Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17487results about "Building insulations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

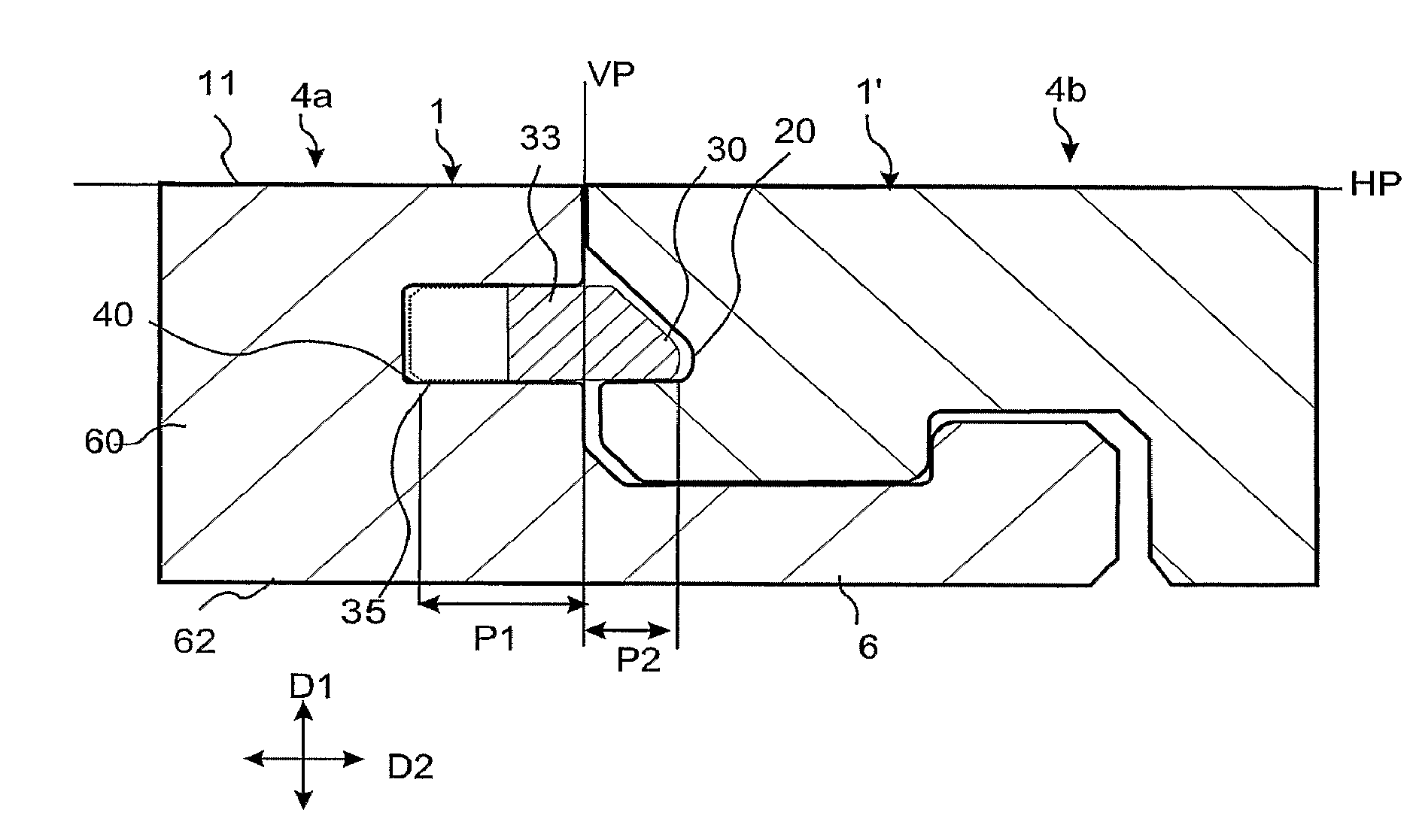

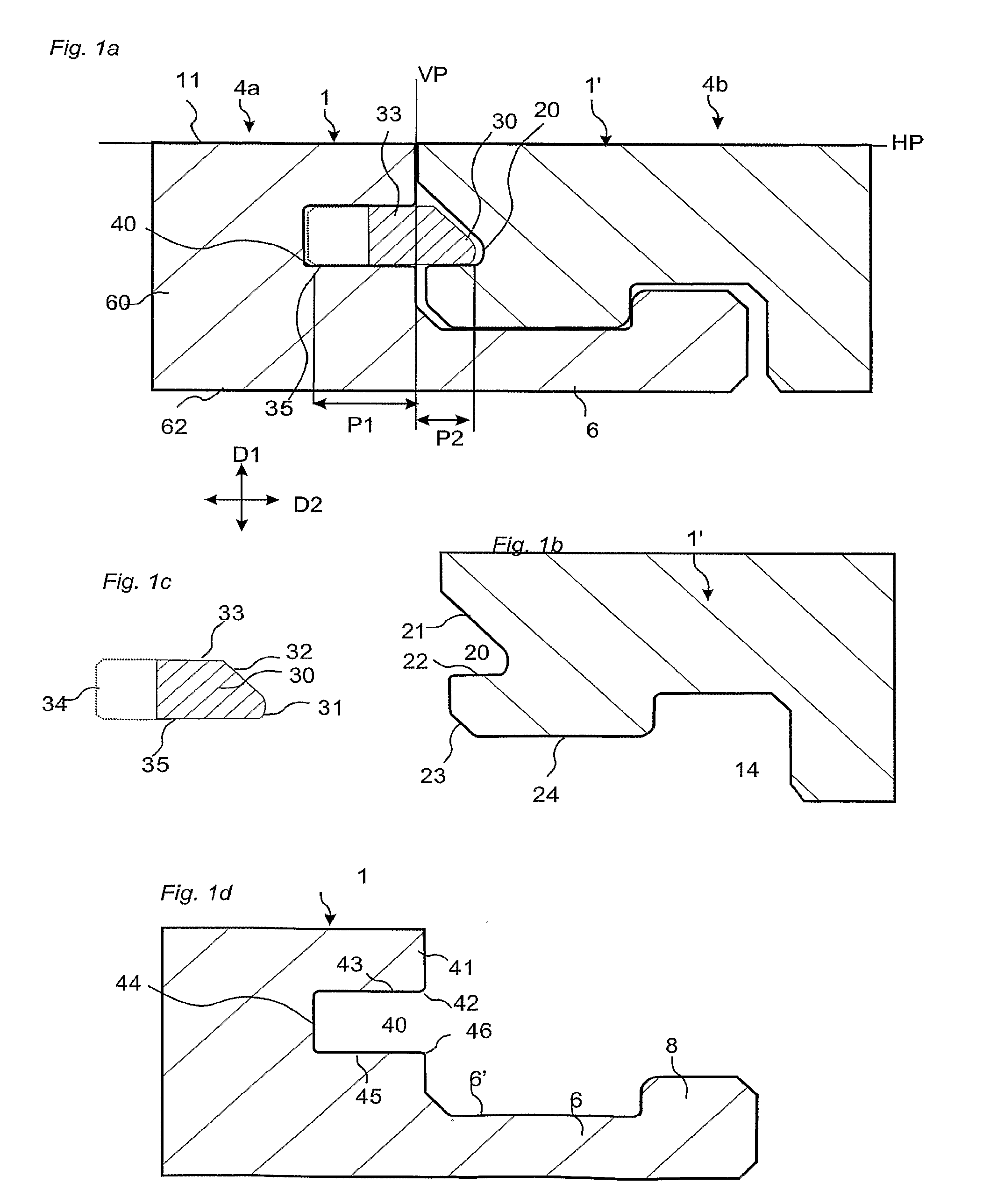

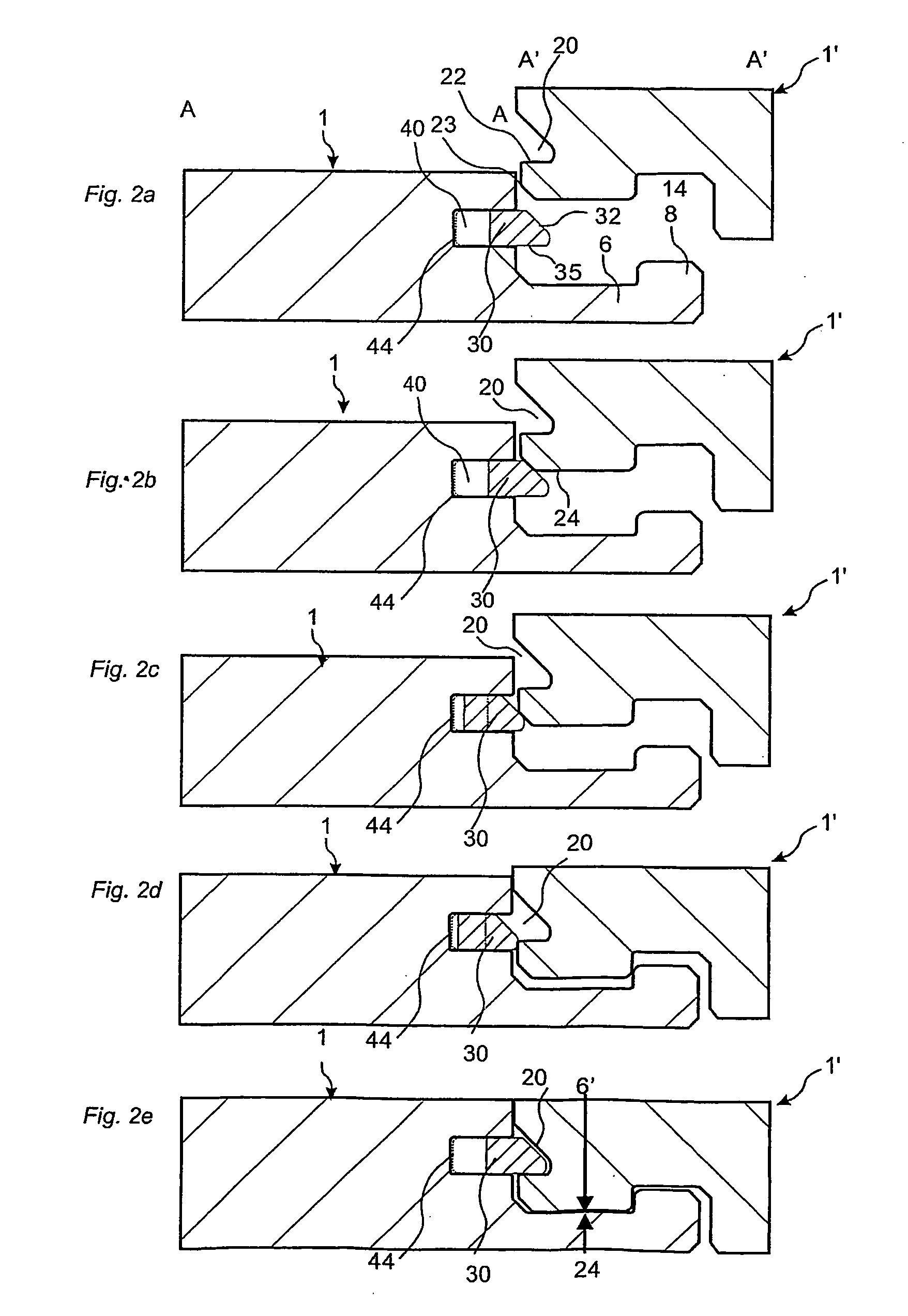

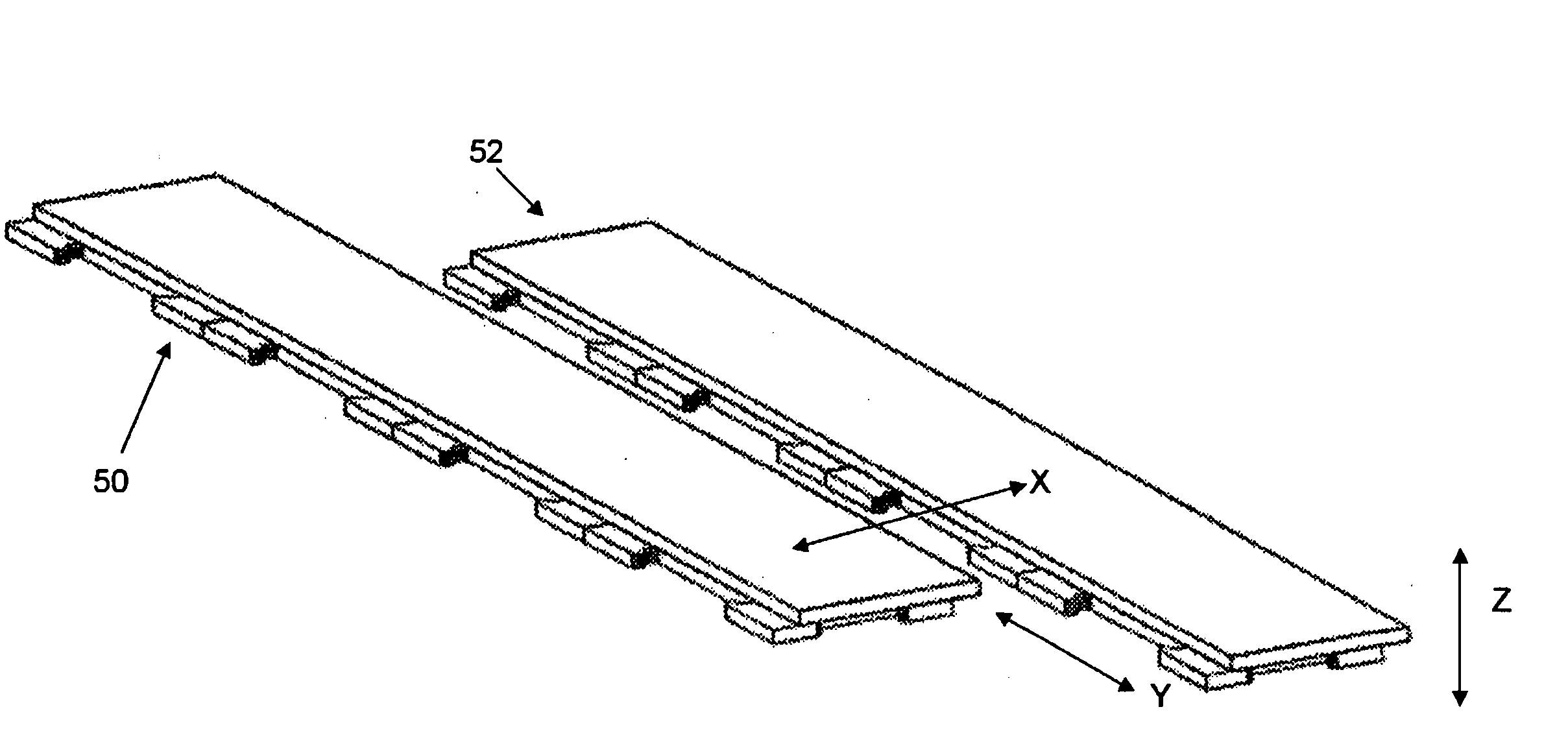

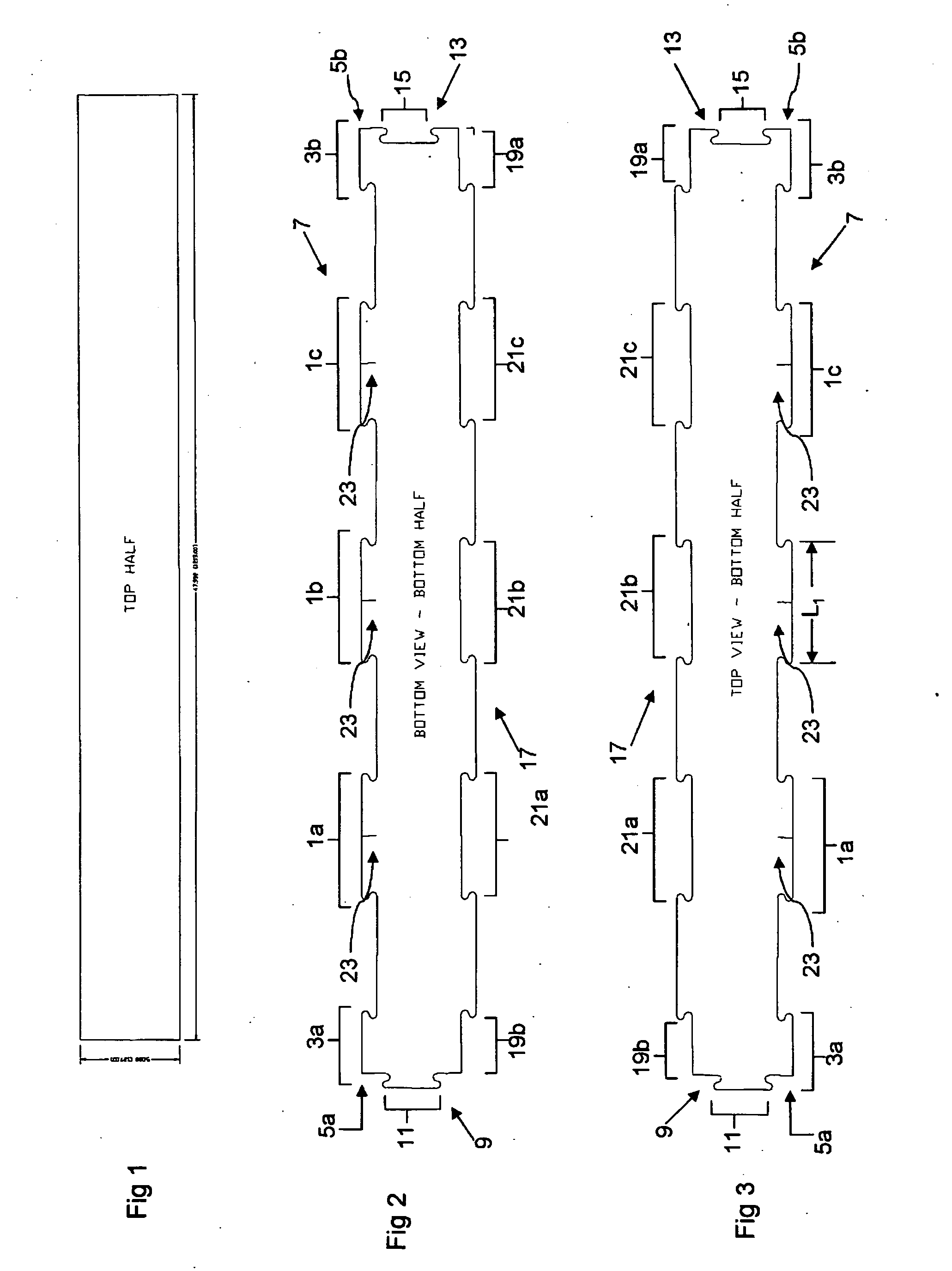

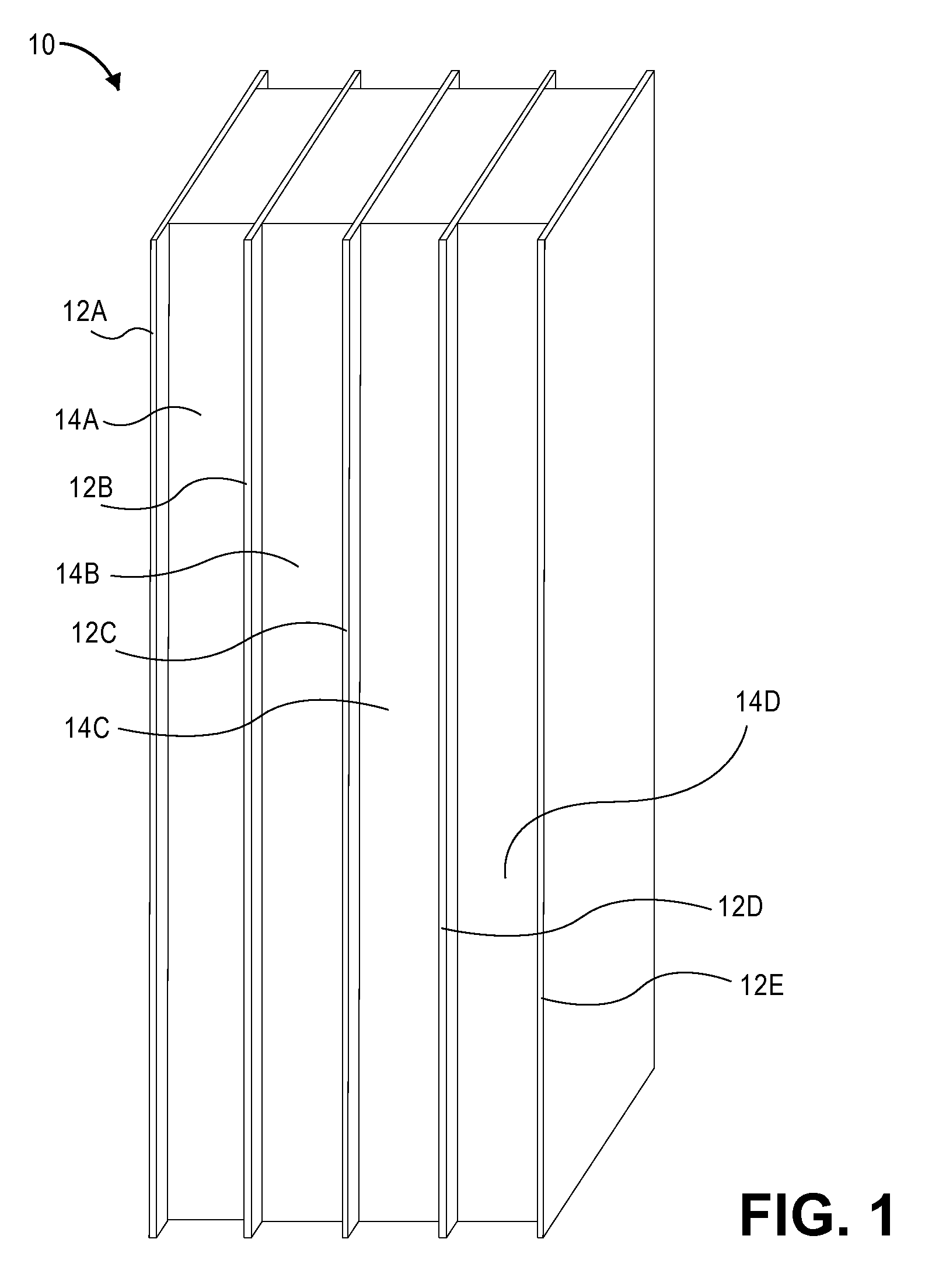

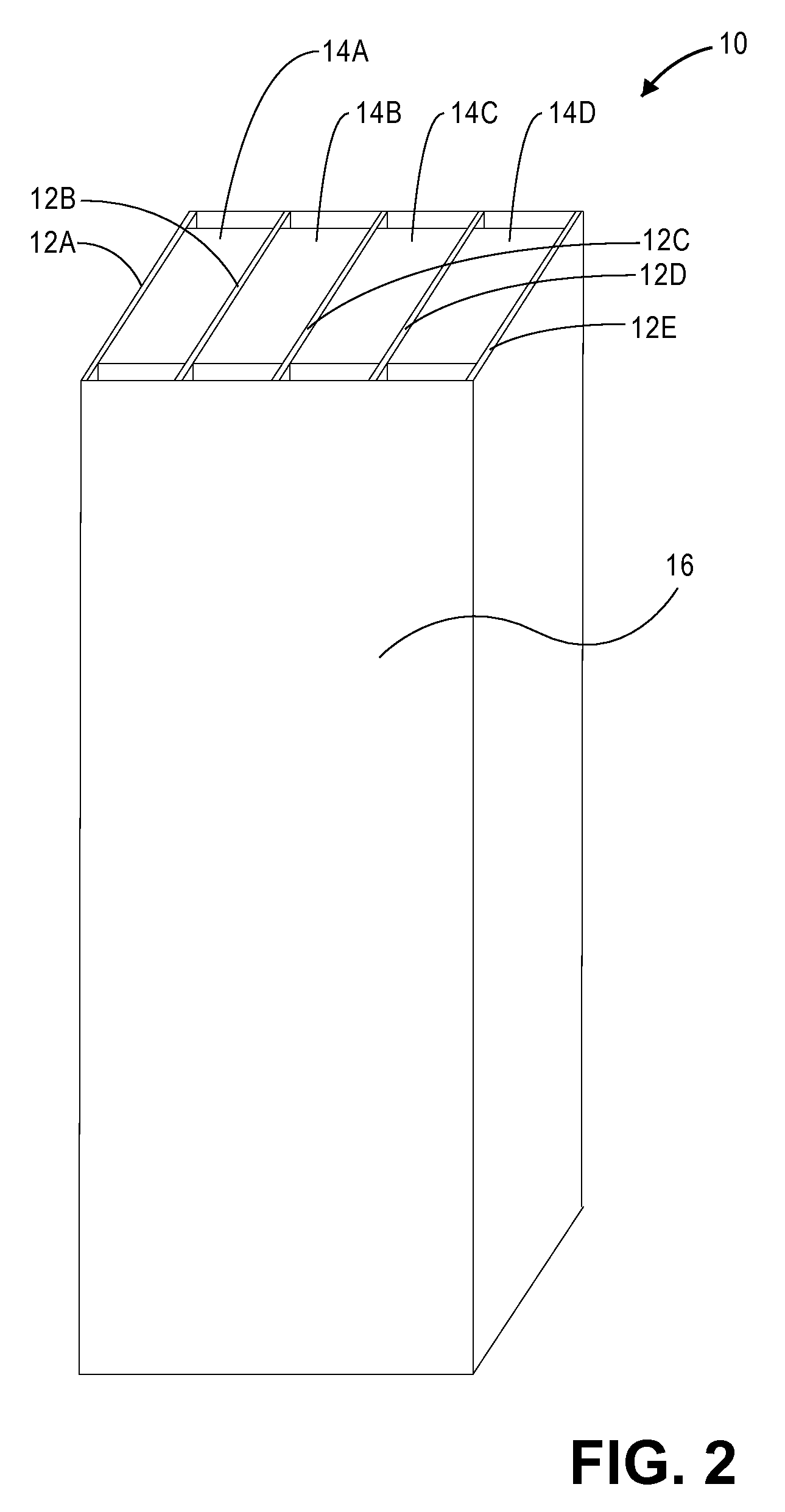

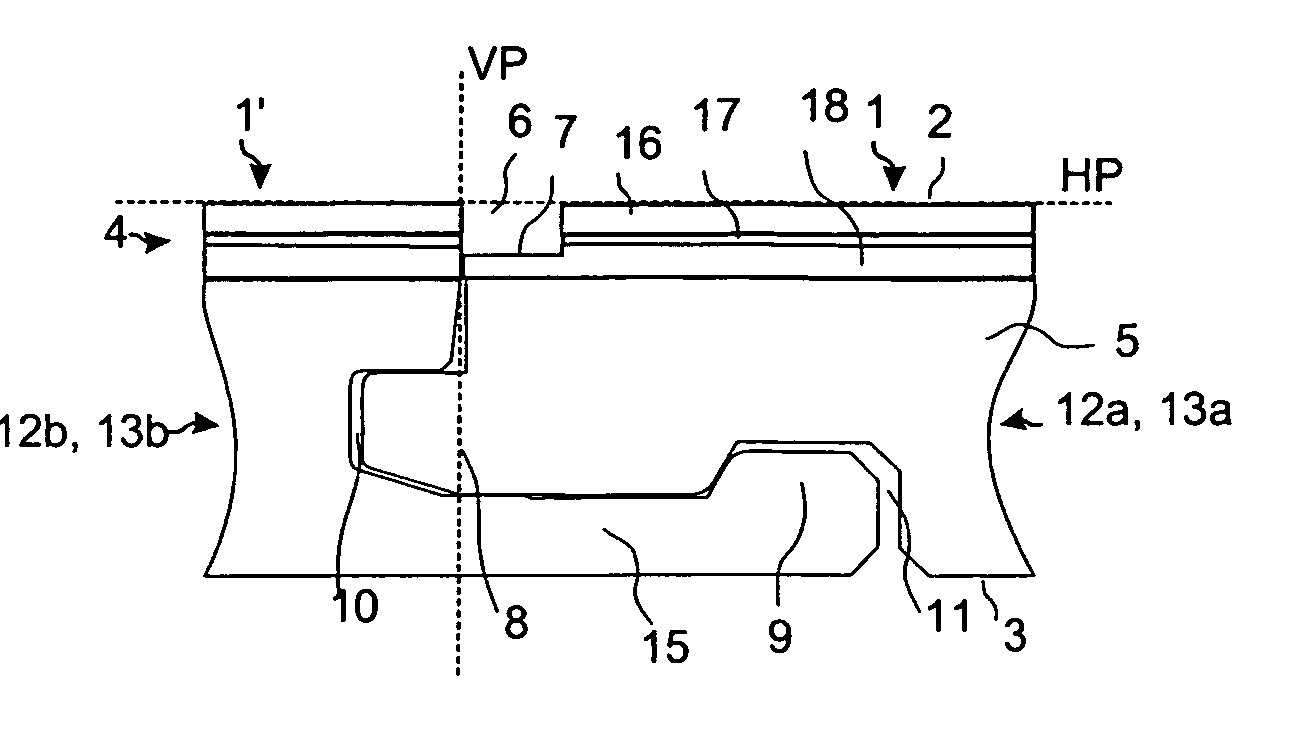

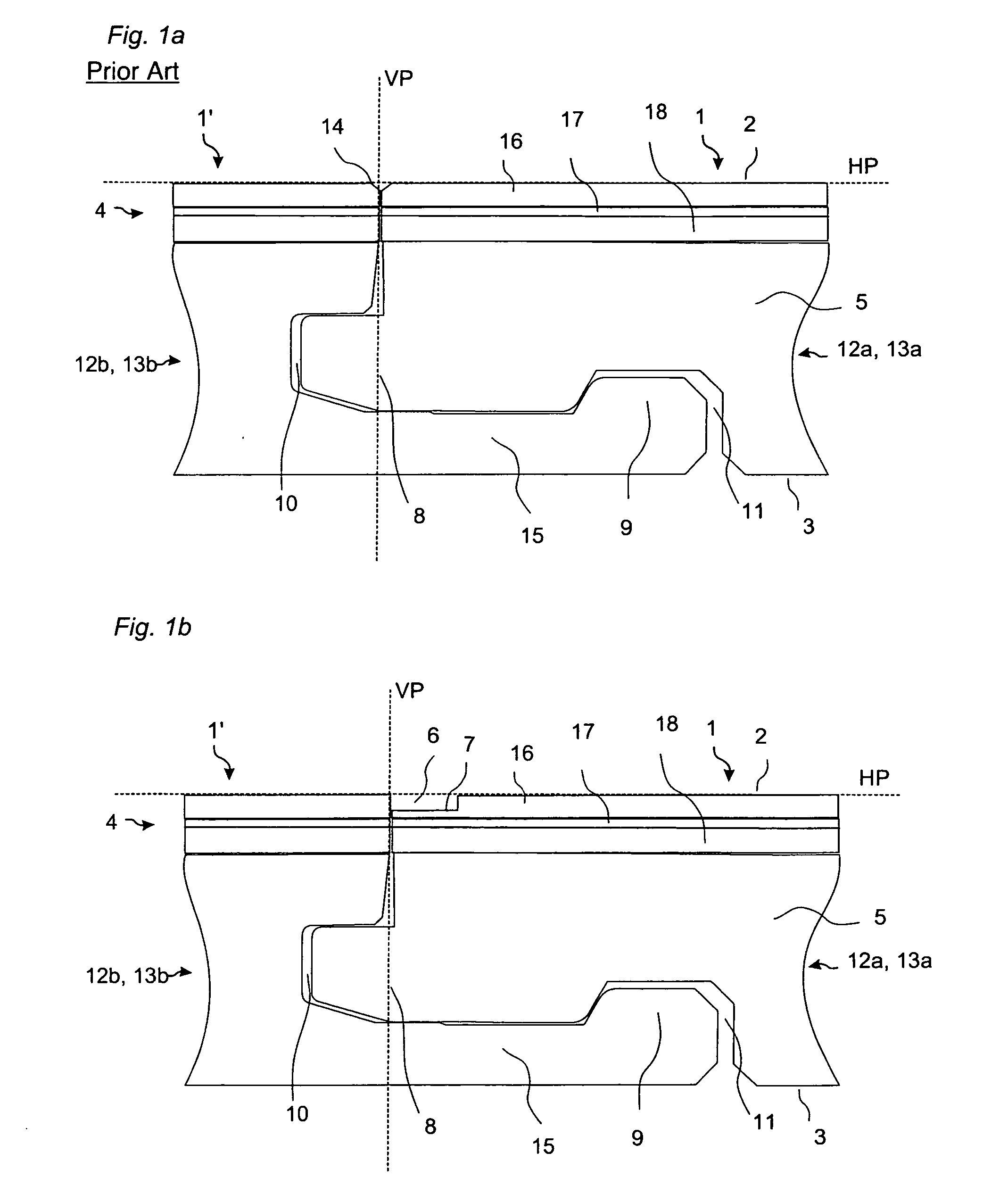

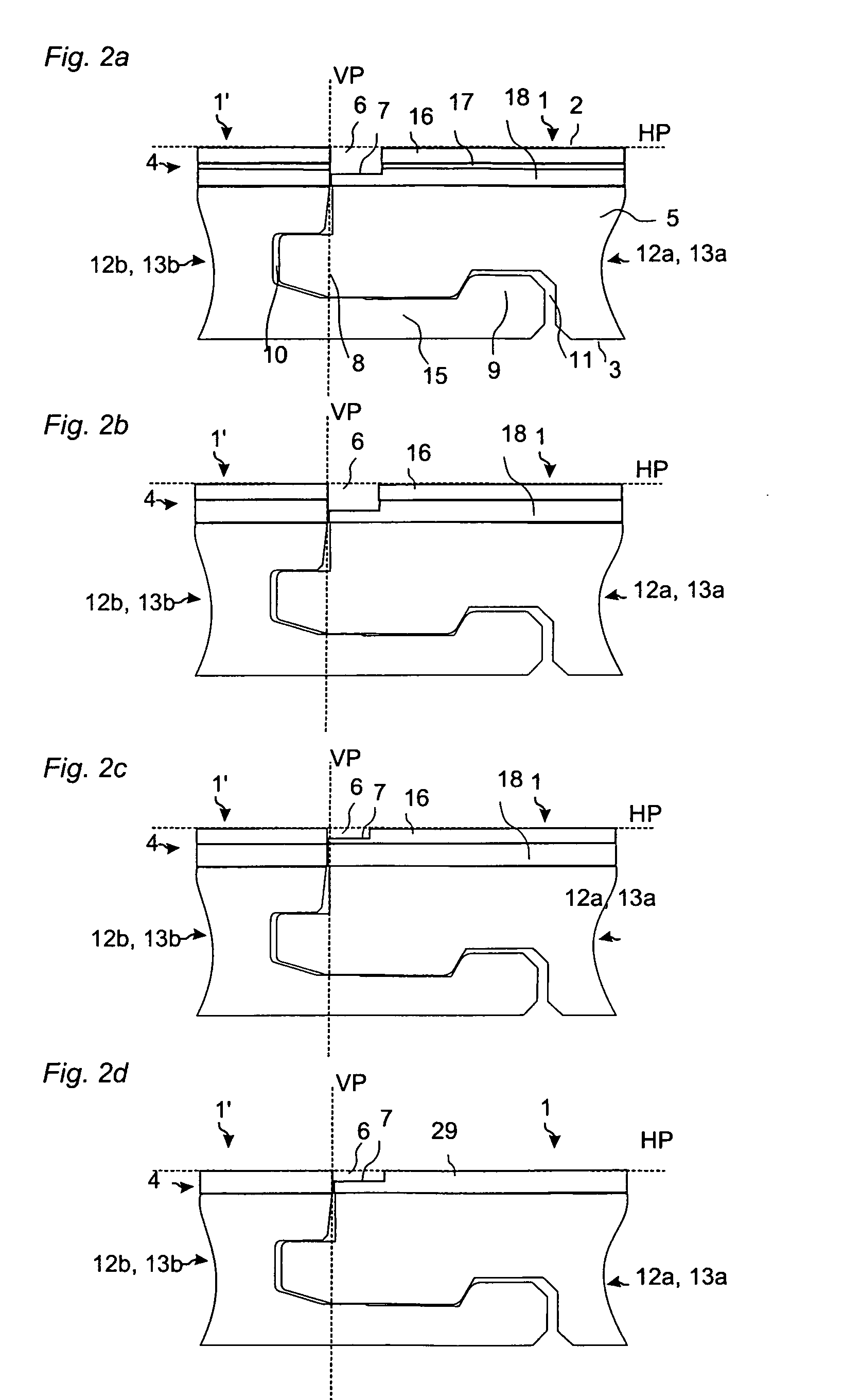

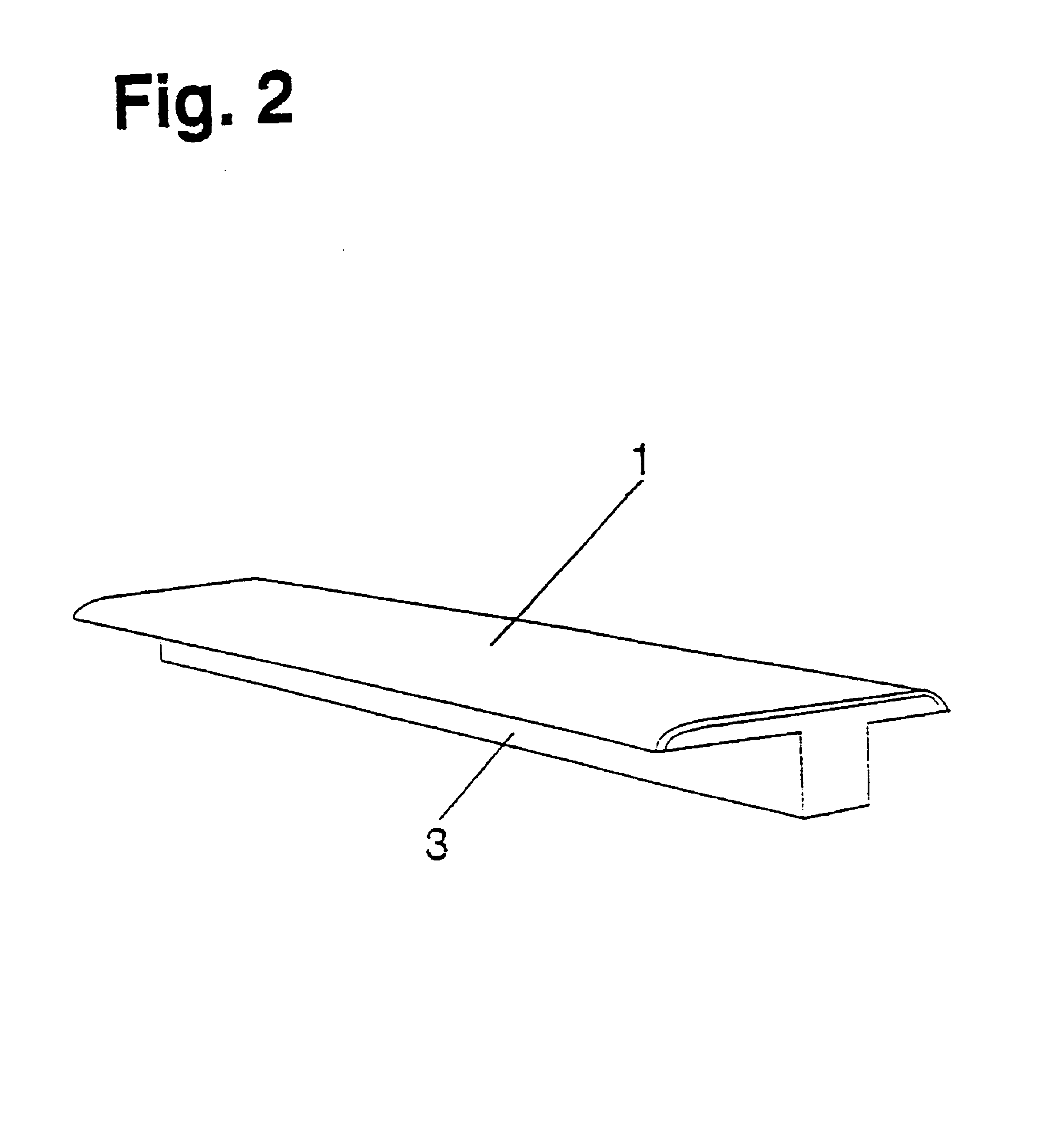

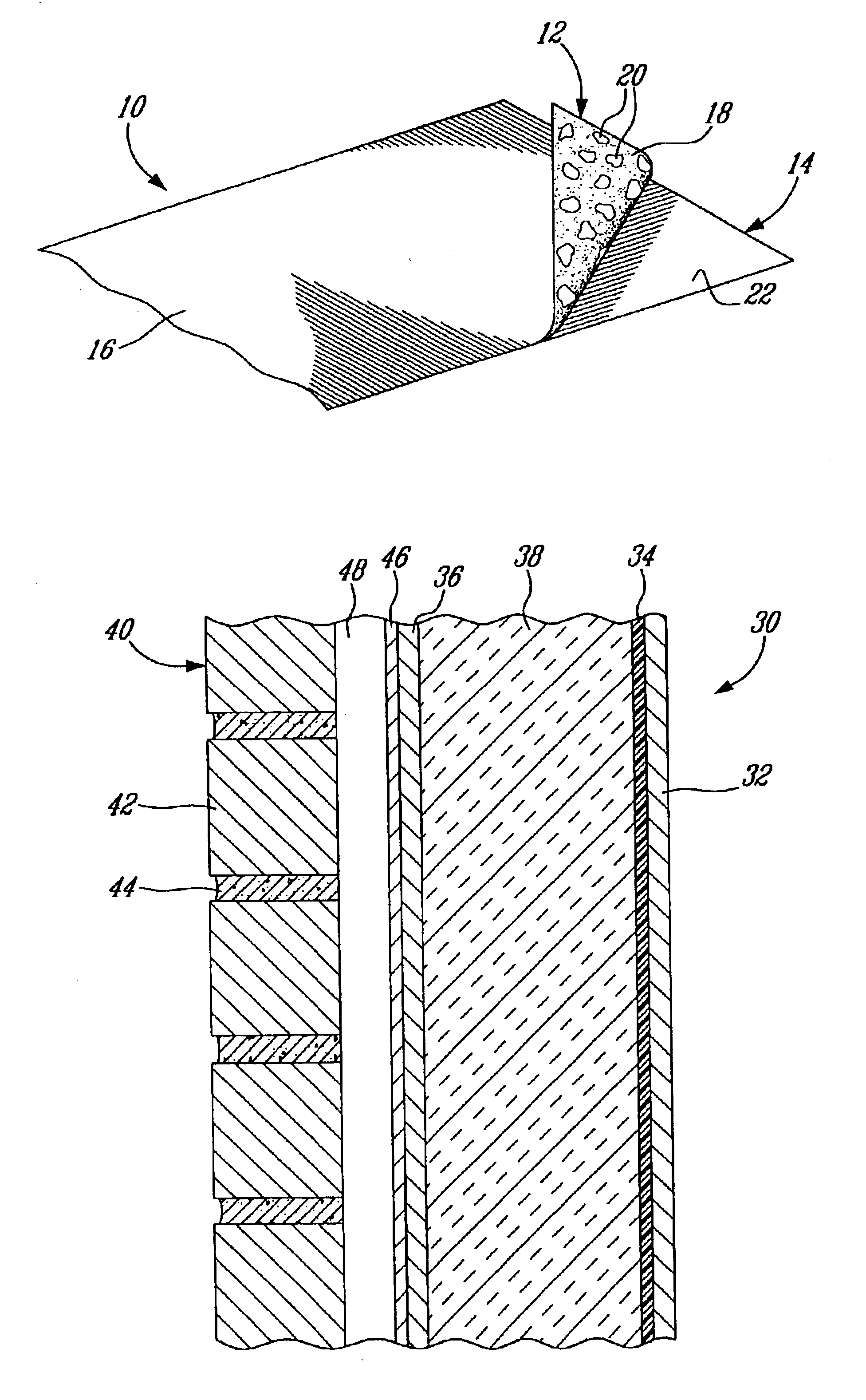

Mechanical Locking of Floor Panels With a Flexible Tongue

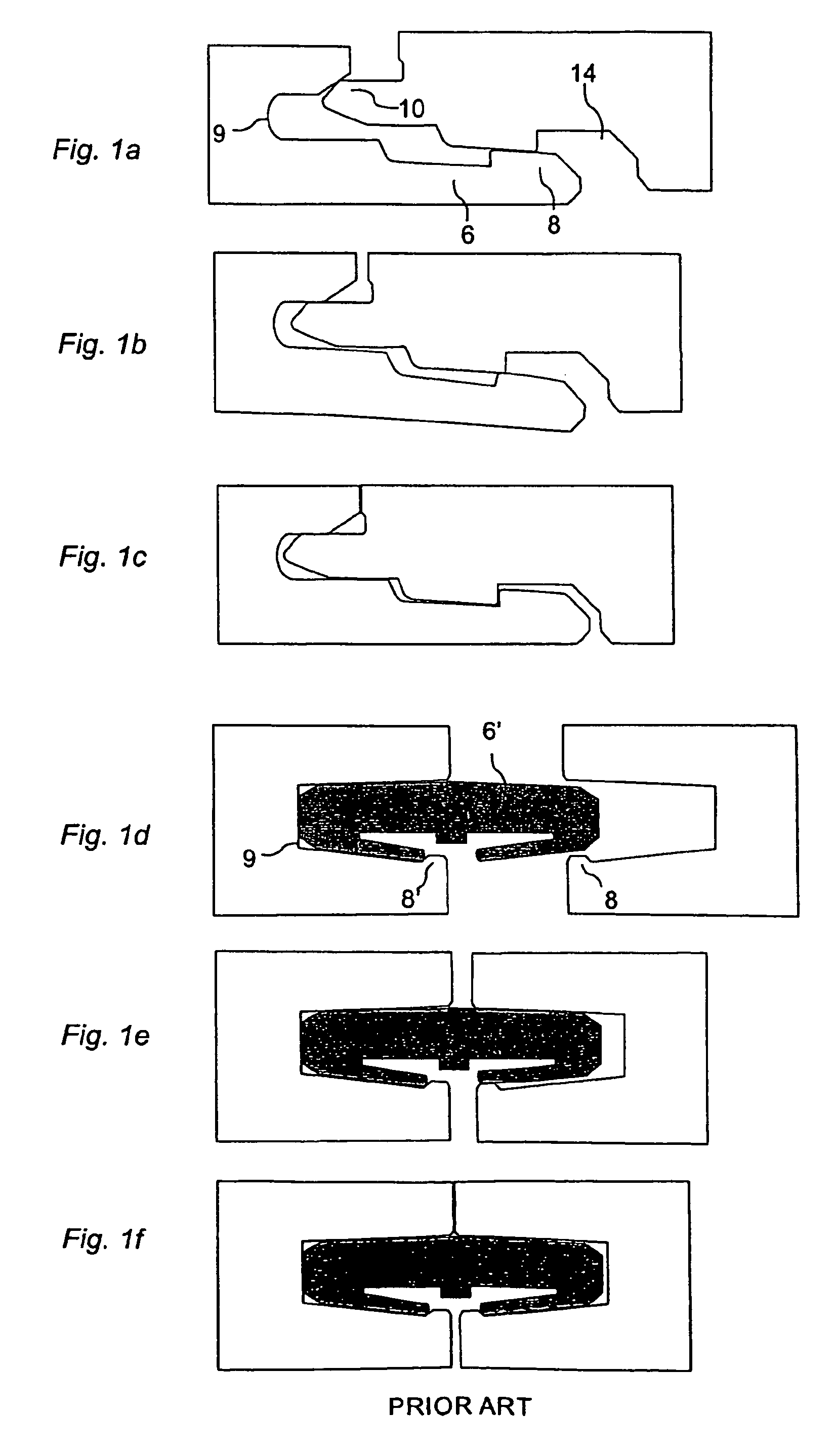

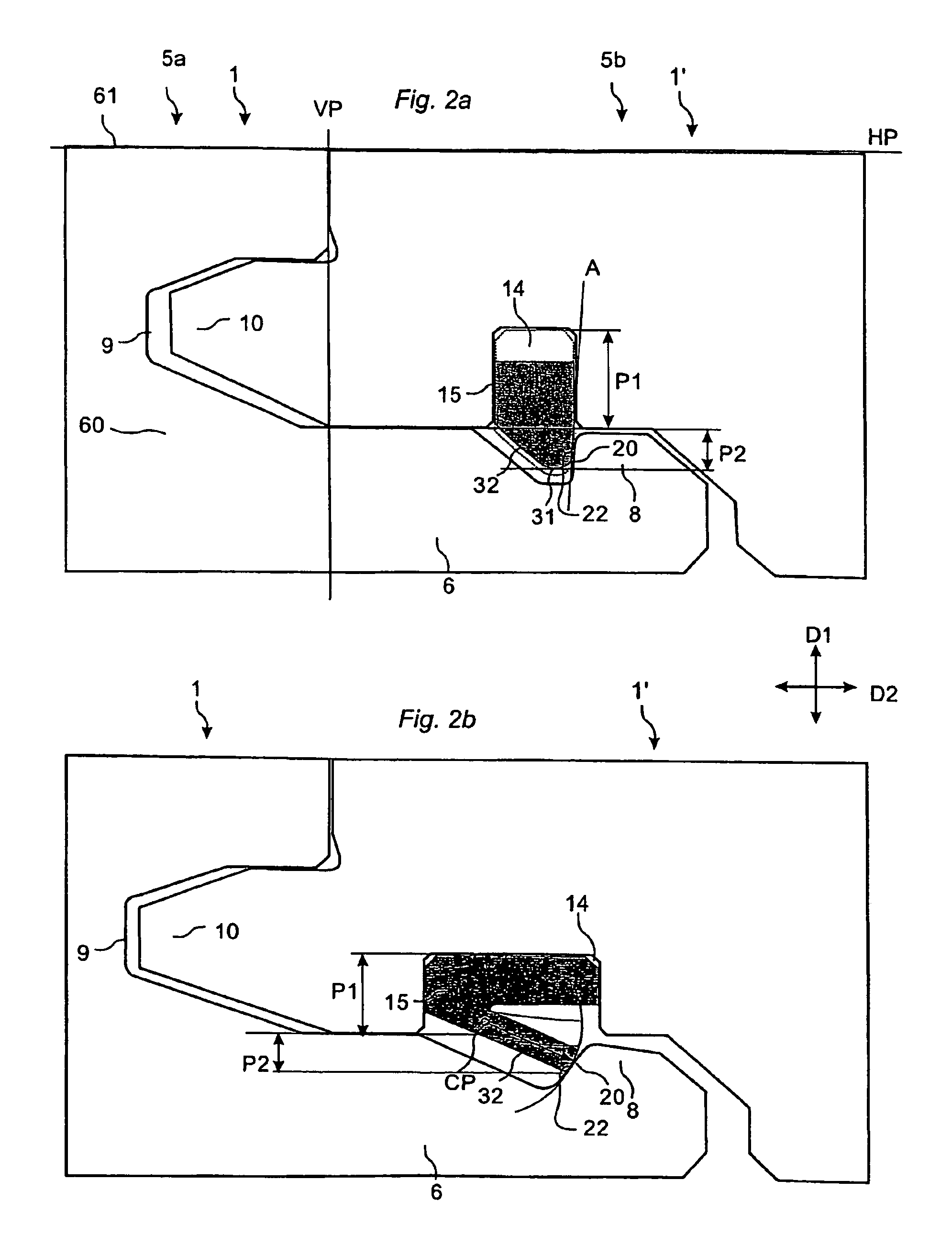

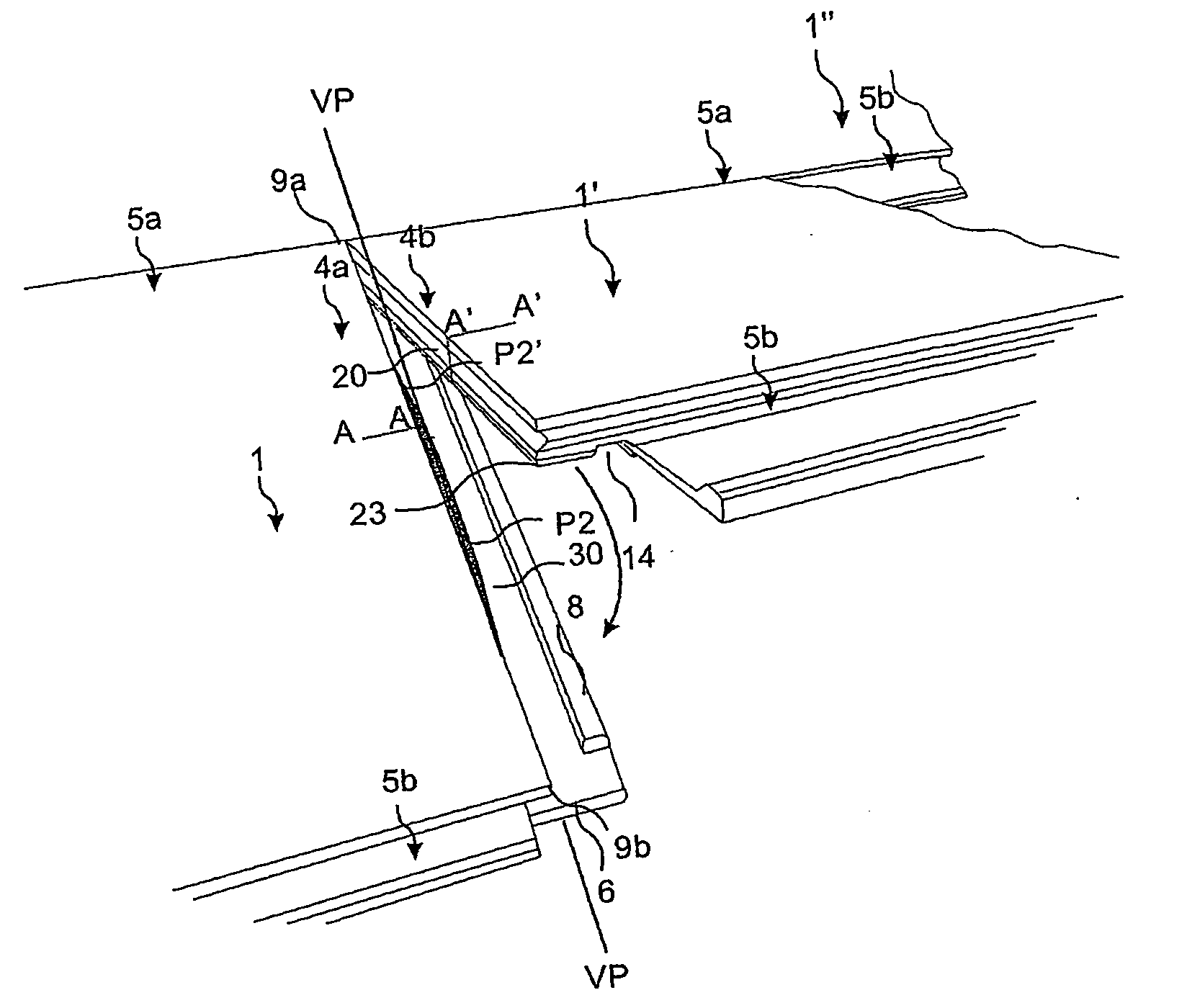

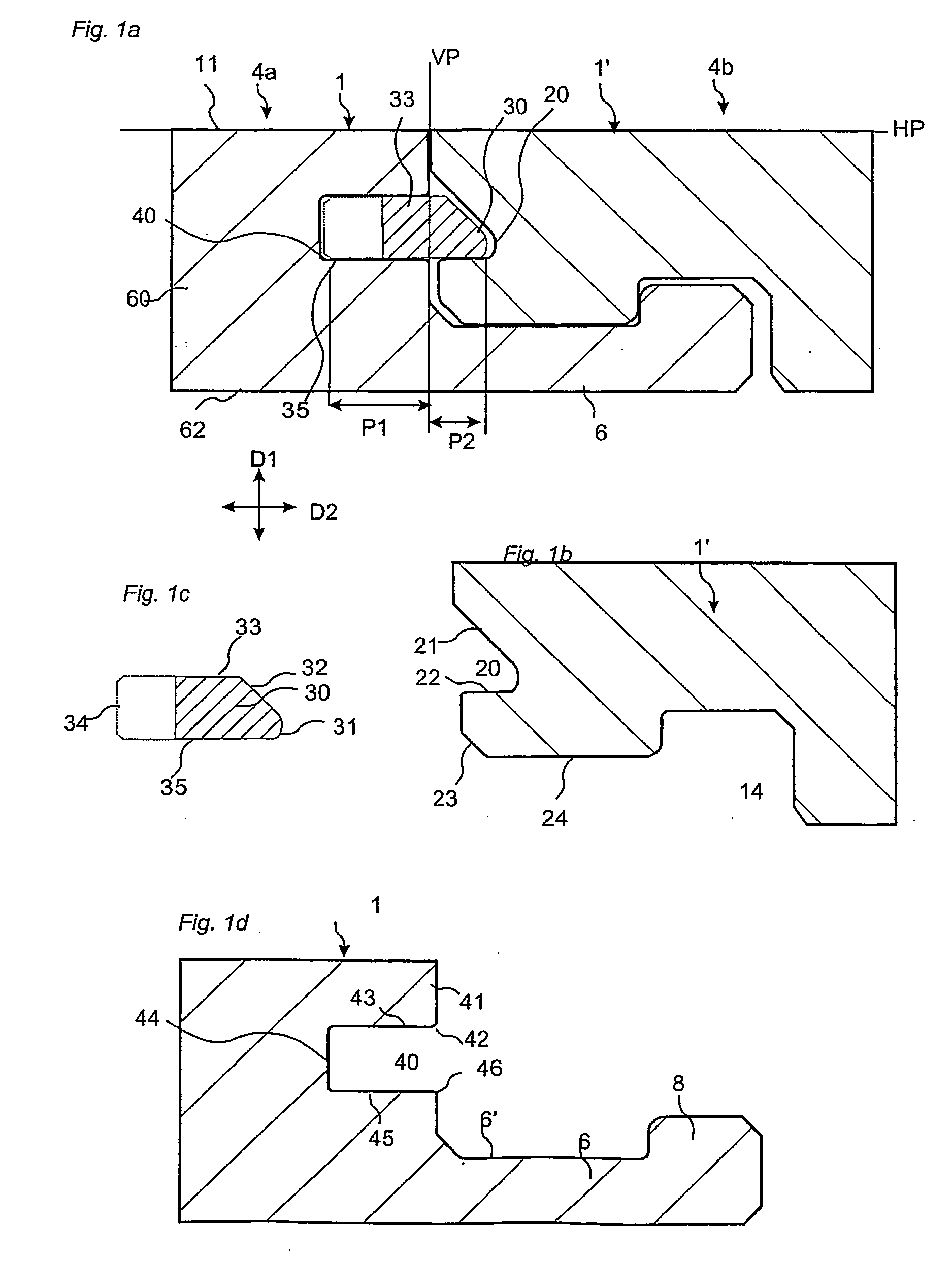

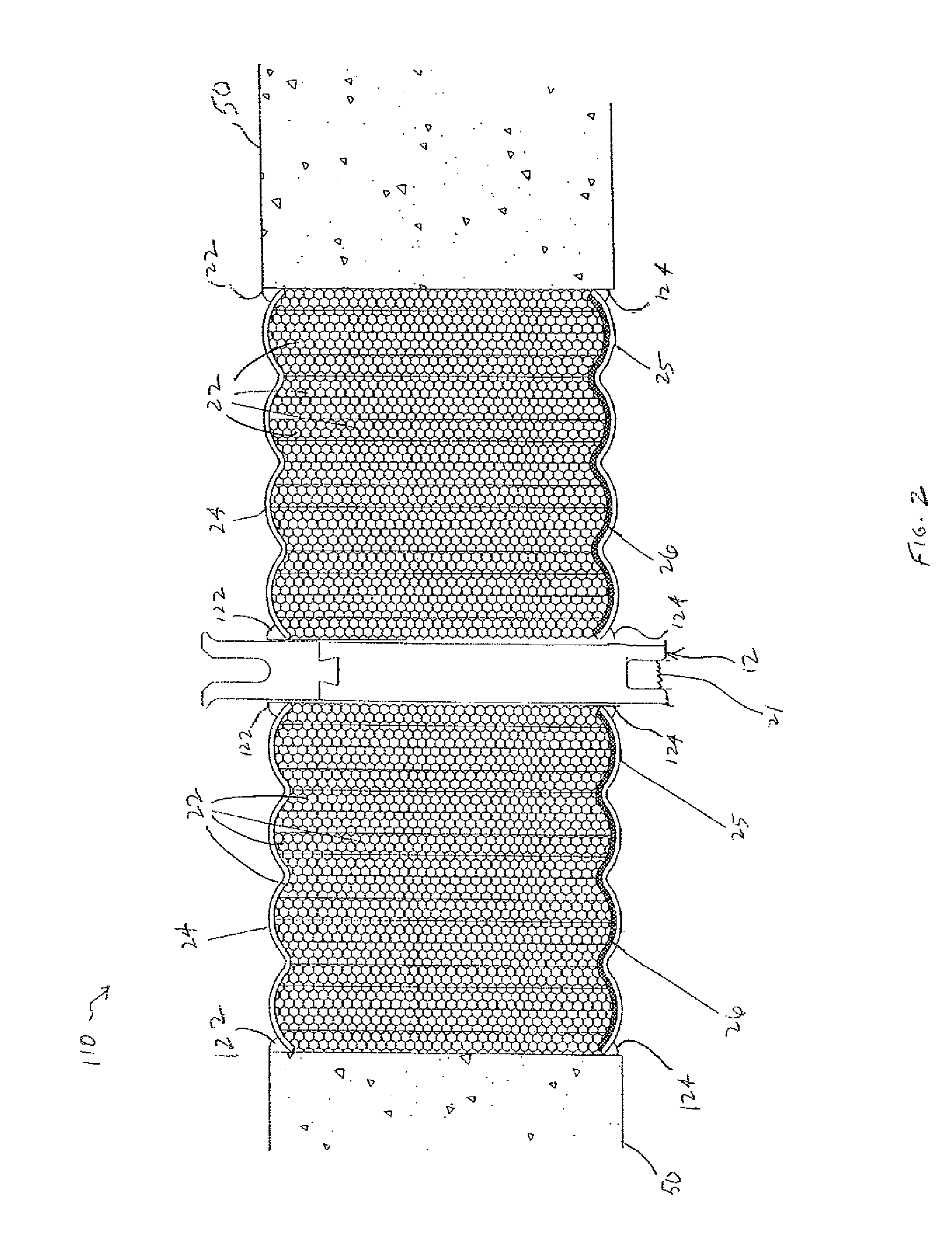

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

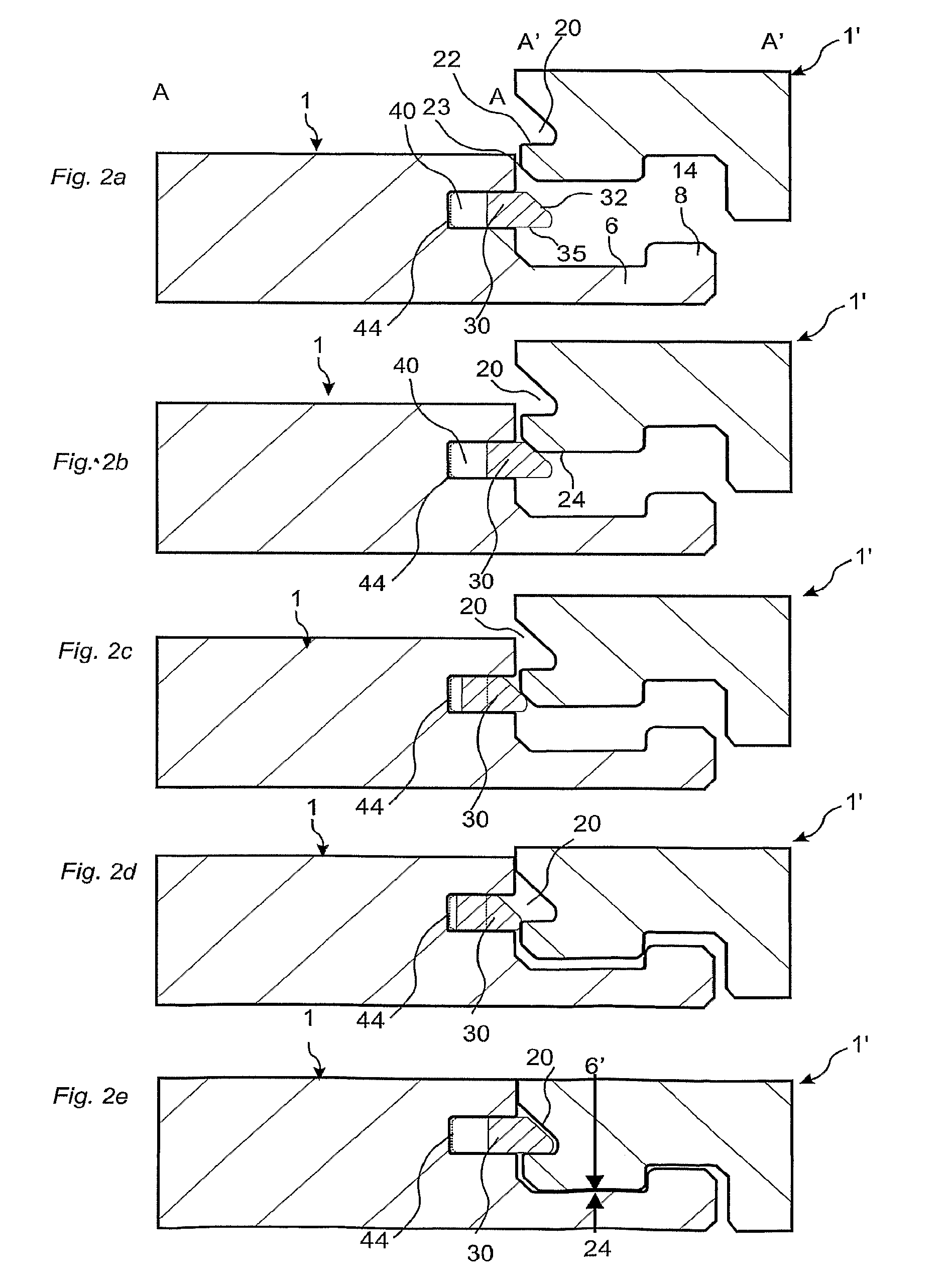

Mechanical locking system for panels and method of installing same

ActiveUS7841145B2Function increaseLower resistanceCovering/liningsWallsEngineeringMechanical engineering

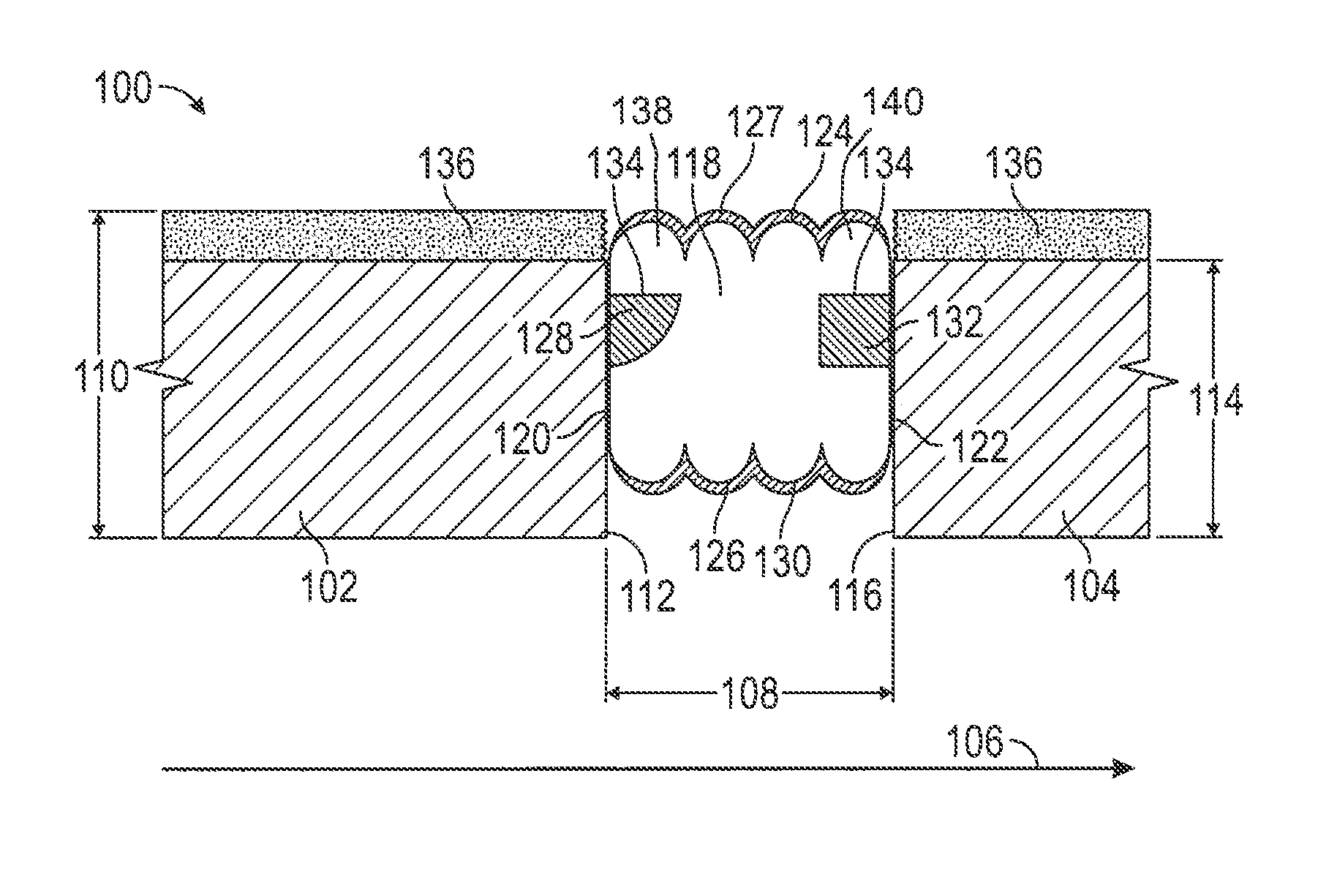

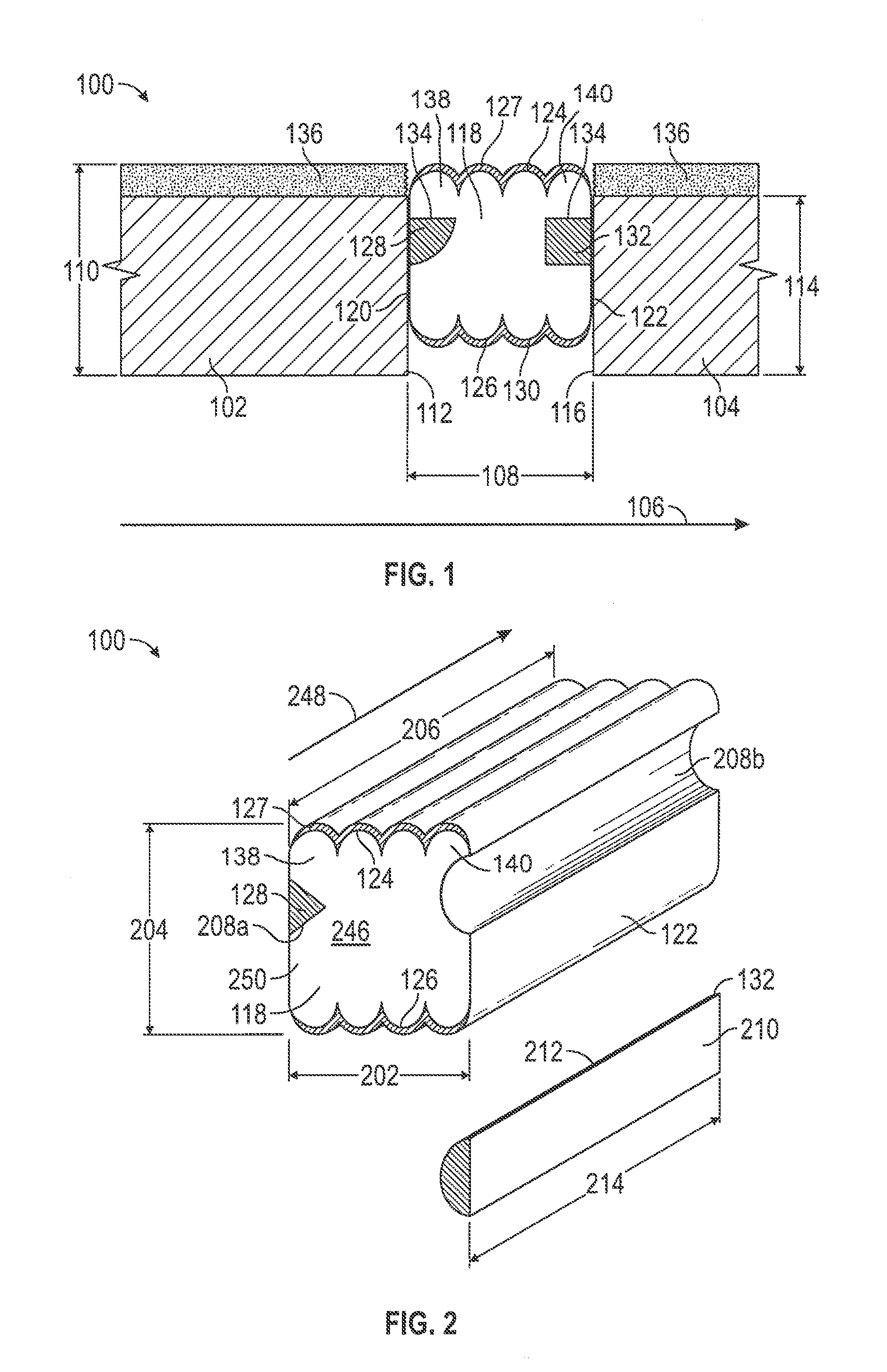

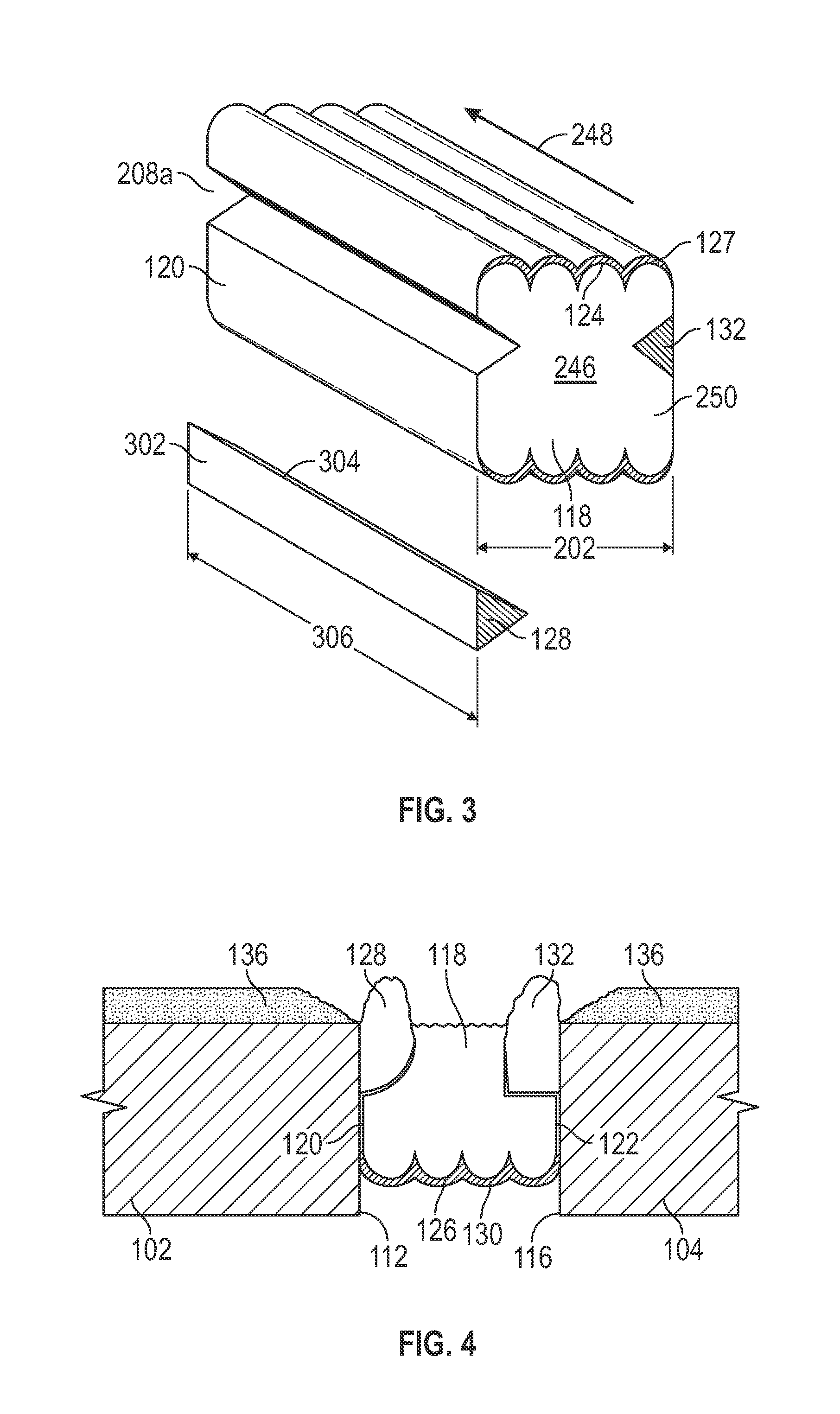

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

Mechanical locking of floor panels with a flexible tongue

Floor panels are shown which are provided with a mechanical locking system consisting of an extruded flexible tongue in a sidewardly open groove which during a vertical folding motion is bent horizontally.

Owner:VÄLINGE INNOVATION AB

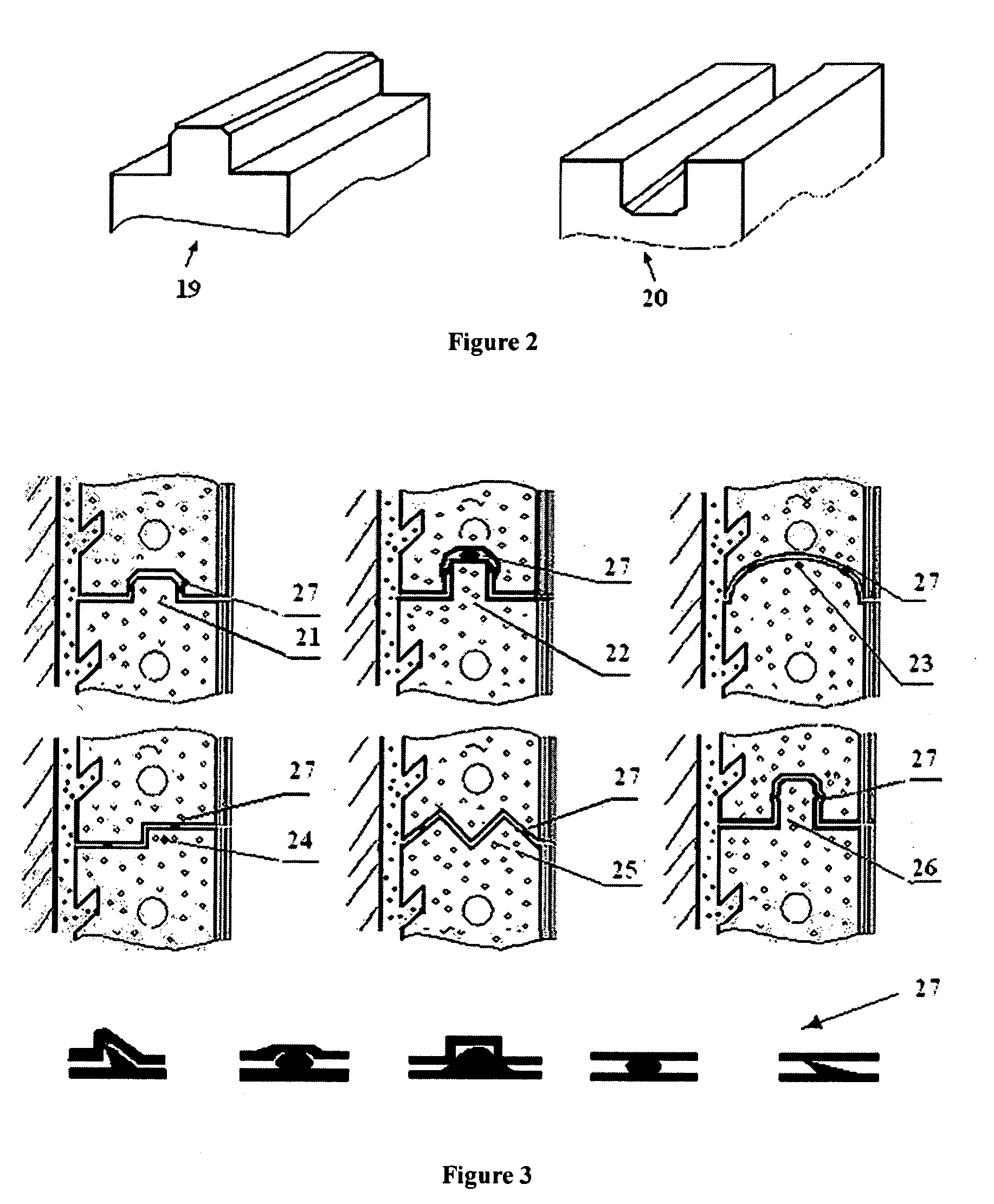

Floor Covering With Interlocking Design

InactiveUS20090031662A1Thin thicknessEasy to assembleCovering/liningsWallsFloor coveringManufacturing engineering

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:NOVALIS HLDG +1

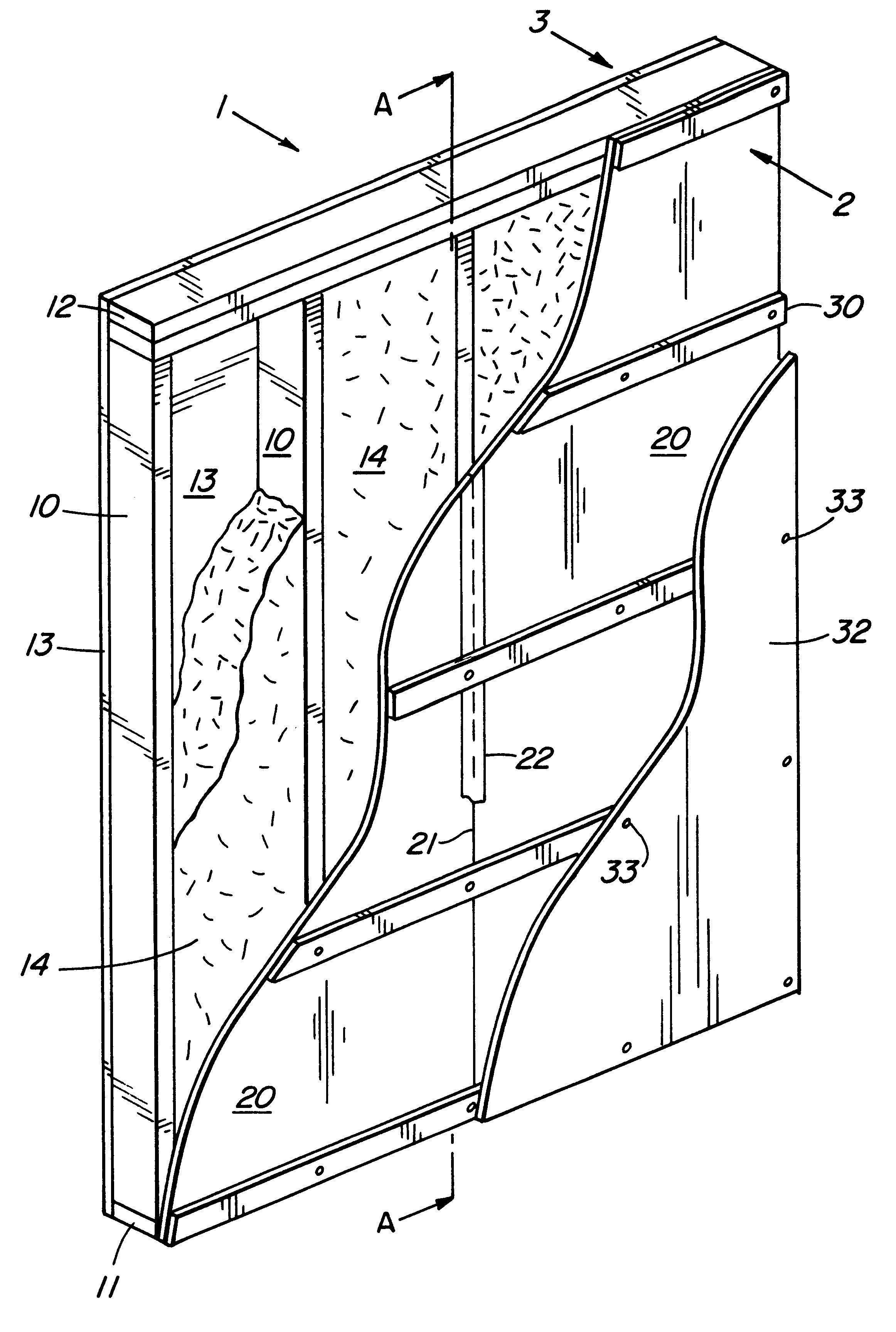

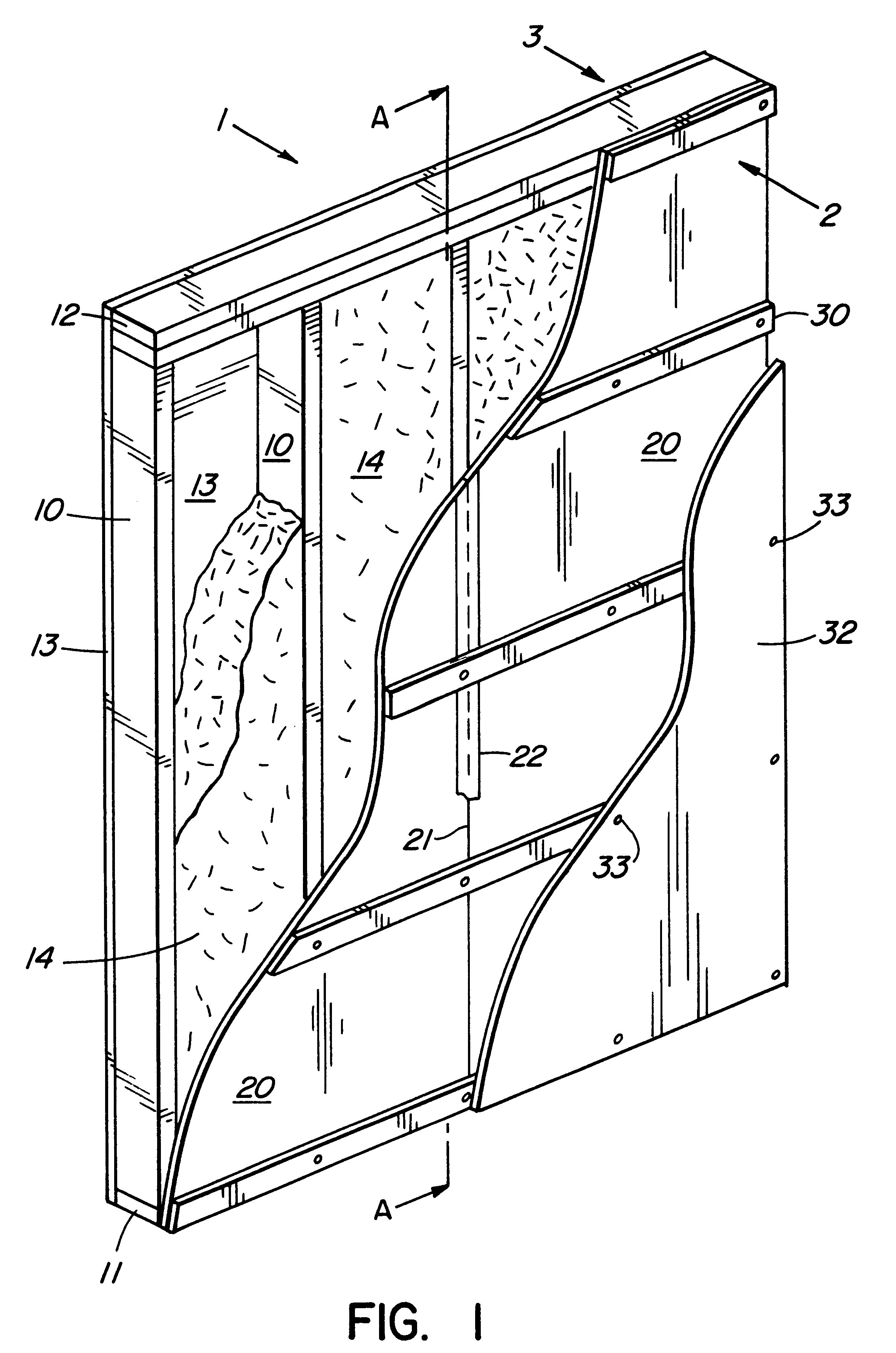

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

Cellular plastic material

An improved cellular plastic material comprises a urethane foam that is the reaction product of soy oil, an isocyanate, and a cross linker. The soy oil replaces the polyol typically generally required in the production of urethanes. Because the replaced polyol is a petrochemical, use of a renewable and environmentally friendly material such as soy oil is most advantageous. Further, plastic materials of many final qualities may be formed using a single vegetable oil. In addition to cellular foams, solid plastic elastomers may be formed.

Owner:URETHANE SOY SYST +1

Fire barrier

A fire barrier operable to be placed within a gap formed between two surfaces. The fire barrier may generally include a first intumescent section, a first foam section coupled with the first intumescent section, and a second intumescent section coupled with the first foam section generally opposite the first intumescent section. In some embodiments, the fire barrier may include a plurality of intumescent sections and a plurality of foam sections with each foam section being positioned between at least two of the intumescent sections.

Owner:BALCO

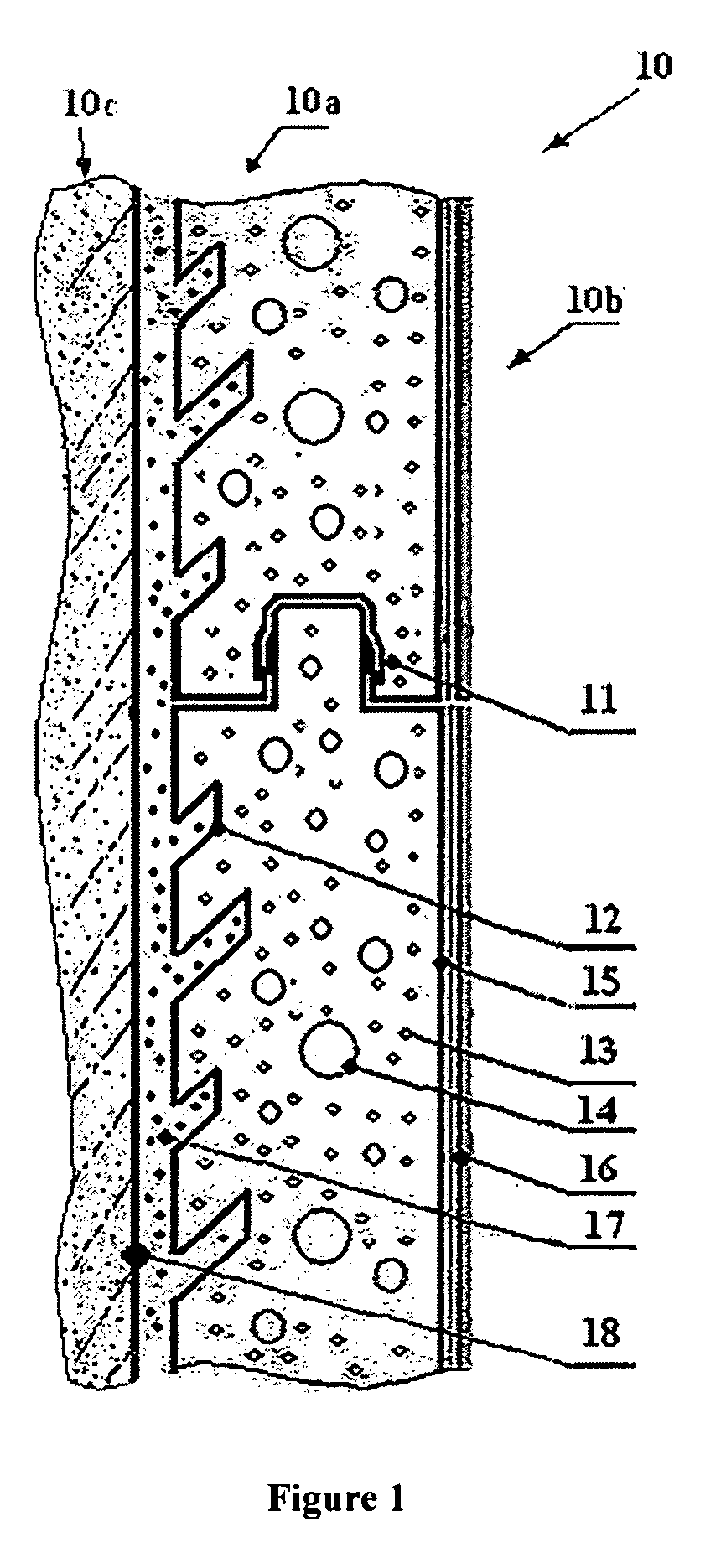

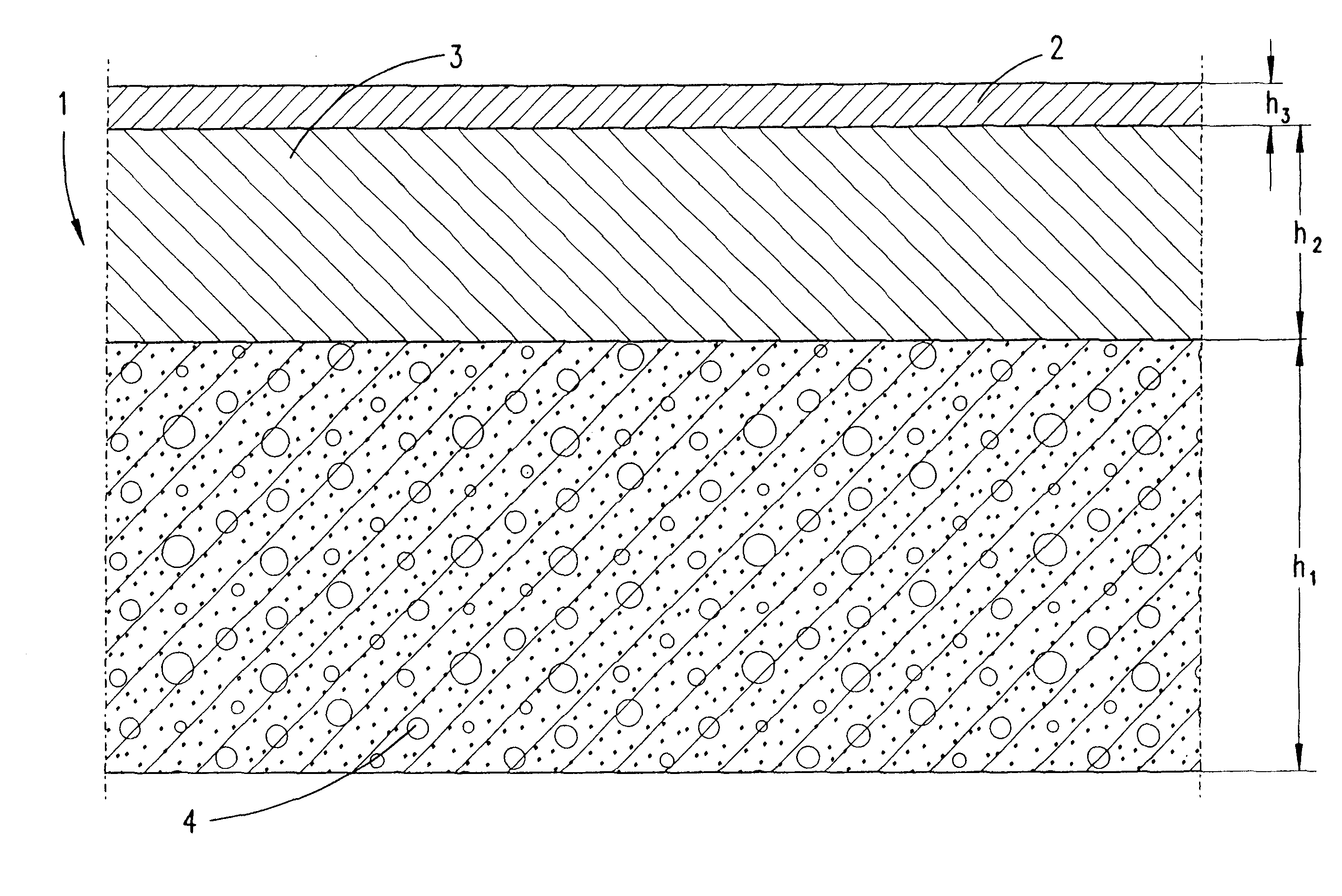

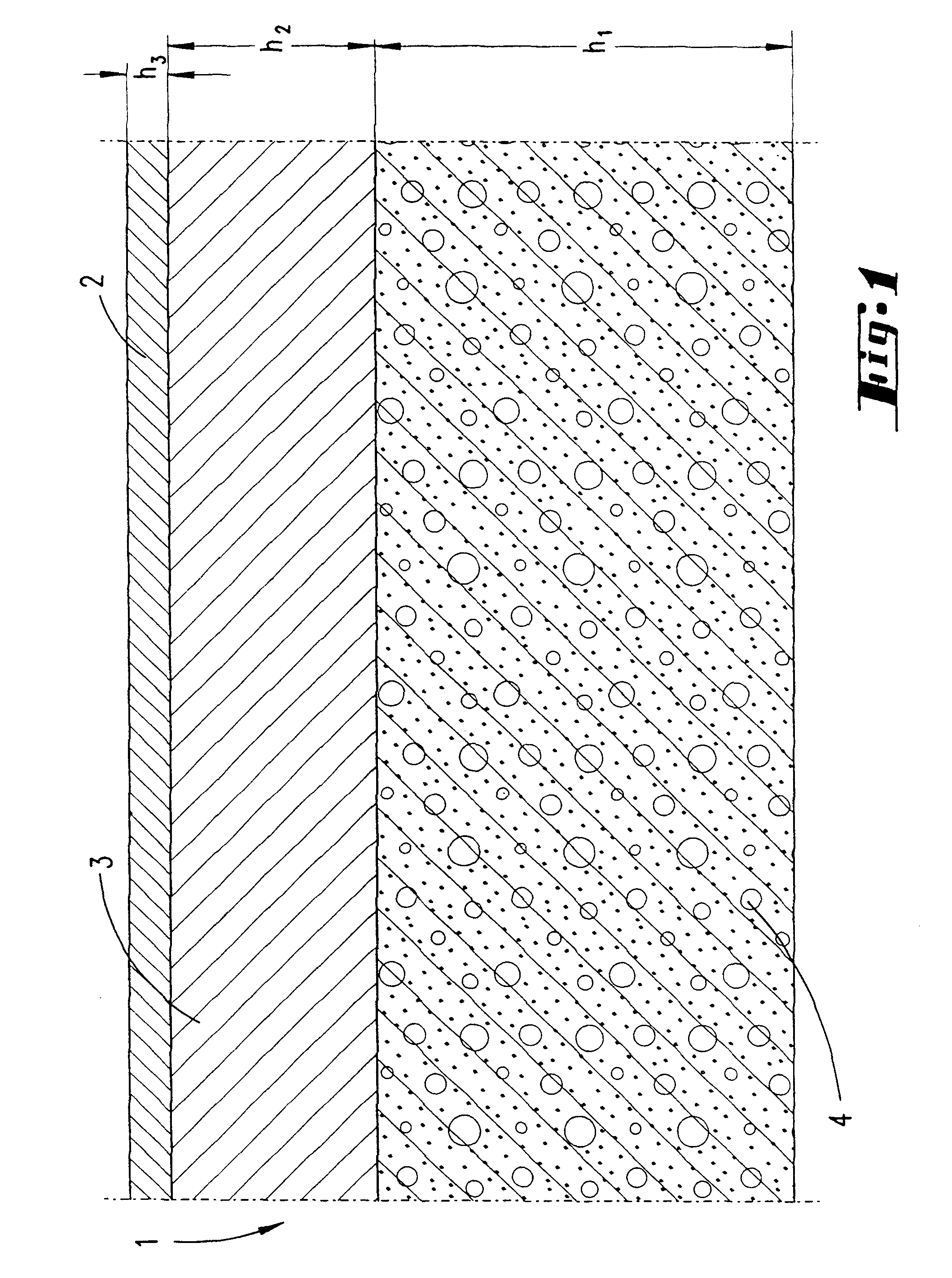

Substrate and the application

InactiveUS20090308001A1Reducing global warmingImprove energy efficiencyPhotovoltaic supportsSolar heating energyThermal energyThermal insulation

This invention relates to a substrate and the application. In particular, this invention discloses a substrate which has at least one contact structure at least on one side and at least one contact structure at least on one surface of the substrate. The substrate includes a thermal insulation material comprising at least two materials selecting from a thermal energy reflecting material, a homogeneous foam material, a heterogeneous foam material, a skin material, a skeleton structured material, an electromagnetic wave shielding material. The substrate may be used to construct various articles with different features of energy saving, decoration and protection as well as simple installation for various applications.

Owner:WU SHAOBING

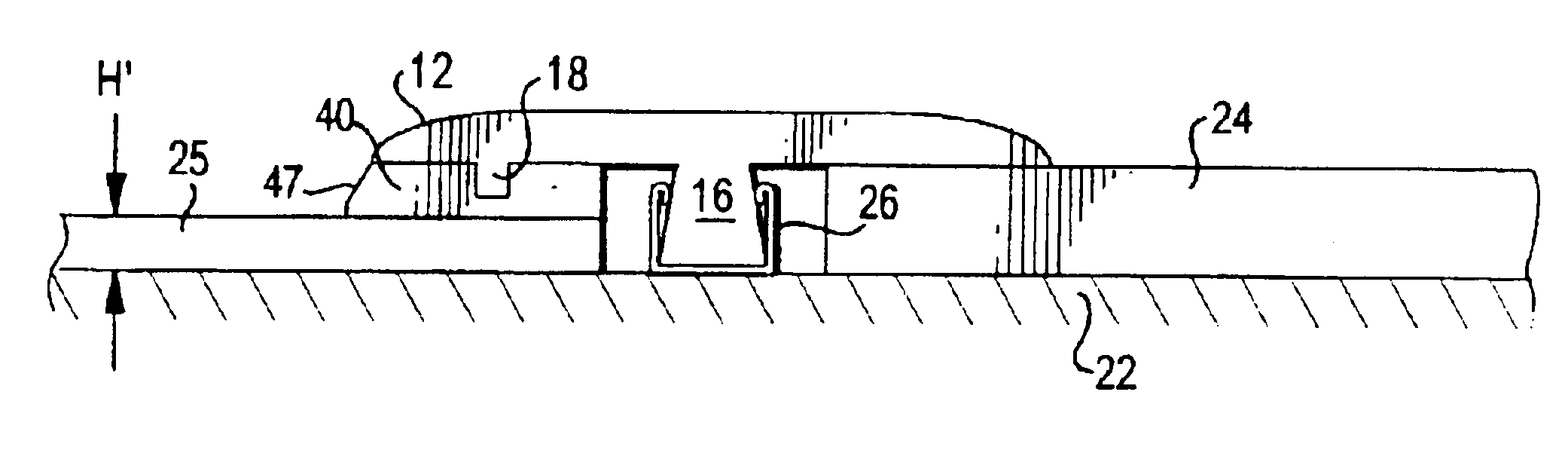

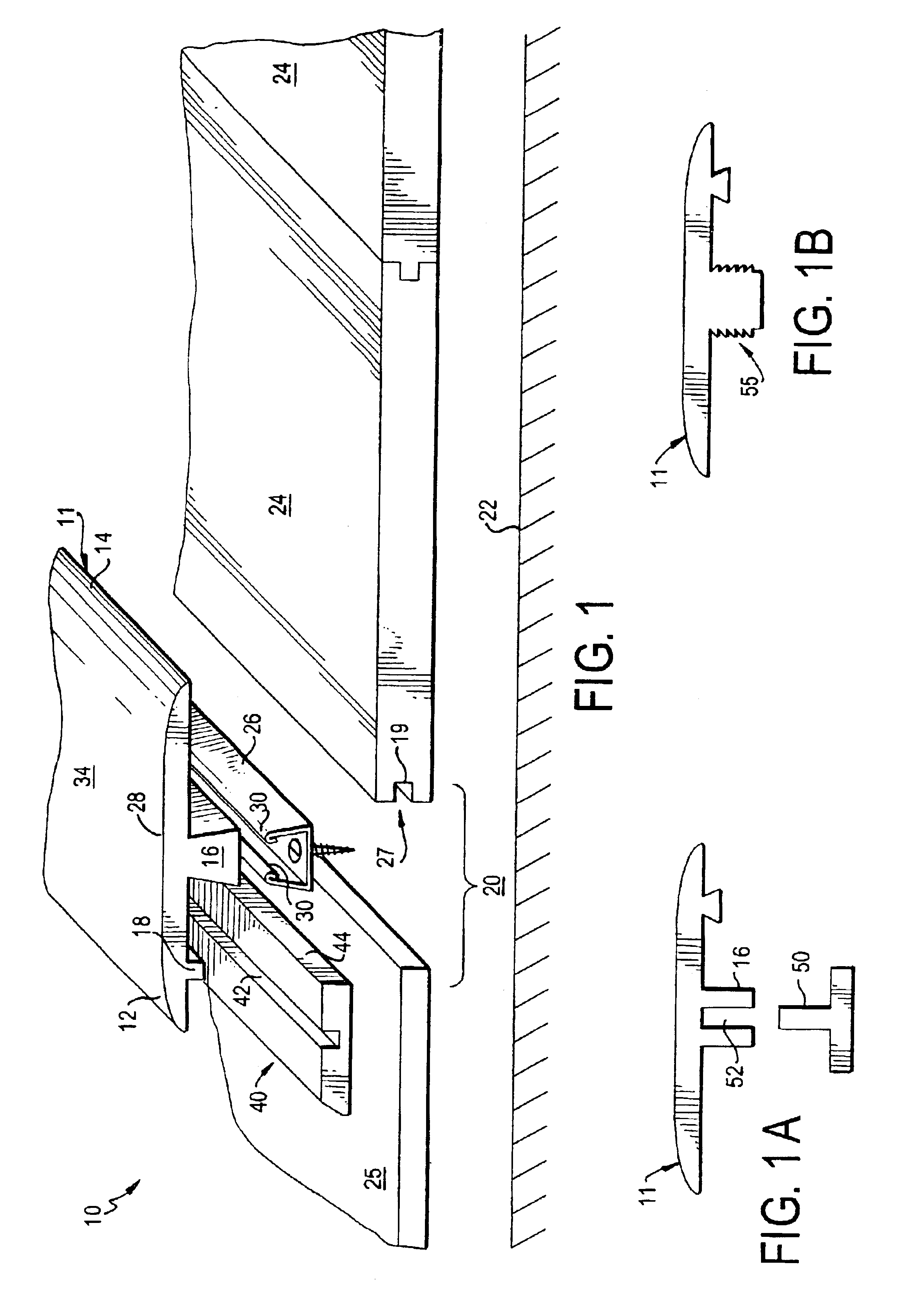

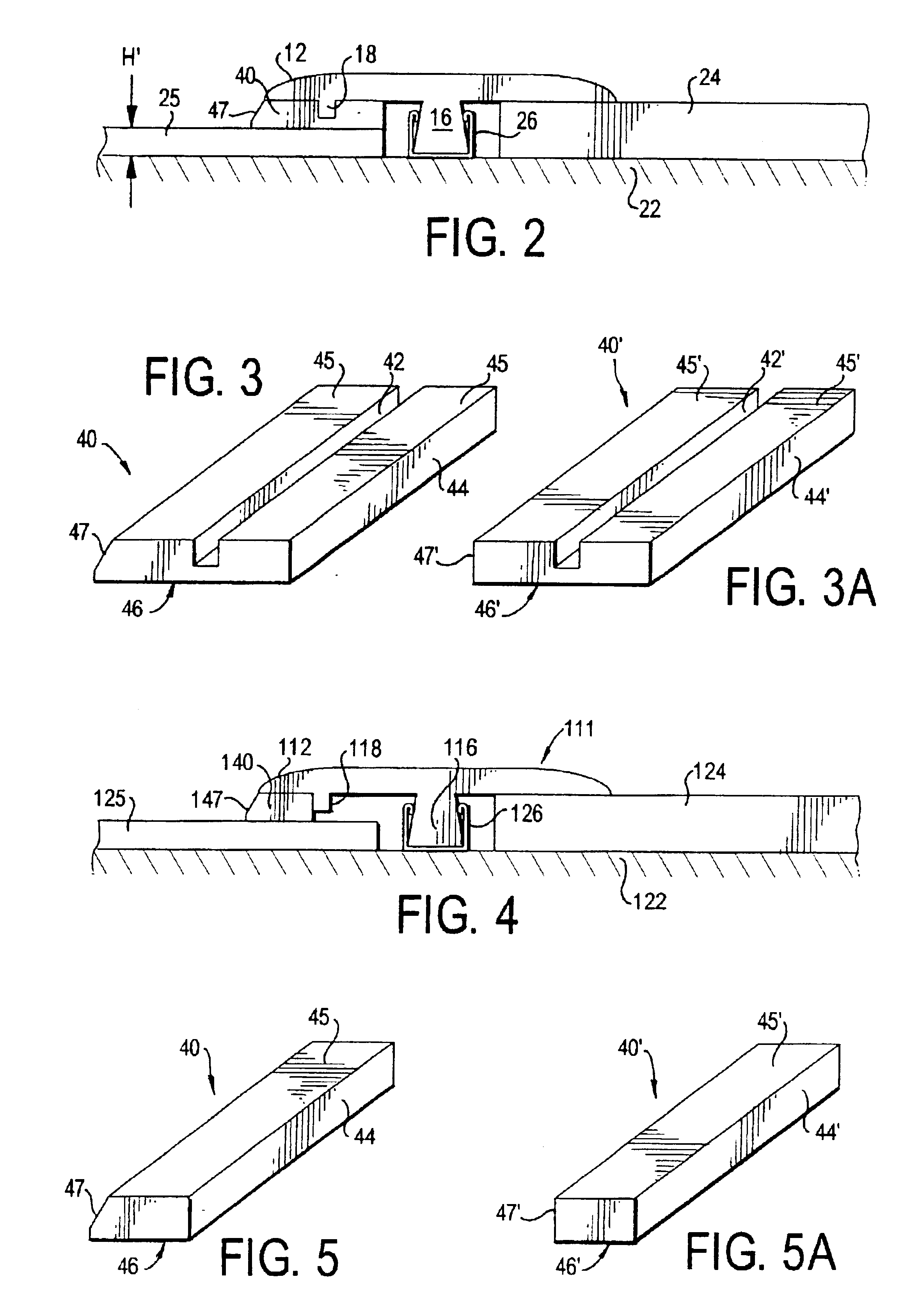

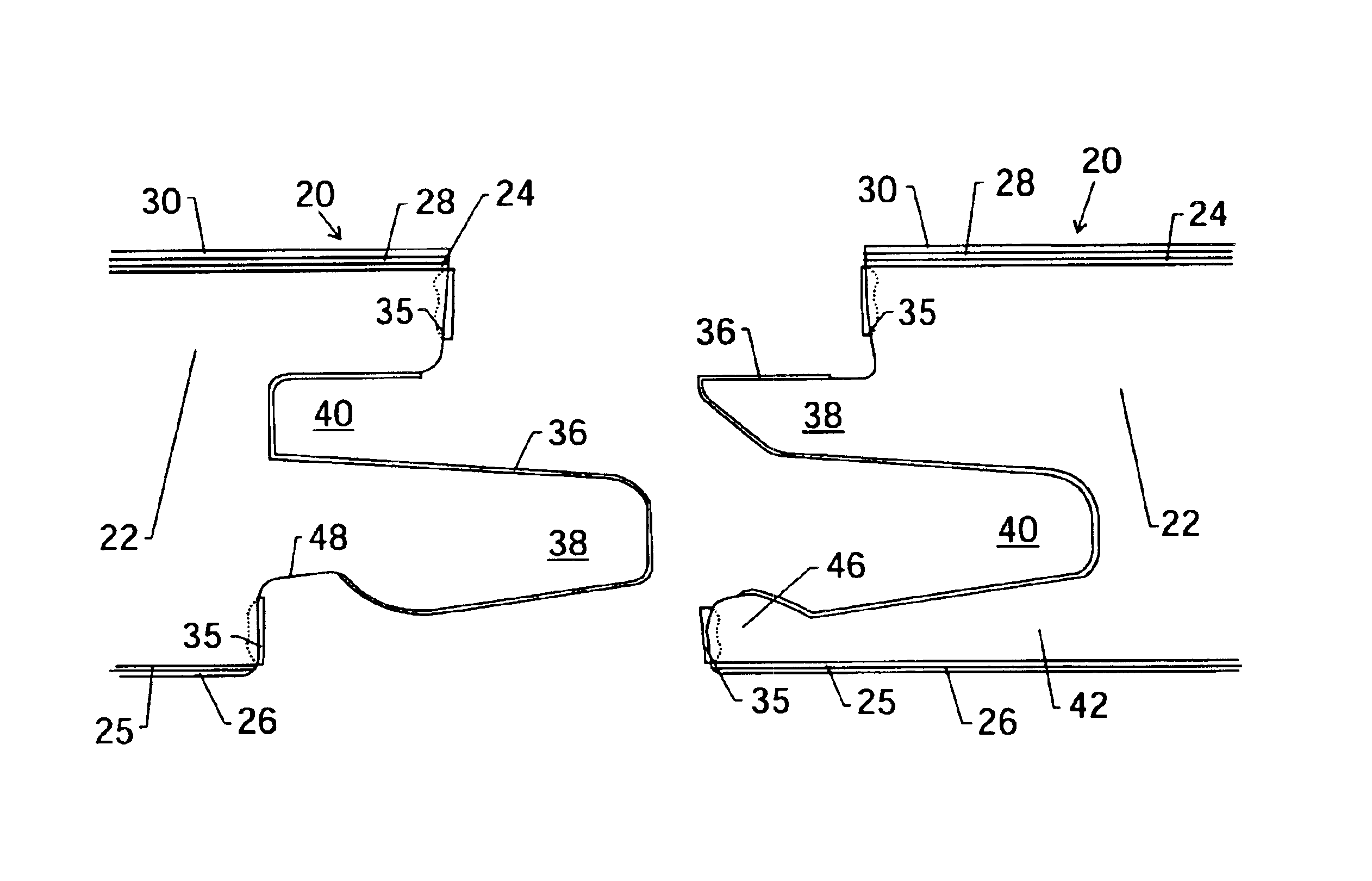

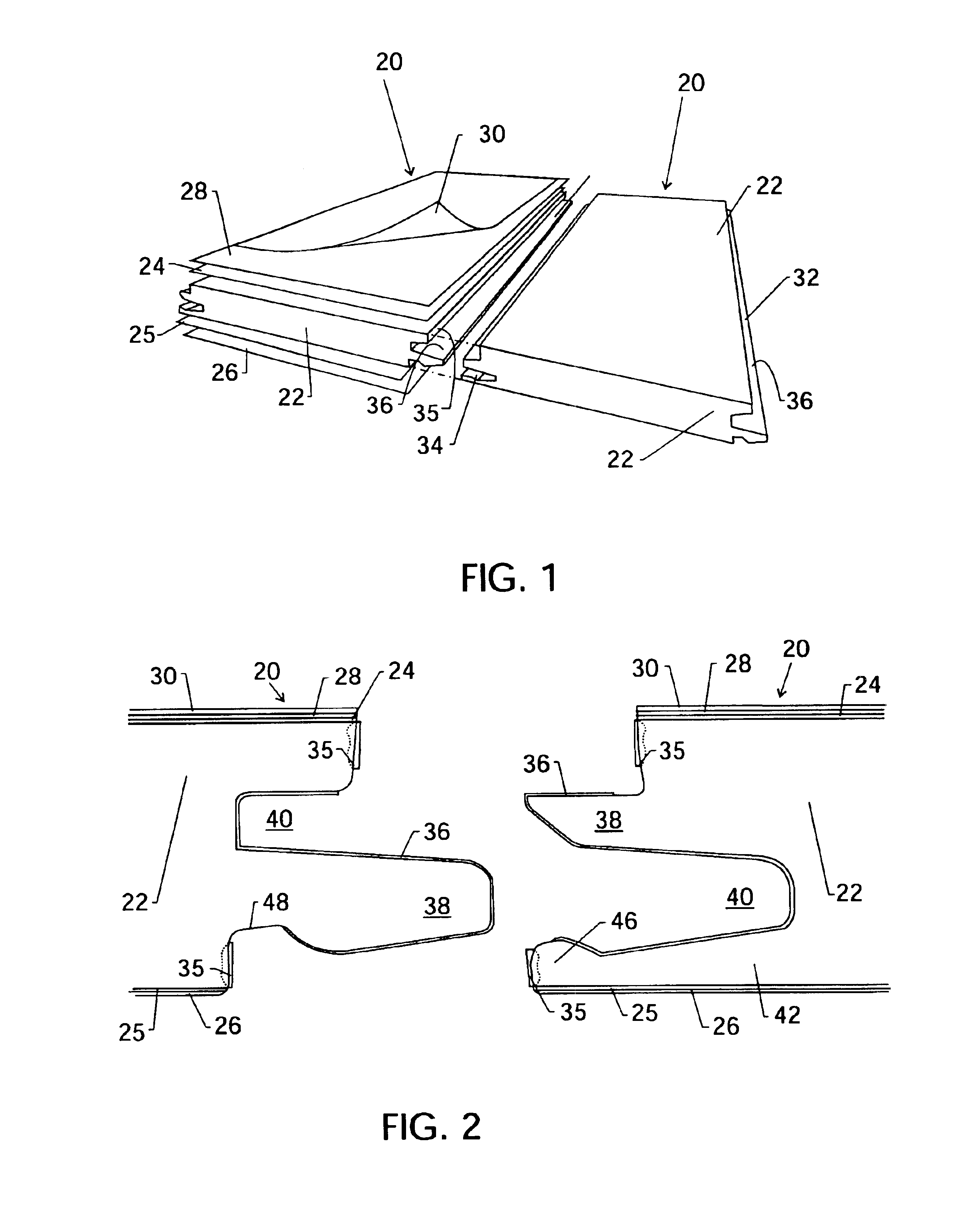

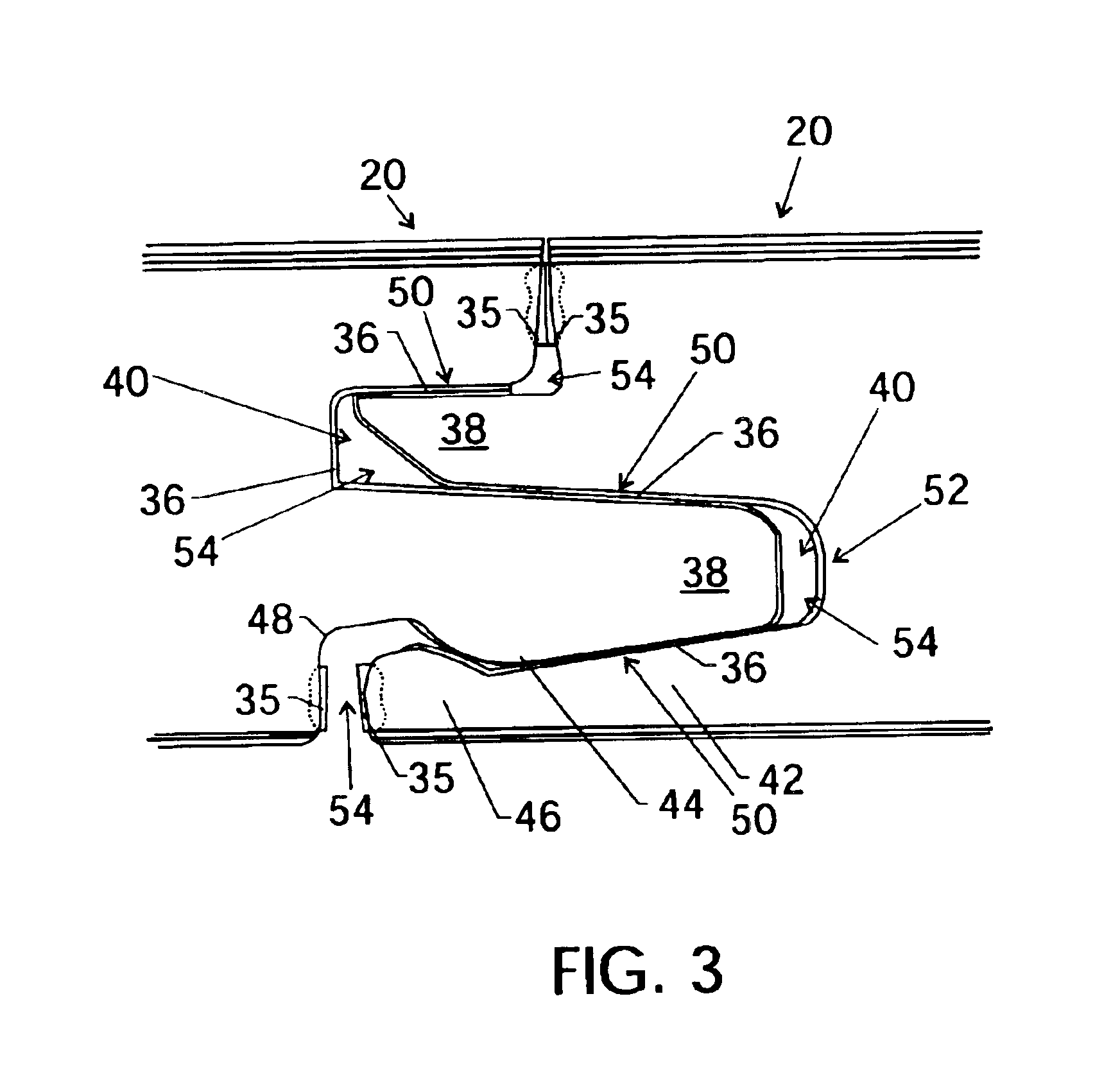

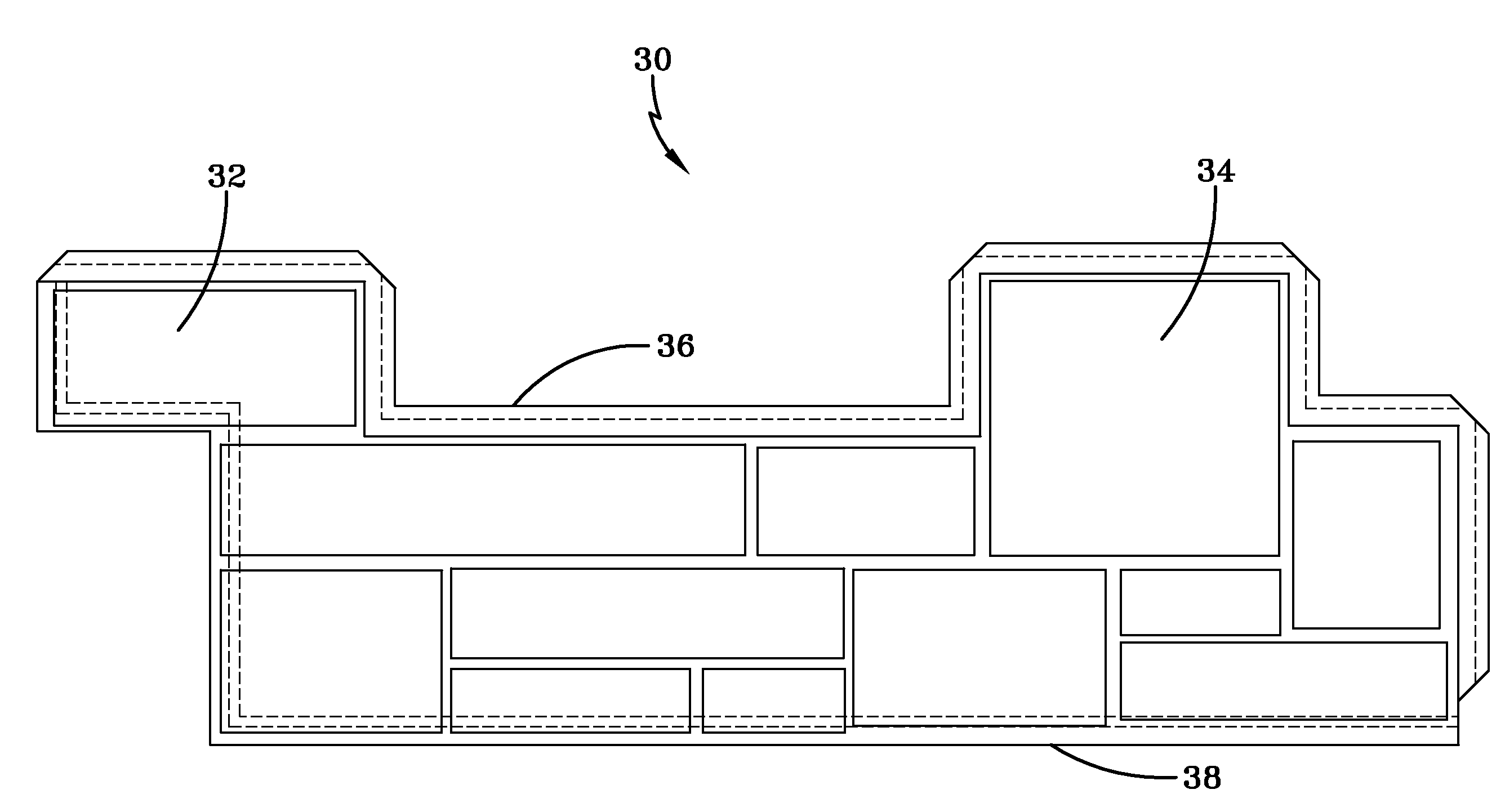

Transition molding

InactiveUS6860074B2Easy to useSmooth transitionTreadsRoof covering using tiles/slatesEngineeringSurface plate

The invention is a joint cover assembly for covering a gap adjacent an edge of a panel that covers a sub-surface, and a method of covering such a gap. The assembly includes a molding having a foot, a first arm, and a second arm. The foot is positioned along a longitudinal axis, and the first arm extends generally perpendicularly from the foot. The second arm extends generally perpendicularly from the foot. A tab depends generally perpendicularly from the first panel engaging surface. At least one of the tab and the foot engage the edge in order to tightly fit within the gap. The method includes the steps of placing the foot in the gap, pressing the respective panel engaging surfaces into contact with respective panels, and configuring at least one of the tab and the foot to cooperate to retain the molding in the gap when the assembly is in an installed condition.

Owner:PERGO

Resilient groove

A set of moisture proof floorboards and a flooring of such floorboards with a resilient surface layer provided with a decorative groove and / or a sealing means.

Owner:VÄLINGE INNOVATION AB

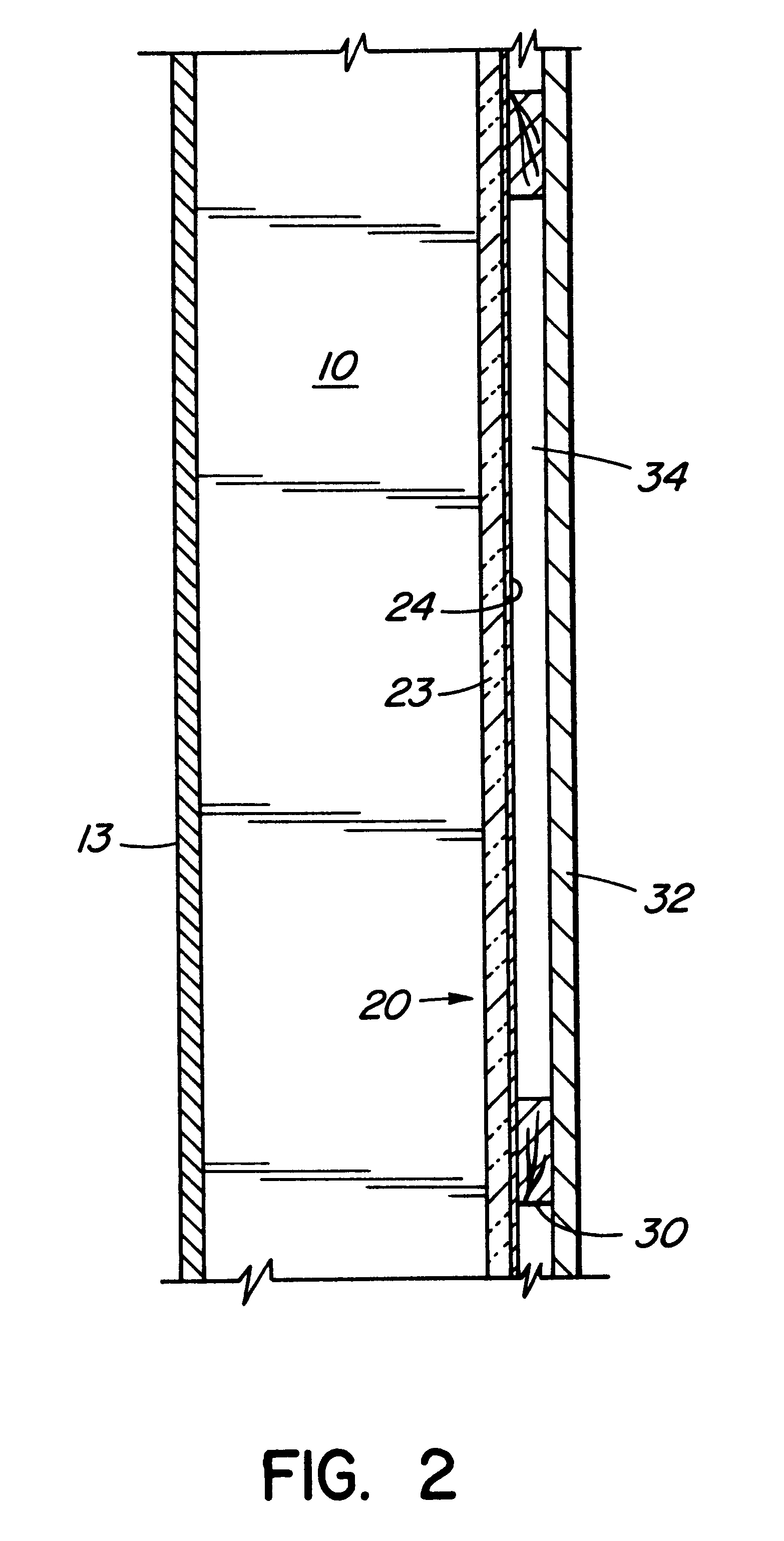

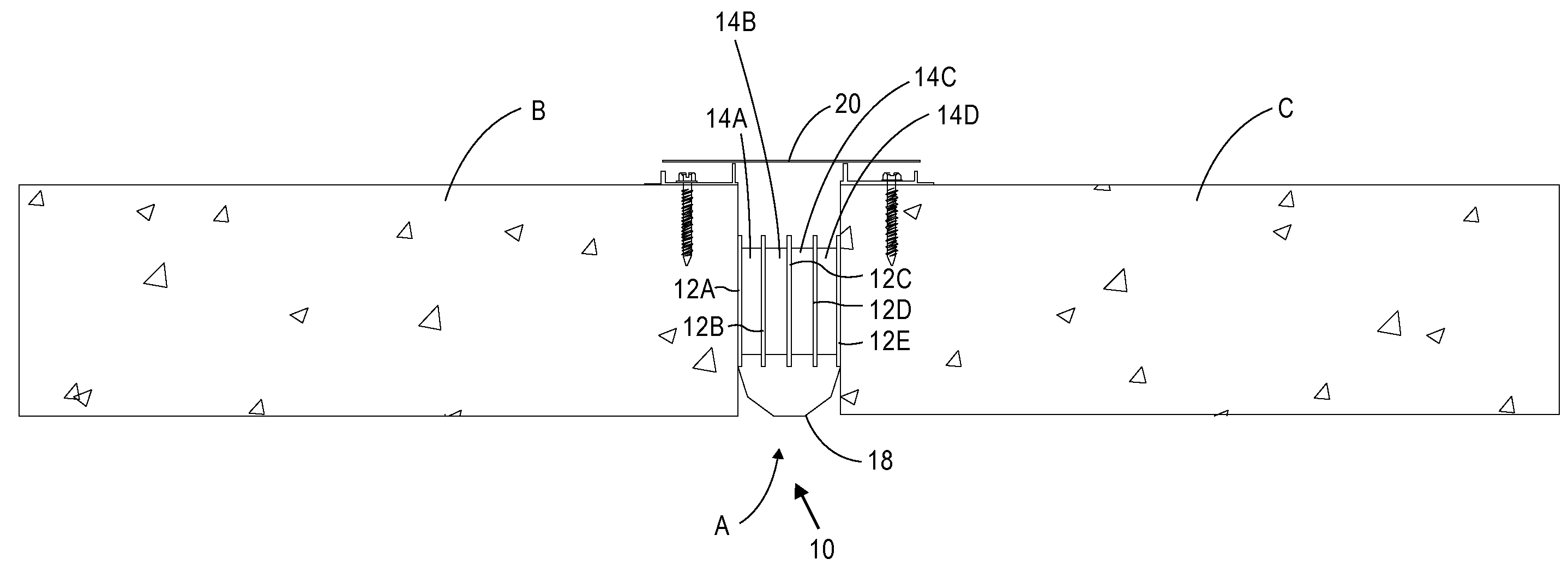

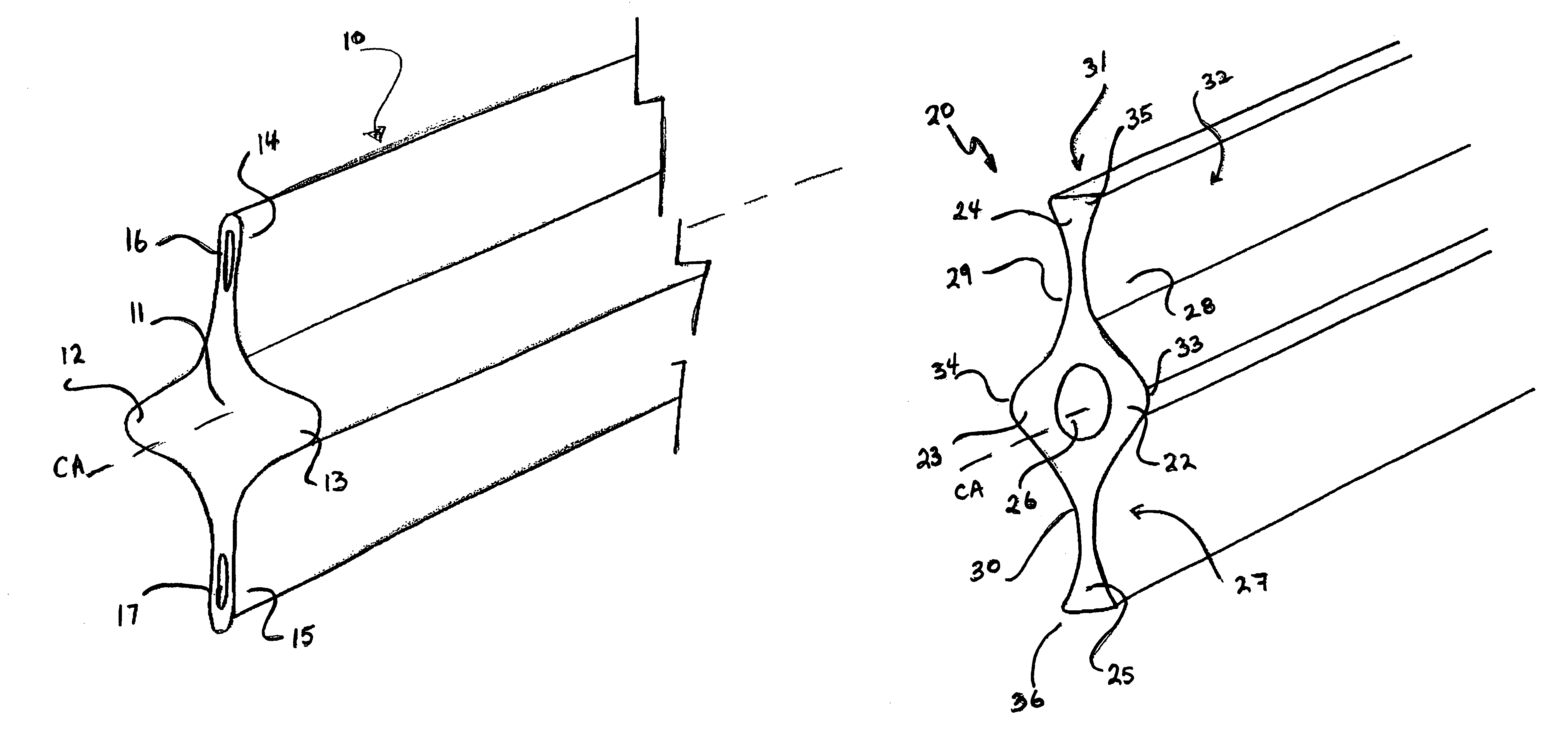

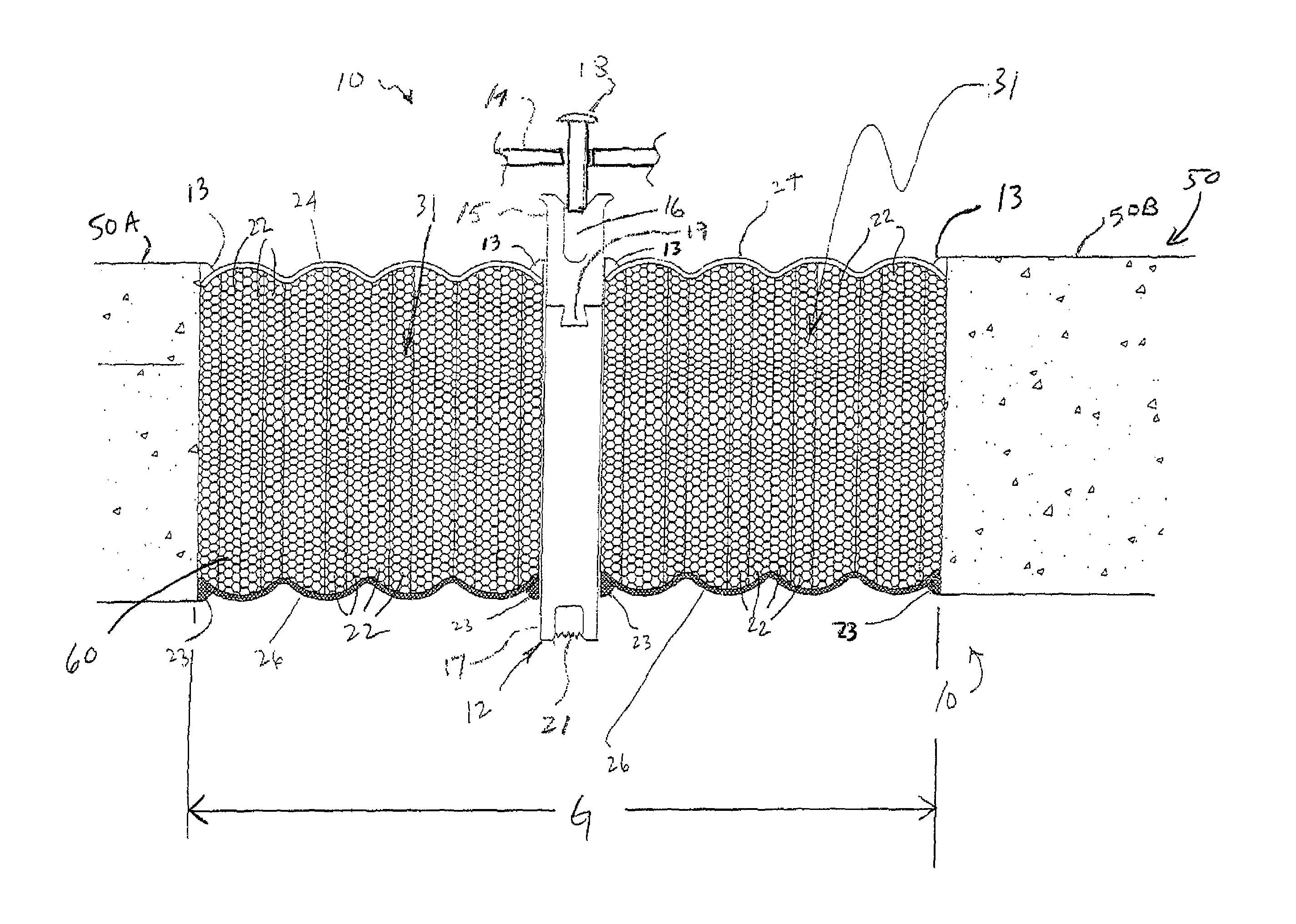

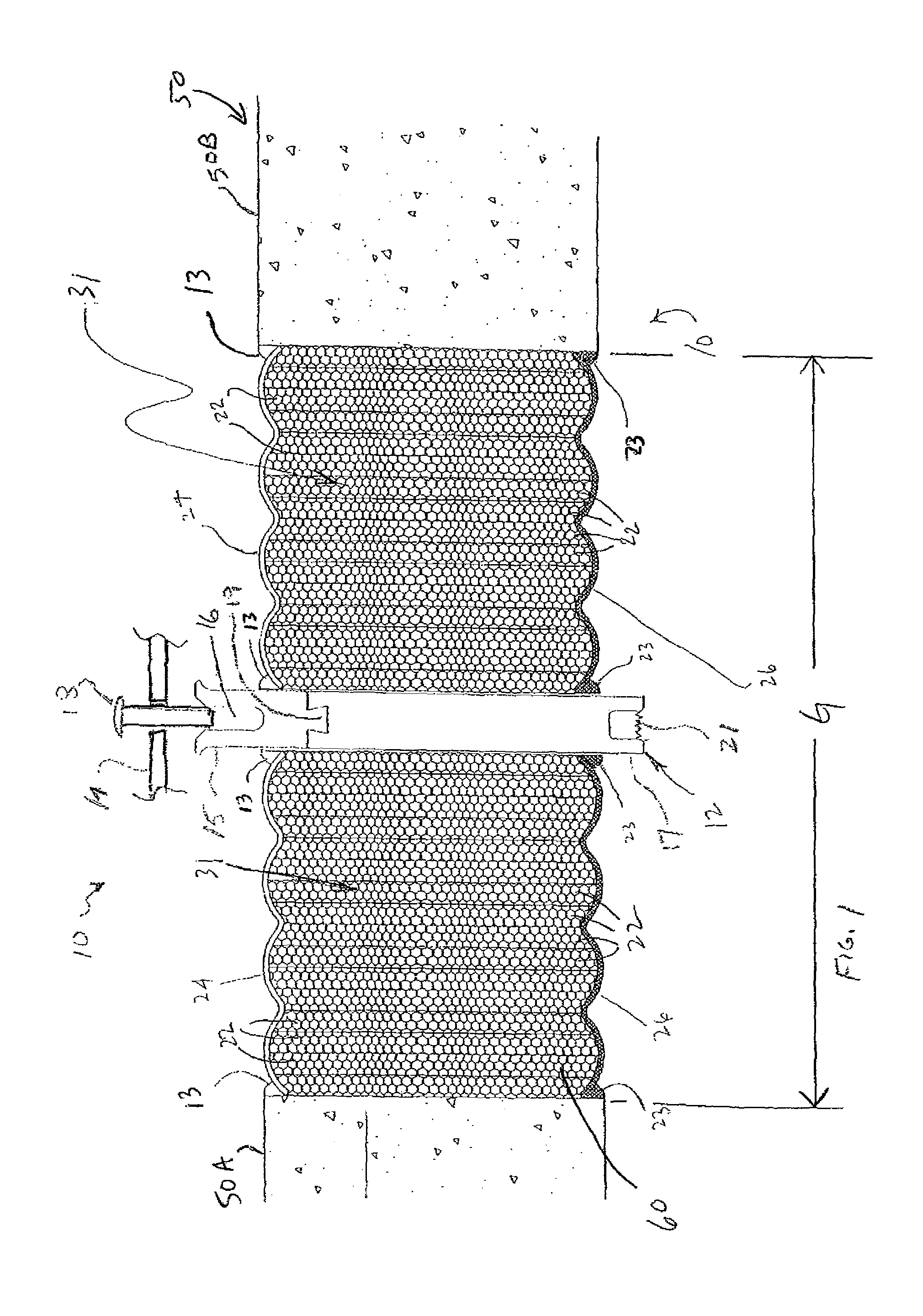

Pavement joint

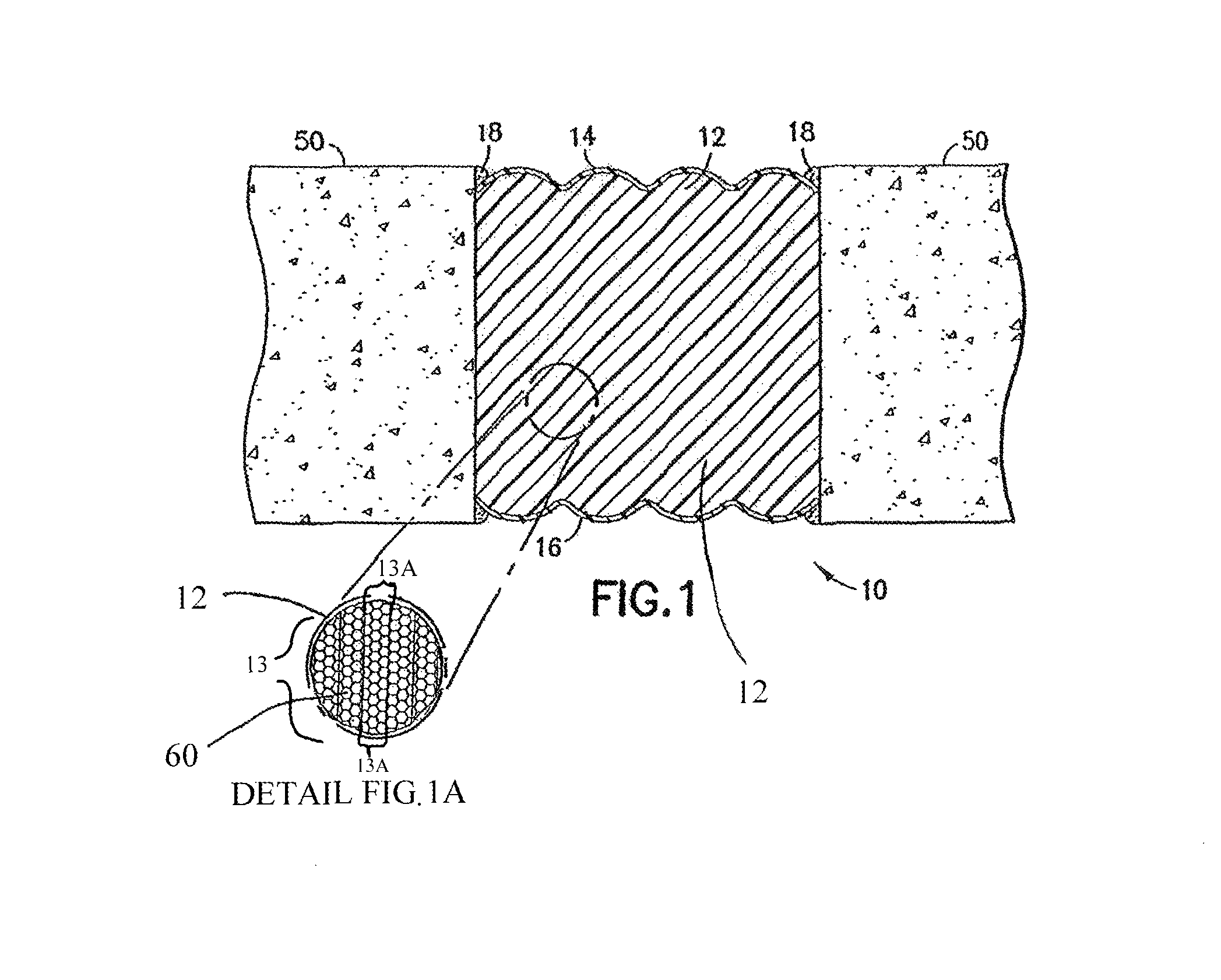

InactiveUS7806624B2Reduce wastePotential tripping hazards to pedestrians are reducedPaving detailsBuilding insulationsRoad surfaceEngineering

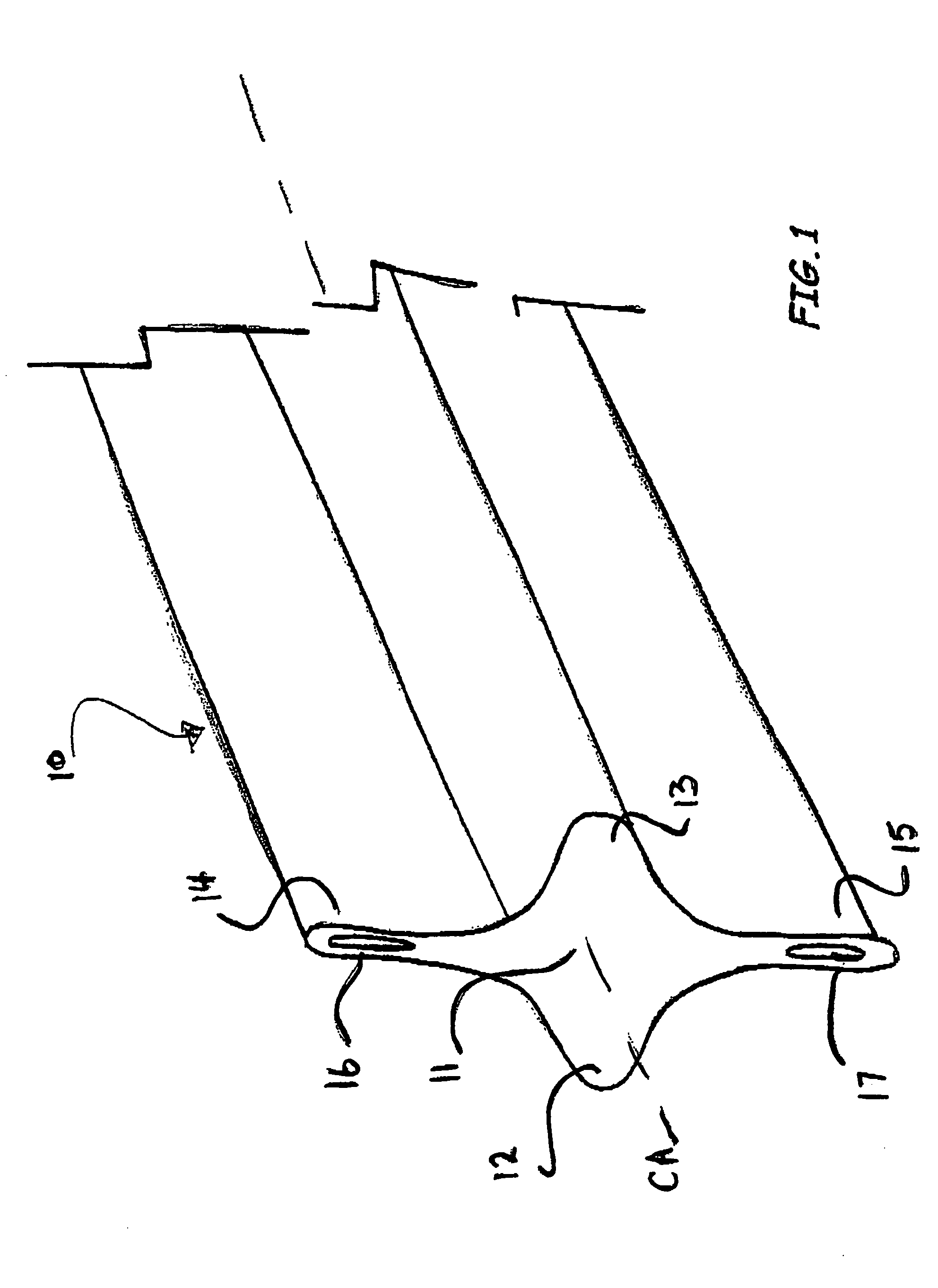

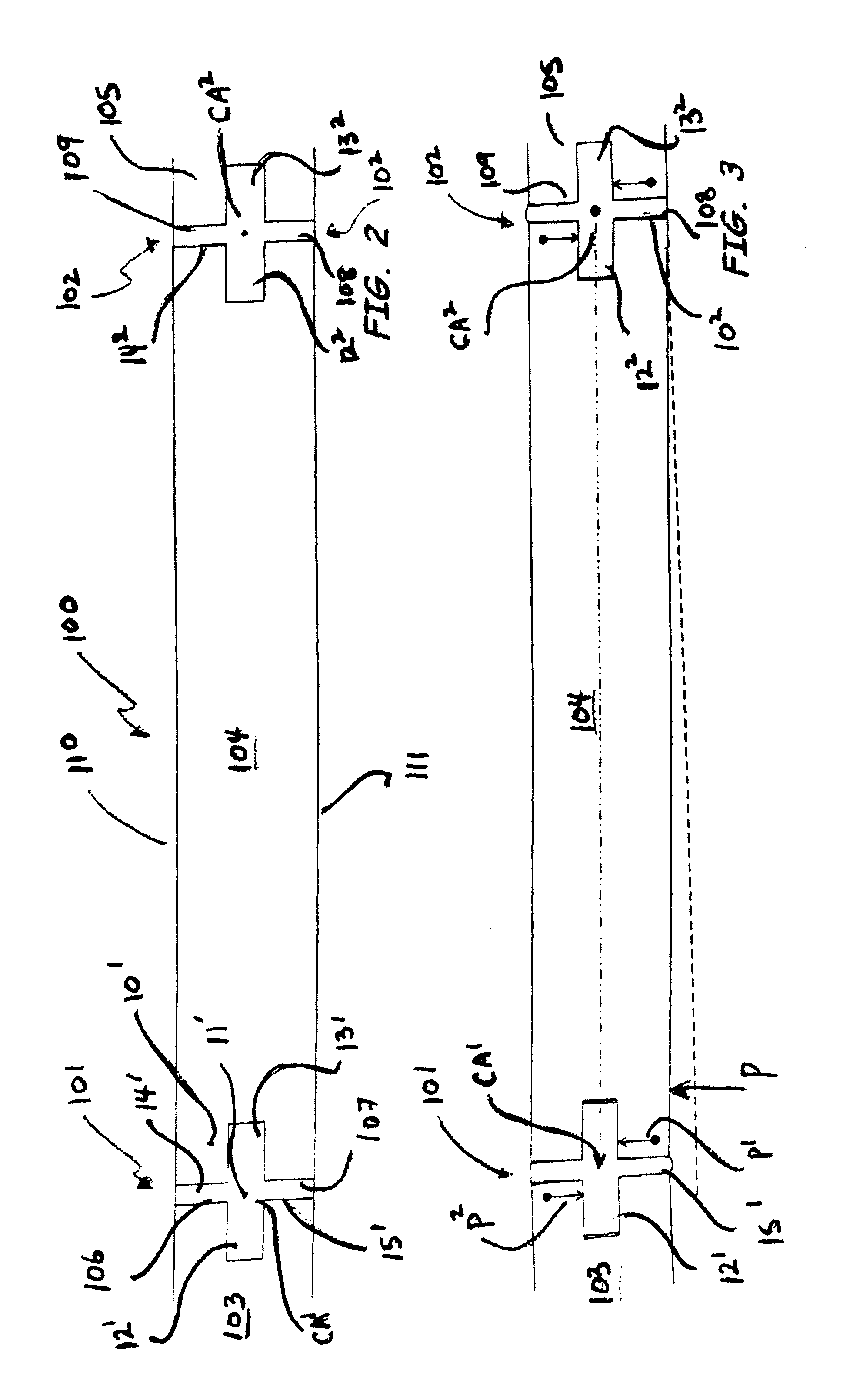

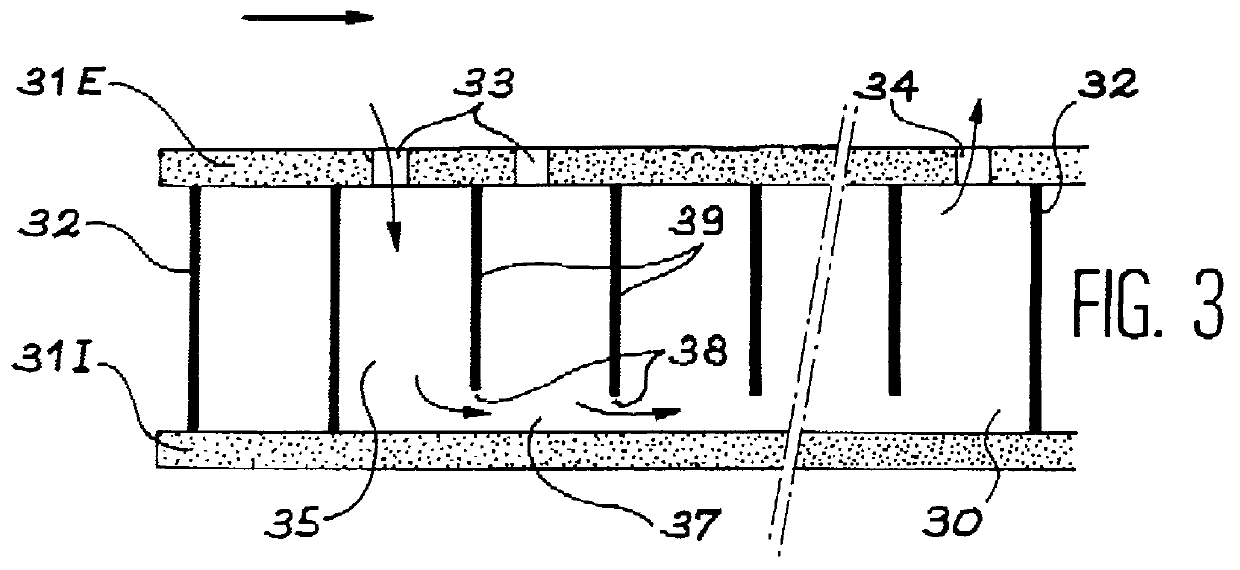

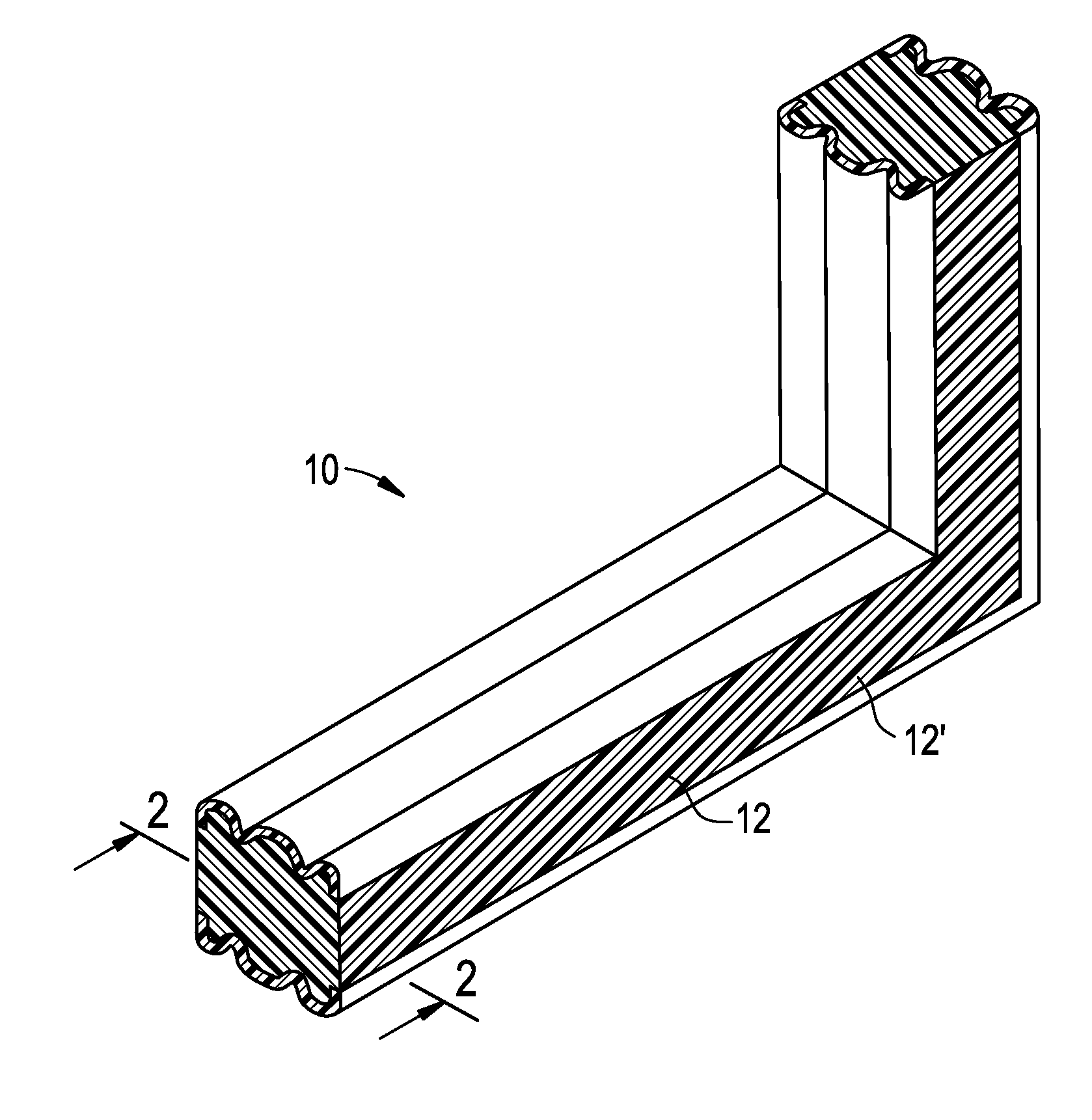

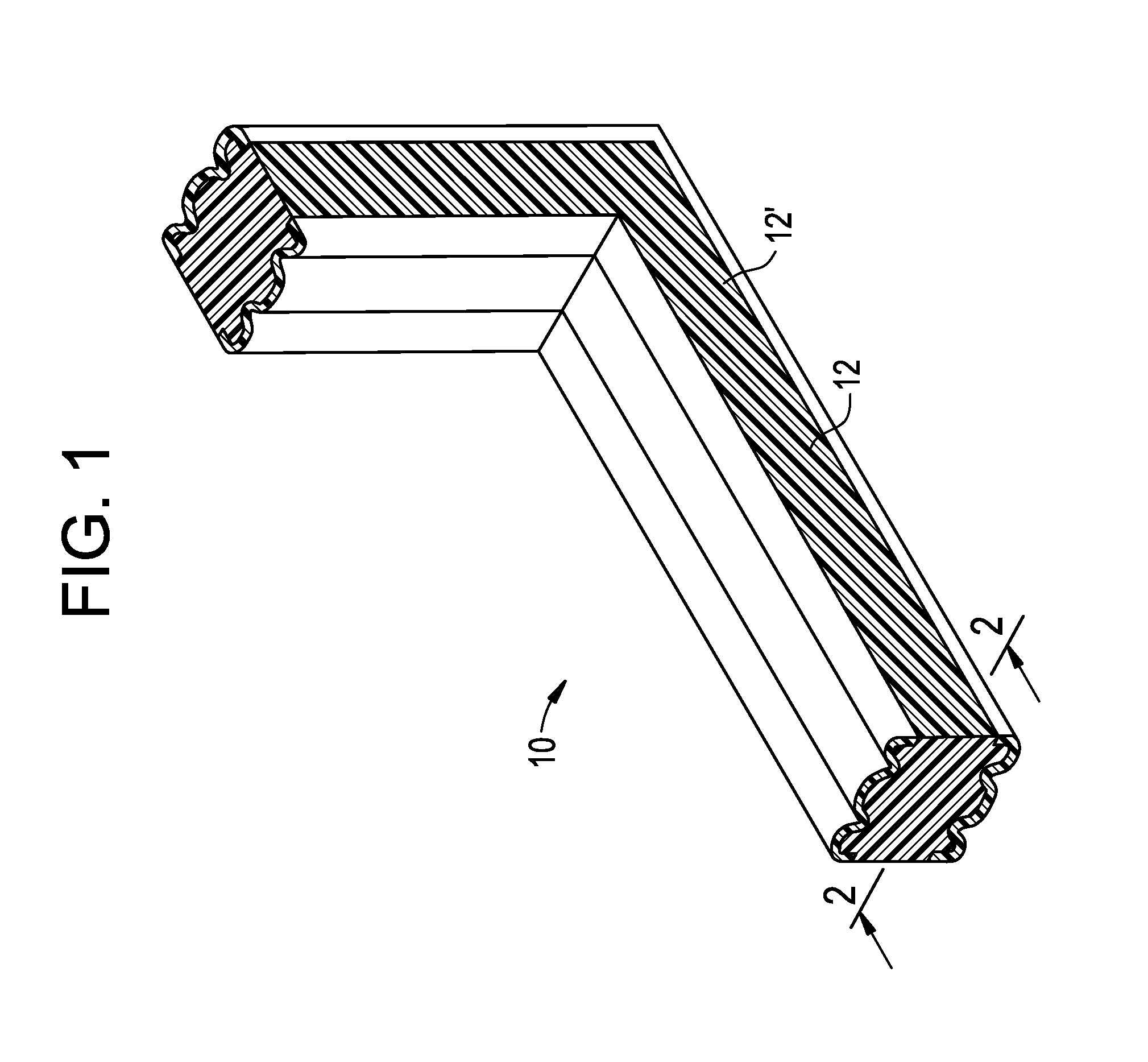

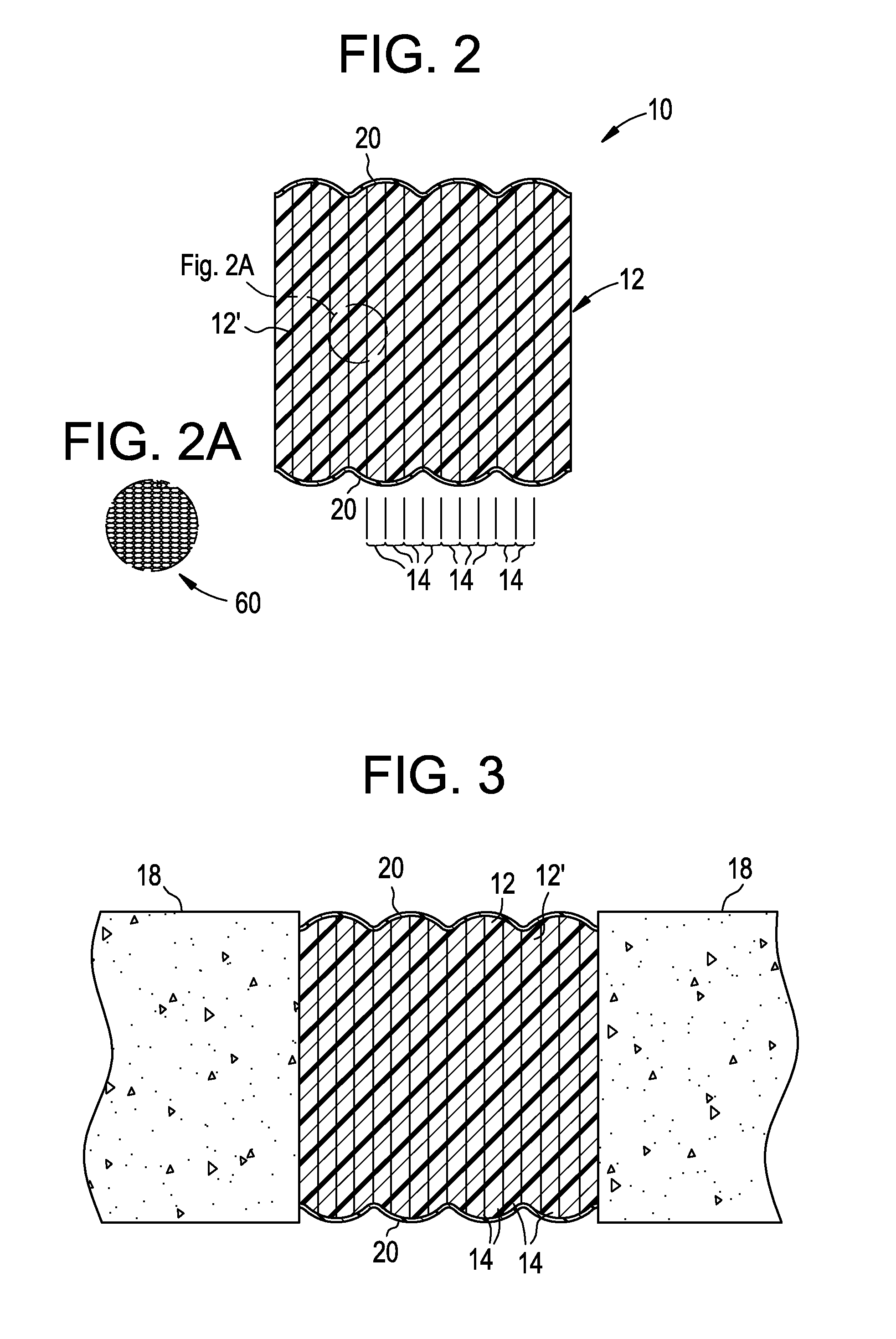

A pavement joint 101, 102 disposed between two contiguous pavement slabs 103, 104 and 105 incorporating a shear key (12, 13, 22 and 23) and at least one hinge (37, 38, 39 and 40). The shear key and the at least one hinge are operative when at least one of the slabs is subjected to out-of-plane action P with the shear key transferring shear between the slabs, and the at least one hinge accommodating angular displacement of the slabs relative to the joint axis in at least one direction. In one form, a joint member 10, 20, 40, 50 and 60 is disposed between the slabs to provide the shear key and hinge. A joint member and pavement slab for use in the joint is also described.

Owner:TRIPSTOP TECH

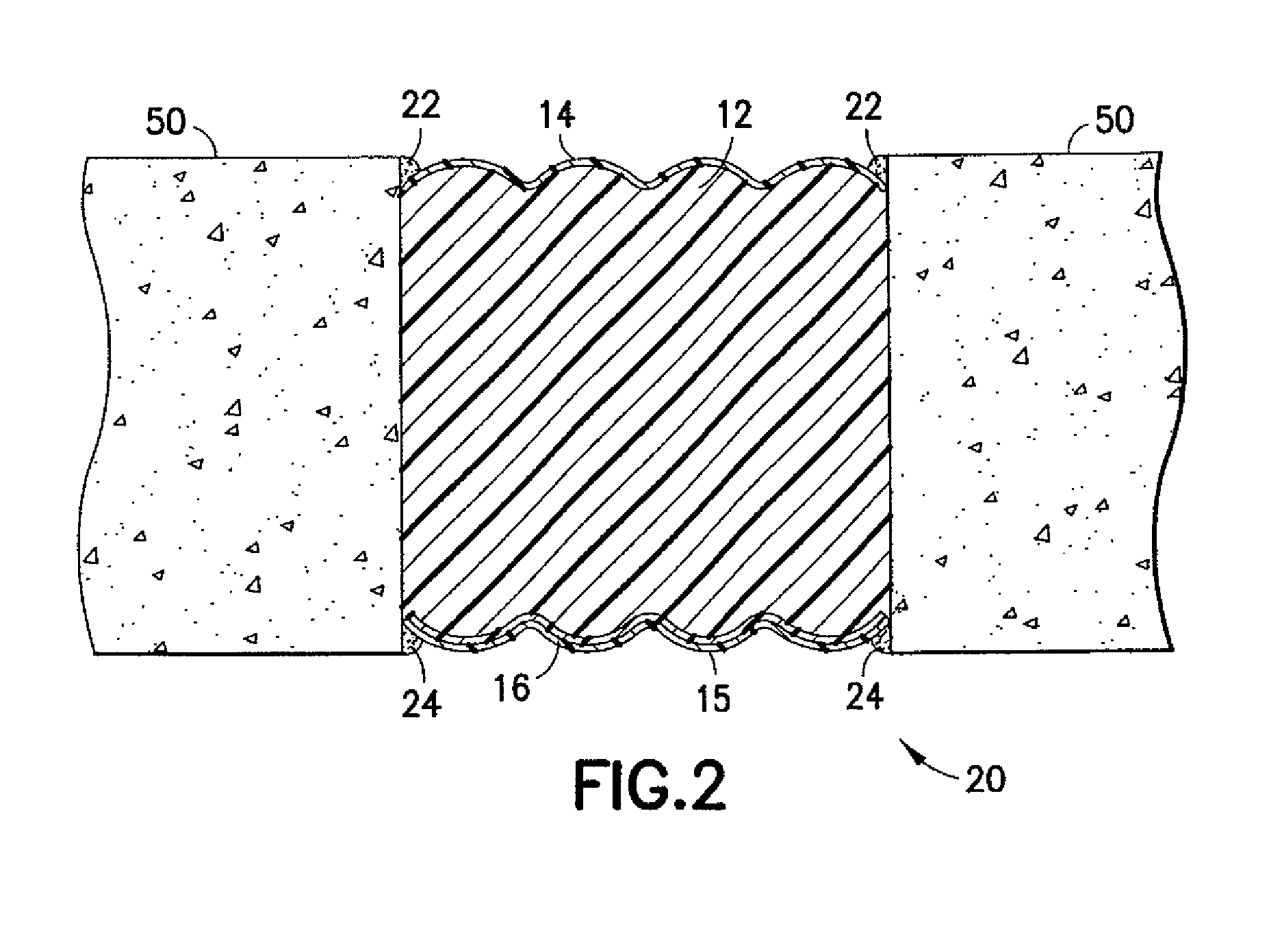

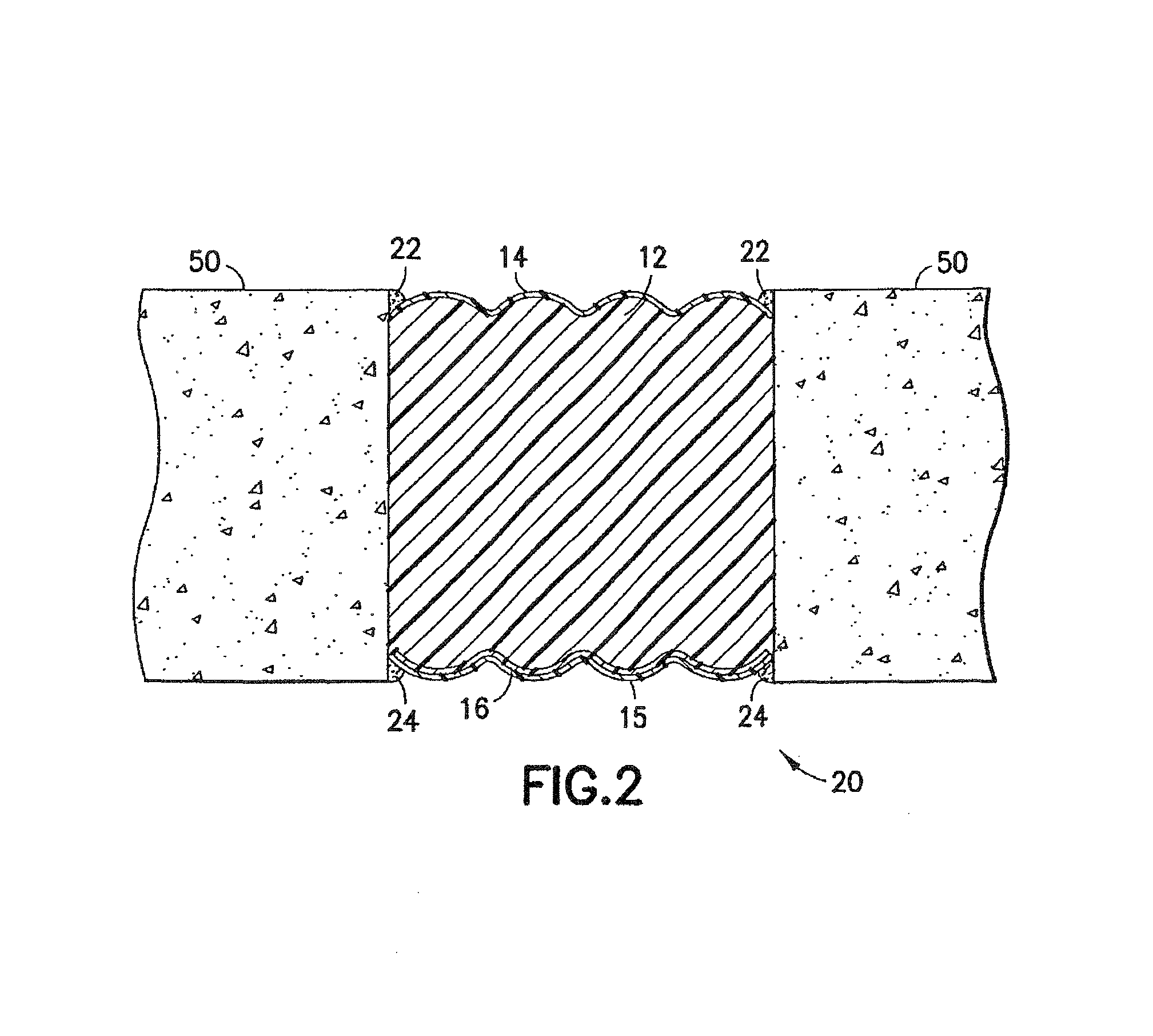

Fire and water resistant expansion joint system

A fire resistant and water resistant expansion joint system comprises a compressed lamination of fire retardant infused open celled foam, one coat of an elastomeric waterproofing or water resistant material on the lamination, and another coat of an intumescent material on an opposing surface of the lamination, thereby providing fire resistance in one direction and water resistance in the opposite direction. The intumescent material may be further coated with a similar elastomeric material, thereby providing fire resistance in one direction and water resistance in both directions. In the alternative, the compressed lamination may comprise first and second opposing layers of intumescent material thereon each having a respective layer of elastomeric material to provide both water resistance and fire resistance in both directions.

Owner:EMSEAL JOINT SYST

Bitumen or asphalt for producing a road topping, road topping and method for the production of bitumen or asphalt

InactiveUS6588974B2Good effectReduction in strengthIn situ pavingsPaving detailsParaffin waxParaffin oils

The invention relates to bitumen or asphalt for producing a road topping, whereby said bitumen or asphalt contains a proportion of paraffin obtained by Fischer-Tropsch synthesis (FT paraffin). The invention also relates to a road topping with said bitumen and to a method for producing a corresponding road topping or roadway / covering using said bitumen.

Owner:SCHUMANN SASOL SOUTH AFRICA

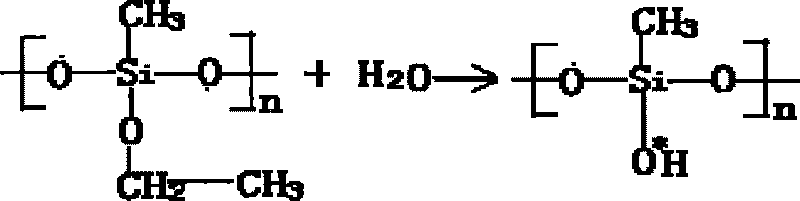

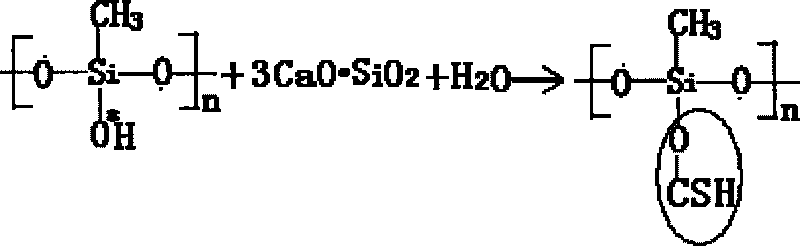

Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

ActiveCN101694114AImprove stabilityIncreased durabilityRoof covering using flexible materialsTextiles and paperAntioxidantPlasticizer

The invention discloses a wet-laying and pre-laying waterproof roll which is made by the following processes: dipping and coating a modified asphalt compound on a blank body, controlling the thickness and sizing, coating a membrane, rolling, and the like, wherein the modified asphalt compound contains modified asphalt, a plasticizer, an antioxidant, a functional auxiliary agent and a filling gent. A preparation method of the waterproof roll comprises the following steps: putting substrate asphalt in a reaction pot, adding a thickening agent, irregular polyethylene and styrene-polybutadiene-styrene segmented copolymer, evenly mixing, heating and stirring for 1.5-2 hours, then reducing the temperature to about 180 DEG C, adding padding, the plasticizer, the antioxidant and the functional auxiliary agent into the reaction pot and stirring for 0.5-1h, evenly mixing and modifying, then conveying into a colloid mill for repeatedly milling to the material, then dipping and coating the modified asphalt on the blank body, controlling the thickness, sizing, coating the membrane and rolling, and finally preparing the waterproof roll which has excellent performance and can carry out chemical bonding and physical crosslinking synergism with the concrete, namely, a CPS waterproof roll for short.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

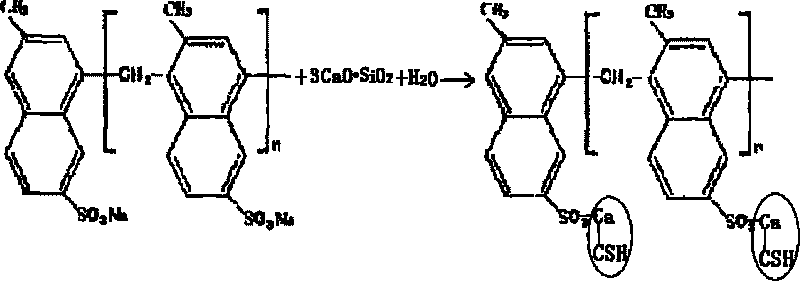

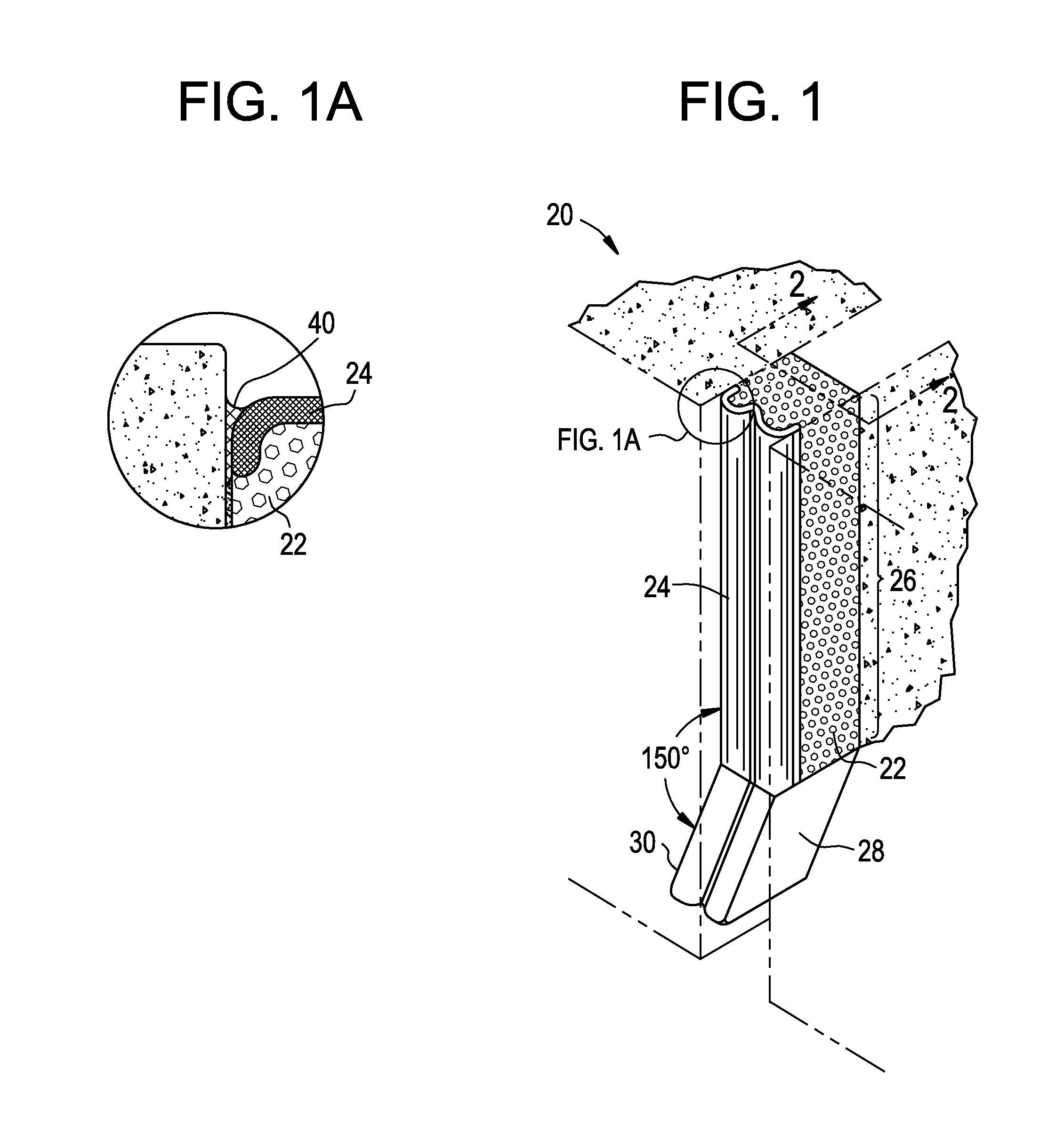

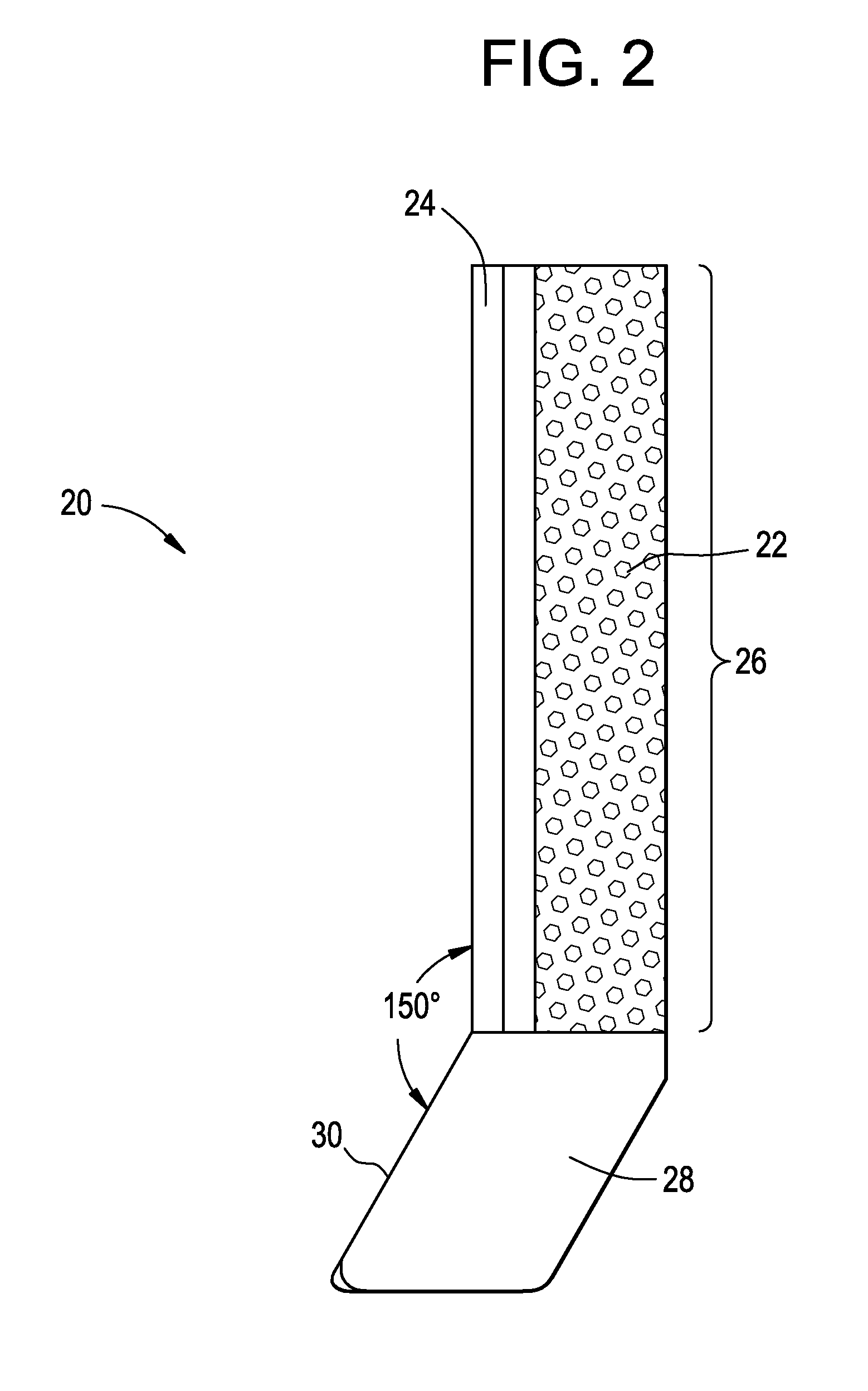

Expansion joint system

An expansion joint system includes: a core; and a layer of an elastomer disposed on the core. The core and the layer of elastomer disposed thereon form an elongated section, the elongated section configured to be oriented vertically between substantially coplanar substrates. The expansion joint system further includes a termination section located at one end of the elongated section and comprising a flared end forming an angle with the elongated section and configured to direct fluid and / or particles and / or solvents away from the expansion joint system.

Owner:EMSEAL JOINT SYST

Floor strip

InactiveUS6898911B2Increase resistanceSmooth transitionWood working apparatusPaper/cardboardReducerEngineering

Owner:PERGO

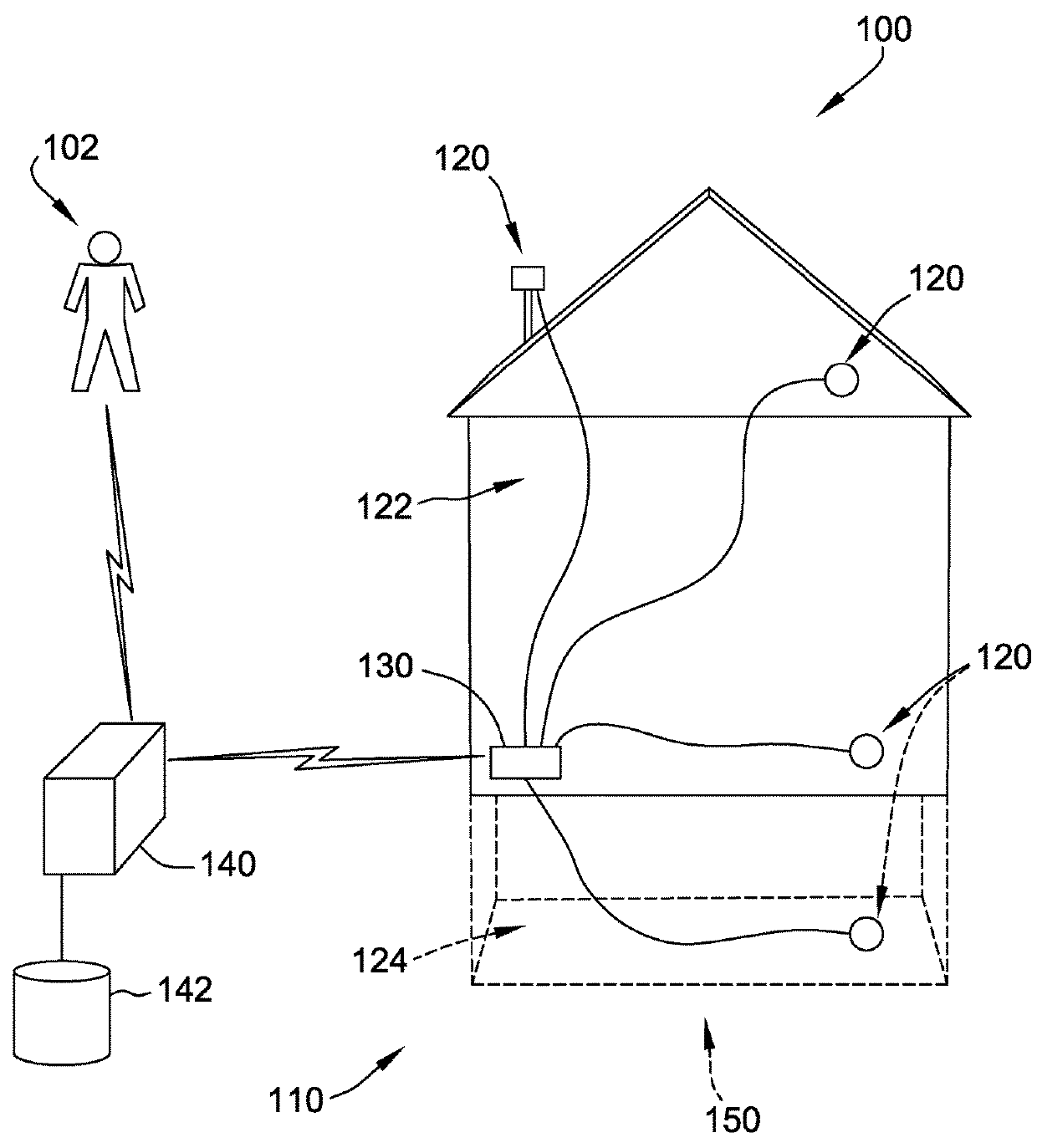

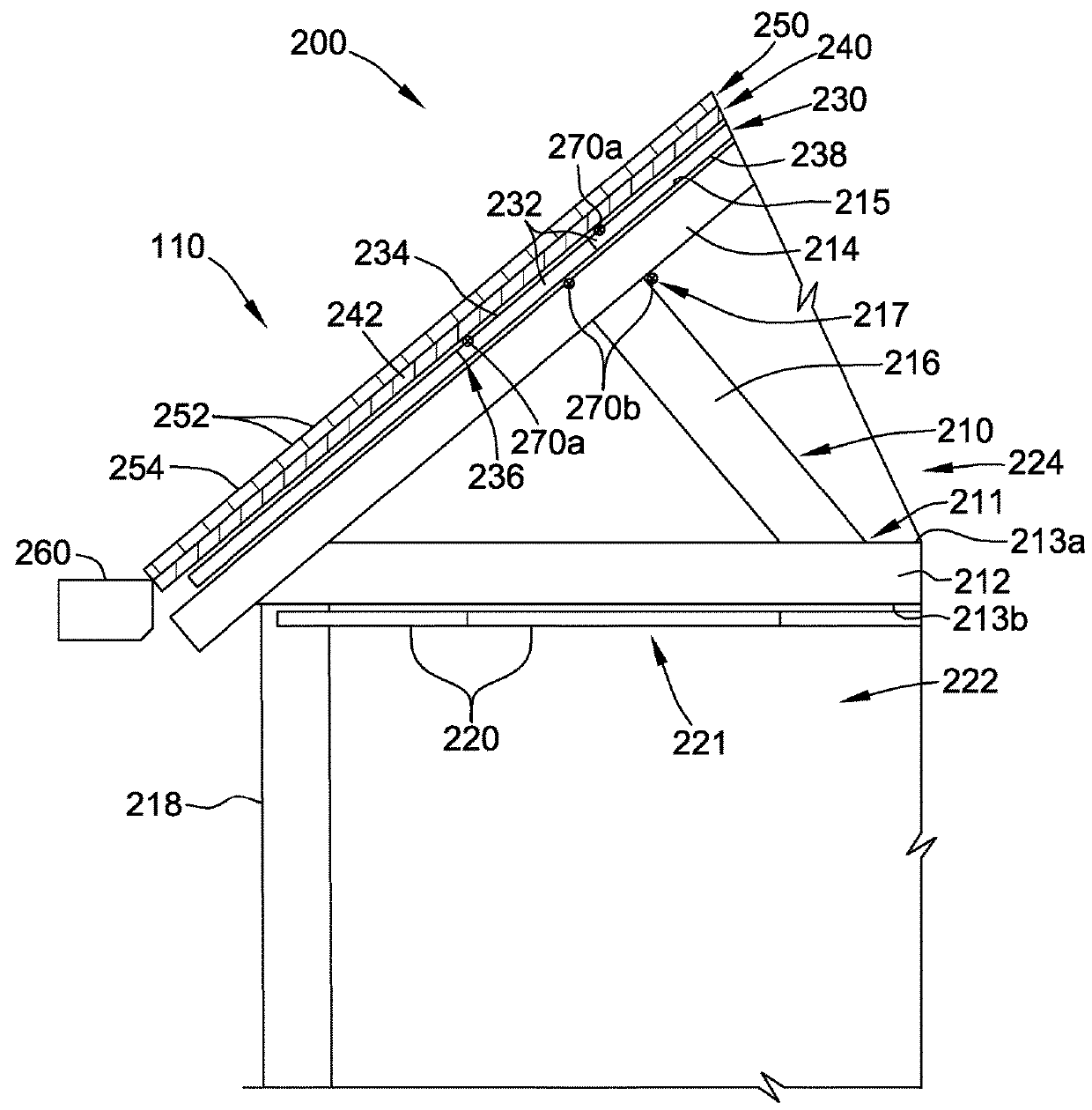

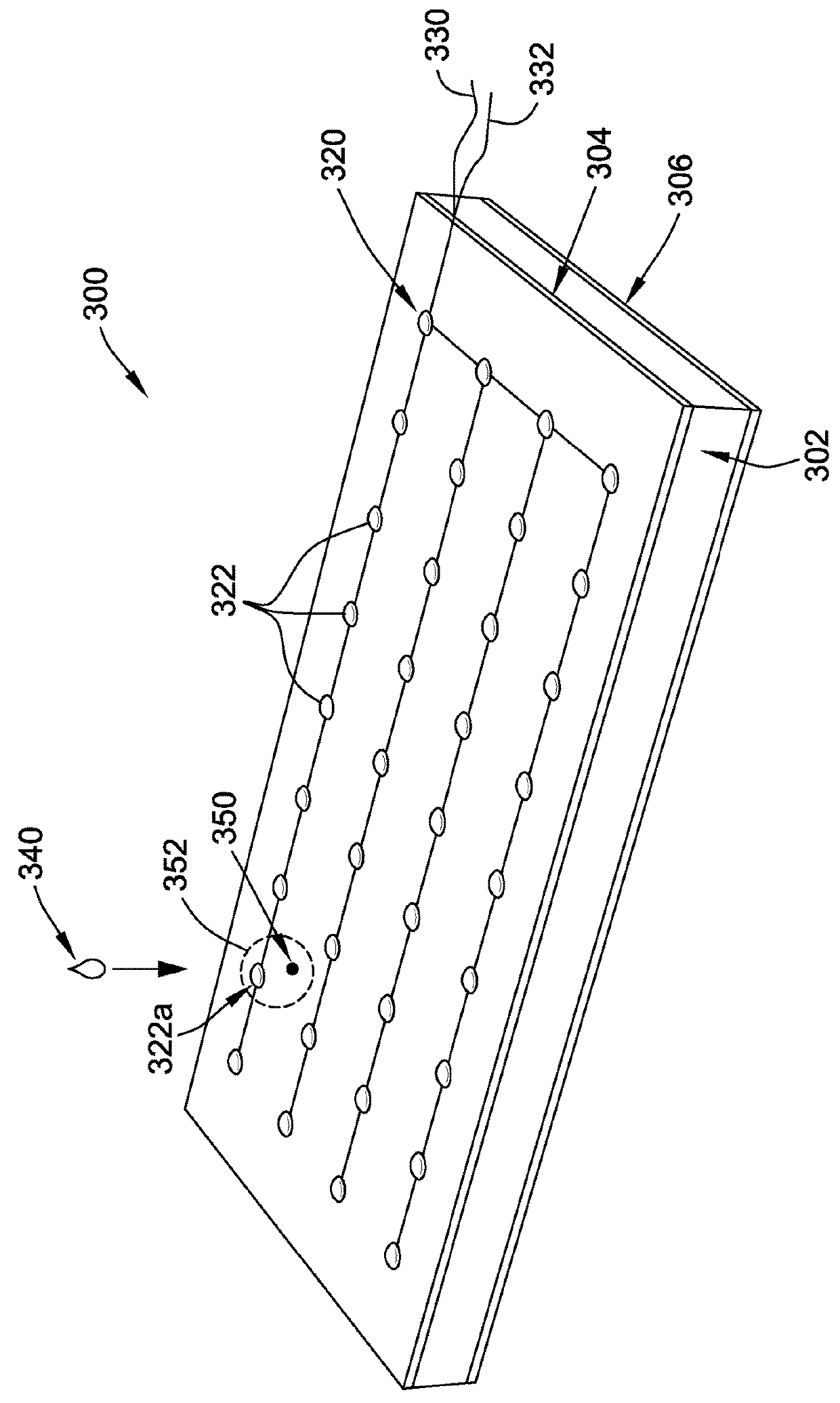

Systems and methods for monitoring building health

ActiveUS10042341B1Early detectionDetection of fluid at leakage pointWallsArchitectural engineeringRemedial action

A building monitoring computer system for monitoring building integrity may be provided. Various types of sensors may be embedded throughout or within certain portions of different types of building or construction material making up the building, such as within roofing, foundation, or structural materials. The sensors may be in wireless communication with a home controller. The sensors may be water, moisture, temperature, vibration, or other types of sensors, and may detect unexpected or abnormal conditions within the home. The sensors and / or home controller may transmit alerts to a mobile device of the home owner associated with the unexpected condition, and / or that remedial actions may be required to repair the home or mitigate further damage to the home. The sensor data may also be communicated to an insurance provider remote server to facilitate the insurance provider communicating insurance-related recommendations, updating insurance policies, or preparing insurance claims for review for home owners.

Owner:STATE FARM MUTUAL AUTOMOBILE INSURANCE

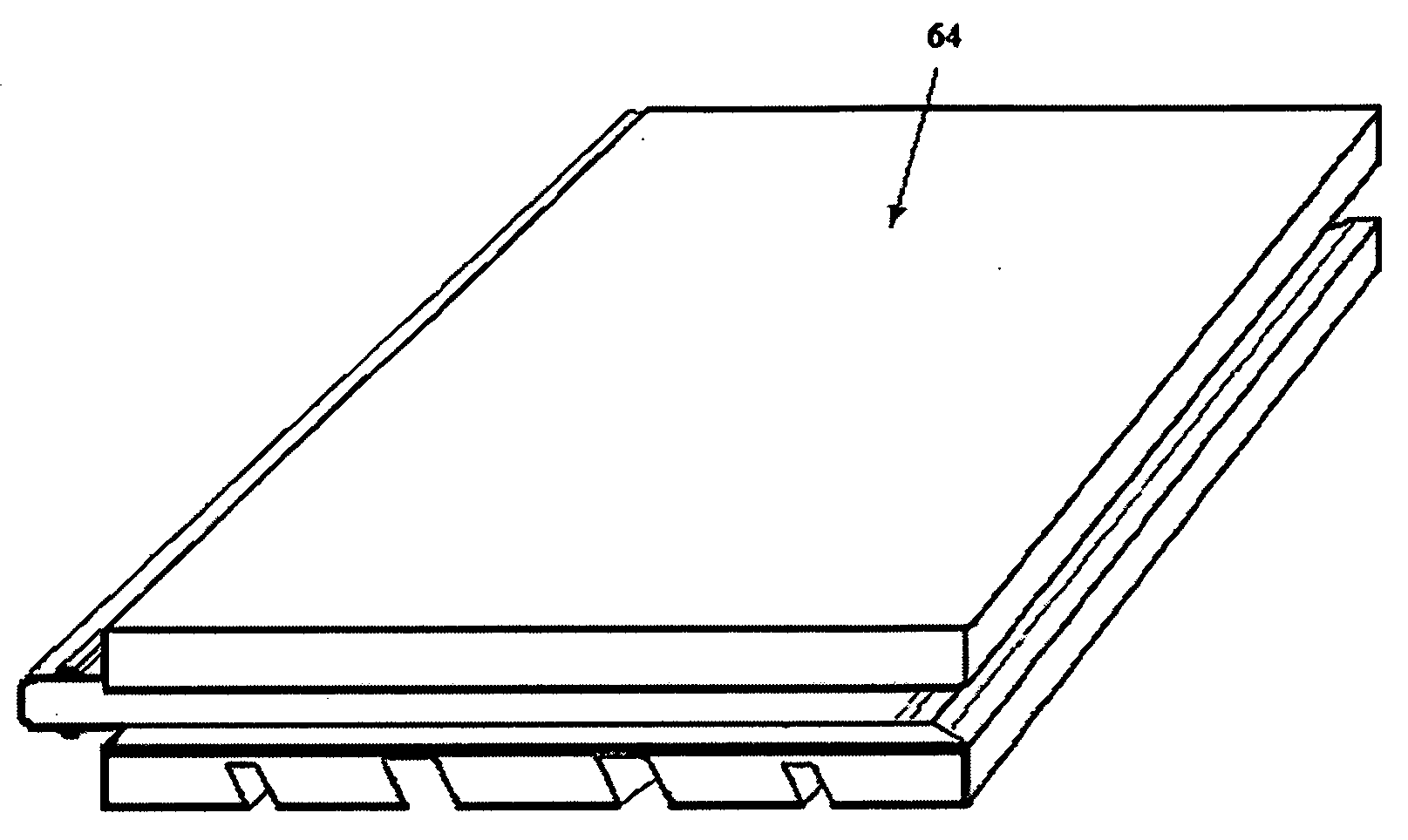

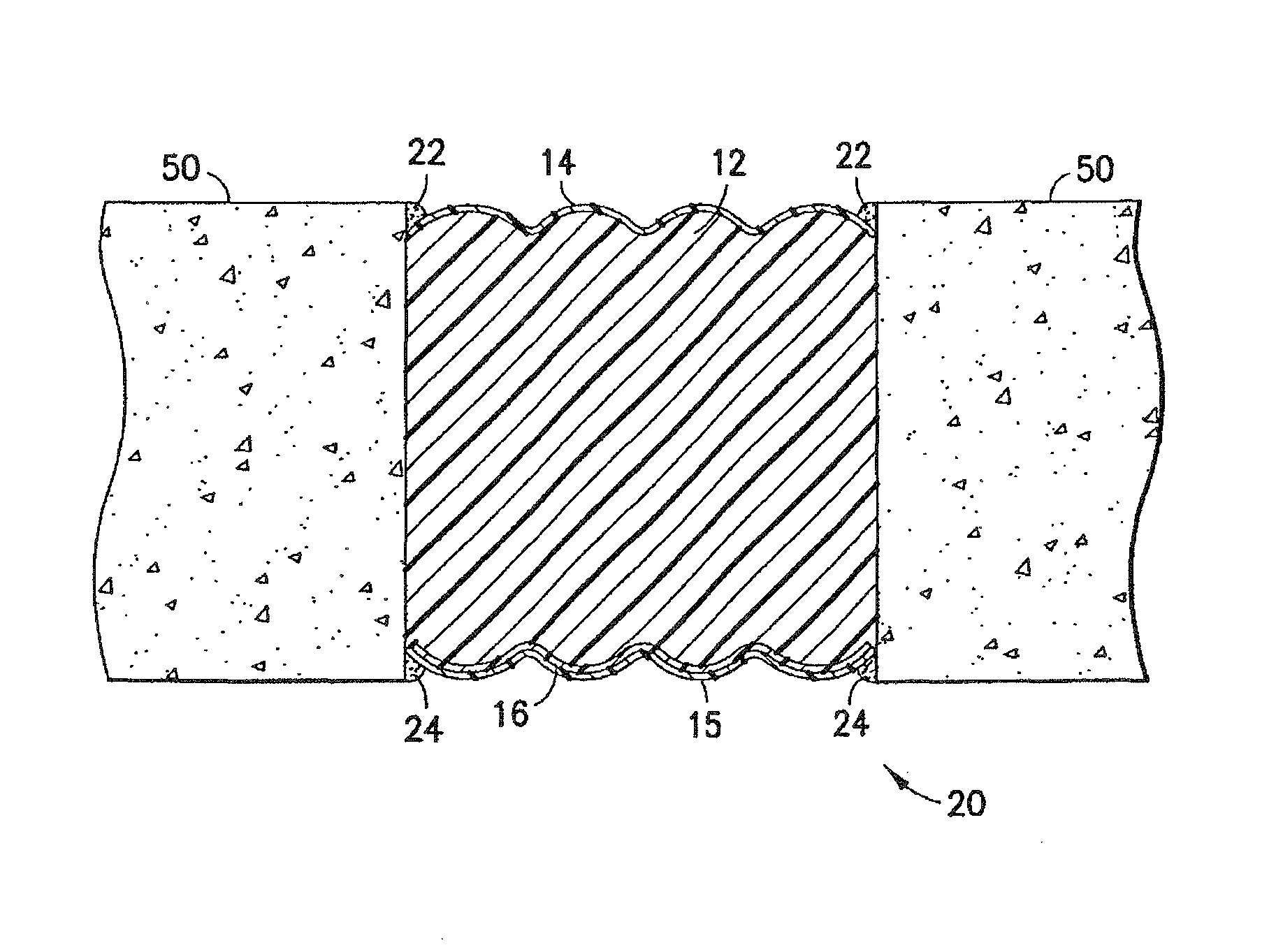

Bonded interlocking flooring

The present technique relates to a floor system that includes panels designed to be joined to one another, with an adhesive coating and a sealant at each joint to facilitate assembly. The panels include mechanically interlocking portions that mate when the system is installed. Disposed on the interlocking portions is a coating adapted to cohesively bond upon contact with itself under ambient conditions and without external activation. The sealant protects the joint and prevents the ingress of moisture following installation. Advantageously, the cohesive bonding of the coating is delayed such that the bonding does not obstruct the installation of the floor panel.

Owner:WILSONART

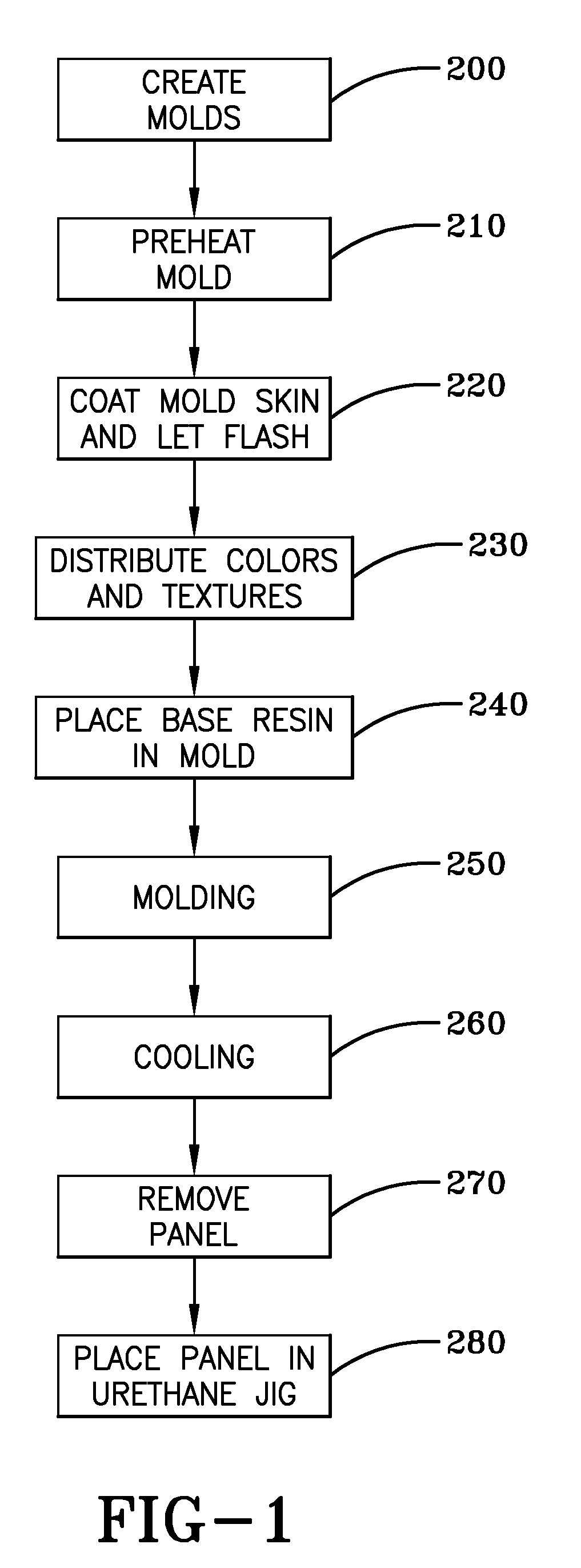

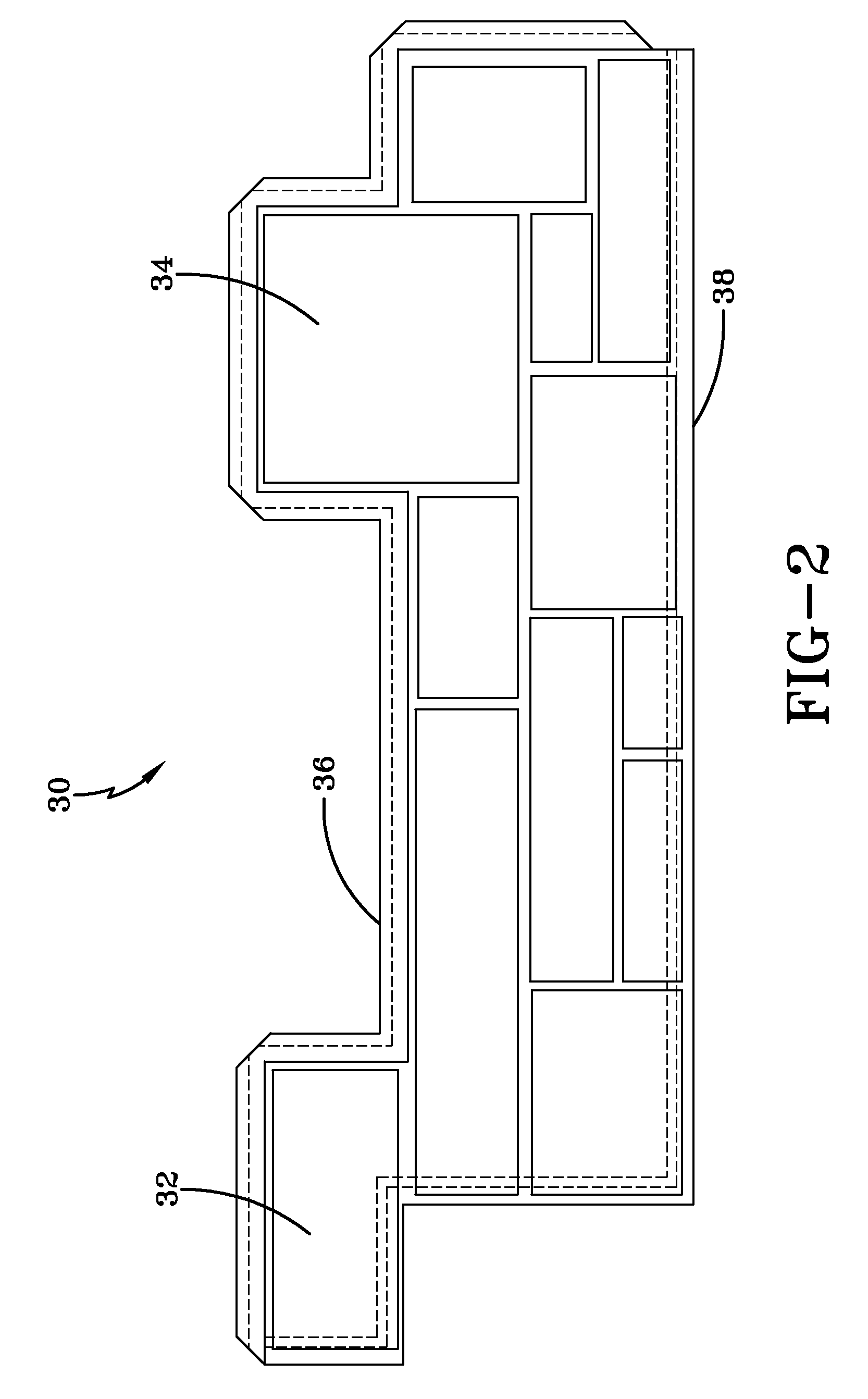

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

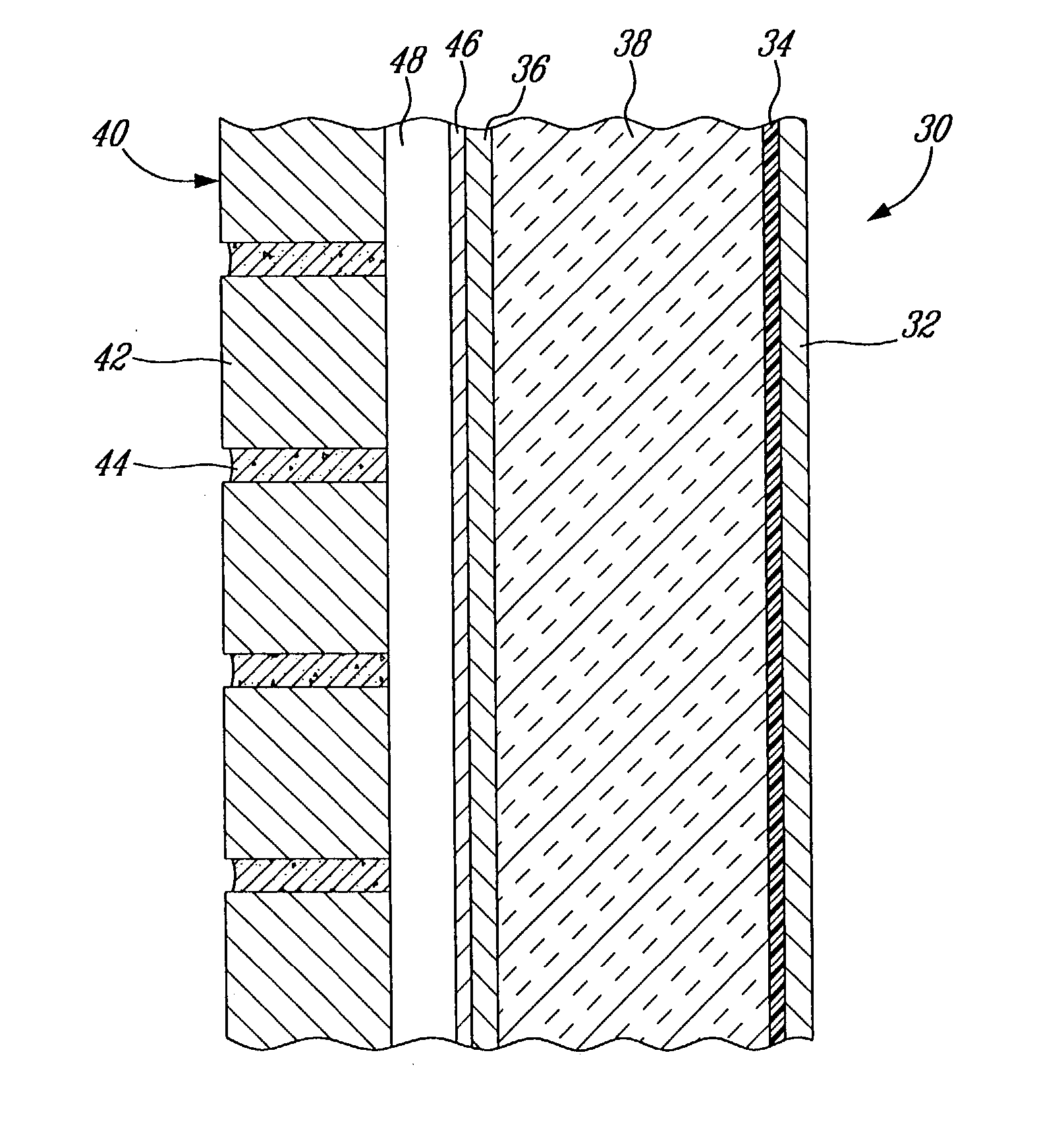

Fire and water resistant expansion and seismic joint system

An expansion joint system has a cover plate; a spline attached to the cover plate along a first edge of the spline; and two portions of open celled foam, each portion being located on an opposing face of the spline. The open celled foam has a fire-retardant material infused therein and layers of waterproof elastomer disposed thereon. The spline depends from the cover plate and is positioned in a gap between substantially coplanar substrates such that the cover plate overlies the gap. Each portion of the open celled foam is compressed between a respective face of the spline and a face of one of the coplanar substrates. An intumescent material may be incorporated into the spline.

Owner:SIKA TECH AG

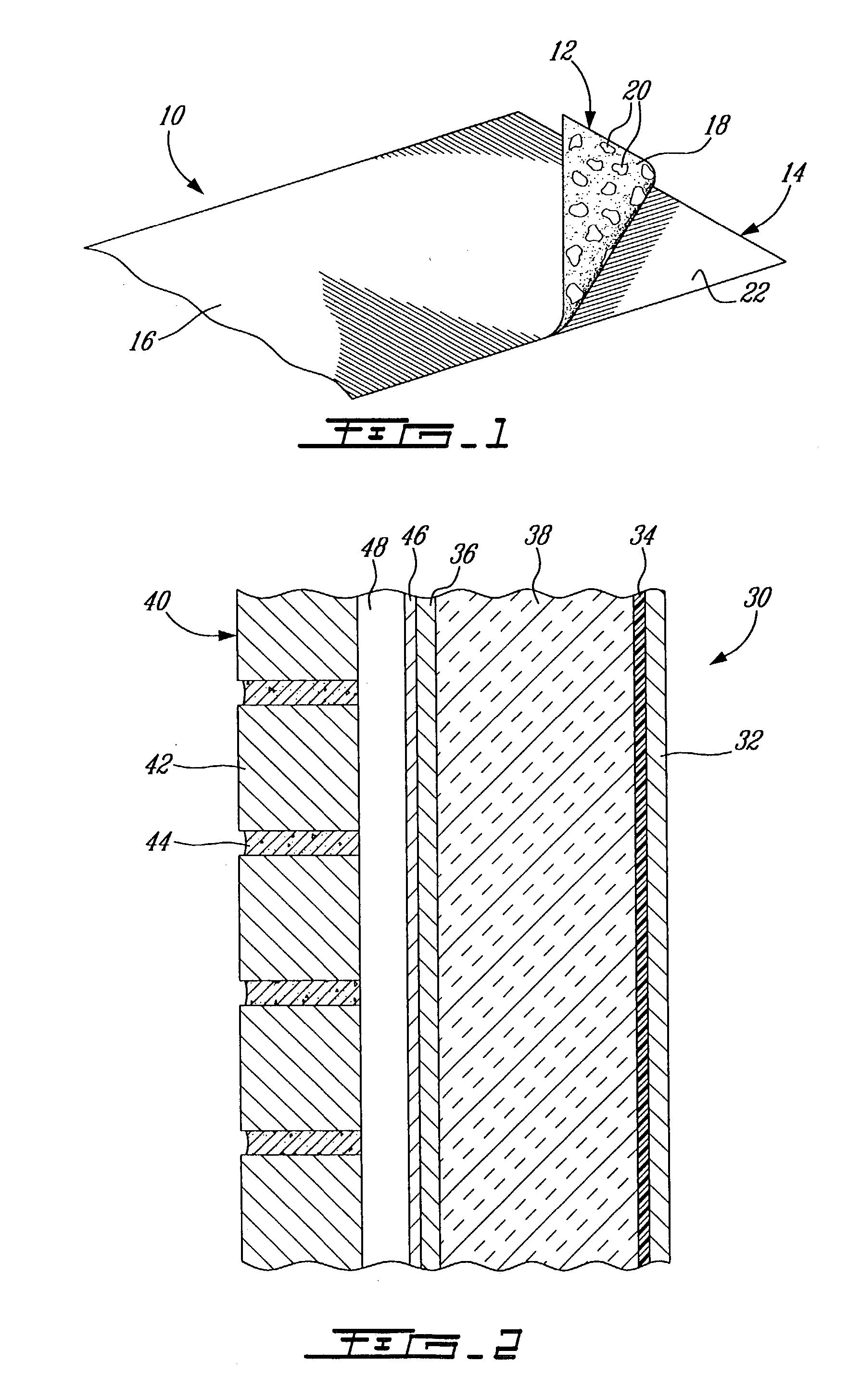

Expansion joint seal system

ActiveUS9206596B1Avoid heatAvoid the needConstruction materialBuilding insulationsEngineeringWater resistant

An expansion joint seal system which includes intumescent to protect uncoated edges of substrates. A fire rated compressed expansion joint sealant is provided having an intumescent proximate, but below the water-resistant top of the fire-retardant foam, so that when exposed to fire, the intumescent expands to protect the exposed vertical surface of the adjacent concrete substrate. The end of the concrete is therefore protected in a manner which does not require joint overlap between the horizontal fire resistant coating and the compressible sealant.

Owner:SCHUL INT COMPANY

Self-adhering vapor permeable air and moisture barrier membrane

InactiveUS6901712B2Prevent lateral movementEliminate channelingCovering/liningsWallsAdhesiveWater vapor

Owner:HENRY COMPANY CANADA

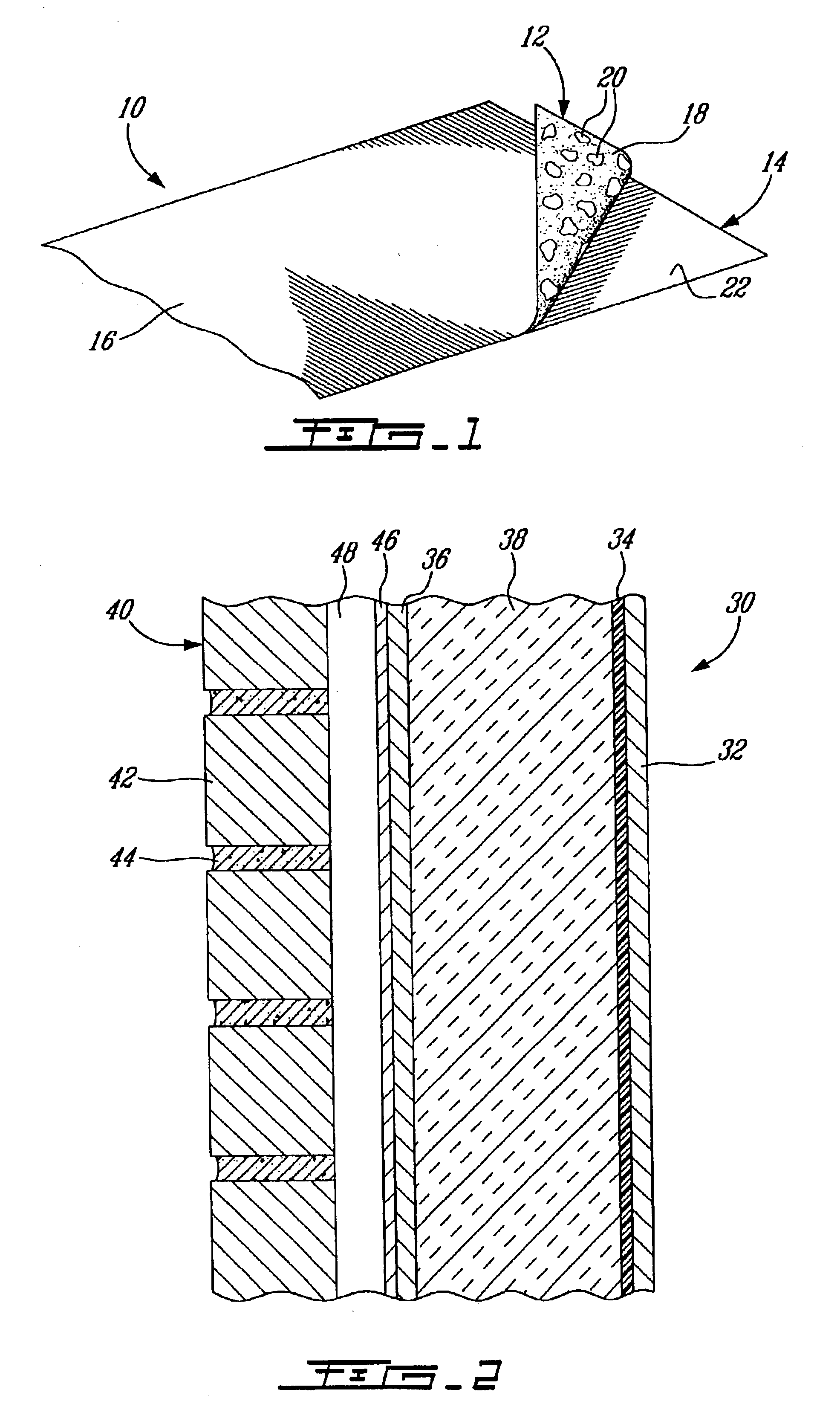

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

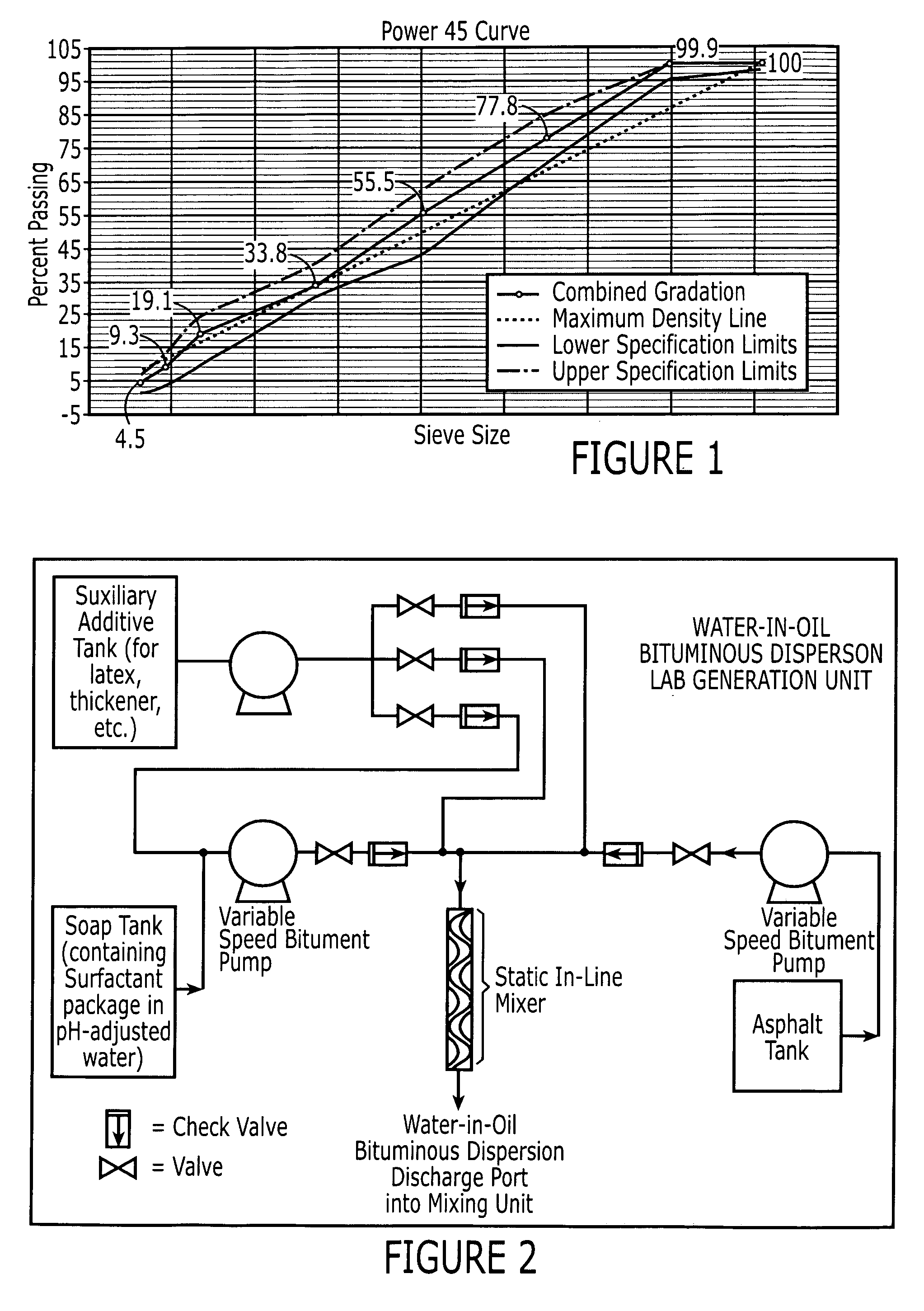

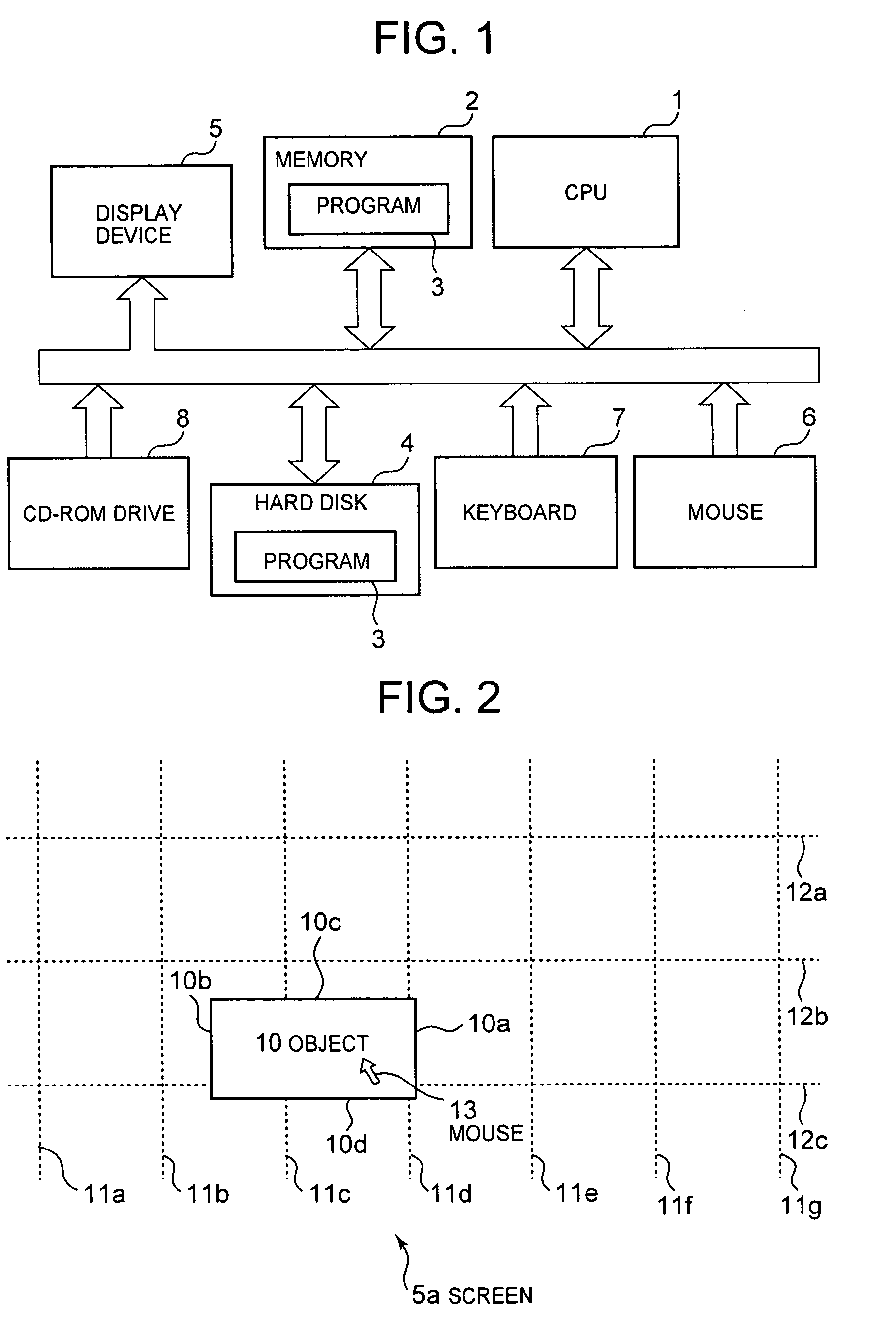

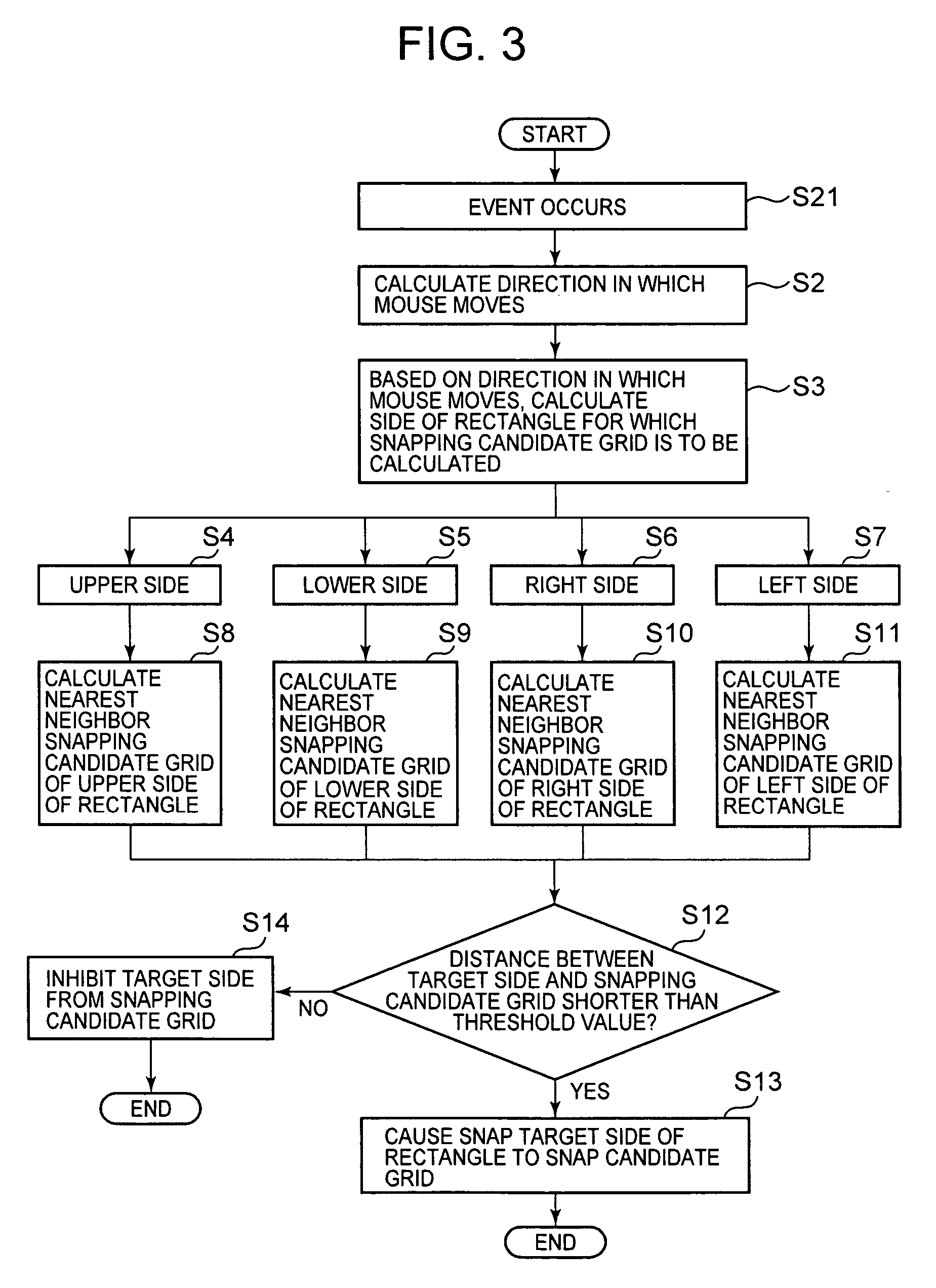

Object editing system, object editing method and object editing program product

InactiveUS20060174568A1Smooth movementWithout deteriorating user operabilityBuilding insulationsInput/output processes for data processingOperabilityMobile object

The present invention provides a snap function that can move an object smoothly, without deteriorating the user operability. According to the present invention, there is provided an object editing system, including: an arrangement system for arranging an object and a snap target in a given display area; a moving system for moving the object in the display area; a snap system for causing the object to snap the snap target on a basis of a distance between the object and the snap target; and a restriction system for inhibiting the object from snapping the snap target on a basis of a direction in which the object is moving. According to the object editing system of the invention, the snap system causes the object to snap the snap target once the distance between the object and the snap target has become smaller than a predetermined threshold value.

Owner:IBM CORP

Bright coloured surface layer

ActiveUS20110177354A1Easy to processImprove stain resistanceSpecial ornamental structuresPretreated surfacesFiberSurface layer

A method to produce a pale and / or plain coloured wear resistant surface layer by using a dry powder layer comprising a mix of refined fibres binder, pigment and wear resistant particles.

Owner:VÄLINGE INNOVATION AB

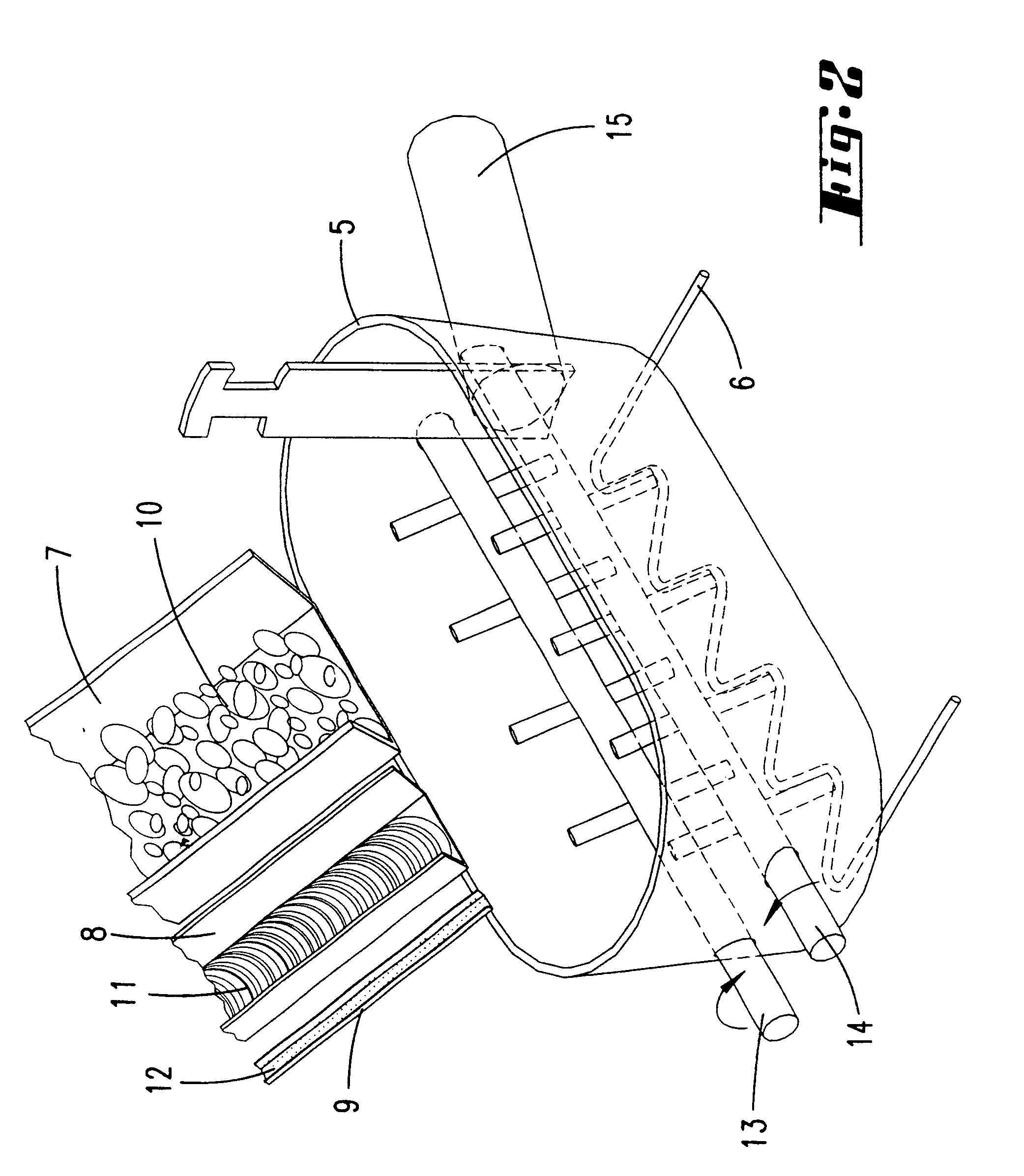

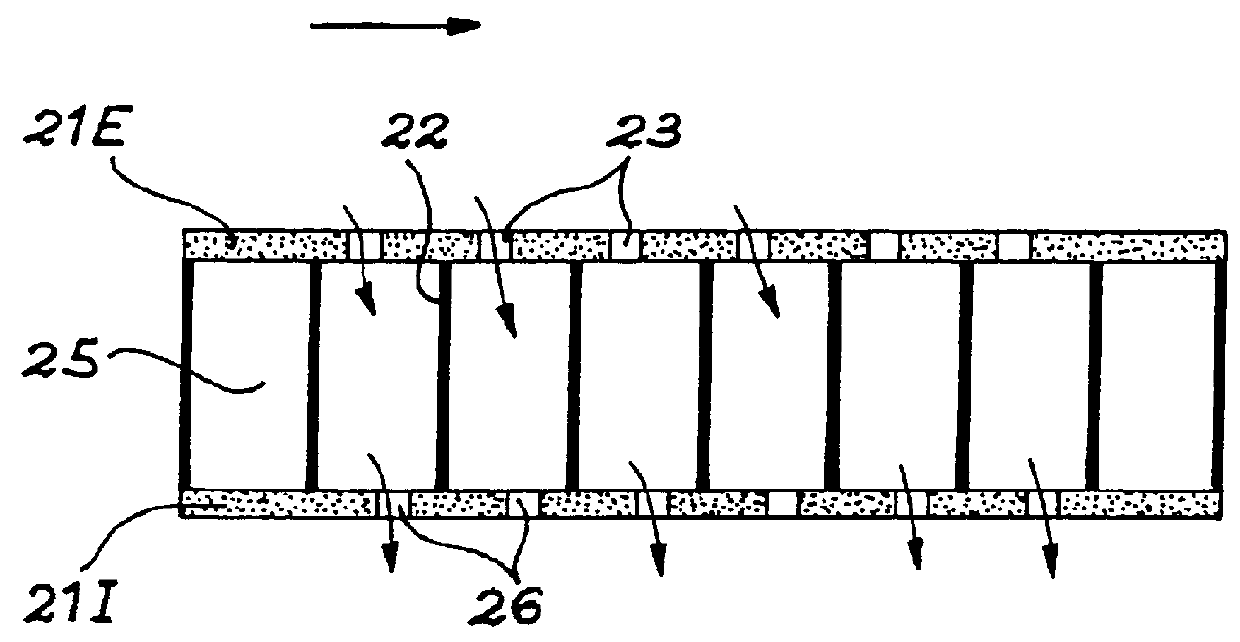

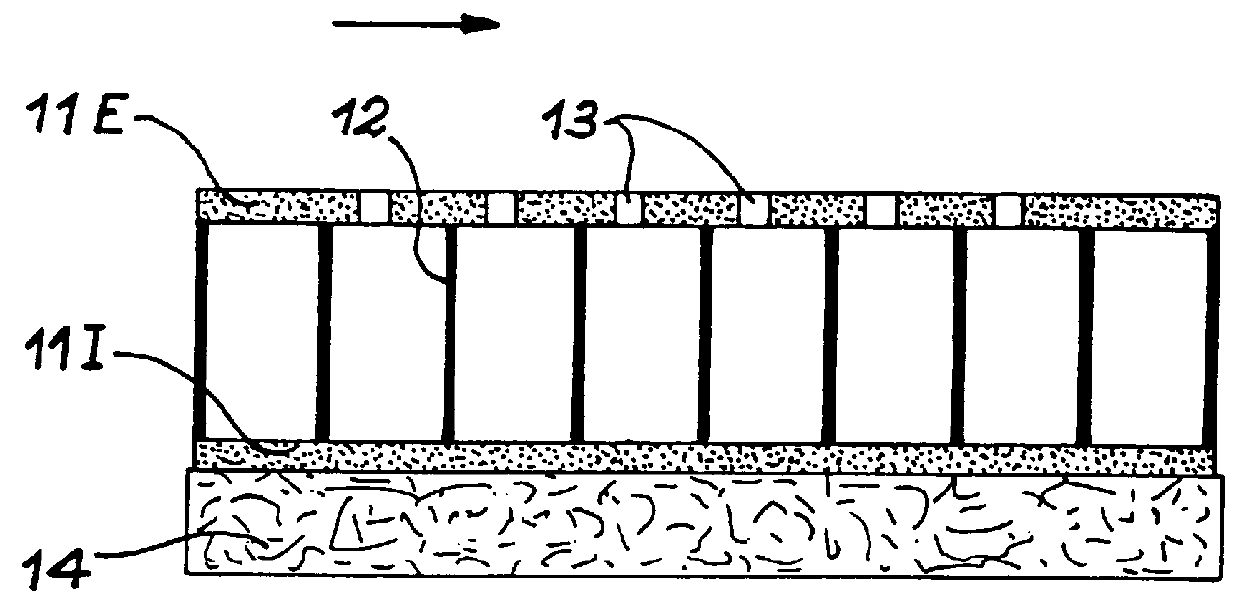

Ventilated honeycomb cell sandwich panel and ventilation process for such a panel

InactiveUS6122892AEasy to shapeSpeed up the flowEngine manufactureLayered productsCells panelHoneycomb

A cell panel for thermal ventilation including a first wall having raised portions which define openings; a second wall; partition walls connected to the first and second walls and that define cells. The openings in the first wall are located upstream of an air flow flowing outside the first wall. The first wall may further include raised portions which define other openings located downstream of the air flow. The second wall may also include raised portions which define openings located downstream of the air flow. The partition walls may define communication holes between adjacent cells.

Owner:SOC HISPANO SUIZA AEROSTRUCTURES

Fire and water resistant expansion joint system

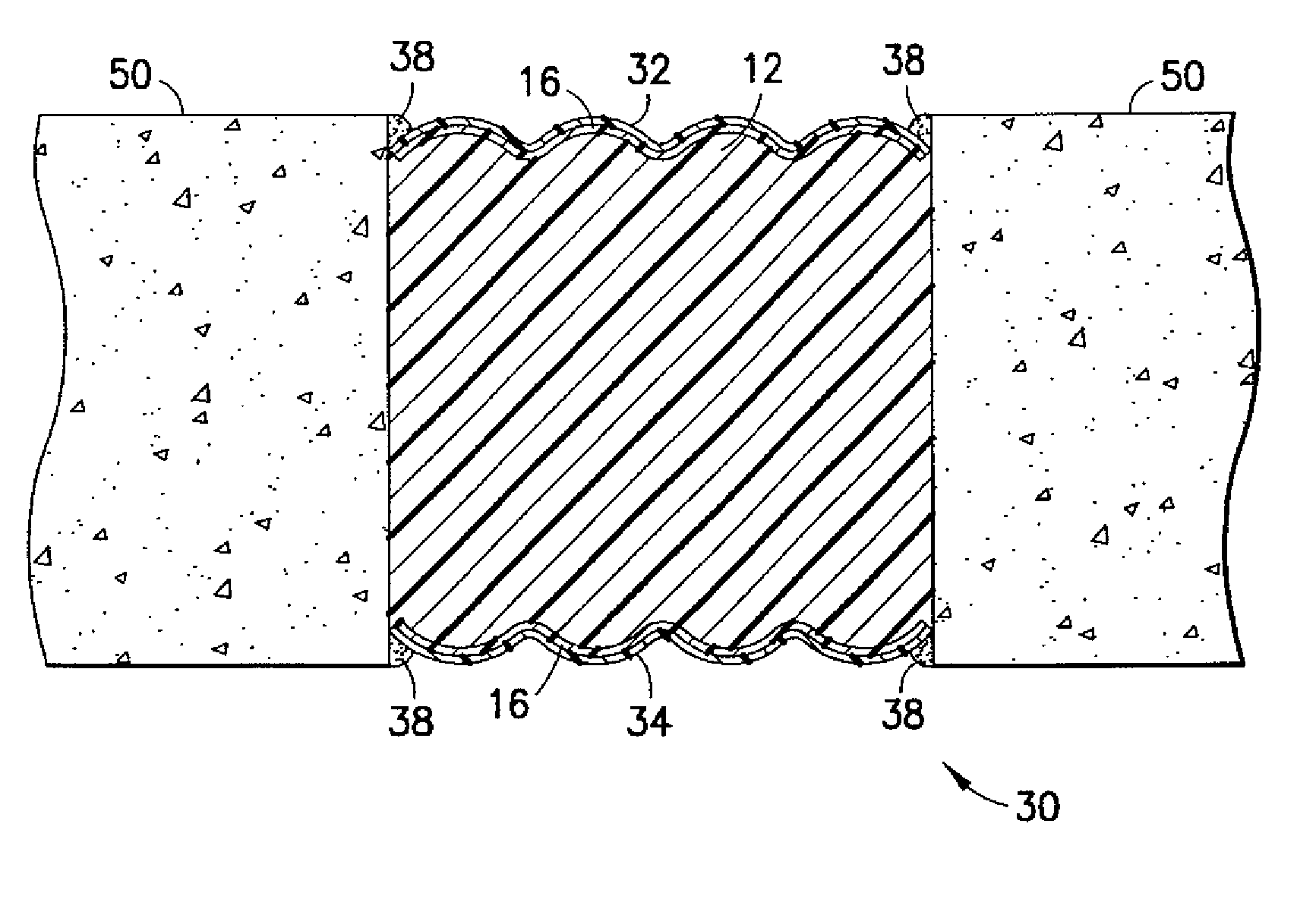

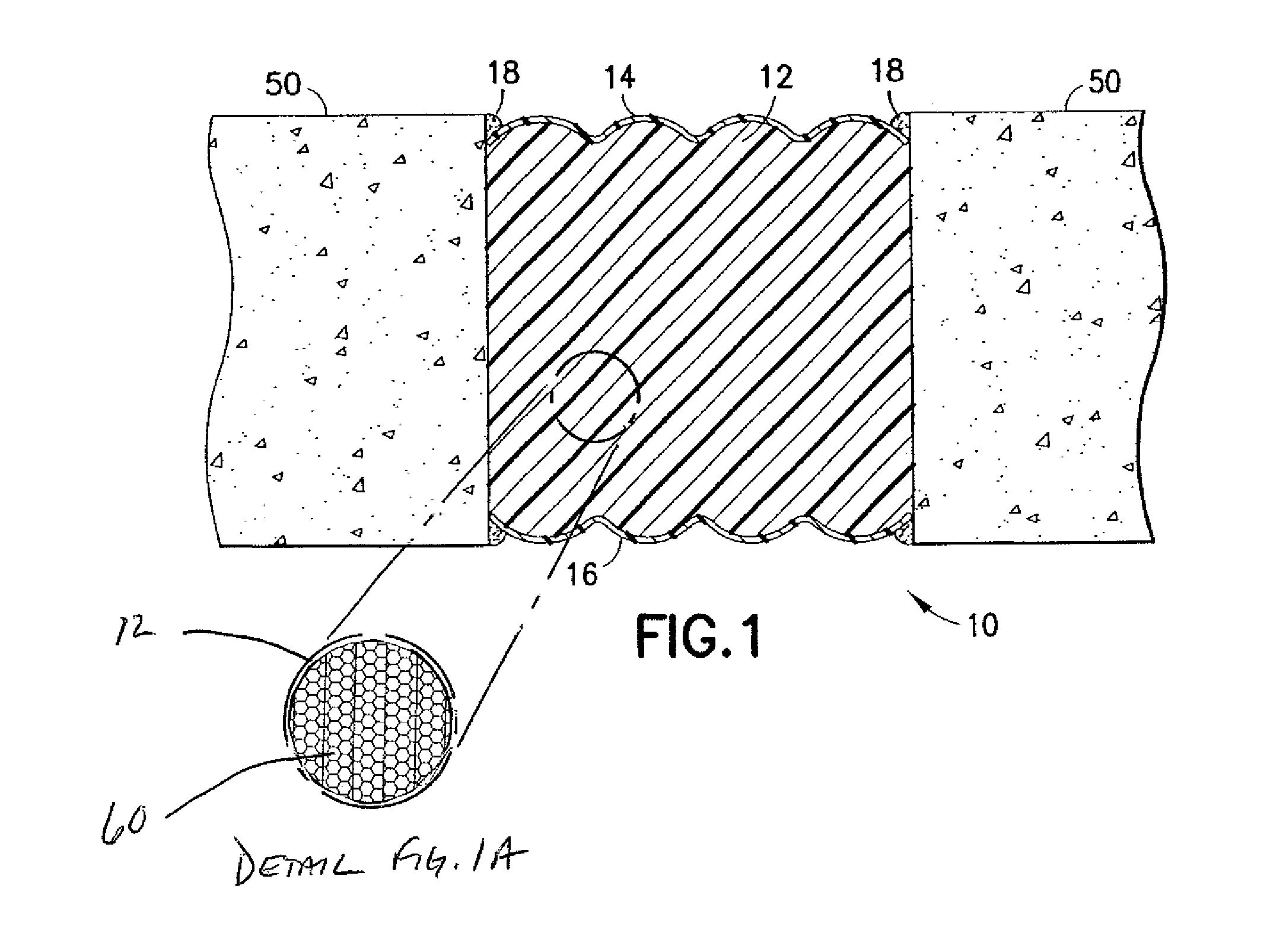

A fire resistant and water resistant expansion joint system comprises a compressed lamination of fire retardant infused open celled foam, one coat of an elastomeric waterproofing or water resistant material on the lamination, and another coat of an intumescent material on an opposing surface of the lamination, thereby providing fire resistance in one direction and water resistance in the opposite direction. The intumescent material may be further coated with a similar elastomeric material, thereby providing fire resistance in one direction and water resistance in both directions. In the alternative, the compressed lamination may comprise first and second opposing layers of intumescent material thereon each having a respective layer of elastomeric material to provide both water resistance and fire resistance in both directions.

Owner:EMSEAL JOINT SYST

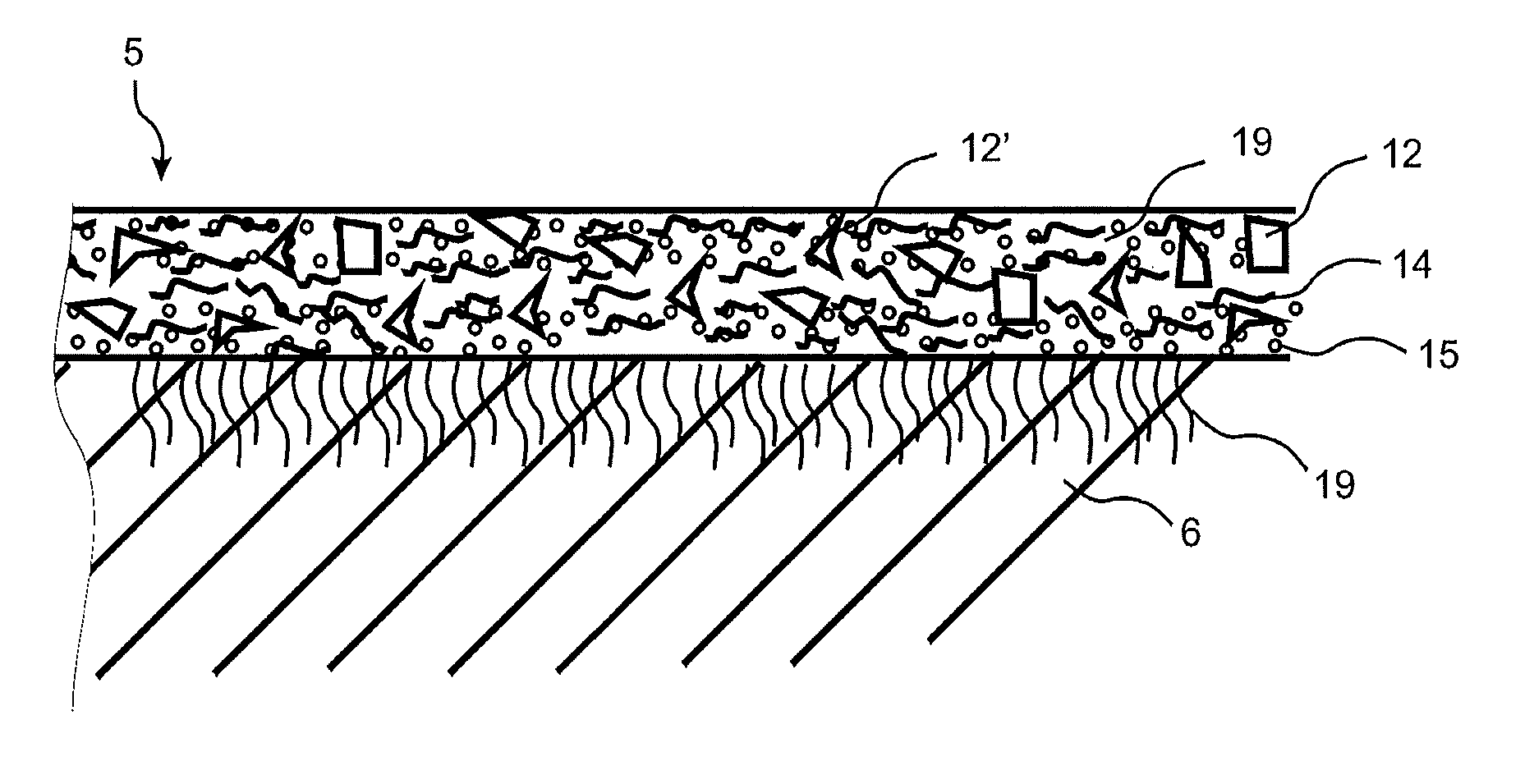

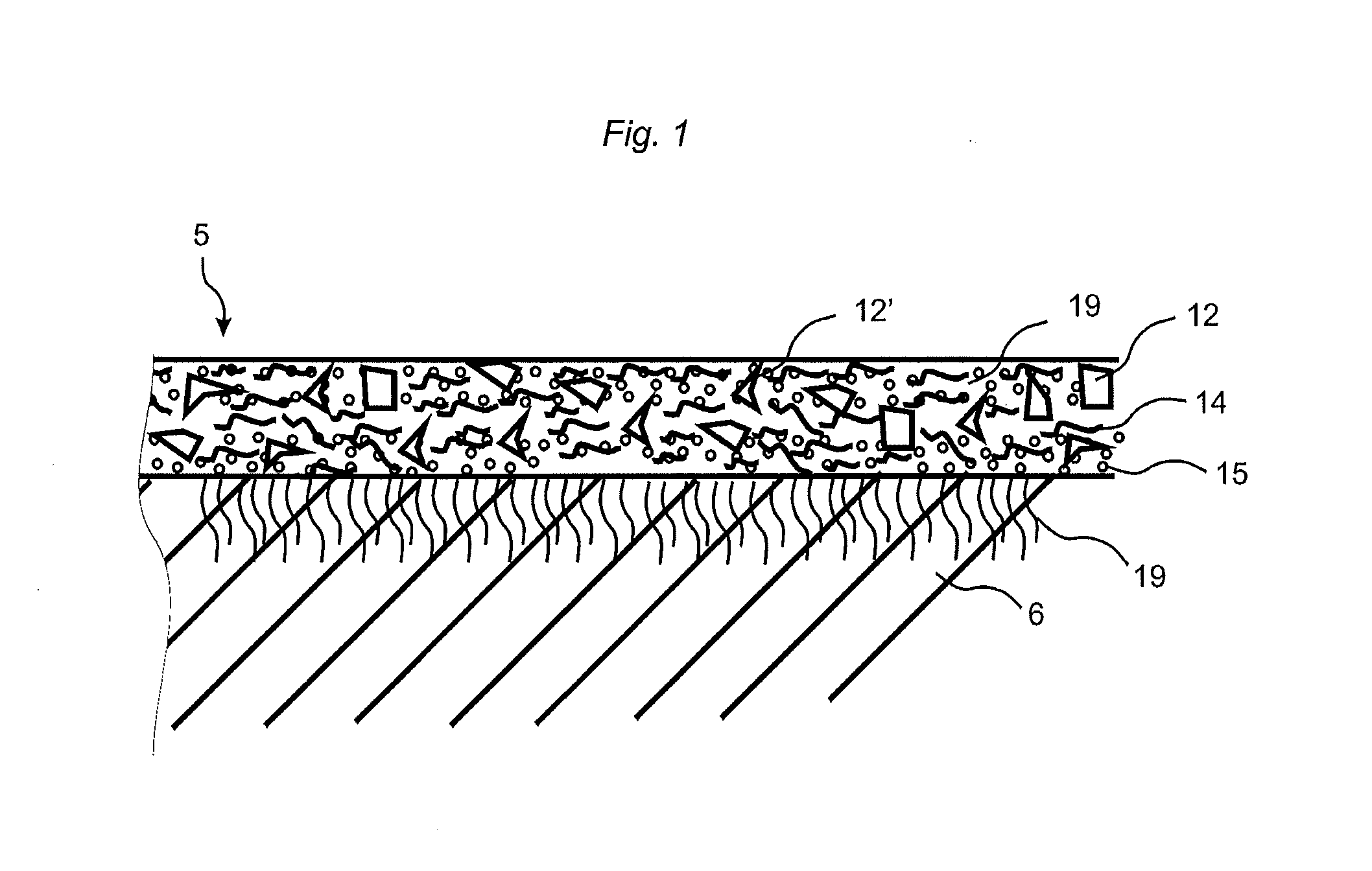

Self-adhering vapor permeable air and moisture barrier membrane

A self-adhering air and moisture barrier sheet membrane for structural surfaces of buildings, which is permeable to the passage of water vapor, is comprised of a water vapor permeable sheet onto one surface of which is applied an adhesive in a non-continuous film.

Owner:HENRY COMPANY CANADA

Factory fabricated precompressed water and/or fire resistant tunnel expansion joint systems, and transitions

InactiveUS20140360118A1On-site operationMinimize opportunityFurnace componentsUnderwater structuresWater resistantExpansion joint

A fire and / or water resistant expansion joint system for installation between substrates of a tunnel. The system includes a coating applied at a predetermined thickness to the substrates and a fire and water resistant expansion joint. The expansion joint includes a core and a fire retardant infused into the core. The core is configured to define a profile to facilitate the compression of the expansion joint system when installed between the substrates. The coating and the fire and water resistant expansion joint are each capable of withstanding exposure to a temperature of at least about 540° C. or greater for about five minutes.

Owner:EMSEAL JOINT SYST

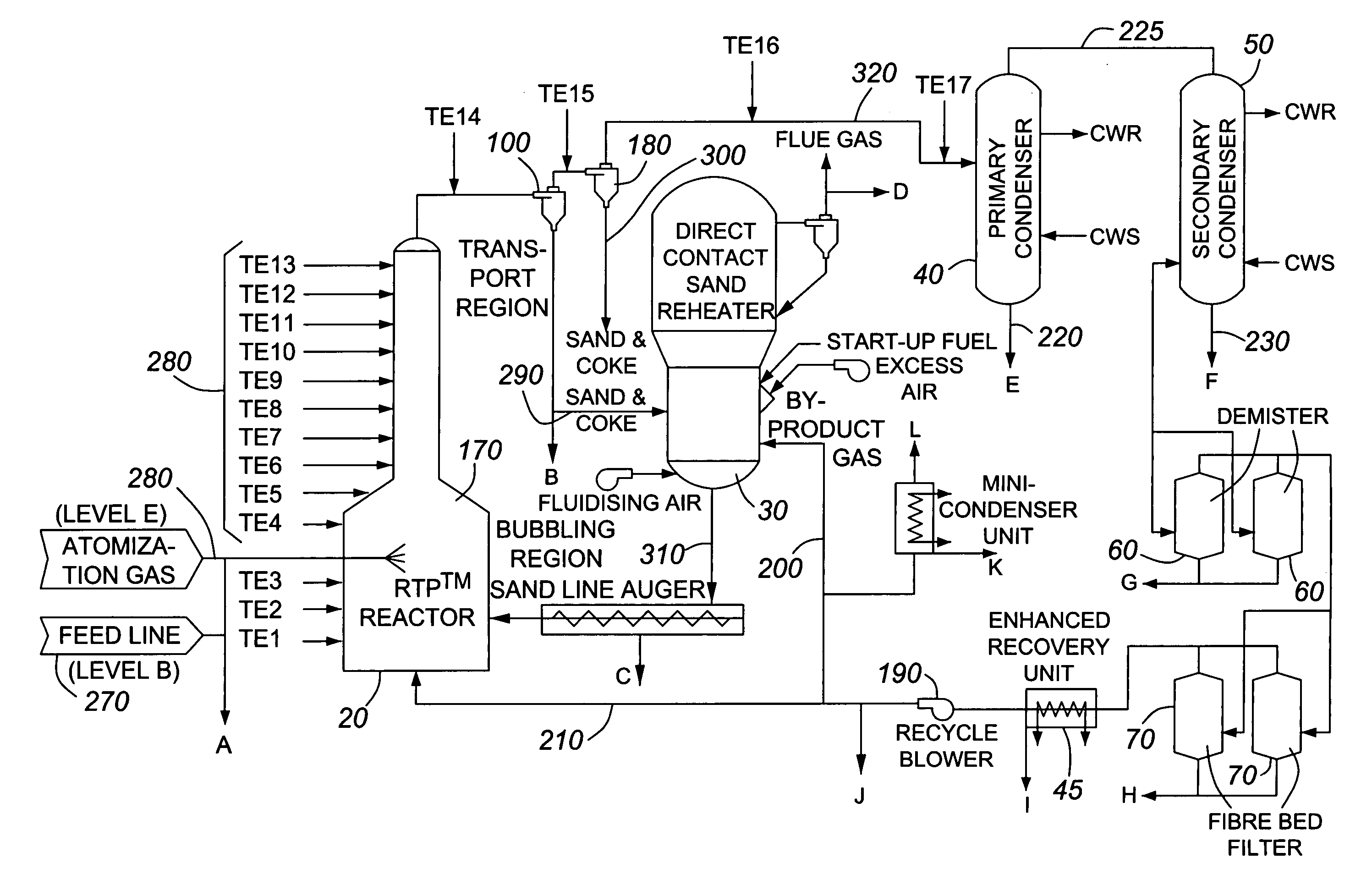

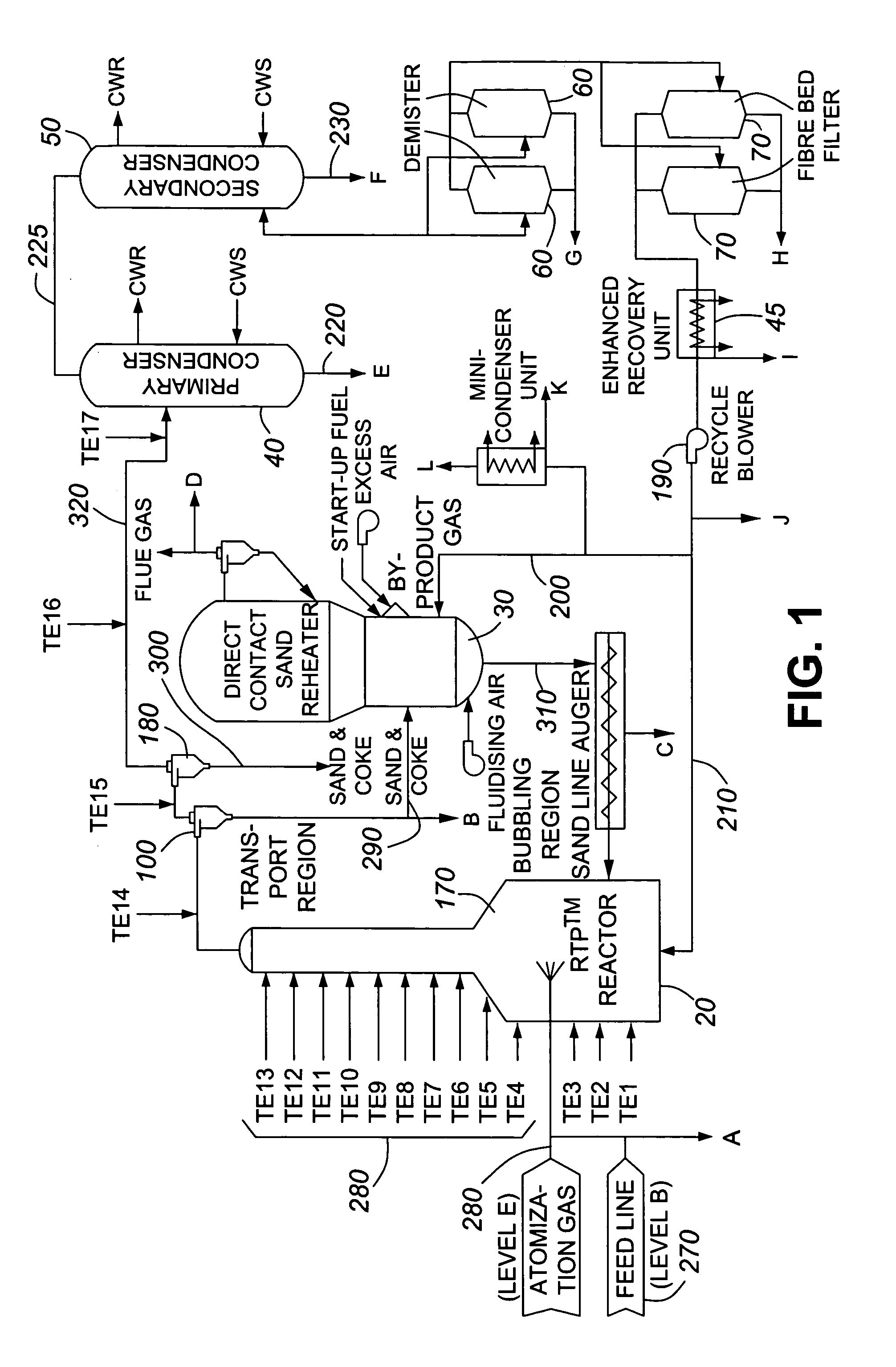

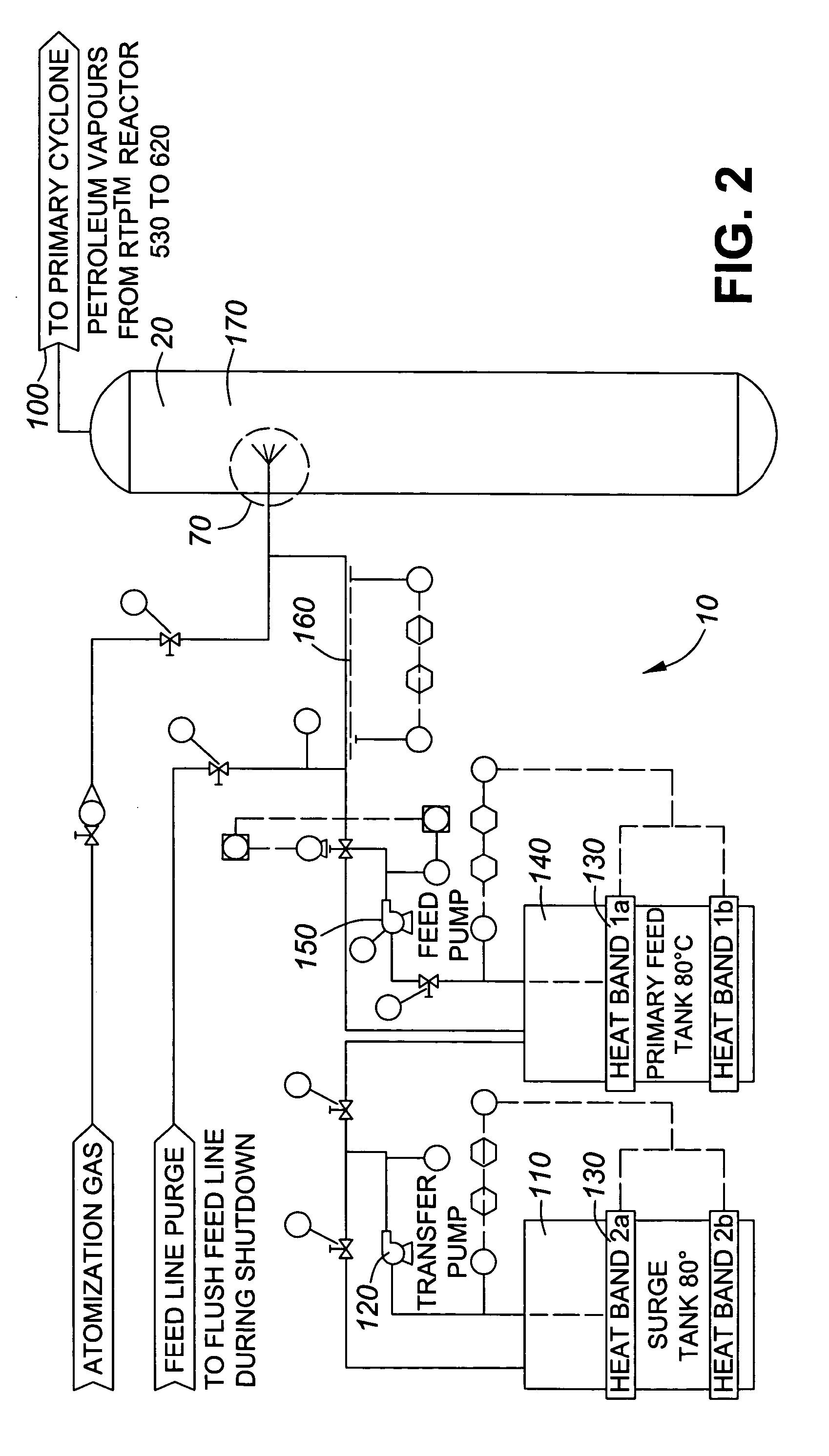

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com