High electrochemistry capacitance oxidization plumbago alkene, low-temperature preparation method and uses

An electrochemical and graphene technology, applied in the field of high electrochemical capacity graphene oxide and its low-temperature preparation, and new electrode materials, to achieve the effects of easy operation, low energy consumption, and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

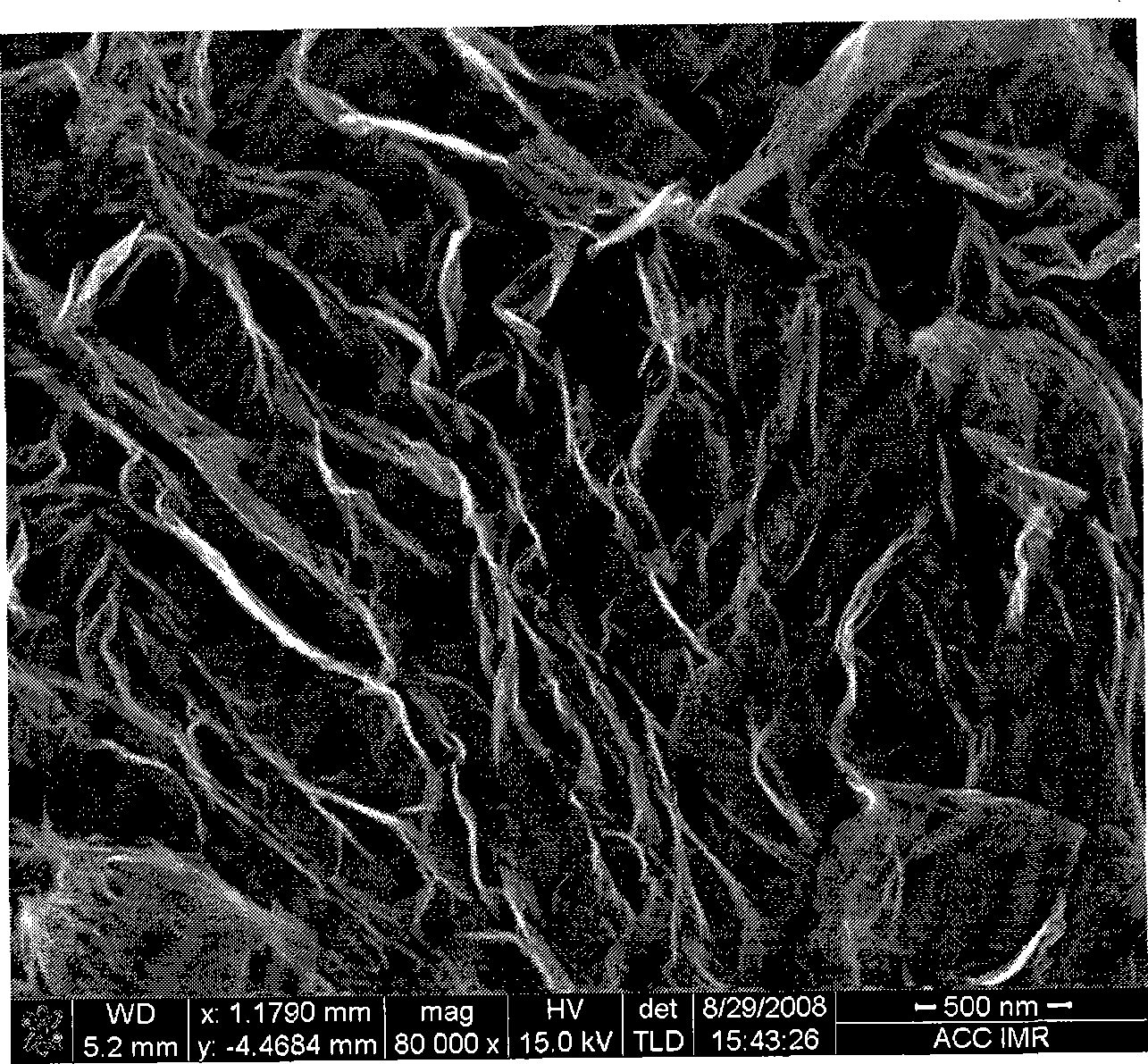

Image

Examples

Embodiment 1

[0012] Mix 2g of graphite powder and 1g of sodium nitrate with 46mL of concentrated sulfuric acid (98% mass concentration), stir in an ice-water bath, and slowly add 6g of KMnO 4 , reacted for 2h, and then transferred it to a constant temperature water bath at 35°C, and reacted for 30min. Gradually add 92 mL of deionized water, the temperature rises to 98 ° C and continue to react for 3 h, then take it out from the water bath, further add deionized water to dilute, and dilute with 20 mL of 30% H 2 o 2 Solution treatment to neutralize unreacted permanganate. Centrifuge and filter while hot, wash the filter cake repeatedly with deionized water, and dry in vacuum at 50°C for 48 hours to obtain graphite oxide.

[0013] Put the dried graphite oxide into the sample tube, start vacuuming, the vacuum degree is 10Pa, and start heating at the same time, the heating rate is 20°C / min, the temperature is raised to 200°C, and maintained for 10h to obtain graphene oxide. Utilize nitrogen ...

Embodiment 2

[0017] Mix 10g of graphite powder and 5g of sodium nitrate with 230mL of concentrated sulfuric acid (mass fraction 98%), stir in an ice-water bath, and slowly add 30g of KMnO 4 , reacted for 2h, and then transferred to a 35°C water bath for 30min. Gradually add 460mL deionized water, the temperature rises to 98°C and continue to react for 40min, take it out from the water bath and further dilute with deionized water, and dilute with 20mL mass fraction 30% H 2 o 2 Solution treatment to neutralize unreacted permanganate. Centrifuge and filter while hot, wash the filter cake repeatedly with deionized water, and dry in vacuum at 50°C for 48 hours to obtain graphite oxide.

[0018] Put the dried graphite oxide into the sample tube, start vacuuming, the vacuum degree is 200Pa, and start heating at the same time, the heating rate is 10°C / min, the temperature is raised to 200°C, and maintained for 8h to obtain graphene oxide. Utilize the specific surface of the sample obtained by n...

Embodiment 3

[0022] Mix 4g of graphite powder and 2g of sodium nitrate with 92mL of concentrated sulfuric acid (mass fraction 98%), stir in an ice-water bath, and slowly add 12g of KMnO 4 , reacted for 2h, and then transferred to a 35°C water bath for 30min. Gradually add 184mL deionized water, the temperature rises to 98°C and continue to react for 3h, take it out from the water bath and further dilute with deionized water, and dilute with 20mL mass fraction 30% H 2 o 2 Solution treatment to neutralize unreacted permanganate. Centrifuge and filter while hot, wash the filter cake repeatedly with deionized water, and dry in vacuum at 50°C for 48 hours to obtain graphite oxide.

[0023] Put the dried graphite oxide into the sample tube, start vacuuming, the vacuum degree is 100Pa, and start heating at the same time, the heating rate is 10°C / min, the temperature is raised to 300°C, and maintained for 15h to obtain graphene oxide. Utilize the specific surface area of the sample obtained b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com