Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50532 results about "Product gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product gas meaning, product gas definition | English Cobuild dictionary. product. 1 n-count A product is something that is produced and sold in large quantities, often as a result of a manufacturing process.

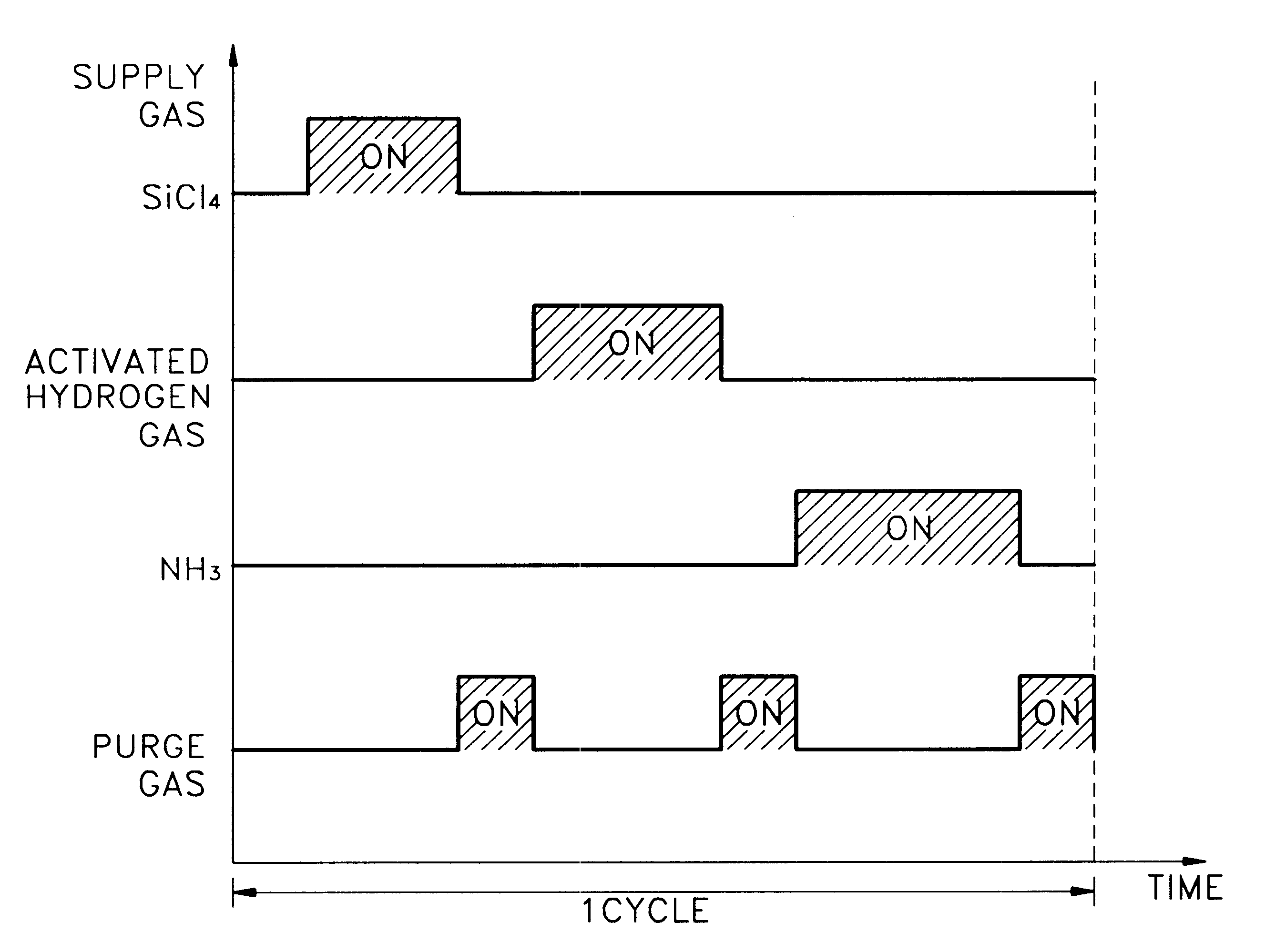

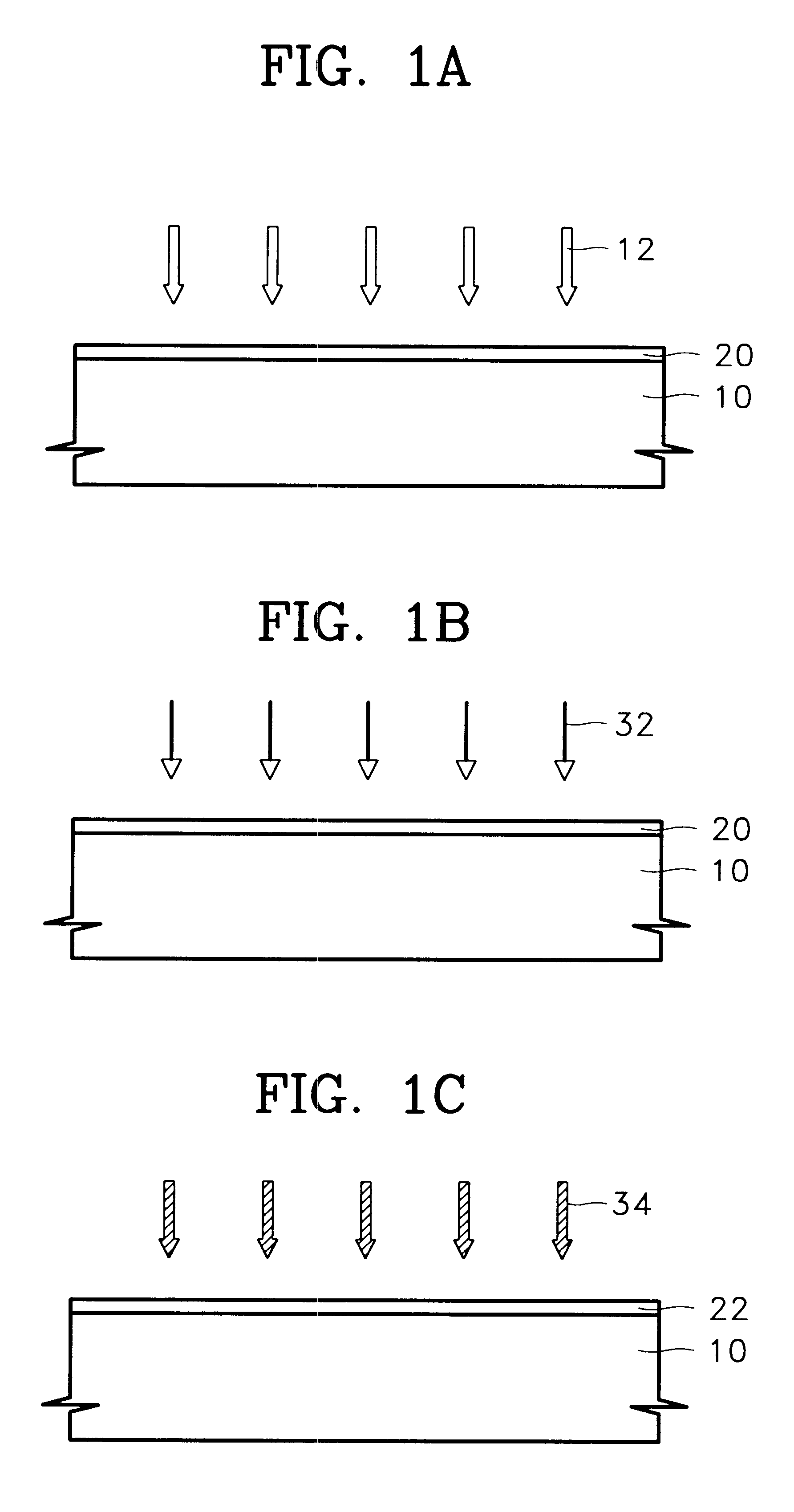

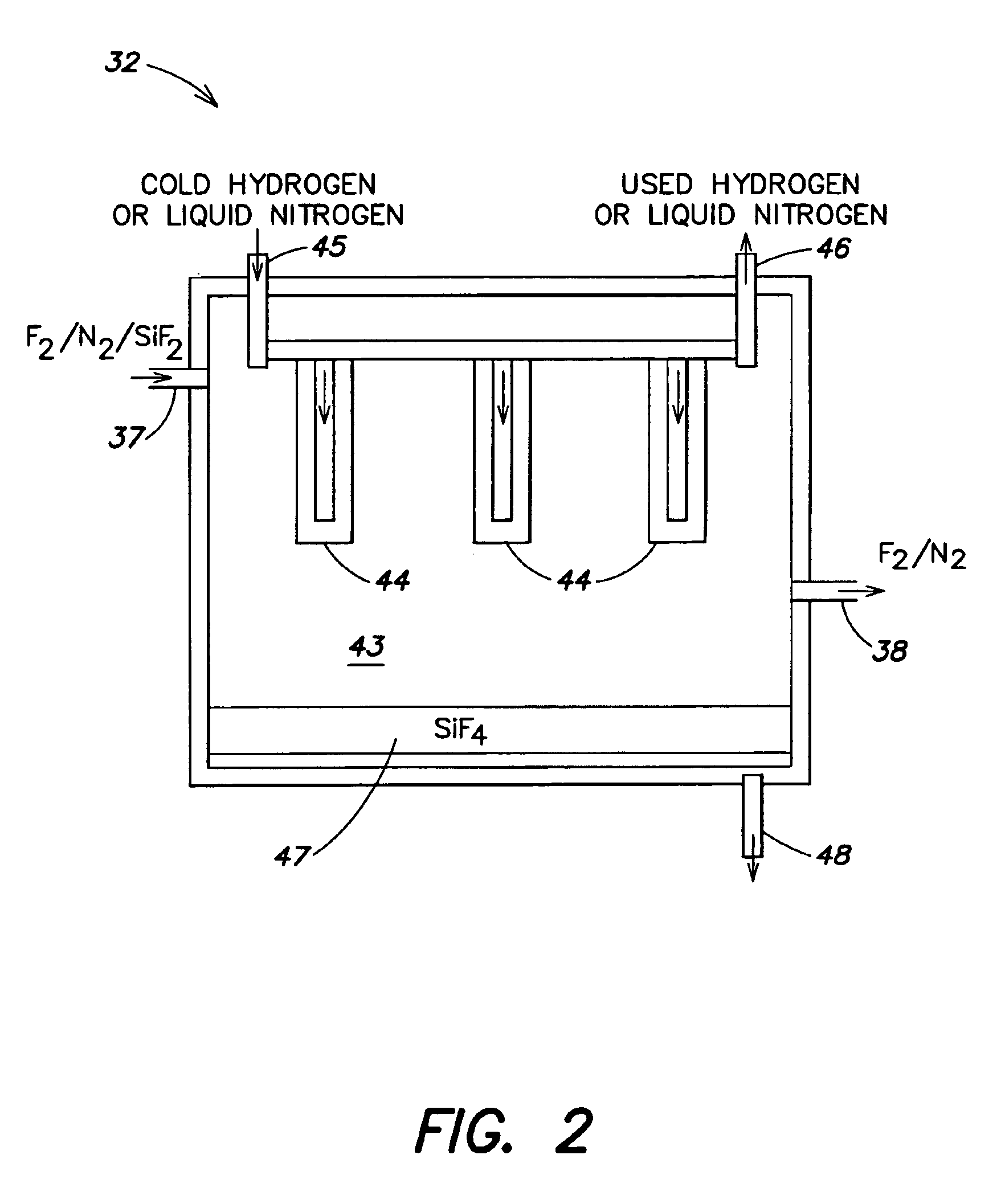

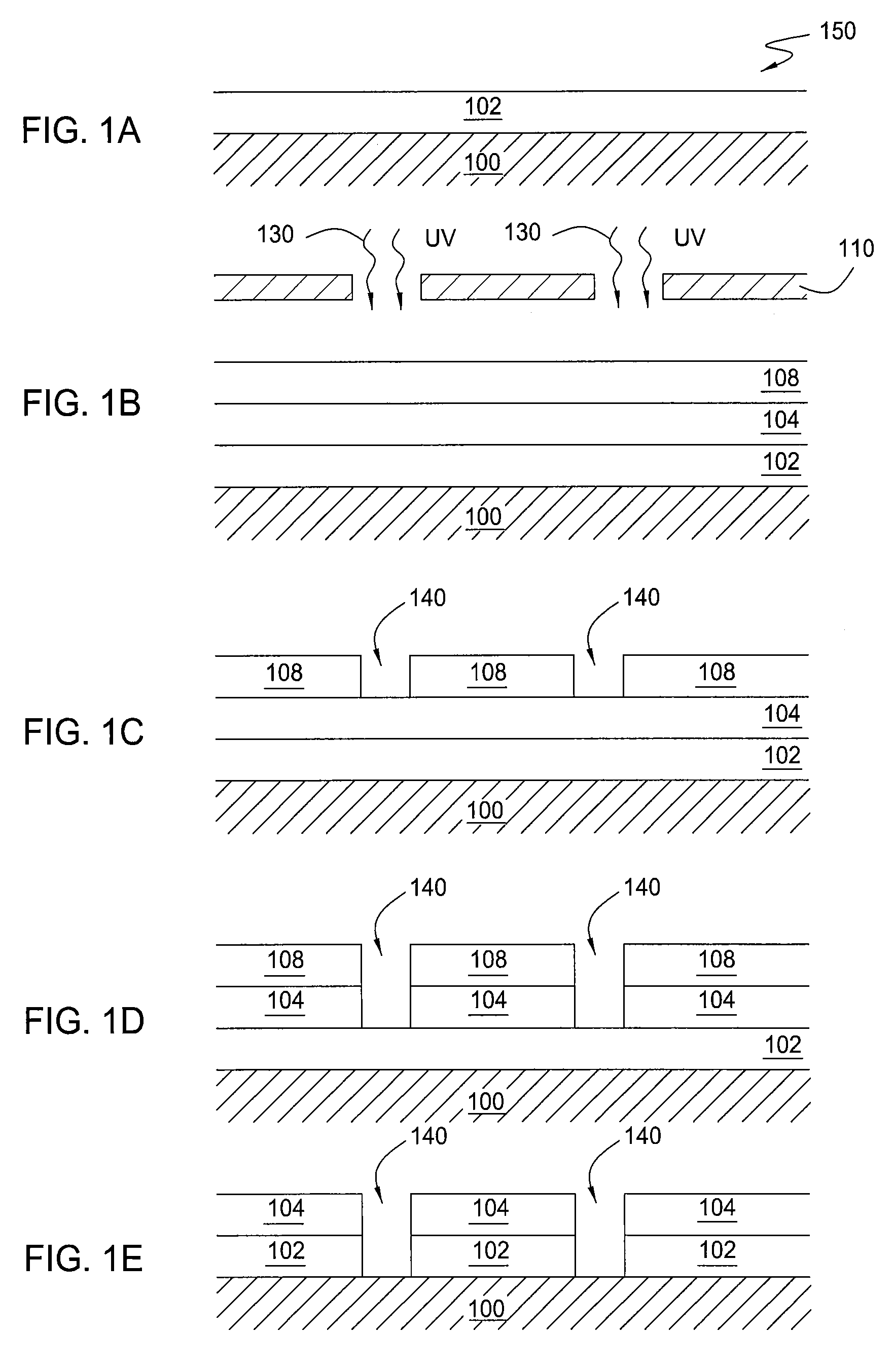

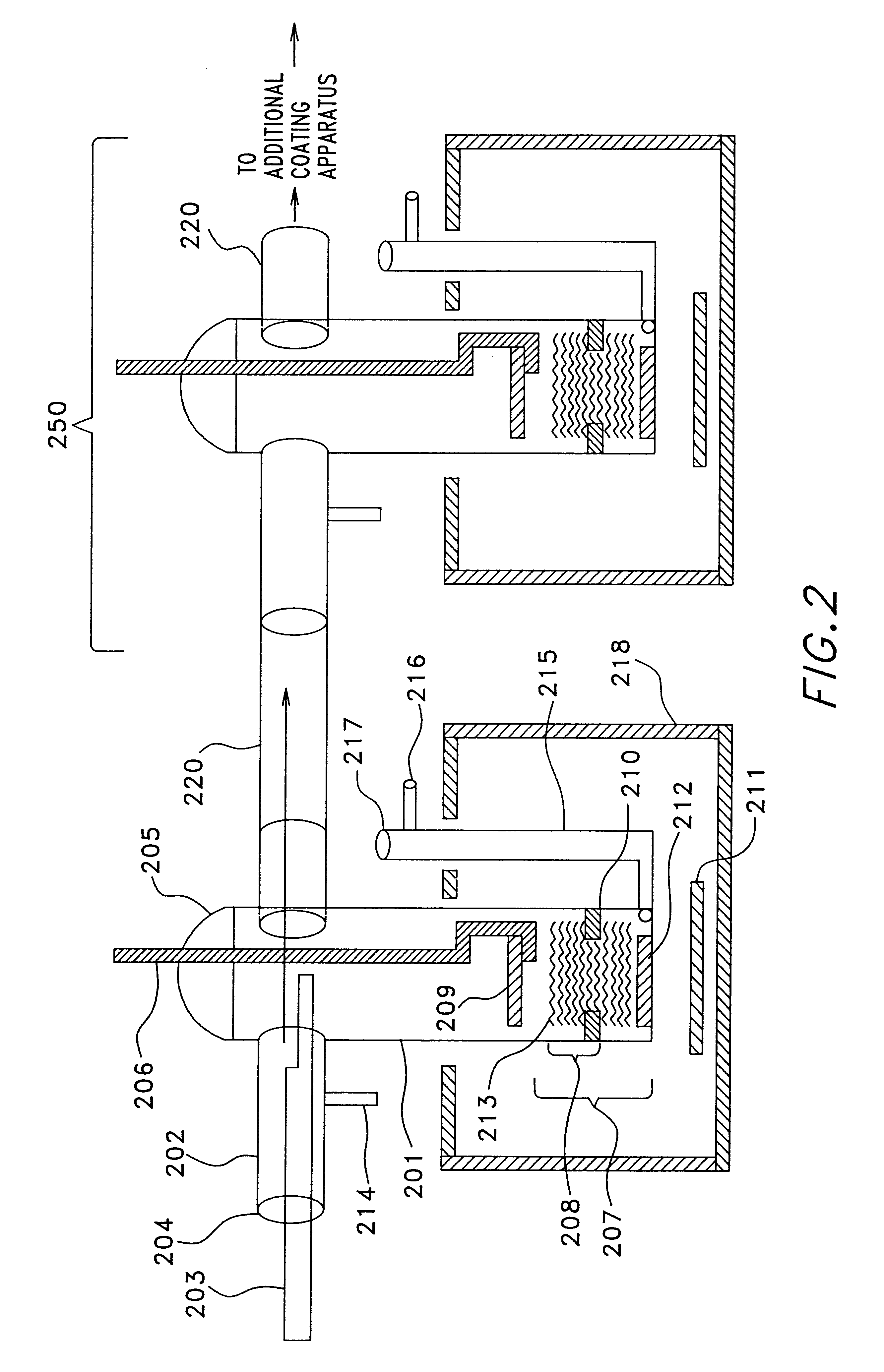

Methods of forming thin films by atomic layer deposition

InactiveUS6468924B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenProduct gas

Methods of forming thin films include forming a first layer comprising a first element that is chemisorbed to a surface of a substrate, by exposing the surface to a first source gas having molecules therein that comprise the first element and a halogen. A step is then performed to expose the first layer to an activated hydrogen gas so that halogens associated with the first layer become bound to hydrogen provided by the activated hydrogen gas. The first layer may then be converted to a thin film comprising the first element and a second element, by exposing a surface of the first layer to a second source gas having molecules therein that comprise the second element.

Owner:SAMSUNG ELECTRONICS CO LTD

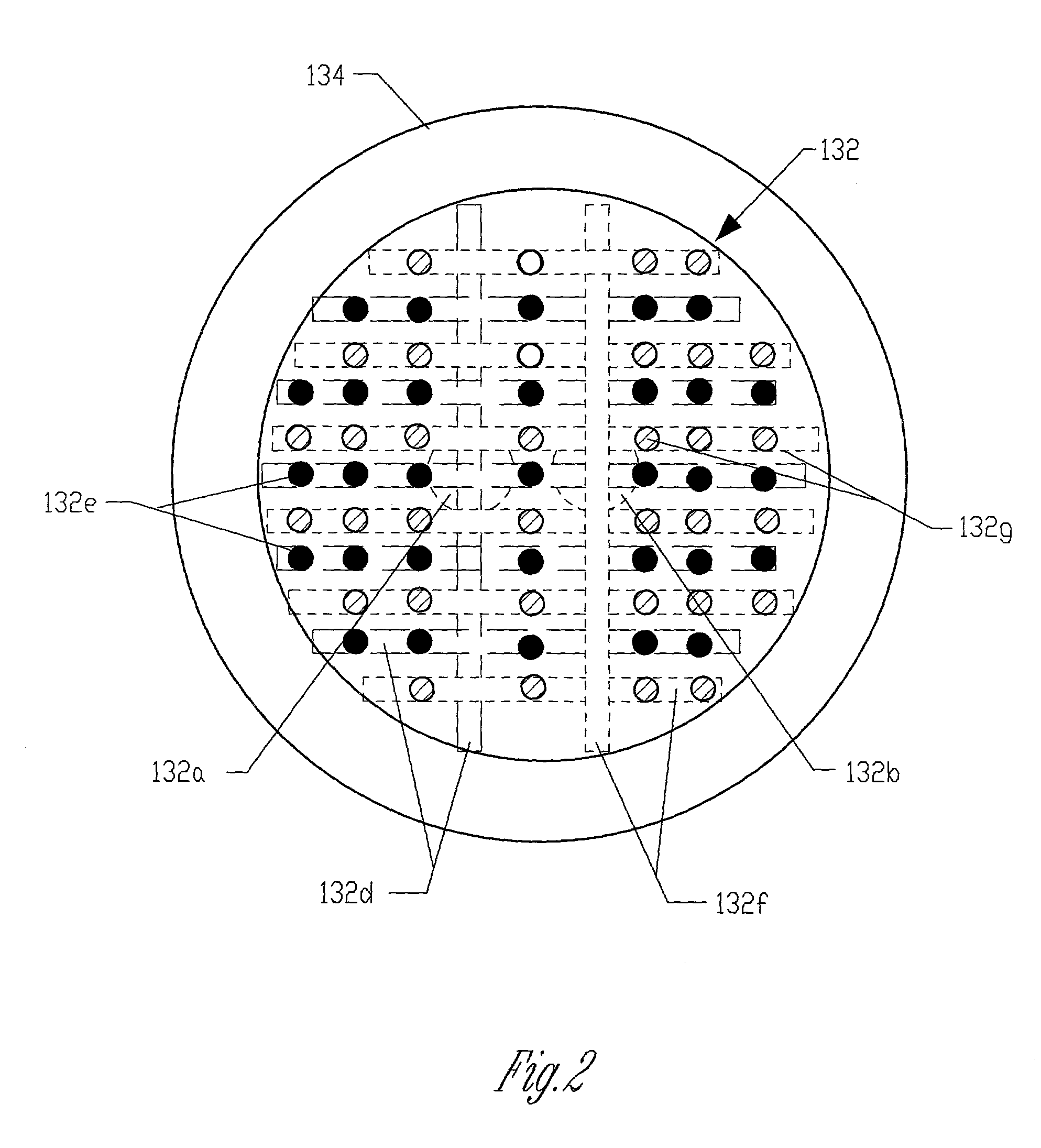

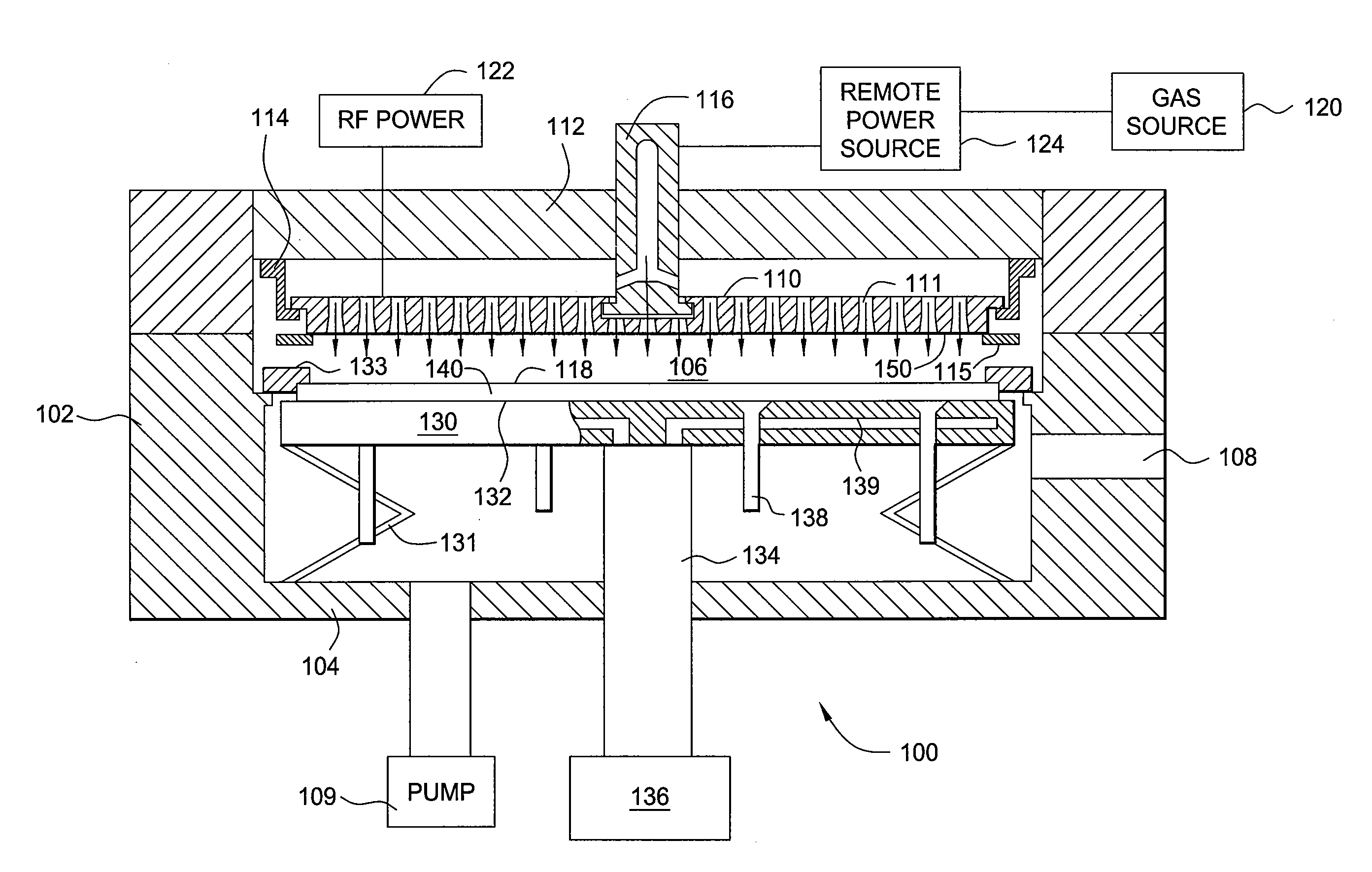

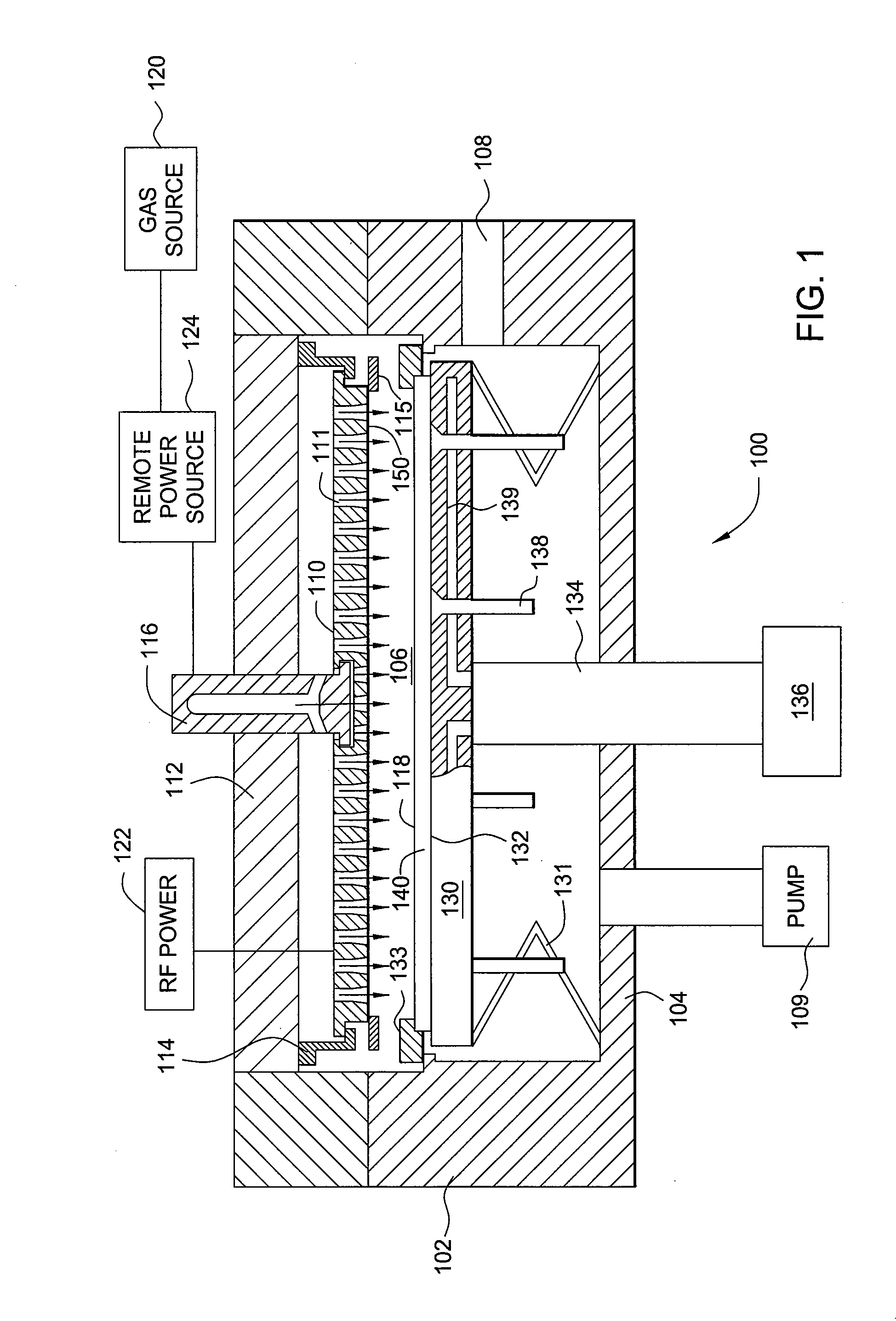

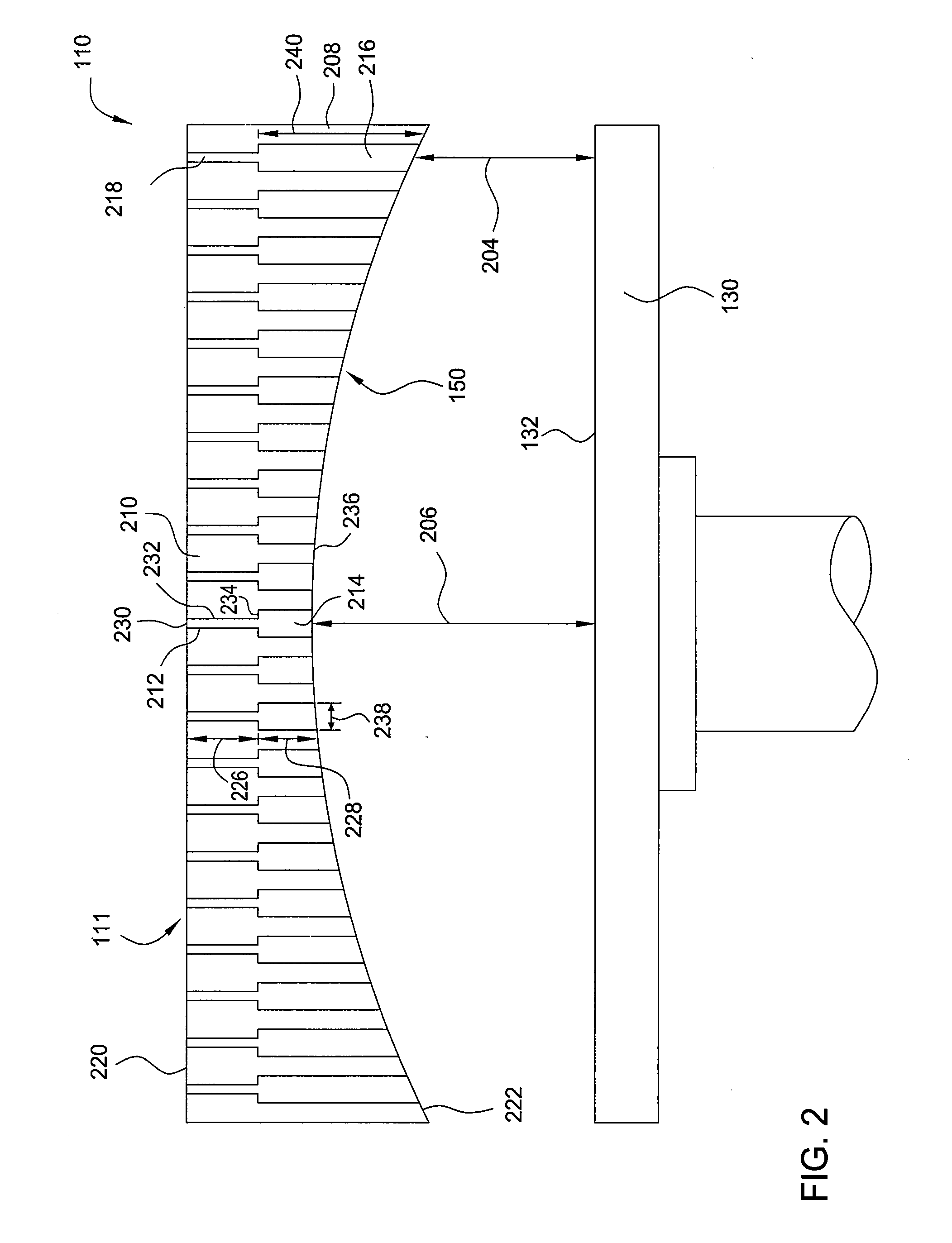

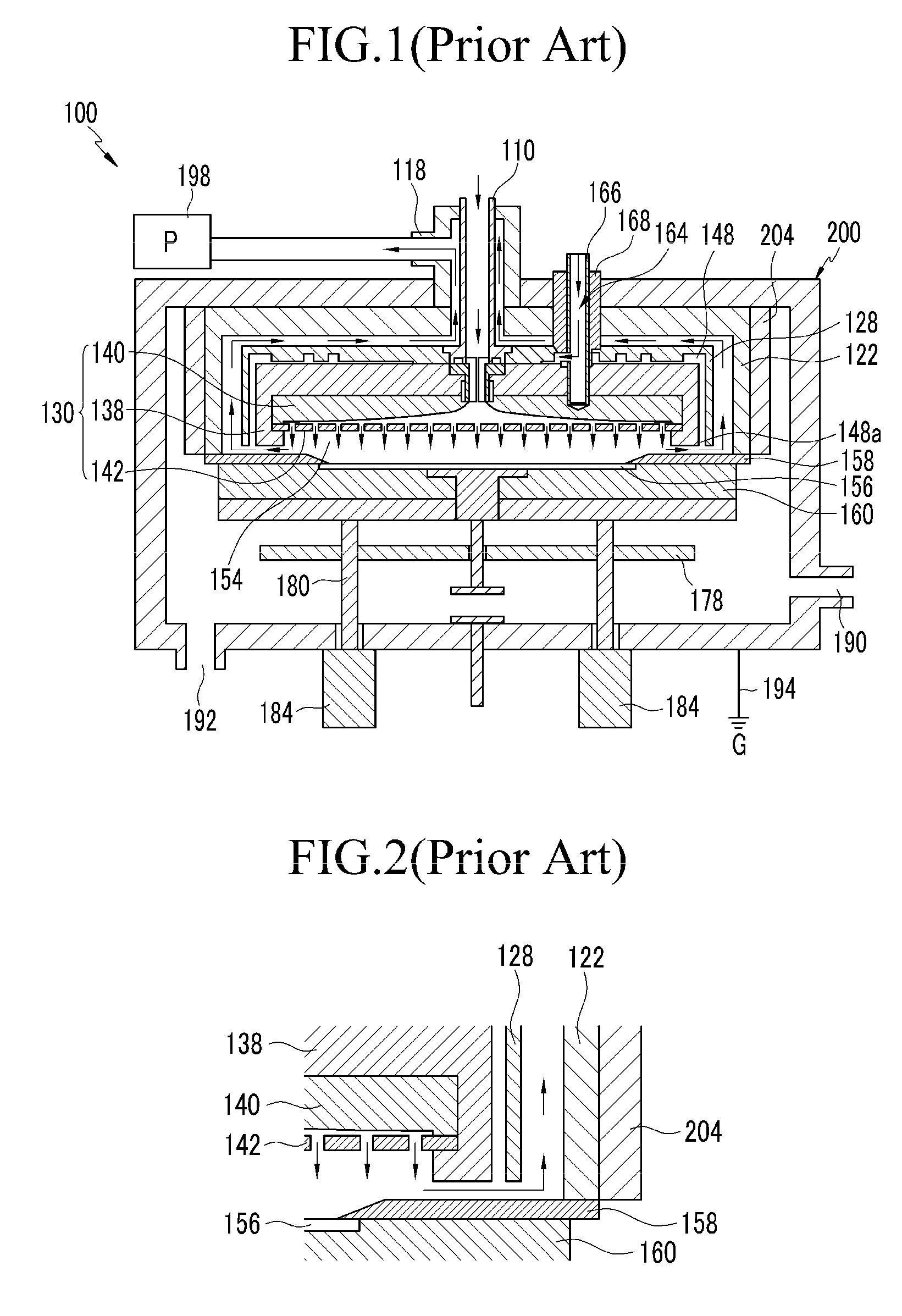

Gas distribution plate assembly for large area plasma enhanced chemical vapor deposition

InactiveUS6942753B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseProduct gas

Embodiments of a gas distribution plate for distributing gas in a processing chamber are provided. In one embodiment, a gas distribution plate includes a diffuser plate having a plurality of gas passages passing between an upstream side and a downstream side of the diffuser plate. At least one of the gas passages includes a first hole and a second hole coupled by an orifice hole. The first hole extends from the upstream side of the diffuser plate while the second hole extends from the downstream side. The orifice hole has a diameter less than the respective diameters of the first and second holes.

Owner:APPLIED MATERIALS INC

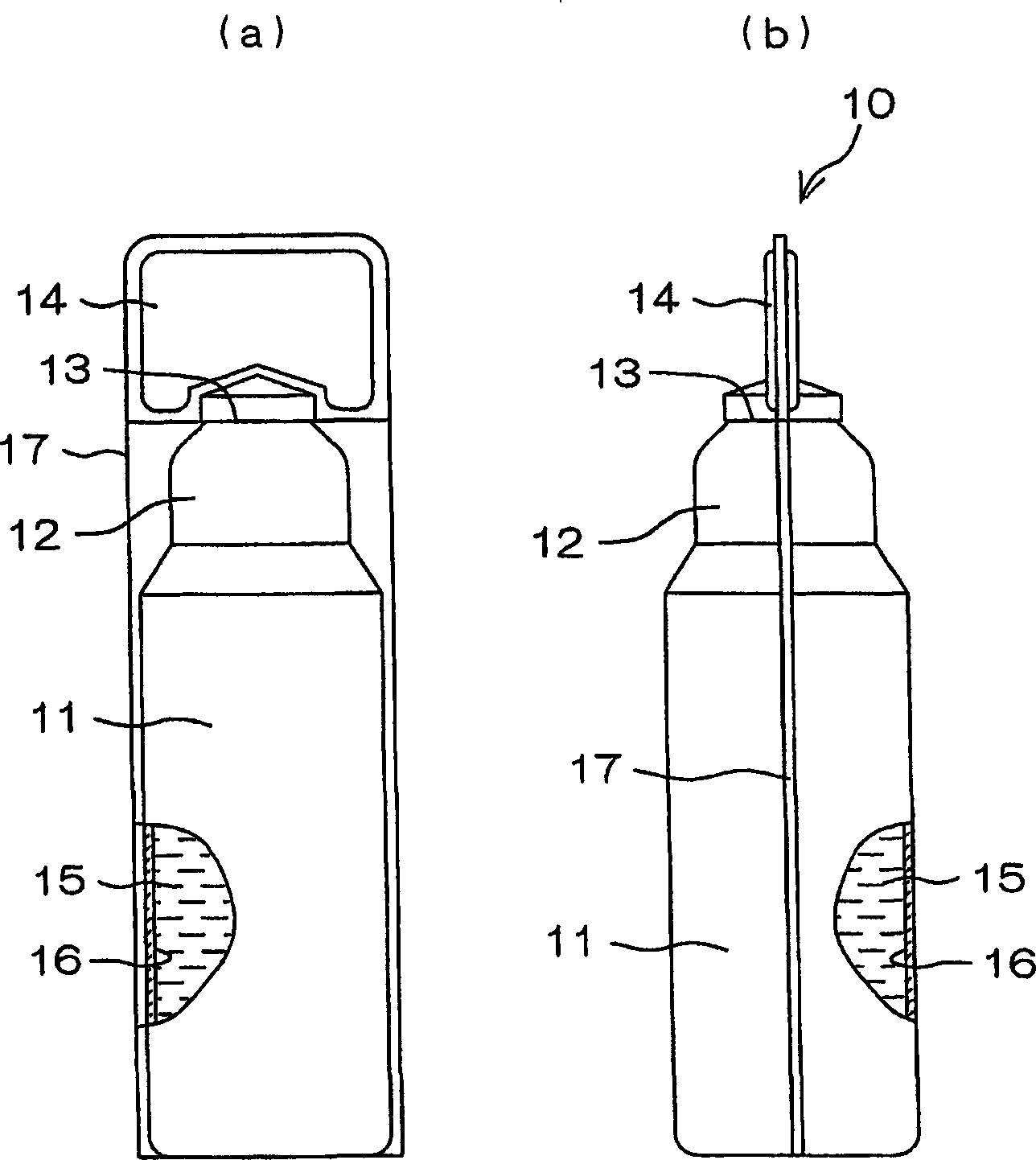

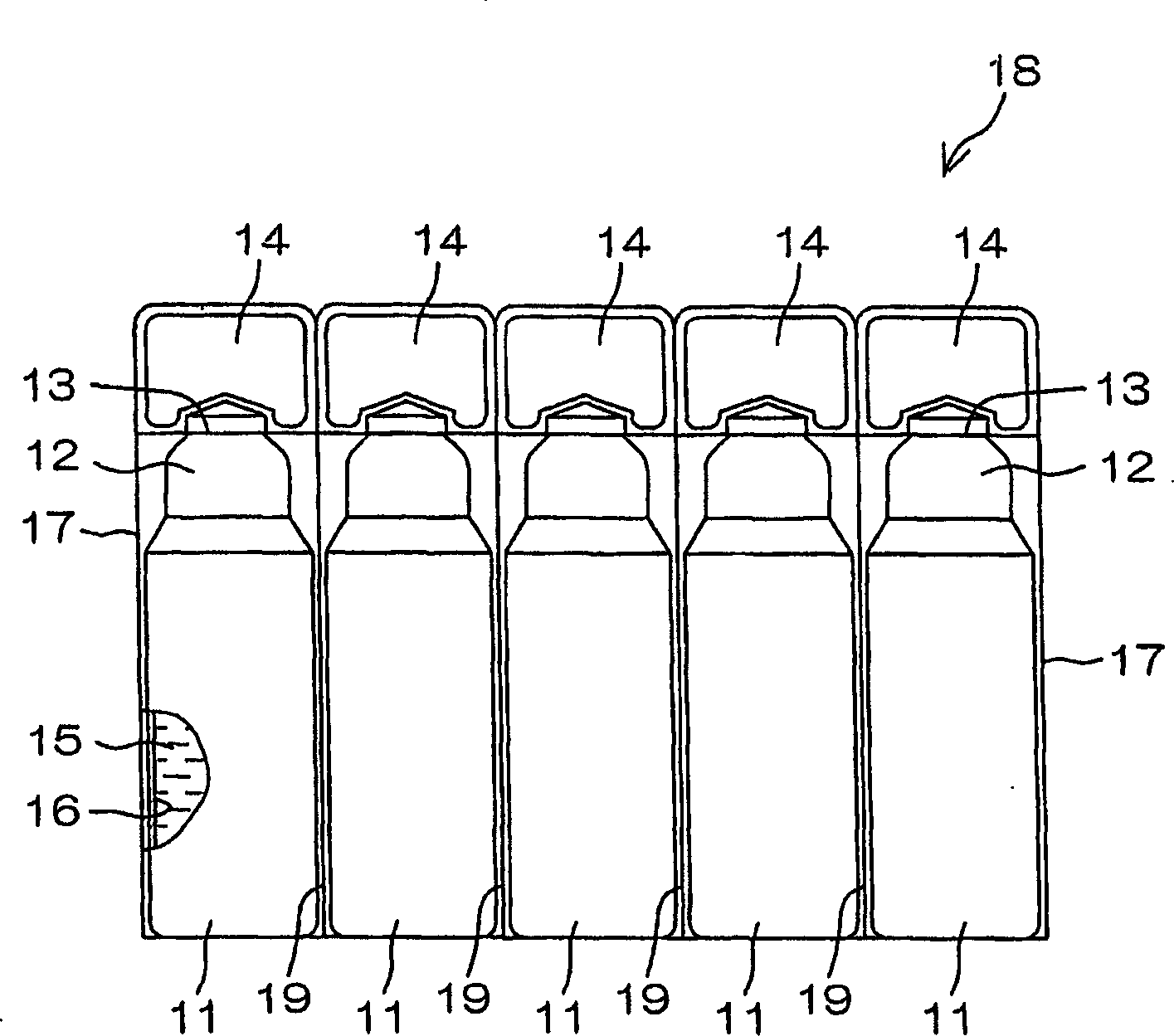

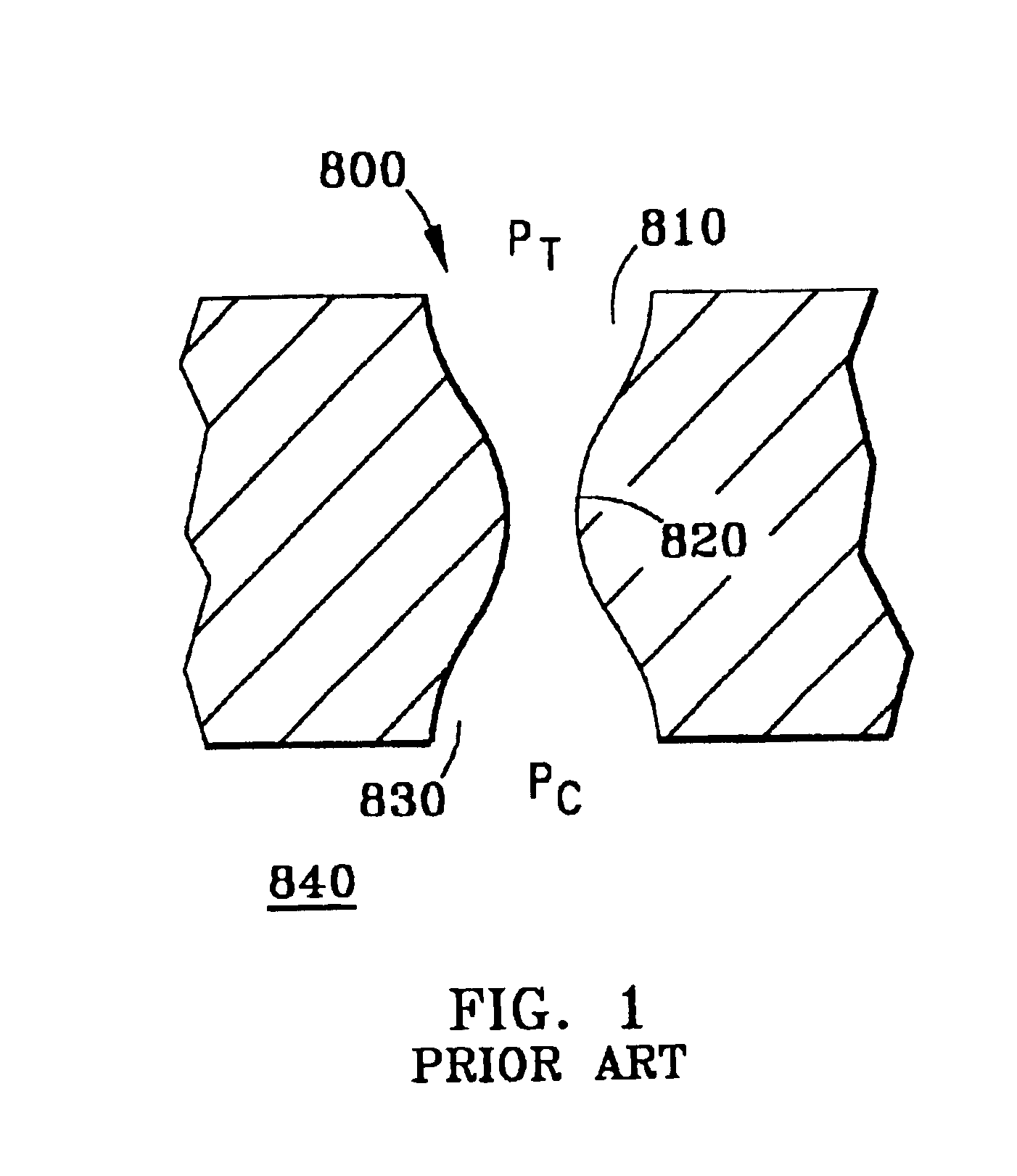

Drug solution filling plastic ampoule and production method therefor

The invention provides a plastic ampoule filled with medicinal liquid, which has the functions of blocking gas, water vapor and light and preventing drug penetration, absorption and adsorption, and a preparation method thereof. The plastic ampoule 10 for filling medicinal solution of the present invention comprises a container main body 11, a fused portion 13 closing its opening 12 and a holding portion 14 connected thereto for twisting. The ampoule 10 is formed using a parison having two or more layers, at least one of which is a material selected from the group consisting of gas transmission, water vapor transmission, light transmission, drug transmission and A functional layer that prevents at least one of drug absorption and adsorption properties. That is, the parison is extruded from a multi-layer blow mold, clamped by the lower parting die to form the main body part 11 of the container, and after filling the liquid medicine 15 therein, the opening part 12 is clamped by the upper parting die to form a fusion joint. Part 13 and holding part 14, thereby making the product of the present invention.

Owner:OTSUKA PHARM FAB INC

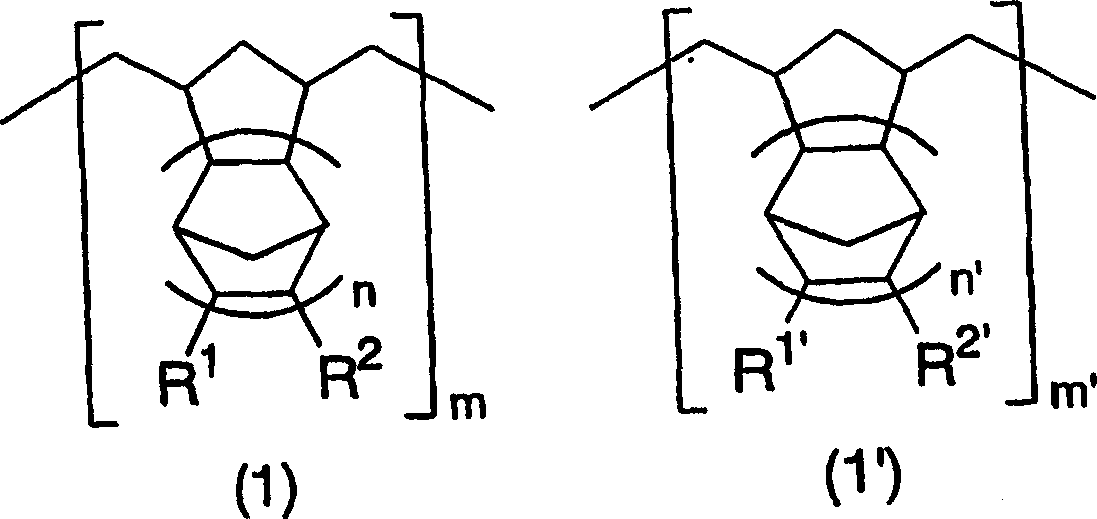

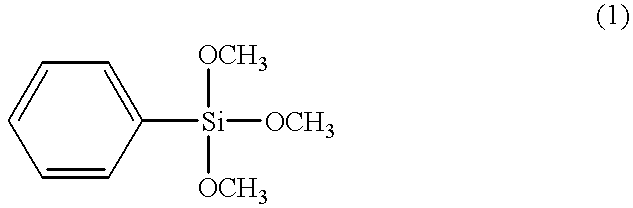

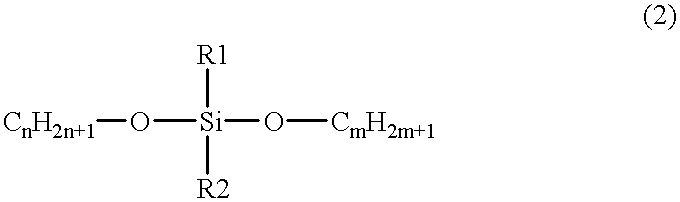

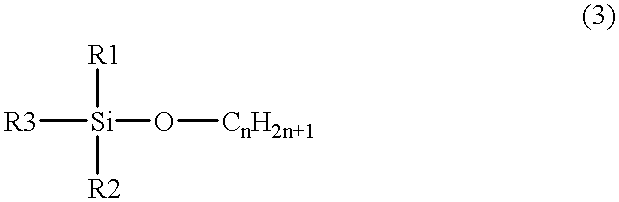

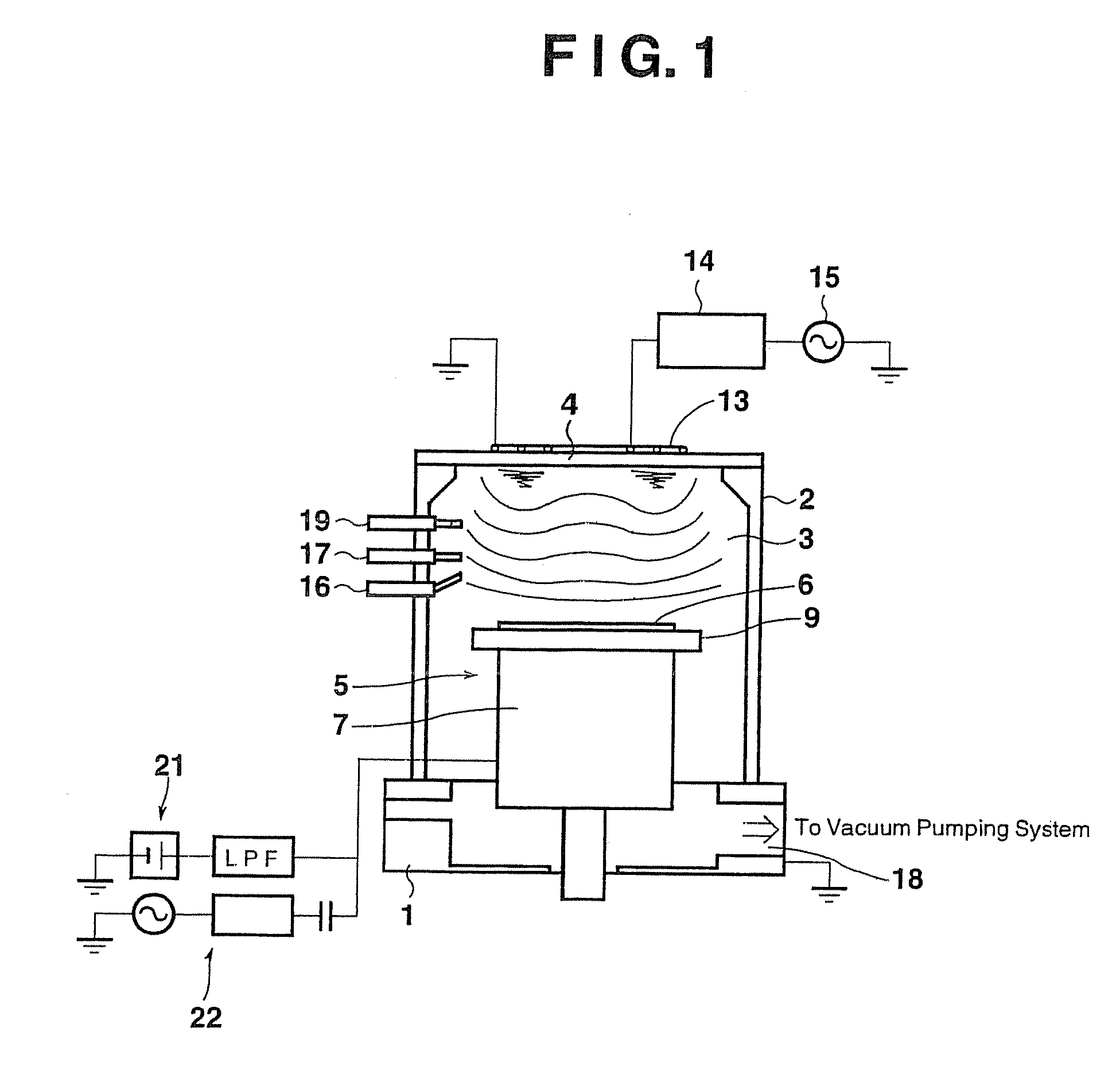

Silicone polymer insulation film on semiconductor substrate and method for forming the film

InactiveUS6352945B1Low dielectric constantImprove thermal stabilityLiquid surface applicatorsSemiconductor/solid-state device detailsPolymer scienceHigh humidity

A method for forming a silicone polymer insulation film having a low relative dielectric constant, high thermal stability and high humidity-resistance on a semiconductor substrate is applied to a plasma CVD apparatus. The first step is introducing a silicon-containing hydrocarbon compound expressed by the general formula SialphaObetaCxHy (alpha, beta, x, and y are integers) to the reaction chamber of the plasma CVD apparatus. The silicon-containing hydrocarbon compound has at most two O-CnH2n+1 bonds and at least two hydrocarbon radicals bonded to the silicon. The residence time of the material gas is lengthened by, for example, reducing the total flow of the reaction gas, in such a way as to form a silicone polymer film having a micropore porous structure with a low relative dielectric constant.

Owner:ASM JAPAN

Substrate processing method, computer readable recording medium and substrate processing apparatus

InactiveUS20070062453A1Low dielectric constantImprove heat resistanceElectric discharge tubesSemiconductor/solid-state device detailsMicrowaveEngineering

In the present invention, Ar gas for plasma generation is supplied to a plasma generation region and butyne gas having a multiple bond is supplied to a film formation region at a substrate side as source gas, inside of a process vessel in an insulating film forming apparatus. A microwave is supplied inside of the process vessel from a radial line slot antenna under a state in which a bias voltage is not applied to a substrate W. A plasma is thereby generated in the plasma generation region, the butyne gas in the film formation region is activated by the plasma, and an insulating film of amorphous carbon is formed on the substrate.

Owner:TOKYO ELECTRON LTD

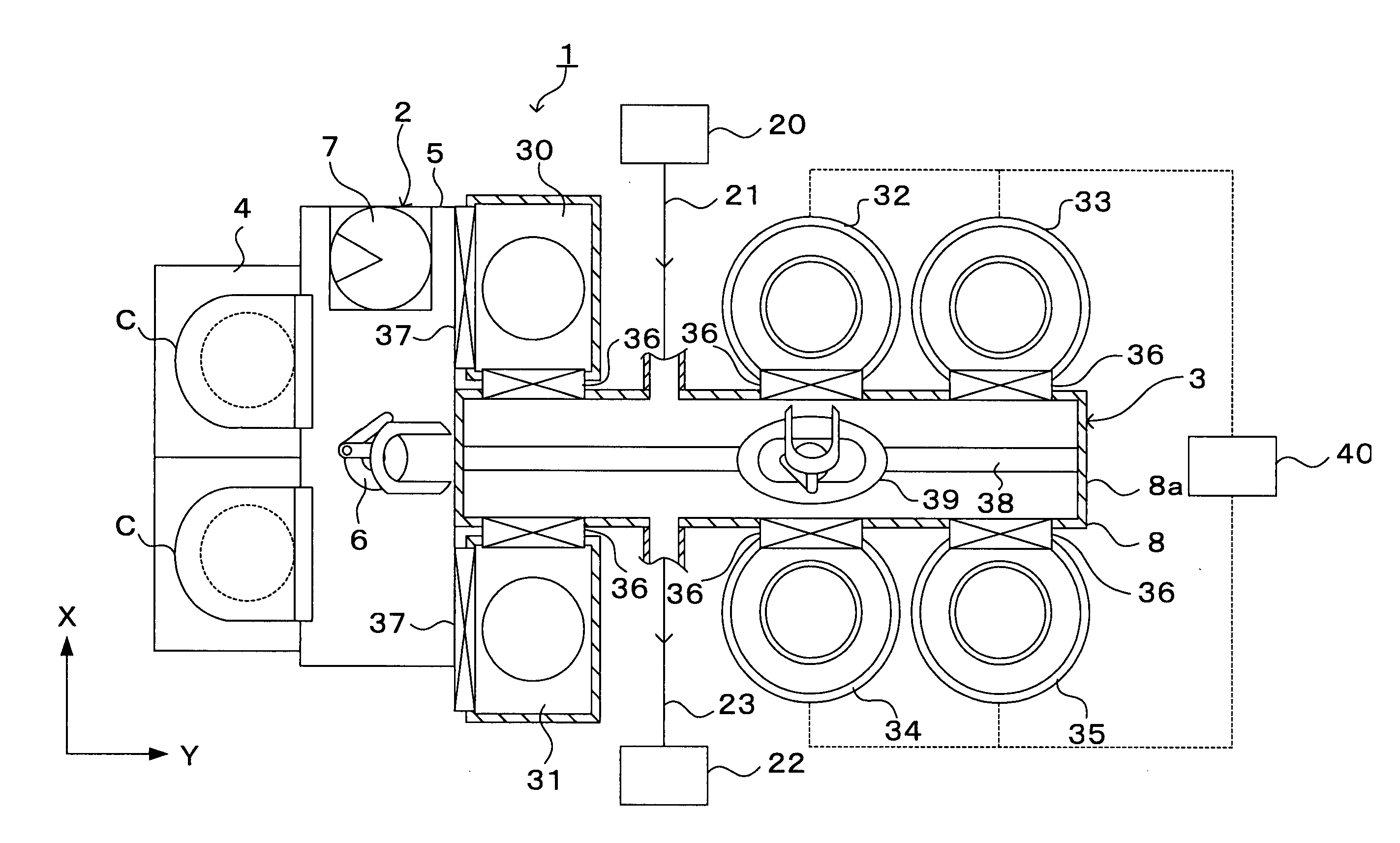

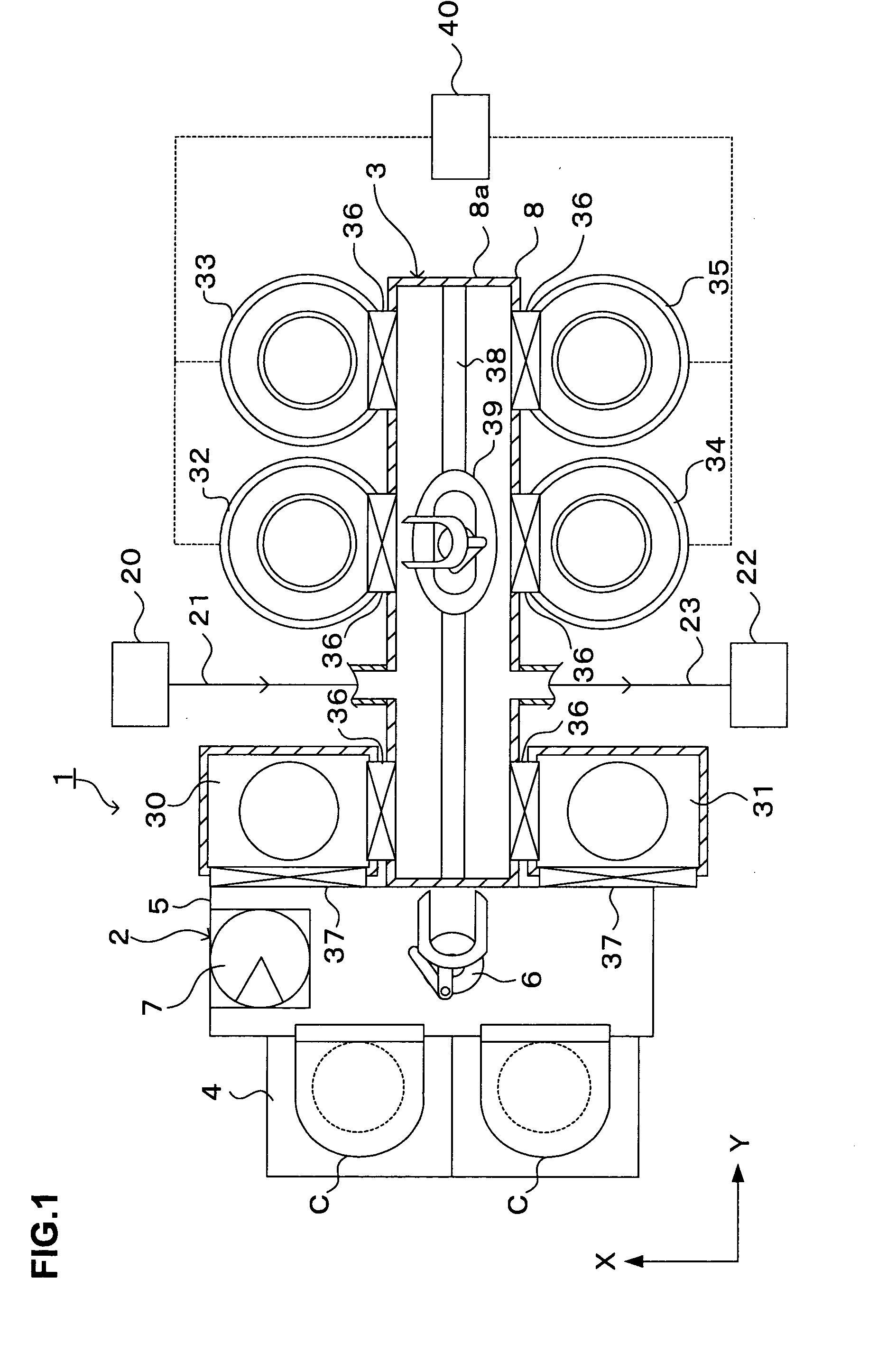

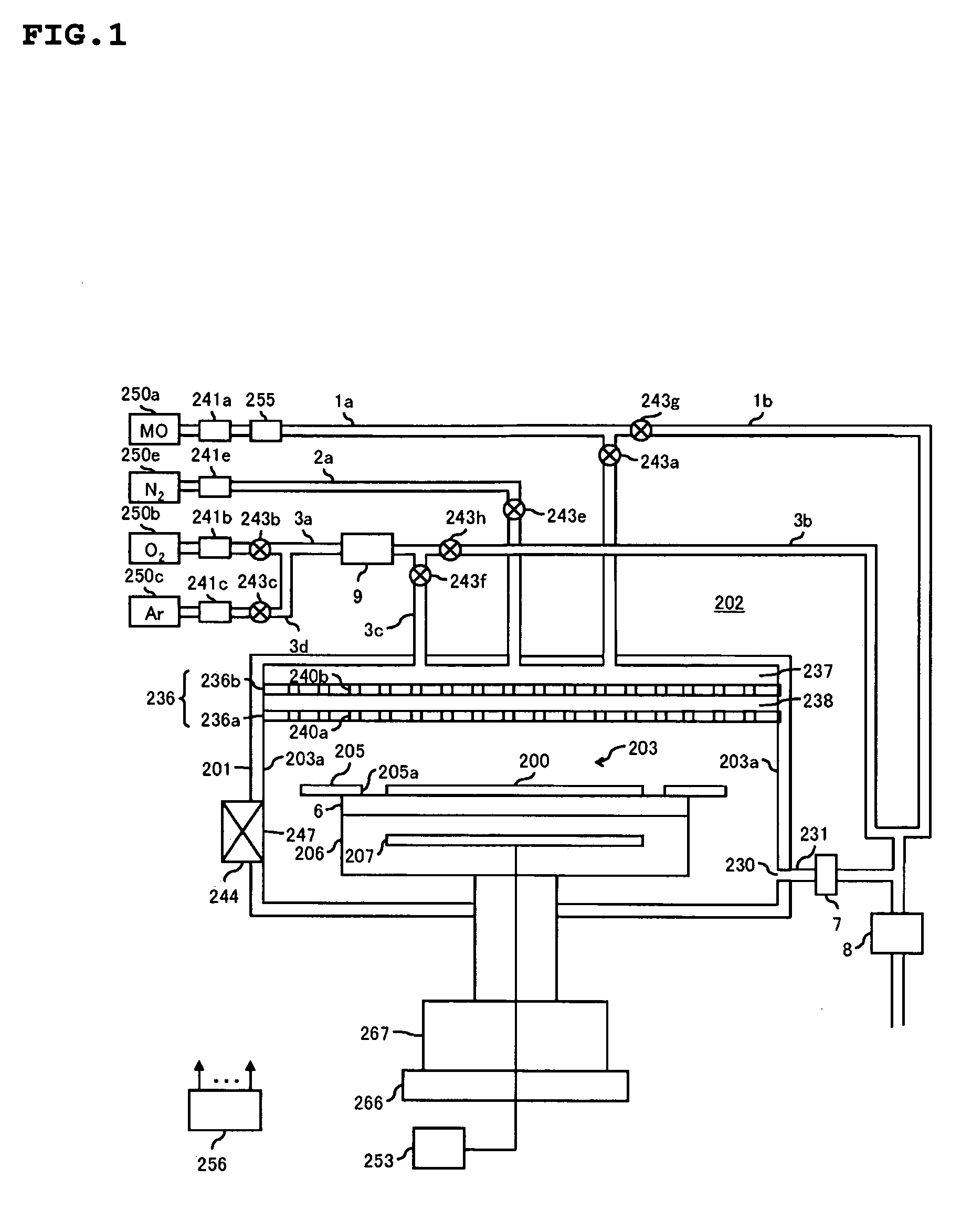

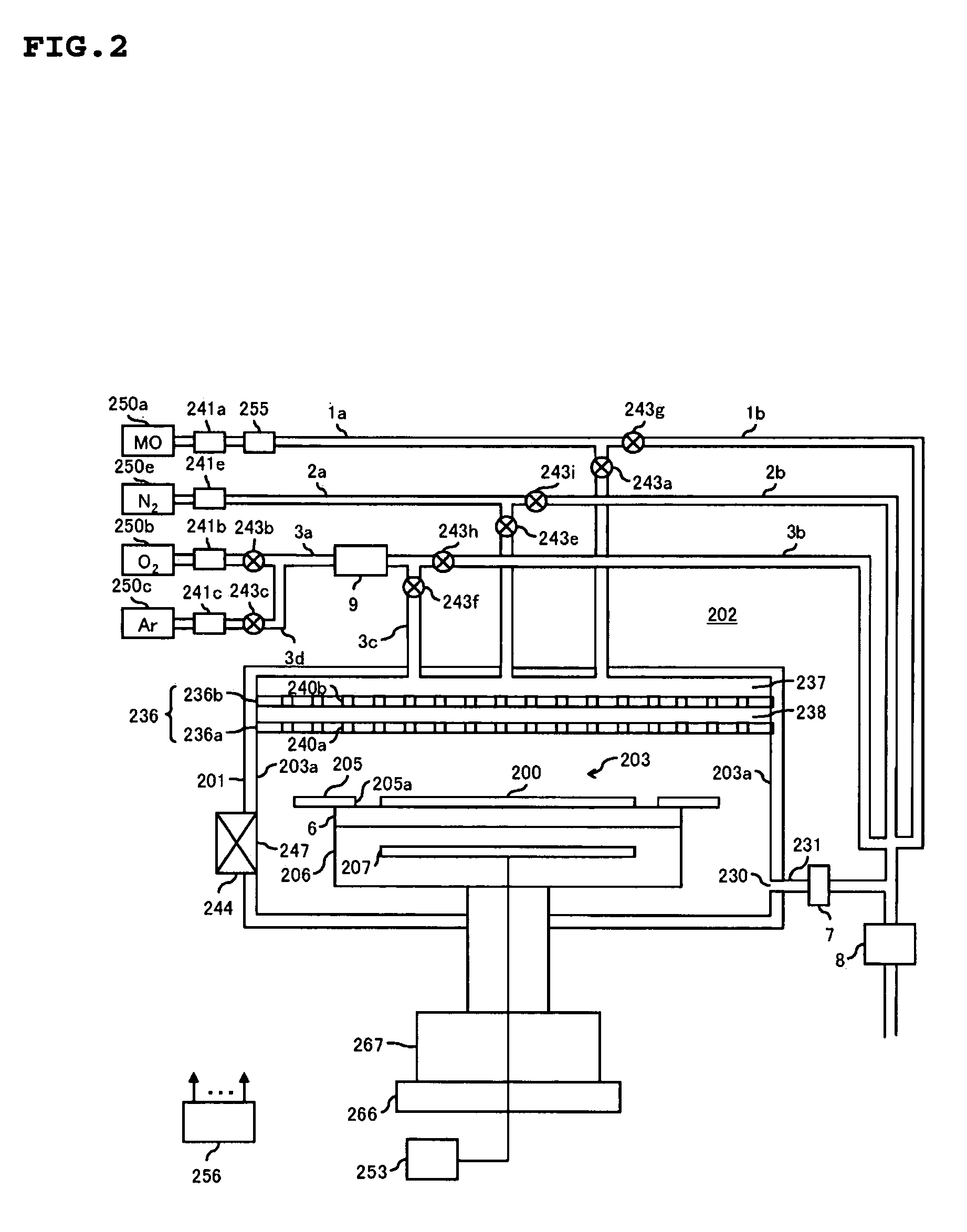

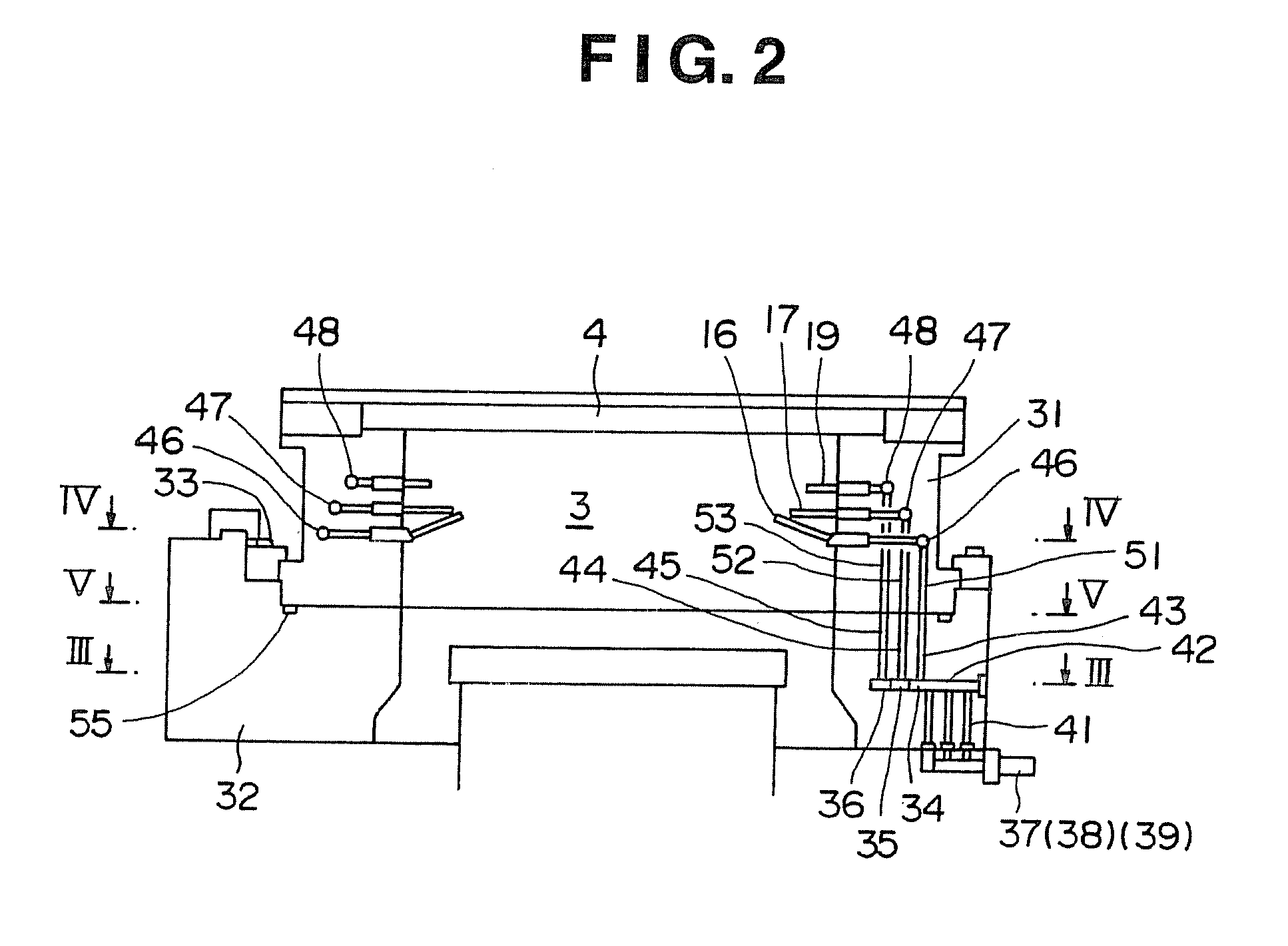

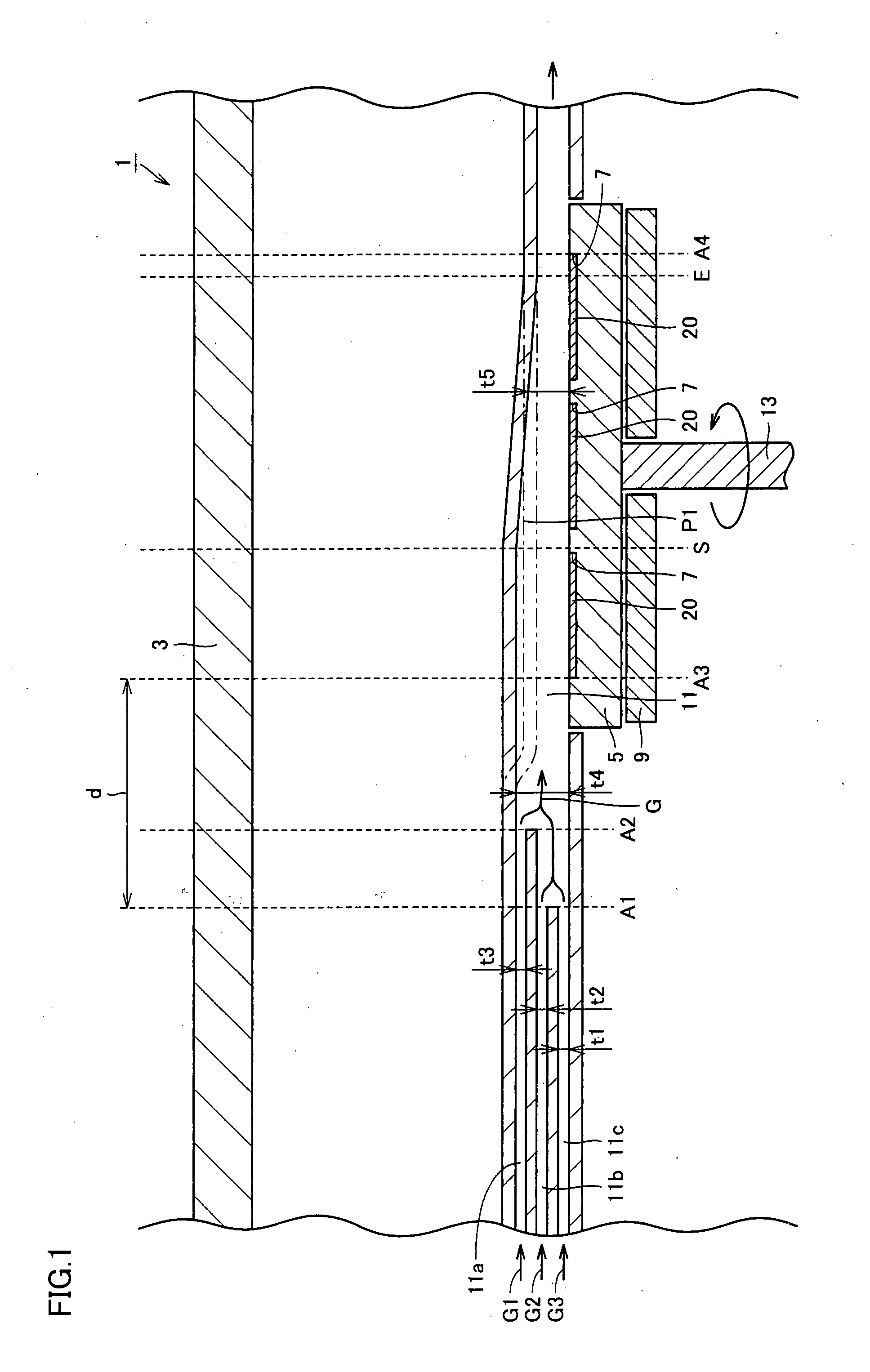

Substrate processing apparatus and method for manufacturing semiconductor device

ActiveUS20080264337A1Suppress agitationForeign matterLiquid surface applicatorsVacuum evaporation coatingForeign matterProduct gas

A substrate processing apparatus and a method for manufacturing a semiconductor device whereby foreign matter can be prevented from being adsorbed on the substrate, by suppressing agitation of foreign matter present in the processing chamber. The substrate processing apparatus comprises a processing chamber for processing a substrate; a processing gas feeding line for feeding a processing gas into the processing chamber; an inert gas feeding line for feeding an inert gas into the processing chamber; an inert gas vent line provided in the inert gas feeding line, for exhausting the inert gas fed into the inert gas feeding line without feeding the inert gas into the processing chamber; a first valve provided in the inert gas feeding line, on a downstream side of a part where the inert gas vent line is provided in the inert gas feeding line; a second valve provided in the inert gas vent line; and an exhaust line that exhausts an inside of the processing chamber.

Owner:KOKUSA ELECTRIC CO LTD

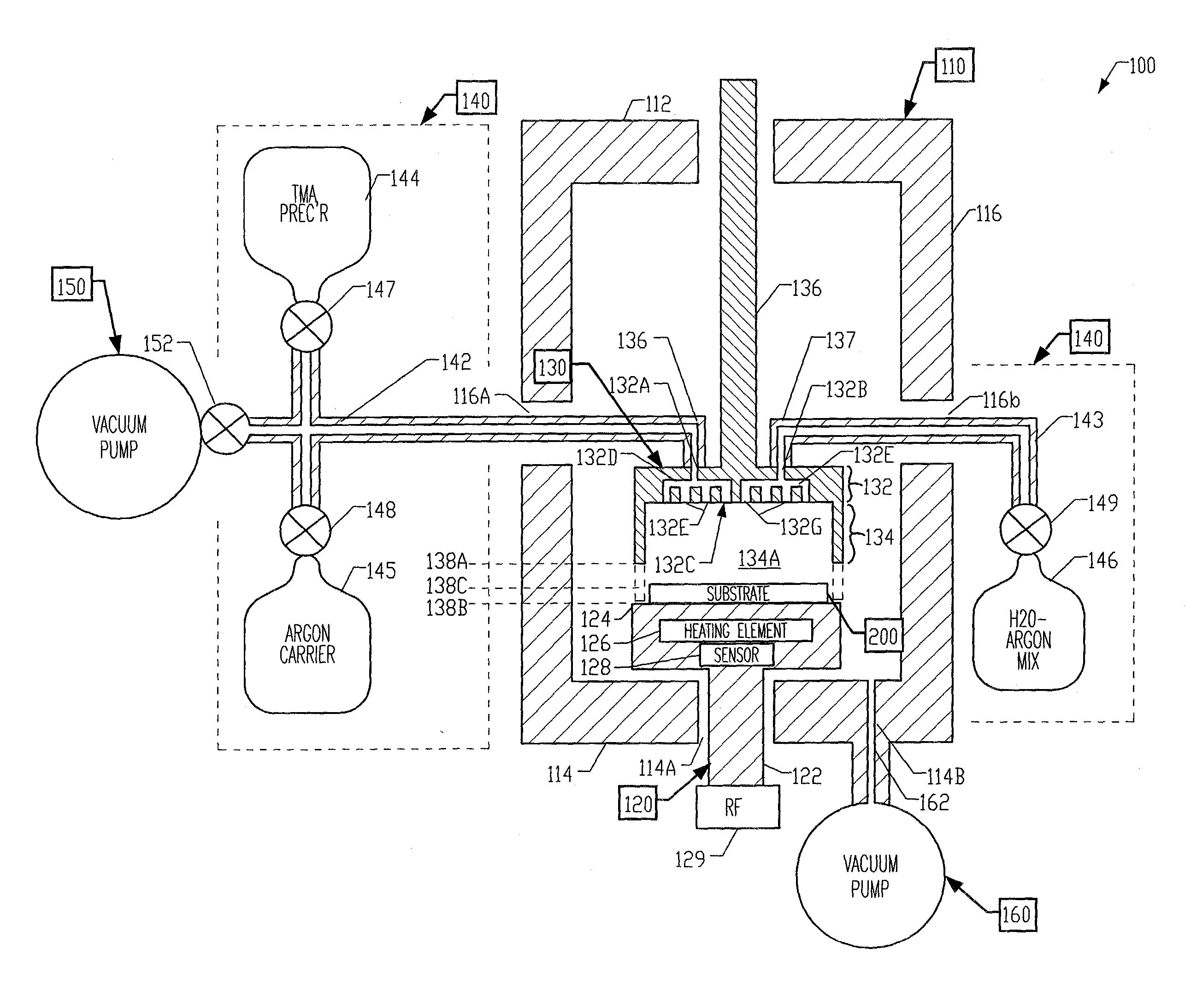

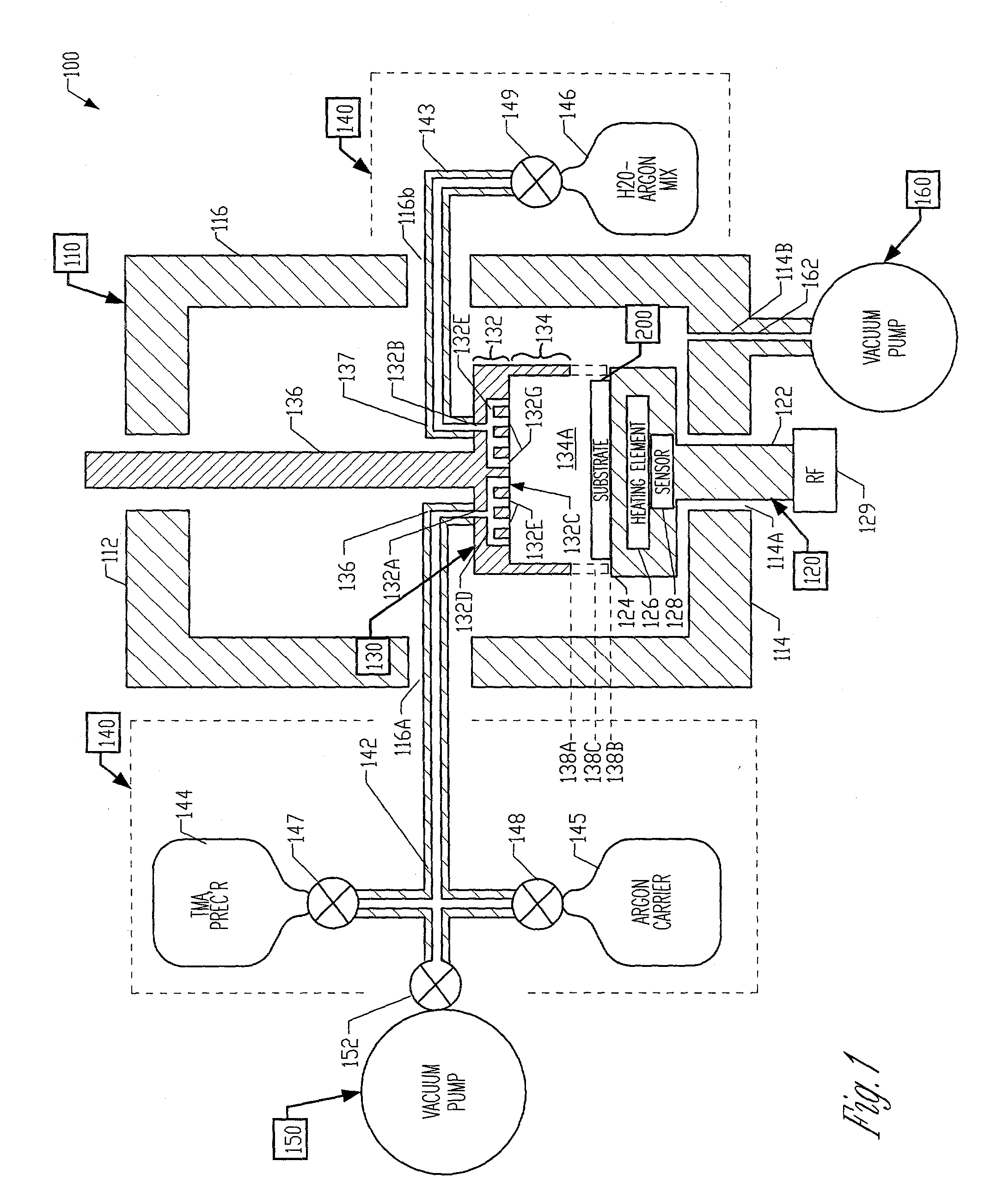

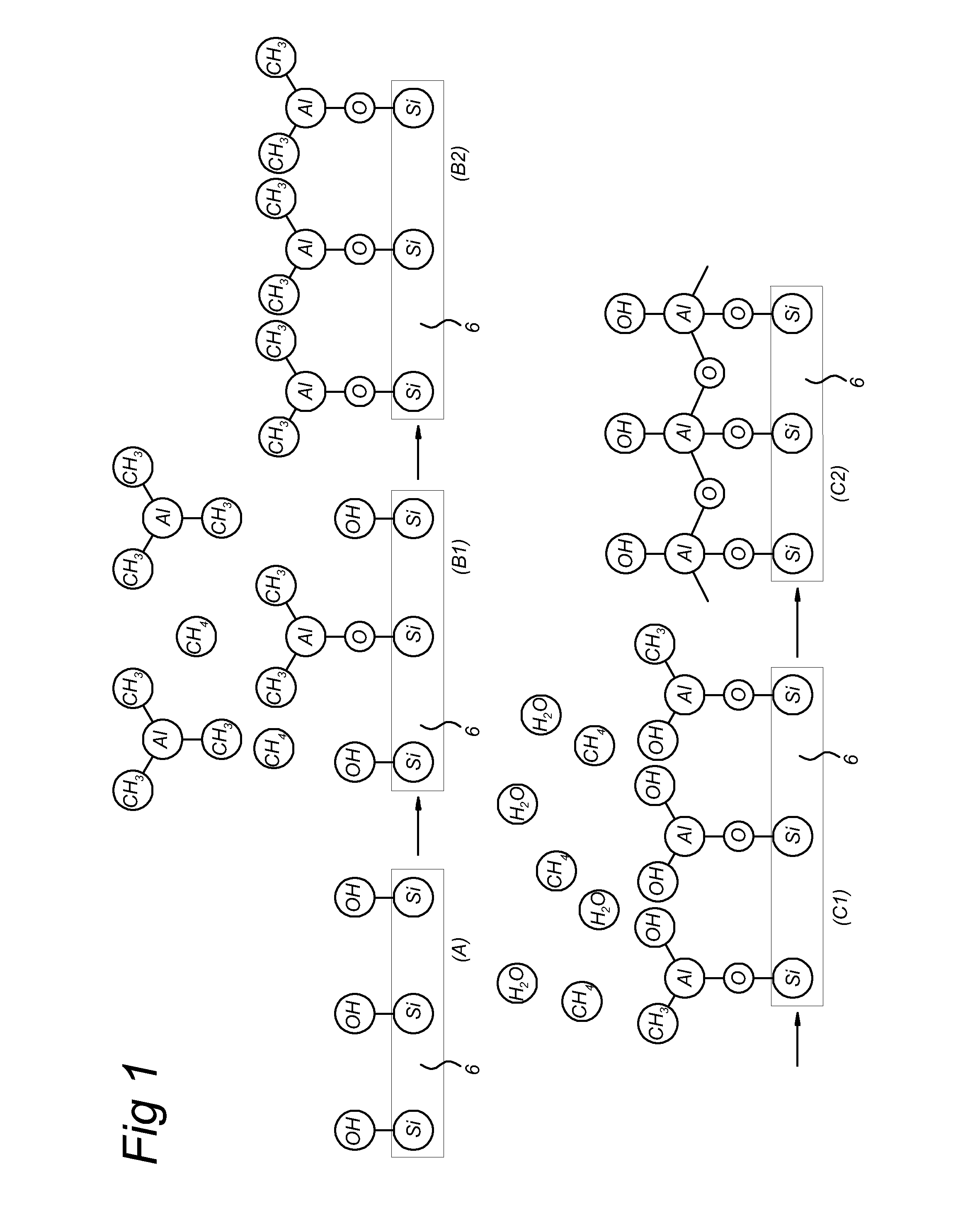

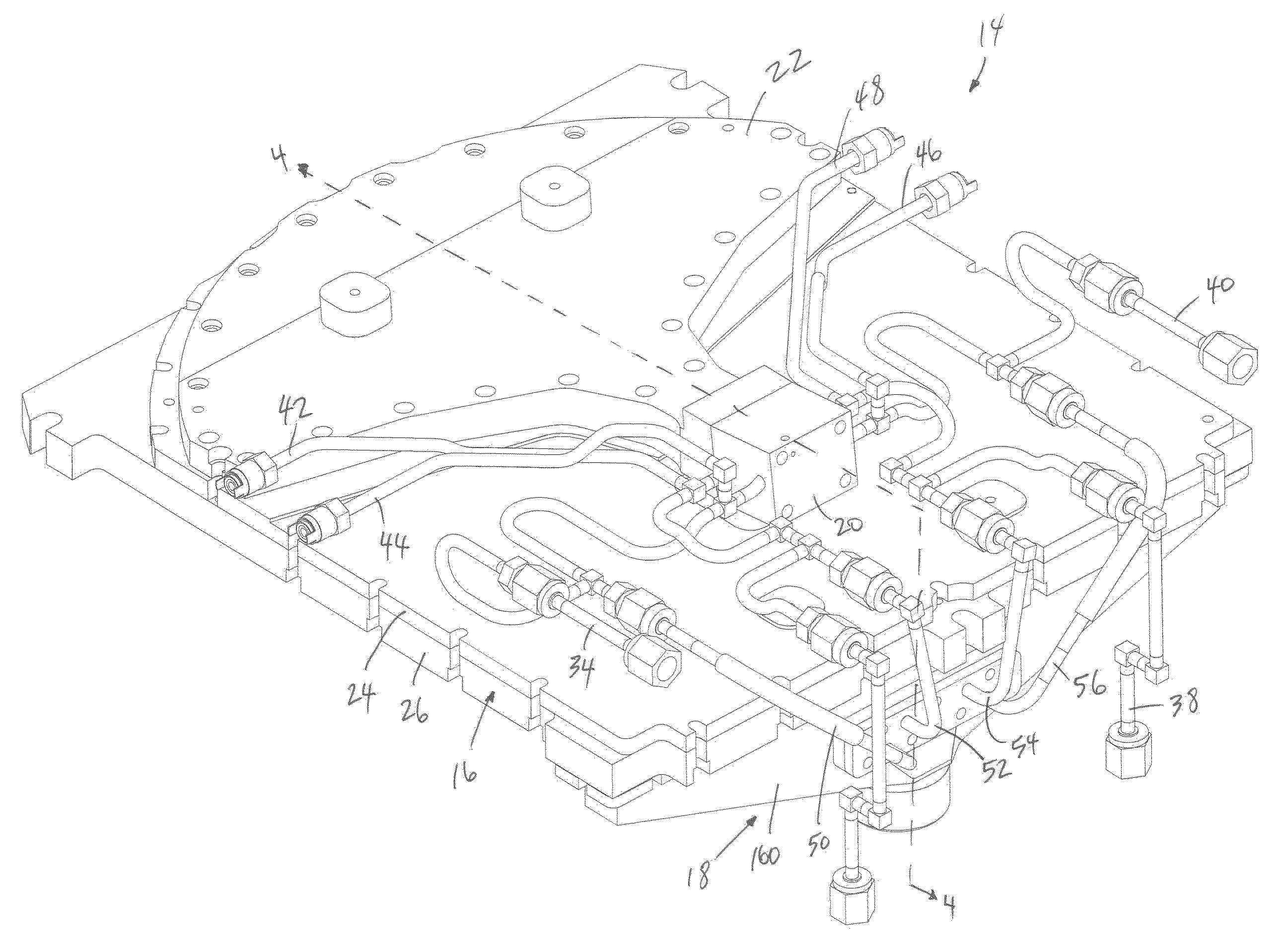

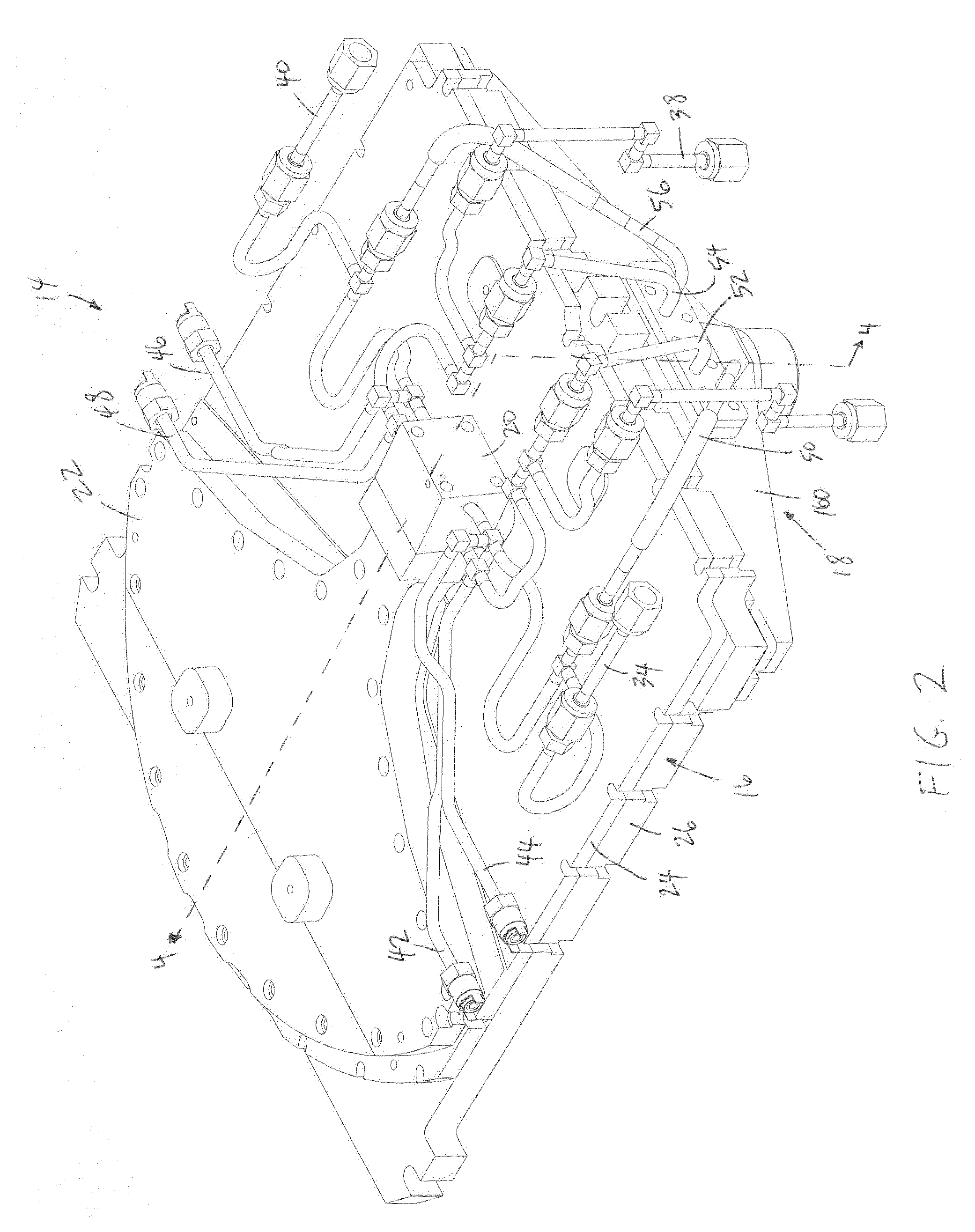

Methods, systems, and apparatus for atomic-layer deposition of aluminum oxides in integrated circuits

InactiveUS20030207032A1Small volumeConsumes less gasPretreated surfacesChemical vapor deposition coatingProduct gasIntegrated circuit layout

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common layer-formation technique, known as chemical-vapor deposition (CVD), produces uneven layers and covers vertical surfaces poorly. An emergent technique, atomic-layer deposition, overcomes these shortcomings, but has others, such as slow deposition rates and longer than desirable cycle times, particularly as applied to deposition of aluminum oxide. Accordingly, the inventors devised unique atomic-layer deposition systems, methods, and apparatus suitable for aluminum-oxide deposition. One exemplary system includes an outer chamber, a substrate holder, and a gas-distribution fixture that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which ultimately requires less time to fill and purge and thus promises to reduce cycle times for deposition of materials, such as aluminum oxide.

Owner:MICRON TECH INC

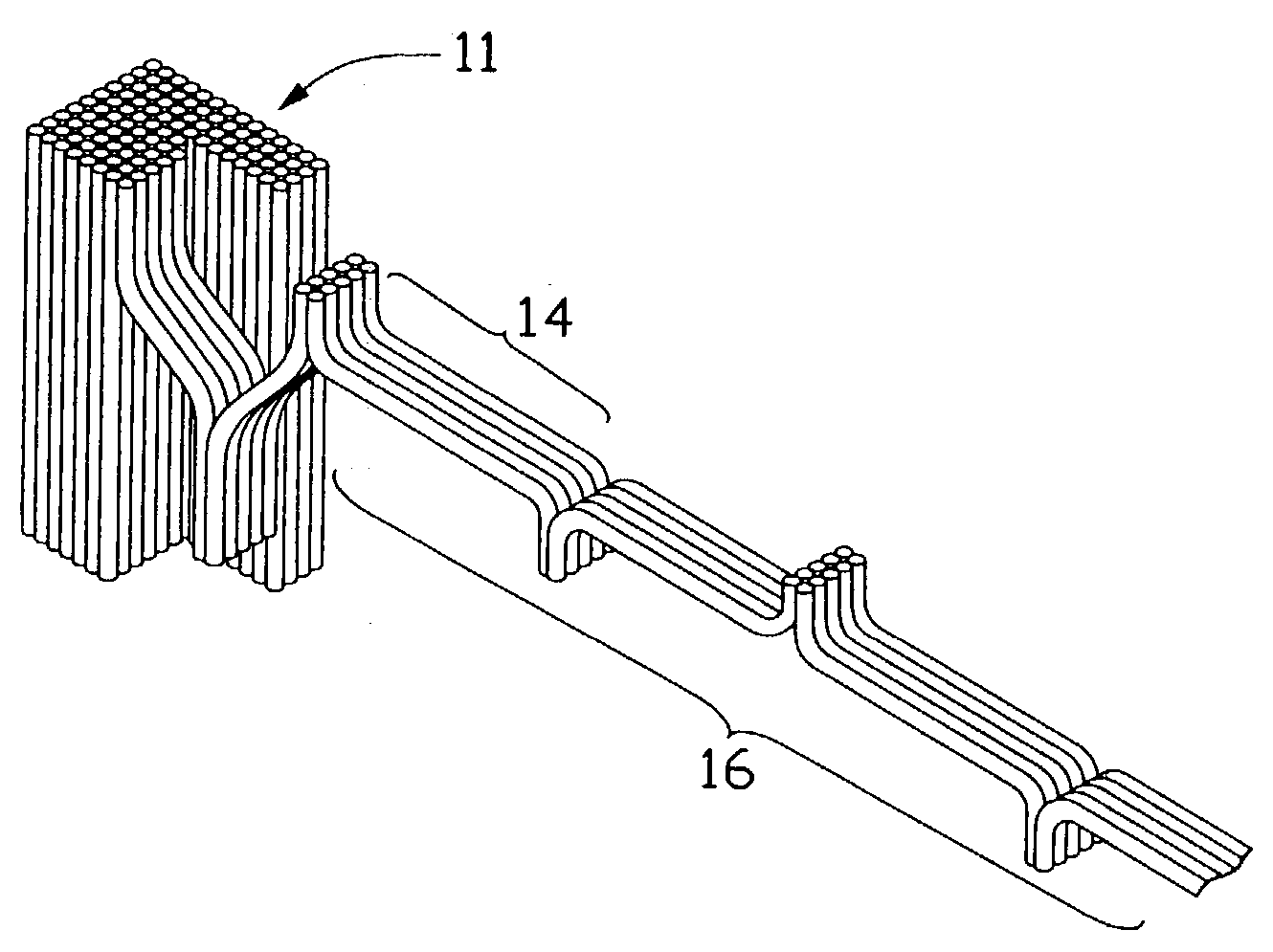

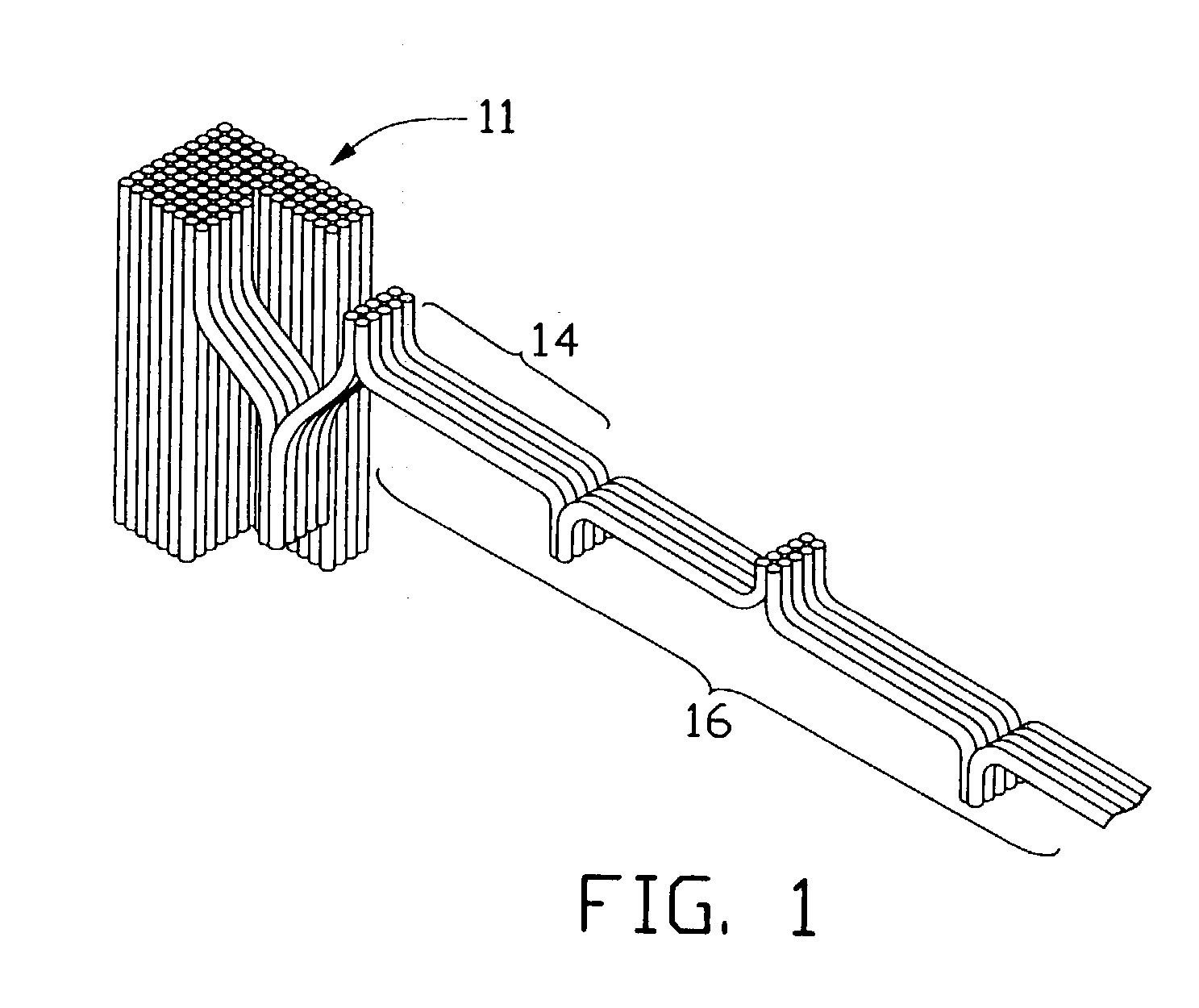

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

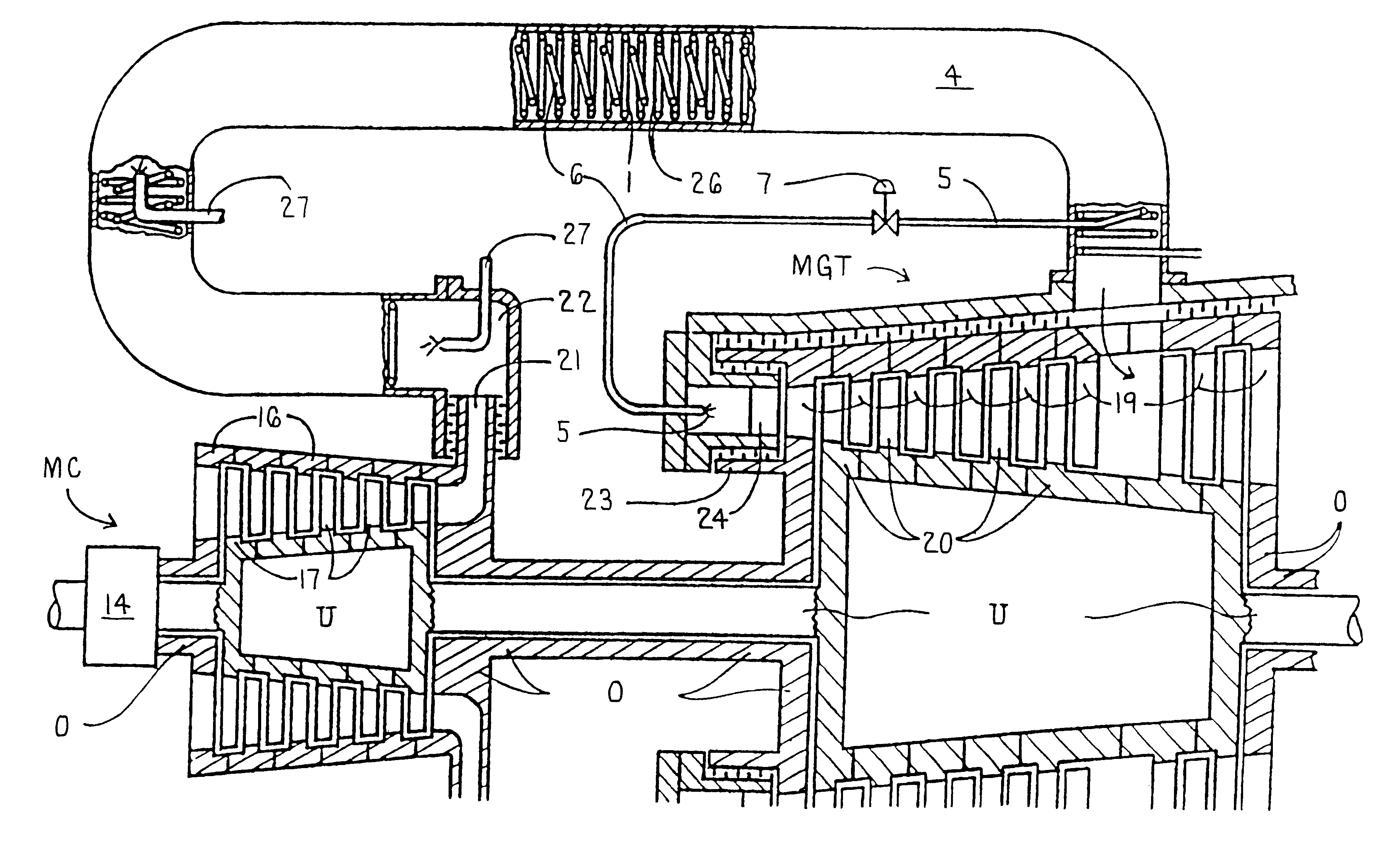

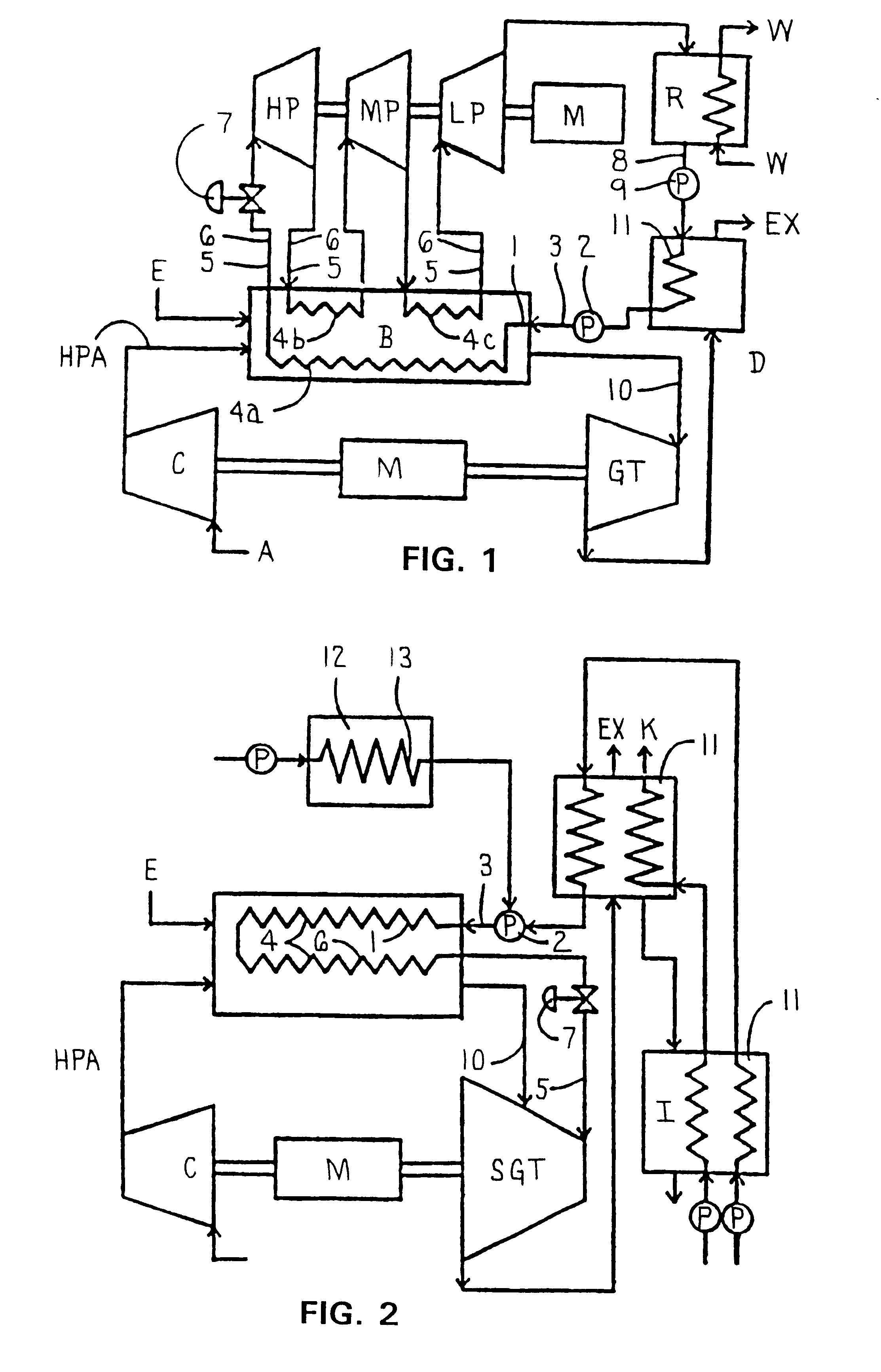

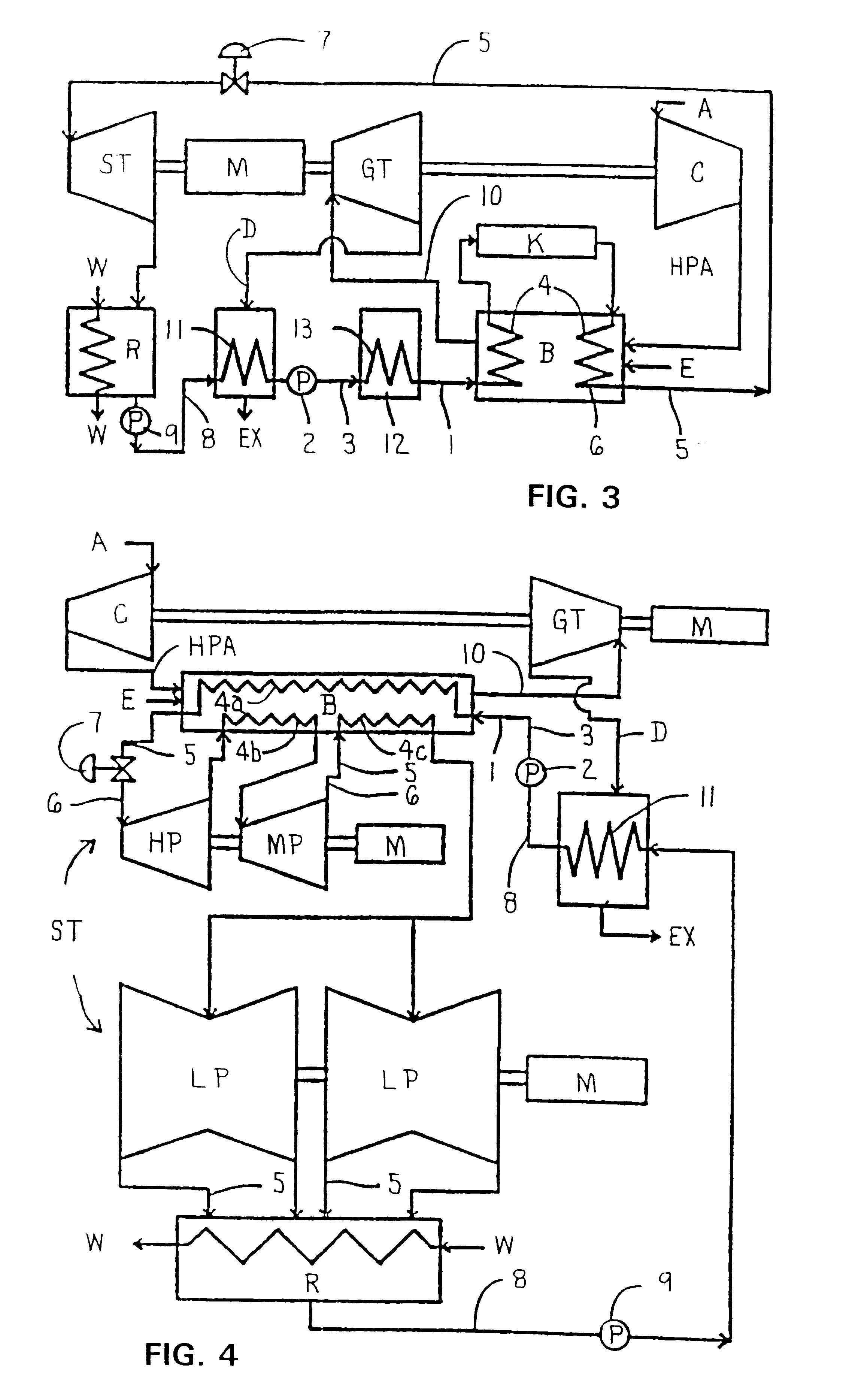

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

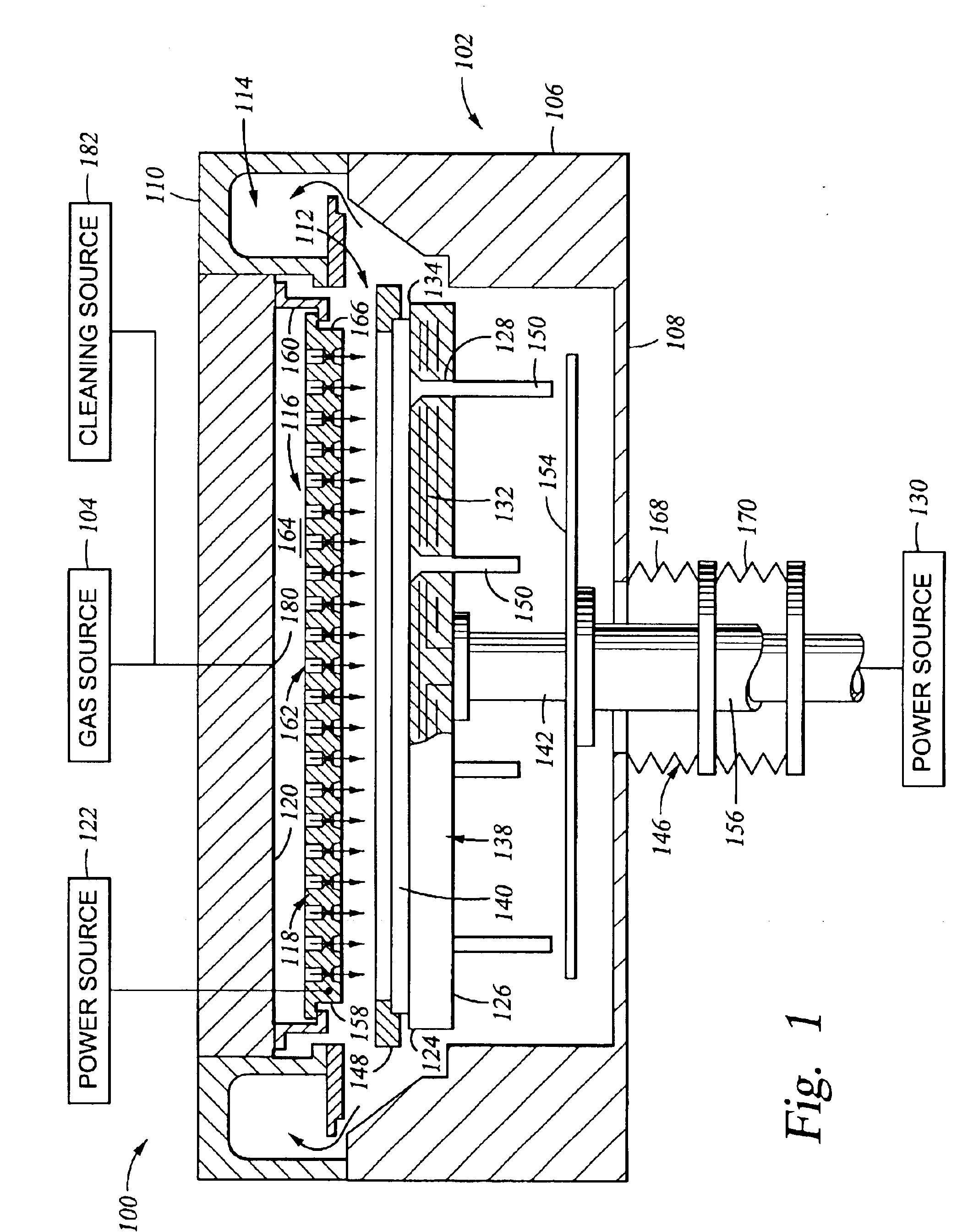

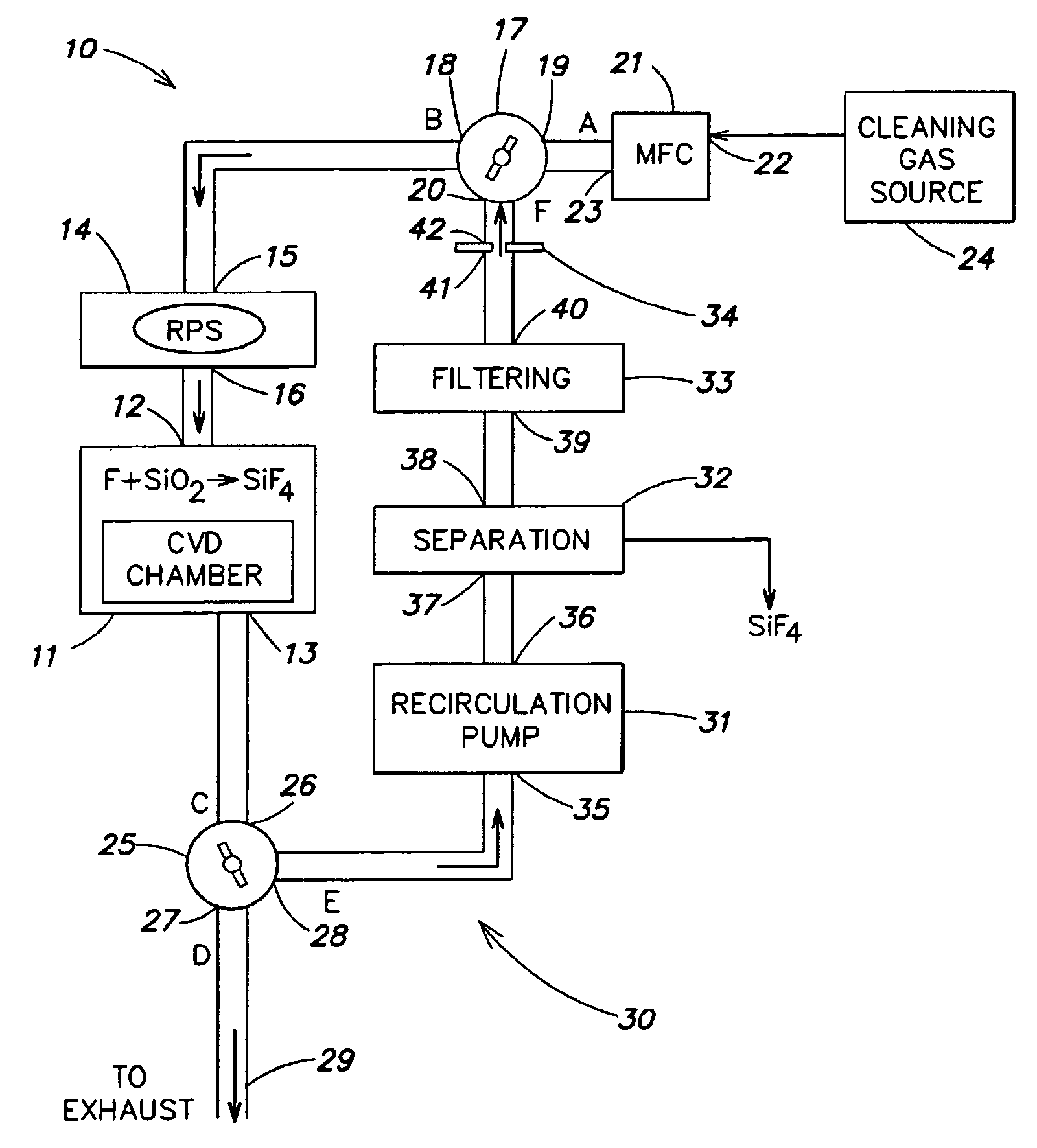

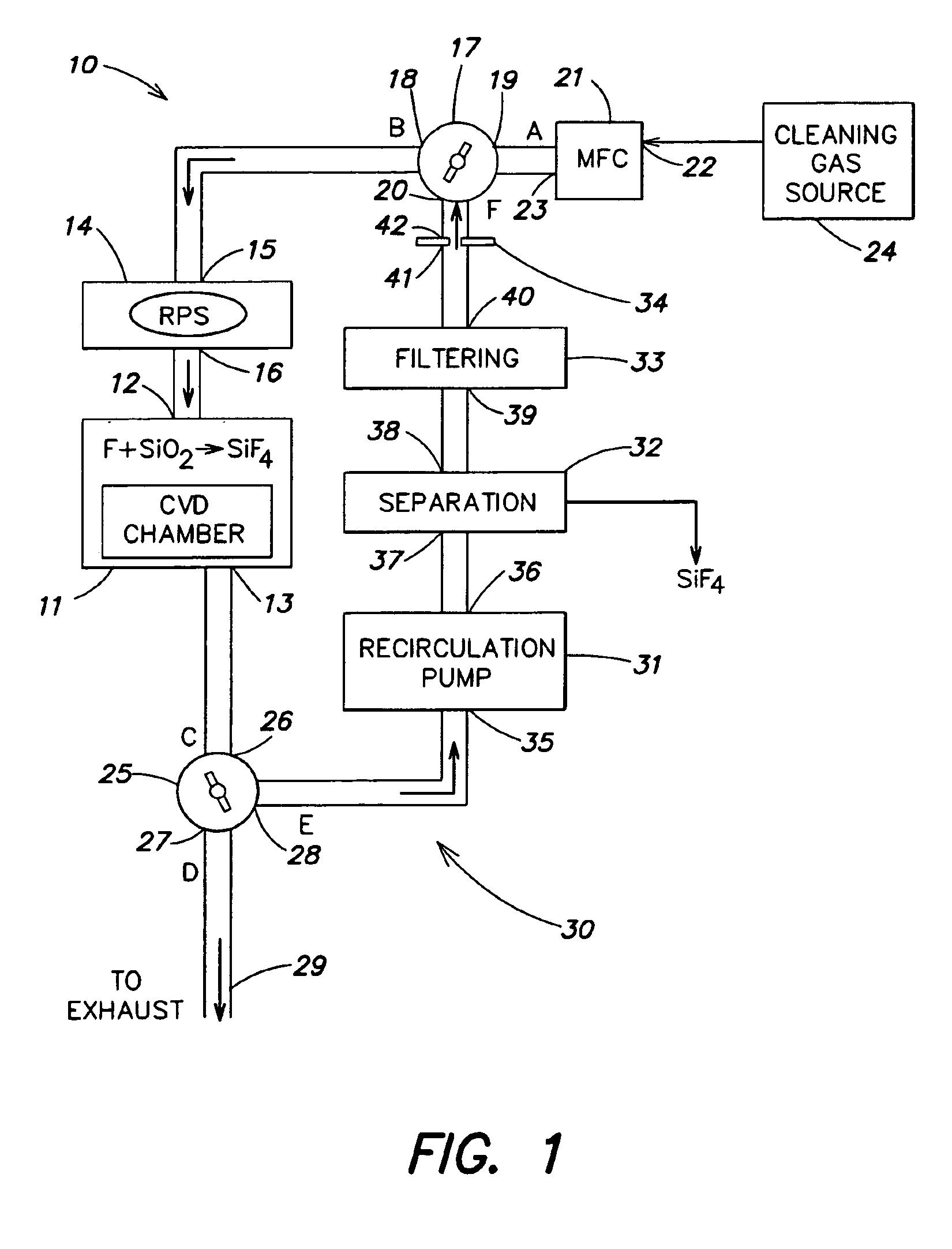

Semiconductor device fabrication chamber cleaning method and apparatus with recirculation of cleaning gas

InactiveUS6863019B2Low costReduce consumptionElectric discharge tubesElectrostatic cleaningNuclear engineeringProduct gas

A method of cleaning a semiconductor fabrication processing chamber involves recirculation of cleaning gas components. Consequently, input cleaning gas is utilized efficiently, and undesirable emissions are reduced. The method includes flowing a cleaning gas to an inlet of a processing chamber, and exposing surfaces of the processing chamber to the cleaning gas to clean the surfaces, thereby producing a reaction product. The method further includes removing an outlet gas including the reaction product from an outlet of the processing chamber, separating at least a portion of the reaction product from the outlet gas, and recirculating a portion of the outlet gas to the inlet of the processing chamber.

Owner:APPLIED MATERIALS INC

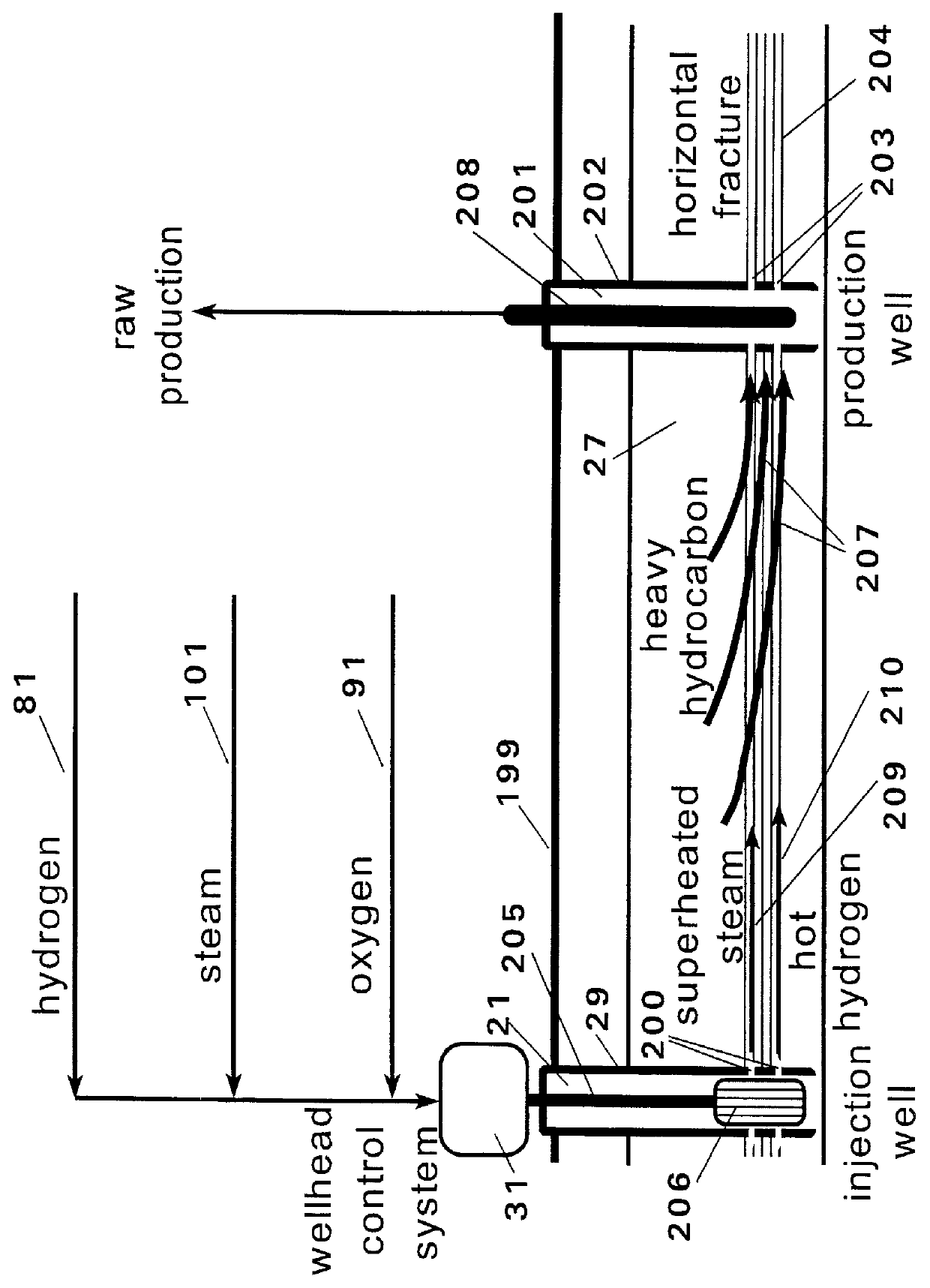

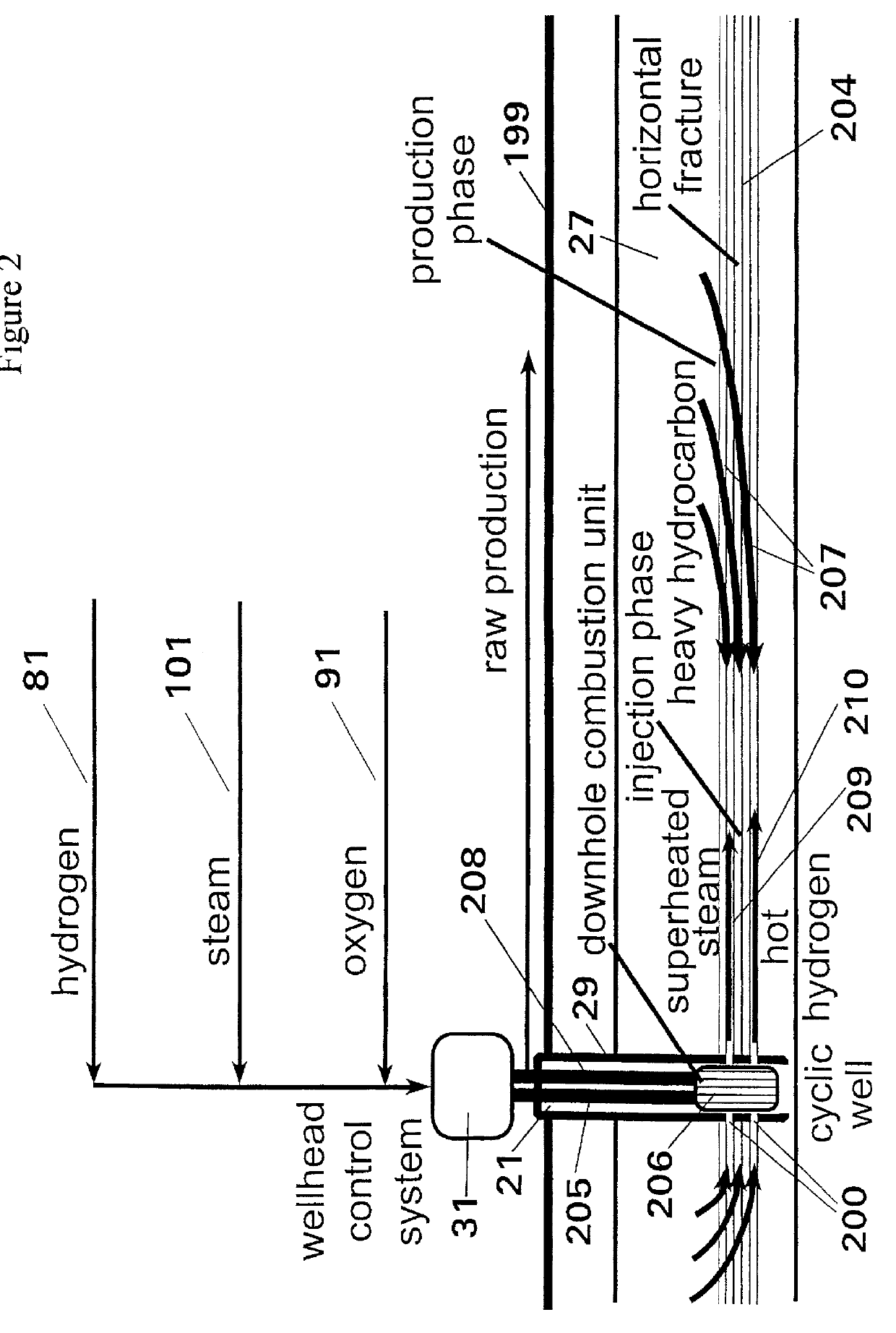

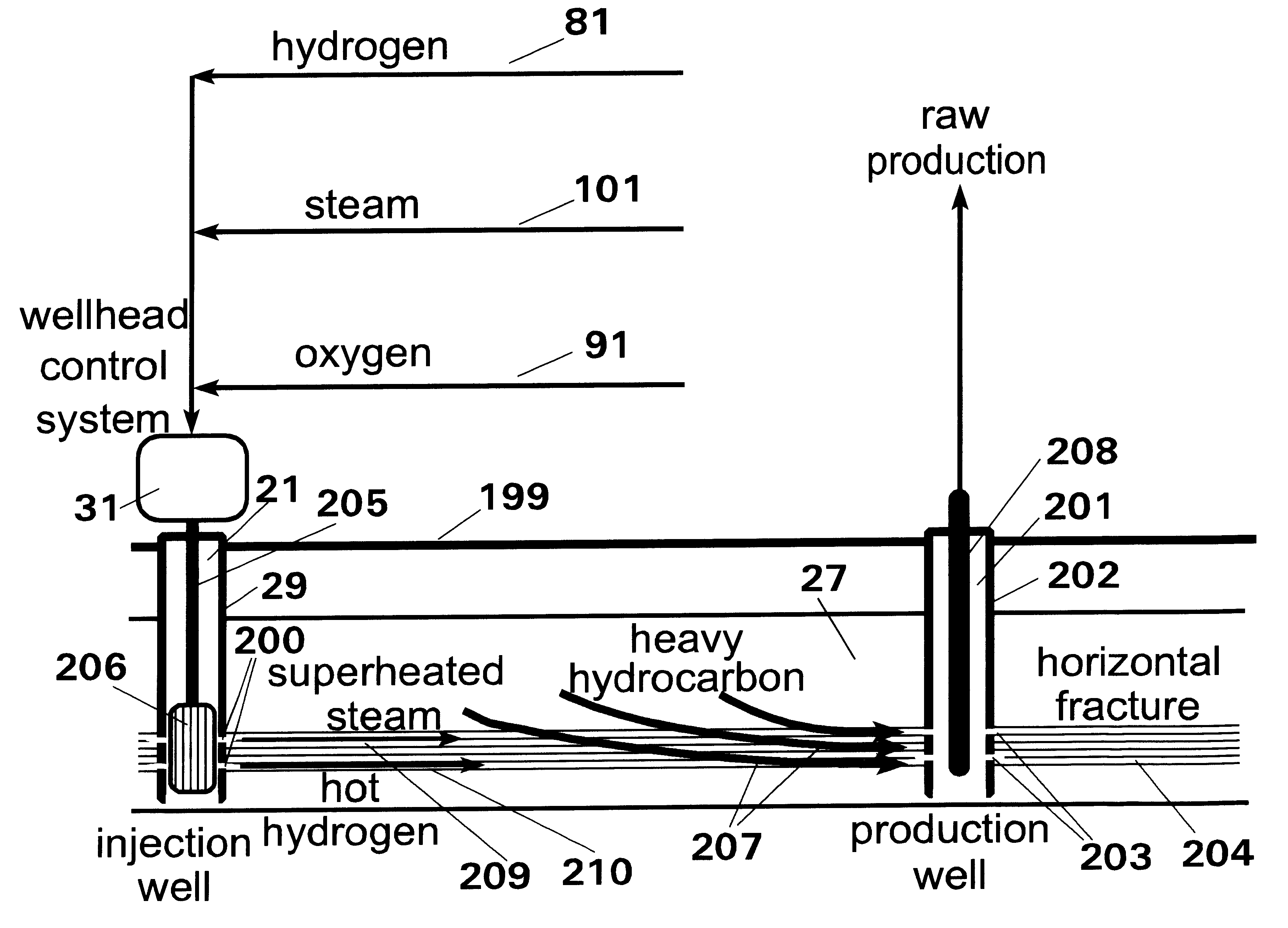

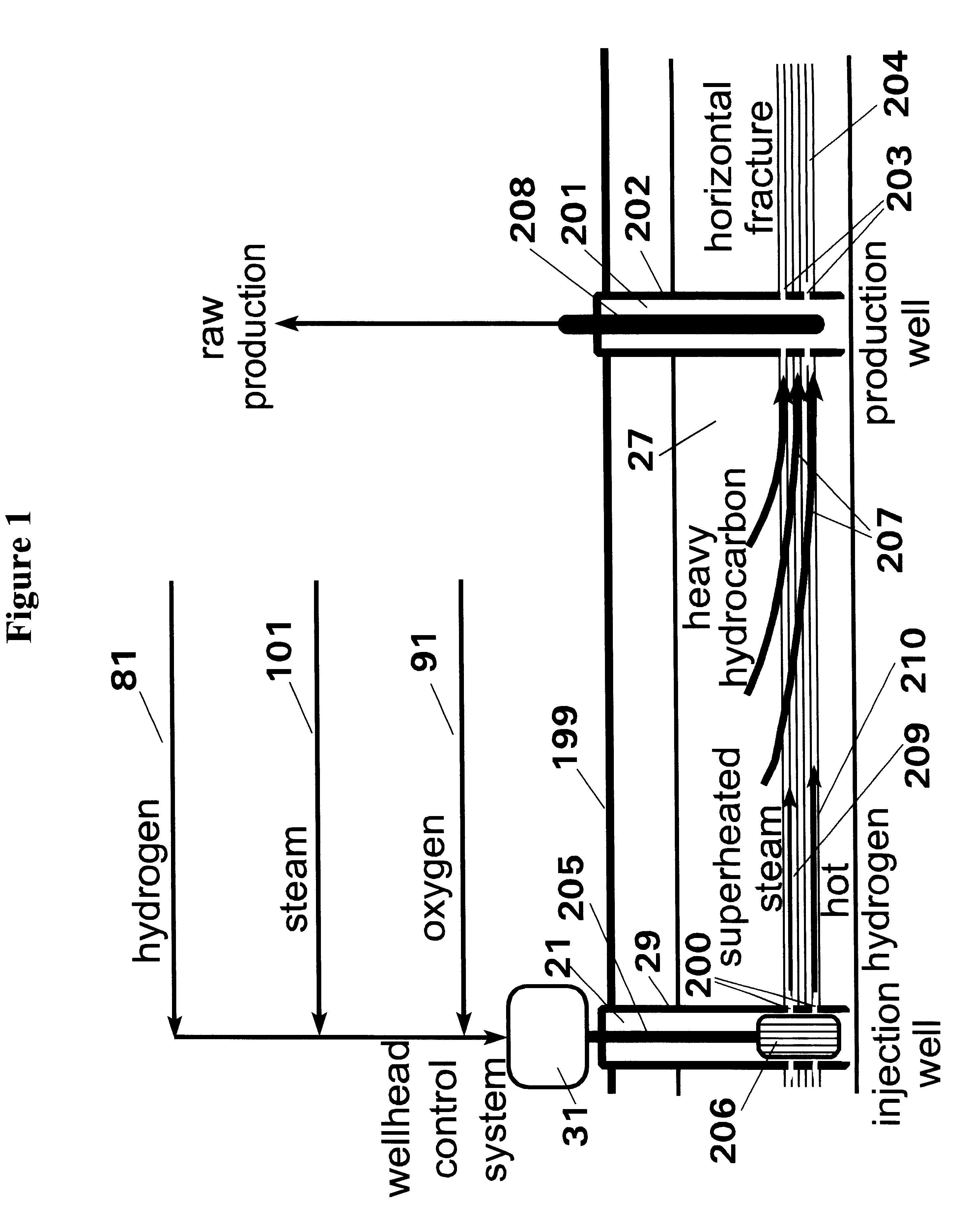

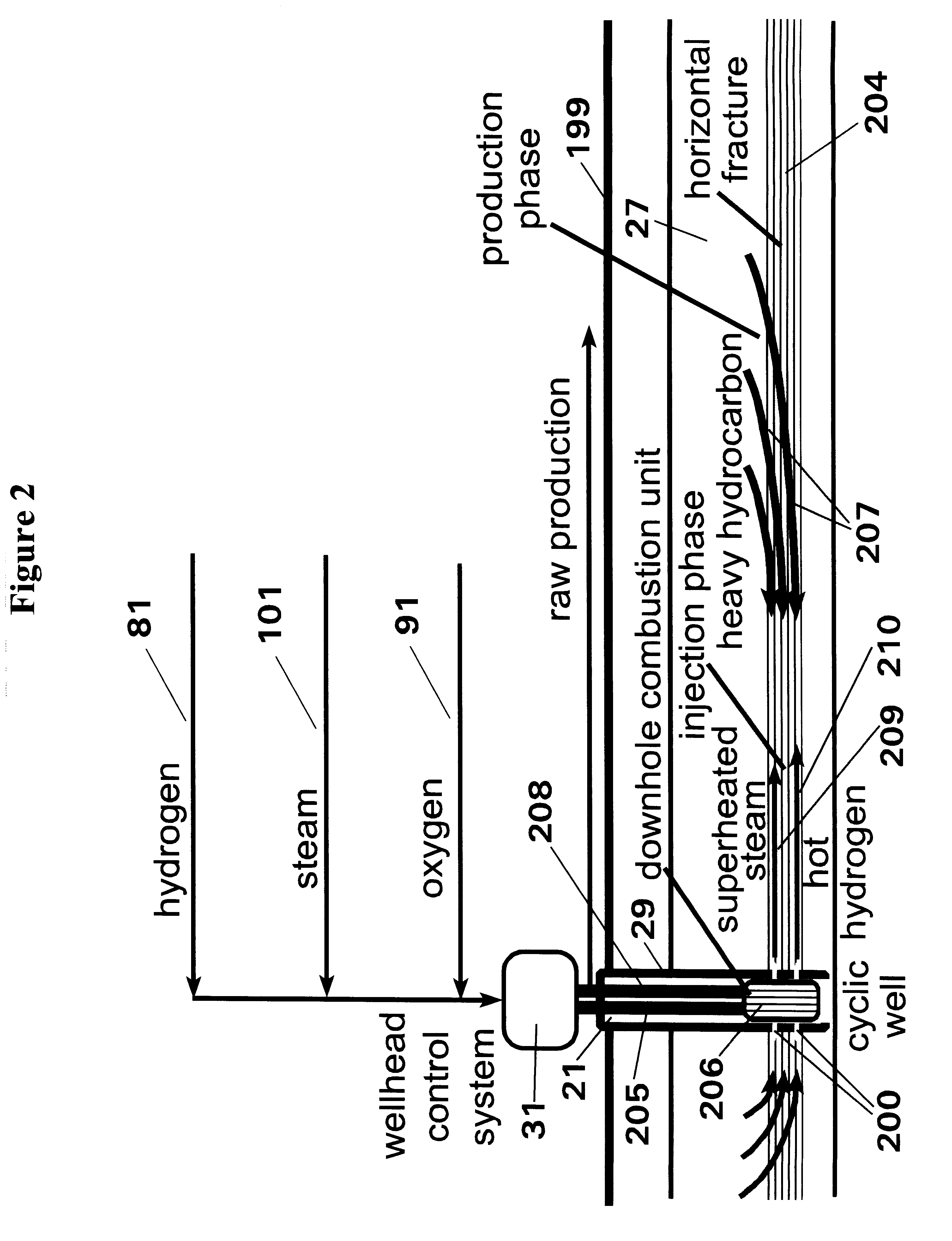

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

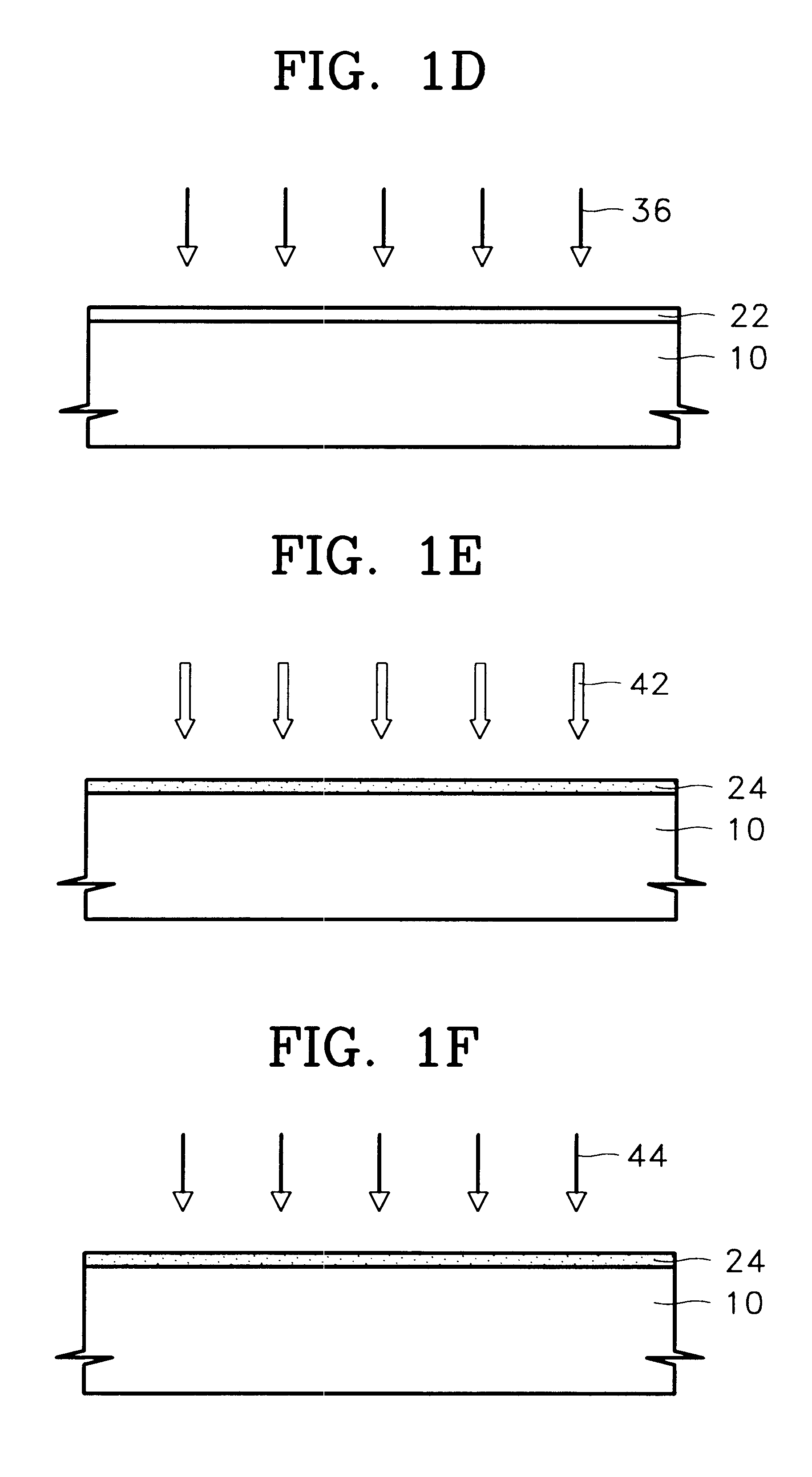

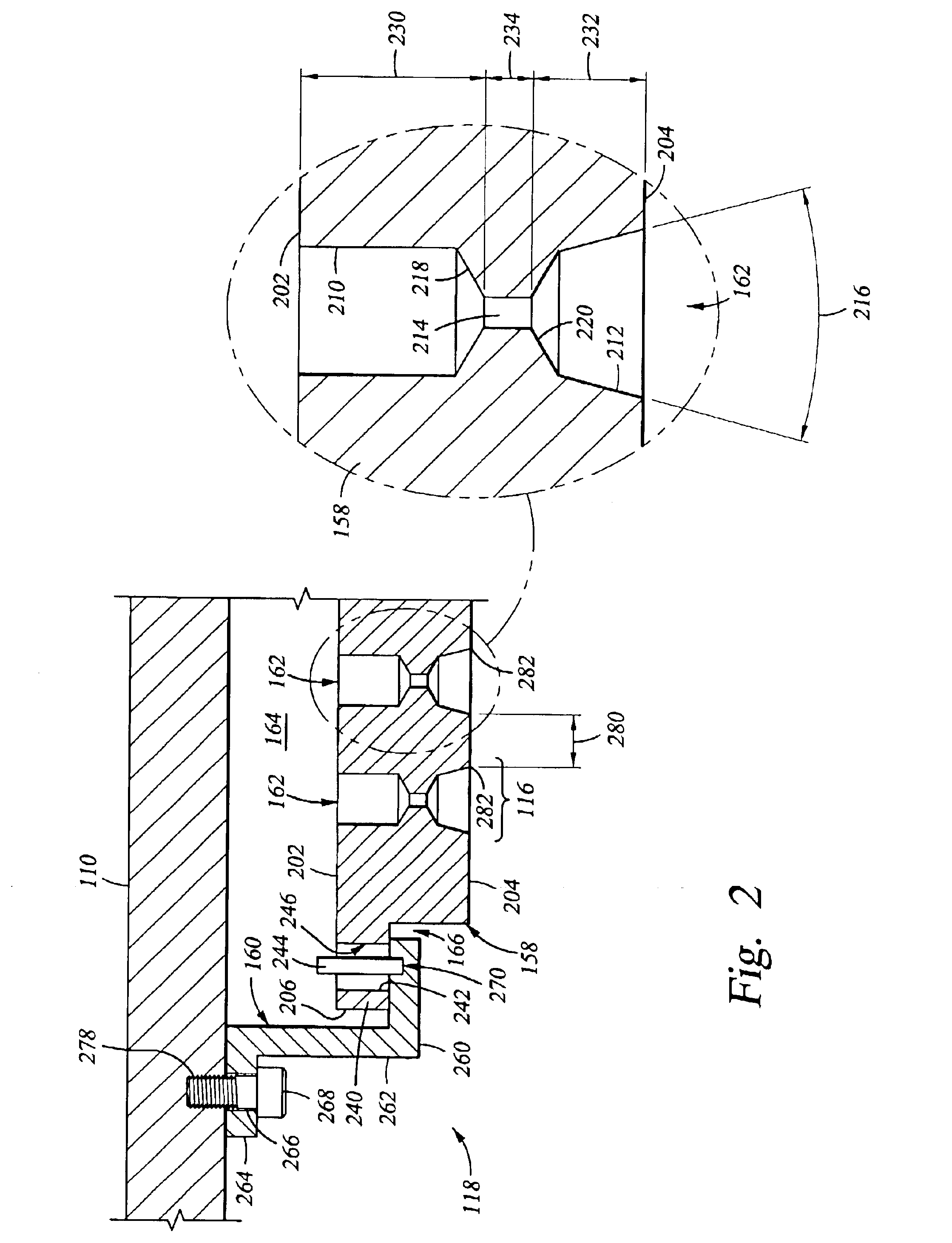

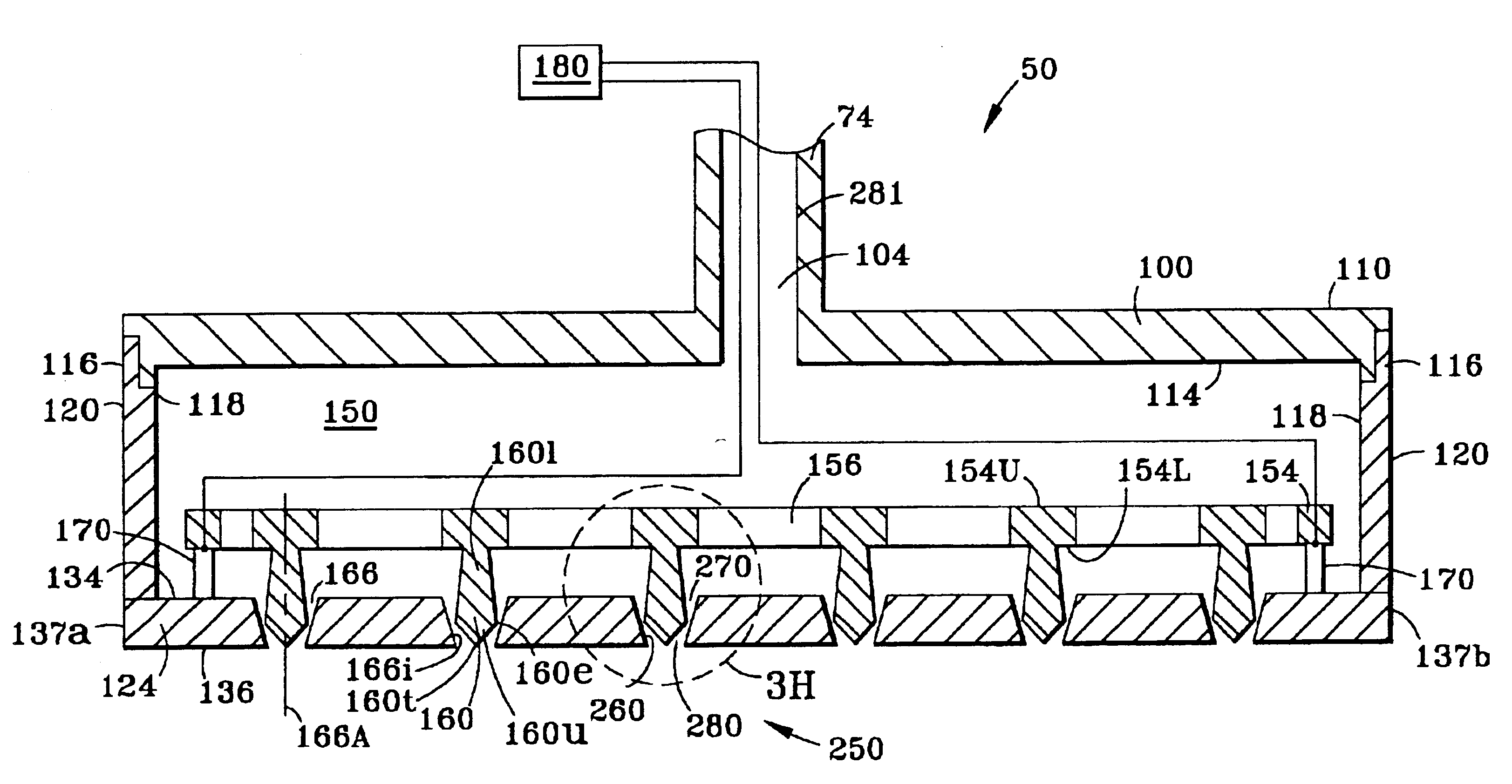

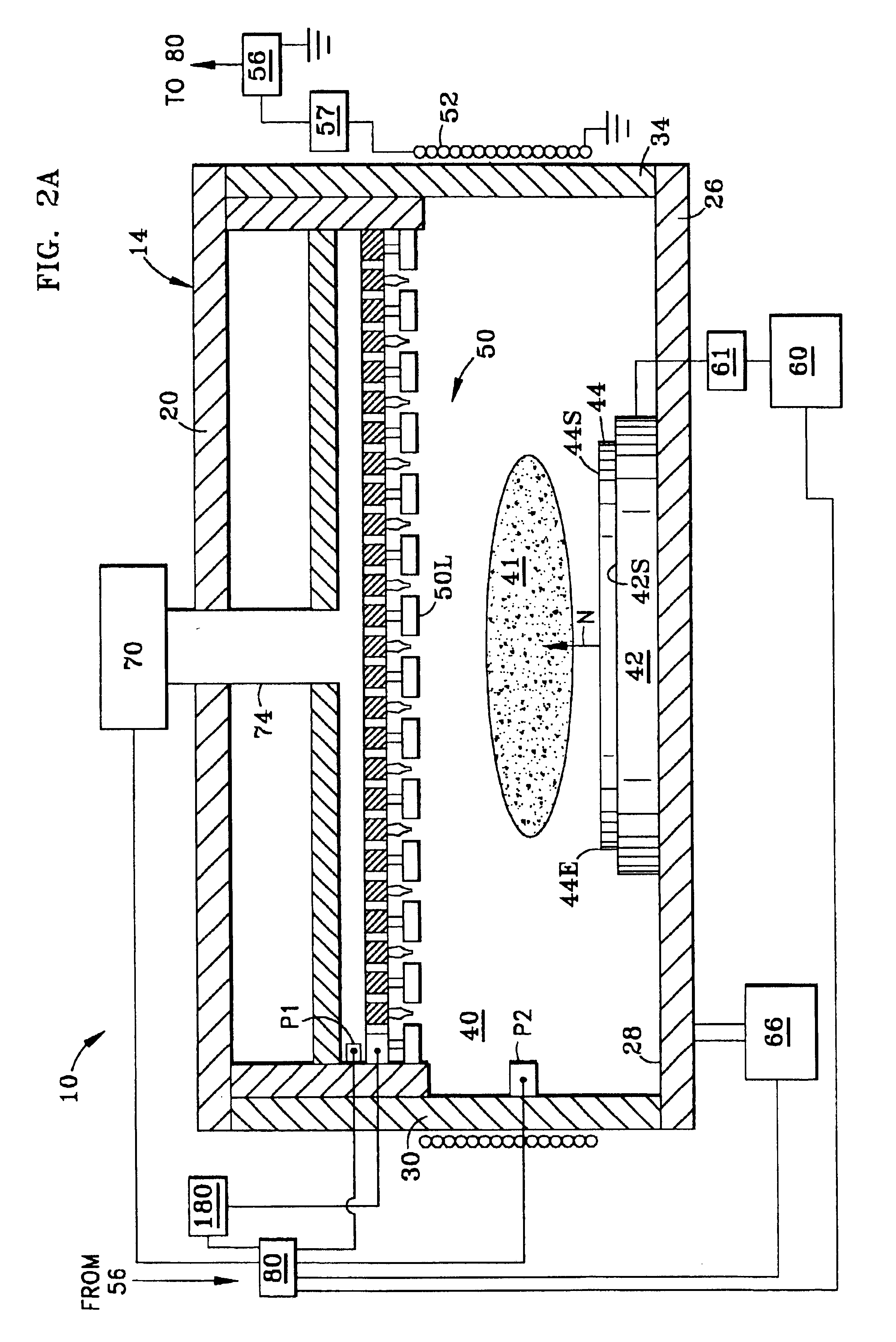

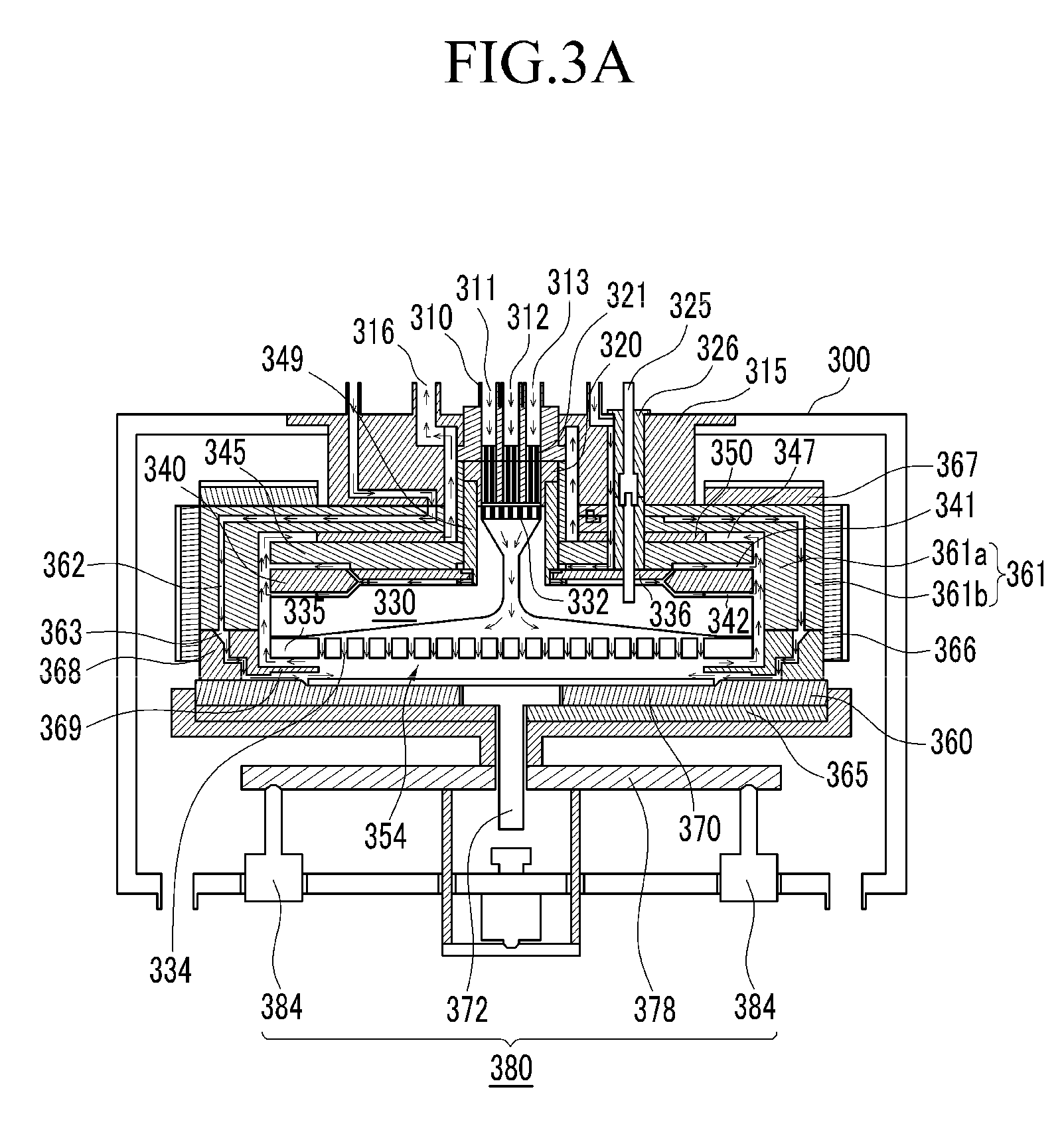

Method of and apparatus for tunable gas injection in a plasma processing system

InactiveUS6872259B2Control expansionElectric discharge tubesSemiconductor/solid-state device manufacturingElectronic communicationProduct gas

A method of and apparatus for providing tunable gas injection in a plasma processing system (10, 10′). The apparatus includes a gas injection manifold (50) having a pressurizable plenum (150) and an array of adjustable nozzle units (250), or an array of non-adjustable nozzles (502, 602), through which gas from the plenum can flow into the interior region (40) of a plasma reactor chamber (14) capable of containing a plasma (41). The adjustable nozzle units include a nozzle plug (160) arranged within a nozzle bore (166). A variety of different nozzle units are disclosed. The nozzle plugs are axially translatable to adjust the flow of gas therethrough. In one embodiment, the nozzle plugs are attached to a plug plate (154), which is displacable relative to an injection plate (124) via displacement actuators (170) connecting the two plates. The displacement actuators are controlled by a displacement actuator control unit (180), which is in electronic communication with a plasma processing system control unit (80). The gas flow into the chamber interior region is preferably controlled by monitoring the pressure in the plenum and in the chamber and adjusting the nozzle units accordingly. Where the nozzle units are not adjustable, a portion of the nozzles are sized to a first flow condition, and another portion of the nozzles are sized to a second flow condition.

Owner:TOKYO ELECTRON LTD

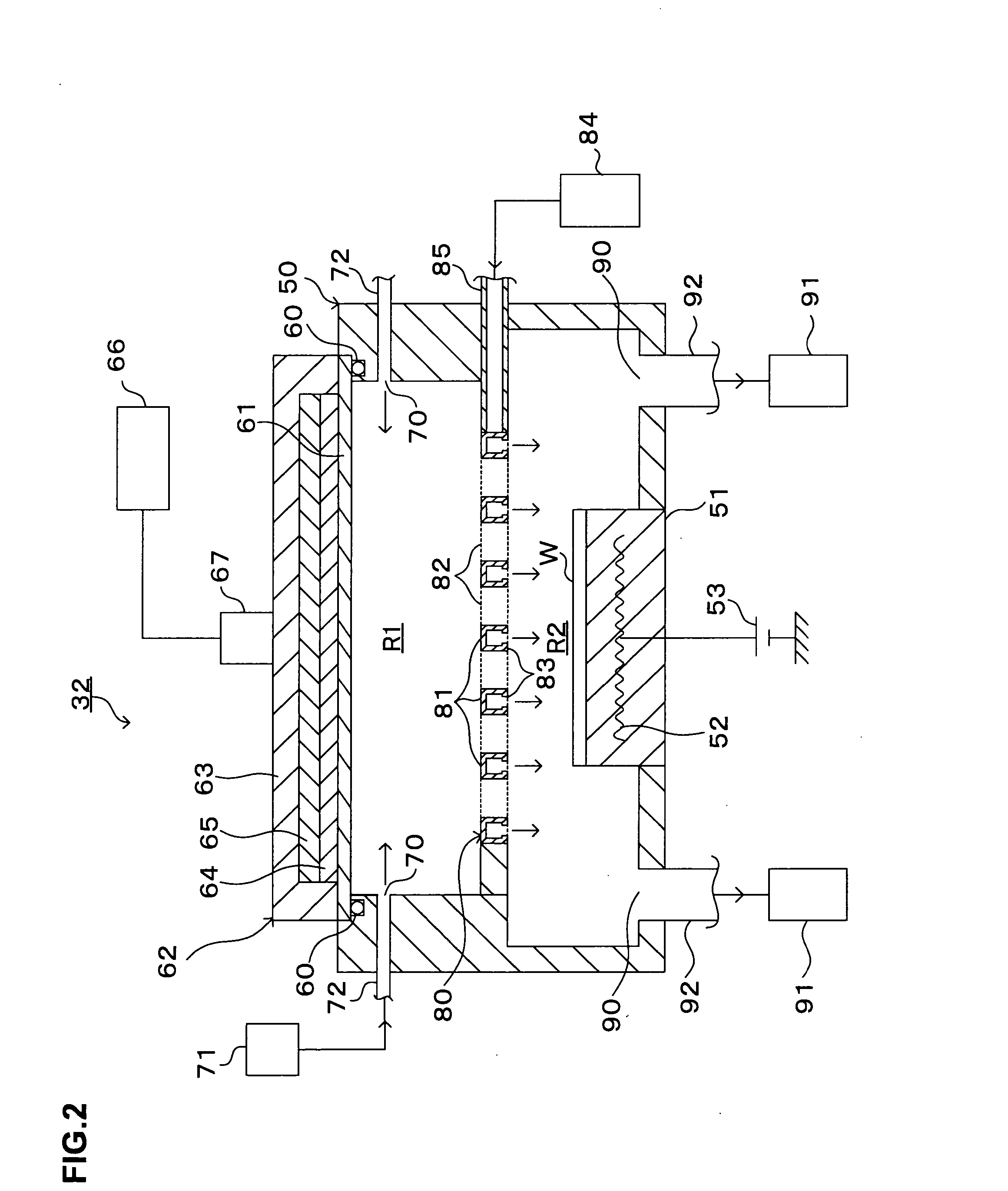

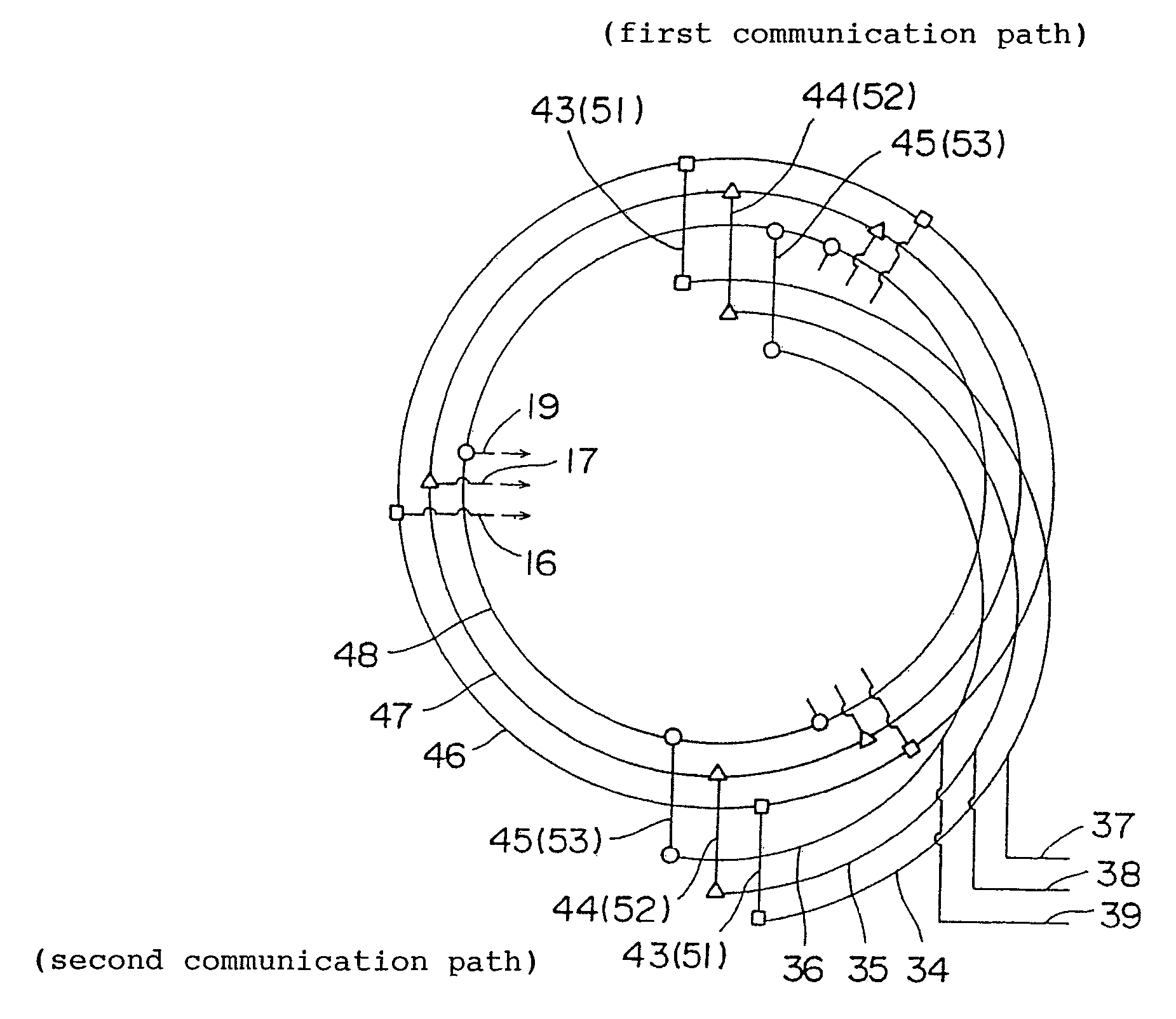

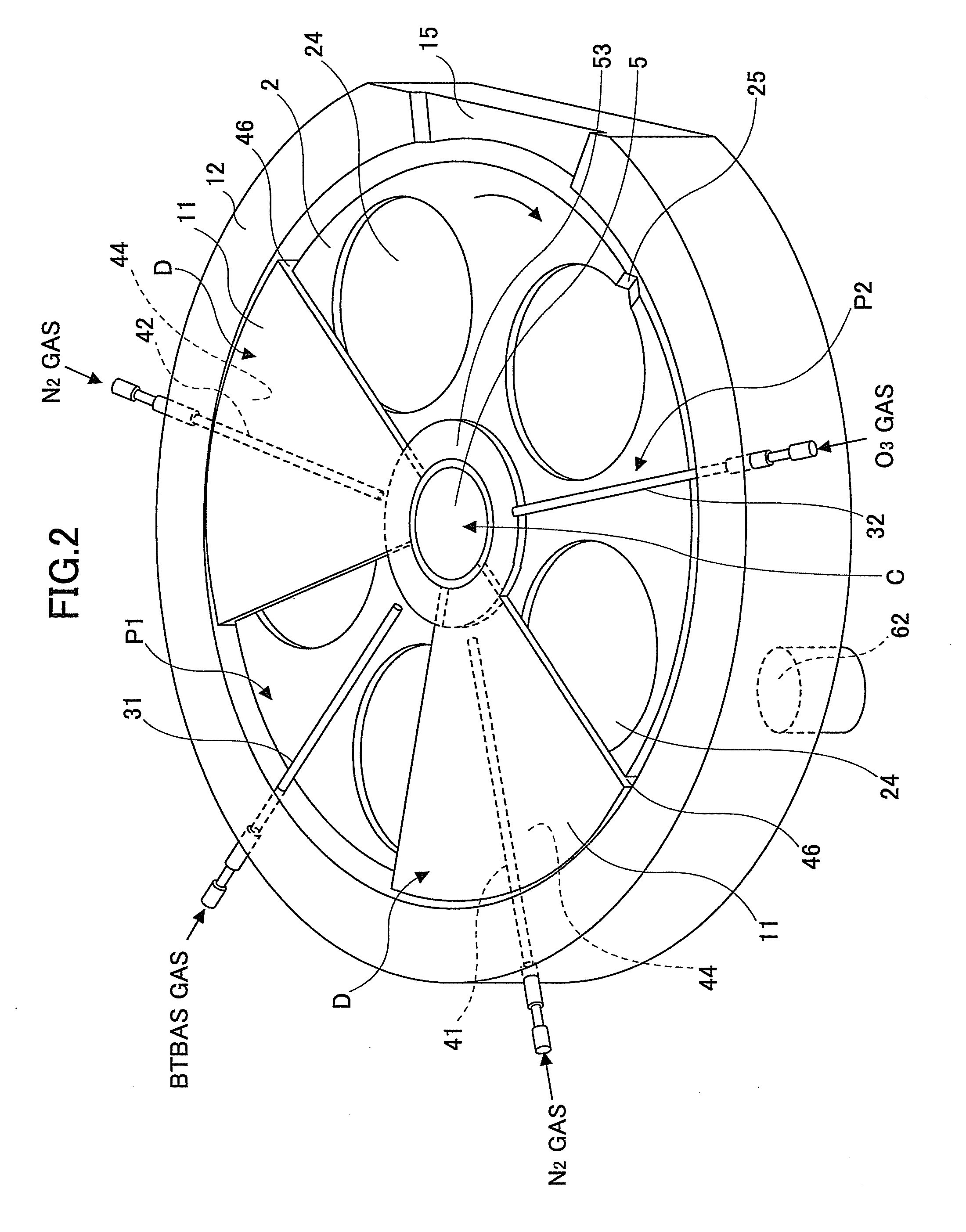

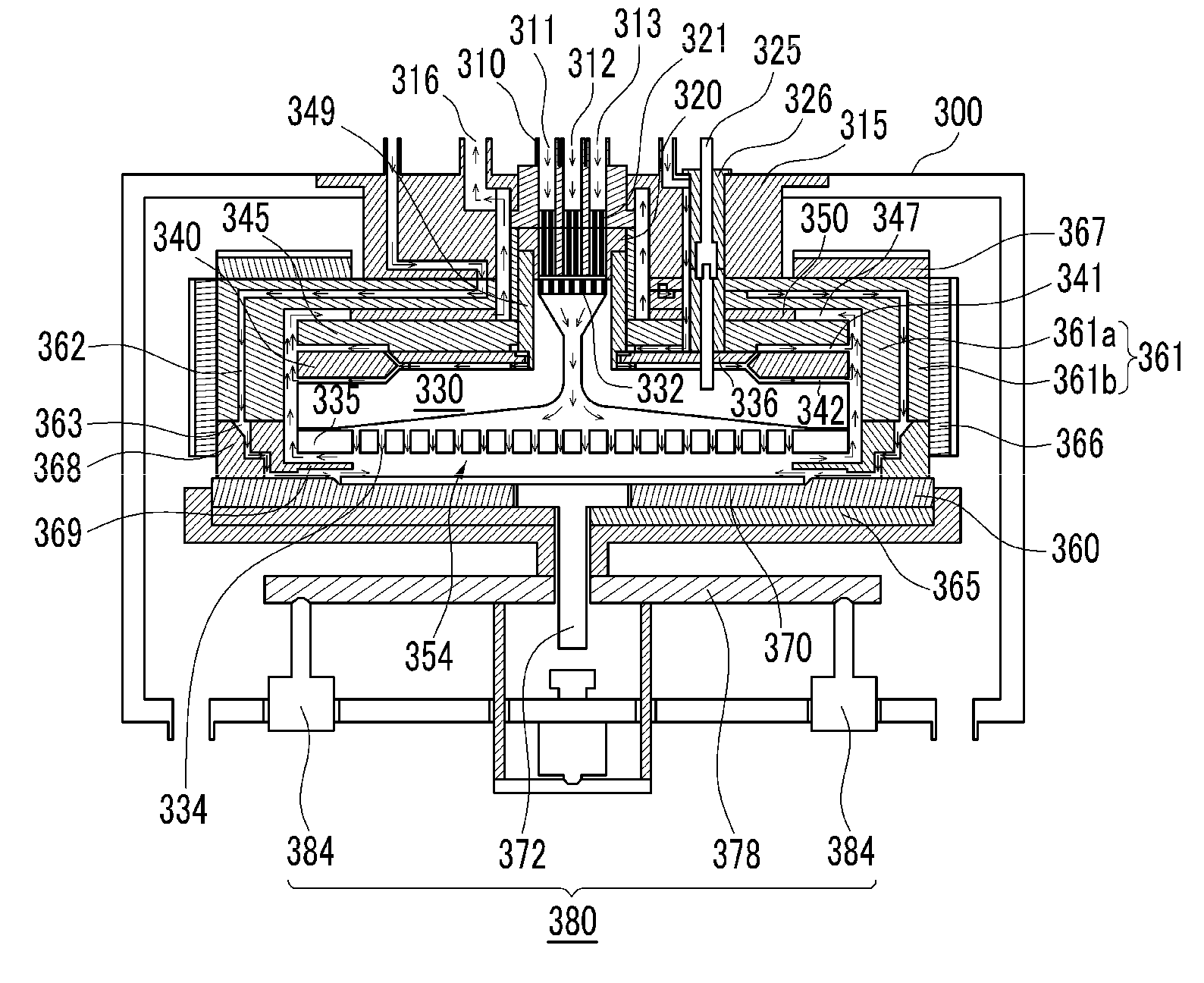

Plasma treatment apparatus

InactiveUS7806078B2Simply the configuration of the containerContainer can be simplifiedElectric discharge tubesSemiconductor/solid-state device manufacturingProduct gasEngineering

A plasma CVD apparatus has a container, and channels composed of introduction grooves and circumferential grooves for different types of gases are formed within the container. The gases introduced through source gas piping, auxiliary gas piping, and cleaning gas piping are equally supplied to a plurality of supply nozzles, a plurality of auxiliary gas supply nozzles, and a plurality of cleaning gas nozzles. The configuration of the container can be simplified without complicating pipings for the gases.

Owner:MITSUBISHI HEAVY IND LTD

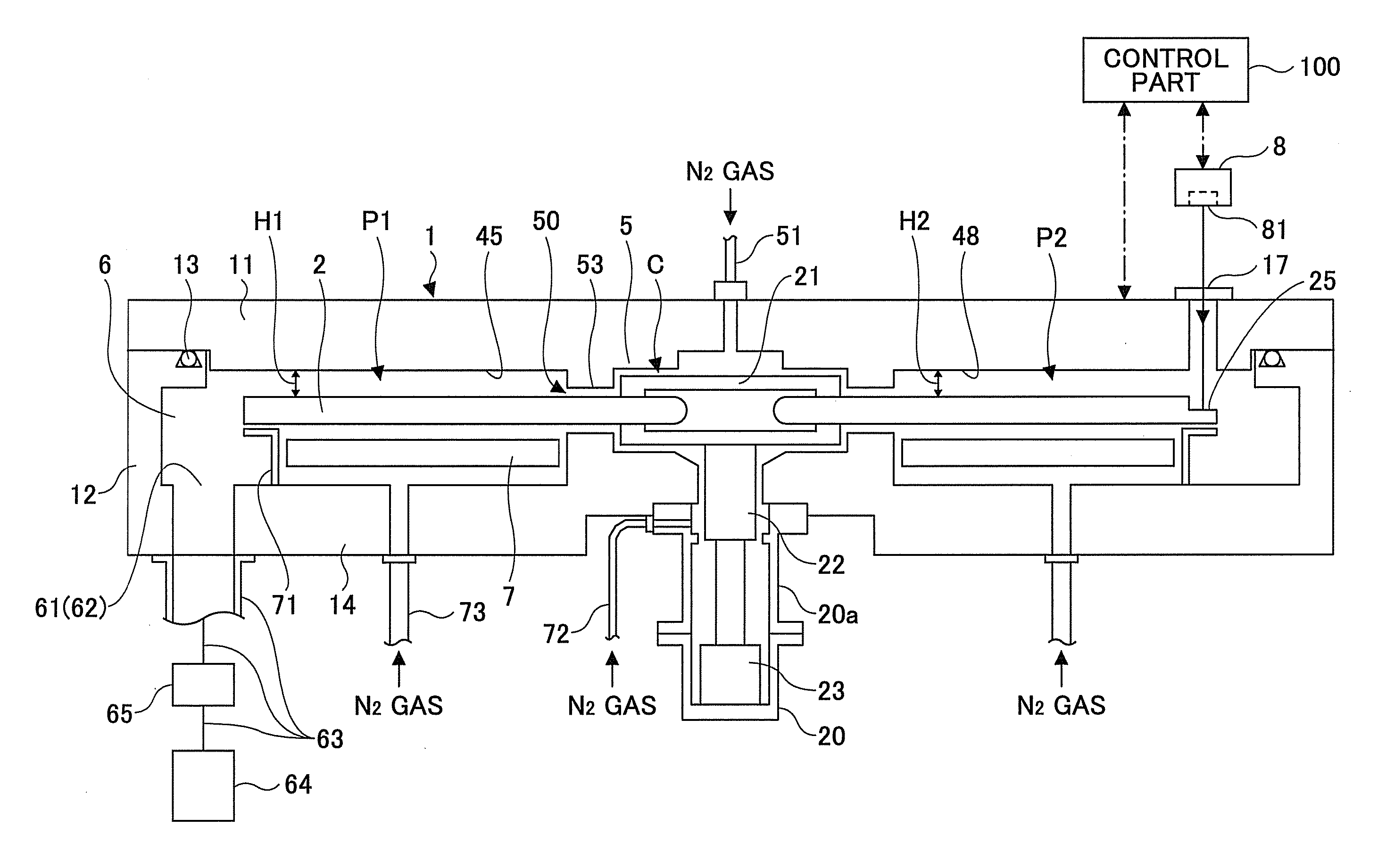

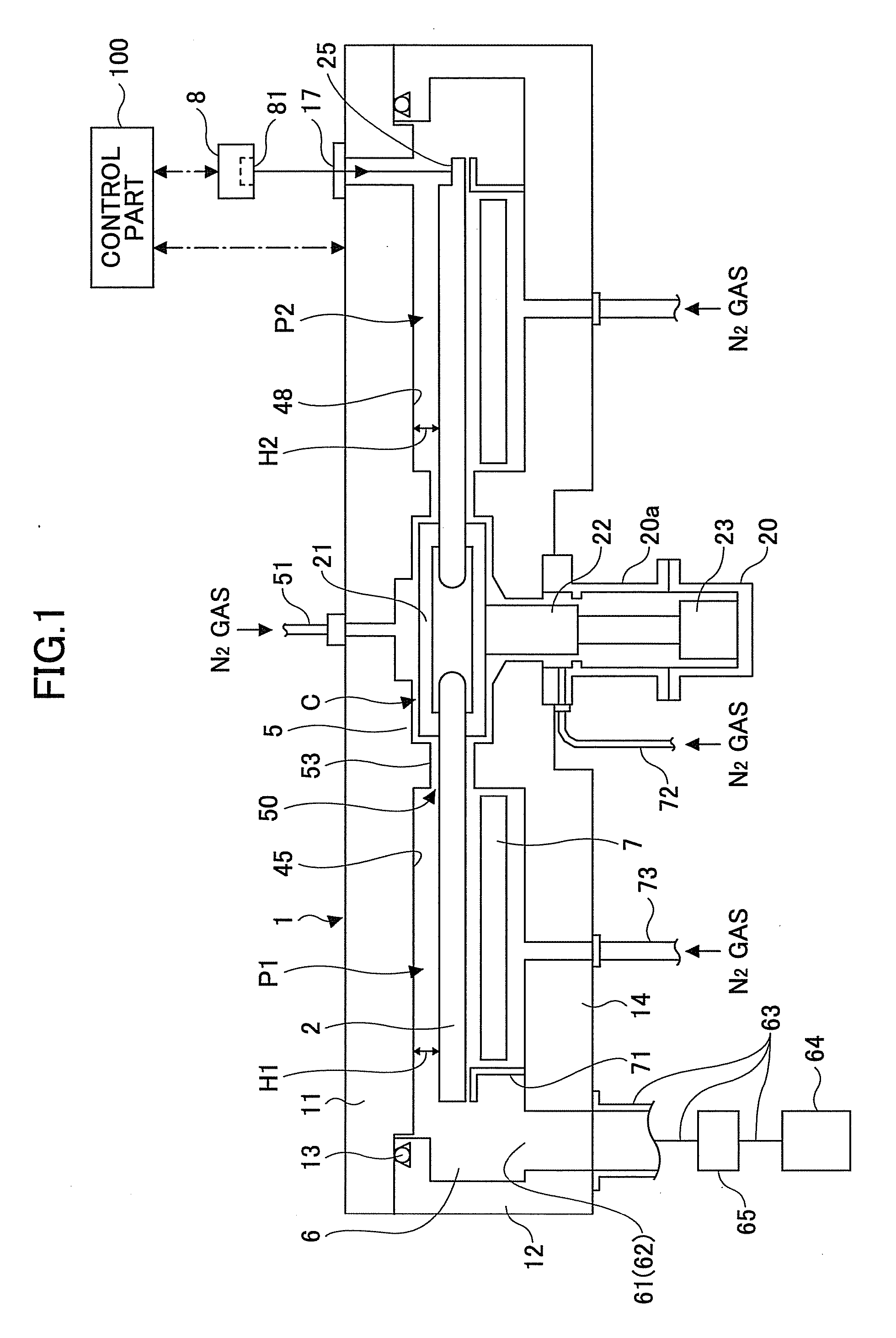

Film deposition apparatus, substrate processing apparatus, film deposition method, and computer-readable storage medium

InactiveUS20100055312A1Accurate detectionAccurate correctionLiquid surface applicatorsVacuum evaporation coatingReactive gasEngineering

In a film deposition apparatus which deposits a thin film on a substrate by supplying first and second reactive gases in a vacuum chamber, there are provided a turntable, a first reactive gas supplying portion and a second reactive gas supplying portion which are arranged to extend from circumferential positions of the turntable to a center of rotation of the turntable, a first separation gas supplying portion arranged between the first and second reactive gas supplying portions, a first space having a first height and including the first separation gas supplying portion, a second space having a second height and including the second reactive gas supplying portion, a third space having a height lower than the first height and the second height and including the first separation gas supplying portion, a position detecting unit detecting a rotation position of the turntable, and a detection part arranged at a circumferential portion of the turntable and detected by the position detecting unit.

Owner:TOKYO ELECTRON LTD

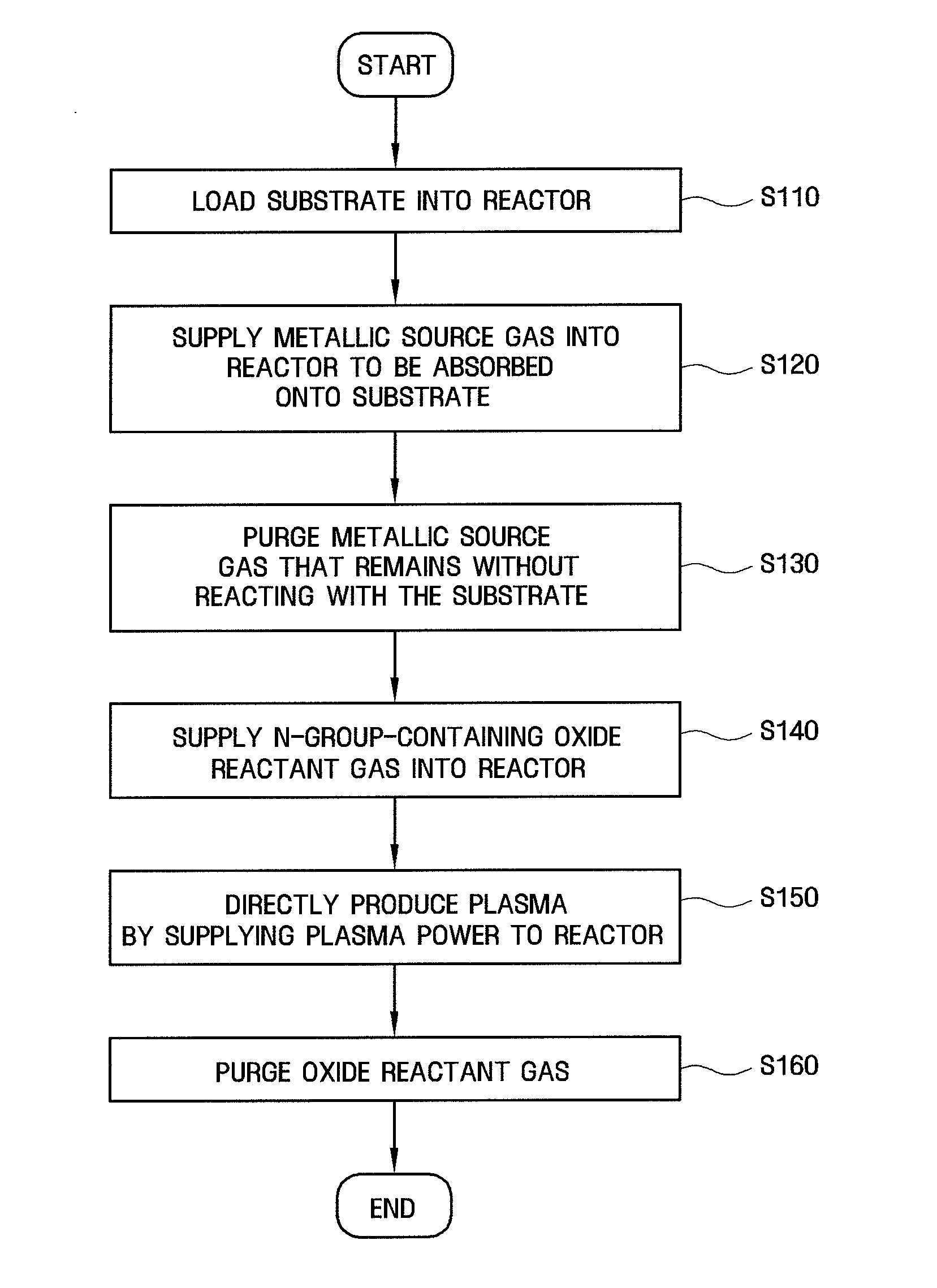

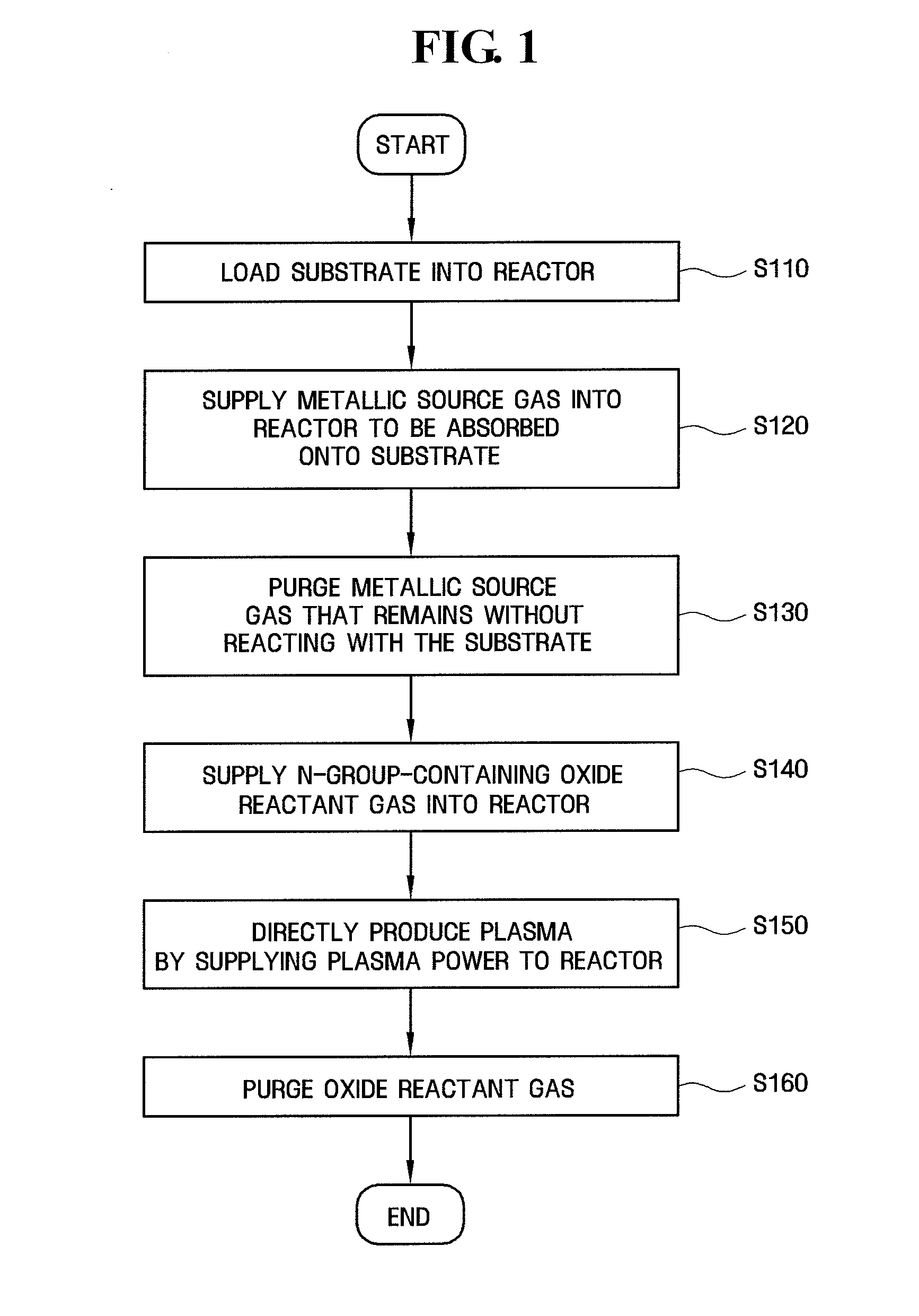

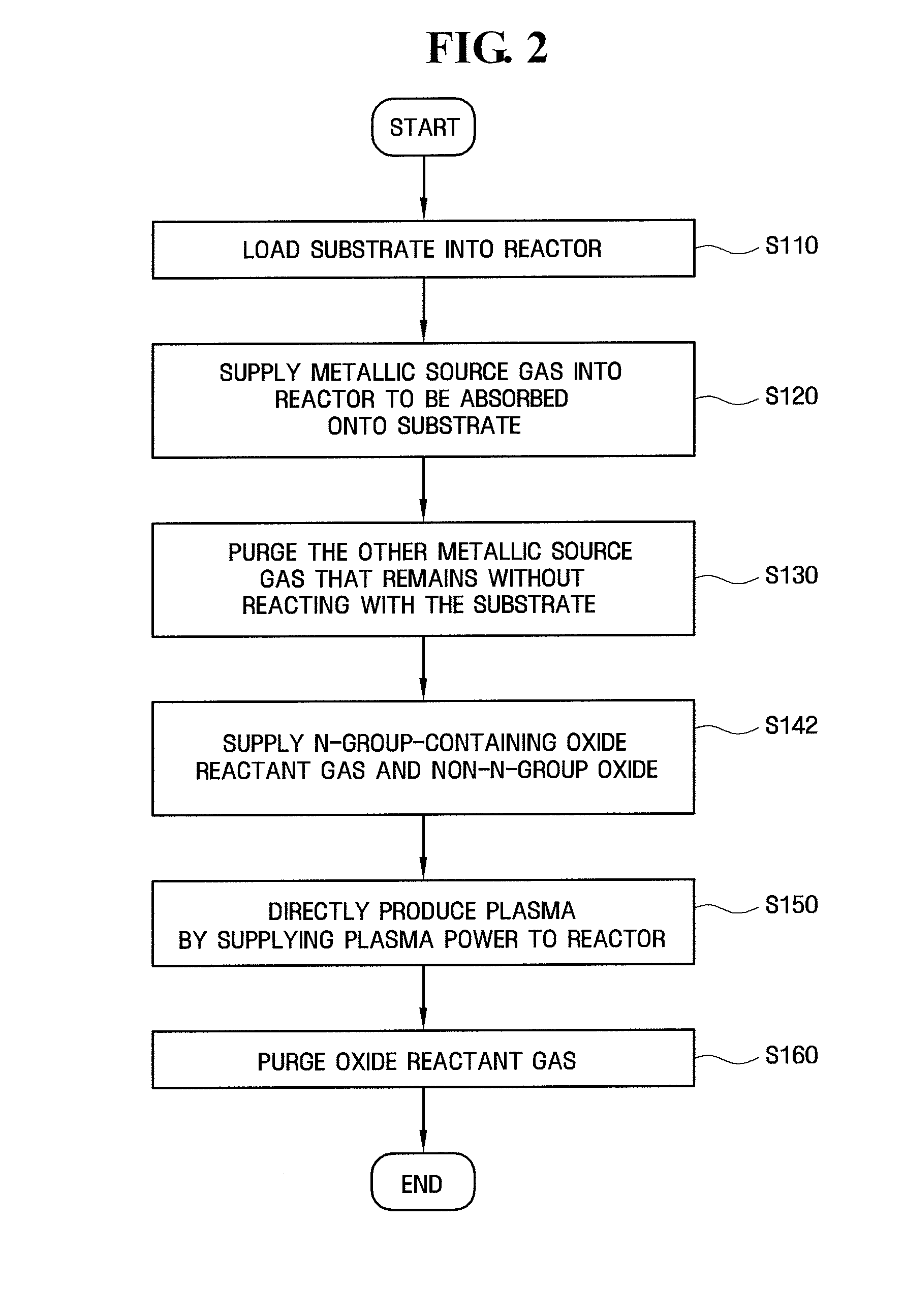

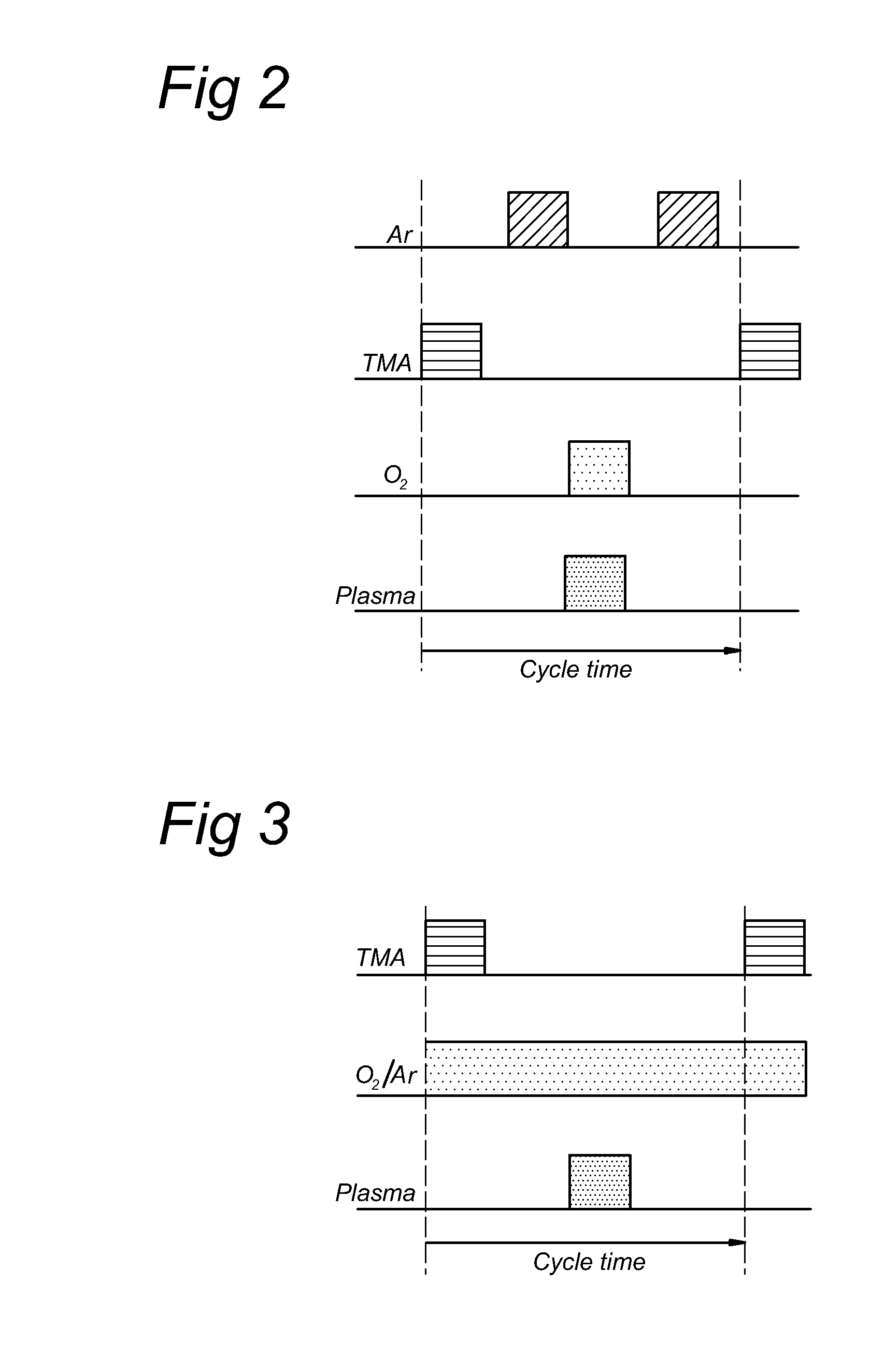

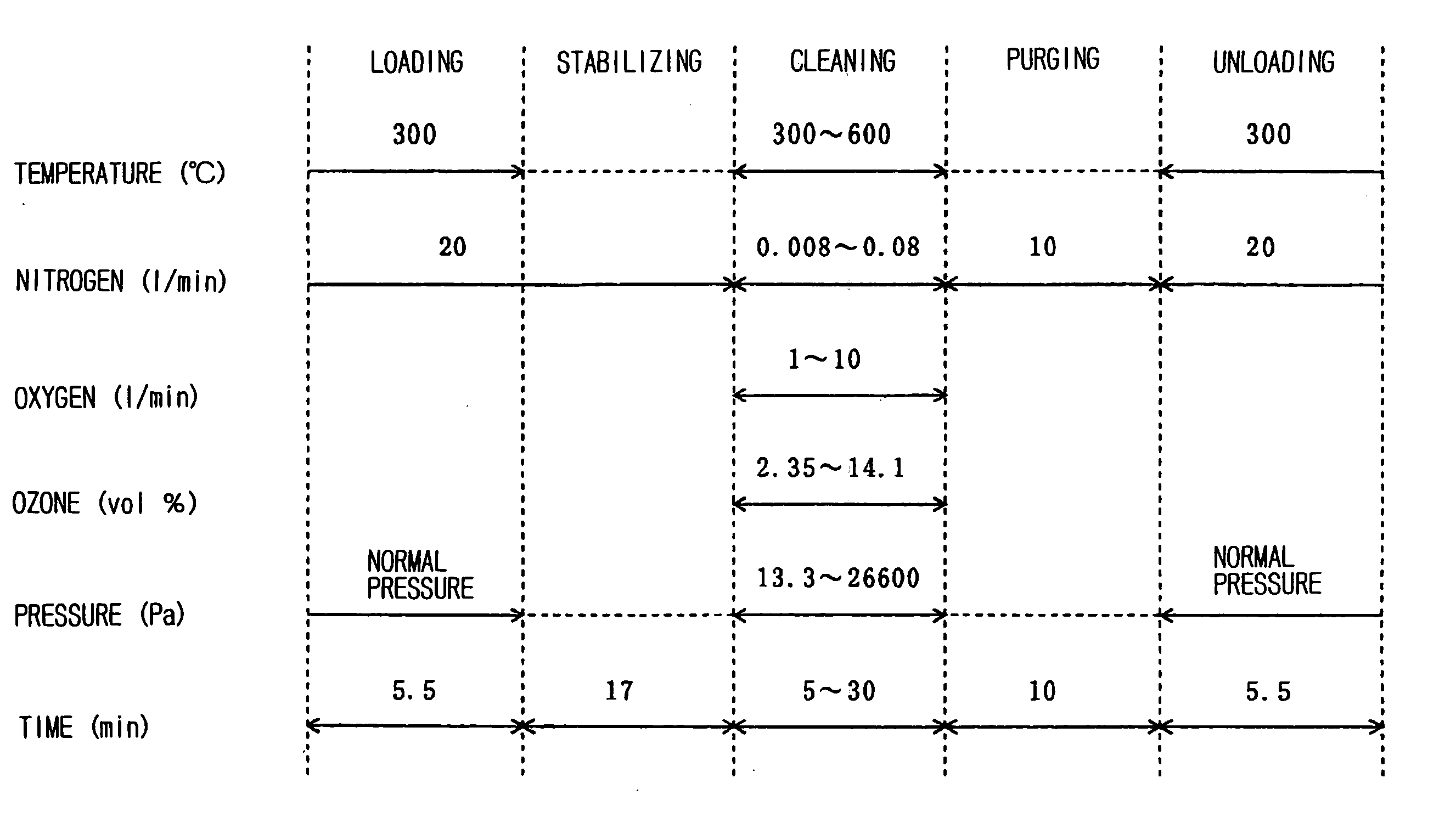

Method of Forming A Metallic Oxide Film Using Atomic Layer Deposition

InactiveUS20080075881A1Chemical vapor deposition coatingPlasma techniqueProduct gasMaterials science

A method of forming a metallic oxide film using atomic layer deposition includes loading a substrate into a reactor, supplying a metallic source gas into the reactor and absorbing the metallic source gas onto the substrate, purging the remaining metallic source gas that does not react, with the substrate, and directly producing plasma of an N-group-containing oxide reactant gas in the reactor.

Owner:SAMSUNG ELECTRONICS CO LTD

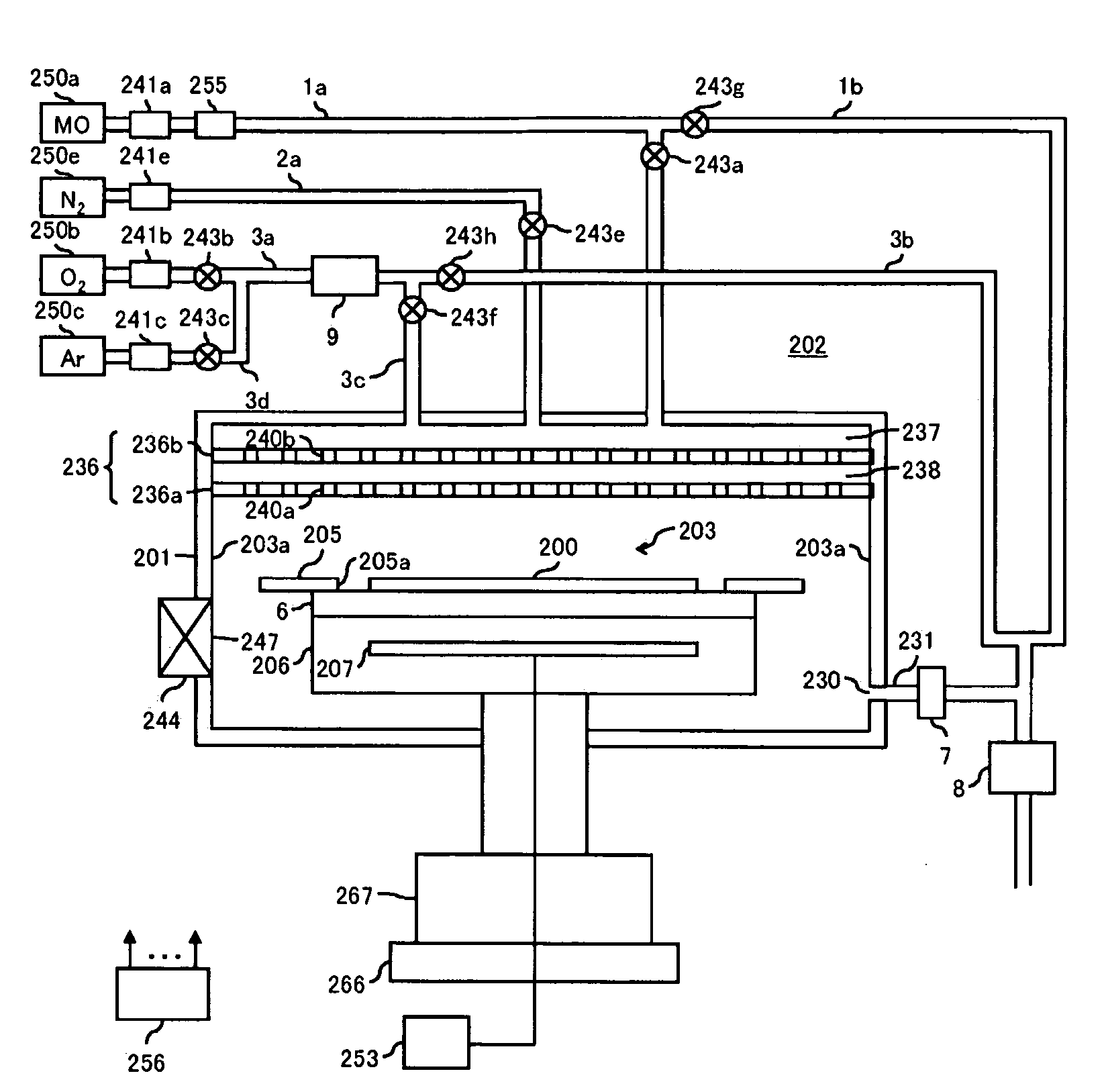

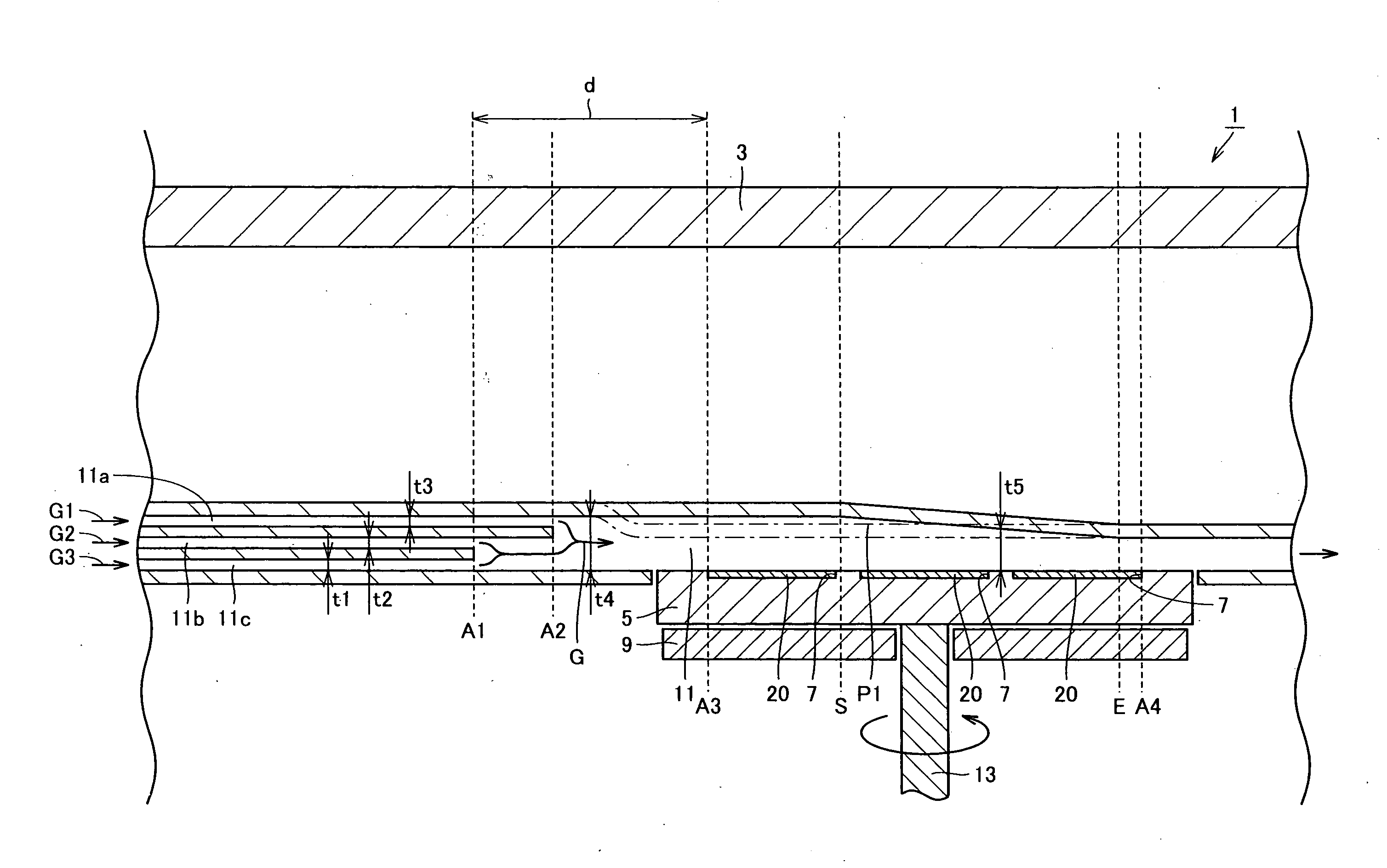

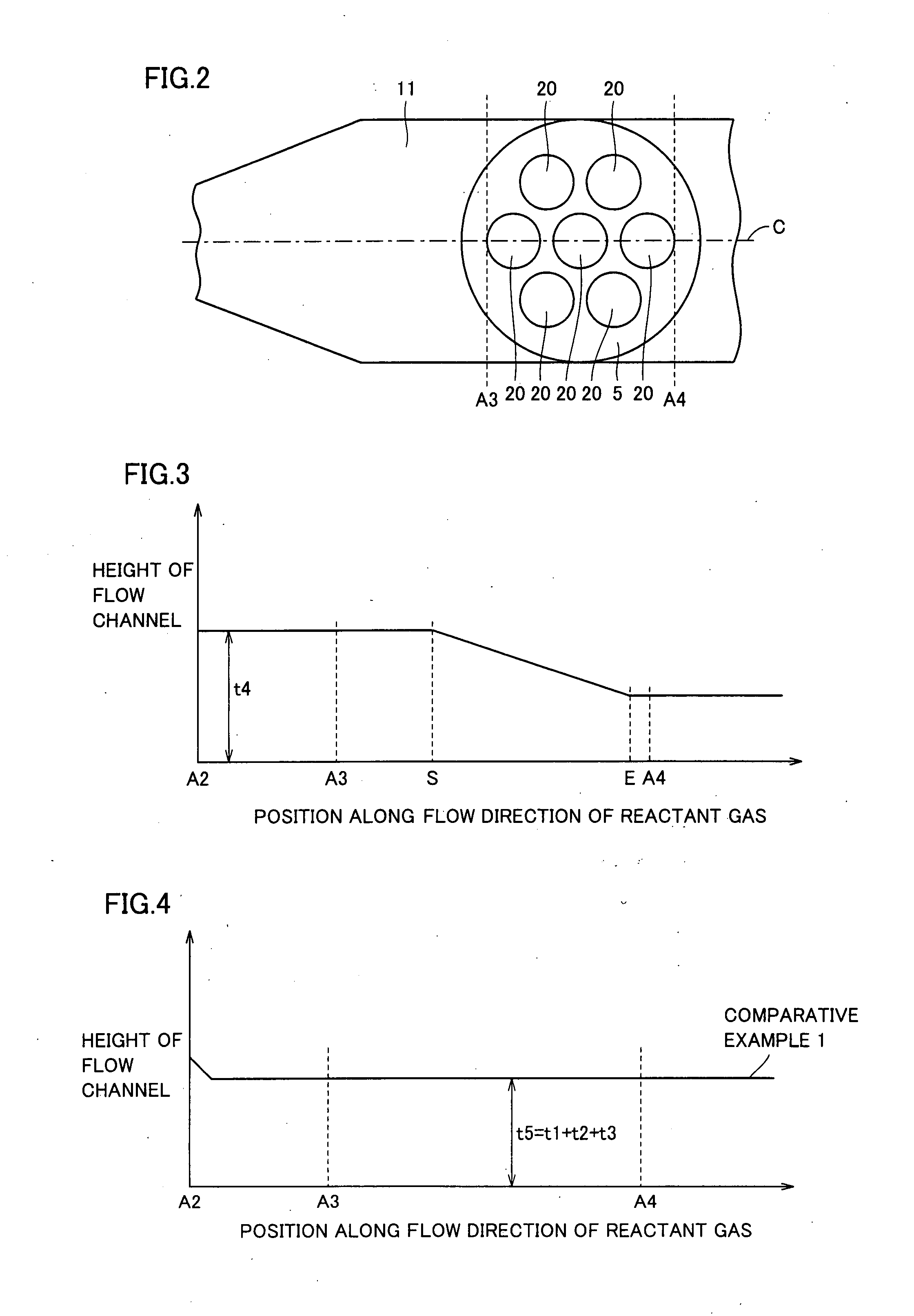

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

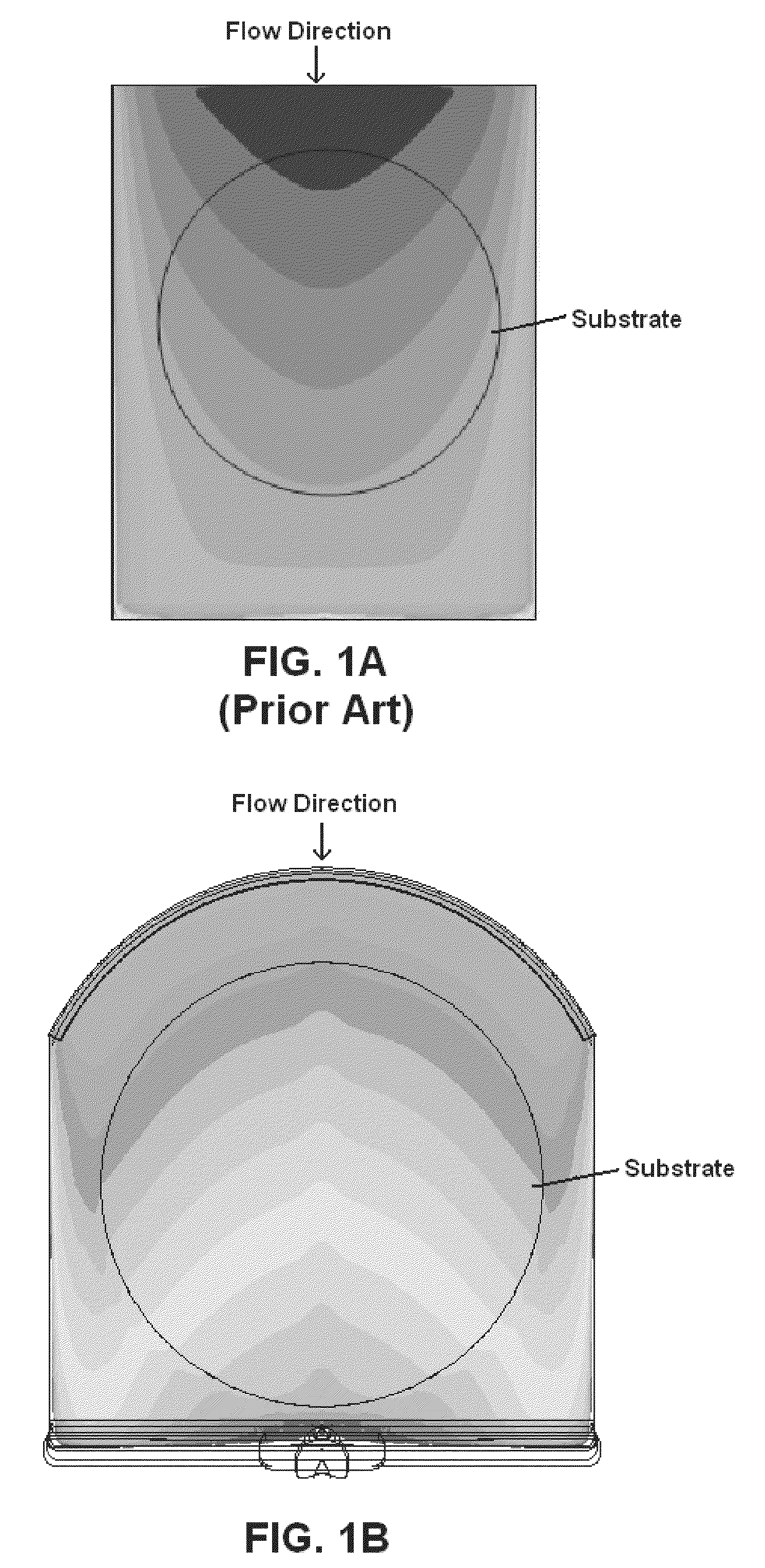

Apparatus for depositing a uniform silicon film and methods for manufacturing the same

InactiveUS20080305246A1Final product manufactureSemiconductor/solid-state device manufacturingSilicon membraneProduct gas

Methods and apparatus having a gradient spacing created between a substrate support assembly and a gas distribution plate for depositing a silicon film for solar cell applications are provided. In one embodiment, an apparatus for depositing films for solar cell applications may include a processing chamber, a substrate support disposed in the processing chamber and configured to support a quadrilateral substrate thereon, and a gas distribution plate disposed in the processing chamber above the substrate support, wherein a bottom surface of the gas distribution plate has a perimeter that includes edges and corners, and wherein the corners of the gas distribution plate are closer to the substrate support than the edges of the gas distribution plate.

Owner:APPLIED MATERIALS INC

Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

This invention discloses a two-layer gas inlet blow head of a metal organic chemical gas phase deposit device including a closed shell having an upper gas inlet cavity and a lower gas inlet cavity, an upper escape pipe communicating with the upper gas cavity and reaction chamber is set between the upper-middle and the base plate and a lower escape pipe communicating with a lower gas inlet cavity and the reaction chamber is set between the lower plate and base plate characterizing that diameter of the lower escape pipe is layer than the upper and the upper is put in the lower. A cooling cavity is designed, the first reaction gas enters into the reaction chamber at the substrate surface from the upper and lower escape pipes separately.

Owner:南昌硅基半导体科技有限公司

Deposition apparatus

ActiveUS20090156015A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A deposition apparatus configured to form a thin film on a substrate includes: a reactor wall; a substrate support positioned under the reactor wall; and a showerhead plate positioned above the substrate support. The showerhead plate defines a reaction space together with the substrate support. The apparatus also includes one or more gas conduits configured to open to a periphery of the reaction space at least while an inert gas is supplied therethrough. The one or more gas conduits are configured to supply the inert gas inwardly toward the periphery of the substrate support around the reaction space. This configuration prevents reactant gases from flowing between a substrate and the substrate support during a deposition process, thereby preventing deposition of an undesired thin film and impurity particles on the back side of the substrate.

Owner:ASM KOREA LTD

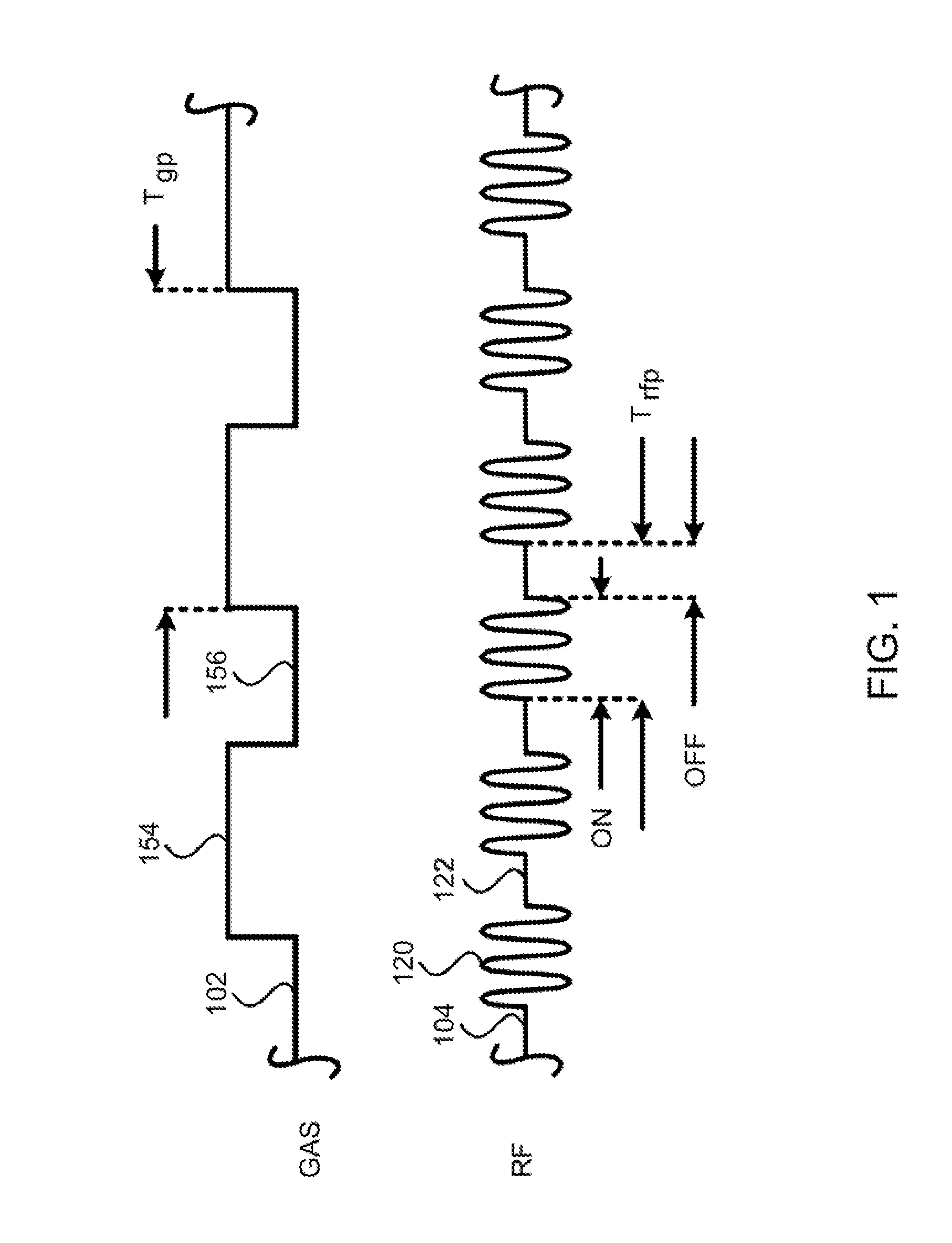

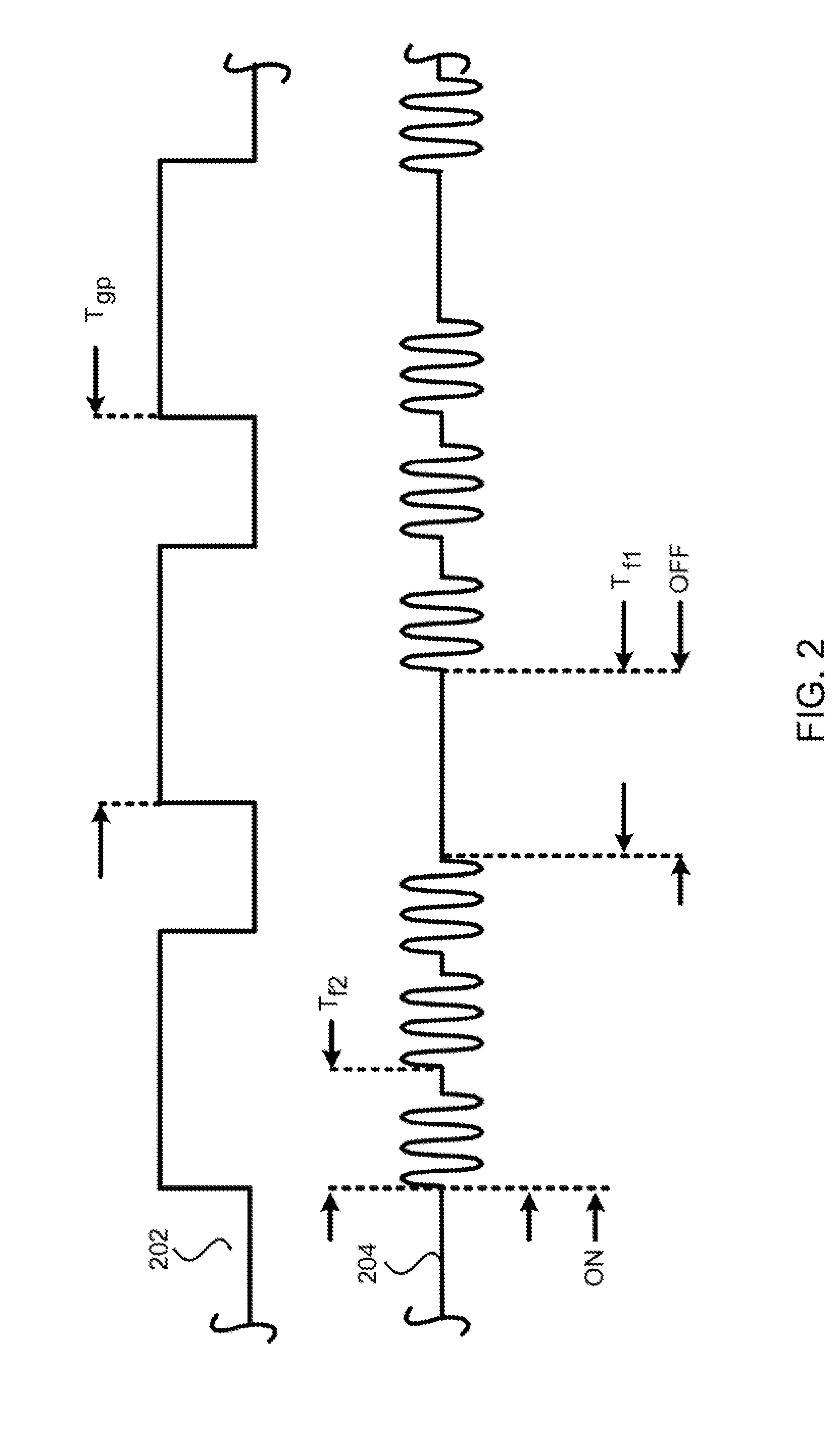

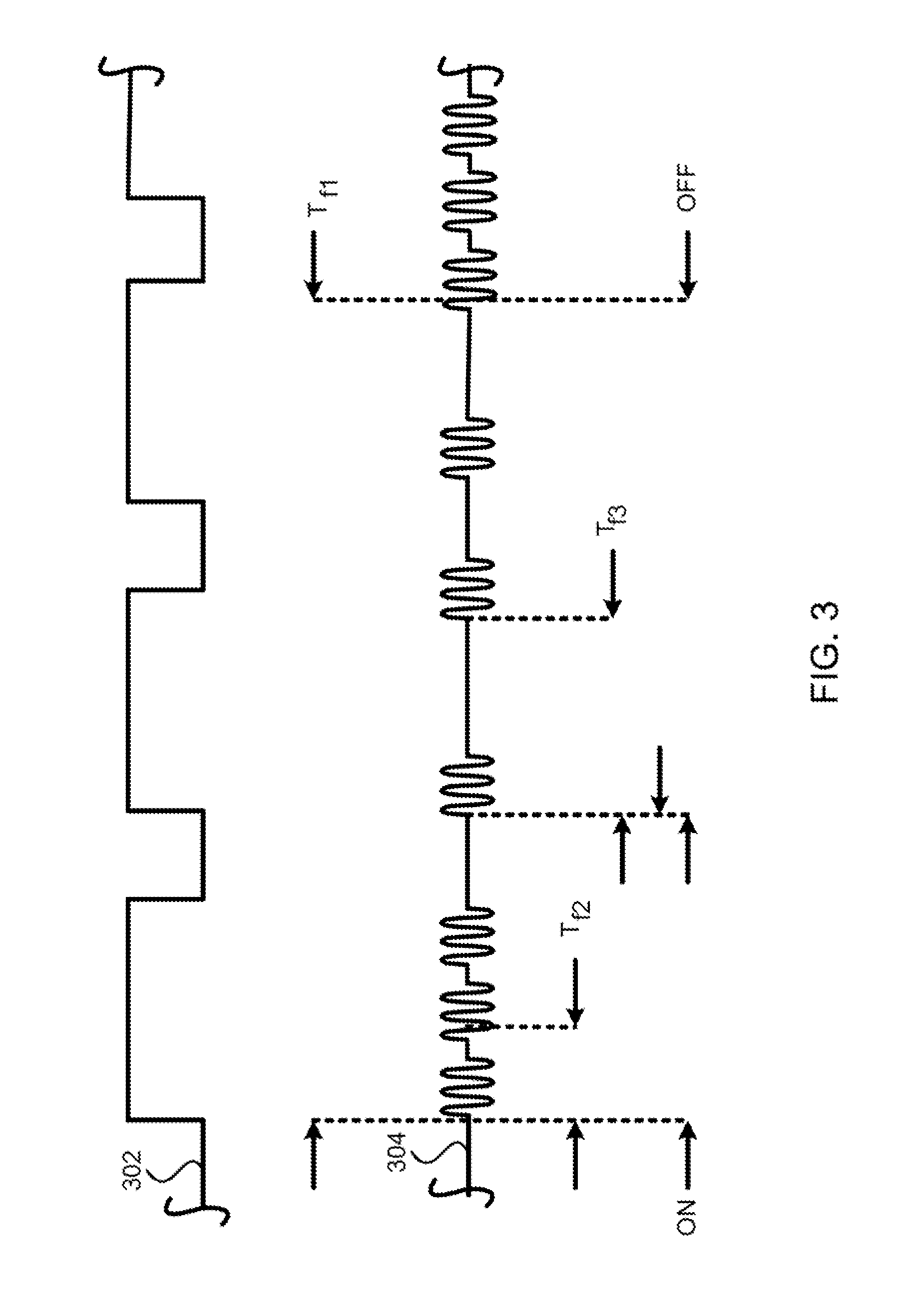

Mixed mode pulsing etching in plasma processing systems

A method for processing substrate in a chamber, which has at least one plasma generating source, a reactive gas source for providing reactive gas into the interior region of the chamber, and a non-reactive gas source for providing non-reactive gas into the interior region, is provided. The method includes performing a mixed-mode pulsing (MMP) preparation phase, including flowing reactive gas into the interior region and forming a first plasma to process the substrate that is disposed on a work piece holder. The method further includes performing a MMP reactive phase, including flowing at least non-reactive gas into the interior region, and forming a second plasma to process the substrate, the second plasma is formed with a reactive gas flow during the MMP reactive phase that is less than a reactive gas flow during the MMP preparation phase. Perform the method steps a plurality of times.

Owner:LAM RES CORP

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

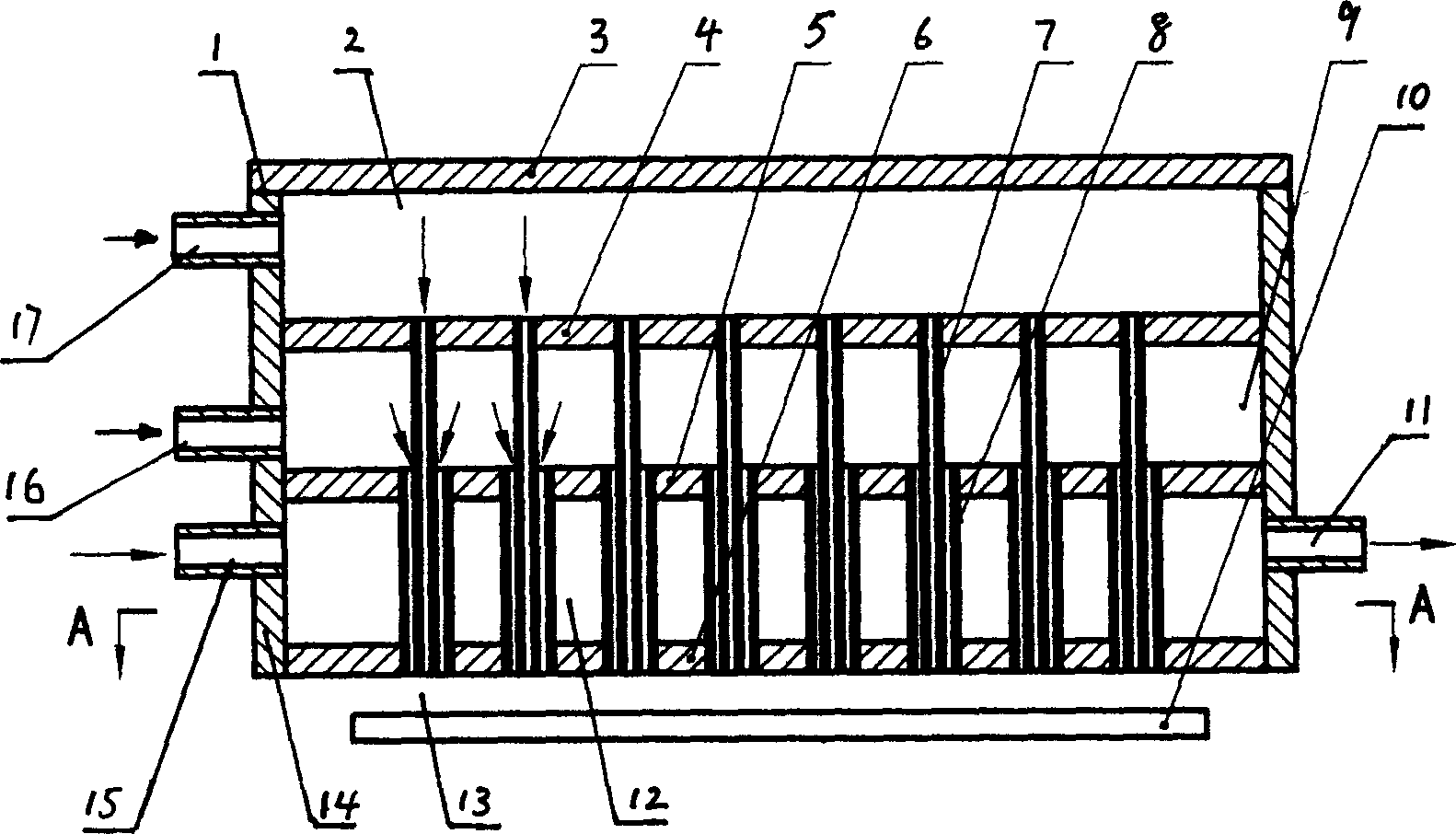

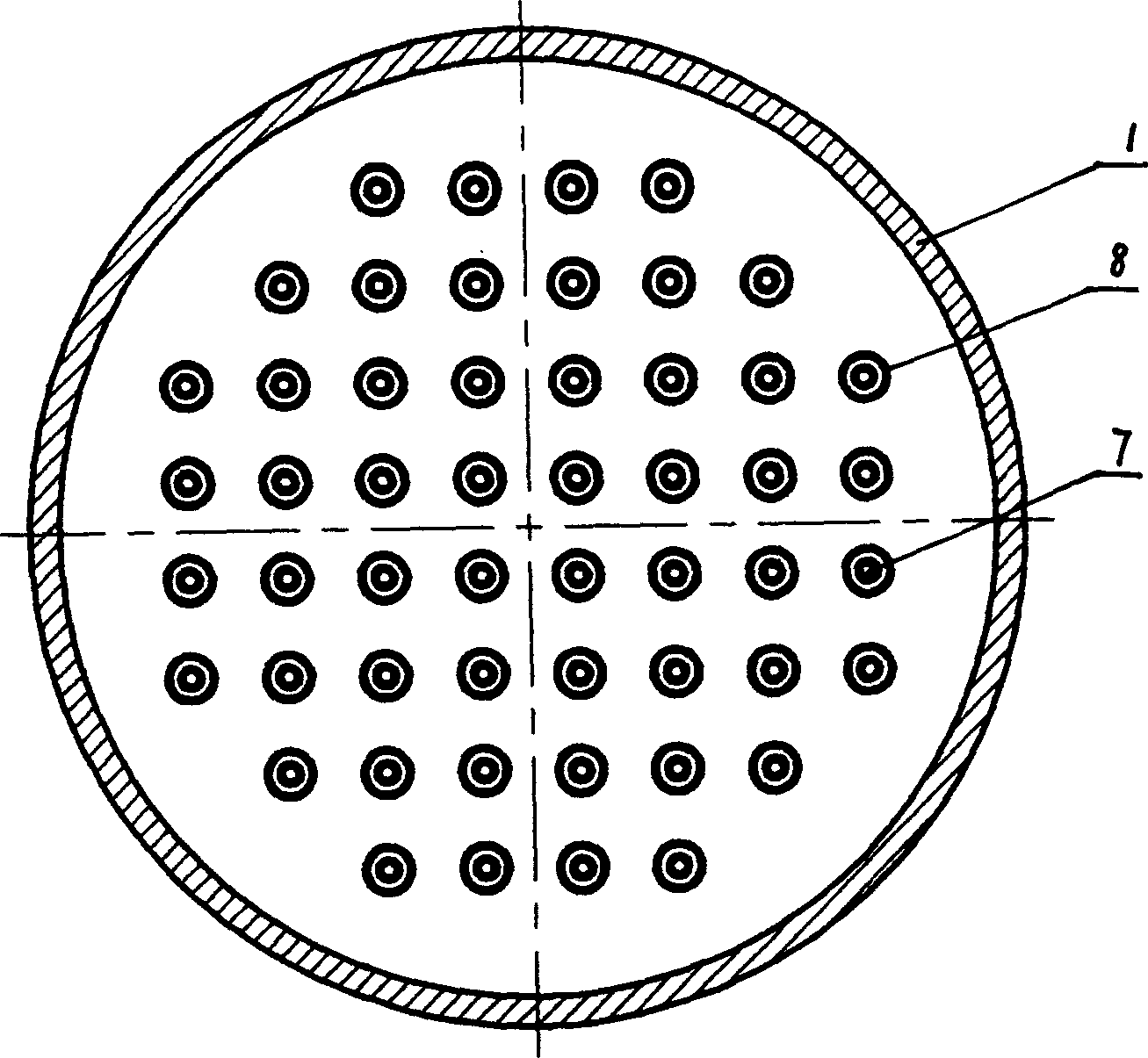

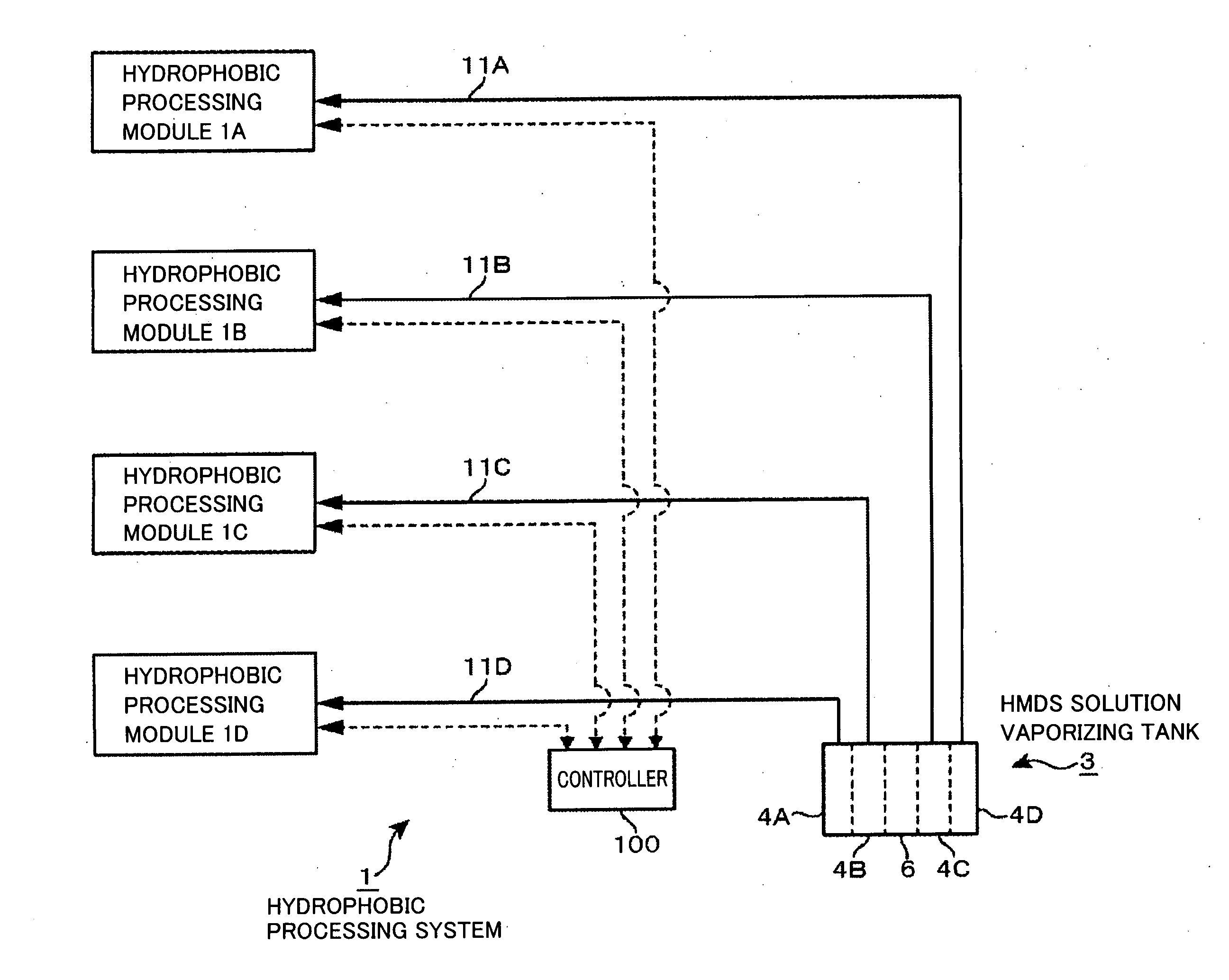

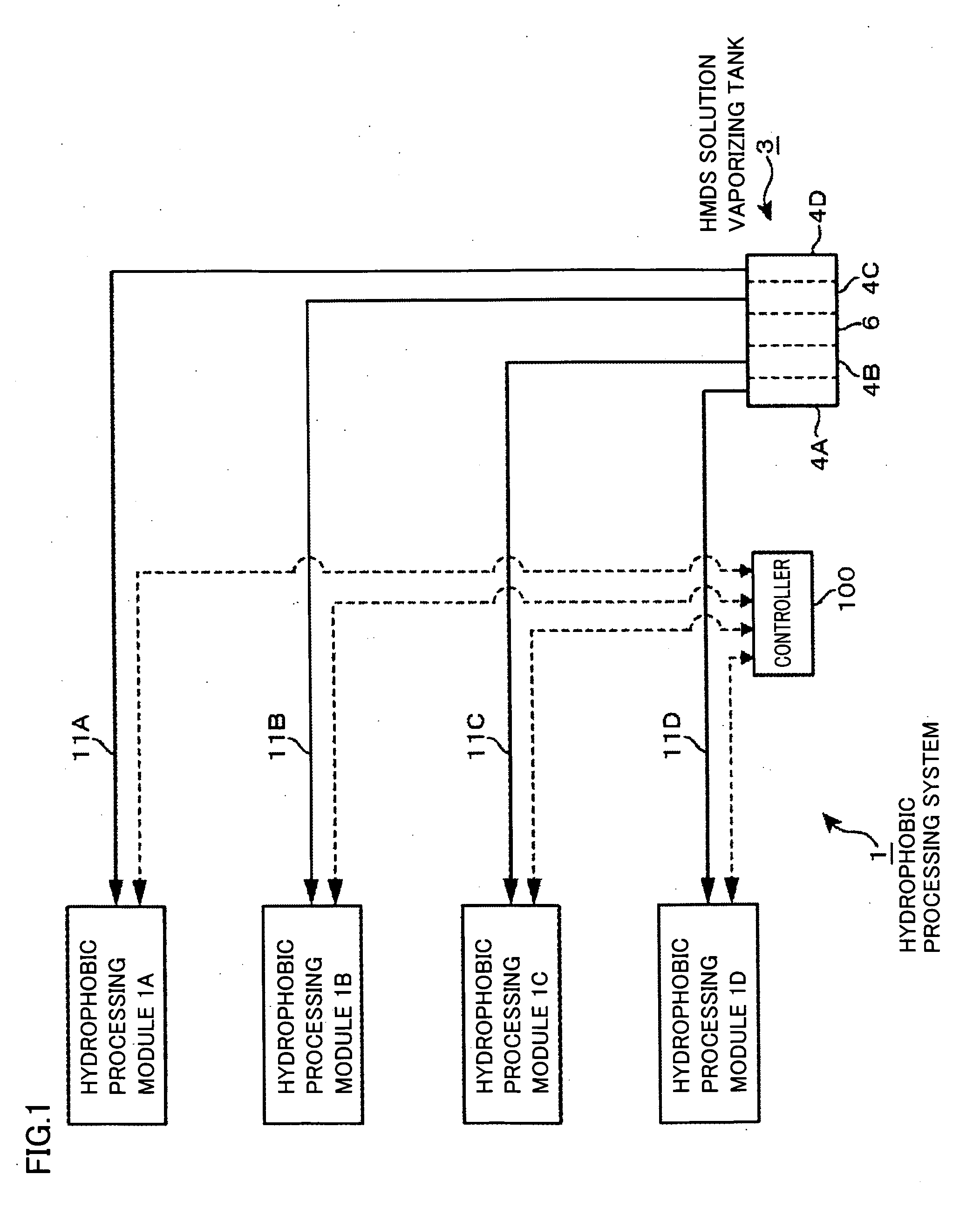

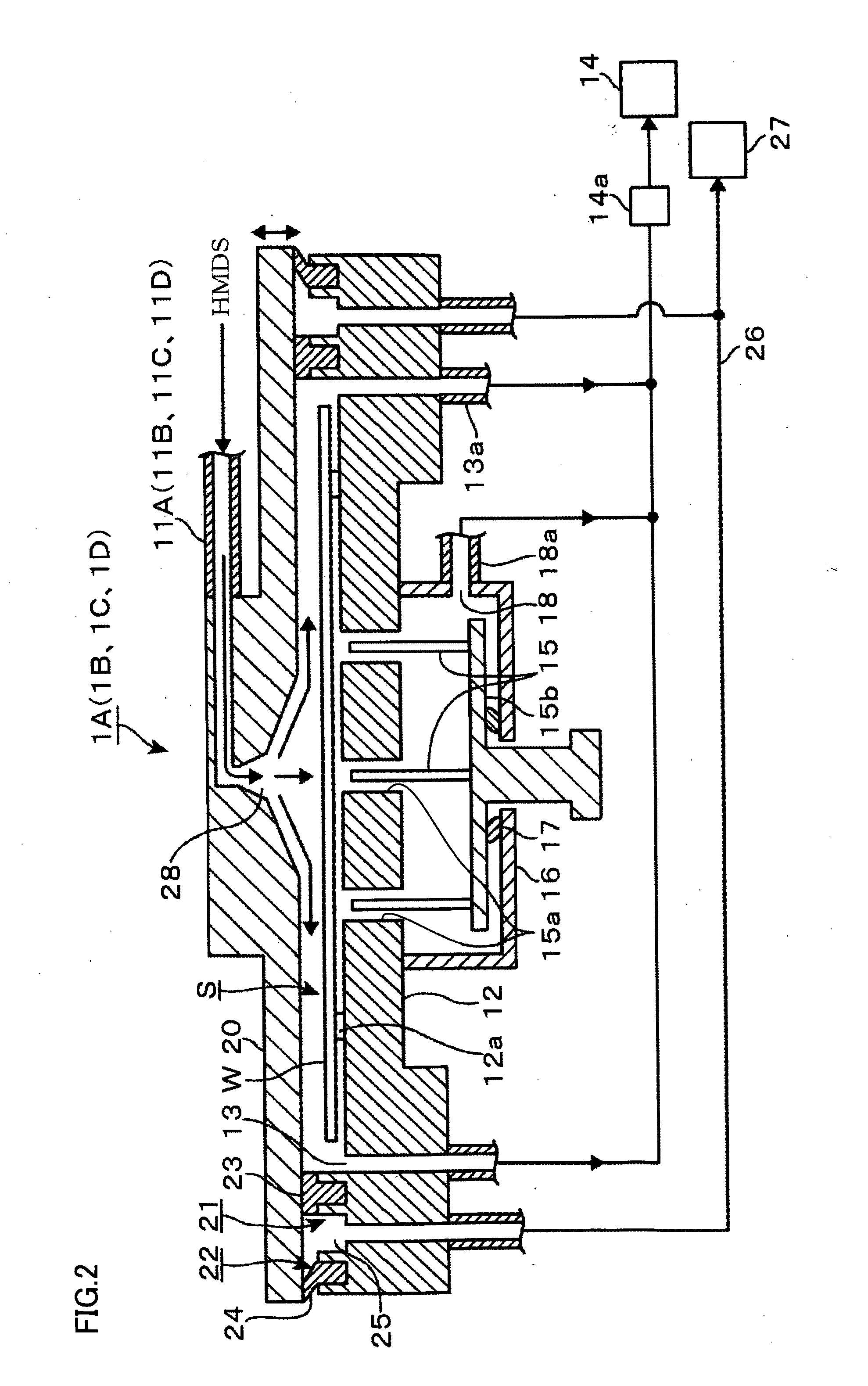

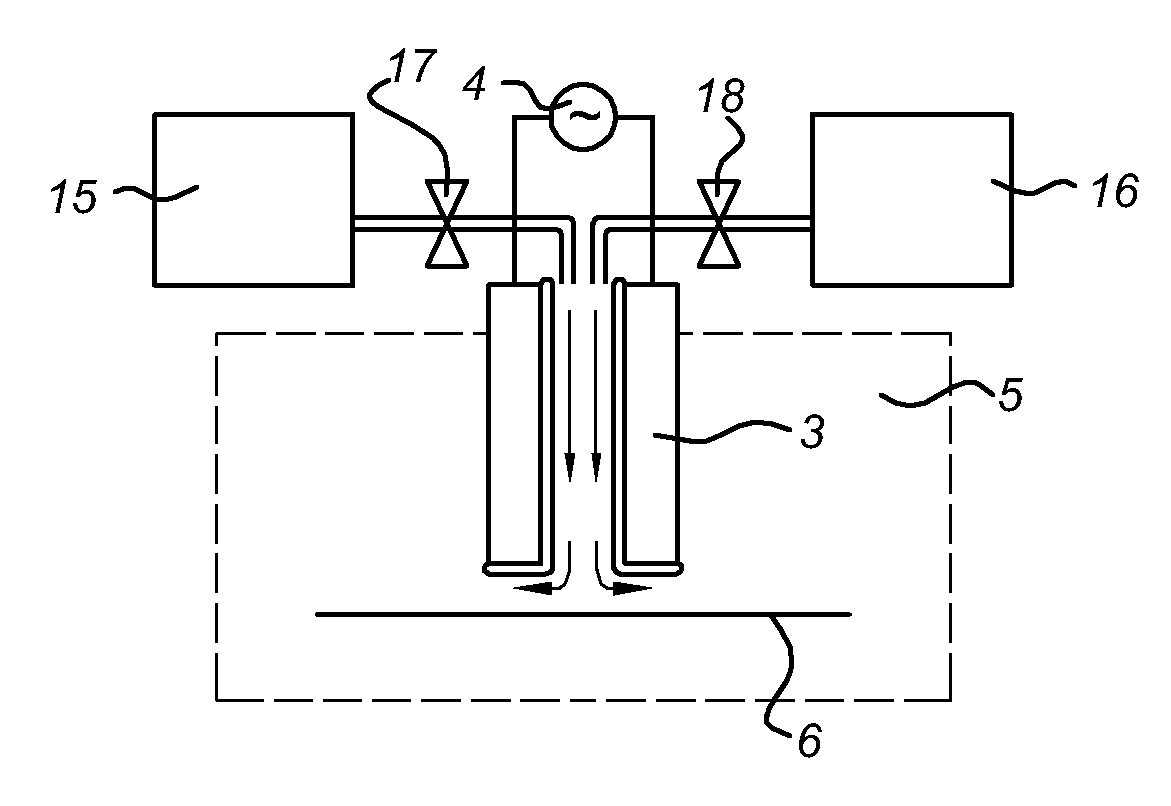

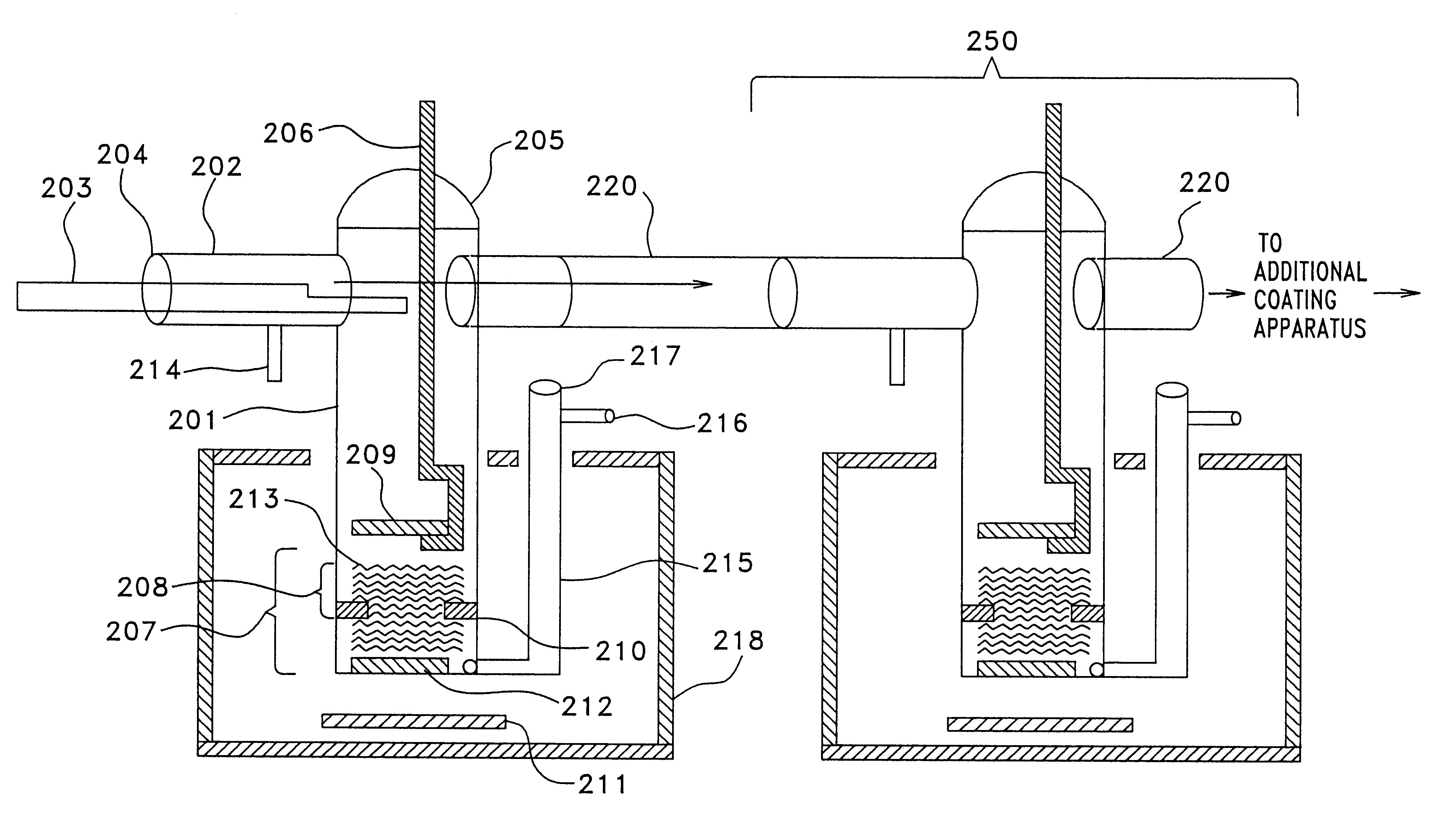

Chemical solution vaporizing tank and chemical solution treating system

ActiveUS20090020072A1Concentration differenceVariations in concentration of the chemical solutions can be suppressedLiquid surface applicatorsSemiconductor/solid-state device manufacturingChemical solutionProduct gas

An object is to suppress differences in concentration between processing gases supplied to a plurality of works in a chemical solution vaporizing tank. The chemical solution vaporizing tank includes a tank body having a plurality of vaporizing chambers formed by laterally and airtightly partitioning an internal space of the tank body, a chemical solution passage located under a liquid level in each vaporizing chamber and formed at each partition member for passing the chemical solution between the vaporizing chambers, and a gas passage located above the liquid level in each vaporizing chamber and formed at the partition member to communicate the vaporizing chambers with each other for uniformizing pressures in the respective vaporizing chambers. A quantity of the channel layer in each vaporizing chamber is controlled by managing, e.g., the liquid level.

Owner:TOKYO ELECTRON LTD

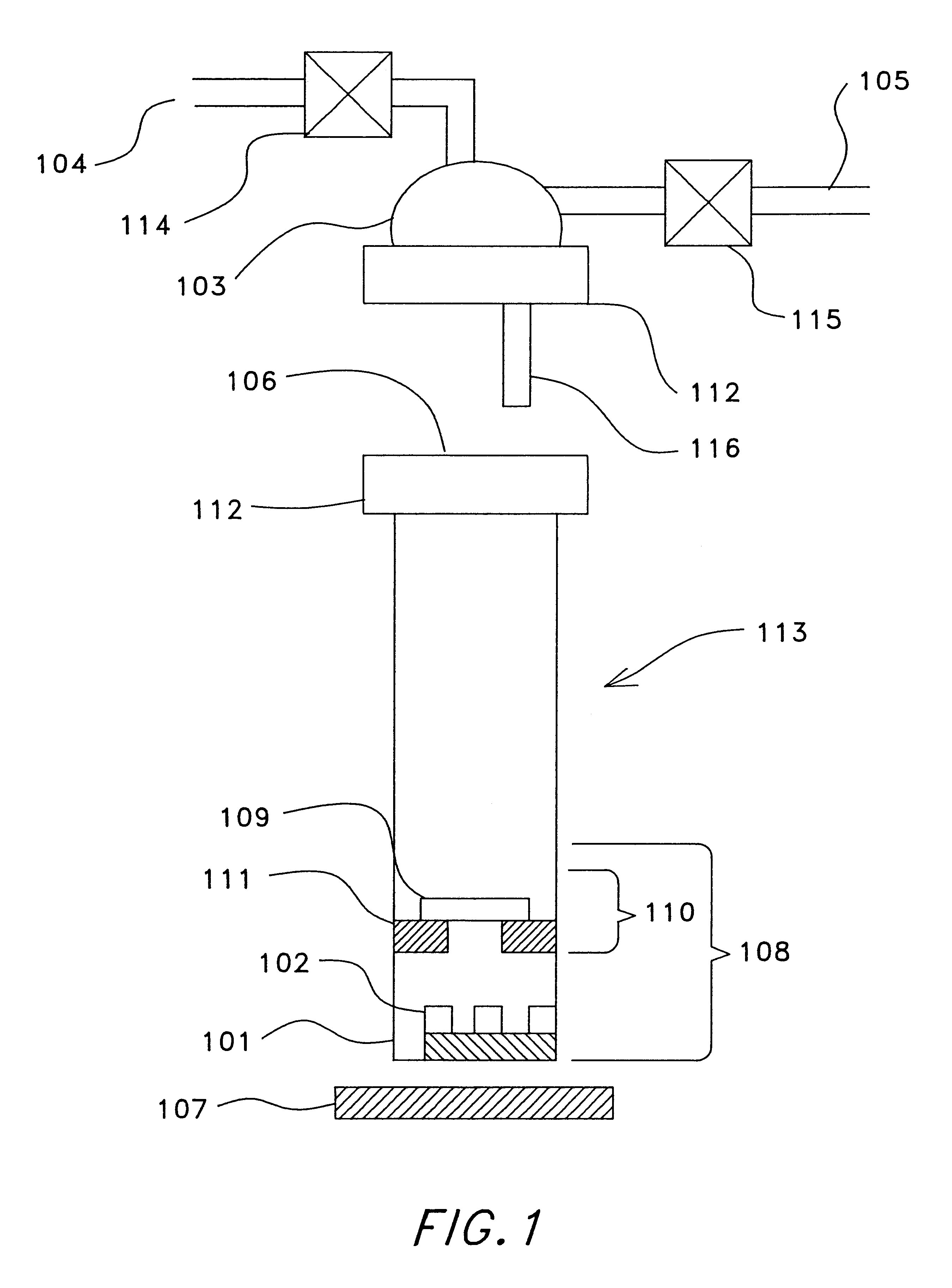

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

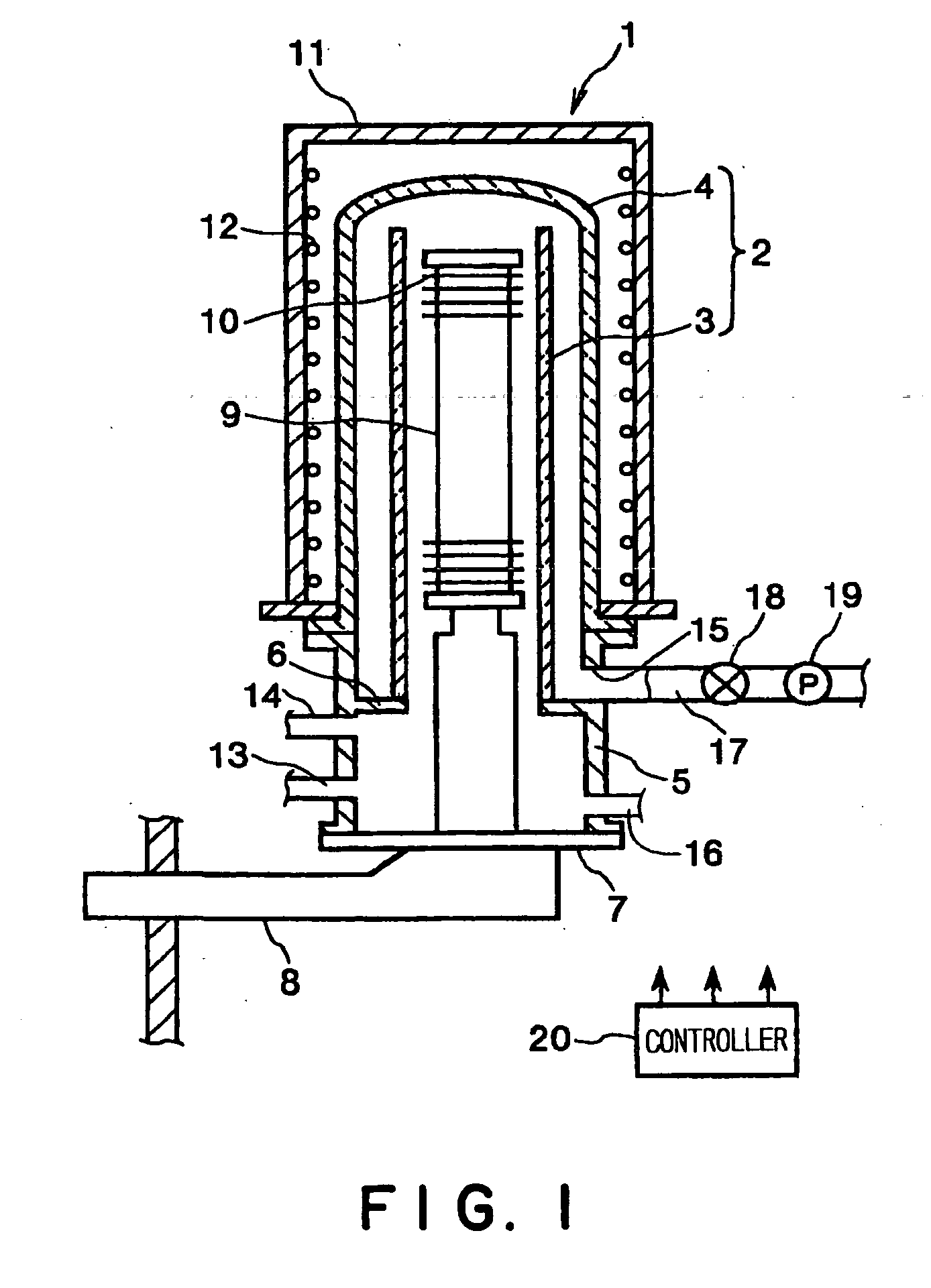

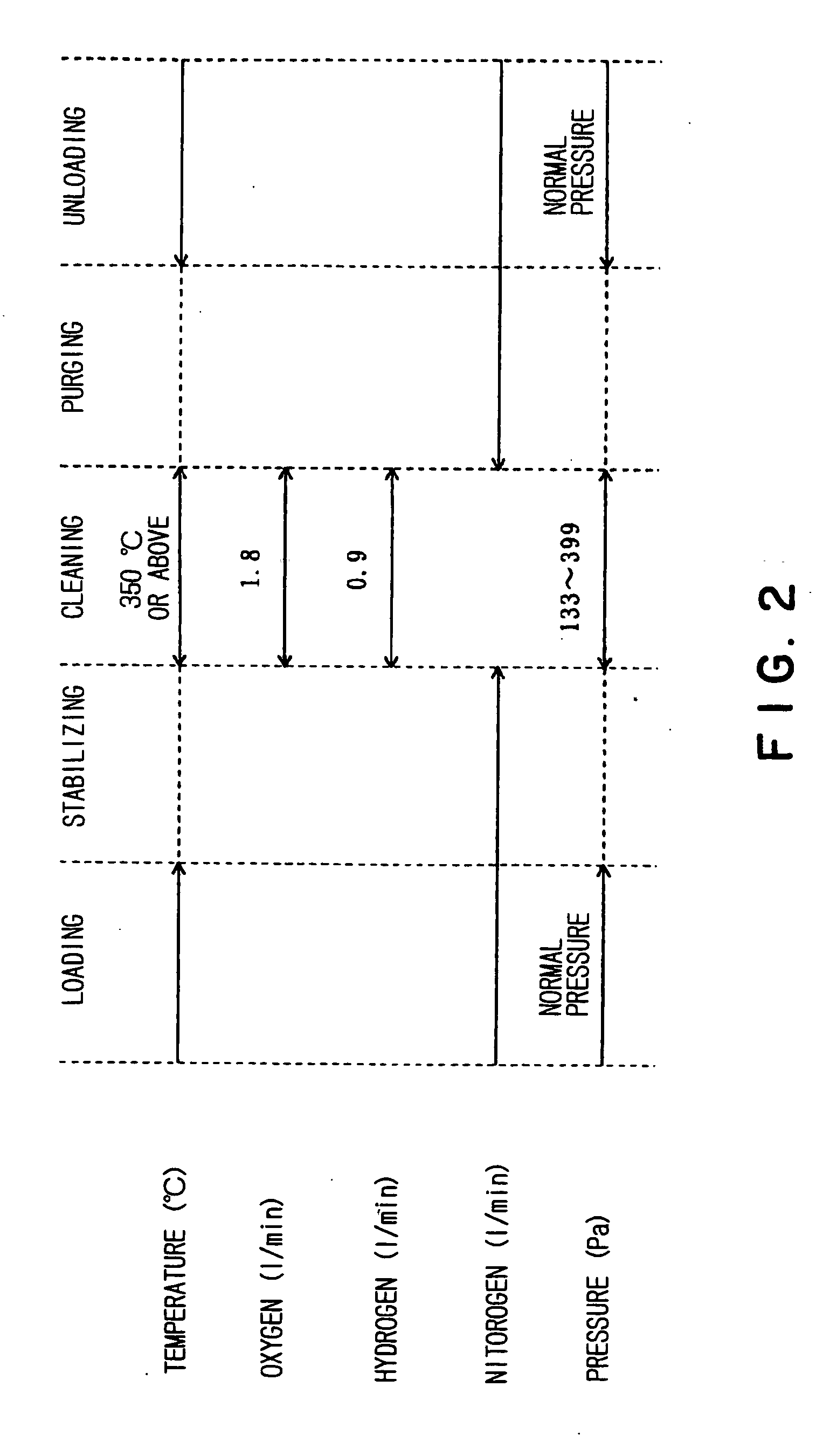

Method and apparatus for treating article to be treated

InactiveUS20040219793A1Efficient removalShort timeAfter-treatment detailsSemiconductor/solid-state device manufacturingCombustionHydrogen

A thermal treatment apparatus 1 includes a reaction tube 2 for containing wafers 10 contaminated with organic substances having a heater 12 capable of heating the reaction tube; a first gas supply pipe 13 for carrying oxygen gas into the reaction tube 2; and a second gas supply pipe 14 for carrying hydrogen gas into the reaction tube 2. Oxygen gas and hydrogen gas are supplied through the first gas supply pipe 13 and the second gas supply pipe 14, respectively, into the reaction tube 2, and the heater 12 heats the reaction tube 2 at a temperature capable of activating oxygen gas and hydrogen gas. A combustion reaction occurs in the reaction tube 2 and thereby the organic substances adhering to the wafers 10 are oxidized, decomposed and removed.

Owner:TOKYO ELECTRON LTD

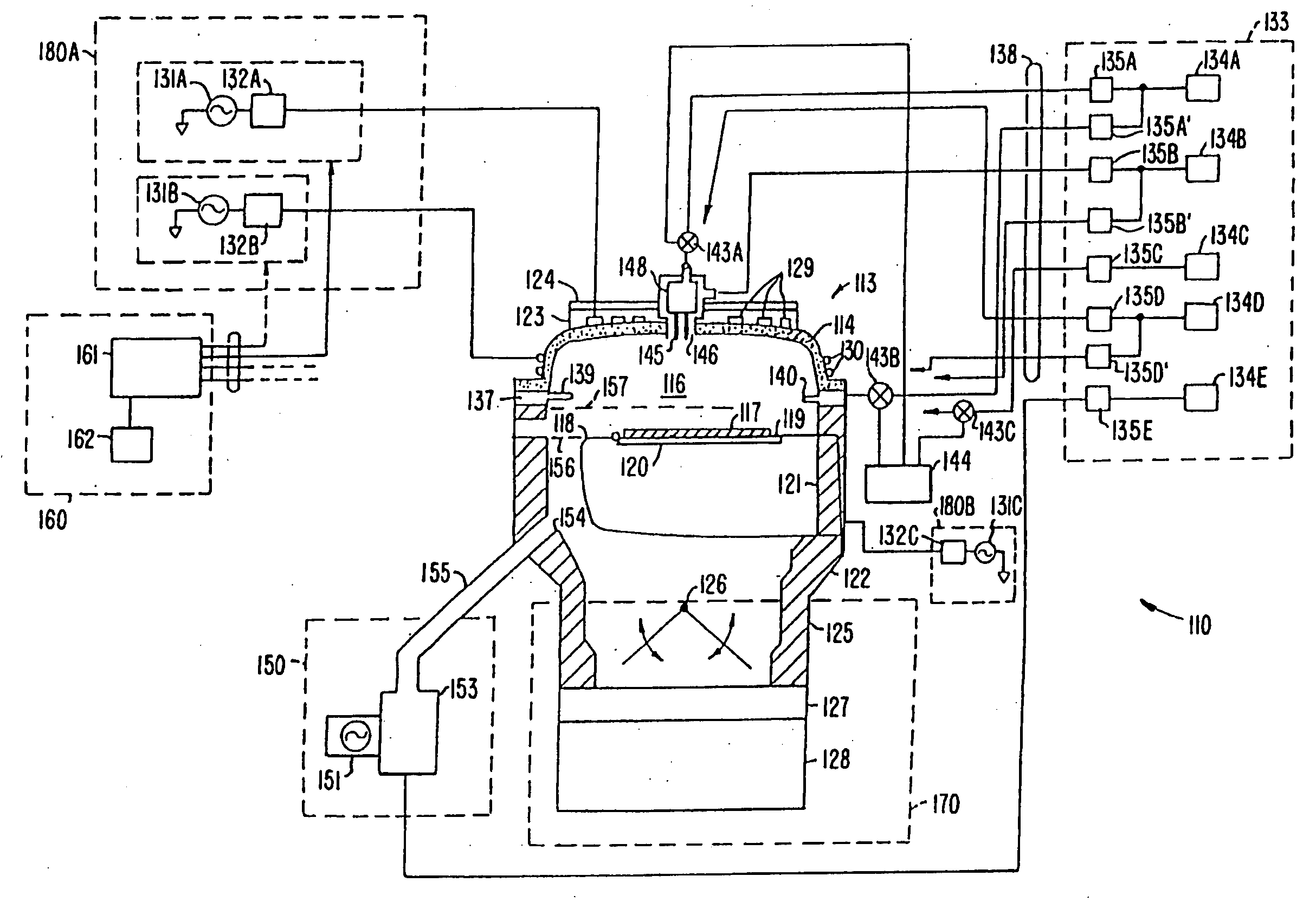

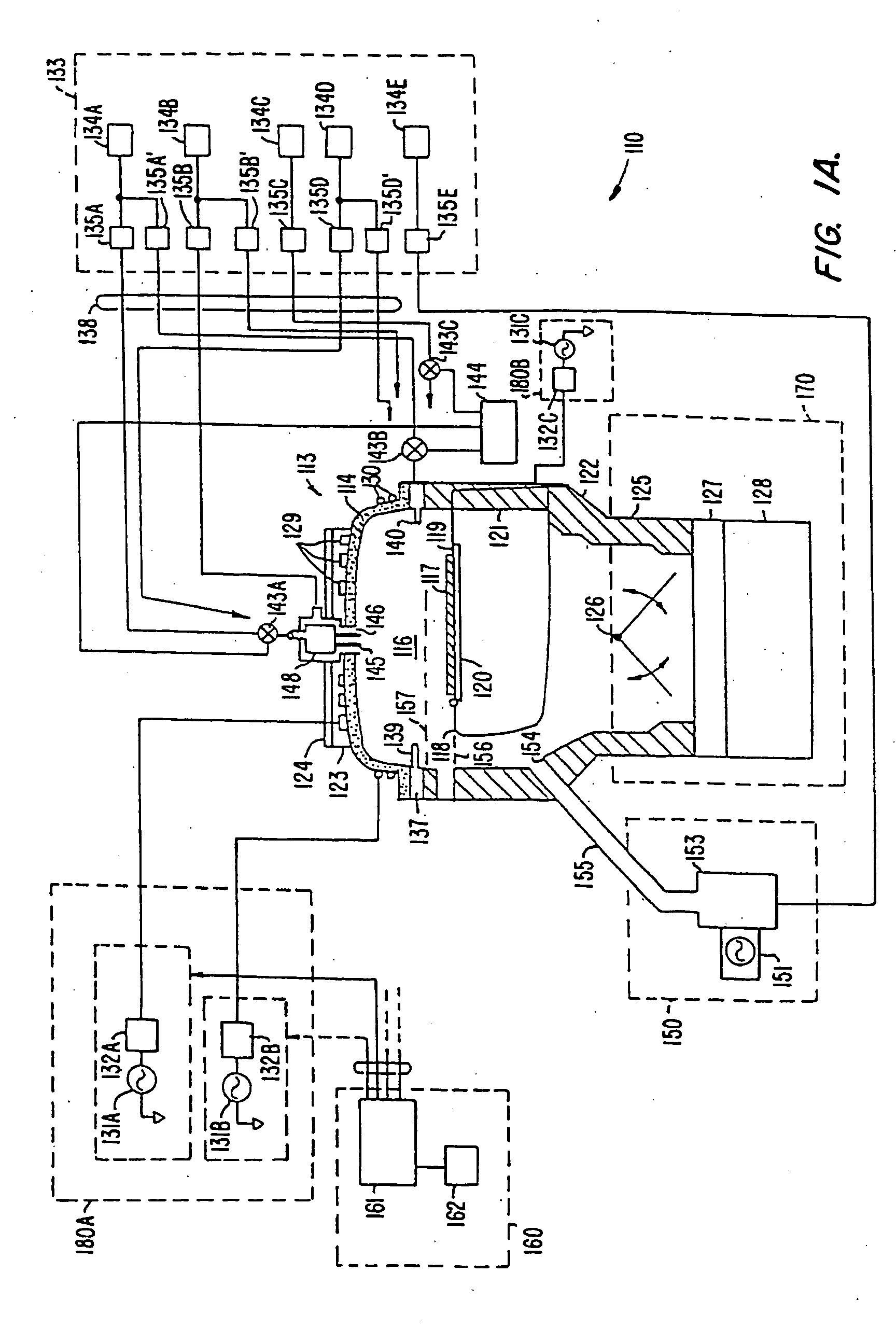

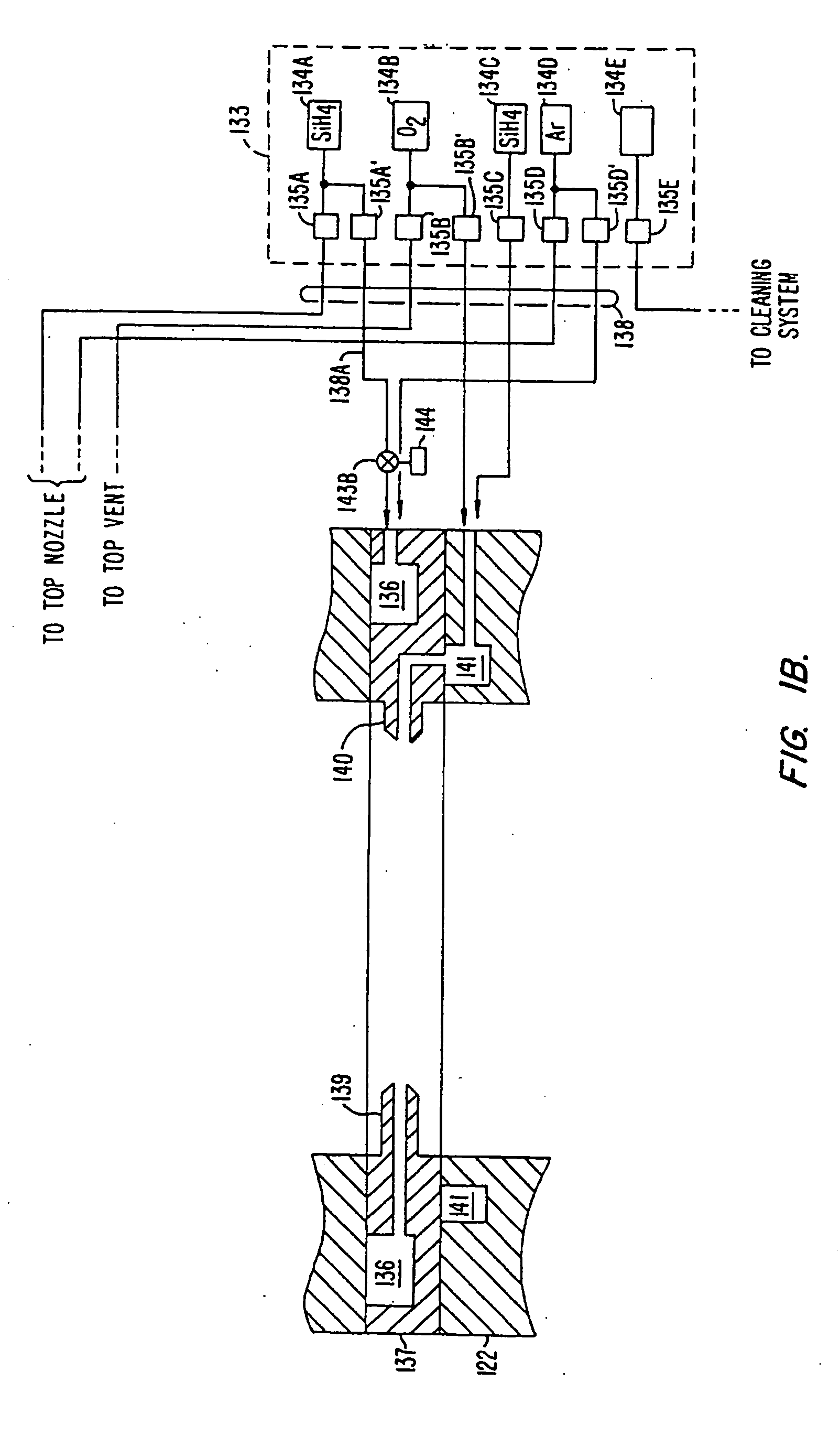

Semiconductor processing reactor and components thereof

ActiveUS20100307415A1Semiconductor/solid-state device manufacturingBranching pipesProcess engineeringProduct gas

A reactor having a housing that encloses a gas delivery system operatively connected to a reaction chamber and an exhaust assembly. The gas delivery system includes a plurality of gas lines for providing at least one process gas to the reaction chamber. The gas delivery system further includes a mixer for receiving the at least one process gas. The mixer is operatively connected to a diffuser that is configured to diffuse process gases. The diffuser is attached directly to an upper surface of the reaction chamber, thereby forming a diffuser volume therebetween. The diffuser includes at least one distribution surface that is configured to provide a flow restriction to the process gases as they pass through the diffuser volume before being introduced into the reaction chamber. The reaction chamber defines a reaction space in which a semiconductor substrate is disposed for processing. The exhaust assembly is operatively connected to the reaction chamber for withdrawing unreacted process gases and effluent from the reaction space.

Owner:ASM IP HLDG BV

Method For Depositing an Amorphous Carbon Film with Improved Density and Step Coverage

ActiveUS20080003824A1High densityLower thermal budgetPretreated surfacesSemiconductor/solid-state device manufacturingCarbon layerKrypton

A method for depositing an amorphous carbon layer on a substrate includes the steps of positioning a substrate in a chamber, introducing a hydrocarbon source into the processing chamber, introducing a heavy noble gas into the processing chamber, and generating a plasma in the processing chamber. The heavy noble gas is selected from the group consisting of argon, krypton, xenon, and combinations thereof and the molar flow rate of the noble gas is greater than the molar flow rate of the hydrocarbon source. A post-deposition termination step may be included, wherein the flow of the hydrocarbon source and the noble gas is stopped and a plasma is maintained in the chamber for a period of time to remove particles therefrom.

Owner:APPLIED MATERIALS INC

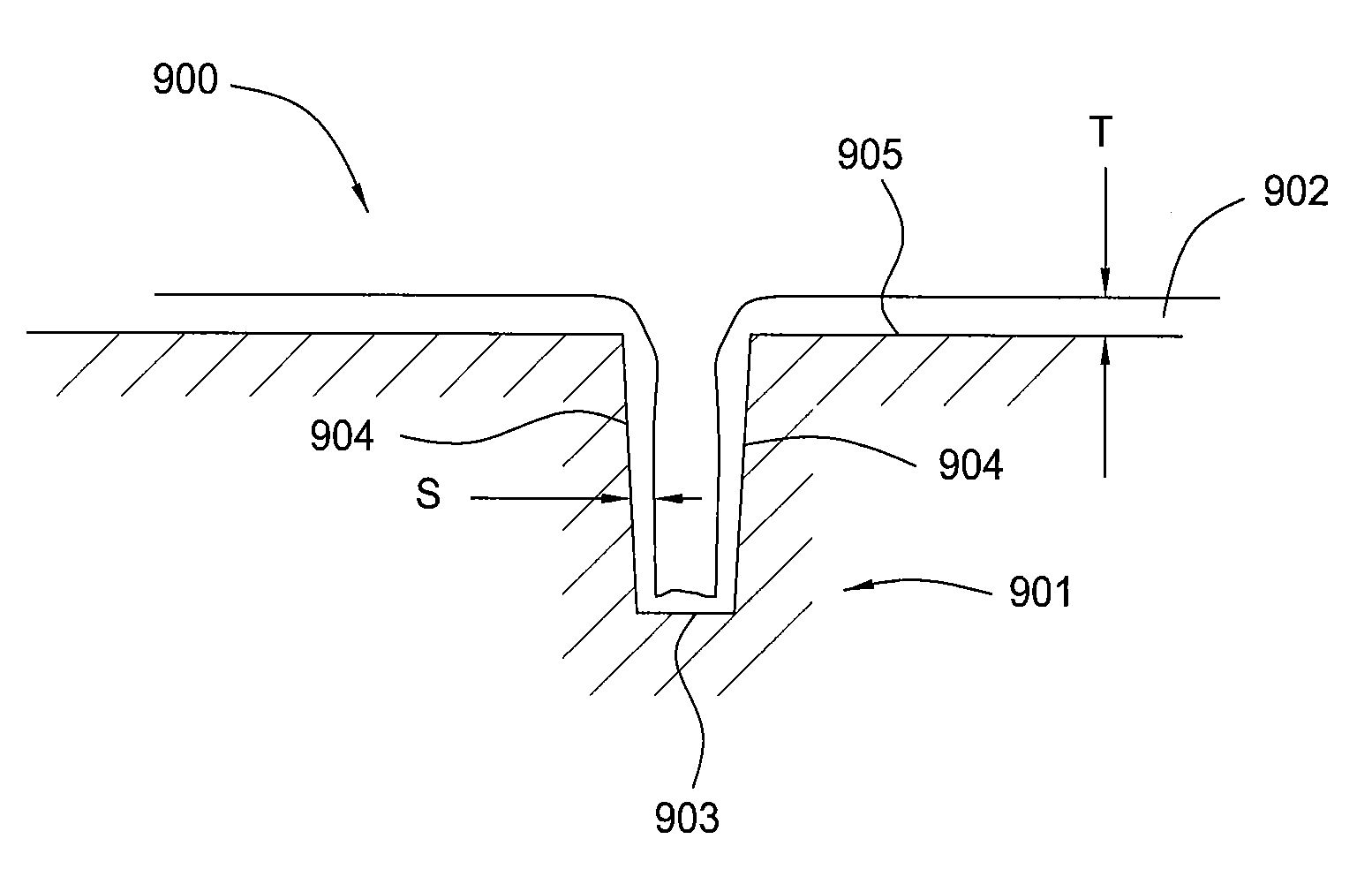

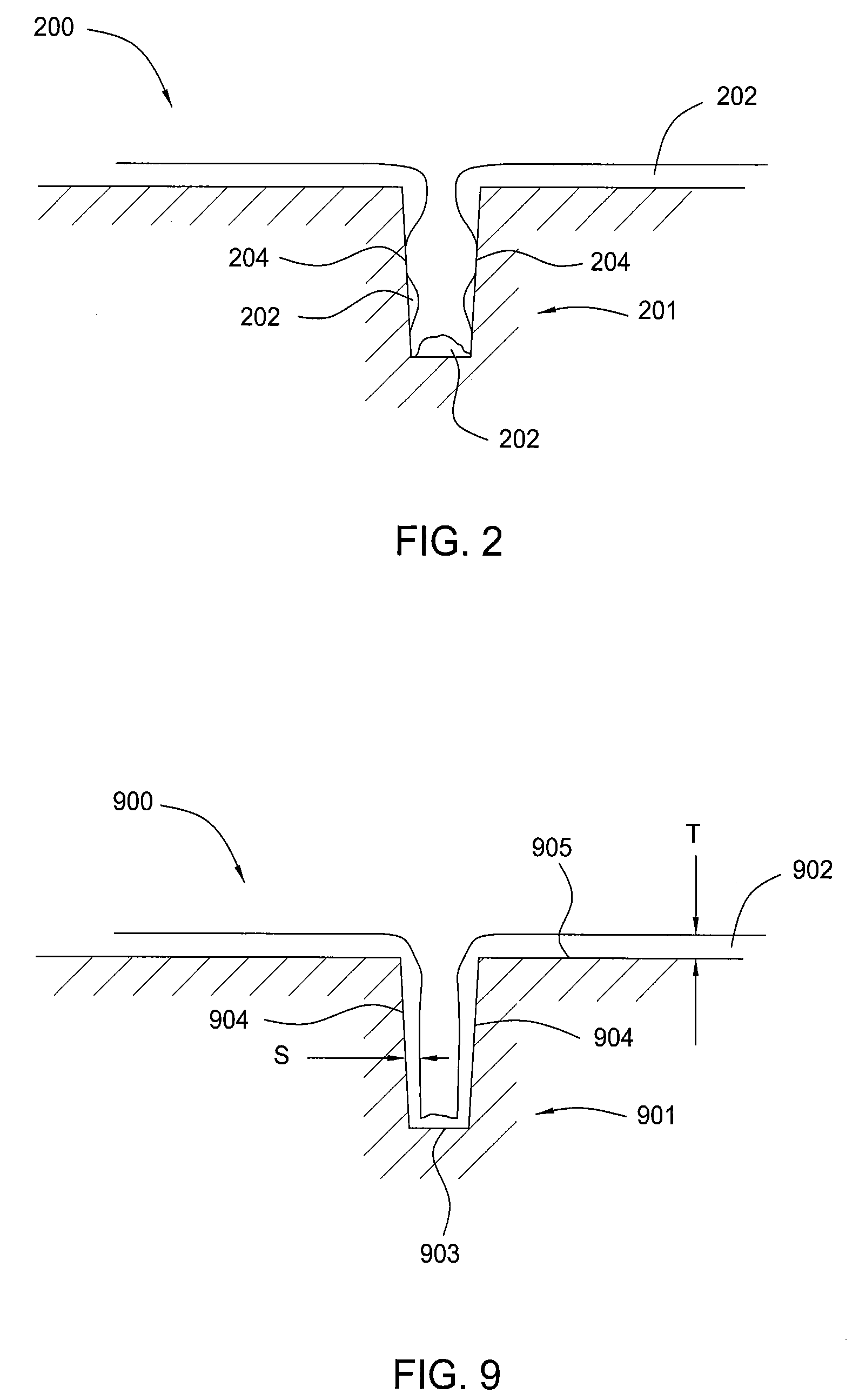

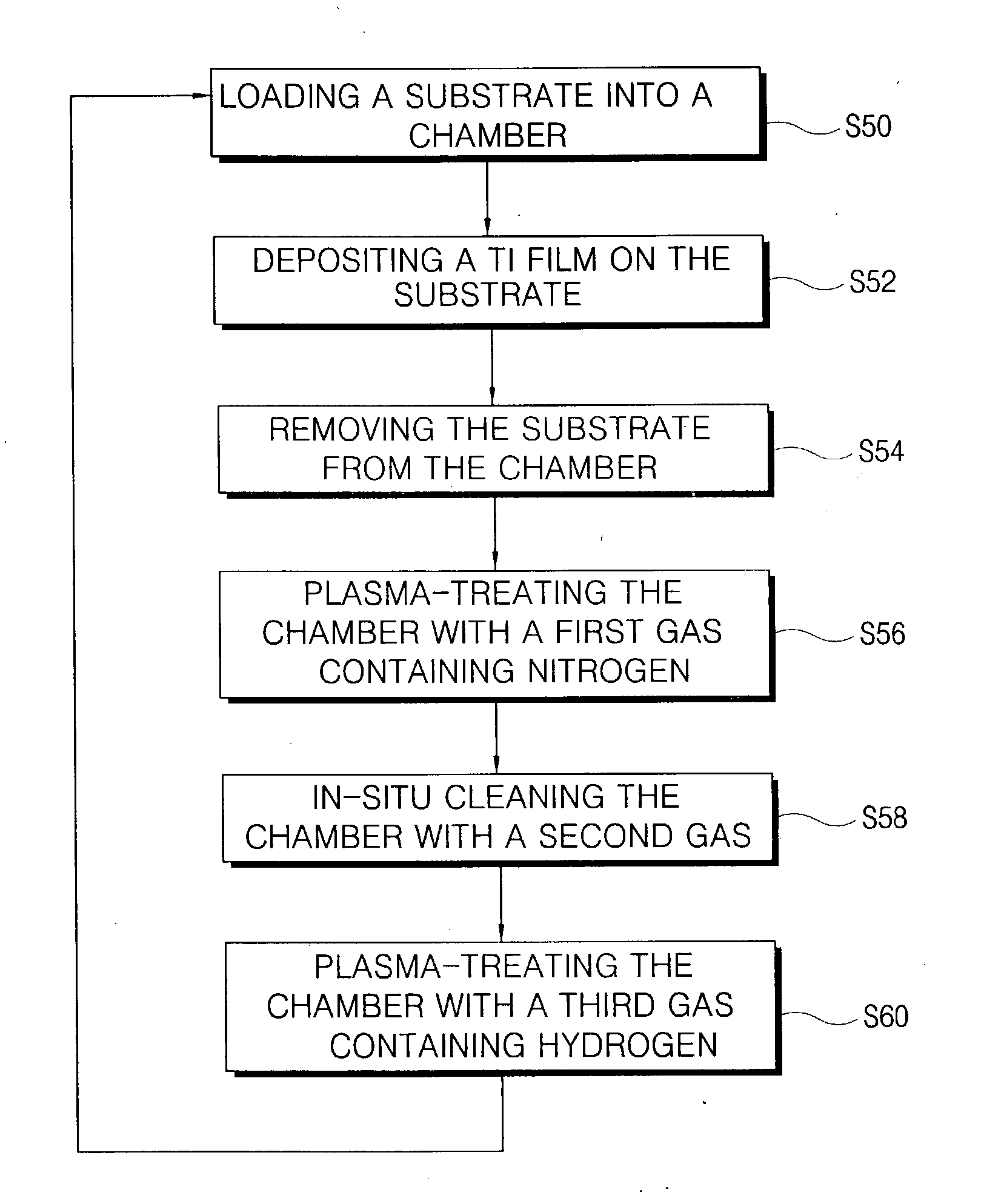

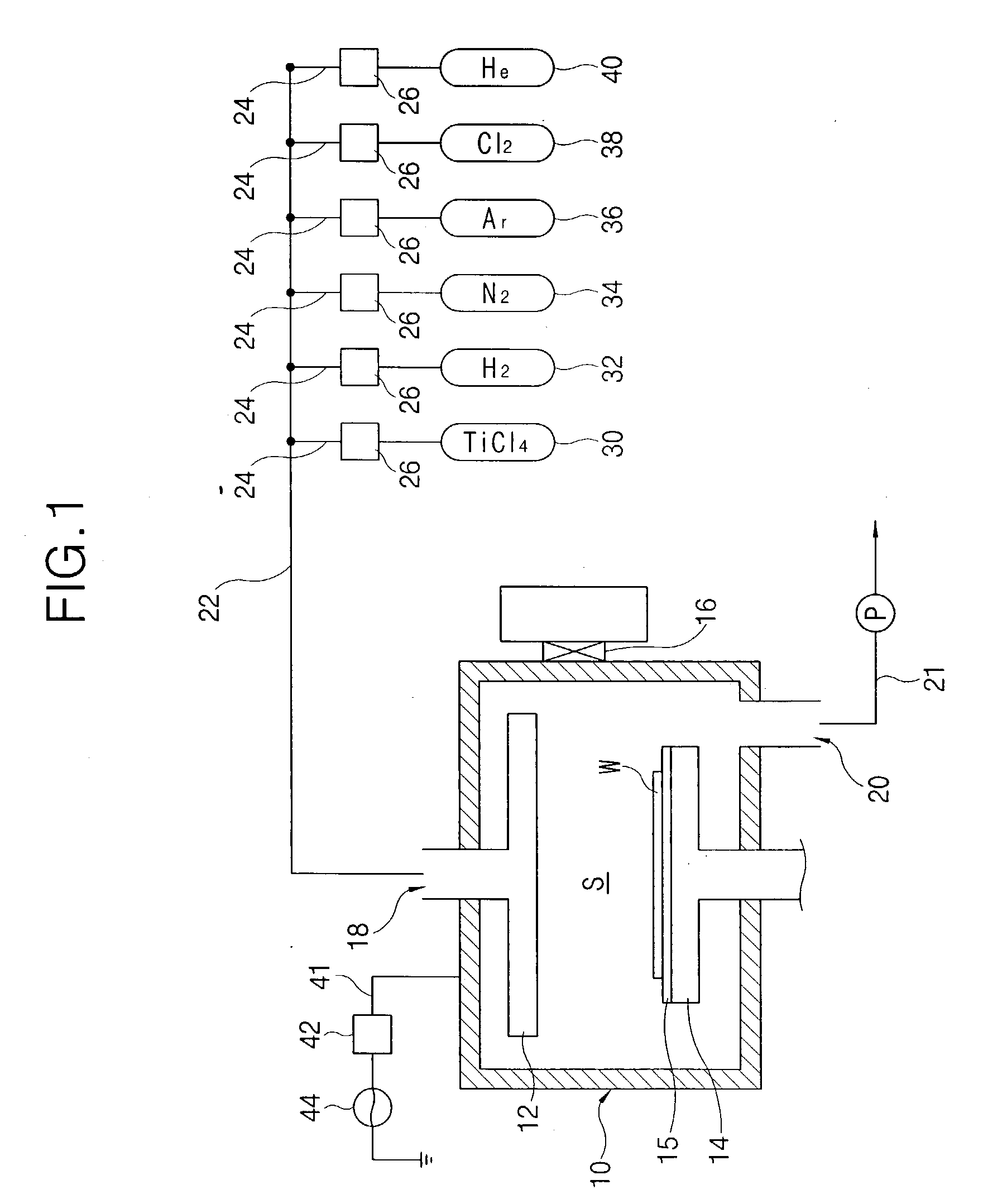

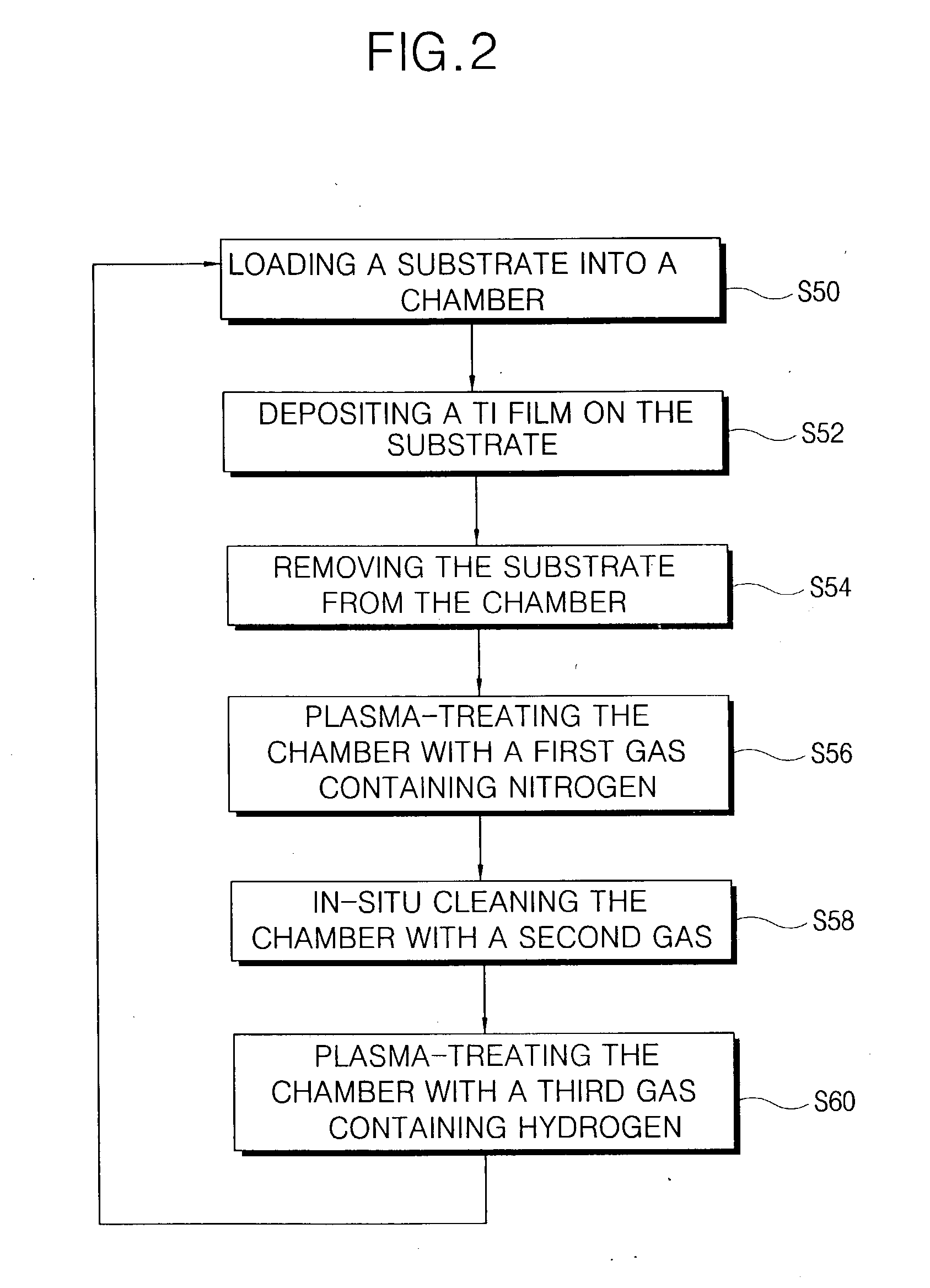

Method of cleaning a chemical vapor deposition chamber

InactiveUS20040013818A1Reduce the amount requiredIncrease resistanceHollow article cleaningElectrostatic cleaningHydrogenNitrogen

After a processing chamber is used to deposit a refractory metal film on a substrate, the chamber is plasma-treated with a gas including either nitrogen and / or hydrogen and in-situ cleaned. By plasma-treating the chamber with a gas including nitrogen, the refractory metal film that forms on interior surfaces of the chamber during substrate processing is nitrided. The nitrided refractory metal film can be removed from the chamber during the in-situ cleaning. By plasma-treating the chamber with a gas including hydrogen, reaction by-products generated in the chamber is diluted and removed. The chamber may be plasma-treated in a gas ambient including both nitrogen and hydrogen. Also, the plasma treatment may be performed before and after the in-situ cleaning.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for Polycrystalline film silicon growth

InactiveUS6281098B1Widely distributedQuality improvementPolycrystalline material growthLiquid surface applicatorsVapor barrierProduct gas

A process for depositing polycrystalline silicon on substrates, including foreign substrates, occurs in a chamber at about atmospheric pressure, wherein a temperature gradient is formed, and both the atmospheric pressure and the temperature gradient are maintained throughout the process. Formation of a vapor barrier within the chamber that precludes exit of the constituent chemicals, which include silicon, iodine, silicon diiodide, and silicon tetraiodide. The deposition occurs beneath the vapor barrier. One embodiment of the process also includes the use of a blanketing gas that precludes the entrance of oxygen or other impurities. The process is capable of repetition without the need to reset the deposition zone conditions.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

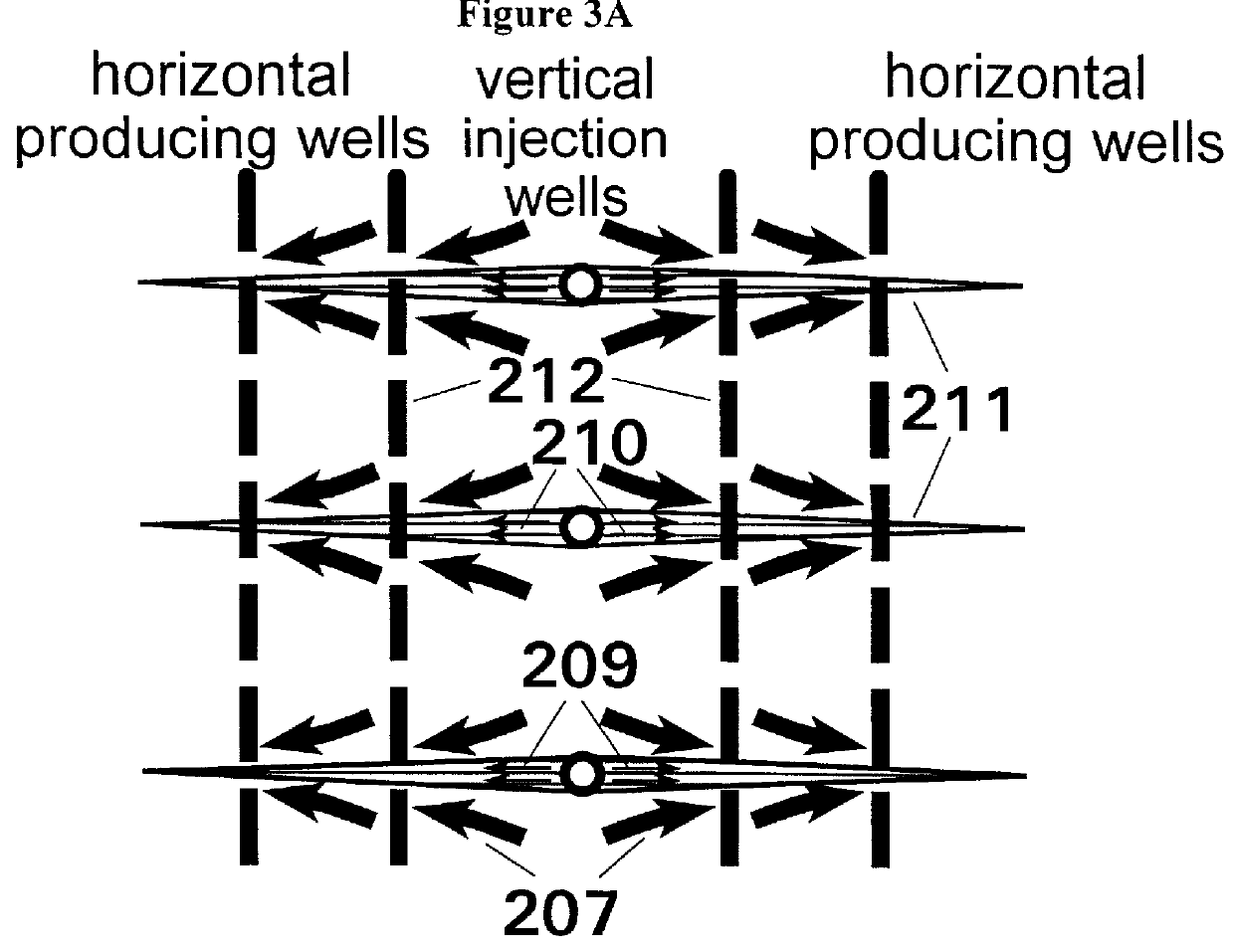

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com