Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3407 results about "Process operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition: Process operations, also called process manufacturing or process production, is the mass production method of producing products in a continuous flow. In other words, this is a conveyer belt system that produces identical, standardized items at a high rate of speed.

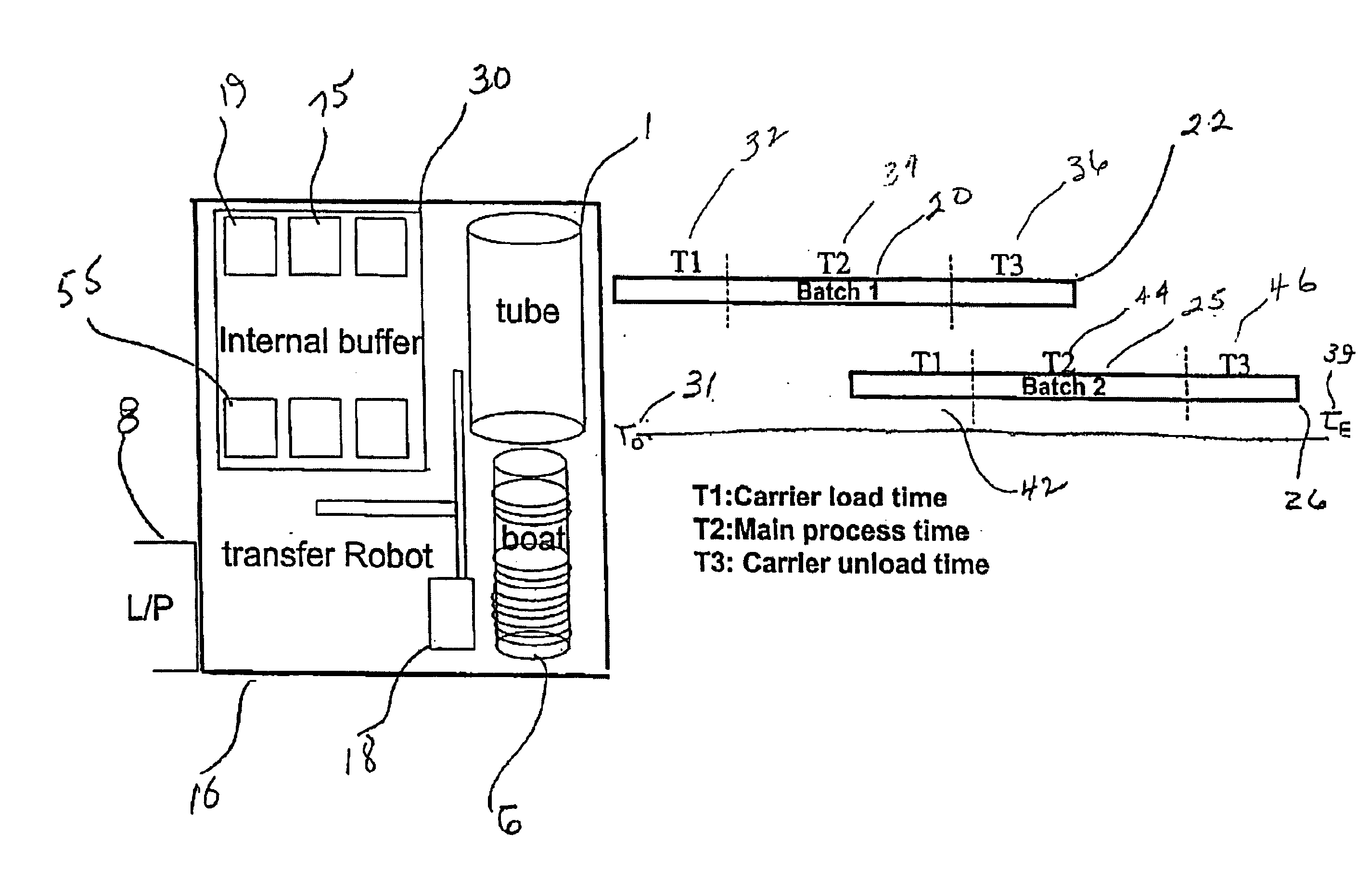

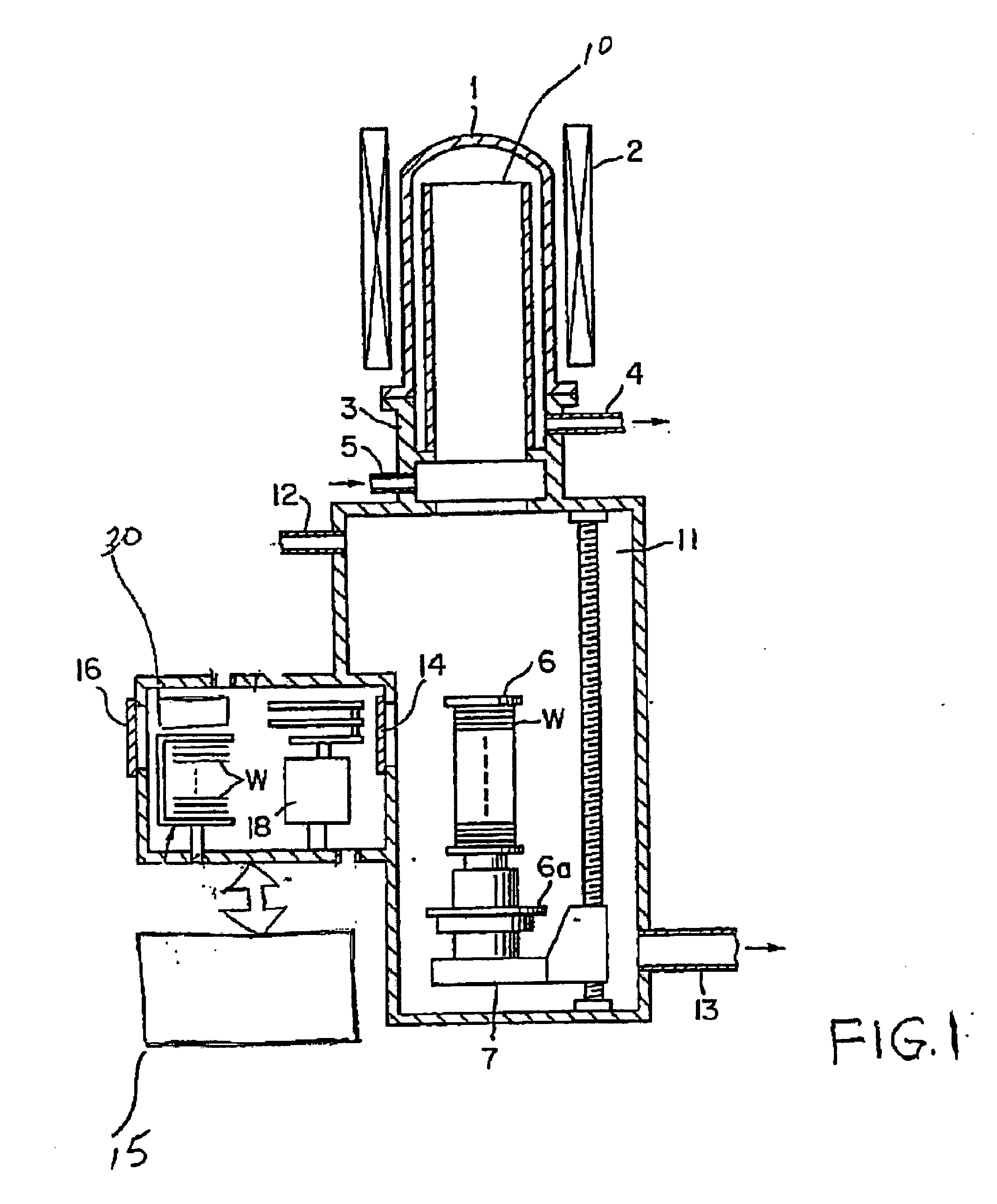

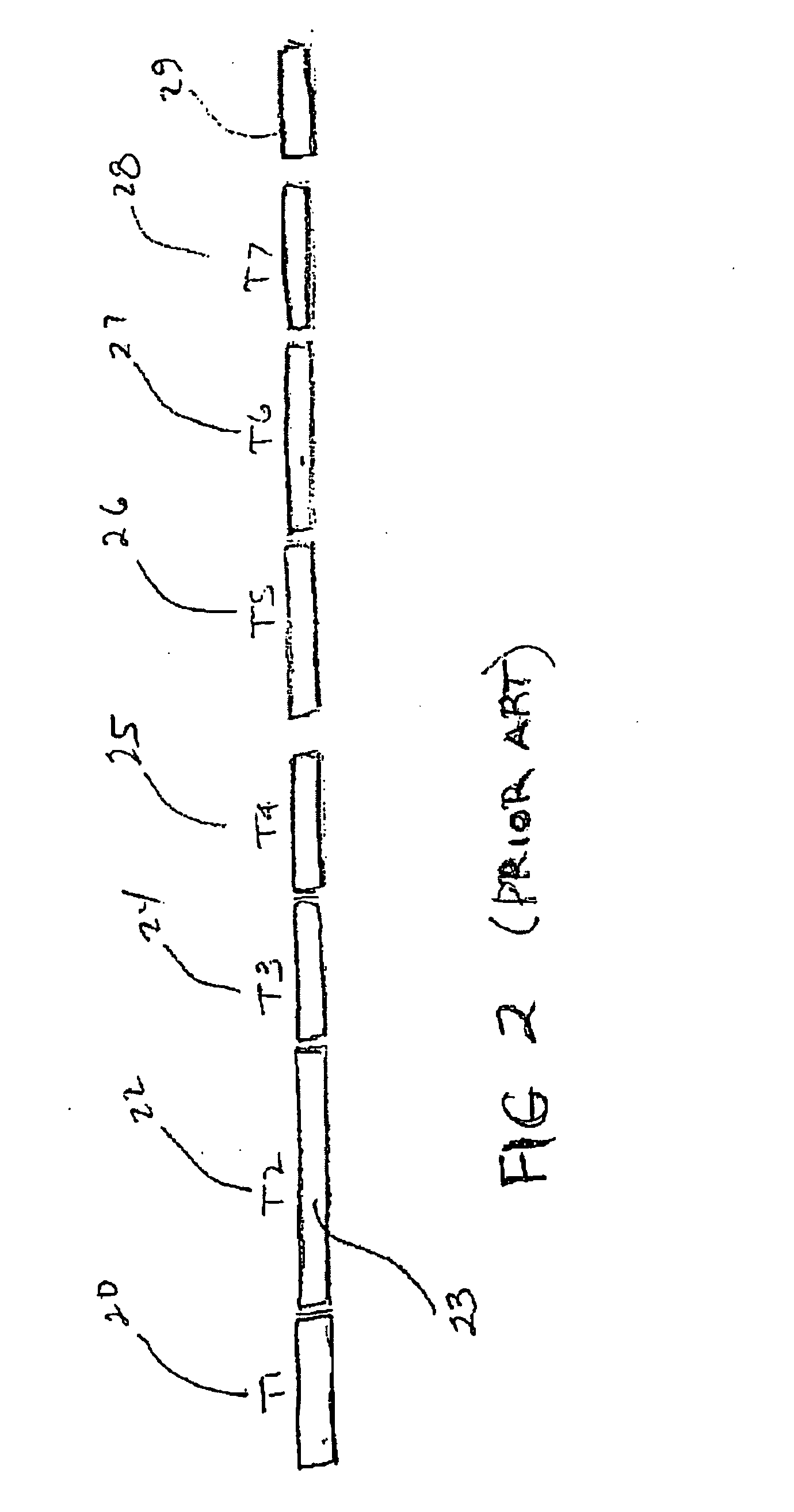

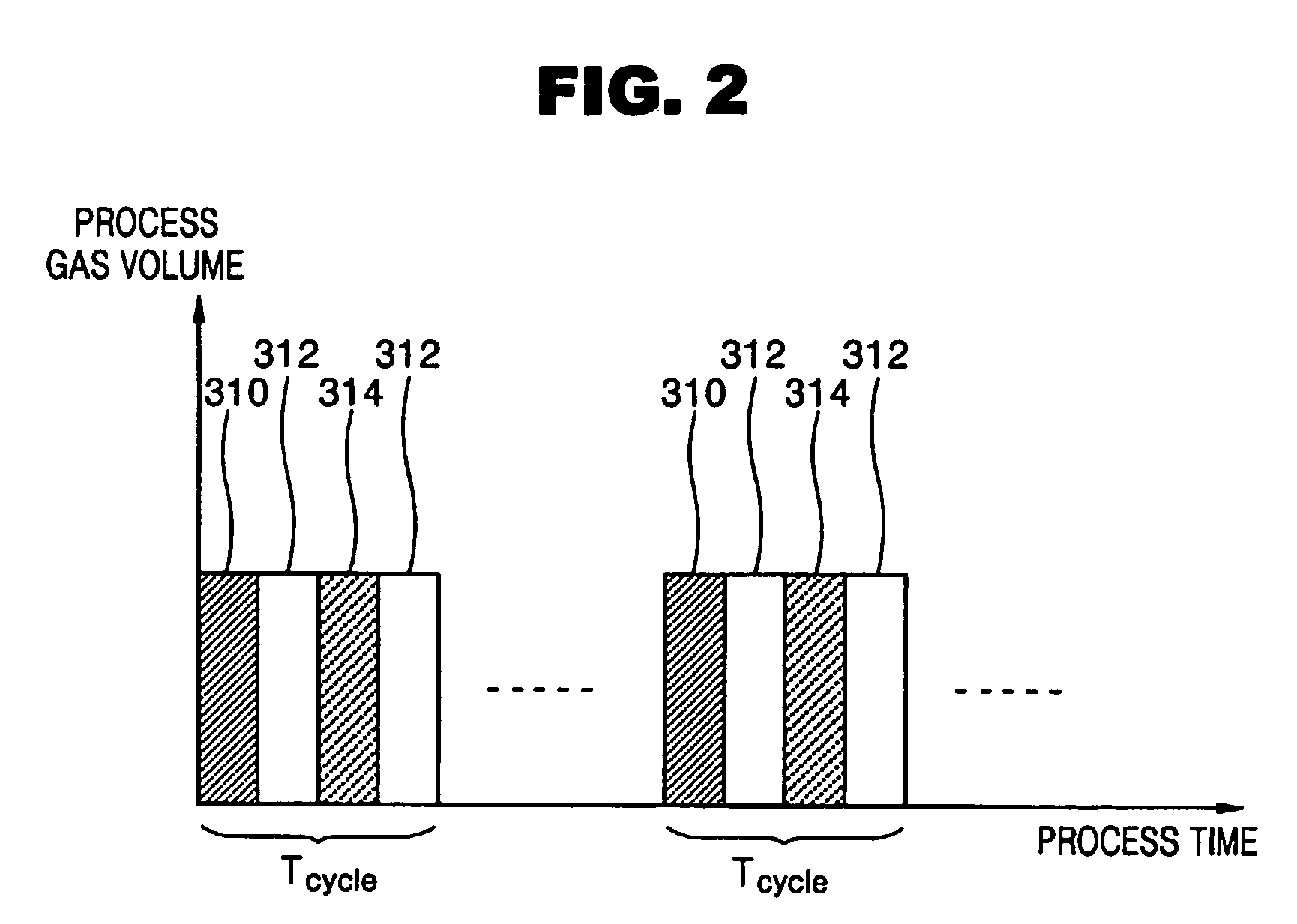

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

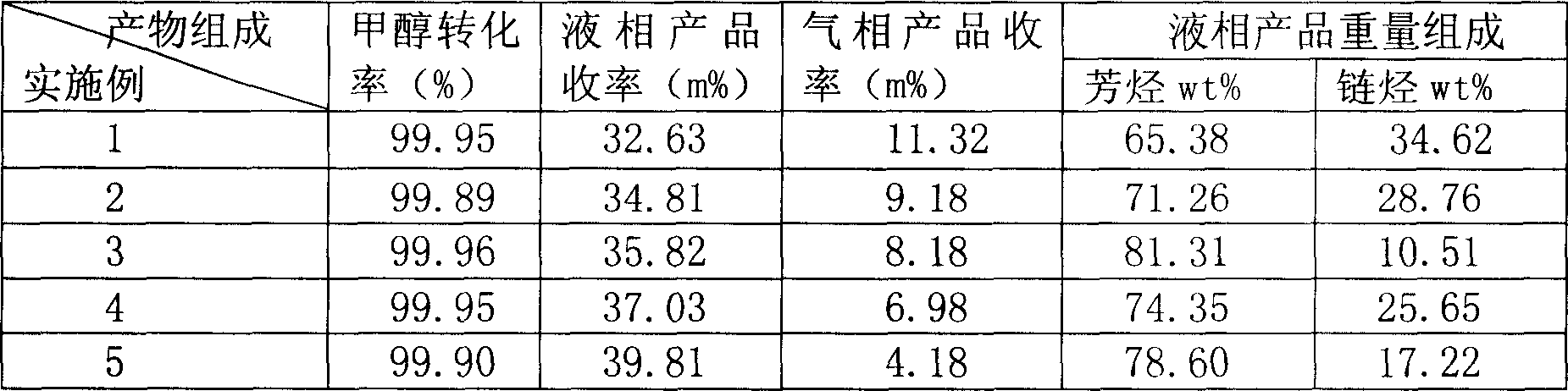

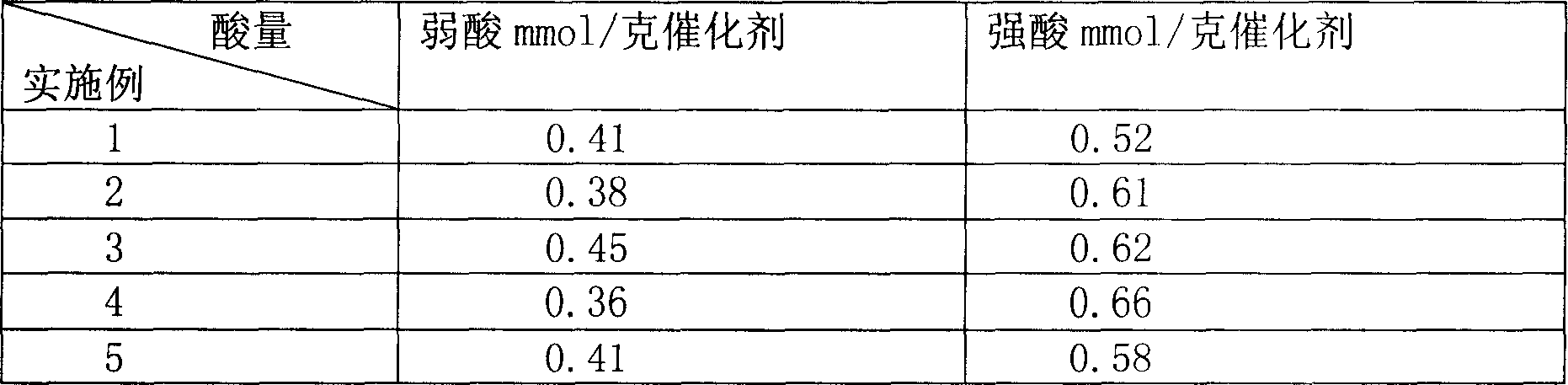

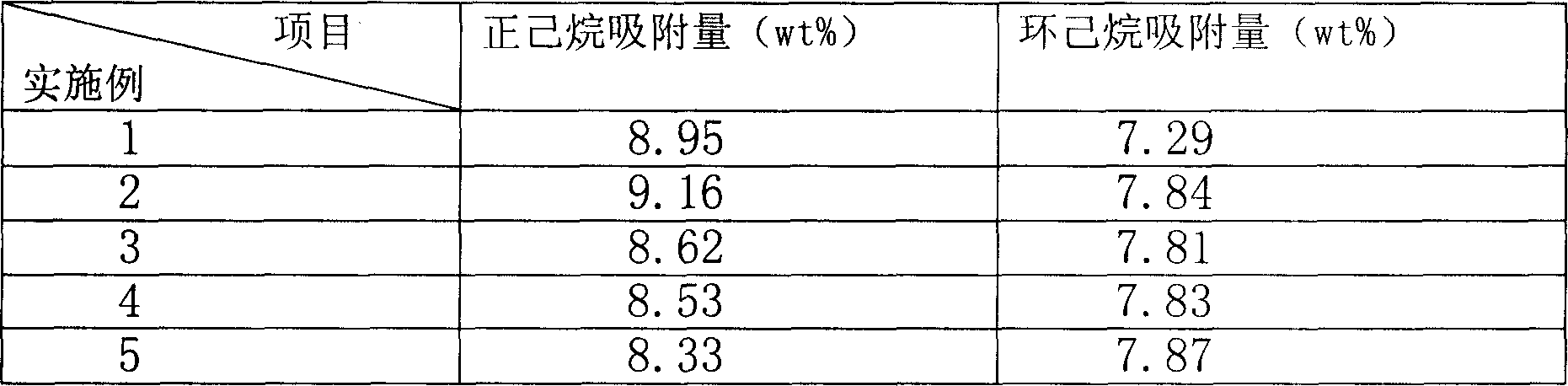

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

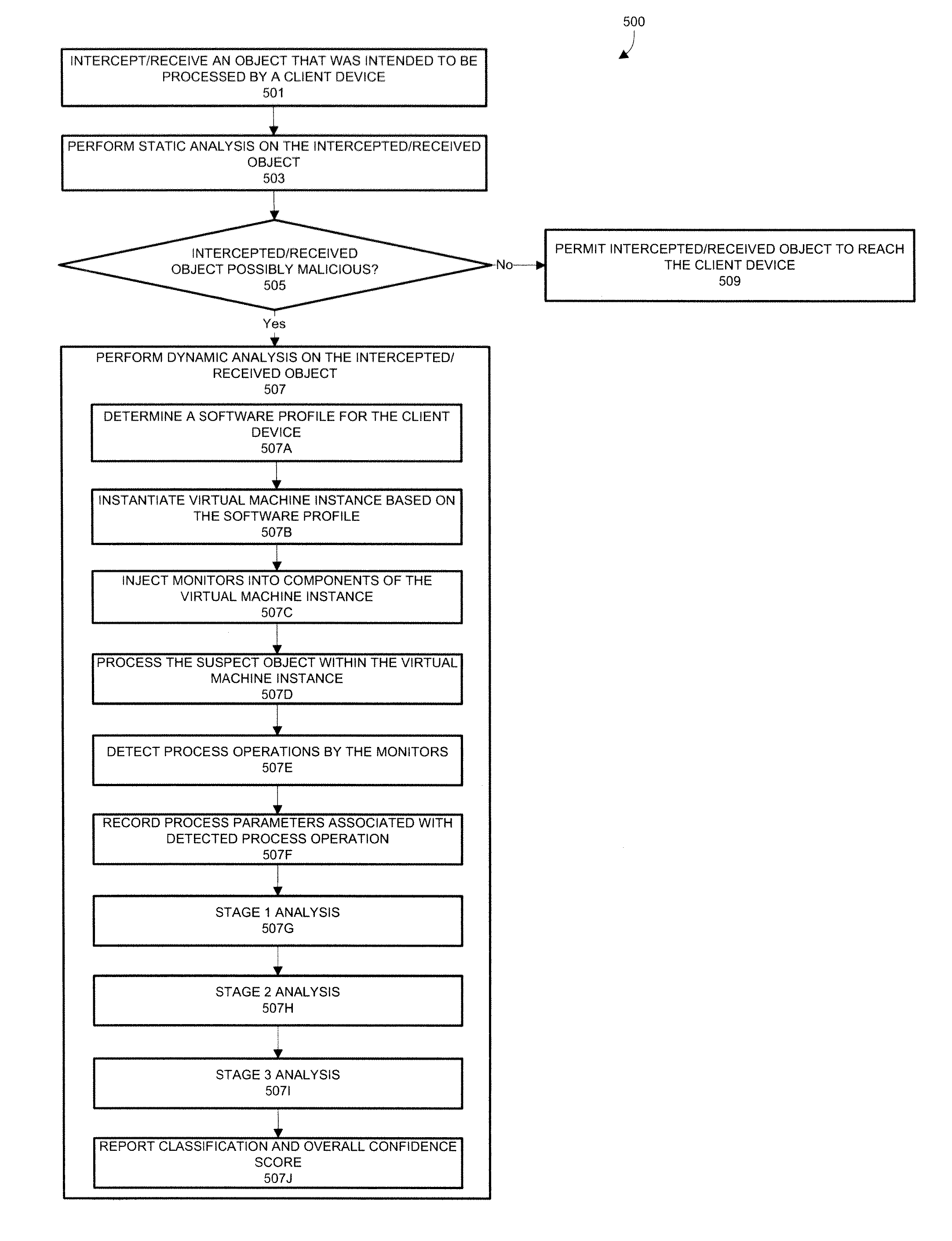

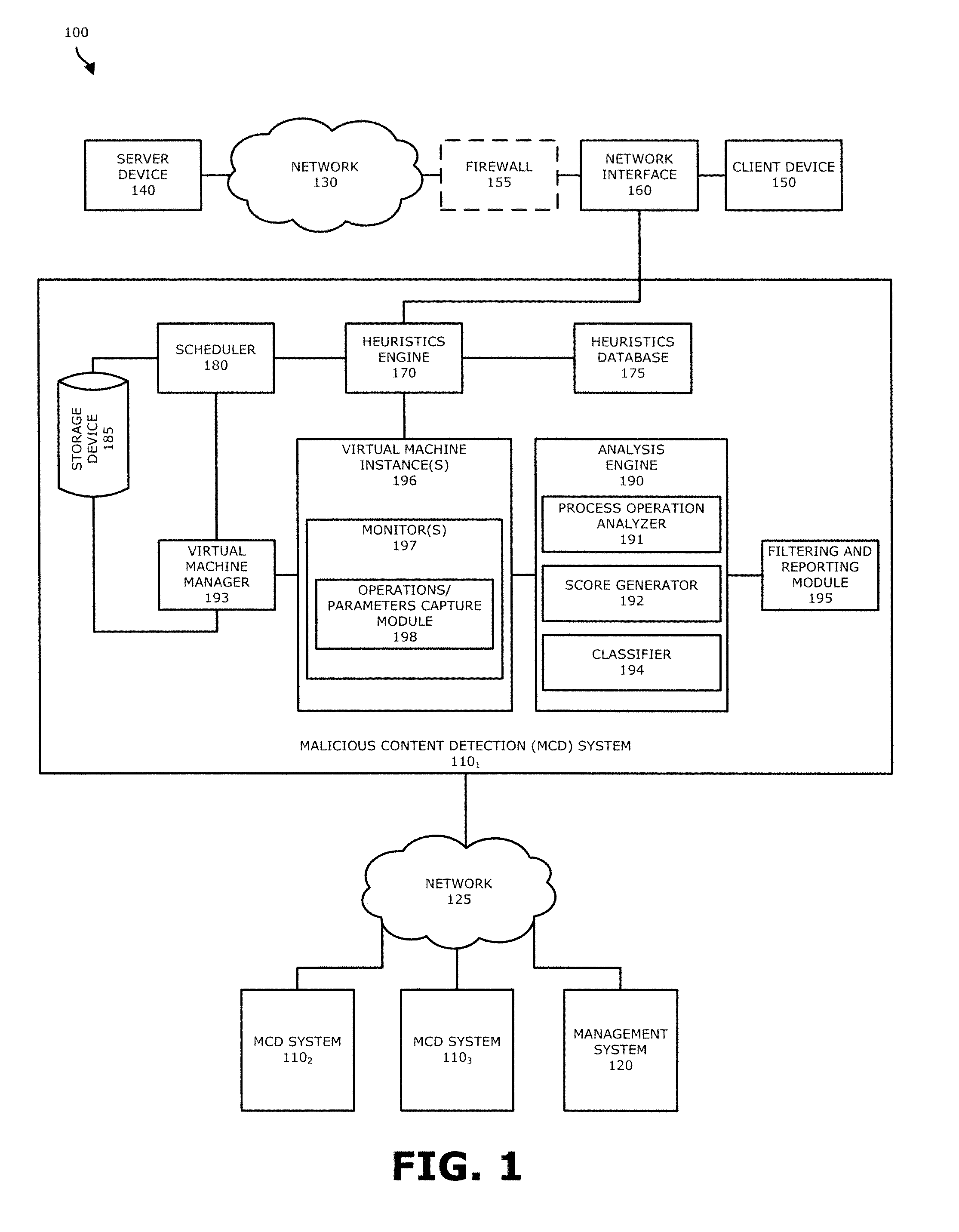

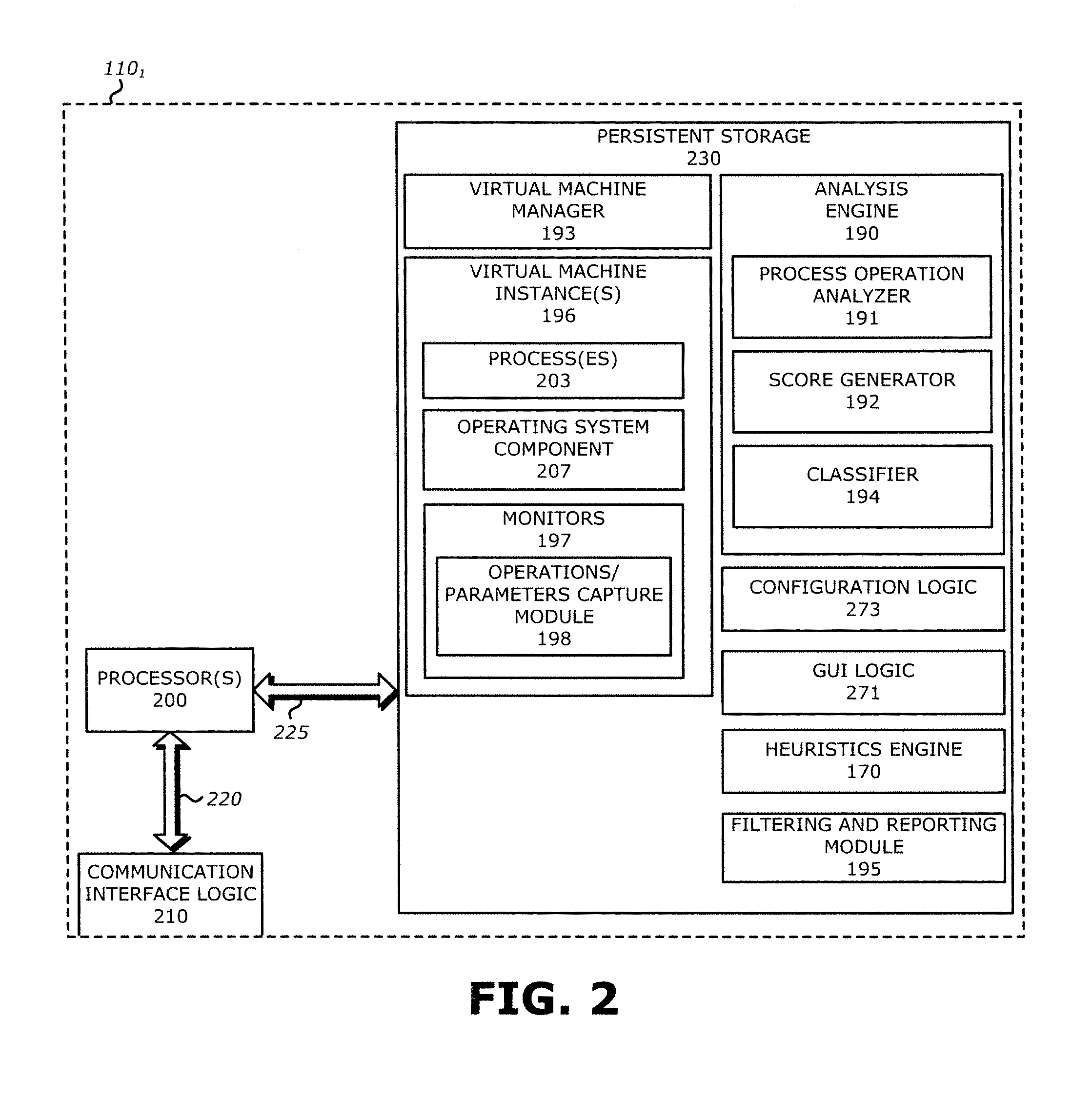

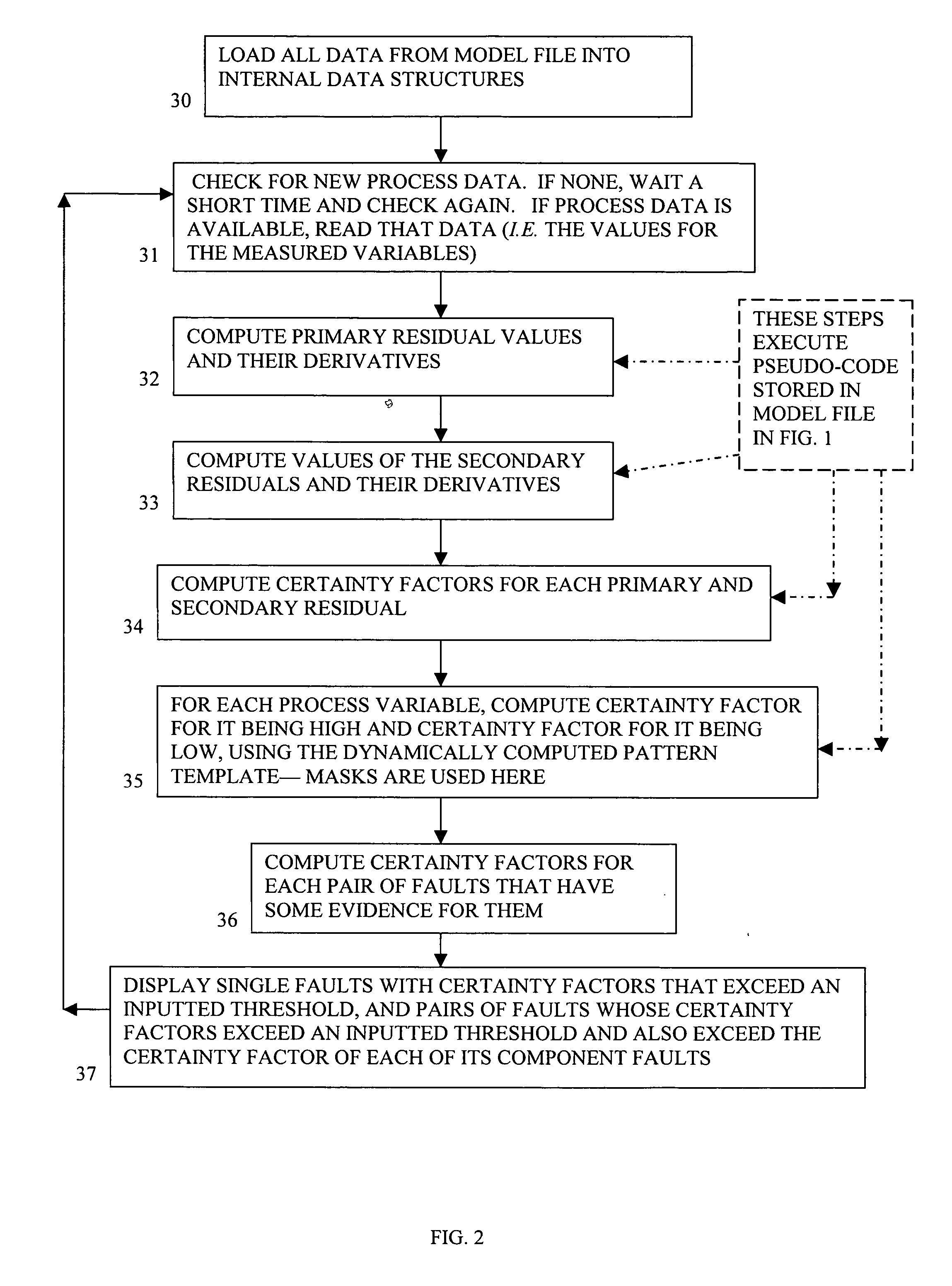

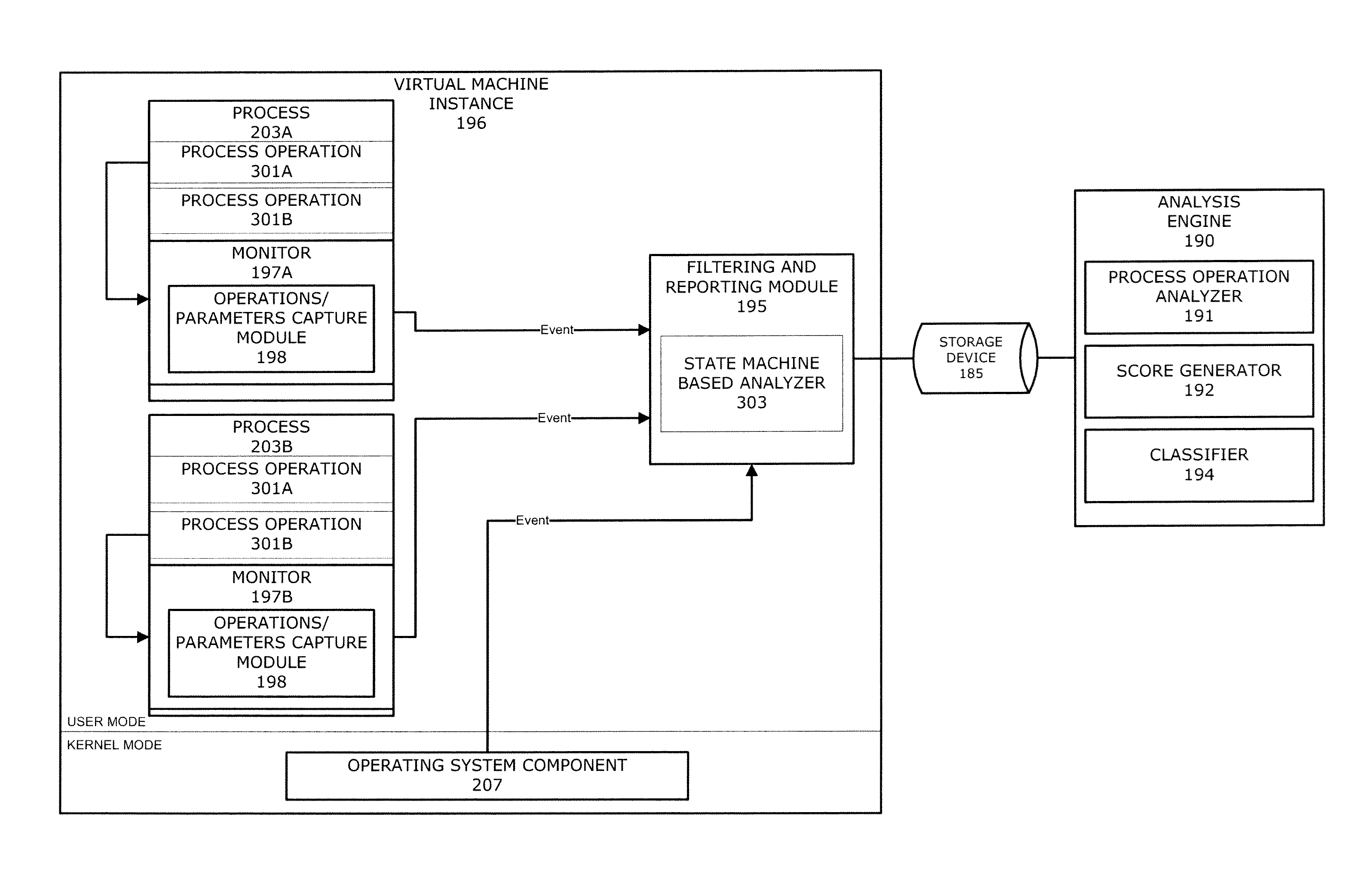

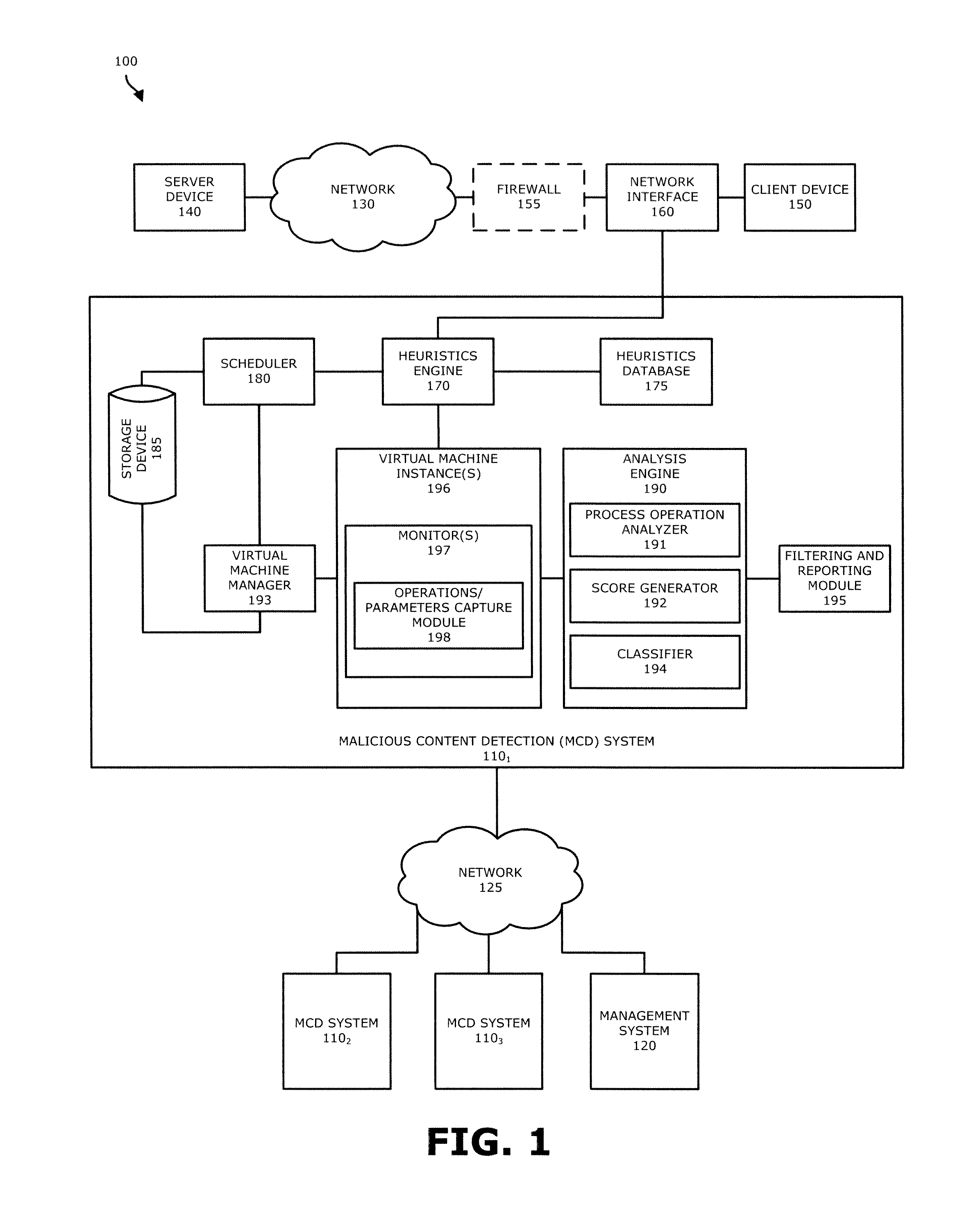

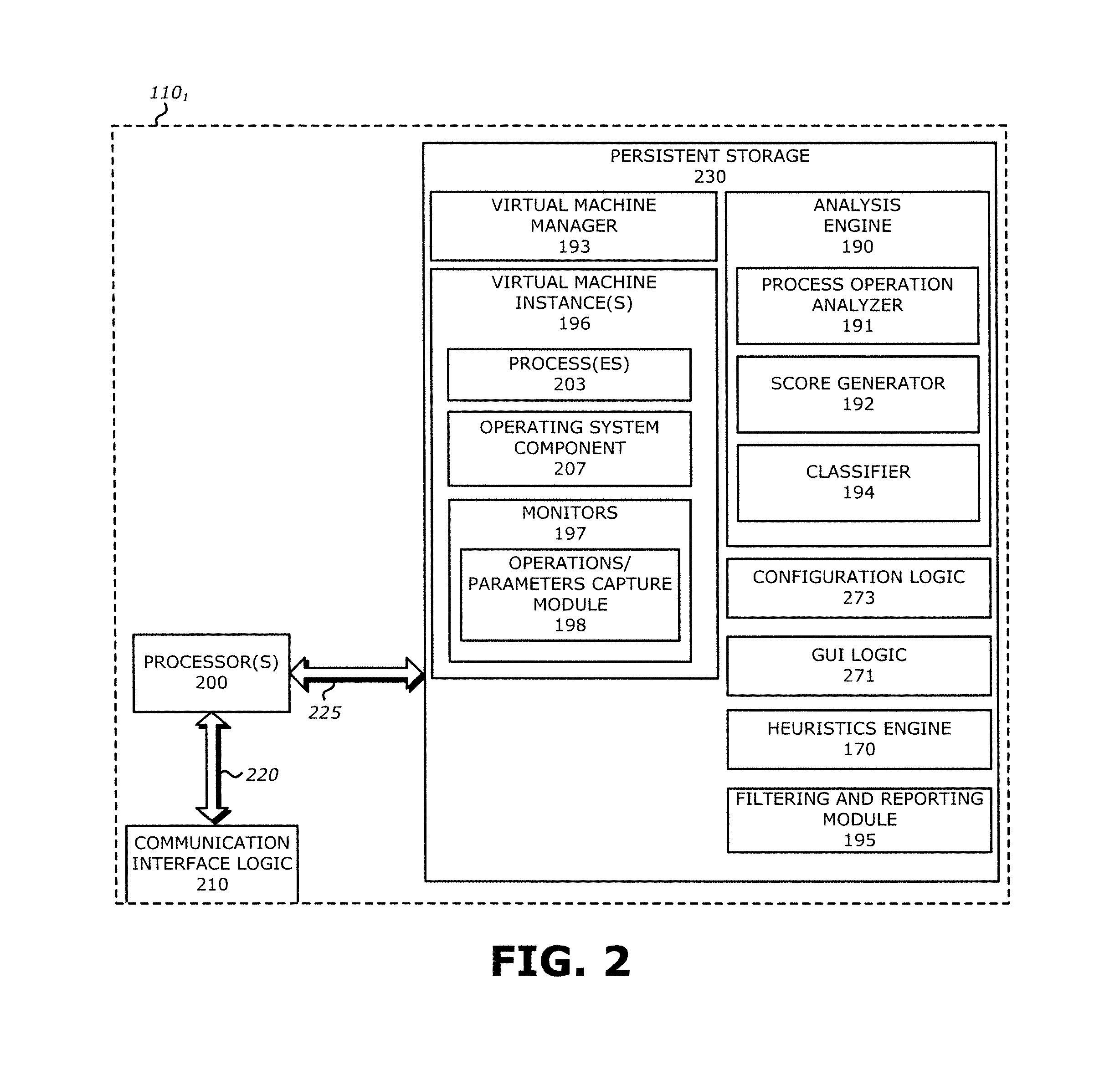

Detection efficacy of virtual machine-based analysis with application specific events

A computerized system and method is described for classifying objects as malicious by processing the objects in a virtual environment and monitoring behaviors during processing by one or more monitors. The monitors may monitor and record selected sets of process operations and capture associated process parameters, which describe the context in which the process operations were performed. By recording the context of process operations, the system and method described herein improves the intelligence of classifications and consequently reduces the likelihood of incorrectly identifying objects as malware or vice versa.

Owner:FIREEYE SECURITY HLDG US LLC +1

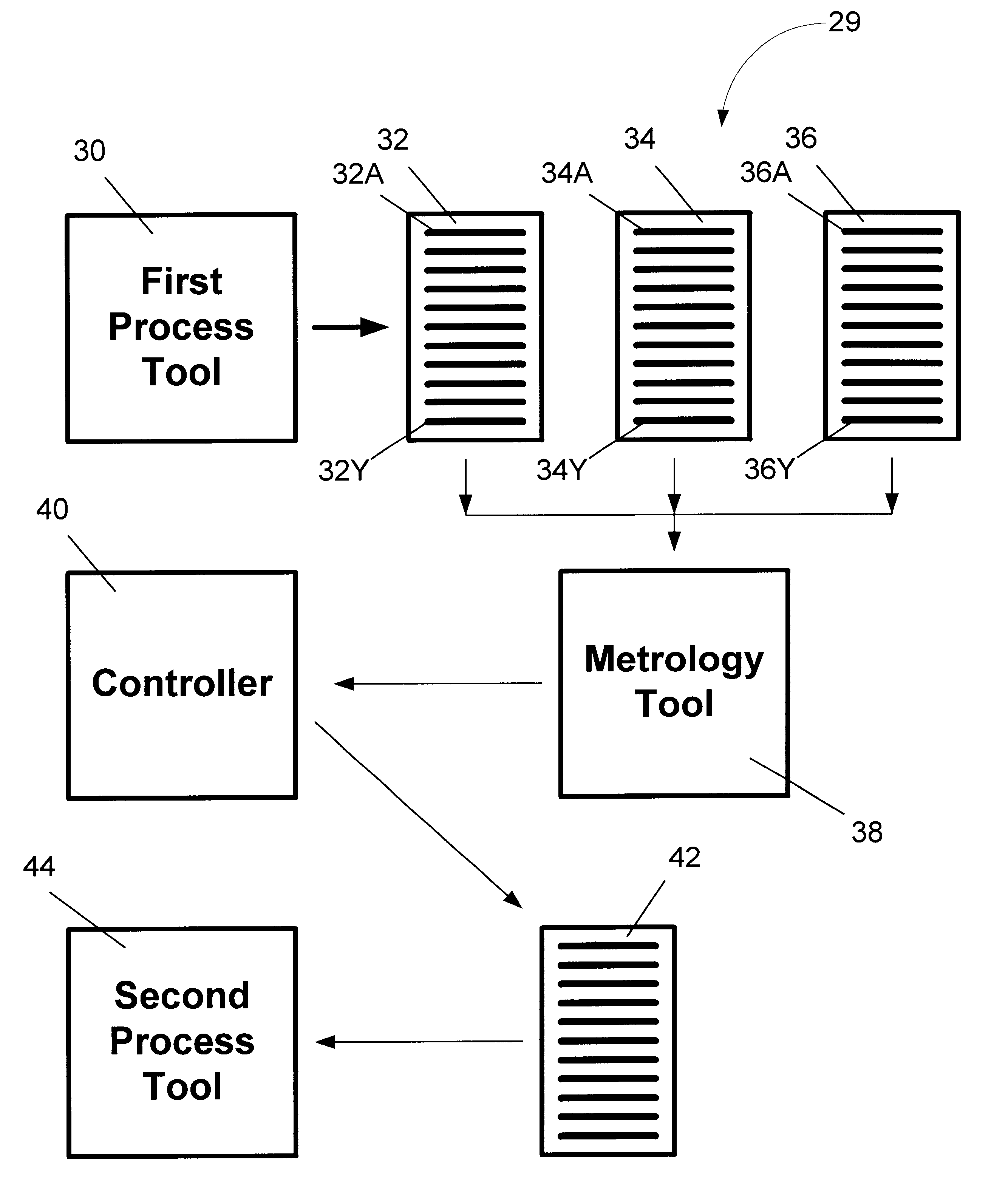

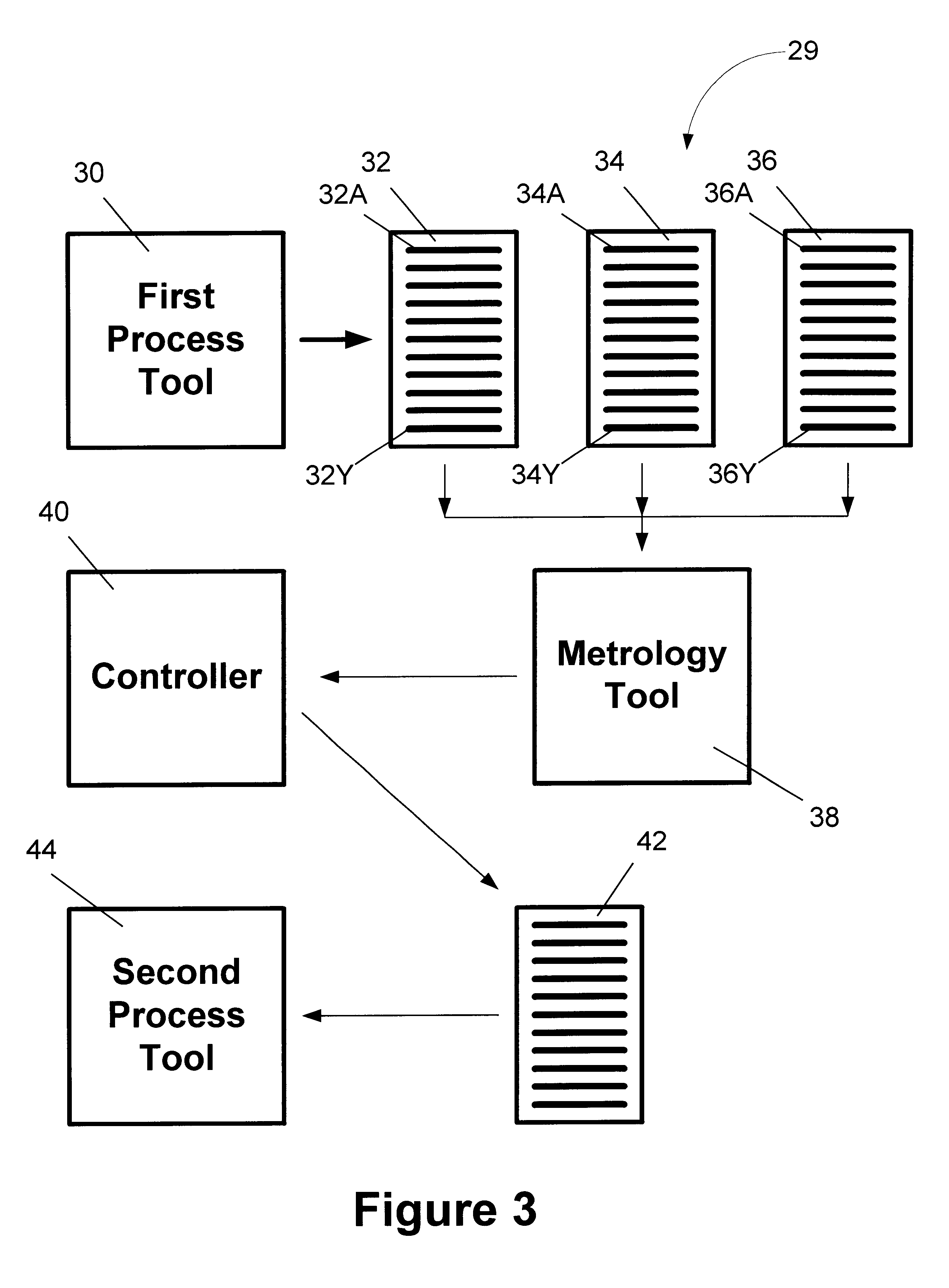

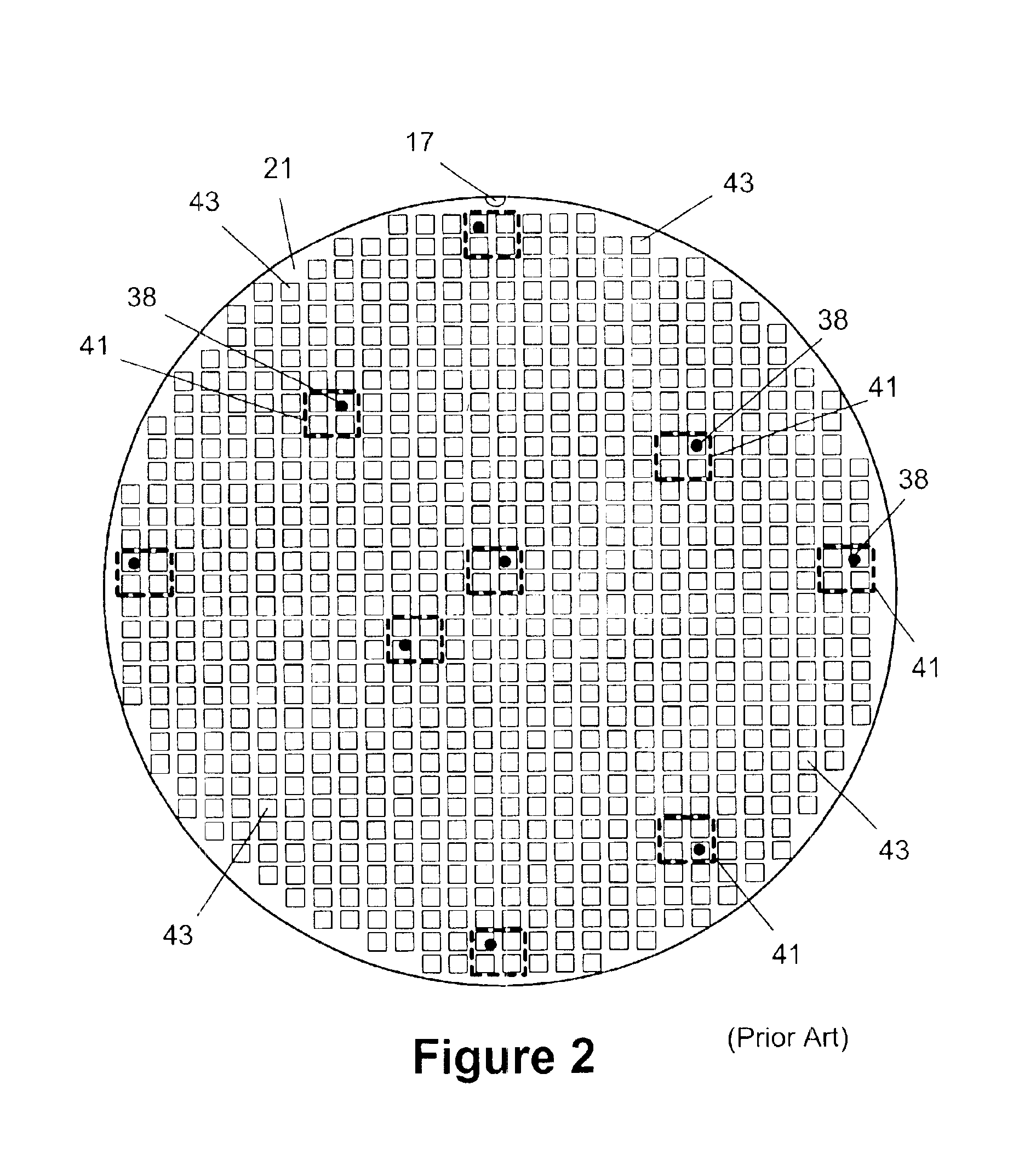

Dynamic lot allocation based upon wafer state characteristics, and system for accomplishing same

InactiveUS6746308B1Semiconductor/solid-state device testing/measurementGrinding feed controlEngineeringProcess operation

In one illustrative embodiment, the method comprises providing a plurality of wafer lots, each of the lots comprising a plurality of wafers, performing at least one process operation on at least some of the wafers in each of the plurality of lots, identifying processed wafers having similar characteristics, re-allocating the wafers to lots based upon the identified characteristics, and performing additional processing operations on the identified wafers having similar characteristics in the re-allocated lots. In one illustrative embodiment, the system comprises a first processing tool for performing processing operations on each of a plurality of wafers in each of a plurality of wafer lots, a controller for identifying processed wafers having similar characteristics and re-allocating the wafers to lots based upon the identified characteristics, and a second processing tool adapted to perform additional processing operations on the identified wafers having similar characteristics in the re-allocated lot.

Owner:GLOBALFOUNDRIES INC

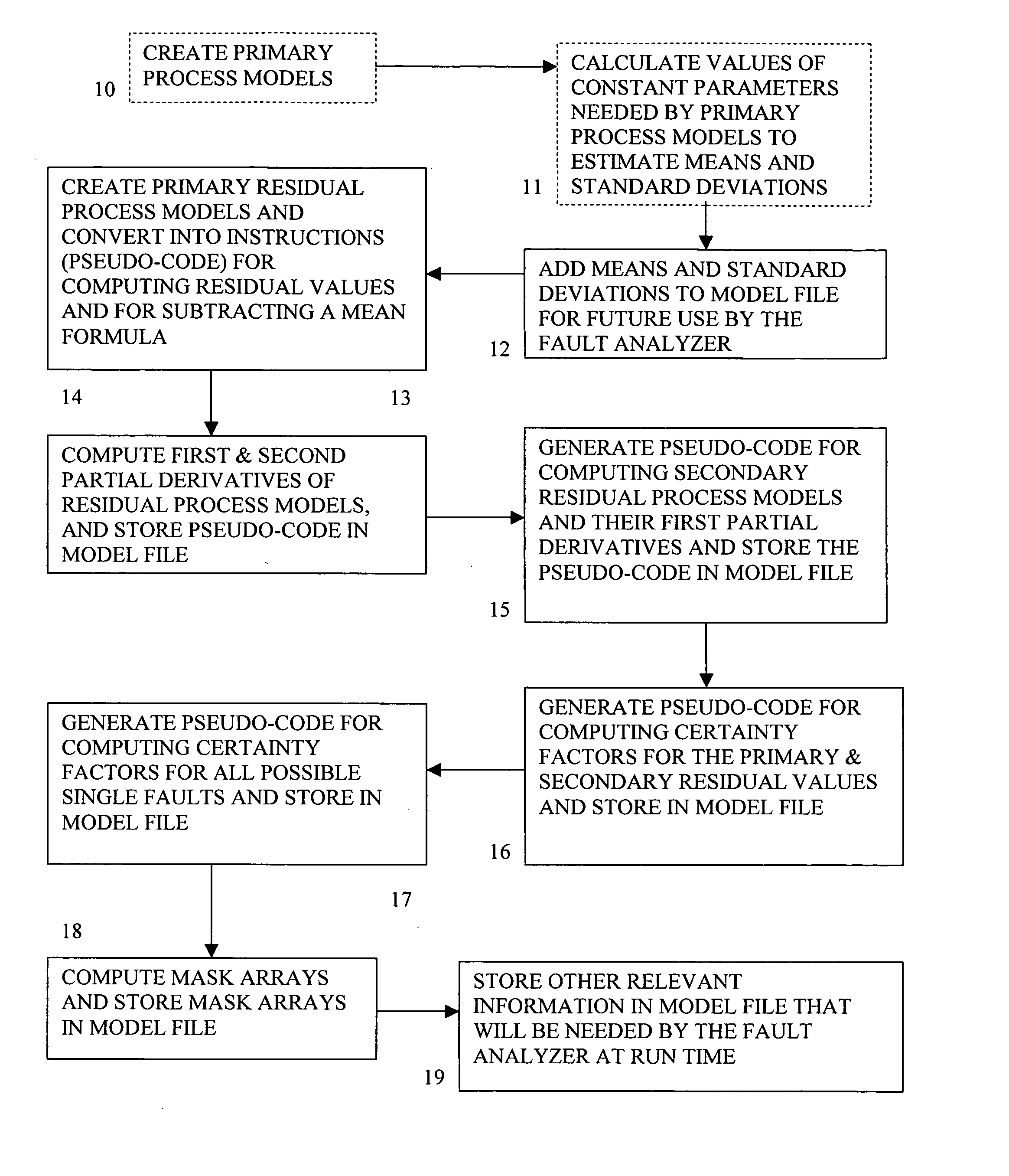

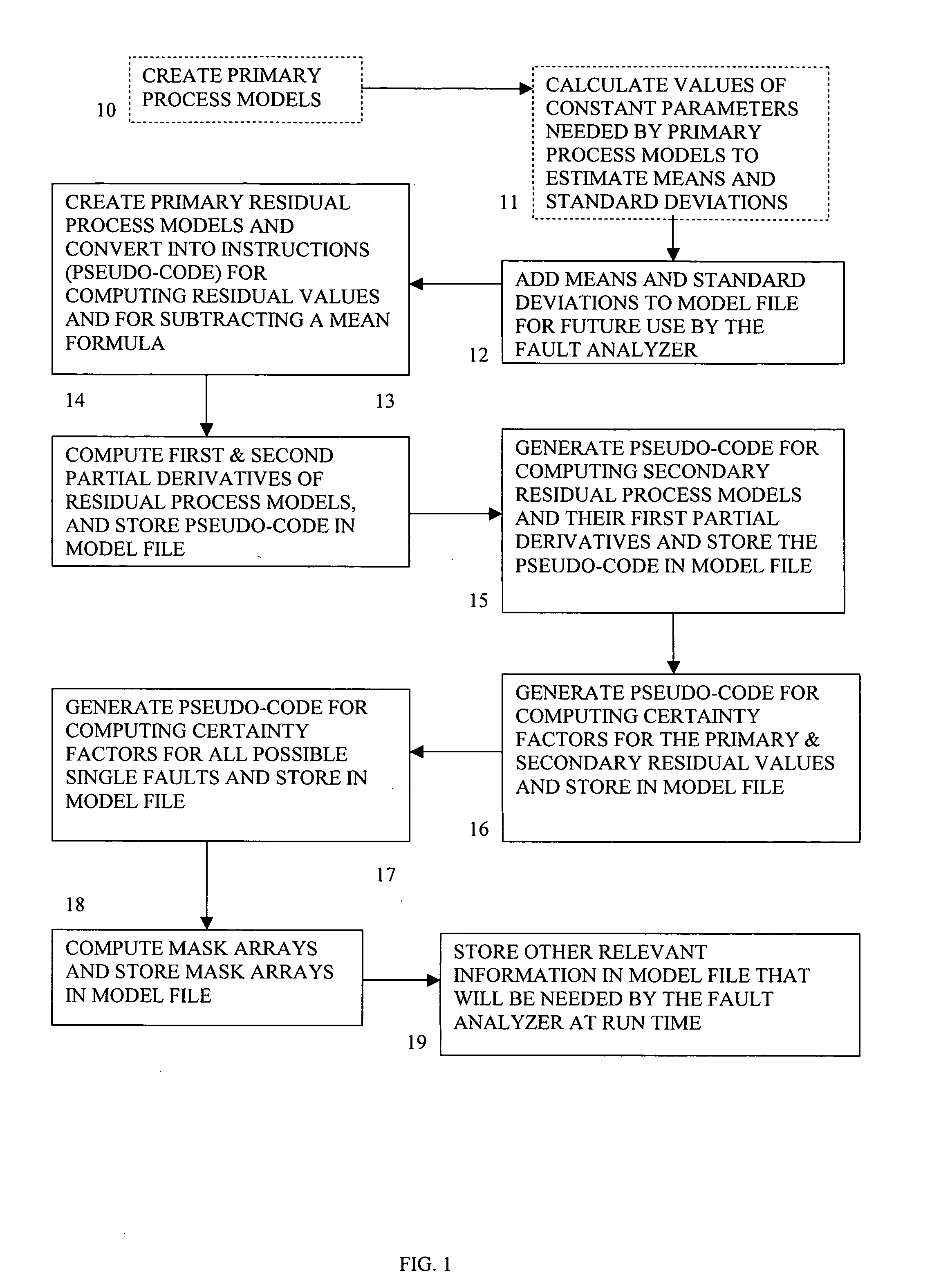

Method and system of monitoring, sensor validation and predictive fault analysis

InactiveUS20050210337A1Simplicity of implementationEasy maintenanceError detection/correctionElectric testing/monitoringLinear correlationPredictive failure analysis

The present invention provides an improved method and system for real-time monitoring, validation, optimization and predictive fault analysis in a process control system. The invention monitors process operations by continuously analyzing sensor measurements and providing predictive alarms using models of normal process operation and statistical parameters corresponding to normal process data, and generating secondary residual process models. The invention allows for the creation of a fault analyzer directly from linearly independent models of normal process operation, and provides for automatic generation from such process models of linearly dependent process models. Fuzzy logic is used in various fault situations to compute certainty factors to identify faults and / or validate underlying assumptions. In one aspect, the invention includes a real-time sensor data communications bridge module; a state transition logic module; a sensor validation and predictive fault analysis module; and a statistical process control module; wherein each of the modules operates simultaneously.

Owner:FALCONEER TECH

Detection efficacy of virtual machine-based analysis with application specific events

A computerized system and method is described for classifying objects as malicious by processing the objects in a virtual environment and monitoring behaviors during processing by one or more monitors. The monitors may monitor and record selected sets of process operations and capture associated process parameters, which describe the context in which the process operations were performed. By recording the context of process operations, the system and method described herein improves the intelligence of classifications and consequently reduces the likelihood of incorrectly identifying objects as malware or vice versa.

Owner:FIREEYE SECURITY HLDG US LLC +1

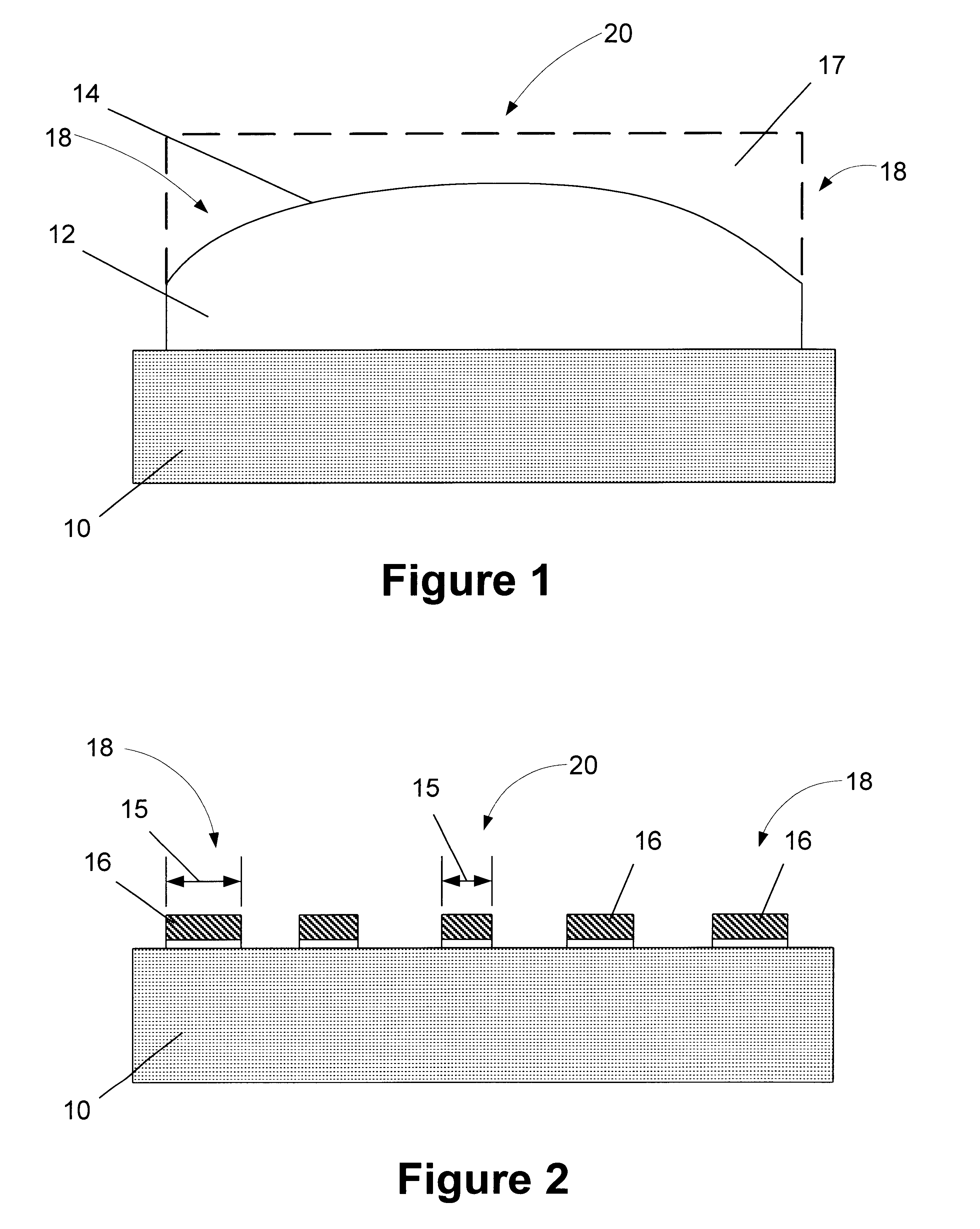

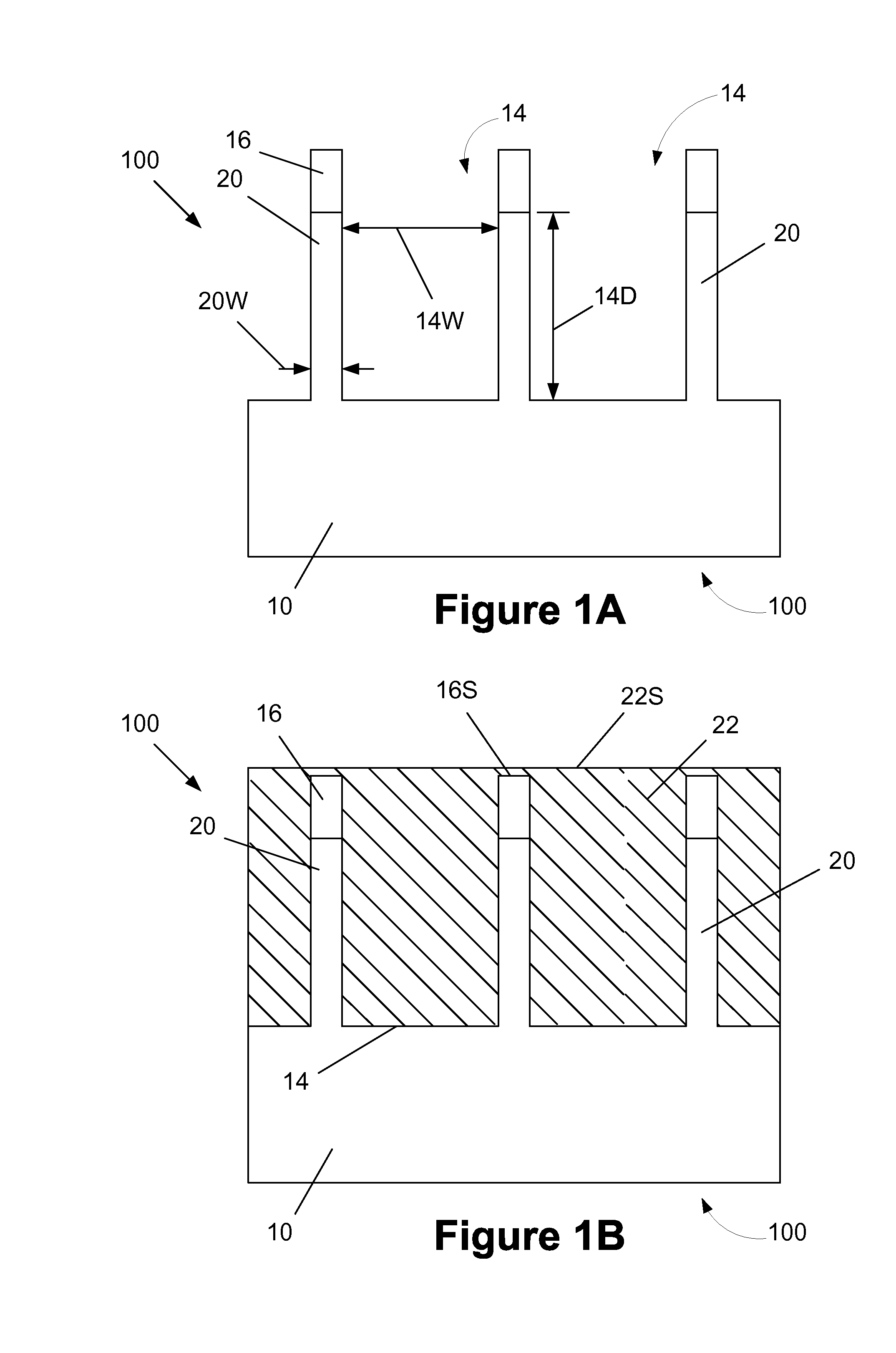

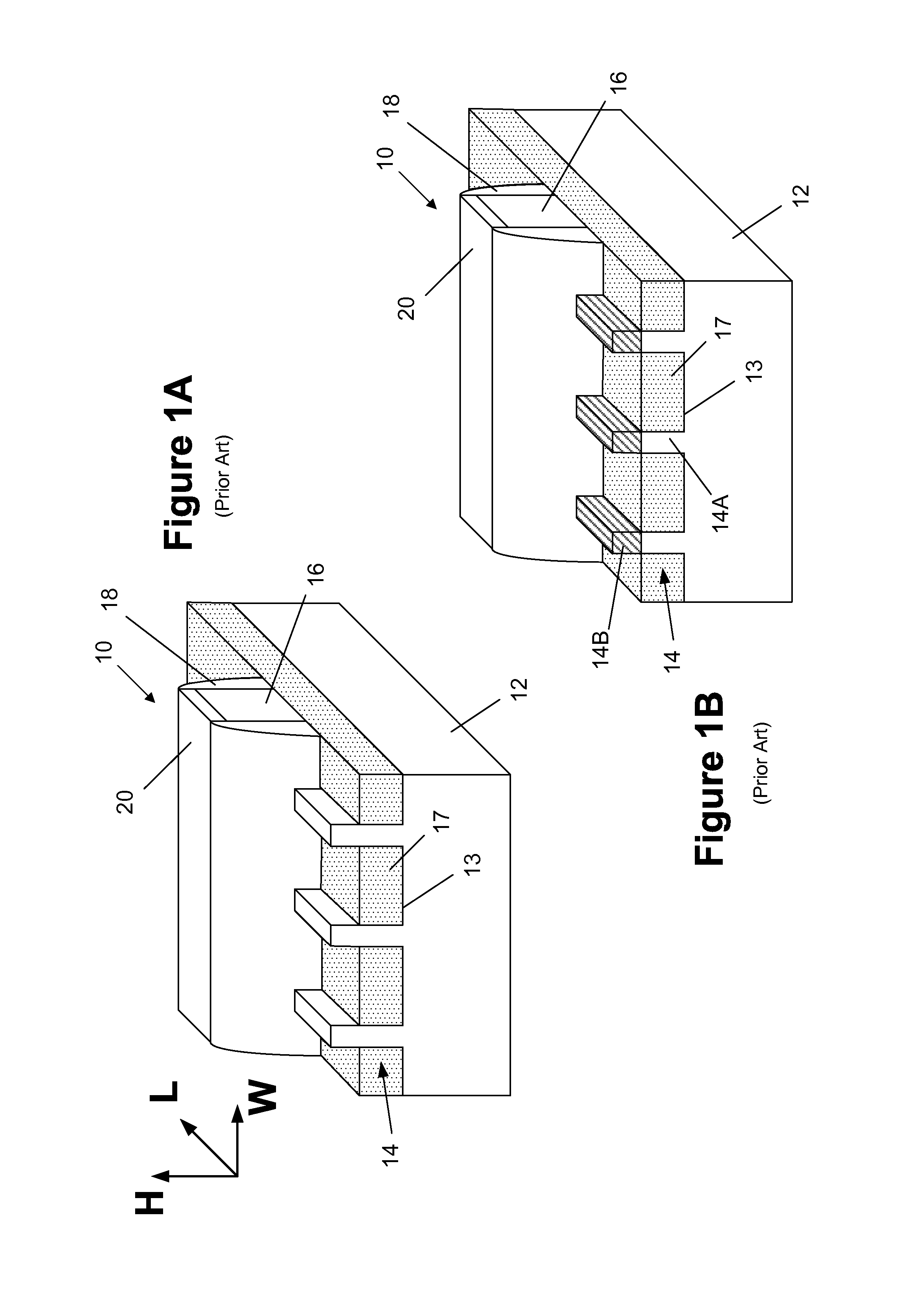

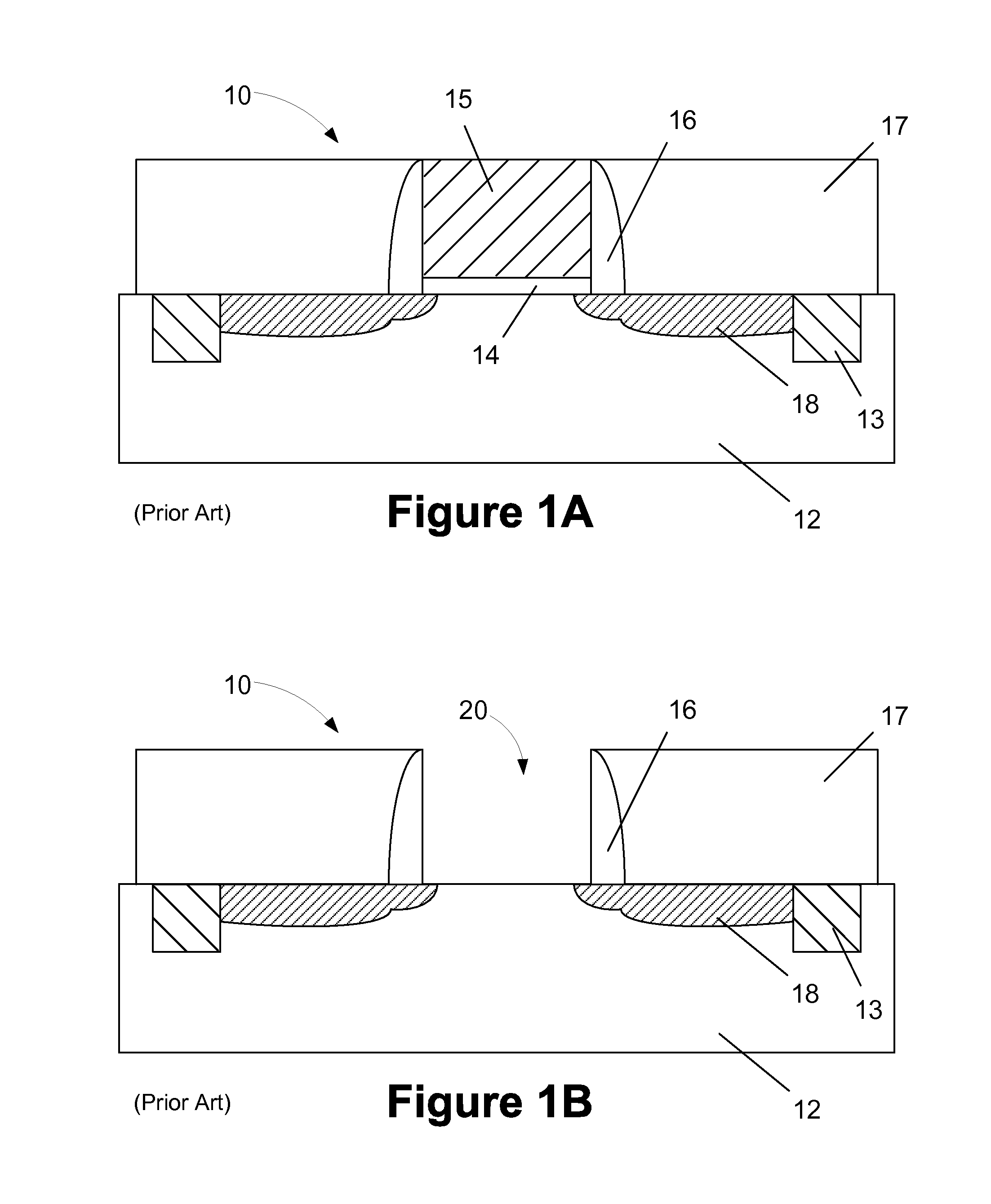

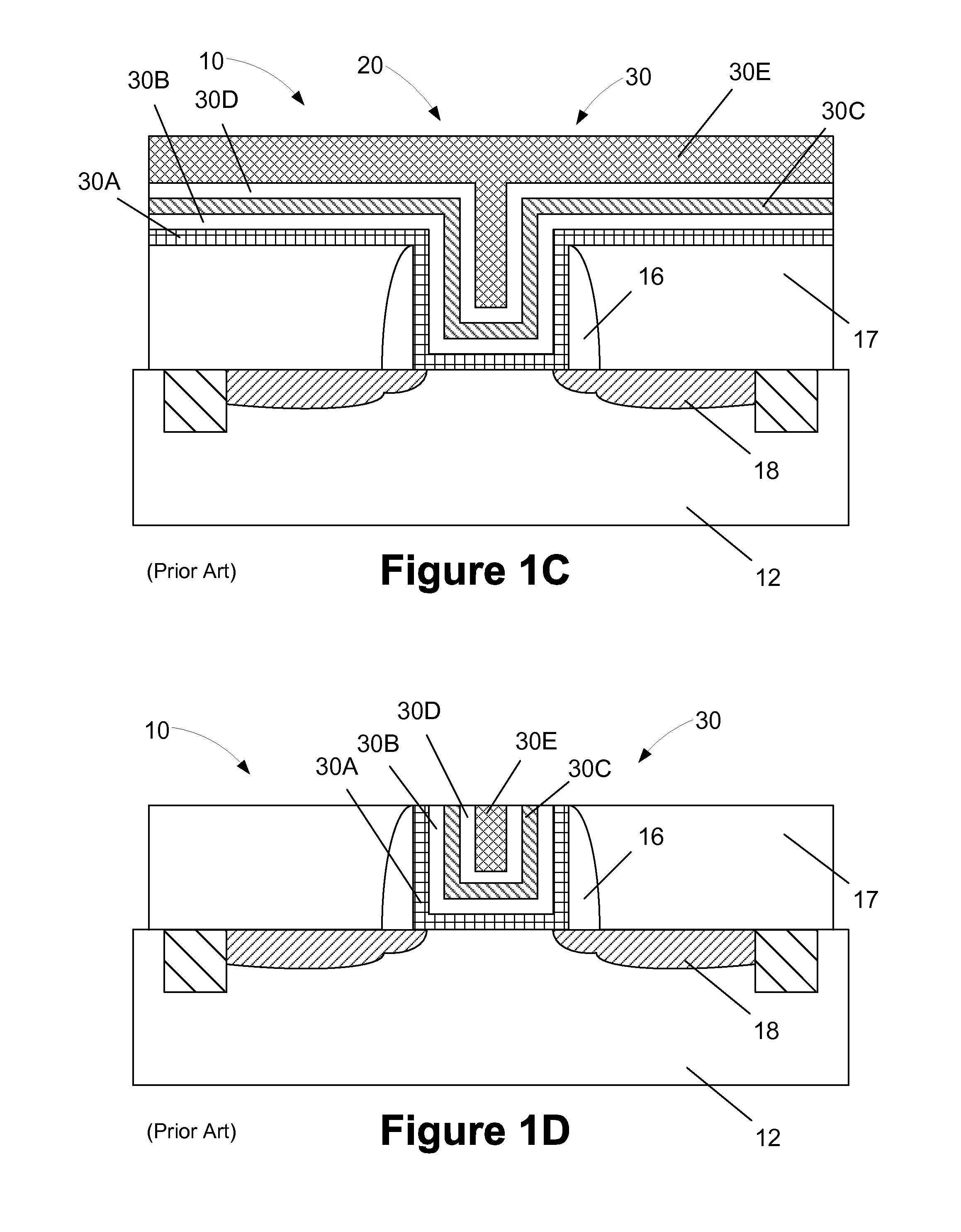

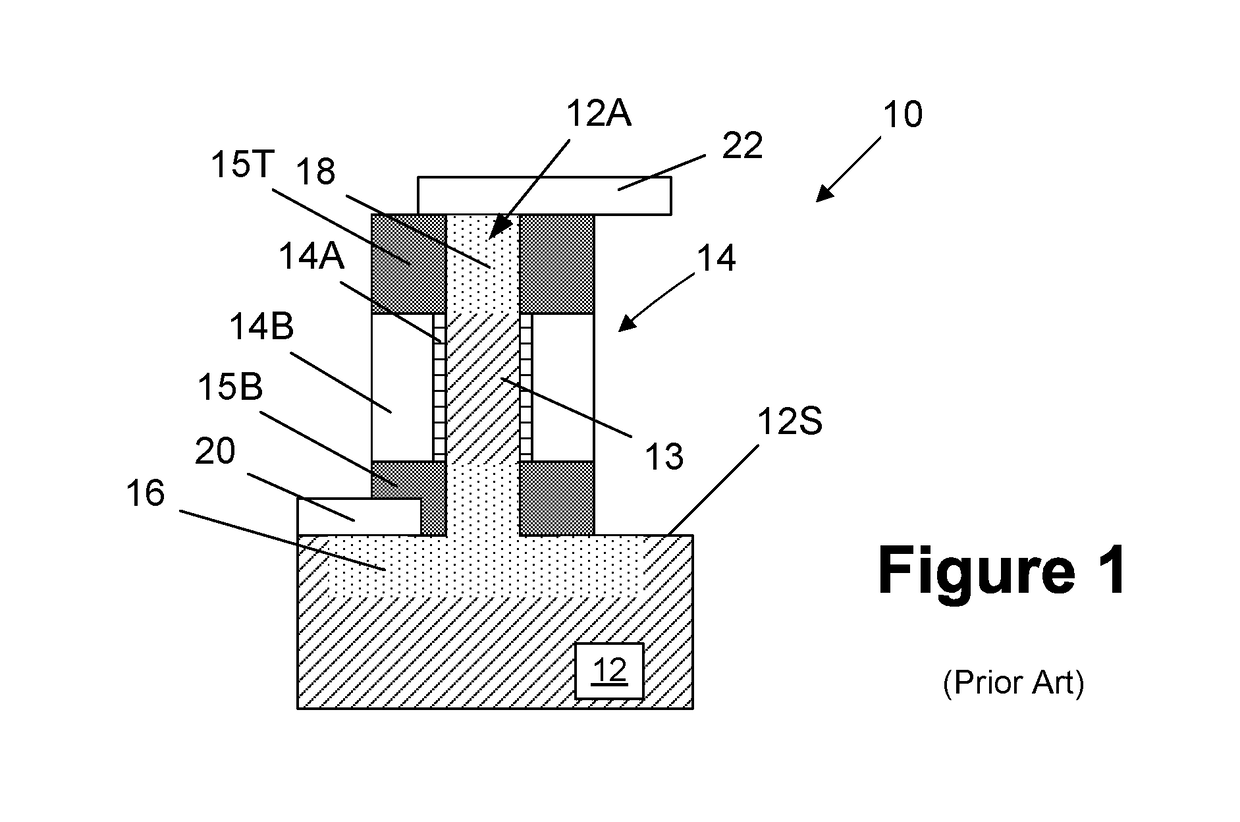

Methods of forming bulk finfet devices so as to reduce punch through leakage currents

ActiveUS20130280883A1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

Disclosed are methods of forming bulk FinFET semiconductor devices to reduce punch through leakage currents. One example includes forming a plurality of trenches in a semiconducting substrate to define a plurality of spaced-apart fins, forming a doped layer of insulating material in the trenches, wherein an exposed portion of each of the fins extends above an upper surface of the doped layer of insulating material while a covered portion of each of the fins is positioned below the upper surface of the doped layer of insulating material, and performing a process operation to heat at least the doped layer of insulating material to cause a dopant material in the doped layer to migrate from the doped layer of insulating material into the covered portions of the fins and thereby define a doped region in the covered portions of the fins that is positioned under the exposed portions of the fins.

Owner:TESSERA ADVANCED TECH

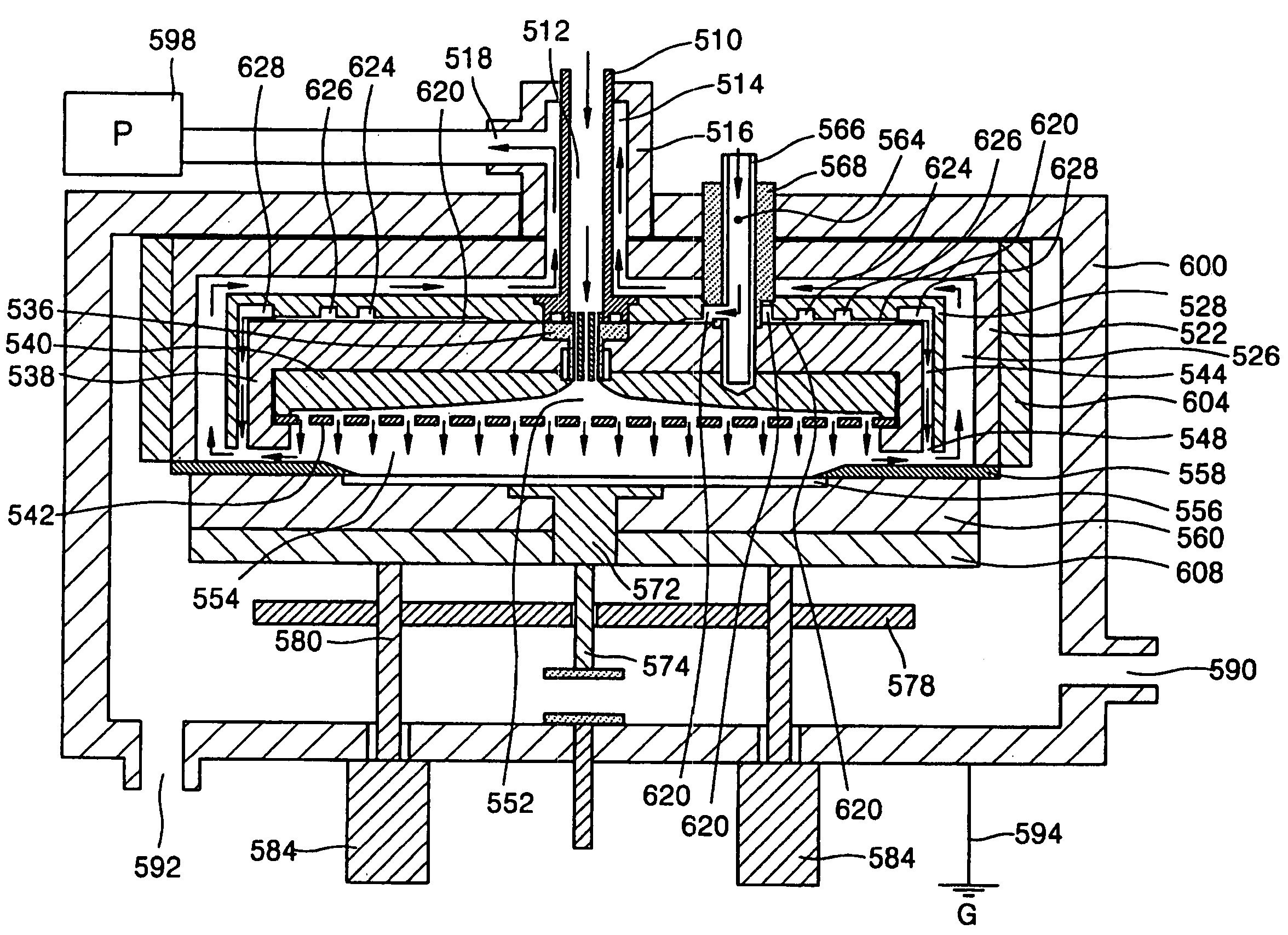

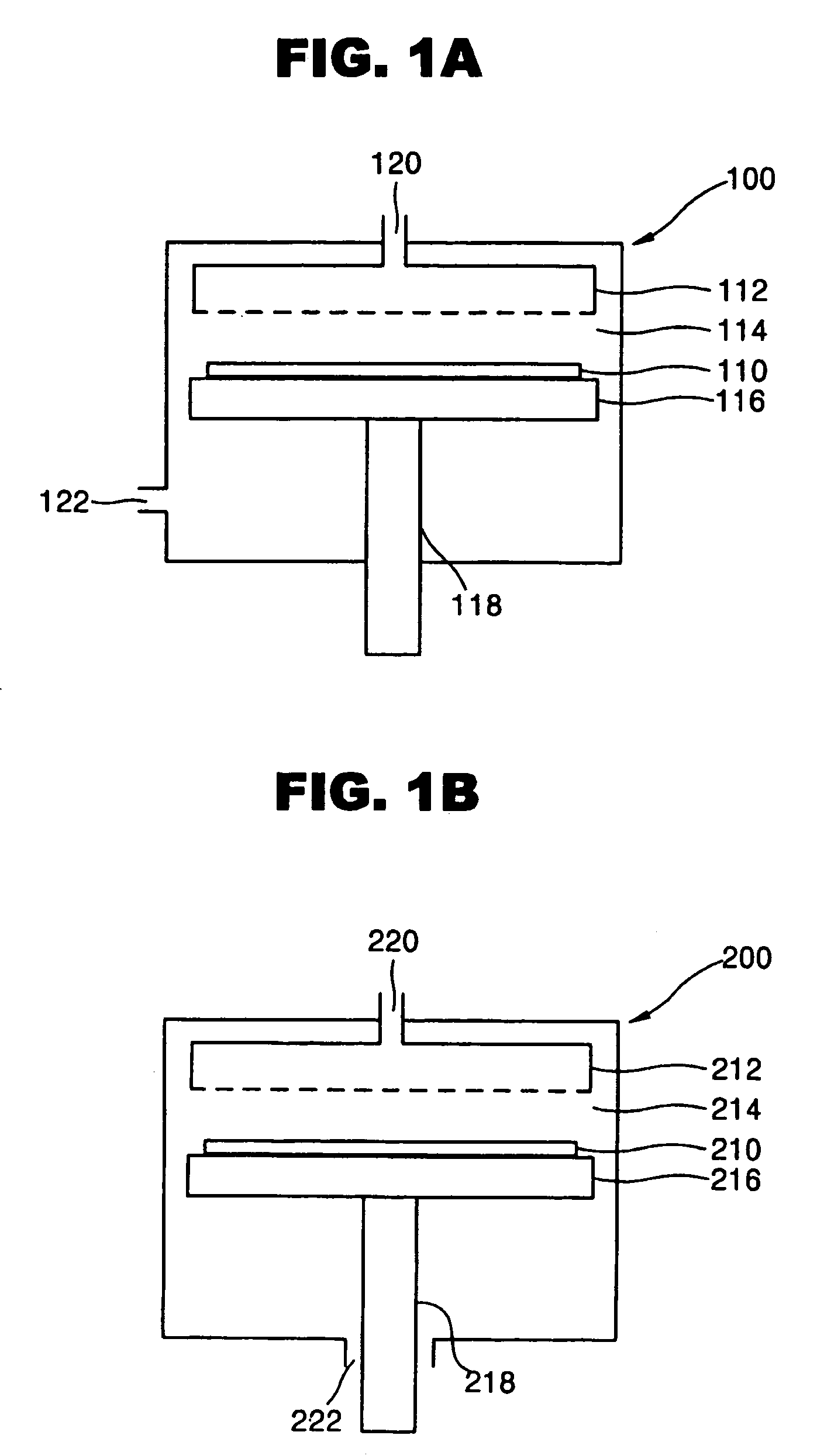

Plasma enhanced atomic layer deposition (PEALD) equipment and method of forming a conducting thin film using the same thereof

InactiveUS7138336B2AtomicEasy to carryElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProduct gas

A plasma enhanced atomic layer deposition (PEALD) apparatus and a method of forming a conductive thin film using the same are disclosed. According to the present invention of a PEALD apparatus and a method, a process gas inlet tube and a process gas outlet tube are installed symmetrically and concentrically with respect to a substrate, thereby allowing the process gas to flow uniformly, evenly and smoothly over the substrate, thereby forming a thin film uniformly over the substrate. A uniquely designed showerhead assembly provides not only reduces the volume of the reactor space, but also allows the process gases to flow uniformly, evenly and smoothly throughout the reation space area and reduces the volume of the reaction space, and the smaller volume makes it easier and fast to change the process gases for sequential and repeated process operation.

Owner:ASM KOREA LTD

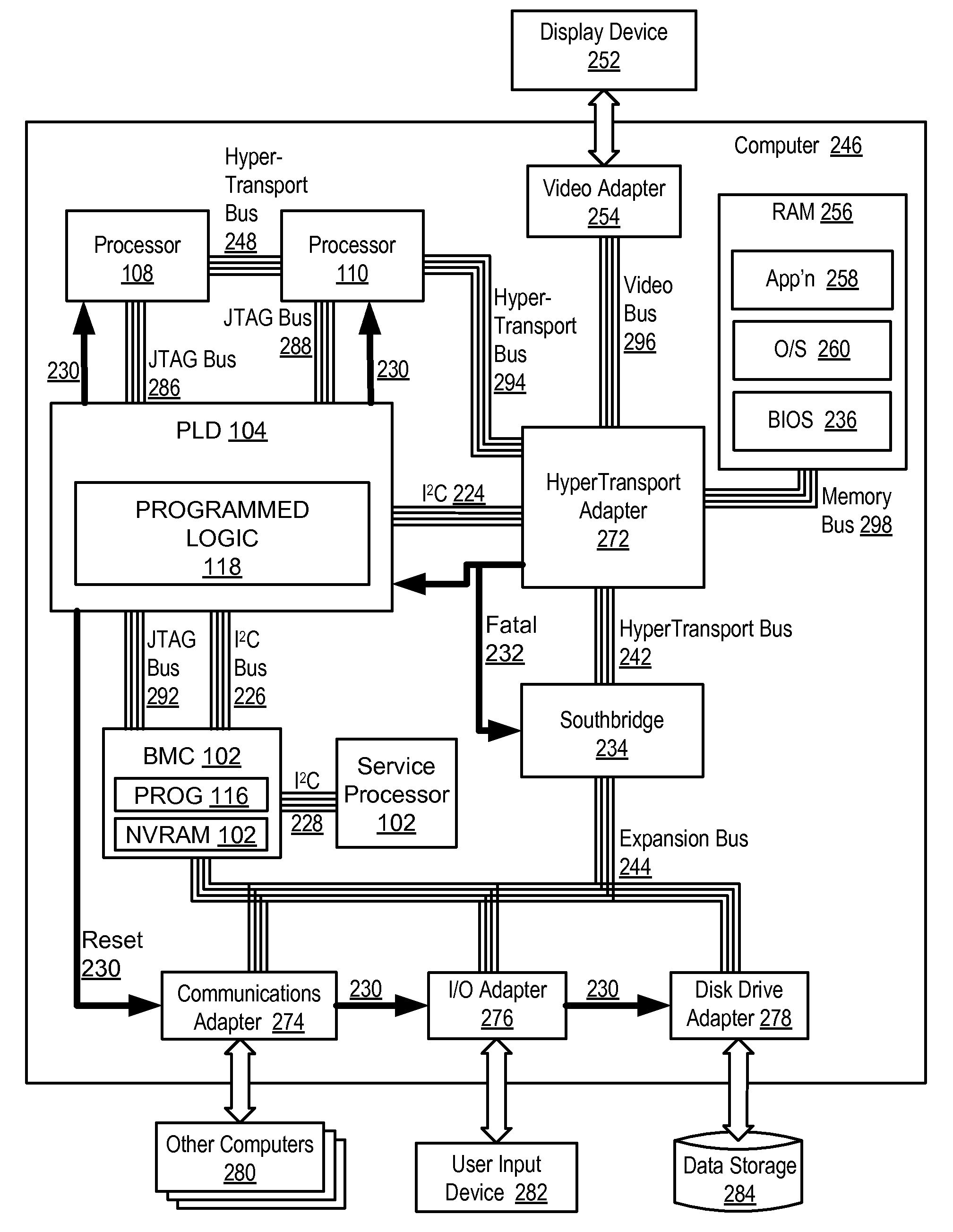

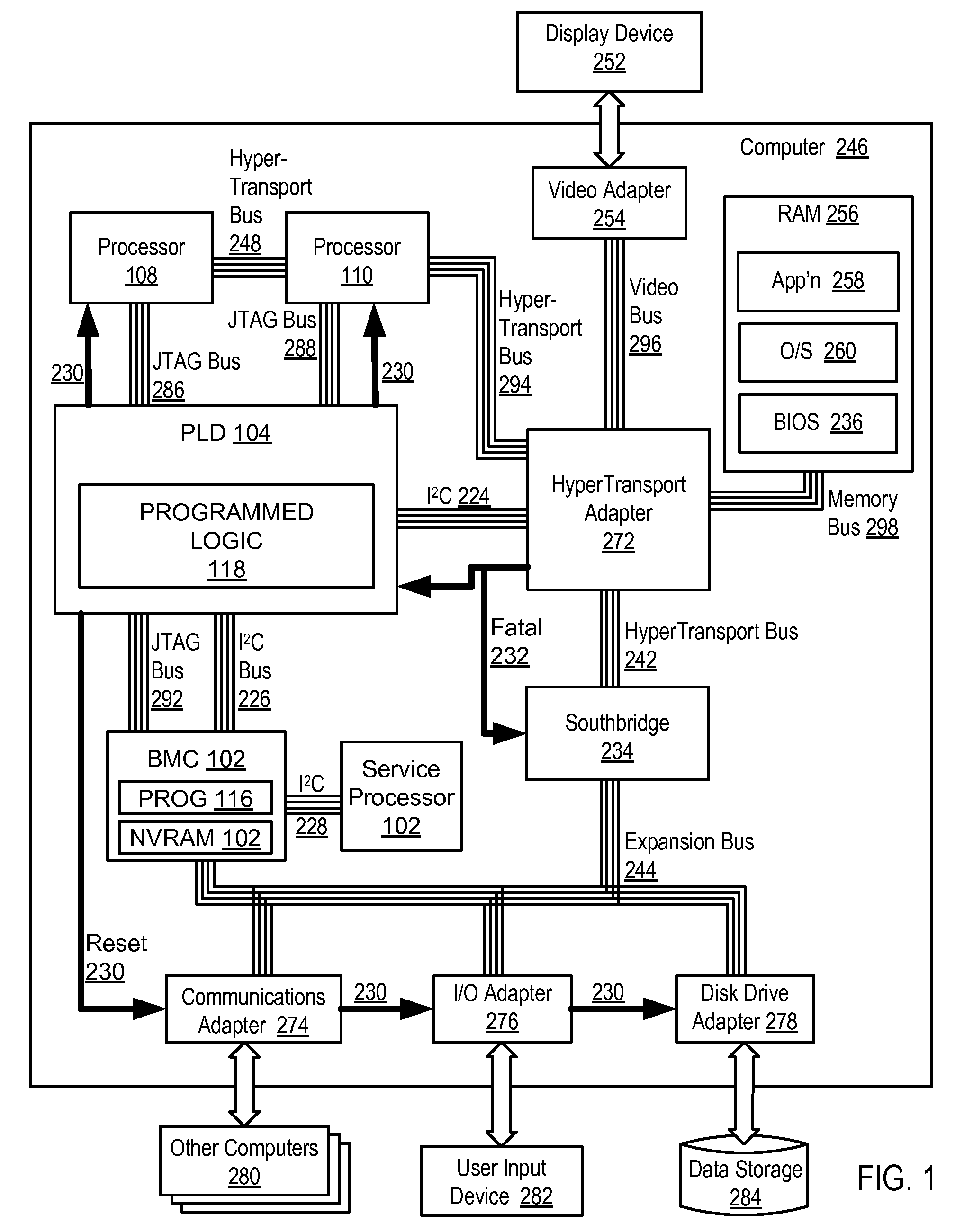

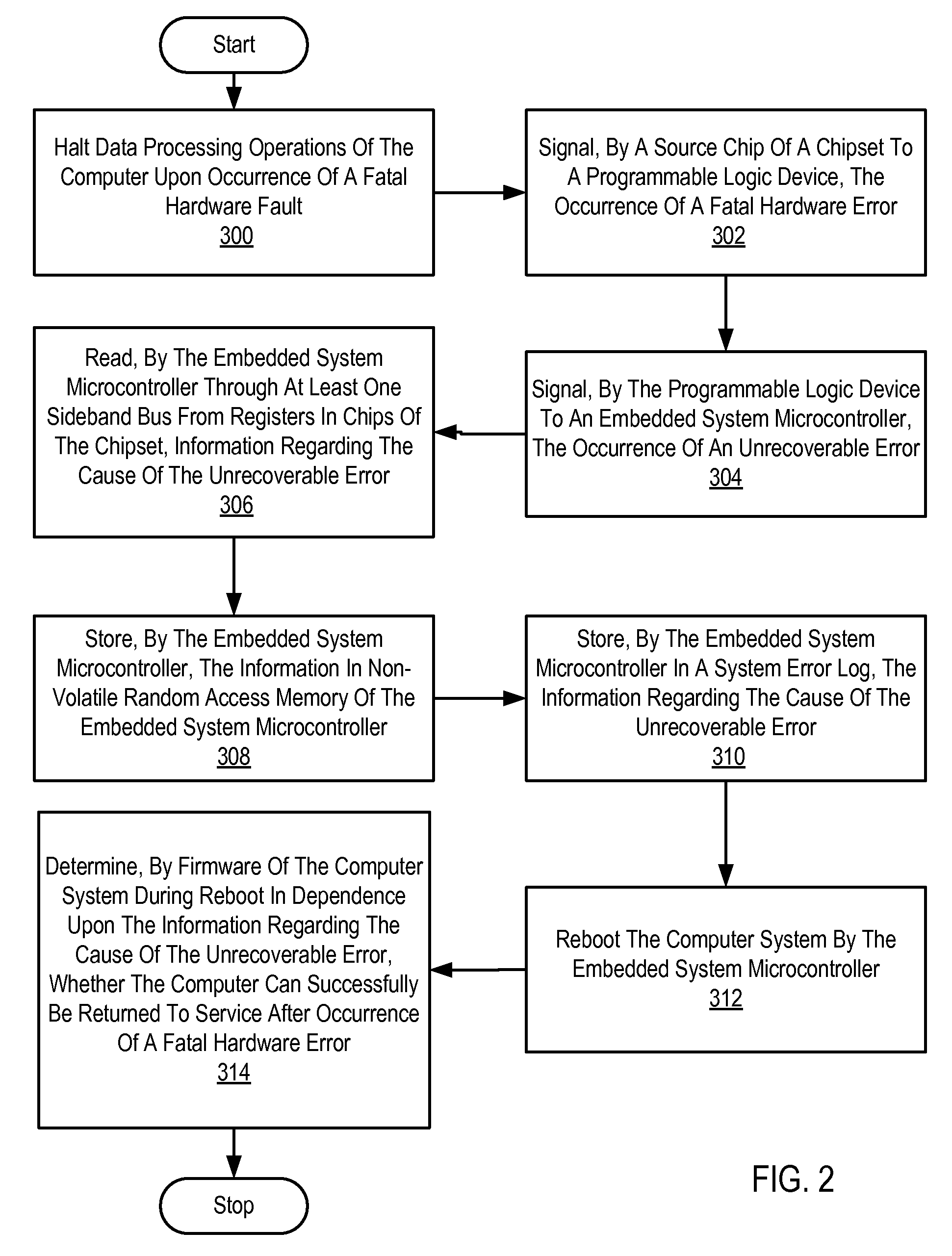

Handling Fatal Computer Hardware Errors

Methods and apparatus are disclosed for handling fatal computer hardware errors on a computer that include halting data processing operations of the computer upon occurrence of a fatal hardware error; signaling by a source chip of a chipset to the programmable logic device the occurrence of a fatal hardware error; signaling by the programmable logic device to an embedded system microcontroller the occurrence of a fatal hardware error; reading by the embedded system microcontroller through at least one sideband bus from registers in chips of the chipset information regarding the cause of the fatal hardware error; and storing by the embedded system microcontroller the information in non-volatile random access memory of the embedded system microcontroller.

Owner:IBM CORP

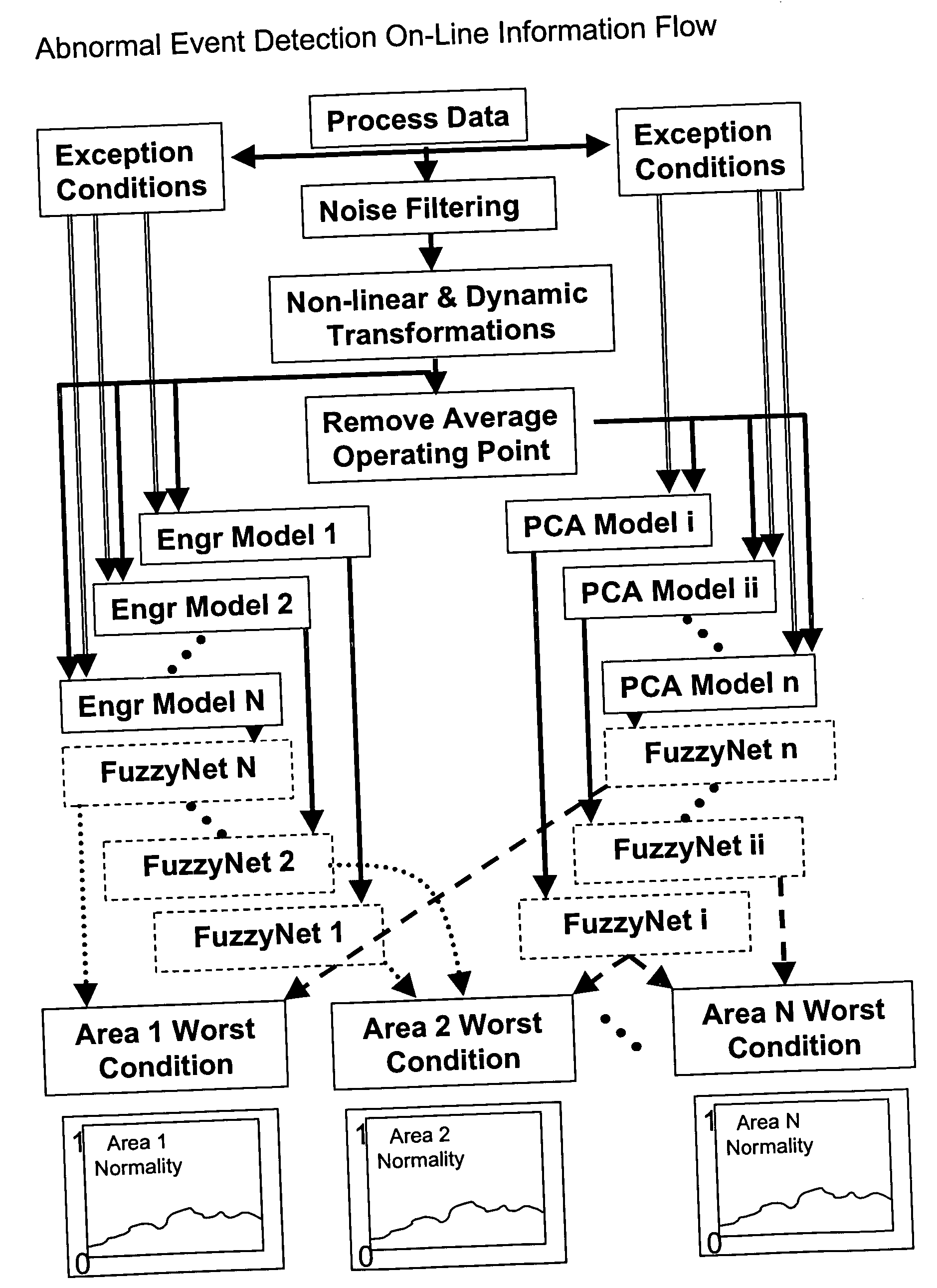

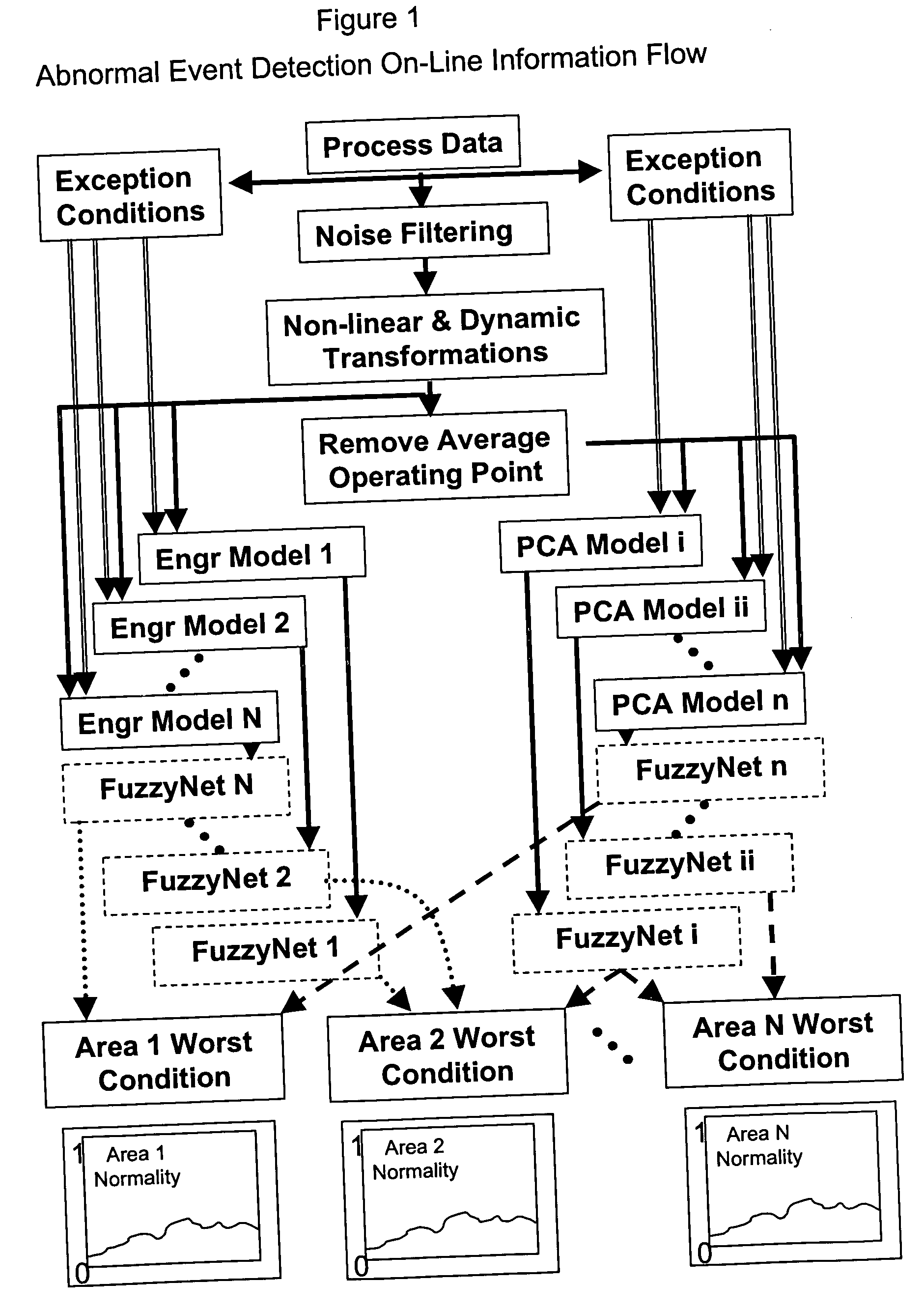

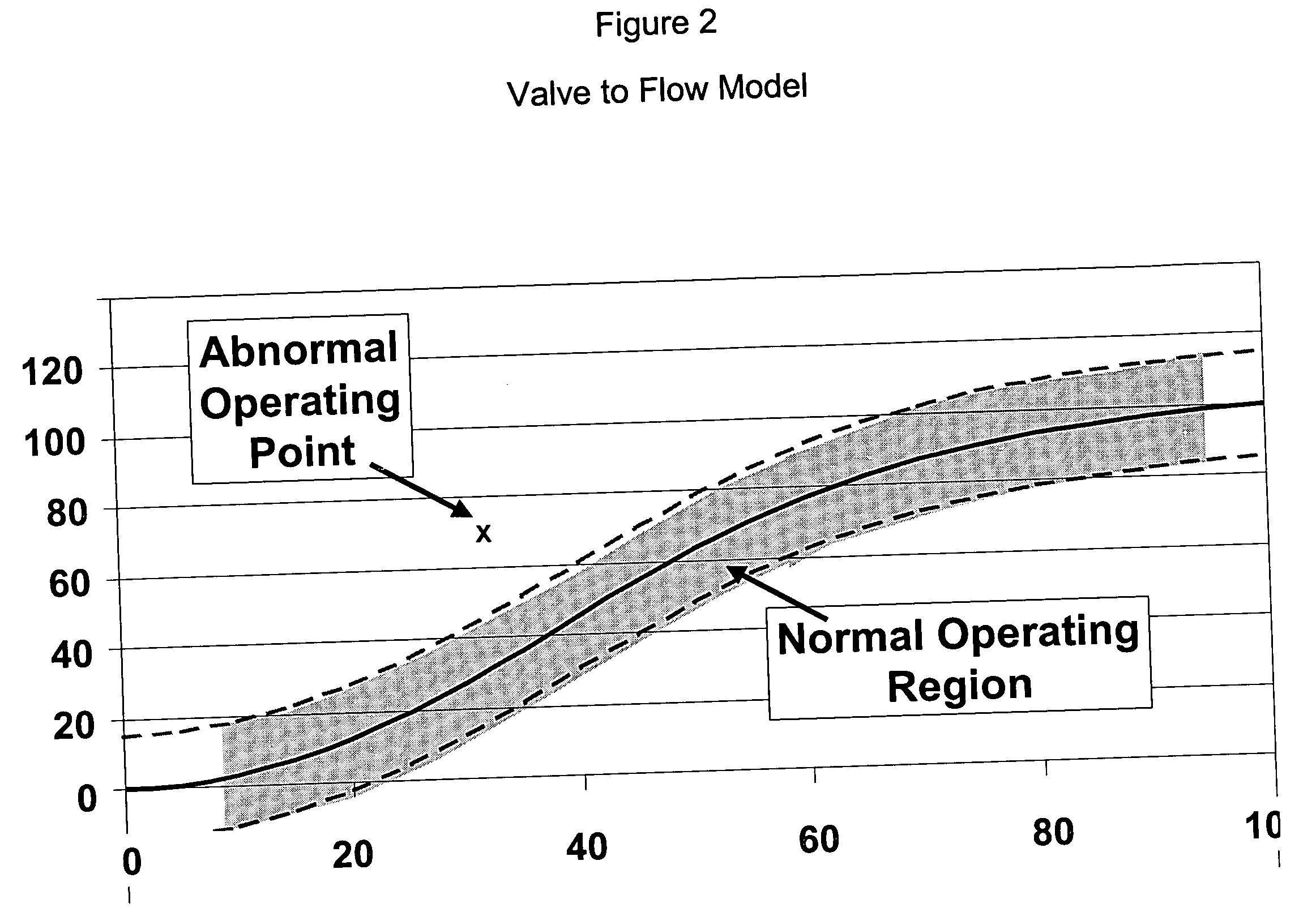

System and method for abnormal event detection in the operation of continuous industrial processes

ActiveUS20060058898A1Eliminate the effects ofEasy to monitorCatalytic crackingTesting/monitoring control systemsMultivariate statisticsPrincipal component analysis

Thousands of process and equipment measurements are gathered by the modern digital process control systems that are deployed in refineries and chemical plants. Several years of these data are historized in databases for analysis and reporting. These databases can be mined for the data patterns that occur during normal operation and those patterns used to determine when the process is behaving abnormally. These normal operating patterns are represented by sets of models. These models include simple engineering equations, which express known relationships that should be true during normal operations and multivariate statistical models based on a variation of principle component analysis. Equipment and process problems can be detected by comparing the data gathered on a minute by minute basis to predictions from these models of normal operation. The deviation between the expected pattern in the process operating data and the actual data pattern are interpreted by fuzzy Petri nets to determine the normality of the process operations. This is then used to help the operator localize and diagnose the root cause of the problem.

Owner:EXXON RES & ENG CO

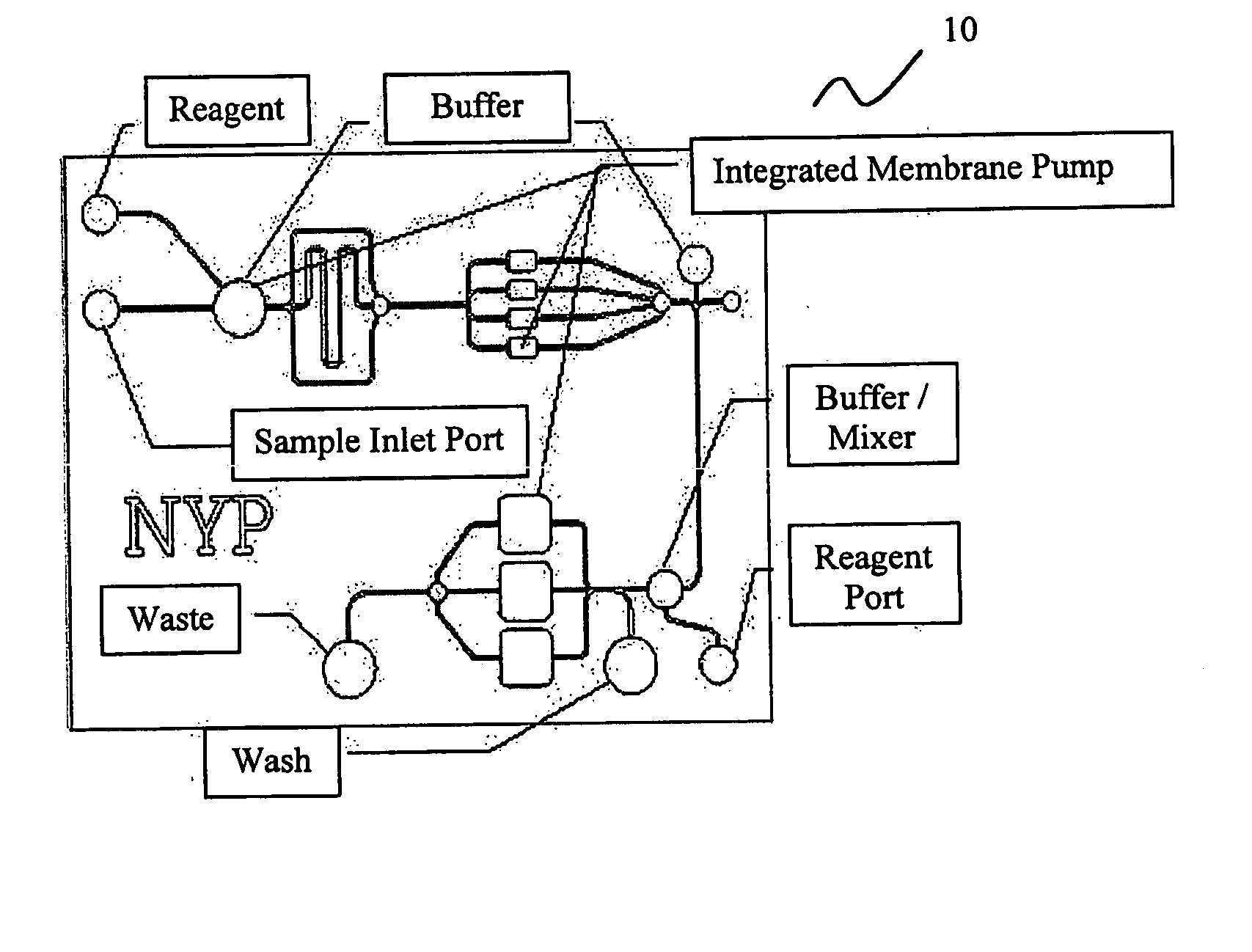

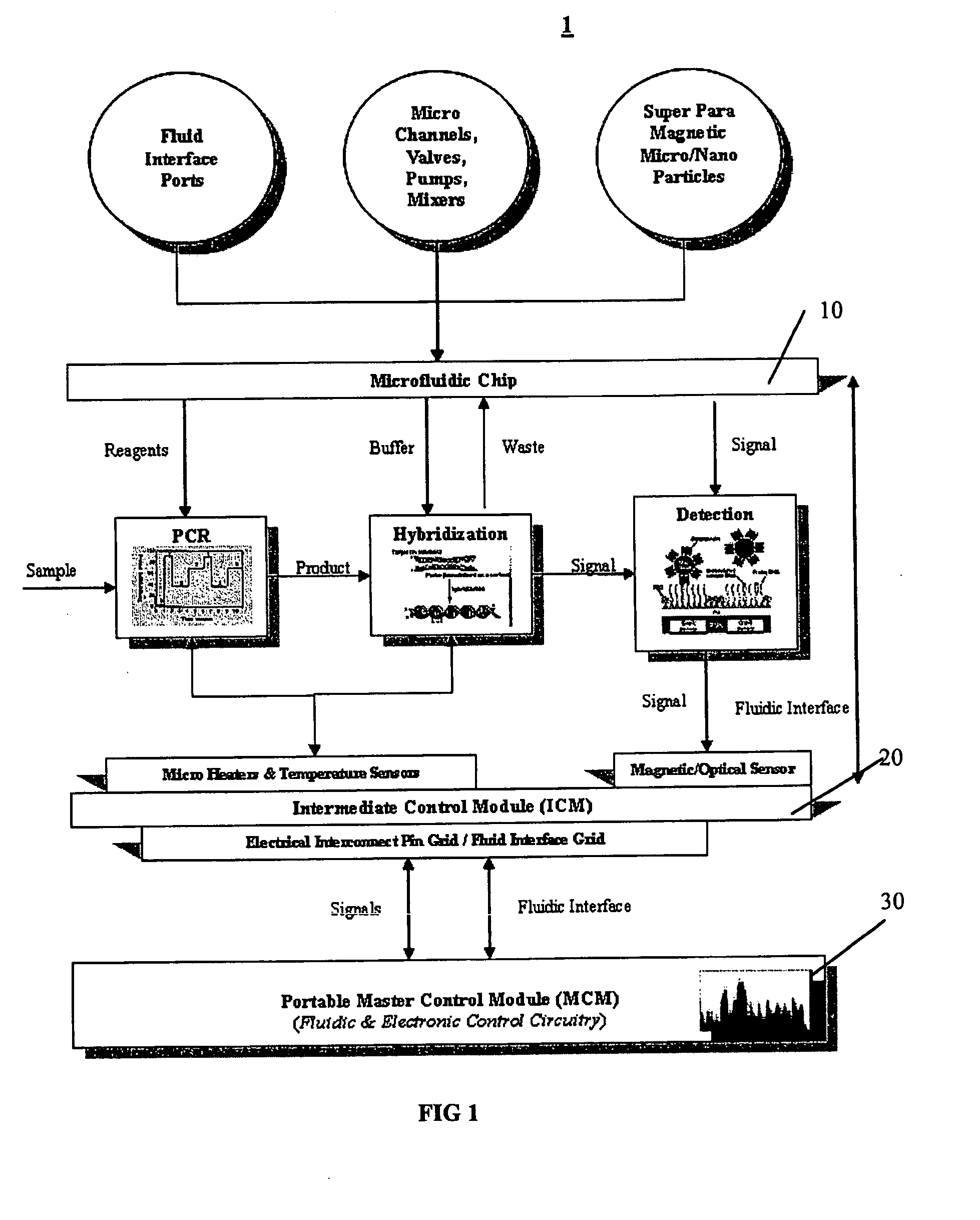

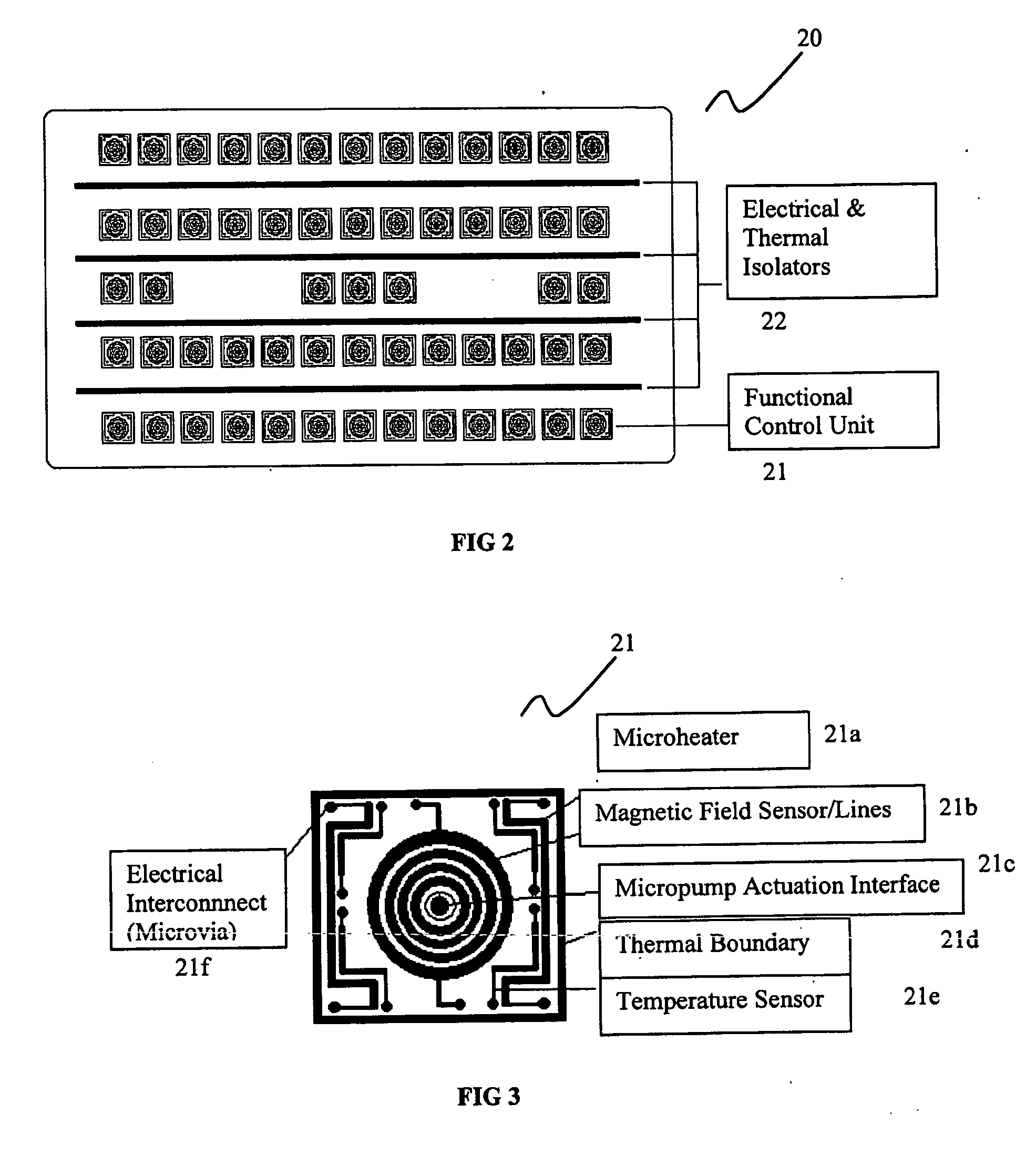

Smart nano-integrated system assembly

InactiveUS20070231213A1Convenience and cost-efficiencyImprove efficiencyAnalysis using chemical indicatorsHeating or cooling apparatusCost effectivenessMechanical components

The present invention provides a nano-integrated system assembly that offers both convenience and cost-efficiency, where multiple fluidic, electronic and mechanical components or chemical processes are optimally embraced effectively and efficiently in a systematic modularized manner. Furthermore, the nano-integrated system assembly has a generic configuration so as to enable and accommodate a wide spectrum of differently combined sequences of analyzing / processing operations to be performed on the identical nano-integrated system assembly.

Owner:NANYANG POLYTECHNIC

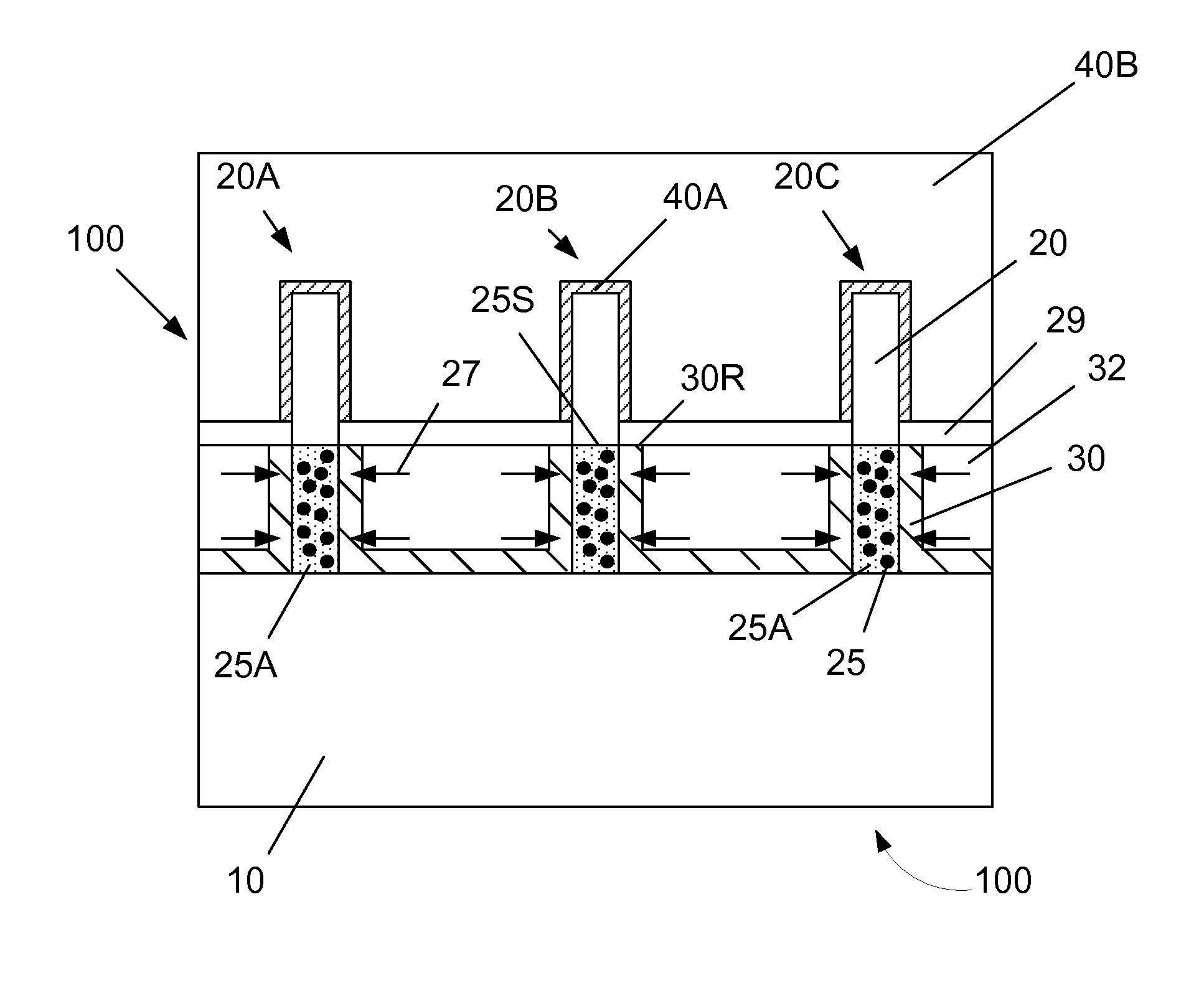

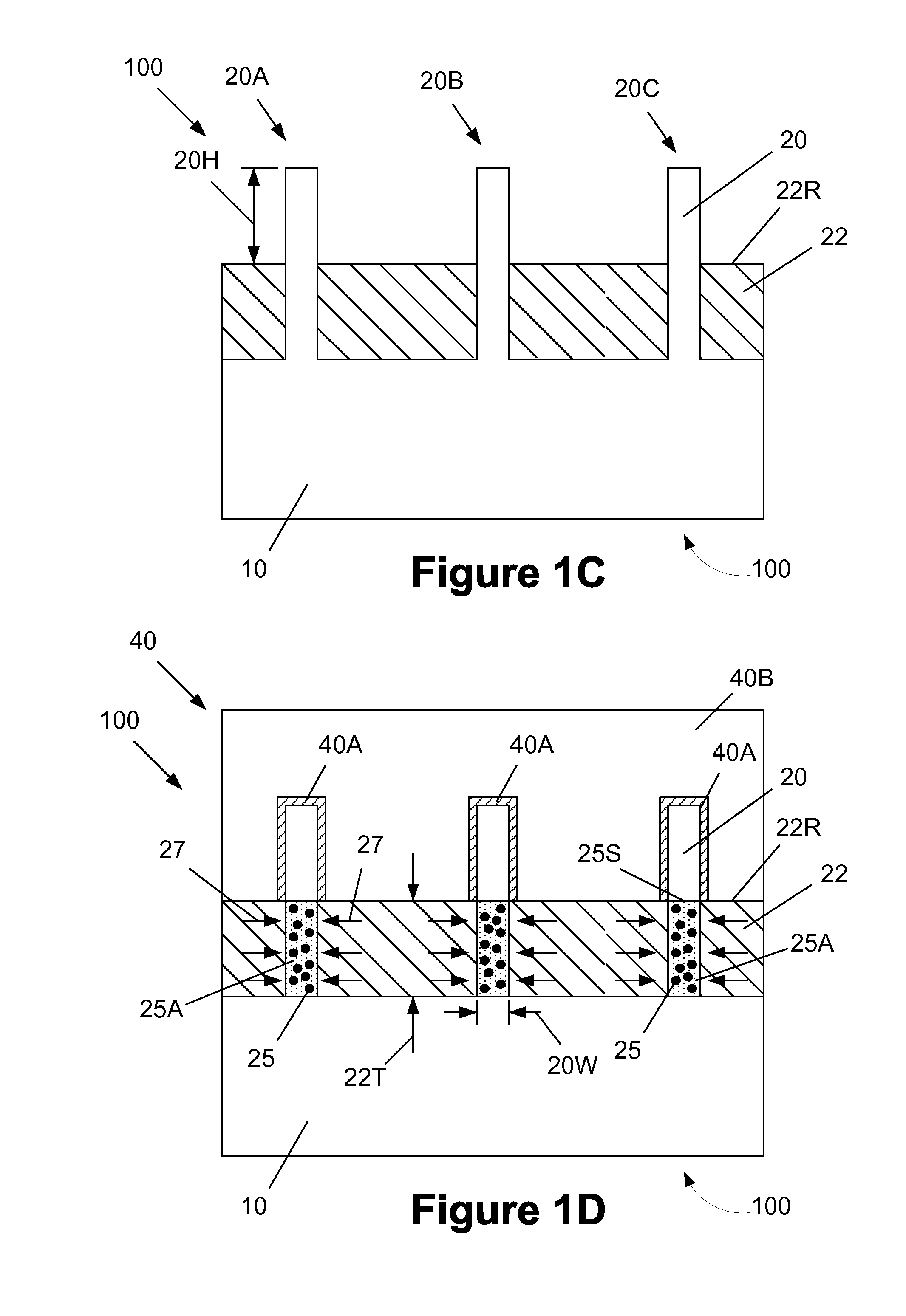

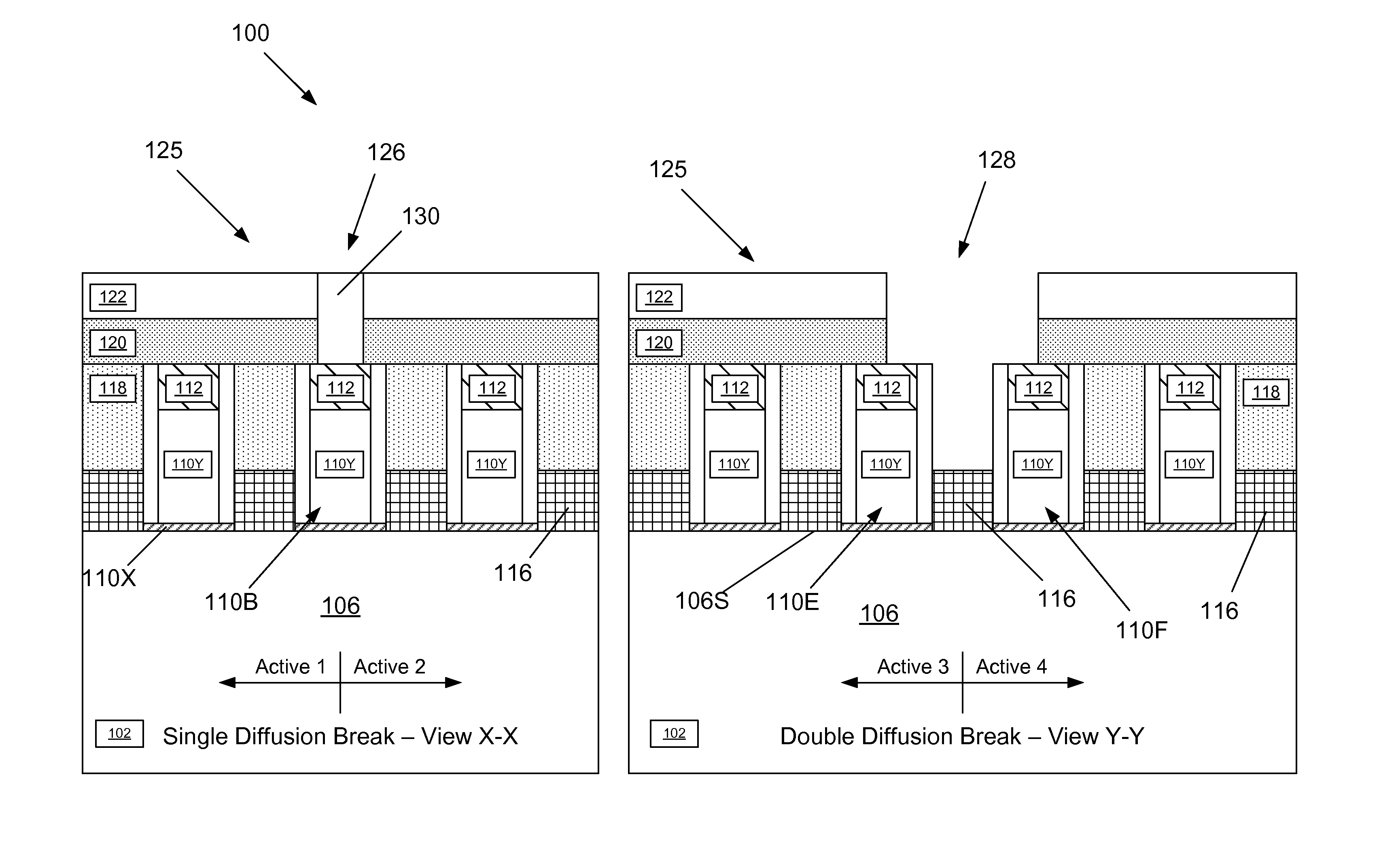

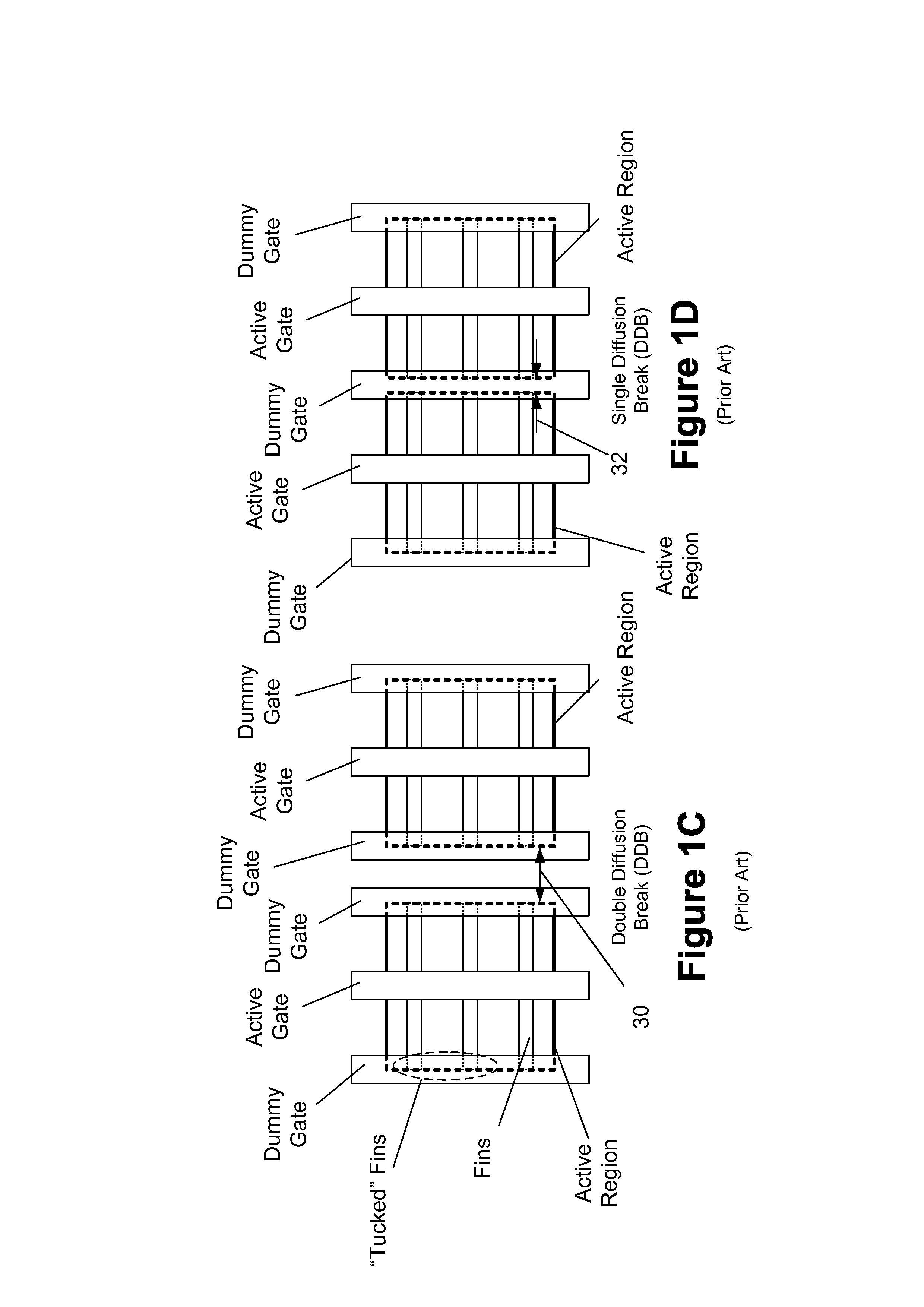

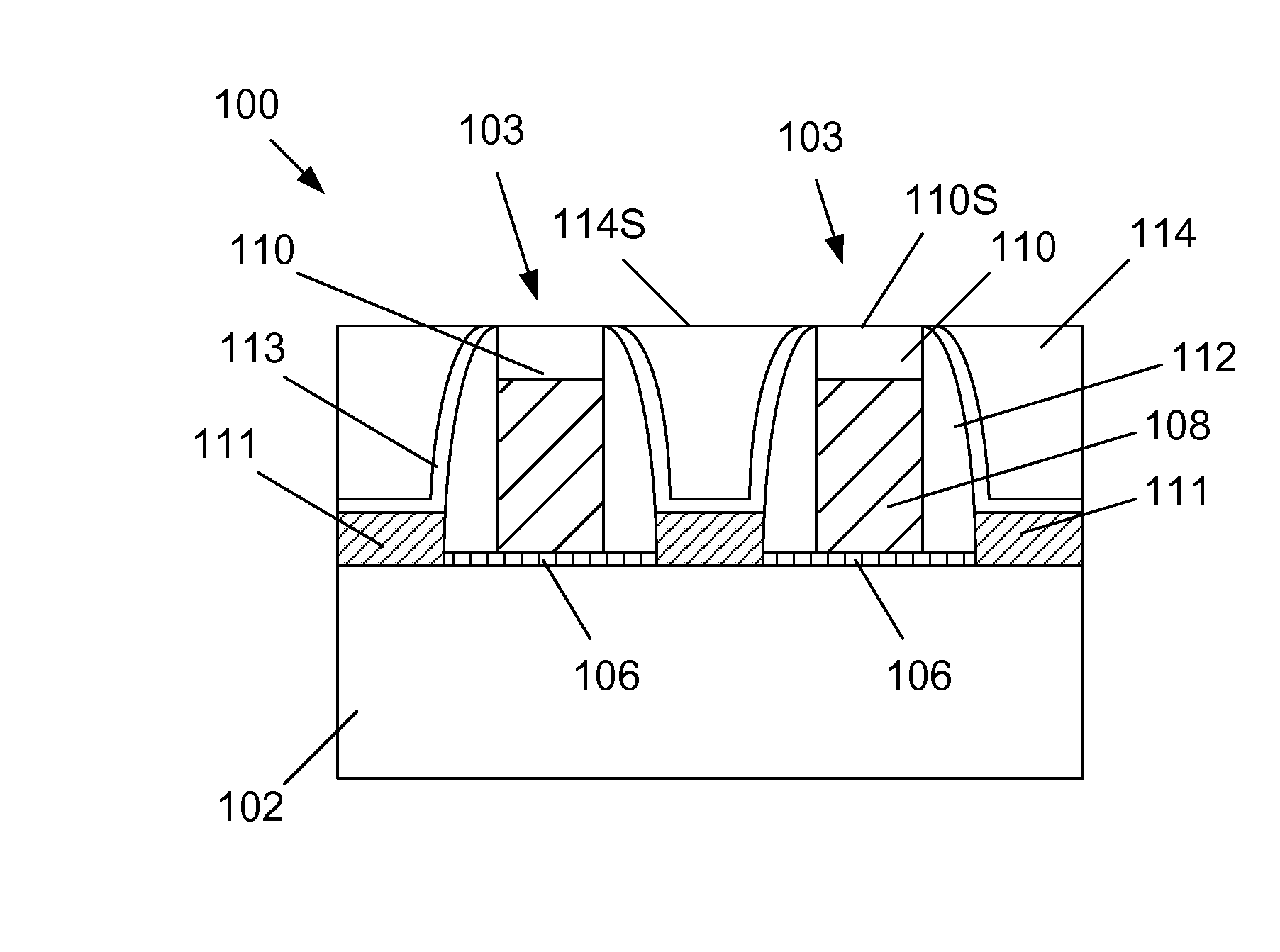

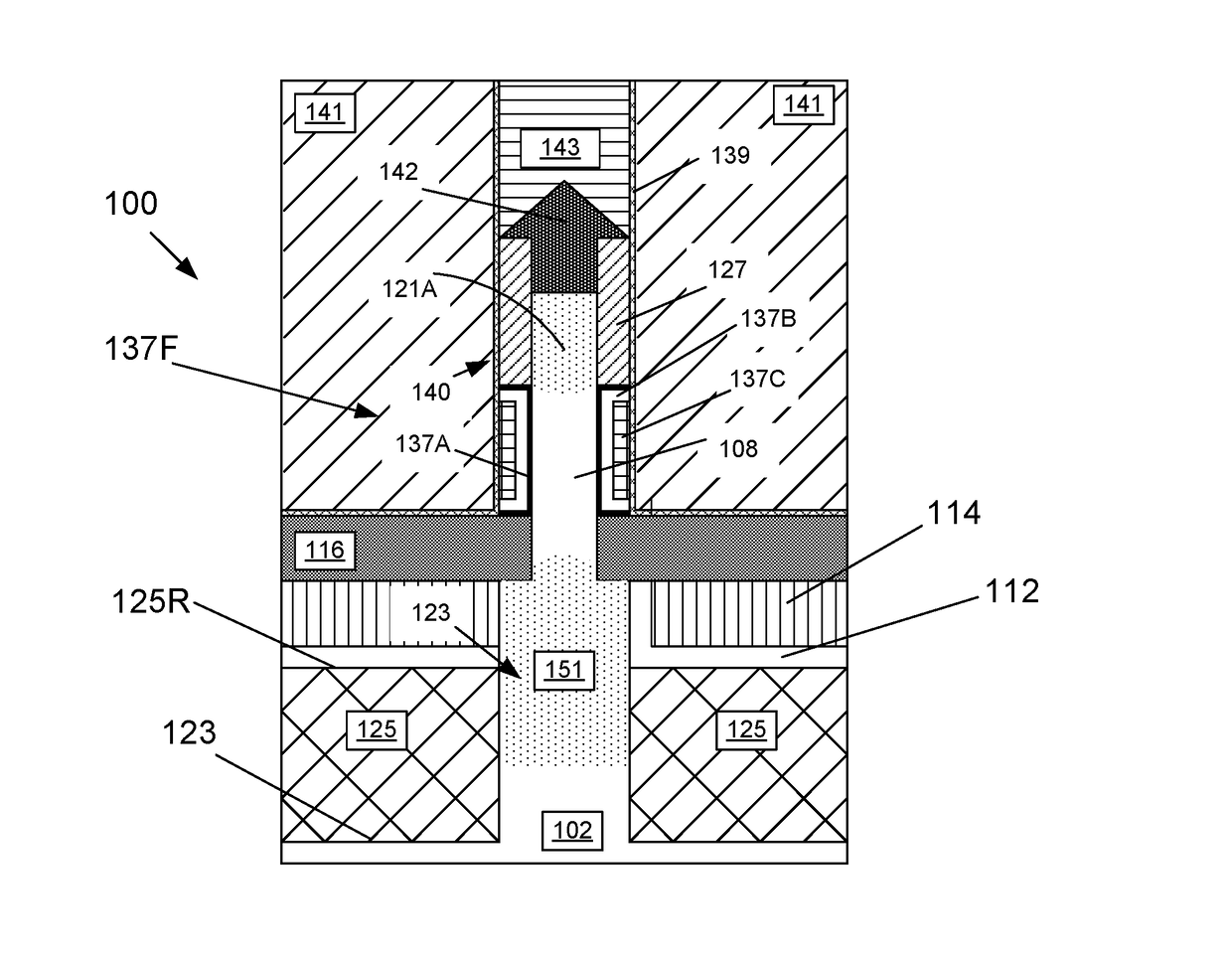

Methods of forming single and double diffusion breaks on integrated circuit products comprised of FinFET devices and the resulting products

ActiveUS9412616B1Well formedSolid-state devicesSemiconductor/solid-state device manufacturingDouble diffusionIntegrated circuit layout

One illustrative method disclosed herein includes, among other things, forming a multi-layer patterned masking layer comprised of first and second layers of material and first and second openings that extend through both of the first and second layers of material, wherein the first opening is positioned above a first area of the substrate where the DDB isolation structure will be formed and the second opening is positioned above a second area of the substrate where the SDB isolation structure will be formed. The method also includes performing a first process operation through the first opening to form the DDB isolation structure, performing a second process operation to remove the second layer of material and to expose the first opening in the first layer of material, and performing a third process operation through the second opening to form the SDB isolation structure.

Owner:GLOBALFOUNDRIES US INC

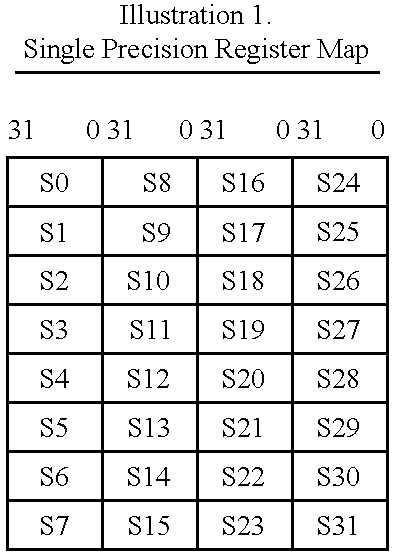

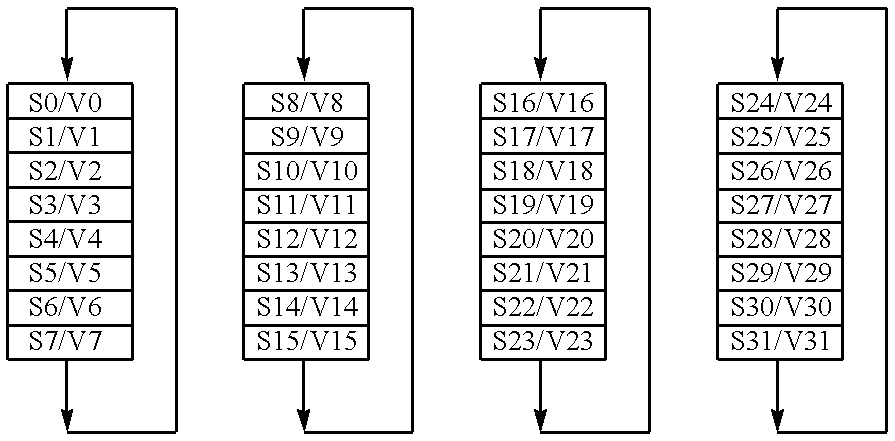

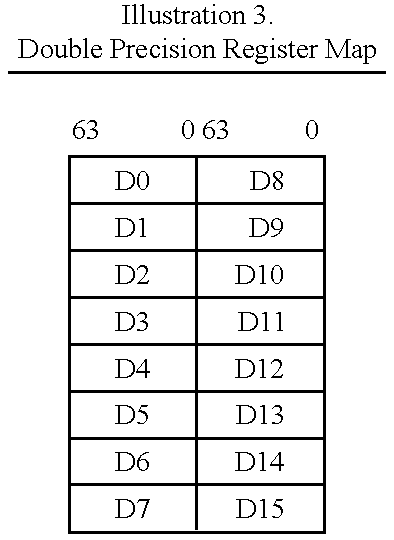

Vector register addressing

InactiveUS6332186B1Without complexityWithout costRegister arrangementsInstruction analysisMemory addressProcessing Instruction

A floating point unit 26 is provided with a register bank 38 comprising 32 registers that may be used as either vector registers V or scalar registers S. Data values are transferred between memory 30 and the registers within the register bank 38 using contiguous block memory access instructions. Vector processing instructions specify a sequence of processing operations to be performed upon data values within a sequence of registers. The register address is incremented between each operation by an amount controlled by a stride value. Accordingly, the register address can be incremented by values such as 0, 1, 2 or 4 between each iteration. This provides a mechanism for retaining block memory access instructions to contiguous memory addresses whilst supporting vector matrix and / or complex operations in which the data values needed for each iteration are not adjacent to one another in the memory 30.

Owner:ARM LTD

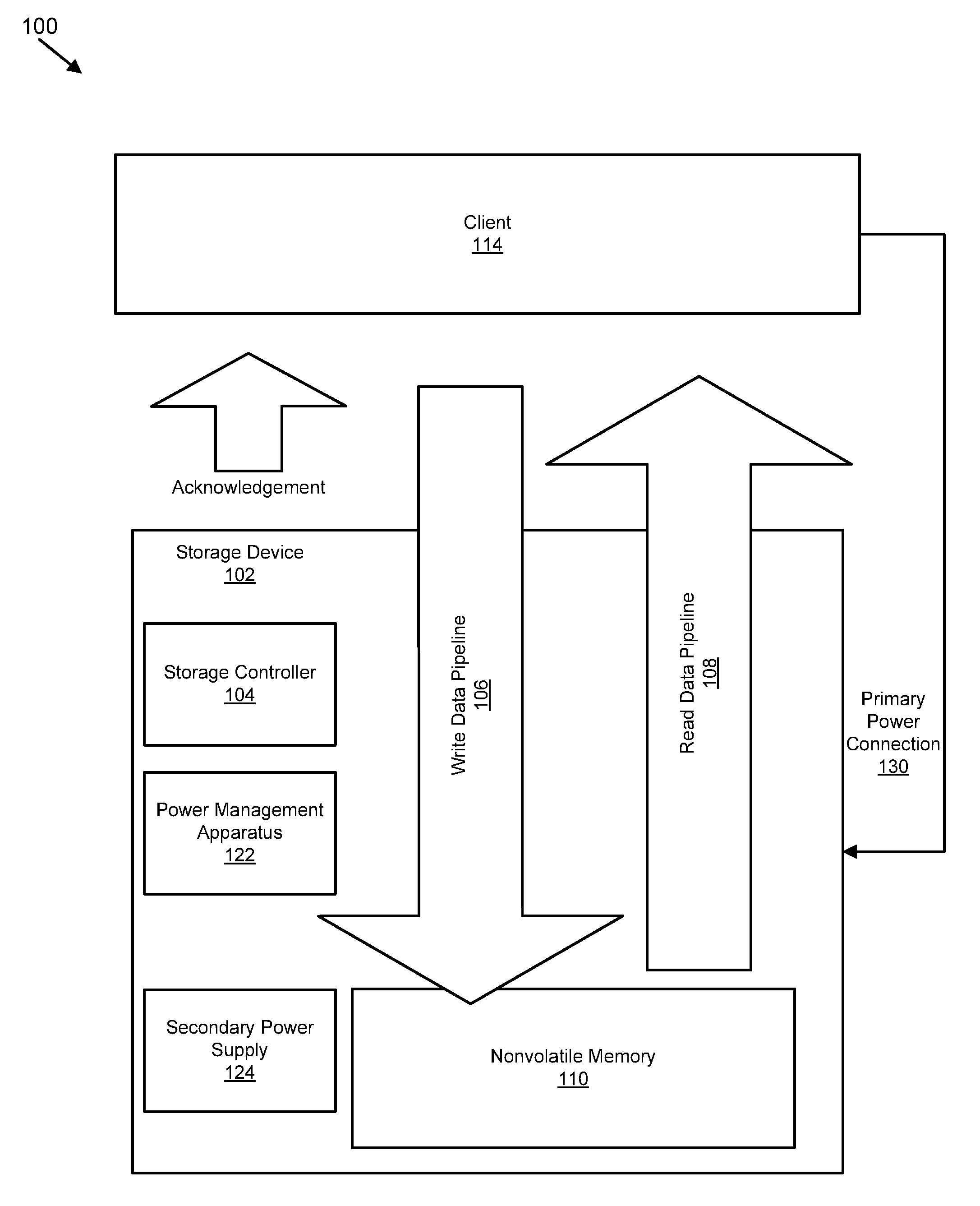

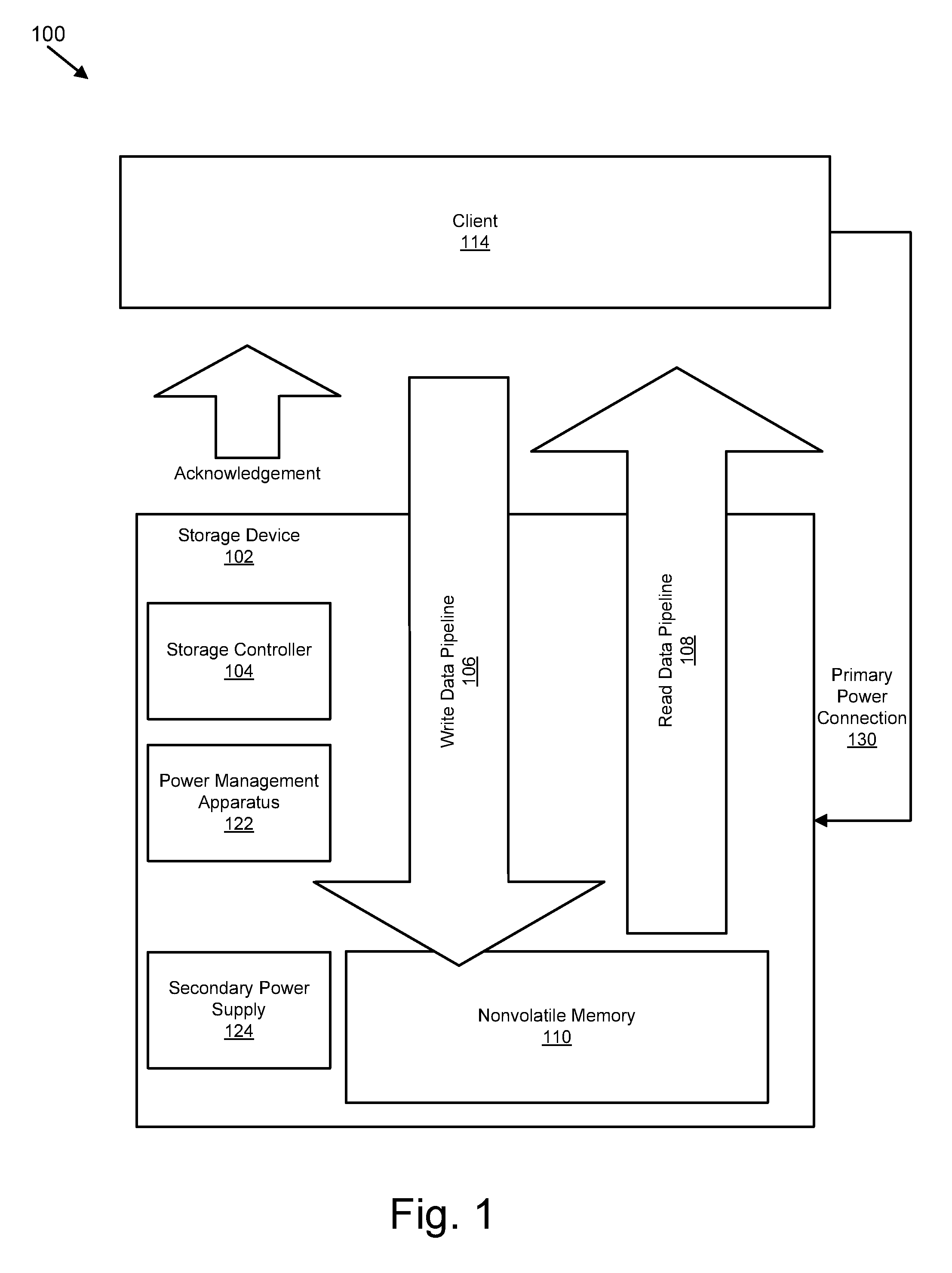

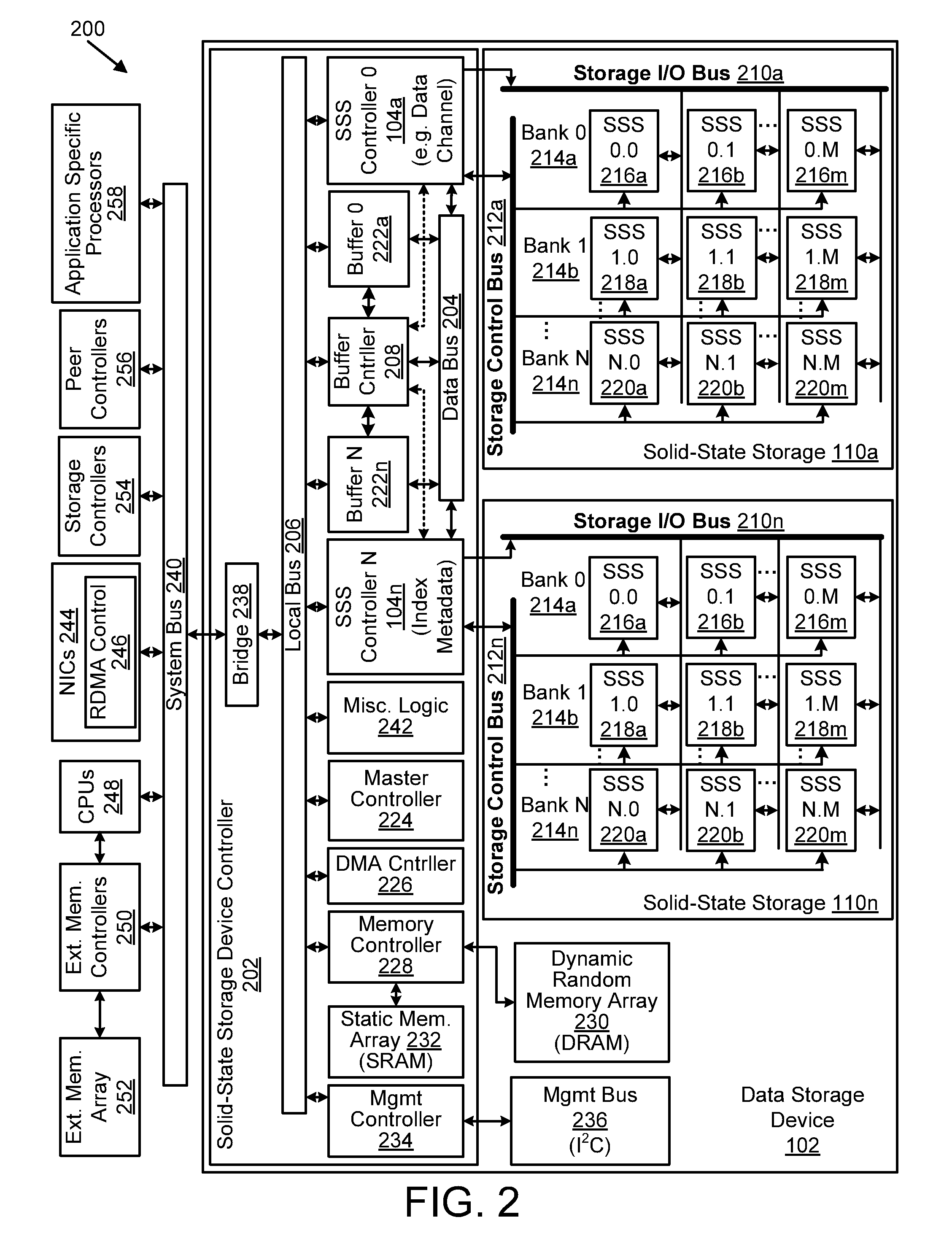

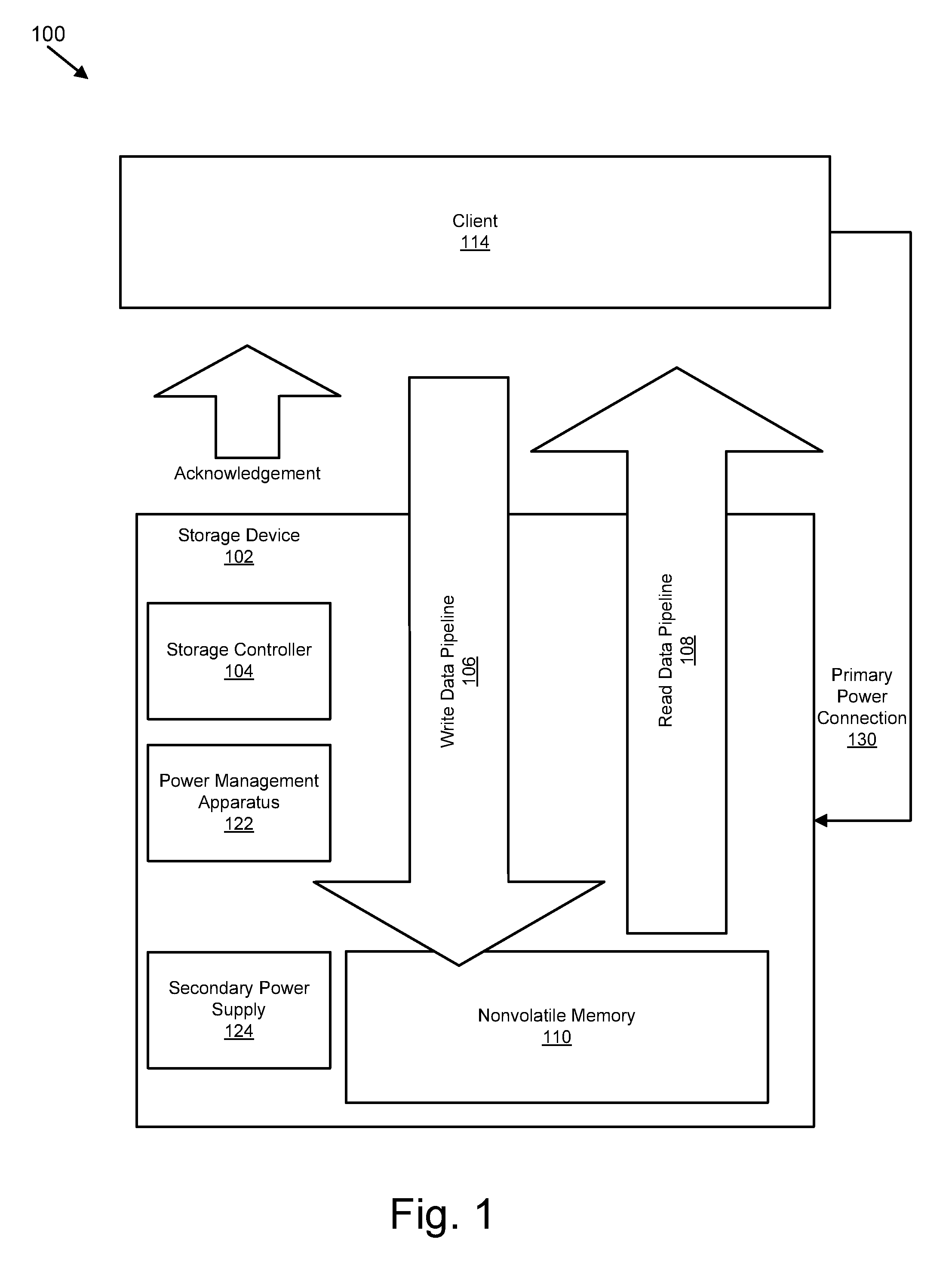

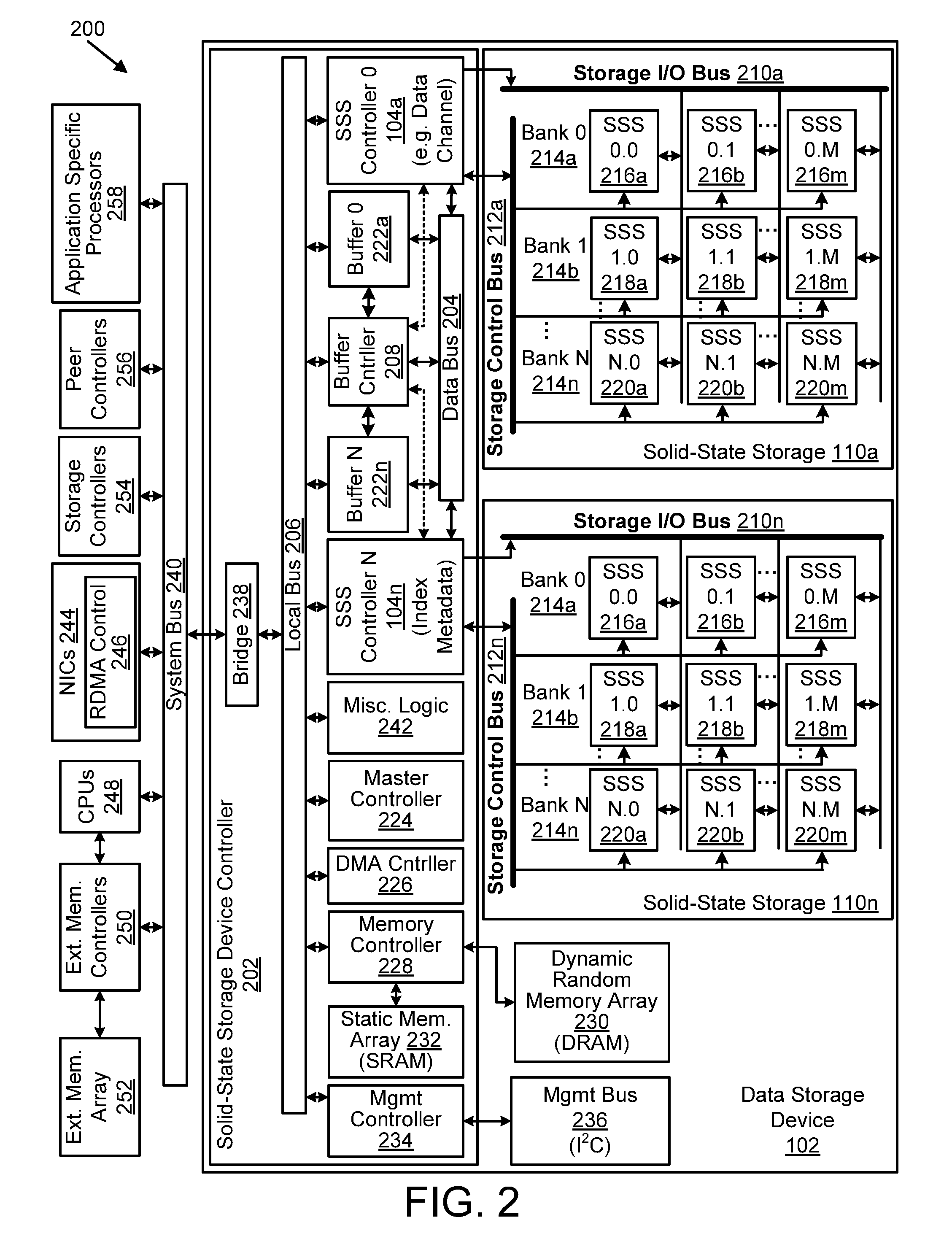

Apparatus, system, and method for power reduction management in a storage device

An apparatus, system, and method are disclosed for power loss management in a nonvolatile data storage device. A monitor module initiates a power loss mode in the nonvolatile data storage device in response to a primary power source failing to supply electric power above a predefined threshold to the nonvolatile data storage device. A secondary power source supplies electric power to the nonvolatile data storage device for at least a power hold-up time during the power loss mode. A power loss module adjusts execution of in-process operations on the nonvolatile data storage device during the power loss mode so that essential in-process operations execute within the power hold-up time.

Owner:SANDISK TECH LLC

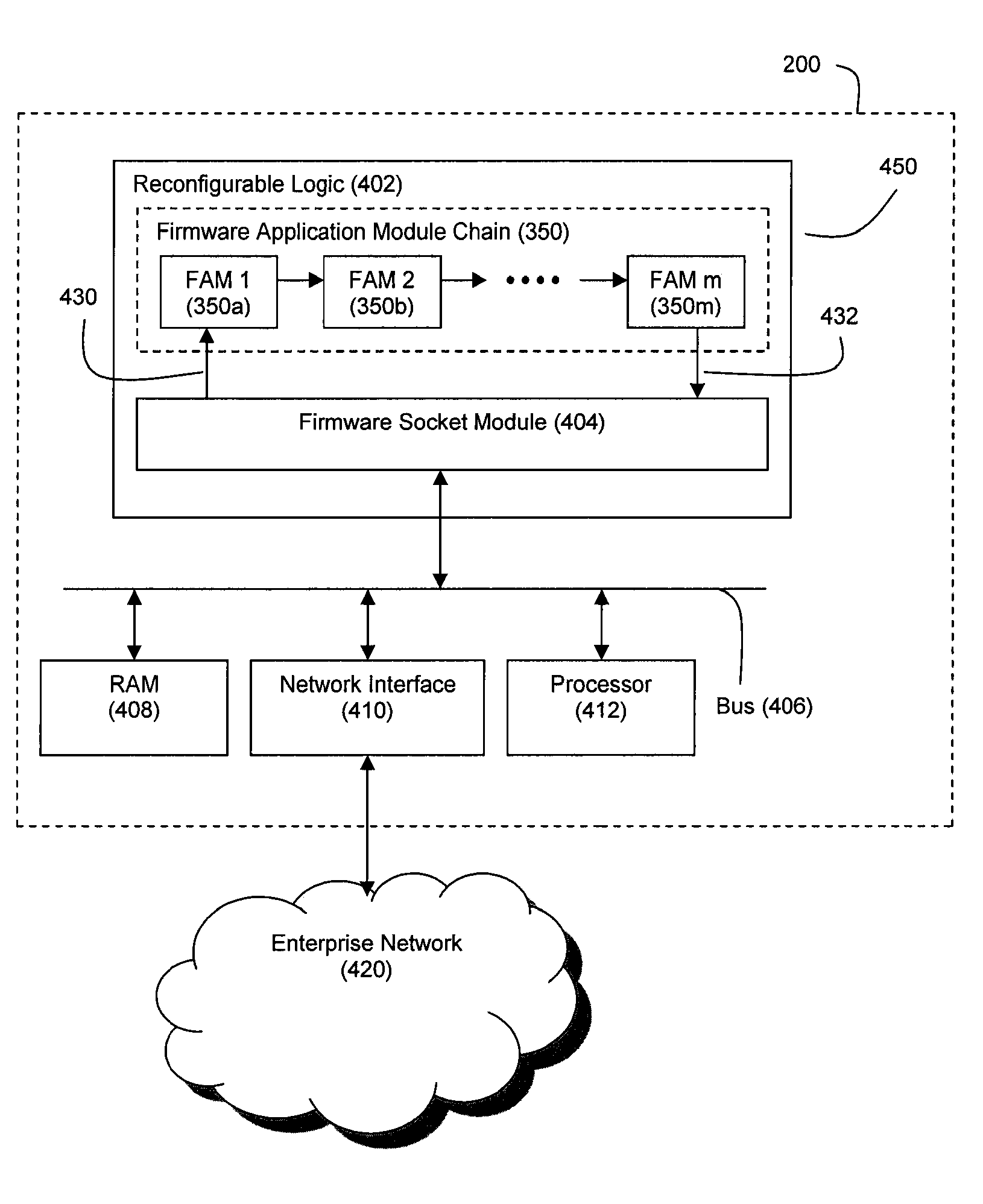

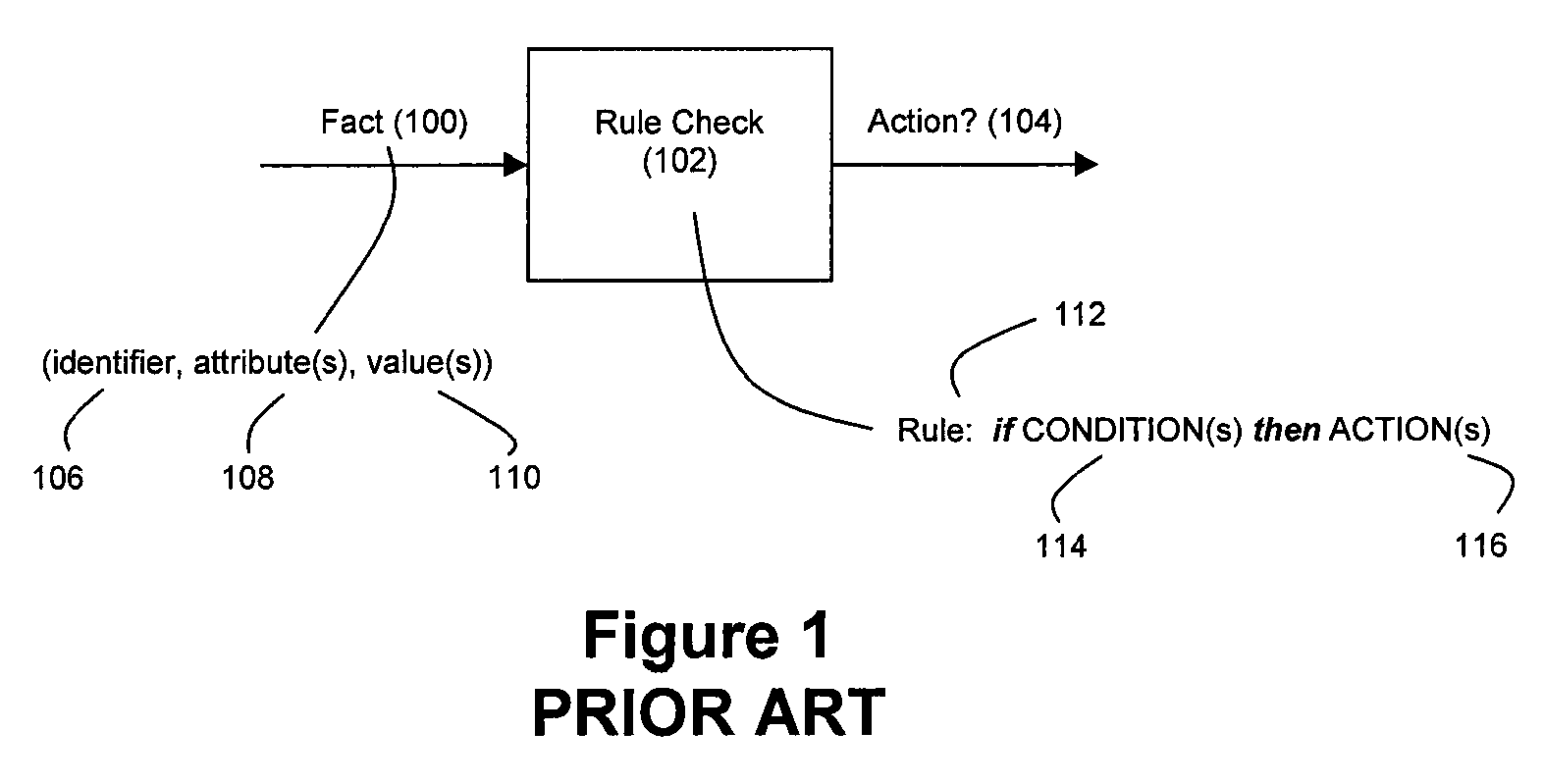

Method and system for accelerated stream processing

ActiveUS8374986B2Low degreeImprove latencyDigital computer detailsCode conversionProgramming languageData stream

Disclosed herein is a method and system for hardware-accelerating various data processing operations in a rule-based decision-making system such as a business rules engine, an event stream processor, and a complex event stream processor. Preferably, incoming data streams are checked against a plurality of rule conditions. Among the data processing operations that are hardware-accelerated include rule condition check operations, filtering operations, and path merging operations. The rule condition check operations generate rule condition check results for the processed data streams, wherein the rule condition check results are indicative of any rule conditions which have been satisfied by the data streams. The generation of such results with a low degree of latency provides enterprises with the ability to perform timely decision-making based on the data present in received data streams.

Owner:IP RESERVOIR

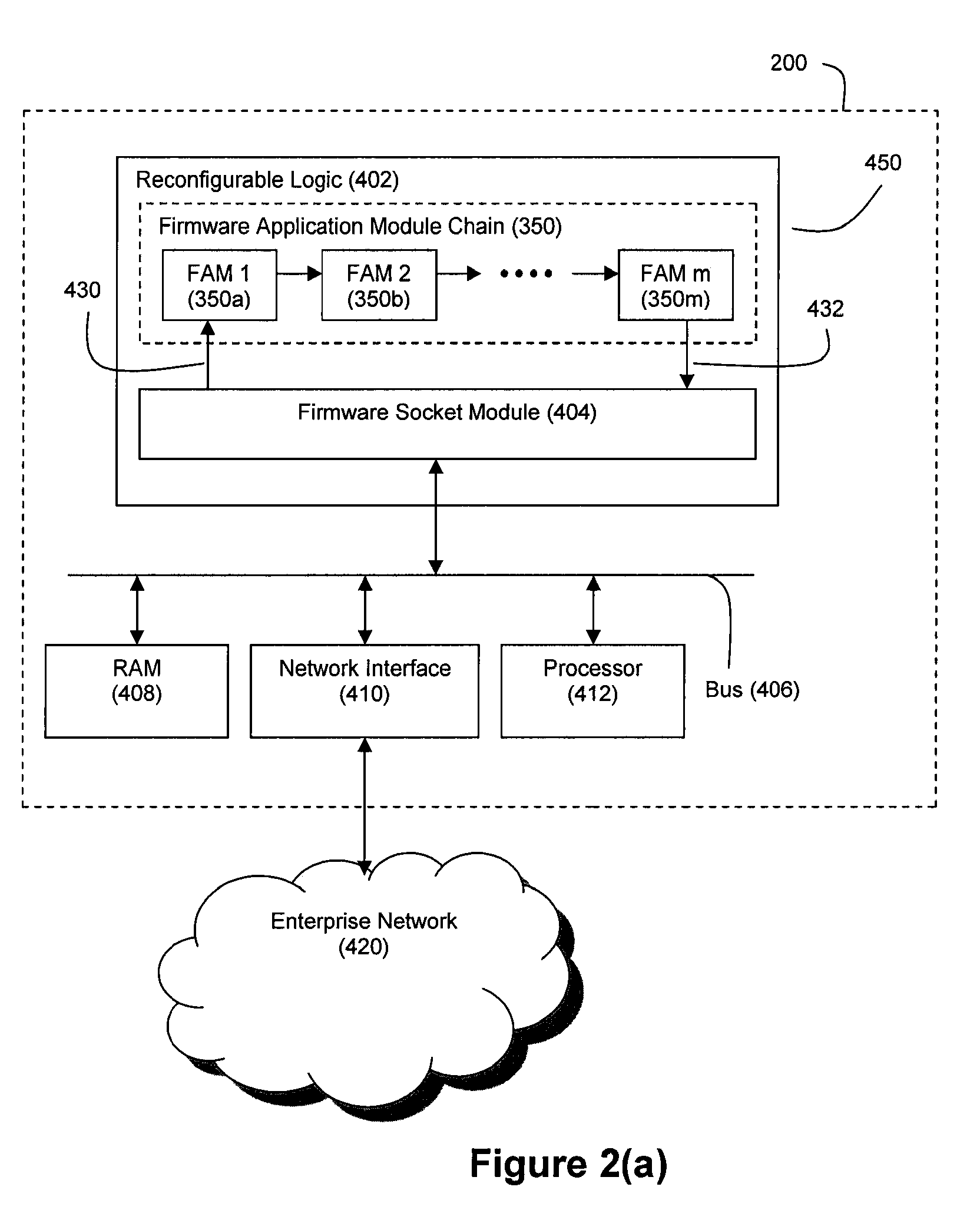

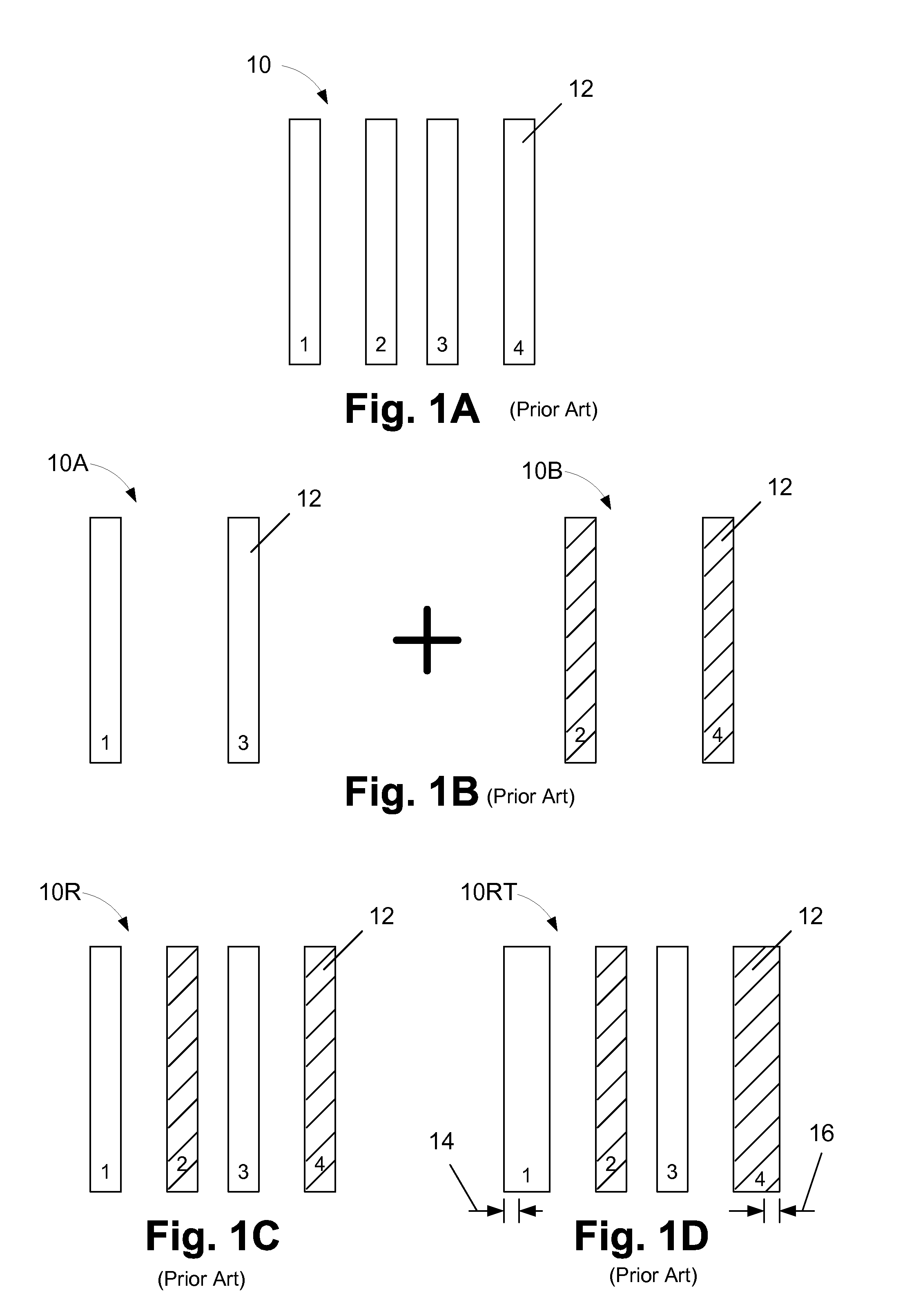

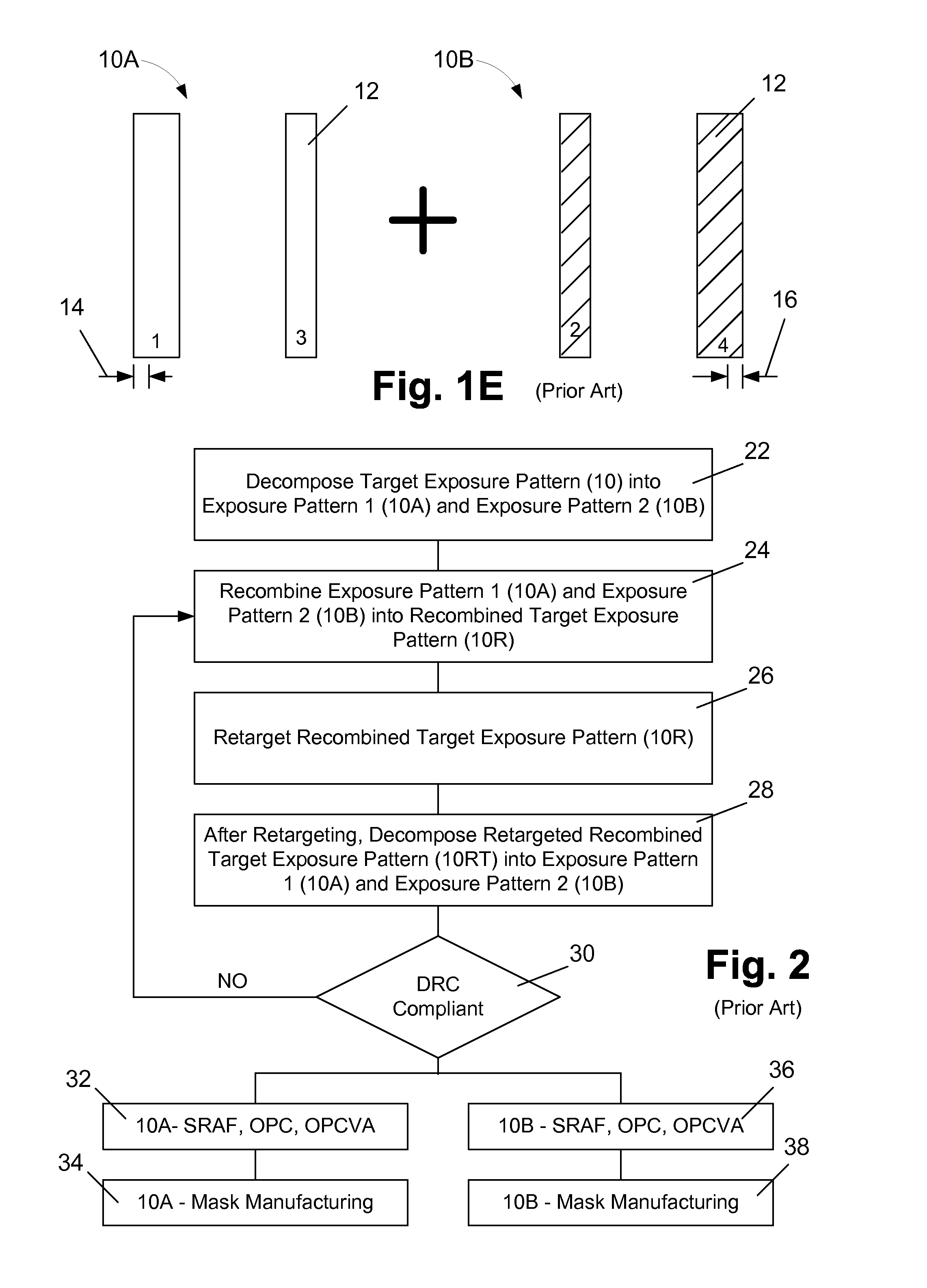

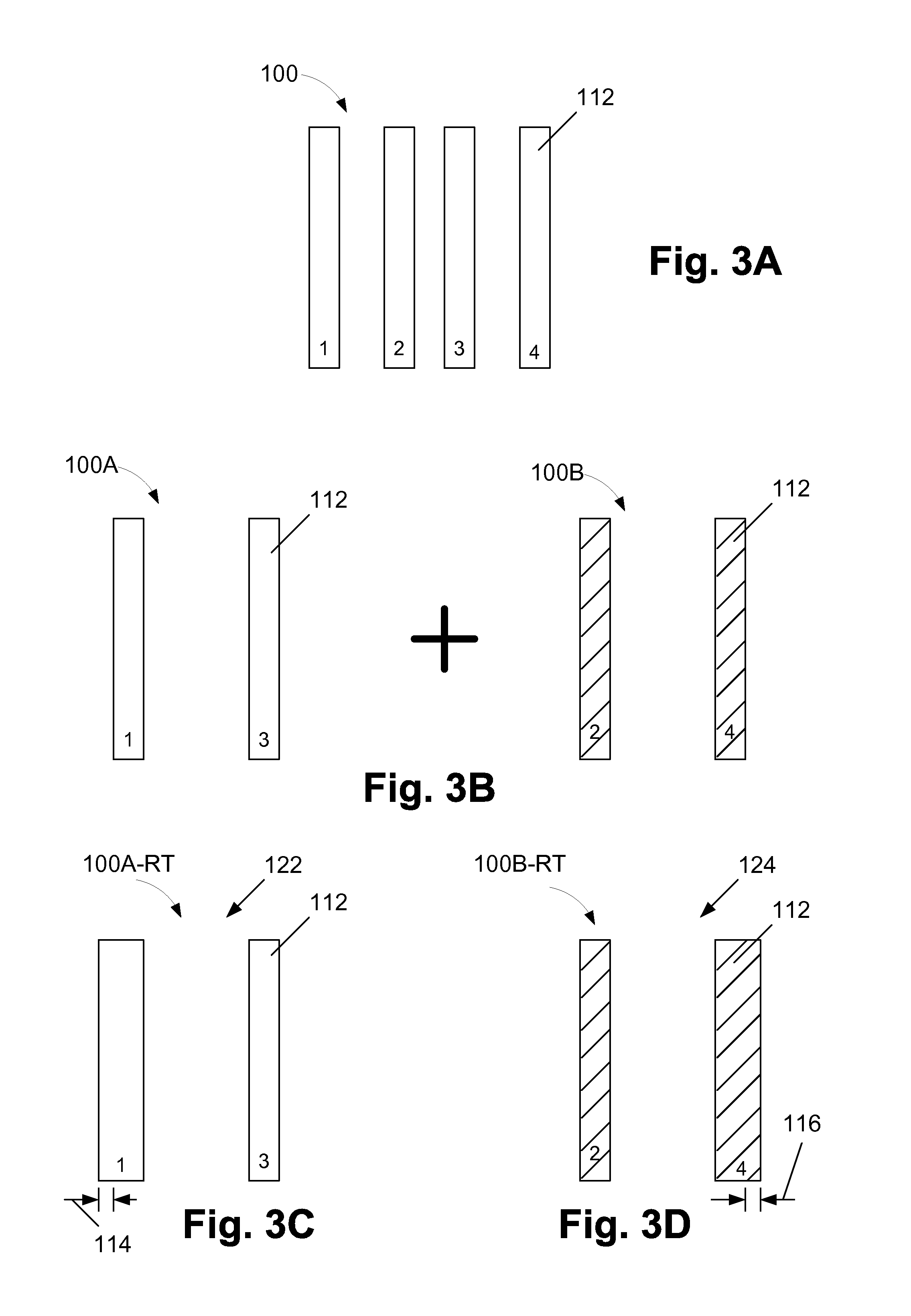

Methods involving color-aware retargeting of individual decomposed patterns when designing masks to be used in multiple patterning processes

InactiveUS8921016B1Originals for photomechanical treatmentSpecial data processing applicationsAlgorithmRetargeting

One illustrative method disclosed herein includes the steps of decomposing an initial overall target exposure pattern into at least a first decomposed sub-target pattern and a second decomposed sub-target pattern, performing first and second retargeting processes on the first and second decomposed sub-target patterns while using the other sub-target pattern as a reference layer, respectively, to thereby define retargeted first and second decomposed sub-target patterns, respectively, and, after performing the first and second retargeting processes, performing at least one process operation to determine if each of the retargeted first decomposed sub-target pattern and the retargeted second decomposed sub-target pattern is in compliance with at least one design rule.

Owner:GLOBALFOUNDRIES INC

Methods of forming semiconductor device with self-aligned contact elements and the resulting devices

InactiveUS20150021683A1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceEngineering

Owner:GLOBALFOUNDRIES INC

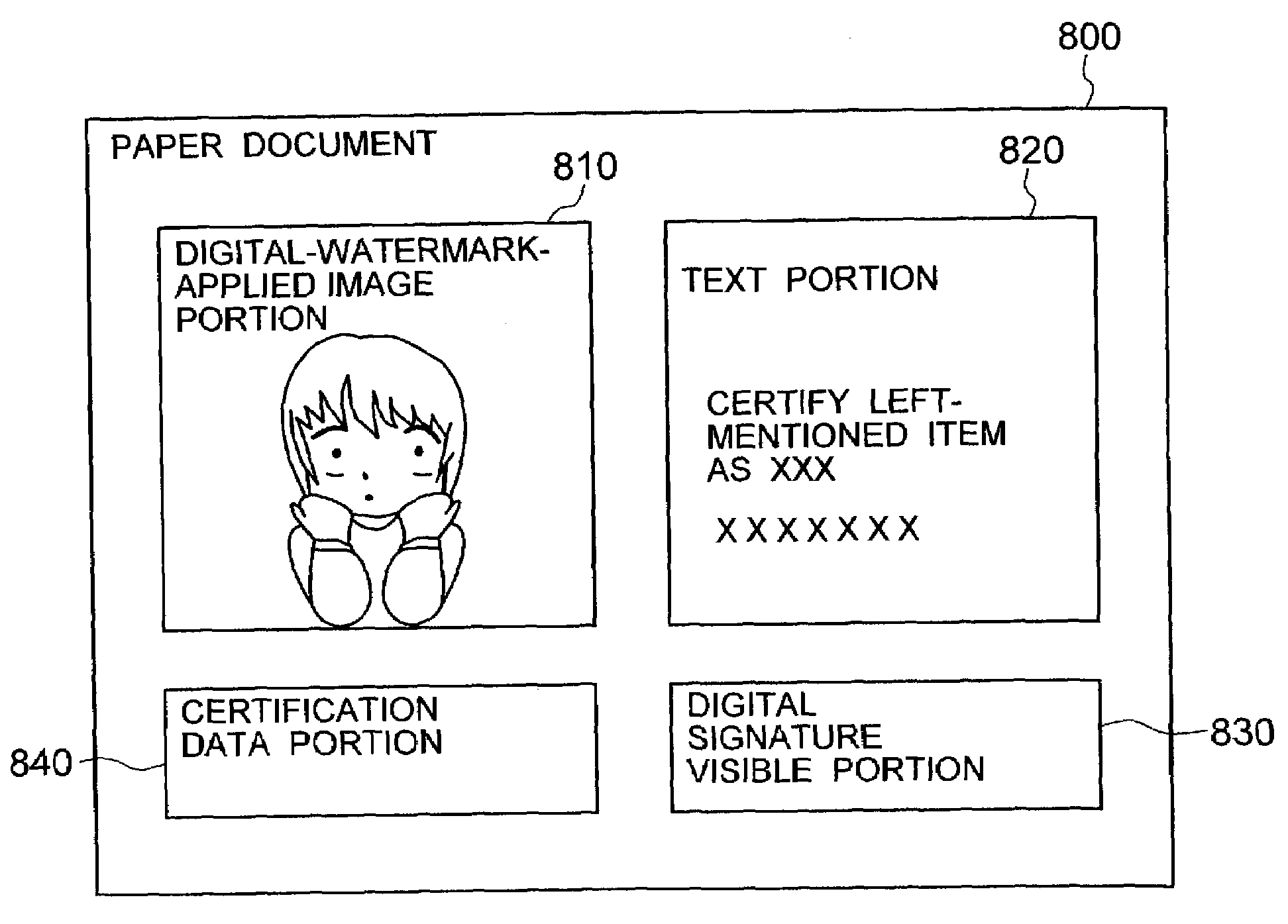

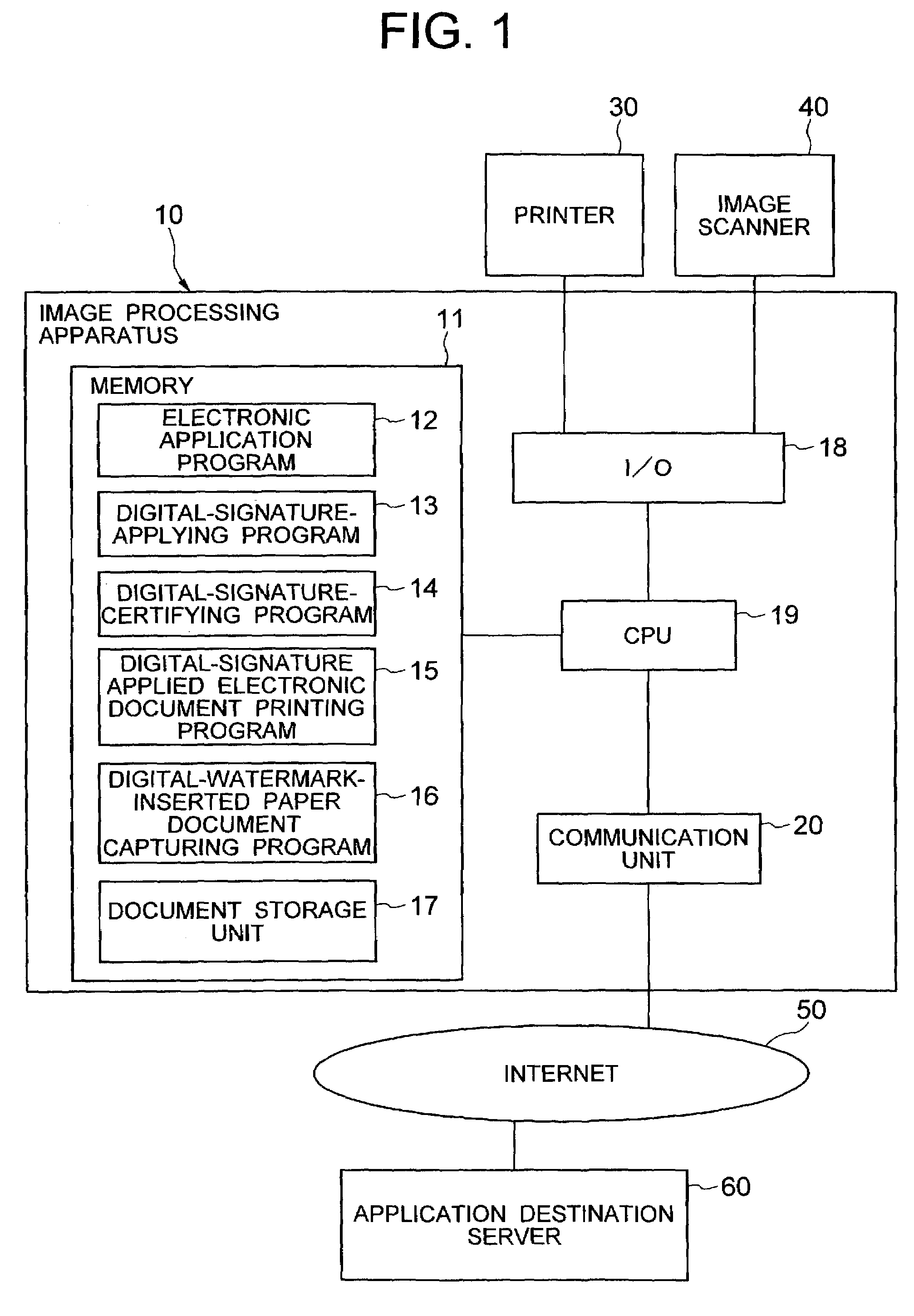

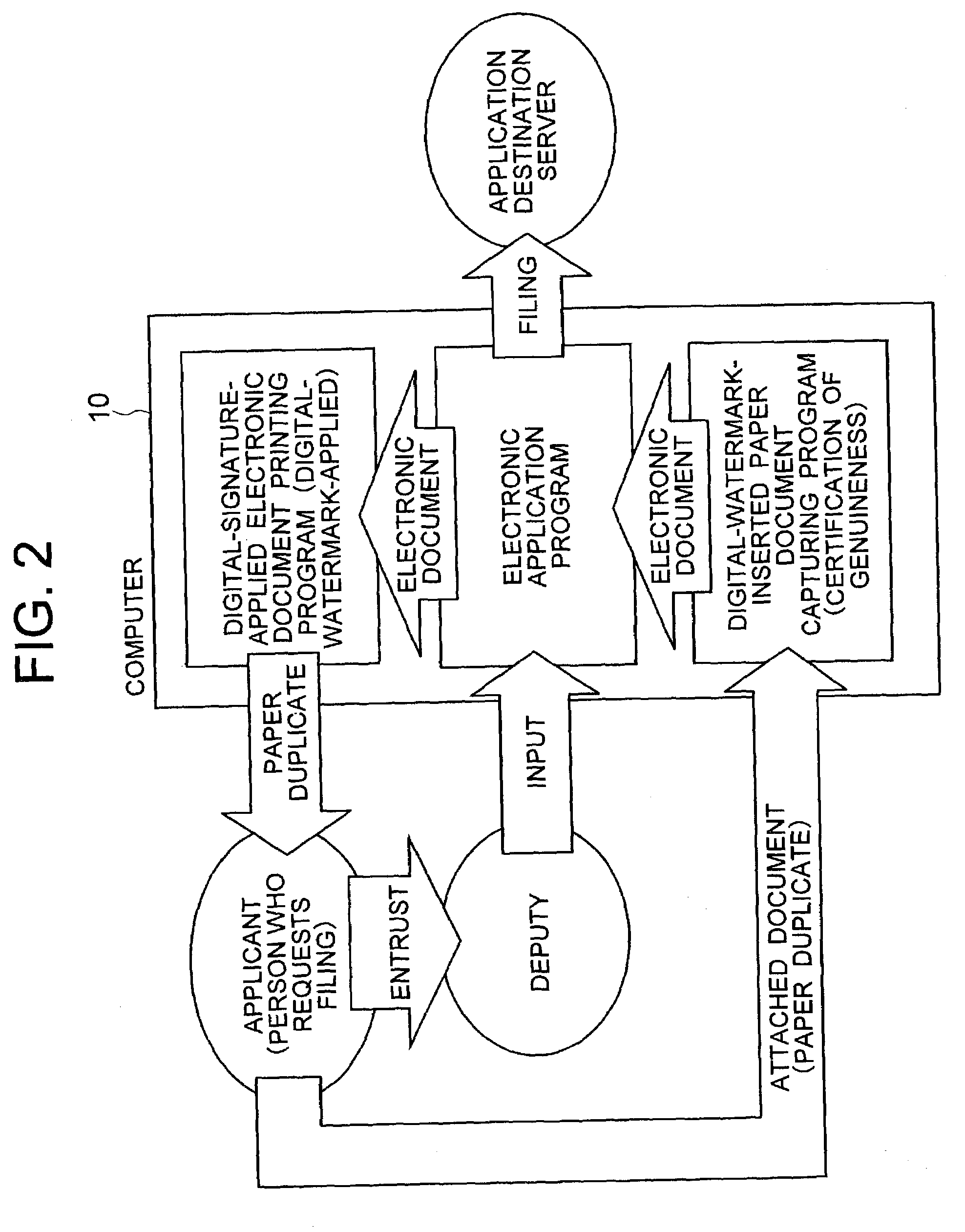

Electronic document, genuineness management method for print medium thereof, genuineness management system, program, and program recording medium

InactiveUS7224820B2User identity/authority verificationCharacter and pattern recognitionElectronic documentComputer graphics (images)

A method for managing genuine characteristics of both an electronic document and a print medium comprising: a step for recognizing image data contained in the electronic document; a step for applying an extraction condition of an image feature previously determined and must be considered to the recognized image data to calculate a coordinate set corresponding to a pixel or a set of pixels, constituting the image feature; a step for recognizing at least a coordinate value among coordinate values and pixel color values, corresponding to each of coordinates constituting the coordinate set, and for embedding the recognized coordinate value as a code of a digital watermark into the pixel or the pixel set, constituting the image feature, or into an area in the vicinity; and a step for outputting the electronic document where the digital watermark embedding process operation has been carried out to the print medium.

Owner:HITACHI LTD

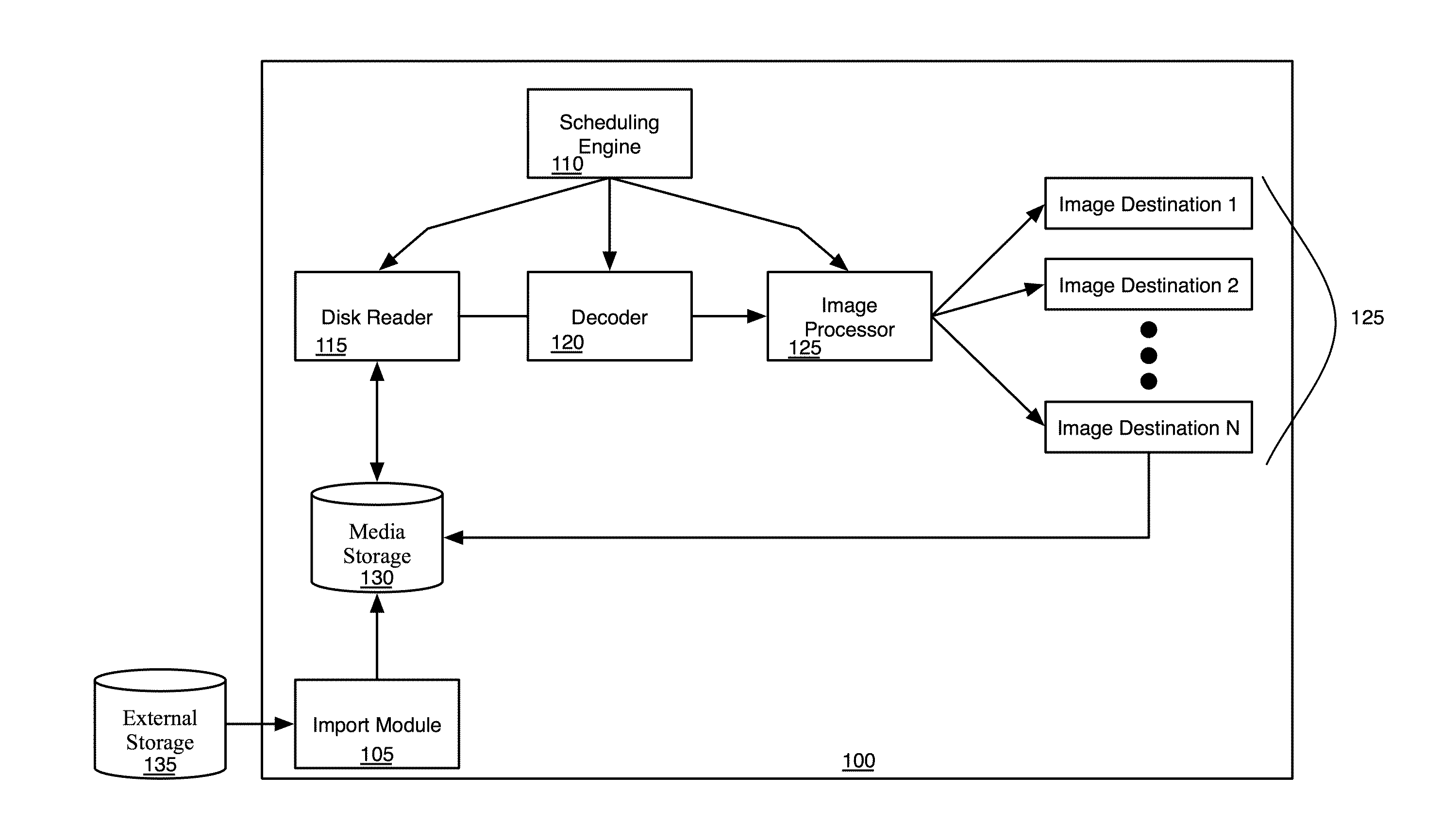

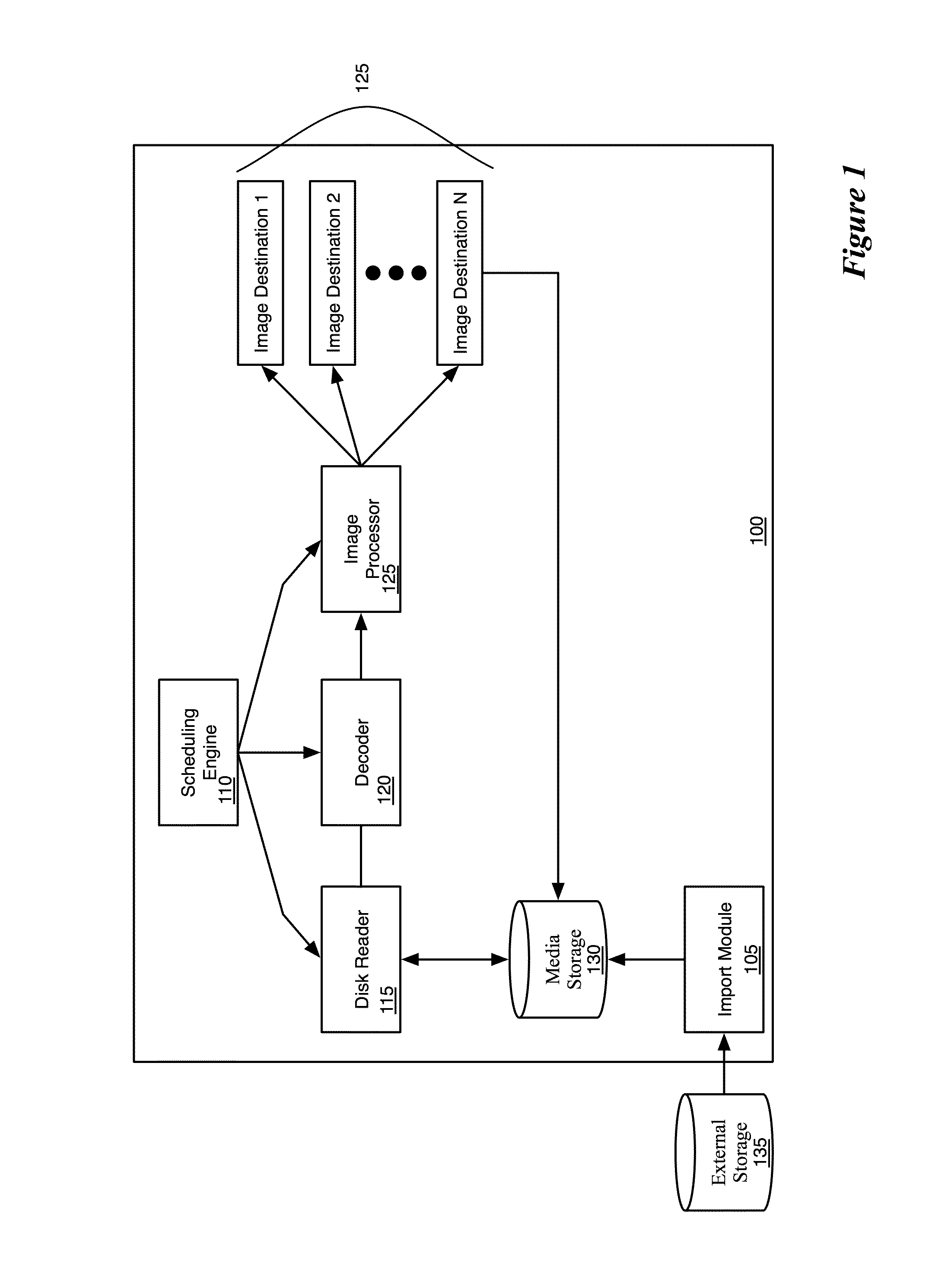

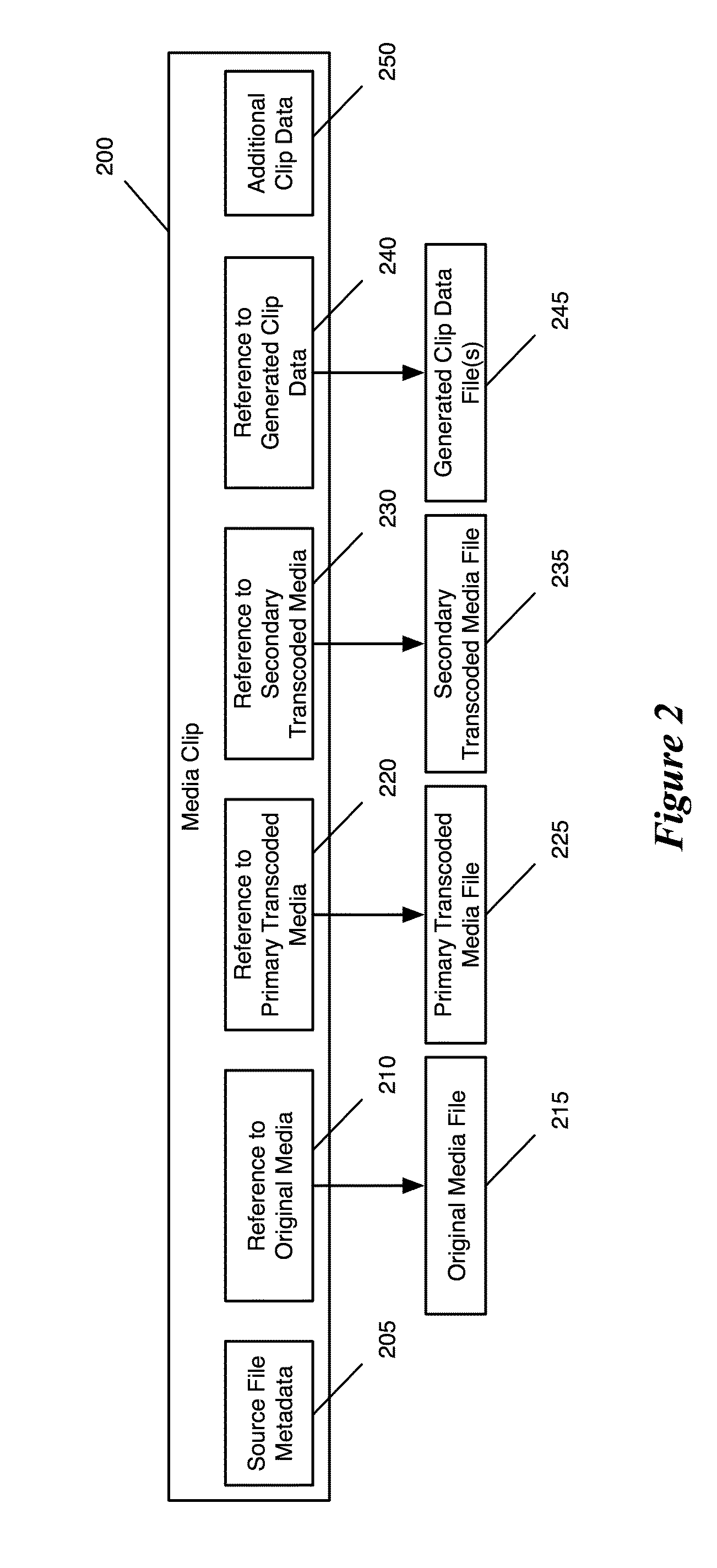

Efficient Media Processing

ActiveUS20120206653A1Improve image qualityEasy to handleTelevision system detailsGeometric image transformationGraphicsImaging processing

Some embodiments provide a media-editing application. The application includes several image processing destinations for performing operations on video images. The application includes a scheduling engine for scheduling disk read, decode, and graphics processing operations to perform on images to prepare the images for the several destinations. The scheduling engine includes a first set of instructions for scheduling images based on a speed at which a particular one of the several destinations processes the images when none of the destinations require images in real-time. The scheduling engine includes a second set of instructions for scheduling images based on a real-time clock when at least one of the several destinations requires images in real-time.

Owner:APPLE INC

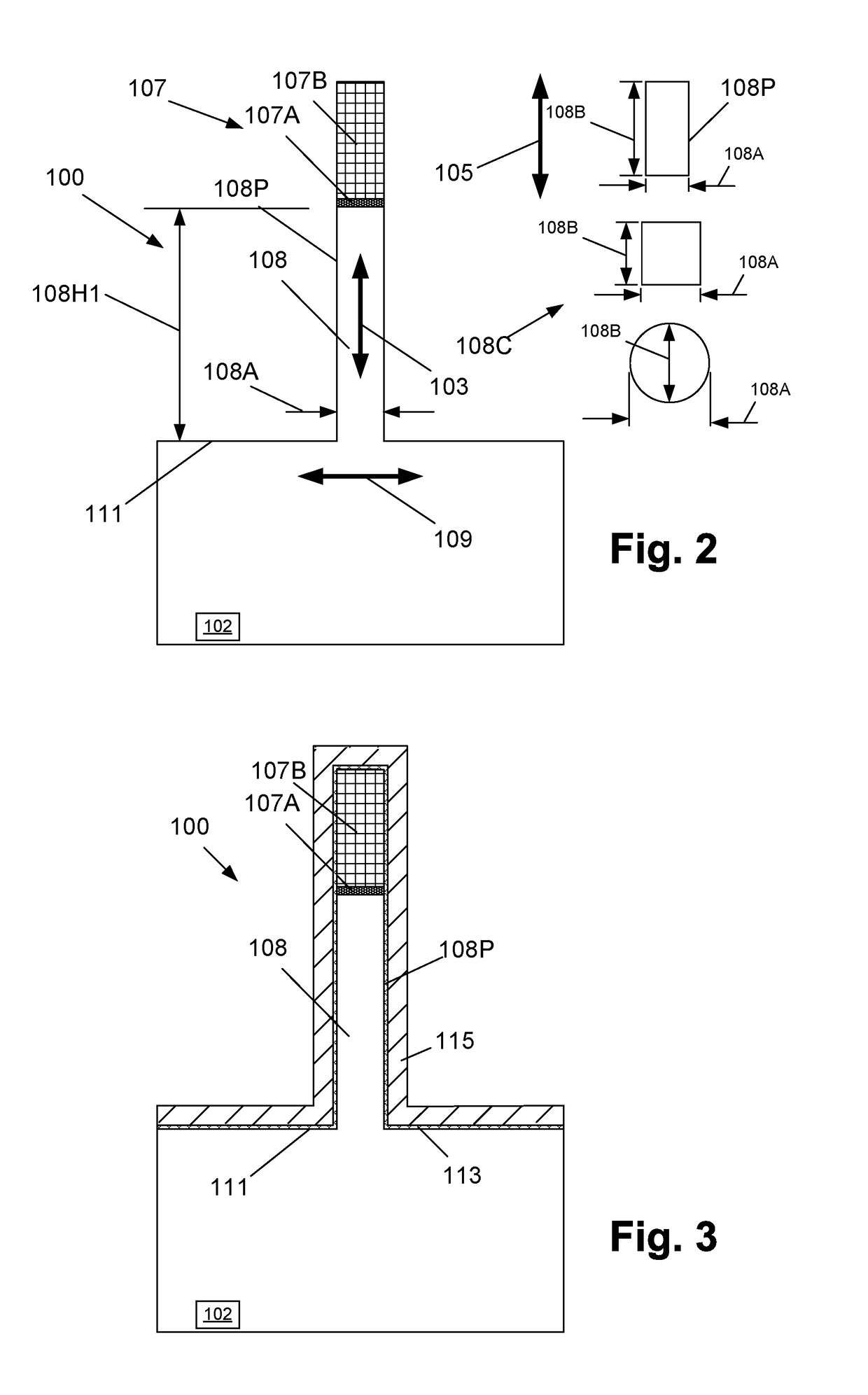

Methods of forming replacement gate structures and bottom and top source/drain regions on a vertical transistor device

ActiveUS9640636B1Well formedSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

One illustrative method disclosed herein includes, among other things, forming an initial vertically oriented channel semiconductor structure having a first height above a substrate, forming a sacrificial spacer structure adjacent the initial vertically oriented channel semiconductor structure and, with the sacrificial spacer in position, performing at least one process operation to define a self-aligned bottom source / drain region for the device that is self-aligned with respect to the sacrificial spacer structure, forming an isolation region in the trench and forming a bottom source / drain electrode above the isolation region. The method also includes removing the sacrificial spacer structure and forming a bottom spacer material around the vertically oriented channel semiconductor structure above the bottom source / drain electrode.

Owner:GLOBALFOUNDRIES US INC

Start working method for hydrocracking process

ActiveCN101492613AHigh vulcanization rateHigh Sulfur Utilization EfficiencyHydrocarbon oil crackingSulfurEconomic benefits

The invention discloses a hydrocracking process operation method. Hydrocracking pre-refining catalyst is treated by precuring outside a reactor while hydrocracking catalyst is not treated or is partially treated by precuring outside the reactor. Curing ingredient introduced by the hydrocracking pre-refining catalyst and the hydrocracking catalyst precured outside the reactor accounts for 90-120% of the theoretical sulfur demand for all the catalyst. The hydro cracking pre-refining catalyst and the hydro cracking catalyst are layered in the reactor and then activated by heating, so that all the catalyst is sulfurated effectively. The method of the invention can precure the hydrocracking pre-refining catalyst outside the reactor or precure the hydrocracking pre-refining catalyst and partial hydrocracking catalyst outside the reactor, thus reducing the catalyst requiring precuring outside the reactor, reducing the production period and production cost of the precuring catalyst and improving the economic benefit and production security.

Owner:CHINA PETROLEUM & CHEM CORP +1

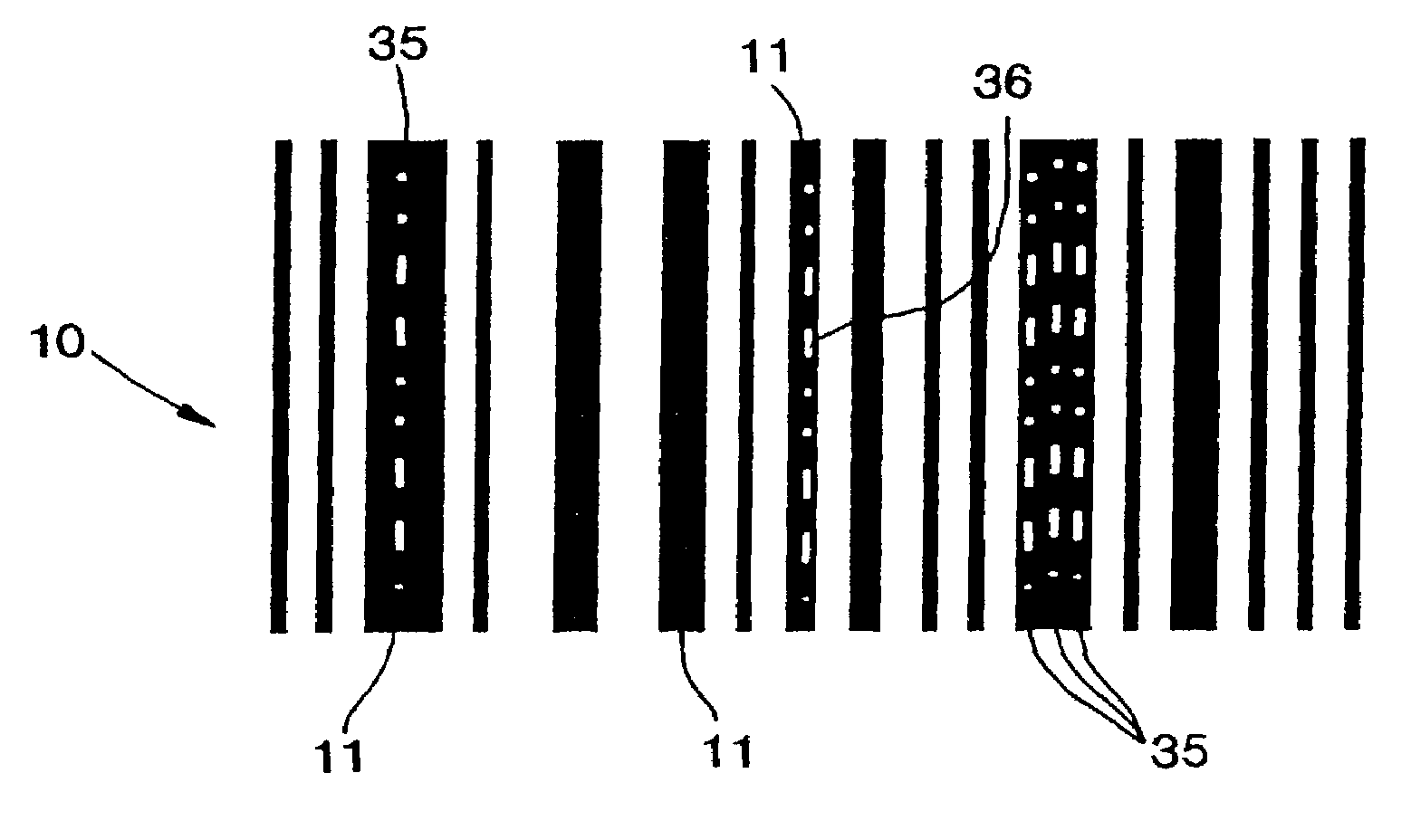

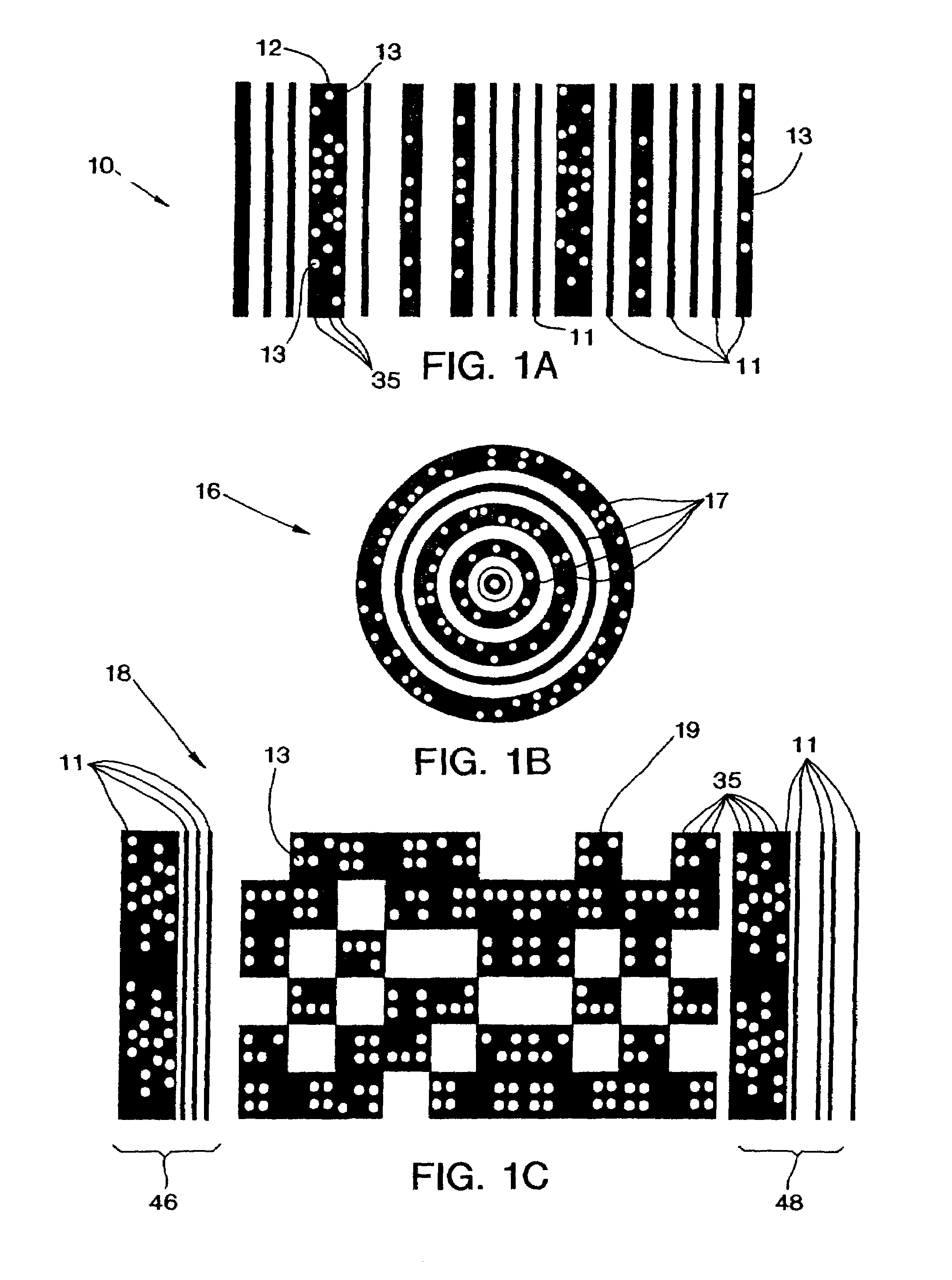

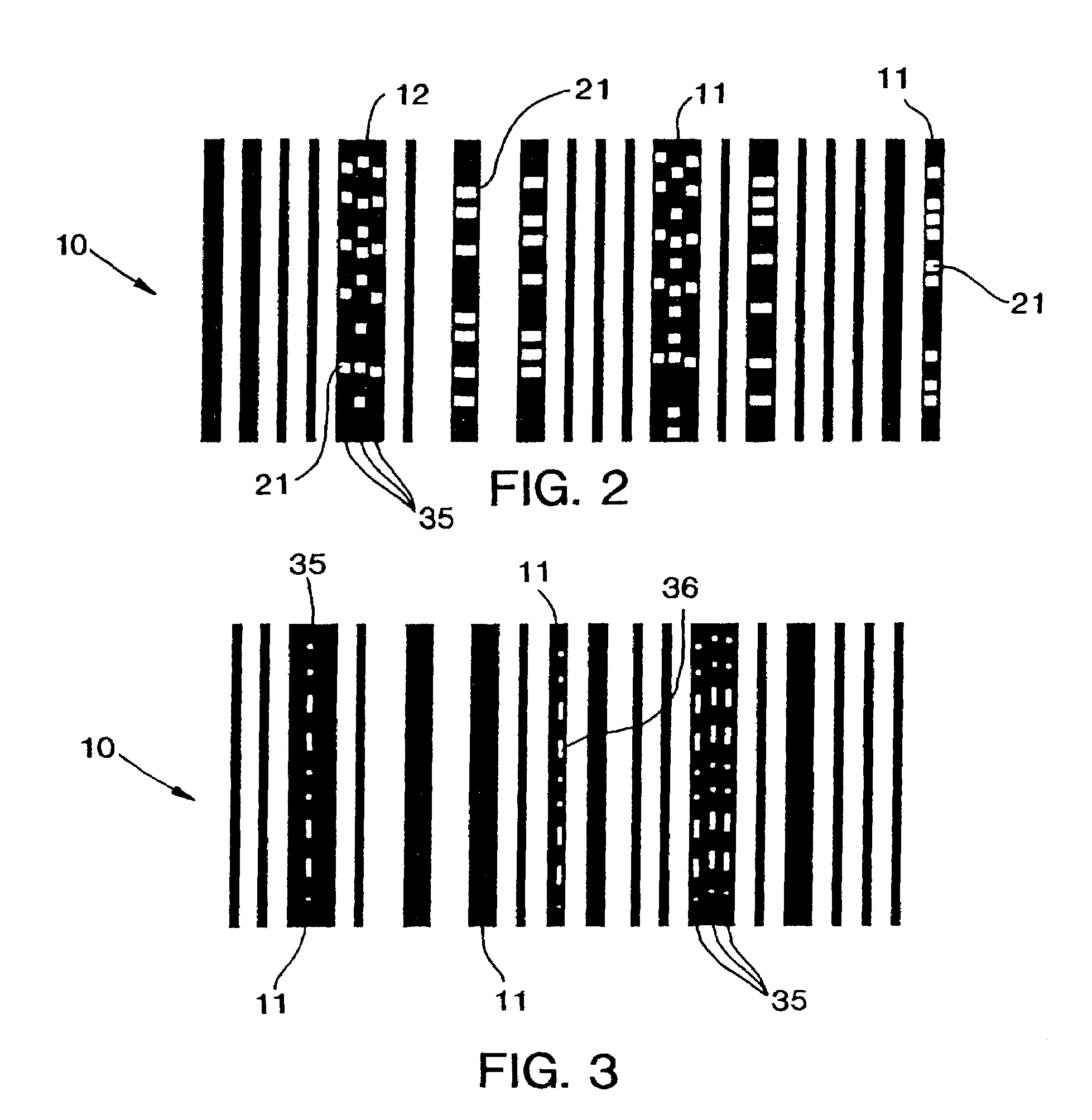

Method and apparatus for encoding and decoding bar codes with primary and secondary information and method of using such bar codes

InactiveUS6991164B2Character and pattern recognitionRecord carriers used with machinesScannerIn plane

A bar code (10) has primary information (46, 48, 50, 51) encoded in one direction (e.g., horizontally) and secondary information (13, 21, 36) encoded in another direction (e.g., vertically) in single (11) or multiple tracks (35) in selected ones of the vertical bars (11) of a bar code (10). Using a non-linear, variable amplitude scanner, all of the bars are scanned in the one direction to obtain all of the primary information and all of those vertical bars having secondary information are scanned in the other direction to obtain all of the secondary information. The one direction which is perpendicular to the vertical bars (11), is determined by first rotating the scan path axis (86, 87) until both start (46) and end (48) code bars are read thereby placing the scan path entirely within the total bar code, and, then, further rotating the scan path (88, 89) to determine the direction of the minimum crossing width (Lsc 80) of the total bar code (10). Secondary information is scanned in planes orthogonal to the one direction after those vertical bars (11) having such information are first identified and selected. In a preferred embodiment, the decoded secondary information may be used to control selected station process operations for selected products in a continuous manufacturing assembly line.

Owner:LEMELSON MEDICAL EDUCATION & RES FOUND PARTNERSHIP

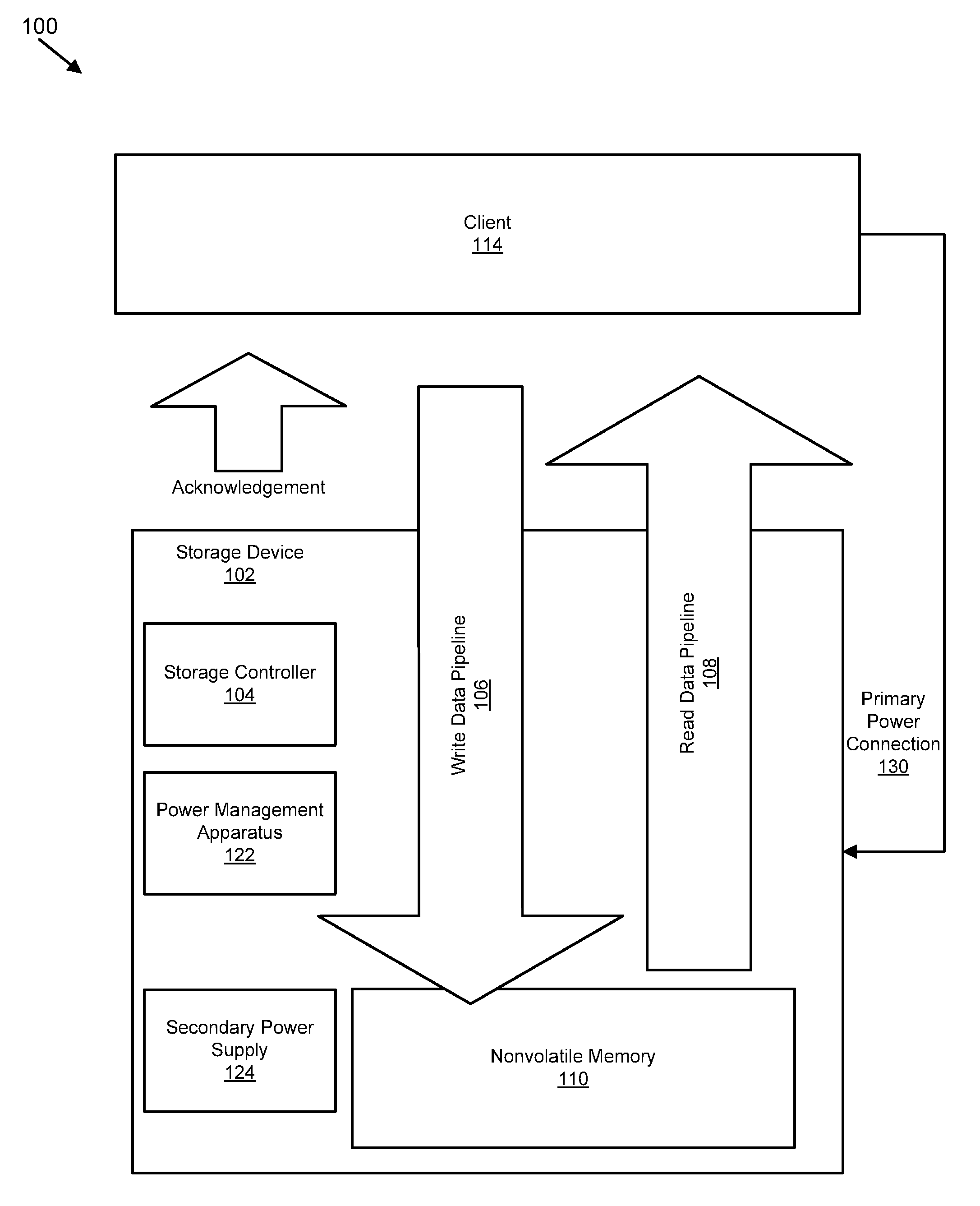

Apparatus, system, and method for power reduction management in a storage device

ActiveUS20110058440A1Save energyError detection/correctionRead-only memoriesComputer moduleElectric power

An apparatus, system, and method are disclosed for power loss management in a nonvolatile data storage device. A monitor module initiates a power loss mode in the nonvolatile data storage device in response to a primary power source failing to supply electric power above a predefined threshold to the nonvolatile data storage device. A secondary power source supplies electric power to the nonvolatile data storage device for at least a power hold-up time during the power loss mode. A power loss module adjusts execution of in-process operations on the nonvolatile data storage device during the power loss mode so that essential in-process operations execute within the power hold-up time.

Owner:SANDISK TECH LLC

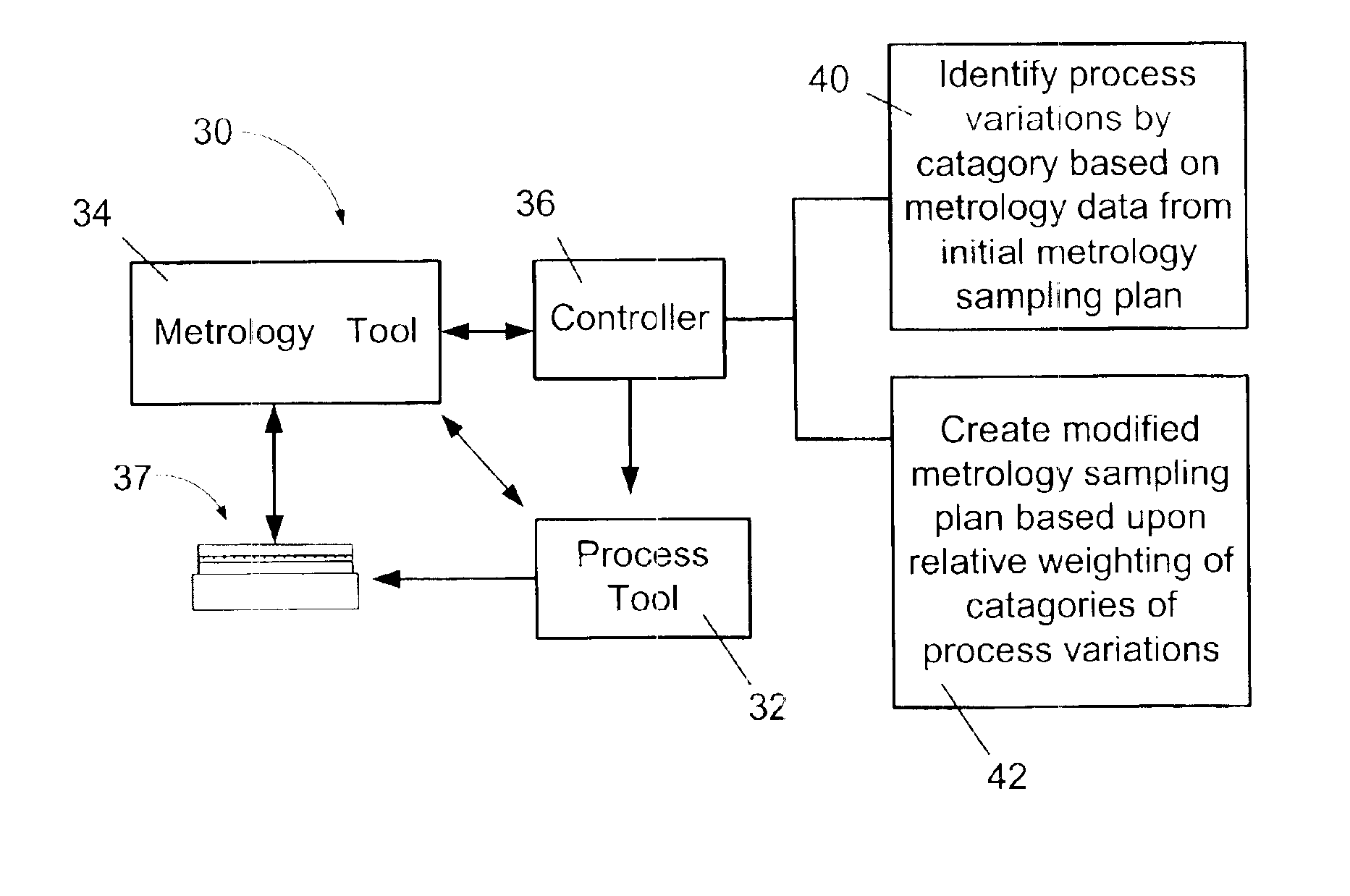

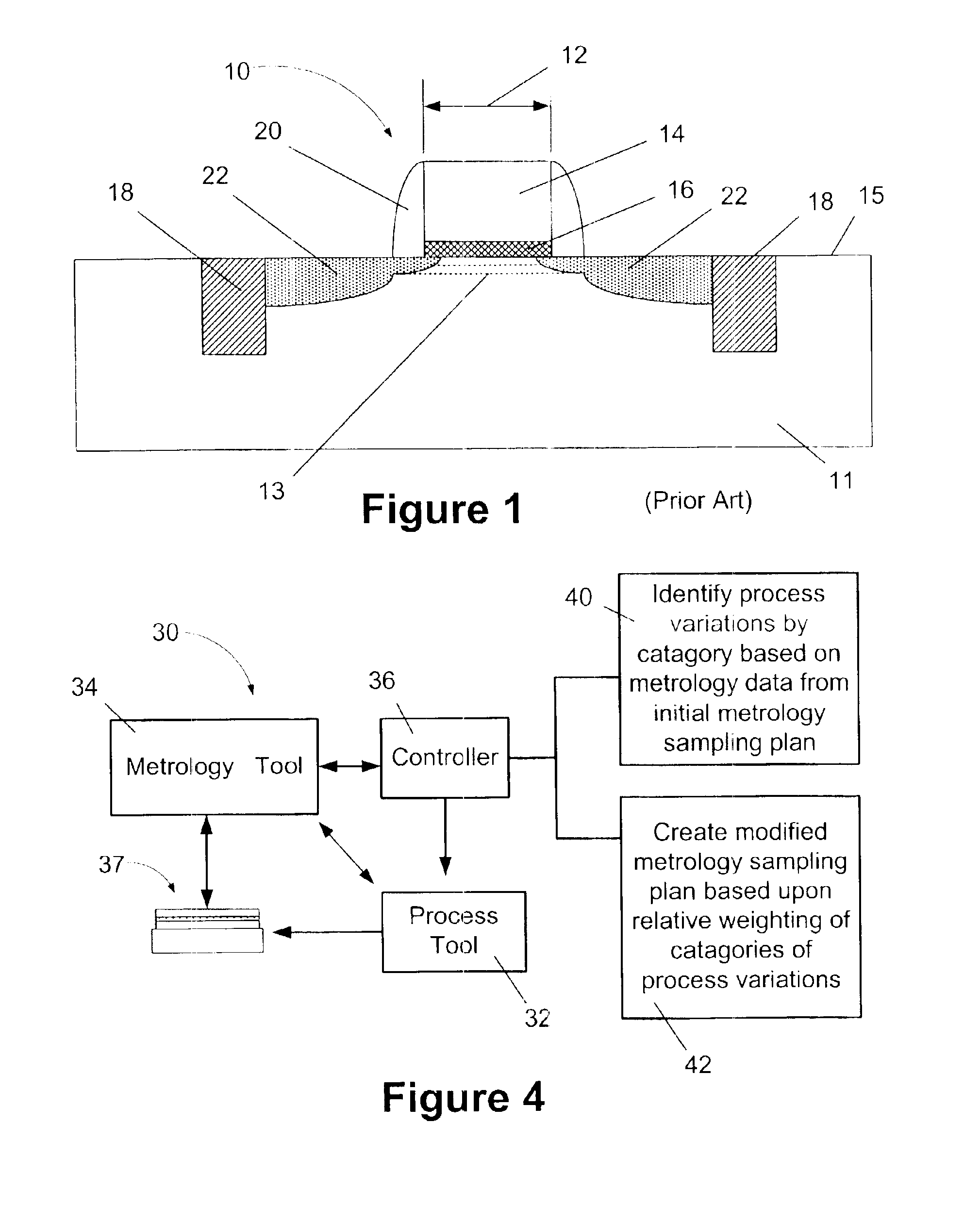

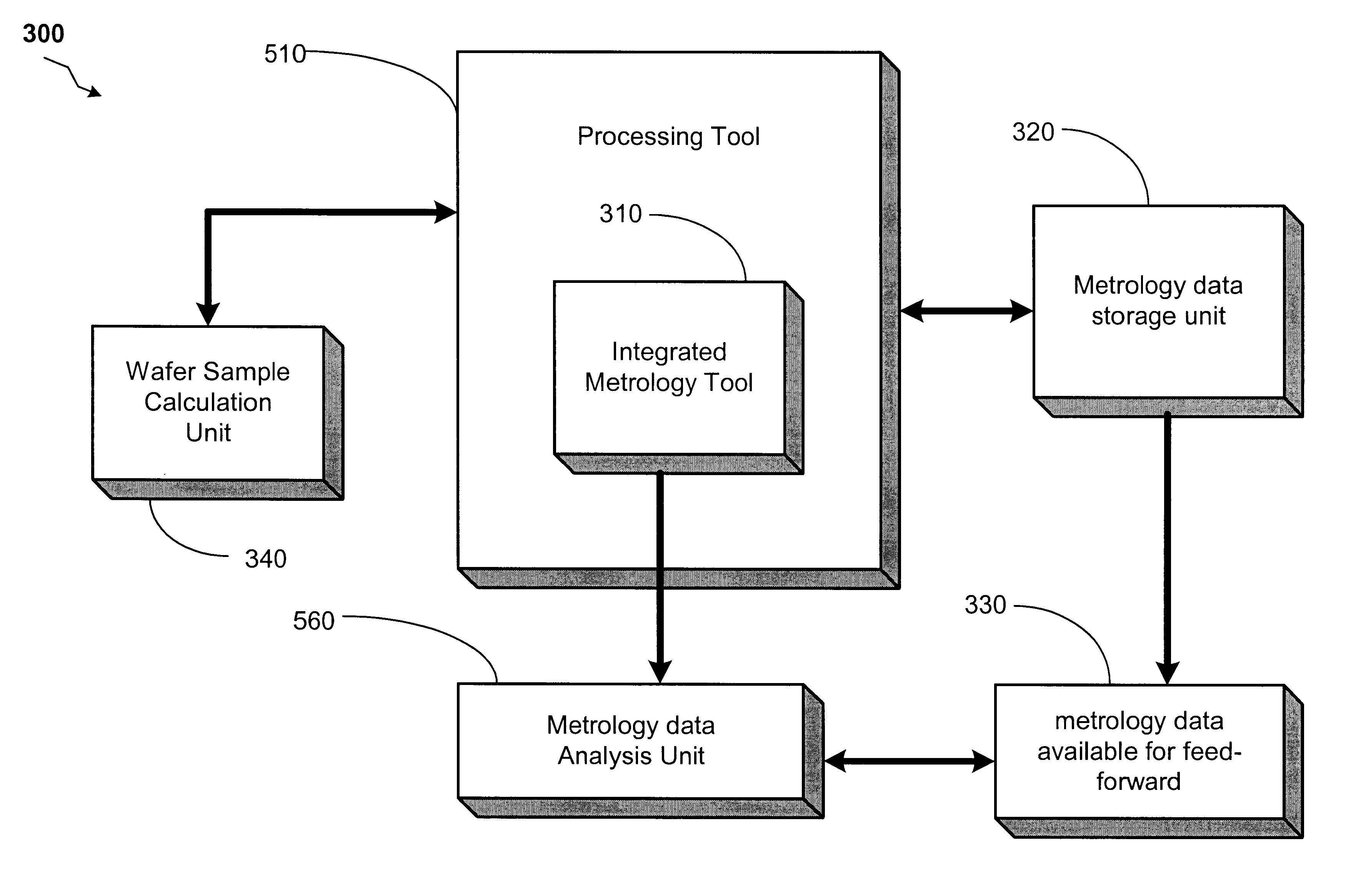

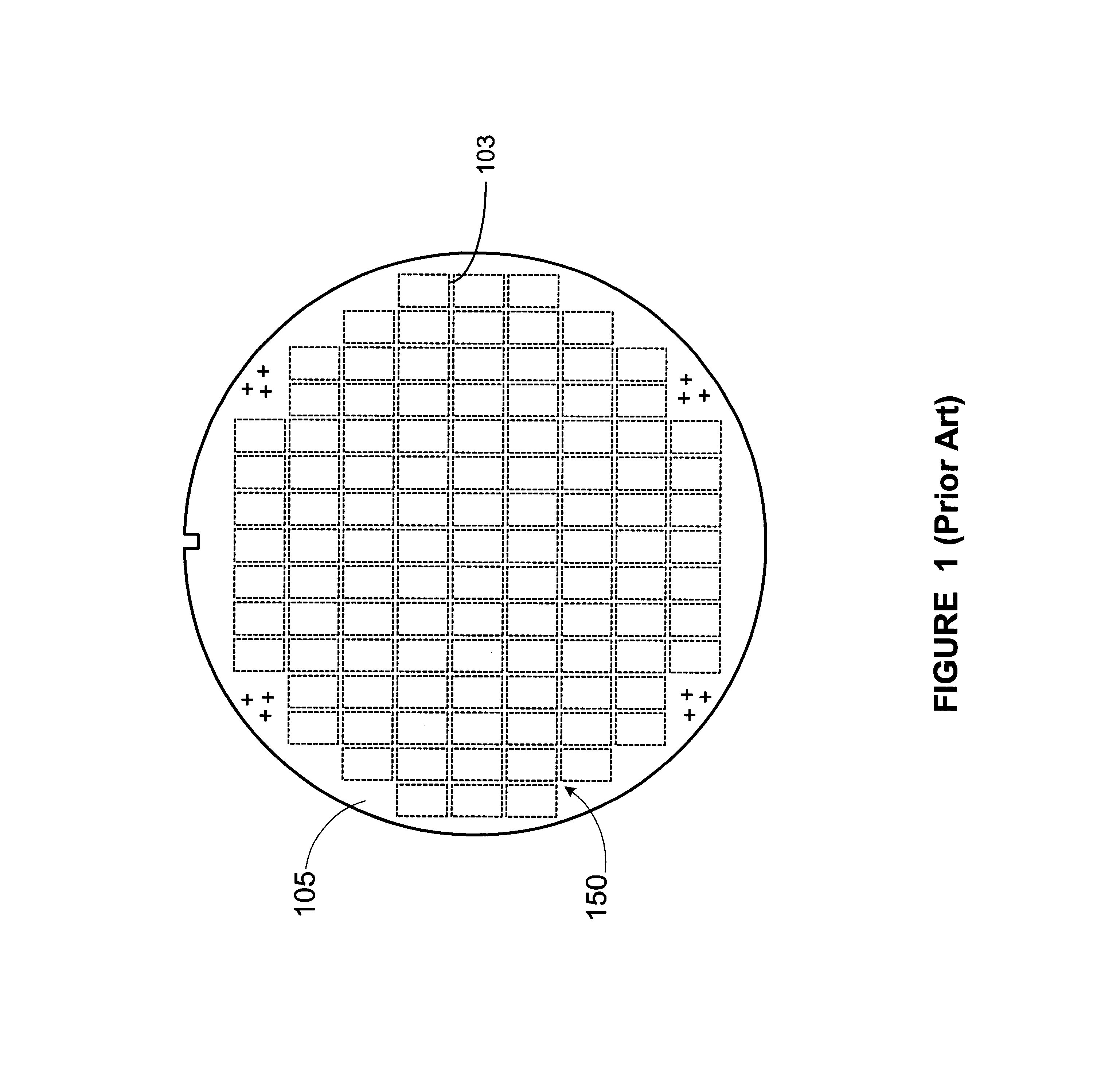

Methods of using adaptive sampling techniques based upon categorization of process variations, and system for performing same

InactiveUS6859746B1Increase volumePhotomechanical apparatusTotal factory controlMetrologyEngineering

Methods of using adaptive sampling techniques based upon categorization of process variations, and a system for performing same are disclosed. In one illustrative embodiment, the method comprises acquiring metrology data regarding at least one process operation performed on a plurality of substrates in accordance with an initial metrology sampling plan, providing the acquired metrology dam to a controller that identifies process variations in the at least one process operation based upon the acquired metrology data and further identifies a plurality of categories of the process variations. The method further comprises creating, using the controller, a modified metrology sampling plan based upon a relative weighing of the identified categories of the process variations, wherein the modified metrology sampling plan differs from the initial metrology sampling plan in at least one aspect, and acquiring metrology data from at least one subsequently processed wafer in accordance with the modified neology sampling plan.

Owner:ADVANCED MICRO DEVICES INC

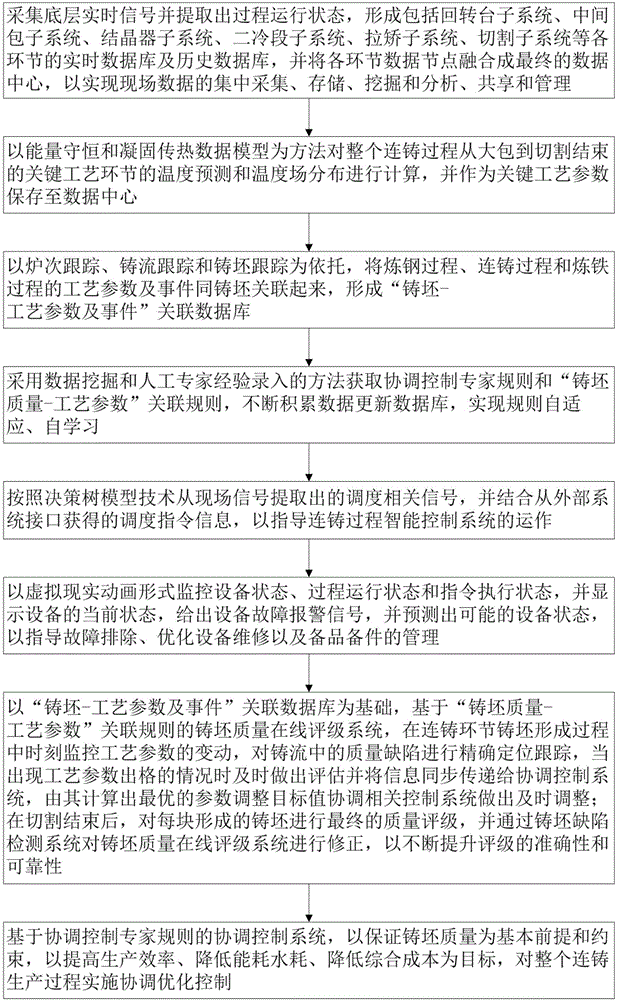

System method for intelligent control over continuous-casting process

The invention discloses a system method for intelligent control over the continuous-casting process. Firstly, signals are collected to form a data center; then a temperature field model is designed to calculate the temperatures of continuous-casting key process nodes, and the temperatures of the continuous-casting key process nodes are stored into the data center; then logistics tracking of the continuous-casting process is achieved, and a 'casting blank-technological parameter and event' related database is formed; then rules and dispatching command information are obtained through data mining and artificial expertise, and virtual reality animation displaying of the equipment state, process operation state and command execution state is conducted; then a casting blank quality online grading system is built and casting blank grading is achieved; and finally, a coordination control system is built, energy consumption and water consumption are optimized, and large-closed-loop quality control and underlying loop control are achieved. Energy conservation and consumption reduction are achieved by optimizing the related parameters of energy consumption and water consumption while the effects that the continuous casting blank quality is stable and the quality is improved continuously are ensured, so that the yield is improved, the cost of per ton of steel is reduced, the comprehensive production cost is reduced continuously, and normal and efficient operation of continuous casting is ensured.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

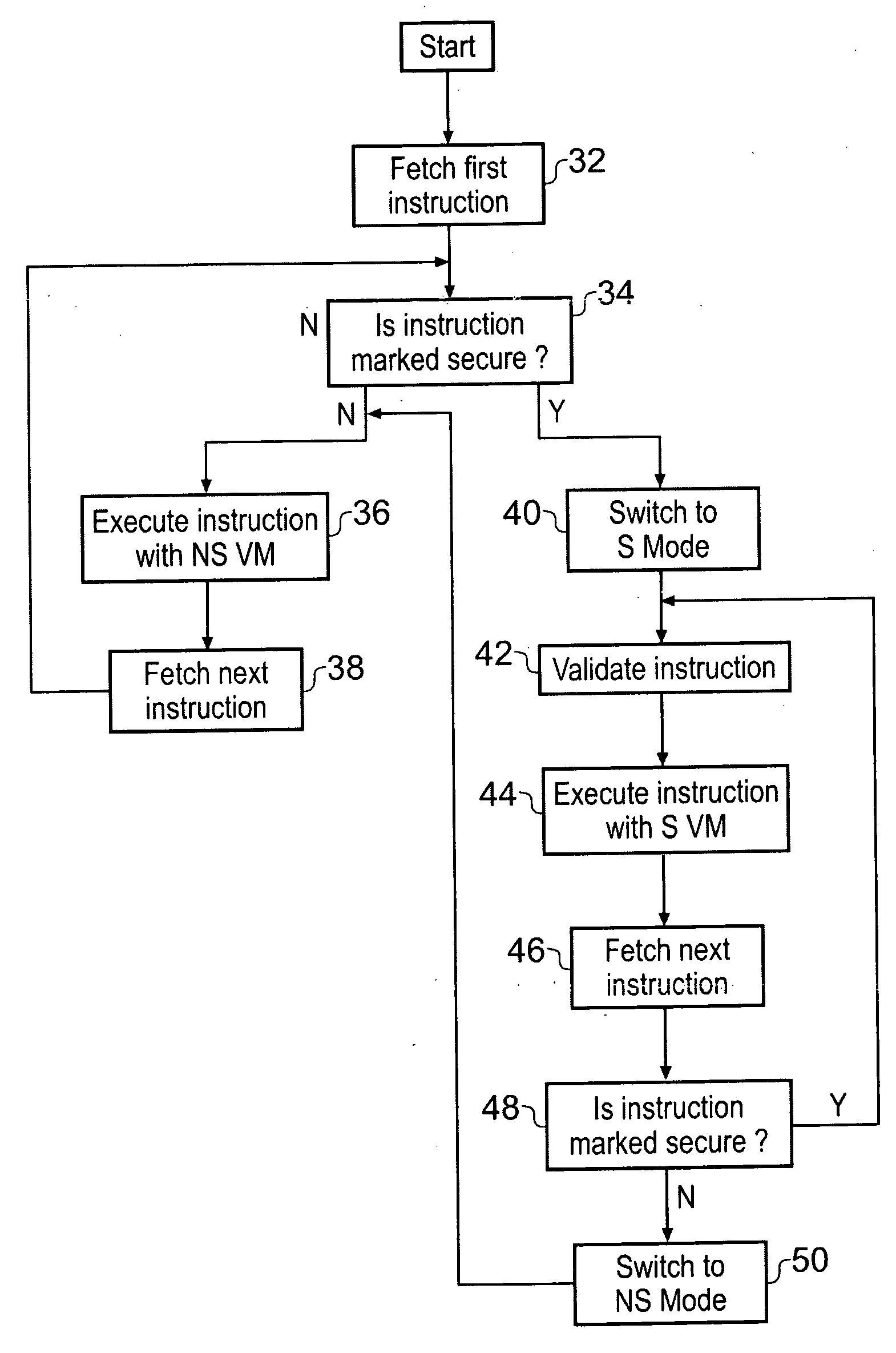

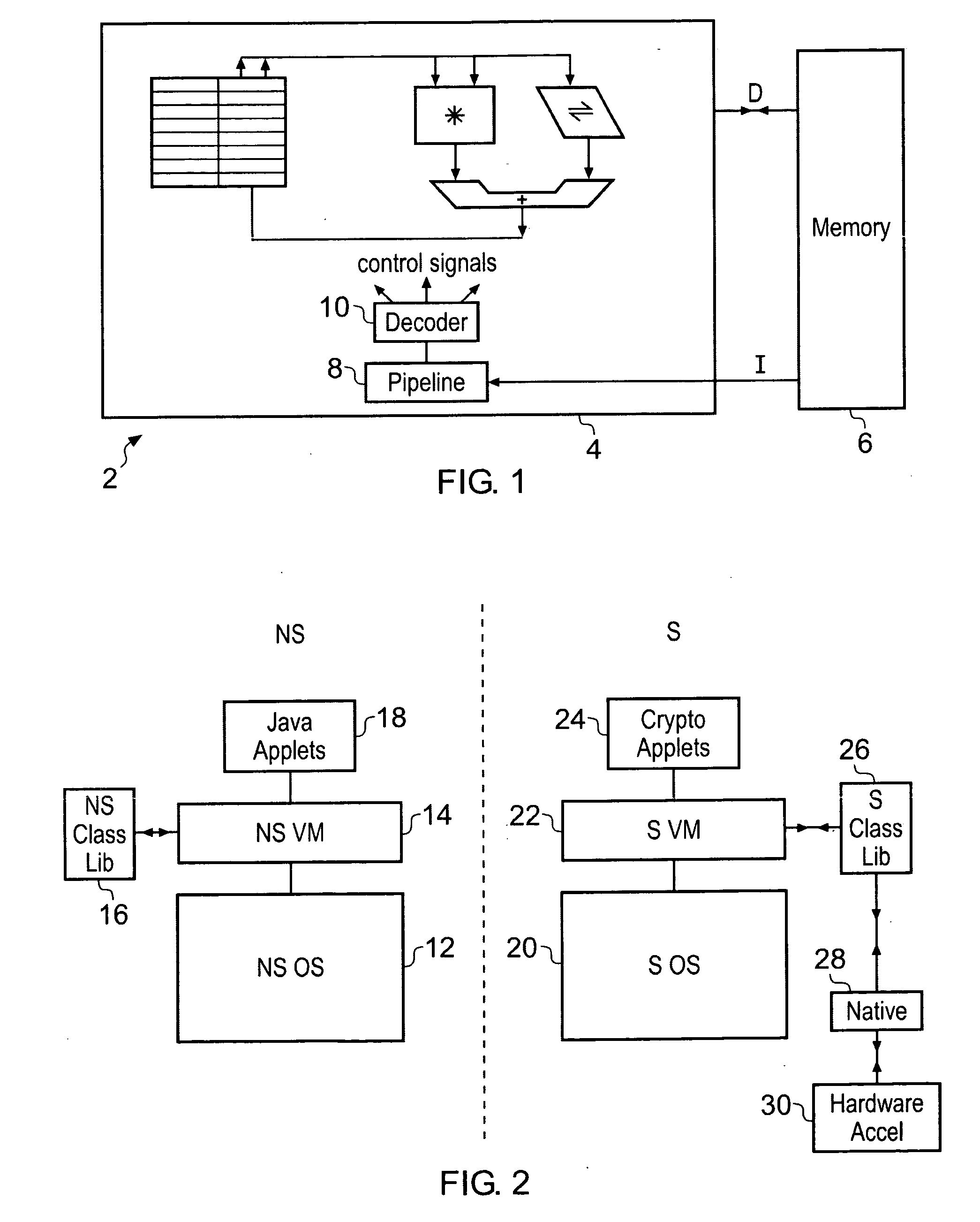

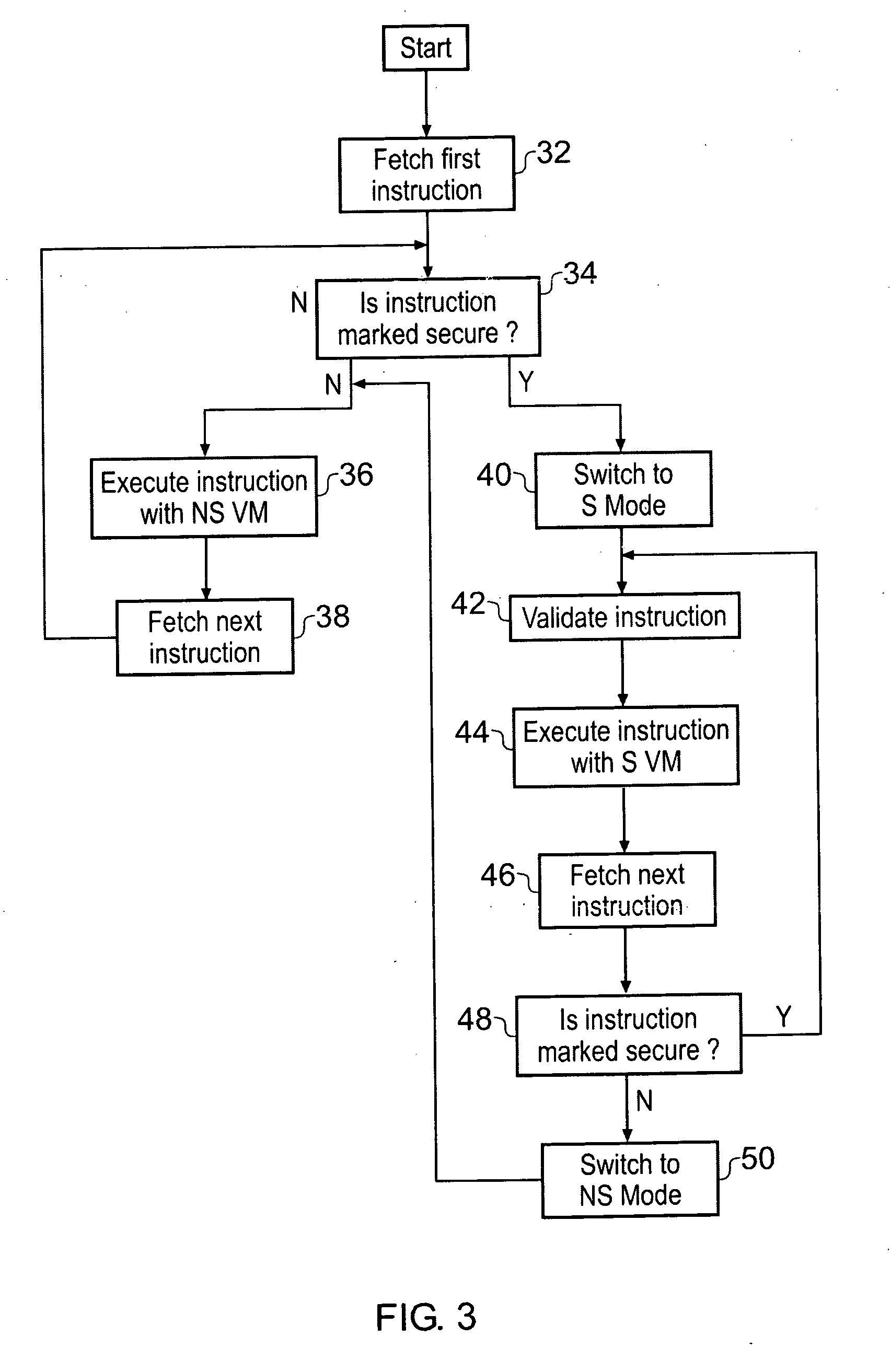

Non-native program execution across multiple execution environments

ActiveUS20090210874A1Improve securityClear partitionDigital computer detailsSoftware simulation/interpretation/emulationData processing systemProgram instruction

A data processing system 2 executes non-native program instructions using either a first execution environment 14 or a second execution environment 22. The first execution environment identifies at runtime if non-native program instructions to be executed are marked as intended for execution by the second execution environment. When such instructions are encountered the first execution environment triggers performance of data processing operations as specified by the one or more marked program instructions performed by the second execution environment. When those processing operations as specified by the one or more marked program instructions have been completed, a return is made to the first execution environment.

Owner:ARM LTD

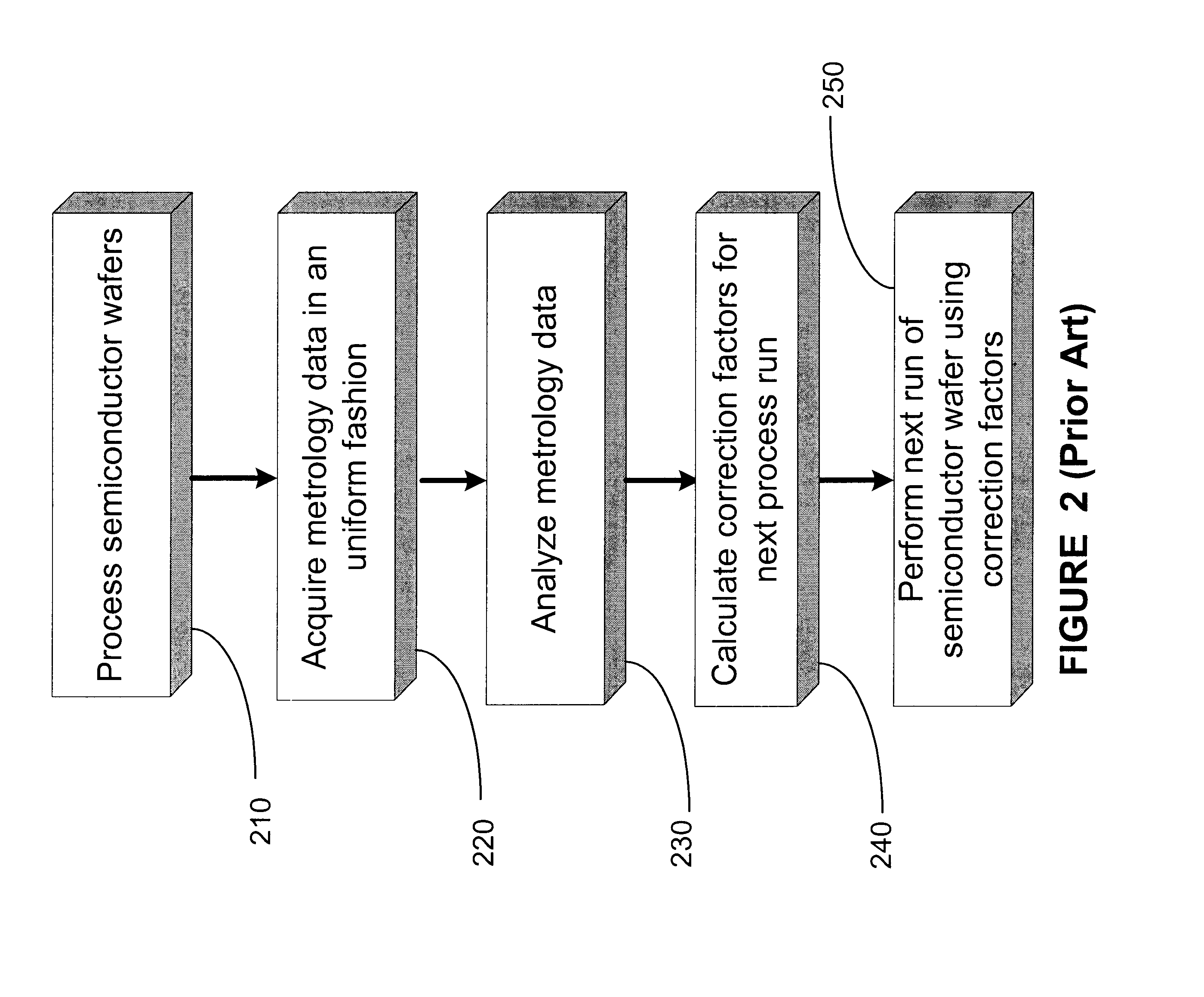

Method and apparatus for wafer-to-wafer control with partial measurement data

InactiveUS6708129B1Semiconductor/solid-state device manufacturingSpecial data processing applicationsMetrologyData acquisition

A method and an apparatus for performing a process control using partial measurement data. A process operation is performed on a semiconductor wafer. Inline metrology data related to the process of the semiconductor wafer is acquired. A partial measurement data acquisition process is performed based upon the inline metrology data, the partial measurement data acquisition process comprising determining a time period for acquiring the inline metrology data, determining a number of wafers to be sampled based upon the time period, and determining a number of wafer sites for data acquisition. At least one of a feedback adjustment on a second semiconductor wafer and a feed-forward adjustment relating to a subsequent processing of the first semiconductor wafer based upon the partial measurement data acquisition process is performed.

Owner:ADVANCED MICRO DEVICES INC

System for identity verification

A system for a dynamically evolving cognitive architecture for the development of a secure key and confidence level based data derived from biometric sensors and a user's behavioral activities. The system comprises one or more processors, one or more sensors, one or more databases, and non-transitory computer readable memory. The non-transitory computer readable memory comprises a plurality of executable instructions wherein the instructions, when executed by the one or more processors, cause the one or more processors to process operations comprising creating a set of policies based on user data sets and inputs, creating a faceted classification, establishing a Trust Level, processing sensor data, comparing data to one or more databases, correlating data, updating Trust Levels, updating security keys, and storing the keys in memory. In certain embodiments, the stored data is used to create a usage schema independent from a user's actual identity.

Owner:PERSONNUS

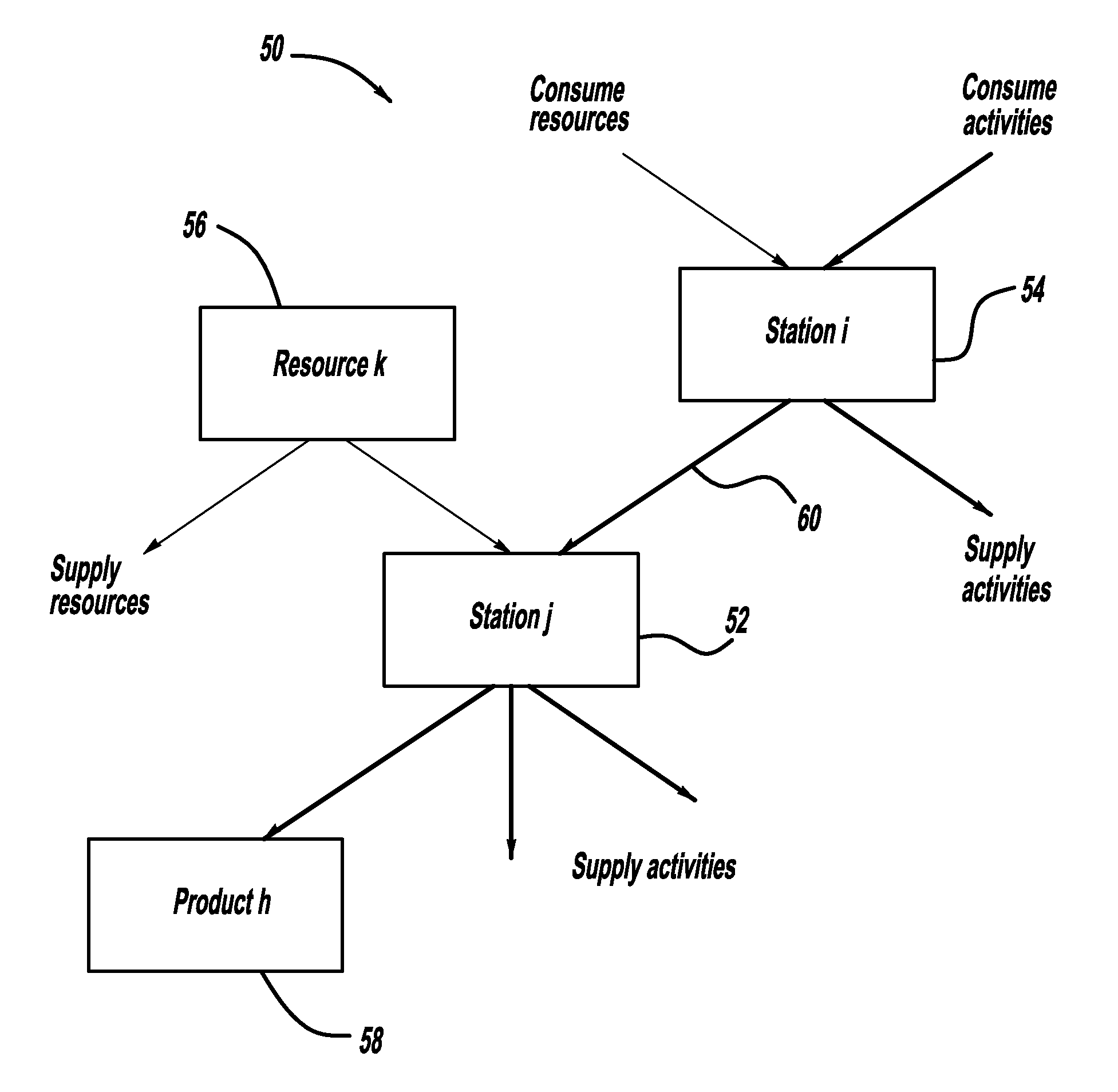

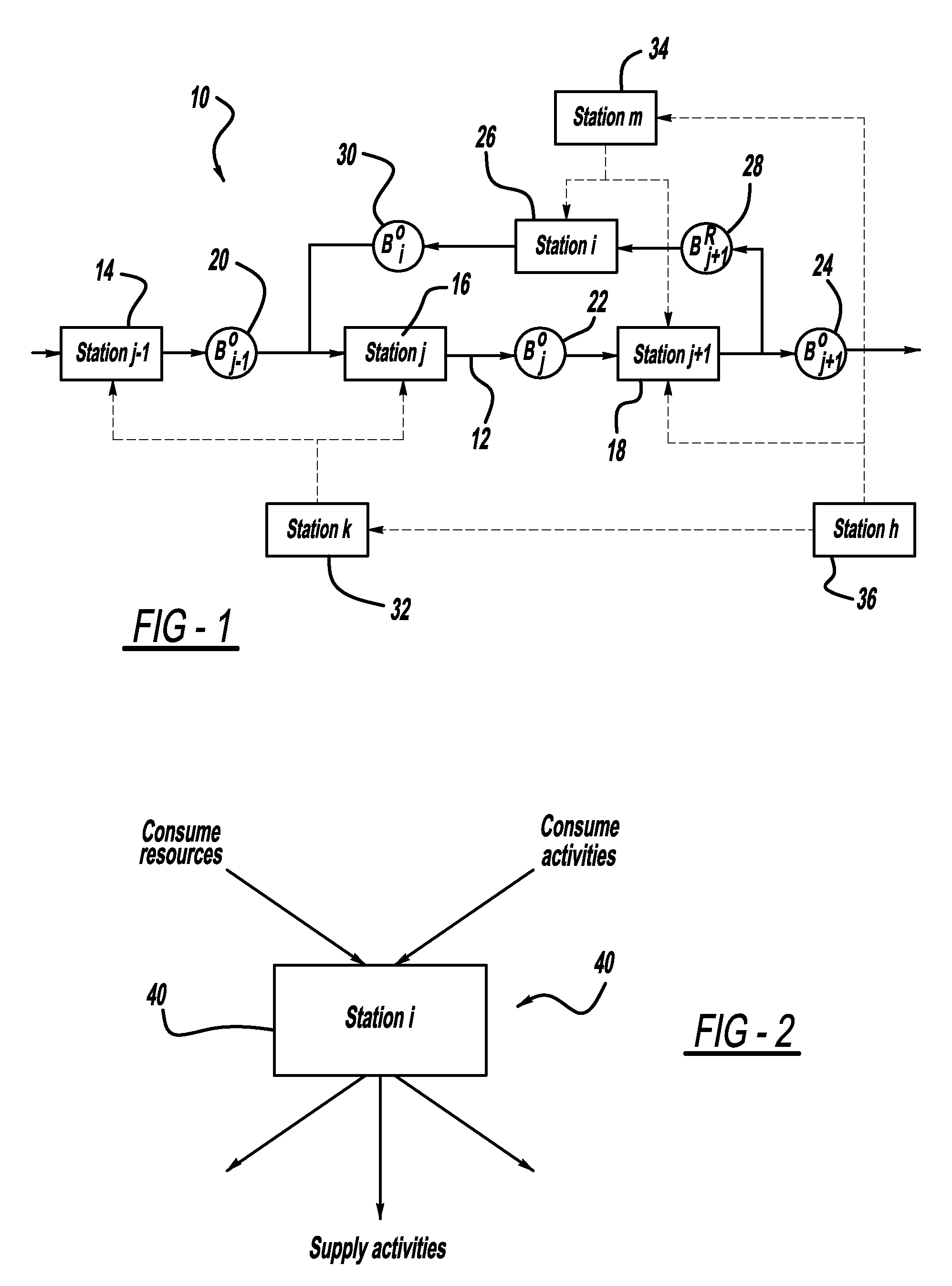

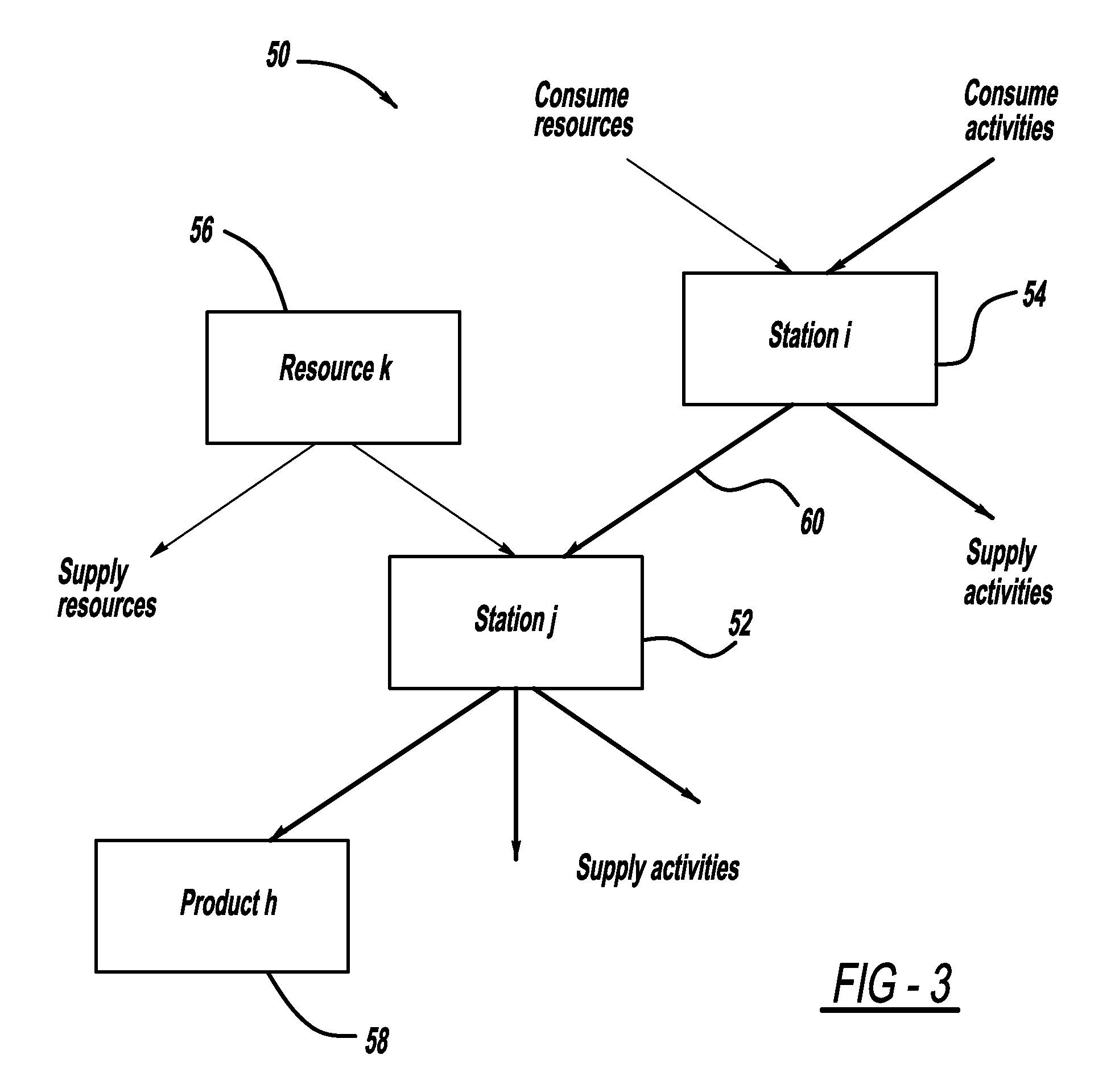

Model-based real-time cost allocation and cost flow

InactiveUS20100042455A1Accurate and timely financial feedbackResourcesTime informationCost distribution

A costing process that takes advantage of real-time information about plant floor activities and provides a more accurate and timely financial feedback about the process efficiencies in response to new changes in the process operation. The costing process includes identifying stations that consume resources, consume activities and supply activities. The costing process also identifies a plurality of resources that are provided to one or more of the stations. The costing process also includes identifying resources from the plurality of resources that are used as needed and resources that are supplied in advance of being used. The costing process allocates costs for each resource to each station that the resource supplies, including calculating a cost rate, calculating a cost of used capacity and calculating a cost of unused capacity. The costing process then determines the cost that each station and product uses based on the allocations.

Owner:GM GLOBAL TECH OPERATIONS LLC

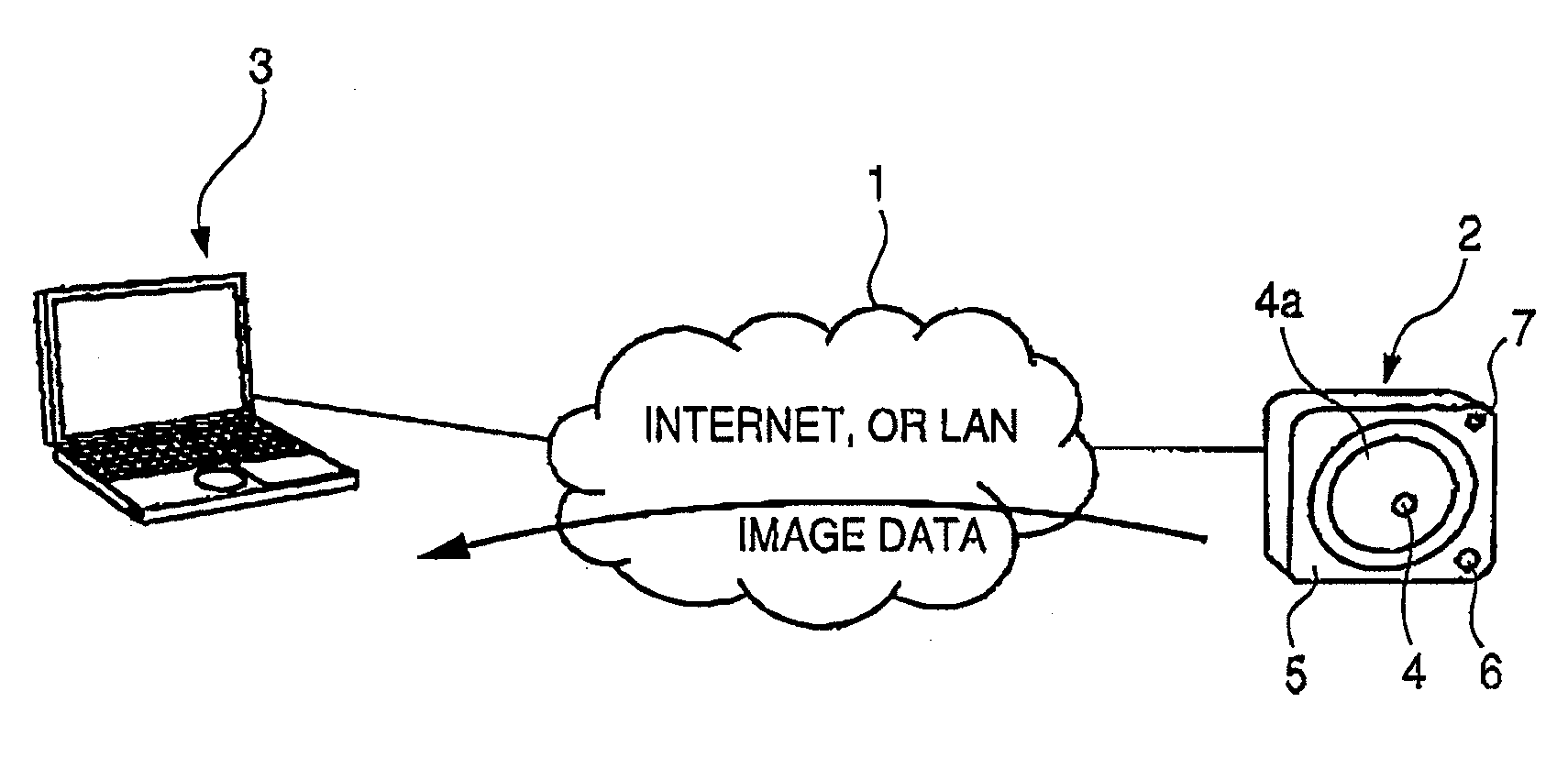

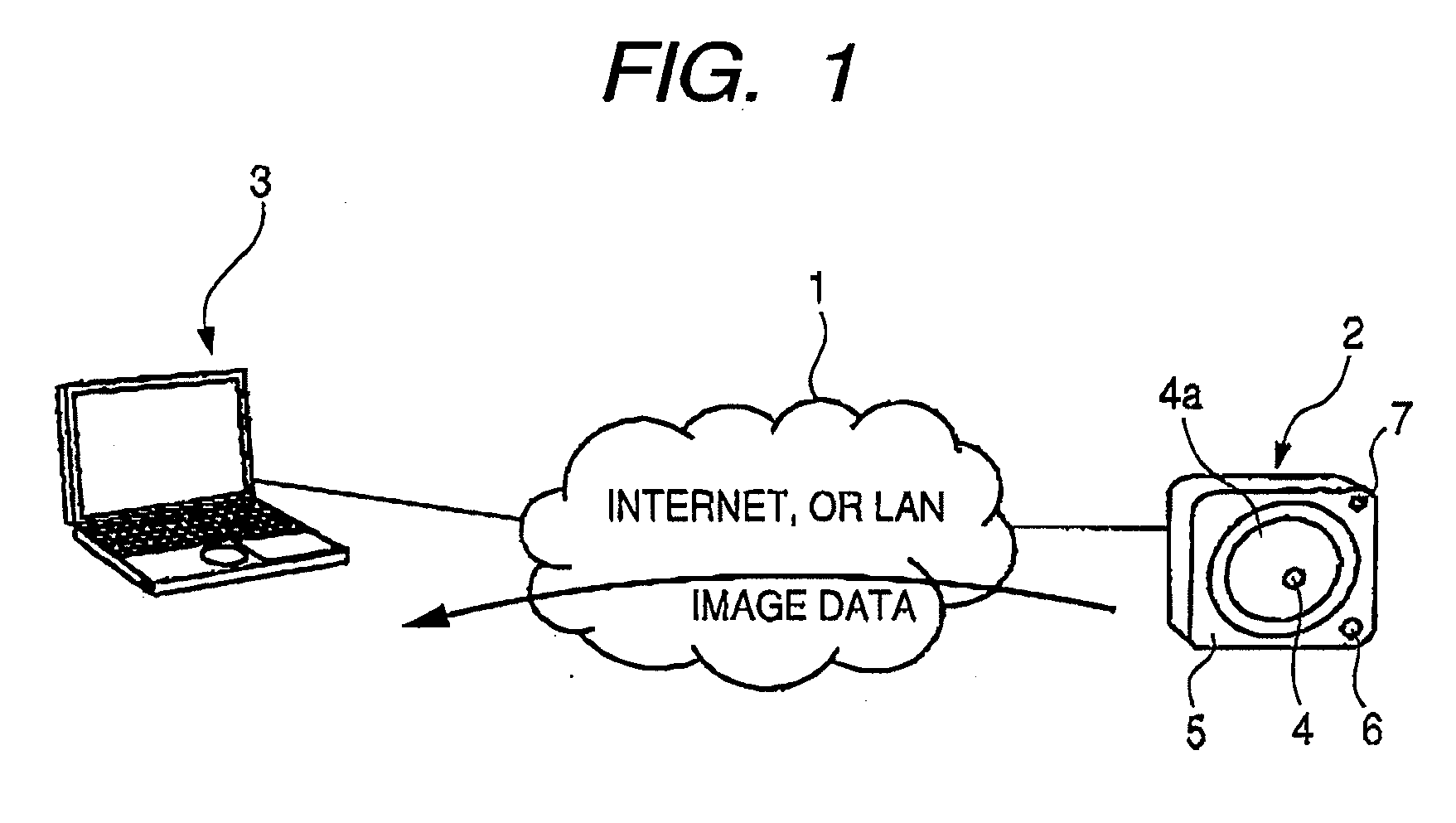

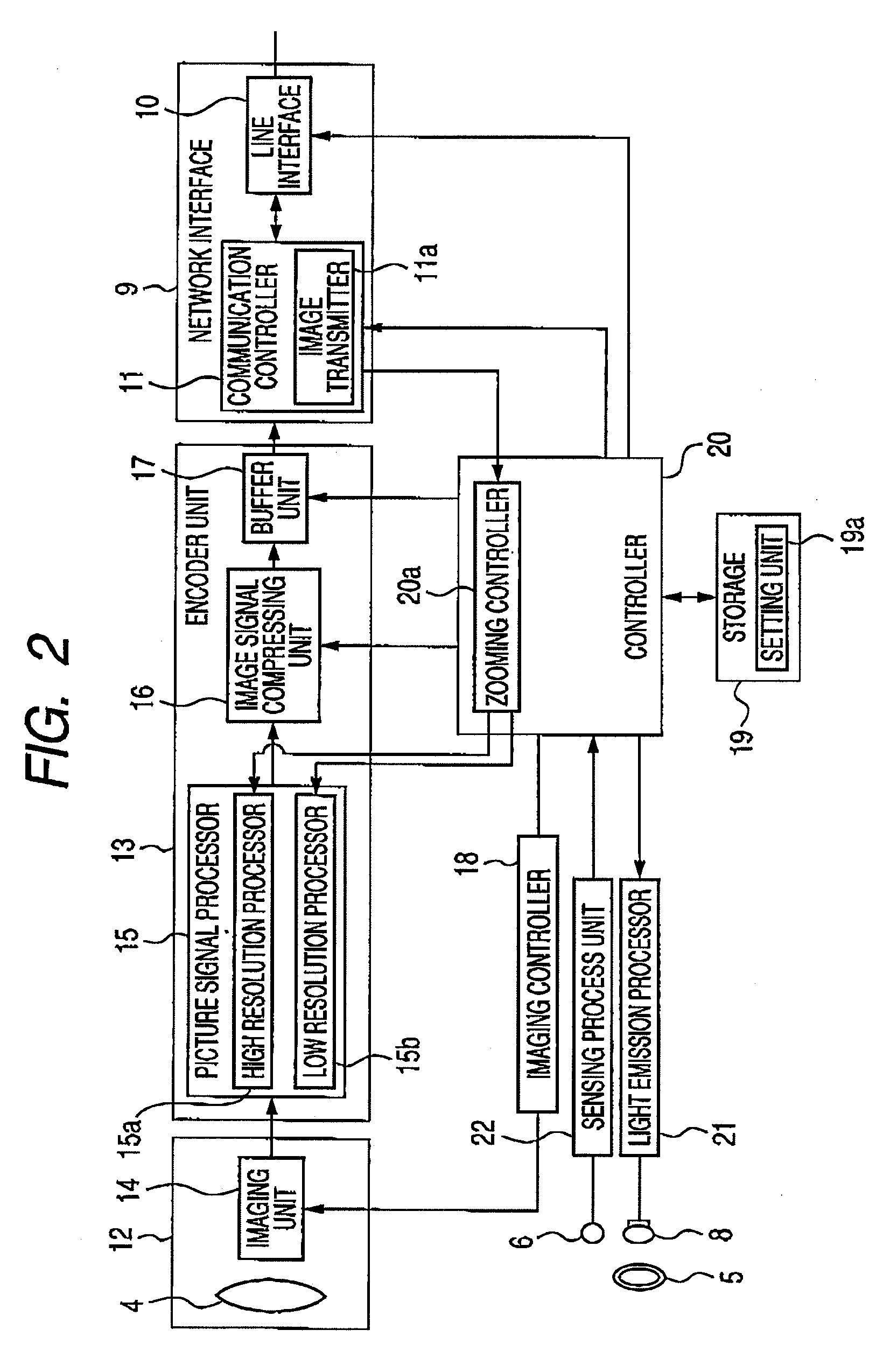

Terminal apparatus, method and computer readable recording medium

ActiveUS20070165103A1Image quality is not deterioratedTelevision system detailsGeometric image transformationImage resolutionComputer graphics (images)

A terminal apparatus displays an enlarge-processed image based upon an image having predetermined resolution while an image having high resolution is acquired, and switches the displayed image to display an image having the high resolution when the acquiring operation of the image having the high resolution is accomplished. The terminal apparatus can performs display operations based upon a panning process operation and a tilting process operation in addition to the enlarging process operation.

Owner:PANASONIC I PRO SENSING SOLUTIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com