Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23507 results about "Alkene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry, an alkene is an unsaturated hydrocarbon that contains at least one carbon–carbon double bond. The words alkene and olefin are often used interchangeably (see nomenclature section below). Acyclic alkenes, with only one double bond and no other functional groups, known as mono-enes, form a homologous series of hydrocarbons with the general formula CₙH₂ₙ. Alkenes have two hydrogen atoms fewer than the corresponding alkane (with the same number of carbon atoms). The simplest alkene, ethylene (C₂H₄), with the International Union of Pure and Applied Chemistry (IUPAC) name ethene, is the organic compound produced on the largest scale industrially. Aromatic compounds are often drawn as cyclic alkenes, but their structure and properties are different and they are not considered to be alkenes.

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

Ethylene/alpha-olefins block interpolymers

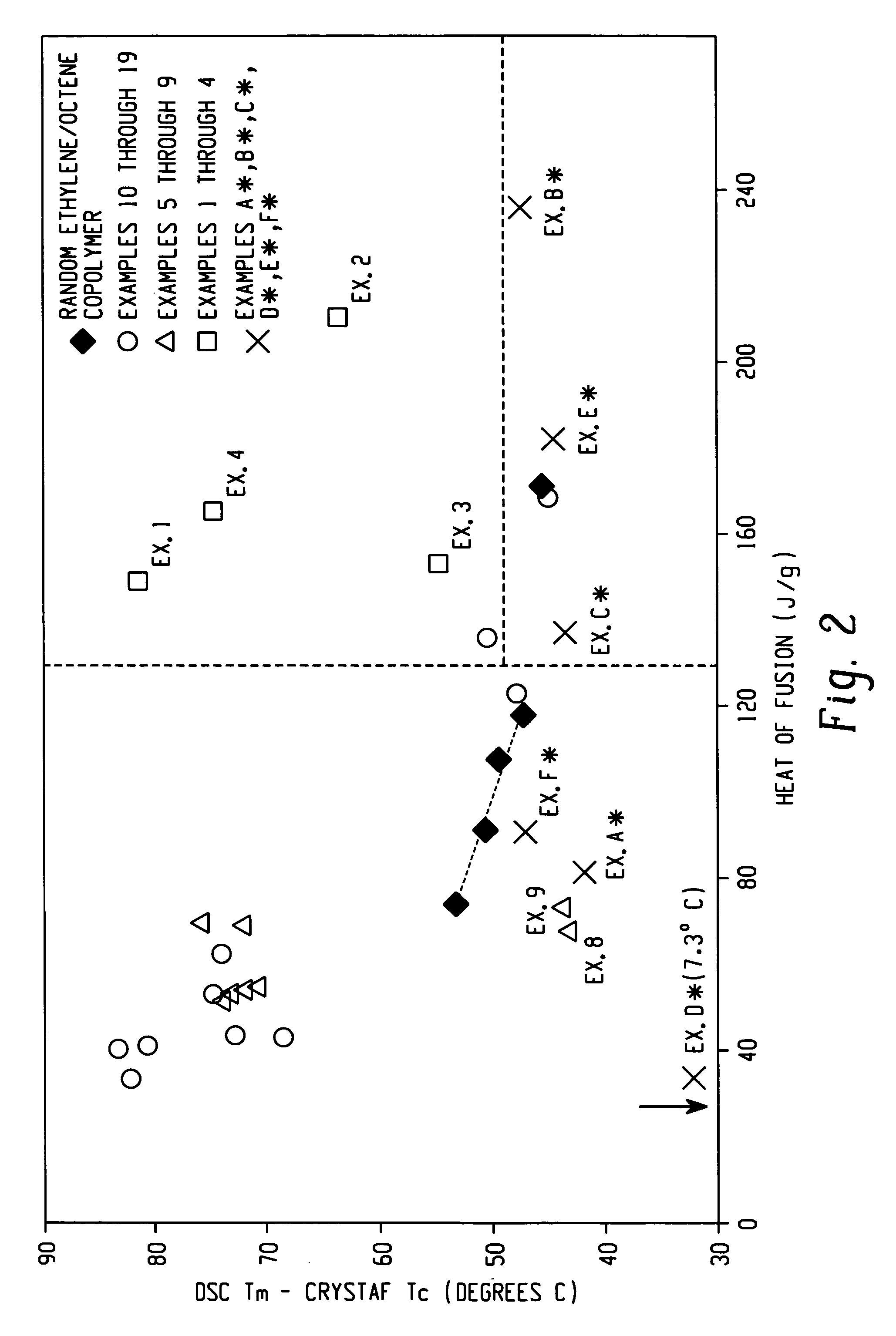

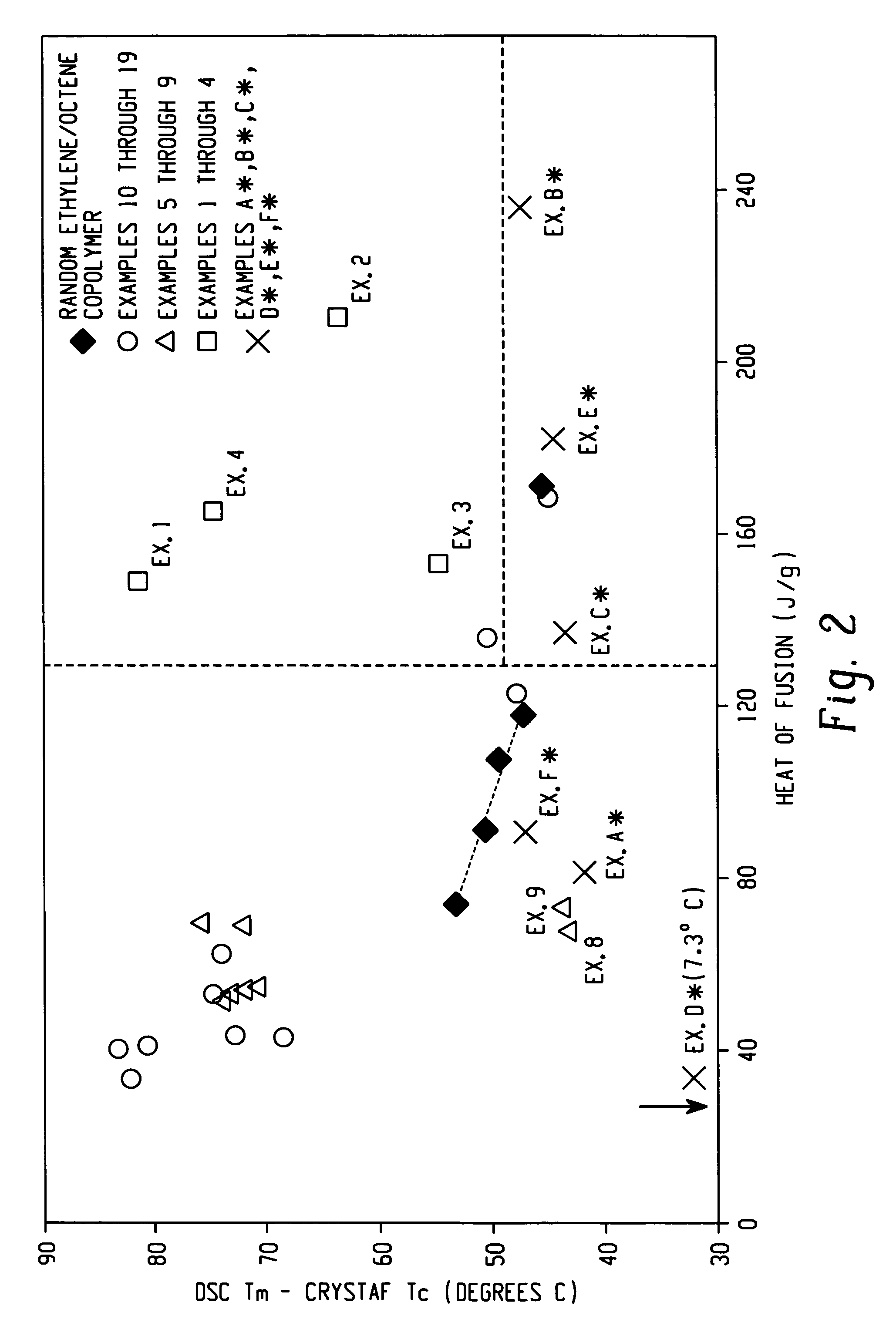

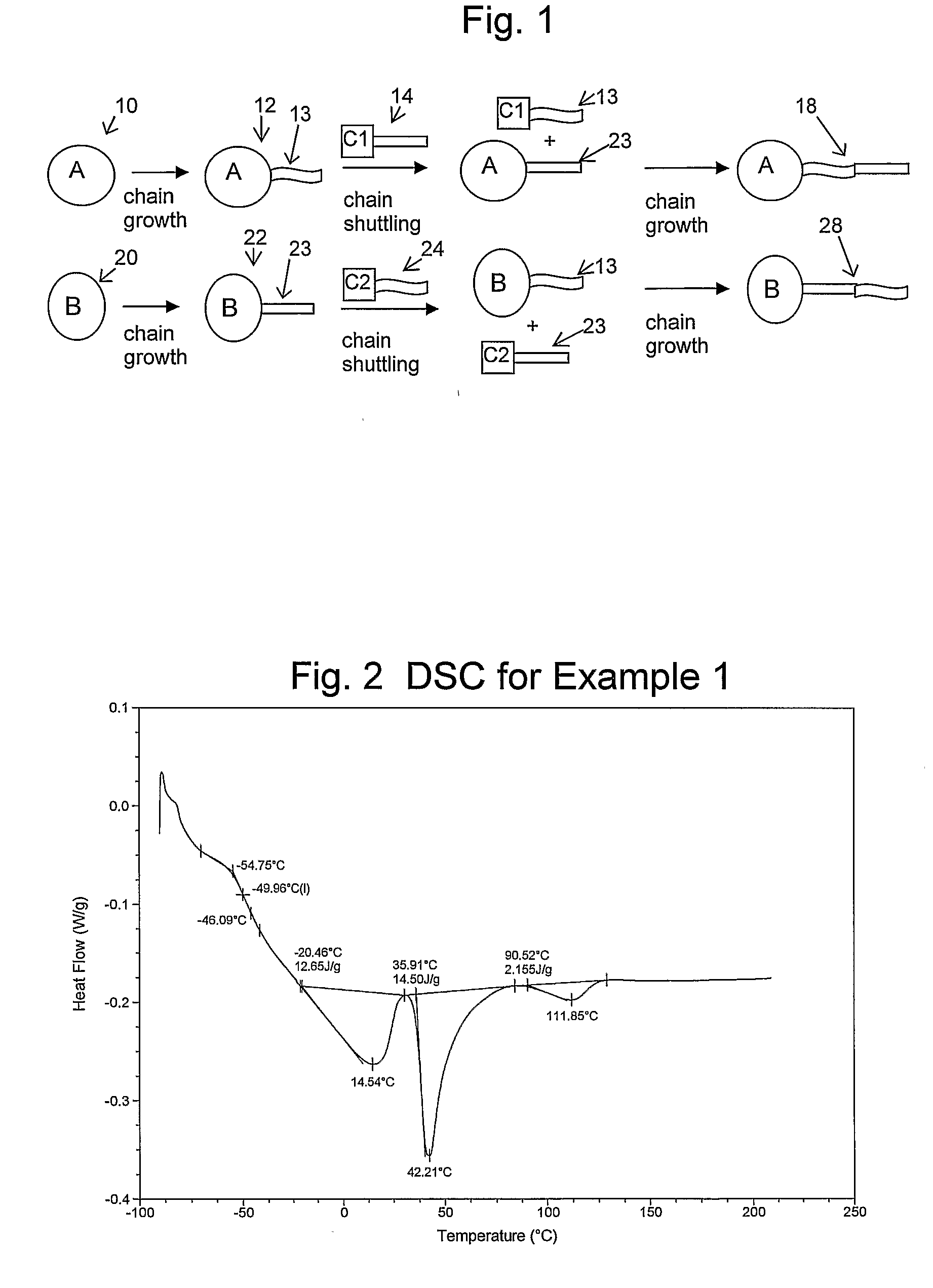

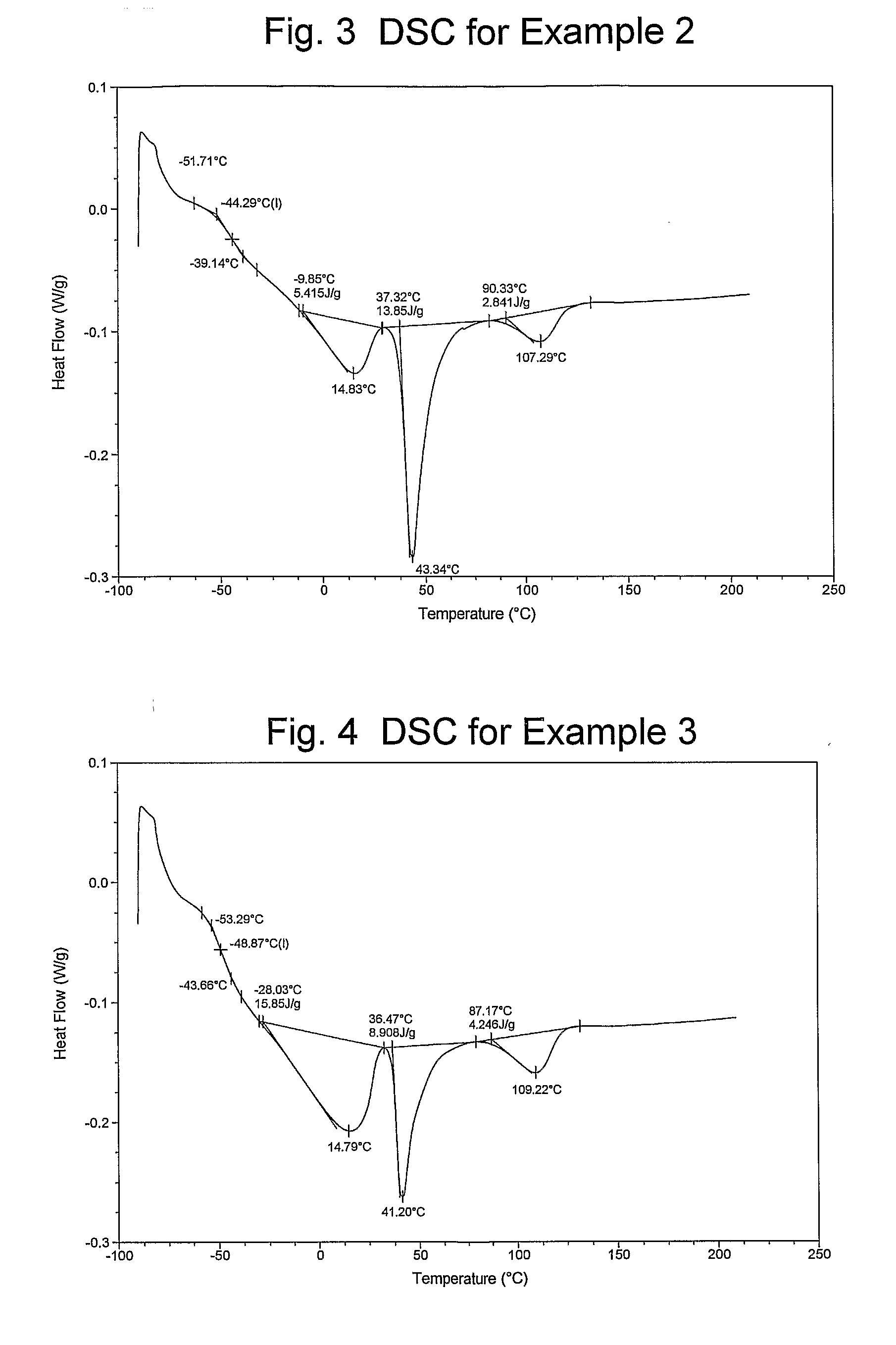

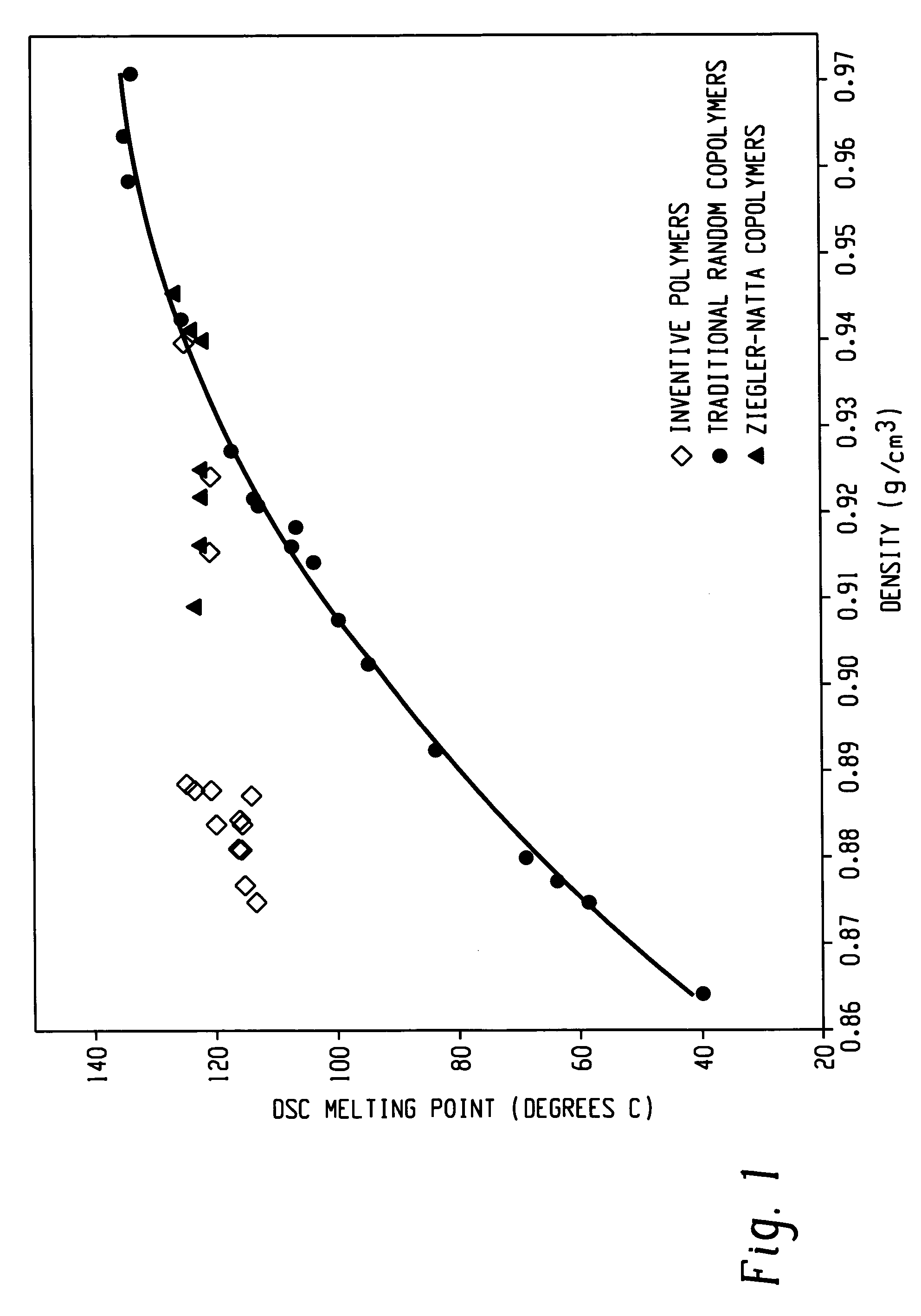

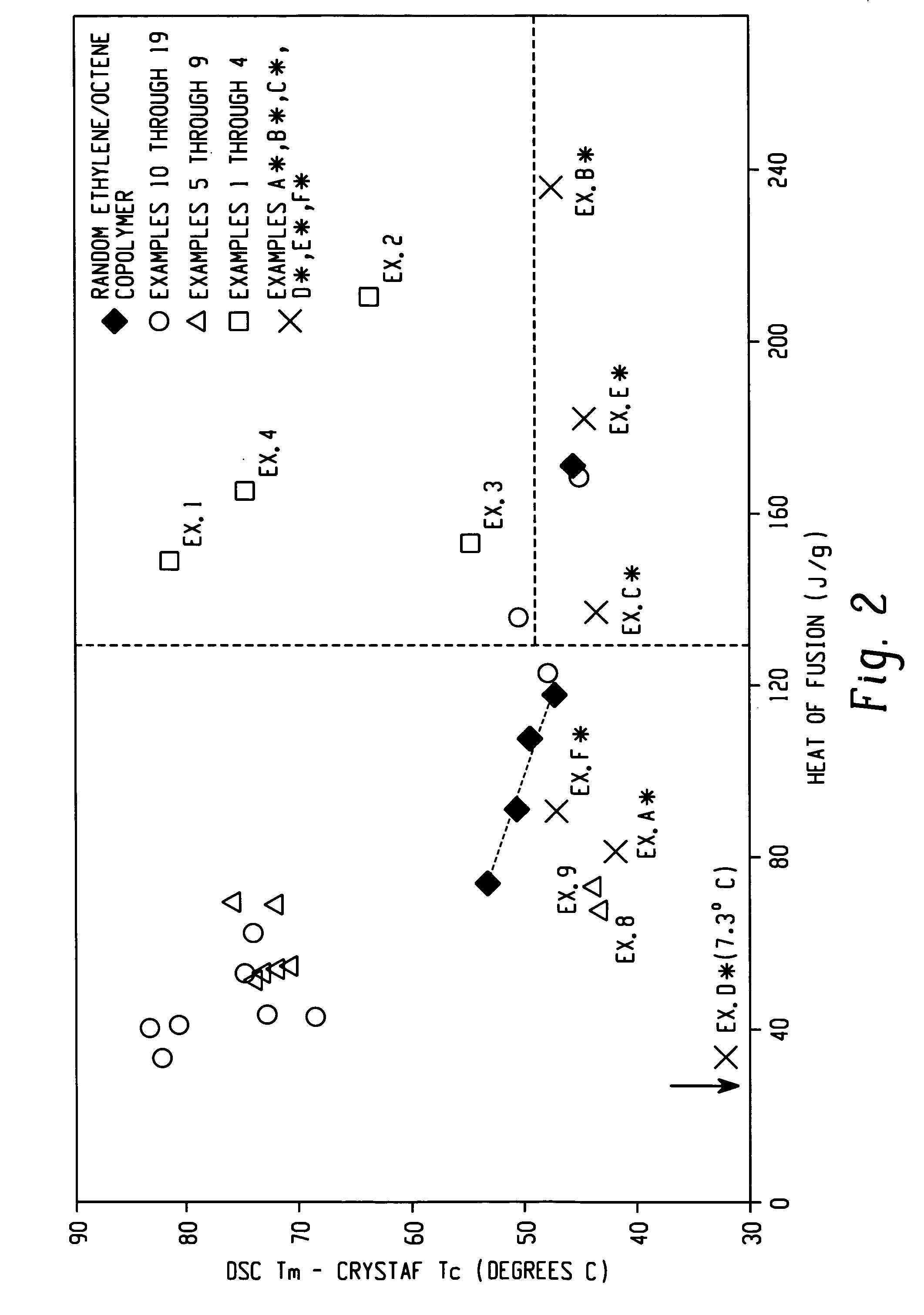

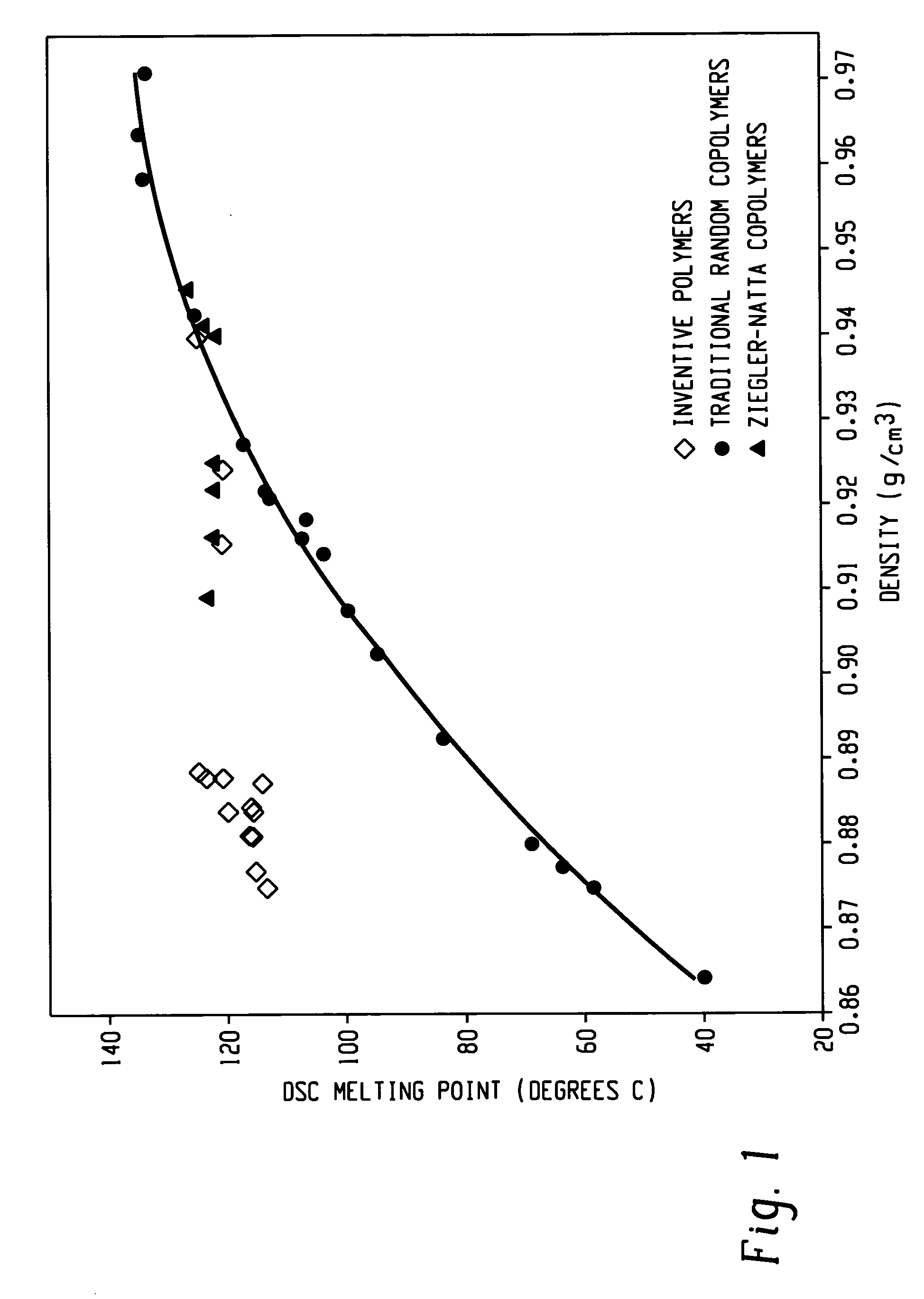

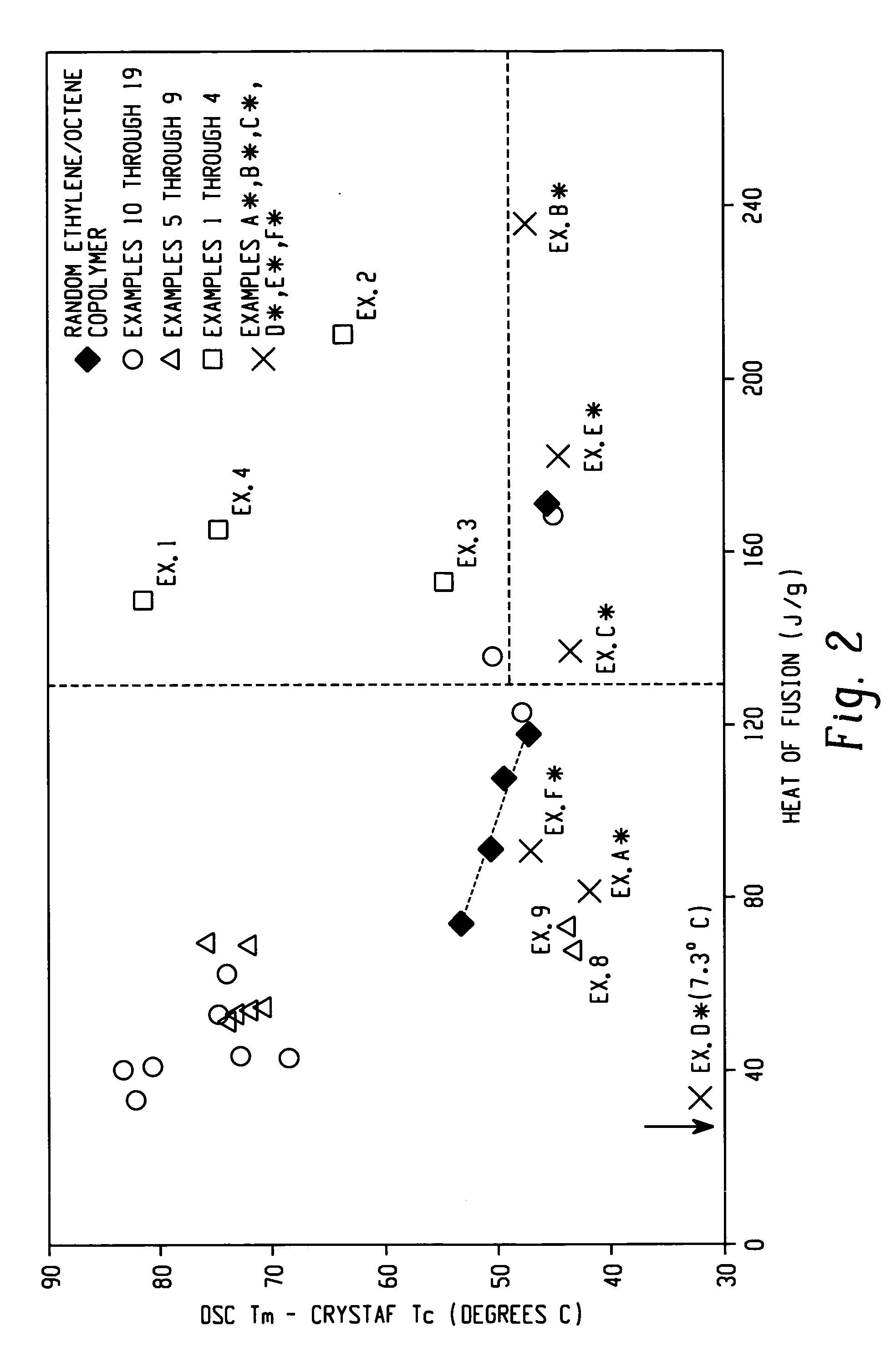

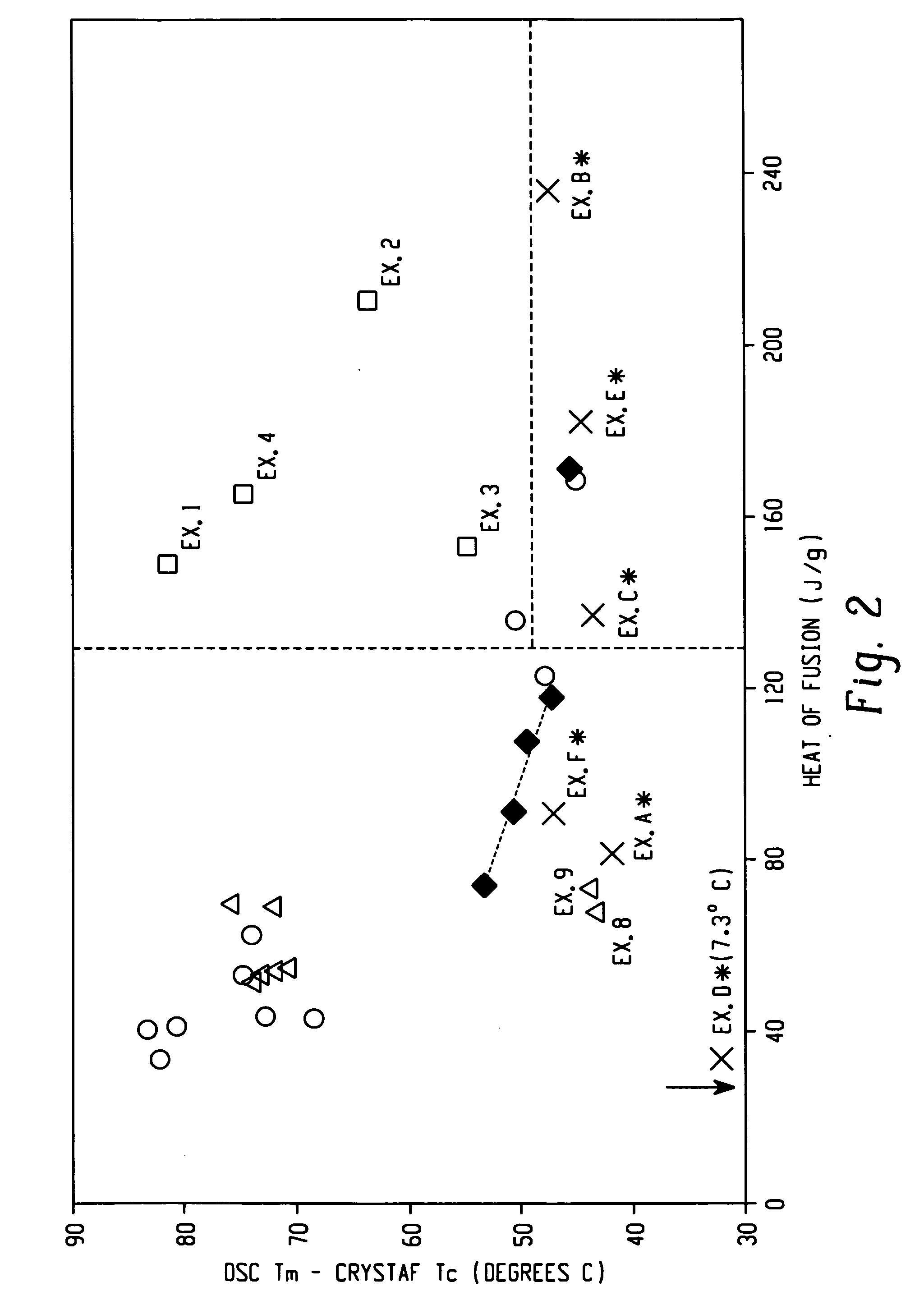

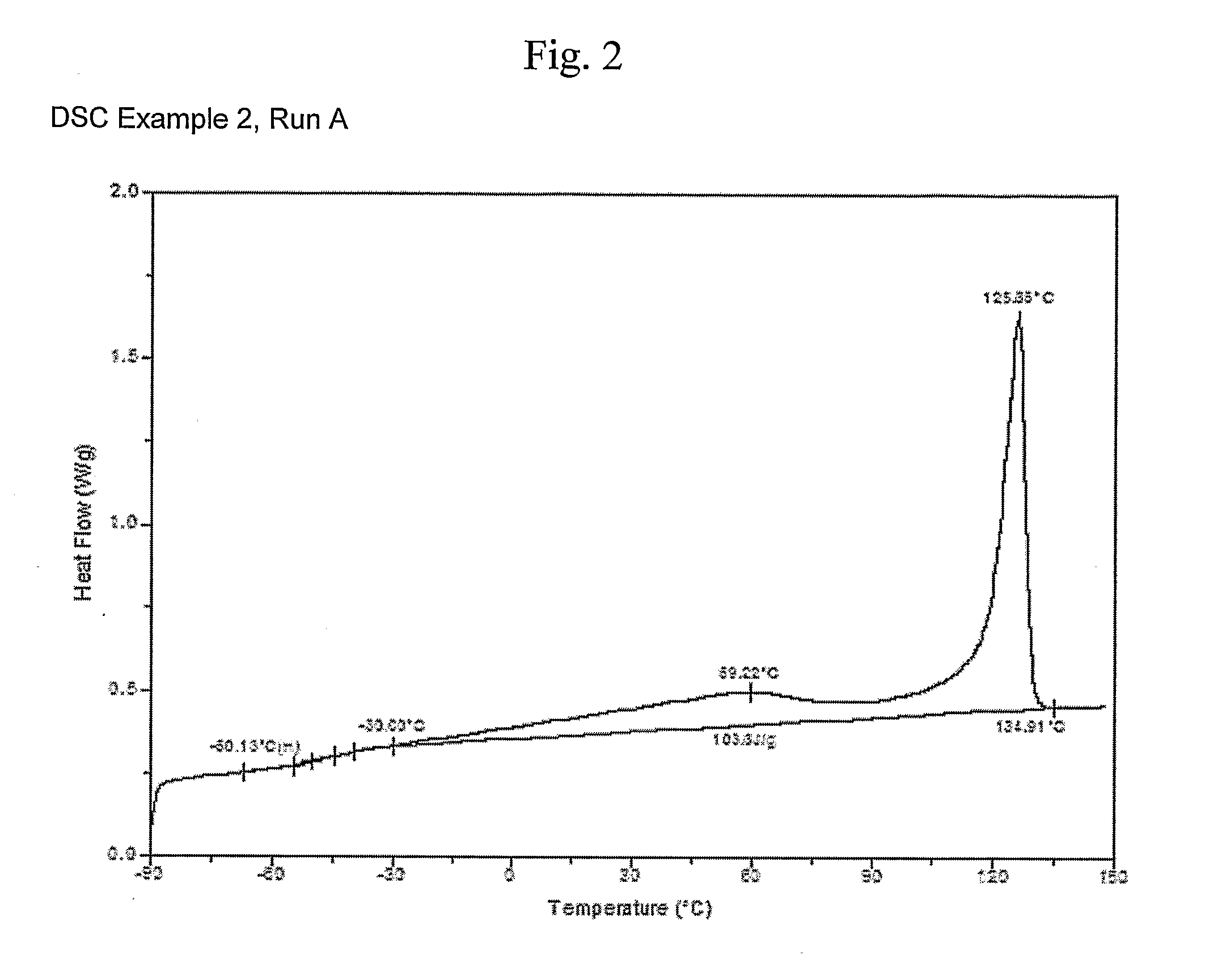

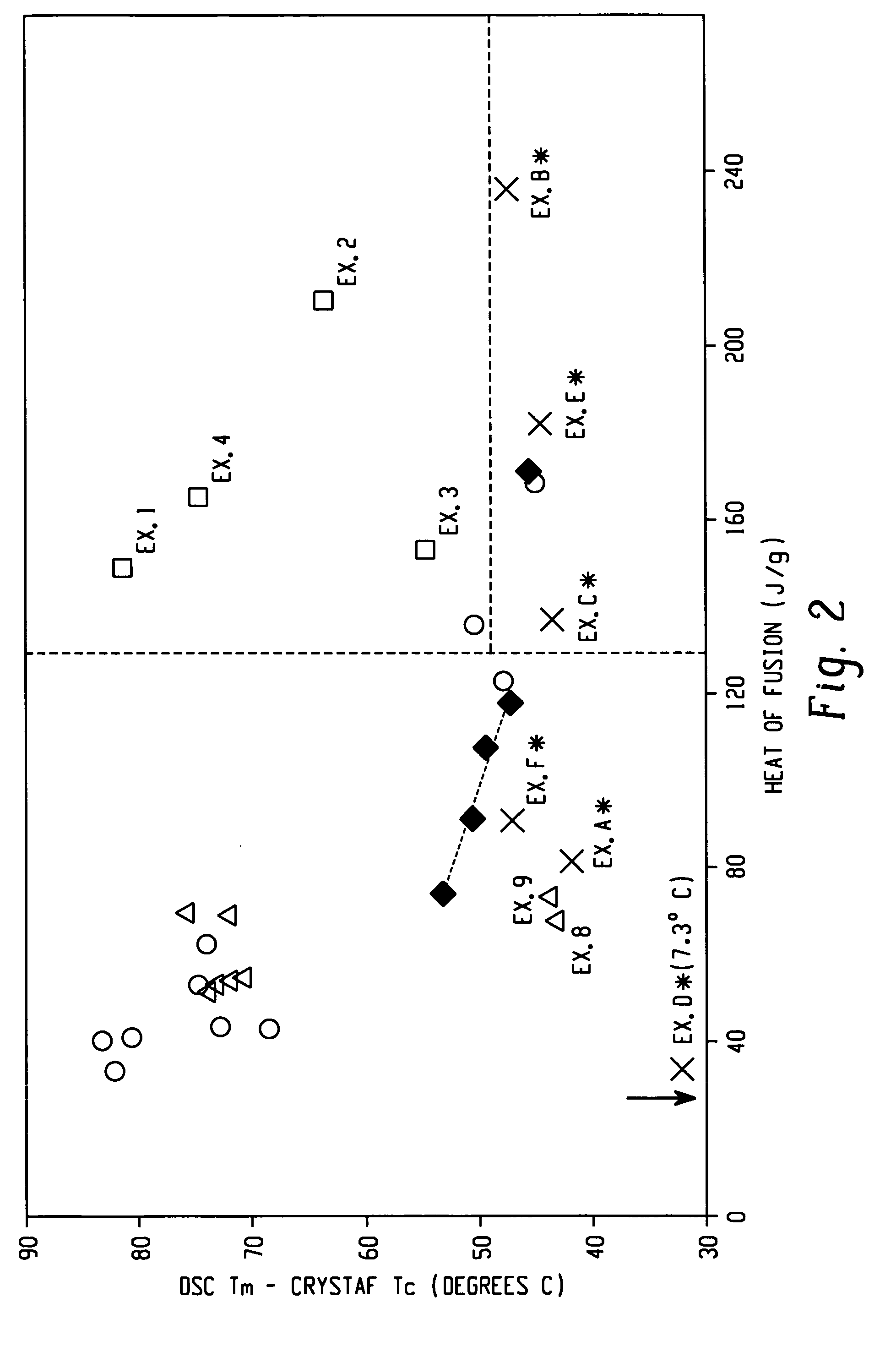

Embodiments of the invention provide a class of ethylene / α-olefin block interpolymers. The ethylene / α-olefin interpolymers are characterized by an average block index, ABI, which is greater than zero and up to about 1.0 and a molecular weight distribution, Mw / Mn, greater than about 1.3. Preferably, the block index is from about 0.2 to about 1. In addition or alternatively, the block ethylene / α-olefin interpolymer is characterized by having at least one fraction obtained by Temperature Rising Elution Fractionation (“TREF”), wherein the fraction has a block index greater than about 0.3 and up to about 1.0 and the ethylene / α-olefin interpolymer has a molecular weight distribution, Mw / Mn, greater than about 1.3.

Owner:DOW GLOBAL TECH LLC

Method for producing fluorinated organic compounds

ActiveUS20070197842A1Preparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystDistillation

Disclosed are processes for the production of fluorinated olefins, preferably adapted to commercialization of CF3CF═CH2 (1234yf). Three steps may be used in preferred embodiments in which a feedstock such as CCl2═CClCH2Cl (which may be purchased or synthesized from 1,2,3-trichloropropane) is fluorinated (preferably with HF in gas-phase in the presence of a catalyst) to synthesize a compound such as CF3CCl═CH2, preferably in a 80-96% selectivity. The CF3CCl═CH2 is preferably converted to CF3CFClCH3 (244-isomer) using a SbCl5 as the catalyst which is then transformed selectively to 1234yf, preferably in a gas-phase catalytic reaction using activated carbon as the catalyst. For the first step, a mixture of Cr2O3 and FeCl3 / C is preferably used as the catalyst to achieve high selectivity to CF3CCl═CH2 (96%). In the second step, SbCl5 / C is preferably used as the selective catalyst for transforming 1233xf to 244-isomer, CF3CFClCH3. The intermediates are preferably isolated and purified by distillation and used in the next step without further purification, preferably to a purity level of greater than about 95%.

Owner:HONEYWELL INT INC

Ethylene/alpha-olefins block interpolymers

Embodiments of the invention provide a class of ethylene / α-olefin block interpolymers. The ethylene / α-olefin interpolymers are characterized by an average block index, ABI, which is greater than zero and up to about 1.0 and a molecular weight distribution, Mw / Mn, greater than about 1.3. Preferably, the block index is from about 0.2 to about 1. In addition or alternatively, the block ethylene / α-olefin interpolymer is characterized by having at least one fraction obtained by Temperature Rising Elution Fractionation (“TREF”), wherein the fraction has a block index greater than about 0.3 and up to about 1.0 and the ethylene / α-olefin interpolymer has a molecular weight distribution, Mw / Mn, greater than about 1.3.

Owner:DOW GLOBAL TECH LLC

Acidic activator-supports and catalysts for olefin polymerization

ActiveUS7294599B2Increase acidityImprove productivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkyneOlefin polymerization

This invention relates to the field of olefin polymerization catalyst compositions, and methods for the polymerization and copolymerization of olefins, typically using a supported catalyst composition. In one aspect, this invention encompasses precontacting a metallocene with an olefin or alkyne monomer and an organoaluminum compound, prior to contacting this mixture with the acidic activator-support.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Compositions comprising a fluoroolefin

The present invention relates to compositions for use in refrigeration, air-conditioning, and heat pump systems wherein the composition comprises a fluoroolefin and at least one other component. The compositions of the present invention are useful in processes for producing cooling or heat, as heat transfer fluids, foam blowing agents, aerosol propellants, and fire suppression and fire extinguishing agents.

Owner:EI DU PONT DE NEMOURS & CO

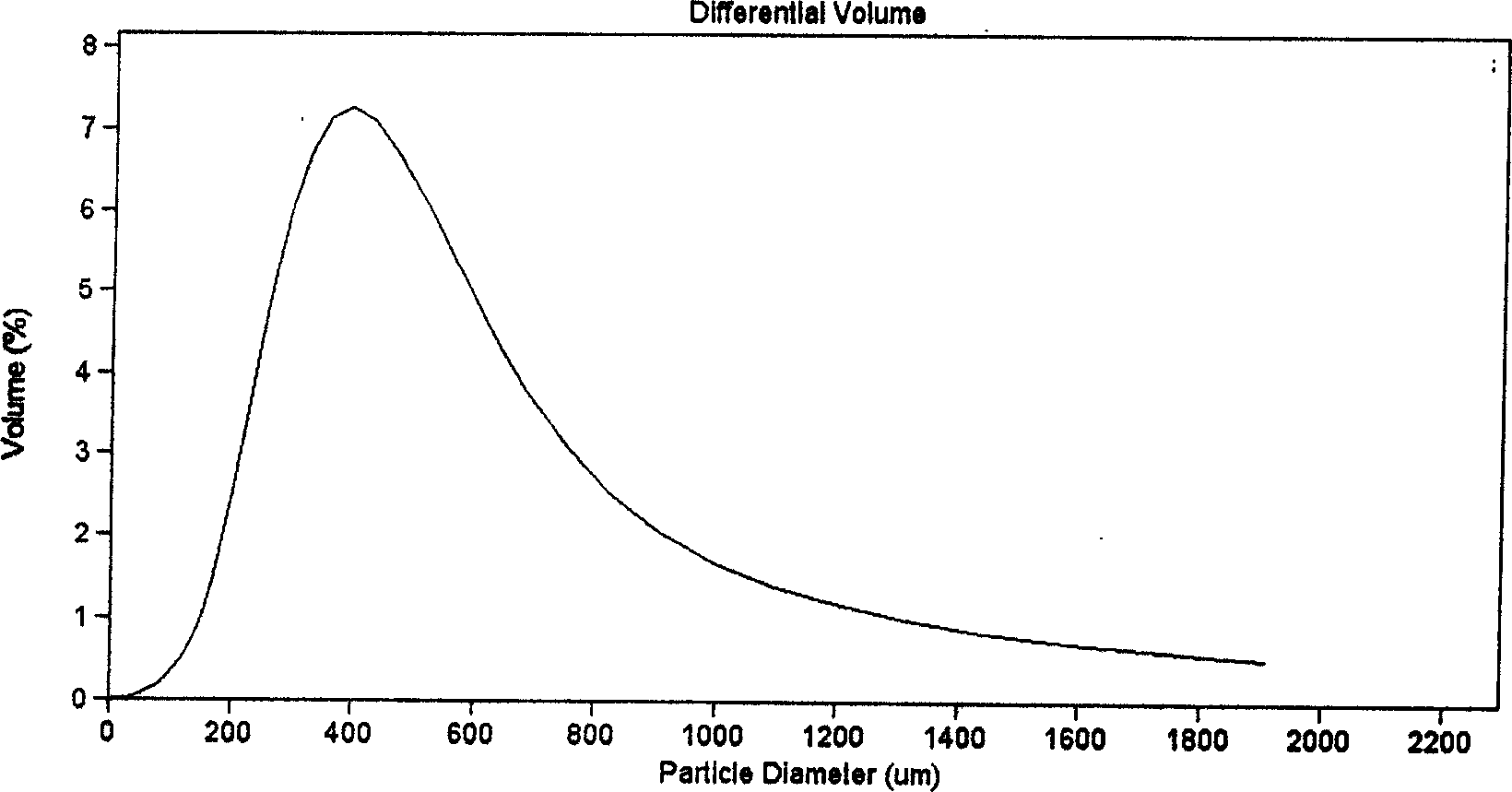

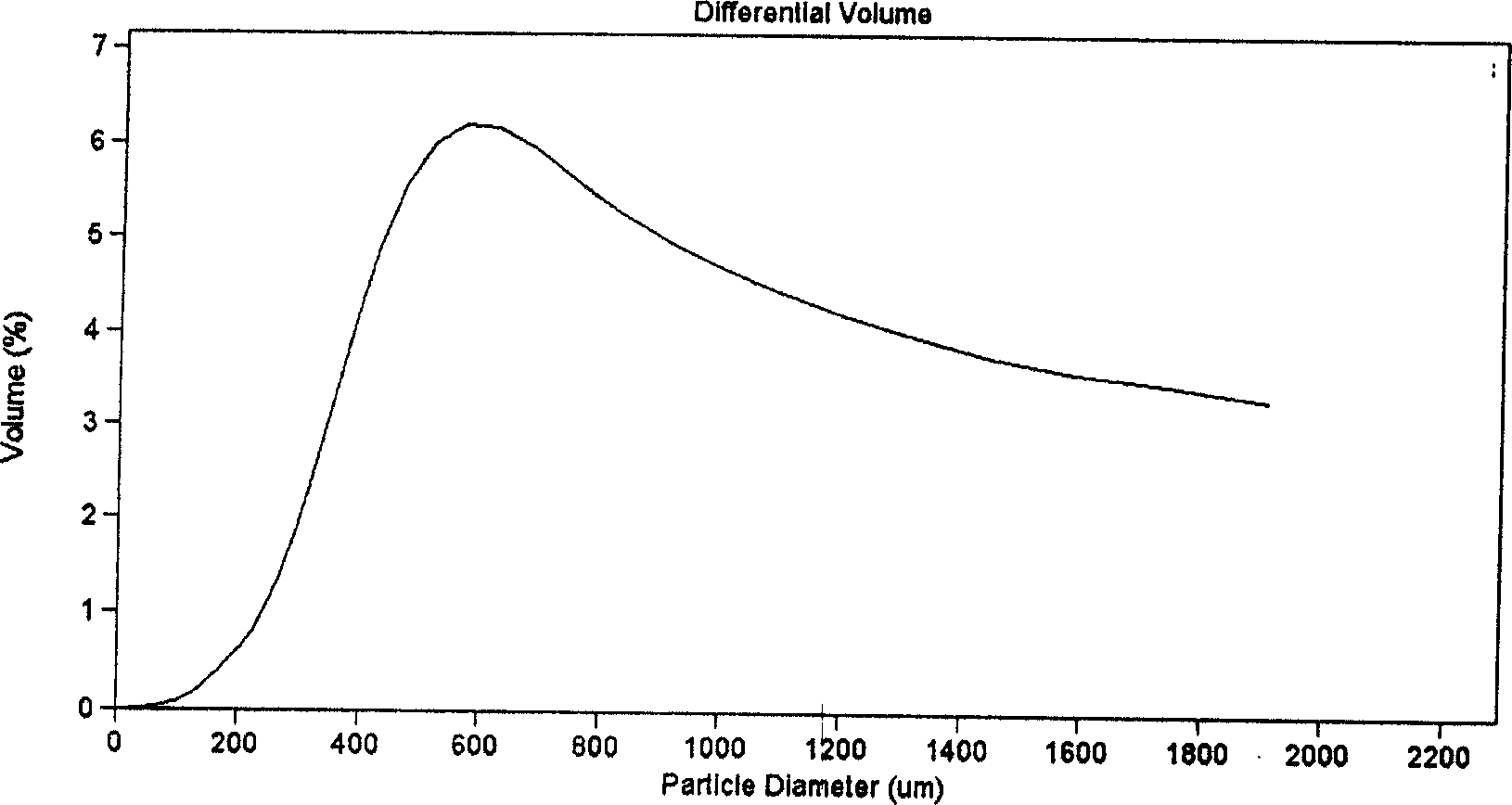

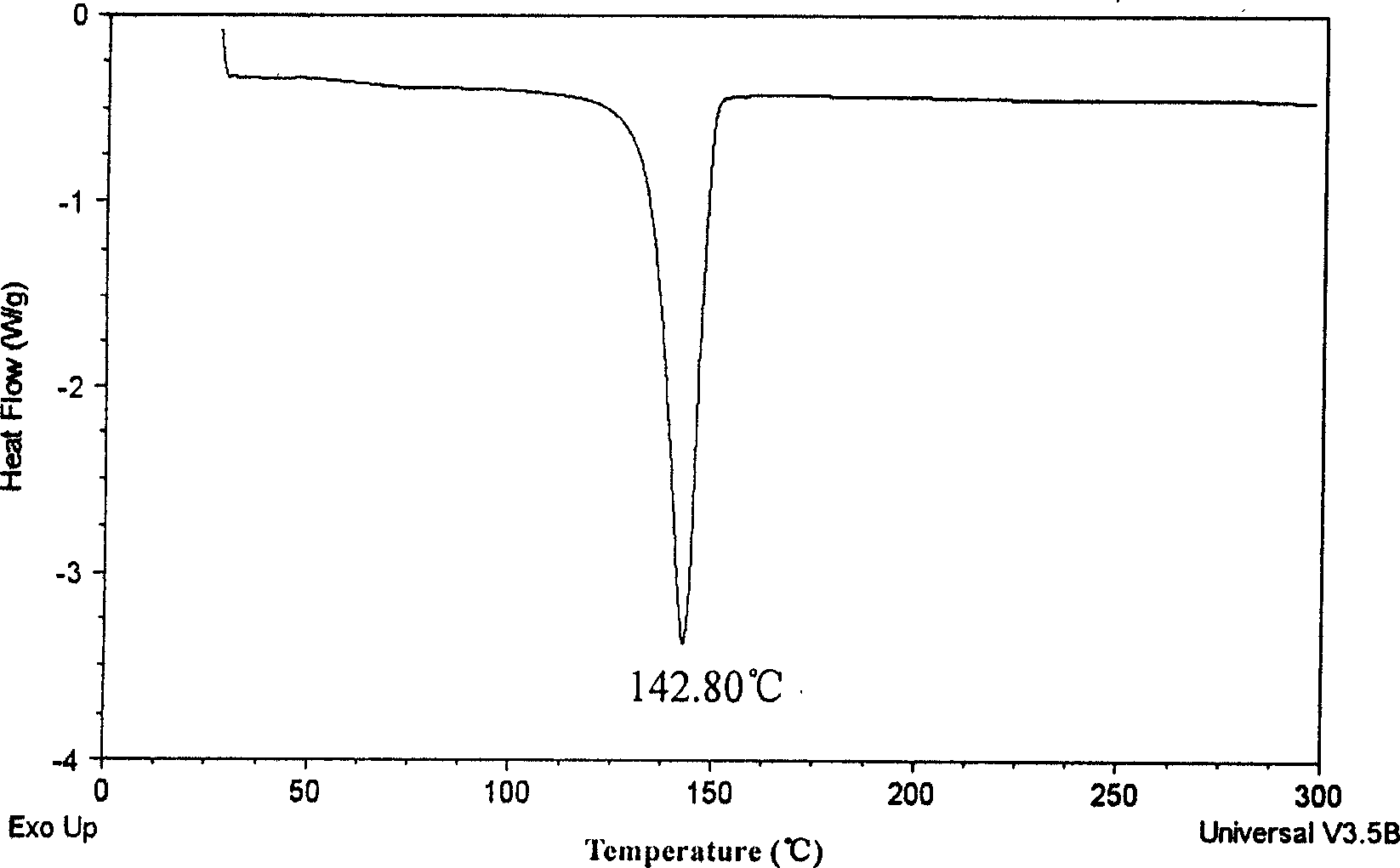

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

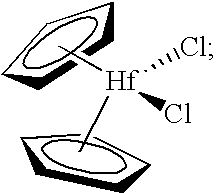

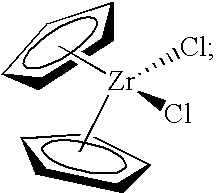

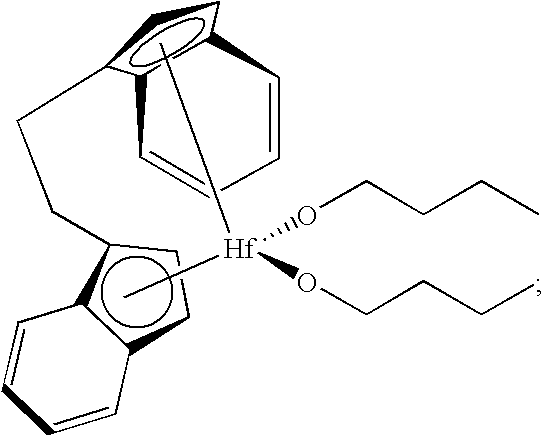

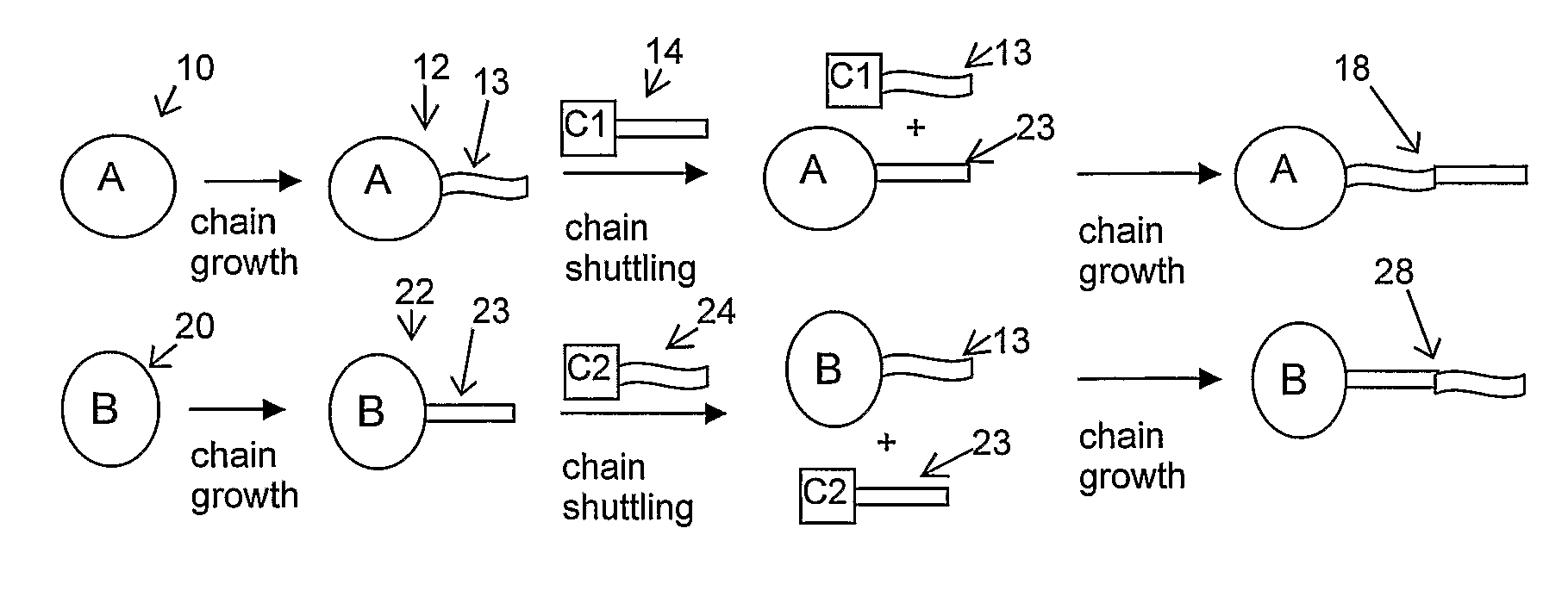

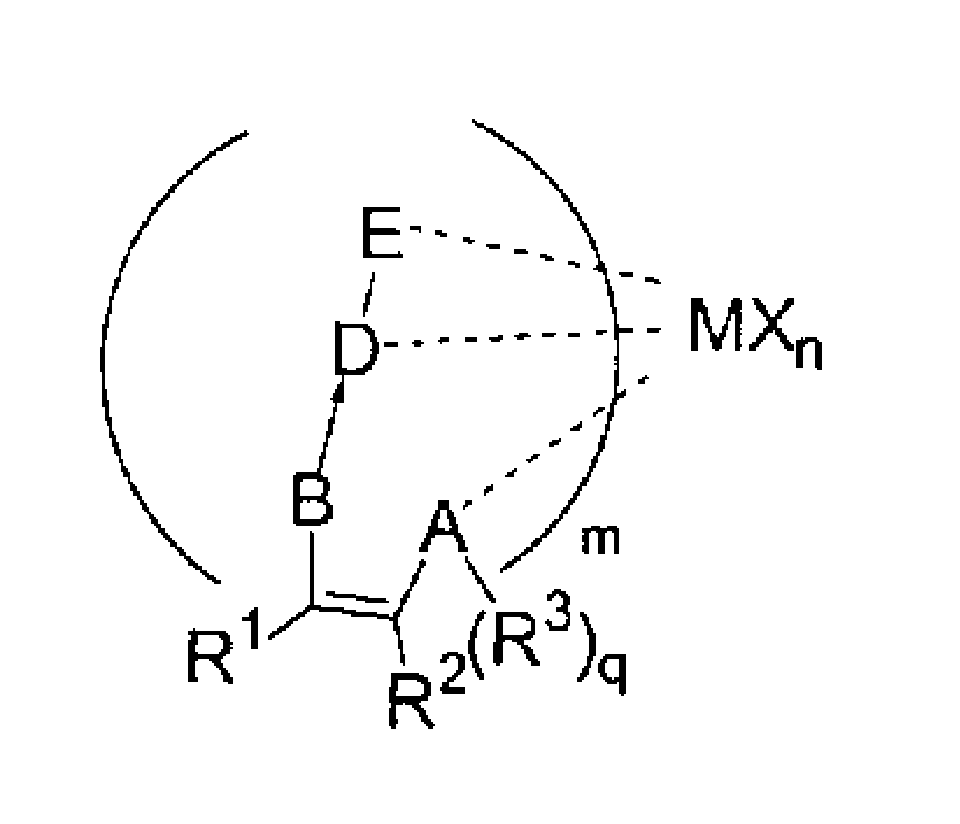

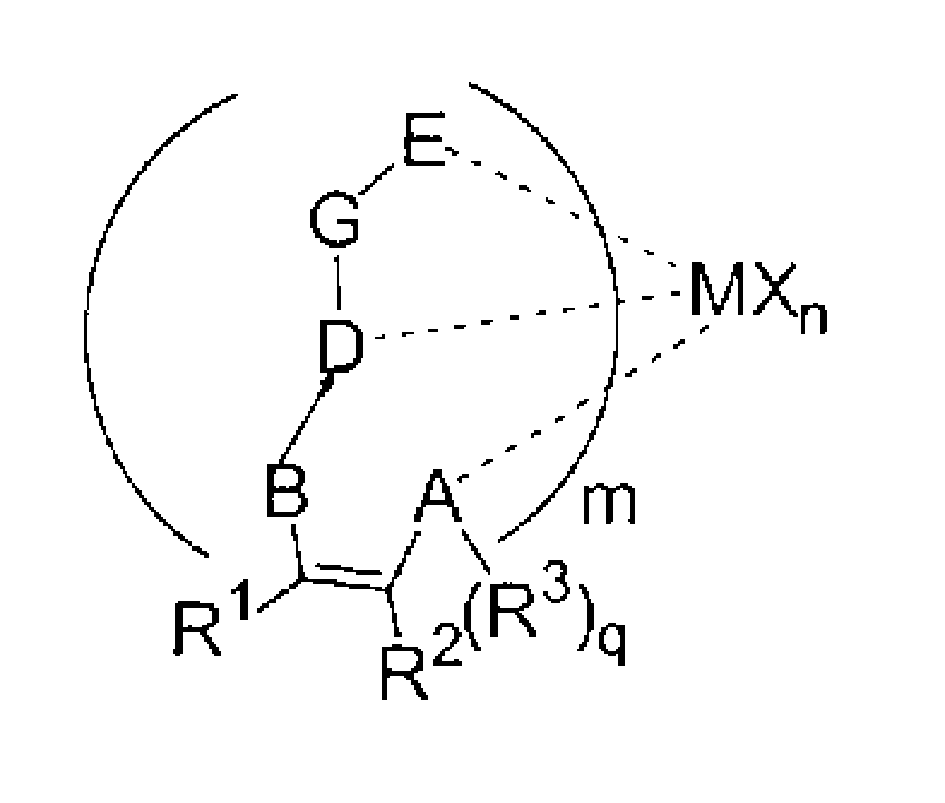

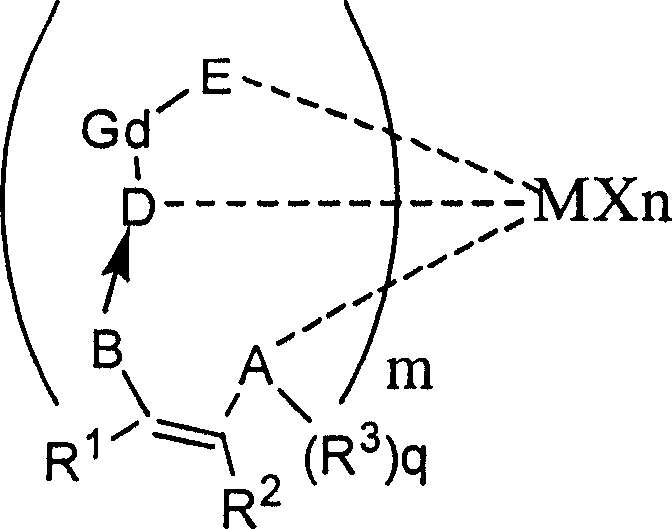

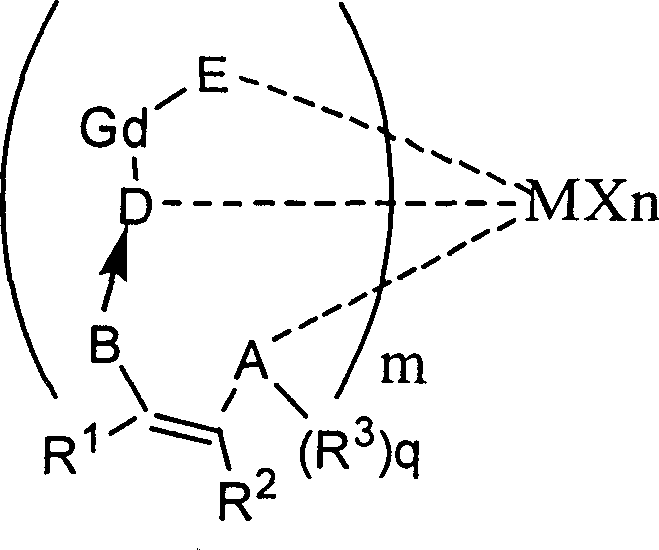

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

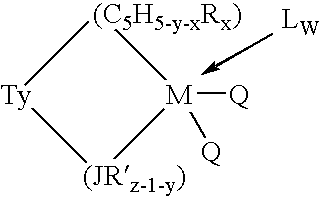

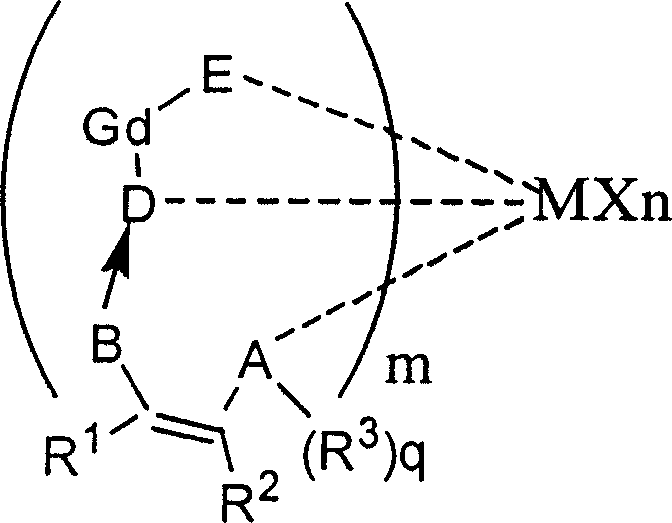

Aluminum-free monocyclopentadienyl metallocene catalysts for olefin polymerization

ActiveUS7163907B1Organic-compounds/hydrides/coordination-complexes catalystsMetallocenesPolymer sciencePolyolefin

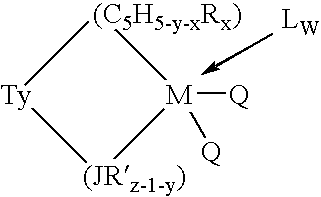

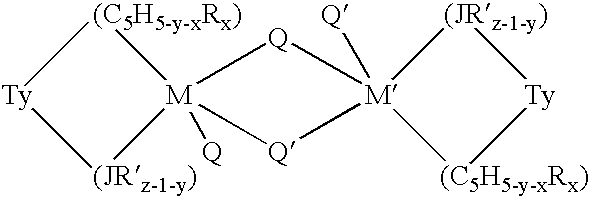

This invention relates to a catalyst system for the production of polyolefins comprising:(A) a Group IV B transition metal component represented by one of the two general formulaewherein(C5H5-y-xRx) is a cylopentadienyl ring(JR′z-l-y) is a heteroatom ligand in which J is an element with a coordination number of three from Group V-A or an element with a coordination number of two rom Group VI-A of the Periodic Table of Elements,each Q is independently, hydride, C1—C20 hydrocarbyl radicals, substituted hydrocarbyl radials wherein one or more hydrogen atoms is replaced by an electron withdrawing group, or C1—C20 hydrocarbyl-substituted metalloid radicals wherein the metalloid is selected from the group consisting of germanium and silicon, provided that Q is not a substituted or unsubstituted cyclopentadienyl ring, or both Q together may be an alkylidene, olefin, acetylene or a cyclometallated hydrocarbyl;“y” is 0 or 1; when “y” is 1, T is a covalent bridging group containing a Group IV-A or V-A element;L is a neutral Lewis base; and “w” is a number from 0 to 3;(B) an activator compound comprising (1) a cation; and (2) a compatible noncoordinating anion.

Owner:EXXONMOBIL CHEM PAT INC

Compositions comprising fluoroolefins and uses thereof

The present invention relates to fluoroolefin compositions. The fluoroolefin compositions of the present invention are useful as refrigerants or heat transfer fluids and in processes for producing cooling or heat. Additionally, the fluoroolefin compositions of the present invention may be used to replace currently used refrigerant or heat transfer fluid compositions that have higher global warming potential.

Owner:EI DU PONT DE NEMOURS & CO

Cap liners, closures and gaskets from multi-block polymers

A polymer composition comprises at least an ethylene / α-olefin interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

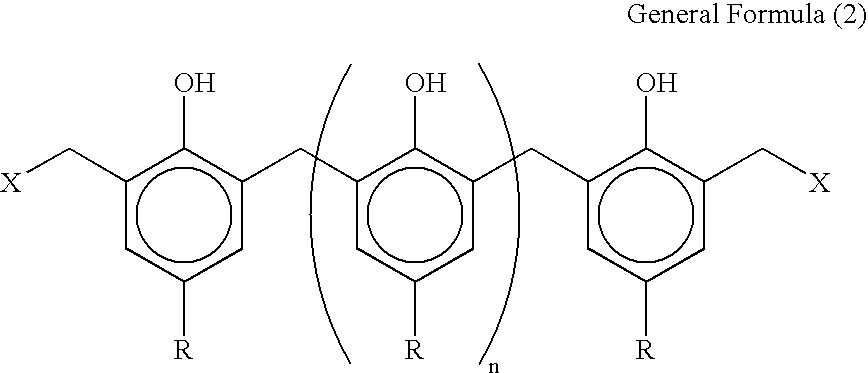

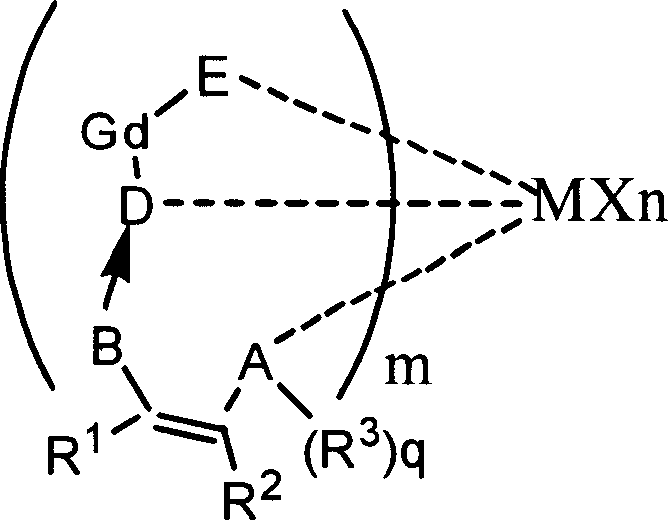

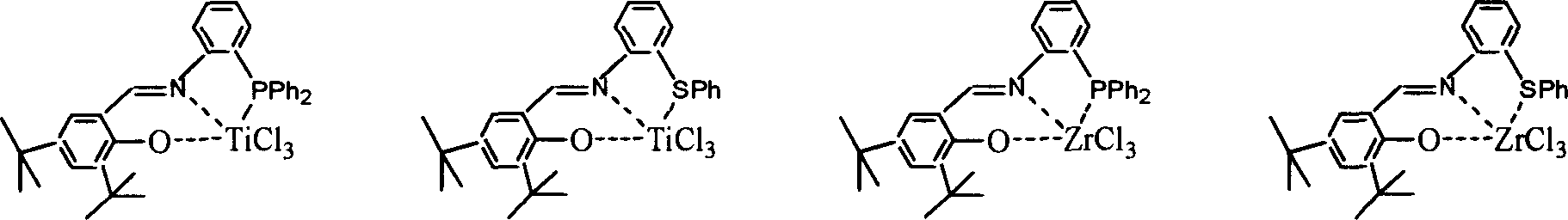

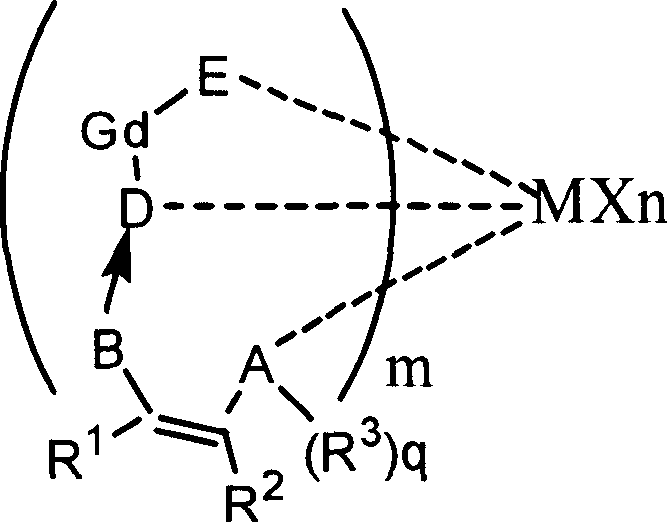

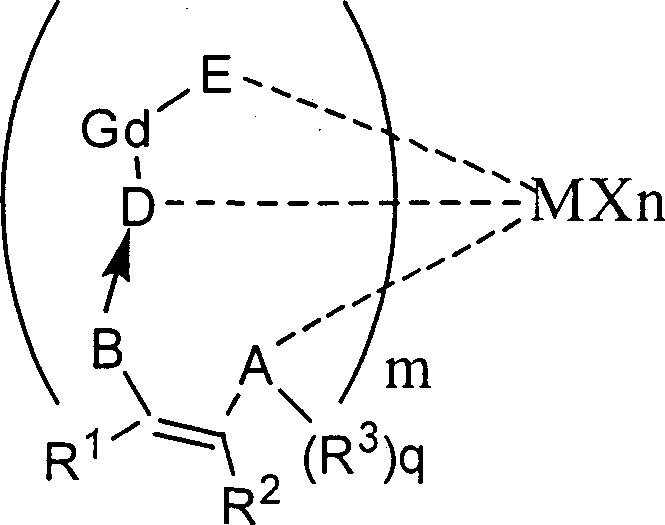

Catalyst for polymerization and copolymerization of olefine and its synthesis and use

The catalyst for polymerization and copolymerization of olefine is one novel kind of group III to group XIII transition metal complex of tridentate ligand.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

New olefine polymerization catalyst

The present invention relates to a catalyst or catalyst system for polymerization and copolymerization of olefine and its synthesis process and the application in catalyzing olefine polymerization. The catalyst is a kind III to XI transition metal compound with multitooth ligand.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

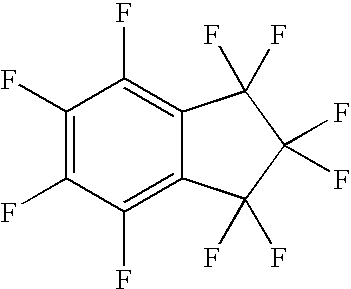

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

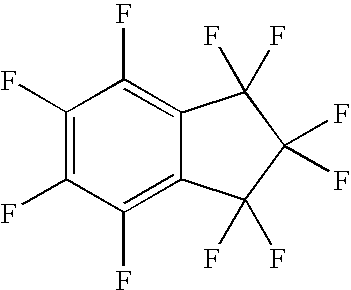

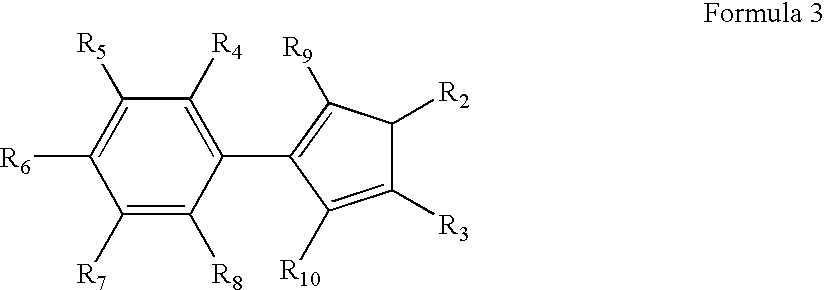

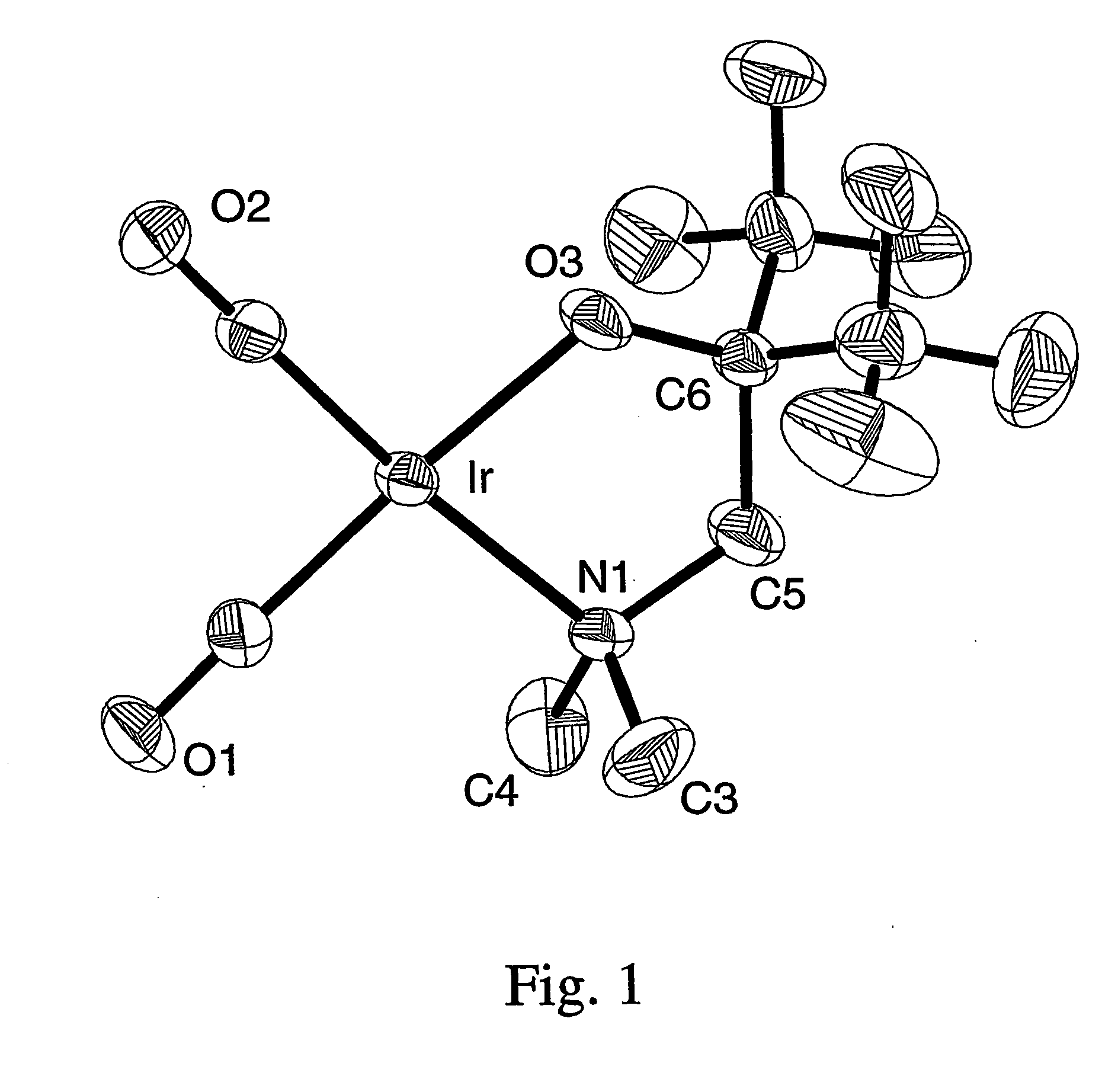

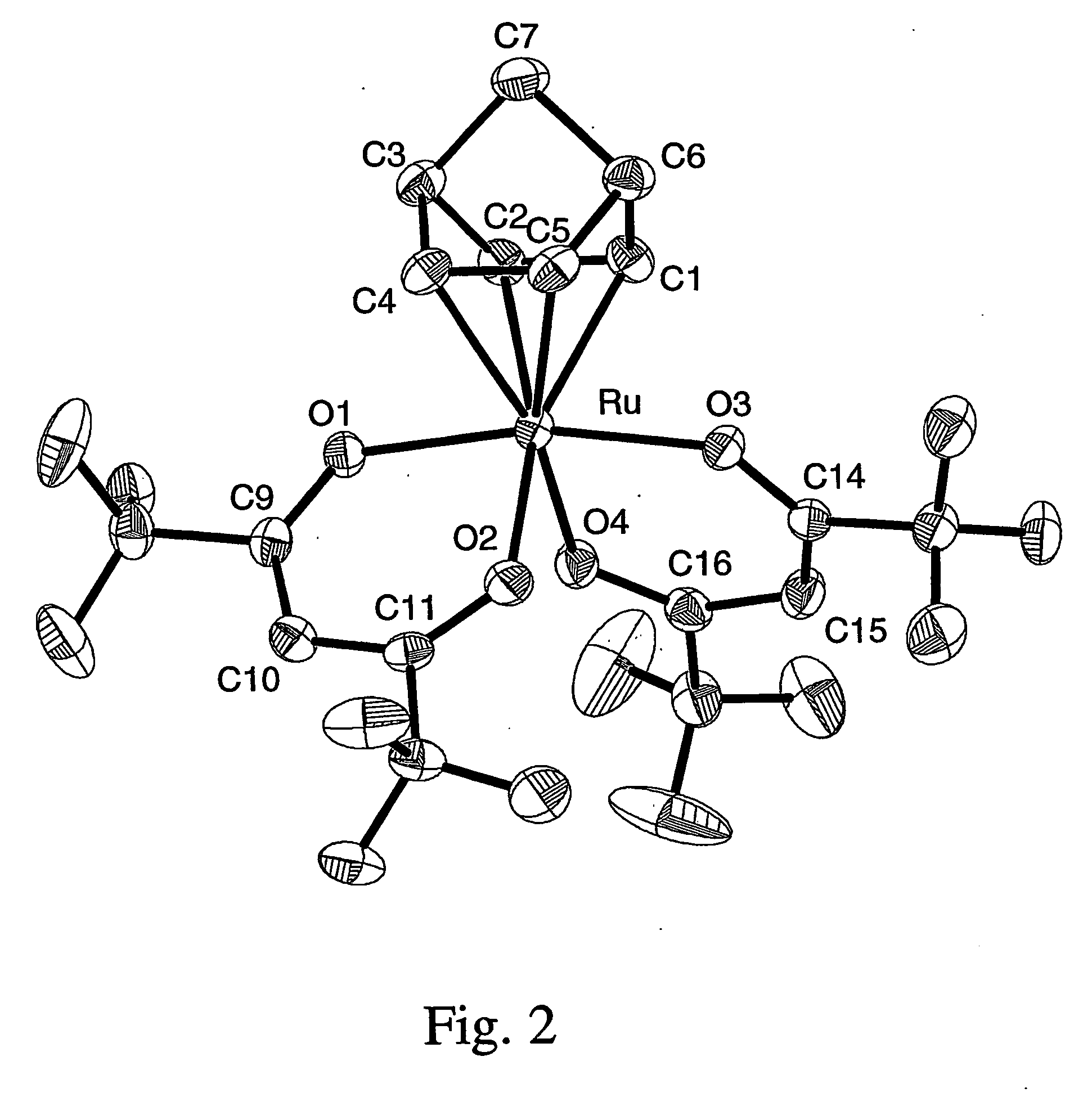

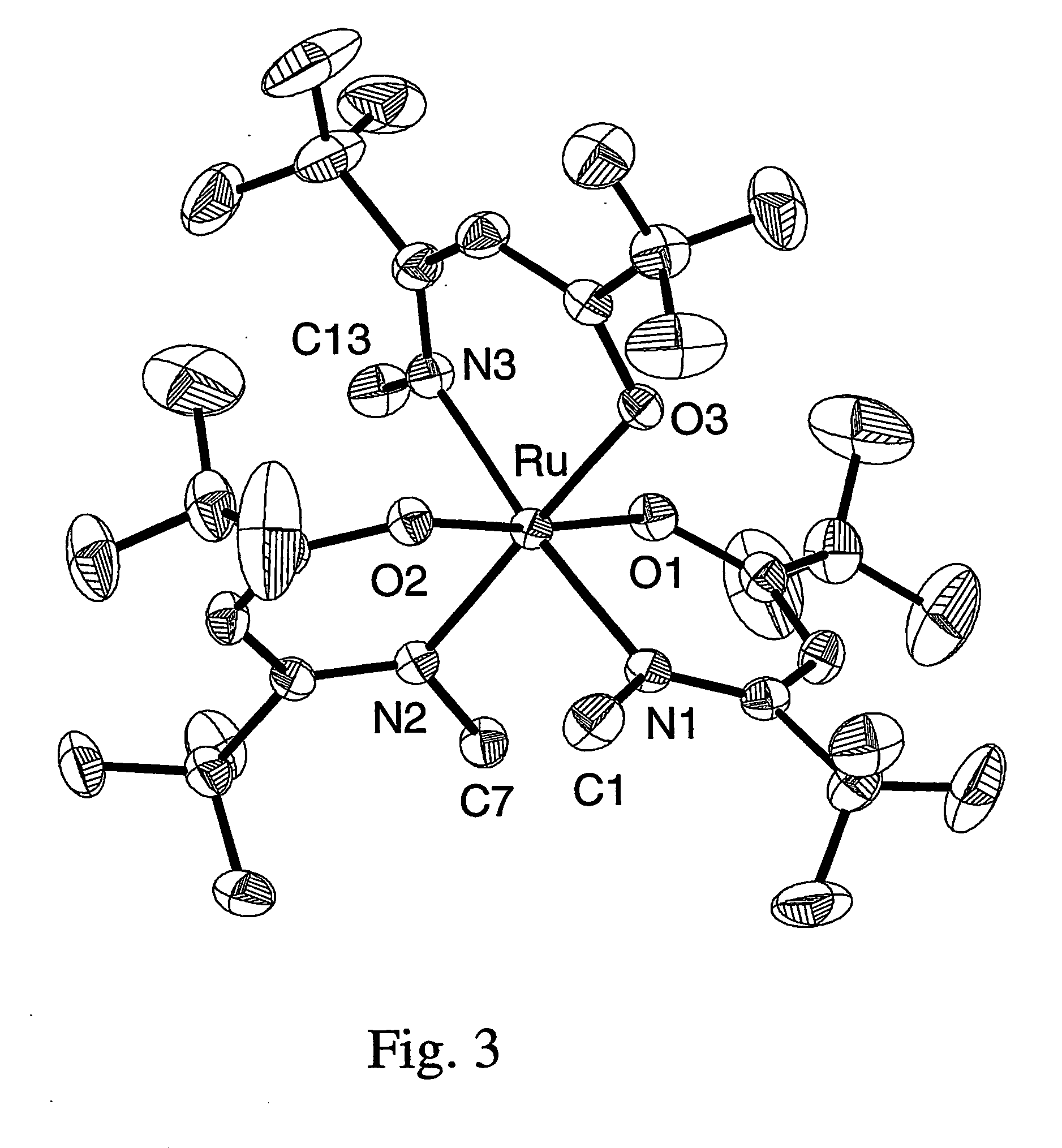

Volatile noble metal organometallic complexes

InactiveUS20050033075A1Reduce Van der Waals interactionBoiling and sublimation temperatureFurnaces without endless coreRuthenium organic compoundsIridiumIodide

A series of noble metal organometallic complexes of the general formula (I): MLaXb(FBC)c, wherein M is a noble metal such as iridium, ruthenium or osmium, and L is a neutral ligand such as carbonyl, alkene or diene; X is an anionic ligand such as chloride, bromide, iodide and trifluoroacetate group; and FBC is a fluorinated bidentate chelate ligand such as beta diketonate, beta-ketoiminate, amino-alcoholate and amino-alcoholate ligand, wherein a is an integer of from zero (0) to three (3), b is an integer of from zero (0) to one (1) and c is an 10 integer of from one (1) to three (3). The resulting noble metal complexes possess enhanced volatility and thermal stability characteristics, and are suitable for chemical vapor deposition(CVD) applications. The corresponding noble metal complex is formed by treatment of the FBC ligand with a less volatile metal halide. Also disclosed are CVD methods for using the noble metal complexes as source reagents for deposition of noble metal-containing films such as Ir, Ru and Os, or even metal oxide film materials IrO2, OsO2 and RuO2.

Owner:NATIONAL TSING HUA UNIVERSITY +1

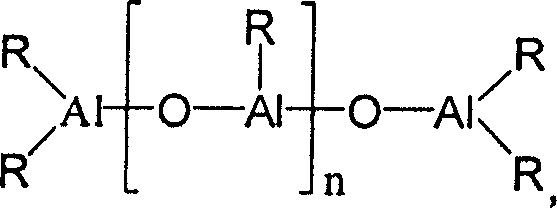

Loaded method of Non-metallocene catalyst loaded by composite carrier and polymerizing application

ActiveCN1539856AGood particle shapeHigh non-metallocene olefin polymerization catalyst contentChemical treatmentAluminoxane

A process for carrying the non-metallocene catalyst by composite carrier includes such steps as thermally activating silica gel, reacting on the solution of magnesium chloride in tetrahydrofuran-alcohol solution to obtain composite carrier, reacting on chemical treating agent to obtain modified composite carrier and carrying non-metallocene catalyst by solution method or dipping method. Said catalyst can be used for the homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

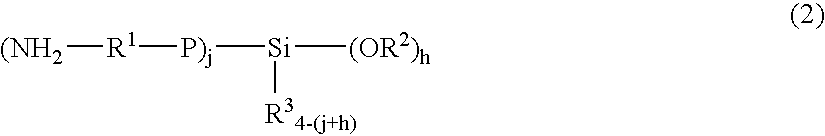

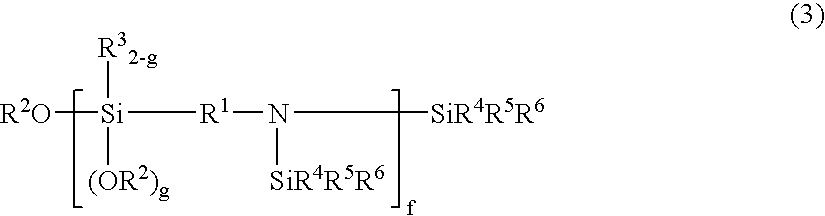

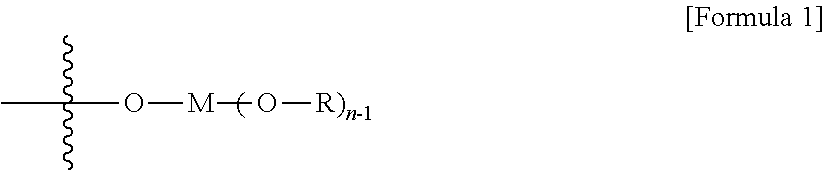

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

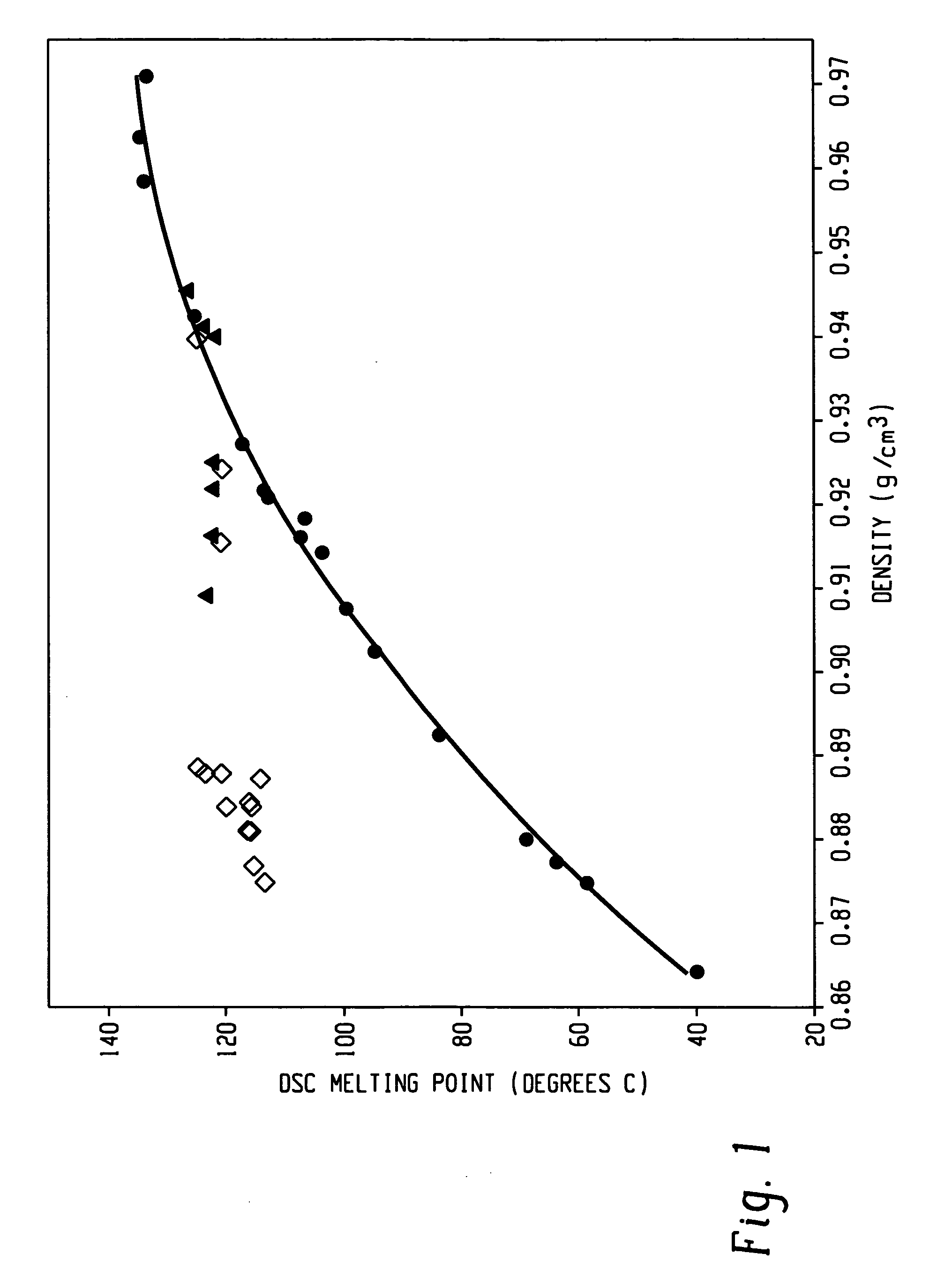

Compositions of ethylene/alpha-olefin multi-block interpolymer suitable for films

ActiveUS20060199912A1Preserve freshnessClose inspection of qualitySynthetic resin layered productsThin material handlingPolymer scienceAlkene

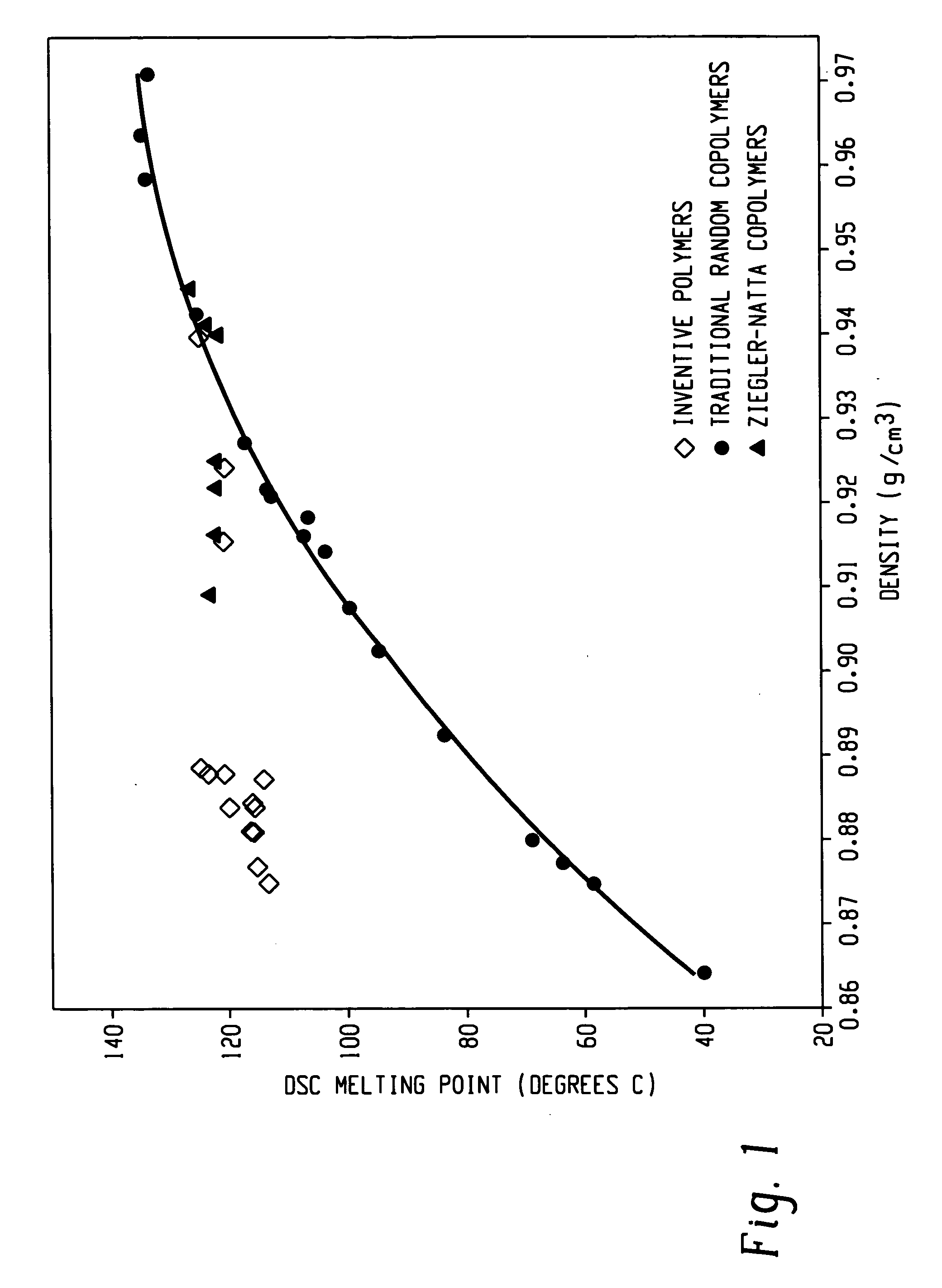

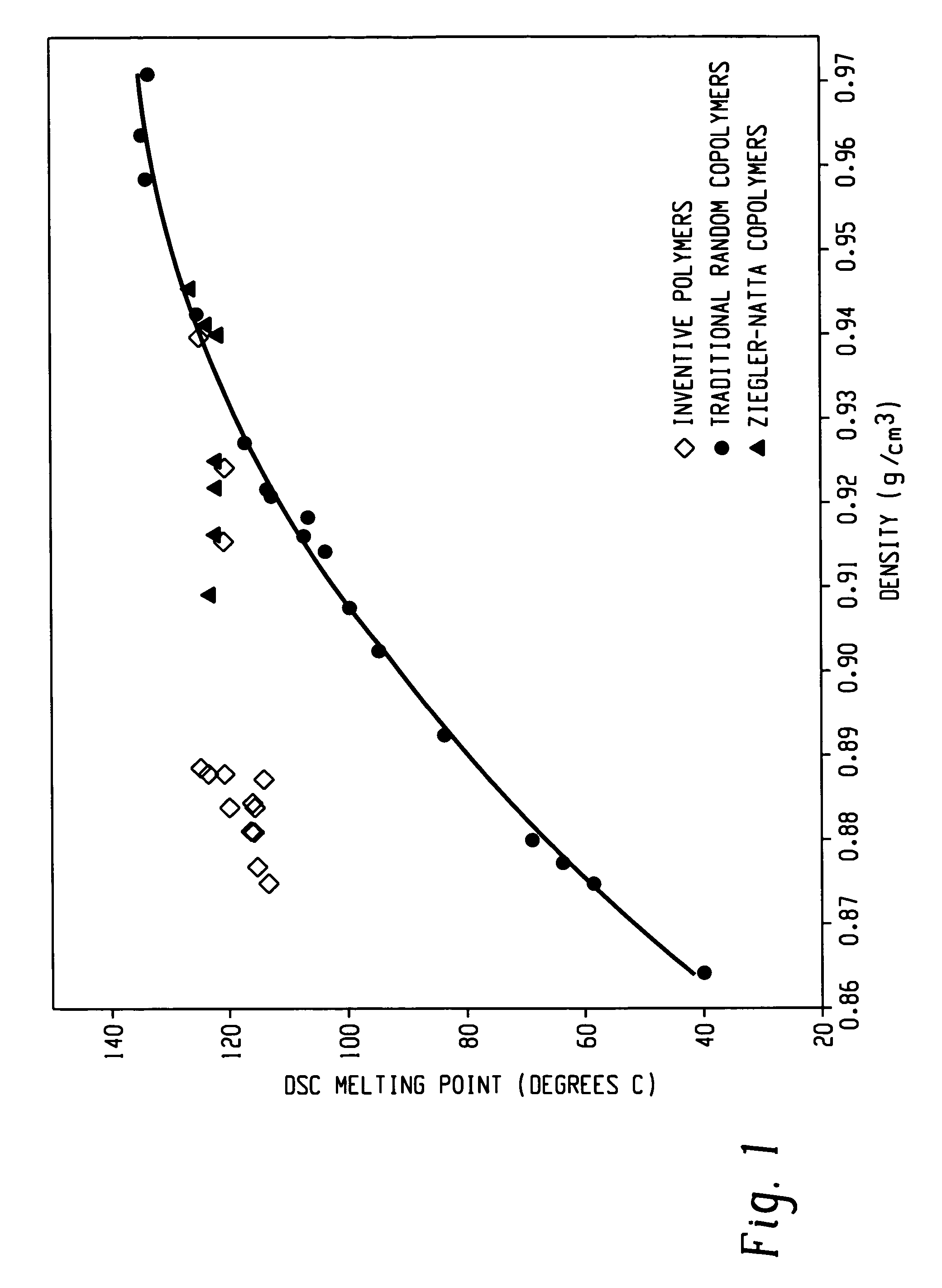

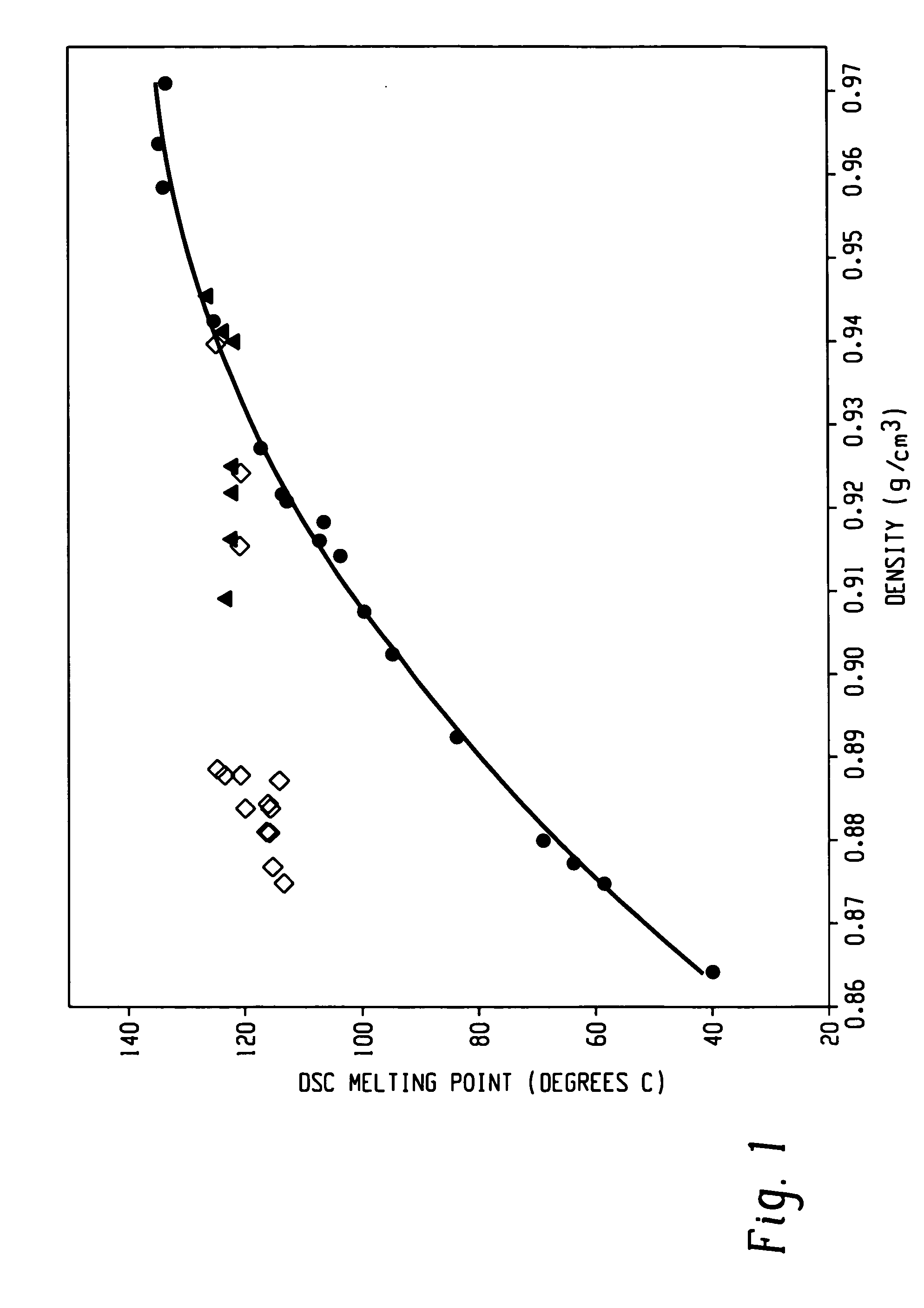

Compositions suitable for film comprise at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship: Tm>−2002.9+4538.5(d)−2422.2(d)2.

Owner:DOW GLOBAL TECH LLC

Polymer blends from interpolymers of ethylene/alpha-olefin with improved compatibility

Disclosed herein are polymer blends comprising at least one ethylene / α-olefin interpolymer and two different polyolefins which can be homopolymers. The ethylene / α-olefin interpolymers are block copolymers comprising at least a hard block and at least a soft block. In some embodiments, the ethylene / α-olefin interpolymer can function as a compatibilizer between the two polyolefins which may not be otherwise compatible. Methods of making the polymer blends and molded articles made from the polymer blends are also described.

Owner:DOW GLOBAL TECH LLC

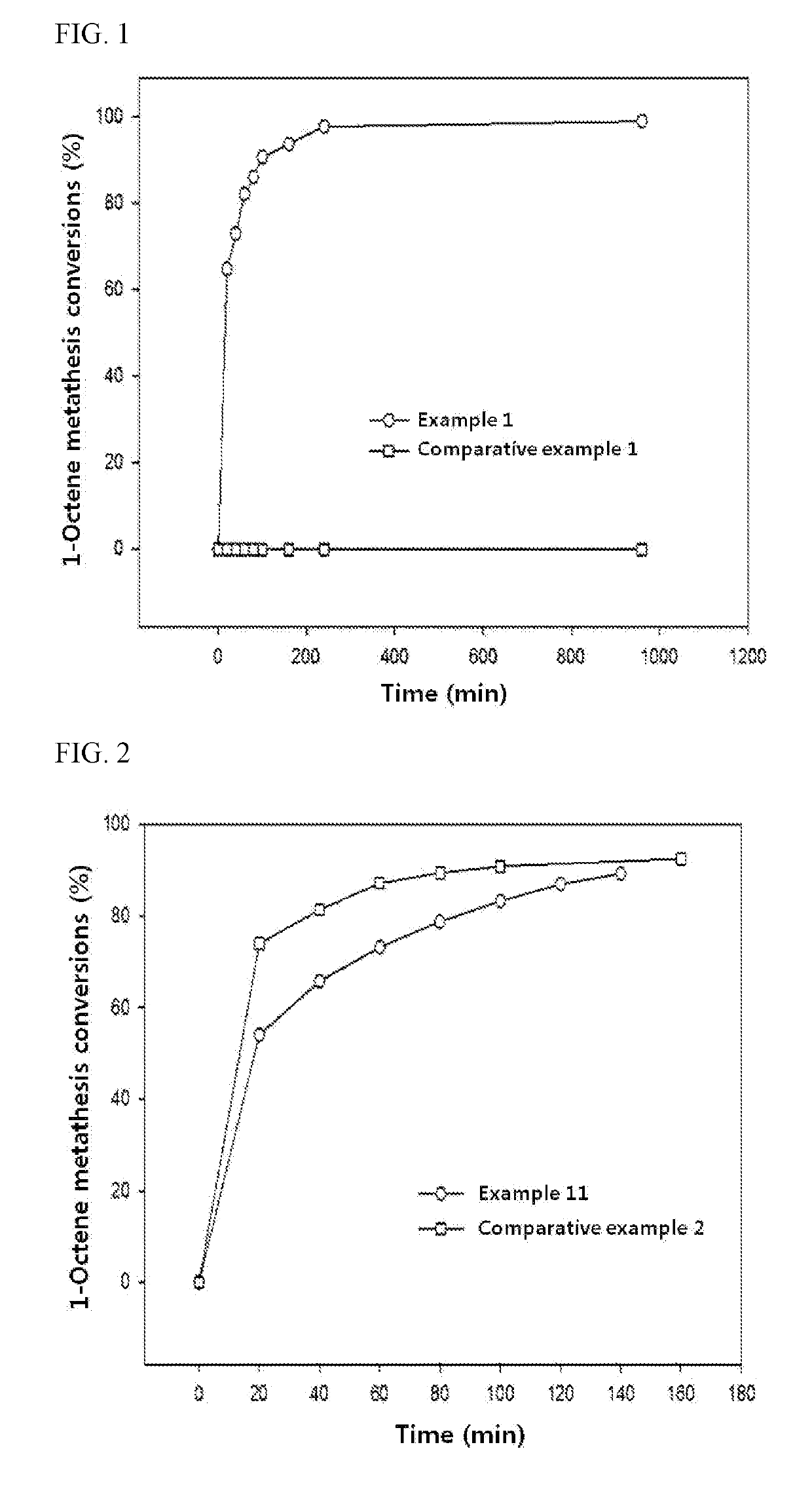

Olefin metathesis reaction catalyst and preparation method therefor

ActiveUS20190217277A1Separated/recovered readilyEasy to useMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumUnsaturated hydrocarbon

The present invention relates to an olefin metathesis reaction catalyst where rhenium (Re) oxide or molybdenum (Mo) oxide is supported, as a catalyst main component, on a surface-modified mesoporous silica or mesoporous alumina support, and a preparation method therefor. The olefin metathesis reaction catalyst of the present invention allows highly efficient metathesis of long-chain unsaturated hydrocarbons having at least eight carbons at a low temperature of 150° C. or lower. The catalyst can be separated readily from reaction solution, regenerated at a low temperature of 400° C. or lower by removing toxins accumulated on it during the metathesis reaction, and used repeatedly in metathesis reaction many times, thereby being made good use in commercial olefin metathesis processes.

Owner:KOREA RES INST OF CHEM TECH

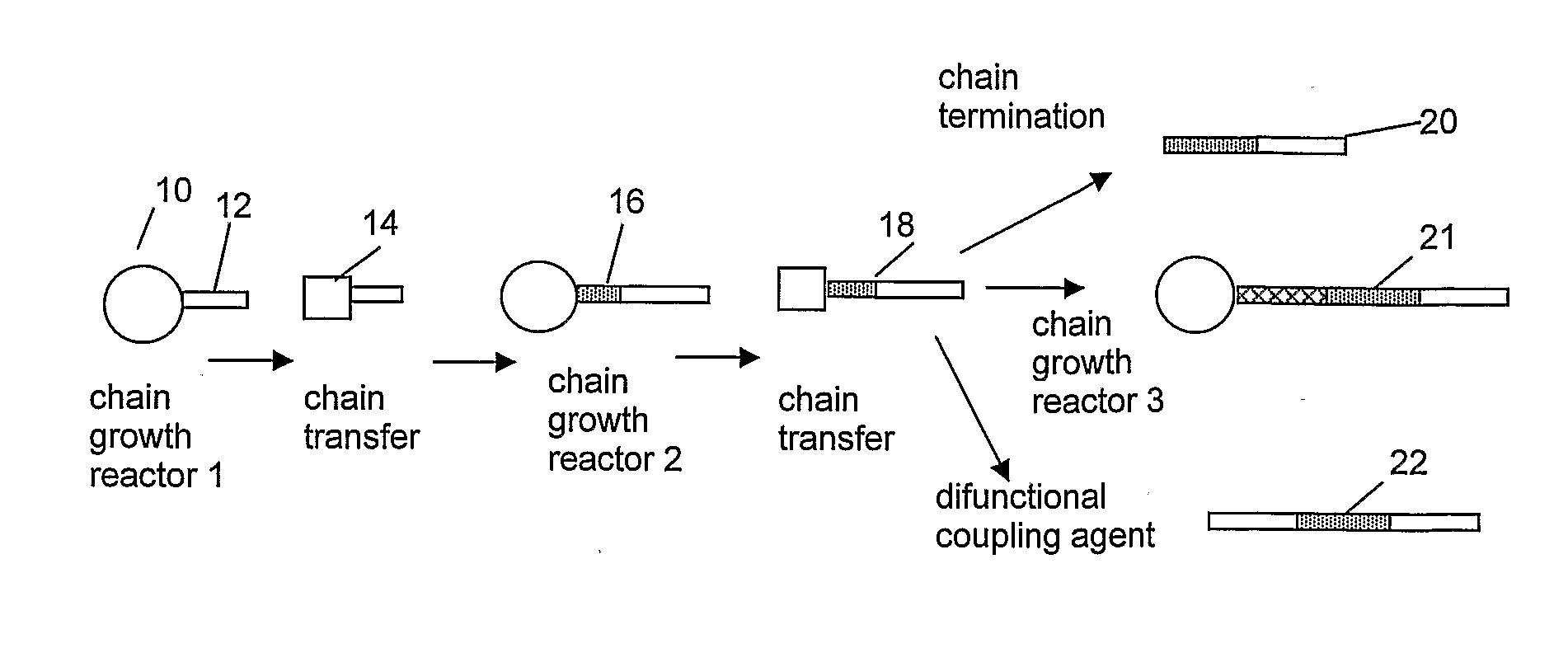

Catalytic Olefin Block Copolymers with Controlled Block Sequence Distribution

A process for the polymerization of one or more addition polymerizable monomers and the resulting polymer products, said process comprising: 1) contacting an addition polymerizable monomer or mixture of monomers under addition polymerization conditions in a reactor or reactor zone with a composition comprising at least one olefin polymerization catalyst and a cocatalyst and characterized by the formation of polymer chains from said monomer or monomers; 2) transferring the reaction mixture to a second reactor or reactor zone and optionally adding one or more additional reactants, catalysts, monomers or other compounds prior to, commensurate with, or after said transfer; and 3) causing polymerization to occur in said second reactor or reactor zone to form polymer chains that are differentiated from the polymer chains formed in step 1); said process being characterized by addition of a chain shuttling agent to the reaction mixture prior to, during, or subsequent to step 1) such that at least some of the resulting polymer molecules from step 3) comprise two or more chemically or physically distinguishable blocks or segments.

Owner:DOW GLOBAL TECH LLC

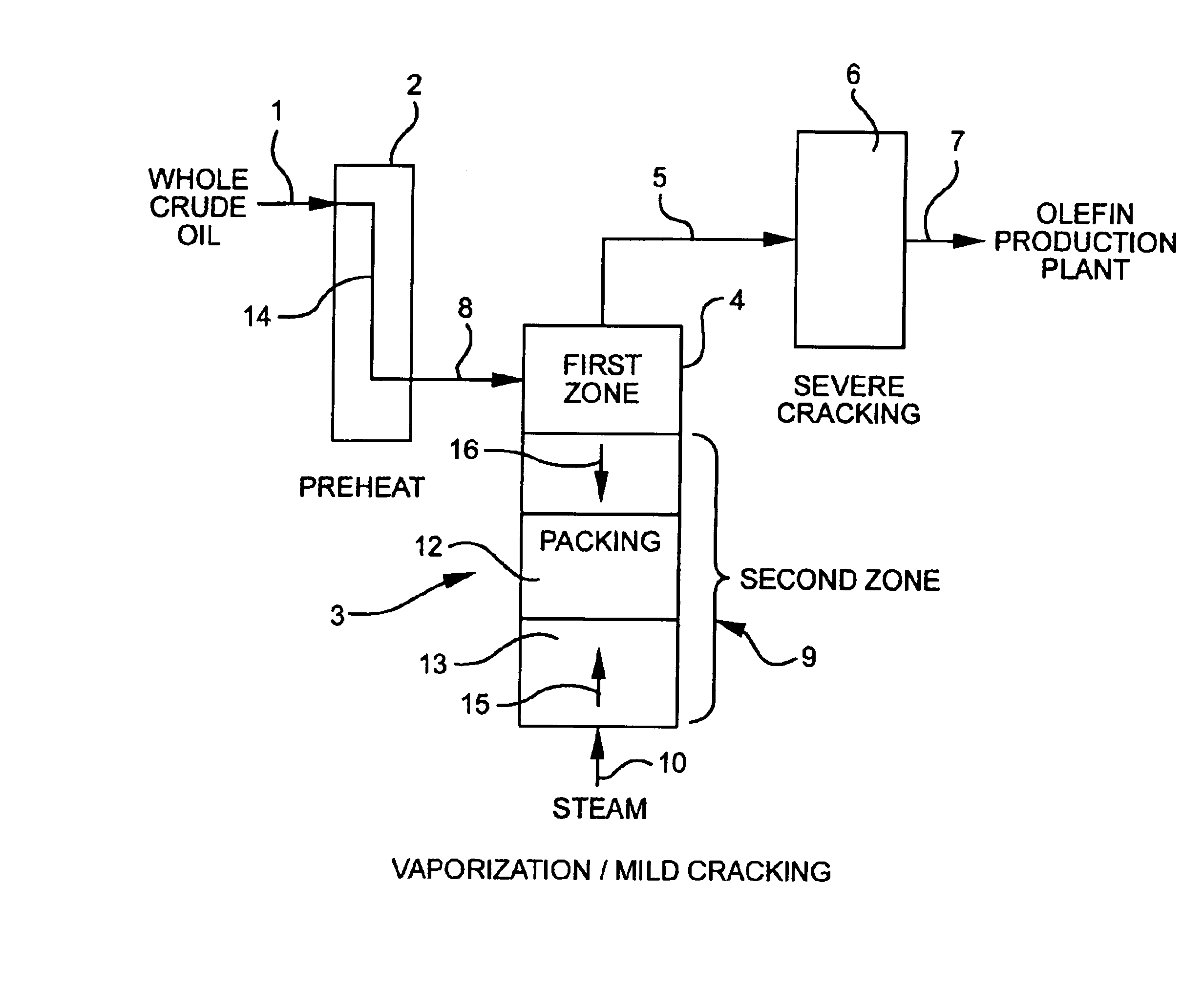

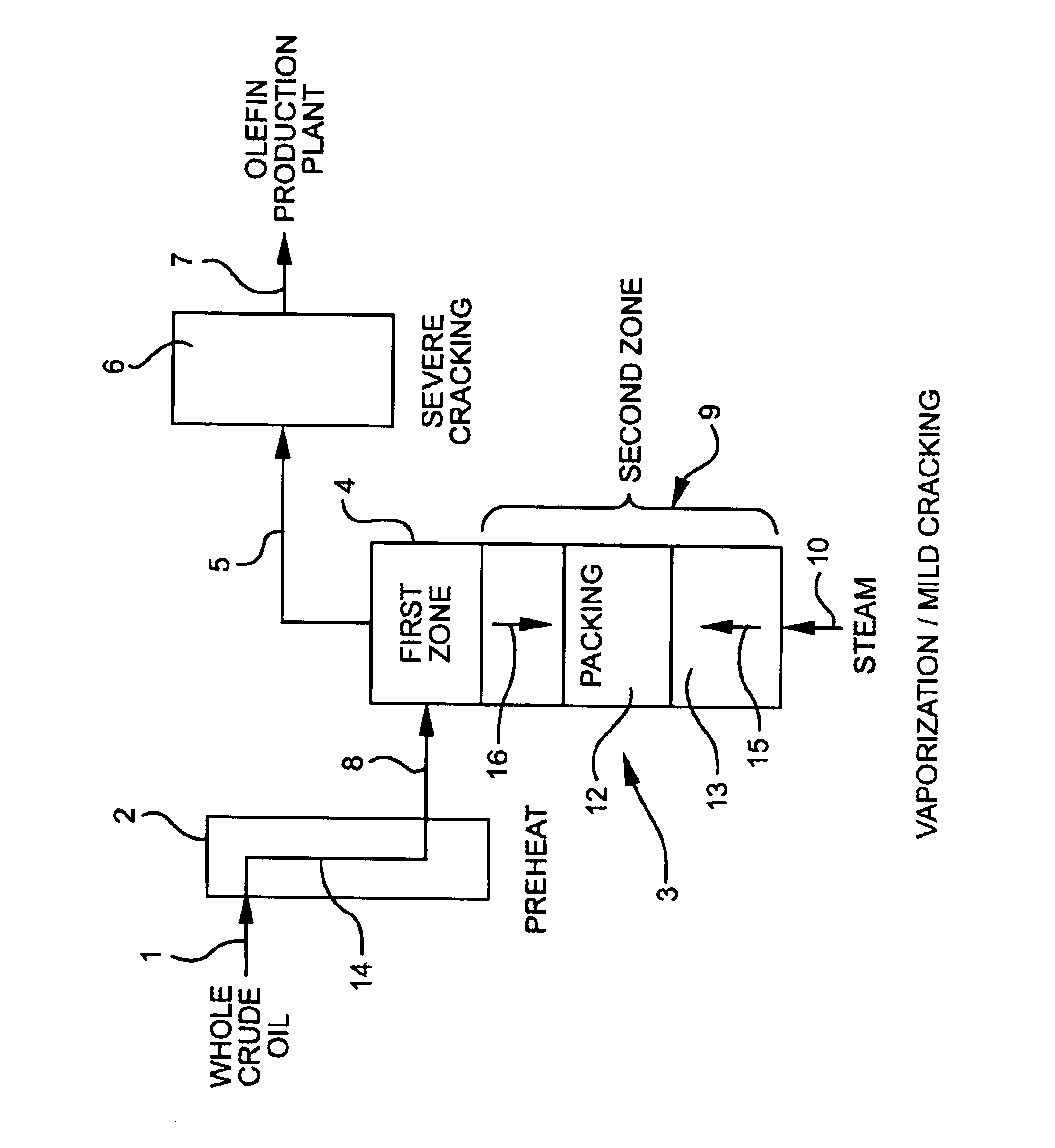

Olefin production utilizing whole crude oil

InactiveUS6743961B2Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Loaded method of load type Non-metallocene catalyst-and polymerizing application

A carrying process for the carried non-metallocene catalyst includes activating the porous carrier, washing, filtering, drying and directly carrying the nno-metallocene catalyst used for olefine polymerization. Said catalyst can be used for the slurry-type or gas-phase homopolymerization or copolymerization of C2-C10 olefin, styrene, or ethylene.

Owner:SINOPEC YANGZI PETROCHEM +1

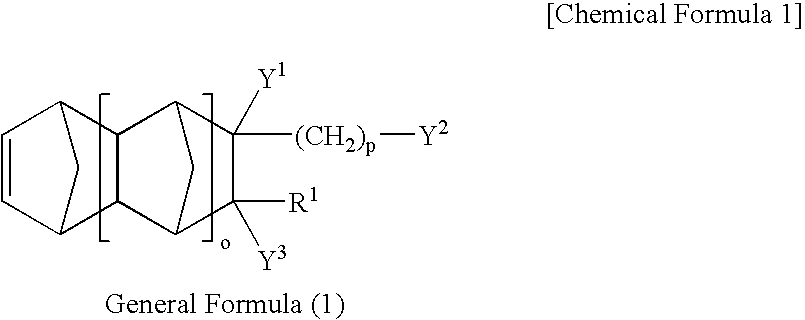

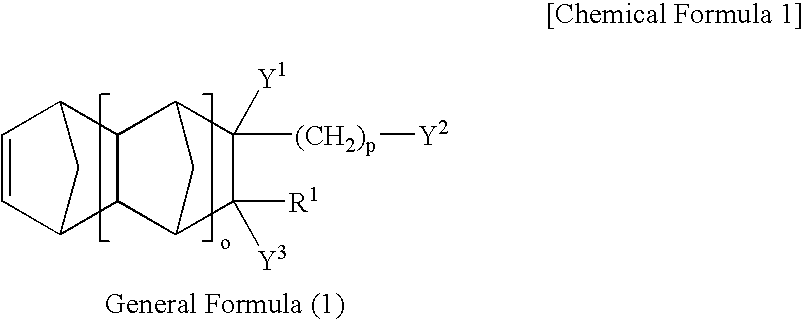

Thermoplastic Elastomer Composition, Method for Producing Same and Formed Article

The invention provides a thermoplastic elastomer composition having mechanical properties equivalent or superior to those of conventional thermoplastic elastomer compositions and having excellent heat resistance and oil resistance and a preparation process thereof, and molded or formed products making use of this thermoplastic elastomer composition. The thermoplastic elastomer composition according to the present invention contains a thermoplastic resin having a polar group and an ethylene•α-olefin elastomer having a functional group. The ethylene•α-olefin elastomer having the functional group is preferably a random copolymer obtained by copolymerizing ethylene, an α-olefin having 3 to 10 carbon atoms, an unsaturated monomer having the functional group and an optional non-conjugated diene.

Owner:JSR CORPORATIOON

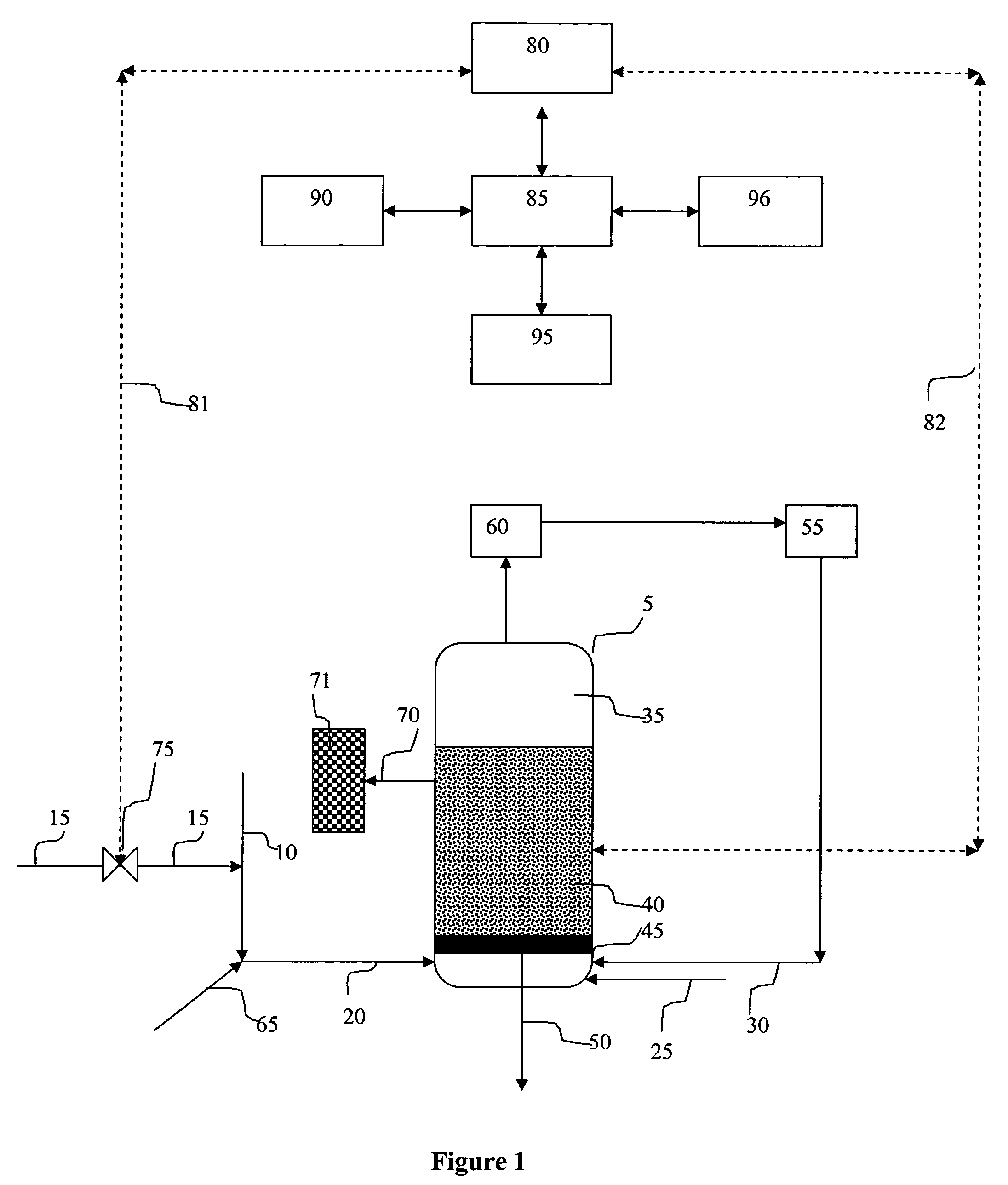

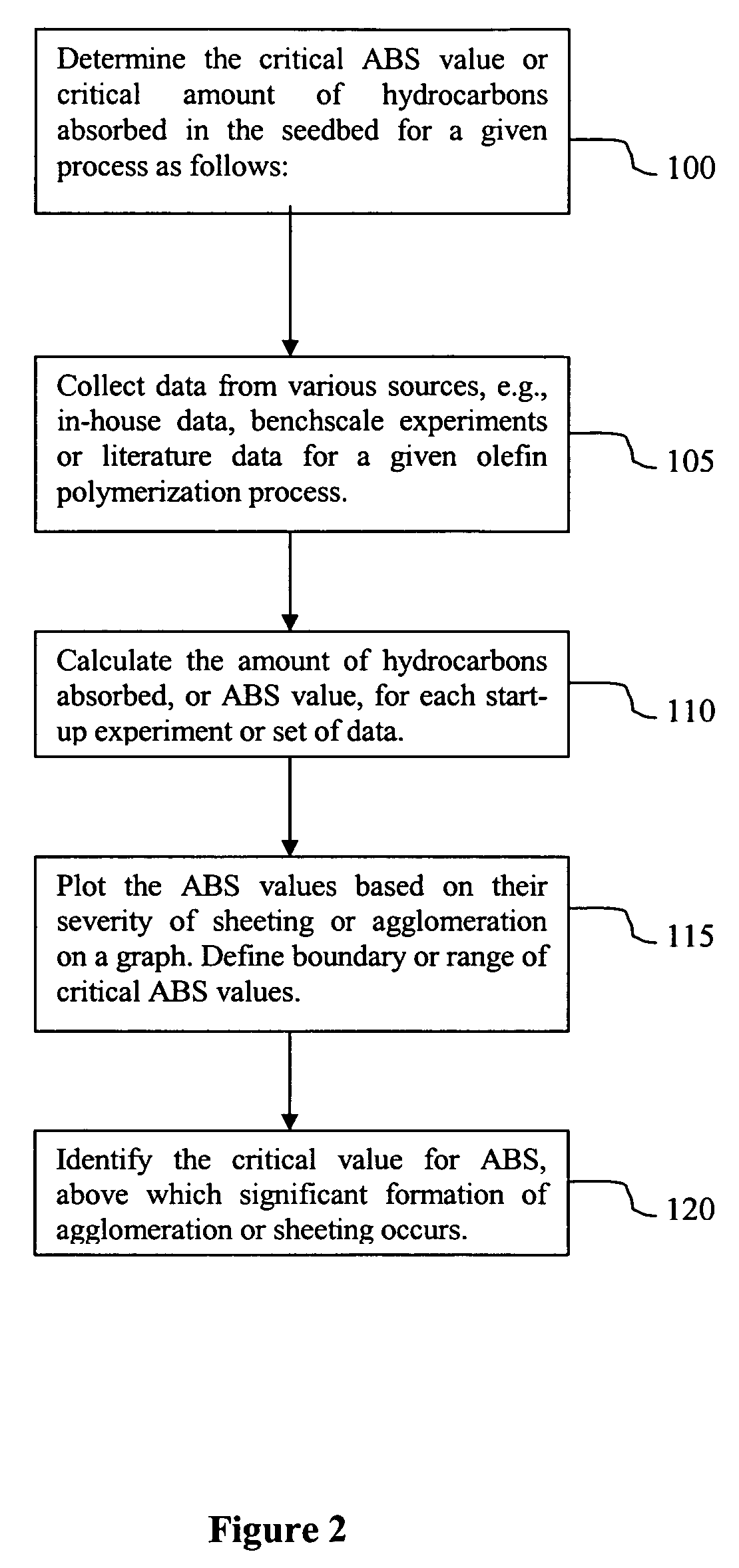

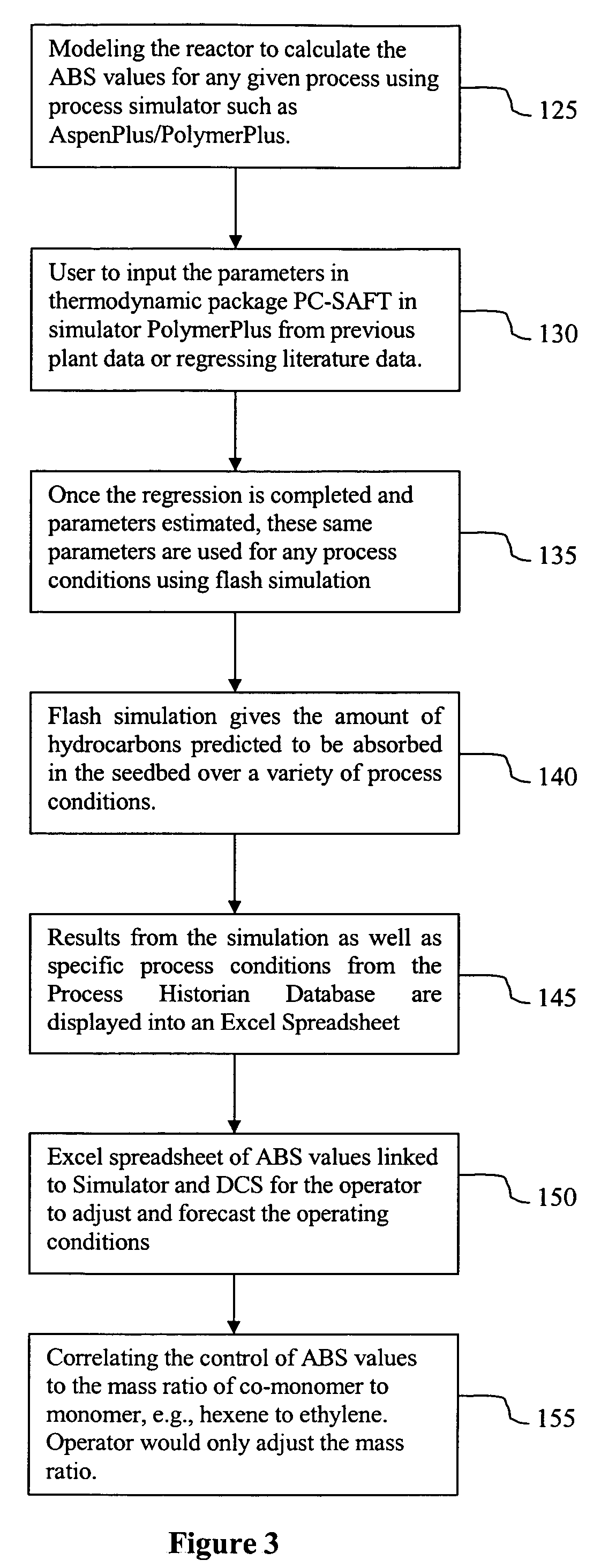

Method for polymerizing olefins in a gas phase reactor using a seedbed during start-up

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

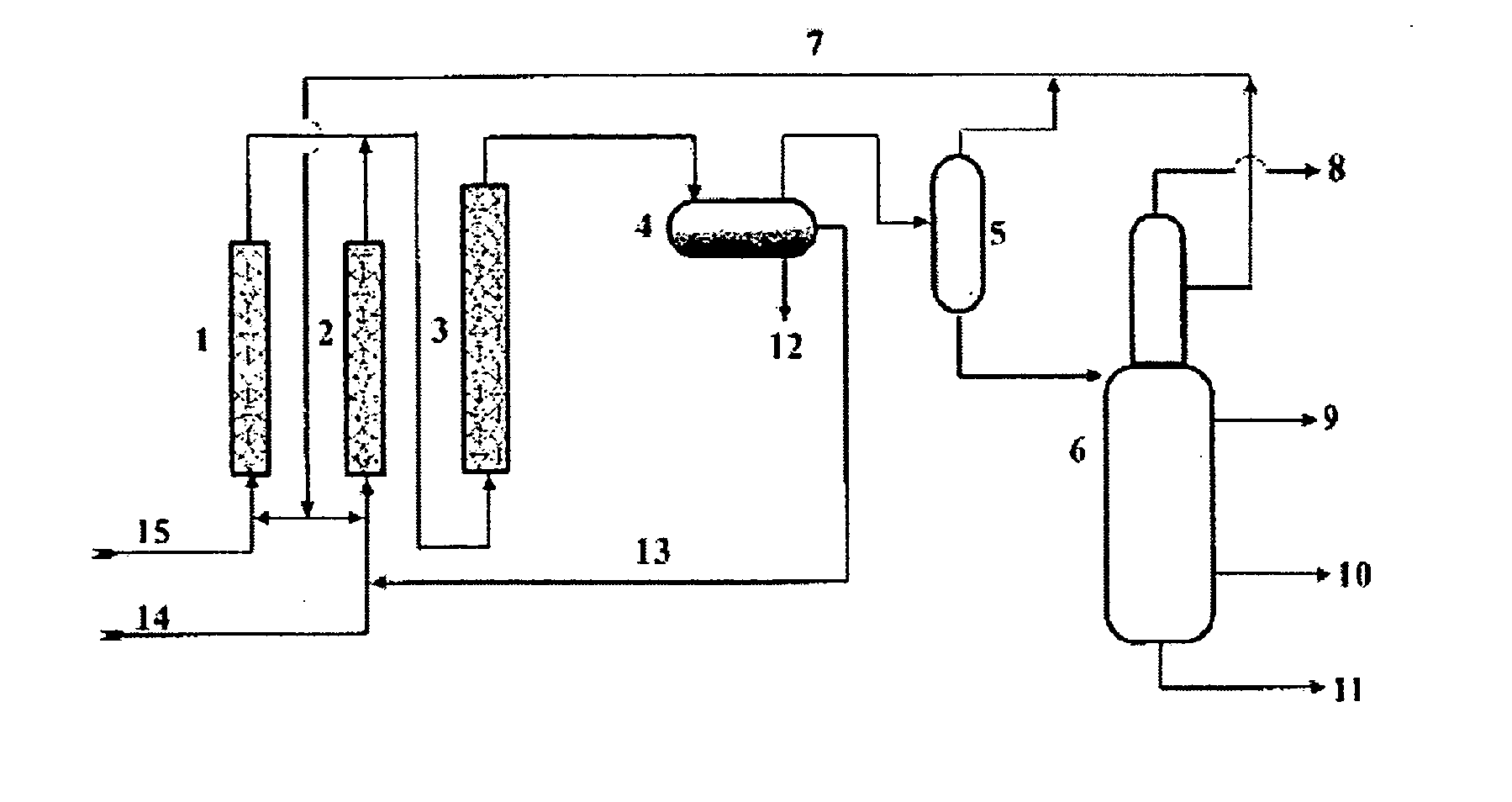

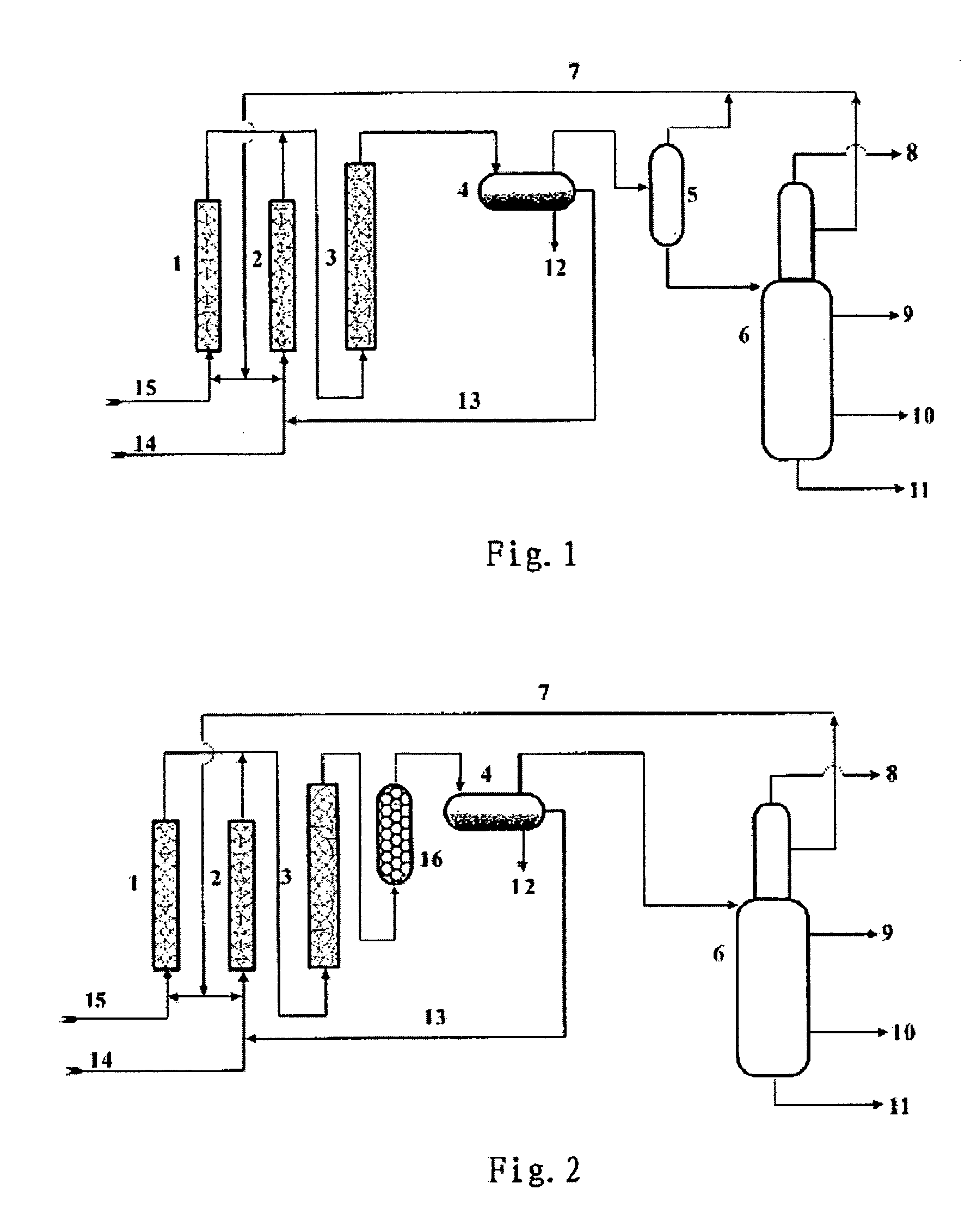

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

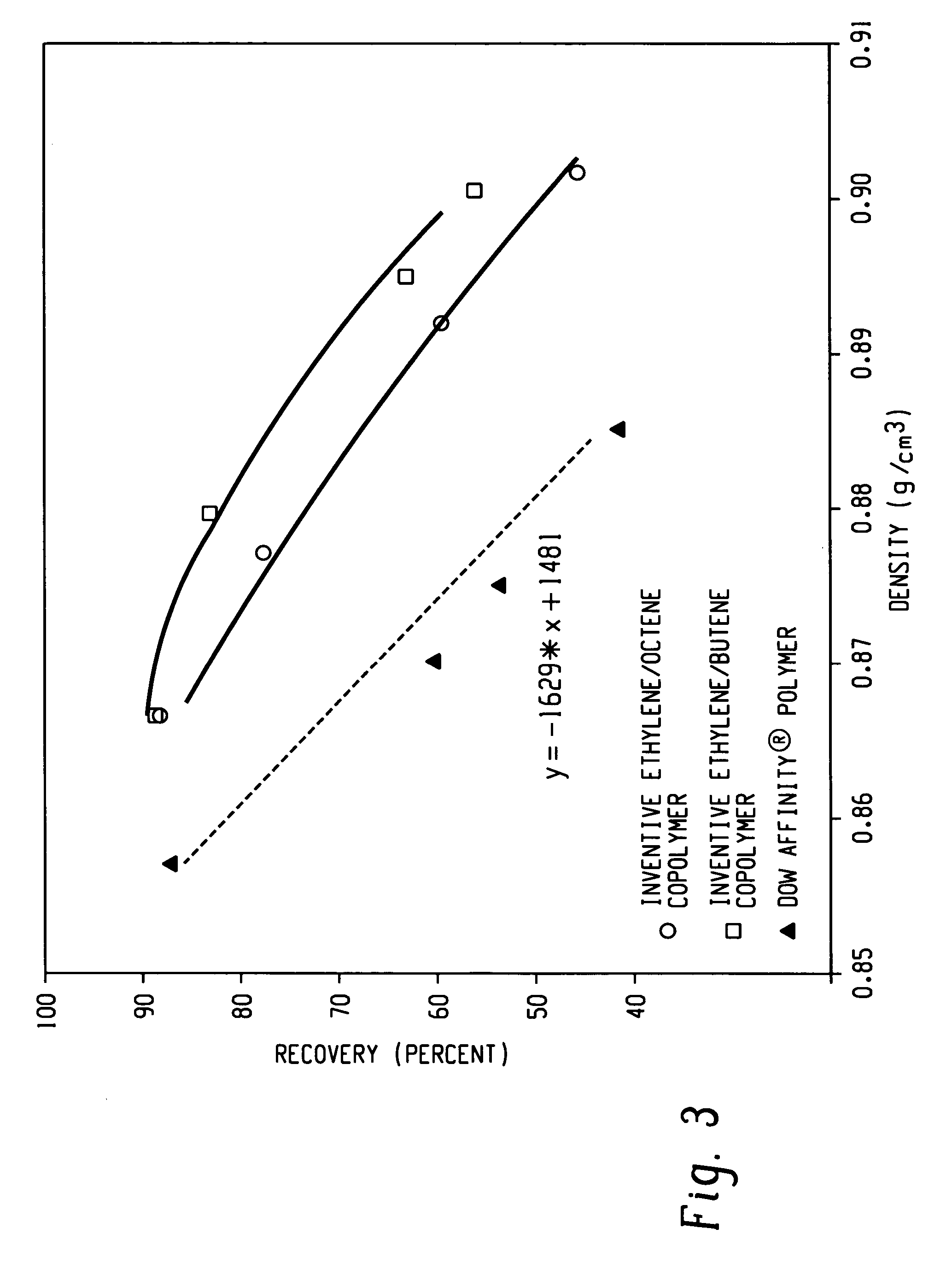

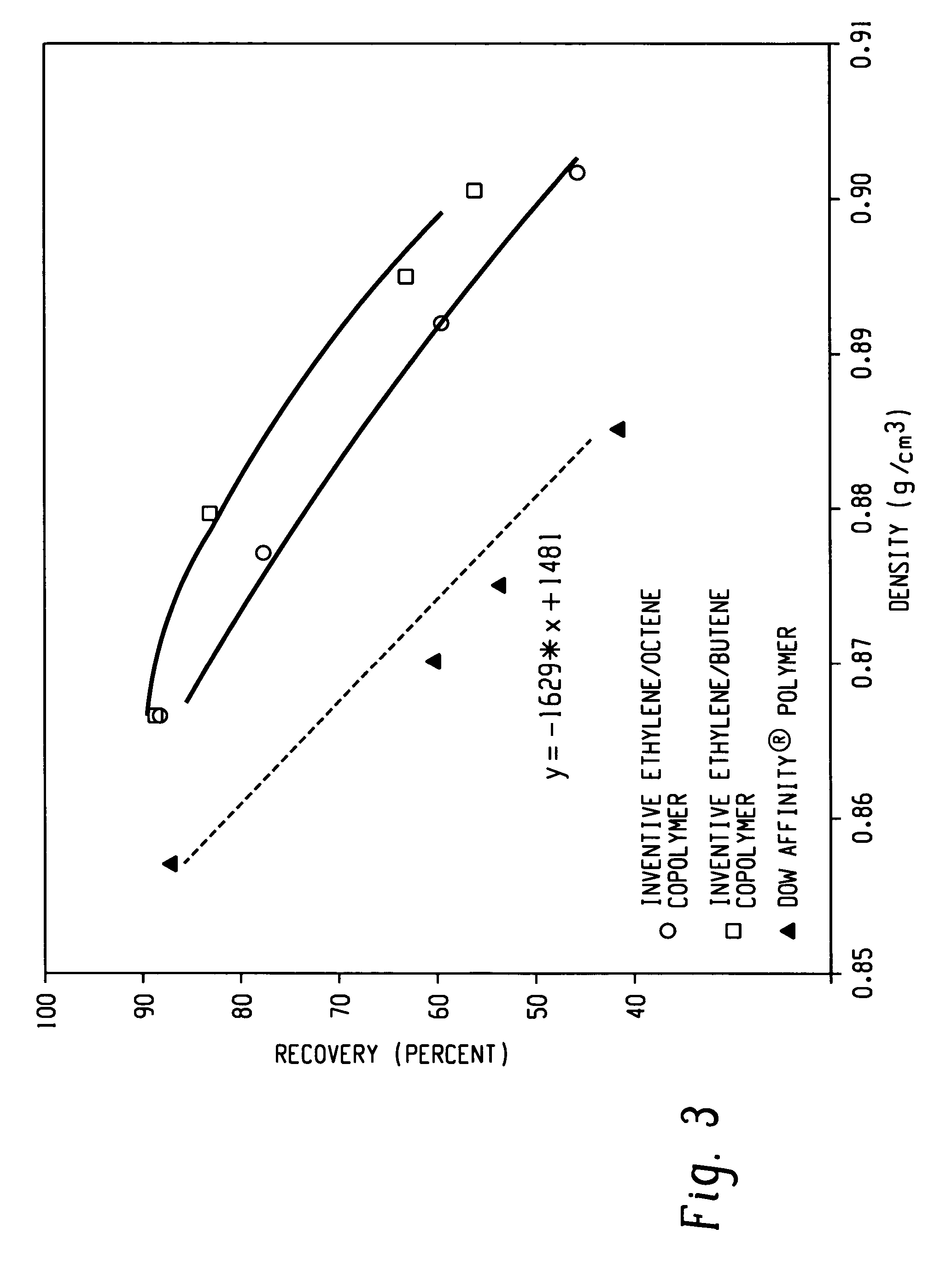

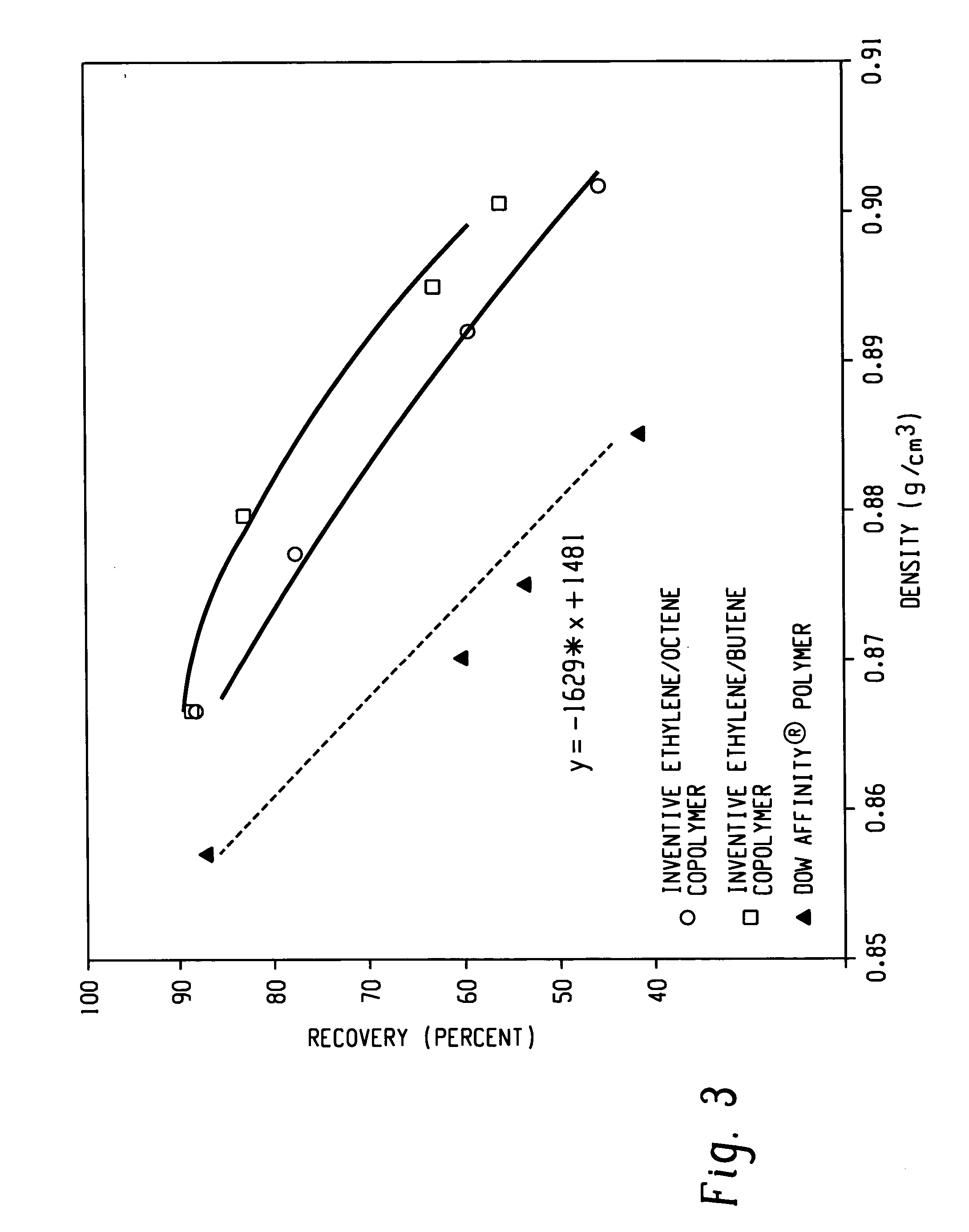

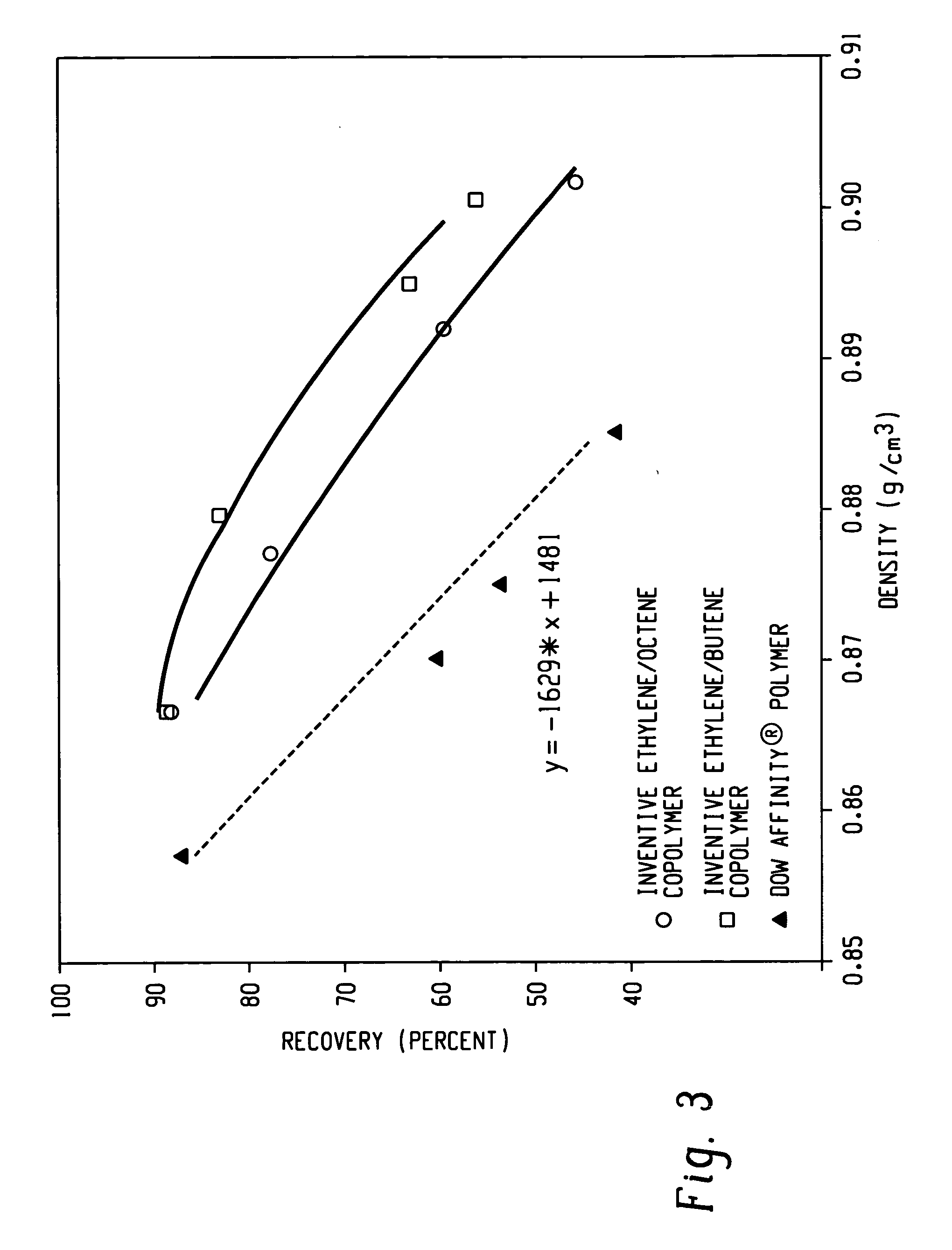

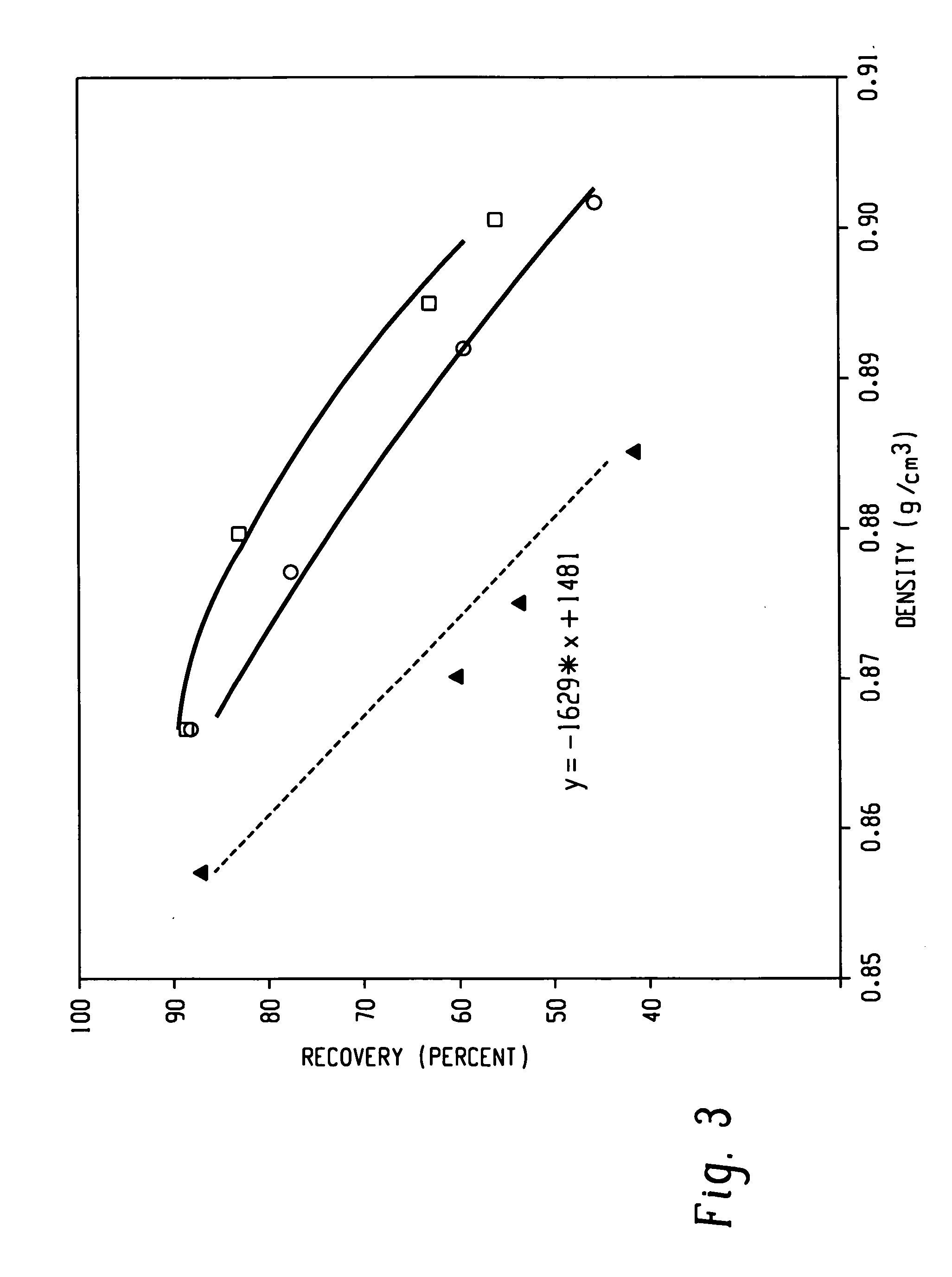

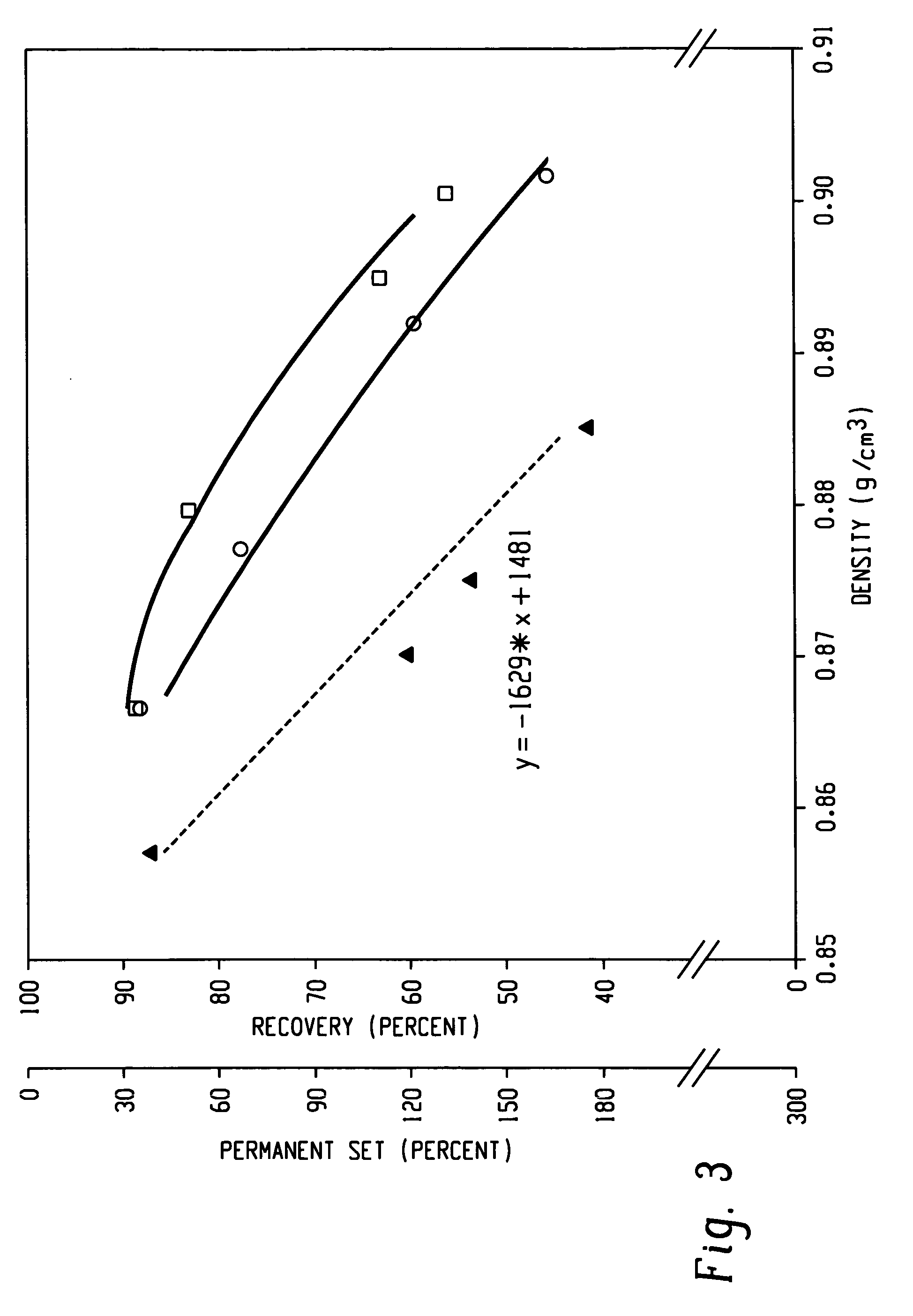

Fibers made from copolymers of ethylene/alpha-olefins

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

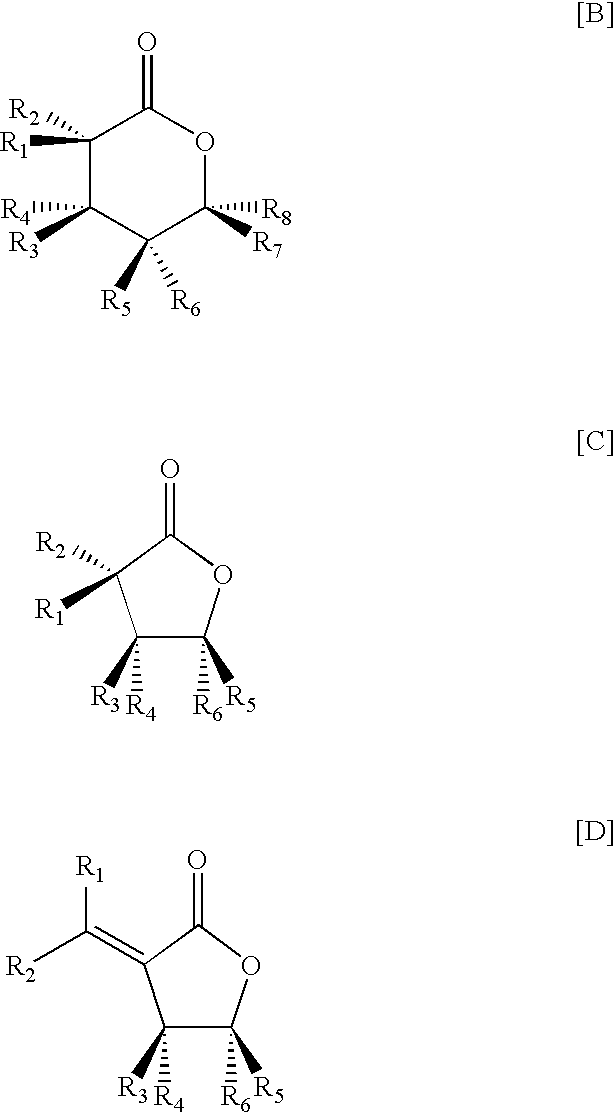

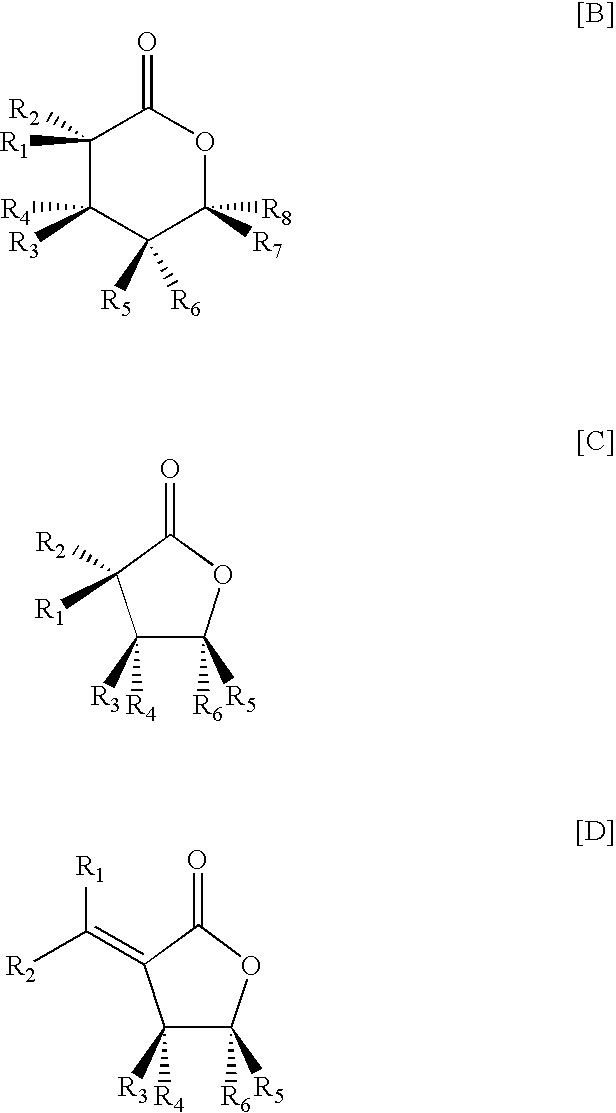

Topologically segregated, encoded solid phase libraries comprising linkers having an enzymatically susceptible bond

The invention relates to libraries of synthetic test compound attached to separate phase synthesis supports. In particular, the invention relates to libraries of synthetic test compound attached to separate phase synthesis supports that also contain coding molecules that encode the structure of the synthetic test compound. The molecules may be polymers or multiple nonpolymeric molecules. Each of the solid phase synthesis support beads contains a single type of synthetic test compound. The synthetic test compound can have backbone structures with linkages such as amide, urea, carbamate (i.e., urethane), ester, amino, sulfide, disulfide, or carbon-carbon, such as alkane and alkene, or any combination thereof. Examples of subunits suited for the different linkage chemistries are provided. The synthetic test compound can also be molecular scaffolds, such as derivatives of monocyclic of bicyclic carbohydrates, steroids, sugars, heterocyclic structures, polyaromatic structures, or other structures capable of acting as a scaffolding. Examples of suitable molecular scaffolds are provided. The invention also relates to methods of synthesizing such libraries and the use of such libraries to identify and characterize molecules of interest from among the library of synthetic test compound.

Owner:AVENTIS PHARMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com