Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4691 results about "Phthalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

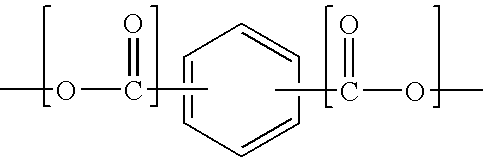

Phthalic acid is an aromatic dicarboxylic acid, with formula C₆H₄(CO₂H)₂. It is an isomer of isophthalic acid and terephthalic acid. Although phthalic acid is of modest commercial importance, the closely related derivative phthalic anhydride is a commodity chemical produced on a large scale.

Pentane compatible polyester polyols

InactiveUS6359022B1Increase valueImprove flame retardant performanceOther chemical processesPolyesterDolichol

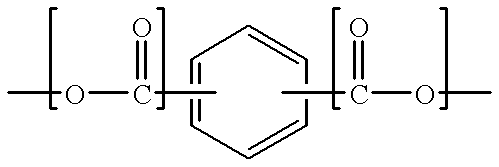

Disclosed are aromatic polyester polyols, polyol based resin blends, and rigid closed-cell polyisocyanate-based foams made using the polyol based resin blends. The resin blends generally comprise:(a) an aromatic polyester polyol reaction product formed by inter-esterification of a phthalic acid based material; a hydroxylated material having a functionality of at least 2; and a hydrophobic material; and(b) a C4-C7 hydrocarbon blowing agent. Also disclosed is a method for preparing rigid closed-cell polyisocyanate-based foams comprising reacting a polyisocyanate and a polyol based resin blend.

Owner:STEPAN COMPANY

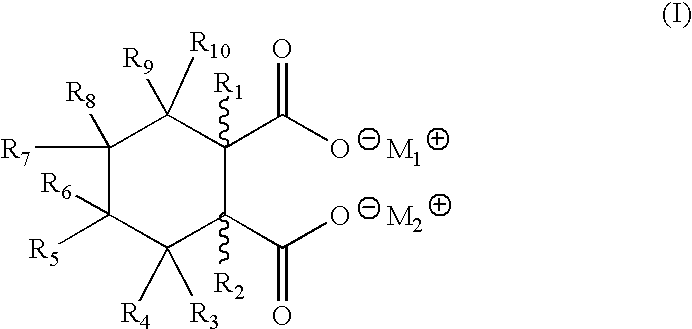

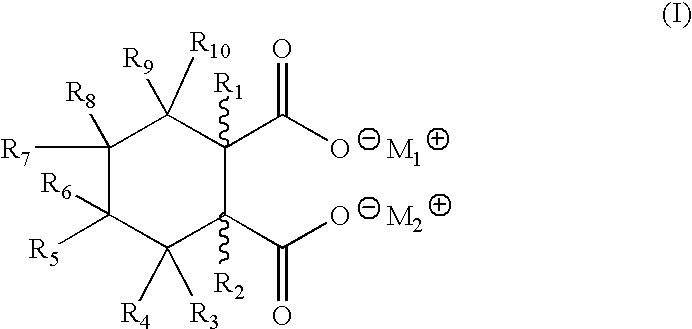

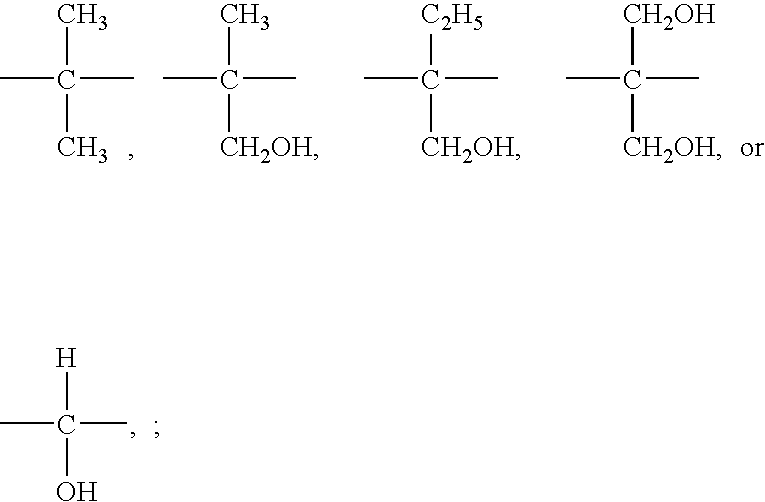

Metal salts of hexahydrophthalic acid as nucleating additives for crystalline thermoplastics

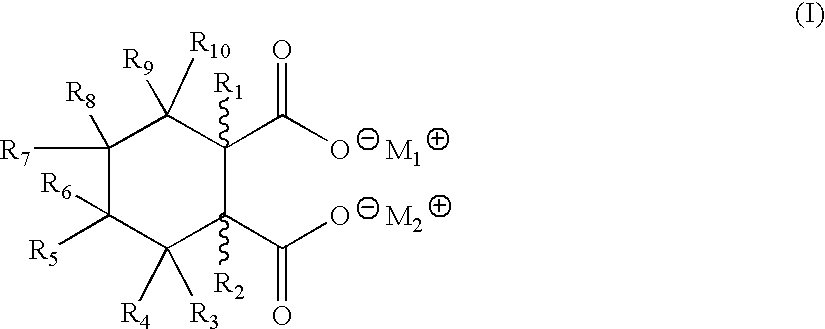

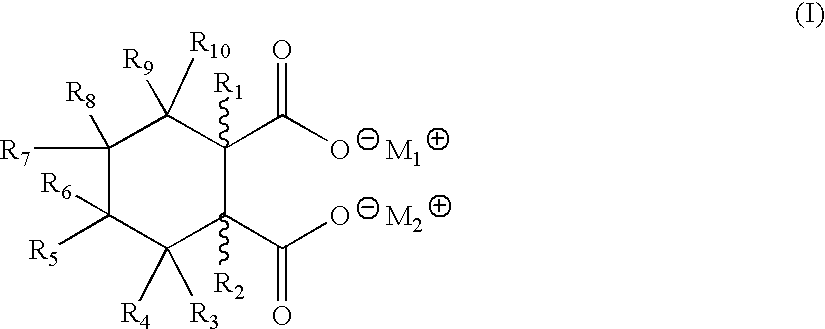

InactiveUS6599971B2Excellent calcium stearate compatibilityExcellent high peak crystallization temperatureOrganic compound preparationFibre treatmentThermoplasticScavenger

Compounds and compositions comprising specific metal salts of hexahydrophthalic acid (HHPA) in order to provide highly desirable properties within thermoplastic articles are provided. The inventive HHPA derivatives are useful as nucleating and / or clarifying agents for such thermoplastics, are practical and easy to handle. Such compounds provide excellent crystallization temperatures, stiffness, and acid scavenger compatibility within target polyolefins. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Thermoplastic additive compositions and methods of producing polymers with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

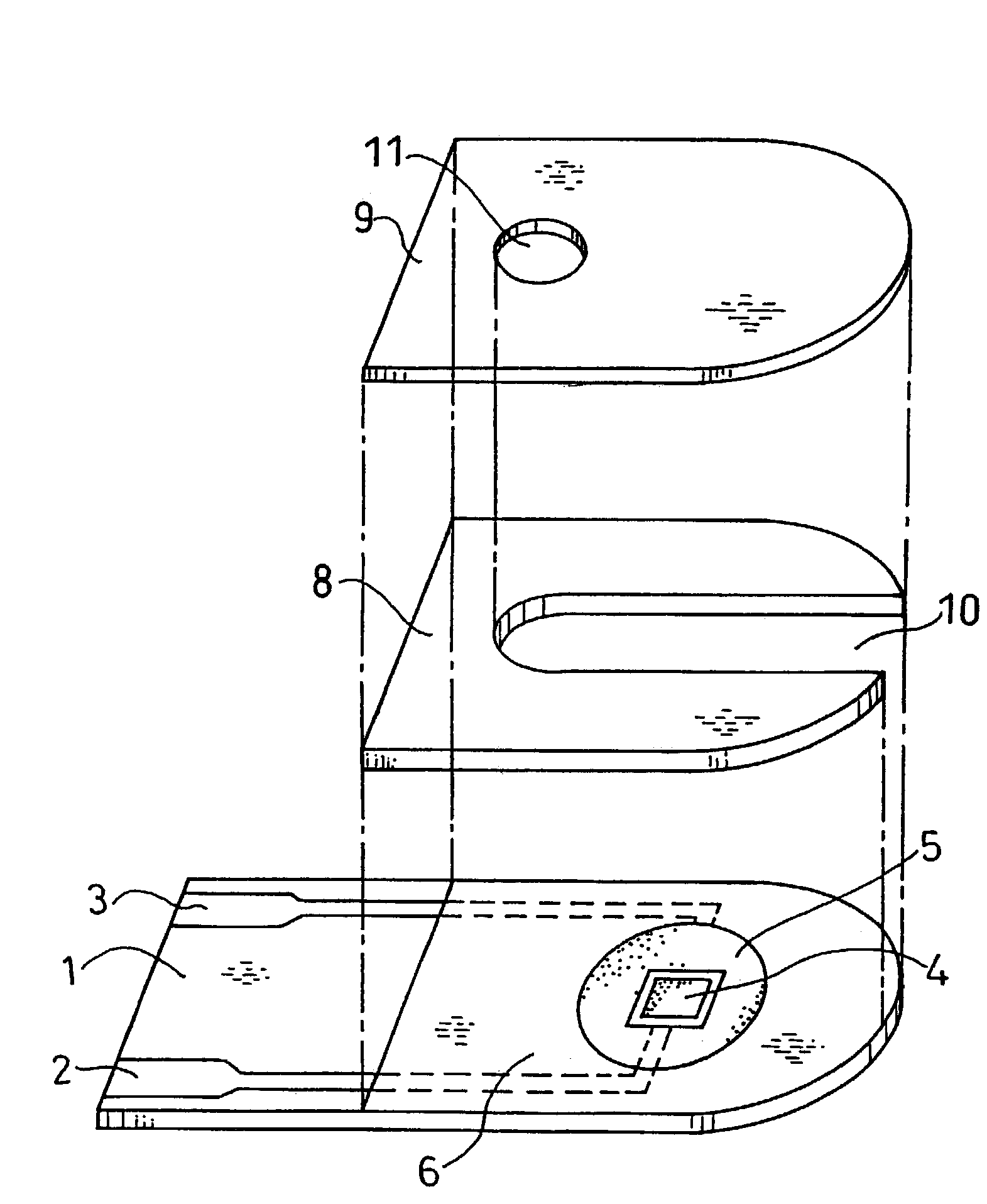

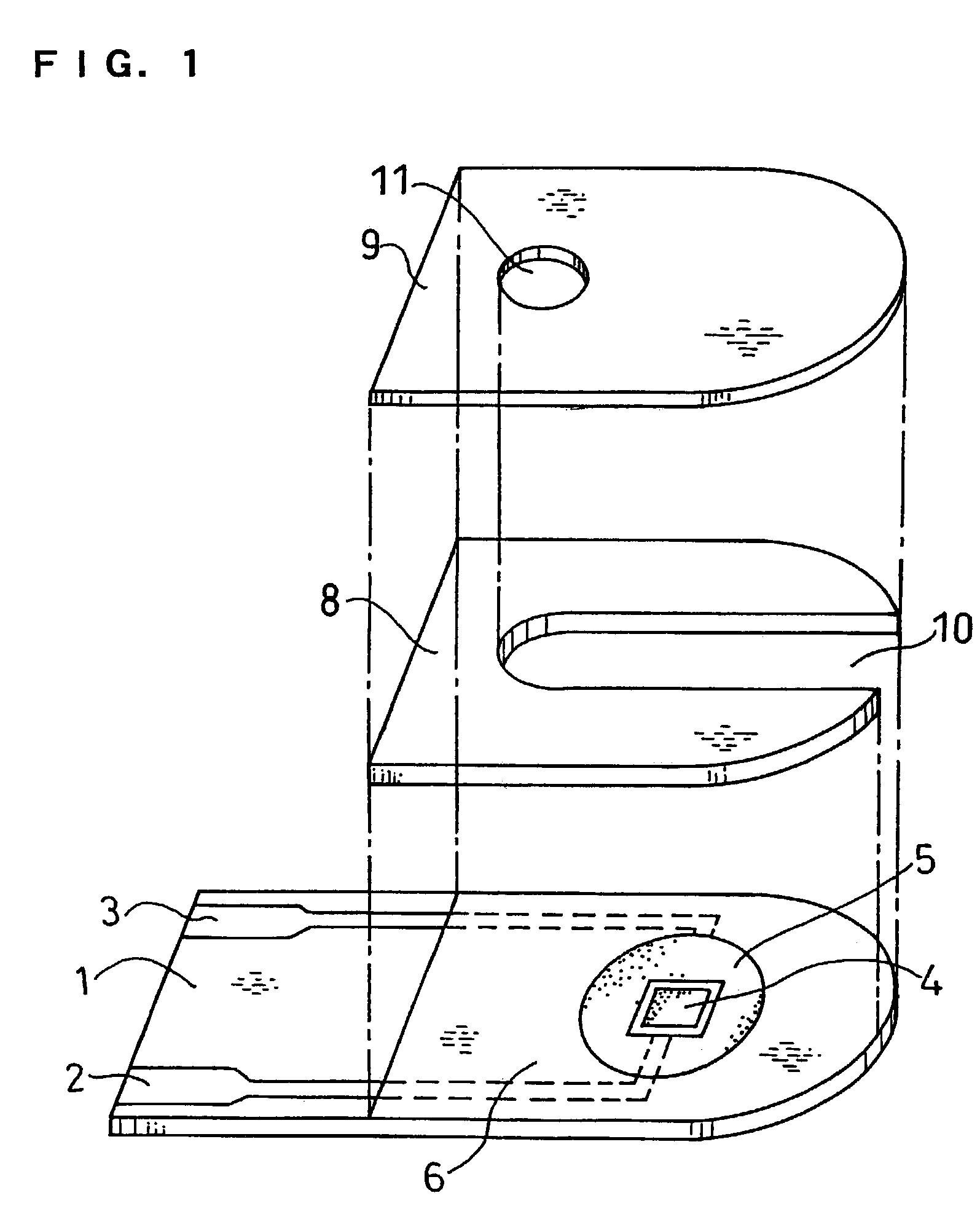

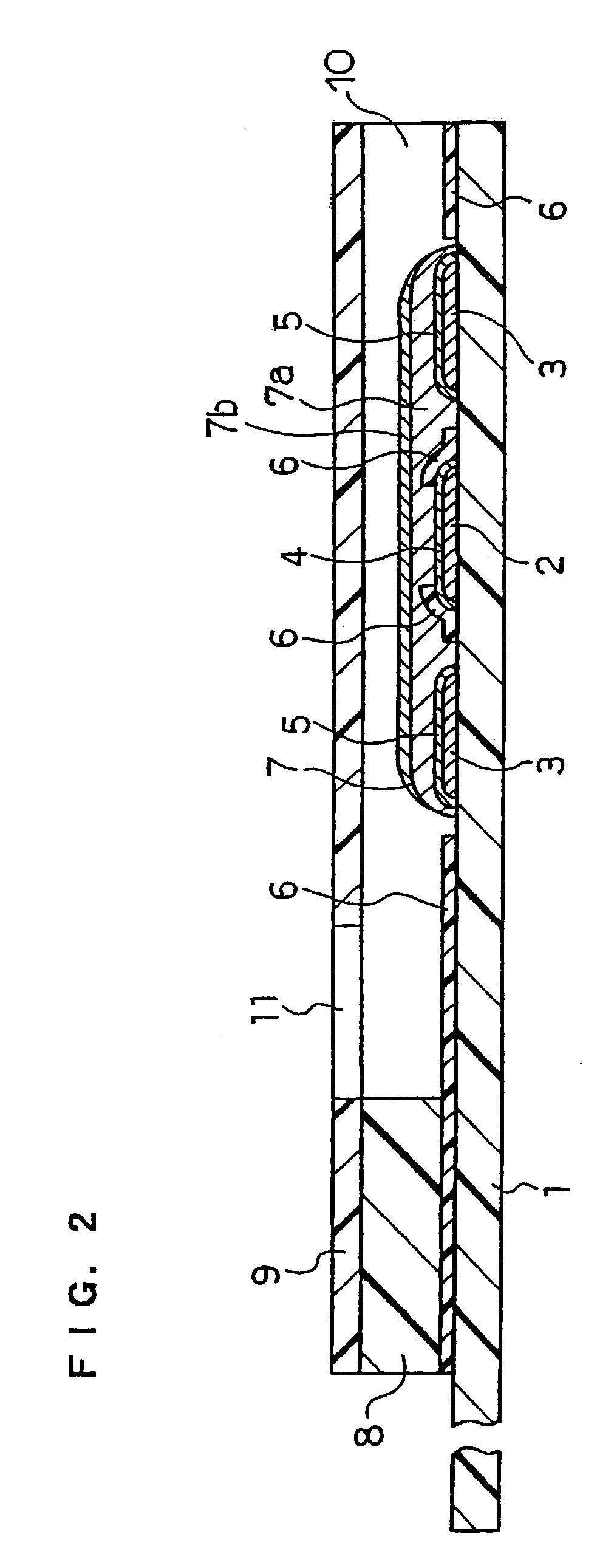

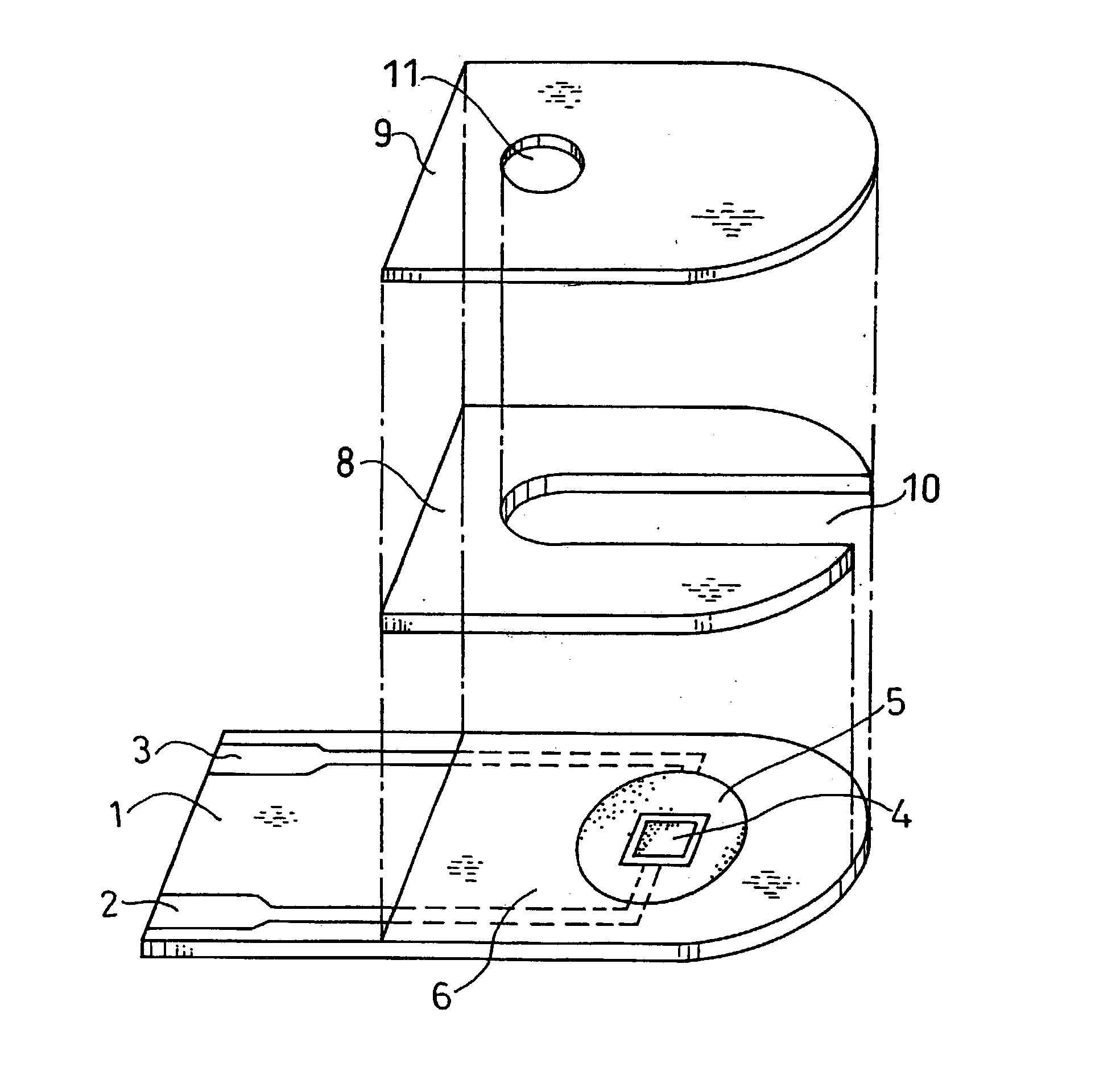

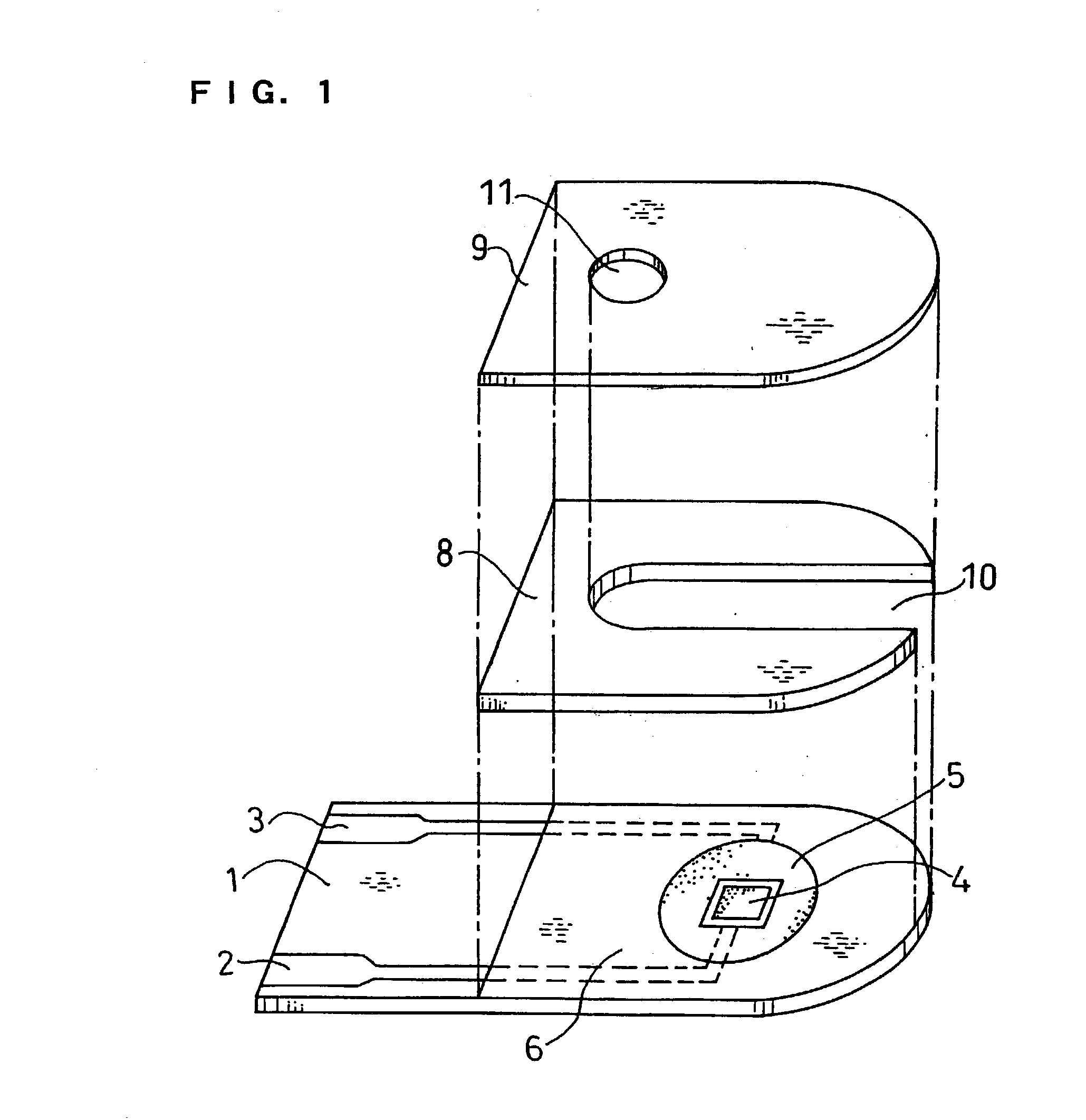

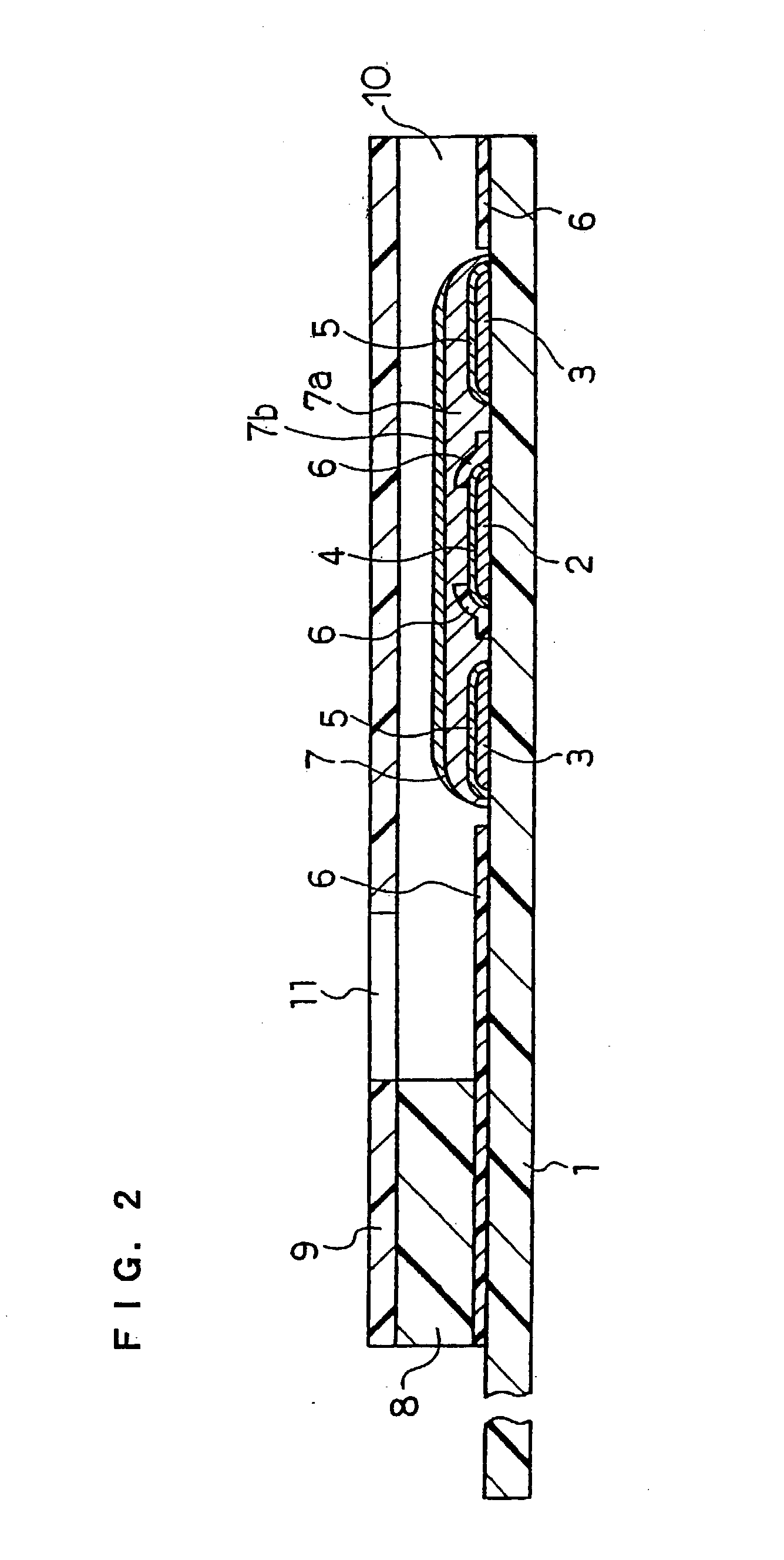

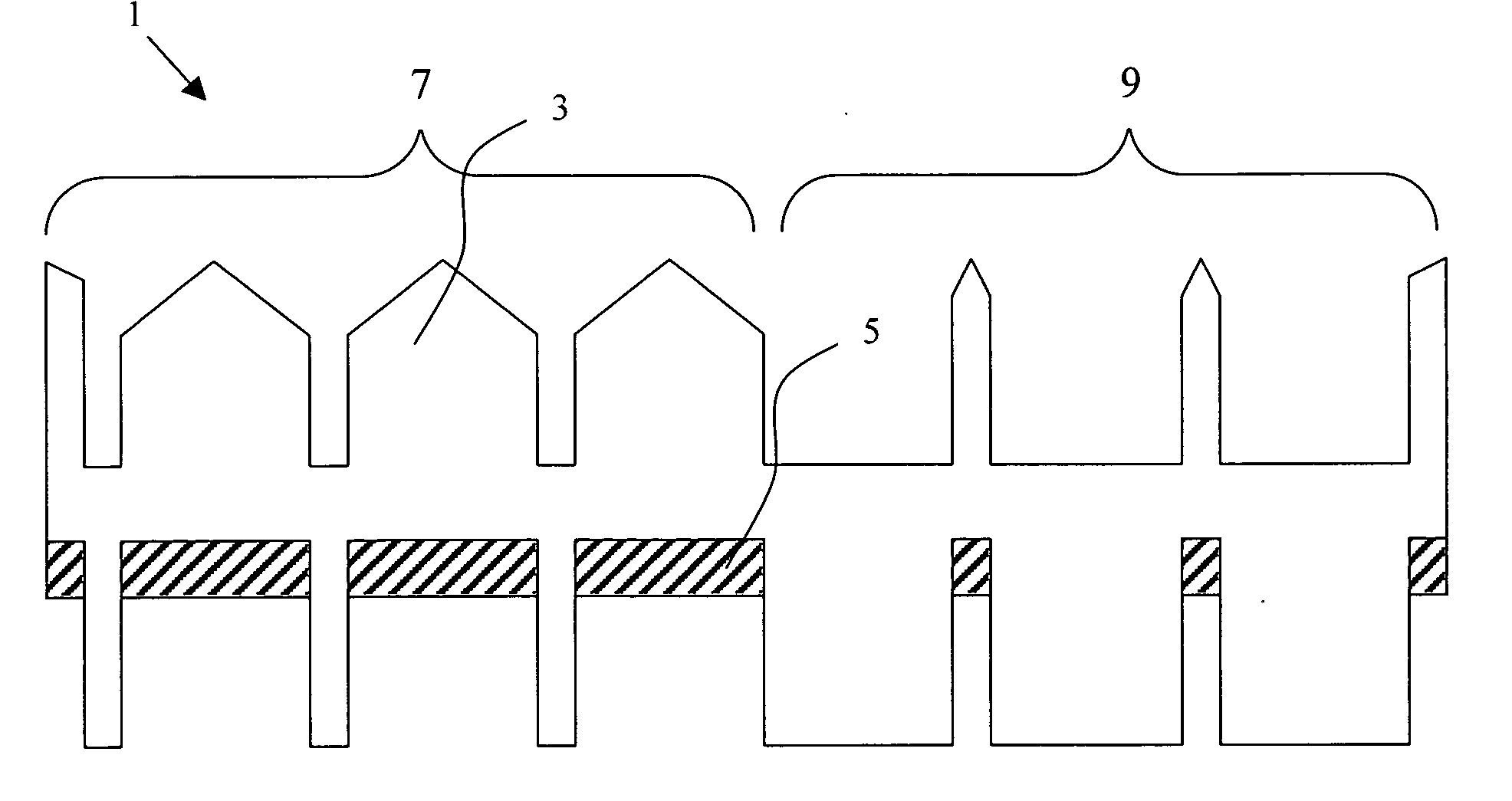

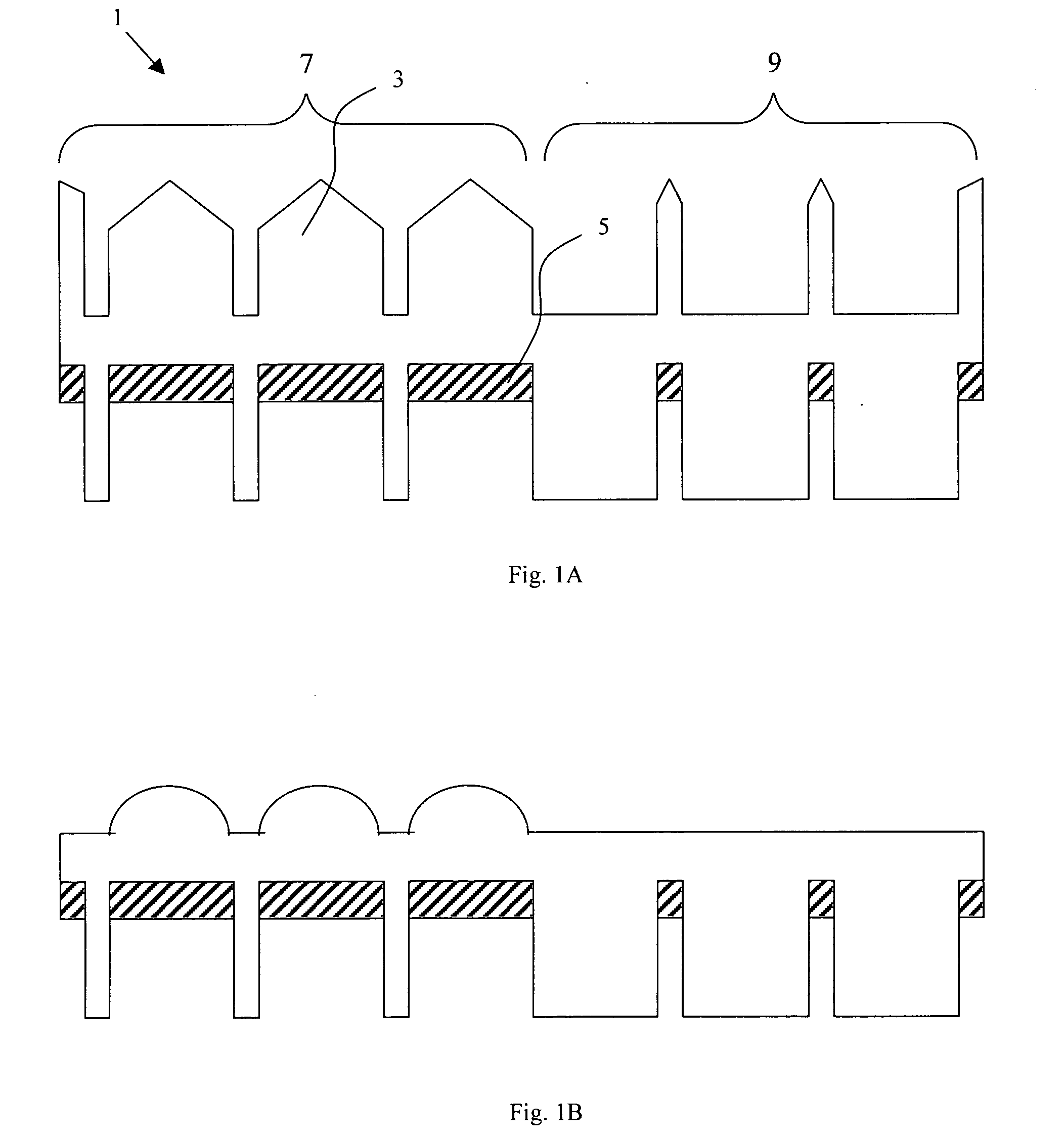

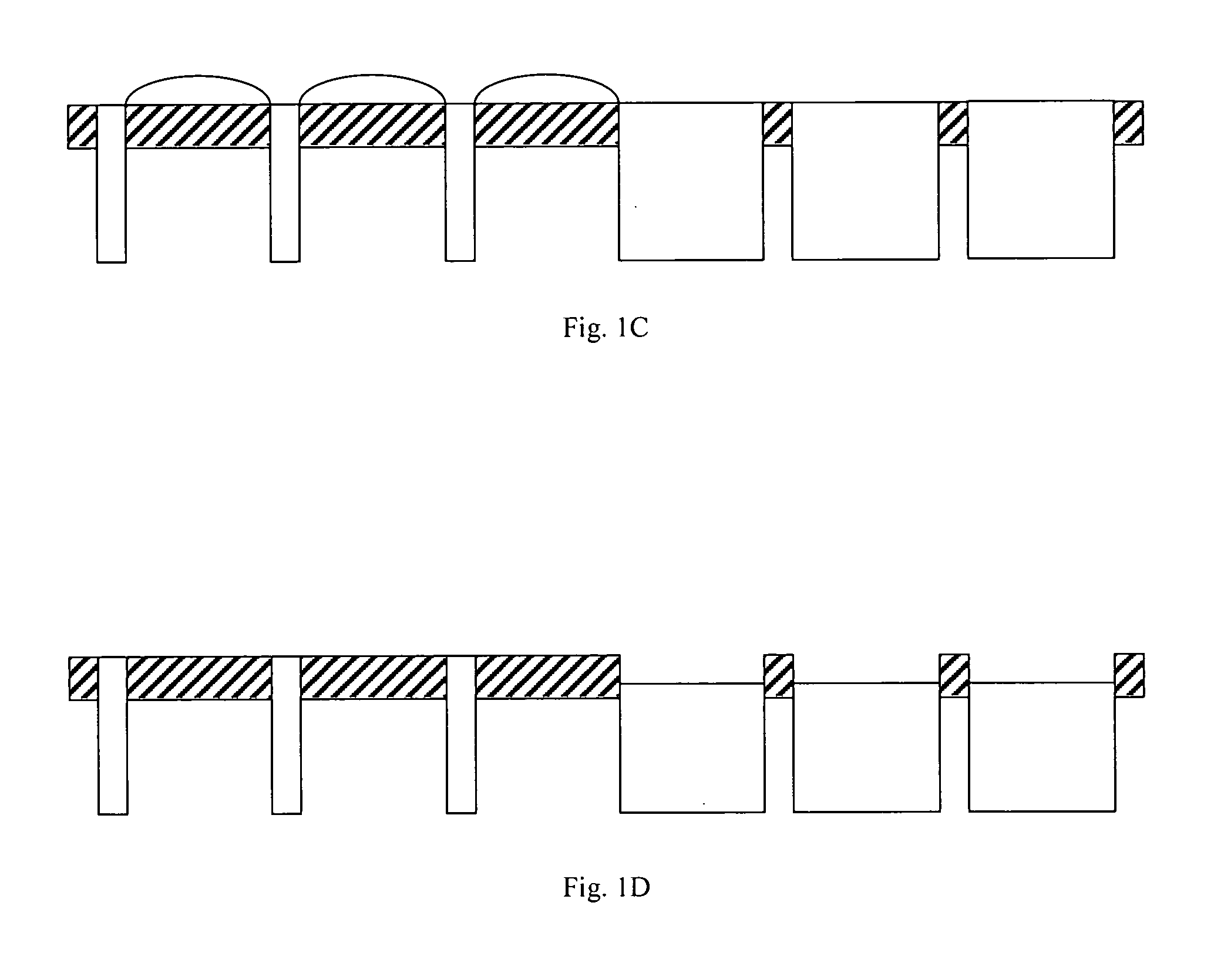

Biosensor

InactiveUS7235170B2Immobilised enzymesBioreactor/fermenter combinationsGluconolactonaseOxidoreductase

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N′-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

Curable composition

InactiveUS20090182091A1Less discolorationGood adhesivenessOther chemical processesEster polymer adhesivesSilylenePlasticizer

The present invention has its object to provide a curable composition which comprises a guanidine compound as a non-organotin type catalyst, is less discolored, has good surface curability, depth curability, strength rise and adhesiveness, and can retain the curability even after storage; the above object can be achieved by a curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiX3 (1) (wherein X represents a hydroxyl group or a hydrolyzable group and the three X groups may be mutually the same or different), (B) a guanidine compound (B-1) as a silanol condensation catalyst, and (C) a plasticizer, wherein the content of the component (B-1) is not lower than 0.1 part by weight but lower than 8 parts by weight per 100 parts by weight of the component (A), and a non-phthalate ester plasticizer accounts for 80 to 100% by weight of the (C) component plasticizer.

Owner:KANEKA CORP

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Biosensor

InactiveUS20030175841A1Avoid influenceReduce solubilityImmobilised enzymesBioreactor/fermenter combinationsGluconolactonaseSuccinic acid

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N'-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

Oleochemical Plasticizers with Thermal and Ultraviolet Radiation Stabilizing Activity for PVC Molding Resins and Process for Obtaining Thereof

The present invention is related with bioplasticizers or primary oleochemical plasticizers and the improved process for obtaining thereof. It refers primarily to epoxydized oleochemical plasticizers produced from vegetable oils, as substitute of traditional petrochemical plasticizers. The process starts with the epoxydized product of natural oils, such as sunflower, linseed, Jatropha curcas, soybean, etc., which are transesterified with an alcohol such as ethylic or methylic, in the presence of a catalyst such as sodium methoxide or sodium hydroxide in order to produce an alkylic esters mixture of the fatty acids that were present in the oil or oil mixture used as raw material in the epoxydized oil production. When the plasticizer obtained by the process already mentioned is used for the formulation of moldable poly(vinyl chloride), PVC, resins; the resulting plastic films get adequate hardness, static and dynamic thermal stability, and plasticizer extractability by solvents, such as n-hexane, gasoline and oil. Besides, when the PVC resin is formulated with a phthalic or terephthalic plasticizers mixture and the bioplasticizer, the bioplasticizer presents a full range solubility and or compatibility with the remainder of the resin compounds. The oxyrane chemical ring of the bioplasticizer is an excellent chemical neutralizer of the HCL that might be formed from the PVC, due to the action or interference of thermal or UV radiation.

Owner:RESINAS & MATERIALES

Polishing fluid and polishing method

ActiveUS20050181609A1Increase chanceSuperior in dimensional accuracy and electric characteristicOther chemical processesSemiconductor/solid-state device manufacturingDevice materialSlurry

A polishing slurry including an oxidant, a metal oxide dissolver, a metal inhibitor and water and having a pH from 2 to 5. The metal oxide dissolver contains one or more types selected from one or more acids (A-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is less than 3.7 and from which five acids of lactic acid, phthalic acid, fumaric acid, maleic acid and aminoacetic acid are excluded, ammonium salts of the A-group and esters of the A-group, and one or more types selected from one or more acids (B-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is 3.7 or more and the five acids, ammonium salts of the B-group and esters of the B-group. The metal inhibitor contains one or more types selected from the group consisting of aromatic compounds having a triazole skeleton and one or more types selected from the group consisting of aliphatic compounds having a triazole skeleton and compounds having any one of pyrimidine skeleton, imidazole skeleton, guanidine skeleton, thiazole skeleton and pyrazole skeleton. The polishing slurry having a high metal-polishing rate, reducing etching rate and polishing friction, results in the production, with high productivity, of semiconductor devices reduced in dishing and erosion in metal wiring.

Owner:HITACHI CHEM CO LTD

Solid catalyst component and catalyst for olefins polymerization

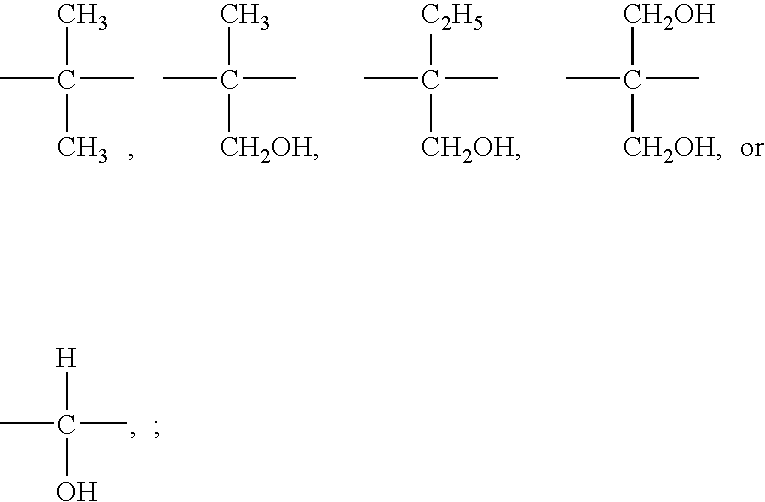

InactiveUS6770586B2Particles in good shapeImprove handlingOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropylene PolymersOlefin polymerization

Owner:TOHO TITANIUM CO LTD

Plasticizer Blends and Use Thereof

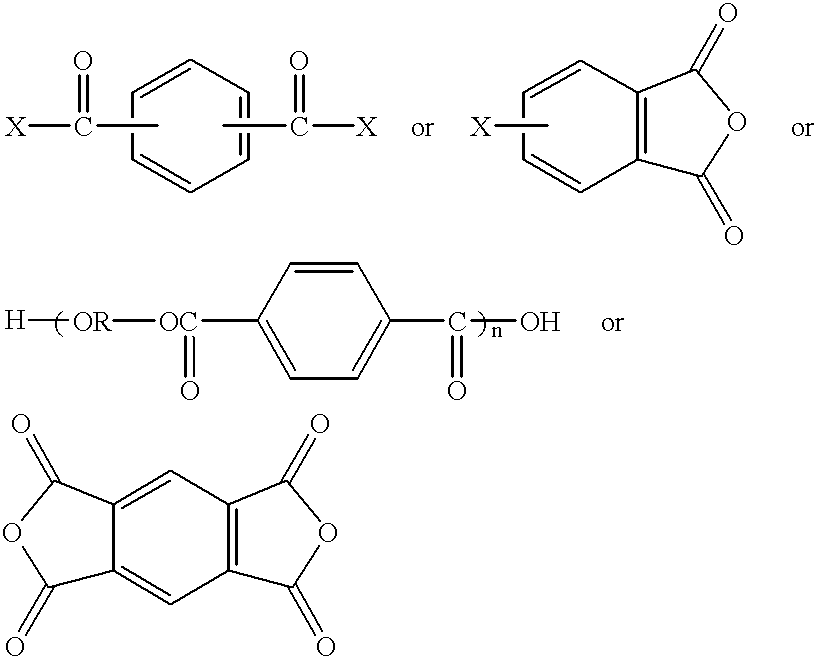

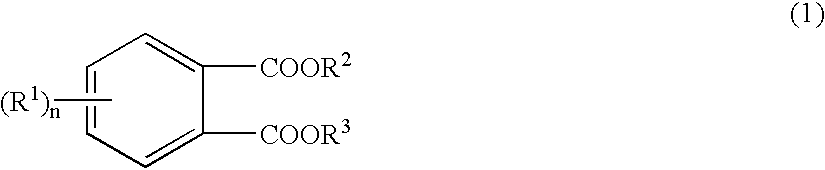

Provided are mixtures of 1) compounds of the formula:wherein R1 is a saturated or unsaturated cyclic hydrocarbon optionally substituted with an alkyl and / or an OXO-ester, and R2 is a C4 to C14 hydrocarbyl; and 2) one or more second plasticizers selected from the group consisting of alkyl terephthalates, alkyl phthalates, alkyl benzoate esters, di-benzoate esters, esters of cyclohexane polycarboxylic acids, and dialkyl adipates. Also provided are plasticized polymer compositions containing said mixtures.

Owner:EXXONMOBIL CHEM PAT INC

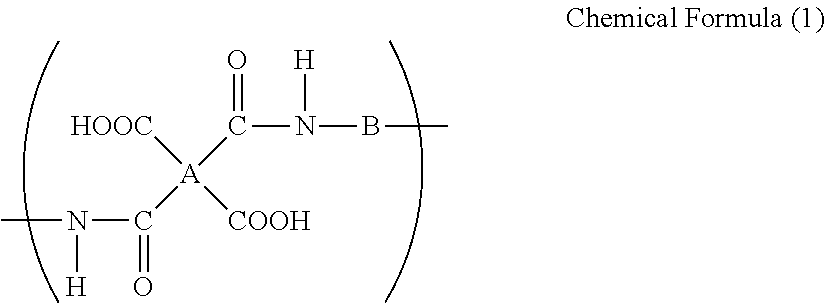

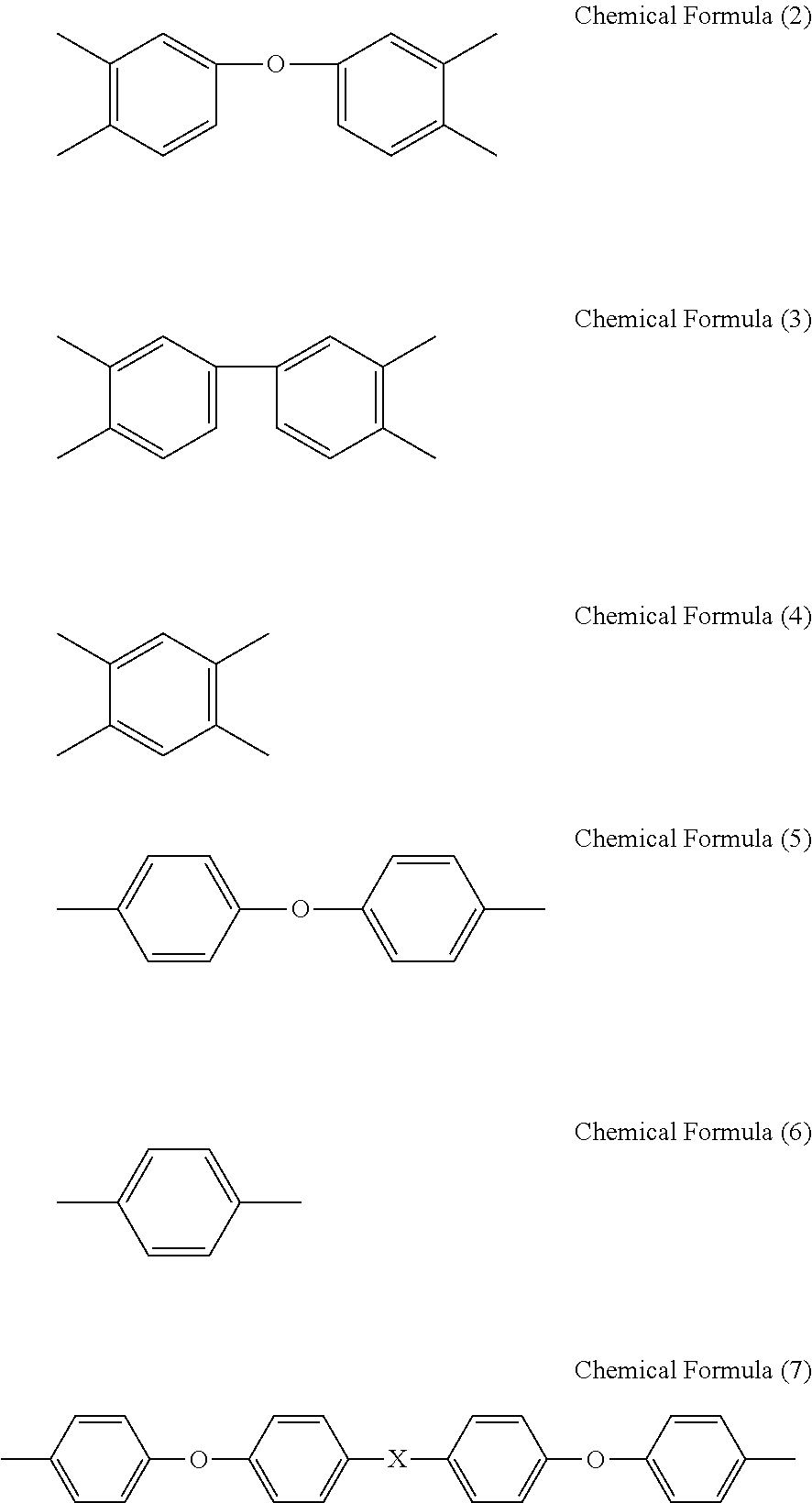

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

InactiveUS20080044639A1Material nanotechnologySynthetic resin layered productsPolymer scienceMicrometer

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component wherein the polyimide has a glass transition temperature of at least 190° C.; wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight; wherein the polyimide has less than 15 molar % of structural units derived from a member selected from the group consisting of biphenyltetracarboxylic acid, a dianhydride of biphenyltetracarboxylic acid, an ester of biphenyltetracarboxylic acid, and a combination thereof.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Polyimide porous membrane and lithium ion battery comprising same

ActiveCN101665580AUniform hole diameter distributionImprove breathabilitySecondary cellsCell component detailsBenzoic acidChlorinated paraffins

The invention discloses a polyimide porous membrane and a lithium ion battery comprising the same. The polyimide porous membrane is prepared by the following method, and the method comprises the following steps: forming a polyamic acid membrane by using the mixture of a mixture containing polyamic acid, pore-forming substance and solvent, and subjecting the polyamic acid membrane to amidation at the temperature higher than the decomposing temperature of the pore-forming substance, wherein the solvent is a solvent which dissolves the polyamic acid but slightly dissolves or does not dissolve thepore-forming substance; and the pore-forming substance may be one or combination of benzoic acid polyol ester, phthalic acid dialkyl ester, polyprotic acid alkyl ester, phenyl alkysulfonate, chlorinated paraffin and epoxidized soybean oil. The service life and the processing yield of the lithium ion battery made of the polyimide porous membrane serving as a battery membrane are improved. Moreover, the polyimide porous membrane also has higher thermal stability, and greatly improves the safety performance of the battery.

Owner:BYD CO LTD

Disodium hexahydrophthalate salt compositions and nucleated polymers comprising such compositions

InactiveUS6562890B2Improve compatibilityExcellent high peak crystallization temperatureChemical/physical processesScavengerPolyolefin

Compositions comprising specific disodium hexahydrophthalate(HHPA) salts in combination with acid scavengers (such as organic calcium salts or dihydrotalcite complexes) that provide highly desirable and effective nucleating properties within polymer articles (such as polyolefins) are provided. Surprisingly, such a combination of HHPA salt and acid scavenger provides high crystallization temperatures, low haze, and / or high flexural modulus to the finished polymer product. Other sodium salt polymer nucleators (such as sodium benzoate) deleteriously react with calcium organic salt acid scavengers such that characteristically high crystallization temperatures are drastically reduced when in combination with calcium salts (such as calcium stearate). Also, sodium benzoate when combined with dihydrotalcite acid scavengers produce extremely high haze levels in the finished target polymer article, whereas the inventive compositions surprisingly reduce haze. The finished polymer articles comprising such an inventive composition are also contemplated within this invention.

Owner:MILLIKEN & CO

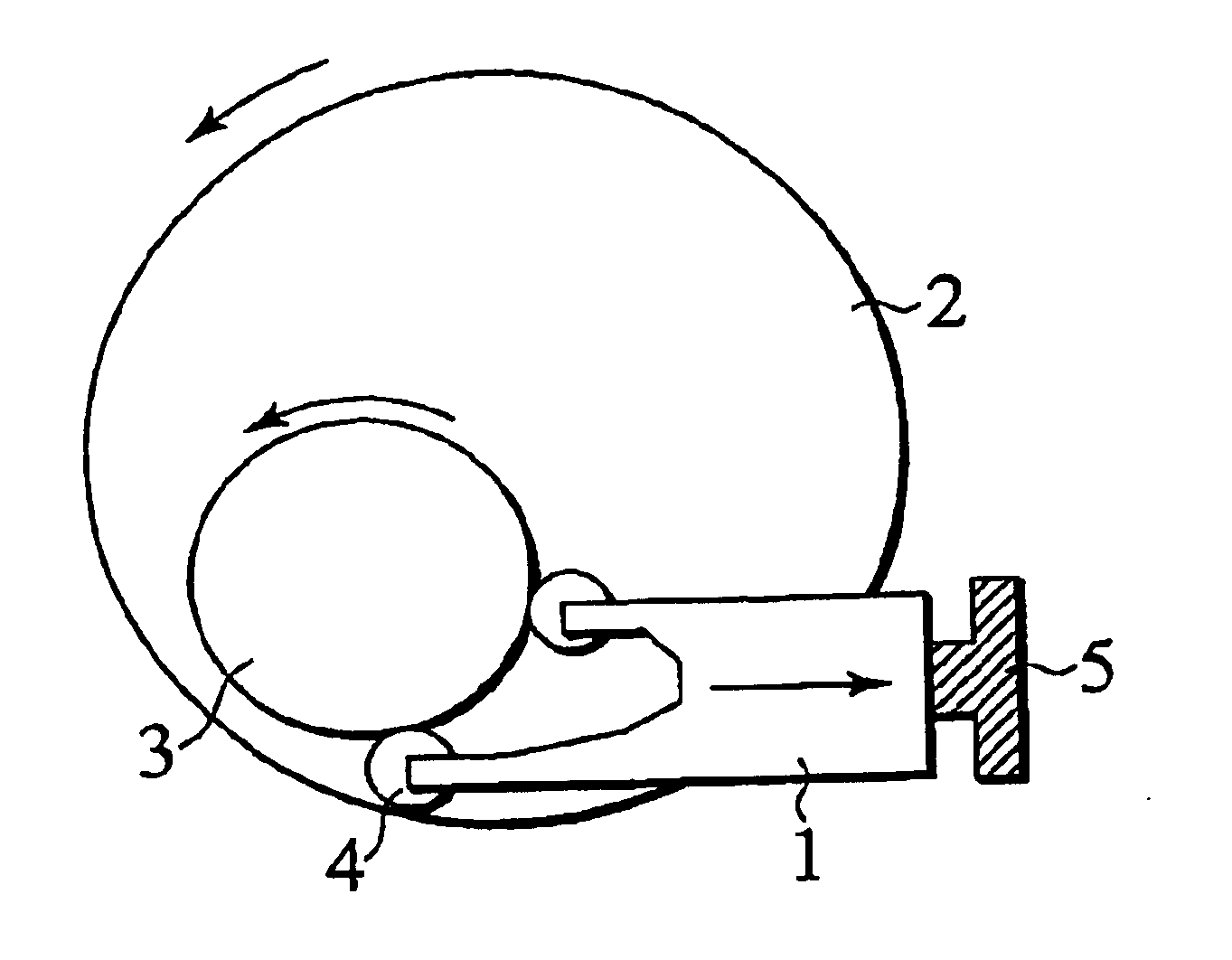

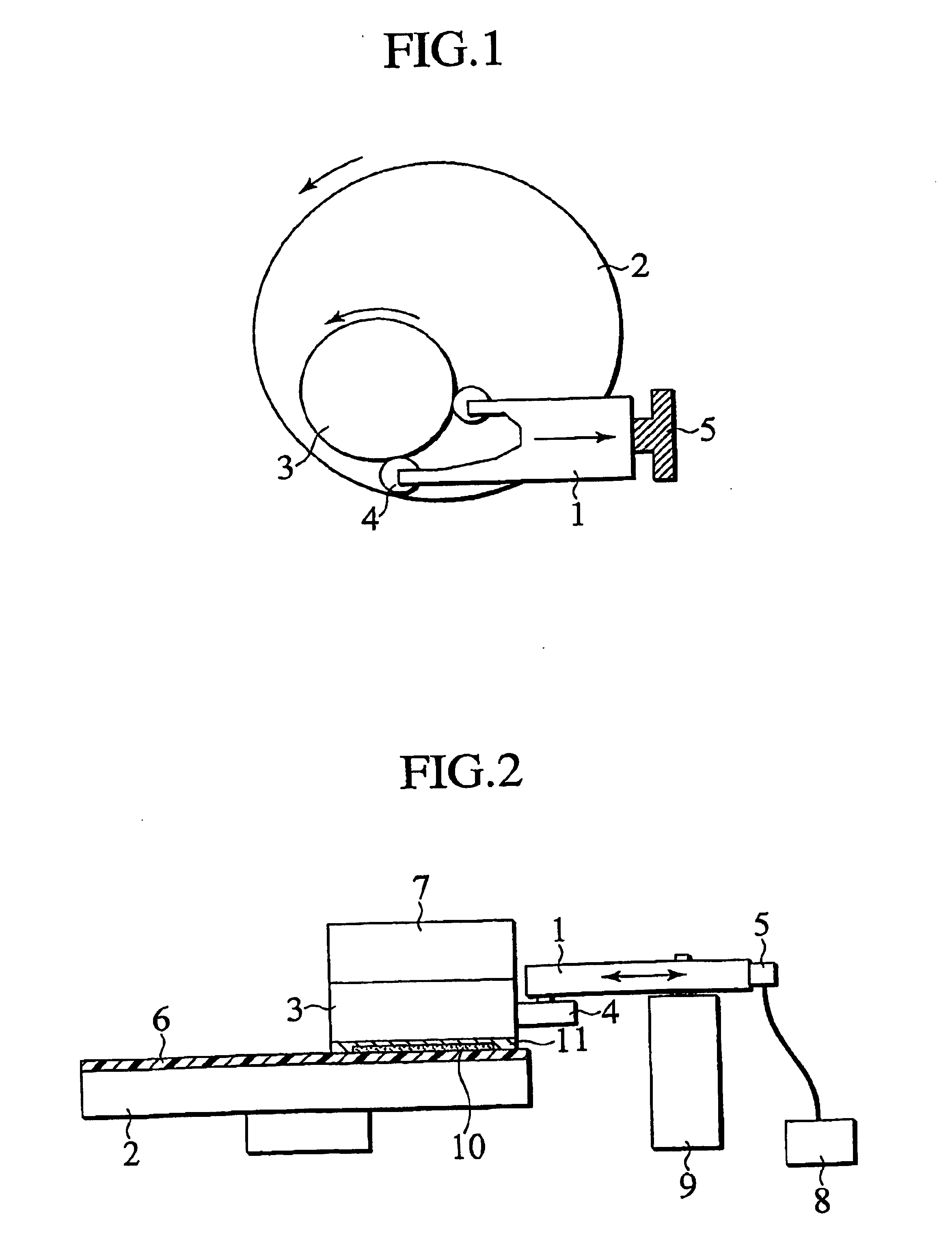

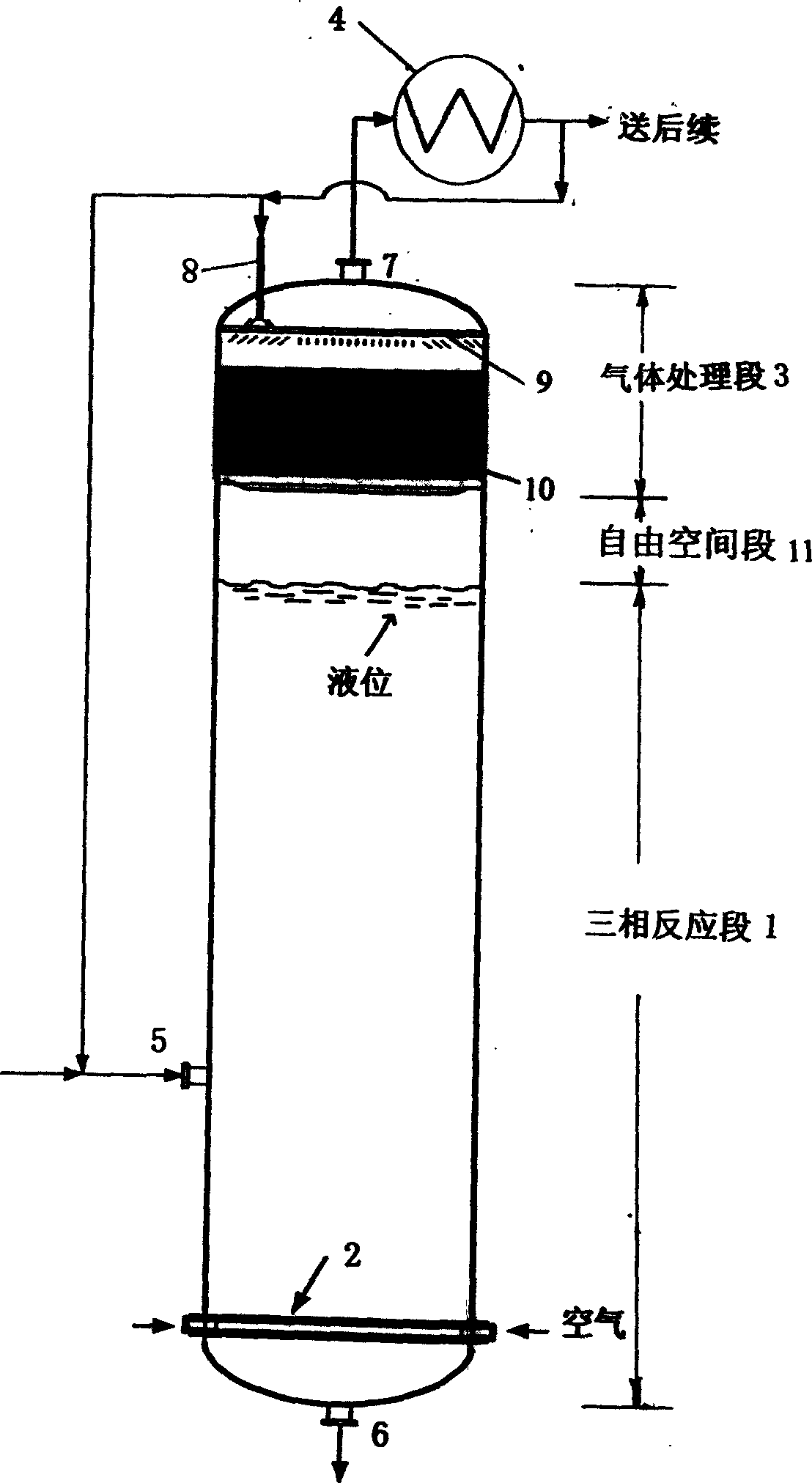

Bubble tower oxidation reaction unit for producing terephthalic acid

InactiveCN1528732ASimple structureLow costOrganic compound preparationCarboxylic compound preparationBubble columnTower

The invention discloses a bubbling column oxidizing reaction device to produce p-phthalic acid, including a uniform straight-cylindrical bubbling column, where there are gas processing segment, free space segment and three phase reaction segment in turn form top to bottom in the bubbling column, there are liquid distributor and filling or liquor-holding board installed in the gas processing segment, there is a gas distributor installed at the bottom of the three phase reaction segment, there is a raw material feeding pipe set at 1 / 4-1 / 2 of the height of reaction segment, there is a discharge pipe set at the bottom of the bubbling column, there is a tail-gas pipe and a liquor condensate reflux pipe on the top of the bubbling column, the inlet of the condenser is linked with the tail-gas pipe, the gas outlet is linked with the follow-up tail-gas processing unit, the liquid outlet of the condenser is linked with raw material feeding pipe, liquor condensate reflux pipe and follow-up dehydration tower. It is applied to the process of preparing p-phthalic acid by high temperature oxidization.

Owner:ZHEJIANG UNIV

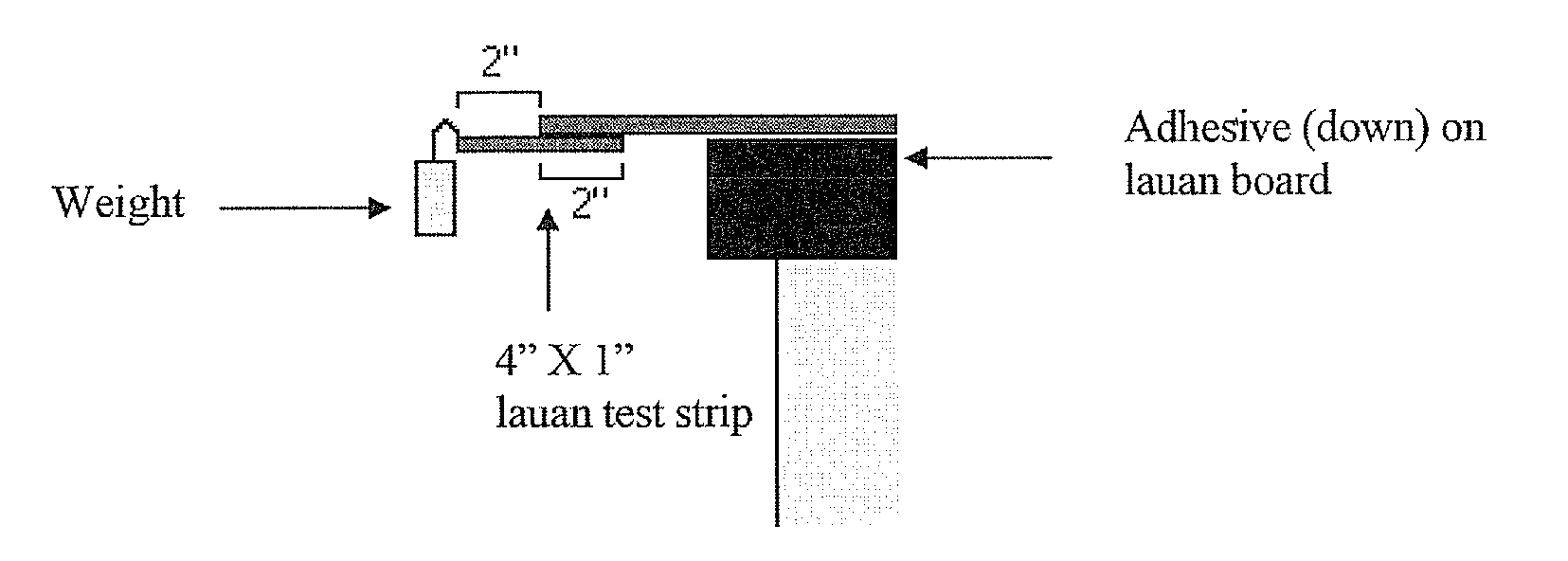

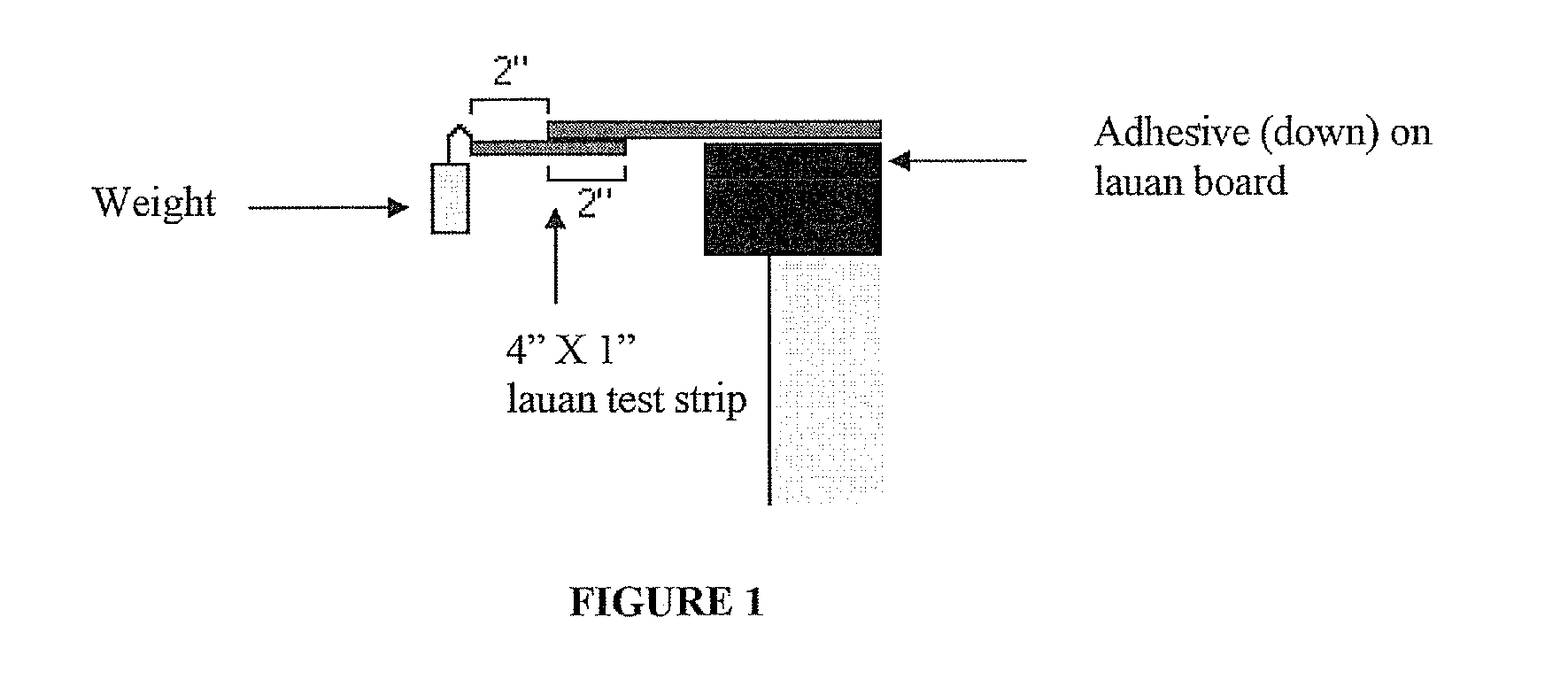

Polyester polyols for polyurethane adhesives

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phahalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:OBRIEN MICHAEL E

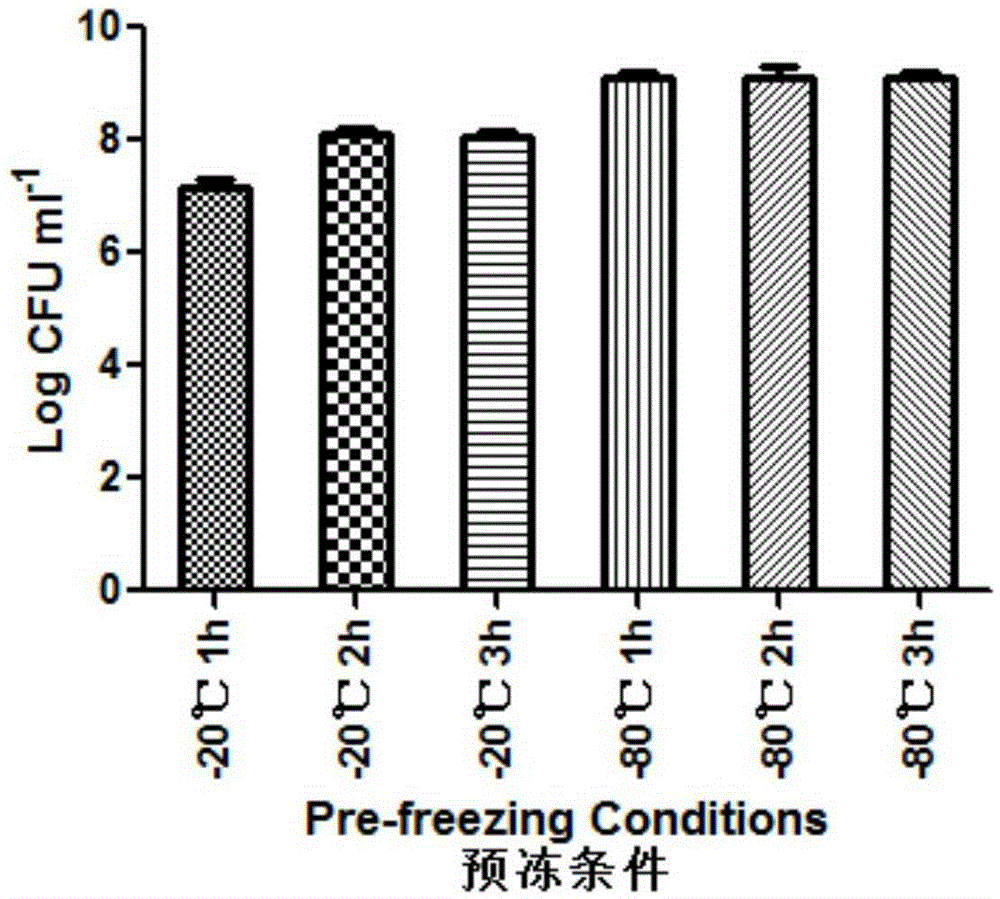

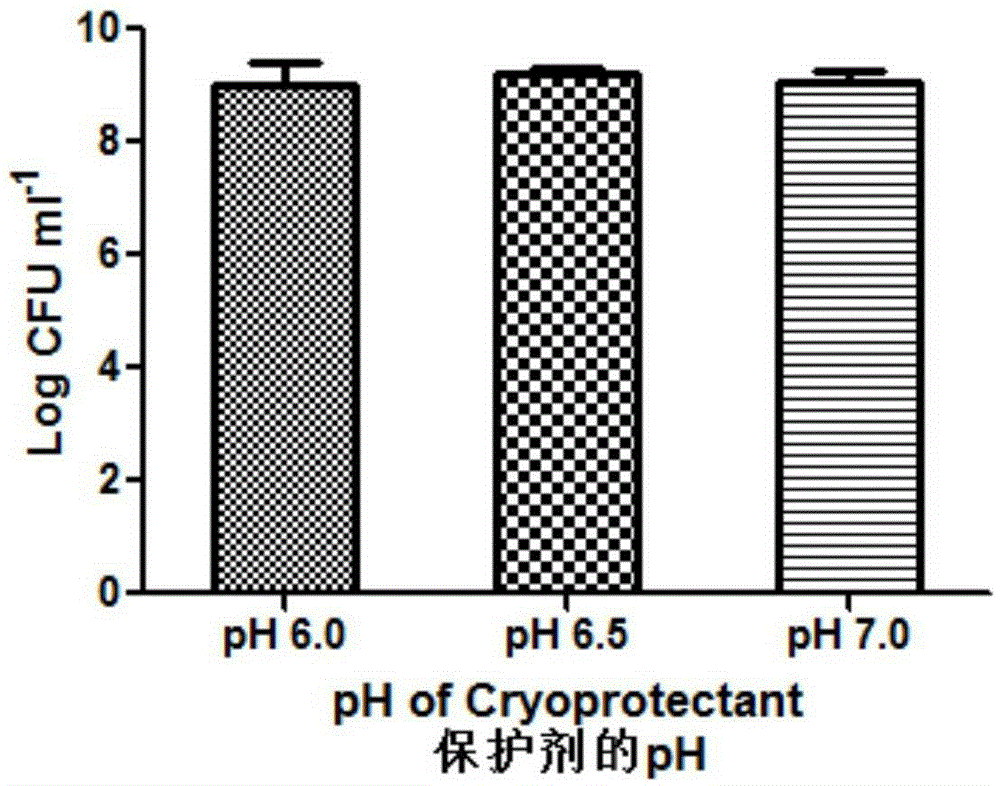

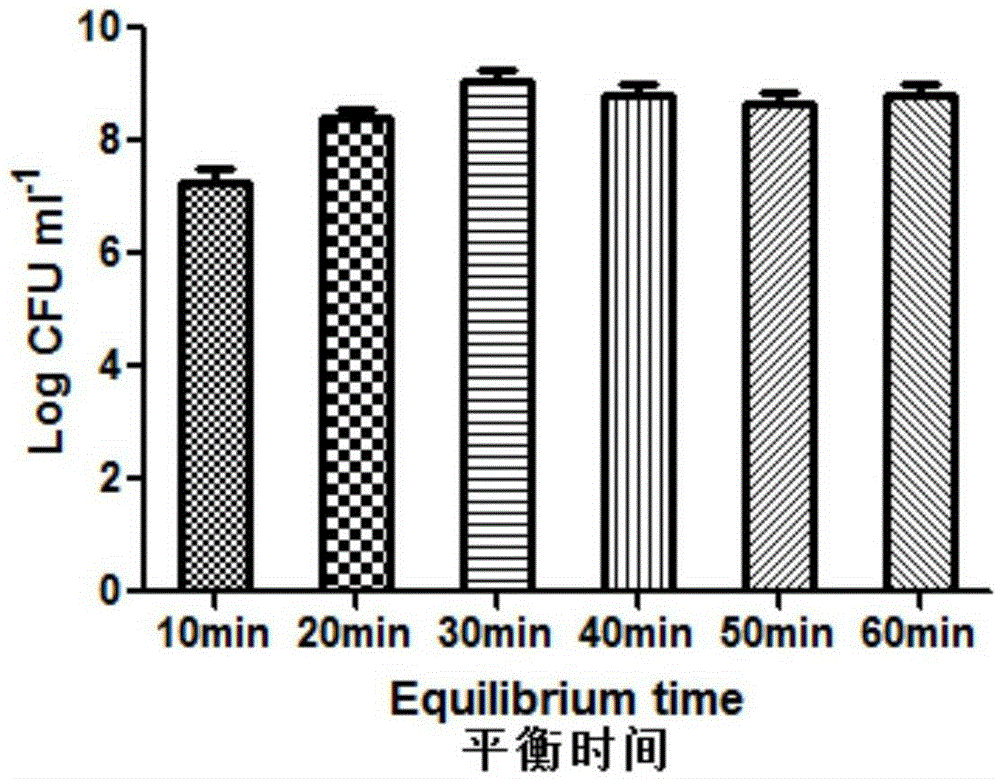

Probiotic microcapsules as well as preparation method and application thereof

ActiveCN105310080AImprove the situation of low freeze-drying survival rateImprove stabilityFood freezingFood shapingFreeze-dryingK carrageenan

The invention relates to probiotic microcapsules as well as a preparation method and application thereof. The probiotic microcapsules comprise a core material and a wall material, wherein the core material is probiotics; the outer layer of the wall material is coated with chitosan; the wall material is prepared from an aqueous solution containing a natural polymer material and a freeze-drying protection agent; the freeze-drying protection agent comprises one or more of glucose, fructose, sucrose, lactose, trehalose, soluble starch, glycerin, mannitol, Arabic gum, dextran 40 and skim milk; the natural polymer material comprises one or more of gellan gum, xanthan gum, k-carrageenan, sodium alginate, cellulose acetate phthalate or gelatin; in the aqueous solution, the volume fraction of the freeze-drying protection agent is 4.0%-20.0% and the volume fraction of the polymer material is 0.5%-5.0%. The probiotic microcapsules can keep excellent acid resistance and storage stability before and after being freeze-dried.

Owner:SUN YAT SEN UNIV

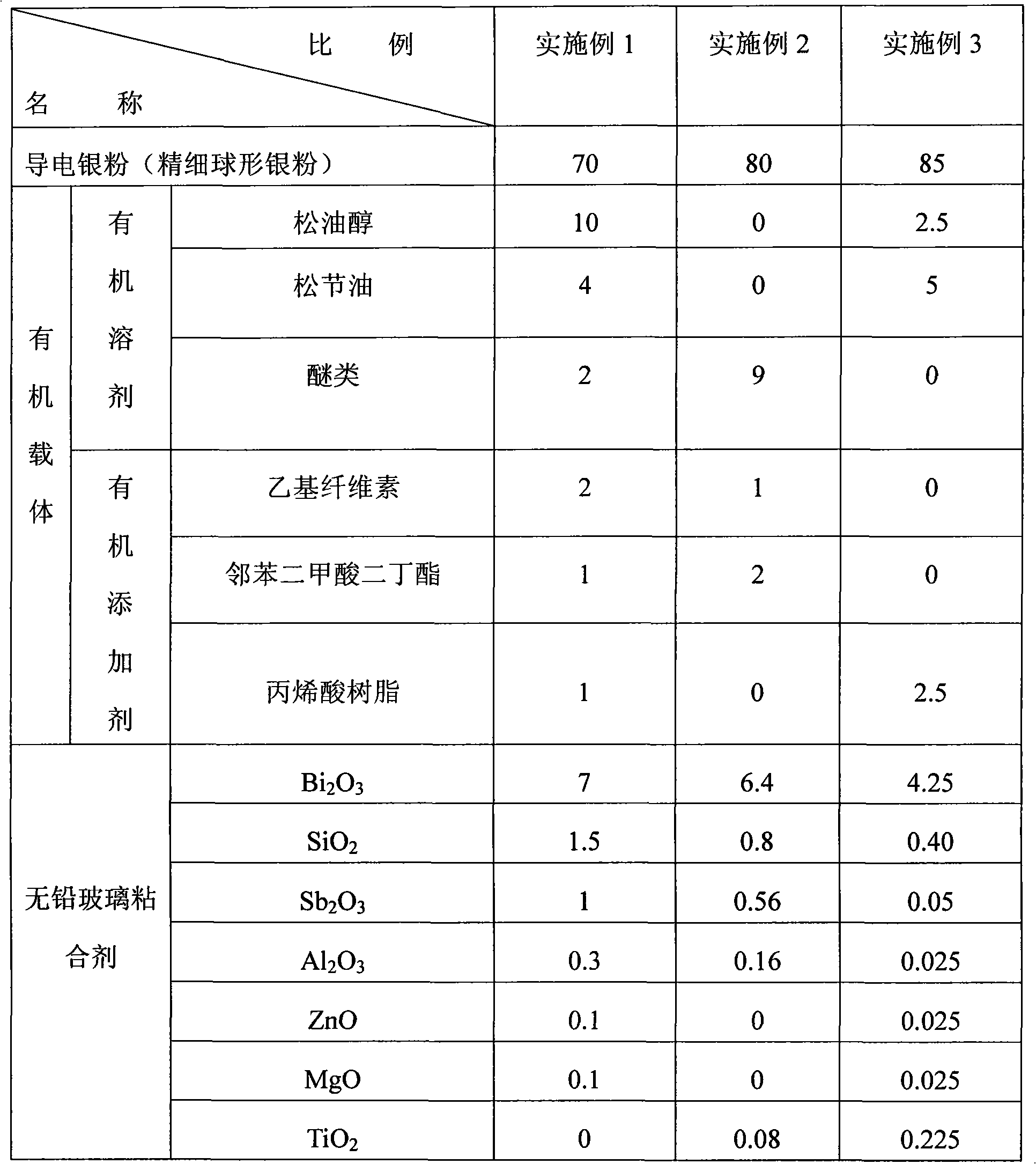

Leadless solar battery silver paste and method for producing the same

InactiveCN101271929AImprove photoelectric conversion efficiencyStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAcrylic resinContact resistance

The invention discloses lead-free solar cell silver serum and a preparation method thereof, which consists of 70-85 percent of conducting silver powder, 5-10 percent of lead-free glass glue and 5.5-25 percent of organic carrier, wherein, the organic carrier consists of organic solvent and organic additive, the organic solvent is any kind of terpineol, terebinth and ethers or their combination; the organic additive is any kind of ethyl cellulose, dibutyl phthalate and acrylic resin or their combination; the particle size of the conducting silver powder is 0.2-2mum; and the lead-free glass glue belongs to bismuth-silicon- antimony glass system. The solar cell silver serum obtained by the method in the invention is lead-free, which complies with requirements of environmental protection, and a conducting electrode with strong adhesive force and low ohm contact resistance can be formed on the surface of the solar cell. The cell has high photoelectric conversion efficiency and is an ideal substituent of the lead silver serum.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

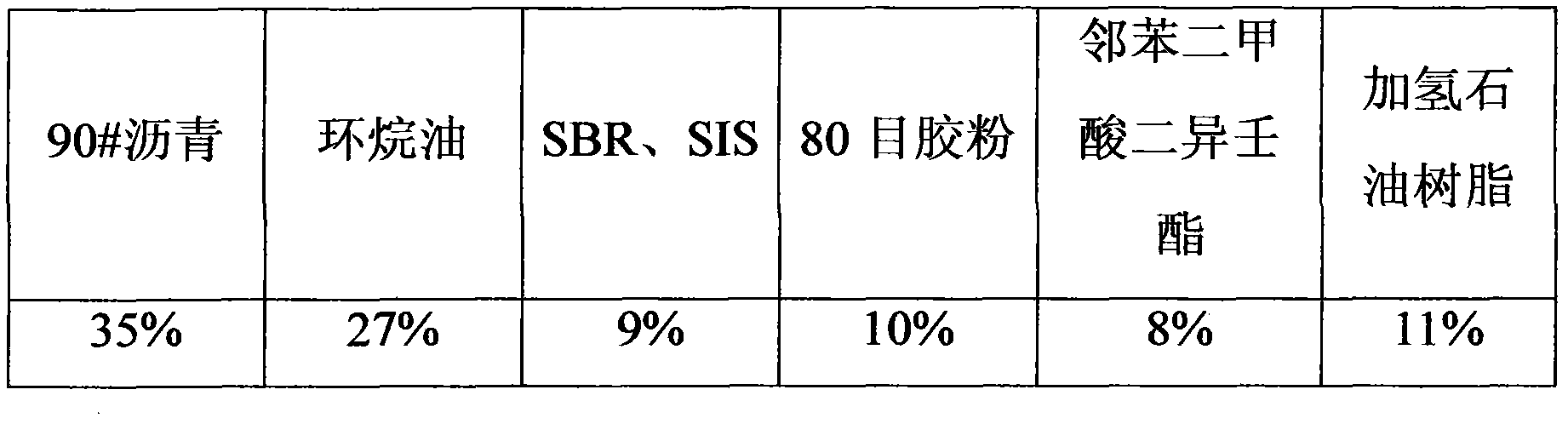

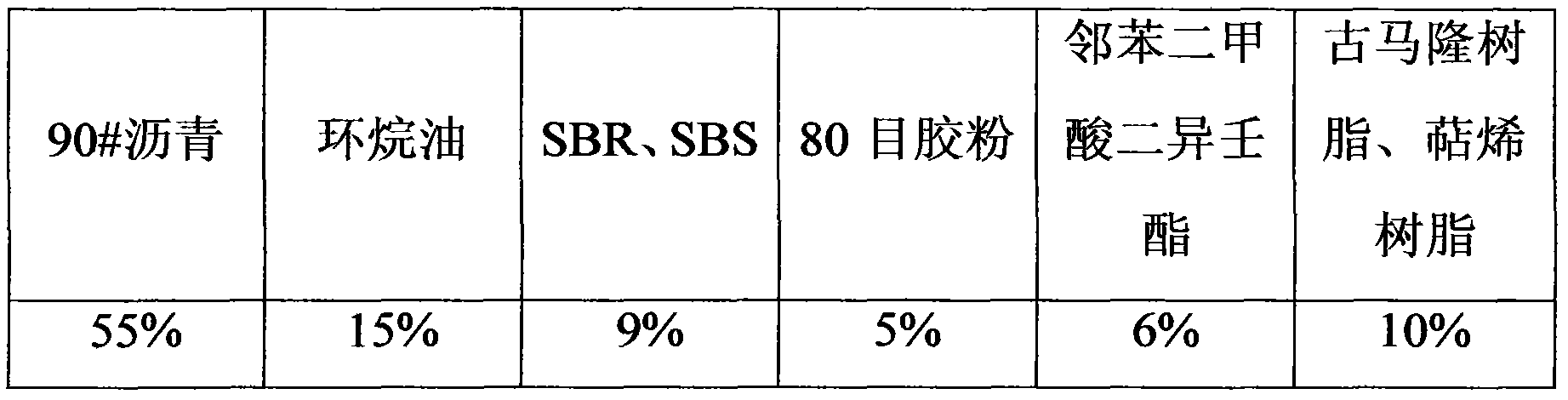

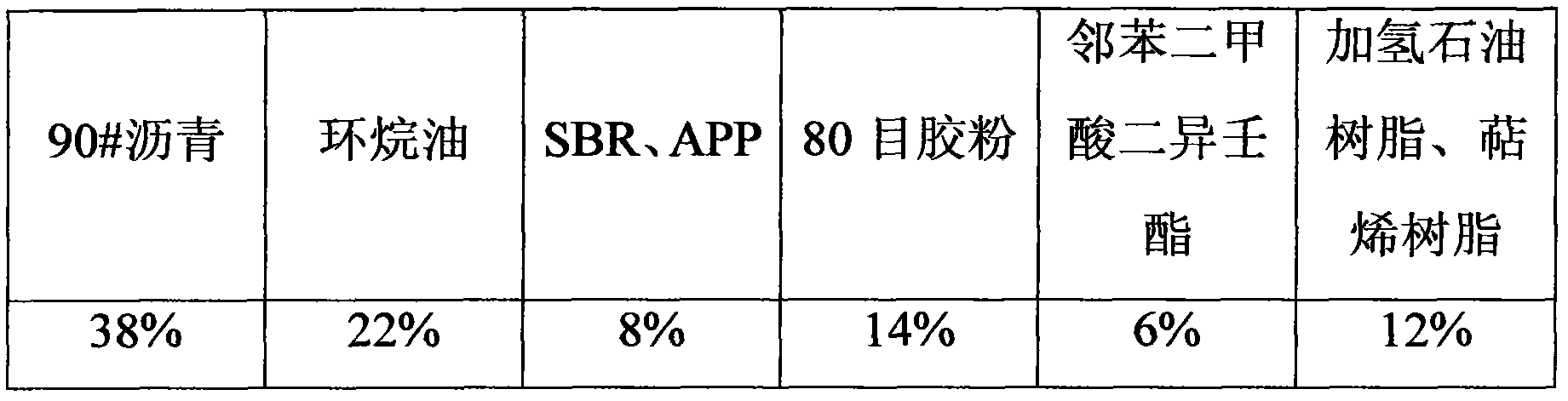

Non-cured asphalt mastic

The invention requests to protect non-cured asphalt mastic comprising the following components in percentage by weight: 35-55 asphalt, 15-30 naphthenic oil, 3-10 polymer modifying agent, 55-20 gelatin powder, 3-10 diisononyl phthalate and 10-20 tackifying resin. The non-cured asphalt mastic can be independently used or can be used with the matched coil to form a waterproof system and can effectively solve the problem of water leakage caused by the crack of a waterproof layer due to the deformation of a base layer.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Aqueous dispersion for chemical mechanical polishing

InactiveUS20010039766A1Improve balanceImprove accuracyPigmenting treatmentOther chemical processesOXALIC ACID DIHYDRATEColloidal silica

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

Multi-step methods for chemical mechanical polishing silicon dioxide and silicon nitride

InactiveUS20060138086A1Other chemical processesSemiconductor/solid-state device testing/measurementAmmonium compoundsCarboxylic acid

The present invention provides a method for polishing silica and silicon nitride on a semiconductor wafer comprising the steps of planarizing the silica with a first aqueous composition comprising by weight percent 0.01 to 5 carboxylic acid polymer, 0.02 to 6 abrasive, 0.01 to 10 polyvinylpyrrolidone, 0 to 5 cationic compound, 0 to 1 phthalic acid and salts, 0 to 5 zwitterionic compound and balance water, wherein the polyvinylpyrrolidone has an average molecular weight between 100 grams / mole to 1,000,000 grams / mole. The method further provides detecting an endpoint to the planarization, and clearing the silica with a second aqueous composition comprising by weight percent 0.001 to 1 quaternary ammonium compound, 0.001 to 1 phthalic acid and salts thereof, 0.01 to 5 carboxylic acid polymer, 0.01 to 5 abrasive and balance water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

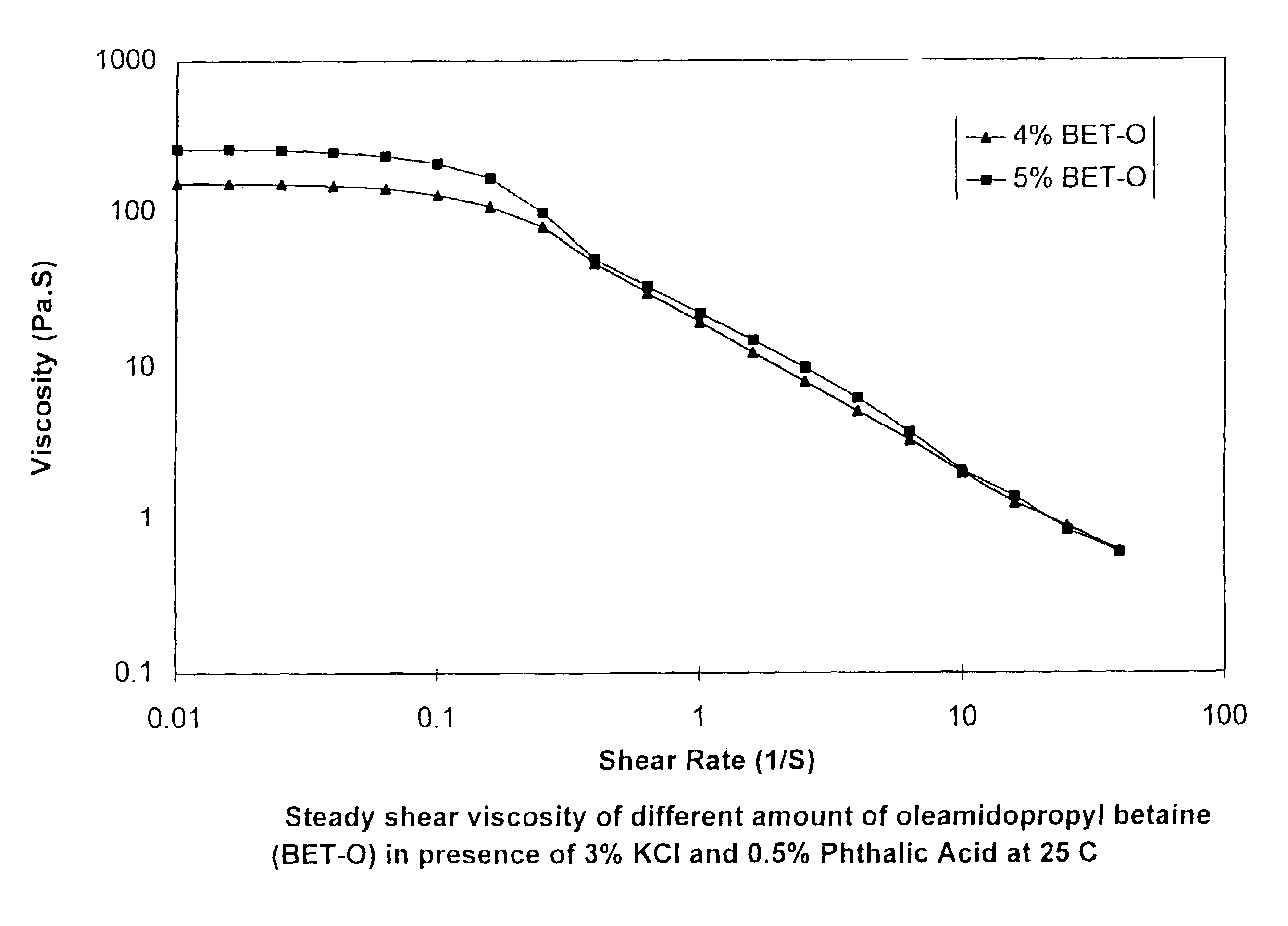

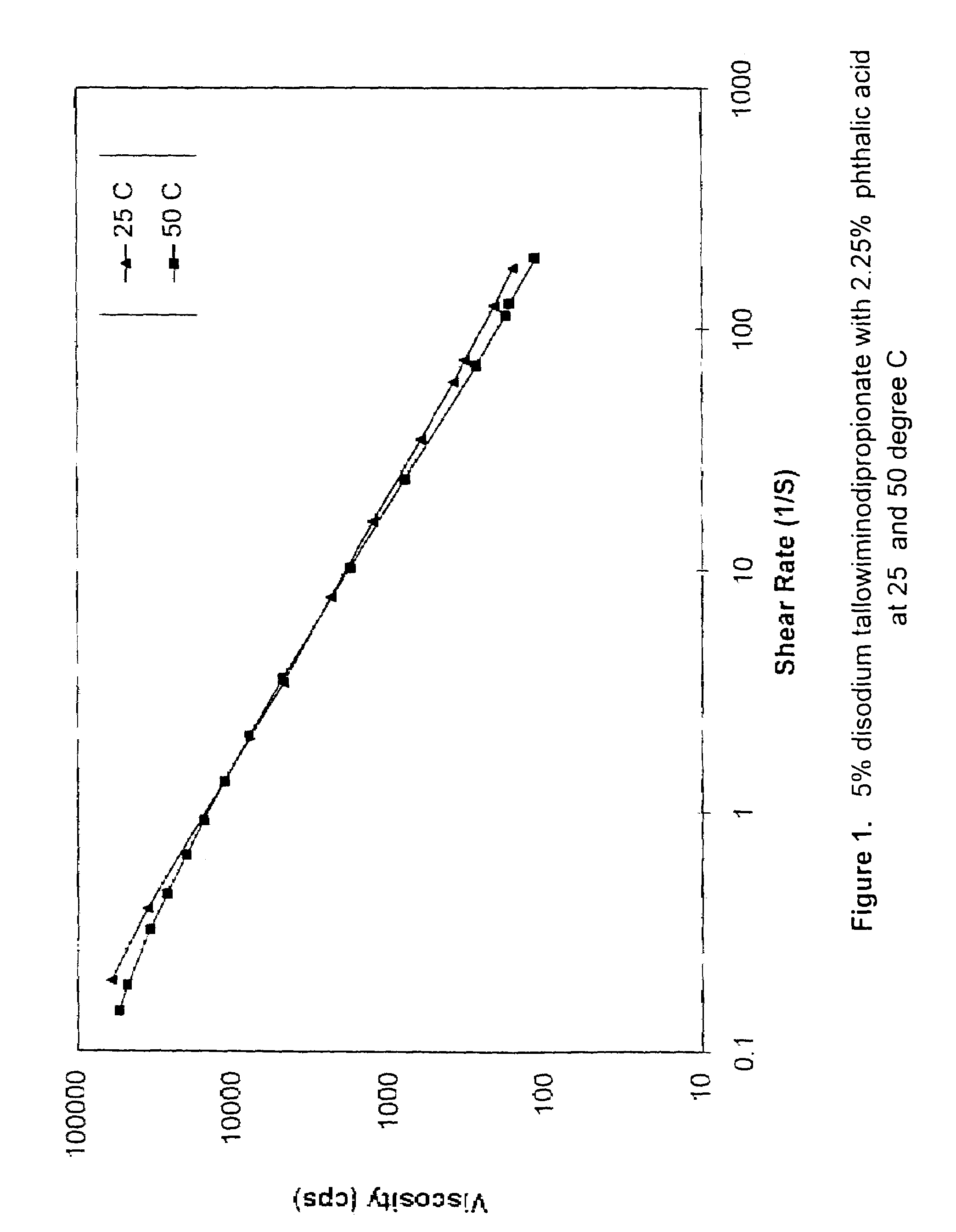

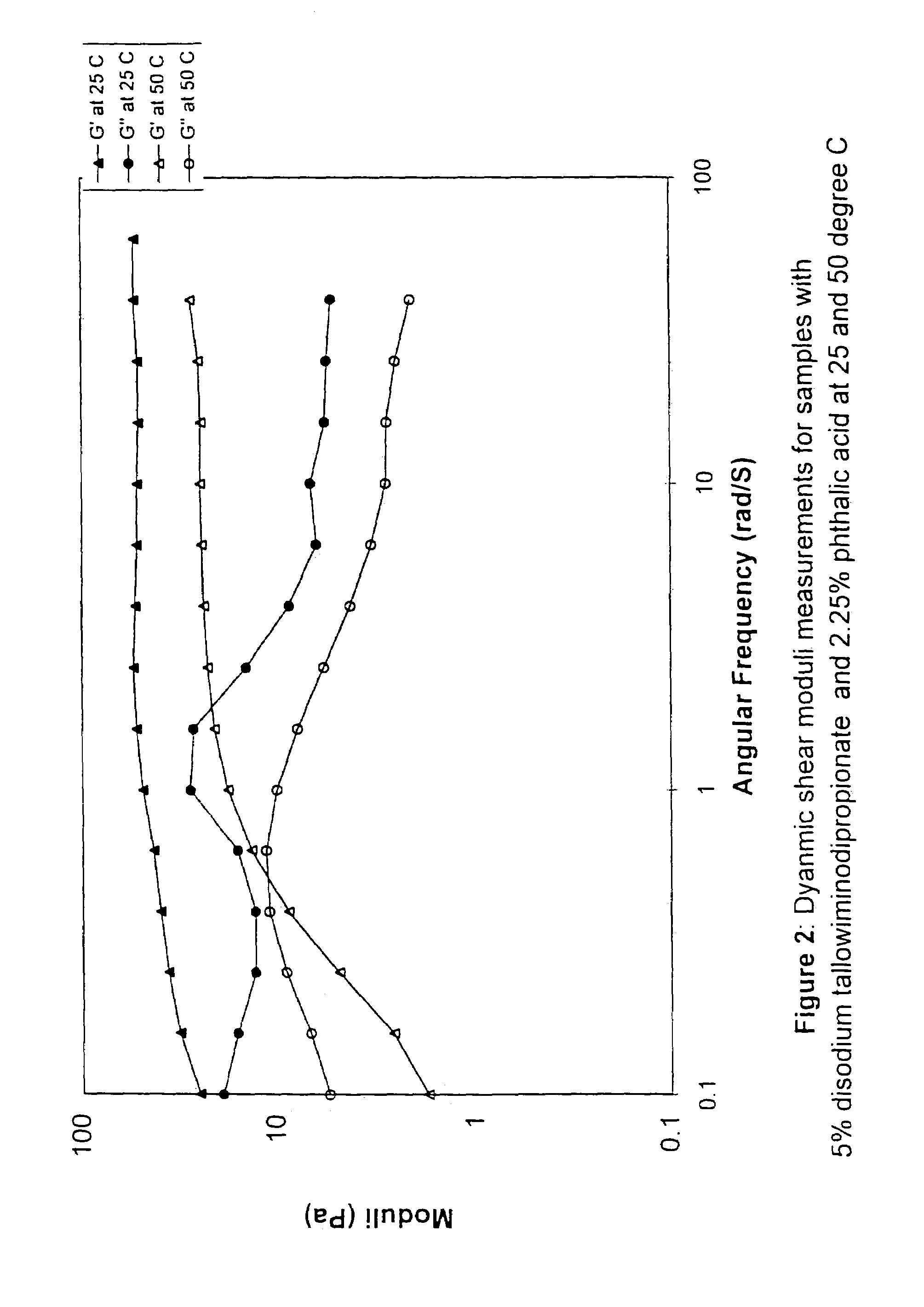

Viscoelastic surfactant fluids and related methods of use

InactiveUS7238648B2Increase droplet sizeIncrease in sizeInorganic/elemental detergent compounding agentsCosmetic preparationsSuspended particlesBetaine

Viscoelastic surfactant based aqueous fluid systems useful as thickening agents in various applications, e.g. to suspend particles produced during the excavation of geologic formations. The surfactants are zwitterionic / amphoteric surfactants such as dihydroxyl alkyl glycinate, alkyl ampho acetate or propionate, alkyl betaine, alkyl amidopropyl betaine and alkylimino mono- or di-propionates derived from certain waxes, fats and oils. The thickening agent is used in conjunction with an inorganic water-soluble salt or organic additive such as phthalic acid, salicylic acid or their salts.

Owner:SCHLUMBERGER TECH CORP

Paint for H grade polyurethane enamelled wire with good saline water needle performace capable of directing welding at low temp.

InactiveCN1597815AImprove heat resistanceQuality improvementPlastic/resin/waxes insulatorsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to an H-grade wire coating enamel that has good salt water pinhole performance and can be directly welded at low temperature, containing hydroxyl component, sealed isocyanate component and solvent, where its hydroxyl component has an acid value less than 2, a hydroxyl value of 150-300, and number-average molecular weight of 1500-5000, and as synthesized, the raw materials has at least m-phthalic acid, p-phthalic acid, adilic acid, glycerin and a kind of dibasic alcohol in the weight ratio of 1 to (0.2-2) to (0.2-0.5) to (0.5-3) to (0.5-1.5); and its sealed isocyanate component is partially added of MDI by mixed polyalcohol that at least has a dibasic alcohol and a tribasic alcohol; in the paint base, the equivalent ratio of isocyanate base to OH is (0.9-1.2) : 1, and it reaches H-grade and has good salt water pinhole property of paint film, tin daubing temperature less than or equal to 375 deg.C.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

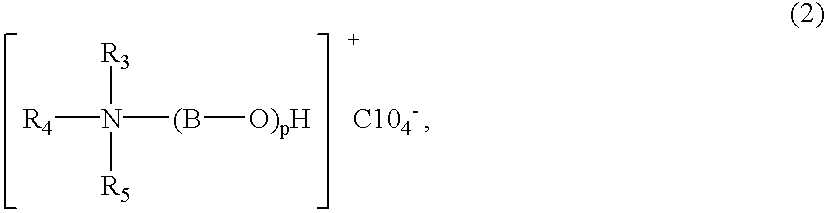

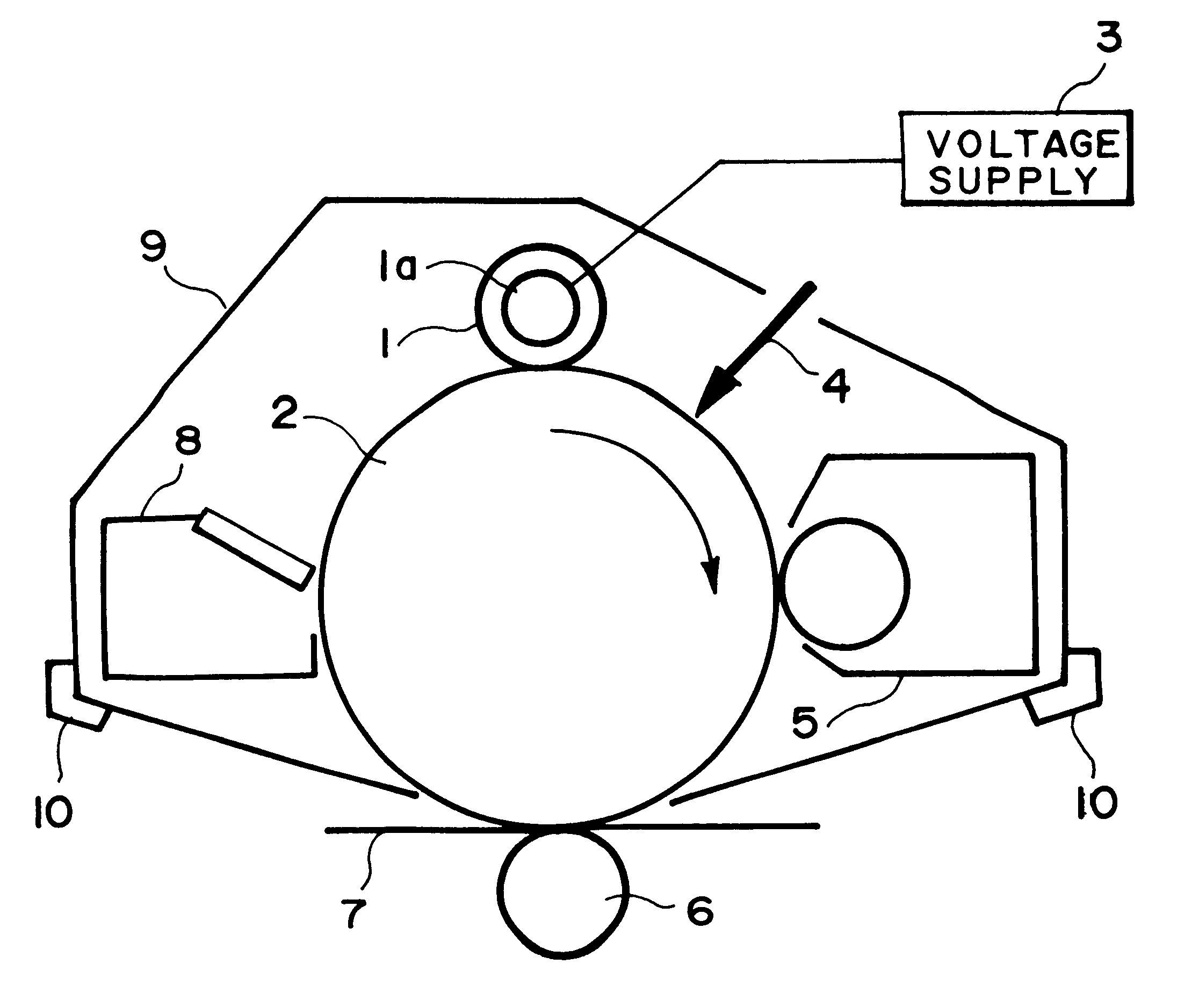

Conductive roller, process cartridge and image forming apparatus

InactiveUS6558781B1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolymer scienceAmmonium compounds

An electroconductive roller is capable of exhibiting stable conductivity regardless of environmental change and is accompanied by small bleed-out of additives. The conductive roller includes an electroconductive support, an electroconductive elastic layer coating the support and a resistance layer coating the elastic layer; wherein the elastic layer comprises at least one species of rubber selected from the group consisting of acrylonitrile-butadiene rubber, epichlorohydrin rubber and chloroprene rubber, an ether oxygen containing alkyl phthalate derivative, a quaternary ammonium perchlorate compound and a fatty oil, and the ether oxygen-containing alkyl phthalate derivative, quaternary ammonium perchlorate compound and fatty oil are contained in a total amount of 0.1-20 wt. parts per 100 wt. parts of the rubber. The conductive roller is suitably used as a contact charging member in an electrophotographic apparatus.

Owner:CANON KK

Anti-skid sole material

The invention relates to the field of a formula for a sole material, especially to an anti-skid sole material. The anti-skid sole material comprises, by mass, 30 to 40 parts of butadiene rubber, 10 to 20 parts of butadiene-acrylonitrile rubber, 5 to 8 parts of white carbon black, 1 to 2 parts of magnesium oxide, 3 to 4 parts of stearic acid, 2 to 5 parts of polyethylene glycol, 1 to 2 parts of zinc oxide, 1 to 2 parts of machine oil, 5 to 7 parts of dibutyl phthalate, 0.5 to 1.3 parts of an antioxidant and 0.8 to 2.4 parts of an activator. The anti-skid sole material has a wet antiskid coefficient of 0.8 and a wet antiskid coefficient of 0.6; and the antiskid performance of the sole material is improved, so safety in usage of the sole material is guaranteed.

Owner:TONGXIANG YIYUAN SHOES

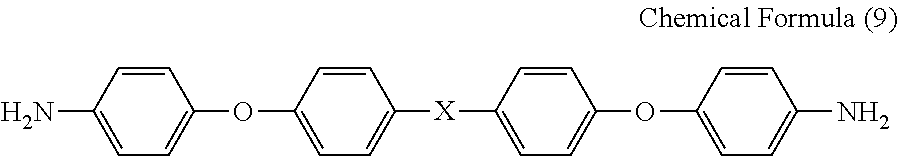

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS20120168688A1Small degree of swellingIncreased fracture energyHybrid capacitor electrodesElectrolytic capacitorsDiaminodiphenyl etherCarboxylic acid

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE IND LTD

Polyester Polyols for Polyurethane Adhesives

InactiveUS20100126664A1Improve adhesionHigh bonding strengthPolyureas/polyurethane adhesivesLaminationPolyesterPolymer science

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phthalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:STEPAN COMPANY

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120AImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

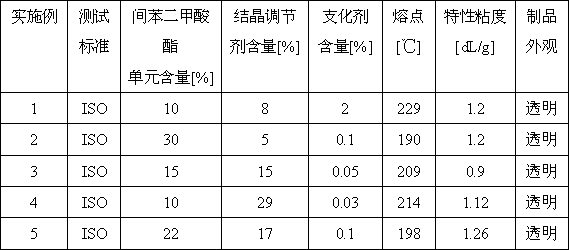

Low-melting point and transparent PET copolyester, its preparation method and application

ActiveCN103102473ASolve problems such as whiteningHigh transparencyMolten statePolyethylene terephthalate glycol

The invention discloses a low-melting point and transparent PET (polyethylene terephthalate) copolyester, its preparation method and application. The PET copolyester comprises, by mass: 60-84% of PET, 10%-30% of a unit derived from isophthalic acid, 5%-29% of a crystallization adjusting agent, and 0.03-2% of a branching agent. According to the preparation method, in a synthesis process of PET, based on p-phthalic acid (PTA) and ethylene glycol (EG), the unit derived from isophthalic acid, the crystallization adjusting agent and the branching agent are added to undergo a chemical reaction together, thus obtaining the low-melting point and transparent PET copolyester. The PET copolyester provided by the invention has an intrinsic viscosity greater than 0.9dL / g and a melting point lower than 230DEG C, can be solidified into an amorphous state from a molten state during injection molding, and has good transparency as well as further improved processing performance.

Owner:KINGFA SCI & TECH CO LTD +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com