Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1534 results about "Square meter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The square metre (international spelling as used by the International Bureau of Weights and Measures) or square meter (American spelling) is the SI derived unit of area with symbol m². Adding and subtracting SI prefixes creates multiples and submultiples; however, as the unit is exponentiated, the quantities grow geometrically by the corresponding power of 10. For example, a kilometre is 10³ (a thousand) times the length of a metre, but a square kilometre is 10 (10⁶, a million) times the area of a square metre, and a cubic kilometre is 10 (10⁹, a billion) cubic metres.

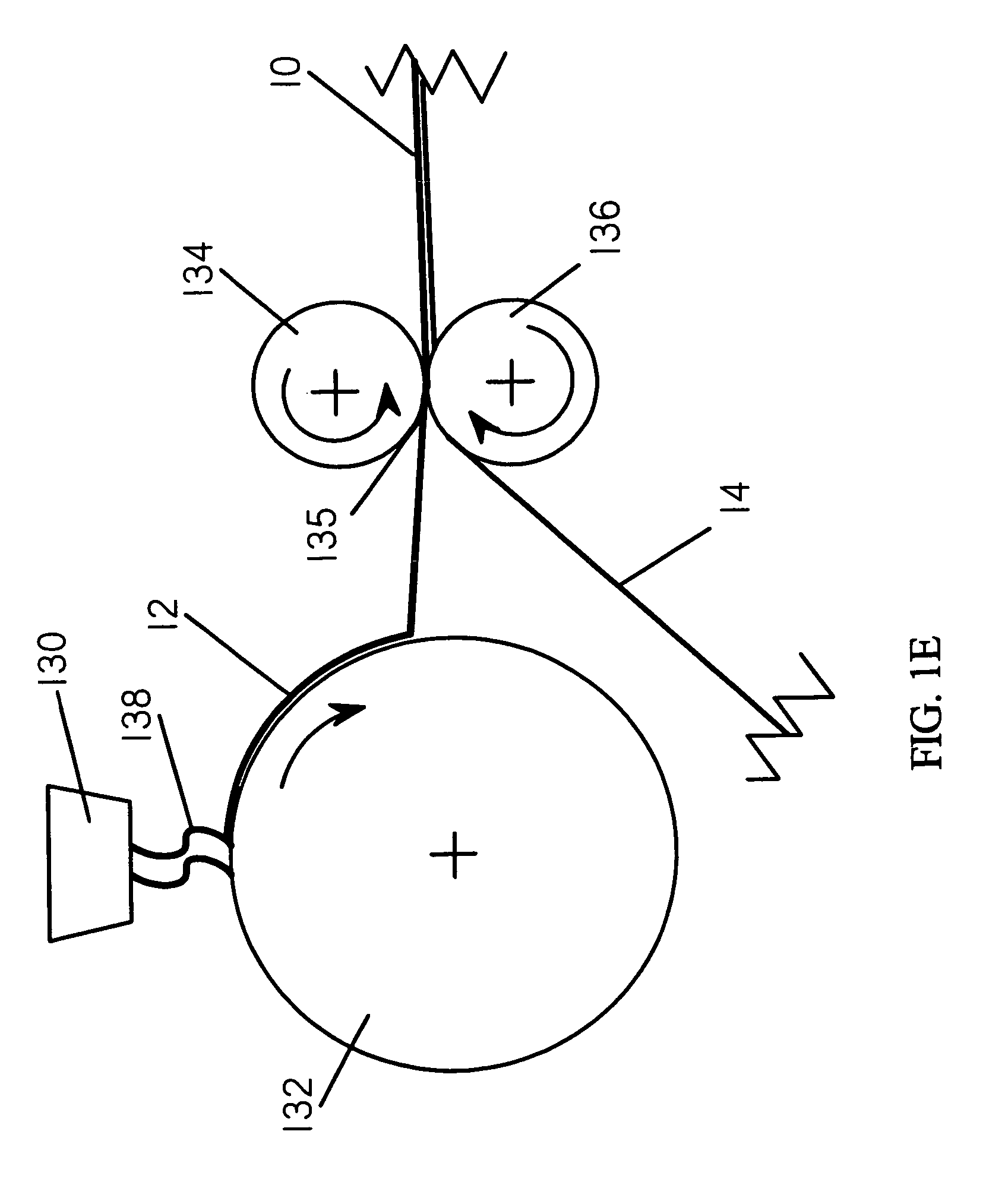

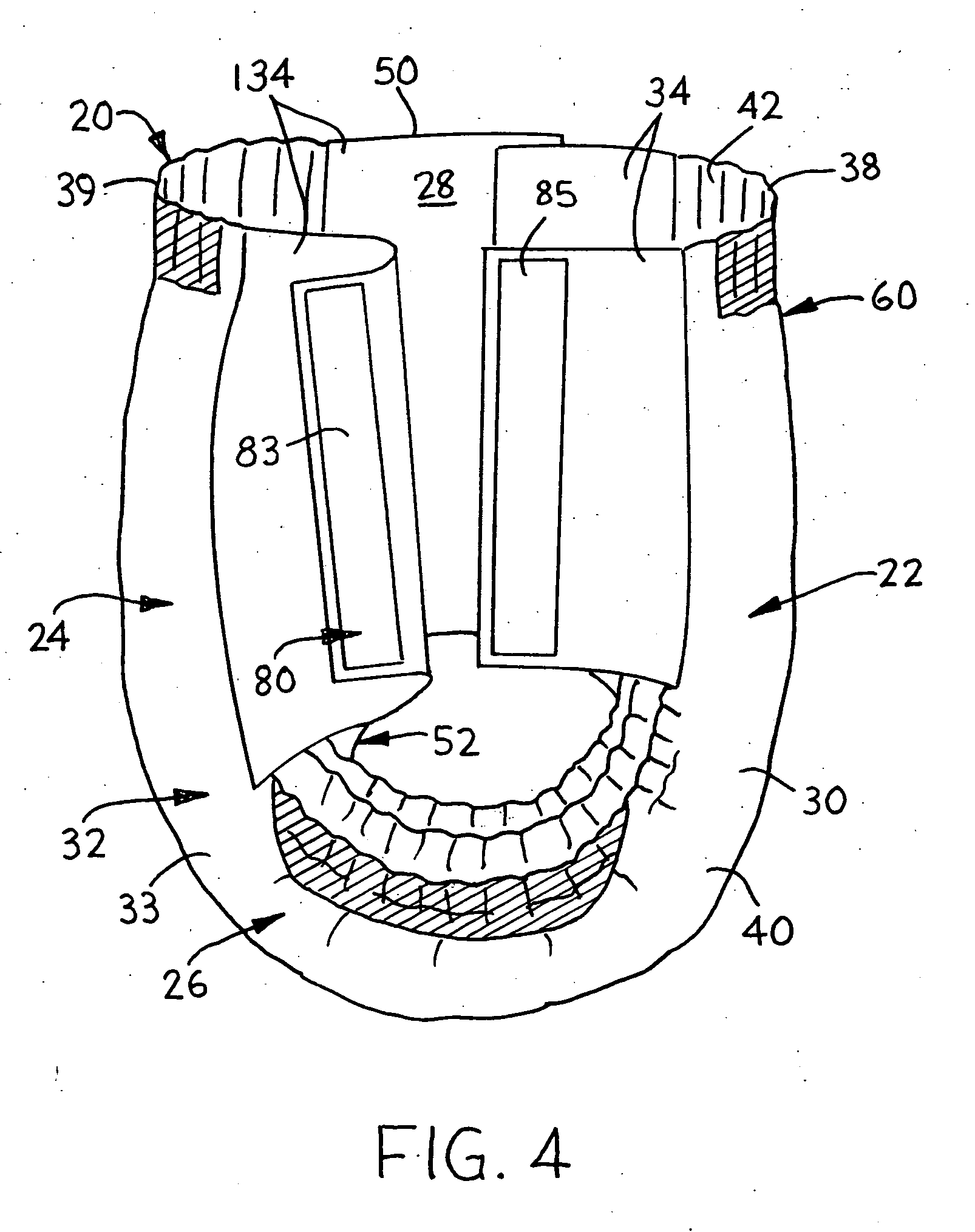

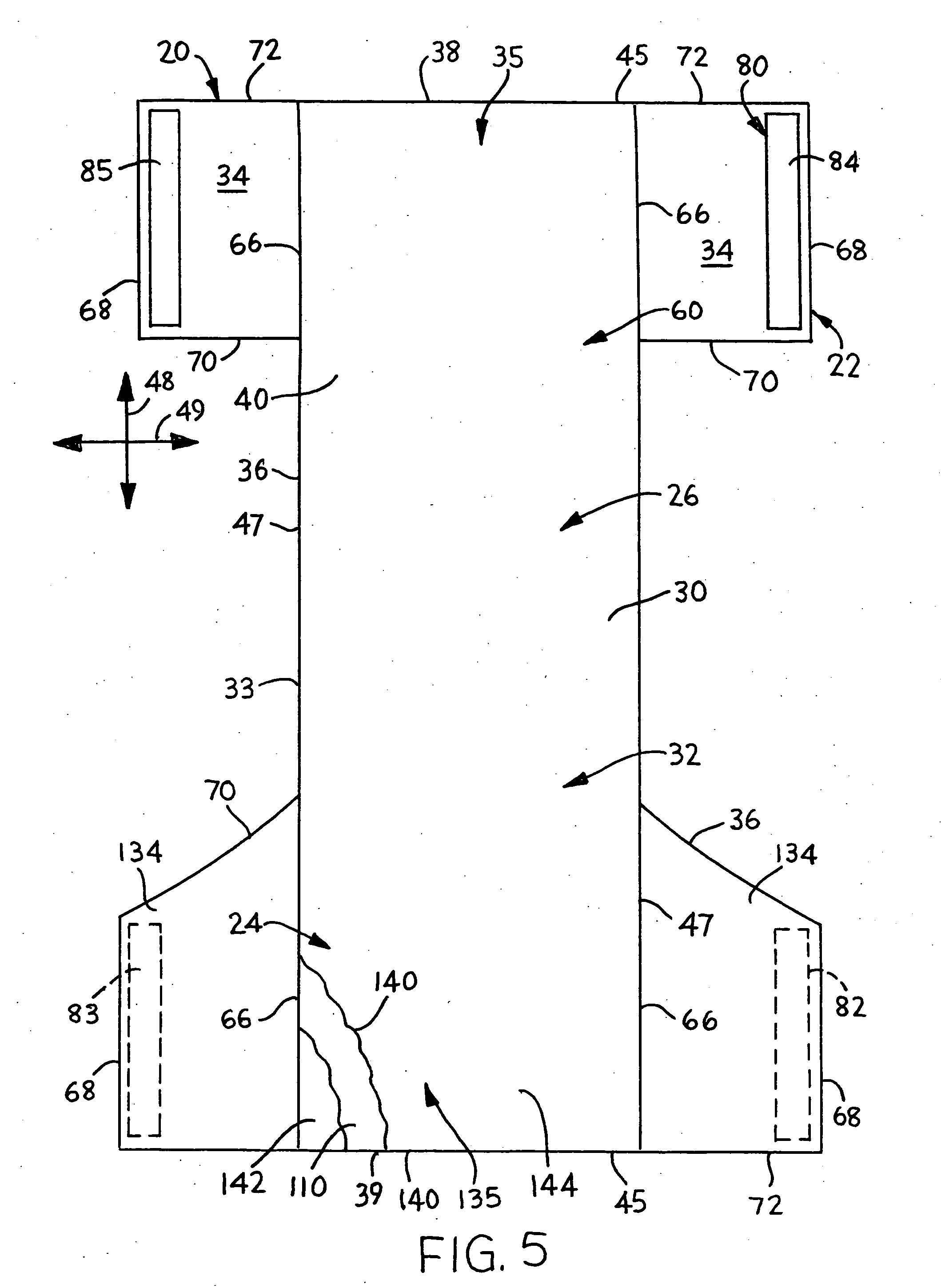

Sign and method for lighting

ActiveUS20070137074A1Good colorIncrease contrastElectric circuit arrangementsCathode-ray tube indicatorsEffect lightDisplay device

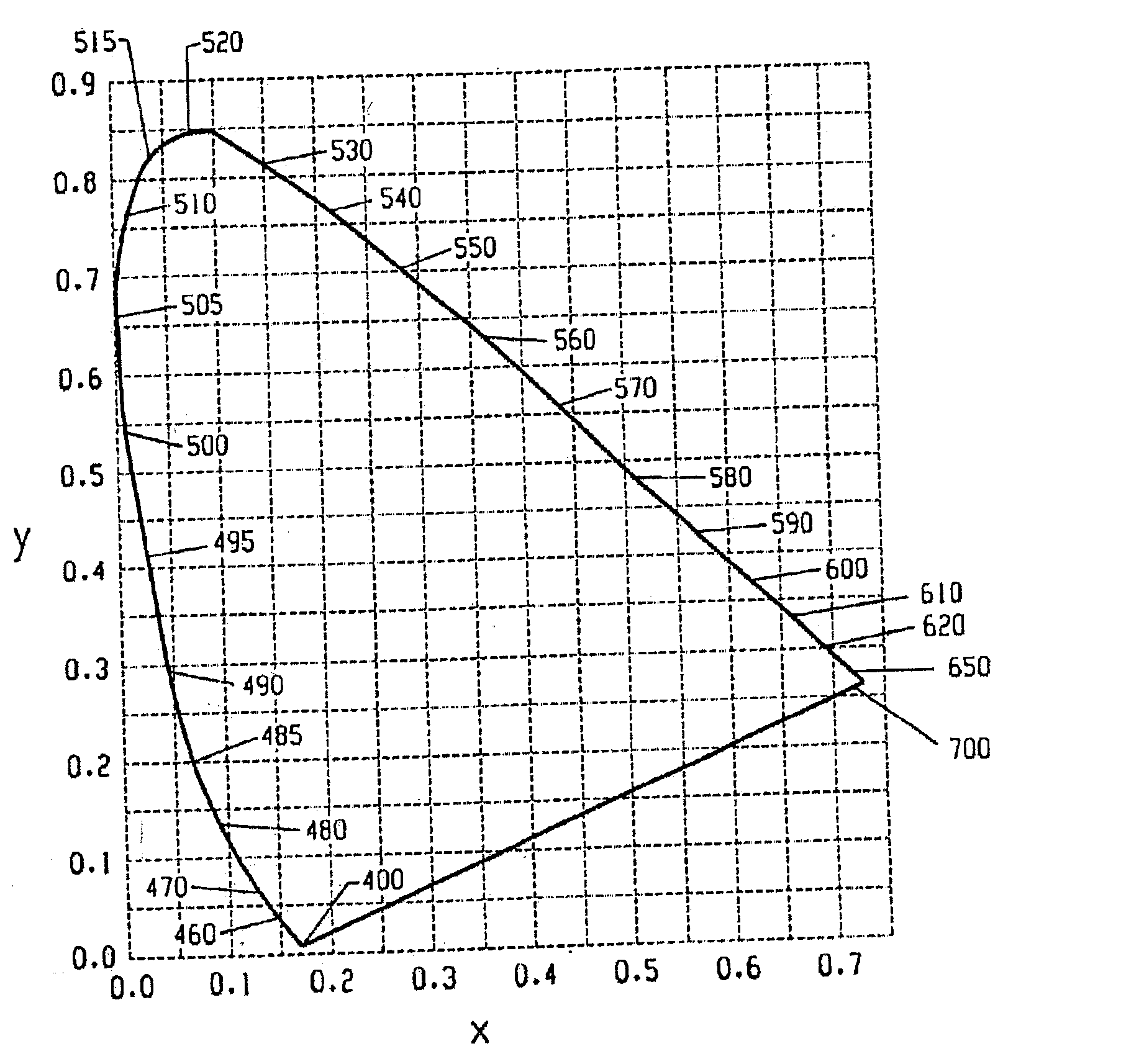

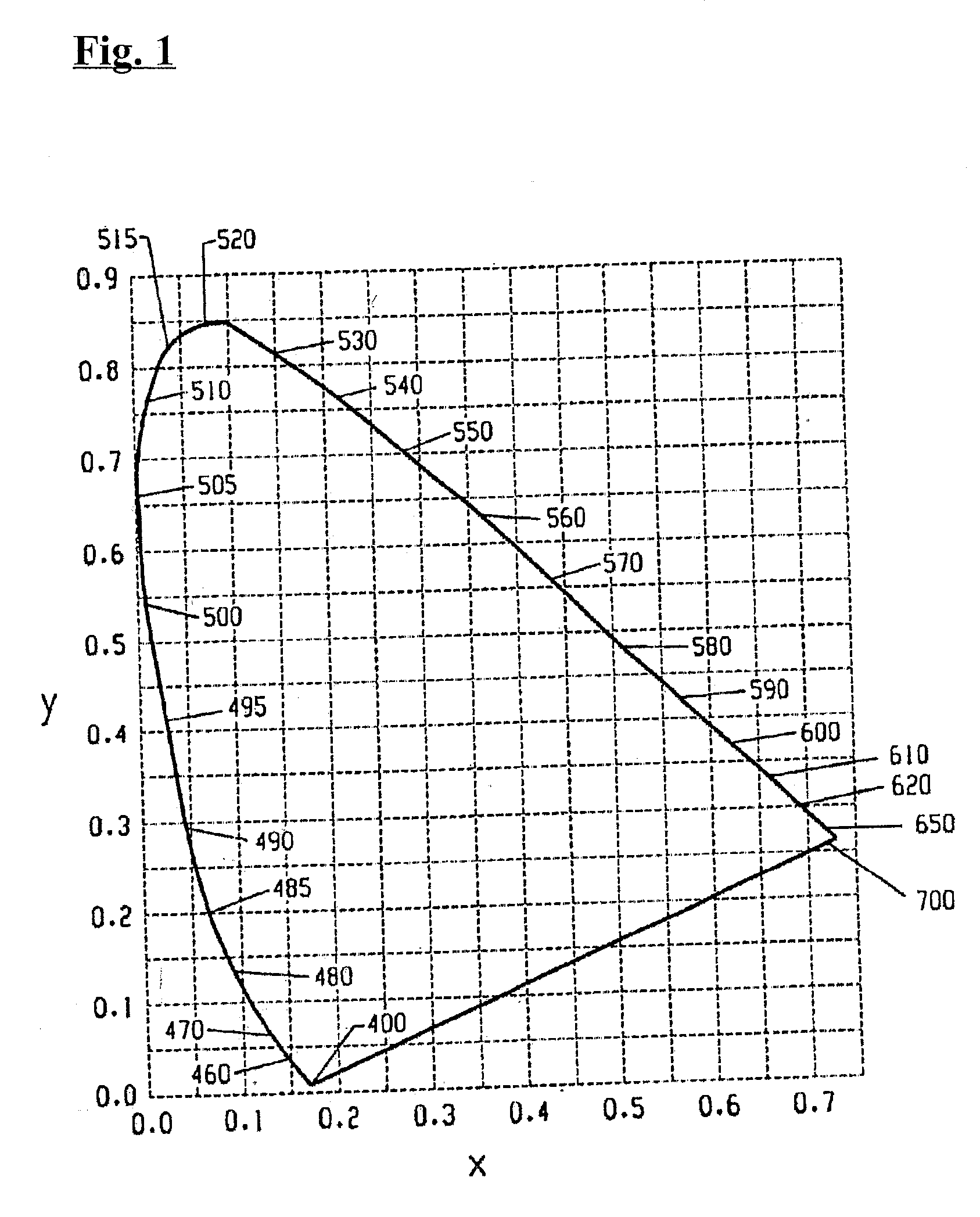

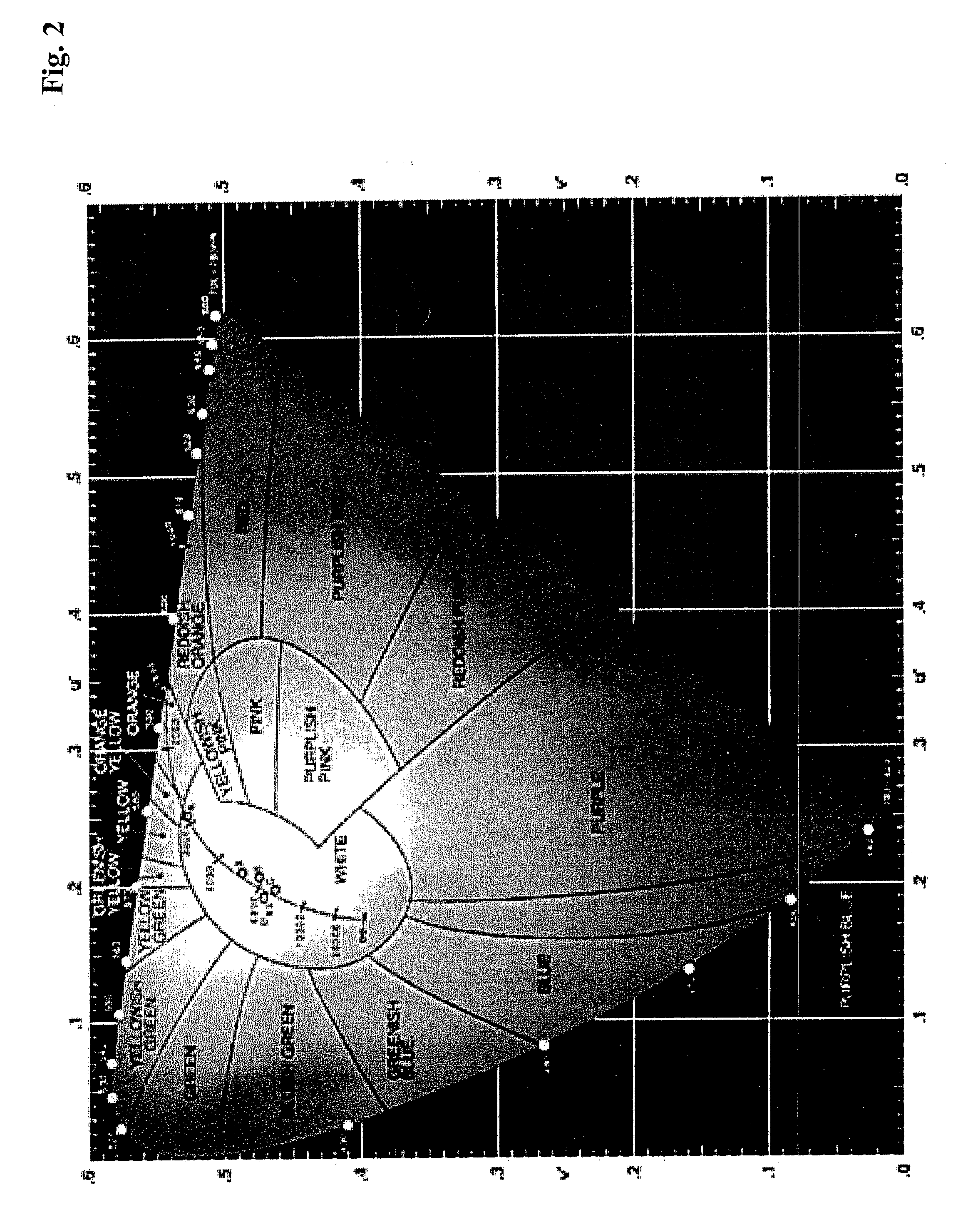

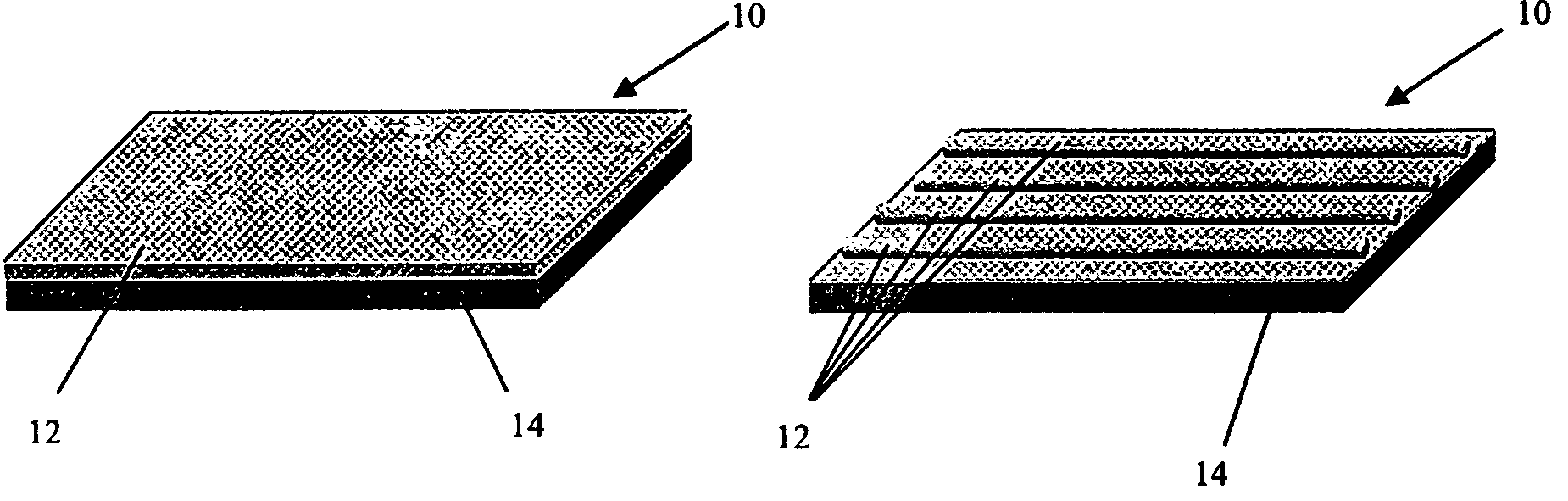

A sign comprising a surface having a display, and a plurality of sources of visible light. The sources of visible light are oriented to illuminate at least a portion of the display, and include solid state light emitters and / or luminescent materials. Line segments drawn on a Chromaticity Diagram connecting coordinates of some of the illumination color hues define a shape which encompasses coordinates of the display color hue(s). Also, a sign comprising a surface having a display having a surface area of at least 4 square meters, and at least 100 sources of visible light including solid state light emitters and / or luminescent materials. Also, a sign comprising a white light source and at least one additional source of light. Also, methods of illuminating signs.

Owner:IDEAL IND LIGHTING LLC

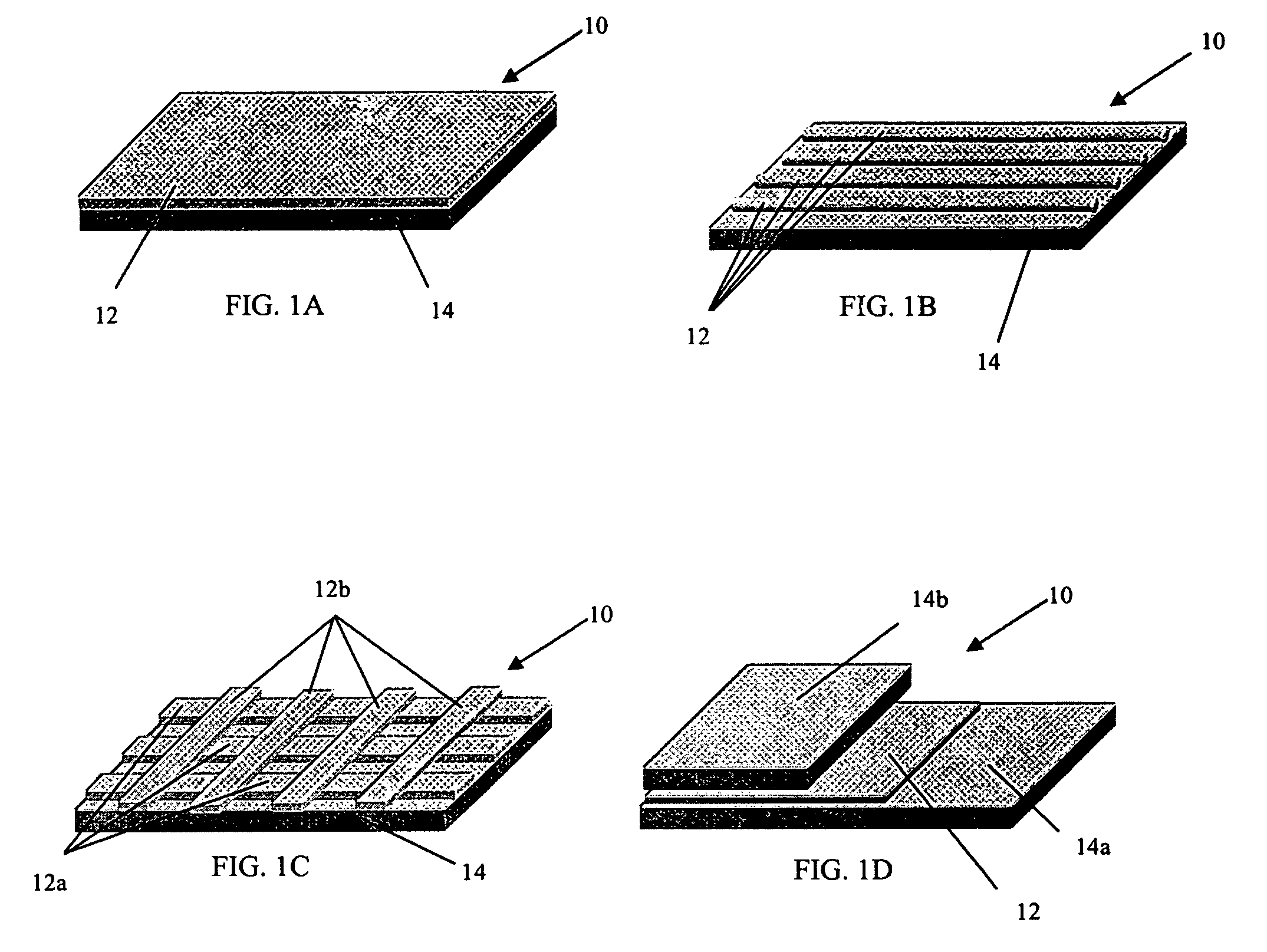

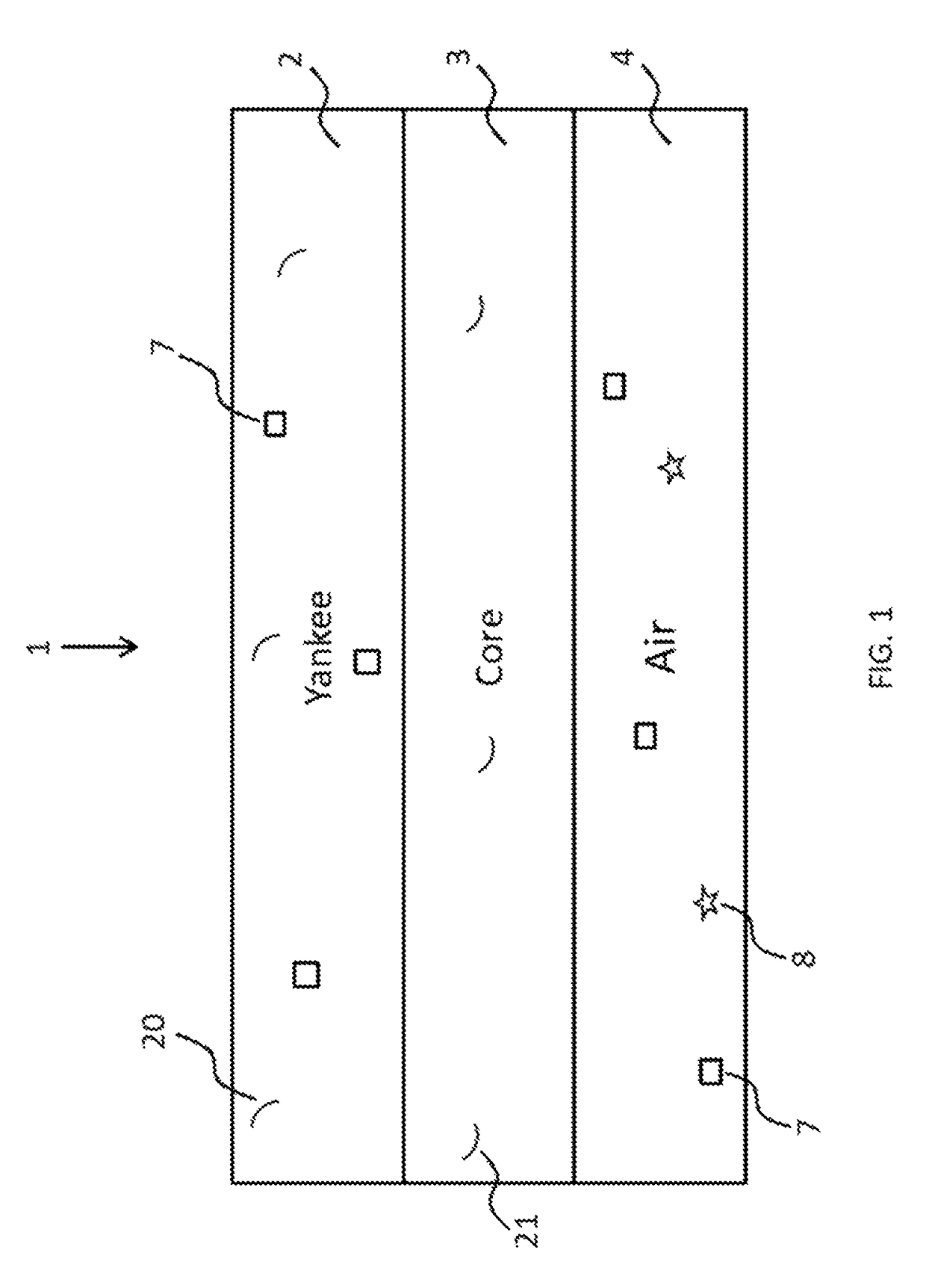

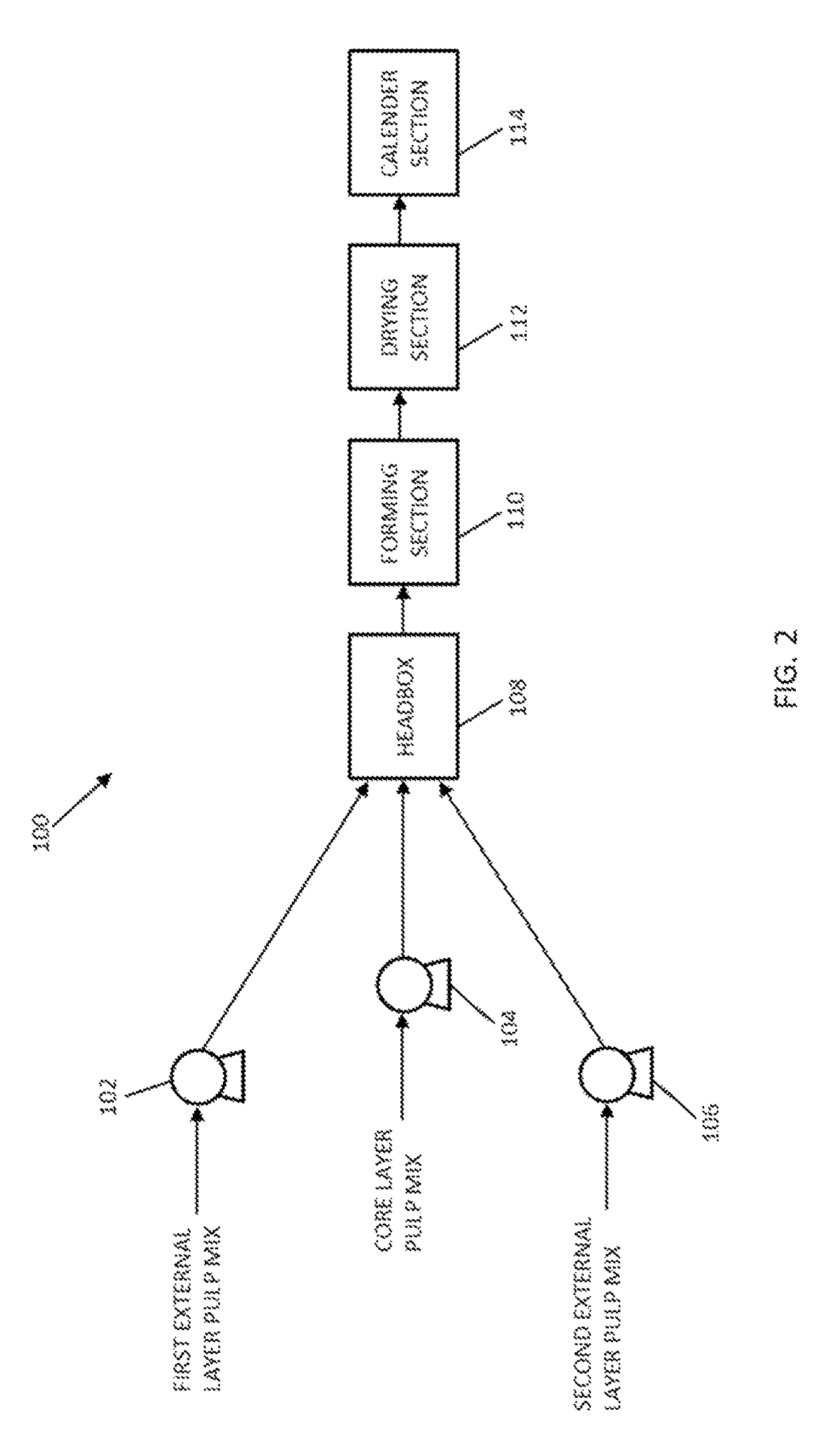

Soft tissue having temporary wet strength

Disclosed is a soft, low density paper product made using papermaking fibers and a cationic temporary wet strength resin. Such paper products have a density less than about 0.6 grams per cubic centimeter, a basis weight is between about 10 and about 65 grams per square meter, a dry strength less than about 500 grams per inch (197 grams per centimeter), a ratio of an initial wet strength to the dry strength greater than about 0.15:1, and a ratio of a thirty minute wet strength to the initial wet strength less than about 0.4. Methods for producing such paper products are also disclosed. The paper products may be produced either as homogeneous structures or as multi-layered structures and may be either creped or uncreped.

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent articles having a breathable stretch laminate

Owner:PROCTER & GAMBLE CO

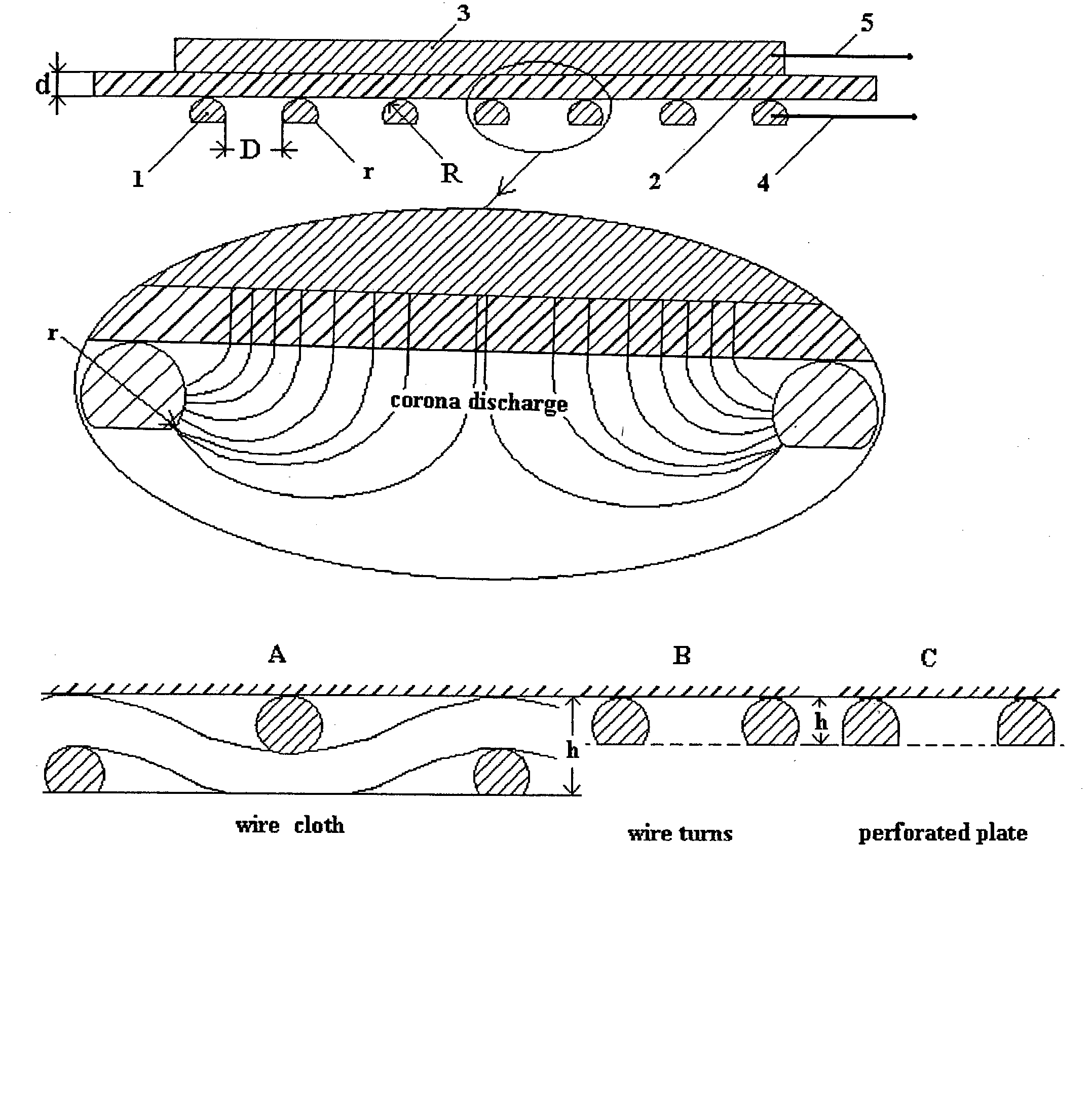

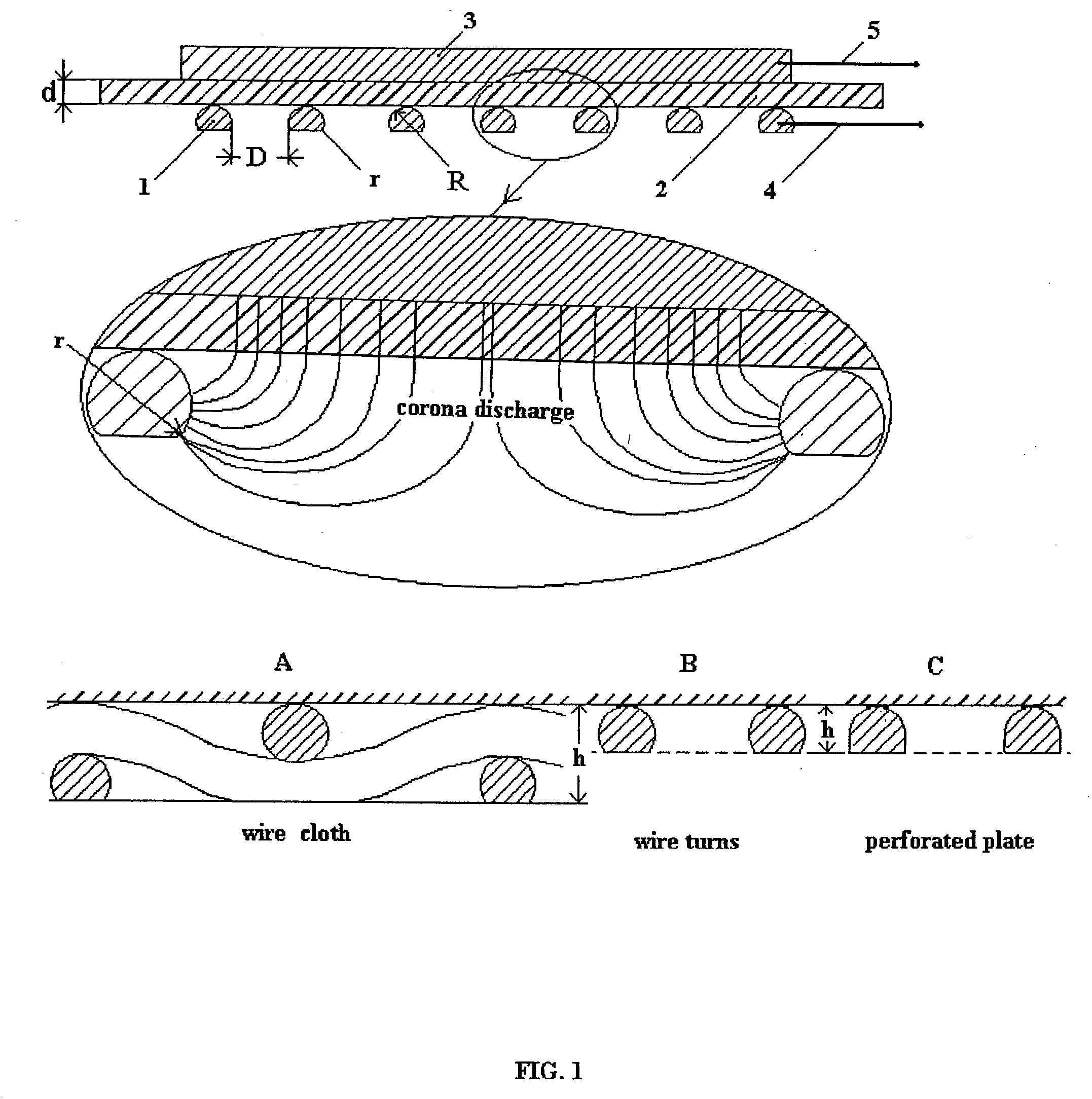

Method for surface corona/ozone making, devices utilizing the same and methods for corona and ozone applications

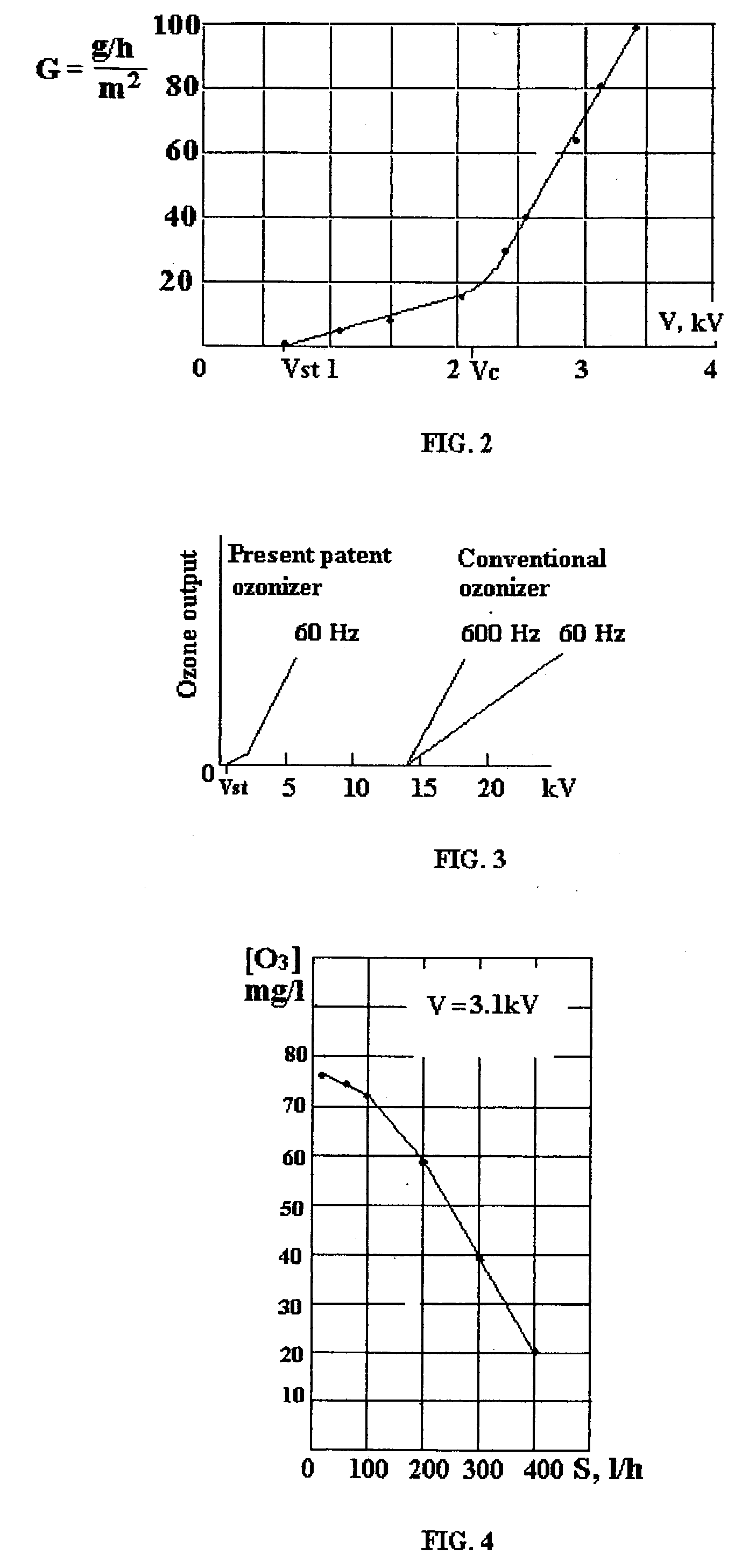

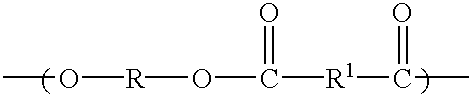

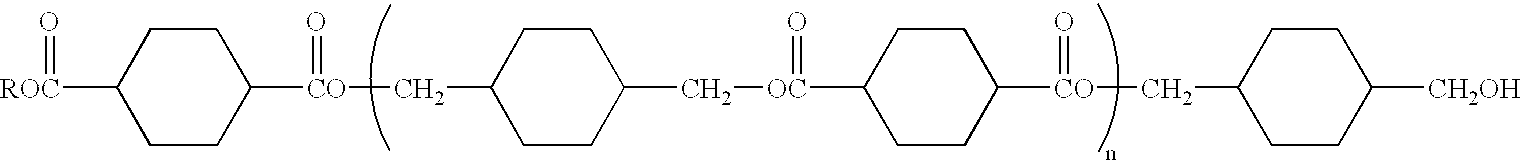

A method for making surface corona discharge, which produces ozone gas and apparatus for producing the same are disclosed, in which a dielectric spacer / film having a specific capacity C' equal to or more than 200 nanofarad per square meter positioned between the base electrode and the net electrode. Said net electrode is a wire net or a perforated metal or a wire winding having an open area not less than about 70%, and a size of hole D equals to or less than about 0.7V / P, where V is a voltage in kilovolts and P is pressure of an ambient air or an oxygen in atmospheres. Net electrode has radius R of wire or radius of an edge of openings in the perforated metal equal to or more than about 1.6d, where d is the thickness of the said dielectric spacer / film, which is determined by a fundamental formula d=9k / C', where d is in millimeters, C' is in nF / m2, and k is dimensionless dielectric constant k of given material. Under disclosed parameters said surface corona is safe for human contact if said net electrode is grounded. Start voltage Vst of ozone production is determined by experimental formula Vst=0.7+60 / C', kV, here C' in nF / m2. The even and high intensity corona surface and high ozone output takes place if the operating voltage is more than about 3Vst. AC power supply is applied to produce ozone gas at "home" voltage 0.7-1.0 kV and produces ozone gas more effectively at 2,5-3.6 kV. A method for disinfection and decontamination of objects by using the direct corona contact and apparatus for making the same is disclosed, in which safe corona surface is placed on said object and is acting by ozone, ultraviolet and ion bombing simultaneously in the unique environment, which takes place inside of the safe corona. A method for ozone disinfection and decontamination and devices for making the same is disclosed, in which said ozone generating element is placed in a closed container / room with or without treated objects and produce a high ozone concentration due to effective ozone dispersion from corona surface without blowing of air / oxygen through said container / room.

Owner:ANDREEV SERGEY I +1

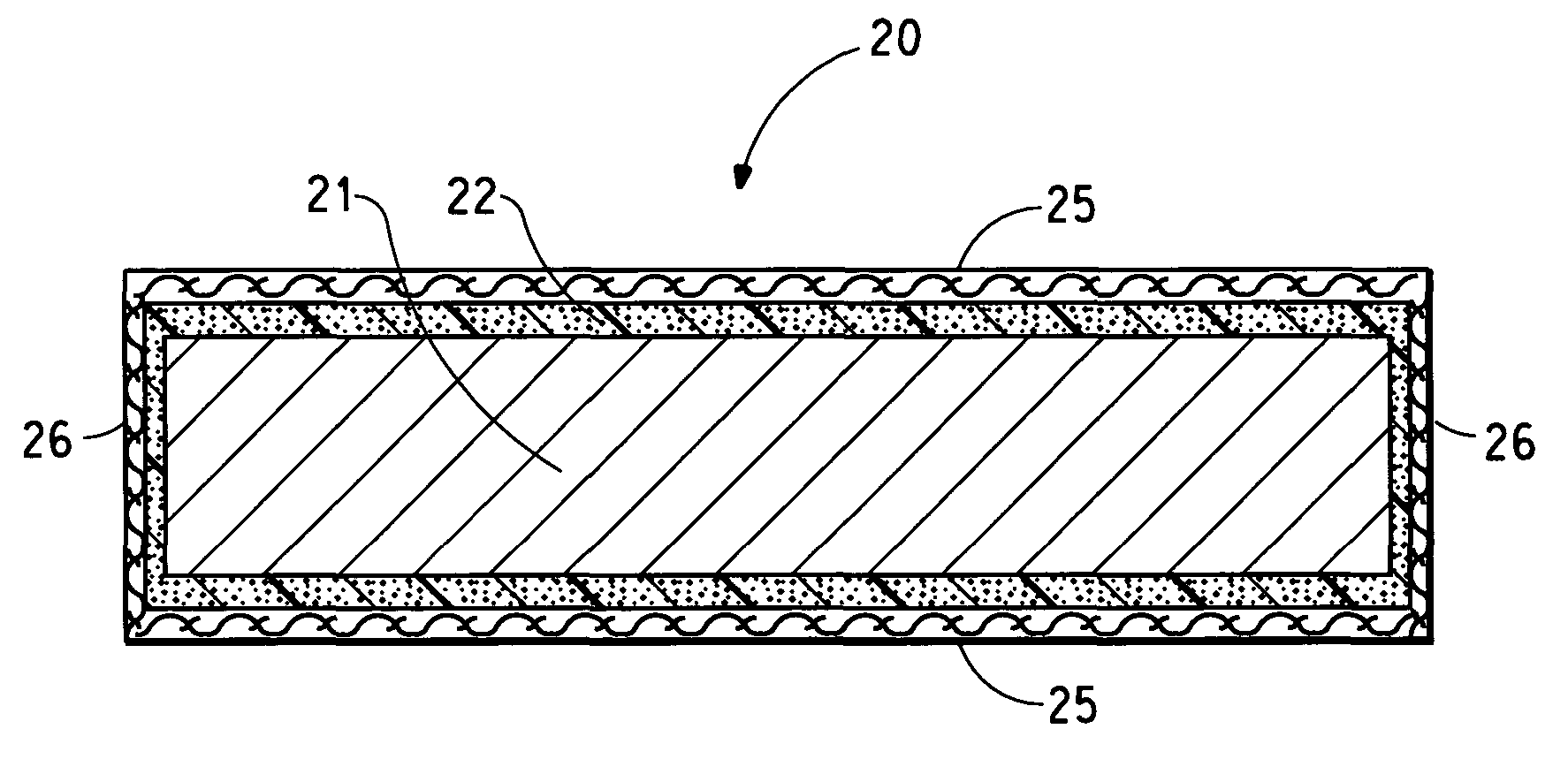

Flame retardant polycarbonate polyester composition

InactiveUS20020128357A1Improve performanceImprove impact performancePlastic/resin/waxes insulatorsDyeing processPass ratePolyester resin

A transparent / translucent flame redardant composition comprises a uniform blend of a miscible resin blend of a polycarbonate resin and a cycloaliphatic polyester resin wherein the composition has at least a 80% pass rate in 10 test specimen in the Norme Francaise NF-P-92-505 flammability test of L'Association Francaise de Normalisation using test specimens with weight between about 1.0 to about 6.0 kilograms per square meter.

Owner:GENERAL ELECTRIC CO

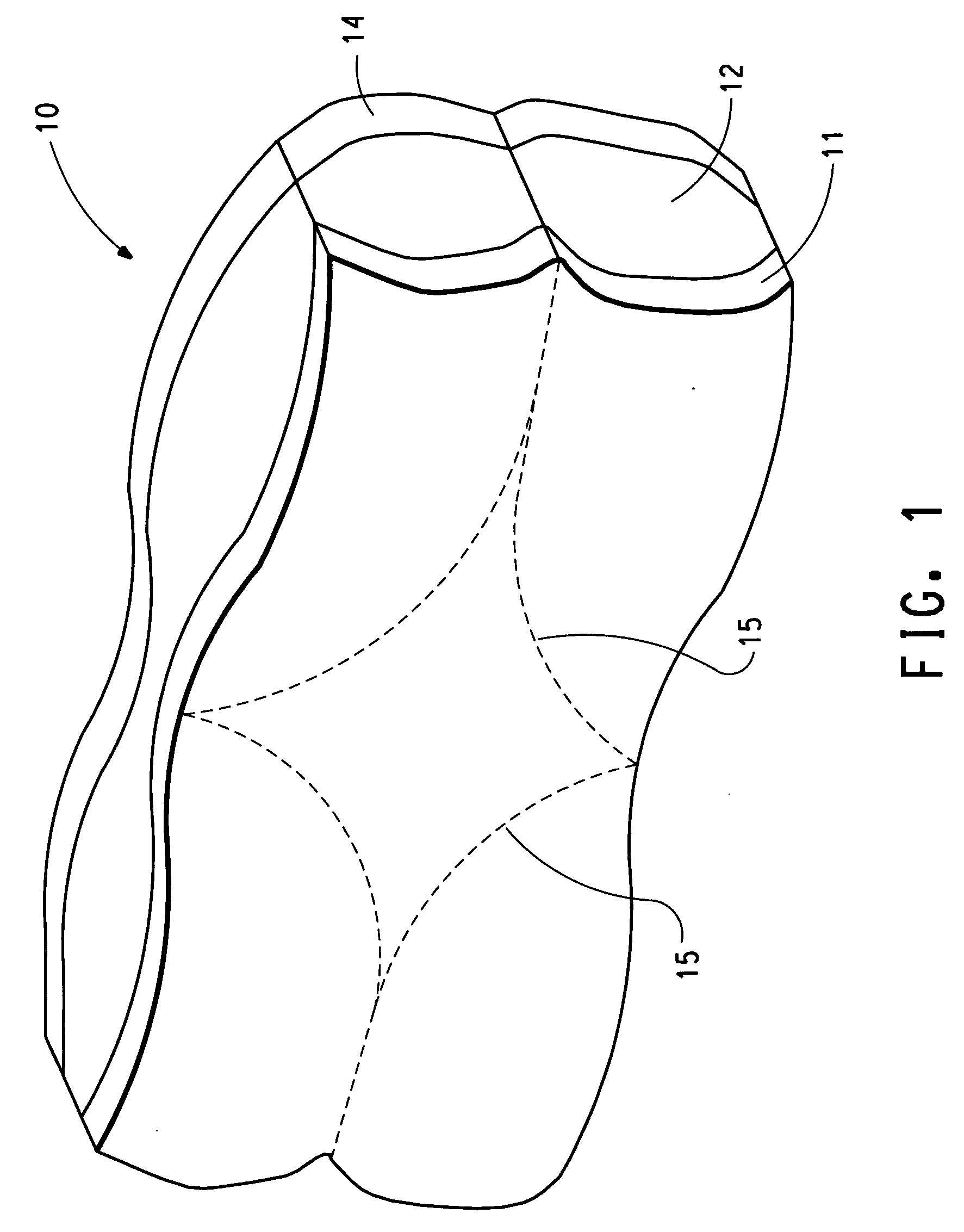

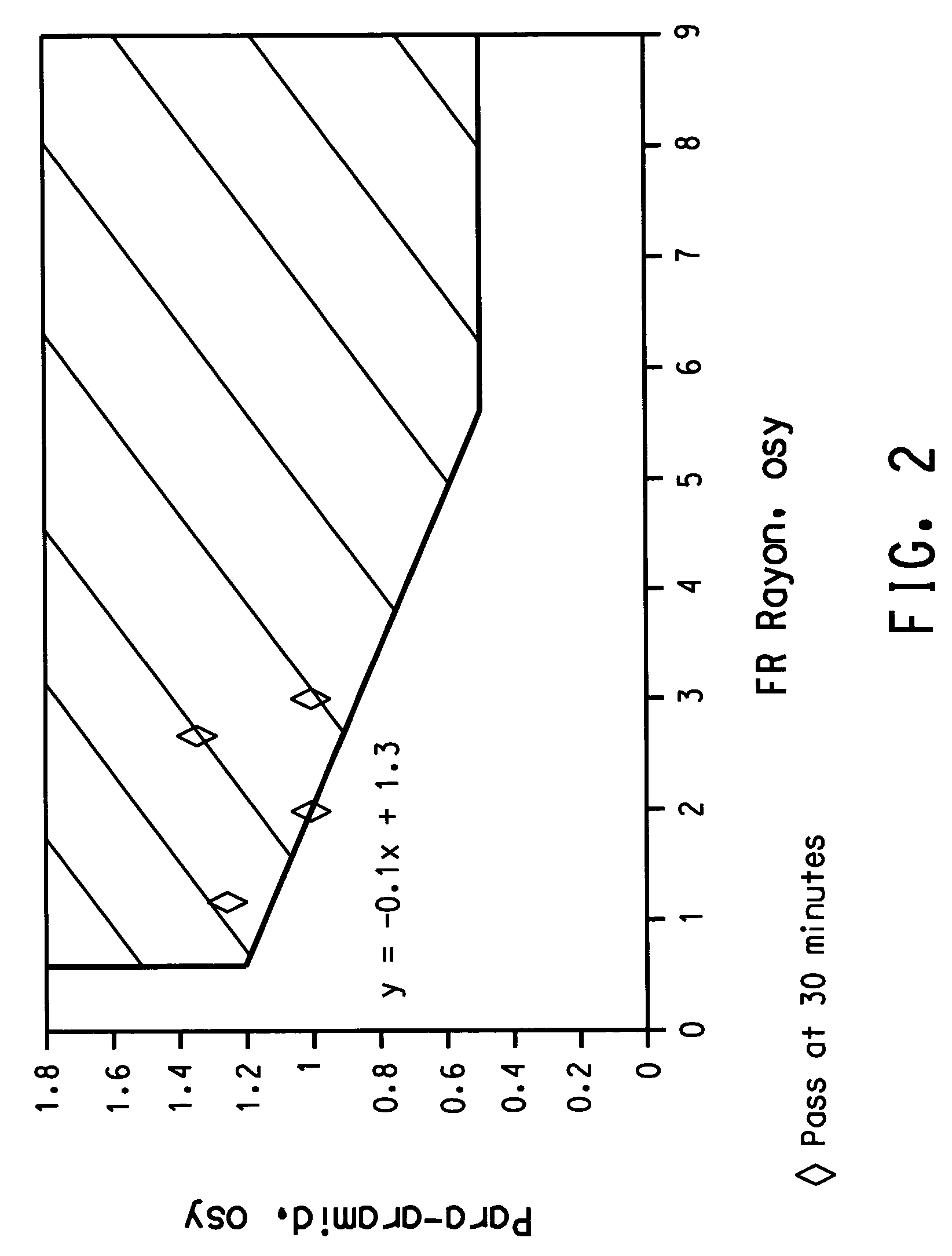

Fire resistant fabric composite, process for fire-blocking a mattress and mattress set, and a mattress and mattress set fire-blocked thereby

This invention relates to a fabric composite for use in fire-blocking a mattress, a fire-blocked mattress set, and a process for fire-blocking mattresses; the fabric composite comprising, in order, (a) sacrificial outer ticking, (b) sacrificial cushioning material, and (c) fire-blocking fabric, the fire-blocking fabric being a single layer of nonwoven fabric comprising at least 0.5 ounces per square yard (17 grams per square meter) of a cellulose fiber that retains at least 10 percent of its fiber weight when heated in air to 700 C at a rate of 20 degrees C. per minute, and at least 0.5 ounces per square yard (17 grams per square meter) of a heat-resistant fiber. Mattress sets fire-blocked with this fabric composite have a peak heat release rate of less than 150 kilowatts within 30 minutes, preferably less that 150 kilowatts within 60 minutes, and a total heat release of less than 25 megajoules within 10 minutes when tested according to Technical Bulletin 603 of the State of California.

Owner:EI DU PONT DE NEMOURS & CO

Method for reducing odor using colloidal nanoparticles

InactiveUS20050084412A1Reduce odorMaterial nanotechnologyNon-fibrous pulp additionGramColloidal nanoparticles

A method for reducing odors is provided. In one embodiment, the method comprises contacting a substrate containing a thin coating of colloidal nanoparticles with an odorous compound. The colloidal nanoparticles have an average size of less than about 500 nanometers, a surface area of from about 50 to about 1000 square meters per gram, and a pore volume of less than about 0.5 milliliters per gram. The colloidal nanoparticles may adsorb at least about 25% of the odorous compound when contacted therewith.

Owner:KIMBERLY-CLARK WORLDWIDE INC

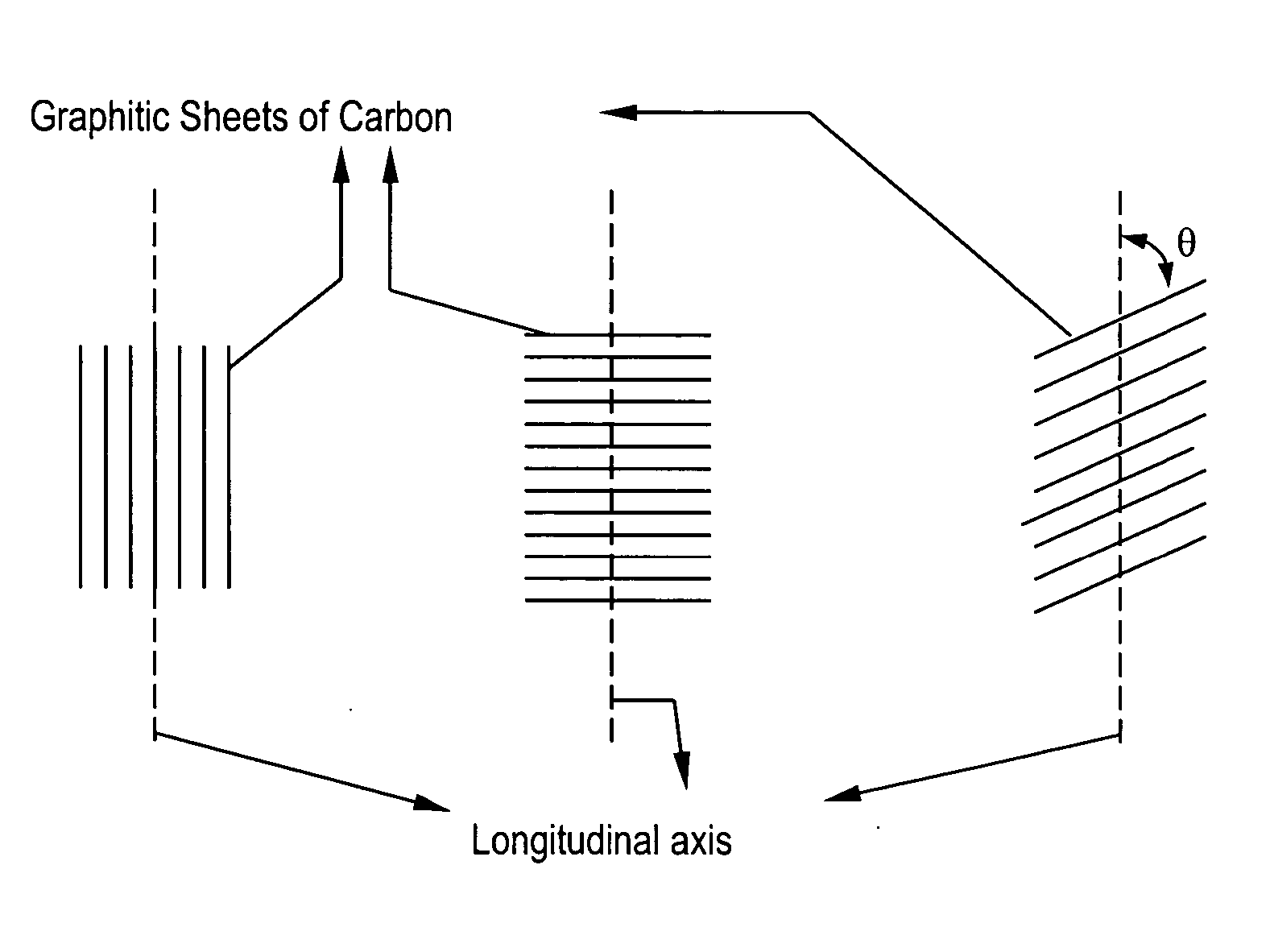

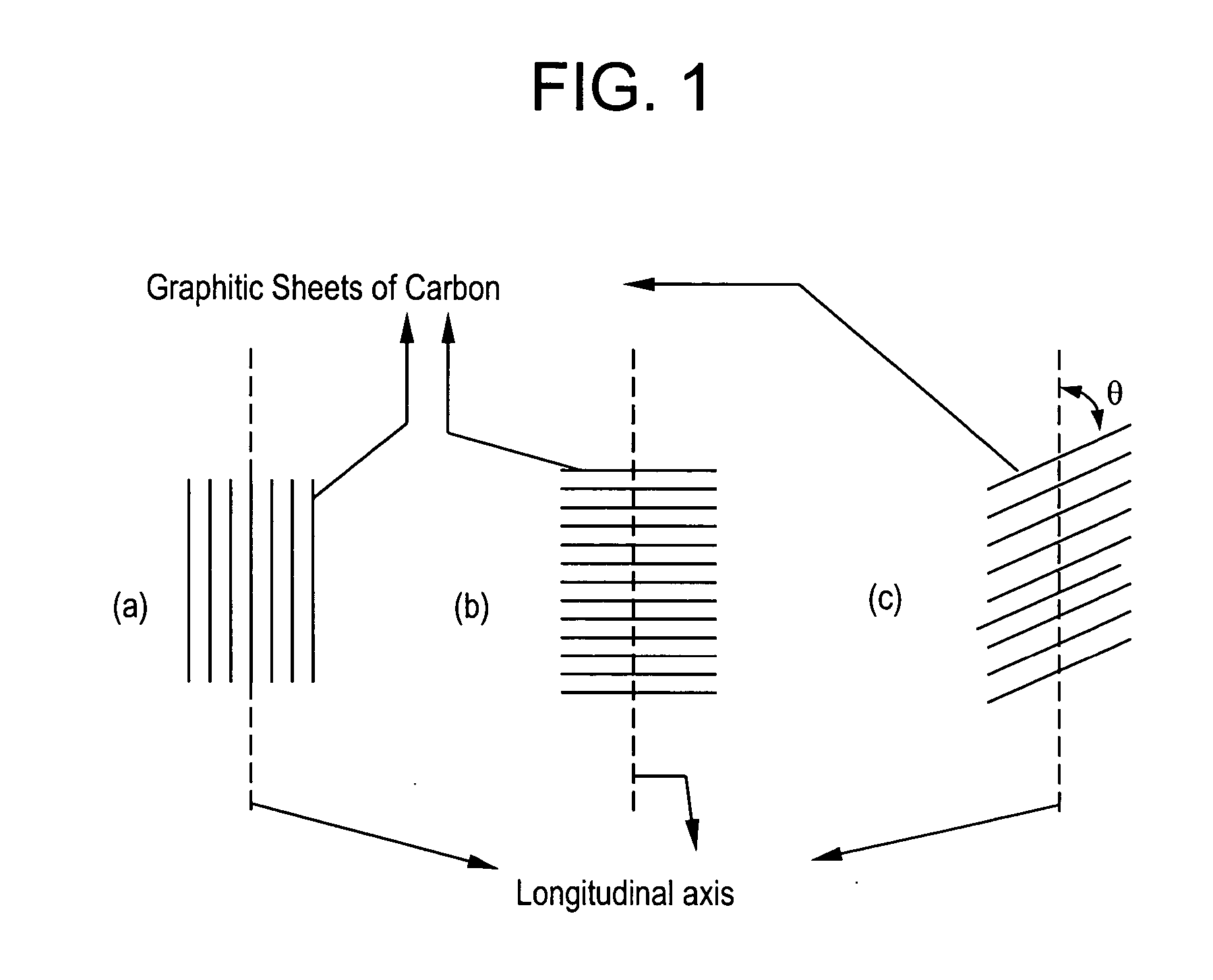

Electrically conductive compositions and method of manufacture thereof

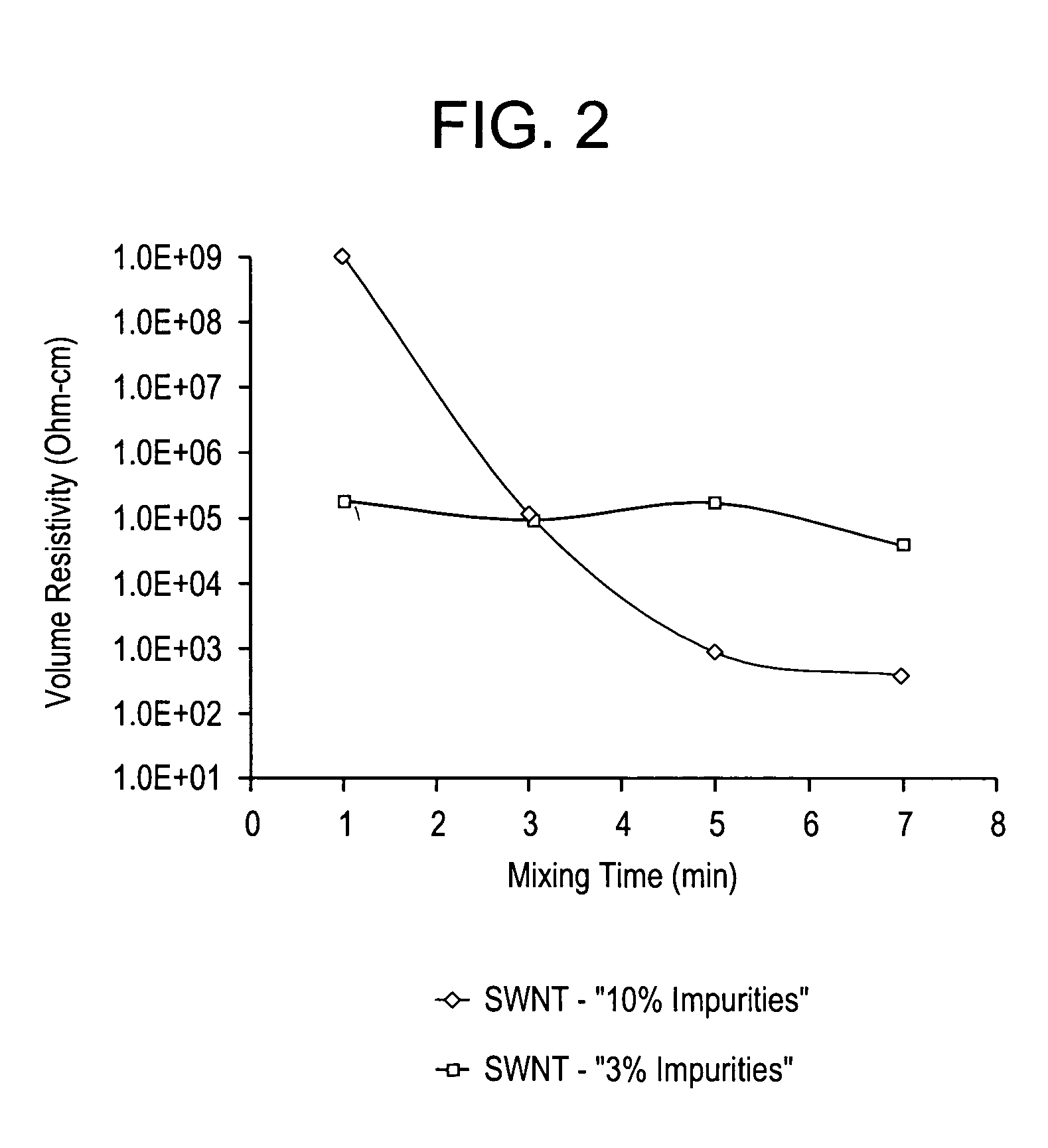

Disclosed herein is an electrically conductive composition comprising an organic polymer; and a carbon nanotube composition, wherein the carbon nanotube composition comprises carbon nanotubes that can rope and have greater than or equal to about 0.1 wt % production related impurities, based on the total weight of the carbon nanotube composition, and wherein the composition has a bulk volume resistivity less than or equal to about 1012 ohm-cm, and a notched Izod impact strength of greater than or equal to about 5 kilojoules / square meter.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Ultraphobic surface for high pressure liquids

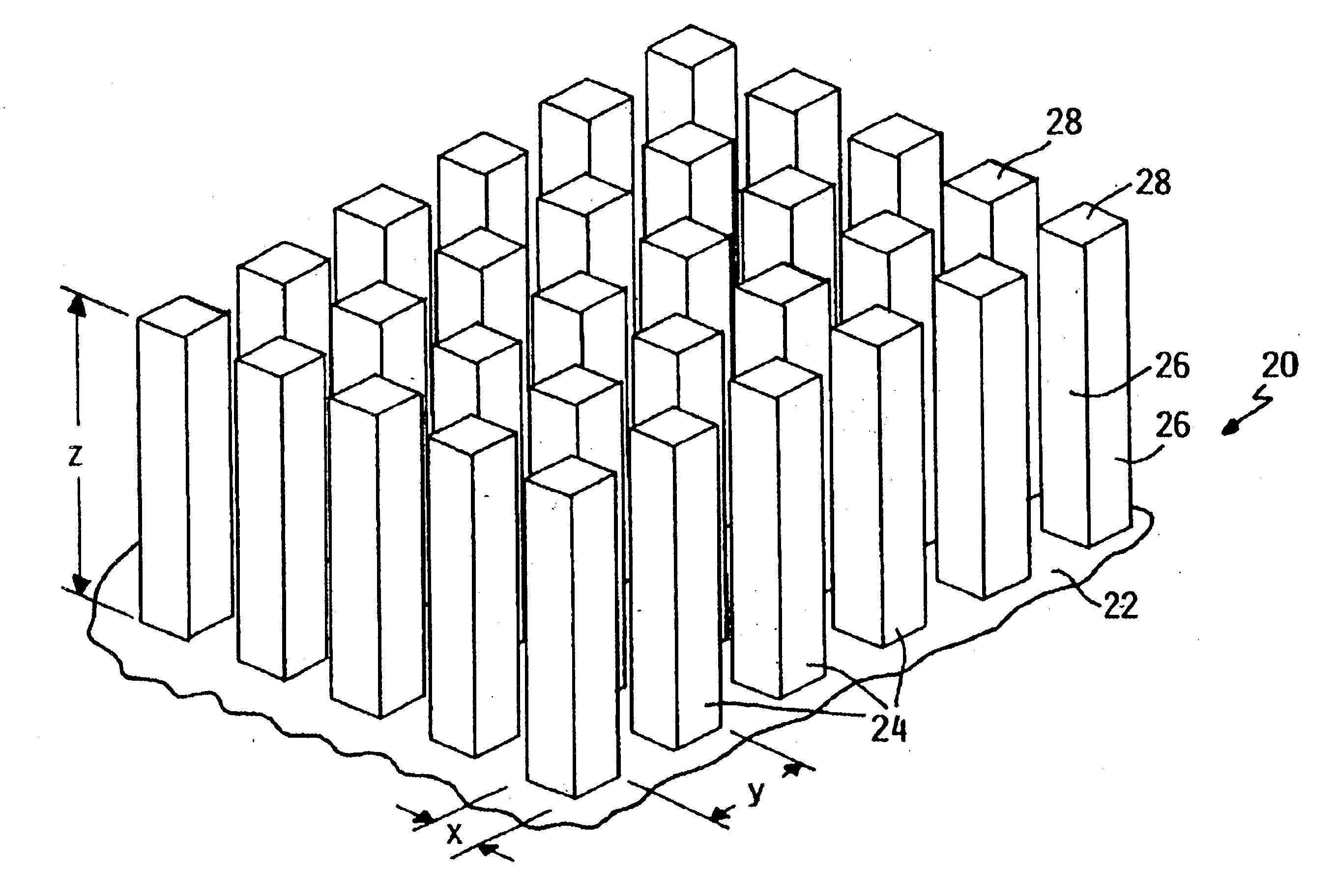

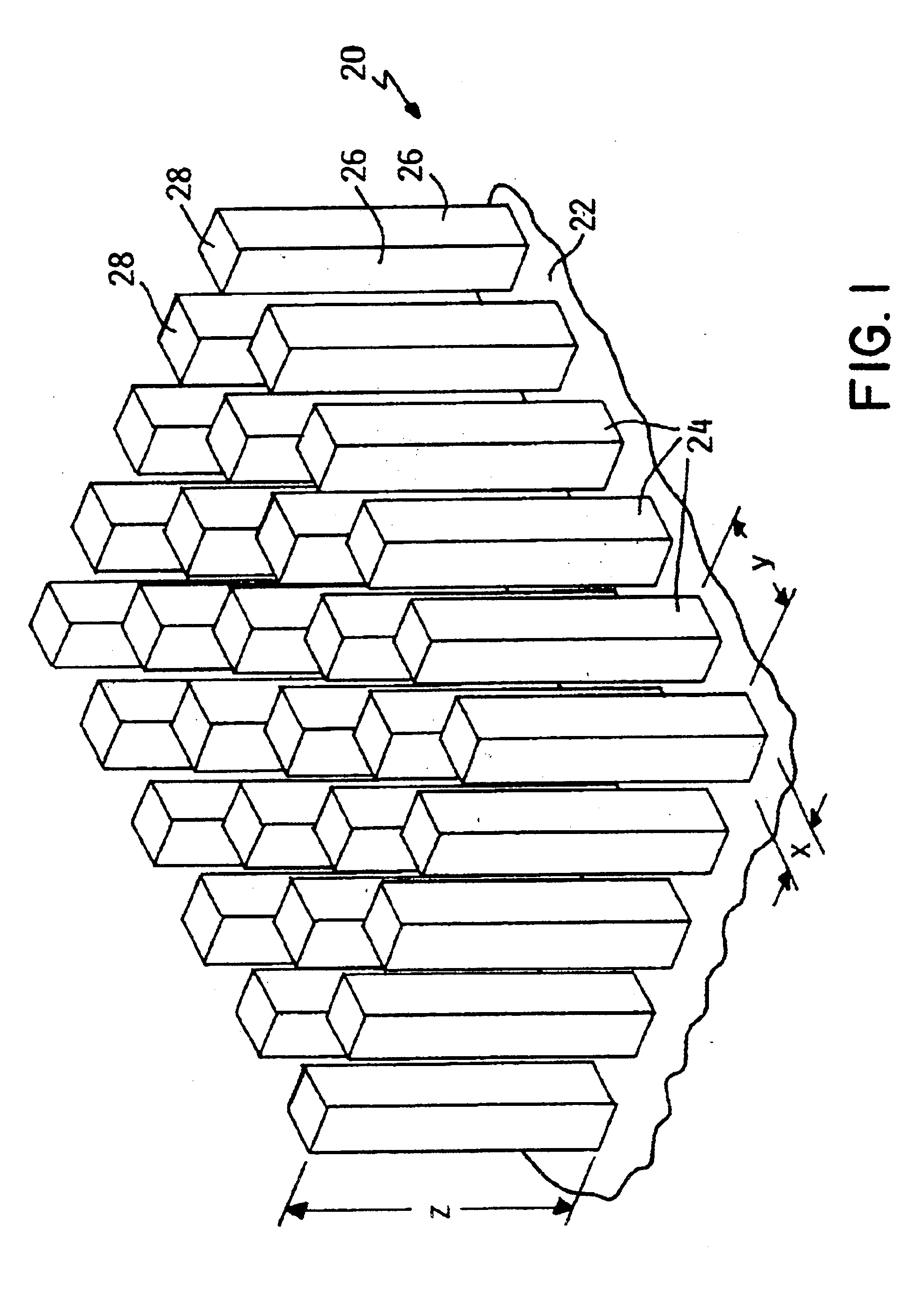

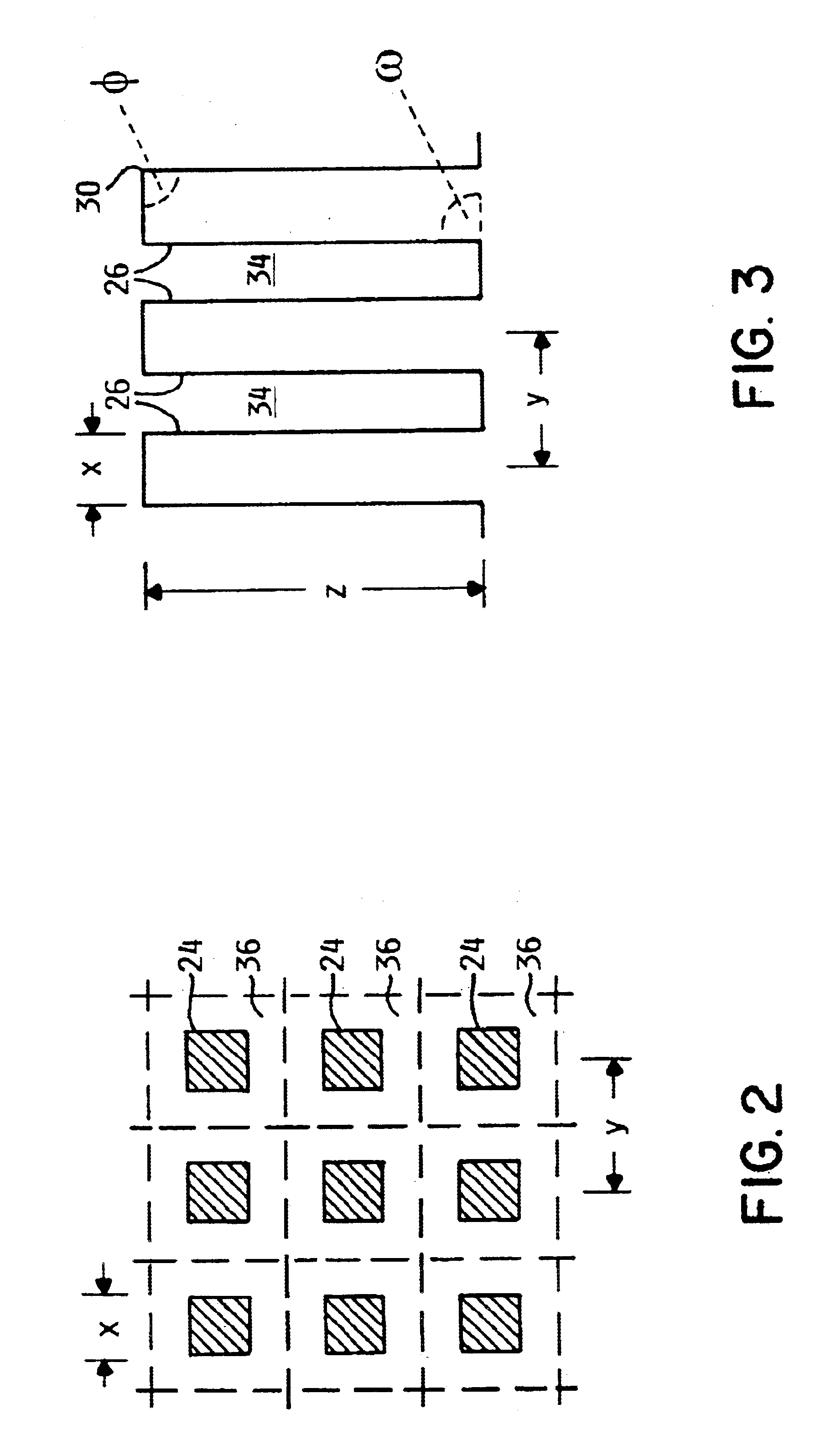

A durable ultraphobic surface that is capable of retaining ultraphobic properties at liquid pressures of one atmosphere and above. The surface generally includes a substrate portion with a multiplicity of projecting regularly shaped microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density measured in meters of contact line per square meter of surface area equal to or greater than a contact line density value “ΛL” determined according to the formula: ΛL=-10,330γcos(θa,0+ω-90°)where γ is the surface tension of the liquid in Newtons per meter, θa,0 is the experimentally measured true advancing contact angle of the liquid on the asperity material in degrees, and ω is the asperity rise angle in degrees.

Owner:ENTEGRIS INC

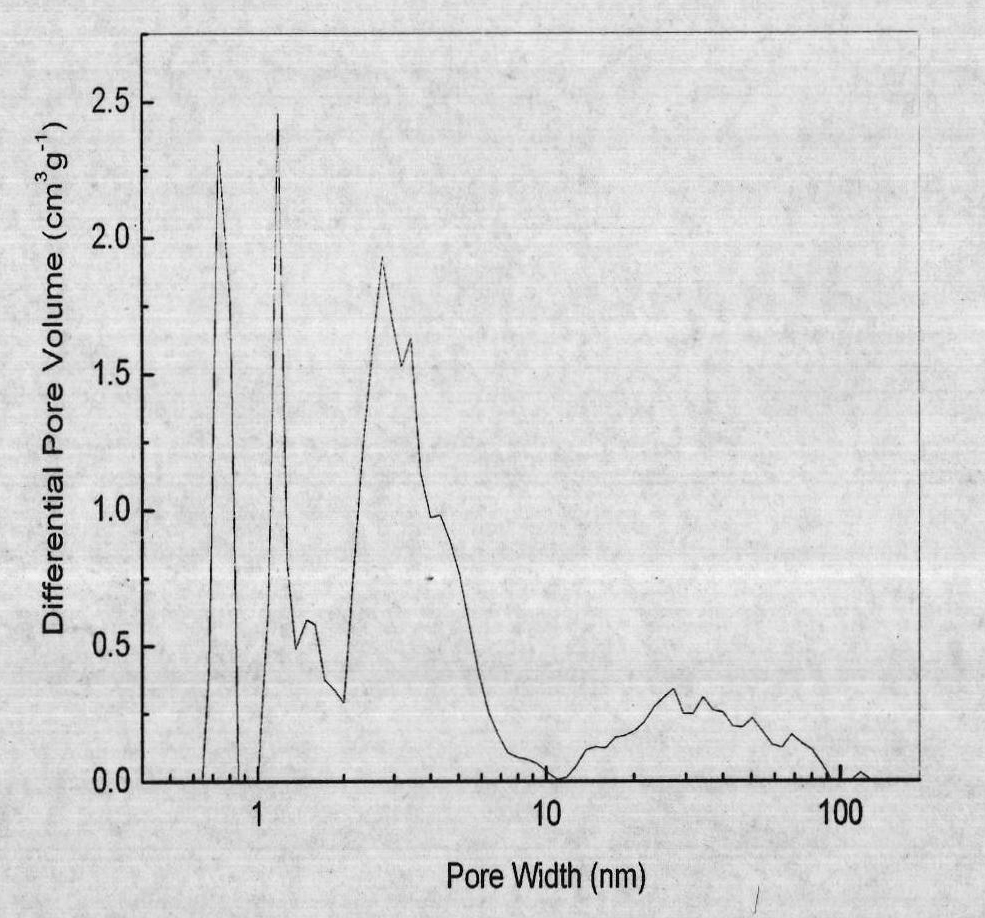

Preparation method of porous structured active carbon

The invention provides a preparation method of porous structured active carbon. The preparation method comprises the following steps of: drying animal bones serving as raw materials; pre-carbonizing at the temperature of 400 to 500 DEG C under the protection of an inert gas; crushing into powder; adding an activating agent into the powder; performing chemical activation under the protection of the inert gas; cooling and taking a product out; and performing aftertreatment process such as acid-washing, water-washing and drying to obtain the porous structured active carbon, wherein the product prepared at 850 DEG C has the specific surface area of 2,157 square meters per gram and the pore volume of 2.26 cubic centimeters per gram; the pores are in a three-dimensional distribution of micropores, mesopores and macropores. By taking organic substances and inorganic substances in the animal bones as a carbon source and a natural template with a special pore structure, the preparation method overcomes the defects of requirement on a template and difficulty in immersing pores in a template by using a carbon precursor, prepares the porous active carbon, and is low in cost and simple in process.

Owner:BEIJING UNIV OF CHEM TECH

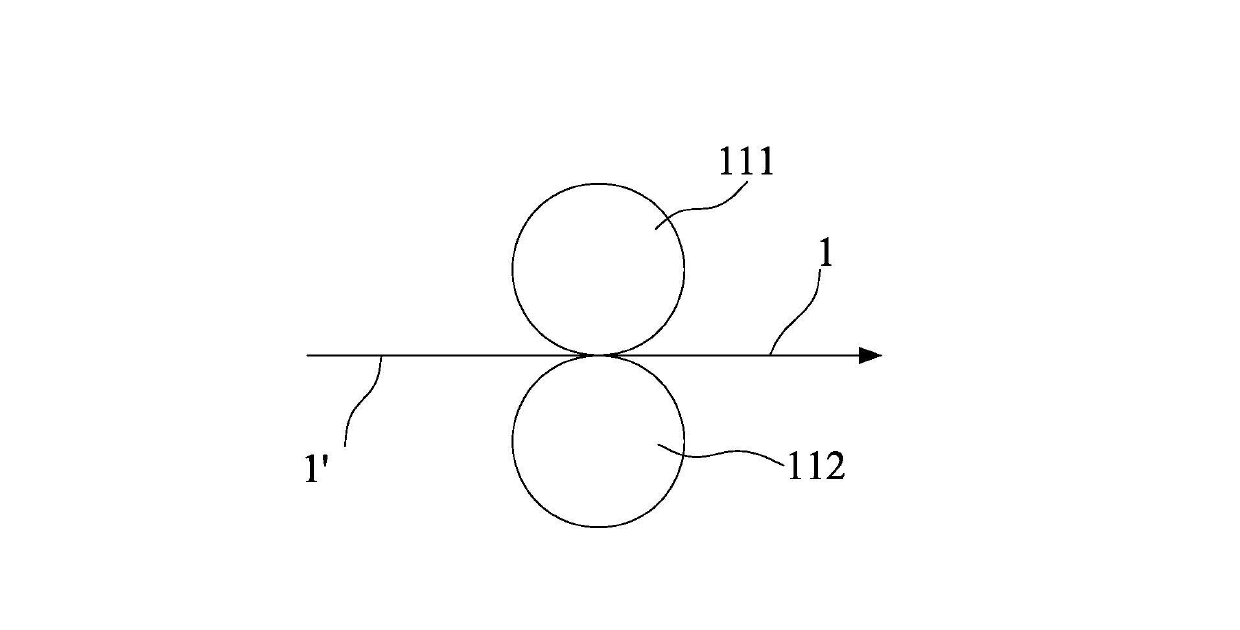

Absorbent articles having a breathable stretch laminate

An absorbent article may comprise a topsheet; a backsheet joined with the topsheet; an absorbent core between the topsheet and backsheet; and an elastic element comprising a breathable stretch laminate. The breathable stretch laminate may comprise a first substrate; and an elastic member joined to the first substrate, wherein said elastic member comprises a polyurethane. The breathable stretch laminate may exhibit a MVTR greater than about 300 grams per square meter per 24 hours and a force relaxation of less than about 50% after about 10 hours at 100° F. and 50% elongation.

Owner:THE PROCTER & GAMBLE COMPANY

Curable composition, underfill, and method

InactiveUS20060147719A1Synthetic resin layered productsCellulosic plastic layered productsGramRefractory

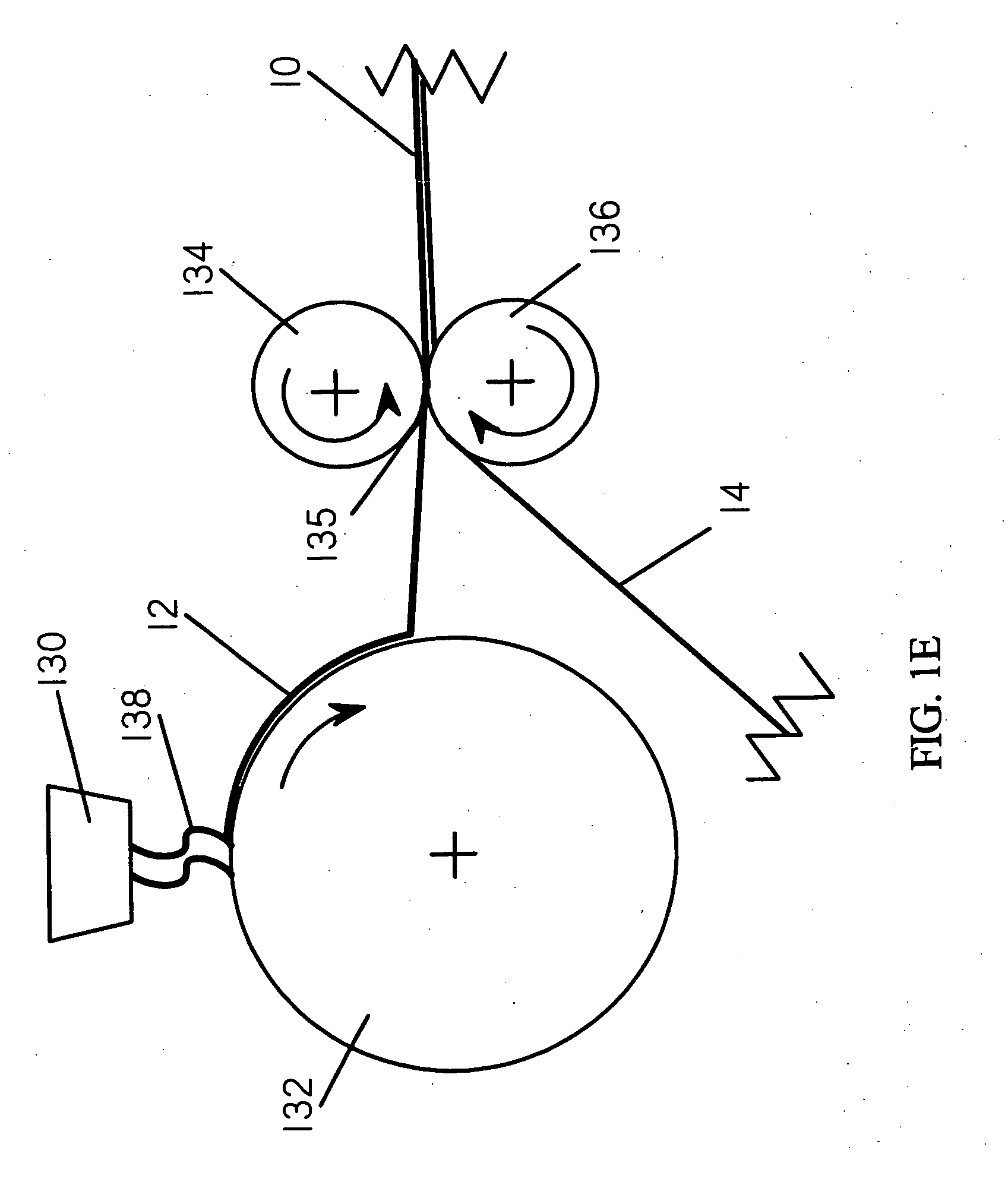

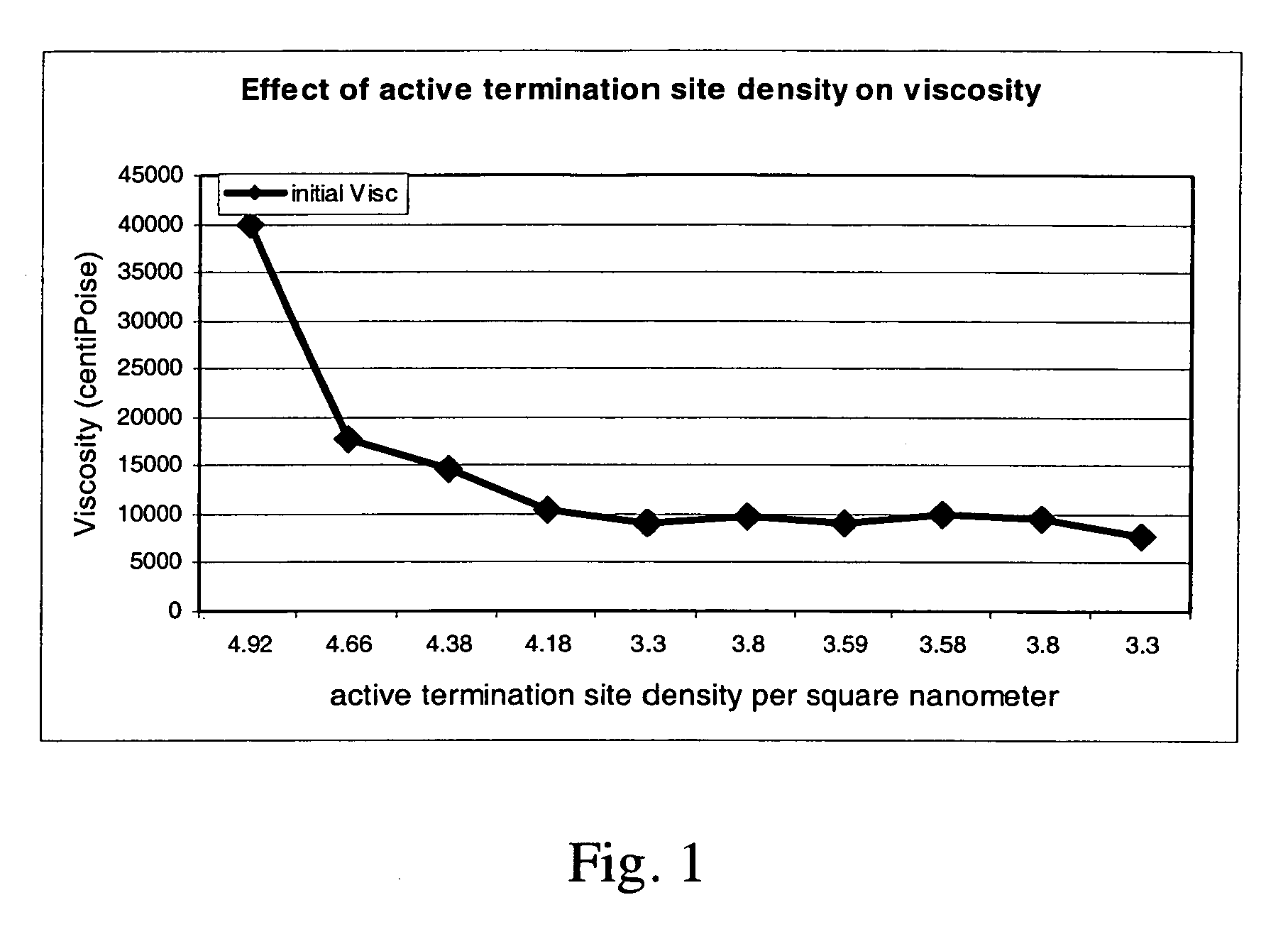

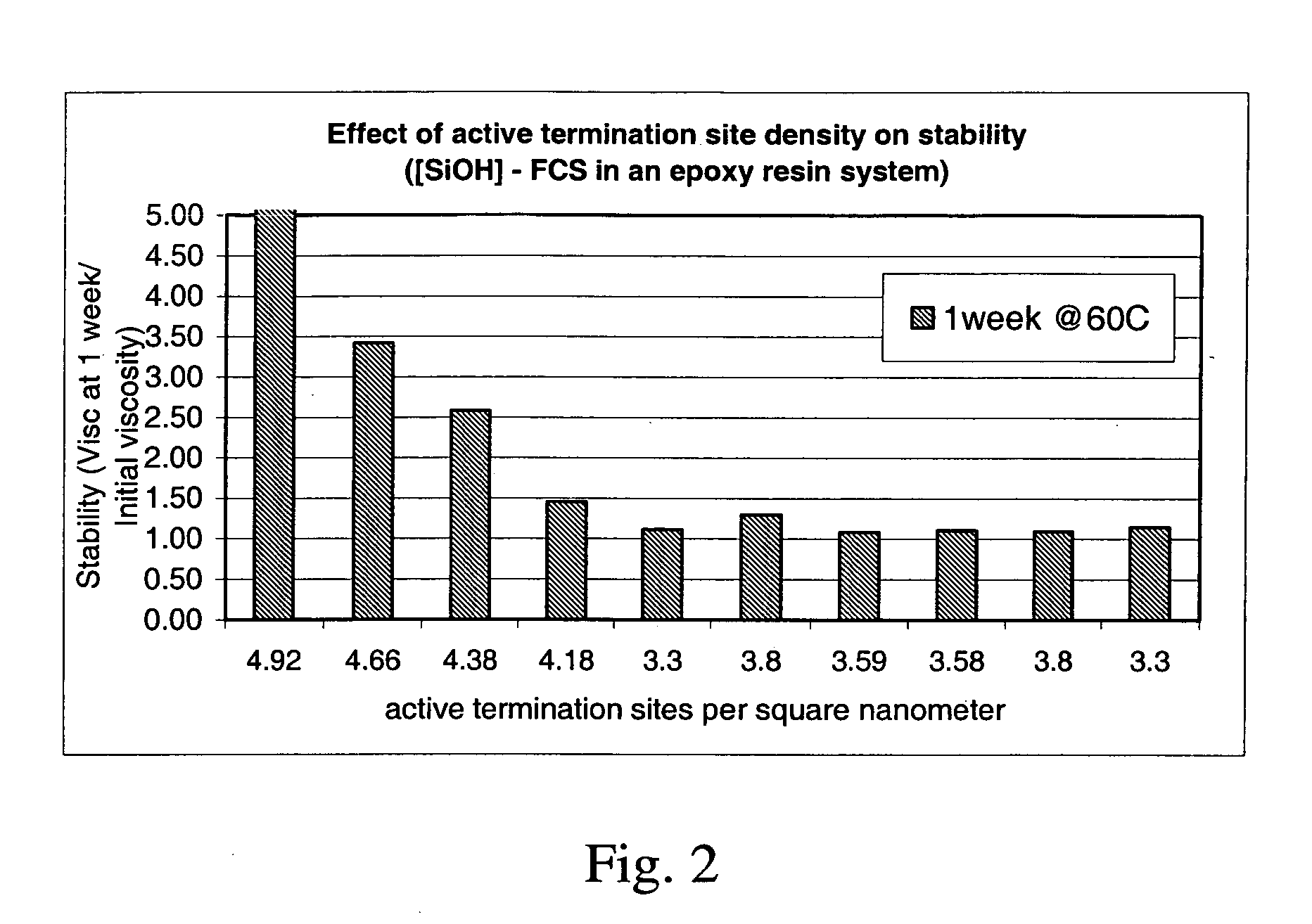

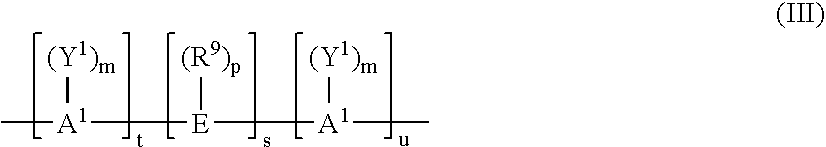

A curable composition is provided, and a method associated therewith. The curable composition may include a curable resin and a finely divided refractory solid. The solid may have a surface area that is greater than about 5 square meters per gram, and a determined density of active surface termination sites per square nanometer of surface area.

Owner:GENERAL ELECTRIC CO

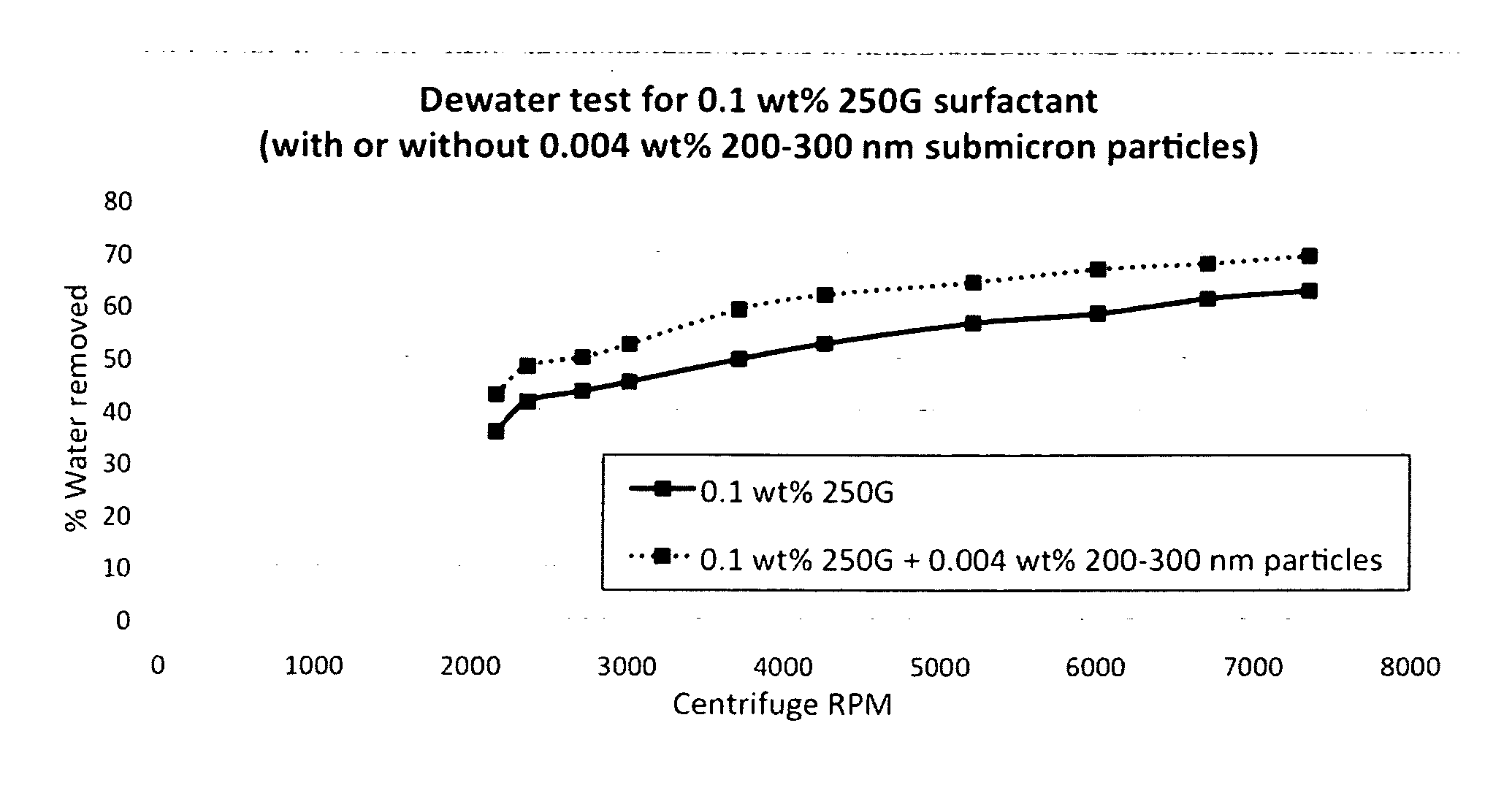

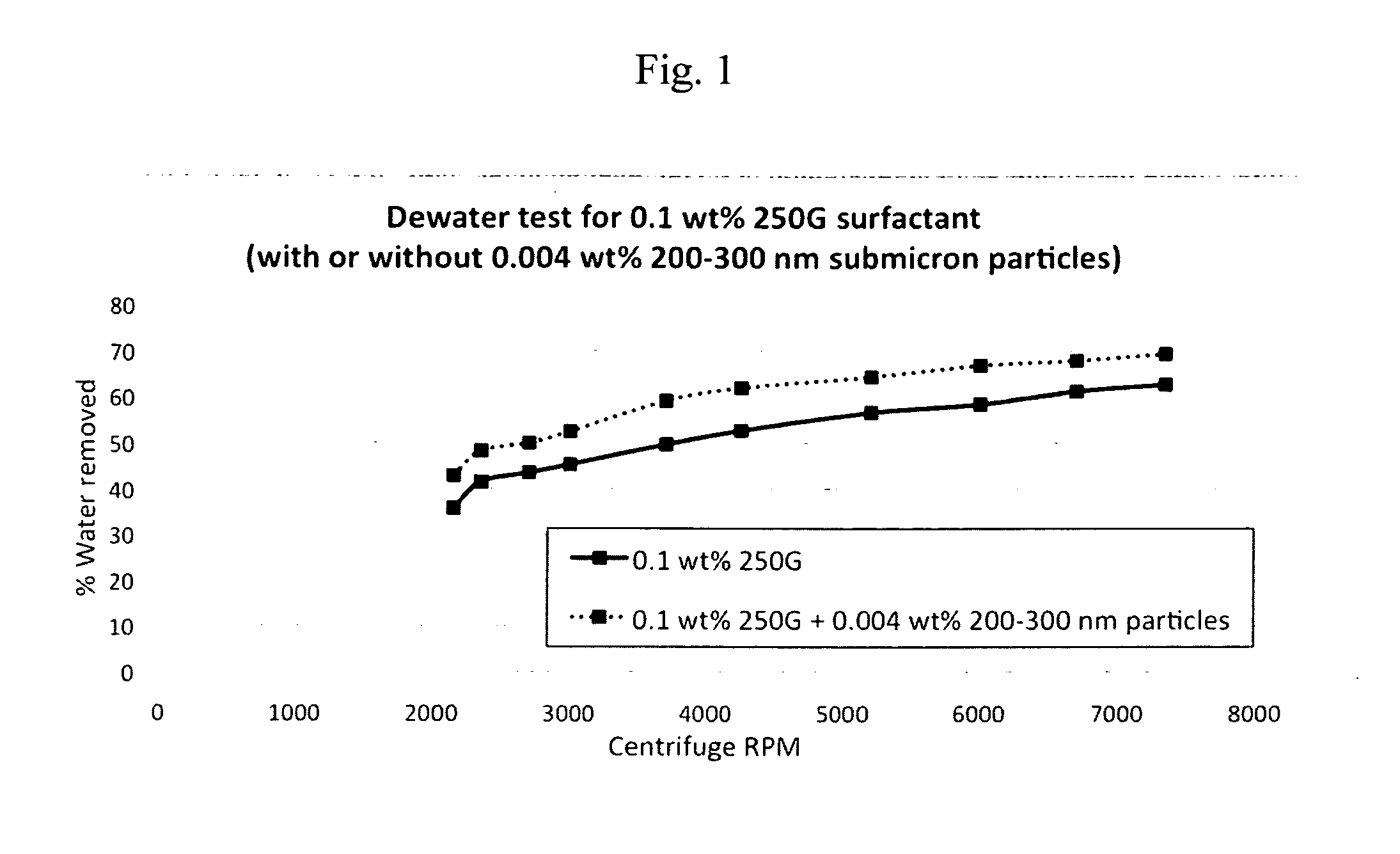

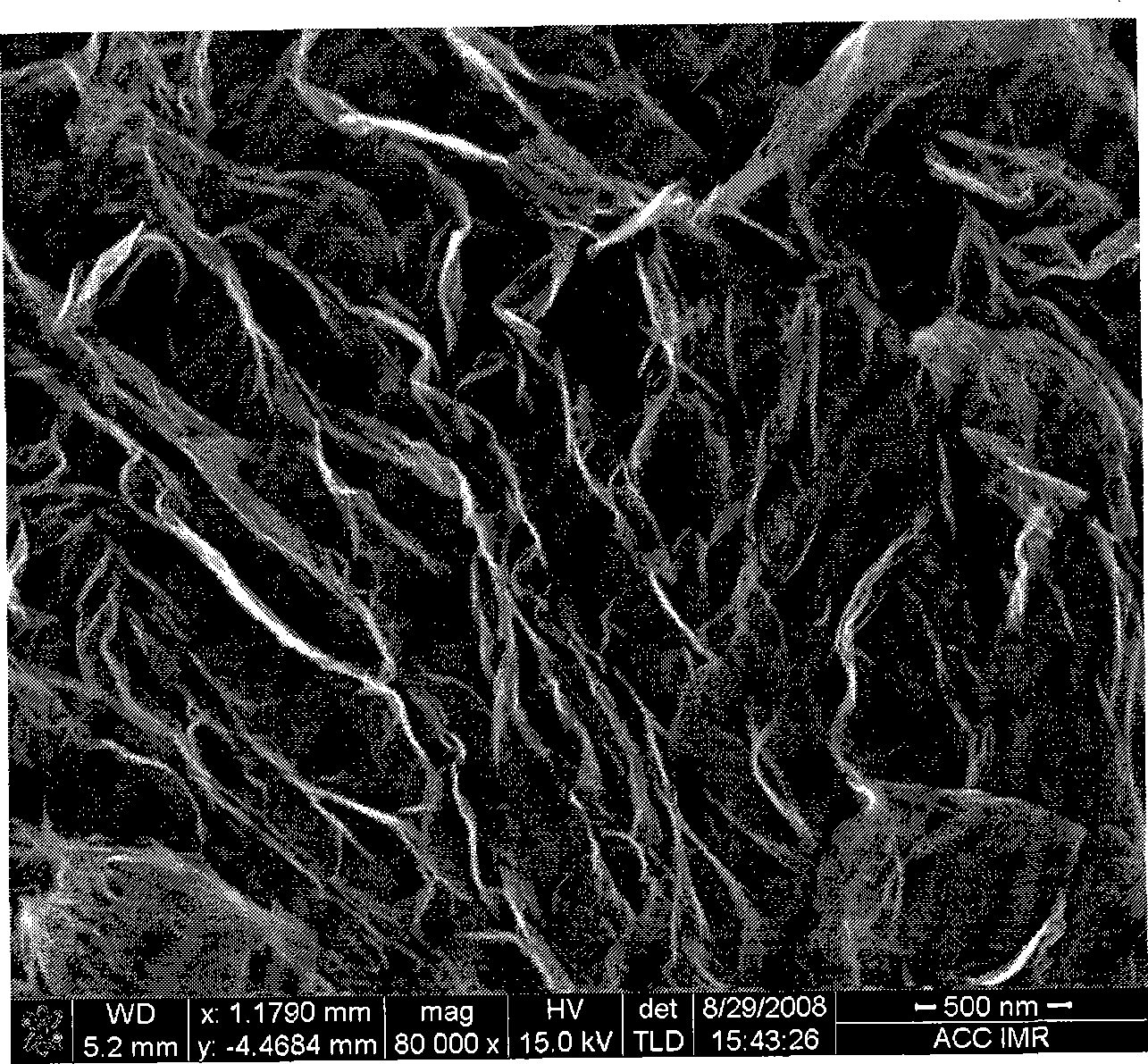

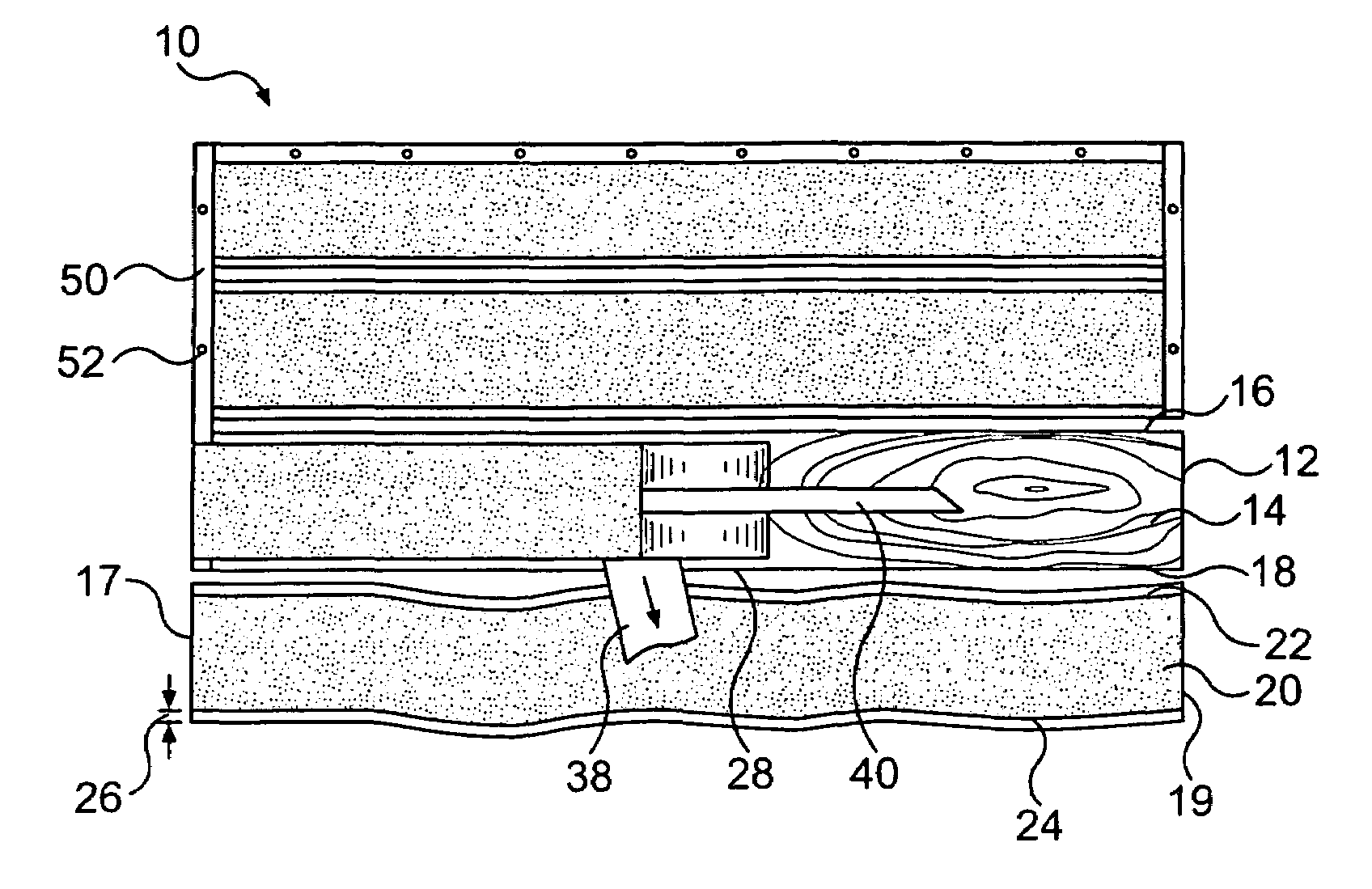

Submicron particles surfactant method for improved oil recovery from subterranean reservoirs

Methods of stimulating a well comprising providing a stimulation fluid comprising at least one surfactant and submicron particles, the submicron particles having a particle size between about 200 nm and about 800 nm and a specific surface area greater than about 5 square meters per gram; and introducing the stimulation fluid into a wellbore. Additional methods to enhance oil recovery from subterranean reservoirs accessible via a well are described.

Owner:CHEMEOR

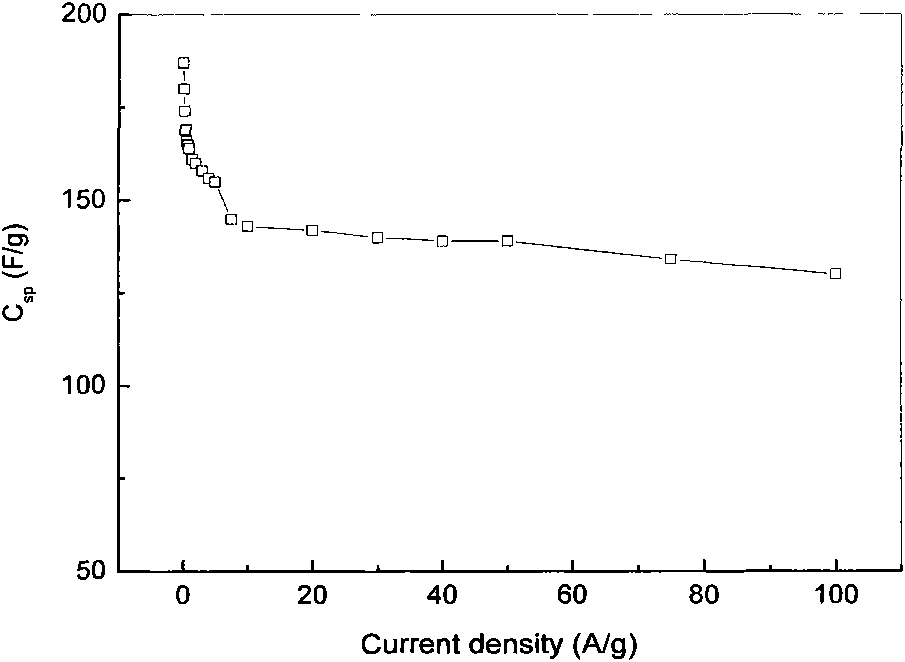

High electrochemistry capacitance oxidization plumbago alkene, low-temperature preparation method and uses

The invention discloses a high electrochemical capacity graphene oxide, and a method for preparing the high electrochemical capacity graphene oxide, and the application thereof. The lamina thickness of the graphene oxide is 0.35 to 20 nm; the specific surface area is 200 to 800 square meters per gram, and the electrochemical specific capacity reaches 50 to 220 F / g. The present invention relates to the method that graphite oxide is heated to 150 to 600 DEG C and is maintained at the temperature for 0.5 to 20 hours in a high vacuum to get the graphene oxide. The material is applied to the electrode material of the super capacitor. The invention has the advantages of simple preparation process, low preparation temperature, easy operation and low energy consumption.

Owner:深圳清研紫光科技有限公司

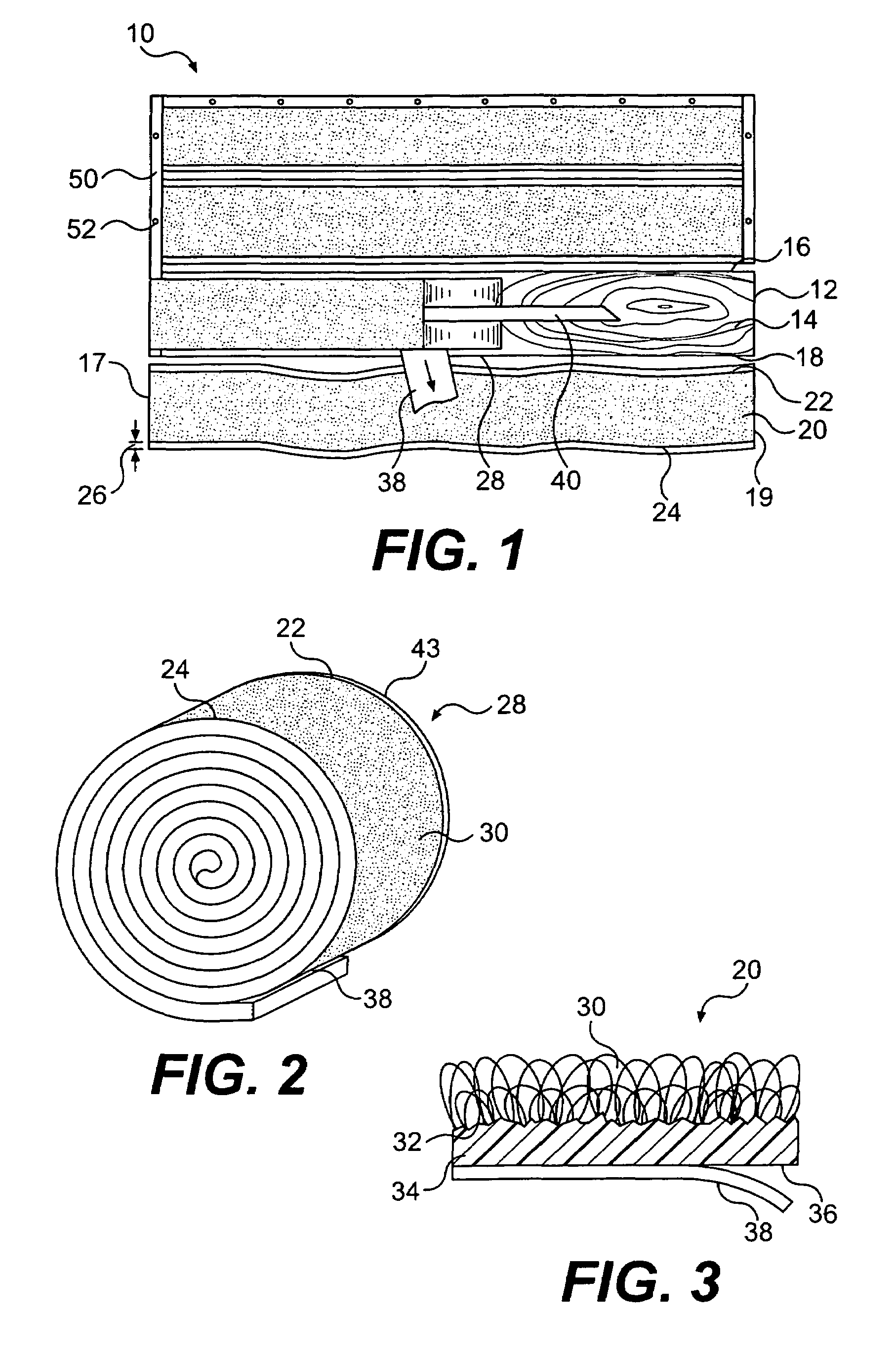

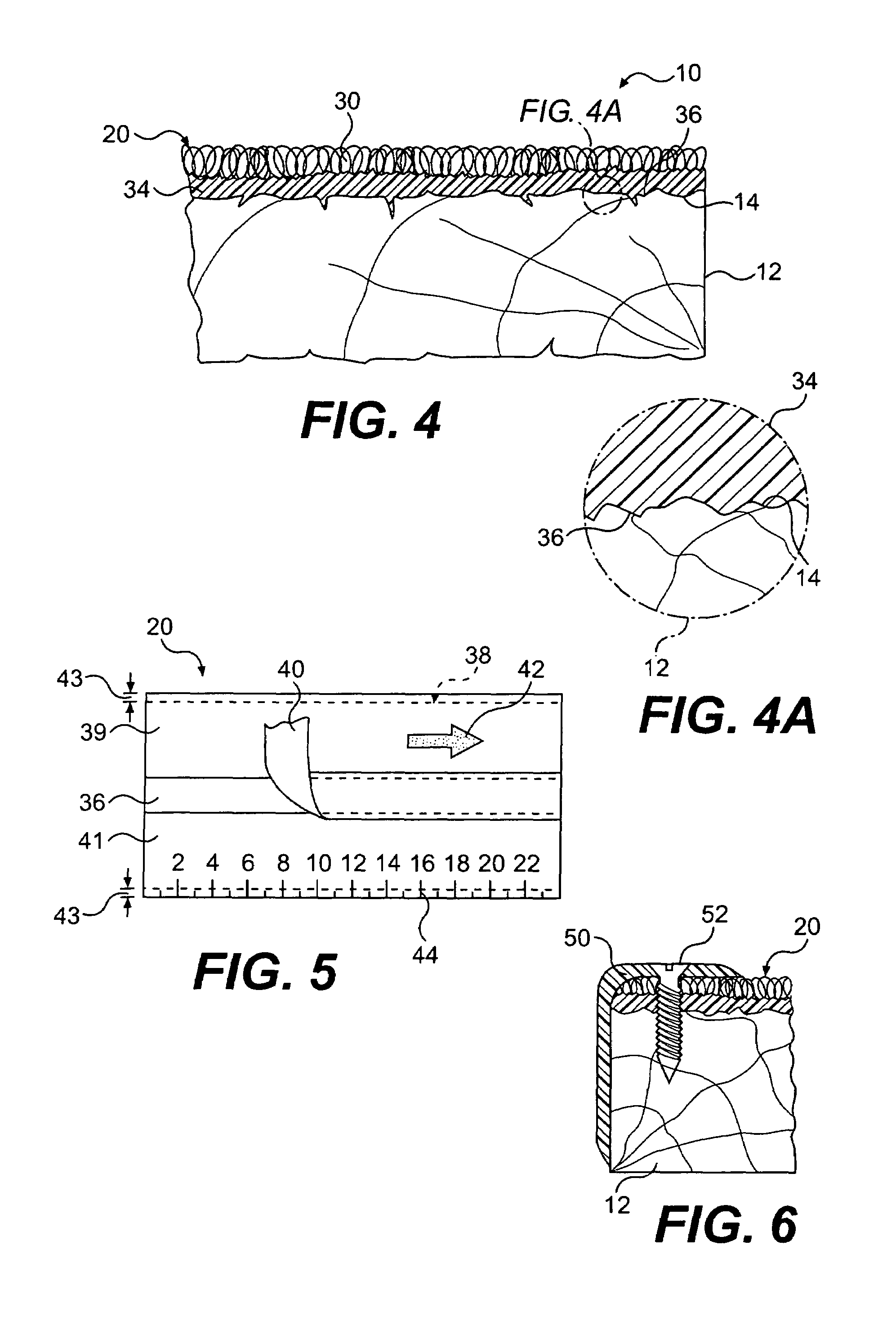

Method of applying a covering for boards

A covering system is designed as an elongated strip of covering material having a fibrous layer and an integral moldable layer for mounting on the upper surface of boards, such as deck planks. In a preferred embodiment, strips are preferably secured to the length of the boards solely by a layer of a hot melt pressure sensitive adhesive carried by the strip. The moldable material is applied in a volume of about at least 185 grams per square meter. A removable release sheet covers the adhesive surface of the moldable material. The release sheet can include a positioning mechanism and indicia such as the direction of the pile and measuring guides. The moldable material provides sufficient adhesion across the width of the strip for both initial application and sufficient thickness for subsequently molding to the board surface for long term adhesion.

Owner:OCONNOR INVESTMENT CORP

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

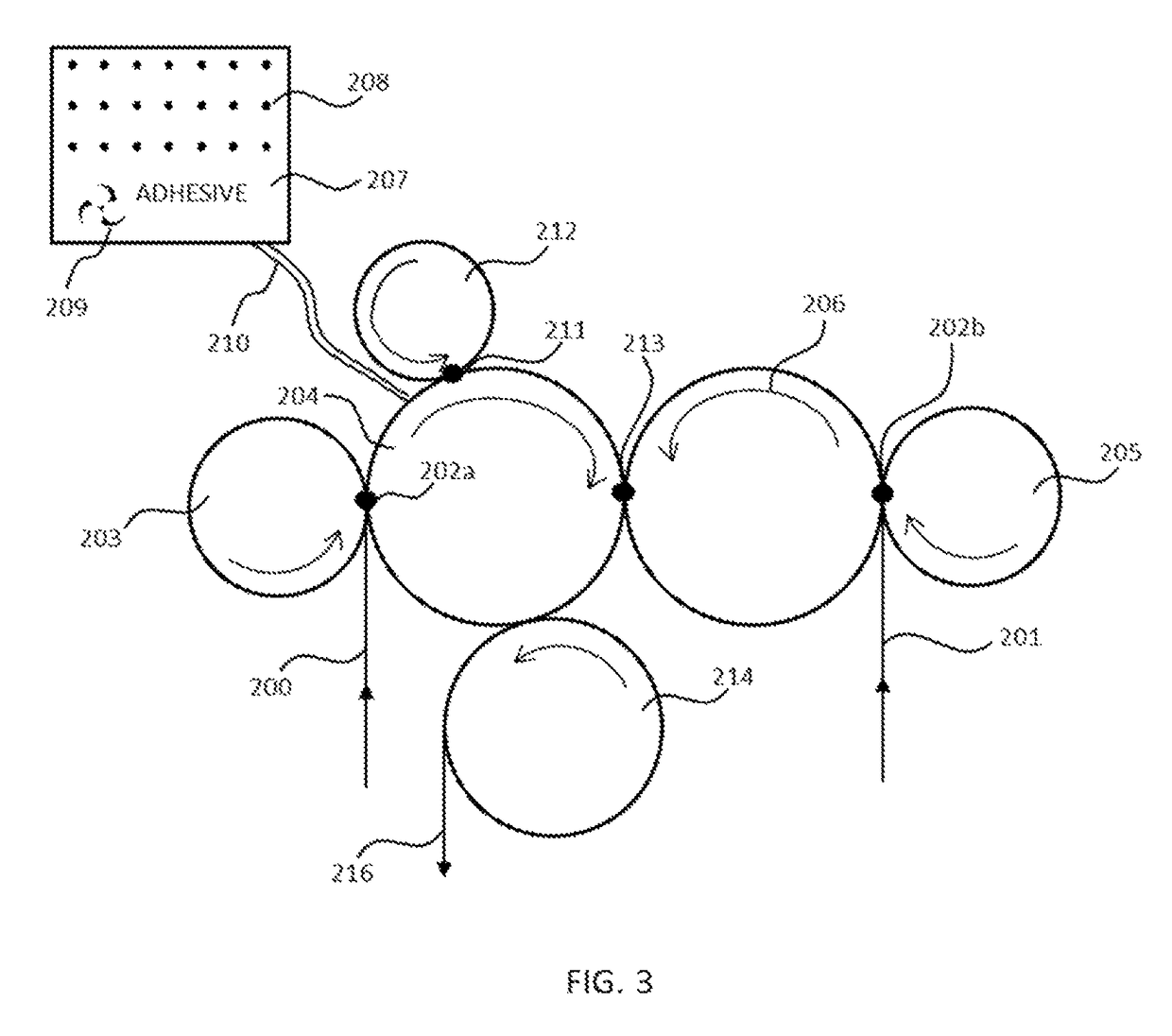

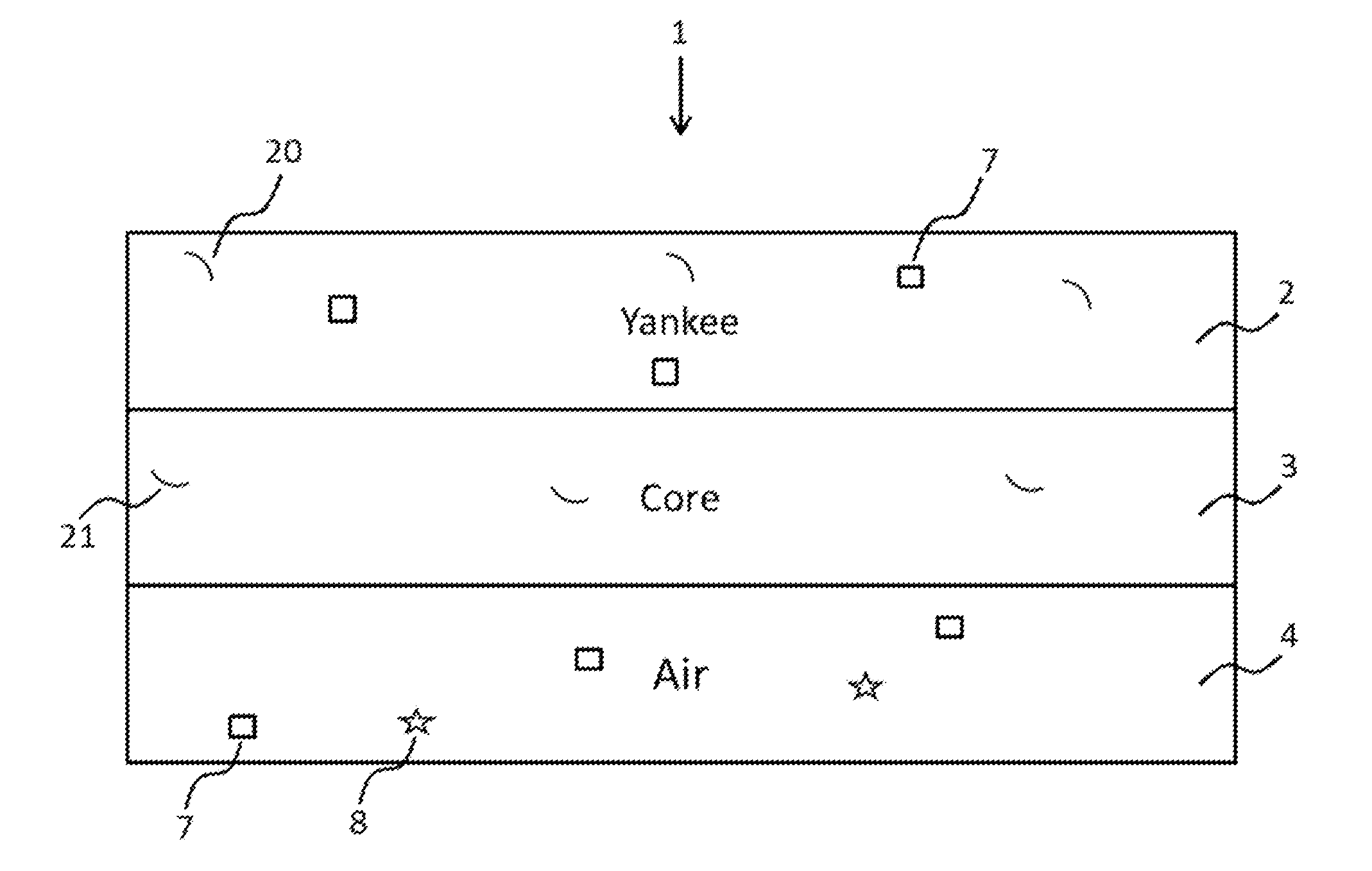

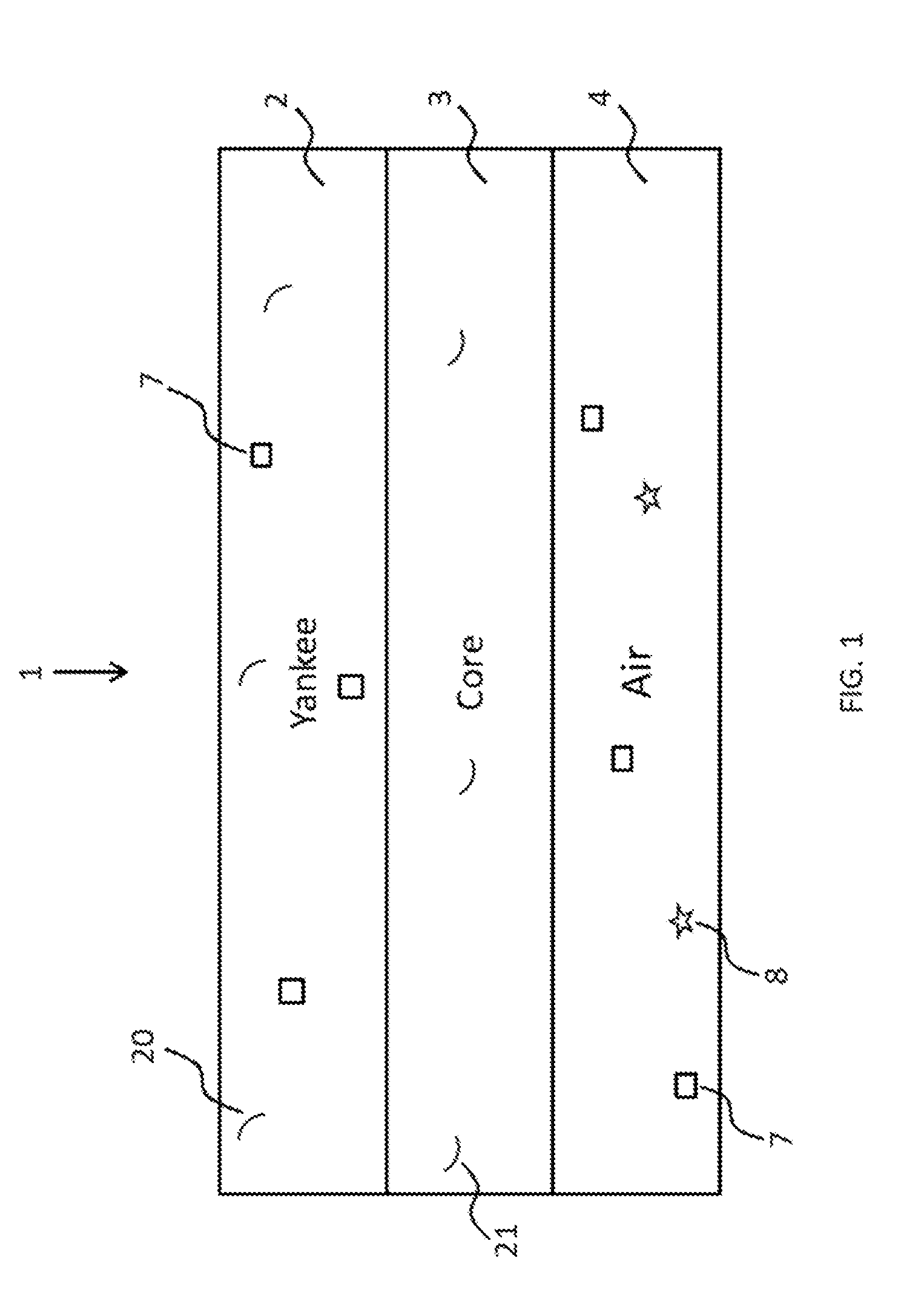

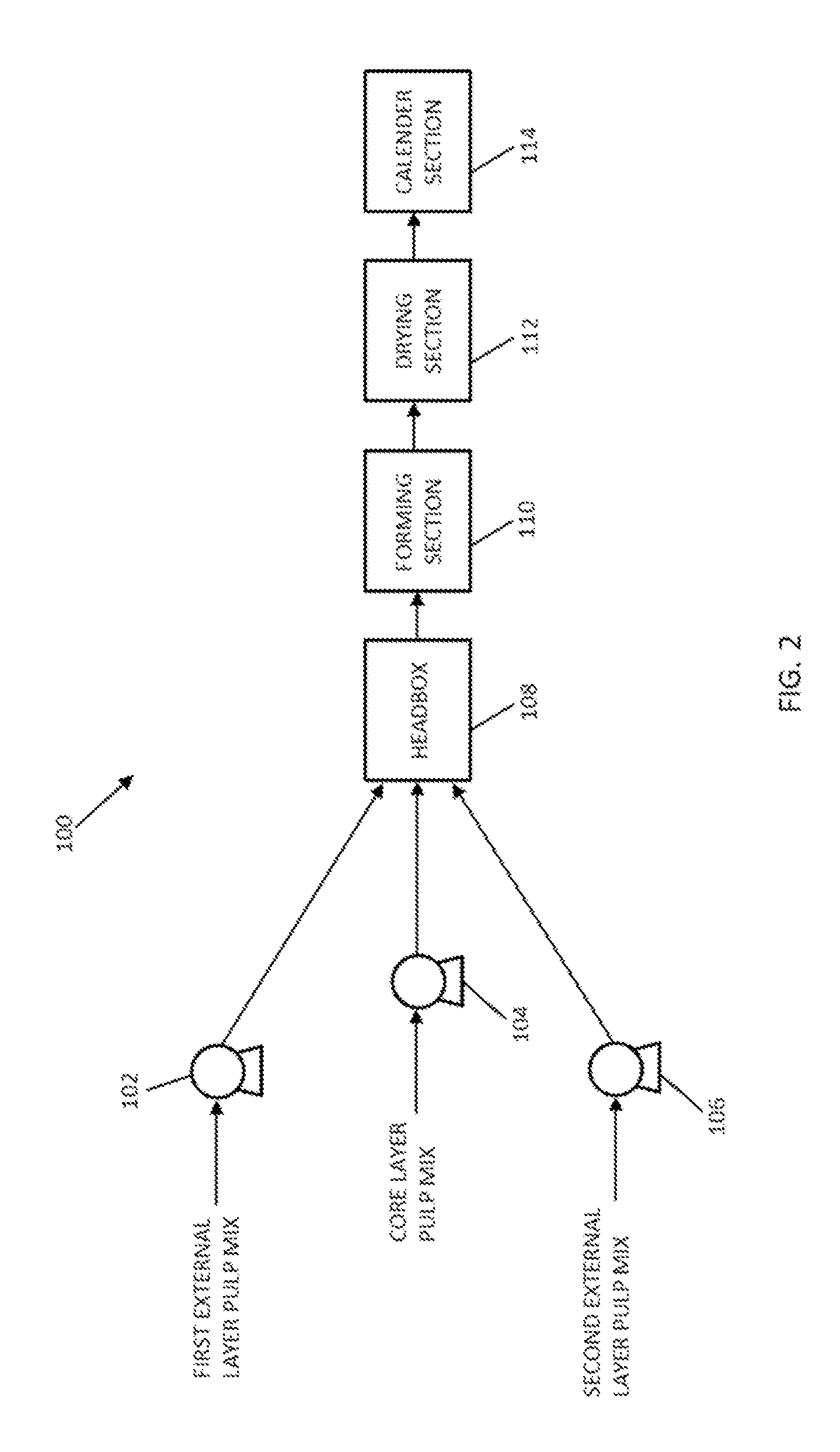

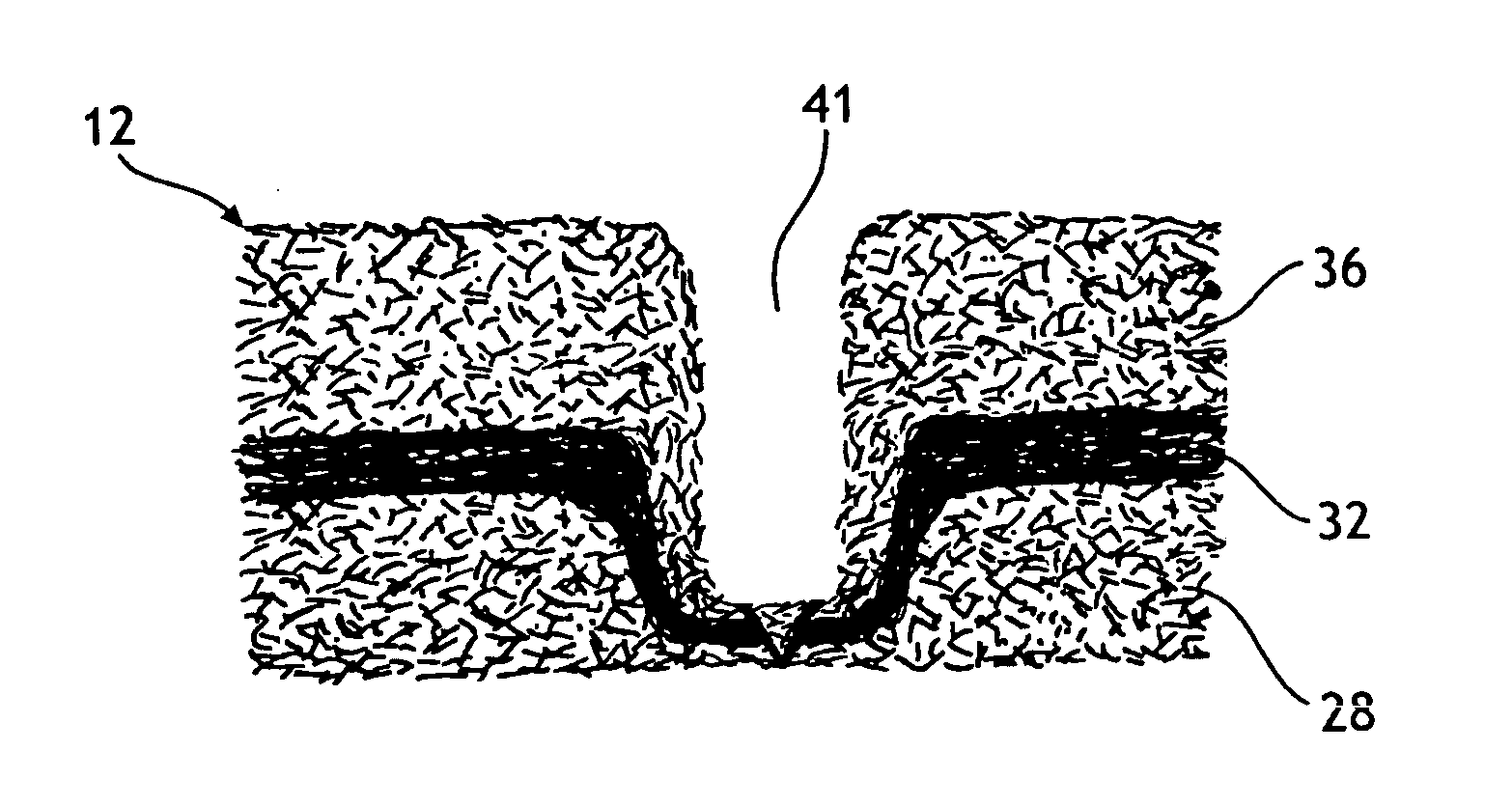

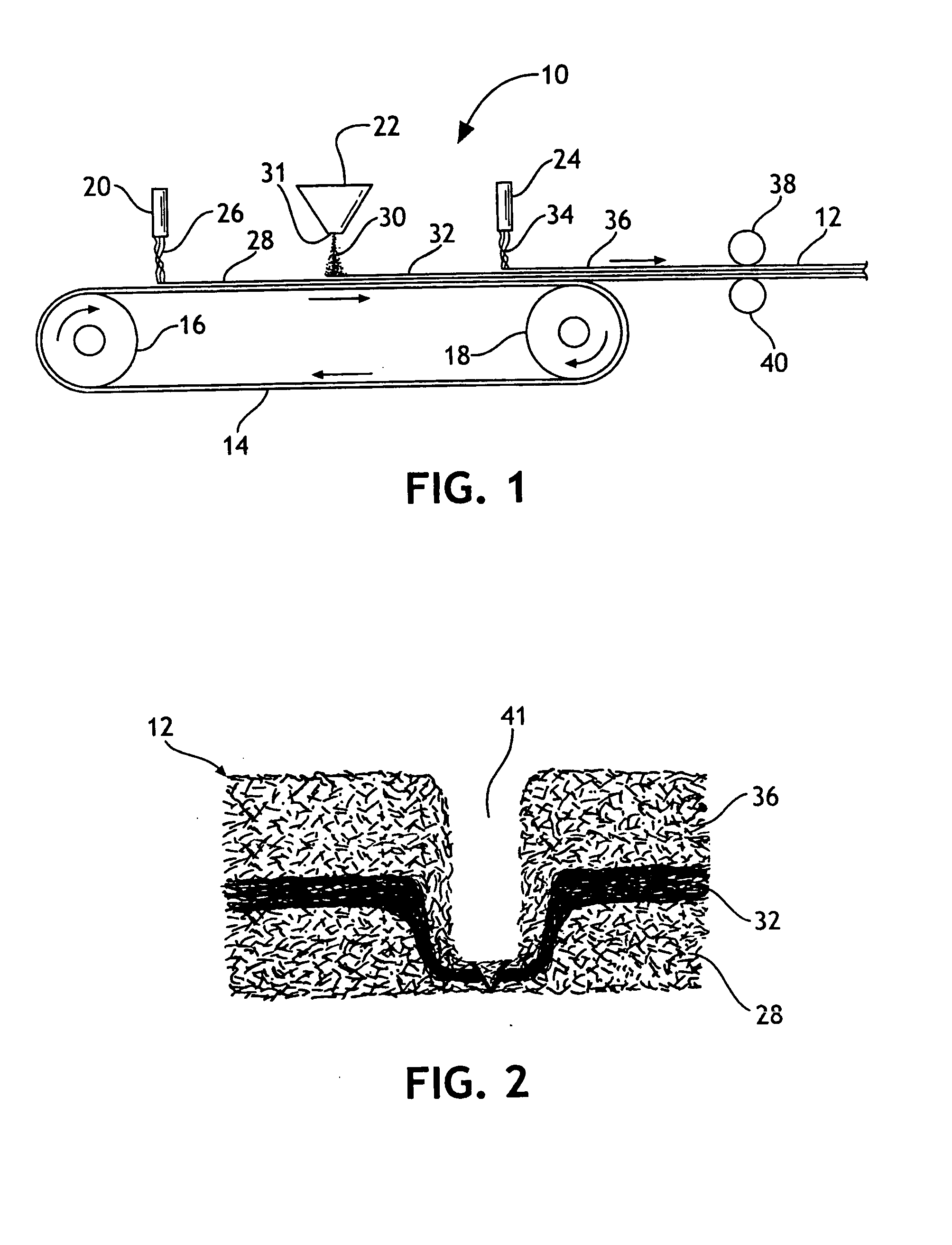

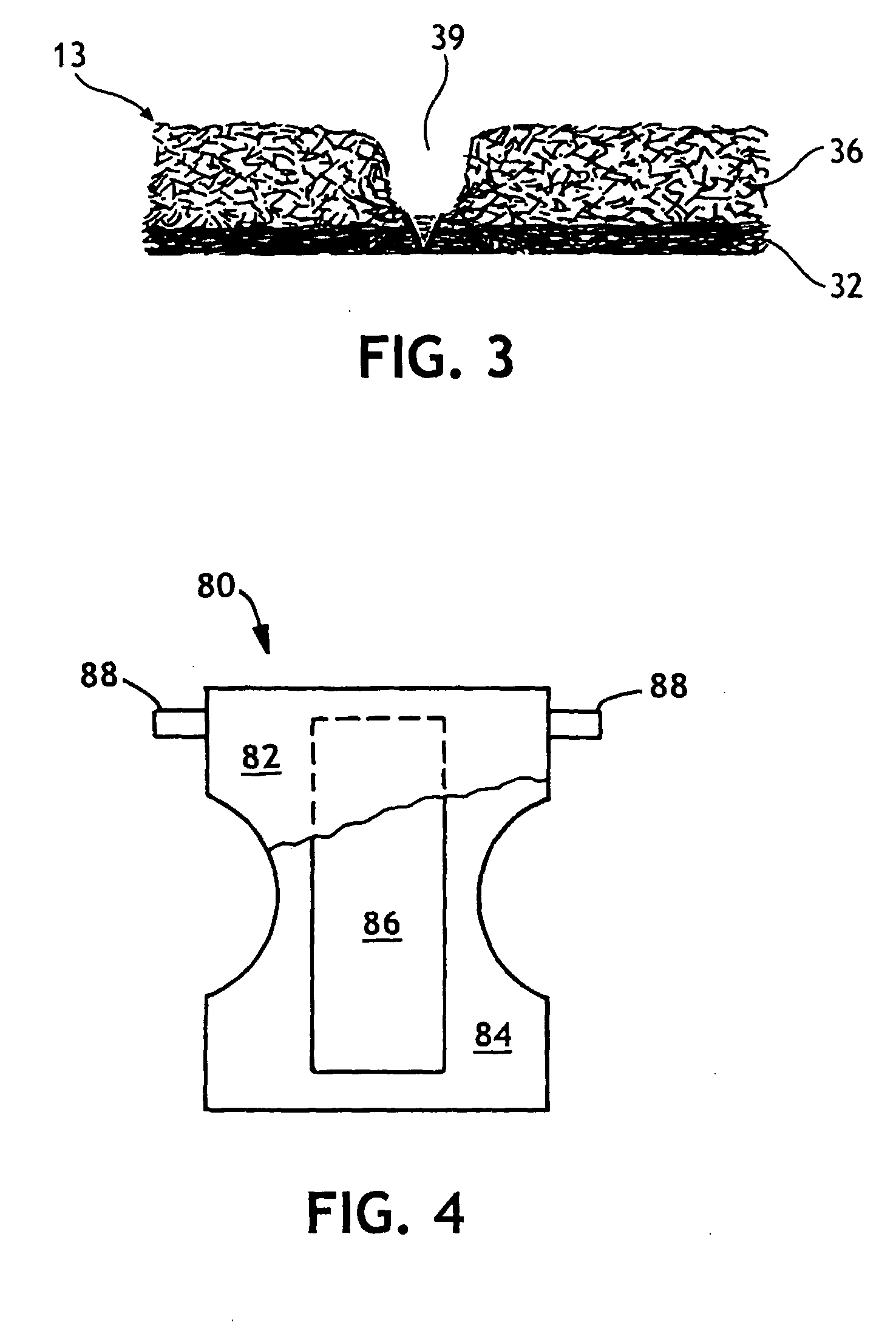

ActiveUS9719213B2Improve the level ofLose weightLamination ancillary operationsLaminationGramAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE LLC

Towel with quality wet scrubbing properties at relatively low basis weight and an apparatus and method for producing same

ActiveUS20160160448A1Improve the level ofLose weightPaper after-treatmentOrnamental structuresFiberAdhesive

A multi-ply absorbent product having a wet scrubbing resistance greater than 120 revolutions and a basis weight of between 30 and 50 grams per square meter. A heated adhesive is applied between two single plies / webs, the multiple plies are embossed according to particular parameters, and the embossed webs are compressed with a marrying roll. The adhesive is heated to a temperature of between approximately 32 degrees C. to 66 degrees C. for application between the multiple plies. For each ply, the embossed area generally occupies between approximately 5 to 15% of the total surface area of a surface of the ply, the depth of embossment of the surface is generally between approximately 0.28 and 0.43 centimeters deep, and the embossment of the surface is generally between approximately 0.04 to 0.08 square centimeters in size.

Owner:FIRST QUALITY TISSUE

Nonwoven fabric laminate that reduces particle migration

The present invention provides a nonwoven fabric laminate that comprises a thin layer of fine fibers that has a basis weight of less than 1.5 grams per square meter. The present invention also provides disposable absorbent garments, such as diapers, that in such a nonwoven fabric laminate to reduce the migration of particles in absorbent garments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Perforated non-woven fabric

InactiveCN102673030AIncrease solid thicknessImprove moisture barrier effectLayered productsBandagesSurface layerGram

The invention provides perforated non-woven fabric, consisting of at least two fibrous layers, wherein a surface layer is such a fibrous layer, with a more than 70 degree contact angle with water and having the gram weight of 3 to 30 grams per square meters; and a bottom layer is such a fibrous layer, with a less than 90 degree contact angle with water and having the gram weight of 3 to 30 grams per square meters. The non-woven fabric has through apertures from the surface layer to the bottom layer, with the aperture ratio of 5 to 50% and the stereo thickness of 0.1 to 1.5mm. On a contact face between the two fibrous layers of the perforated non-woven fabric, the fibrous layers with mutually intersected fiber are usefully wetted by body fluid in use, so that the body fluid rapidly reaches the fibrous layer with the less than 90 degree contact angle with the water under the action of capillary tubes and energy level differences; the fibrous layer with the more than 70 degree contact angle with the water is a face contacting a user; and therefore, after being absorbed, the body fluid is difficultly adsorbed around the fiber due to the more than 70 degree contact angle between the fiber and the water, as well as is prevented from returning to the surface of the perforated non-woven fabric under the action of the capillary tubes, thereby achieving a dry and comfortable effect.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

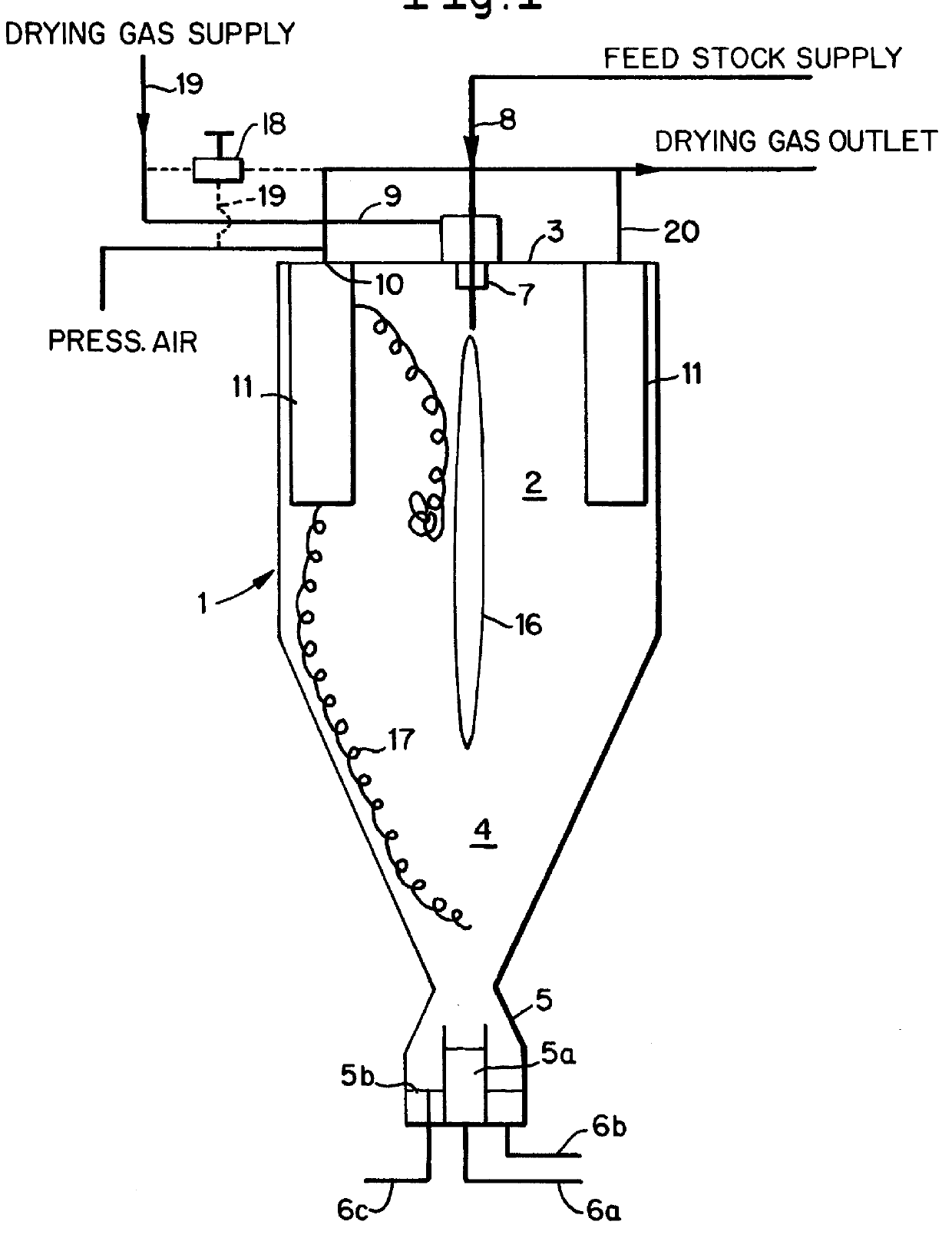

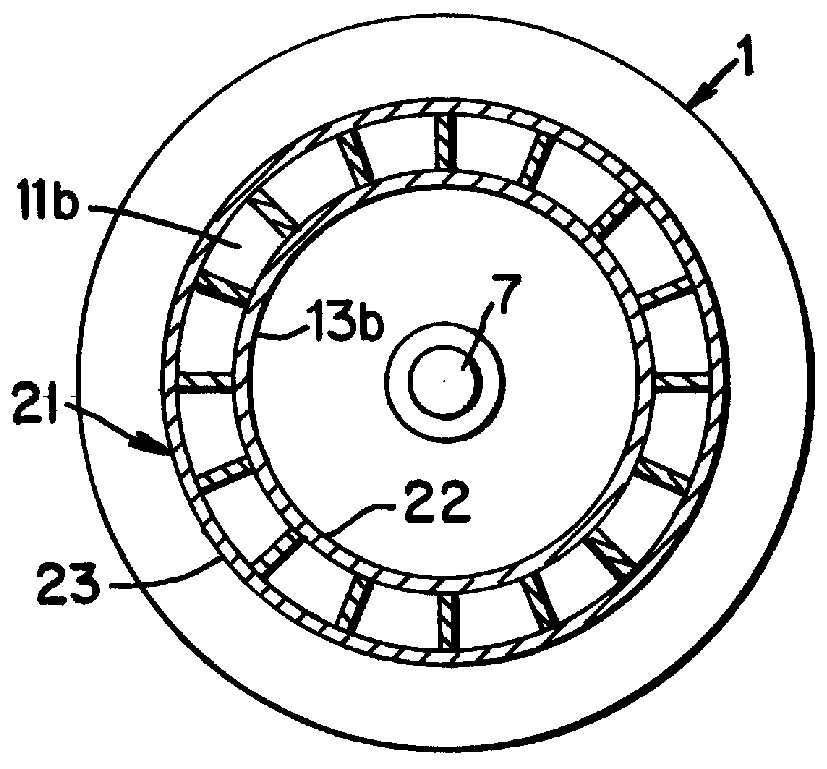

Spray drying method and apparatus and cleaning method for such an apparatus

InactiveUS6058624ALess complicated and more compact overall structureEasy to cleanDrying using combination processesDrying solid materials with heatEngineeringCleaning methods

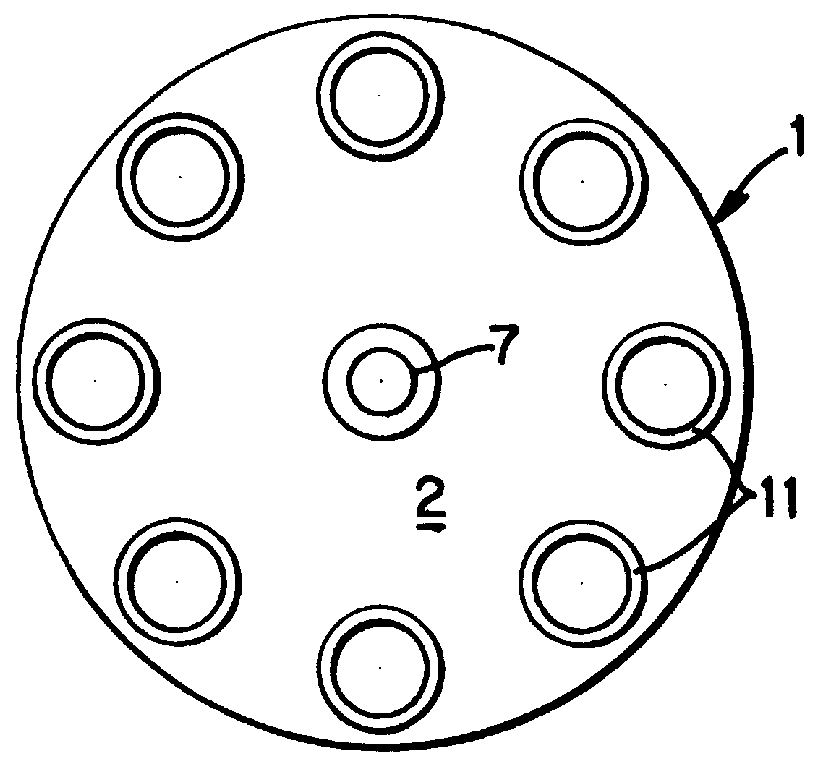

PCT No. PCT / DK97 / 00078 Sec. 371 Date Feb. 25, 1997 Sec. 102(e) Date Feb. 25, 1997 PCT Filed Feb. 20, 1997 PCT Pub. No. WO97 / 14288 PCT Pub. Date Apr. 24, 1997In fluidized spray drying of a feedstock to produce an agglomerate product by means of at least one spraying device (7) arranged in the upper part (2) of a vertically disposed drying chamber (1), in a lower part of which a fluid-bed is accommodated, a drying gas introduced into a processing zone (16) of the chamber (1) is exhausted through an integrated arrangement of filter elements (11) in the upper chamber part (2) to retain and allow agglomeration of the particles carried by the flow of drying gas on the filter elements (11). By intermittent supply of reverse flow gas pulses to the filter elements (11) the retained particles are released and returned to agglomeration zones (16, 17). The drying gas is introduced at a rate producing at the filter walls (13) a flow rate amounting to at least 150 cubic meters per hour per square meter of filter wall surface. In the non-operative condition of the spray drying apparatus the filter elements (11) may be cleaned-in-place by supplying a cleaning liquid to the interior of the elements.

Owner:NIRO

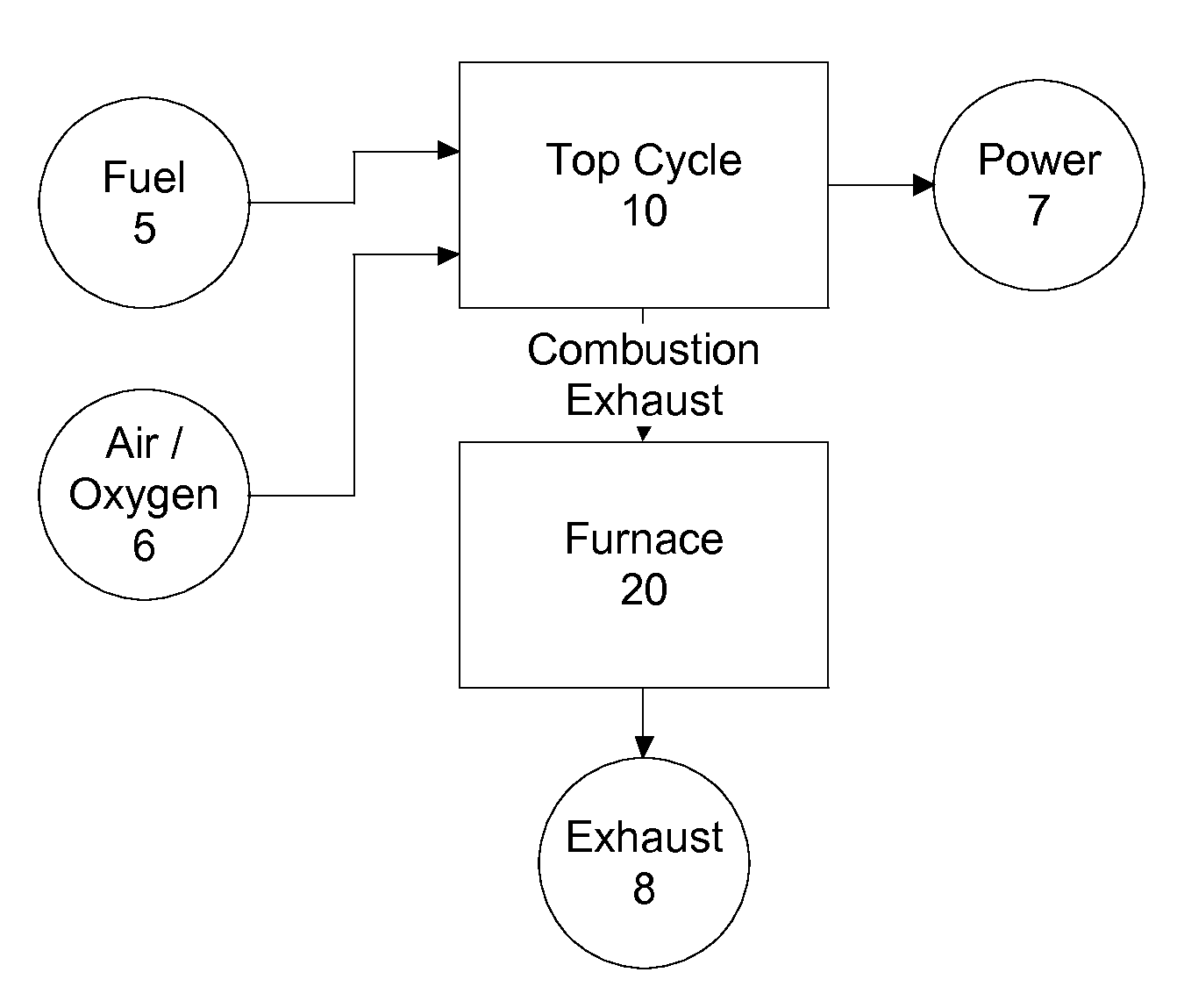

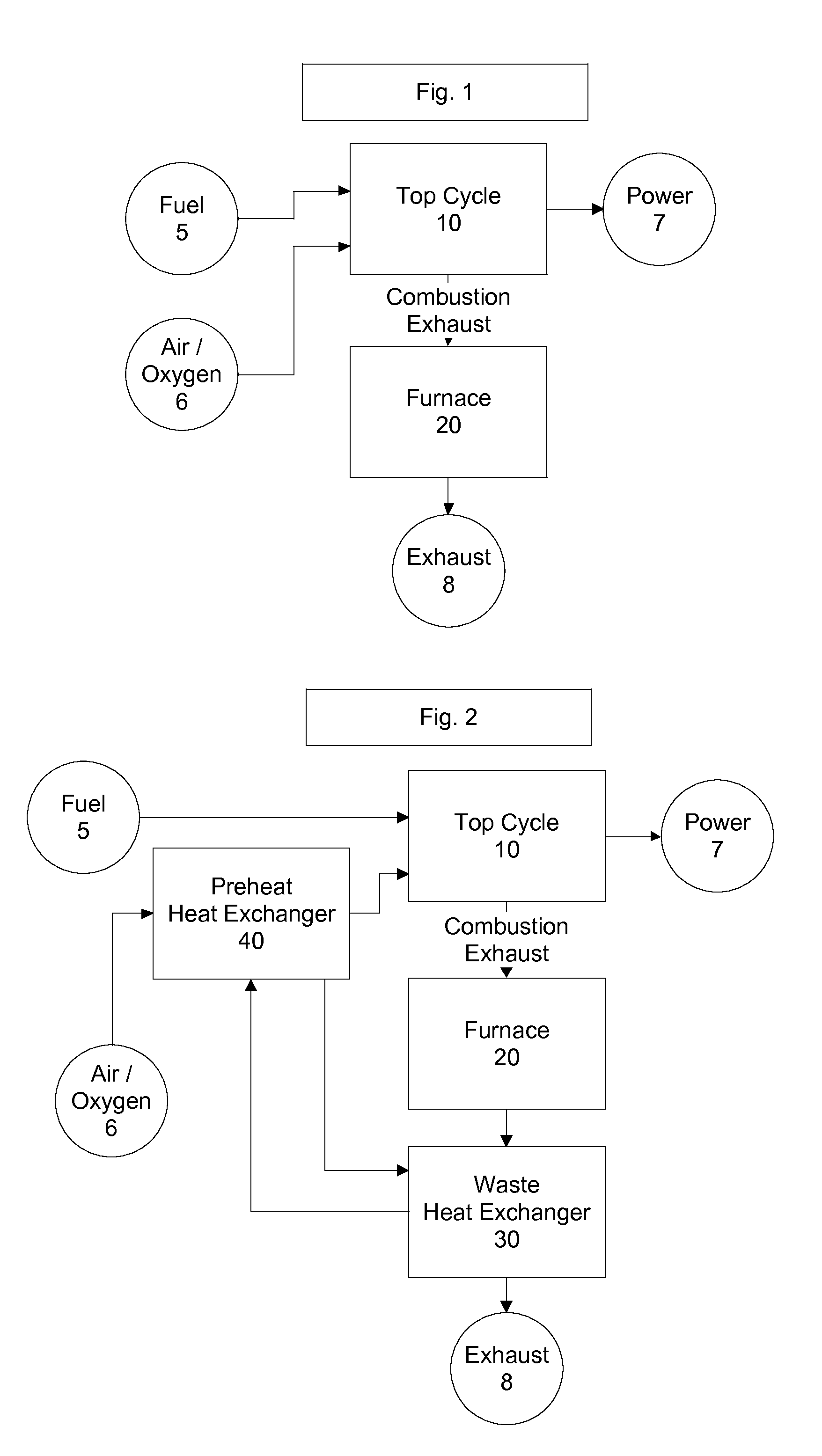

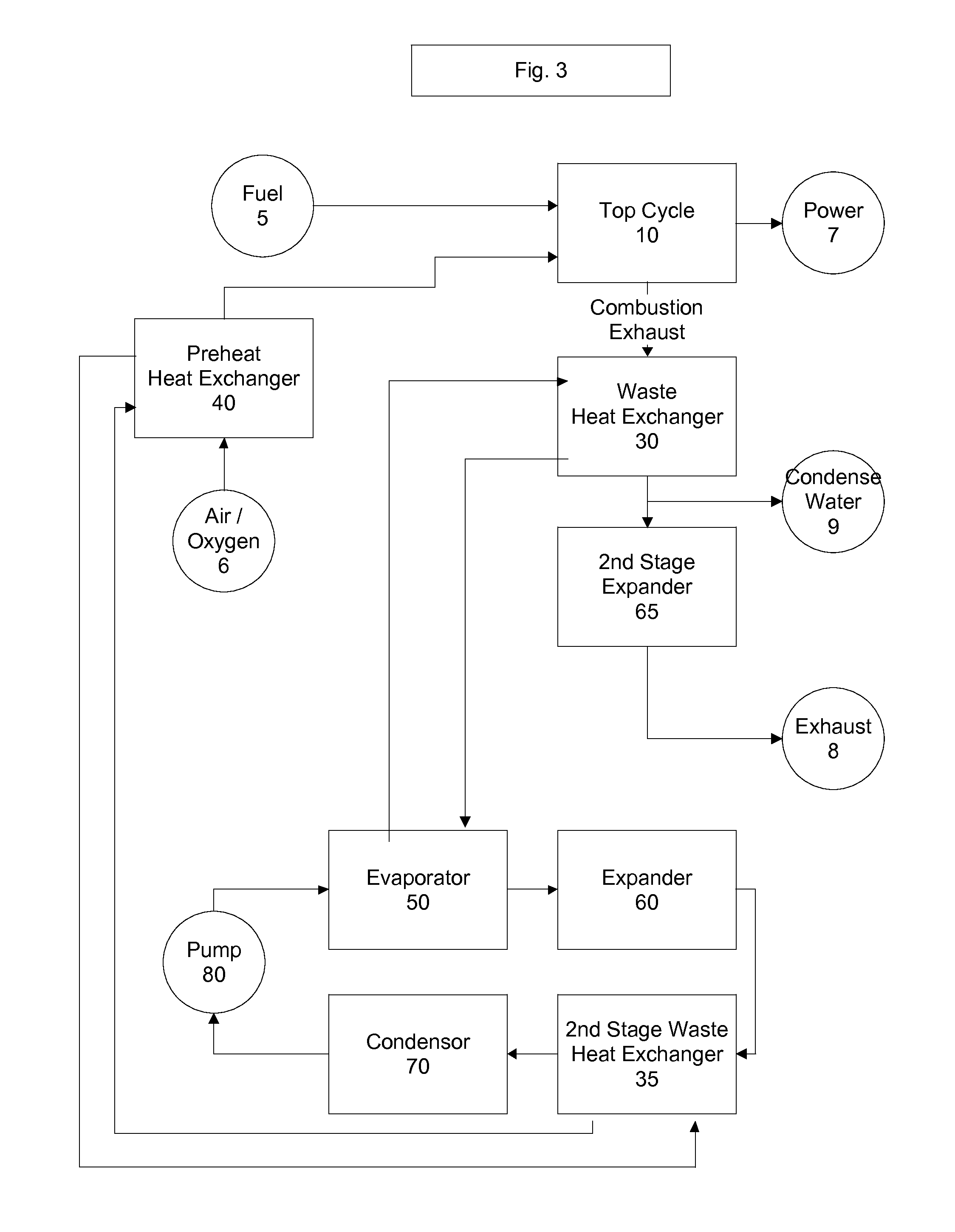

Top cycle power generation with high radiant and emissivity exhaust

The present invention generally relates to power generation methods and secondary processes requiring high radiant and emissivity homogeneous combustion to maximize production output. In one embodiment, the present invention relates to a top cycle power generator with combustion exhaust modified to have radiant flux in excess of 500 kW per square meter and emissivity greater than 0.90, and supercritical CO2 power generating cycle to maximize exergy efficiency.

Owner:GURIN MICHAEL

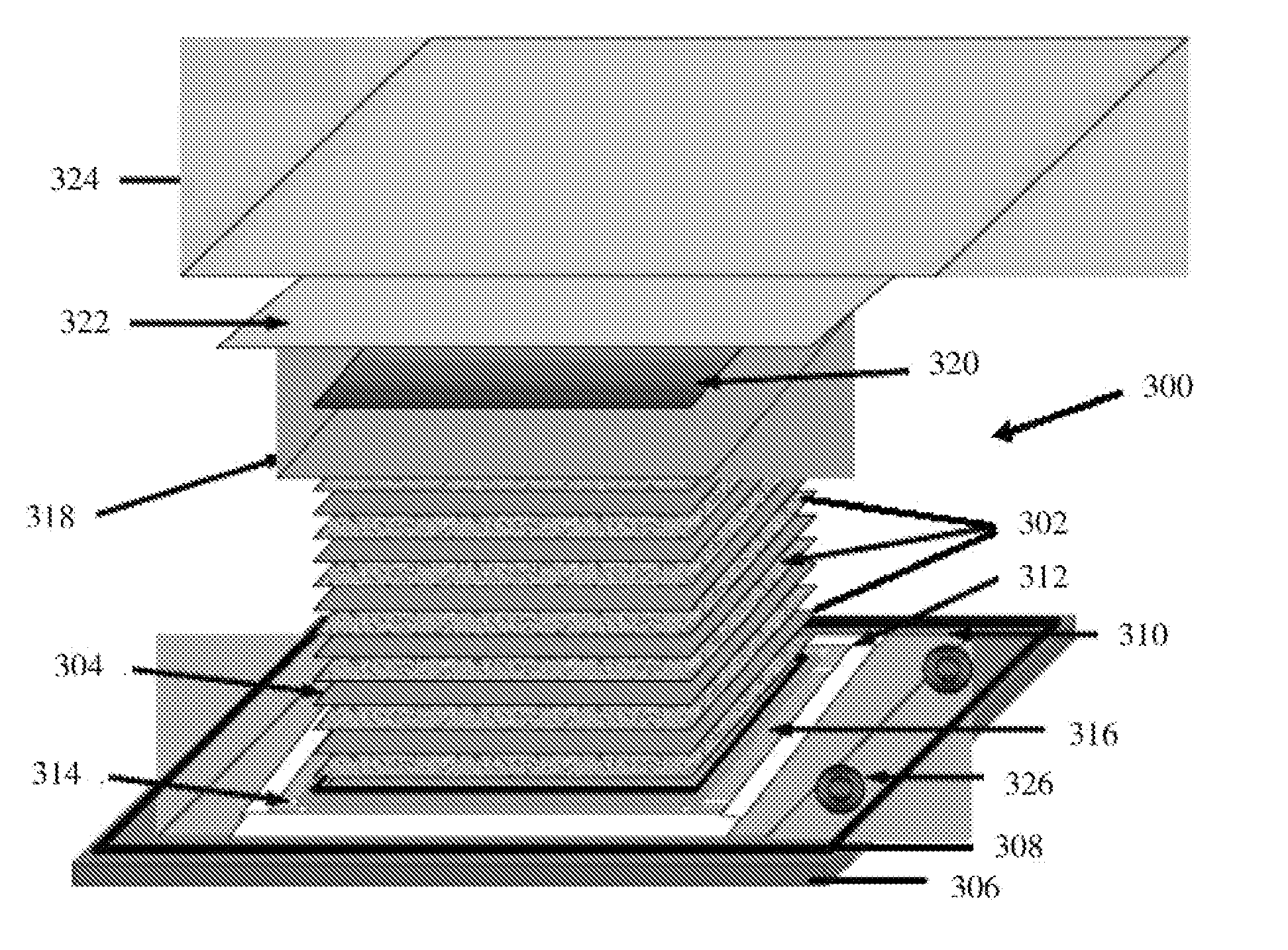

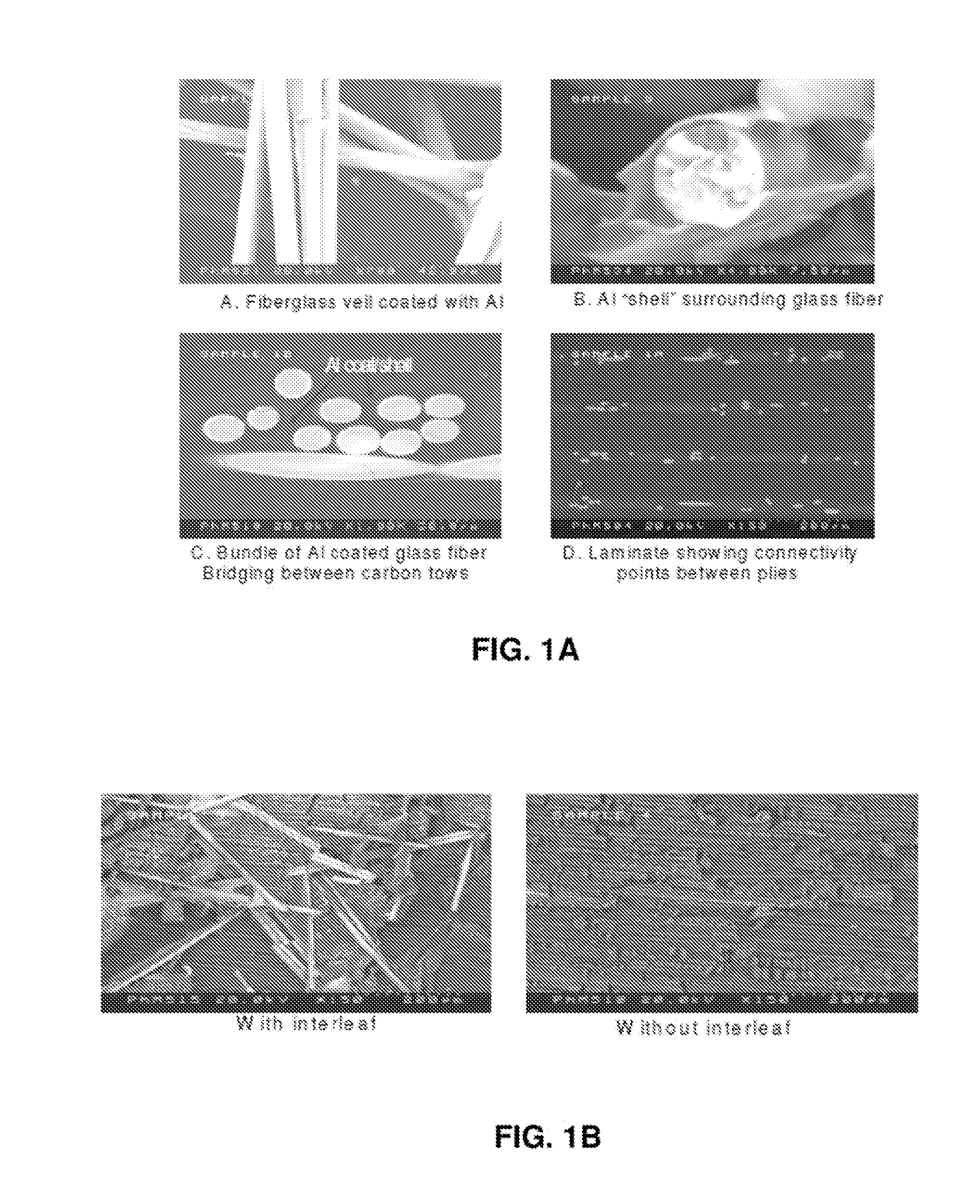

Methods of imparting conductivity to materials used in composite article fabrication & materials thereof

ActiveUS20110159764A1Increased impact valueReduce harmAircraft lighting protectorsLaminationLightning strikeGas phase

Embodiments of the invention are directed to metal- or metal alloy-coated sheet materials (hereinafter, “metal-coated sheet material”) including, but not limited to, fabrics and veils which have a metal content of between one (1) and fifty (50) grams per square meter (gsm). The metal-coated sheet materials may be used as-is or in conjunction with prepregs, adhesives or surfacing films to provide lightning strike protection (LSP) and / or bulk conductivity, among other benefits, to the resultant composite article. In one embodiment, the metal-coated sheet material is impregnated with a resin. According to embodiments of the invention, a metal is applied to one or two sides of the fabric or veil by a physical vapor deposition coating process. The resultant metal-coated fabric or veil may be used as a carrier in surfacing films to impart surface conductivity; may be used as a carrier in adhesives to form conductive adhesive-bonded joints; may be interleaved (one or more metal-coated veils) between layers of prepreg to impart surface and / or bulk conductivity as well as toughness; or may be used to fabricate composite articles.

Owner:CYTEC TECH CORP

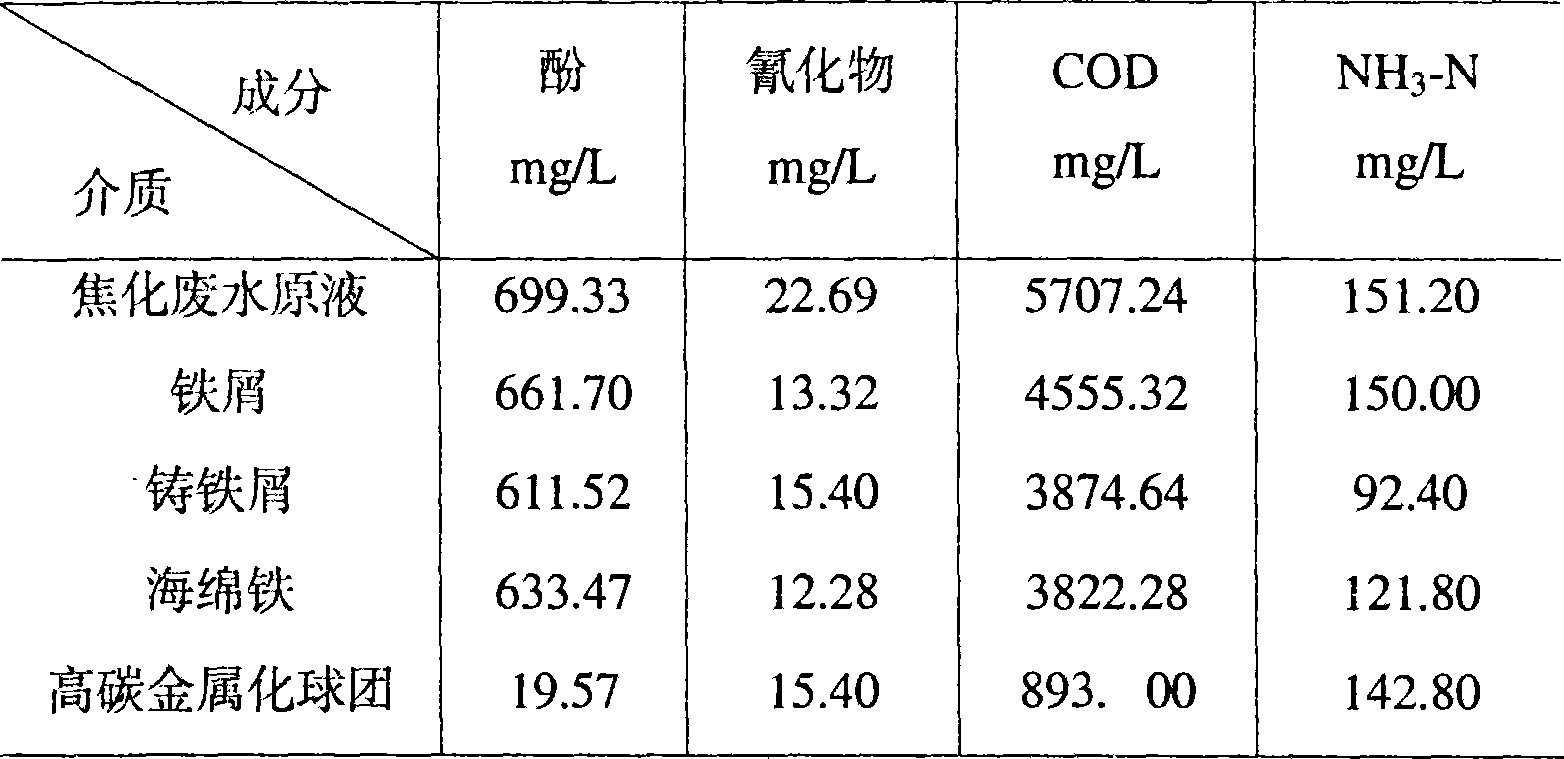

High-carbonaceous metallized pellet for treating waste water and preparation method

ActiveCN101200320AImprove adsorption capacitySmall bulk densityWater/sewage treatment by electrochemical methodsWater/sewage treatment by flocculation/precipitationElectrolysisHigh carbon

The invention relates to a preparation method of high carbon metalized pellet for waste water treatment, belonging to a technical field of metallurgical products, which is used to solve the problem that the surface passivation is easy to be generated in the material filtering in iron carbon by the method of electrolysis so as to affect waste water treatment effect. The invention is characterized in that: the high carbon metalized pellet contains single iron, activated carbon and few impurities, wherein the particle diameter of the single iron is less than 0.2mm, the activated carbon is a pore structure, the specific surface area reaches 500-800 square meter per gram. The method of the invention is composed of raw material preparation, pellet building, drying, reduction and other steps. Experiments evidence: the product in the invention has rich pore structures and huge specific surface, and has strong capability of absorbing contaminations in waste water, moreover the product has higher reaction activities, good osmosis, easy fluidization and no agglomeration. Compared with the conventional electrolysis process, the COD removal ratio of the used filling is improved by above 50 percent under equal time, the waste water with large variable concentration and wide PH value range can be treated.

Owner:唐山助纲炉料有限公司

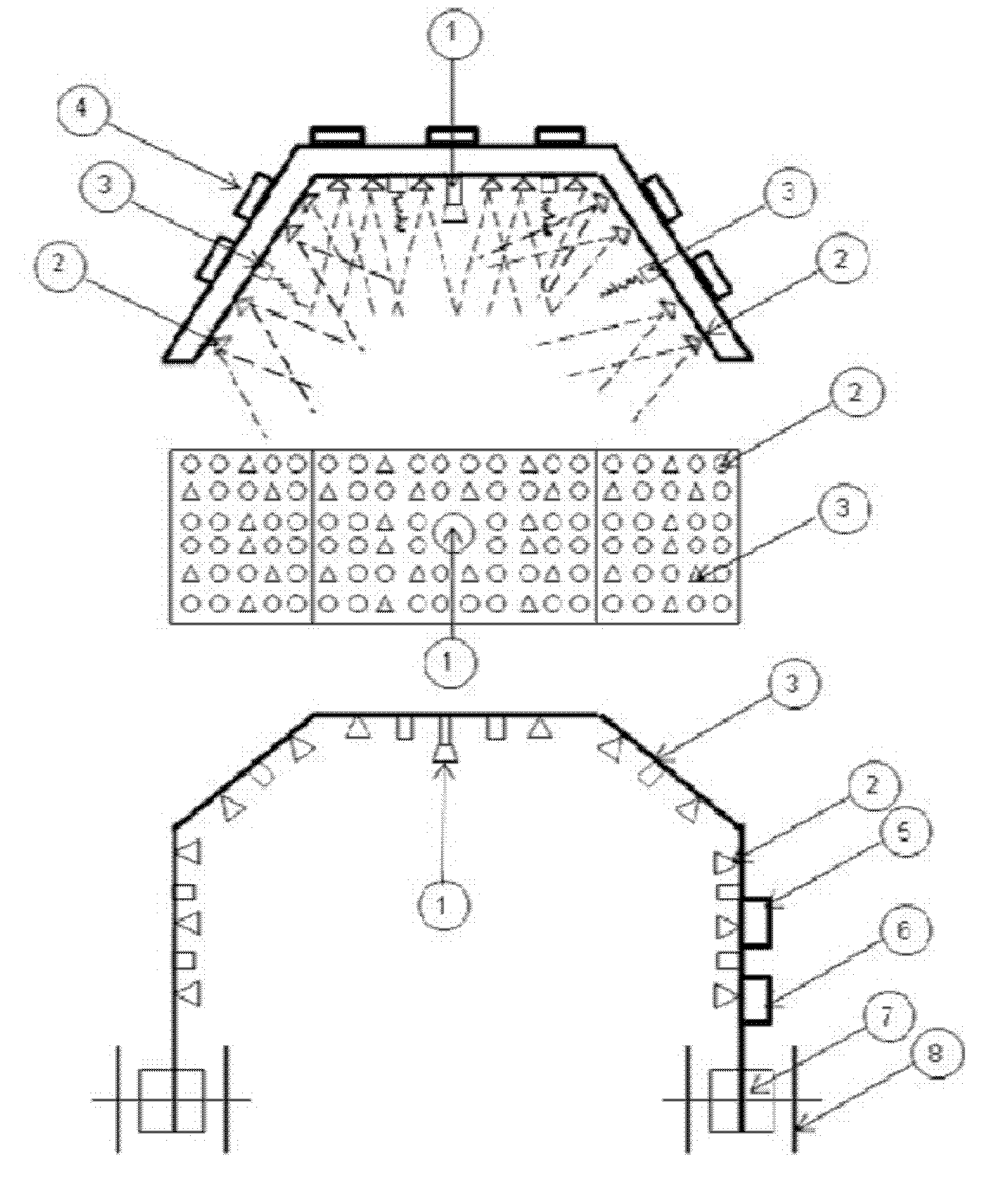

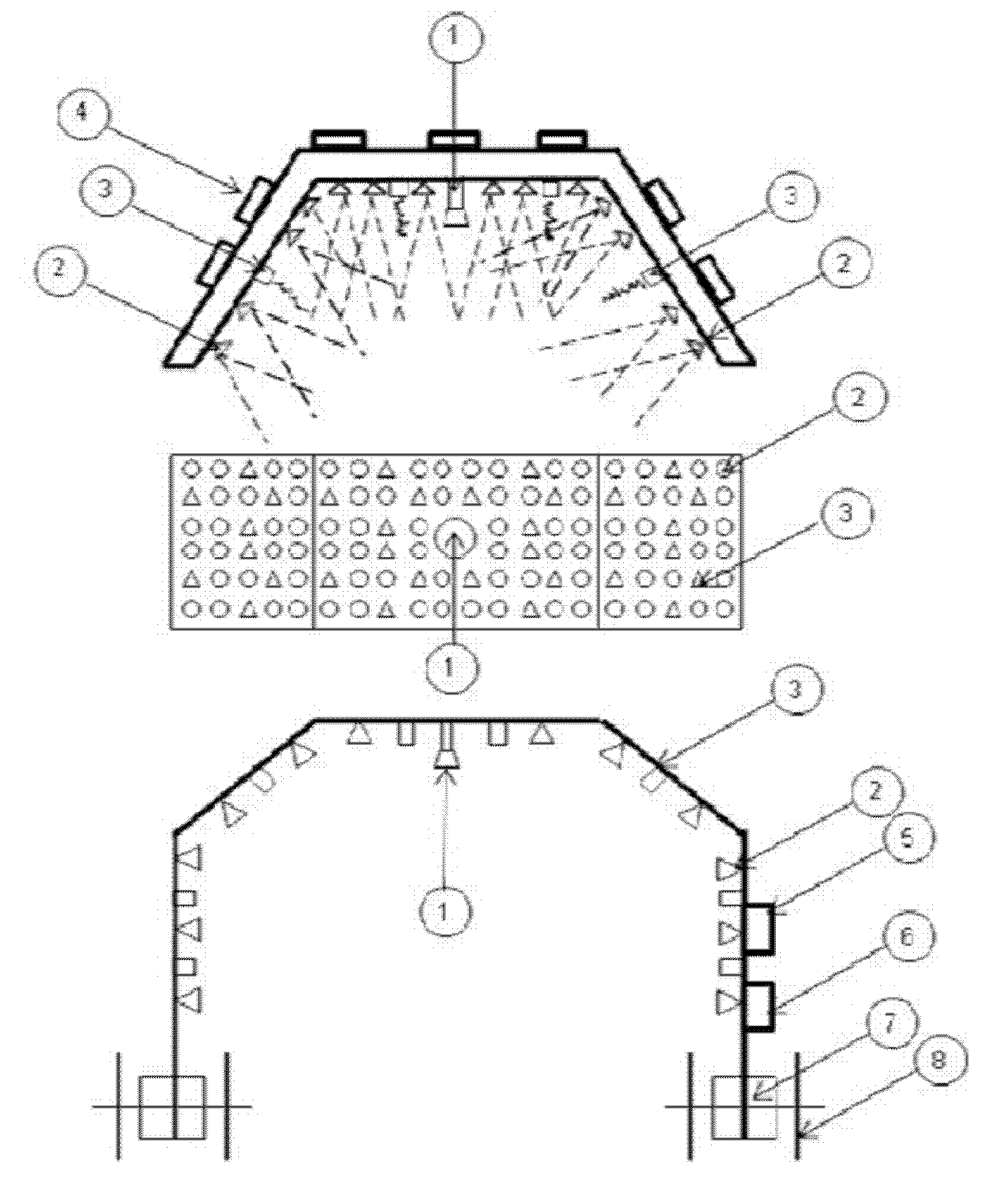

Method and apparatus for plant protection

InactiveUS20130255150A1Improve pathogen resistanceReduce infectionRoot feedersSaving energy measuresHigh intensityLength wave

A method of improving the growth and / or pathogen resistance of a plant, comprising the step of exposing at least part of the plant to a transient period of high intensity illumination providing a photon flux at the plant surface having at least one of the following characteristics: (a) a red photon flux comprising at least 100 micromoles photons per square metre per second, and having a wavelength of between 600 and 700 nm; (b) a blue photon flux comprising at least 100 micromoles photons per square metre per second, having a wavelength of between 420 and 480 nm. The Invention also provides apparatus for providing such conditions to growing plants.

Owner:KARPINSKI STANISLAW +1

Single layer fireblocking fabric for a mattress or mattress set and process to fireblock same

This invention relates to a single layer nonwoven fabric useful as a fireblocking component for mattresses, and a mattress or mattress set comprising the nonwoven fabric, and a process for fireblocking said mattress and mattress set; the nonwoven fabric comprising at least 0.5 ounces per square yard (17 grams per square meter) of a cellulose fiber that retains at least 10 percent of its fiber weight when heated in air to 700° C. at a rate of 20 degrees C. per minute, and at least 0.5 ounces per square yard (17 grams per square meter) of an organic fiber that retains 90 percent of its fiber weight when heated in air to 500° C. at a rate of 20 degrees C. per minute, the fabric having a basis weight having at least 2.5 ounces per square yard (85 grams per square meter), a density of at least 0.16 gram / cm3, and an air permeability of 70 meters / min (225 ft / min) or less.

Owner:EI DU PONT DE NEMOURS & CO

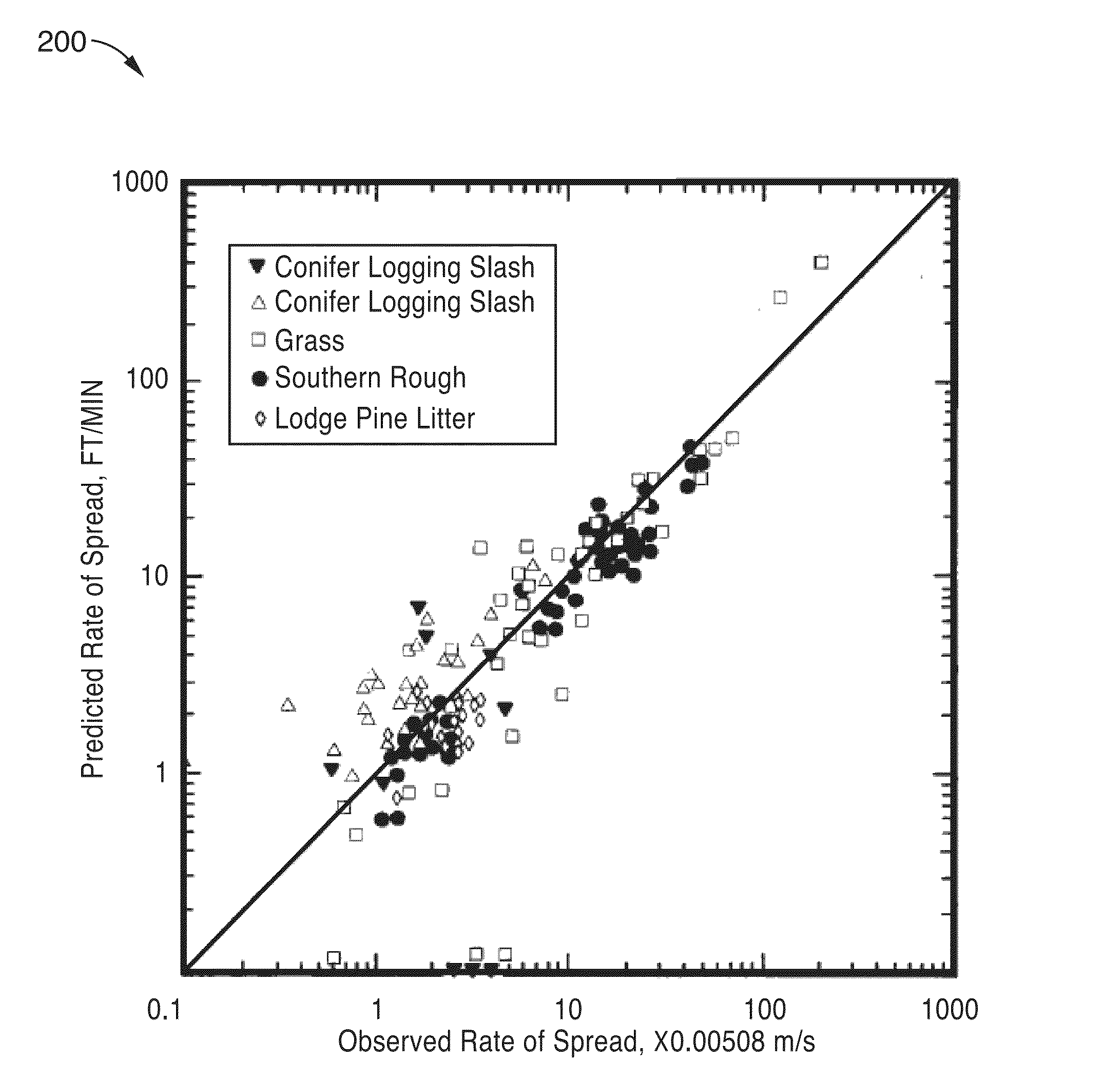

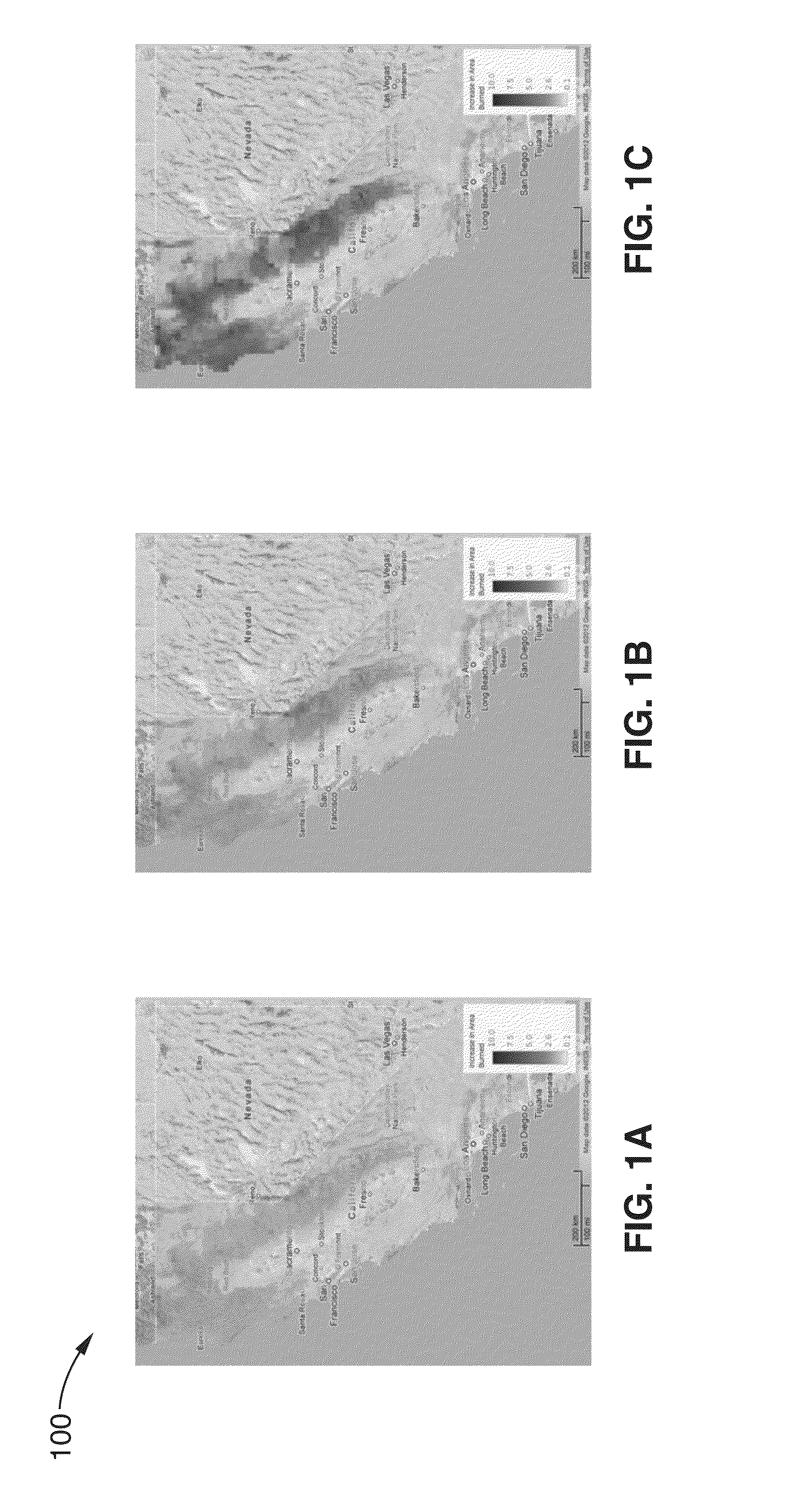

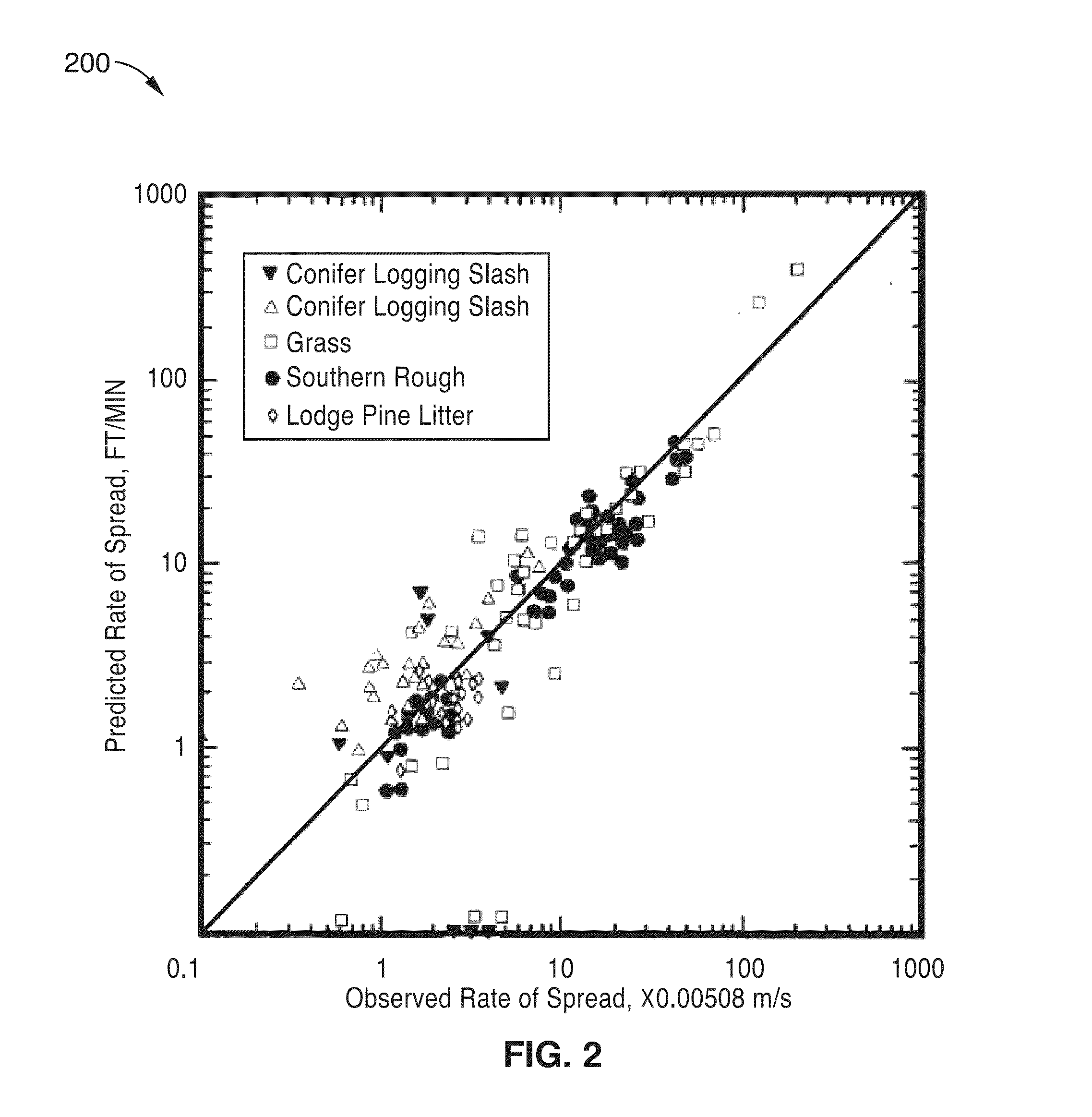

Fire urgency estimator in geosynchronous orbit (FUEGO)

ActiveUS20160132714A1Quality improvementEliminate artifactsTelevision system detailsImage enhancementFire detectorSignal-to-noise ratio (imaging)

A fire detector is disclosed that successively images a particular area from geosynchronous Earth orbit satellite to attain very good signal-to-noise ratios against Poisson fluctuations within one second. Differences between such images allow for the automatic detection of small fires greater than 12 square meters. Imaging typically takes place in transparent bands of the infrared spectrum, thereby rendering smoke from the fire and light clouds somewhat transparent. Several algorithms are disclosed that can help reduce false fire alarms, and their efficiencies are shown. Early fire detection and response would be of great value in the United States and other nations, as wild land fires destroy property and lives and contribute around five percent of the US global carbon dioxide contribution. Such apparatus would incorporate modern imaging detectors, software, and algorithms able to detect heat from early and small fires, and yield detection times on a scale of minutes.

Owner:RGT UNIV OF CALIFORNIA

Culture medium for cultivating agaricus bisporus and cultivating process thereof

InactiveCN101284750ALow costNot easy to stickSuperphosphatesBio-organic fraction processingCaladiumPhosphoric acid

The invention discloses a culture medium used for cultivating bisporic mushrooms as well as the cultivating method thereof. Per 100 square meters of culture medium contain the following cultural materials: cotton seed hull 1800 to 3200 catties, waste cotton 0 to 1200 catties, corncobs 0 to 1200 catties, cottonseed meal 0 to 200 catties, cattle manure 2 to 4 cubic meters, chicken manure 0 to 1.2 cubic meters, urea 0 to 60 catties, quicklime 80 to 120 catties, plaster powder 0 to 120 catties, calcium superphosphate 0 to 120 catties, enzyme microorganisms 2 to 4 catties, and water of proper amount. The method includes the following steps: firstly, the cultural materials are mixed; secondly, the mixed cultural materials are composted and fermented; thirdly, the cultural materials are processed in a shed; fourthly, sowing is carried out; fifthly, the culture medium is distributed; sixthly, the soil is covered; seventhly, the mushrooms are obtained. The culture medium has low cost, the conglutination of the cultural materials is not easy to happen, and the cultural materials have easy pile-turning, thereby causing the composting and the fermentation to be laborsaving and timesaving; the enzyme microorganisms can not only speed up the fermentation of the cultural materials and improve the fermentation quality, but also facilitate the absorption and utilization of the culture medium by the mycelium of the bisporic mushrooms.

Owner:贾恩茂

Lightning strike protection

ActiveUS20110049292A1Carbon fibresWarp knittingElectrical resistance and conductanceLightning strike

An aircraft component having an external surface includes an improved lightning strike protection surface film disposed on or proximate to the external surface. The surface film includes a preform that includes a substrate having a first areal weight density and a plurality of spaced carbon nanotubes grown on the substrate, the nanotubes having a second areal weight density. The sum of the first areal weight density and the second areal weight density is less than about 500 grams per square meter, and the preform has a surface resistance less than about 1 ohm / square.

Owner:ROHR INC +1

Adhesive for bonding polyimide resins

ActiveUS20120321879A1Film/foil adhesivesSynthetic resin layered productsPolyimide substratePolymer science

One embodiment relates to an, article and a method for producing an article including a plurality of substrates, and an adhesive bonded between at least two of the plurality of substrates. The adhesive can include a polycarbonate copolymer that includes reacted resorcinol, siloxane, and bisphenol-A. Another embodiment relates to an article having a first polyimide substrate, a second polyimide substrate, and an adhesive bonded between the first substrate and the second substrate. The article can have a 2 minute integrated heat release rate of less than or equal to 65 kilowatt−minutes per square meter (kW−min / m2) and a peak heat release rate of less than 65 kilowatts per square meter (kW / m2) as measured using the method of FAR F25.4, in accordance with Federal Aviation Regulation FAR 25.853(d).

Owner:SHPP GLOBAL TECH BV

Reduced-noise composite materials and disposable personal care devices employing same

ActiveUS20050112338A1High sensitivityReduce capacityDecorative surface effectsLayered productsPersonal careGram

A method to reduce the noise produced by movement of a substrate is disclosed. One embodiment of the method includes applying a noise-reducing coating material at an add-on rate of at least about three grams per square meter to a target region of a first surface of a substrate so as to substantially completely coat the target area, wherein the noise-reducing coating material comprises a polymeric material. Also disclosed is a reduced-noise composite material that can be employed in a disposable personal care device. The reduced-noise composite material can include a substrate layer which defines a first surface having a surface area and a target area, and a noise-reducing layer which substantially completely coats the target region. The noise-reducing layer has a basis weight of at least about three grams per square meter. Also disclosed is a reduced-noise disposable personal care device, which may in particular embodiments be a disposable absorbent article. One embodiment of the disposable absorbent article includes a body-side liner and a garment-side outer cover. The outer cover includes a liquid-impermeable substrate layer comprised of a thermoplastic, polymeric material and which defines a first surface having a surface area and a target area. The outer cover further includes a noise-reducing layer which substantially completely coats the target region, and which has a basis weight of at least about three grams per square meter. The disposable absorbent article further includes an absorbent assembly disposed between the body-side liner and the garment-side outer cover.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com