Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

914 results about "Flow ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The operating cash flow ratio is a measure of how well current liabilities are covered by the cash flows generated from a company's operations. The ratio can help gauge a company's liquidity in the short term.

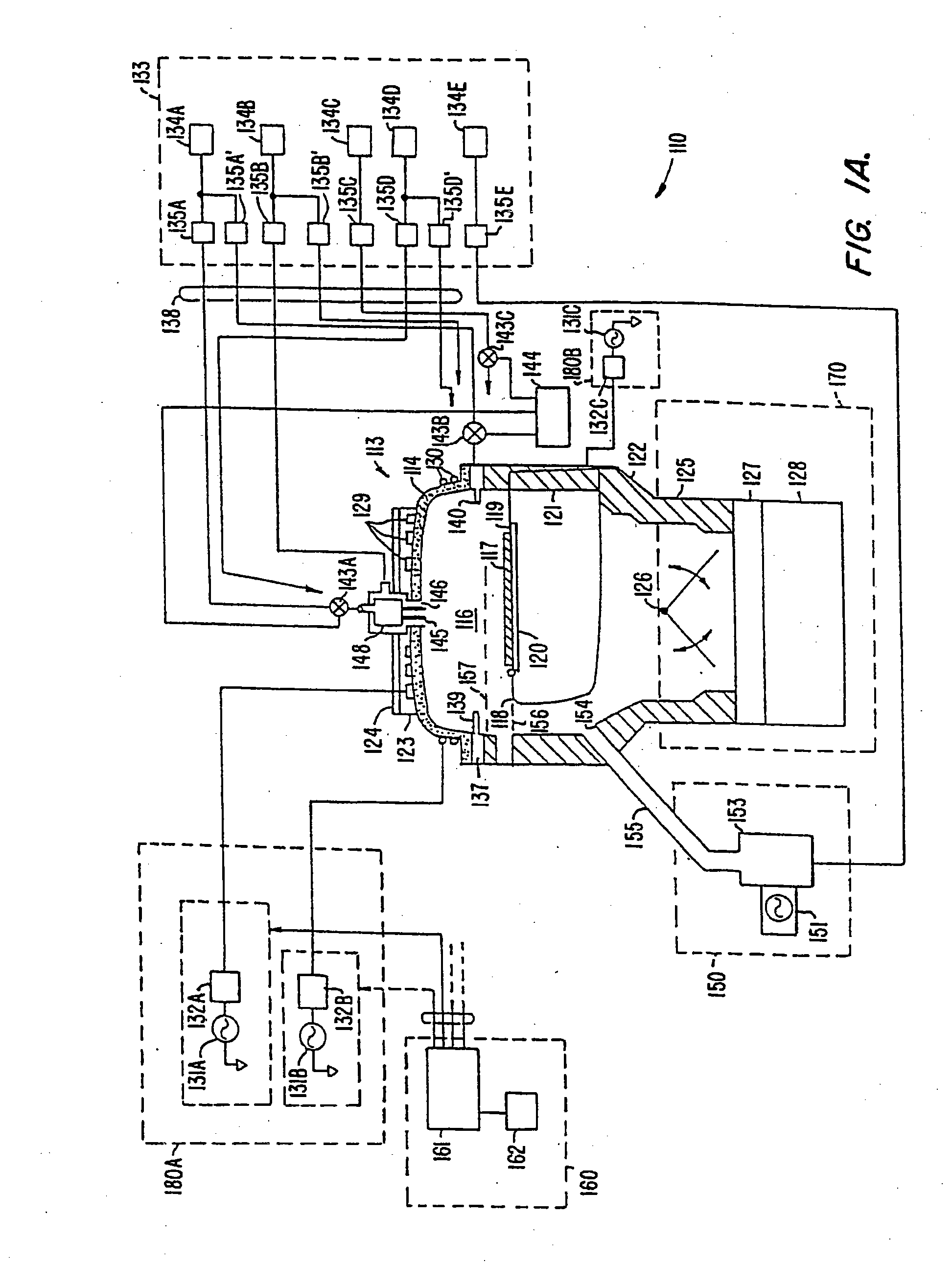

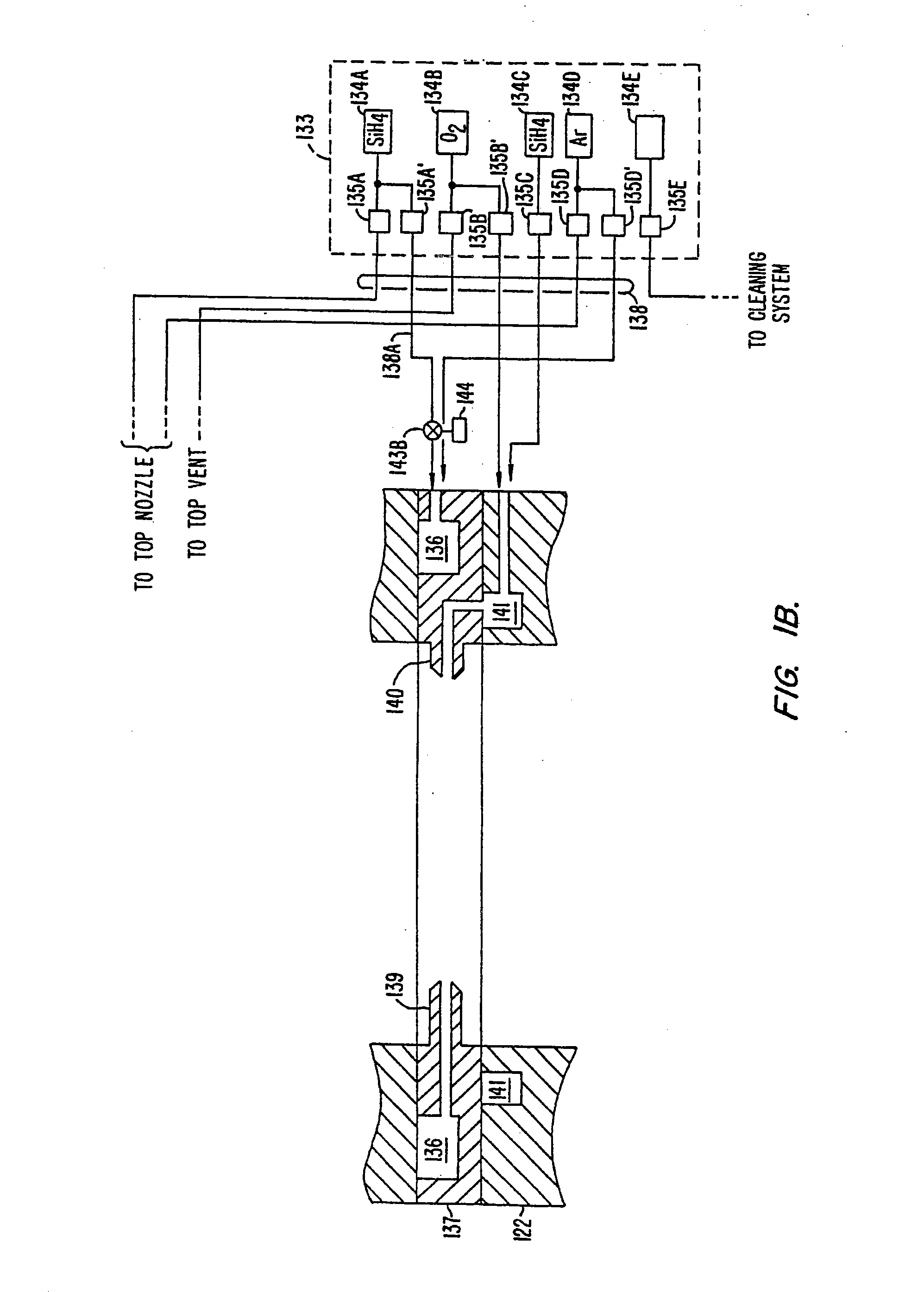

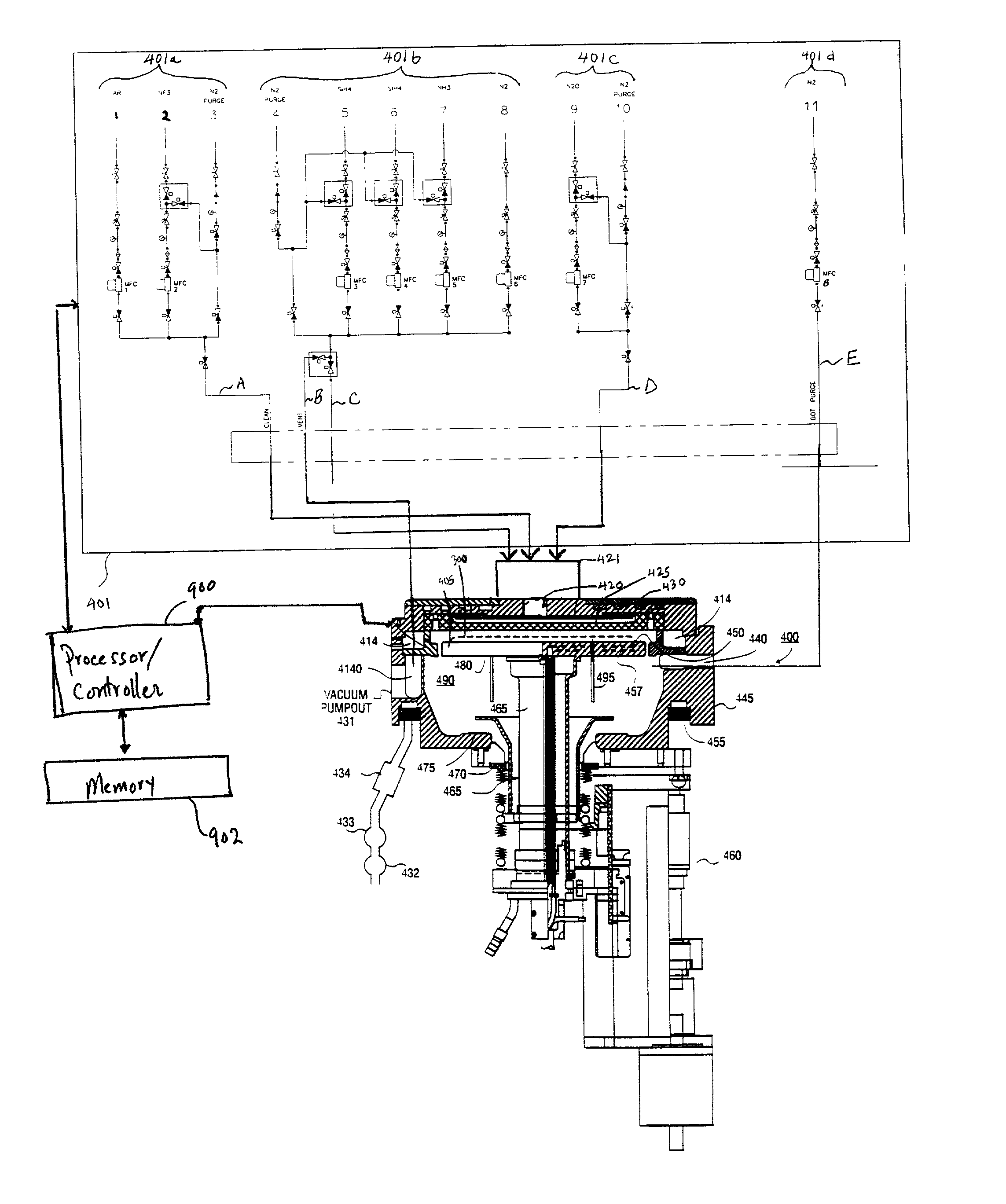

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

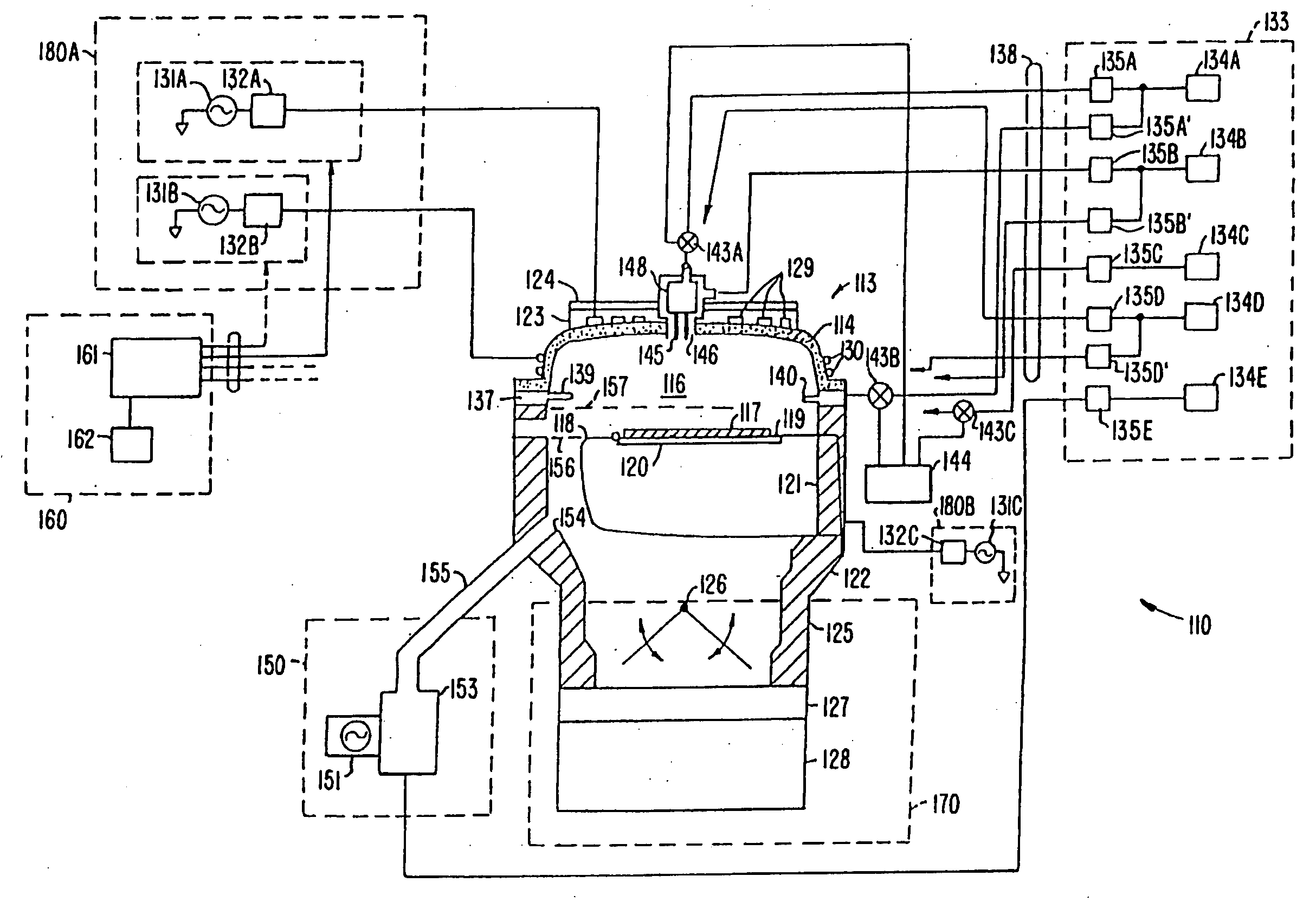

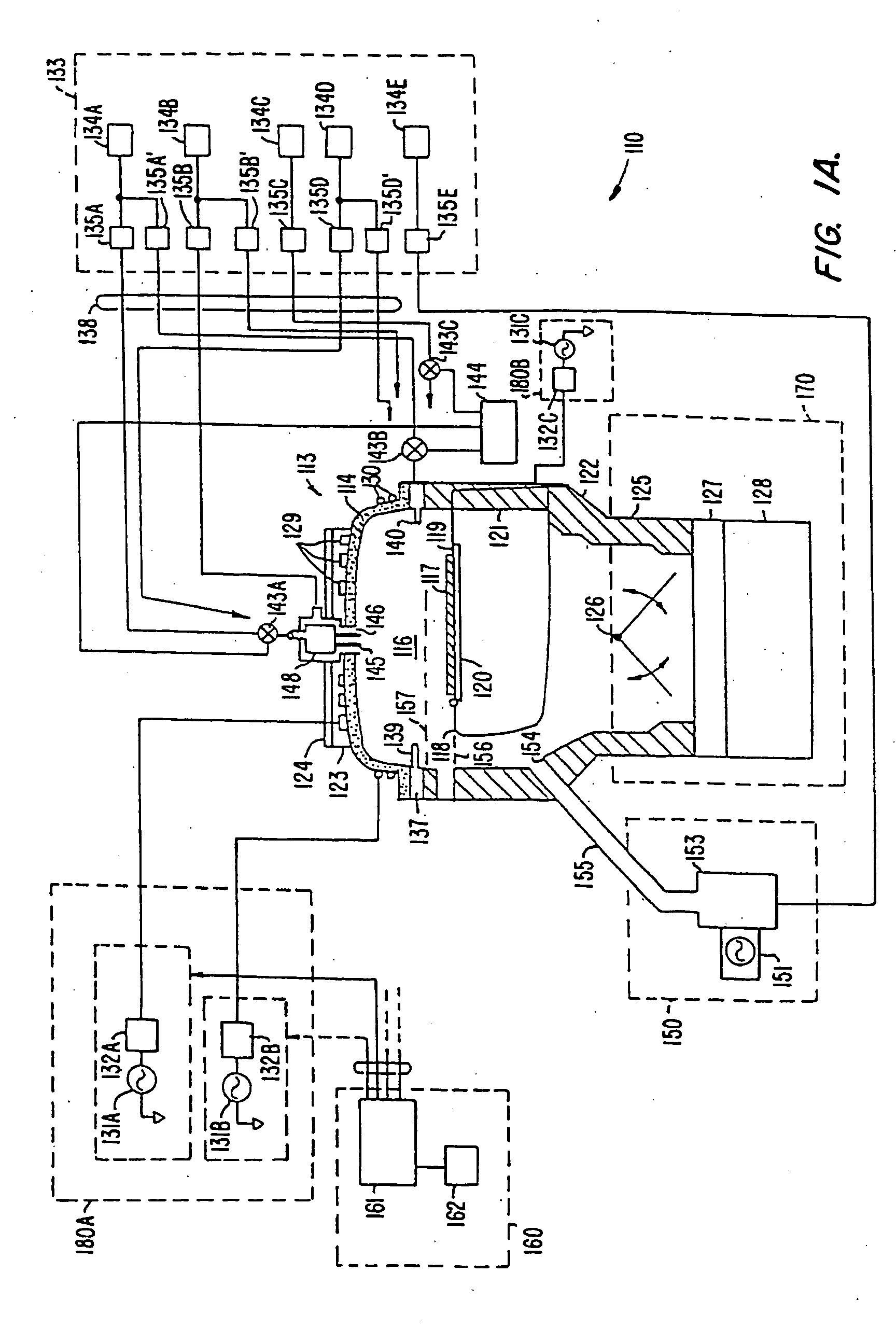

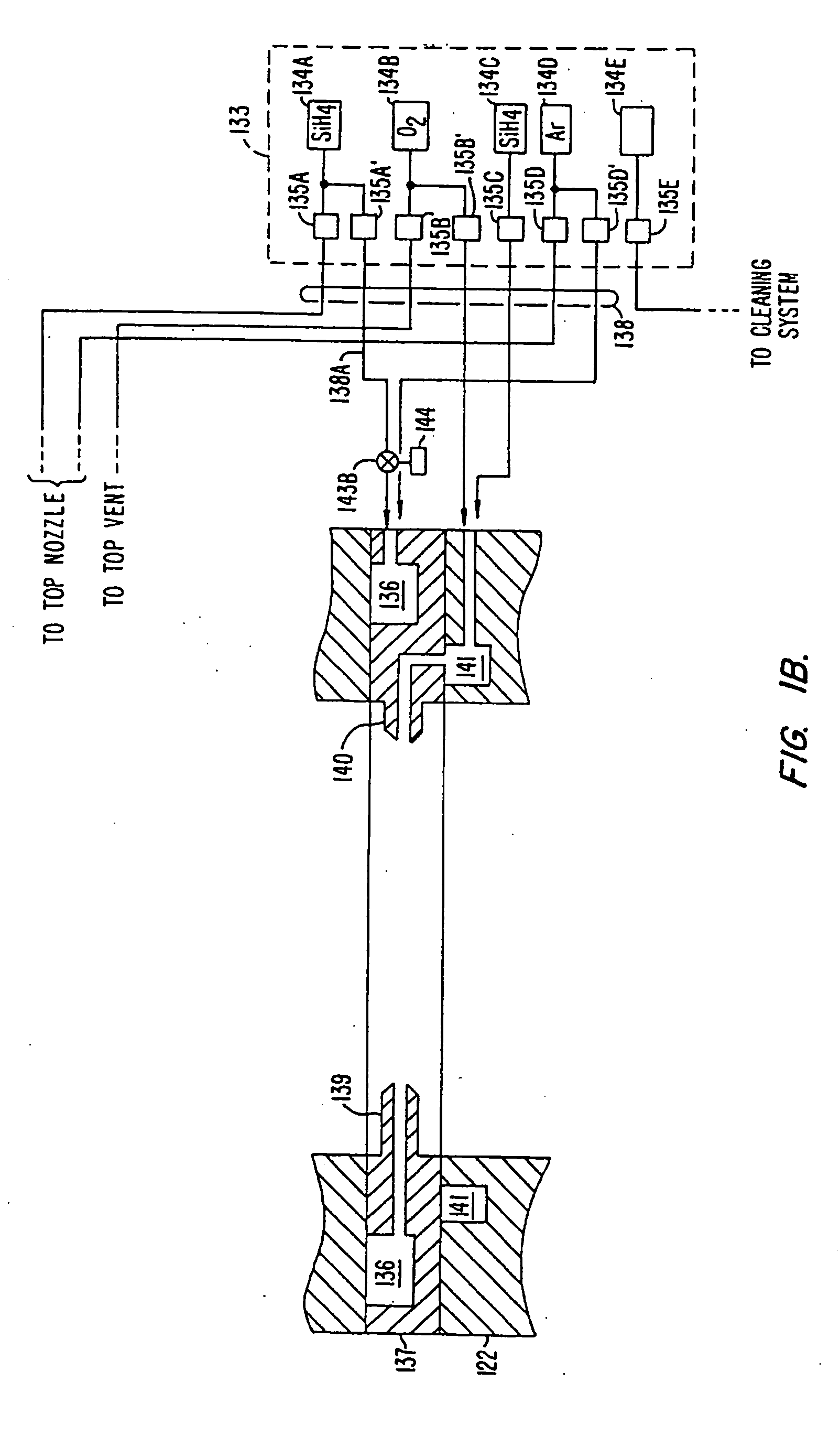

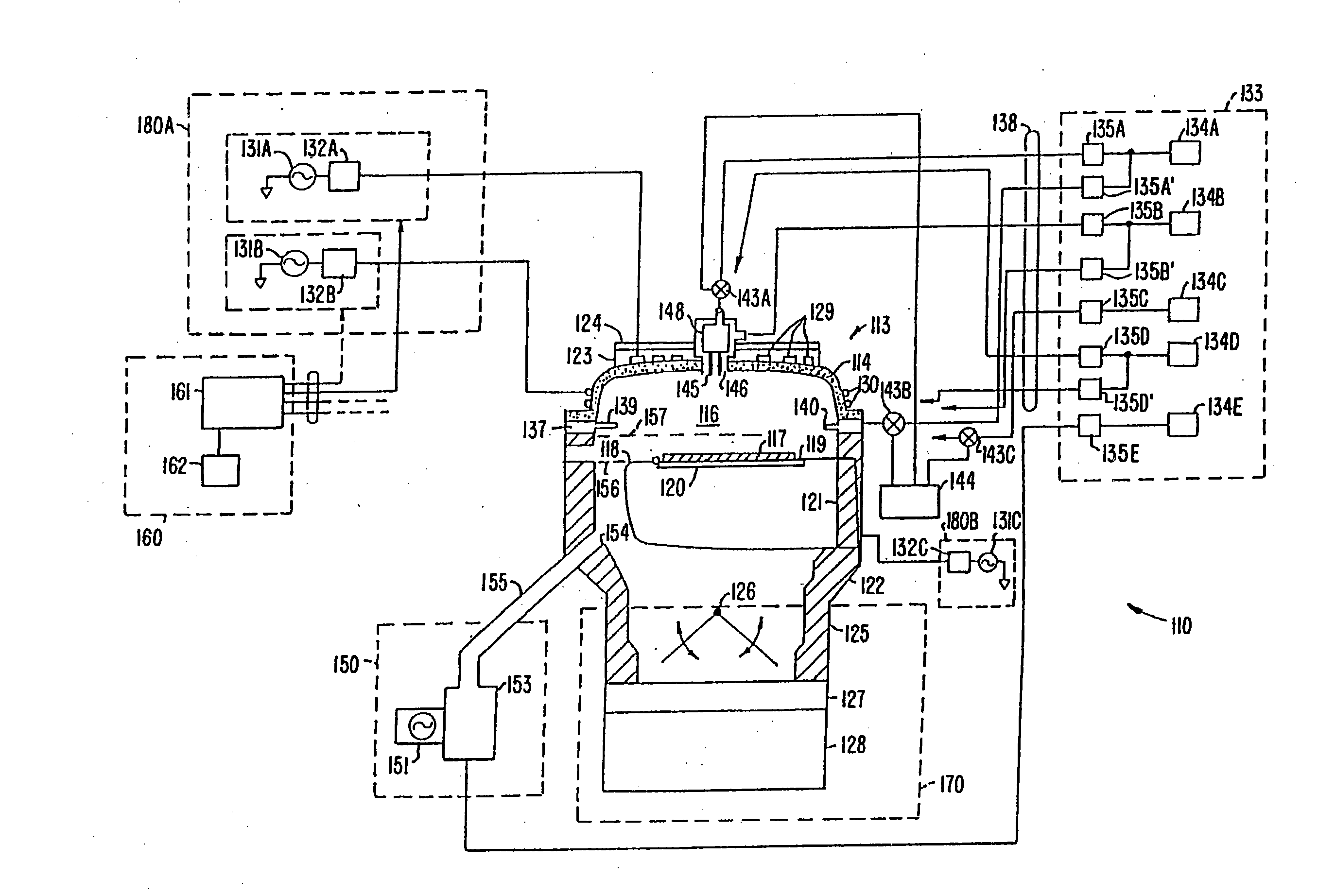

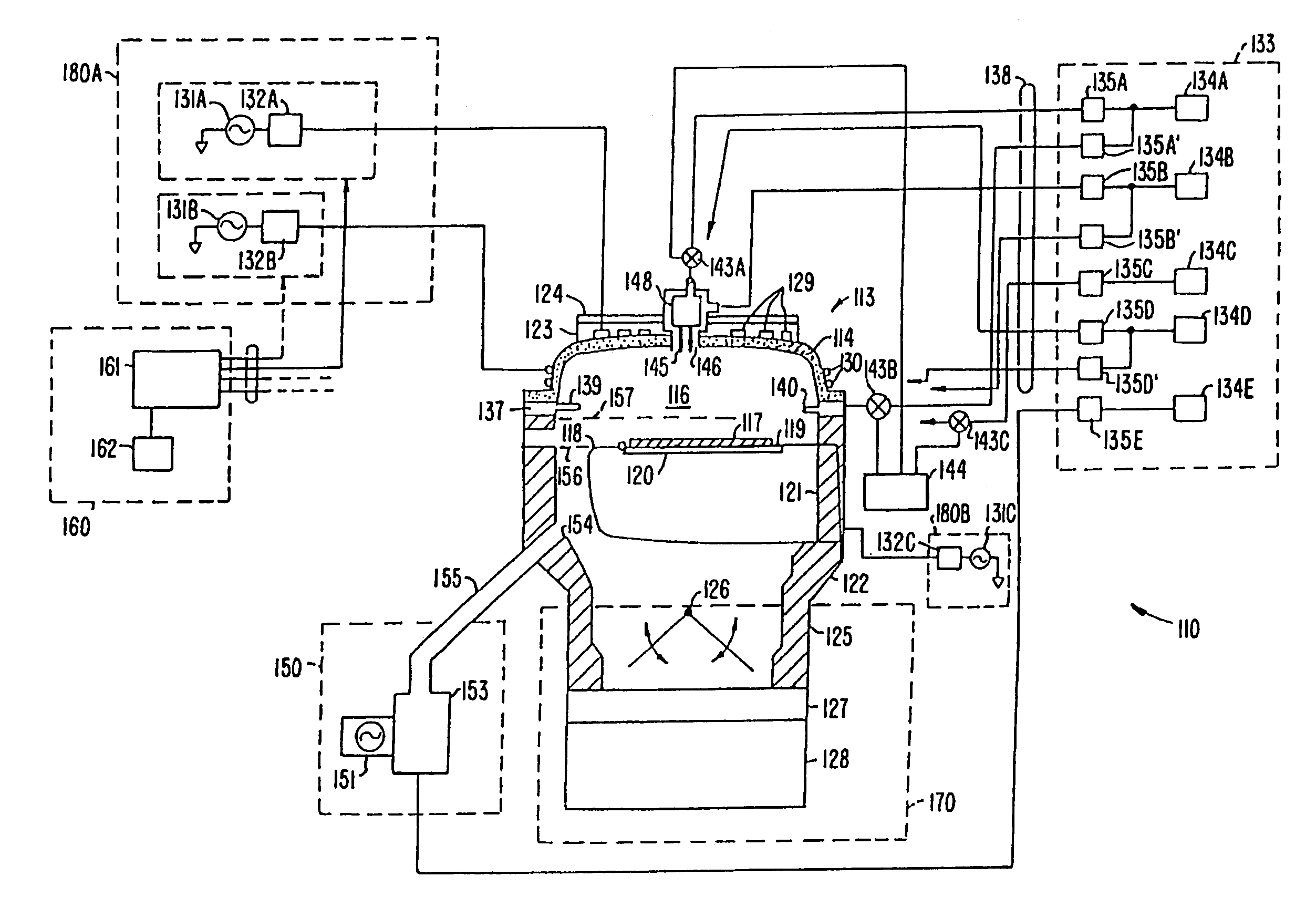

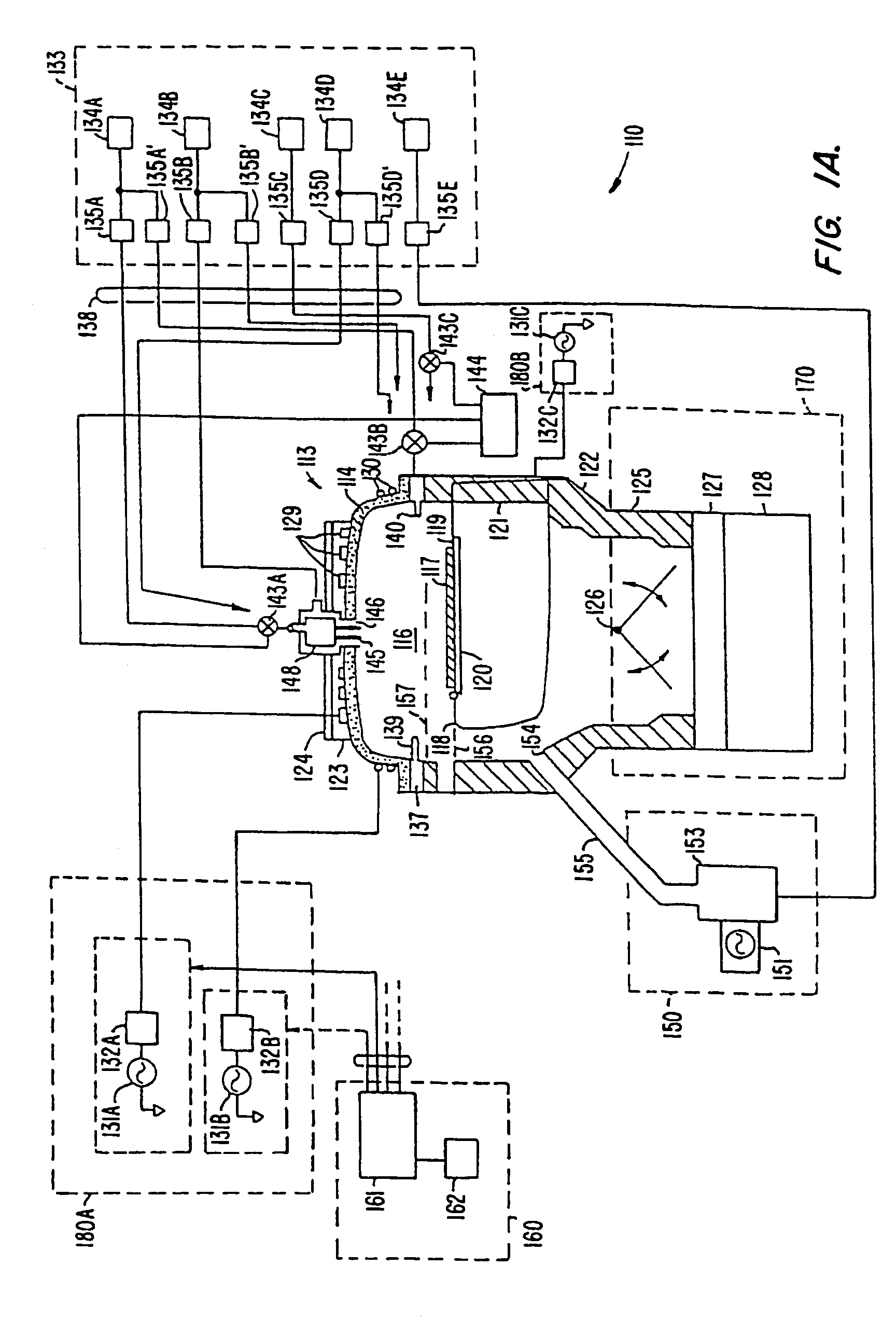

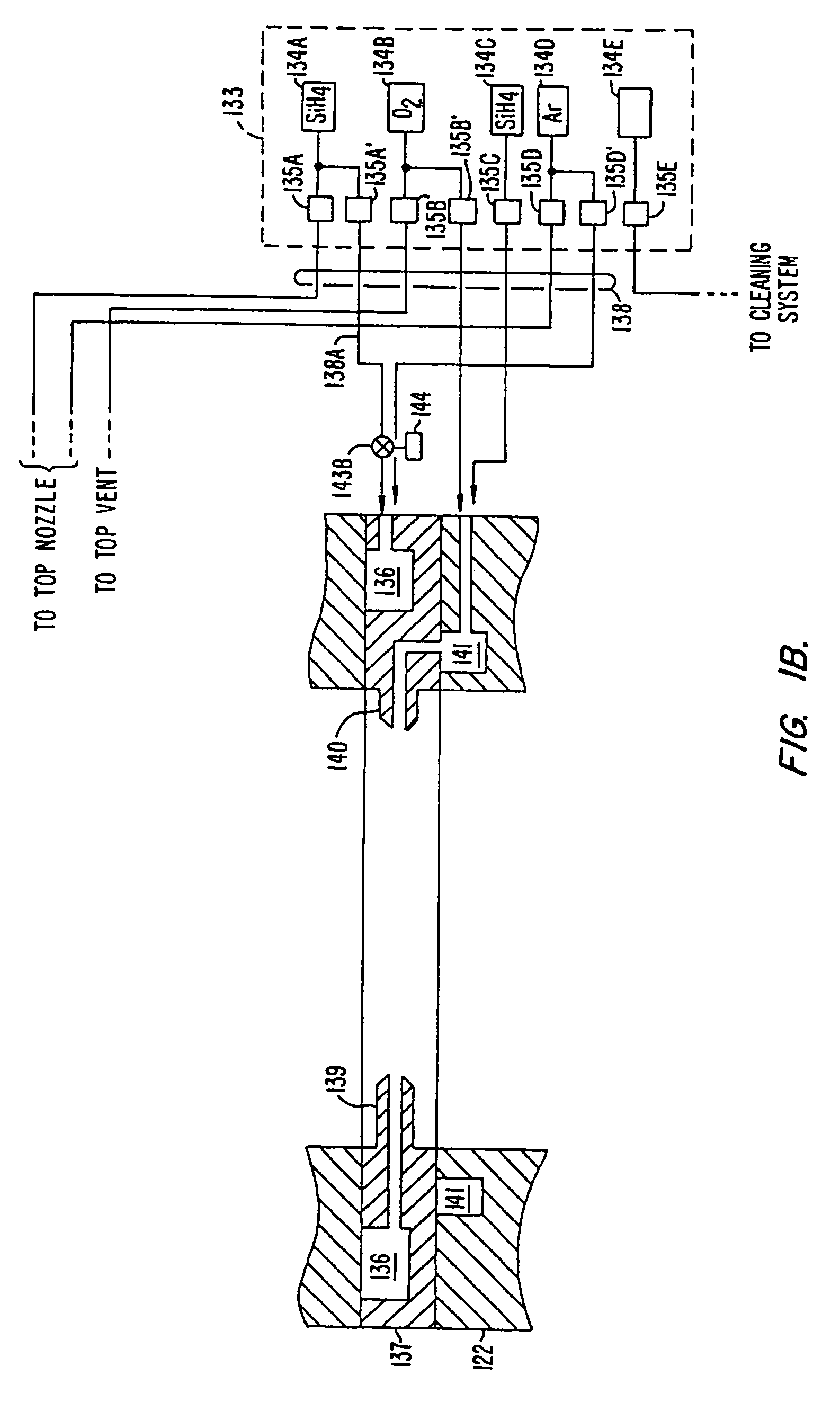

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

Hdp-cvd seasoning process for high power hdp-cvd gapfil to improve particle performance

InactiveUS20060219169A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

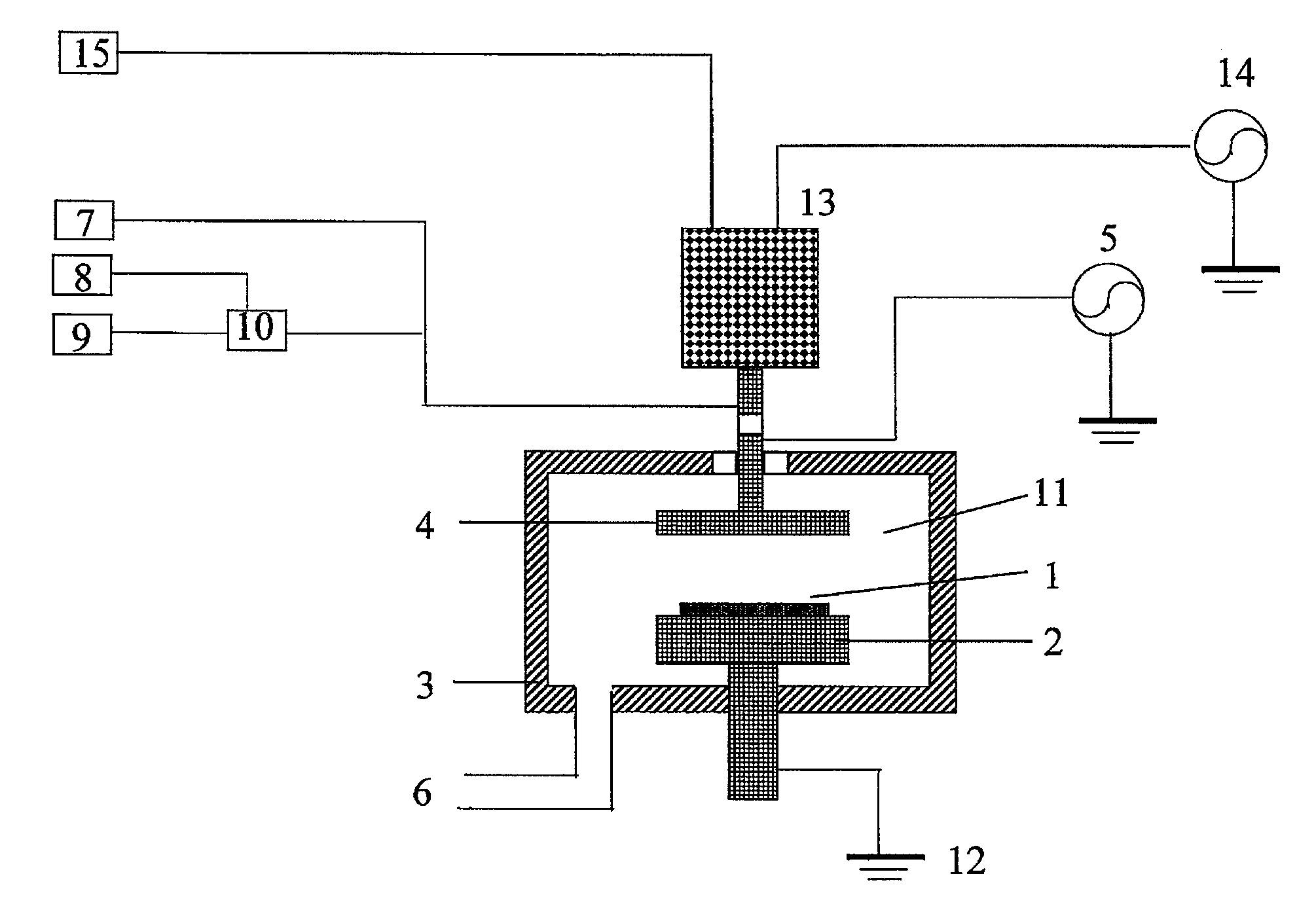

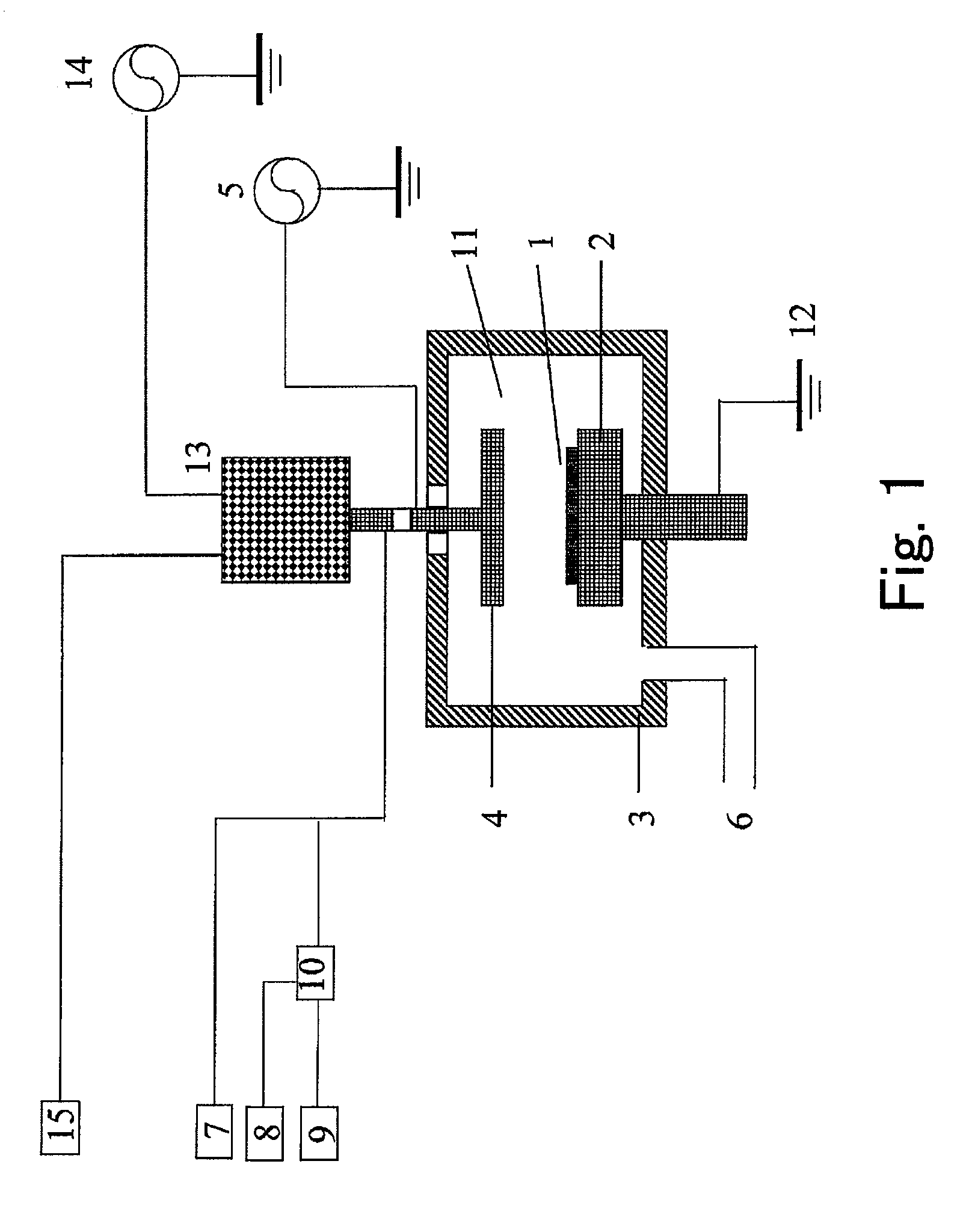

Method of forming a high transparent carbon film

ActiveUS7632549B2Improve featuresRich varietyLiquid surface applicatorsSemiconductor/solid-state device manufacturingCarbon filmProduct gas

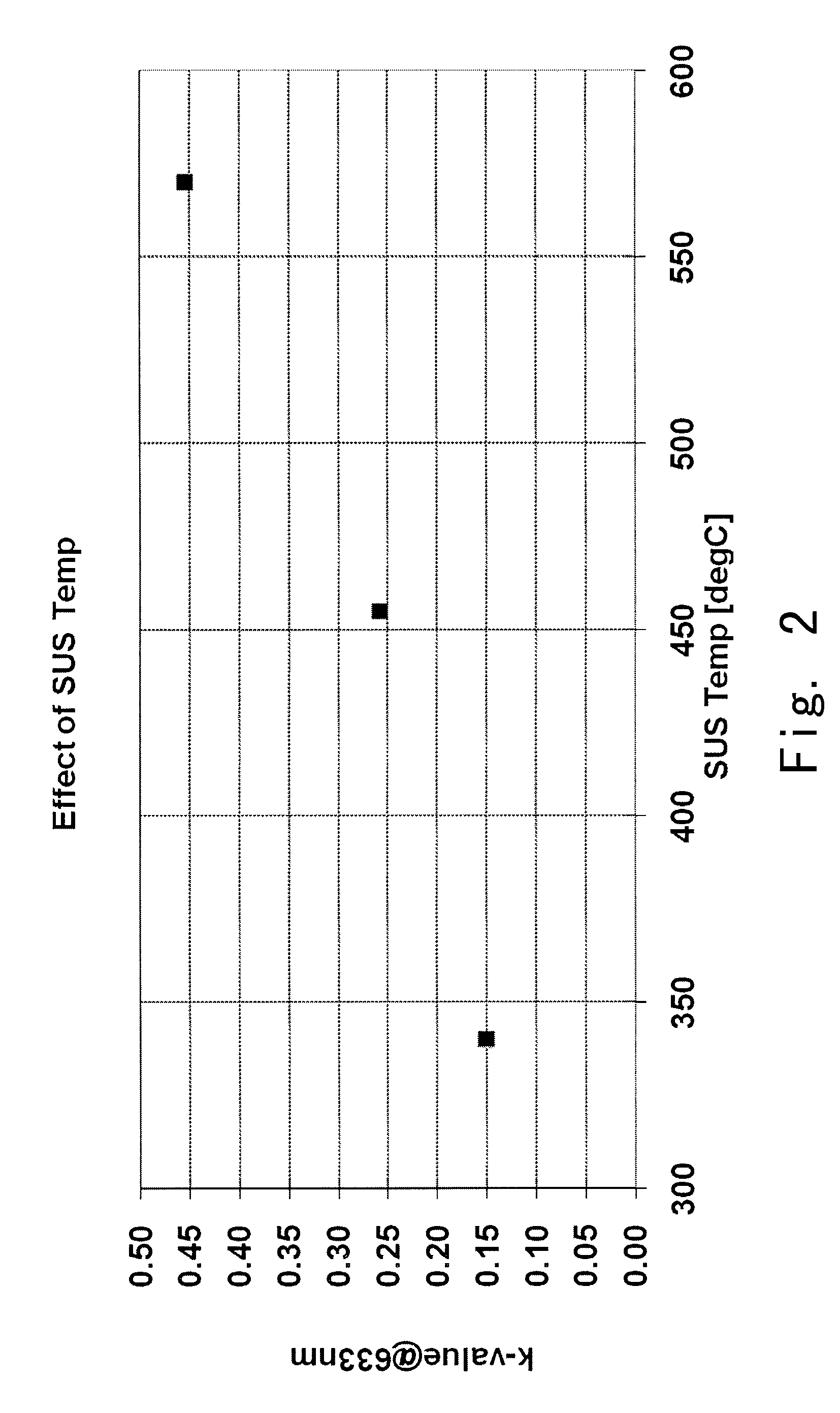

A method of forming a transparent hydrocarbon-based polymer film on a substrate by plasma CVD includes: introducing a main gas consisting of a hydrocarbon gas (CαHβ, wherein α and β are natural numbers) and an inert gas at a flow ratio (R) of CαHβ / inert gas of 0.25 or less into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-based polymer film on the substrate by plasma polymerization of the gas at a processing temperature (T) wherein T≦(−800R+500).

Owner:ASM JAPAN

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS7109114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

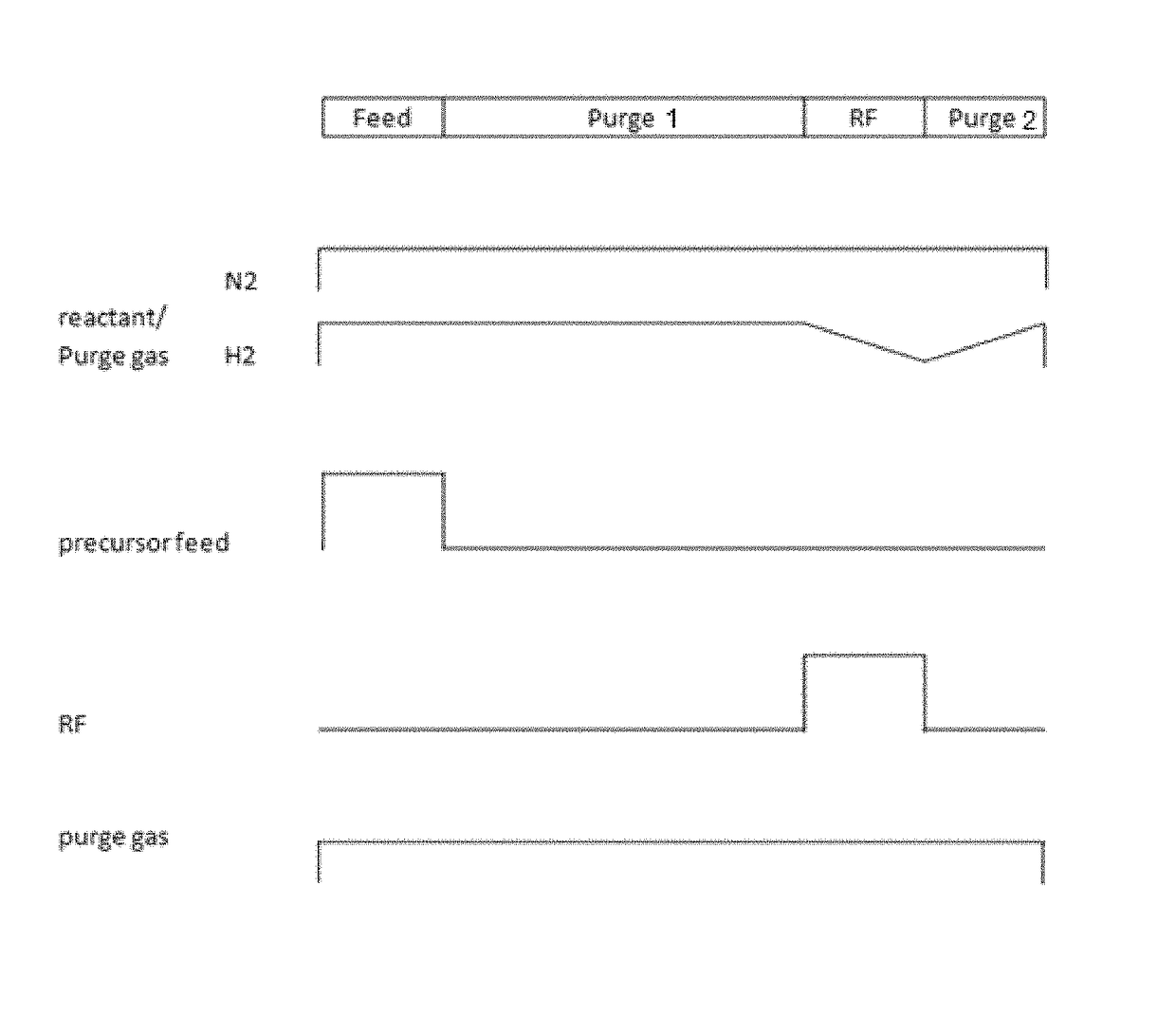

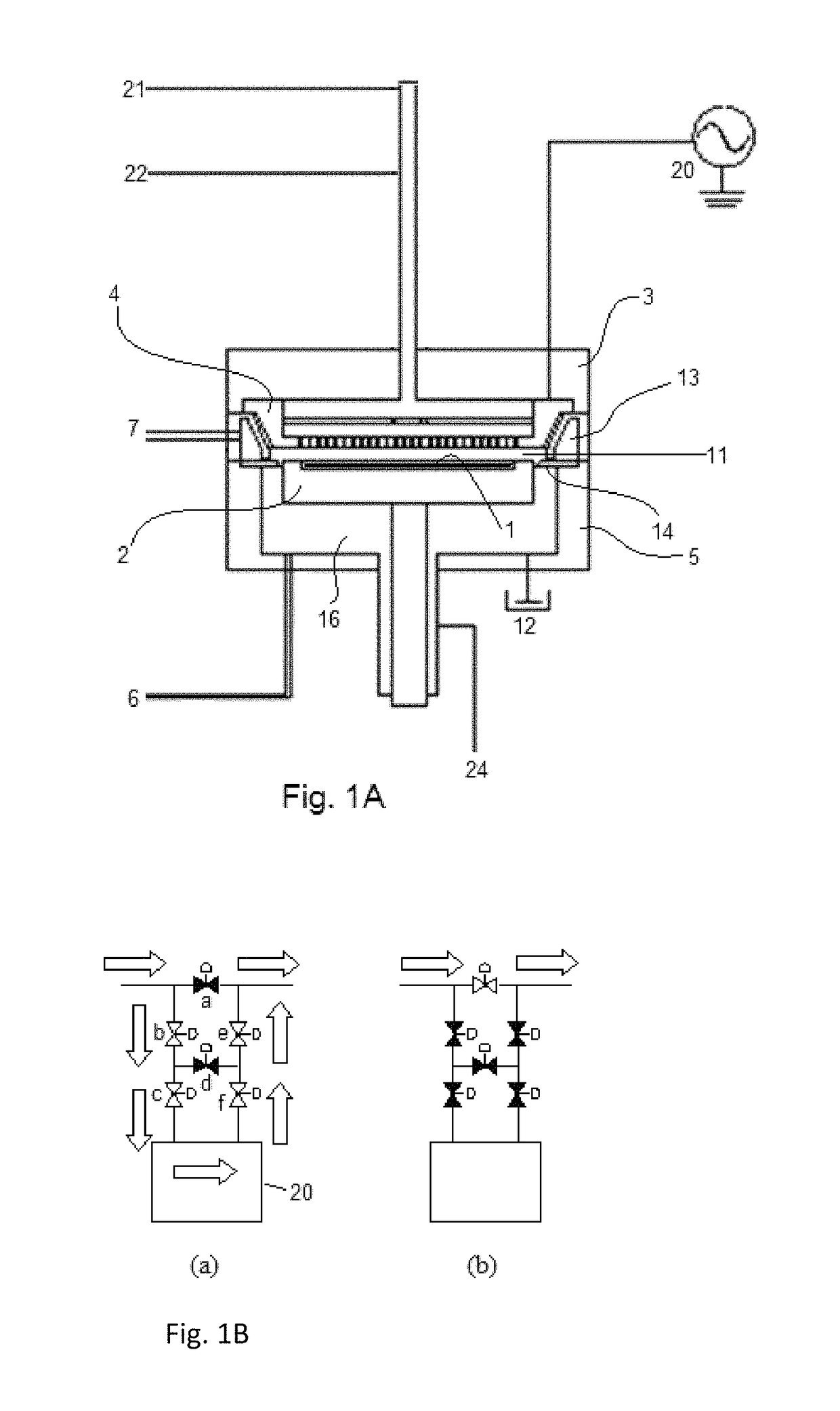

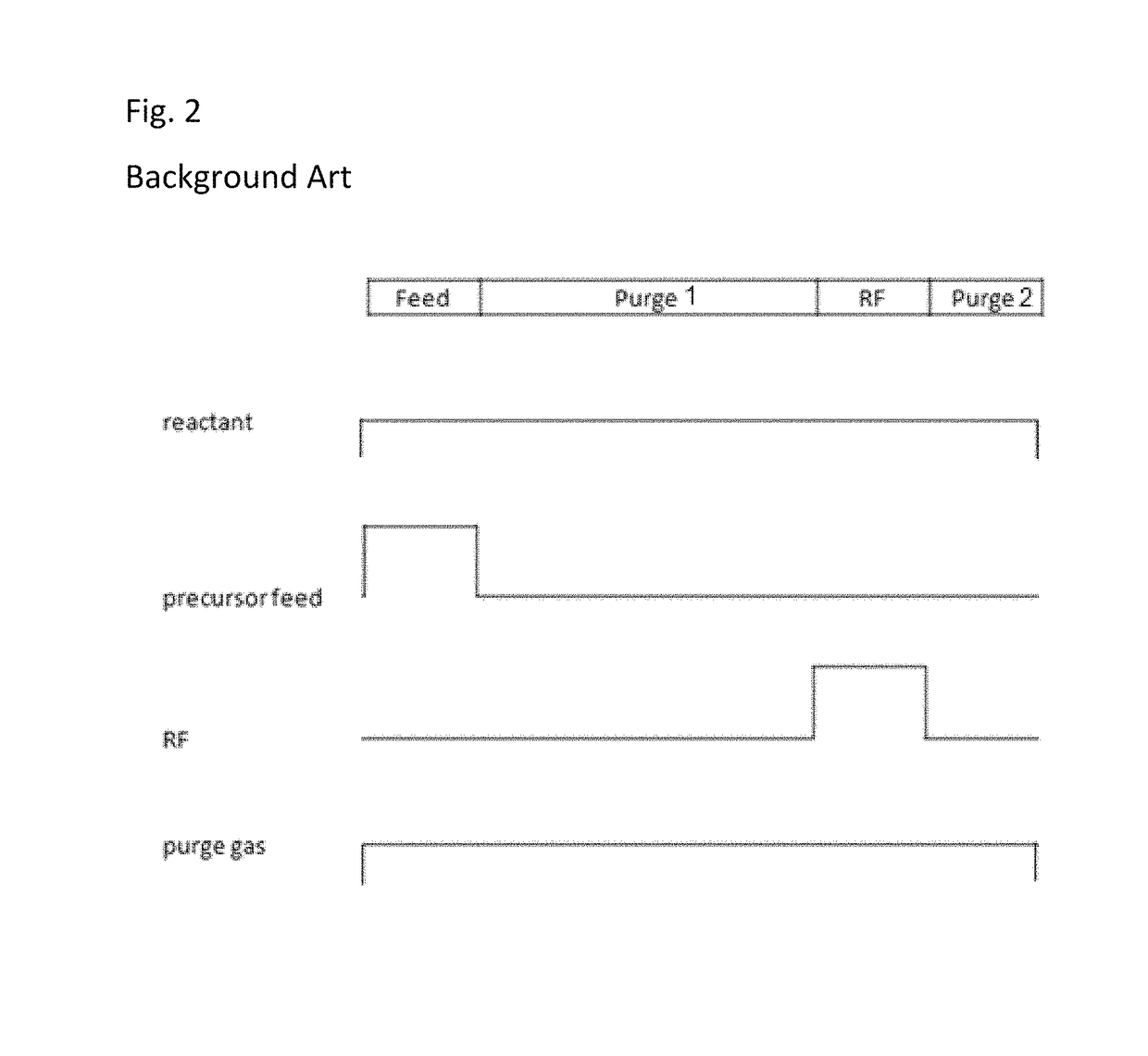

Method of plasma-assisted cyclic deposition using ramp-down flow of reactant gas

ActiveUS9984869B1Electric discharge tubesSemiconductor/solid-state device manufacturingHydrogenOxygen

A method is for forming a nitride or oxide film by plasma-assisted cyclic deposition, one cycle of which includes: feeding a first reactant, a second reactant, and a precursor to a reaction space where a substrate is placed, wherein the second reactant flows at a first flow ratio wherein a flow ratio is defined as a ratio of a flow rate of the second reactant to a total flow rate of gases flowing in the reaction space; and stopping feeding the precursor while continuously feeding the first and second reactants at a flow ratio which is gradually reduced from the first flow ratio to a second flow ratio while applying RF power to the reaction space to expose the substrate to a plasma. The second reactant is constituted by a hydrogen-containing compound or oxygen-containing compound.

Owner:ASM IP HLDG BV

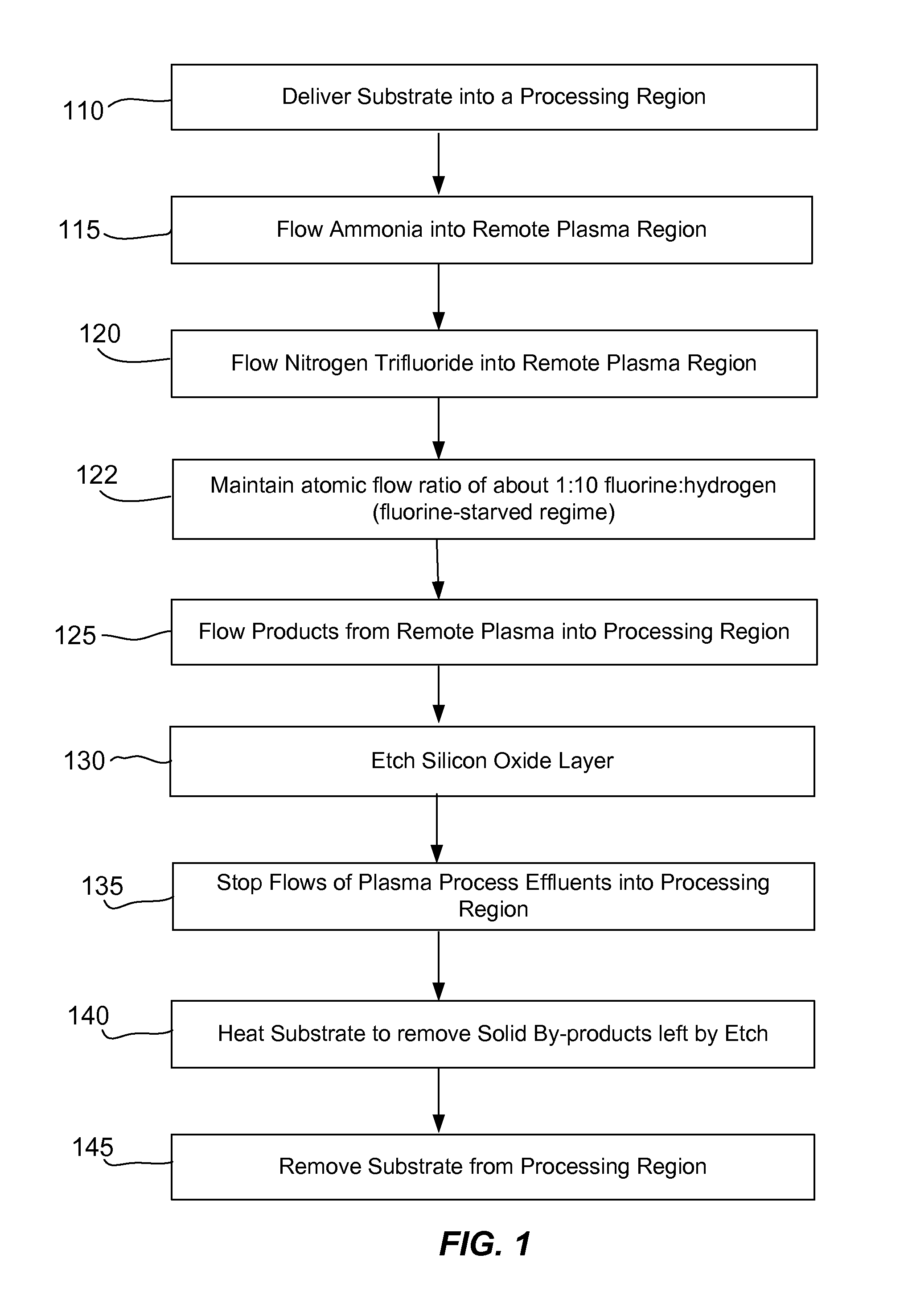

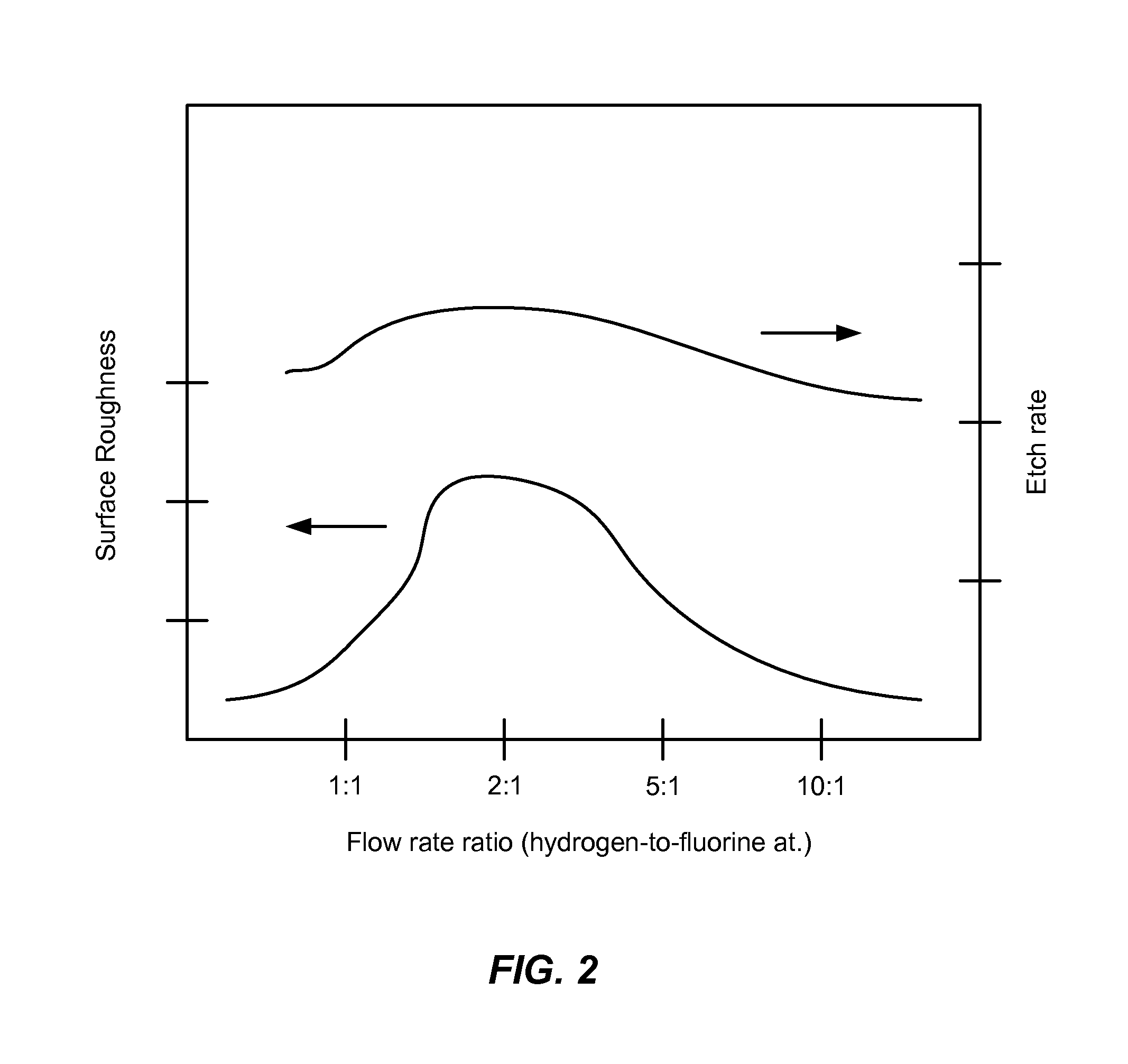

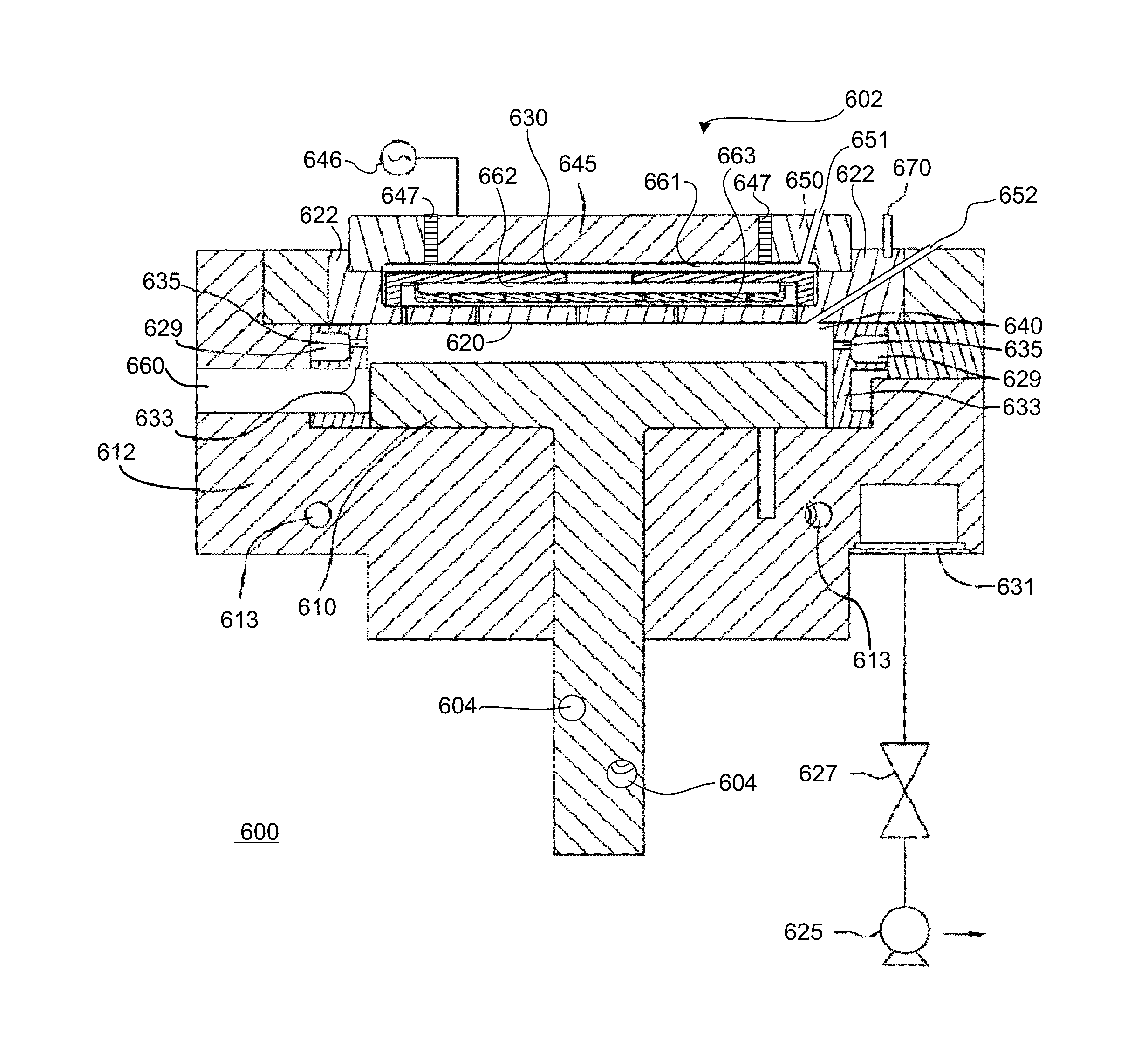

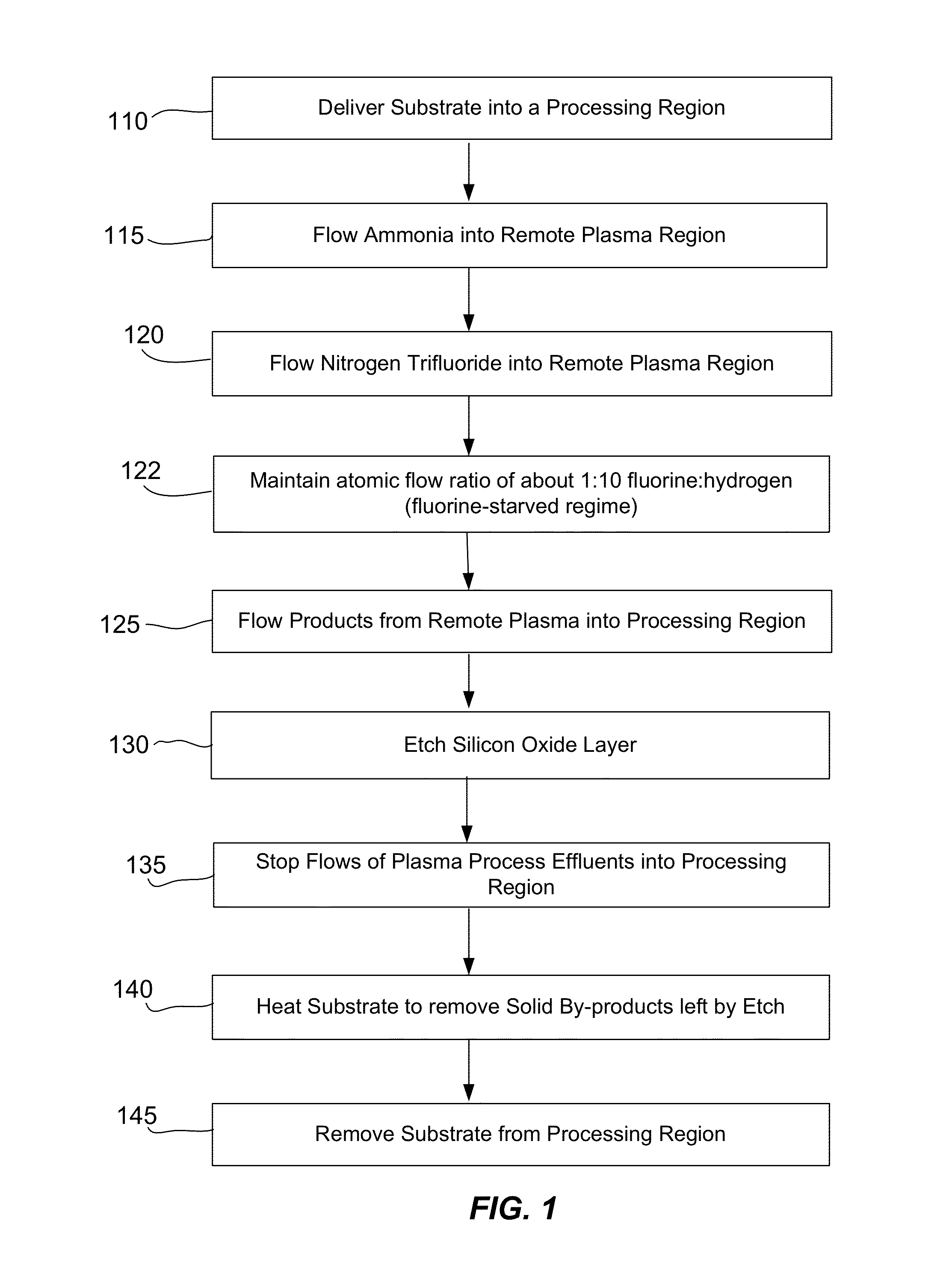

Smooth siconi etch for silicon-containing films

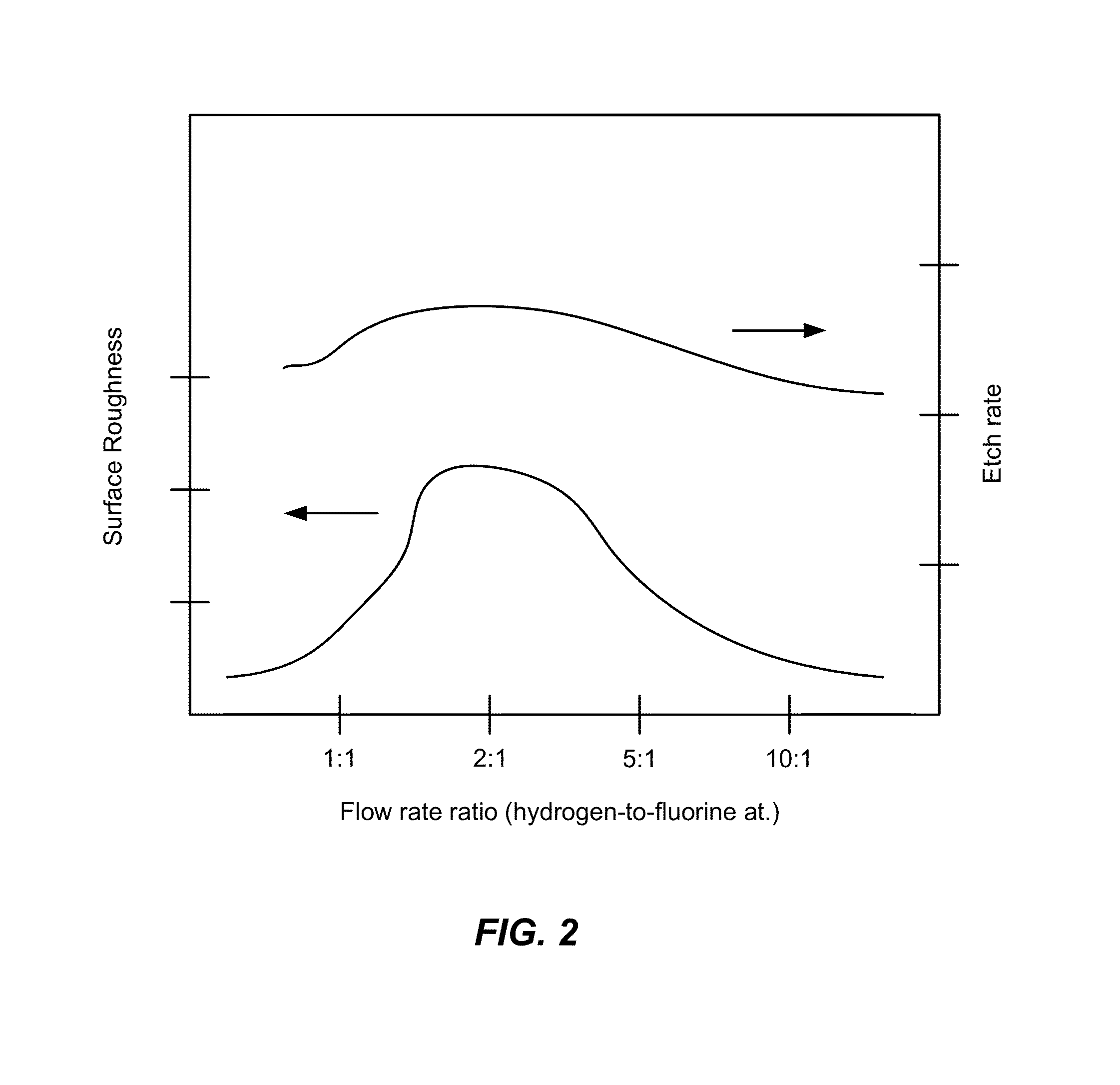

ActiveUS20110151674A1Great and less flow ratioReduce roughnessElectric discharge tubesDecorative surface effectsHydrogenSurface roughness

A method of etching silicon-containing material is described and includes a SiConi™ etch having a greater or lesser flow ratio of hydrogen compared to fluorine than that found in the prior art. Modifying the flow rate ratios in this way has been found to reduce roughness of the post-etch surface and to reduce the difference in etch-rate between densely and sparsely patterned areas. Alternative means of reducing post-etch surface roughness include pulsing the flows of the precursors and / or the plasma power, maintaining a relatively high substrate temperature and performing the SiConi™ in multiple steps. Each of these approaches, either alone or in combination, serve to reduce the roughness of the etched surface by limiting solid residue grain size.

Owner:APPLIED MATERIALS INC

Smooth SiConi etch for silicon-containing films

ActiveUS8501629B2Great and less flow ratioReduce roughnessElectric discharge tubesDecorative surface effectsHydrogenSurface roughness

Owner:APPLIED MATERIALS INC

Staged reactor process

In a process for the in situ blending of polymers comprising contacting ethylene and one or more comonomers in two or more fluidized bed reactors with a catalyst system comprising (i) a magnesium / titanium based precursor containing an electron donor and (ii) a hydrocarbyl aluminum cocatalyst, the improvement comprising (A) increasing or decreasing the melt flow ratio and / or molecular weight of the blend by, respectively, decreasing or increasing the mole ratio of a precursor activator compound to the electron donor or (B) increasing or decreasing the bulk density of the blend by, respectively, increasing or decreasing the mole ratio of a precursor activator compound to the electron donor, both (A) and (B) subject to defined provisos including partial pre-activation of the precursor.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

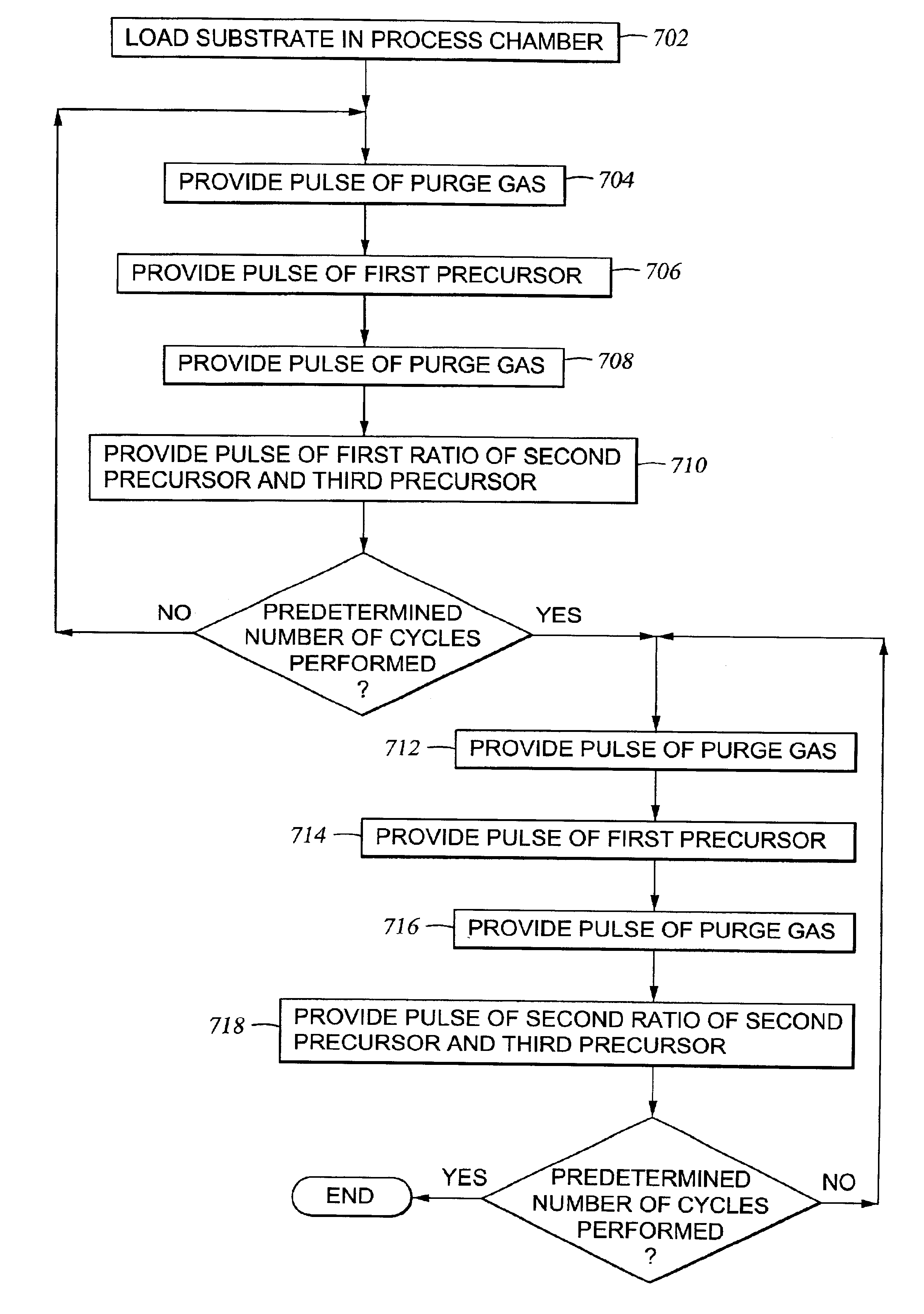

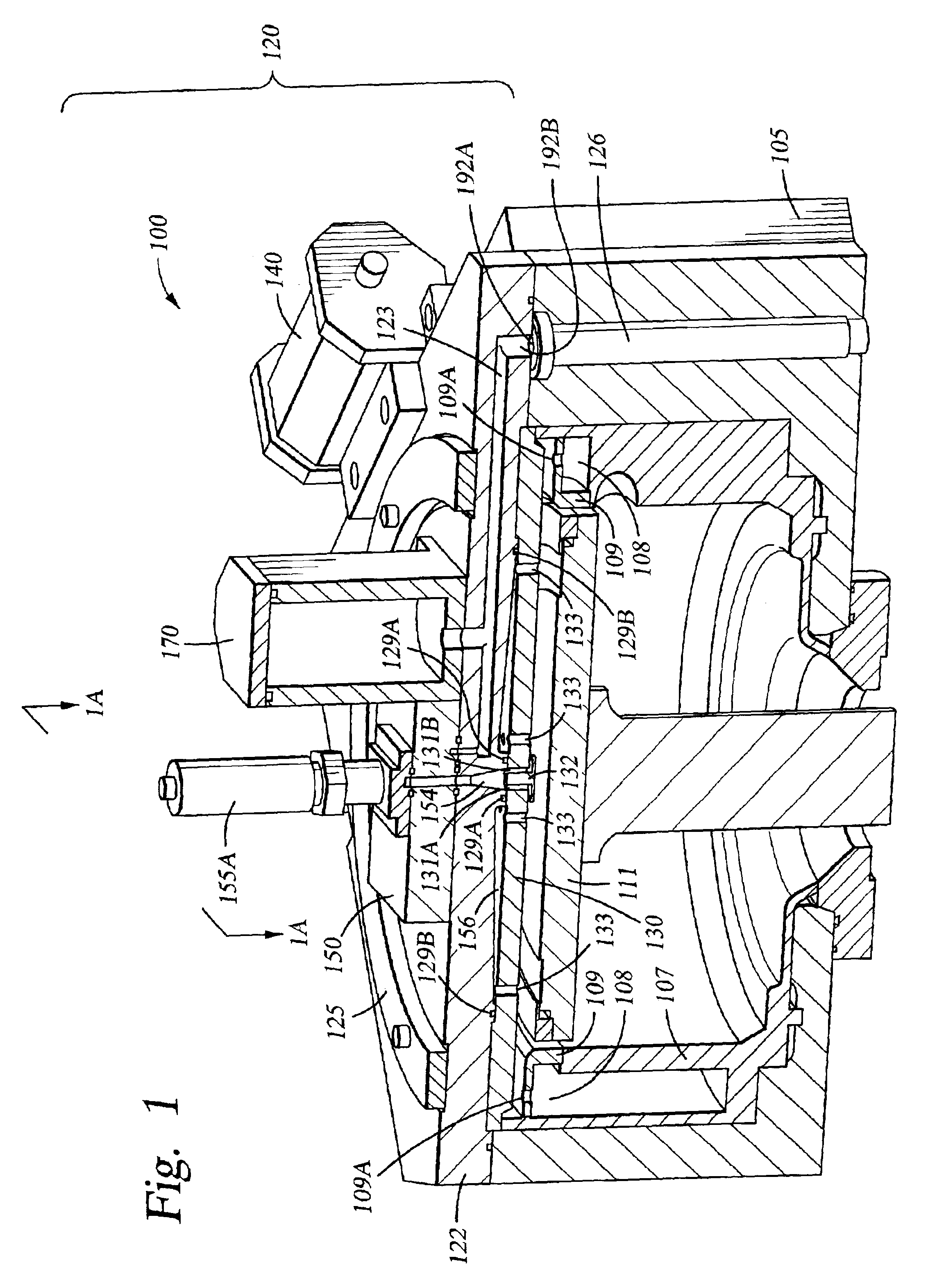

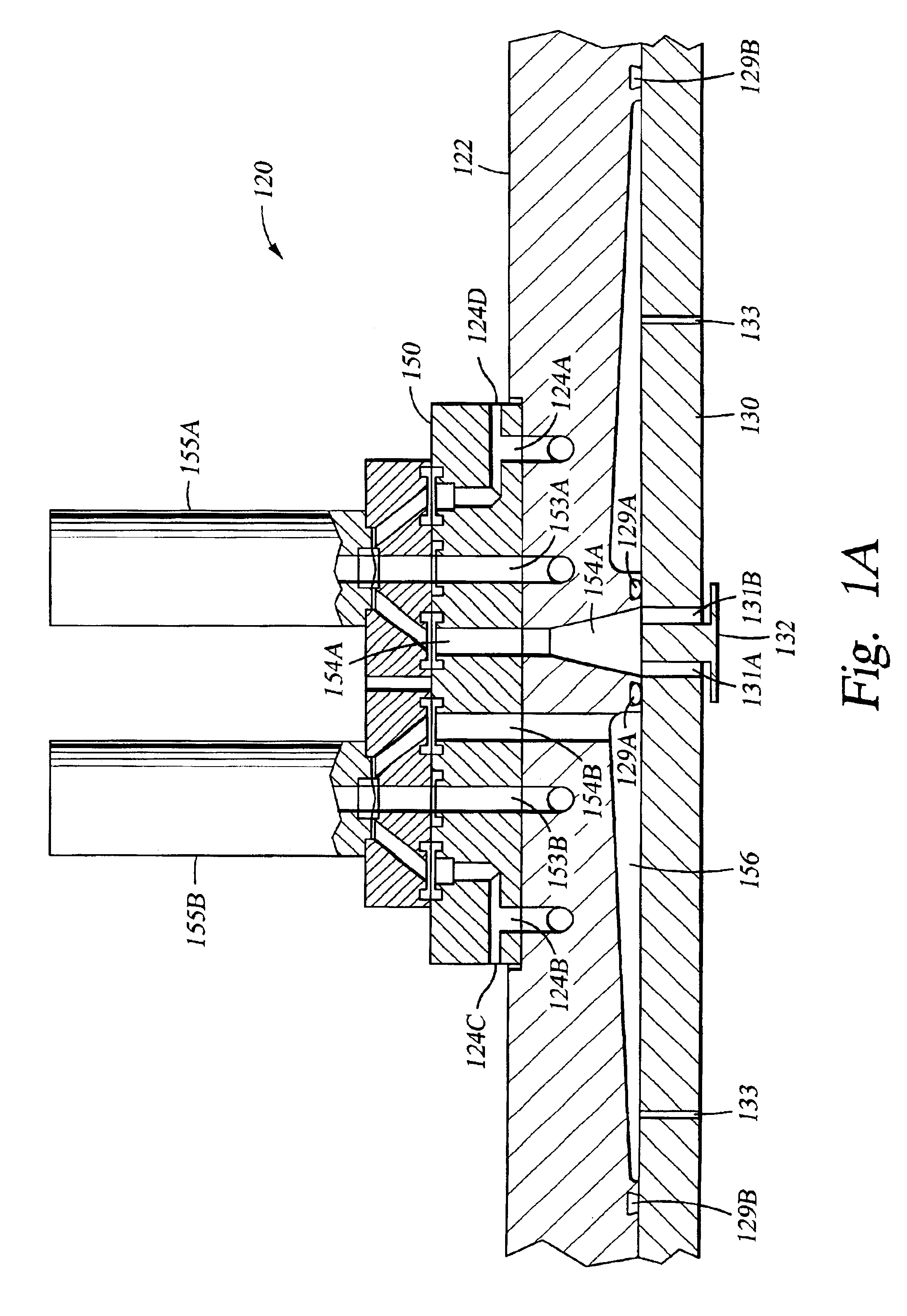

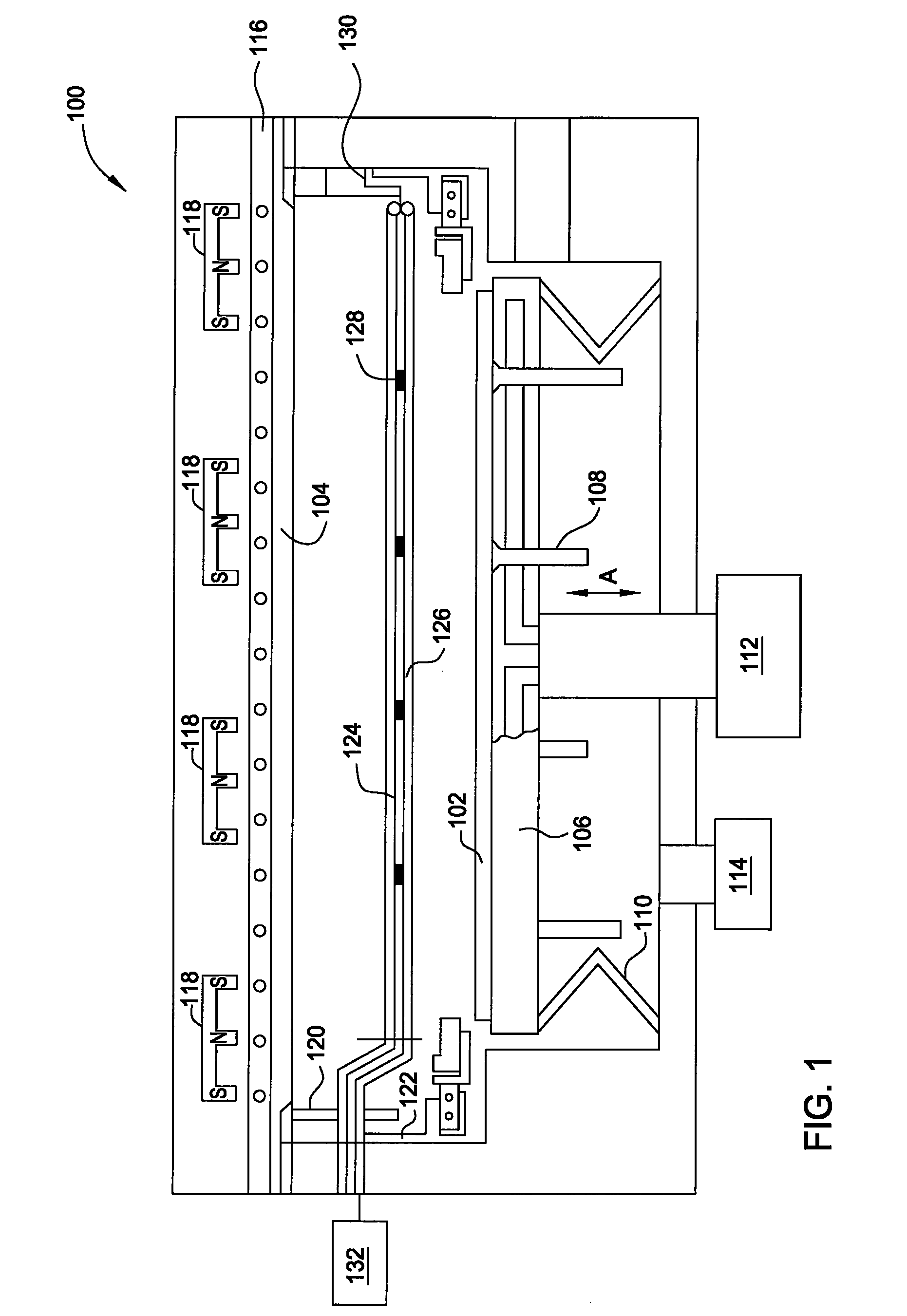

Multiple precursor cyclical deposition system

Embodiments of the present invention relate to an apparatus and method of cyclical deposition utilizing three or more precursors in which delivery of at least two of the precursors to a substrate structure at least partially overlap. One embodiment of depositing a ternary material layer over a substrate structure comprises providing at least one cycle of gases to deposit a ternary material layer. One cycle comprises introducing a pulse of a first precursor, introducing a pulse of a second precursor, and introducing a pulse of a third precursor in which the pulse of the second precursor and the pulse of the third precursor at least partially overlap. In one aspect, the ternary material layer includes, but is not limited to, tungsten boron silicon (WBxSiy), titanium silicon nitride (TiSixNy), tantalum silicon nitride (TaSixNy), silicon oxynitride (SiOxNy), and hafnium silicon oxide (HfSixOy). In one aspect, the composition of the ternary material layer may be tuned by changing the flow ratio of the second precursor to the third precursor between cycles.

Owner:APPLIED MATERIALS INC

Atomic layer deposition of tungsten material

InactiveCN101308794ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseNucleation

An implementing mode of the invention provides an improved technology for depositing materials containing tungsten. The technology utilizes an infusion technology and a gaseous phase deposition technology, such as atomic layer deposition (ALD), to provide tungsten-containing materials with obviously improved surface evenness and yield. In one implementing mode, a method for forming tungsten-containing materials on a substrate is provided. The method comprises deposing a substrate, which contains a bottom coating deposited thereon, in a technological chamber; exposing the substrate orderly in a precursor of tungsten and reducing gases so as to deposit a tungsten nucleation layer on the bottom coating, during the ALD technology; and depositing a tungsten block layer on the tungsten nucleation layer. The invention is characterized in that the reducing gases comprise a hydrogen gas / hydride flow ratio of 40:1, 100:1, 500:1, 800: 1, 1000:1 or more, and comprise hydride such as diborane, silicane or silicoethane.

Owner:APPLIED MATERIALS INC

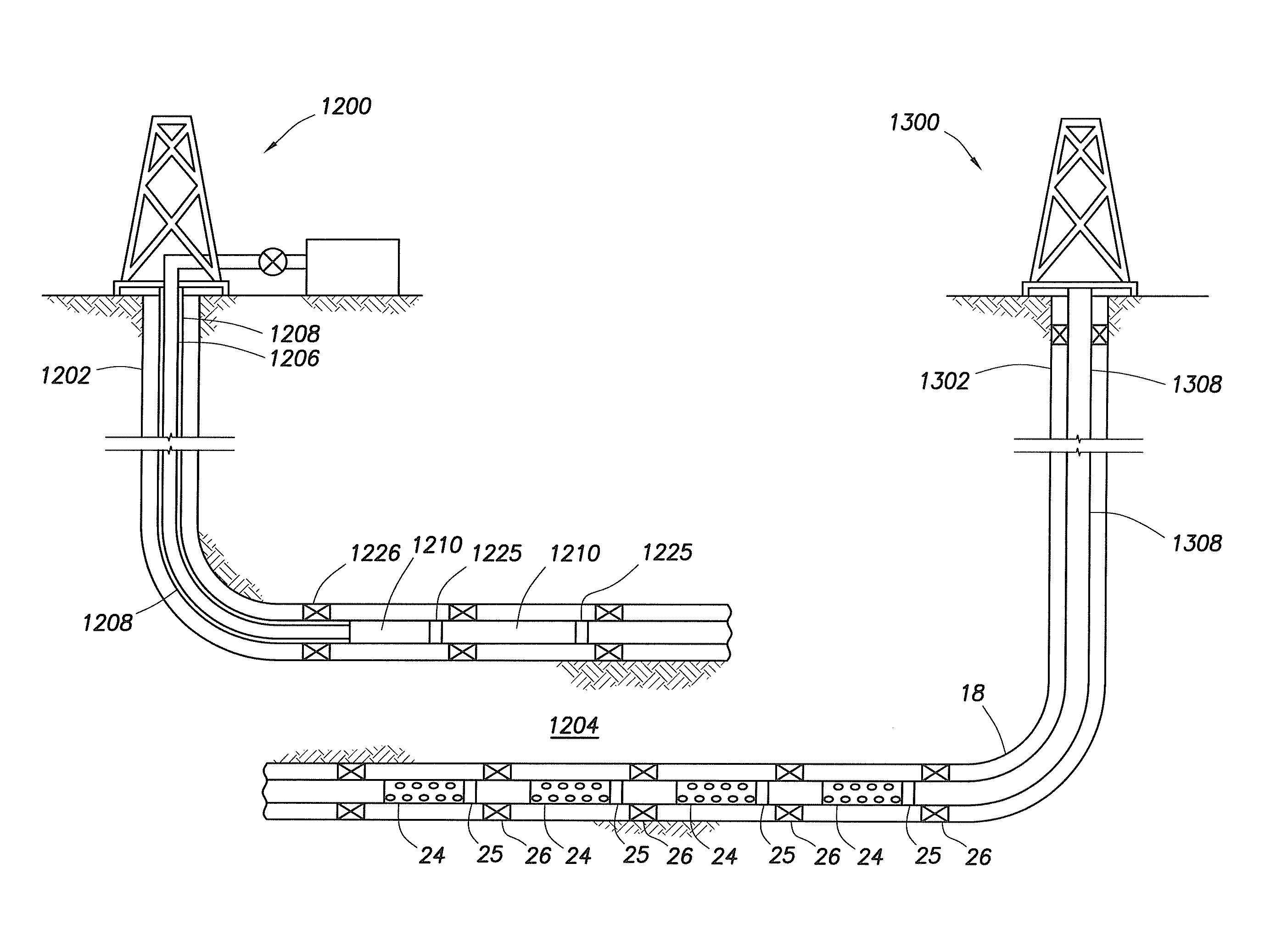

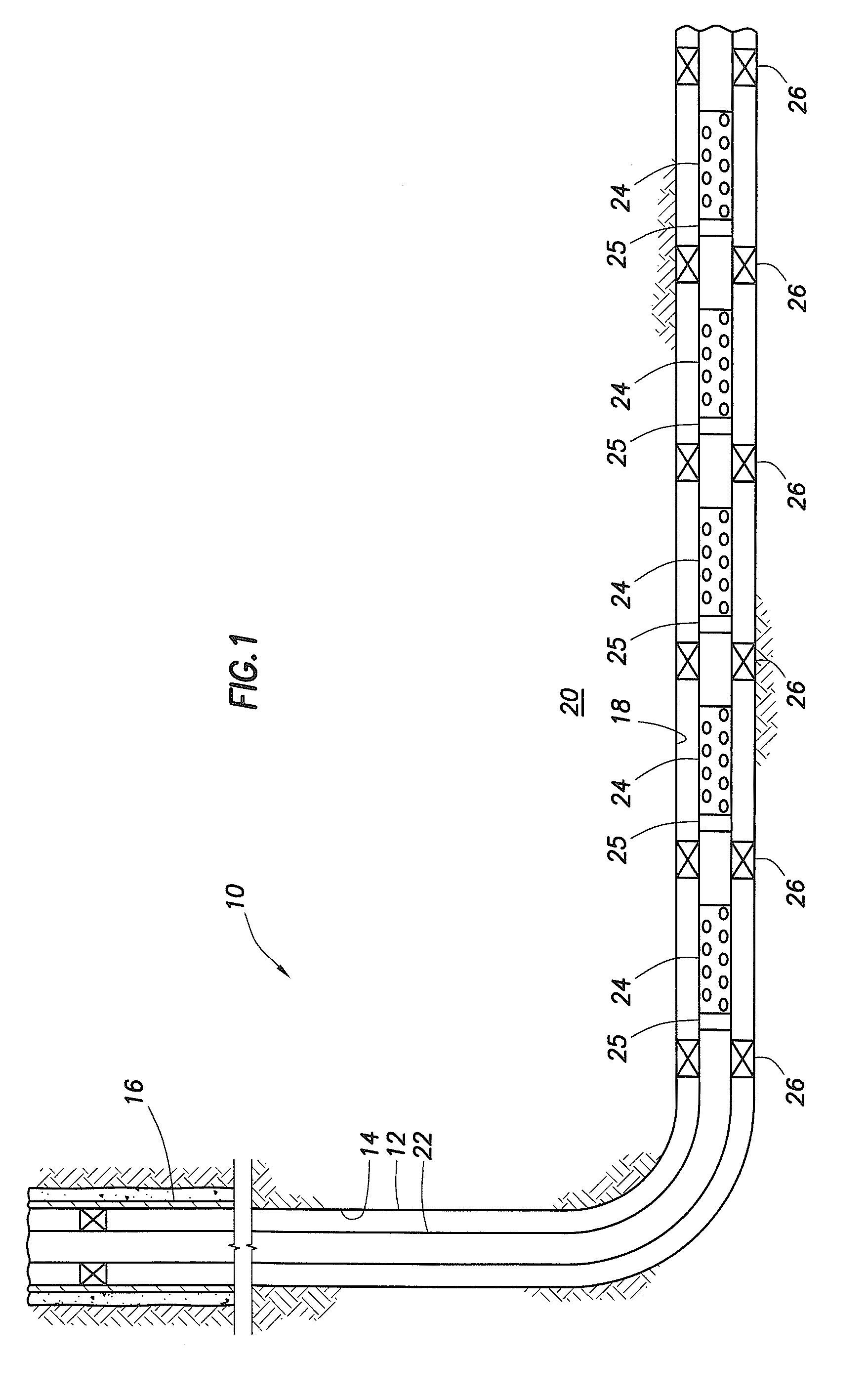

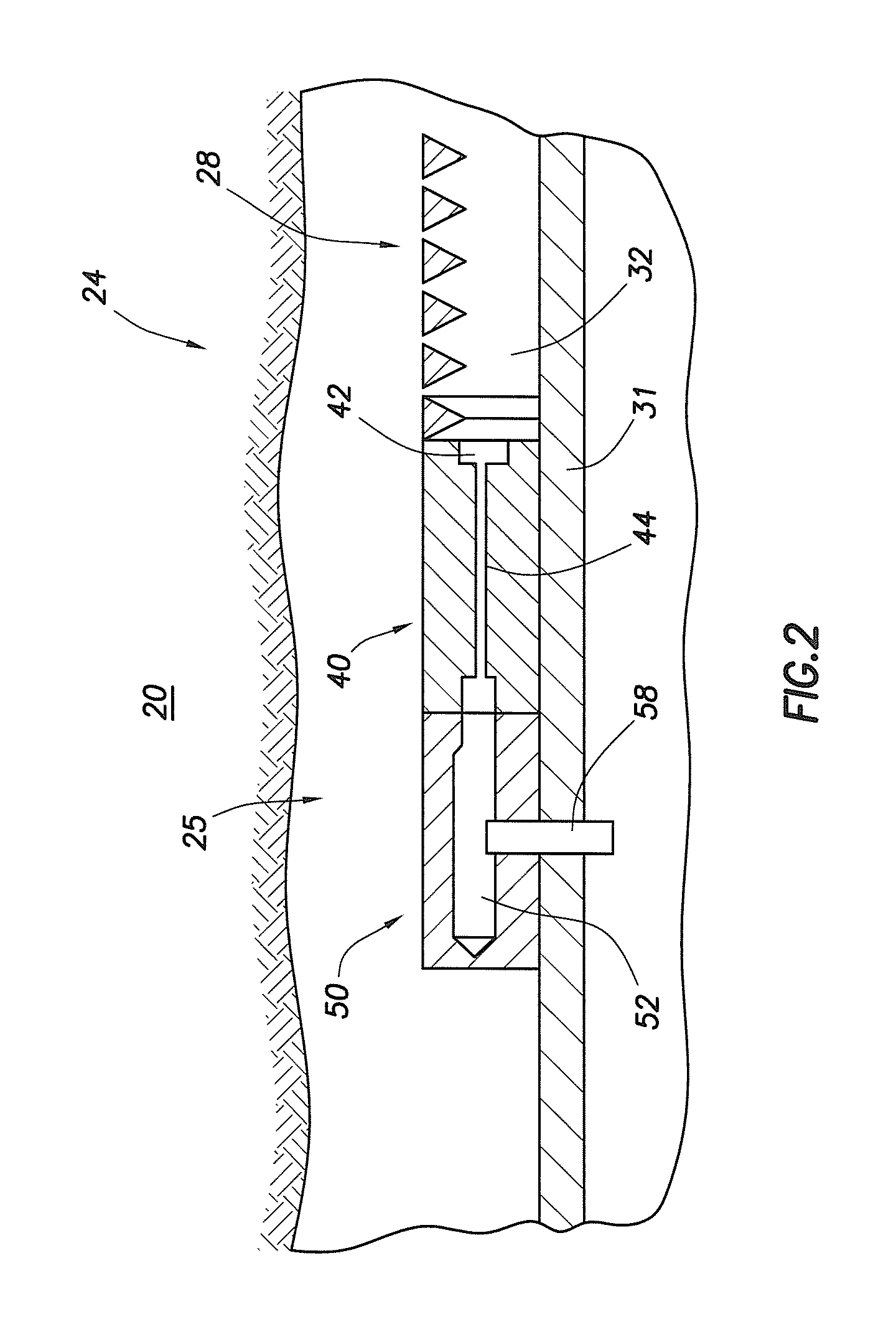

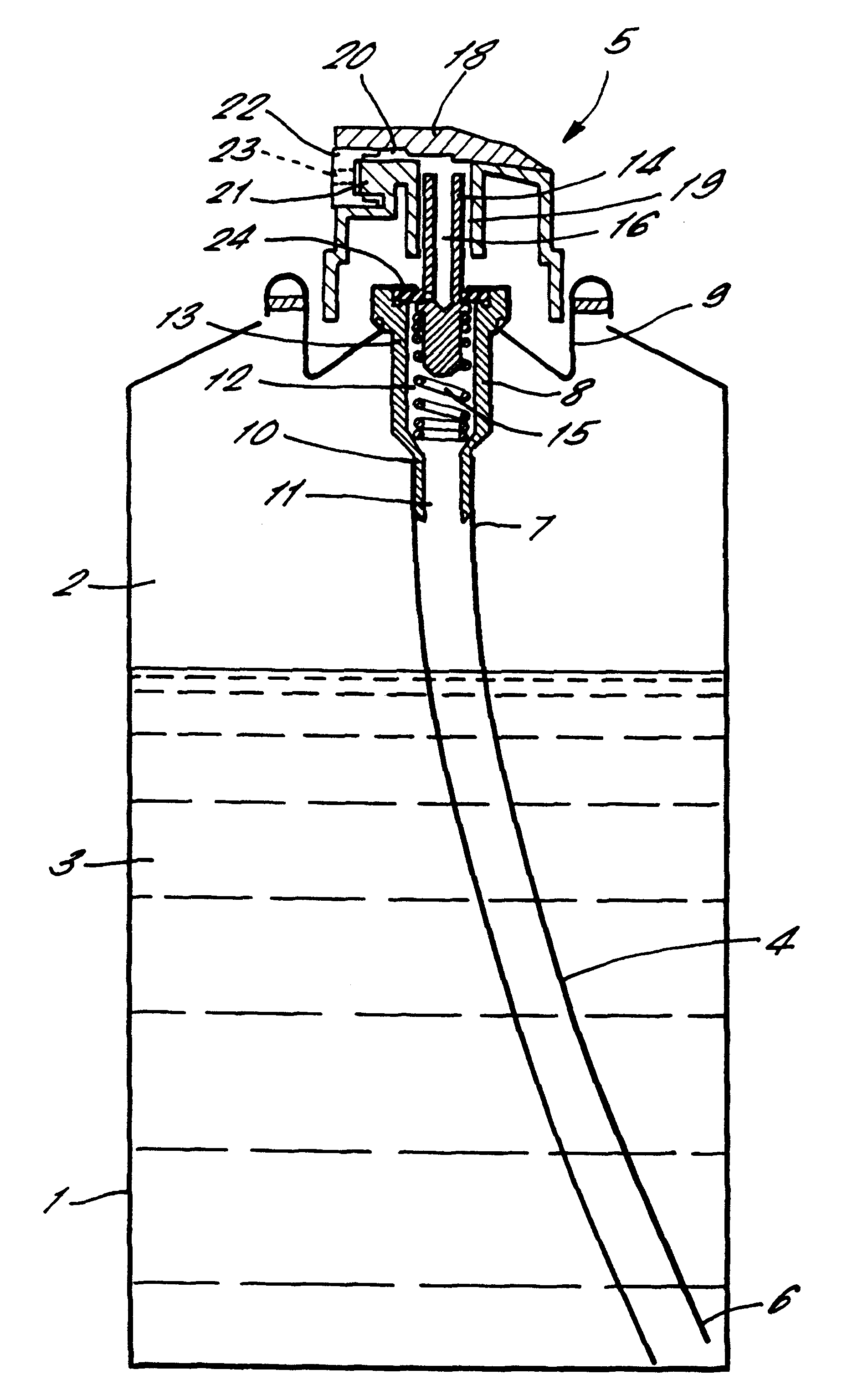

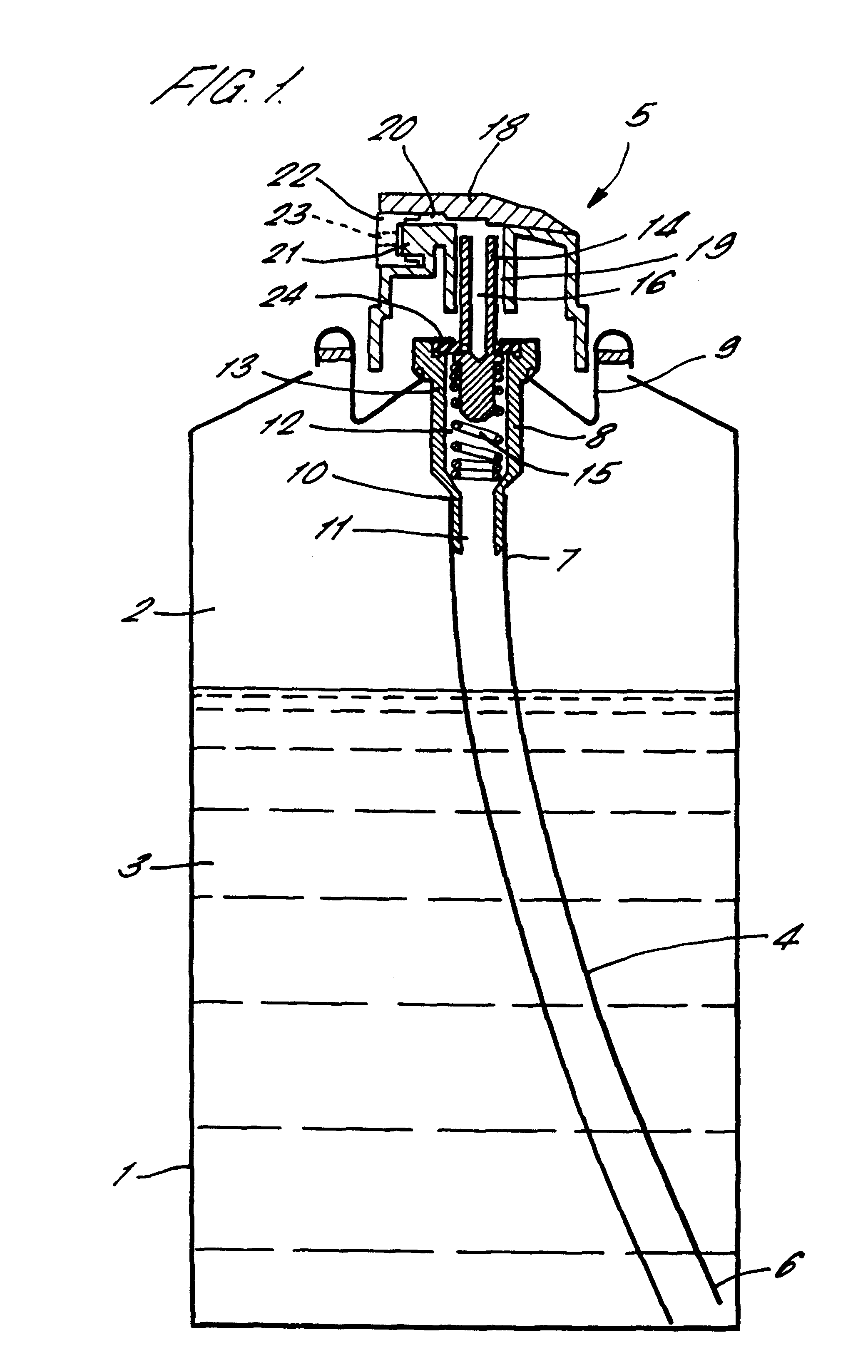

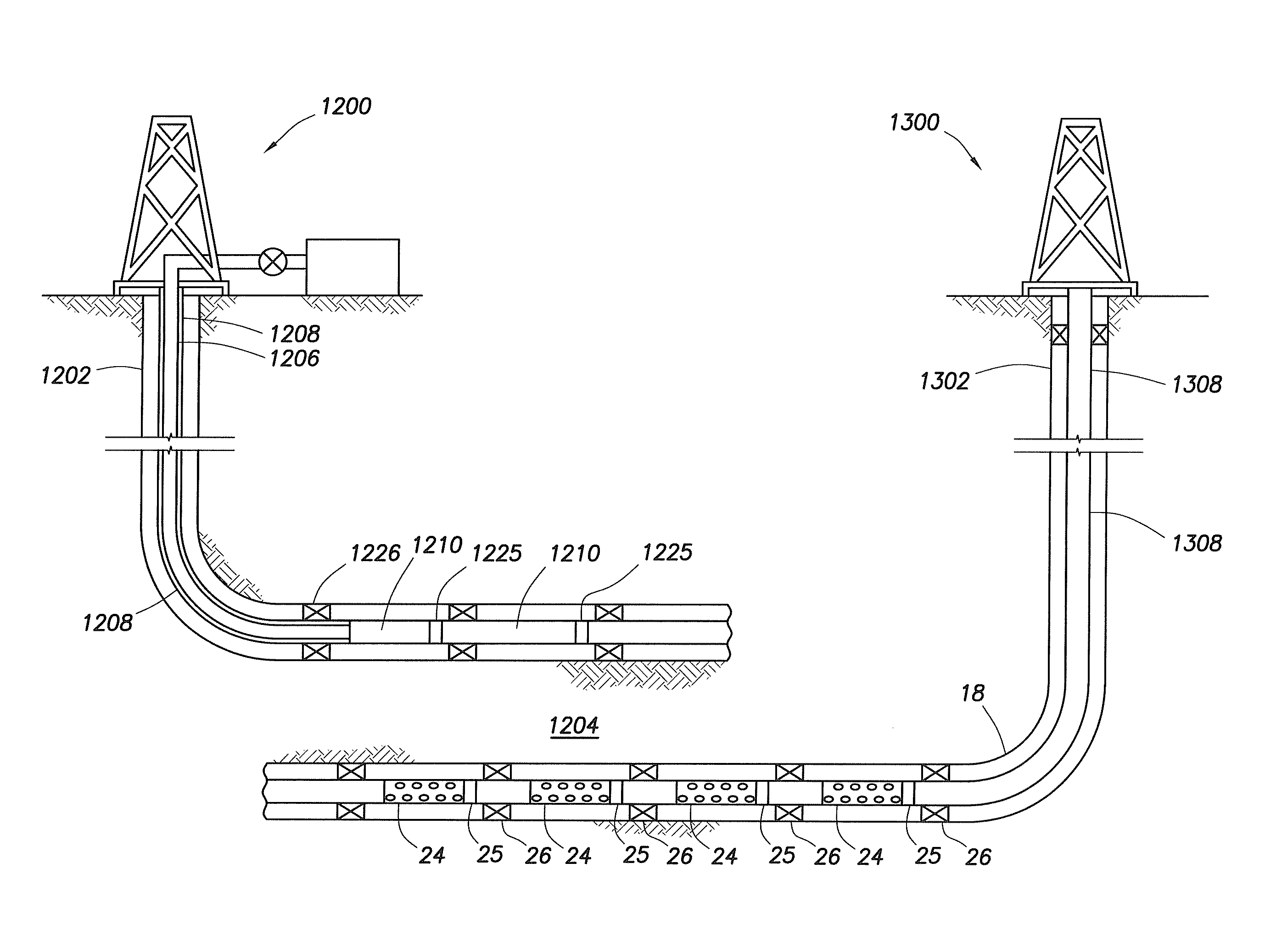

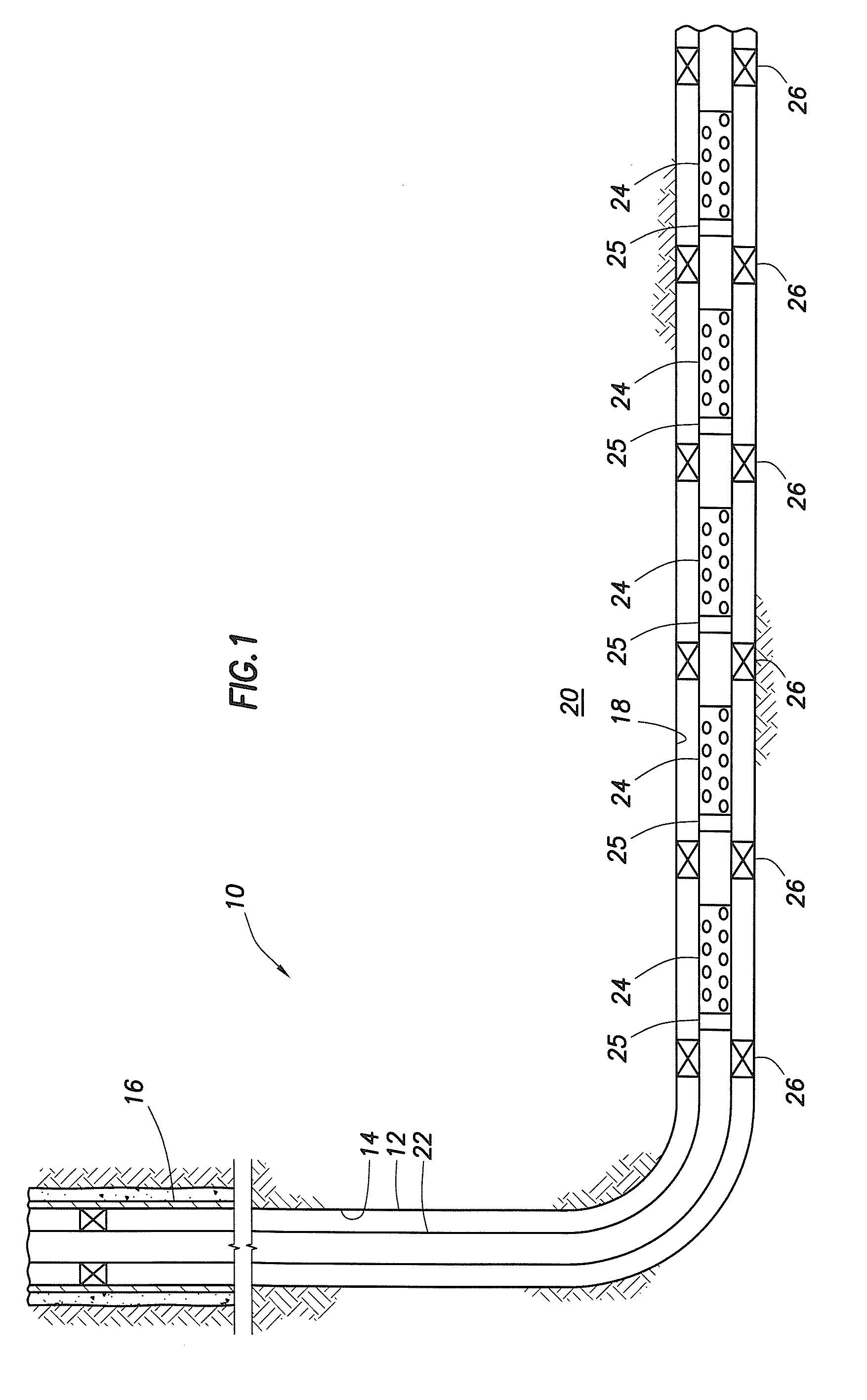

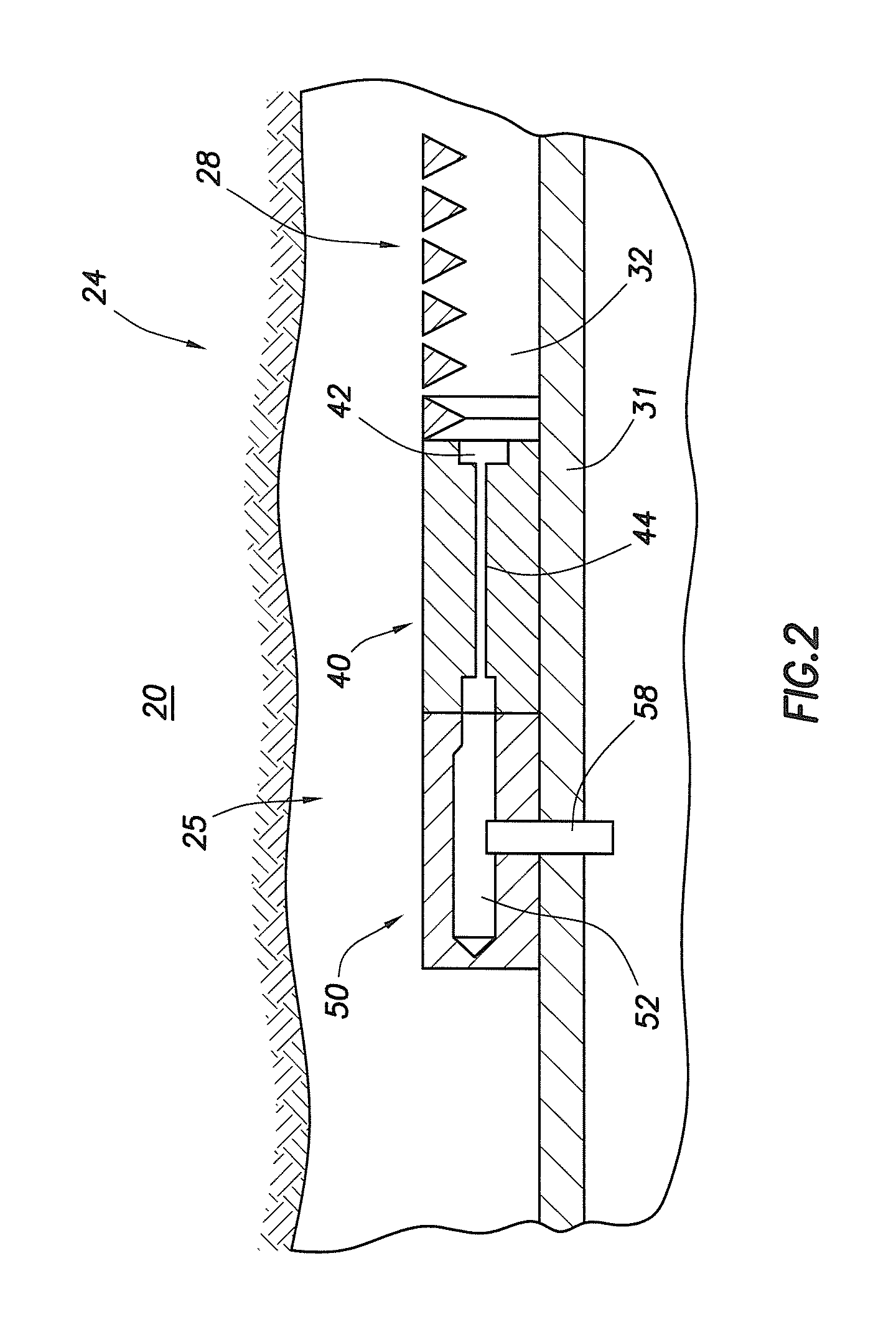

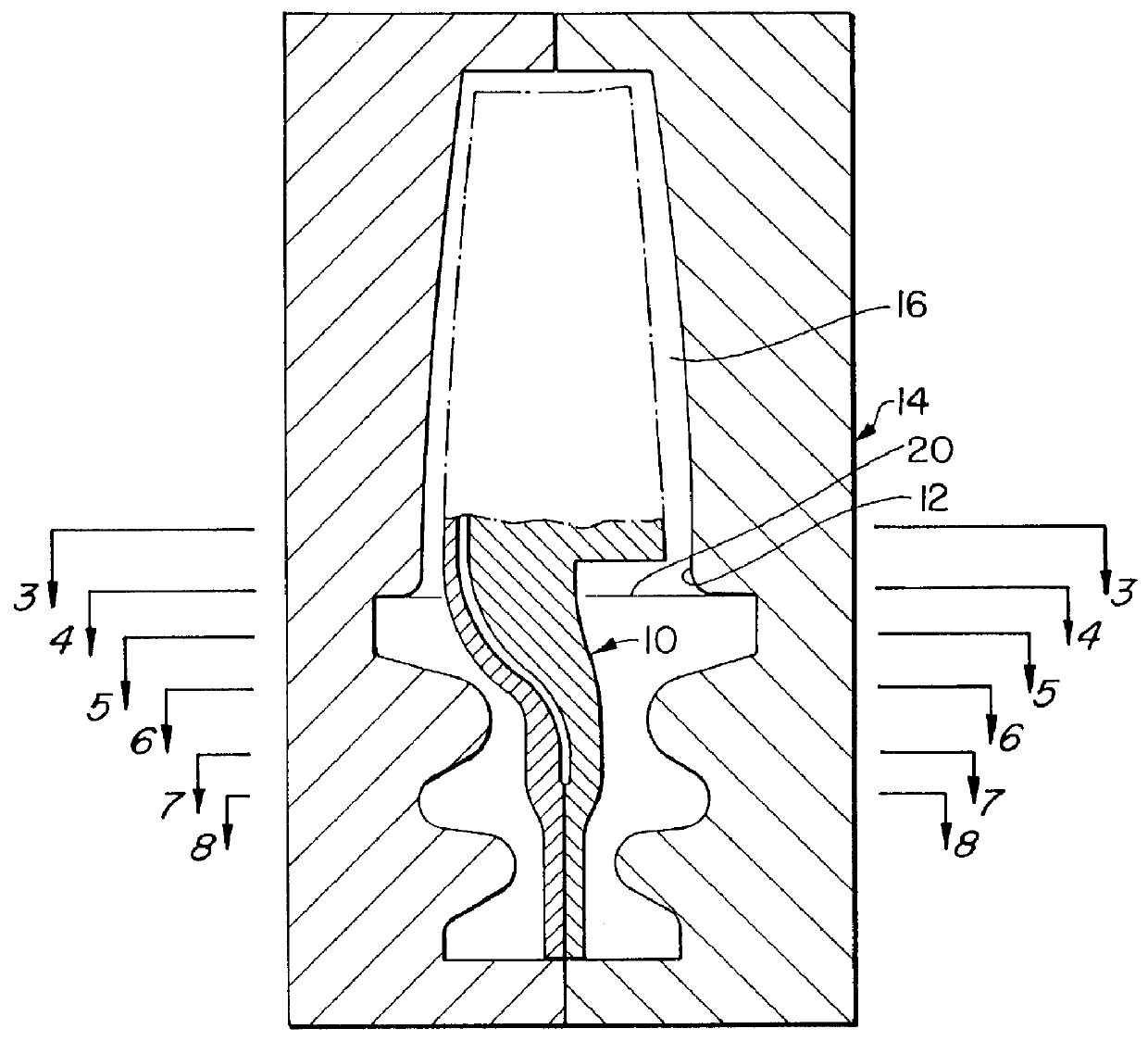

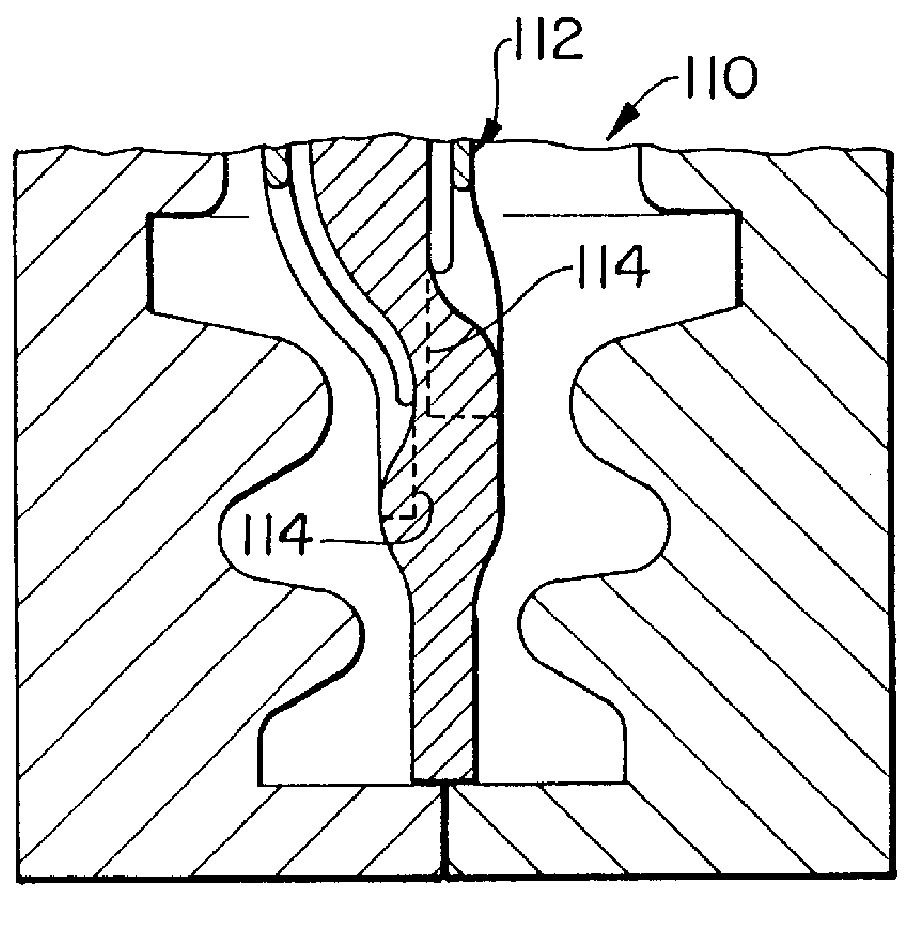

Method and apparatus for autonomous downhole fluid selection with pathway dependent resistance system

An apparatus is described for controlling flow of fluid in a tubular positioned in a wellbore extending through a subterranean formation. A flow control system is placed in fluid communication with a main tubular. The flow control system has a flow ratio control system and a pathway dependent resistance system. The flow ratio control system has a first and second passageway, the production fluid flowing into the passageways with the ratio of fluid flow through the passageways related to the characteristic of the fluid flow. The pathway dependent resistance system includes a vortex chamber with a first and second inlet and an outlet, the first inlet of the pathway dependent resistance system in fluid communication with the first passageway of the fluid ratio control system and the second inlet in fluid communication with the second passageway of the fluid ratio control system. The first inlet is positioned to direct fluid into the vortex chamber such that it flows primarily tangentially into the vortex chamber, and the second inlet is positioned to direct fluid such that it flows primarily radially into the vortex chamber. Undesired fluids, such as natural gas or water, in an oil well, are directed, based on their relative characteristic, into the vortex primarily tangentially, thereby restricting fluid flow when the undesired fluid is present as a component of the production fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

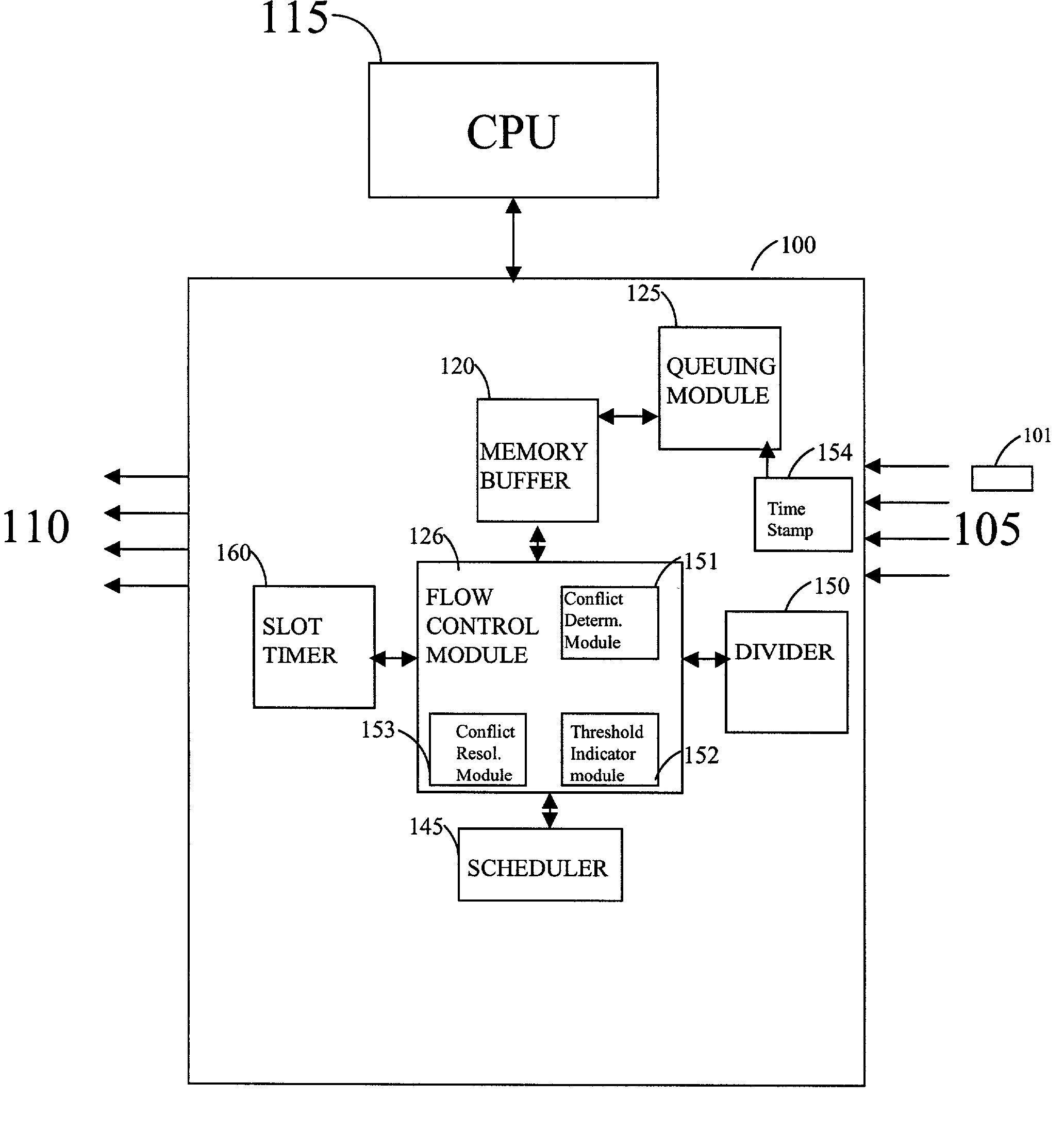

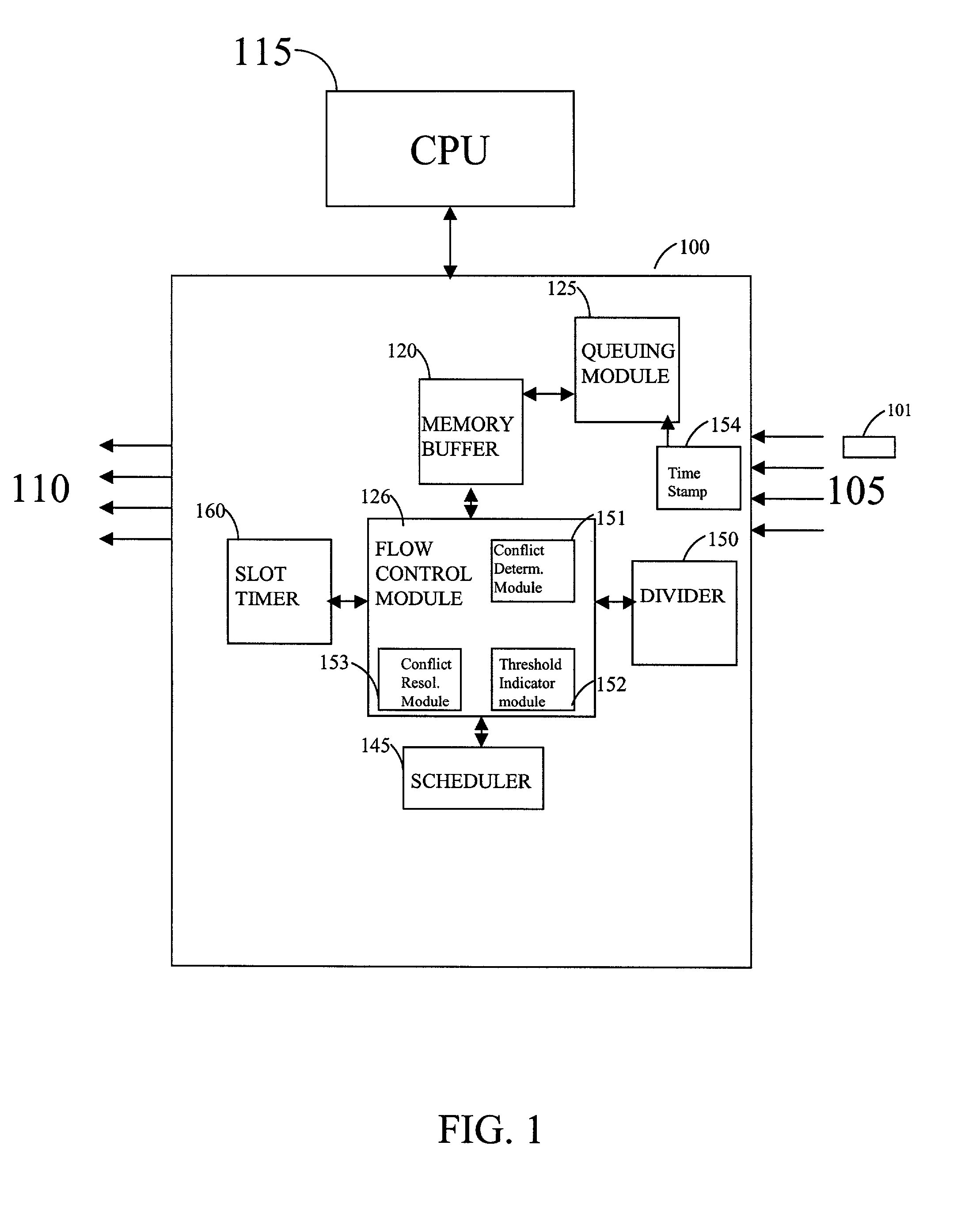

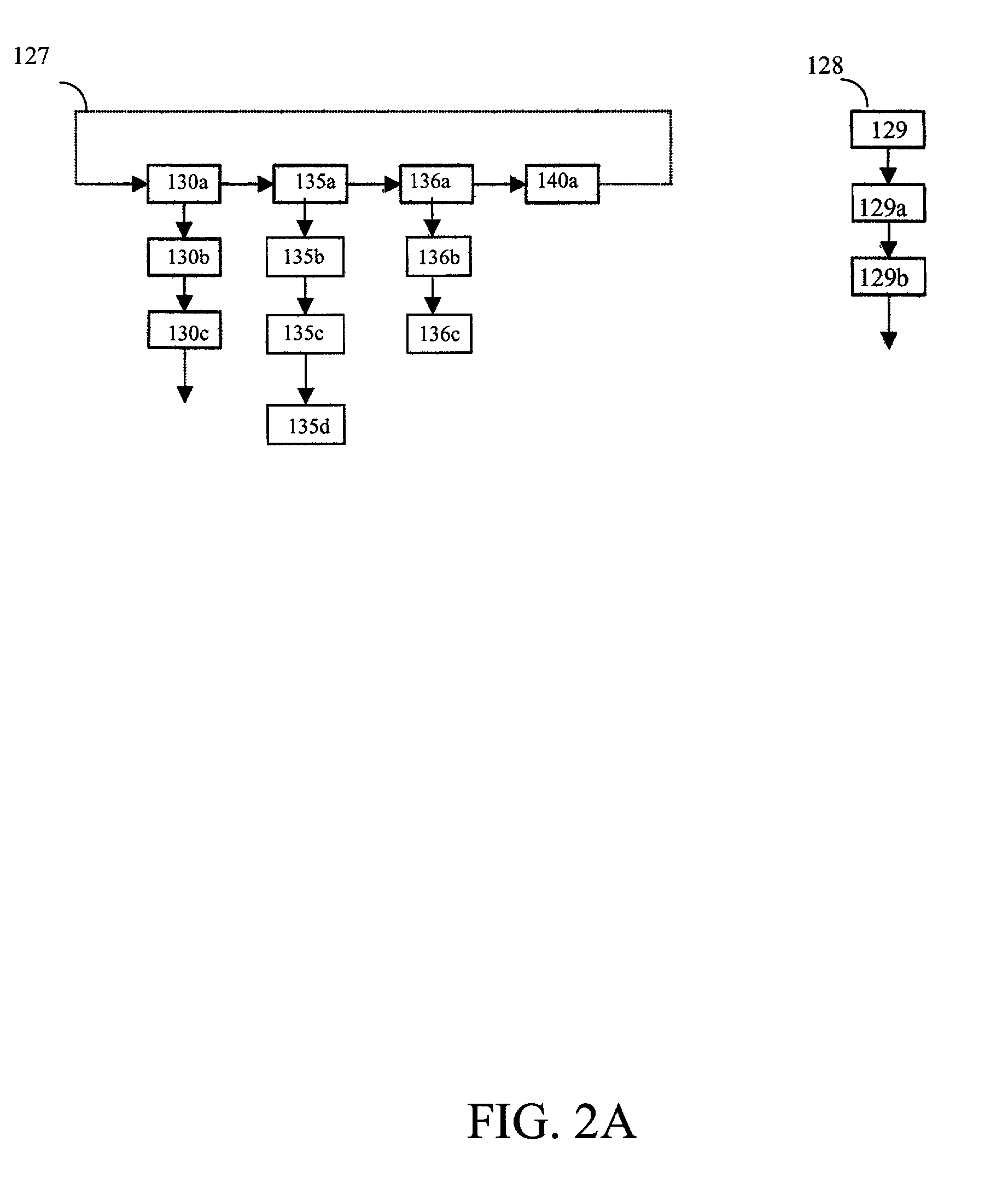

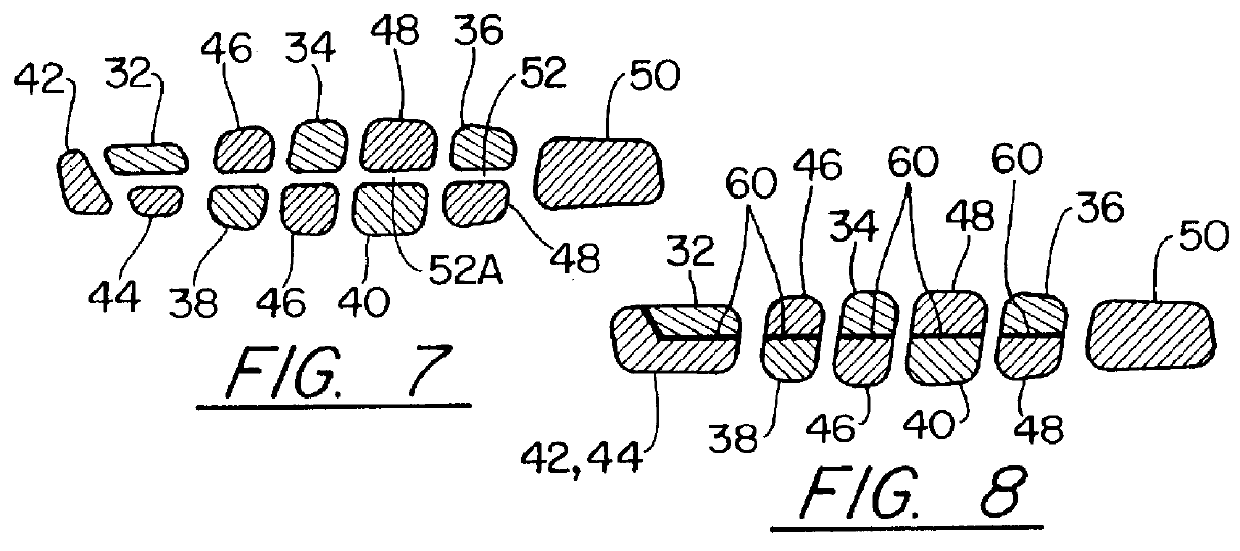

Algorithm for time based queuing in network traffic engineering

The present invention provides a method for prioritizing packet flows within a switching network. The method includes the steps of receiving packets at an input port, stamping the packets with an arrival time, and classifying the packet into a flow, wherein the flow is determined based upon at least a class of service of the packet, assigning the packet to a queuing ring according to the flow of the packet, and maintaining a flow ratio pending within the switch based upon the classification of the packet.

Owner:AVAGO TECH INT SALES PTE LTD

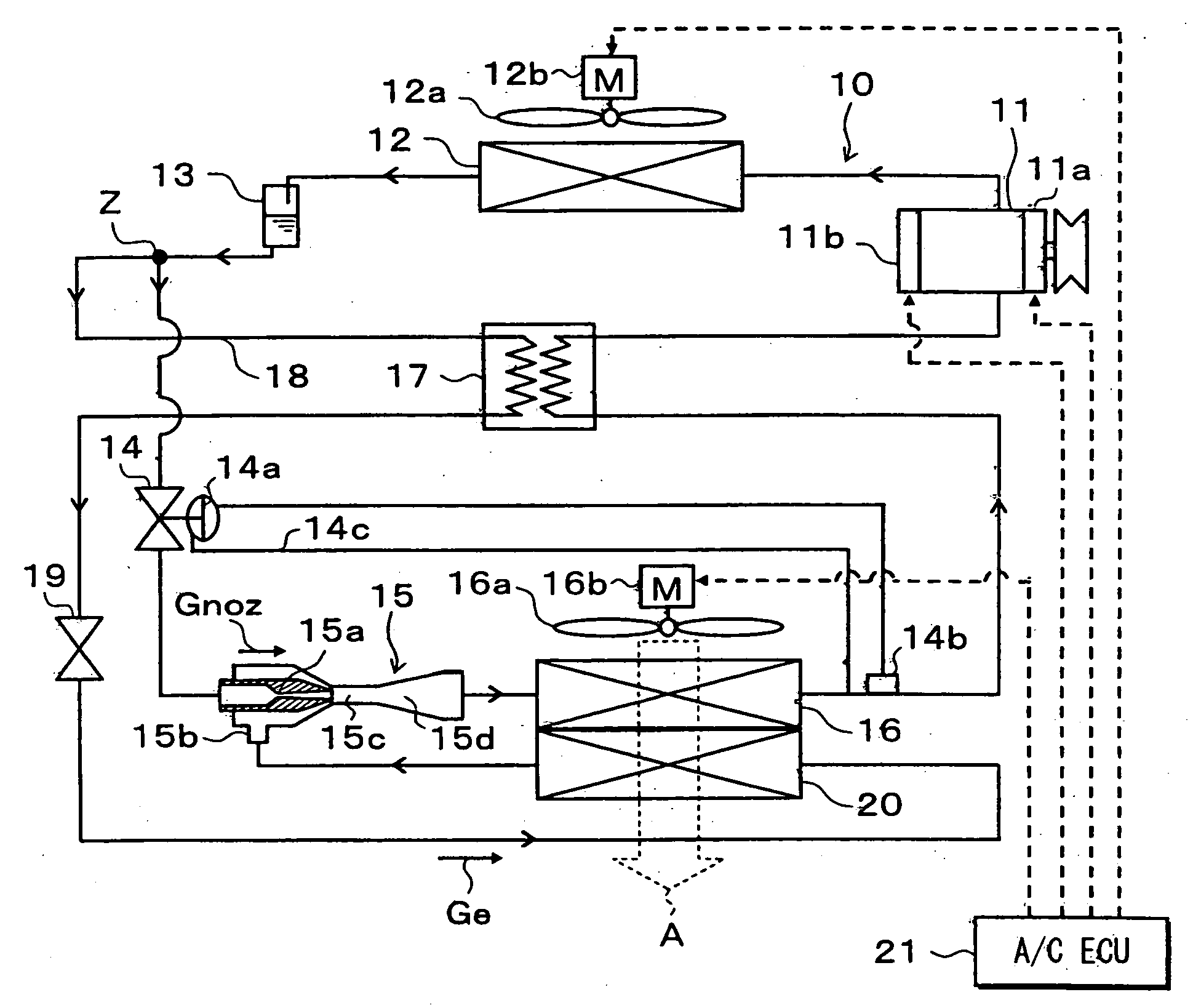

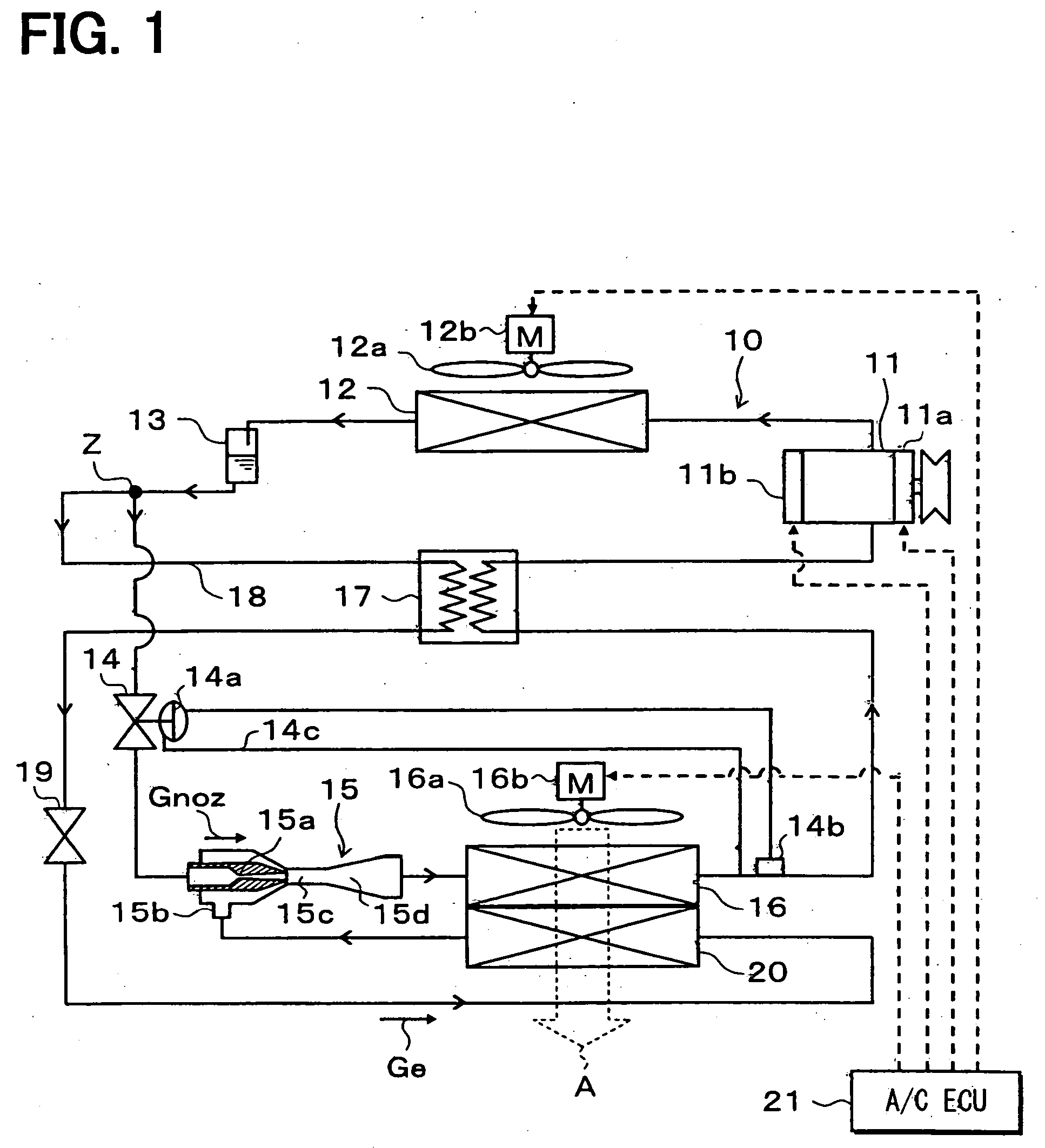

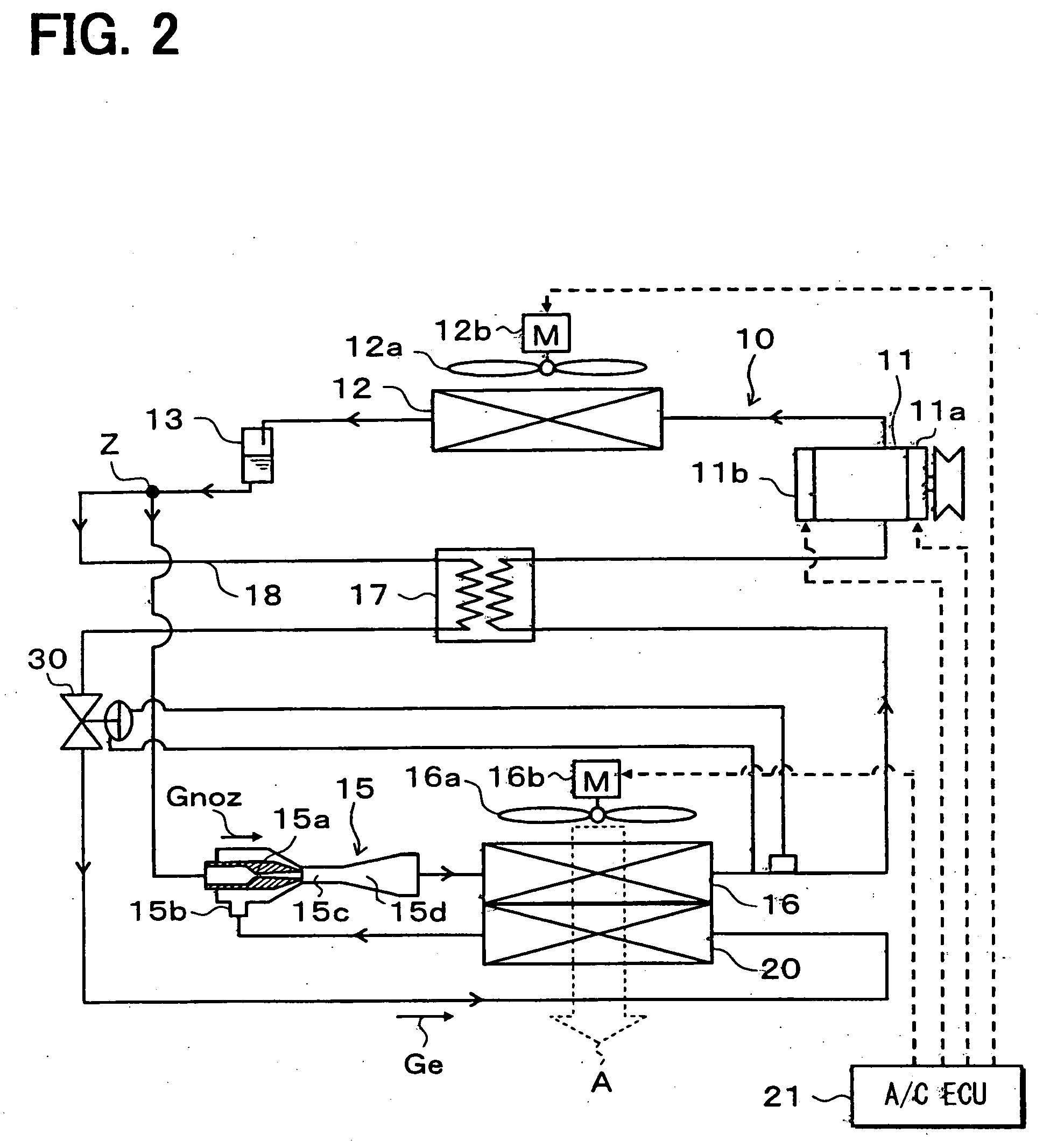

Ejector cycle system

InactiveUS20070000262A1Efficiently returnedCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

An ejector cycle system with a refrigerant cycle through which refrigerant flows includes an ejector disposed downstream of a radiator, a first evaporator that evaporates refrigerant flowing out of the ejector, a throttling unit located in a branch passage and depressurizes refrigerant to adjust a flow rate of refrigerant, and a second evaporator located downstream of the throttling unit. In the ejector cycle system, a flow ratio adjusting means adjusts a flow ratio between a first refrigerant flow amount depressurized and expanded in a nozzle portion of the ejector and a second refrigerant flow amount drawn into a refrigerant suction port of the ejector, based on a physical quantity related to at least one of a state of refrigerant in the refrigerant cycle, a temperature of a space to be cooled by the first and second evaporators, and an ambient temperature of the space.

Owner:DENSO CORP

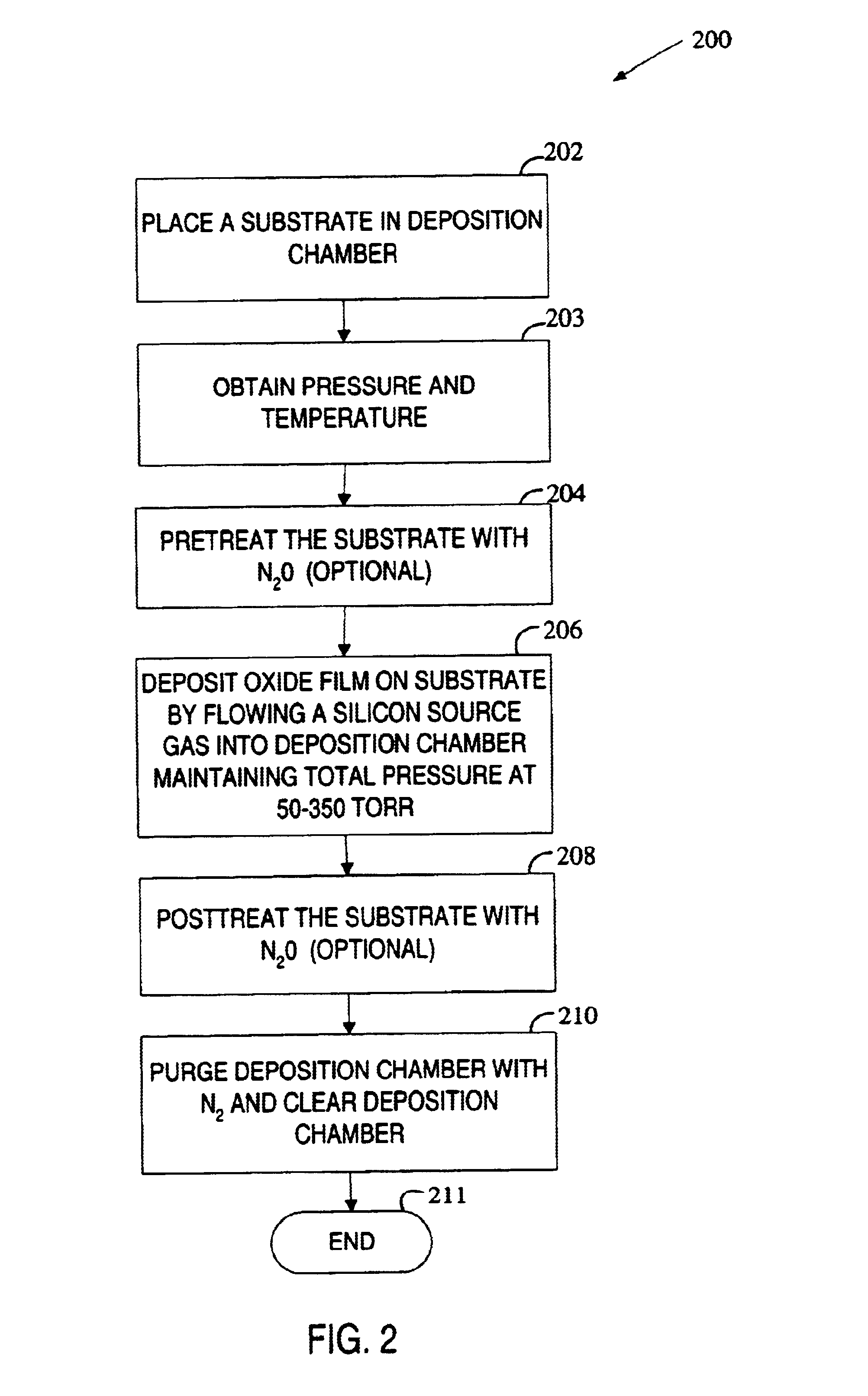

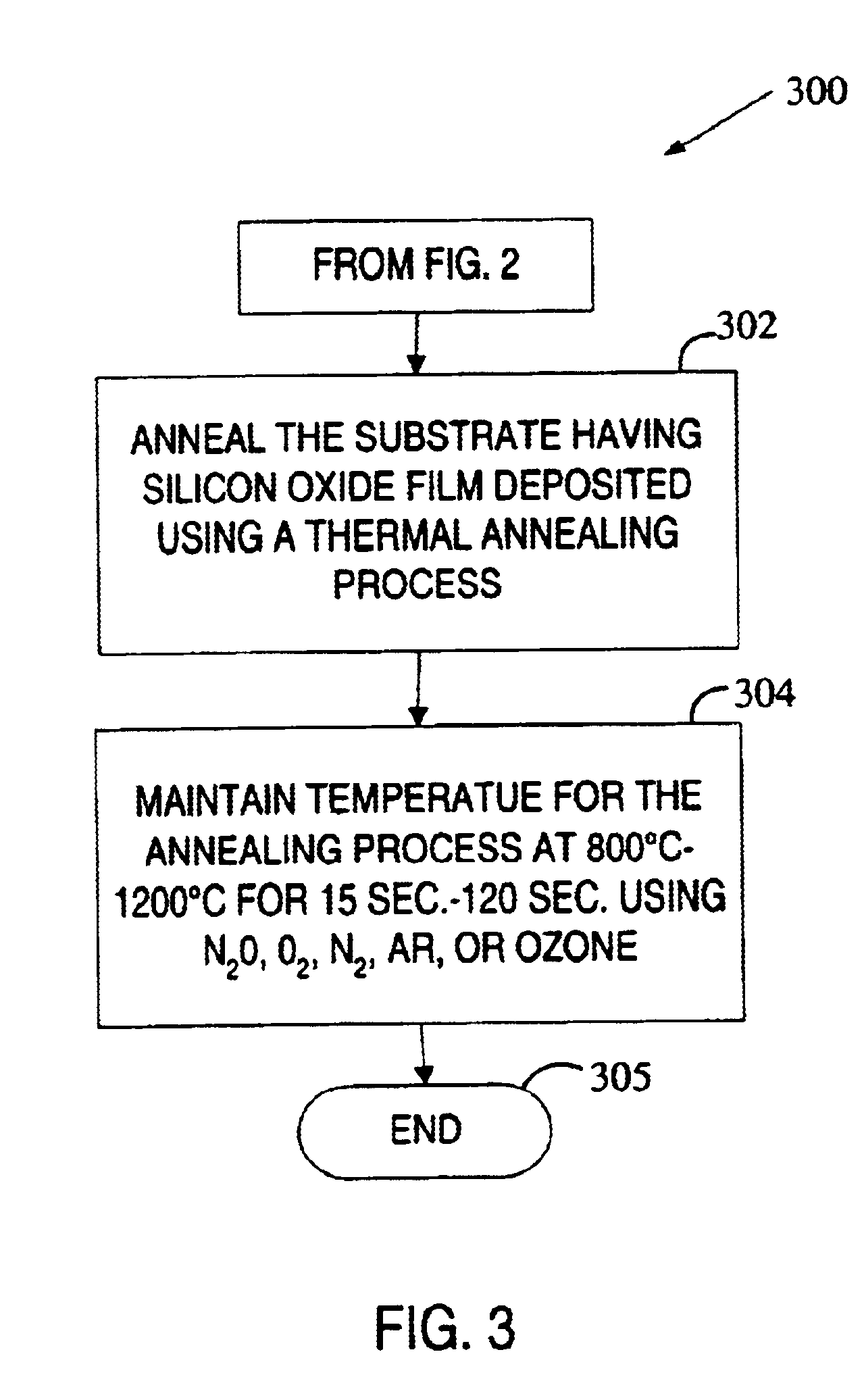

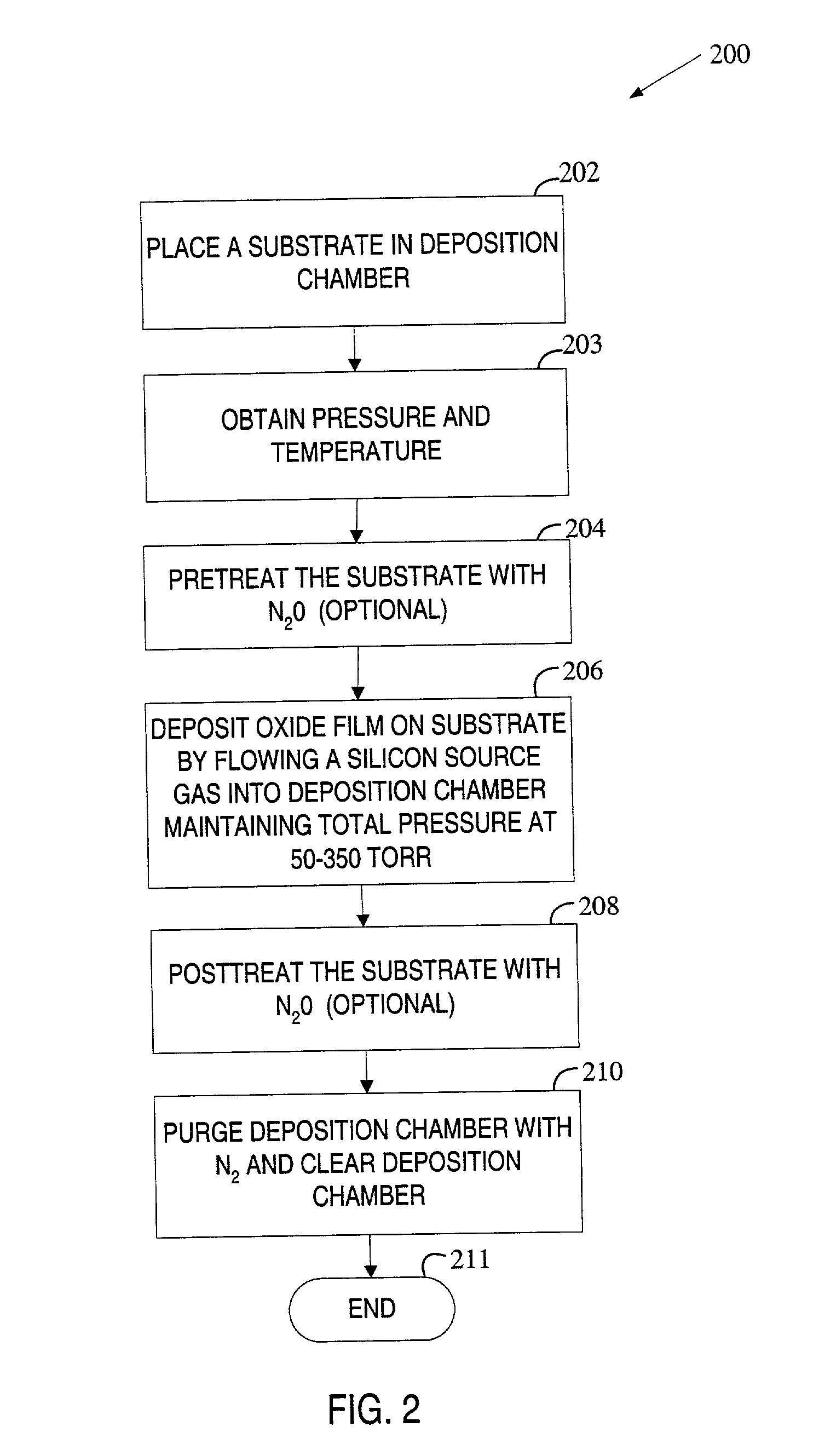

Methods for silicon oxide and oxynitride deposition using single wafer low pressure CVD

InactiveUS6713127B2Pretreated surfacesSemiconductor/solid-state device manufacturingThermal energySilicon oxide

An oxide and an oxynitride films and their methods of fabrication are described. The oxide or the oxynitride film is grown on a substrate that is placed in a deposition chamber. A silicon source gas (or a silicon source gas with a nitridation source gas) and an oxidation source gas are decomposed in the deposition chamber using a thermal energy source. A silicon oxide (or an oxynitride) film is formed above the substrate wherein total pressure for the deposition chamber is maintained in the range of 50 Torr to 350 Torr and wherein a flow ratio for the silicon source gas (or the silicon source gas with the nitridiation source gas) and the oxidation source gas is in the range of 1:50 to 1:10000 during a deposition process.

Owner:APPLIED MATERIALS INC

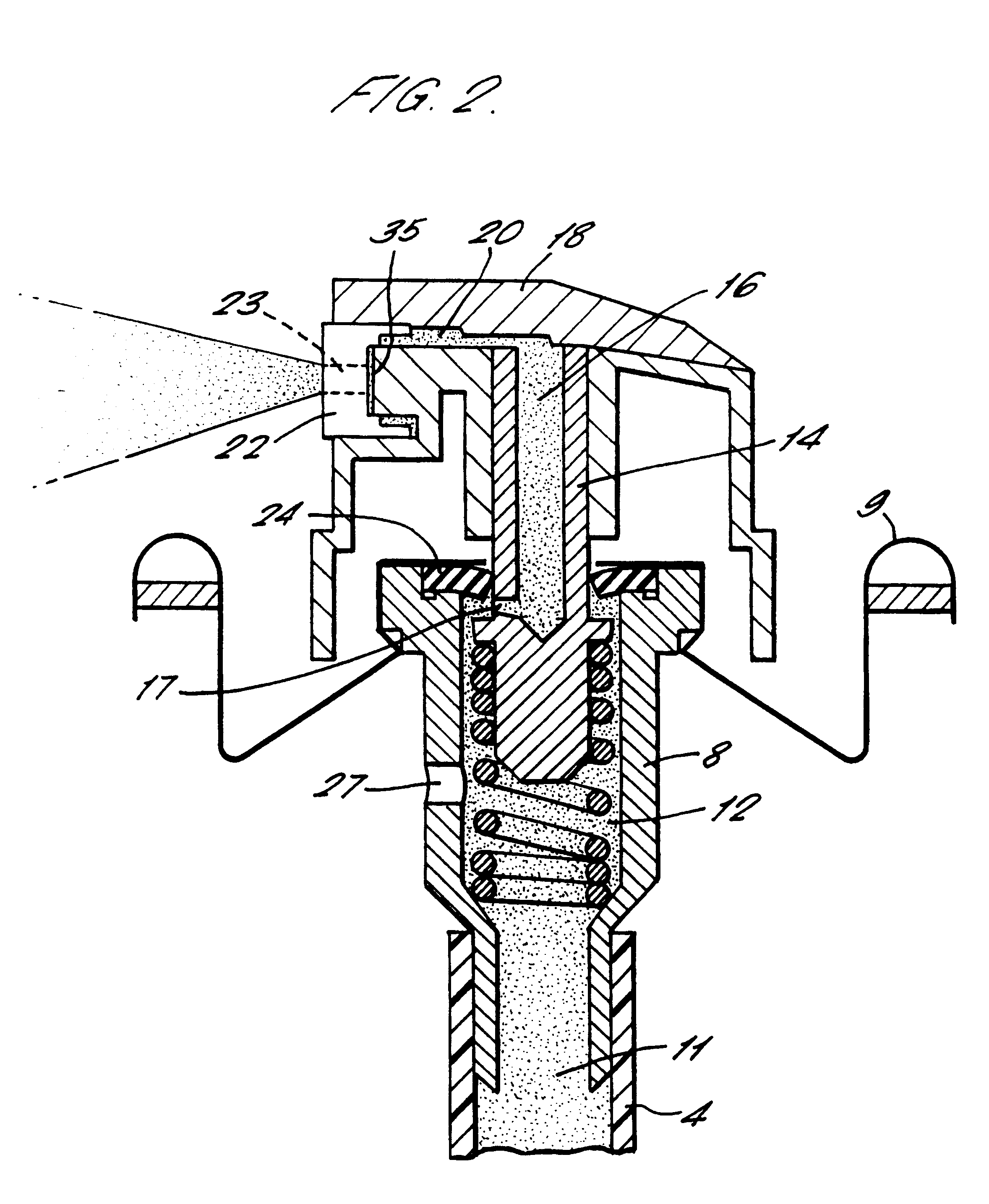

Targeting of flying insects with insecticides and apparatus for charging liquids

InactiveUS6199766B1Improve targetingIncrease ratingsLiquid supply arrangementsSpray nozzlesAerosol sprayGram

A method of killing flying insects which method comprises spraying into the air in which insects are flying liquid droplets of an insecticidal composition, a unipolar charge being imparted to the said liquid droplets by double layer charging and charge separation during spraying, the unipolar charge being at a level such that the said droplets have a charge to mass ratio of at least + / -1x10-4 C / kg. An aerosol spray device which is capable of imparting a unipolar charge by double layer charging and charge separation to liquid droplets of a composition sprayed therefrom has a spraying head in the form of an insert in an actuator, the spraying head having a bore through which liquid is expelled having an outlet, preferably with a tortuous periphery, having an L / a ratio of at least 8 (preferably at least 10) where L is the length of the periphery defining the bore outlet in mm and a is the cross-sectional area of the bore outlet in mm2 and the apparatus being constructed such that the droplets are expelled from the spraying head at a flow ratio of at least 0.4 (preferably at least 0.5) grams per second and have a charge to mass ratio of at least + / -1x10-4 C / kg.

Owner:UNIV OF SOUTHAMPTON +1

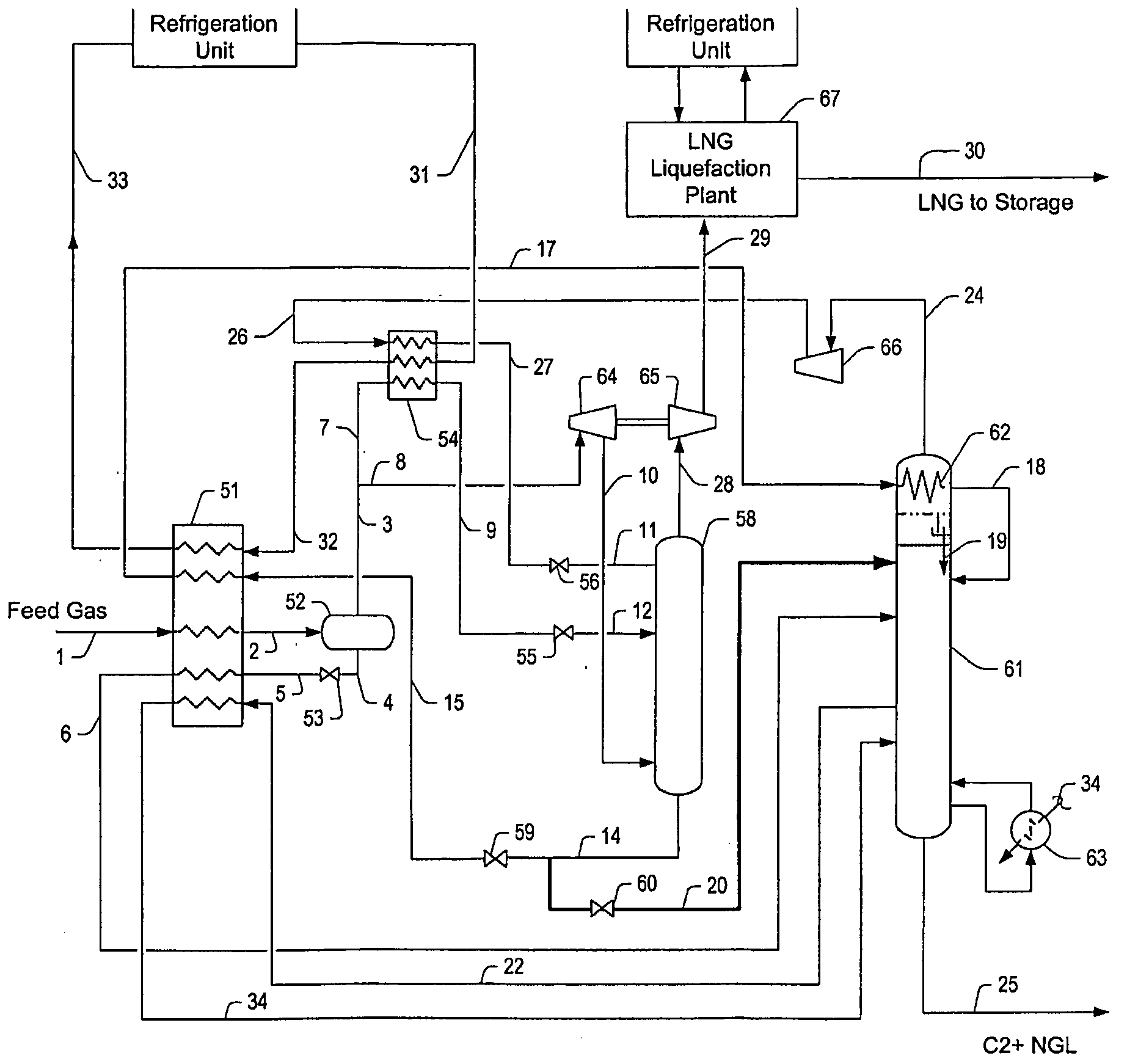

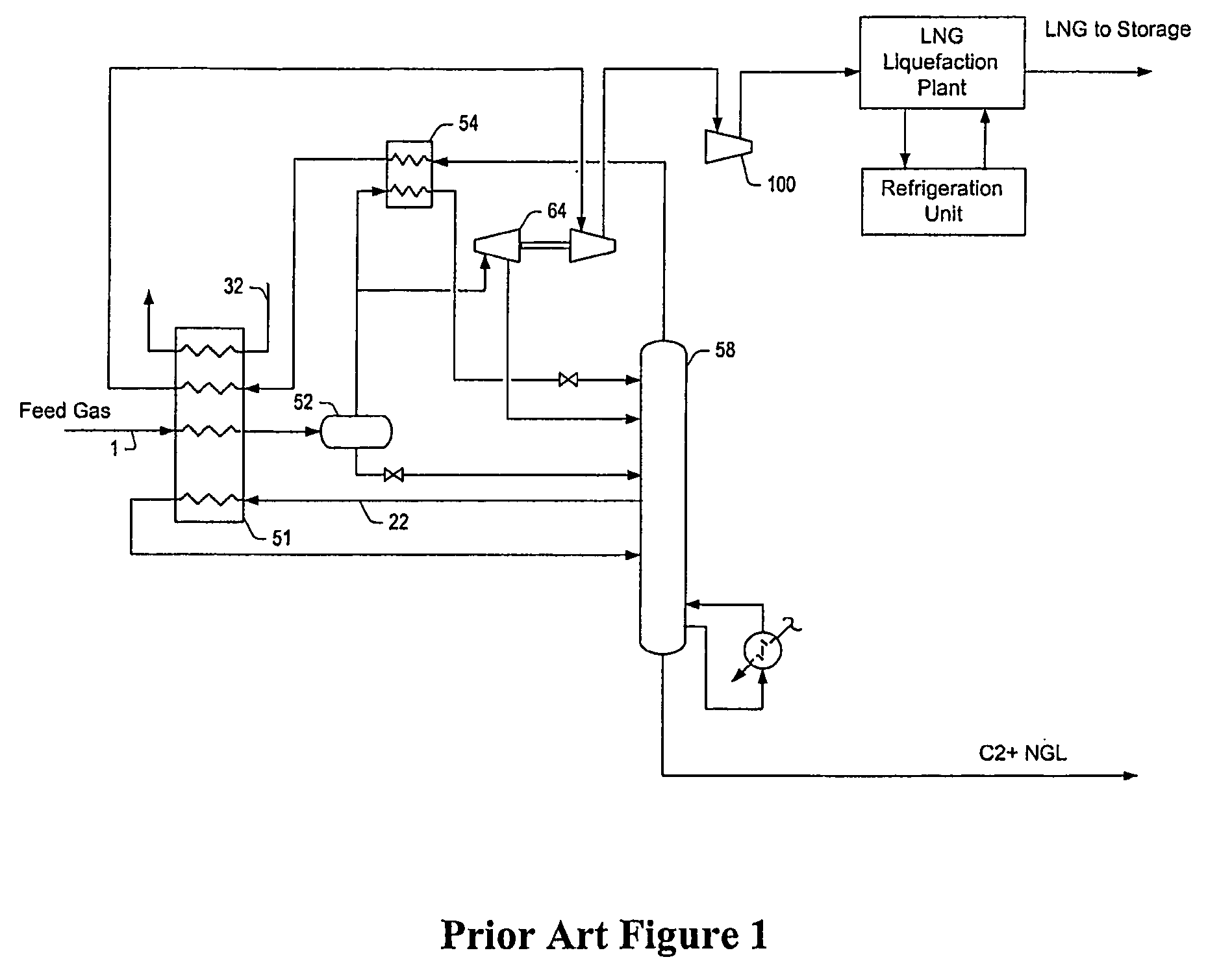

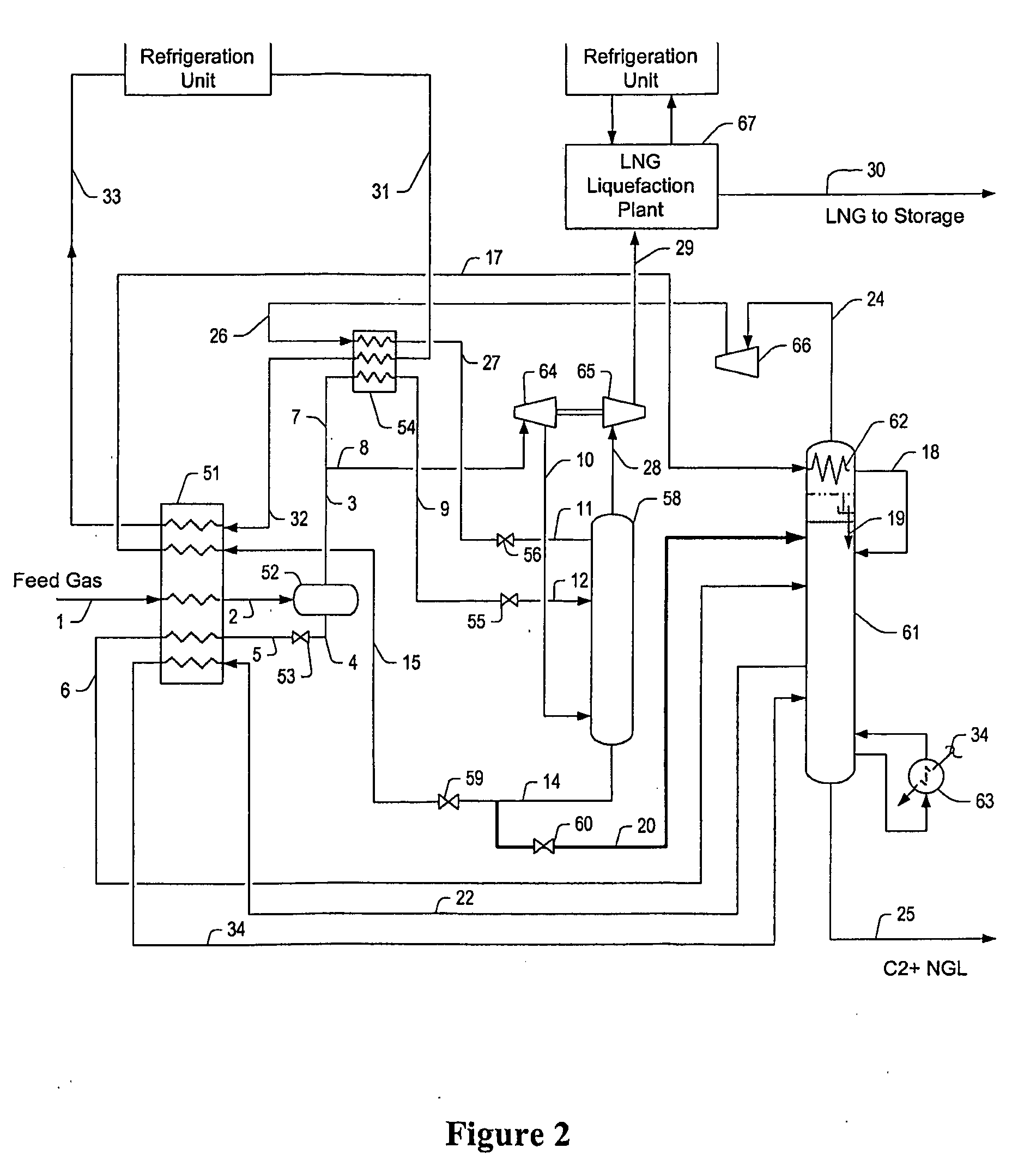

Intergrated Ngl Recovery and Lng Liquefaction

Contemplated plants include a refluxed absorber and a distillation column, wherein the absorber is operated at a higher pressure than the distillation column to thereby produce a cryogenic pressurized lean gas. The lean gas is further compressed to a pressure suitable for liquefaction using energy from feed gas vapor expansion. Desired separation of C2 products is ensured by temperature control of the absorber and distillation column using flow ratios of various streams within the plant, and by dividing the separation process into two portions at different pressures.

Owner:FLUOR TECH CORP

Stretch wrap films

InactiveUS6093480AImprove clingImproved maximum stretchWrappers shrinkageSynthetic resin layered productsStretch wrapGram

A multilayer, thermoplastic stretch wrap film containing at least three polymeric film layers and comprised of a first layer and a second layer. The first and second layers may comprise a polymer of two or more monomers, wherein a first monomer is ethylene, in a major amount by weight, and a second monomer is an alpha olefin of from about 3 to about 12 carbon atoms, in a minor amount by weight. If the first and second layers are outer layers, they have a cling force to each other of at least about 140 grams / inch. The stretch wrap film also has at least one inner polymeric layer, located between the first and second layers. The inner polymeric layer comprises a low polydispersity polymer having a polydispersity of from about 1 to about 4, a melt index (I.sub.2) of from about 0.5 to about 10 g / 10 min., and a melt flow ratio (I.sub.20 / I.sub.2) of from about 12 to about 22. The inner layer(s) comprise(s) from about 5 wt. % to about 40 wt. % of the stretch wrap film so as to produce a film having a maximum stretch of at least 340%, a F-50 dart drop value of at least about 130 g / mil, a machine directional tear resistance of at least about 125 g / mil and a transverse directional tear resistance of at least about 500 g / mil. It is contemplated that additional outer layers may be added such an outer high cling layer or an outer slip layer, as well as additional inner layers.

Owner:BERRY PLASTICS CORP

Method and apparatus for autonomous downhole fluid selection with pathway dependent resistance system

An apparatus is described for controlling flow of fluid in a tubular positioned in a wellbore extending through a subterranean formation. A flow control system is placed in fluid communication with a main tubular. The flow control system has a flow ratio control system and a pathway dependent resistance system. The flow ratio control system has a first and second passageway, the production fluid flowing into the passageways with the ratio of fluid flow through the passageways related to the characteristic of the fluid flow. The pathway dependent resistance system includes a vortex chamber with a first and second inlet and an outlet, the first inlet of the pathway dependent resistance system in fluid communication with the first passageway of the fluid ratio control system and the second inlet in fluid communication with the second passageway of the fluid ratio control system. The first inlet is positioned to direct fluid into the vortex chamber such that it flows primarily tangentially into the vortex chamber, and the second inlet is positioned to direct fluid such that it flows primarily radially into the vortex chamber. Undesired fluids, such as natural gas or water, in an oil well, are directed, based on their relative characteristic, into the vortex primarily tangentially, thereby restricting fluid flow when the undesired fluid is present as a component of the production fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

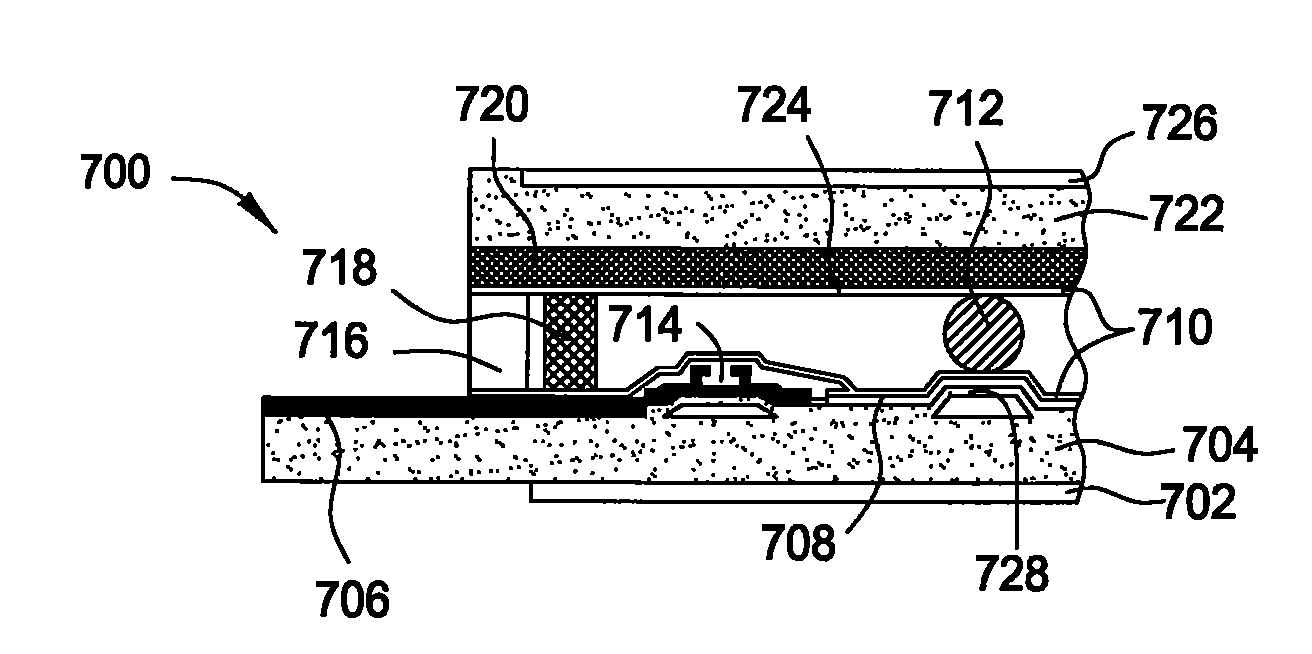

Thin film transistors using thin film semiconductor materials

The present invention generally comprises TFTs having semiconductor material comprising oxygen, nitrogen, and one or more element selected from the group consisting of zinc, tin, gallium, cadmium, and indium as the active channel. The semiconductor material may be used in bottom gate TFTs, top gate TFTs, and other types of TFTs. The TFTs may be patterned by etching to create both the channel and the metal electrodes. Then, the source-drain electrodes may be defined by dry etching using the semiconductor material as an etch stop layer. The active layer carrier concentration, mobility, and interface with other layers of the TFT can be tuned to predetermined values. The tuning may be accomplished by changing the nitrogen containing gas to oxygen containing gas flow ratio, annealing and / or plasma treating the deposited semiconductor film, or changing the concentration of aluminum doping.

Owner:APPLIED MATERIALS INC

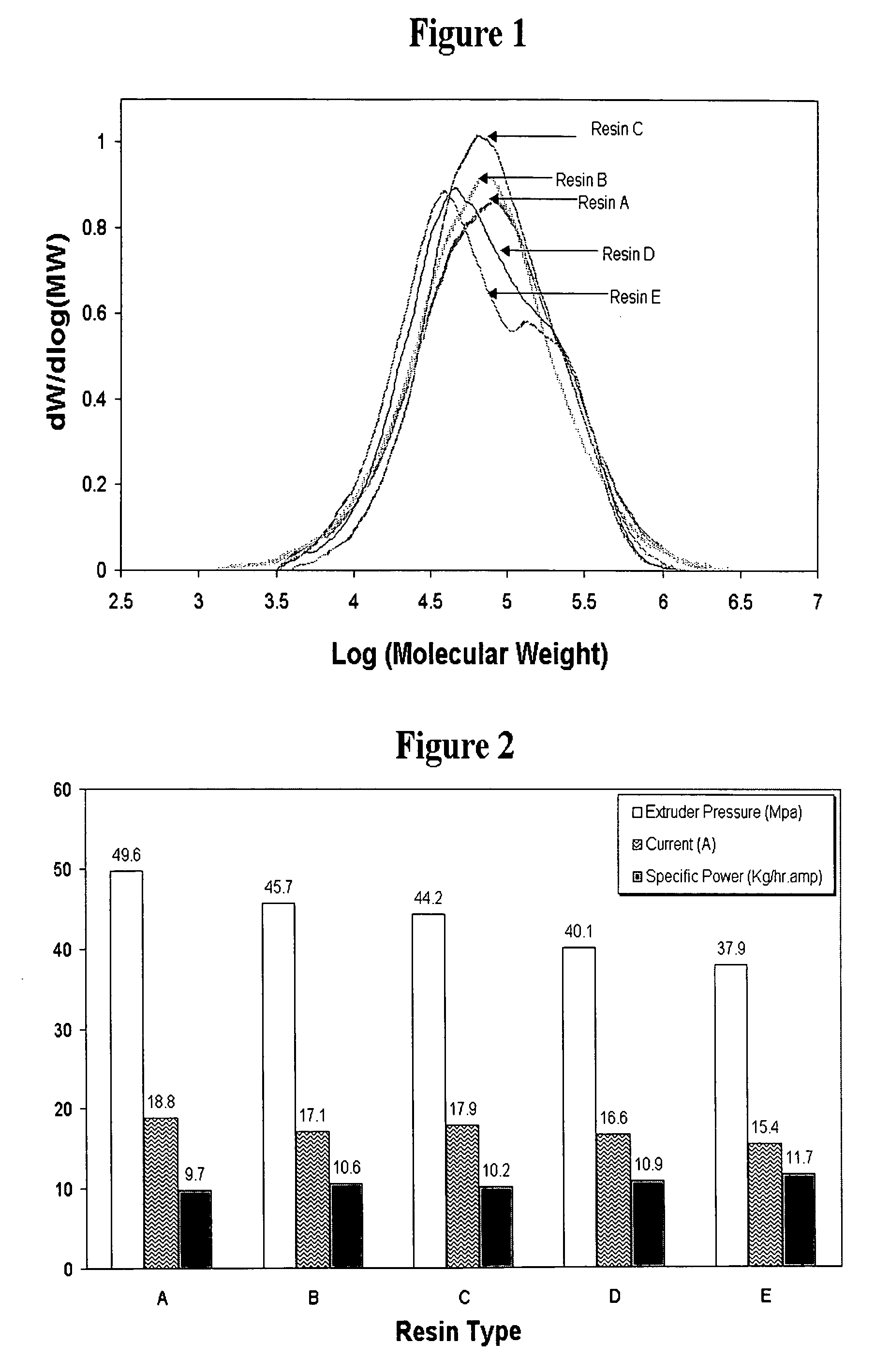

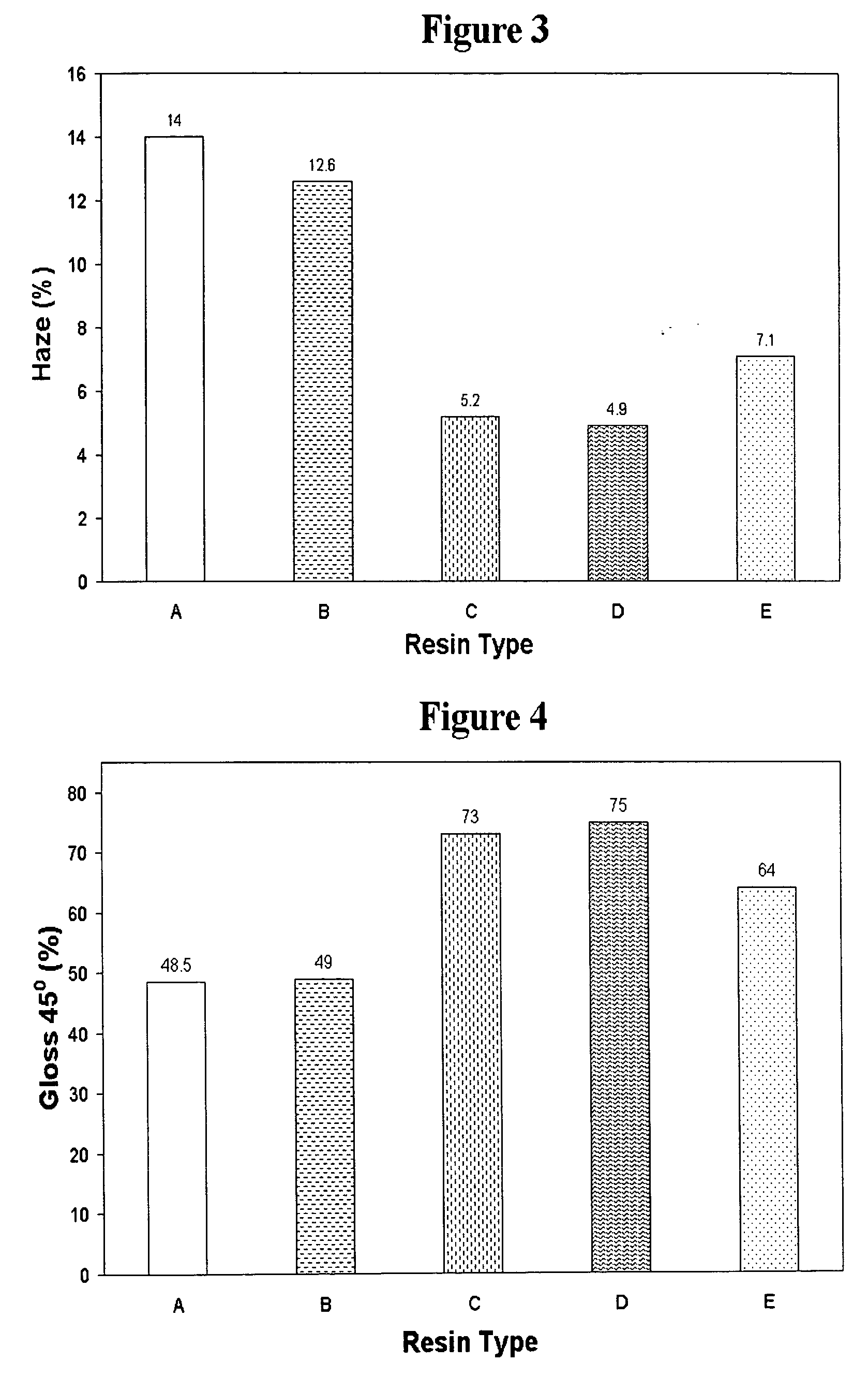

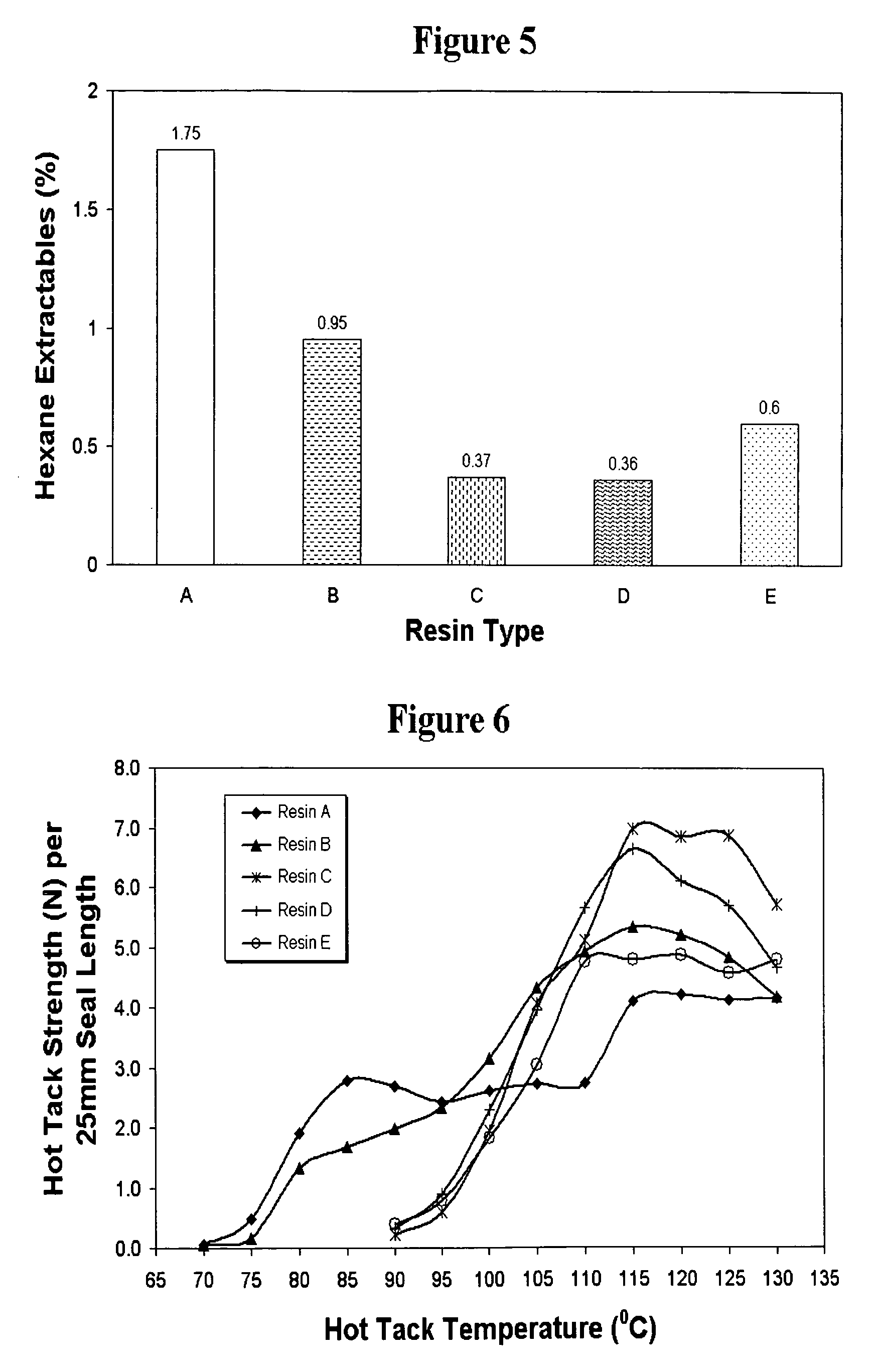

Dual reactor polyethylene resins for electronic packaging-films, tapes, bags and pouches

InactiveUS20060247373A1Good optical performanceHeat sealabilityLinear low-density polyethylenePolymer science

Owner:NOVA CHEM (INT) SA

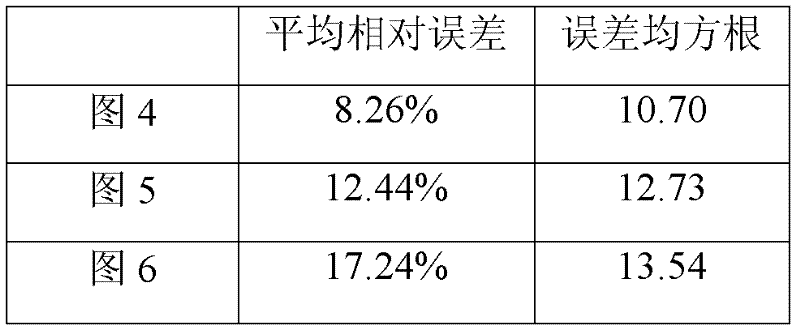

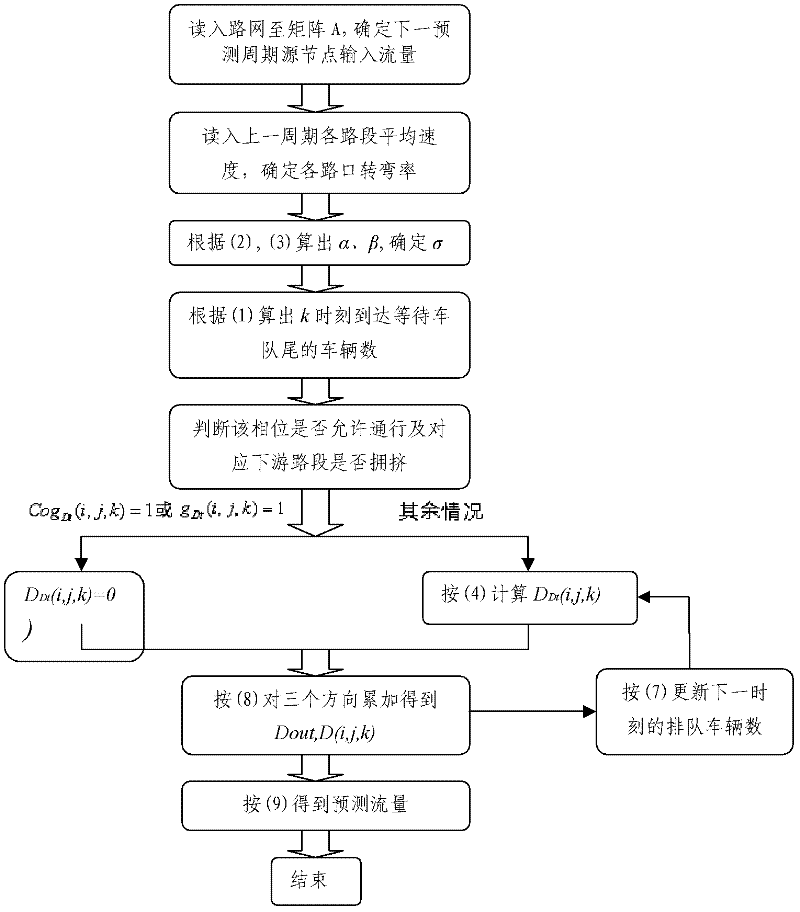

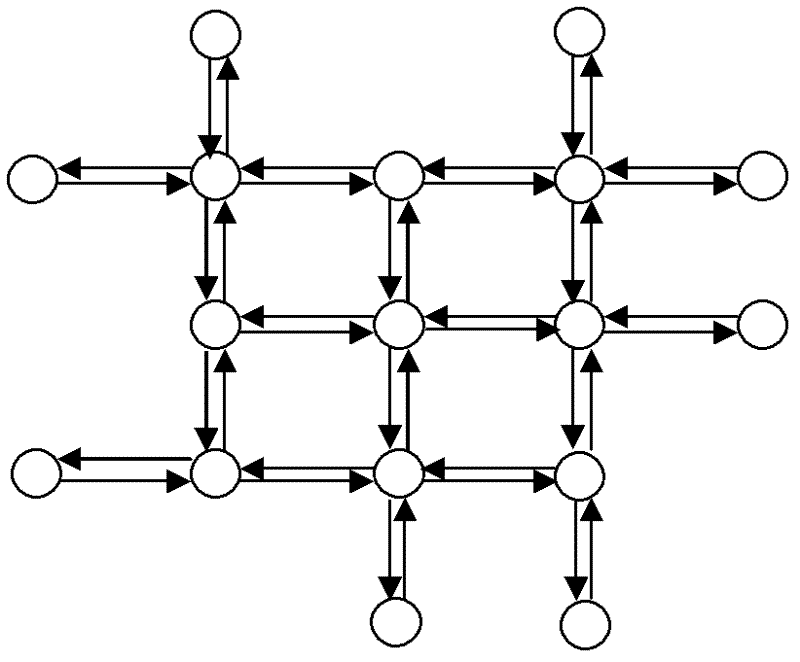

Short-time forecasting method for traffic flow based on urban macroscopic road network model

InactiveCN102436751AEasy extractionImprove performanceRoad vehicles traffic controlNODALRoad networks

The invention relates to a short-time forecasting method for a traffic flow based on a macroscopic road network model, which comprises the following steps: (1) obtaining the input flow of the source node of a road network at a forecasting period, extracting the average speed of each road section at a previous forecasting period and determining the flow ratio of different turning directions at each intersection; (2) calculating the time of vehicles running to the tail of a queued vehicle queue, which are input on a road so as to obtain the number of the vehicles arriving at the tail of the queue at an iterative period; (3) determining the number of the vehicles which are correspondingly turned to leave the intersections by the conditions of the number of the vehicles queued at the intersections, the saturated leaving flow and the like; (4) accumulating to obtain the total number of the vehicles leaving the intersections at one forecasting period and converting to obtain the traffic flow within the forecasting period; and (5) updating the number of the queued vehicles as known data for iterative forecasting at the next time. The short-time forecasting method for the traffic flow based on the macroscopic road network model aims at the defects that the adaptability of the road network is poor, a great deal of training data are needed, the operation quantity in a microscopic model is large and the like, which exist in the prior art. The spatial information of an urban road network is fully utilized. The short-time forecasting method for the traffic flow based on the macroscopic road network model is based on a macroscopic traffic flow model, and the forecasting of the traffic flow of a road with high accuracy and good real-time property can be realized. Moreover, the short-time forecasting method for the traffic flow based on the macroscopic road network model is suitable for most of urban road networks.

Owner:SHANGHAI JIAO TONG UNIV

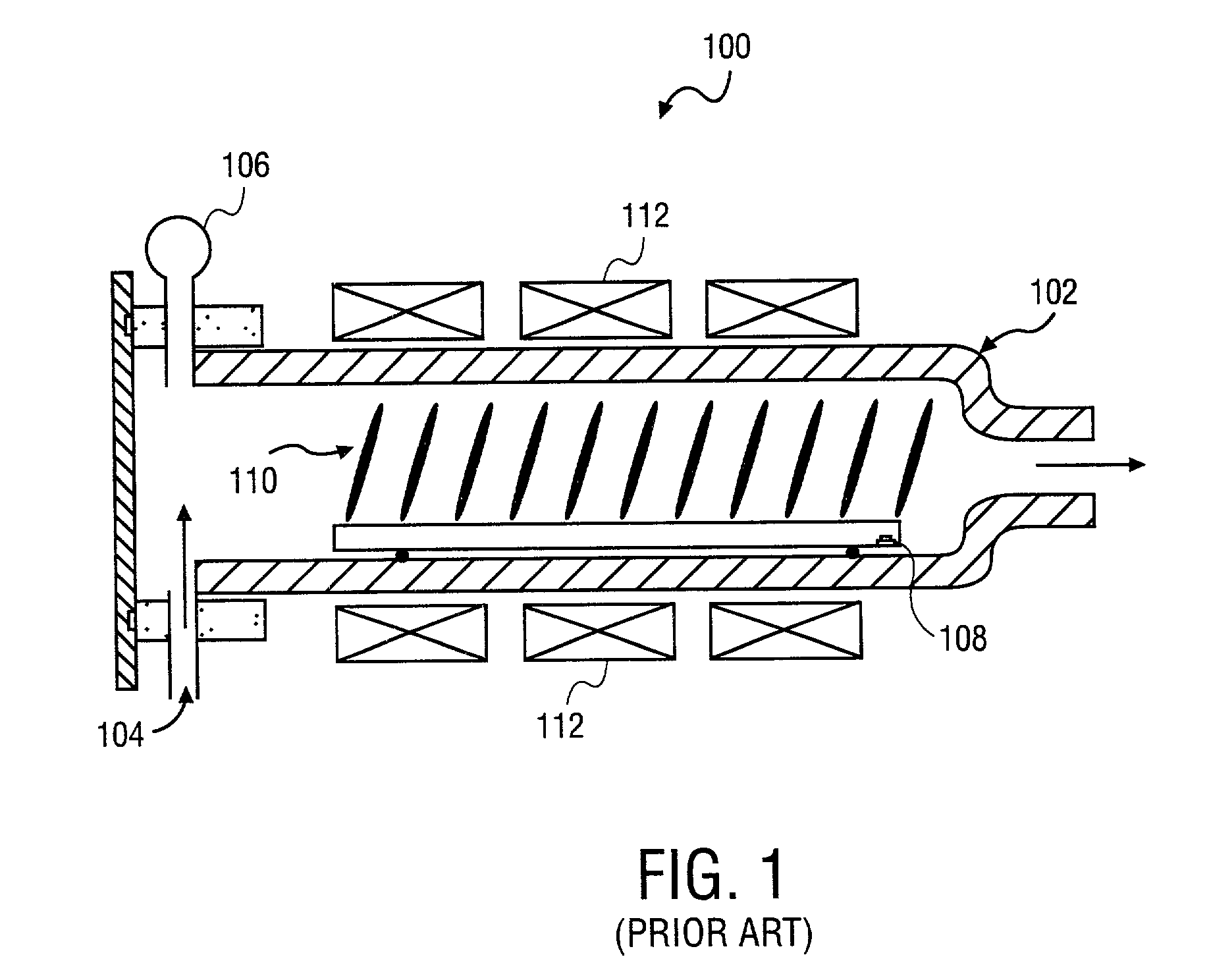

Method of configuring a ceramic core for casting a turbine blade

The internally air cooled turbine cast blade is molded with a ceramic core for defining the interior cavity with coolant passages where the ceramic core is configured to fair radially inwardly at the attachment portion of the blade until they form a single wall, parallel to and centered in the blade attachment. The blade is cast in the mold by pouring molten metal into the mold, curing and the core is leached once the metal is cured and the mold removed. Another embodiment includes a metering plate attached to the root of the blade for metering coolant to provide a coolant to gas flow ratio at the film cooling holes.

Owner:UNITED TECH CORP

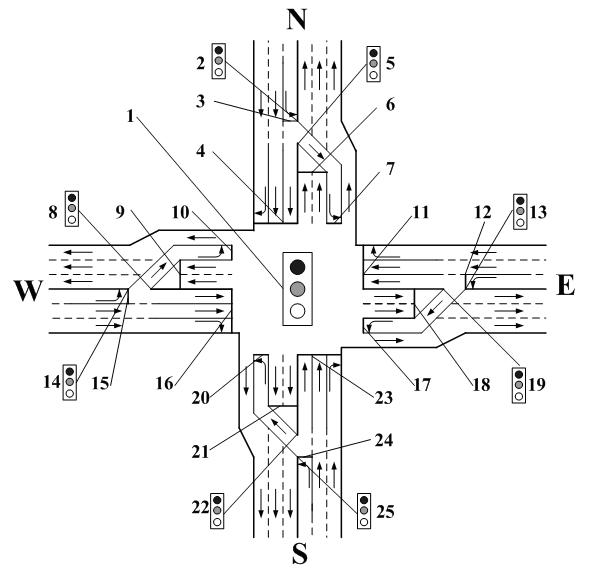

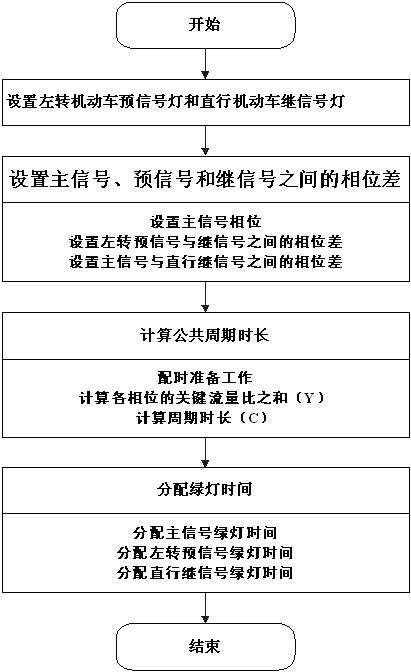

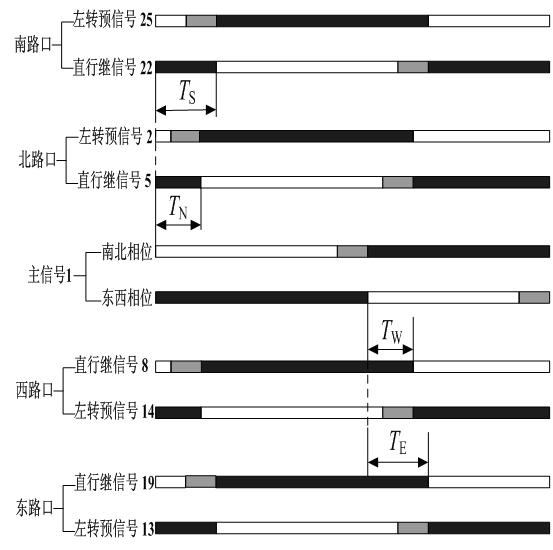

Coordination control method for crossroad left-turning pre-signal and straight-going successive signal

InactiveCN102024329AEnsure driving safetyAvoid cloggingControlling traffic signalsPhase differenceEngineering

The invention discloses a coordination control method for a crossroad left-turning pre-signal and a straight-going successive signal, which comprises the steps that: a main signal lamp is arranged at first in the middle of a crossroad, left-turning pre-signal lamps are respectively arranged at first stop lines of four left-turning entrance lanes for left turning vehicles, straight-going successive signal lamps are respectively arranged in front of second stop lines of four exit lanes for straight-going vehicles; a main signal phase, a phase difference between the left-turning pre-signals and the straight-going successive signals, and a phase difference between the straight-going successive signals and the main signal are then configured, time allocation is prepared, the sum of key flow ratios of the phases is calculated, and the time for green light is finally allocated; according to the method disclosed by the invention, the contradiction in the aspect of time between the left-turning vehicles and the straight-going vehicles is thoroughly settled by means of the coordination control for the main signal, the pre-signals and the successive signals, thereby guaranteeing drive safety; the entire cycle for the coordination control only needs to be calculated once, which is fast and convenient, and the method effectively avoids that the adoption of traditional time allocation method is likely to lead to the jam of left-turning vehicles.

Owner:JIANGSU UNIV

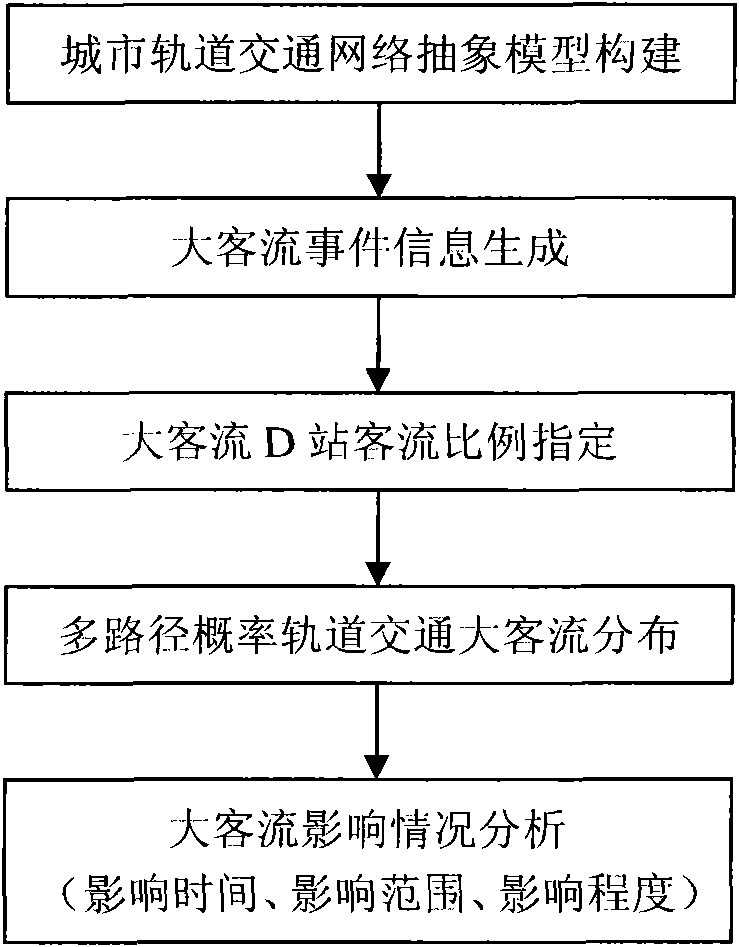

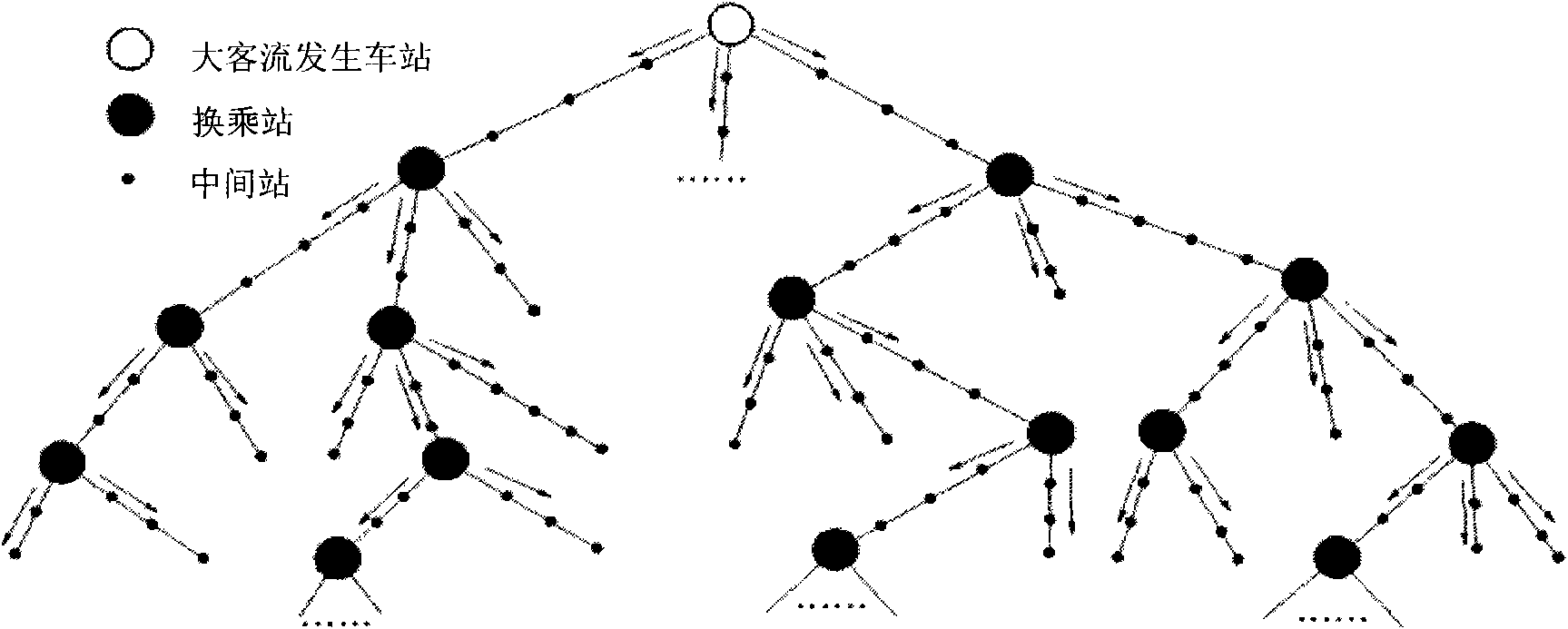

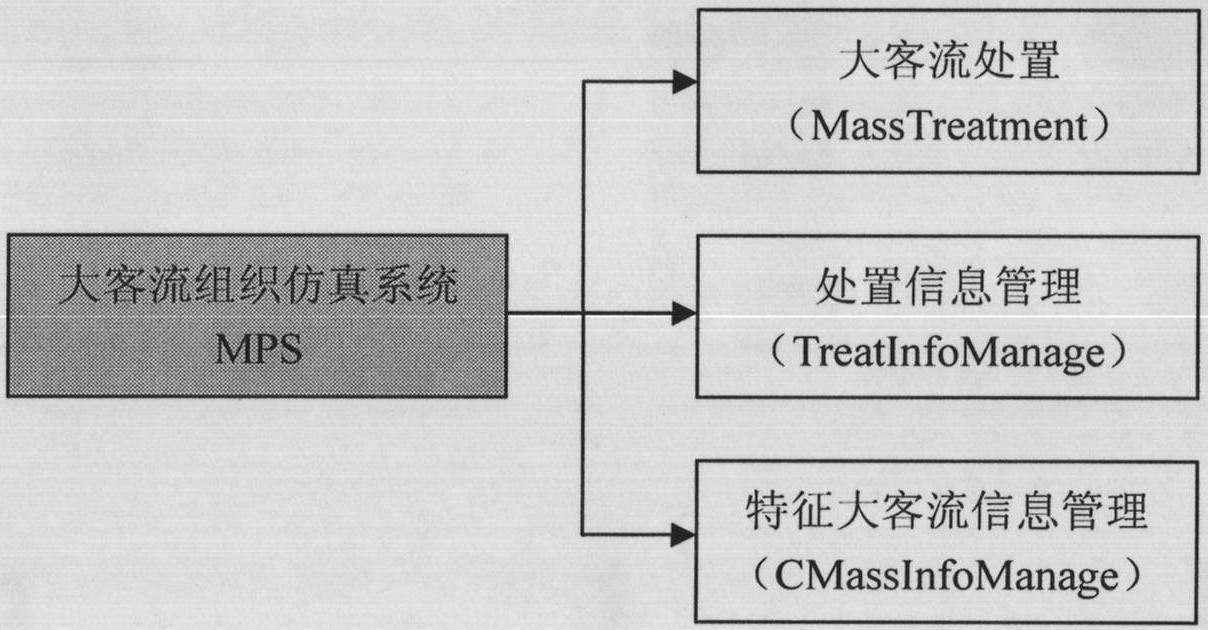

Method for predicting influence of heavy passenger flow of urban rail transit network

The invention discloses a method for predicting the influence of a heavy passenger flow of an urban rail transit network, which comprises the following step: (1) constructing an abstract model of the urban rail transit network; (2) generating a heavy passenger flow event; (3) setting the passenger flow ratio of a destination station / source station of a heavy passenger flow; and (4) analyzing the influence of the heavy passenger flow on the network. The method can be applied to the development of an urban rail transit network heavy passenger flow organization simulation system. The system can be used in an emergency handling center of the urban rail transit network to realize the automation and intellectualization of the analysis on the influence of the heavy passenger flow event and emergency handling. Meanwhile, the system is often used by an emergency handling department in a daily emergency monitoring process for simulating the handling process of the heavy passenger flow event anddeveloping the emergency handling capability of emergency handling personnel, and the system obtains good actual effect and enterprise benefit.

Owner:TONGJI UNIV

Ethylene copolymer compositions, film and polymerization processes

ActiveUS20140100343A1Easy to processGood physical propertiesAgricultural articlesSynthetic resin layered productsPolymer scienceFractionation

Ethylene copolymers having a relatively high melt flow ratio and a multimodal profile in a temperature rising elution fractionation (TREF) plot are disclosed. The copolymers can be made into film having good dart impact values and good stiffness properties under decreased extruder pressures.

Owner:NOVA CHEM (INT) SA

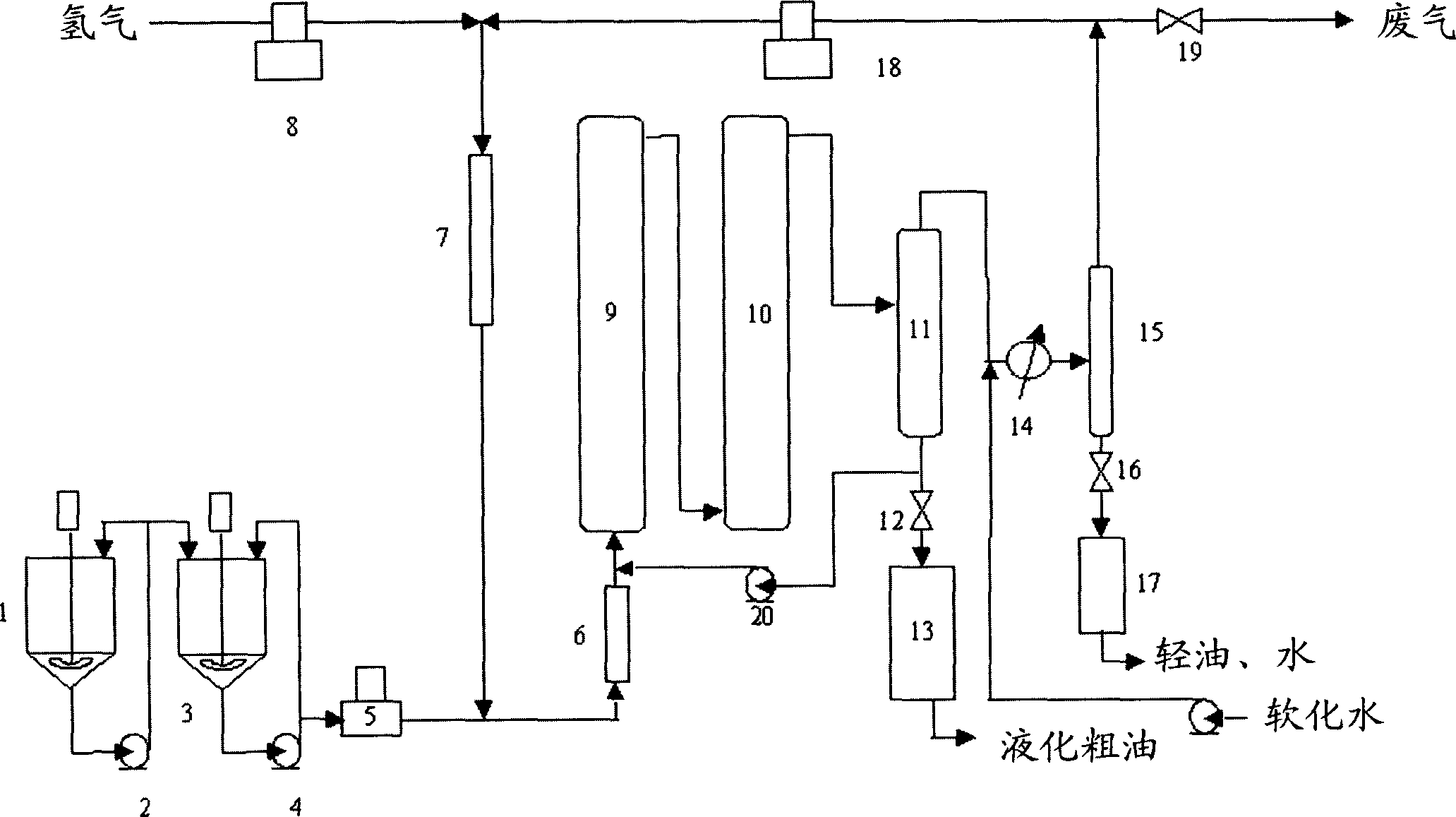

Method of directly liquifying coal

ActiveCN1869159AHigh yieldAvoid secondary decompositionLiquid hydrocarbon mixture productionCoal dustPre treatment

The invention relates to a coal direct liquefaction method. It includes the following steps: mixing coal slurry which is made up of coal dust, hydrogenation cycle solvent, and iron catalyst with freshness or cycle hydrogen; reacting by the first and second reactor; sending the product from the second reactor to high temperature separator to separate; the weight flow ratio of the recycle and freshness materials is 2-20. The method can reduce hydrogen consumption and gas yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for manufacturing surface antimicrobial, abrasion-proof metal/ceramic nano-multilayer film

ActiveCN101220454AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingWear resistantNitrogen gas

The invention which discloses a preparation method for metal / ceramic nanometer multilayer films with antibacterial and wear resistant surfaces relates to a preparation method for nanometer multilayer films and solves the problem of high cost and great difficulty in preparing wholly antibacterial materials and low wear resistance of surfaced treated antibacterial materials. The method comprises the following steps: a magnetron sputtering method is adopted, the background vacuum degree is 10<- 4> to 10<- 2> Pa; sputtering against targets in the conditions of the gas flow ratio of 2 to 17:1 of argon to one gas of the three gases of nitrogen, acetylene or methane, total air pressure of 0.1 - 1.0Pa, magnetron sputtering currents of 0.2 - 50A, voltage of 300 - 600V, substrate bias voltage of minus 50 to minus 400V and deposition temperatures of 80 - 400 DEG C. The nanometer ceramic / metal multilayer films prepared by the invention have good wear resistance and the antibacterial rate of more than 95 percent; the invention has the advantages of no pollution, low cost, easy realization and good industrial application prospects.

Owner:HARBIN INST OF TECH

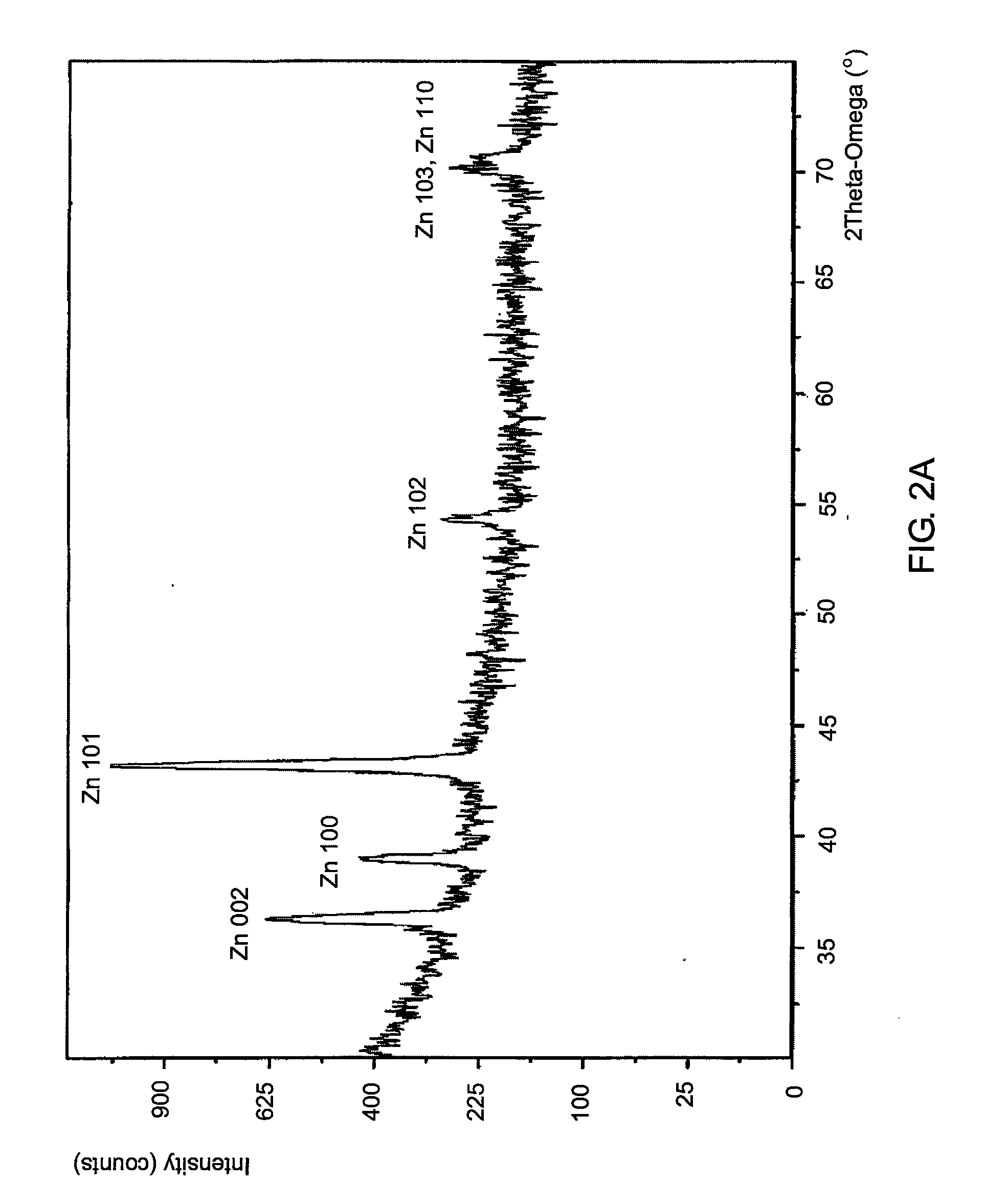

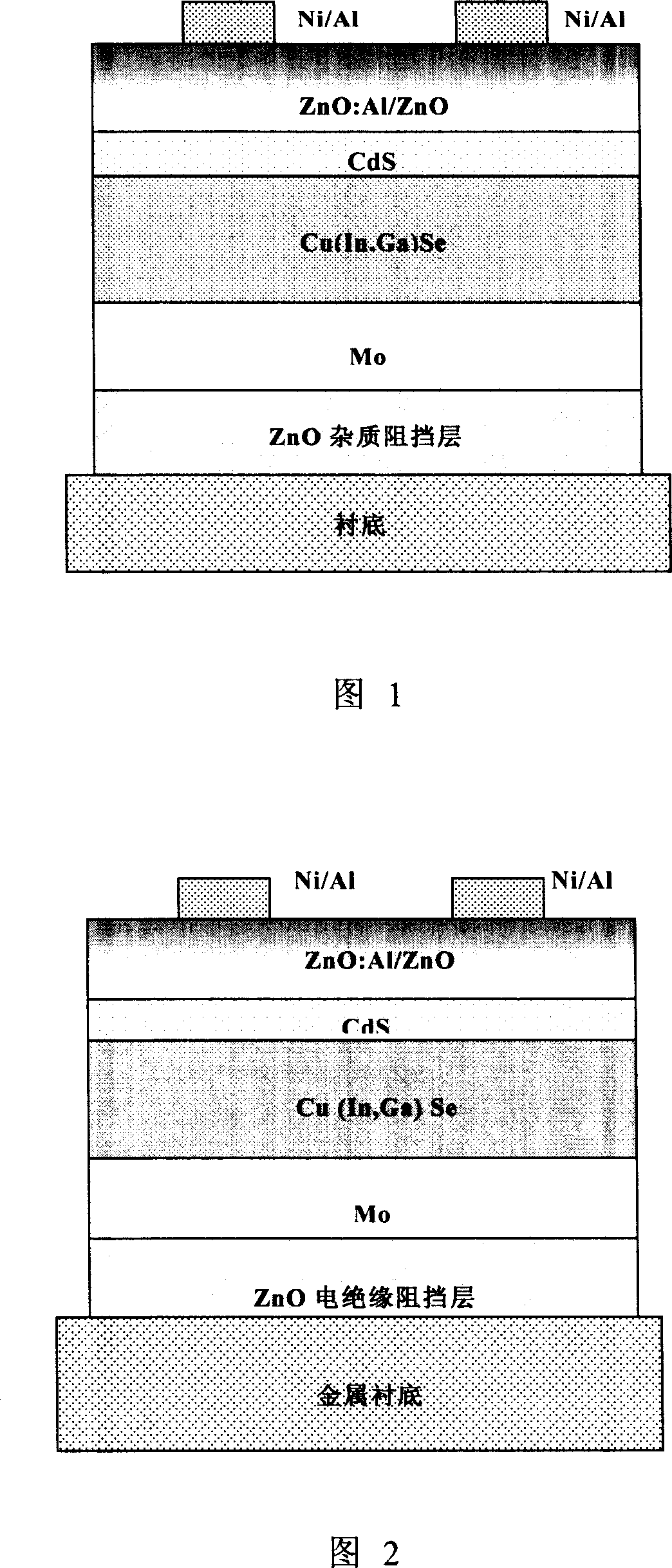

Thin film solar cell of using ZnO as electrical isolation layer and impurity barrier layer, and preparation method

InactiveCN101093863AImprove performanceQuality improvementFinal product manufacturePhotovoltaic energy generationZincFlow ratio

The disclosed ZnO impurity barrier layer and electrical isolation layer on metallic substrate is suitable to flexible photo-volt battery. Using pure zinc target or ZnO ceramics target etc, through sputtering technique, the invention deposits ZnO thin film on metal substrate. Adjusting flow ratio between Ar and O2 obtains ideal ZnO film. The ZnO film with compact structure of thin film possesses better effect for blocking off impurity inside metal substrate, and better effect of insulation. The disclosed ZnO is in use for preparing batteries and subassembly with flexible metal substrate.

Owner:NANKAI UNIV

Methods for silicon oxide and oxynitride deposition using single wafer low pressure CVD

InactiveUS20030138562A1Pretreated surfacesSemiconductor/solid-state device manufacturingThermal energySilicon oxide

An oxide and an oxynitride films and their methods of fabrication are described. The oxide or the oxynitride film is grown on a substrate that is placed in a deposition chamber. A silicon source gas (or a silicon source gas with a nitridation source gas) and an oxidation source gas are decomposed in the deposition chamber using a thermal energy source. A silicon oxide (or an oxynitride) film is formed above the substrate wherein total pressure for the deposition chamber is maintained in the range of 50 Torr to 350 Torr and wherein a flow ratio for the silicon source gas (or the silicon source gas with the nitridiation source gas) and the oxidation source gas is in the range of 1:50 to 1:10000 during a deposition process.

Owner:APPLIED MATERIALS INC

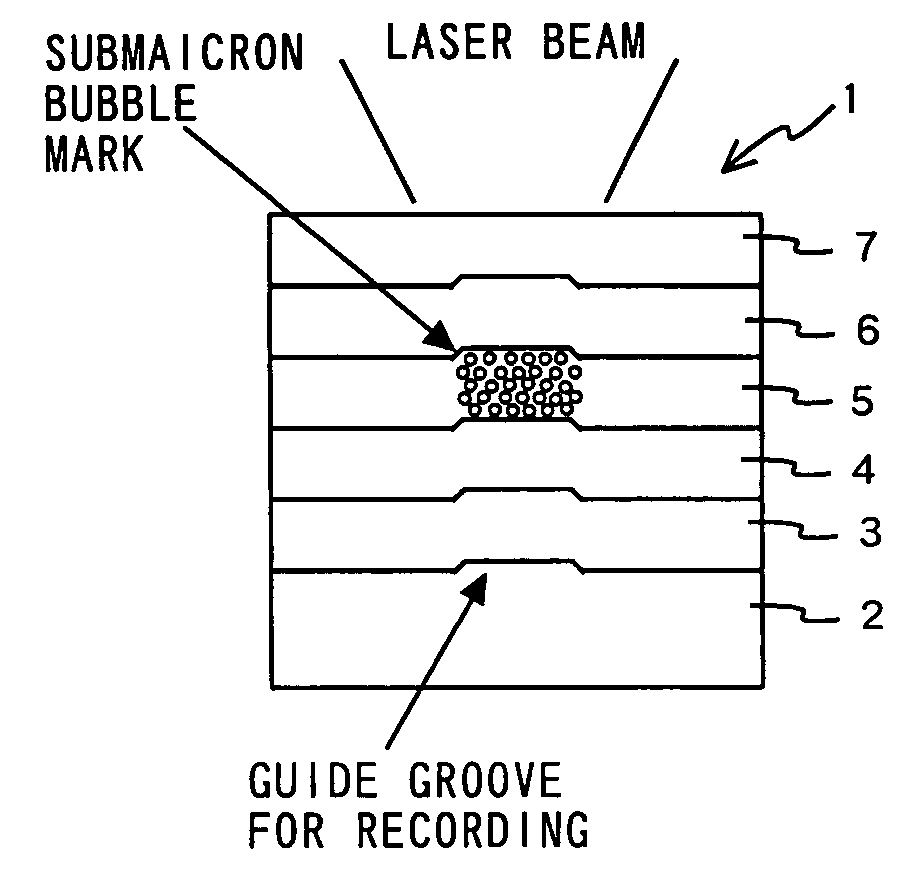

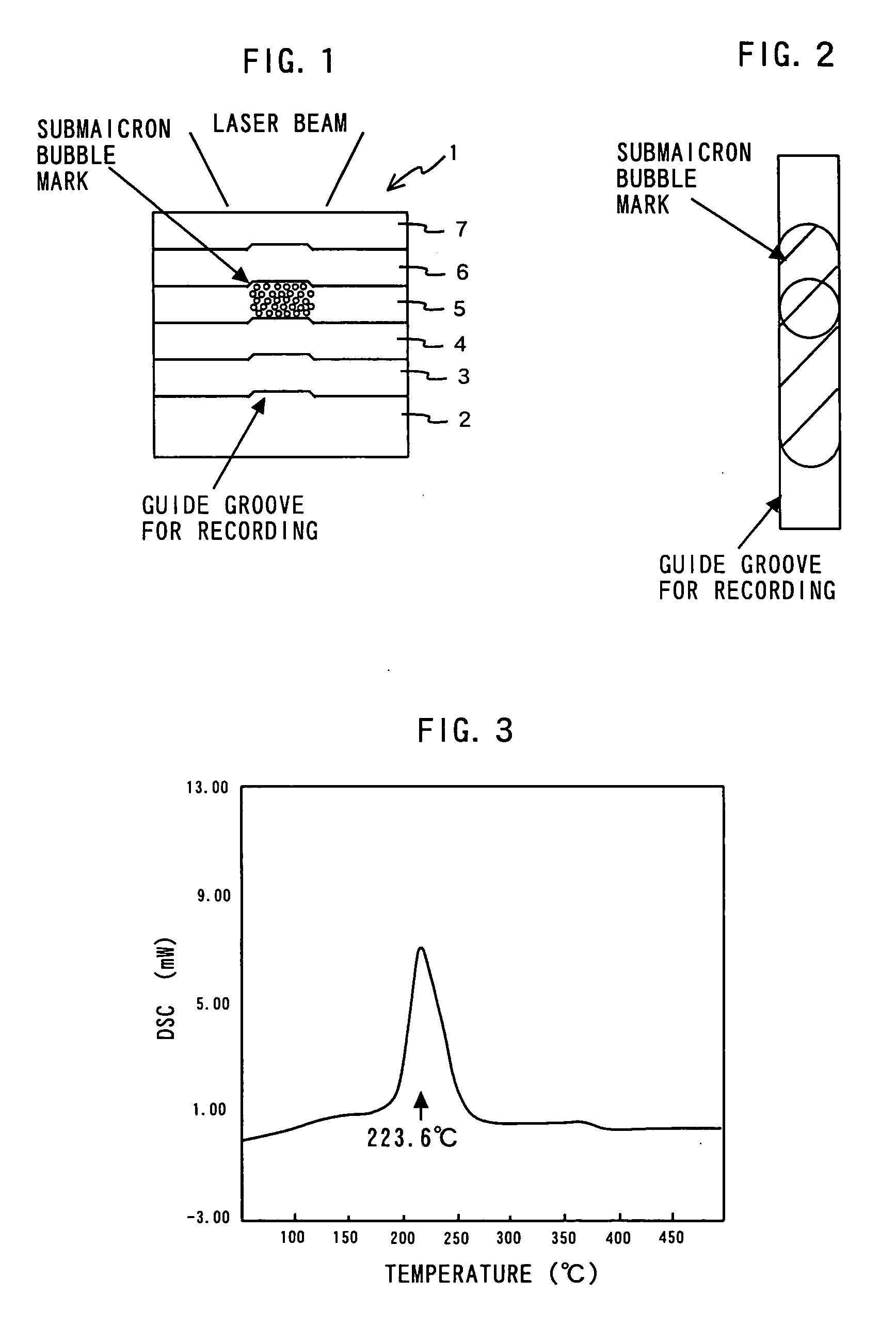

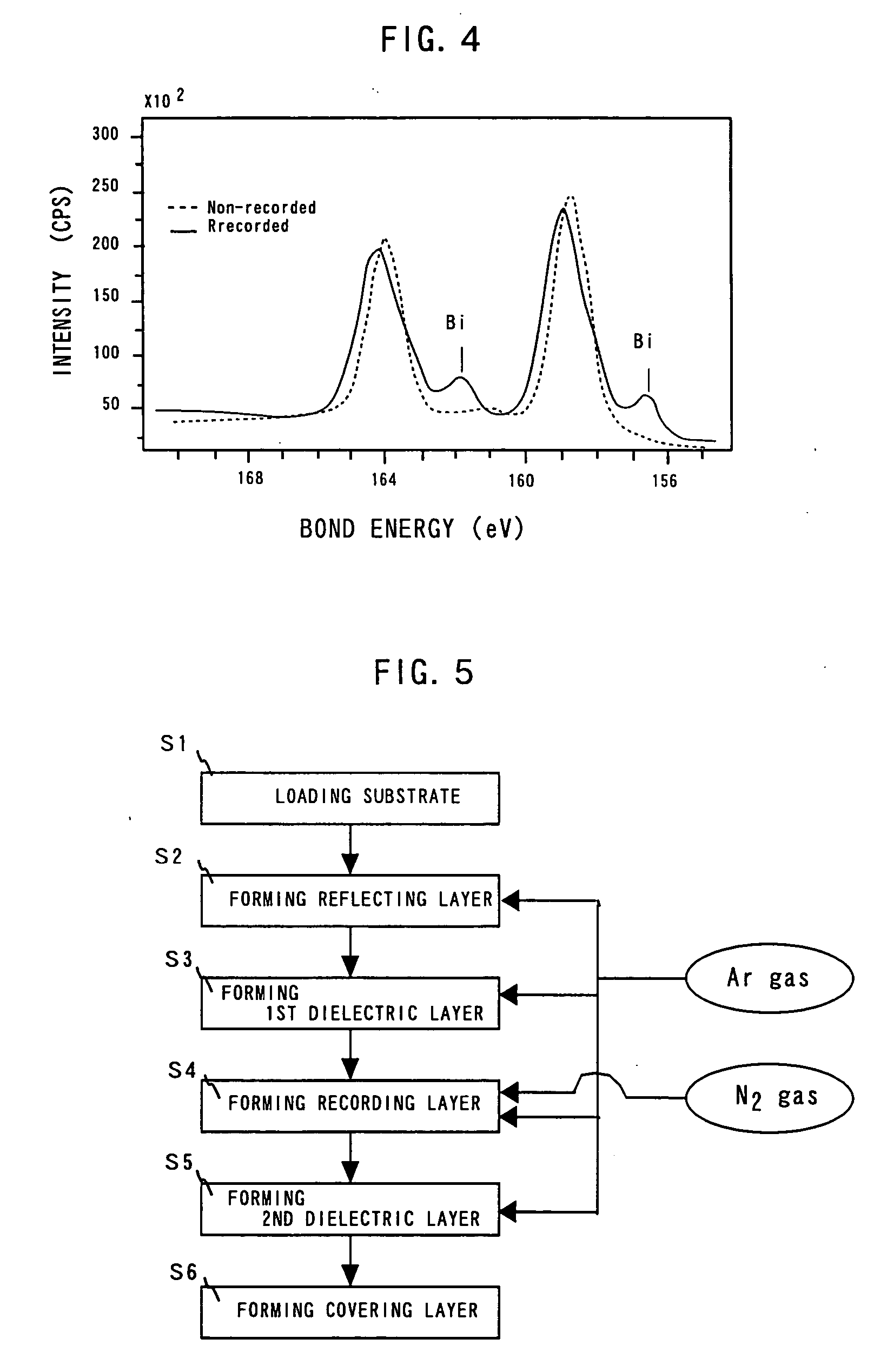

Information recording medium and process for producing the same

ActiveUS20050233247A1Excellent in reproduction propertyMaintain good propertiesRadiation applicationsMechanical record carriersLight beamRecording layer

An information recording medium has an excellent jitter characteristic with a considerable difference in reflectance between prior to and subsequent to recording. The information recording medium includes a recording layer which contains a material having a reflectance which varies by irradiation of a light beam, on which information is recorded as reflectance variations, and a substrate for supporting the recording layer, the recording layer including a metal nitride as a major component. In a method of manufacturing the information recording medium having a recording layer which includes a material having a reflectance which varies by irradiation of a light beam, on which information is recorded as reflectance variations, and the substrate for supporting the recording layer, the recording layer including a metal nitride as a major component, the method includes a recording layer forming step for forming the recording layer by a reactive sputtering method which uses a target comprised of a metal constituting a metal nitride, wherein a flow ratio Ar:N2 in an atmosphere including Ar and N2 in the recording layer forming step is set within the range of 80:10 to 10:80.

Owner:PIONEER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com