Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1054results about How to "Narrow distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst and process for ethylene oligomerization

InactiveUS6184428B1Narrow distributionOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionMetallic NickelChelating ligands

A catalyst and a process are provided for oligomerizing ethylene. A heterogeneous catalyst system comprises: (1) a chelating ligand, preferably 2-diphenyl phosphino benzoic acid (DPPBA); (2) a nickel precursor, preferably nickel chloride hexahydrate (NiCl2.6H2O); (3) a catalyst activator, preferably sodium tetraphenylborate (NaBPh4); and (4) silica. A 1:1:1 molar ratio of Ni:DPPBA:BPh4 catalyst components are fixed on a silica support using low-temperature fixation. The catalyst components are dispersed in a diluent, preferably ethanol, and silica is added. The ethanol is evaporated using freeze-drying equipment to form a silica-supported catalyst system. The silica-supported catalyst is slurried in ethanol in a reactor, and ethylene is added. The reactor pressure and temperature are maintained at about 725 psig and 100° C., respectively, for about two hours. The oligomer product formed has a narrower weight percent distribution, typically having about 96 weight percent C4's to C10's, compared to product formed using a homogeneous catalyst system.

Owner:SANDI BASIC INDS CORP

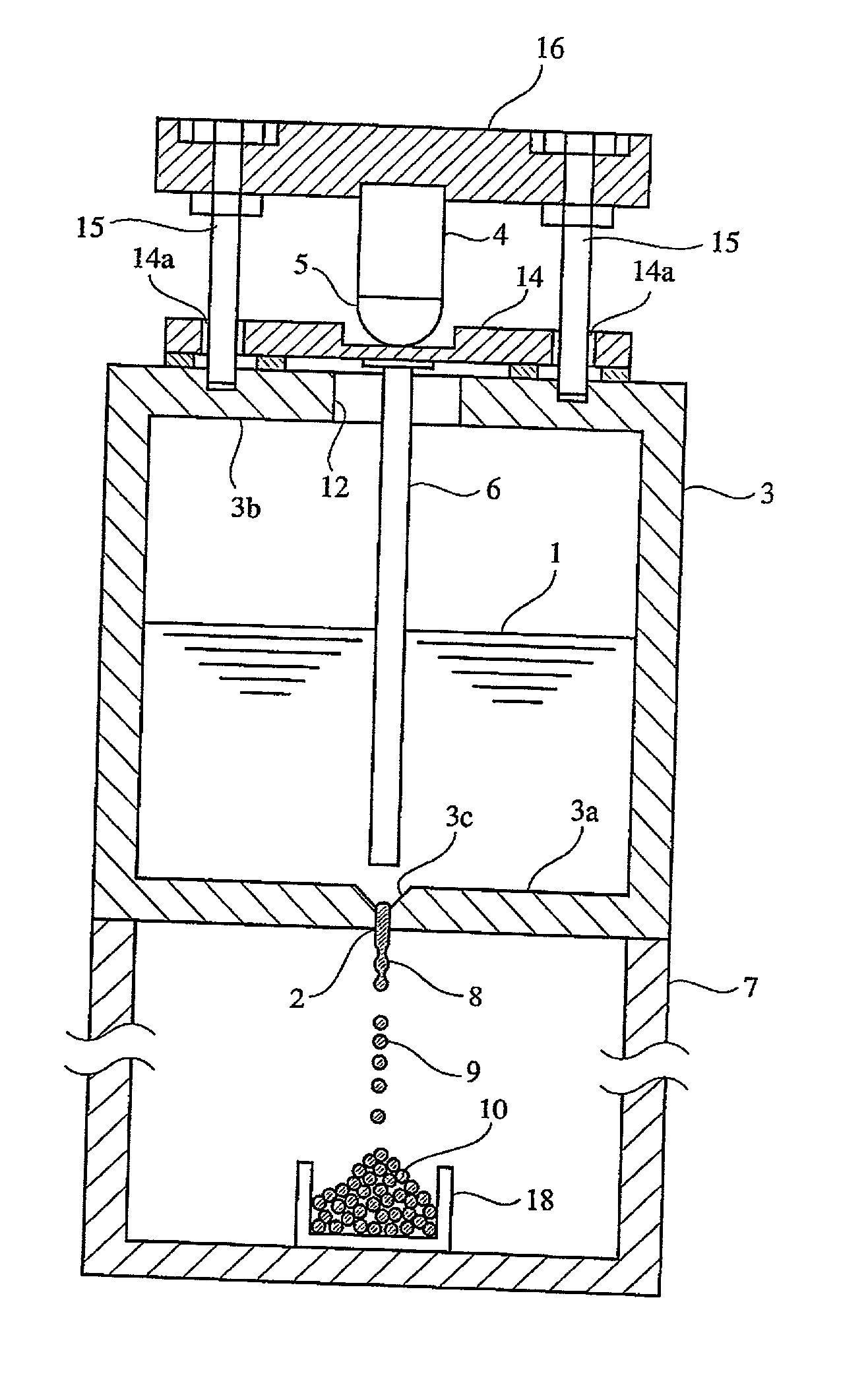

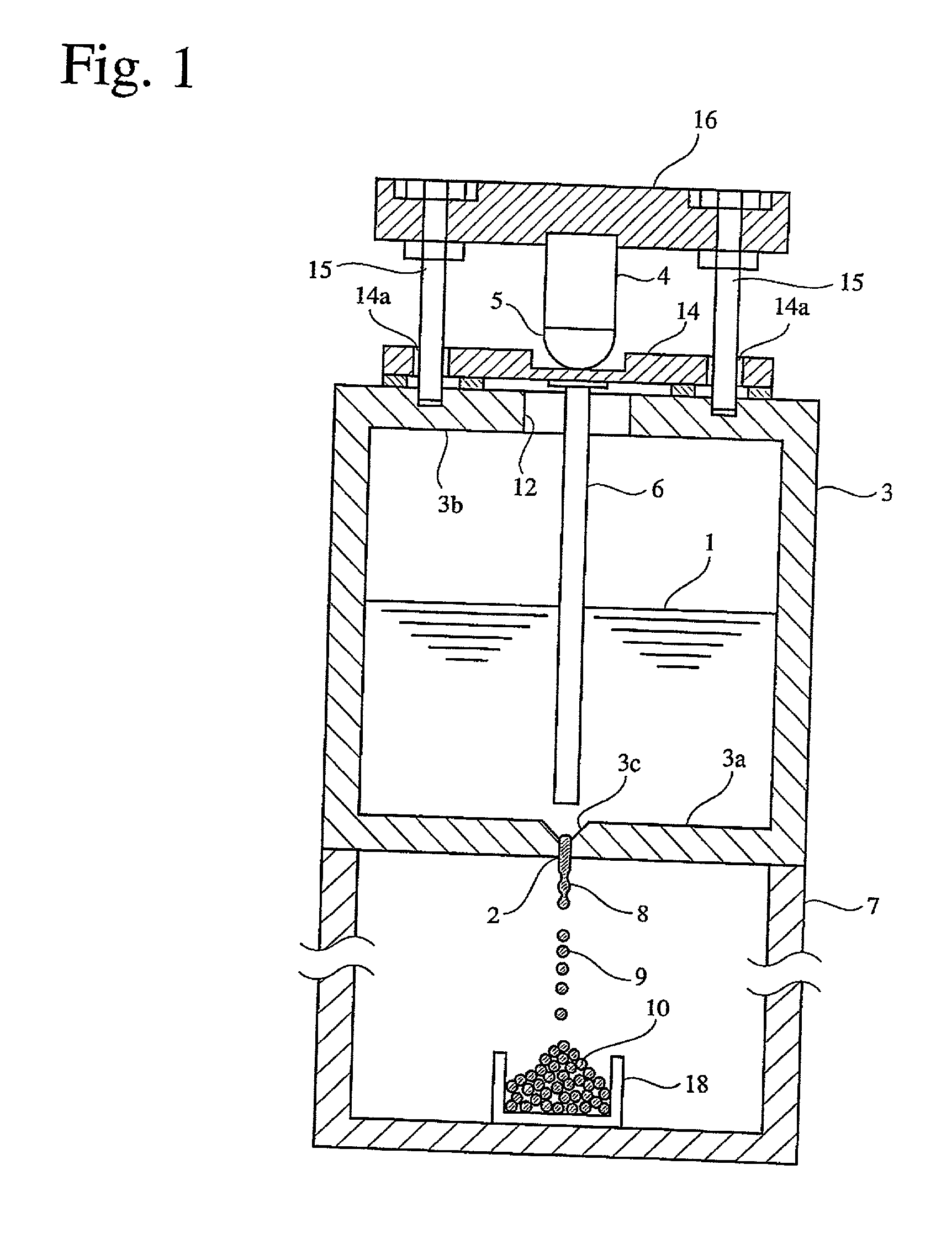

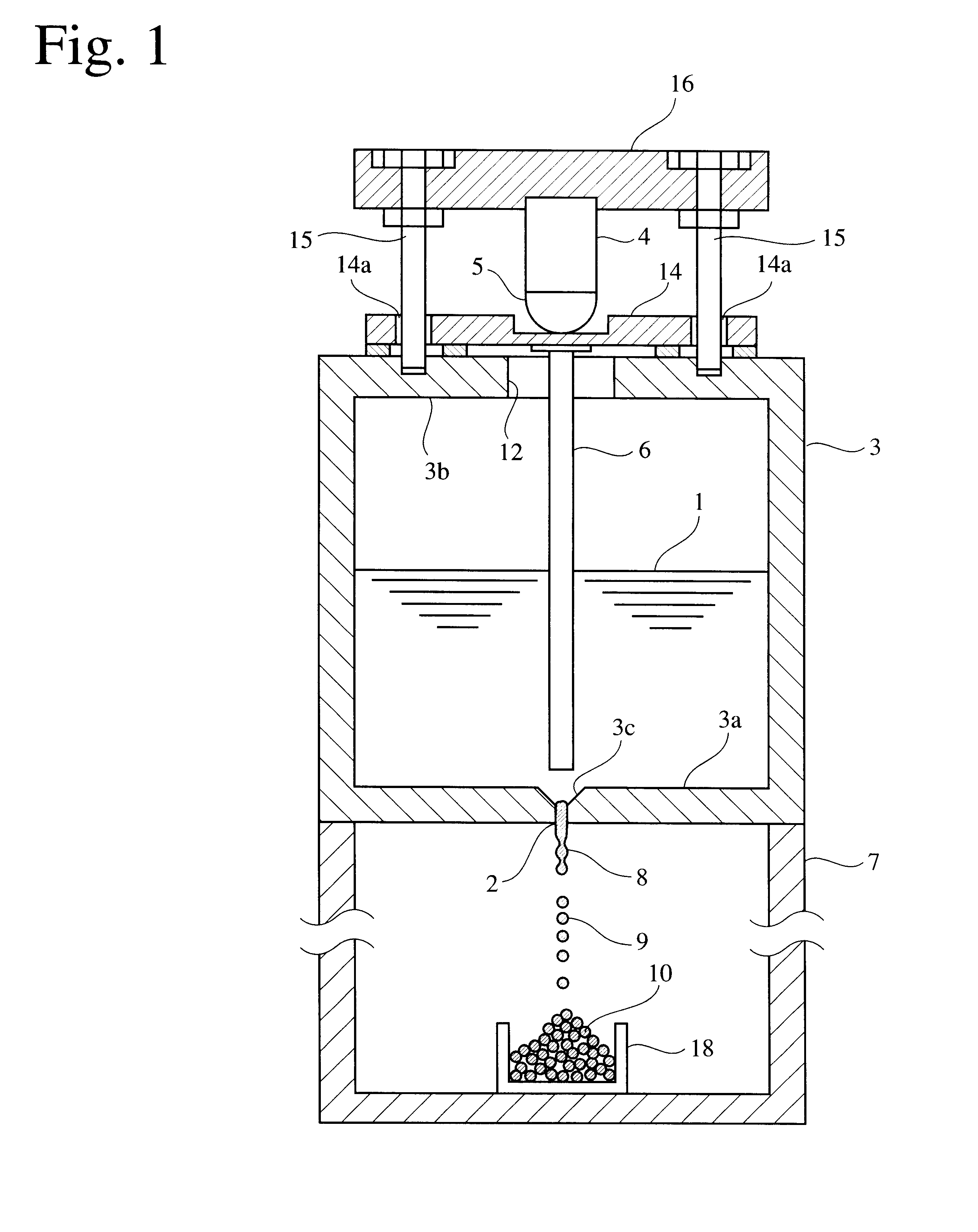

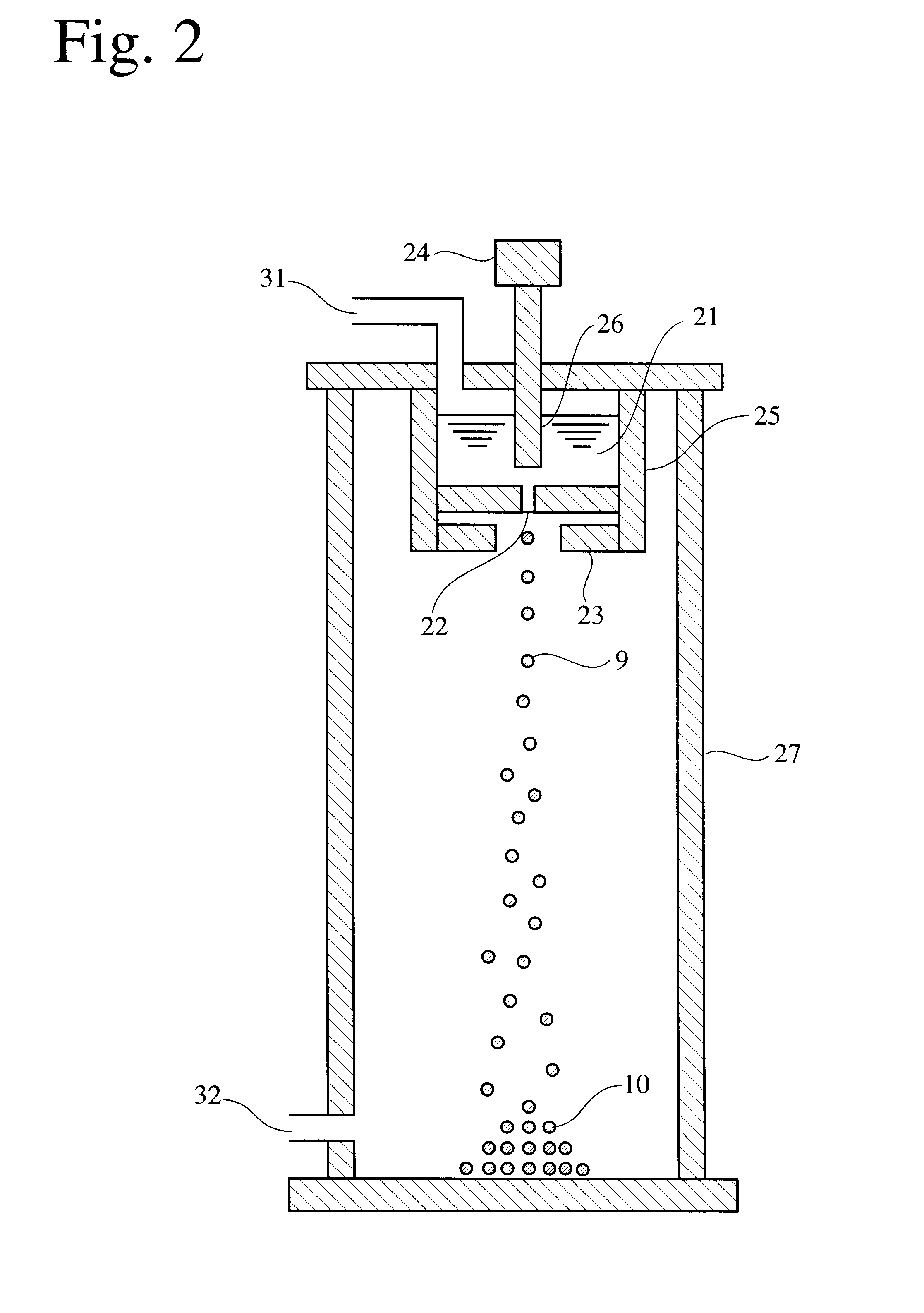

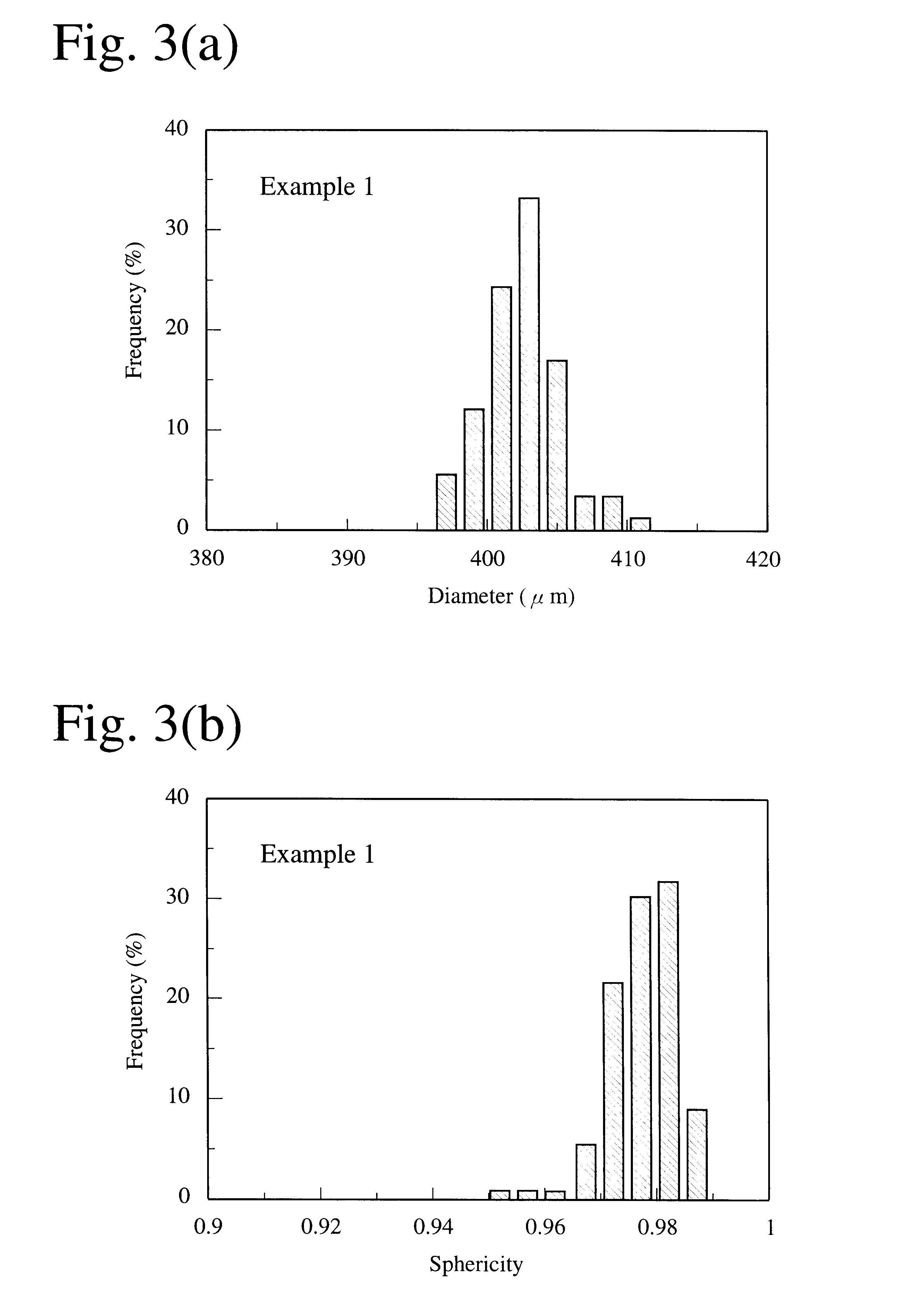

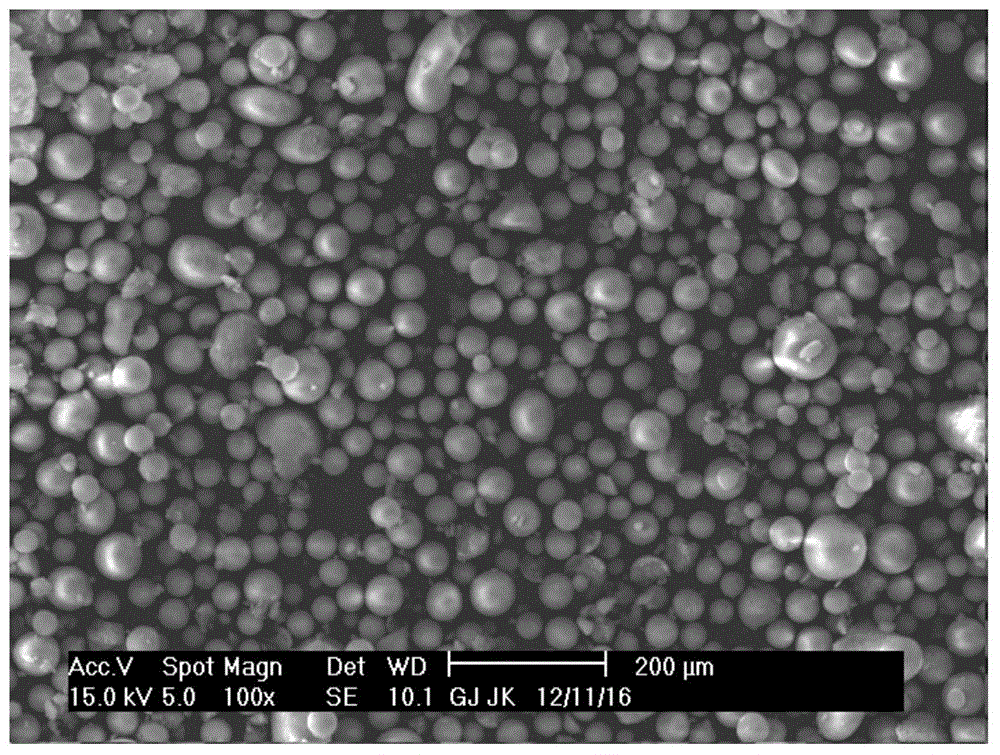

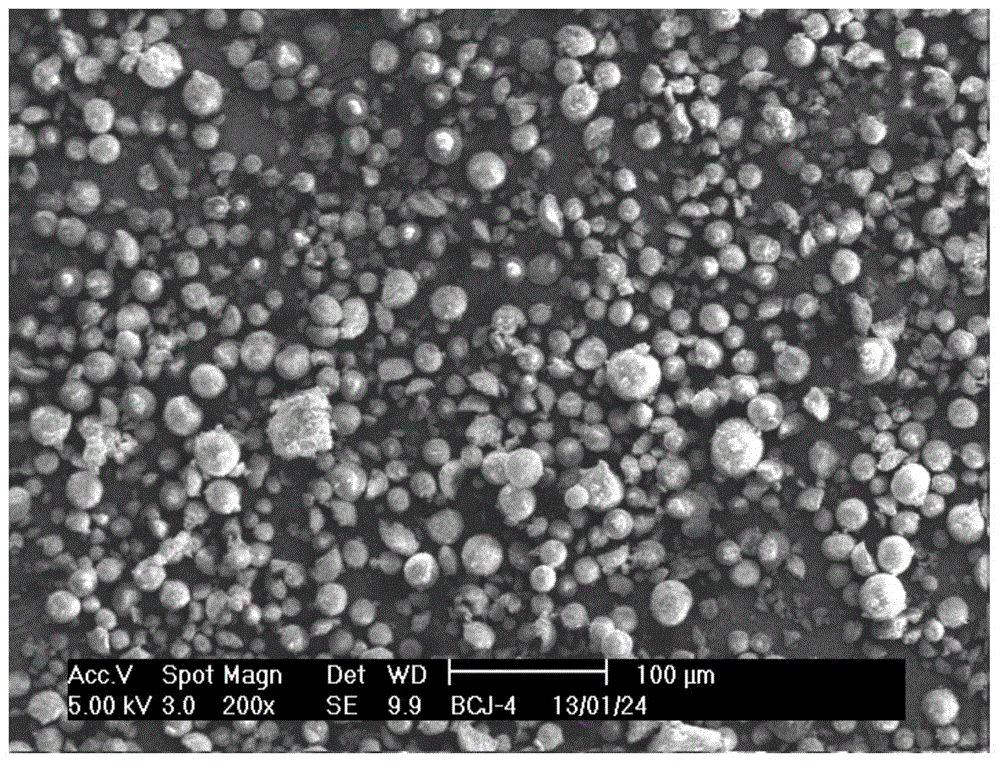

Solder ball and method for producing same

InactiveUS20020051728A1High degree of sphericityNarrow dimension distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass% of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

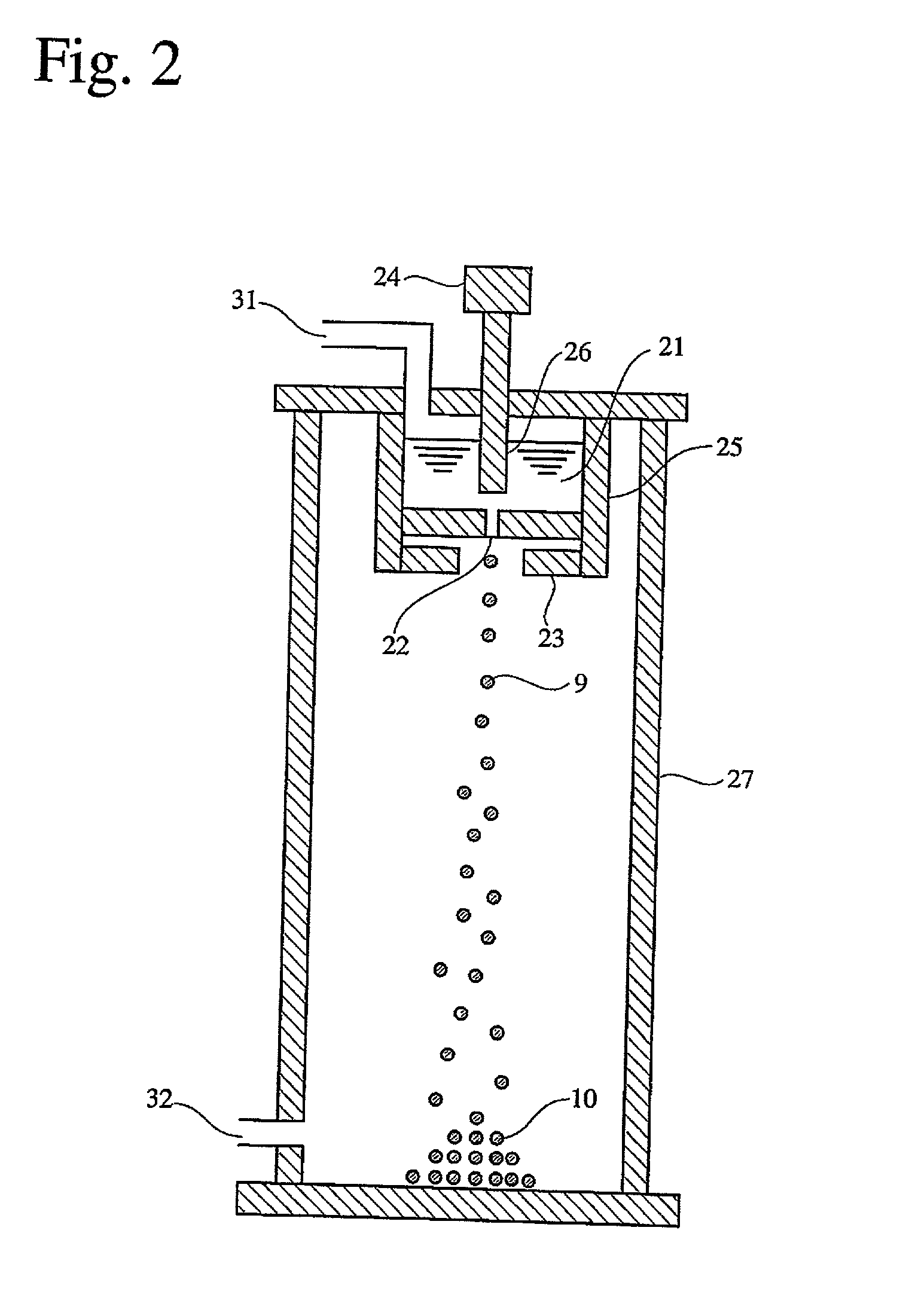

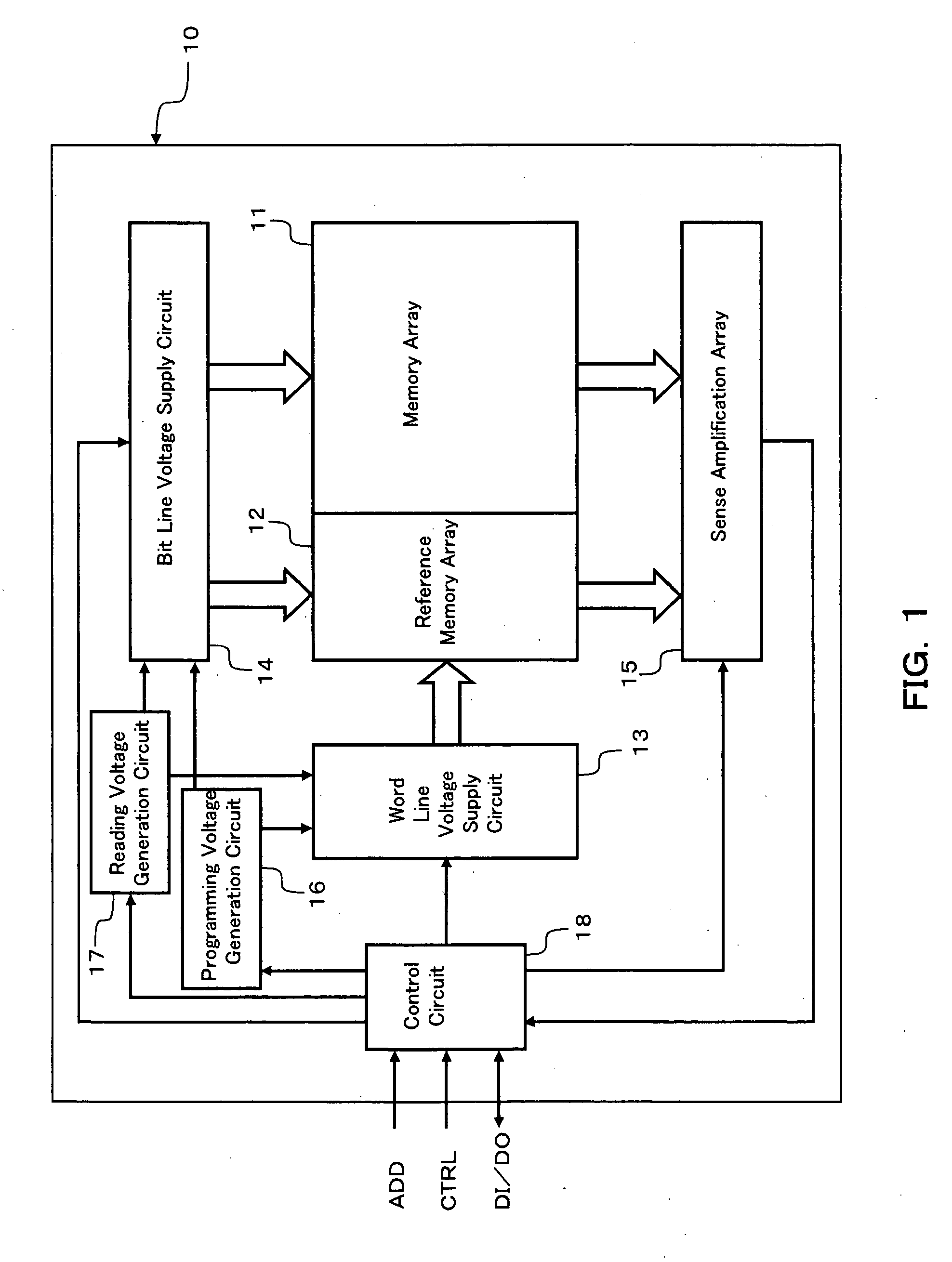

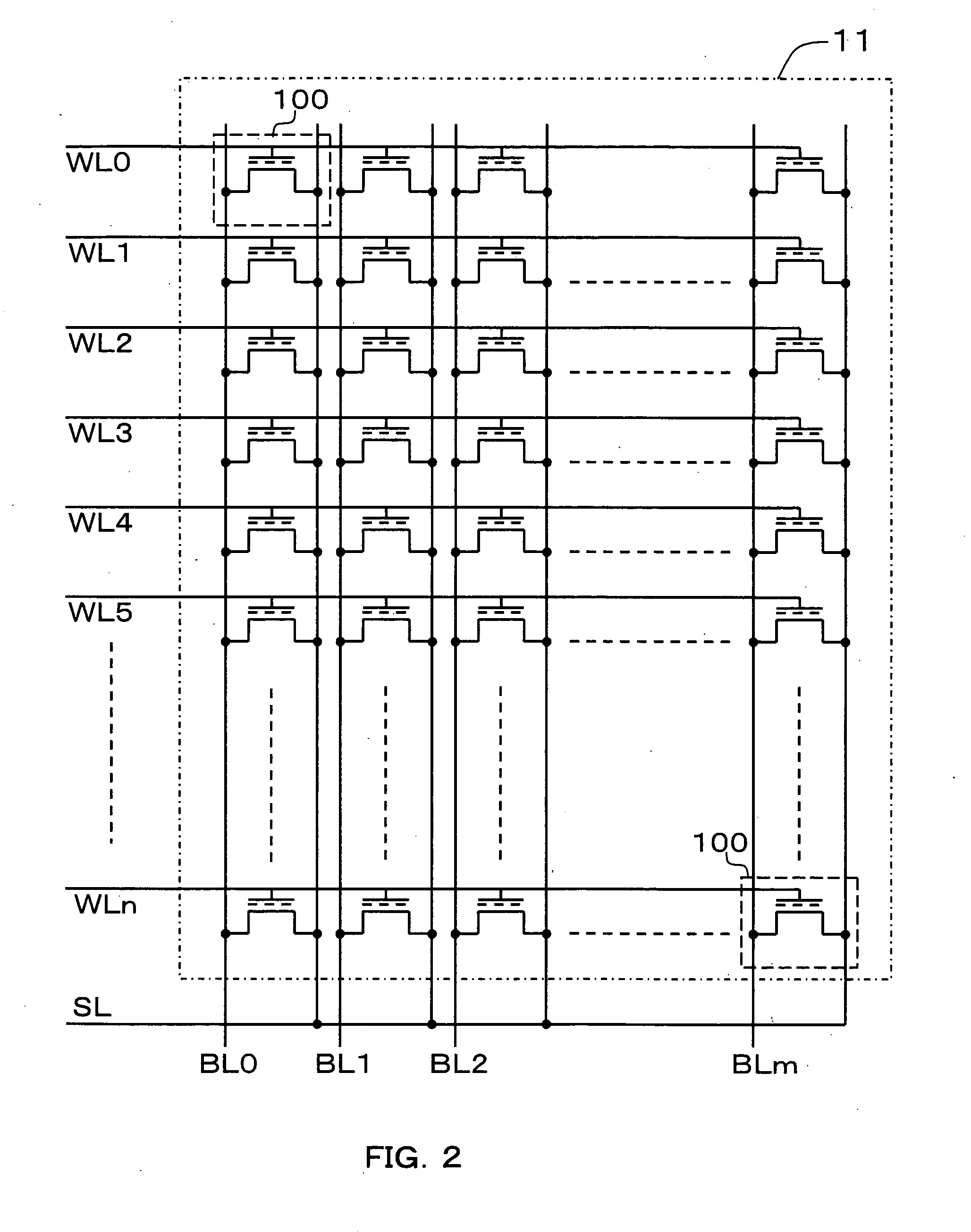

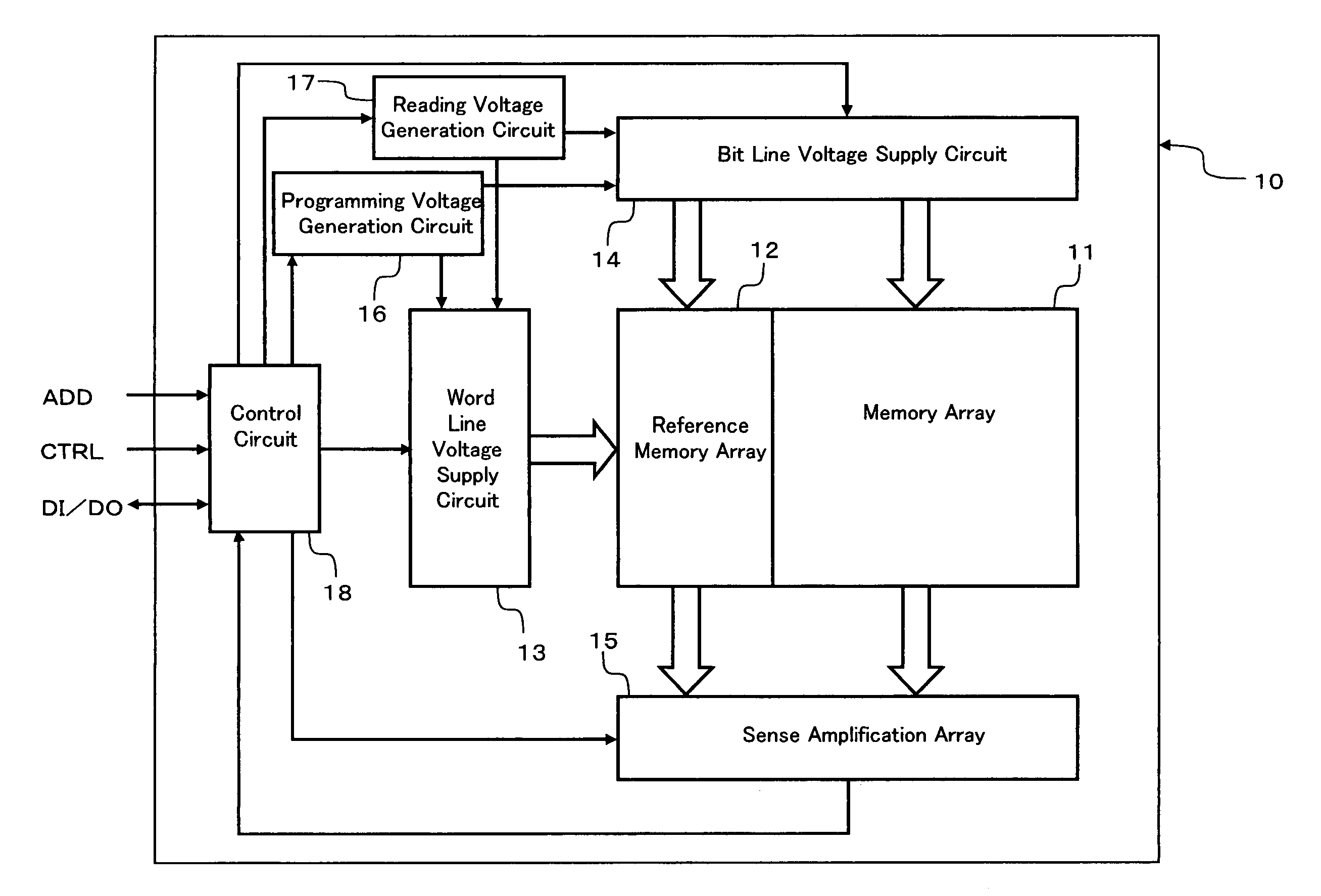

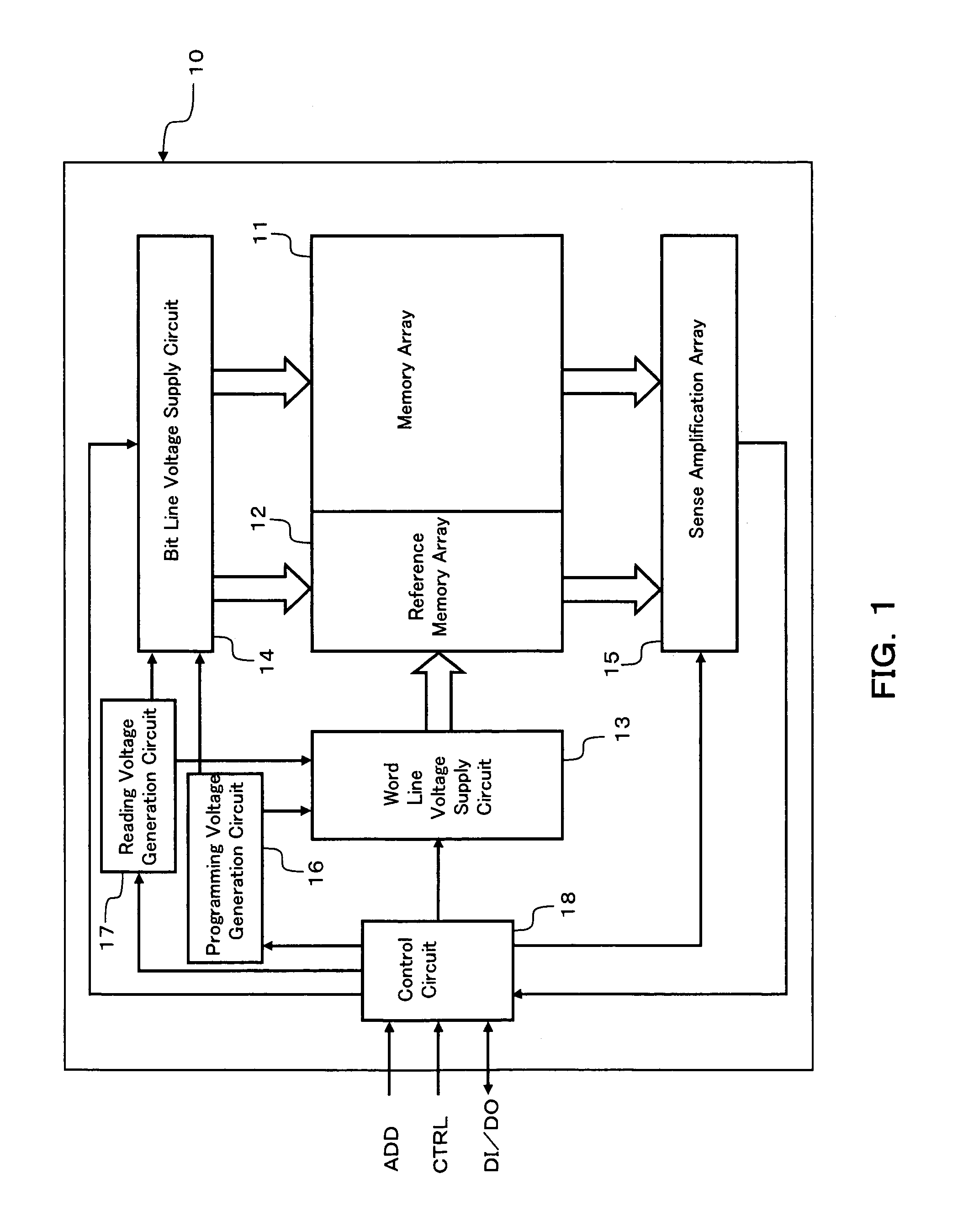

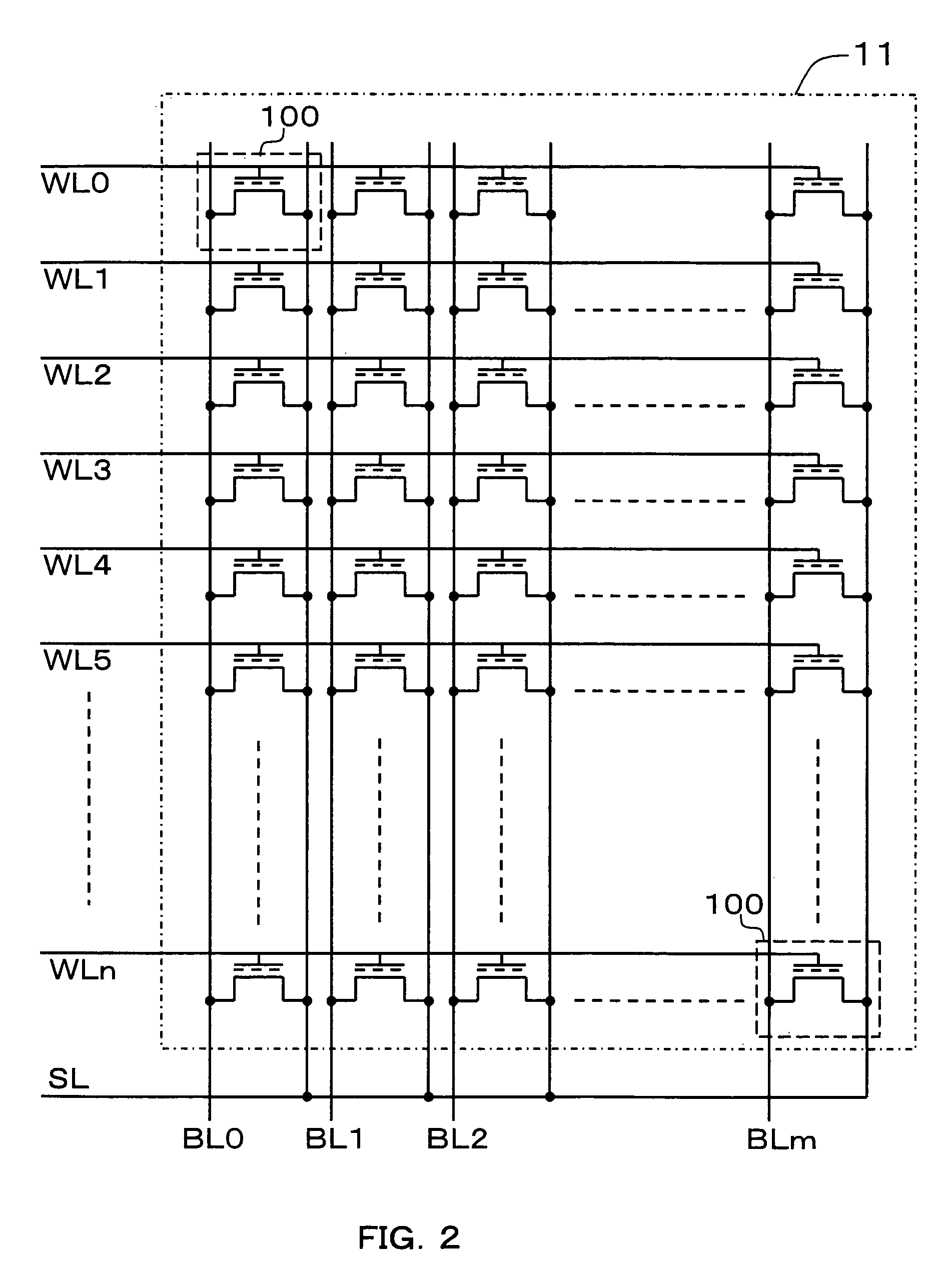

Nonvolatile semiconductor memory device

ActiveUS20050157555A1Suppressing “ over-programming ”High speedTransistorSolid-state devicesVoltageEngineering

In a nonvolatile floating-gate semiconductor memory device, a word line voltage supply circuit is configured to be able to apply gate voltages to the same memory cells such that the gate voltage applied at and after the second time is different from the gate voltage applied at the first time. At least one of the word line voltage supply circuit and the bit line voltage supply circuit is set to be able to apply a voltage to the same memory cells for a longer application period at the first time than at and after the second time. With this configuration, the threshold voltage distribution of the memory cells is controlled to be narrow.

Owner:SHARP KK +1

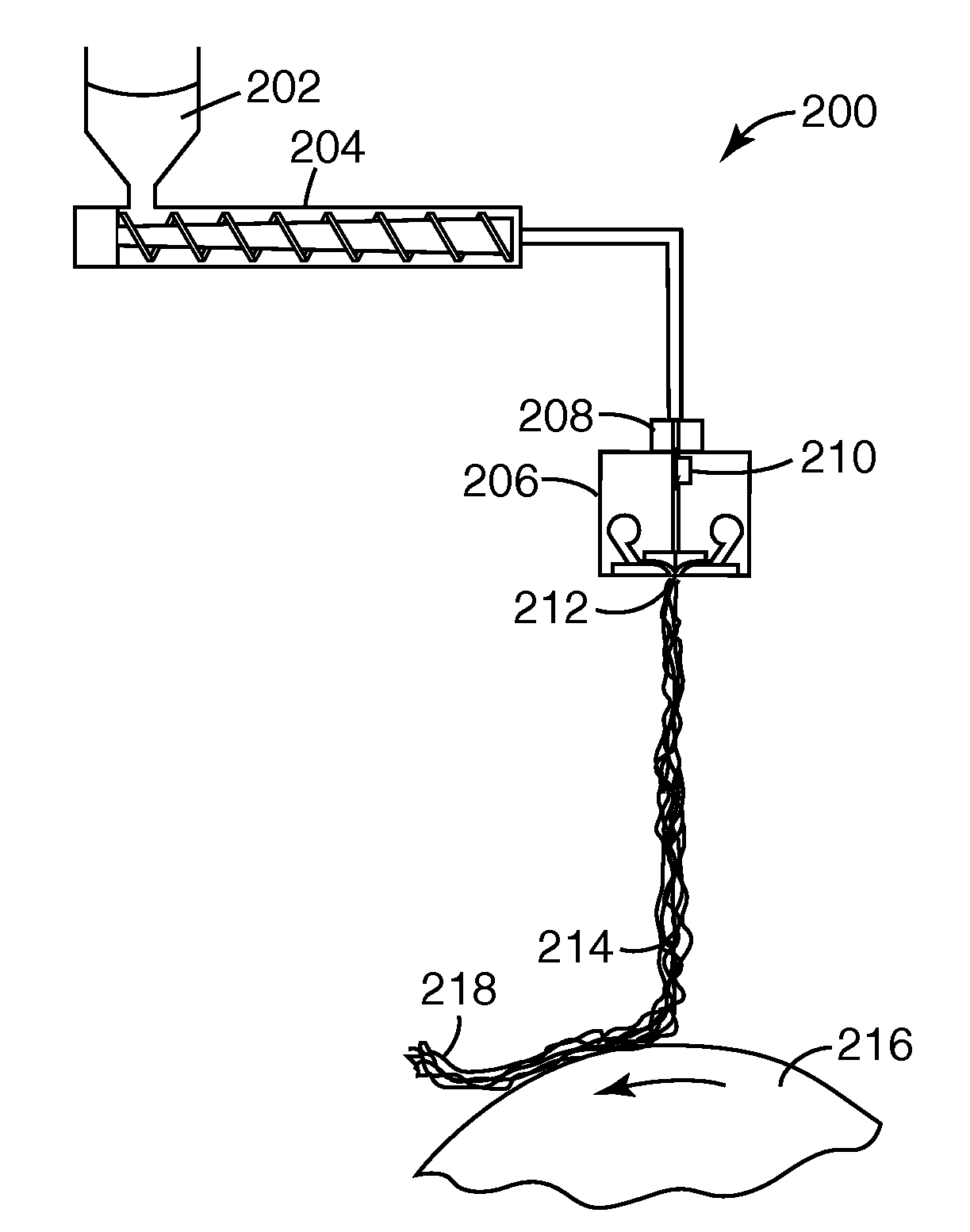

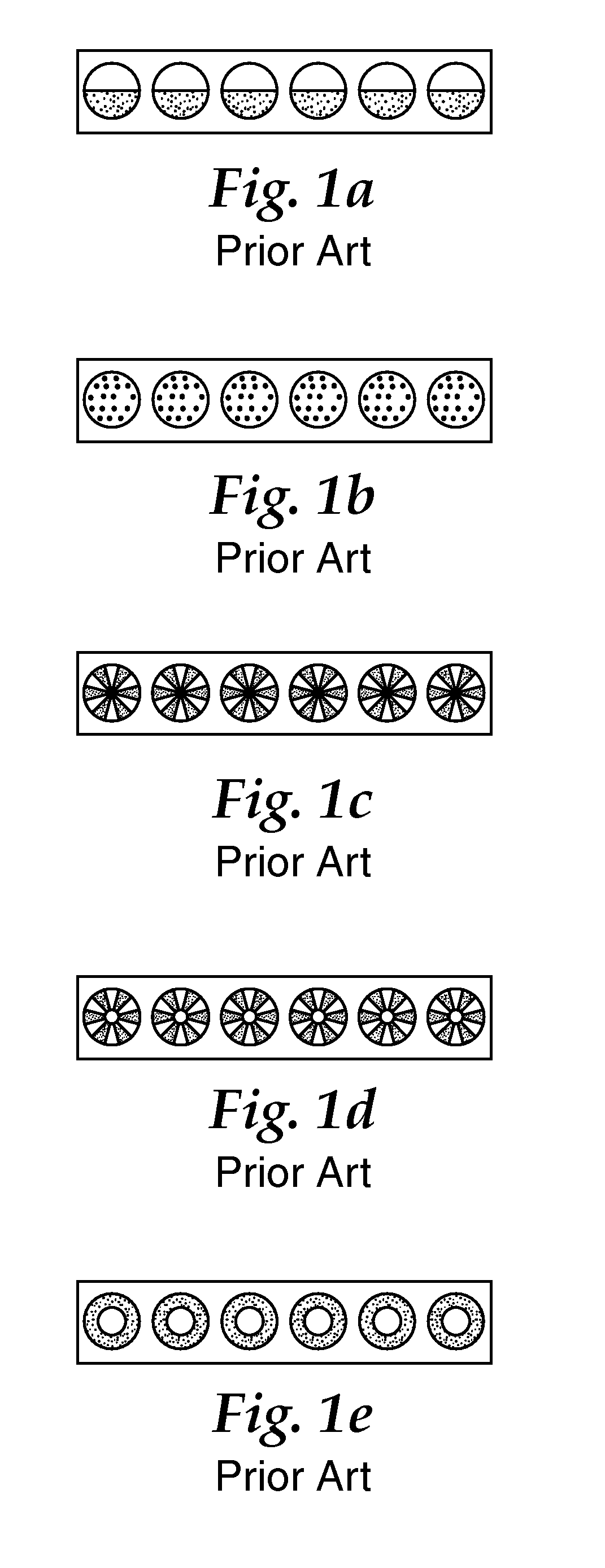

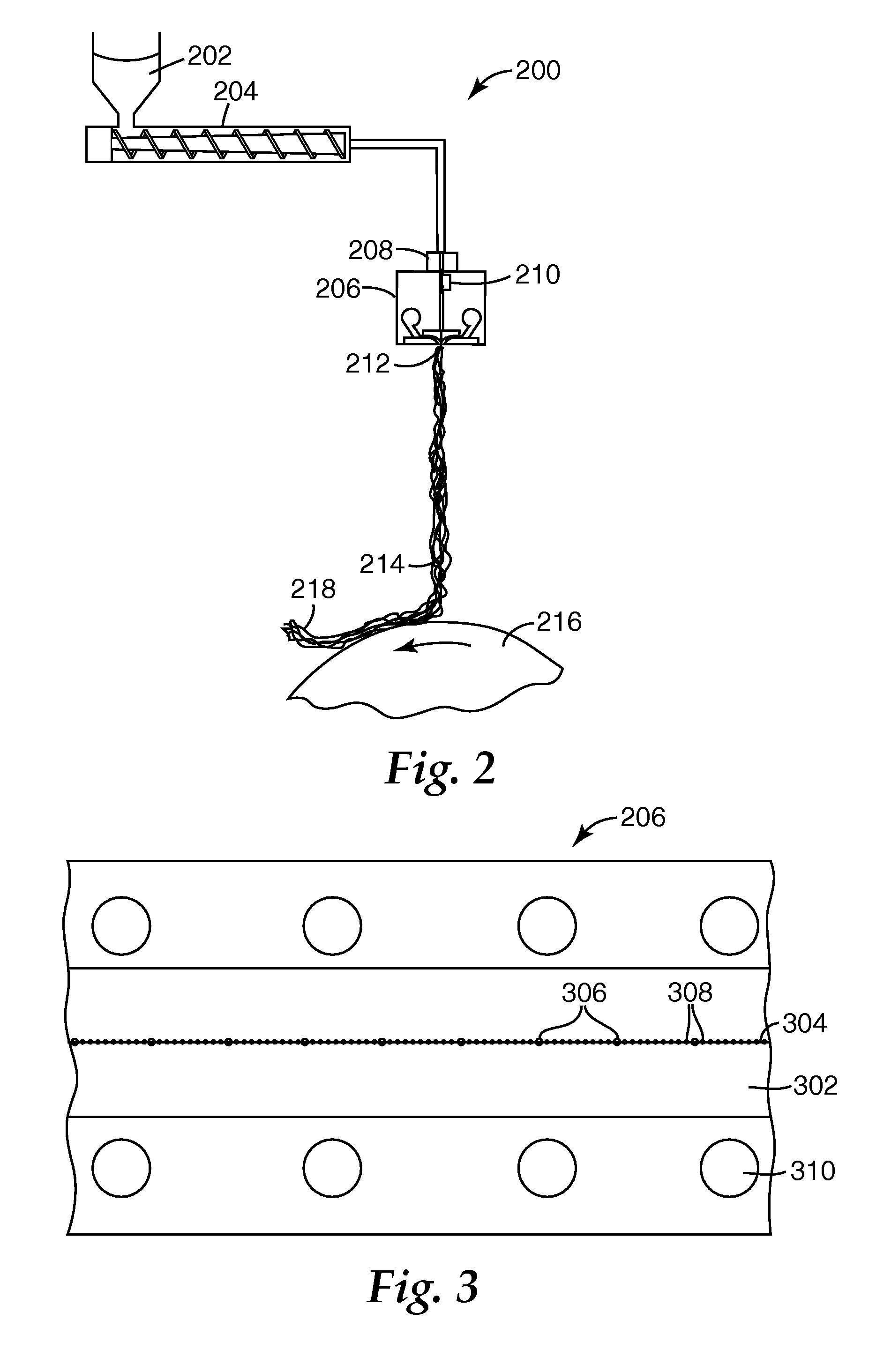

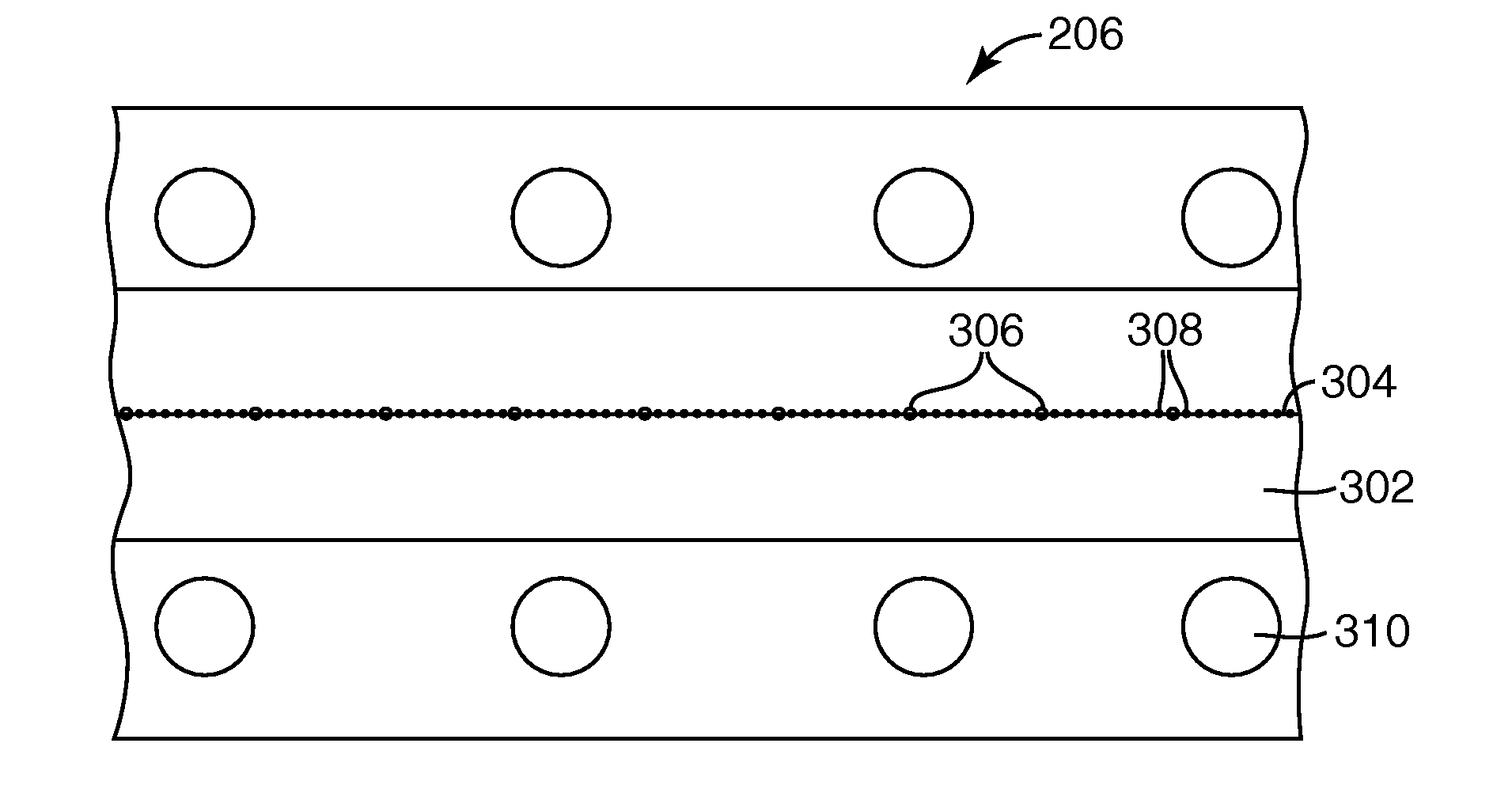

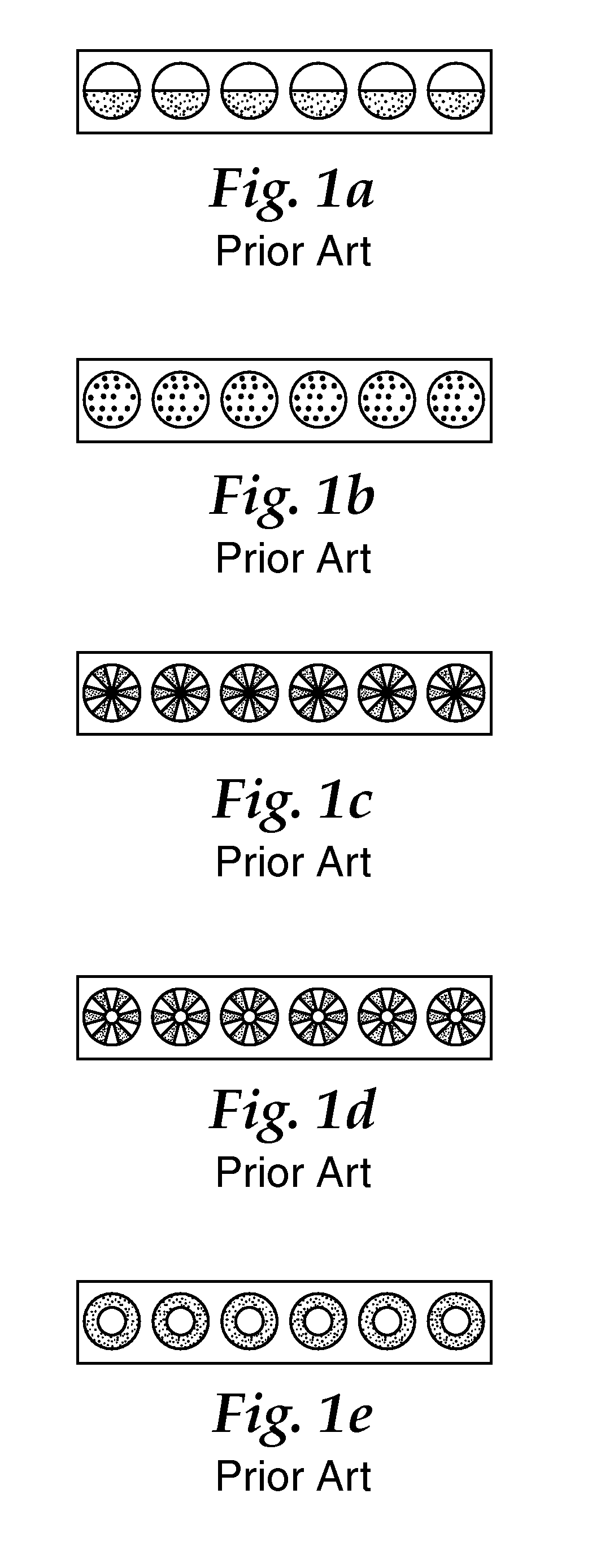

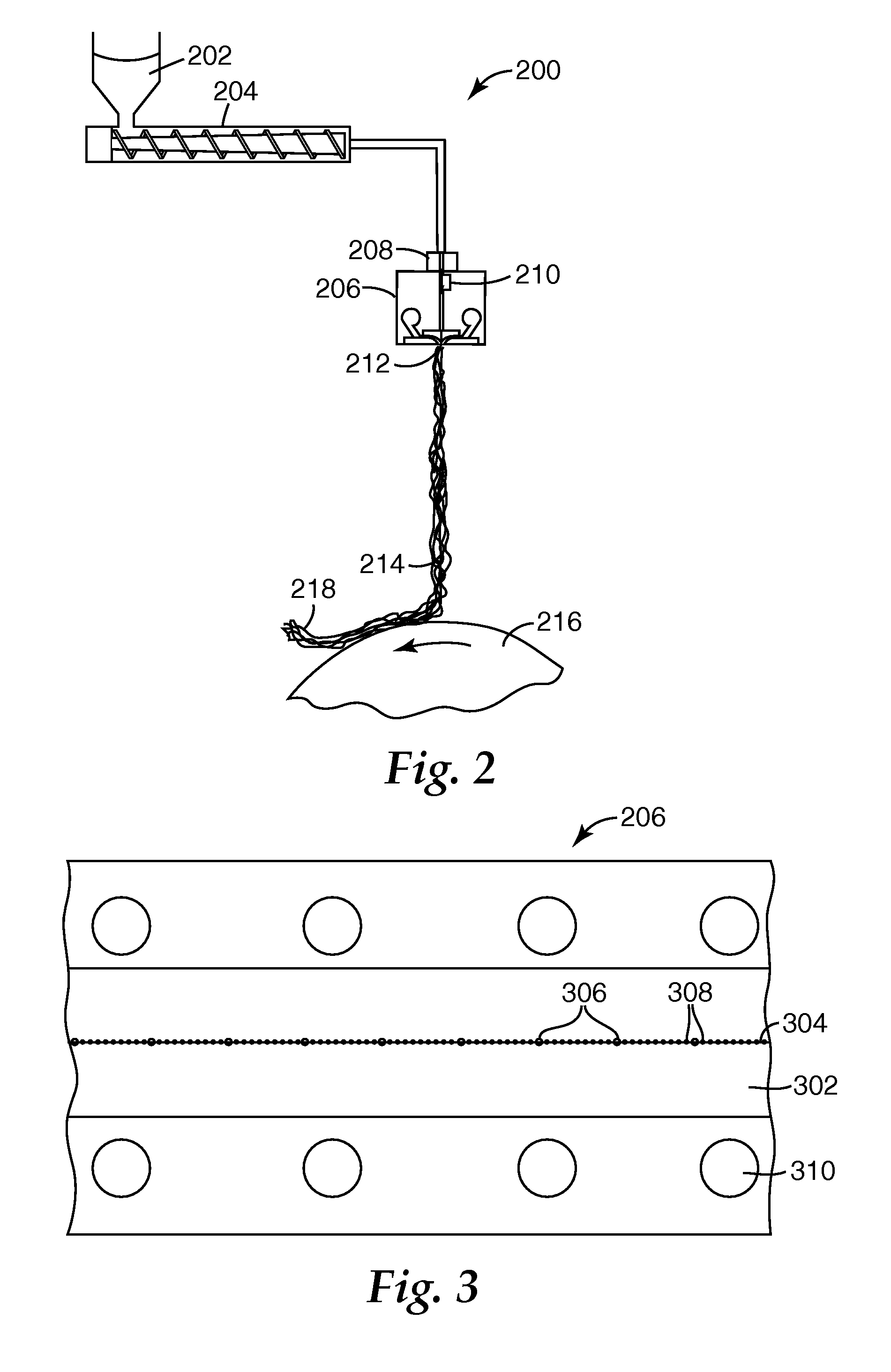

Monocomponent Monolayer Meltblown Web And Meltblowing Apparatus

ActiveUS20080026659A1Good molding effectIncrease fiber surface areaDispersed particle filtrationMagnetic materials for record carriersPolymer scienceRespirator

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

Monocomponent monolayer meltblown web and meltblowing apparatus

ActiveUS7902096B2Narrow distributionReduced service lifeDispersed particle filtrationFilament/thread formingPolymer scienceAir filter

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

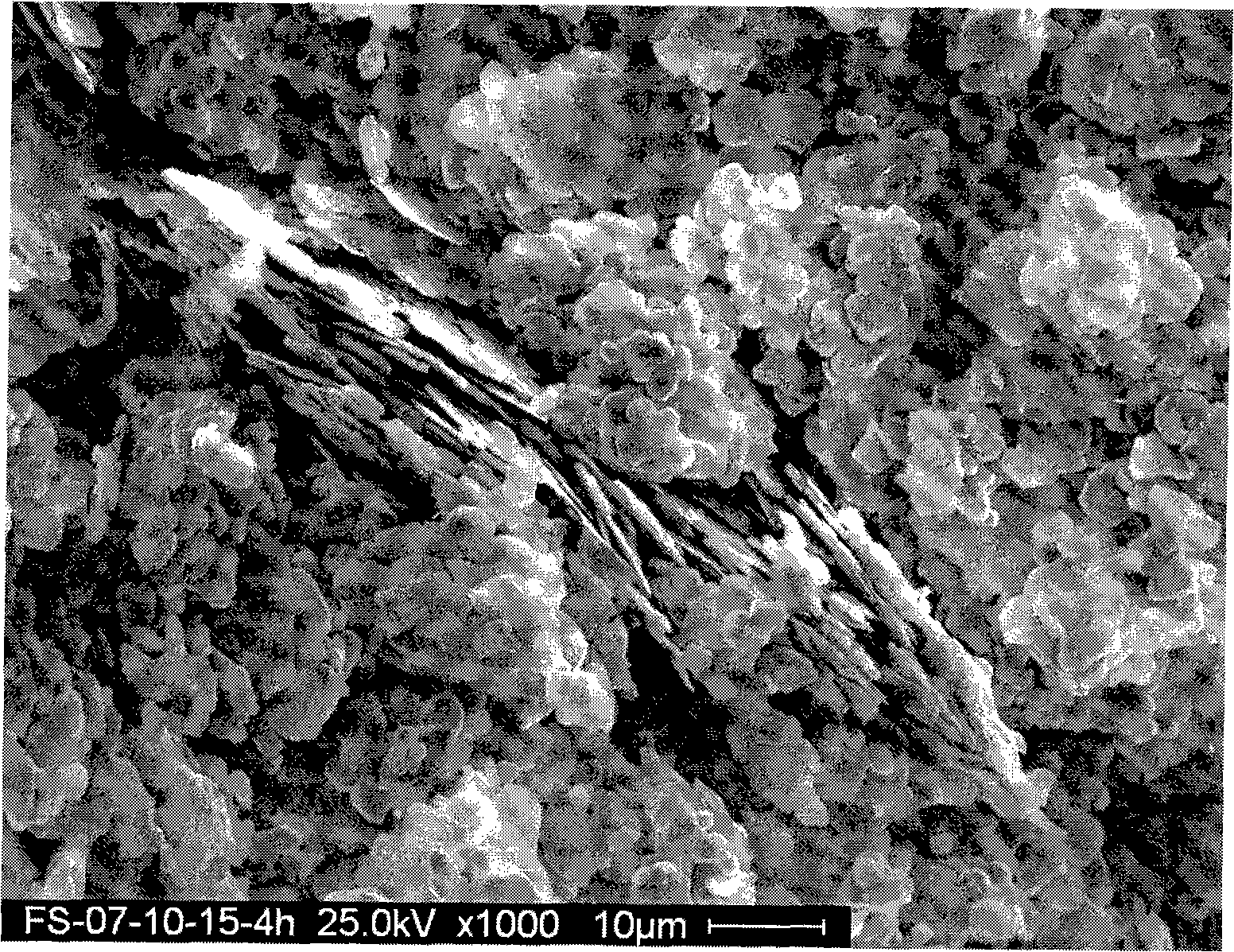

Method for recovering waste/used lithium iron phosphate positive-pole material by acid leaching method

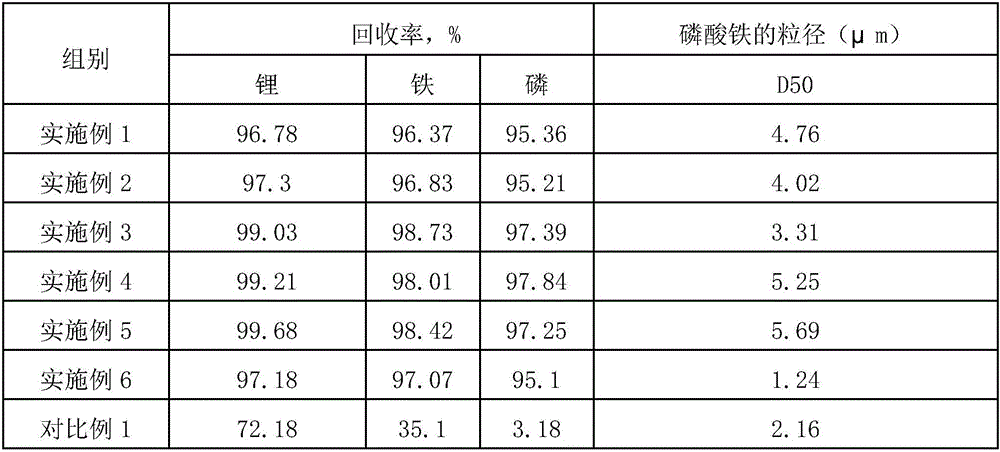

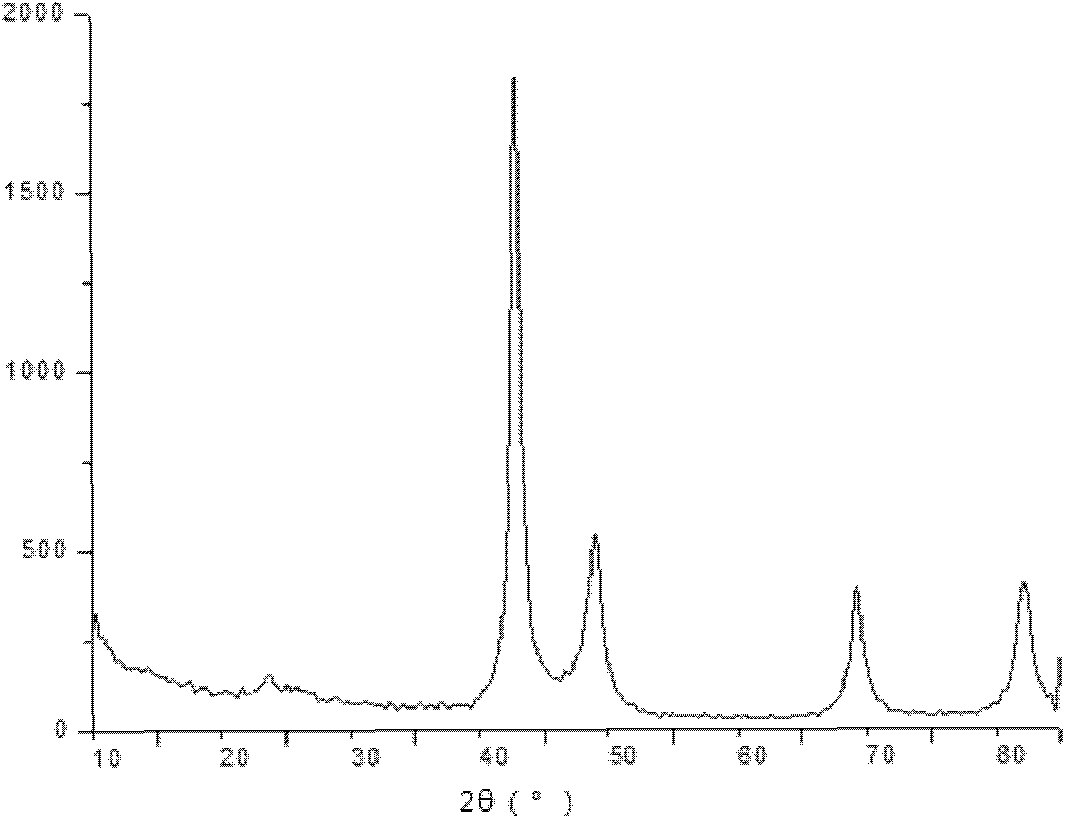

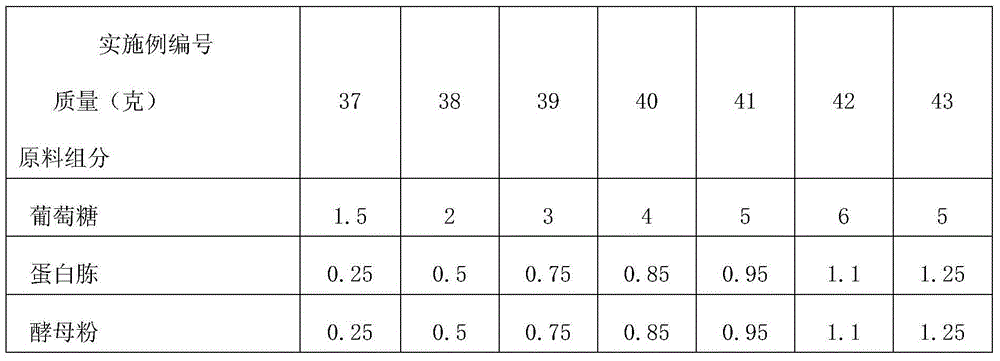

ActiveCN106684485AHigh recovery rateLow impurity contentWaste accumulators reclaimingBattery recyclingLithium electrodePhosphate

The invention belongs to the technical field of recovery of lithium-ion batteries and particularly relates to a method for recovering a waste / used lithium iron phosphate positive-pole material by an acid leaching method. The method provided by the invention comprises the following steps: (a) carrying out acid leaching: adding acid into the lithium iron phosphate positive-pole material for acid leaching so as to obtain a suspension, and carrying out filtration, so as to obtain filtrate; (b) carrying out oxidation: adjusting the pH value of the filtrate obtained in the step (a) to be smaller than 1, and adding an oxidant into the filtrate to oxidate ferrous ions in the filtrate into ferric ions, so as to obtain a mixed solution; (c) carrying out separation: adjusting the pH value of the mixed solution obtained in the step (b) to be 1.5 to 4, carrying out a reaction for 1 to 3 hours at the temperature of 60 DEG C to 95 DEG C so as to produce ferric phosphate precipitates, and carrying out filtrating and washing, thereby obtaining lithium-containing filtrate and ferric phosphate. The method provided by the invention is simple in process, continuous in cycle, low in cost and easy to industrialize and is environmentally friendly; the recovery rate of Li, Fe and P reaches 95% or more, subsequent prepared FePO4 is low in impurity content, the particle size is 1 to 6 microns, is uniform and is narrow in distribution, and the morphology is controllable, so that the FePO4 is battery-grade ferric phosphate.

Owner:TIANQI LITHIUM CORP

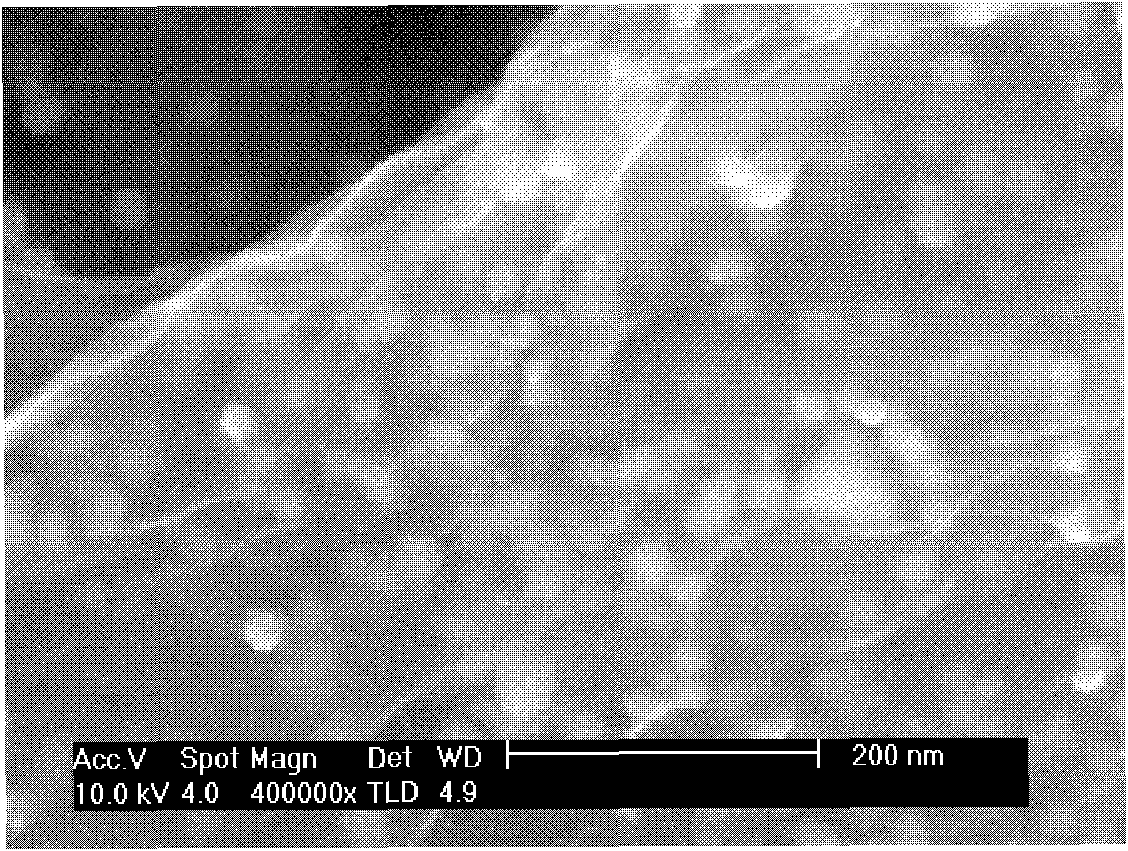

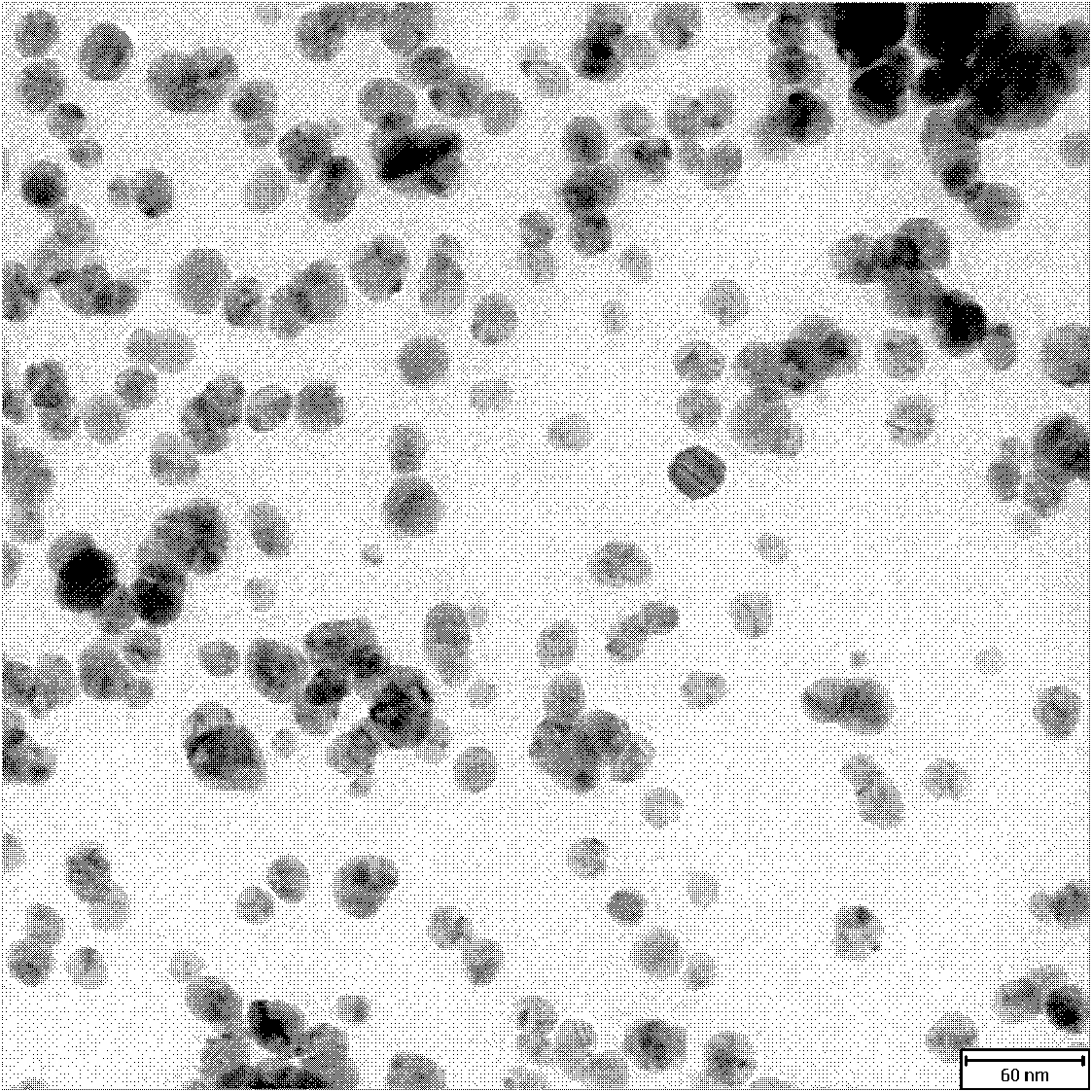

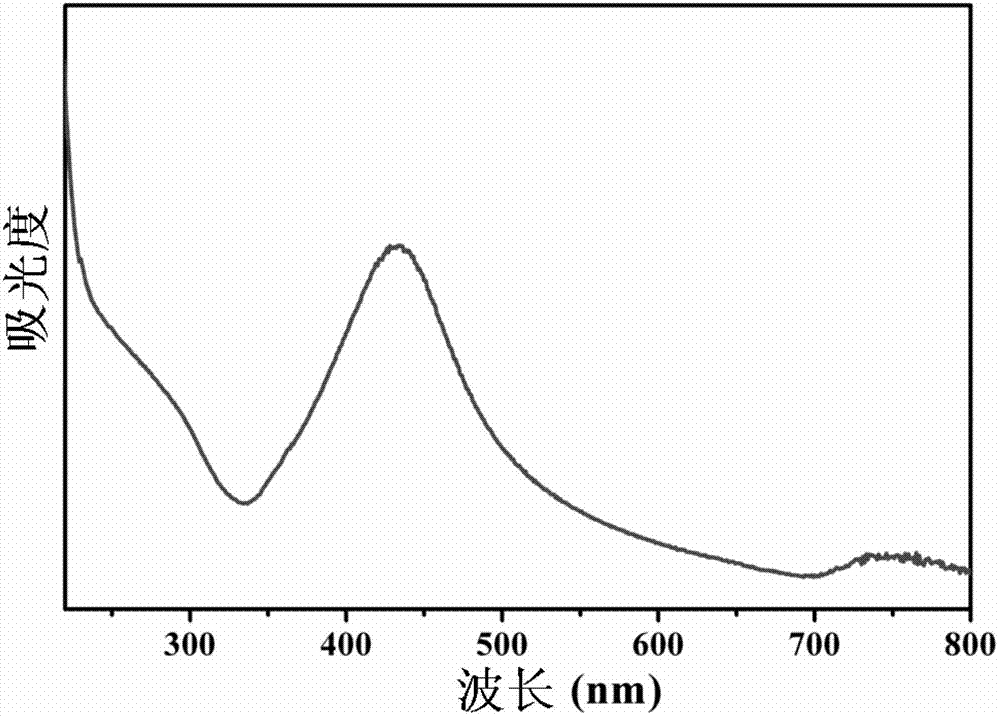

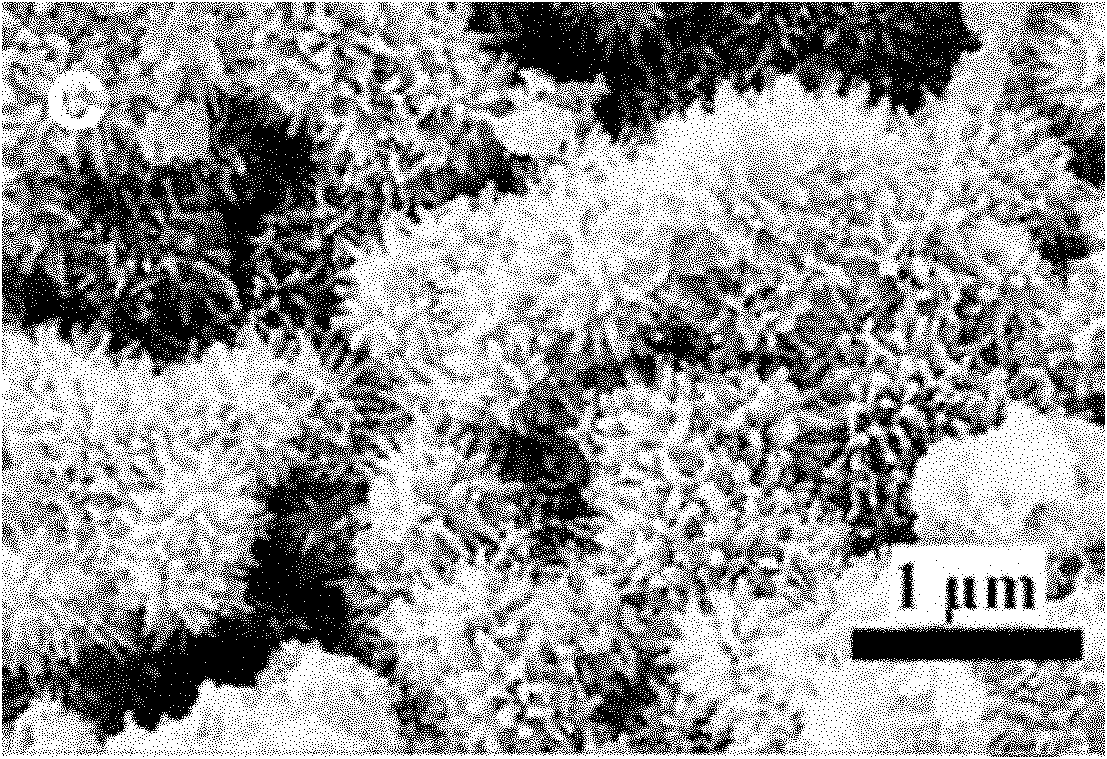

Preparation method of graphene-silver nano particle composite material

InactiveCN102160998AEasy to insertNarrow distributionNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsFiltrationMaterials science

The invention provides a preparation method of a graphene-silver nano particle composite material. A specific preparation process comprises the following steps of: preparing solution of silver ammonia at certain concentration from the solution of silver nitrate and aqueous solution of dilute ammonia, adding the prepared solution of silver-ammonia into the solution of graphene oxide which is subjected to ultrasonic processing, preheating the solution at a certain temperature for a certain time; adding an appropriate amount of glucose into the mixed solution of graphene oxide and silver ammonia, and reacting the mixed solution at the set temperature for a certain time with stirring; performing suction-filtration on a reaction product by using deionized water for many times, and then drying the product to obtain the graphene-silver nano particle composite material. The method is simple, convenient, easy, environment-friendly and efficient; and silver nano particles in the prepared composite material are distributed narrowly, have a uniform particle size (about 25 nm), can be better inserted into graphene slices and can effectively prevent aggregation of the graphene.

Owner:BEIHANG UNIV

Nonvolatile semiconductor memory device

ActiveUS6937520B2High voltage“over-programming” can be suppressedTransistorSolid-state devicesTime segmentEngineering

In a nonvolatile floating-gate semiconductor memory device, a word line voltage supply circuit is configured to be able to apply gate voltages to the same memory cells such that the gate voltage applied at and after the second time is different from the gate voltage applied at the first time. At least one of the word line voltage supply circuit and the bit line voltage supply circuit is set to be able to apply a voltage to the same memory cells for a longer application period at the first time than at and after the second time. With this configuration, the threshold voltage distribution of the memory cells is controlled to be narrow.

Owner:SHARP KK +1

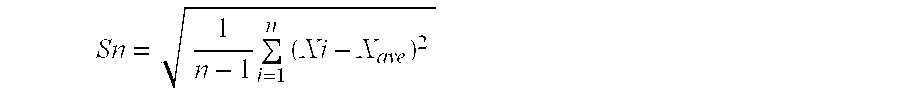

Stretch nonwoven fabric and method for production thereof

ActiveUS20060141883A1Feel goodNarrow distributionWoven fabricsNon-woven fabricsPolymer scienceThermoplastic polyurethane

A spunbonded elastic nonwoven fabric according to the invention comprises fibers formed from a polymer comprising a thermoplastic polyurethane elastomer, wherein the thermoplastic polyurethane elastomer has a solidifying point of 65° C. or above as measured by a differential scanning calorimeter (DSC) and contains 3.00×106 or less polar-solvent-insoluble particles per g as counted on a particle size distribution analyzer, which is based on an electrical sensing zone method, equipped with an aperture tube having an orifice of 100 μm in diameter, and wherein the fibers have diameters such that the standard deviation of fiber diameters (Sn) divided by the average fiber diameter (Xave) (Sn / Xave) gives a value of 0.15 or less.

Owner:MITSUI CHEM INC

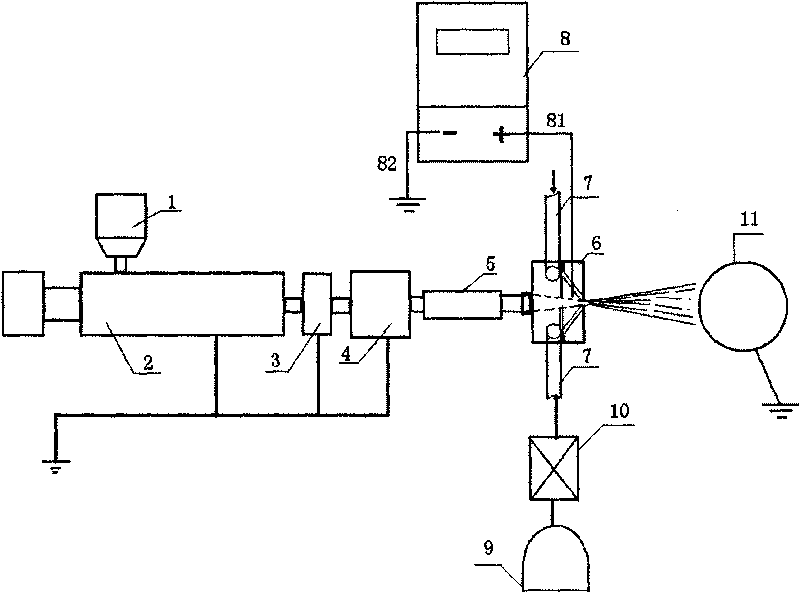

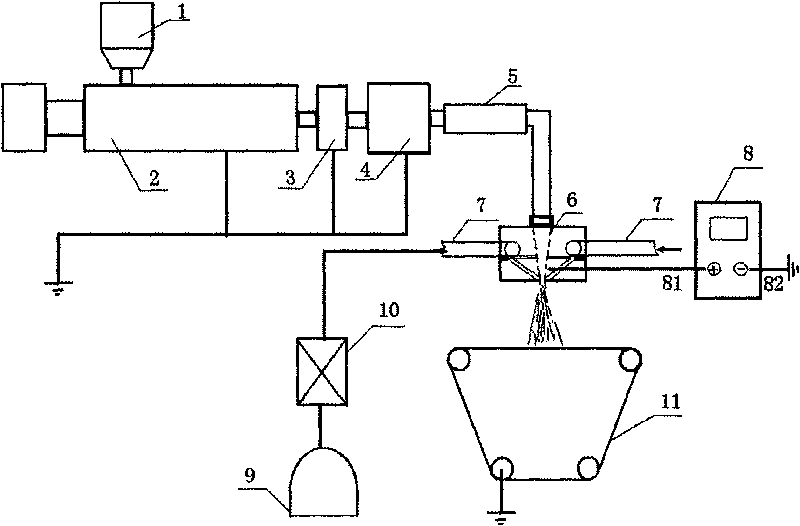

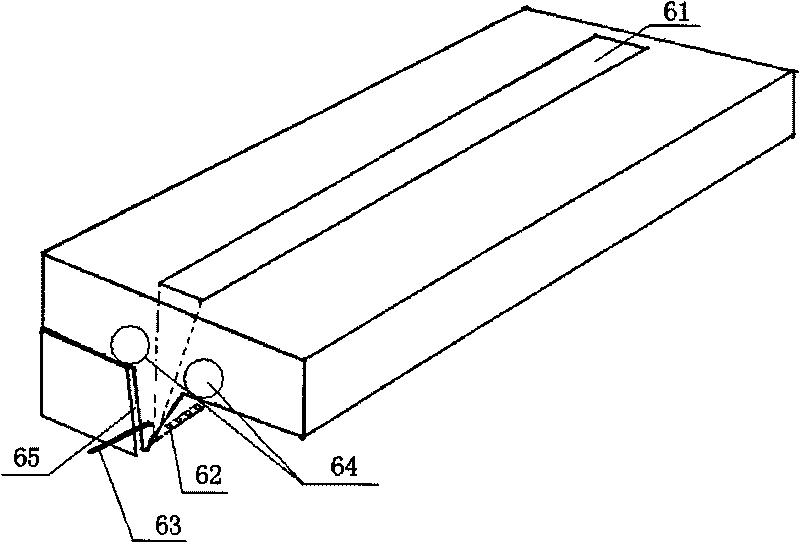

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

Solder ball and method for producing same

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

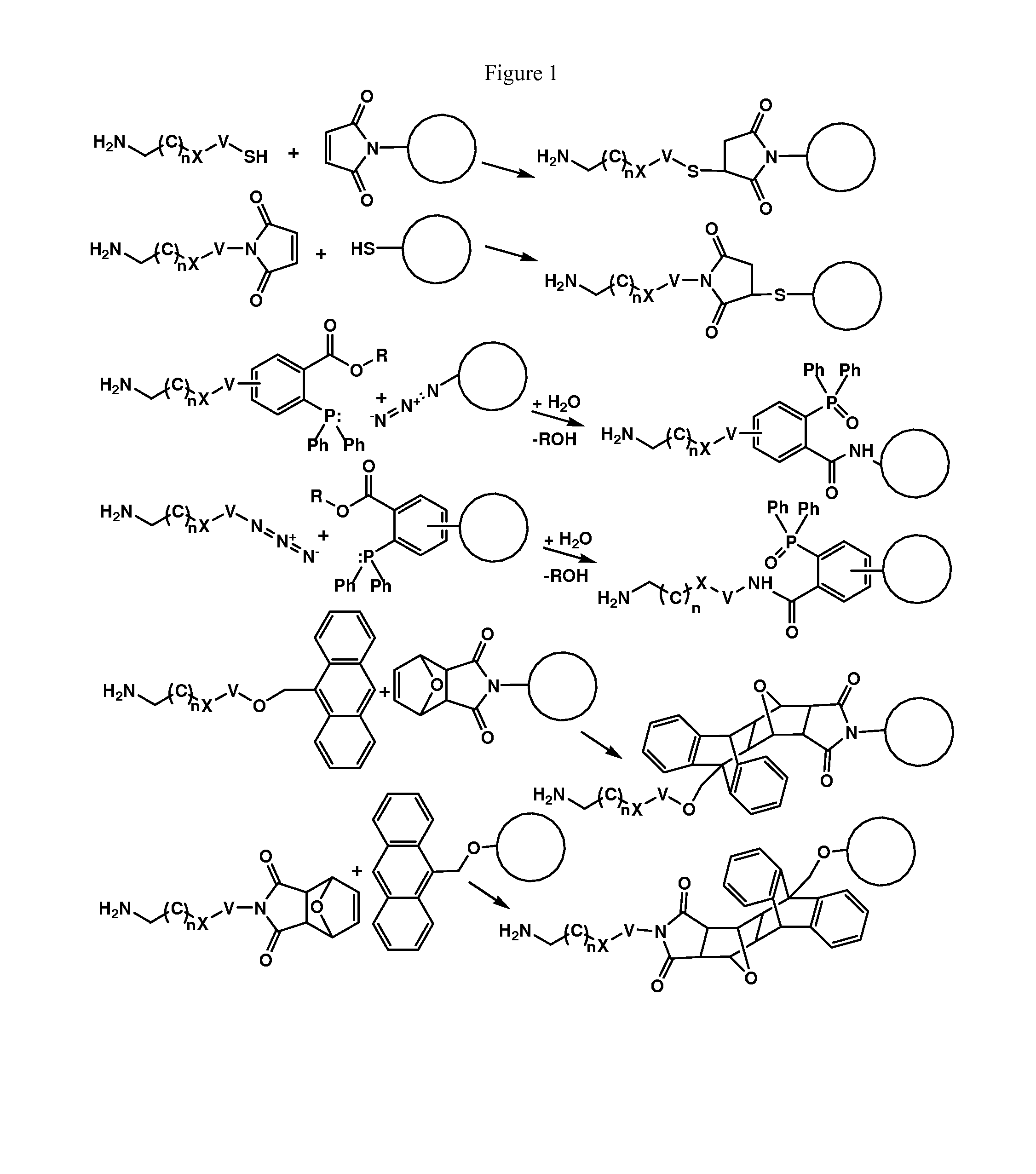

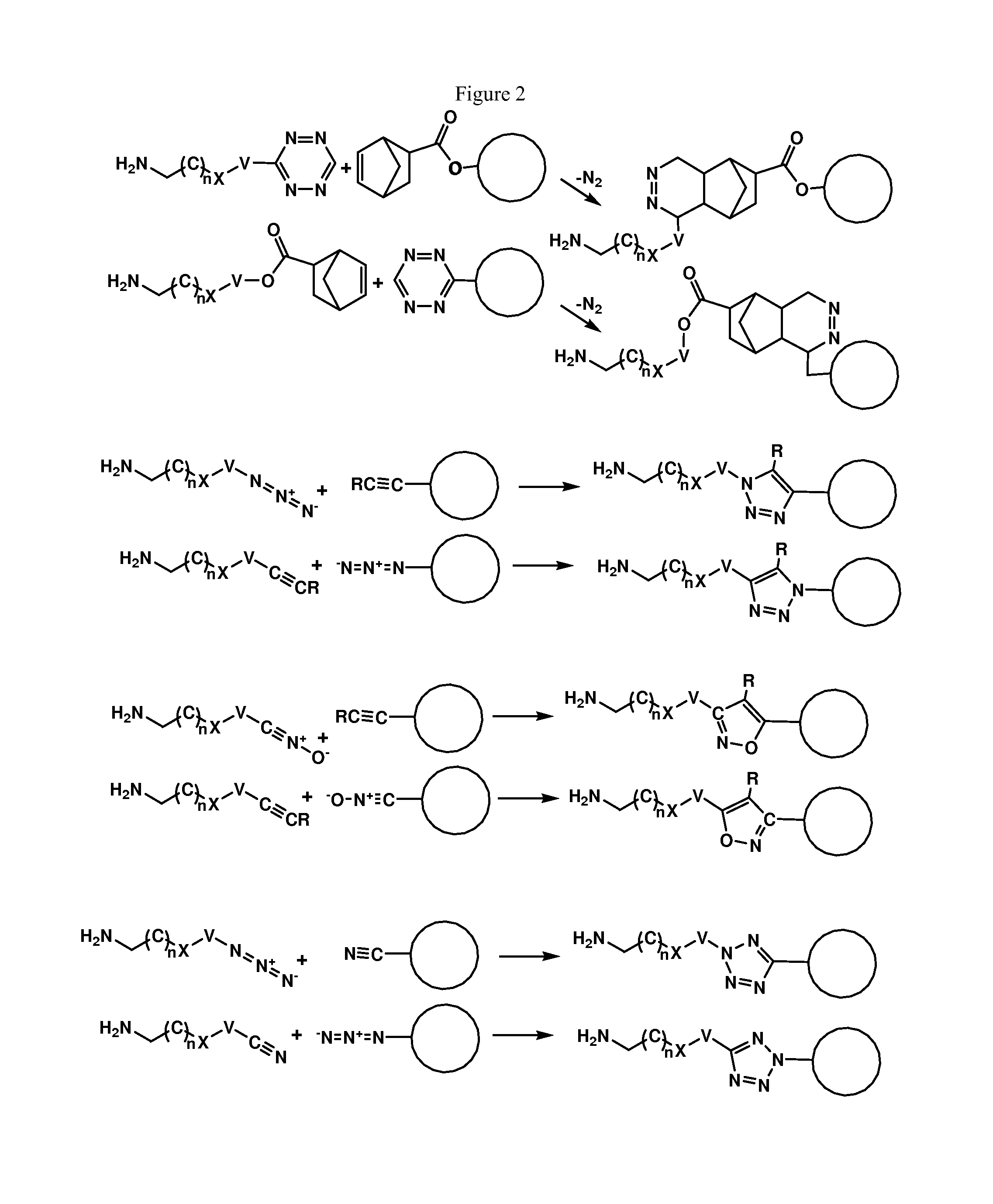

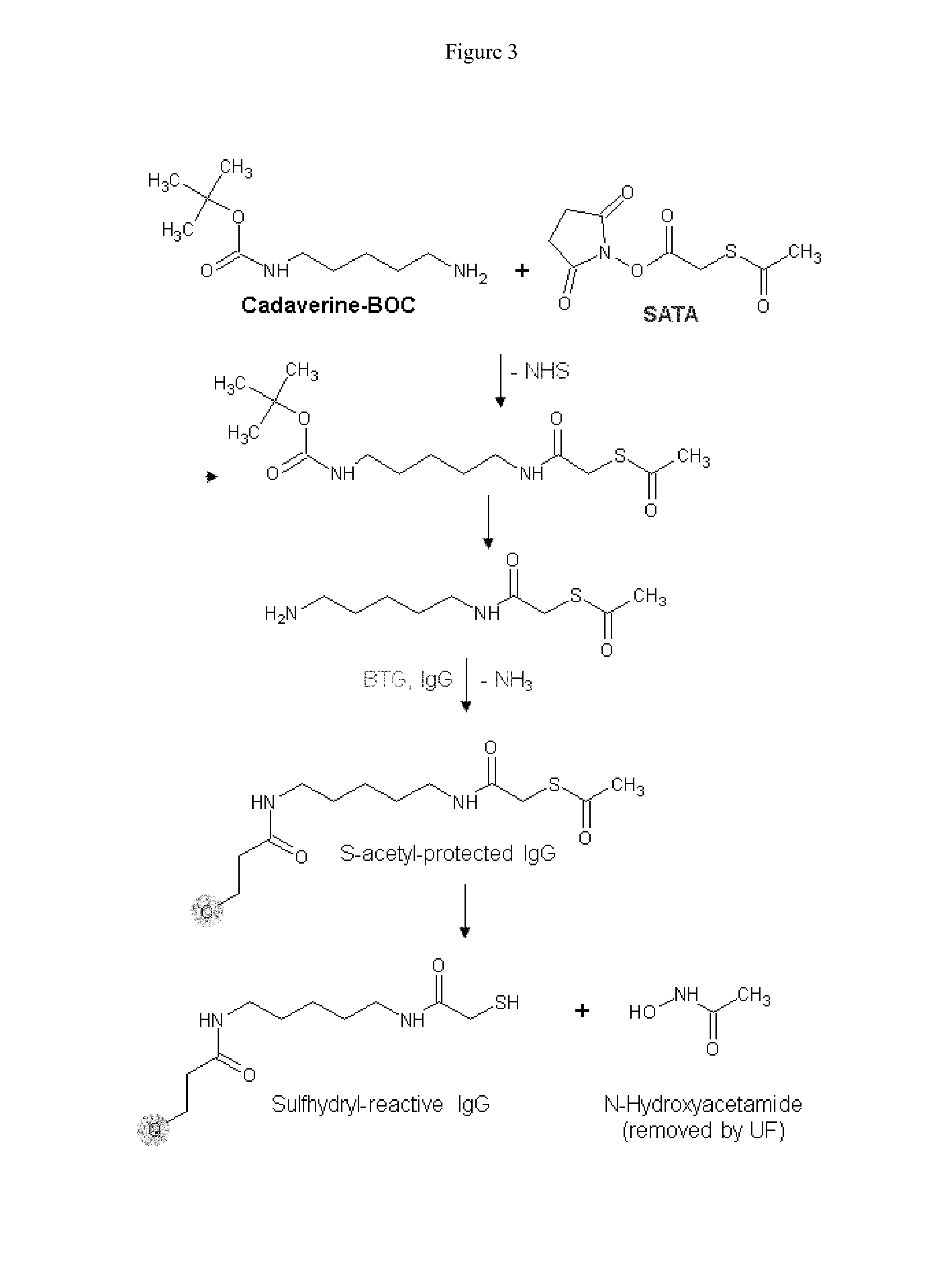

Enzymatic conjugation of antibodies

ActiveUS20140356385A1Improve stabilityNarrow distributionGroup 5/15 element organic compoundsImmunoglobulinsDiseaseEnzyme

The present application relates to methods for the functionalization of immunoglobulins, in particular with drugs. Also disclosed herein are linking reagents, functionalized antibodies, pharmaceutical compositions, and method of treating disease and / or conditions.

Owner:INNATE PHARMA SA +1

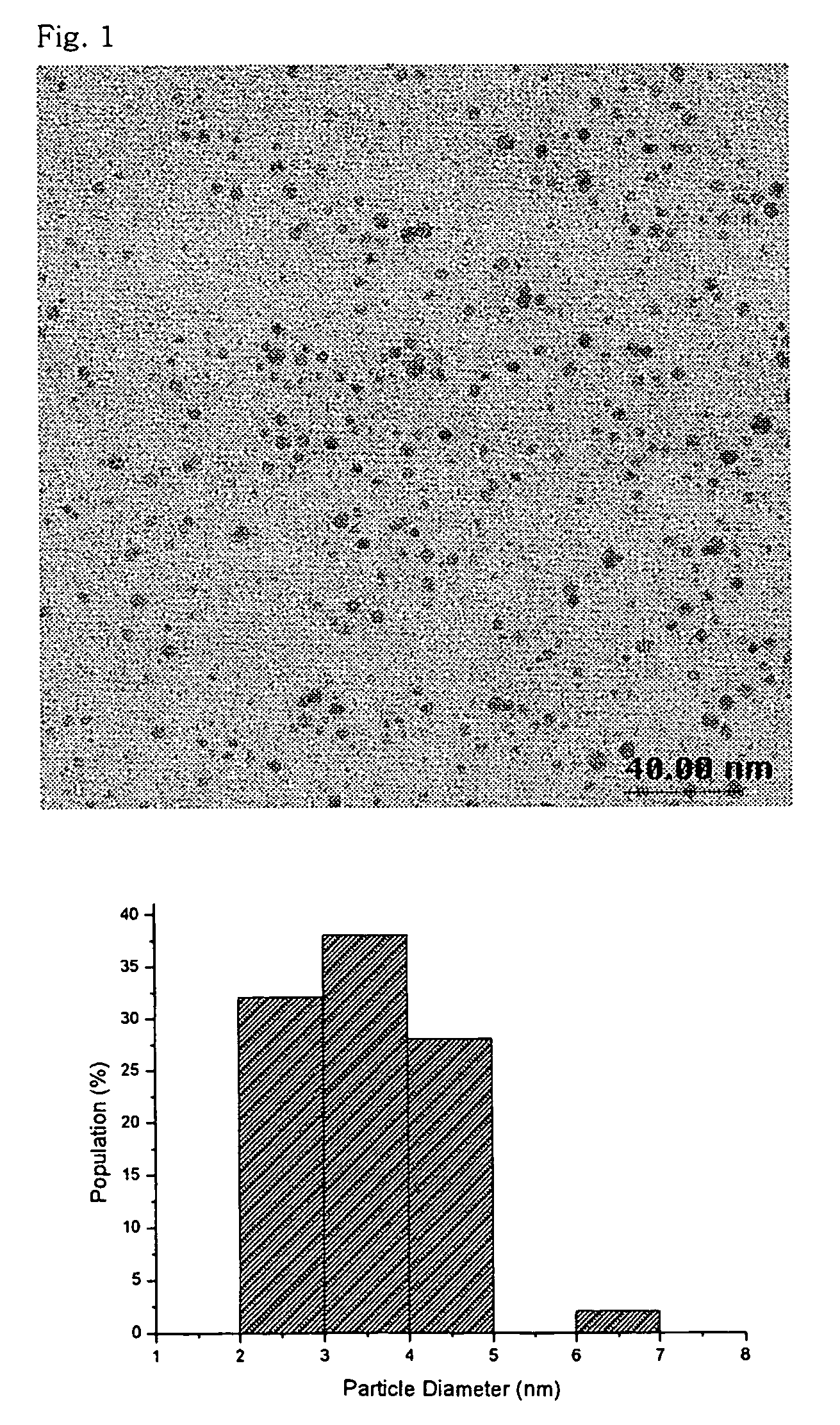

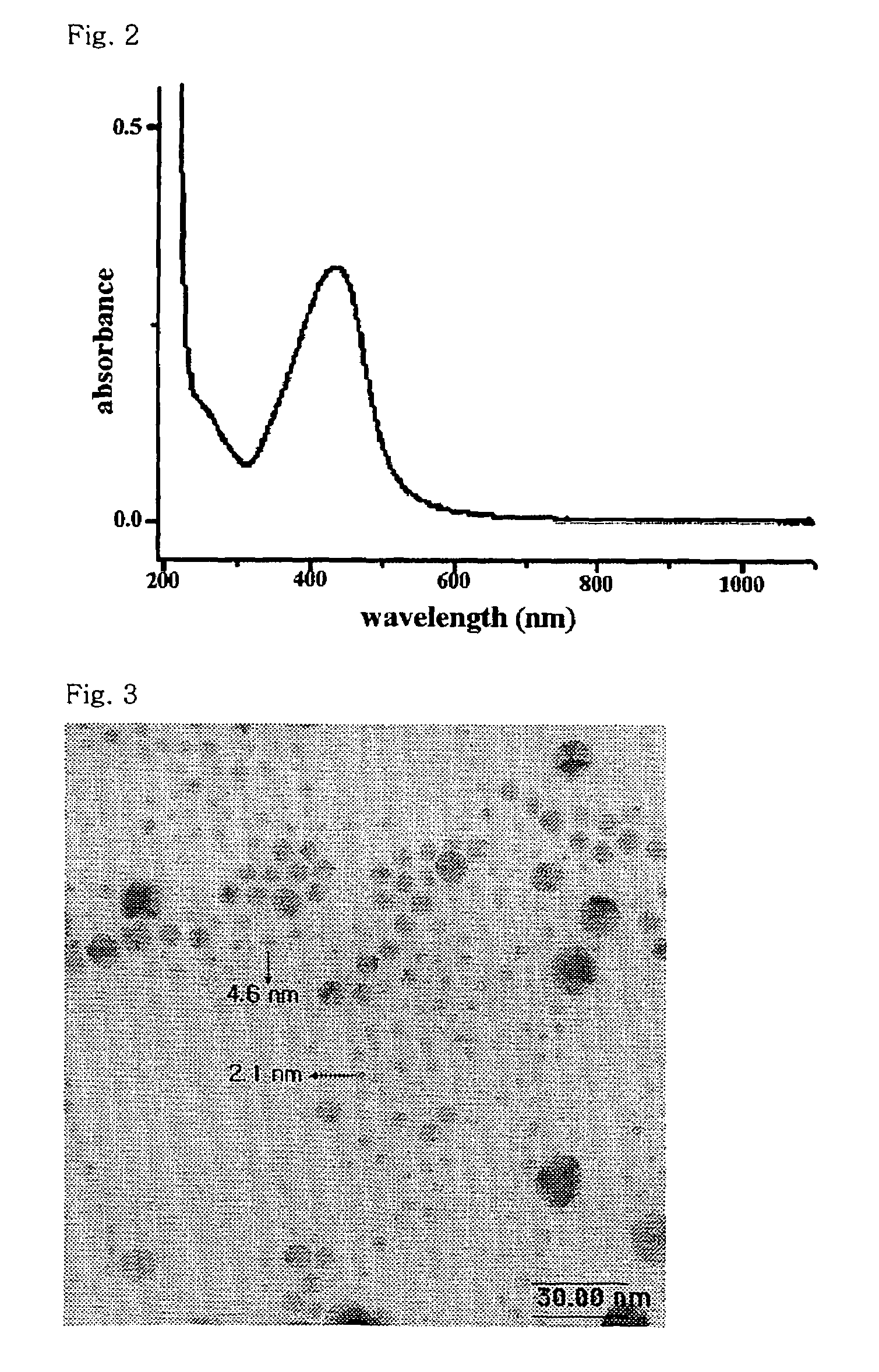

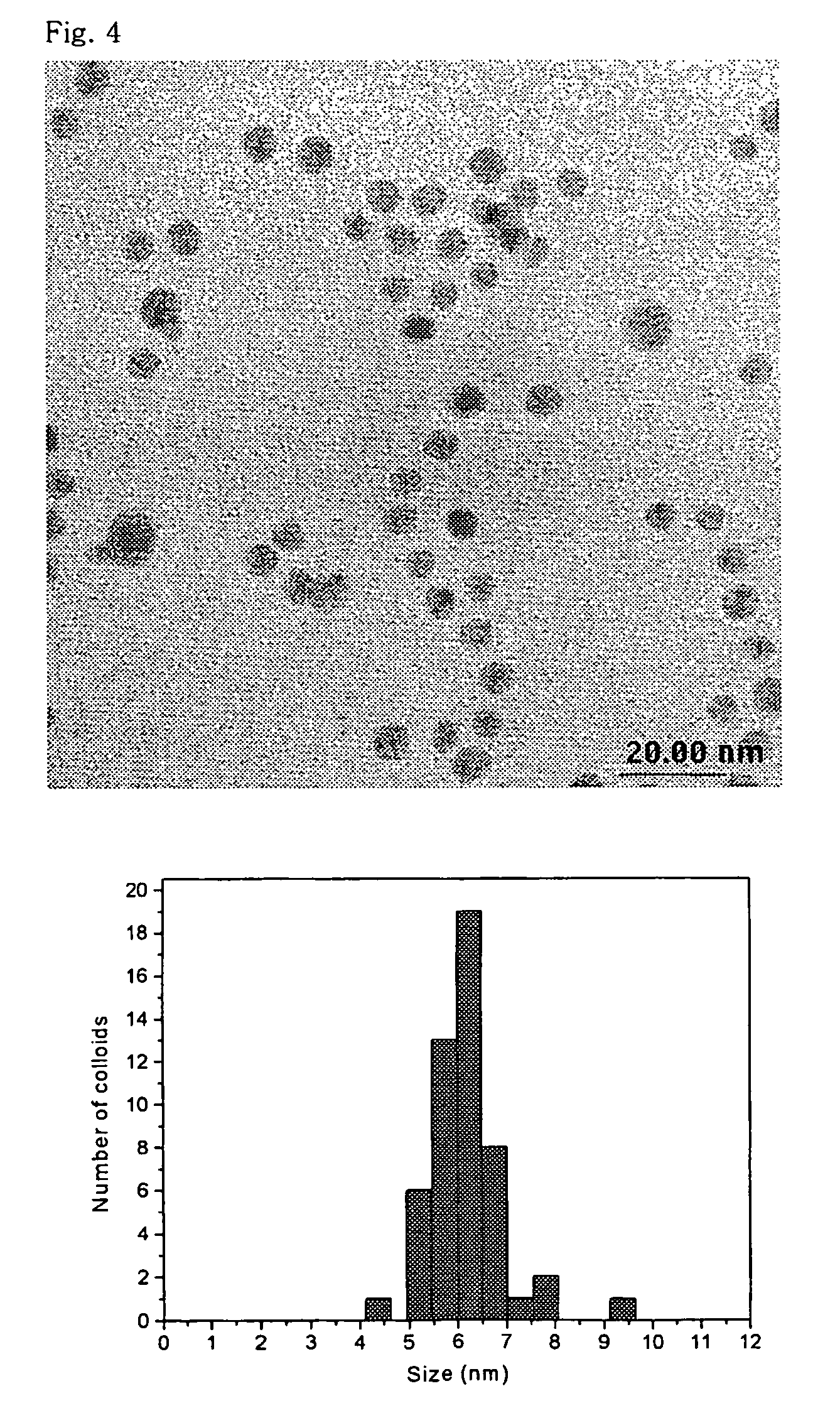

Colloid solution of metal nanoparticles, metal-polymer nanocomposites and methods for preparation thereof

InactiveUS7348365B2Easy to controlGood effectOther chemical processesTransportation and packagingStabilizer for polymersNanometre

A metal nanoparticle colloid solution, metal-polymer nanocomposites, and methods for preparing the same are provided. The metal nanoparticle colloid solution and the metal-polymer nanocomposites can be prepared with a variety of polymeric stabilizers and have uniform particle diameter and shape. The metal nanoparticle colloid solution and the metal-polymer nanocomposites have wide applications, for example, as an antibacterial agent, a sterilizer, a conductive adhesiv, conductive ink or an electromagnetic wave shielder for an image display.

Owner:POSTECH ACAD IND FOUND +1

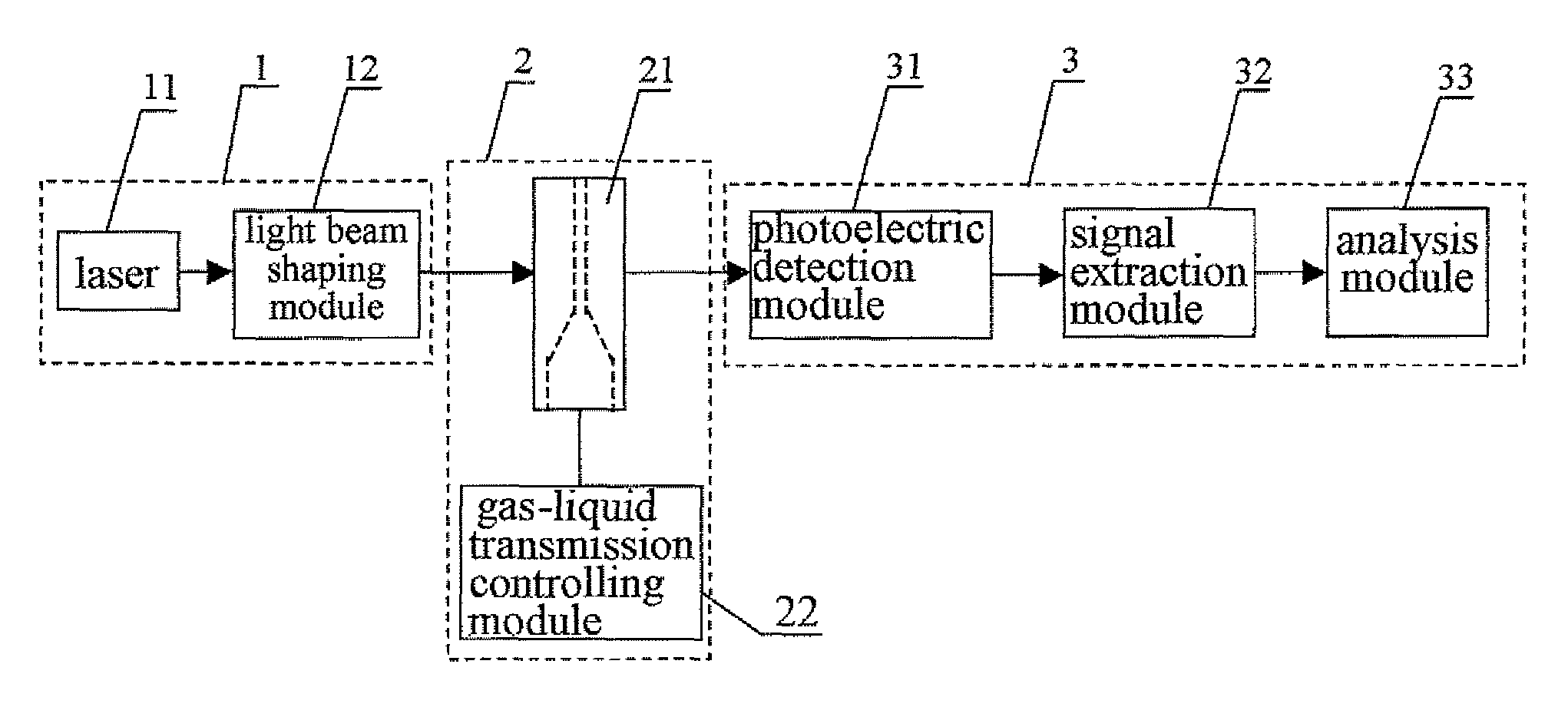

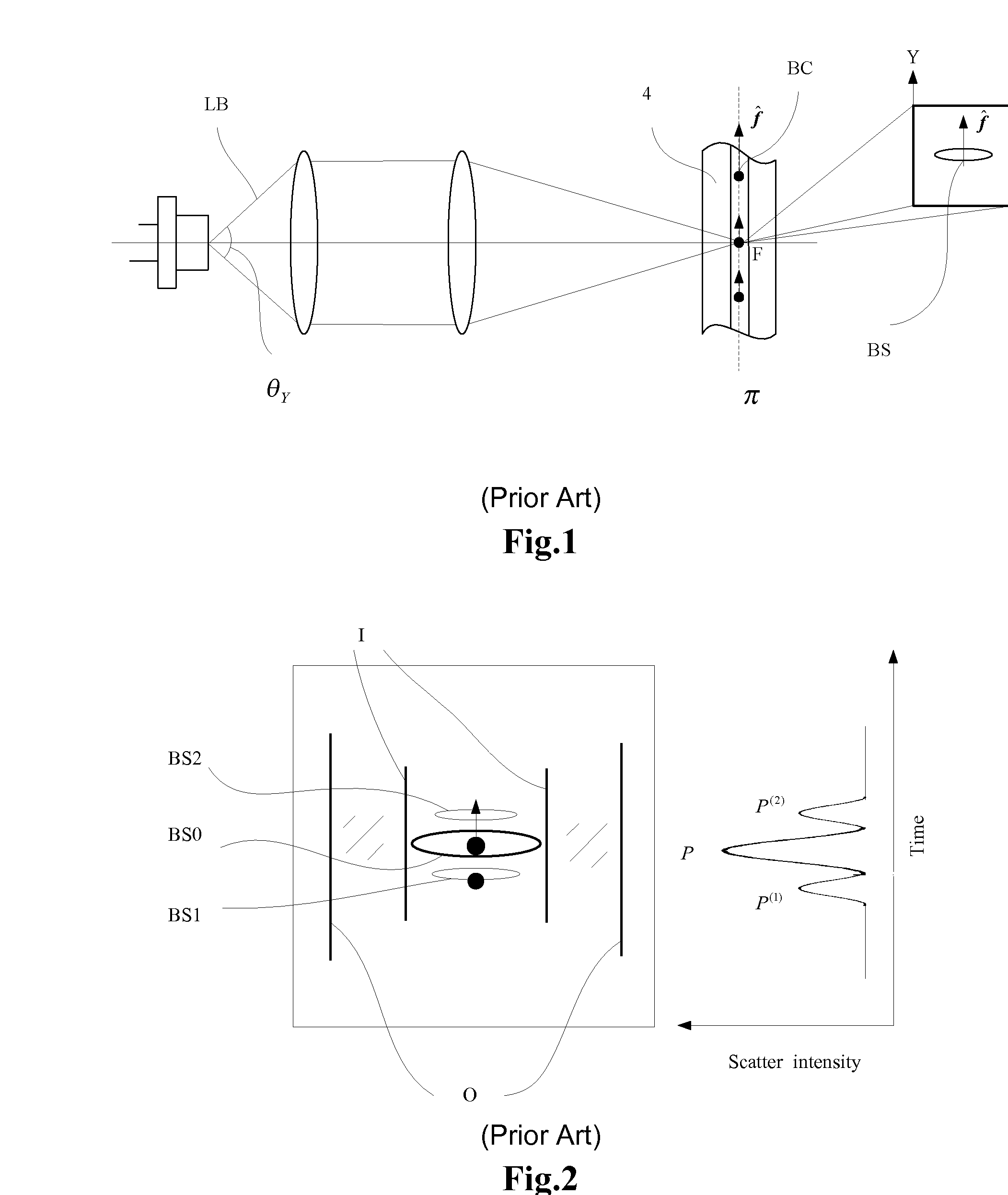

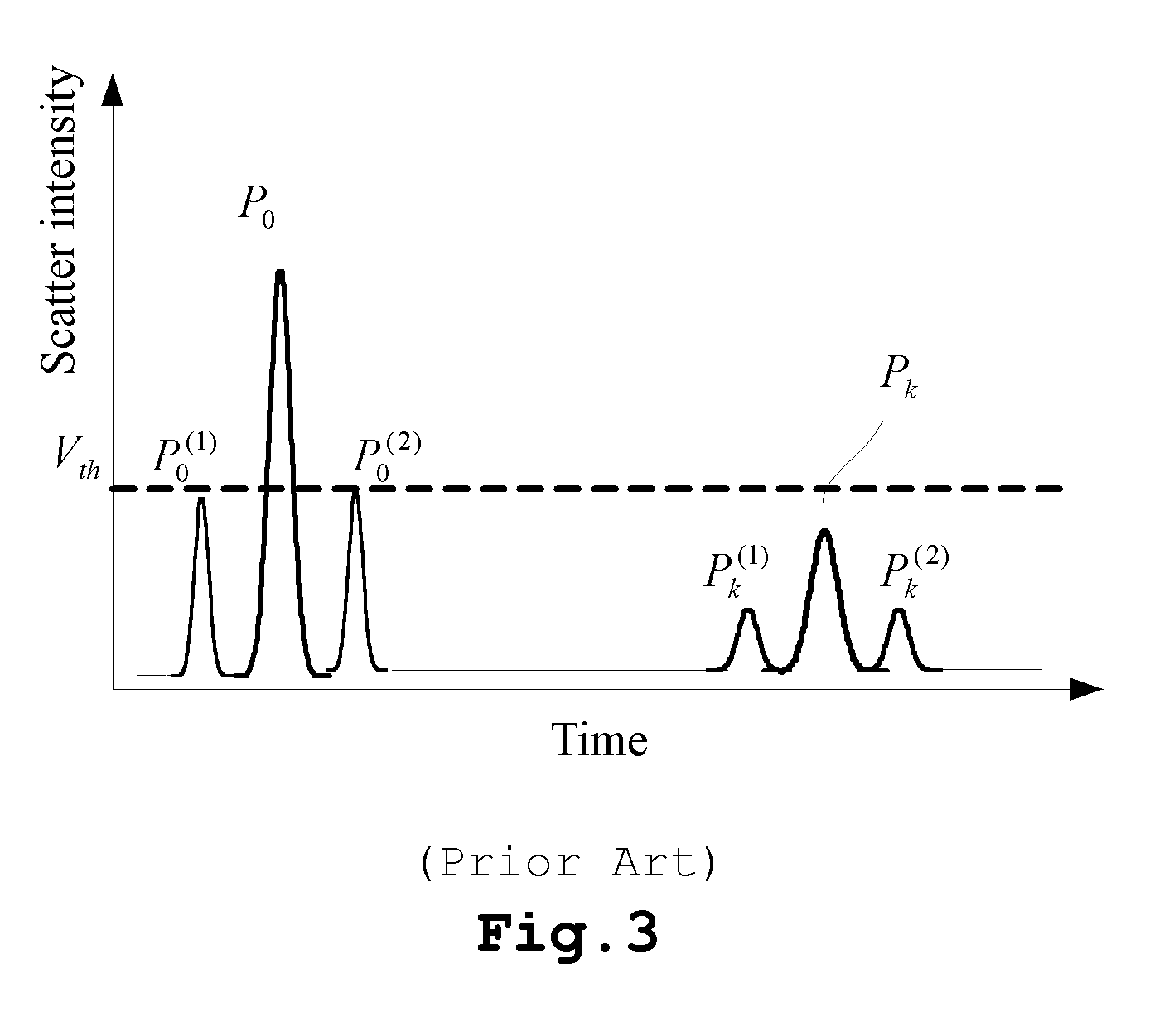

Flow cytometer

ActiveUS7561267B2Improve stabilityNarrow distributionMaterial analysis by optical meansParticle size analysisInstabilityLight beam

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Catalyst used for methanation of carbon dioxide, preparation method therefor and applications thereof

ActiveCN104148065ASmall particle sizeNarrow distributionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsElectrolysisMethanation

The invention provides a catalyst used for methanation of carbon dioxide, a preparation method therefor and applications thereof. The catalyst employs precious metal Ru or Rh as a main catalytic activity component, employs one or more selected from elements of the I and II main groups and the II, III and VII subgroups as auxiliary agents, and employs one or more selected from SiO2, TiO2, Al2O3, CeO2 and ZrO2 as carriers. The above catalyst is used in graininess or the carriers, the auxiliary agents and the activity component are subjected to coating (wall loading) on a whole structural catalyst and metal honeycombs. The catalyst has characteristics of high activity and selectivity and wide temperature and pressure operation windows. The catalyst can be used for hydrogenation methanation removal of CO2 in a space station, then generated H2O is subjected to electrolysis, and circulation supply of oxygen is achieved. The catalyst also can be used for processes of other CO2 conversion utilization of coal-made natural gases and process gases and the like and new energy development and energy saving and emission reduction are achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

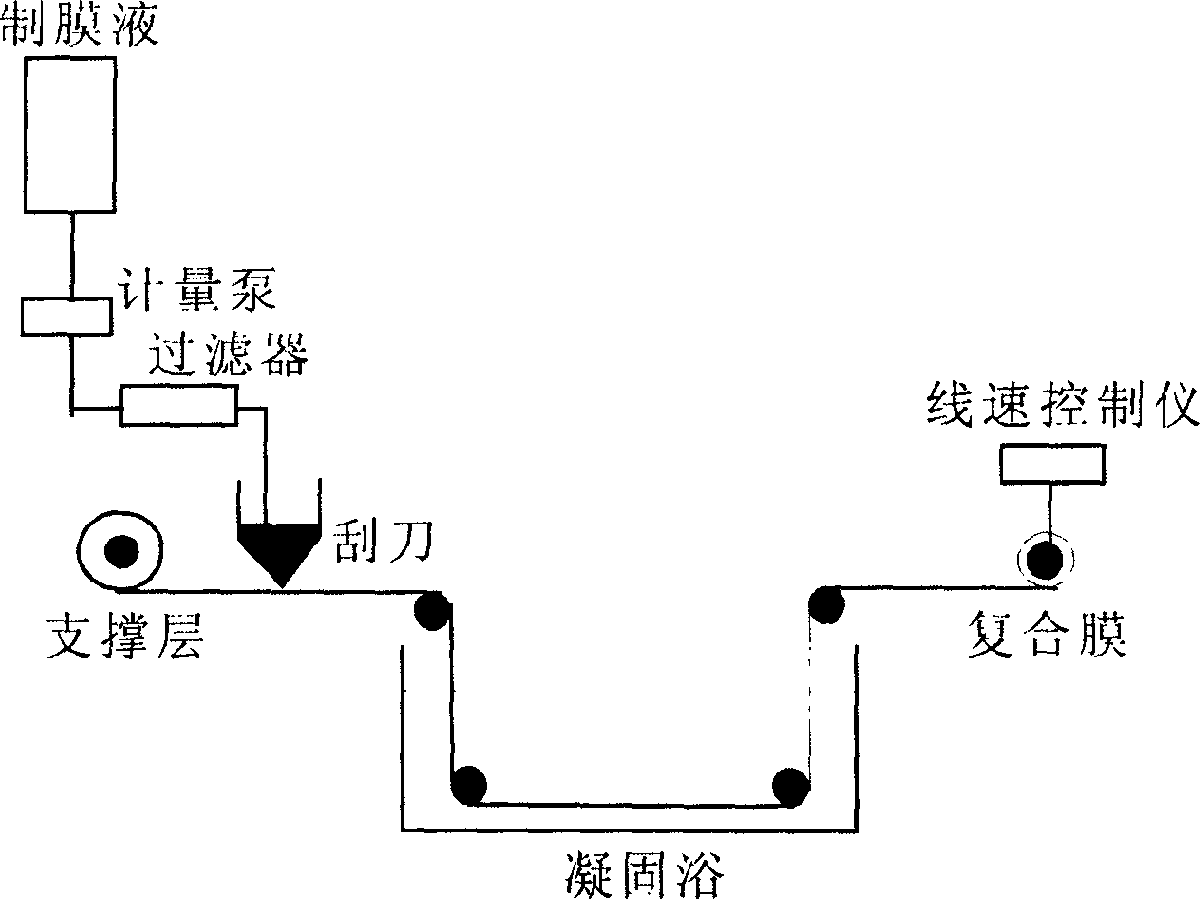

Method for preparing polyvinylidene fluoride flat plate microporous compound film

InactiveCN1621140AReduce energy consumptionEasy temperature controlSemi-permeable membranesComposite filmEngineering

The present invention is preparation process of plate microporous composite polyvinylidene fluoride film. The preparation process includes: mounting the support layer on composite film scraping machine and regulating the cloth speed; regulating the interval between the support layer and the scraper with plug gage; feeding filming liquid into the film scraping machine and coating the liquid to the support layer to form film, running the film in the air for some time, soaking the film in solidifying bath to form the composite film of polyvinylidene fluoride and the support layer. The composite film features large pore size, high strength and high water flux. The composite film is measured to have pore size of 0.1-1.5 micron, pure water flux of 400-2100 L / hr.sq m (at 0.1MPa), thickness of 150-220 microns, radial tensile strength of 35.2 MPa, radial elongation at breaking of 51.92 %, transverse tensile strength of 18.2 MPan and transverse elongation at breaking of 68.7 %.

Owner:ZHEJIANG UNIV

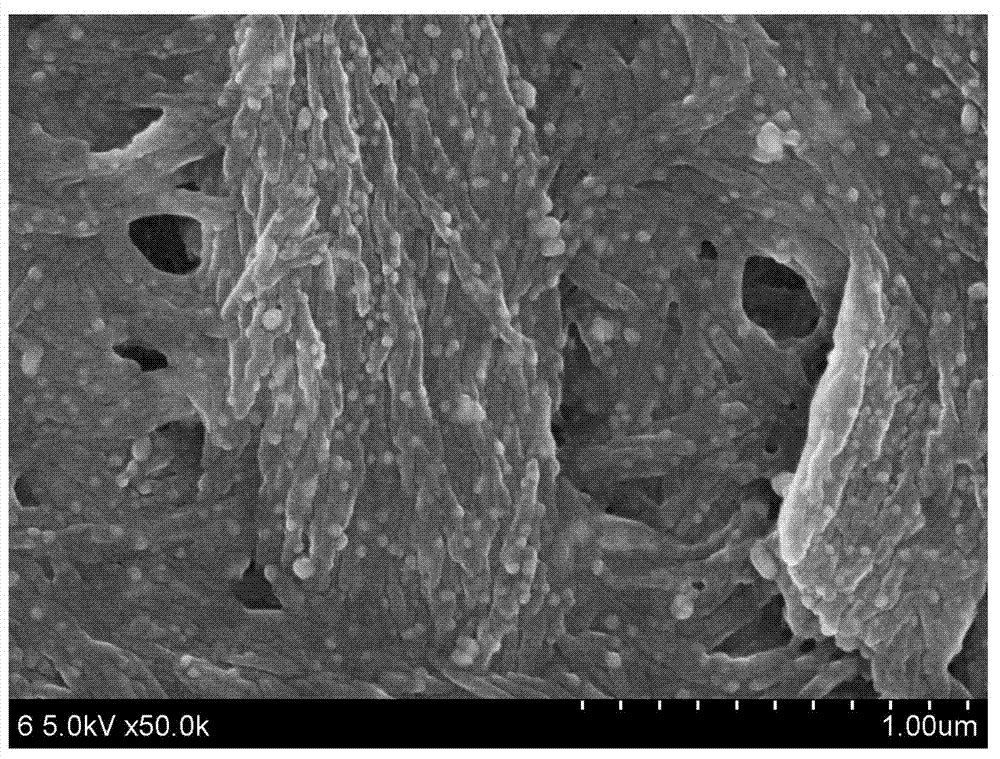

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

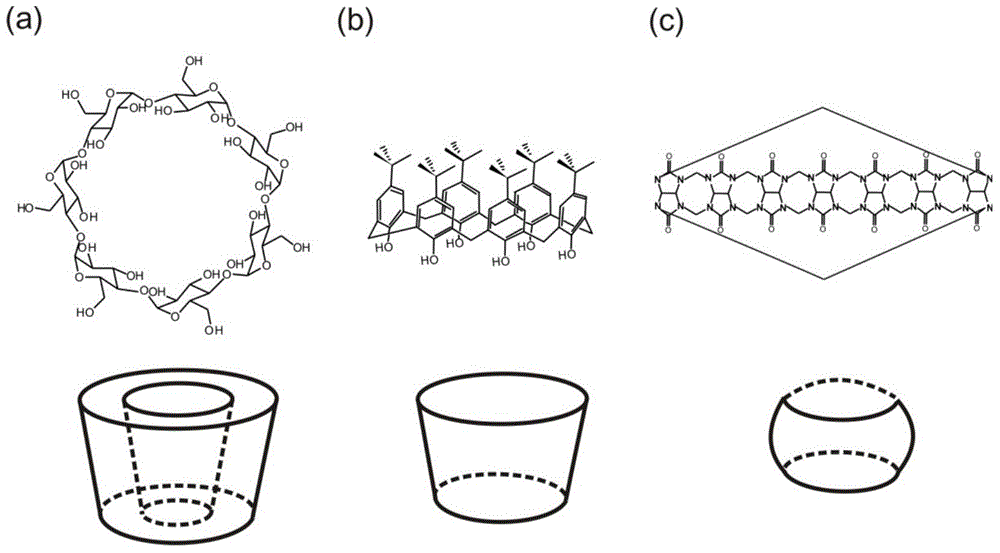

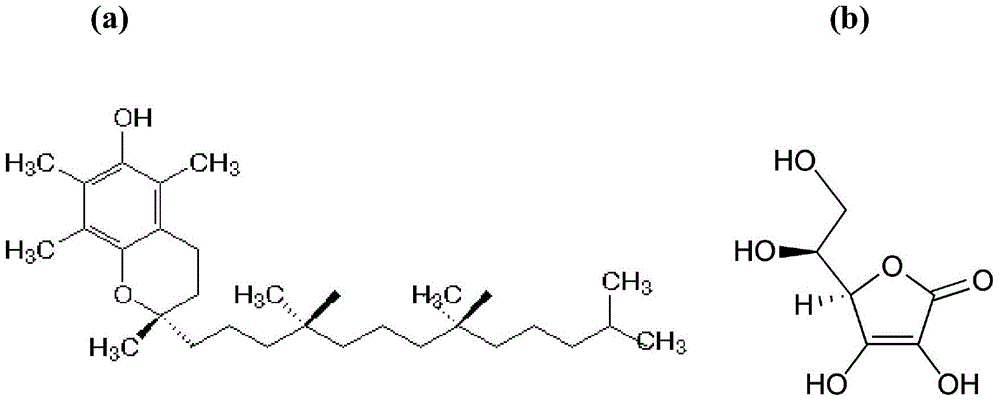

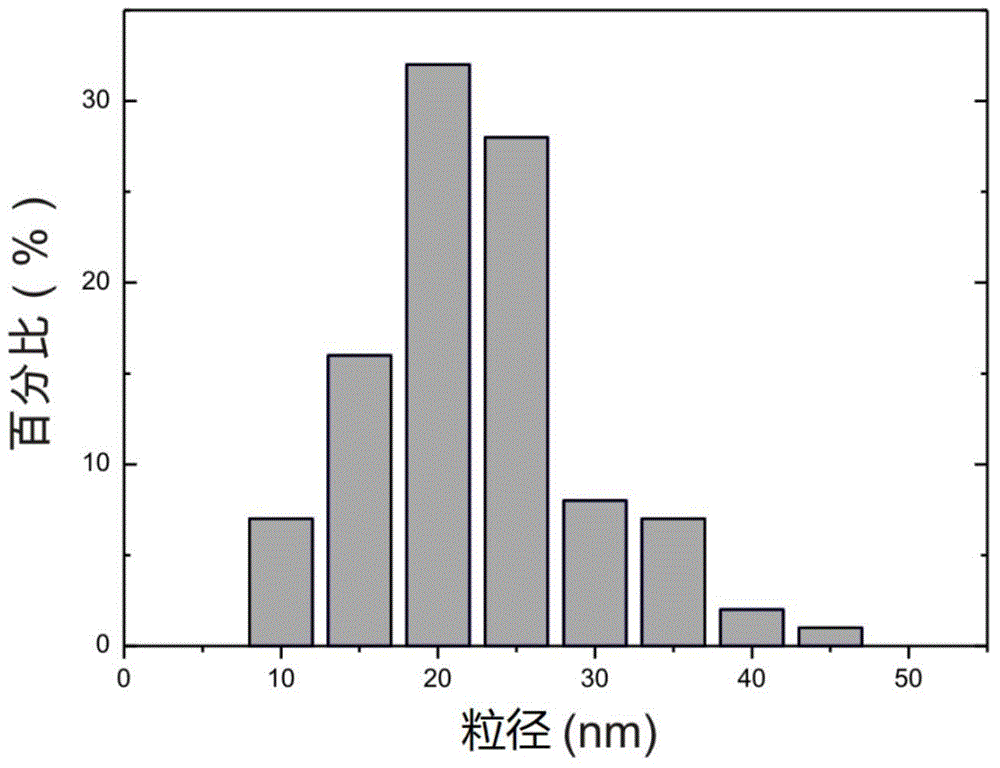

Cosmetic active ingredient-containing lipidosome as well as preparation method and application thereof

ActiveCN104606063ASmall particle sizeNarrow distributionCosmetic preparationsToilet preparationsMedicineCuticle

The invention relates to cosmetic active ingredient-containing lipidosome as well as a preparation method and application thereof. The cosmetic active ingredient-containing lipidosome is small and uniform in particle size, so that the wrapped active ingredients can permeate the cuticles to the deep layer of skin so as to effectively realize deep skin care. Moreover, due to the small particle size, the collision and sedimentation probability of the finished lipidosome product is decreased and the stability of the lipidosome cosmetic is improved. The cosmetic active ingredient-containing lipidosome is prepared by a host-guest chemical method, so that the lipoid molecules and the active ingredient molecules are uniformly mixed on the molecular level, so that the gathering inactivation phenomenon of the active ingredients is avoided; the preparation condition is mild, so that the active ingredients are prevented from damage.

Owner:王海龙

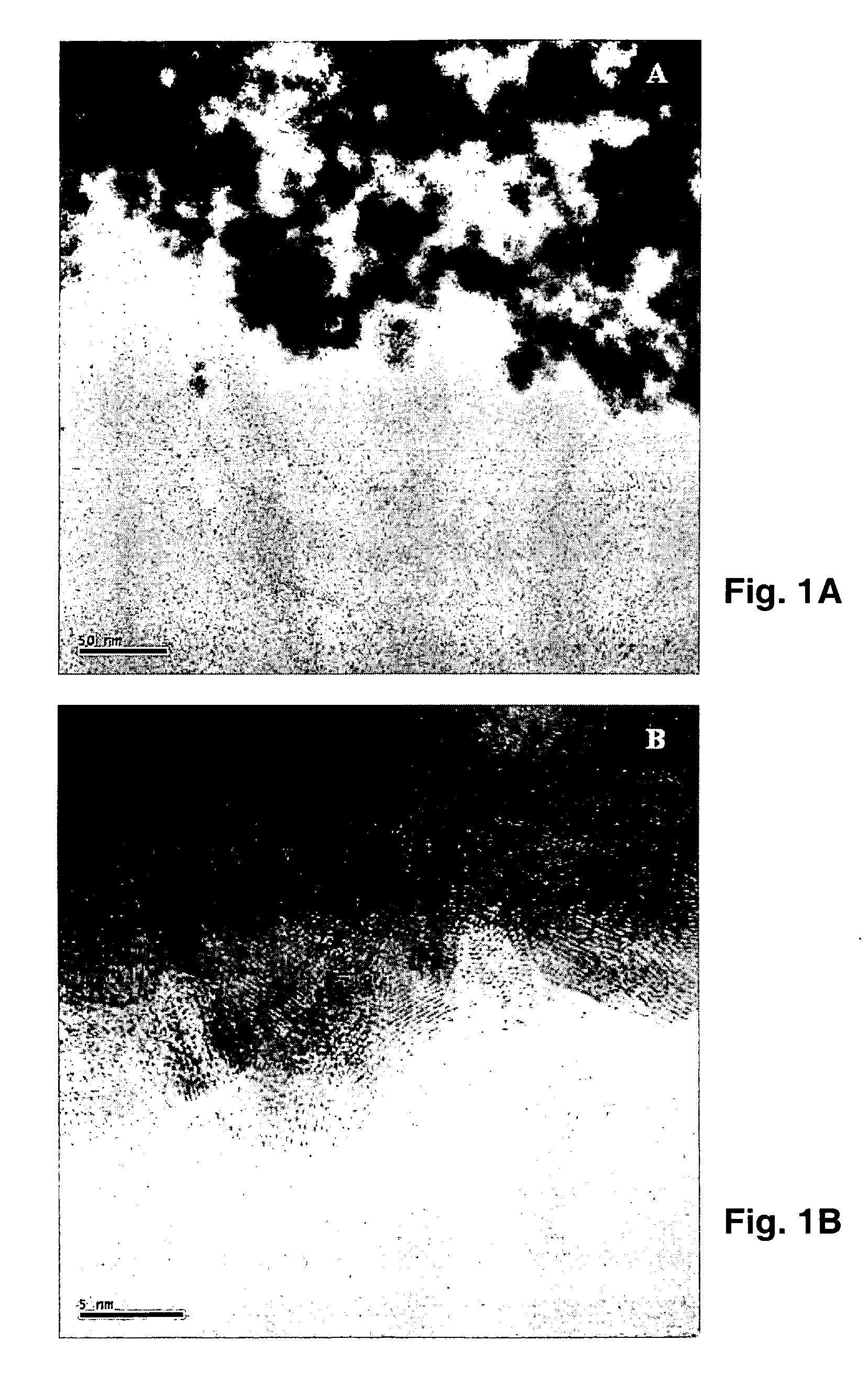

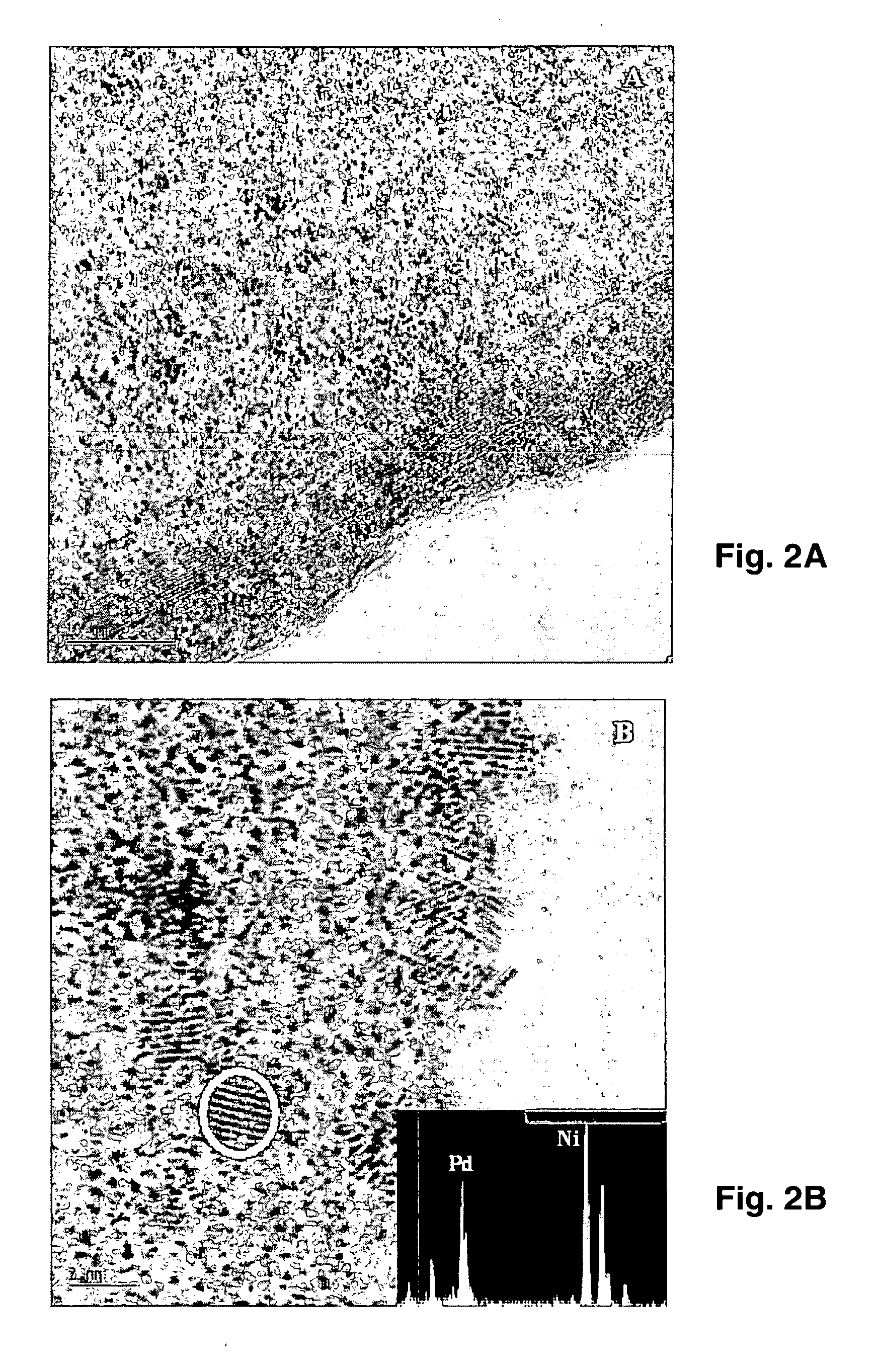

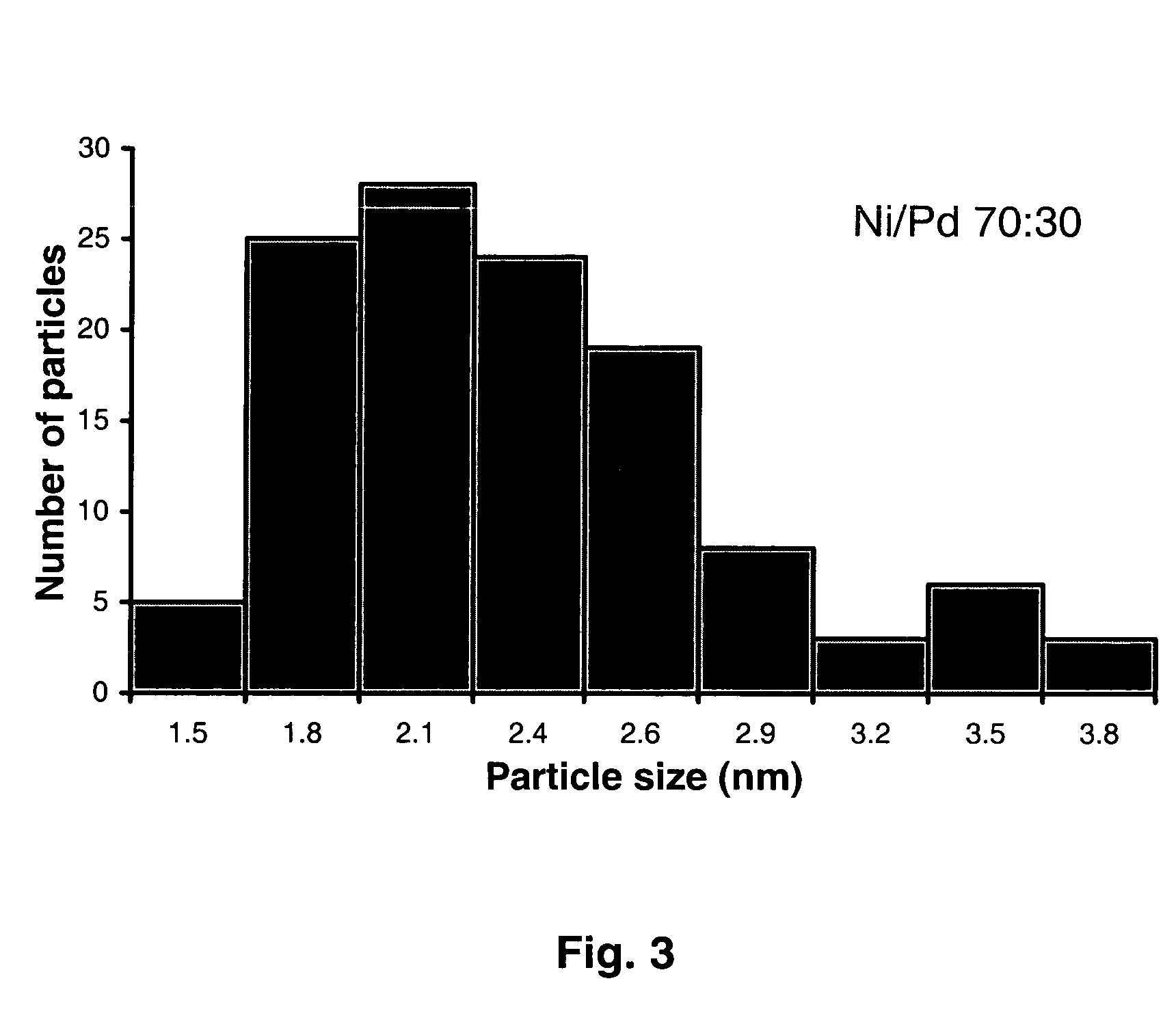

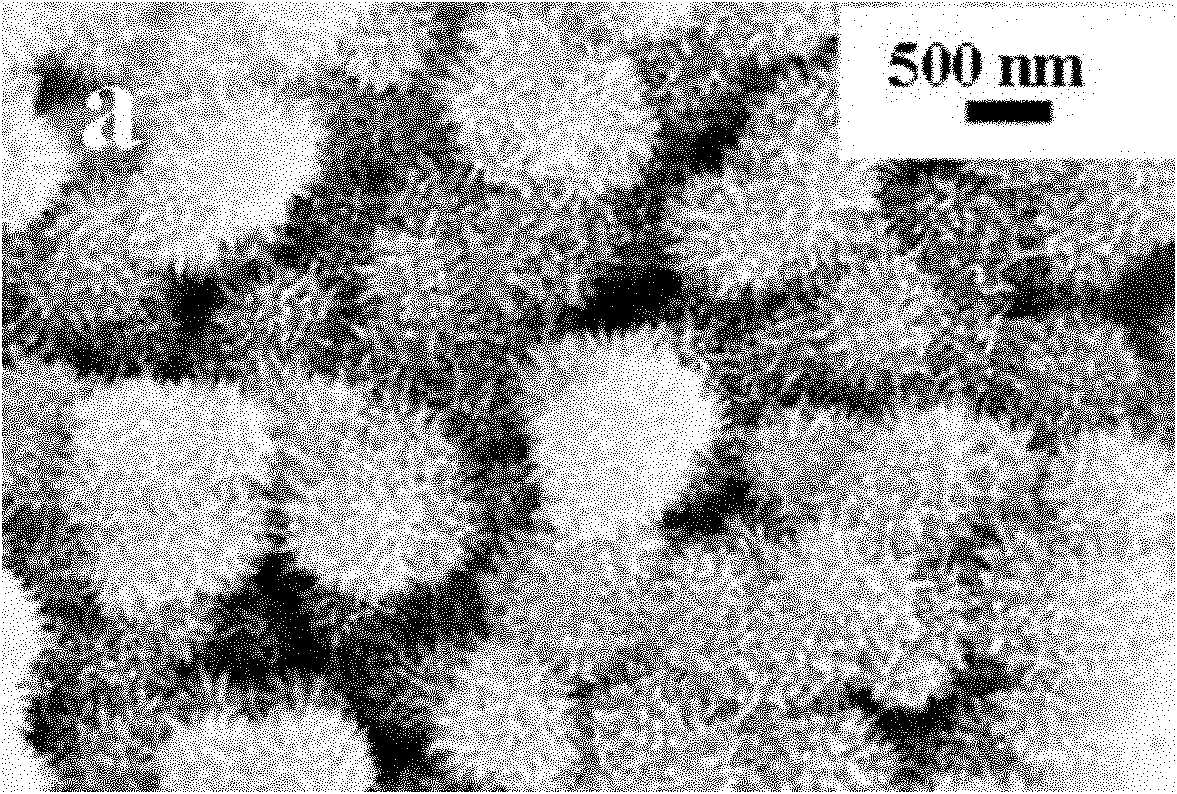

Nanoparticle colloid, method for its production and its use in the growth of carbon nanotubes

InactiveUS20070202304A1Small sizeStable chemical degradationMaterial nanotechnologyDecorative surface effectsCarbon nanotubeMaterials science

A method for producing a colloid of metallic nanoparticles including the steps of: providing metal ions in solution; providing a stabilizing agent; and reducing said metal ions in the presence of said stabilizing agent, so that metallic nanoparticles are formed with a surrounding layer of said stabilizing agent, wherein the reduction step is carried out at a temperature of not less than 20° C. and not more than 150° C. The metallic nanoparticles are formed of a mixture of transition metal and noble metal, such as Ni—Pd. The resultant nanoparticles have a high stability in terms of size and chemical degradation and so can be stored for long periods. They are therefore particularly suited for forming patterned nanoparticle arrays on a substrate by nanocontact printing for the subsequent formation of a corresponding array of carbon nanotubes or nanofibers via plasma enhanced CVD.

Owner:CAMBRIDGE UNIV TECH SERVICES LTD

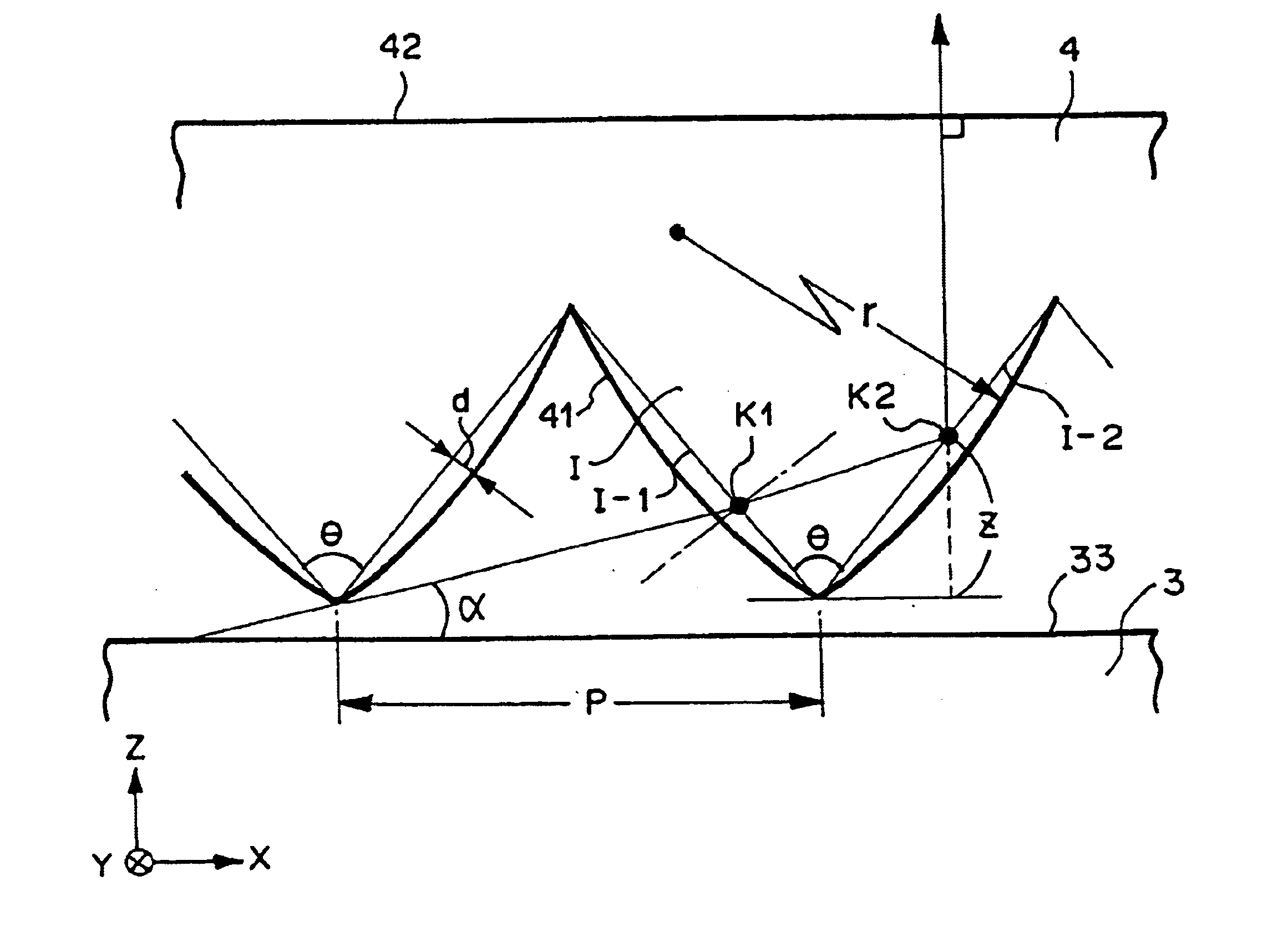

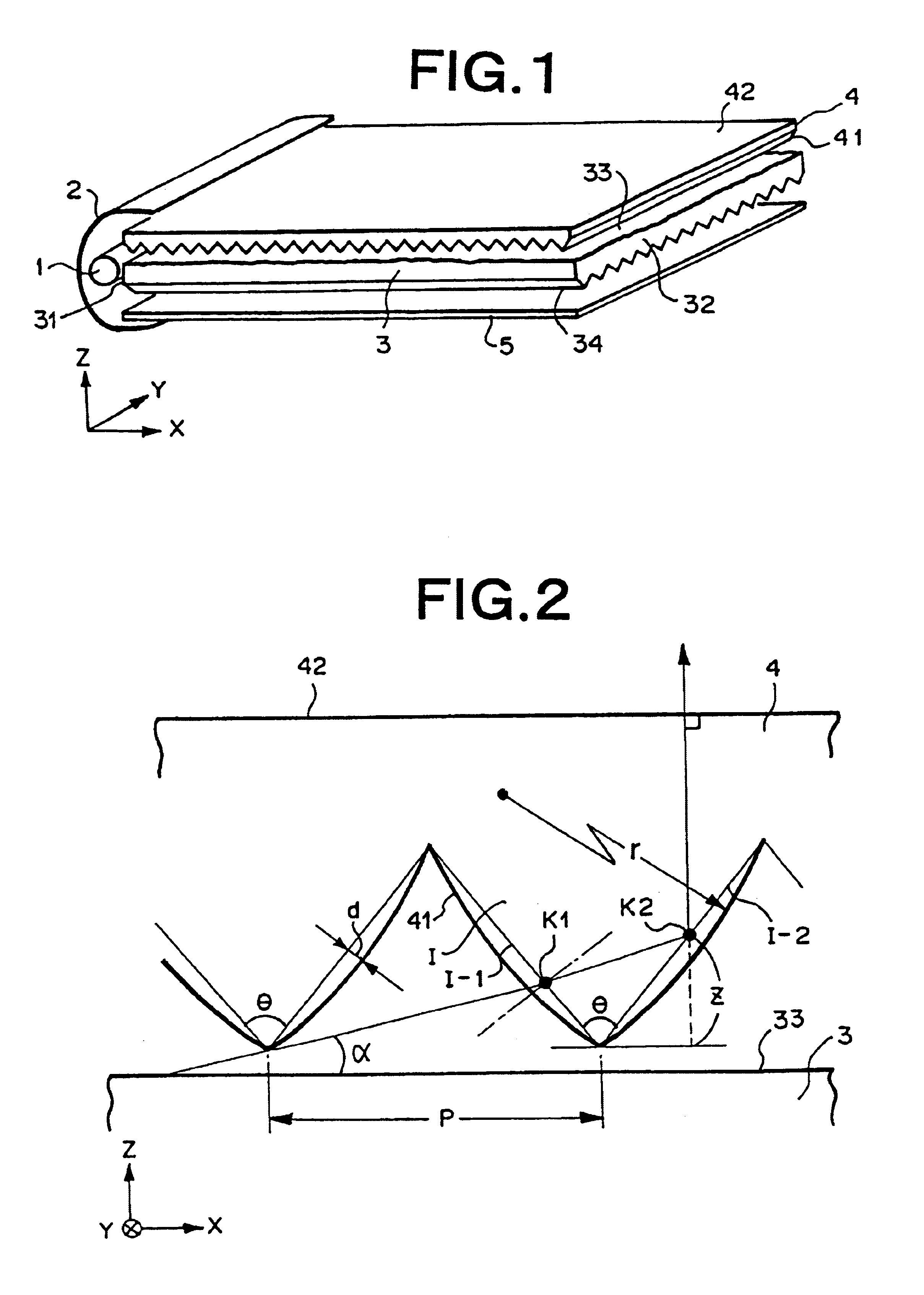

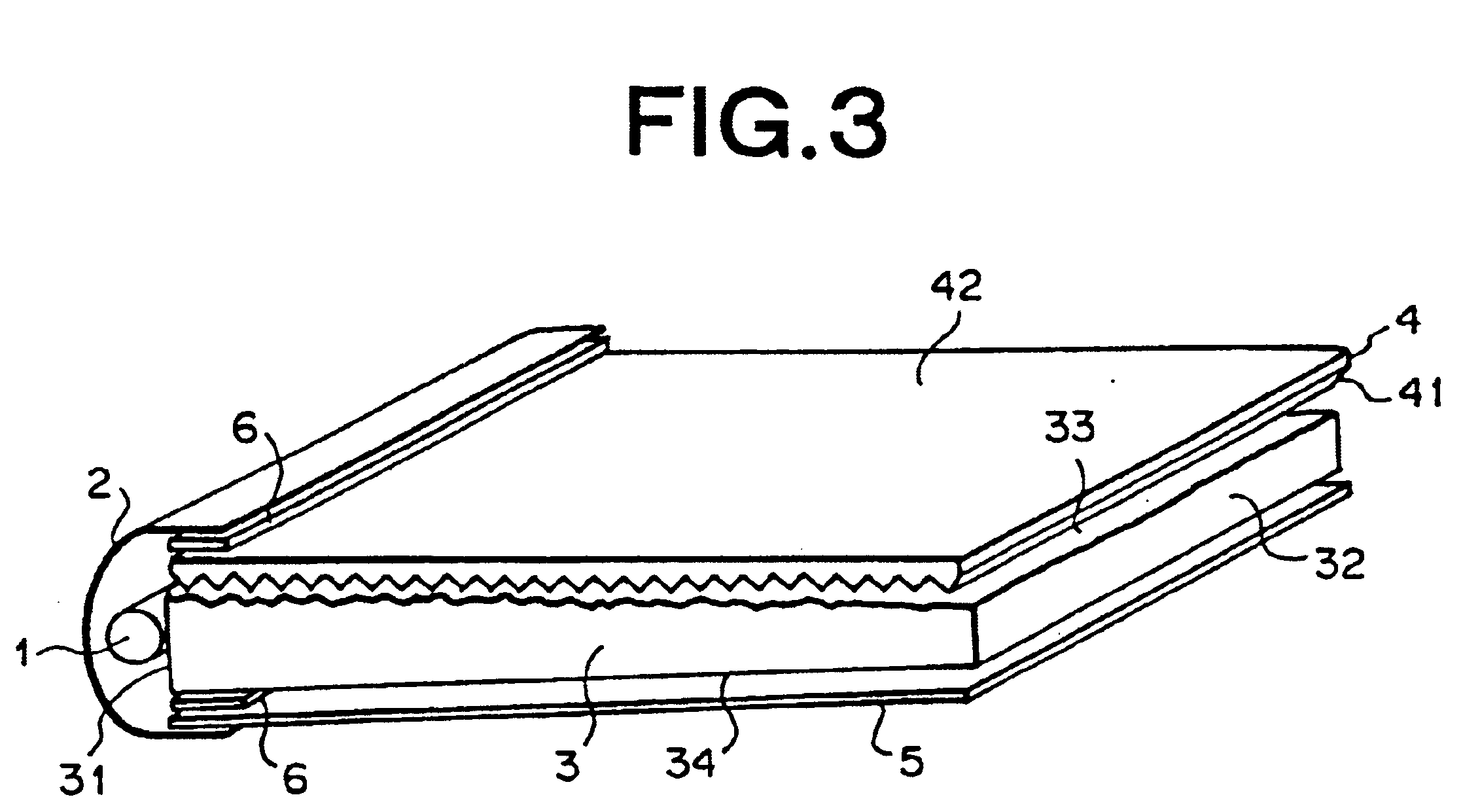

Light source device

InactiveUS6874902B2Using efficiency of the light amount of a primary light source can be enhancedIncrease brightnessPrismsMechanical apparatusLight guideConvex side

A light source device having a light guide (3) for guiding light emitted from a primary light source and emitting light obliquely from a light emission face (33) thereof, and a light deflecting device (4) disposed so as to be adjacent to the light emission face. Plural elongated prisms are arranged in parallel to one another at a light incident surface (41) of the light deflecting device. Virtual elongated prisms (I) each having a vertical angle θ of 50 to 70° arranged in the same arrangement pitch as the elongated prisms are assumed so that the peak emission light in the light emission distribution of light emitted from the light emission face is incident on one virtual prism face of the virtual elongated prism, internally totally reflected by another virtual prism face and then emitted in a desired direction from a light emission surface (42) of the light deflecting device. A prism face of each elongated prism at the far side from the primary light source is designed to have a convex surface shape with respect to the shape of the virtual elongated prism. The value (r / P) of the radius of curvature r normalized by the arrangement pitch P is equal to 7 to 30, and the ratio (d / P) of the maximum distance between the convex-surface-shaped prism face of the elongated prism and the virtual prism face to the arrangement pitch P is equal to 0.05 to 5%.

Owner:MITSUBISHI RAYON CO LTD

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

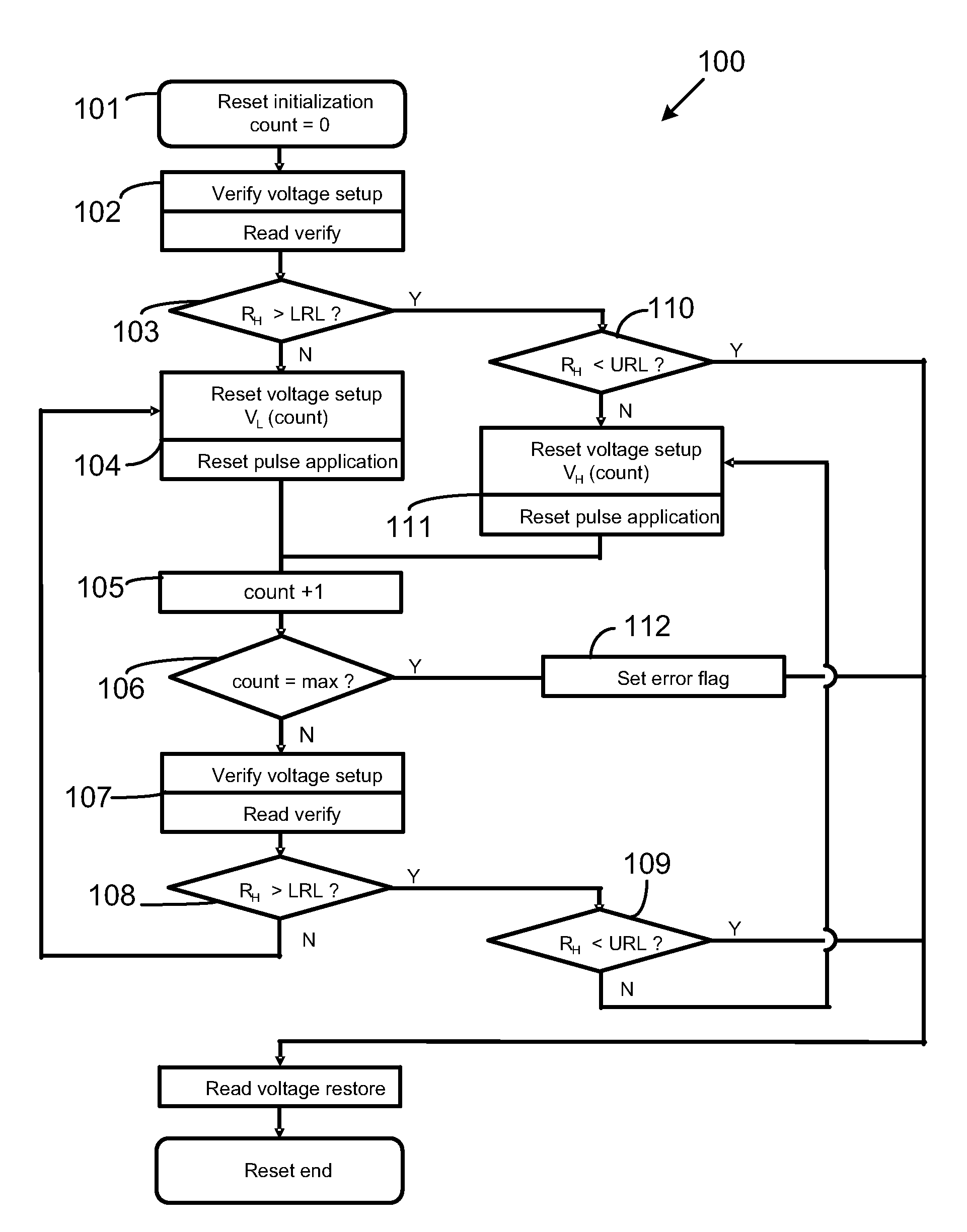

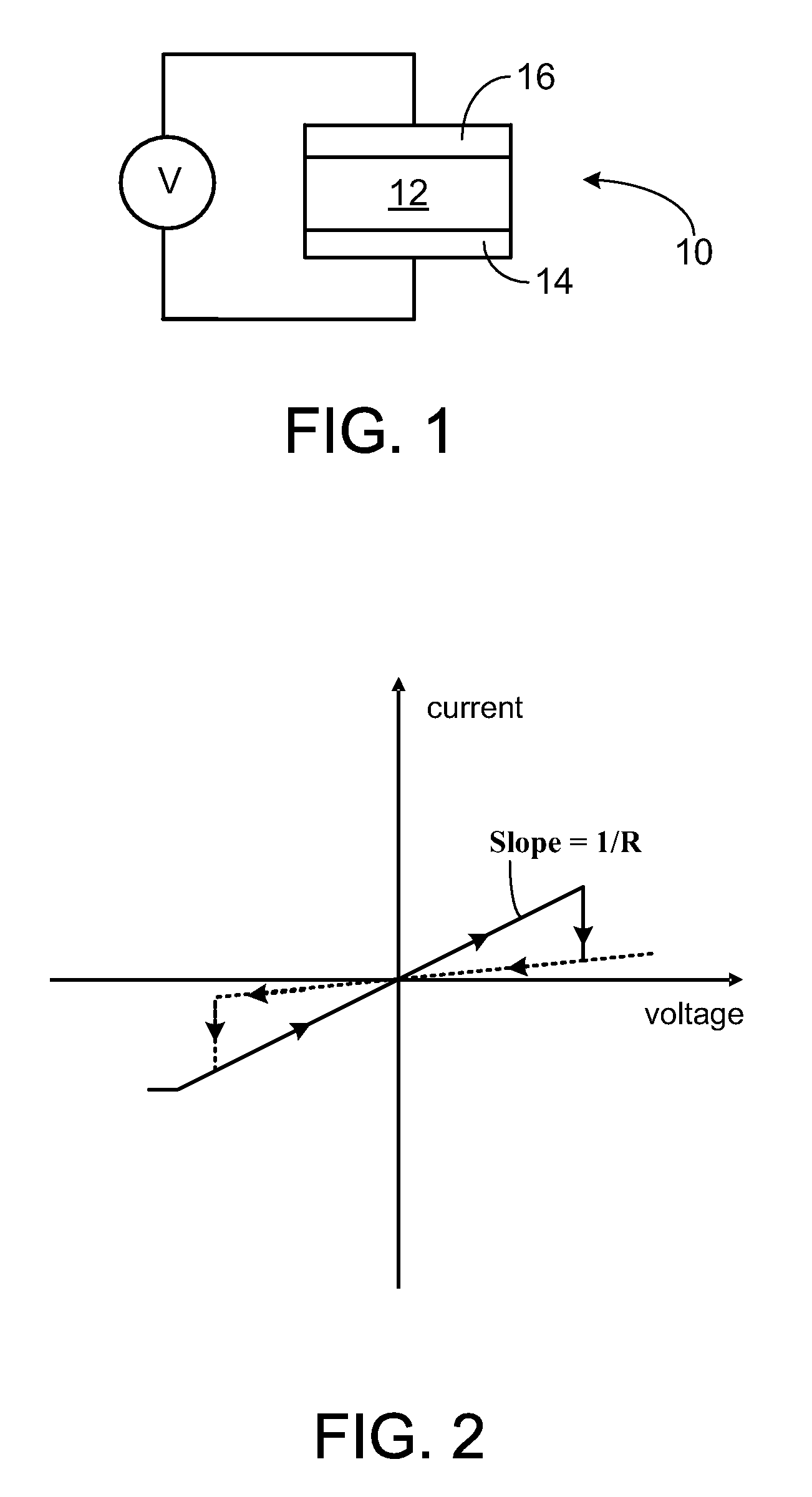

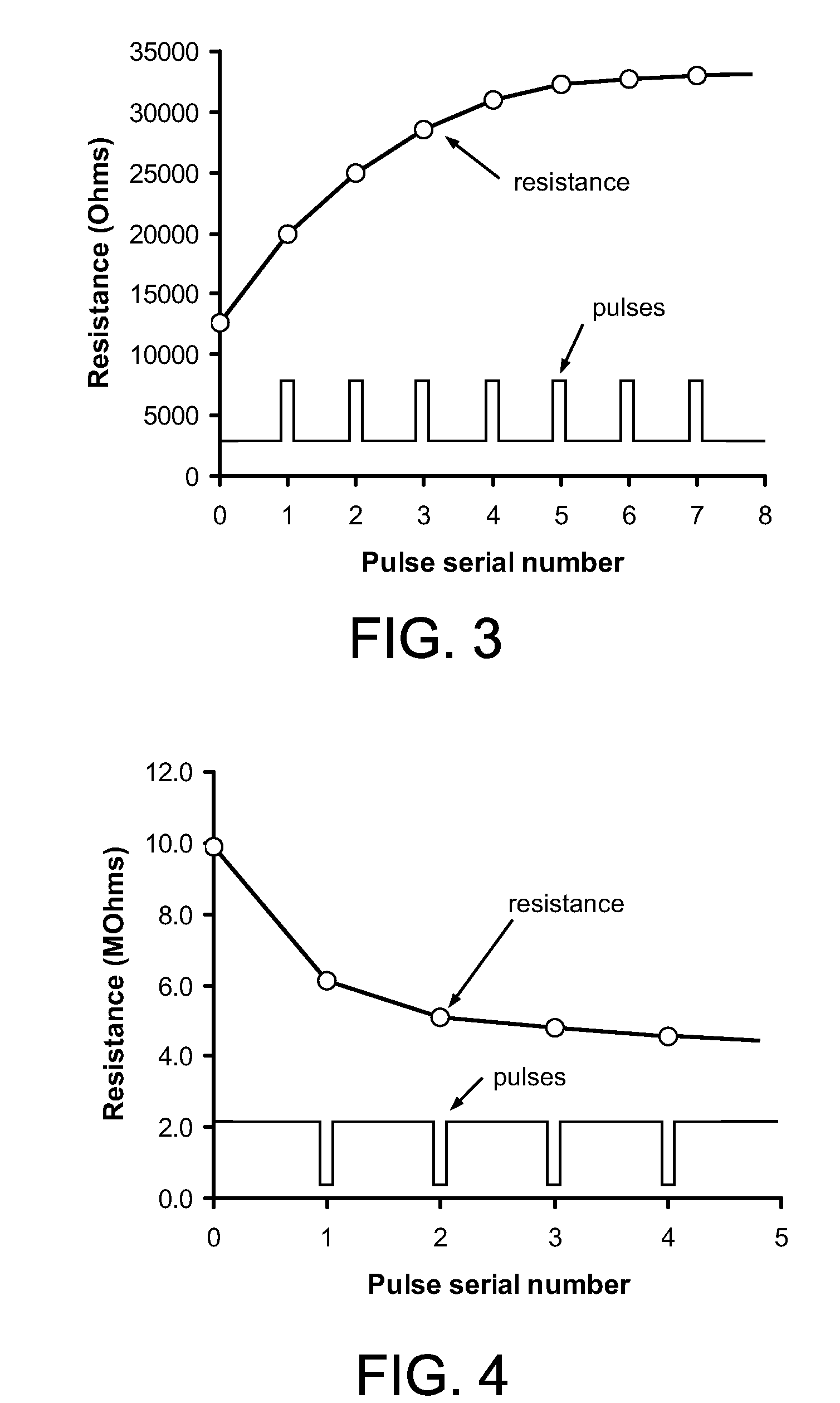

Write verify method for resistive random access memory

Owner:SEAGATE TECH LLC

Self-dispersion type nanometer gamma A100H and its preparation method and use

A gamma-AlOOH nanocrystal powder able to be automatically dispersed in aqueous and some organic solvents for preparing self-dispersing superfine non-toxic aluminum hydroxide flame-retarding agent, or the high-molecular polymer / inorganic nano-material composition, or the microcrystalline alumina ceramics or high-performance alumina ceramics as grinding medium is prepared through reaction of sodium aluminate or Al salt solution in alkaline medium, extracting the generated deposit, adding peptizing agent and disperser, peptizing and dispersing to obtain aluminum hydroxide colloid, reacting on additive and surfactant for surface modifying, and spray drying.

Owner:GUANGXI UNIV FOR NATITIES

Preparation method for nano-sliver/cellulose nanocrystalline composite particle

InactiveCN102775643AIncrease loadDoes not destroy the glycosidic ring structureNanotechnologyCelluloseFree cooling

The invention relates to a preparation method for a nano-sliver / cellulose nanocrystalline composite particle. The preparation method comprises the following steps of: (1) adding a cellulose raw material into an acid-mixed solution and reacting at the temperature of 50-90DEG C for 1-20 hours; after the reaction is ended, washing a reaction product with deionized water to neutral and obtaining aldehyde cellulose nanocrystalline; and (2) adding the aldehyde cellulose nanocrystalline into a silver nitrate solution; reacting at the temperature of 60-105DEG C for 10-60 minutes; and after naturally cooling, diluting a reaction product with the deionized water, centrifuging and then carrying out free drying or vacuum drying to obtain a nano-silver / CNC (Cellulose Nanocrystalline) composite material. The preparation method disclosed by the invention is simple and convenient in process, easy in operation and environment friendly and can be used for shortening the preparation period; the prepared CNC / nano-silver has the advantages of small size, easy adjustment, large specific area, firmness in combination of the CNC and the nano-silver, durable antibacterial effect, antibacterial and enhancing functions and broad application prospect.

Owner:DONGHUA UNIV

Preparation method of echinoid titanium dioxide microspheres in single/double layer cavity structure

InactiveCN101941736ALarge specific surface areaEasy to shapeTitanium dioxideMicrosphereSilicon dioxide

The invention relates to a preparation method of echinoid titanium dioxide microspheres in single / double layer cavity structure, belonging to the field of nano composite materials. The method comprises the following steps: (1) preparing monodisperse silicon dioxide microspheres with uniform particle size; (2) by using silicon dioxide as a template, coating a titanium dioxide layer on the surface of the silicon dioxide microspheres by using a sol-gel method to obtain core-shell type silicon dioxide / titanium dioxide composite microspheres; (3) regulating the concentration of sodium hydroxide solution, the hydrothermal reaction time and other conditions, and preparing echinoid titanium-base microspheres in the single / double layer cavity structure in a controllable way; and (4) treating the echinoid titanium-base microspheres in the single / double layer cavity structure with hydrochloric acid with a certain concentration, and calcining at high temperature to obtain anatase-type echinoid titanium dioxide microspheres in the single / double layer cavity structure. The material prepared by the method has the high-activity pure-phase titanium dioxide crystal structure, and has the advantages of large specific area, complete appearance and high yield; the technical process is controllable and easy to operate; and the invention also has the advantages of low preparation cost, no pollution and low energy consumption.

Owner:UNIV OF SCI & TECH BEIJING

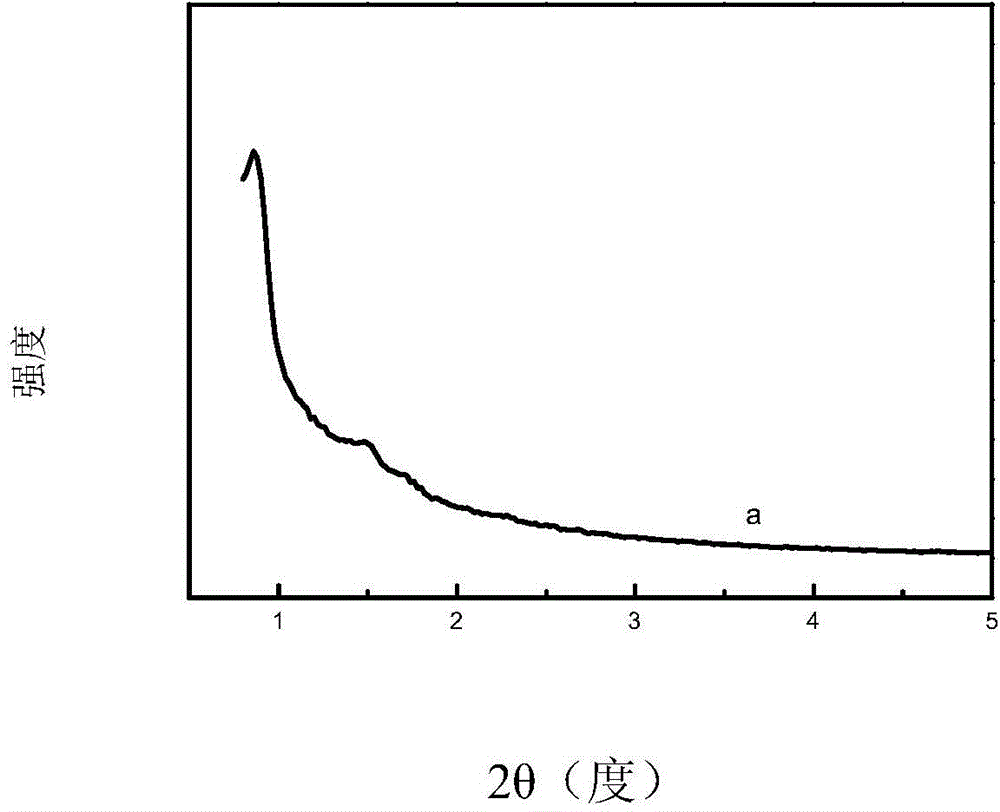

Process for producing cavity type ZSM-5 modified zeolite molecular sieve

ActiveCN101428817ANarrow distributionRelatively low crystallinityMolecular sieve catalystsPentasil aluminosilicate zeoliteSodium bicarbonatePotassium hydroxide

The invention relates to a method for preparing hollow cavity type ZSM-5 modified zeolite molecular sieve, and aims to solve the problems that the microcellular structure diffusion admittance is narrow, the modified zeolite molecular sieve has lower relative degree of crystallinity, and the adjustable range of apertures inside molecular sieve is small, thereby facilitating macromolecule reaction limited by diffusion. The invention adopts at least one 0.1-8.5 mol / L acid solution of hydrochloric acid, nitric acid, sulphuric acid or acetic acid to treat ZSM-5 molecular sieve raw powder with the silica alumina ratio SiO2 / Al2O3 being 20-1000 and the particle size being 0.4-10 Mum for 1-8 h; then at least one 0.1-5.0 mol / L aqueous alkali of sodium hydroxide, magnesium hydrate, potassium hydroxide, sodium carbonate or sodium bicarbonate is used for treatment for 1-48 h at 20-90 DEG C; and at least one 0.1-8.5 mol / L acid solution of hydrochloric acid, nitric acid, sulphuric acid or acetic acid is used for treatment for 1-48 h at 20-90 DEG C to obtain the modified ZSM-5 molecular sieve. The problems are well solved, and the invention can be used in industrial production of macromolecule catalysis and transformation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing organosilicon modified acrylic ester binding agent

InactiveCN101423734AThe emulsion system is stableImprove stabilityFibre treatmentEster polymer adhesivesHigh concentrationPolymer science

The invention relates to a method for preparing a silicone-modified acrylate adhesive, which comprises the following: (1) a step of the pre-polymerization of a modified monomer, in which the modified monomer, a modified monomer catalyst, an emulsifying agent and deionized water are pre-polymerized to obtain a silicone pre-polymerization emulsion; (2) a step of emulsification, in which the silicone pre-polymerization emulsion and a basic monomer are emulsified to obtain an intermediate pre-emulsion; and (3) a step of the polymerization of acrylic ester, in which the intermediate pre-emulsion is polymerized with a basic monomer catalyst and the deionized water to obtain a finished product. The method adopts a fractional step method to emulsify according to the hydrophilicity of various monomers. During the emulsification step by step, a polymeric monomer with stronger hydrophobicity which is added first can be effectively and steadily dispersed under the condition of relatively higher concentration of the emulsifying agent, which strengths the stability of a monomer pre-emulsion. The grain diameter of the prepared adhesive emulsion is smaller and has narrower distribution, the emulsion system is also more stable, and various application performances are superior to those of adhesive products prepared by the prior method.

Owner:WUHAN TEXTILE UNIV

Supported polyethylene catalyst ingredient and preparation method thereof, and supported polyethylene catalyst and application thereof

ActiveCN105330768ALarge specific surface areaLarge hole volumeBulk chemical productionMolecular sieveMagnesium salt

The invention discloses a supported polyethylene catalyst ingredient and a preparation method thereof, and a supported polyethylene catalyst and an application thereof. The supported polyethylene catalyst ingredient comprises a spherical composite carrier, and magnesium salt and titanium salt supported on the spherical composite carrier, wherein the spherical composite carrier contains a molecular sieve material having a one-dimensional hexagonal tunnel structure, the molecular sieve material having a two-dimensionl hexagonal tunnel structure and silica gel, an average particle size of the spherical composite carrier is 30-60 micrometers, a specific surface area is 150-600 square meter / g, a pore volume is 0.5-1.5milliliters / g, apertures present three-peak distribution, three peaks can be respectively corresponded to a first most probable aperture, a second most probable aperture and a third most probable aperture, the first most probable aperture is 2-4 nanometers, the second most probable aperture is 5-15 nanometers, and the third most probable aperture is 10-40 nanometers. The provided supported polyethylene catalyst has high catalysis efficiency during an ethene catalysis / polymerization process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of nano-silver alginate fiber

ActiveCN103147167ASmall particle sizeUniform particle size distributionAlginate artificial filamentsWet spinning methodsFiberBiocompatibility Testing

The invention discloses a preparation method of a nano-silver alginate fiber. The preparation method comprises the following steps of: preparing an alginic acid silver complex which is a precursor of nano-silver by using algal polysaccharides and soluble silver salts, and then preparing a sodium alginate based nano-silver colloid system through a chemical reduction method; then adding fiber-grade sodium alginate into the sodium alginate based nano-silver colloid system to obtain a nano-silver algae spinning solution; and finally, obtaining a nano-silver algae primary fiber through wet spinning, and carrying out stretching, sizing, drying and oiling treatments to obtain the nano-silver alginate fiber. The prepared nano-silver alginate fiber integrates the excellent performances of the nano-silver and the alginate fiber, so that the novel fiber has excellent flame retardance, biocompatibility, moisture absorption permeability and the like, also has excellent antimicrobial performance, antistatic performance and irradiation resistance and can be widely used in medical treatment, the fire-fighting field, the military field, the aerospace field, the health textile field and the like.

Owner:QINGDAO UNIV

Preparation method for non-ionic reactive water-borne epoxy resin emulsion

InactiveCN104558524AImprove water-based effectGood dispersionEpoxy resin coatingsFreeze thawingEpoxy

The invention provides a preparation method for non-ionic reactive water-borne epoxy resin emulsion. A preparation process for the non-ionic reactive water-borne epoxy resin emulsion comprises the following steps: simultaneously adding a certain amount of non-ionic hydrophilic segment polyethylene glycol and boron trifluoride diethyl etherate serving as a catalyst into epoxy resin, performing stable reaction for 3-8 hours to obtain non-ionic reactive epoxy resin, then strongly stirring at the temperature of 50 DEG C, and uniformly and dropwise adding distilled water to form water-dispersed epoxy resin emulsion by a phase inversion technology. The preparation method has the benefits that the particle size of the dispersion phase of the prepared non-ionic reactive water-borne epoxy resin emulsion is dozens to hundreds of nanometer; both under high-speed centrifugation and long-time storage, the non-ionic reactive water-borne epoxy resin emulsion is high in stability; furthermore, the emulsion is higher in dilutability, salt resistance, alkali resistance, high temperature resistance, and freeze-thaw stability. The raw materials used in the method are simple, efficient, environment-friendly, safe and non-toxic and can be widely applied to the fields of coatings, composite materials and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com