Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3886 results about "Comonomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In polymer chemistry, a comonomer refers a polymerizable precursor to a copolymer aside from the principal monomer. In some cases, only small amounts of a comonomer are employed, in other cases substantial amounts of comonomers are used. Furthermore, in some cases, the comonomers are statistically incorporated within the polymer chain, whereas in other cases, they aggregate. The distribution of comonomers is referred to as the "blockiness" of a copolymer. 1-Octene, 1-hexene, and 1-butene are used comonomers in the manufacture of polyethylenes. The advantages to such copolymers has led to a focus on catalysts that facilitate the incorporation of these comonomers, e.g., constrained geometry complexes.

Isotactic propylene copolymers, their preparation and use

InactiveUS6960635B2Group 4/14 element organic compoundsOther chemical processesFiberZiegler–Natta catalyst

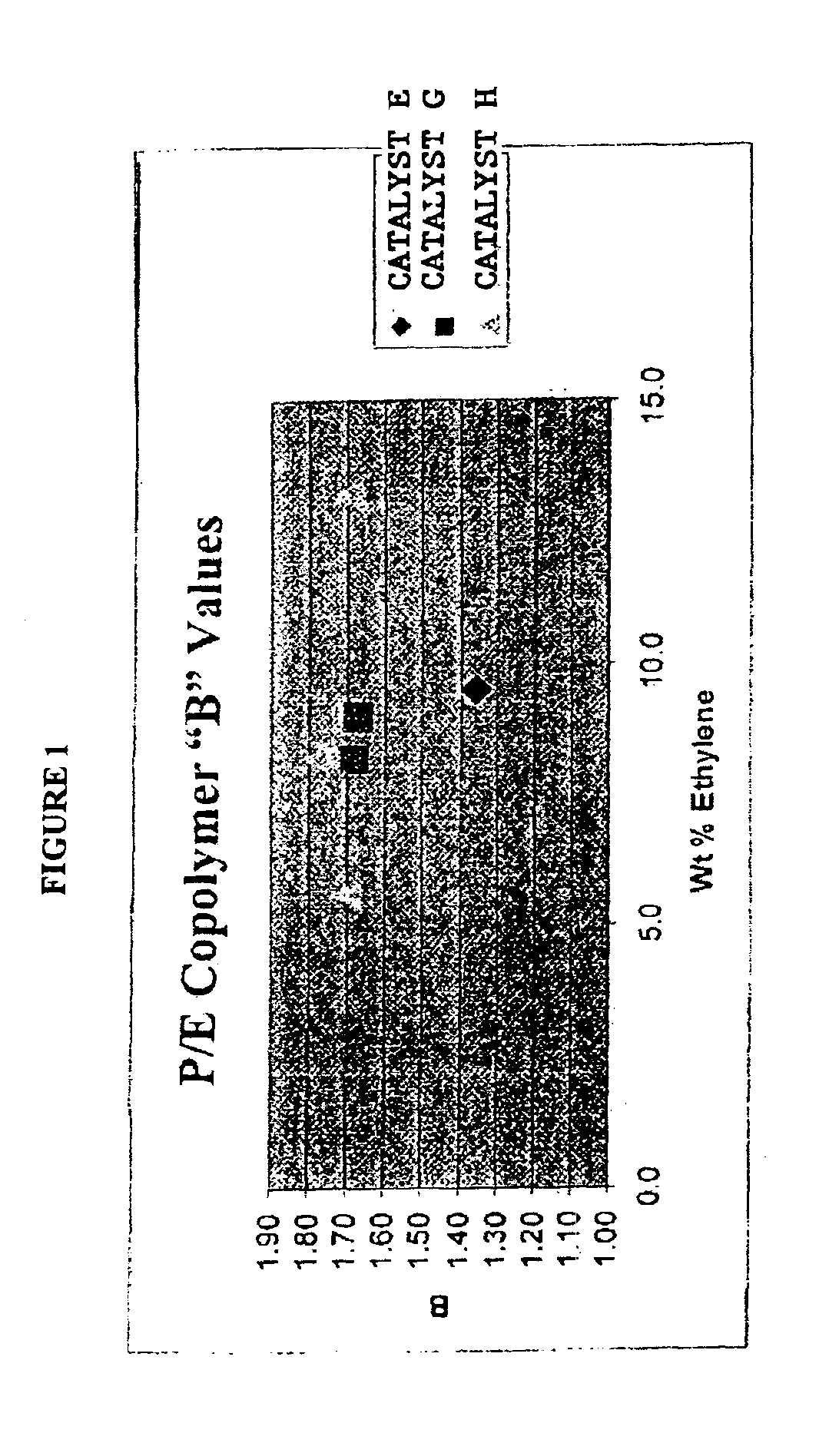

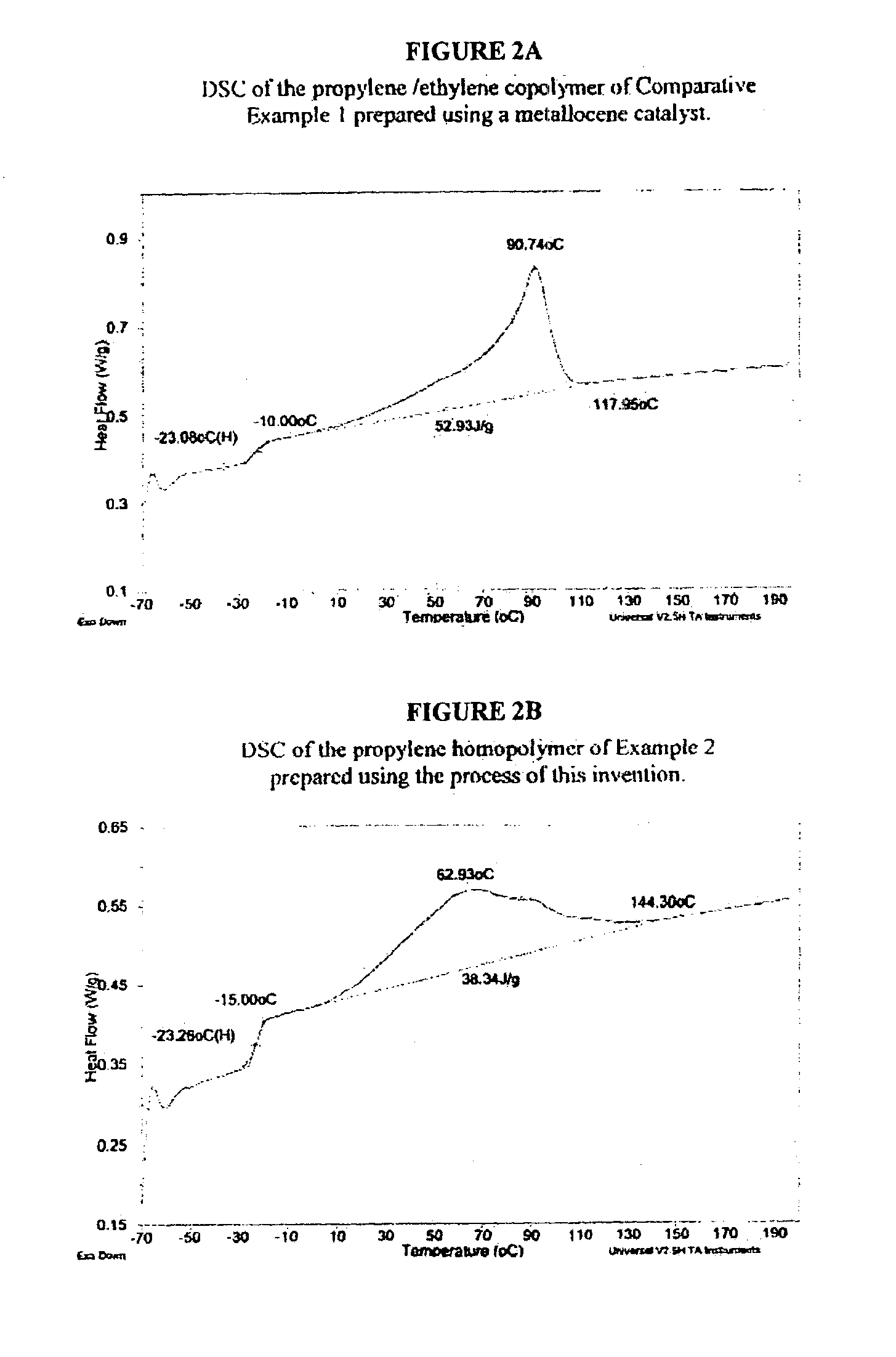

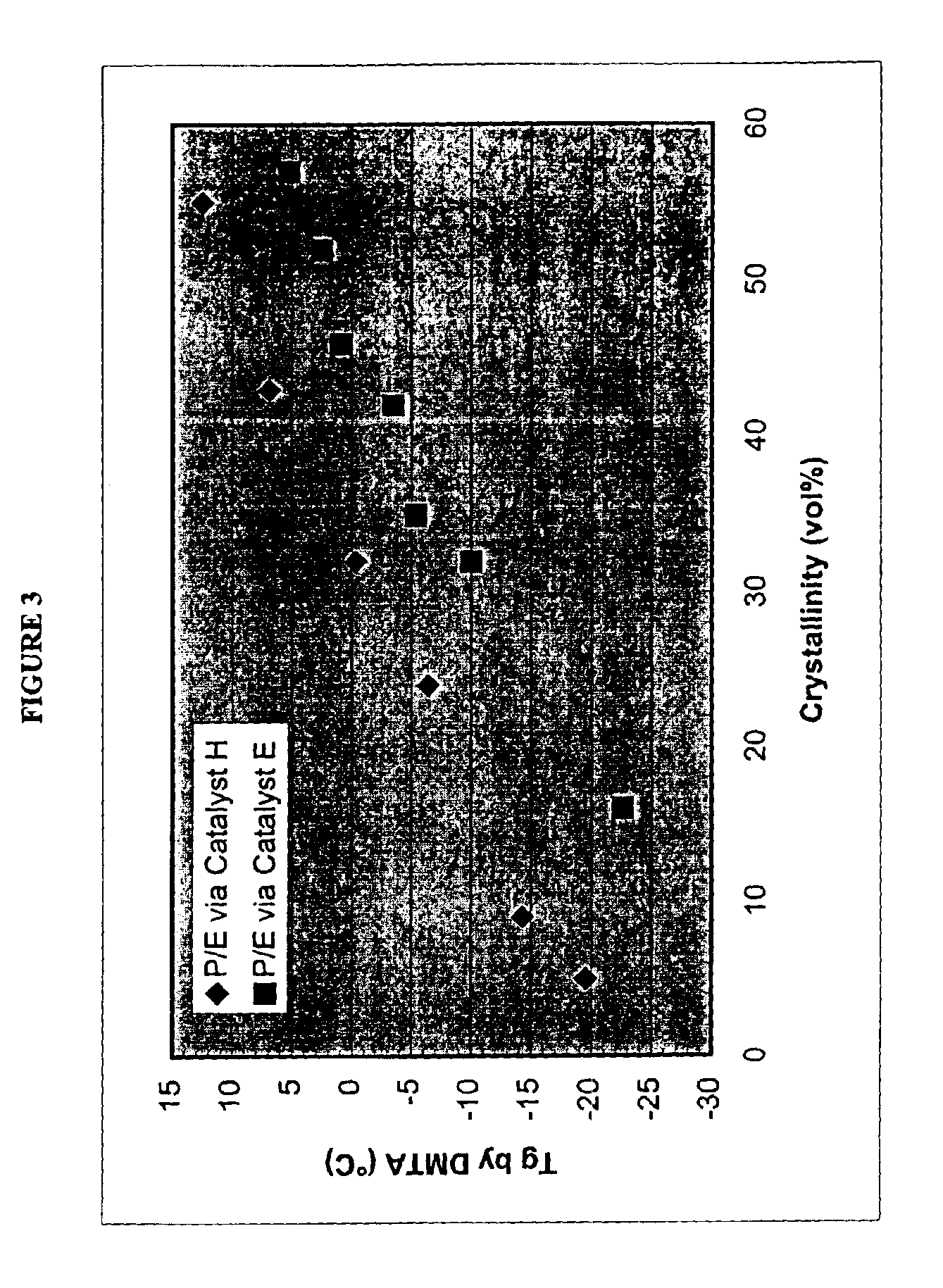

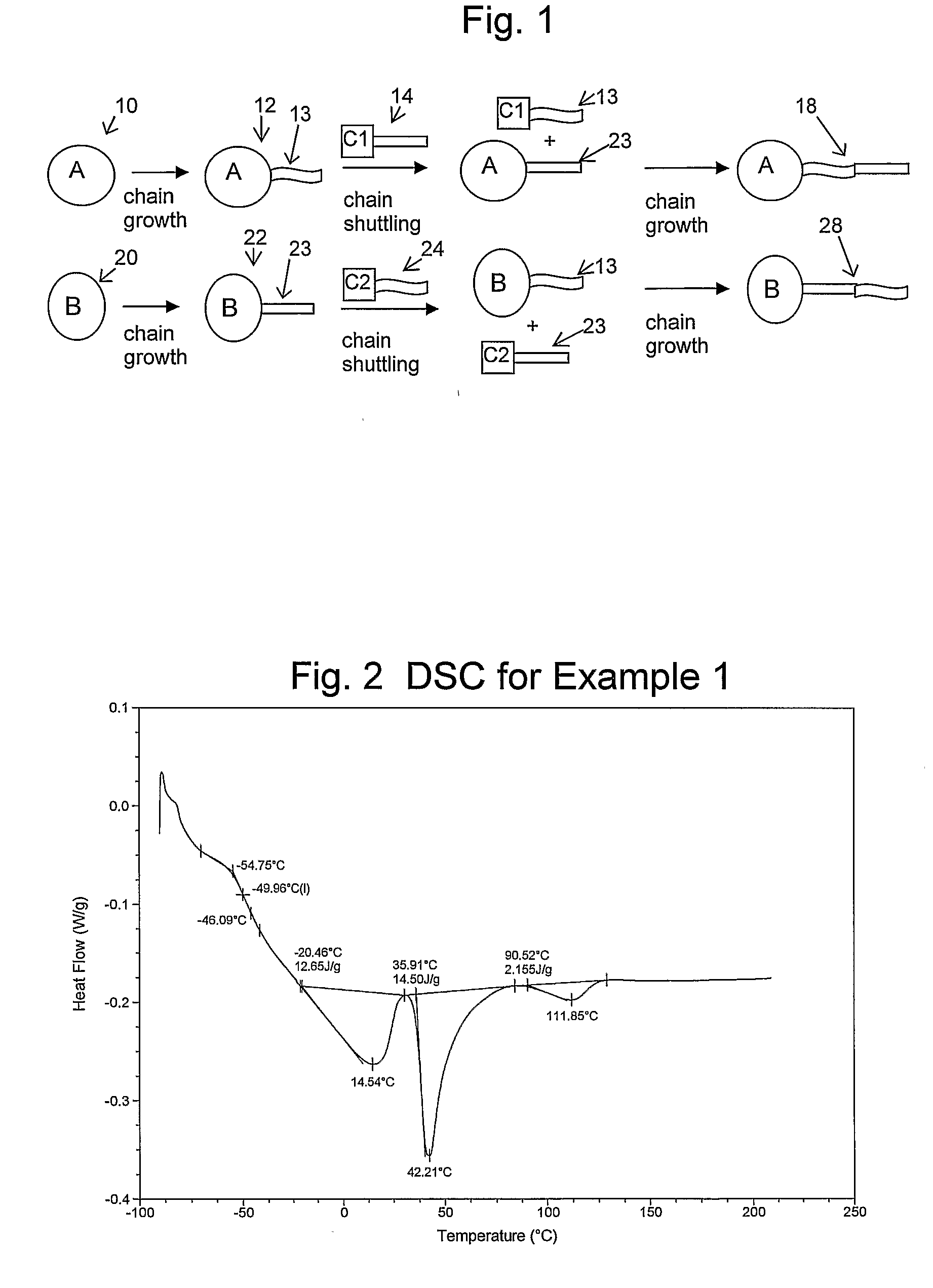

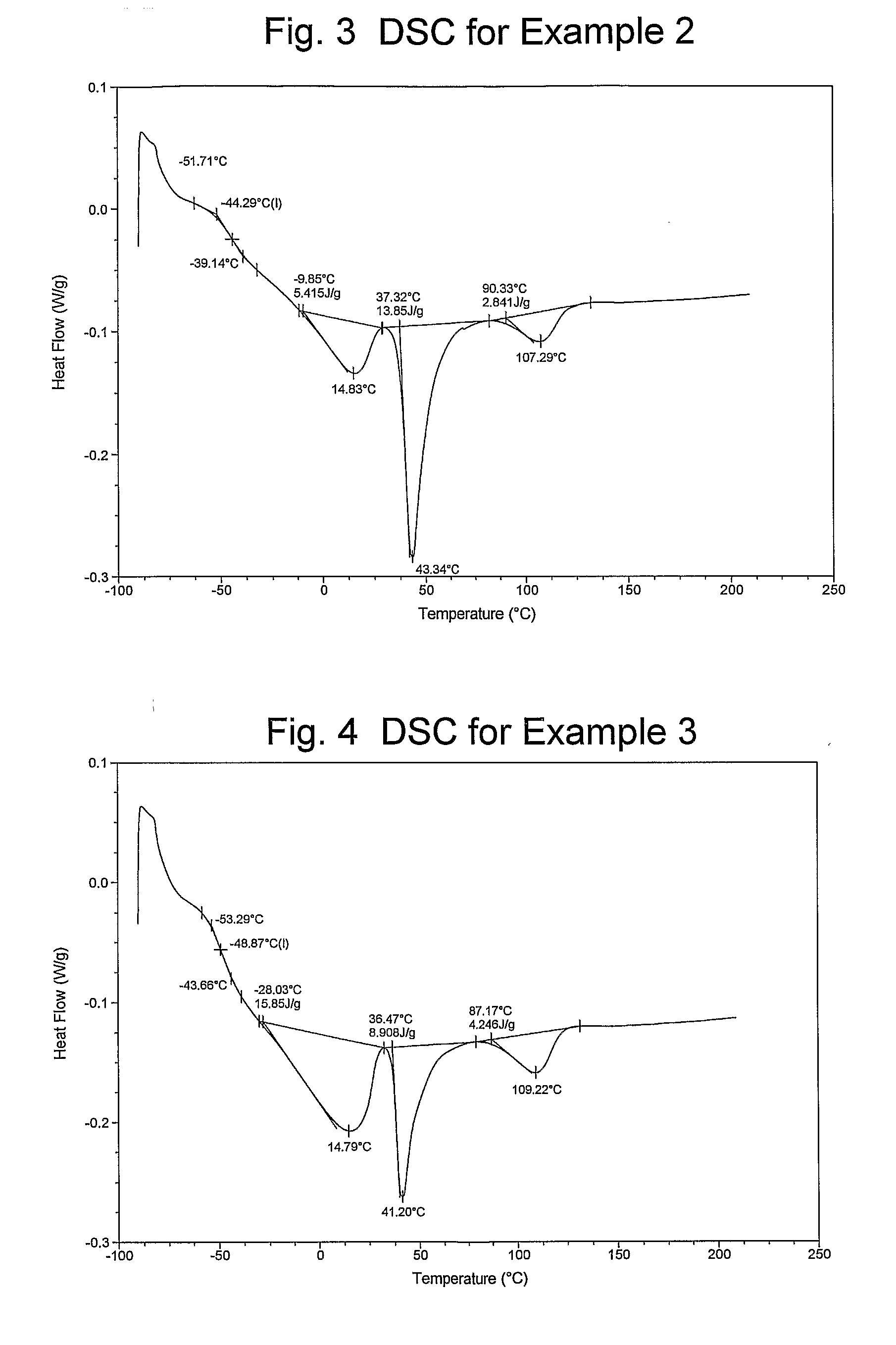

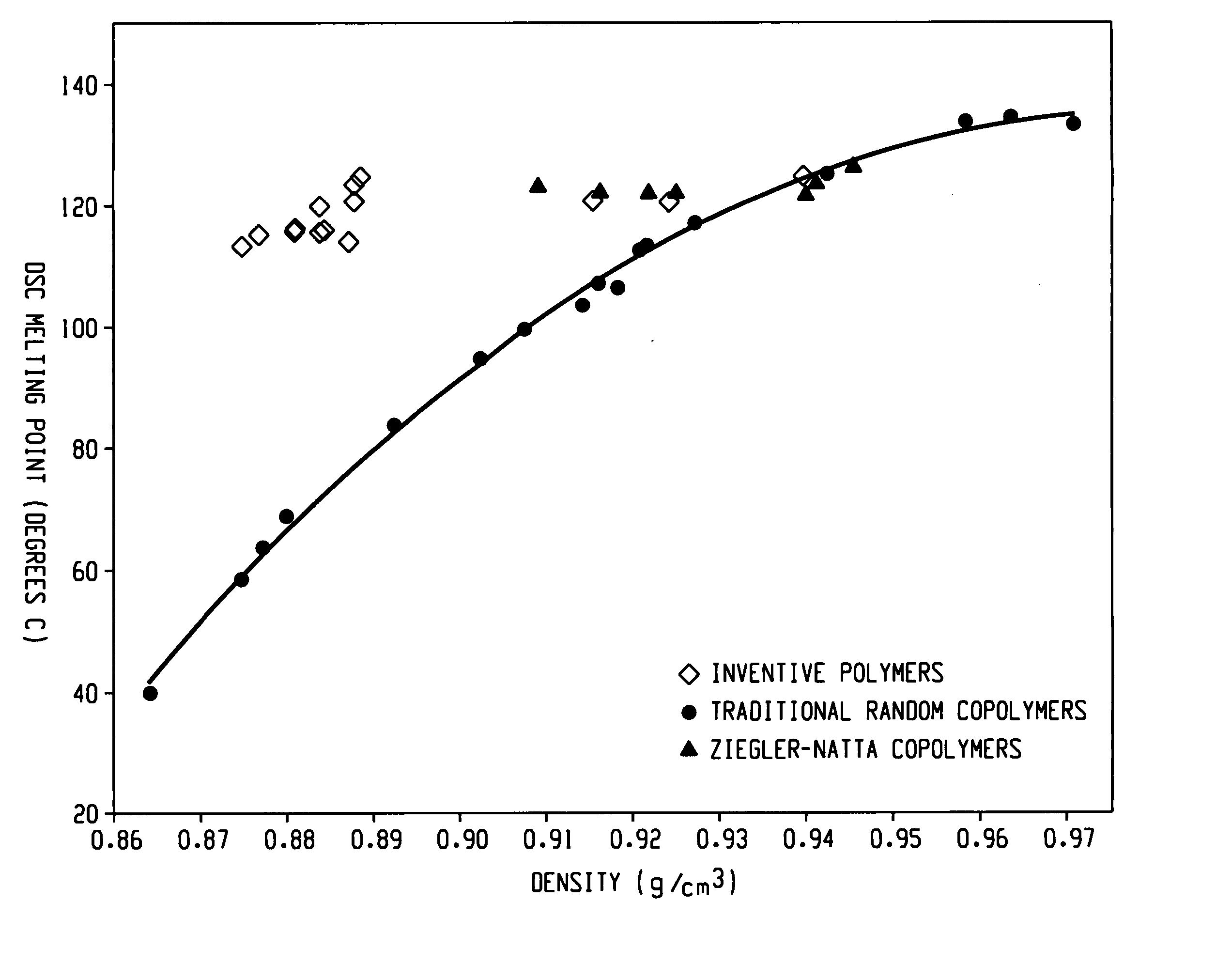

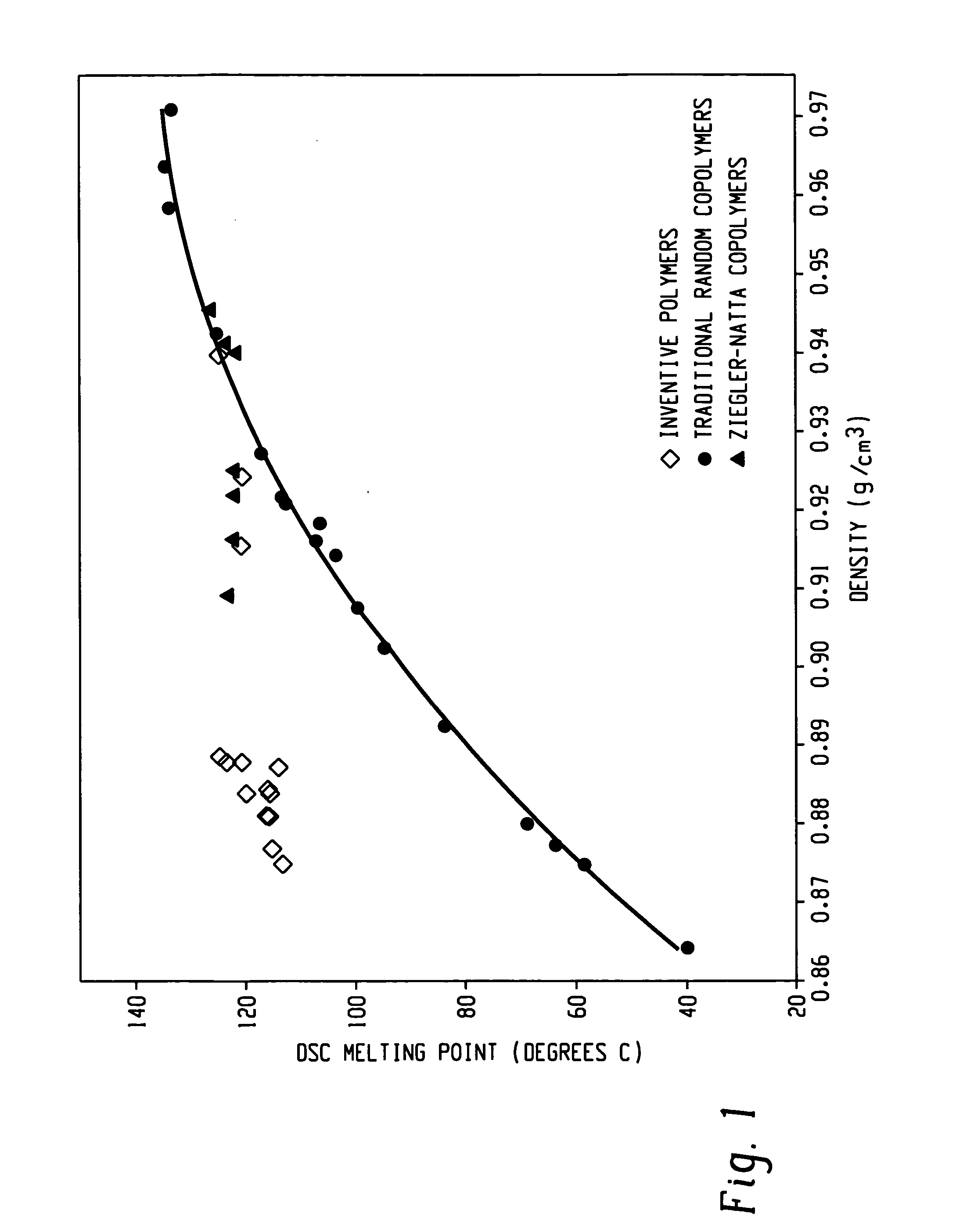

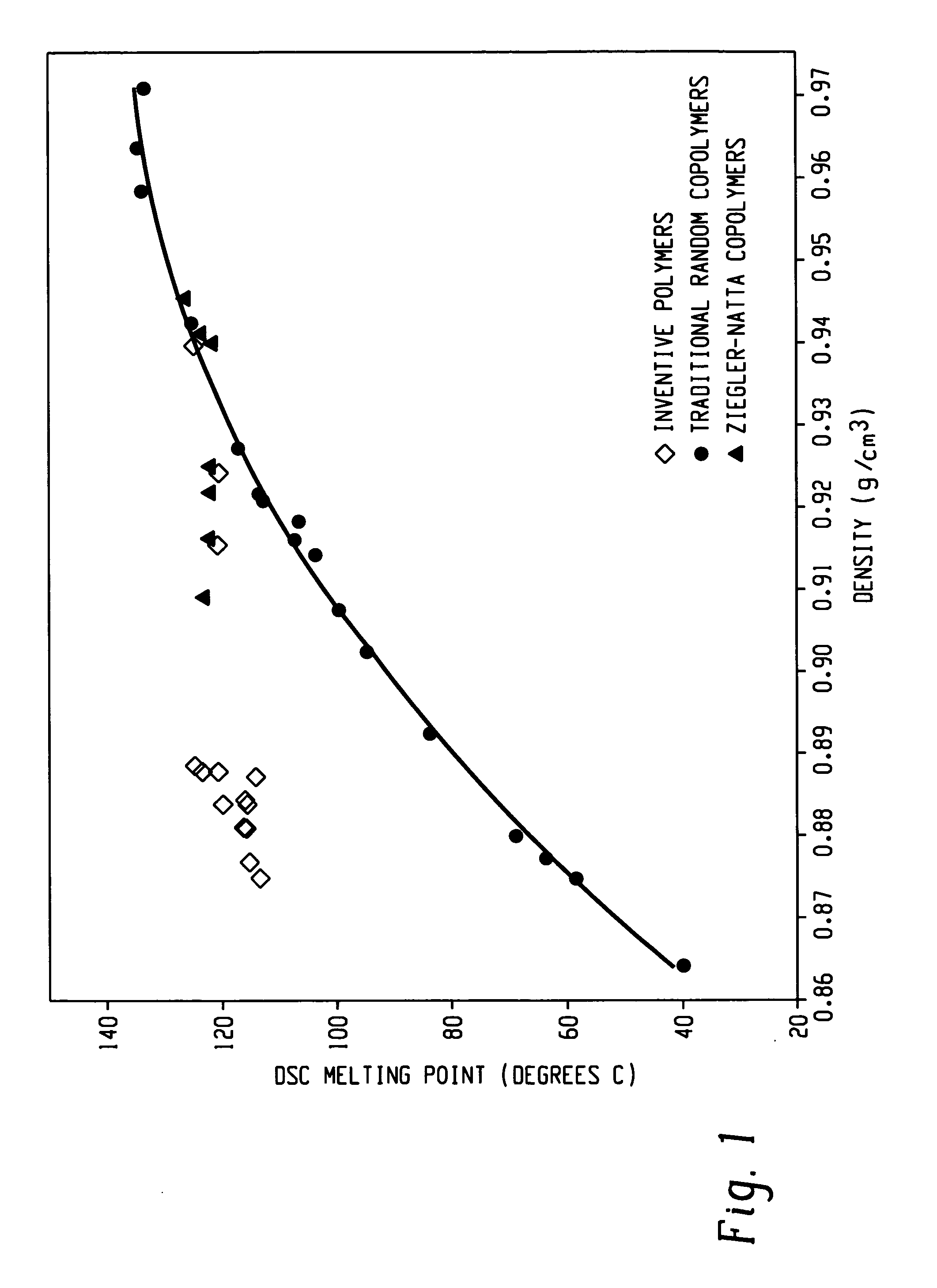

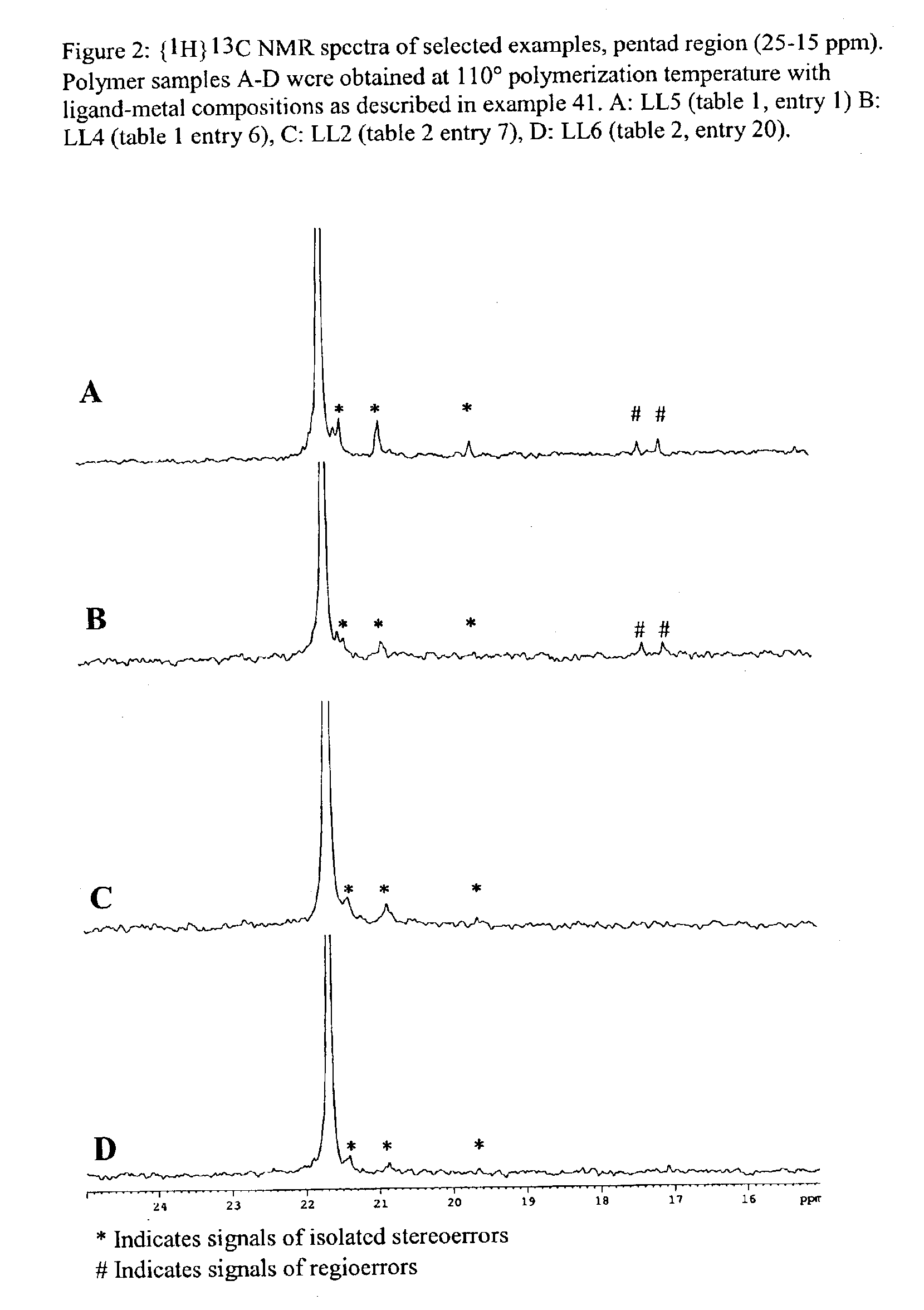

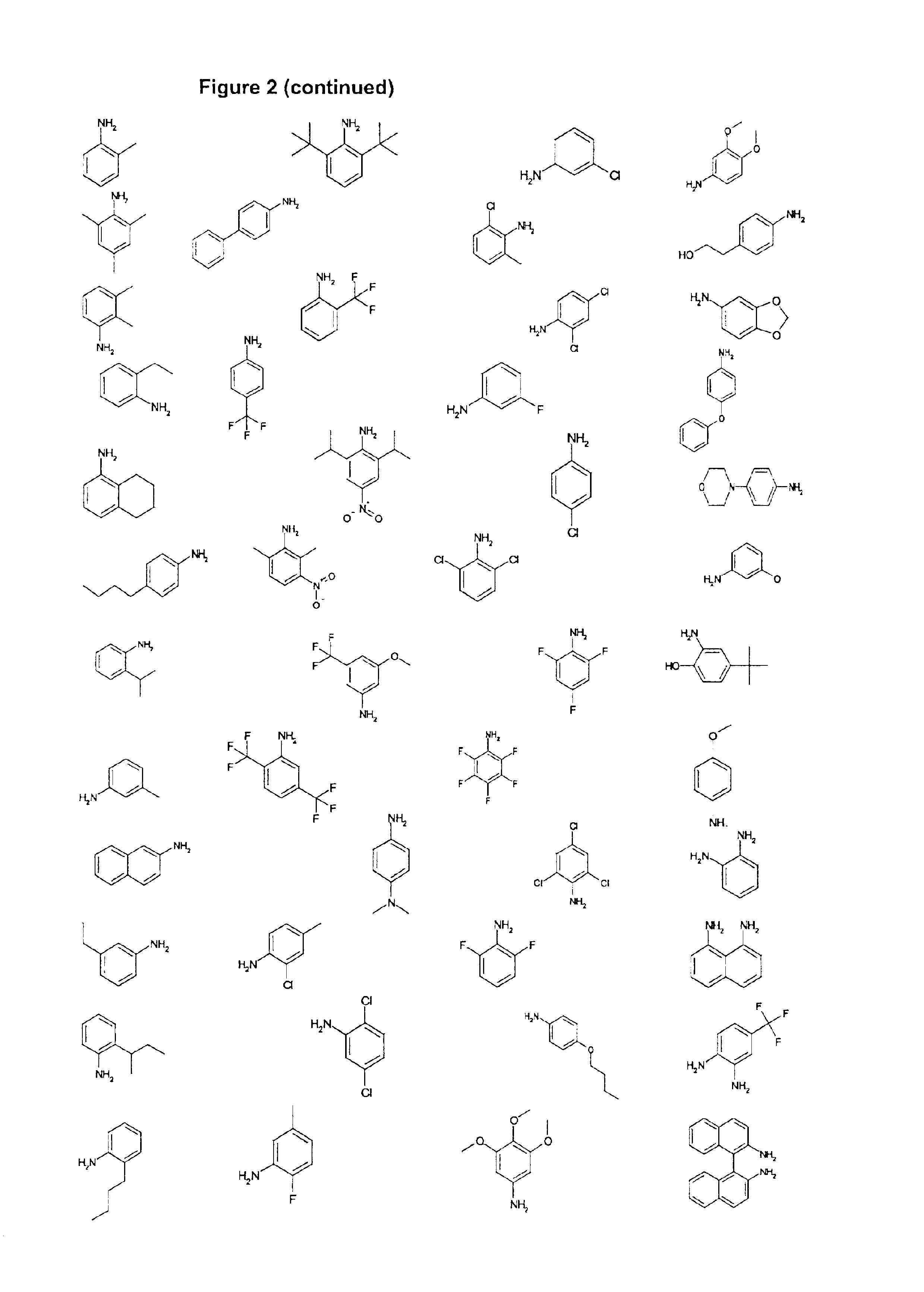

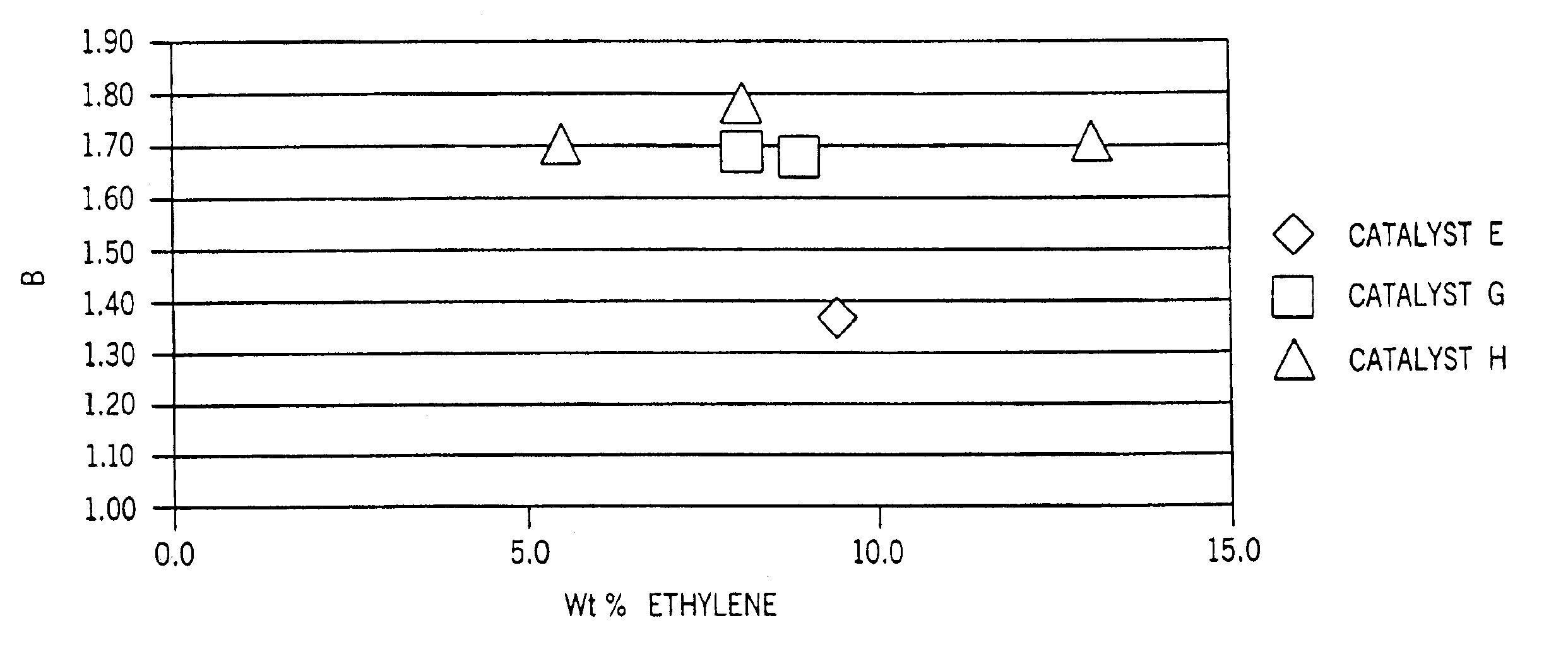

Unique copolymers comprising propylene, ethylene and / or one or more unsaturated comonomers are characterized as having: at least one, preferably more than one, of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta catalyst. These polypropylene polymers are made using a nonmetallocene, metal-centered, heteroaryl ligand catalyst. These polymers can be blended with other polymers, and are useful in the manufacture of films, sheets, foams, fibers and molded articles.

Owner:DOW GLOBAL TECH LLC

Copolymers of tetrafluoroethylene

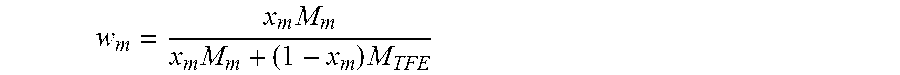

ActiveUS7531611B2Synthetic resin layered productsThin material handlingBreaking strengthTetrafluoroethylene

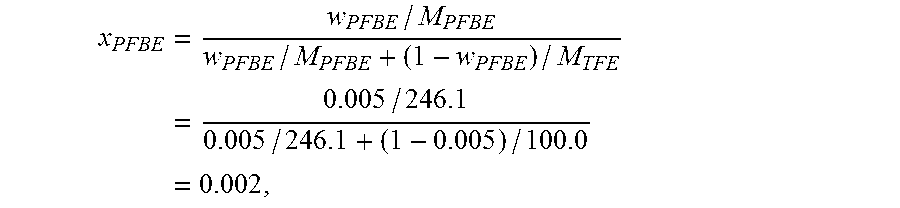

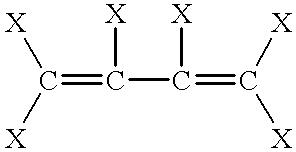

A polymerization process for producing a tetrafluoroethylene copolymer, and the copolymer produced thereby, are provided. The copolymer is of the dispersion / fine powder type and contains polymerized tetrafluoroethylene monomer units and co-polymerized higher homologous comonomer units having the formula (CnF(2n+1))CH═CH2, wherein 6≦n<10, in which the primary particles are believed to have a core and shell structure and the polymerized comonomer units are present in an amount from 0.01 mol % to 0.3 mol %, based upon total copolymer composition. The copolymer has a raw dispersion primary particle size (RDPS) of less than 0.210 microns coupled with a standard specific gravity (SSG) of less than 2.143. Preferably the copolymer has comonomer units present in an amount from 0.05 mol % and 0.25 mol % and the RDPS is within the range between 0.178 microns and 0.200 microns, coupled with a SSG of less than 2.140. Copolymers produced according to the invention, (perfluorohexyl)ethylene (PFHE) and (perfluorooctyl)ethylene (PFOE), may be shaped into the form of 0.1 inch diameter expanded beading, which expanded beading can have a break strength of at least 10.0 lbs, and which may exceed 13.0 lbs.

Owner:WL GORE & ASSOC INC

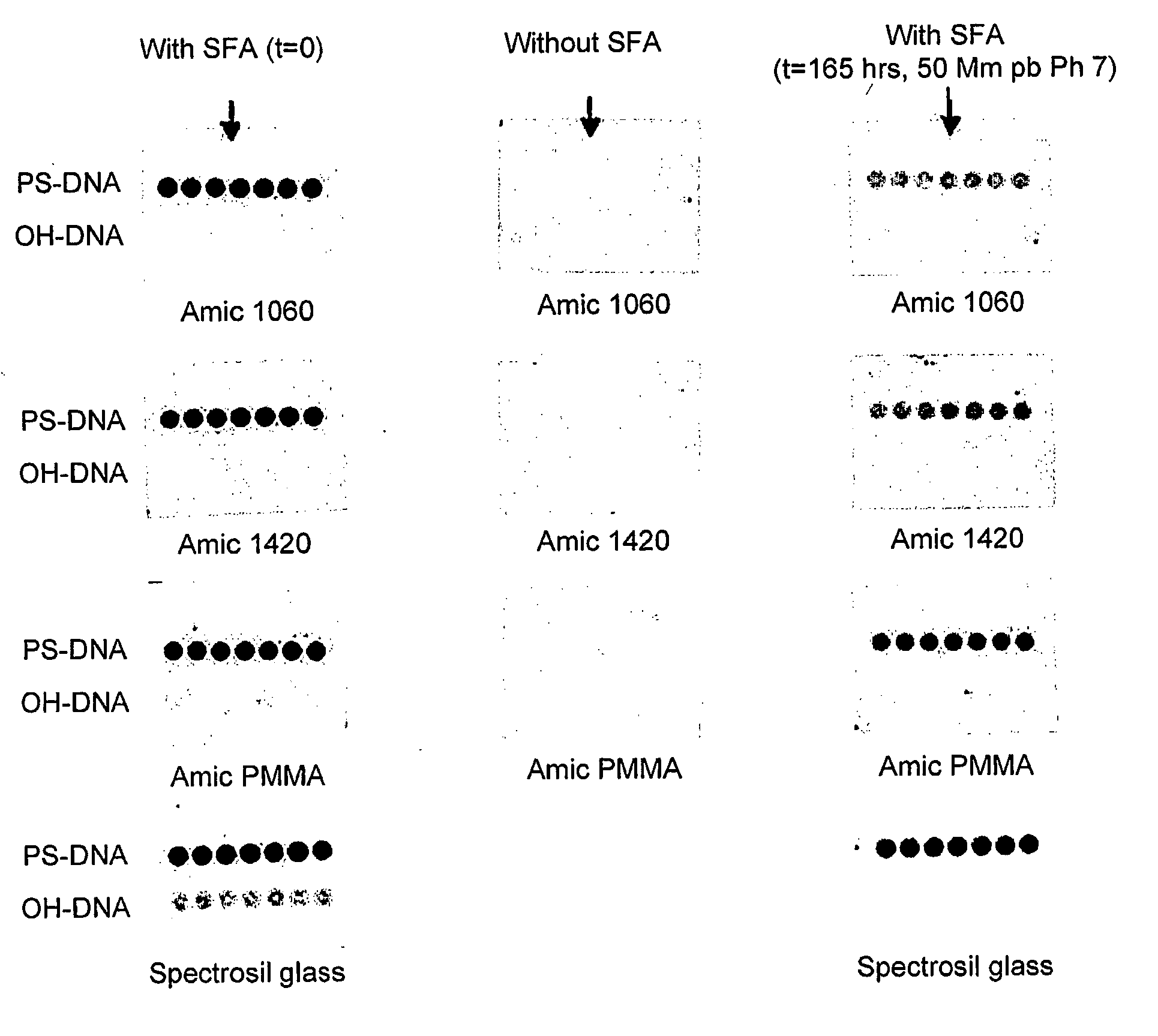

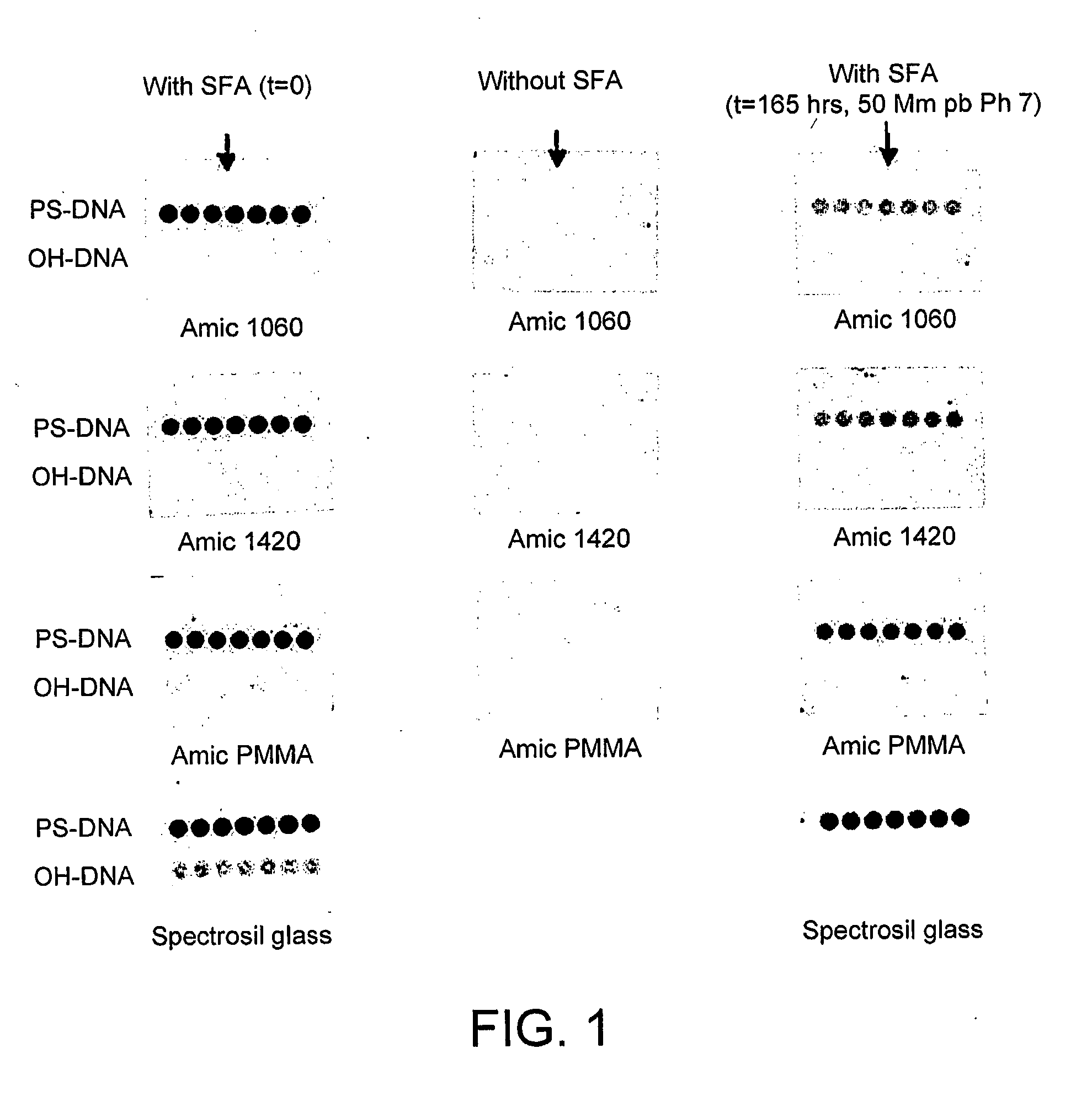

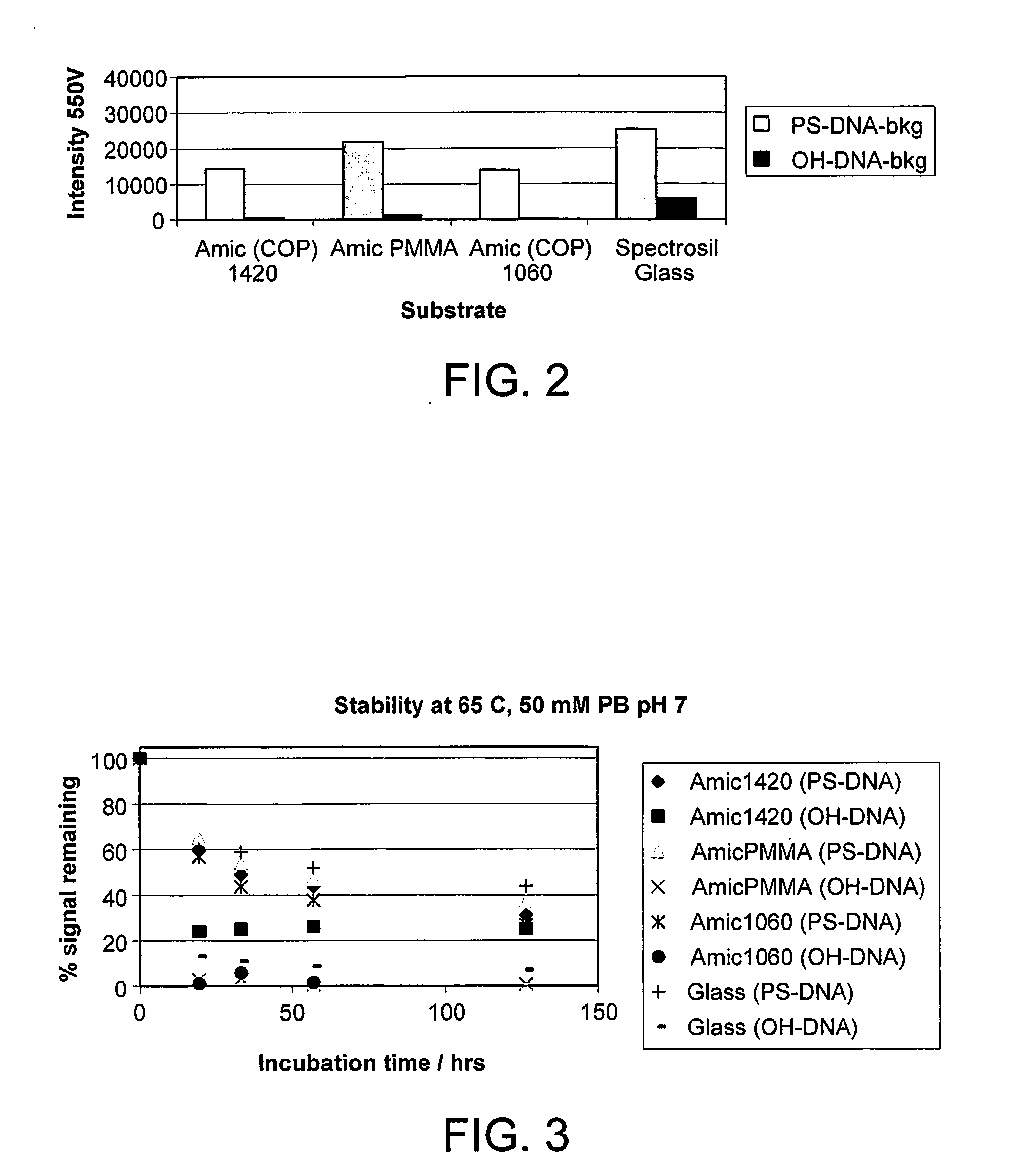

Modified Molecular Arrays

InactiveUS20110059865A1Less reactiveAccelerated programSequential/parallel process reactionsNucleotide librariesMolecular array(Hydroxyethyl)methacrylate

The invention relates to the preparation of a hydrogel surface useful in the formation and manipulation of arrays of molecules, particularly polynucleotides and to the chemical modification of these and other arrays. In particular, the invention relates to a method of preparing a hydrogel immobilised to a solid support comprising polymerising on the support a mixture of a first comonomer which is acrylamide, methacrylamide, hydroxyethyl methacrylate or N-vinyl pyrrolidinone and a second comonomer which is a functionalised acrylamide or acrylate.

Owner:ILLUMINA CAMBRIDGE LTD

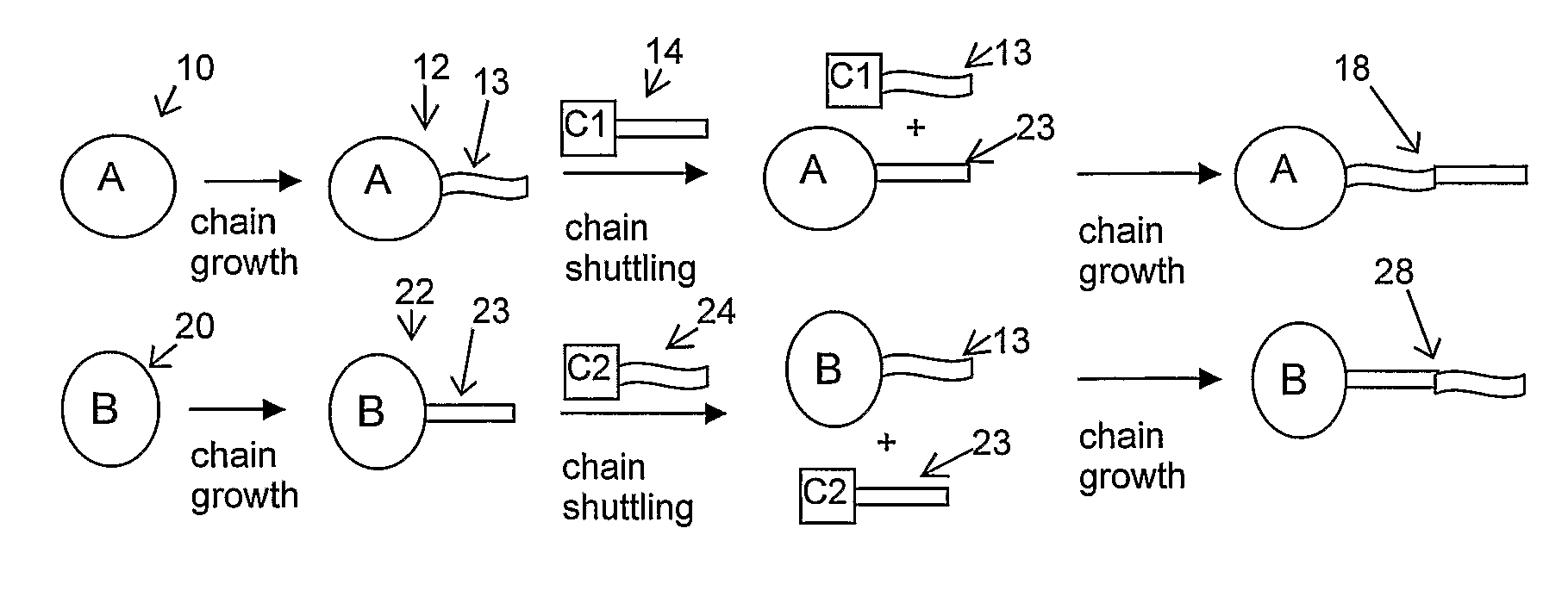

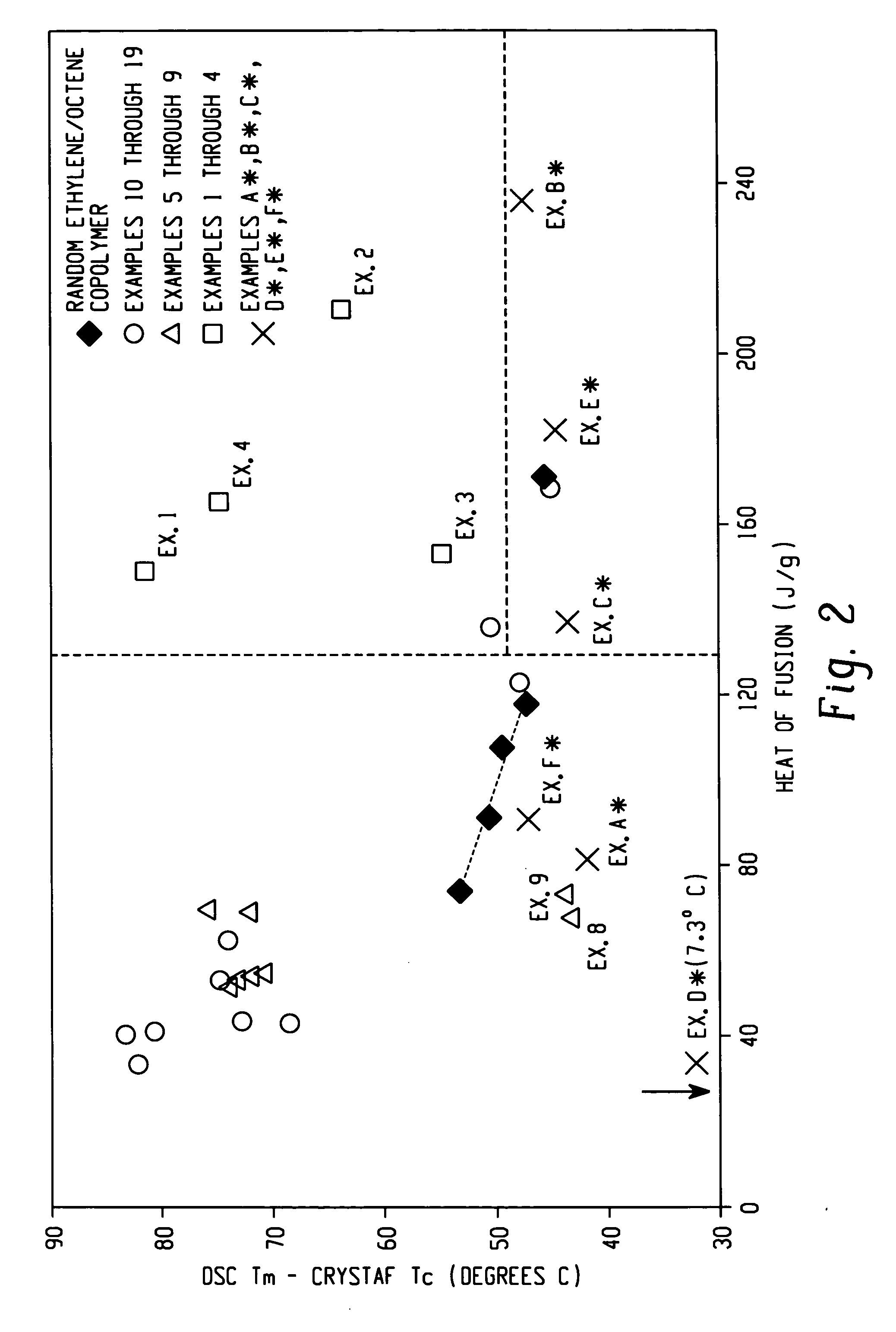

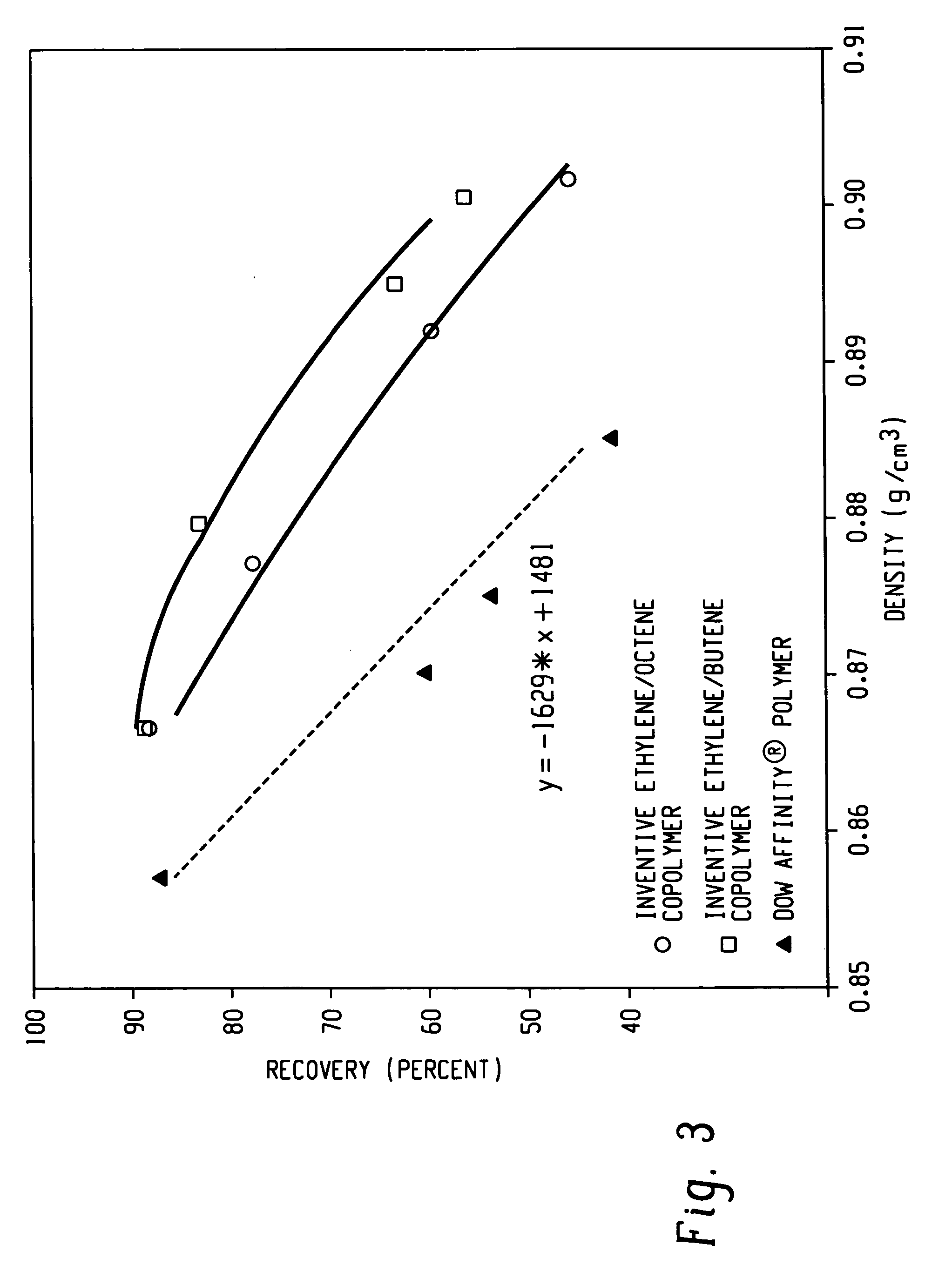

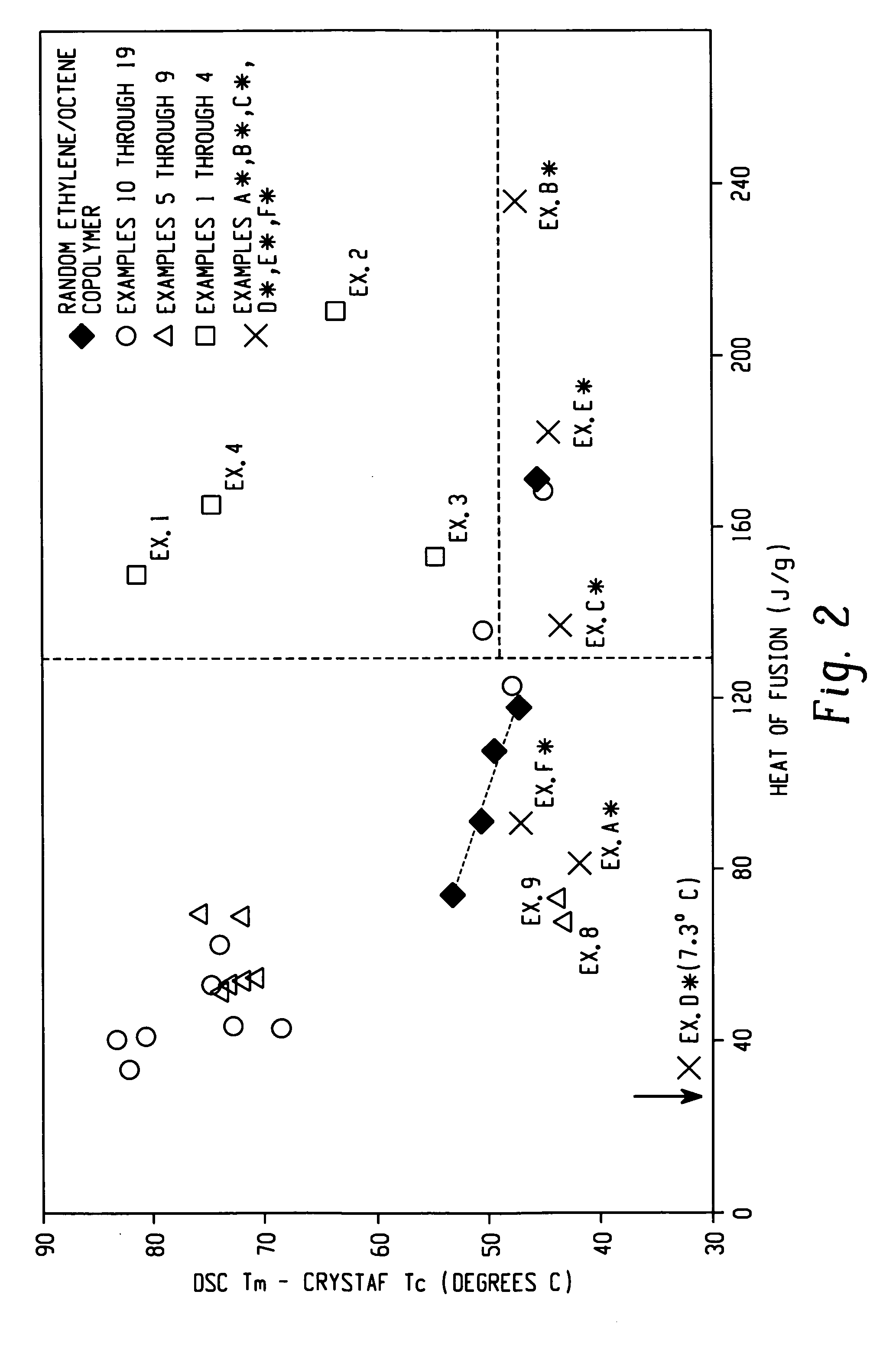

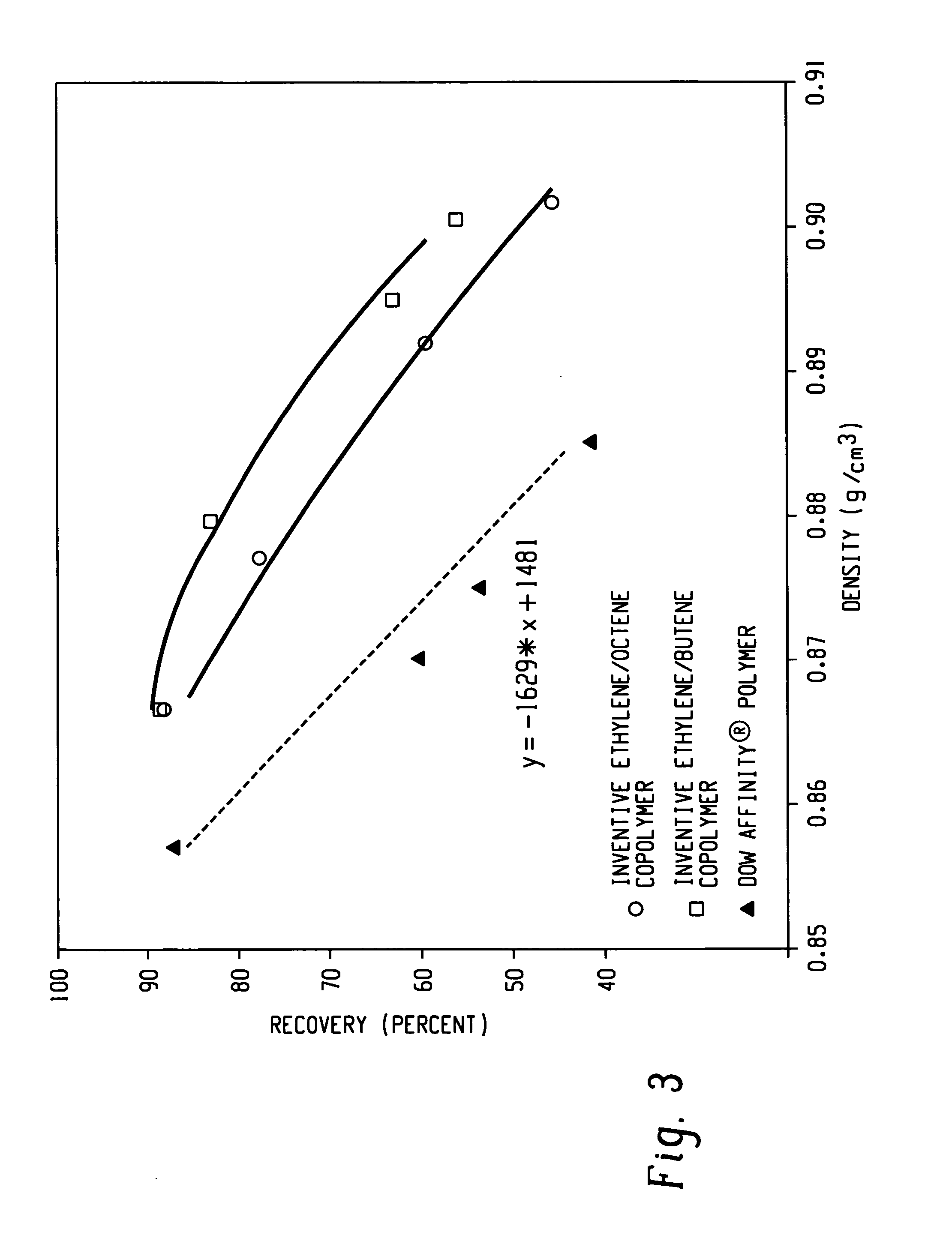

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

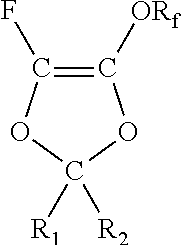

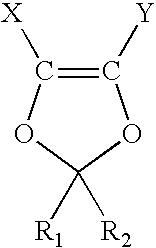

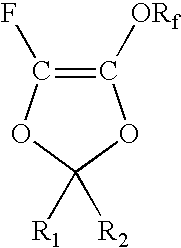

Expandable Functional TFE Copolymer Fine Powder, the Expandable Functional Products Obtained Therefrom and Reaction of the Expanded Products

A functional TFE copolymer fine powder is described, wherein the TFE copolymer is a polymer of TFE and at least one functional comonomer, and wherein the TFE copolymer has functional groups that are pendant to the polymer chain. The functional TFE copolymer fine powder resin is paste extrudable and expandable. Methods for making the functional TFE copolymer are also described. The expanded functional TFE copolymer material may be post-reacted after expansion.

Owner:WL GORE & ASSOC INC

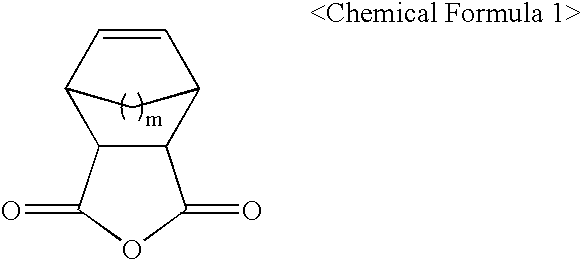

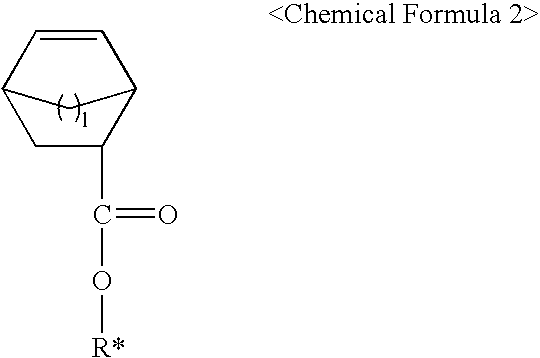

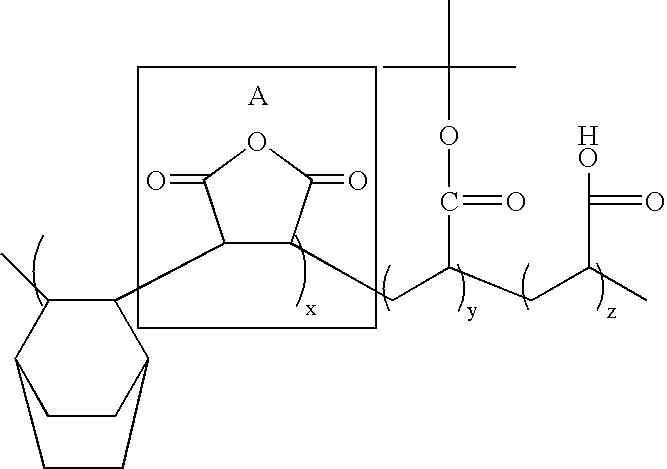

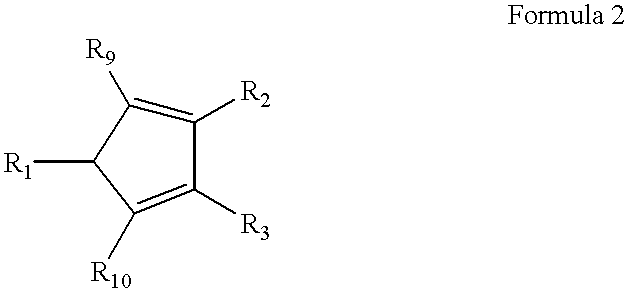

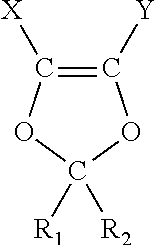

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

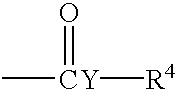

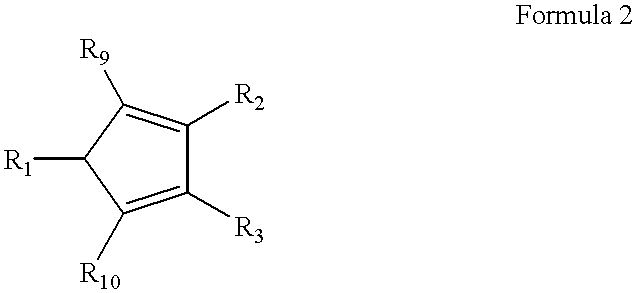

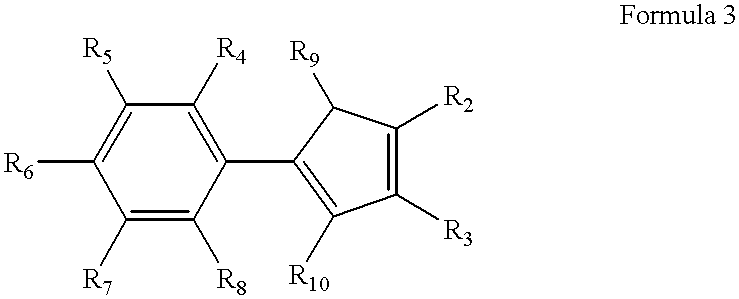

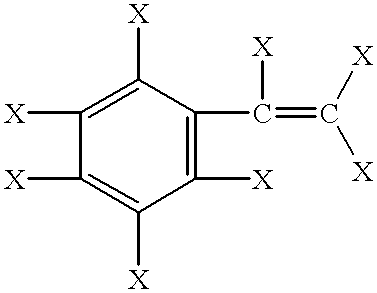

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

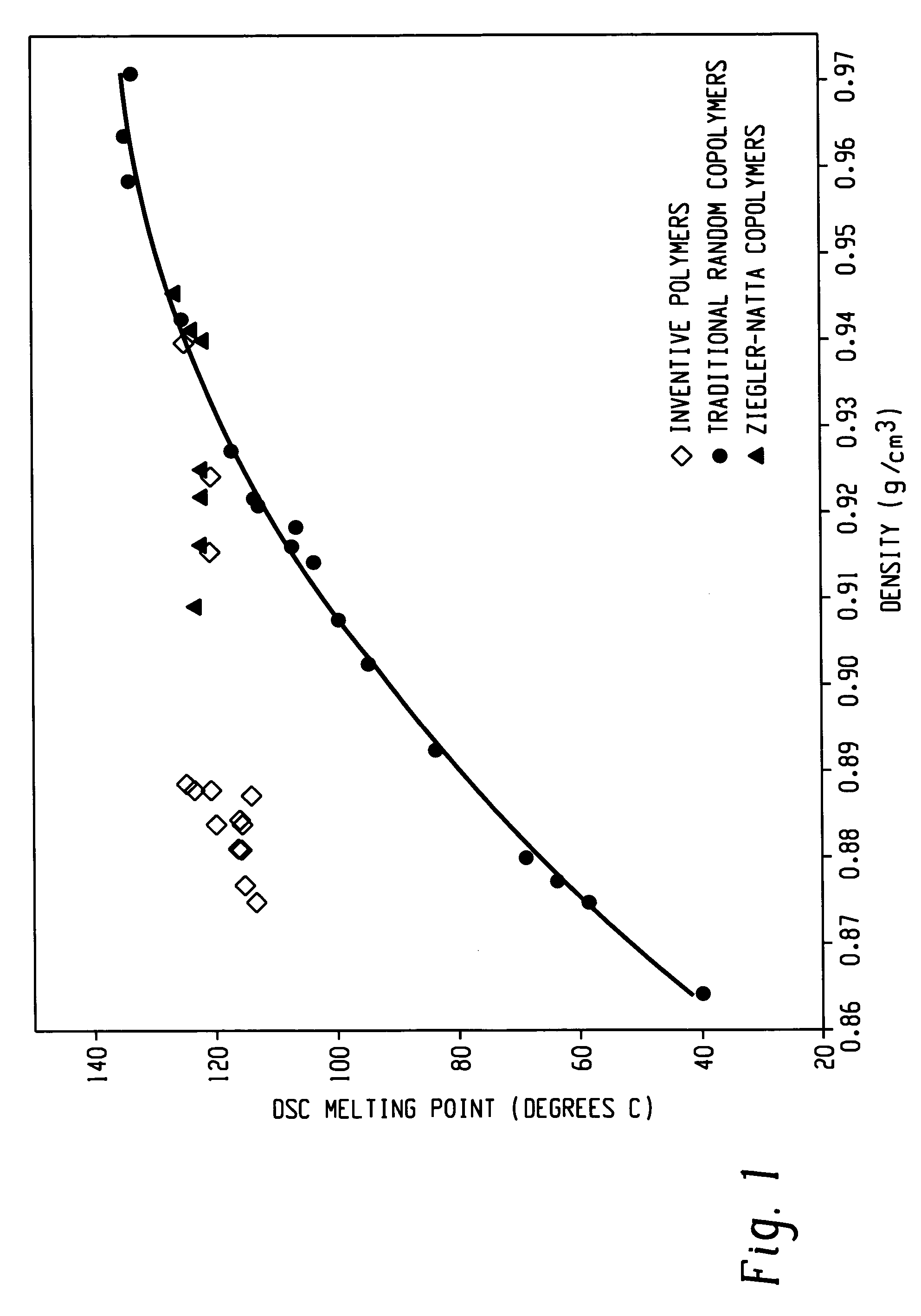

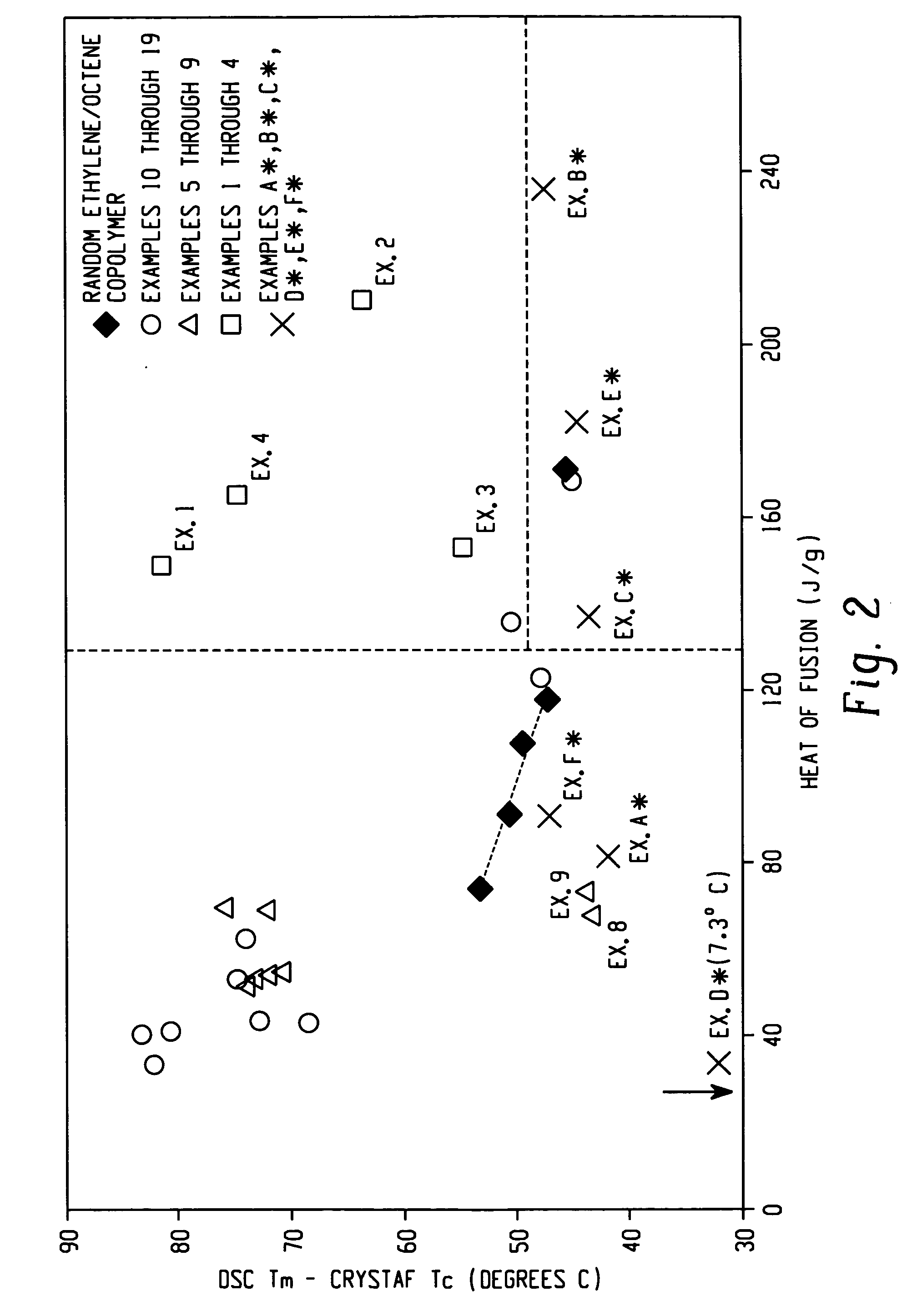

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

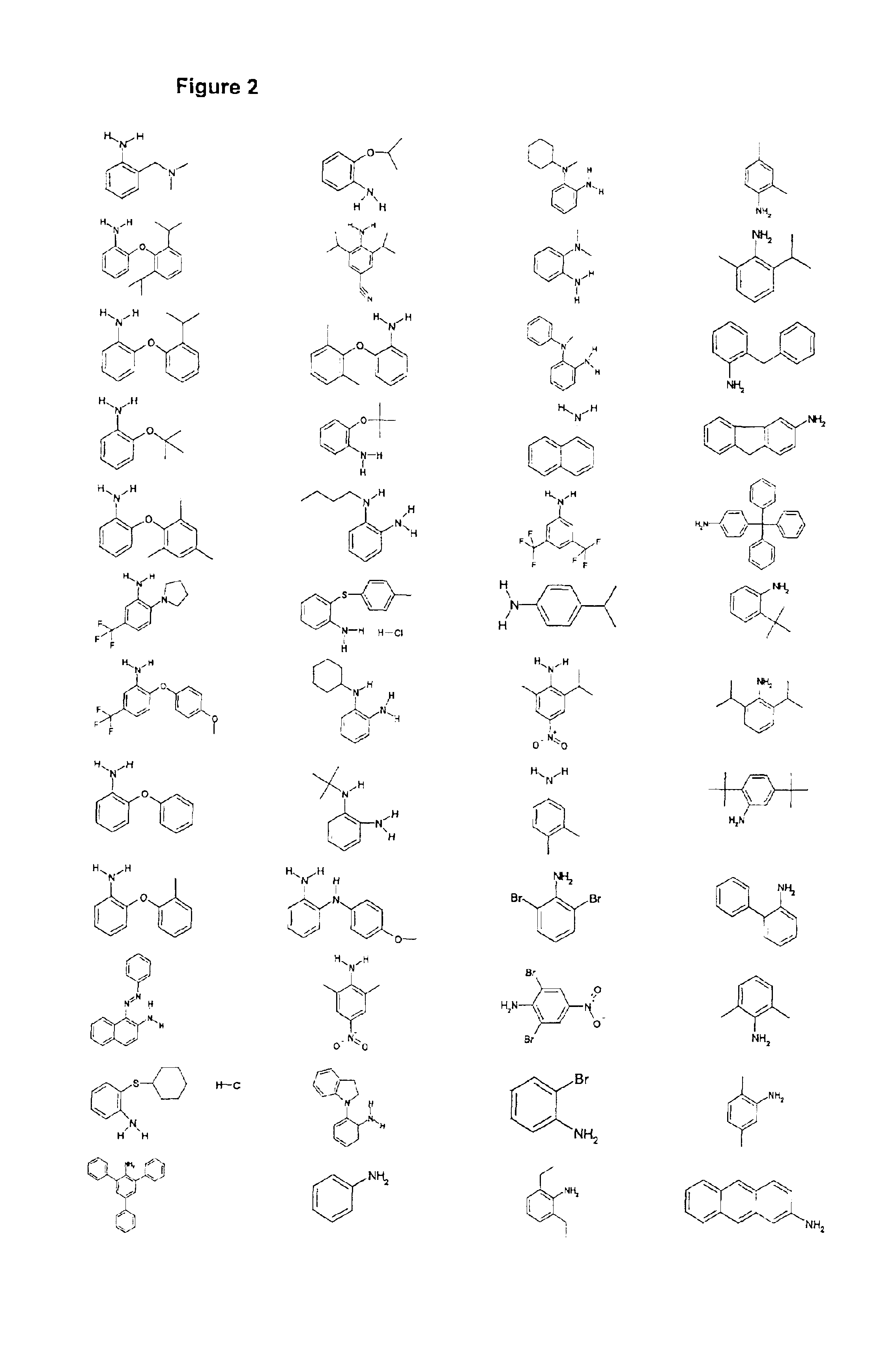

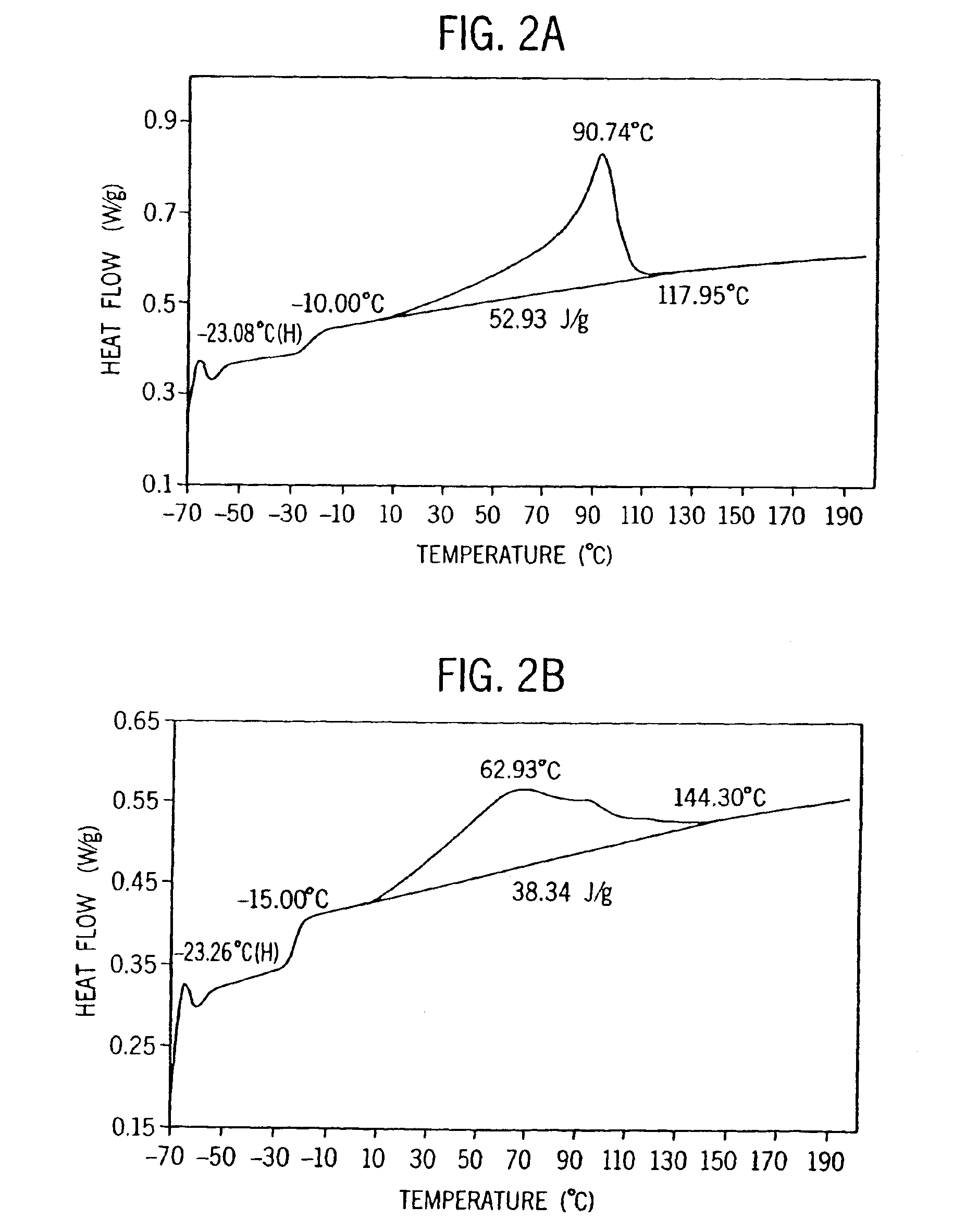

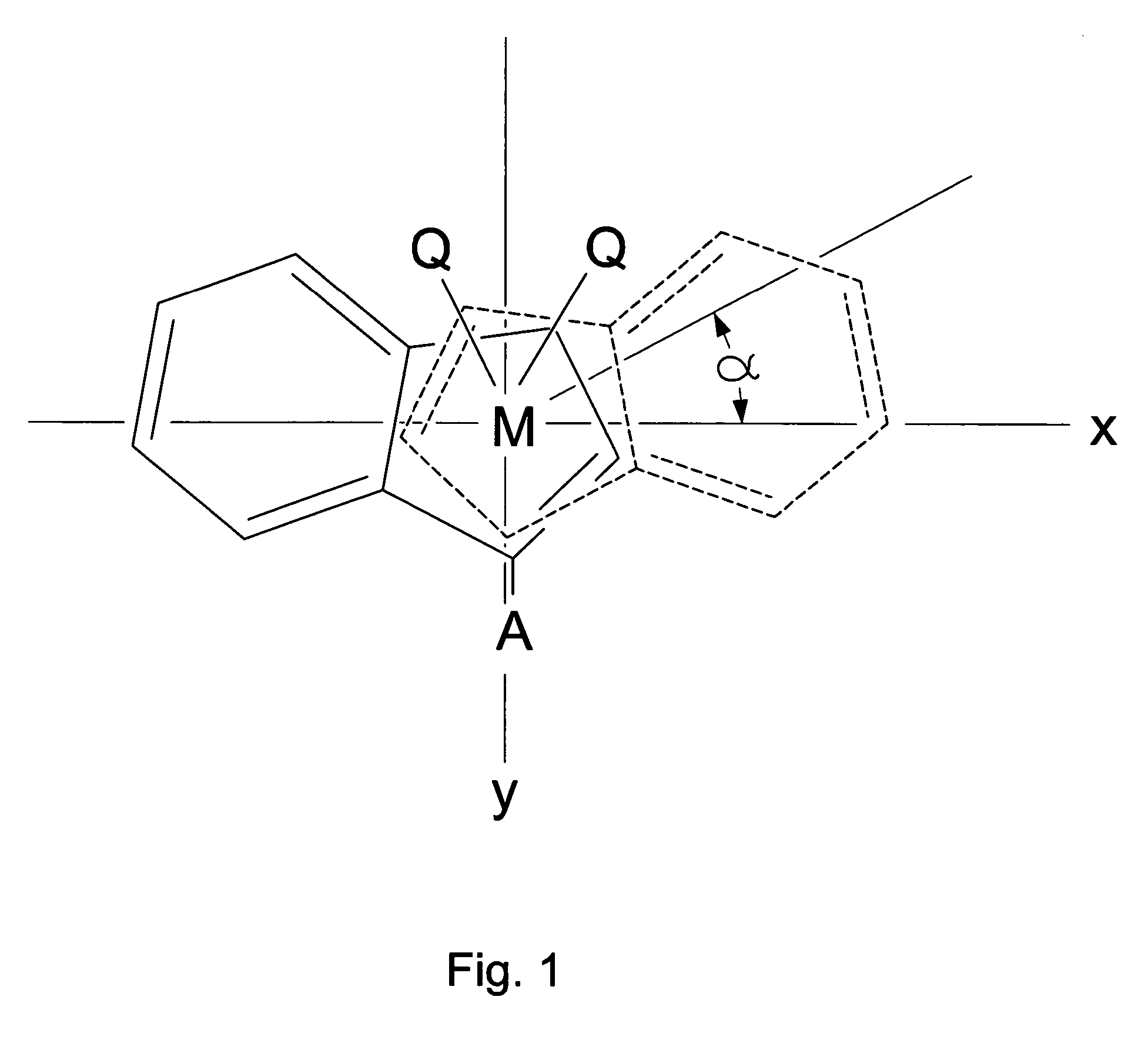

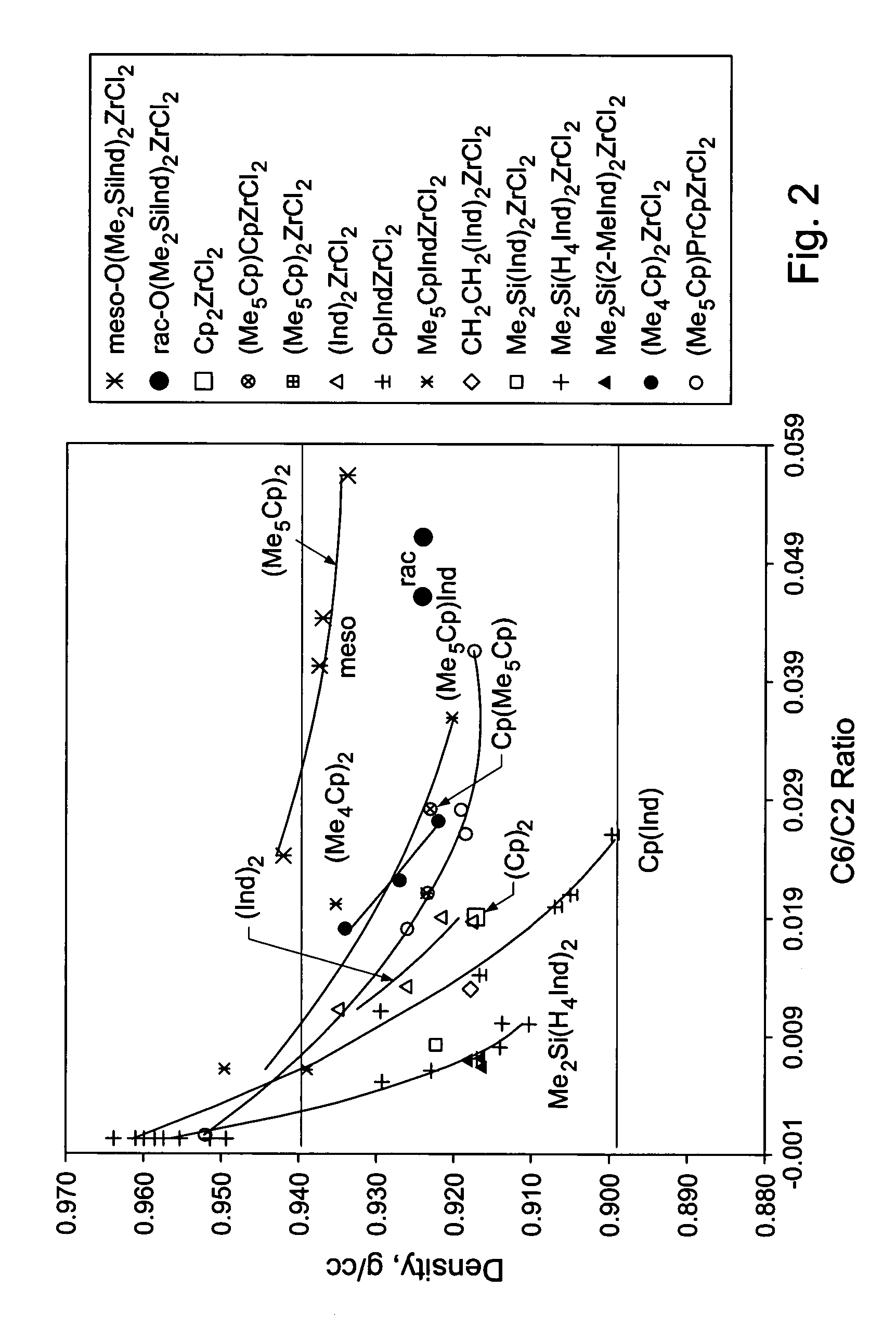

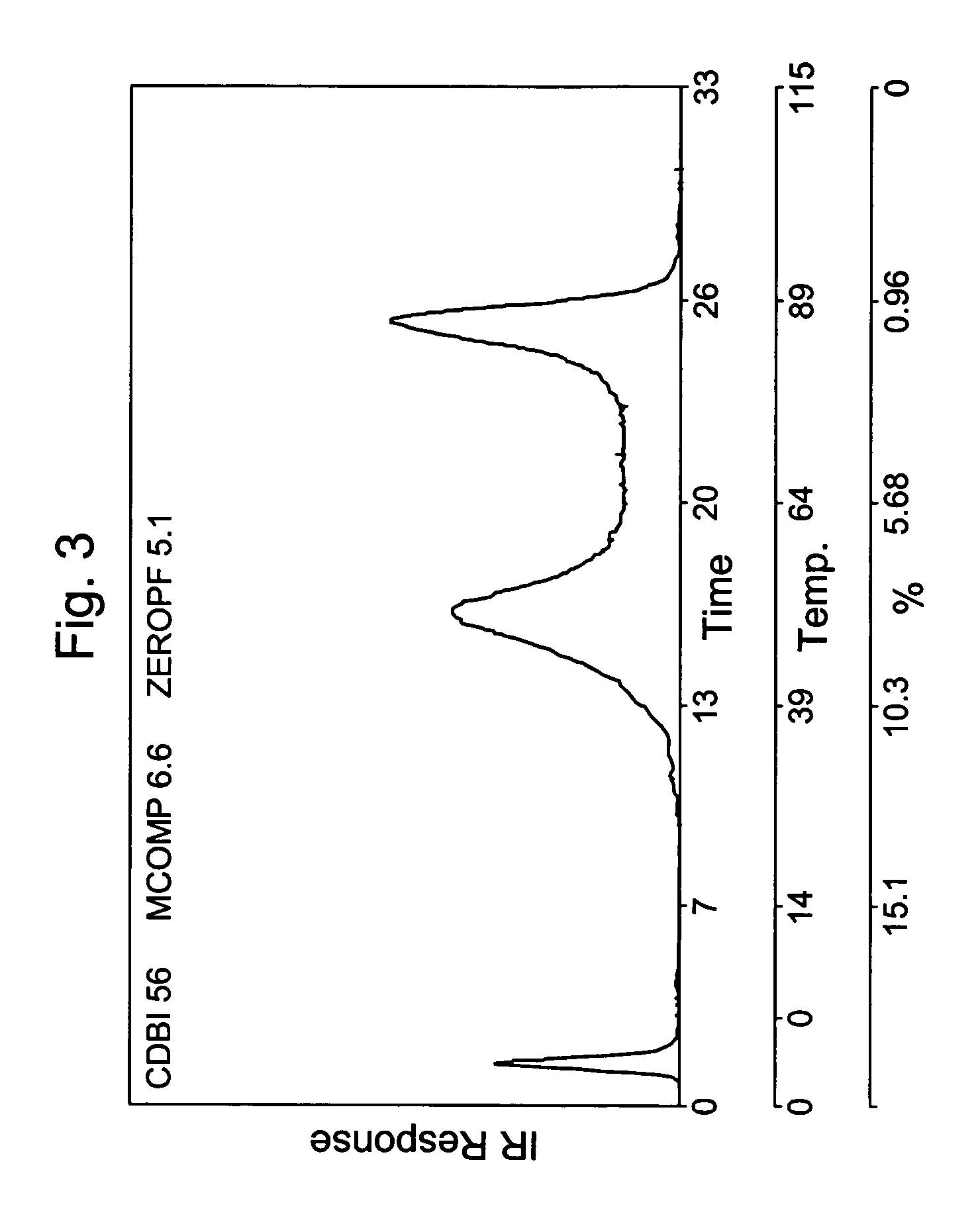

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Cap liners, closures and gaskets from multi-block polymers

A polymer composition comprises at least an ethylene / α-olefin interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

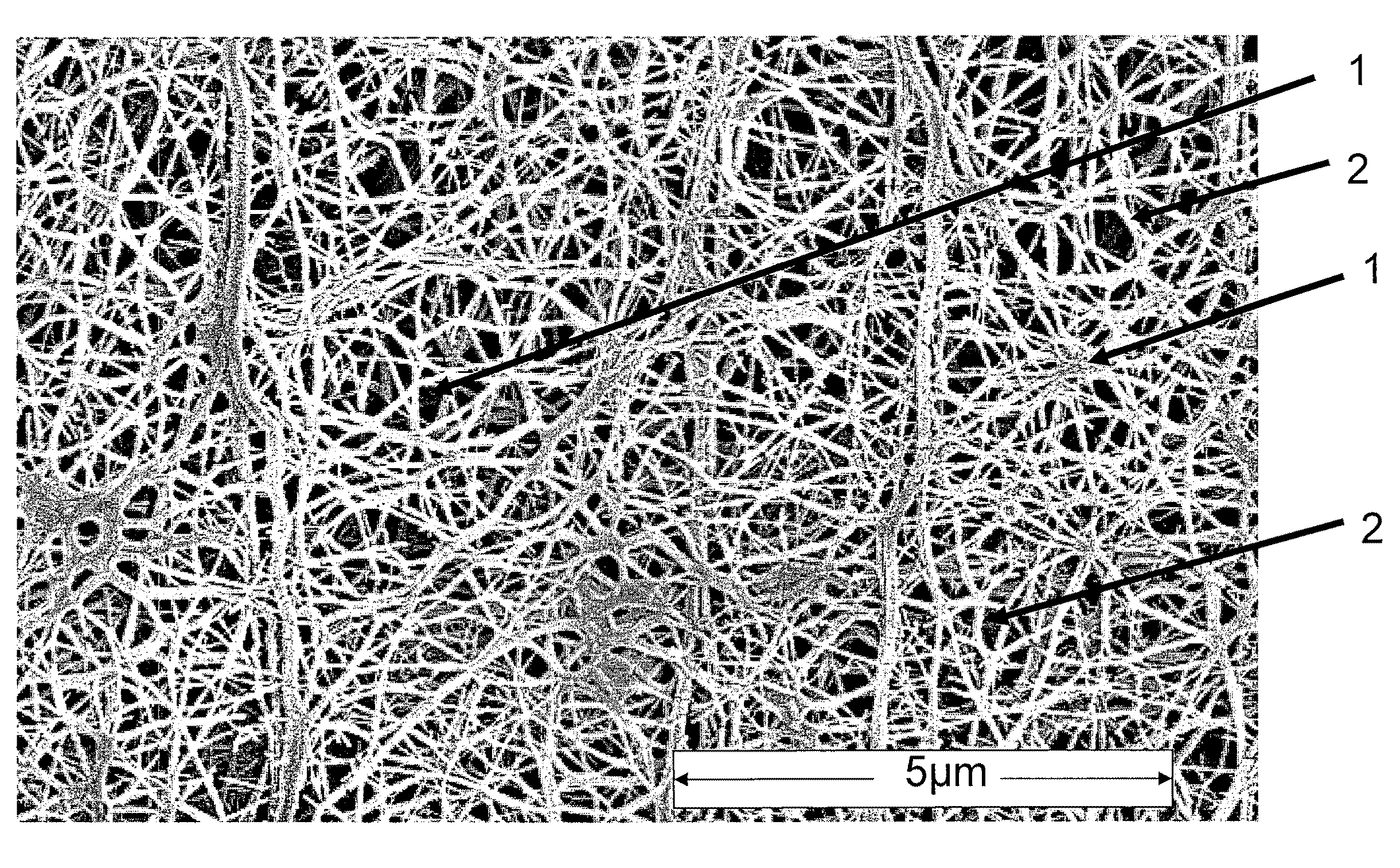

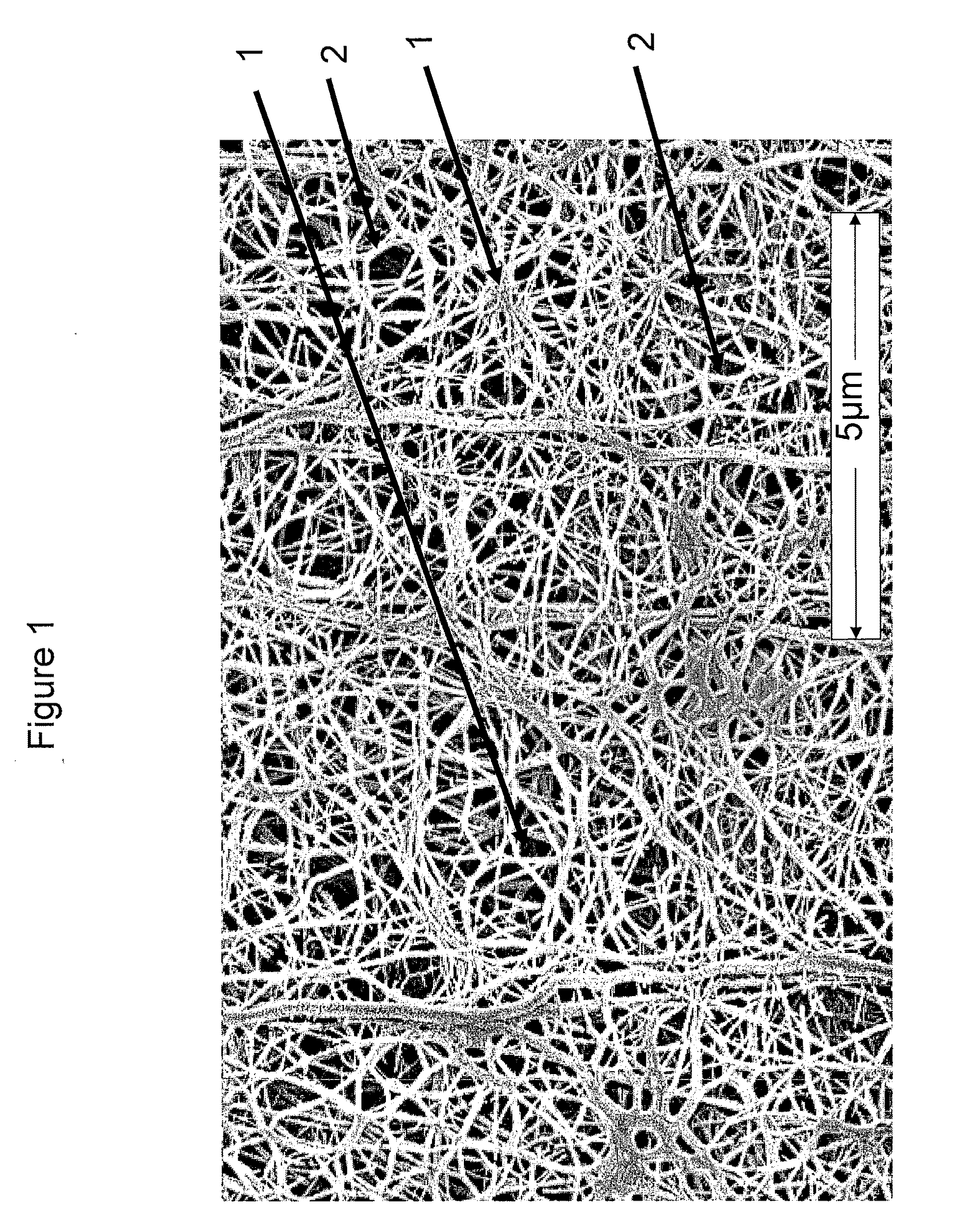

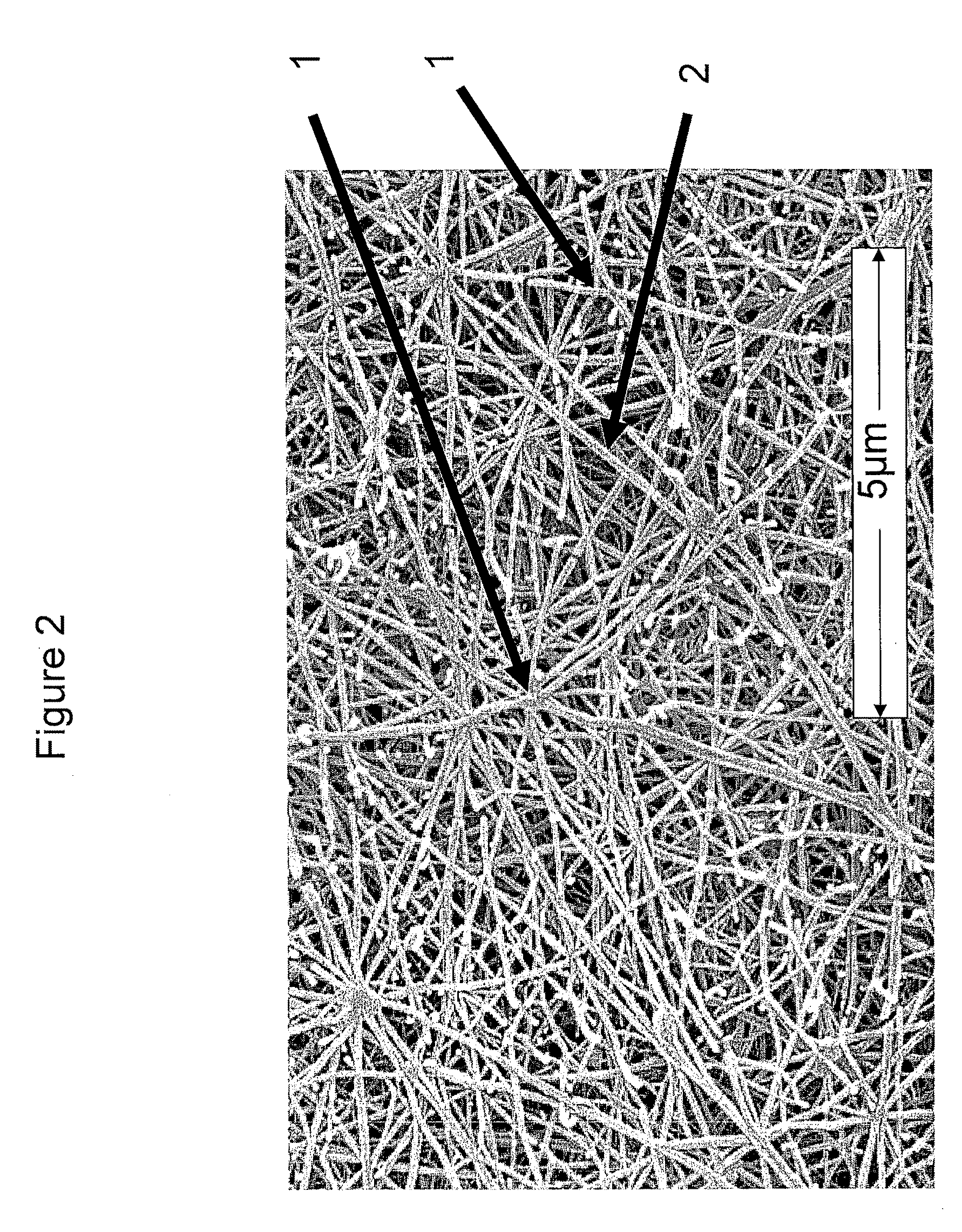

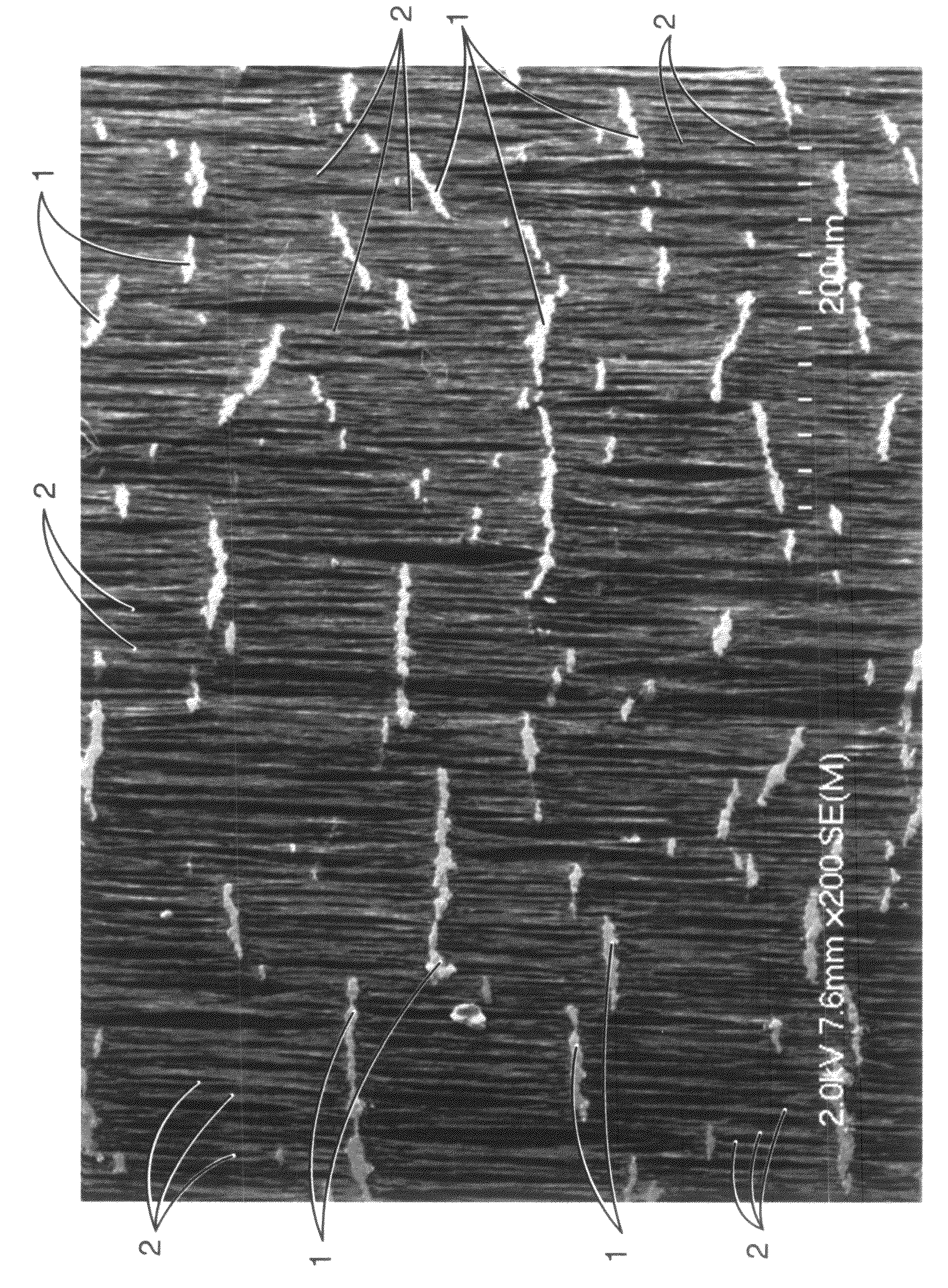

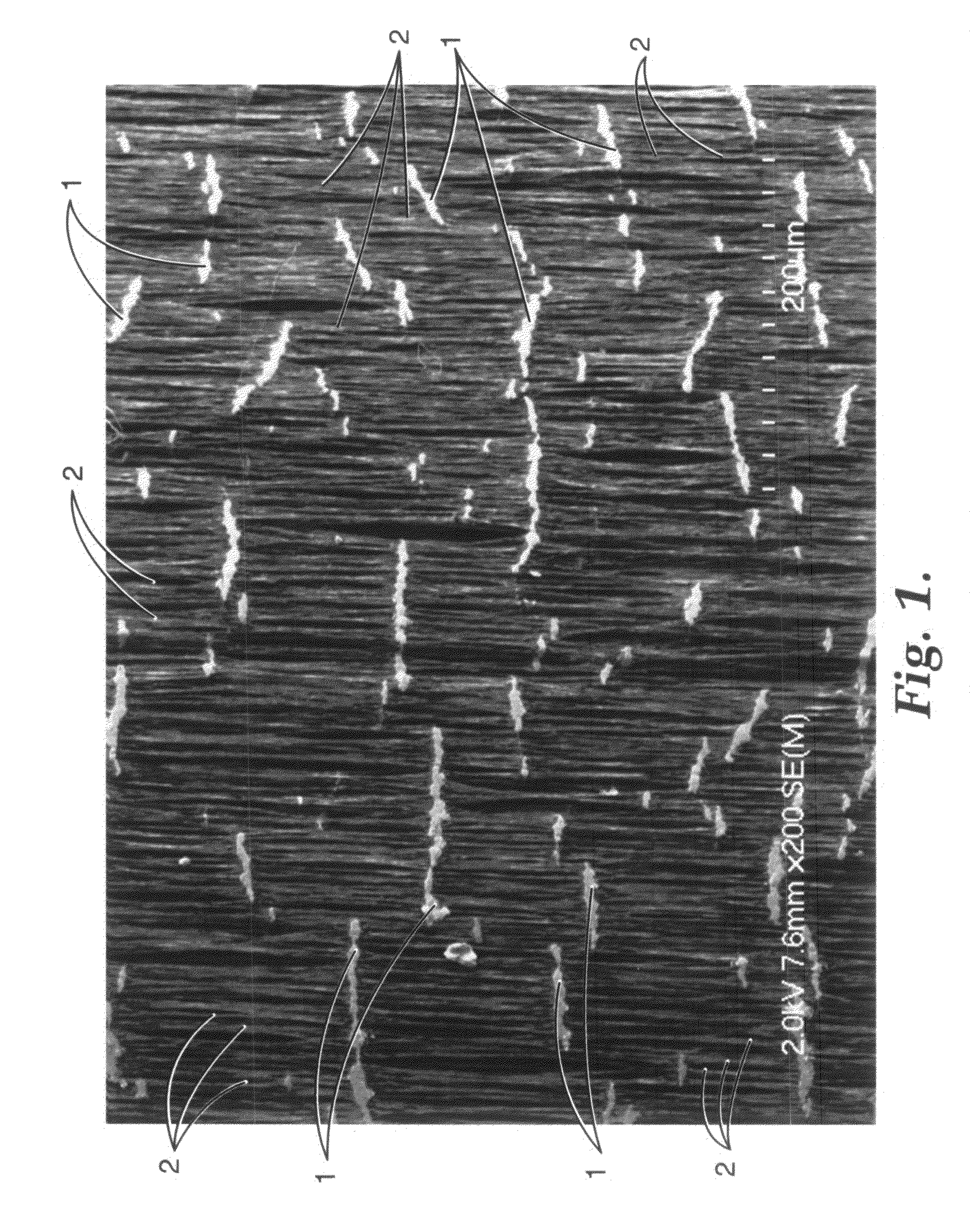

Expandable TFE copolymers, method of making, and porous, expended articles thereof

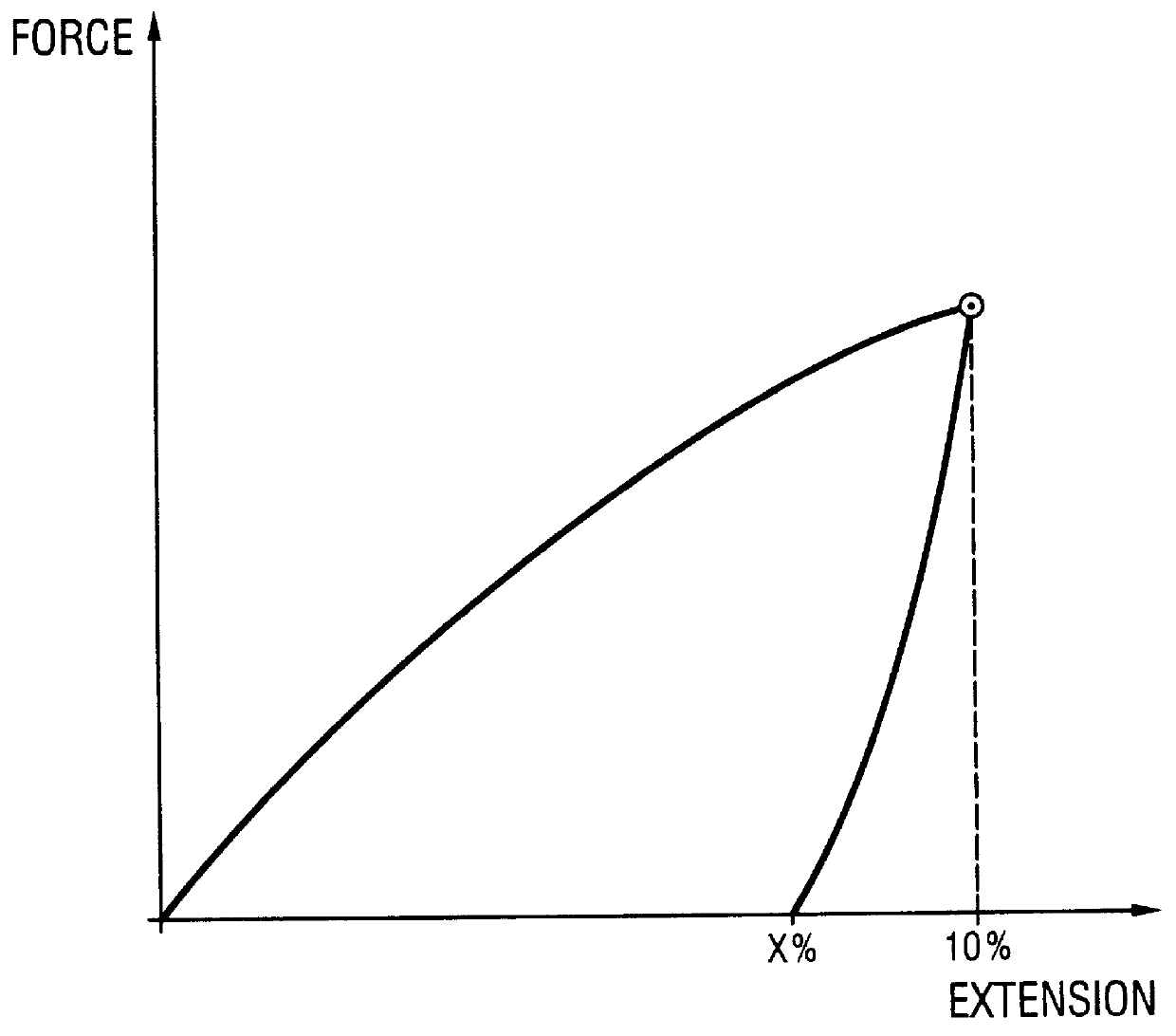

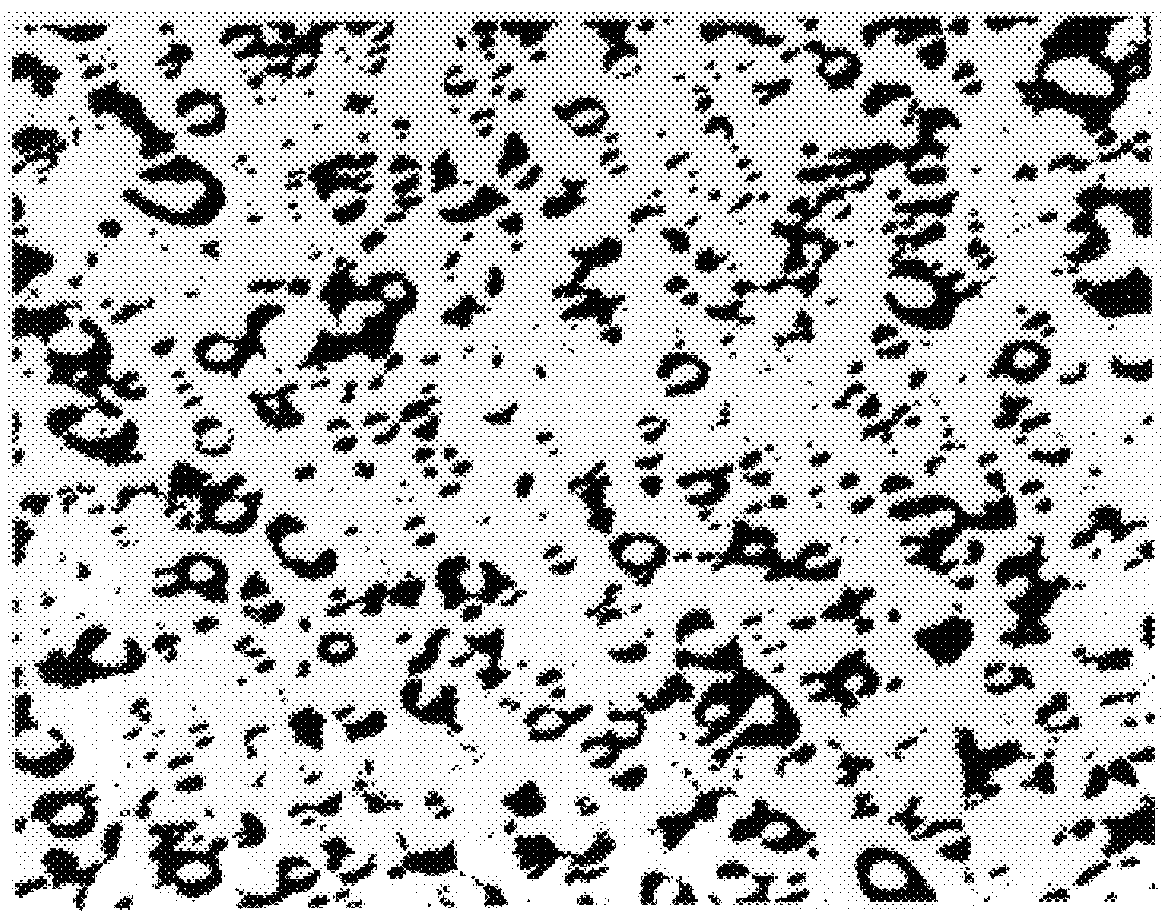

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

Expandable TFE copolymers, method of making, and porous, expended articles thereof

ActiveUS20090093602A1Improve the extrusion effectStretch smoothlyThin material handlingFiberTetrafluoroethylene

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

Filled polymer compositions made from interpolymers of ethylene/a-olefins and uses thereof

A filled polymer composition comprises (i) an ethylene / α-olefin interpolymer, and (ii) a filler. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. The filled polymer compositions provided herein, in certain embodiments, have relatively higher heat resistance and improved noise, vibration and harshness properties and can be used in automotive floorings, roofings, wire and cable coating applications.

Owner:DOW GLOBAL TECH LLC

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

Staged reactor process

In a process for the in situ blending of polymers comprising contacting ethylene and one or more comonomers in two or more fluidized bed reactors with a catalyst system comprising (i) a magnesium / titanium based precursor containing an electron donor and (ii) a hydrocarbyl aluminum cocatalyst, the improvement comprising (A) increasing or decreasing the melt flow ratio and / or molecular weight of the blend by, respectively, decreasing or increasing the mole ratio of a precursor activator compound to the electron donor or (B) increasing or decreasing the bulk density of the blend by, respectively, increasing or decreasing the mole ratio of a precursor activator compound to the electron donor, both (A) and (B) subject to defined provisos including partial pre-activation of the precursor.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Rheology modification of interpolymers of ethylene/alpha-olefins and articles made therefrom

Rheology modification of an ethylene / α-olefin interpolymer is achieved by blending the interpolymer with at least one branched polyolefin. The polyolefins can be homopolymers or interpolymers and have a branching index of less than 1. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Rheology-modified ethylene / α-olefin interpolymer, i.e., the resulting polymer blends, can be extruded or molded into many useful articles, such as films, sheets, profiles, gaskets, foams, etc.

Owner:DOW GLOBAL TECH LLC

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Interpolymers of ethylene/a-olefins blends and profiles and gaskets made therefrom

Polymer blends comprise at least an ethylene / α-olefin interpolymers and at least one polyolefin. The polyolefins can be homopolymers or interpolymers and have a melt strength of at least about 6 cN. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. The polymer blends can be profiled extruded to make profiles, gaskets, and other products.

Owner:DOW GLOBAL TECH LLC

Low molecular weight ethylene/alpha-olefin interpolymer as base lubricant oils

A lubricant composition comprises an ethylene / α-olefin interpolymer having a number average molecular weight of less than 10,000 g / mol as a base oil and at least one oil additive. The ethylene / α-olefin interpolymer has at least one molecular fraction which elutes between 40° C. and 130° C. when fractionated using TREF, characterized in that the fraction has a molar comonomer content of at least 5 percent higher than that of a comparable random ethylene interpolymer fraction eluting between the same temperatures, wherein said comparable random ethylene interpolymer has the same comonomer(s) and has a melt index, density, and molar comonomer content (based on the whole polymer) within 10 percent of that of the ethylene / α-olefin interpolymer.

Owner:DOW GLOBAL TECH LLC

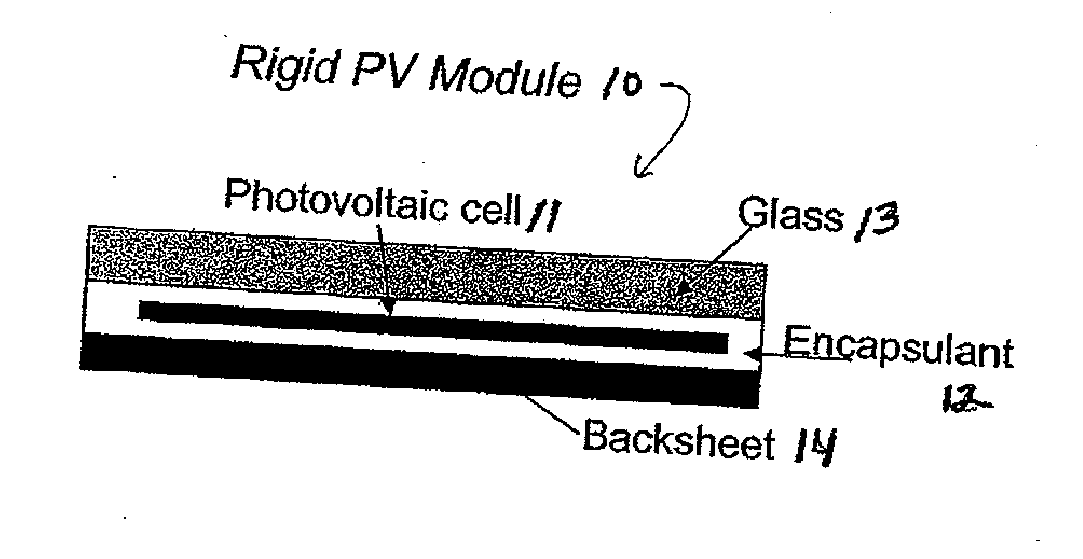

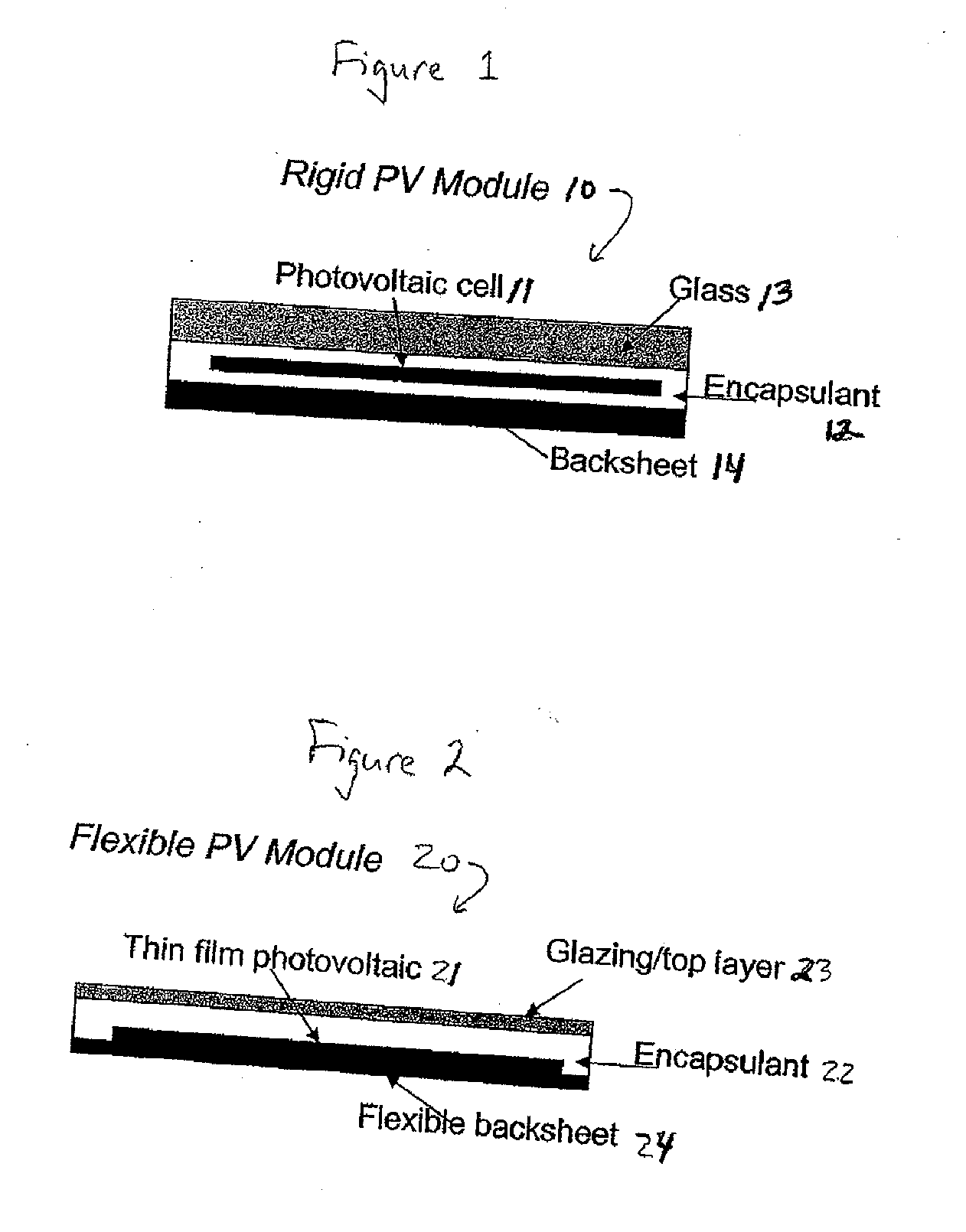

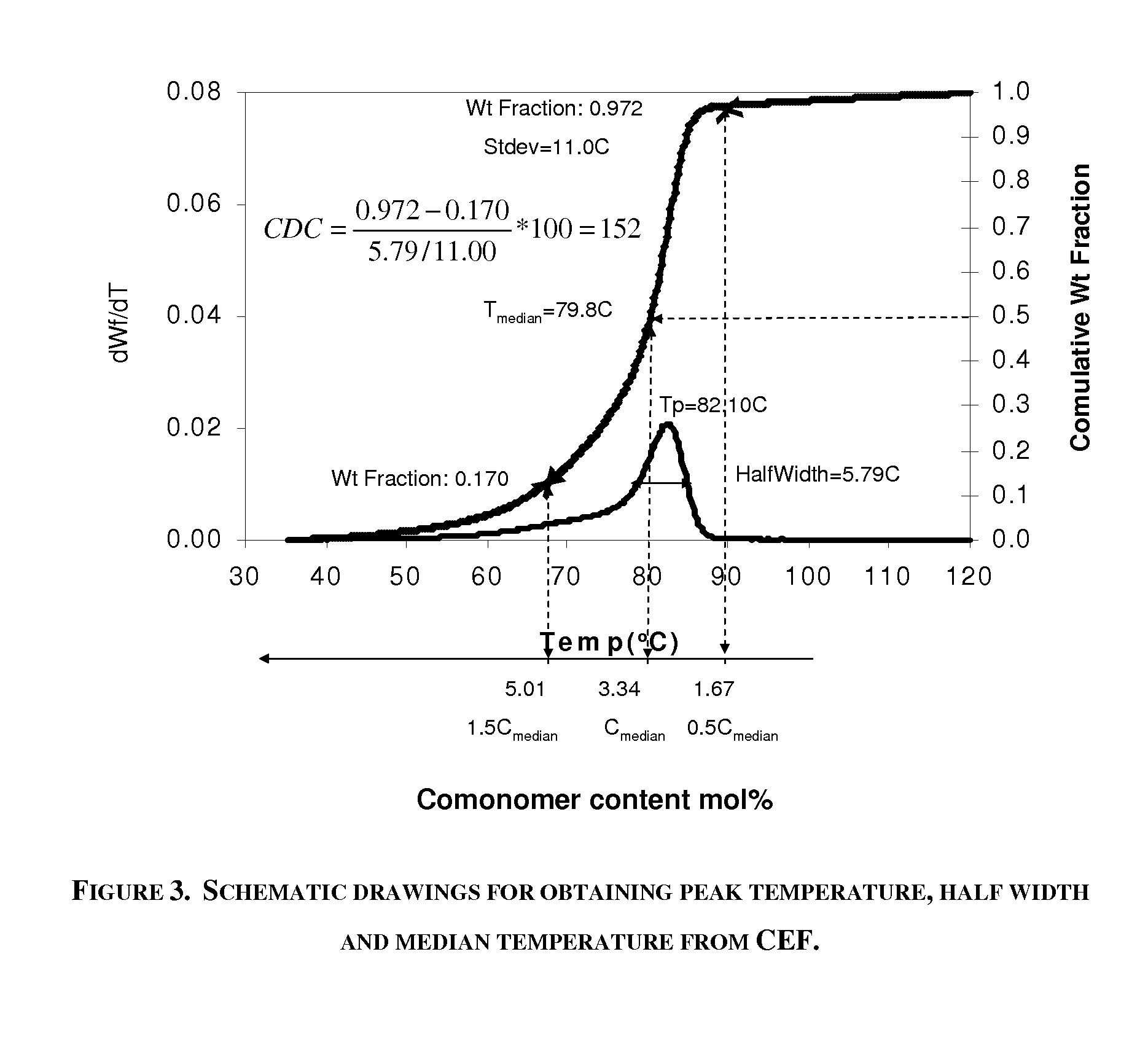

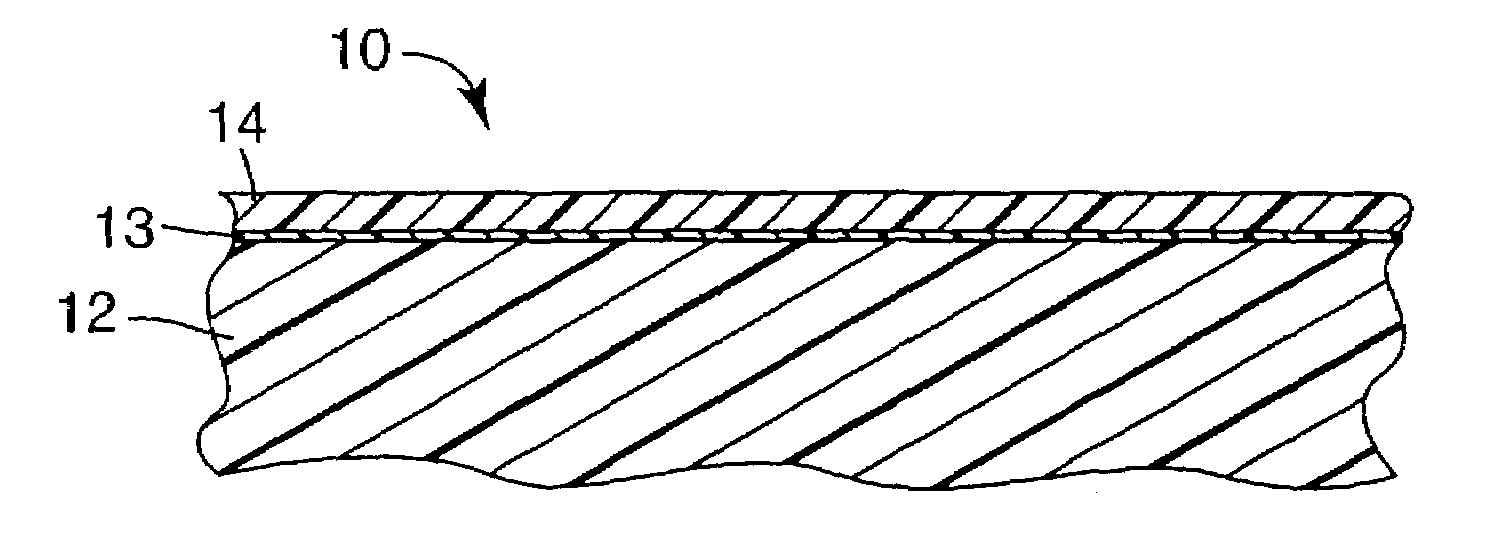

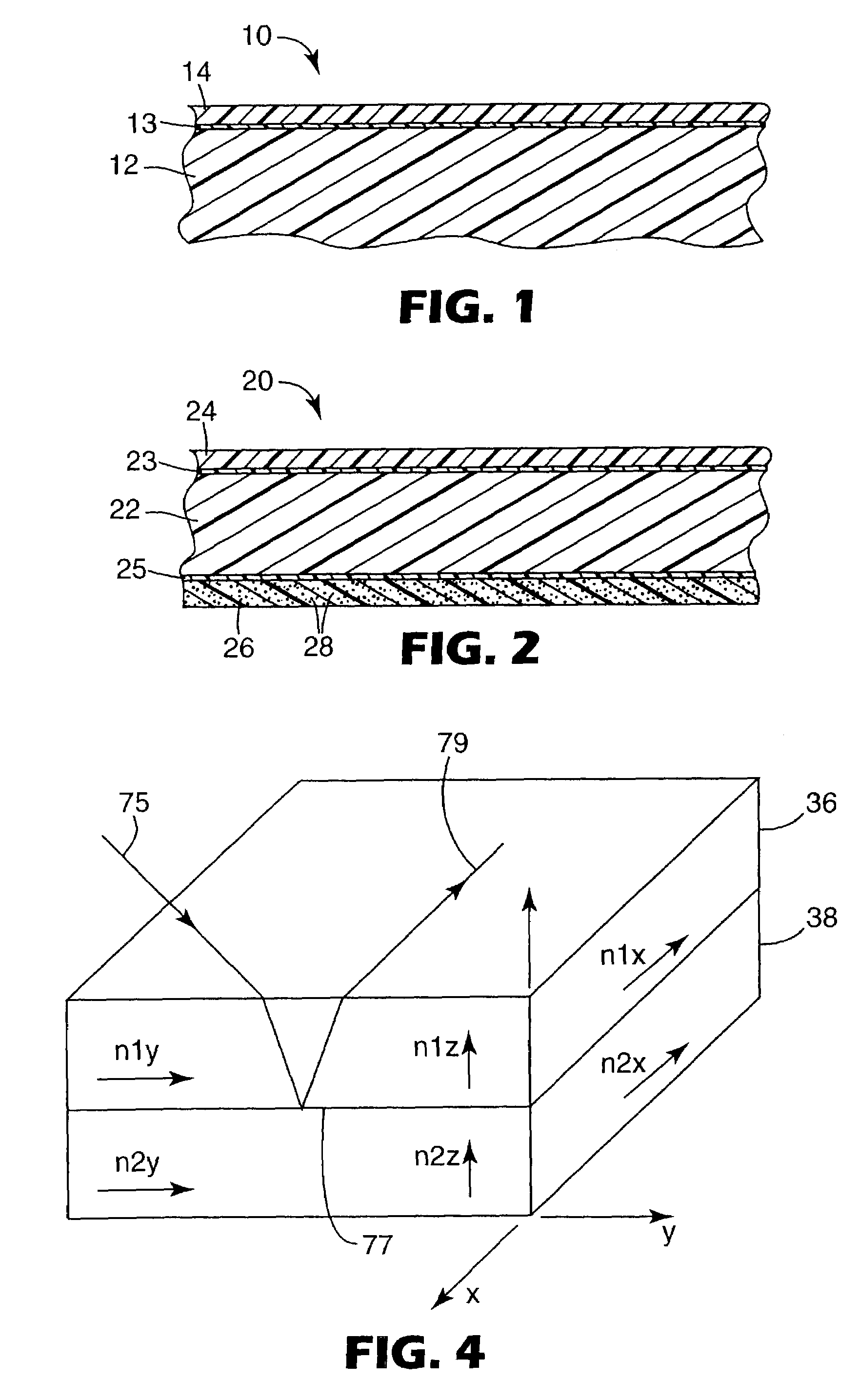

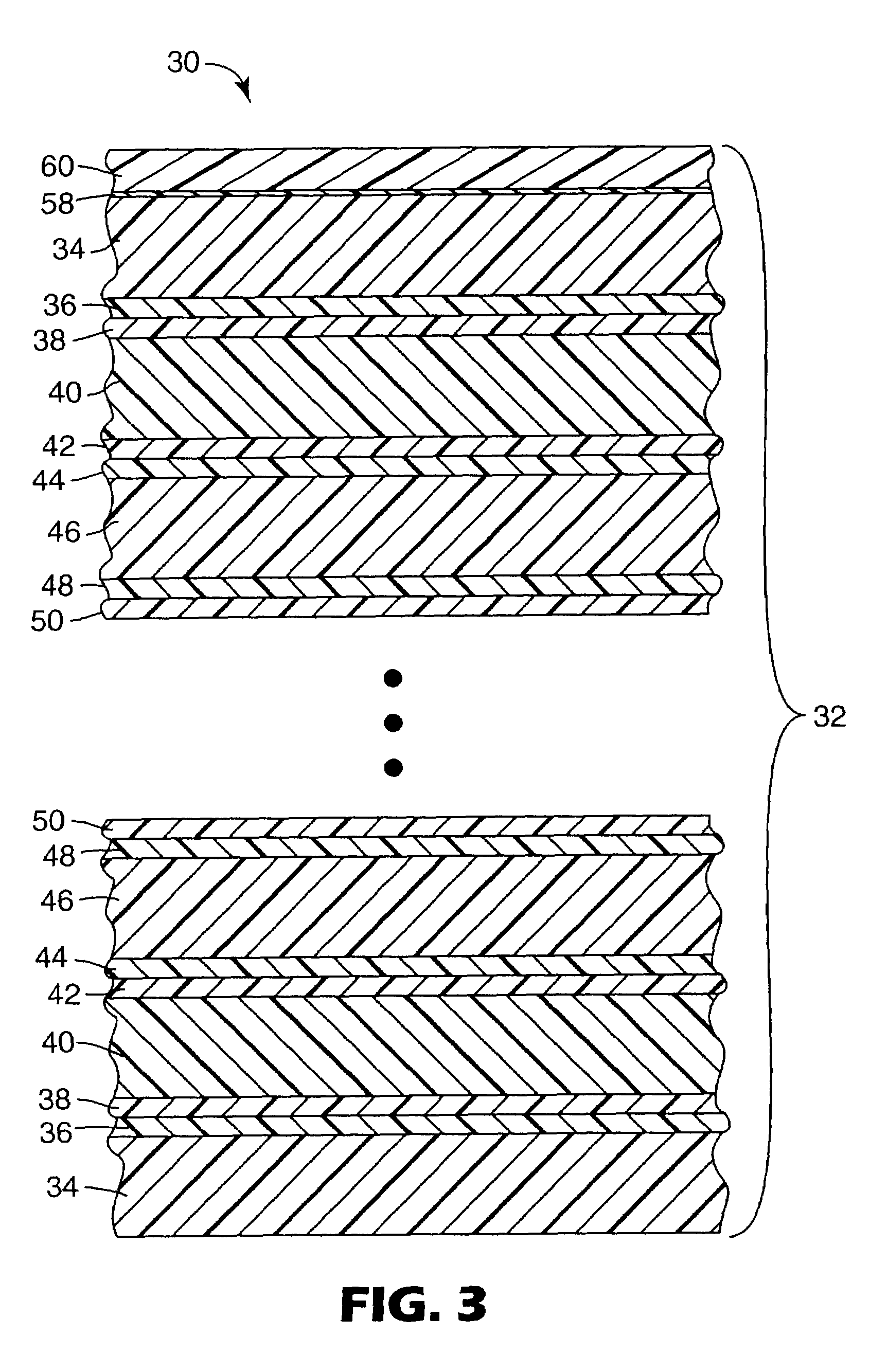

Electronic device module comprising polyolefin copolymer with low unsaturation and optional vinyl silane

InactiveUS20110290317A1Improve adhesionHigh processing temperatureGlass/slag layered productsPhotovoltaic energy generationPolymer sciencePolyolefin

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene-based polymer composition characterized by a Comonomer Distribution Constant greater than about 45, more preferably greater than 50, most preferably greater than 95, and as high as 400, preferably as high as 200, wherein the composition has less than 120 total unsaturation unit / 1,000,000C, preferably the ethylene-based polymer compositions comprise up to about 3 long chain branches / 1000 carbons, more preferably from about 0.01 to about 3 long chain branches / 1000 carbons; the ethylene-based polymer composition can have a ZSVR of at least 2; the ethylene-based polymer compositions can be further characterized by comprising less than 20 vinylidene unsaturation unit / 1,000,000C; the ethylene-based polymer compositions can have a bimodal molecular weight distribution (MWD) or a multi-modal MWD; the ethylene-based polymer compositions can have a comonomer distribution profile comprising a mono or bimodal distribution from 35° C. to 120° C., excluding purge; the ethylene-based polymer compositions can comprise a single DSC melting peak; the ethylene-based polymer compositions can comprise a weight average molecular weight (Mw) from about 17,000 to about 220,000, (2) optionally, a vinyl silane, (3) optionally, a free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (4) optionally, a co-agent.

Owner:NAUMOVITZ JOHN +3

UV resistant naphthalate polyester articles

ActiveUS7153588B2Extend life of and protectReduce solubilitySynthetic resin layered productsPretreated surfacesPolyesterBenzene

Naphthalate polyester articles can be coated with polymerizable compositions containing a vinyl-functional crosslinkable film former, a large amount of benzotriazole and a copolymerizable monomer that solubilizes the benzotriazole. The cured compositions help protect the naphthalate polyester from UV exposure and other weathering effects.

Owner:3M INNOVATIVE PROPERTIES CO

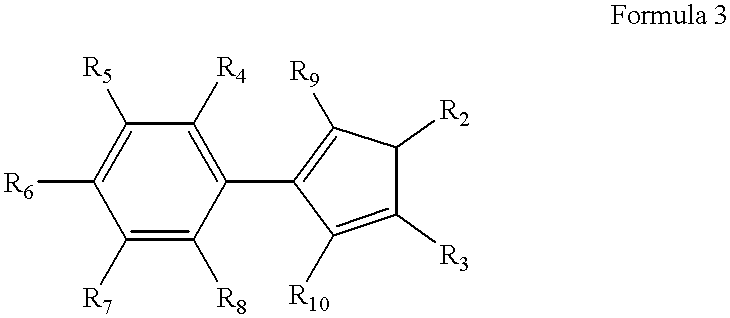

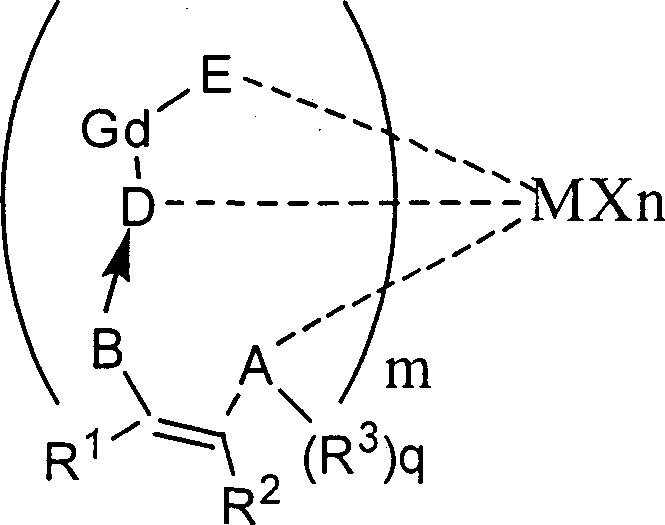

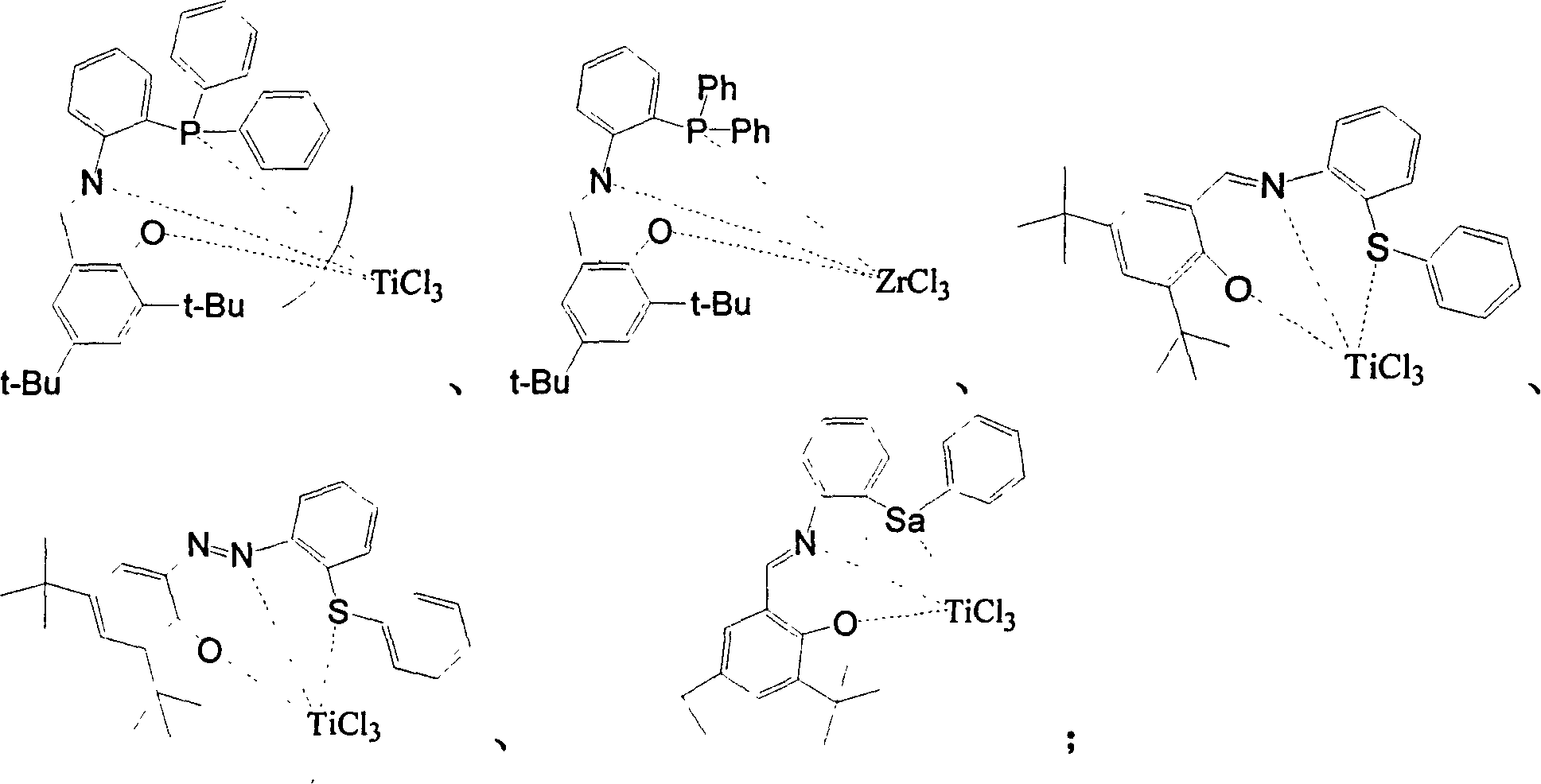

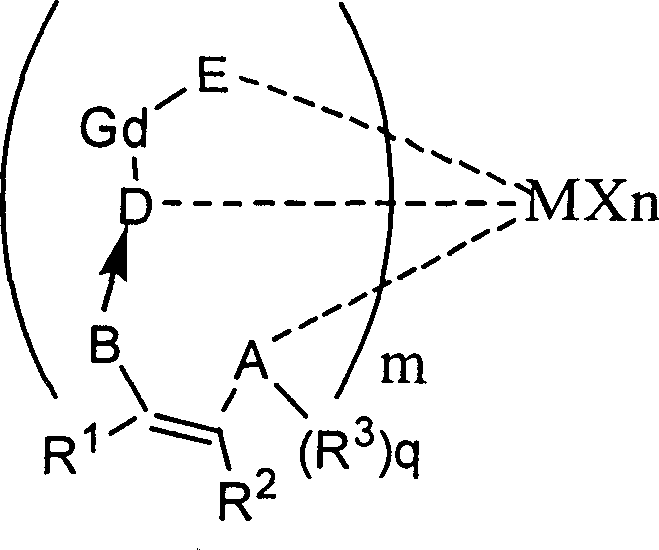

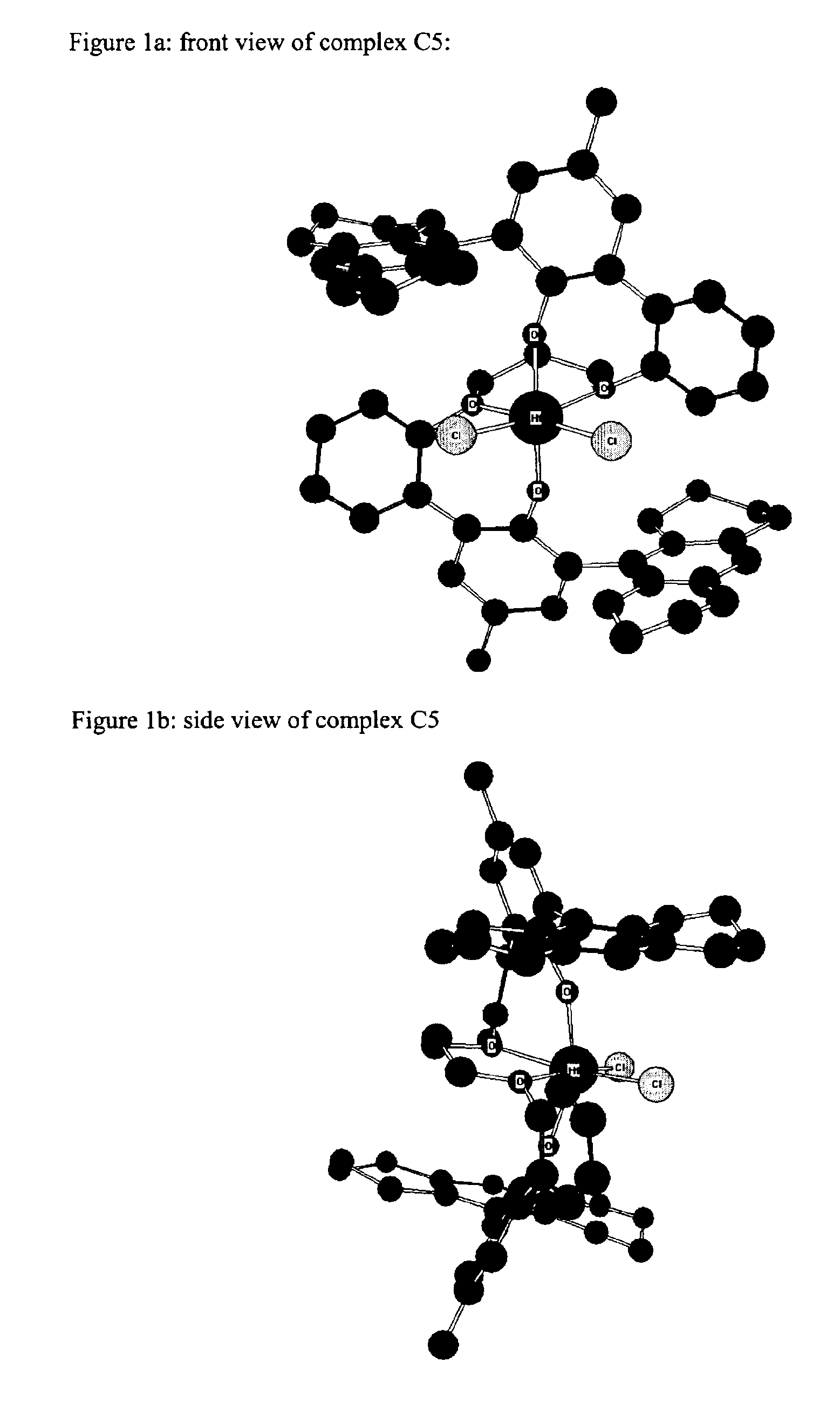

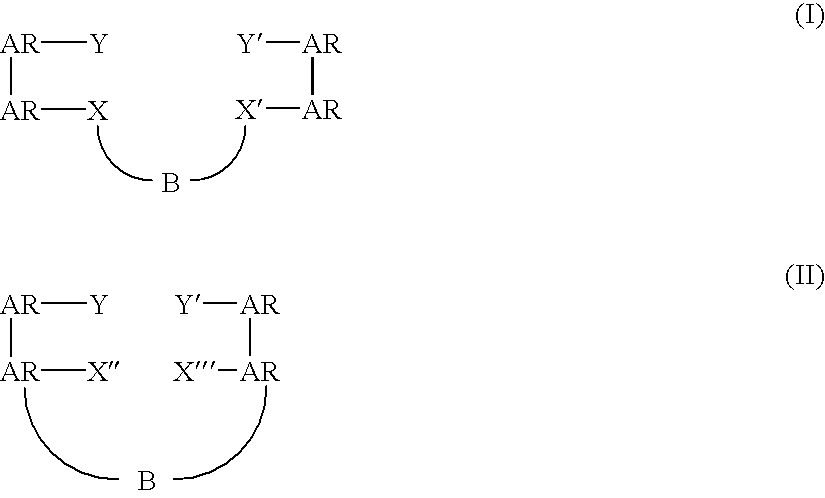

Bridged bi-aromatic ligands, catalysts, processes for polymerizing and polymers therefrom

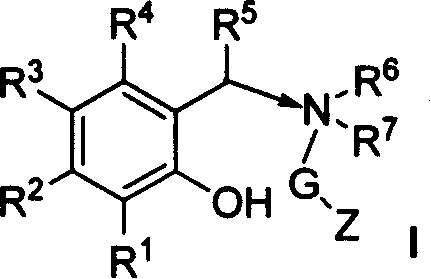

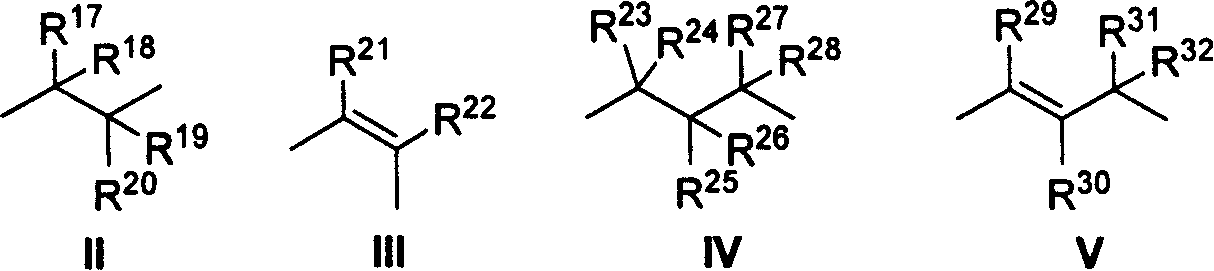

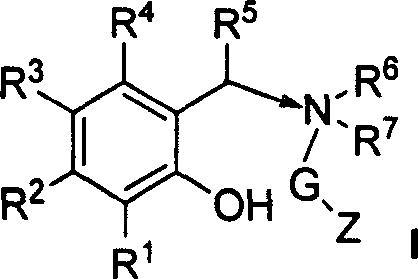

InactiveUS6869904B2Improve catalytic performanceOrganic compound preparationGroup 4/14 organic compounds without C-metal linkages1-OctenePolypropylene

New ligands, compositions, metal-ligand complexes and arrays with bridged bis-aromatic ligands are disclosed that catalyze the polymerization of monomers into polymers. These catalysts with metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts also polymerize propylene into isotactic polypropylene.

Owner:DOW GLOBAL TECH LLC

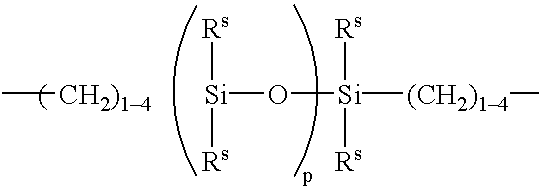

Hydrogel from polysiloxane-containing urethane prepolymer, tris (trimethylsiloxy) silylpropyl methacrylate, and a hydrophilic comonomer

A polyurethane based prepolymer is provided and useful in biomedical devices which provides high oxygen permeability and superior physical properties. A hydrogel is produced from a comonomer mixture containing a polysiloxane-containing urethane prepolymer, tris(trimethylsiloxy)-silylpropyl methacrylate and a hydrophilic comonomer. The hydrogel is especially useful for biomedical materials such as contact lenses and implants.

Owner:BAUSCH & LOMB INC

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6518378B2Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElastomerPolyolefin

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:BP AMOCO CORP +1

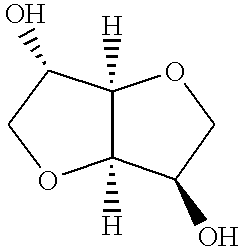

Polyesters including isosorbide as a comonomer blended with other thermoplastic polymers

A polymer blend including a polyester and another thermoplastic polymer. The polyester includes terephthaloyl moieties and, optionally, other aromatic diacid moieties; and ethylene glycol moieties; optionally diethylene glycol moieties; isosorbide moieties; and, optionally one or more other diol moieties. The polyester has an inherent viscosity of at least about 0.35 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

Polyolefin film containing cycloolefin polymer, process for the production thereof, and the use thereof

InactiveUS6068936AHigh strength valueGood barrier effectFlexible coversWrappersPolymer sciencePolyolefin

A polyolefin film which includes at least one layer containing polyolefin and cycloolefin polymer (COP), where the cycloolefin polymer is amorphous and has a mean molecular weight Mw in the range from 200 to 100,000, and this mean molecular weight Mw of the cycloolefin polymer is at most 50% of the mean molecular weight Mw of the polyolefin, and the cycloolefin polymer is a homopolymer or a copolymer containing at most 20% by weight of comonomer.

Owner:TICONA GMBH

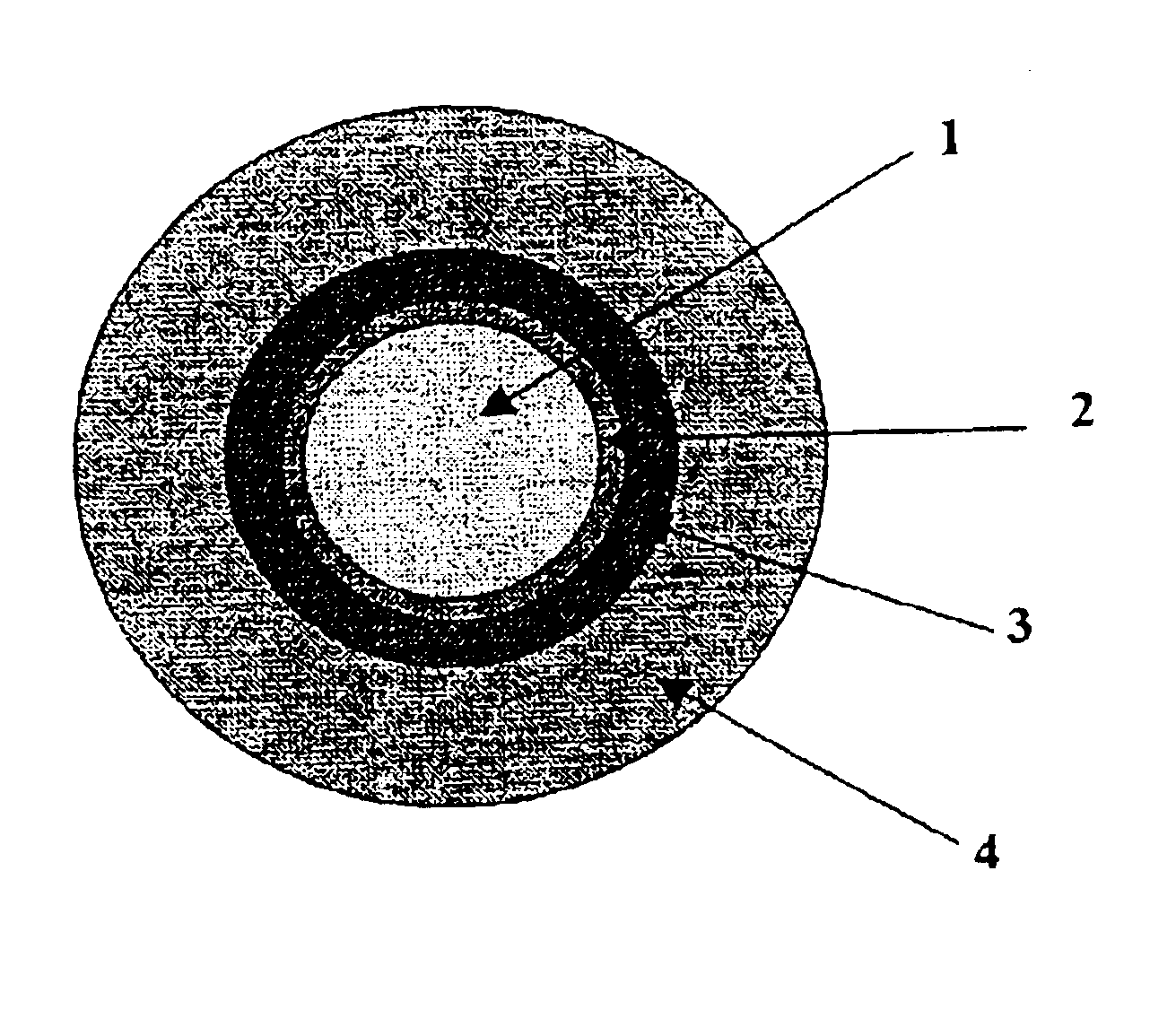

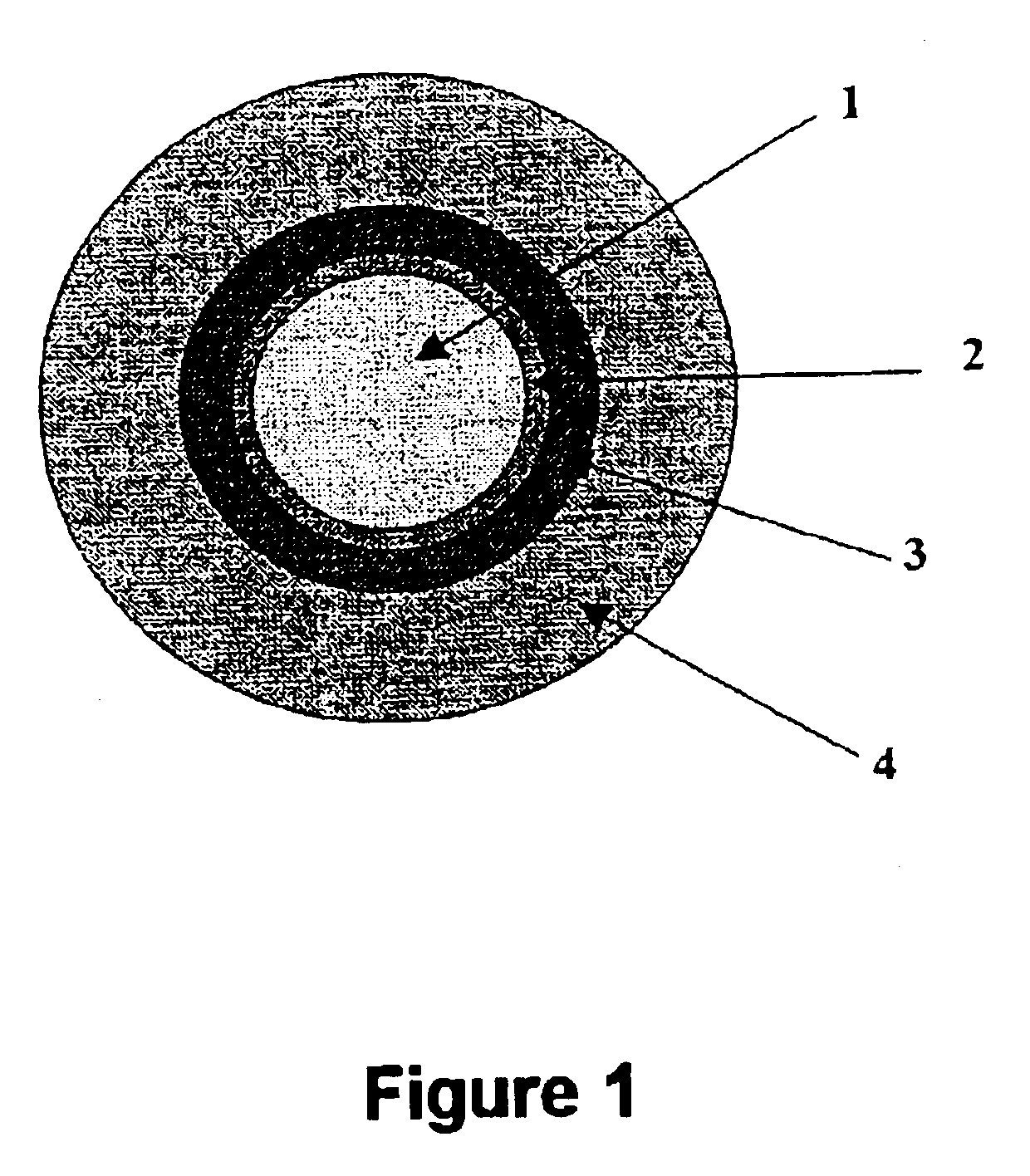

Polymeric optical conductors

InactiveUS6766091B2Glass optical fibreOptical fibre with graded refractive index core/claddingFiberZero shear viscosity

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

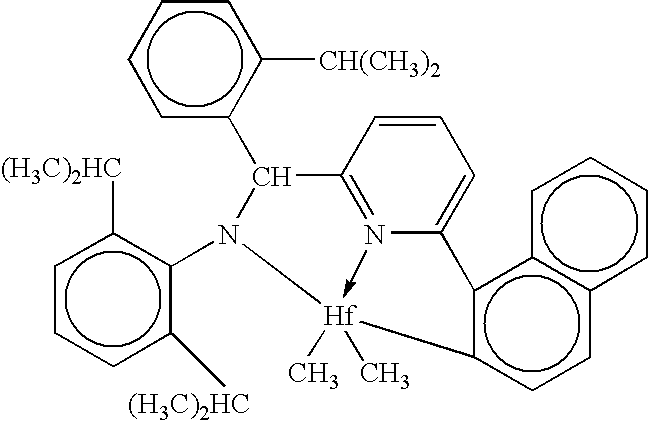

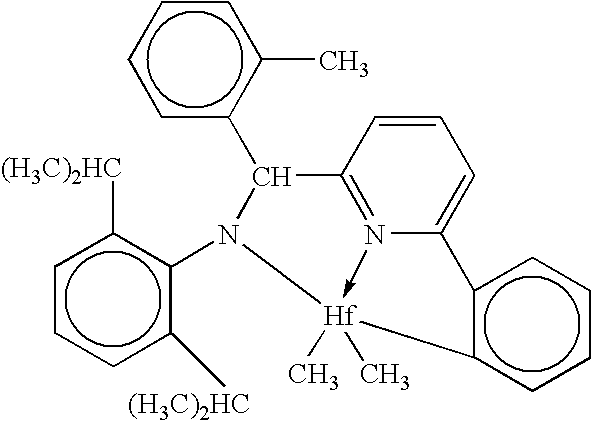

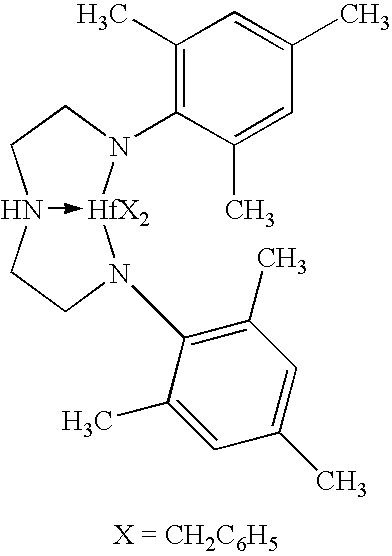

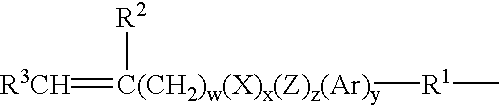

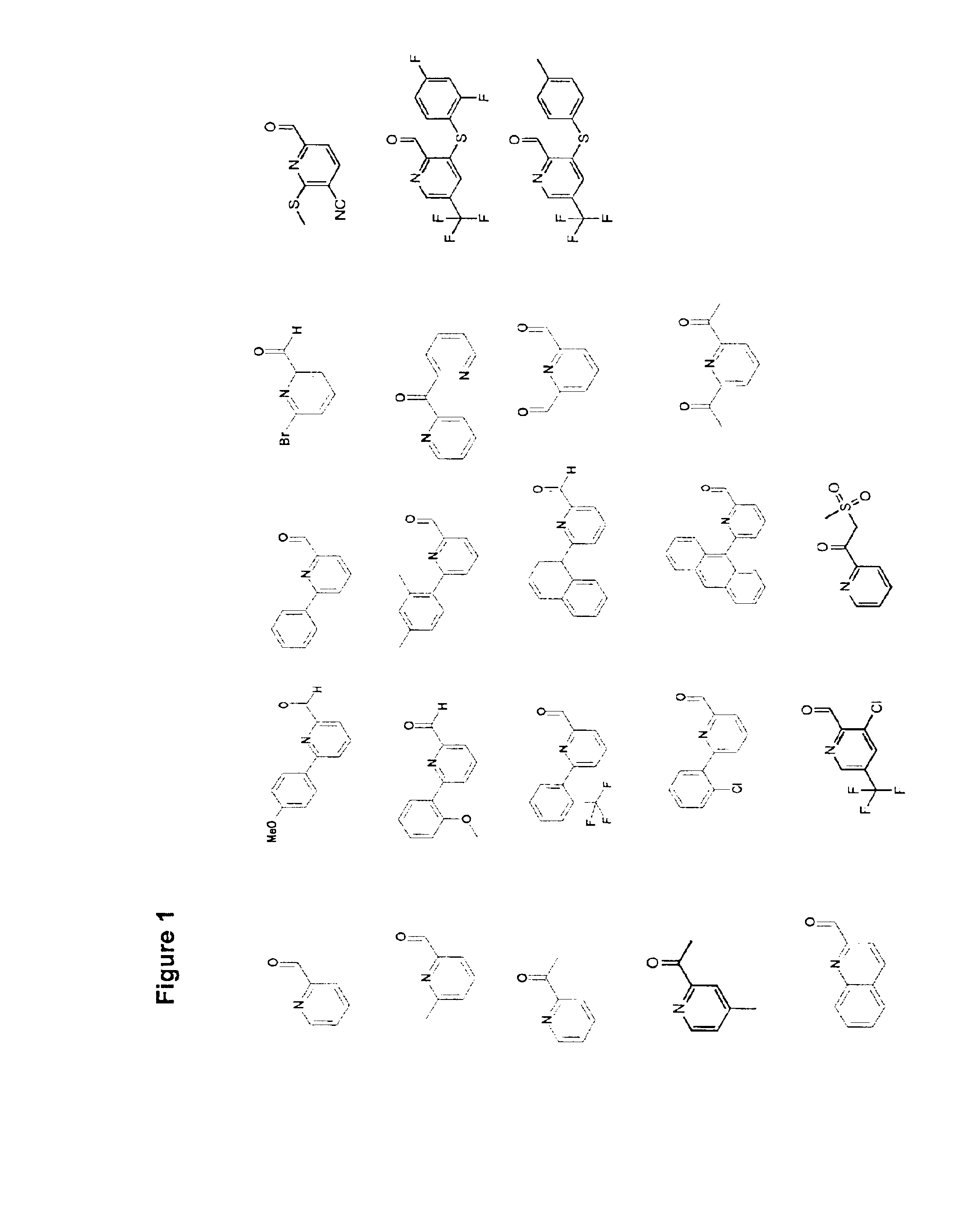

Substituted pyridyl amine complexes, and catalysts

InactiveUS6900321B2Improve catalytic performanceIncrease temperatureSilicon organic compoundsMacromolecular libraries1-OcteneHafnium

New ligands, compositions, metal-ligand complexes and arrays with pyridylamine ligands are disclosed that catalyze the polymerization of monomers into polymers. Certain of these catalysts with hafnium metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, isobutylene or styrene. Certain of the catalysts are particularly effective at polymerizing propylene to high molecular weight isotactic polypropylene in a solution process at a variety of polymerization conditions.

Owner:FREESLATE

Blends and sealant compositions comprising isotactic propylene copolymers

Films with excellent machine direction (MD) tear properties comprise at least one layer made from a polymer comprising:(A) at least 50 weight percent (wt %) propylene; and(B) at least 5 wt % ethylene and / or one or more unsaturated comonomers.Representative of component (B) unsatuarated comonomers are the C4-20 α-olefins, C4-20 dienes, styrenic compounds, and the like. Preferably, the film has at least one of a (i) haze value of less than about 10, (ii) 45 degree gloss of greater than about 65, and (iii) dart value of greater than about 100 g / mil. In one preferred embodiment, the layer comprises a compolymer characterized as having at least one of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta (Z-N) catalyst.

Owner:DOW GLOBAL TECH LLC

Mixed metallocene catalyst systems containing a poor comonomer incorporator and a good comonomer incorporator

The present invention provides polymerization catalyst compounds, catalyst systems including these catalyst compounds, and to their use in the polymerization of ethylene and at least one comonomer. In particular, the invention provides a catalyst system comprising a poor comonomer incorporating catalyst compound and a good comonomer incorporating catalyst compound. Preferably, the low comonomer incorporating catalyst compound is a metallocene containing at least one substituted or unsubstituted fused ring cyclopentadienyl based ligand which is substantially directed to the front of the molecule, contains a long bridging group, or which contains a methyl substitution pattern which correlates to poor comonomer incorporation. The invention also provides methods of selecting the poor comonomer incorporating metallocene to pair with the good comonomer incorporating metallocene to produce polymers that are easy to process into a variety of articles, especially polyethylene based film, having enhanced properties.

Owner:UNIVATION TECH LLC

Crosslinked blends of amorphous and crystalline polymers and their applications

The present invention is broadly directed to a polyolefin polymer composition produced by copolymerizing one or more alpha-olefins and one or more di-olefin monomers in the presence of at least one stereospecific metallocene catalyst system and at least one non-stereospecific metallocene catalyst system. The polymer composition so produced contains amorphous polymer segments and crystalline polymer segments in which at least some of the segments are crosslinked. Both the amorphous and the crystalline polymer segments are copolymers of one or more alpha-olefins and one or more di-olefin monomers. Crosslinking of at least a portion of the mixture of polymer segments is accomplished during the polymerization of the composition by incorporation of single di-olefin comonomers into two polymer segments.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com