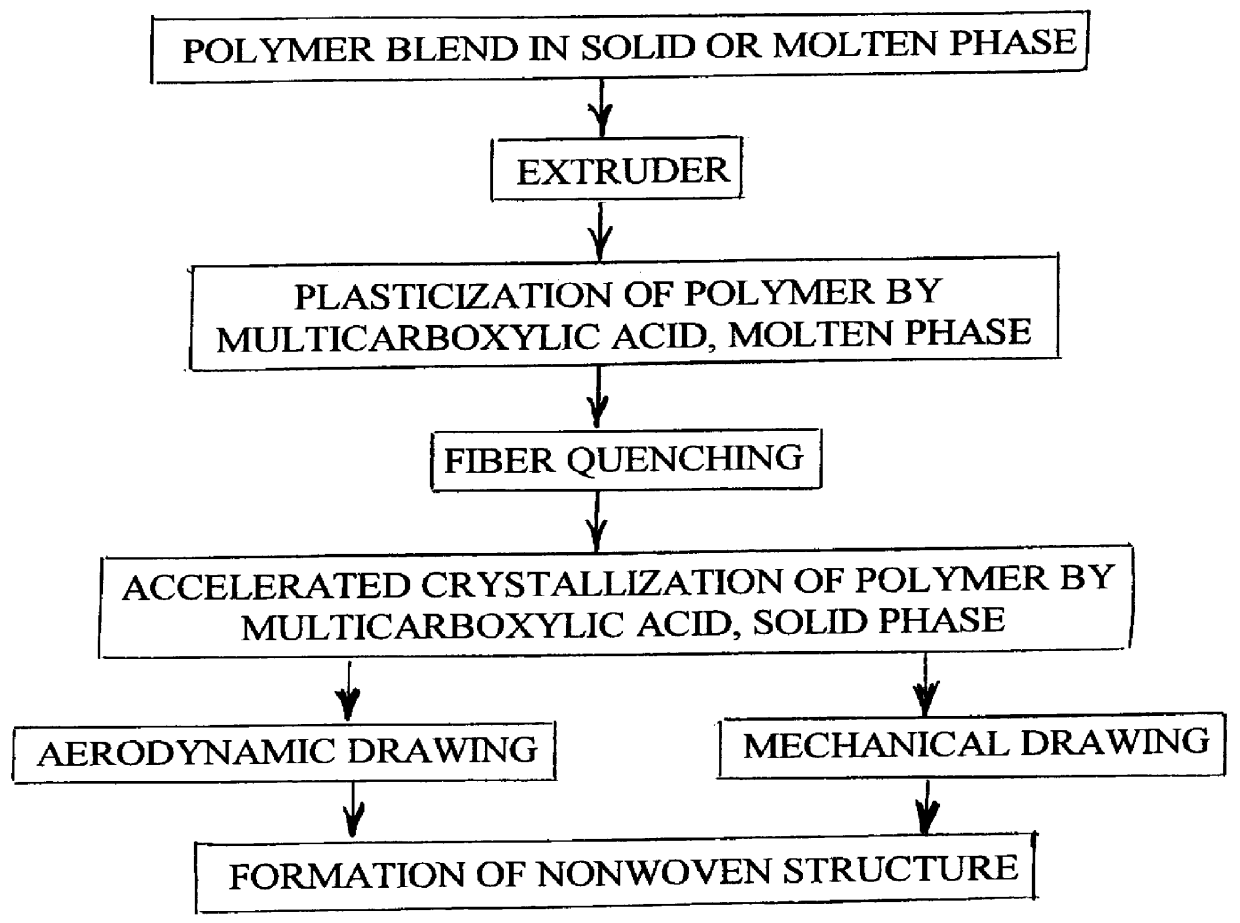

Synthetic fiber

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Pentane compatible polyester polyols

InactiveUS6359022B1Increase valueImprove flame retardant performanceOther chemical processesPolyesterDolichol

Disclosed are aromatic polyester polyols, polyol based resin blends, and rigid closed-cell polyisocyanate-based foams made using the polyol based resin blends. The resin blends generally comprise:(a) an aromatic polyester polyol reaction product formed by inter-esterification of a phthalic acid based material; a hydroxylated material having a functionality of at least 2; and a hydrophobic material; and(b) a C4-C7 hydrocarbon blowing agent. Also disclosed is a method for preparing rigid closed-cell polyisocyanate-based foams comprising reacting a polyisocyanate and a polyol based resin blend.

Owner:STEPAN COMPANY

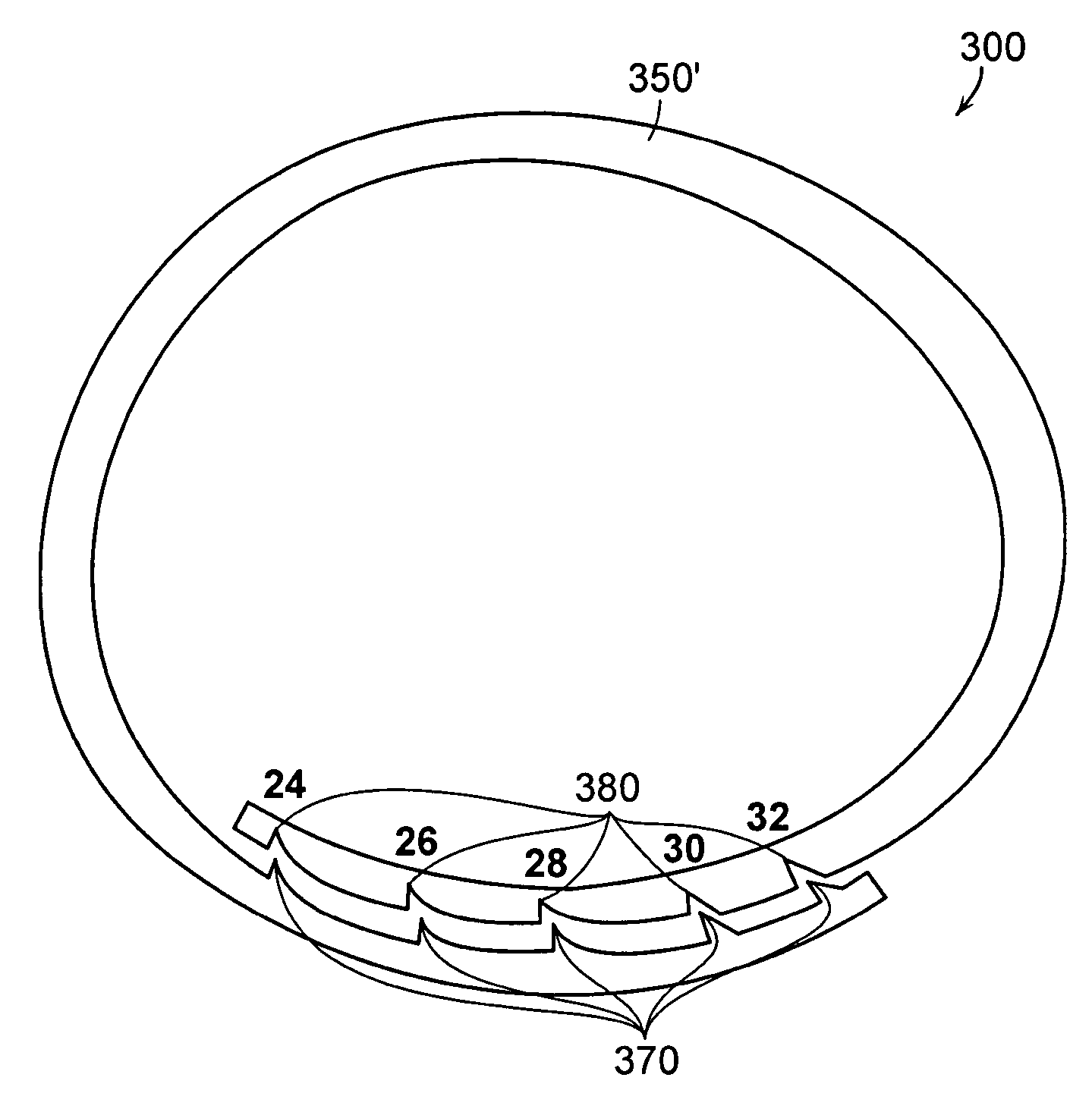

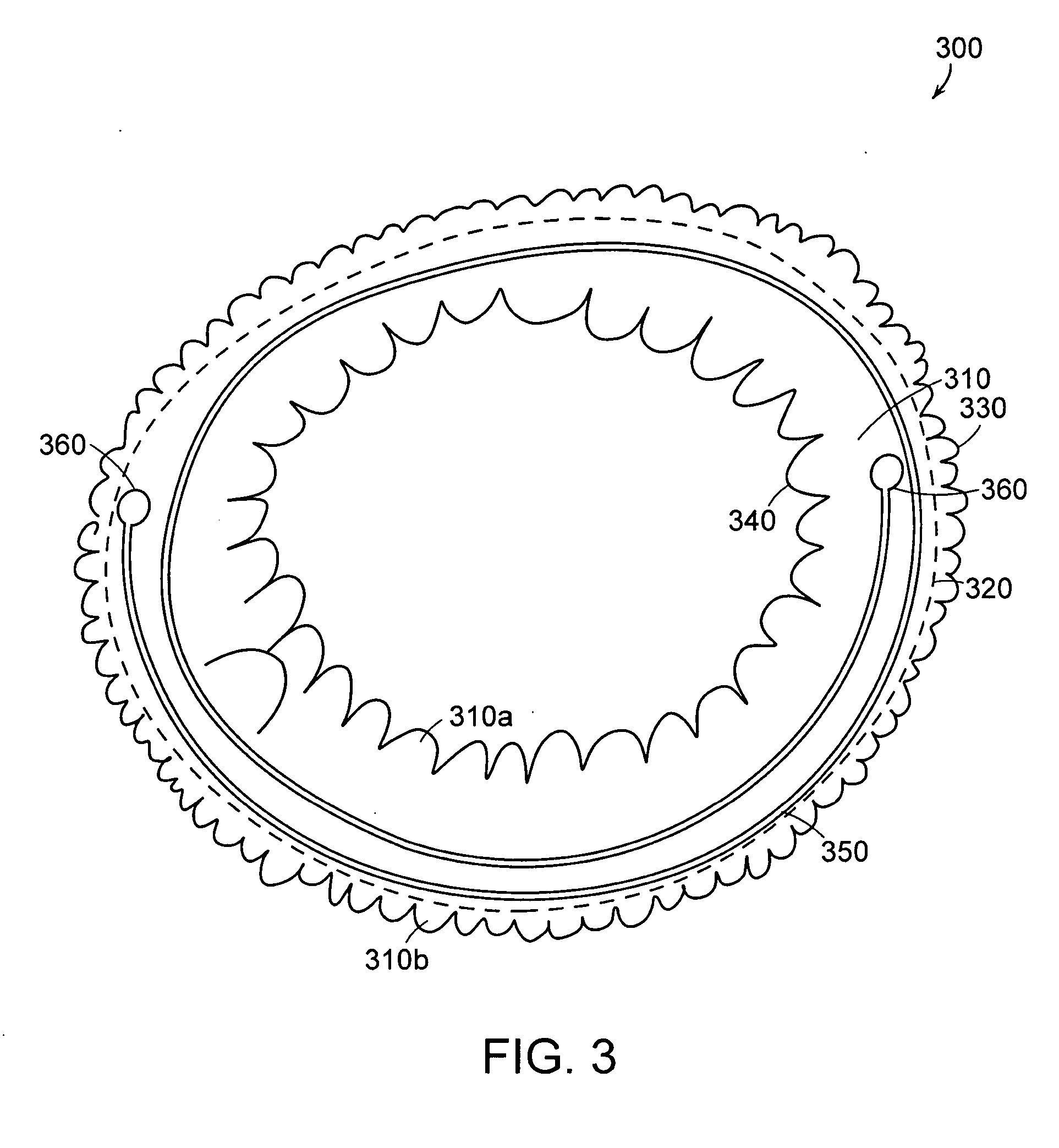

Mitral valve ring for treatment of mitral valve regurgitation

An active bodily ring having a housing adapted to be sutured to a bodily component and a loop disposed in the housing, the loop capable of actively expanding and compressing during the bodily components normal function. The housing defines a first chamber and a second chamber, the first chamber containing the loop and the second chamber providing a region capable of being sutured to the bodily component. In one embodiment, the housing can be a crimped-fabric housing. In another embodiment, the housing can be a woven-fabric housing having elastic properties. The housing can be made from polyester.

Owner:ALAMEDDINE ABDALLAH K

Compositions and methods for manufacturing thermoplastic starch blends

InactiveUS6235816B1Improved chemical and physical propertyPromote degradationFireproof paintsPaper coatingPolyesterPolymer science

A biologically degradable polymer mixture containing at least one biopolymer made from renewable raw materials and a polymer selected from the following materials: an aromatic polyester; a polyester-copolymer with both aliphatic and aromatic blocks; a polyesteramide; a polyglycol; a polyester urethane; and / or mixtures of these components. The preferred renewable raw material is starch, more preferably native starch, most preferably native starch that has been predried.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

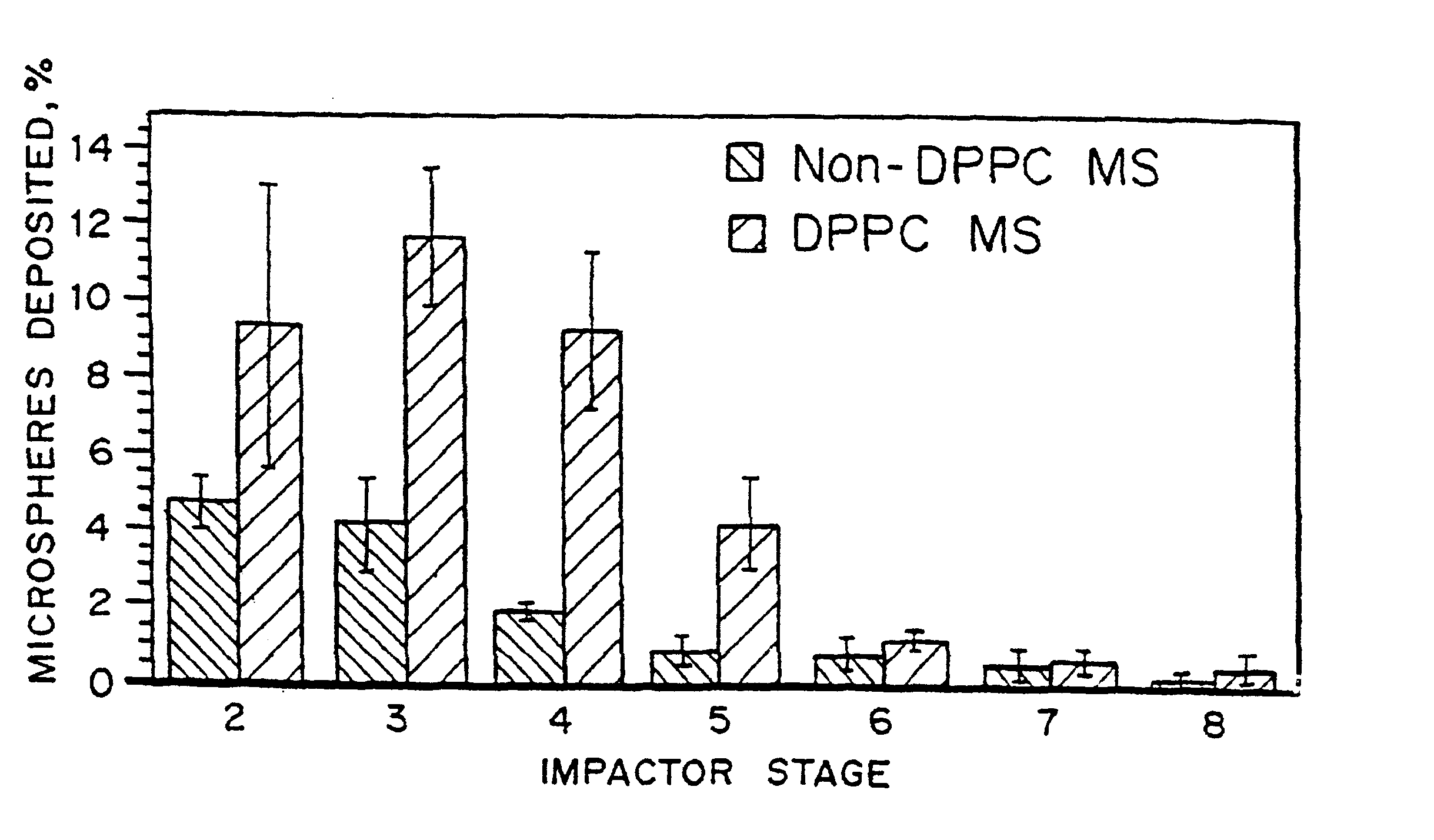

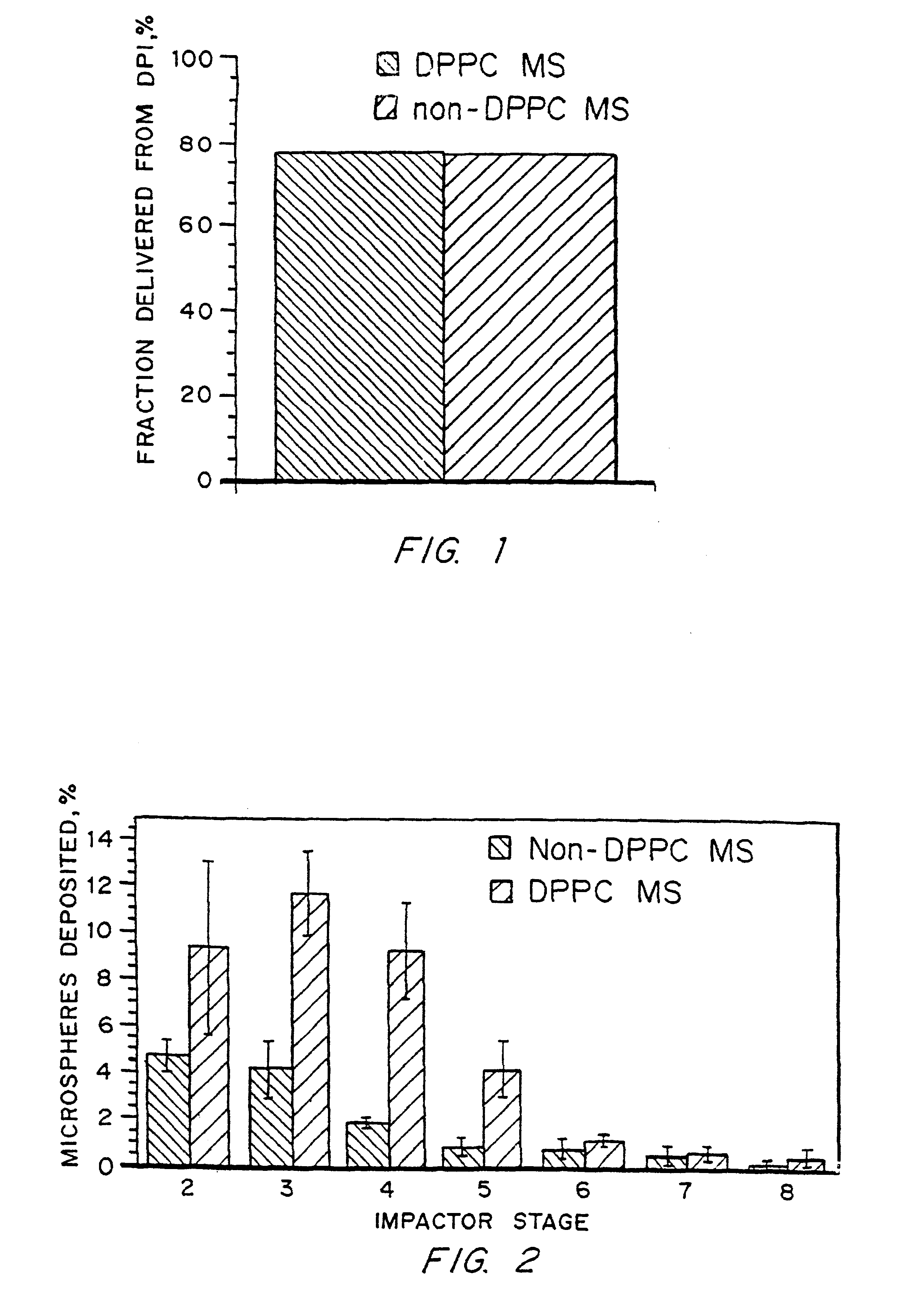

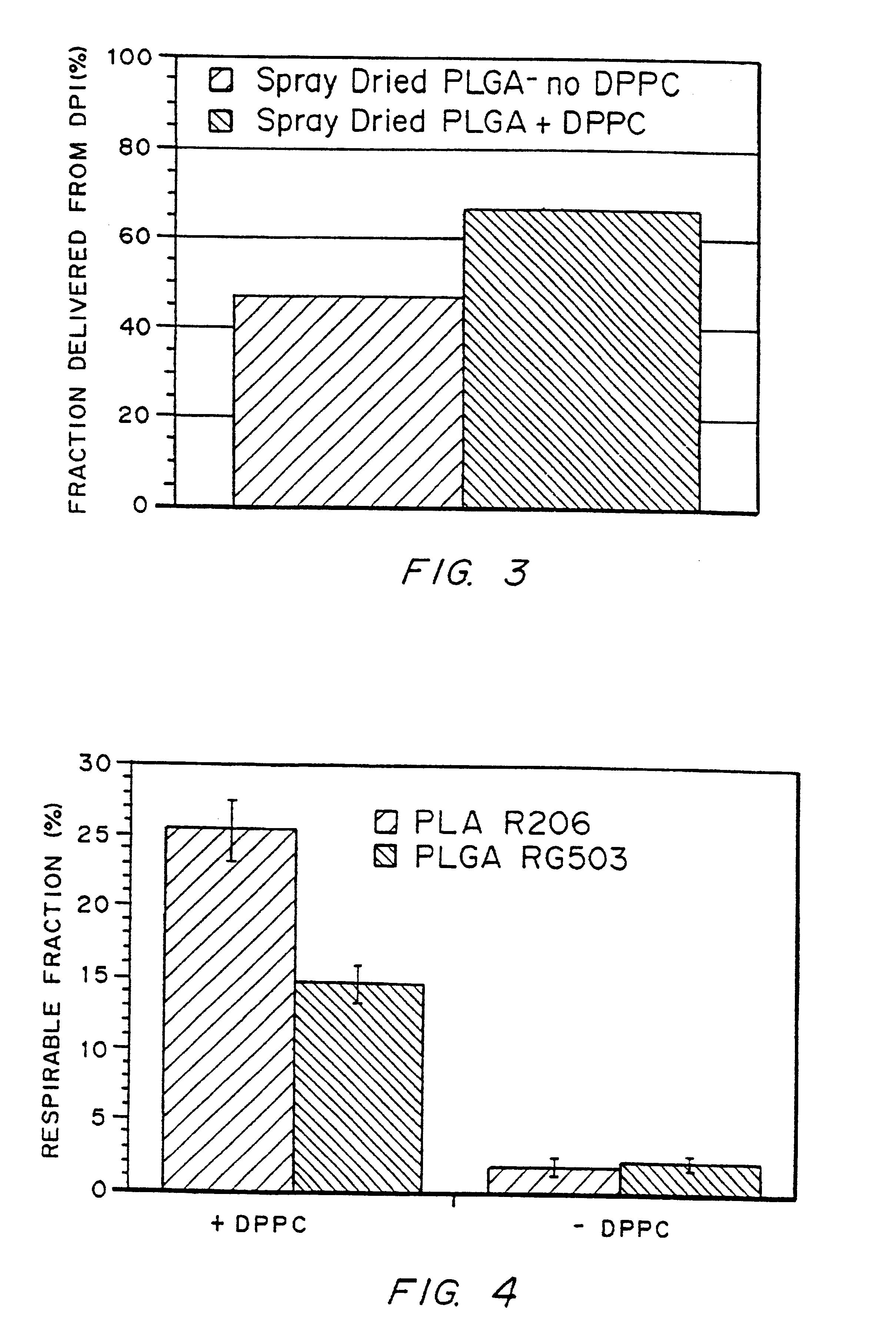

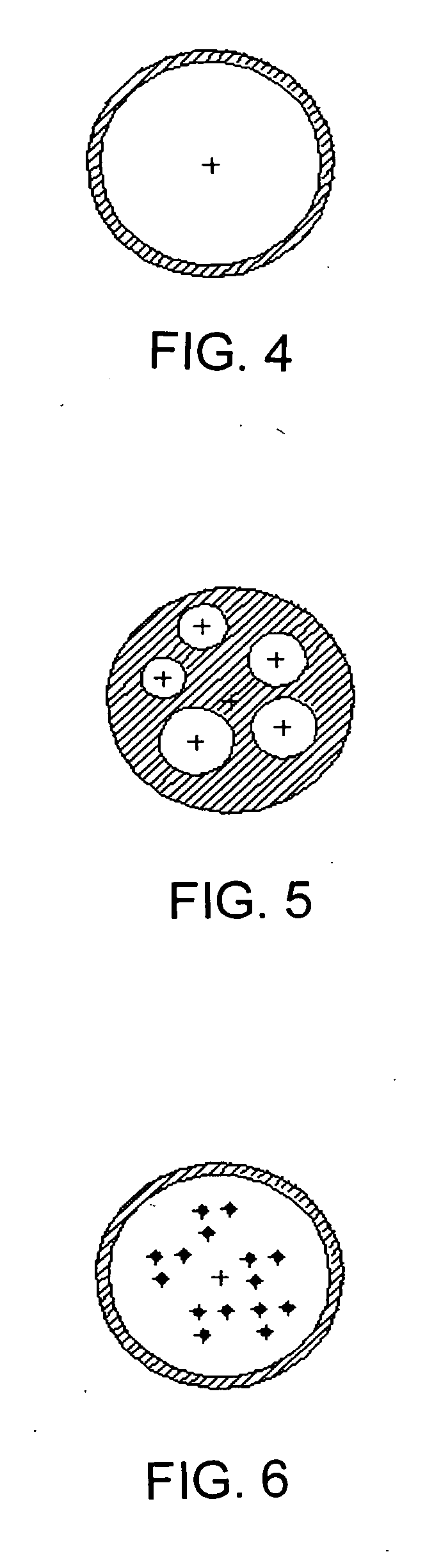

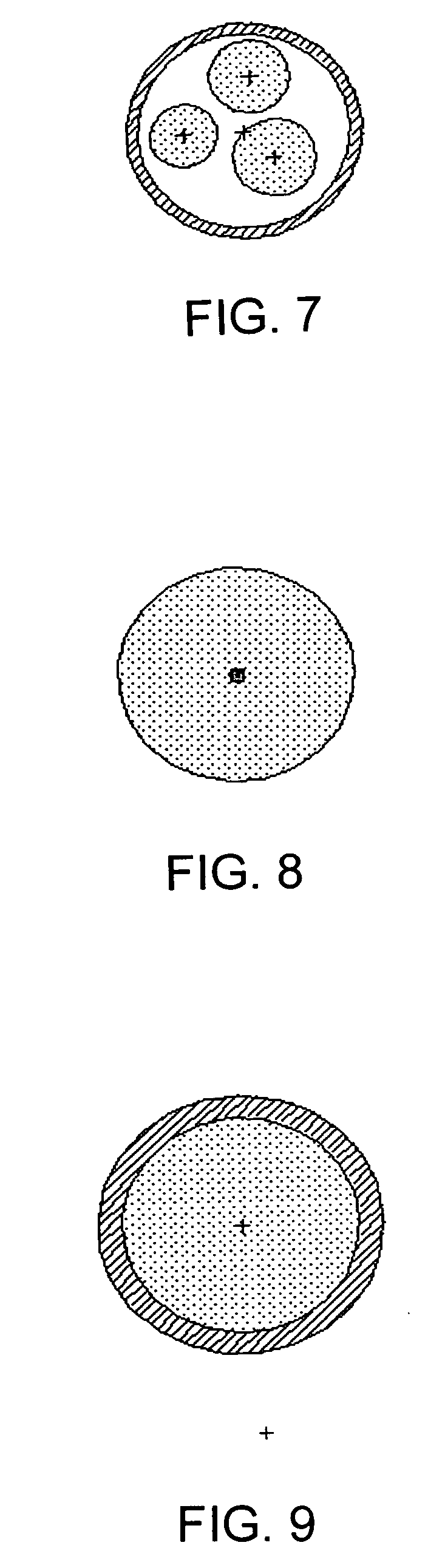

Particles incorporating surfactants for pulmonary drug delivery

Improved aerodynamically light particles for drug delivery to the pulmonary system, and methods for their synthesis and administration are provided. In a preferred embodiment, the aerodynamically light particles are made of a biodegradable material and have a tap density less than 0.4 g / cm3 and a mass mean diameter between 5 mum and 30 mum. The particles may be formed of biodegradable materials such as biodegradable polymers. For example, the particles may be formed of a functionalized polyester graft copolymer consisting of a linear alpha-hydroxy-acid polyester backbone having at least one amino acid group incorporated therein and at least one poly(amino acid) side chain extending from an amino acid group in the polyester backbone. In one embodiment, aerodynamically light particles having a large mean diameter, for example greater than 5 mum, can be used for enhanced delivery of a therapeutic agent to the alveolar region of the lung. The aerodynamically light particles incorporating a therapeutic agent may be effectively aerosolized for administration to the respiratory tract to permit systemic or local delivery of wide variety of therapeutic agents.

Owner:MASSACHUSETTS INST OF TECH

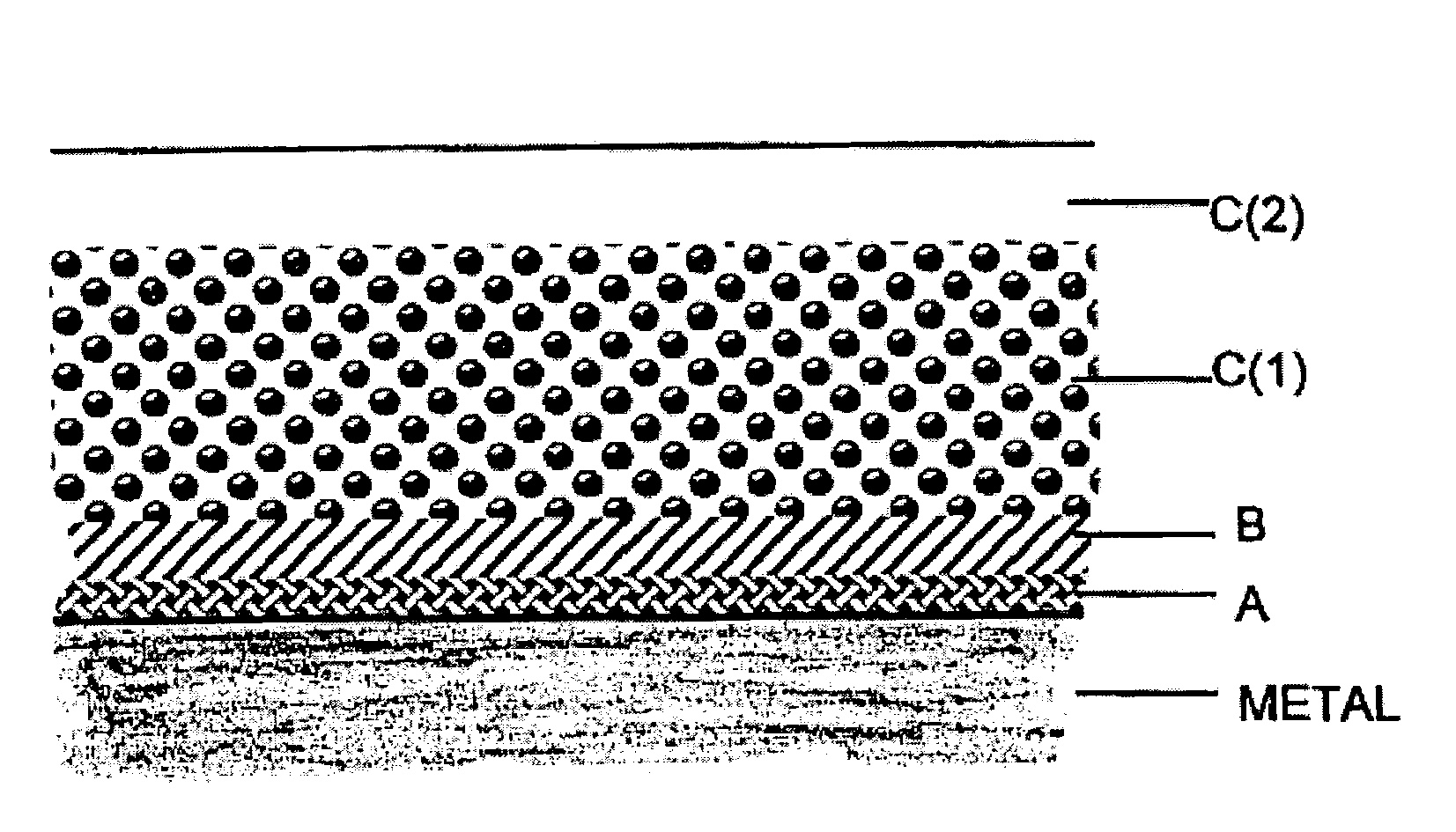

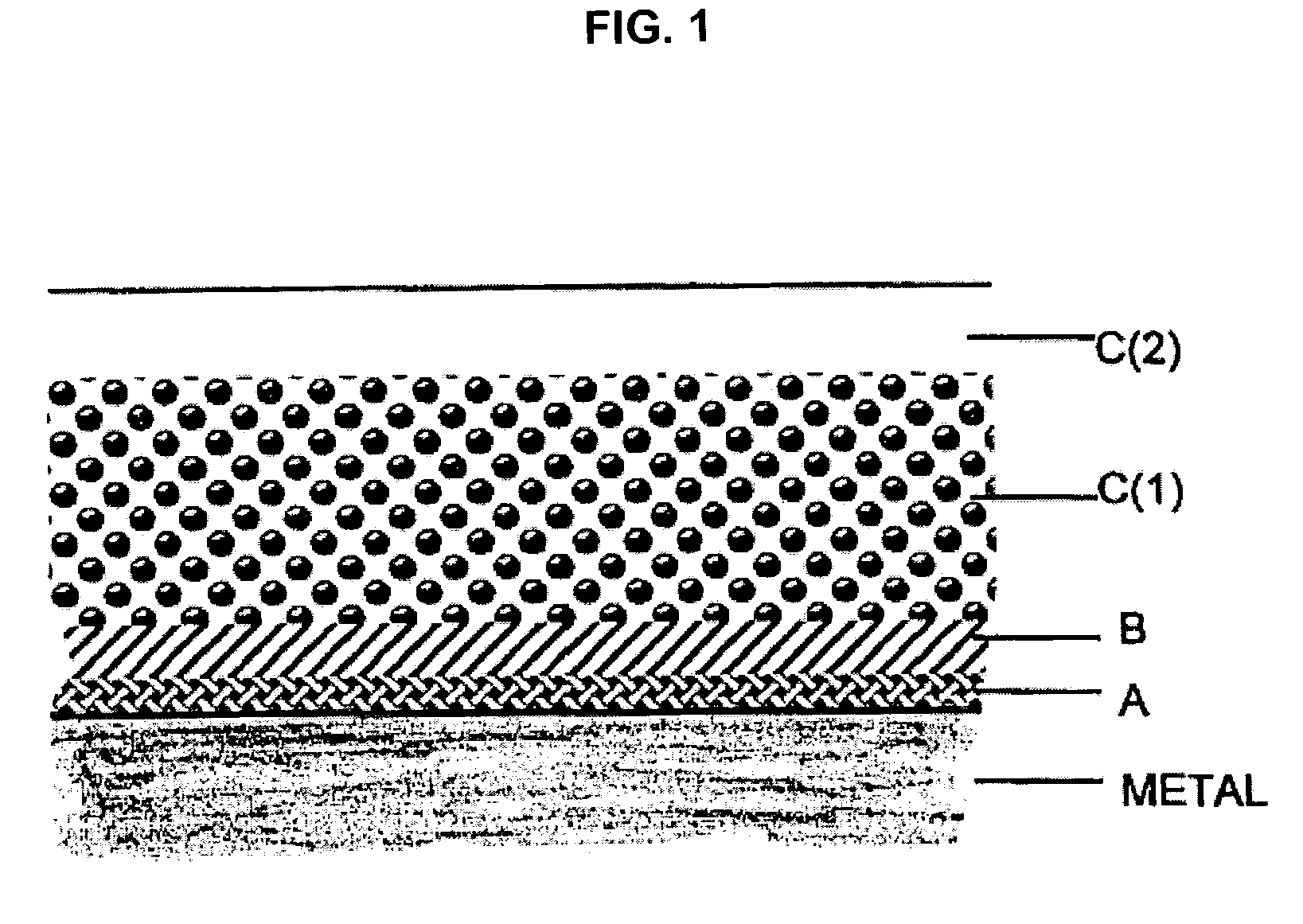

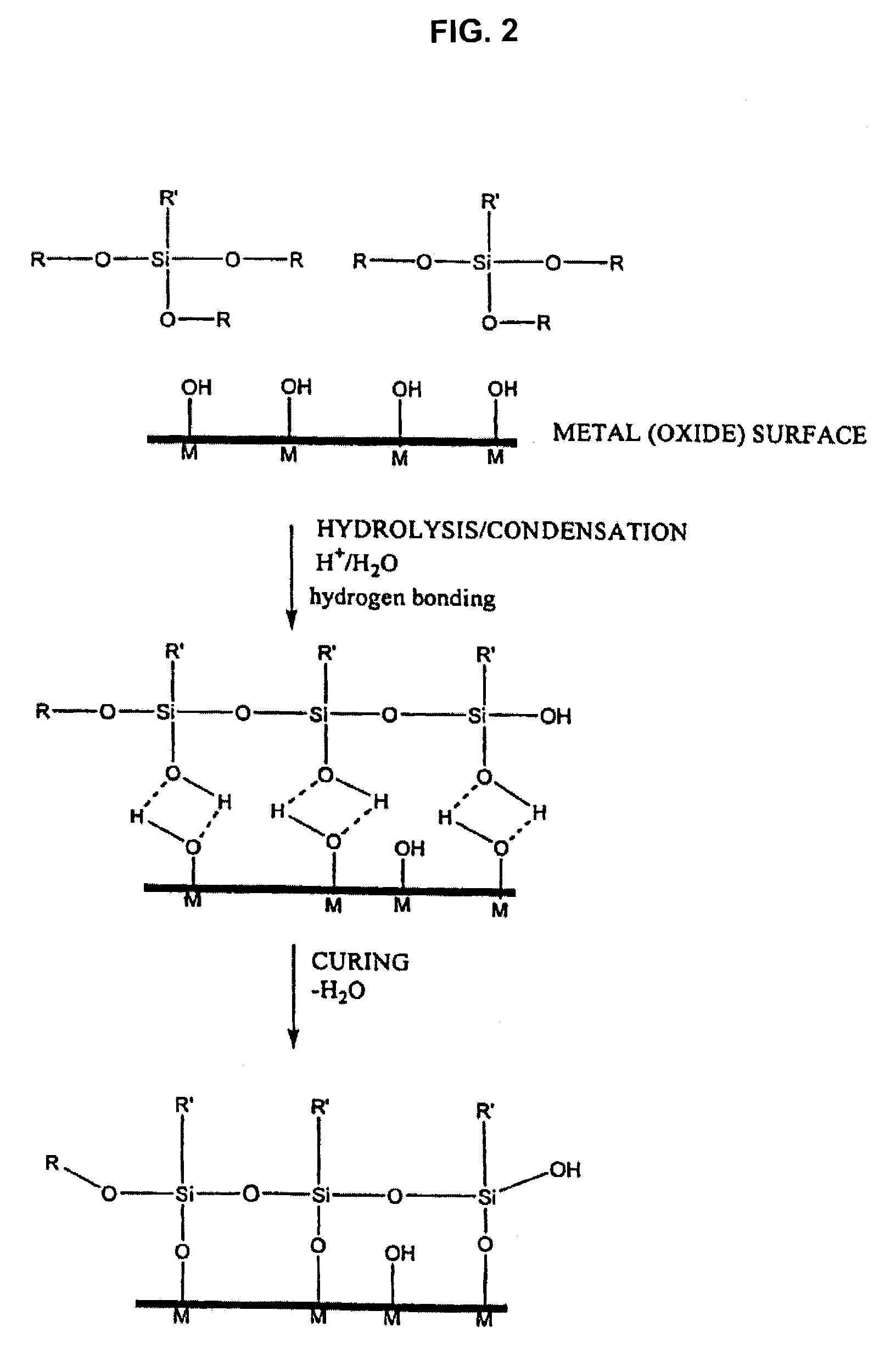

Polymer coating for medical devices

Coatings are provided in which surfaces may be activated by covalently bonding a silane derivative to the metal surface, covalently bonding a lactone polymer to the silane derivative by in situ ring opening polymerization, and depositing at least one layer of a polyester on the bonded lactone. Biologically active agents may be deposited with the polyester layers. Such coated surfaces may be useful in medical devices, in particular stents.

Owner:CV THERAPEUTICS INC

Mechanical apparatus and method for artificial disc replacement

InactiveUS7442210B2Easy to integrateFree from painSuture equipmentsBone implantPolyesterPolypropylene

Owner:OUROBOROS MEDICAL INC

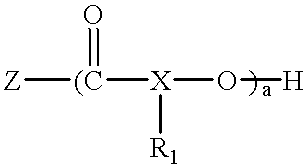

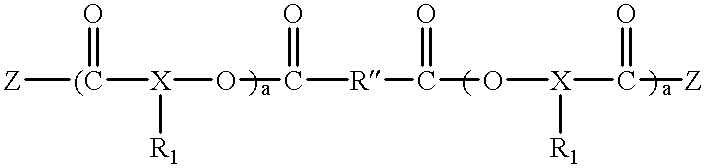

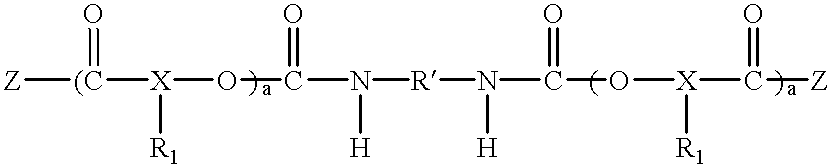

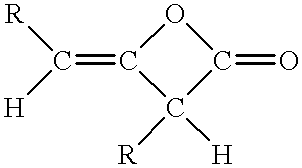

Design of poly(ester amides) for the control of agent-release from polymeric compositions

The present invention generally encompasses a medical article, such as a medical device or coating comprising an agent or combination of agents, wherein the agent is distributed throughout a polymeric matrix. The polymeric matrix comprises an agent and a poly(ester amide) having a design that was preselected to provide a predetermined release rate of the combination of agents from the medical article.

Owner:ABBOTT CARDIOVASCULAR

High strength suture with collagen fibers

InactiveUS20050033362A1High strengthGood tissue compatibilitySuture equipmentsSurgical needlesPolyesterTissue remodeling

Owner:ARTHREX

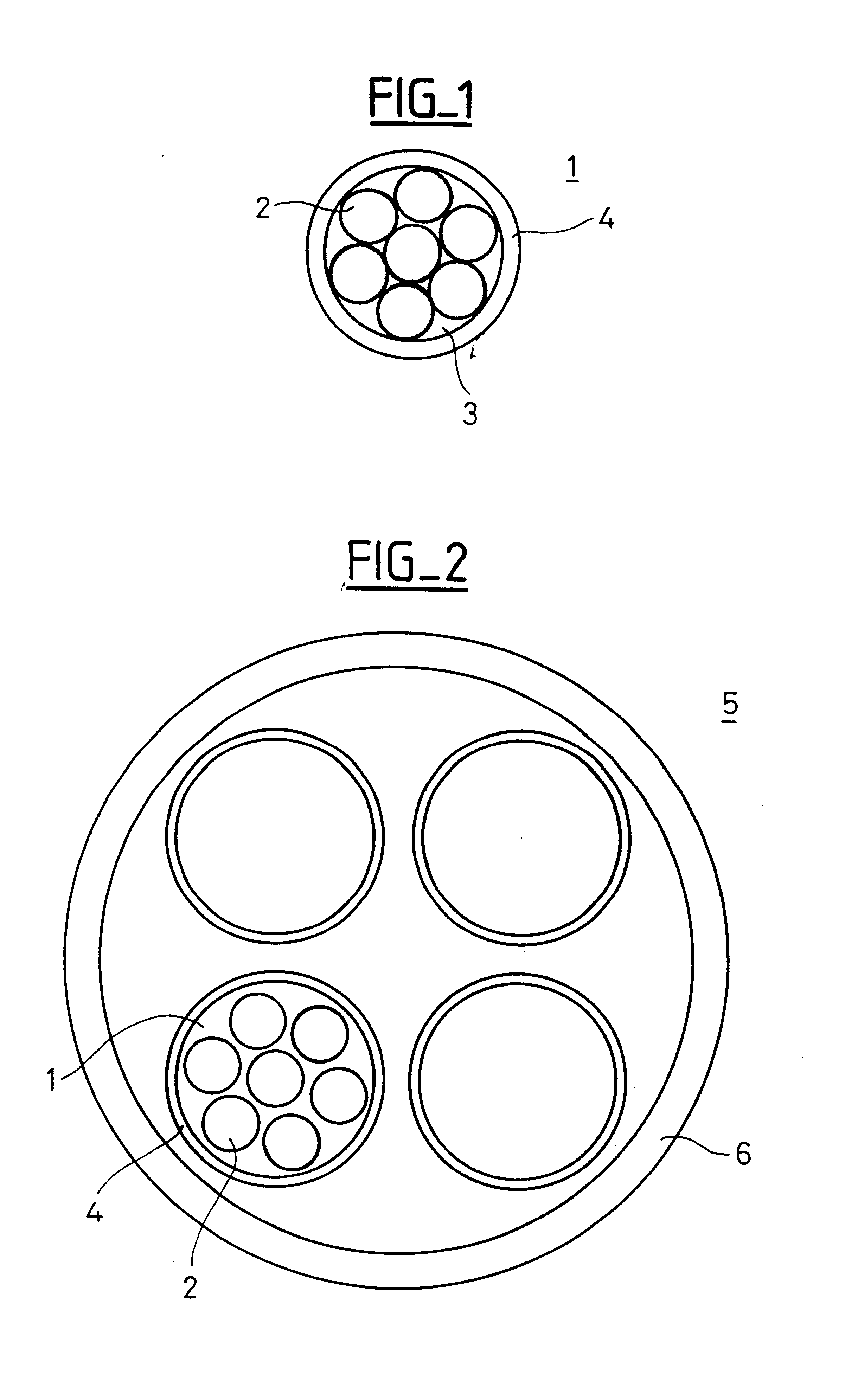

Protective skin for optical fibers

Owner:ALCATEL LUCENT SAS

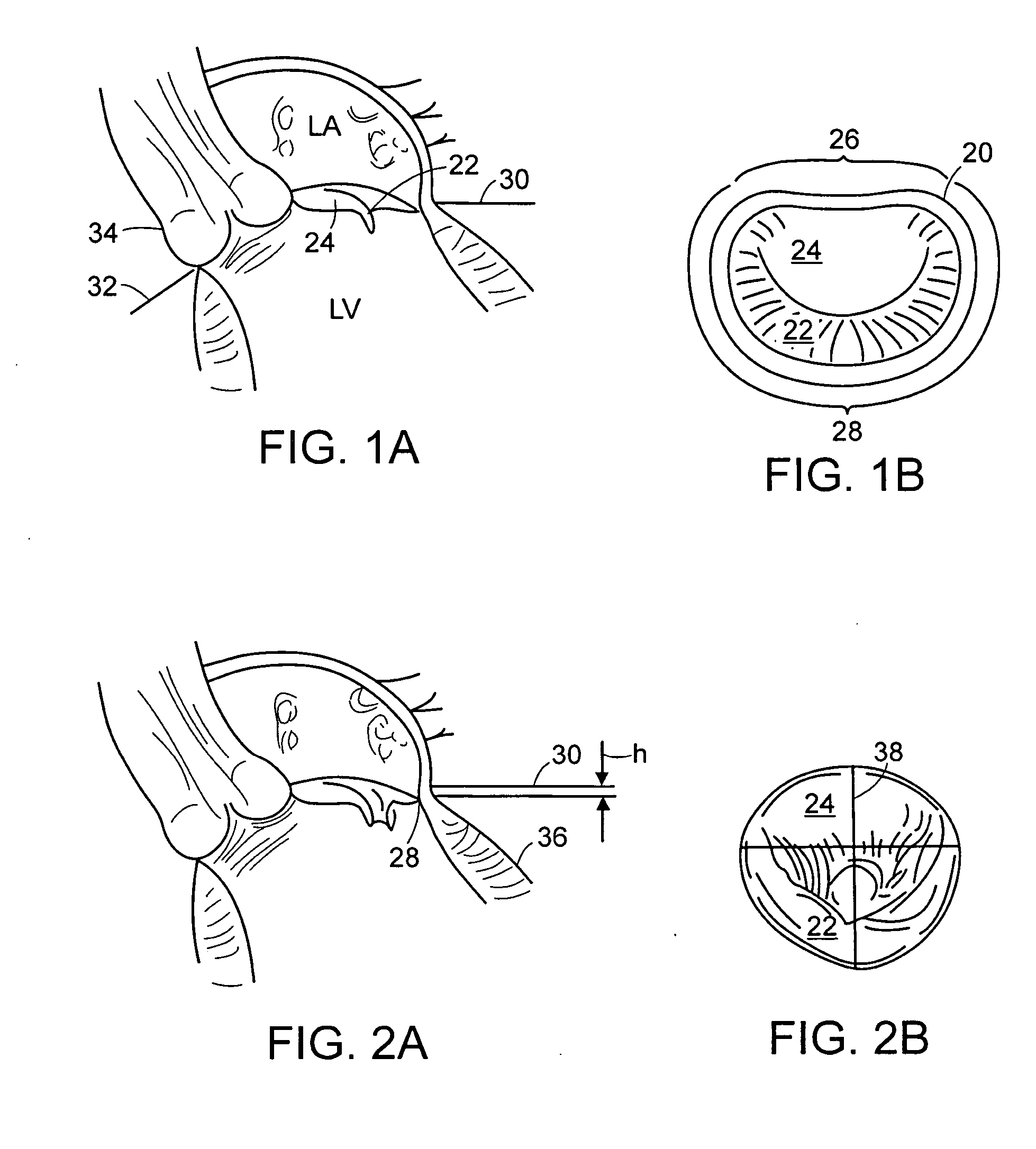

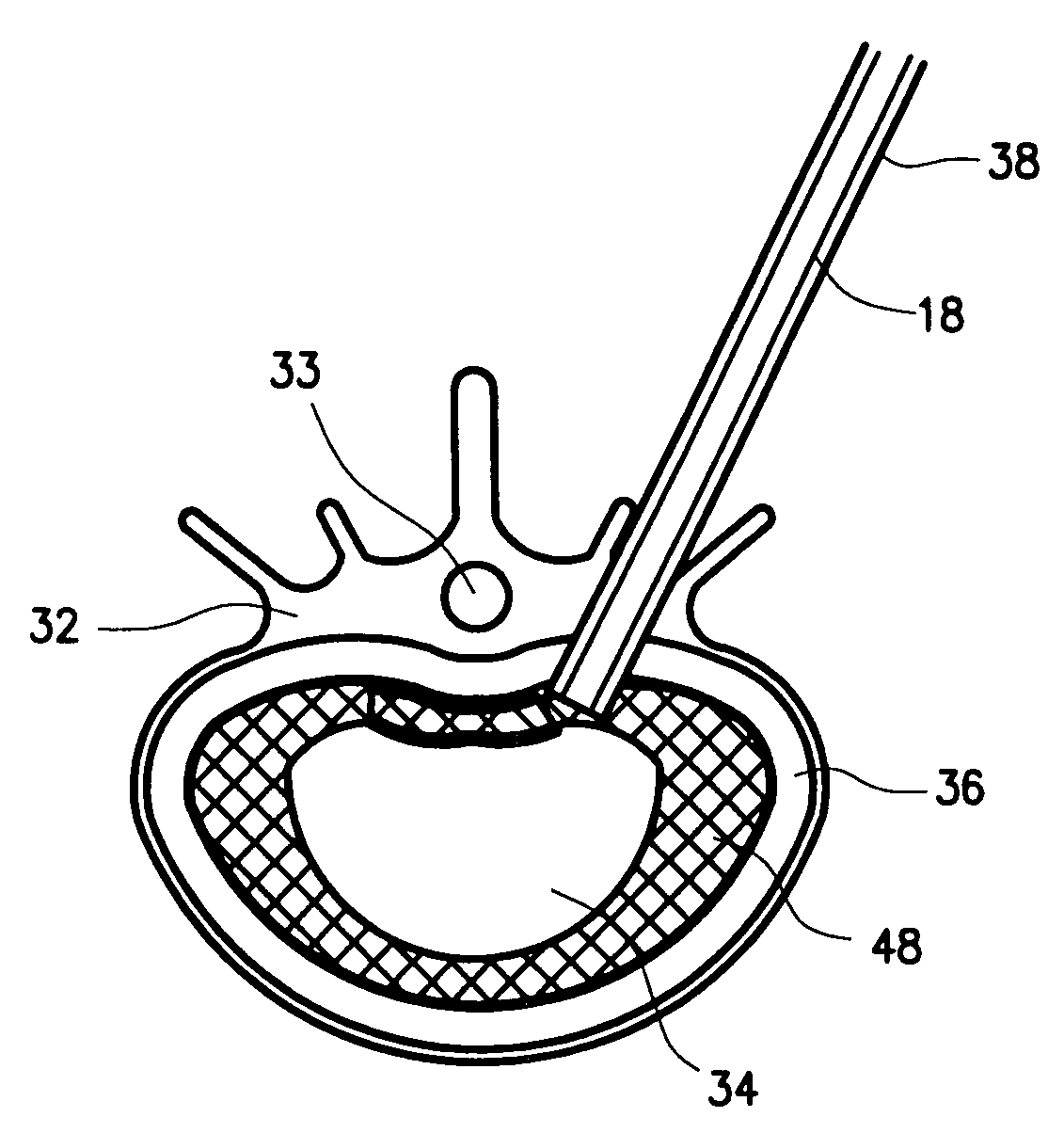

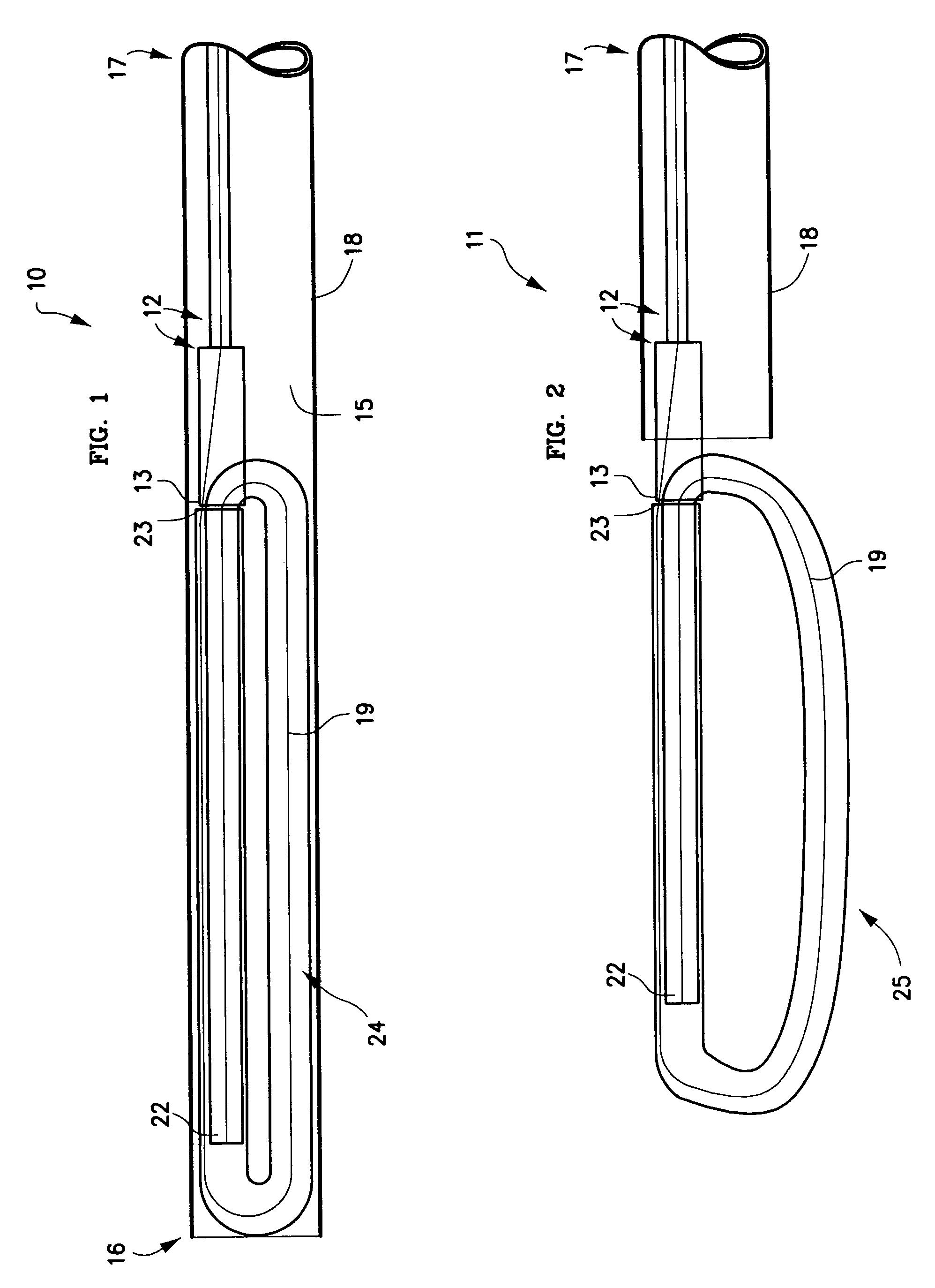

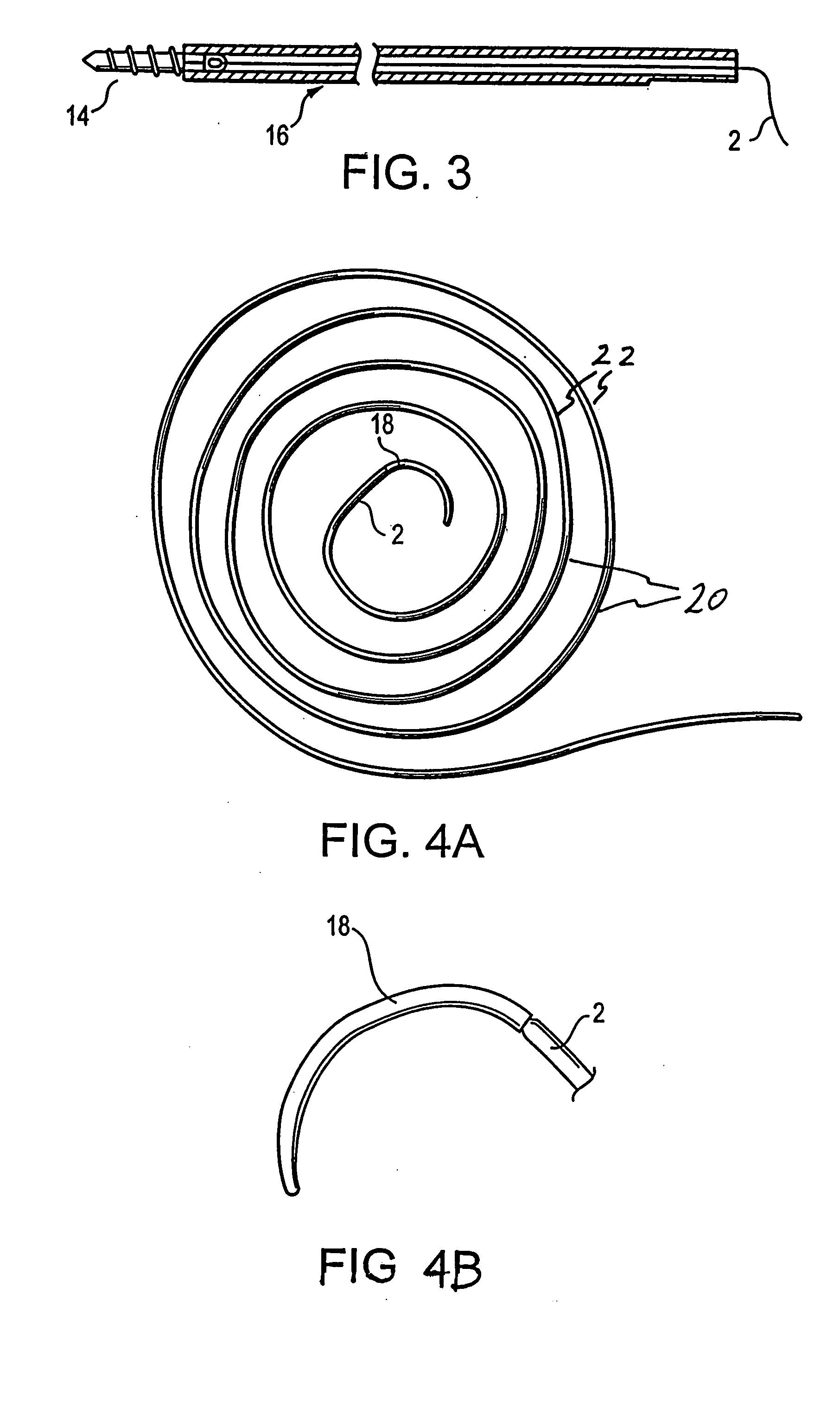

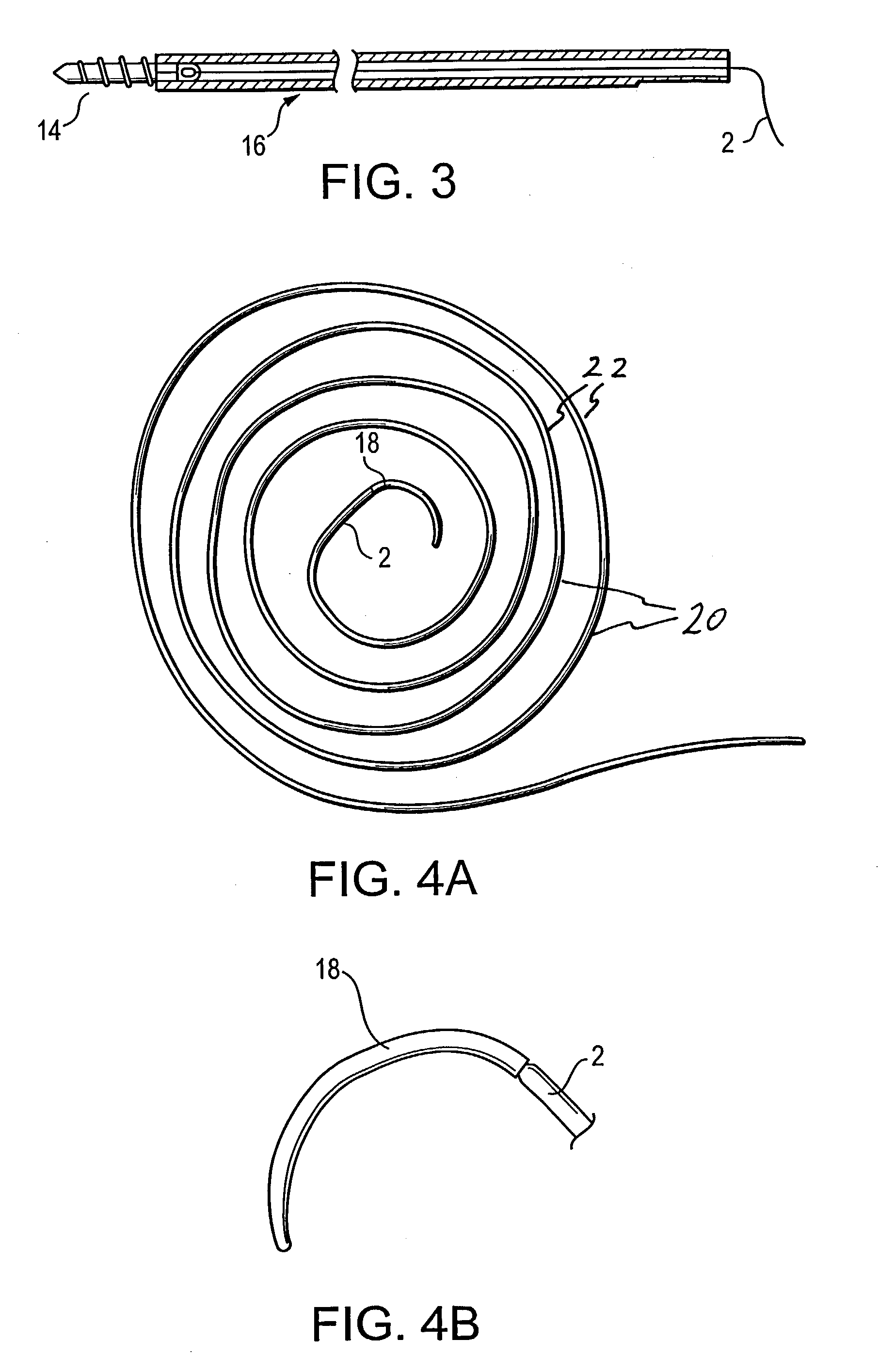

Mechanical apparatus and method for artificial disc replacement

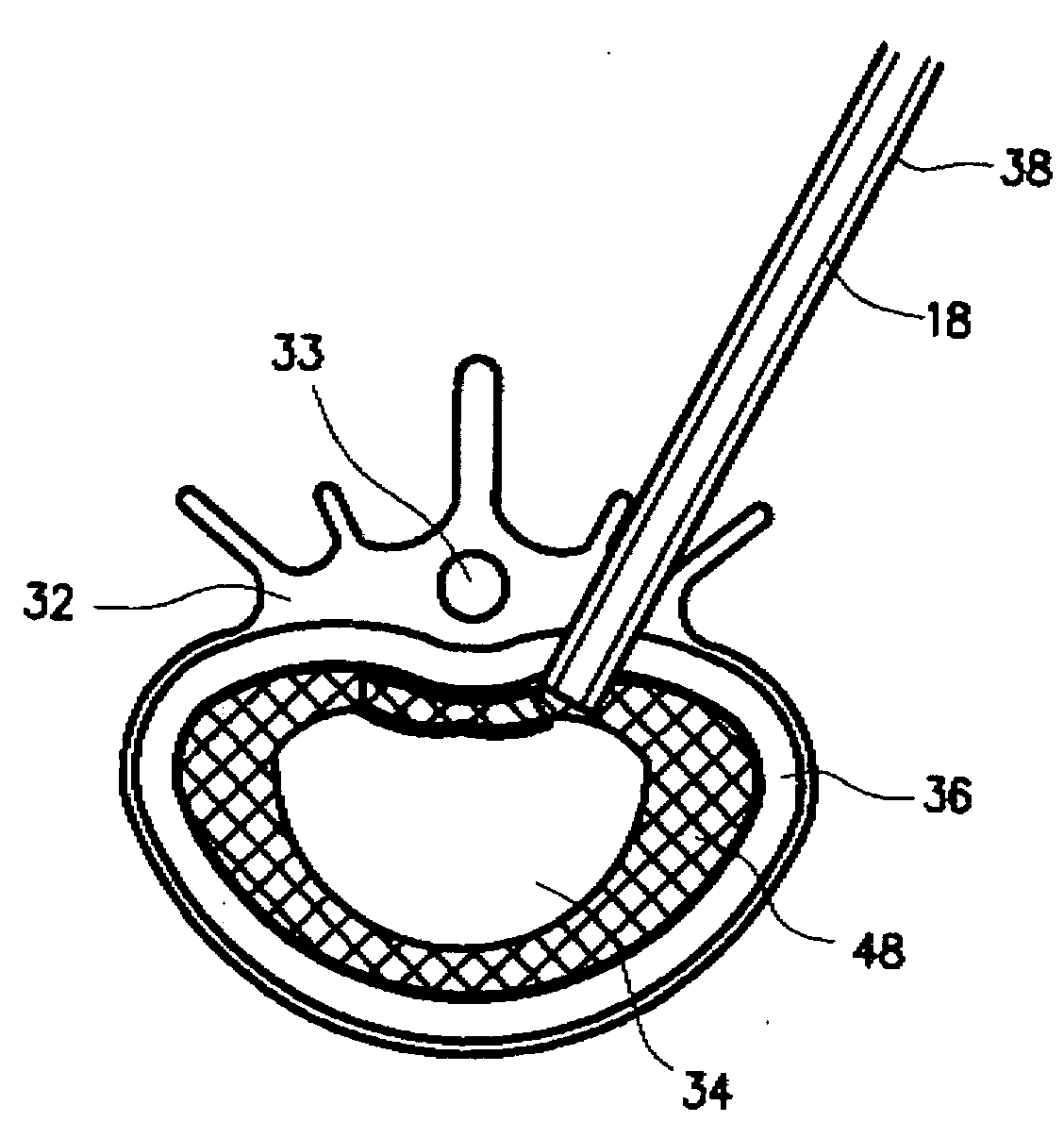

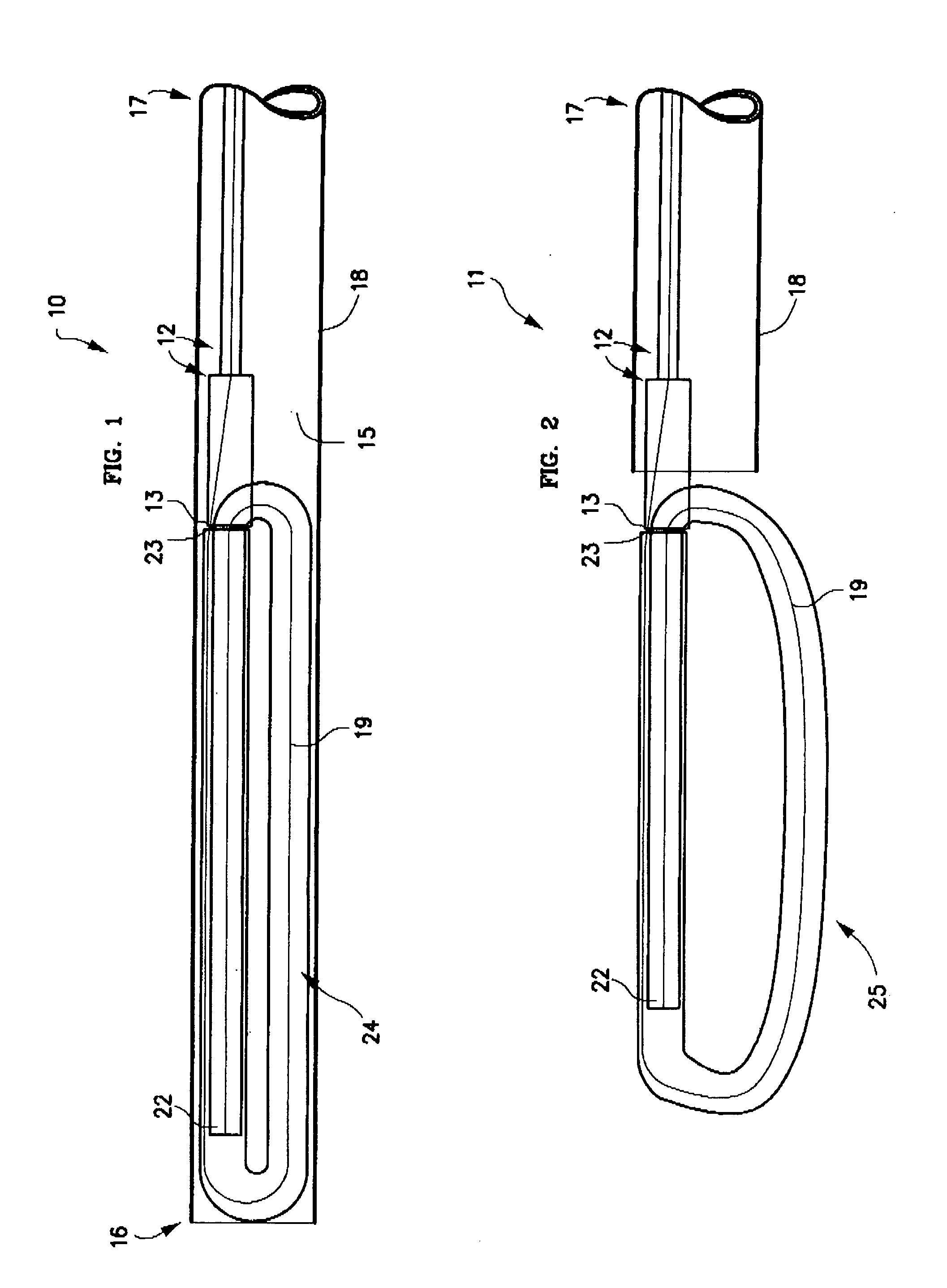

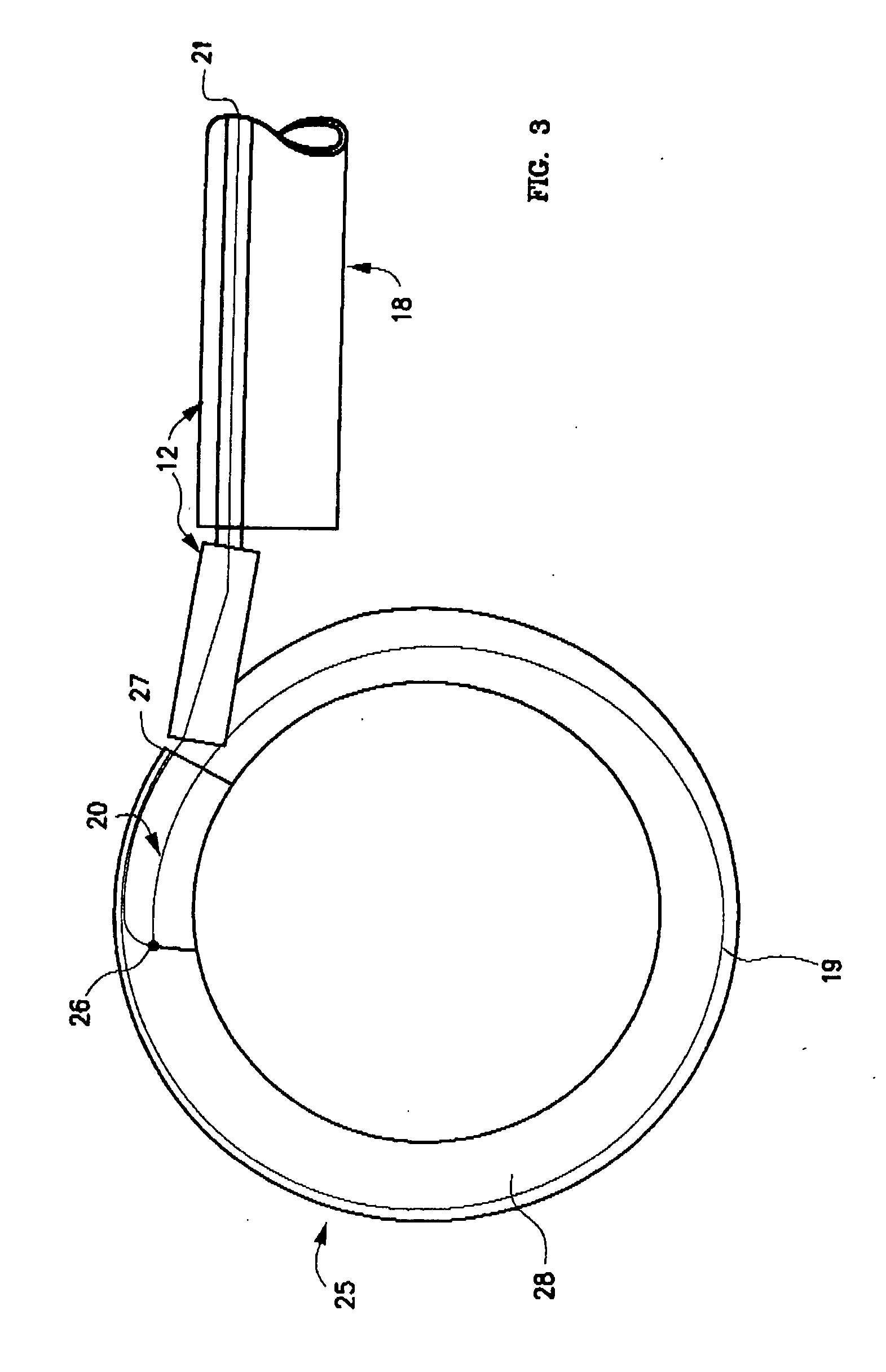

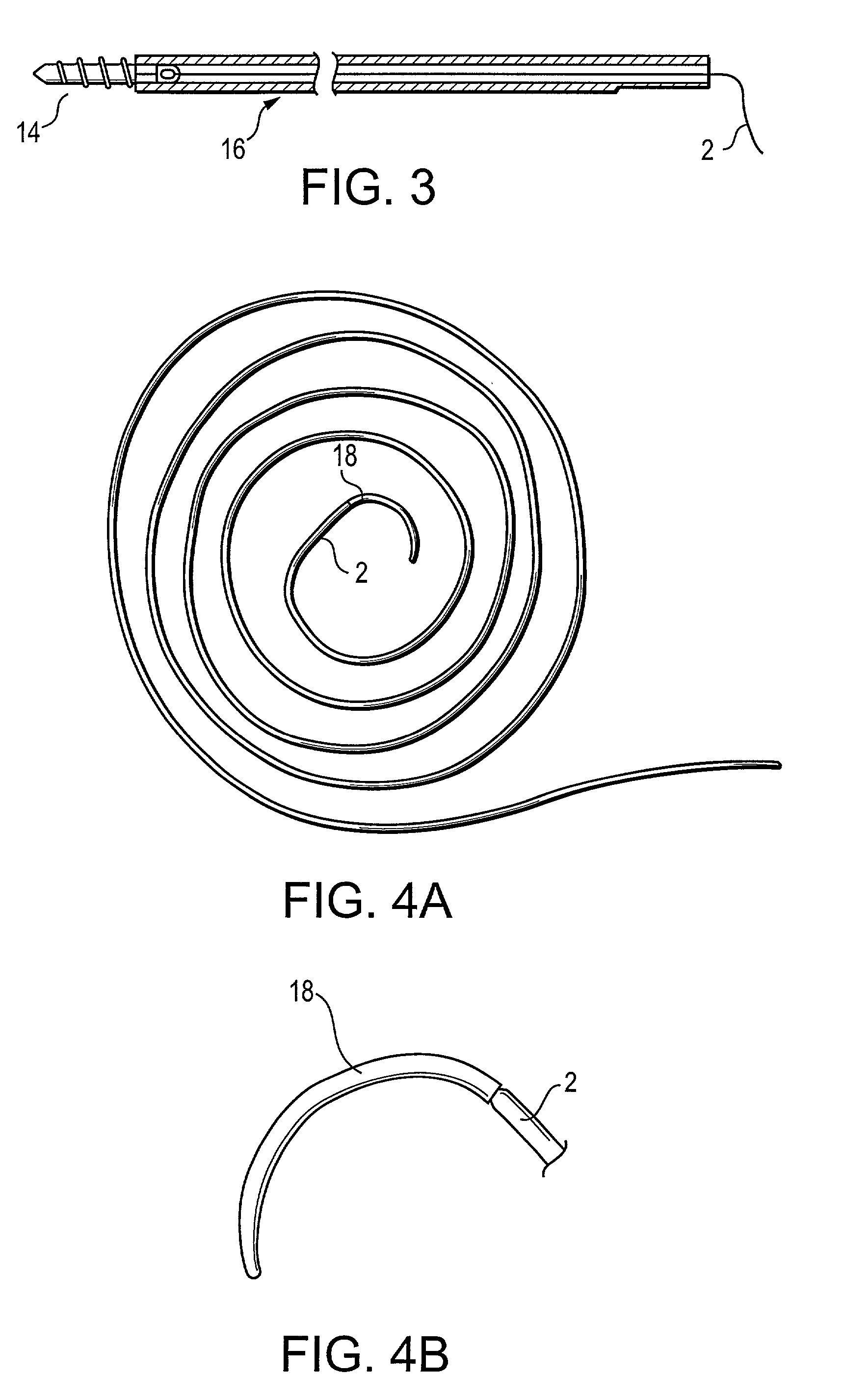

InactiveUS20060287726A1Easy to integrateFree from painSuture equipmentsInternal osteosythesisPolyesterClosed loop

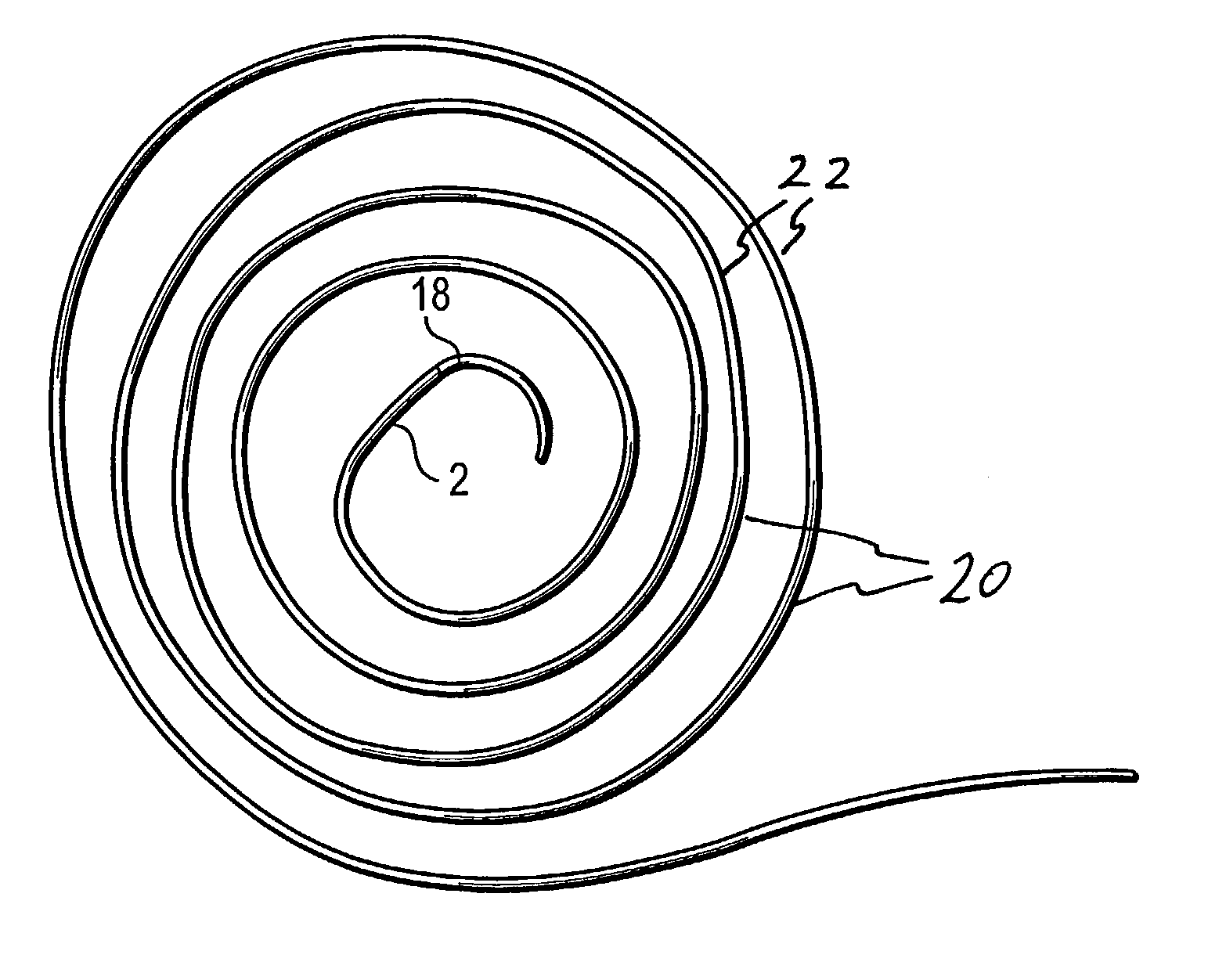

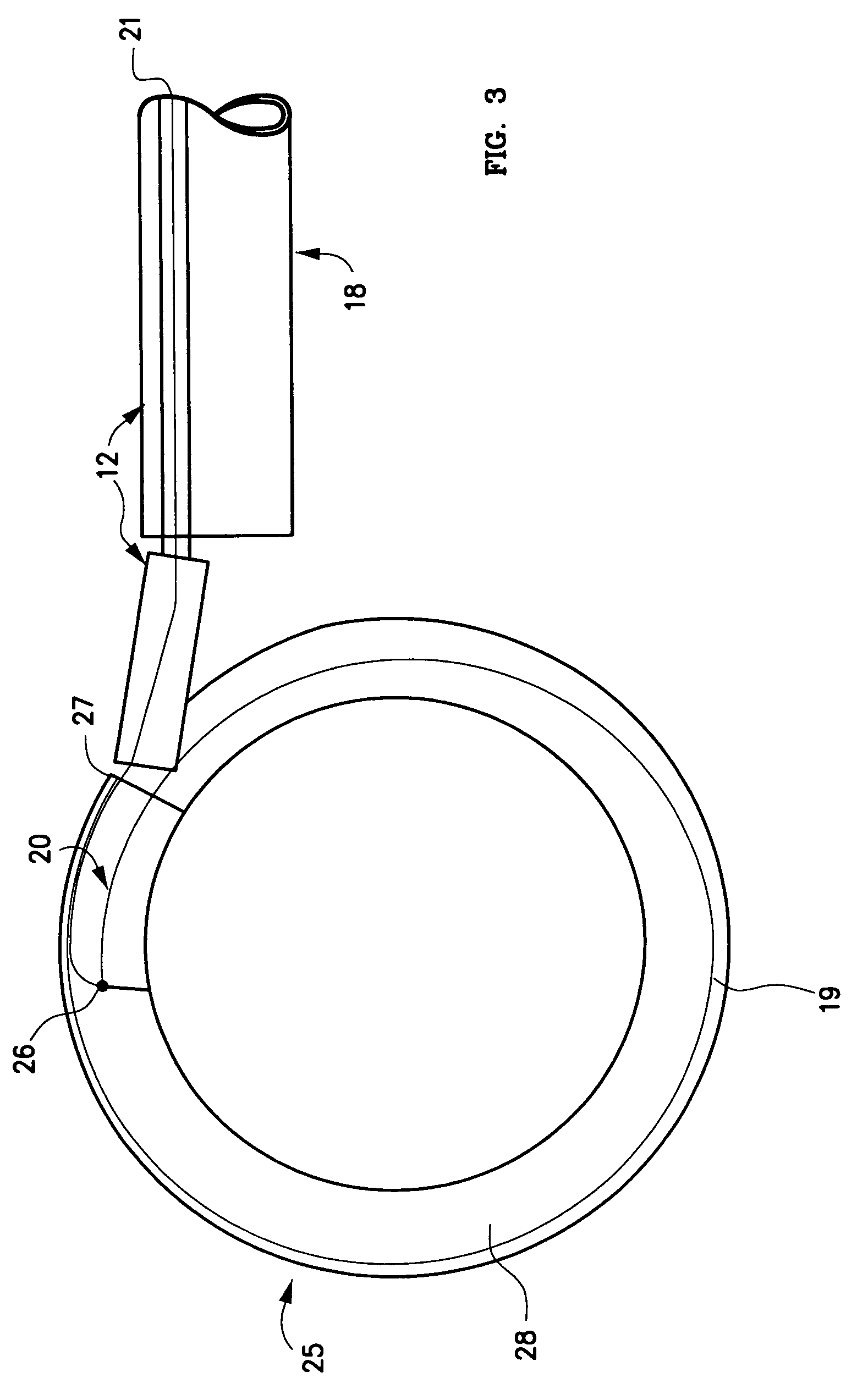

The present invention relates to a device and method which may be used to reinforce the native annulus during spinal surgery. The device is a catheter based device which is placed into the inter-vertebral space following discectomy performed by either traditional surgical or endoscopic approaches. The distal end of the catheter is comprised of an expansile loop which may be increased in diameter by advancement of a portion of the catheter via its proximal end, such proximal end remaining external to the body. The expansile loop may be formed of a woven or braided material and may be made of a polymer such as nylon, polyurethane, polyester, polyethylene, polypropylene or any of the well known and biocompatible polymers. Alternatively the expansile portion of the catheter may be formed from a metallic braid of stainless steel, elgiloy, Nitinol, or other biocompatible metals. The expansile loop may be formed such that when the loop is diametrically contracted the loop feeds into its other end, similar to a snake eating its own tail. Stabilization of the outer portion of the loop and pulling out the inner portion will thereby increase the overall diameter of the loop while maintaining it as a closed loop or torus. The present invention comprises four embodiments and can be used to 1) facilitate disk fusing, 2) perform an artificial replacement of the nucleus, 3) perform an artificial replacement of the annulus, or 4, perform an artificial replacement of both the nucleus and annulus.

Owner:OUROBOROS MEDICAL INC

Polyester compound for preparing olefine polymerizing catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Miscible high Tg polyester/polymer blend compositions and films formed therefrom

InactiveUS20060270806A1Minimizes and eliminates drying stepIncrease temperatureOptical light guidesPolyesterPolymer science

Disclosed is a high Tg polyester / polymer blend composition for a sheet or film. The composition comprises about 80 to about 99.8 percent by weight of a miscible blend of a polyester with a polymer. Also disclosed is a process for the preparation of a film or sheet from this composition. Compensationa and protective films and sheets prepared from this composition are useful for backlight displays.

Owner:EASTMAN CHEM CO

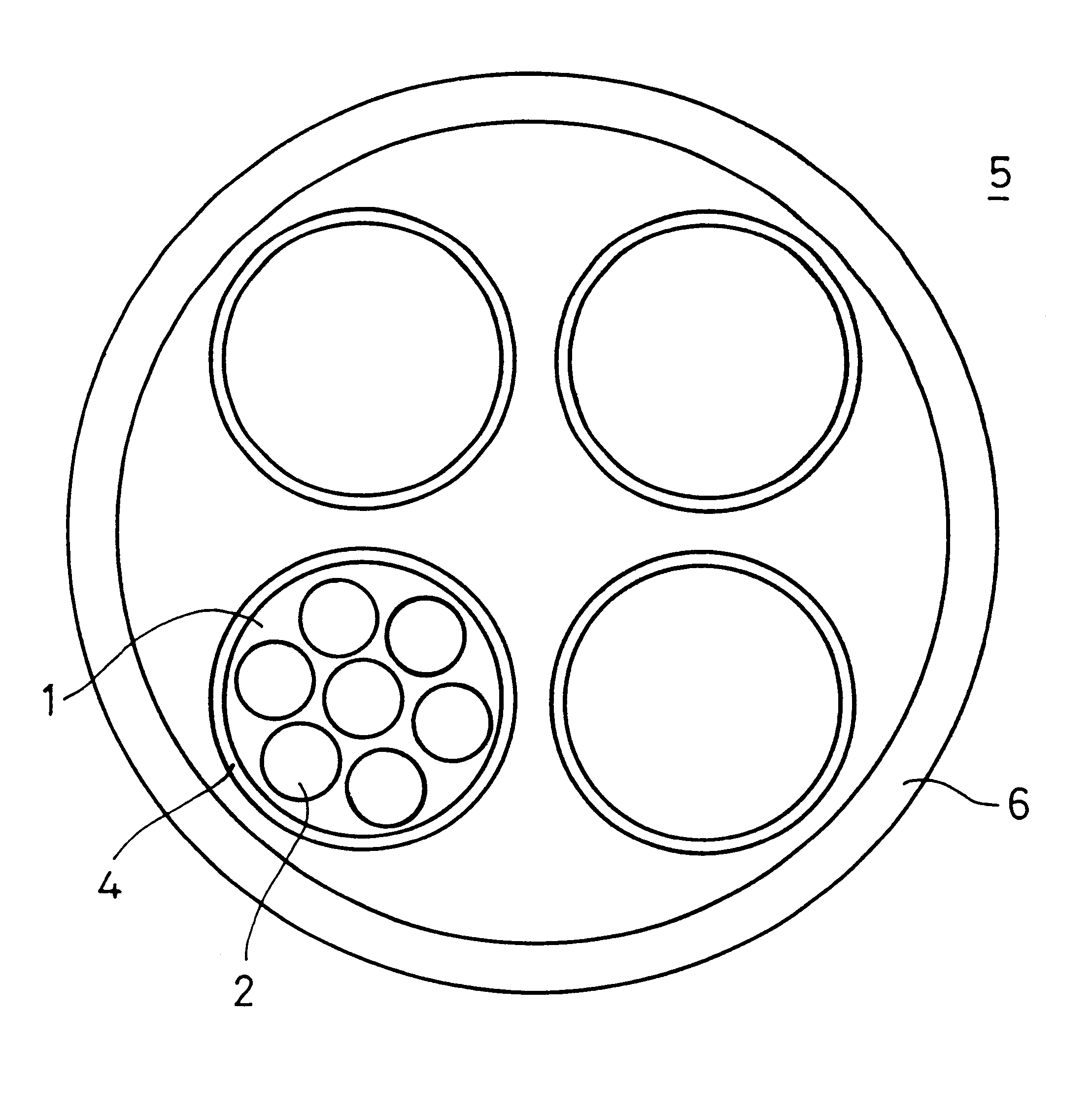

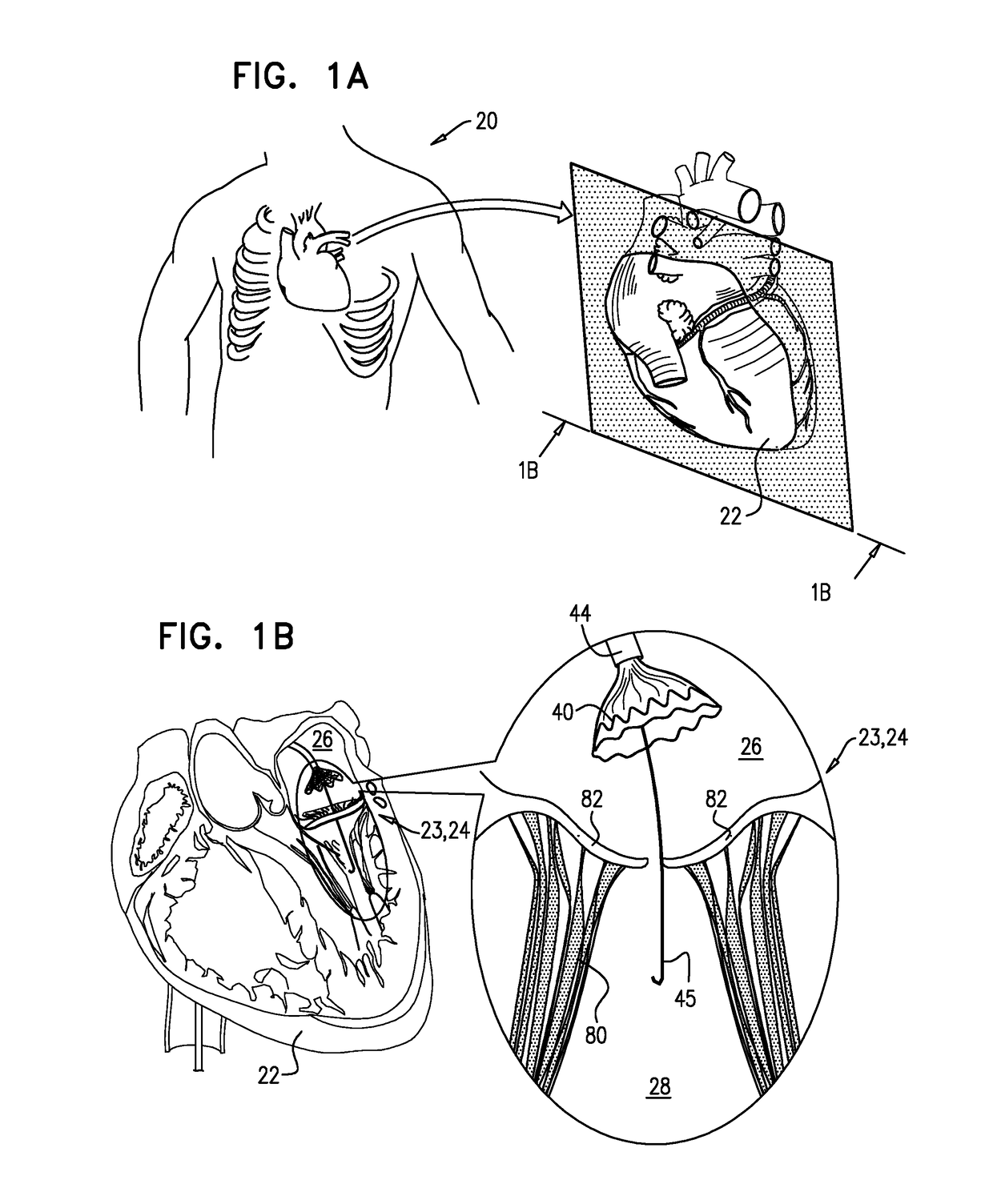

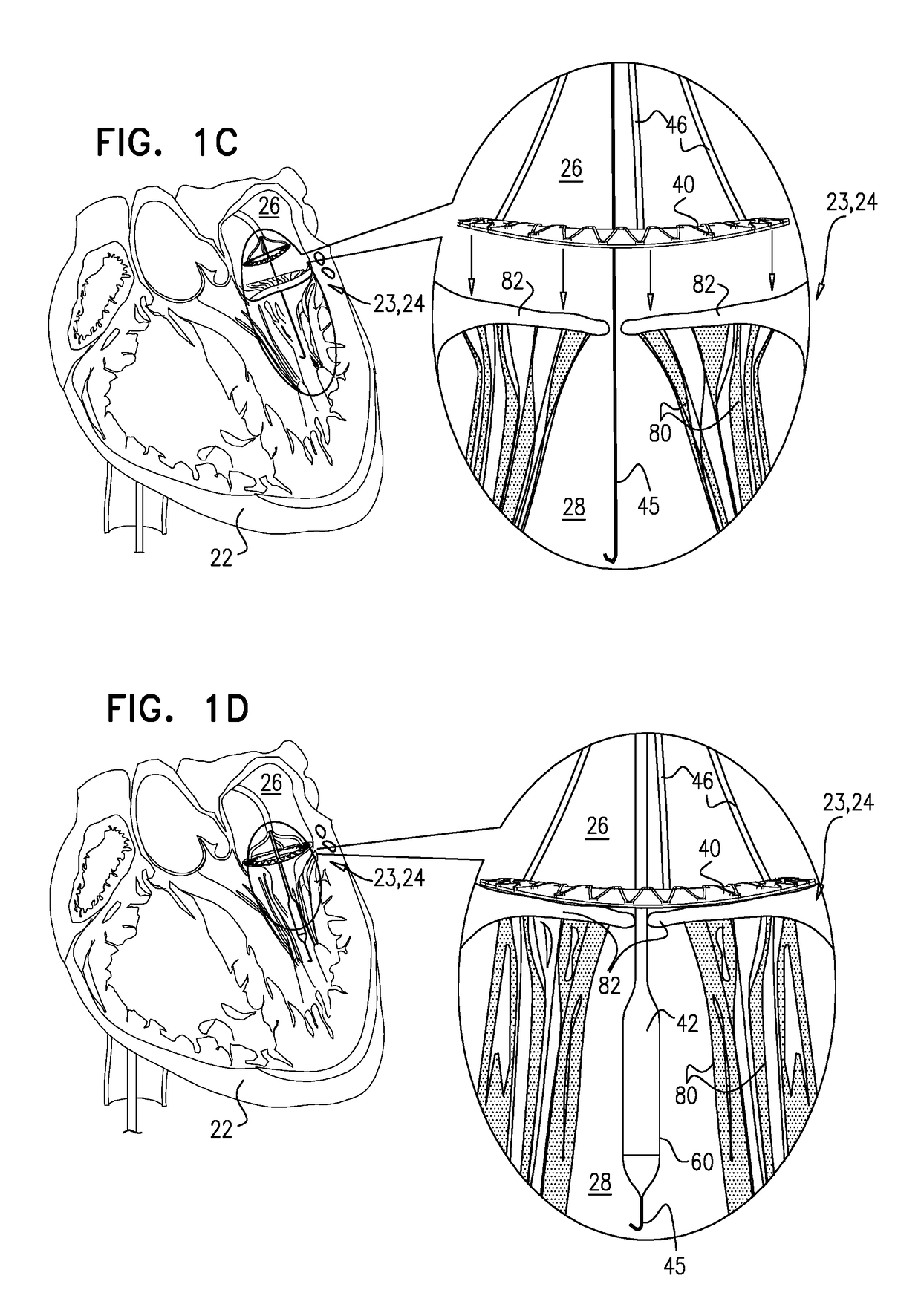

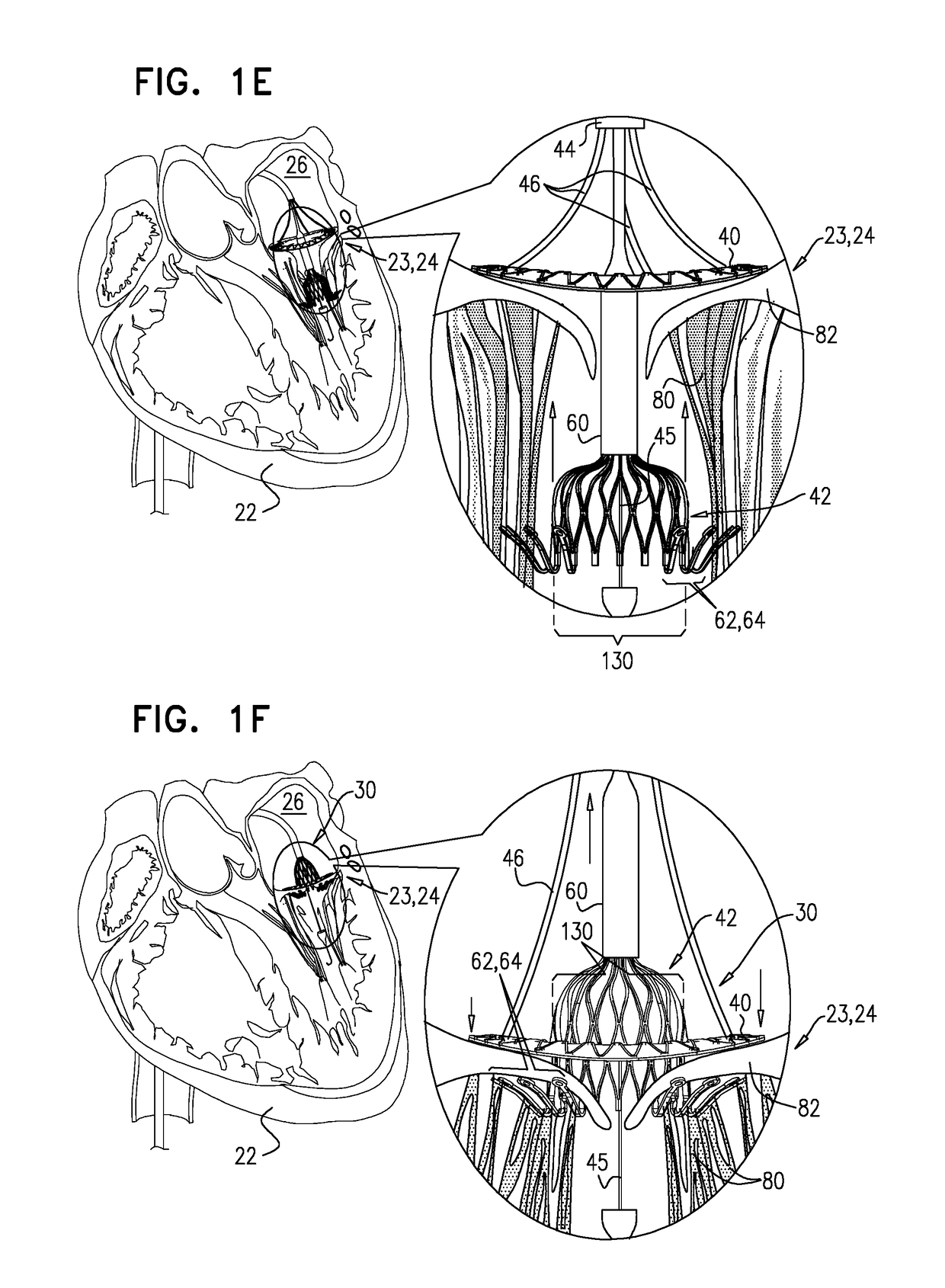

Techniques for percutaneous mitral valve replacement and sealing

ActiveUS20180344457A1Promote expansionFacilitate compressionStentsBalloon catheterEngineeringBioprosthetic mitral valve replacement

Apparatus is provided for use with a native valve of a heart of a subject. The apparatus includes: (1) an annular upstream support portion, comprising an expandable first frame, the upstream support portion configured to be placed against an upstream surface of the native valve; (2) a flexible polyester connector; and (3) an anchoring element, flexibly coupled to the upstream support portion by the connector, and configured to anchor the upstream support portion to the native valve by engaging tissue of the native valve.

Owner:CARDIOVALVE LTD

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

High strength suture with colored trace at one end

Owner:ARTHREX

High strength suture with coating and colored trace

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

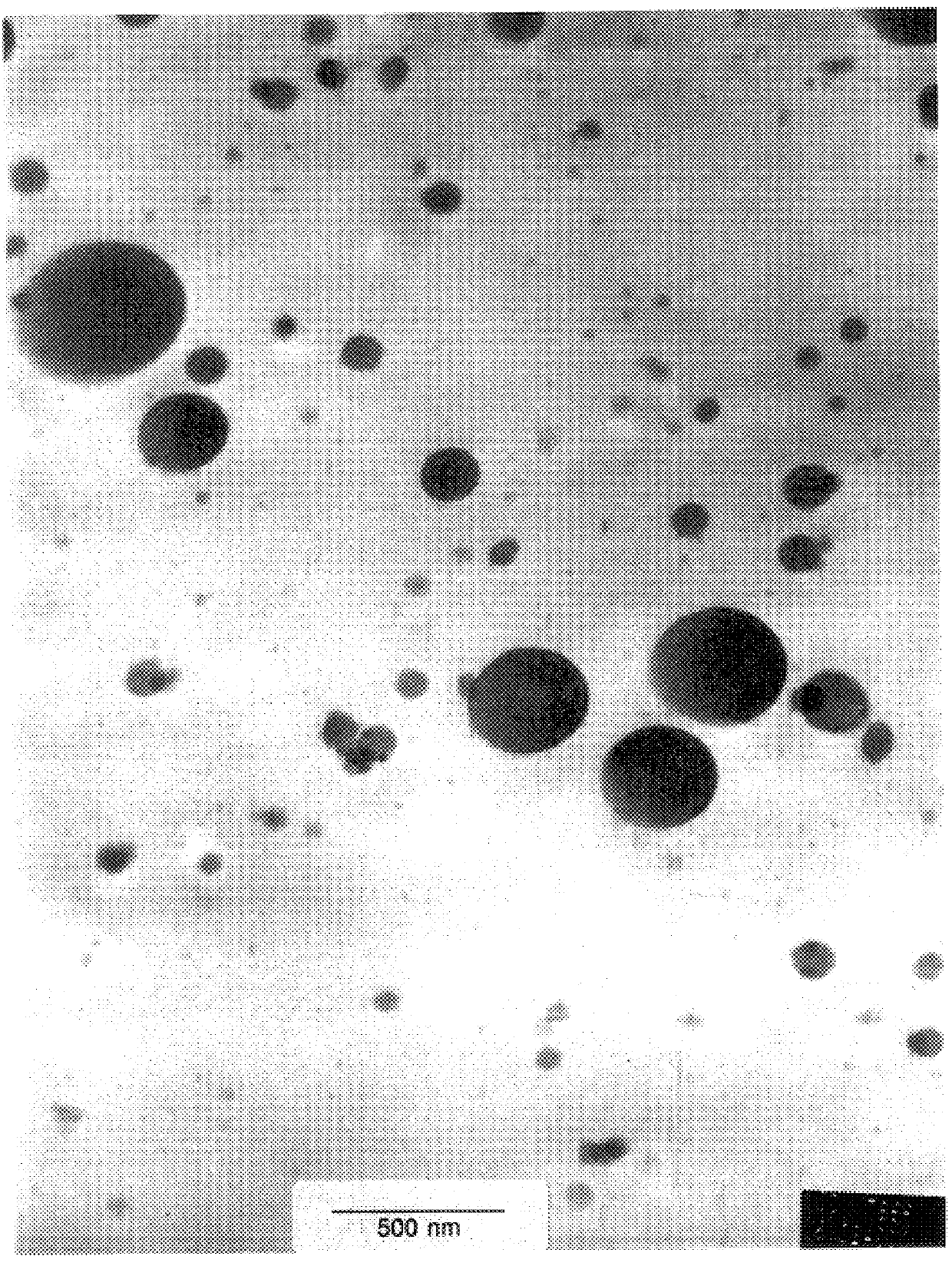

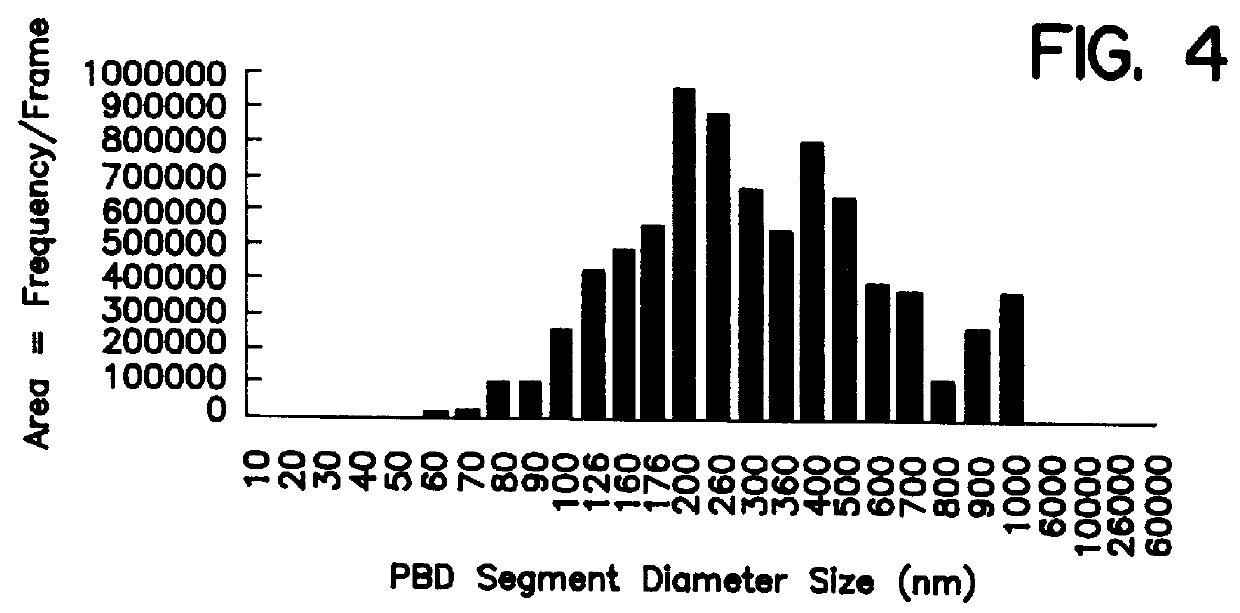

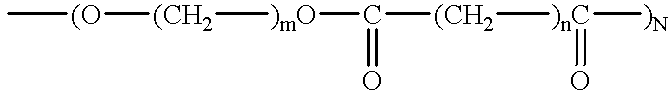

Polymer particles for delivery of macromolecules and methods of use

InactiveUS20070134332A1Slow down rate of bio-degradationImprove stabilityPowder deliveryNervous disorderPolyesterBound water

The present invention provides biodegradable polymer particle delivery compositions for delivery of macromolecular biologics, for example in crystal form, based on polymers, such as polyester amide (PEA), polyester urethane (PEUR), and polyester urea (PEU) polymers, which contain amino acids in the polymer. The polymer particle delivery compositions can be formulated either as a liquid dispersion or a lyophilized powder of polymer particles containing bound water molecules with the macromolecular biologics, for example insulin, dispersed in the particles. Bioactive agents, such as drugs, polypeptides, and polynucleotides can also be delivered by using particles sized for local, oral, mucosal or circulatory delivery. Methods of delivering a macromolecular biologic with substantial native activity to a subject, for example orally, are also included.

Owner:MEDIVAS LLC

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com