Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14283 results about "Crucible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crucible is a ceramic or metal container in which metals or other substances may be melted or subjected to very high temperatures. While crucibles historically were usually made from clay, they can be made from any material that withstands temperatures high enough to melt or otherwise alter its contents.

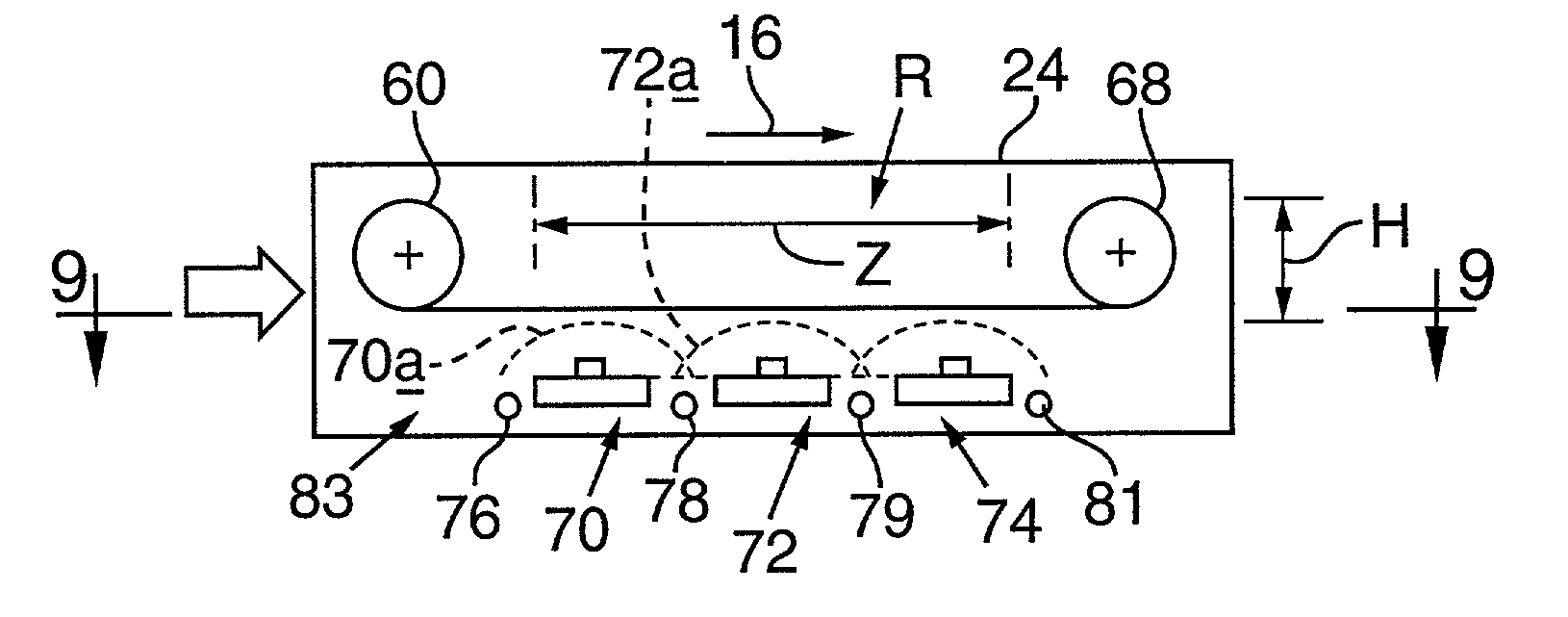

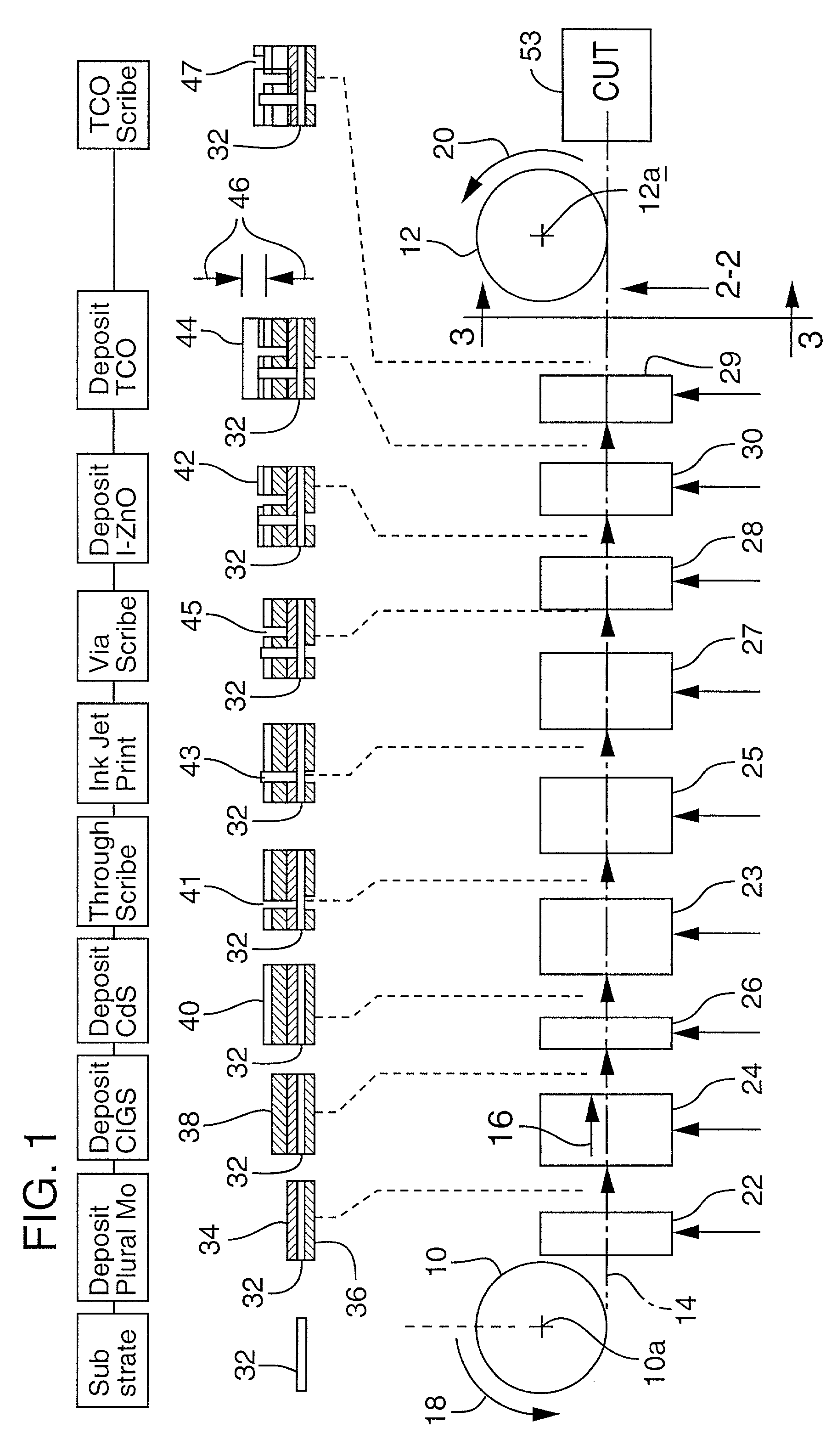

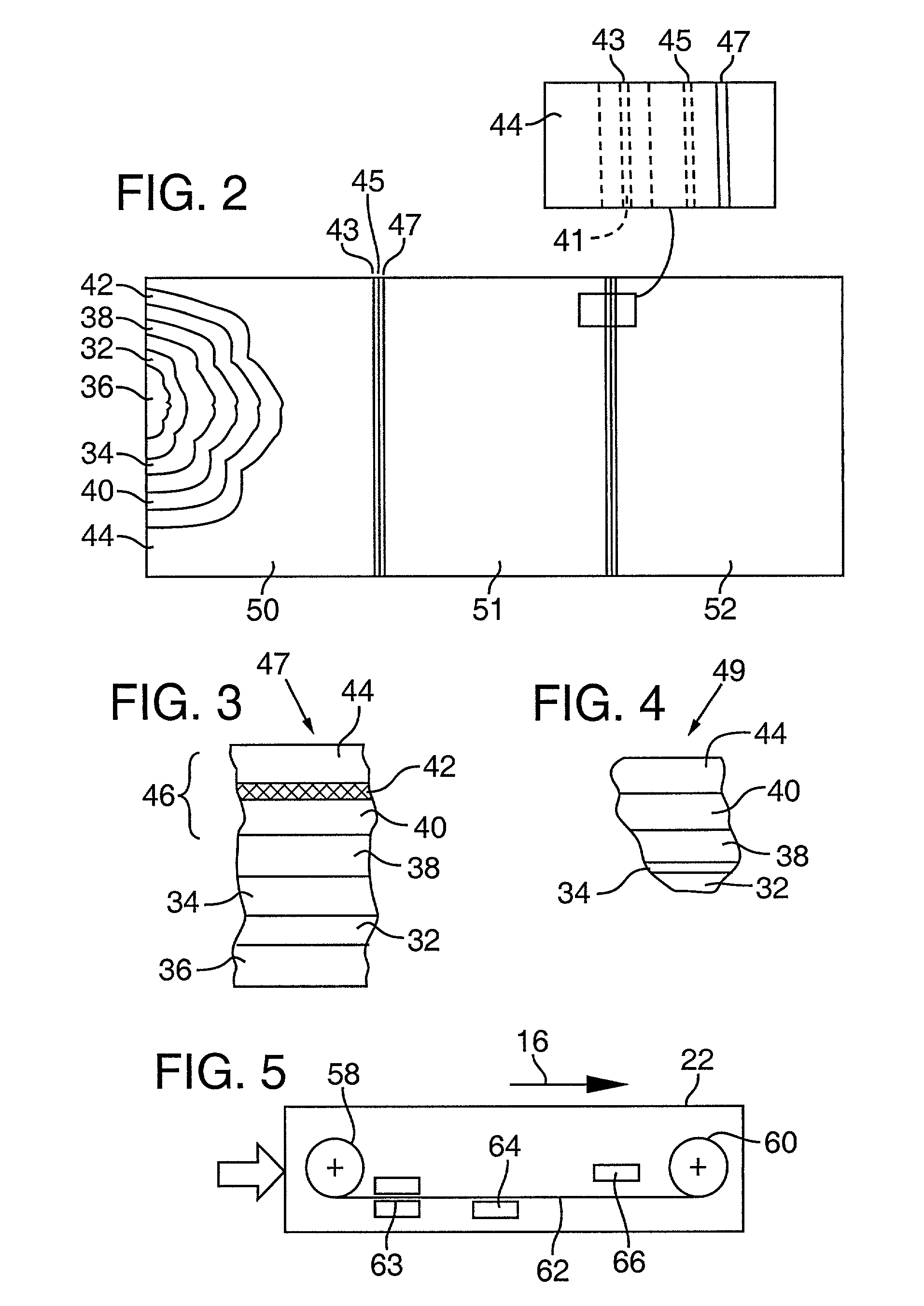

Nozzle-based, vapor-phase, plume delivery structure for use in production of thin-film deposition layer

Owner:UD TECH CORP +2

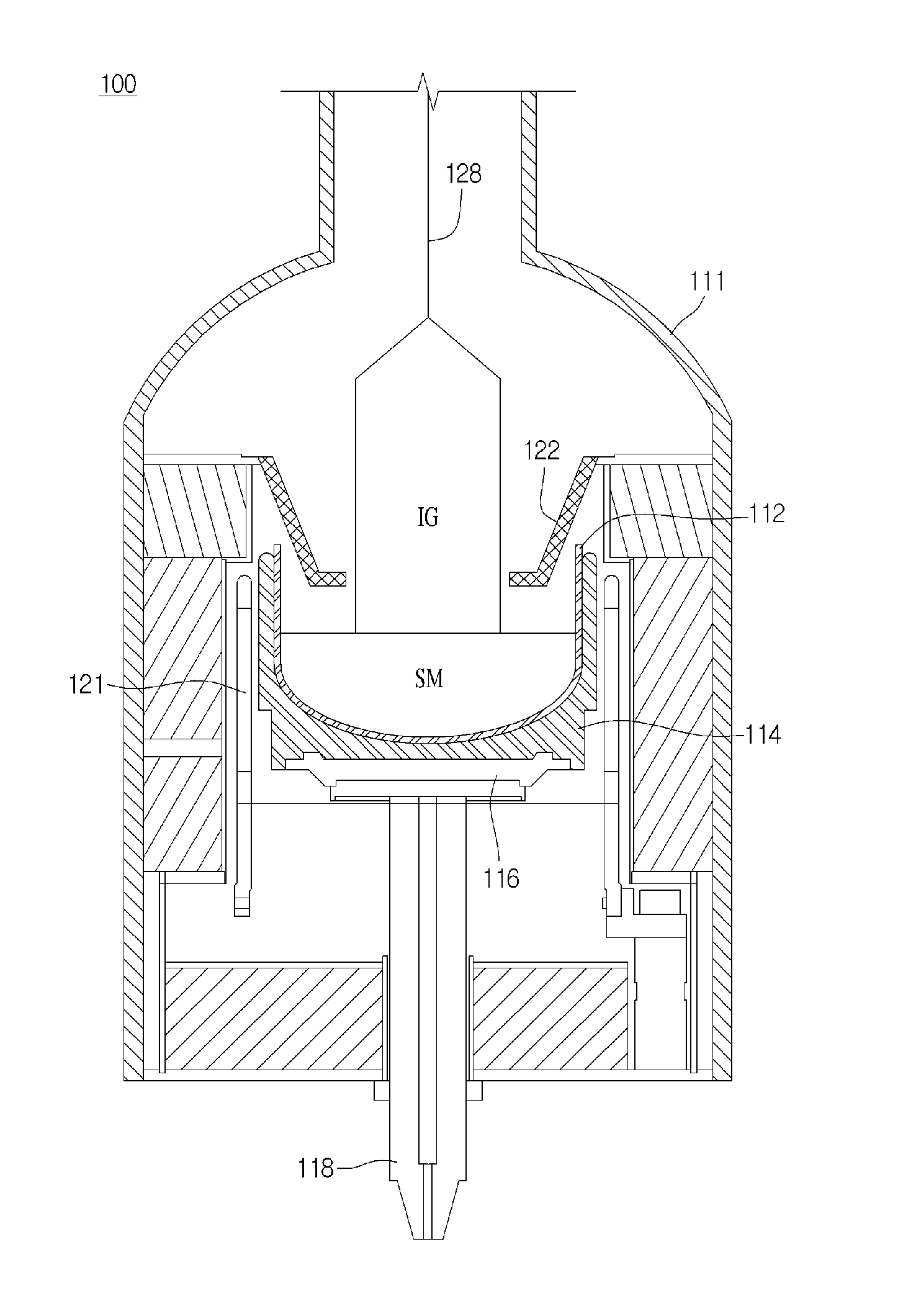

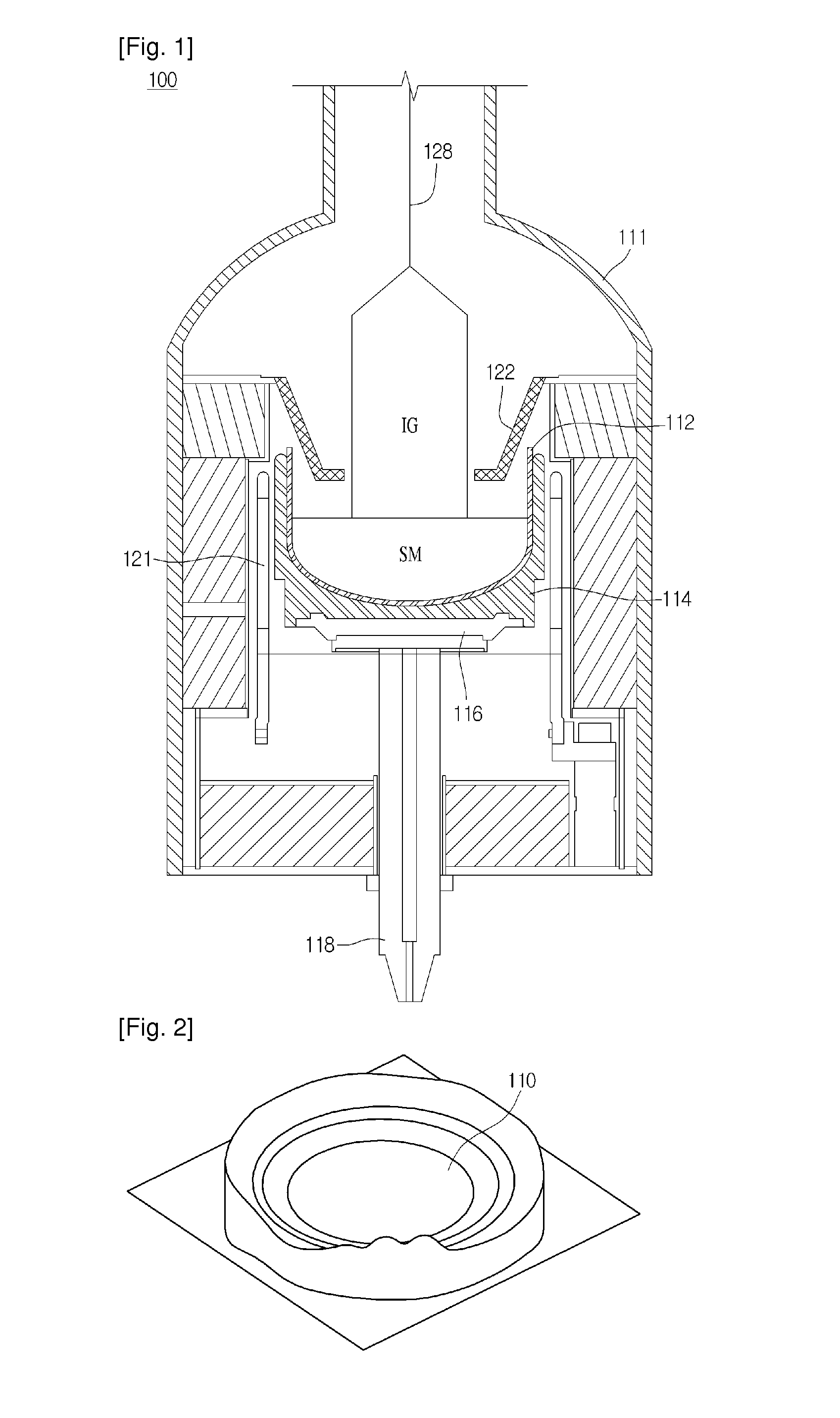

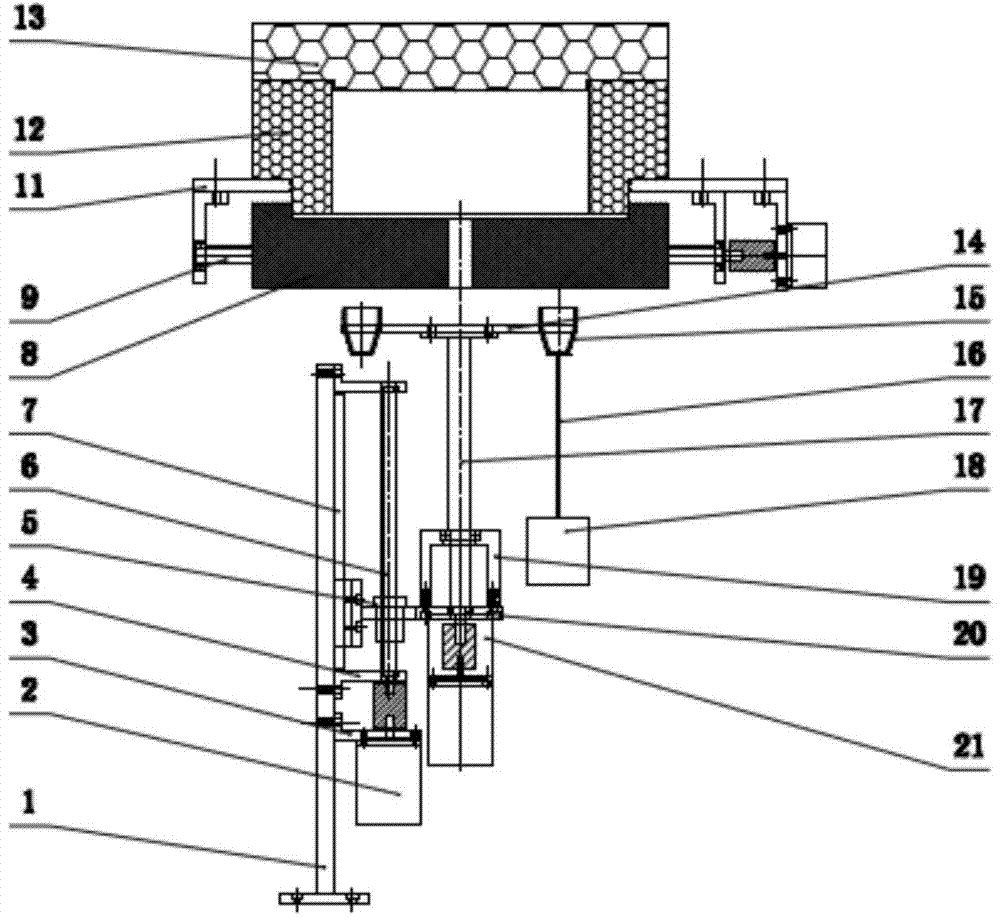

Method of manufacturing single crystal ingot, and single crystal ingot and wafer manufactured thereby

InactiveUS20140015108A1Increase productionPolycrystalline material growthSemiconductor/solid-state device manufacturingCrucibleIngot

A method of manufacturing a single crystal ingot, and a single crystal ingot and a wafer manufactured thereby are provided. The method of manufacturing a single crystal ingot according to an embodiment includes forming a silicon melt in a crucible inside a chamber, preparing a seed crystal on the silicon melt, and growing a single crystal ingot from the silicon melt, and pressure of the chamber may be controlled in a range of 90 Torr to 500 Torr.

Owner:LG SILTRON

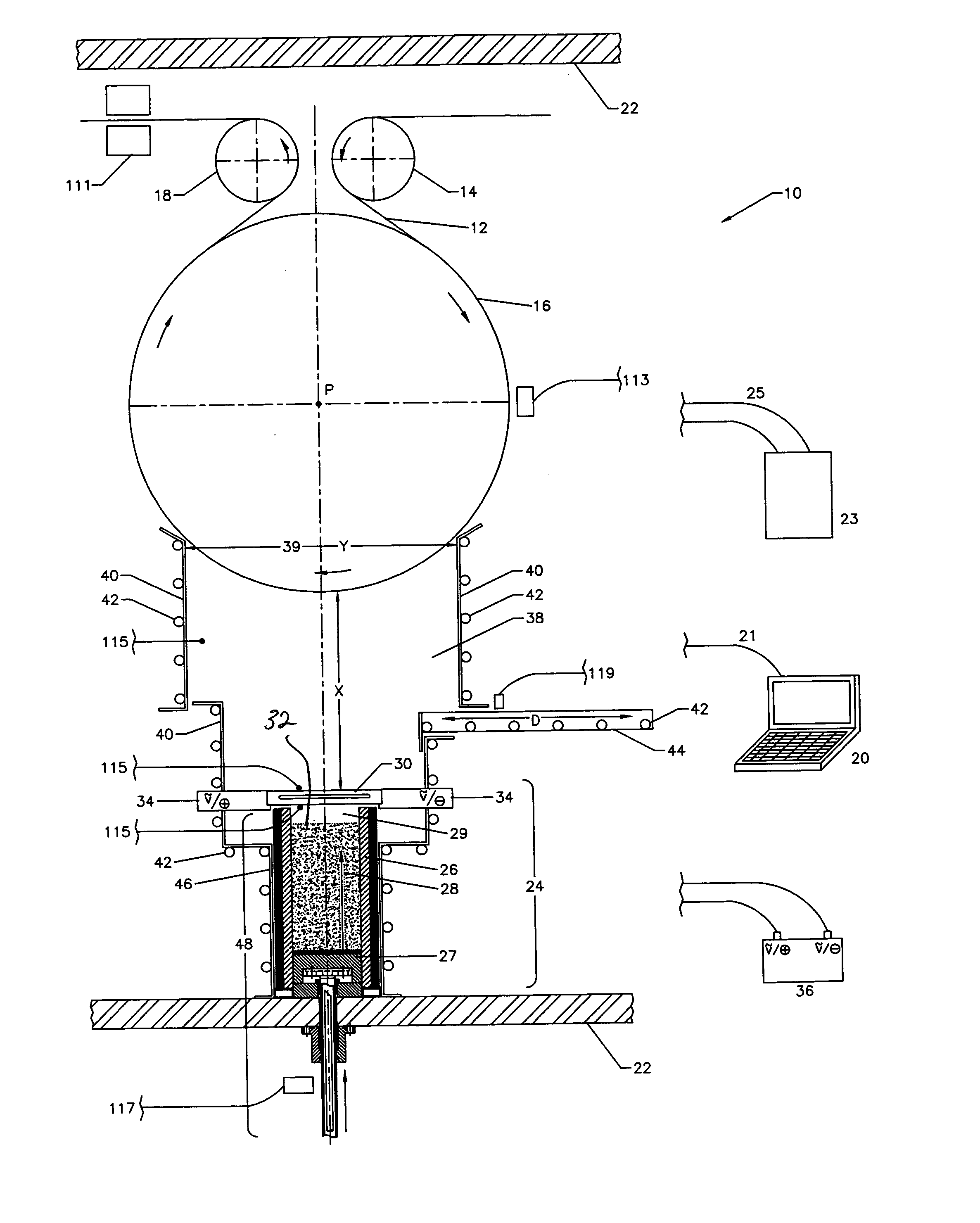

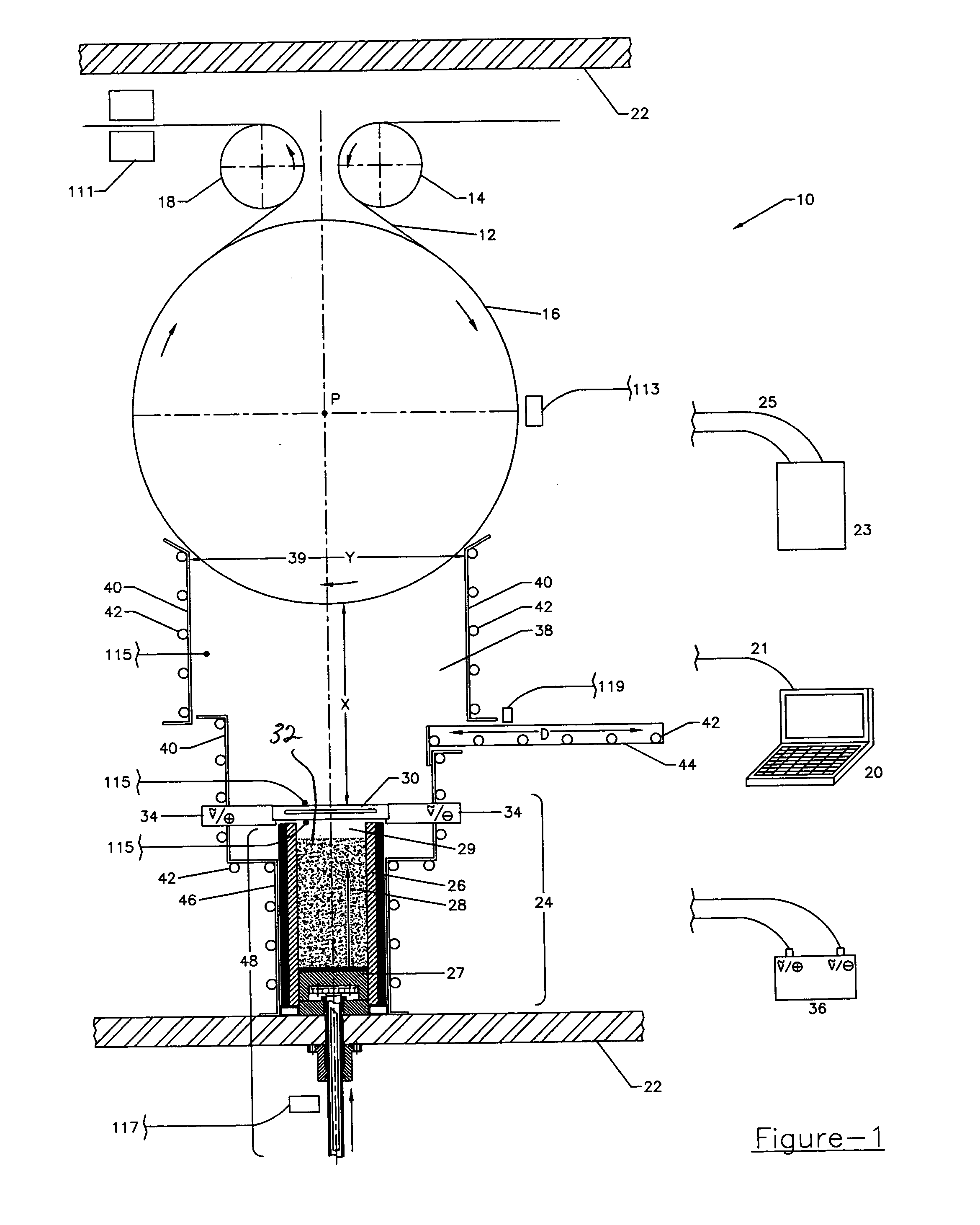

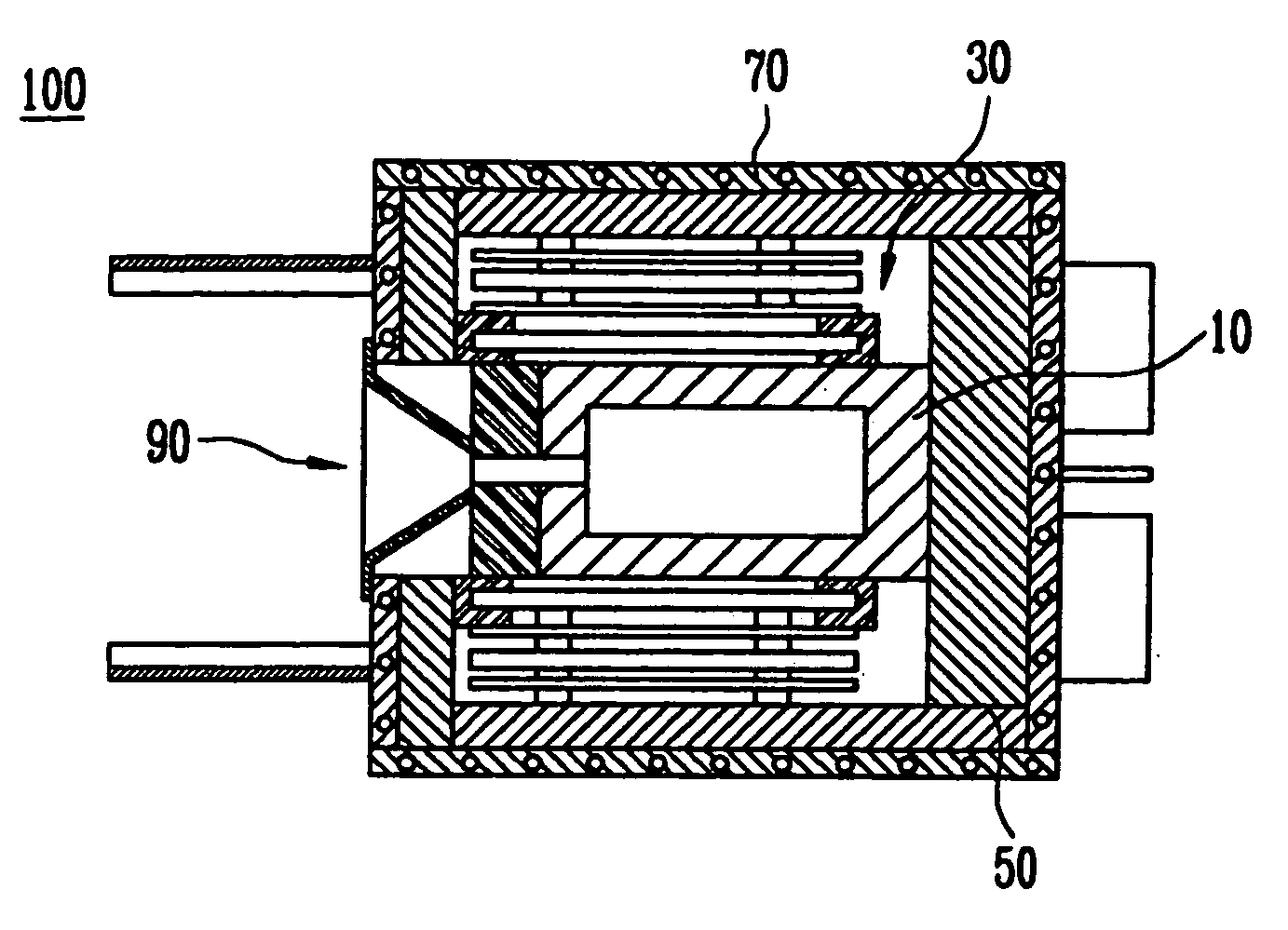

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

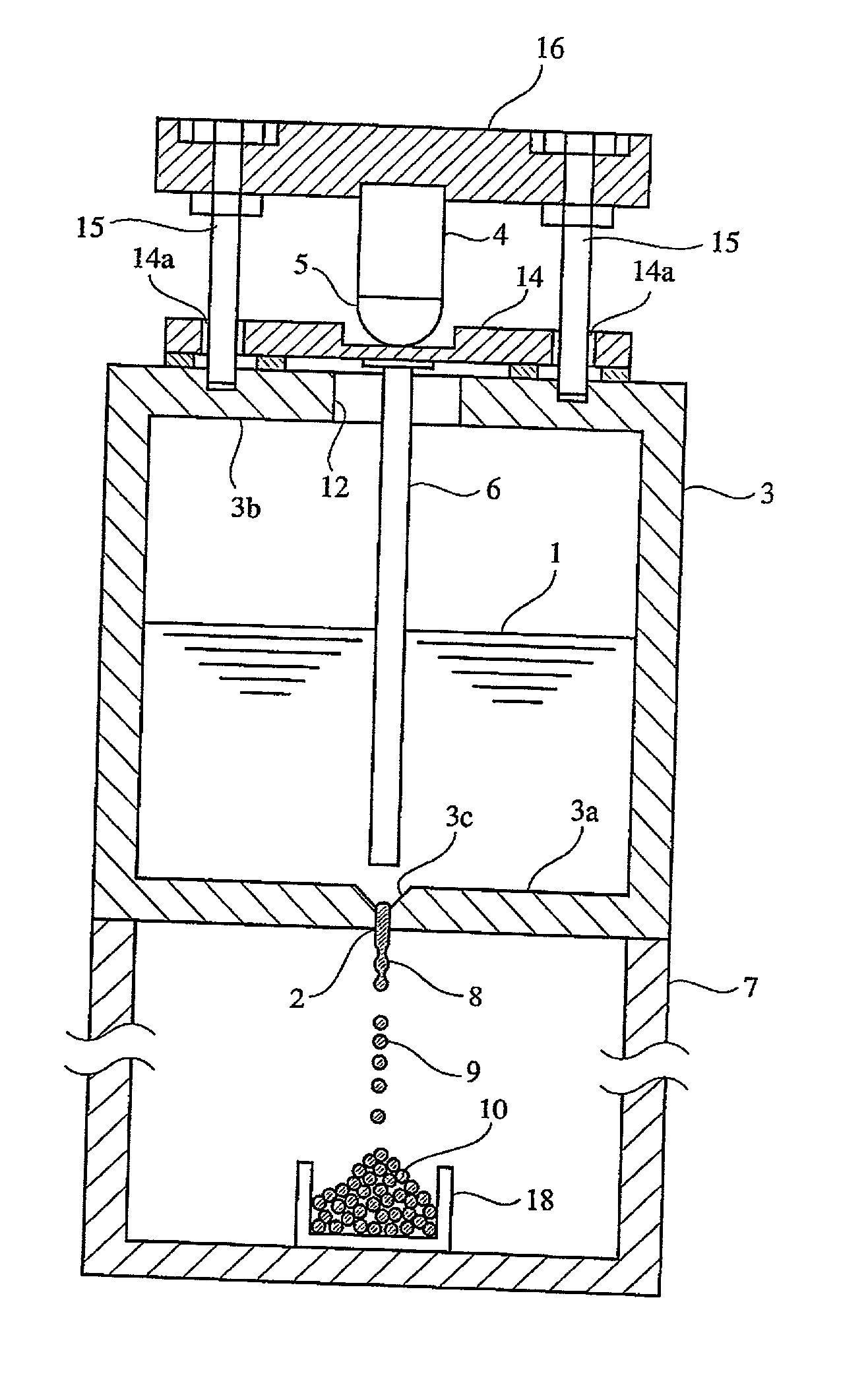

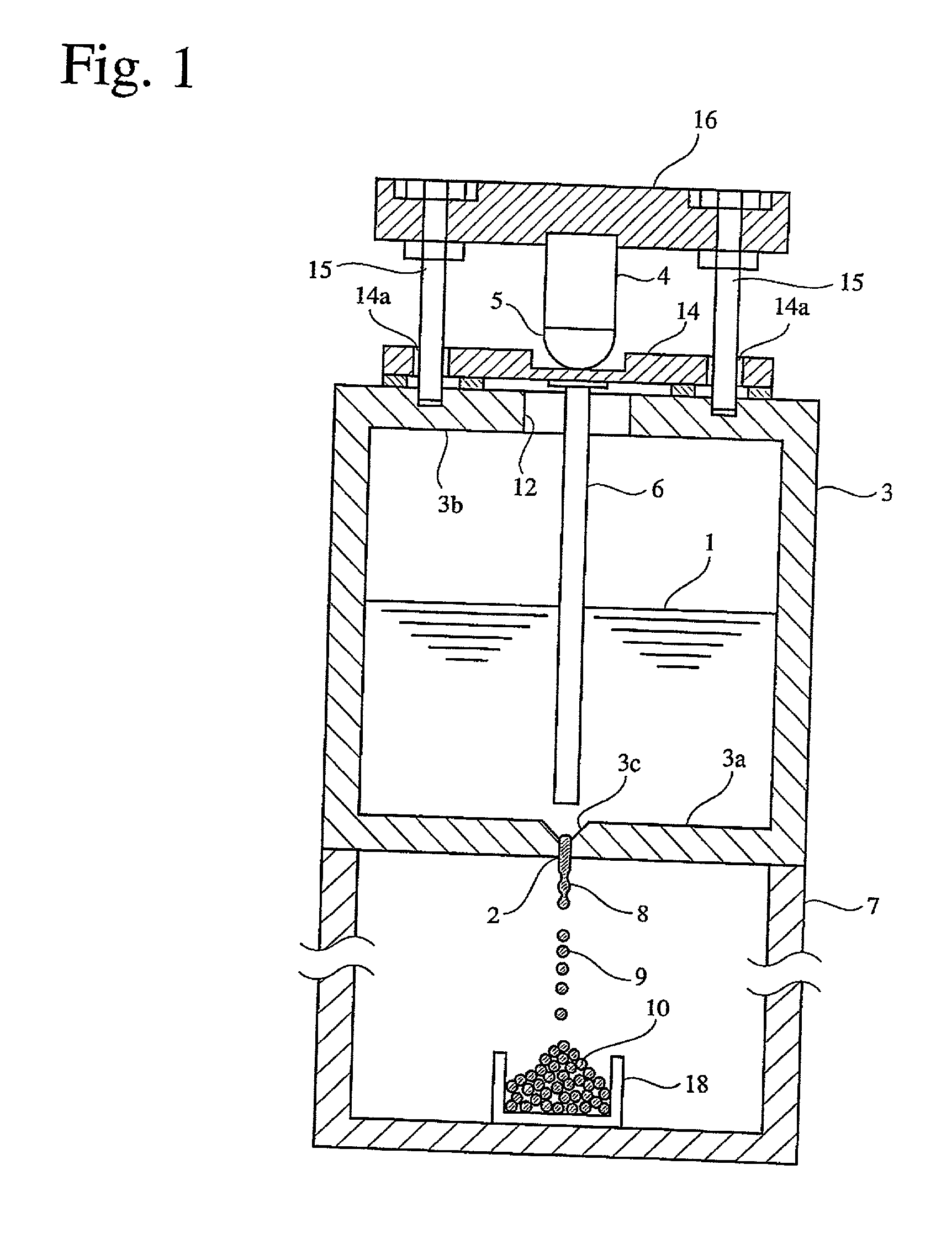

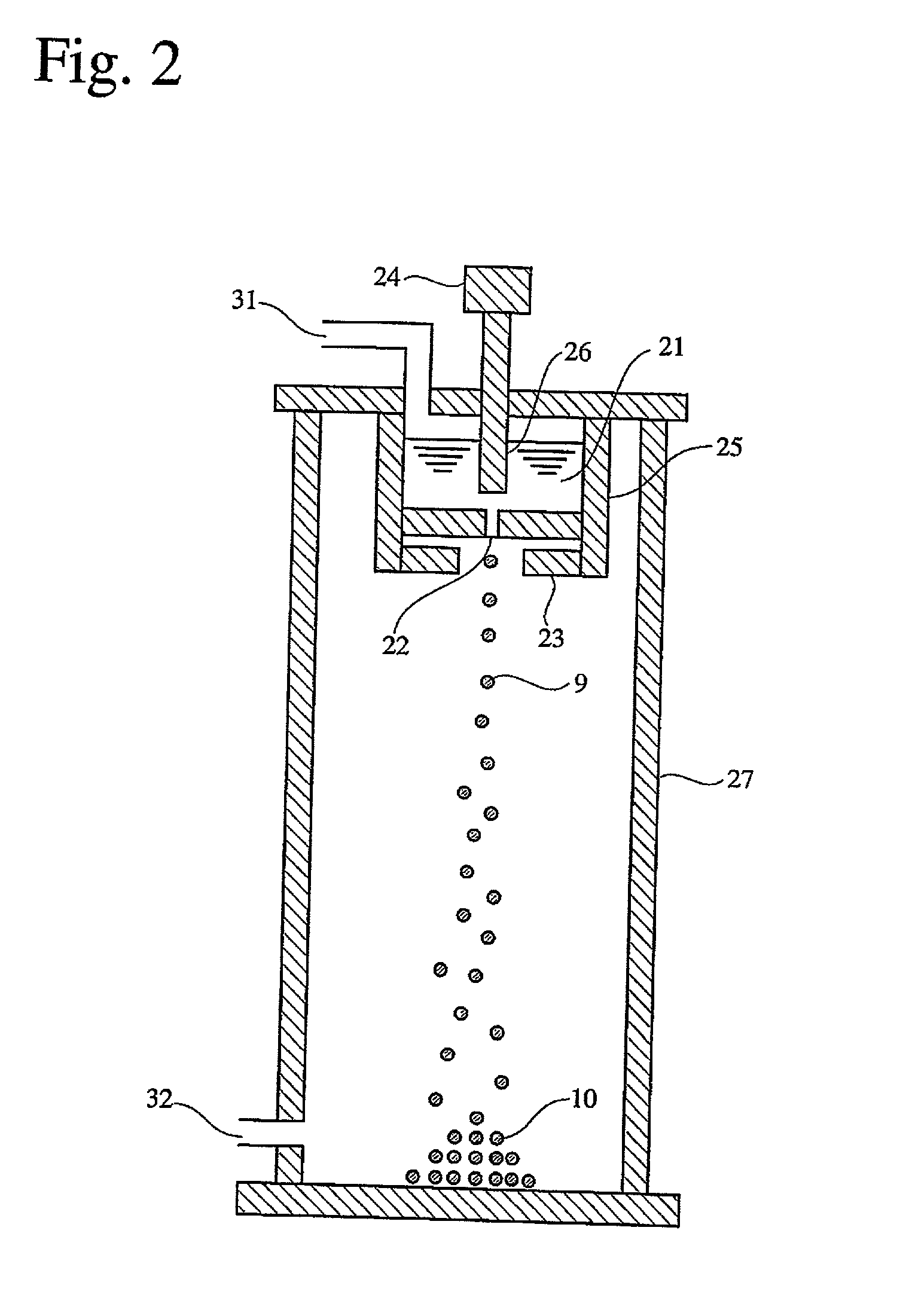

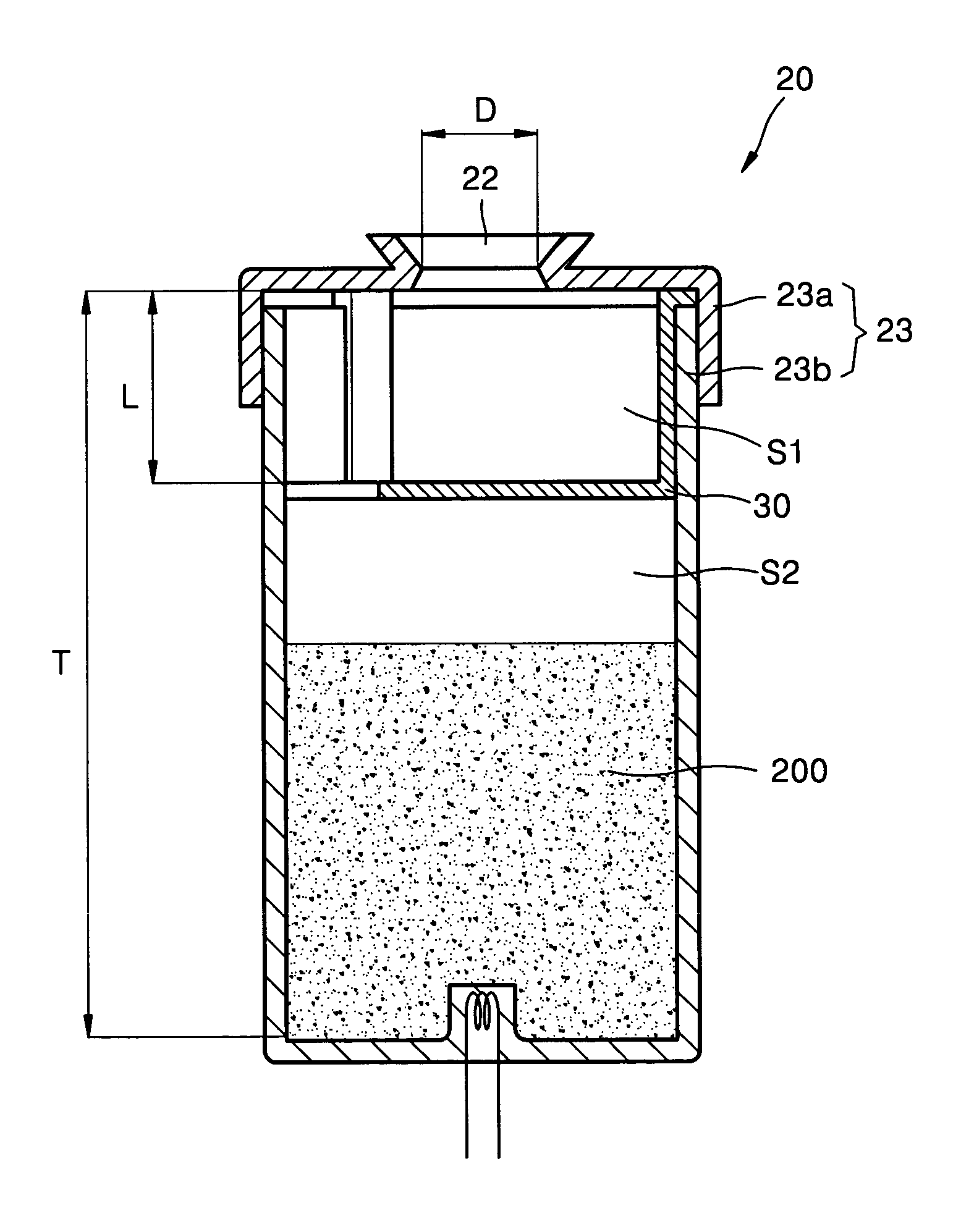

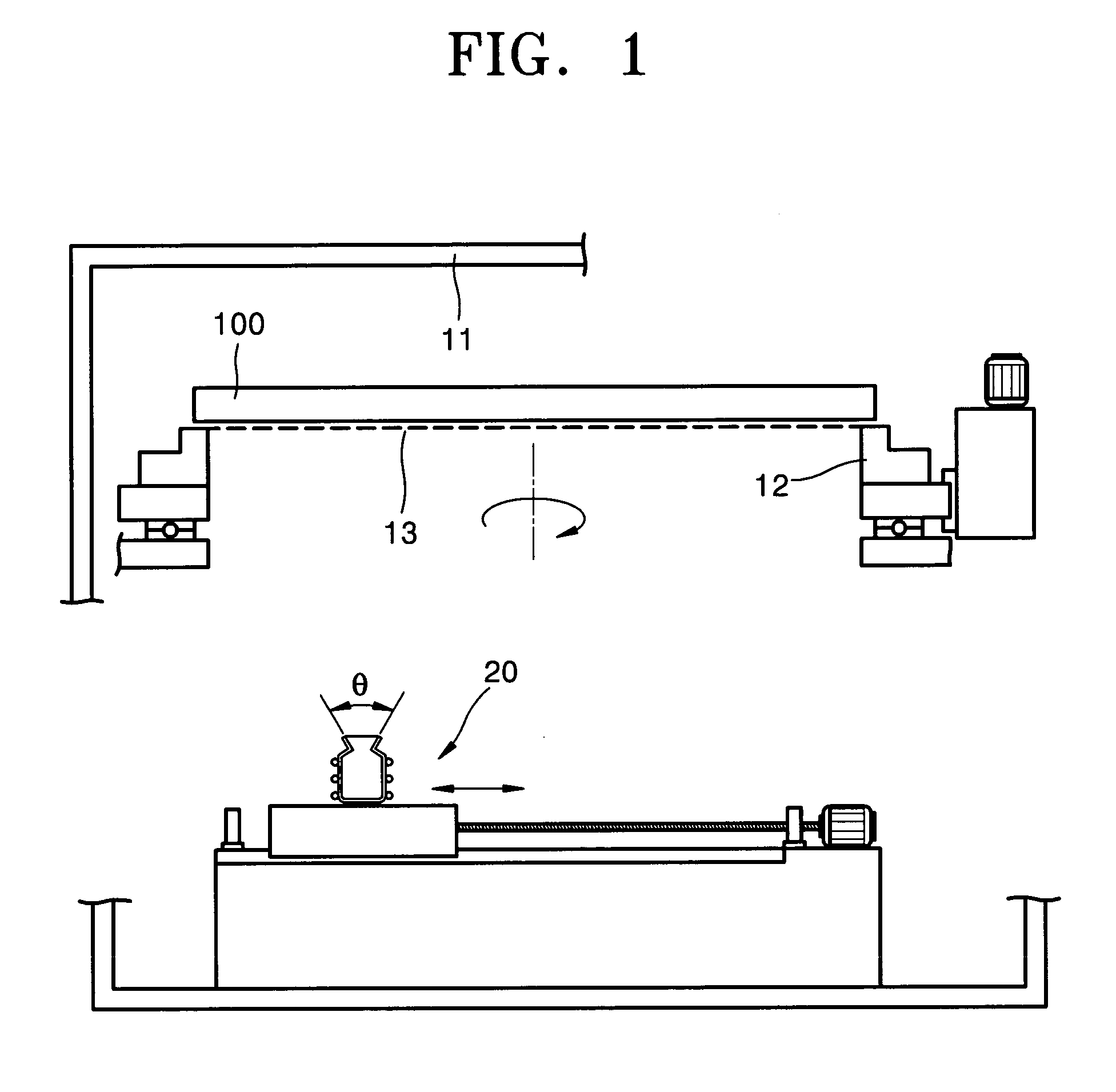

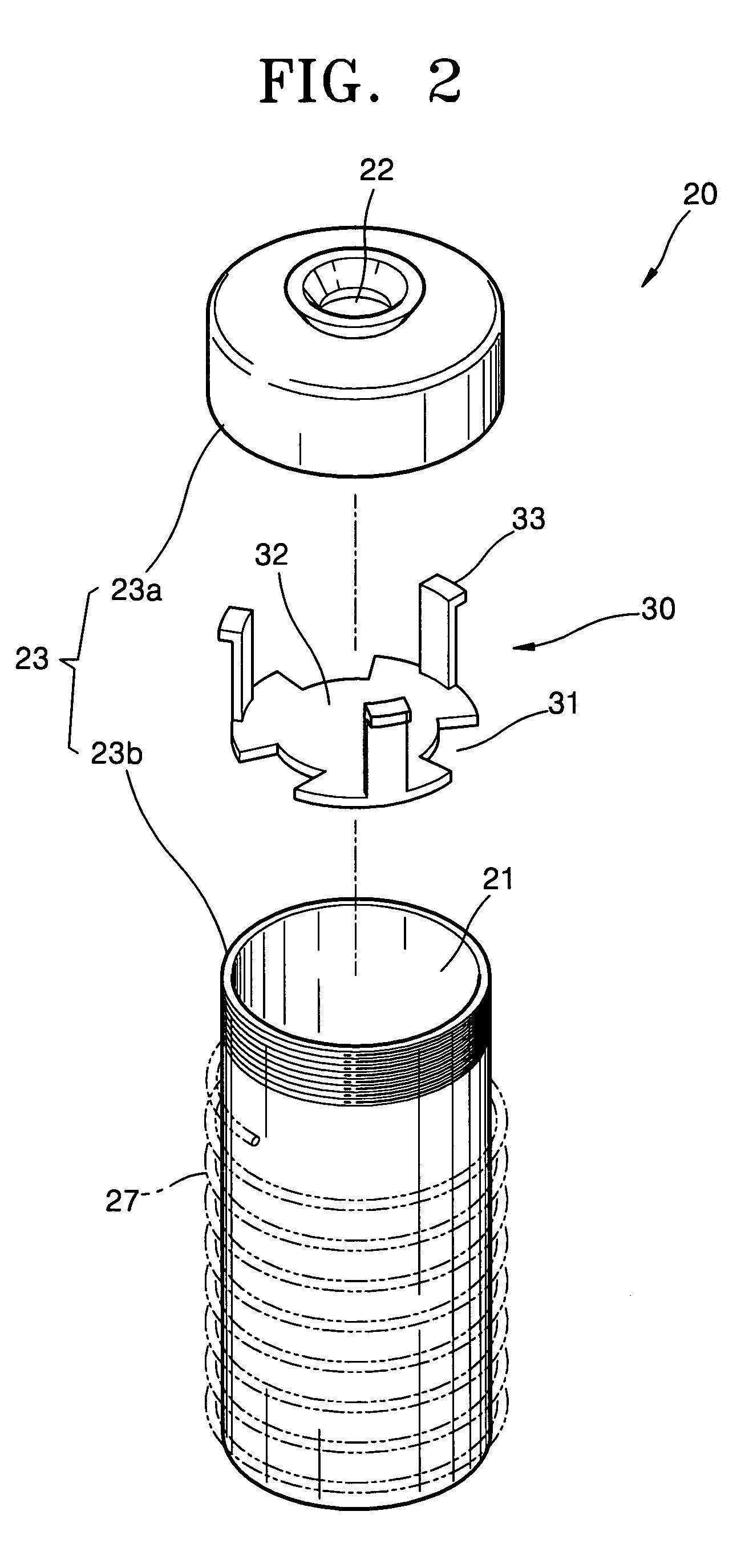

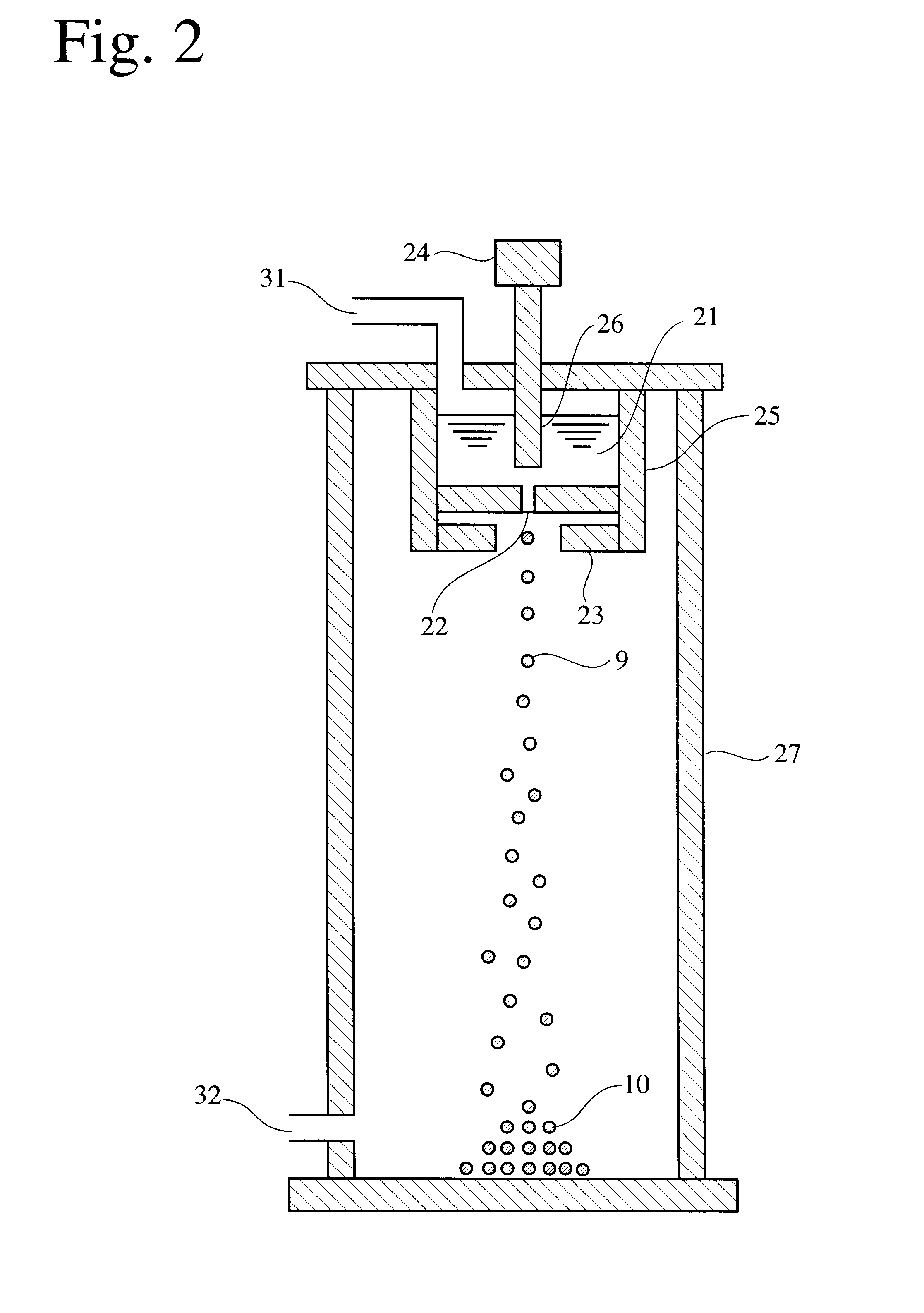

Solder ball and method for producing same

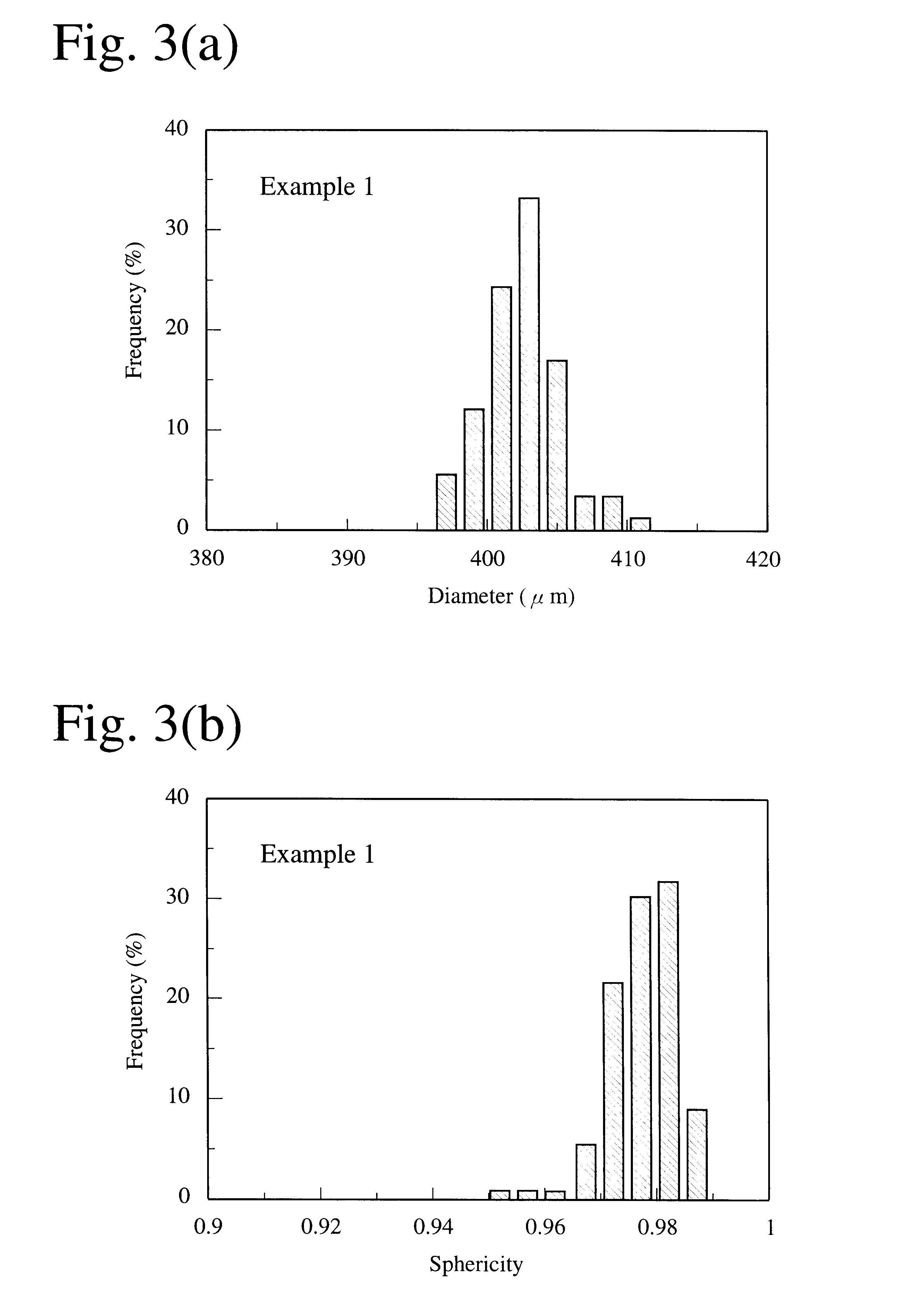

InactiveUS20020051728A1High degree of sphericityNarrow dimension distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

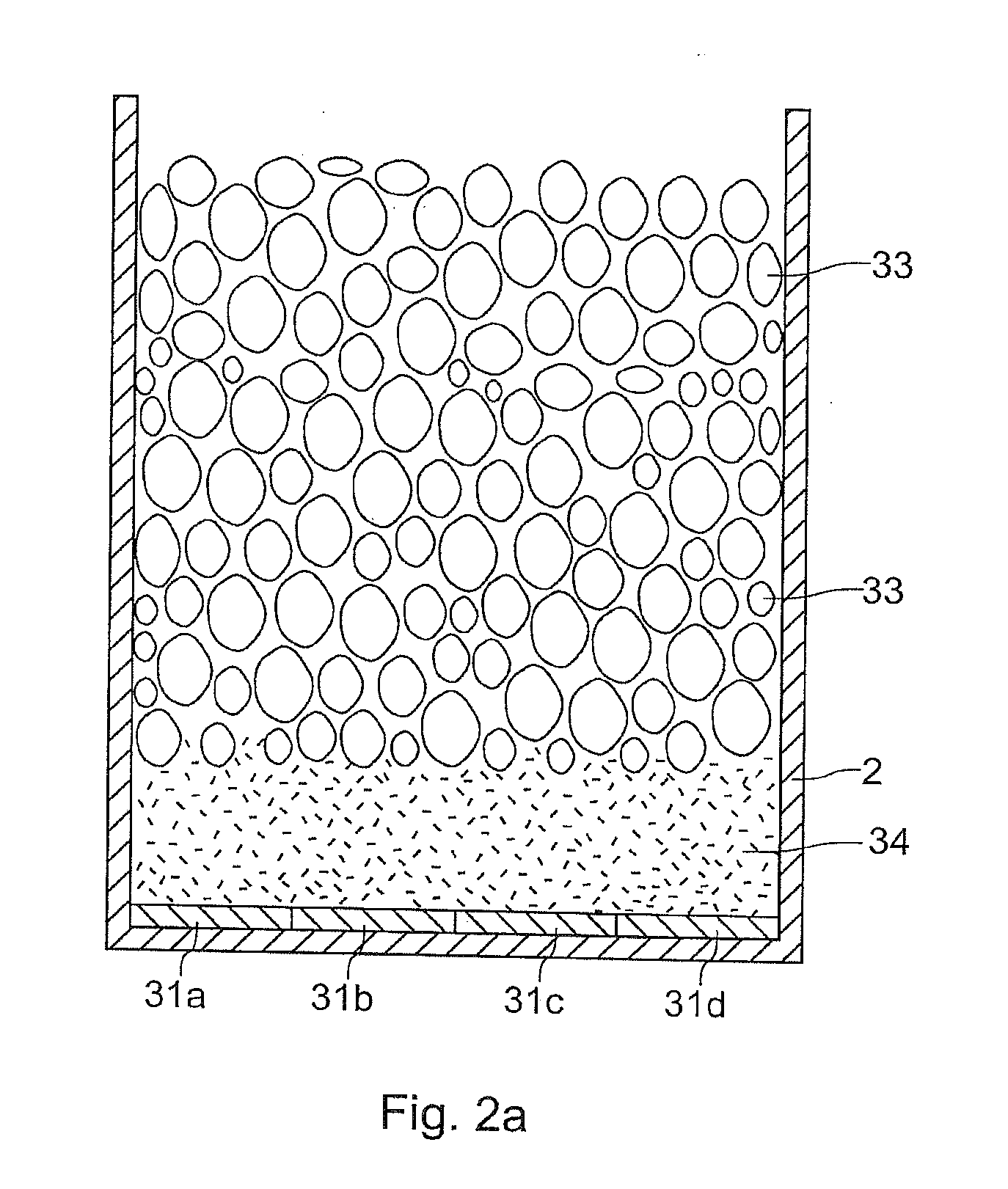

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass% of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

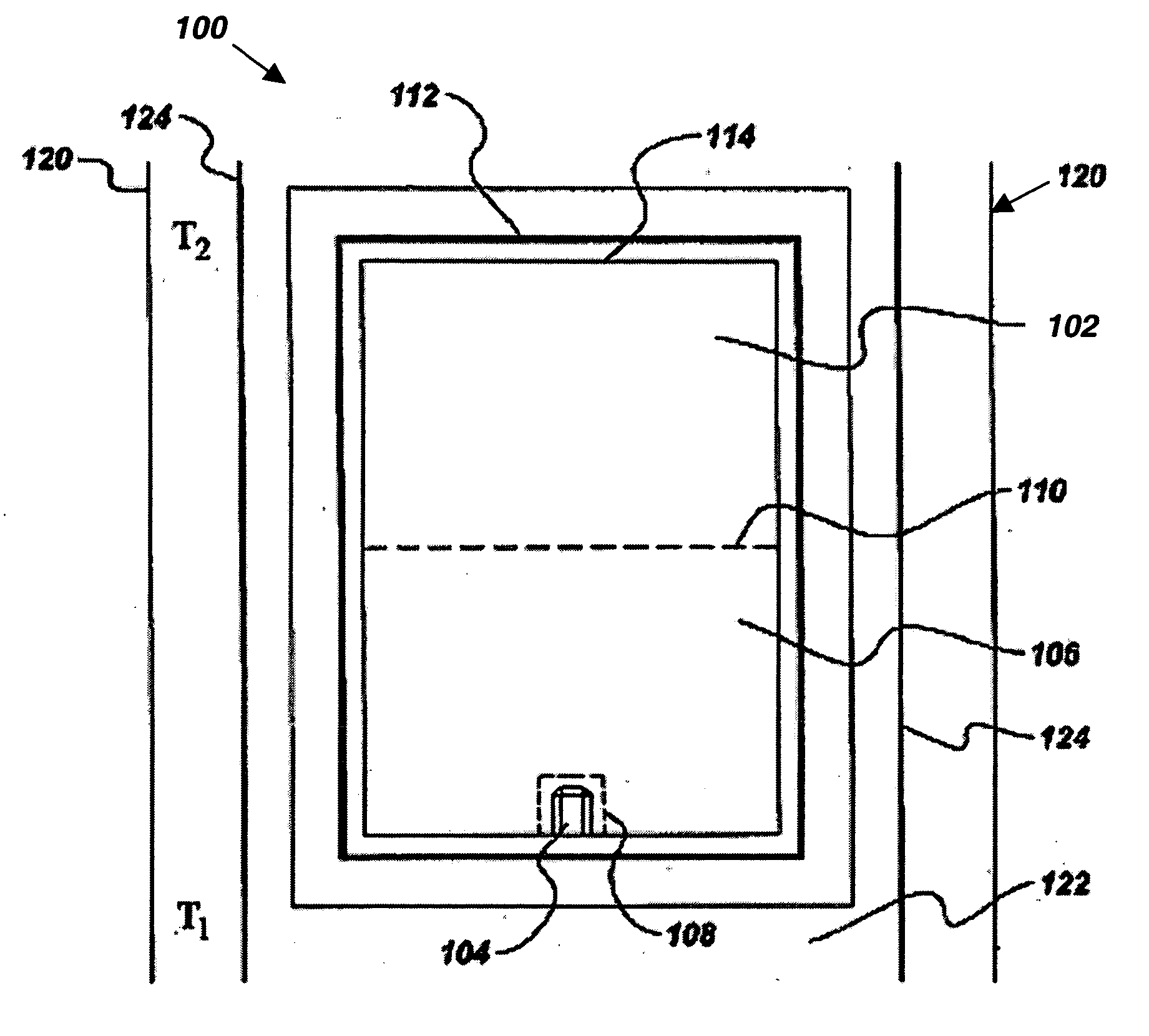

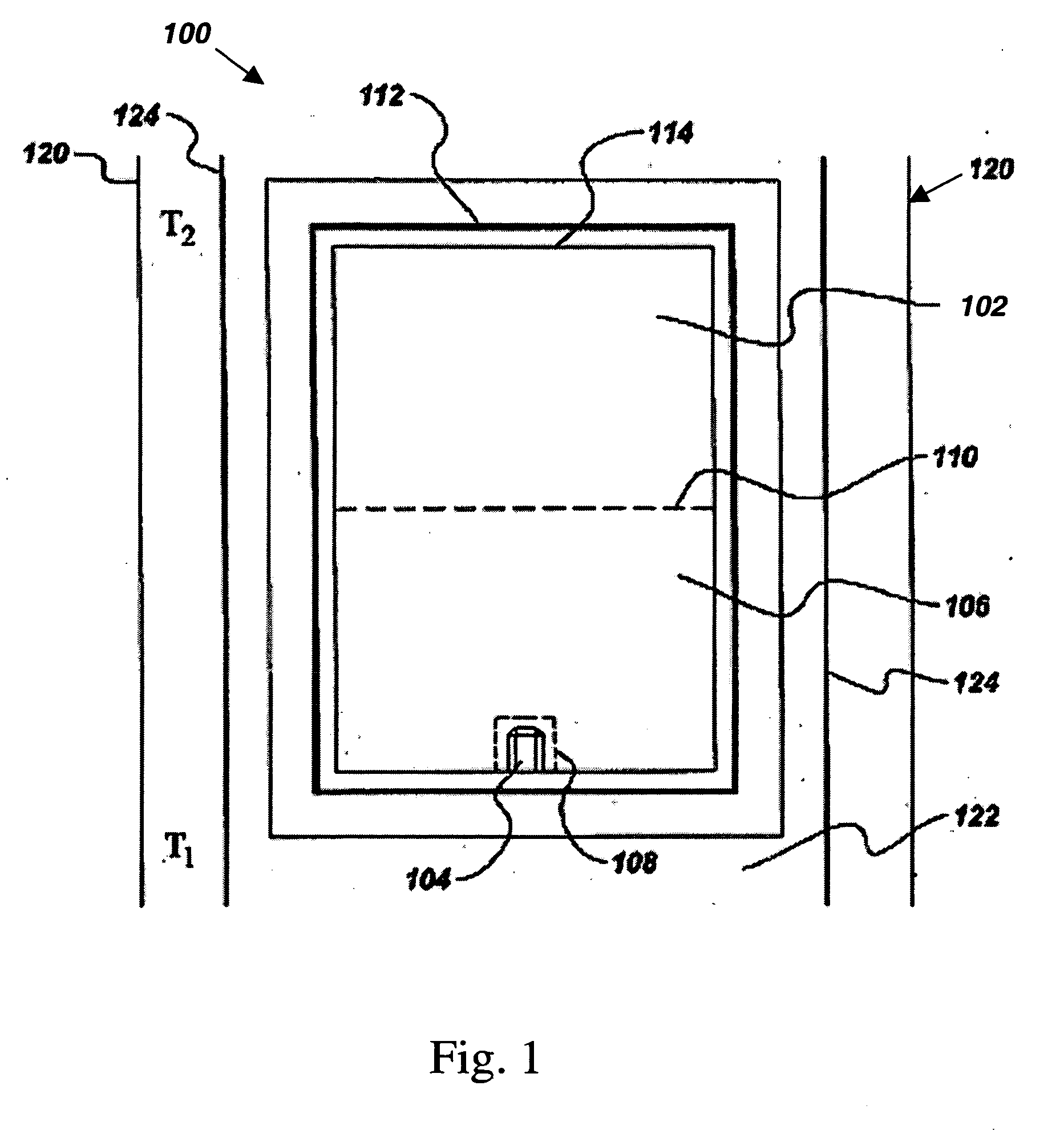

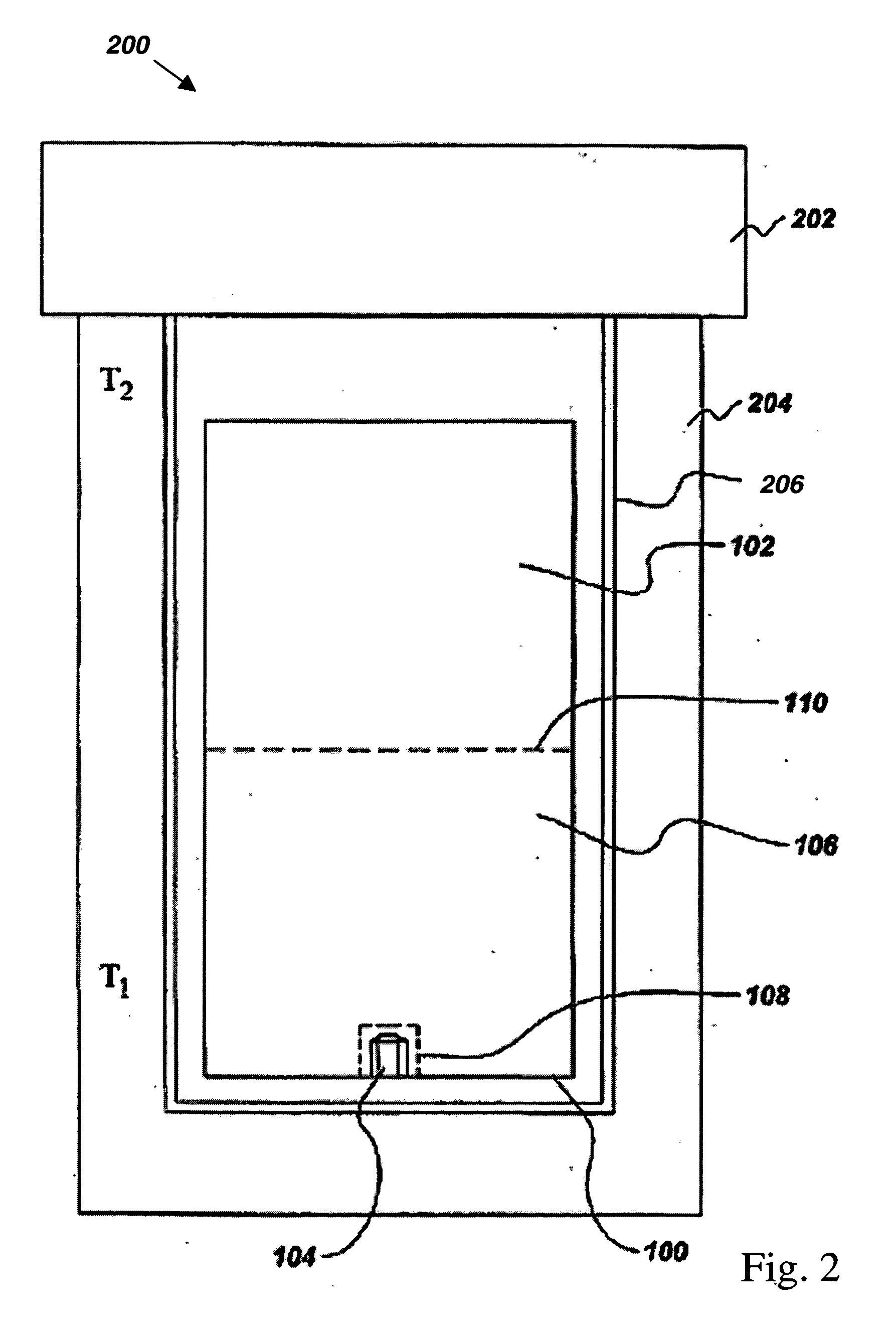

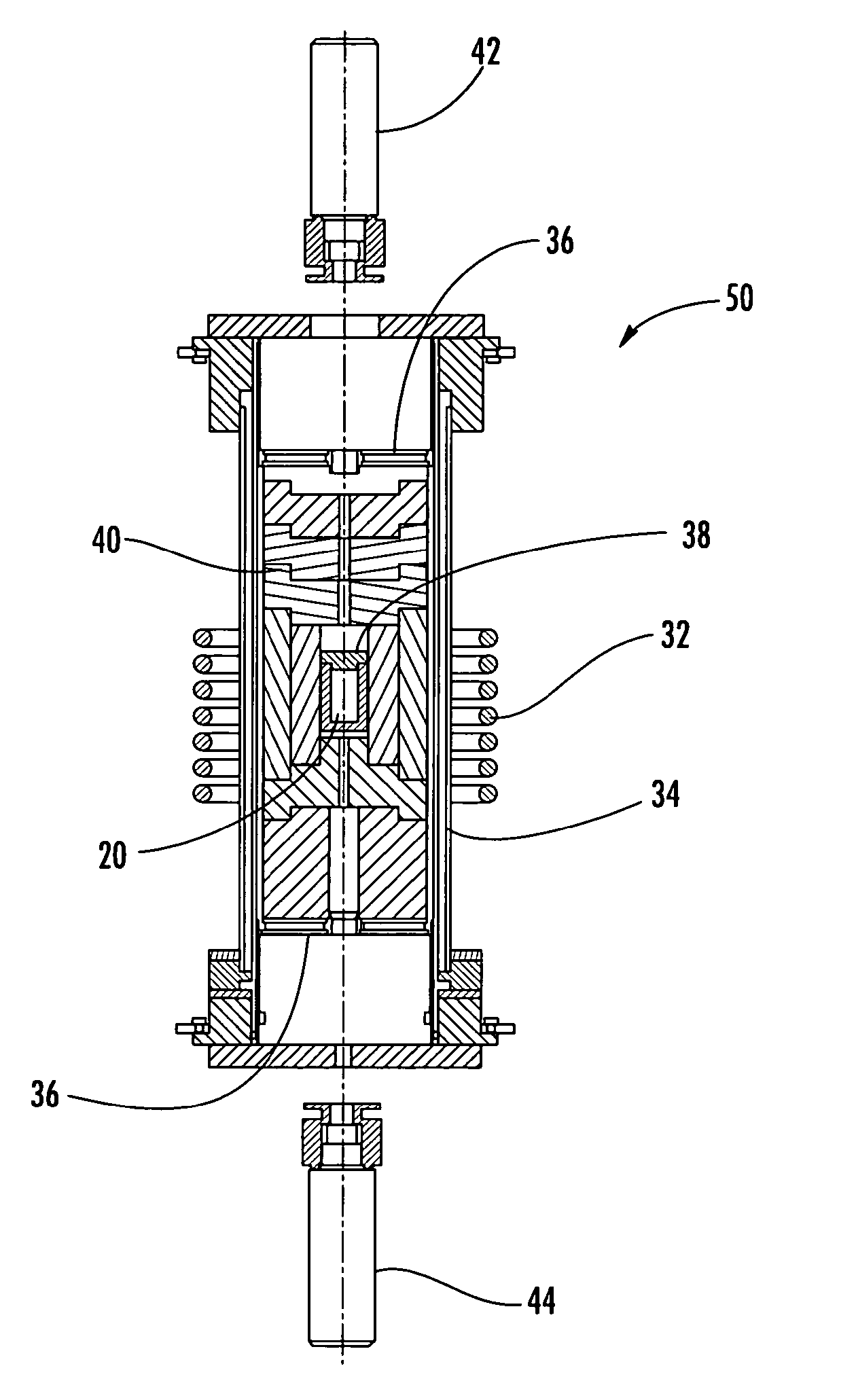

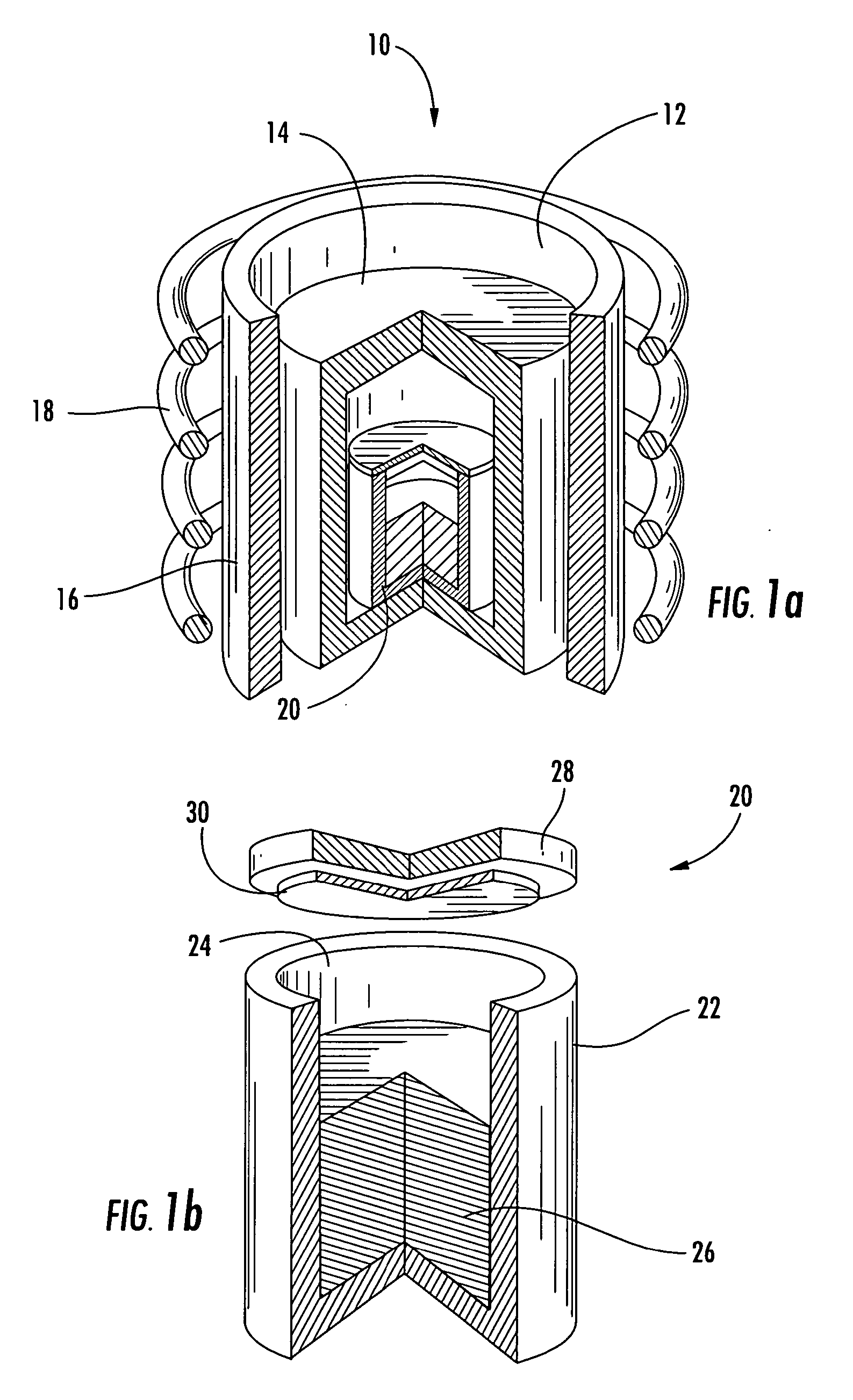

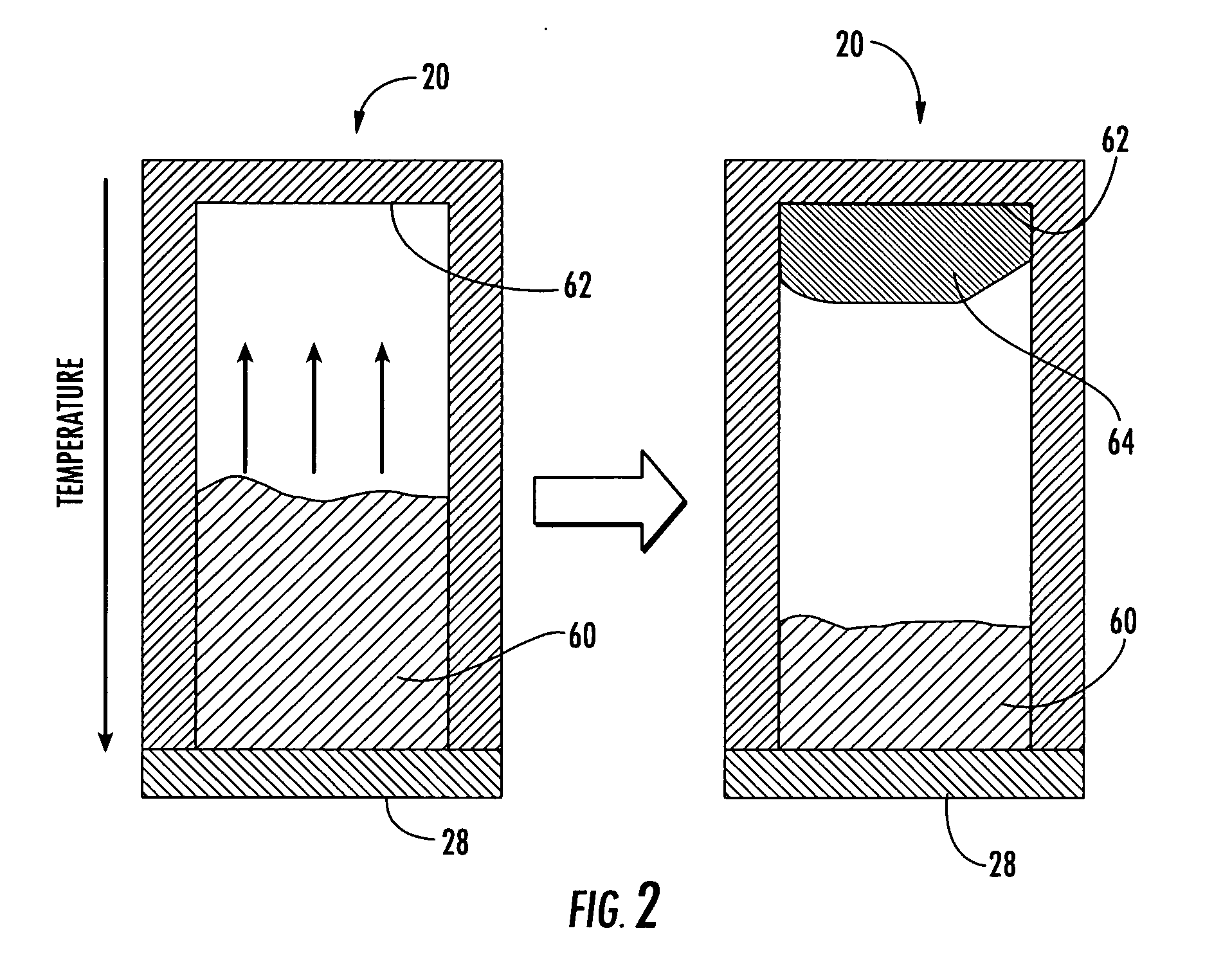

Apparatus for producing single crystal and quasi-single crystal, and associated method

An apparatus including a crucible, an energy source, and a controller is provided. The crucible may be sealed to a nitrogen-containing gas, and may be chemically inert to at least ammonia at a temperature in a range of about 400 degrees Celsius to about 2500 degrees Celsius. The energy source may supply thermal energy to the crucible. The controller may control the energy source to selectively direct sufficient thermal energy to a predefined first volume within the crucible to attain and maintain a temperature in the first volume to be in a range of from about 400 degrees Celsius to about 2500 degrees Celsius. The thermal energy may be sufficient to initiate, sustain, or both initiate and sustain growth of a crystal in the first volume. The first temperature in the first volume may be controllable separately from a second temperature in another volume within the crucible. The first temperature and the second temperature differ from each other. Associated methods are provided.

Owner:SLT TECH

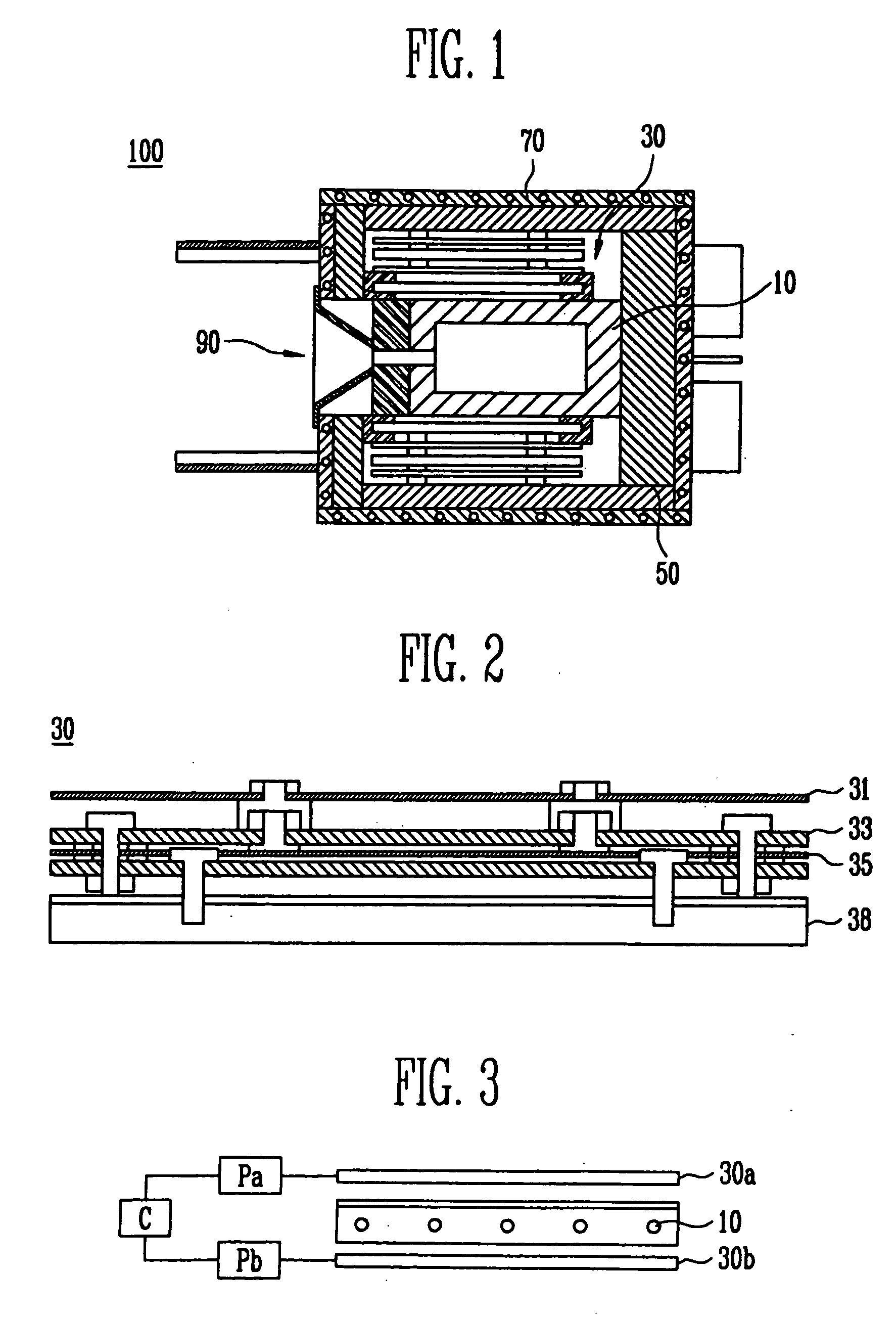

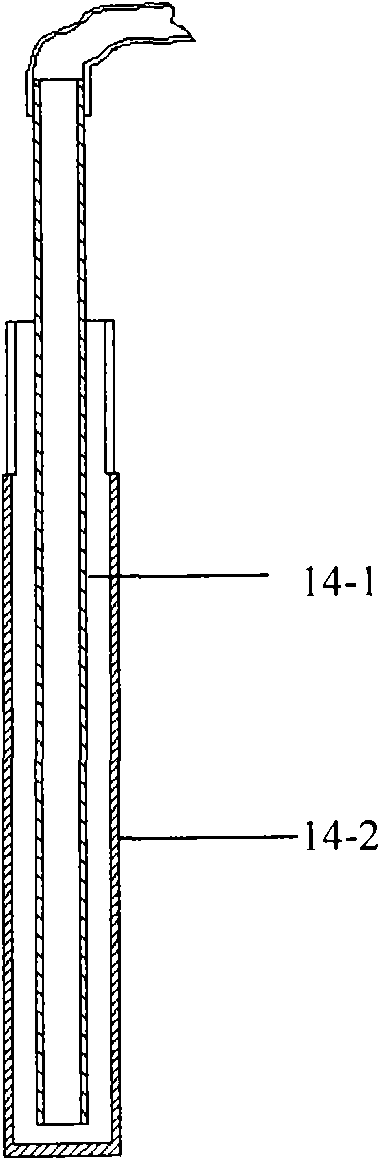

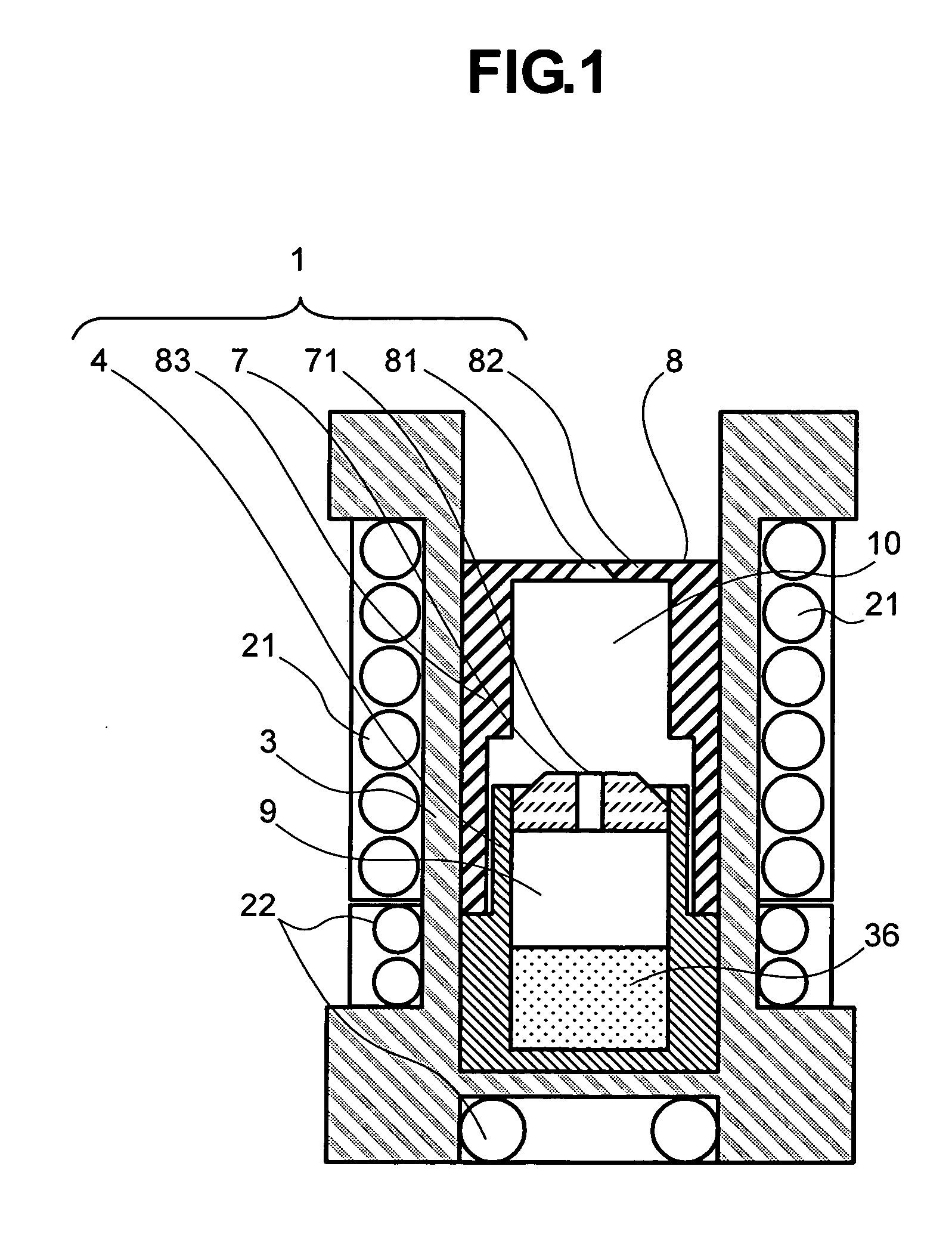

Apparatus for depositing an organic layer and method for controlling a heating unit thereof

InactiveUS20070077358A1Improve heating efficiencyMinimize timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

An apparatus for depositing an organic layer and a method for controlling the heating unit thereof are provided. The apparatus includes a crucible positioned in a deposition chamber and containing materials for evaporation. The apparatus also includes a heating unit having first and second heat sources for heating the crucible. A housing isolates the heat emitted from the heating unit and an outer wall anchors the crucible. A nozzle sprays the materials evaporated from the crucible. The first and second heat sources are positioned on first and second sides of the crucible, respectively, and are independently controlled to minimize the time required to stabilize the deposition rate.

Owner:SAMSUNG DISPLAY CO LTD

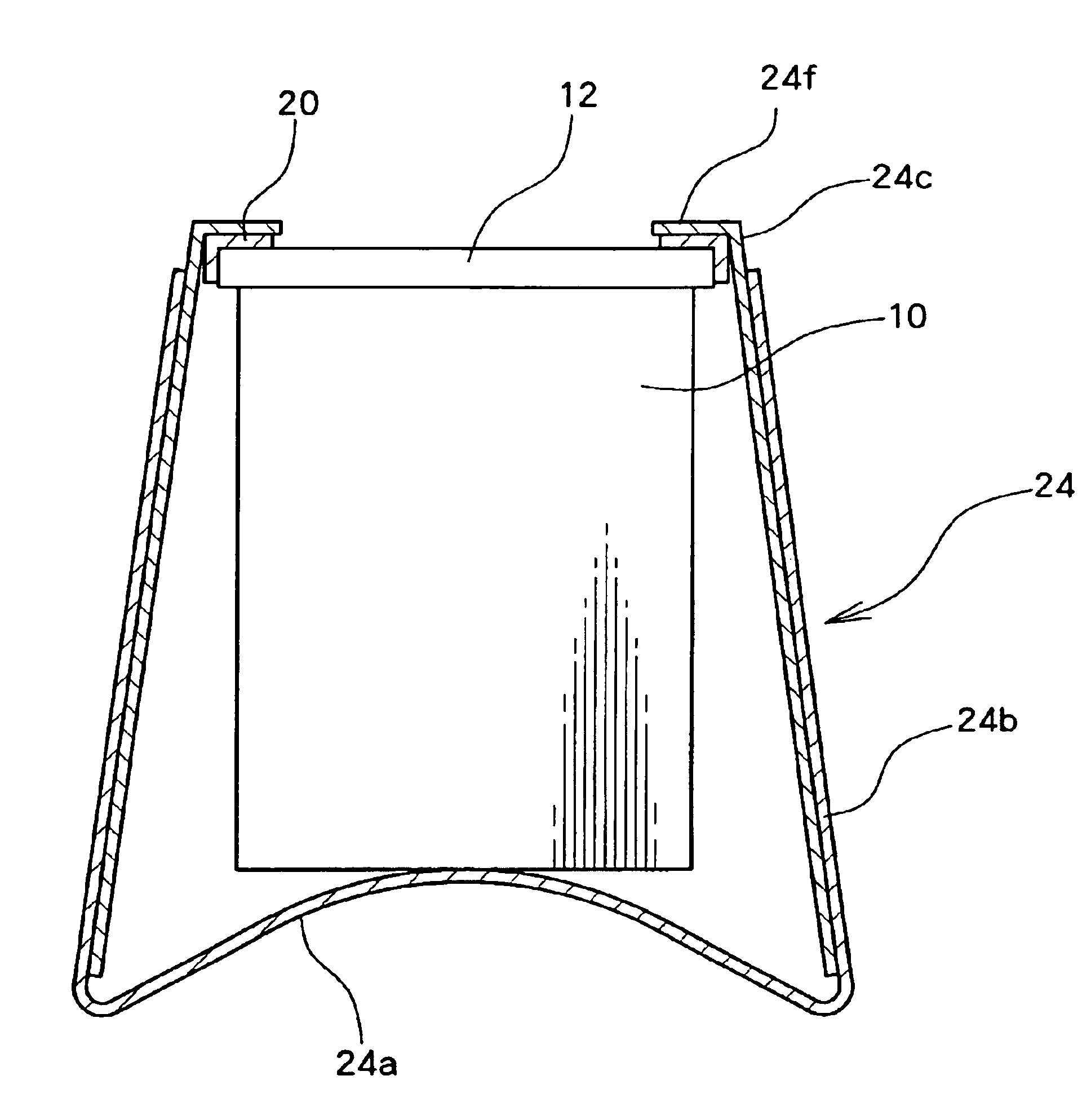

Fixing member for evaporation apparatus

InactiveUS6881271B2Uniform dischargeEfficient heatingSnap fastenersElectric lighting sourcesCrucibleEvaporation

An electric heater is placed so as to cover an upper opening of a crucible. Then, a plurality of angle members are disposed along the side portions of the electric heater and are pressed and fixed by clamps. The clamp includes, at its bottom, a curved portion formed by bending a plate-like spring member into a convex shape, and generates pressing force between the curved portion and corresponding claw portions at the upper edge, thereby clamping the crucible.

Owner:SANYO ELECTRIC CO LTD

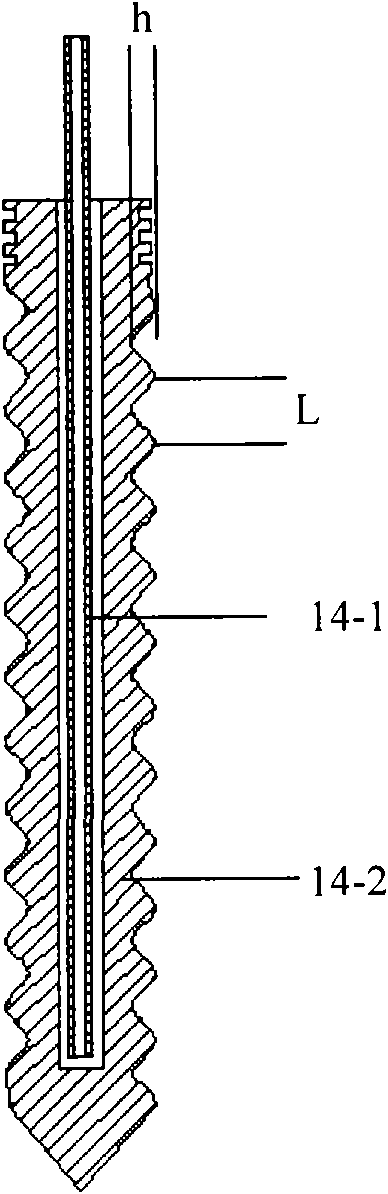

Method for manufacturing a potted bundle of hollow fibers

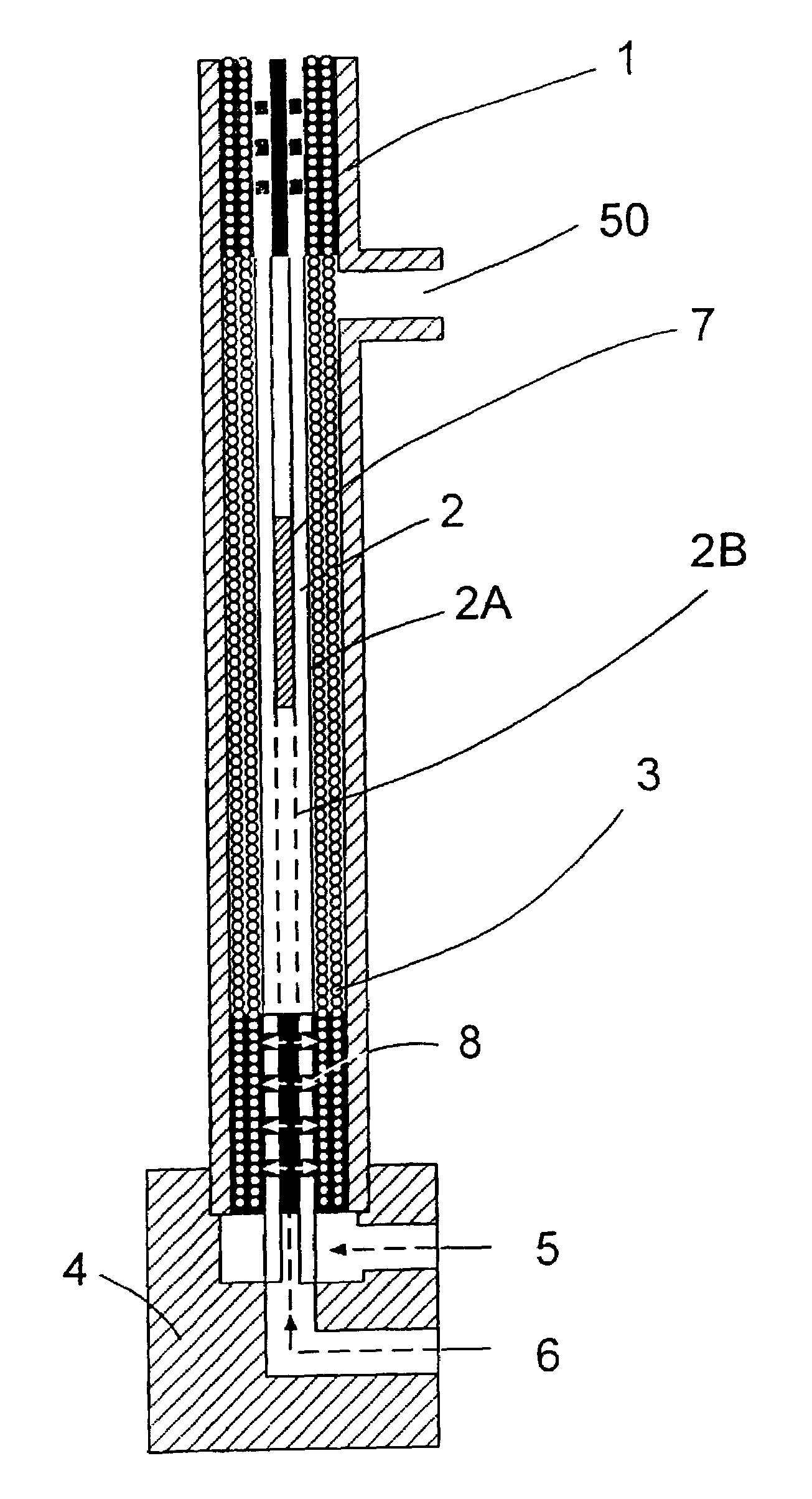

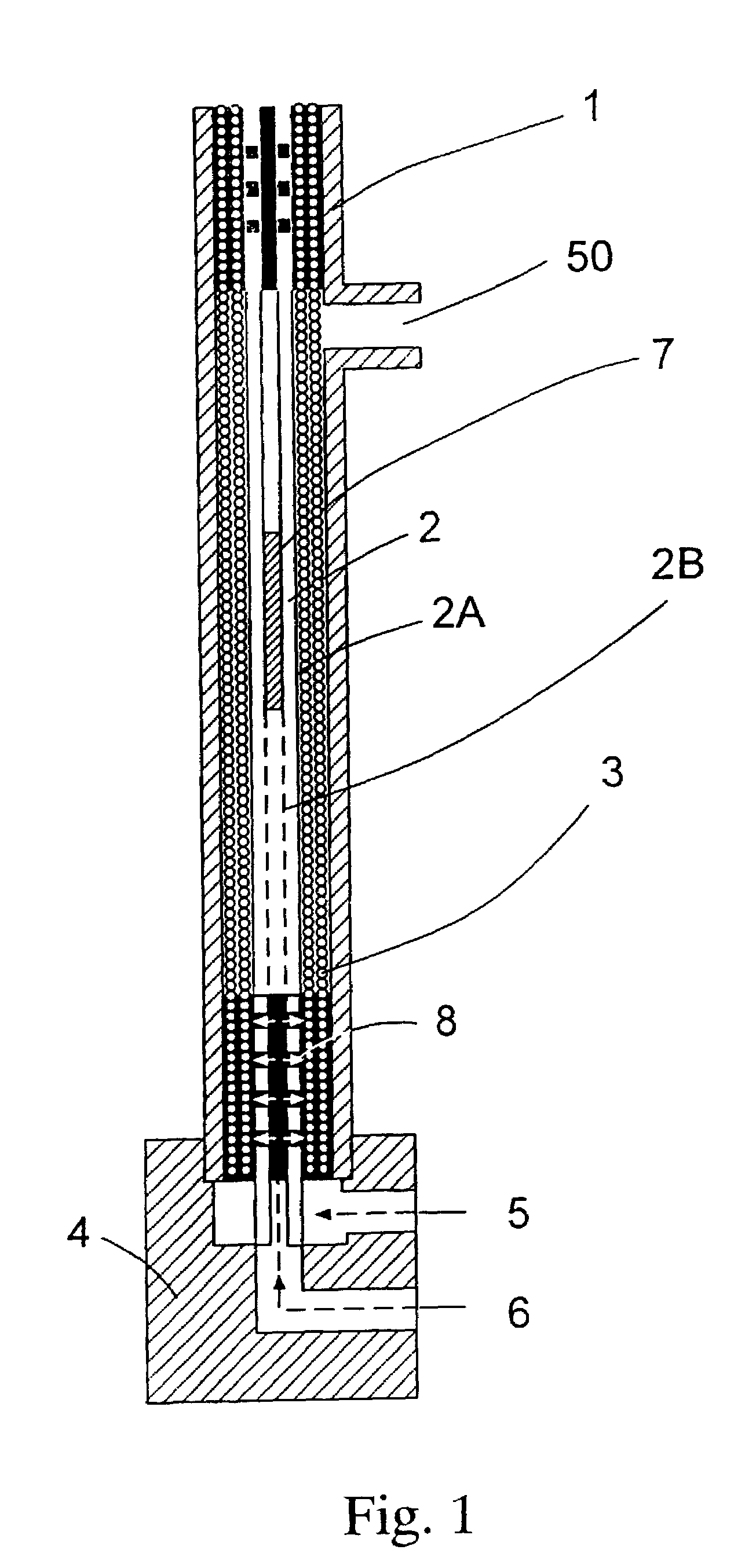

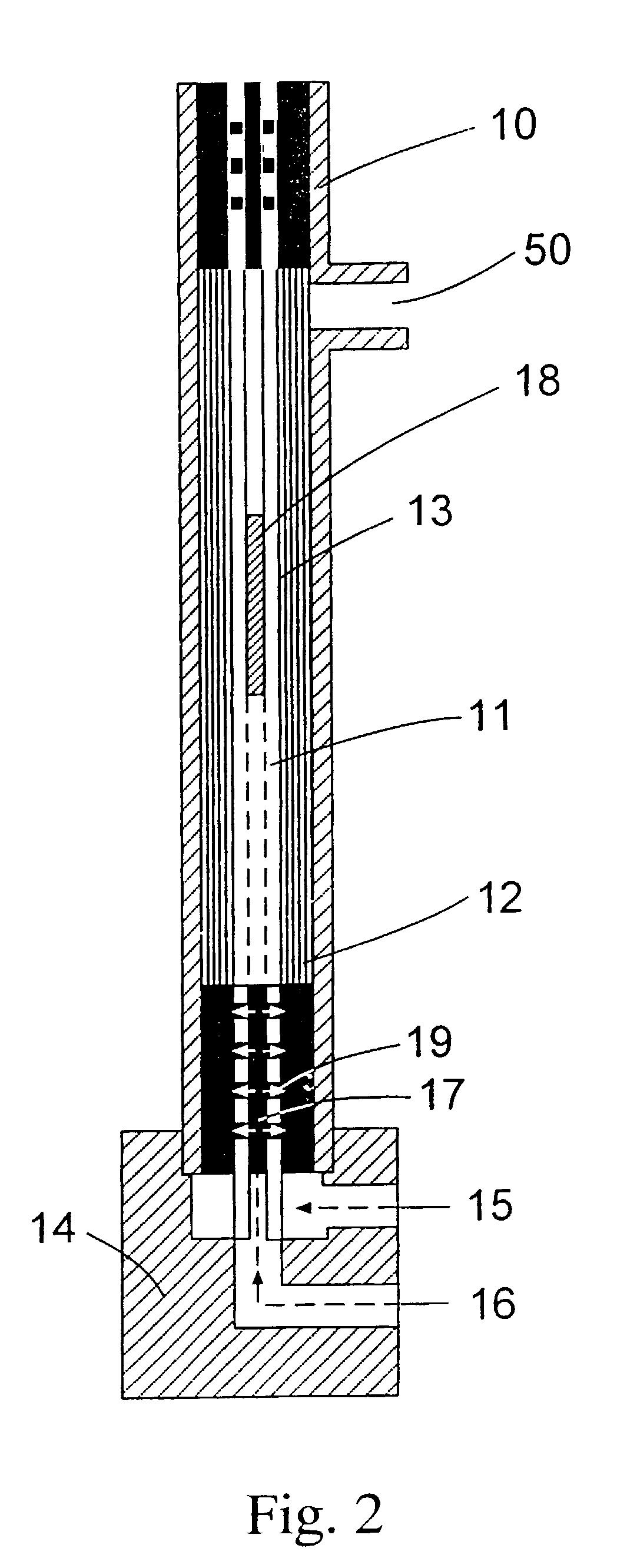

The present invention involves a process that includes injecting a potting compound such as an epoxy through a hollow portion (2B) of the central mandrel (2) and onto the inner layer(s) of a multi-layered fiber bundle (3) and through the outside of the bundle and onto the outer layer(s) of the bundle. By potting through the central mandrel (2), the potting compound distributes evenly throughout the inner fibers of the bundle (3). The steps may be sequentially or simultaneously. Preferably it is done as a two-step process, with the first step being to apply the potting compound through the central mandrel (2) and onto the inner fibers first. The second step is to pot around the outer layer of the fiber bundle (3) to finish the process. The resultant product is also disclosed.

Owner:MILLIPORE CORP

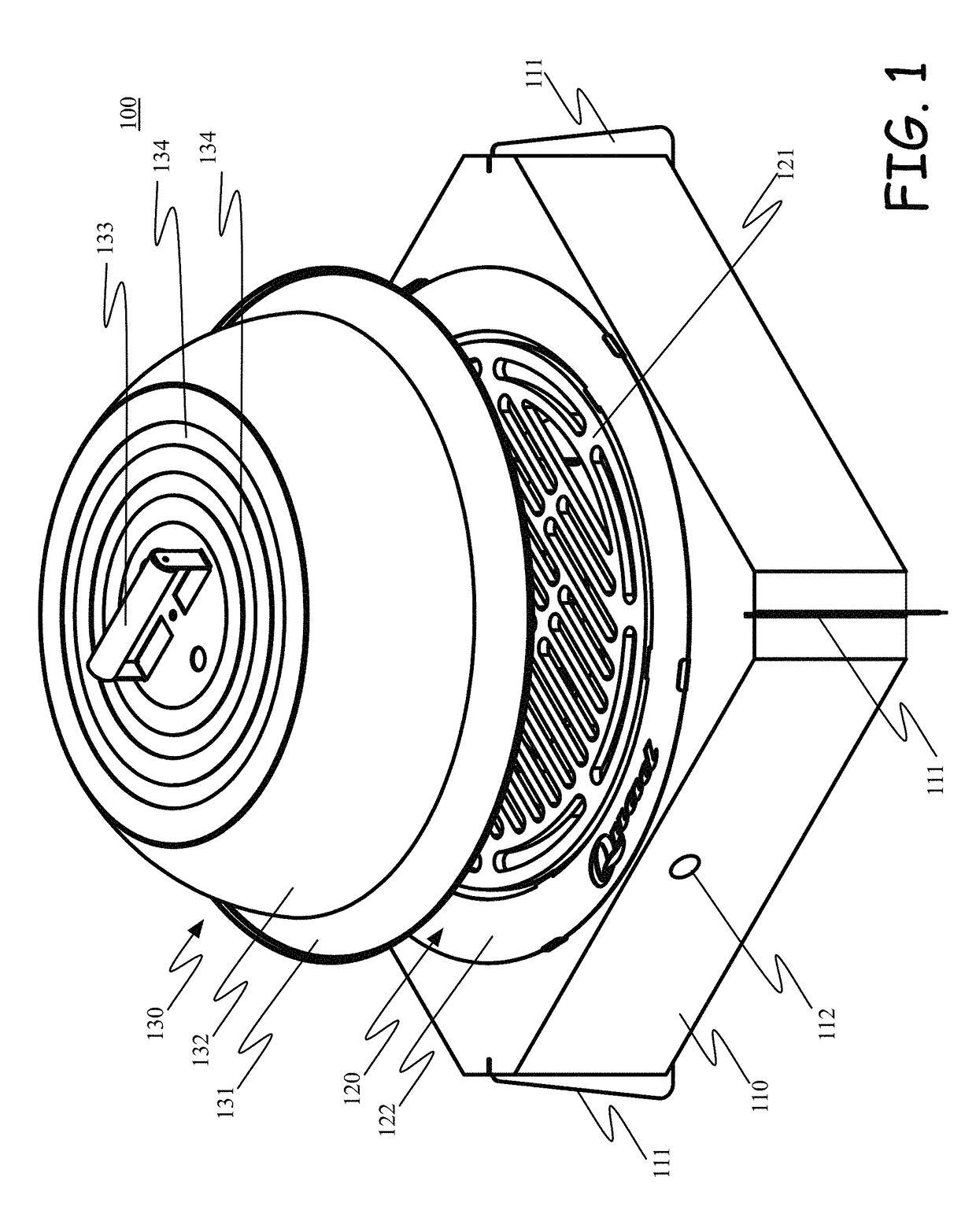

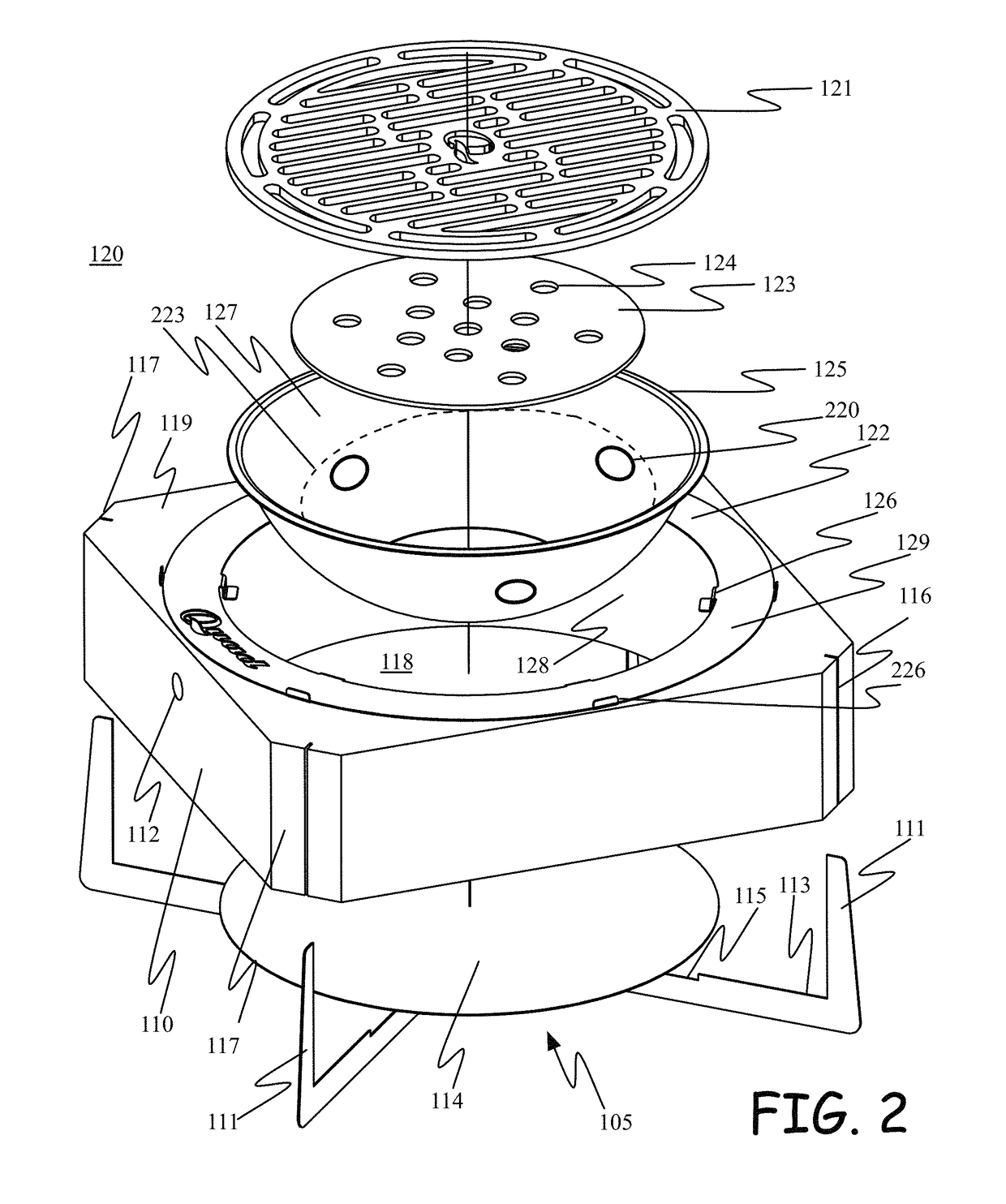

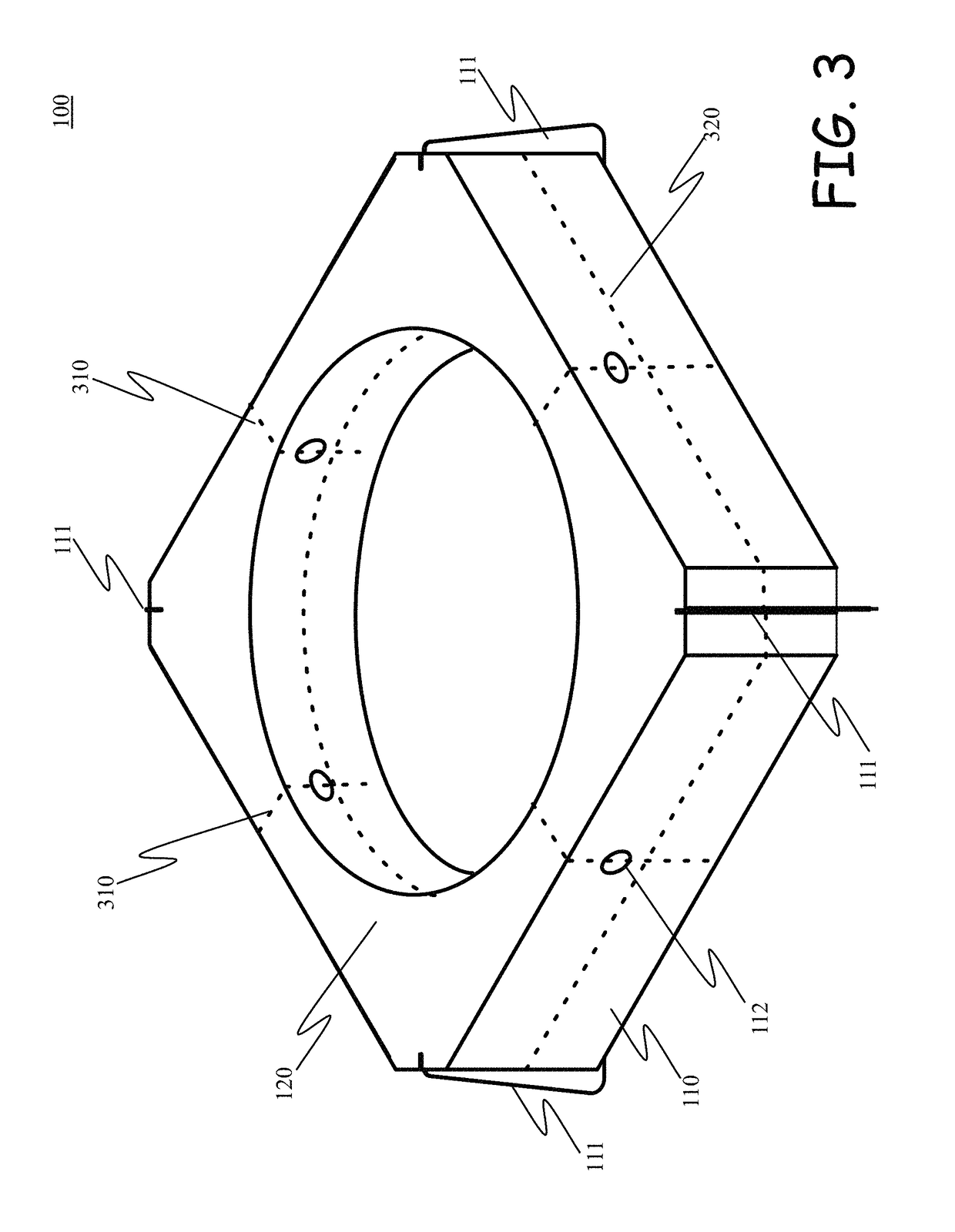

Versatile cooker

A versatile cooker that includes a crucible or base, a fire bowl with a cooking surface on top of it and, a cover / lid or dome that rests over the cooking surface. An exemplary embodiment of the cooker can be described as a naturally fired outdoor cooker constructed of a light weight, thermally insulated material such as Autoclaved Aerated Concrete (AAC) as the crucible, a stainless steel fire bowl and a dome lid. A grilling surface constructed out of carbon steel and ceramic disks are used as internal heat sinks.

Owner:COOKING WITH FIRE

Method for producing monocrystalline metal or semi-metal bodies

InactiveUS20090047203A1Cheap methodCost effective productionPolycrystalline material growthSiliconVertical gradientCrucible

Owner:SCHOTT AG

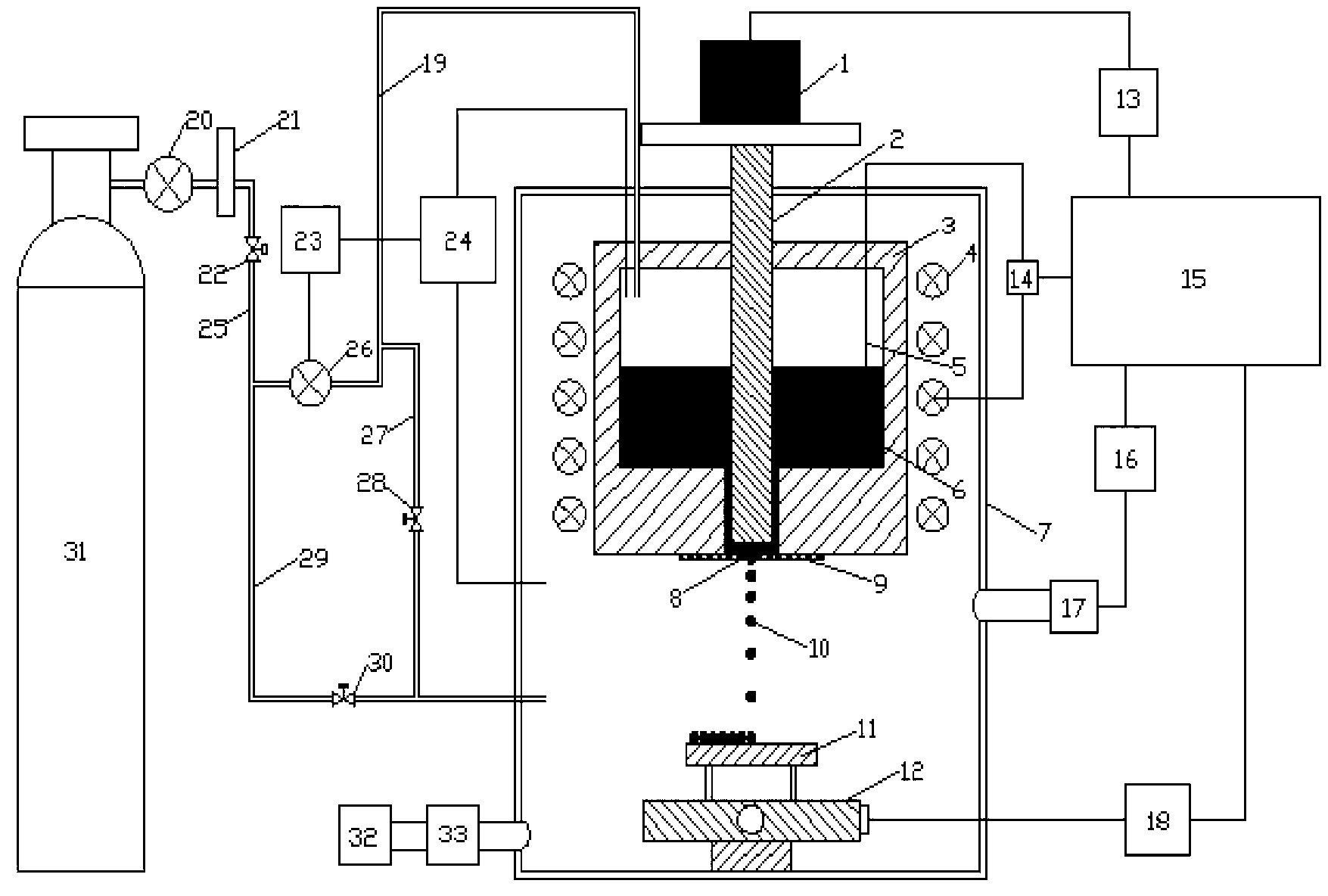

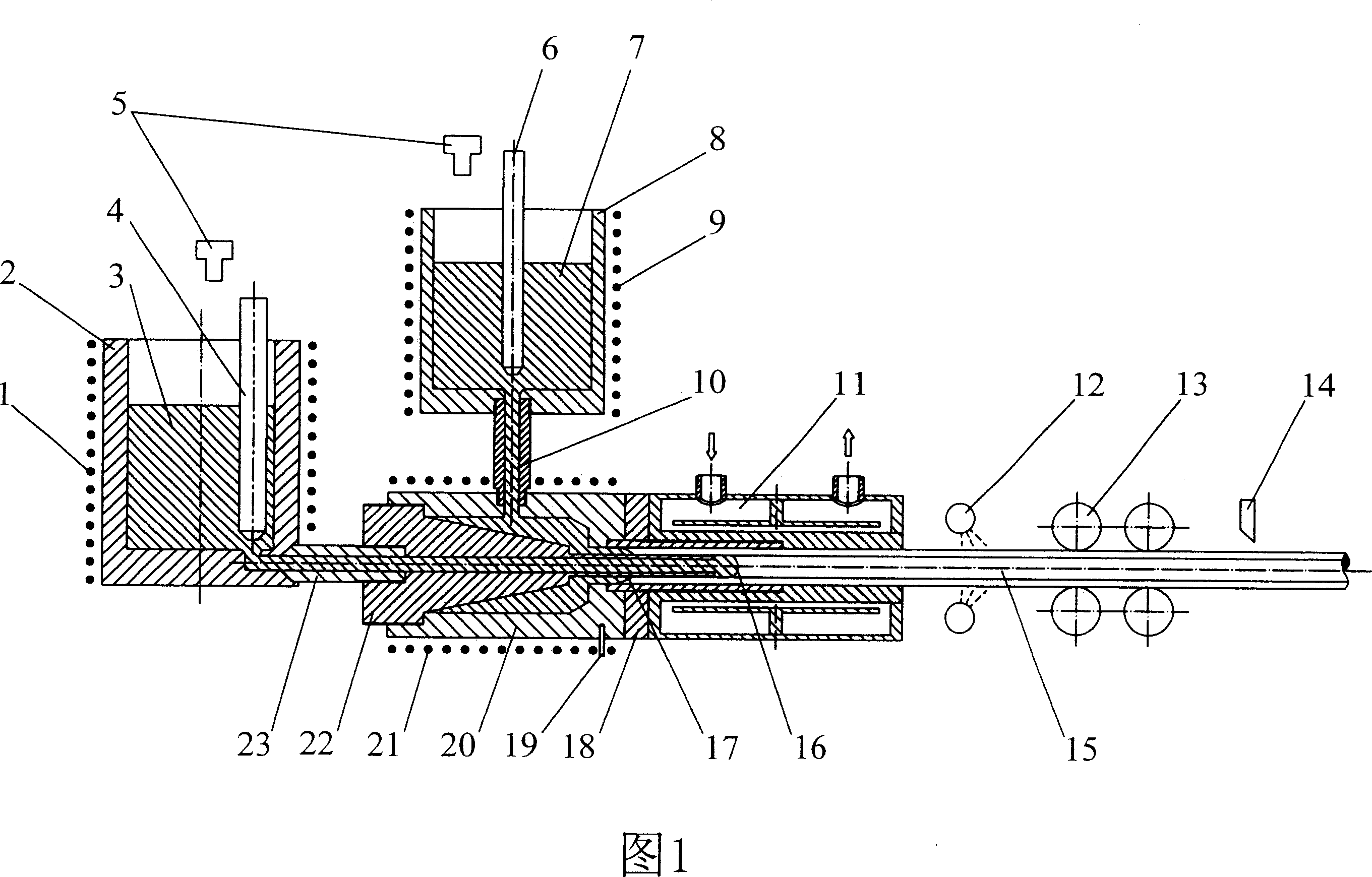

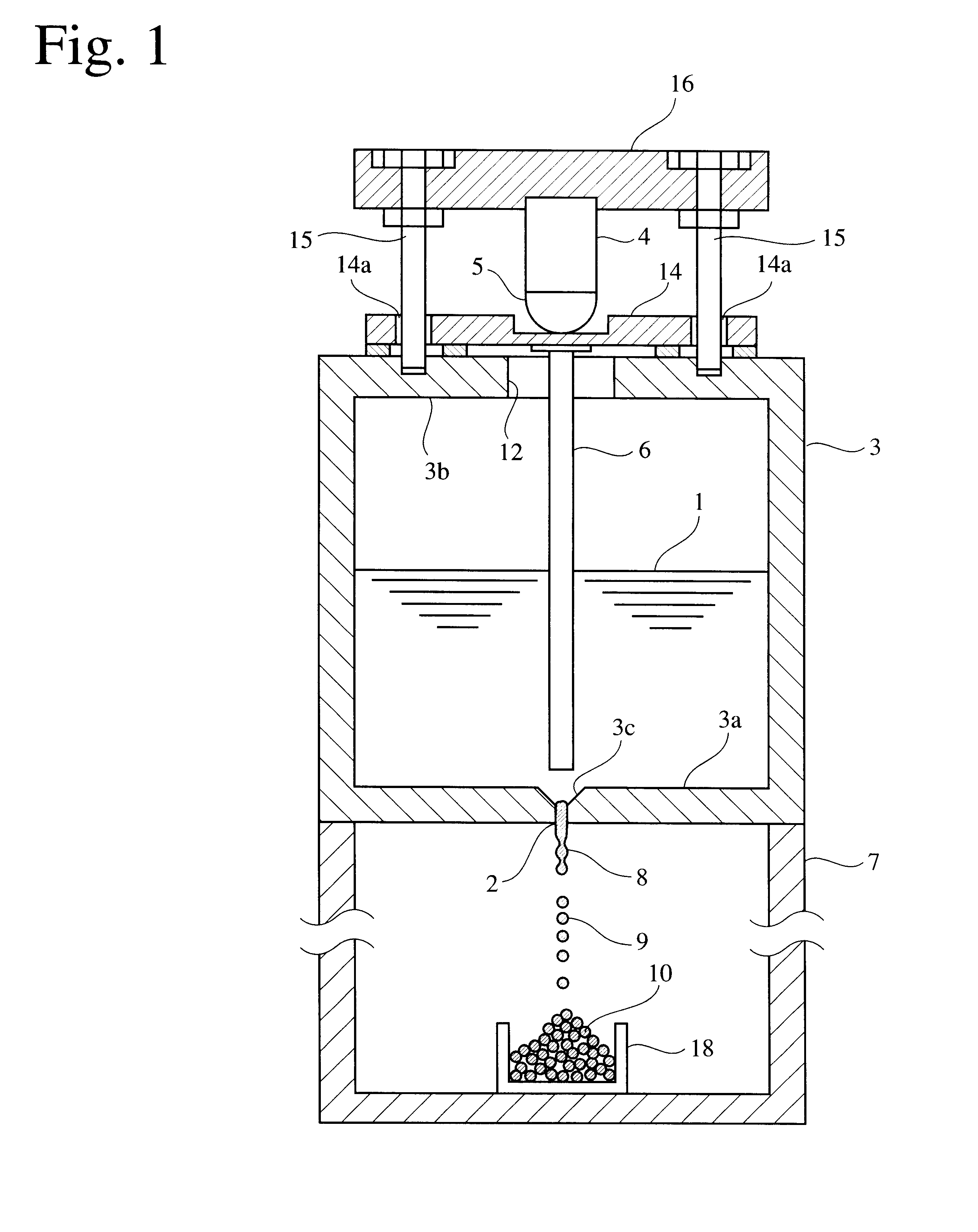

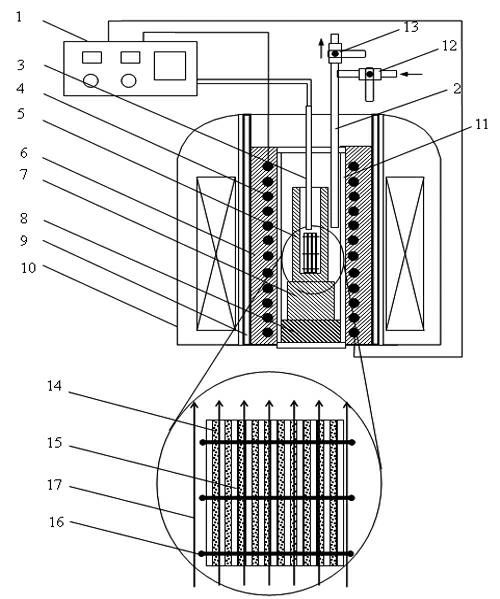

Three-dimensional rapid prototyping method and device based on pulse small hole droplet injection

The invention relates to a three-dimensional rapid prototyping method and device based on pulse small hole droplet injection and belongs to the technical field of three-dimensional rapid prototyping. The three-dimensional rapid prototyping method is characterized in that a heater is used for heating a crucible until the metals in the crucible are in the molten state, a positive differential pressure value is set between the interior of the crucible and a vacuum chamber, simultaneously a piezoelectric ceramic driver applies certain pulse signals to piezoelectric ceramics to lead the piezoelectric ceramics to drive a transmission bar to generate longitudinal infinitesimal displacement, the infinitesimal displacement acts on the metal melt at the bottom of the crucible, tiny droplets are injected from small holes arranged at the bottom of the crucible, one droplet can be formed at the position of the small holes once the piezoelectric ceramics move for one time, size data of the droplets are timely analyzed through a photograph system, further the optimum parameter is obtained through adjustment; and the droplets fall to a moving three-dimensional motion platform to be deposited, and accordingly needed metal parts are formed through depositing. The three-dimensional rapid prototyping method and device based on pulse small hole droplet injection have the advantages that the pulse small holes inject to generate the metal droplets with uniform and controllable sizes, prototyped products are fine and uniform in microstructure, the prototyping process is strong in controllability, and the formed parts are high in accuracy.

Owner:DALIAN UNIV OF TECH

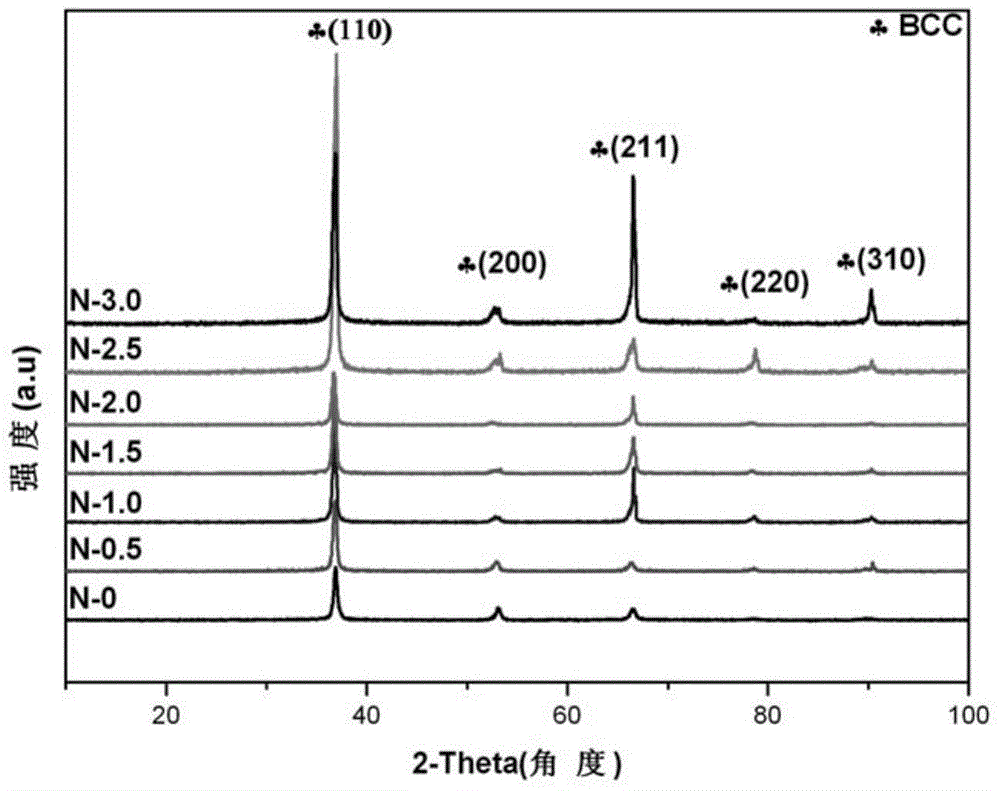

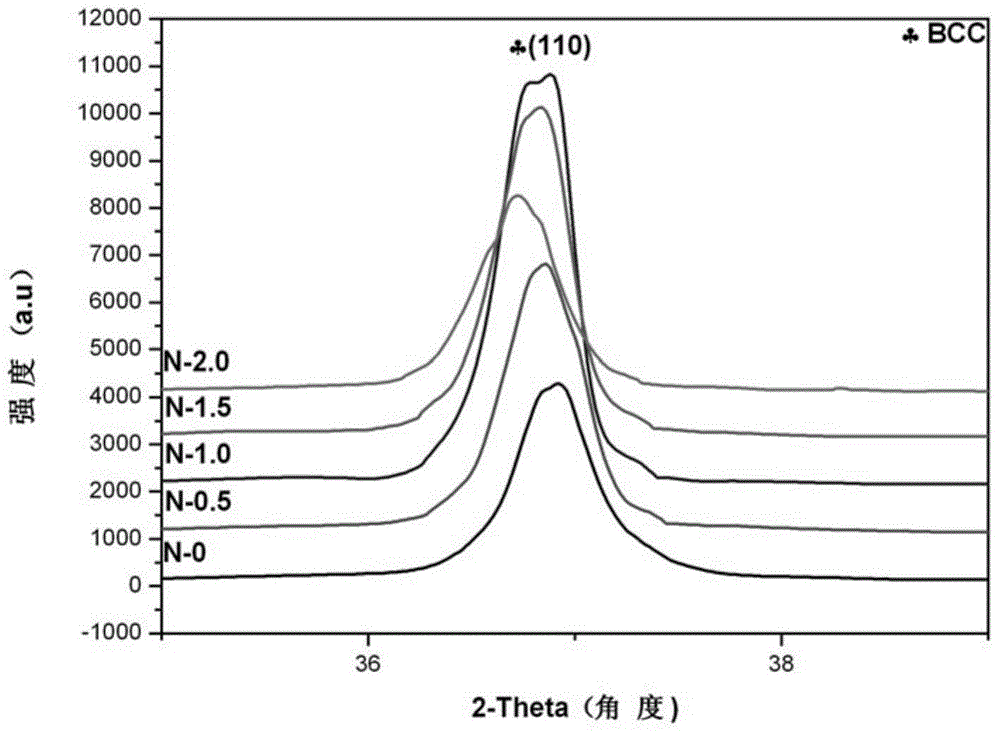

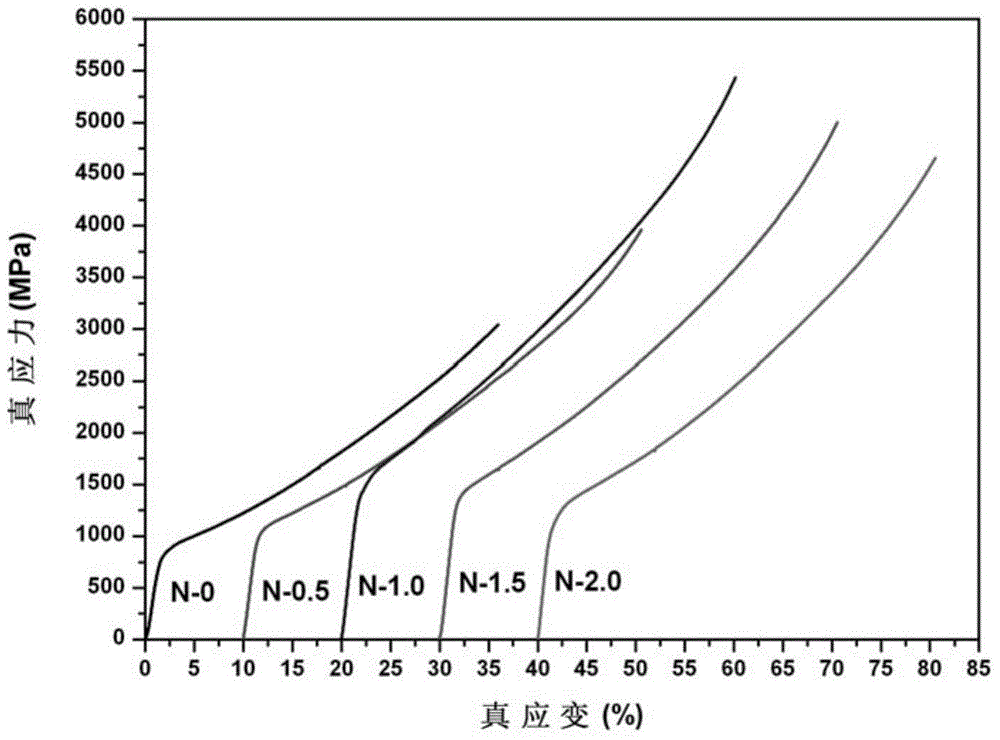

Nitrogen-strengthened TiZrHfNb-based high-entropy alloy and preparation method thereof

ActiveCN105671392AThe scope of application of large ingredientsBroad preparation conditionsCrucibleHigh entropy alloys

Owner:UNIV OF SCI & TECH BEIJING

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

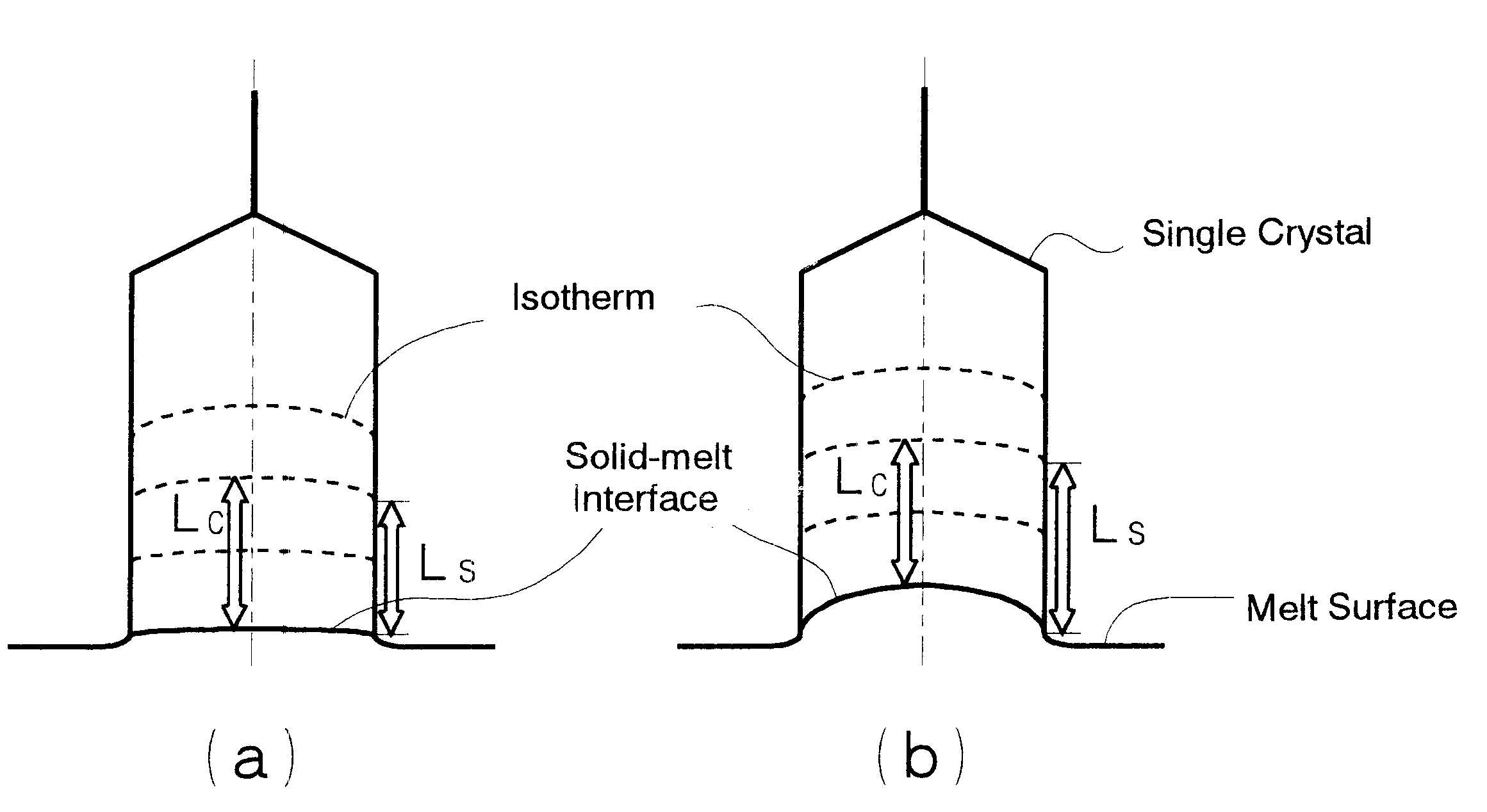

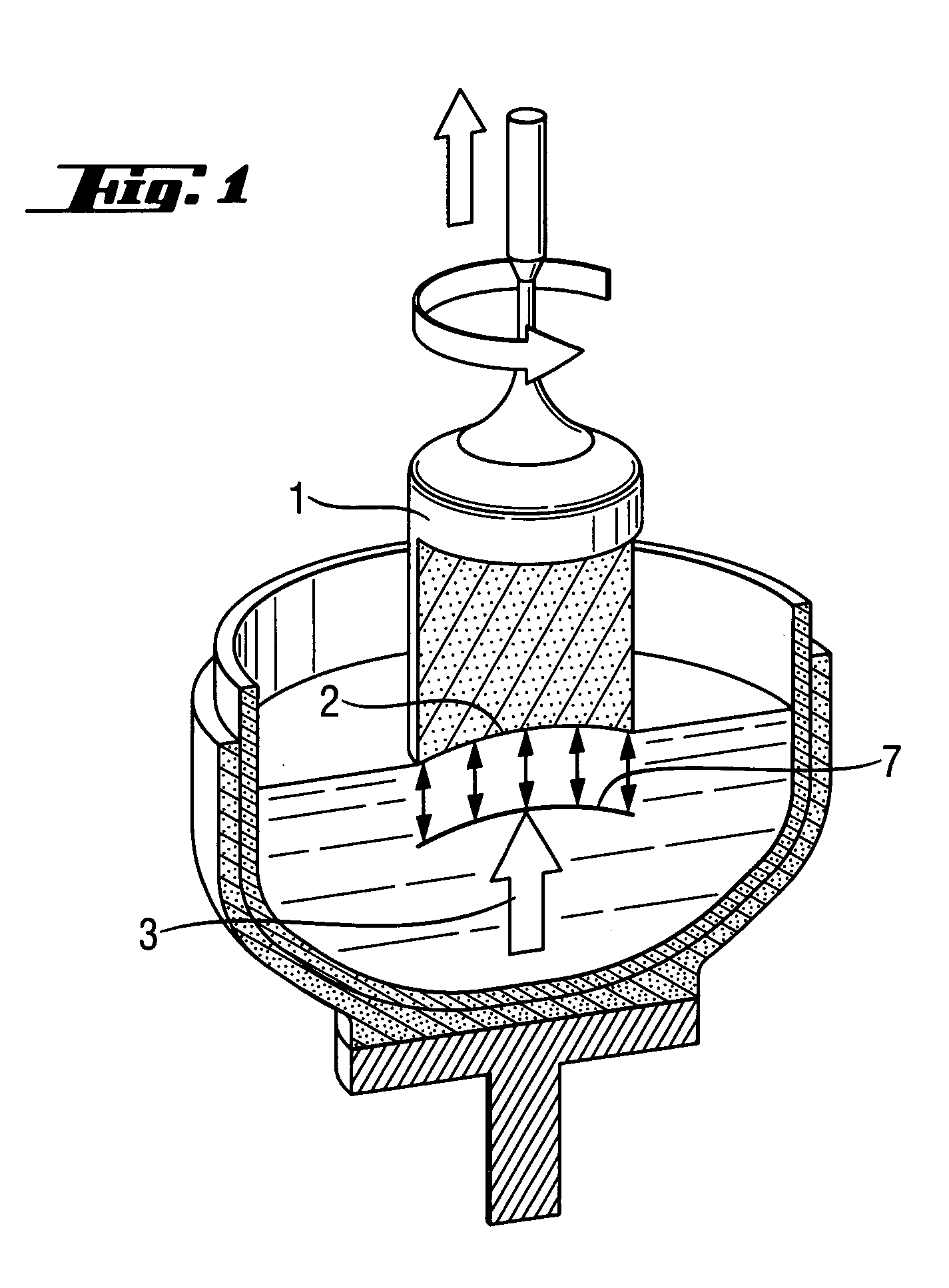

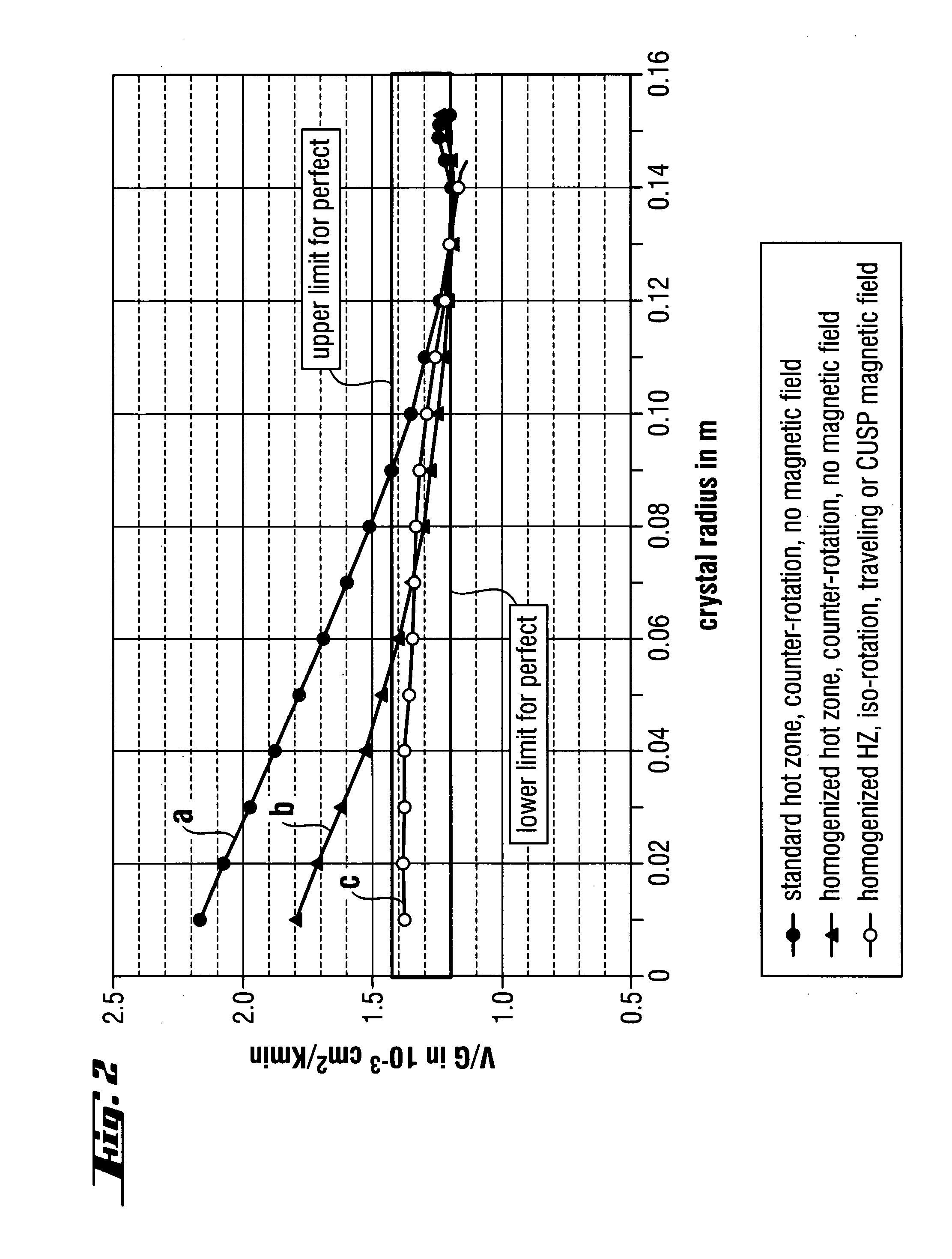

Method of producing high-quality silicon single crystals

InactiveUS6458204B1Polycrystalline material growthSemiconductor/solid-state device manufacturingLaser scatteringSingle crystal

A method of producing high-quality and large-diameter single crystals by the Czochralski method is disclosed which can provide wafers with a minimized number of such grown-in defects as dislocation clusters and laser scattering tomography defects. Specifically, it is a method of producing silicon single crystals which comprises carrying out the crystal pulling while maintaining the solid-melt interface during pulling in the shape of an upward convex with the central portion of the interface being higher by at least 5 mm than the peripheral region thereof and while applying a magnetic field, and optionally in addition to the above, while maintaining the temperature gradient in the direction of axis of pulling in the peripheral region at a level lower than that in the central portion in the range of from the melting point to 1,200° C. In this case, it is desirable that the portion of the single crystal surface lying at least 50 mm above the melt surface be shielded from direct radiant heat from the heater and / or crucible wall, that a horizontal magnetic field of 0.08 to 0.3 T be applied in parallel with the melt surface or a cusped magnetic field showing an intensity of 0.02 to 0.07 T at a crucible wall site on the melt surface be applied and that the crucible be rotated at a speed of not more than 5 min-1 and the single crystal at a speed of not less than 13 min-1.

Owner:SUMITOMO MITSUBISHI SILICON CORP

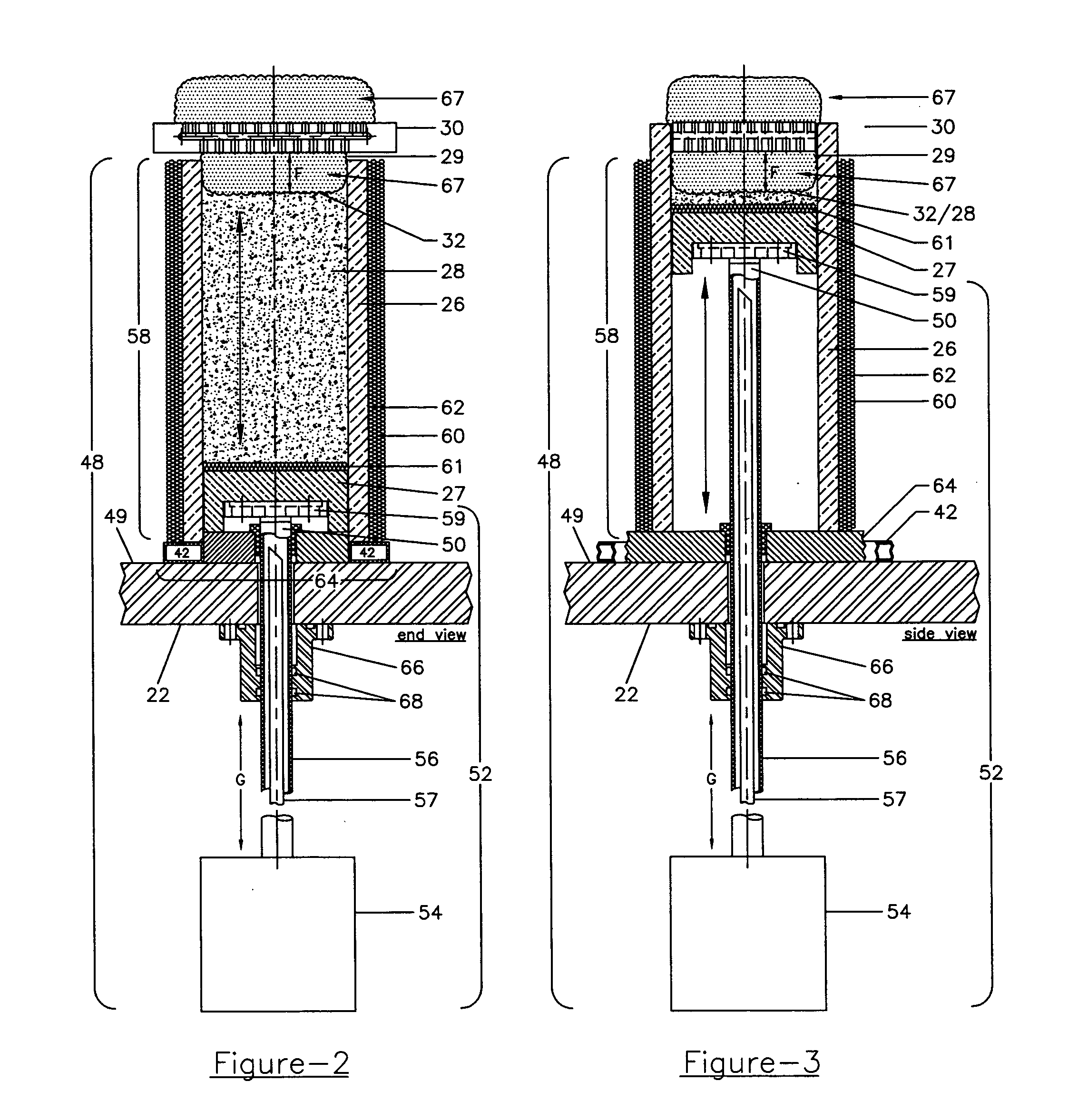

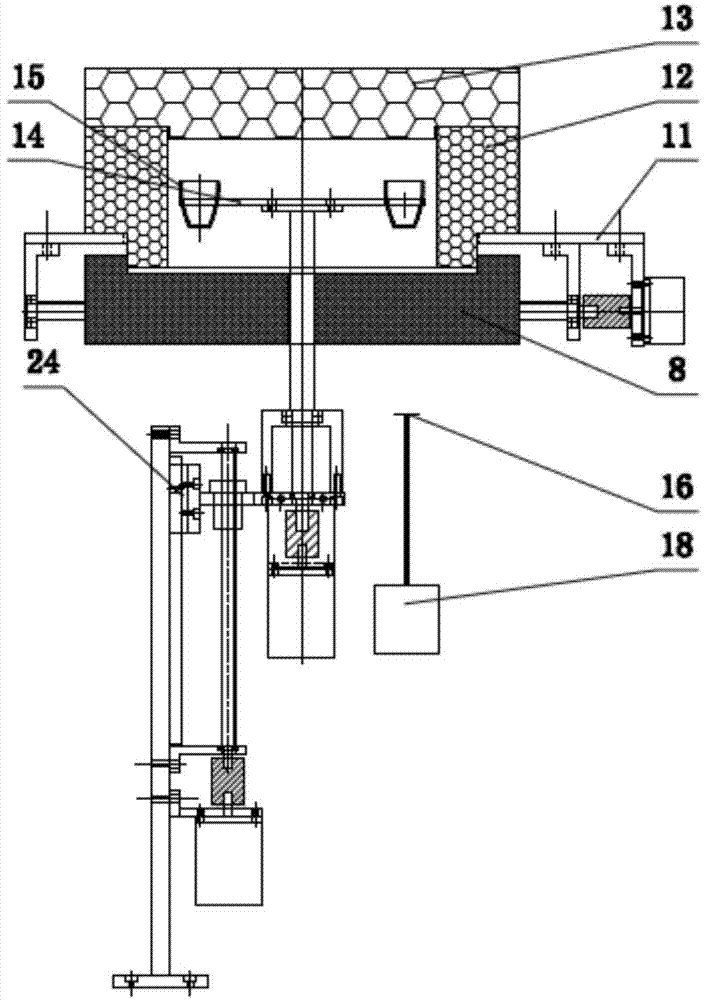

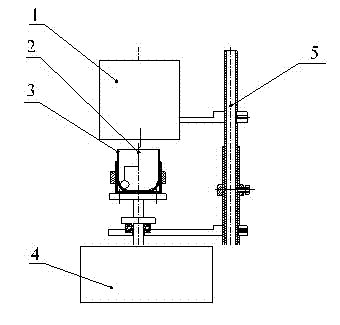

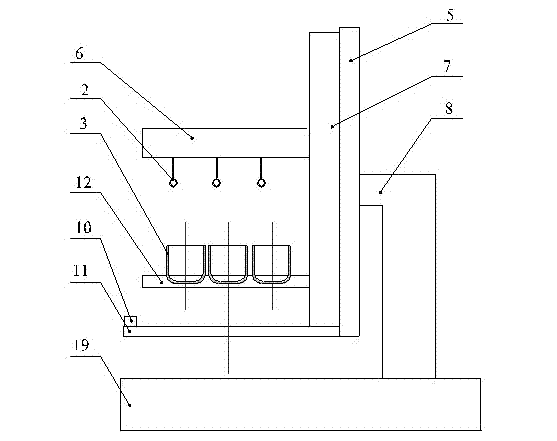

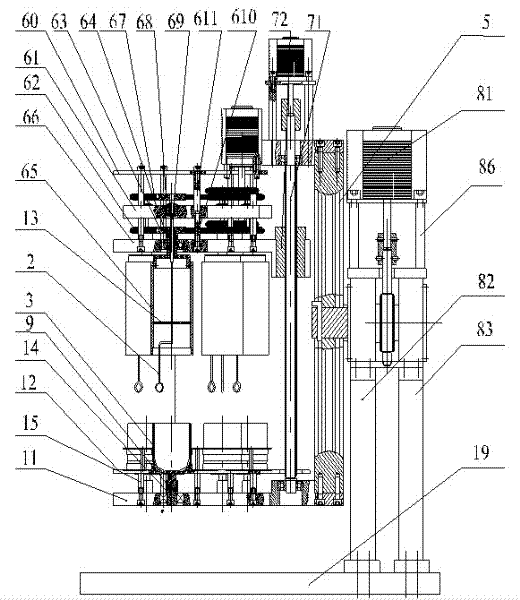

Automatic test equipment for volatiles of bituminous coal

InactiveCN104749066AImprove scienceIncrease authenticityWeighing by removing componentAutomatic test equipmentCrucible

The invention discloses automatic test equipment for the volatiles of bituminous coal. The automatic test equipment comprises a bituminous coal heating module and a bituminous coal weighing module, wherein the bituminous coal heating module has the function of automatically opening / closing a furnace door, and the bituminous coal weighing module is capable of automatically weighing the masses of each crucible containing bituminous coal before and after an experiment; experimenters only need to place the crucibles on a crucible tray and do not need to participate in the later experiment process. The invention discloses automatic test equipment which is simple and compact in structure, convenient to operate, capable of automatically weighing the masses of each crucible before and after the experiment, and capable of carrying out a volatile experiment on 20 crucibles simultaneously.

Owner:CHANGZHOU UNIV

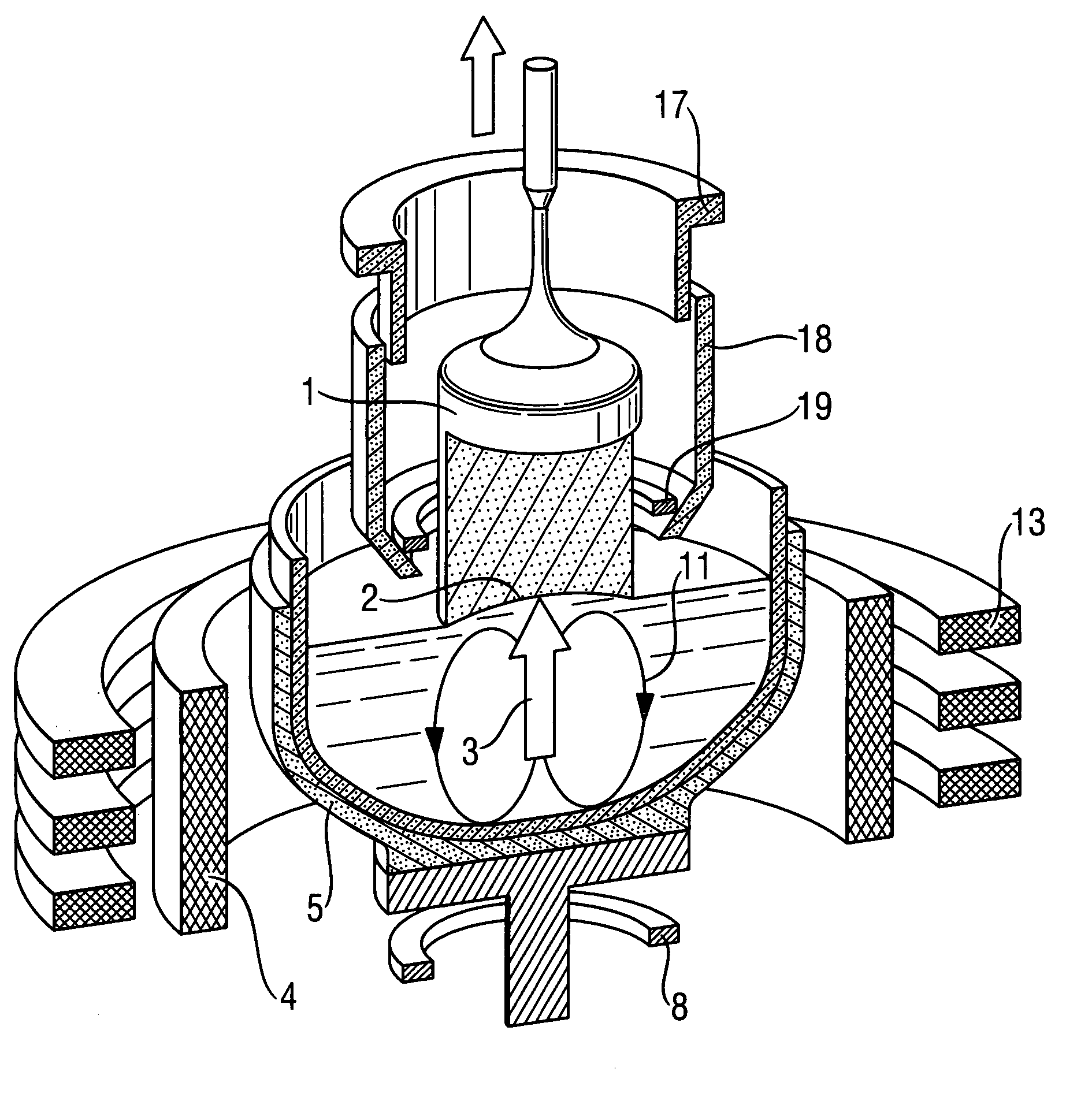

Method and device for the production of a silicon single crystal, silicon single crystal, and silicon semiconductor wafers with determined defect distributions

InactiveUS20040192015A1Increase productionMinimize thermal dissipationPolycrystalline material growthFrom solid stateVacancy defectHeat flux

A method for the production of a silicon single crystal by pulling the single crystal, according to the Czochralski method, from a melt which is held in a rotating crucible, the single crystal growing at a growth front, heat being deliberately supplied to the center of the growth front by a heat flux directed at the growth front. The method produces a silicon single crystal with an oxygen content of from 4*10<17 >cm<-3 >to 7.2*10<17 >cm<-3 >and a radial concentration change for boron or phosphorus of less than 5%, which has no agglomerated self-point defects. Semiconductor wafers are separated from the single crystal. These semiconductor wafers have may have agglomerated vacancy defects (COPs) as the only self-point defect type or may have certain other defect distributions.

Owner:SILTRONIC AG

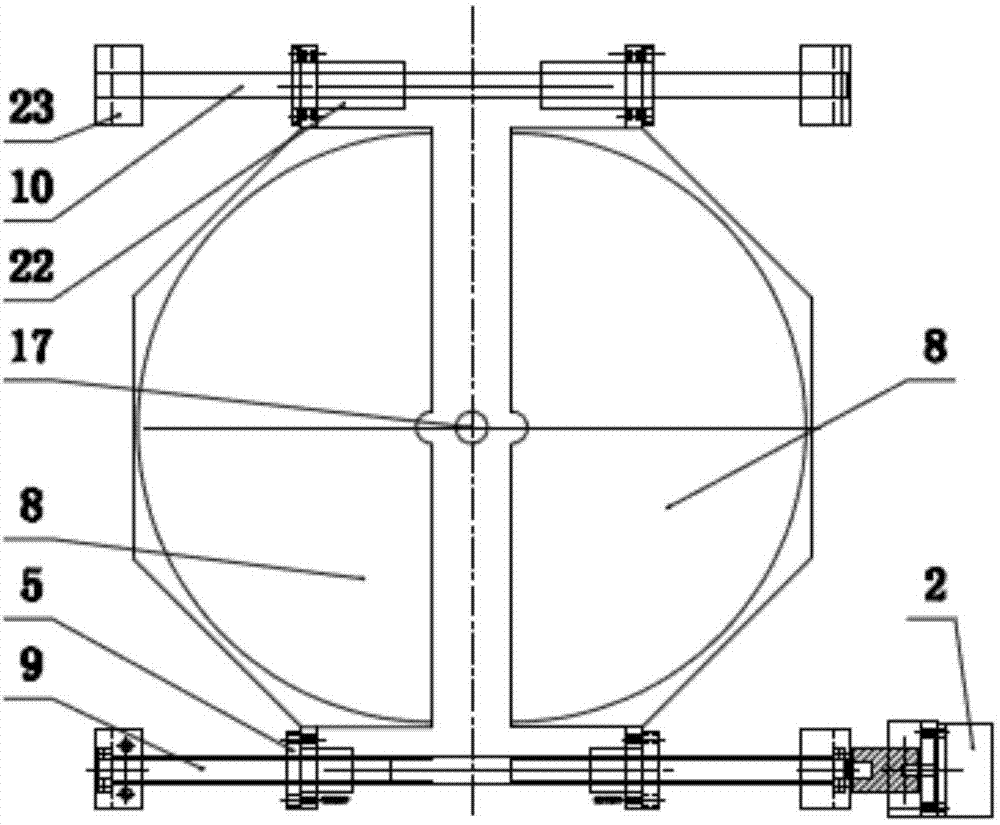

Stirring device with transmission type multi-crucible

ActiveCN102380328AIncrease profitAvoid unstable rotationMixing methodsMixer accessoriesBiochemical engineeringCrucible

The invention discloses a stirring device with a transmission type multi-crucible, which is characterized that a control mechanism is fixed on a bottom plate, a lifting device, an inclination device, a heterodromous rotation device and a crucible tray are fixed on the bottom plate. The transmission driven crucible and the heterodromous rotation device capable of heterodromously rotating a mixing wire are arranged on the upper part of the lifting device, the crucible tray capable of placing the multi-crucible is placed on the lower part of the lifting device, the inclination device fixed on the fixed pedestal is communicated with the heterodromous rotation device. The stirring device of the invention has the advantages of simple and compact structure, and simple operation, and is capable of effectively solving the problem for batch producing anthracite samples, and increasing the production number and the quality of the anthracite caking index samples.

Owner:江苏双星特钢有限公司

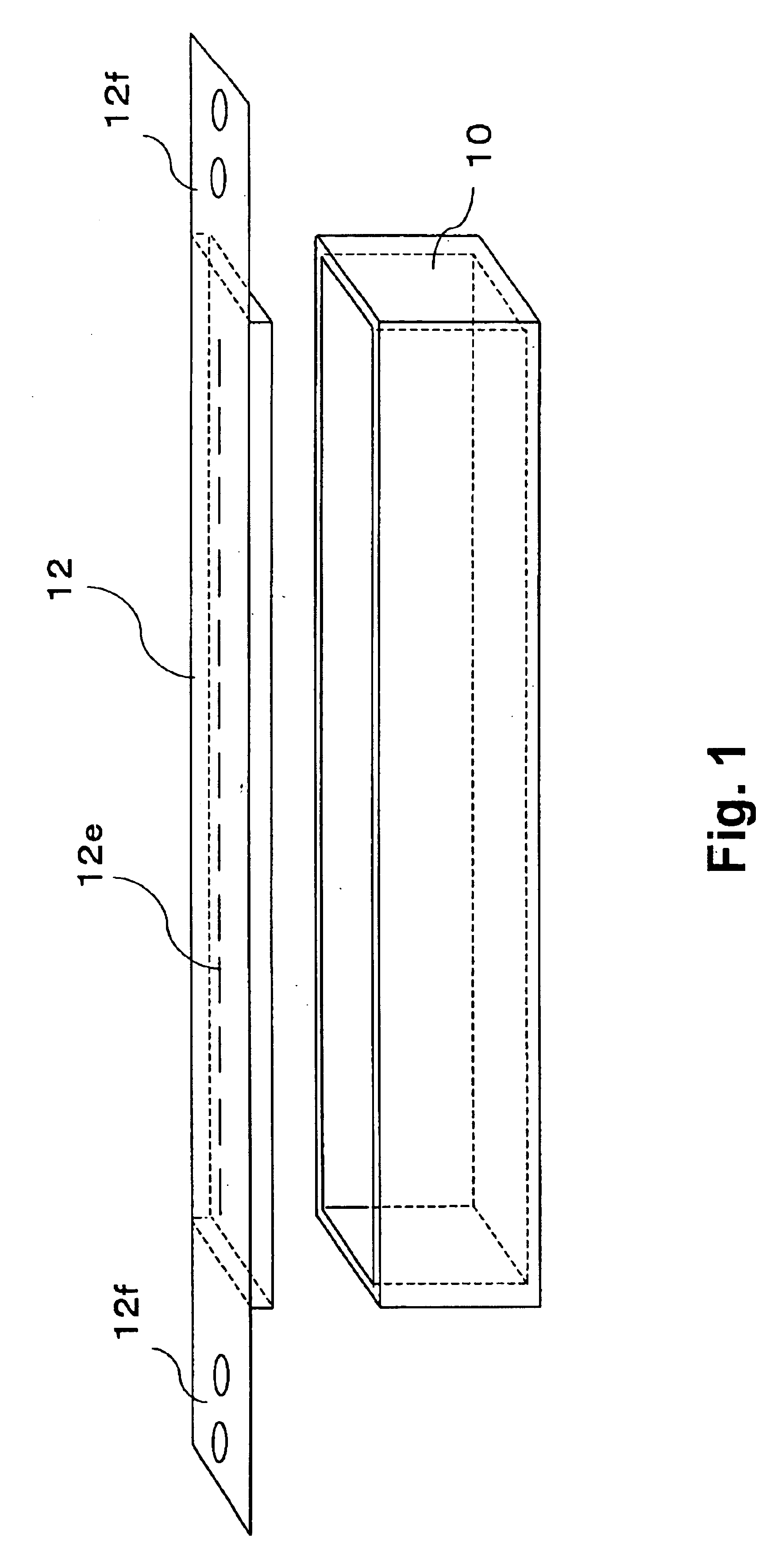

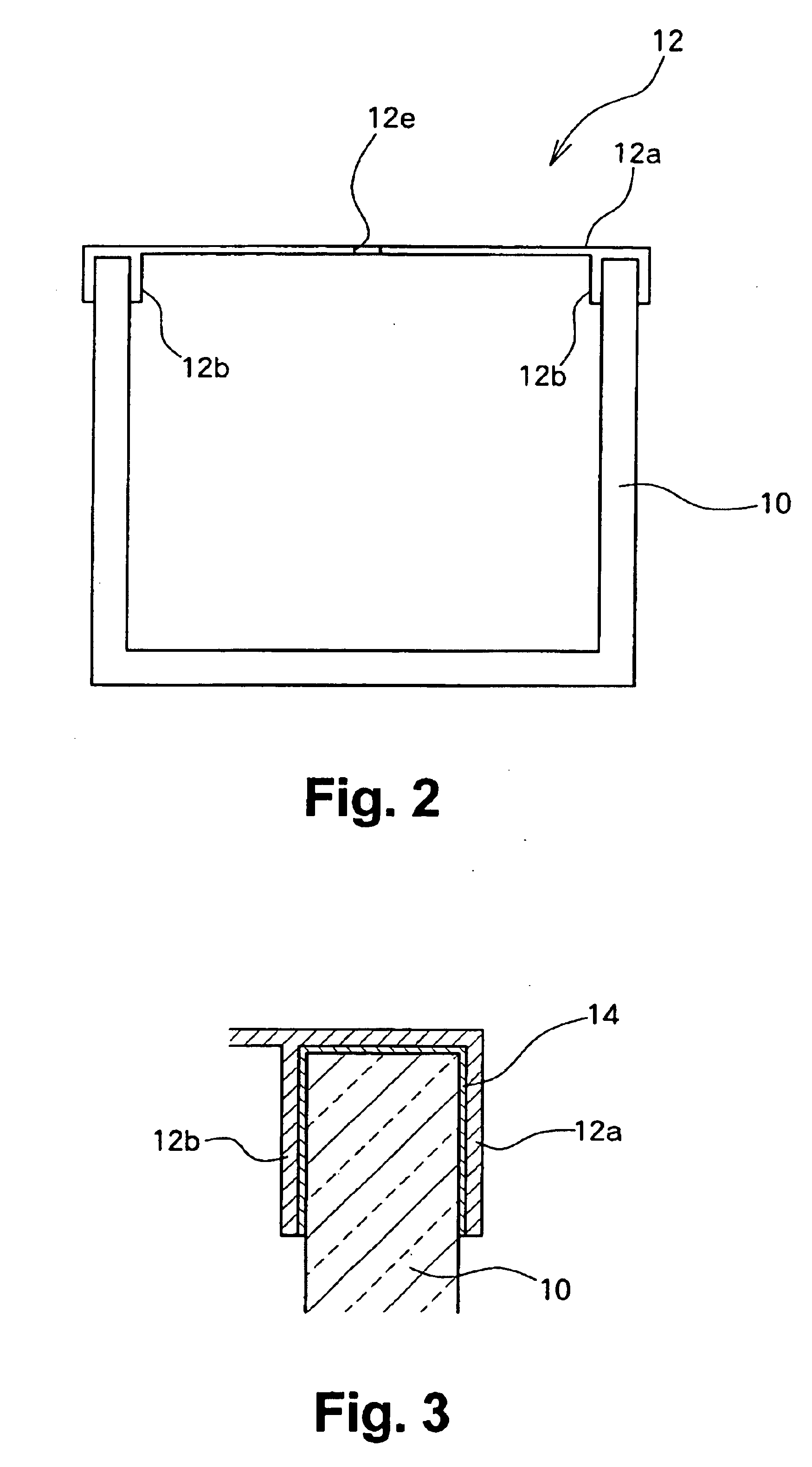

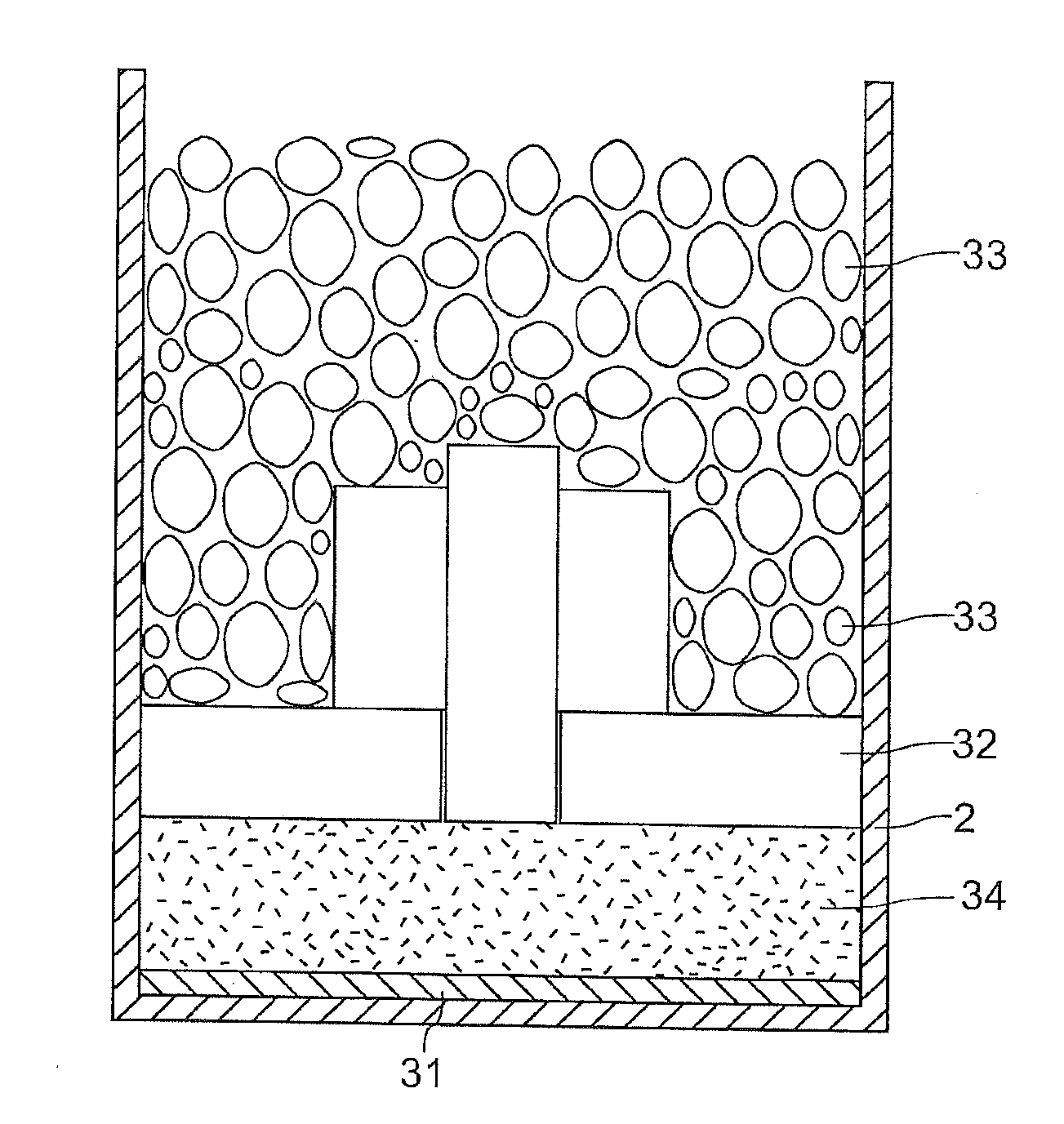

Heating crucible and deposition apparatus using the same

A deposition apparatus includes a vacuum chamber and a heating crucible. A substrate, on which deposition films are formed, is installed in the vacuum chamber. The heating crucible is installed opposite to the substrate so as to vaporize an organic compound. The heating crucible includes a main body and an inner plate. The main body includes a space which contains the organic compound and a nozzle through which the organic compound that is vaporized is discharged. The inner plate is installed within the main body and includes at least one opening formed around an edge of an area facing the nozzle, so as to transmit the vaporized organic compound.

Owner:SAMSUNG DISPLAY CO LTD

Device for preparing semi-solid alloy rheological slurry or blank

ActiveCN101618438AOvercome the disadvantages of large and complex structure and high investment costLow investment costCrucibleSemi solid

The invention discloses a device for preparing semi-solid metal and alloy slurry, which mainly comprises an electromagnetic stirrer, an insulating layer, an external cooling controller, a valve, a draft tube, a preparation crucible, an insulating crucible cover, a standing crucible, a melting crucible and a thermocouple. The middle part of the preparation crucible is provided with an internal cooling controller, and the outer wall of the internal cooling controller forms a clearance with the inner wall of the preparation crucible. The device can be connected with a press-casting machine, an extruder, a continuous casting machine and a forging machine, wherein the press-casting machine consists of a press-casting fixed die, a press-casting movable die, an injection chamber and a punch head; the extruder consists of a right extrusion die profile, a left extrusion die profile, an extrusion cylinder and an extrusion rod; the continuous casting machine consists of a tundish, a crystallizer, a cooling water nozzle and a traction mechanism; and the forging machine consists of a forging die cavity and a forging die. The device has the advantages that the device has simple and compact structure, low investment cost and strong practicability; the temperature field and tissue of the prepared slurry are distributed evenly; the semi-solid alloy slurry is pure, does not bubble and has good self cleanness; and the device can produce large-specification semi-solid slurry or blank, and is quite suitable for the preparation and formation of the semi-solid slurry or the blank.

Owner:有研金属复材技术有限公司

Preparation process of fluorescent powder for white light LED excited by blue light

InactiveCN100999662ASimple preparation processProduction conditions are easy to controlGas discharge lamp usageLuminescent compositionsCruciblePhosphor

The present invention is preparation process of phosphor powder for blue light excited white light LED. The phosphor powder has the chemical formula of (R3-x-yCexLny)A5O12, where, R is at least one of Y, La, Gd, Tb, Lu and Sc; Ln is at least one of Pr, Dy, Nd, Sm, Dy and Bi; A is at least one of B, Al, Ga, Si, Mn and Mg; x is 0.01-1.2; and y is 0-0.2. The preparation process of the phosphor powder includes mixing oxides, hydroxides or salts corresponding to the elements in the formula and proper amount of flux; setting the mixture into the inner crucible with an unsealed cover, setting graphite or carbon between the outer crucible and the inner crucible, and covering the outer crucible with sealing cover; igniting inside a high temperature furnace at 1350-1700 deg.c, for 1-8 hr; cooling, crushing, washing and stoving to obtain the phosphor powder.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

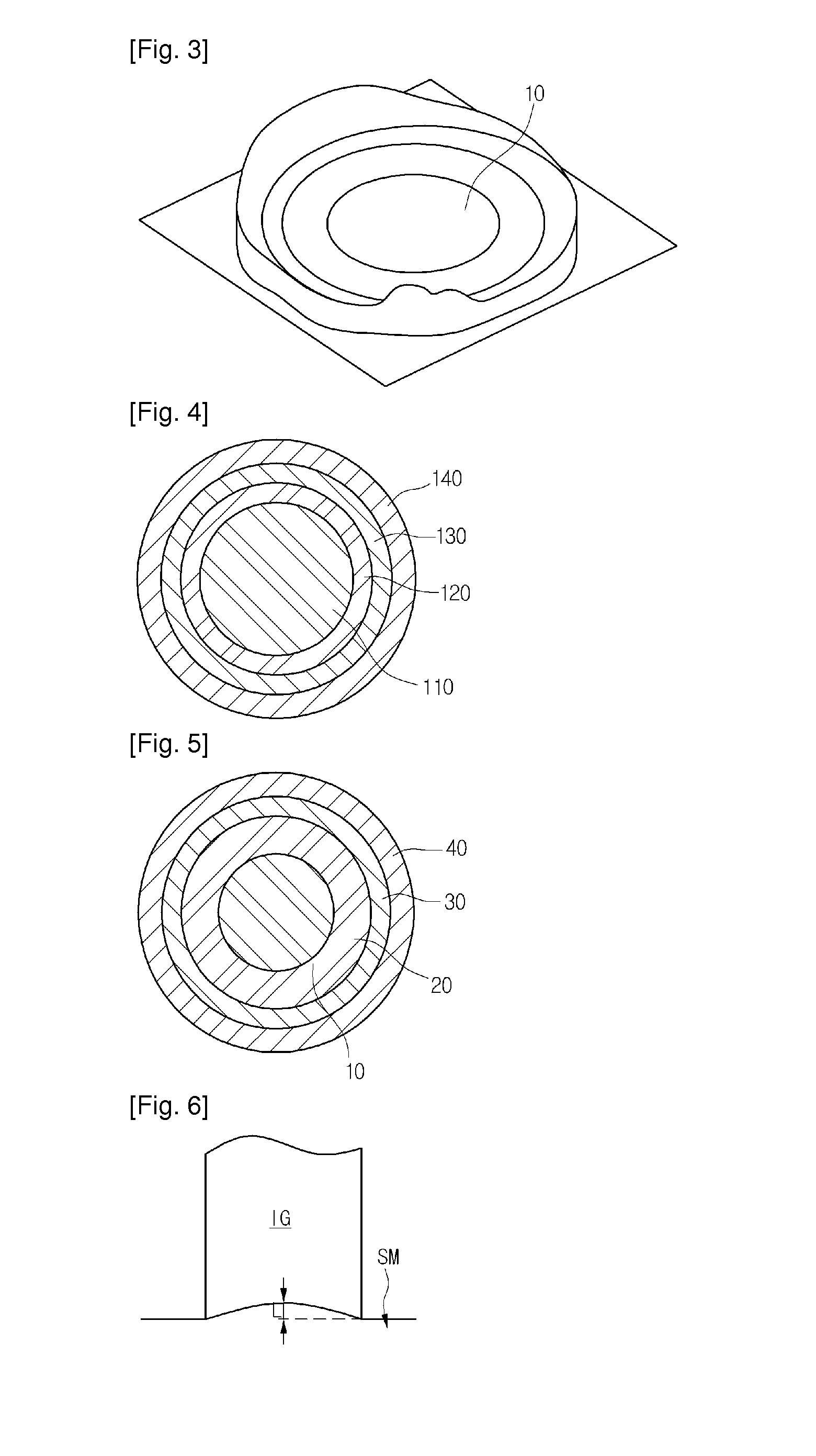

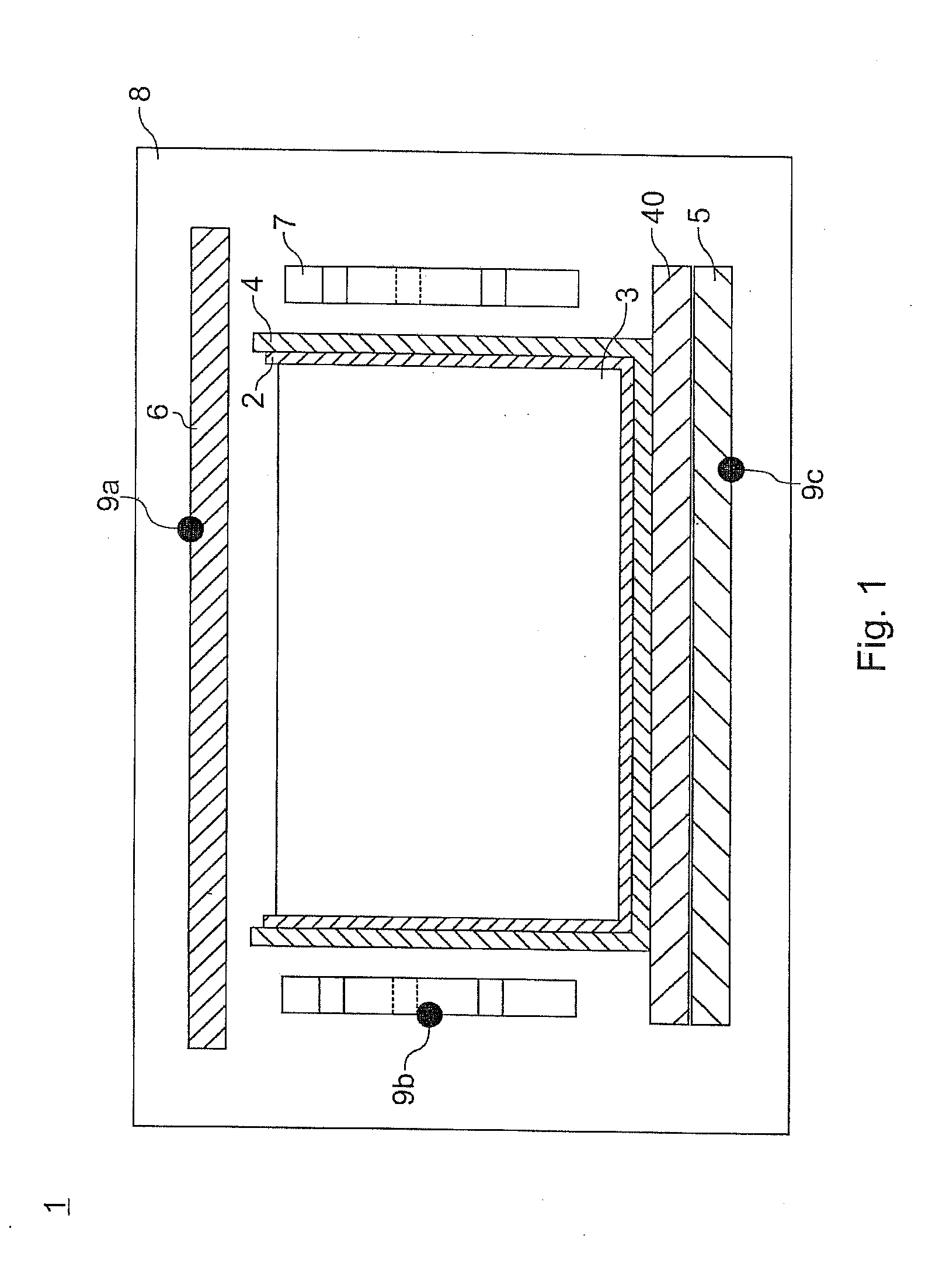

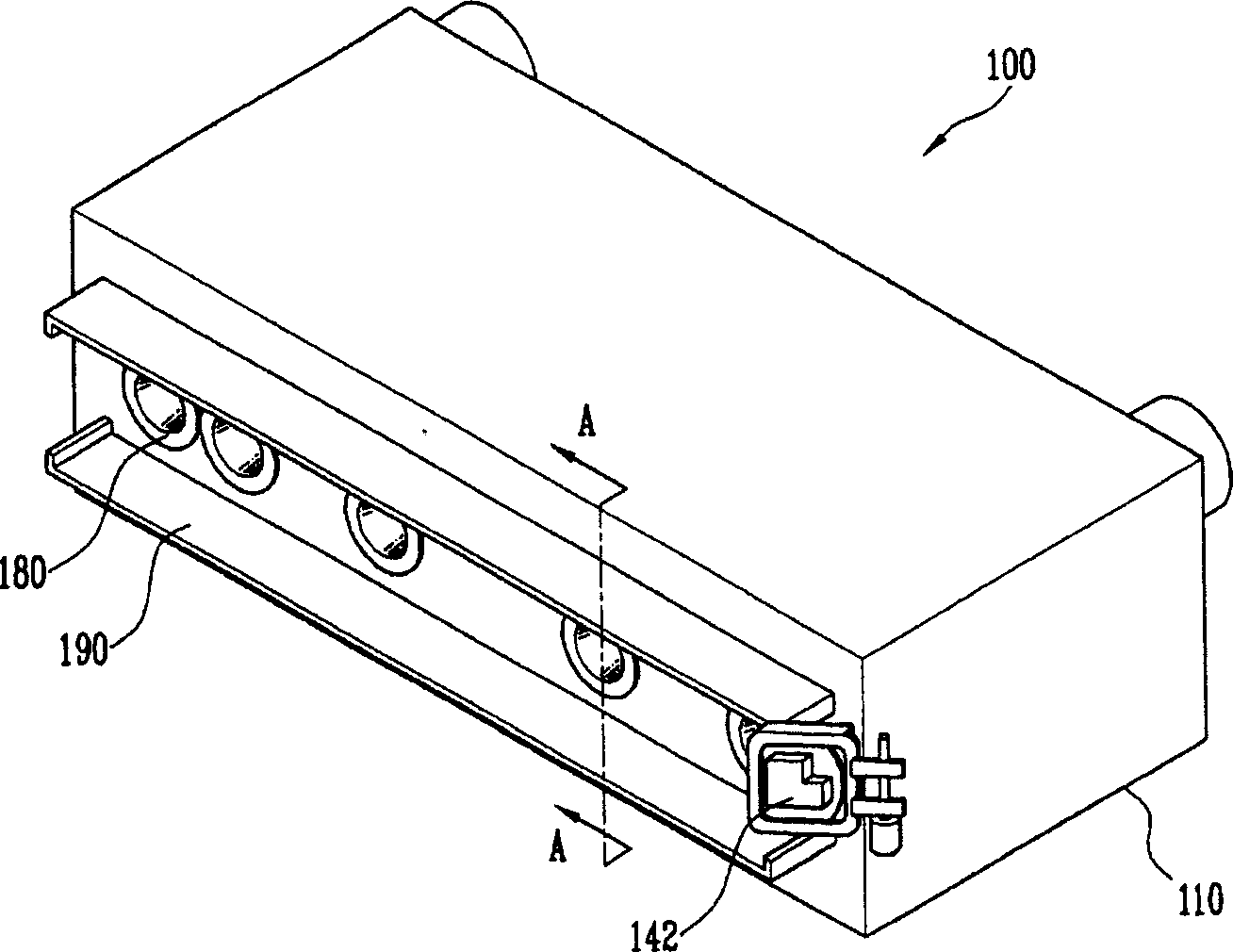

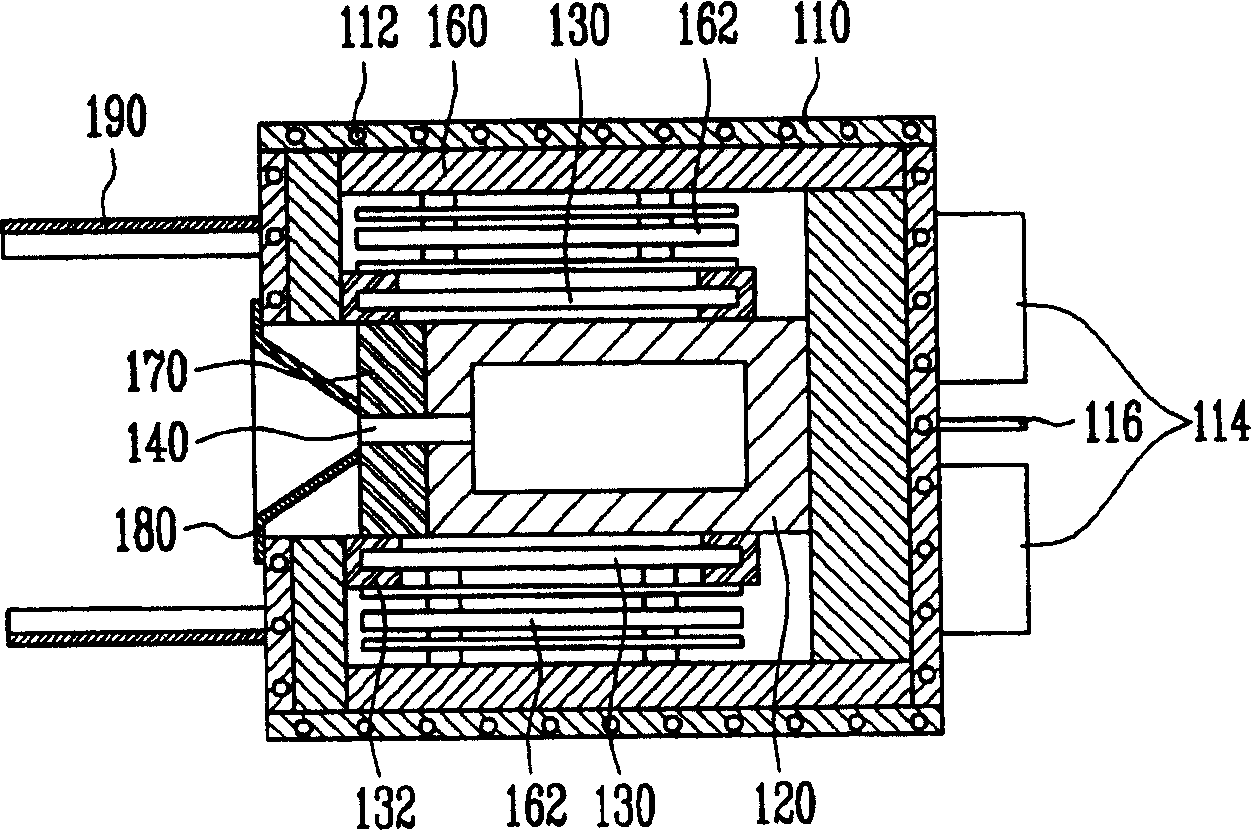

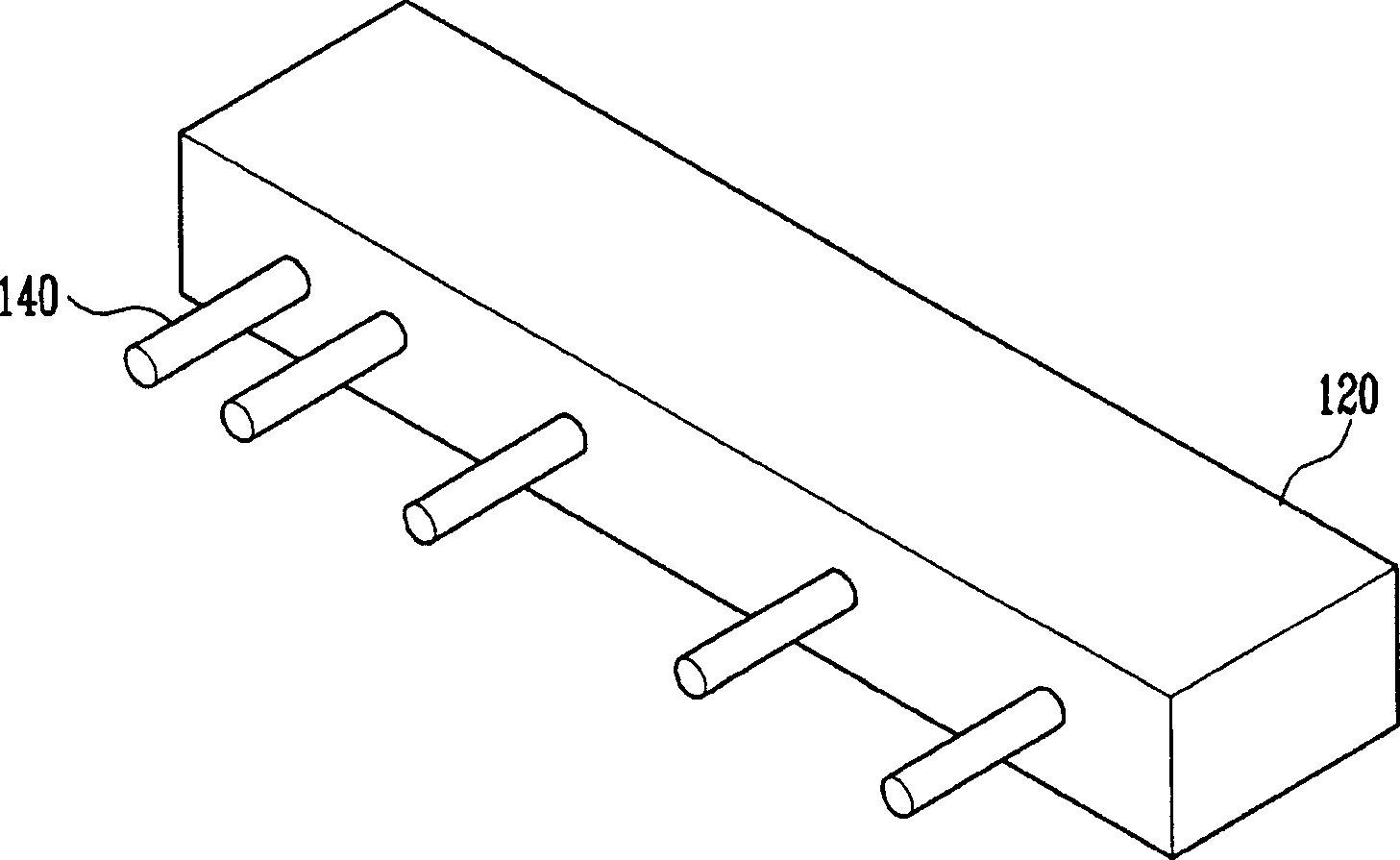

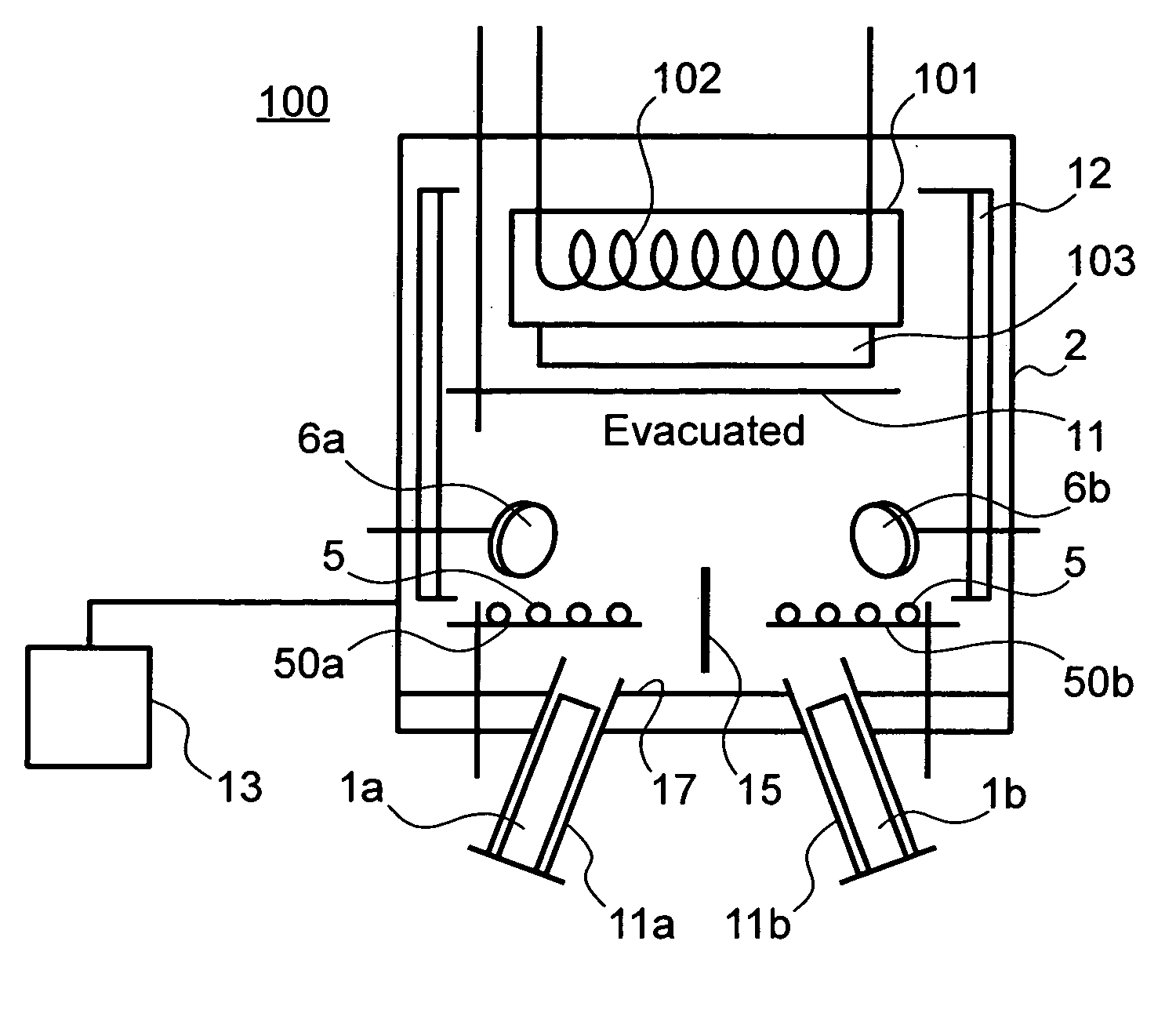

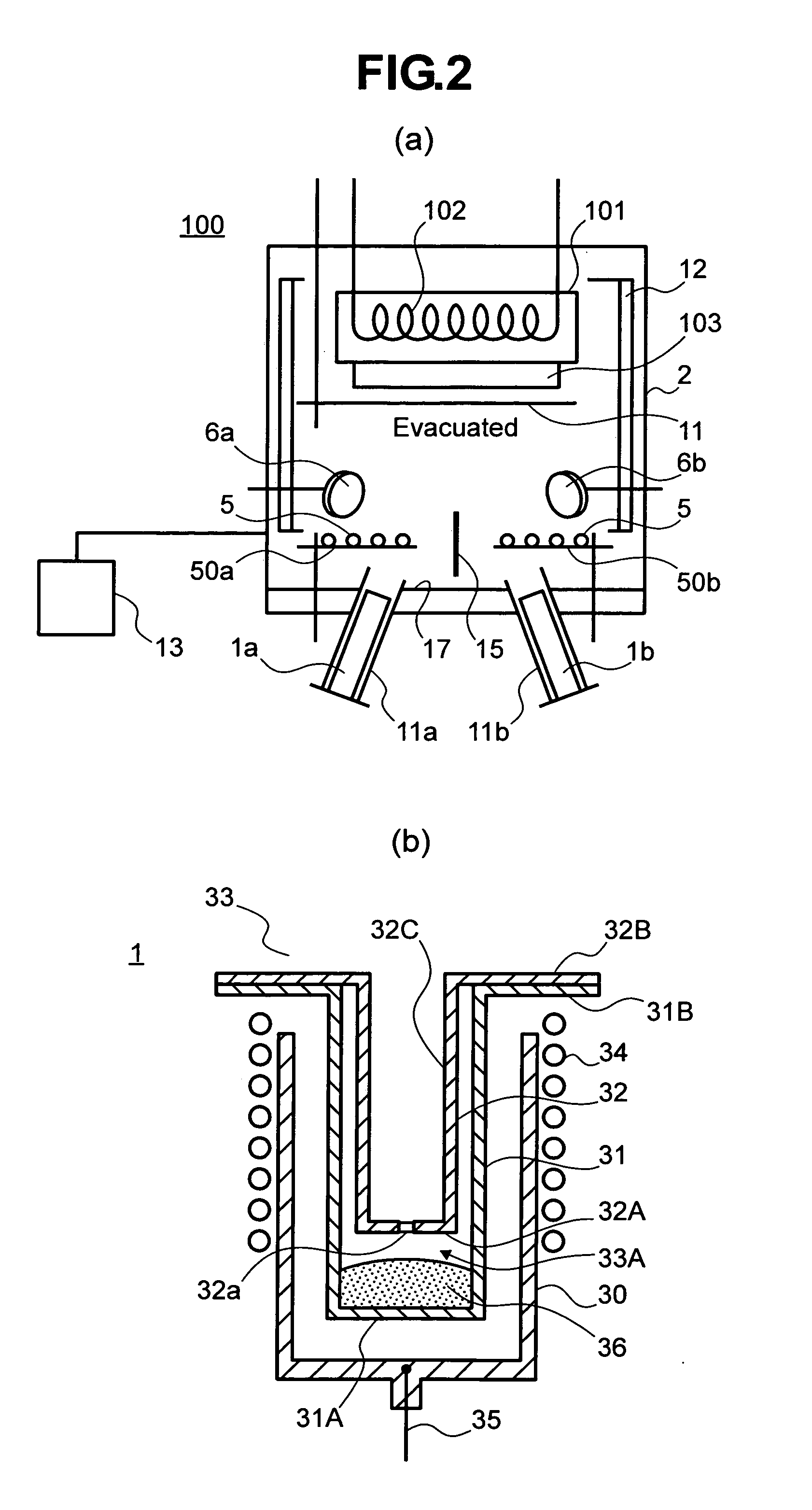

Vapor deposition source and vapor deposition apparatus having the same

ActiveCN1814854AUniform vapor depositionLow powerVacuum evaporation coatingSputtering coatingCrucibleVaporization

The invention provides a vaporization source, wherein a crucible, a heating portion and a nozzle portion are arranged in one partitioned space so as to reduce the size, and a vapor deposition apparatus for depositing deposition materials on a substrate using the vaporization source. The apparatus includes a housing 100, a crucible 120 built in the housing 110, a heating portion which is positioned around the crucible 12 built in the housing 110 in order to heat the crucible 12, and a nozzle portion injecting the deposition materials vaporized from the crucible 120 into a substrate 220 disposed at an exterior of the housing 110 through an injection nozzle 140.

Owner:SAMSUNG DISPLAY CO LTD

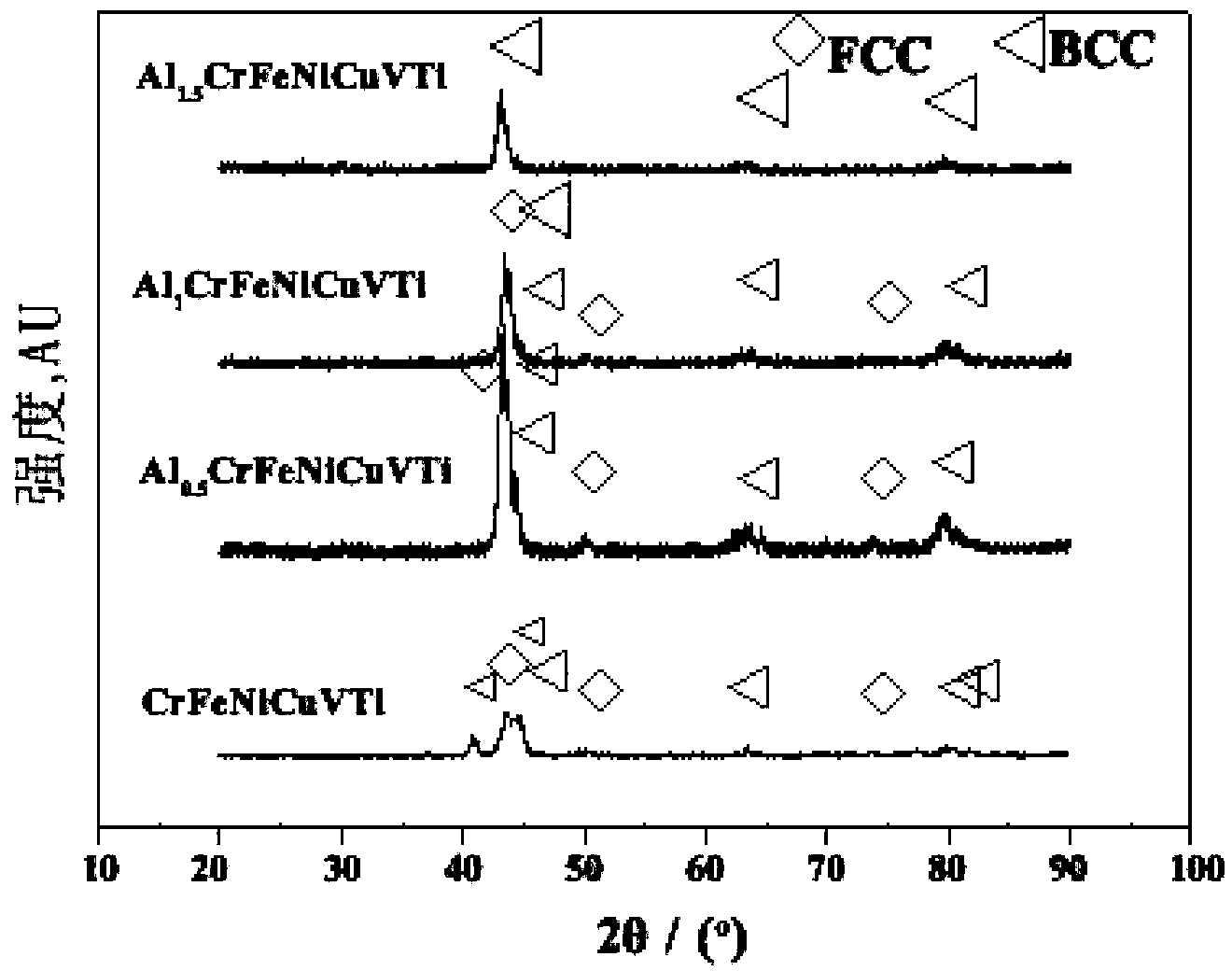

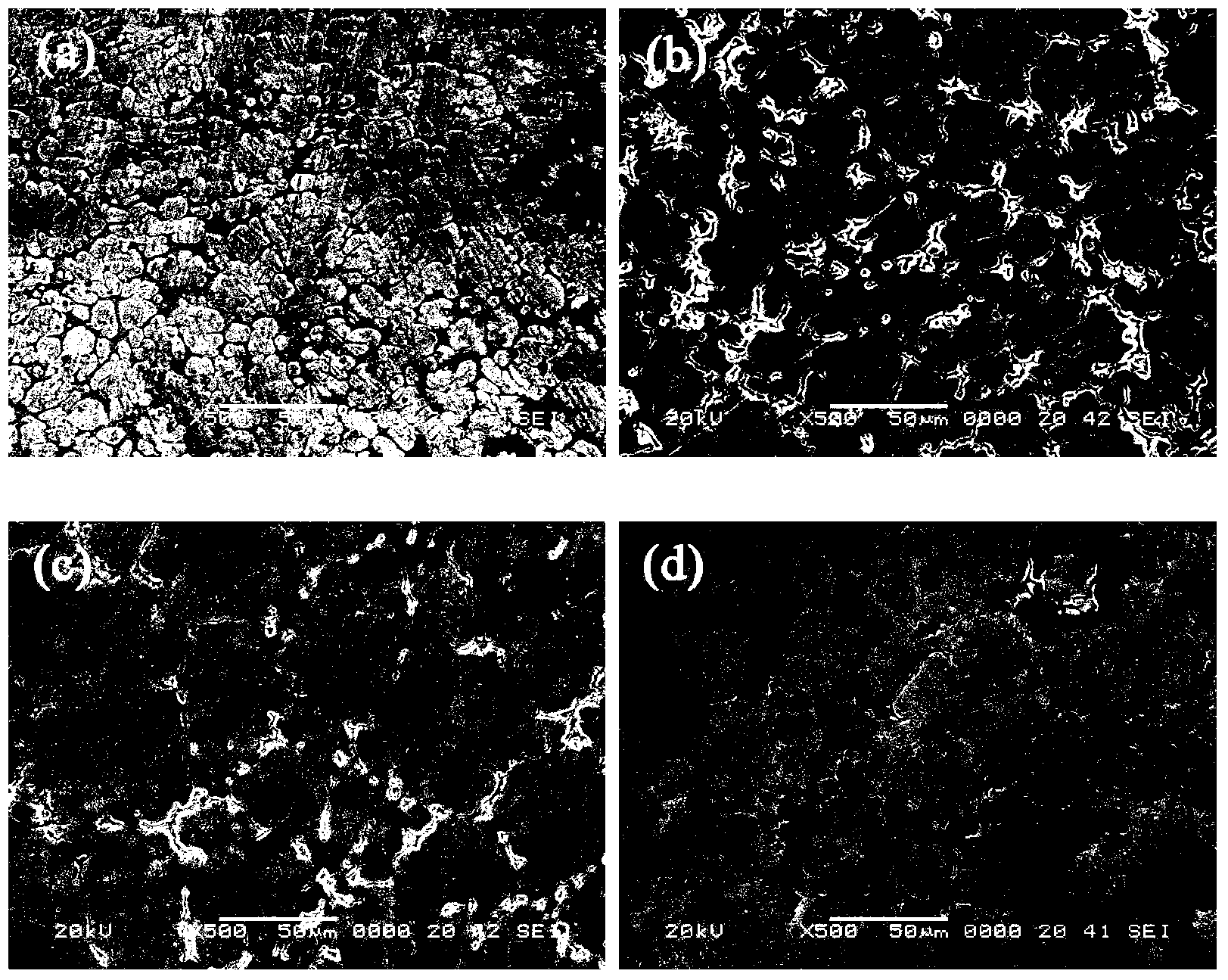

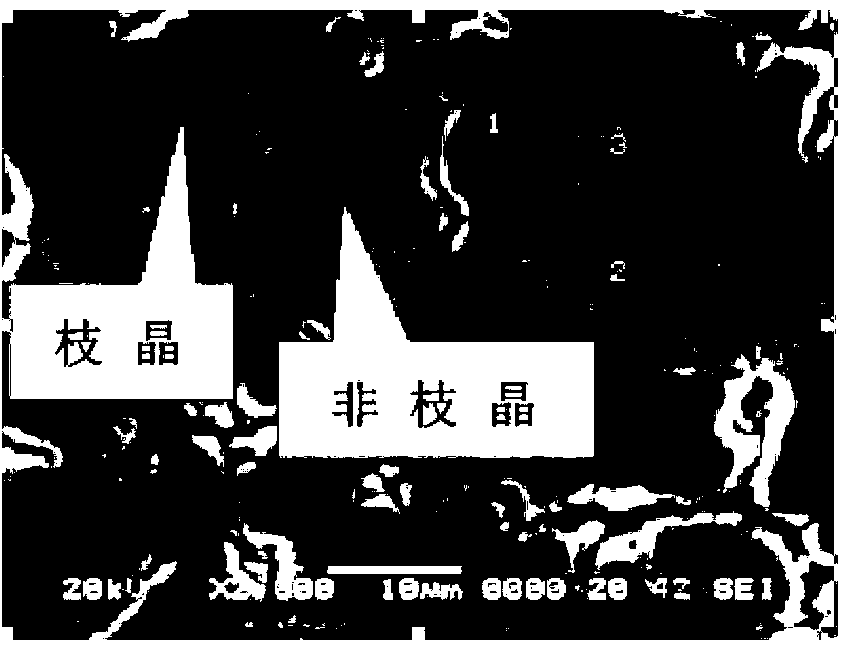

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

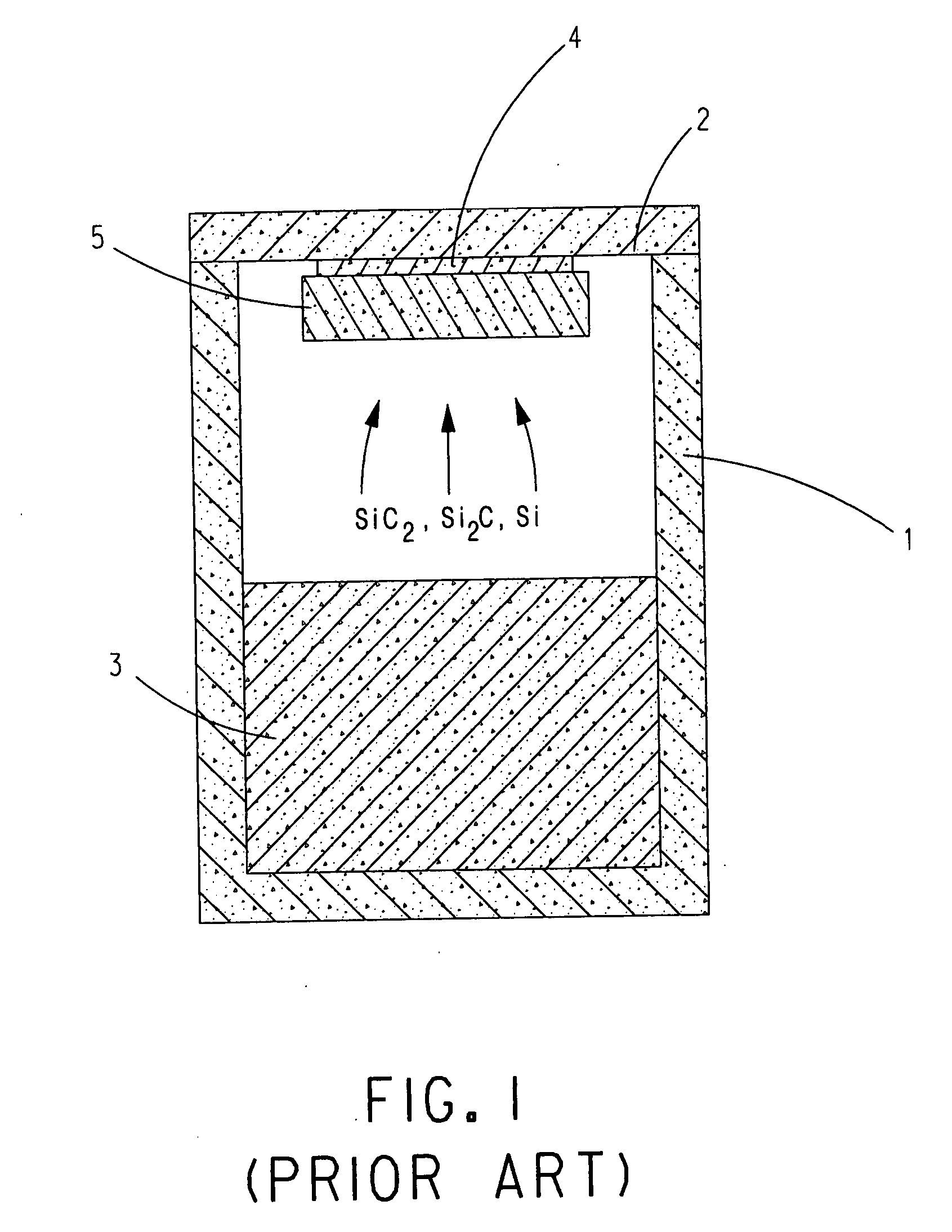

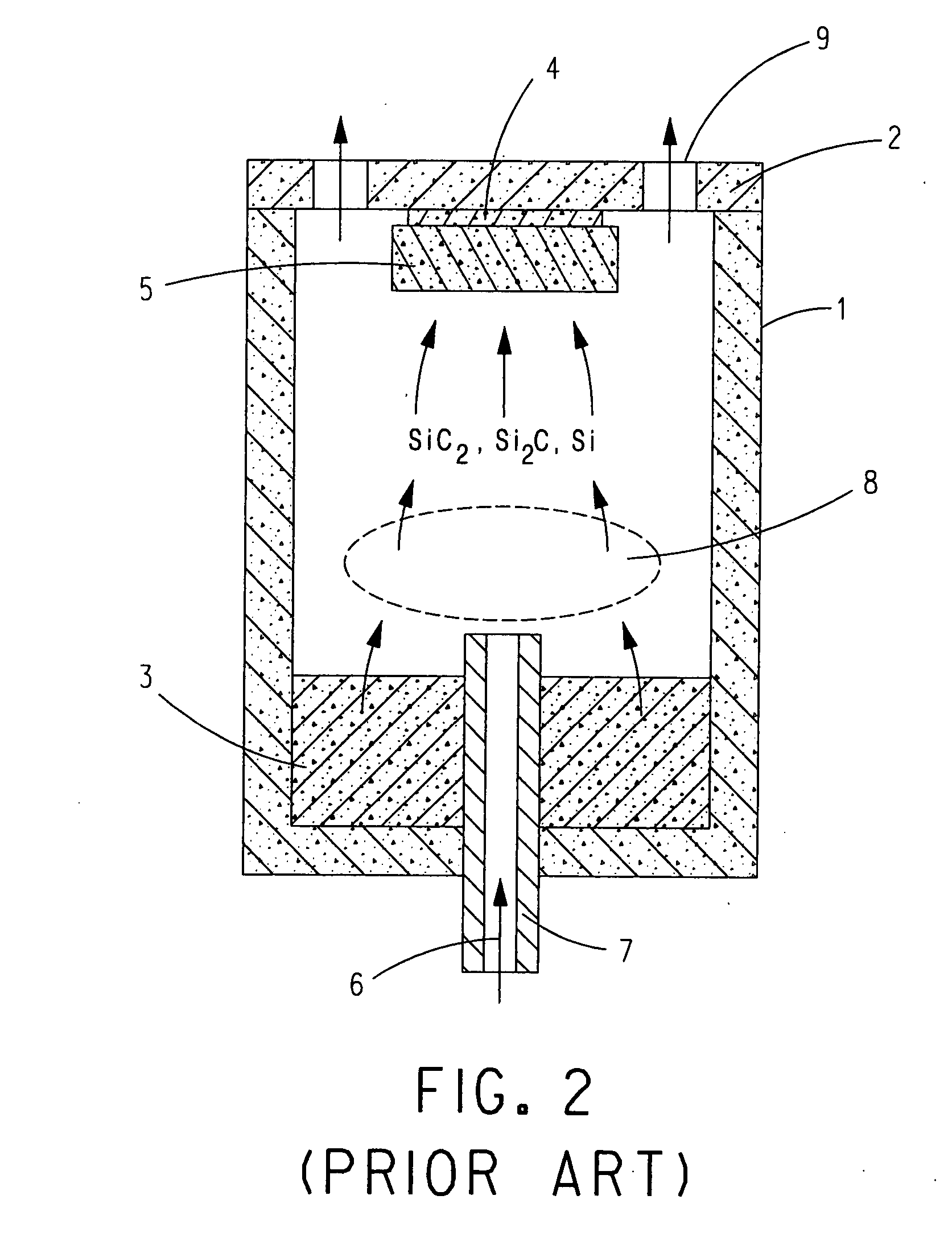

Silicon carbide single crystals with low boron content

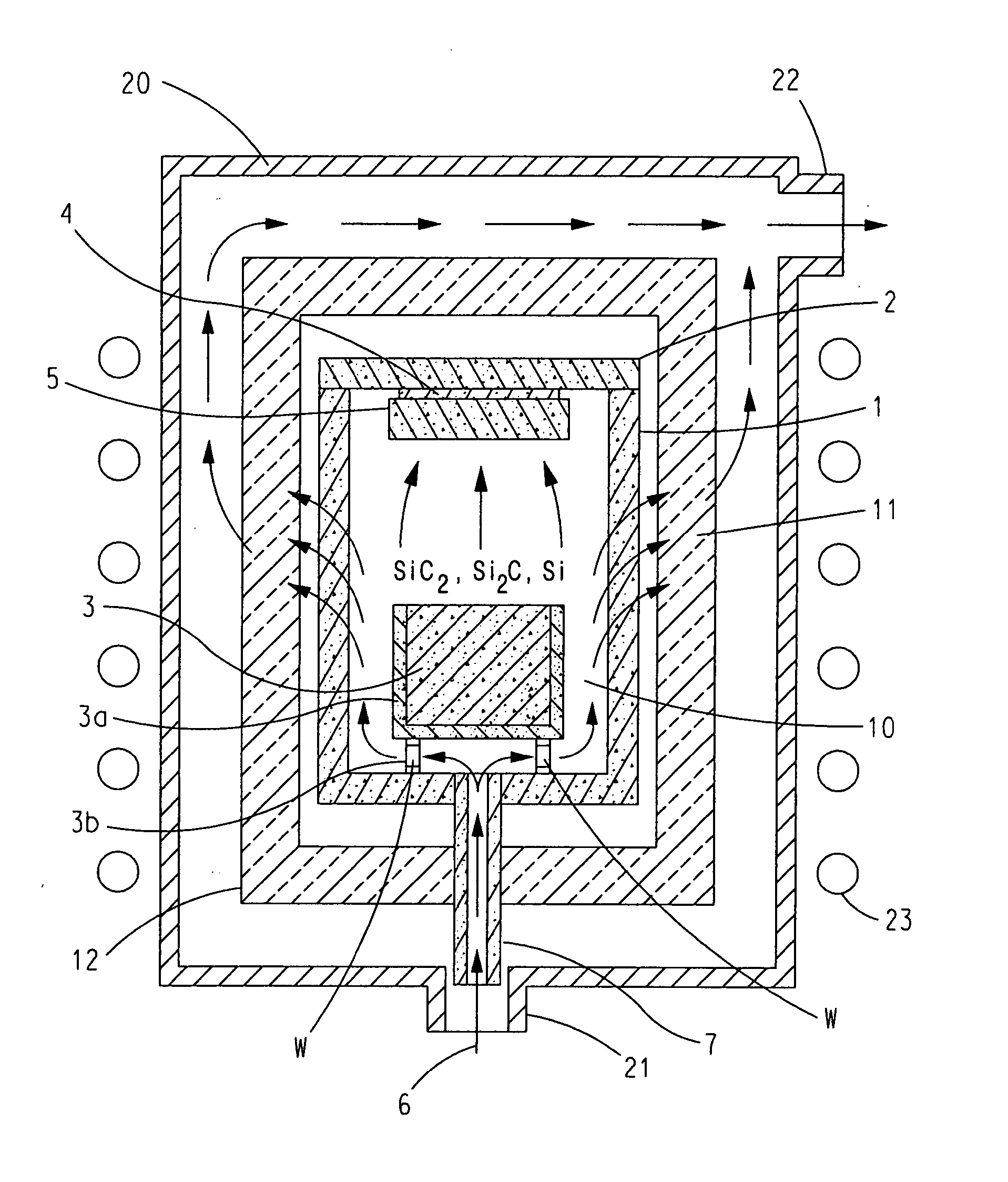

ActiveUS20080072817A1Reduce lossesReduce chemical attackPolycrystalline material growthFrom chemically reactive gasesCarbide siliconSource material

In a crystal growth method, an enclosed growth crucible is provided inside of a growth chamber. The growth crucible has polycrystalline source material and a seed crystal disposed in spaced relation therein. The interior of the growth crucible is heated whereupon a temperature gradient forms between the source material and the seed crystal. The temperature gradient is sufficient to cause the source material to sublimate and be transported to the seed crystal where it precipitates on the seed crystal. A gas mixture is caused to flow into the growth crucible and between the polycrystalline source material and an interior surface of the growth crucible. The gas mixture reacts with an unwanted element in the body of the growth crucible to form a gaseous byproduct which then flows through the body of the growth crucible to the exterior of the growth crucible.

Owner:II VI DELAWARE INC

Solder ball and method for producing same

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

Seeded growth process for preparing aluminum nitride single crystals

ActiveUS20070257333A1Accelerate evaporationAvoid depositionPolycrystalline material growthFrom chemically reactive gasesCrucibleSource material

A method of growing bulk single crystals of an AlN on a single crystal seed is provided, wherein an AlN source material is placed within a crucible chamber in spacial relationship to a seed fused to the cap of the crucible. The crucible is heated in a manner sufficient to establish a temperature gradient between the source material and the seed with the seed at a higher temperature than the source material such that the outer layer of the seed is evaporated, thereby cleaning the seed of contaminants and removing any damage to the seed incurred during seed preparation. Thereafter, the temperature gradient between the source material and the seed is inverted so that the source material is sublimed and deposited on the seed, thereby growing a bulk single crystal of AlN.

Owner:INTERSOUTH PARTNERS VI +6

Vapor deposition crucible, thin-film forming apparatus comprising the same, and method of producing display device

InactiveUS20070178225A1Material is facilitatedPrevent solidificationSolid-state devicesVacuum evaporation coatingVena contracta diameterGas phase

For lasting stable vapor deposition of a material for a long term, the present invention provides the vapor deposition crucible comprising an evaporation chamber defined by a container part of the material and an orifice plate controlling vapor pressure of the material evaporated therein, and a pressure-controlling chamber defined in a space between the orifice plate and a discharge plate through which the material is discharged to the exterior of the vapor deposition crucible. A protrusion extending outwardly from the pressure-controlling chamber and having a second opening on its distal end may be provided on the upper surface of the discharge plate, and a heater may be provided on the side surface of the protrusion to oppose the side surface of the protrusion with an insulation mechanism provided at a position higher than the heater but lower than the second opening. In the vapor deposition crucible, temperature of the pressure-controlling chamber may be kept higher than that of the evaporation chamber by the other heaters.

Owner:HITACHI DISPLAYS

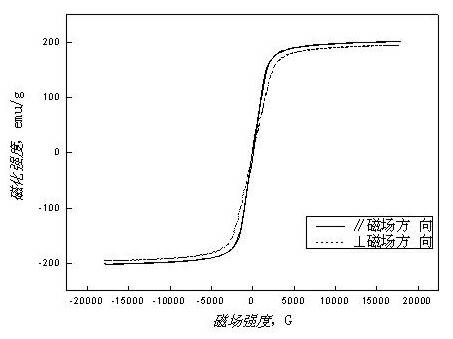

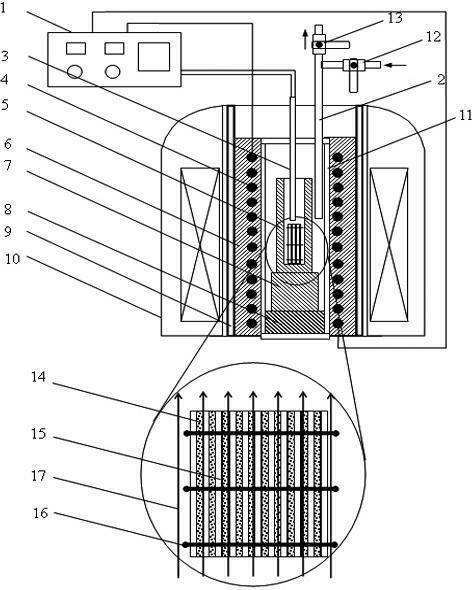

Method and device for preparing high-silicon silicon steel sheet in static magnetic field with powder sintering method

ActiveCN102658367AAccurate control of silicon contentHigh densityInorganic material magnetismInlet valveExhaust pipe

The invention relates to a method and device for preparing a silicon steel sheet in a static magnetic field with a powder sintering method. The specific process of the method consists of the following steps of: mixing Fe-Si powder; rolling into a plate blank; and sintering a Fe-6.5 weight percent Si green compact in a static magnetic field. In the method, 6.5 percent by weight of Si high-silicon steel with high density is obtained by using the influence of the magnetic field on the sintering densification and orientation process of a Fe-6.5 weight percent Si powder green compact, and an easily-magnetized axis is oriented along the magnetic field. An atmosphere / vacuum sintering device in a static magnetic field consists of a temperature control device, an exhaust pipe, a thermocouple, a heating element, a corundum crucible, a refractory fiber, a support block, a heat insulating block, a water-cooled bush, a static magnetic field generating device, a sealed corundum pipe, an inert gas inlet valve, a vacuum pumping valve, a Fe-6.5weight percent Si green compact, a thin corundum plate interlayer and a fixing molybdenum wire. The 6.5 percent Si silicon steel sheet prepared with the method has the advantages of near net molding, superior magnetic property, high orientation degree and the like, and has a remarkable industrial application prospect.

Owner:SHANGHAI UNIV

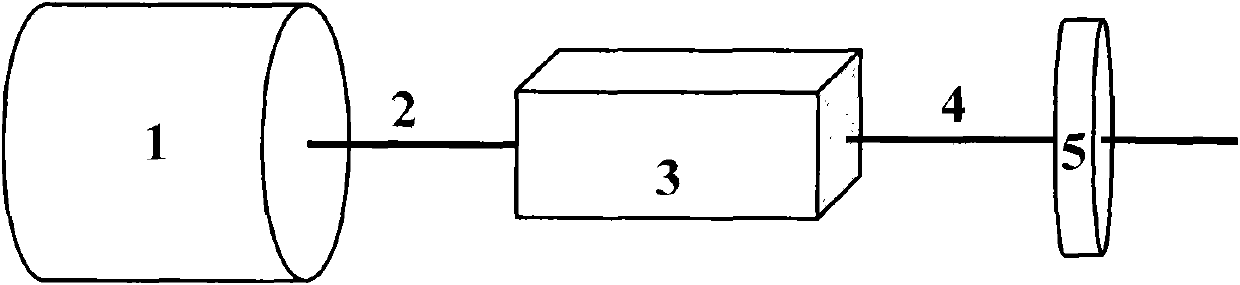

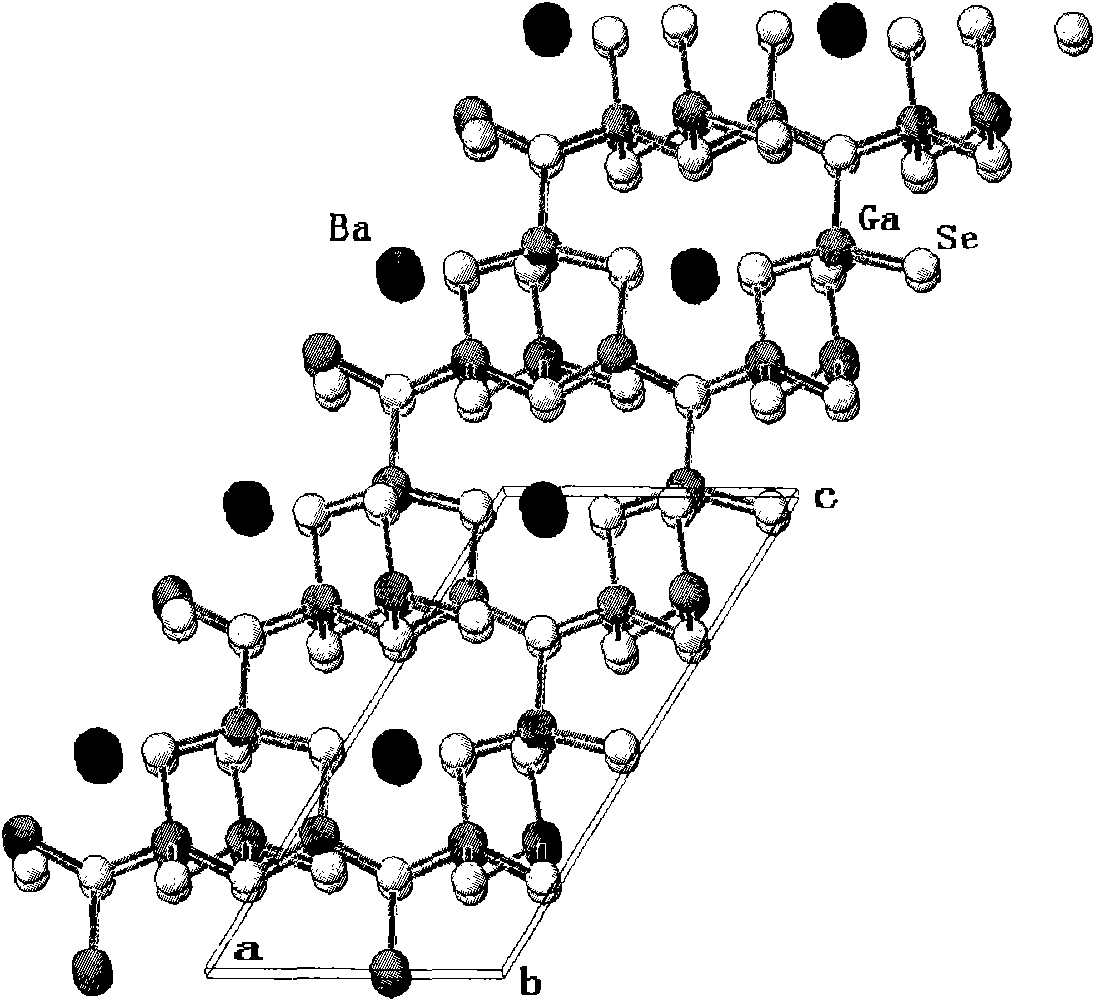

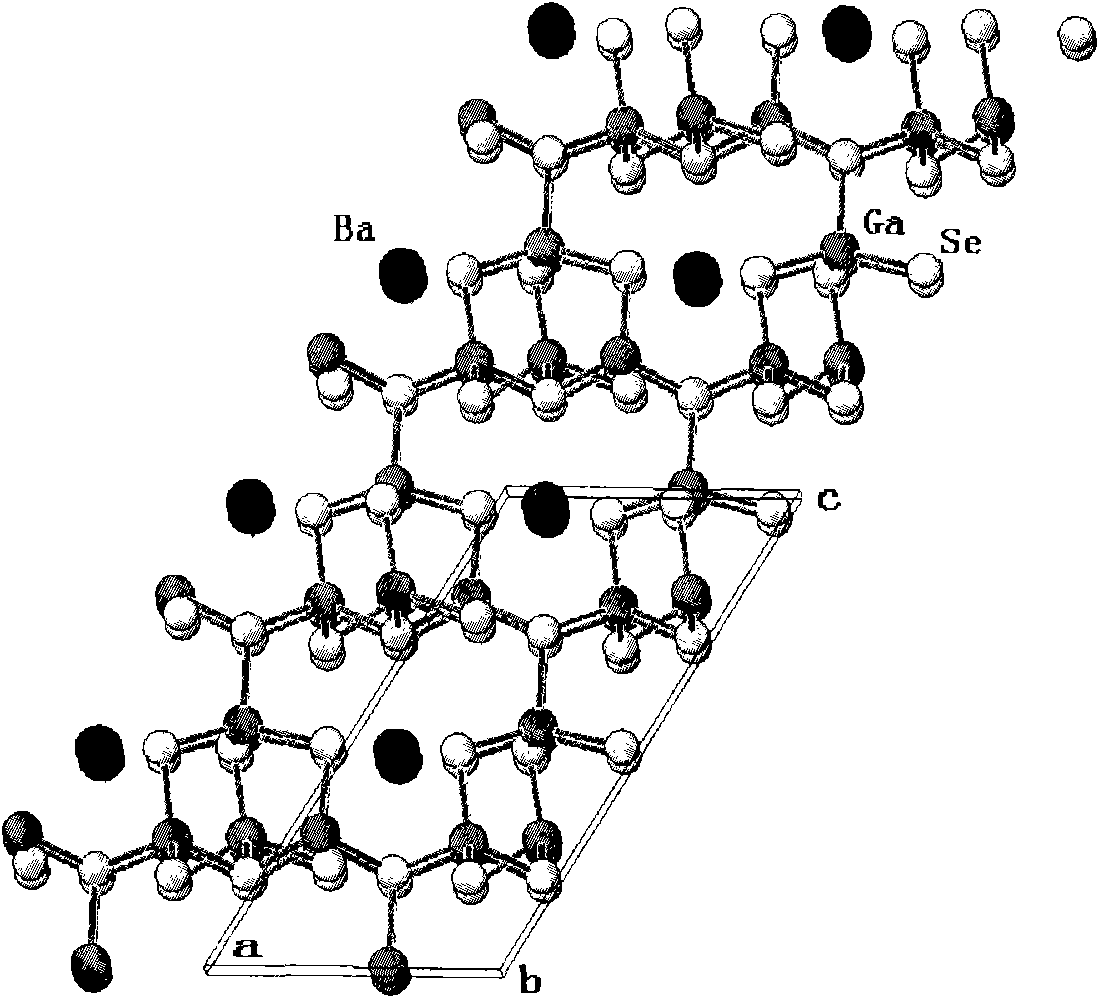

BaCa4Se7 compound, BaCa4Se7 nonlinear optical crystal, preparation method and application

ActiveCN101767778AWide band of light transmissionHigh hardnessPolycrystalline material growthAfter-treatment detailsNonlinear optical crystalOptical transparency

The invention relates to a BaCa4Se7 compound, a BaCa4Se7 nonlinear optical crystal, a preparation method and application. The BaCa4Se7 compound is prepared by adopting a solid-phase reaction, and the BaCa4Se7 nonlinear optical crystal is grown by adopting a high-temperature melt spontaneous crystallization method, a flux growth method or a Bridgman method. In the growth of the BaCa4Se7 nonlinear optical crystal, the crystal is easy to grow and transparent and has no package and the advantages of higher growing speed, low cost, easy obtaining of a crystal in a larger size, and the like. The obtained BaCa4Se7 nonlinear optical crystal has the advantages of wider optical transparency range, larger hardness, good mechanical property, difficult cracking and deliquescence, easy processing and storage, and the like. The BaCa4Se7 nonlinear optical crystal can be used for preparing a nonlinear optical device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

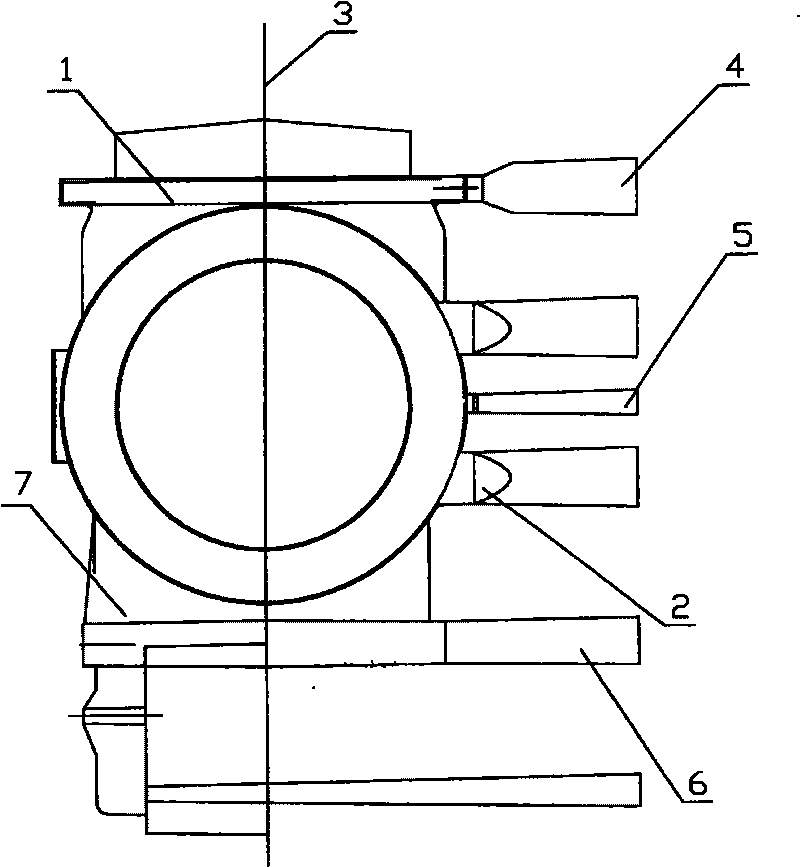

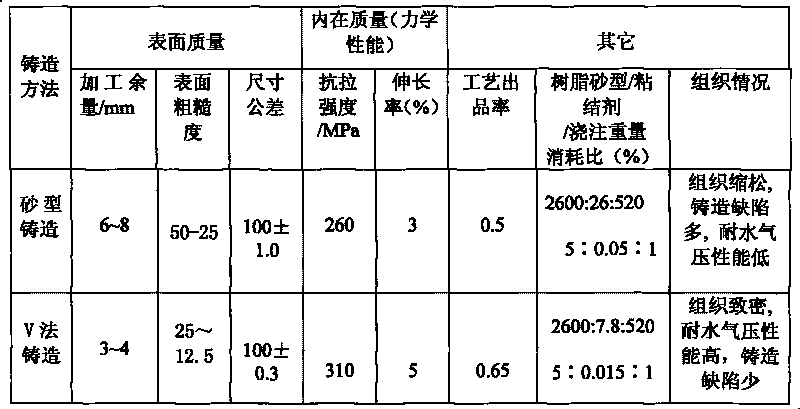

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

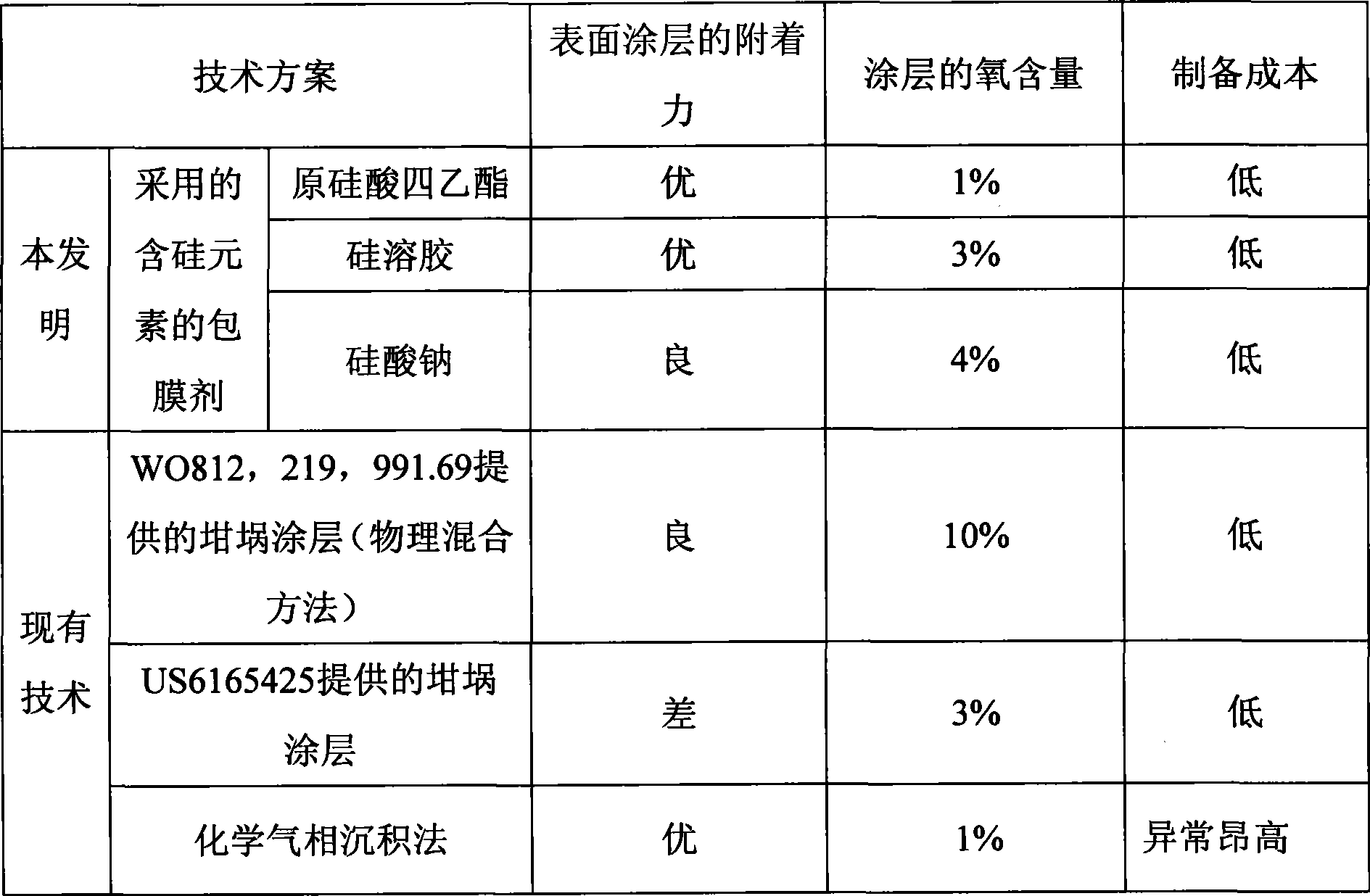

Crucible pot coating for polysilicon casting ingot and preparation method

InactiveCN101508590AReduce oxygen contentReduce the risk of contaminationPolycrystalline material growthSiliconCrucibleIngot

The invention relates to a crucible coating, in particular to a ceramic crucible coating used in producing polycrystalline silicon cast ingot, and also relates to a preparation method of ceramic crucible coating used for polycrystalline silicon cast ingot. The solid content in the formulation of the crucible coating used for polycrystalline silicon cast ingot comprises 80-99% of silicon nitride and 1-20% of filming agent containing silicon element by weight percentage; after sintering the total oxygen content is 0.2-4.9% by weight percentage. The invention aims at providing a crucible coating used for polycrystalline silicon cast ingot and a preparation method; in the invention, a technique proposal in which the coating contains lower oxygen content is adopted as far as possible, so that potential pollution can be reduced, and meanwhile filming and spraying technologies are adopted to guarantee the stability of the silicon nitride layer and the quality of the silicon ingot in the use process of the crucible.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com