Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9721 results about "Indium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indium is a chemical element with the symbol In and atomic number 49. Indium is the softest metal that is not an alkali metal. It is a silvery-white metal that resembles tin in appearance. It is a post-transition metal that makes up 0.21 parts per million of the Earth's crust. Indium has a melting point higher than sodium and gallium, but lower than lithium and tin. Chemically, indium is similar to gallium and thallium, and it is largely intermediate between the two in terms of its properties. Indium was discovered in 1863 by Ferdinand Reich and Hieronymous Theodor Richter by spectroscopic methods. They named it for the indigo blue line in its spectrum. Indium was isolated the next year.

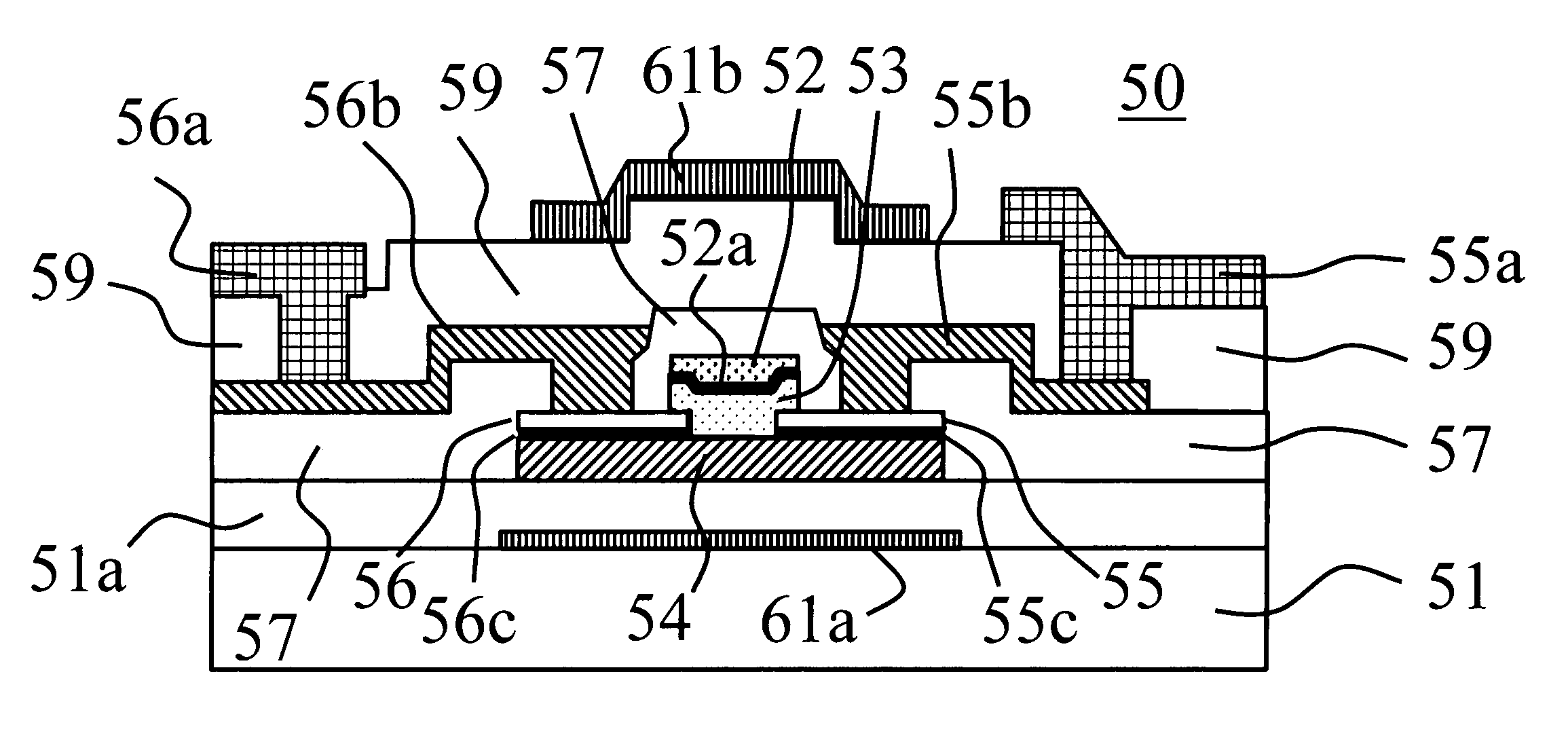

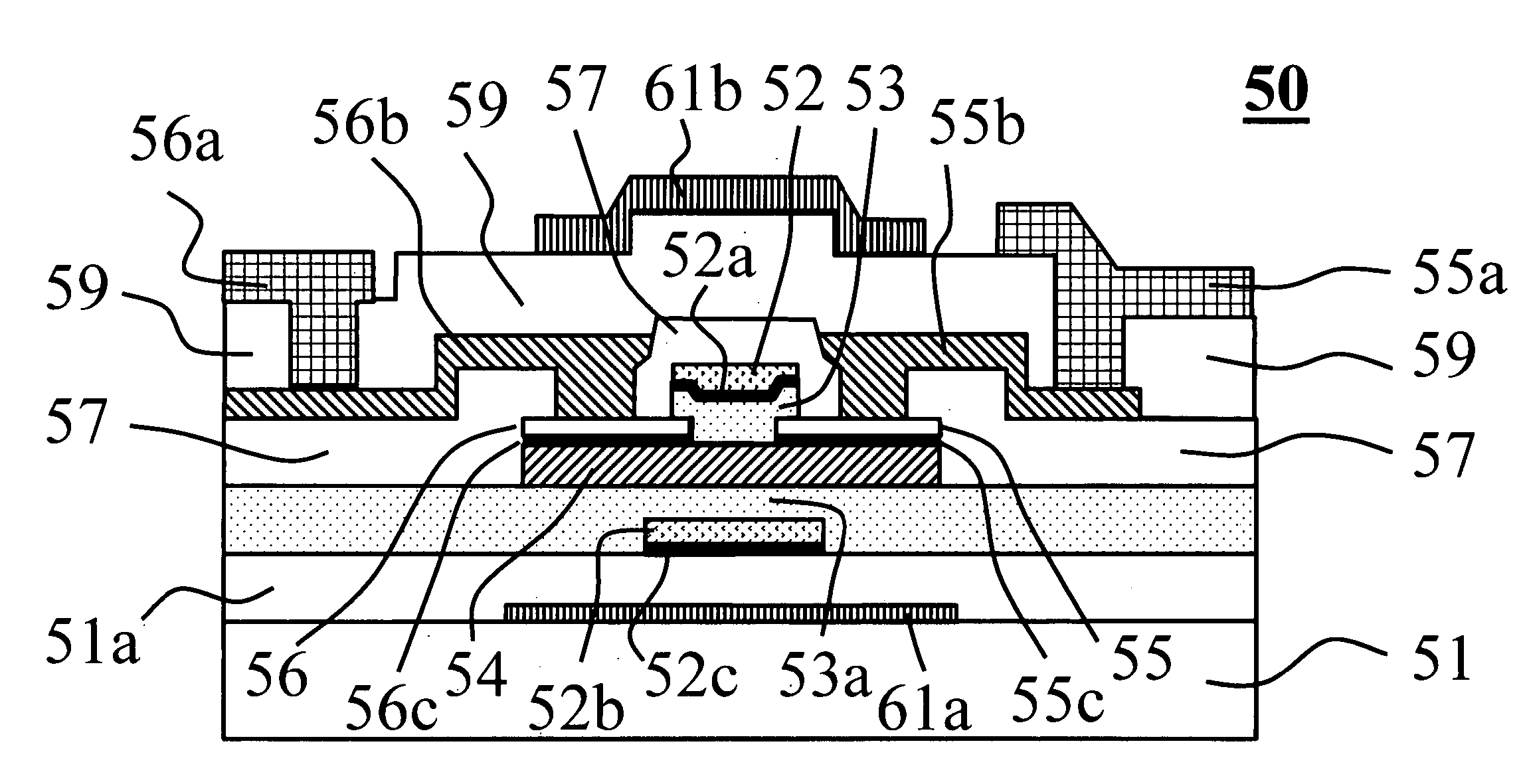

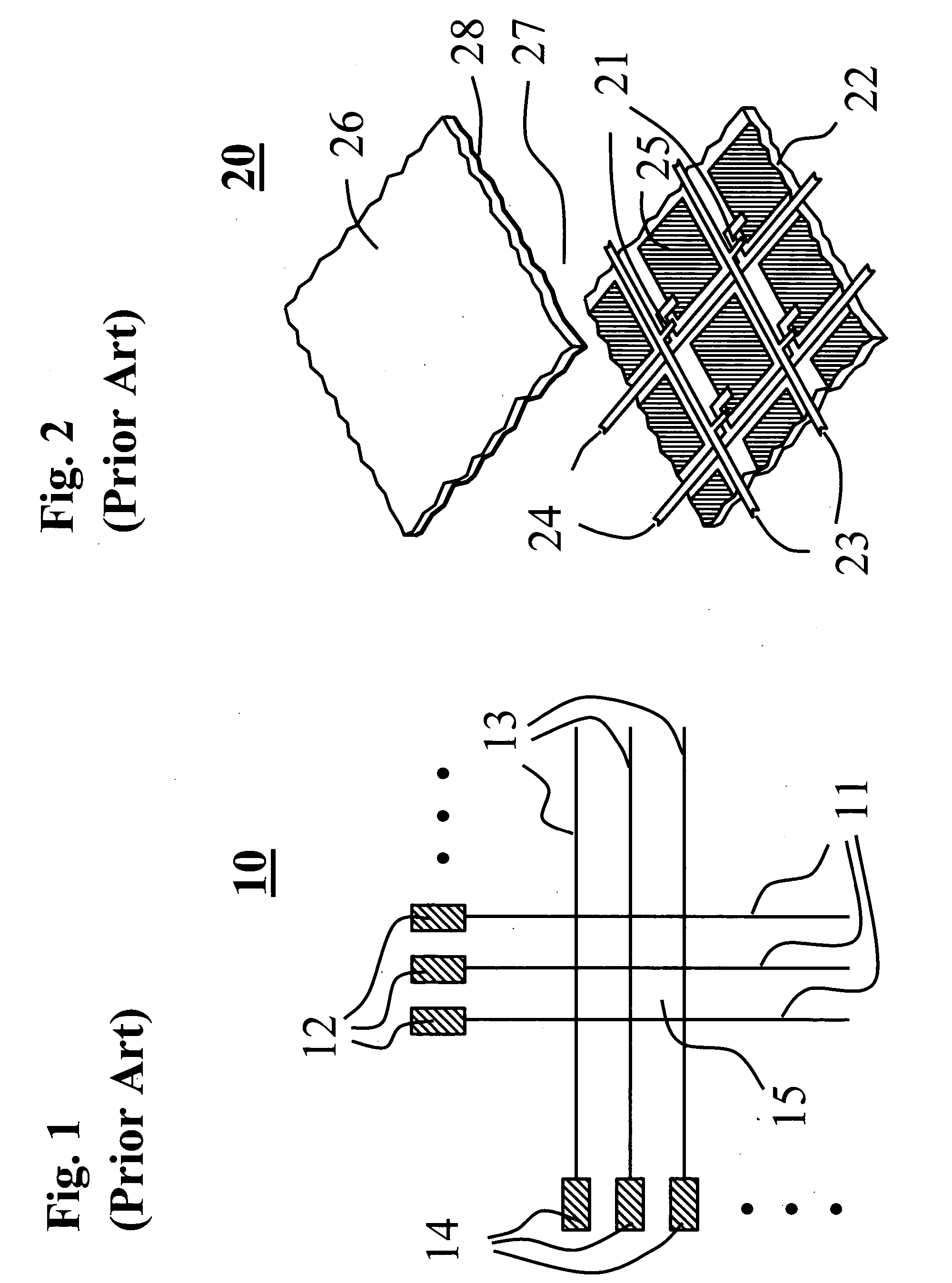

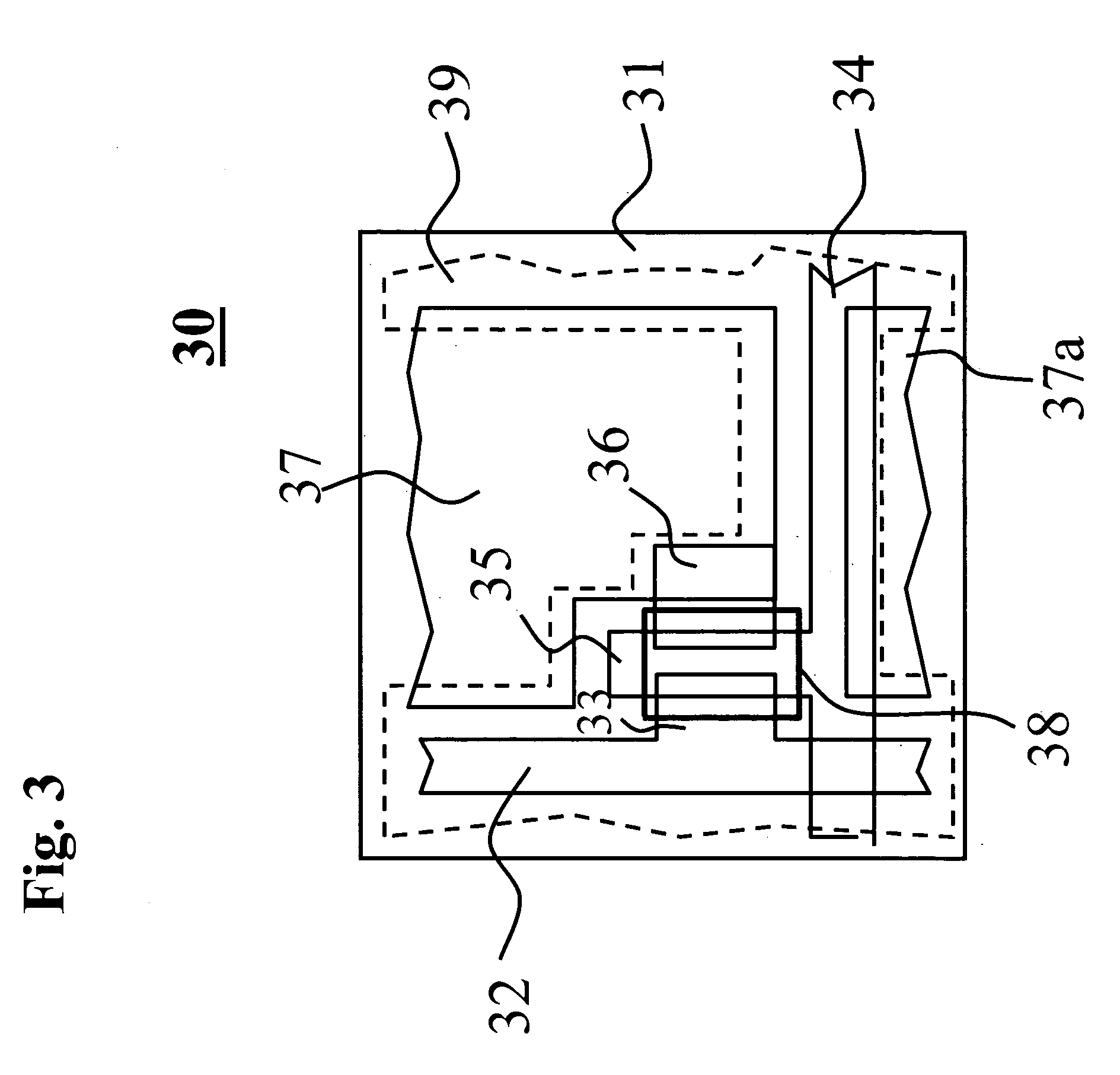

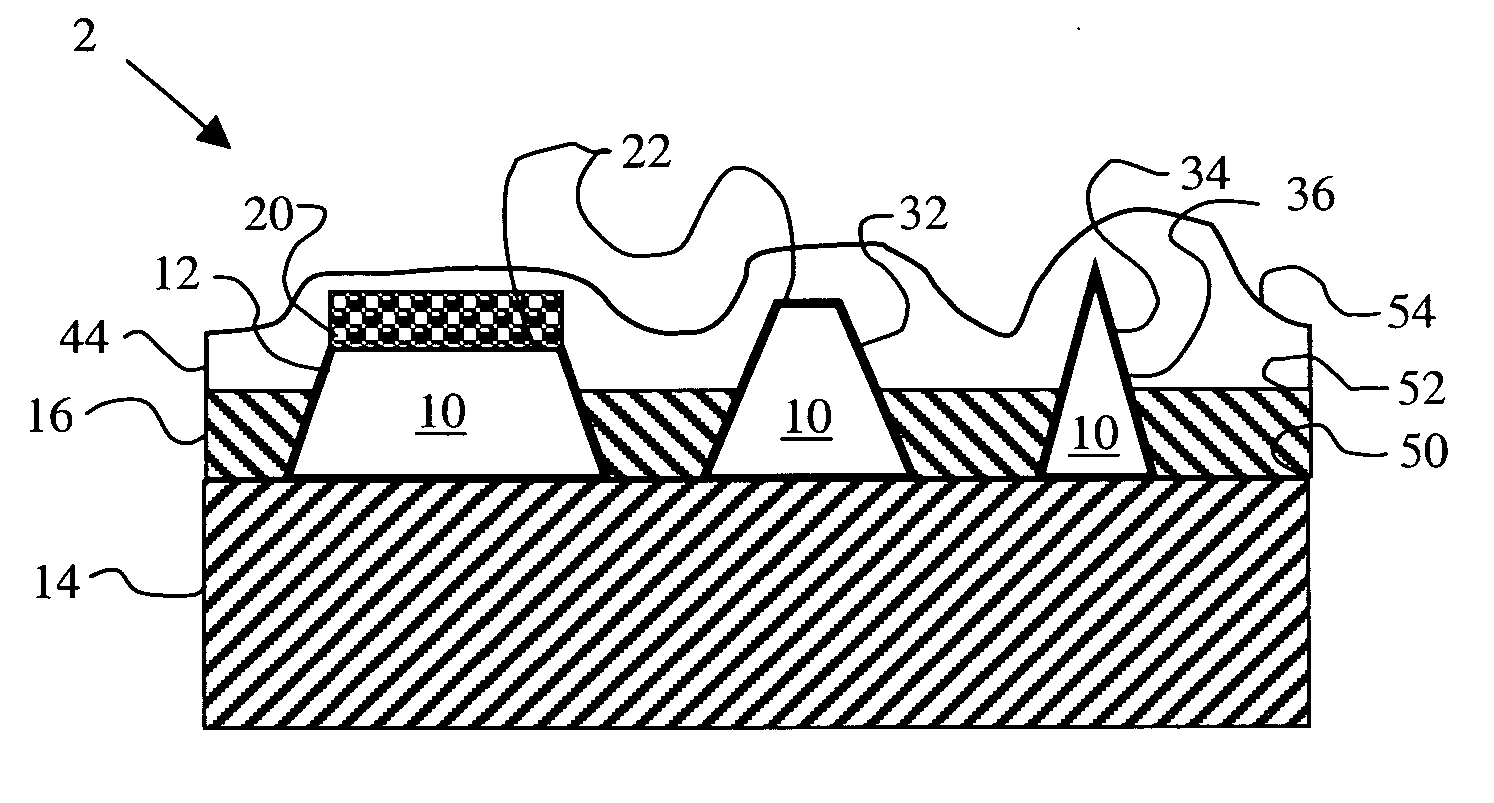

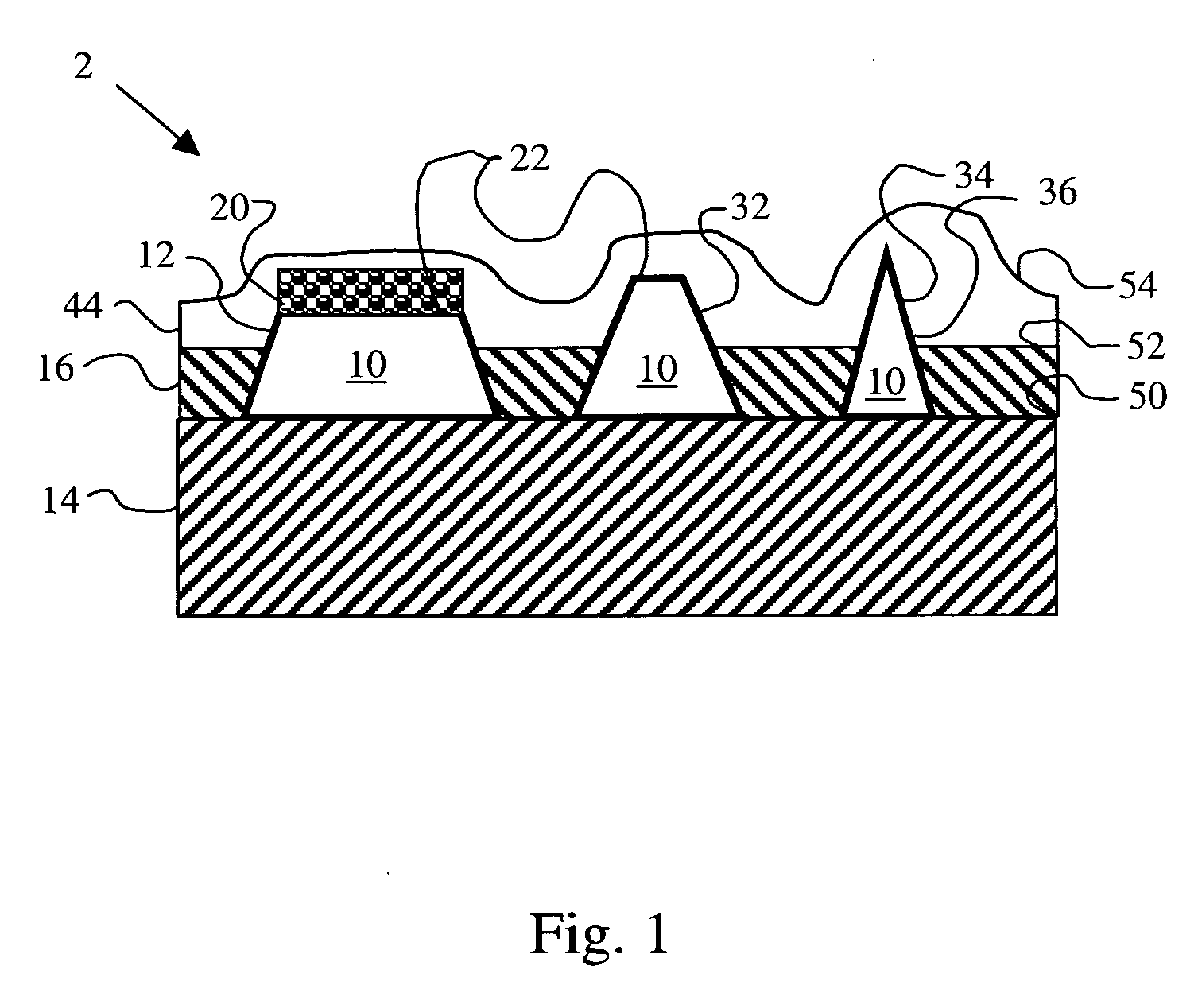

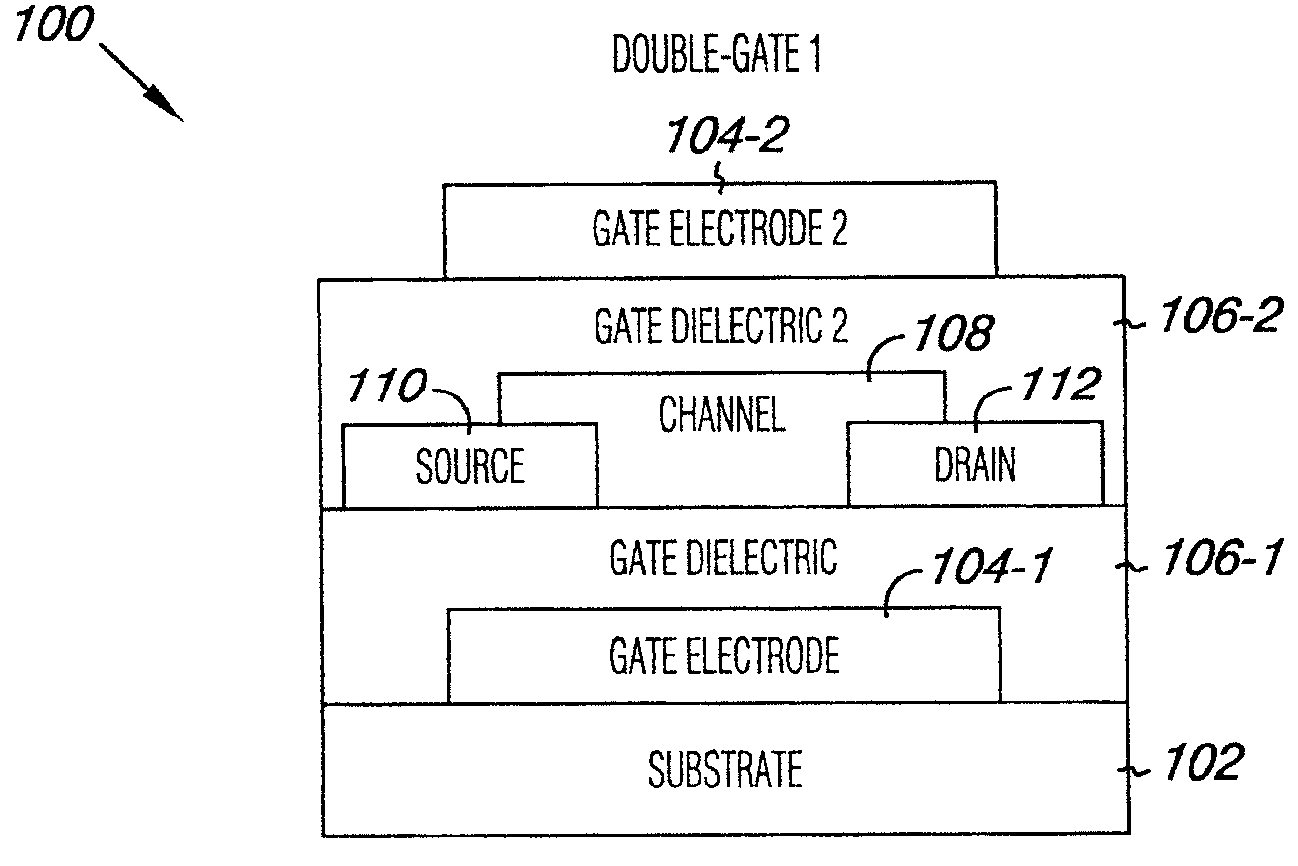

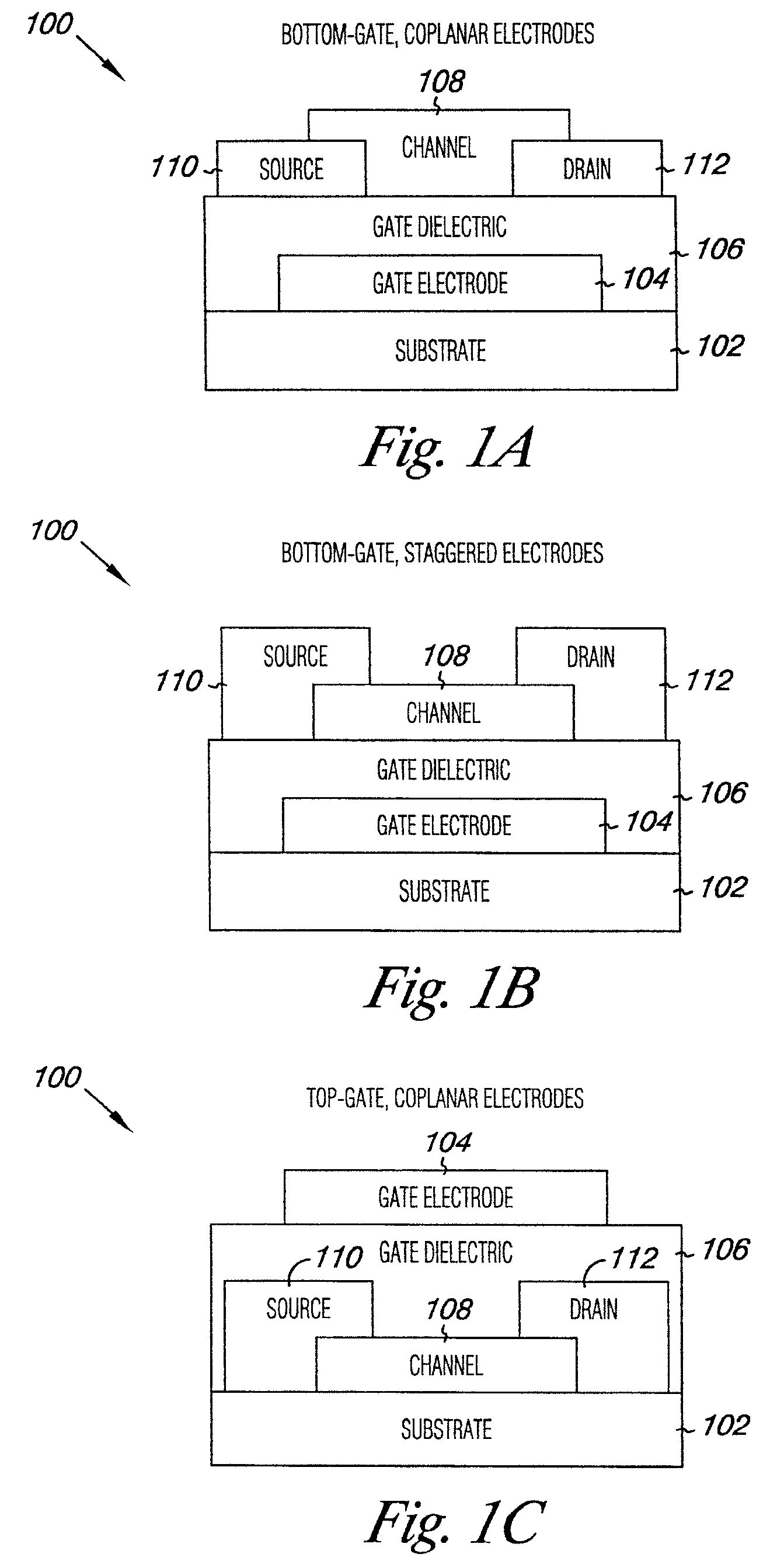

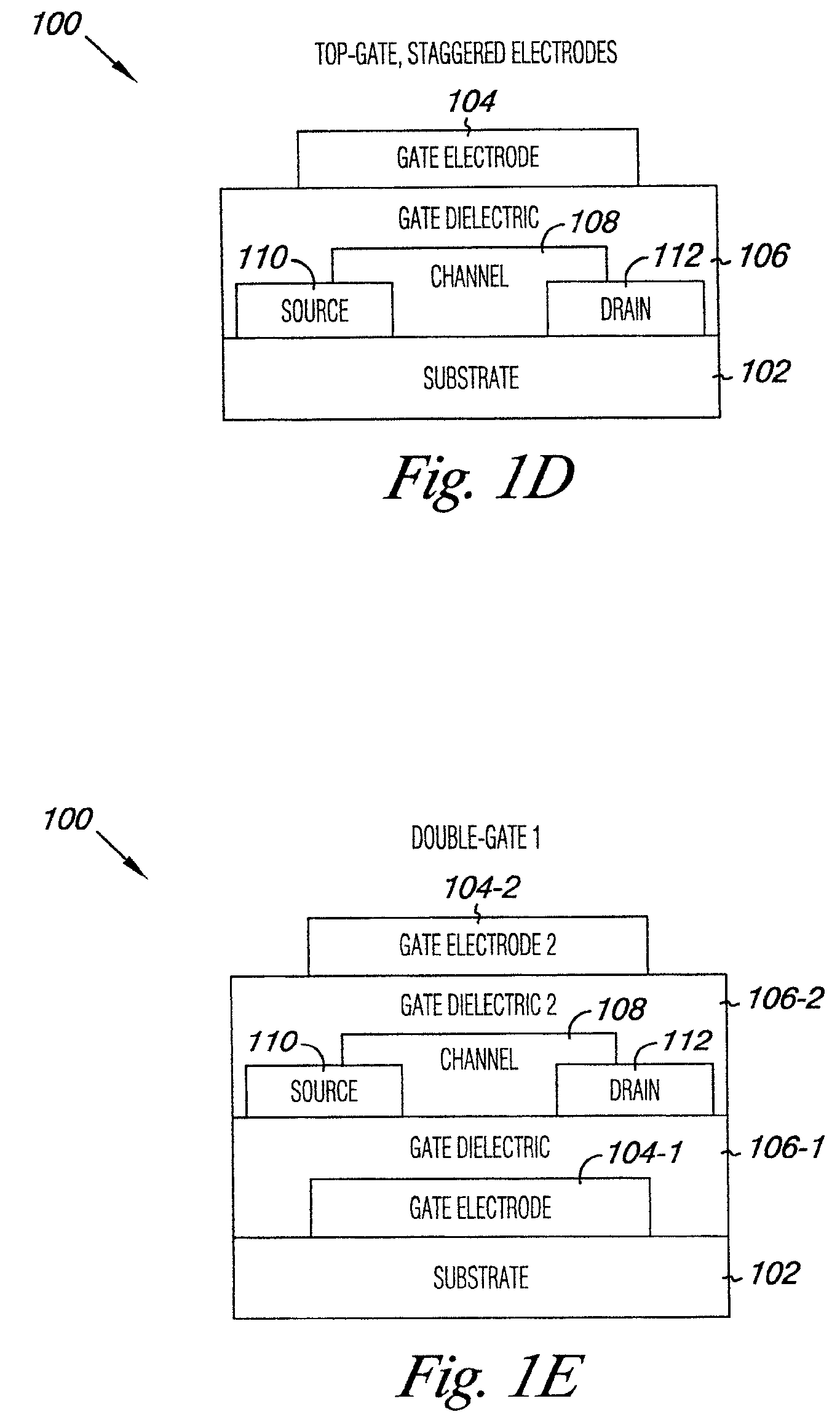

Indium oxide-based thin film transistors and circuits

In electronic displays or imaging units, the control of pixels is achieved by an array of transistors. These transistors are in a thin film form and arranged in a two-dimensional configuration to form switching circuits, driving circuits or even read-out circuits. In this invention, thin film transistors and circuits with indium oxide-based channel layers are provided. These thin film transistors and circuits may be fabricated at low temperatures on various substrates and with high charge carrier mobilities. In addition to conventional rigid substrates, the present thin film transistors and circuits are particularly suited for the fabrication on flexible and transparent substrates for electronic display and imaging applications. Methods for the fabrication of the thin film transistors with indium oxide-based channels are provided.

Owner:SHIH YI CHI +3

Indium oxide-based thin film transistors and circuits

In electronic displays or imaging units, the control of pixels is achieved by an array of transistors. These transistors are in a thin film form and arranged in a two-dimensional configuration to form switching circuits, driving circuits or even read-out circuits. In this invention, thin film transistors and circuits with indium oxide-based channel layers are provided. These thin film transistors and circuits may be fabricated at low temperatures on various substrates and with high charge carrier mobilities. In addition to conventional rigid substrates, the present thin film transistors and circuits are particularly suited for the fabrication on flexible and transparent substrates for electronic display and imaging applications. Methods for the fabrication of the thin film transistors with indium oxide-based channels are provided.

Owner:SHIH YI CHI +3

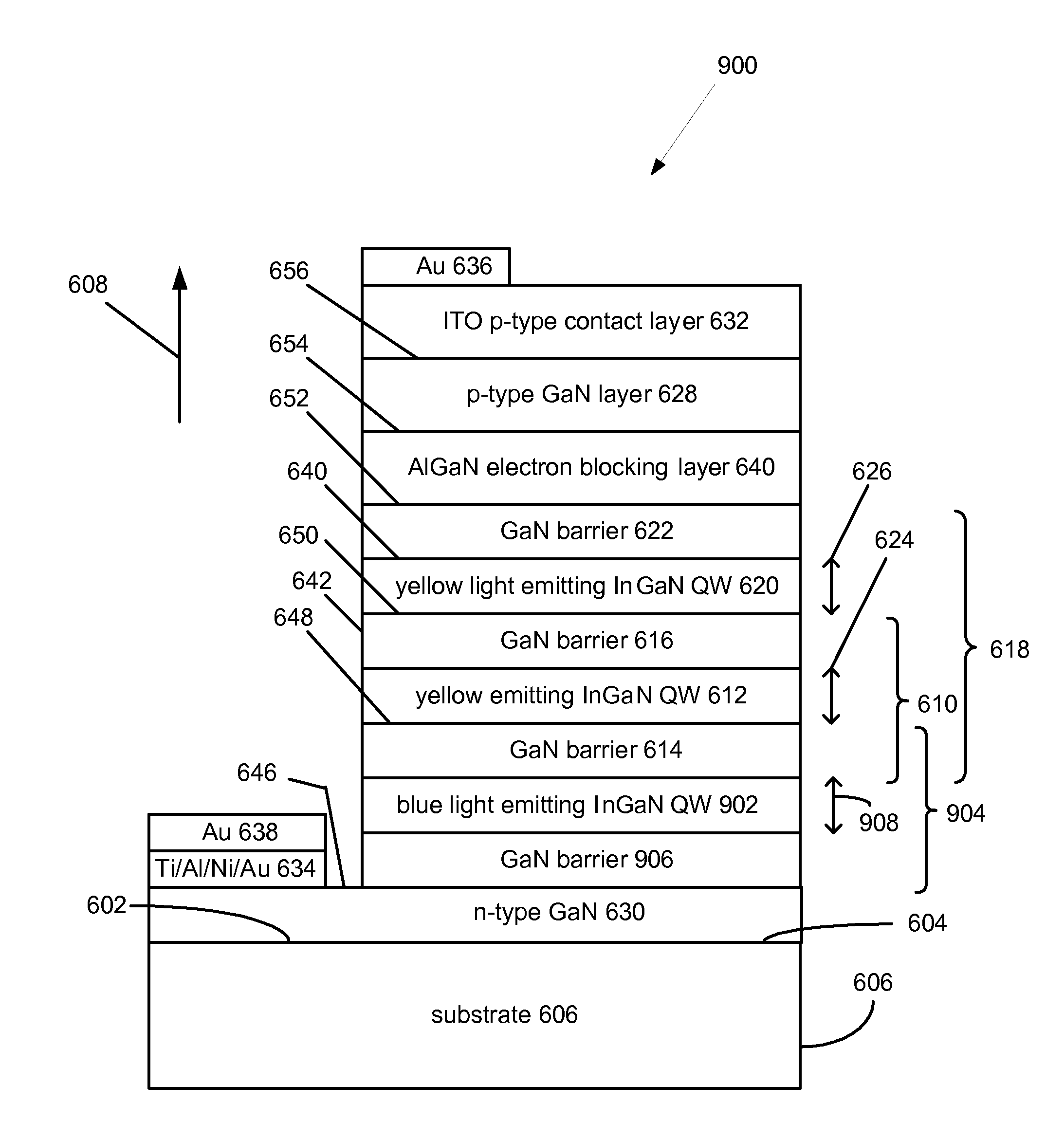

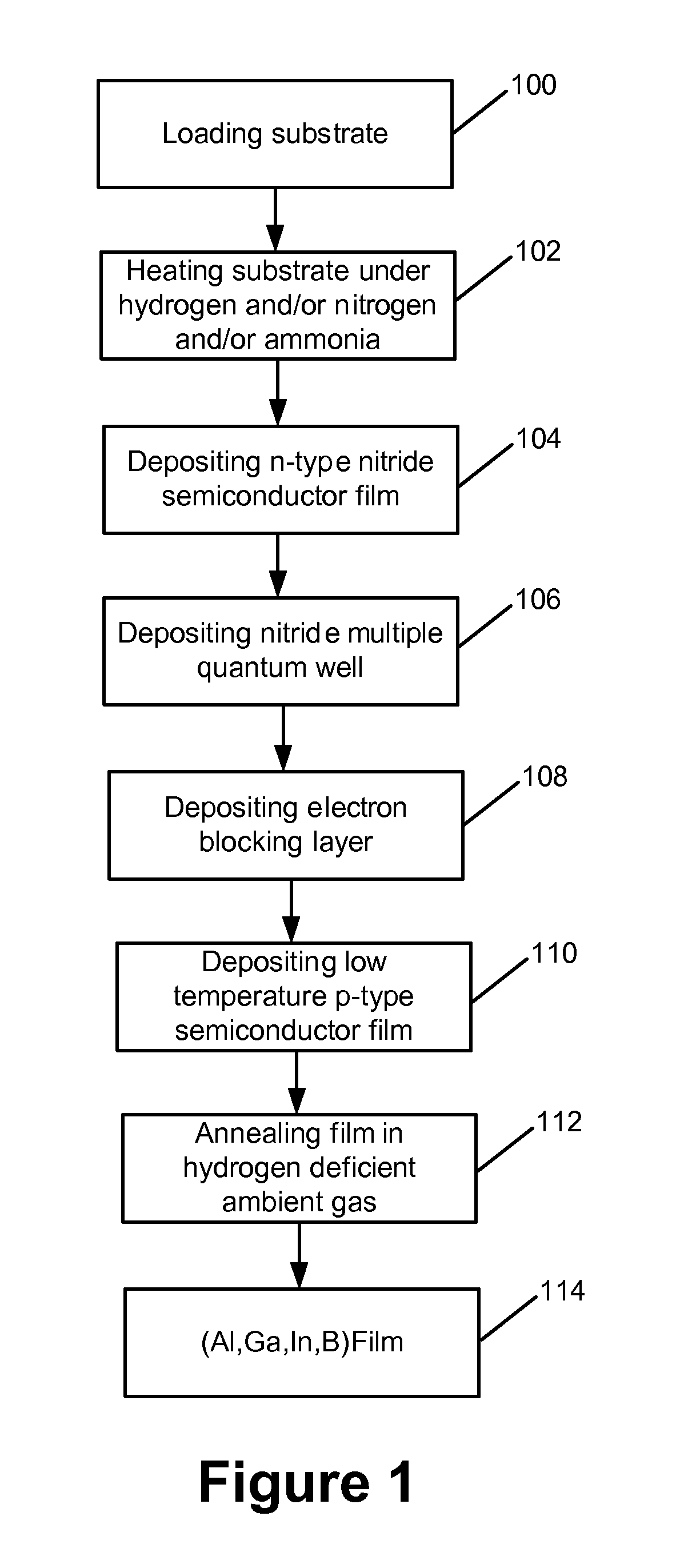

METHOD FOR FABRICATION OF SEMIPOLAR (Al, In, Ga, B)N BASED LIGHT EMITTING DIODES

A yellow Light Emitting Diode (LED) with a peak emission wavelength in the range 560-580 nm is disclosed. The LED is grown on one or more III-nitride-based semipolar planes and an active layer of the LED is composed of indium (In) containing single or multi-quantum well structures. The LED quantum wells have a thickness in the range 2-7 nm. A multi-color LED or white LED comprised of at least one semipolar yellow LED is also disclosed.

Owner:RGT UNIV OF CALIFORNIA

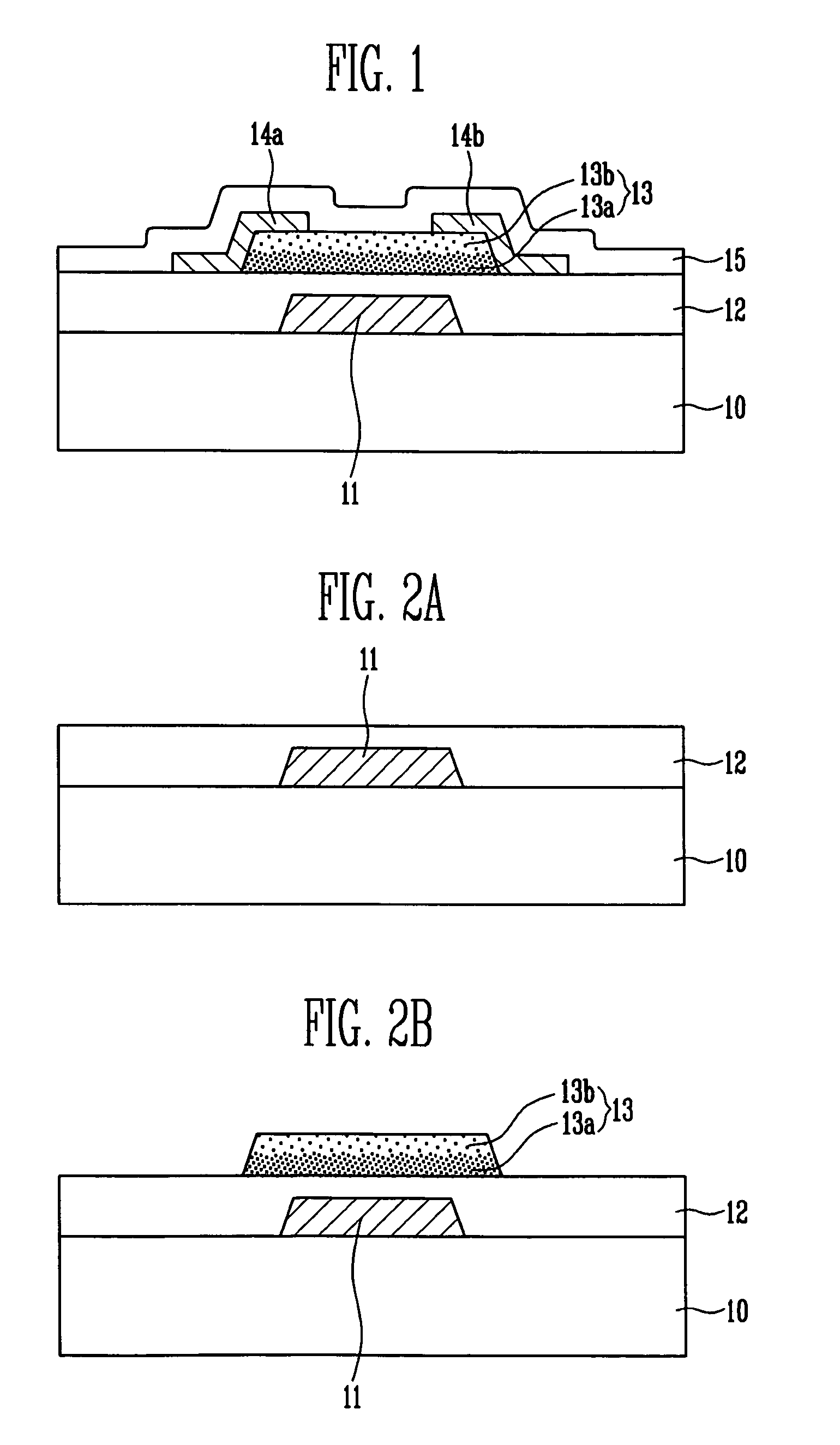

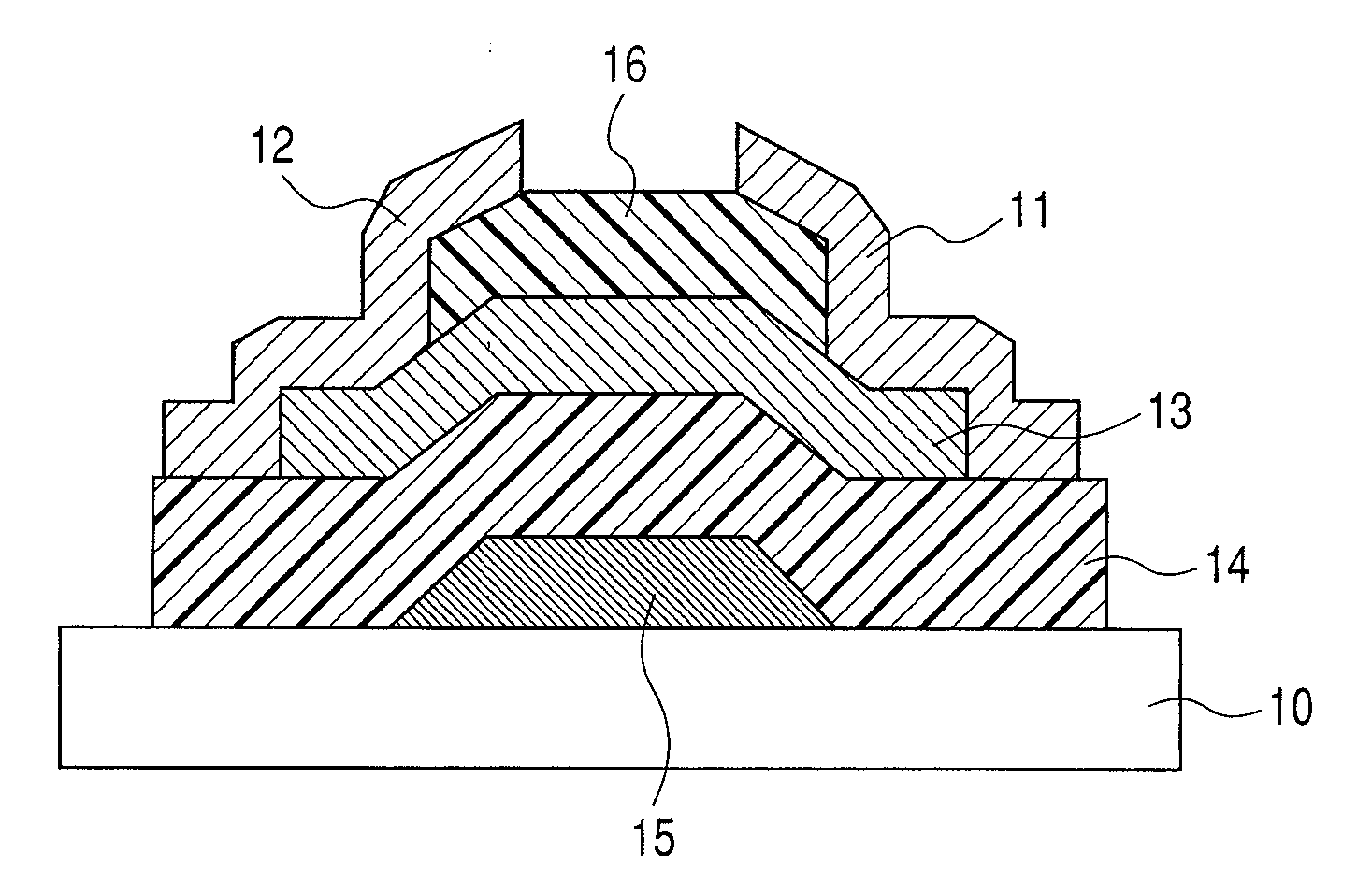

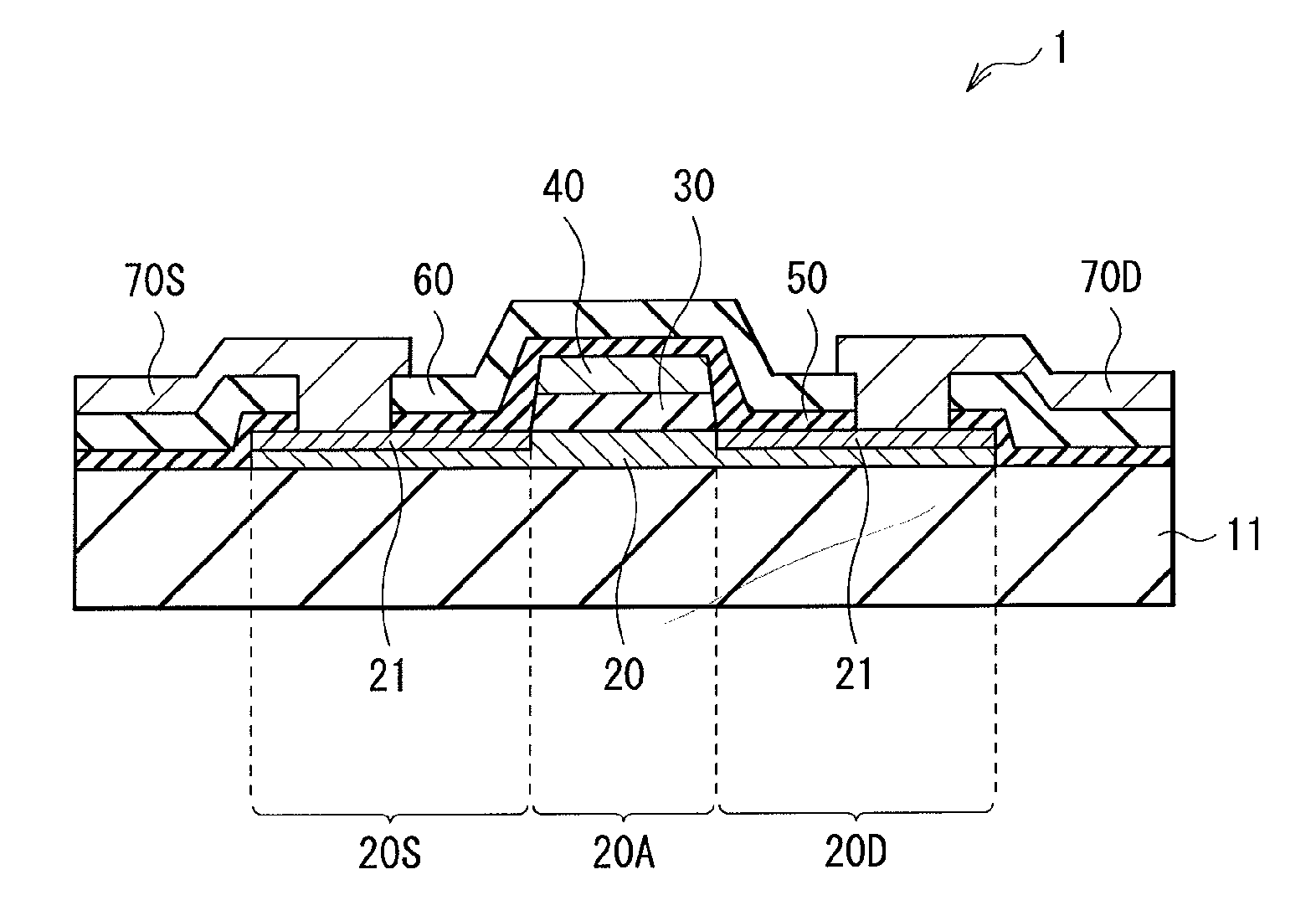

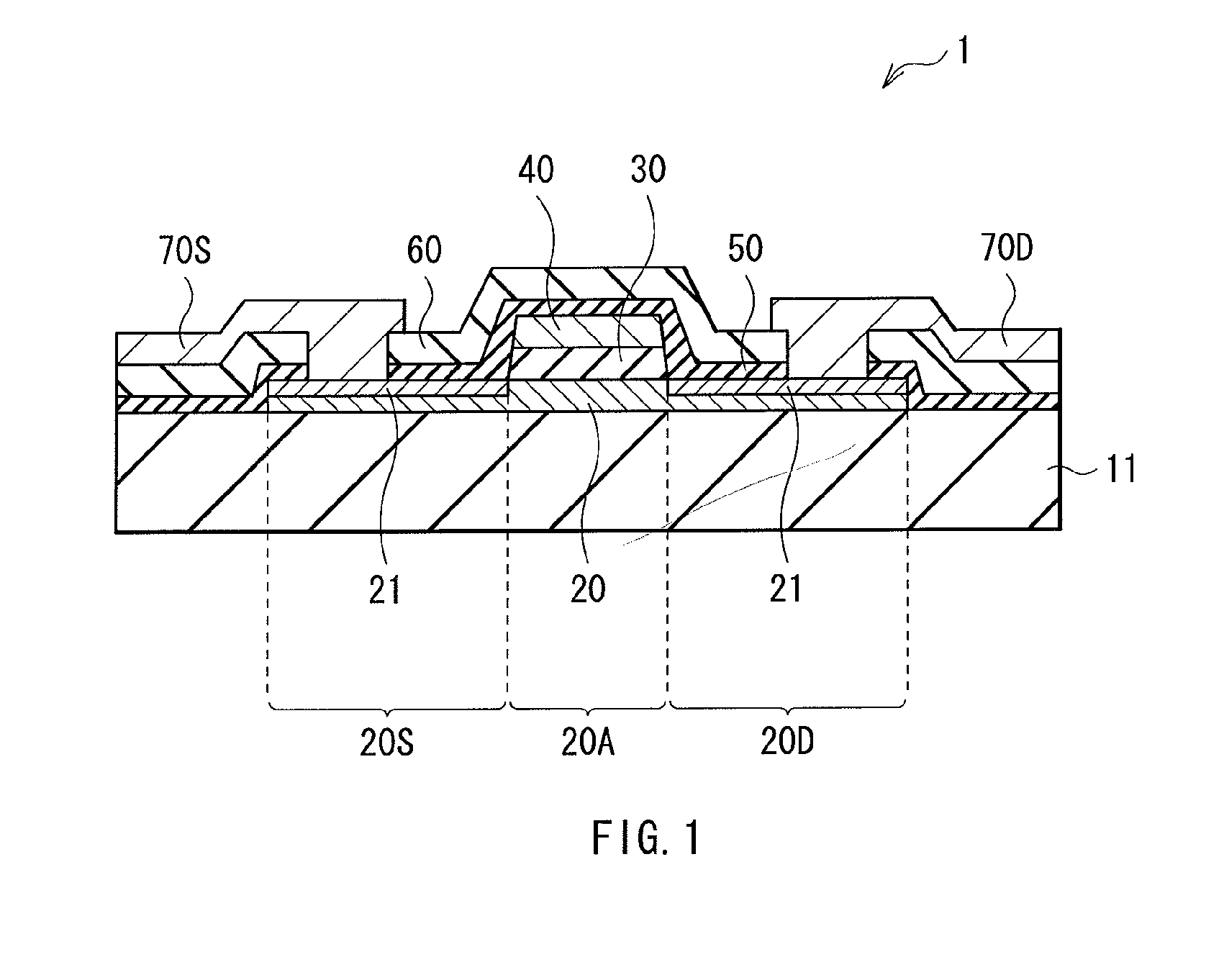

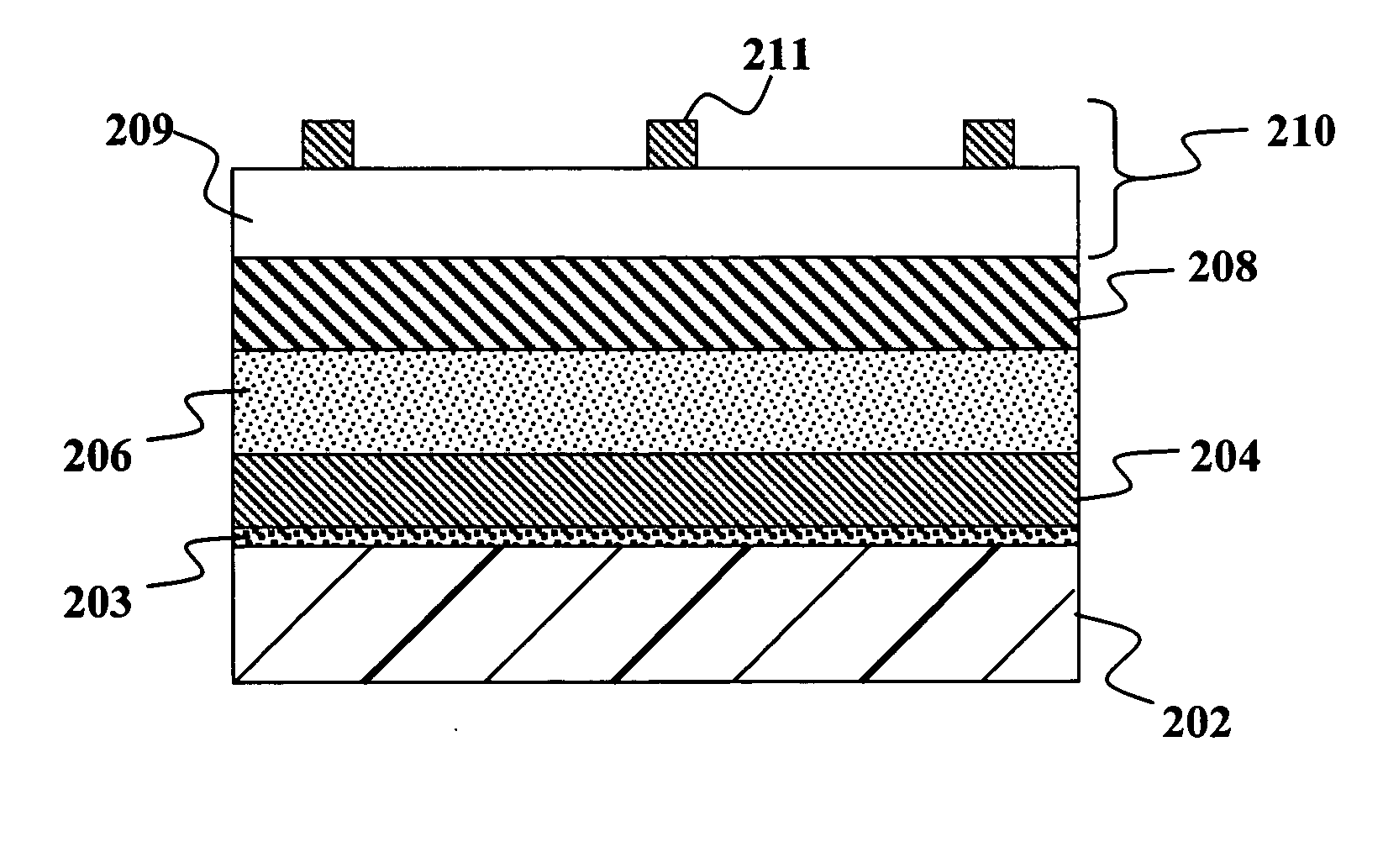

Thin film transistor, display device, including the same, and associated methods

InactiveUS8058645B2Excellent electrical propertiesMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingIndiumDisplay device

A thin film transistor (TFT), including a substrate, a gate electrode on the substrate, an oxide semiconductor layer including a channel region, a source region, and a drain region, a gate insulating layer between the gate electrode and the oxide semiconductor layer, and source and drain electrodes in contact with the source and drain regions of the oxide semiconductor layer, respectively, wherein the oxide semiconductor layer has a GaInZnO (GIZO) bilayer structure including a lower layer and an upper layer, and the upper layer has a different indium (In) concentration than the lower layer.

Owner:SAMSUNG DISPLAY CO LTD

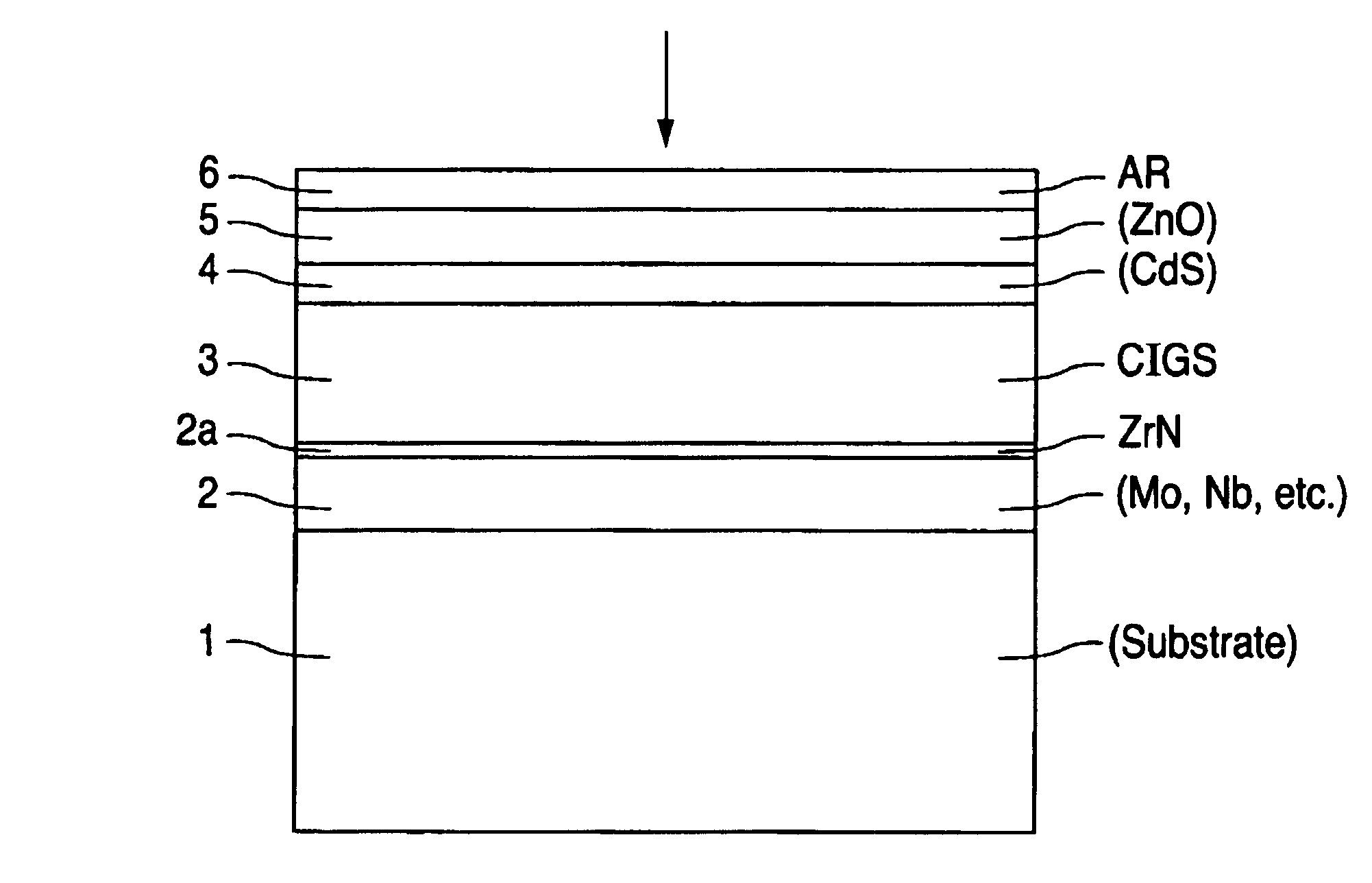

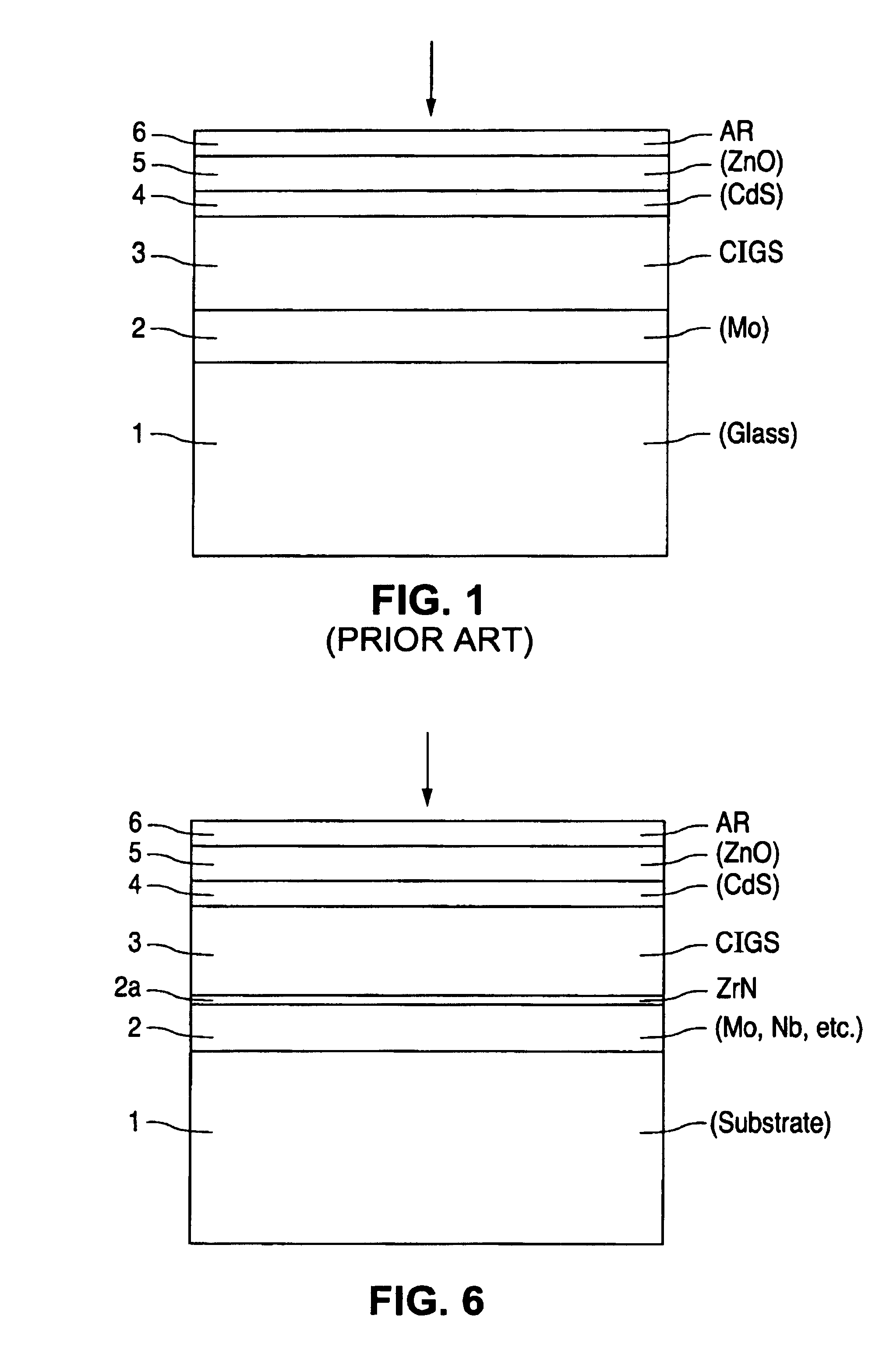

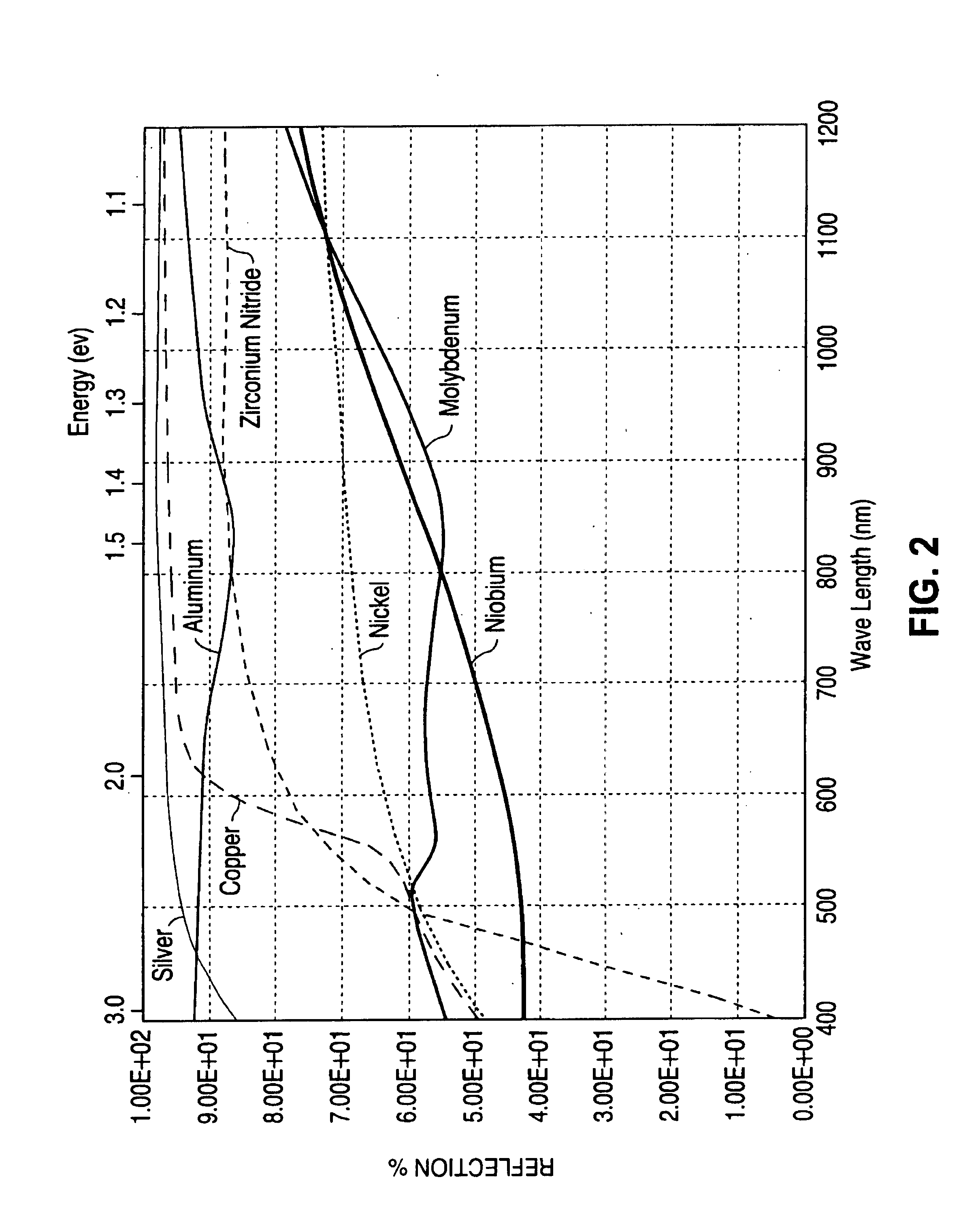

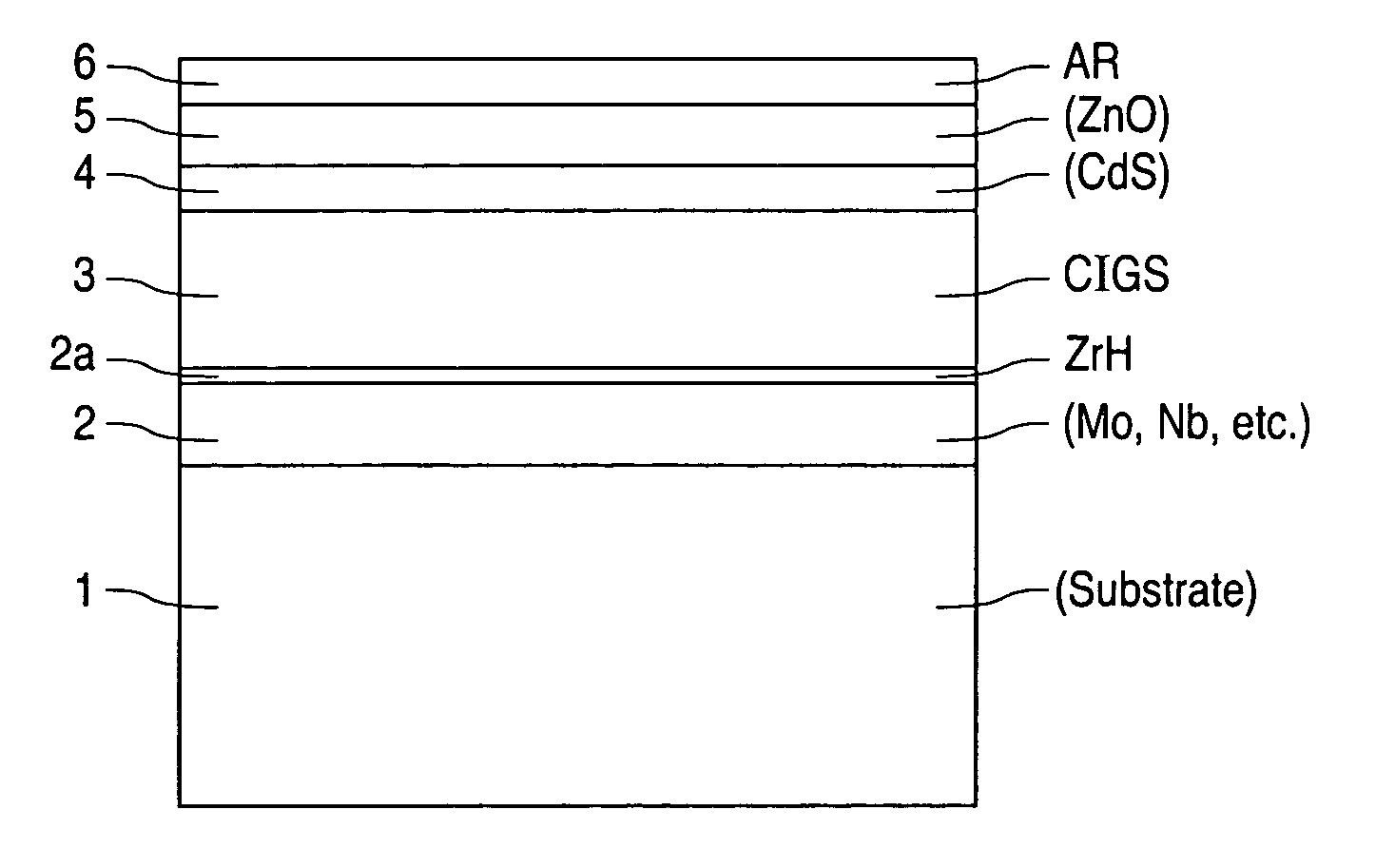

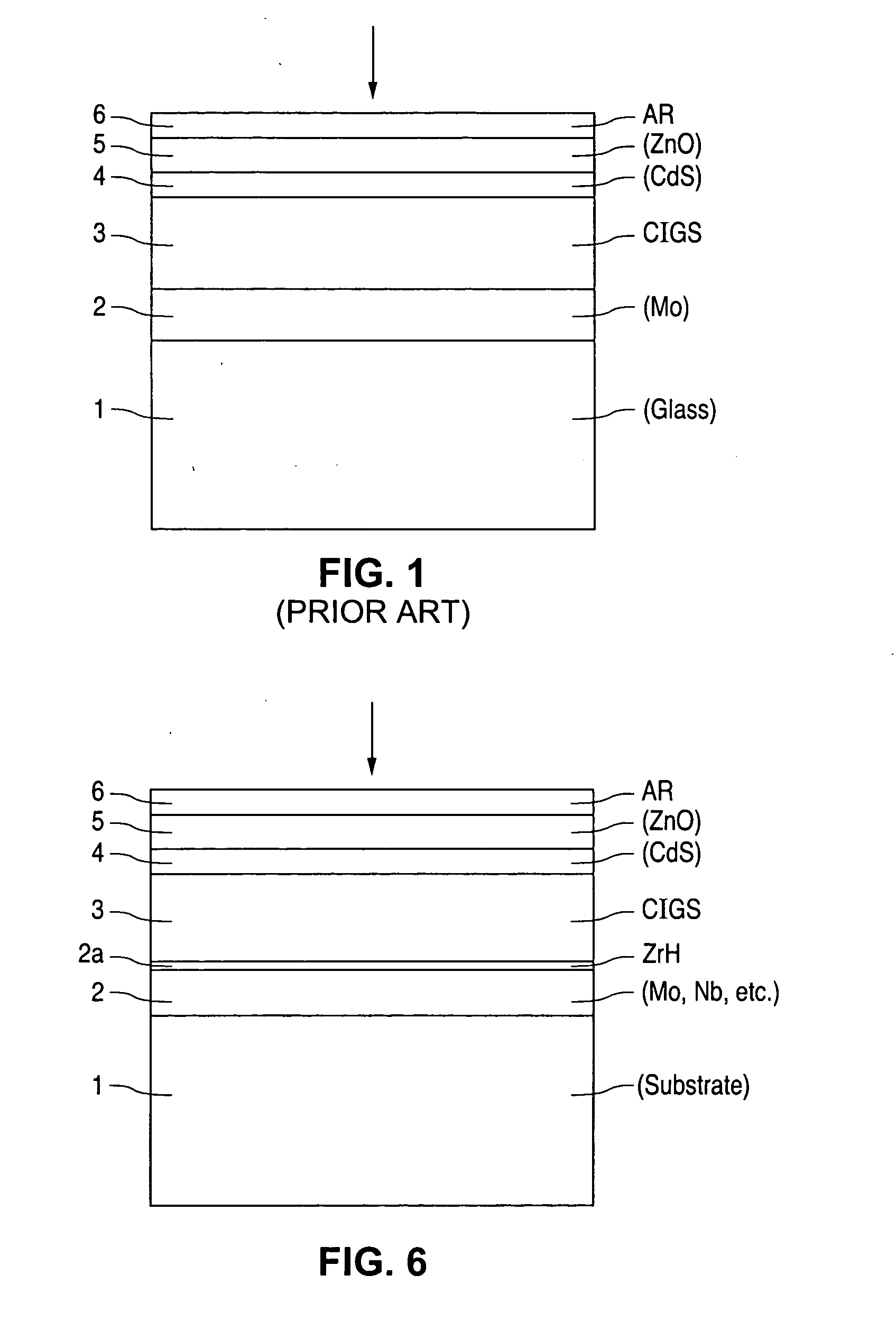

Thin-film solar cells

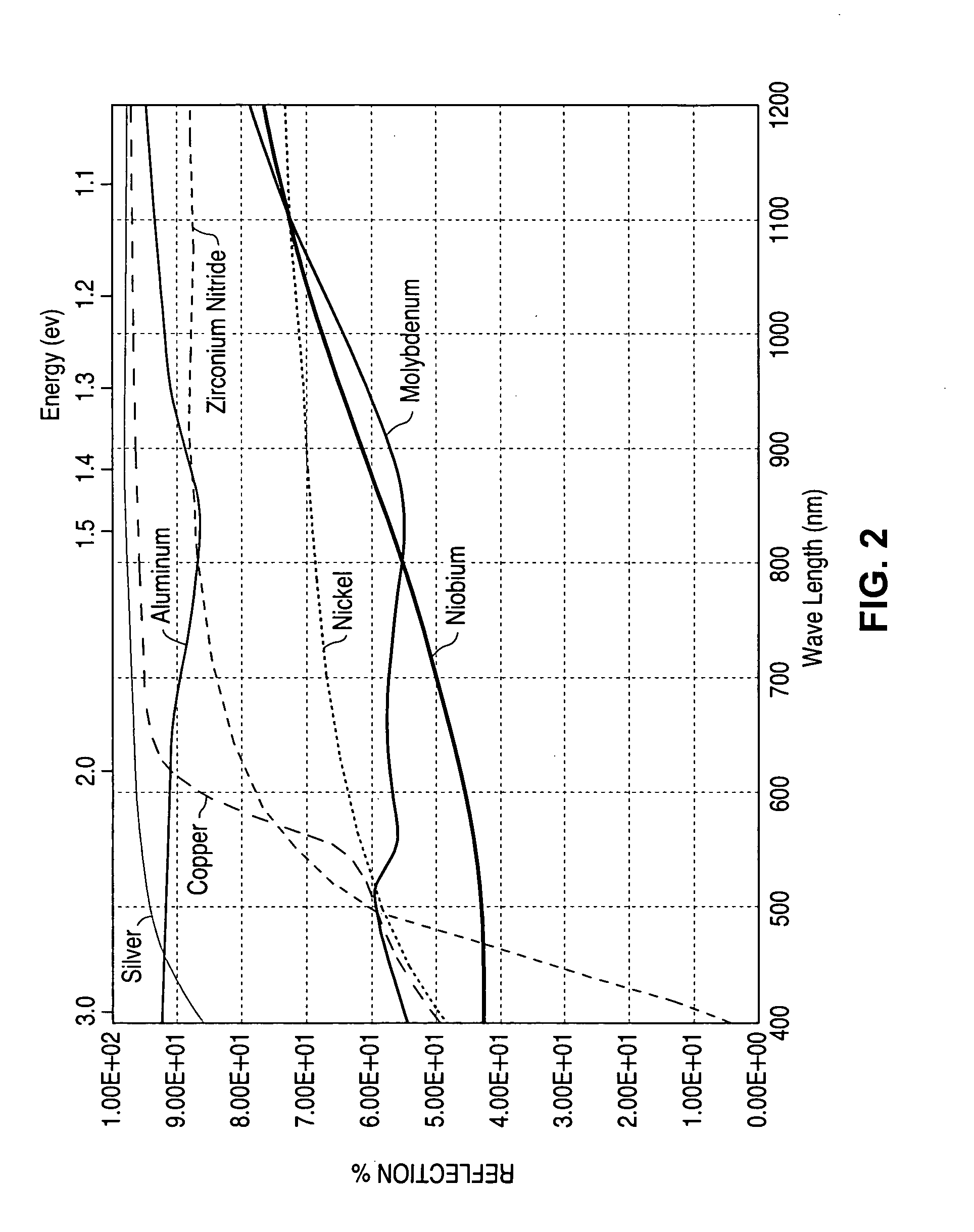

InactiveUS6974976B2Increase reflectionInhibition formationFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1−X)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

Method for achieving improved epitaxy quality (surface texture and defect density) on free-standing (aluminum, indium, gallium) nitride ((al,in,ga)n) substrates for opto-electronic and electronic devices

A III-V nitride homoepitaxial microelectronic device structure comprising a III-V nitride homoepitaxial epi layer on a III-V nitride material substrate, e.g., of freestanding character. Various processing techniques are described, including a method of forming a III-V nitride homoepitaxial layer on a corresponding III-V nitride material substrate, by depositing the III-V nitride homoepitaxial layer by a VPE process using Group III source material and nitrogen source material under process conditions including V / III ratio in a range of from about 1 to about 105, nitrogen source material partial pressure in a range of from about 1 to about 103 torr, growth temperature in a range of from about 500 to about 1250 degrees Celsius, and growth rate in a range of from about 0.1 to about 500 microns per hour. The III-V nitride homoepitaxial microelectronic device structures are usefully employed in device applications such as UV LEDs, high electron mobility transistors, and the like.

Owner:WOLFSPEED INC

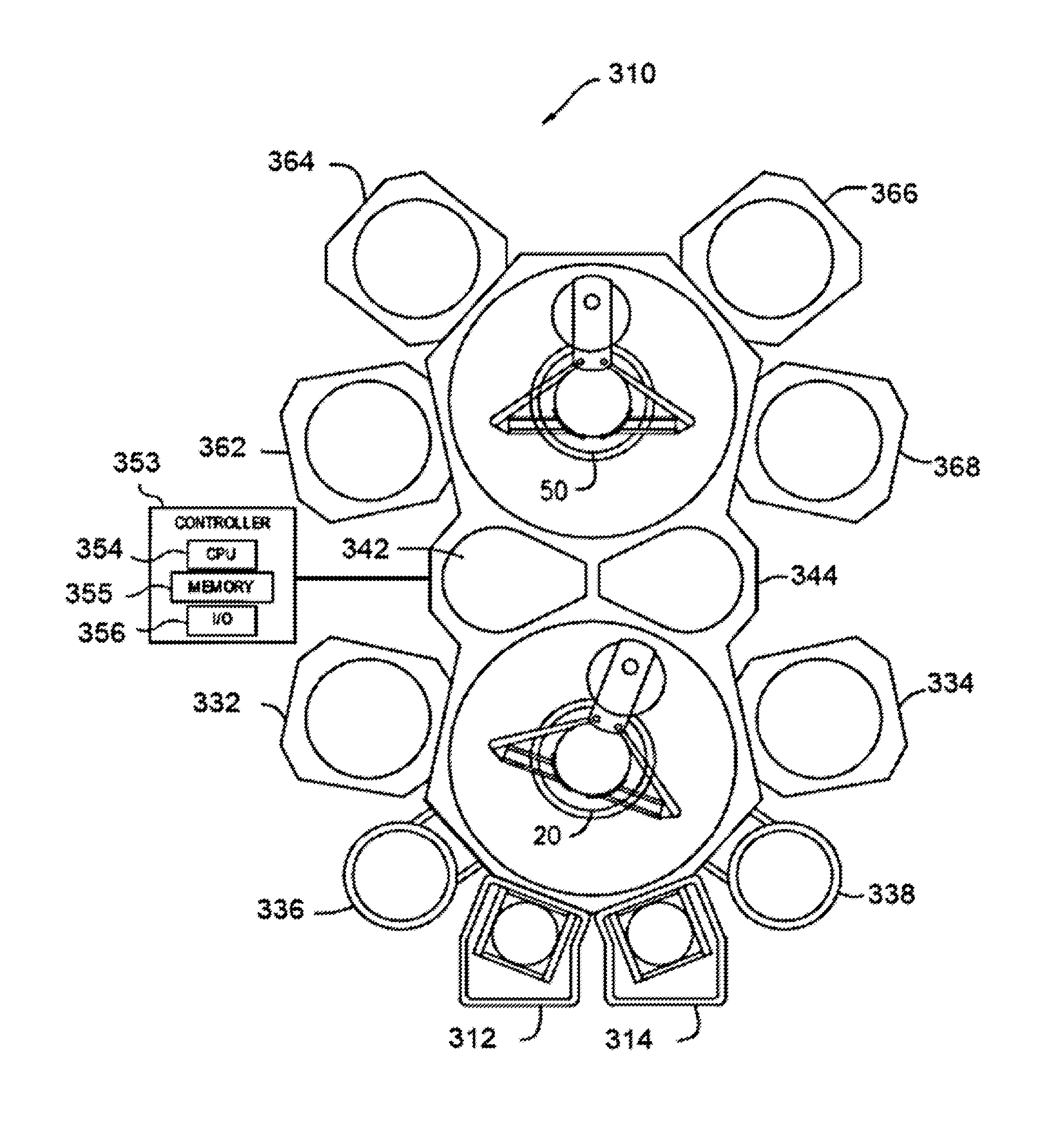

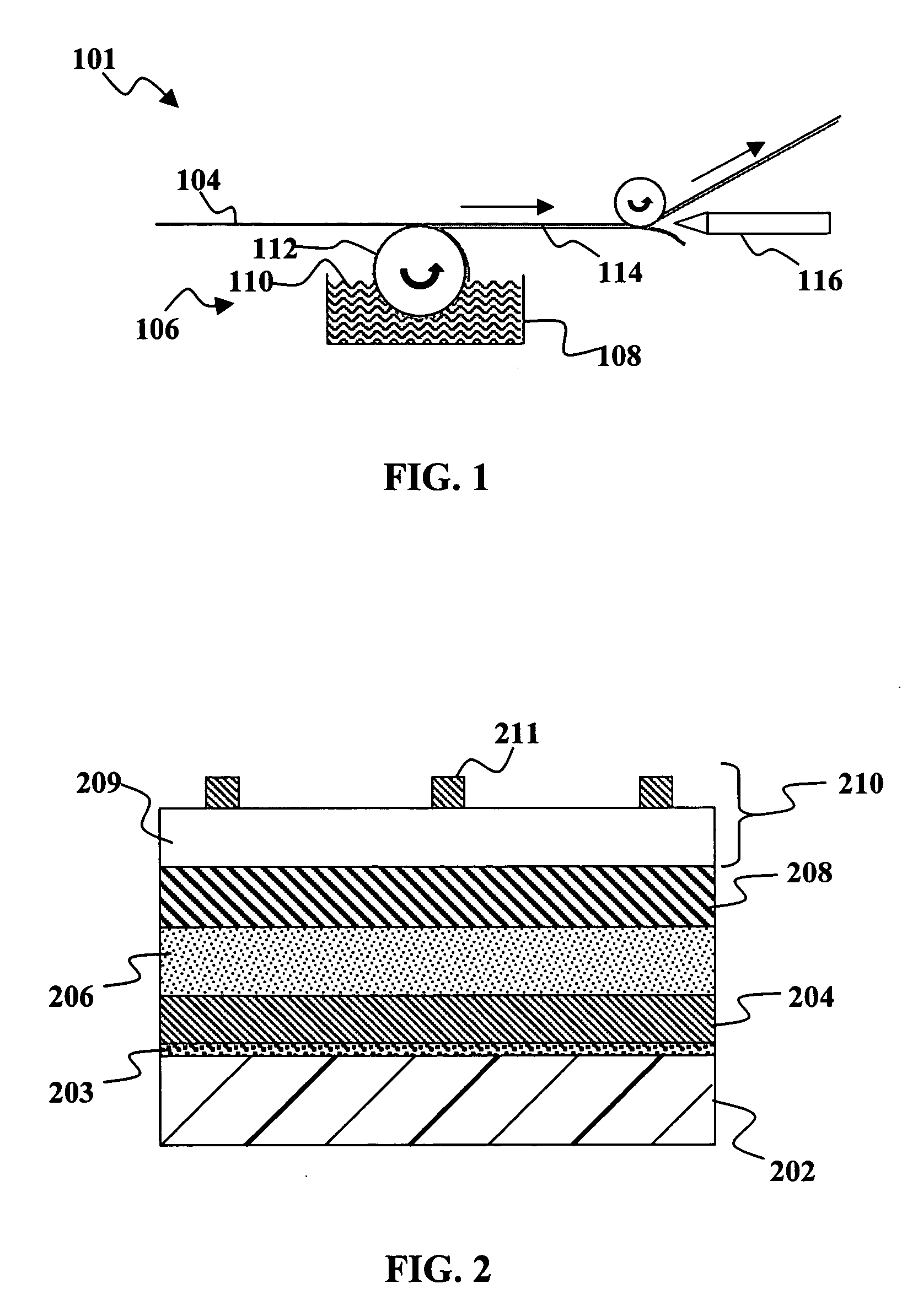

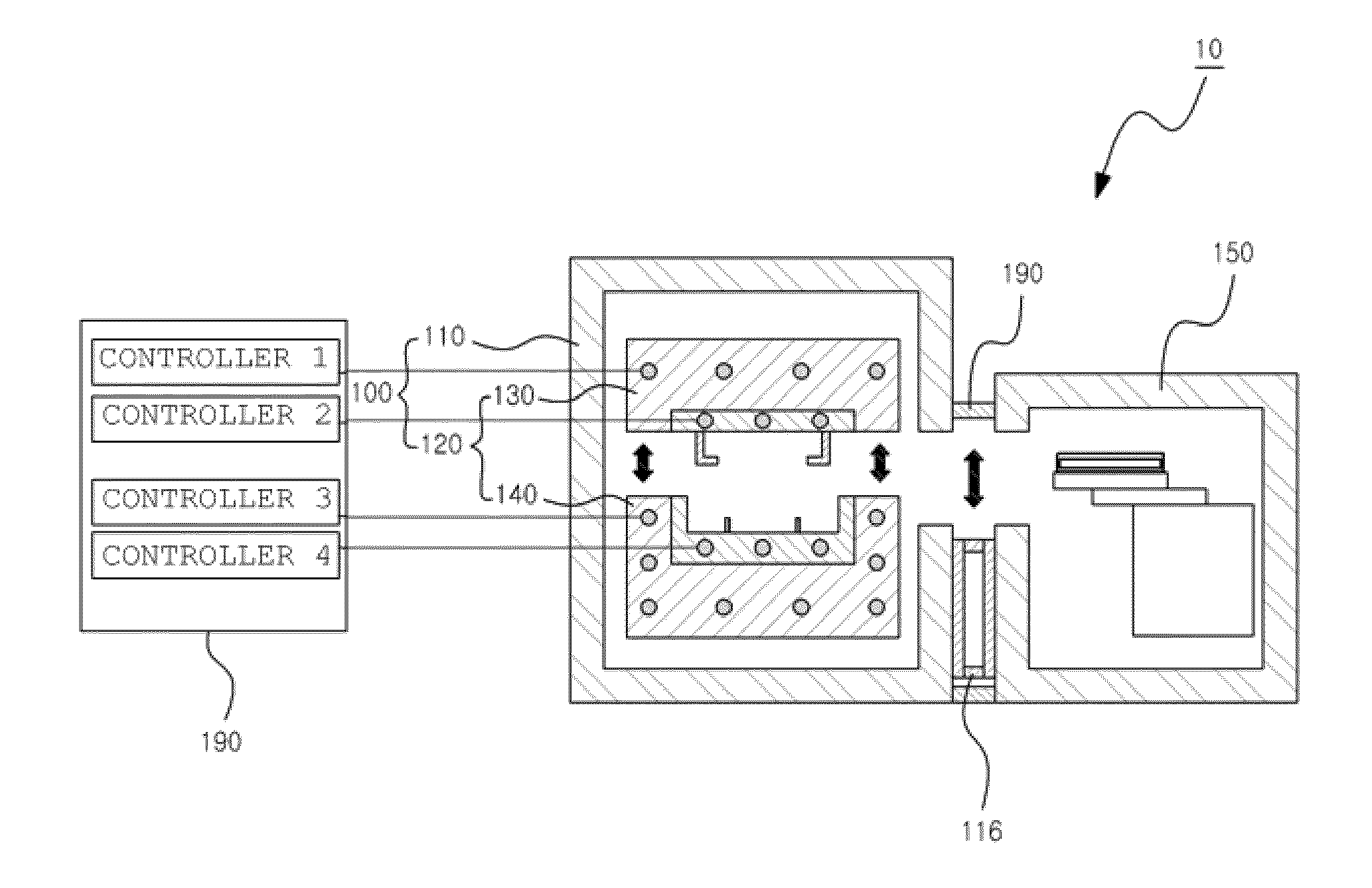

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

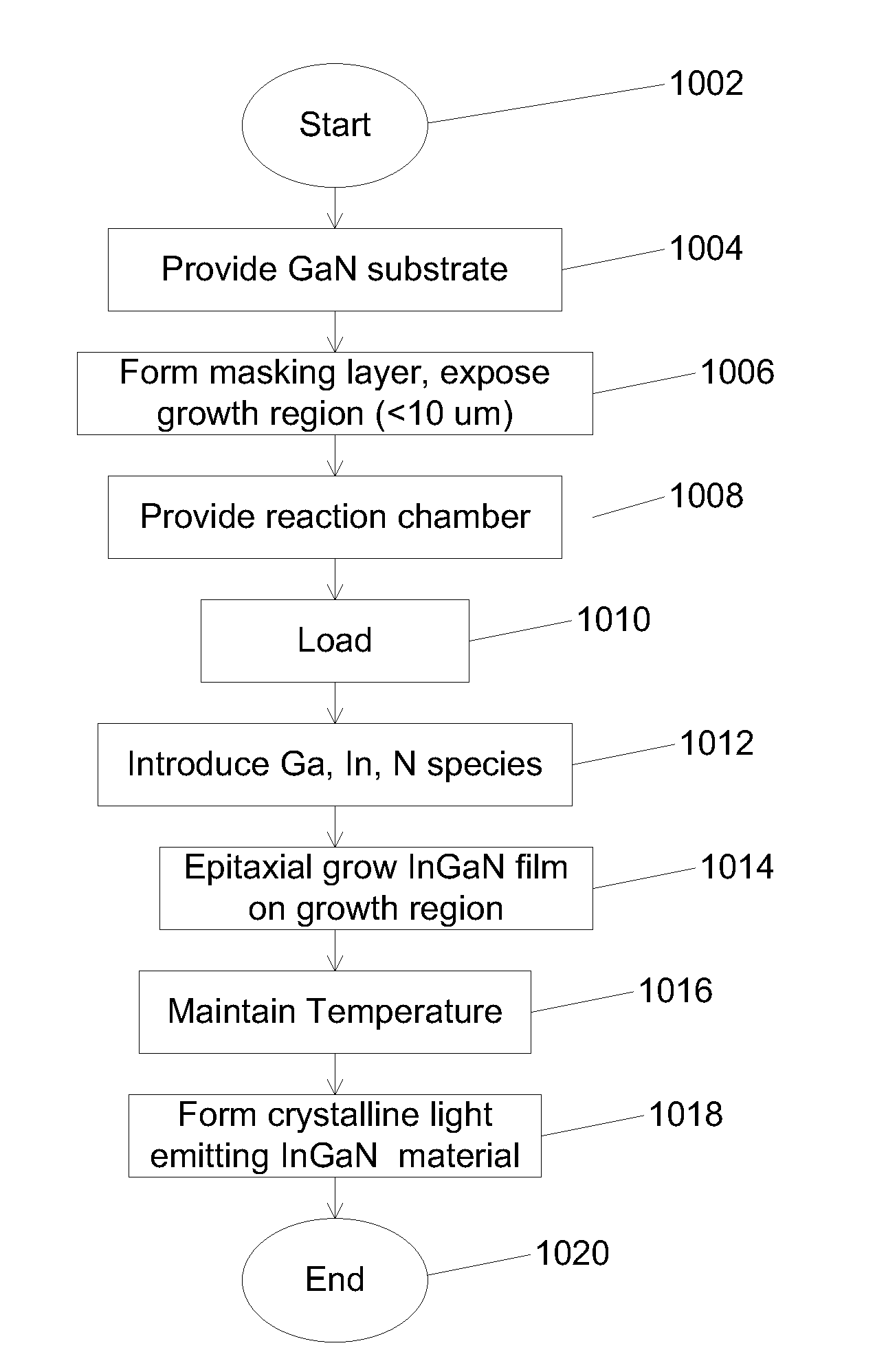

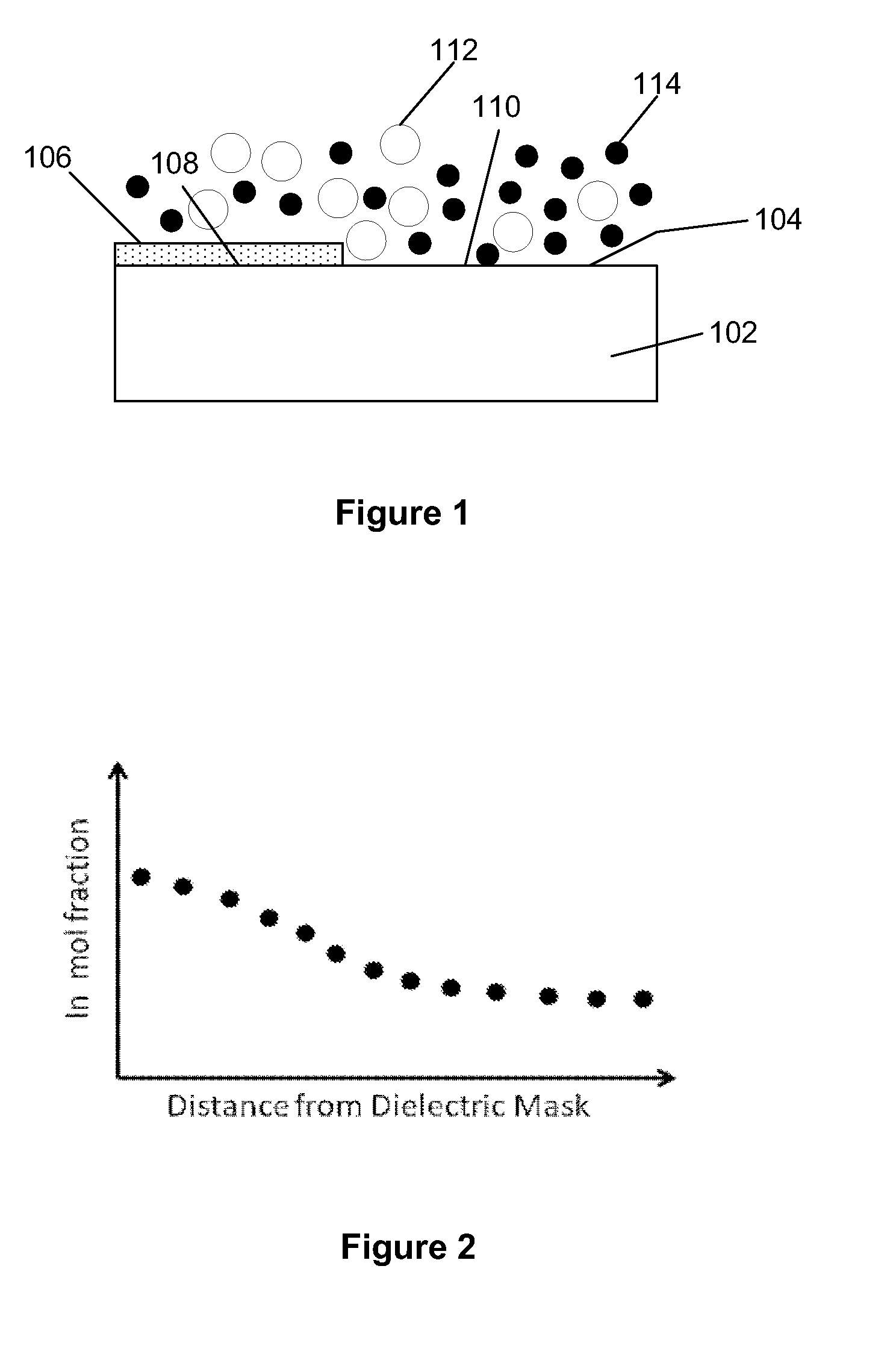

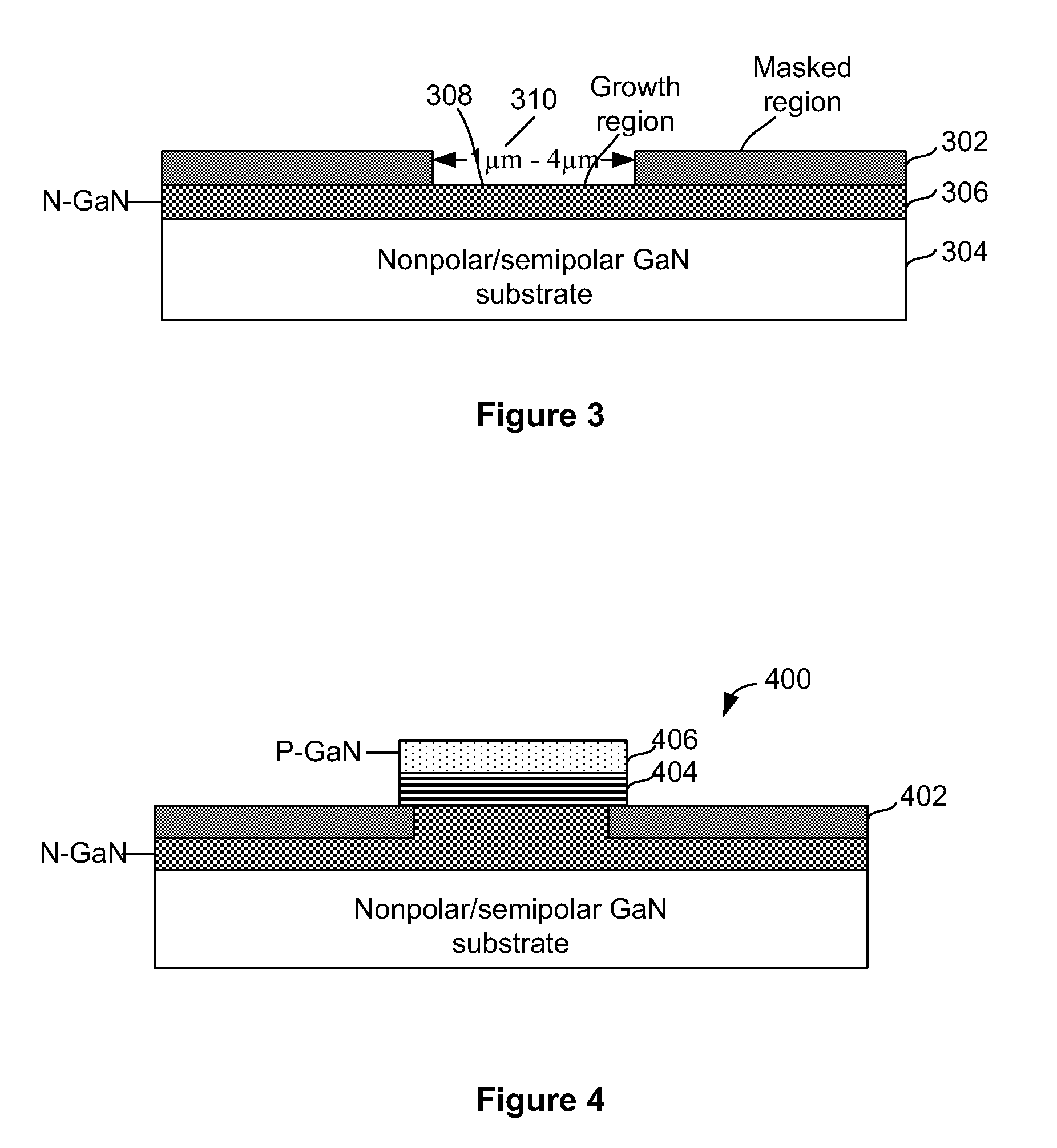

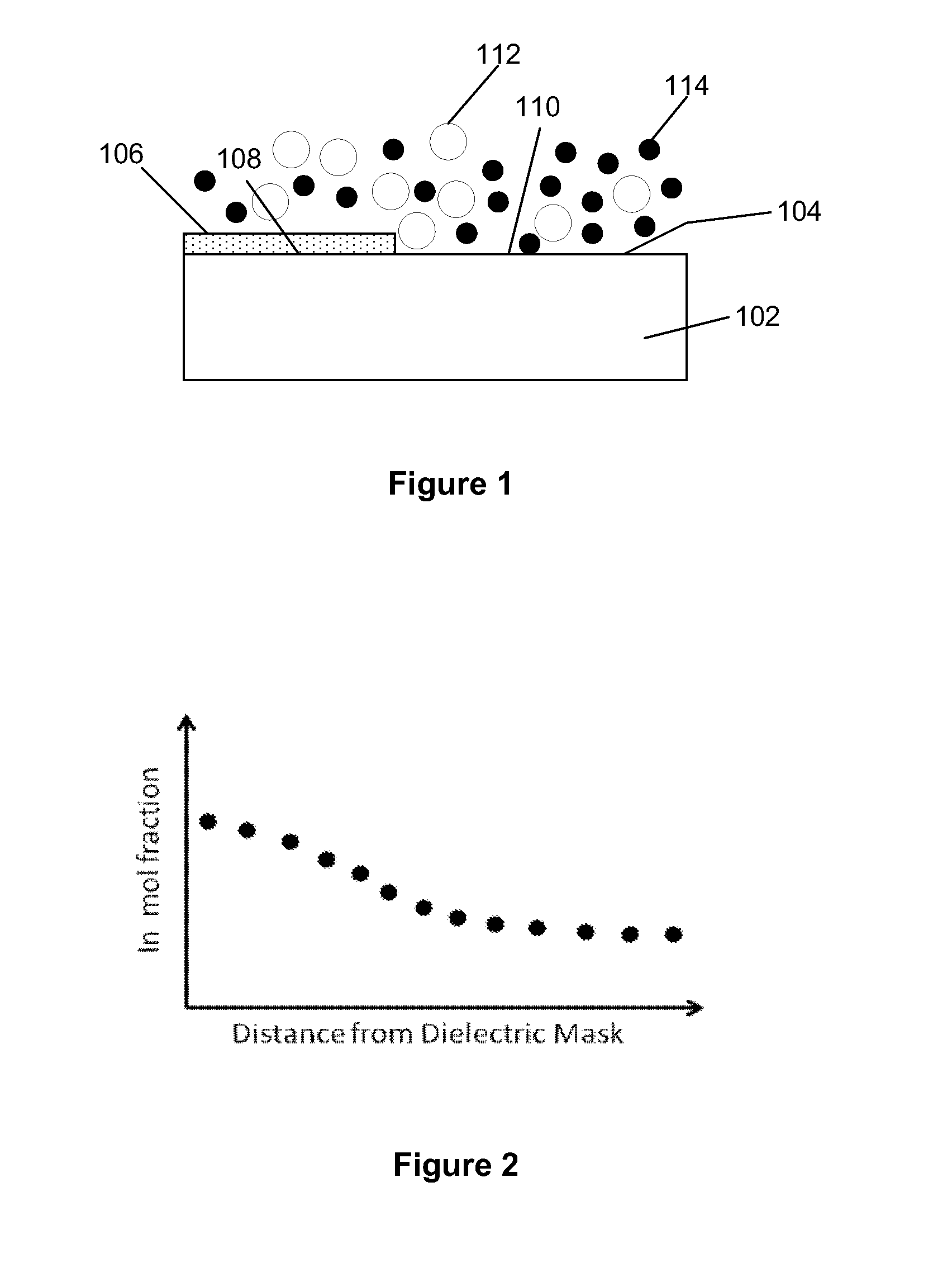

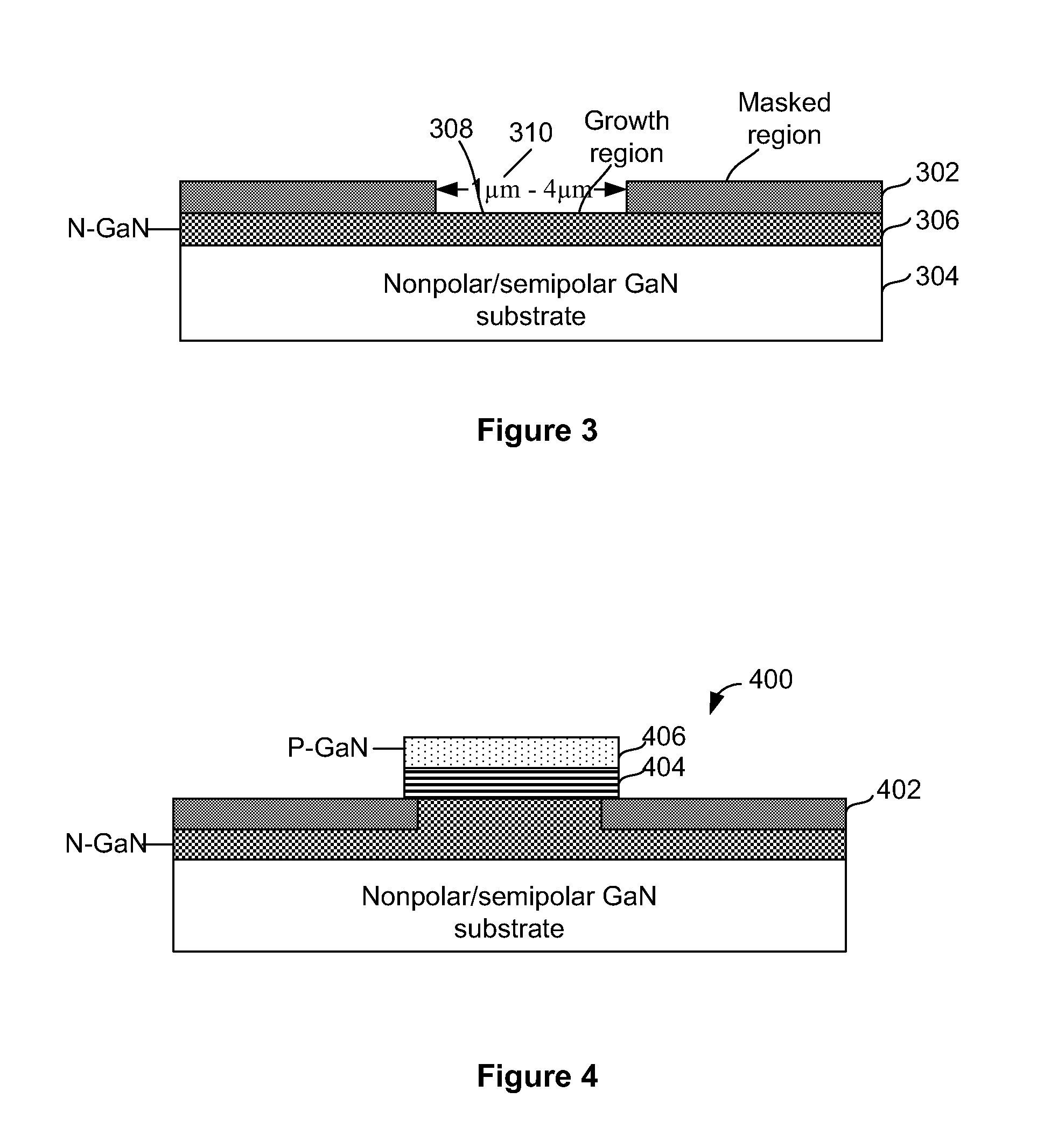

Selective area epitaxy growth method and structure for multi-colored devices

InactiveUS20090309110A1Improve the level ofImprove surface mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesIndiumSelective area epitaxy

A multicolored LED device made of a semipolar material having different indium containing regions provided on different spatial features of GaN material. Other materials such as non-polar materials can also be used.

Owner:SLT TECH

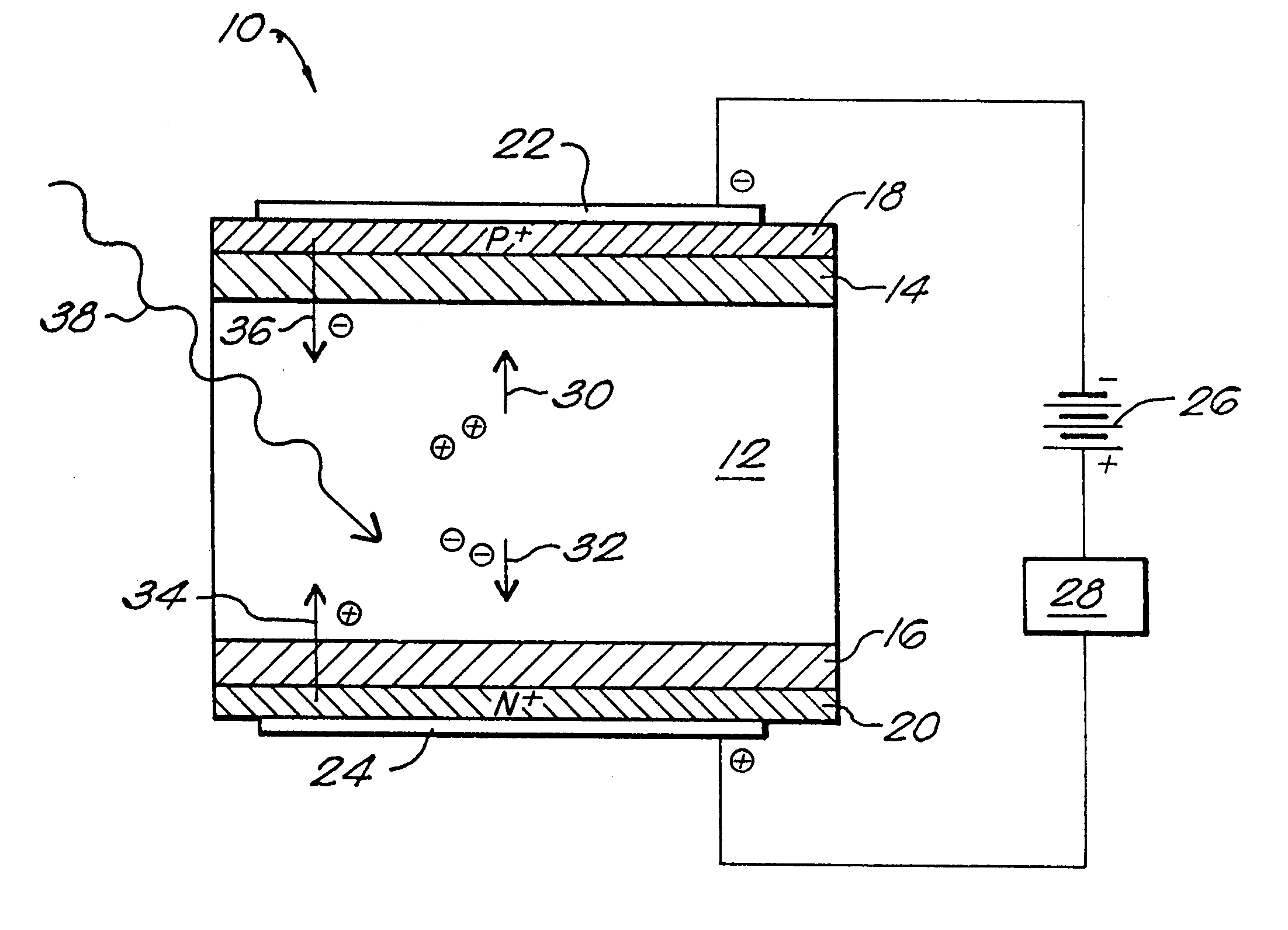

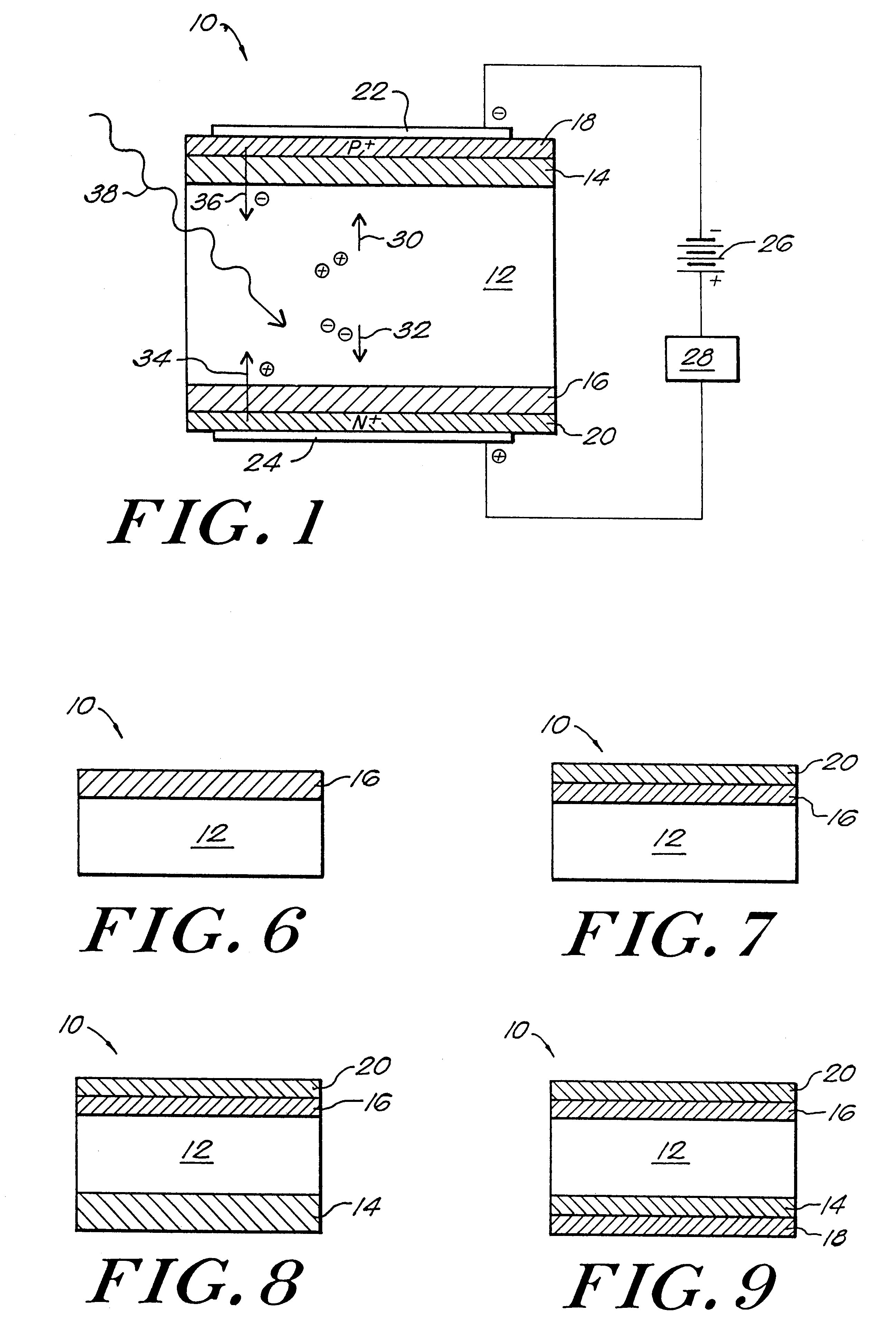

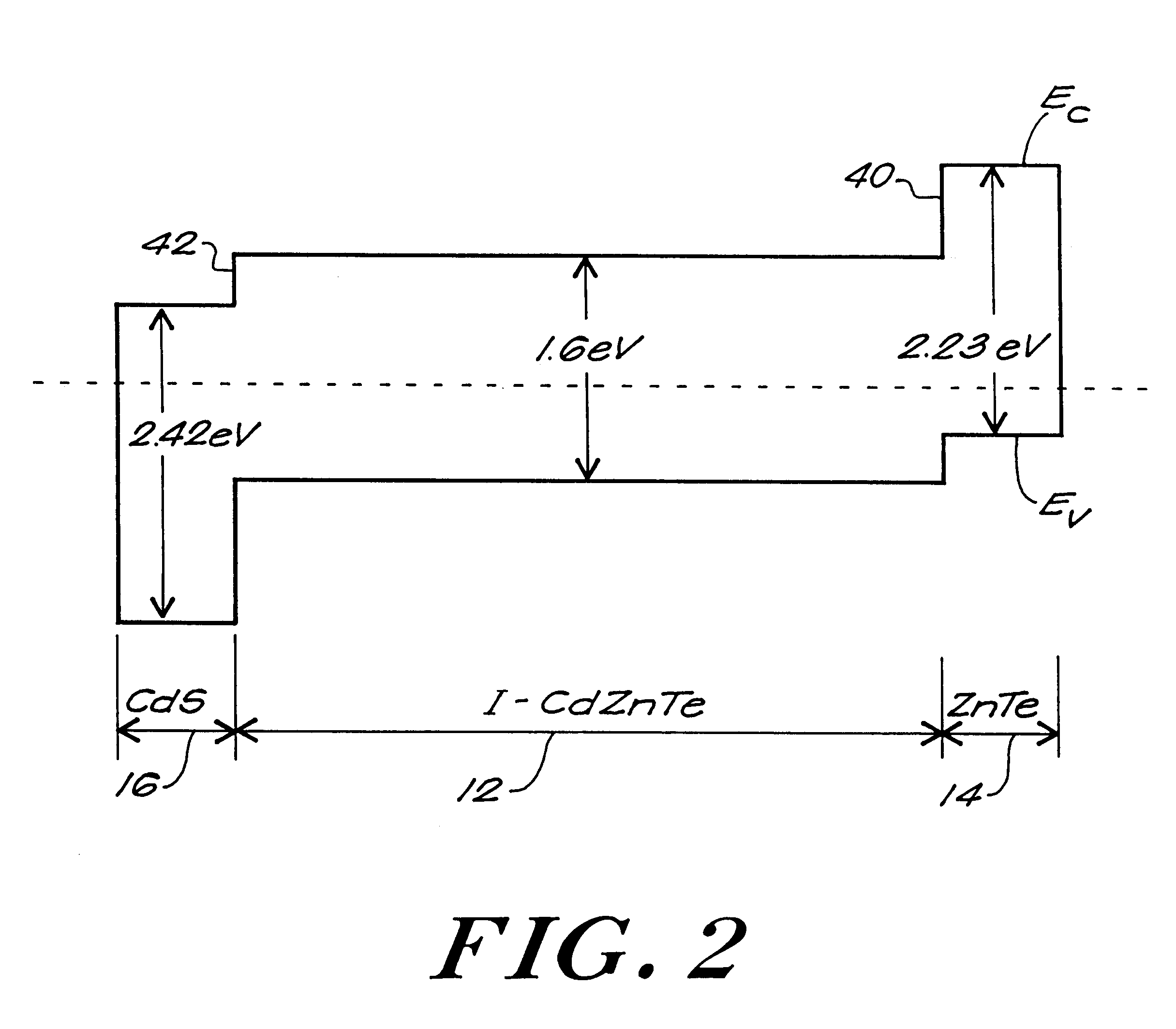

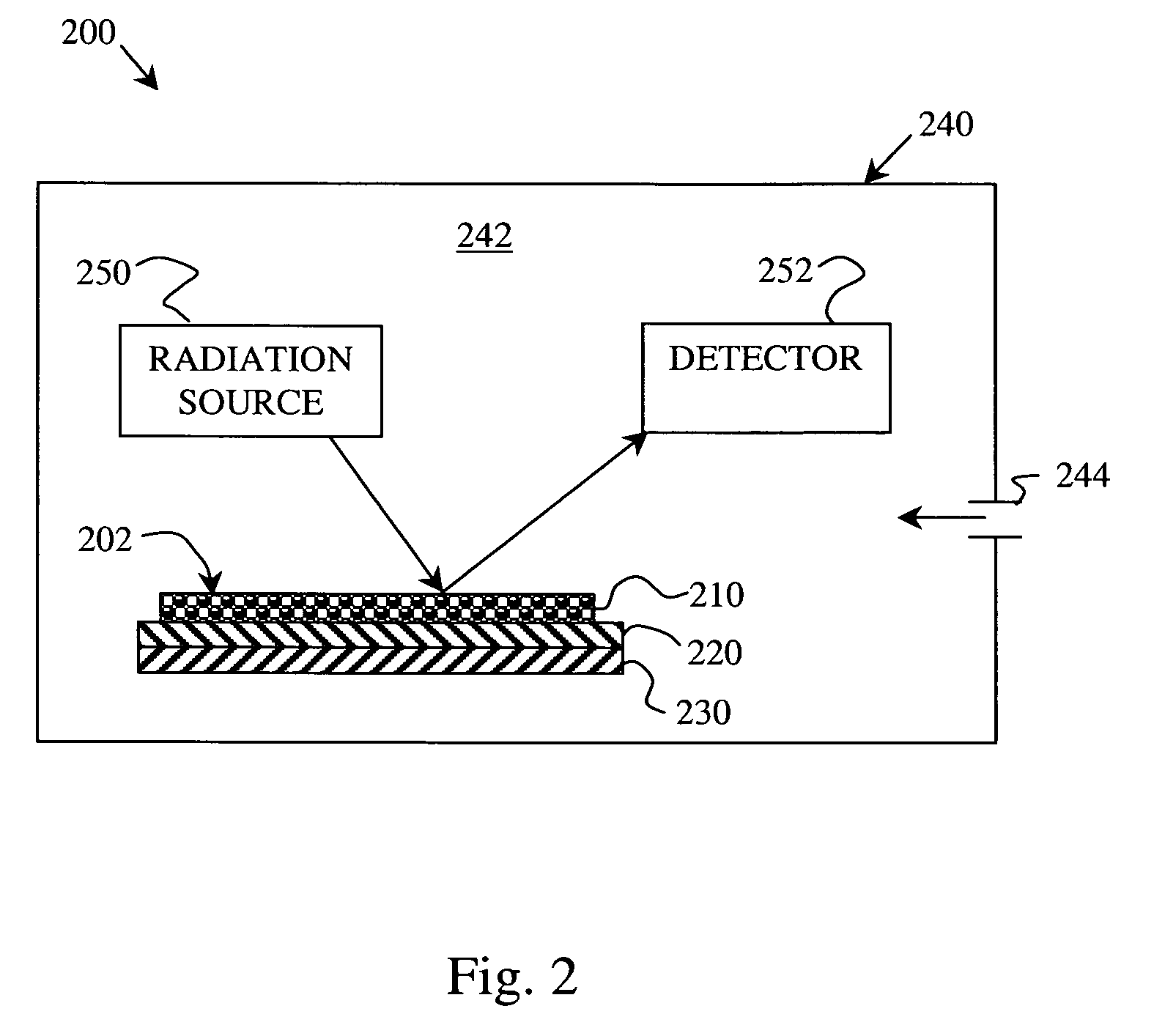

Semiconductor P-I-N detector

InactiveUS6255708B1Reduce leakage currentMitigating dopant diffusionSolid-state devicesSemiconductor/solid-state device manufacturingDopantIndium

A semiconductor P-I-N detector including an intrinsic wafer, a P-doped layer, an N-doped layer, and a boundary layer for reducing the diffusion of dopants into the intrinsic wafer. The boundary layer is positioned between one of the doped regions and the intrinsic wafer. The intrinsic wafer can be composed of CdZnTe or CdTe, the P-doped layer can be composed of ZnTe doped with copper, and the N-doped layer can be composed of CdS doped with indium. The boundary layers is formed of an undoped semiconductor material. The boundary layer can be deposited onto the underlying intrinsic wafer. The doped regions are then typically formed by a deposition process or by doping a section of the deposited boundary layer.

Owner:MASIMO SEMICON +2

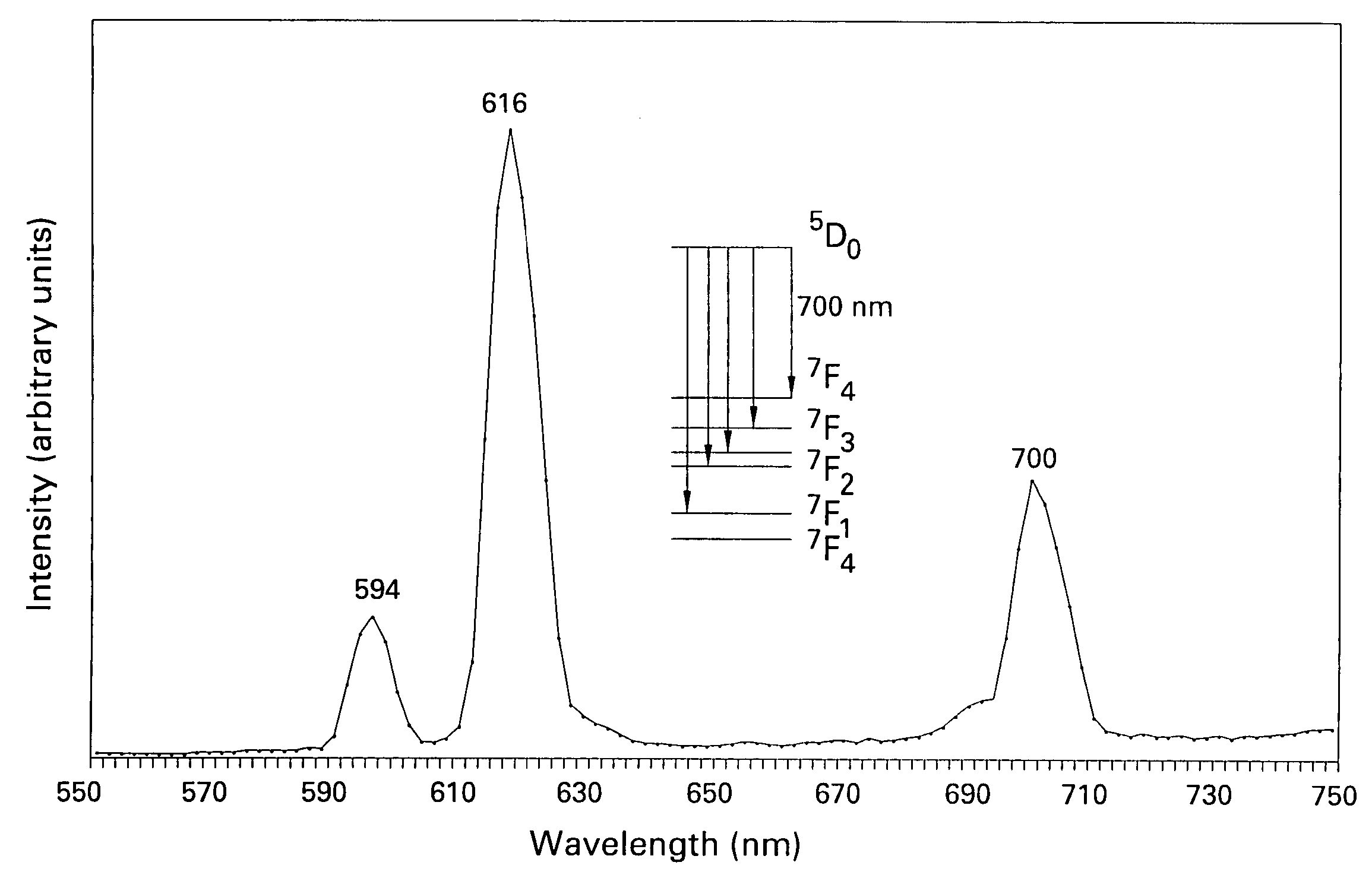

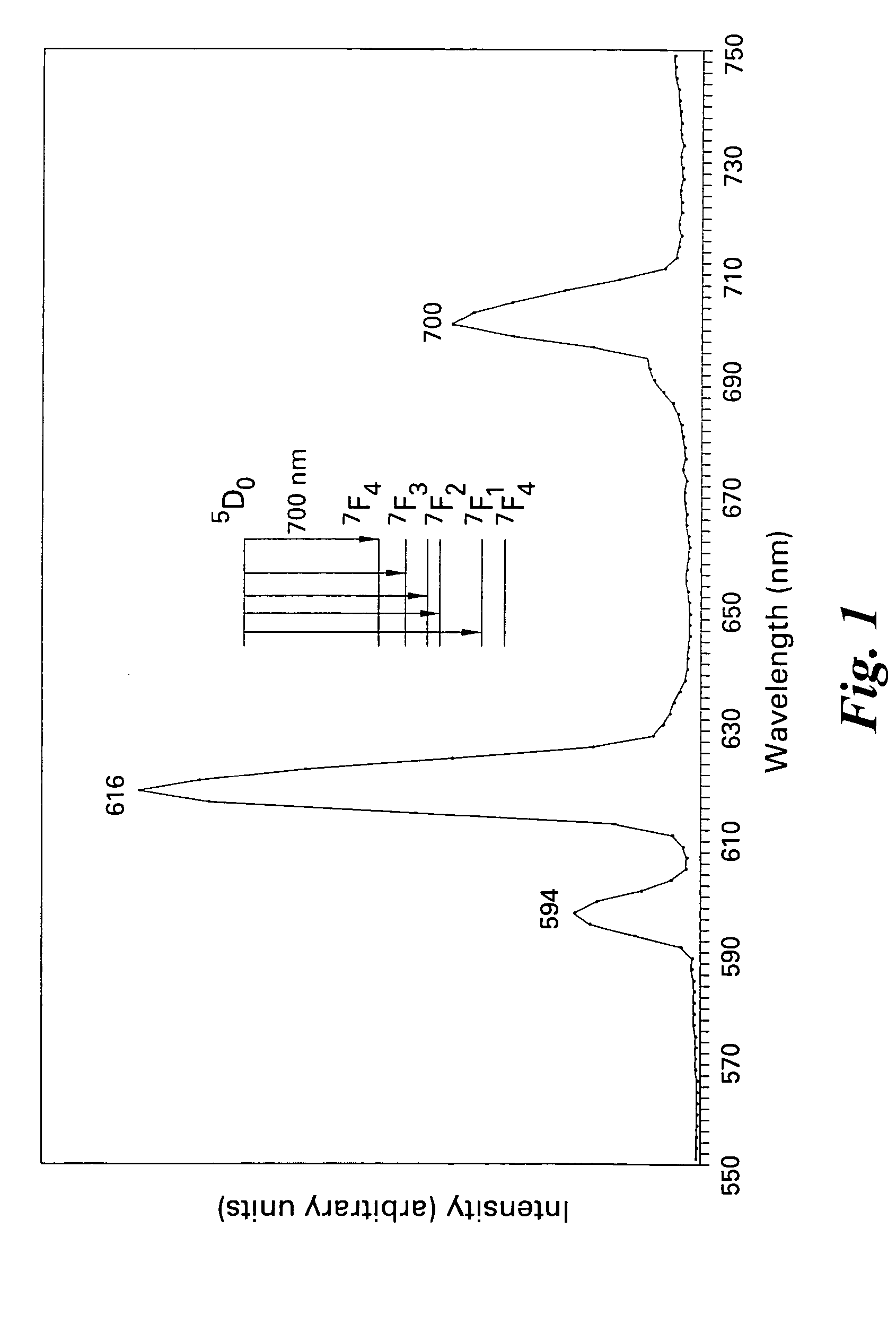

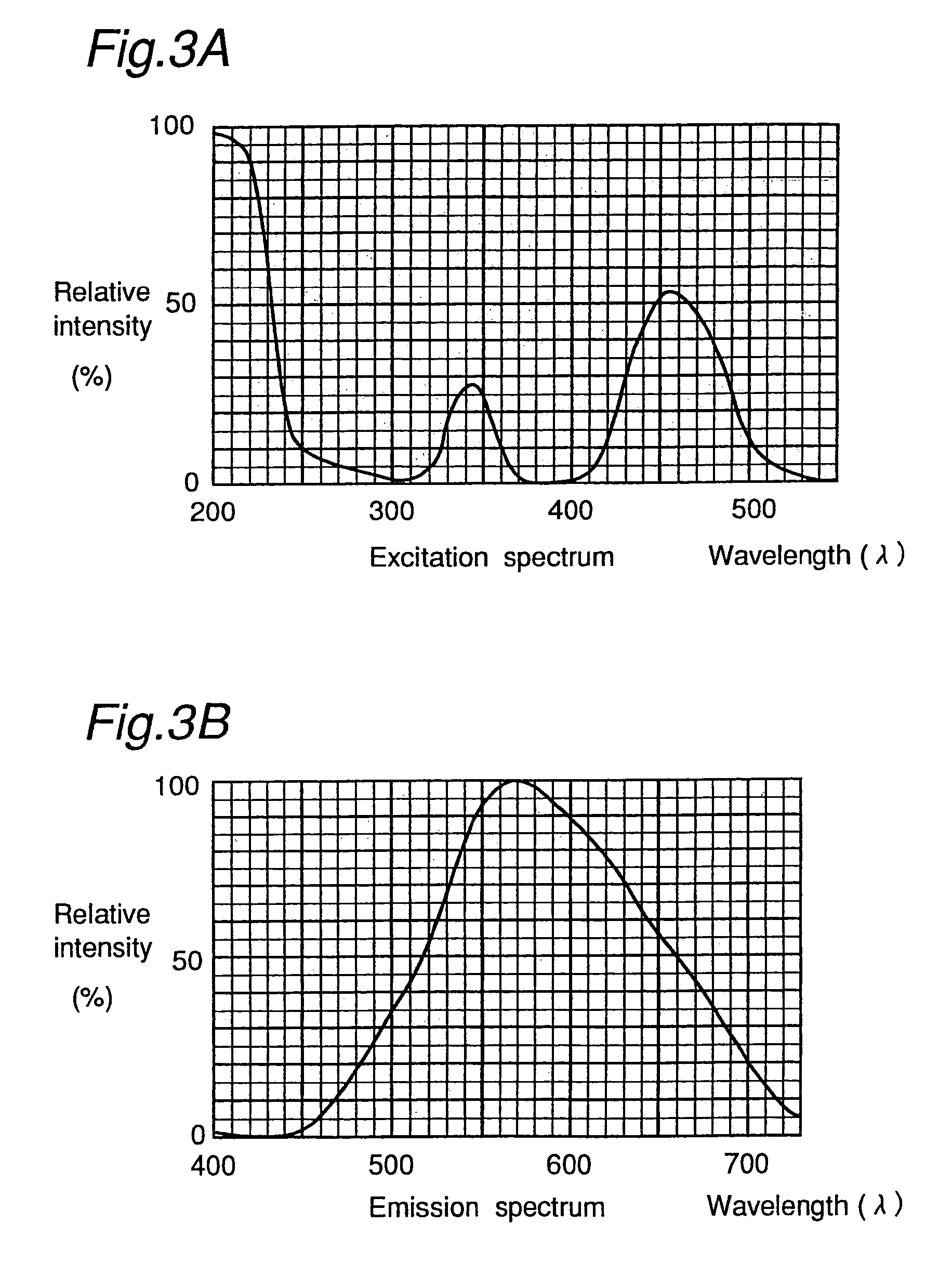

Phosphors containing boron and metals of Group IIIA and IIIB

A phosphor comprises: (a) at least a first metal selected from the group consisting of yttrium and elements of lanthanide series other than europium; (b) at least a second metal selected from the group consisting of aluminum, gallium, indium, and scandium; (c) boron; and (d) europium. The phosphor is used in light source that comprises a UV radiation source to convert UV radiation to visible light.

Owner:GENERAL ELECTRIC CO

Selective area epitaxy growth method and structure

InactiveUS20090309127A1Improve the level ofSmall sizePolycrystalline material growthNanoinformaticsIndiumPhotoluminescence

A gallium containing crystalline material. The material comprises a bulk semi-polar gallium indium containing crystalline material having a thickness of about 20 nanometers to about 1000 nanometers. The material includes a spatial width dimension of no greater than about 10 microns characterizing the thickness of the bulk semi-polar gallium indium containing crystalline material. The material includes a photoluminescent characteristic of the crystalline material having a first wavelength, which is at least five nanometers greater than a second wavelength, which is derived from an indium gallium containing crystalline material grown on a growth region of greater than about 15 microns.

Owner:SORAA +1

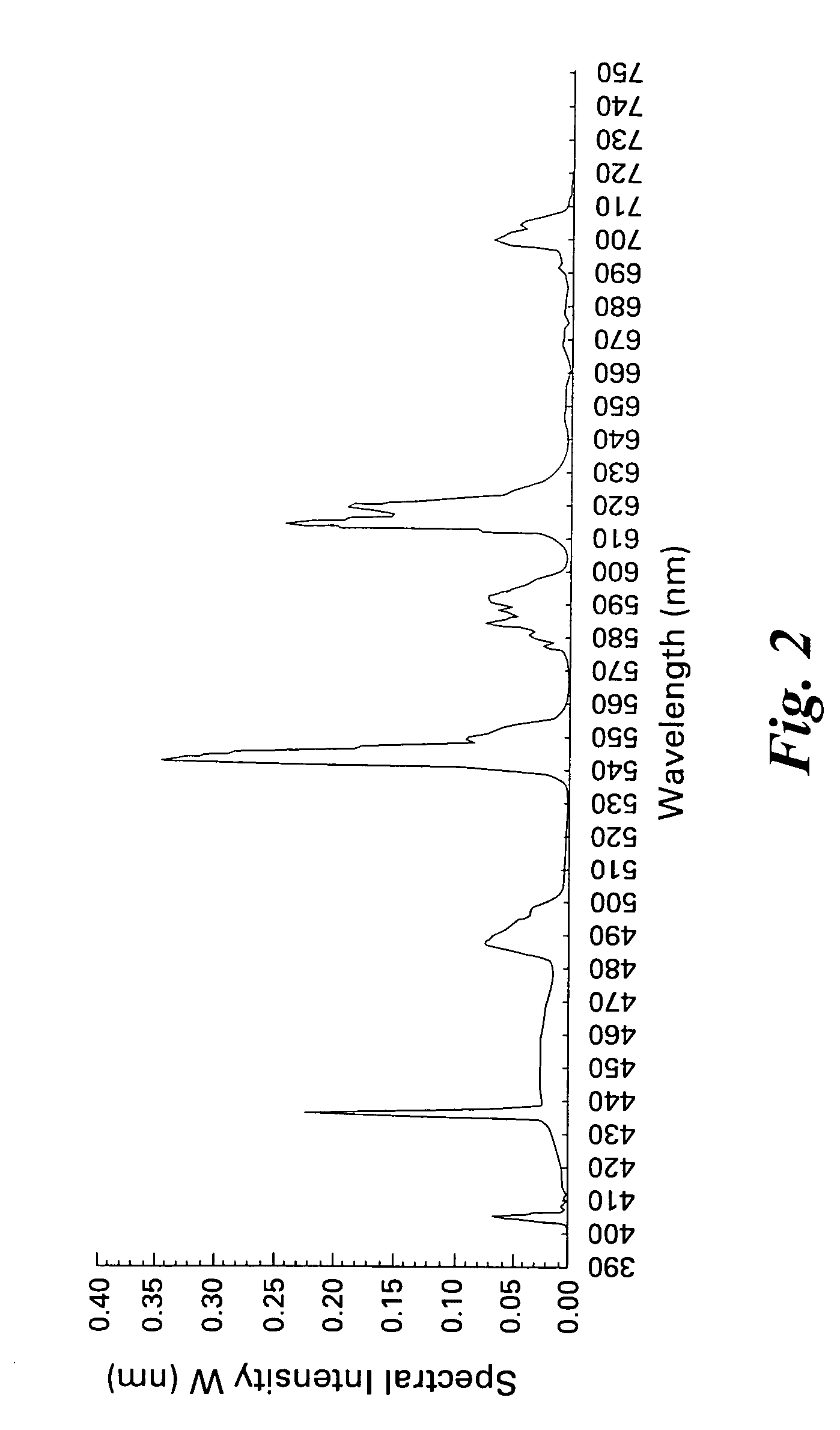

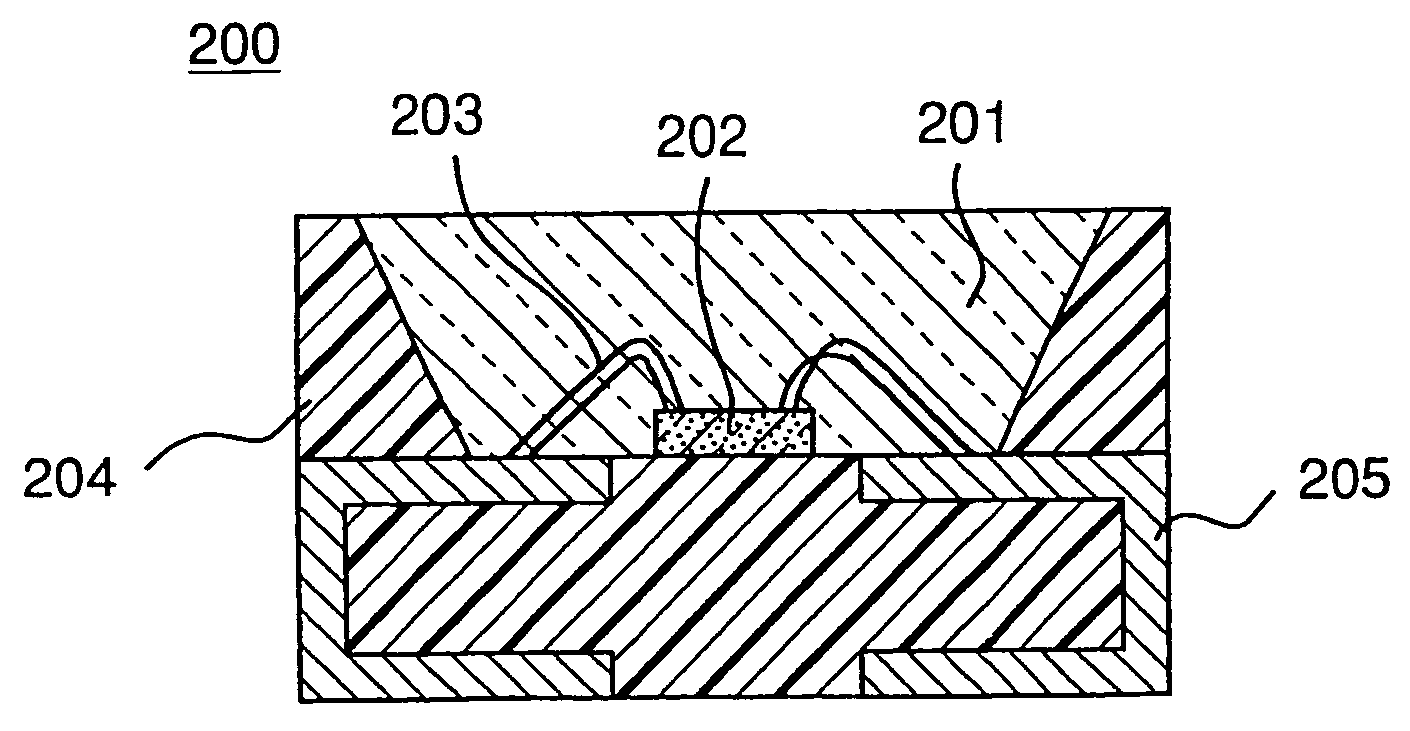

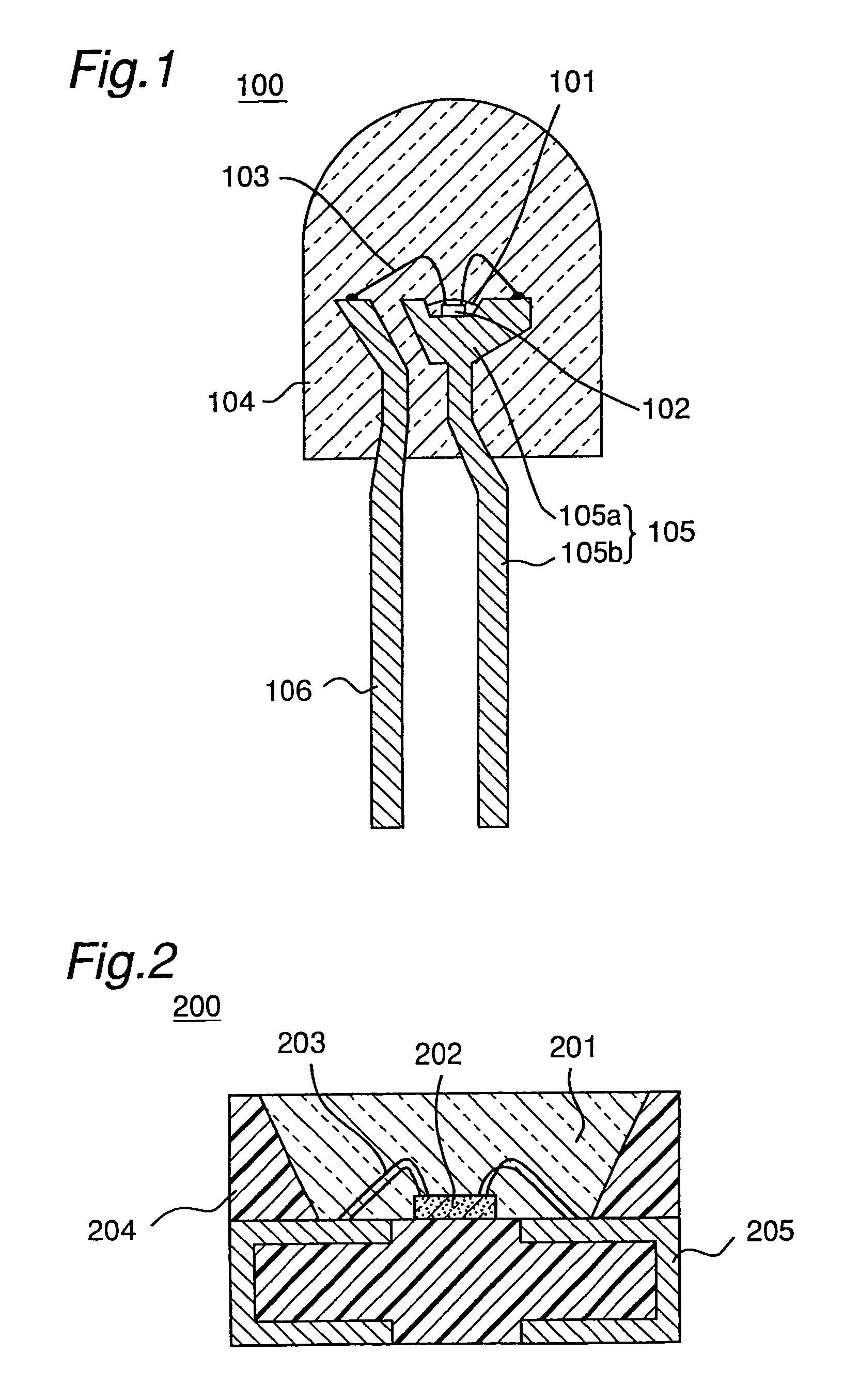

Light emitting device with blue light LED and phosphor components

InactiveUS7026756B2Low degree of deterioration in emission light intensityIncrease brightnessMechanical apparatusDischarge tube luminescnet screensIndiumPhosphor

A light emitting device includes a light emitting component having an active layer of a semiconductor and a phosphor capable of absorbing a part of light emitted from the light emitting component and emitting light of wavelength different from that of the absorbed light, wherein the light emitting component is a LED which has an active layer constituting a gallium nitride based semiconductor containing Indium and is capable of emitting a blue color light with a peak wavelength within the range from 420 to 490 nm. The phosphor is a garnet fluorescent material activated with cerium which is capable of absorbing a part of the blue color light and thereby emitting light having a broad emission spectrum with a peak wavelength existing around the range from 510 to 600 nm and a tail continuing into the region from 700 to 750 nm.

Owner:NICHIA CORP

Faceted structure, article, sensor device, and method

A faceted structure is provided that includes a crystalline composition comprising a metal nitride. The metal comprises one or more of aluminum, boron, indium, or gallium. The crystalline composition has at least one exposed surface that is a grain boundary, an etched surface, or a naturally formed facet, and the surface has the same crystallographic orientation of a substrate on which the crystalline composition is grown. A sensor device is provided that includes a faceted structure. Associated methods of making and using the faceted structure in a sensor device are provided.

Owner:MORPHO DETECTION INC

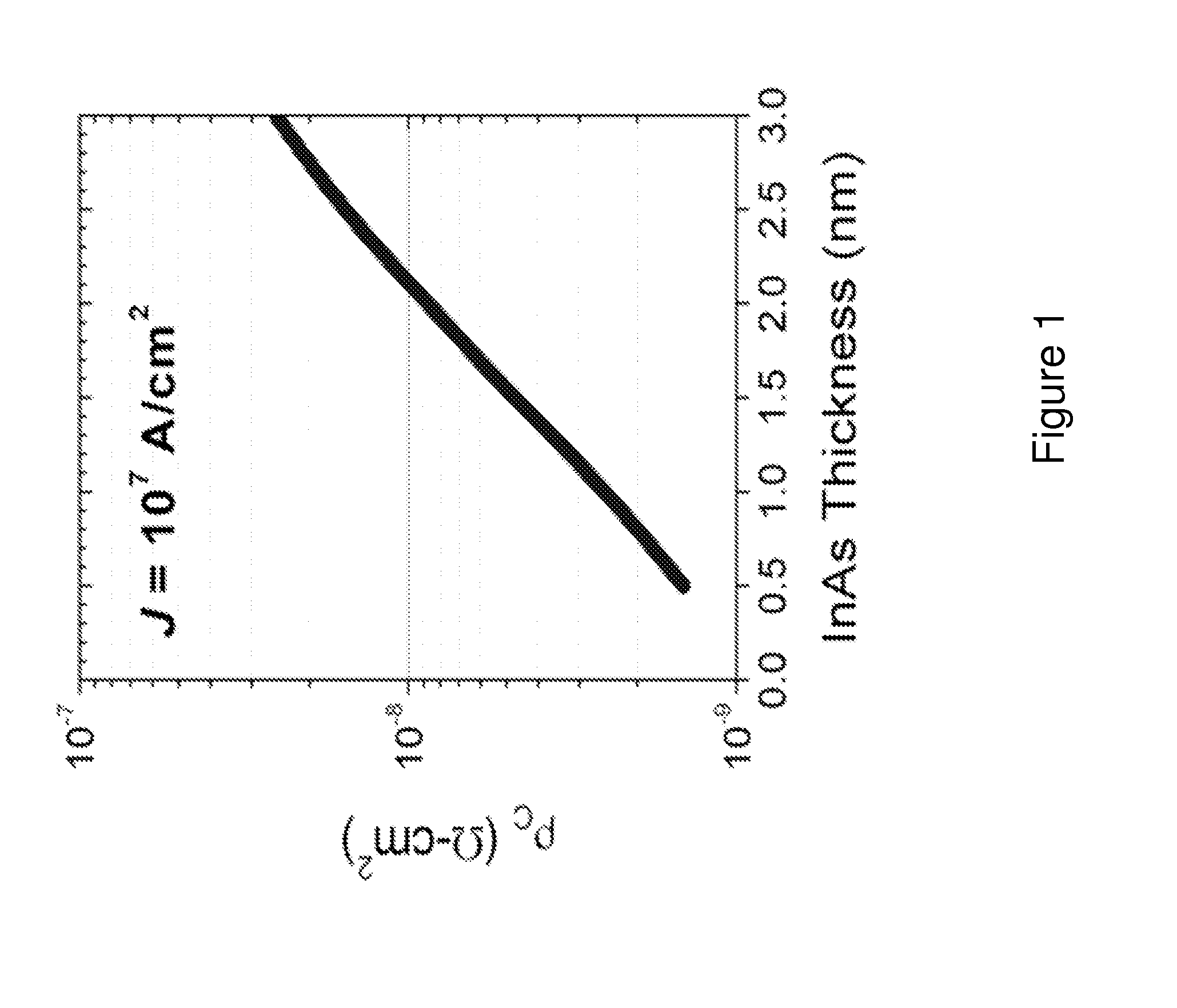

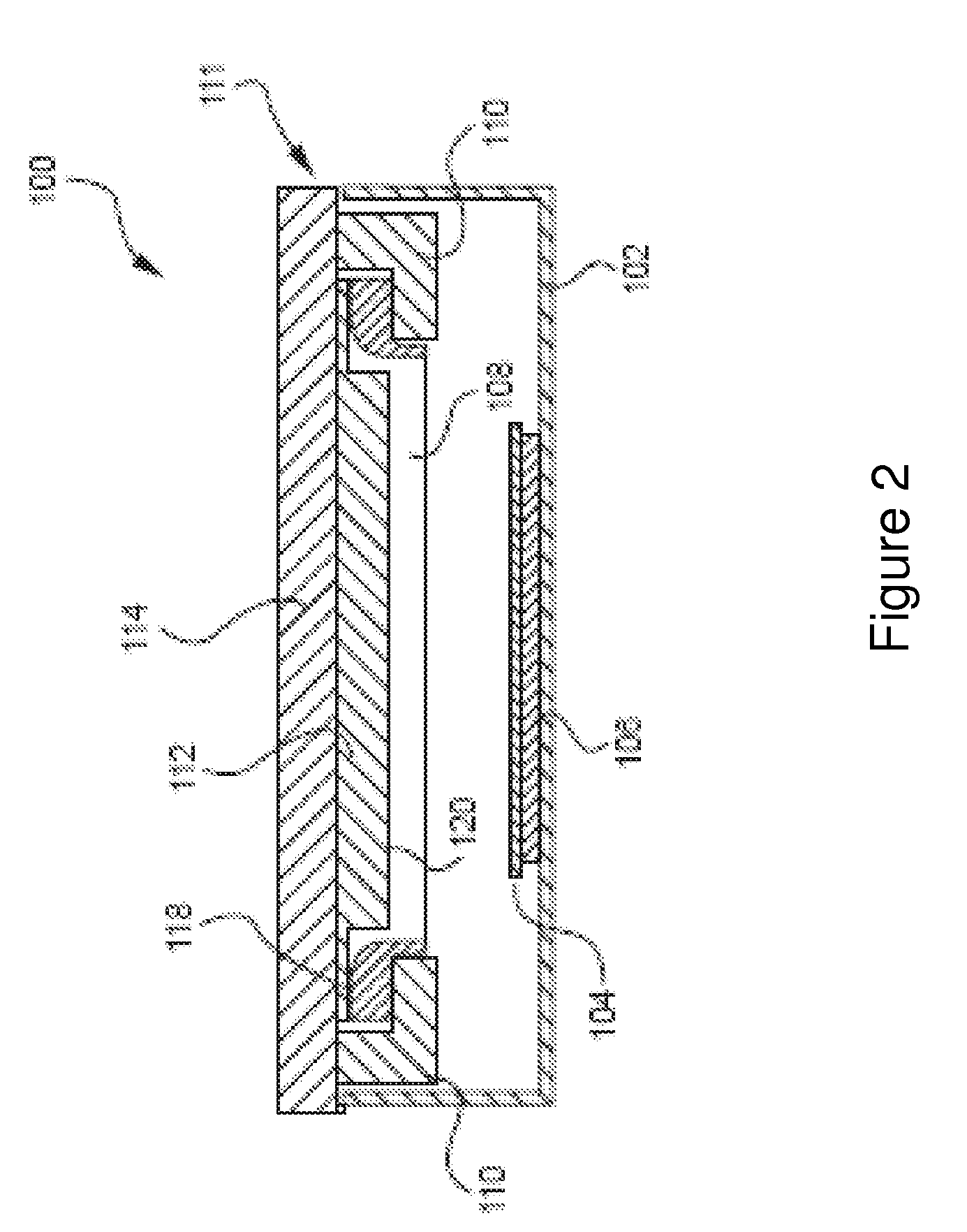

Devices Including Metal-Silicon Contacts Using Indium Arsenide Films and Apparatus and Methods

Described are apparatus and methods for forming films comprise indium and arsenic. In particular, these films may be formed in a configuration of two or more chambers under “load lock” conditions. These films may include additional components as dopants, such as aluminum and / or gallium. Such films can be used in metal / silicon contacts having low contact resistances. Also disclosed are devices including the films comprising indium arsenide.

Owner:APPLIED MATERIALS INC

Method of making a semiconductor device having a multicomponent oxide

One exemplary embodiment includes a semiconductor device. The semiconductor device can include a channel including one or more of a metal oxide including zinc-gallium, cadmium-gallium, cadmium-indium.

Owner:HEWLETT PACKARD DEV CO LP

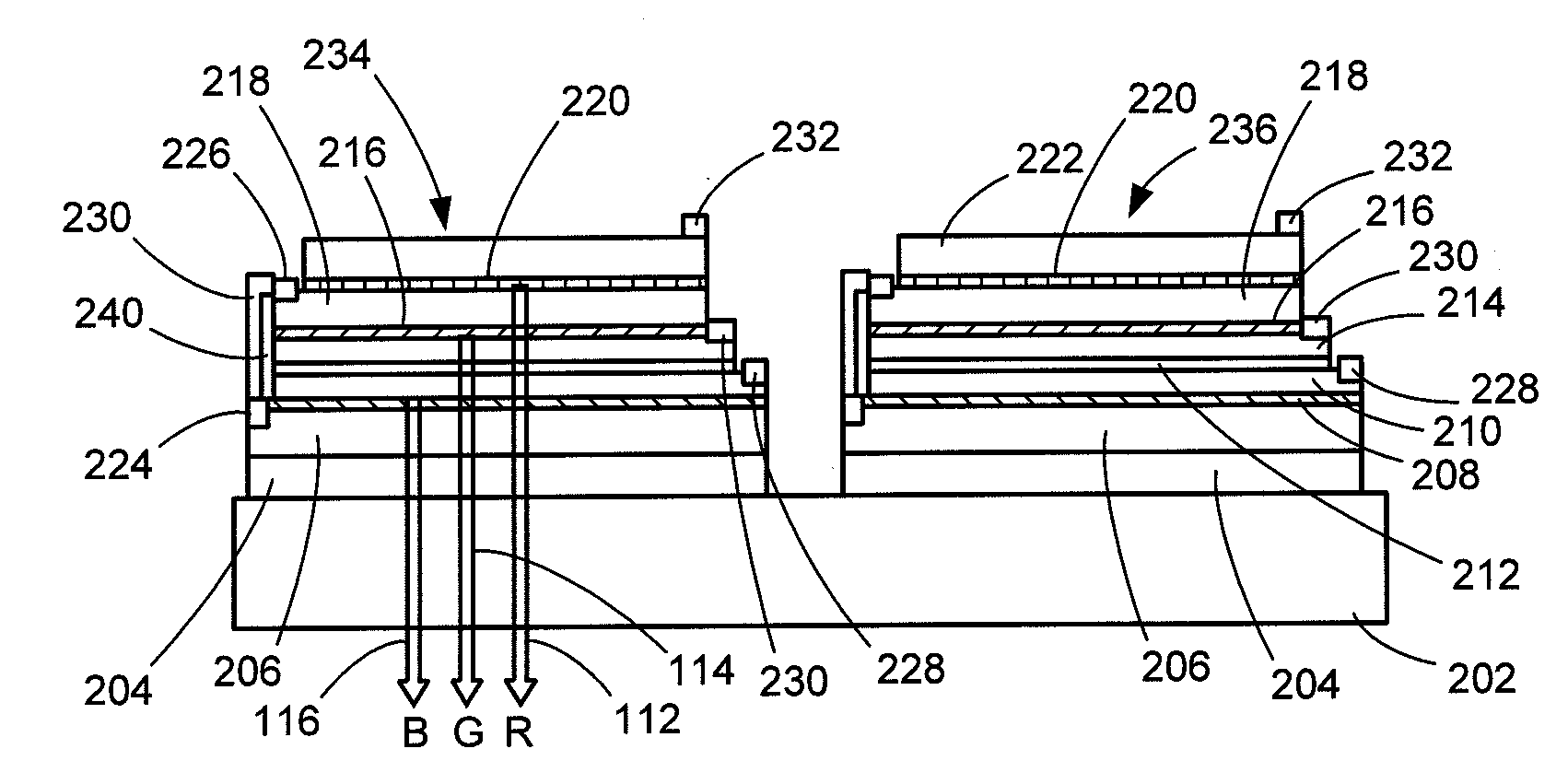

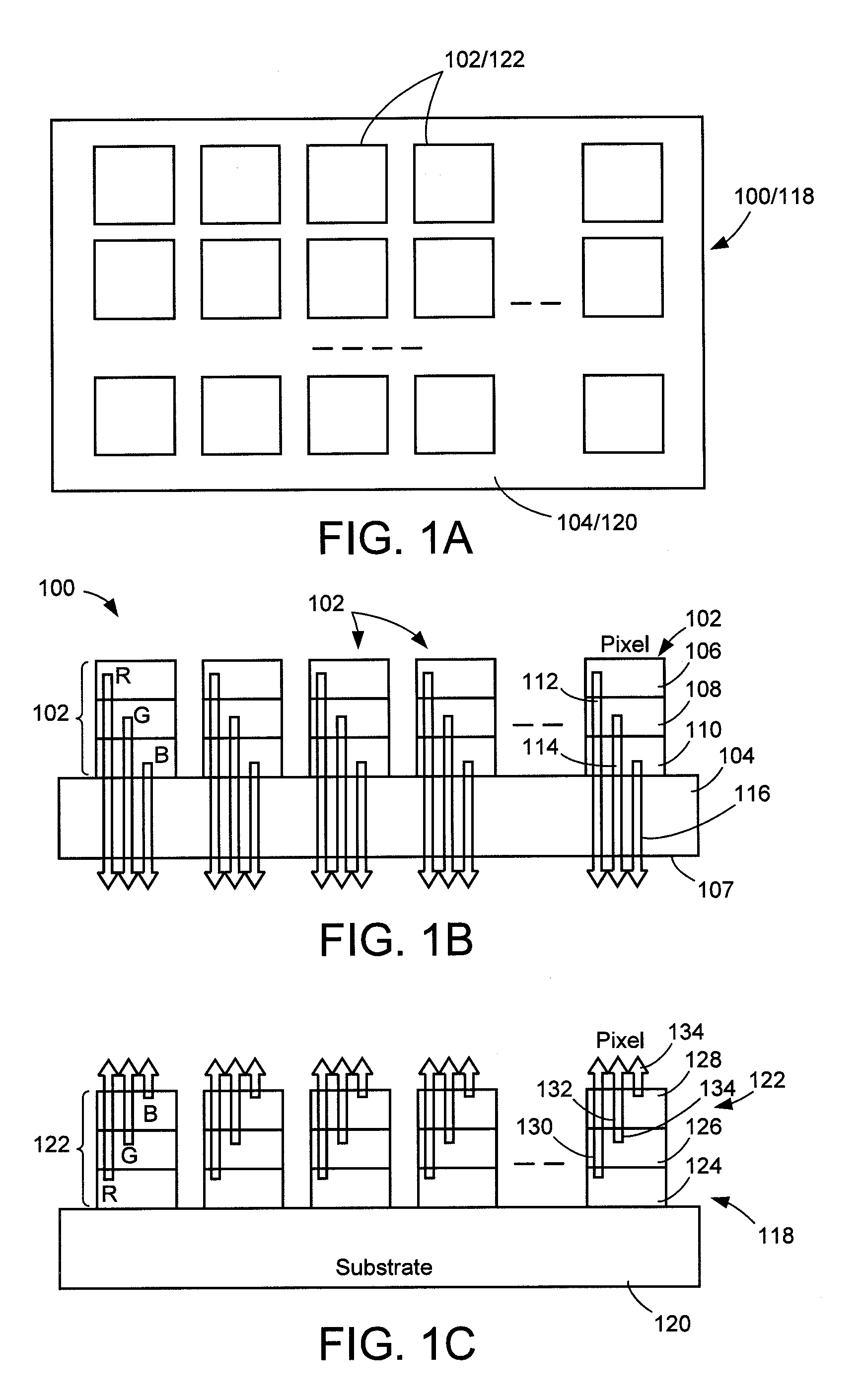

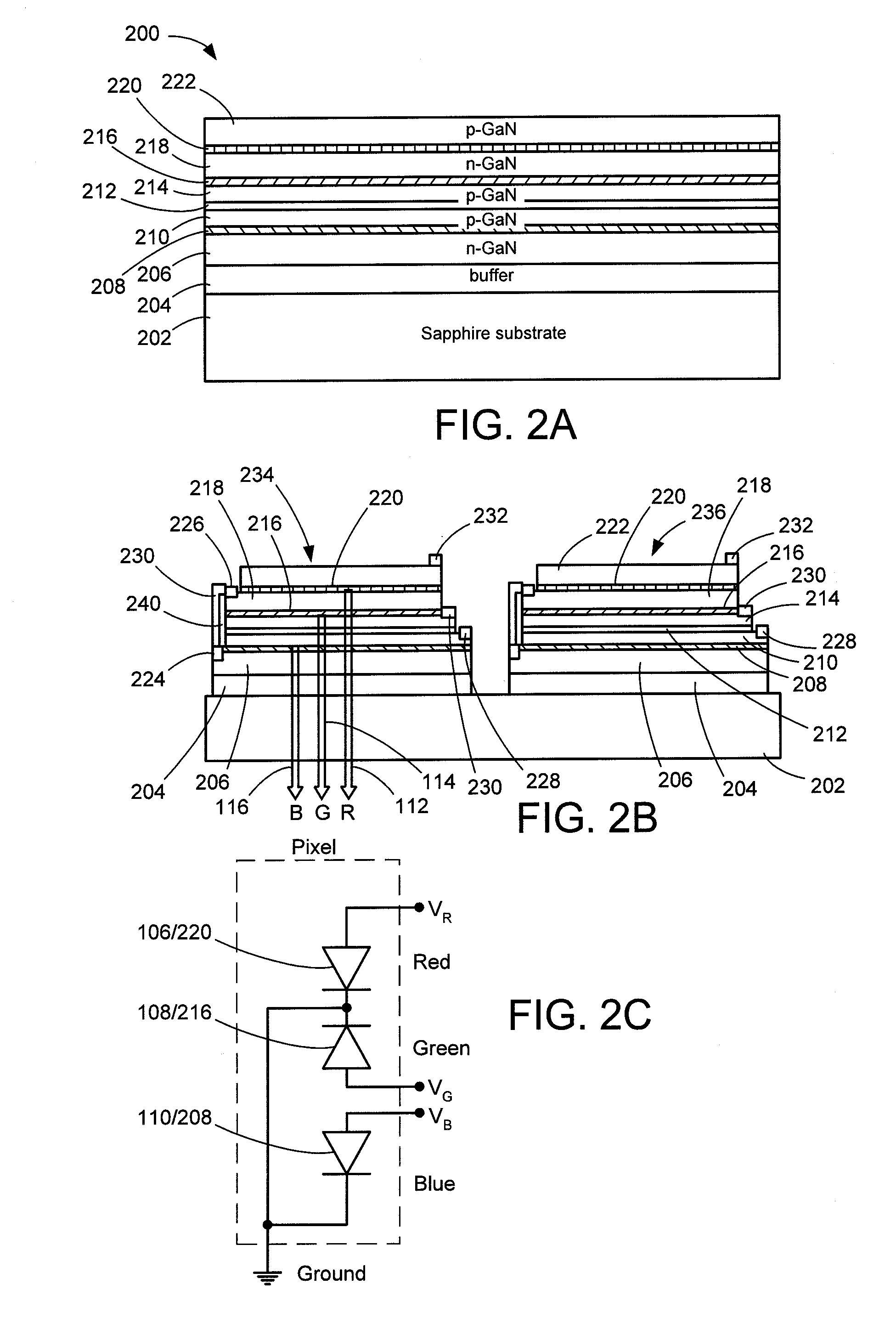

Micro-Emitter Array Based Full-Color Micro-Display

ActiveUS20090078955A1Avoid problemsSolid-state devicesSemiconductor/solid-state device manufacturingIndiumDisplay device

Disclosed is a semiconductor micro-emitter array for use in a full-color microdisplay. Each pixel includes three vertically-stacked red, green, and blue micro-emitters which minimizes pixel size. The microdisplay may be exclusively based on Group III-nitride semiconductors, with differing indium concentrations in three respective InGaN / GaN active regions for emitting the three RGB colors. Alternatively the microdisplay may be based on hybrid integration of InGaN based III-nitride semiconductors for blue and green emissions, and AlGaInP based (e.g., Group III-V) semiconductors for red emissions.

Owner:III N TECH

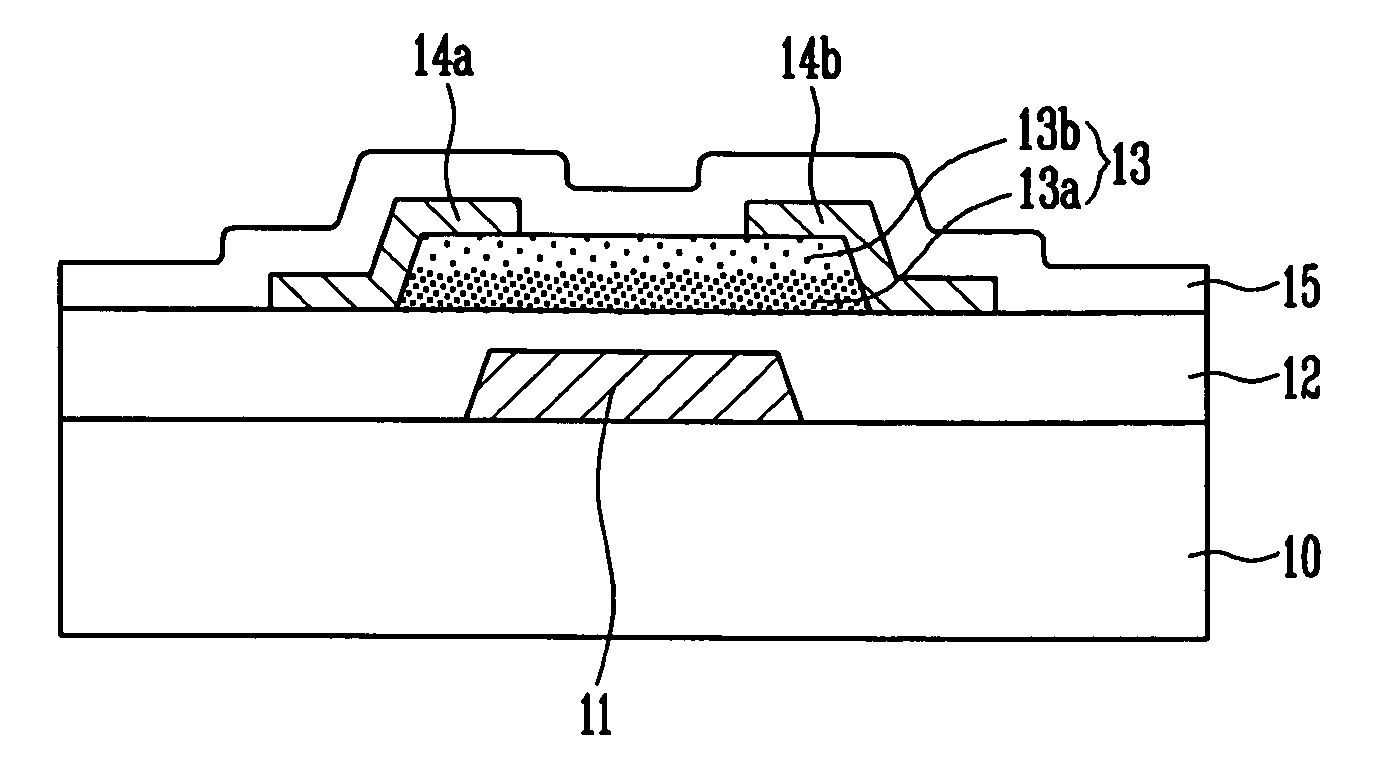

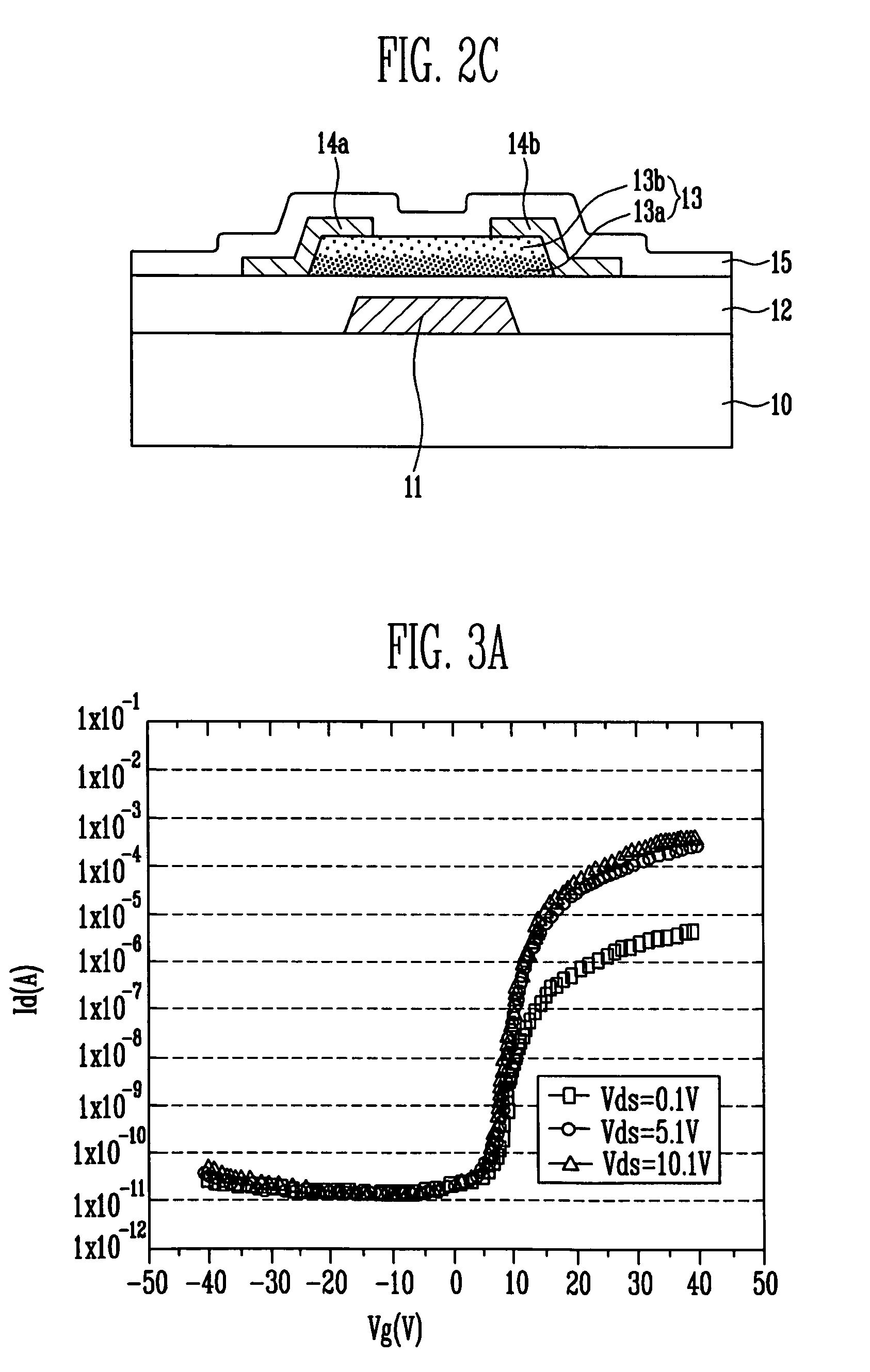

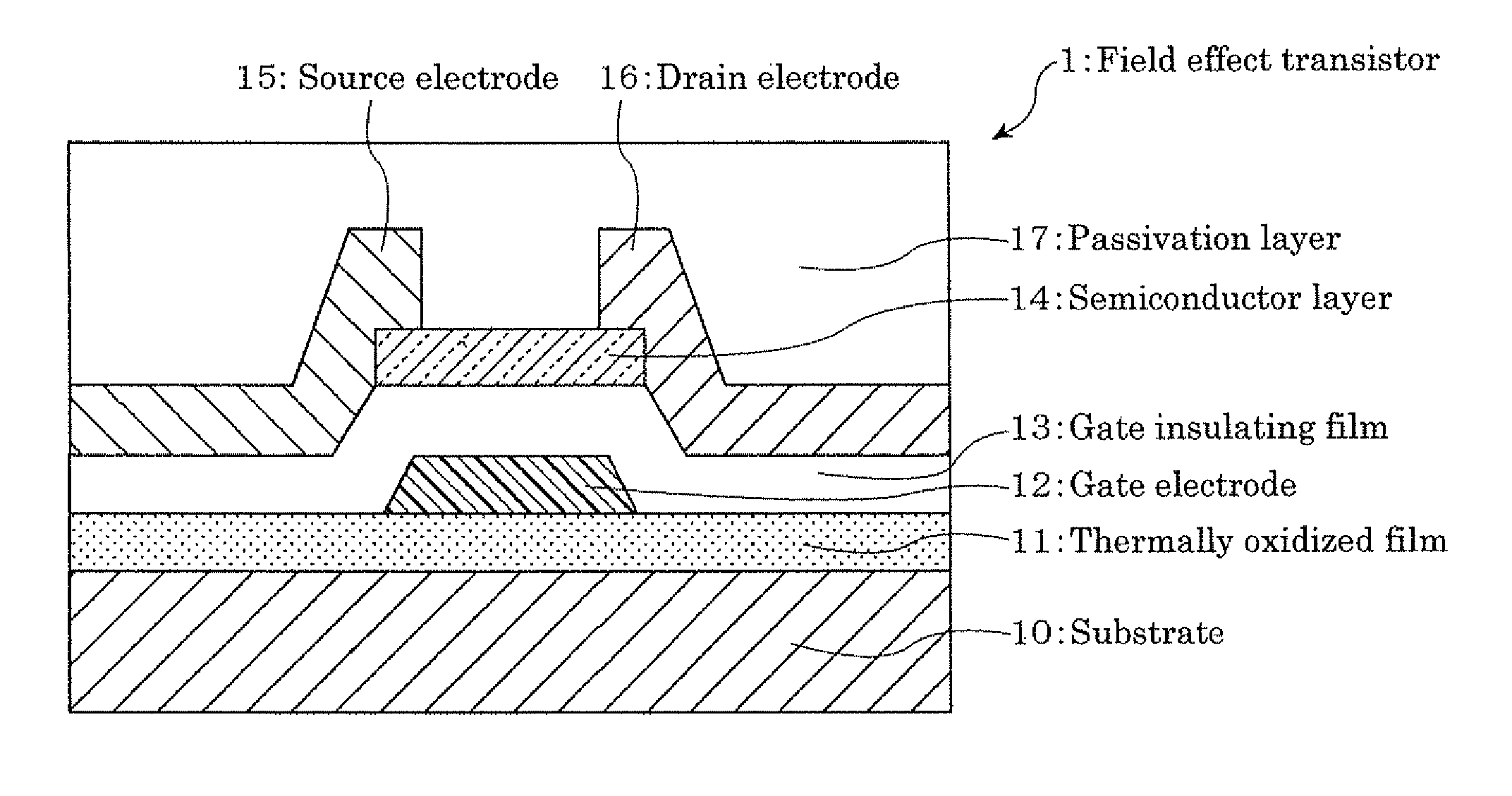

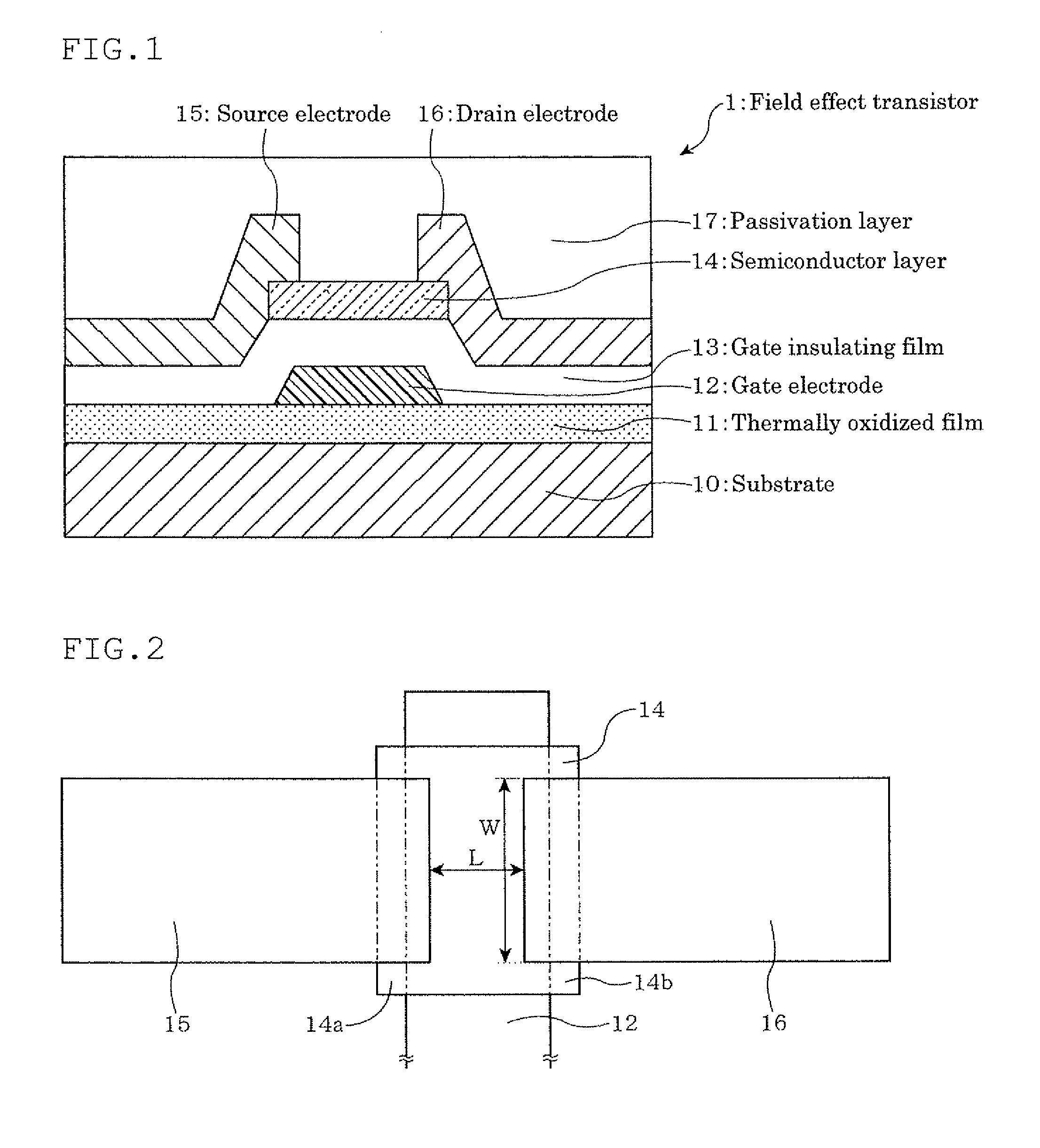

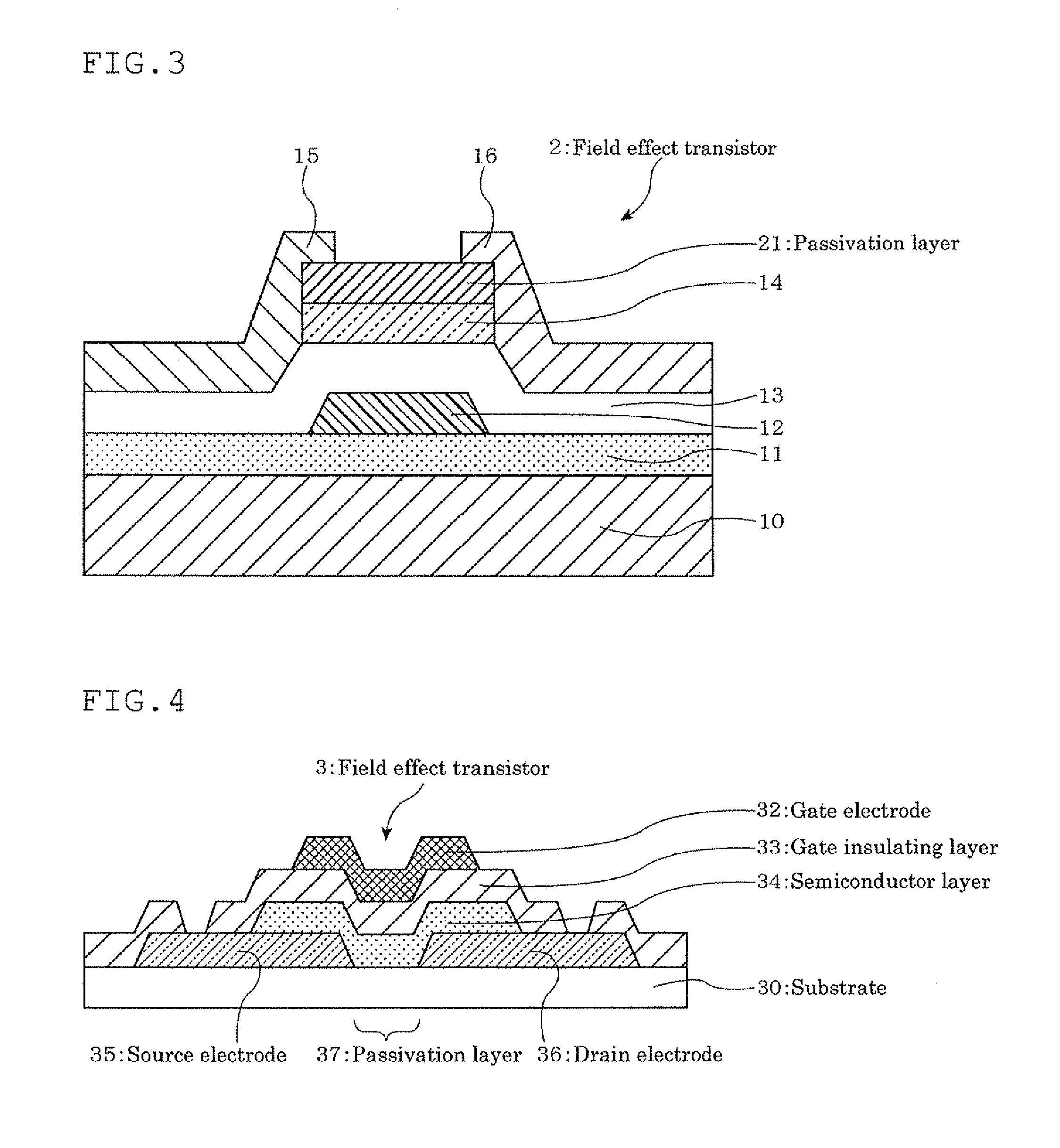

Field effect transistor using oxide semicondutor and method for manufacturing the same

ActiveUS8384077B2Easy to produceLower resistanceSemiconductor/solid-state device manufacturingDiodeIndiumField-effect transistor

A field effect transistor which includes, on a substrate, at least a semiconductor layer, a passivation layer for the semiconductor layer, a source electrode, a drain electrode, a gate insulating film and a gate electrode, the source electrode and the drain electrode being connected through the semiconductor layer, the gate insulating film being present between the gate electrode and the semiconductor layer, the passivation layer being at least on one surface side of the semiconductor layer, and the semiconductor layer including a composite oxide which comprises In (indium), Zn (zinc) and Ga (gallium) in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+Ga)=0.59 to 0.99 (2)Zn / (Ga+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

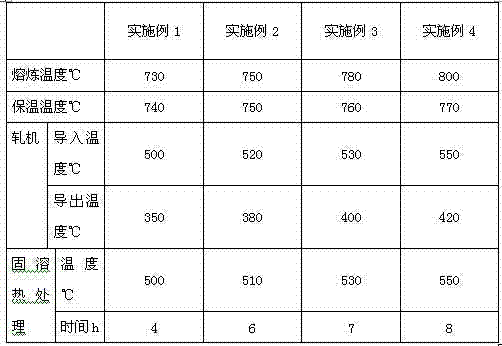

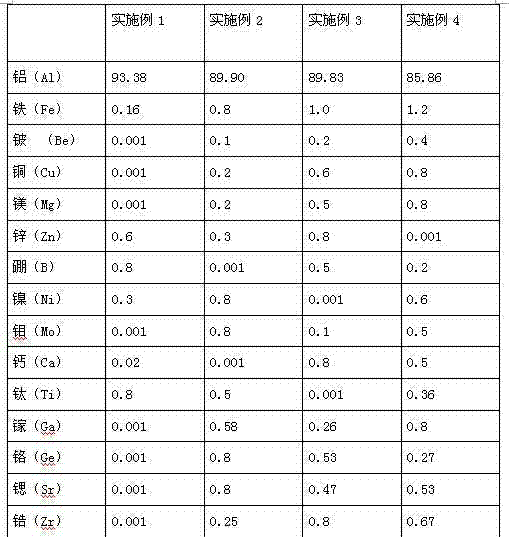

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

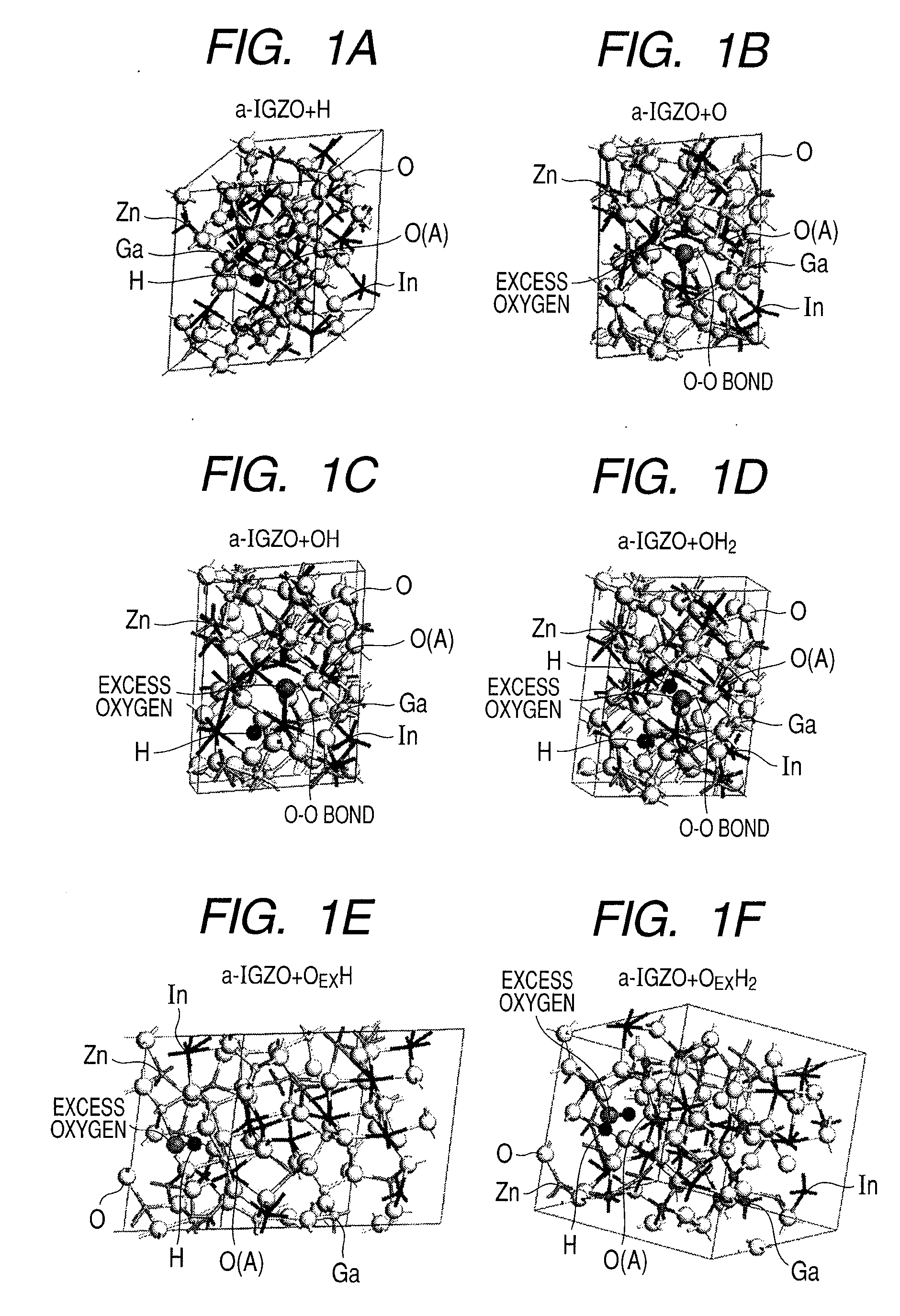

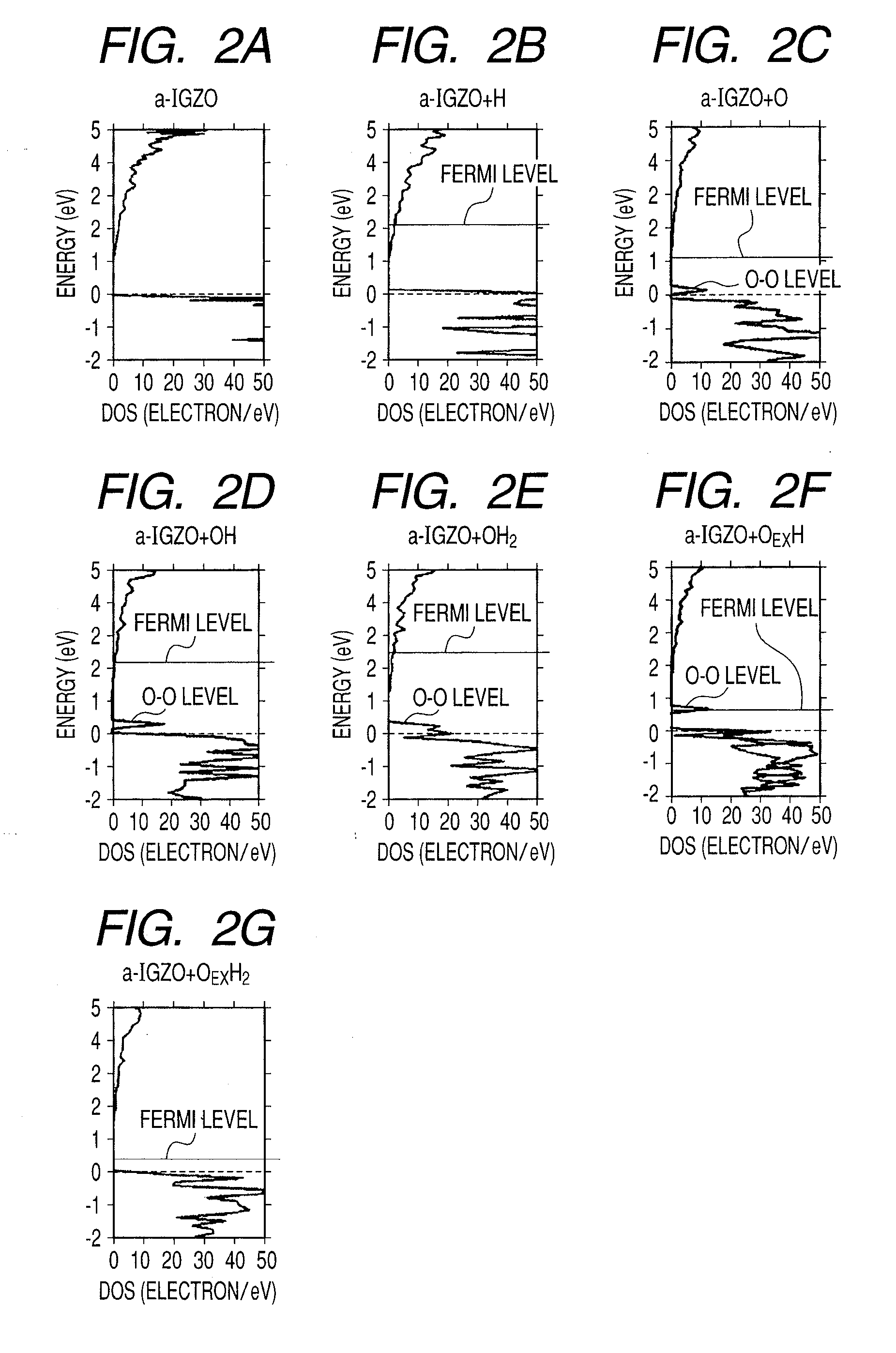

Amorphous oxide semiconductor and thin film transistor using the same

InactiveUS20100051938A1Improve transistor characteristicsLow costTransistorSemiconductor/solid-state device manufacturingIndiumHydrogen

There is provided an amorphous oxide semiconductor including hydrogen and at least one element of indium (In) and zinc (Zn), the amorphous oxide semiconductor containing one of hydrogen atoms and deuterium atoms of 1×1020 cm−3 or more to 1×1022 cm−3 or less, and a density of bonds between oxygen and hydrogen except bonds between excess oxygen (OEX) and hydrogen in the amorphous oxide semiconductor being 1×1018 cm−3 or less.

Owner:CANON KK

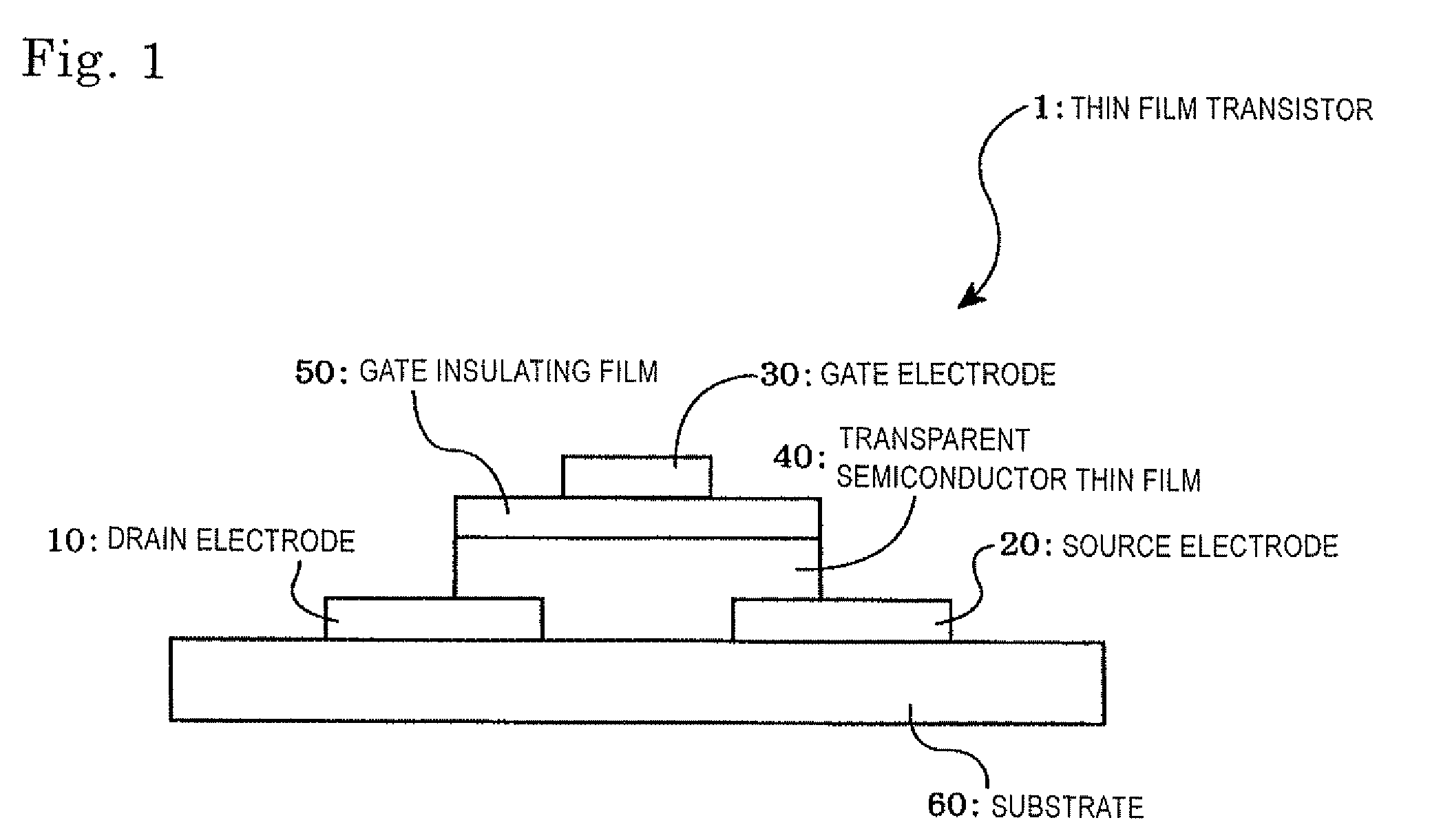

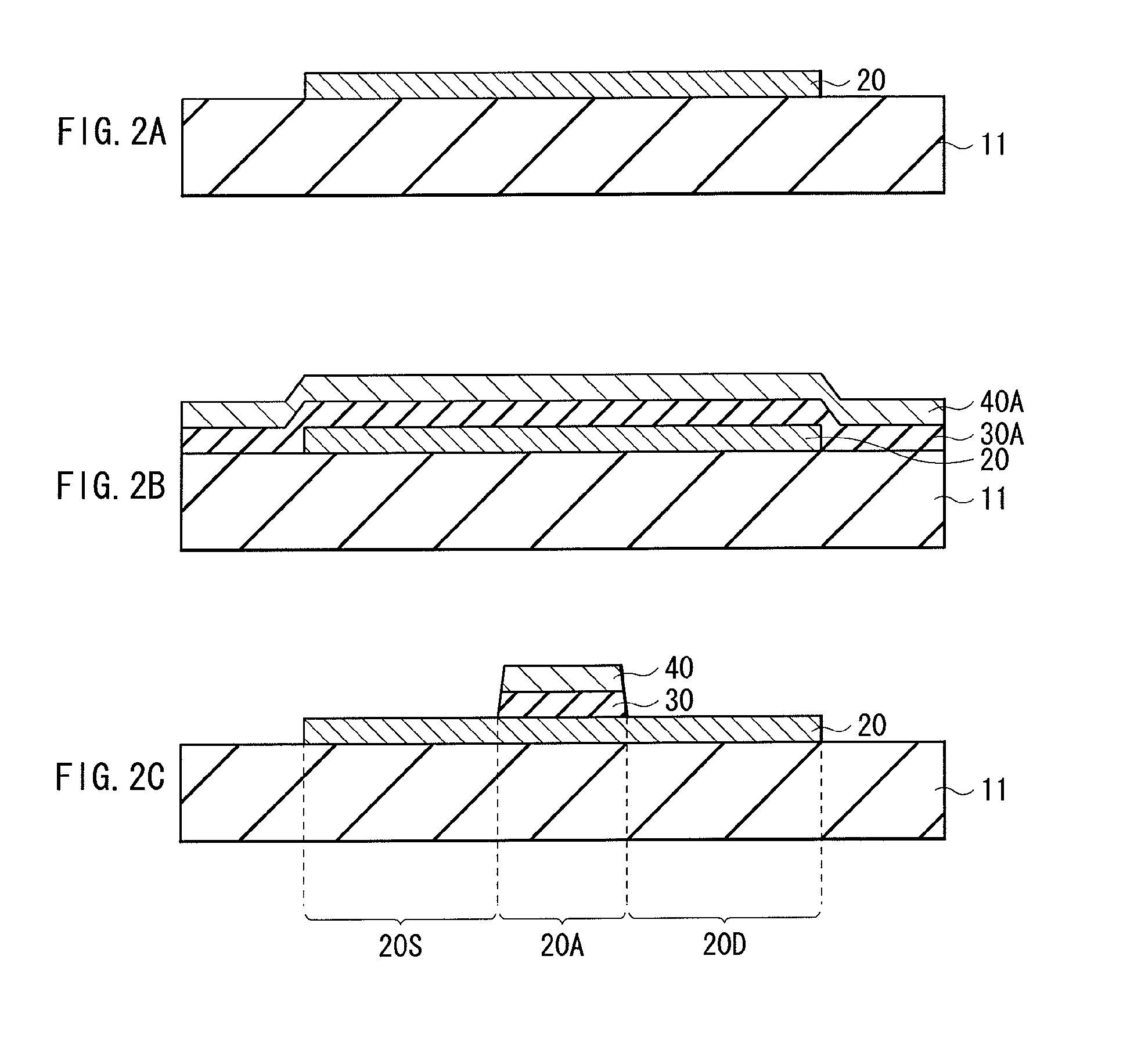

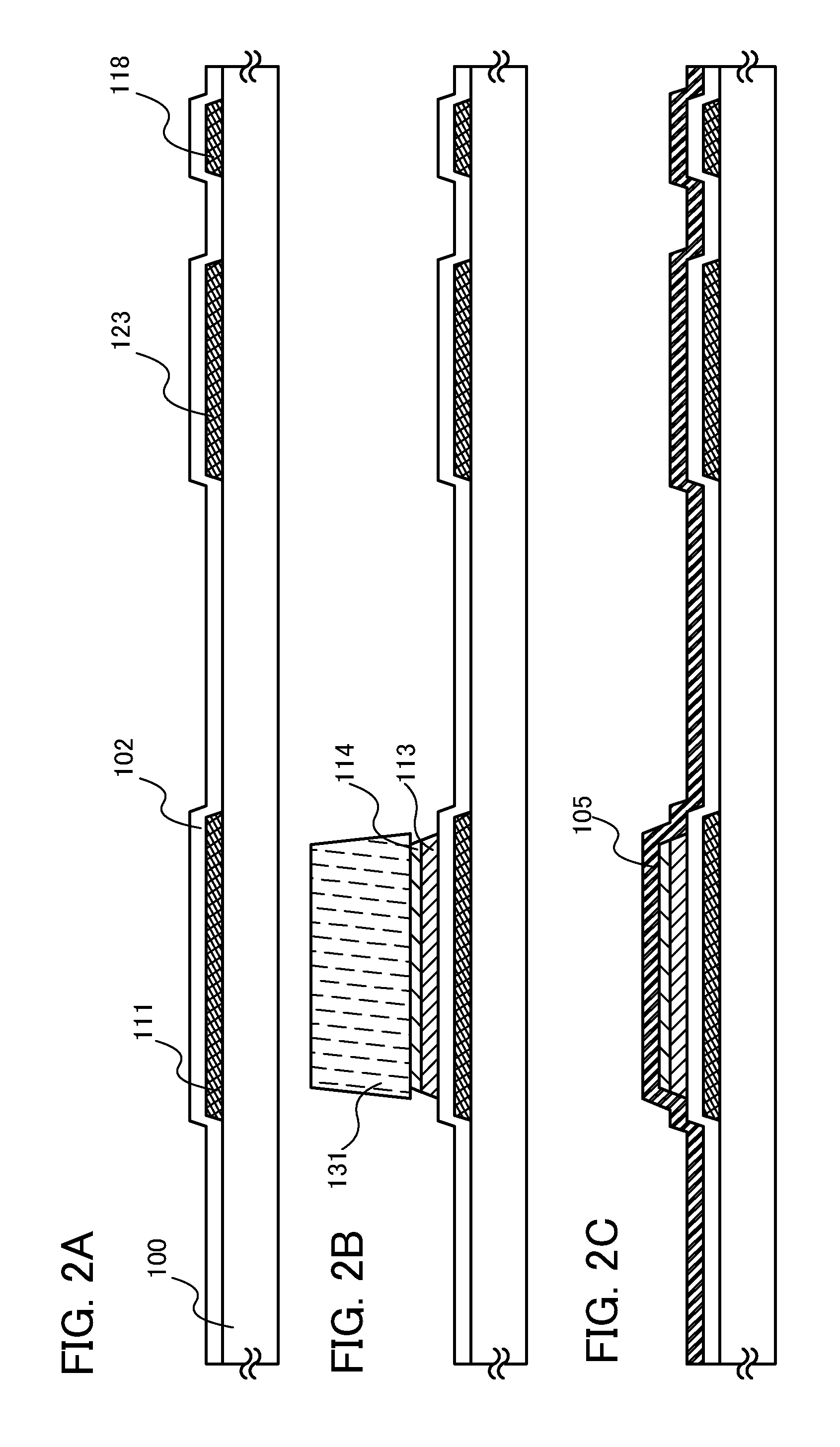

Semiconductor thin film, method for manufacturing the same, thin film transistor, and active-matrix-driven display panel

ActiveUS7998372B2Hardly erroneously operatesSmall currentNanotechConductive materialIndiumActive matrix

Disclosed is a semiconductor thin film which can be formed at a relatively low temperature even on a flexible resin substrate. Since the semiconductor thin film is stable to visible light and has high device characteristics such as transistor characteristics, in the case where the semiconductor thin film is used as a switching device for driving a display, even when overlapped with a pixel part, the luminance of a display panel does not deteriorate. Specifically, a transparent semiconductor thin film 40 is produced by forming an amorphous film containing zinc oxide and indium oxide and then oxidizing the film so that the resulting film has a carrier density of 10+17 cm−3 or less, a Hall mobility of 2 cm2 / V·sec or higher, and an energy band gap of 2.4 EV or more.

Owner:IDEMITSU KOSAN CO LTD

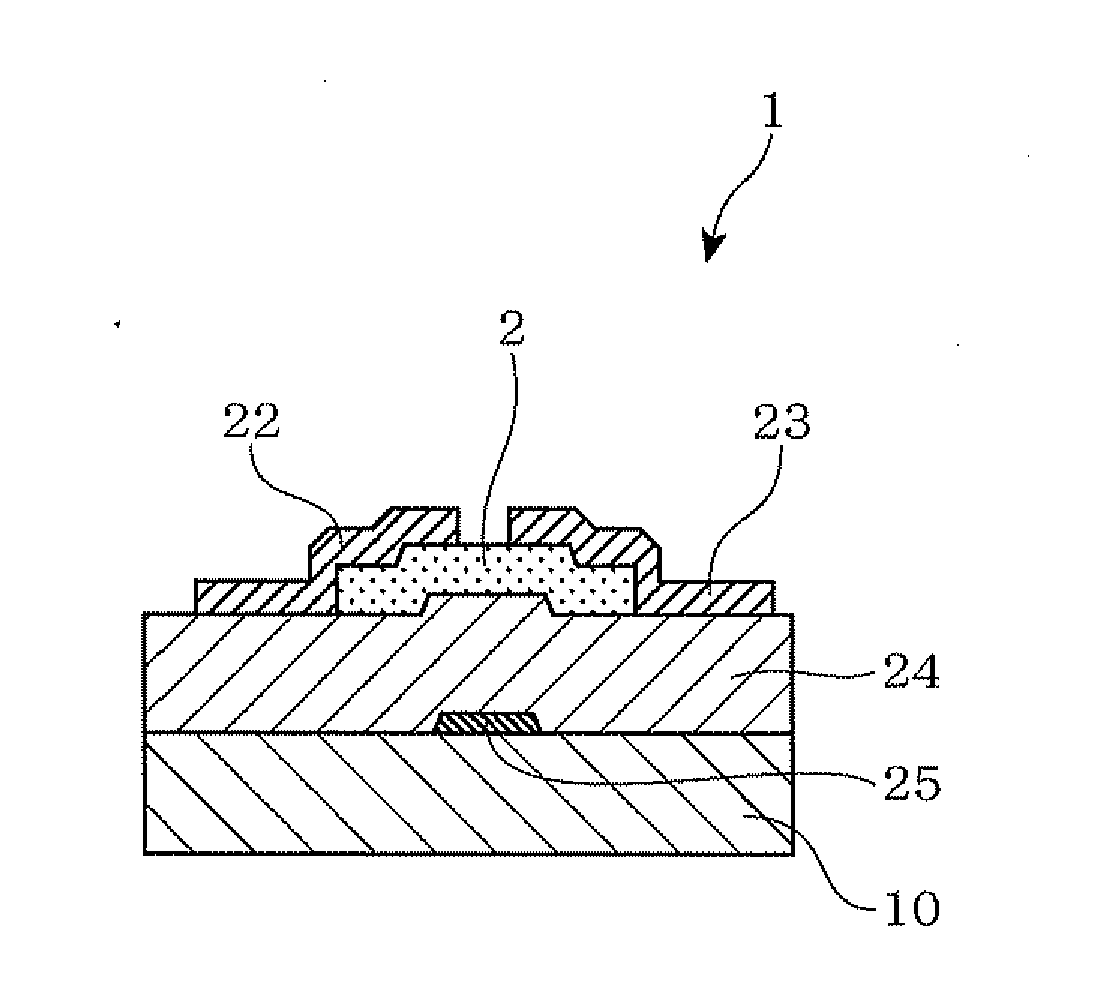

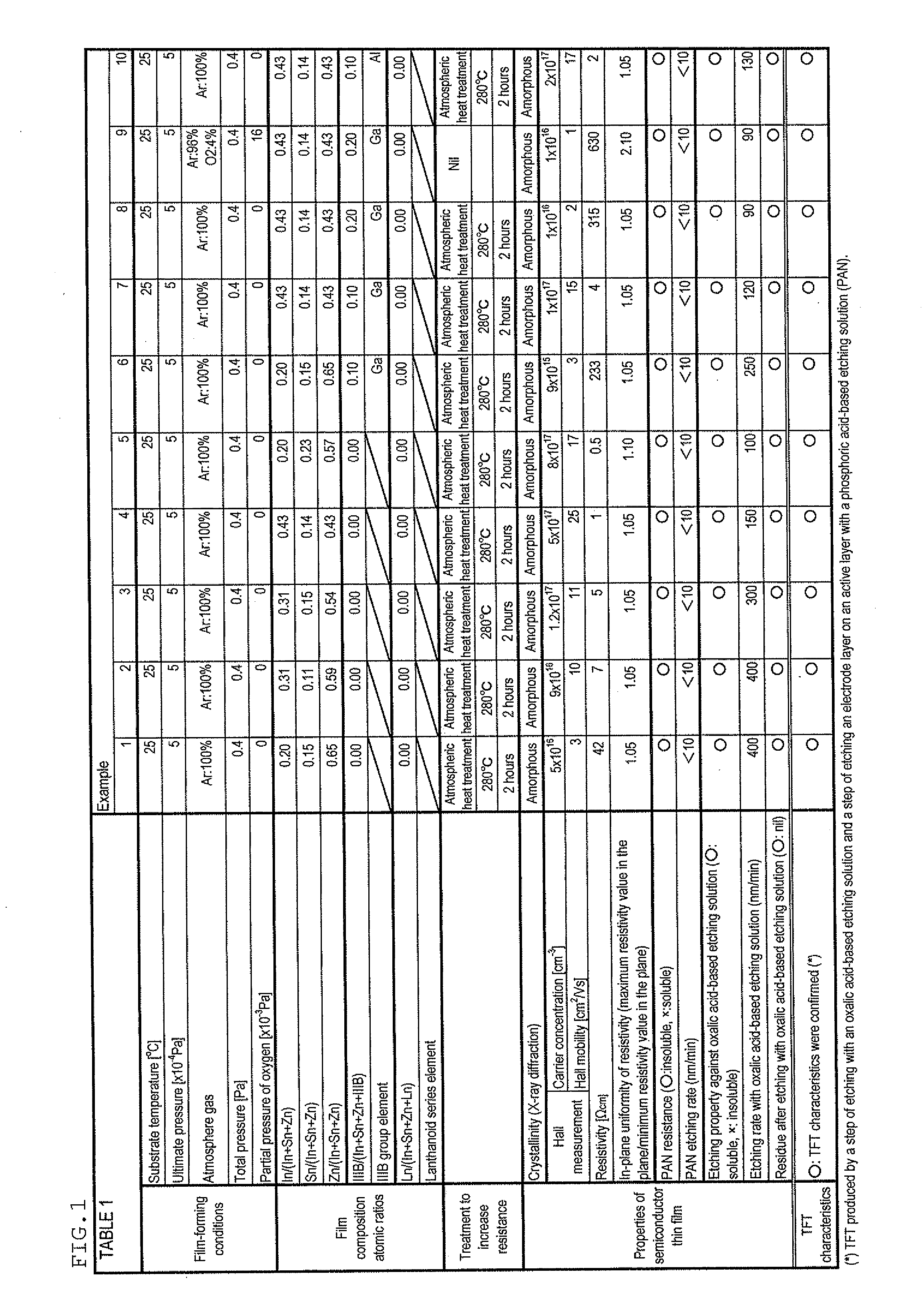

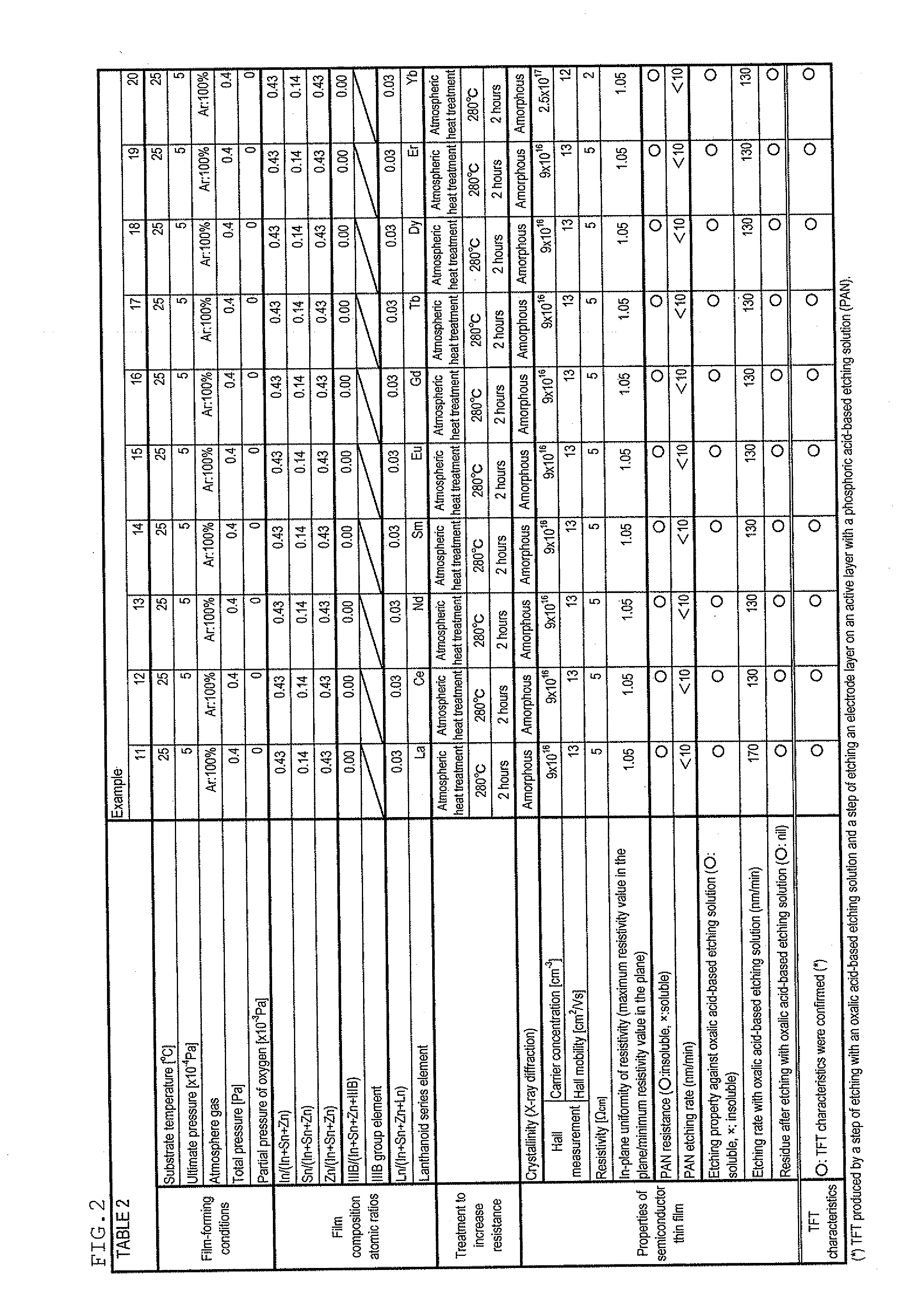

Noncrystalline oxide semiconductor thin film, process for producing the noncrystalline oxide semiconductor thin film, process for producing thin-film transistor, field-effect-transistor, light emitting device, display device, and sputtering target

ActiveUS20100155717A1Improve the immunityEasy to uniformlyCellsVacuum evaporation coatingIndiumPhosphoric acid

This invention provides an amorphous oxide semiconductor thin film, which is insoluble in a phosphoric acid-based etching solution and is soluble in an oxalic acid-based etching solution by optimizing the amounts of indium, tin, and zinc, a method of producing the amorphous oxide semiconductor thin film, etc. An image display device (1) comprises a glass substrate (10), a liquid crystal (40) as a light control element, a bottom gate-type thin film transistor (1) for driving the liquid crystal (40), a pixel electrode (30), and an opposing electrode (50). The amorphous oxide semiconductor thin film (2) in the bottom gate-type thin film transistor (1) has a carrier density of less than 10+18 cm−3, is insoluble in a phosphoric acid-based etching liquid, and is soluble in an oxalic acid-based etching liquid.

Owner:IDEMITSU KOSAN CO LTD

Thin-film transistor, method of manufacturing the same, and display device

A thin film transistor is provided. The thin film transistor includes an oxide semiconductor layer including a source region, a drain region, and a channel region wherein a portion of the source and drain regions has an oxygen concentration less than the channel region. Further provided is a thin film transistor that includes an oxide semiconductor layer including a source region, a drain region, and a channel region, wherein a portion of the source and drain regions includes a dopant selected from the group consisting of aluminum, boron, gallium, indium, titanium, silicon, germanium, tin, lead, and combinations thereof.

Owner:JOLED INC

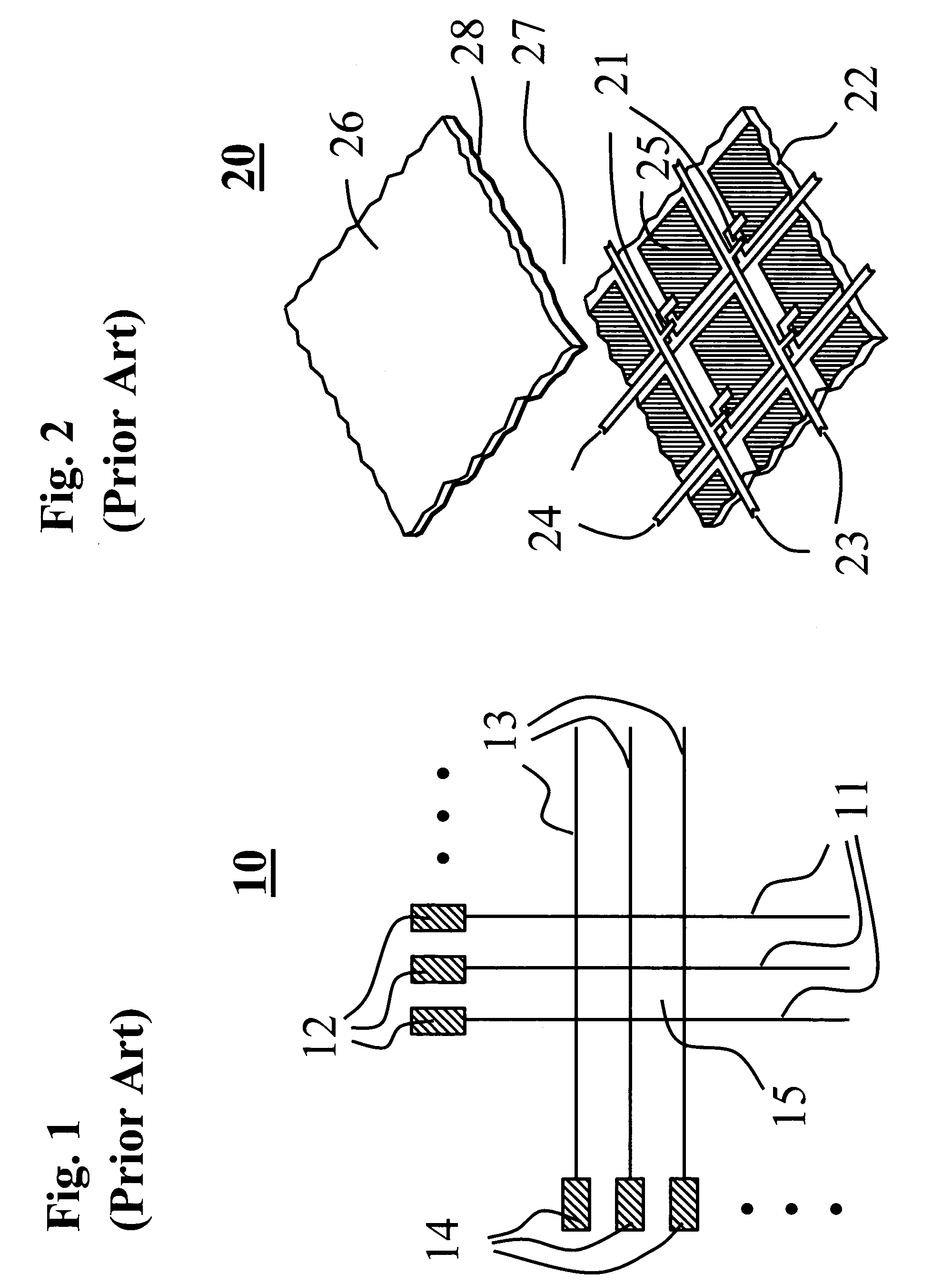

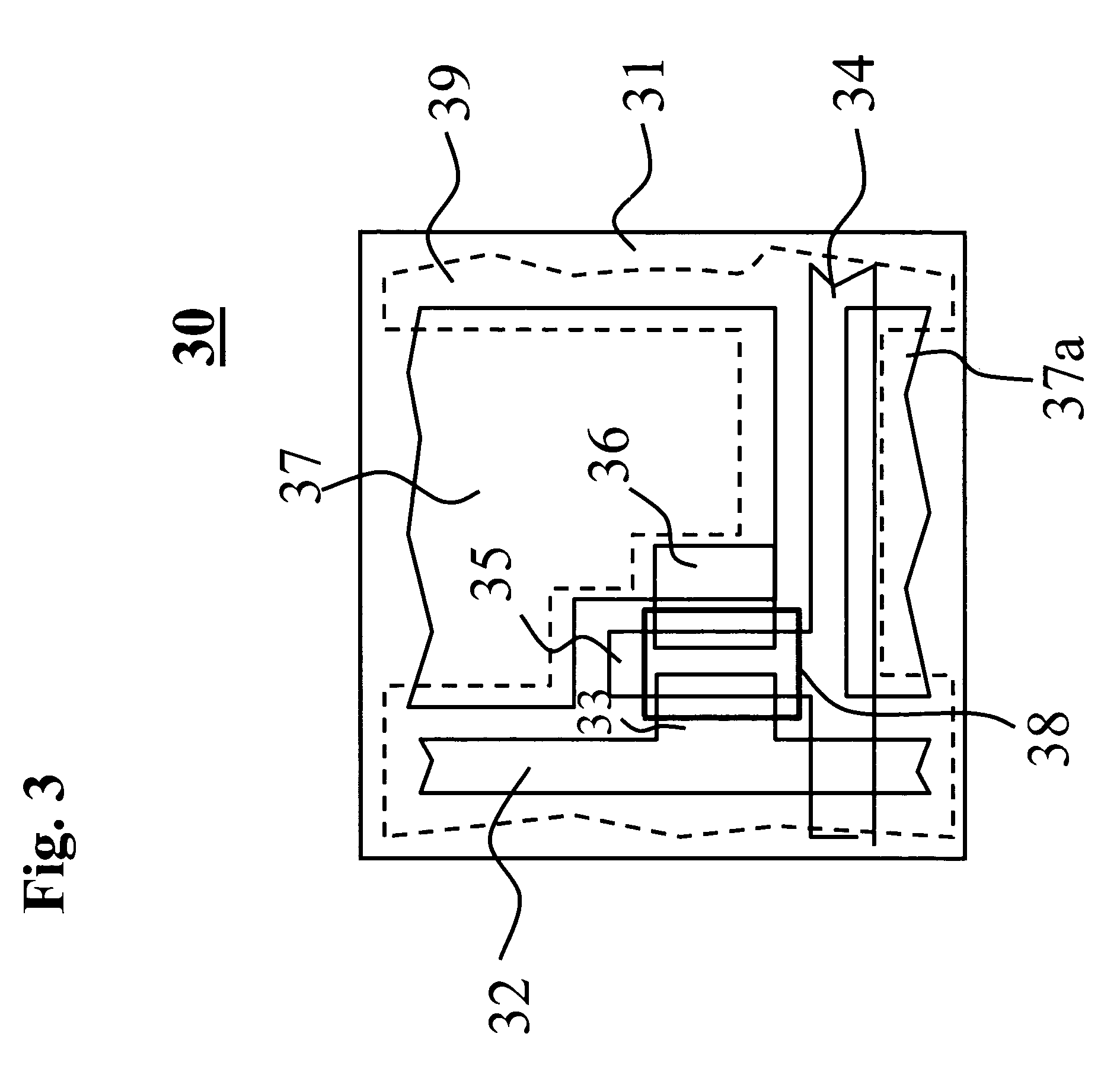

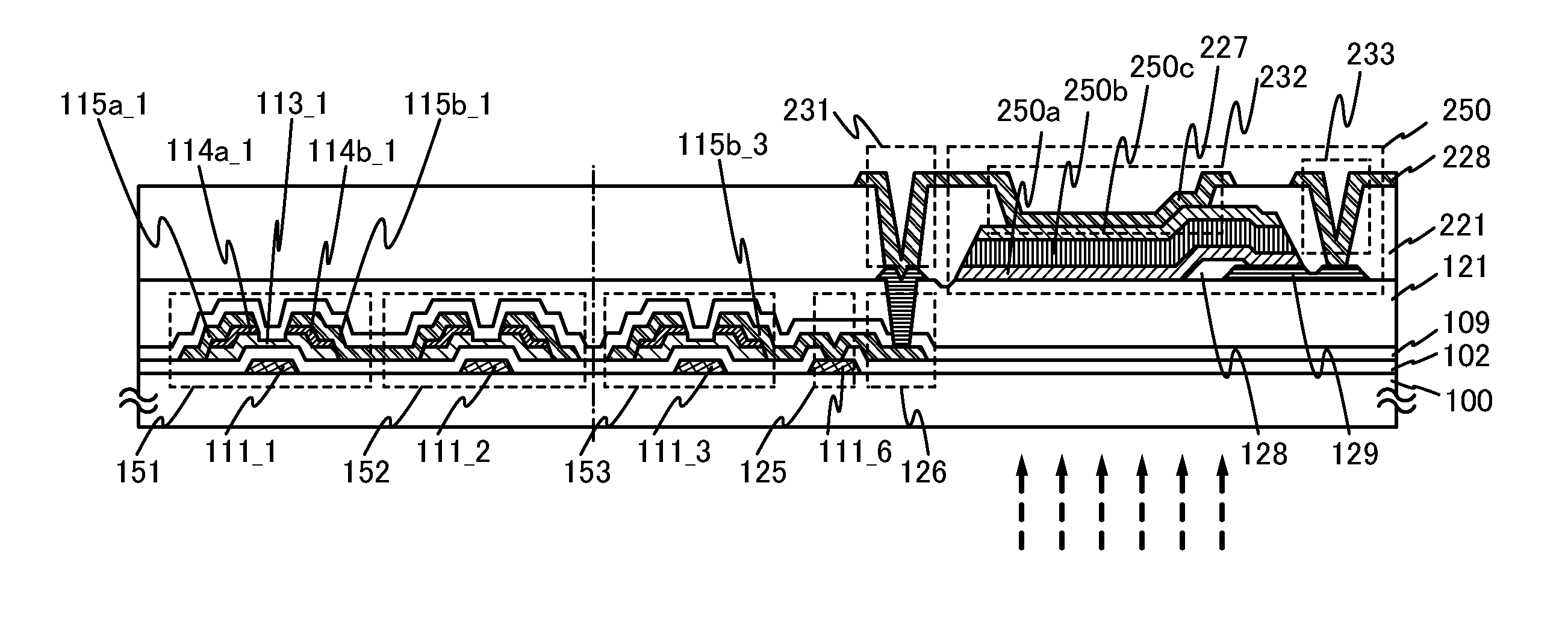

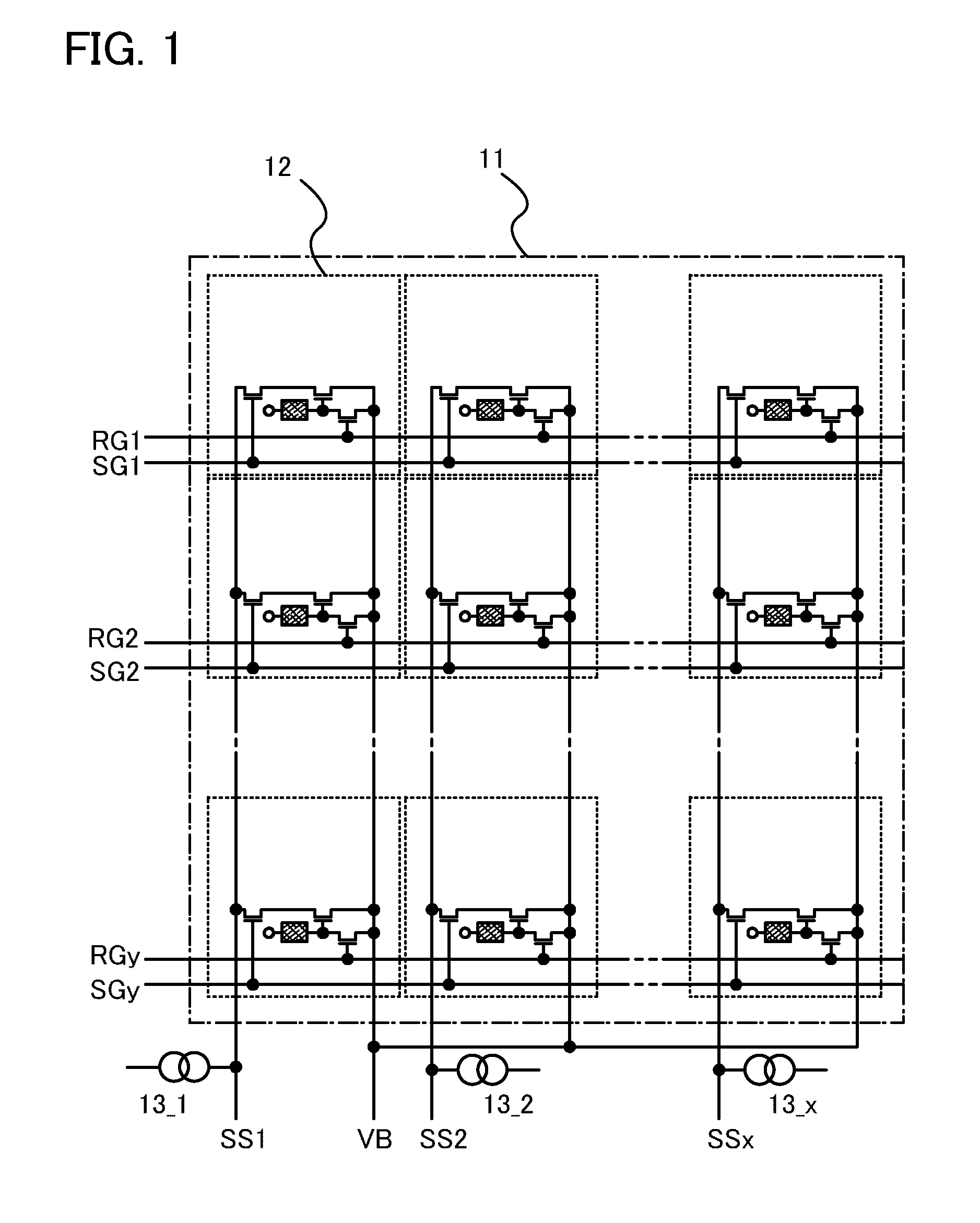

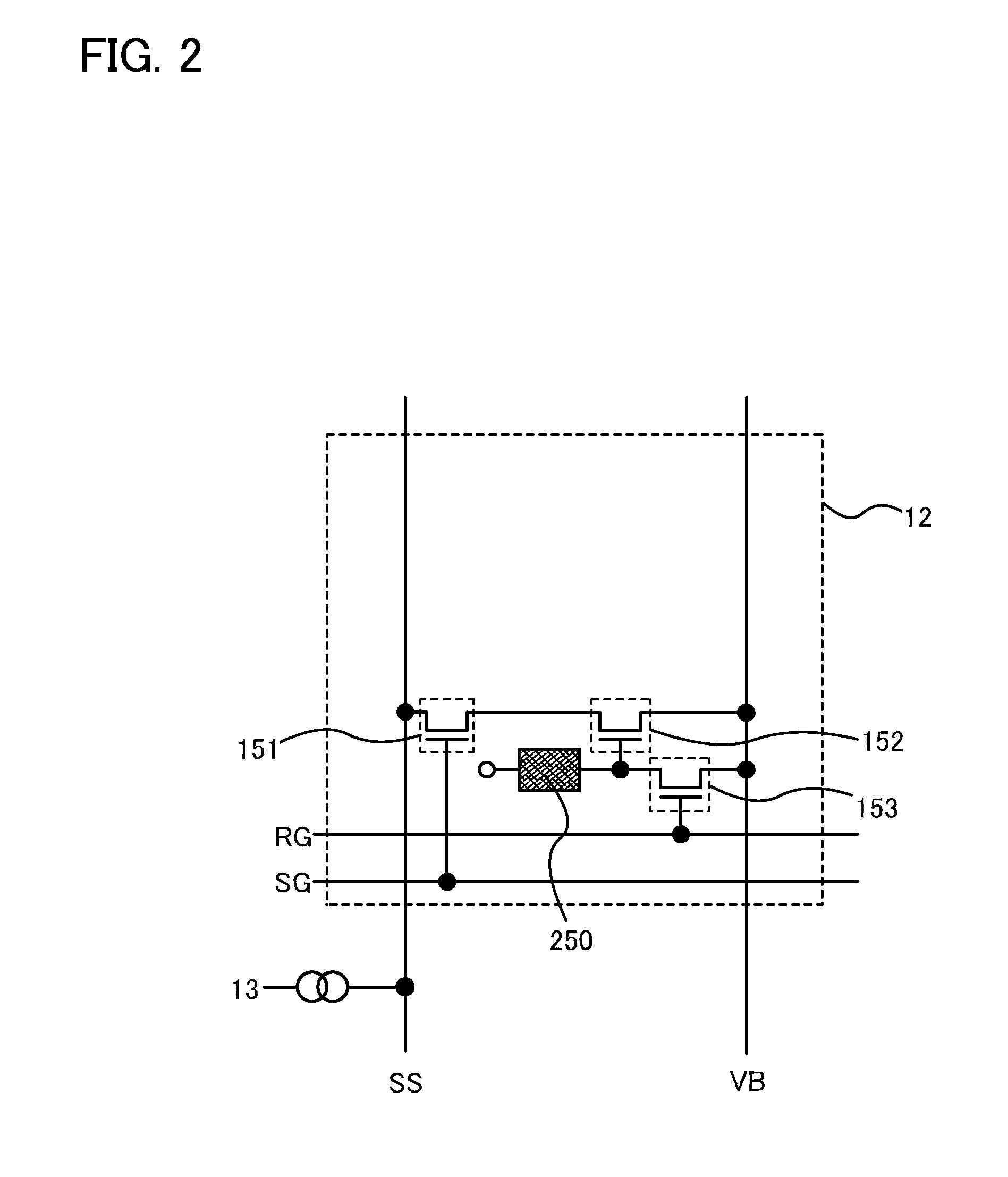

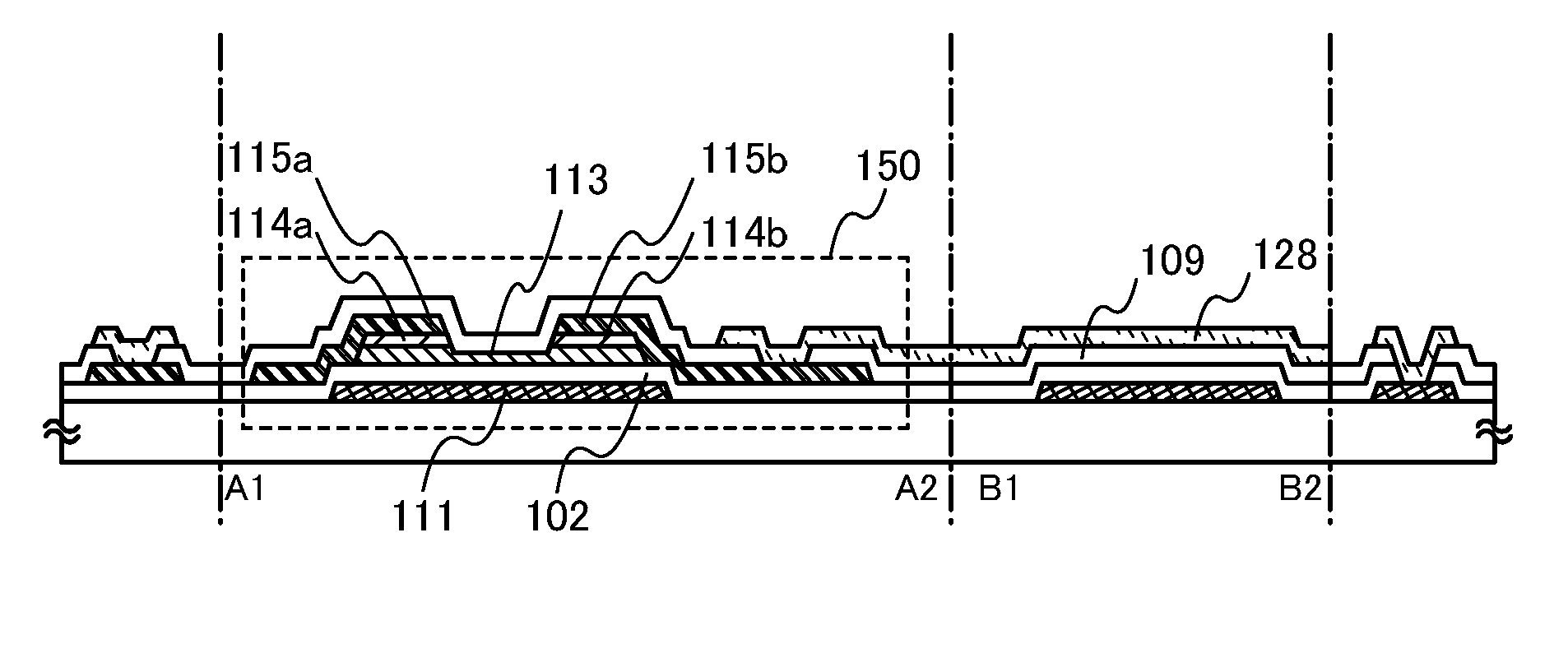

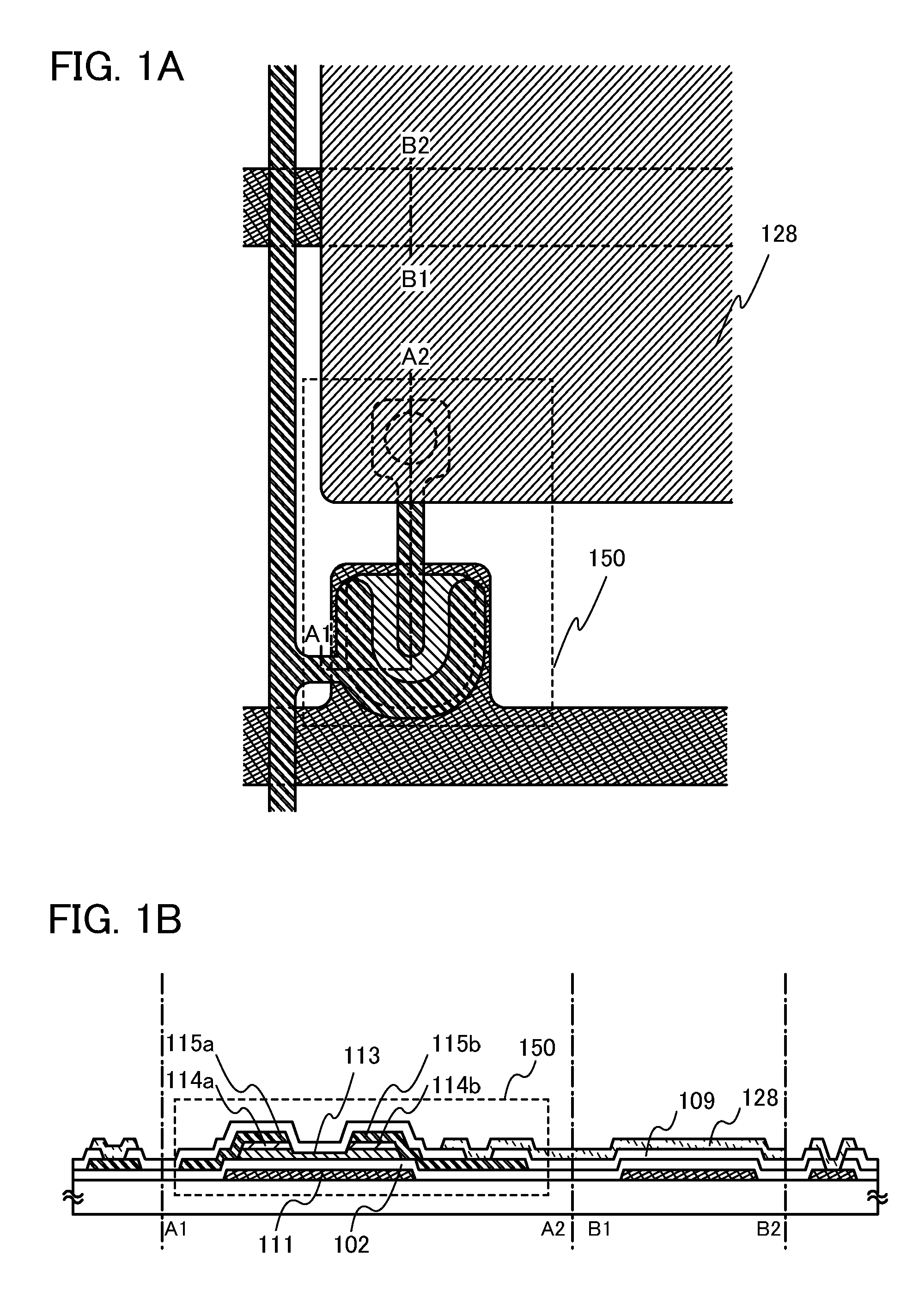

Photosensor and display device

ActiveUS20100134735A1Good reproducibilitySmall display unevennessTransistorStatic indicating devicesDriver circuitIndium

Thin film transistors including an oxide semiconductor containing indium, gallium, and zinc are easily arranged in a matrix over a large substrate and have small characteristic variations. With amplifier circuits and driver circuits of display elements which include the thin film transistors including an oxide semiconductor containing indium, gallium, and zinc with small characteristic variations, intensity distribution of light received by the photodiodes arranged in a matrix is converted into electrical signals with high reproducibility and output, and the display elements arranged in a matrix can be uniformly driven.

Owner:SEMICON ENERGY LAB CO LTD

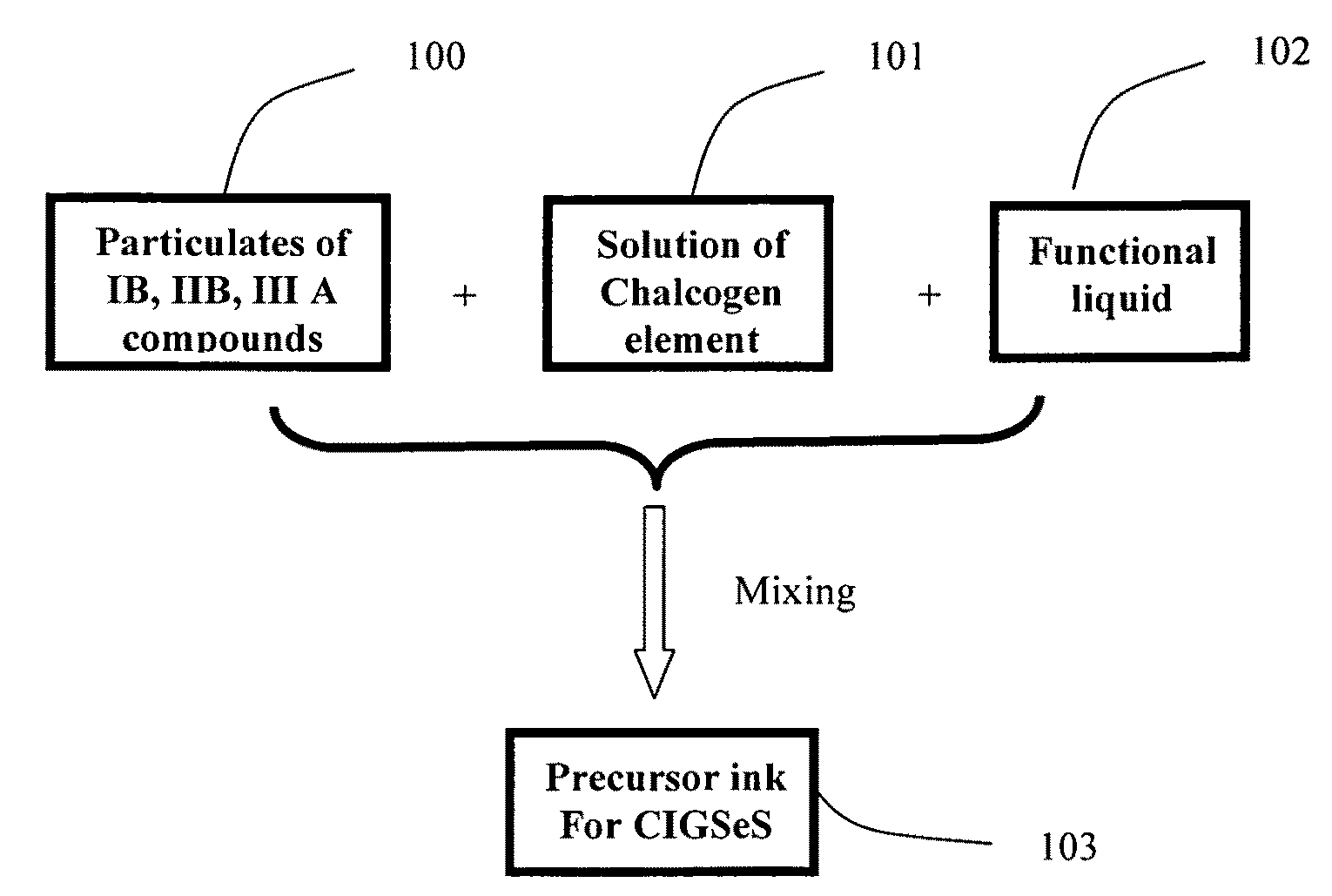

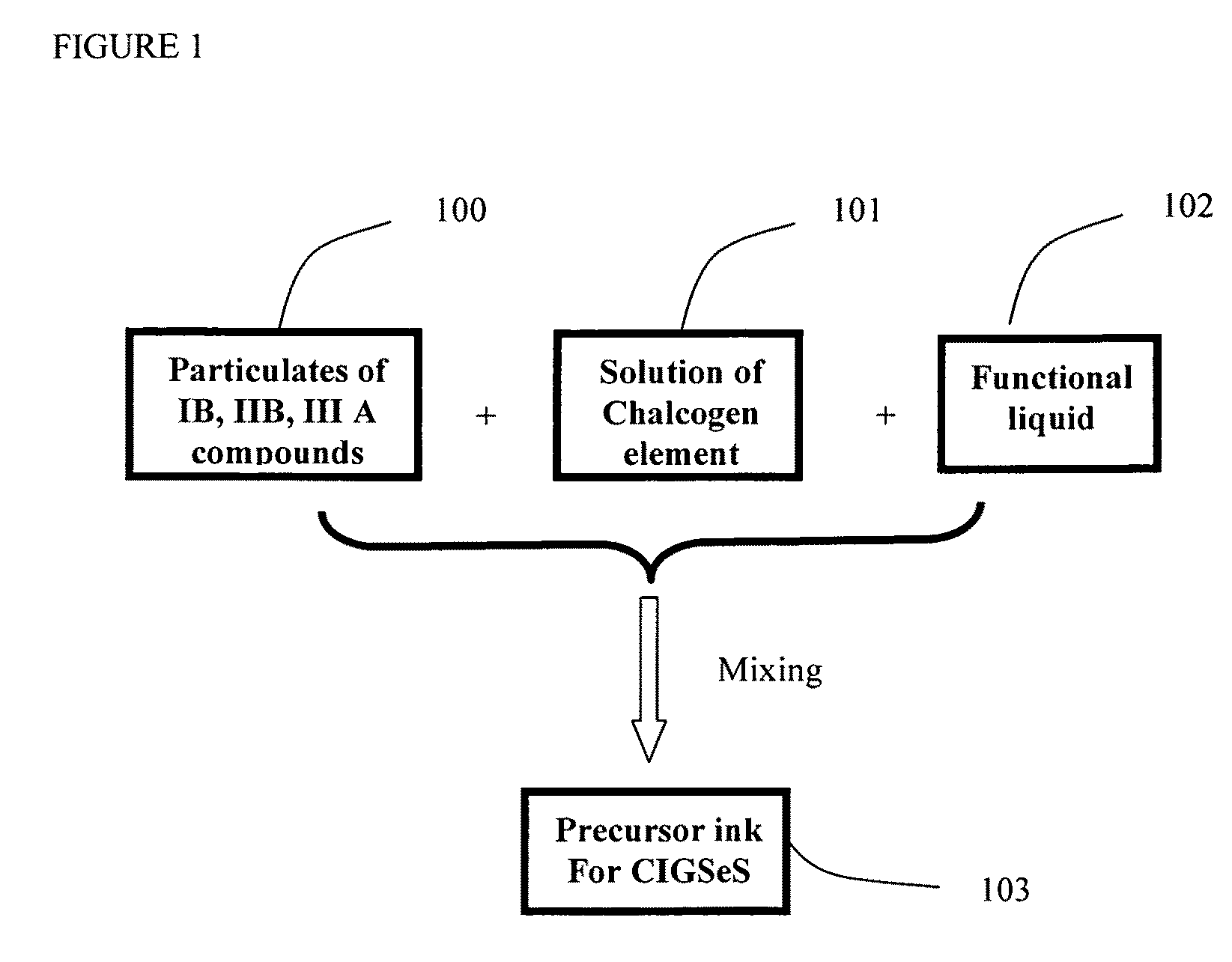

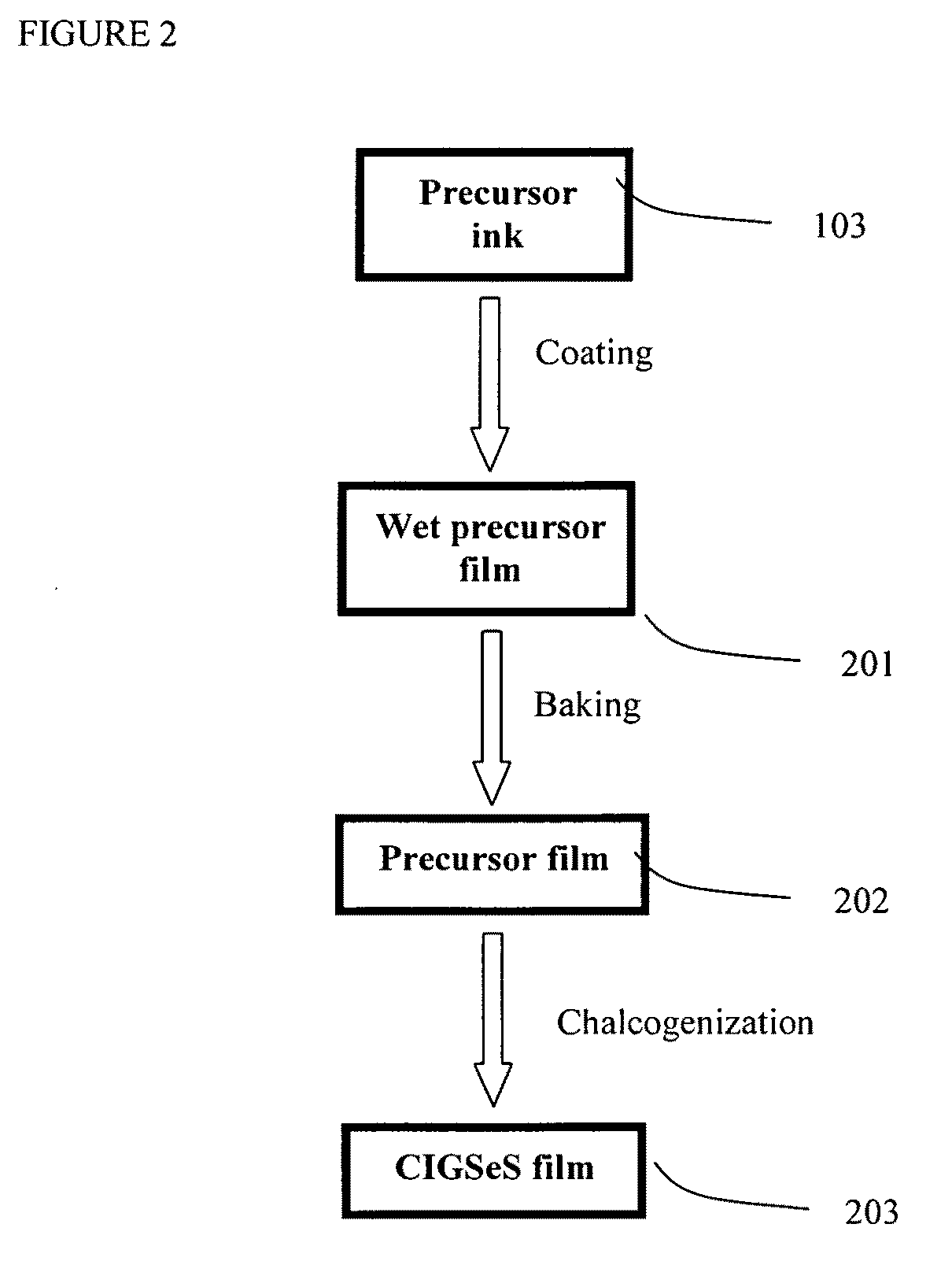

Precursor ink for producing IB-IIIA-VIA semiconductors

InactiveUS20090260670A1Overcome disadvantagesFinal product manufacturePV power plantsIndiumSemiconductor thin films

Copper indium diselenide, copper indium gallium diselenide, and other IB-IIIA-VIA compounds are produced by the liquid deposition on a substrate of a precursor-containing ink, followed by heating to produce the desired material. The precursor containing ink is a mixture of three parts. The first part is plurality of particulates of metal compounds of IB, IIIA. The second part is chalcogen source of selenium, sulfur, or organic chalcogen compounds dissolved in a liquid organic solvent. The third part solution function as viscosity adjustment, as introduction of dopant of sodium ion and / or as ink stabilizer. The precursor ink can be coated on substrate at room temperature and it can be transferred into copper indium (gallium) chalcogenide semiconductor thin film upon baking and a chalcogenization process. The resulting thin film semiconducting material can be incorporated into photovoltaic and other electronic devices.

Owner:LI XIAO CHANG CHARLES

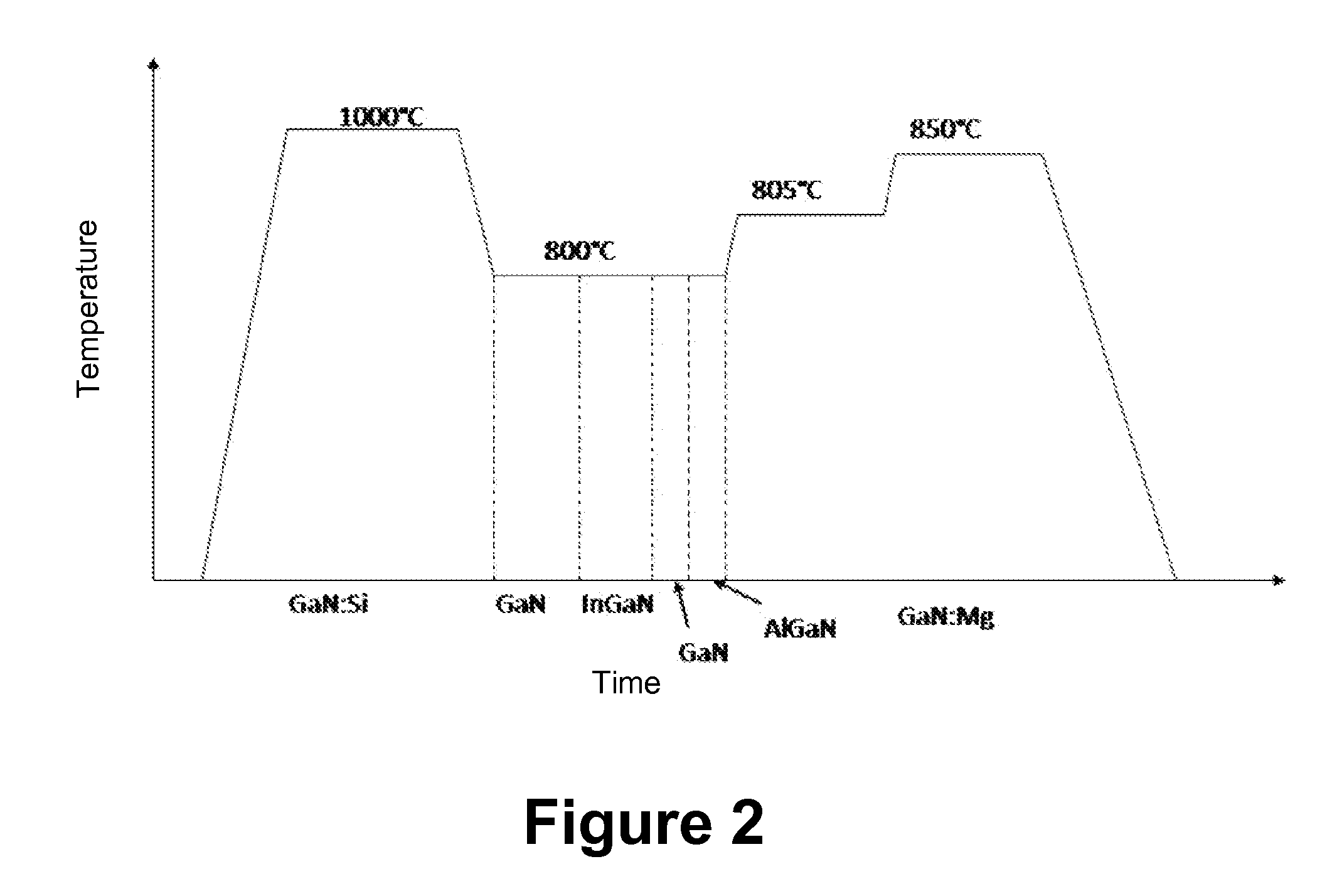

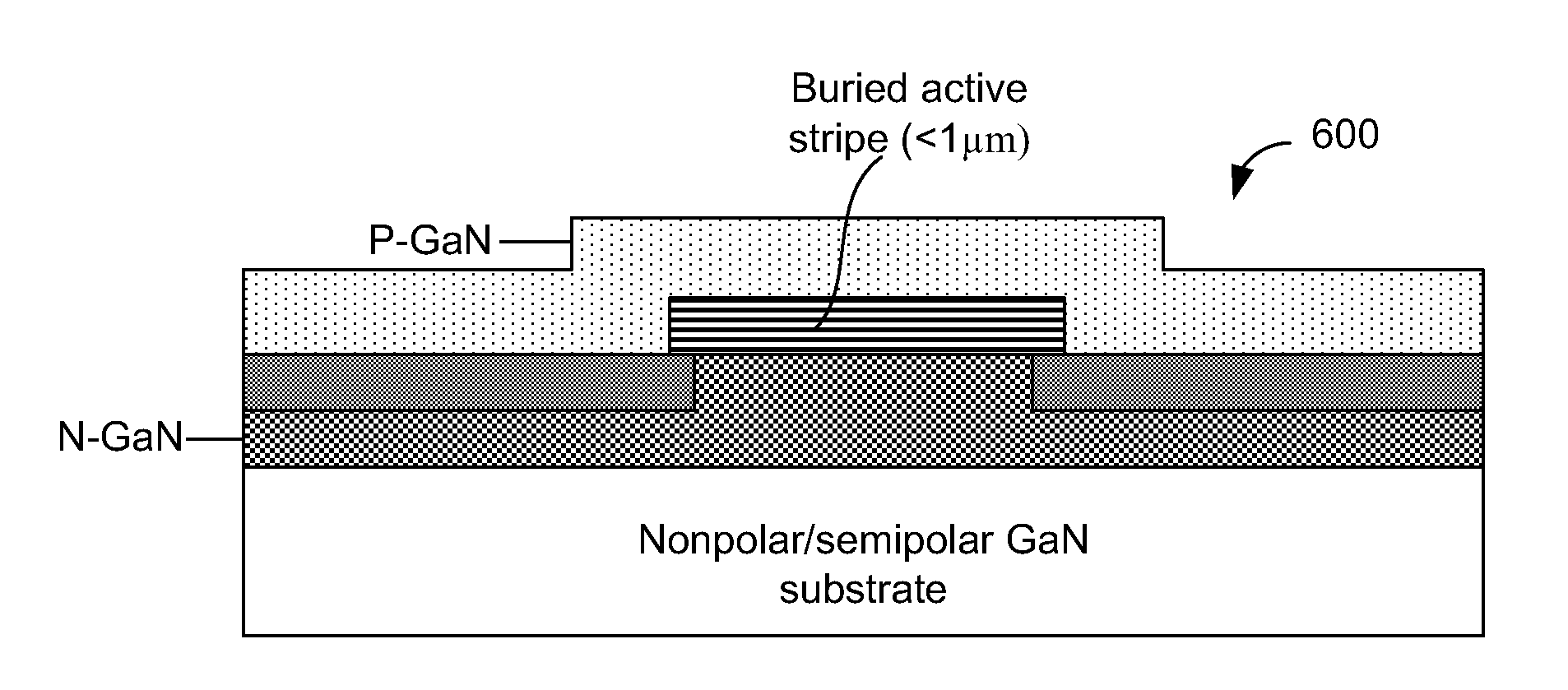

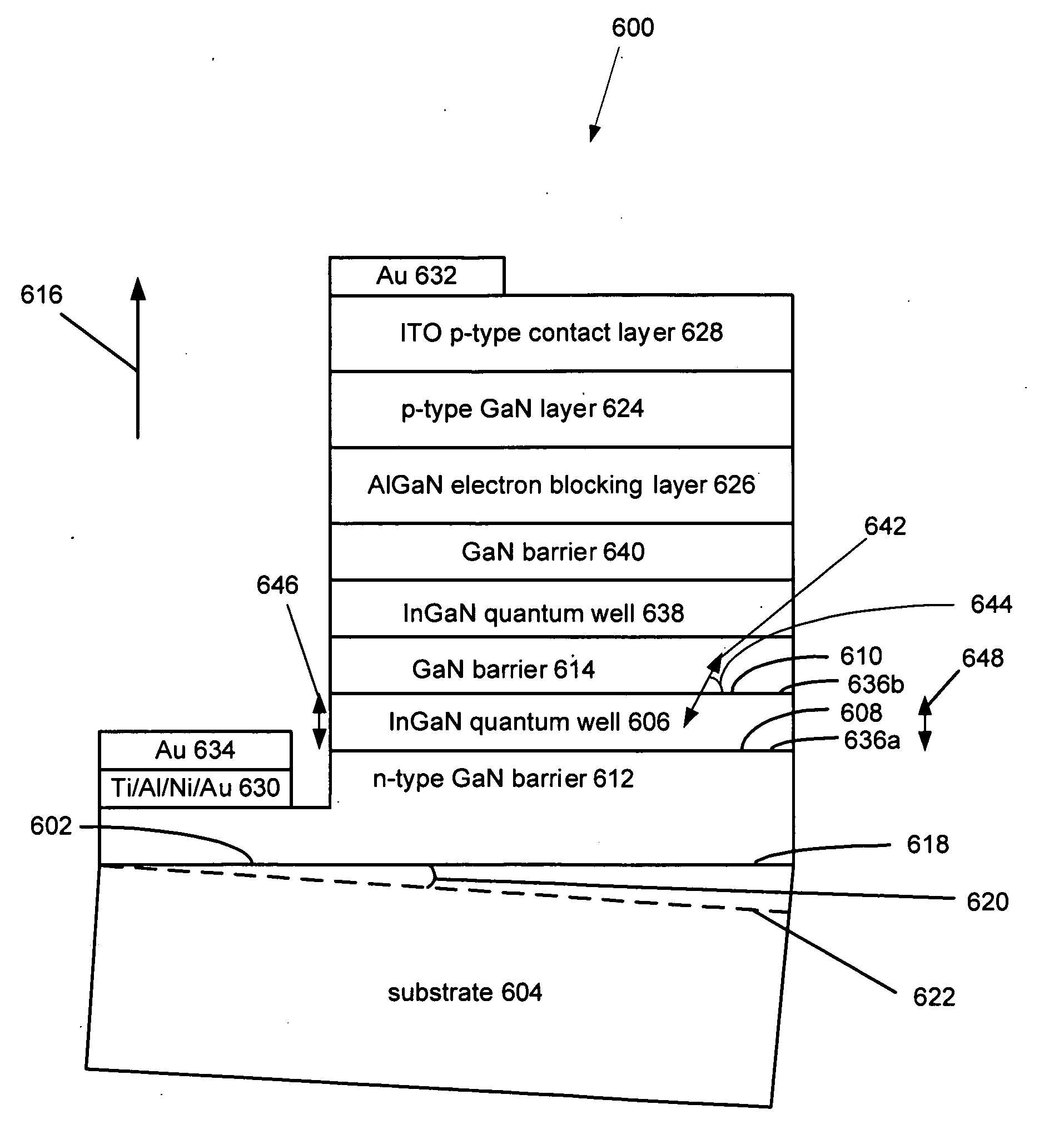

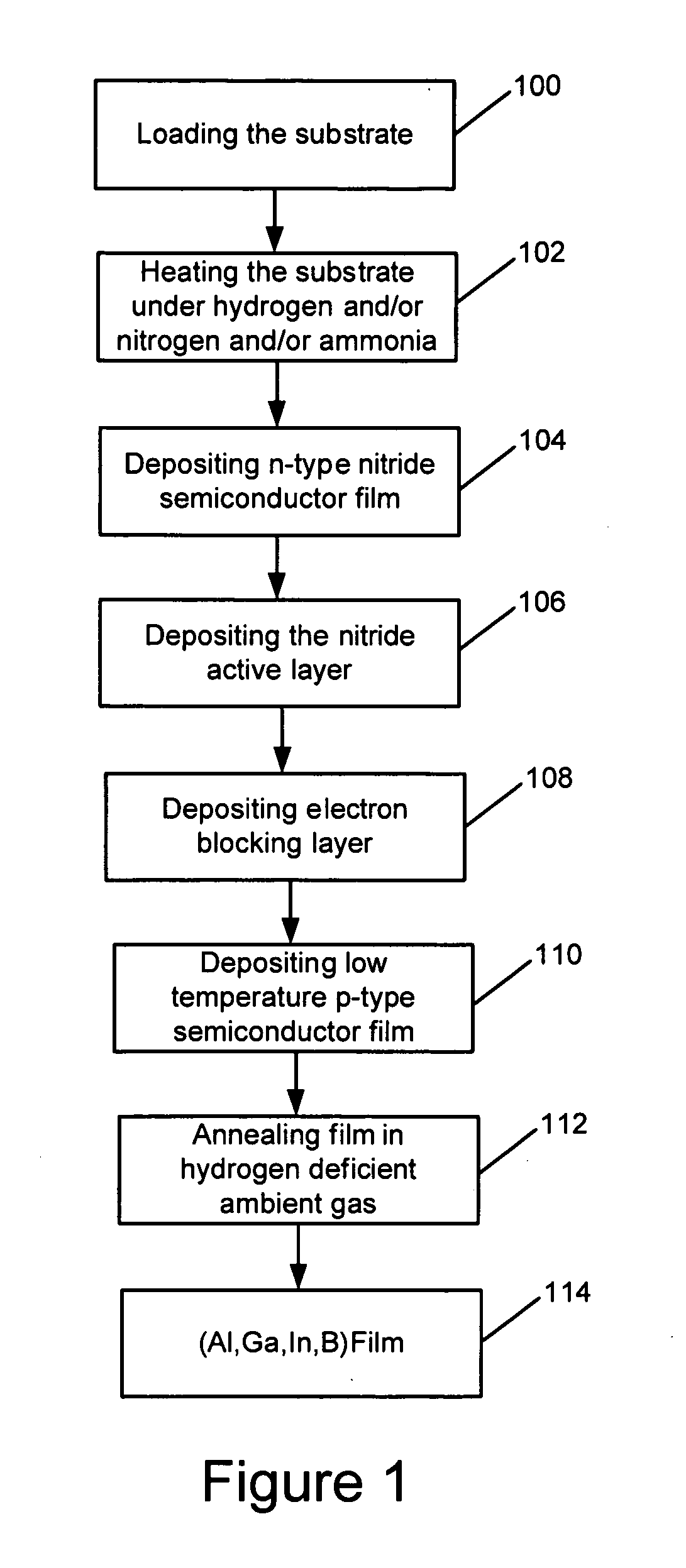

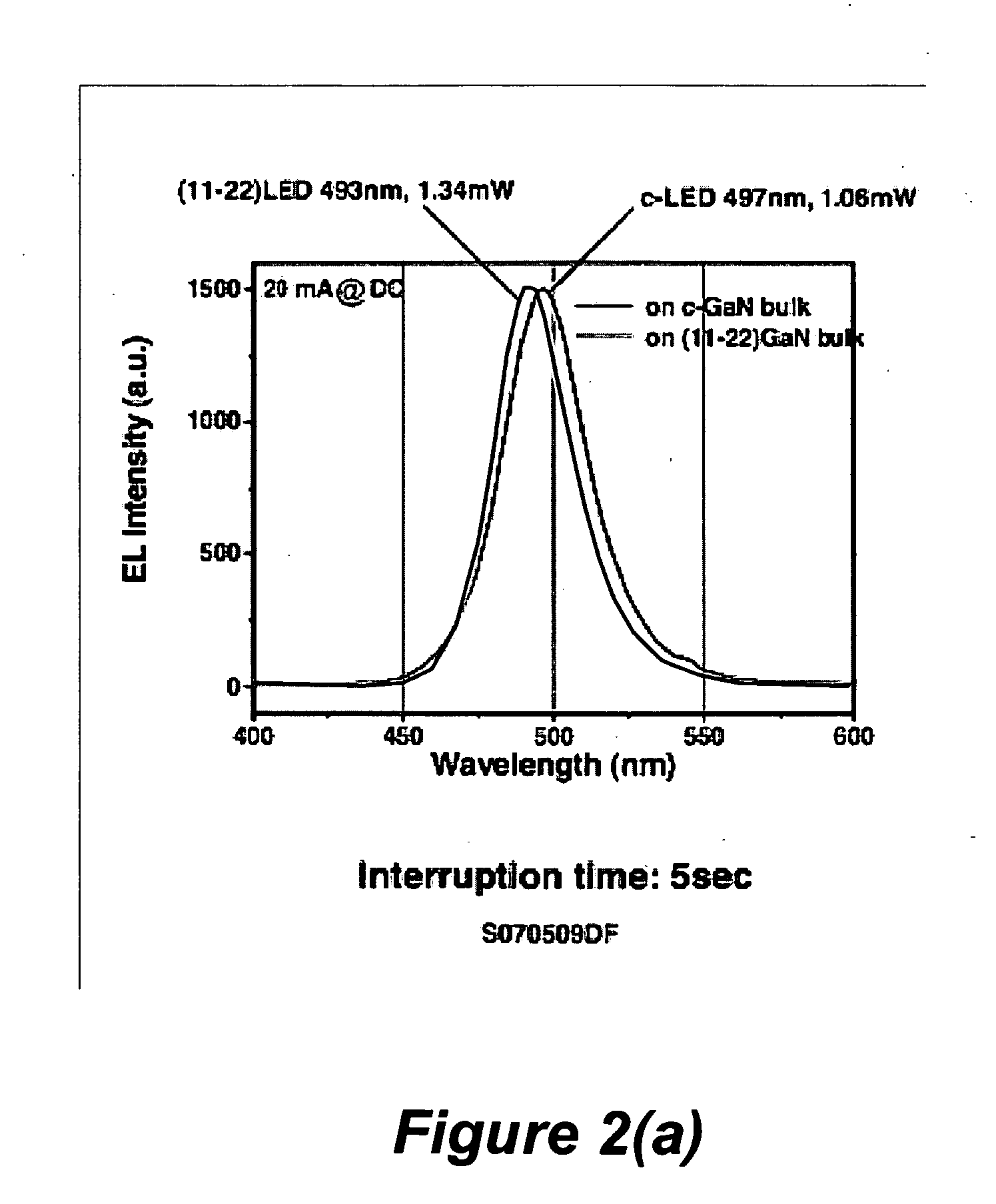

MOCVD GROWTH TECHNIQUE FOR PLANAR SEMIPOLAR (Al, In, Ga, B)N BASED LIGHT EMITTING DIODES

InactiveUS20090310640A1Quality improvementReduced internal electric fieldLaser detailsSemiconductor/solid-state device manufacturingIndiumLength wave

A III-nitride optoelectronic device comprising a light emitting diode (LED) or laser diode with a peak emission wavelength longer than 500 nm. The III-nitride device has a dislocation density, originating from interfaces between an indium containing well layer and barrier layers, less than 9×109 cm−2. The III-nitride device is grown with an interruption time, between growth of the well layer and barrier layers, of more than 1 minute.

Owner:RGT UNIV OF CALIFORNIA

Photovoltaic thin-film cell produced from metallic blend using high-temperature printing

The metallic components of a IB-IIIA-VIA photovoltaic cell active layer may be directly coated onto a substrate by using relatively low melting point (e.g., less than about 500° C.) metals such as indium and gallium. Specifically, CI(G)S thin-film solar cells may be fabricated by blending molten group IIIA metals with solid nanoparticles of group IB and (optionally) group IIIA metals. The molten mixture may be coated onto a substrate in the molten state, e.g., using coating techniques such as hot-dipping, hot microgravure and / or air-knife coating. After coating, the substrate may be cooled and the film annealed, e.g., in a sulfur-containing or selenium-containing atmosphere.

Owner:AERIS CAPITAL SUSTAINABLE IP

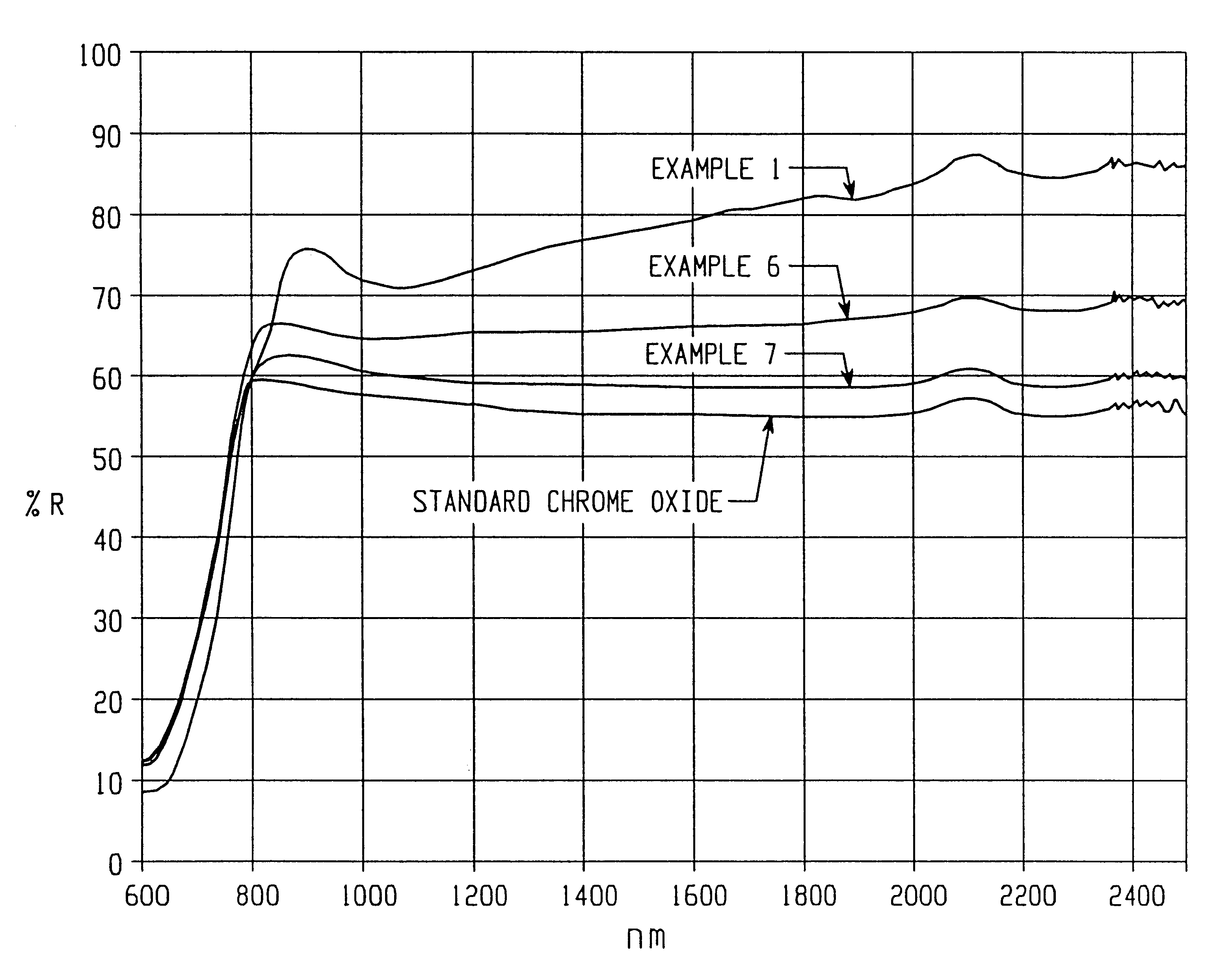

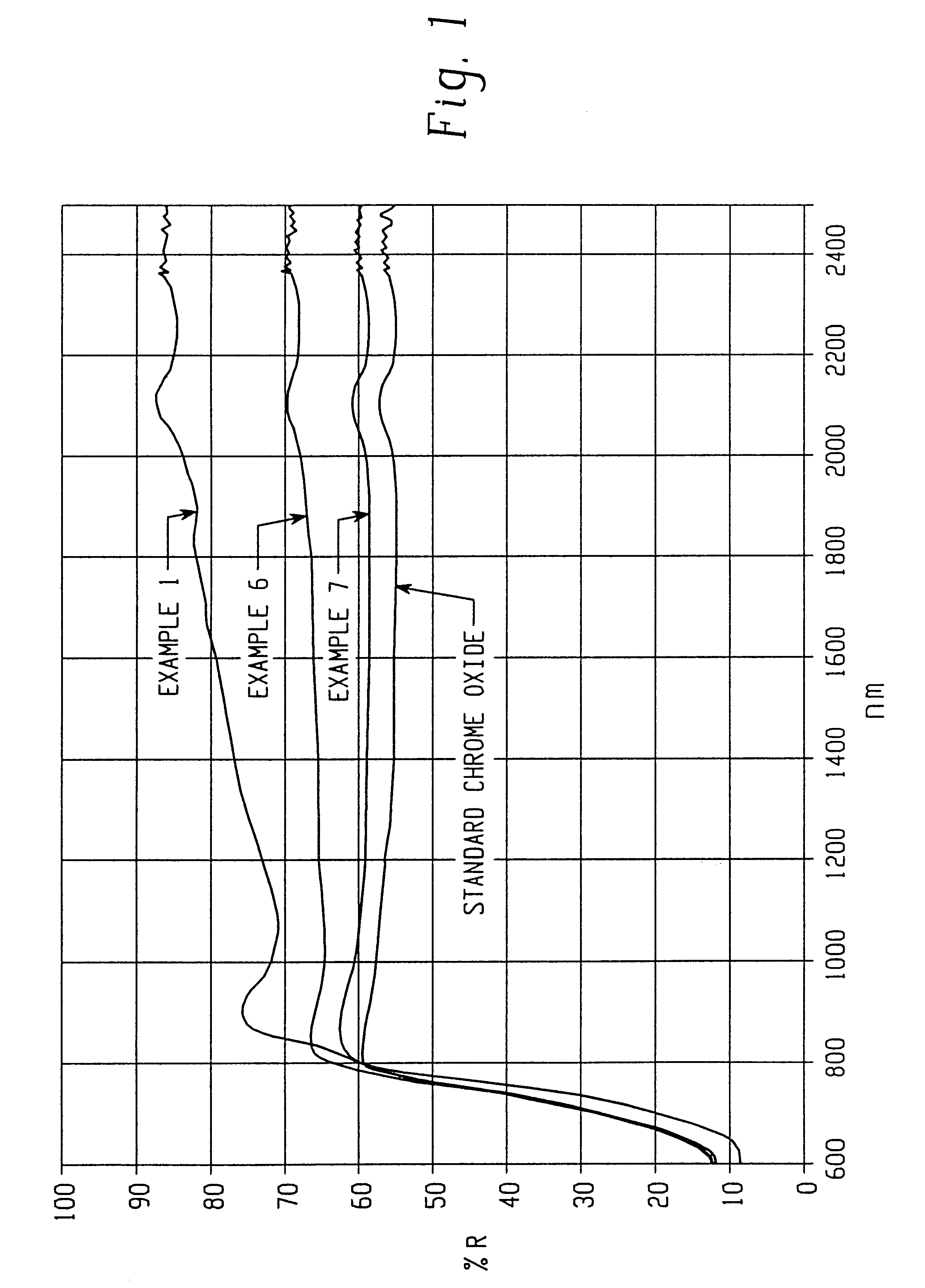

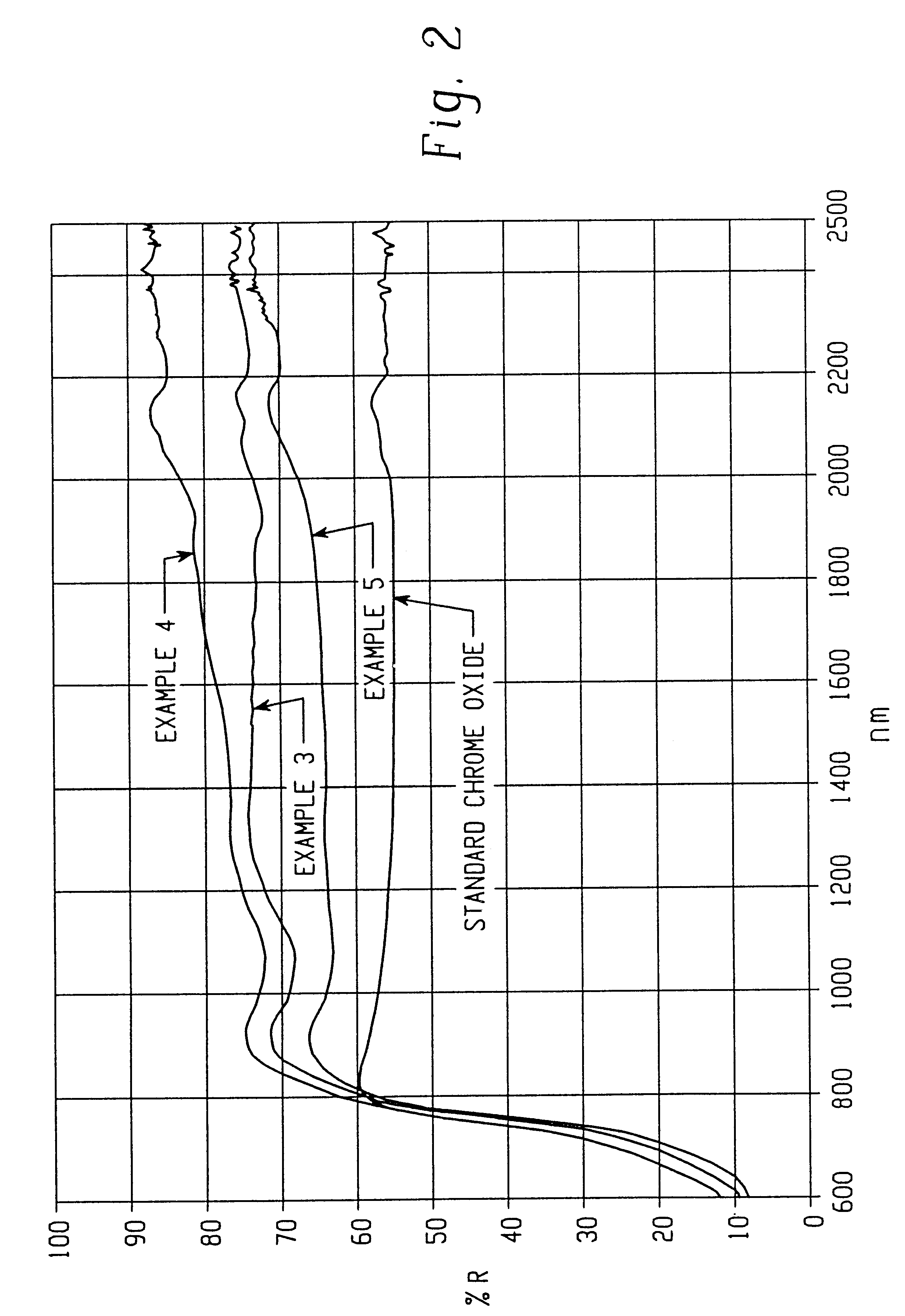

Infrared reflective color pigment

InactiveUS6454848B2Reduce heat buildupReduce energy costsInorganic pigment treatmentCoatingsIndiumCobalt

The present invention provides new solid solutions having a corundum-hematite crystalline structure which are useful as inorganic color pigments. Solid solutions according to the present invention include a host component having a corundum-hematite crystalline structure which contains as guest components one or more elements from the group consisting of aluminum, antimony, bismuth, boron, chrome, cobalt, gallium, indium, iron, lanthanum, lithium, magnesium, manganese, molybdenum, neodymium, nickel, niobium, silicon, tin, titanium, vanadium, and zinc. Solid solutions according to the present invention are formed by thoroughly mixing compounds, usually metal oxides or precursors thereof, which contain the host and guest components and then calcining the compounds to form the solid solutions having the corundum-hematite crystalline structure. Some of the new solid solutions according to the present invention exhibit relatively low Y CIE tri-stimulus values and relatively high near infrared reflectance.

Owner:FERRO CORP

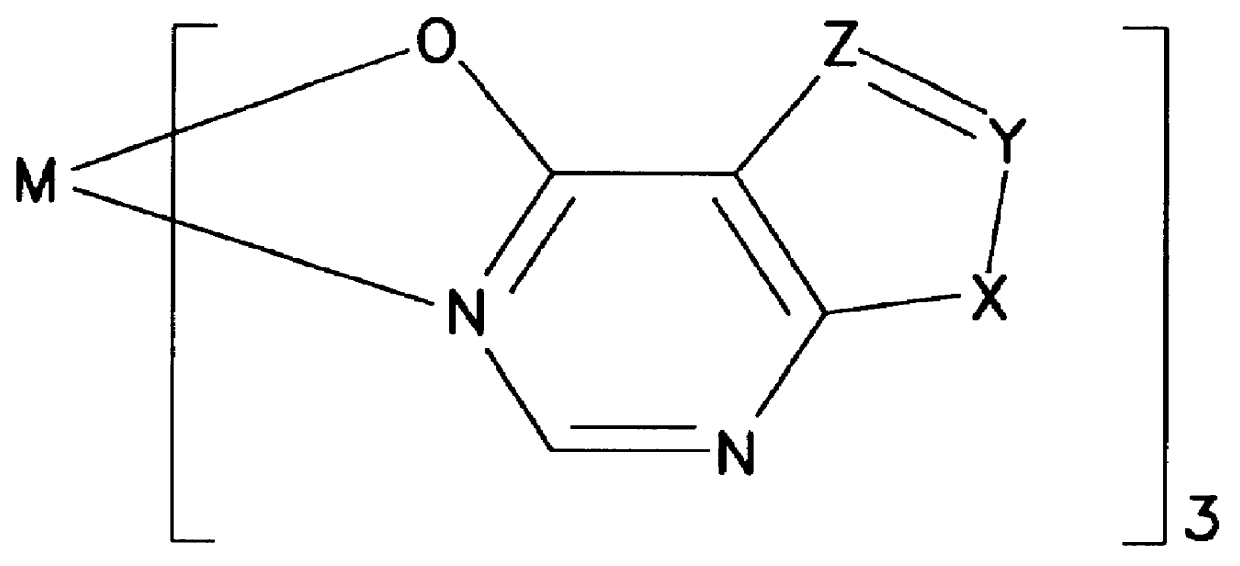

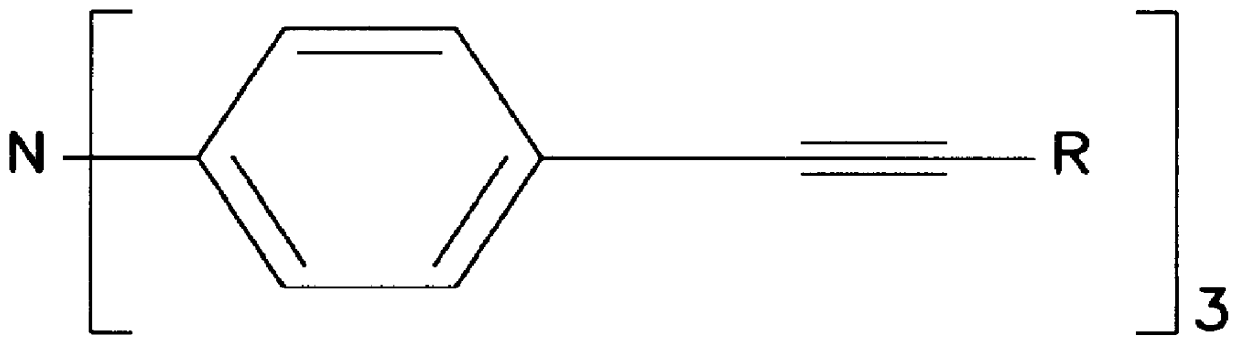

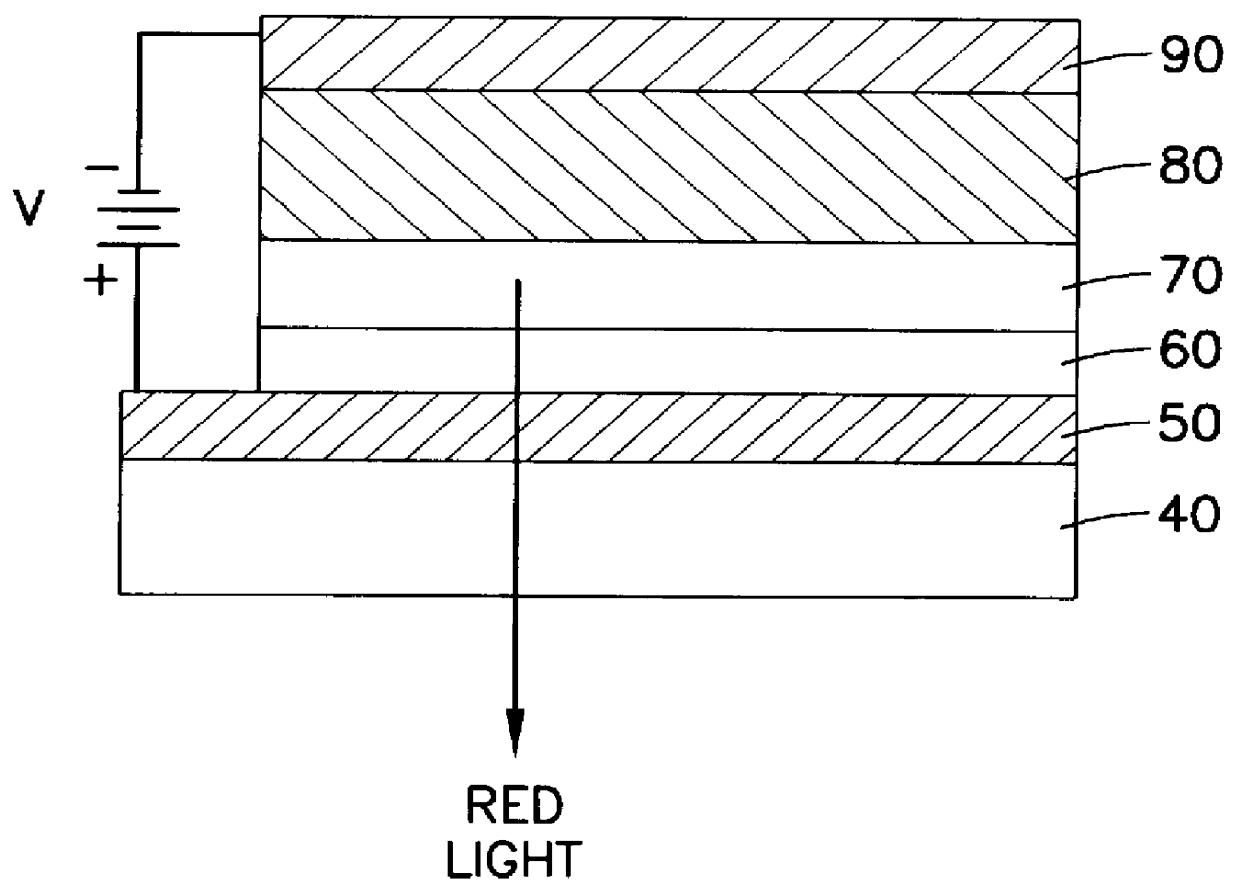

Materials for multicolor light emitting diodes

InactiveUS6045930ADischarge tube luminescnet screensElectroluminescent light sourcesIndiumOrganic light emitting device

Disclosed herein are organic light emitting devices in which emitting layers (EL) comprise a suitable receiving compound according to Formulas I and II: ##STR1## wherein M is an ion of a divalent or trivalent metal atom, wherein n=3 when M is trivalent, and n=2 when M is divalent, wherein the metal atom is selected from the group consisting of aluminum, gallium, indium, and zinc, and wherein X, Y, and Z are each individually and independently C or N, such that at least two of X, Y and Z are N; and ##STR2## wherein R is alkyl, phenyl, substituted alkyl, substituted phenyl, trimethylsilyl, or substituted trimethylsilyl. Also disclosed are OLED's utilizing device elements comprising the above compounds and display devices based on those OLED's.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Semiconductor device and method for manufacturing the same

ActiveUS20100117073A1Small parasitic capacitanceHigh on-off ratioTransistorElectroluminescent light sourcesIndiumNitrogen

In a thin film transistor which uses an oxide semiconductor, buffer layers containing indium, gallium, zinc, oxygen, and nitrogen are provided between the oxide semiconductor layer and the source and drain electrode layers.

Owner:SEMICON ENERGY LAB CO LTD

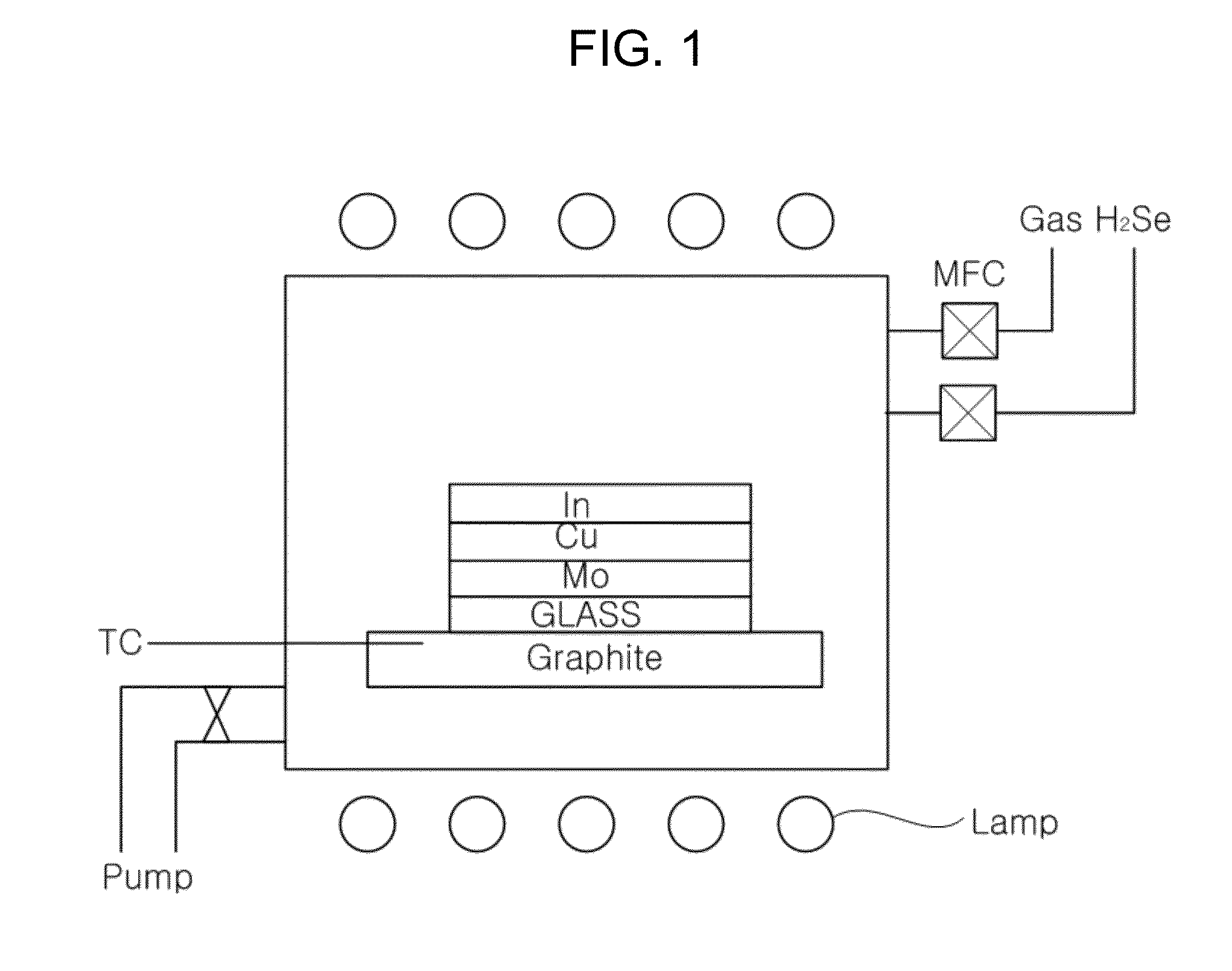

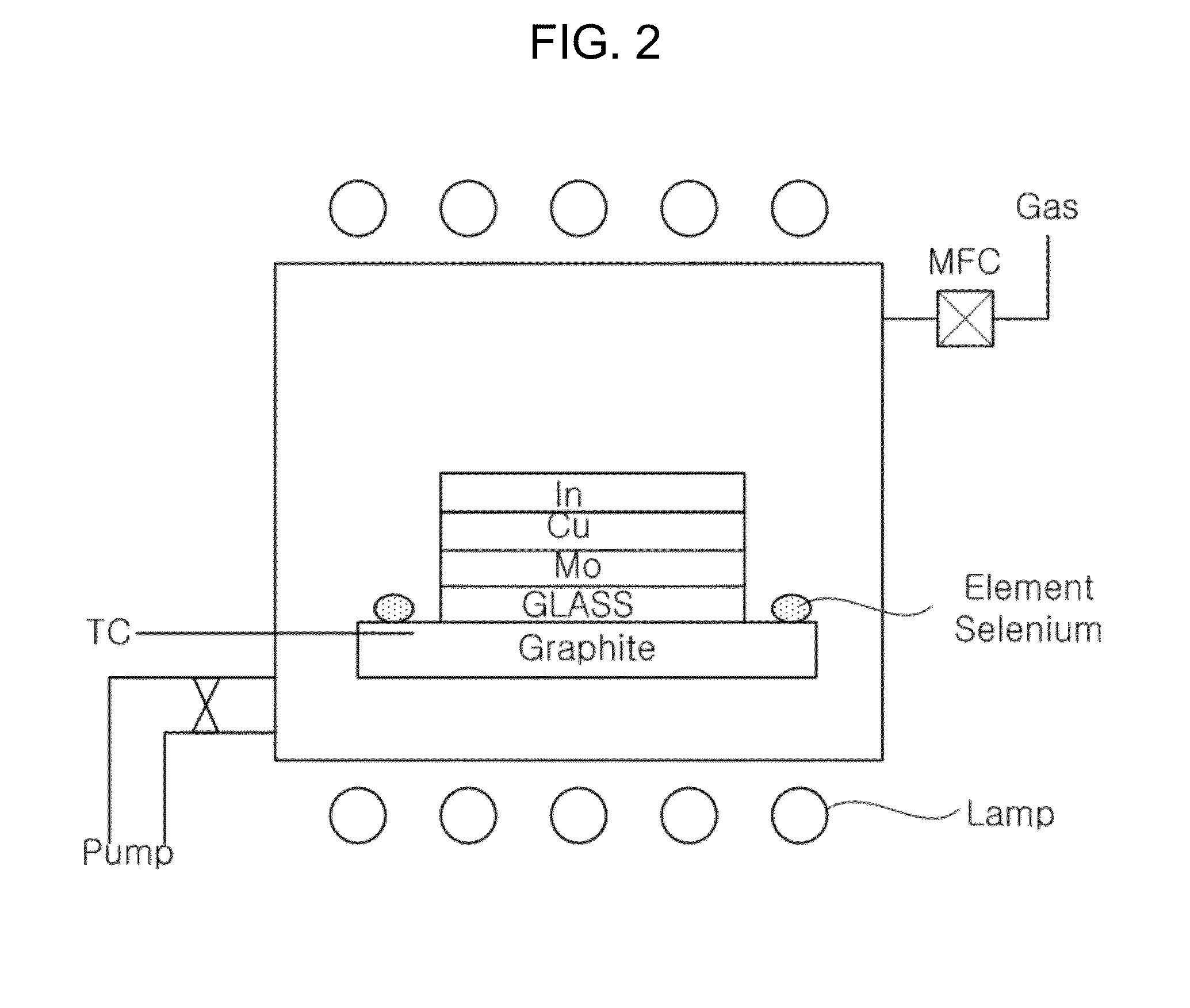

Method of manufacturing light - absorbtion layer of solar cell through selenization process under elemental selenium vapor atmosphere and thermal processing apparatus for manufacturing light - absorbing layer

InactiveUS20140073082A1Low production costImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSusceptorIndium

The method of manufacturing a light absorbing layer for a solar cell by performing thermal treatment on a specimen configured to include thin films of one or more of copper, indium, and gallium on a substrate and element selenium, includes steps of: (a) heating a wall of a chamber up to a predefined thin film formation temperature in order to maintain a selenium vapor pressure; (b) mounting the specimen and the element selenium on the susceptor at the room temperature and loading the susceptor in the chamber; and (c) heating the specimen in the lower portion of the susceptor and, at the same time, heating the element selenium in the upper portion of the susceptor, wherein, in the step (c), in order for liquefied selenium not to be condensed on the specimen which is loaded at the room temperature and is not yet heated, the temperature of the element selenium and the specimen loaded in the chamber are individually controlled, so that the selenium vapor pressure of an inner space of the chamber does not exceed a saturation vapor pressure corresponding to the temperature of the specimen.

Owner:SOLARDIN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com