Metal organic chemical vapor deposition equipment

a technology of metal organic chemical vapor deposition and equipment, which is applied in the direction of chemically reactive gases, coatings, crystal growth processes, etc., can solve the problems of uniform thickness of formed films and is not conventionally possible to improve film formation efficiency, so as to achieve the effect of improving film formation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

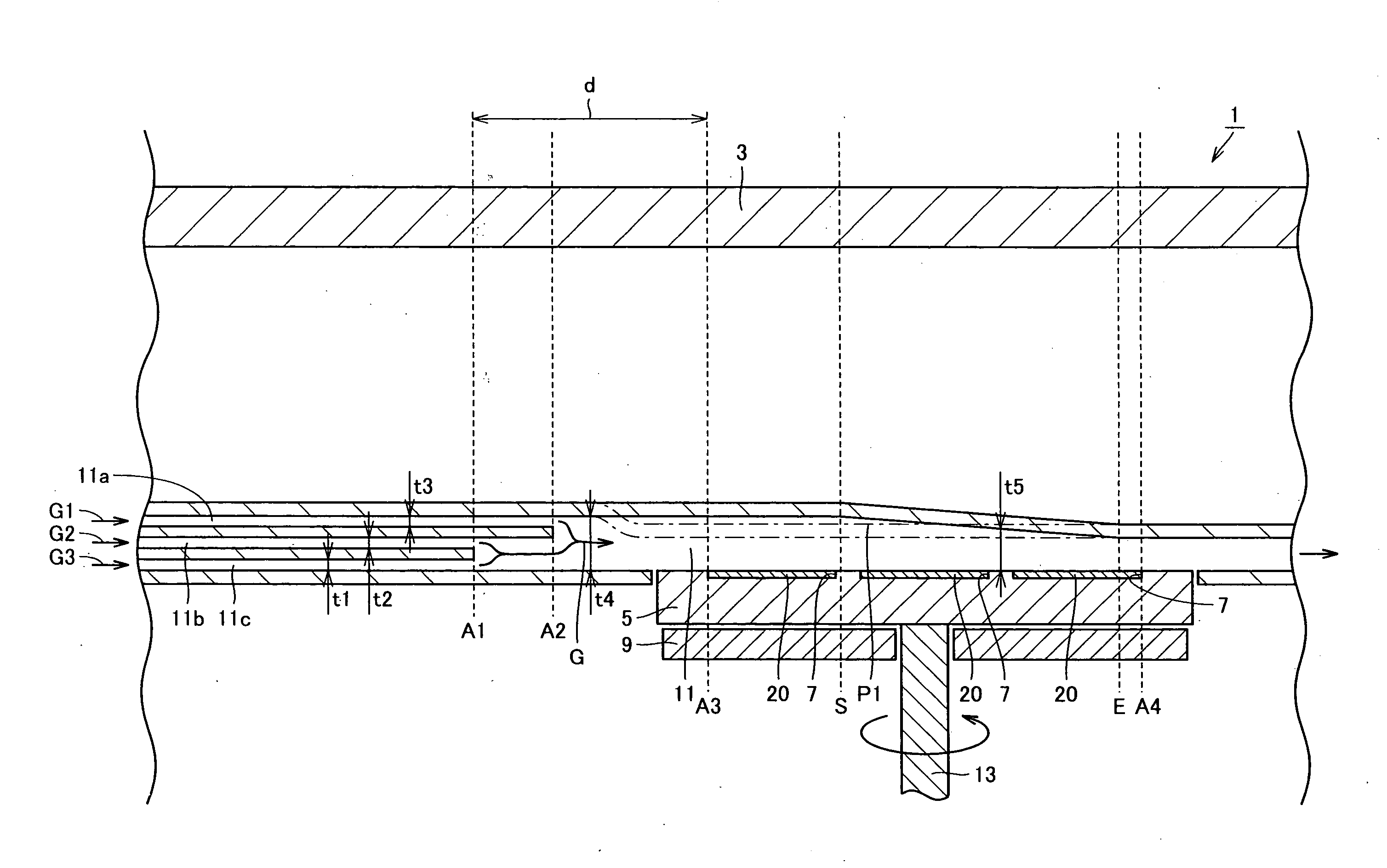

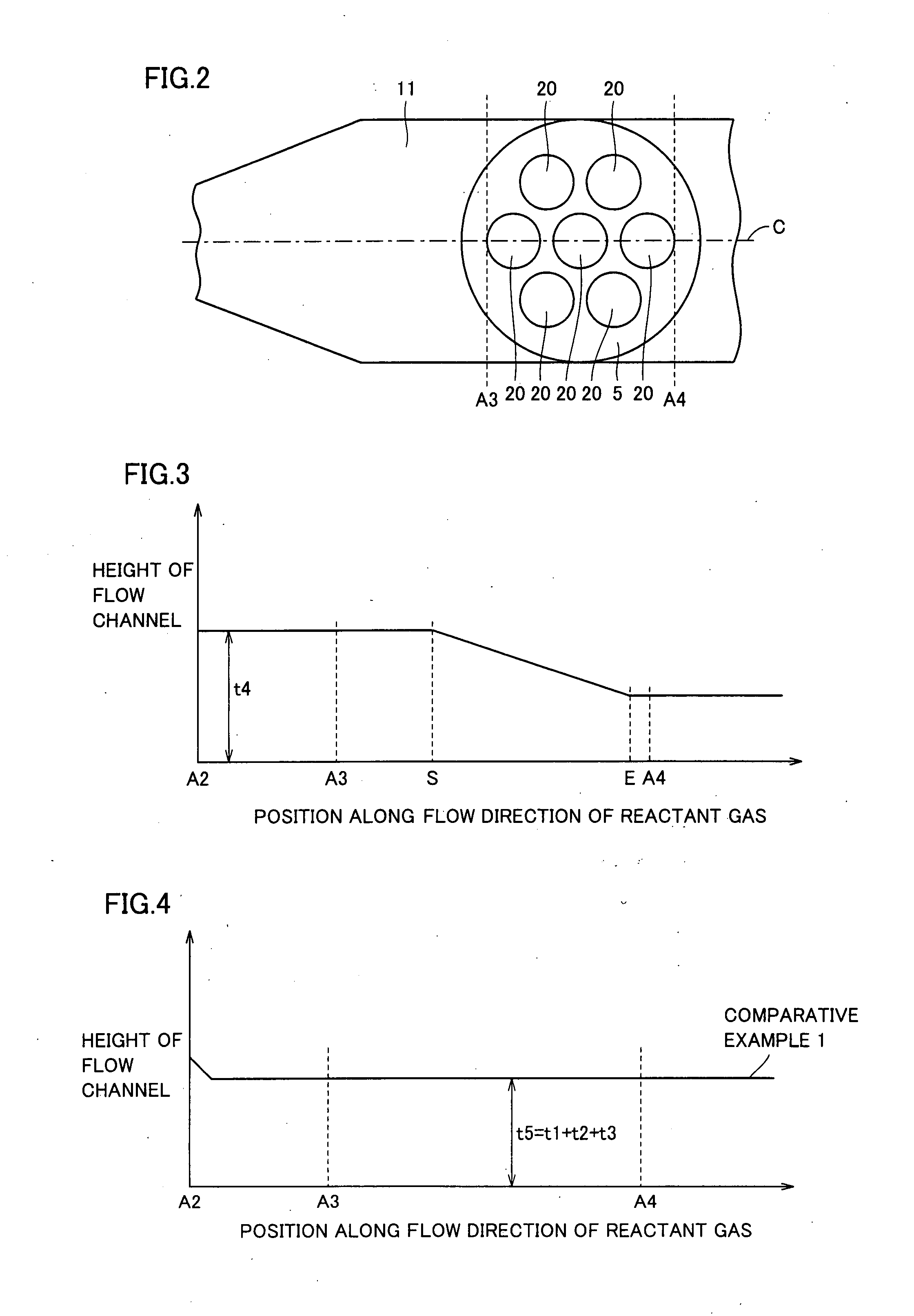

[0040]Referring to FIGS. 1 and 2, MOCVD equipment 1 according to the present embodiment includes a chamber 3, a susceptor 5 serving as a heating component, a heater 9, and a flow channel 11. Susceptor 5, heater 9, and flow channel 11 are placed in chamber 3. Flow channel 11 extends in a transverse direction in FIG. 1. A holding surface (a top surface in FIG. 1) of susceptor 5 faces an inner portion of flow channel 1.

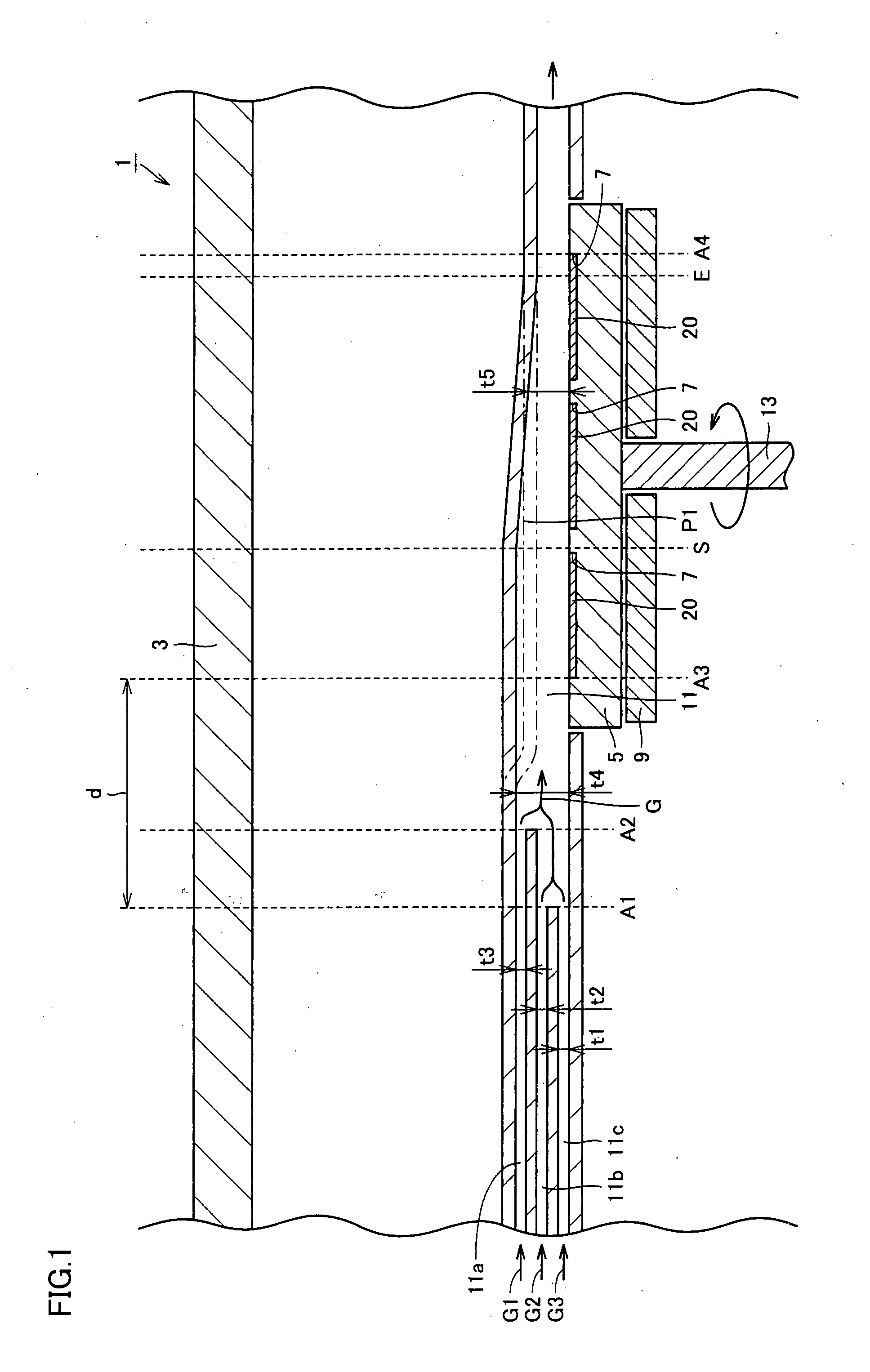

[0041]Susceptor 5, which has a disk shape, is placed on heater 9, which also has a disk shape. A rotary shaft 13 is attached to a lower part of susceptor 5, so that susceptor 5 is rotatable with the holding surface thereof kept facing the inner portion of flow channel 11. A plurality of concave portions 7, each having a circular shape in a plan view, are formed in the holding surface of susceptor 5. Substrates 20 are held in concave portions 7, respectively, and hence substrates 20 are heated. Referring to FIG. 2, in particular, seven concave portions 7 are formed in the...

second embodiment

[0059]Referring to FIGS. 8 and 9, in MOCVD equipment 1 according to the present embodiment, a height of flow channel 11 along the width direction thereof at the holding surface of susceptor 5 is monotonically decreased in a linear manner from each end portion (a height h1) to a central portion (a height h2) of the holding surface of susceptor 5. As shown in FIG. 10, the height of flow channel 11 along the width direction thereof at the holding surface of susceptor 5 may be monotonically decreased in a curved manner from each of the end portions (height h1) to the central portion (height h2) of the holding surface of susceptor 5. This causes an increase in reaction rate of the reactant gas at the central portion of the holding surface of susceptor 5, so that the reaction rate of flow channel 11 in the width direction thereof can be made uniformized.

third embodiment

[0060]Referring to FIG. 11, flow channel 11 according to the present embodiment has a bottleneck portion 30 near position A3. The height of flow channel 11 at bottleneck portion 30 is once decreased, kept constant at its local minimum value, and then increased. In FIG. 11, a top surface of flow channel 11 at bottleneck portion 30 has a convex shape. As shown in FIG. 12, however, a bottom surface of flow channel 11 at bottleneck portion 30 may have a concave shape.

[0061]With the MOCVD equipment according to the present embodiment, it is possible to increase a growth rate on the upstream side of position S and obtain the growth rate as approximately the same as the one at the downstream side of position S. As a result, it is possible to grow a uniform.

[0062]In other words, as also seen from Examples 1 and 2 of the present invention in FIG. 7, there is exhibited a three times or more difference in growth rate at the holding surface between the upstream side and the downstream side. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| reaction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com