Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248397 results about "Manufacturing engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing Engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical,chemical, electrical and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital.

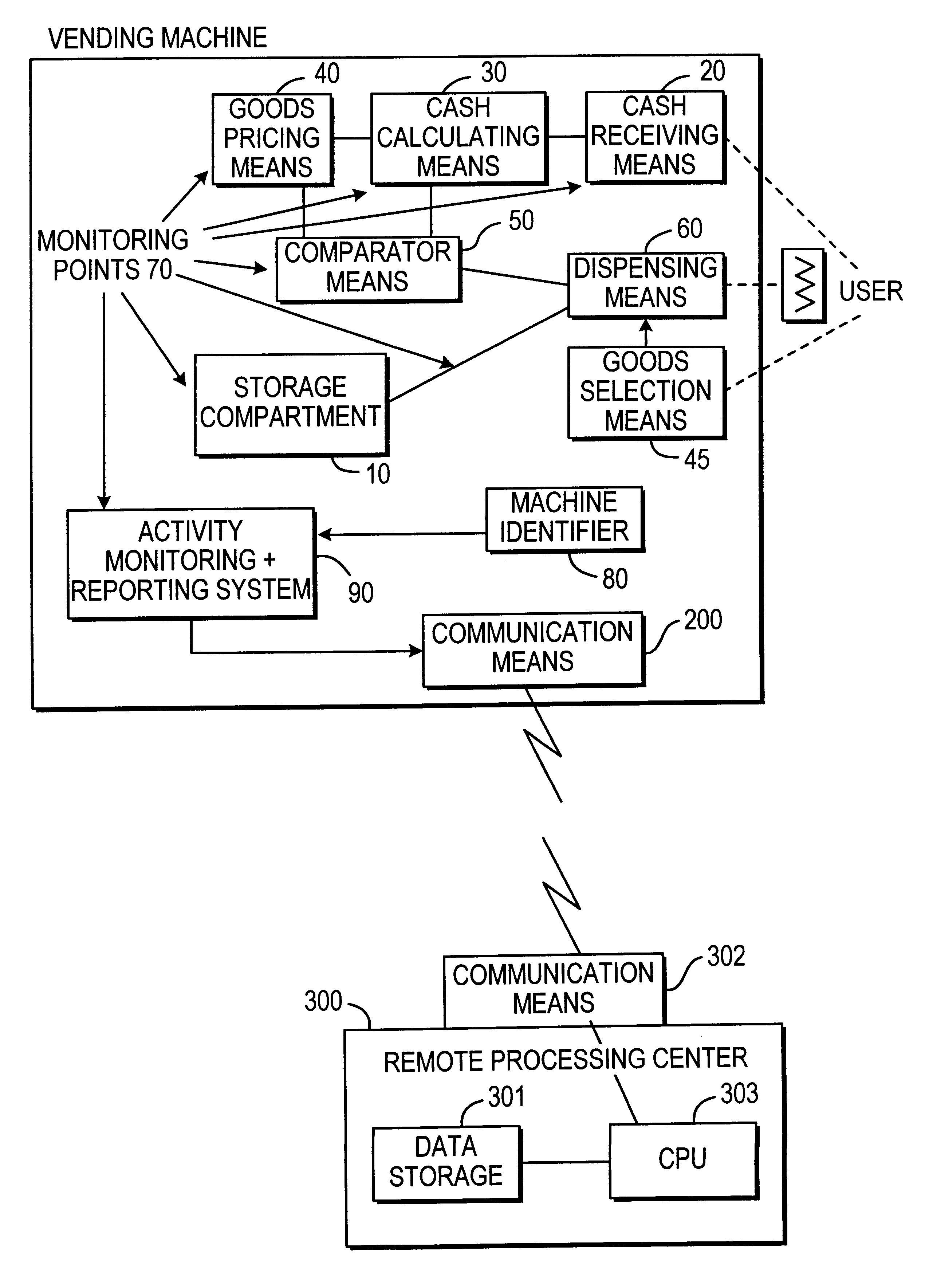

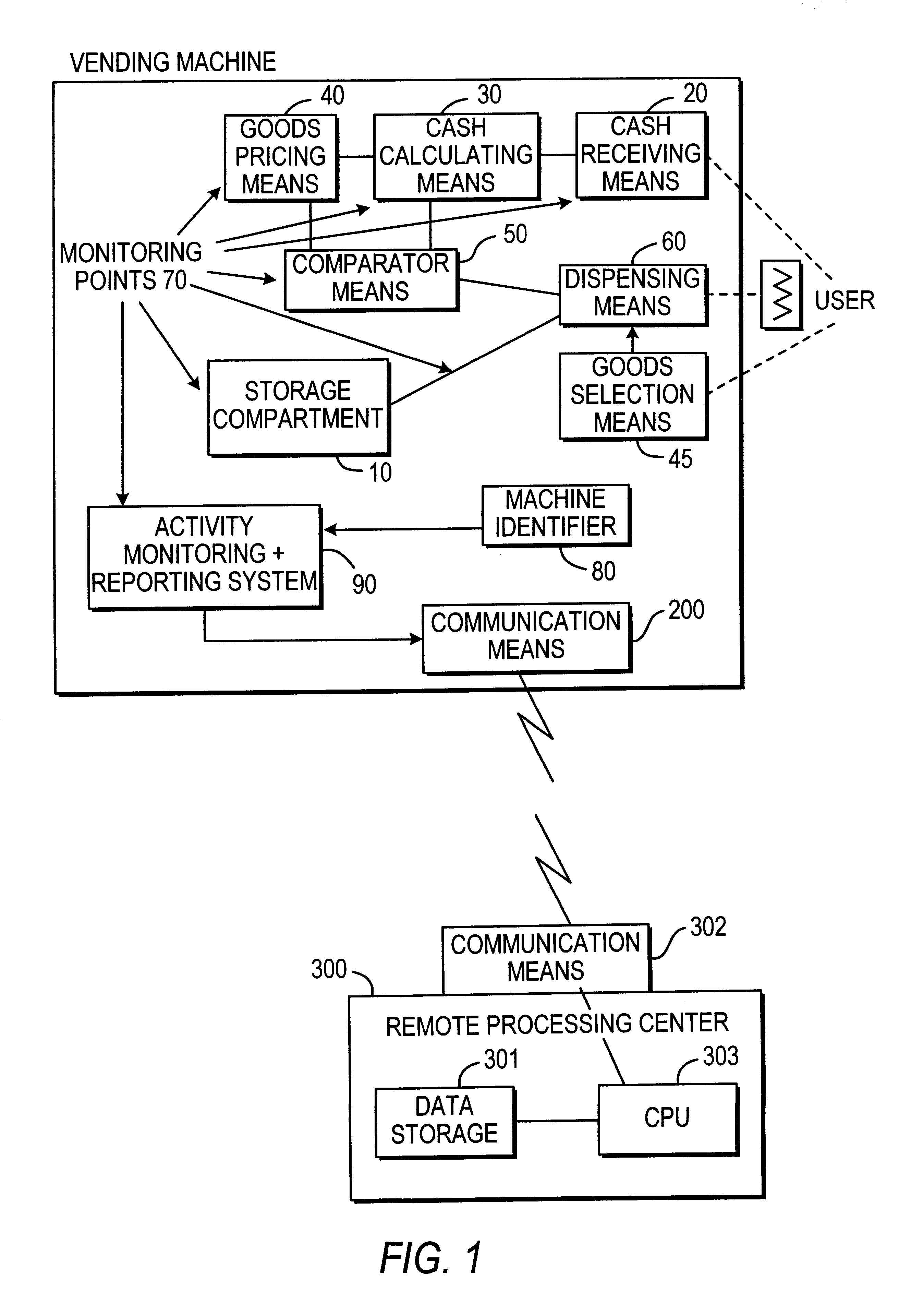

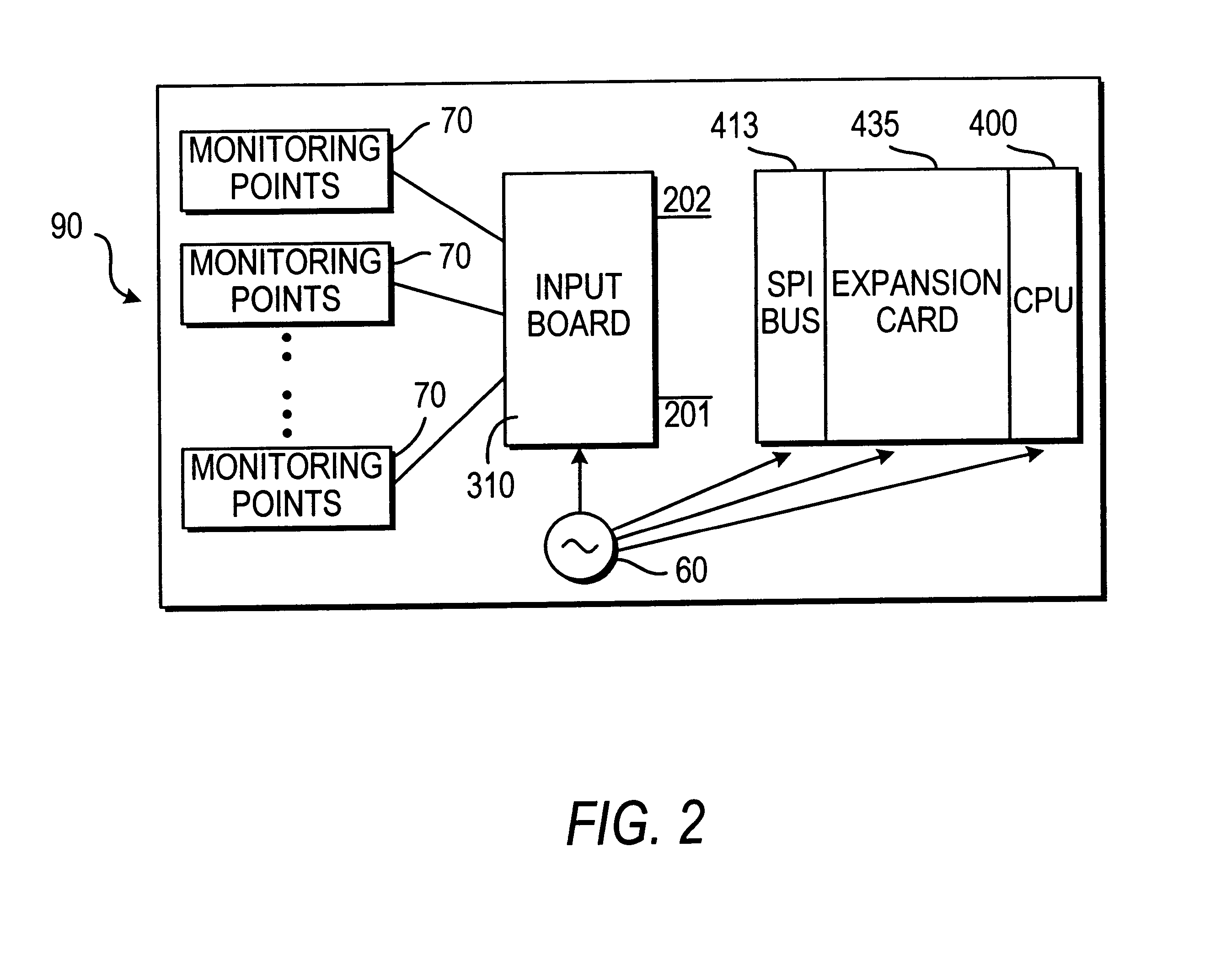

Apparatus and method for improved vending machine inventory maintenance

InactiveUS6181981B1Efficient schedulingEfficient restockingControlling coin-freed apparatusCoin-freed apparatus detailsTime scheduleUnique identifier

Inventory maintenance is improved for a system of one or more vending machines by providing one or more vending machines with unique identifiers, and means for collecting and transmitting information concerning goods dispensed and other status to a remote location where processing means provide an efficient service schedule.

Owner:VENDING MANAGEMENT SERVICES

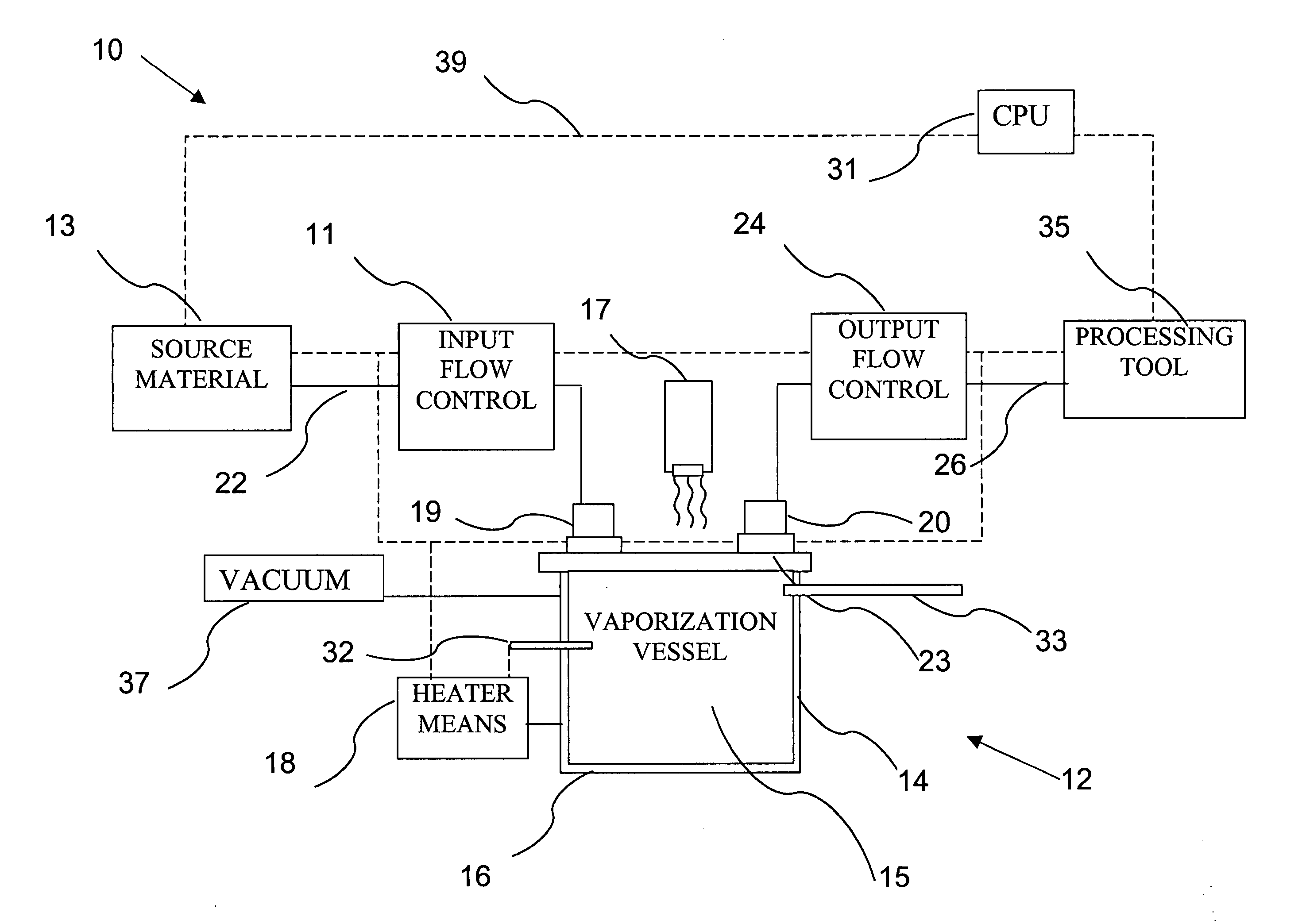

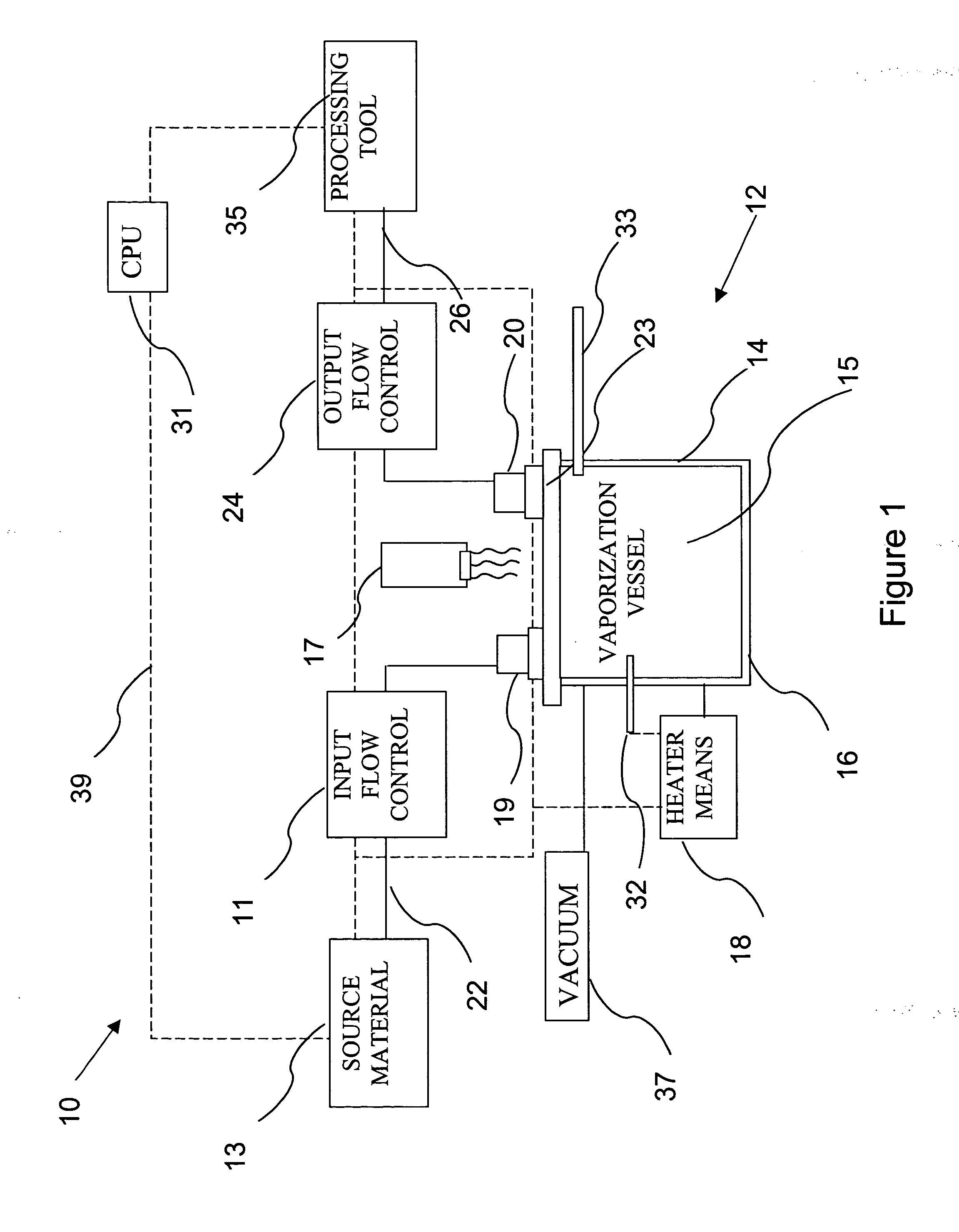

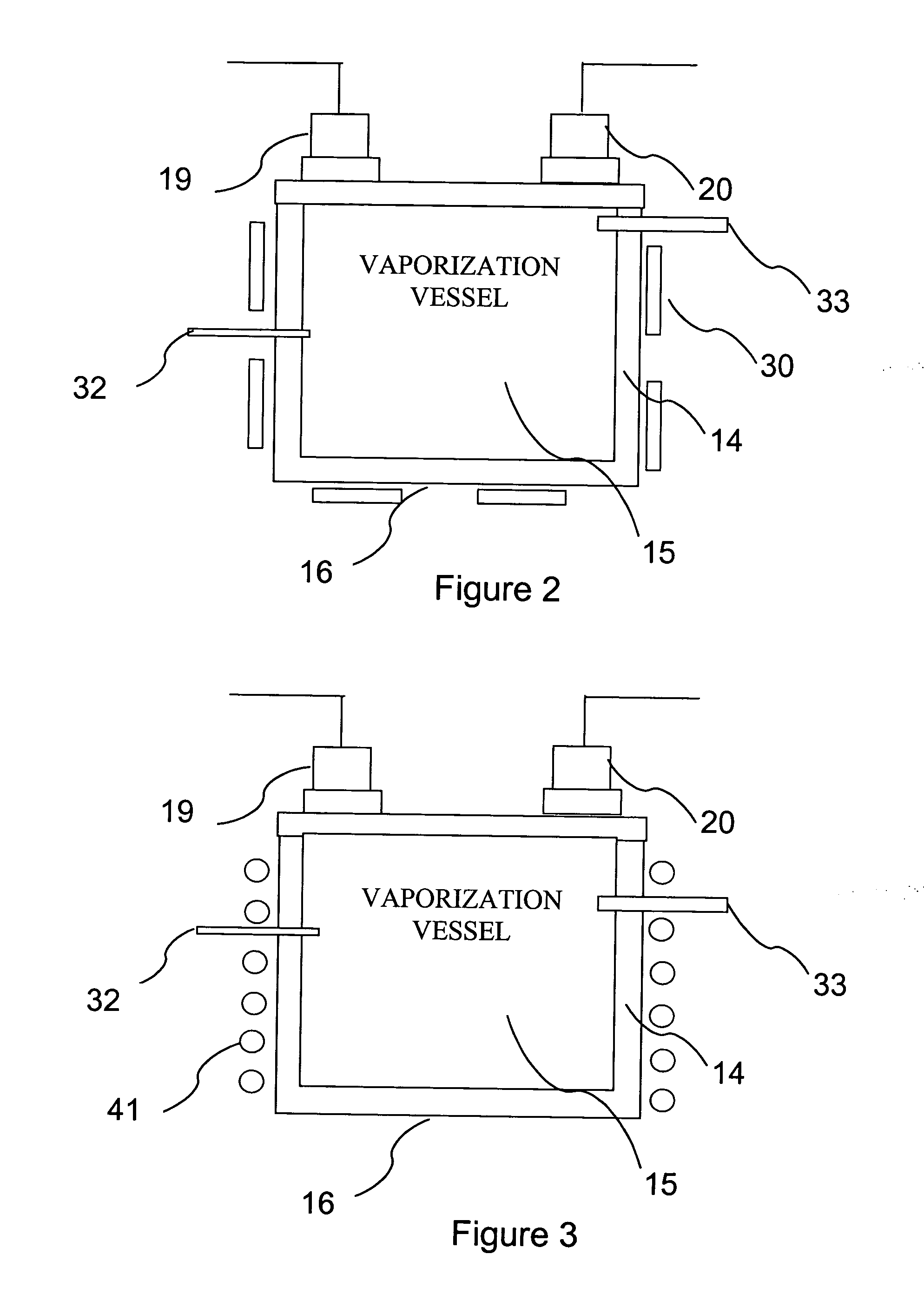

Delivery systems for efficient vaporization of precursor source material

InactiveUS20050019026A1Precise deliveryVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl flowSource material

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

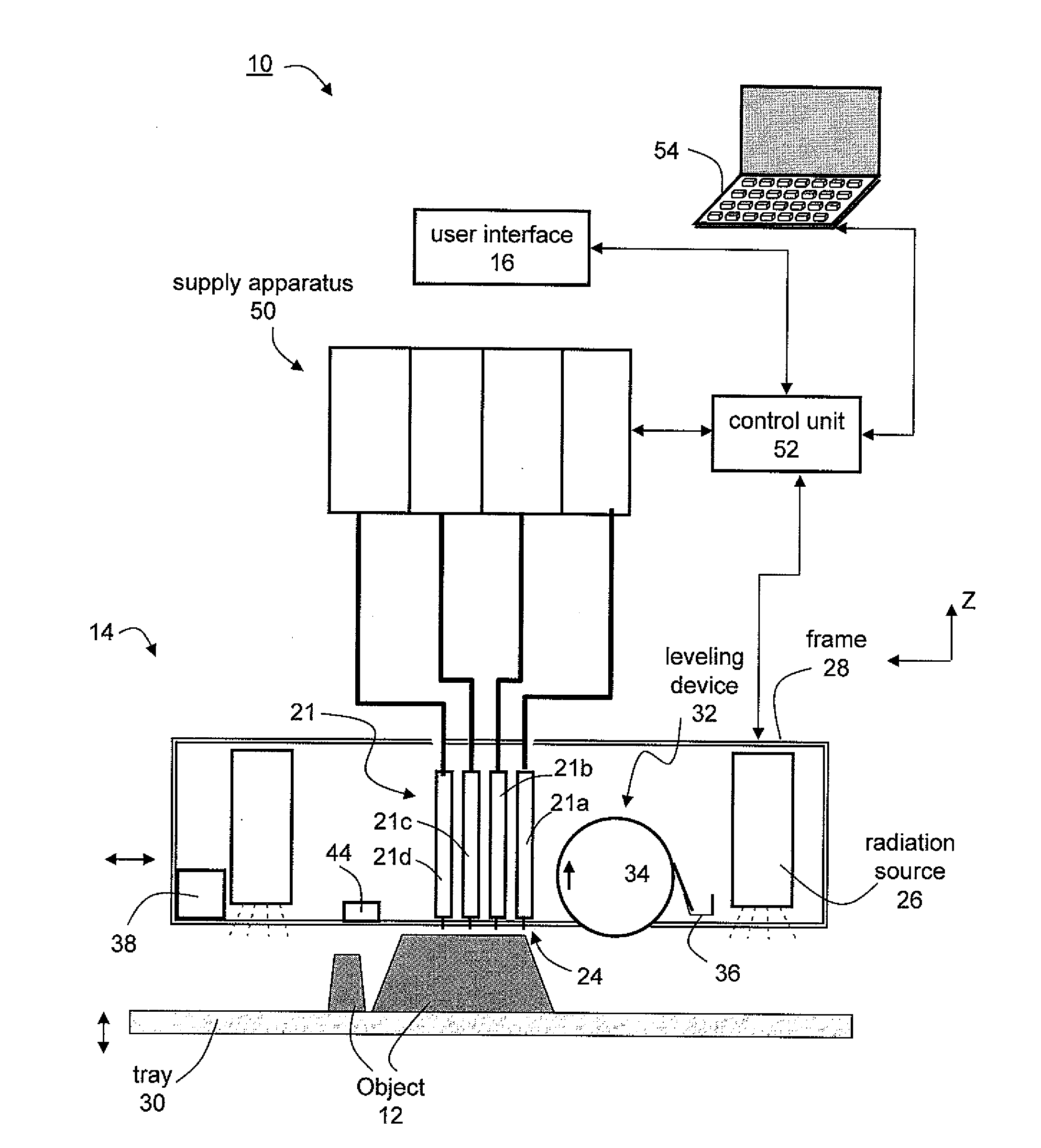

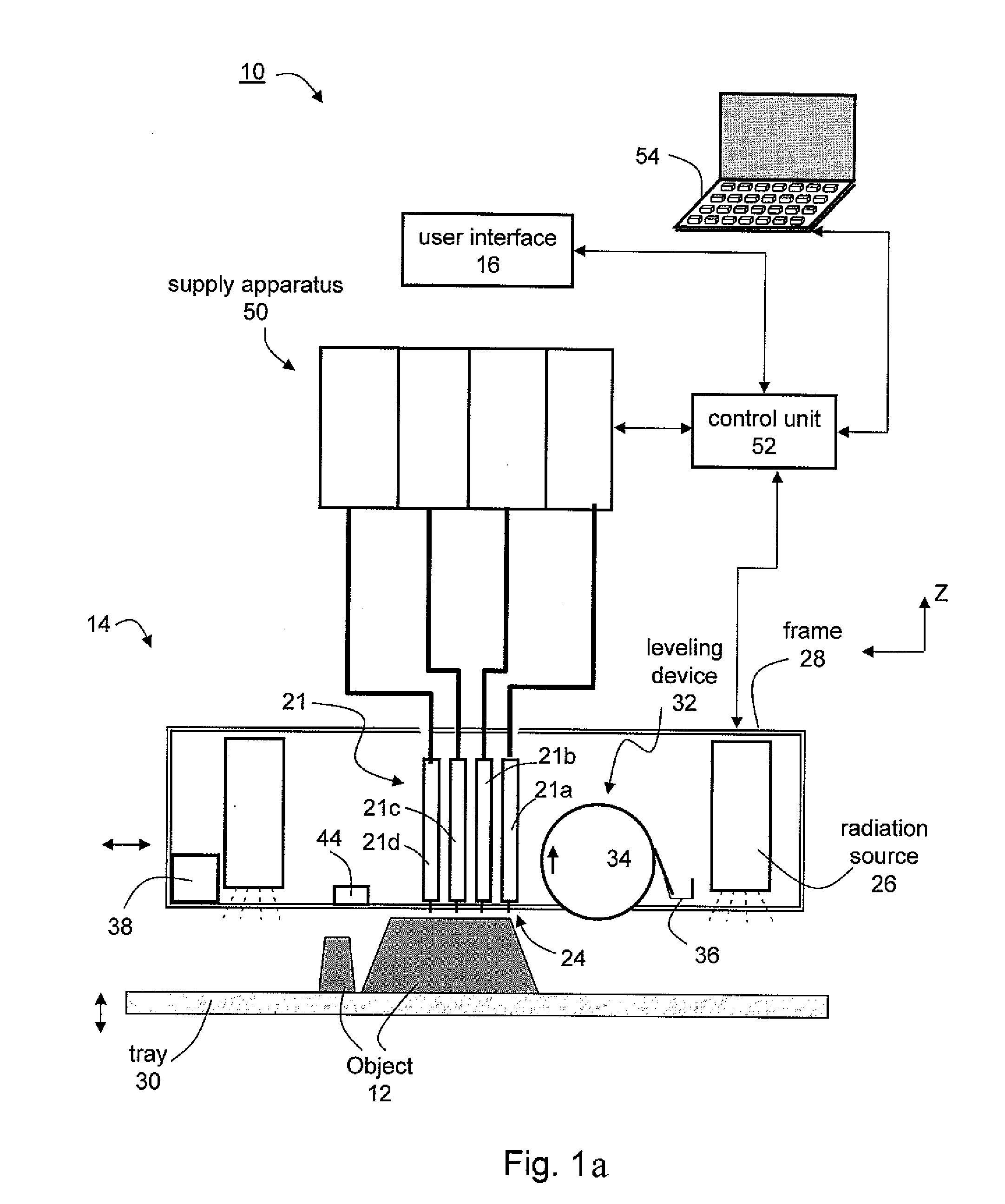

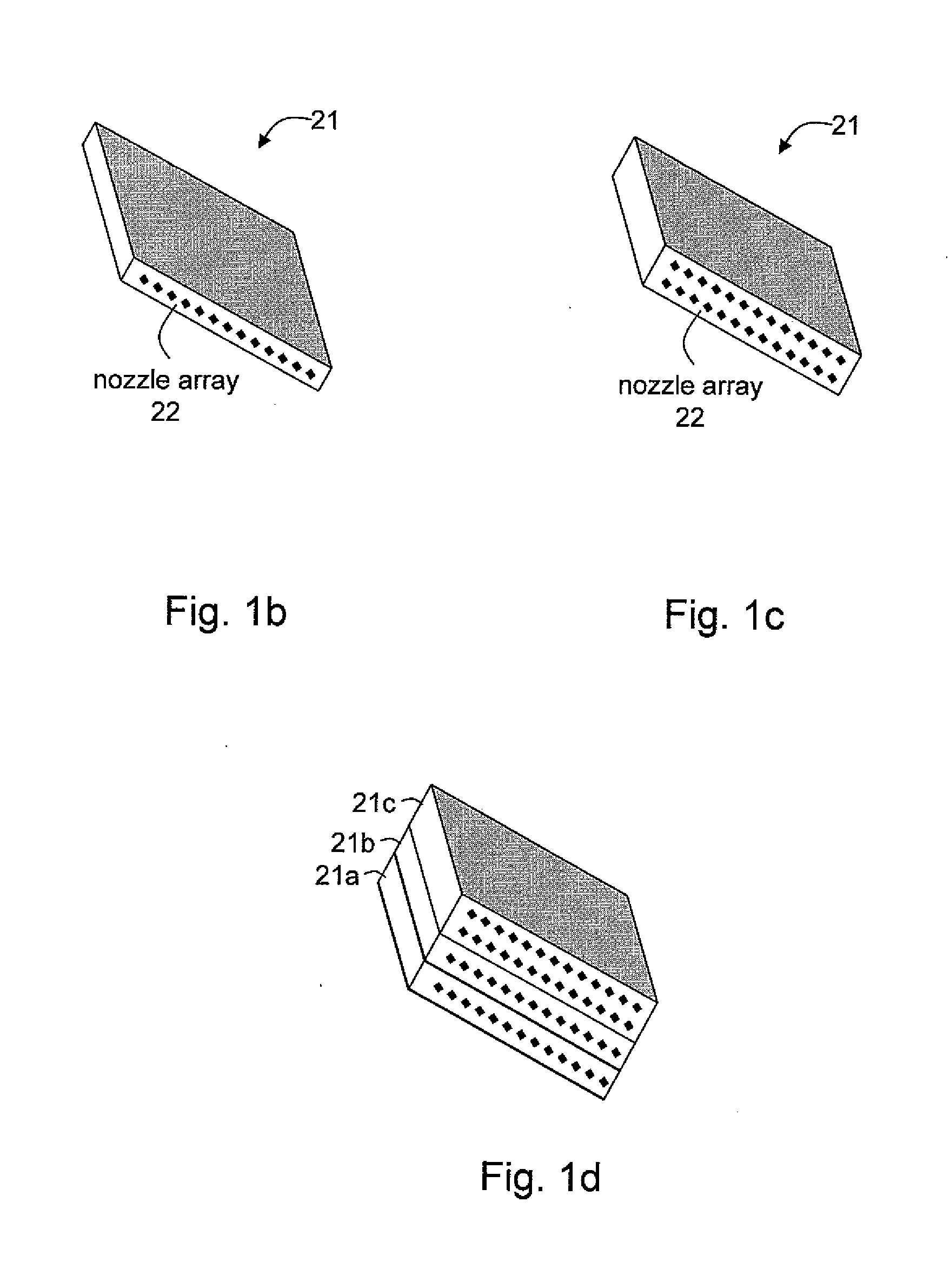

Solid freeform fabrication using a plurality of modeling materials

InactiveUS20100191360A1Easy to burnImprove shrinkageAdditive manufacturing apparatusAdditive manufacturing with liquidsOperation modeMaterial supply

A system and methods for solid freeform fabrication of an object is disclosed. The system comprises a solid freeform fabrication apparatus having a plurality of dispensing heads, a building material supply apparatus configured to supply a plurality of building materials to the fabrication apparatus, and a control unit configured for controlling the fabrication apparatus and the supply apparatus based on an operation mode selected from a plurality of predetermined operation modes.

Owner:OBJET GEOMETRIES

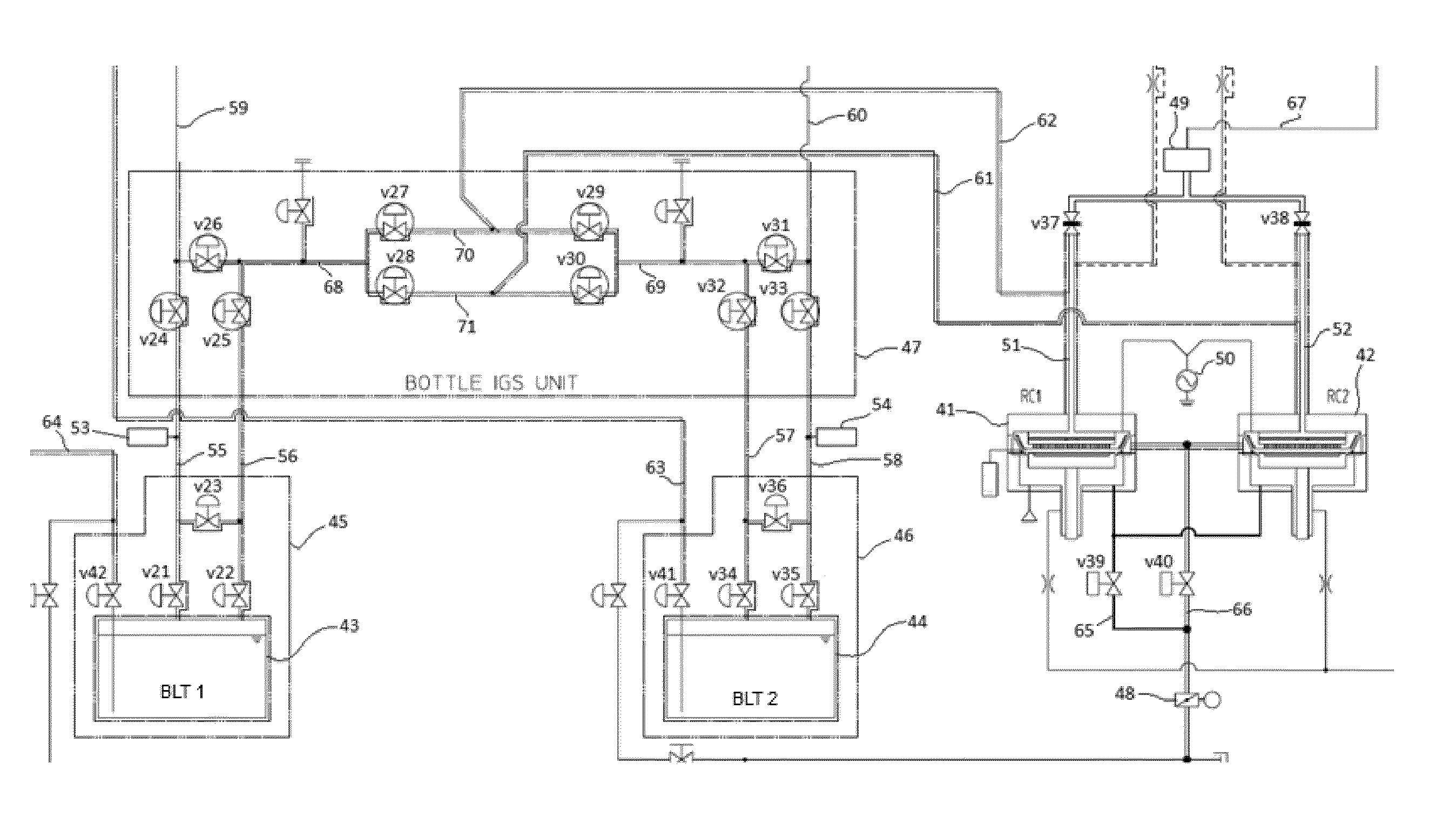

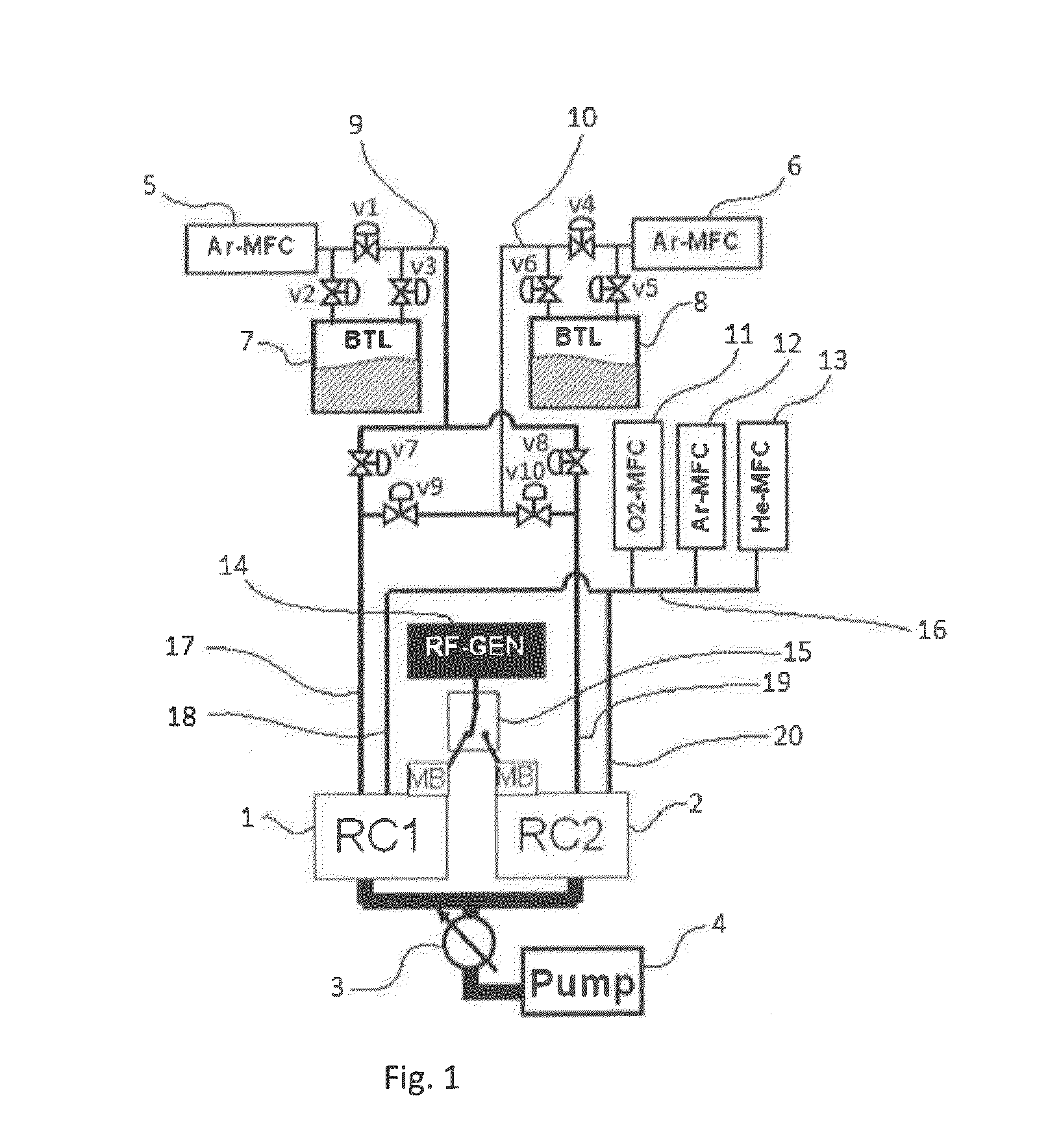

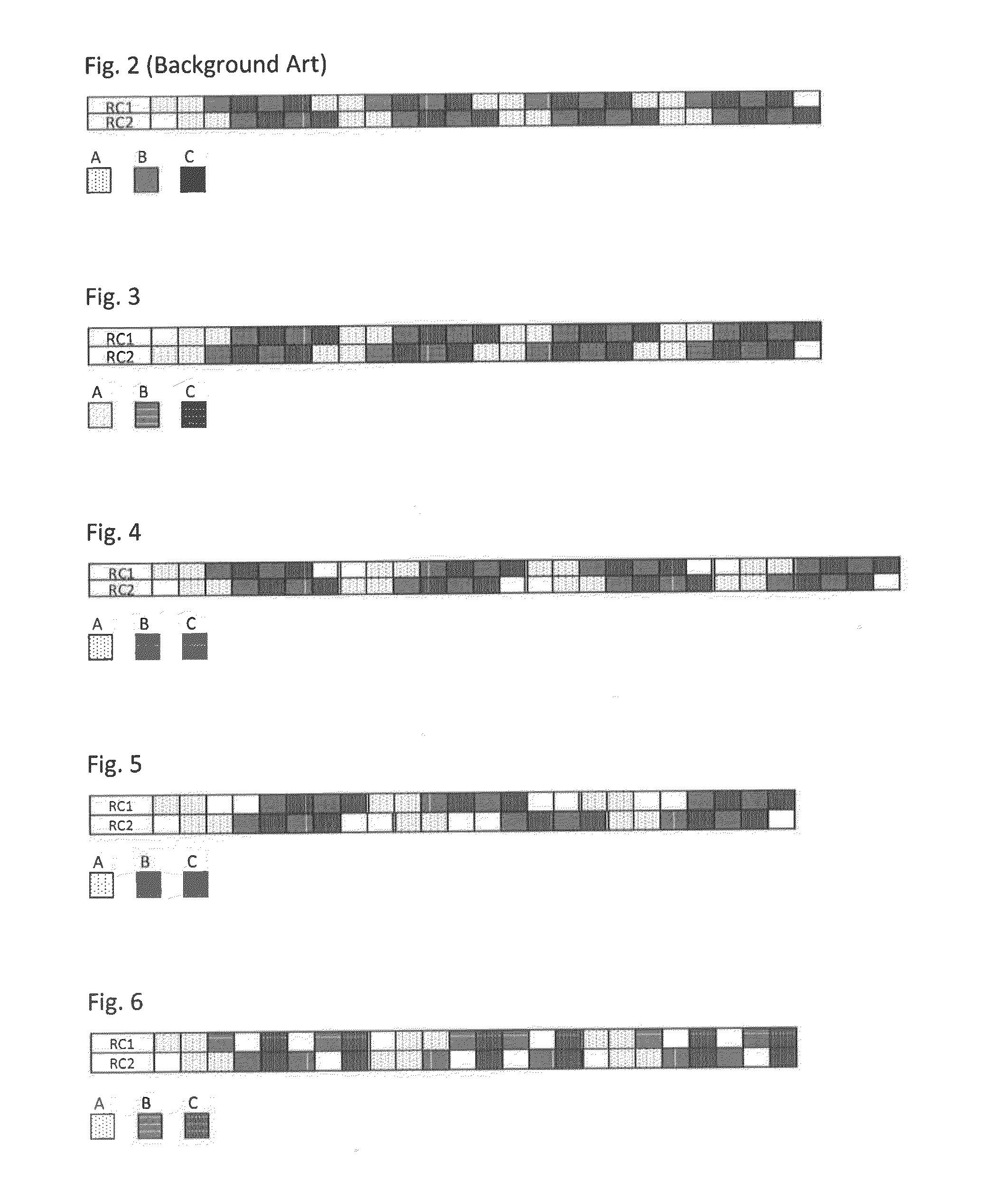

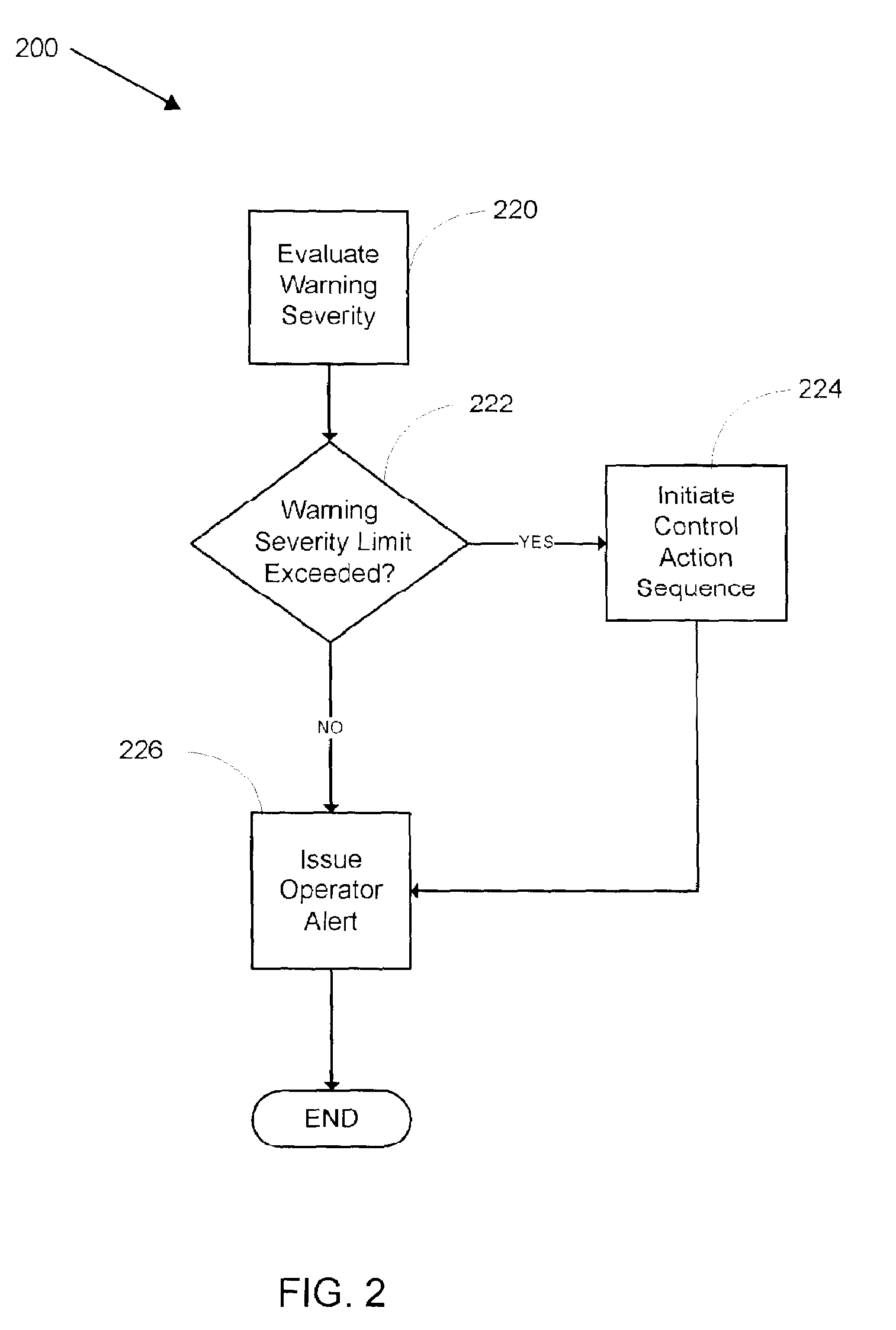

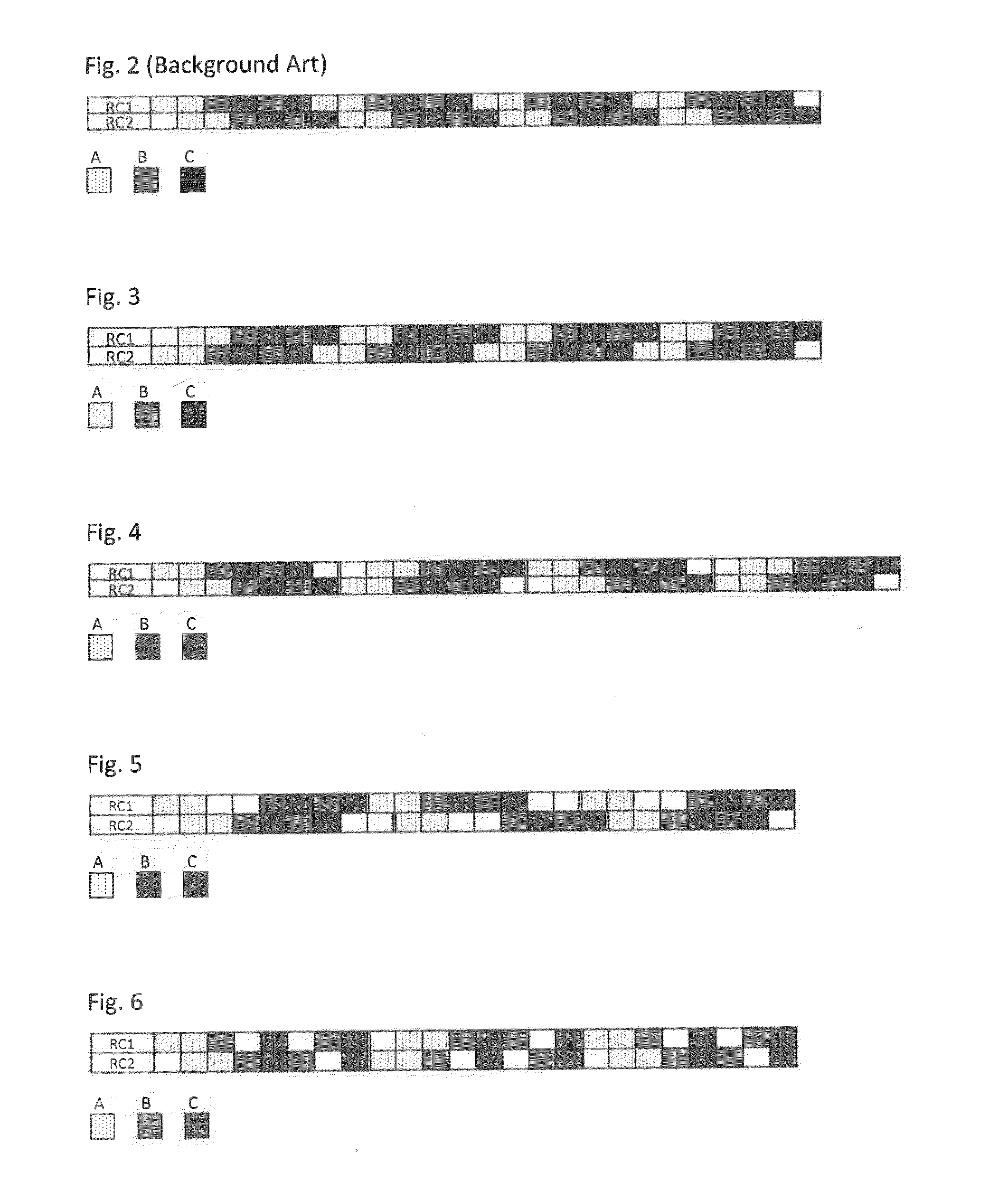

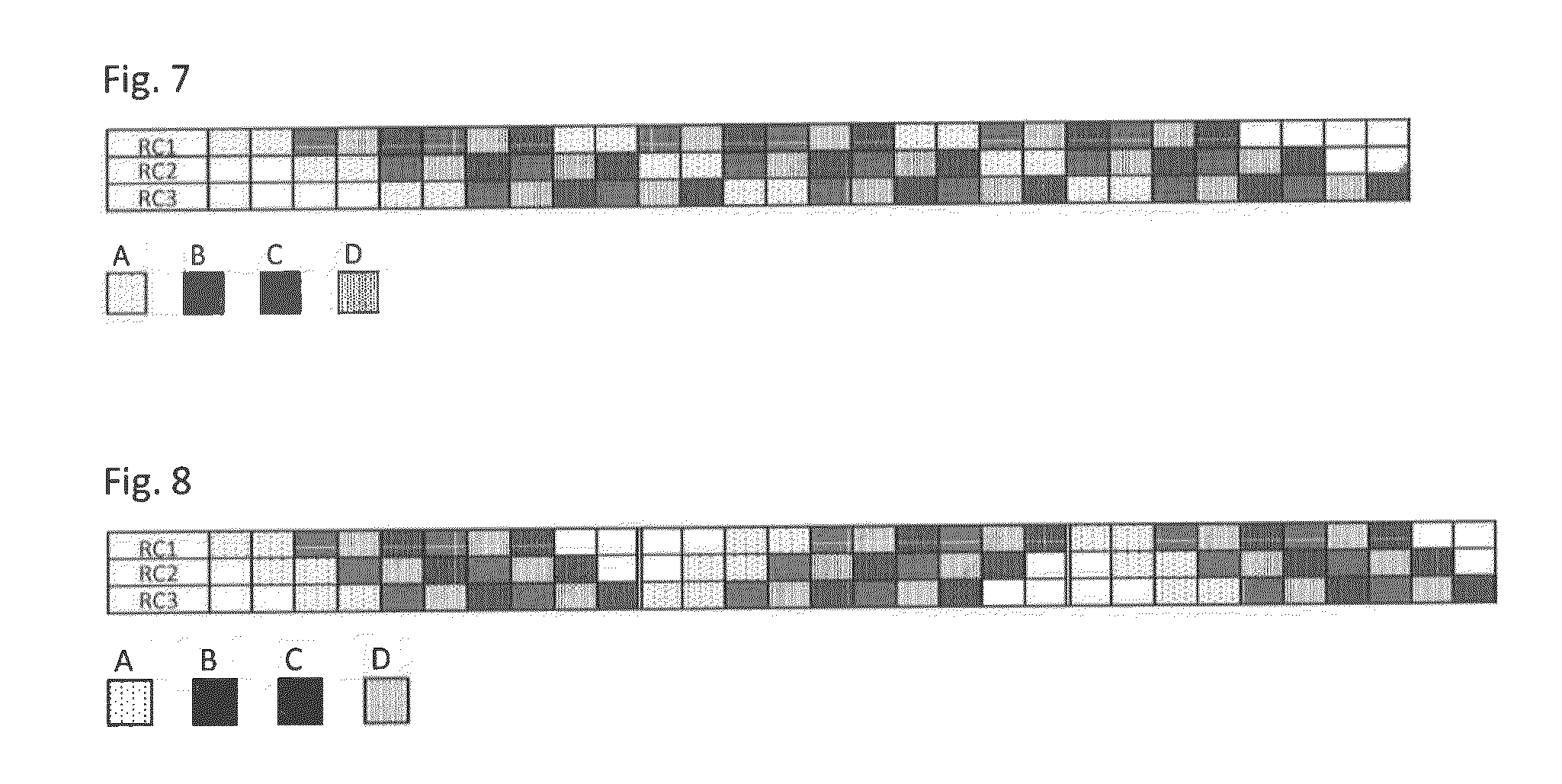

Method for Performing Uniform Processing in Gas System-Sharing Multiple Reaction Chambers

ActiveUS20150267297A1Improve uniformityEffectively be suppressedVacuum evaporation coatingSputtering coatingChemistryReaction chamber

A method for performing uniform processing in multiple reaction chambers includes (a) conducting a cycle constituted by steps in each reaction chamber according to the order of the reaction chambers at which the steps are conducted; and then (b) conducting the steps in each reaction chamber after changing the immediately prior order of the reaction chambers at which the steps are conducted; and then (c) repeating process (b) until a target treatment is complete at the multiple reaction chambers. The target treatment conducted on a substrate in each reaction chamber is the same.

Owner:ASM IP HLDG BV

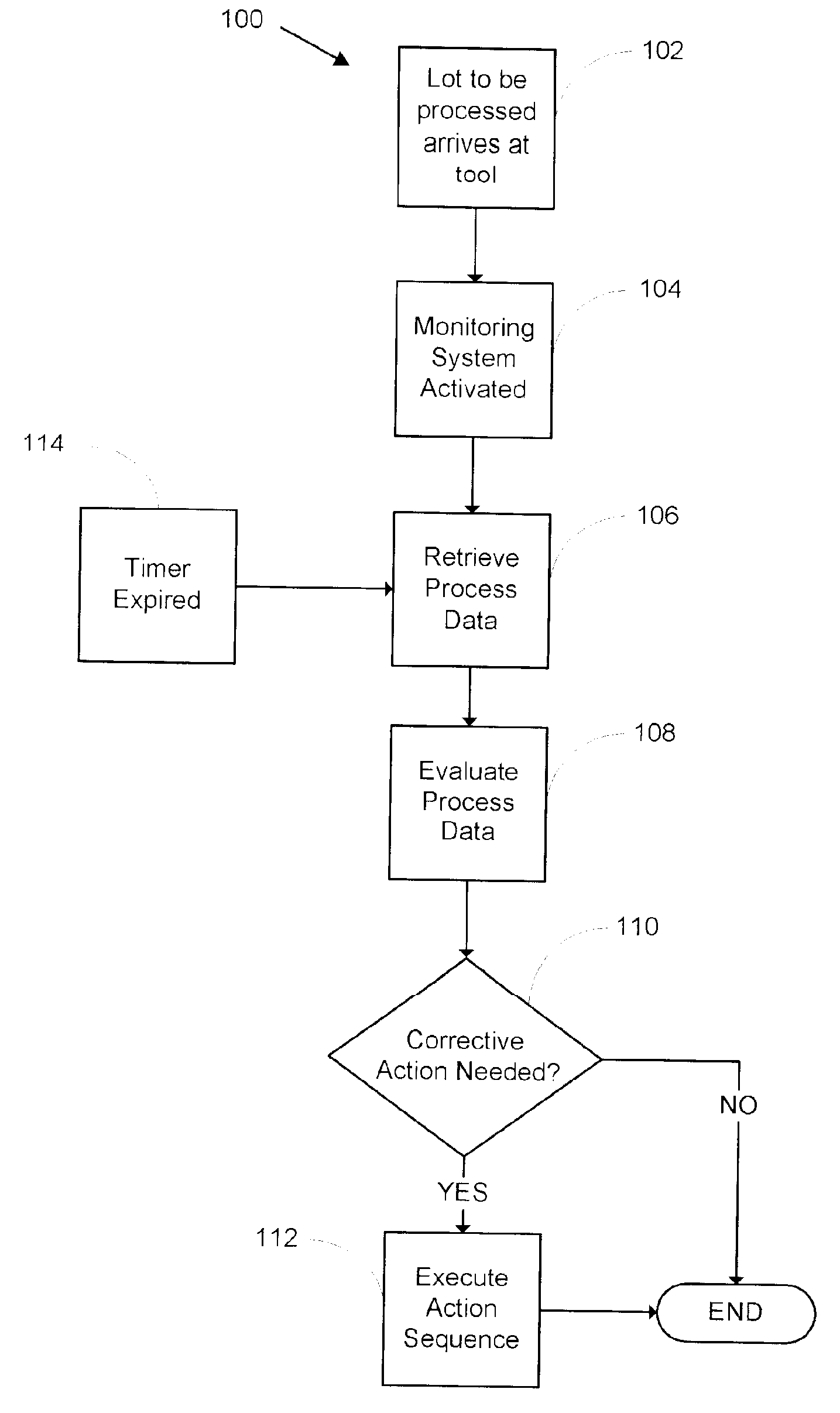

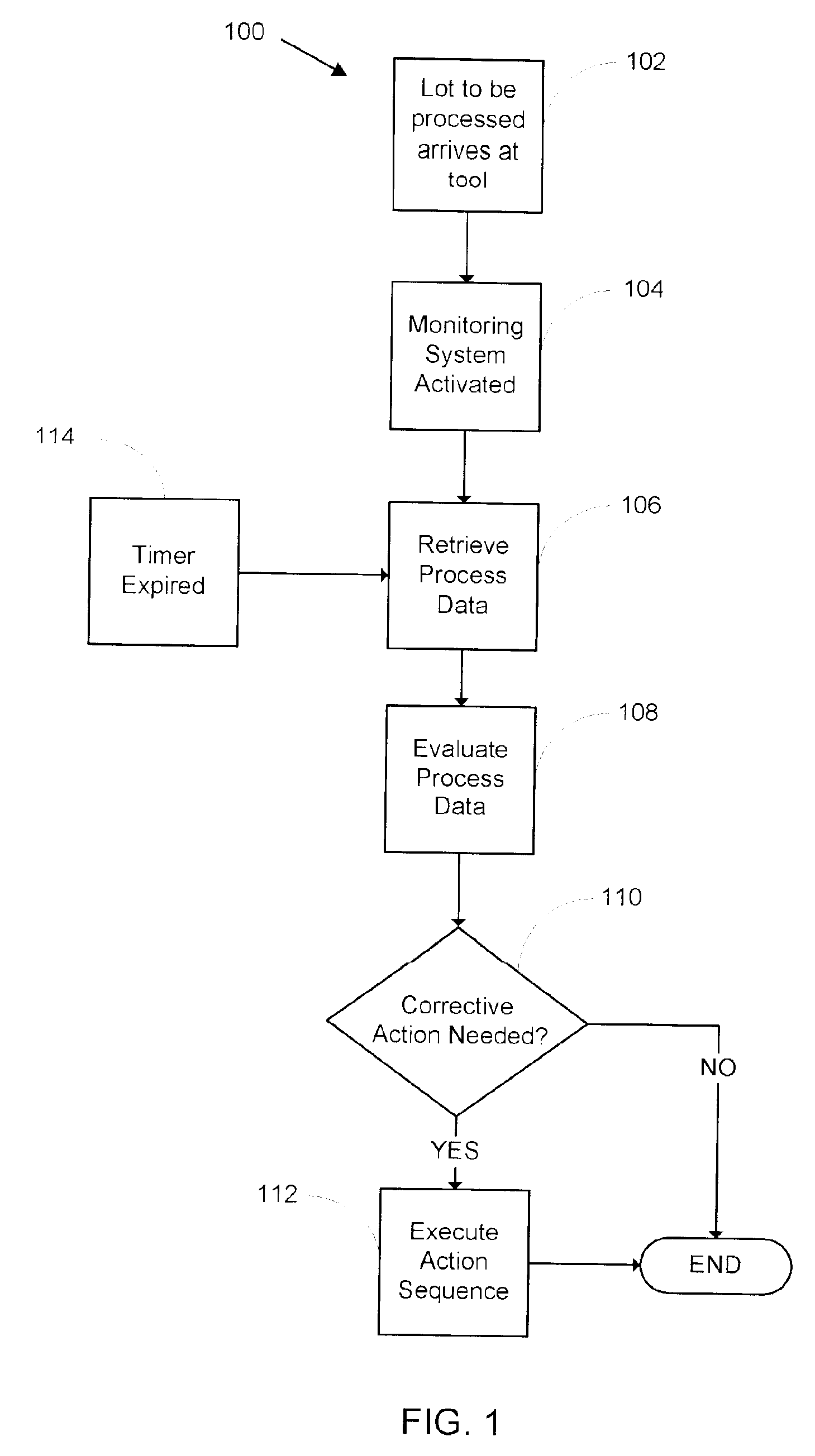

Semiconductor manufacturing process monitoring

A system and method for monitoring a semiconductor manufacturing process is disclosed. The system communicates with one or more process tools, and monitors each tool during a predetermined process window time. Errors and warnings are provided to users, allowing corrective action to be taken. Additionally, the system of the present invention can initiate automatic adjustment of the process tools to maintain an efficient manufacturing operation.

Owner:GLOBALFOUNDRIES INC

Method for performing uniform processing in gas system-sharing multiple reaction chambers

ActiveUS9447498B2Improve uniformityEffectively be suppressedChemical vapor deposition coatingOrganic chemistryReaction chamber

Owner:ASM IP HLDG BV

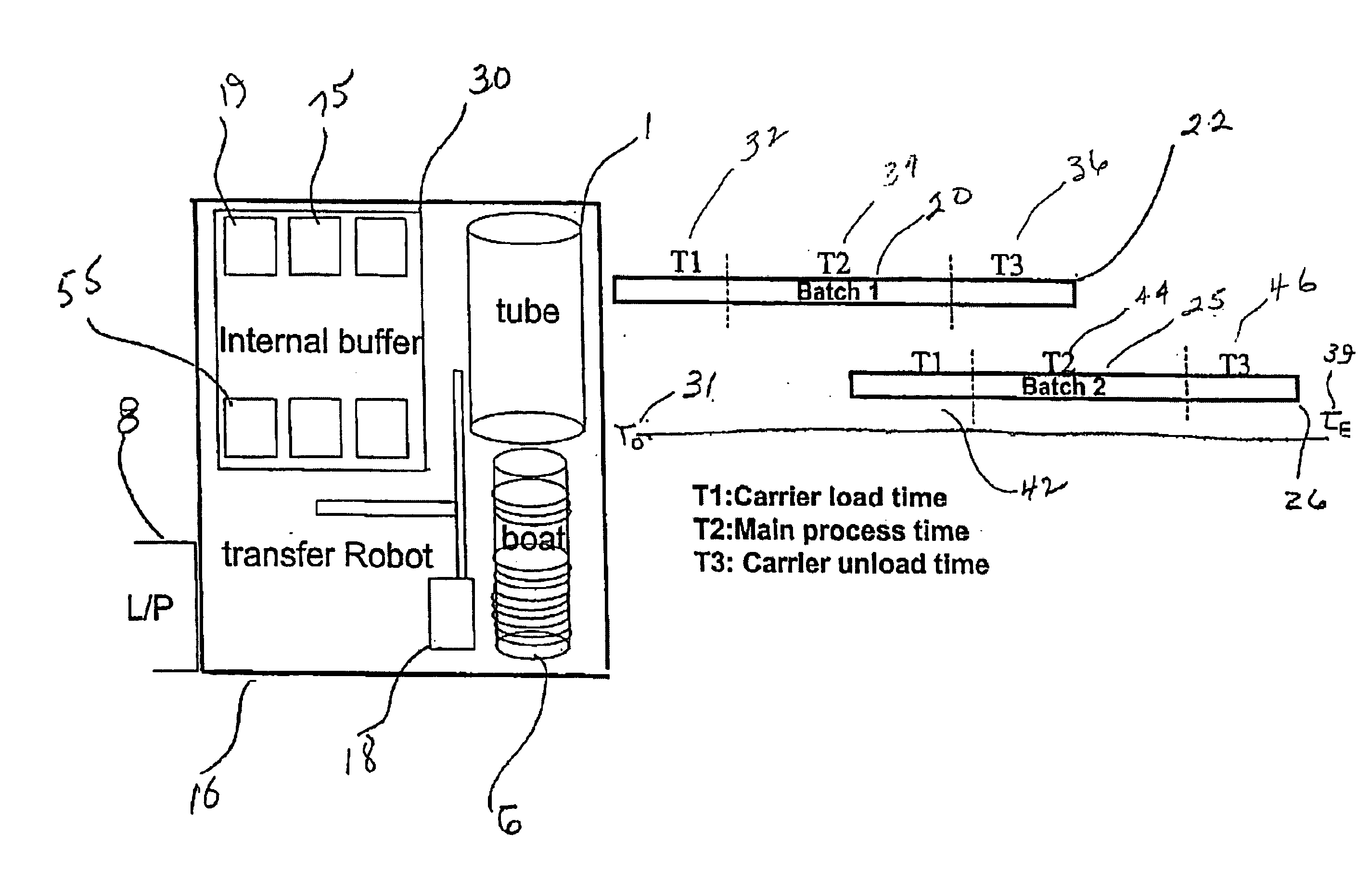

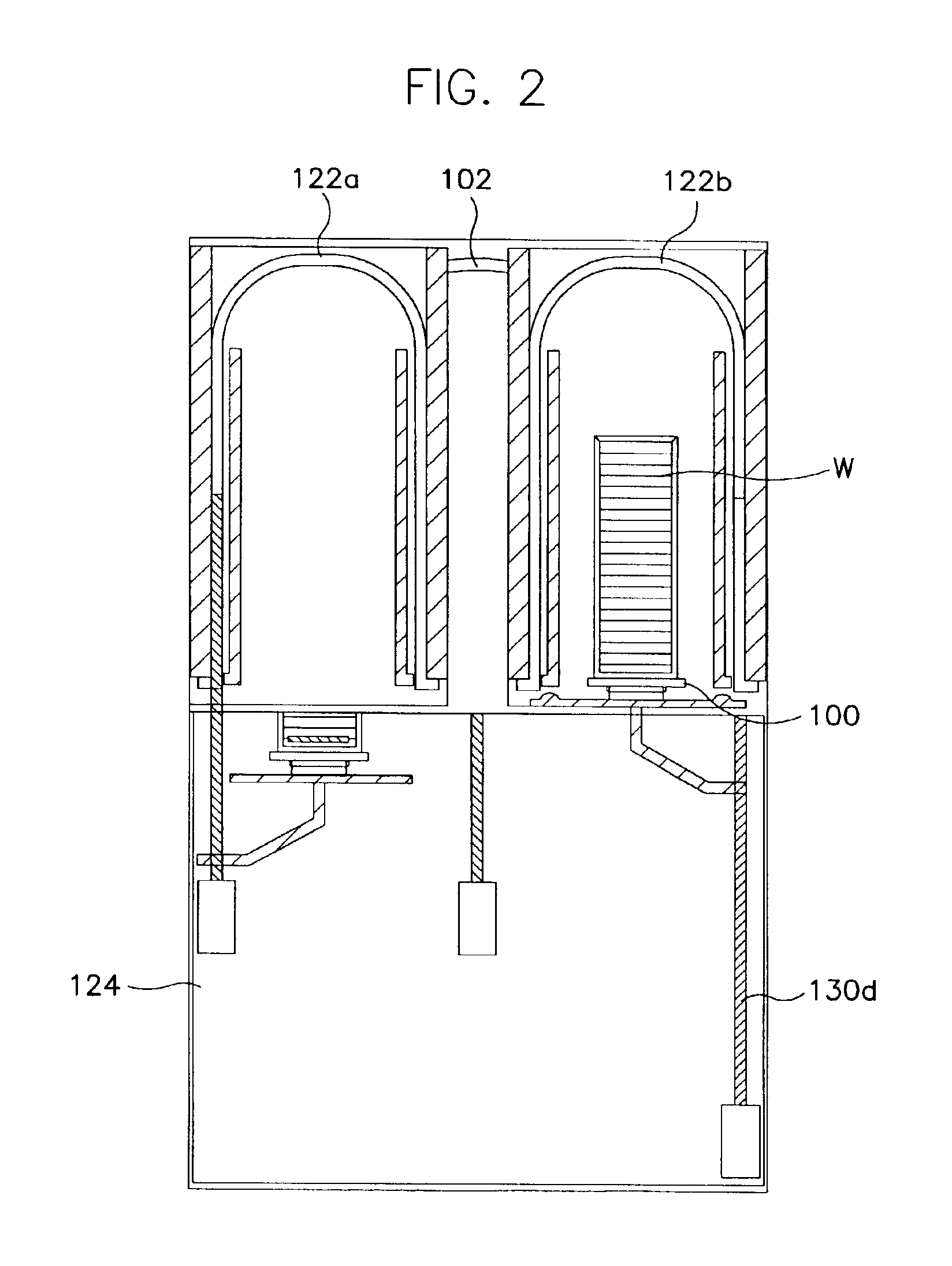

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

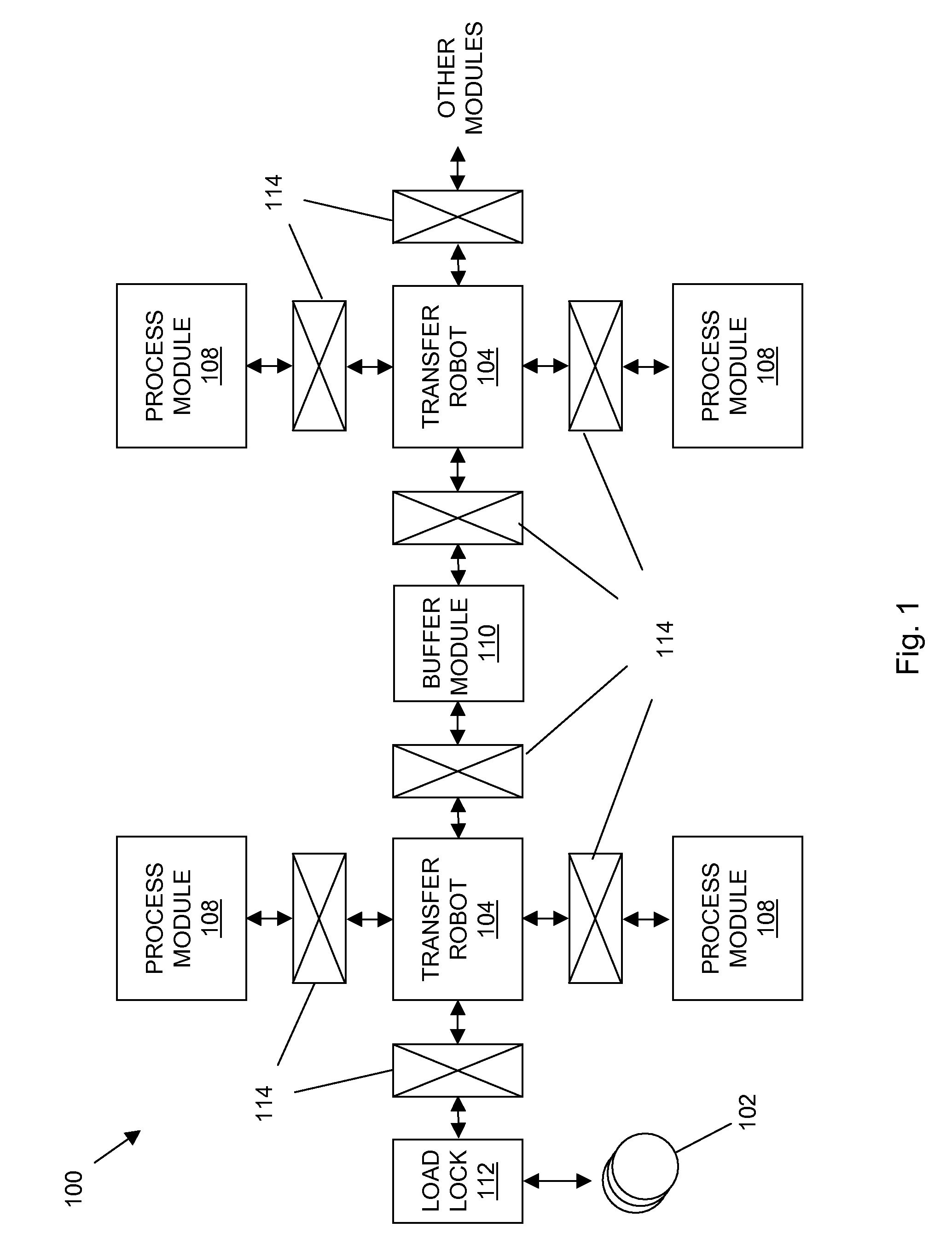

Semiconductor manufacturing process modules

ActiveUS20080124197A1Balance processing loadSemiconductor/solid-state device manufacturingConveyor partsProcess moduleSemiconductor

Owner:BOOKS AUTOMATION US LLC

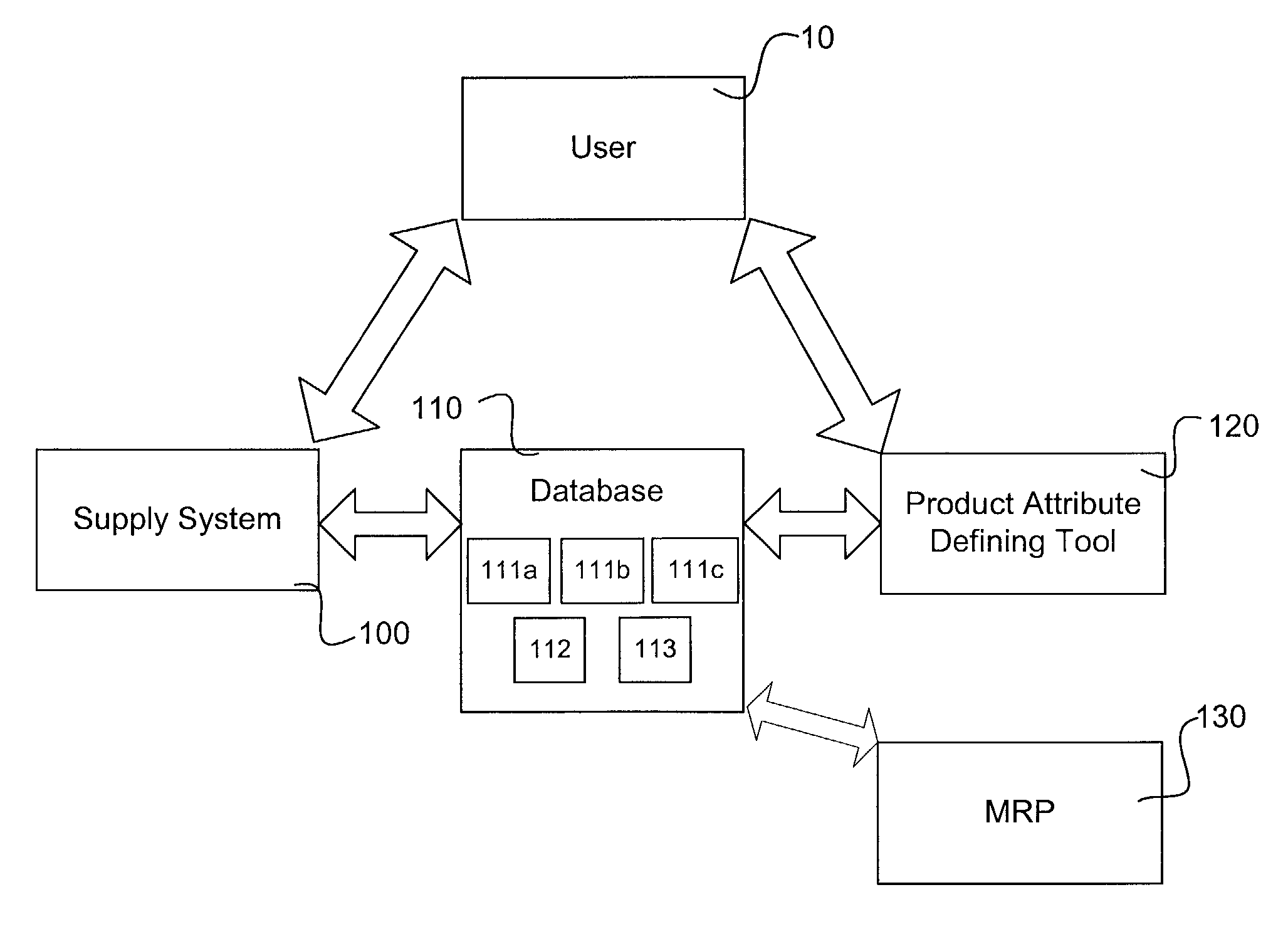

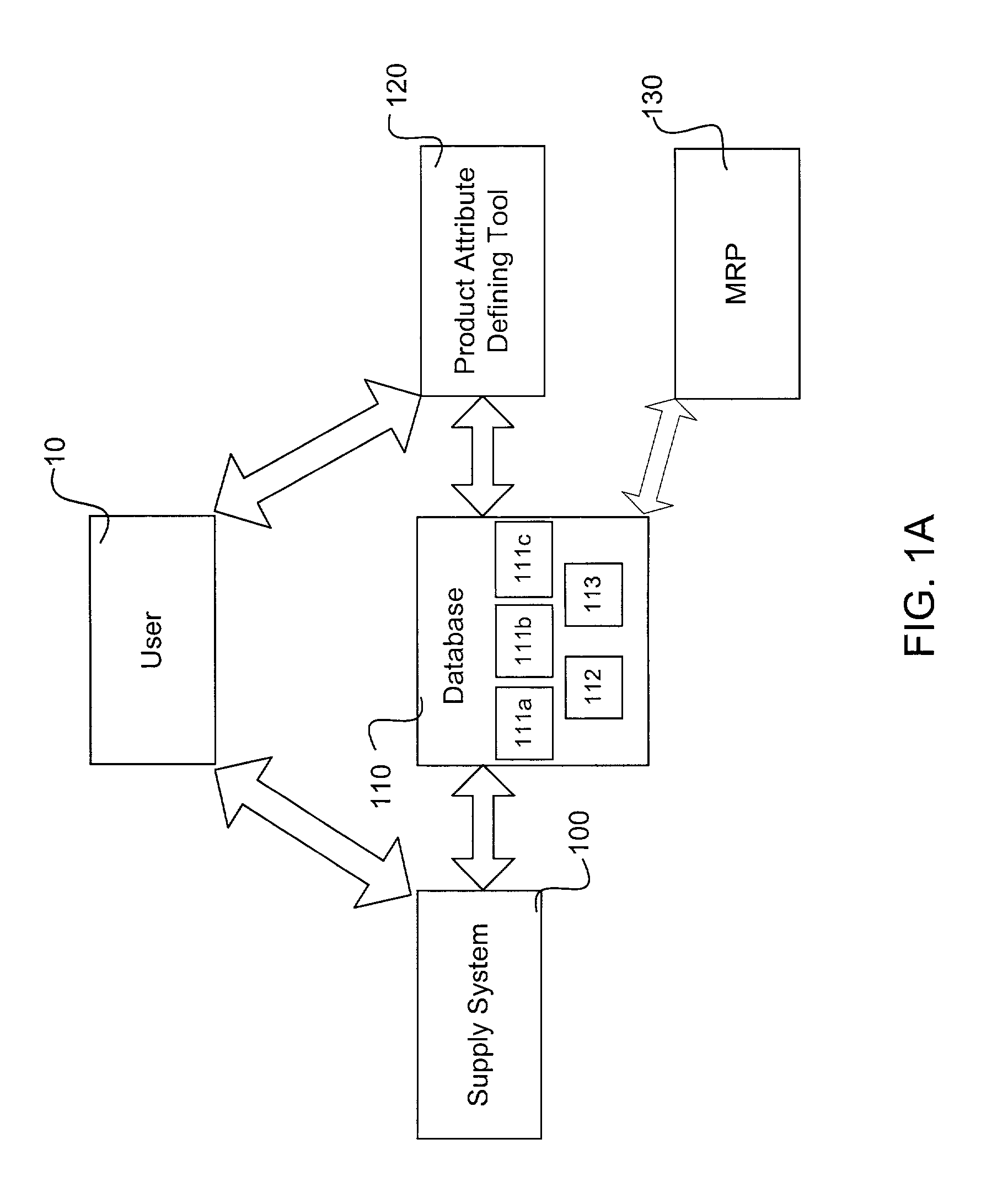

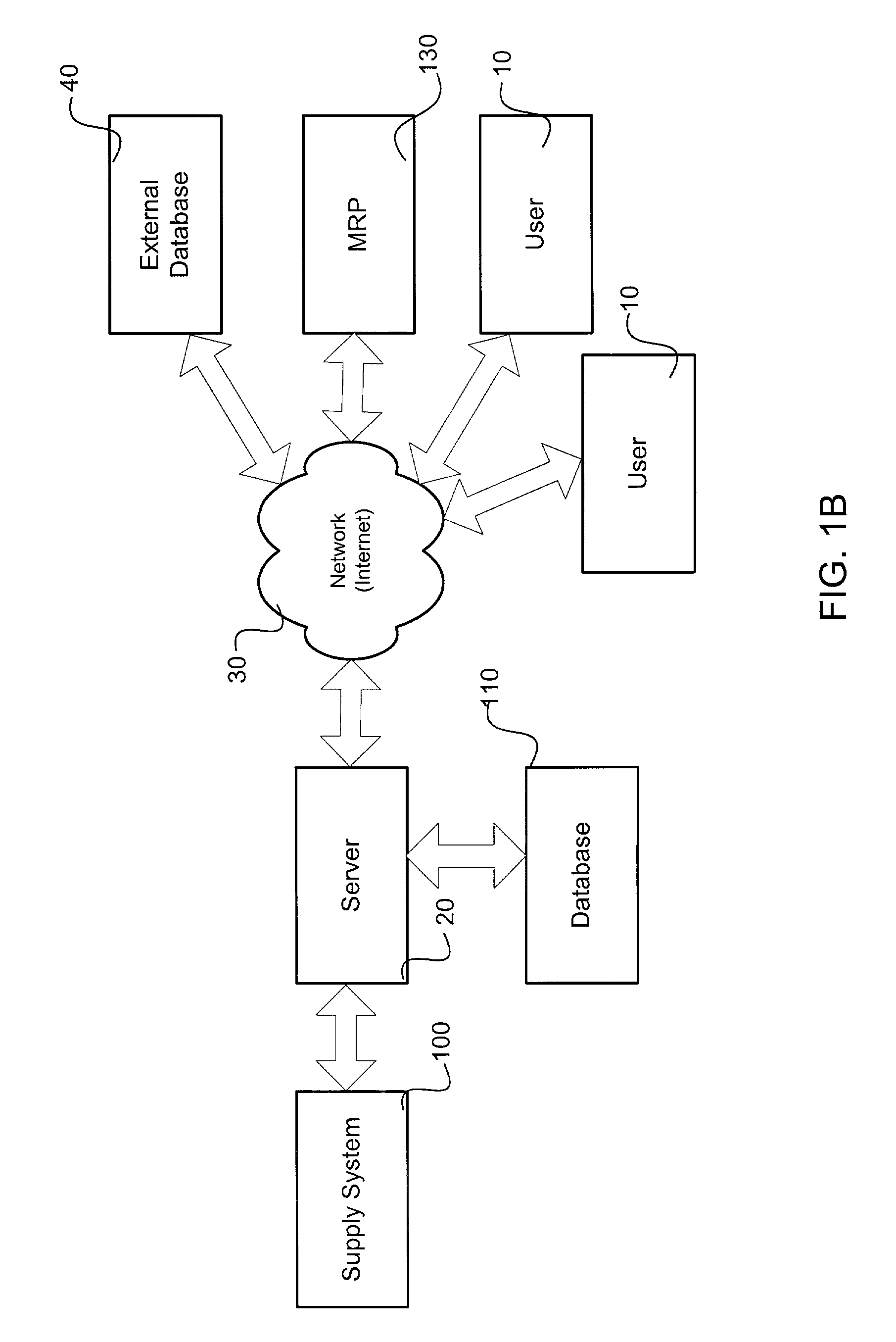

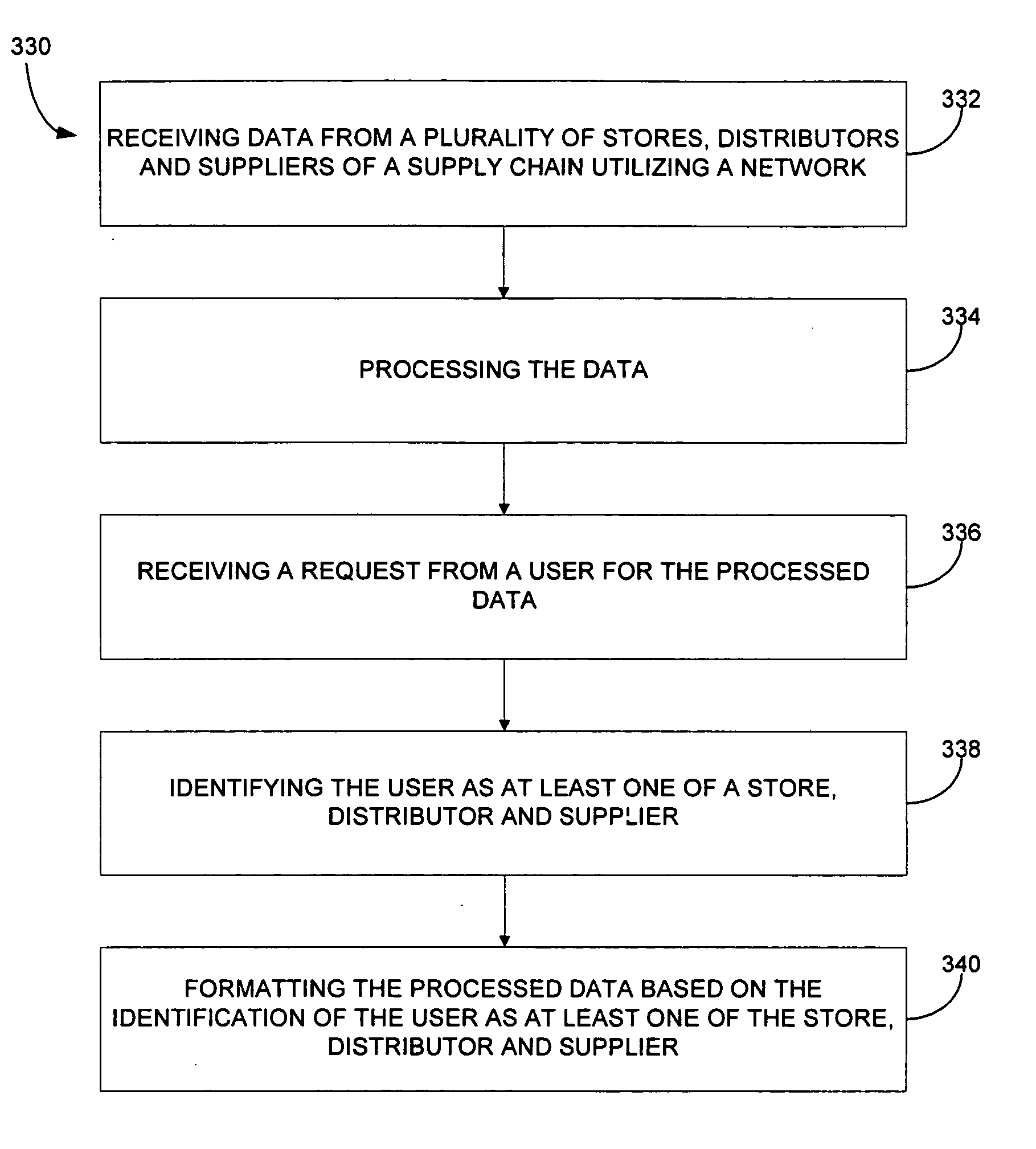

System and method for allocating the supply of critical material components and manufacturing capacity

InactiveUS7058587B1Improve responsivenessMaximize inventory useResourcesSpecific program execution arrangementsProgram planningChange analysis

The present invention allocates the supply of critical components and manufacturing capacity by optimizing critical material planning decisions and dynamically allocating constrained materials using advanced substitution logic that considers alternate suppliers and supports product life cycle from design through end-of-life. The present invention may utilize unique synchronized allocations and matched sets logic. The synchronized allocations ensure that all materials necessary for production are available in the appropriate time-phased allocation before beginning production to minimize wasted production capacity and materials. The supply system may include various combination of components, including a Supply Planner, a Resource Optimizer, a Constraint Based Master Planner, a Product Change Analyzer, a Comparer, a Resource Requirements Planner, a Finite Resource Planner, a Customer Promiser, and an Interactive Master Scheduler. Another embodiment of the supply system includes a tool that allows users to define products using engineering specifications.

Owner:BLUE YONDER GRP INC

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

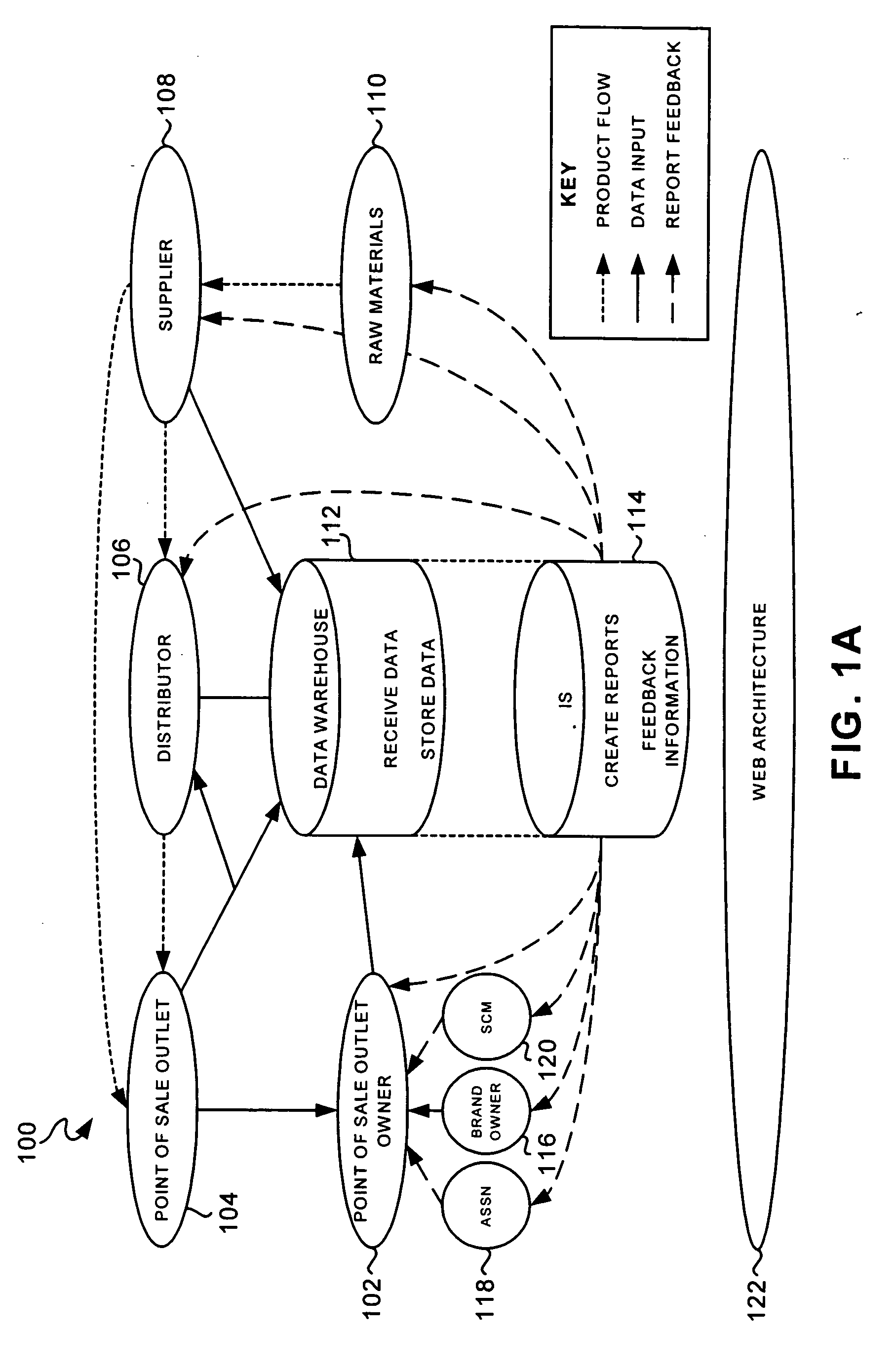

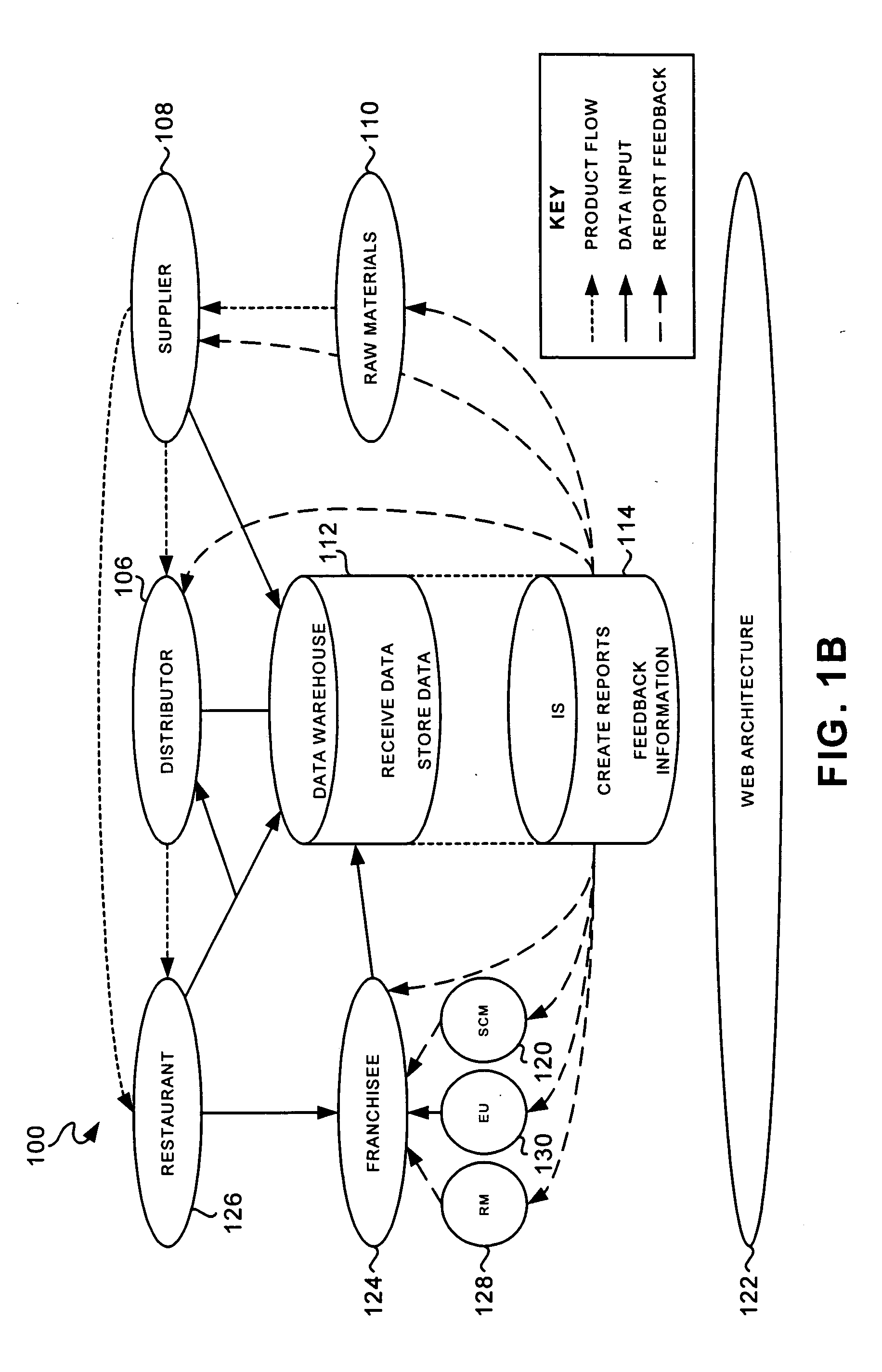

System, method and computer program product for utilizing market demand information for generating revenue

InactiveUS20060015416A1Billing/invoicingBuying/selling/leasing transactionsSystems approachesComputer program

A system, method and computer program product are disclosed for risk management in a supply chain management framework. A supply chain manager is appointed for at least one buying supply chain participant. The supply chain manager is given authority to negotiate supply agreements for at least one good on behalf of the at least one buying supply chain participant. One or more supply agreements are entered into for the at least one good, wherein provisions of the supply agreement include: (i) pricing for each one good shall be based upon factors including an actual market price of at least one commodity when the supply chain manager has not established a commodity position price; and (ii) pricing for each one good shall be based upon factors including a commodity position price of at least one commodity when the supply chain manager has established a commodity position price. Periodically, a commodity position price is established through the supply chain manager.

Owner:RESTAURANT SERVICES

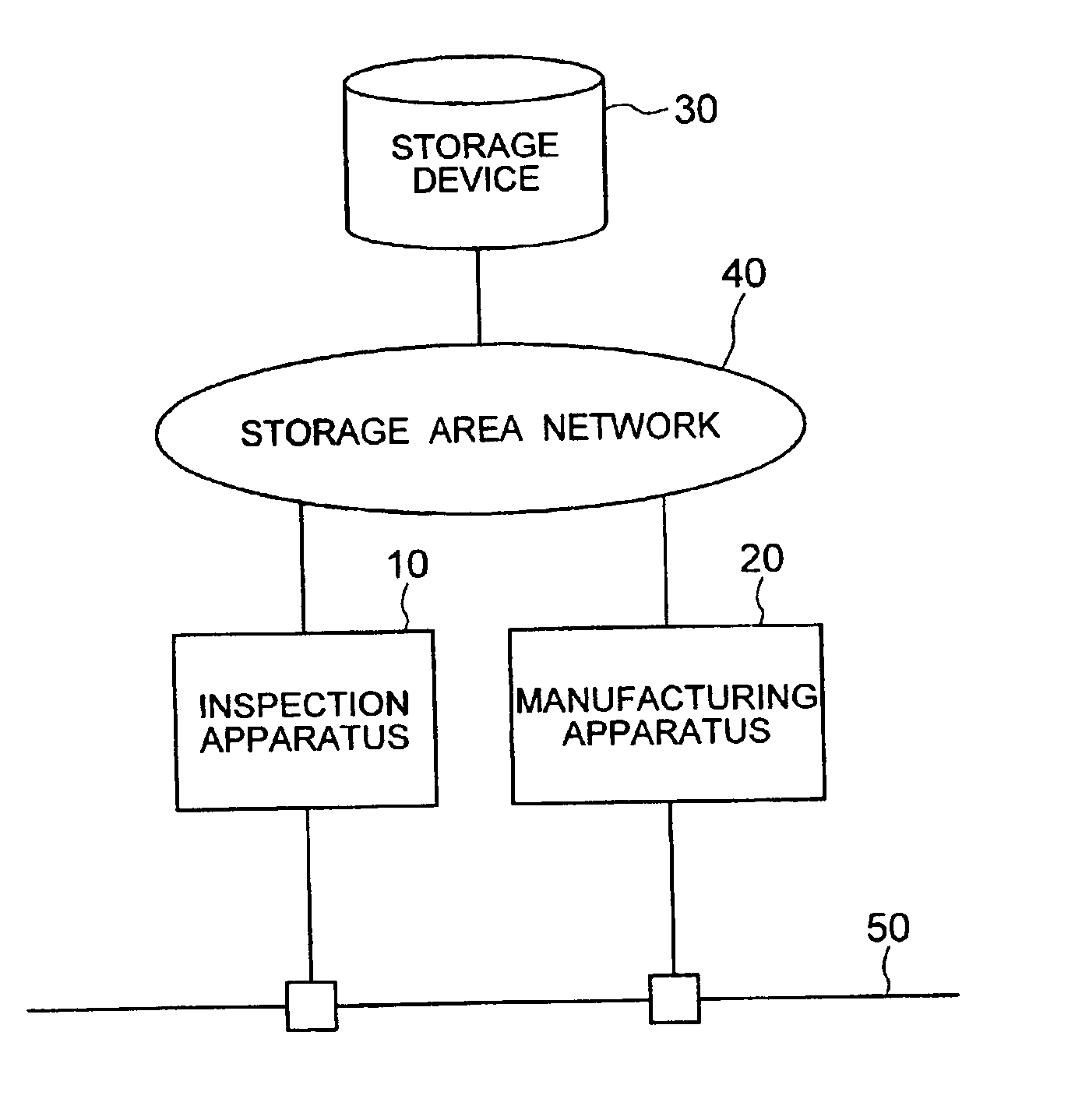

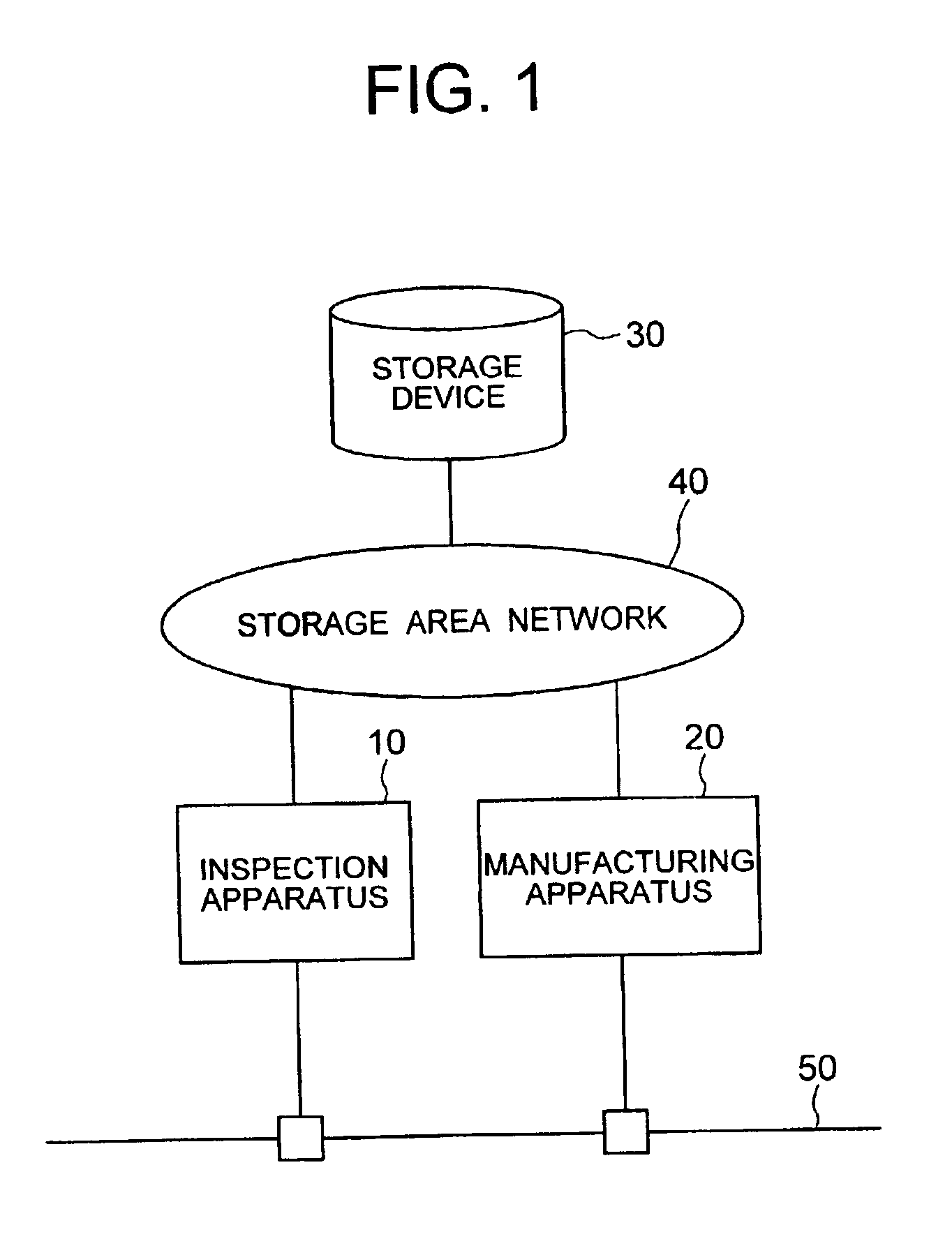

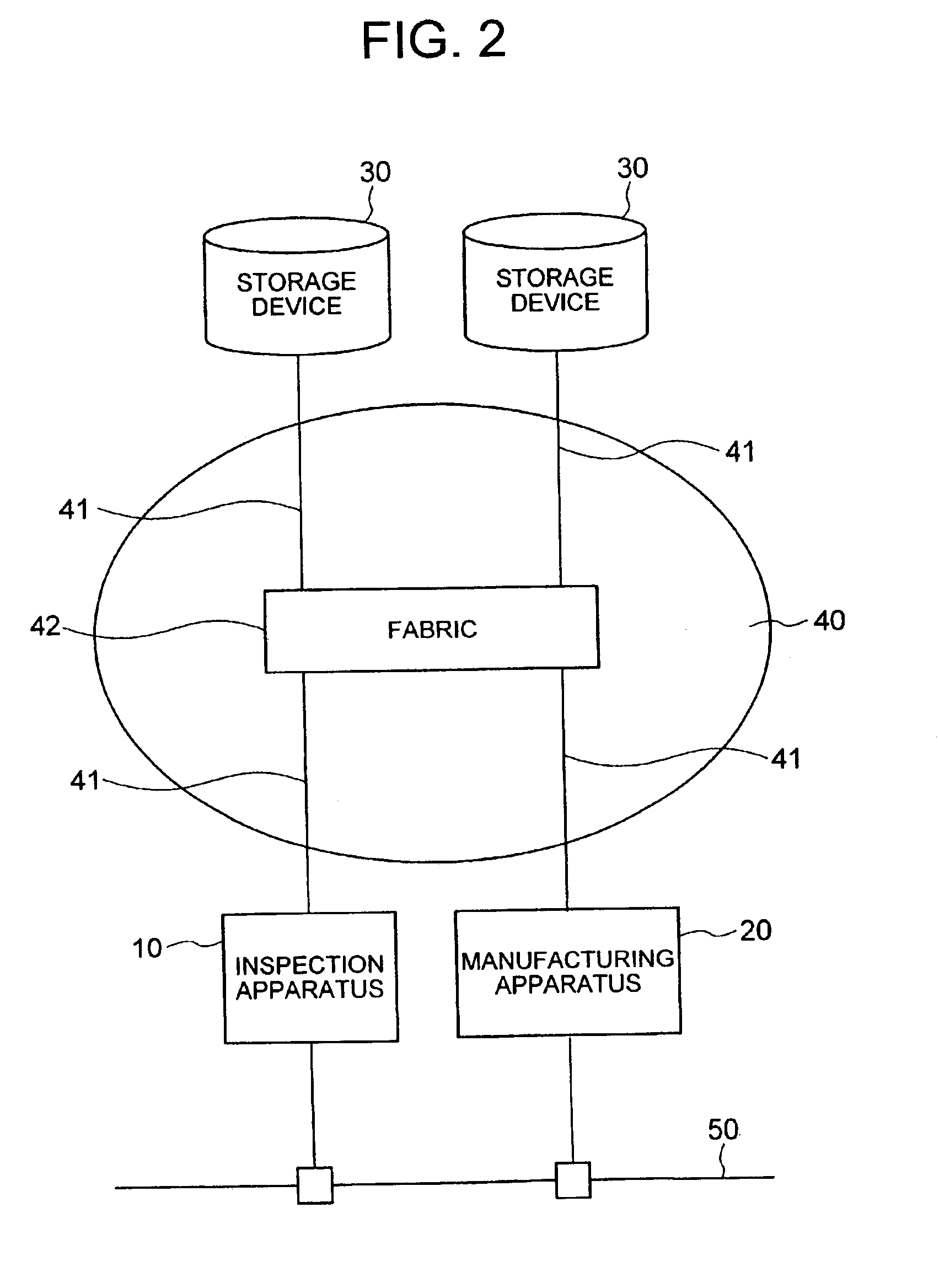

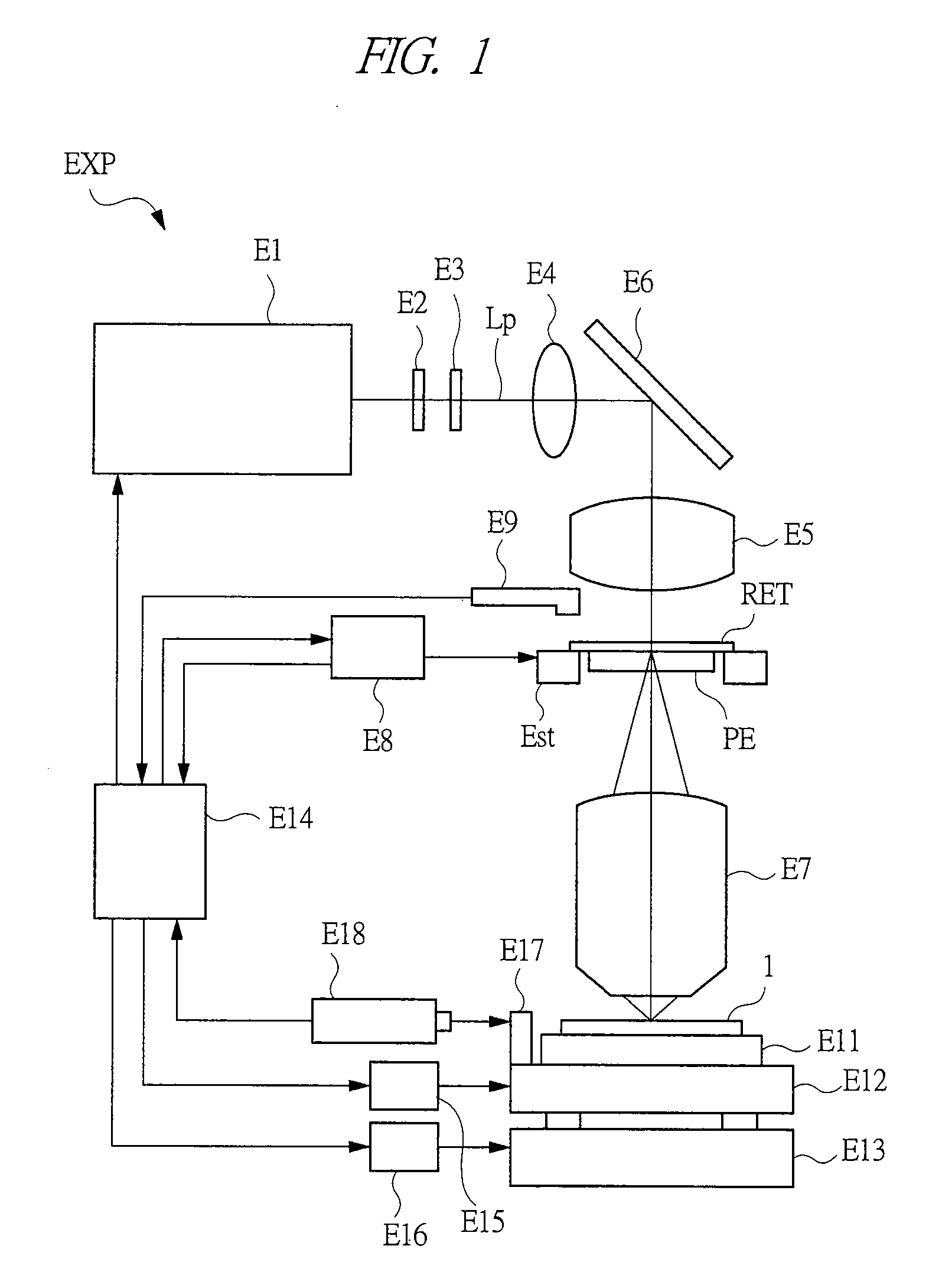

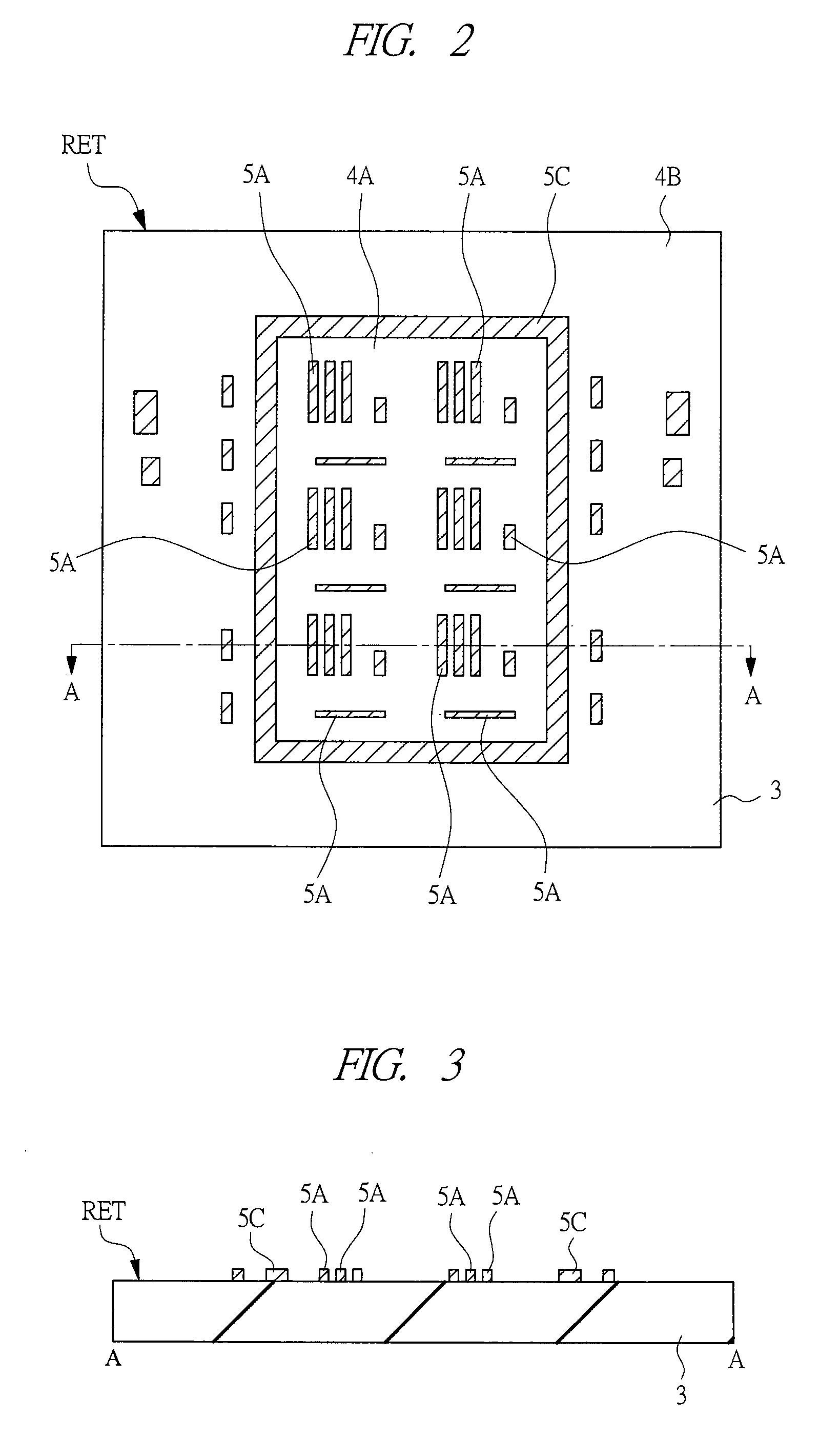

Semiconductor production system

InactiveUS6850854B2Improve system throughputIncrease in sizeSemiconductor/solid-state device testing/measurementElectronic circuit testingStorage area networkObservation unit

A semiconductor production system has a semiconductor manufacturing apparatus having an exposure unit, a control unit for controlling the exposure unit and a storage device; a semiconductor inspection apparatus having an observation unit, a control unit for controlling the observation unit and a storage device; and a storage device commonly used by the semiconductor manufacturing apparatus and the semiconductor inspection apparatus. The manufacturing apparatus, the inspection apparatus and the commonly used storage device are interconnected via a storage area network. With the semiconductor manufacturing apparatus and the storage device linked together via the storage area network, a large volume of image data or design data can be communicated at high speed, thus improving the system throughput.

Owner:HITACHI LTD

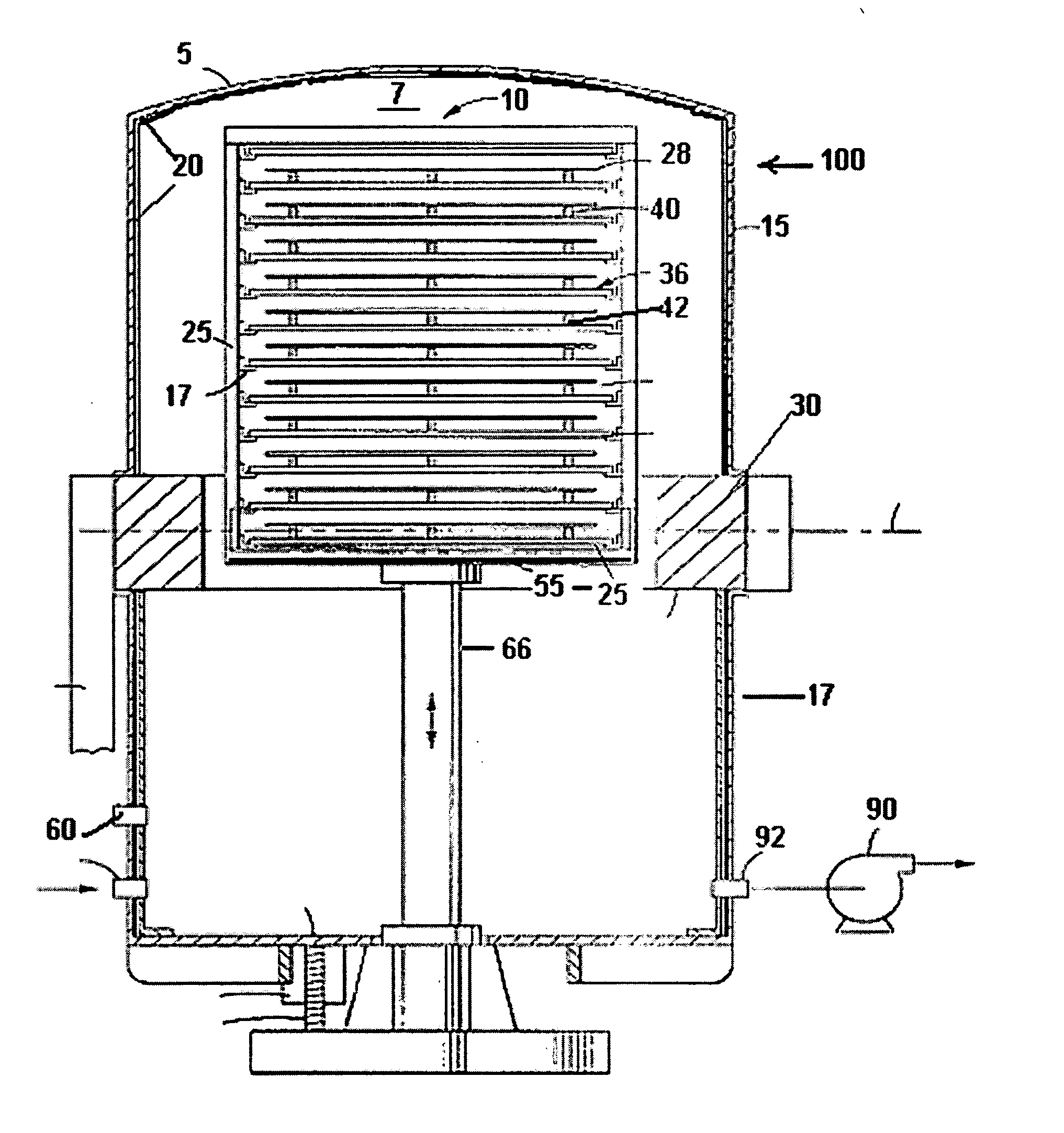

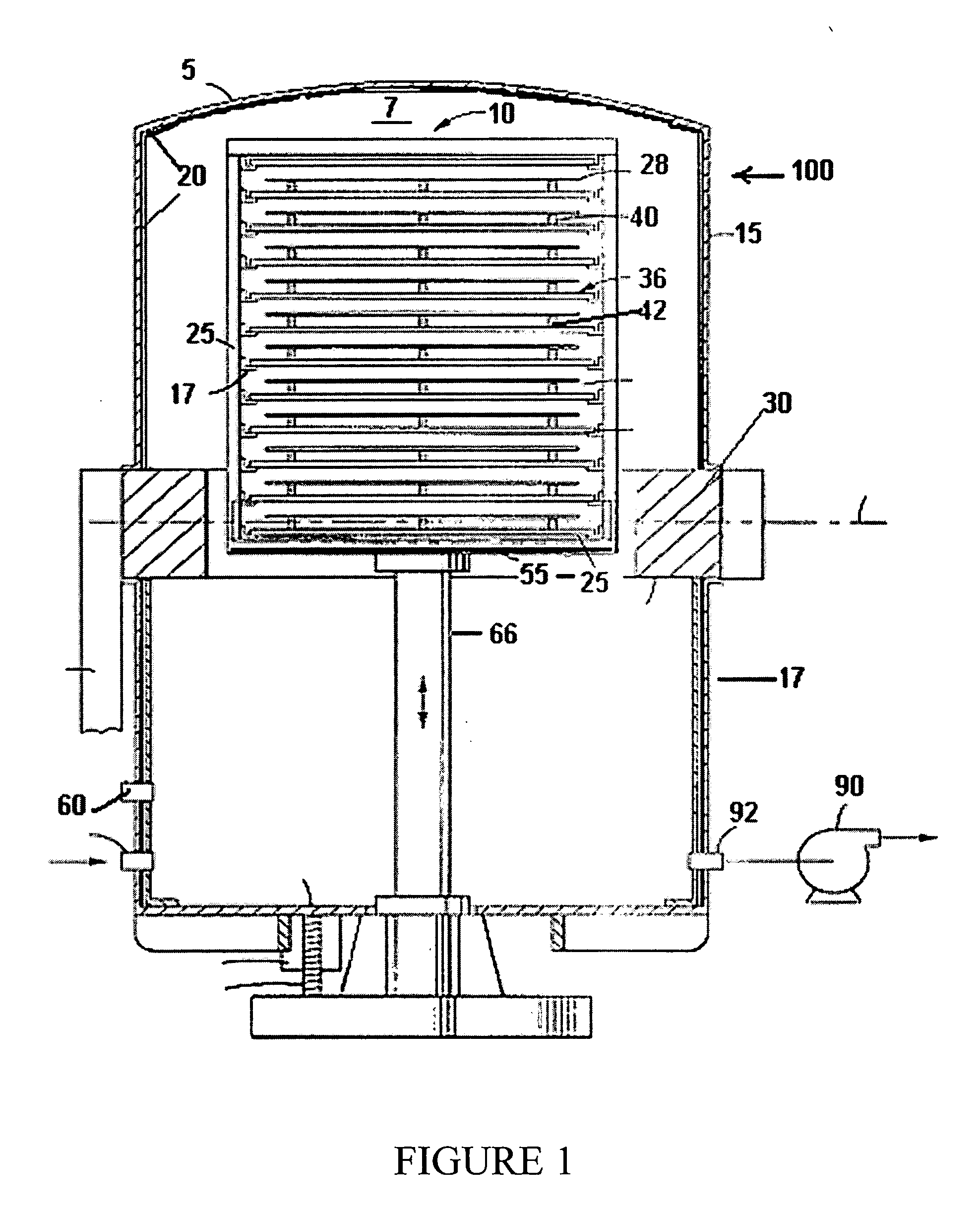

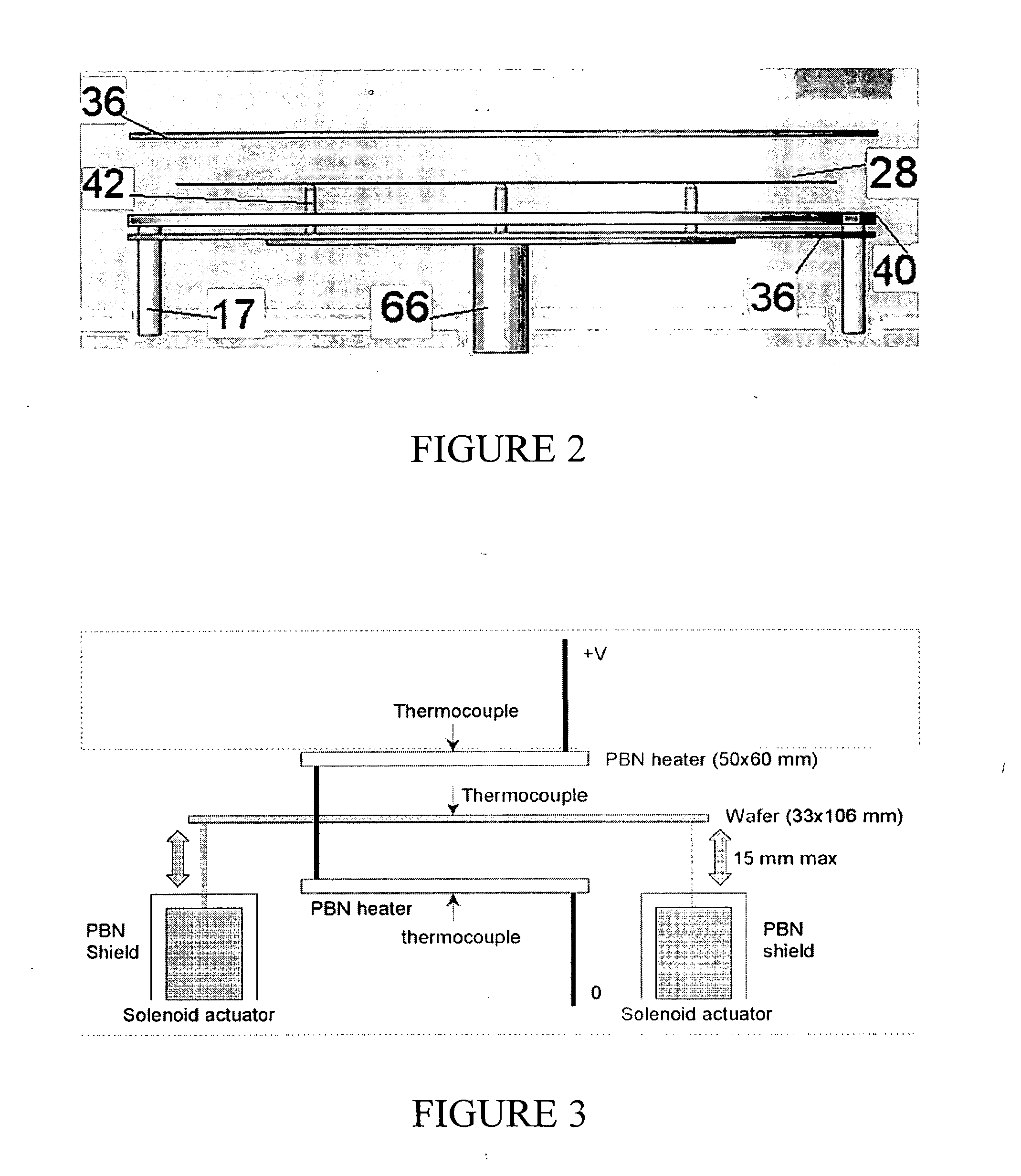

Fast heating and cooling wafer handling assembly and method of manufacturing thereof

InactiveUS20060127067A1Muffle furnacesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceThermal control

A thermal control device for wafer processing which comprises a) a platform for placement of an object of various sizes to be heated, b) at least a shaft extending substantially transverse to the platform; and c) a plurality of resistance heating elements patterned in a plurality of circuits defining at least one zone for independent controlled heating of objects of varying sizes on the platform.

Owner:GENERAL ELECTRIC CO

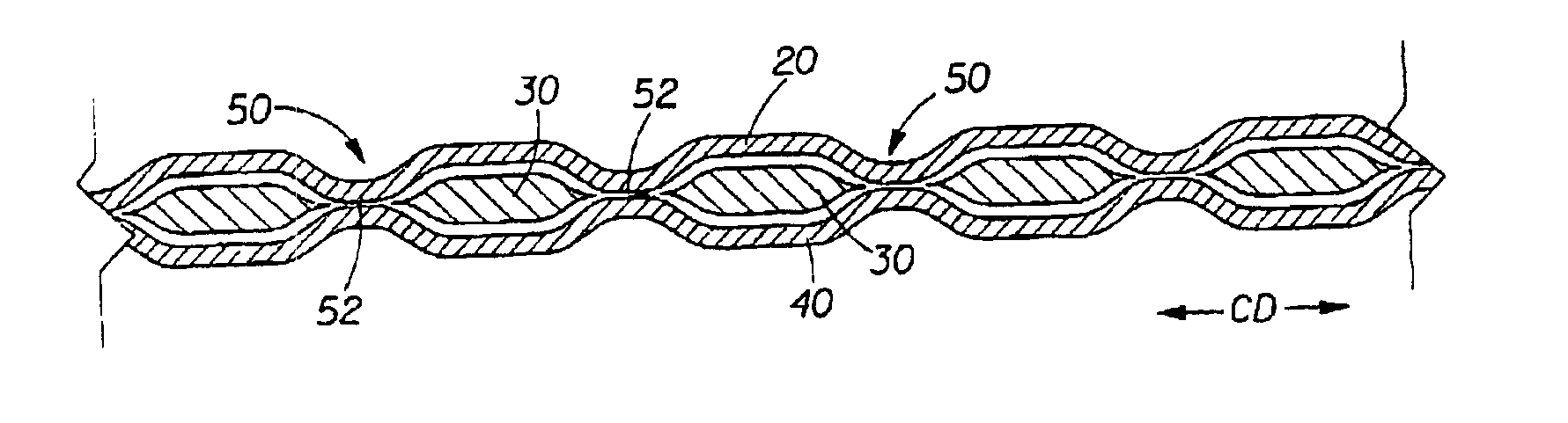

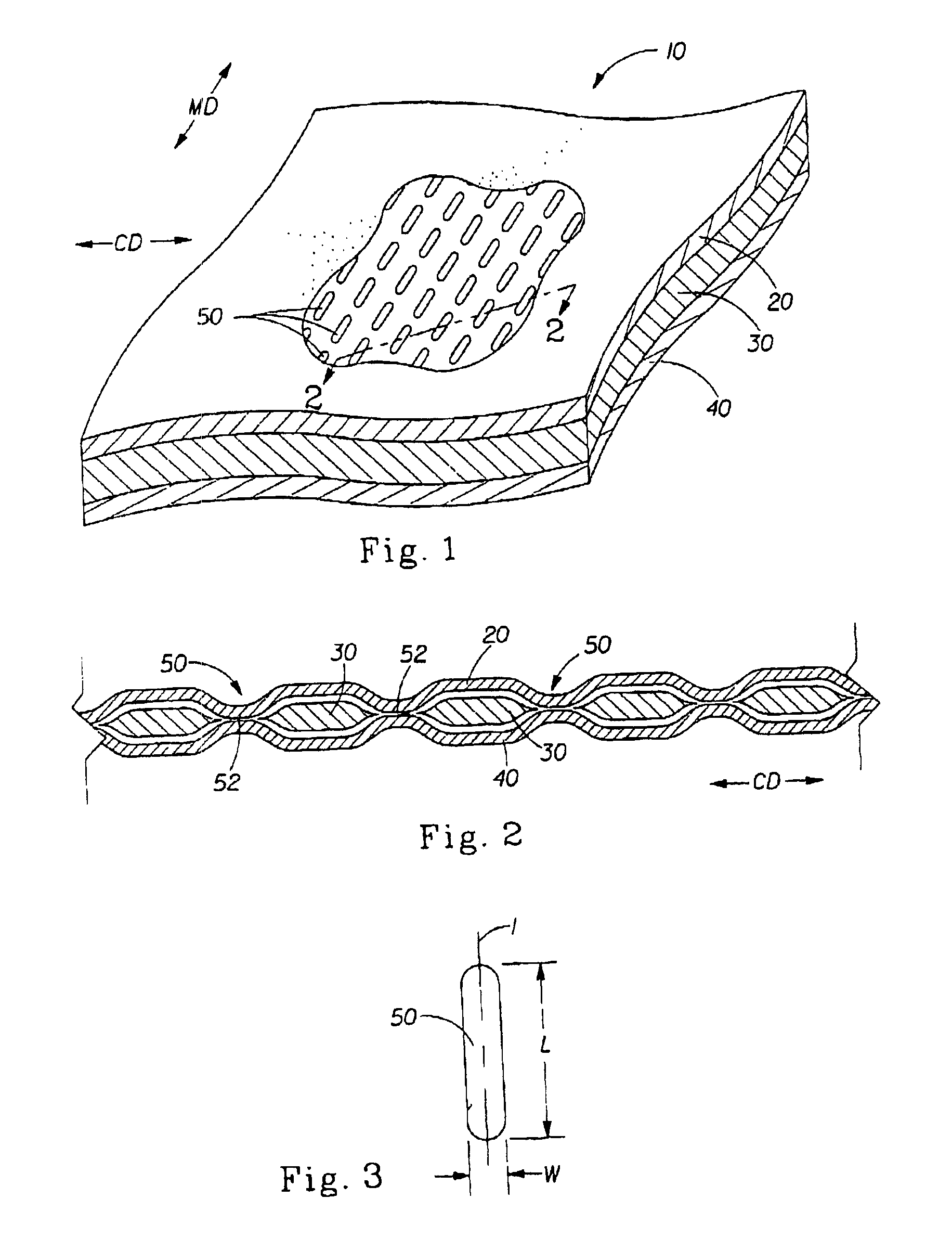

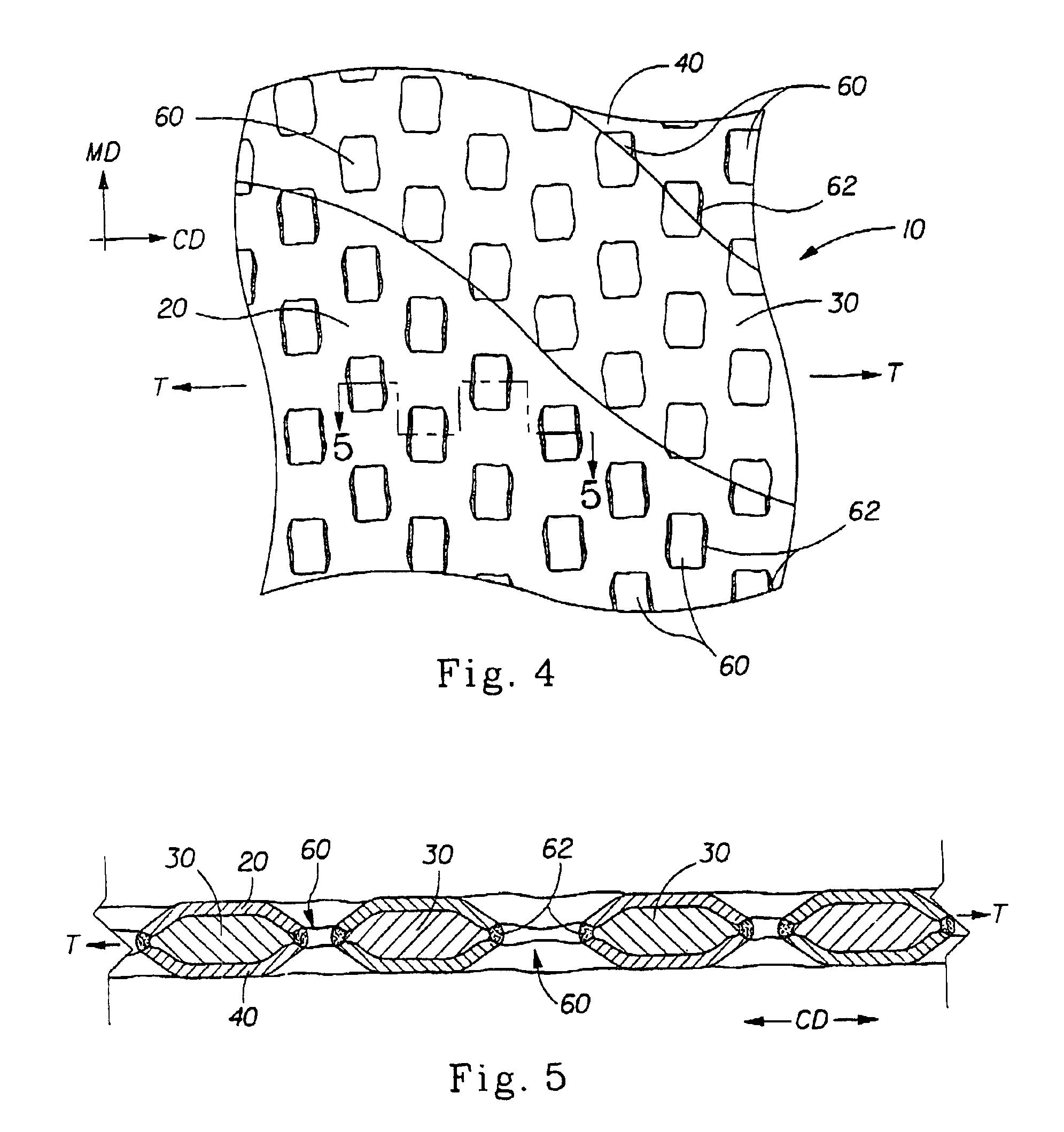

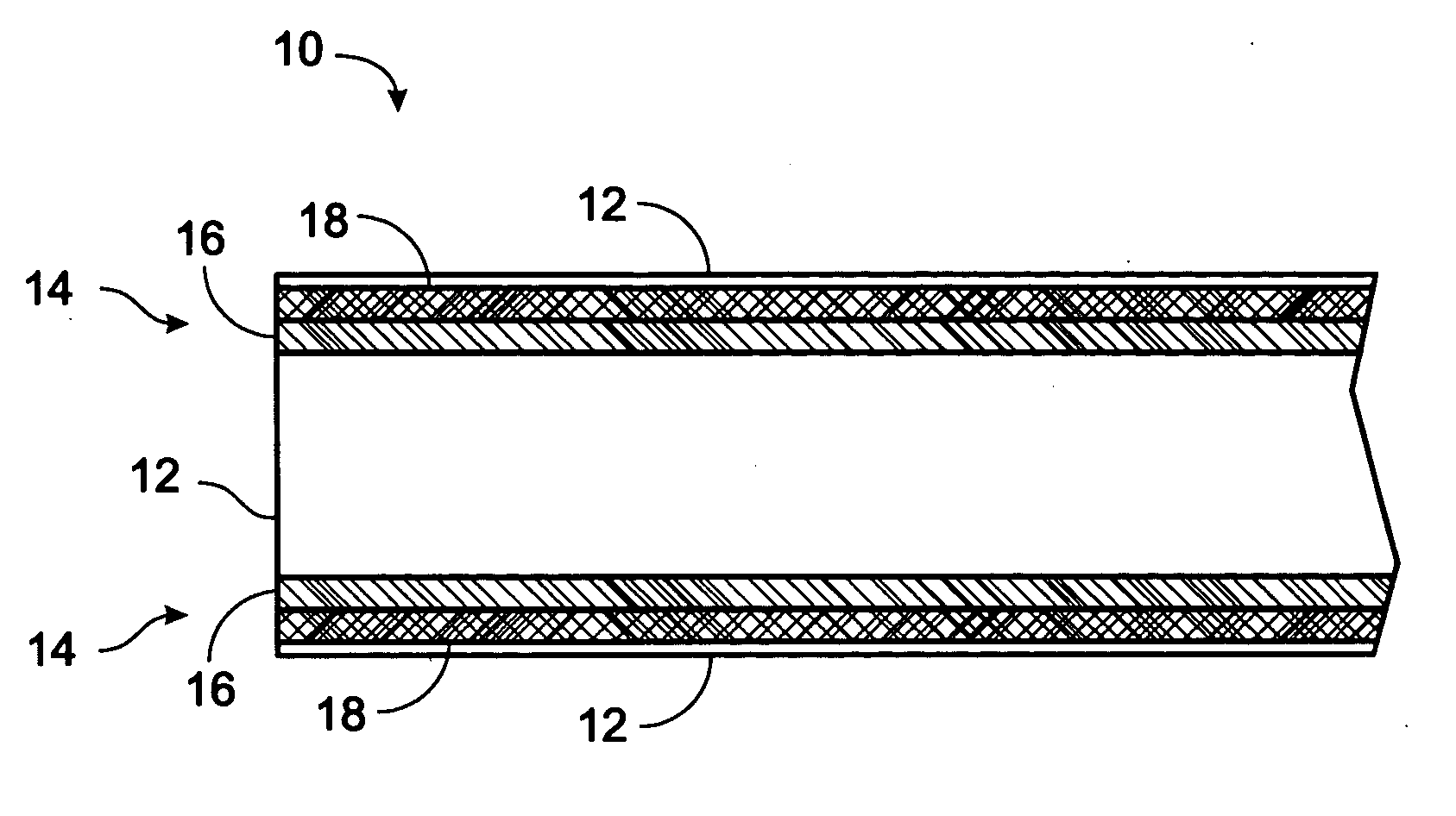

Laminate web comprising an apertured layer and method for manufacturing thereof

A laminate web comprising a first web, a second web joined to the first web at a plurality of discrete bond sites; and a third material disposed between at least a portion of the first and second nonwovens. The third material is apertured in regions adjacent the bond sites, such that the first and second nonwoven webs are joined through the apertures. In one embodiment an apertured laminate web is disclosed, having a first extensible web having a first elongation to break, and a second extensible web joined to the first extensible web at a plurality of bond sites, the second extensible web having elongation to break. A third web material is disposed between the first and second nonwovens, the third web material having a third elongation to break which is less than both of the first or second elongations to break. In a further embodiment, an apertured laminate web is disclosed, having first and second extensible webs being joined at a plurality of discrete bond sites and a third material disposed between the first and second nonwoven webs. The first and second nonwoven webs are in fluid communication via the apertures and have distinct regions being differentiated by at least one property selected from the group consisting of basis weight, fiber orientation, thickness, and density.

Owner:THE PROCTER & GAMBLE COMPANY

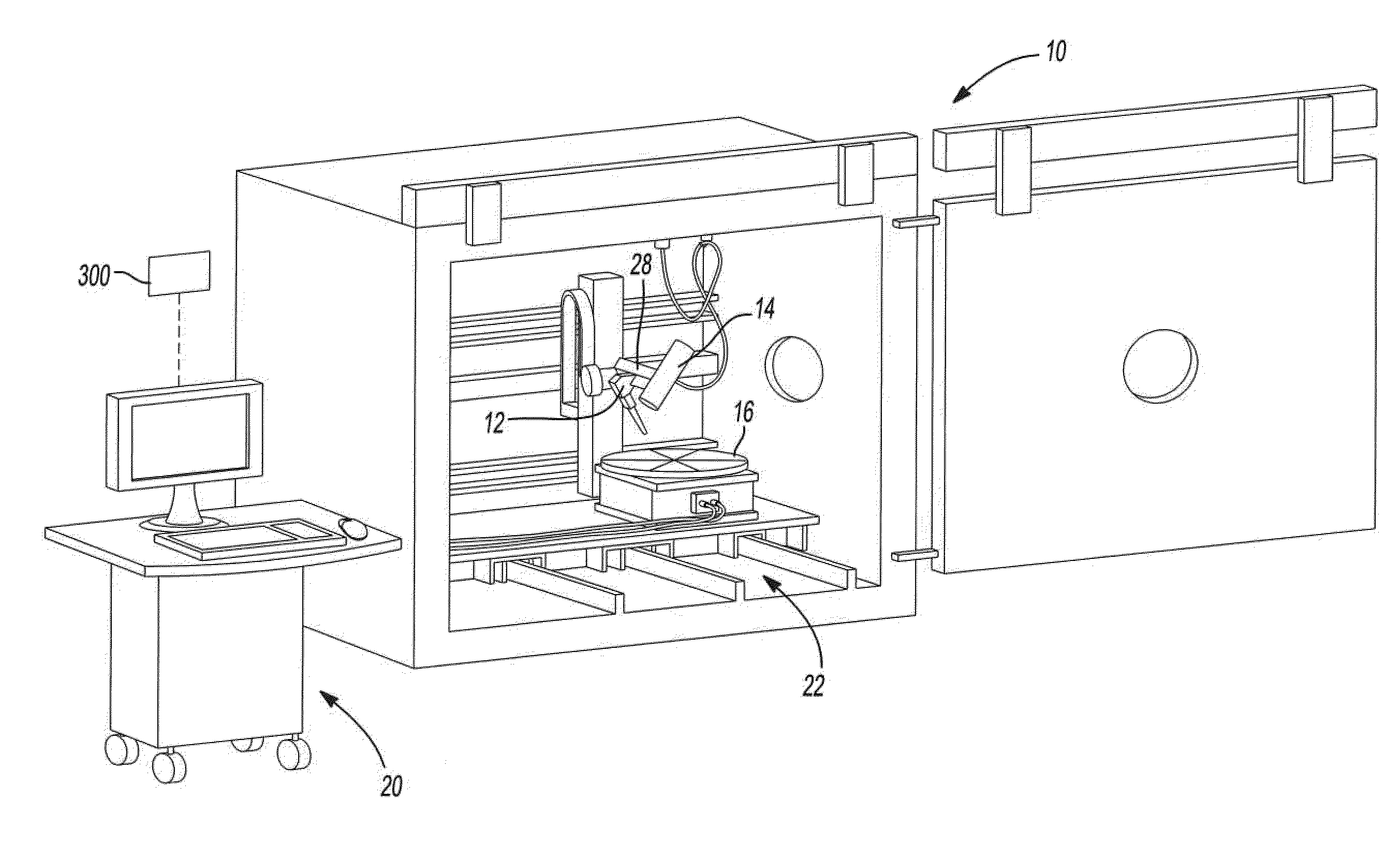

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

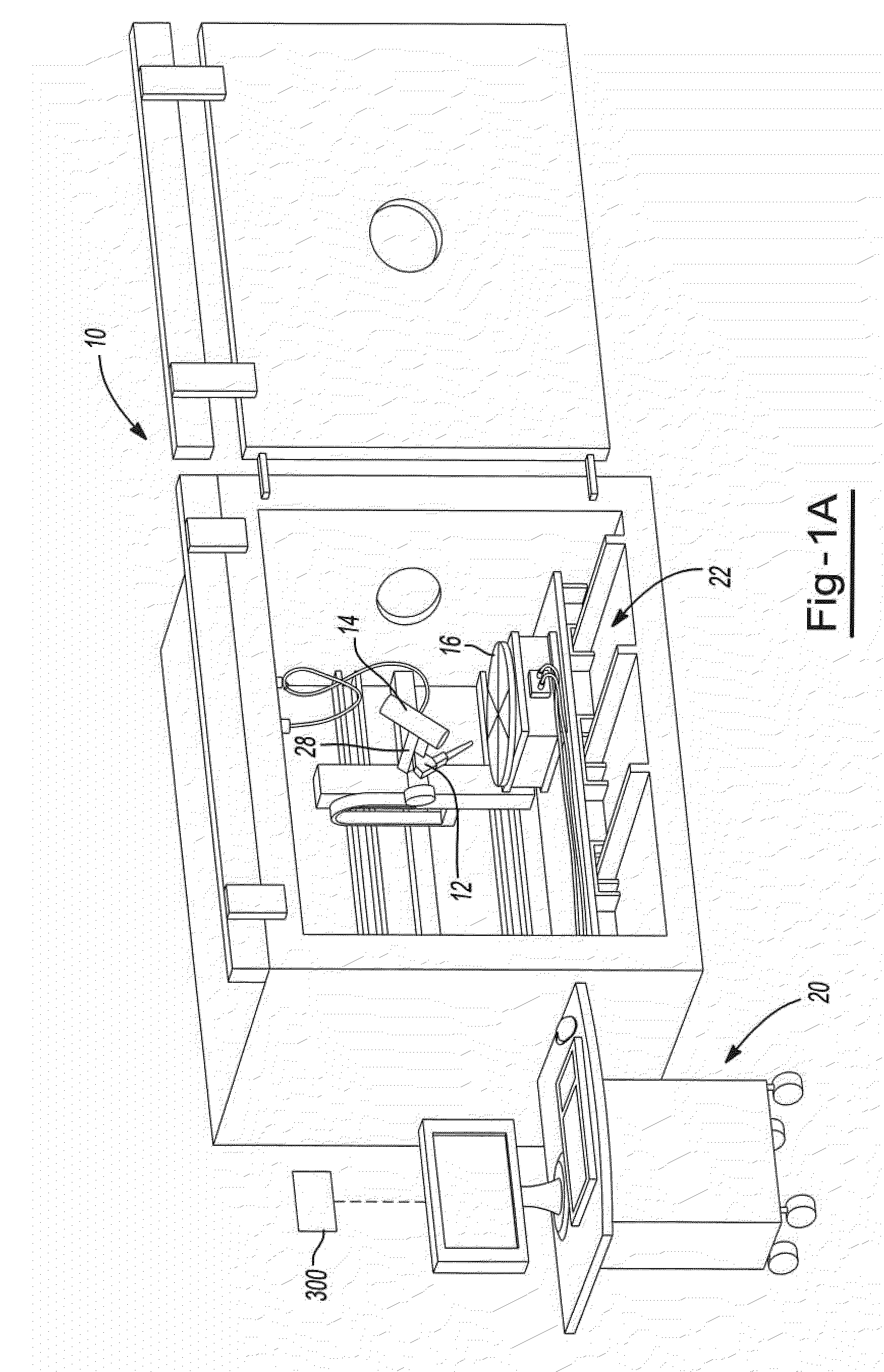

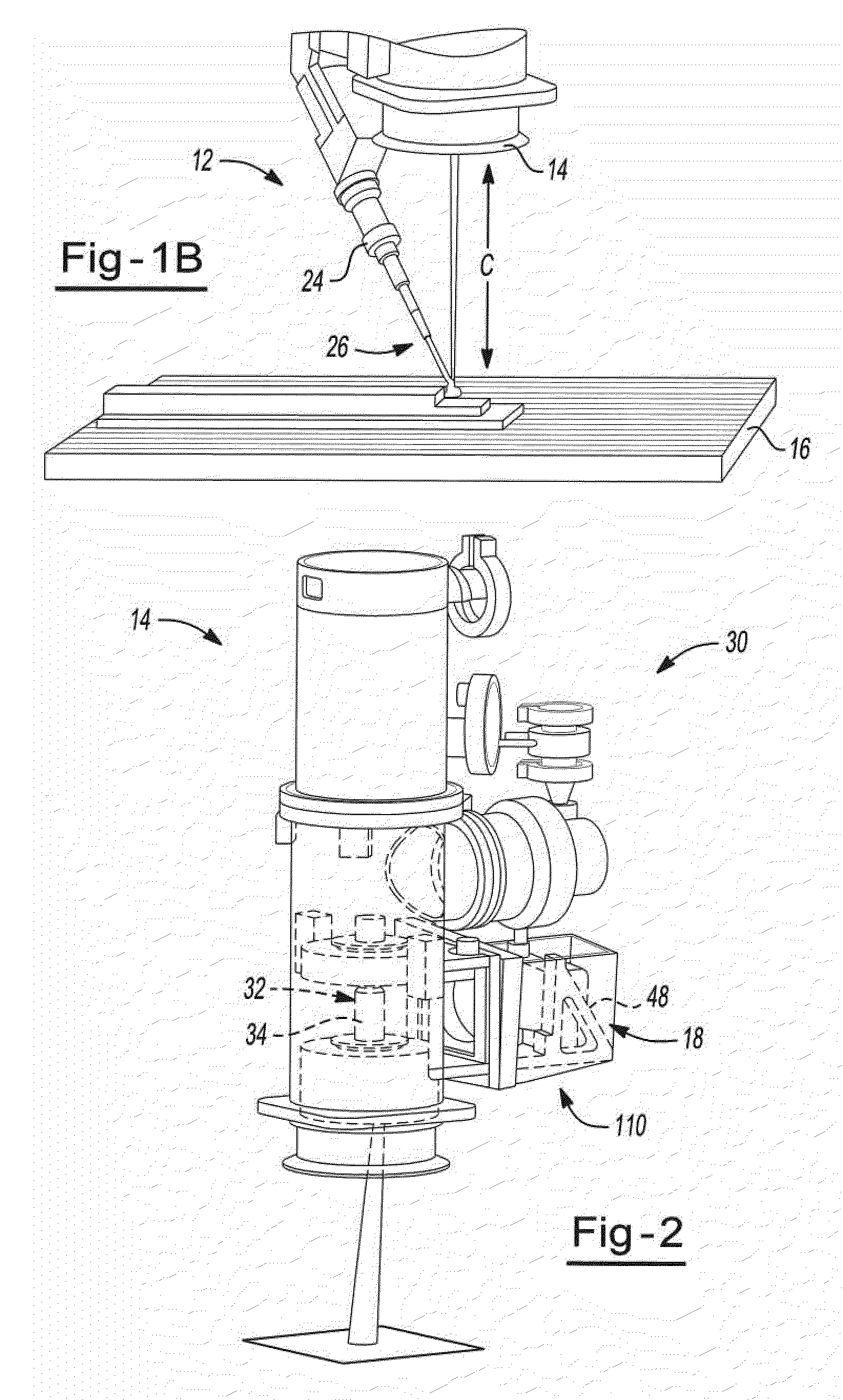

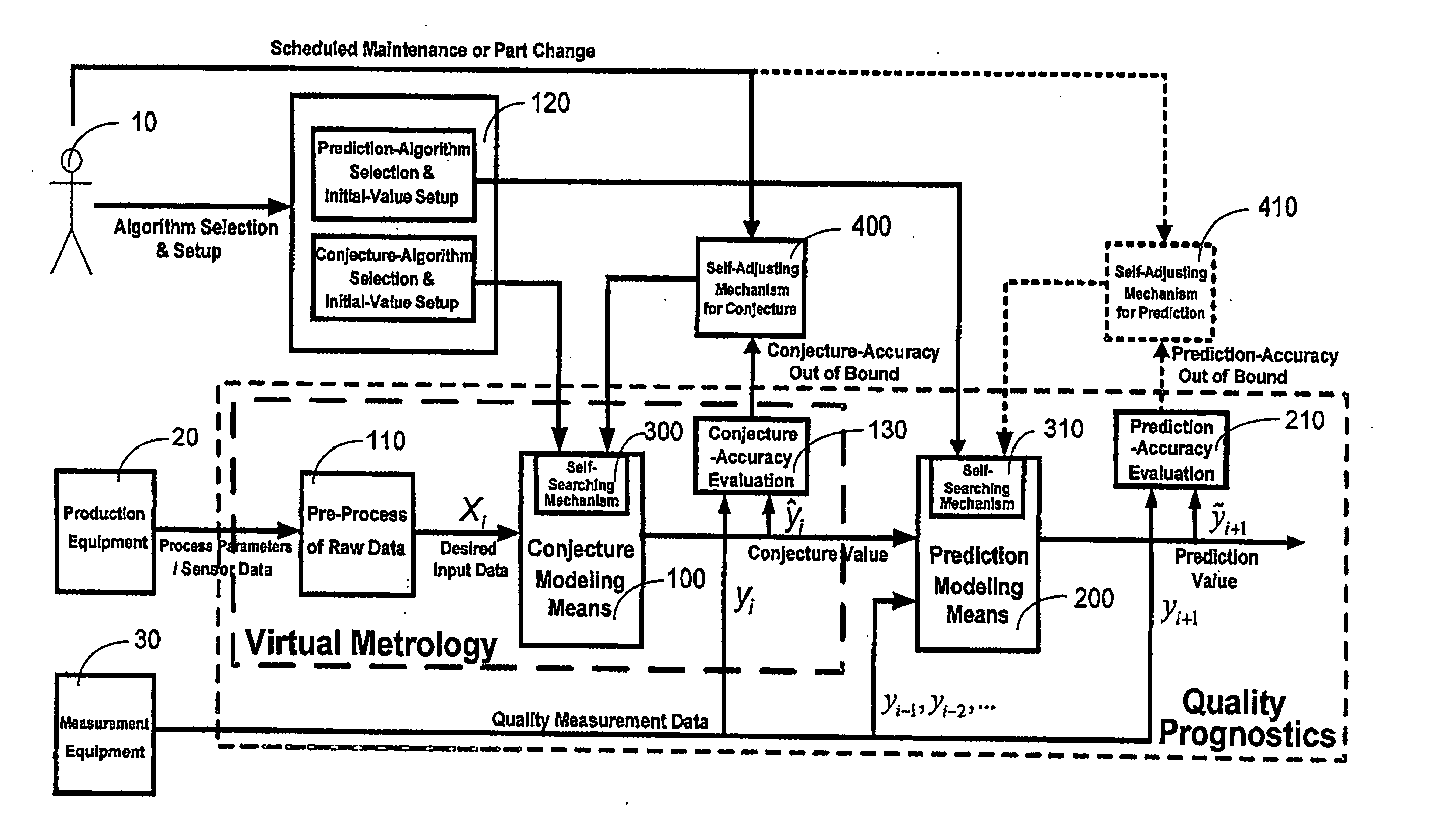

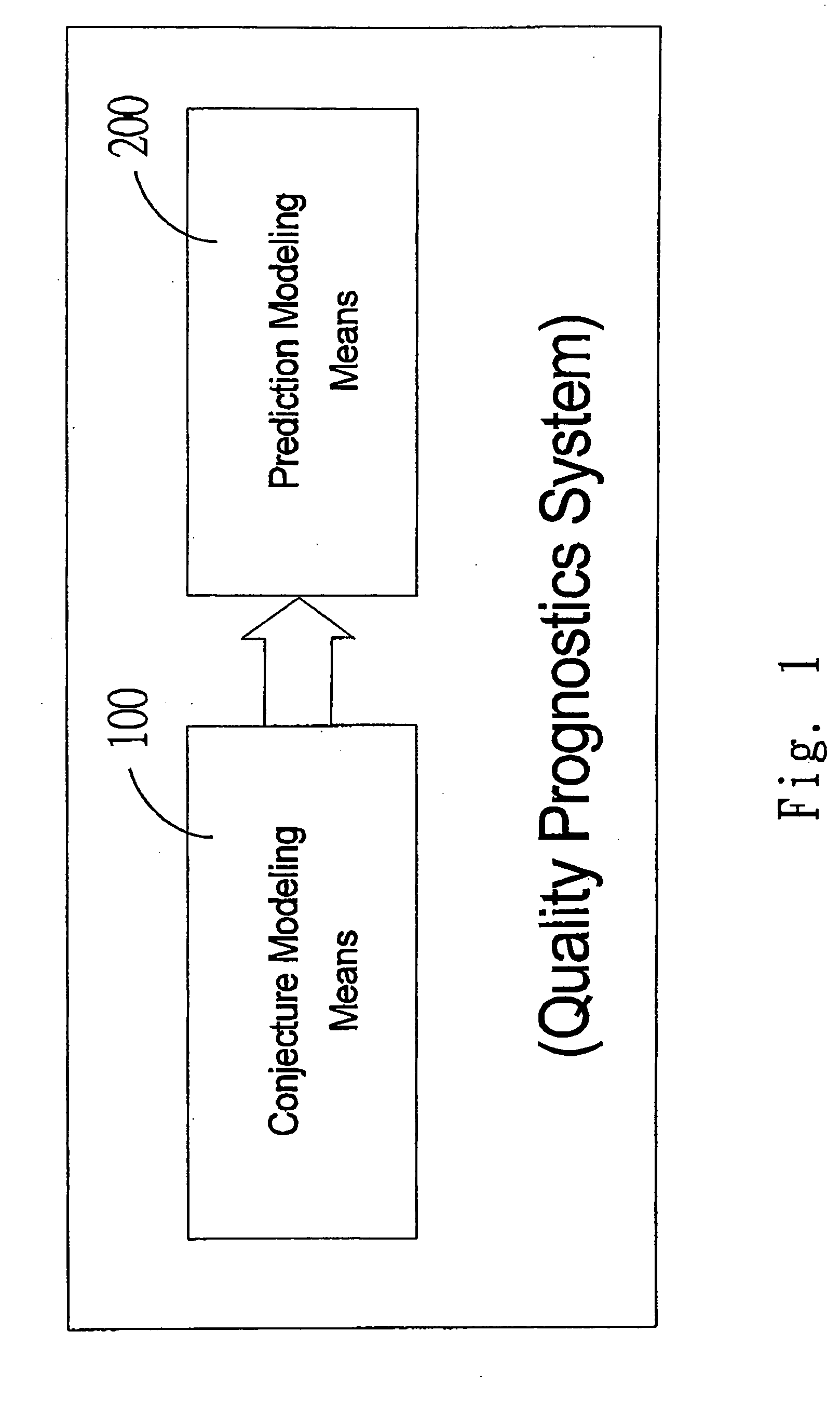

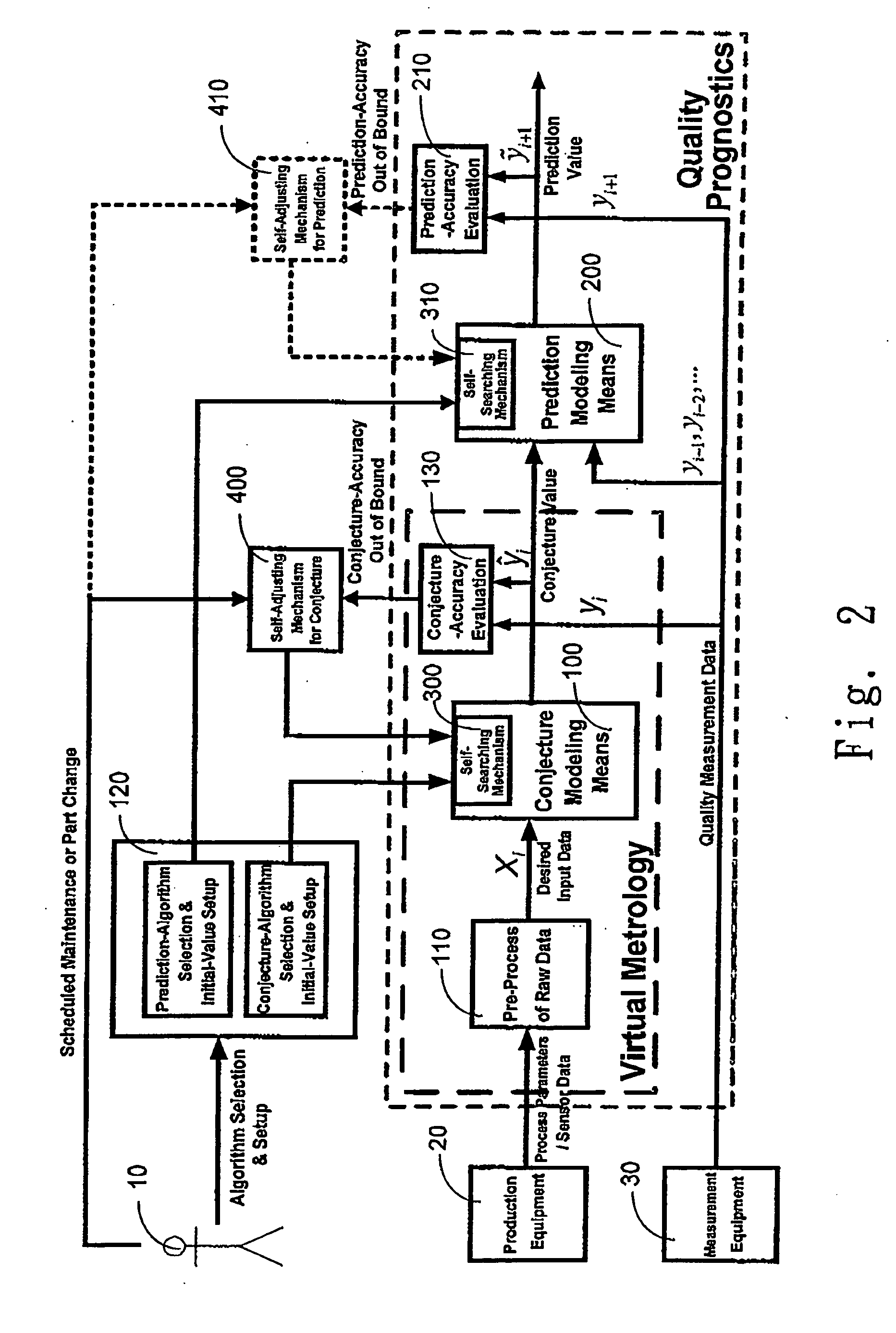

Quality prognostics system and method for manufacturing processes

ActiveUS20050288812A1Reduce disadvantagesImprove availabilityDigital computer detailsSemiconductor/solid-state device manufacturingPredictive systemsPrediction algorithms

A quality prognostics system and a quality prognostics method for predicting the product quality during manufacturing processes are disclosed. The present invention utilizes the current production tool parameters sensed during the manufacturing process and several previous quality data collected from the measurement tool to predict the future product quality. The quality prognostics system is composed of conjecture modeling means and prediction modeling means. The conjecture modeling means itself also can be applied for the purpose of virtual metrology. Further, the quality prognostics method possesses a self-searching means and a self-adjusting means for searching the best combination of various parameters / functions used by the conjecture algorithm or prediction algorithm; and meeting the requirements of new equipment parameters and conjecture / prediction accuracy.

Owner:NAT CHENG KUNG UNIV

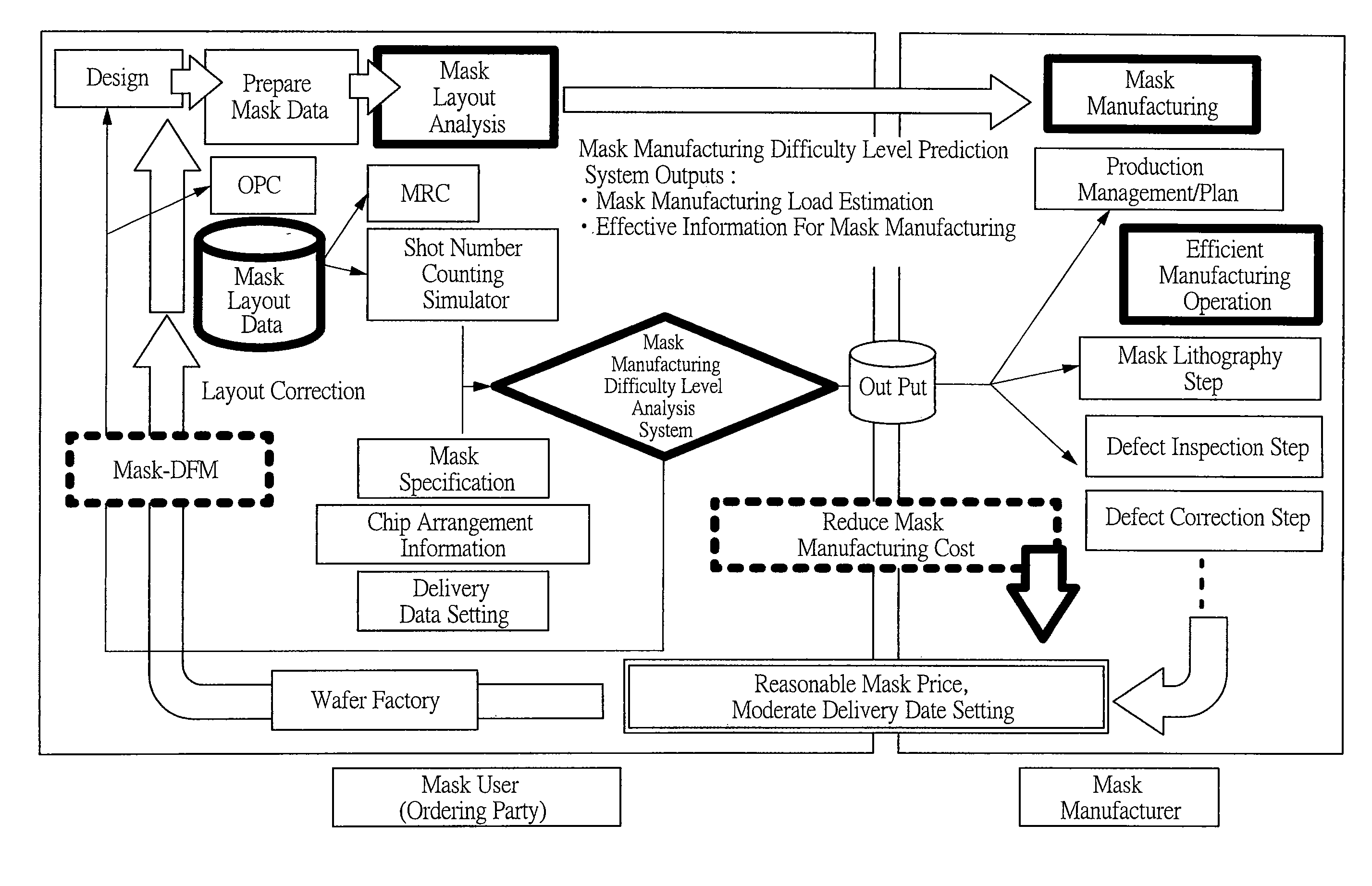

Method of manufacturing photomask

InactiveUS20090077524A1Efficient preparationImprove efficiencyOriginals for photomechanical treatmentSpecial data processing applicationsPrediction systemPhotomask

A technique for quantitatively expressing a manufacturing difficulty level of a photomask and for efficiently manufacturing the photomask is provided. A mask manufacturing difficulty level different for each mask layout, product, and mask layer is relatively recognized with a mask manufacturing load index calculated by a mask manufacturing load prediction system, and when layout correction is possible, the final layout is corrected to a layout with a low difficulty level, and a mask ordering party provides a mask manufacturer with information regarding the mask manufacturing difficulty level in an early stage. The mask manufacturing load index is expressed with a defect guarantee load index and a lithography load index.

Owner:DAI NIPPON PRINTING CO LTD +1

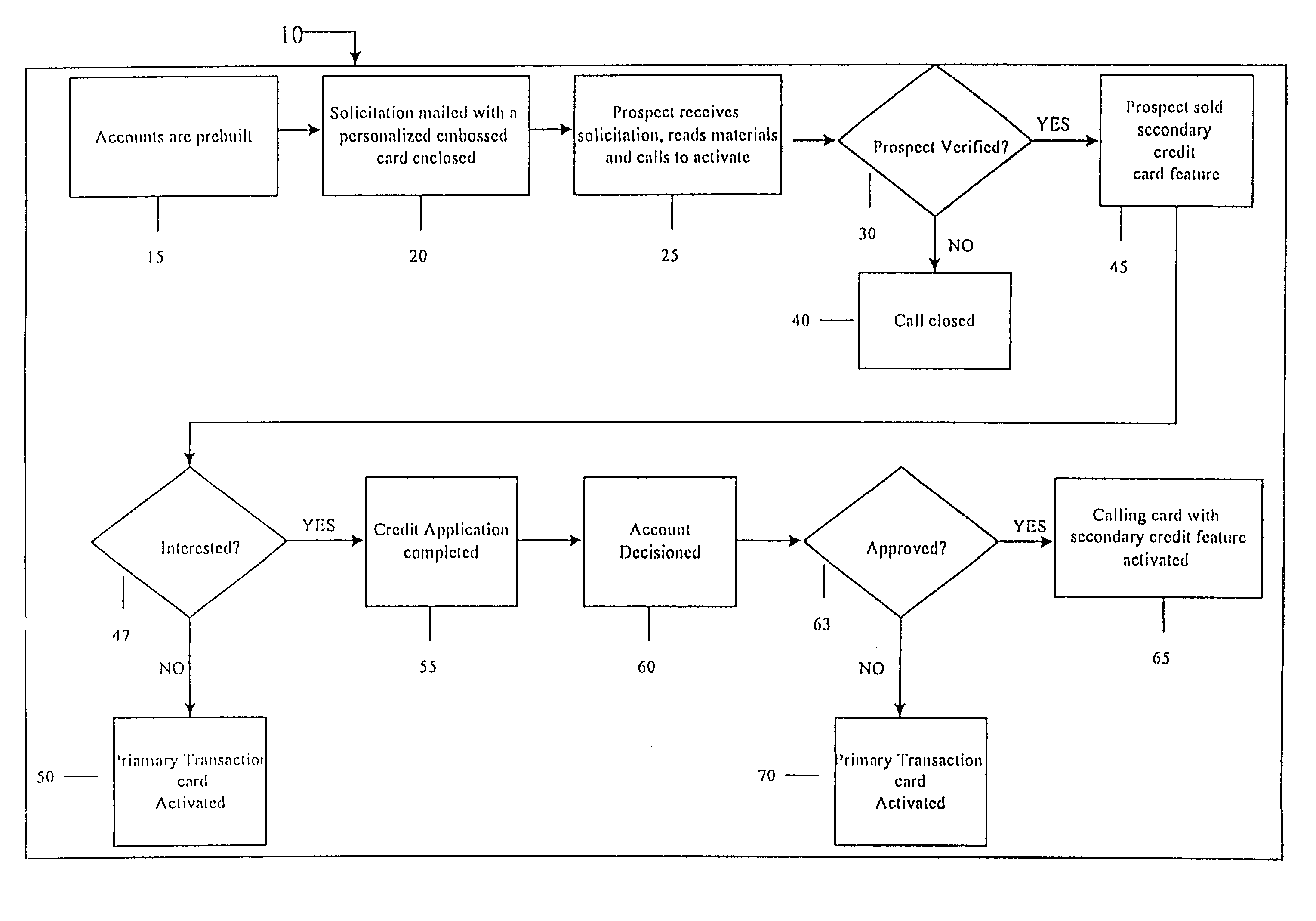

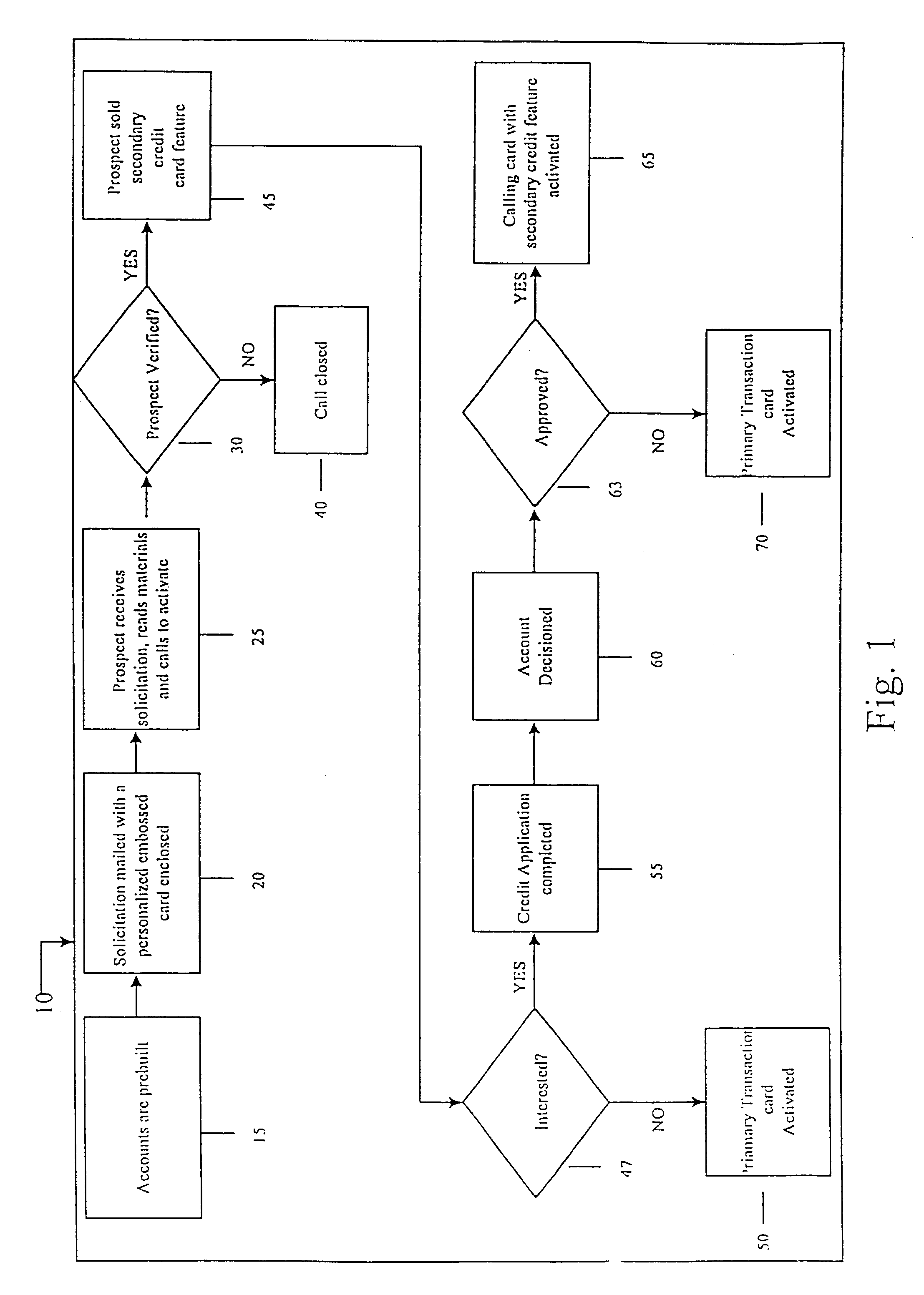

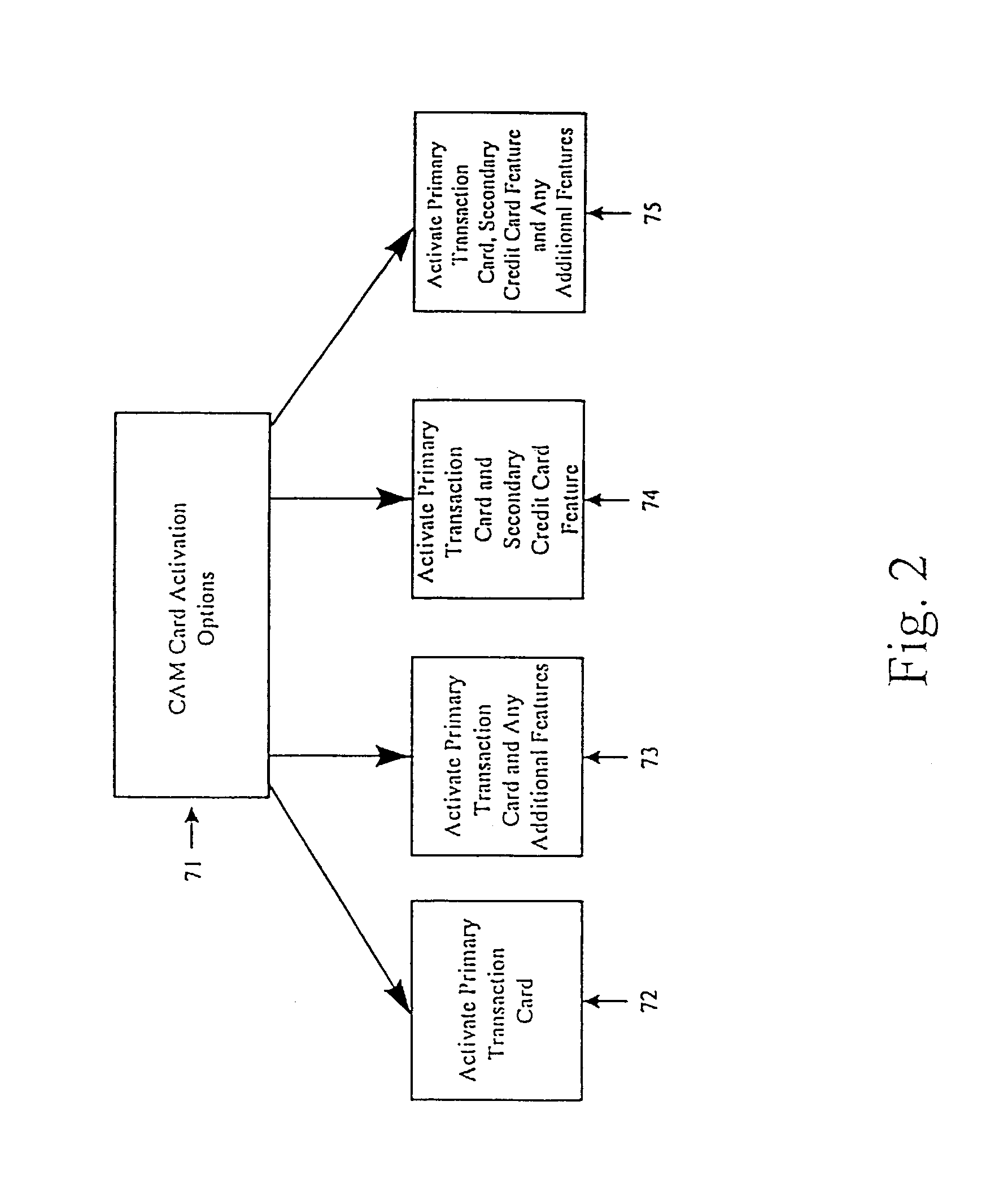

Customer activated multi-value (CAM) card

InactiveUS7072864B2Easy to useCredit registering devices actuationDiscounts/incentivesCredit cardTelephone card

The Customer Activated Multi-Value (CAM) card provides a customer with a primary use as a transaction card which can be further activated to have a secondary use as a credit card. The CAM card can be activated as a transaction card or as a transaction card with a credit card feature. Activation of the CAM card as a transaction card allows the customer to purchase goods and services from one specific vendor and to establish a relationship with that vendor for the goods or services rendered (for example, telephone calling card or gasoline product purchasing card) while enjoying reward benefits based on those purchases. Activation of the credit feature of the card allows the customer to interact with any merchant that accepts traditional credit cards such as VISA®, MASTERCARD®, AMERICAN EXPRESS®, or DISCOVER®. The combination of features allows a customer to purchase various goods and services from several different merchants. If the customer chooses to activate the CAM card as both a transaction card and a credit card, the customer is given the benefit of using the card in both manners described above.

Owner:BANK ONE DELAWARE NAT ASSOC

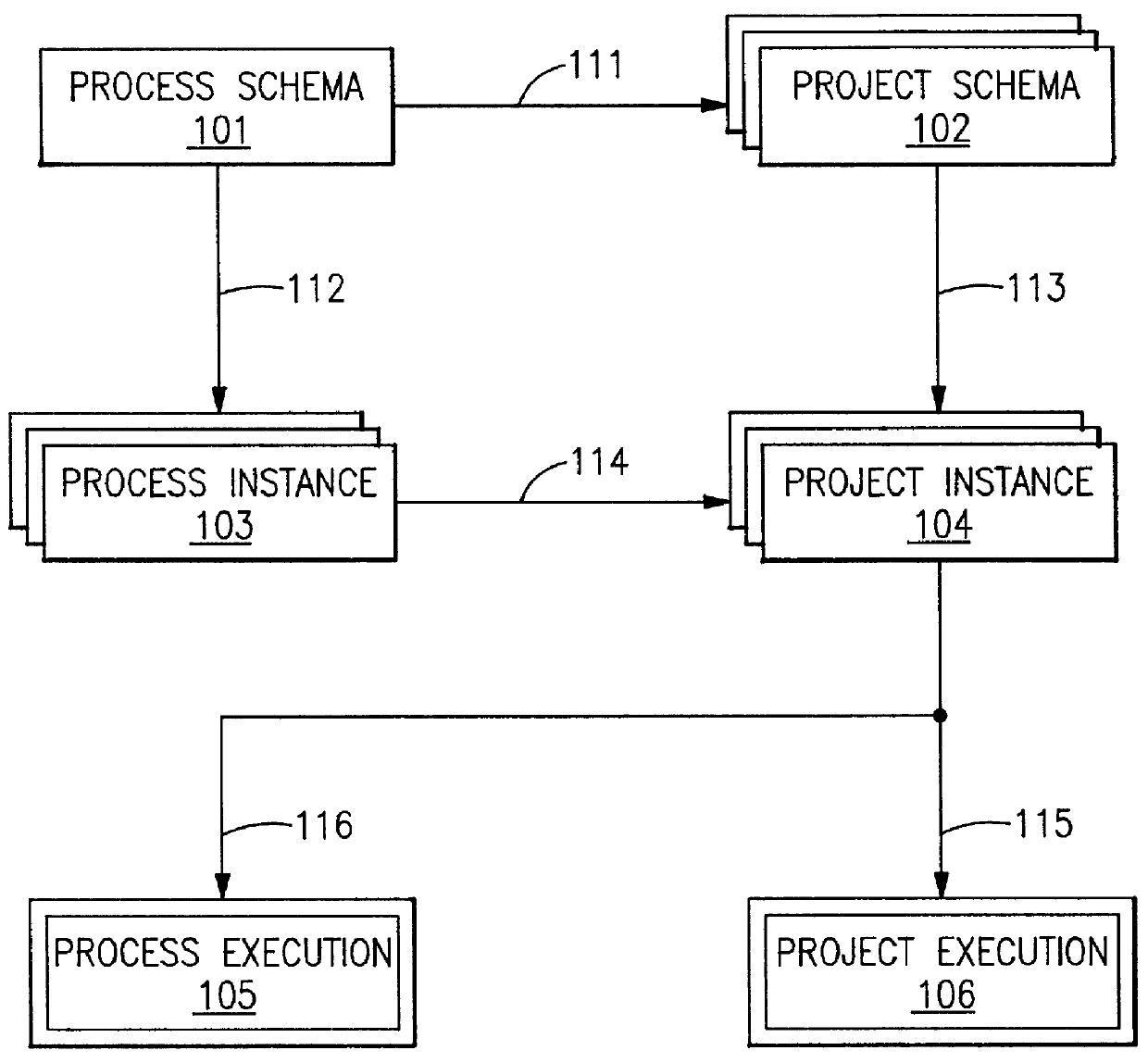

Method and apparatus for a process and project management computer system

InactiveUS6023702AReduce storageImprove performanceProgram control using stored programsResourcesDigital dataModularity

PCT No. PCT / EP95 / 03289 Sec. 371 Date Dec. 10, 1998 Sec. 102(e) Date Dec. 10, 1998 PCT Filed Aug. 18, 1995 PCT Pub. No. WO97 / 07472 PCT Pub. Date Feb. 27, 1997The inventive concept comprises a system platform for a synergistic, role modular work process environment. A work process object (WPO) (1001) is created, residing in a data base, and stored in a memory of the process and project management computer system (1030). All data concerning the process and project management are reported to said work process object (WPO) (1001) and said work process object (WPO) (1001) is used as a common data base. According to the inventive concept, each view must be supported by a specific workplace, represented by digital data and enforcing the rules for the specific role. A work process information model supports the dynamic definition and use of a data base object representing a work process, boch in its process and project planning modes and its execution. According to the inventive concept, one object supports simultaneously all modes delimited by dynamically moving boundaries. Workplace implementation enforces over-all rules for each role in the inventive system.

Owner:IBM CORP

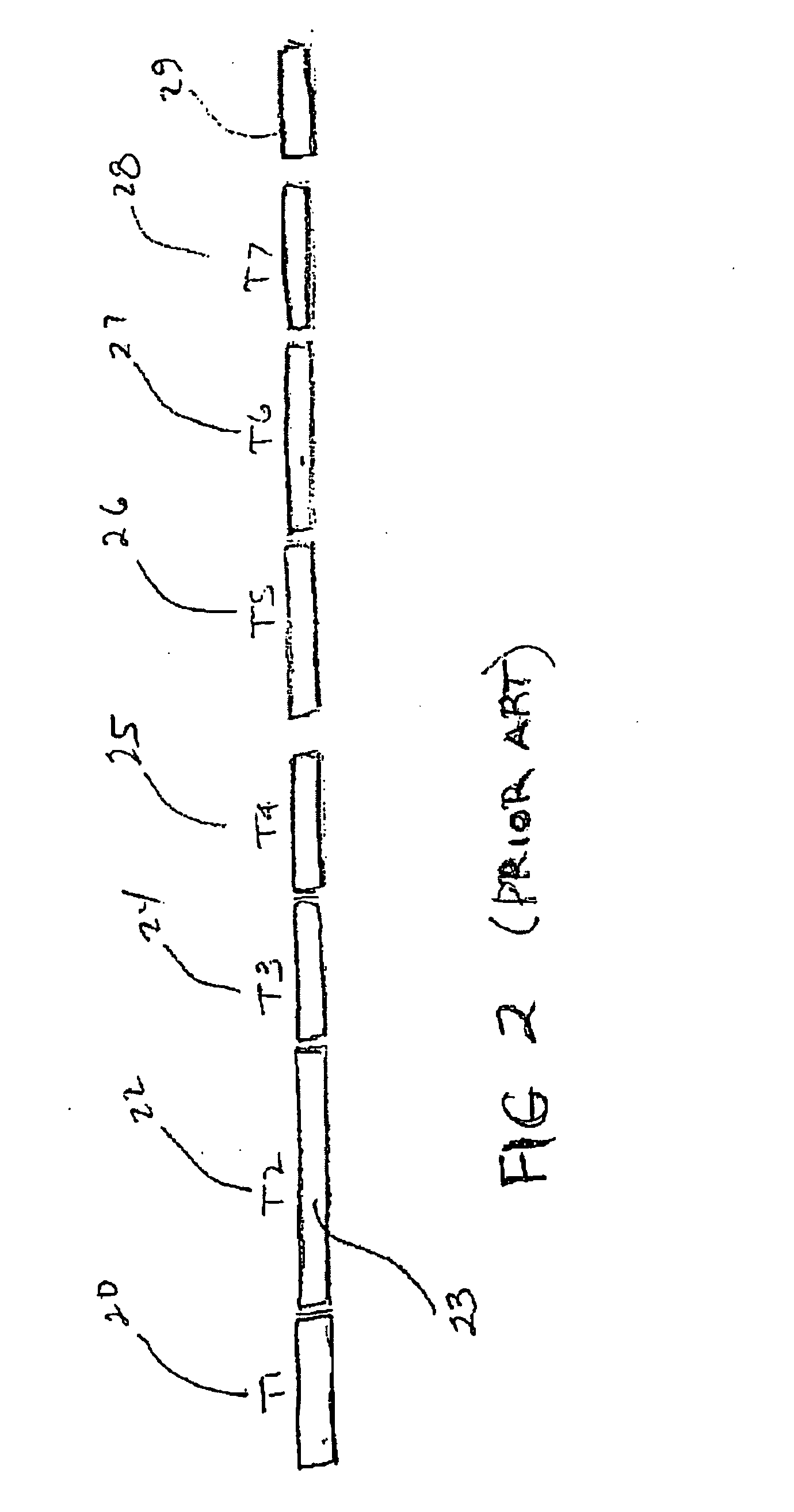

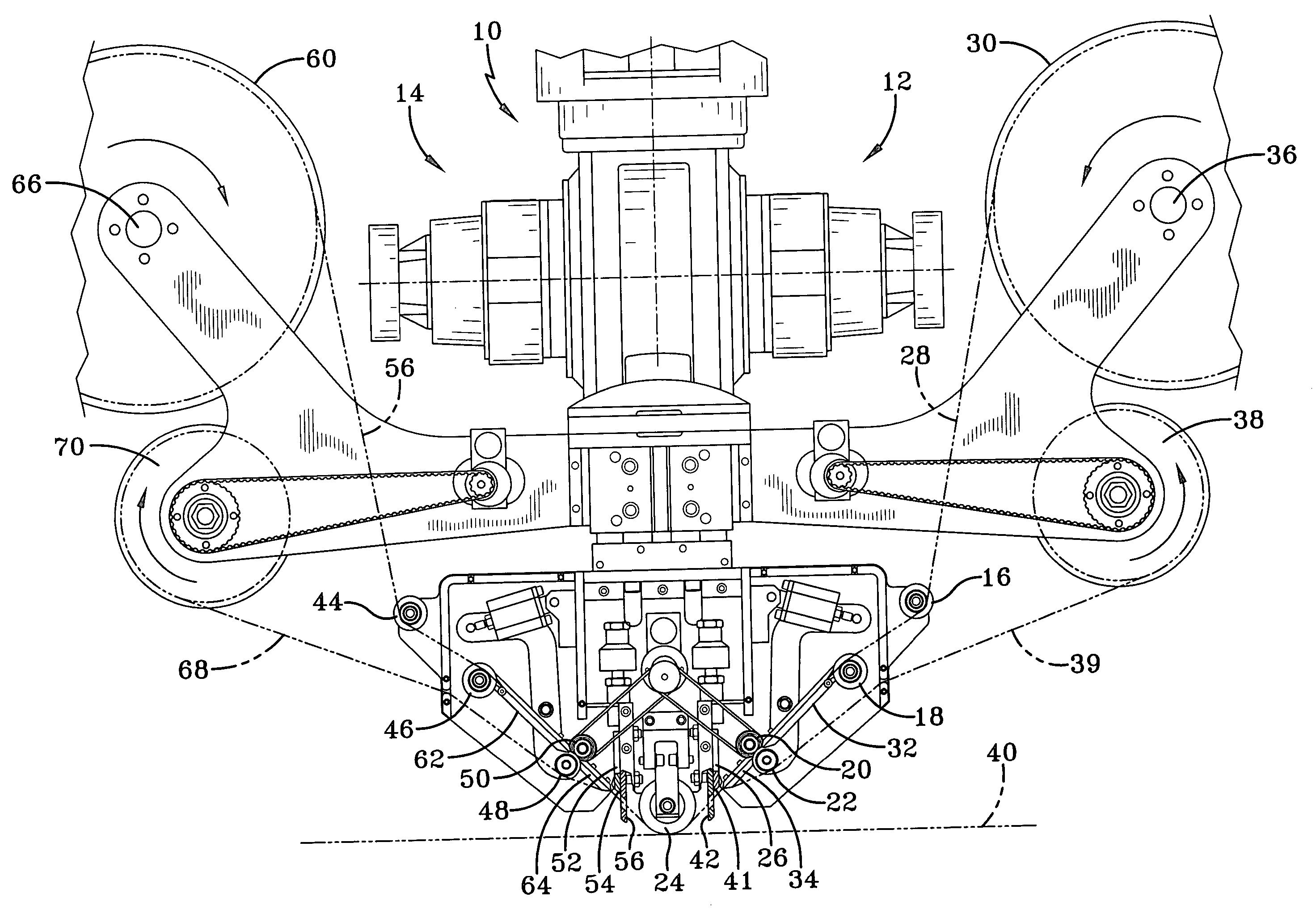

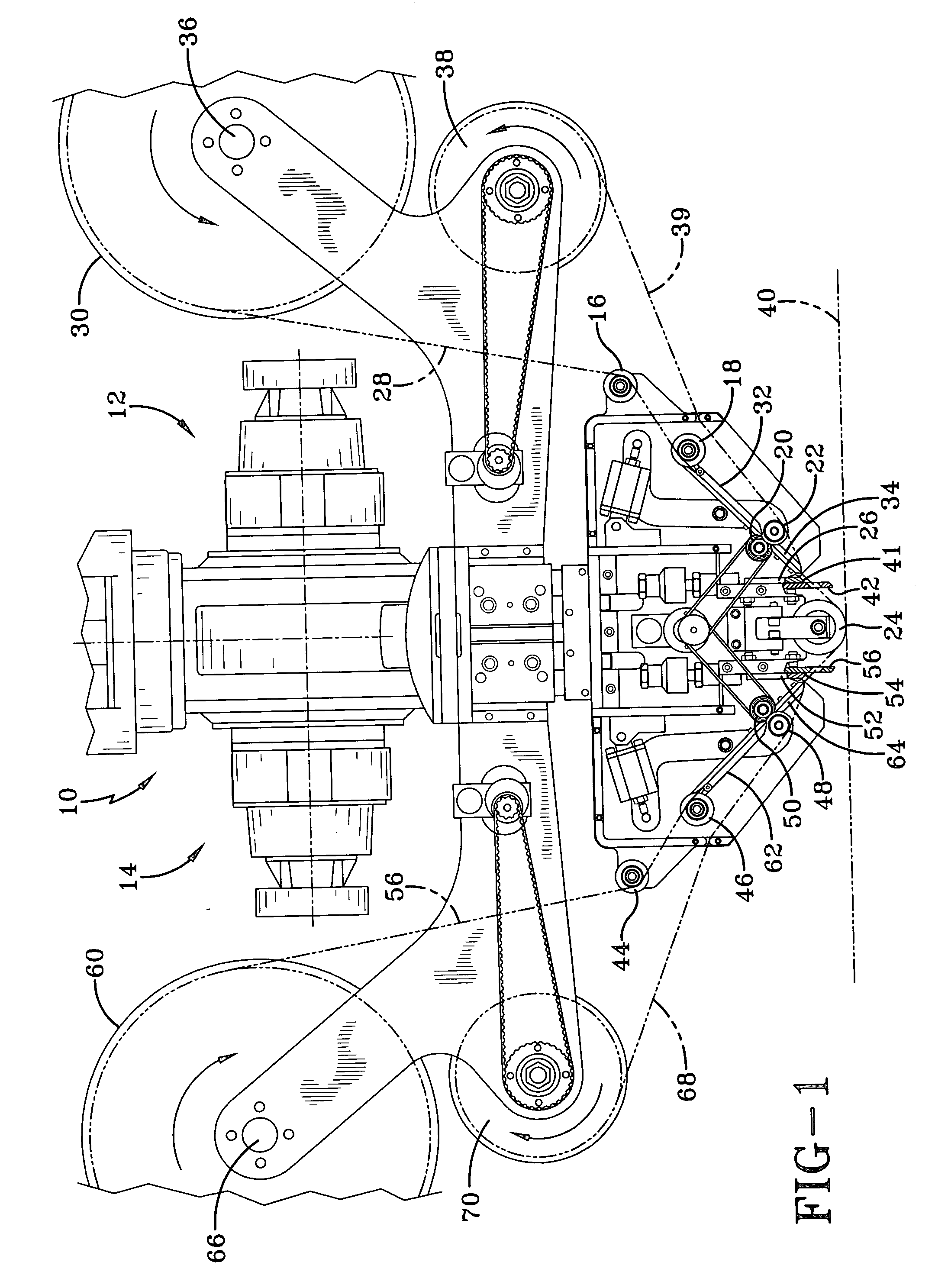

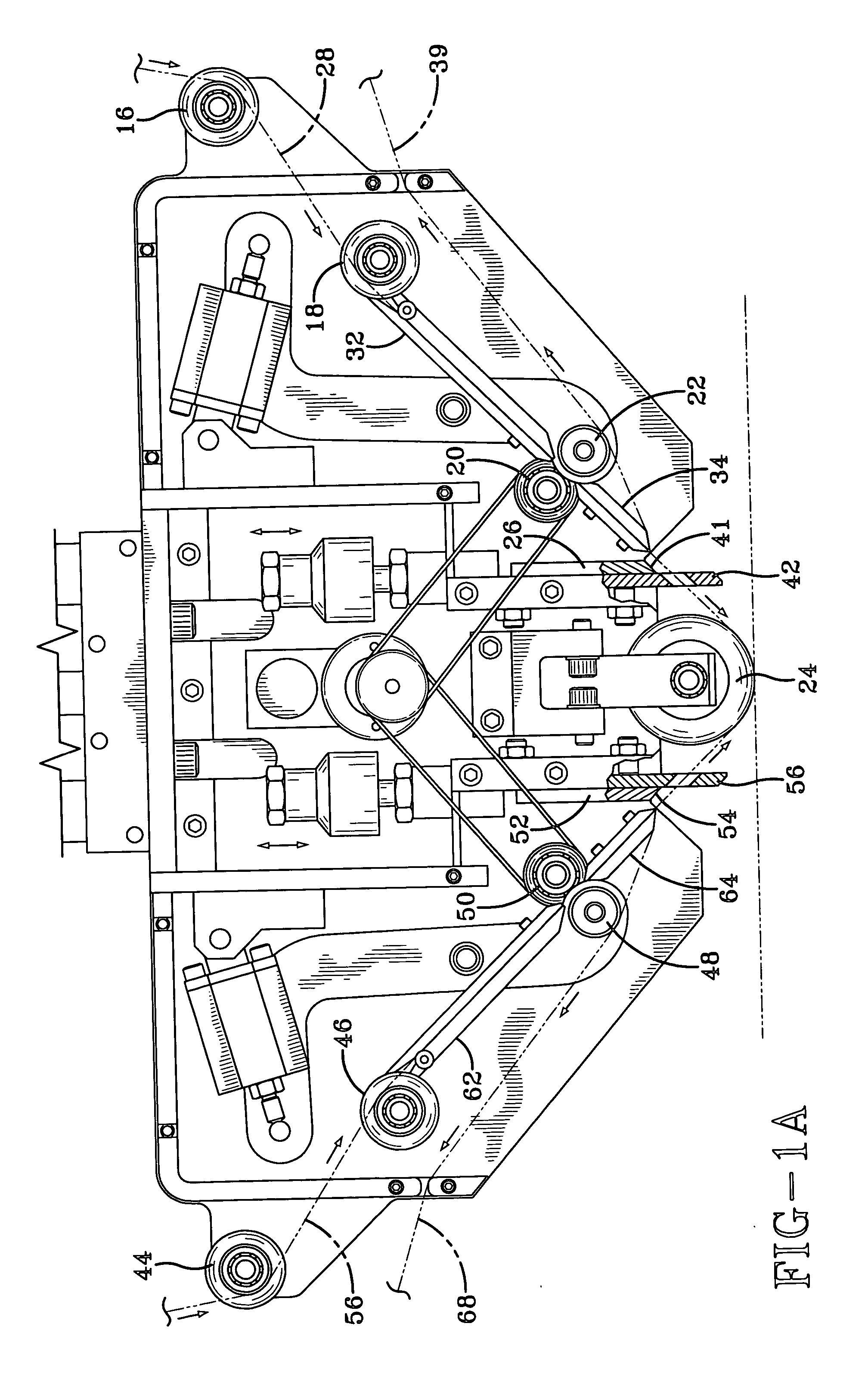

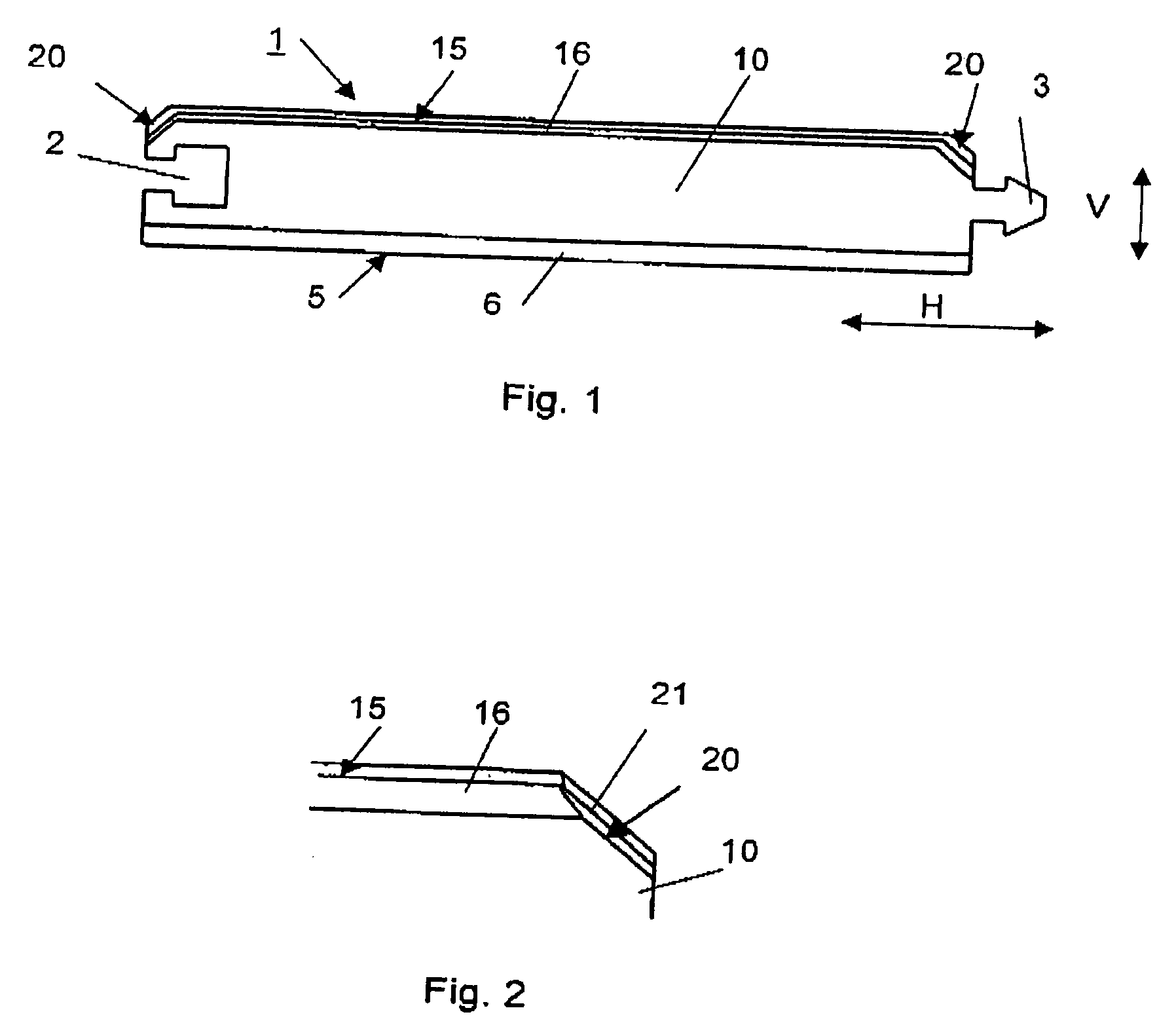

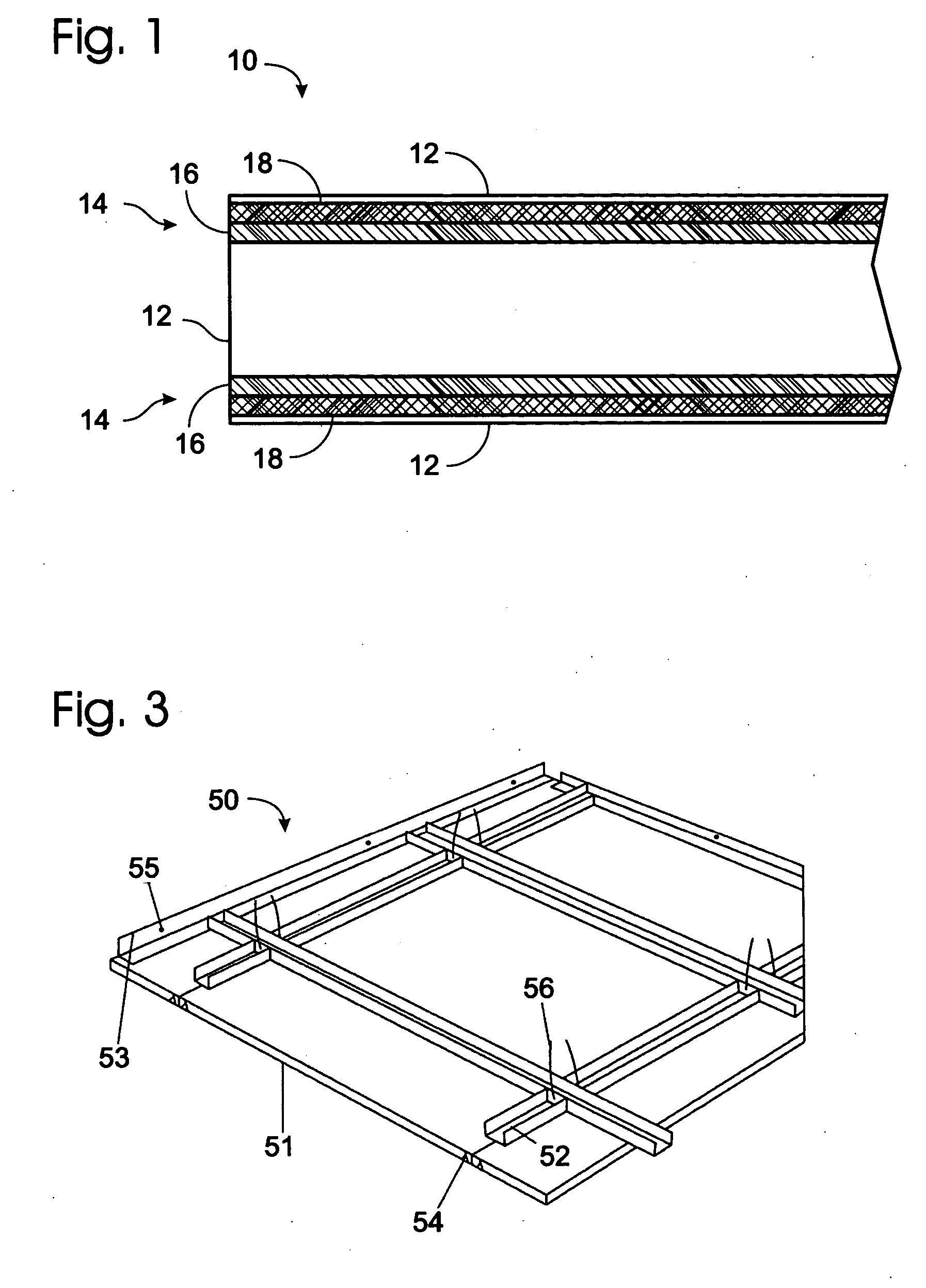

Multiple tape laying apparatus and method

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

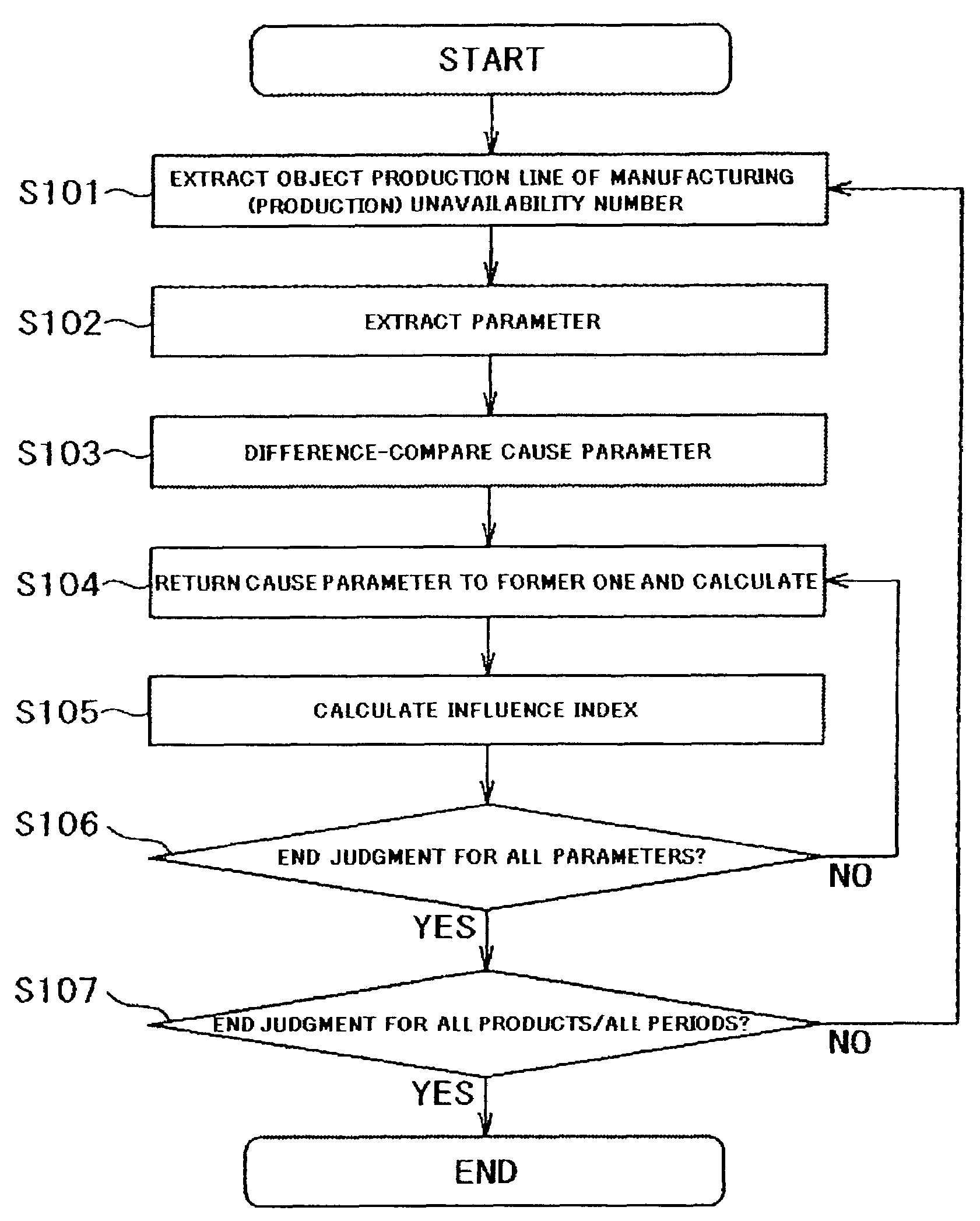

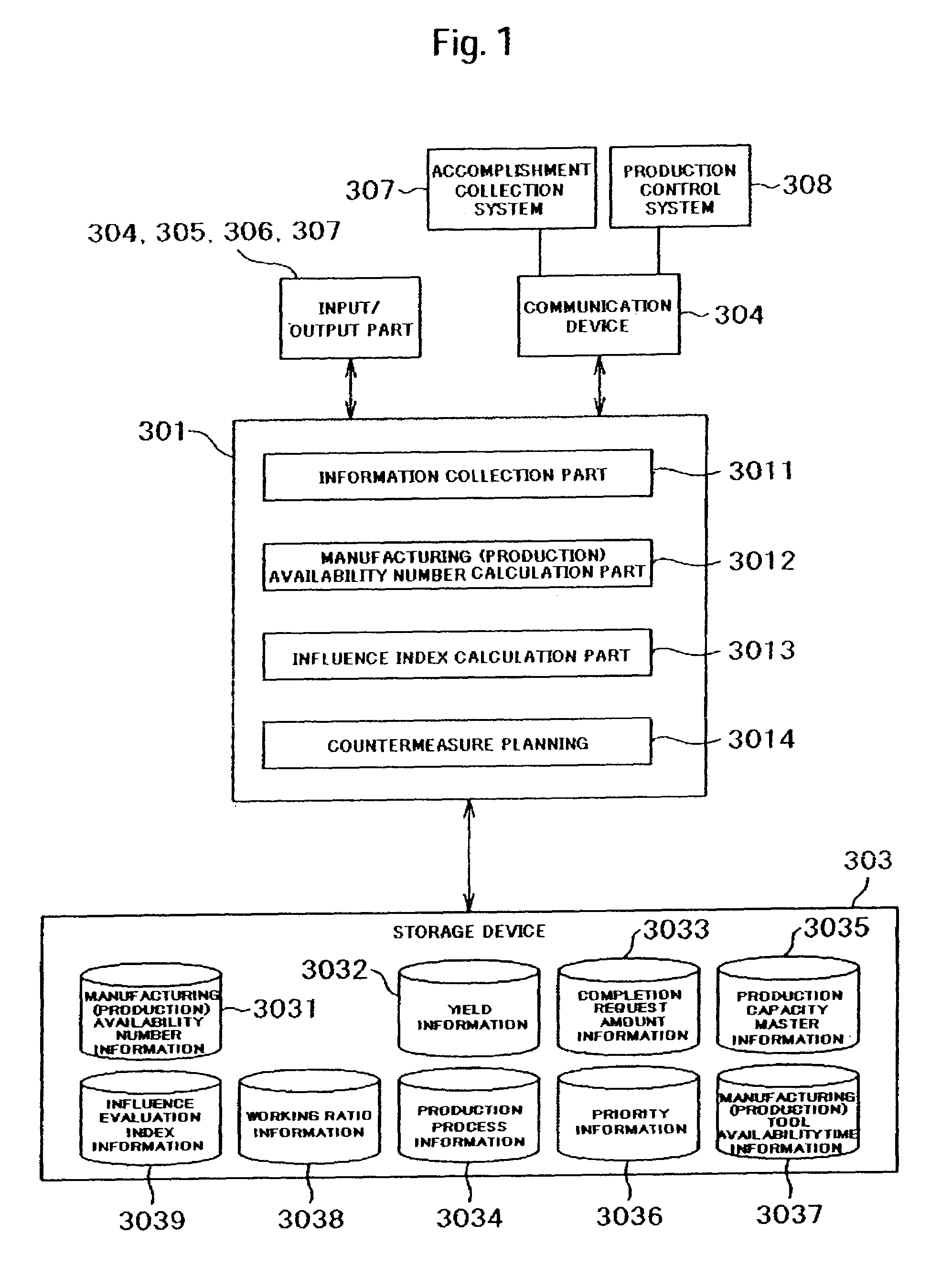

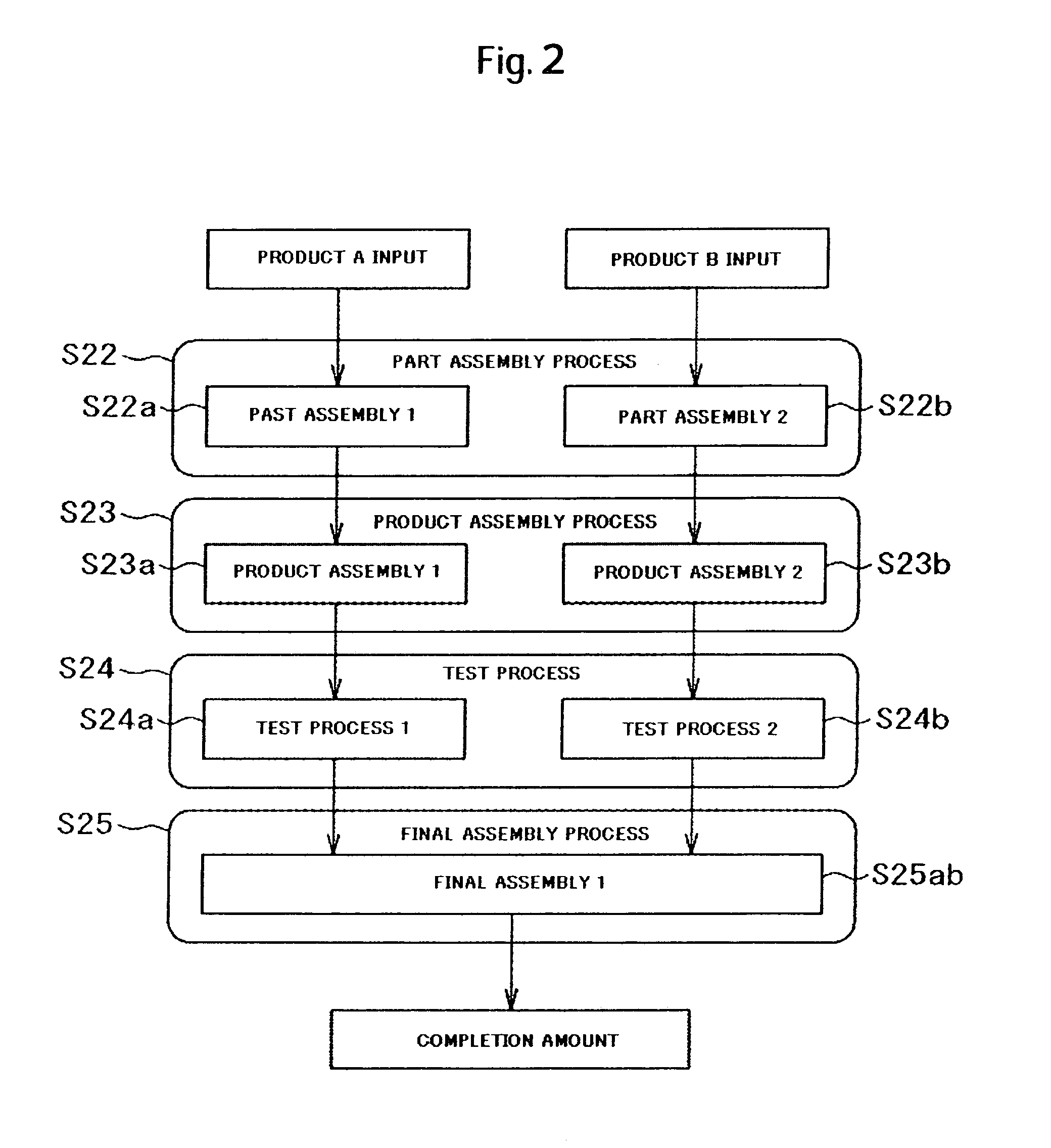

Production planning method and production planning system

InactiveUS7693593B2Change in yield of the production line is vigorousComplicated processingForecastingResourcesProduction lineUnavailability

Embodiments of the present invention provide a production planning method and system. Where a manufacturing apparatus is shared by a plurality of products in a production line, if a manufacturing (production) availability number is changed, a cause parameter is automatically investigated so that a production plan with high precision can be prepared in a short time. With respect to a production plan as the previous / current comparison objects, a production process used in the production plan in which a change occurs, is extracted. From the production process, a parameter item to be used in the production capacity evaluation is extracted for all products, a difference comparison is made between the value of the previous parameter and the value of the current parameter, so that the parameter item as the cause is specified. The combination of the cause parameter items is calculated, and a cause parameter list is prepared. Next, from the specified parameter list, the parameter item is sequentially changed, and the manufacturing (production) availability number is recalculated. An influence index given to the manufacturing (production) unavailability number by the cause parameter, is calculated.

Owner:WESTERN DIGITAL TECH INC

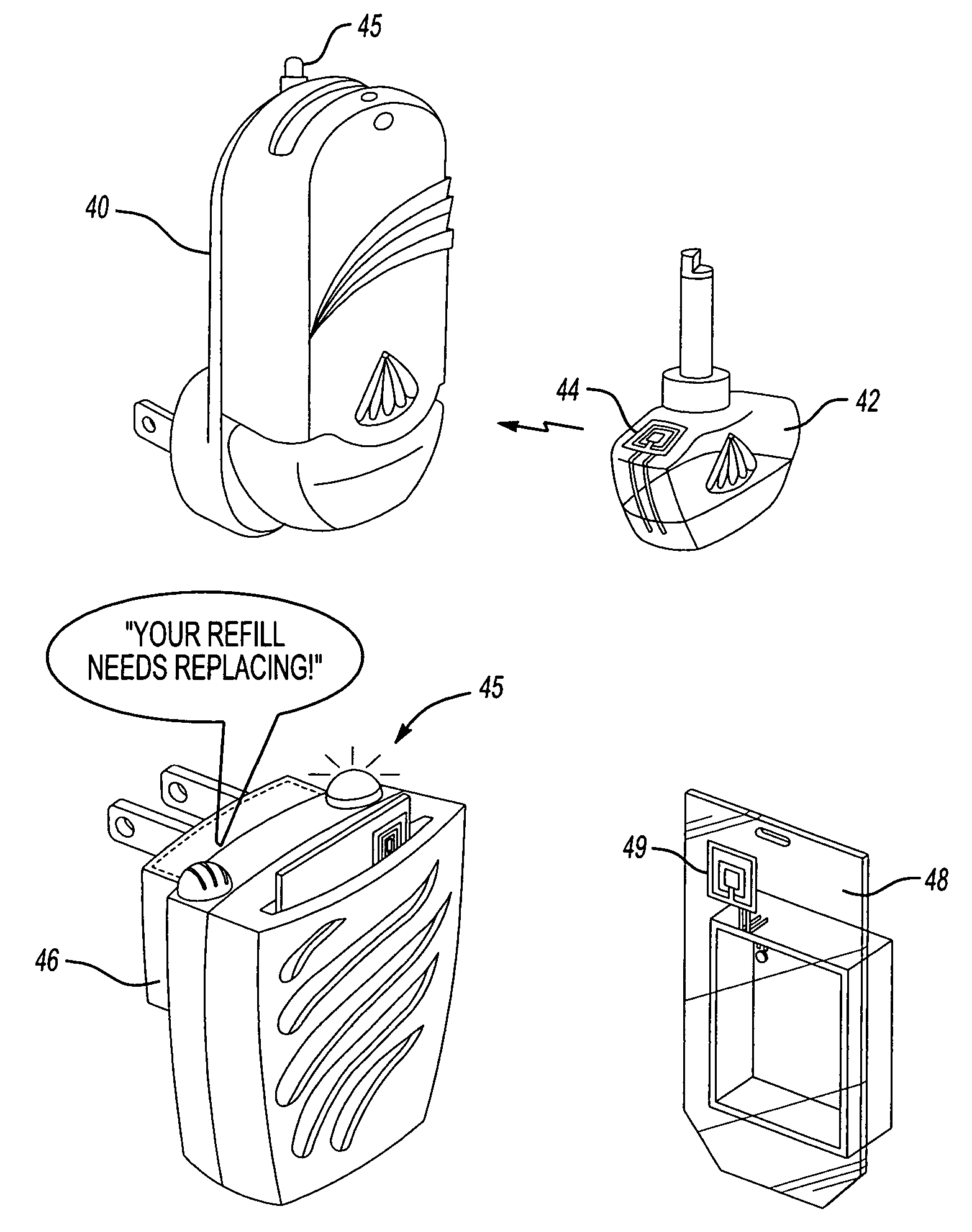

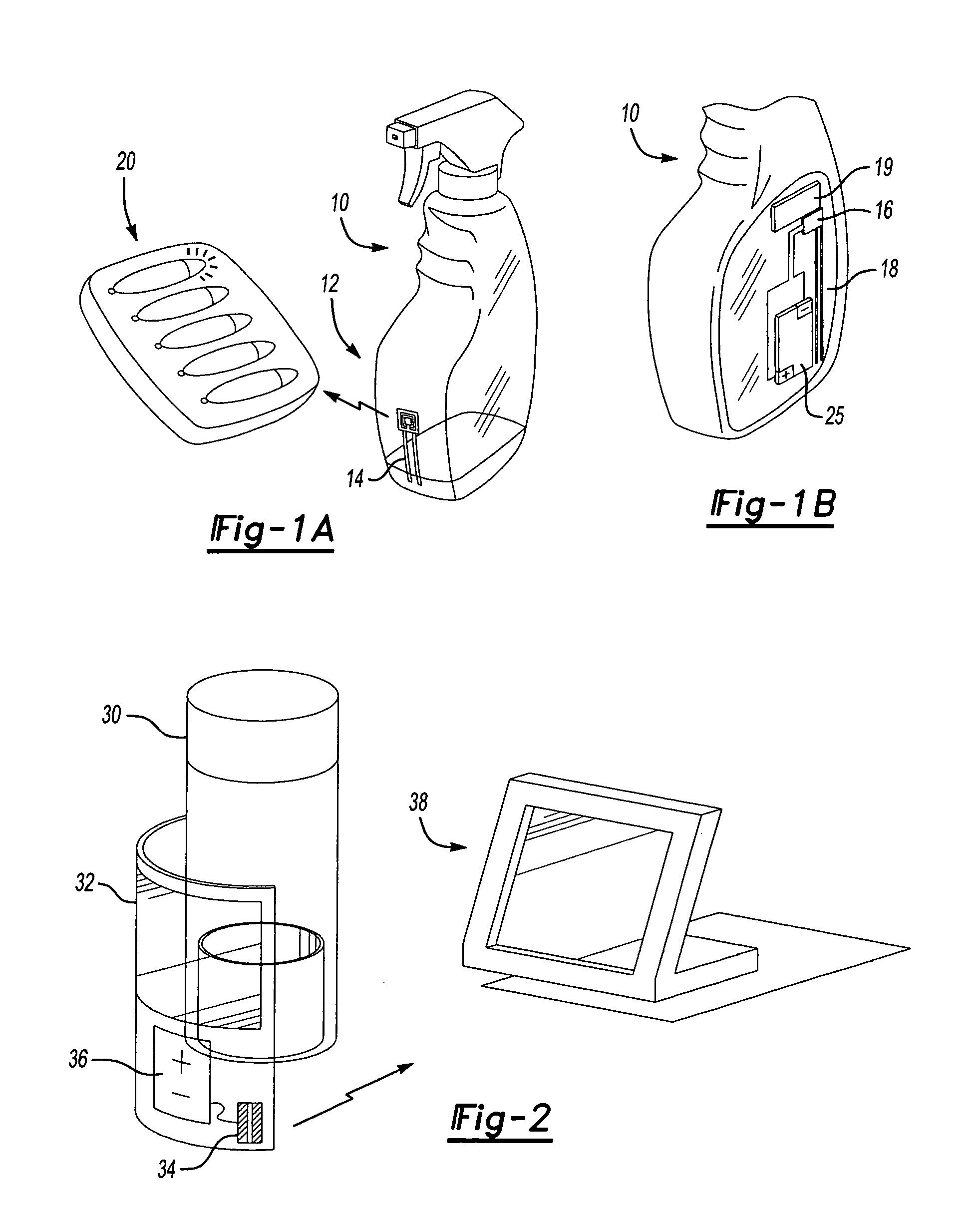

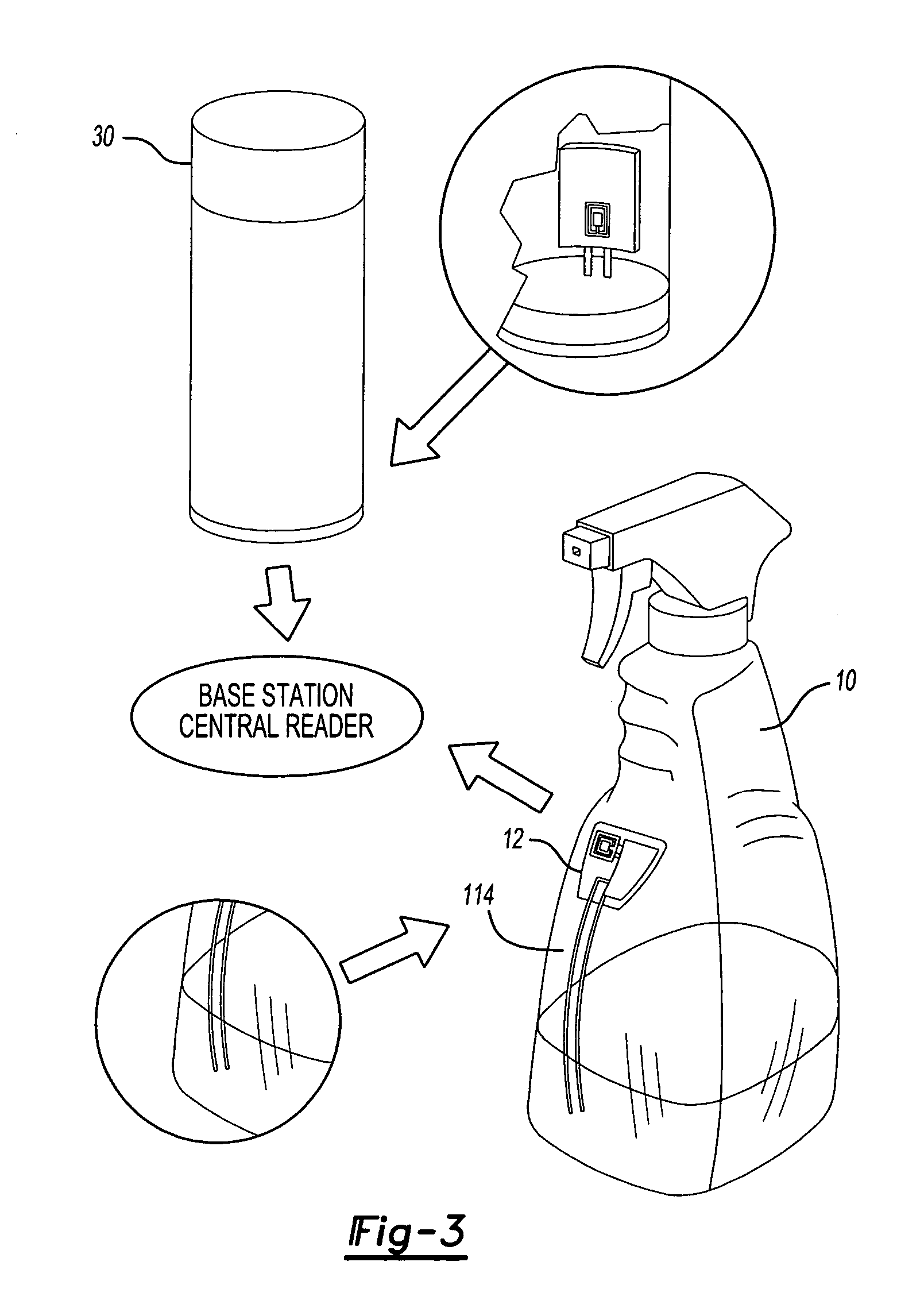

Product dispensing controlled by RFID tags

ActiveUS7009519B2Provide informationContainer decorationsLevel indicationsTimerManufacturing engineering

RFID tags attached to a product contain information regarding the product and communicate this information to a reader. This information can include the age of the product, the amount of product left and preparation or care instructions for the product. To record the age of a product, a timer is initiated in the RFID tag. Thereafter, the elapsed time on the timer can be read and displayed by the reader. For other products, the RFID tag can have contacts monitoring the level of remaining product. Once the contacts sense that the amount of product is low, this information can be transmitted and communicated by the reader. Preparation and care instructions are prerecorded on the tag. Instructions can also be communicated between a product and a base, such as a heater.

Owner:SC JOHNSON & SON INC

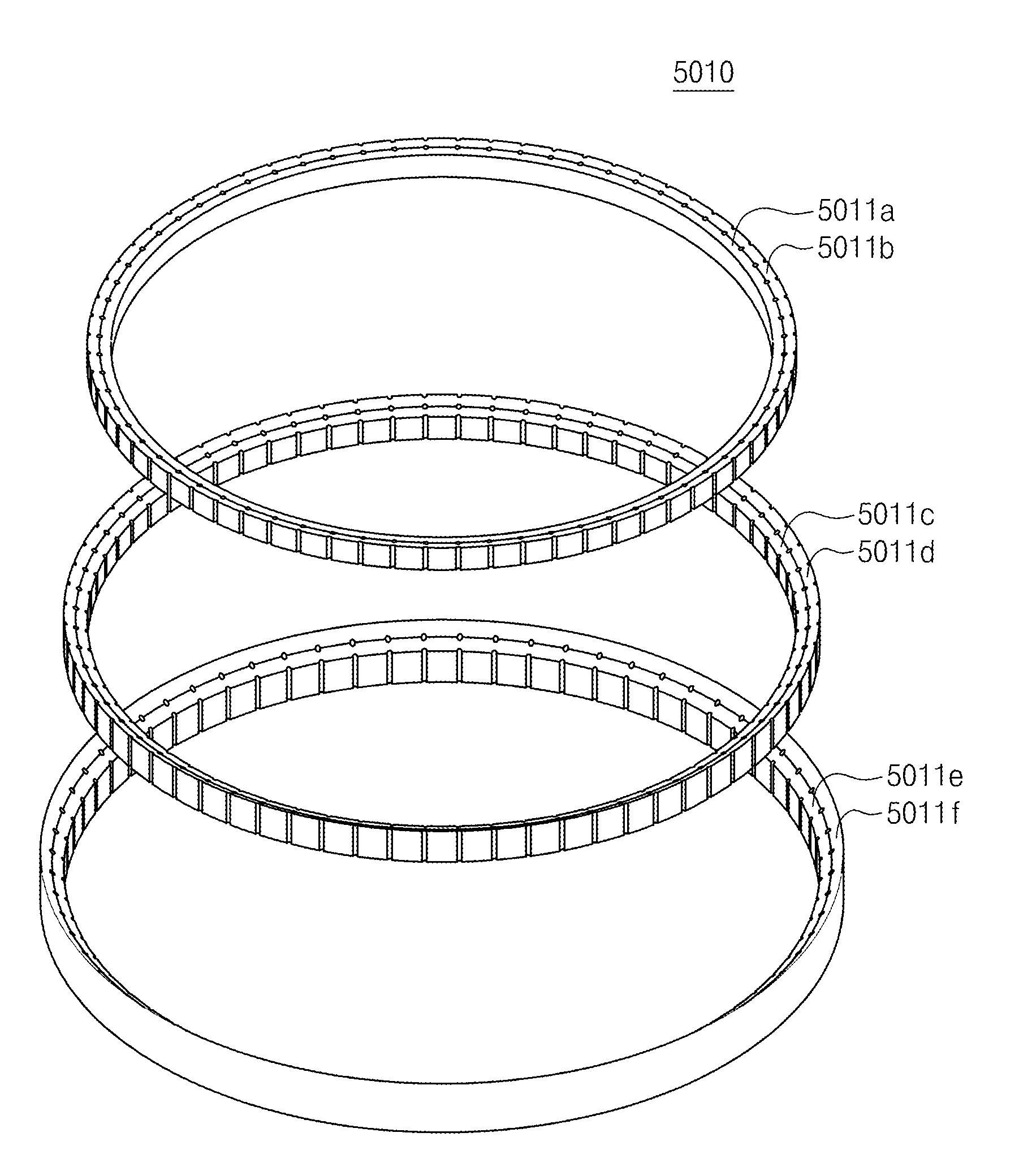

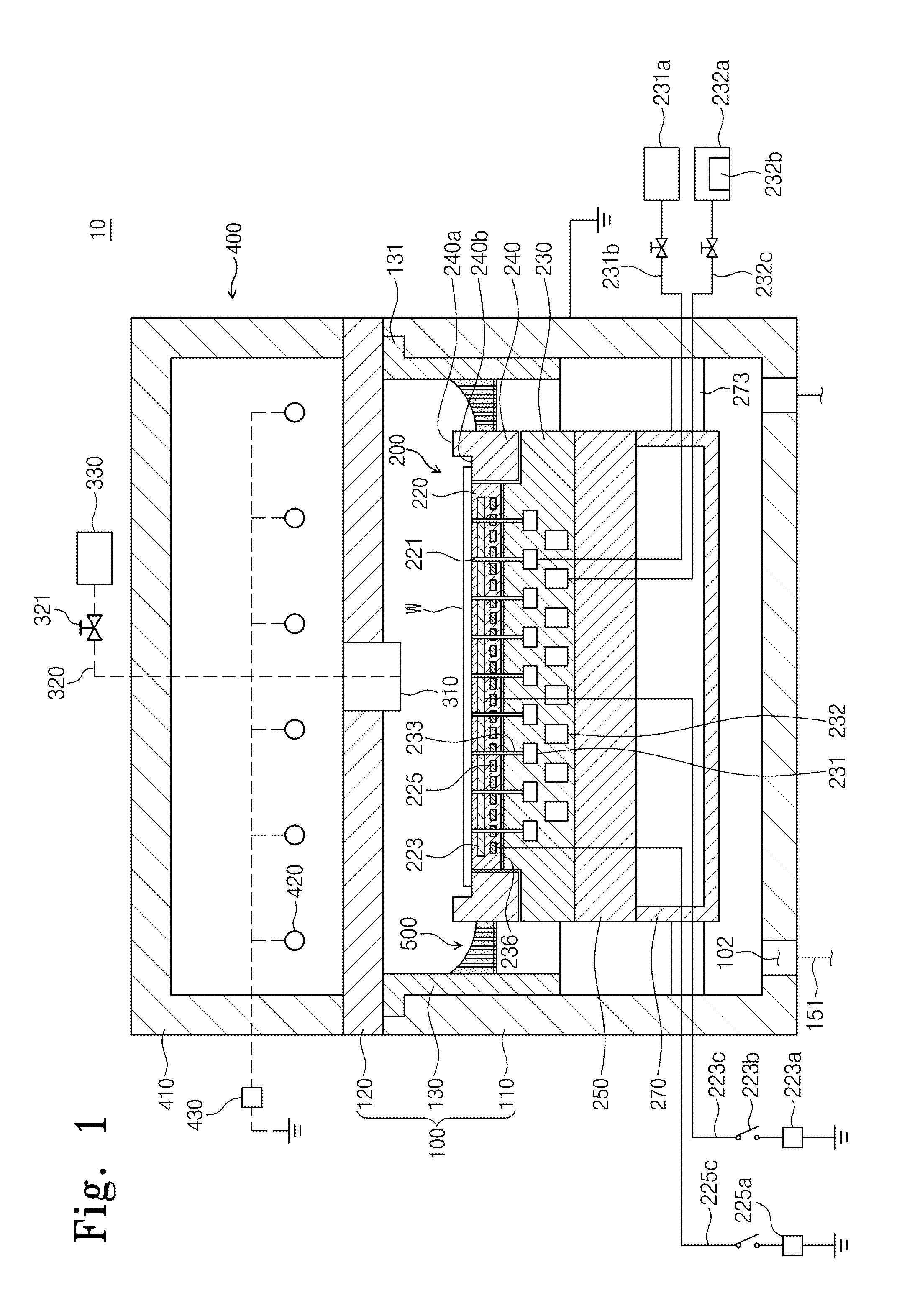

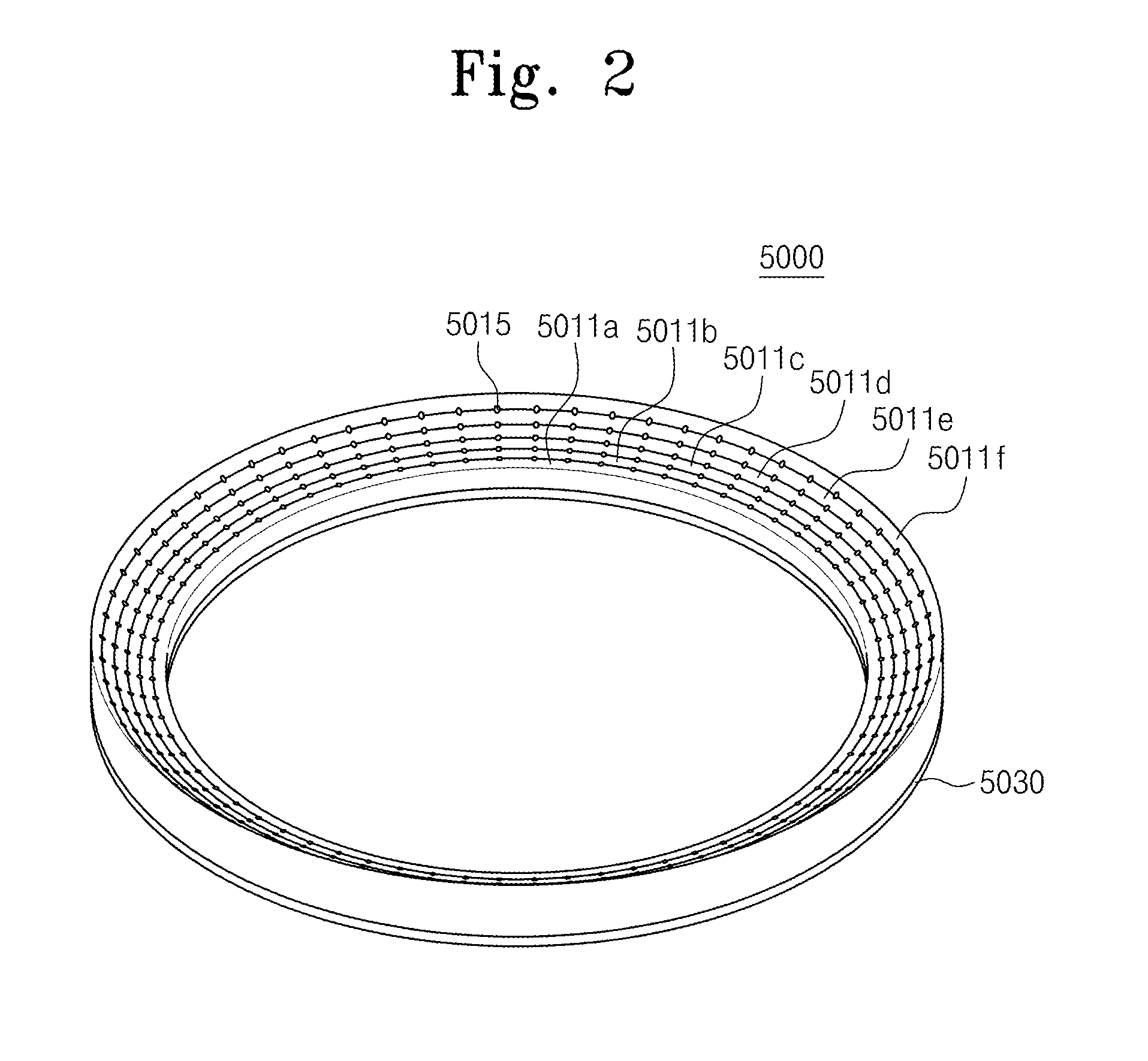

Apparatus for treating substrate

ActiveUS20140034240A1Prevent archingElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceMetallic materials

Provided is a substrate treatment apparatus using plasma. The substrate treatment apparatus includes a housing having an inner space in which a substrate is treated, a support member disposed within the housing to support the substrate, a gas supply unit supplying a gas into the housing, a plasma source generating plasma from the gas supplied into the housing, and a baffle unit disposed to surround the support member within the housing, the baffle unit including a baffle in which through holes for exhausting the gas into the inner space of the housing are defined. The baffle is divided into a plurality of areas when viewed from an upper side, and each of portions of the plurality of areas is formed of a metallic material, and each of the other portions of the plurality of areas is formed of a nonmetallic material.

Owner:SEMES CO LTD

Filtration monitoring and control system

InactiveUS6077435AUseful controlAccurate CalibrationDispersed particle filtrationUltrafiltrationFouling indexFiltration

PCT No. PCT / AU96 / 00144 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 28236 PCT Pub. Date Sep. 19, 1996A method and apparatus for determining the fouling effect of a feedstream on a filter having known characteristics disclosed. The method comprises passing the feedstream through a filter (5) having known characteristics; determining the change in resistance to flow of the feedstream across the filter, either continuously or over a number of time intervals and from this data, calculating a feed fouling index (FFI) representative of the fouling characteristics of the feedstream with respect to the filter. A method and apparatus for monitoring the operation of a filtration system is also disclosed the method comprising sampling system parameter values at selected locations within the filtration system at a predetermined sampling rate; generating a parameter profile characteristic from the sampled parameter values at predetermined intervals of time; and analysing the parameter profile characteristic to determine correct operation of the filtration system. A further method and apparatus of monitoring and controlling a filtering system based on backwash efficiency is also disclosed, the method comprising determining resistance values of filtering elements used in the filtering system at predetermined times during the backwash cycle of the system by monitoring a number of operating parameters of the system; calculating a backwash efficiency value representative of the efficiency of the backwash cycle of the filtering system using the resistance values determined; and controlling the operation of the filtering system in dependence on the value of the backwash efficiency calculated.

Owner:EVOQUA WATER TECH LLC

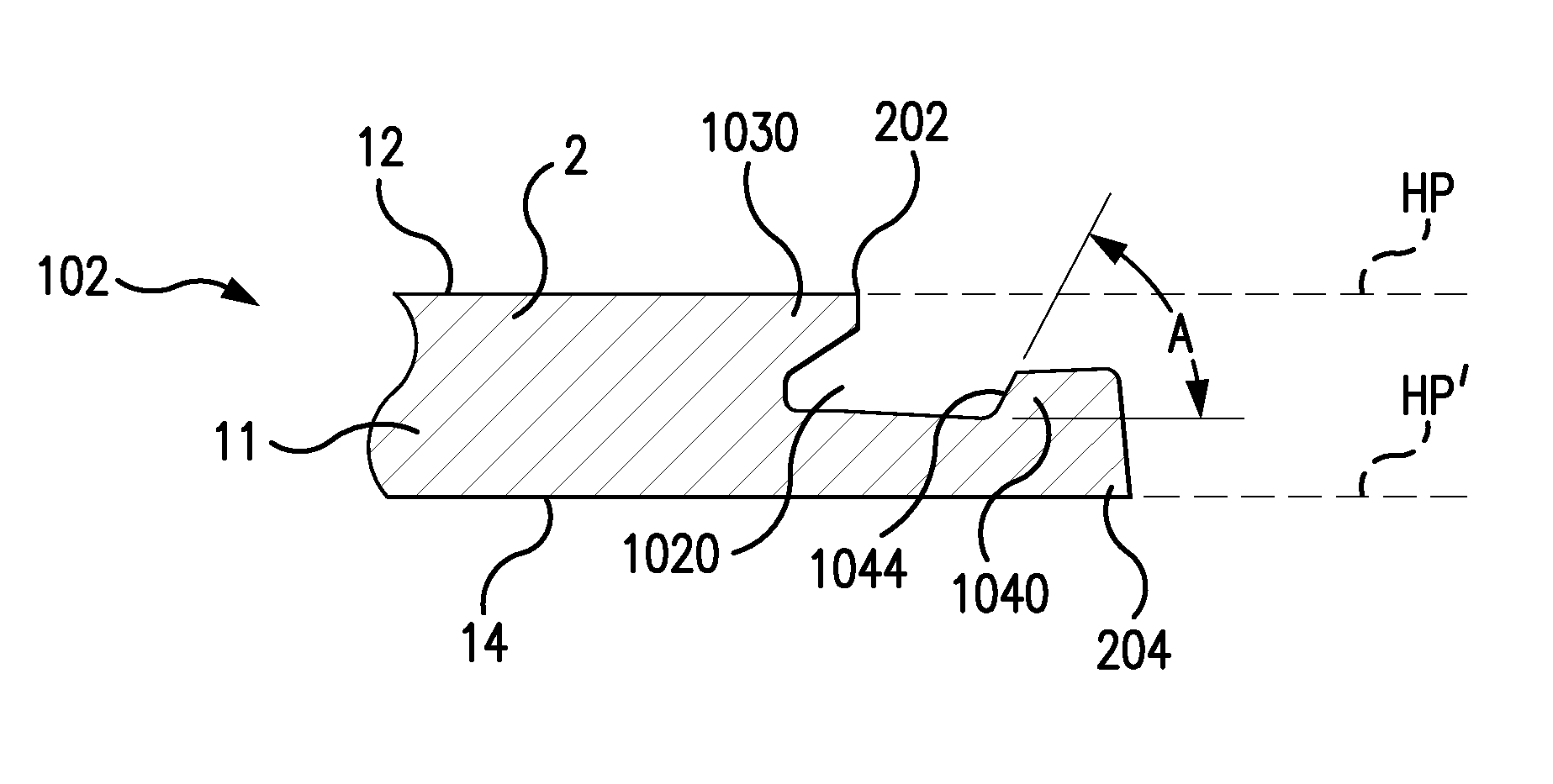

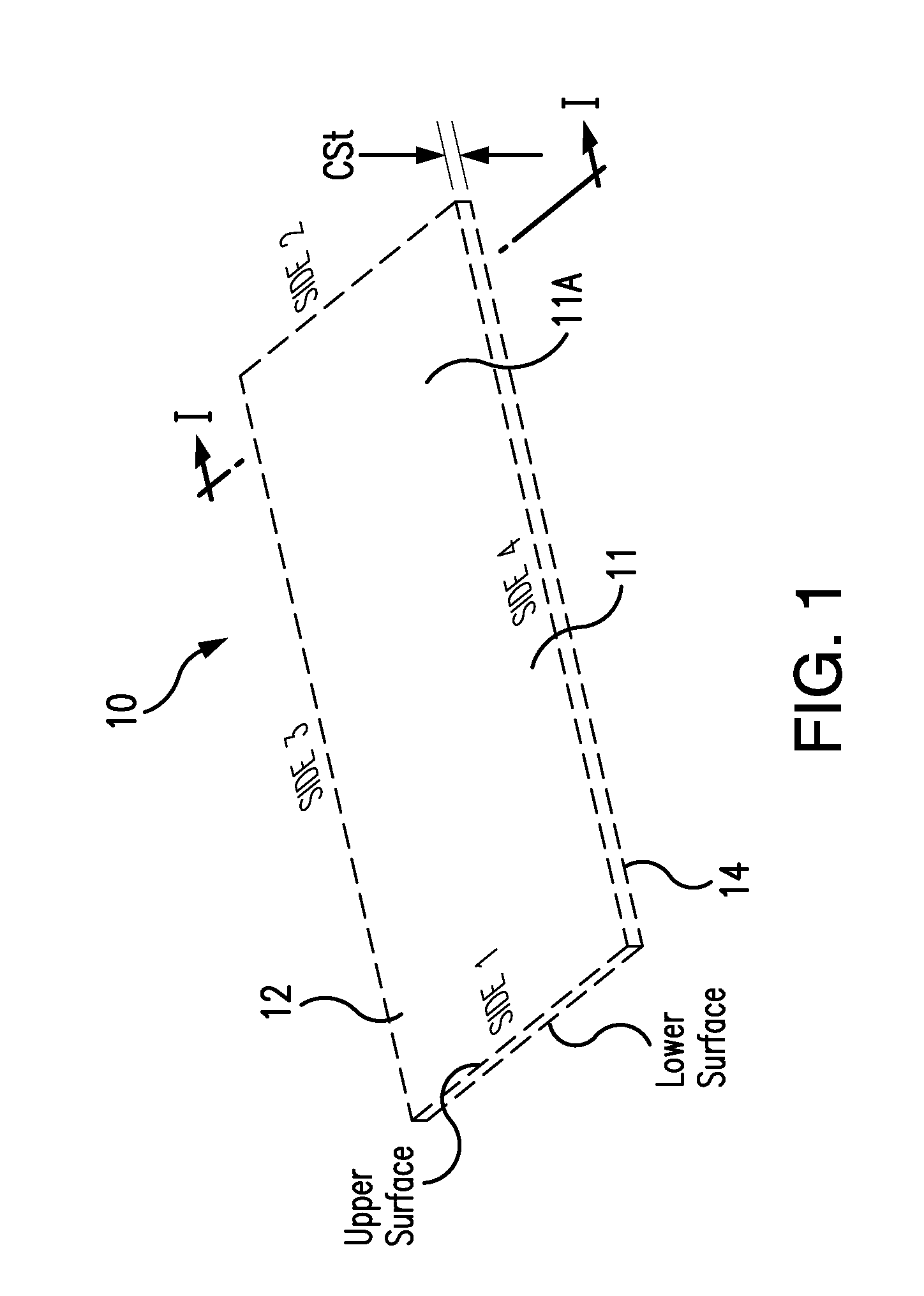

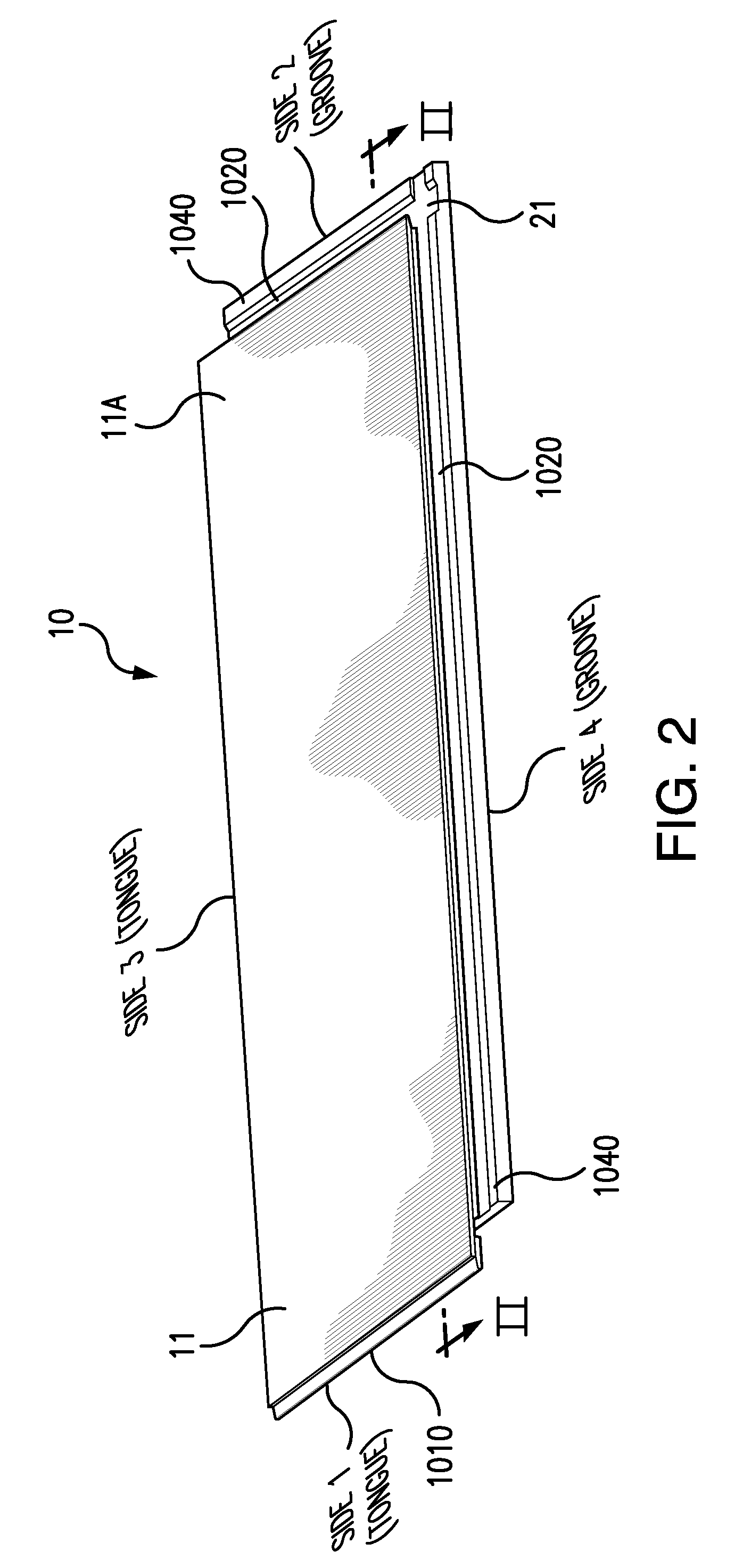

Floor Covering With Interlocking Design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

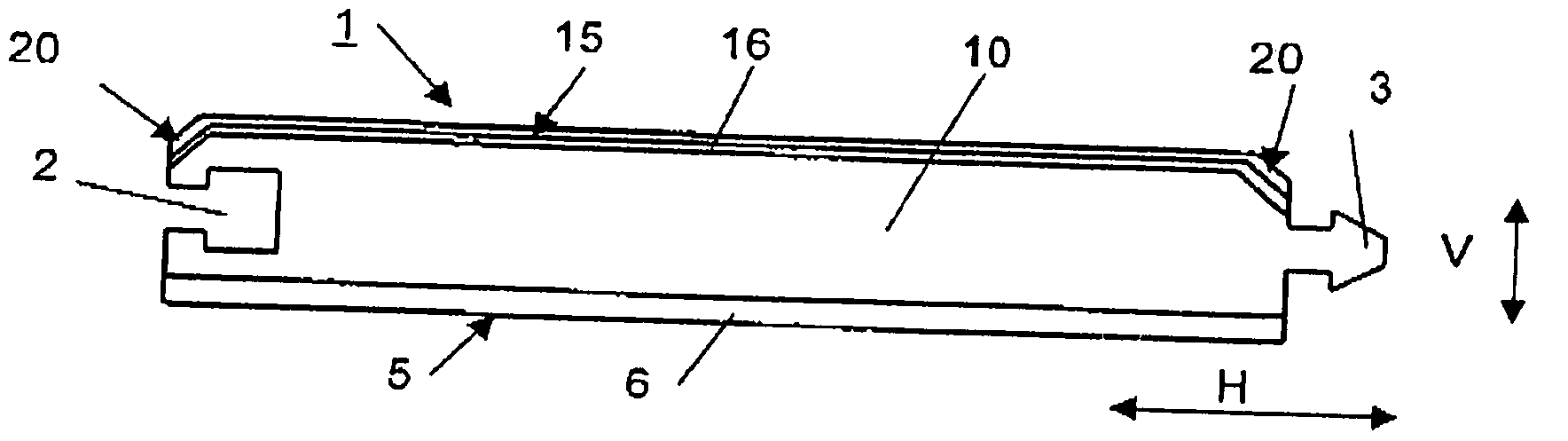

Flooring panel

A panel, in particular a flooring panel, of a wood material which is provided with a mechanism for the detachable connection of a least two panels, whereby form-fitting elements for locking in the vertical direction and in the horizontal direction with another panel are embodied on at least one lateral edge of a first panel, whereby a chamfer is embodied on at least one lateral edge starting from an upper side. The chamfer or the form-fitting elements are coated or impregnated with at least one melamine layer.

Owner:KRONOTEC

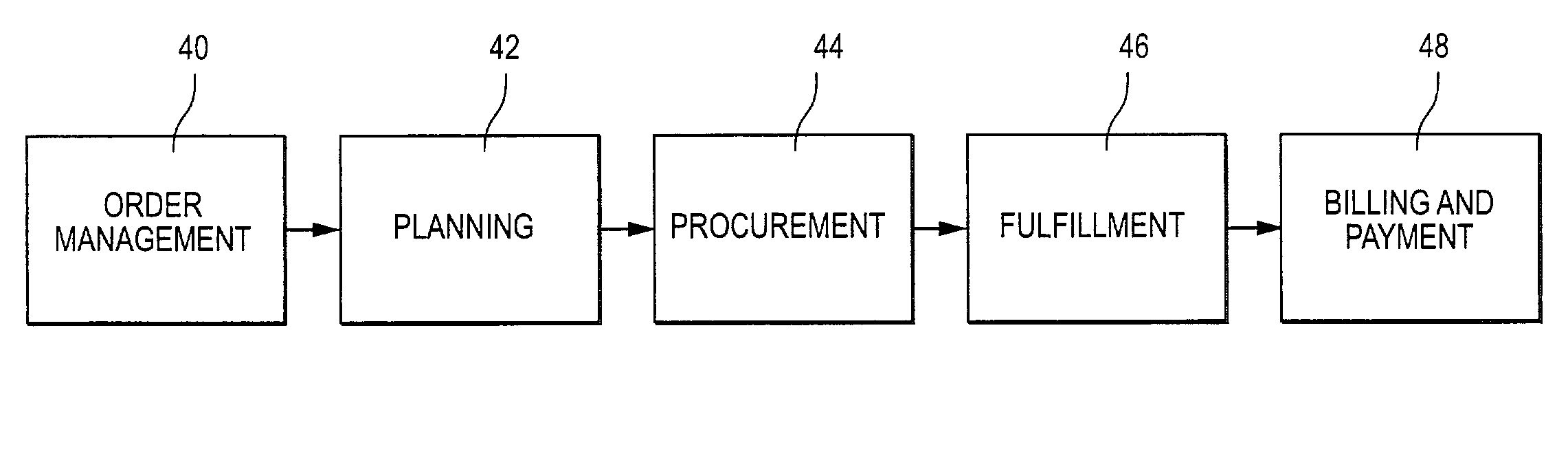

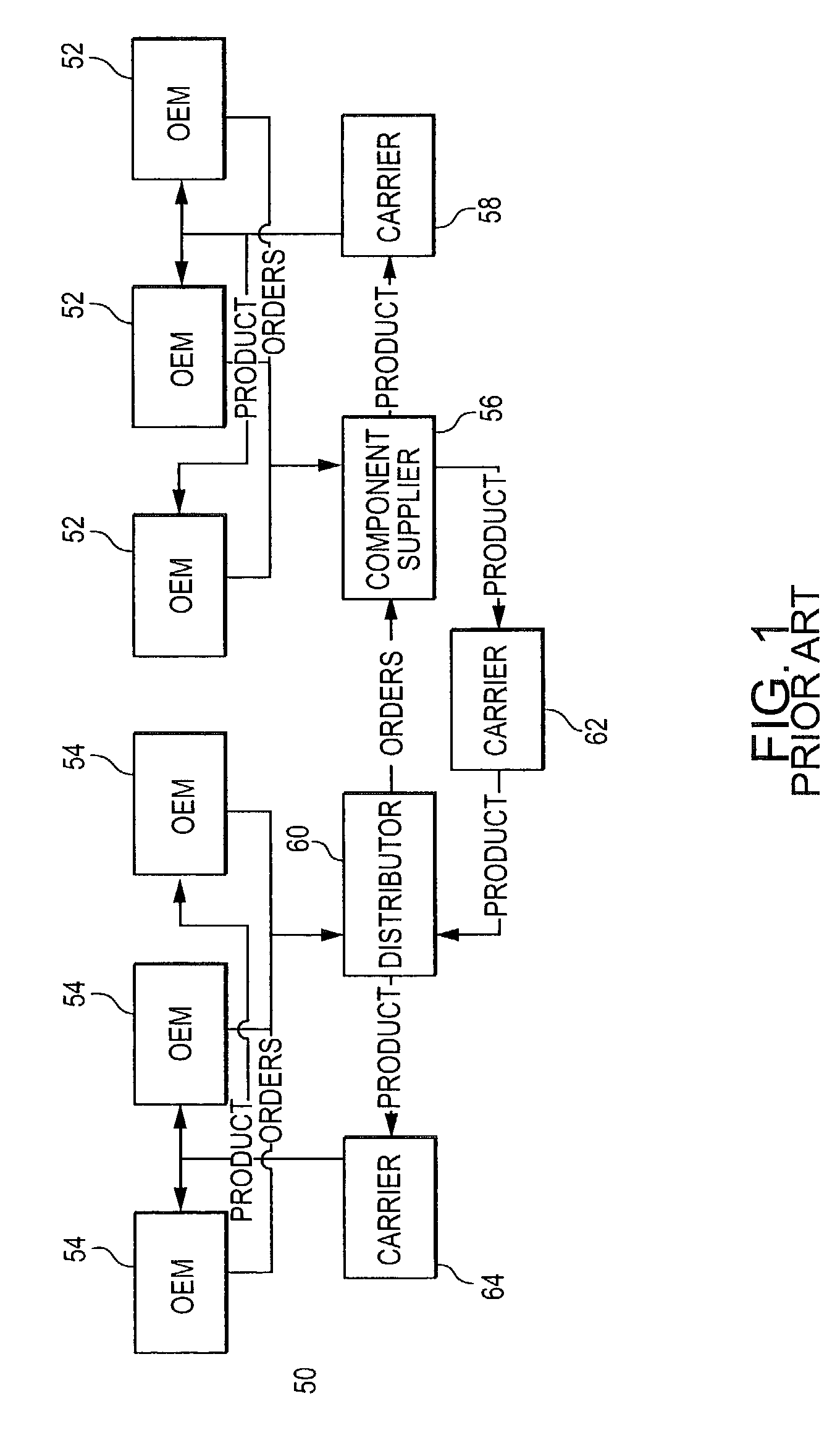

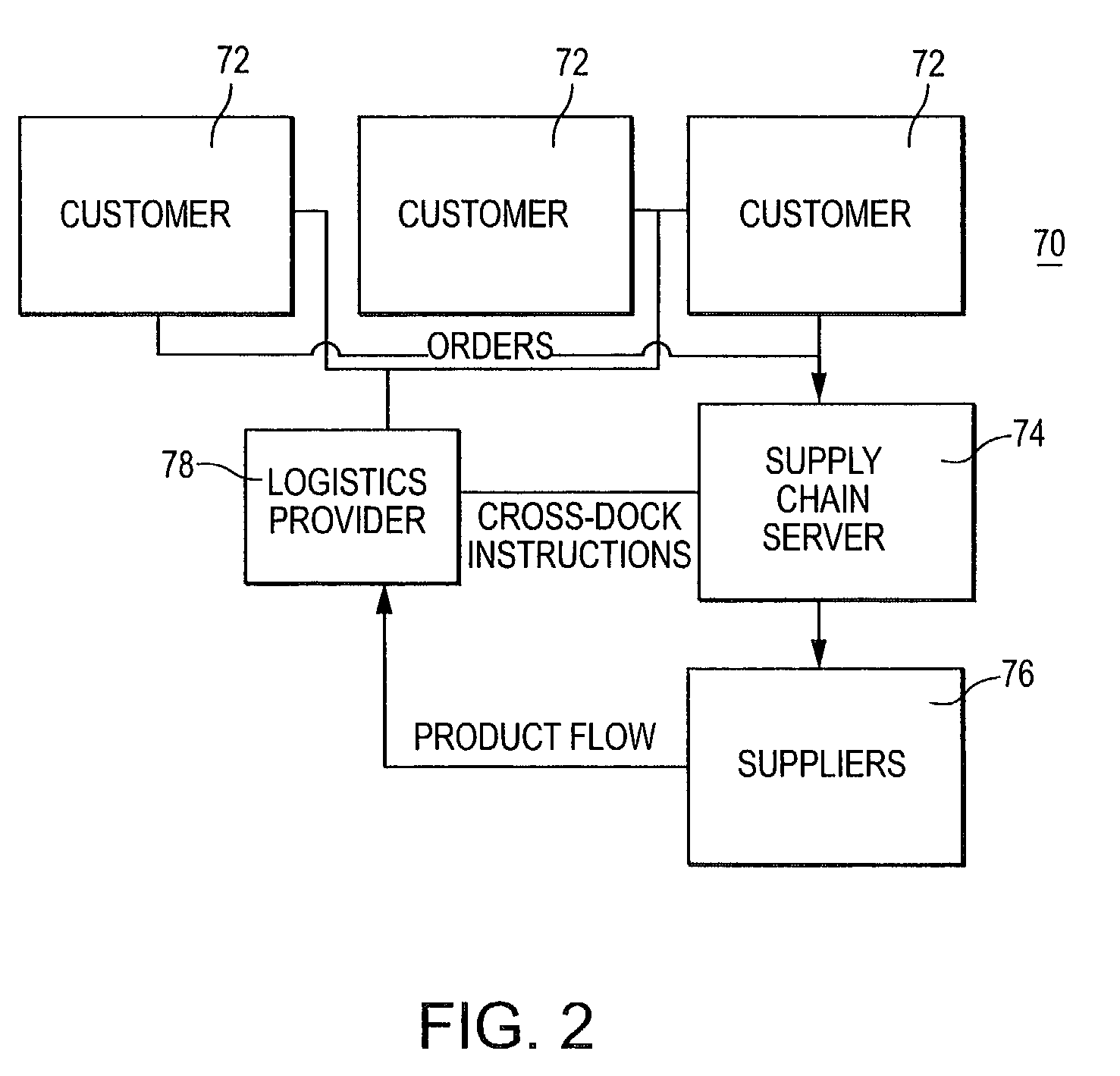

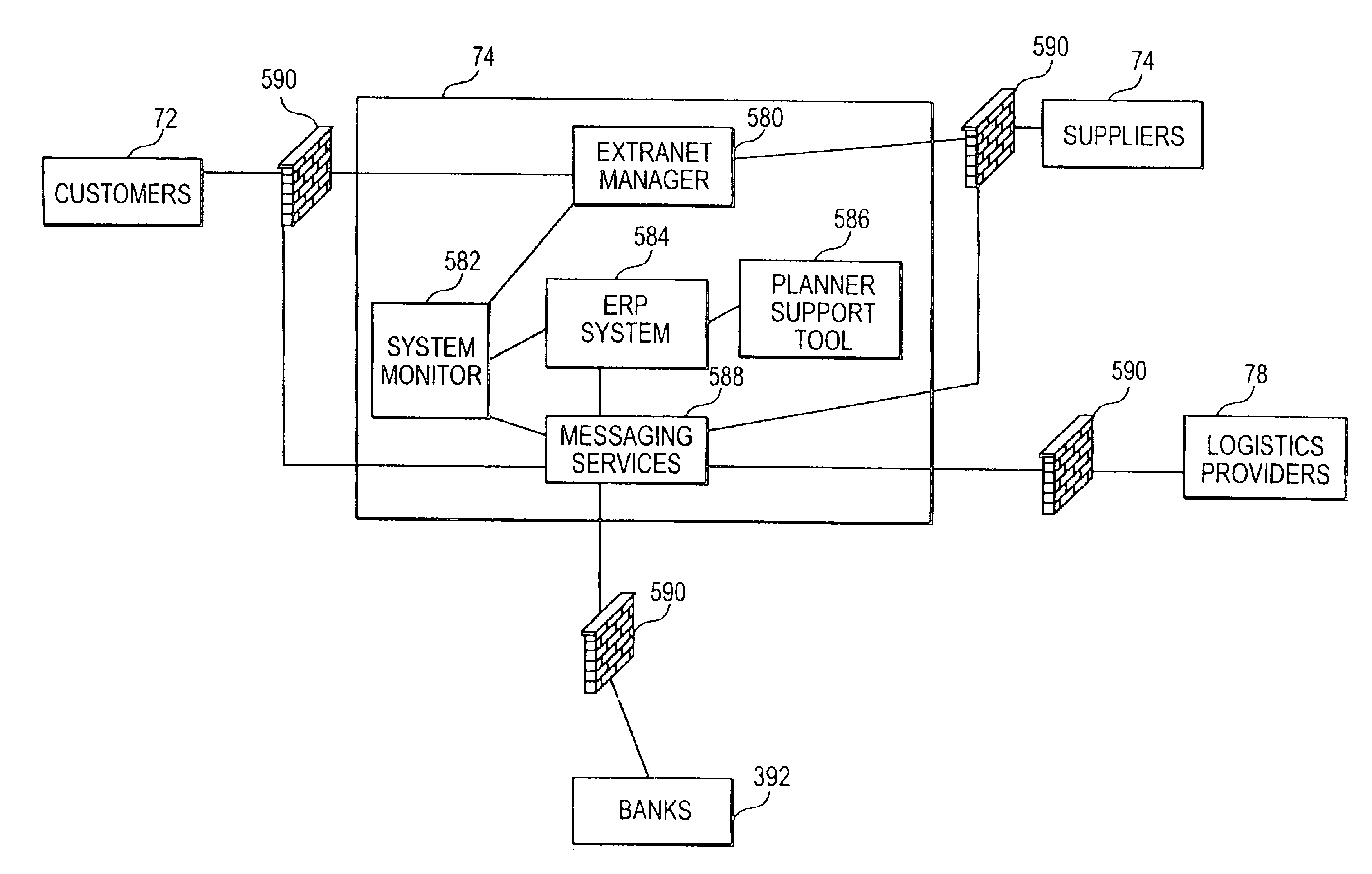

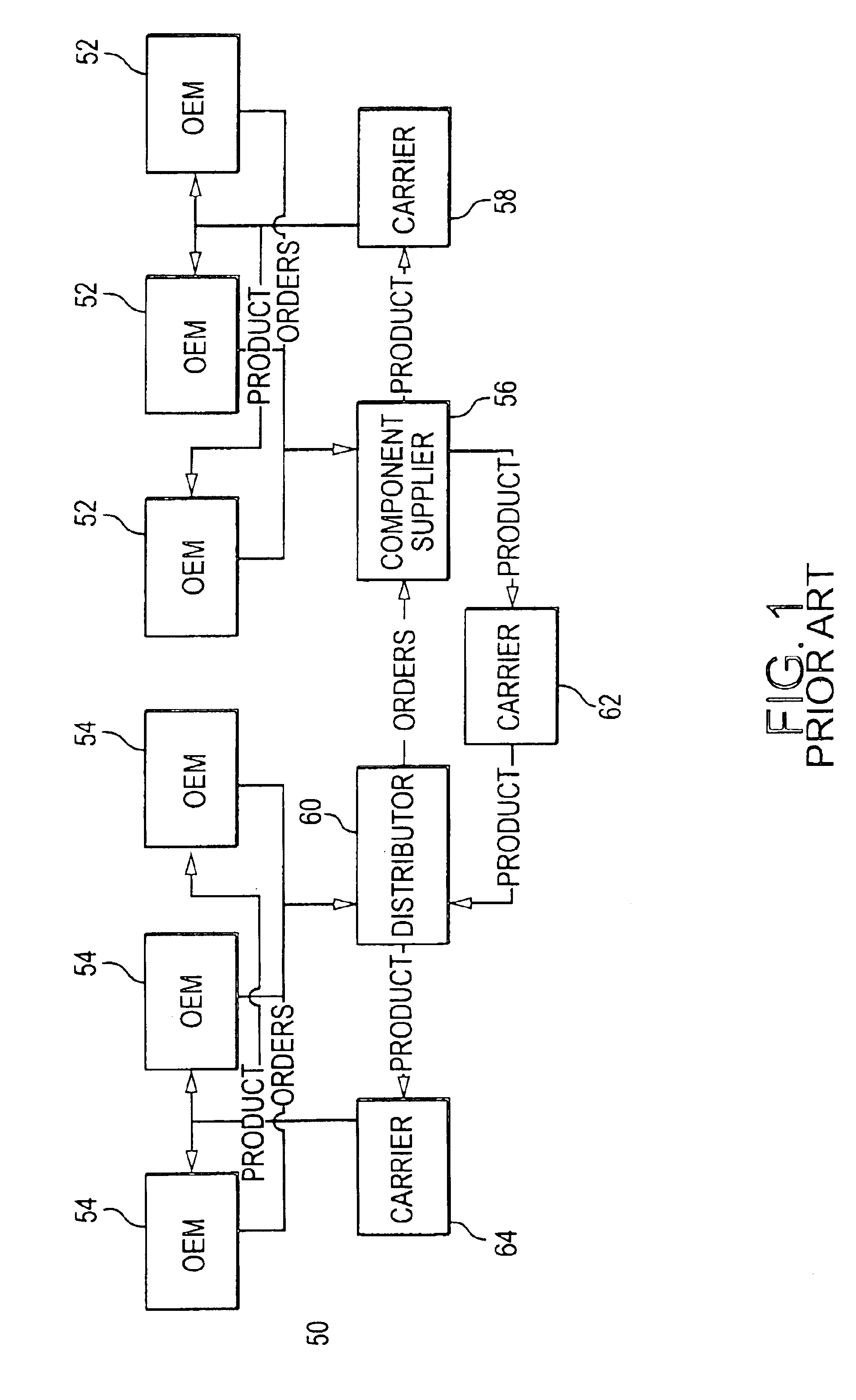

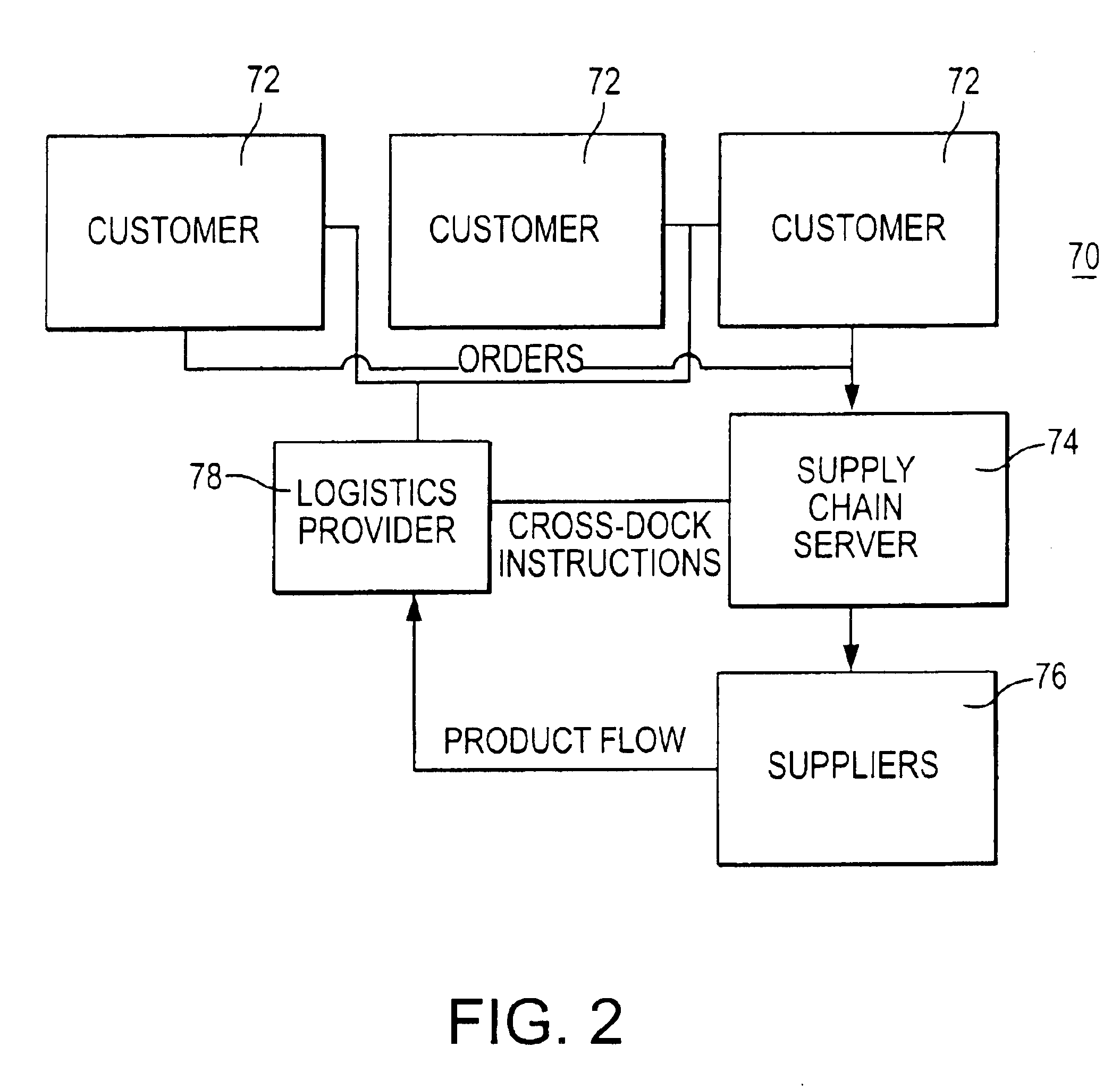

Supply chain architecture

InactiveUS7003474B2Improve the supplier's accounting booksReservationsResourcesPaymentLogistics management

A supply chain network where customers, suppliers, logistics providers, carriers, and financial institutions are all connected to a centralized supply chain server. The server receives forecasts from the customers detailing the orders that the customers desire. These forecasts are analyzed by the supply chain server to ensure that they conform to contractual agreements and do not contain errors. The forecasts are also used to warn the suppliers of future demands so that the suppliers can anticipate demands and plan inventory accordingly. Once supplier demand issues are resolved, the forecasts are sent to the suppliers in groups so that the suppliers prepare a smaller number of large orders. The supply chain server also controls the processes involved in distributing the product from the suppliers to the customers including the generation and payment of invoices. A form of financing the customers' purchases, made possible by the supply chain architecture, is also disclosed.

Owner:ISUPPLI

Supply chain architecture

InactiveUS6889197B2Improve the supplier's accounting booksReservationsResourcesPaymentLogistics management

A supply chain network where customers, suppliers, logistics providers, carriers, and financial institutions are all connected to a centralized supply chain server. The server receives forecasts for direct material procurement from the customers detailing the orders that the customers desire. These forecasts are analyzed by the supply chain server to ensure that they conform to contractual agreements and do not contain errors. The supply chain server sends the forecasted demands to at least one supplier after determining the forecasts are valid. The supply chain server controls the processes involved in distributing the product from the suppliers to the customers including the generation and payment of invoices. A form of financing the customers' purchases, made possible by the novel supply chain architecture, is also disclosed.

Owner:ISUPPLI

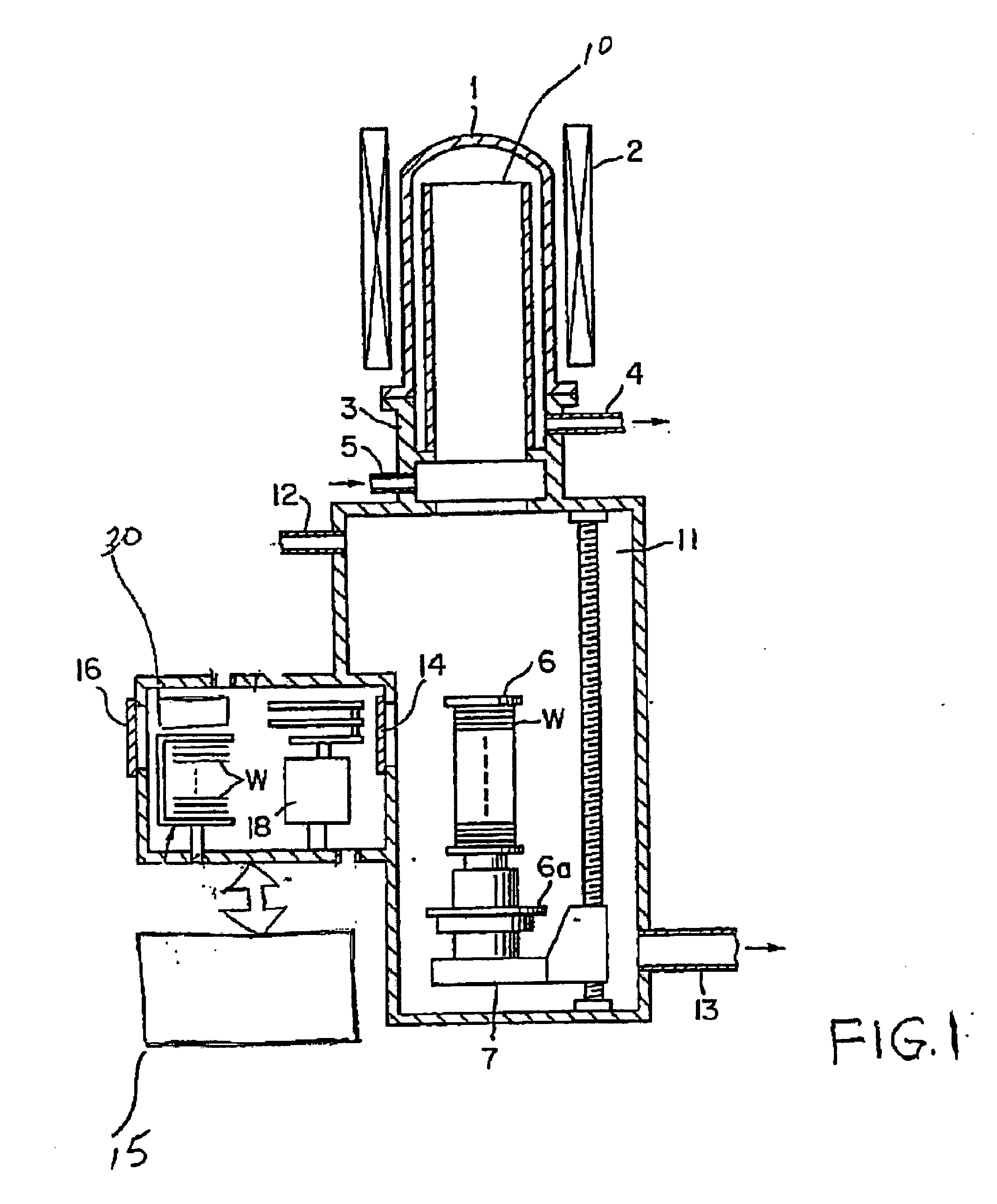

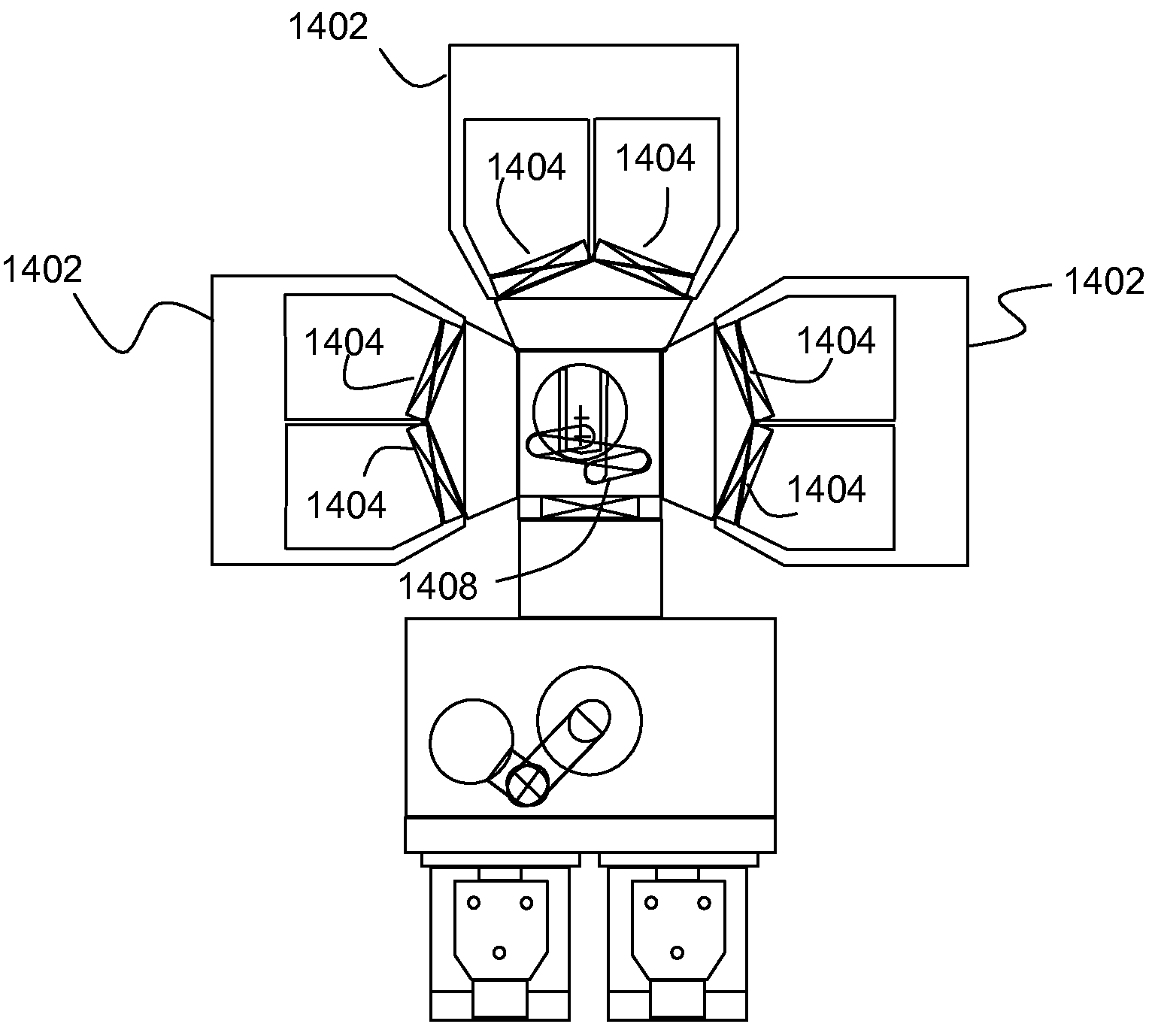

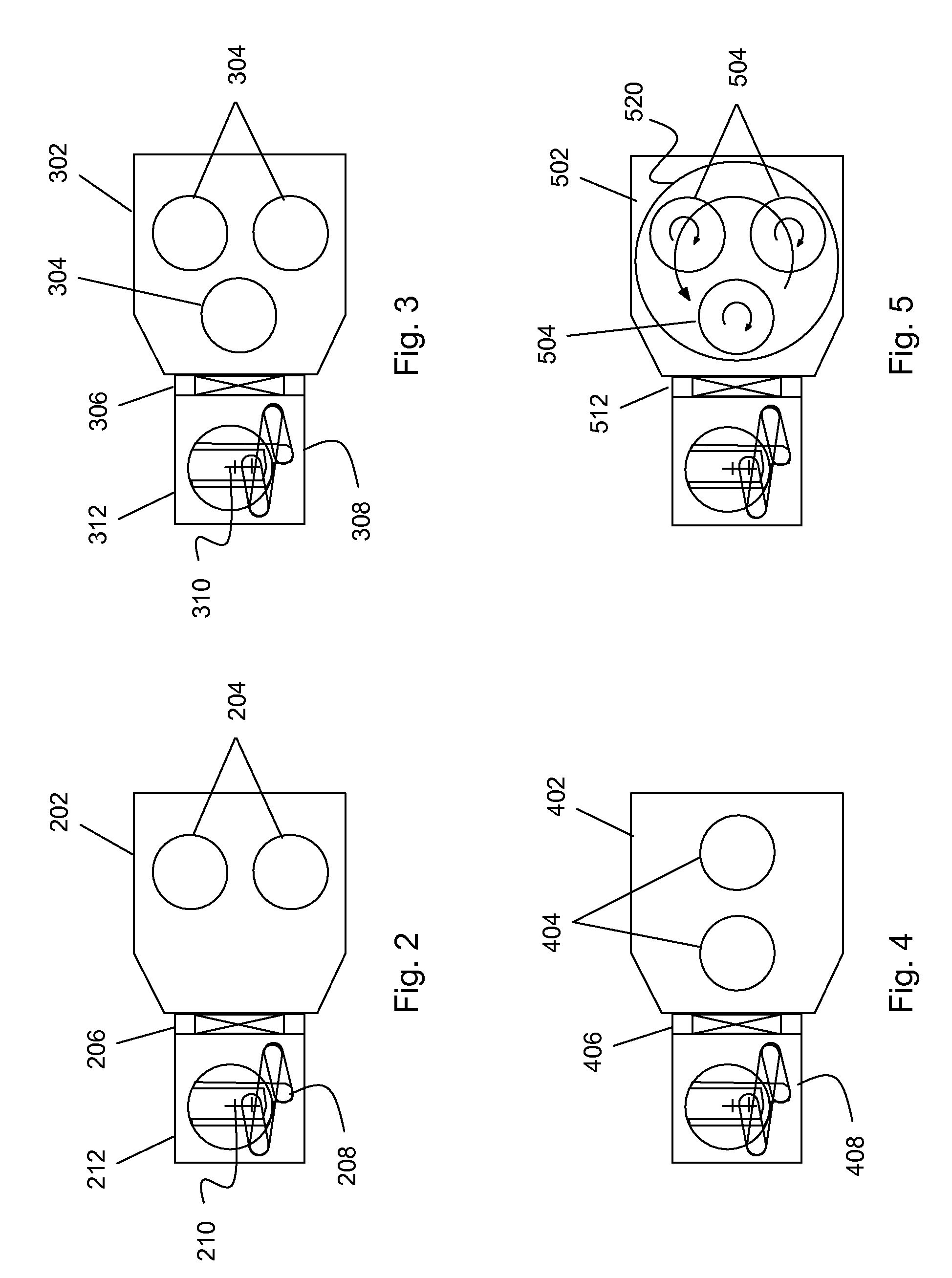

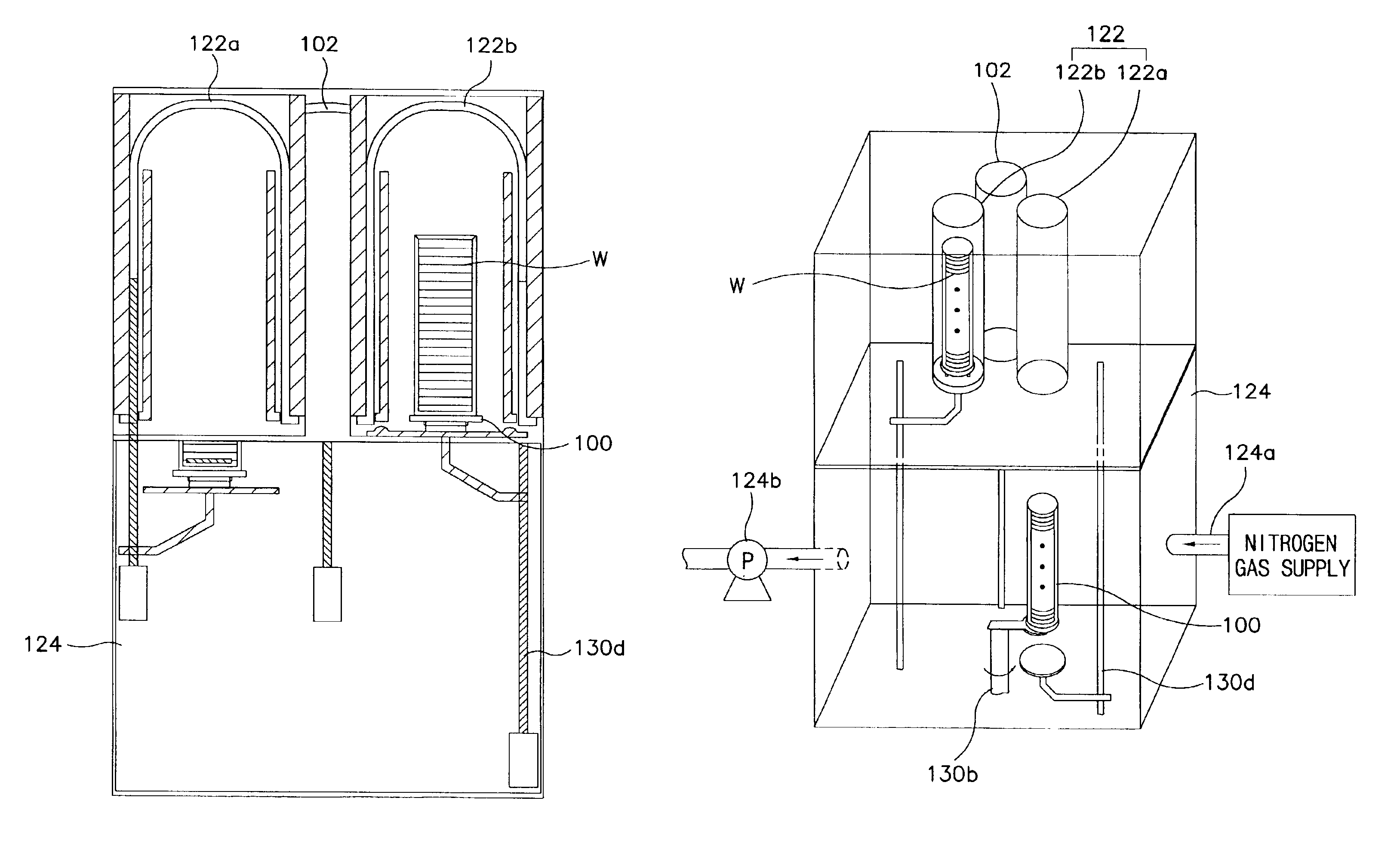

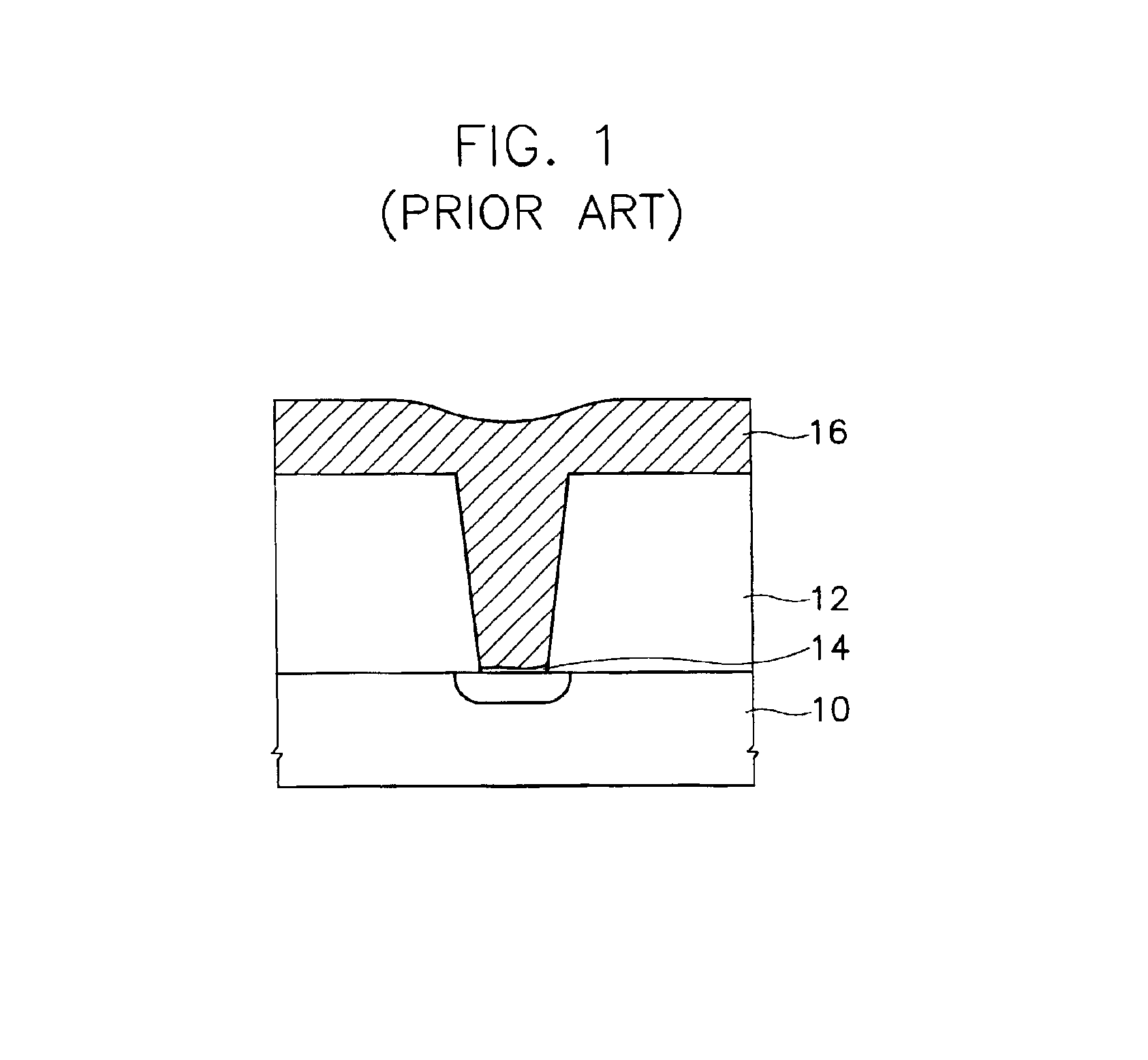

Method of and apparatus for performing sequential processes requiring different amounts of time in the manufacturing of semiconductor devices

InactiveUS6911112B2Without need for significant downtimeHigh productSemiconductor/solid-state device manufacturingCharge manipulationProduction rateDevice material

A method of manufacturing a semiconductor device includes first and second processes, the latter requiring more processing time. An apparatus for performing the semiconductor manufacturing process includes a first reactor, and a plurality of second reactors for each first reactor. A first group of wafers are subjected to the first process within the first reactor, and are then transferred into a second reactor as isolated from the outside air. The first group of wafers is subjected to the second process within the second reactor. At the same time, a second group of wafers are subjected to the first process within the first reactor. After the first process is completed, the second group of wafers is transferred into an unoccupied one of the second reactors as isolated from the outside air. There, the second group of wafers is subjected to the second process. Accordingly, process failures otherwise due to the exposure of the wafers are minimized, and productivity is high despite the difference in the processing times.

Owner:SAMSUNG ELECTRONICS CO LTD

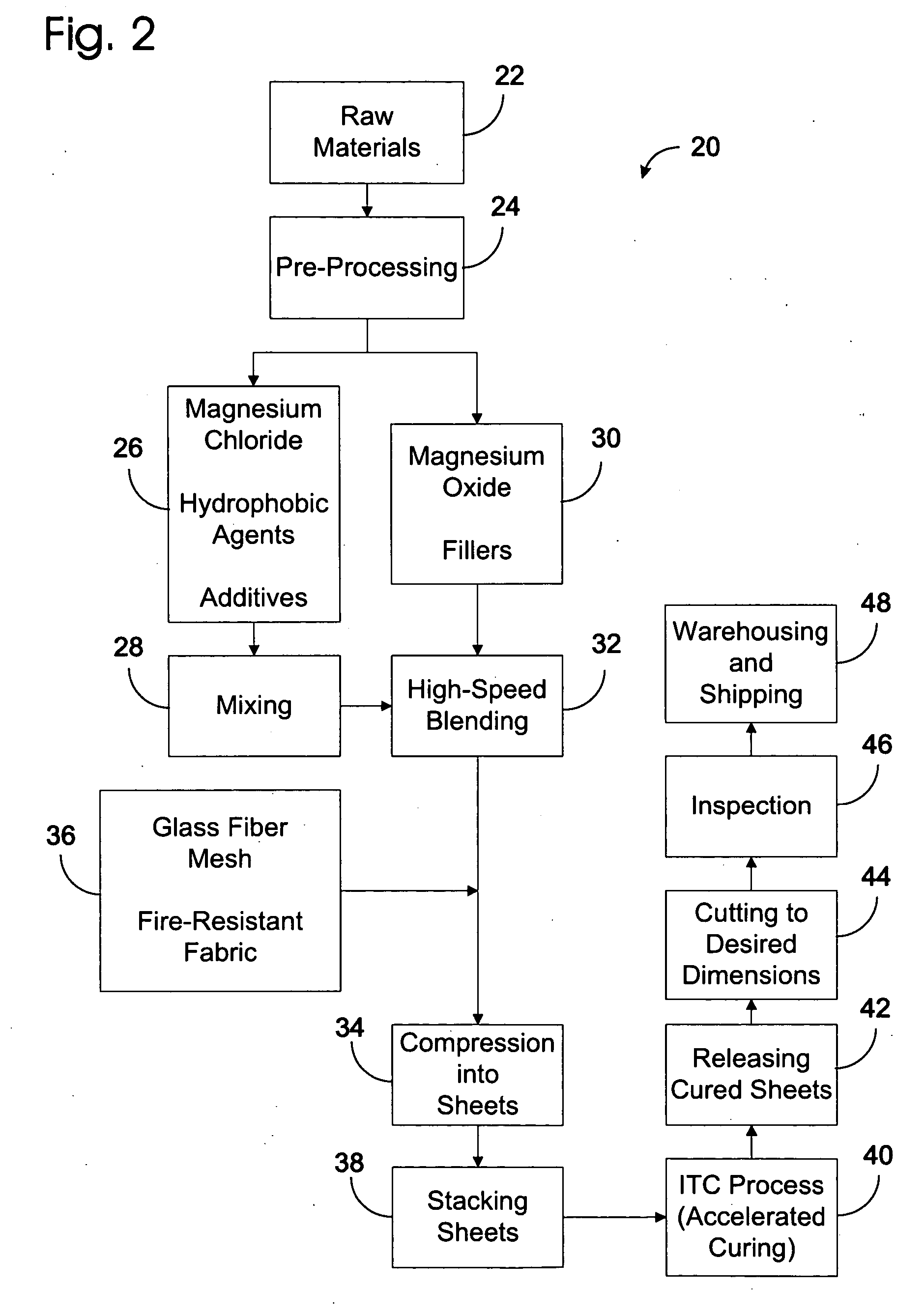

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com