Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24522 results about "Chromium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard and brittle transition metal. Chromium is the main additive in stainless steel, to which it adds anti-corrosive properties. Chromium is also highly valued as a metal that is able to be highly polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, with almost 90% of infrared light being reflected. The name of the element is derived from the Greek word χρῶμα, chrōma, meaning color, because many chromium compounds are intensely colored.

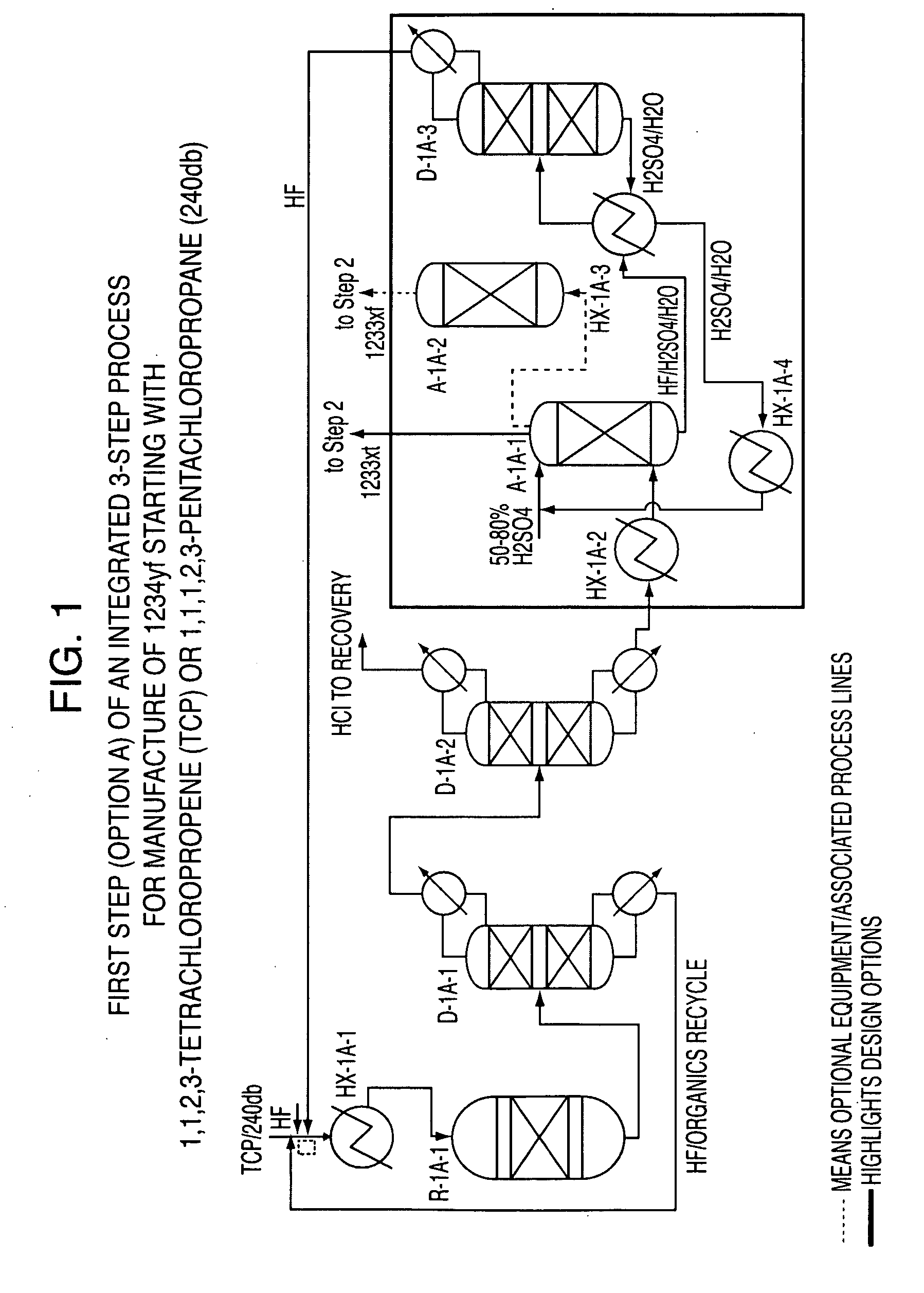

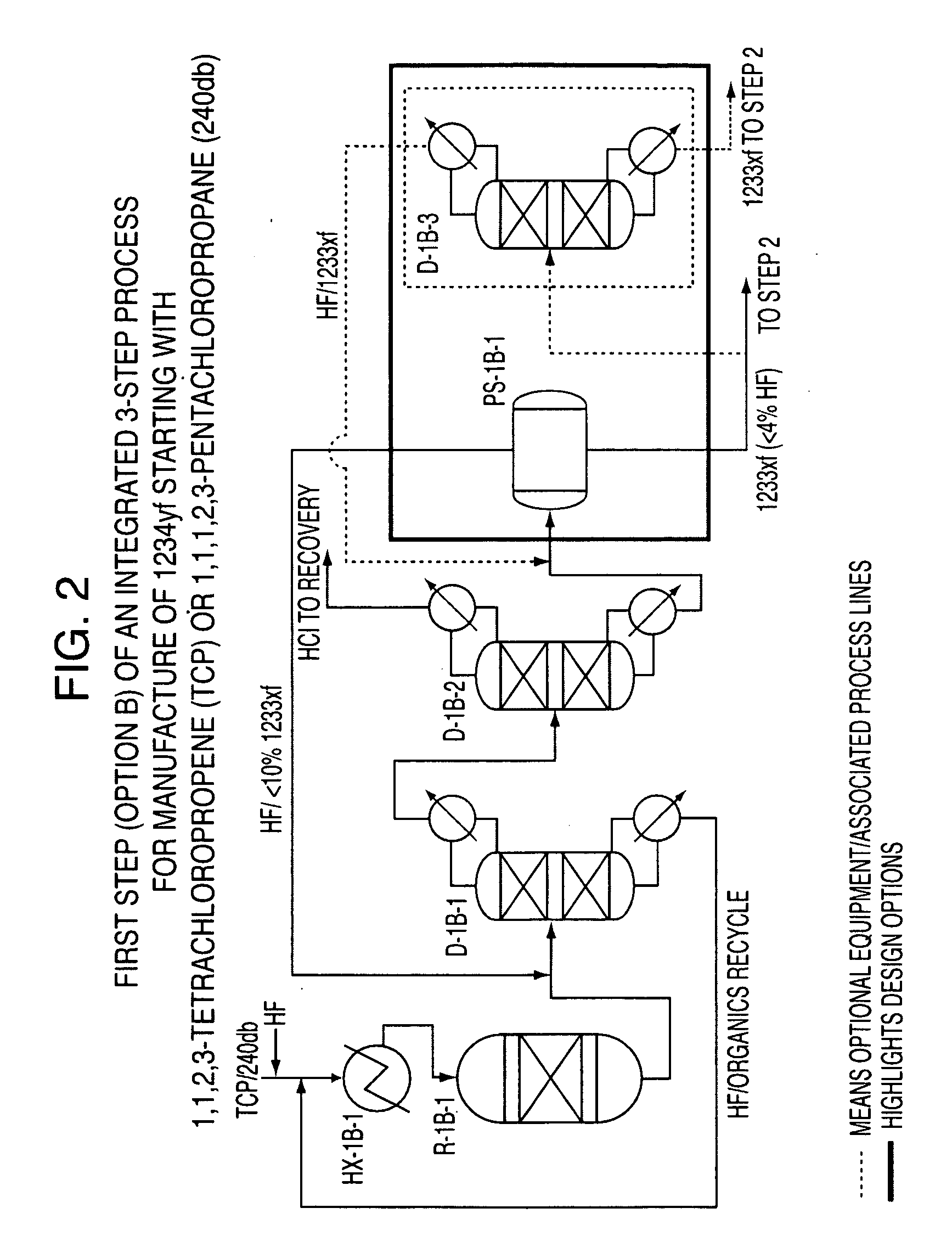

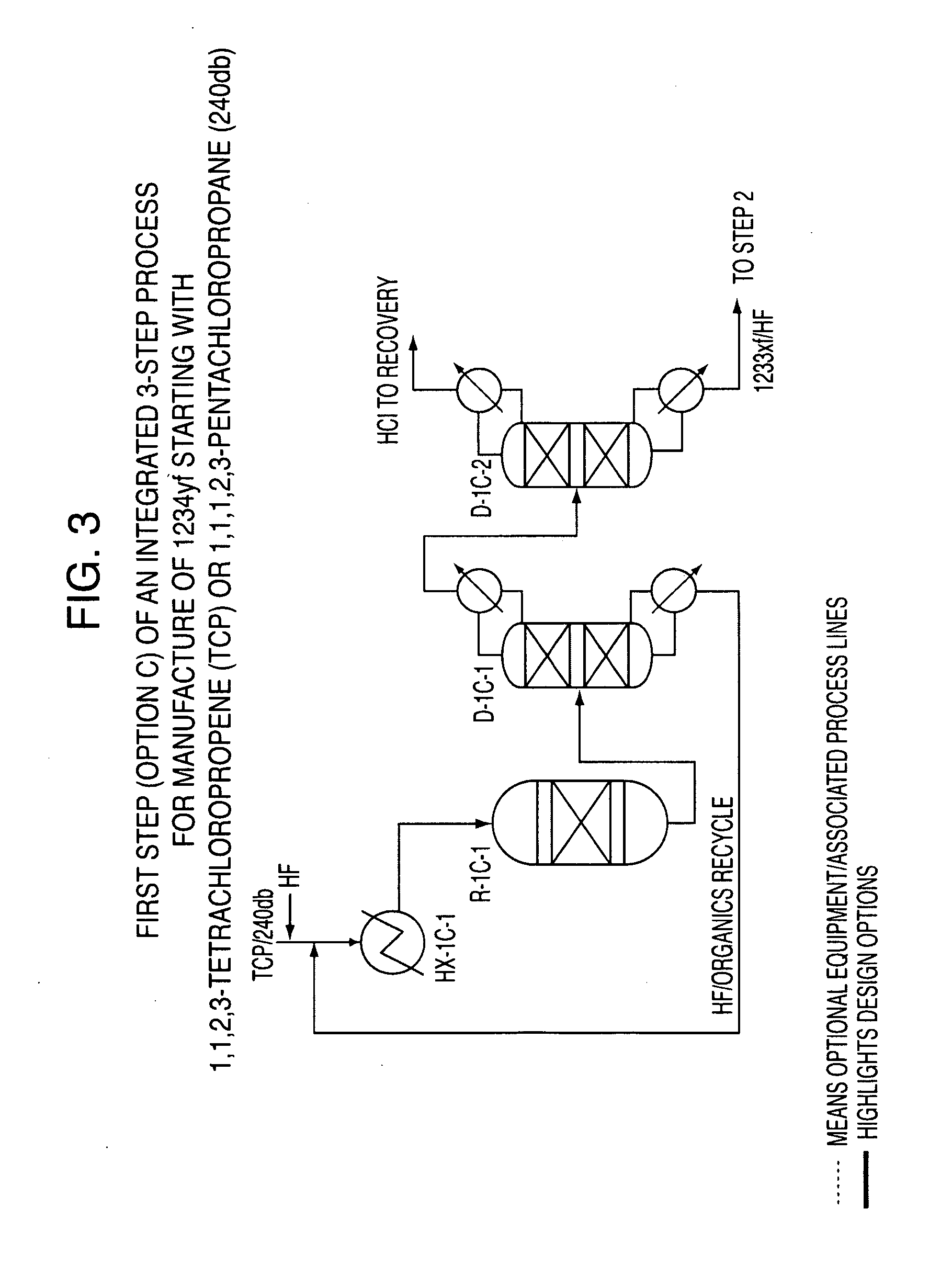

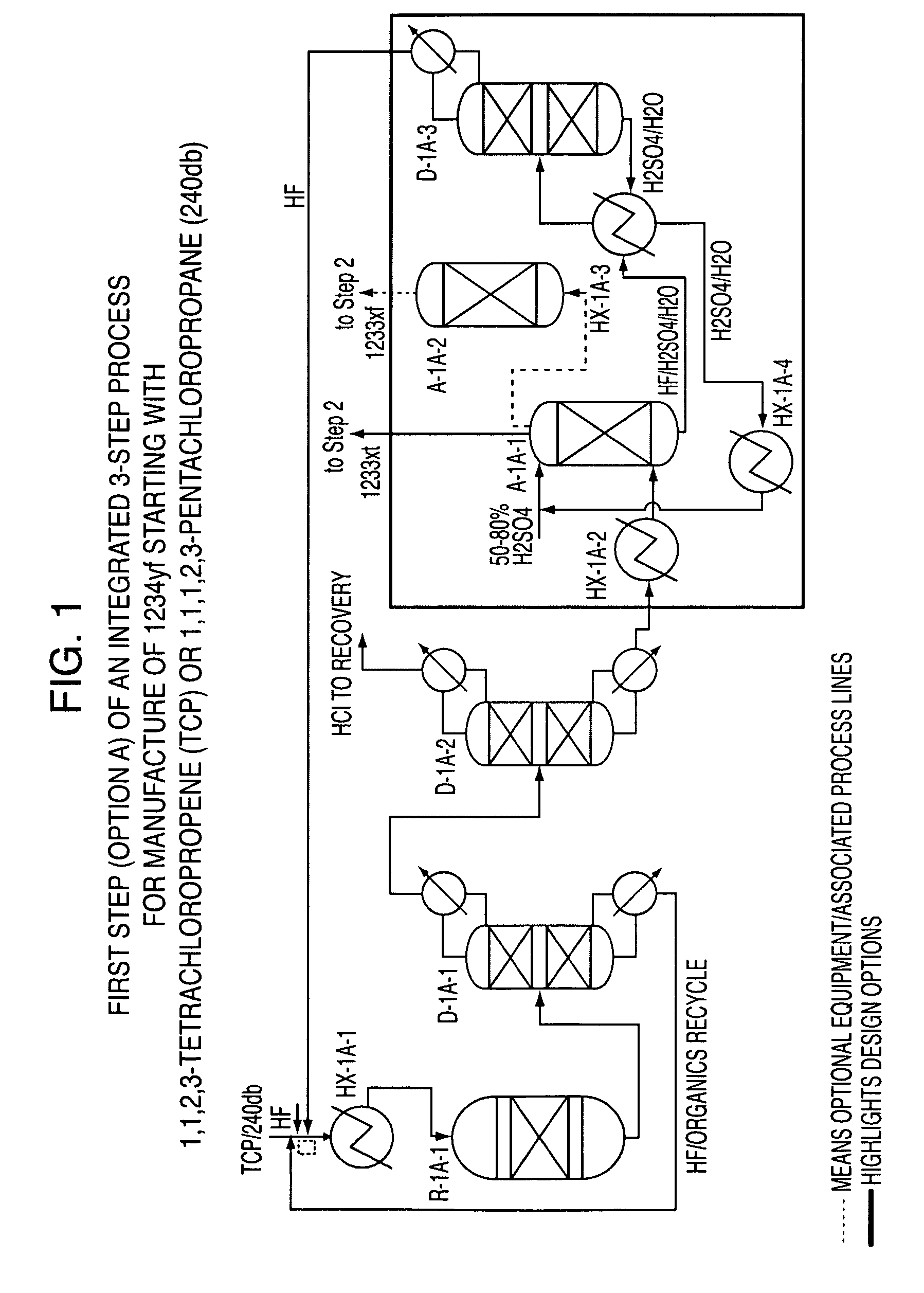

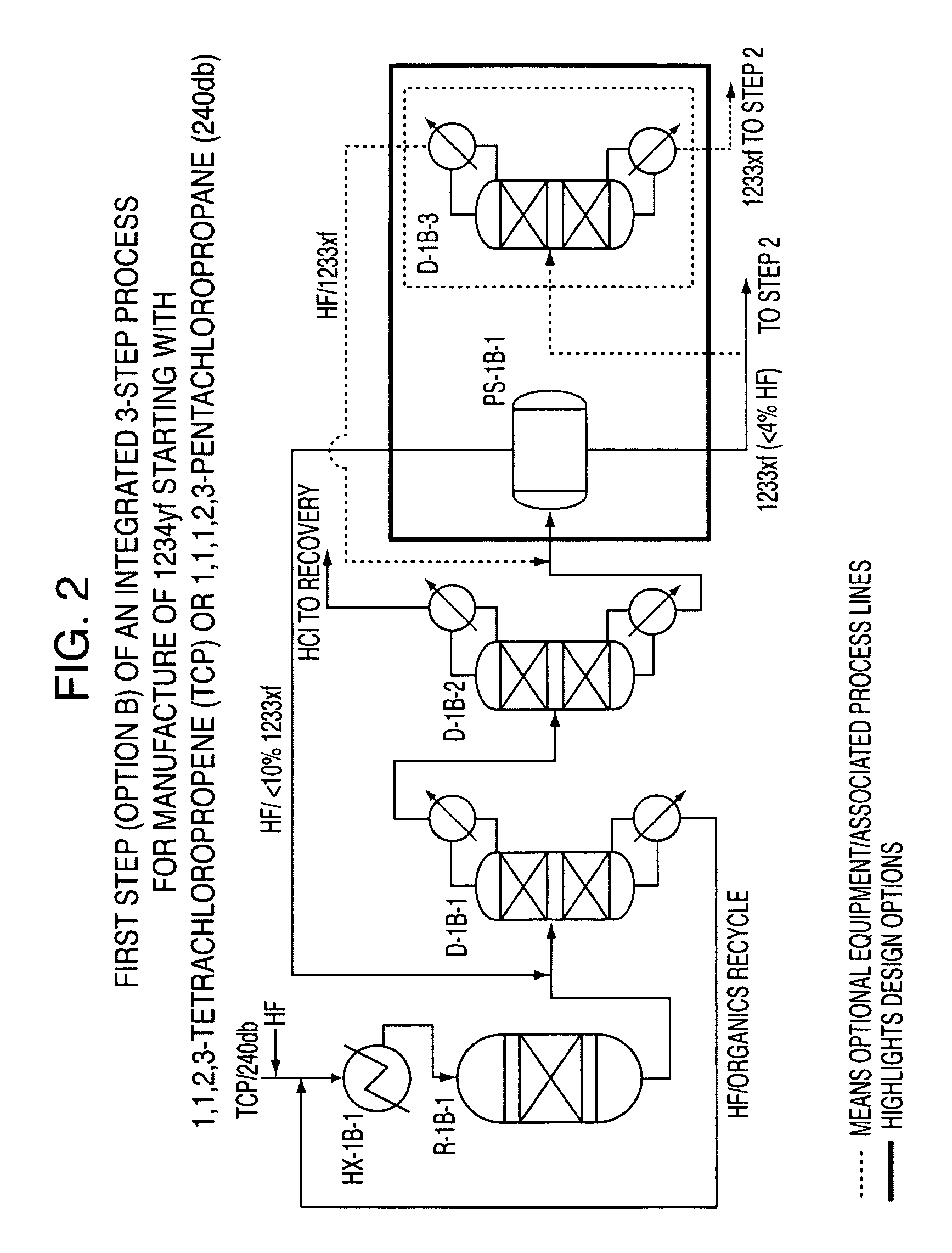

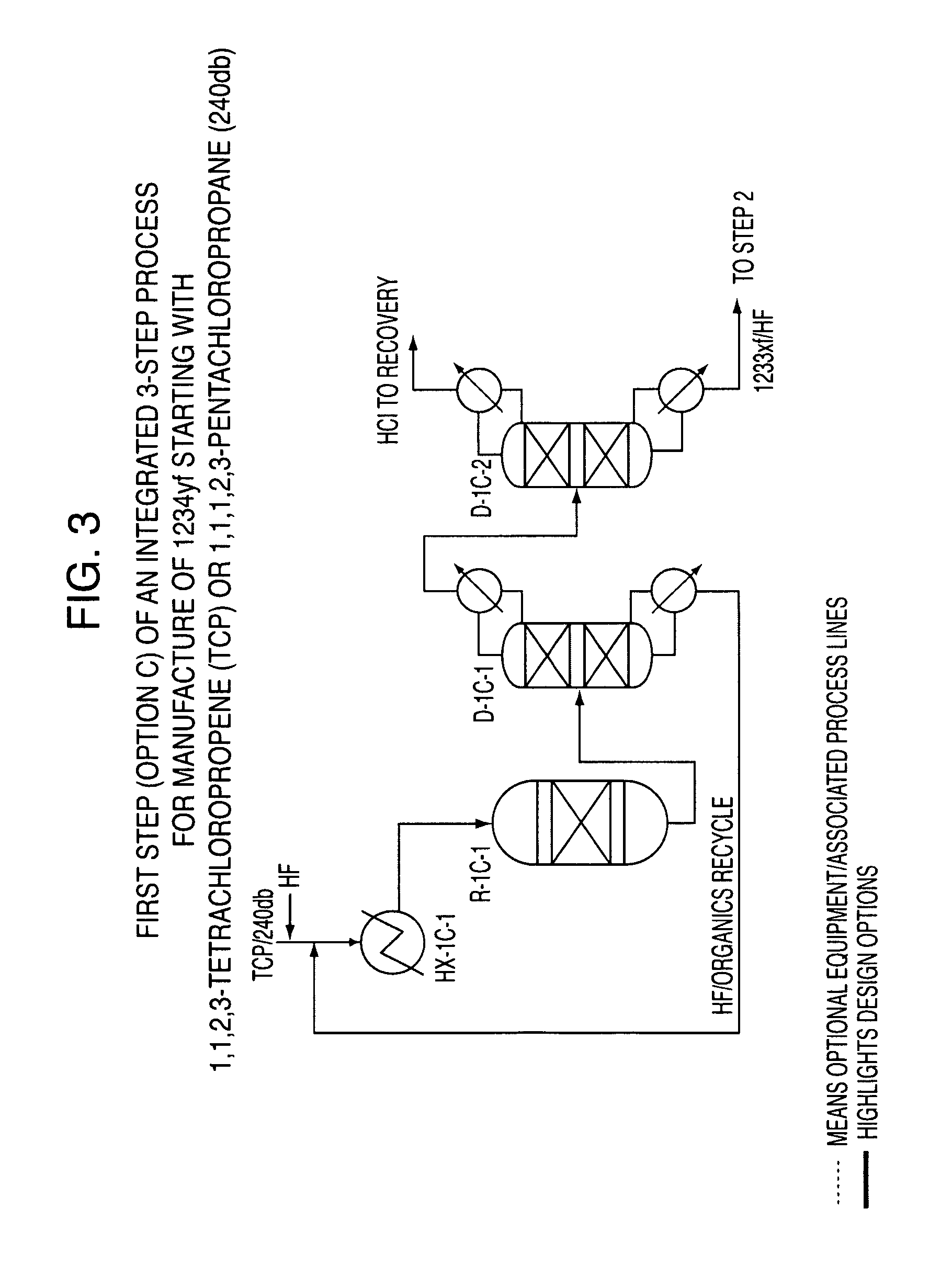

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS20090240090A1Maximize raw material utilizationMaximize product yieldPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

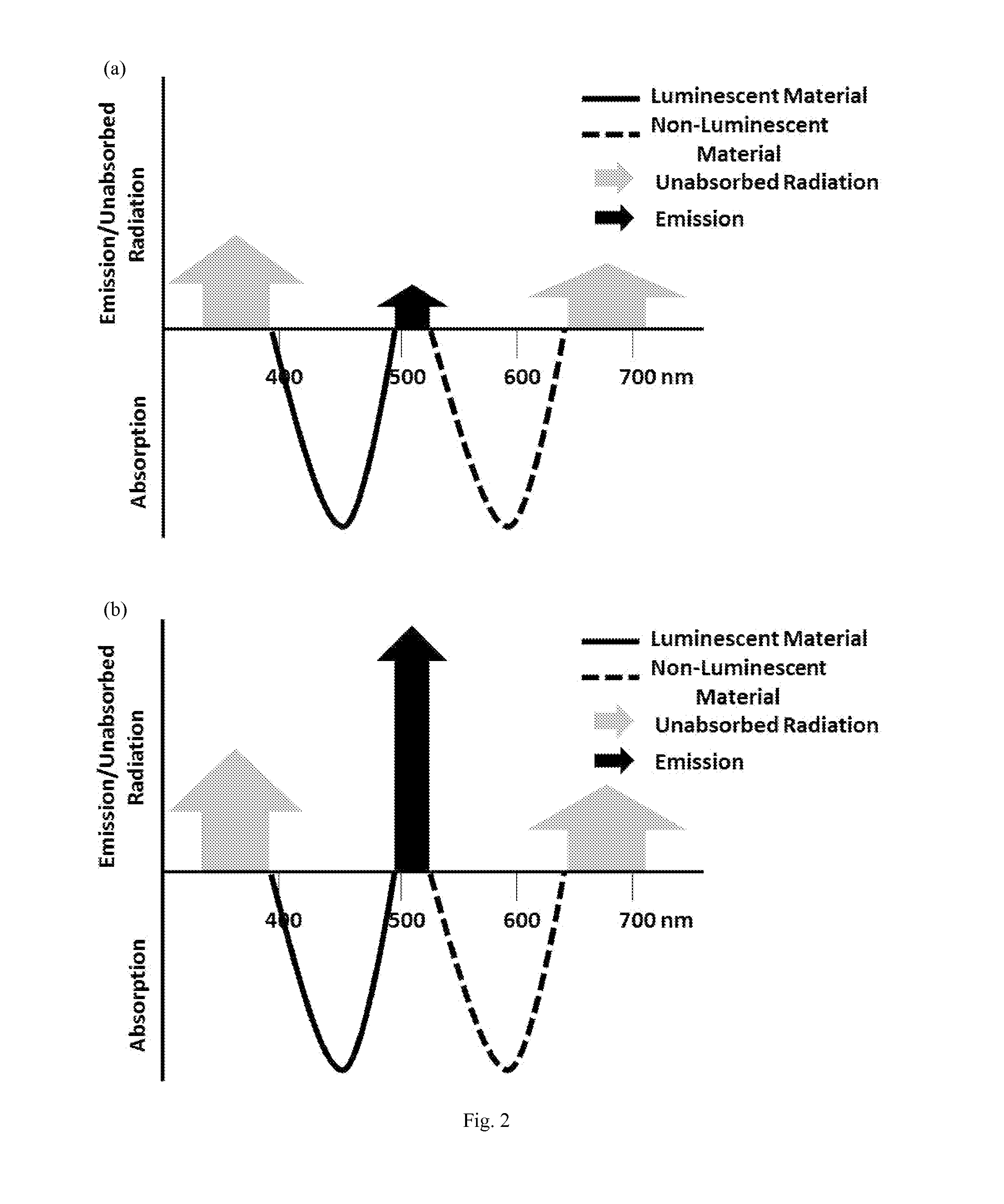

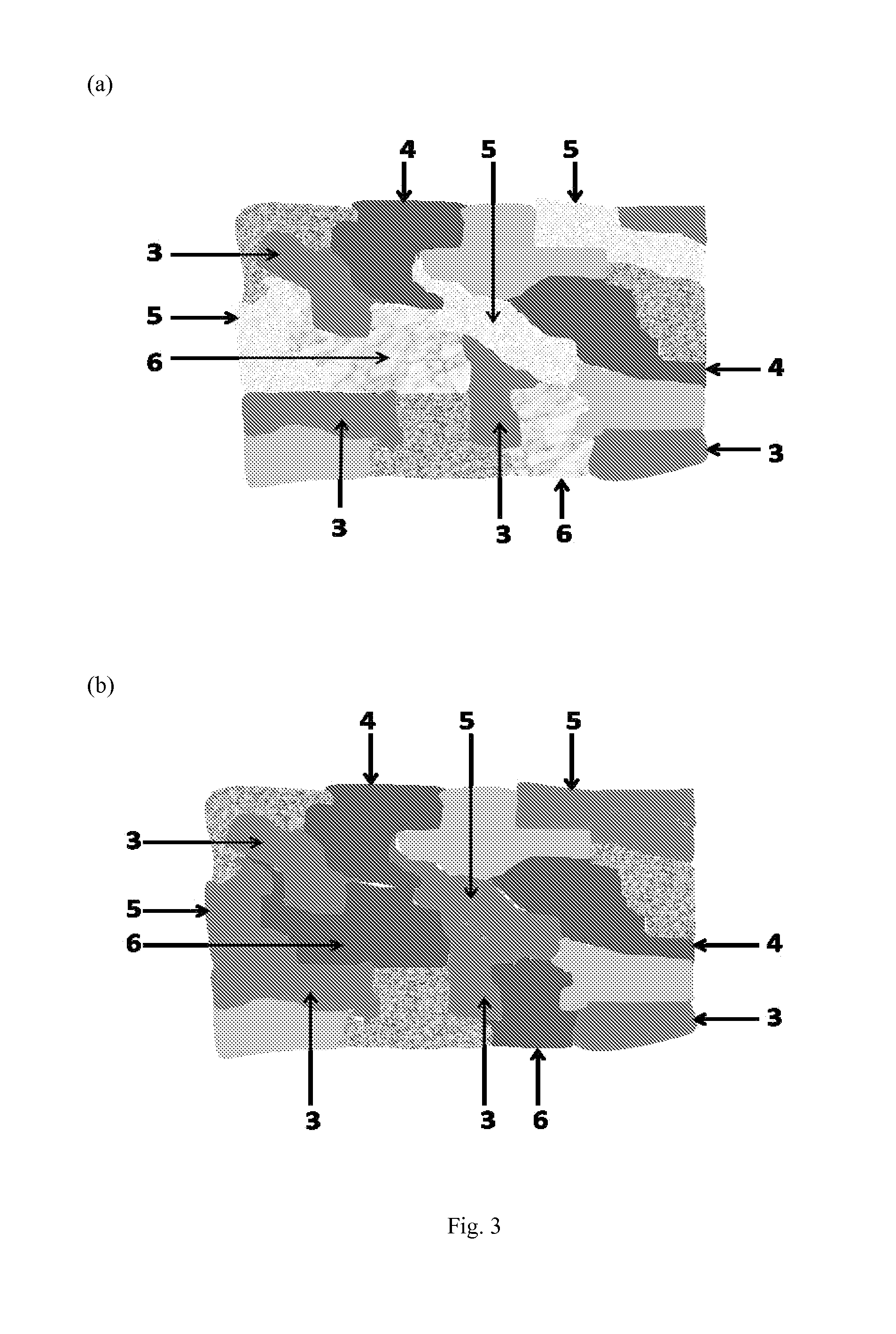

Chromic luminescent compositions and textiles

ActiveUS20140103258A1Electrical apparatusElectroluminescent light sourcesElectromagnetic radiationLength wave

Owner:PERFORMANCE INDICATOR LLC

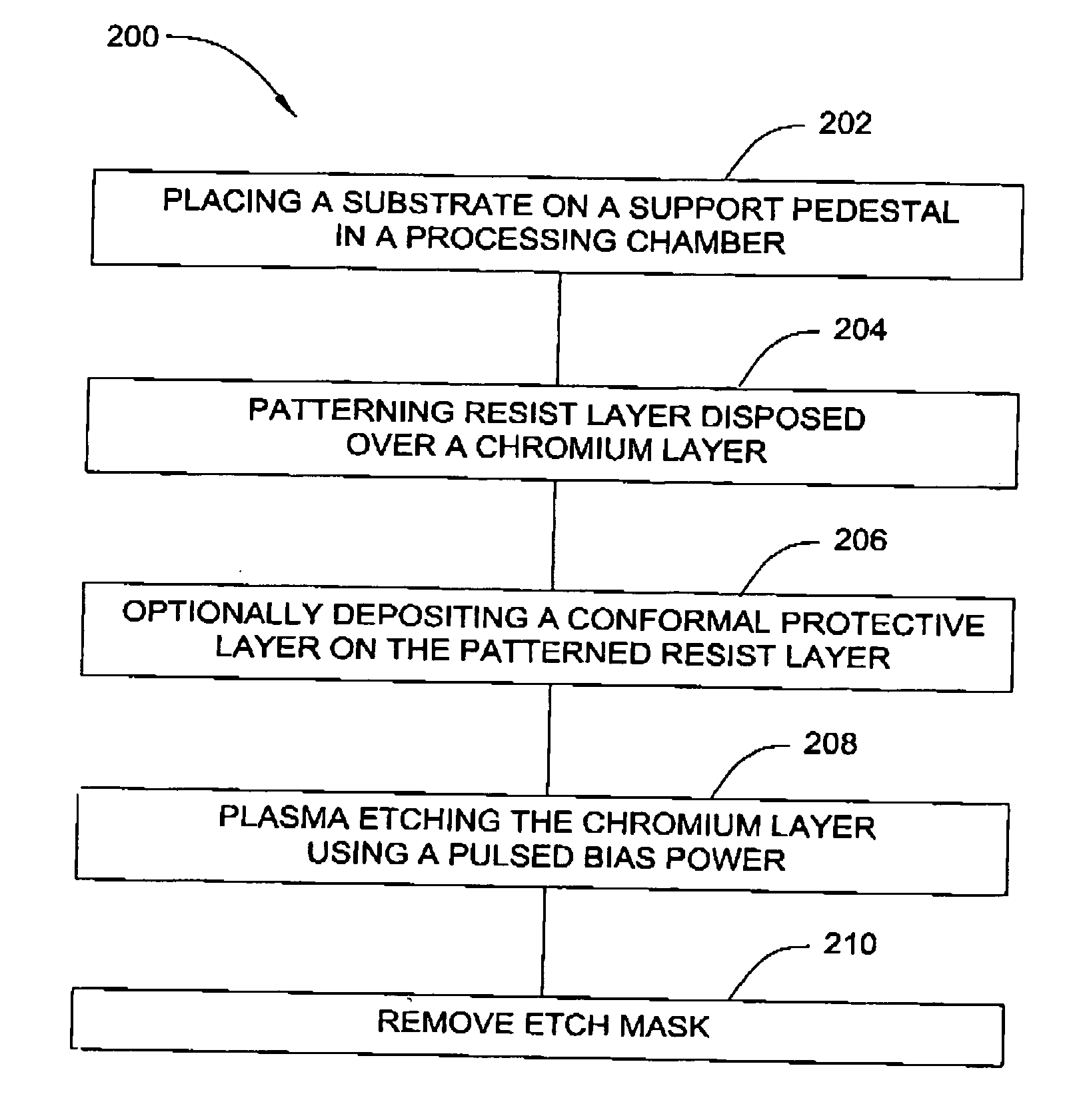

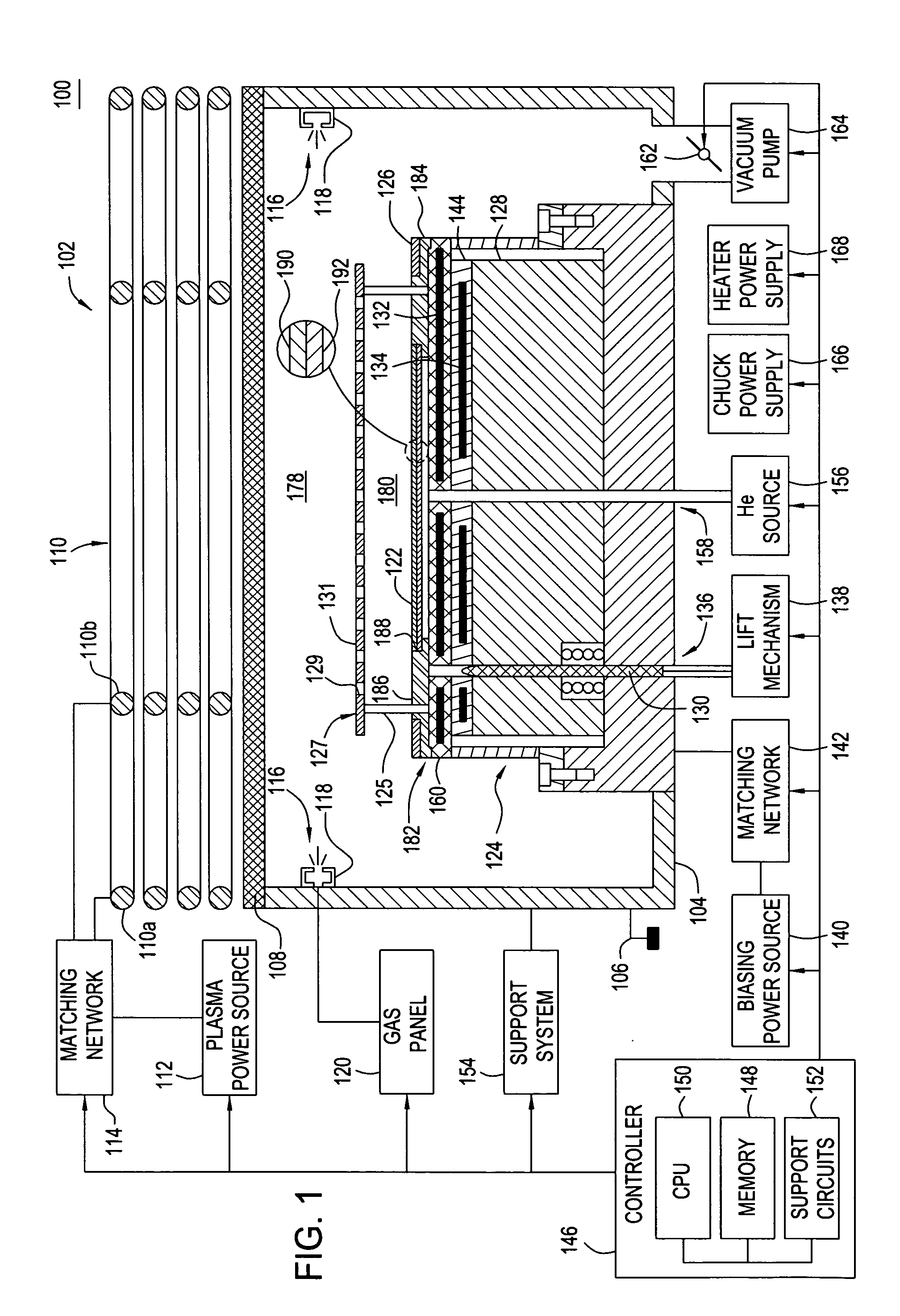

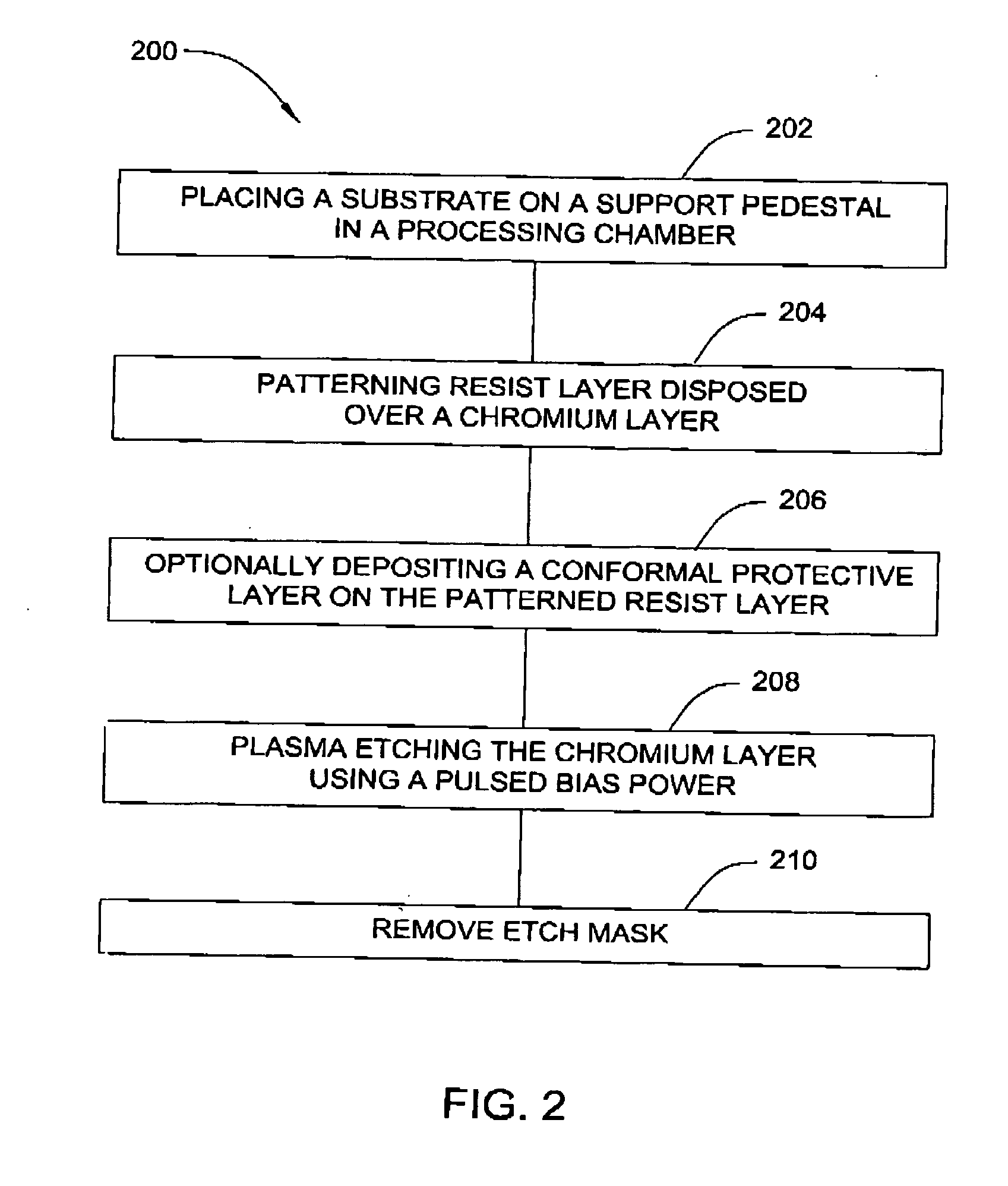

Method for plasma etching a chromium layer suitable for photomask fabrication

A method for etching a chromium layer is provided herein. In one embodiment, a method for etching a chromium layer includes providing a filmstack in an etching chamber, the filmstack having a chromium layer partially exposed through a patterned layer, providing at least one halogen containing process gas to a processing chamber, biasing the layer disposed on a substrate support in the processing chamber with a plurality of power pulses less than 600 Watts, and etching the chromium layer through a patterned mask. The method for plasma etching a chromium layer described herein is particularly suitable for fabricating photomasks.

Owner:APPLIED MATERIALS INC

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS8058486B2Maximize utilizationYield maximizationPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

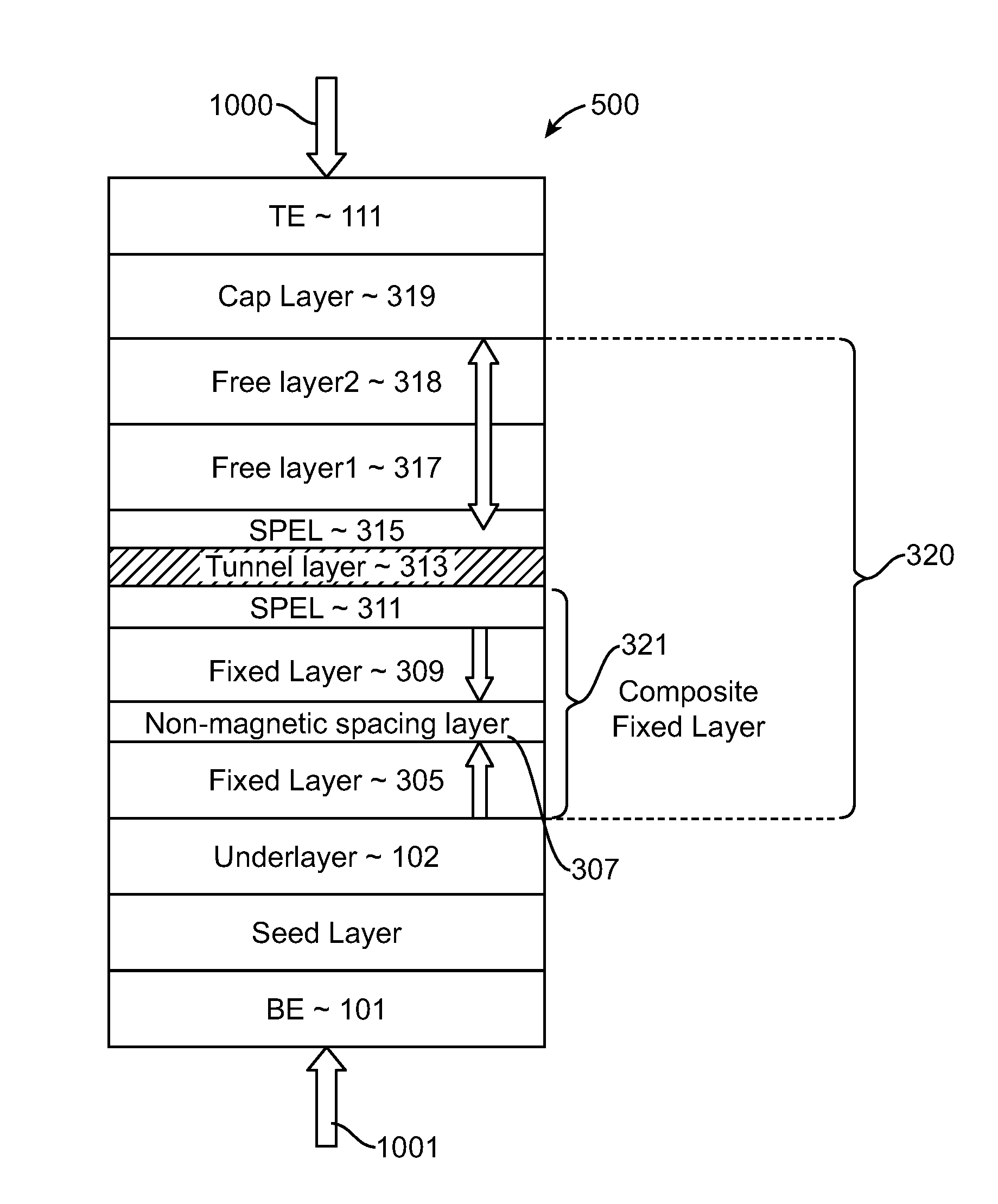

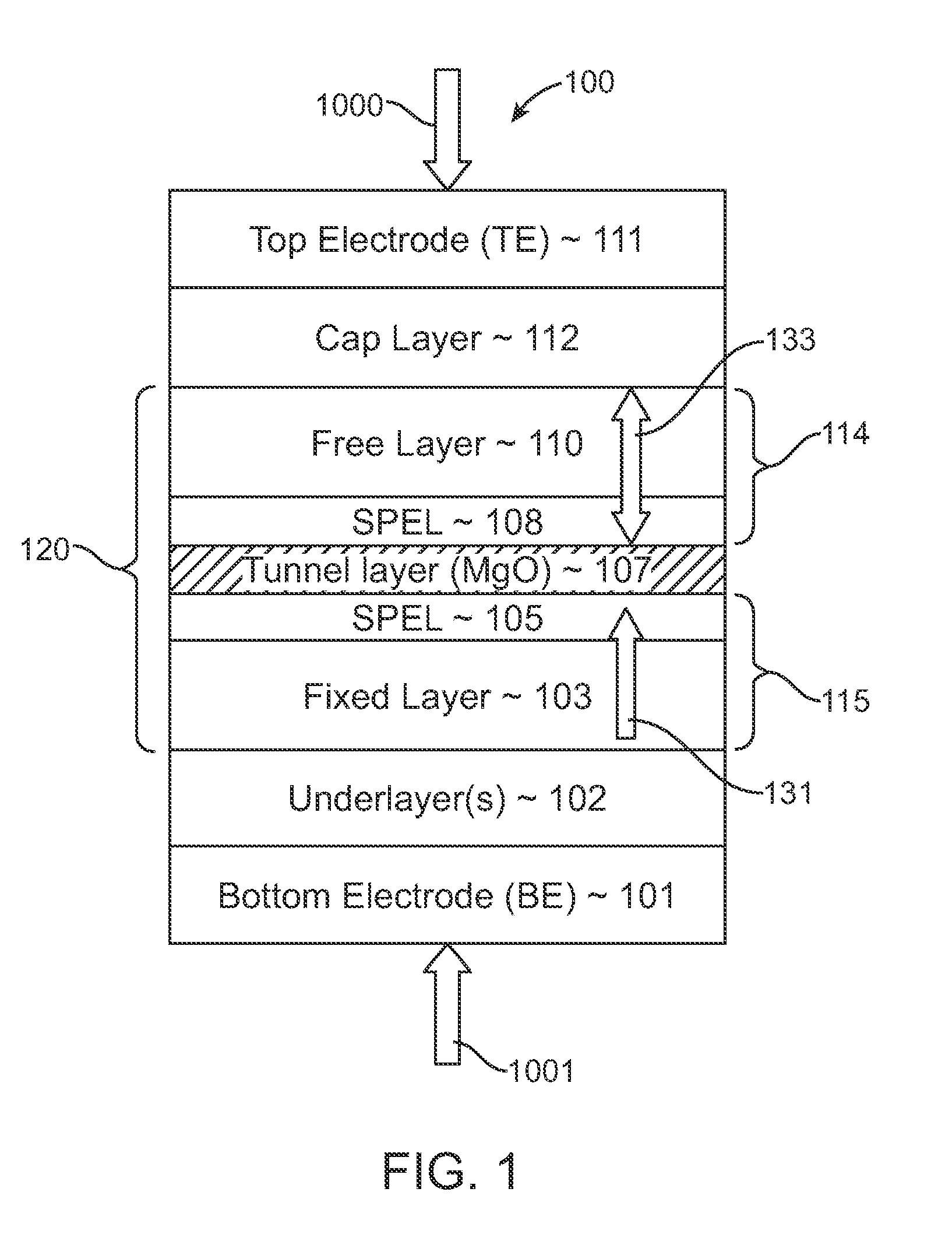

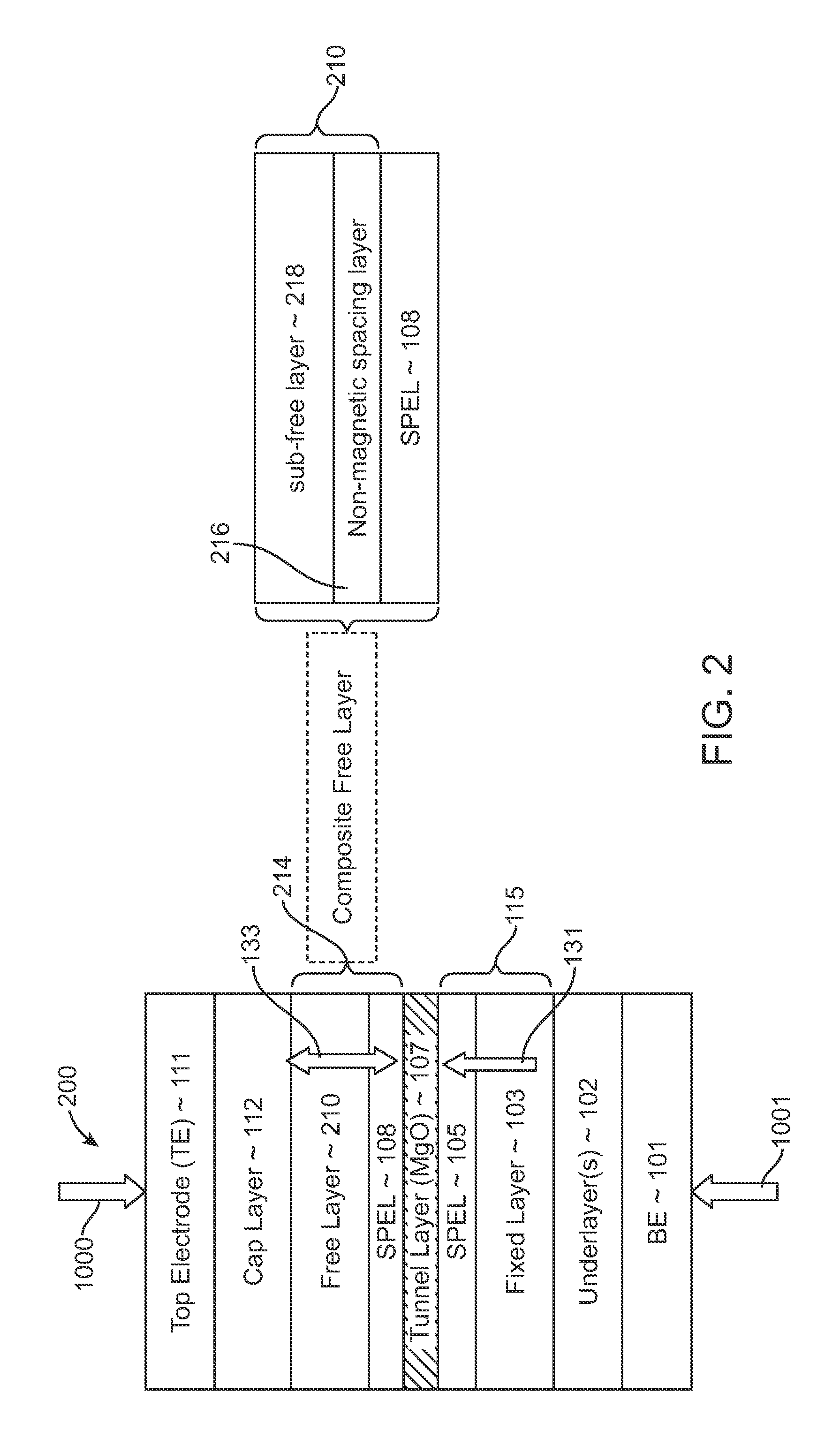

Spin-transfer torque magnetic random access memory having magnetic tunnel junction with perpendicular magnetic anisotropy

A spin-torque transfer memory random access memory (STTMRAM) element includes a fixed layer formed on top of a substrate and a a tunnel layer formed upon the fixed layer and a composite free layer formed upon the tunnel barrier layer and made of an iron platinum alloy with at least one of X or Y material, X being from a group consisting of: boron (B), phosphorous (P), carbon (C), and nitride (N) and Y being from a group consisting of: tantalum (Ta), titanium (Ti), niobium (Nb), zirconium (Zr), tungsten (W), silicon (Si), copper (Cu), silver (Ag), aluminum (Al), chromium (Cr), tin (Sn), lead (Pb), antimony (Sb), hafnium (Hf) and bismuth (Bi), molybdenum (Mo) or rhodium (Ru), the magnetization direction of each of the composite free layer and fixed layer being substantially perpendicular to the plane of the substrate.

Owner:AVALANCHE TECH

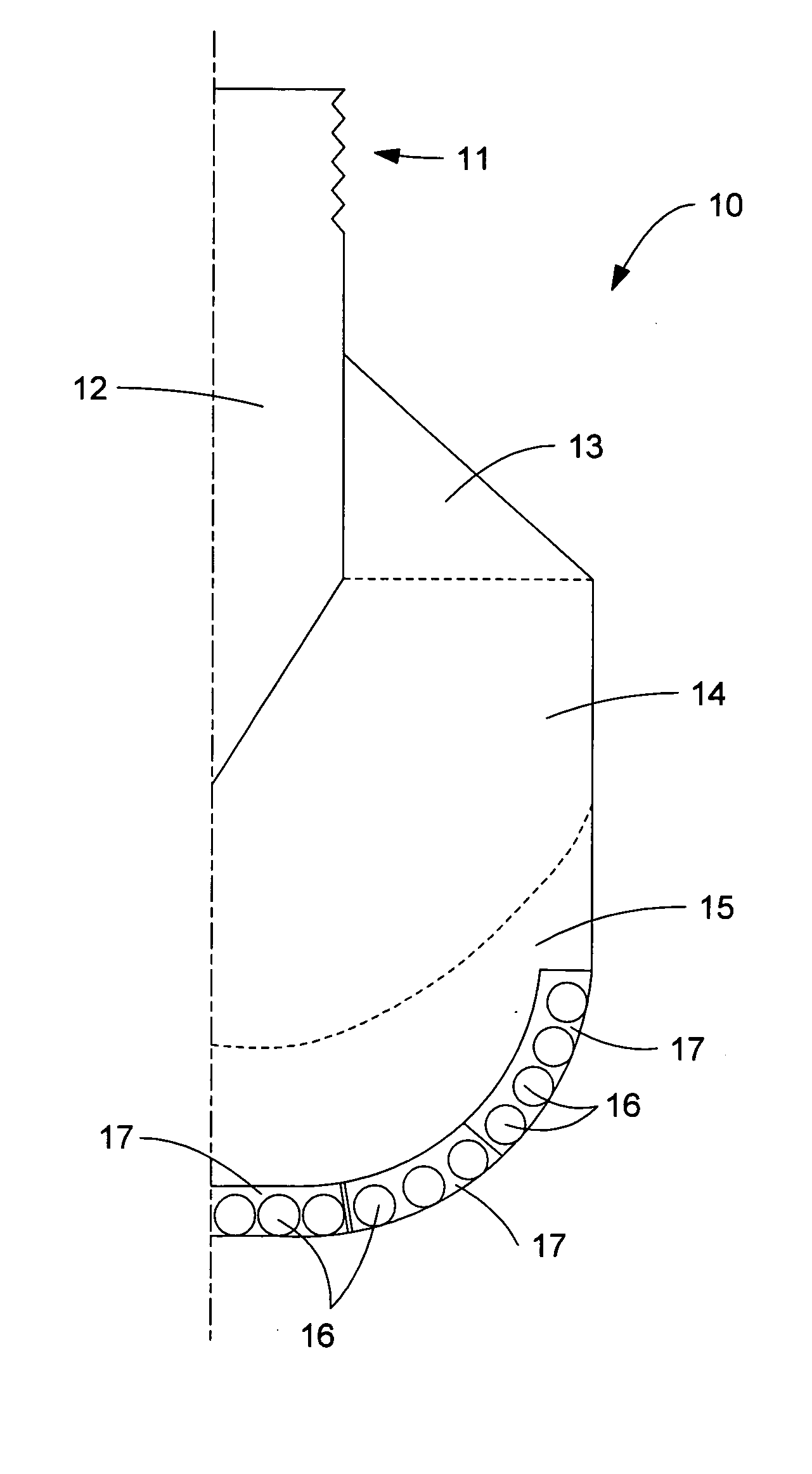

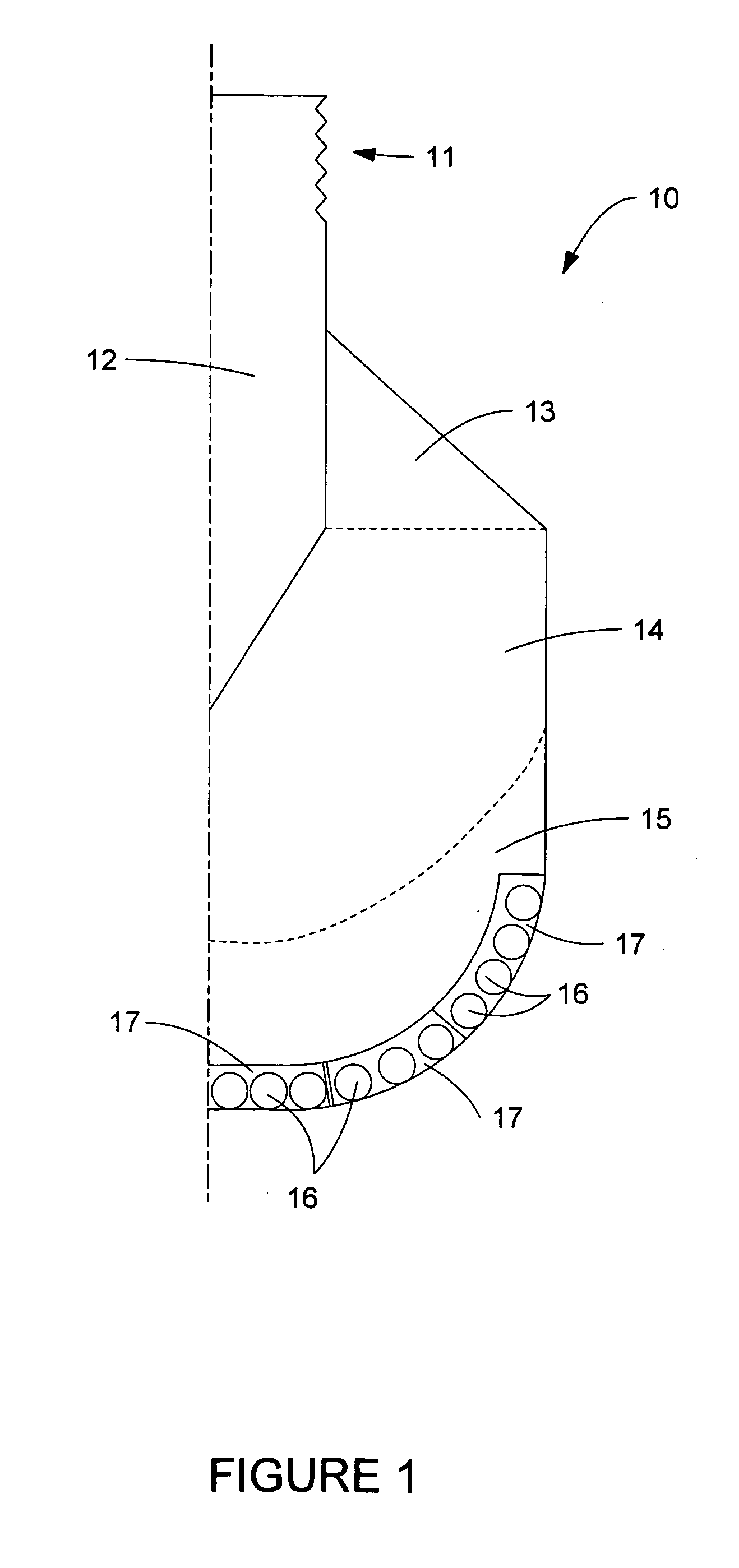

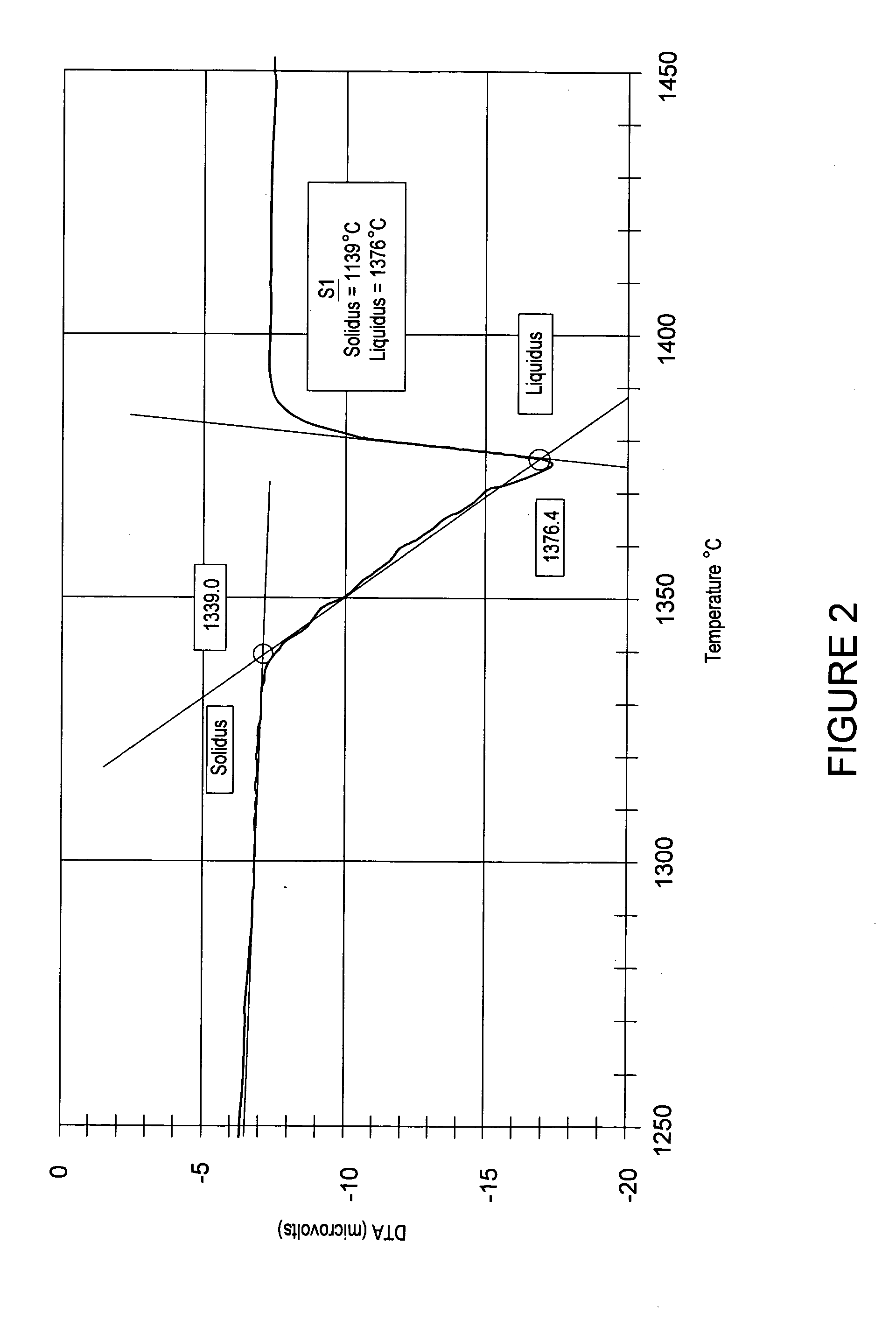

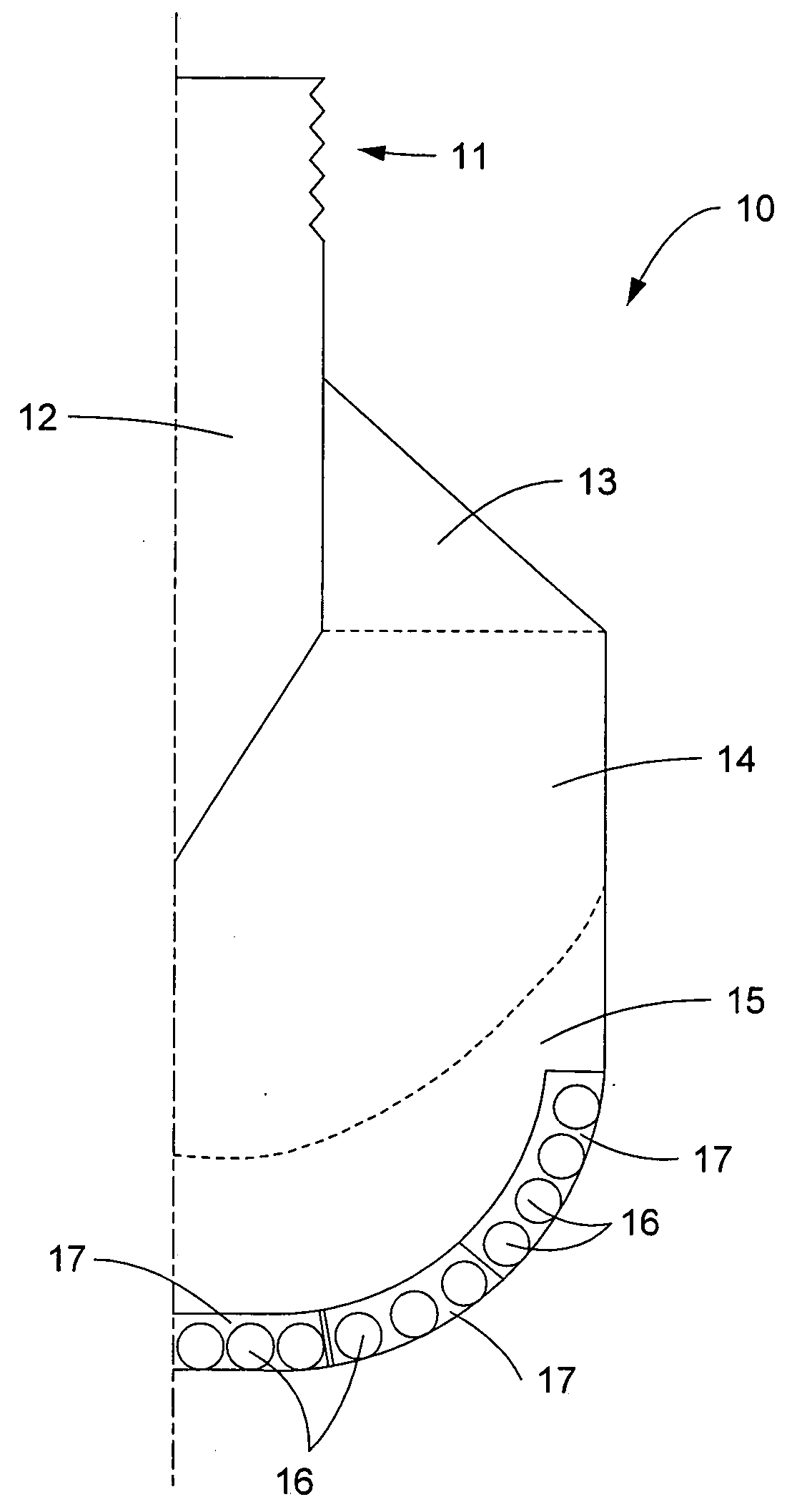

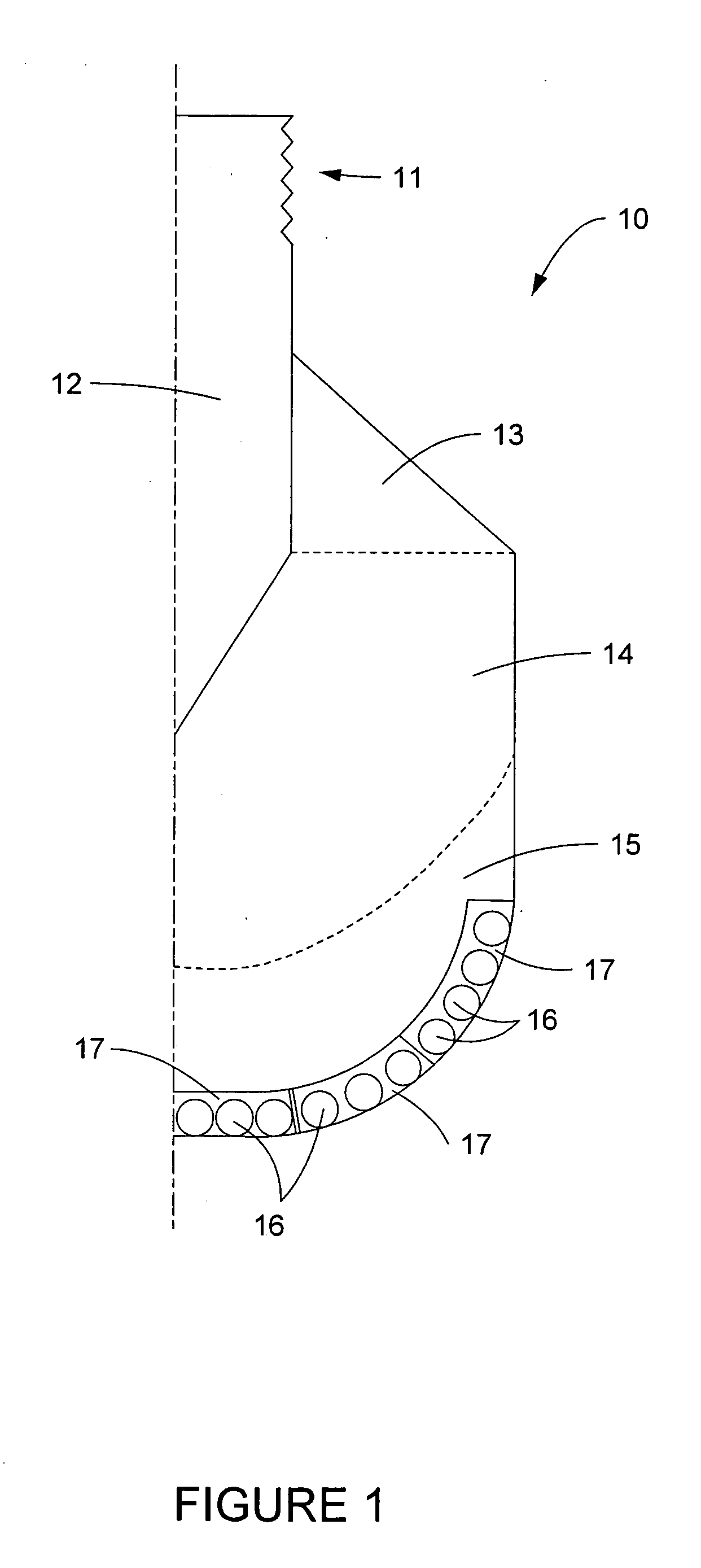

Earth-boring bits

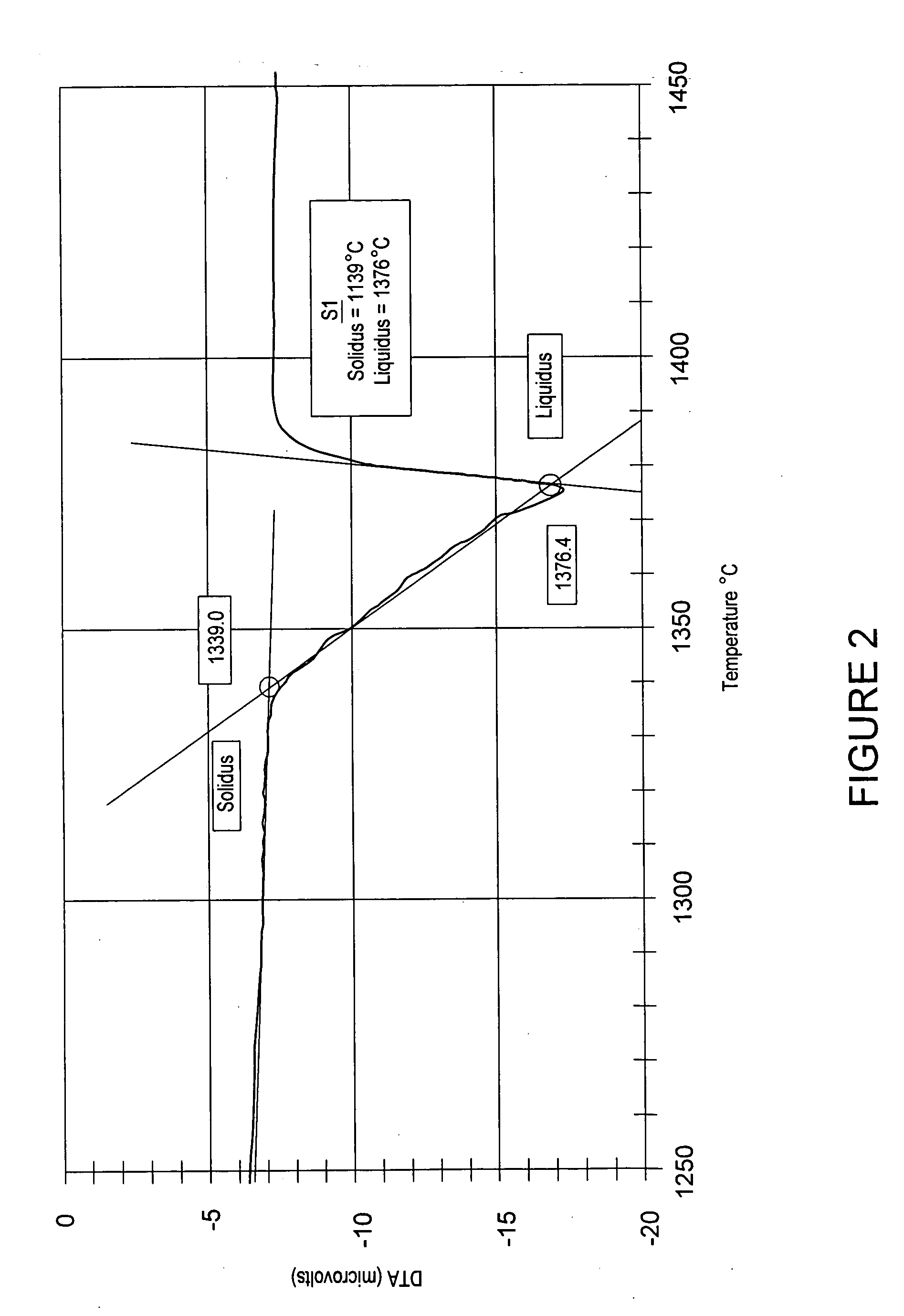

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

Preparation of recombinant factor VIII in a protein free medium

InactiveUS6171825B1Eliminate and at least greatly reduce riskImprove productivityFactor VIICulture processFactor iiManganese

Recombinant Factor VIII can be produced in relatively large quantities on a continuous basis from mammalian cells in the absence of any animal-derived proteins such as albumin by culturing the cells in a protein free medium supplemented with polyol copolymers, preferably in the presence of trace metals such as copper. In very preferred embodiments, the medium includes a polyglycol known as Pluronic F-68, copper sulfate, ferrous sulfate / EDTA complex, and salts of trace metals such as manganese, molybdenum, silicon, lithium and chromium. With an alternative medium which included trace copper ions alone (without polyol copolymers) we were also able to enhance the productivity of Factor VIII in recombinant cells such as BHK cells that are genetically engineered to express Factor VIII.

Owner:BAYER HEALTHCARE LLC +1

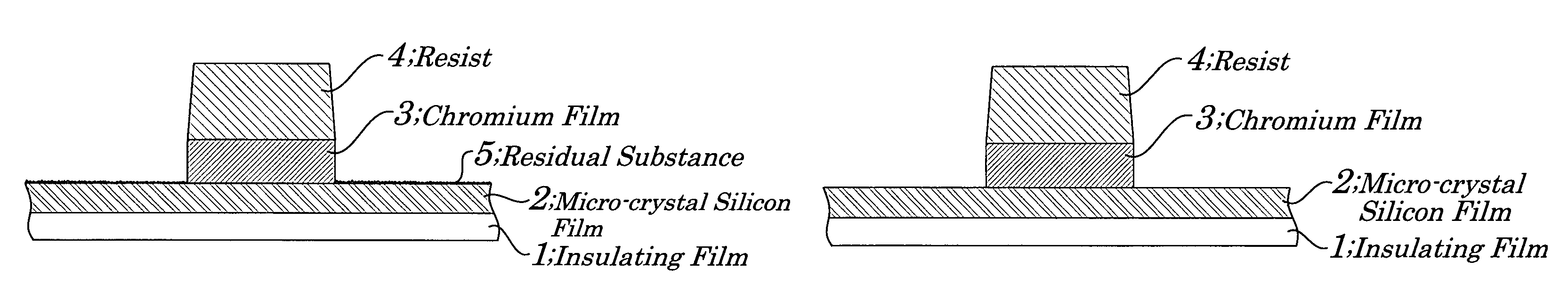

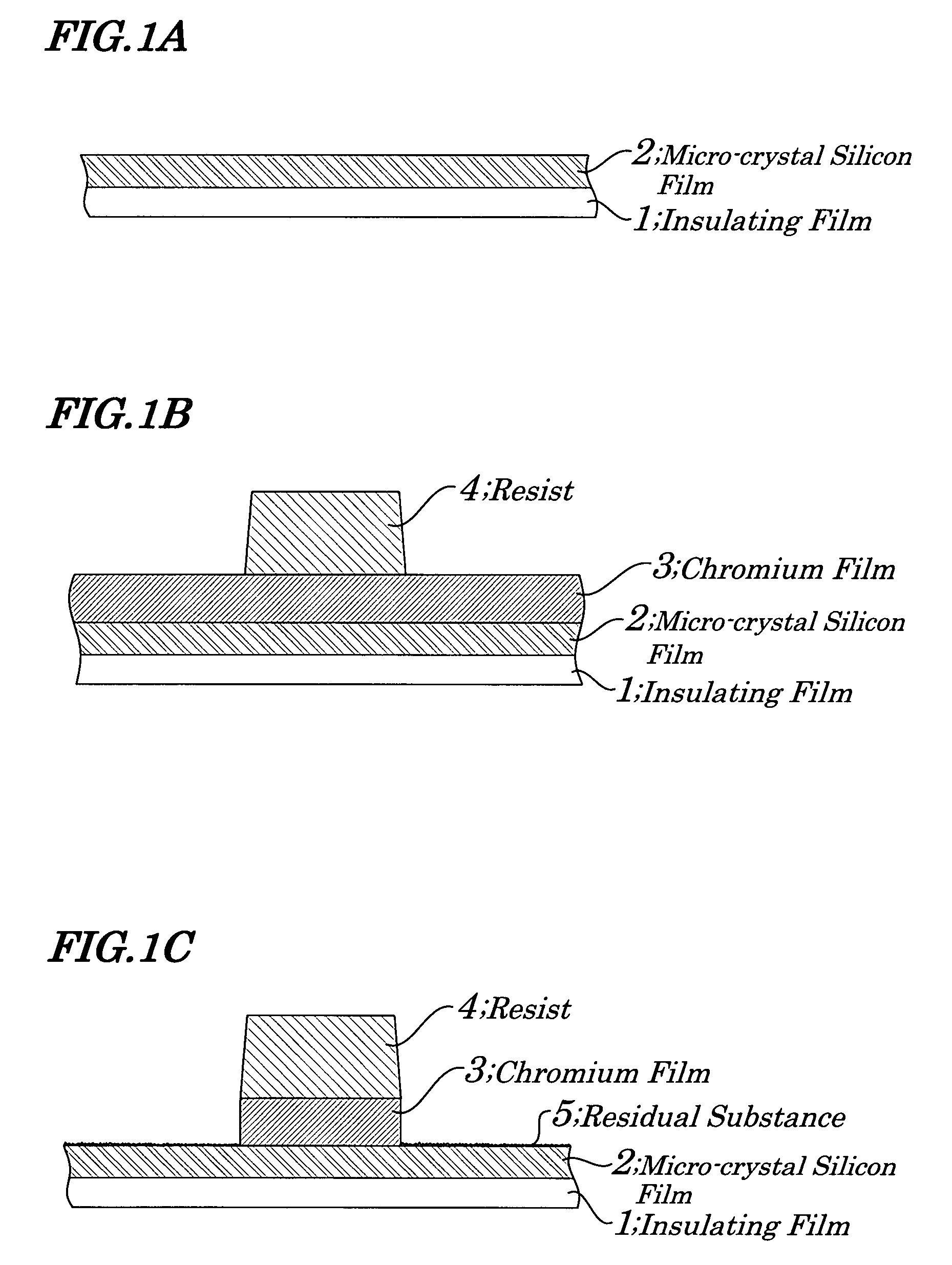

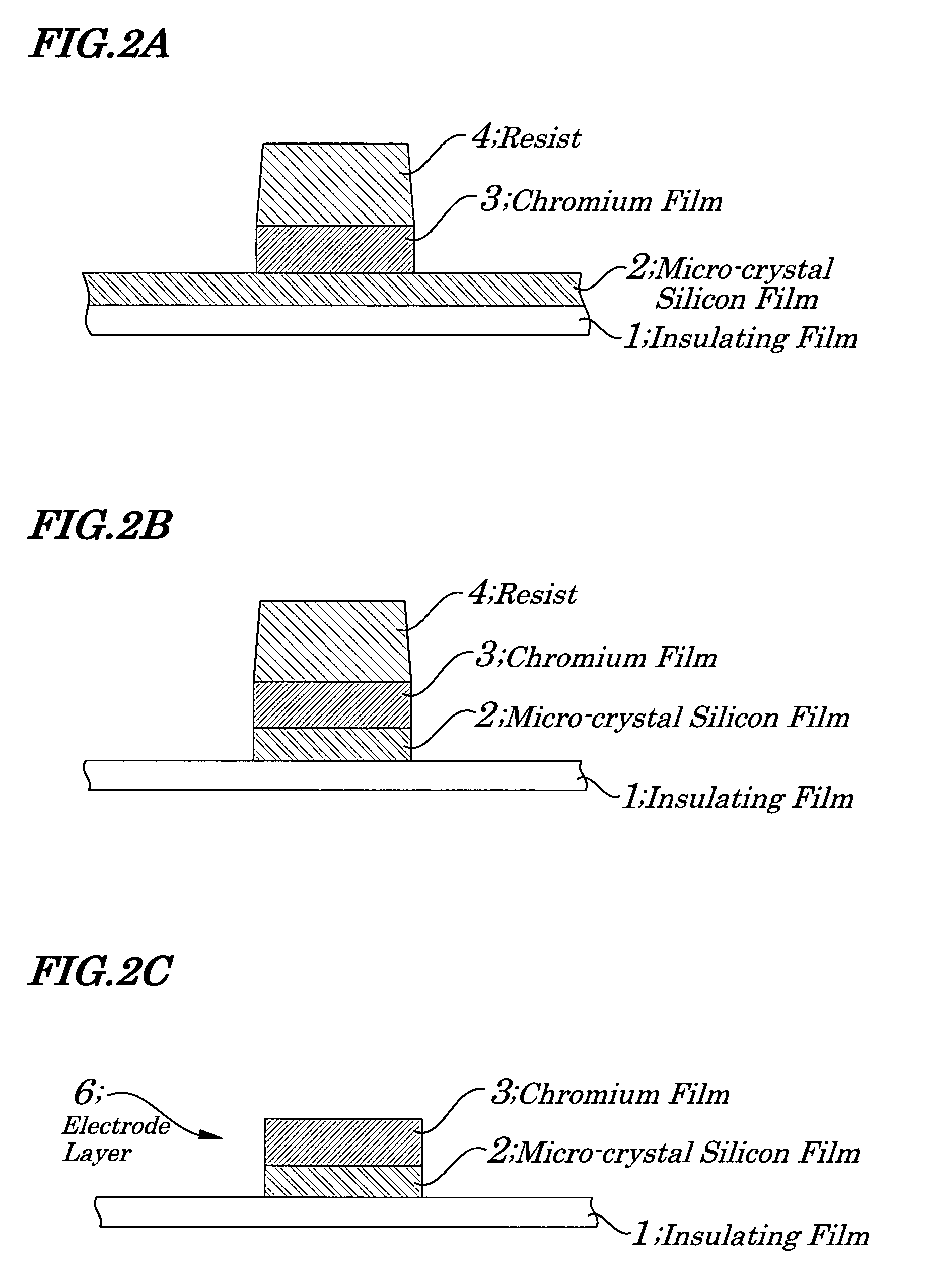

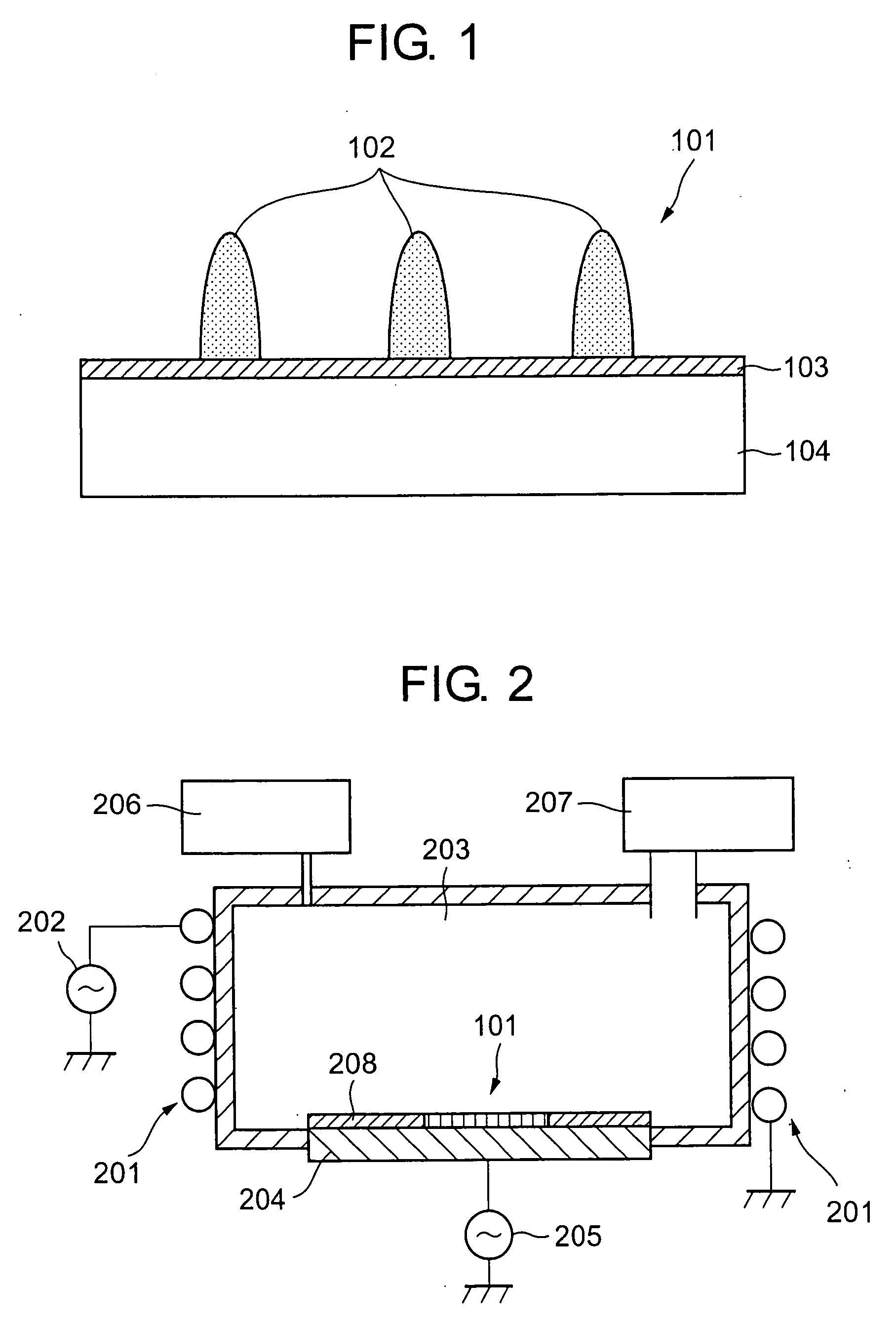

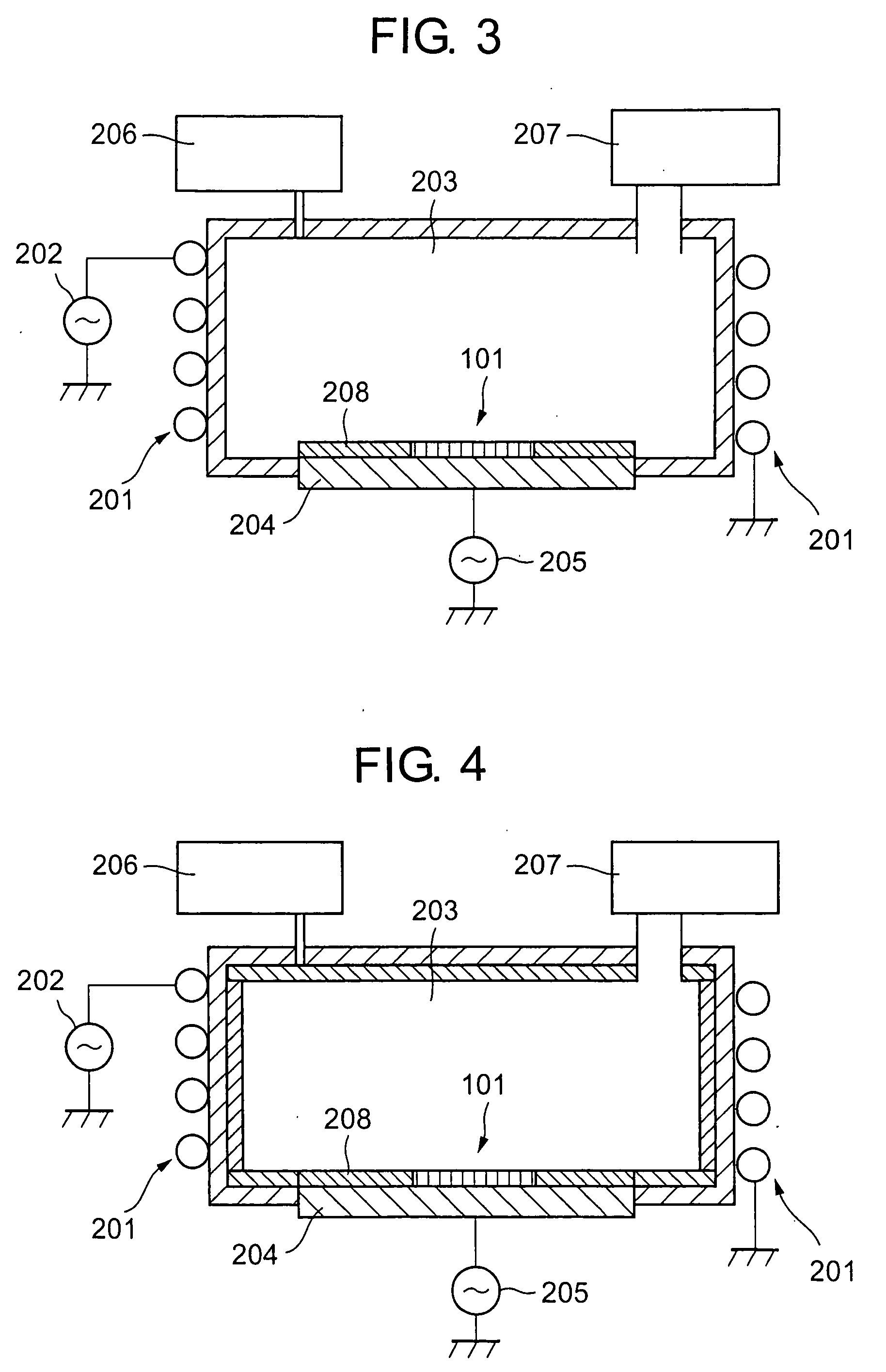

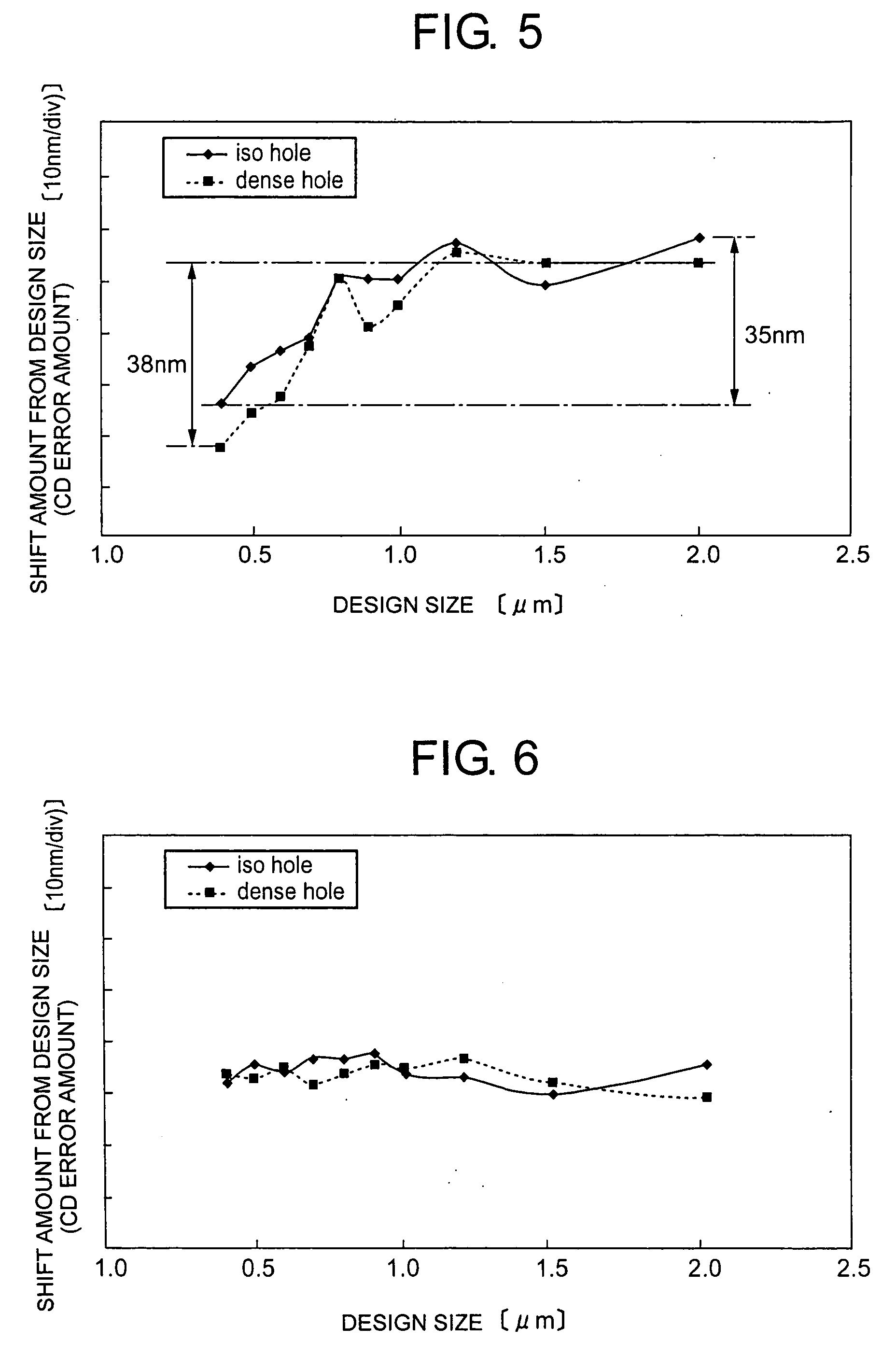

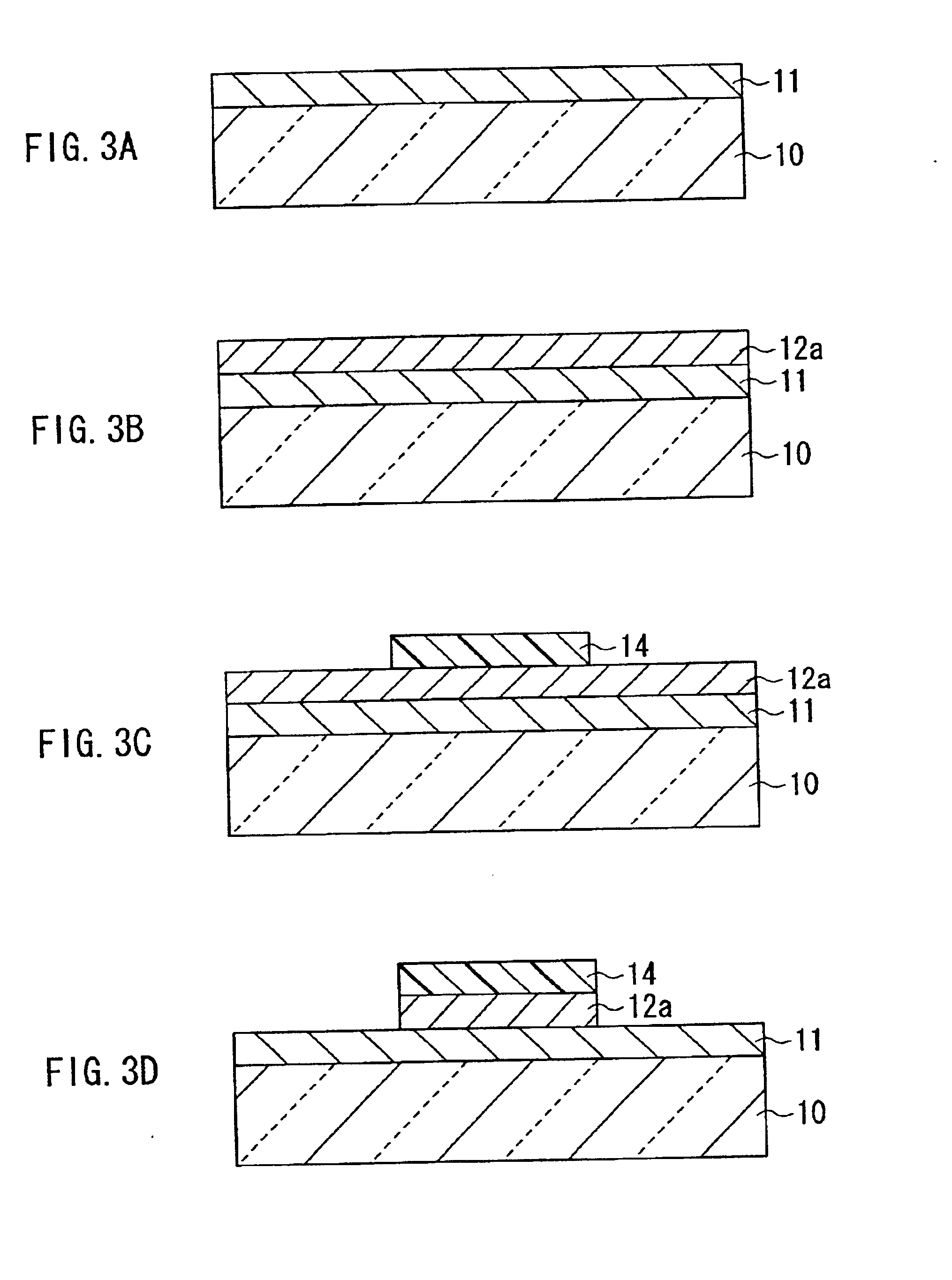

Stacked film patterning method and gate electrode forming method

InactiveUS7723221B2Improve uniformityAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesResistMixed gas

A stacked film patterning method is provided which is capable of reliably removing residual substances remaining after etching of a metal film, improving etching uniformity of a silicon film, and preventing an occurrence of etching residues. A micro-crystal film and a chromium film are sequentially formed on an insulating film serving as a front-end film and the chromium film is etched to be patterned by using a resist as a mask. Next, a micro-crystal silicon film on which the residual substances exist is exposed to plasma of a mixed gas including chlorine gas and oxygen gas to selectively etch the residual substances on a surface of the micro-crystal silicon film. After that, the micro-crystal silicon film is dry etched.

Owner:NEC LCD TECH CORP

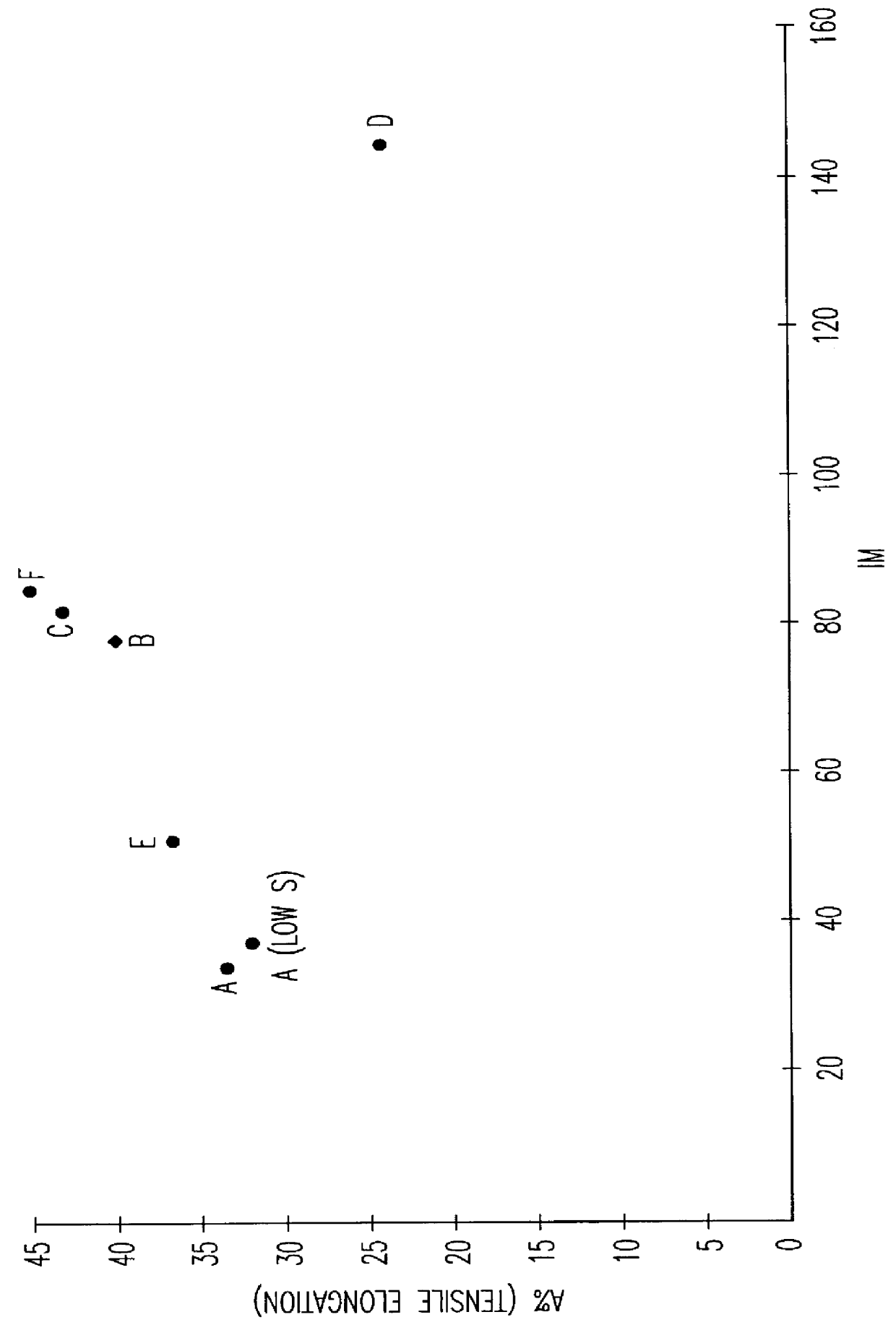

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

Heat and corrosion resistant cast CF8C stainless steel with improved high temperature strength and ductility

A CF8C type stainless steel alloy and articles formed therefrom containing about 18.0 weight percent to about 22.0 weight percent chromium and 11.0 weight percent to about 14.0 weight percent nickel; from about 0.05 weight percent to about 0.15 weight percent carbon; from about 2.0 weight percent to about 10.0 weight percent manganese; and from about 0.3 weight percent to about 1.5 weight percent niobium. The present alloys further include less than 0.15 weight percent sulfur which provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. The disclosed alloys also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon.

Owner:UT BATTELLE LLC

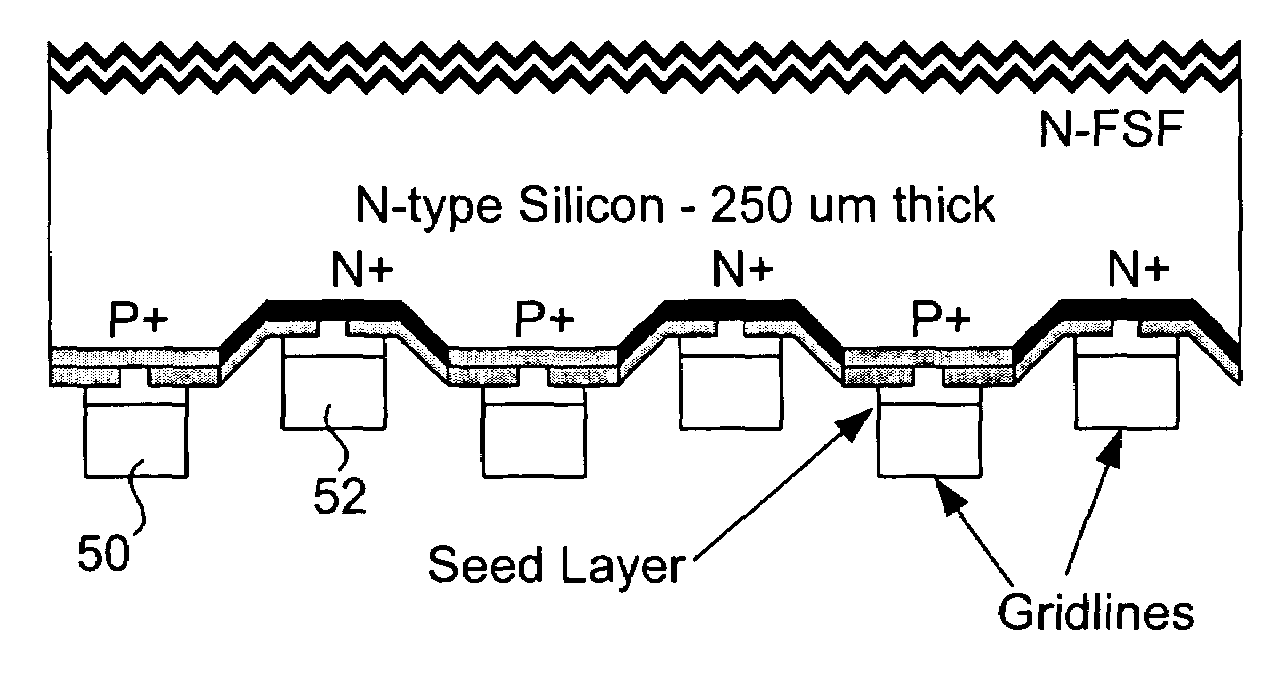

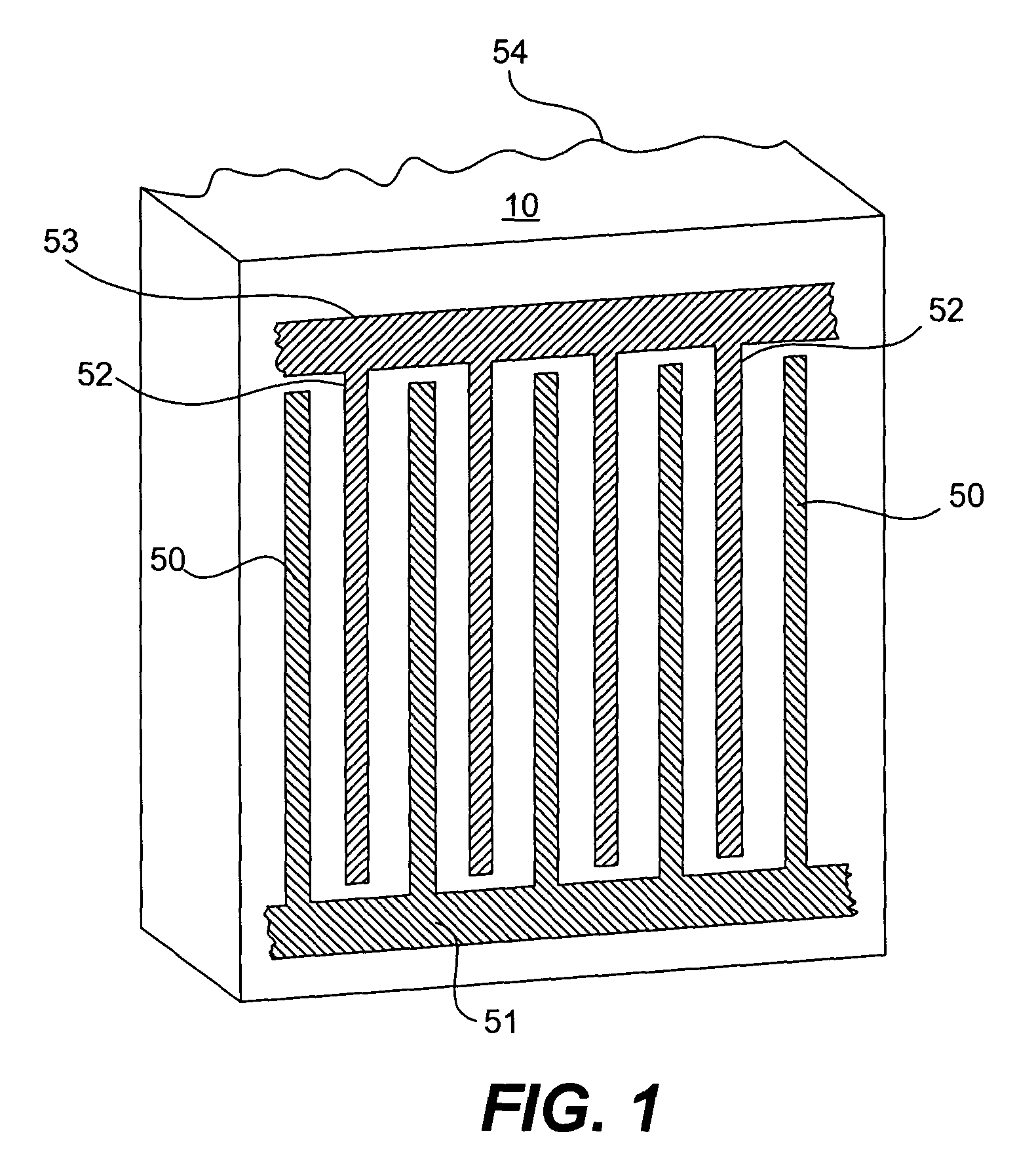

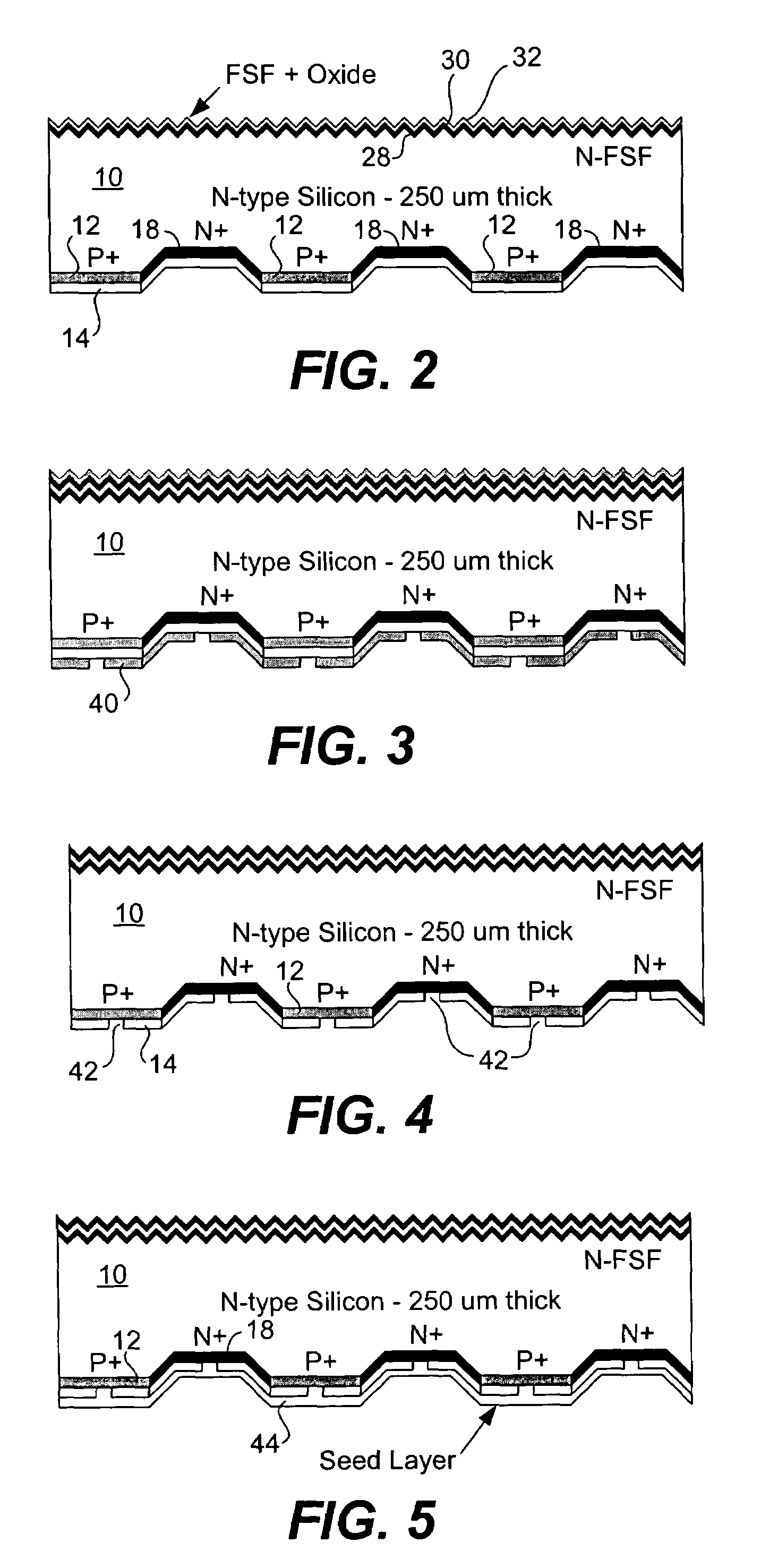

Metal contact structure for solar cell and method of manufacture

In a solar cell having p doped regions and n doped regions alternately formed in a surface of a semiconductor wafer in offset levels through use of masking and etching techniques, metal contacts are made to the p regions and n regions by first forming a base layer contacting the p doped regions and n doped regions which functions as an antireflection layer, and then forming a barrier layer, such as titanium tungsten or chromium, and a conductive layer such as copper over the barrier layer. Preferably the conductive layer is a plating layer and the thickness thereof can be increased by plating.

Owner:CREDIT SUISSE CAYMAN ISLANDS BRANCH +1

Method for etching chromium thin film and method for producing photomask

ActiveUS20060102587A1Decorative surface effectsSemiconductor/solid-state device manufacturingResistChemical species

An object to be processed has a chromium-based thin film made of a material containing chromium. The thin film is etched using a resist pattern as a mask. The thin film is etched by the use of a chemical species produced by preparing a dry etching gas containing a halogen-containing gas and an oxygen-containing gas and supplying a plasma excitation power to the dry etching gas to thereby excite plasma. The thin film is etched using, as the plasma excitation power, a power lower than a plasma excitation power at which plasma density jump occurs.

Owner:HOYA CORP

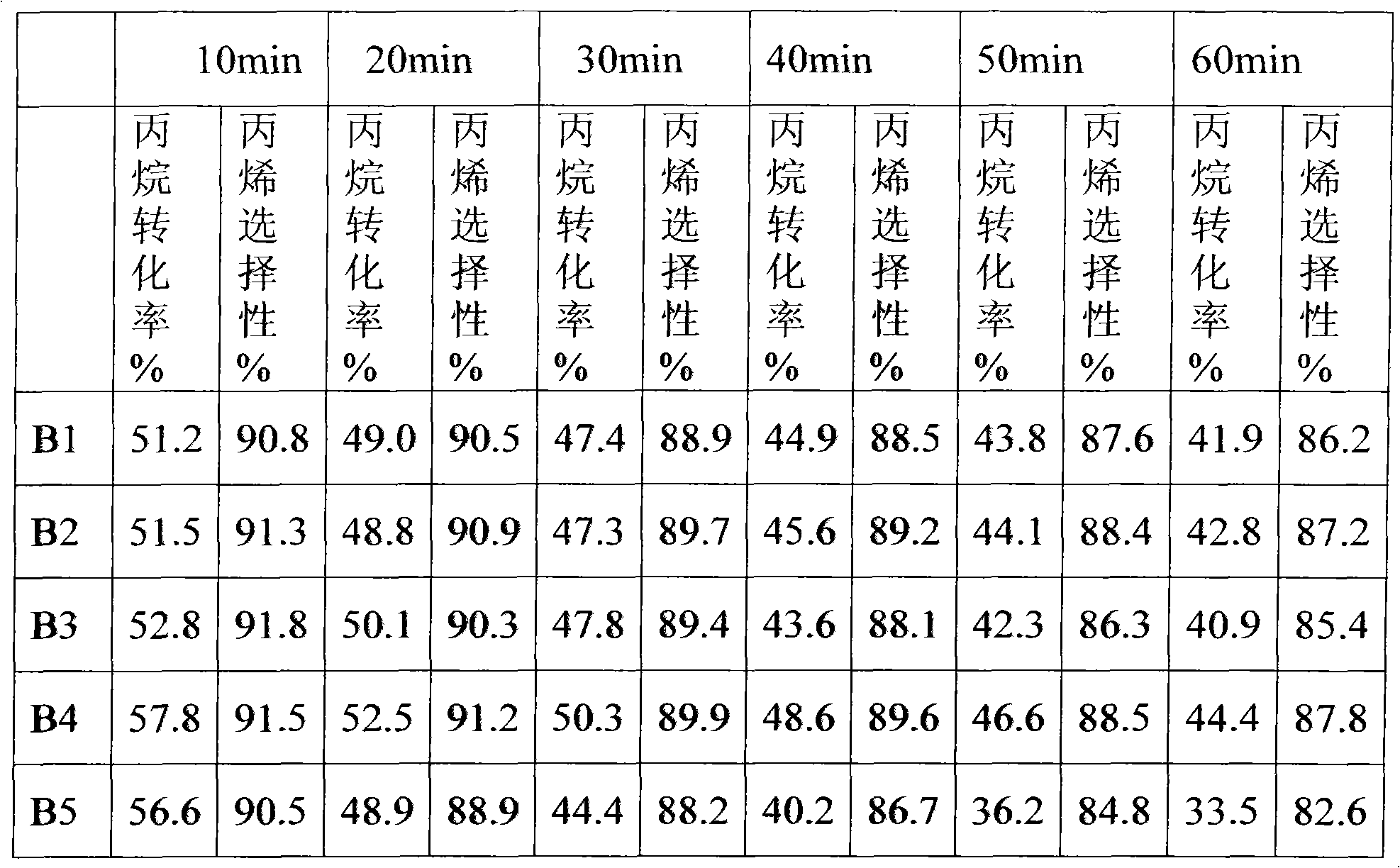

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922AEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

The invention discloses a low-carbon alkane dehydrogenation catalyst and a preparation method thereof. The catalyst is prepared from chromium serving as an active metal ingredient, alkali metal serving as an auxiliary catalytic ingredient and chromium-containing aluminum oxide serving as a carrier, wherein the weight content of the chromium oxide in the carrier is 2.0 to 15.0 percent. In the method, the active metal ingredient, namely chromium, is introduced into the aluminum oxide carrier by partially using a kneading method and partially using an immersion method; pseudo-boehmite mixed with chromium is processed by adopting a three-step roasting method and a hydrothermal method; and thus, the porous structure and the surface character of the carrier can be improved, the content and the distribution of the active metal chromium in the carrier and the mutual effect between the active metal and the aluminum oxide are further modulated, the activity and the stability of the catalyst are improved, the carbon depositing resistance of the catalyst is enhanced, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

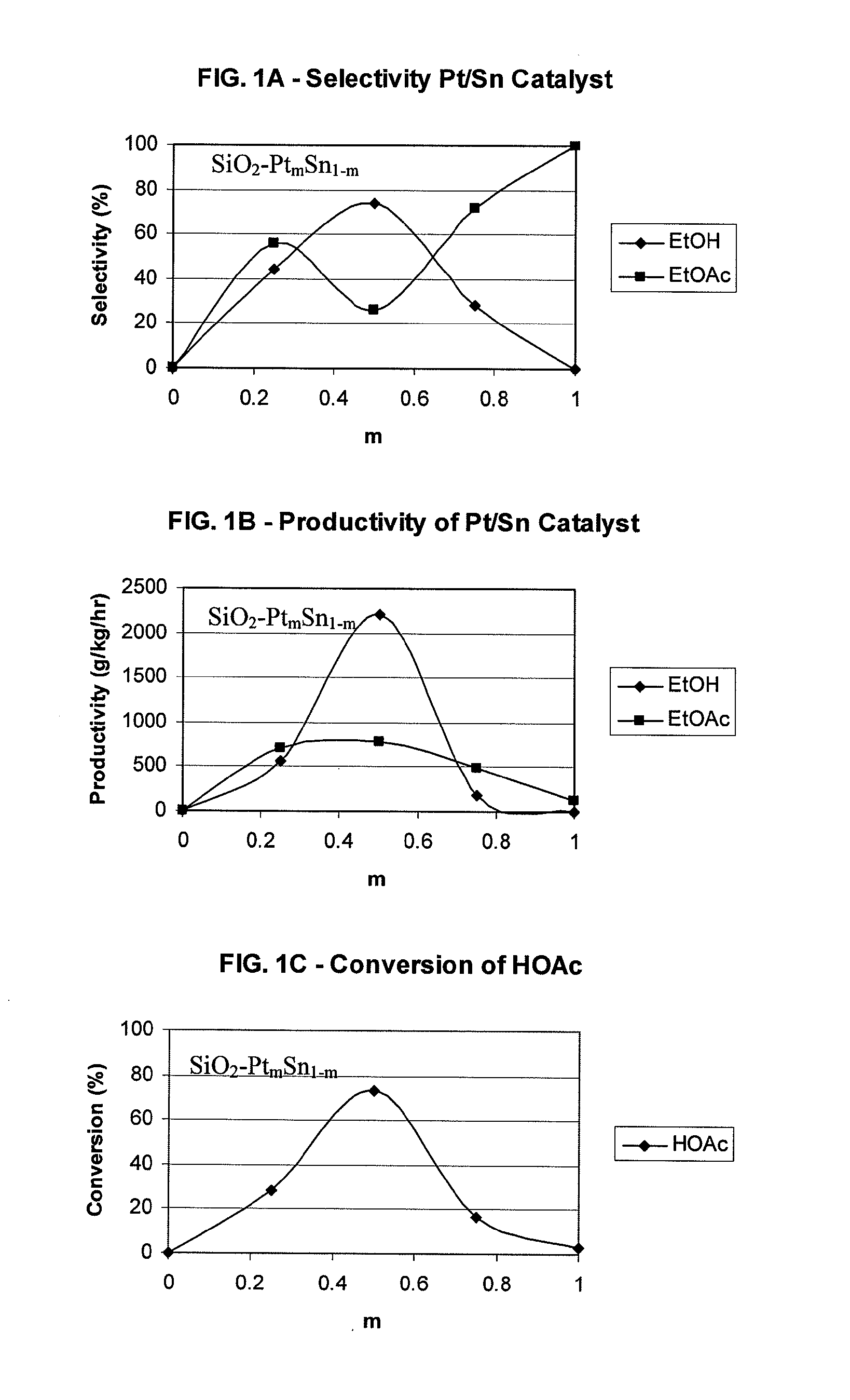

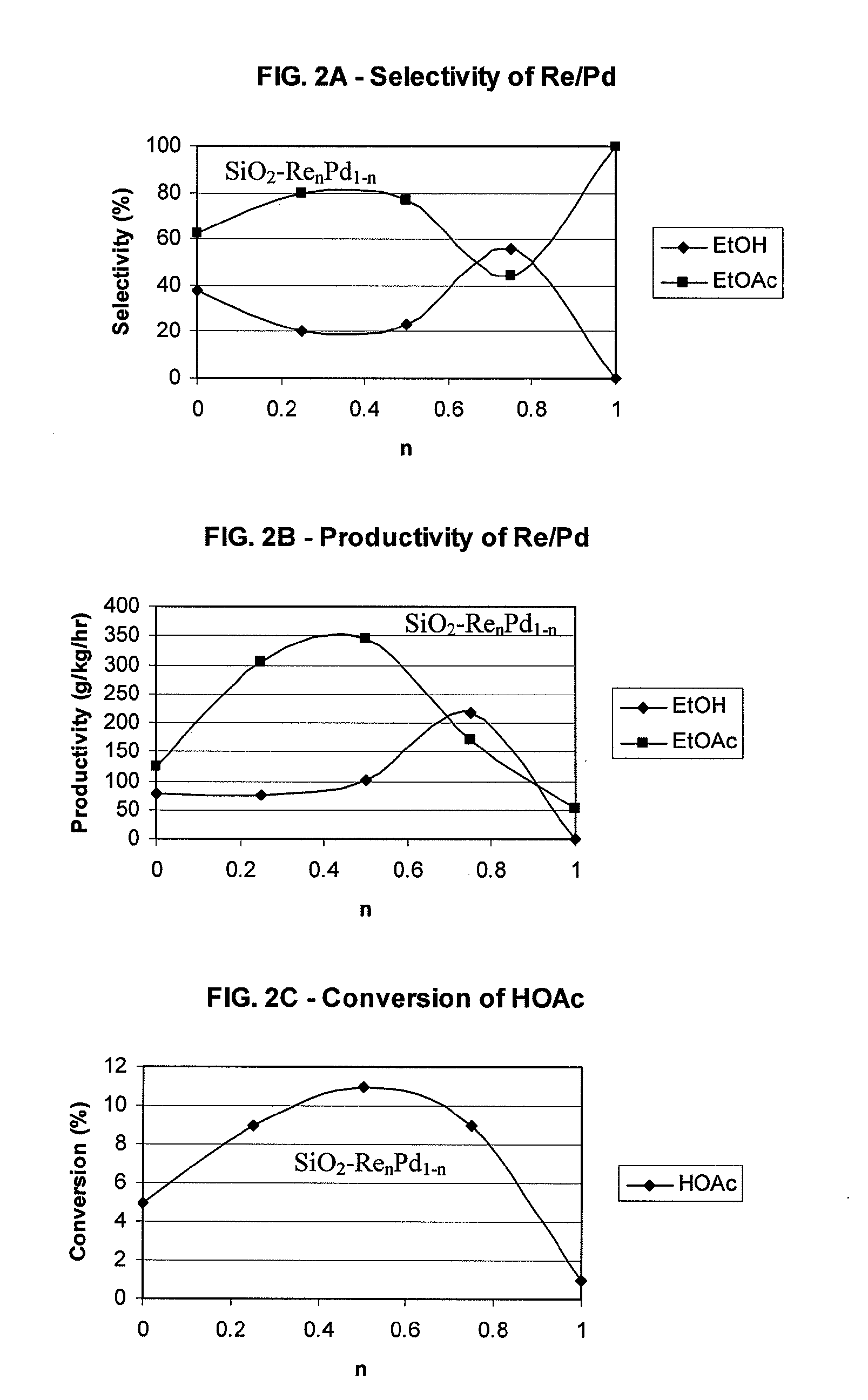

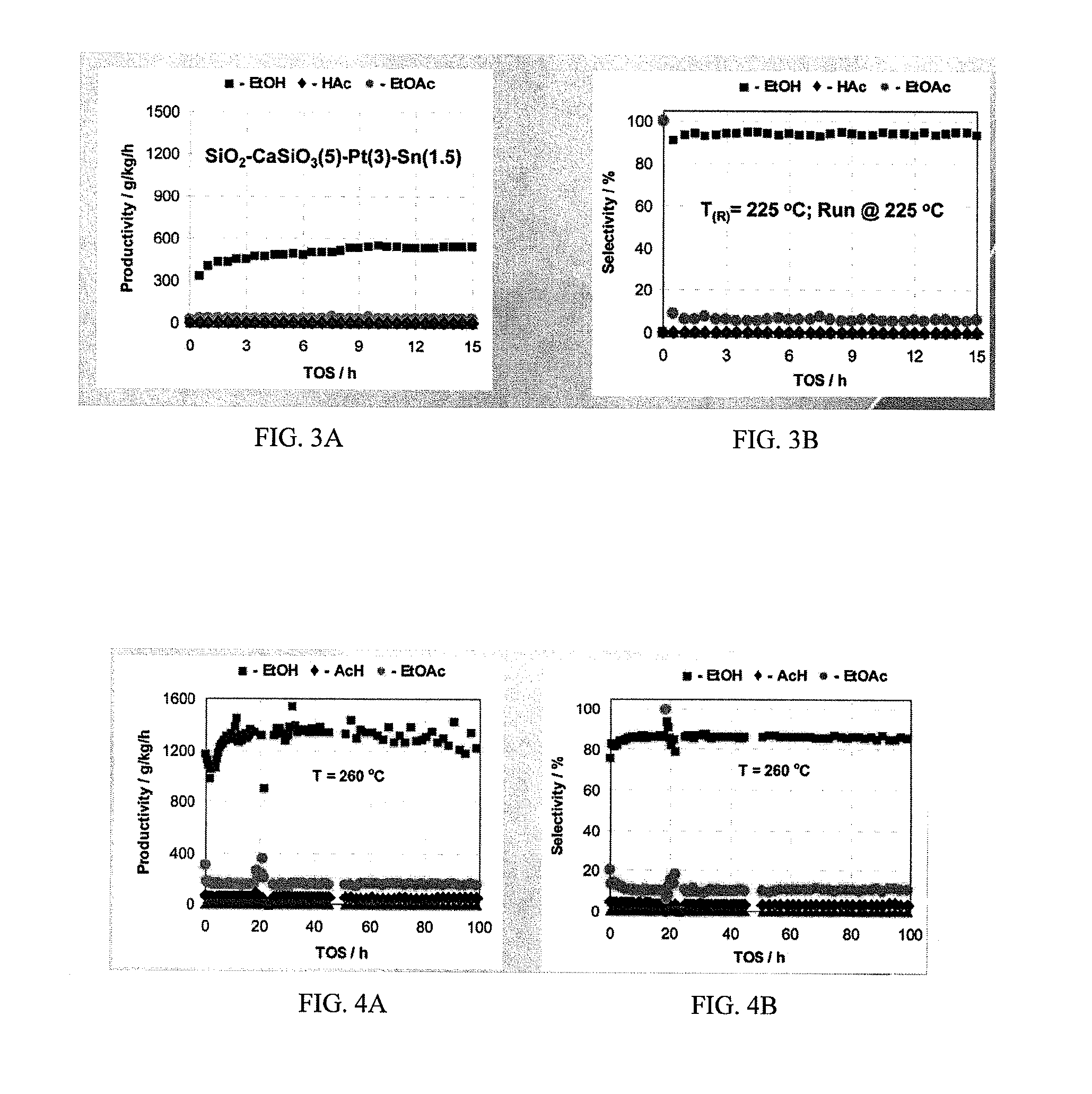

Processes for making ethanol from acetic acid

InactiveUS20100197985A1High selectivityPreparation by oxo-reaction and reductionEthylene productionCeriumCobalt

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

Anti-fingerprint coating construction

InactiveUS20060110537A1Easy to cleanImprove anti-corrosion performanceMaterial nanotechnologyFouling preventionNanometreAntibacterial property

An anti-fingerprint coating construction (23) for application to a surface of a substrate (21) includes a layer formed of a material selected from the group consisting of a hydrophobic nano-composite material, an oleophobic nano-composite material, and a super-amphiphobic nano-composite material. When the anti-fingerprint coating construction is employed on a metal surface or a nonmetal surface, sweat or / and grease on fingers of a user is not liable to be adhered to the surface. Therefore a fingerprint of the user is prevented from being imprinted on the surface, and the surface can remain clean and aesthetically pleasing. Because the anti-fingerprint coating construction is easy to clean, the anti-fingerprint coating construction has good anti-corrosion and antibacterial properties. The anti-fingerprint coating construction contains no chromium, and therefore does not need to be processed by an acid or alkali solution. This makes the anti-fingerprint coating construction environmentally friendly.

Owner:HON HAI PRECISION IND CO LTD

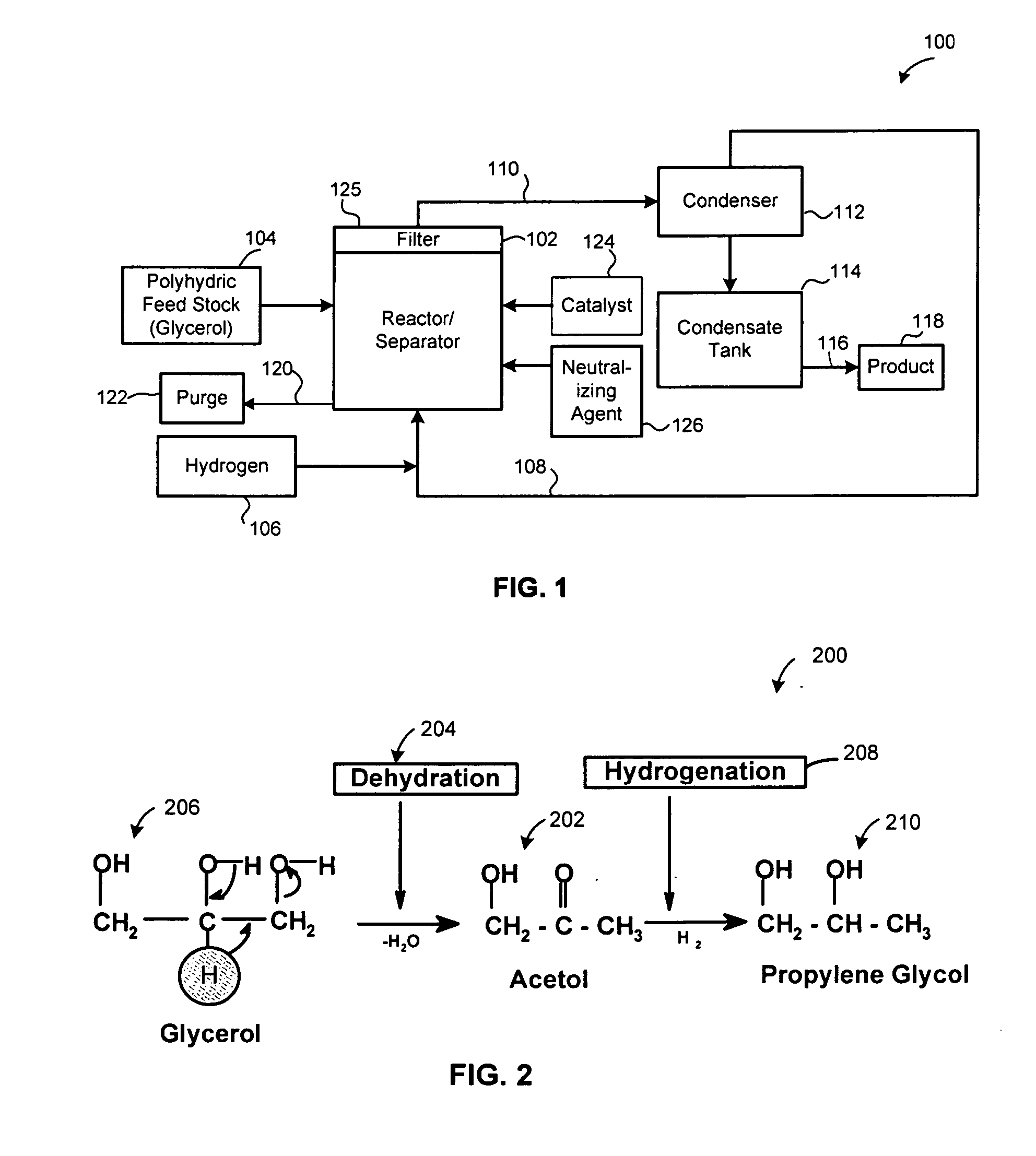

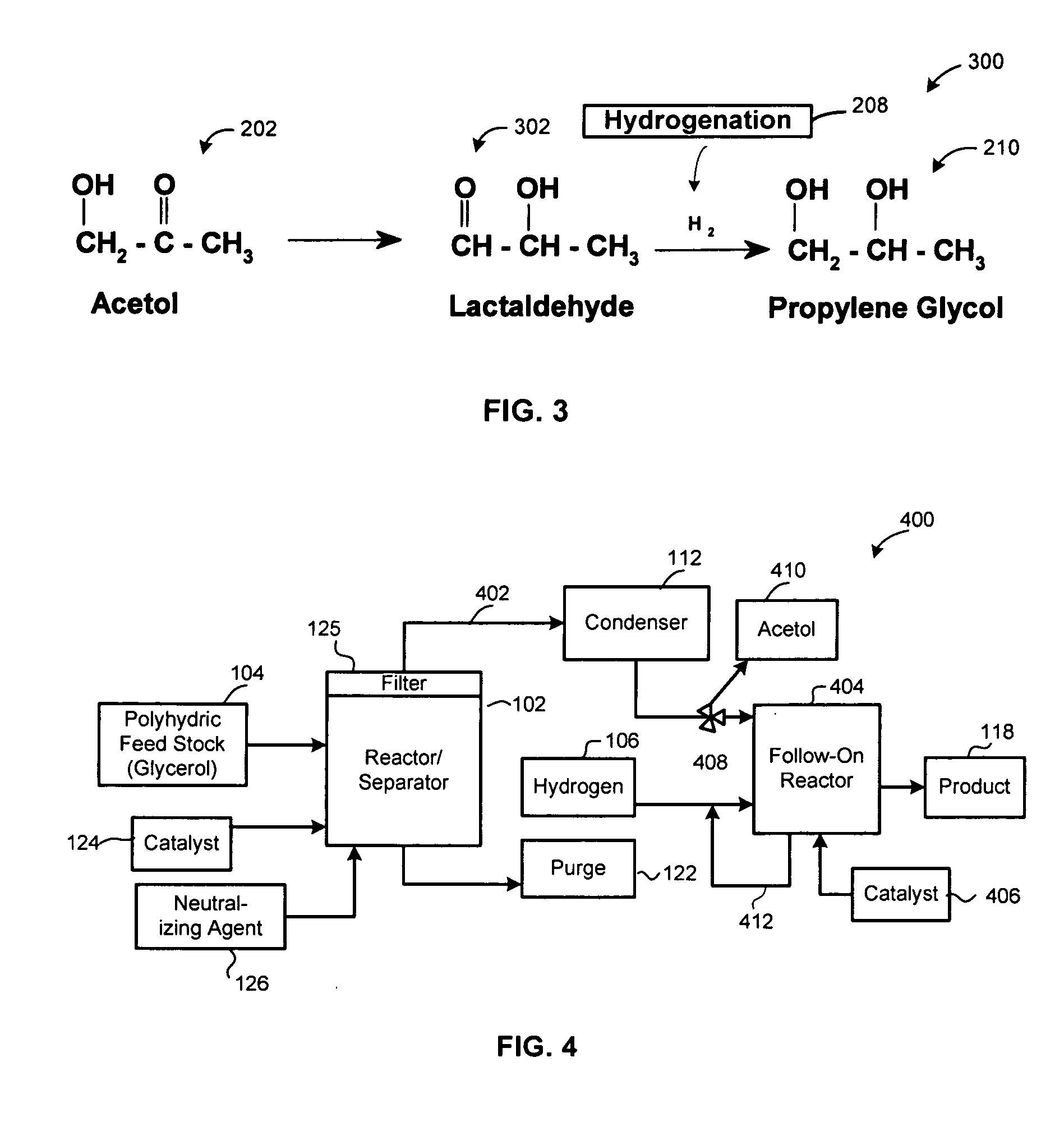

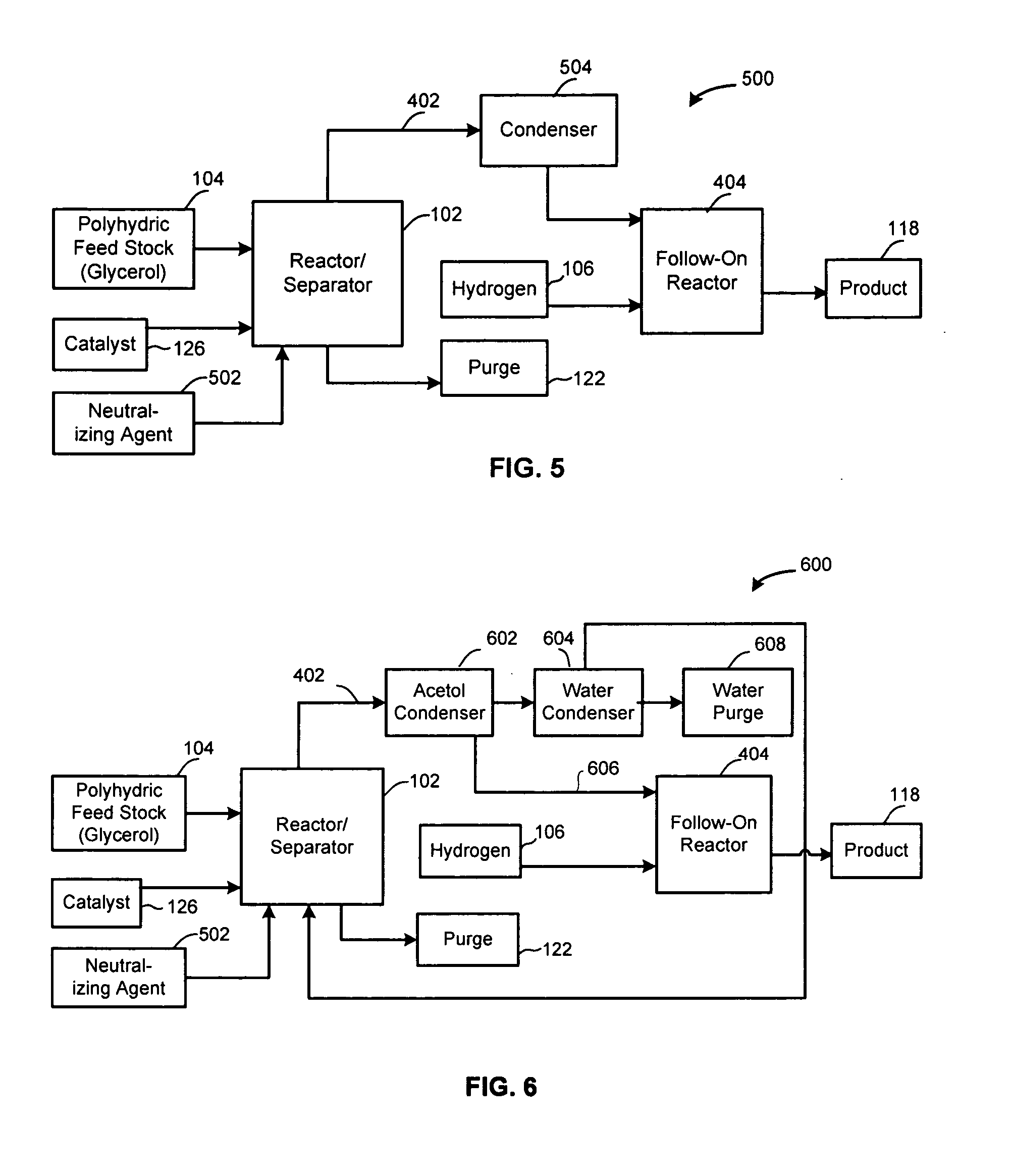

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

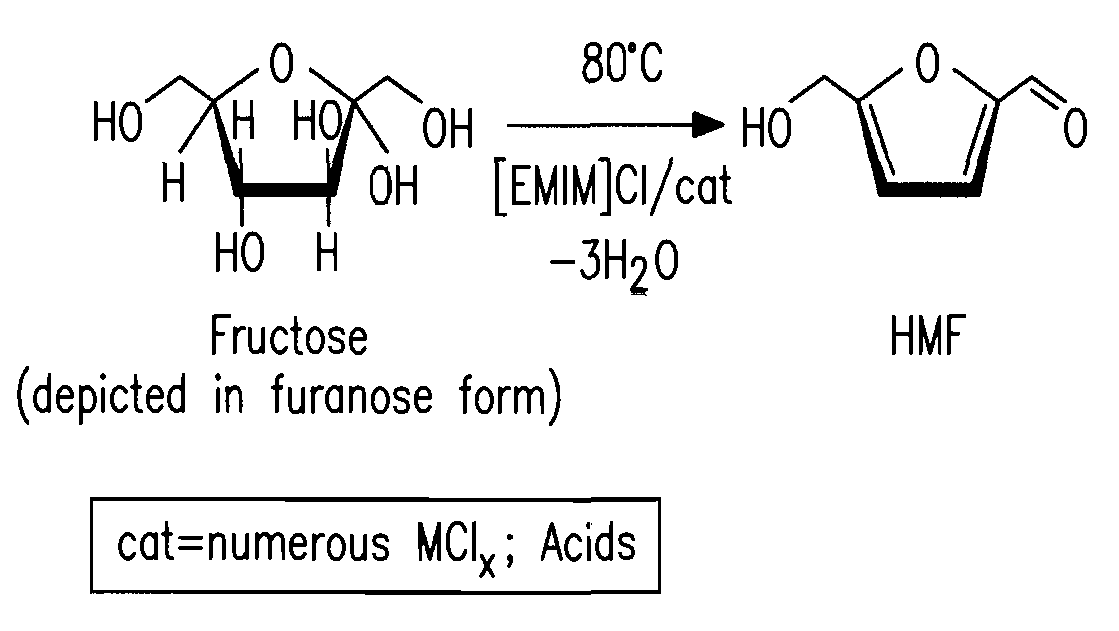

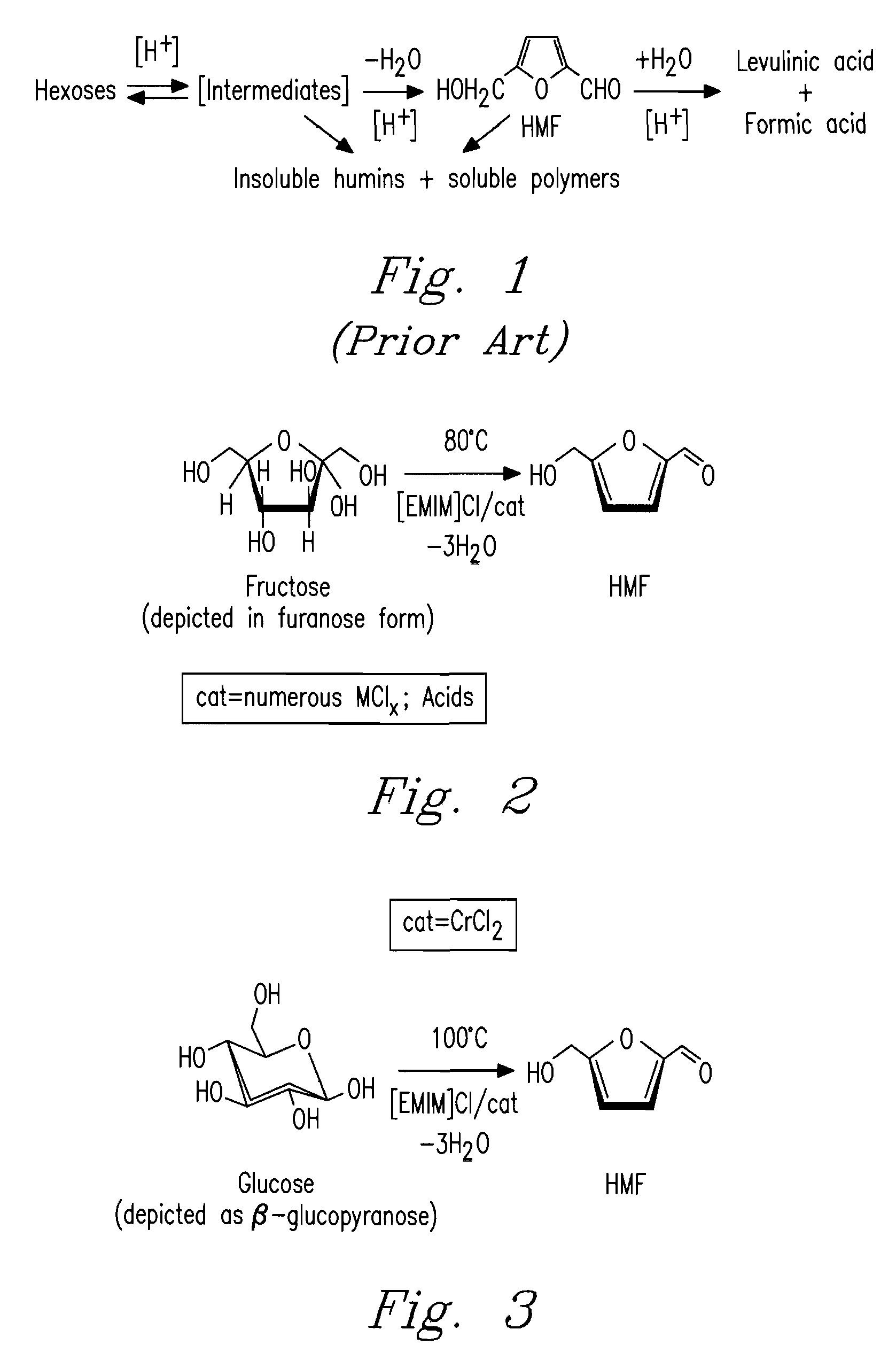

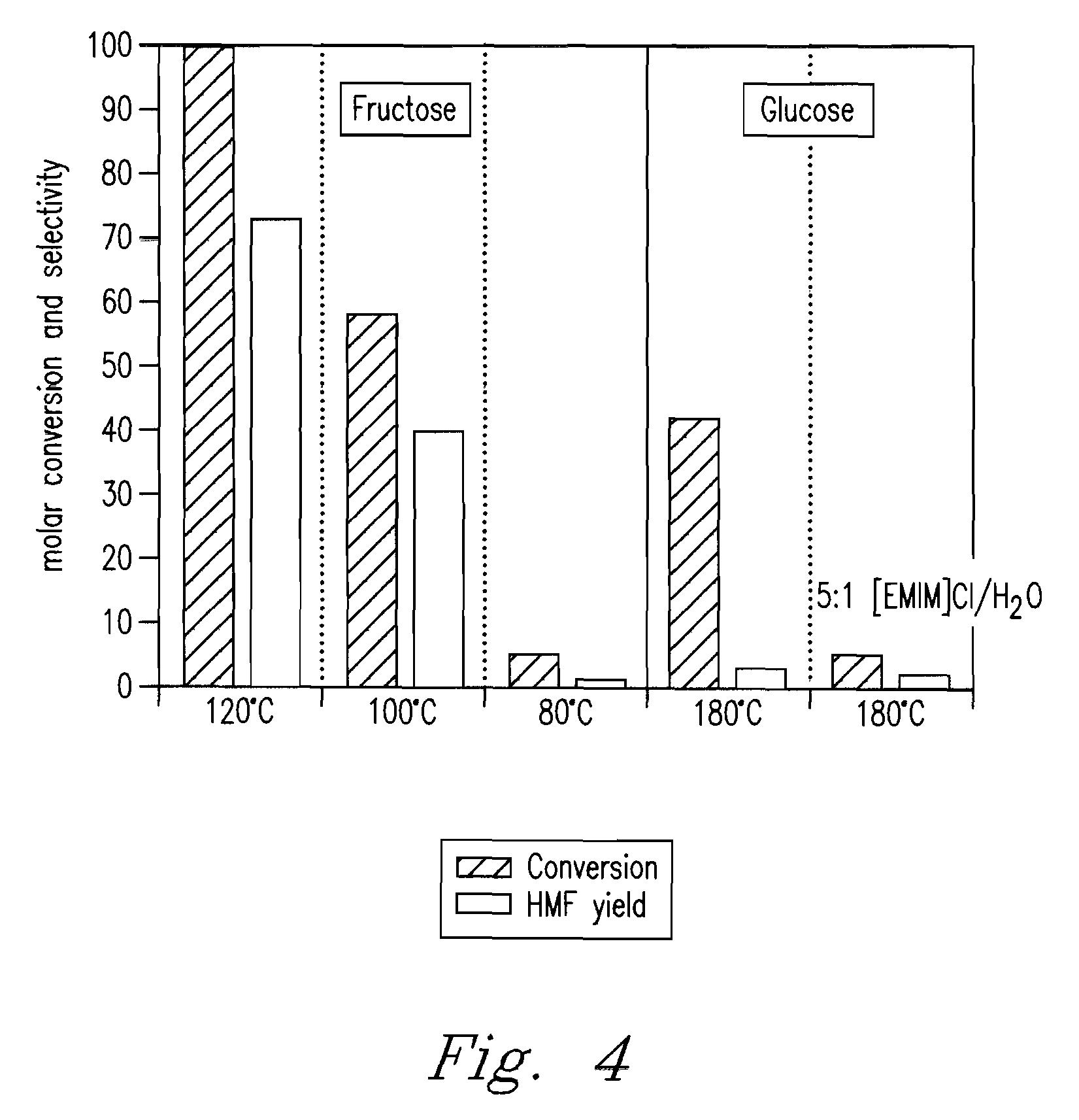

Methods for conversion of carbohydrates in ionic liquids to value-added chemicals

Methods are described for converting carbohydrates including, e.g., monosaccharides, disaccharides, and polysaccharides in ionic liquids to value-added chemicals including furans, useful as chemical intermediates and / or feedstocks. Fructose is converted to 5-hydroxylmethylfurfural (HMF) in the presence of metal halide and acid catalysts. Glucose is effectively converted to HMF in the presence of chromium chloride catalysts. Yields of up to about 70% are achieved with low levels of impurities such as levulinic acid.

Owner:BATTELLE MEMORIAL INST

Catalyst for preparing alcohol by acetic ester hydrogenation as well as preparation method and application thereof

InactiveCN101934228AHigh reactivityLow investment costOrganic compound preparationHydroxy compound preparationManganeseCopper oxide

The invention discloses a catalyst for preparing alcohol by acetic ester hydrogenation as well as a preparation method and an application thereof, which is characterized in that the main catalyst of the catalyst is copper or copper oxide or a mixture of the copper and the copper oxide, and the cocatalyst can be also added, wherein the cocatalyst is one or more of oxides of zinc, manganese, chromium, calcium, barium, iron, nickel and magnesium; and the carrier is alumina or silica sol. The catalyst has high activity and high selectivity under the condition of low temperature and low pressure, thus greatly reducing the investment cost of permanent plants, lowering production energy consumption, being extremely beneficial for the industrial production, and having good stability and long service life. The catalyst of the invention is used to cause percent conversion of a reaction of converting the acetic ester into the alcohol is more than or equal to 80% and the selectivity of the alcohol is more than or equal to 95%.

Owner:江苏丹化煤制化学品工程技术有限公司

Anti-seepage burnon casting paint made from alcohol base or aqueous sand powder

InactiveCN1666828AExcellent anti-seepage and sticky sand effectSmall specific surface areaFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to the melting coating of alcohol-base or water-base anti-penetrating sands, which uses the fireproofing bone materials, the floating agent, the felting agent, the reinforcing agent and the carrier as the preparing coating. The weight shares of the said coating are: 100,3-8,3-7,0.2-1.0 and 30-40. The invention uses chrome iron minerals as the main materials and is prior to any kinds of the traditional coating.

Owner:HUBEI UNIV OF TECH

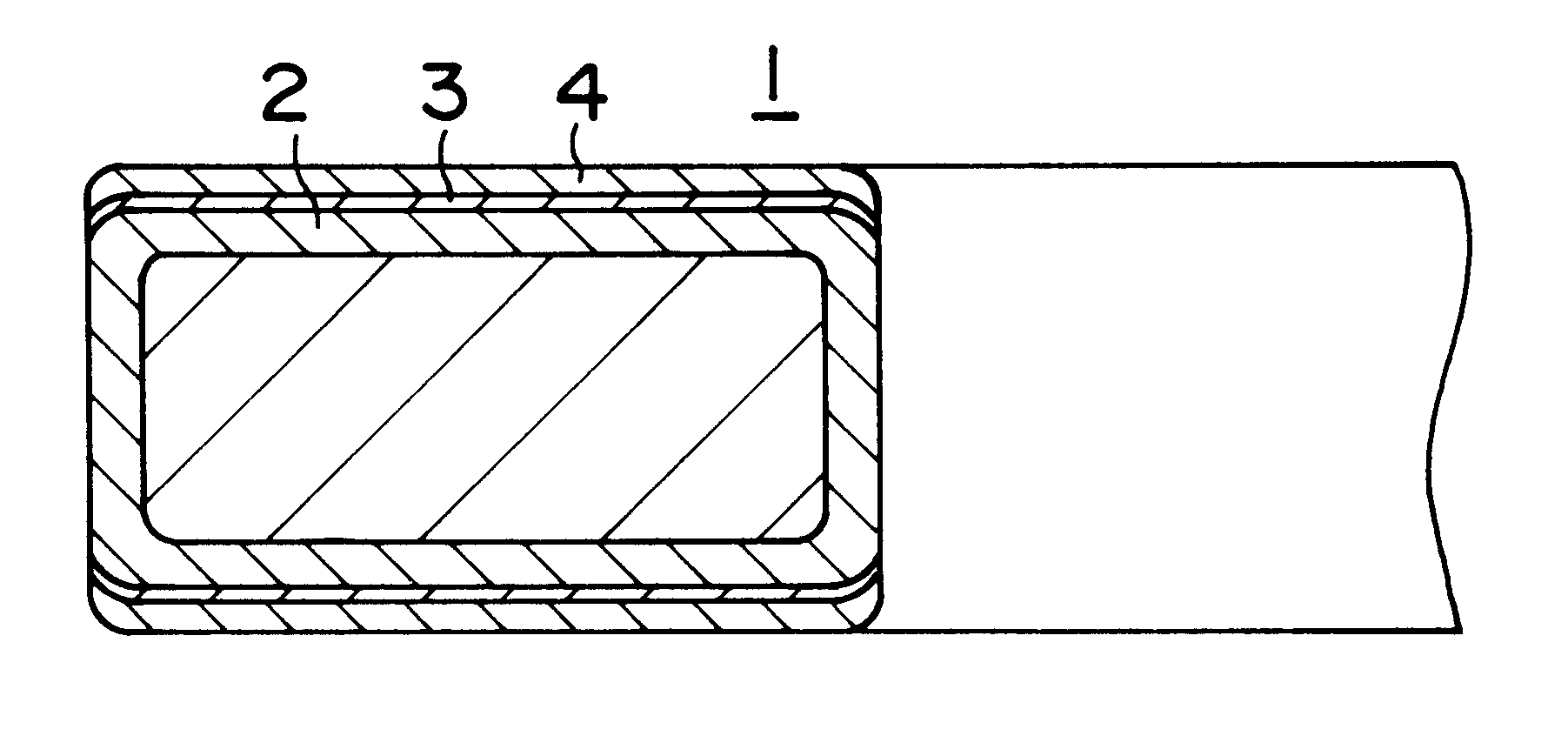

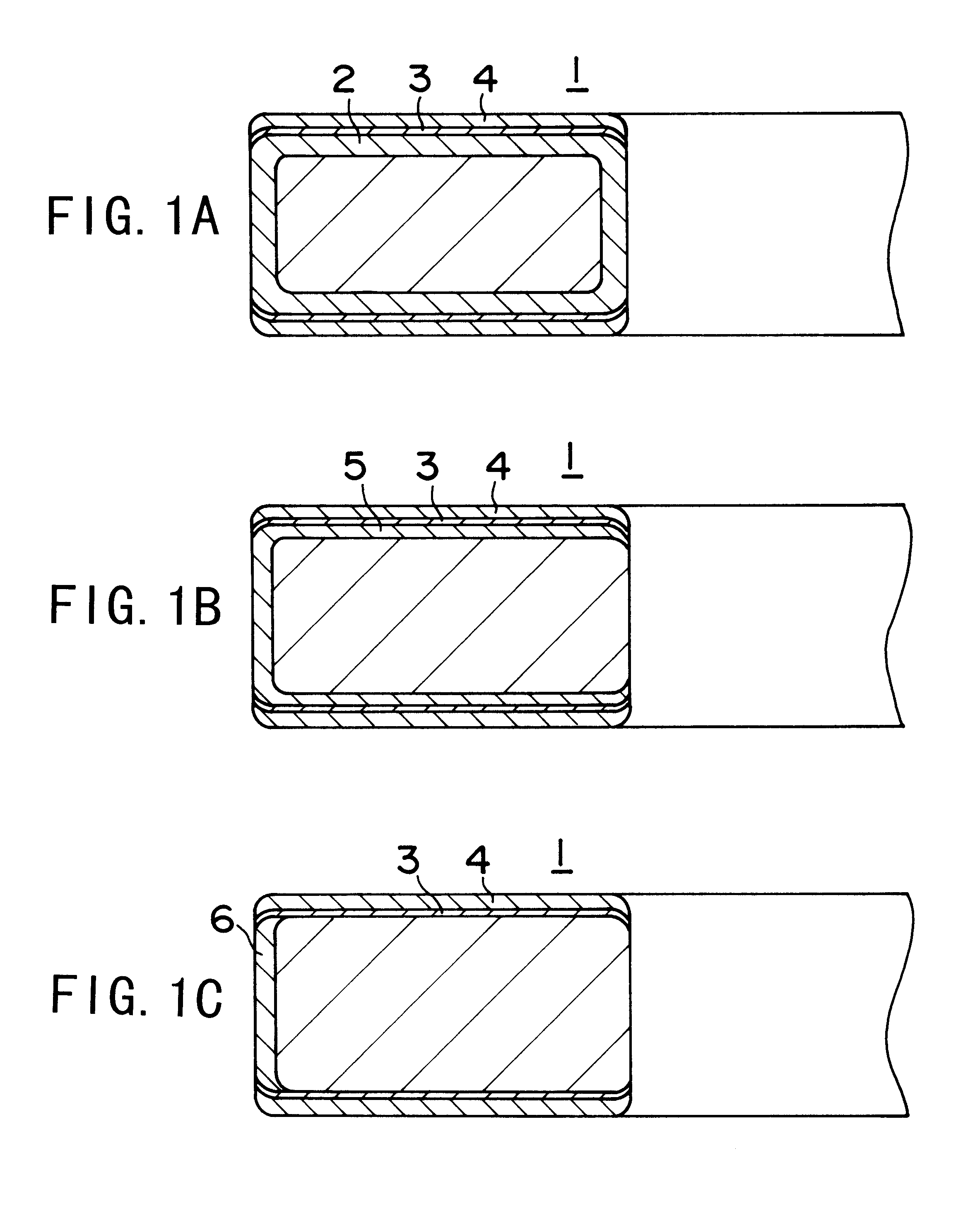

Piston ring

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

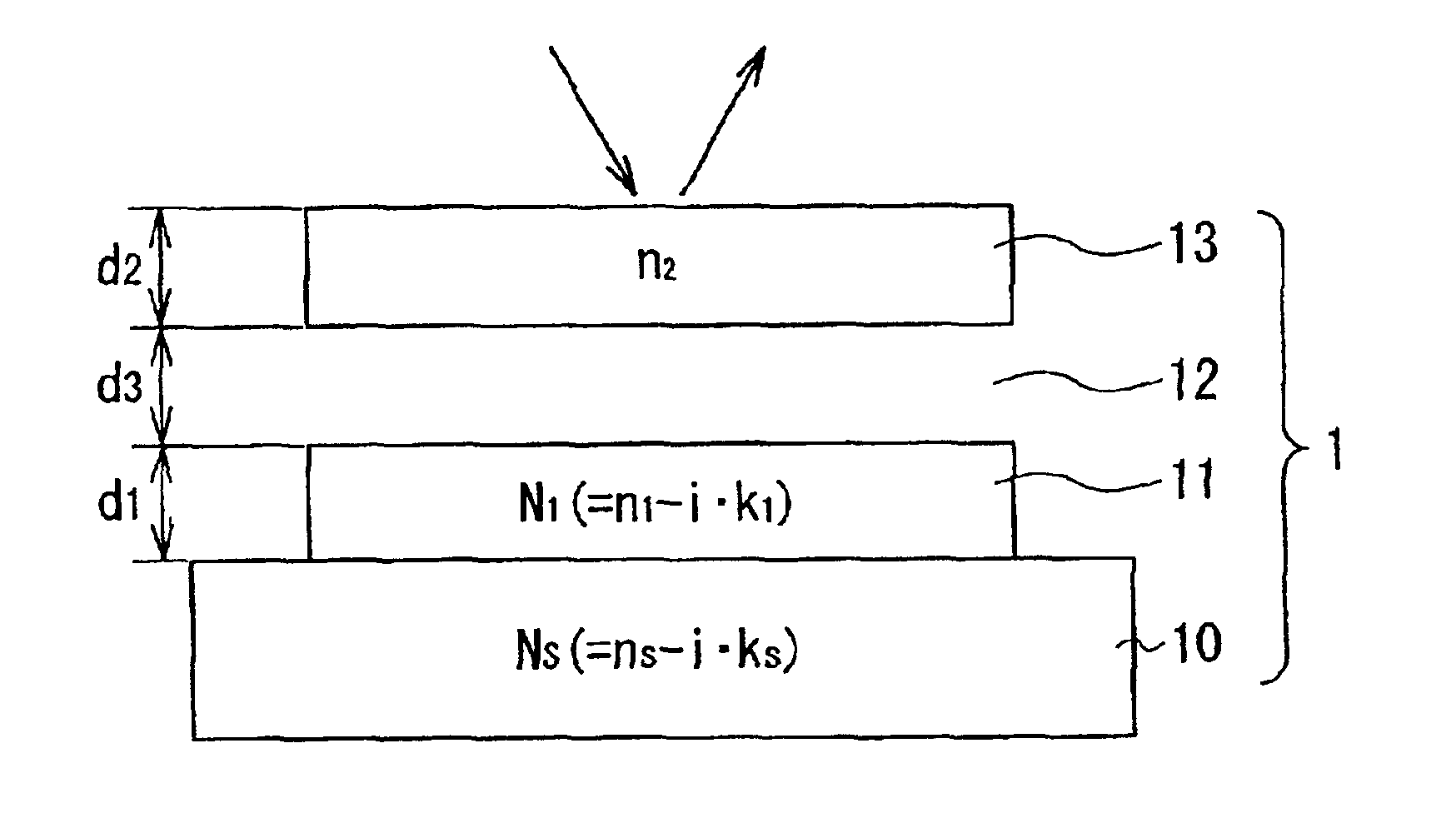

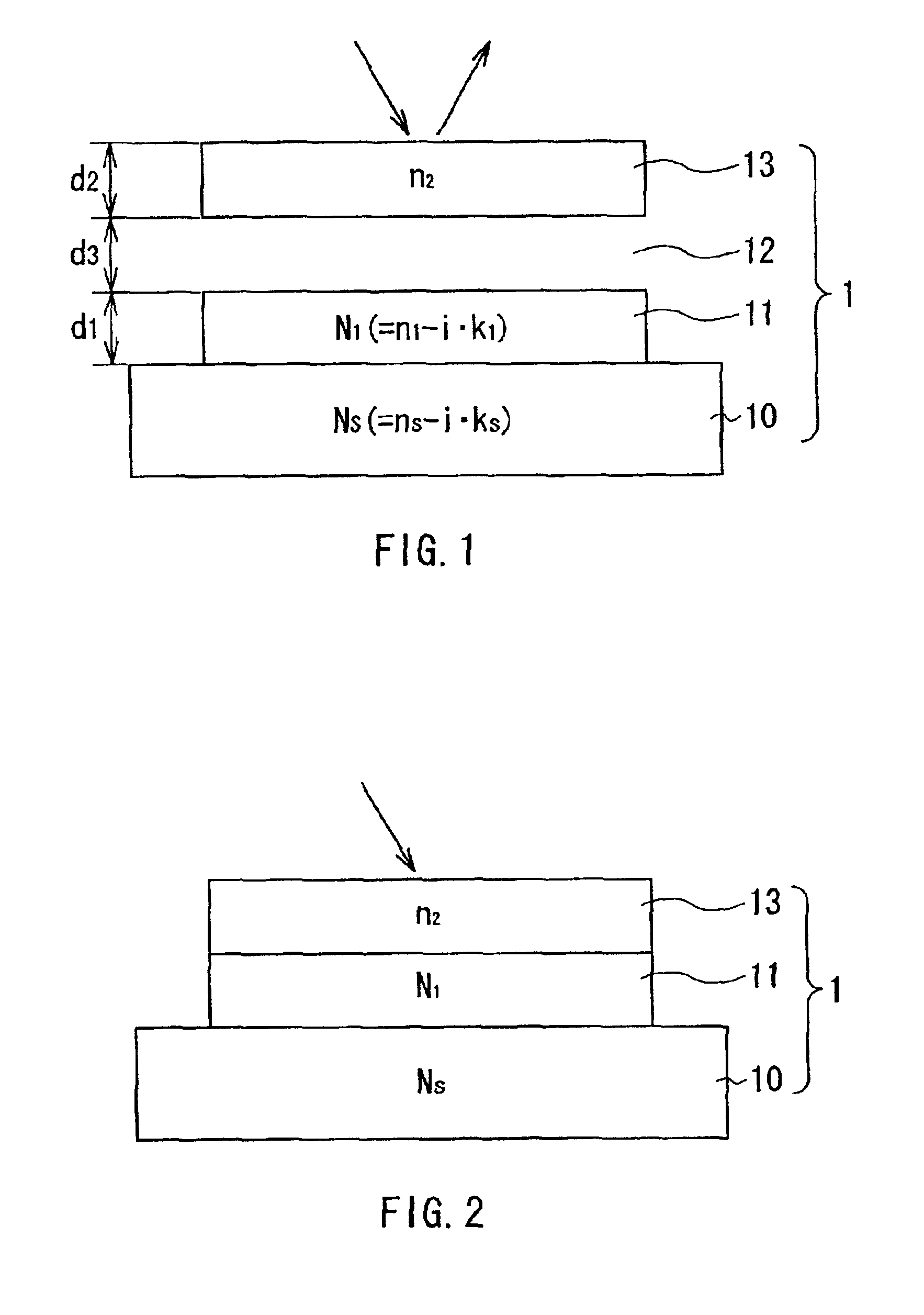

Optical multilayer structure, optical switching device, and image display

InactiveUS6940631B2Simple configurationSmall structureCathode-ray tube indicatorsCoupling light guidesInterference phenomenonRefractive index

An optical multilayer structure has a substrate, a light-absorbing first layer in contact with the substrate, a gap portion having a changeable size capable of causing an optical interference phenomenon, and a second layer. By changing the size of the gap portion, an amount of reflection, transmission, or absorption of incident light can be changed. For example, the substrate is made of carbon (C), the first layer is made of tantalum (Ta), and the second layer is made of silicon nitride (Si3N4). Also in a visible light area, high response is realized. Consequently, the optical multilayer structure can be suitably used for an image display. The optical multilayer structure may be obtained by stacking, on a substrate made of a metal such as chromium (Cr), a first transparent layer made of a material having a high refractive index such as TiO2 (n=2.40), a second transparent layer made of a material having a low refractive index such as MgF2 (n=1.38), a gap portion having a changeable size capable of causing an optical interference phenomenon, and a third transparent layer made of a material having a high refractive index such as TiO2.

Owner:SONY CORP

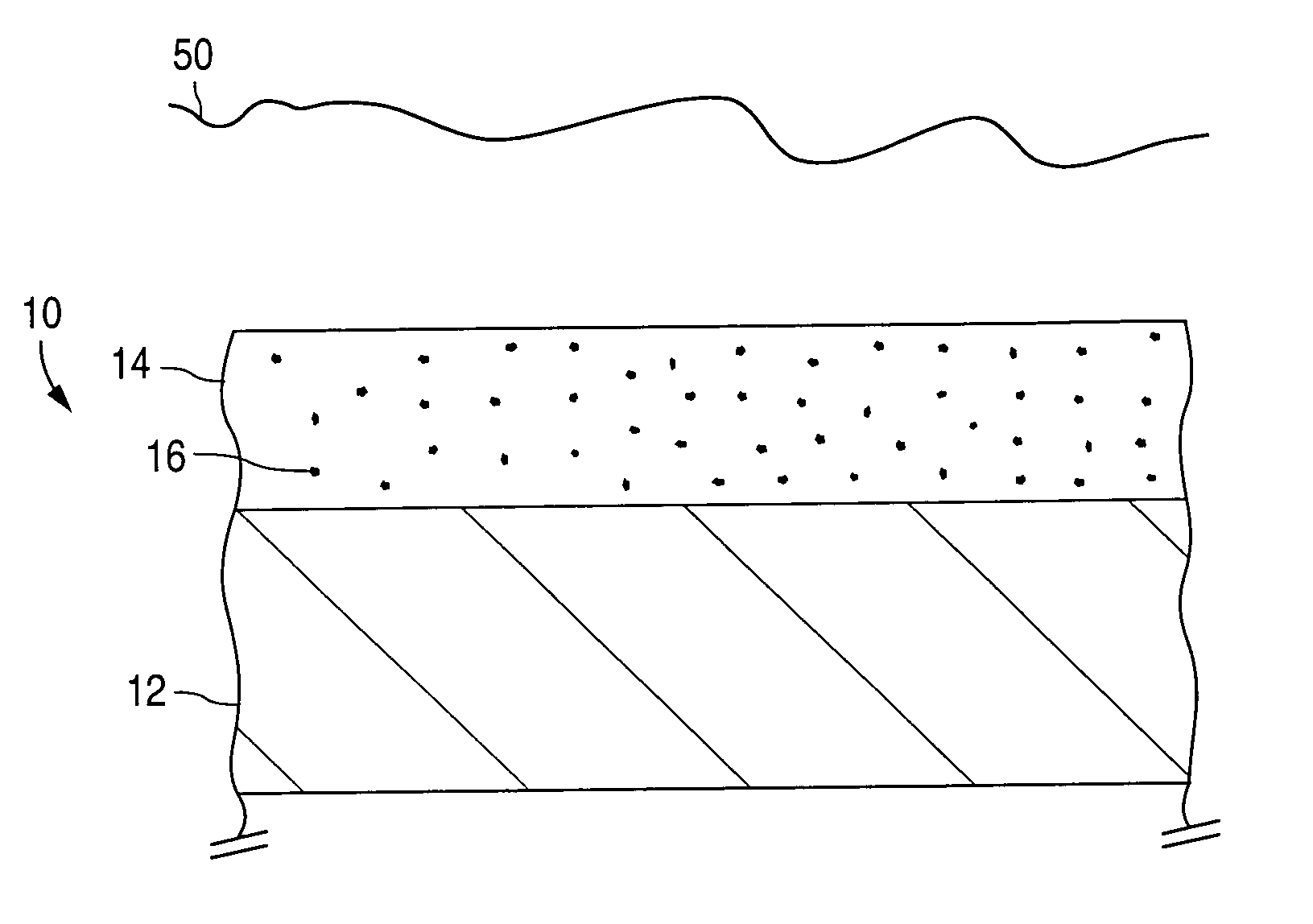

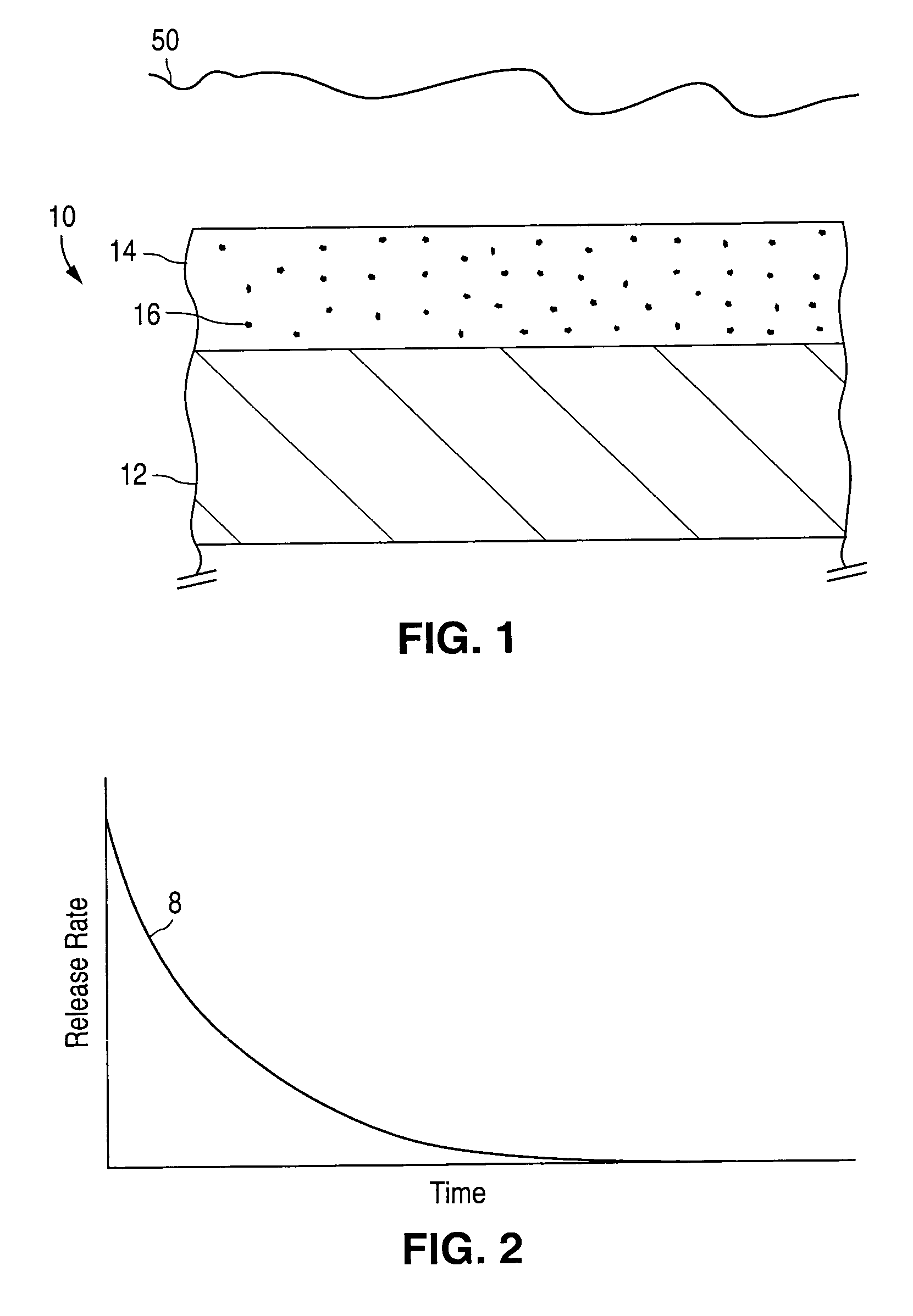

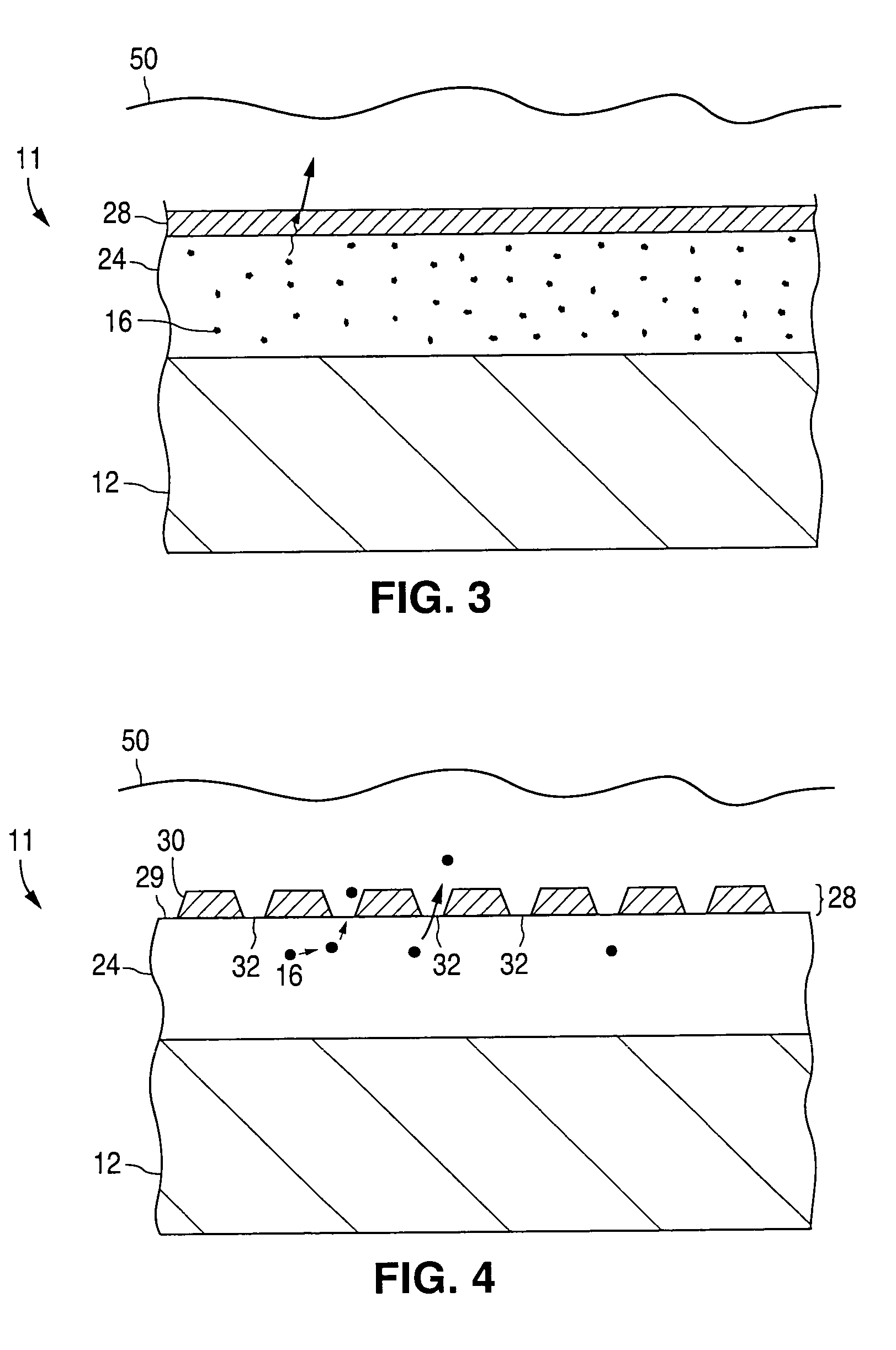

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

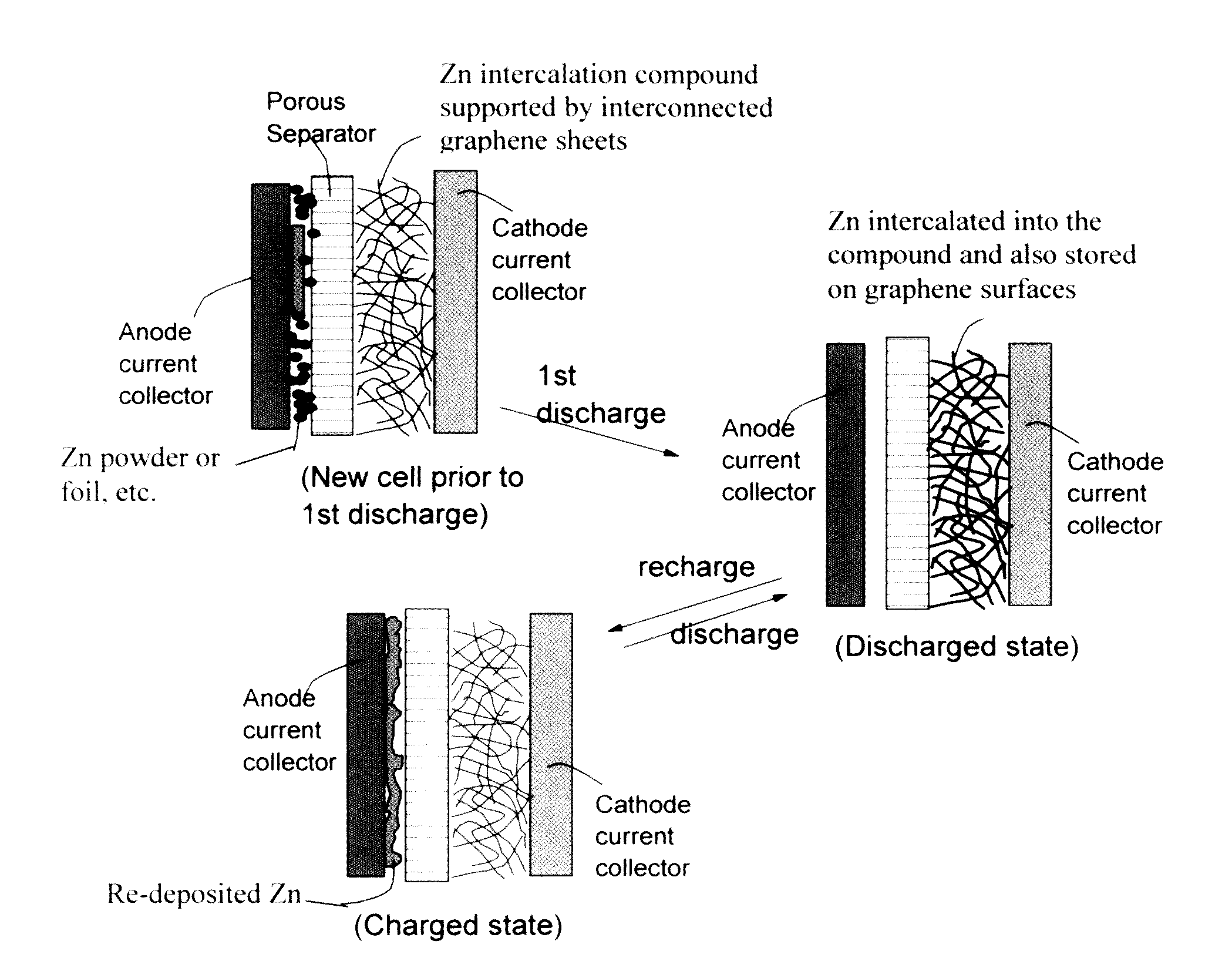

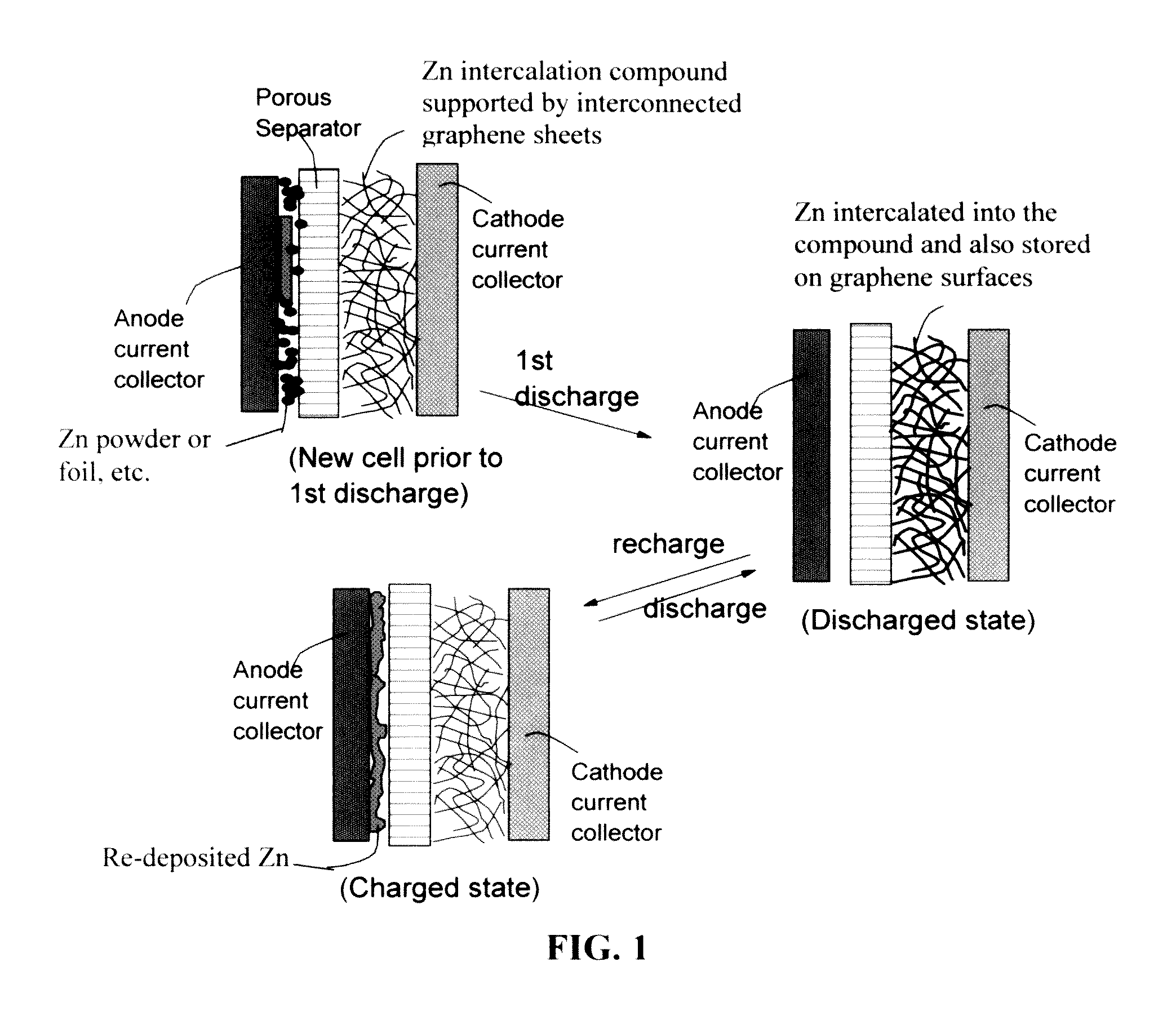

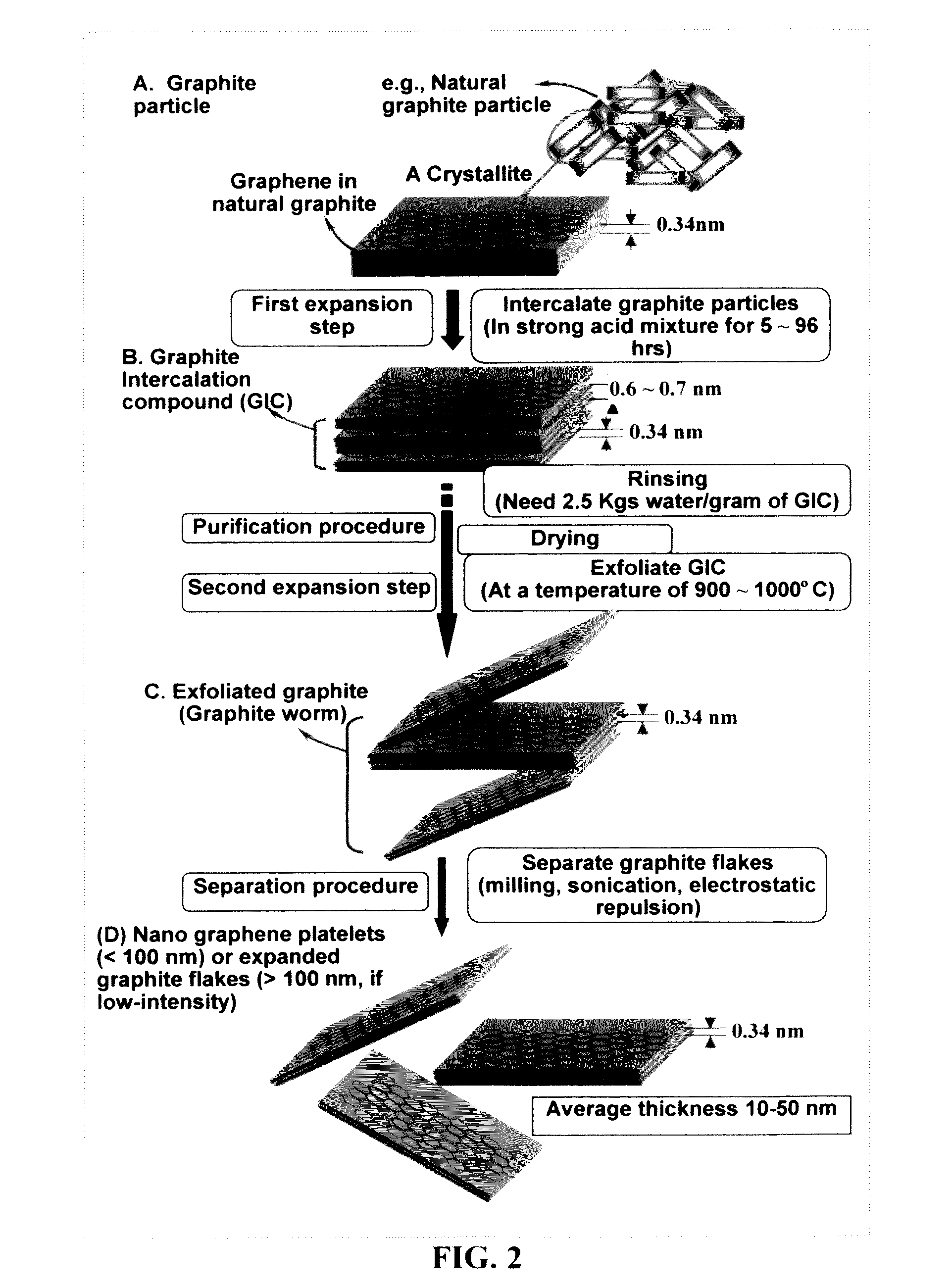

Zinc Ion-Exchanging Energy Storage Device

ActiveUS20160301096A1Quick releaseRapid depositionHybrid capacitor electrolytesAlkaline accumulatorsChemical treatmentZinc metal

A zinc ion-exchanging battery device comprising: (A) a cathode comprising two cathode active materials (a zinc ion intercalation compound and a surface-mediating material); (B) an anode containing zinc metal or zinc alloy; (C) a porous separator disposed between the cathode and the anode; and (D) an electrolyte containing zinc ions that are exchanged between the cathode and the anode during battery charge / discharge. The zinc ion intercalation compound is selected from chemically treated carbon or graphite material having an expanded inter-graphene spacing d002 of at least 0.5 nm, or an oxide, carbide, dichalcogenide, trichalcogenide, sulfide, selenide, or telluride of niobium, zirconium, molybdenum, hafnium, tantalum, tungsten, titanium, vanadium, chromium, cobalt, manganese, iron, nickel, or a combination thereof. The surface-mediating material contains exfoliated graphite or multiple single-layer sheets or multi-layer platelets of a graphene material.

Owner:GLOBAL GRAPHENE GRP INC

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

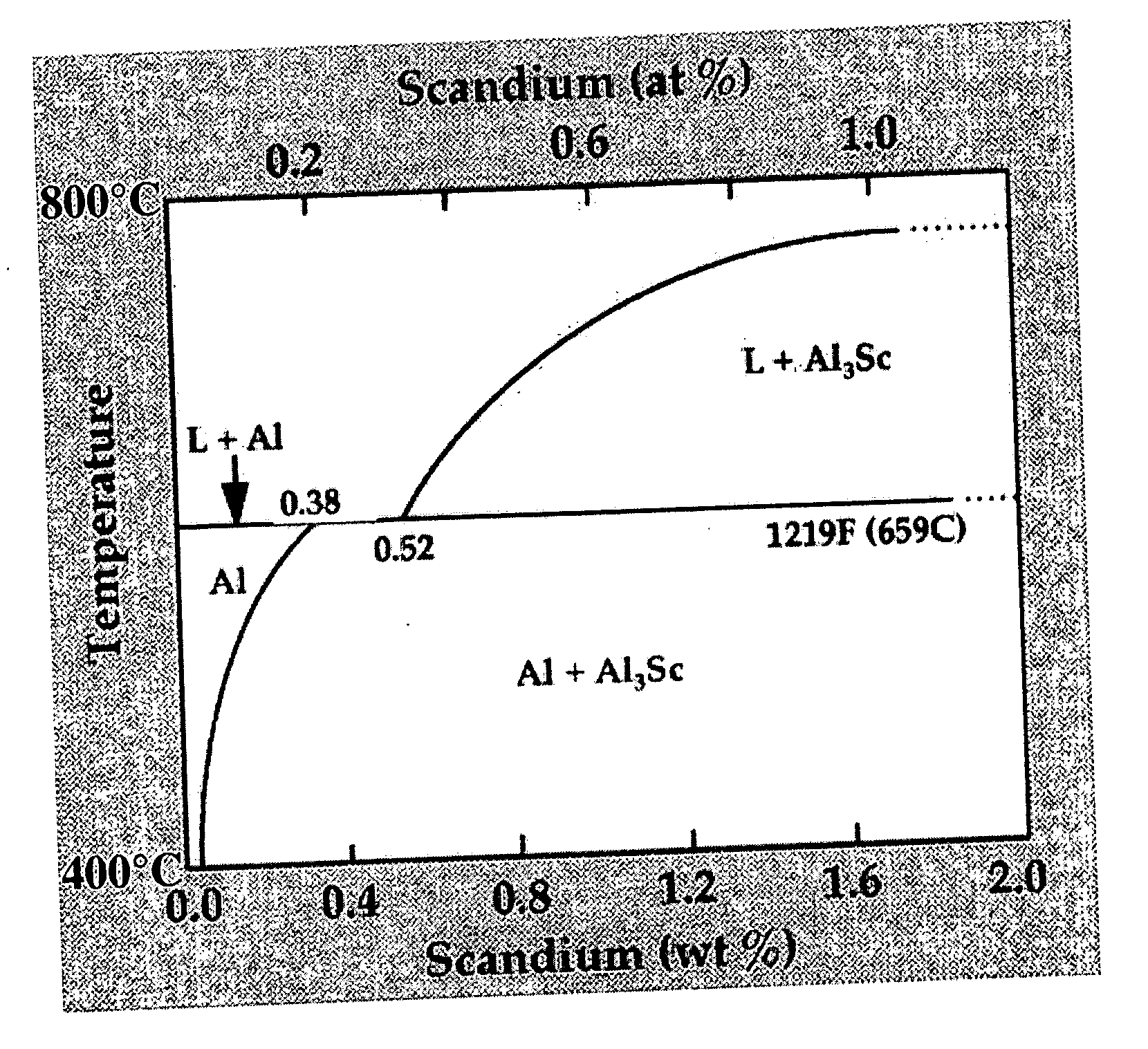

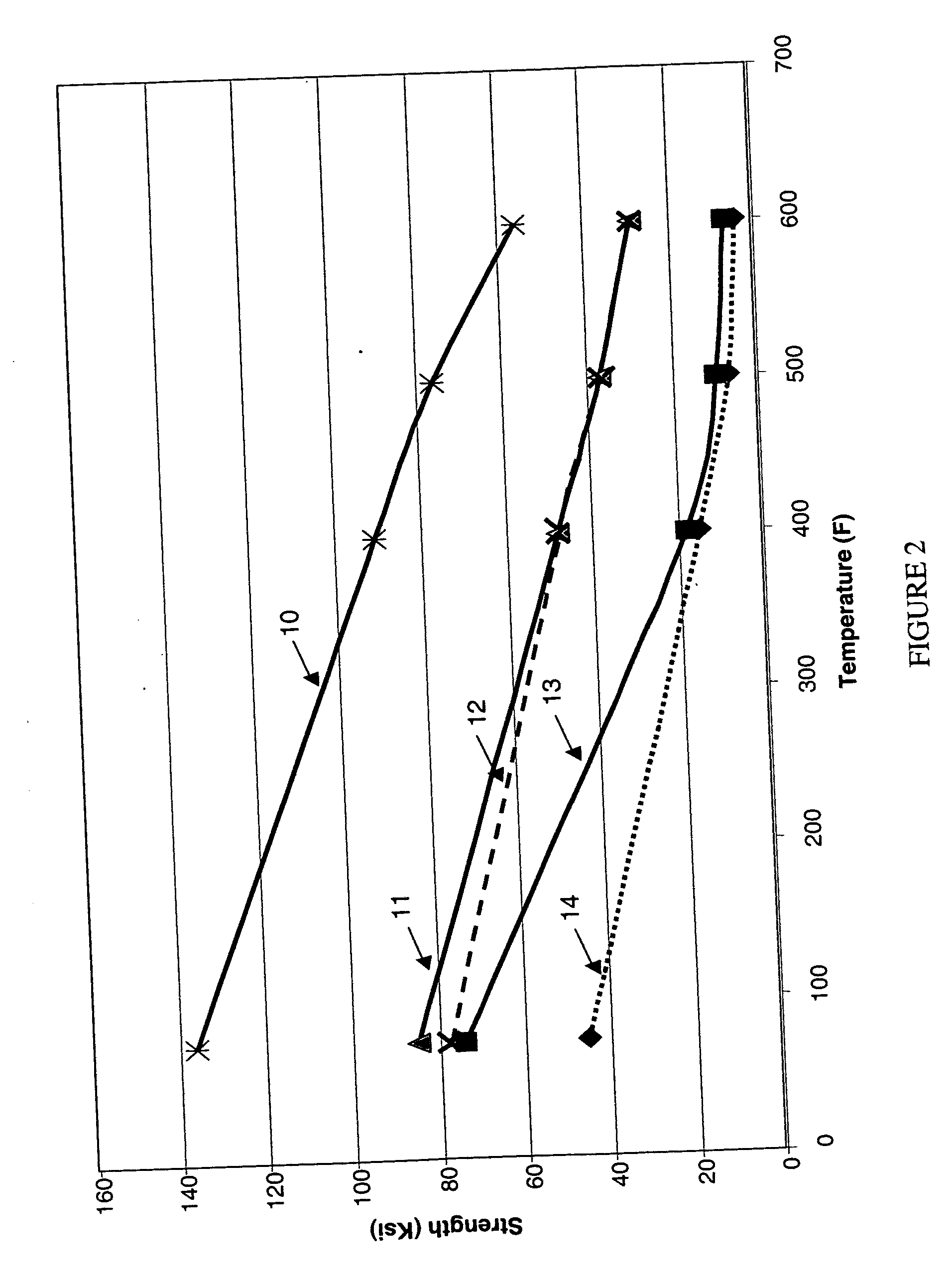

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

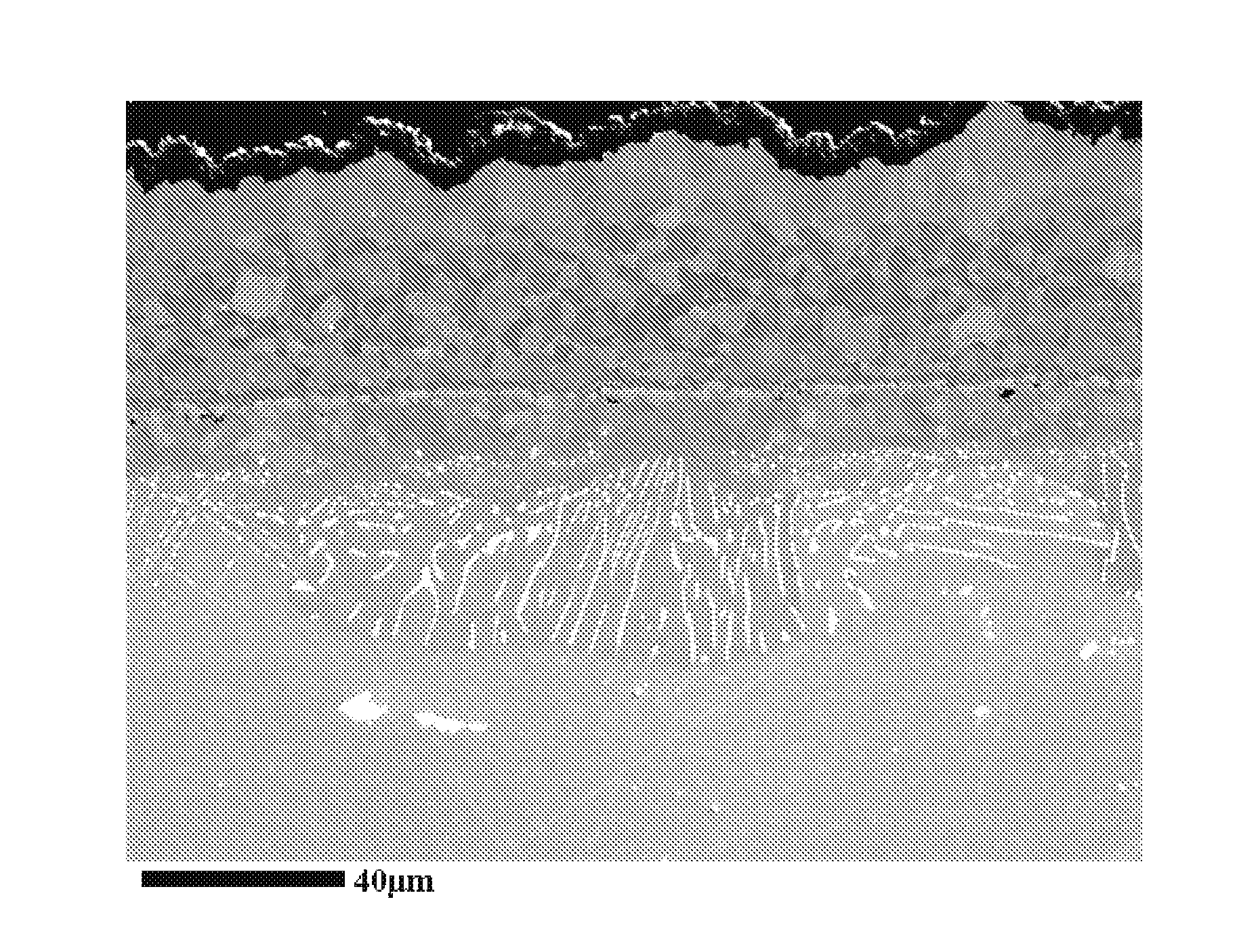

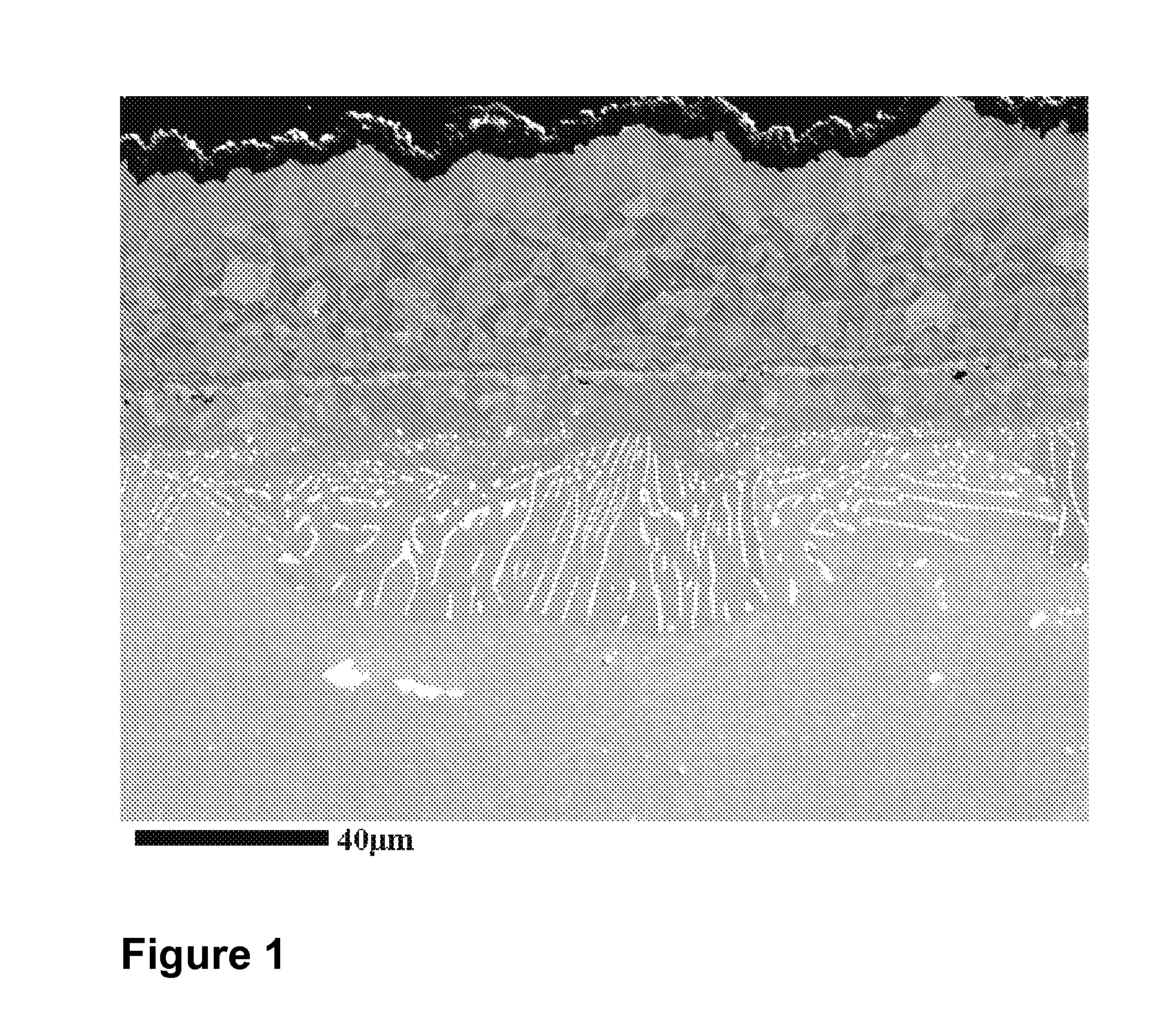

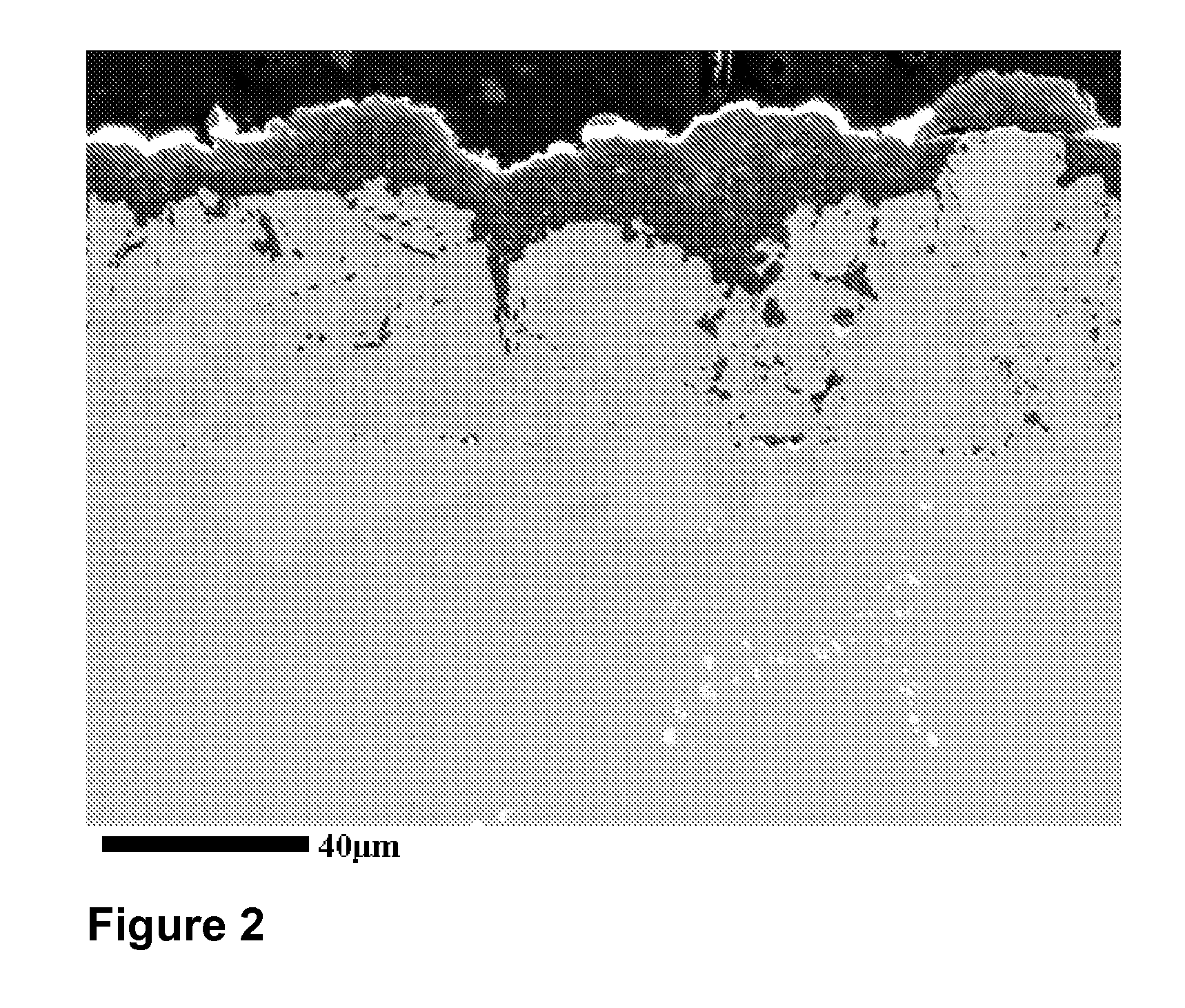

Metallic coating for single crystal alloys

InactiveUS20110256421A1Polycrystalline material growthMolten spray coatingSingle crystal superalloySingle crystal

A metallic coating for use in a high temperature application is created from a nickel base alloy containing from 5.0 to 10.5 wt % aluminum, from 4.0 to 15 wt % chromium, from 2.0 to 8.0 wt % tungsten, from 3.0 to 10 wt % tantalum, and the balance nickel. The metallic coating has particular utility in protecting single crystal superalloys used in high temperature applications such as turbine engine components.

Owner:UNITED TECH CORP

Articles with electroplated zinc-nickel ternary and higher alloys, electroplating baths, processes and systems for electroplating such alloys

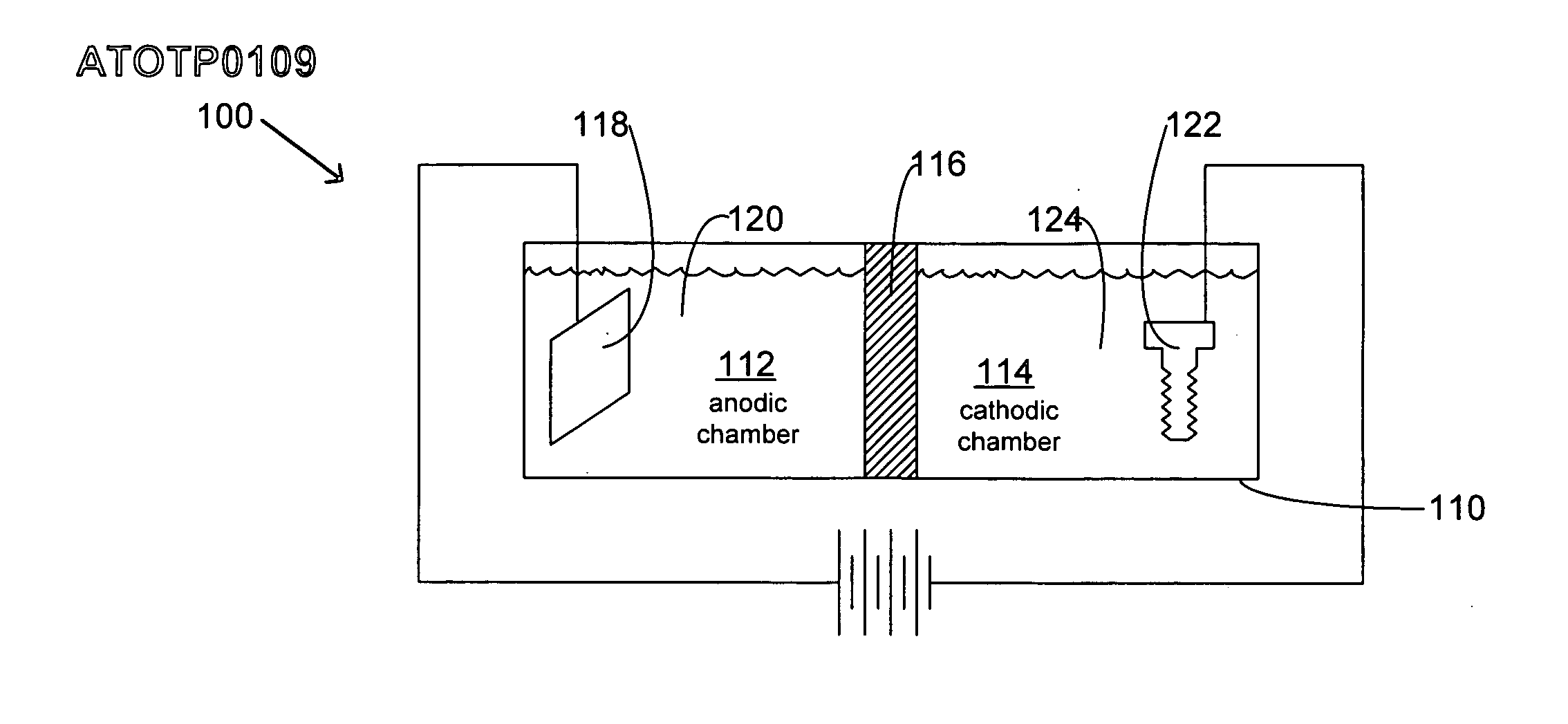

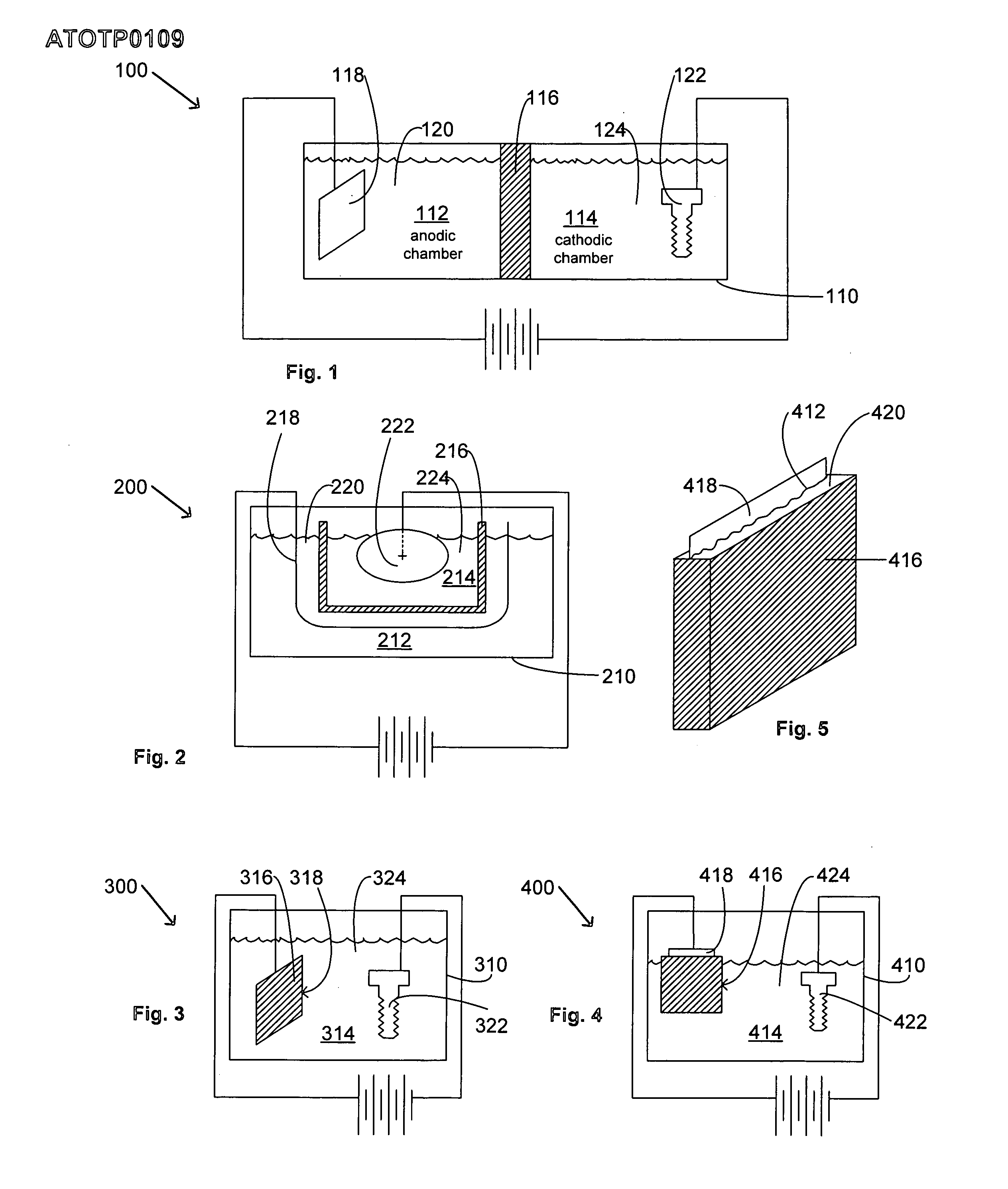

An electroplating bath, a system, a process for, and the article obtained from, depositing a zinc-nickel ternary or higher alloy, a) zinc ions; b) nickel ions; and c) one or more ionic species selected from ions of Te+4, Bi+3 and Sb+3, and in some embodiments, further including one or more additional ionic species selected from ions of Bi+3, Sb+3, Ag+1, Cd+2, Co+2, Cr+3, Cu+2, Fe+2, In+3, Mn+2, Mo+6, P+3, Sn+2 and W+6. In some embodiments, the system includes a divider forming a cathodic chamber and an anodic chamber, with the electroplating bath in the cathodic chamber only. In various embodiments, the zinc-nickel ternary and higher alloys may provide improved properties to the conductive substrates upon which the alloys are deposited.

Owner:ATOTECH DEUT GMBH

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

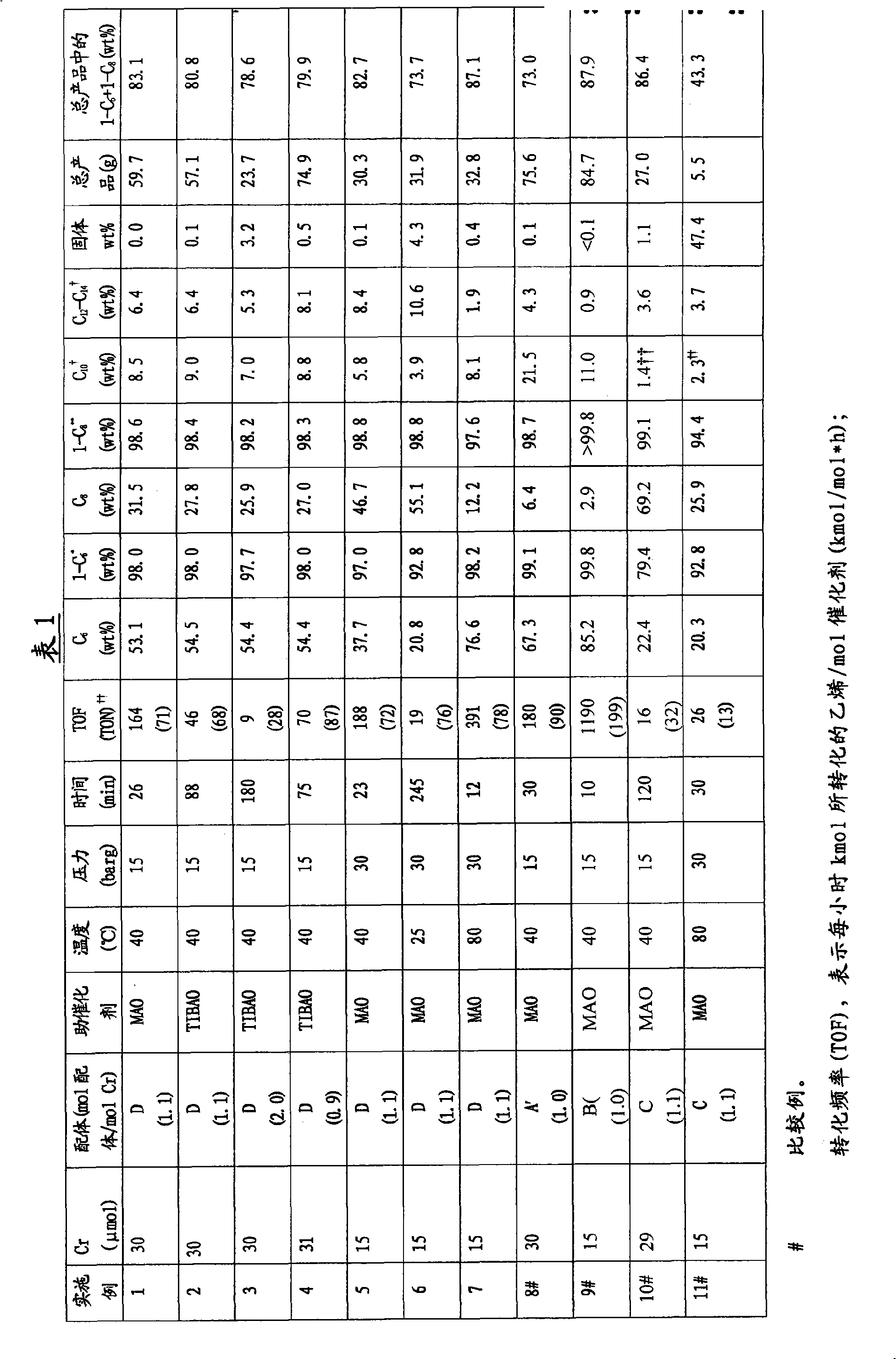

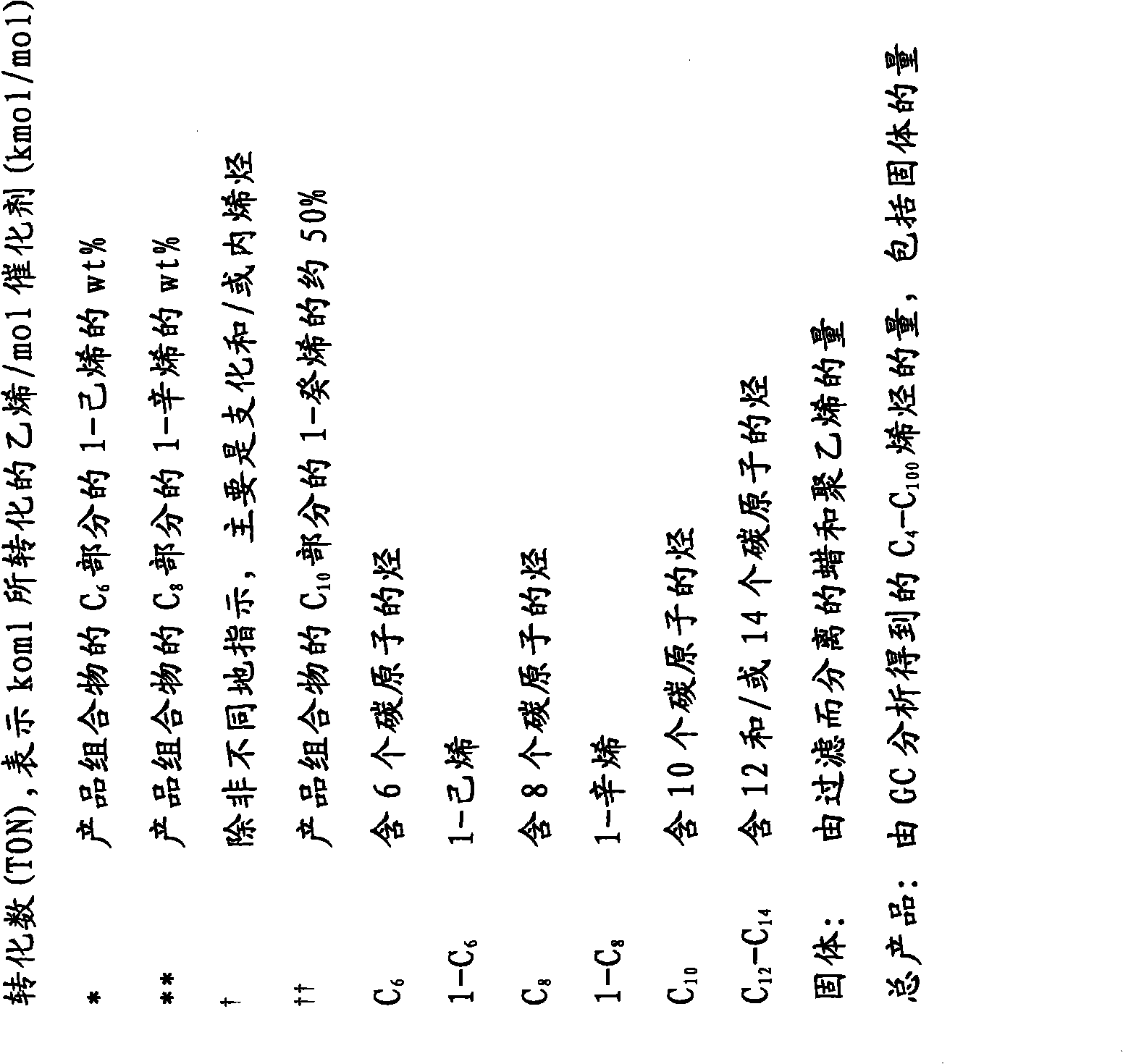

Catalytic process for the oligomerization of olefinic monomers

InactiveCN101351424AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilylene1-Octene

A process for the simultaneous trimerization and tetramerization of olefinic monomers , wherein the process comprises contacting at least one olefinic monomer with catalyst system comprising : a) a source of chromium, molybdenum or tungsten; b) a ligand having the general formula (I) ; (R<1>)2P-X-P (R<1>)m(R<2>)n wherein : X is a bridging group of the formula -N(R<3>)-, wherein R<3> is selected from hydrogen, a hydrocarbyl group, a substituted hydrocarbyl group, a heterohydrocarbyl group, a substituted heterohydrocarbyl group, a silyl group or derivative thereof; the R<1> groups are independently selected from an optionally substituted aromatic group bearing a polar substituent on at least one of the ortho-positions; and the R<2> groups are independently selected from hydrocarbyl, substituted hydrocarbyl, heterohydrocarbyl and substituted heterohydrocarbyl groups and c) a cocatalyst. The present invention further relates to a process for the simultaneous trimerization and tetramerization of ethylene to 1-hexene and 1-octene.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com