Earth-boring bits

a technology of earthboring bits and earthboring holes, which is applied in the direction of drill bits, earth drilling and mining, cutting machines, etc., can solve the problems of difficult to prevent premature freezing and formation of pin holes in castings, and achieve the effect of reducing the melting point of iron, nickel and/or cobalt, and facilitating proper infiltration of the mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

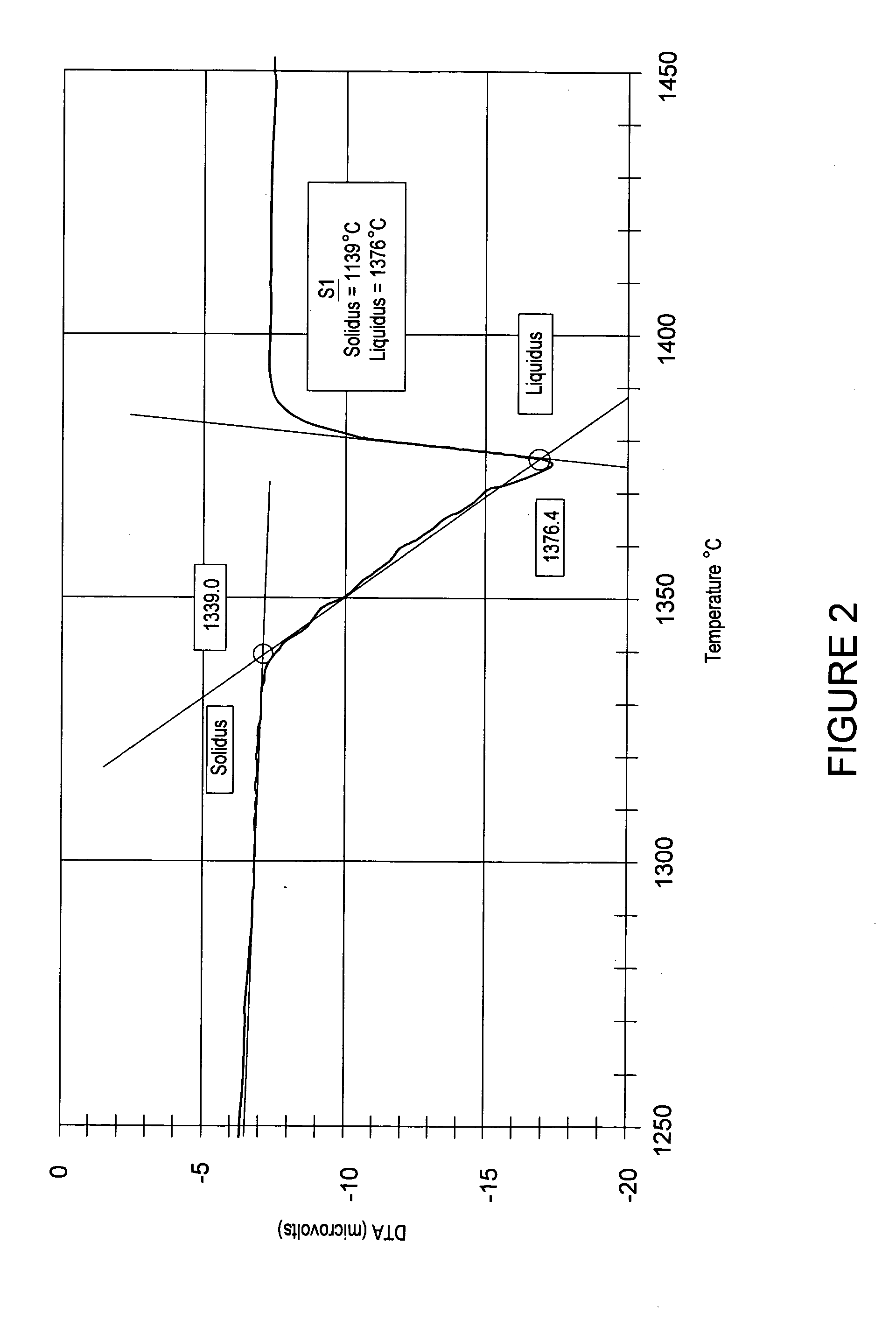

[0039] Embodiments of the present invention relate to a composition for the formation of bit bodies for earth-boring bits, roller cones, insert roller cones, cones and teeth for roller cone drill bits and methods of making a bit body for such articles. Additionally, the method may be used to make other articles. Certain embodiments of a bit body of the present invention comprise at least one discontinuous hard phase and a continuous binder phase binding together the hard phase. Embodiments of the compositions and methods of the present invention provide increased service life for the bit body, roller cones, insert roller cones, teeth, and cones produced from the composition and method and thereby improve the service life of the earth-boring bit or other tool. The body material of the bit body, roller cone, insert roller cone, cone provides the overall properties to each region of the article.

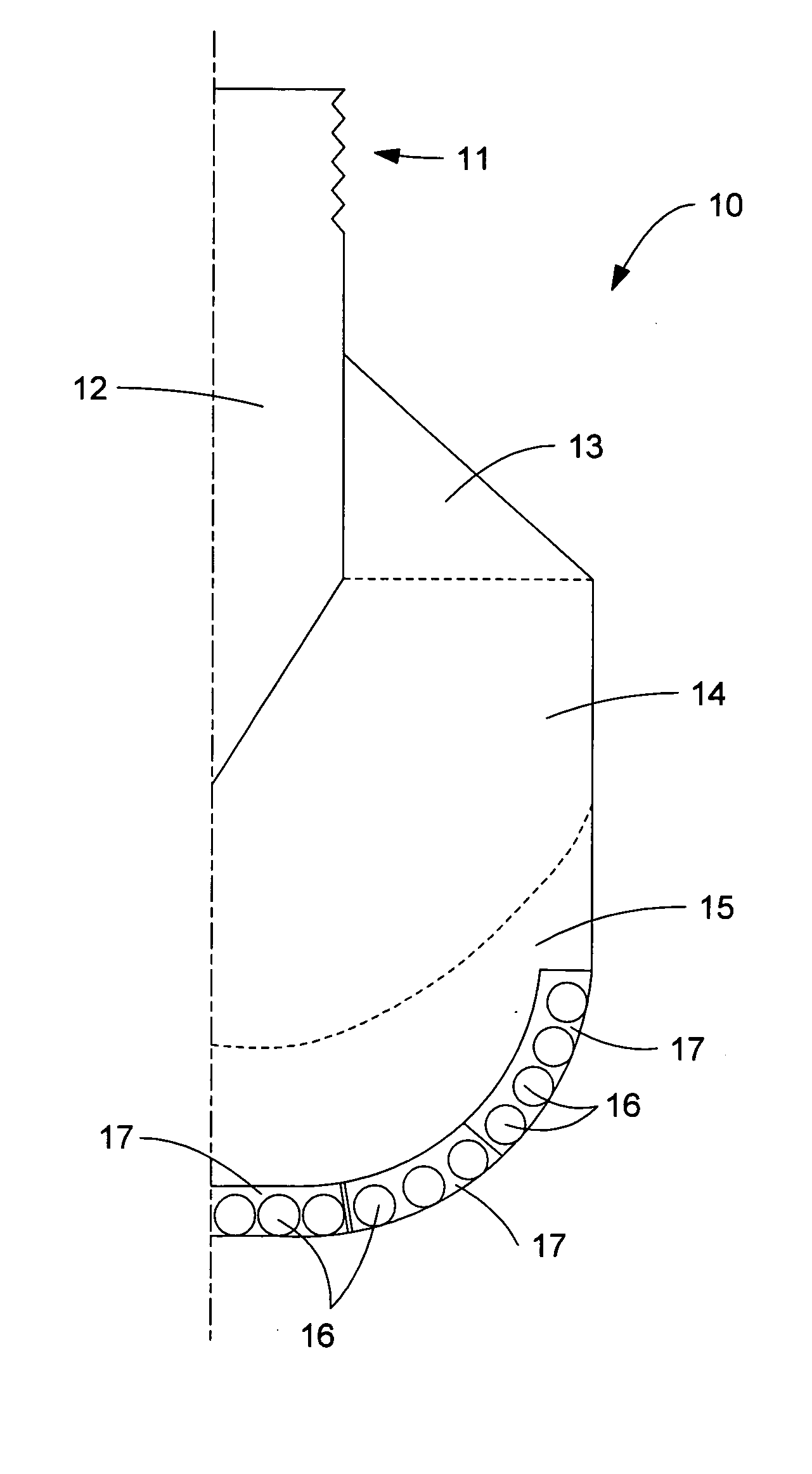

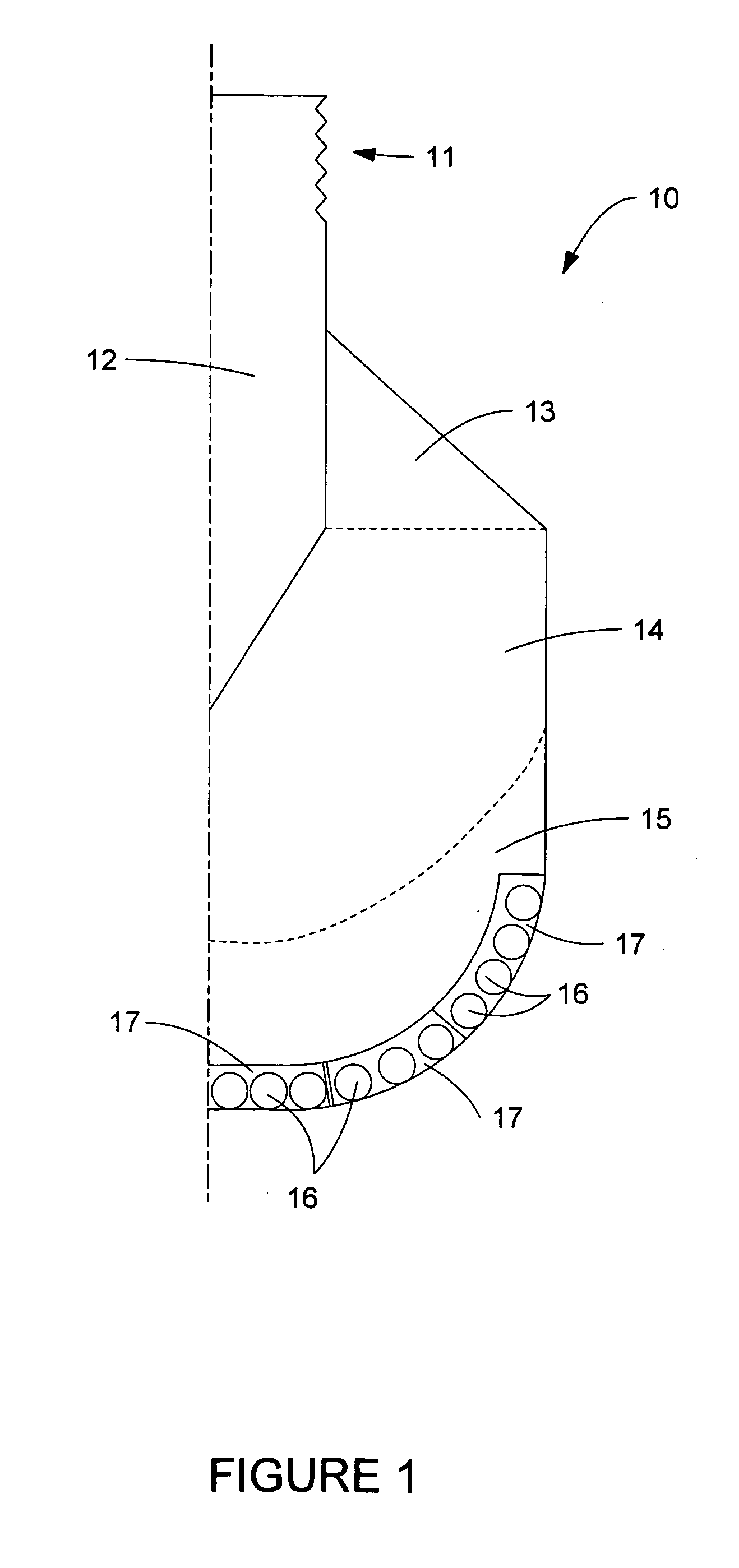

[0040] A typical bit body 10 of a fixed cutter earth-boring bit is shown in FIG. 1. General...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com