Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2147 results about "Boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A boride is a compound between boron and a less electronegative element, for example silicon boride (SiB₃ and SiB₆). The borides are a very large group of compounds that are generally high melting and are covalent more than ionic in nature. Some borides exhibit very useful physical properties. The term boride is also loosely applied to compounds such as B₁₂As₂ (N.B. Arsenic has an electronegativity higher than boron) that is often referred to as icosahedral boride.

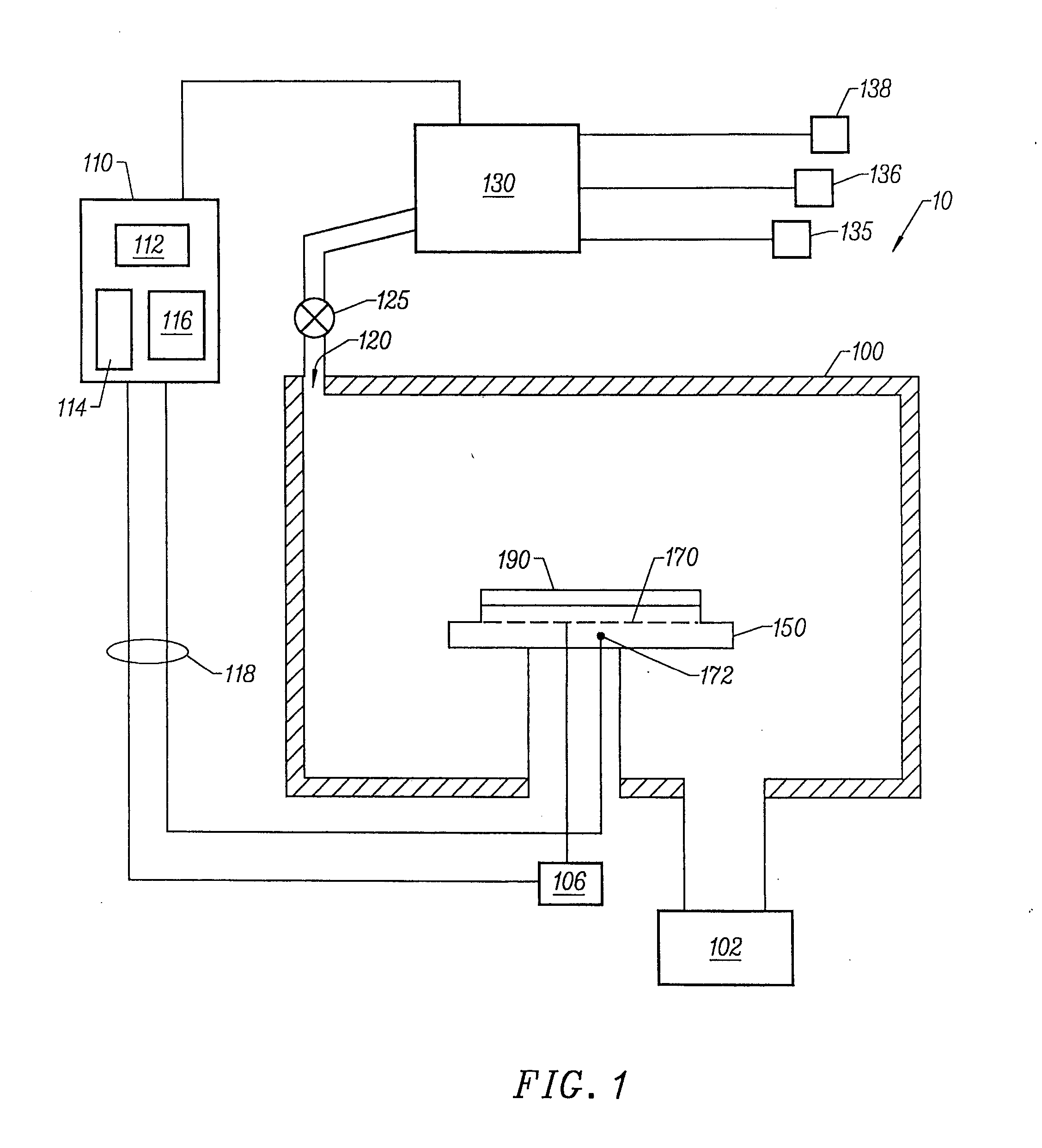

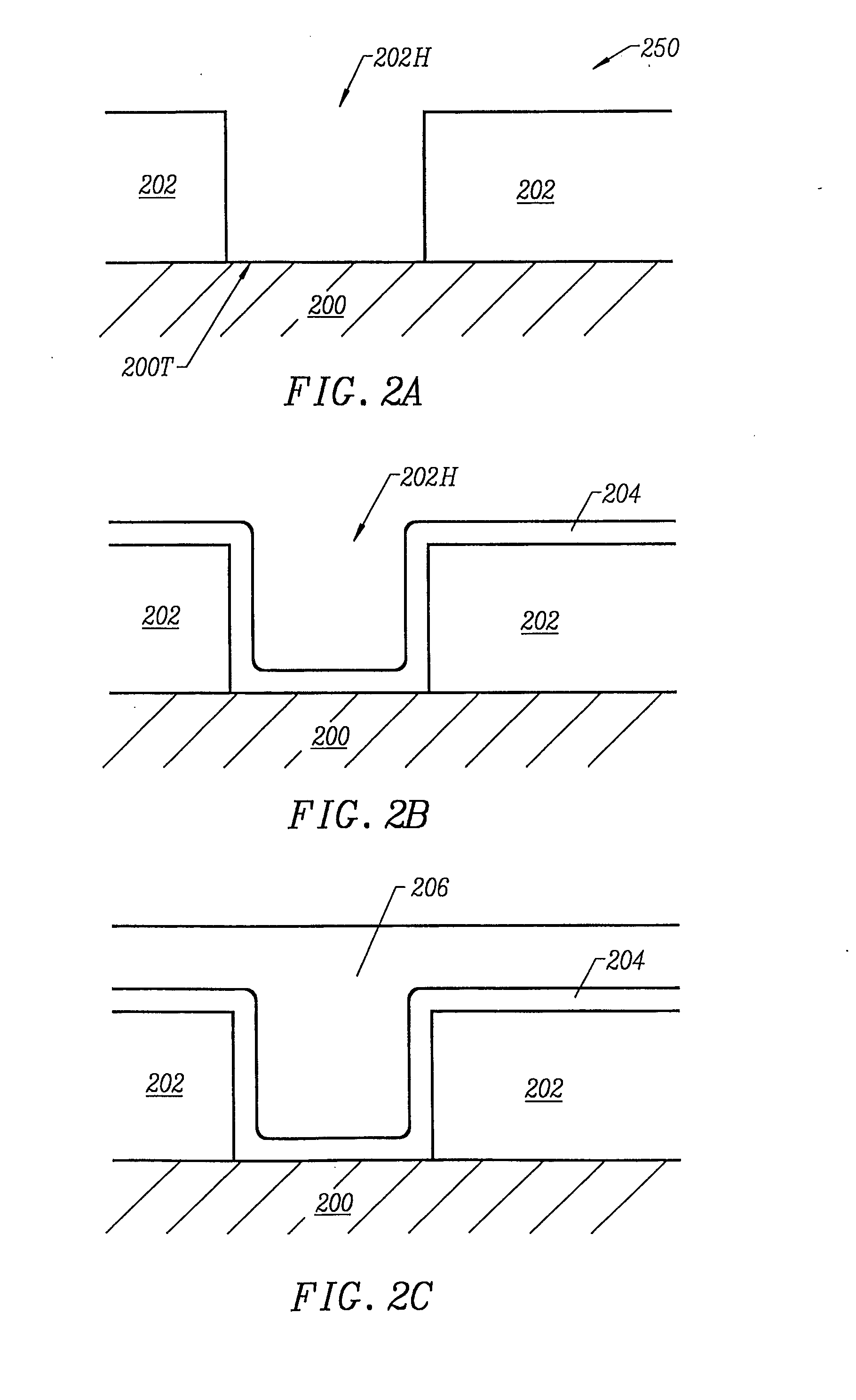

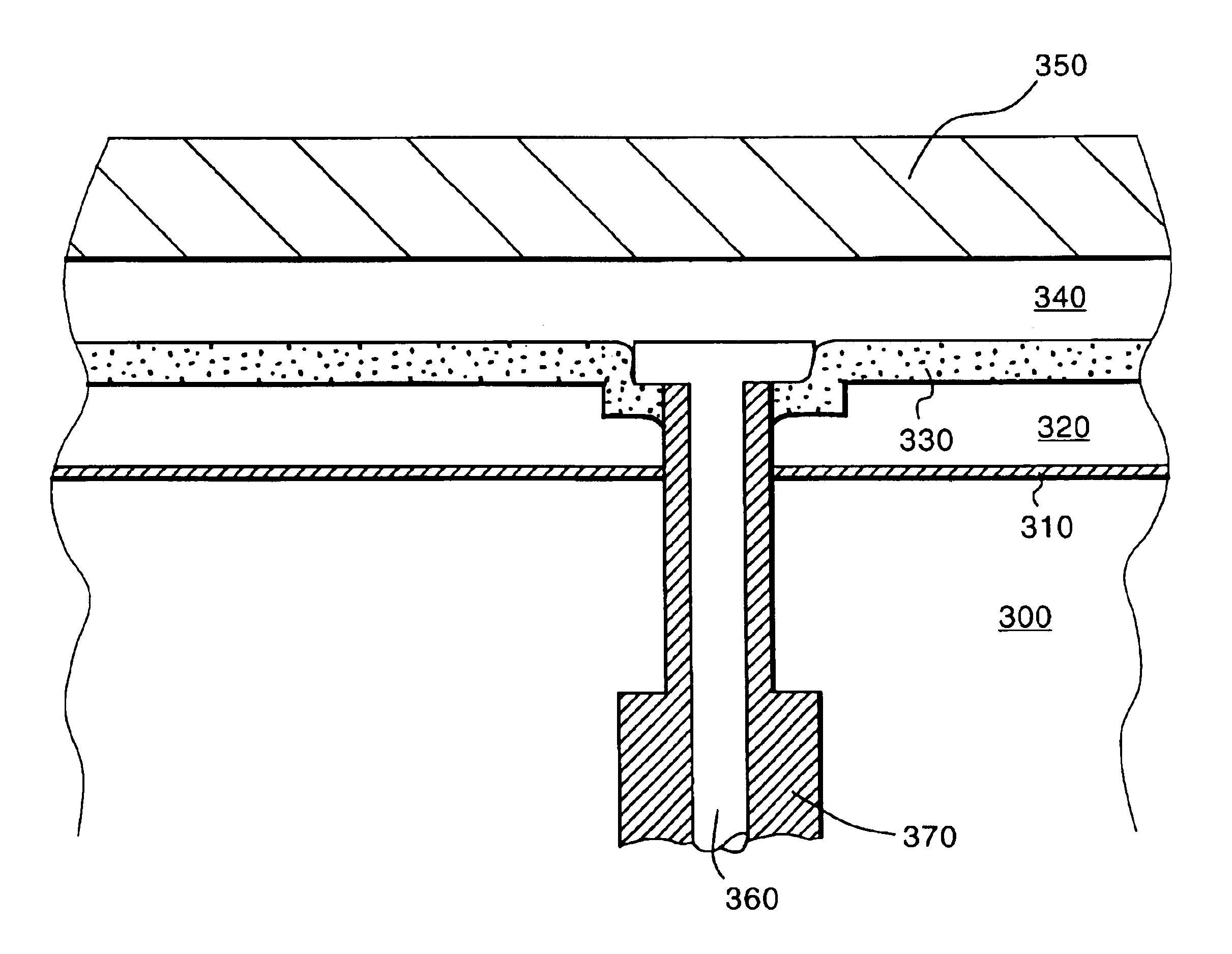

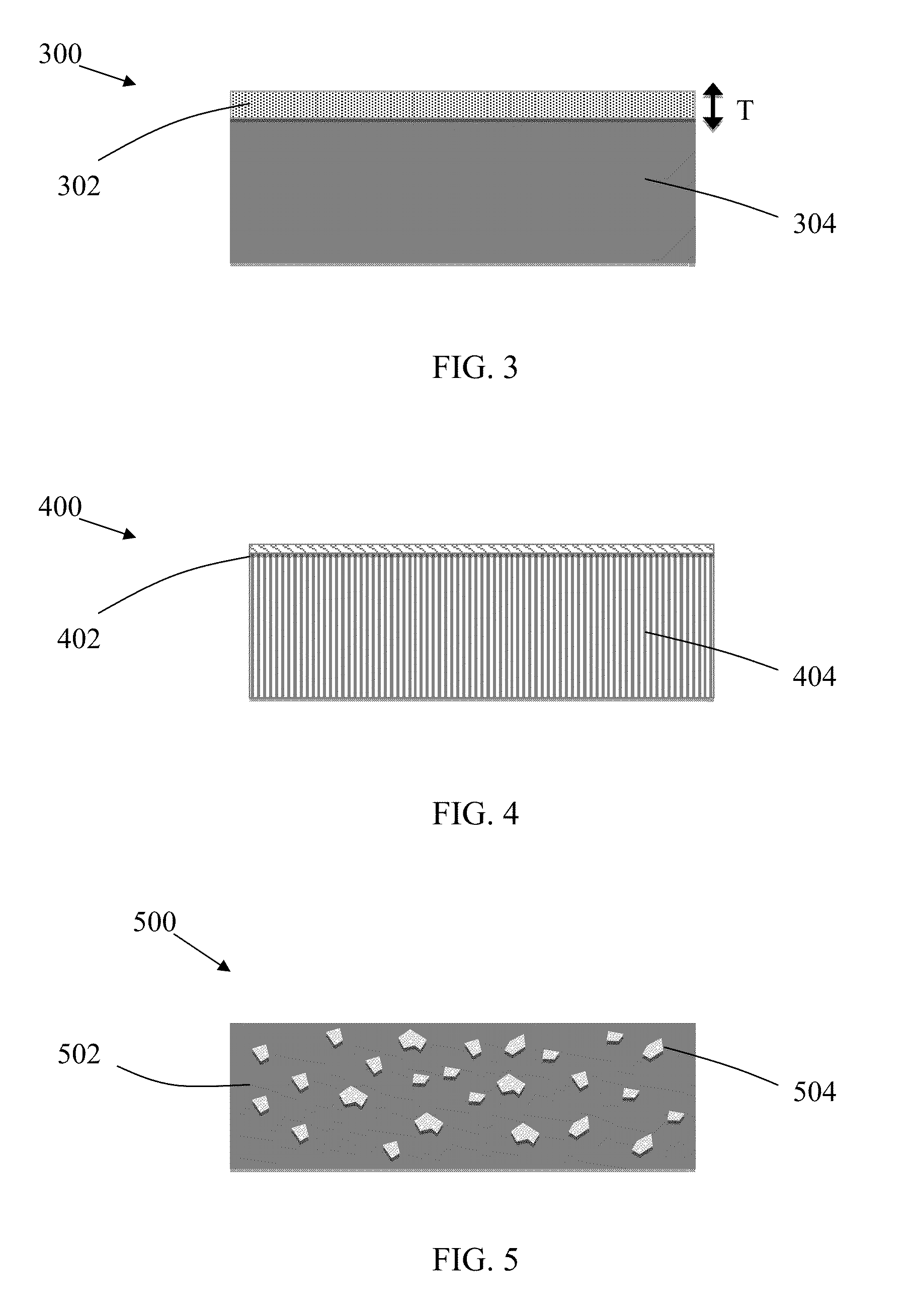

Formation of boride barrier layers using chemisorption techniques

InactiveUS7208413B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideBoron containing

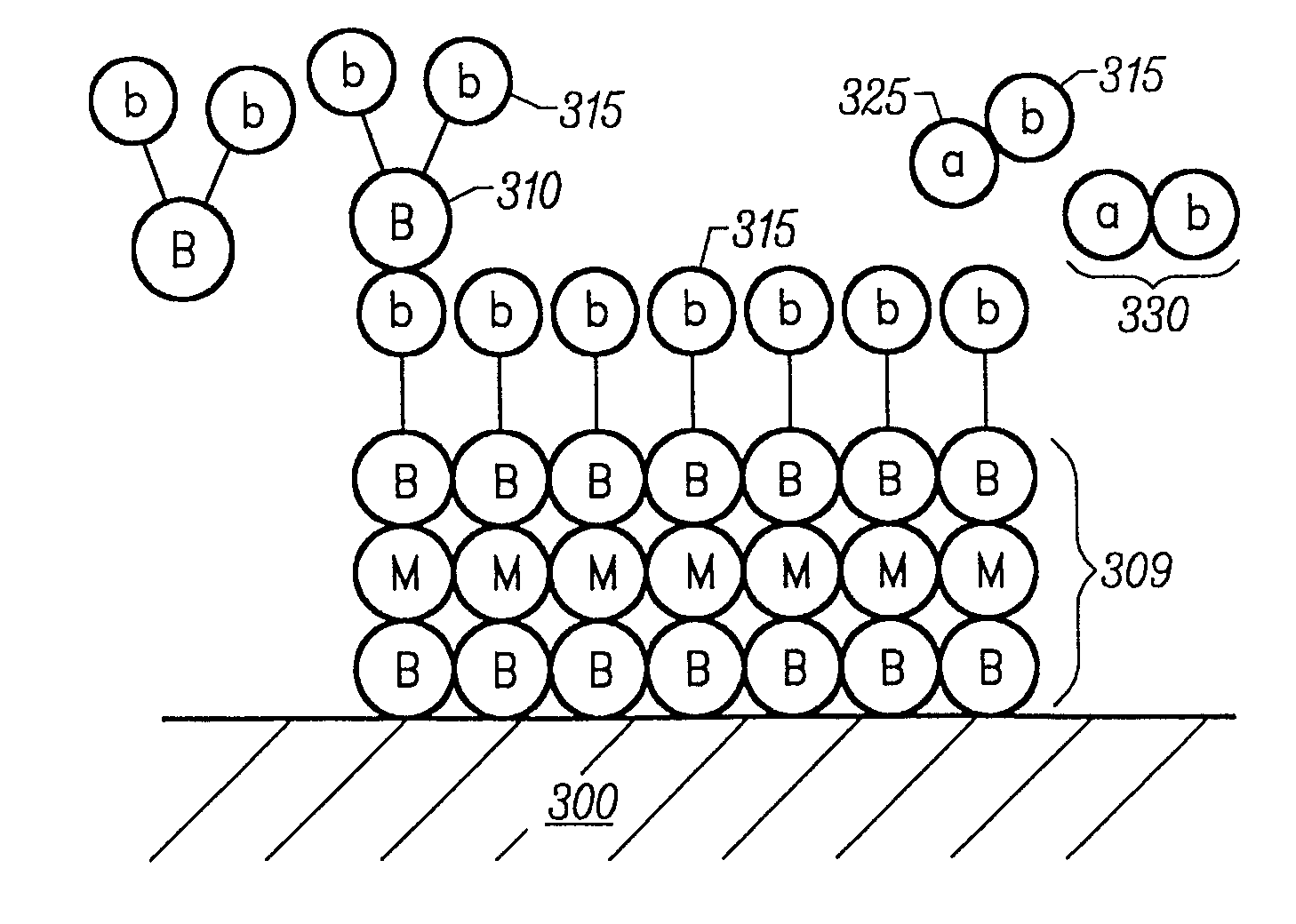

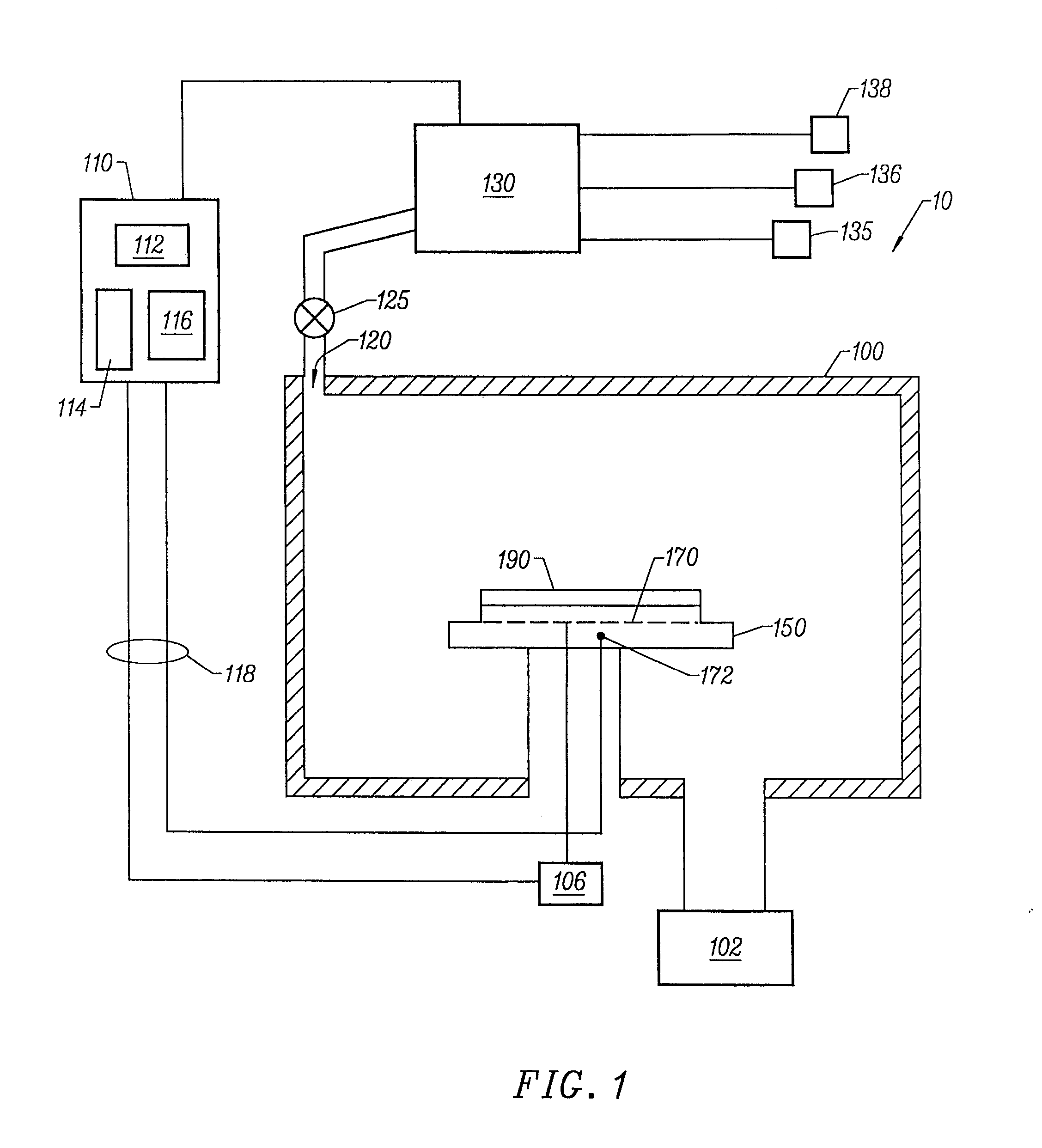

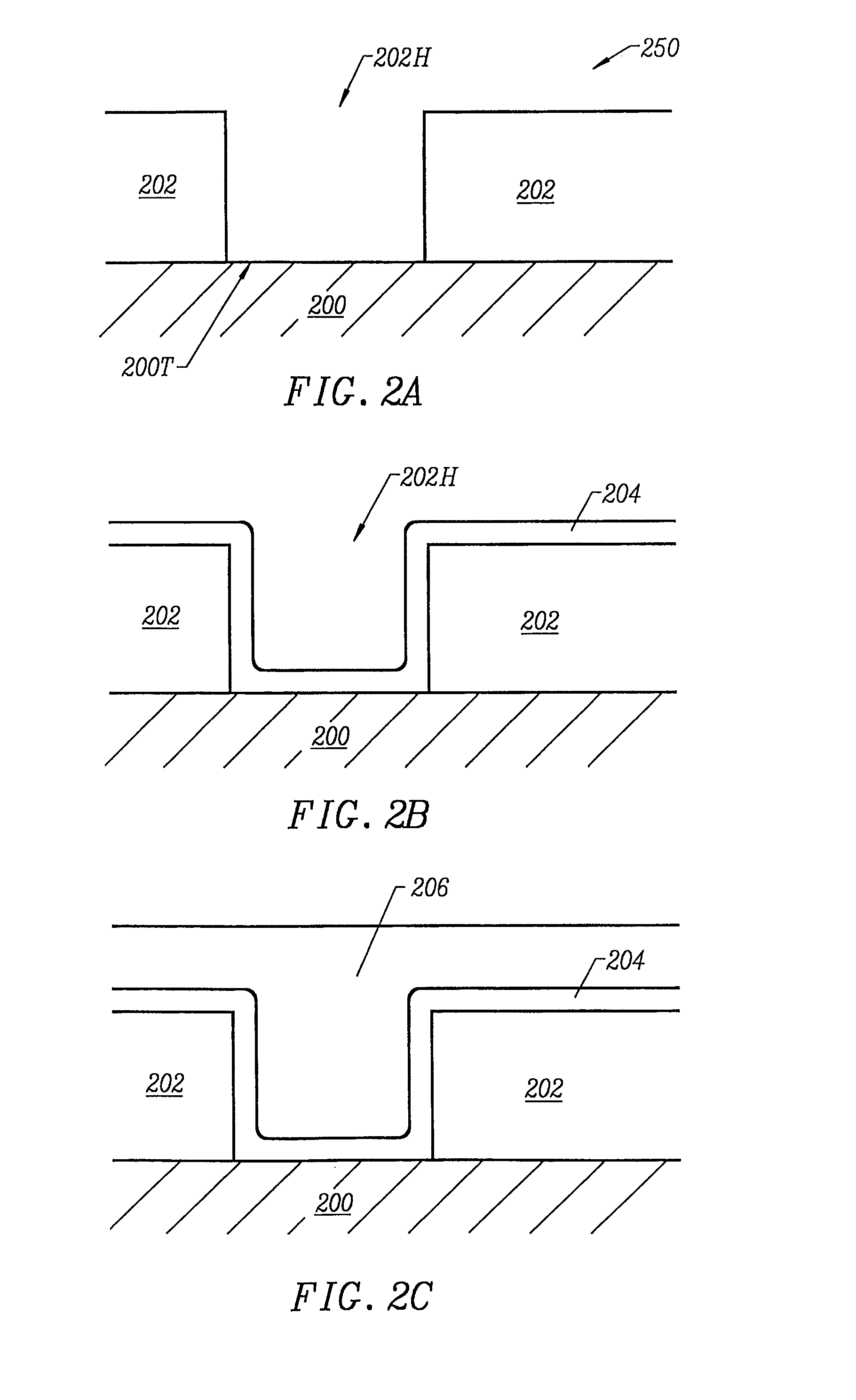

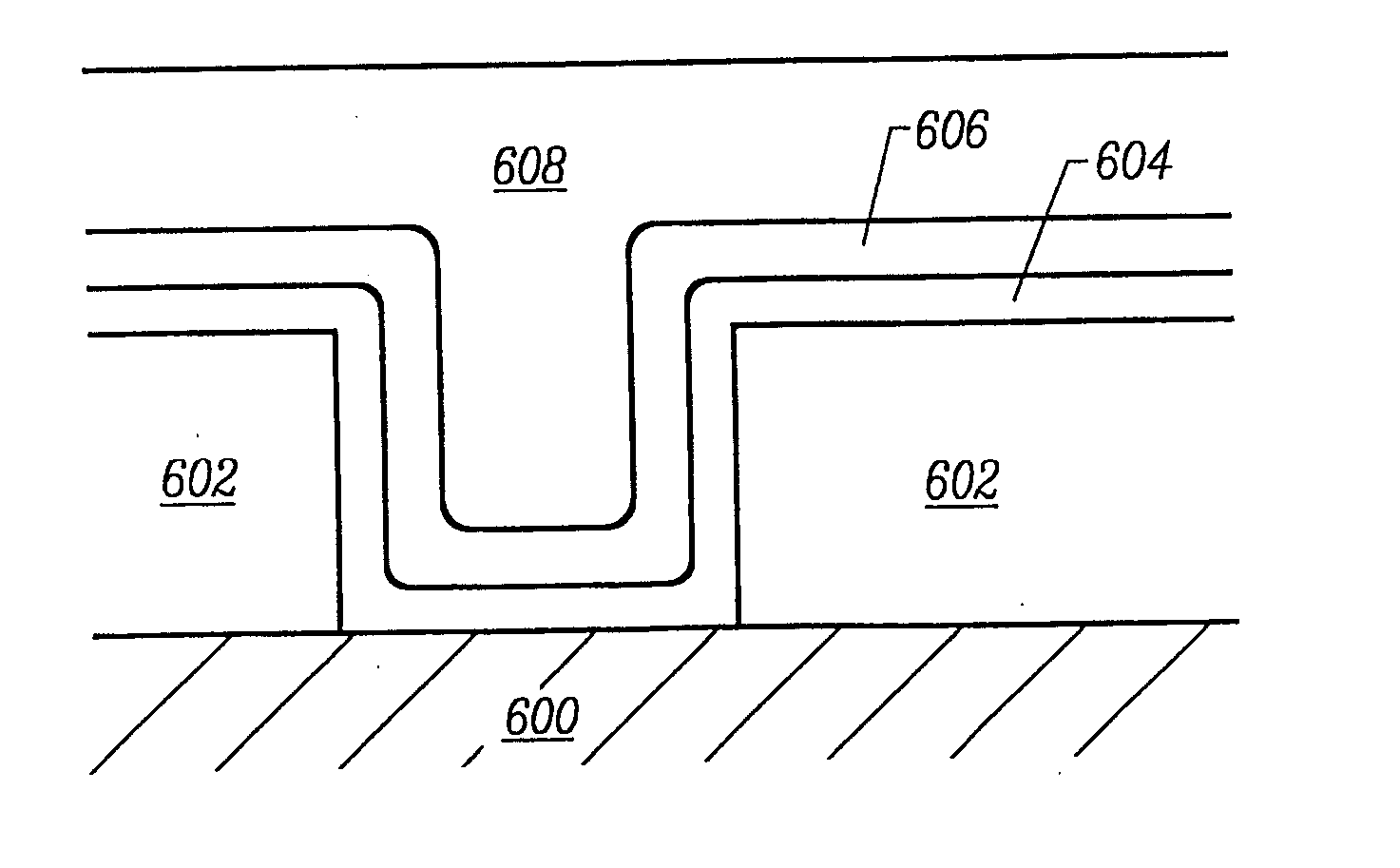

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

Formation of boride barrier layers using chemisorption techniques

InactiveUS20050118804A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingBorideChemisorption

A method of forming a boride layer for integrated circuit fabrication is disclosed. In one embodiment, the boride layer is formed by chemisorbing monolayers of a boron-containing compound and one refractory metal compound onto a substrate. In an alternate embodiment, the boride layer has a composite structure. The composite boride layer structure comprises two or more refractory metals. The composite boride layer is formed by sequentially chemisorbing monolayers of a boron compound and two or more refractory metal compounds on a substrate.

Owner:APPLIED MATERIALS INC

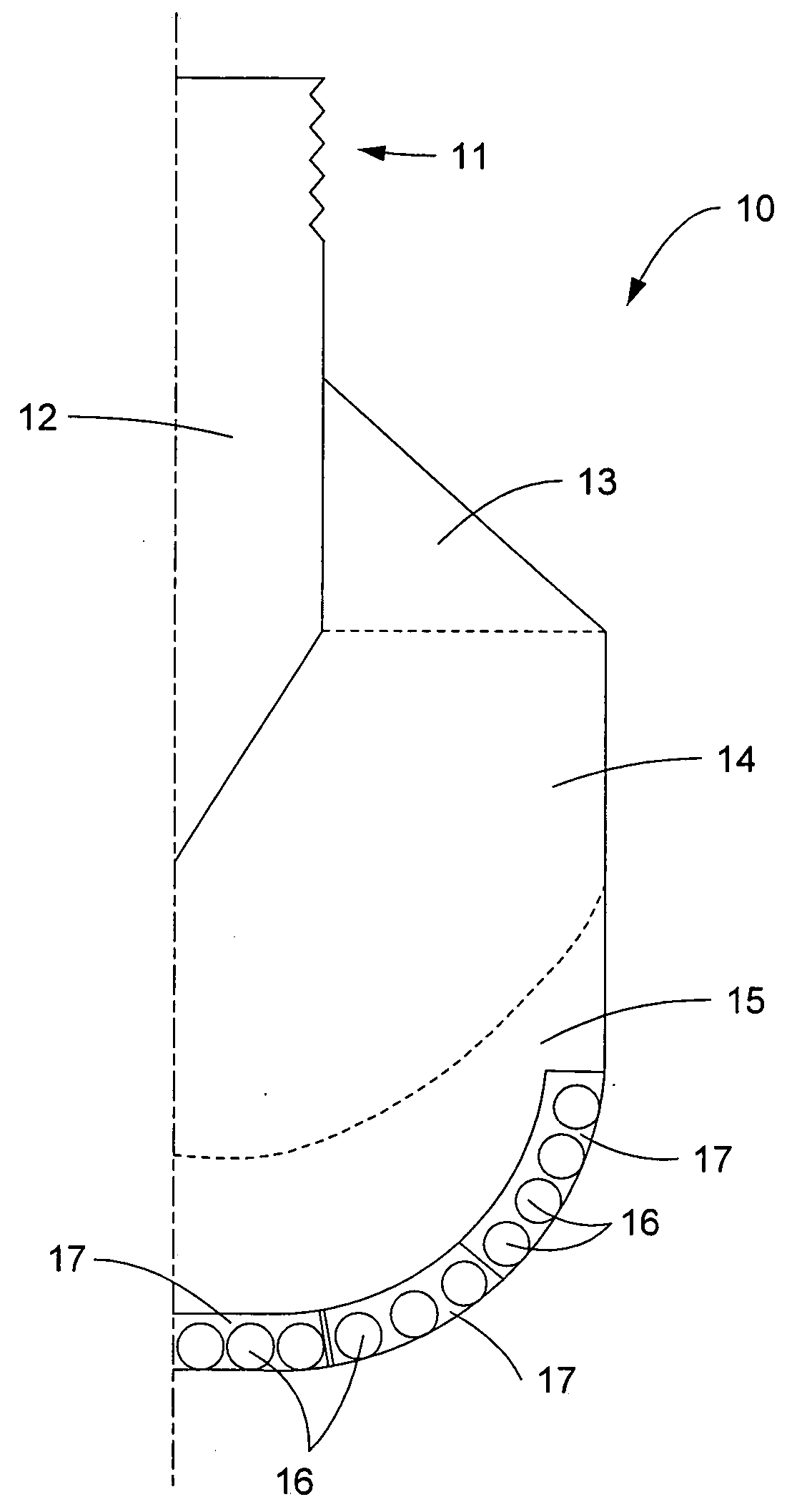

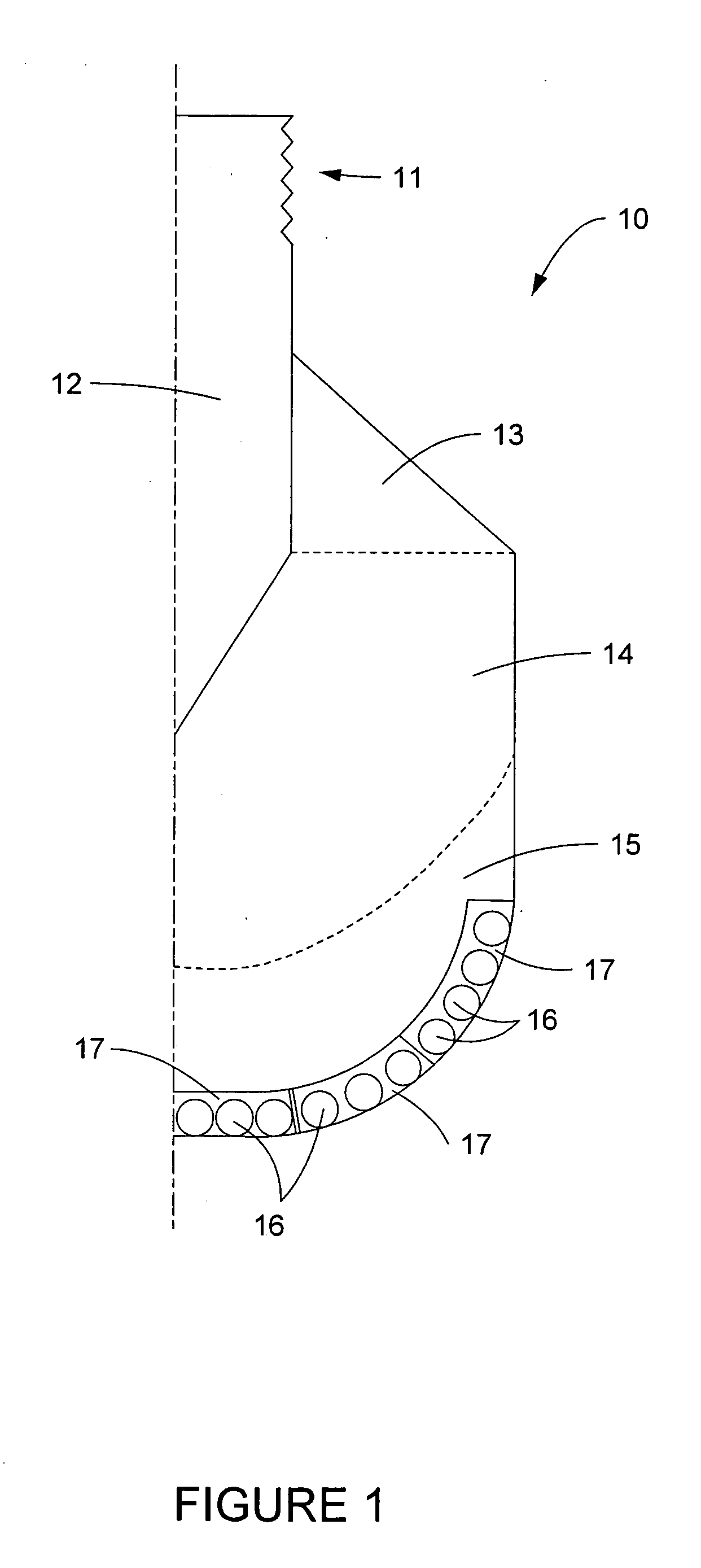

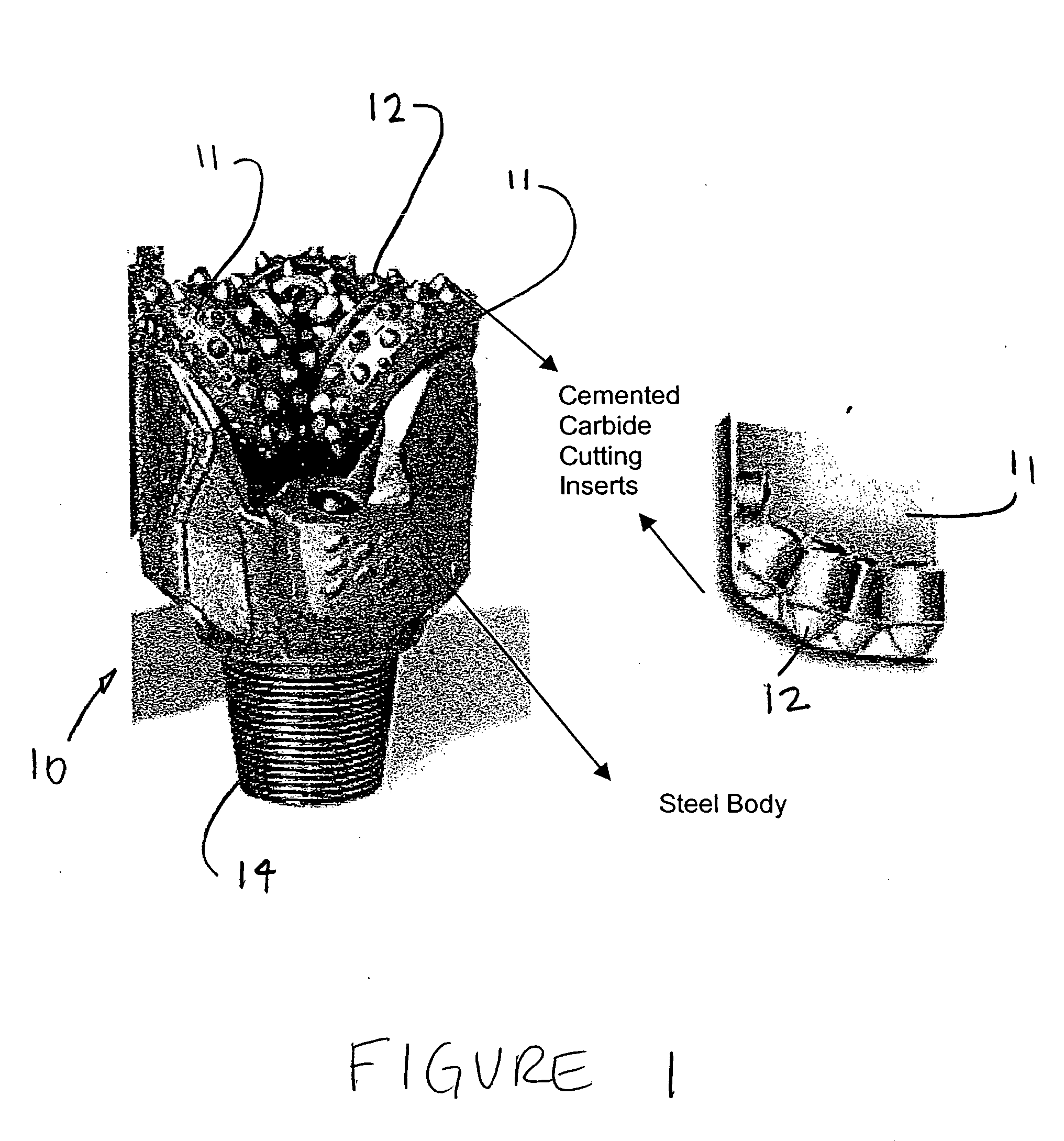

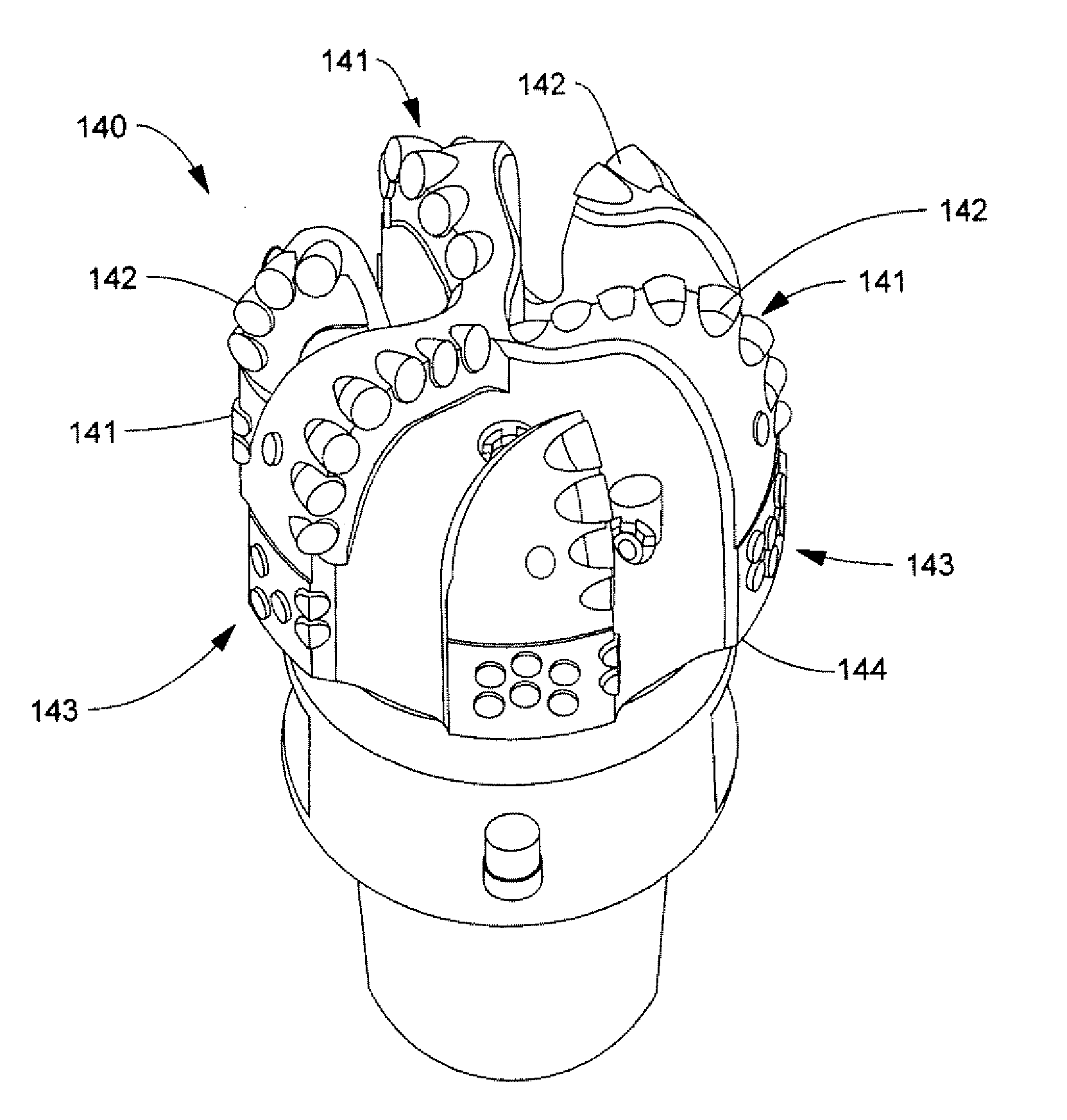

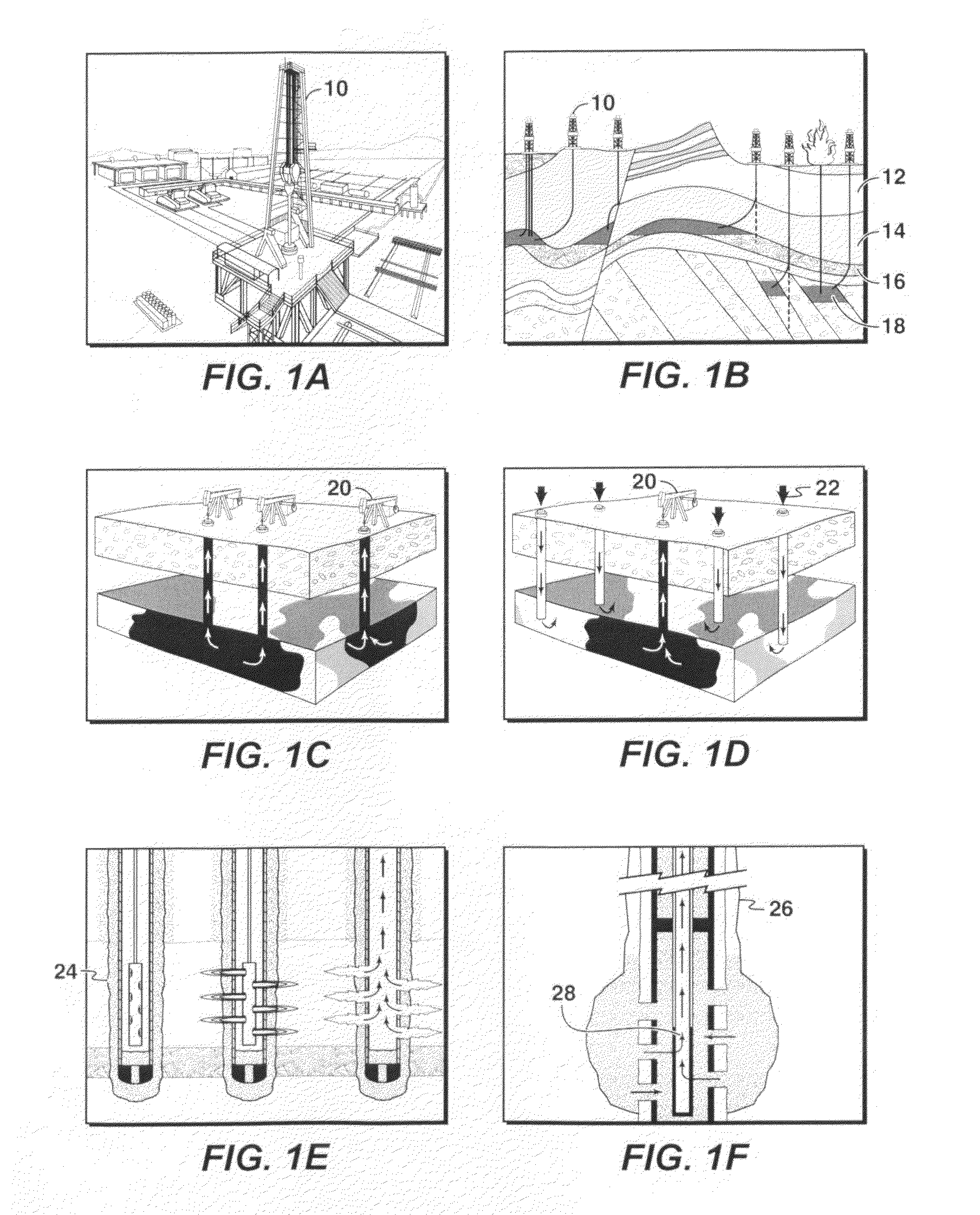

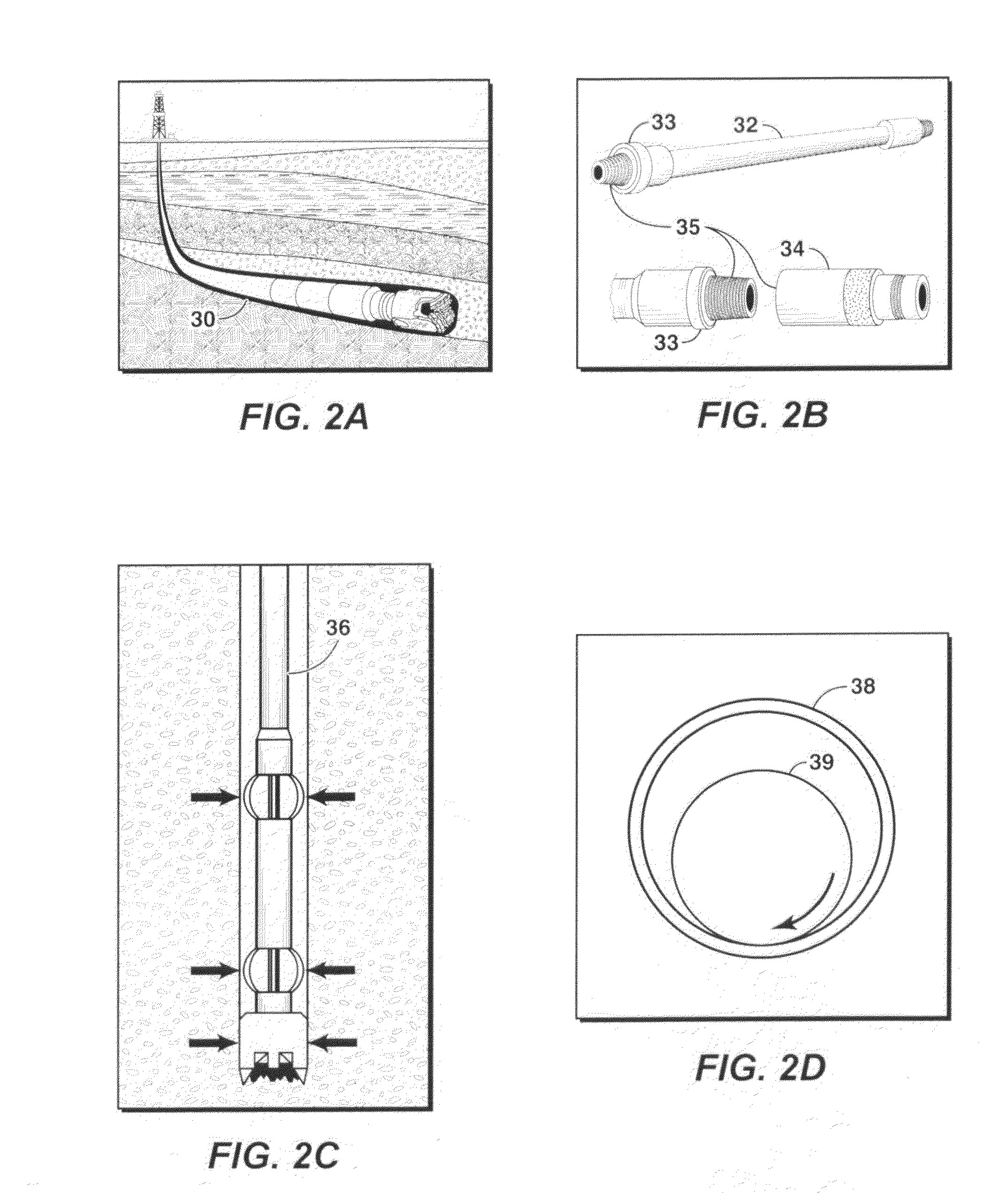

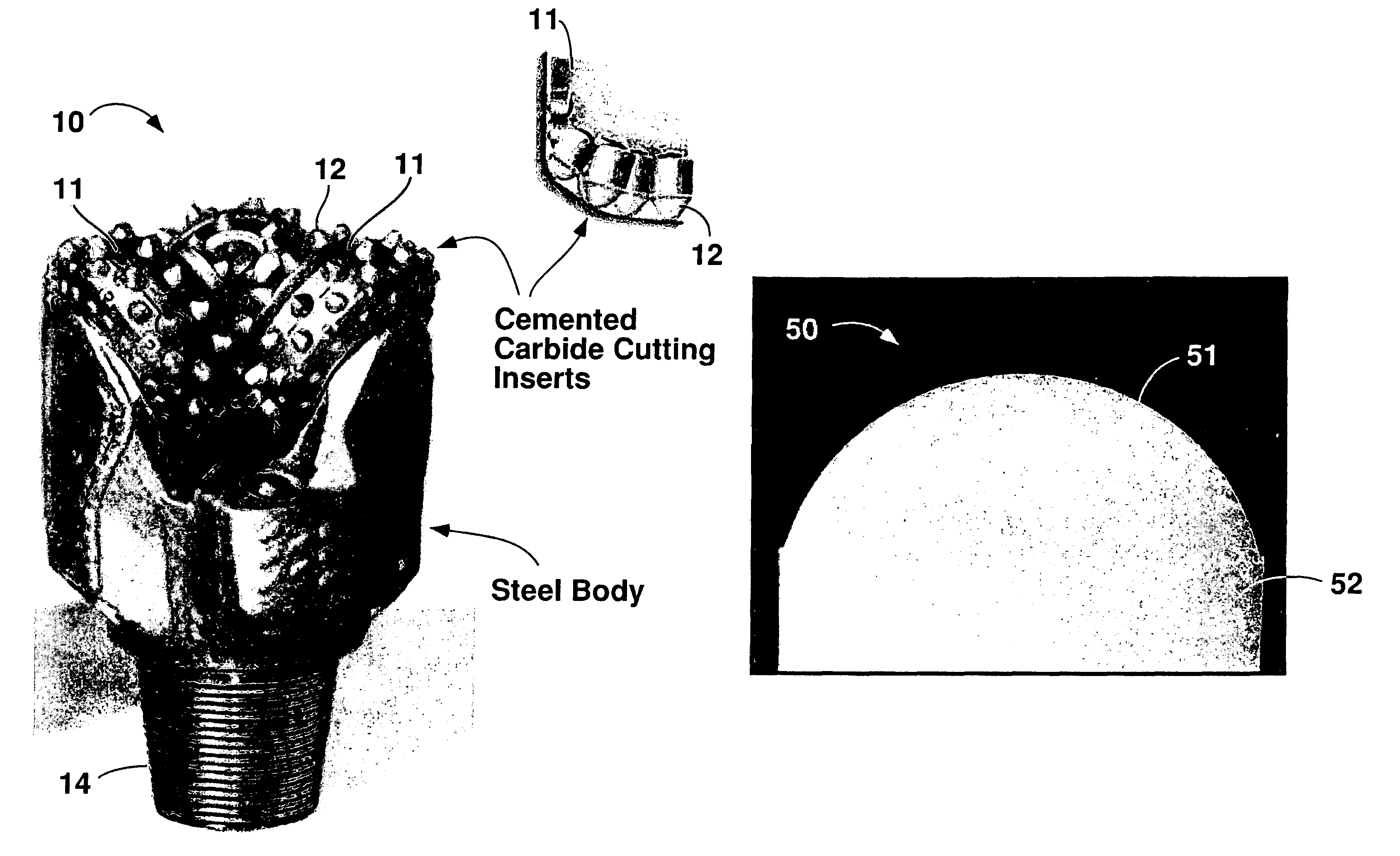

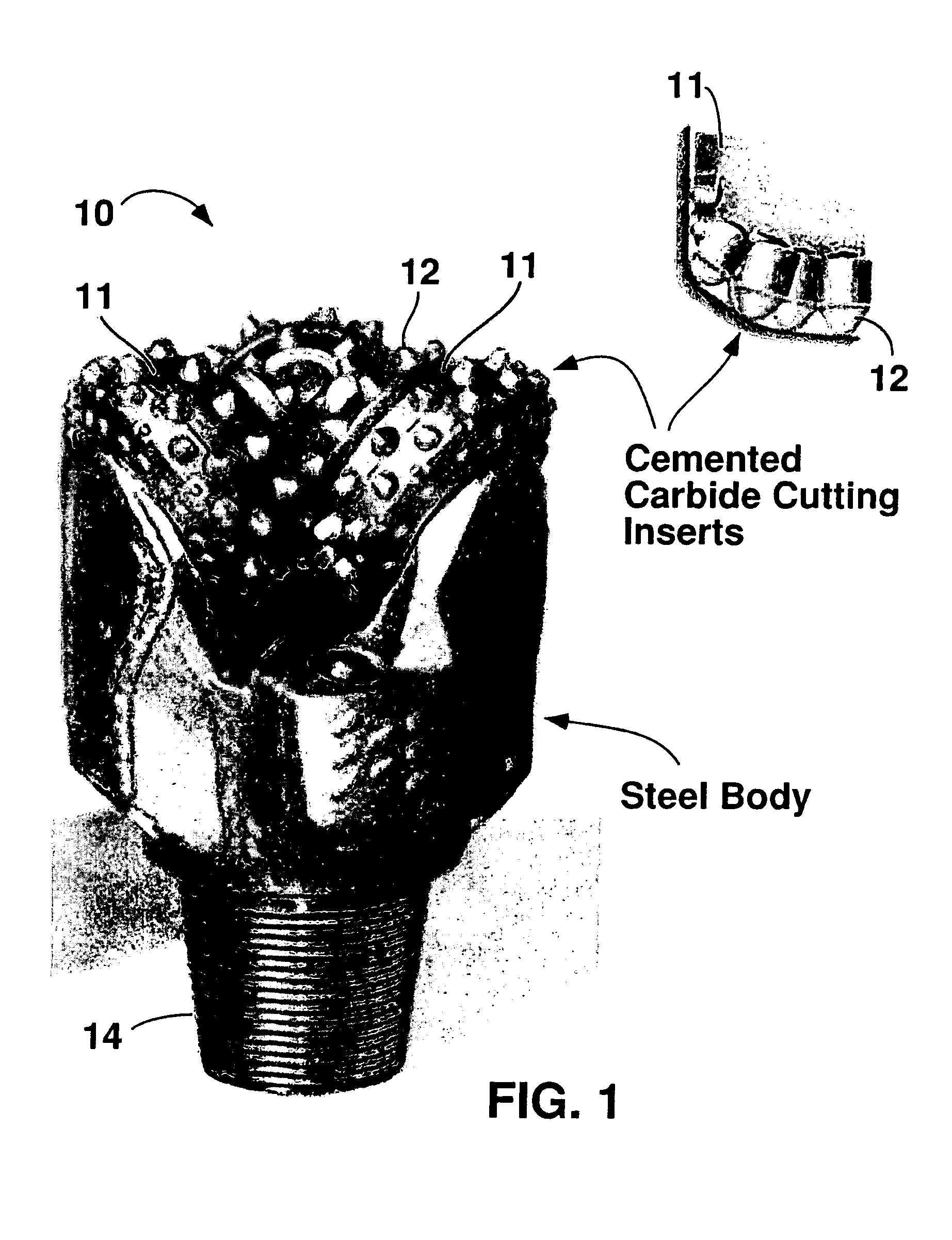

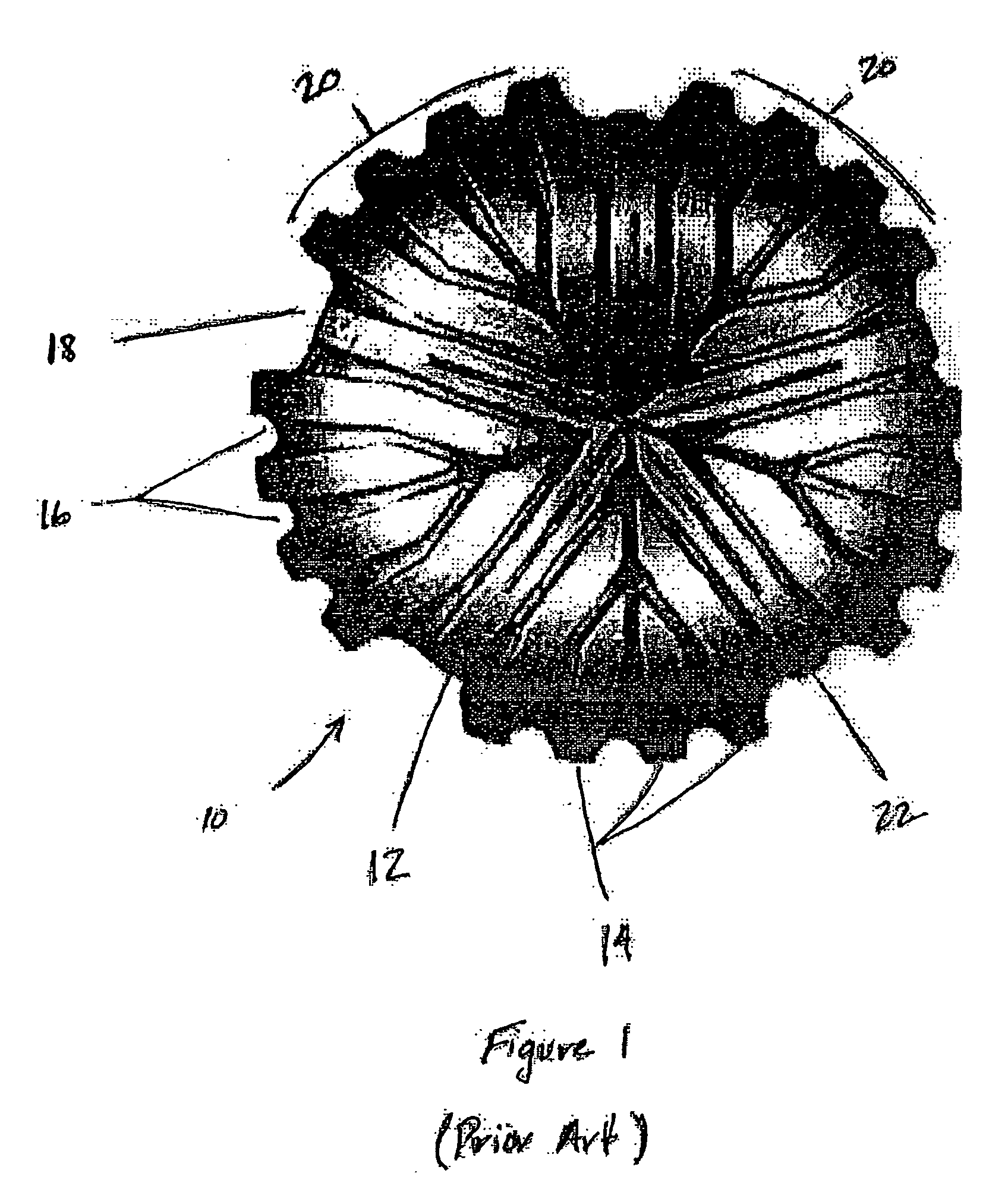

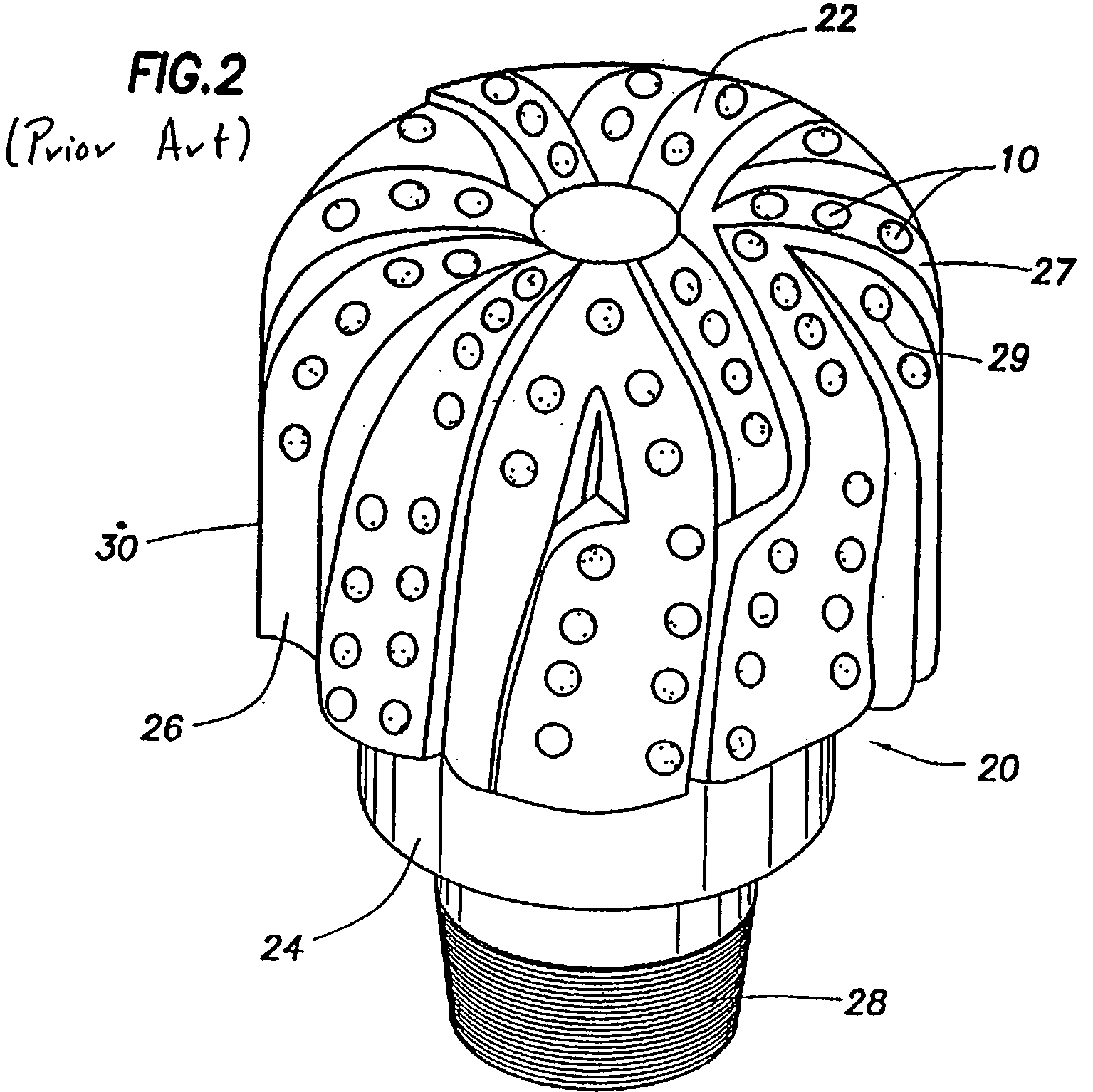

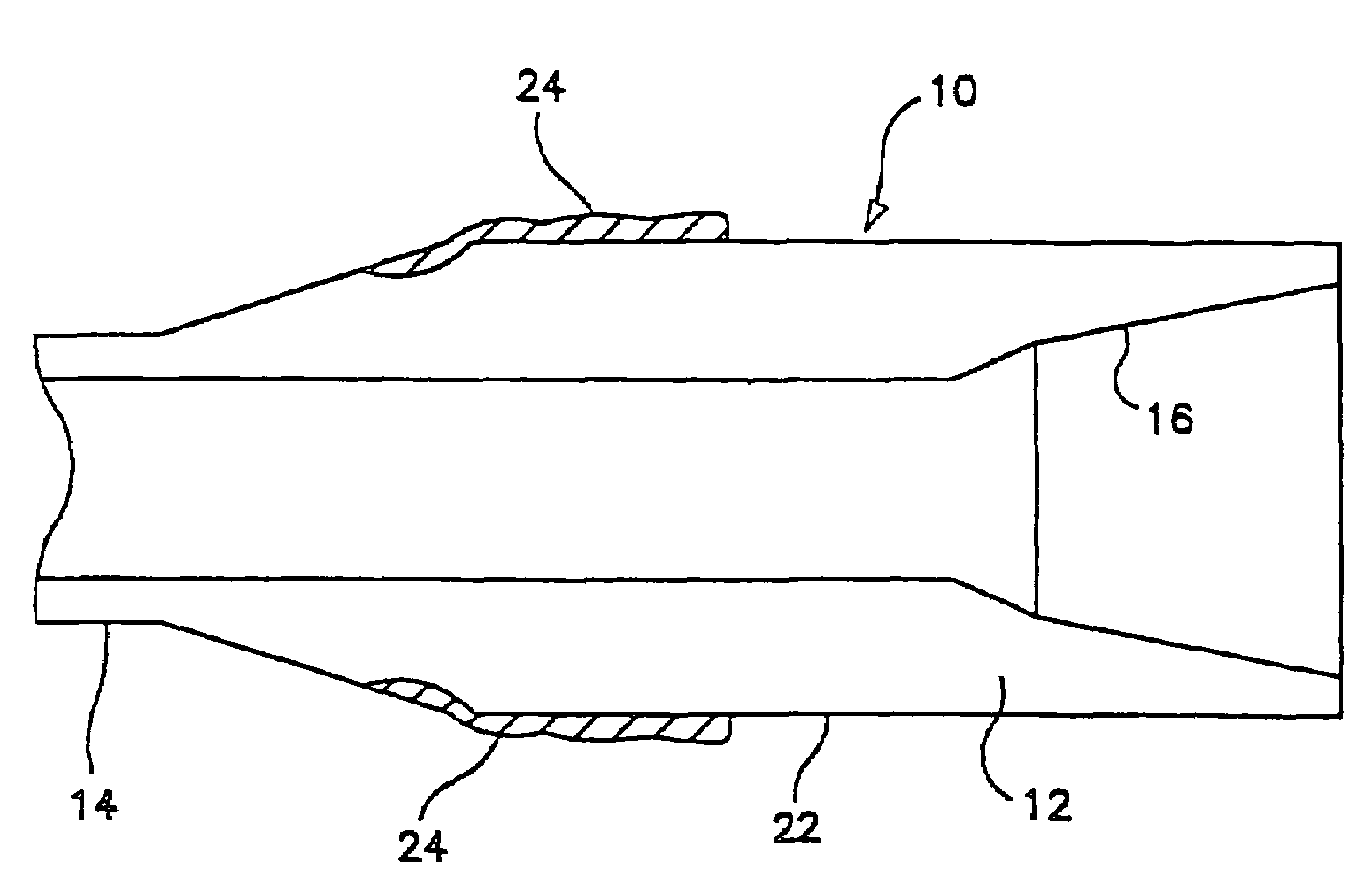

Earth-boring bits

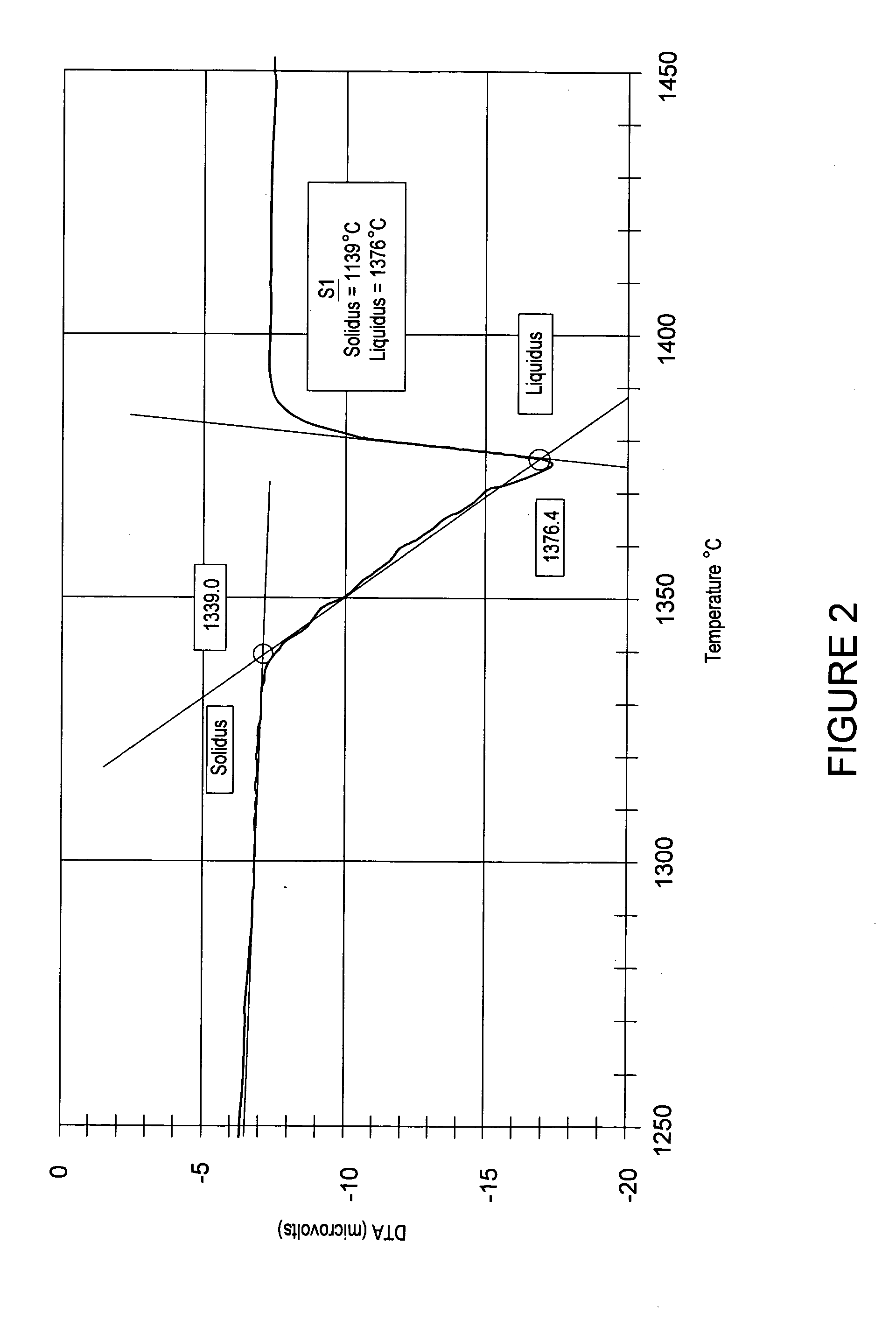

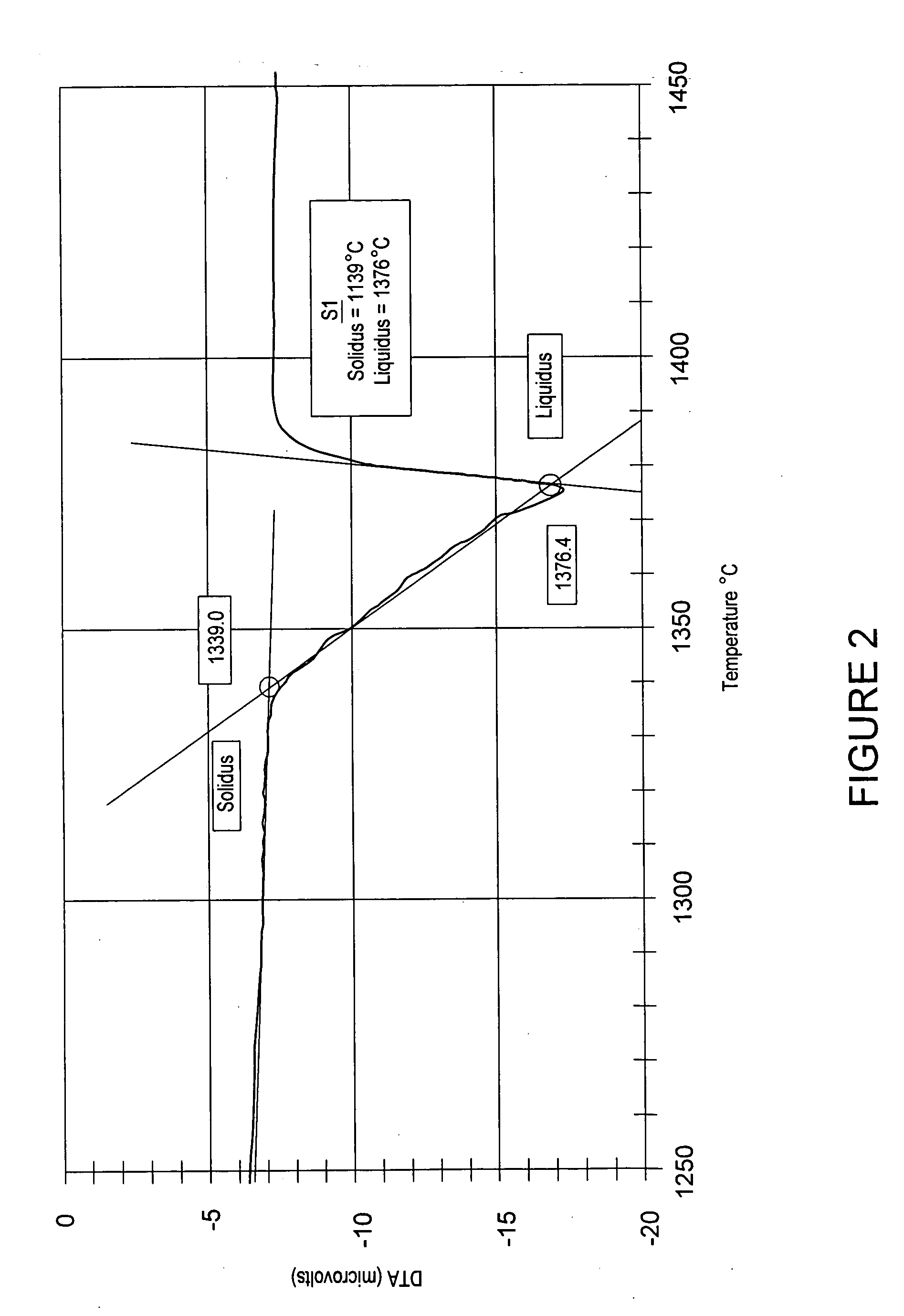

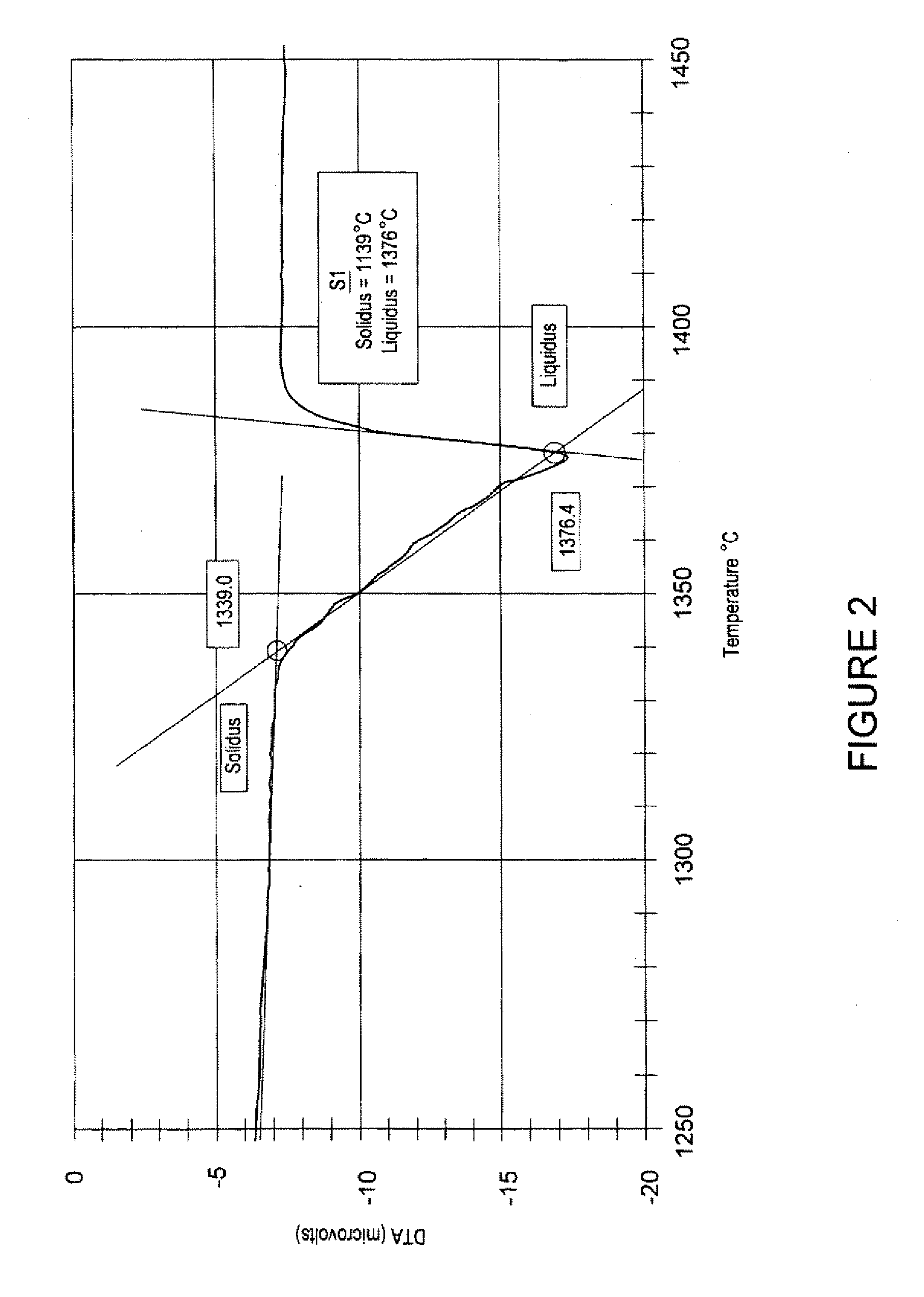

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

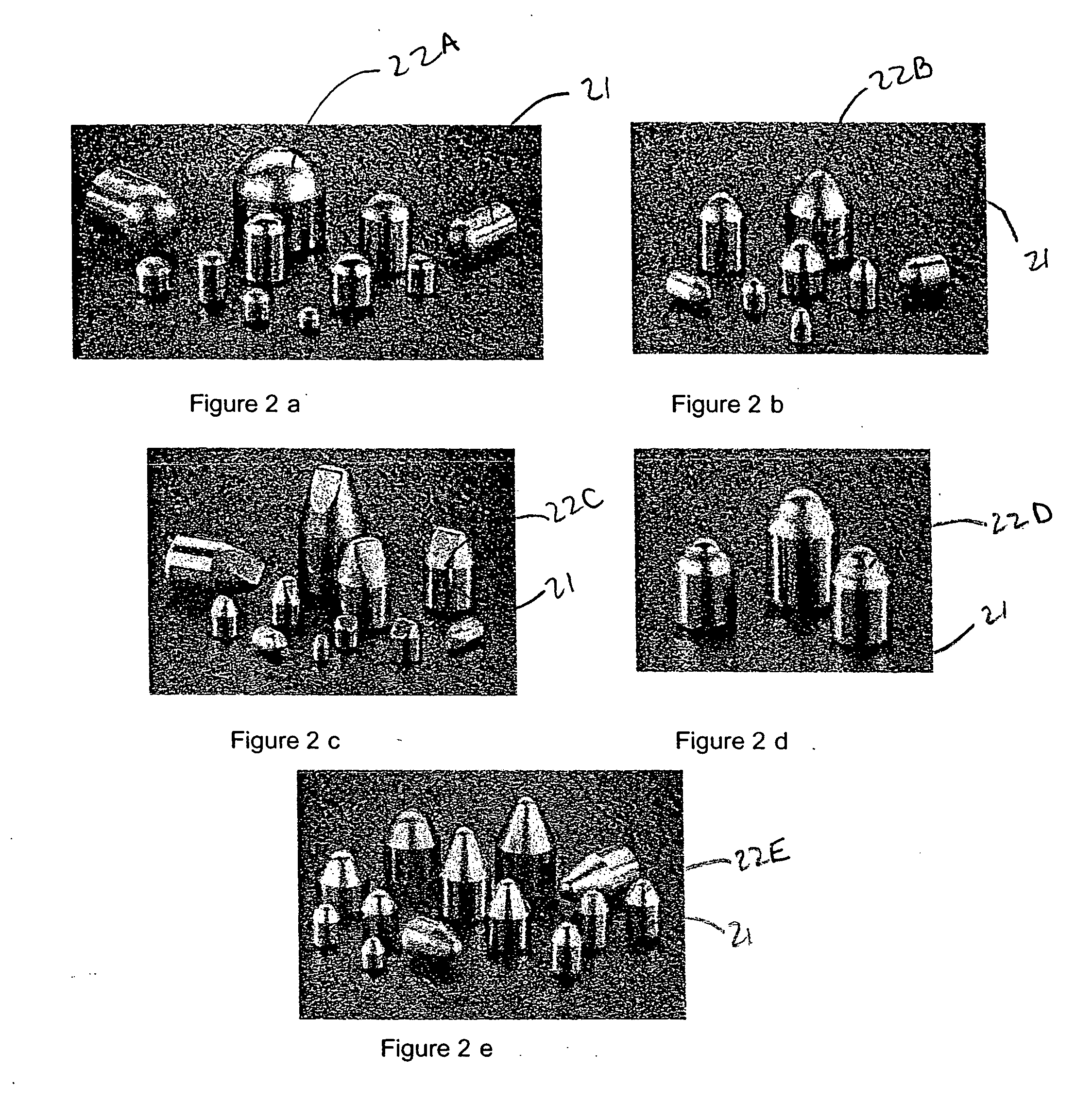

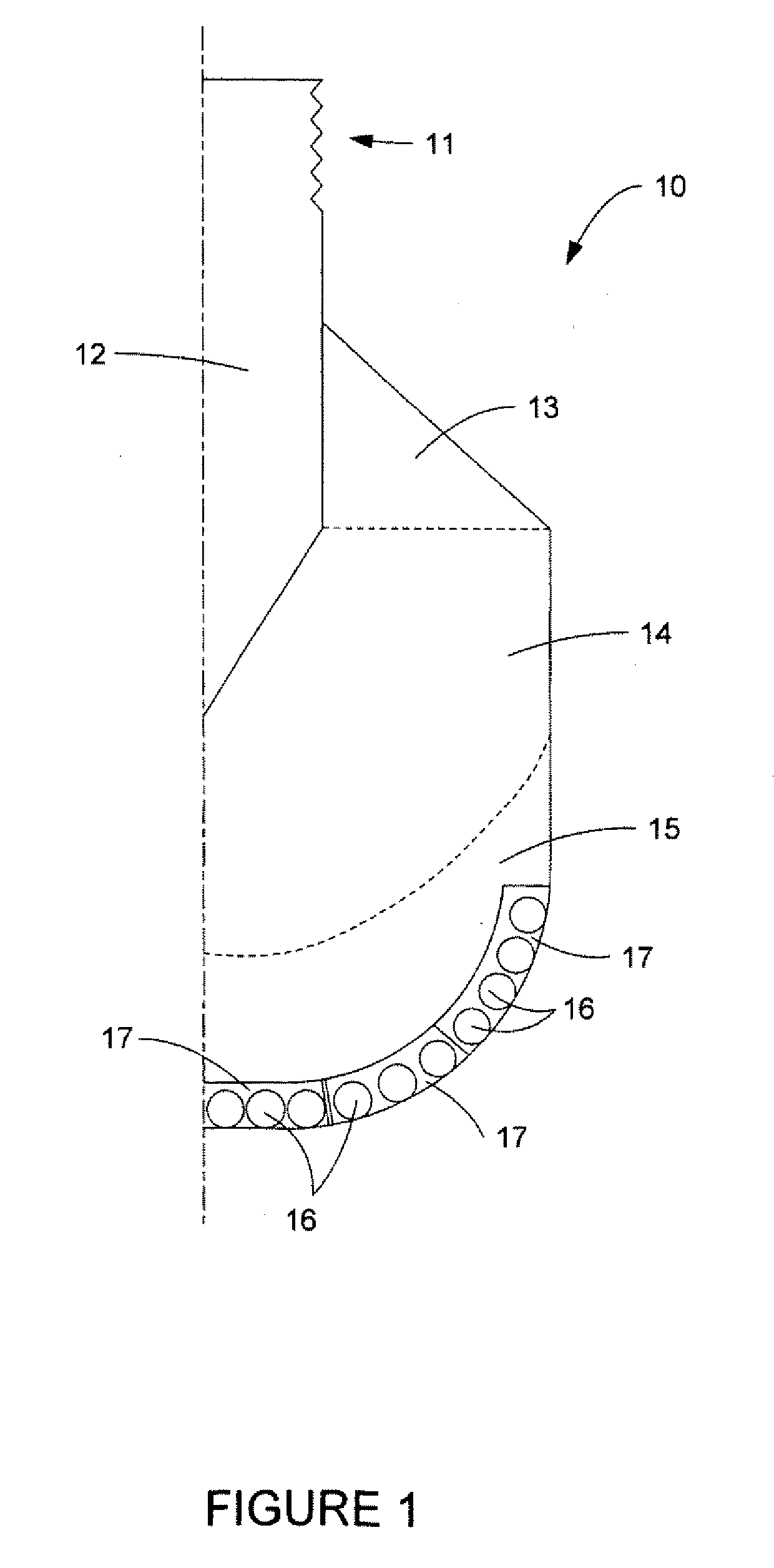

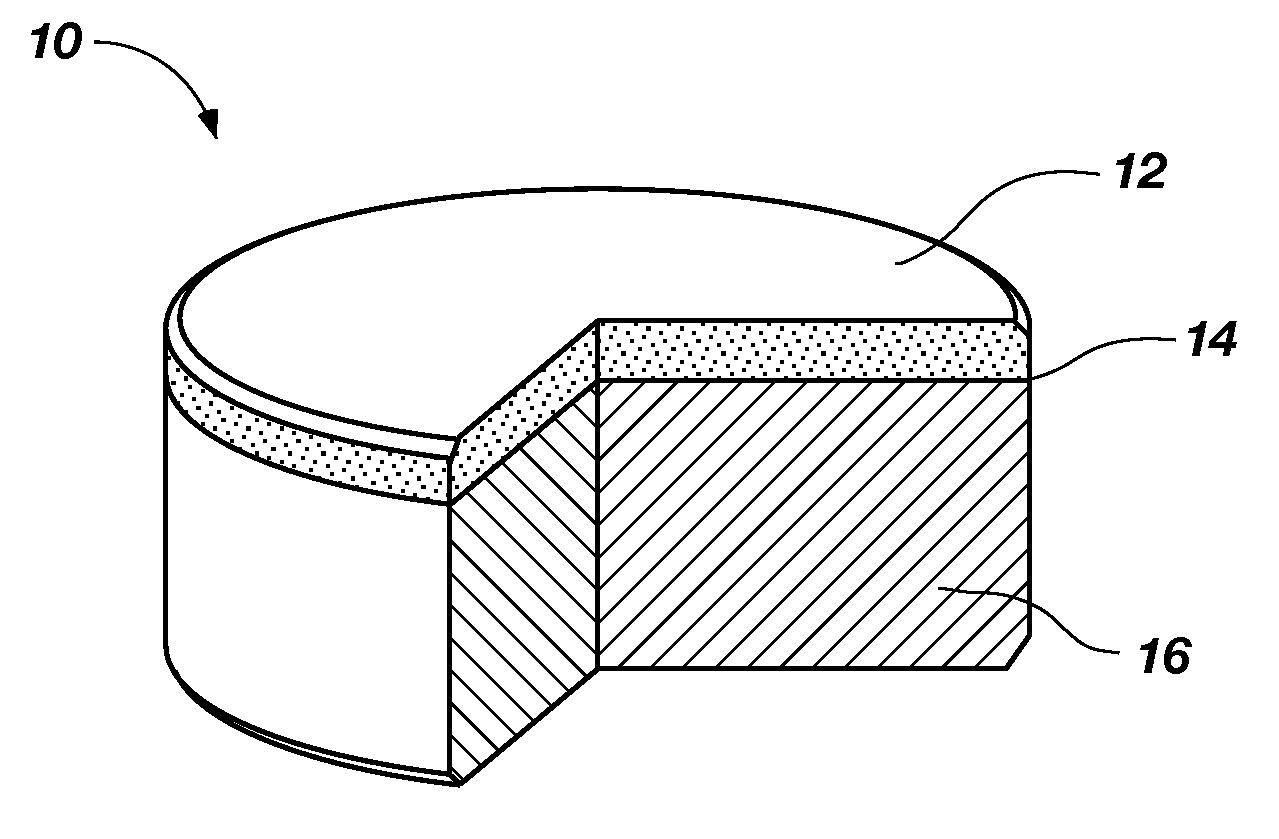

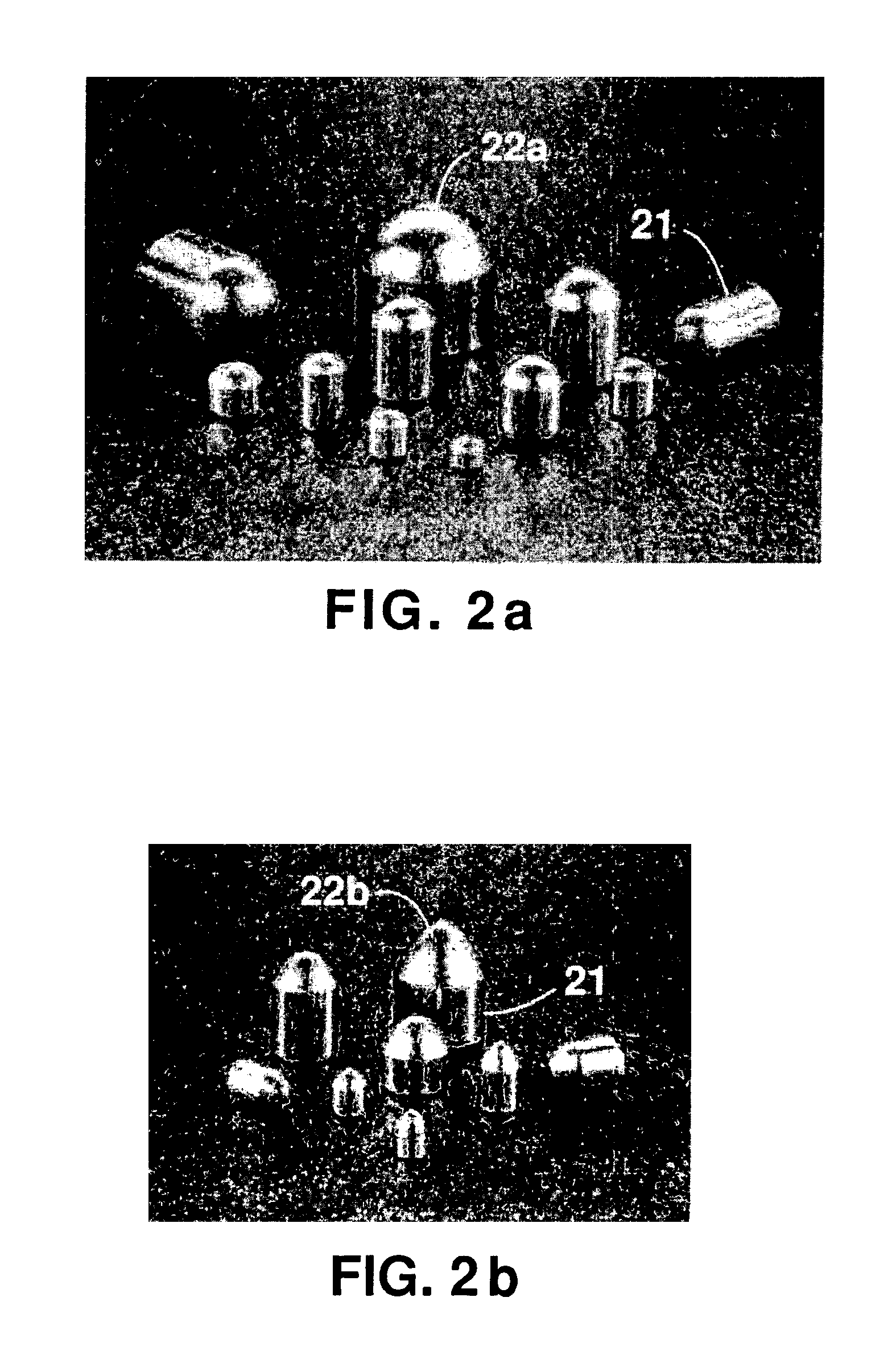

Cemented carbide inserts for earth-boring bits

This invention relates to cutting inserts for earth boring bits comprising a cutting zone, wherein the cutting zone comprises first cemented hard particles and a body zone, wherein the body zone comprises second cemented hard particles. The first cemented hard particles may differ in at least one property from the second cemented hard particles. As used herein, the cemented hard particles means a material comprising hard particles in a binder. The hard particles may be at least one of a carbide, a nitride, a boride, a silicide, an oxide, and solid solutions thereof and the binder may be at least one metal selected from cobalt, nickel, iron and alloys of cobalt, nickel or iron.

Owner:KENNAMETAL INC

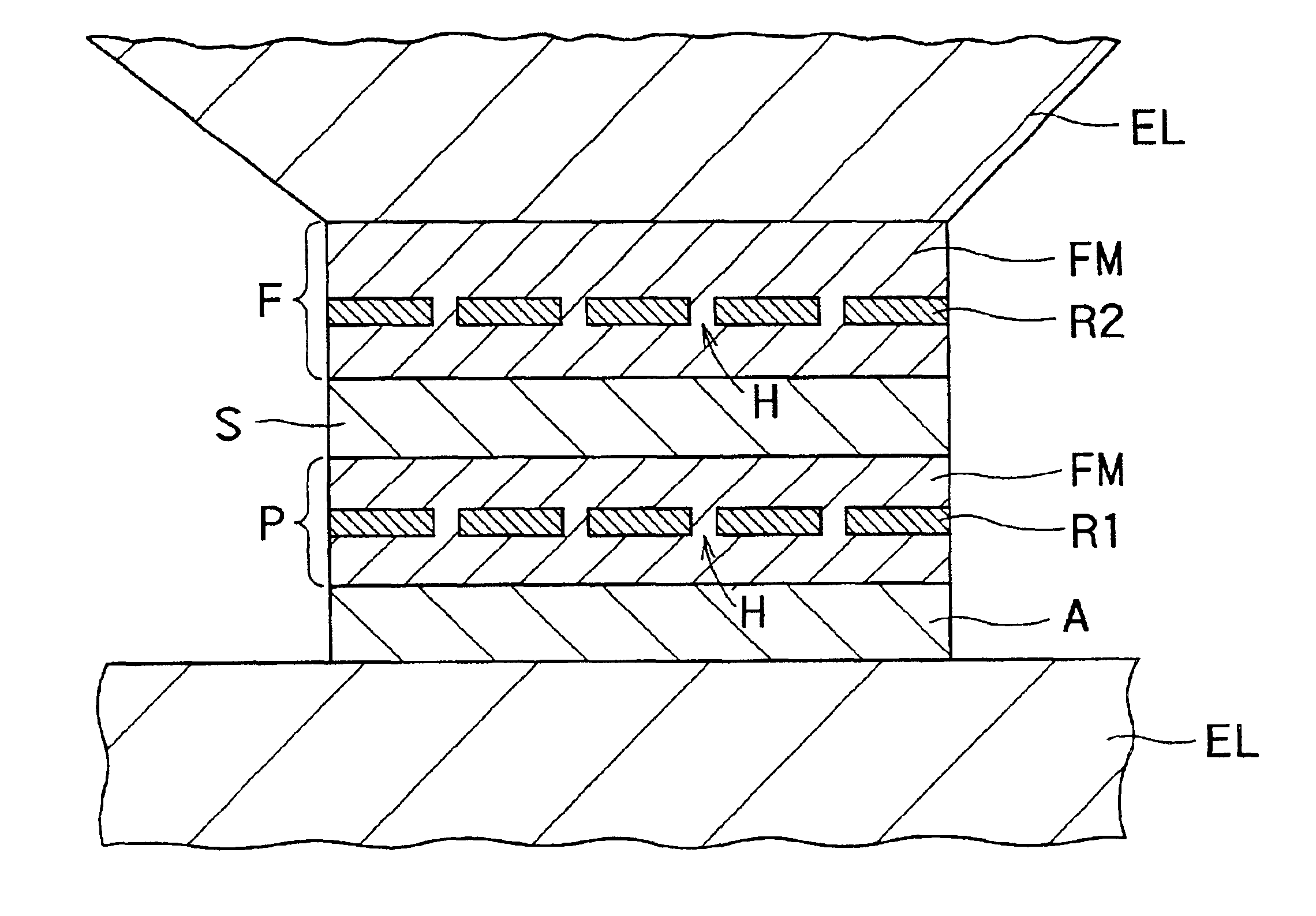

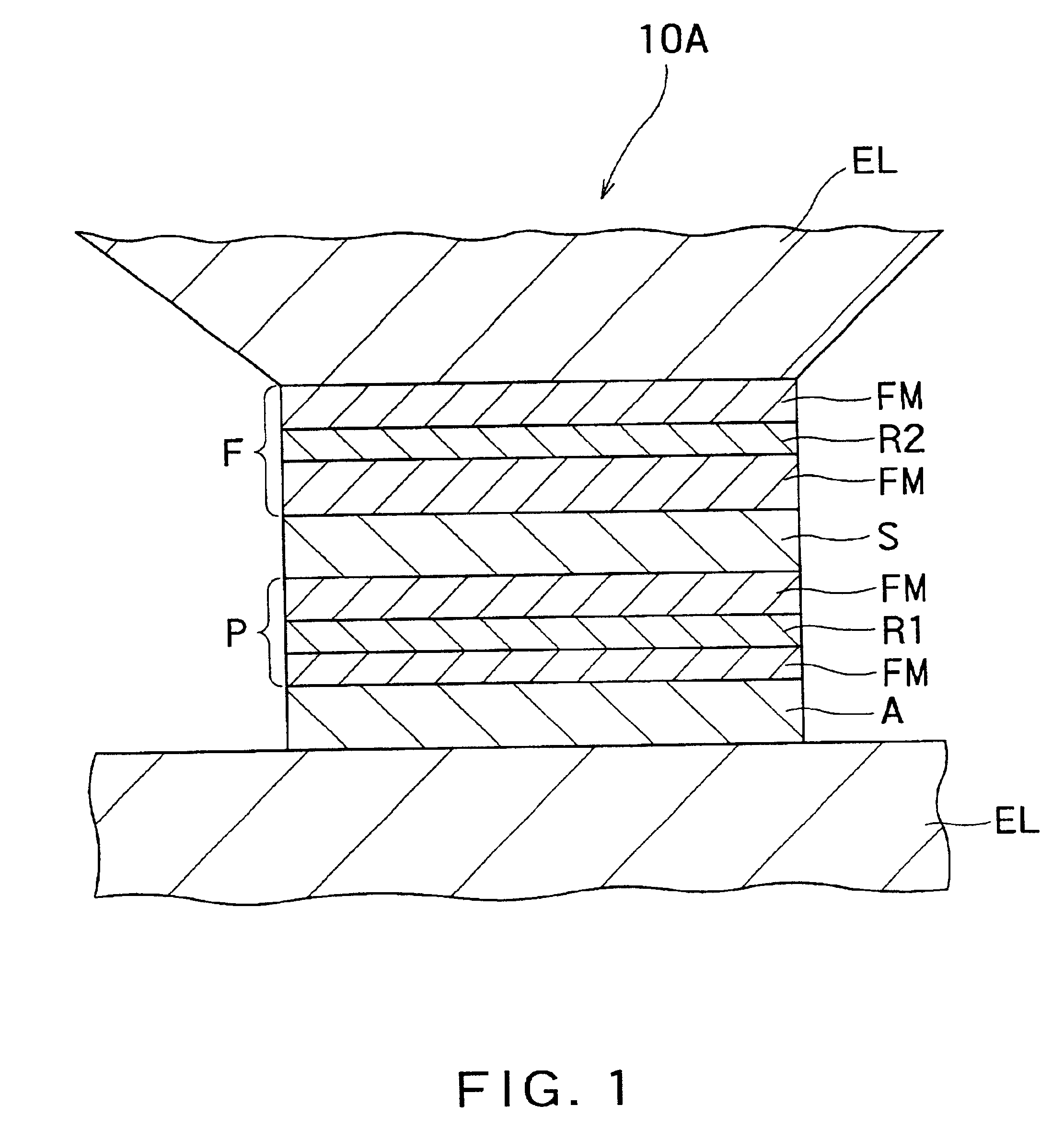

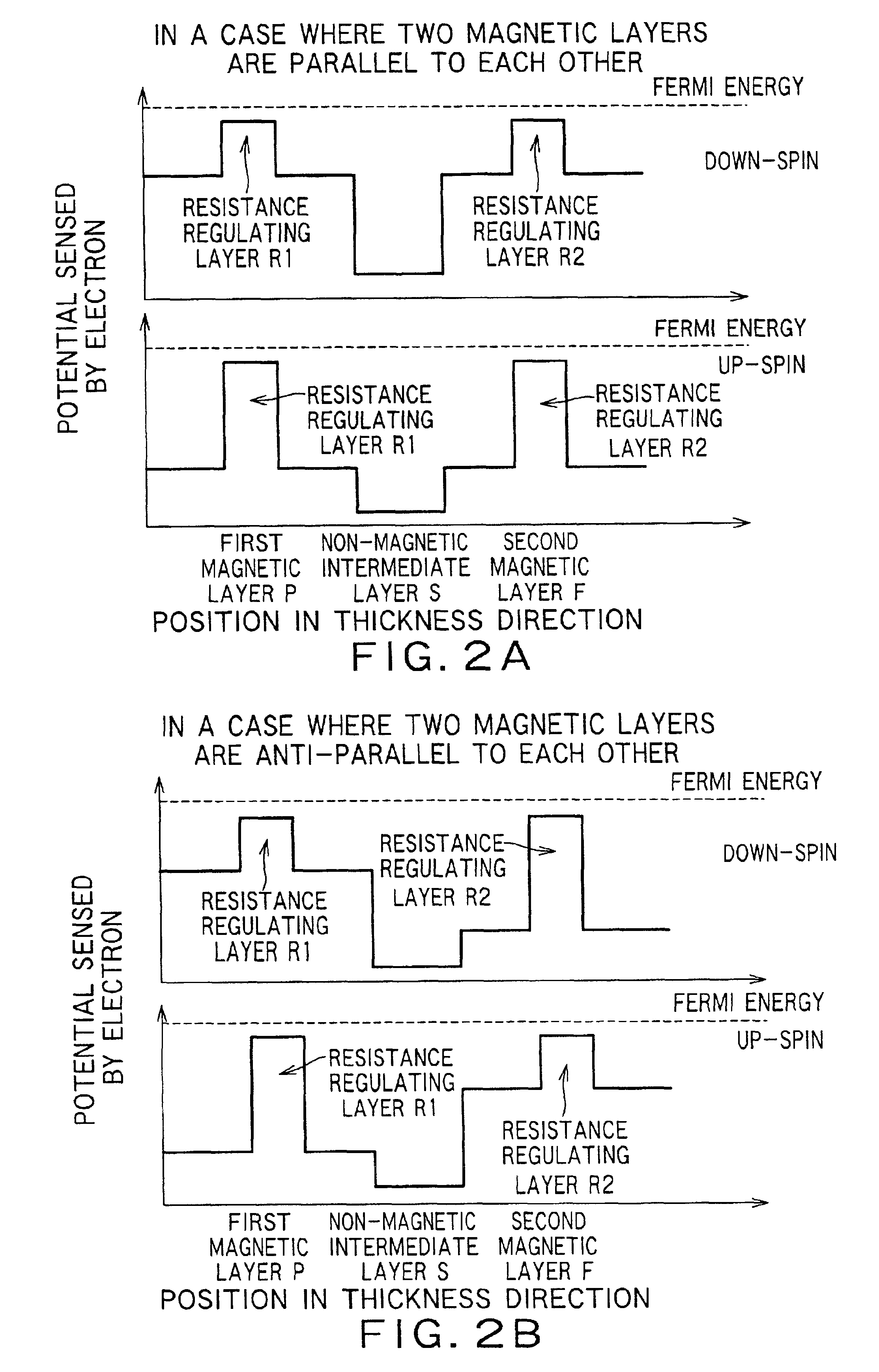

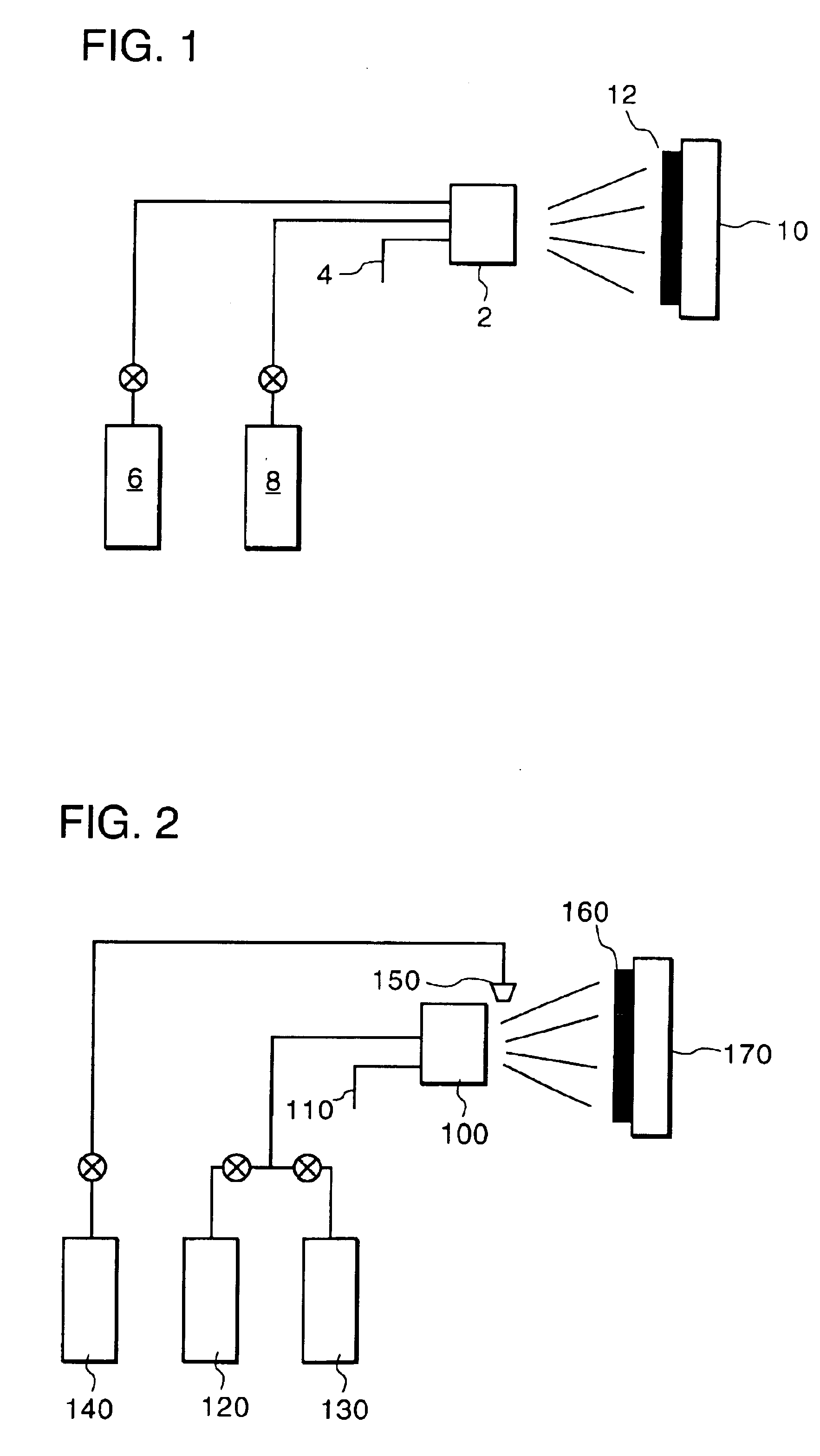

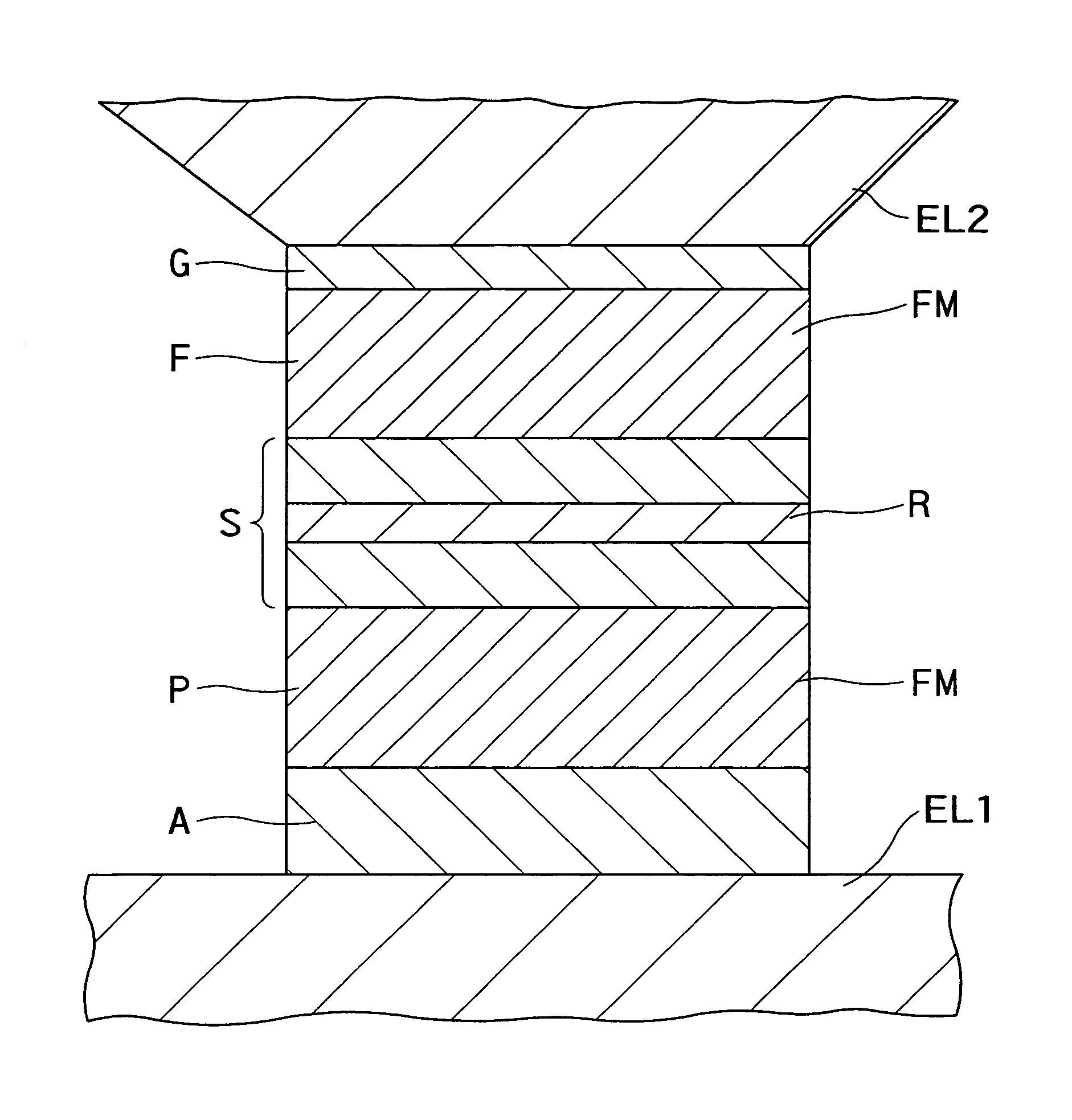

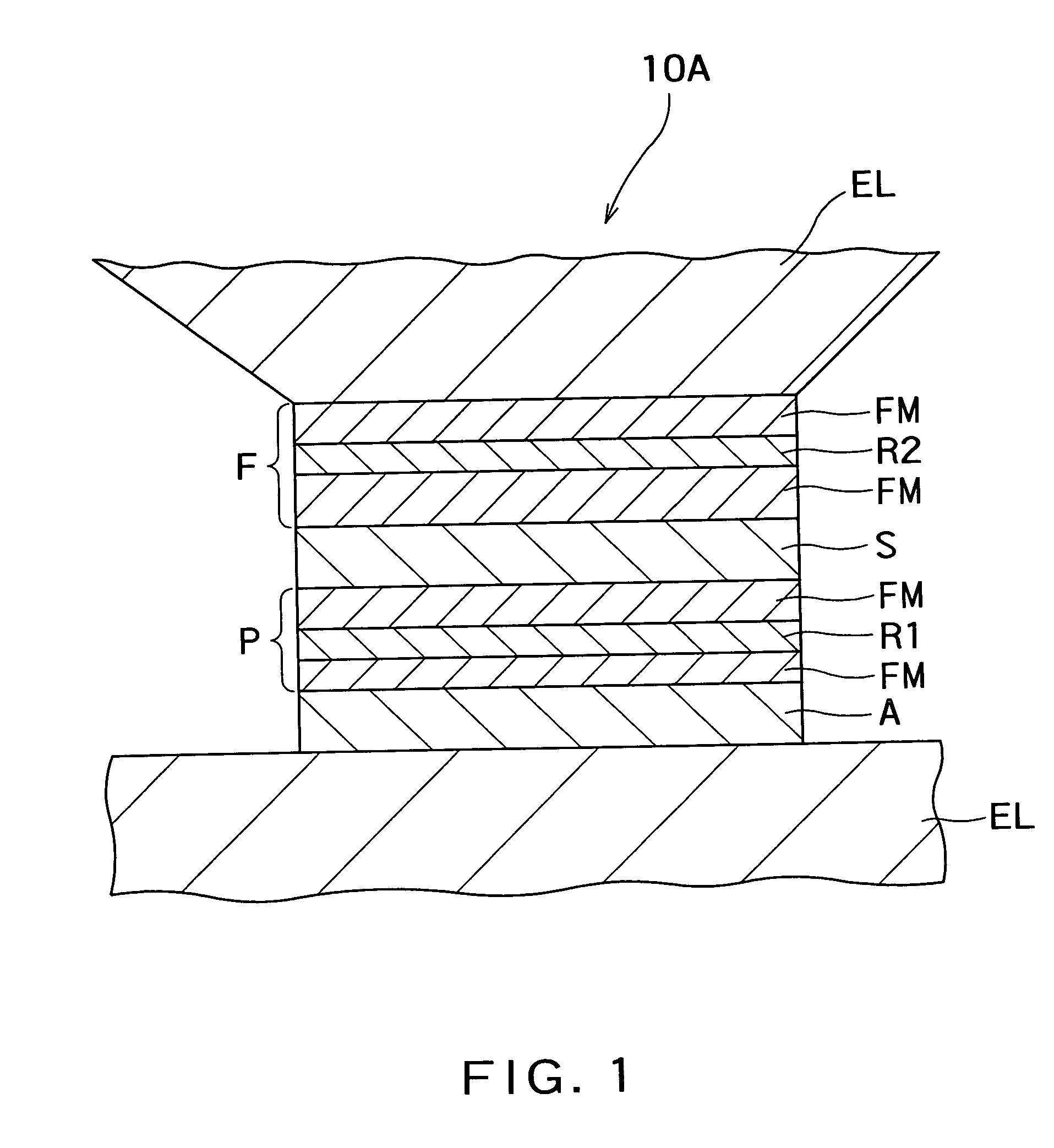

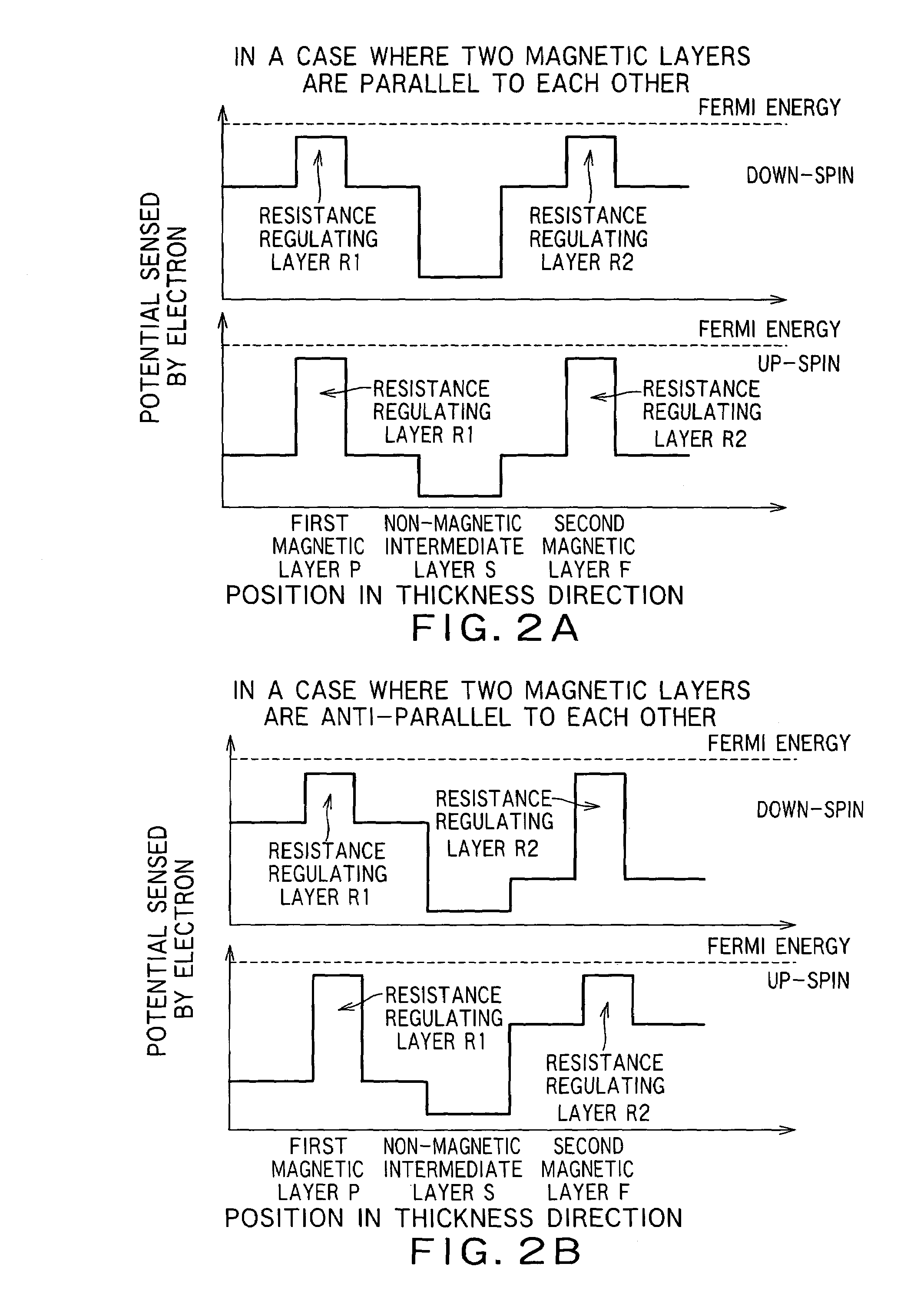

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS6937446B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

Sintered bodies for earth-boring rotary drill bits and methods of forming the same

InactiveUS20080101977A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:EASON JIMMY W +2

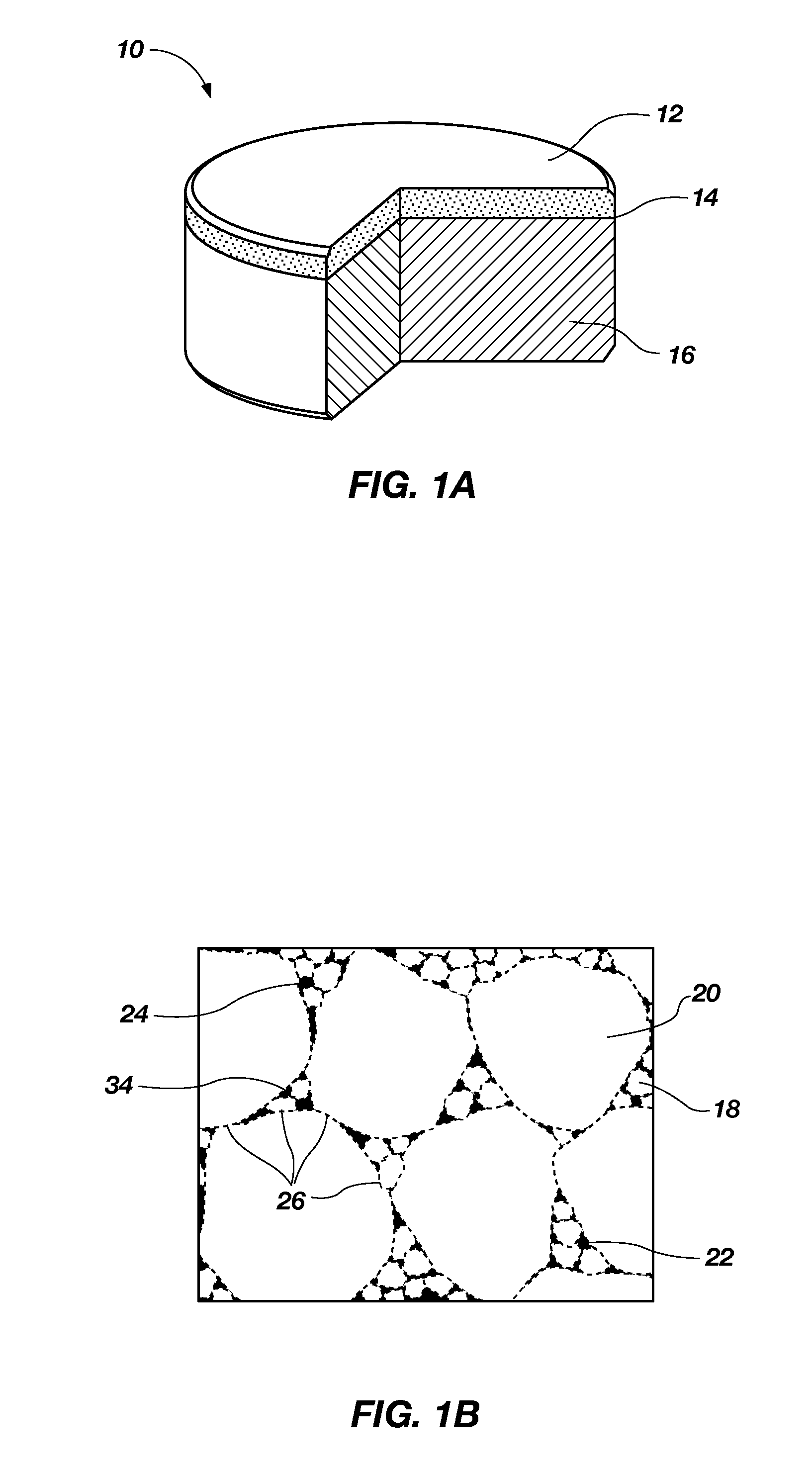

Polycrystalline compacts having material disposed in interstitial spaces therein, cutting elements and earth-boring tools including such compacts, and methods of forming such compacts

Polycrystalline compacts include smaller and larger hard grains that are interbonded to form a polycrystalline hard material. The larger grains may be at least about 150 times larger than the smaller grains. An interstitial material comprising one or more of a boride, a carbide, a nitride, a metal carbonate, a metal bicarbonate, and a non-catalytic metal may be disposed between the grains. The compacts may be used as cutting elements for earth-boring tools such as drill bits, and may be disposed on a substrate. Methods of making polycrystalline compacts include coating smaller hard particles with a coating material, mixing the smaller particles with larger hard particles, and sintering the mixture to form a polycrystalline hard material including interbonded smaller and larger grains. The sizes of the smaller and larger particles may be selected to cause the larger grains to be at least about 150 times larger than the smaller grains.

Owner:BAKER HUGHES INC

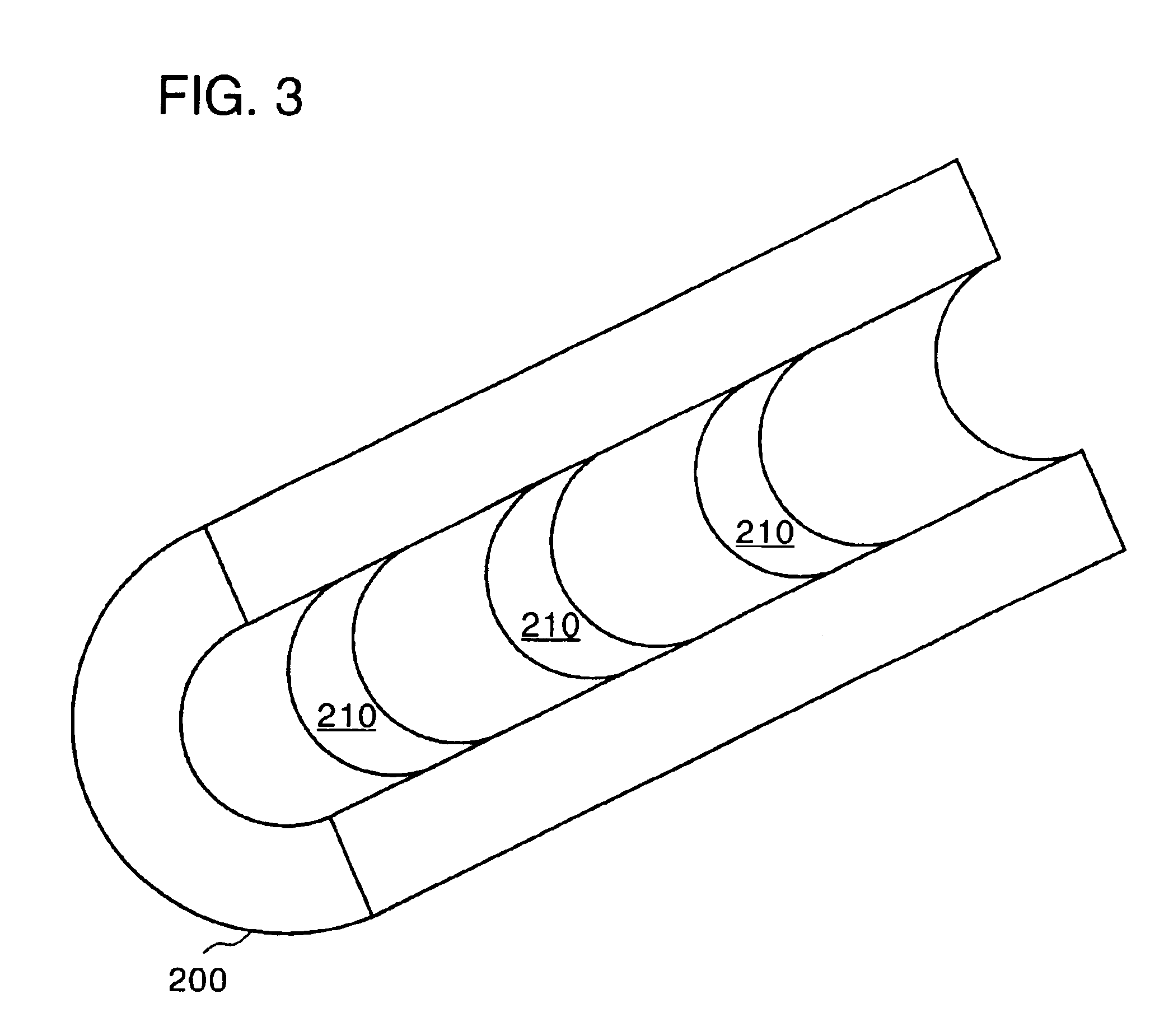

Coated sleeved oil and gas well production devices

Provided are coated sleeved oil and gas well production devices and methods of making and using such coated sleeved devices. In one form, the coated sleeved oil and gas well production device includes an oil and gas well production device including one or more bodies and one or more sleeves proximal to the outer or inner surface of the one or more bodies, and a coating on at least a portion of the inner sleeve surface, outer sleeve surface, or a combination thereof, wherein the coating is chosen from an amorphous alloy, a heat-treated electroless or electro plated based nickel-phosphorous composite with a phosphorous content greater than 12 wt %, graphite, MoS2, WS2, a fullerene based composite, a boride based cermet, a quasicrystalline material, a diamond based material, diamond-like-carbon (DLC), boron nitride, and combinations thereof. The coated sleeved oil and gas well production devices may provide for reduced friction, wear, erosion, corrosion, and deposits for well construction, completion and production of oil and gas.

Owner:EXXONMOBIL UPSTREAM RES CO

Resistive heaters and uses thereof

InactiveUS6919543B2Thermally matched wellAvoid bendingMolten spray coatingLinings repairBorideCarbide

A metallic resistive heater and a method of production are described. The resistive heater has a metallic component that is electrically conductive (i.e. has low resistivity) and an oxide, nitride, carbide, and or boride derivative of the metallic component that is electrically insulating (i.e., has high resistivity). The resistivity is controlled by controlling the amount of oxide, nitride, carbide, and boride formation during the deposition of the metallic component and the derivative.

Owner:REGAL WARE

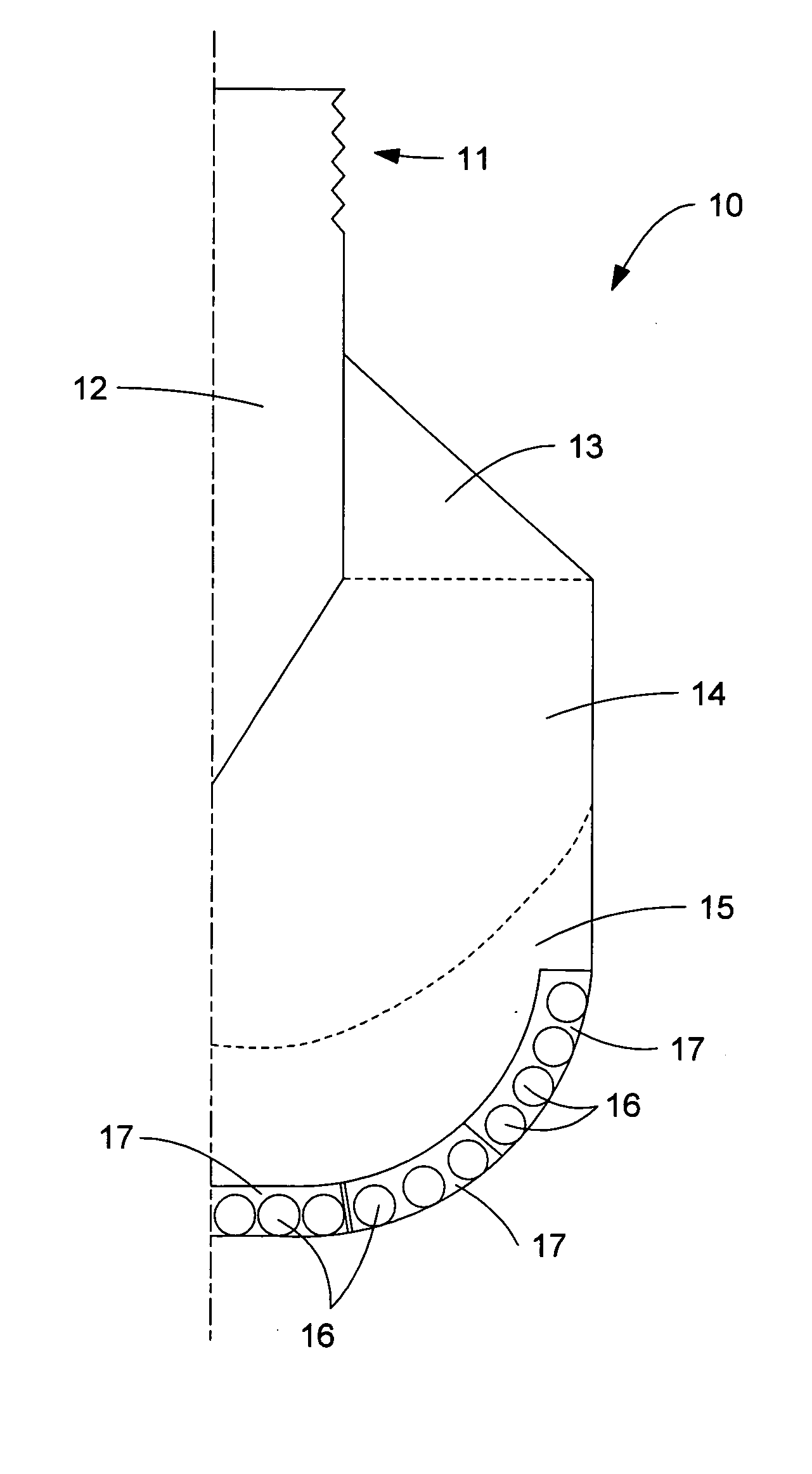

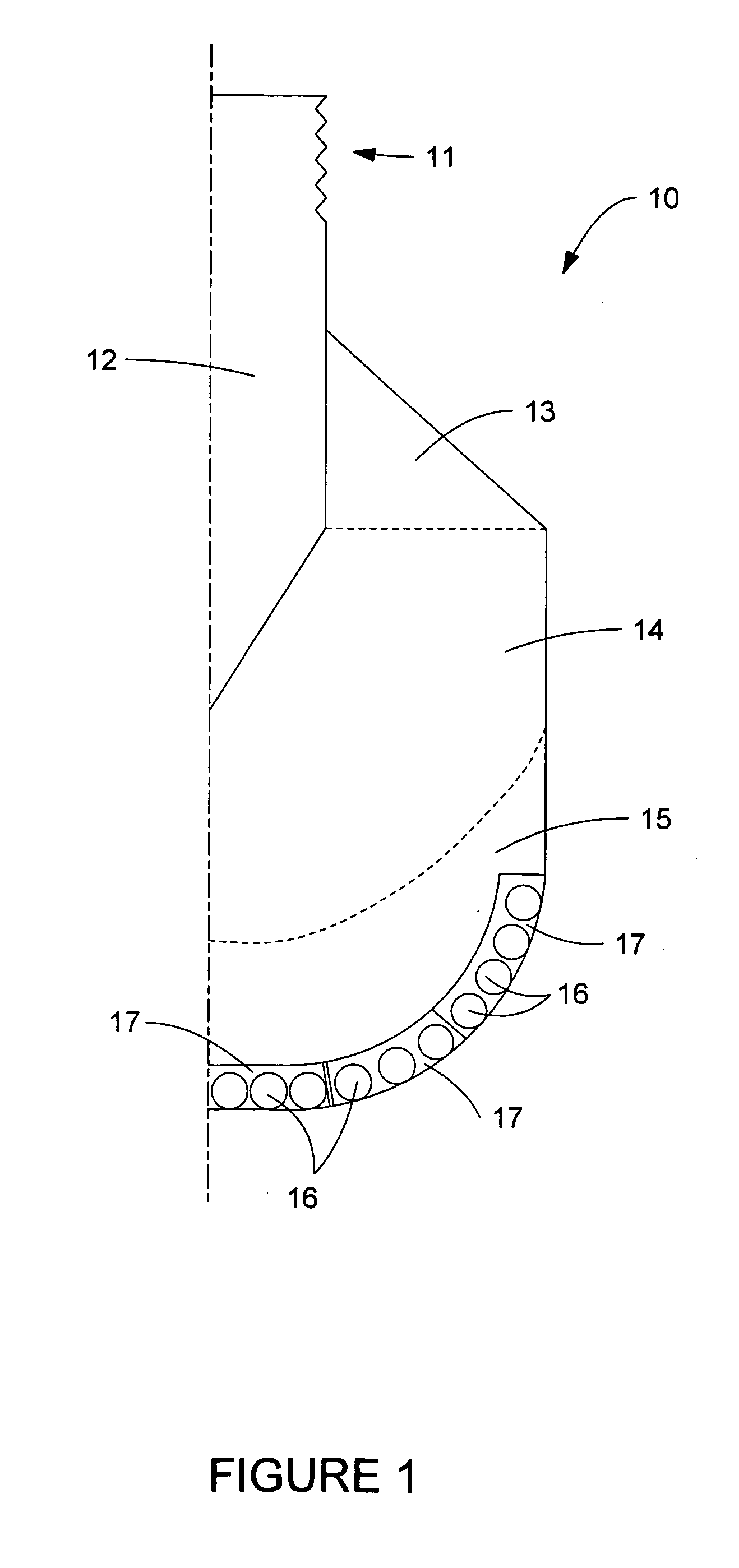

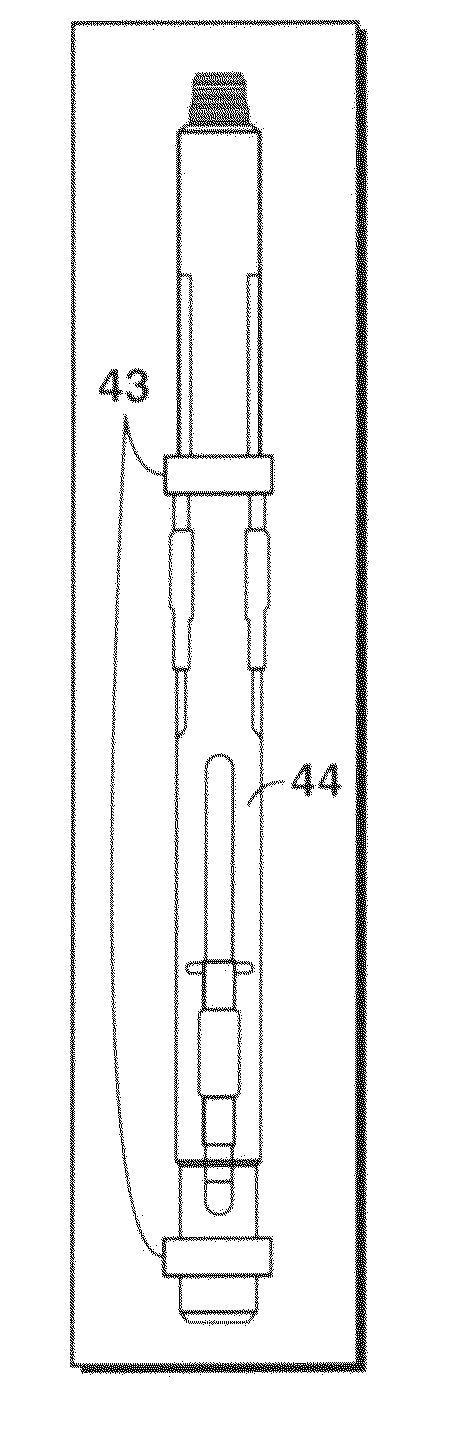

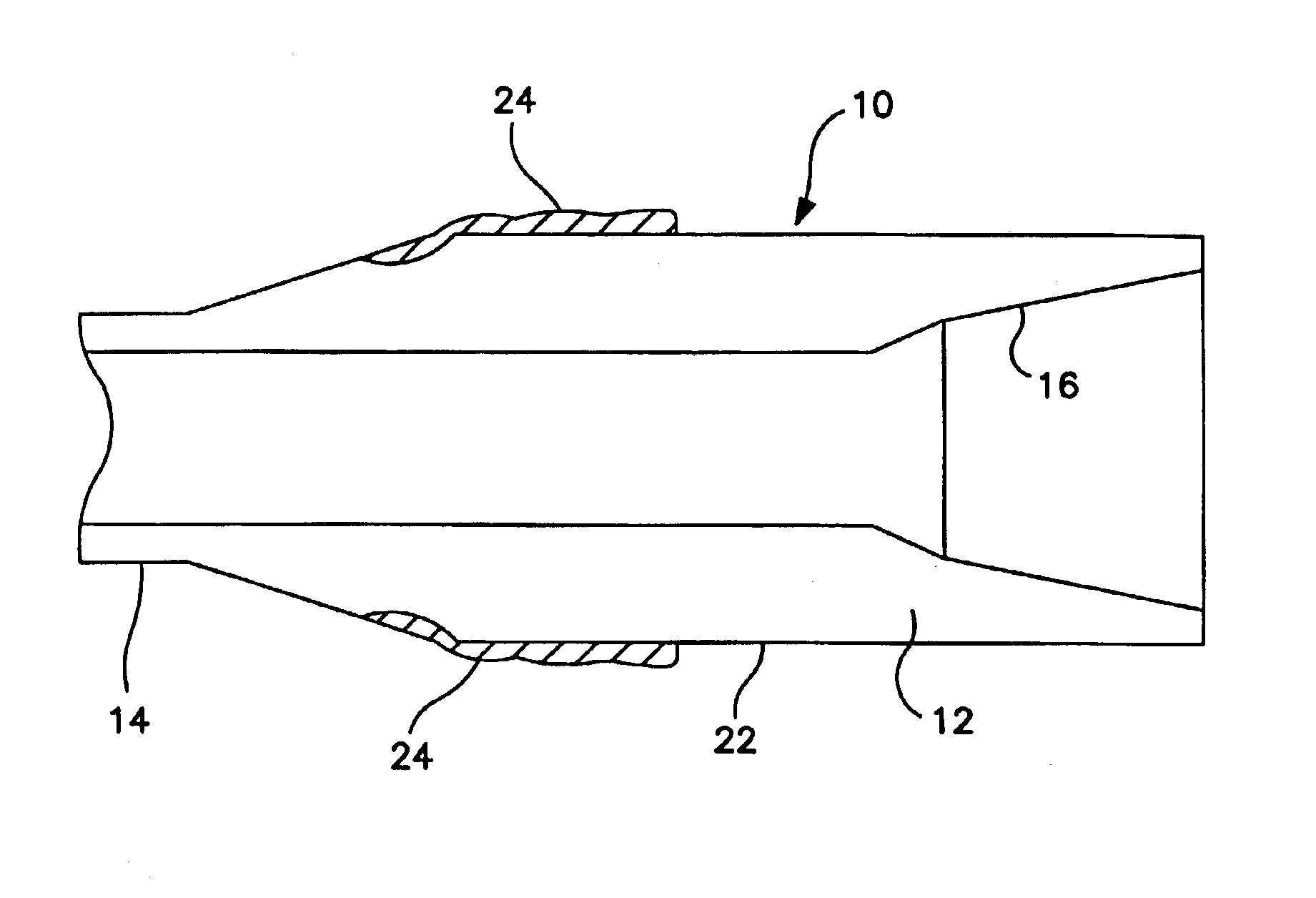

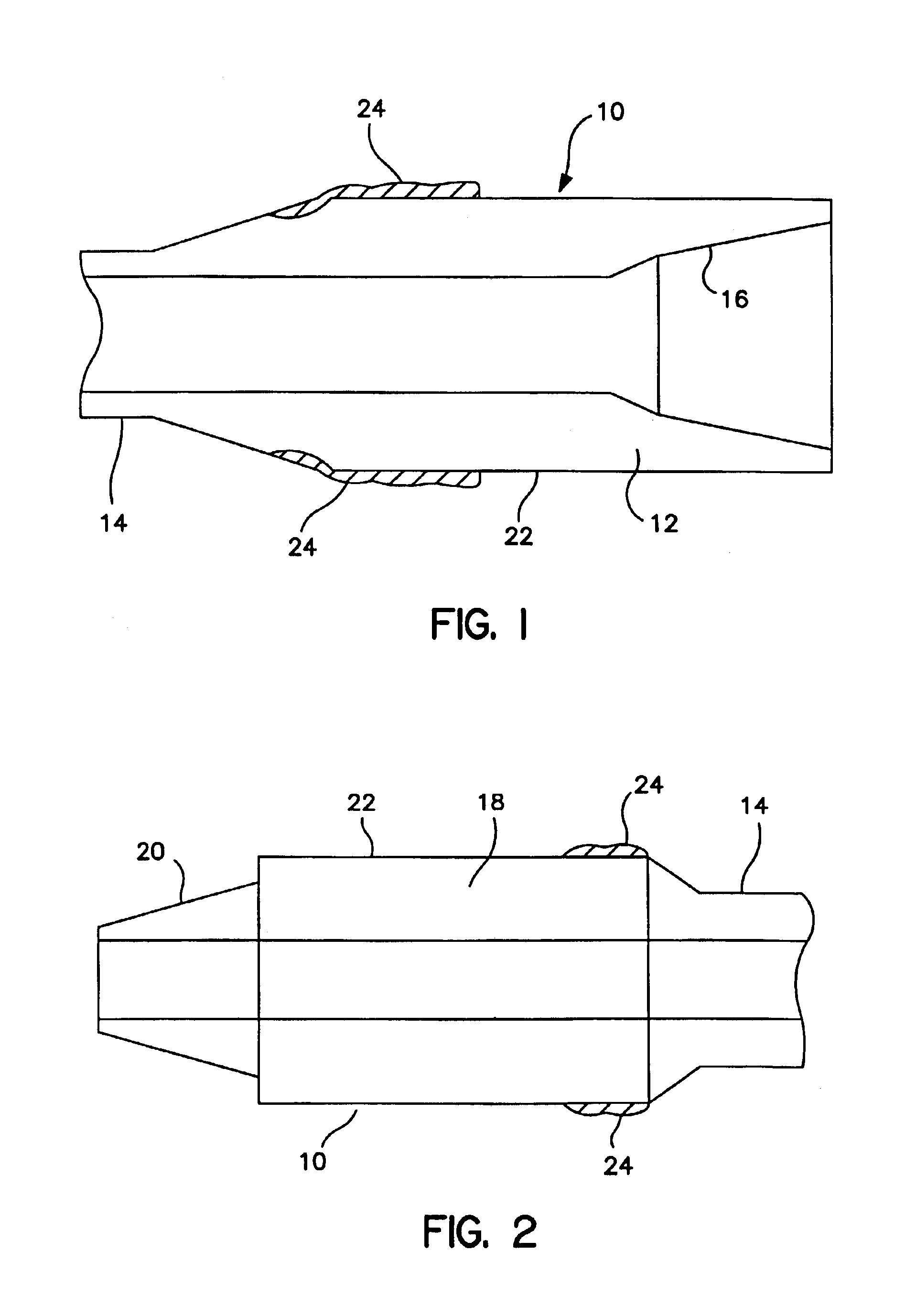

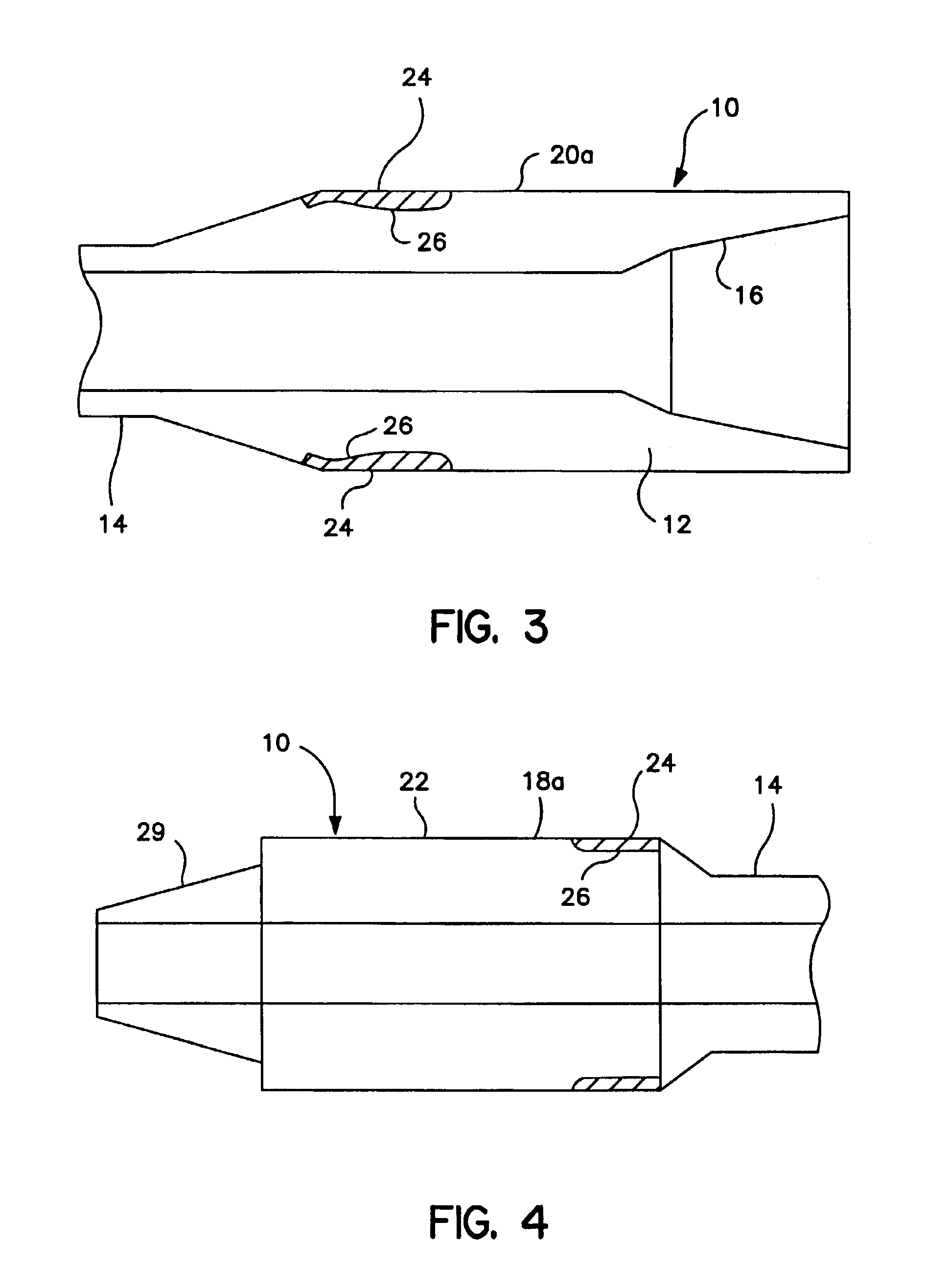

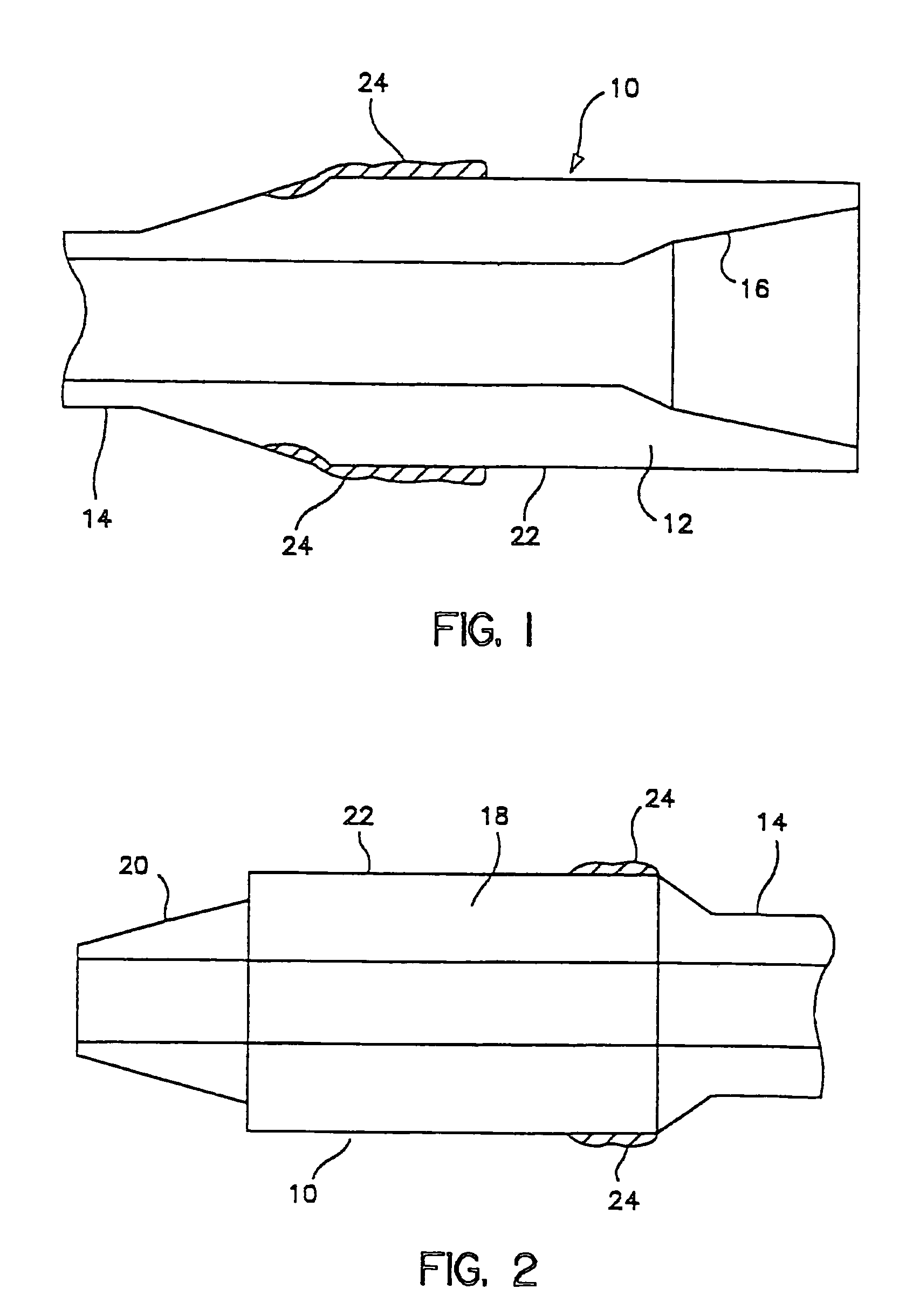

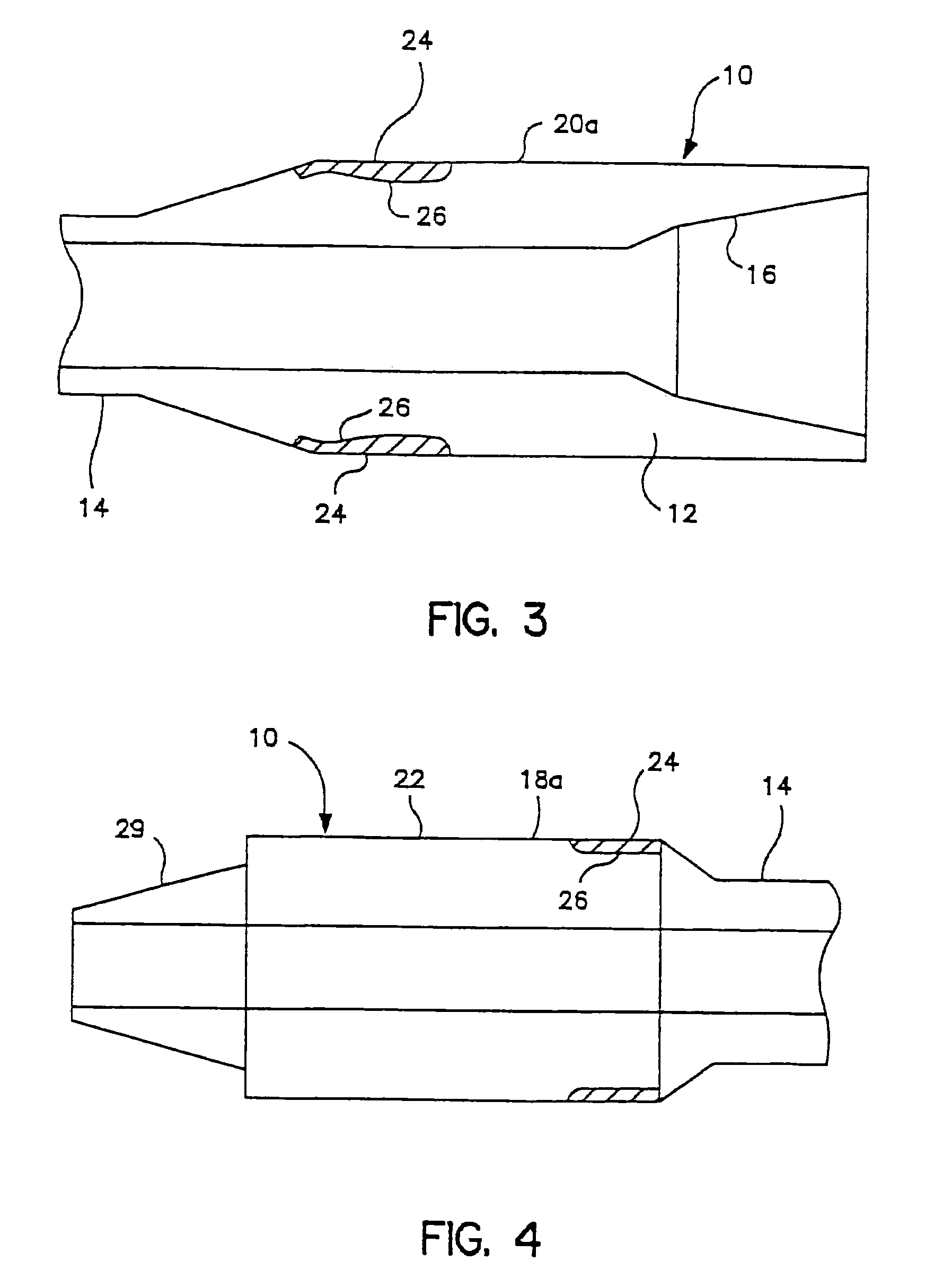

Hardfacing alloy, methods, and products

ActiveUS7361411B2Extended service lifeReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD D B A ARNCO TECH TRUST +1

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS7046489B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

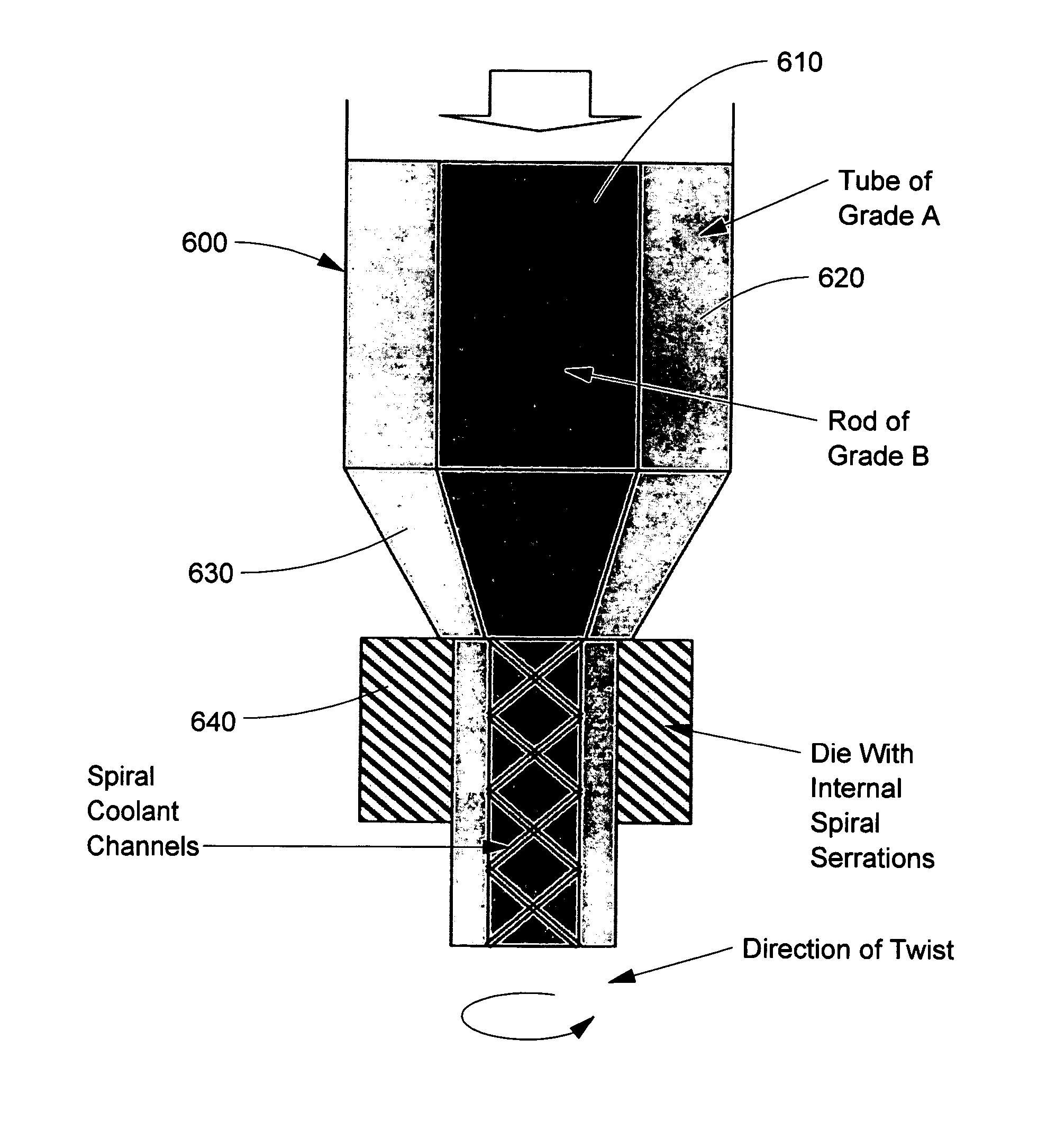

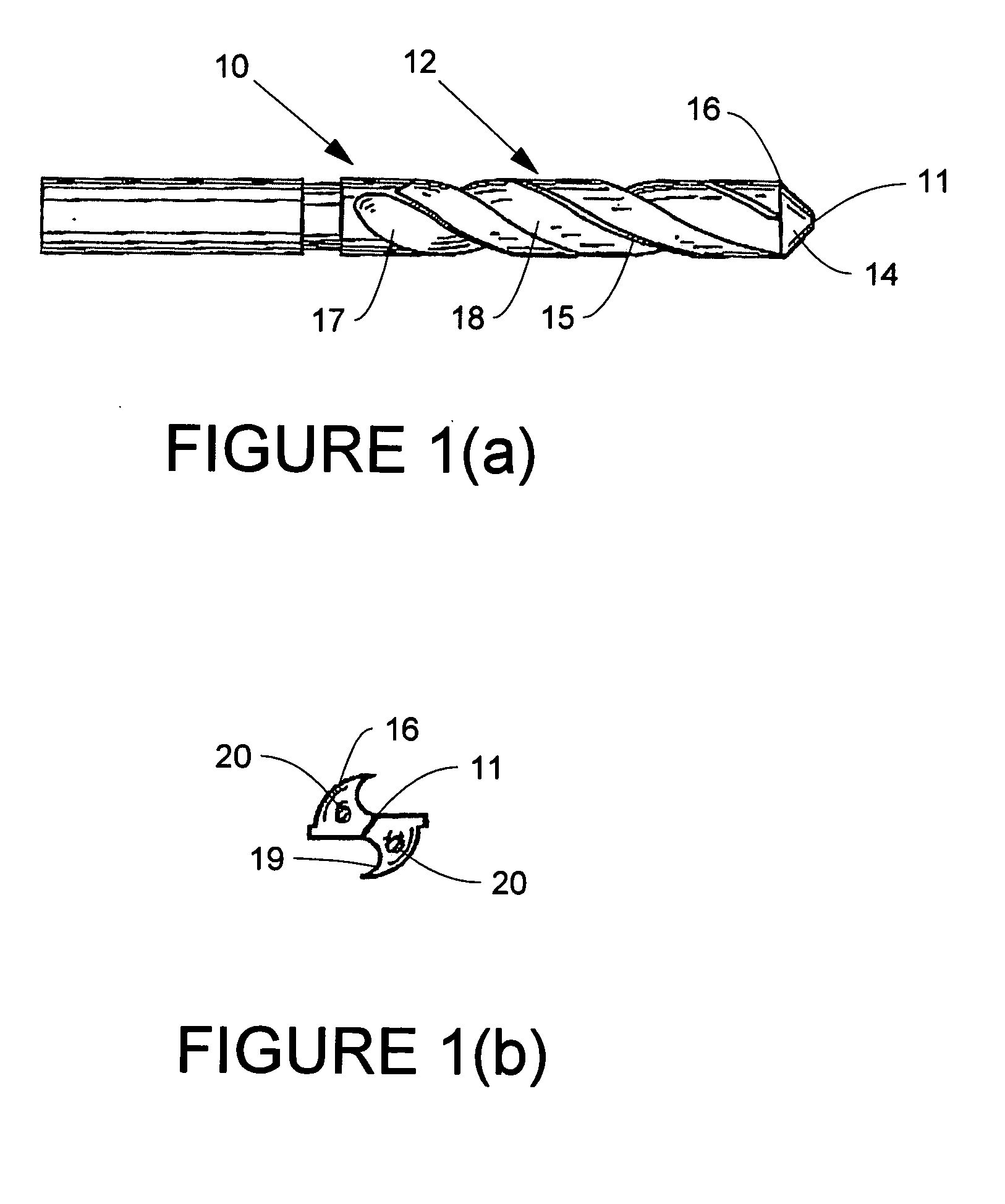

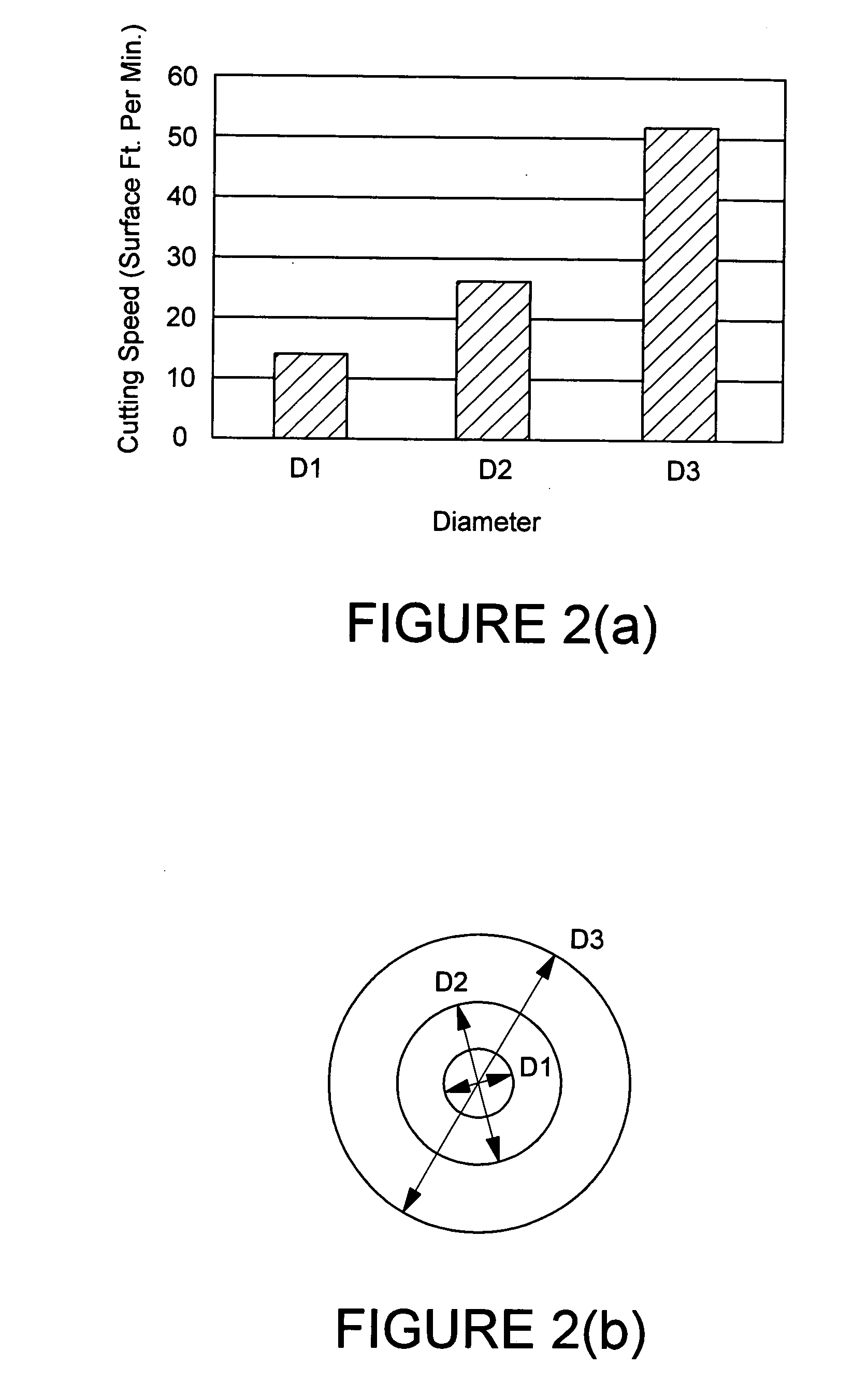

Composite article with coolant channels and tool fabrication method

Embodiments of the present invention include composite articles comprising at least a first region and a second region and methods of making such articles. The first region may comprise a first composite material, wherein the first region comprises less than 5 wt. % cubic carbides by weight, and the second region may comprise a second composite material, wherein the second composite material differs from the first composite material in at least one characteristic. The composite article may additionally comprise at least one coolant channel. In certain embodiments, the first and second composite material may individually comprise hard particles in a binder, wherein the hard particles independently comprise at least one of a carbide, a nitride, a boride, a silicide, an oxide, and solid solutions thereof and the binder comprises at least one metal selected from cobalt, nickel, iron and alloys thereof. In specific embodiments, the first composite material and the second composite material may individually comprise metal carbides in a binder, such as a cemented carbide.

Owner:KENNAMETAL INC

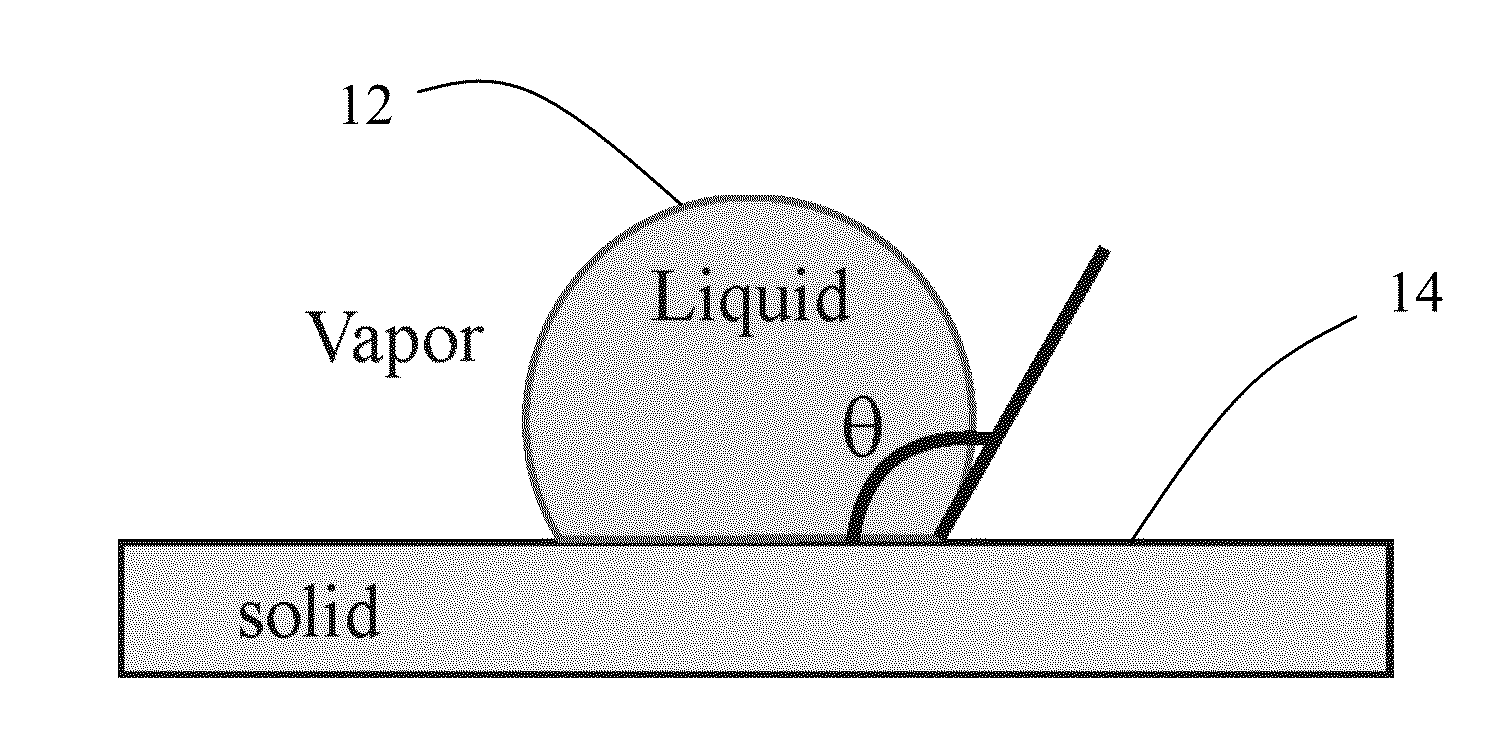

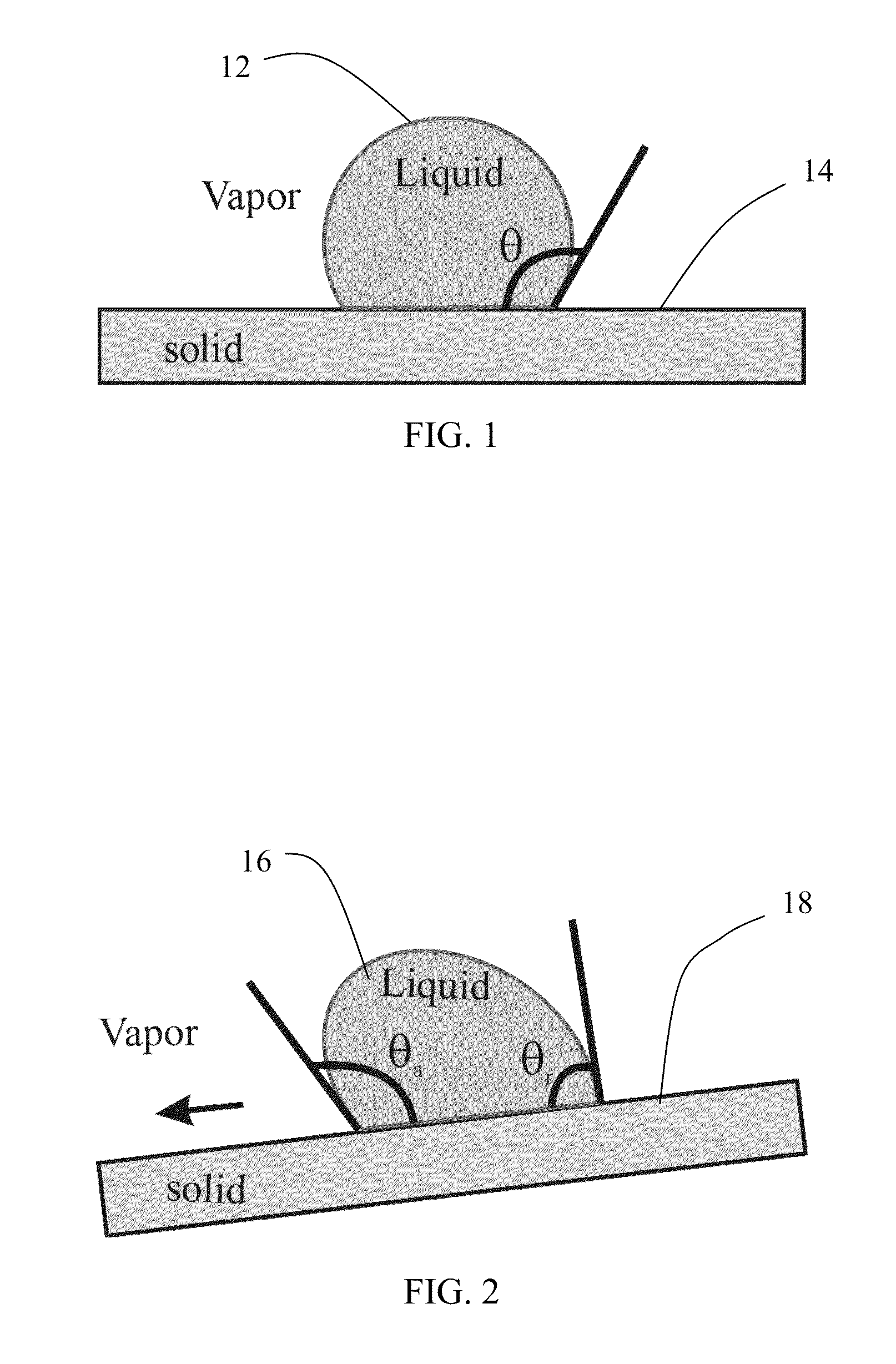

Hydrophobic Materials Incorporating Rare Earth Elements and Methods of Manufacture

InactiveUS20130251942A1Improve waterproof performanceGood for condensationVacuum evaporation coatingSputtering coatingRare-earth elementBoride

This invention relates generally to an article that includes a base substrate and a hydrophobic coating on the base substrate, wherein the hydrophobic coating includes a rare earth element material (e.g., a rare earth oxide, a rare earth carbide, a rare earth nitride, a rare earth fluoride, and / or a rare earth boride). An exposed surface of the hydrophobic coating has a dynamic contact angle with water of at least about 90 degrees. A method of manufacturing the article includes providing the base substrate and forming a coating on the base substrate (e.g., through sintering or sputtering).

Owner:MASSACHUSETTS INST OF TECH

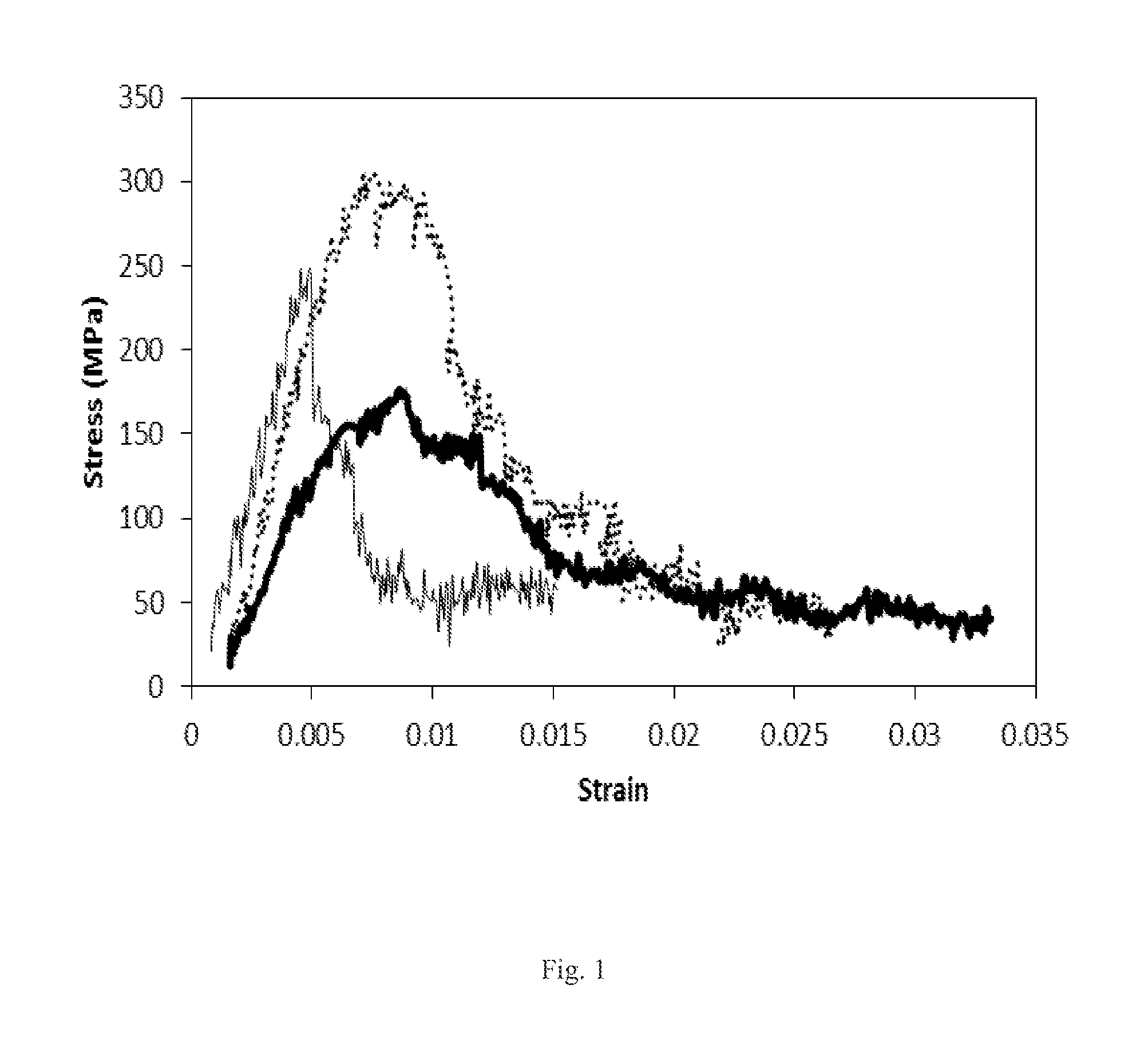

High-strength discontinuously-reinforced titanium matrix composites and method for manufacturing the same

The invention relates to manufacturing the flat or shaped titanium matrix composite articles having improved mechanical properties such as lightweight plates, sheets for aircraft and automotive applications, heat-sinking lightweight electronic substrates, armor plates, etc. High-strength discontinuously-reinforced titanium metal matrix composite (TMMC) comprises (a) titanium matrix or titanium alloy as a major component, (b) ceramic and / or ≦50 vol. % intermetallic hard particles dispersed in matrix, (c) complex carbide- and / or boride particles at least partially soluble in matrix at sintering or forging temperatures such as ≦50 vol. % AlV2C, AlTi2Si3, AlTi6Si3, VB2, TiVSi2, TiVB4, Ti2AlC, AlCr2C, TiAlV2, V2C, VSi2, Ta3B4, NbTiB4, Al3U2C3 dispersed in matrix. Method for manufacturing these TMMC materials is disclosed. Sintered TMMC density exceeds 98% and closed discontinuous porosity allows performing hot deformation in air without encapsulating. Near-full density near-net shape TMMC parts with acceptable mechanical properties were manufactured without hot deformation.

Owner:ADVANCED MATERIALS PRODS

Cemented carbide inserts for earth-boring bits

This invention relates to cutting inserts for earth boring bits comprising a cutting zone, wherein the cutting zone comprises first cemented hard particles and a body zone, wherein the body zone comprises second cemented hard particles. The first cemented hard particles may differ in at least one property from the second cemented hard particles. As used herein, the cemented hard particles means a material comprising hard particles in a binder. The hard particles may be at least one of a carbide, a nitride, a boride, a silicide, an oxide, and solid solutions thereof and the binder may be at least one metal selected from cobalt, nickel, iron and alloys of cobalt, nickel or iron.

Owner:KENNAMETAL INC

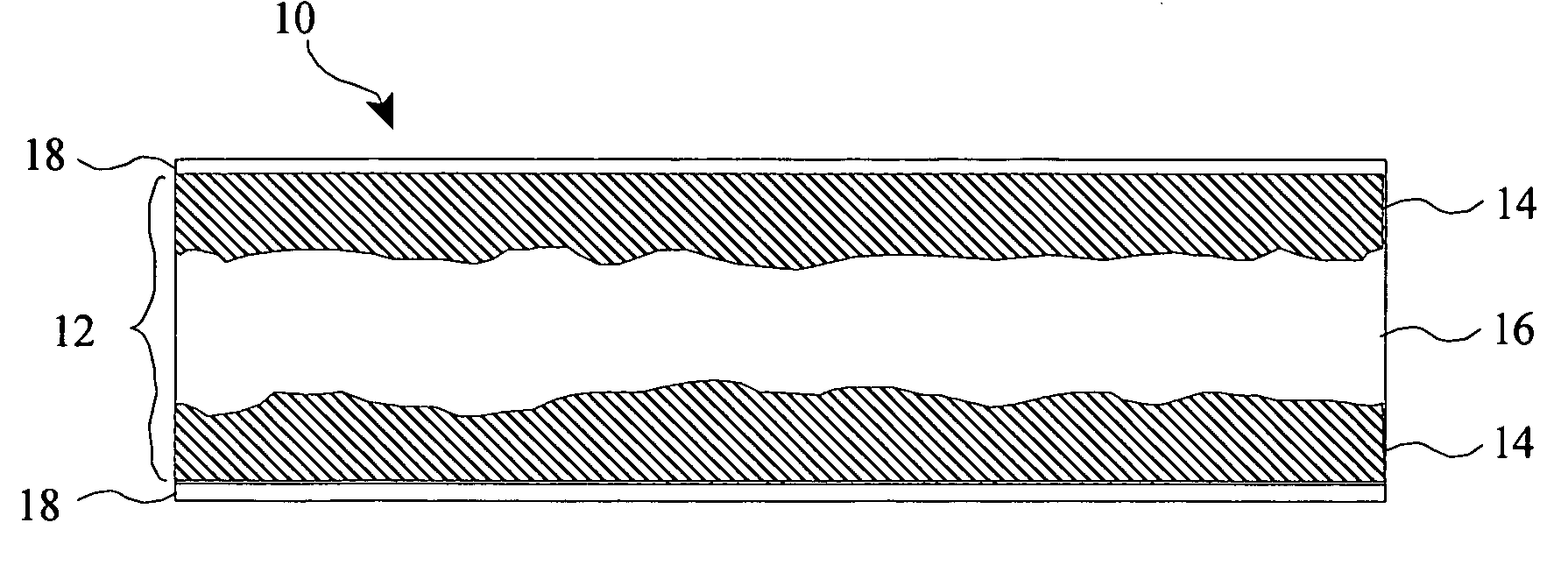

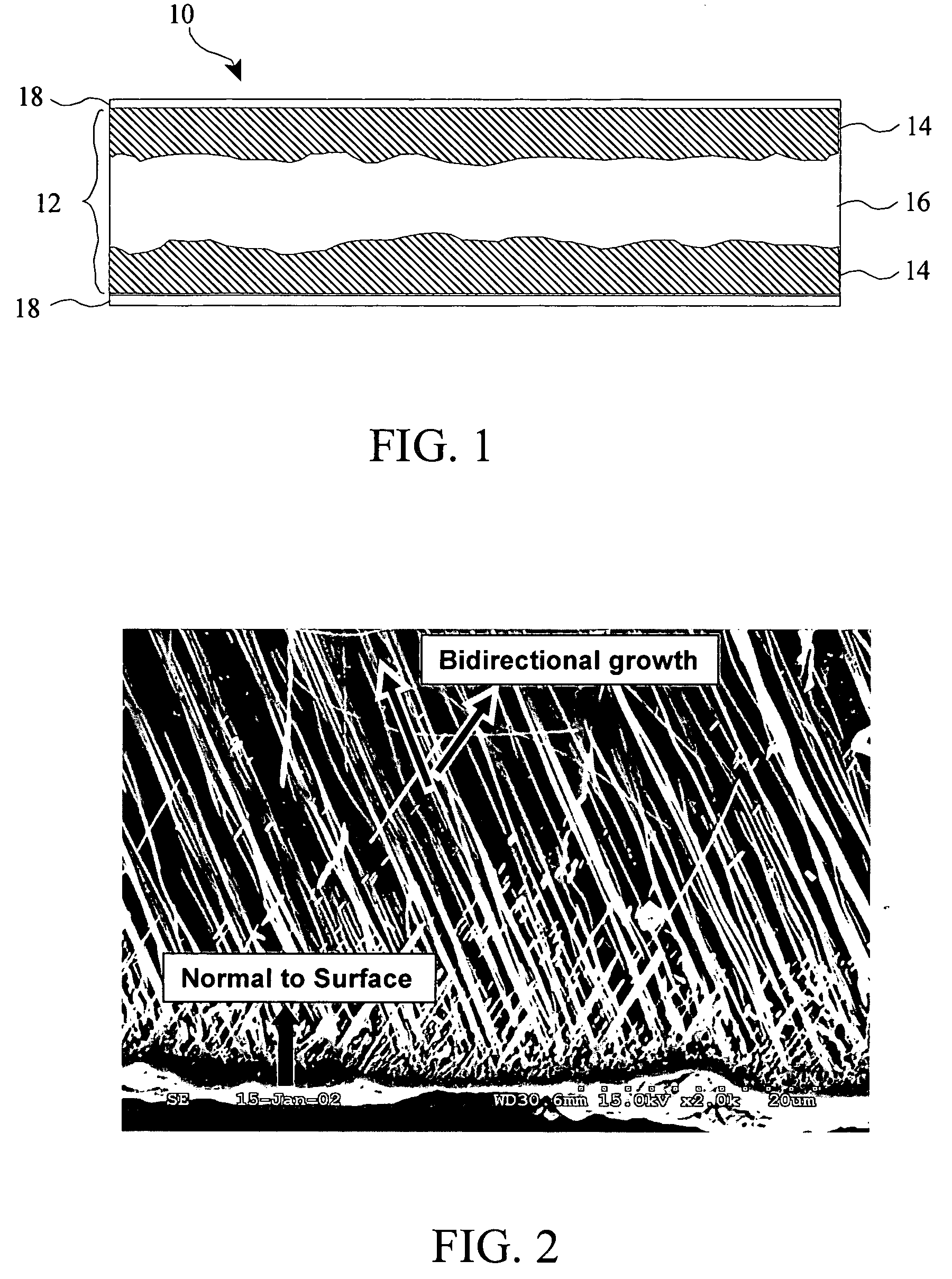

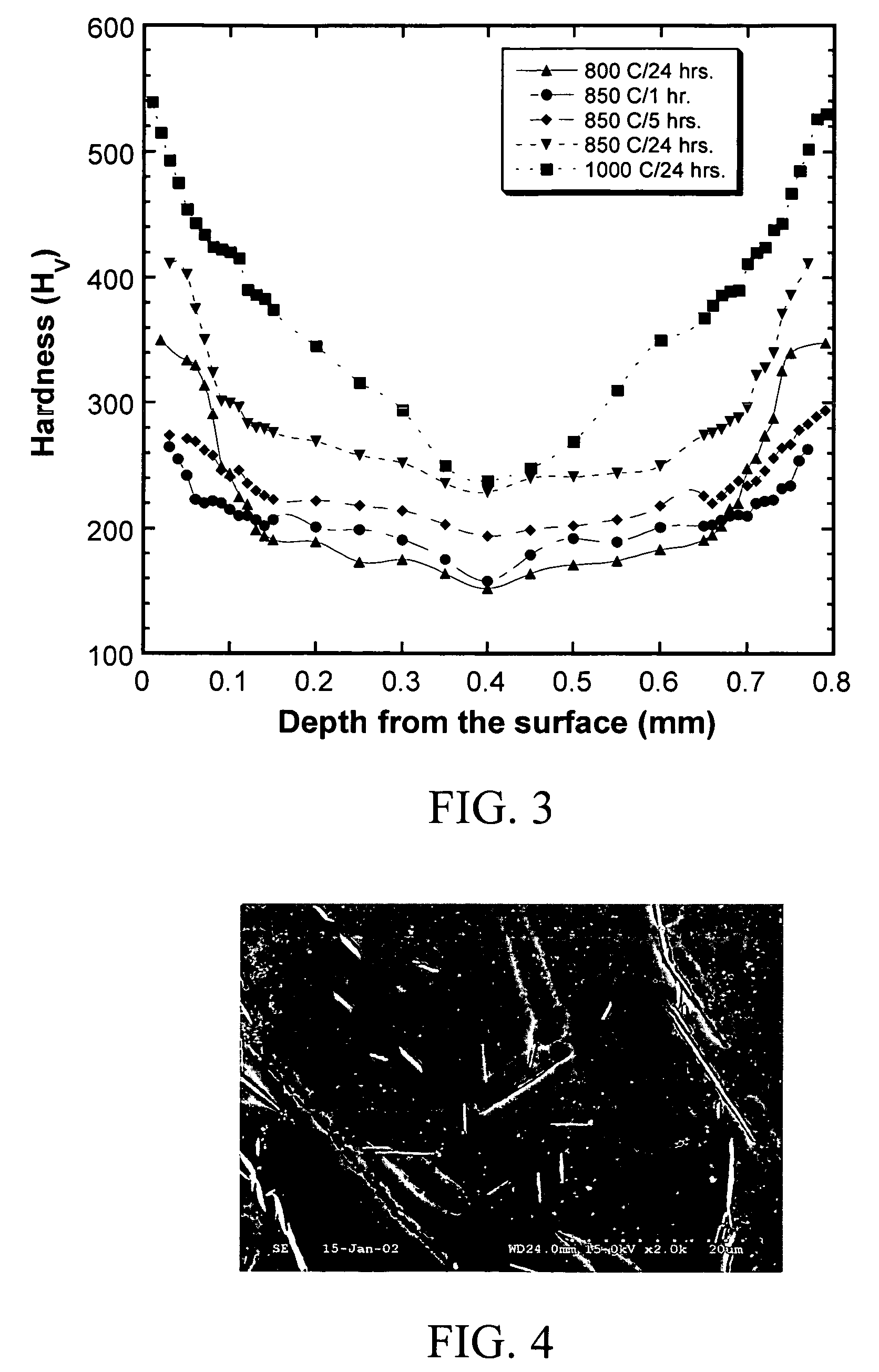

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS7264682B2High wear and corrosion and oxidation resistanceResistance to galling and seizureSolid state diffusion coatingMetal boridesBorideTitanium surface

Owner:UNIV OF UTAH RES FOUND

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Non-oxide composite low-carbon magnesia-carbon brick

A non-oxide compound magnesite-graphite brick containing carbon less than 6% belongs to a fire resisting material. The material contains magnesia of 75-94%, carbon of 1-5%, non-oxide such as nitride and boride of 0.4-20%, additive of 0-5%, and binder containg carbon. Such magnesite-graphite brick with low carbon has a low heat conductivity, a small acierating to the molten steel and less pollution to the low carbon steel compared to the common magnesite-graphite brick. The magnesite-graphite brick has a good slag resistance because the magnesia is the primary component. And it also has a good heat shock capacity because the carbon is one of the primary components. The carbon prevents said non-oxide from being oxidated. The brick maintains a good heat and shock resistance and slag resistance when reducing the proportion of the carbon because said non-oxide has a low heat expansion and a wet resistance to the slag.

Owner:江苏苏嘉集团新材料有限公司

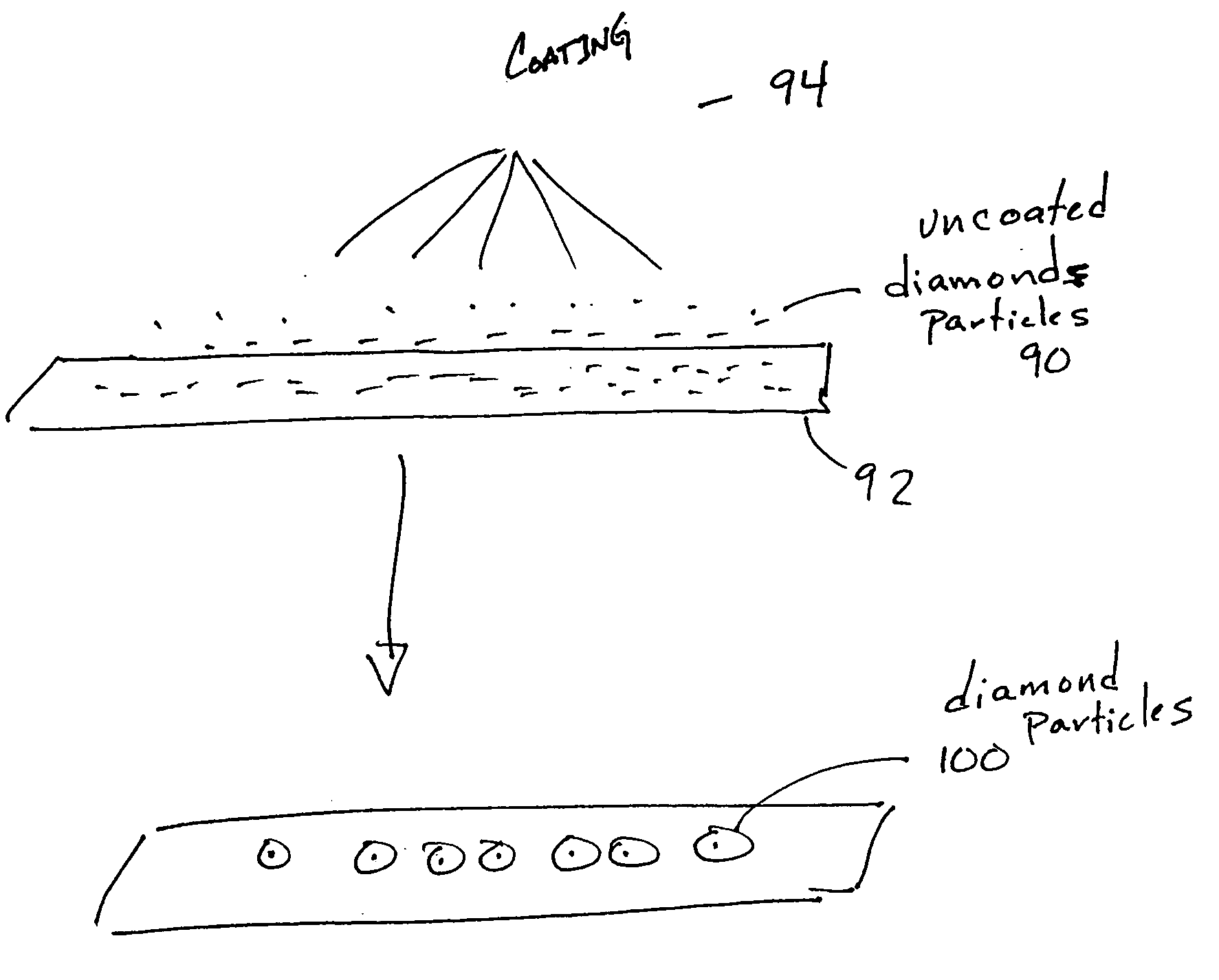

Coated diamonds for use in impregnated diamond bits

An insert for an impreg bit that includes coated diamond particles disposed in a matrix material, wherein the coated diamond particles include a boride, a nitride, and a carbide of a group IVA, VA, VI transition metal or silicon disposed on synthetic, natural, TSP diamonds, or combinations thereof is disclosed. A method of forming a diamond-impregnated insert, including coating a plurality of diamond particles with a coating formed from a boride, a nitride, and a carbide of a group IVA, VA, VI transition metal or silicon or mixtures thereof, and forming a diamond impregnated insert body is also disclosed.

Owner:SMITH INT INC

Microstructured high-temperature hybrid material, its composite material and method of making

This invention provides a hybrid material that exhibits strength, stiffness and ability to resist high temperatures. This hybrid material essentially consists of component A and component B. Component A is selected from the group consisting of inorganic compounds, oxides, carbides, nitrides, borides, and combinations thereof. Component B is selected from the group comprising elemental carbon, inorganic compounds, oxides, carbides, nitrides, borides, and combinations thereof. Component B comprises a plurality of units, each of the units substantially exhibiting a shape, such that this shape substantially exhibits a long dimension and a short dimension, with the short dimension being in a direction that is essentially perpendicular to the direction of the long dimension and the short dimension being in the range from 0.1 nm to 0.5 μm. Each of the units of component B is substantially in contact with and substantially bonded to at least one of the units of component A.

Owner:CHUNG DEBORAH D L

Hardfacing alloy, methods and products

InactiveUS7569286B2Increase resistanceReduce coefficient of frictionDrill bitsDrilling rodsBorideCasing wear

Disclosed is a hardfacing alloy capable of withstanding service abrasion of the order of silicious earth particles and weldable on industrial products, such as tool joints and stabilizers used in oil and gas well drilling, and other industrial products. The hardfacing alloy has a low coefficient of friction resulting from excellent metal to metal resistance and significant reduction in industrial wear on industrial products, such as casing wear. Other embodiments of the invention include tool joints having the hardbanding alloy welded to the outer cylindrical surface to its box and pin members and to stabilizer ribs on the stabilizer used in earth boring, such as boring for oil and gas, other industrial products, and methods of applying the hardfacing alloy to their surfaces. The hardfacing alloy does not require any post weld treatment, has primary borides in its microstructure, the carbons in the alloy are tied up in the formation of secondary carbides which add to the abrasion resistance, and have a quadratic crystallographic structure and a hardness of about 1725 Hv comparable to the prior art hardness of the chromium carbide primary carbide alloys of the prior art but is substantially less brittle than C—Cr—Fe hardfacing alloys.

Owner:ATT TECH LTD

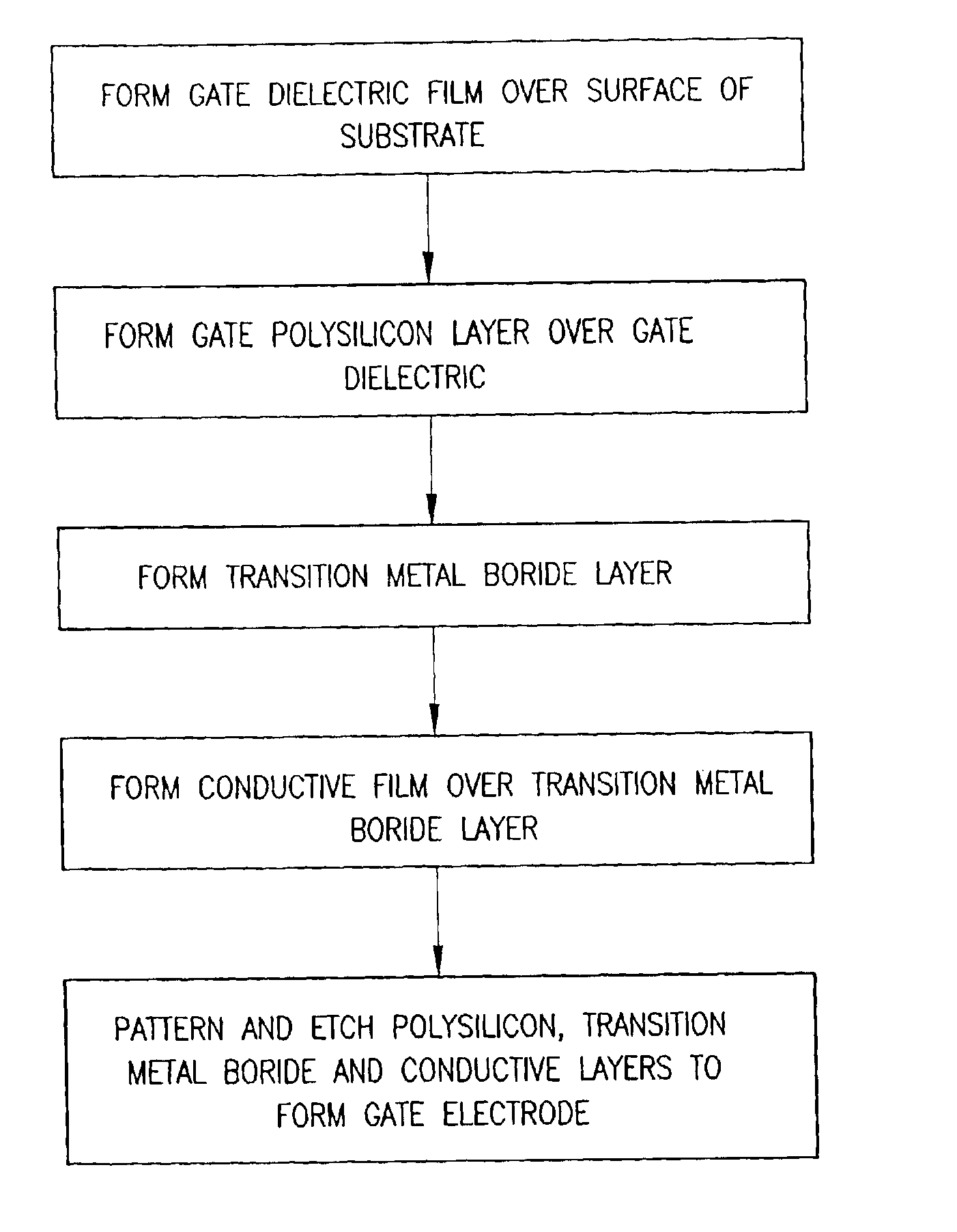

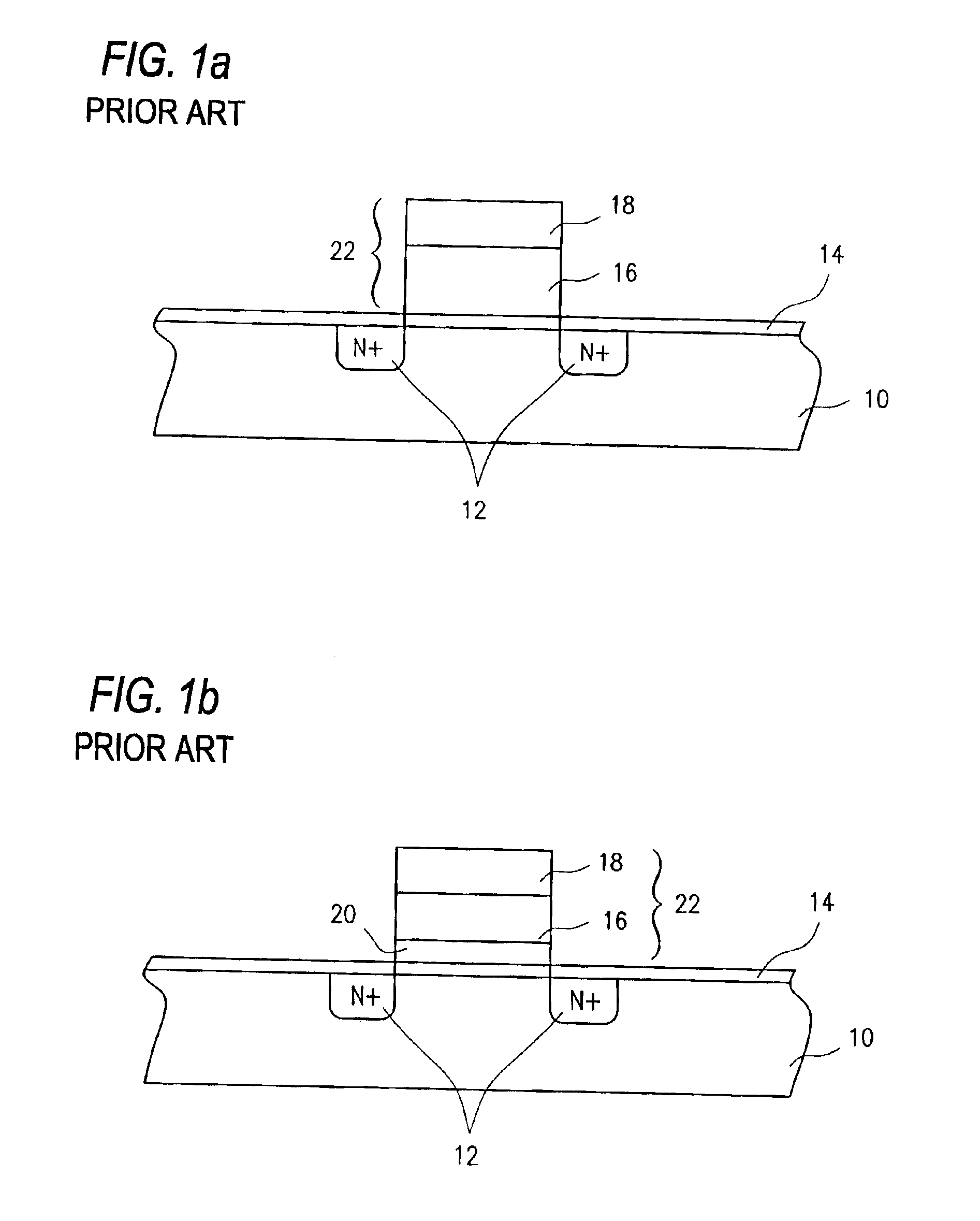

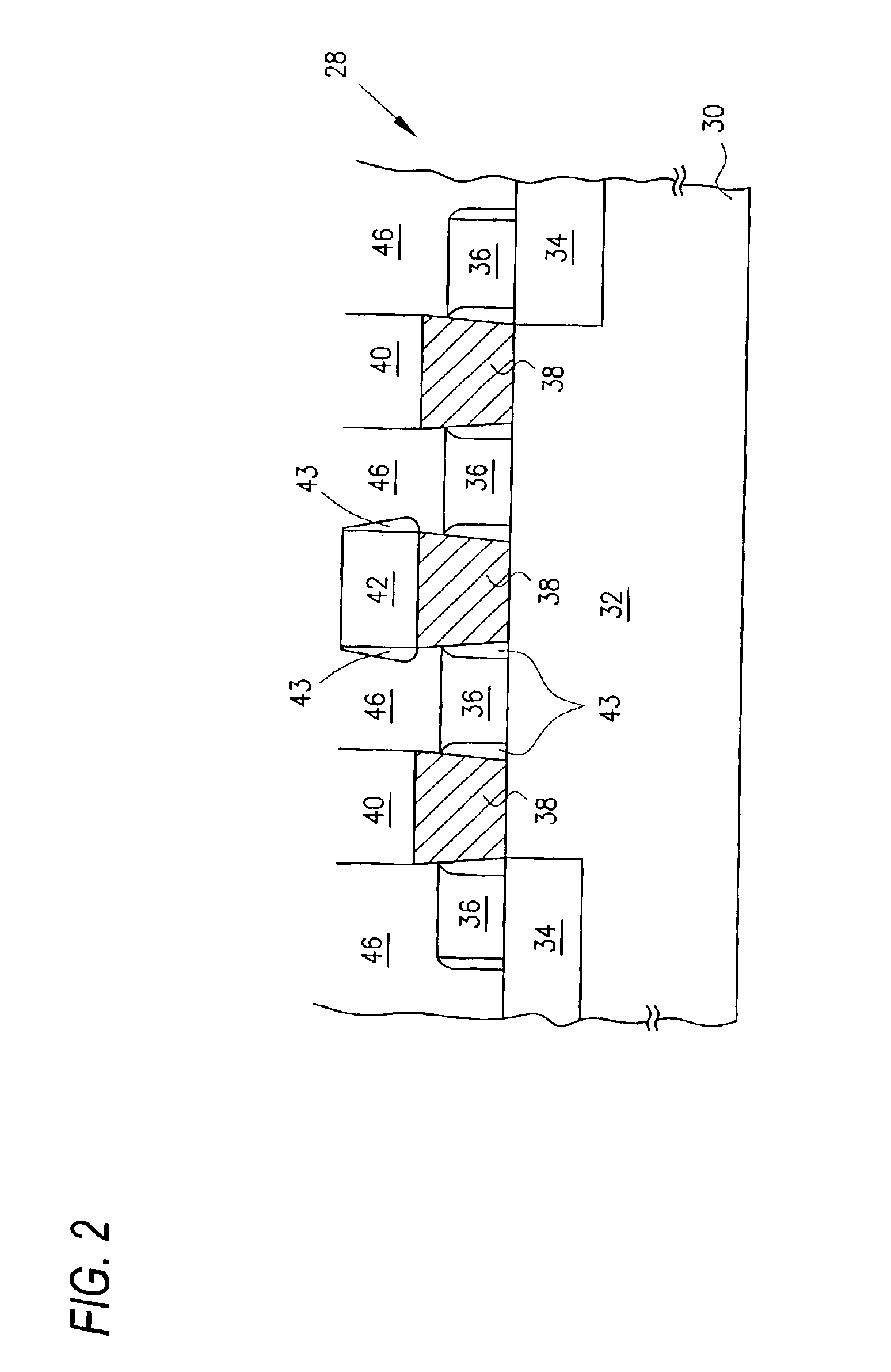

Fabrication of semiconductor devices with transition metal boride films as diffusion barriers

InactiveUS6872639B2Device property can be enhancedImprove propertiesTransistorSemiconductor/solid-state device detailsBorideGate dielectric

An integrated circuit has a multi-layer stack such as a gate stack or a digit line stack disposed on a layer comprising silicon. A conductive film is formed on the transition metal boride layer. A process for fabricating such devices can include forming the conductive film using a vapor deposition process with a reaction gas comprising fluorine. In the case of a gate stack, the transition metal boride layer can help reduce or eliminate the diffusion of fluorine atoms from the conductive film into a gate dielectric layer. Similarly, in the case of digit line stacks as well as gate stacks, the transition metal boride layer can reduce the diffusion of silicon from the polysilicon layer into the conductive film to help maintain a low resistance for the conductive film.

Owner:MICRON TECH INC

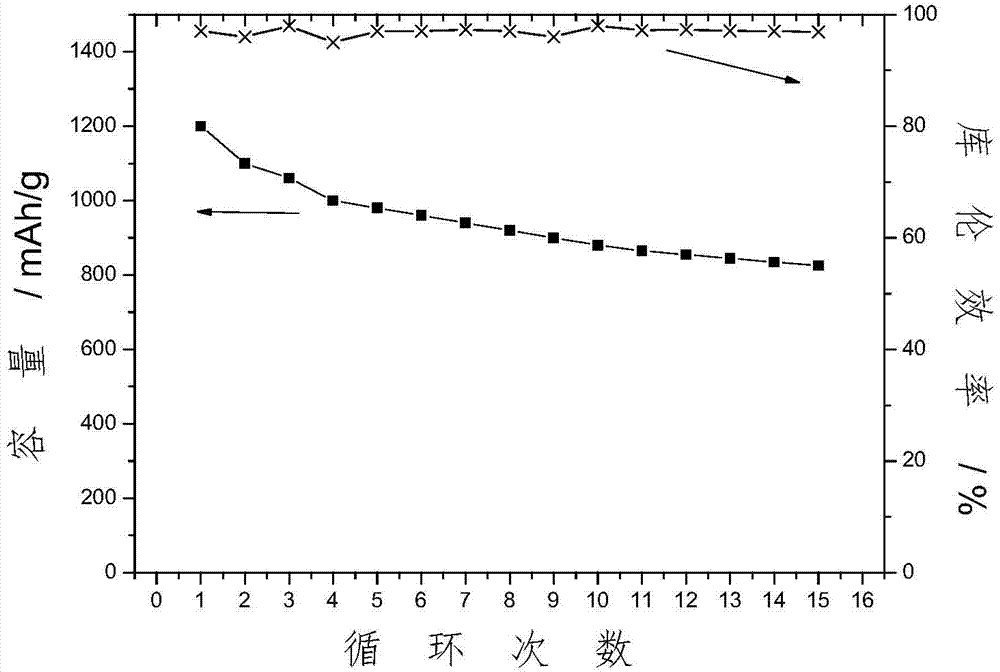

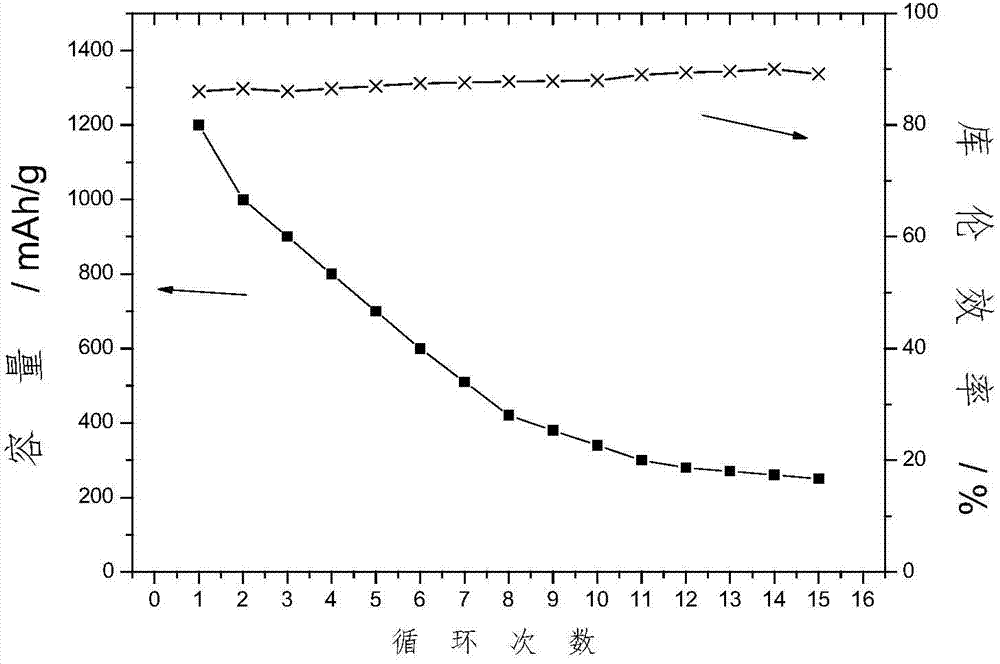

Method for protecting negative electrode of lithium sulfur battery

InactiveCN104716381ADoes not affect the assembly processPracticalFinal product manufactureLi-accumulatorsBorideLithium metal

The invention discloses a method for protecting the negative electrode of a lithium sulfur battery. A lithium sulfur battery negative electrode protection additive layer is adhered to the surface of the anode of the lithium sulfur battery. An additive component forming the protection additive layer can be an inorganic compound or an organic compound; the inorganic compound is one or above two of metal oxides, nonmetal oxides, sulfides, phosphides, nitrides, borides and fluorides; and the organic compound is one or above two of ionic liquid molecules, amino acids, polycation electrolytes, polyanion electrolytes, cationic surfactants, polyoxyether and polythioether. The morphology of the liquid metal protection layer is dynamically changing, and does not physically shed or crack due to continuous dissolution and deposition of the lithium metal in order to effectively protect the negative electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

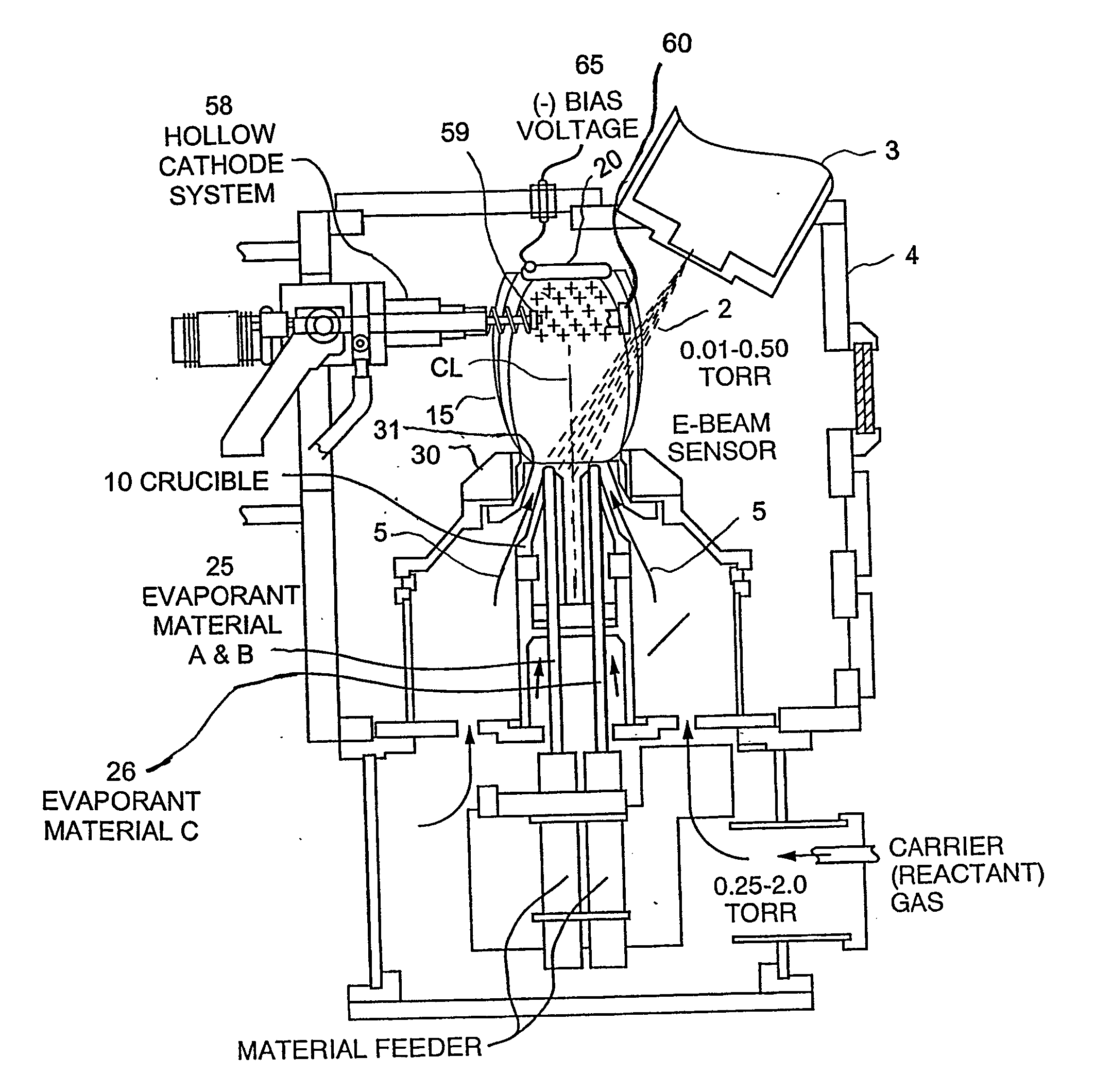

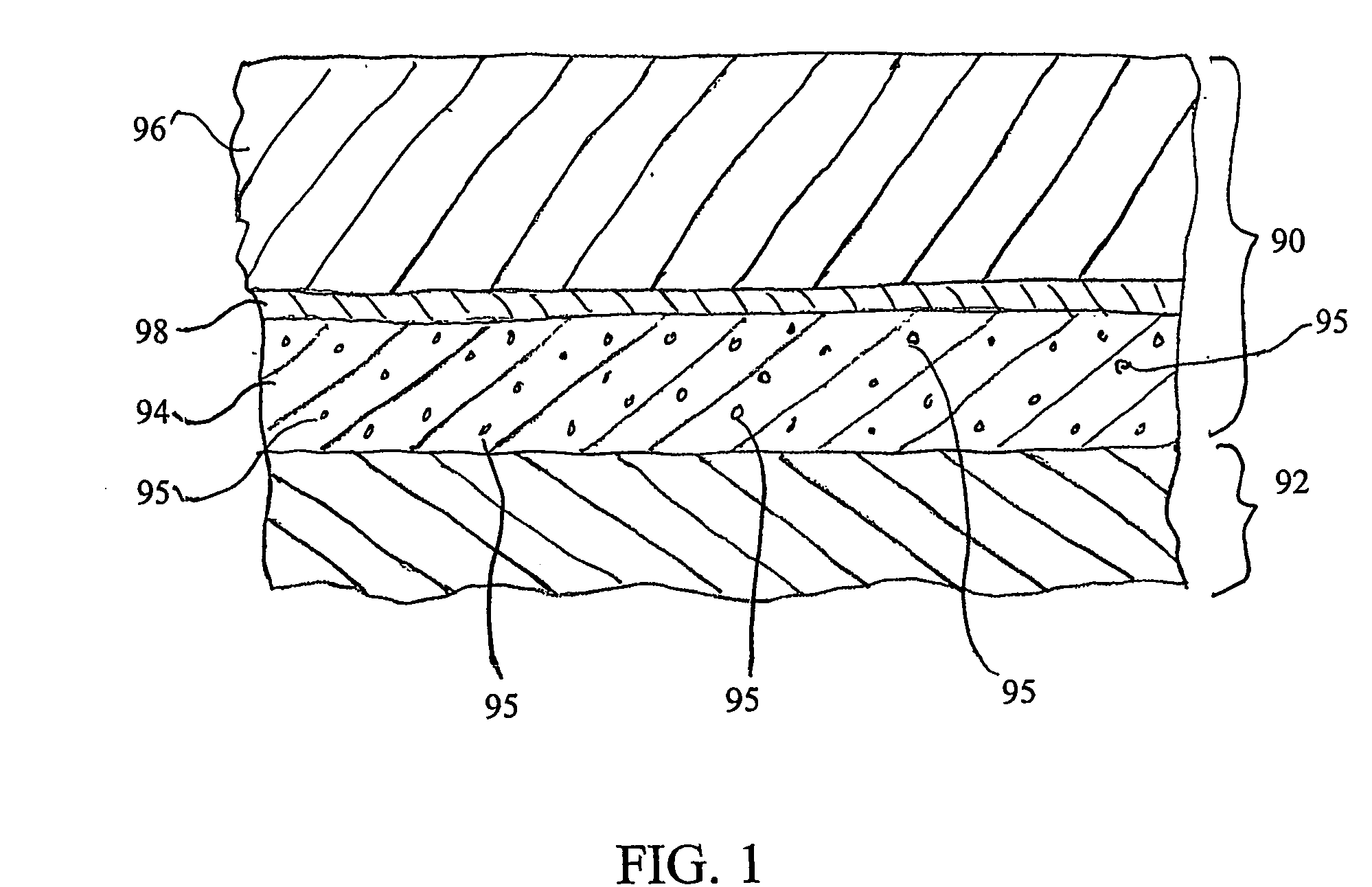

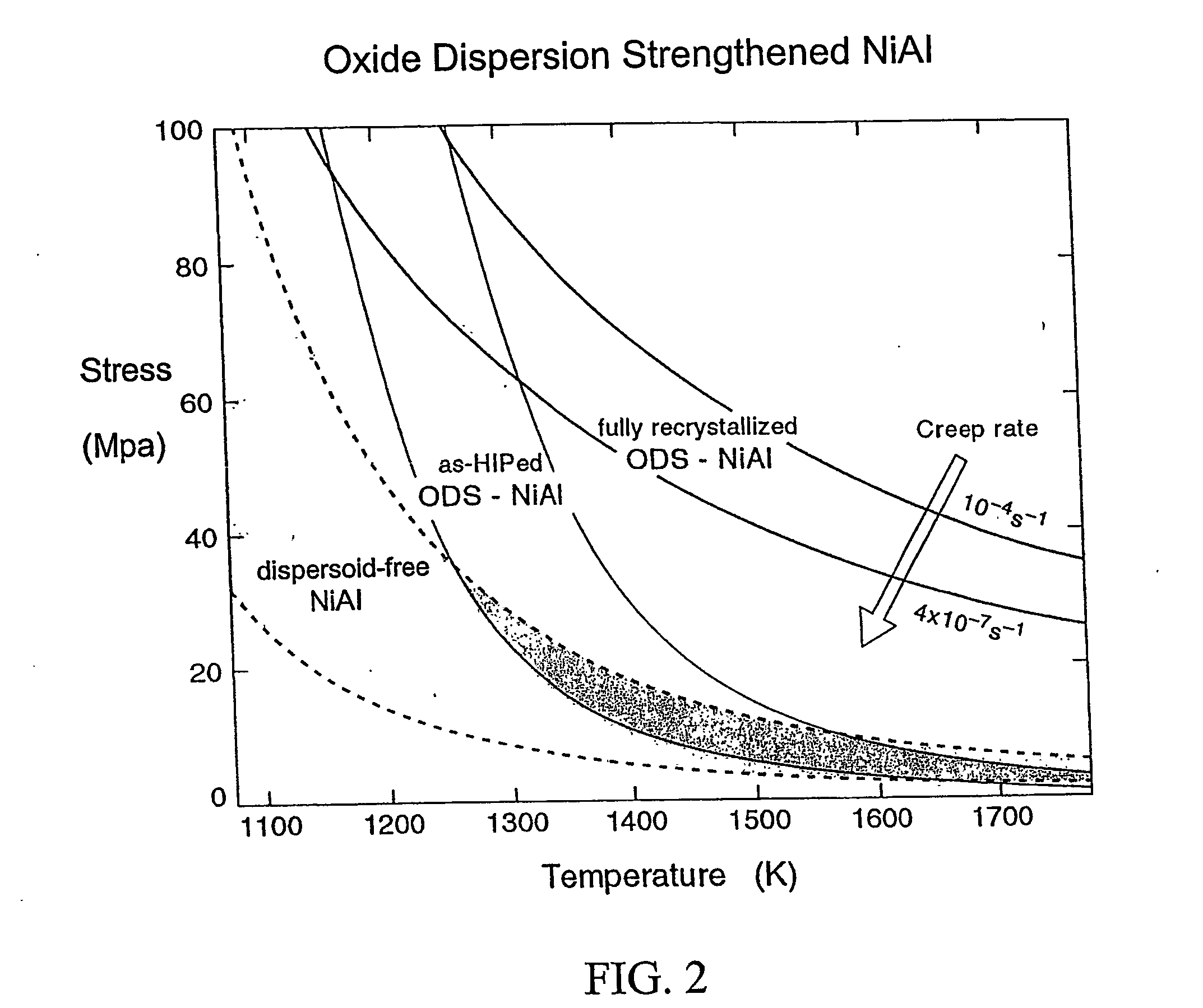

Method and apparatus for dispersion strengthened bond coats for thermal barrier coatings

InactiveUS20050287296A1Effective applicationIncrease chanceEngine manufactureElectric discharge tubesBorideGas phase

A directed vapor deposition (DVD) method and system for applying at least one bond coating on at least one substrate for thermal barrier coating systems. The method and system provides for alloy strengthening in high temperature metallic alloys that can be melt or solid state processed to materials that one applies by vapor deposition. The creep strengthened coating contains nanoscopic particles of oxides, nitrides, borides, carbides, and other materials which are formed by reactive codeposition. An approach for reactive codeposition is plasma assisted directed vapor deposition. Accordingly, the resultant structure may be utilized for, but not limited thereto, high temperature coatings, e.g. for protecting rocket or power turbines, or diesel engine components. The resultant structure is has a greatly extended lifetime attributed in part to the elimination of coating spallation by the “rumpling” mechanism.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

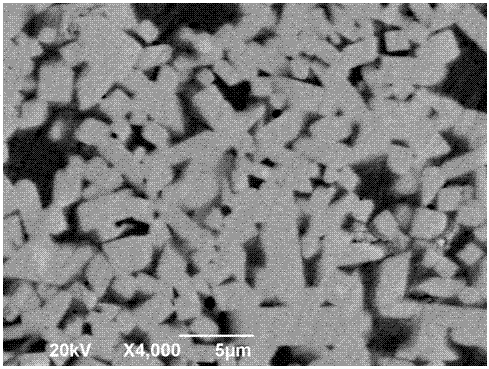

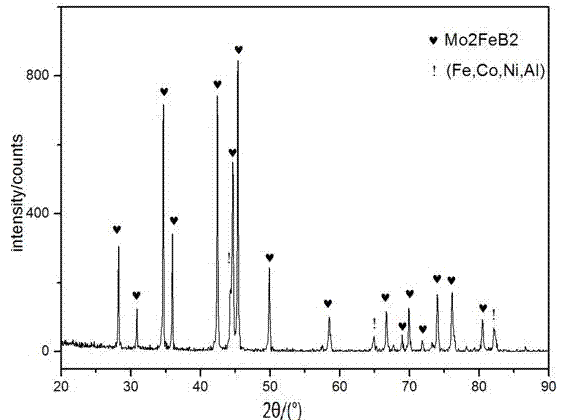

Multiple boride metal ceramic based on high-entropy alloy adhesion agent and preparation method thereof

InactiveCN102787267AImprove mechanical propertiesOvercoming the defect of a single principal element in the binder phaseBorideHigh entropy alloys

The invention discloses a multiple boride metal ceramic based on a high-entropy alloy adhesion agent and a preparation method thereof. According to the boride metal ceramic, high-entropy alloy serves as an adhesion phase, multiple boride serves as a hard phase, the high-entropy alloy adhesion phase is composed of at least four of iron, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum and manganese, and the content mole ratio of each element is between 5% and 35%. The multiple boride hard phase comprises W2M1B2 or / and Mo2M2B2, wherein M1 and M2 are at least one of Fe, Ni, Co and Cr. The preparation method of the multiple boride metal ceramic based on the high-entropy alloy adhesion agent comprises the steps of ball-milling mixing, forming and low-pressure sintering.

Owner:SICHUAN UNIV

Coated pressing surfaces for abrasion resistant laminate and making laminates therefrom

A press plate for producing decorative laminate from resin impregnated paper, with alumina particles on its pressing surface, is coated with diborides selected from the group consisting of hafnium diboride, molybdenum diboride, tantalum diboride, titanium diboride, tungsten diboride, vanadium diboride, or zirconium diboride or mixtures thereof for making the press plate resistant to scratching. The preferred diborides are titanium and zirconium. The most preferred diboride is titanium. The color, gloss and surface appearance of laminate pressed with a titanium diboride coated press plate is substantially the same as laminate pressed with the press plate before coating.

Owner:WILSONART

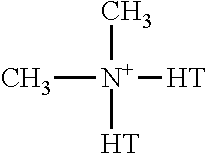

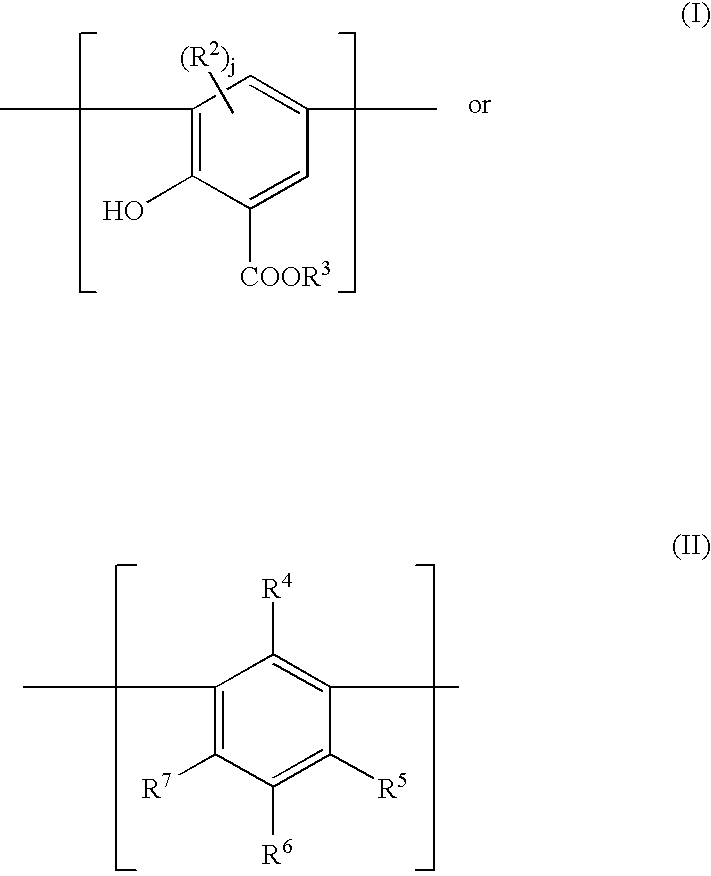

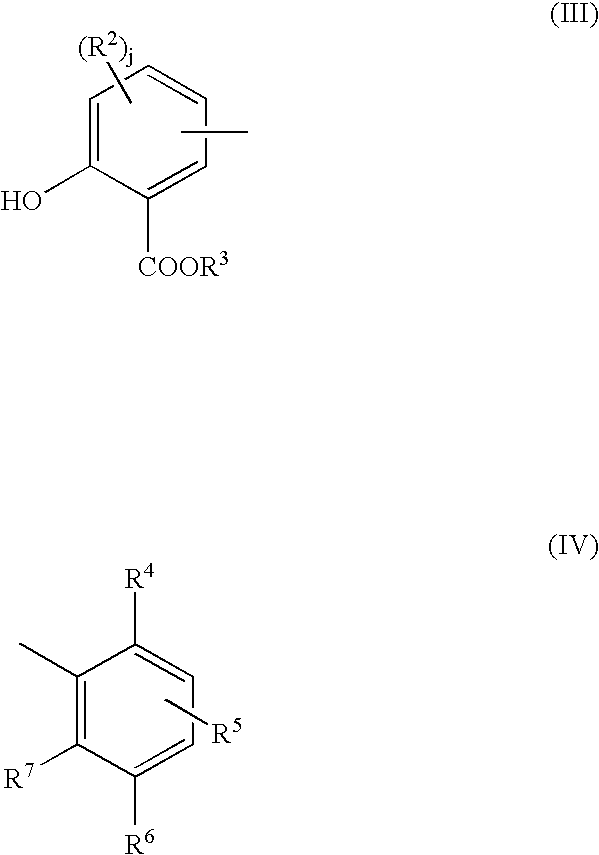

Lubricated part having partial hard coating allowing reduced amounts of antiwear additive

InactiveUS20070197407A1Reduce wearReduces clogged filtersVacuum evaporation coatingSputtering coatingBorideSulfide

A lubricated part composition containing (a) a part with at least a partial hard surface coating of average thickness less than about 25 micrometres, said coating containing at least one moiety selected from the group consisting of silicides, nitrides, carbides, borides, oxides, sulphides and mixtures thereof; (b) a detergent selected from at least one of the group consisting of a phenate salt, a sulphonate salt, a salixarate salt and mixtures thereof; and (c) an oil of lubricating viscosity. The invention further relates to the use of the composition to decrease engine wear, decrease sludge formation, filter plugging, decrease sulphur emissions and decrease phosphorus emissions.

Owner:THE LUBRIZOL CORP

Hard-coated member

ActiveUS7537822B2Improve the lubrication effectIncrease resistanceVacuum evaporation coatingSputtering coatingBorideCarbide

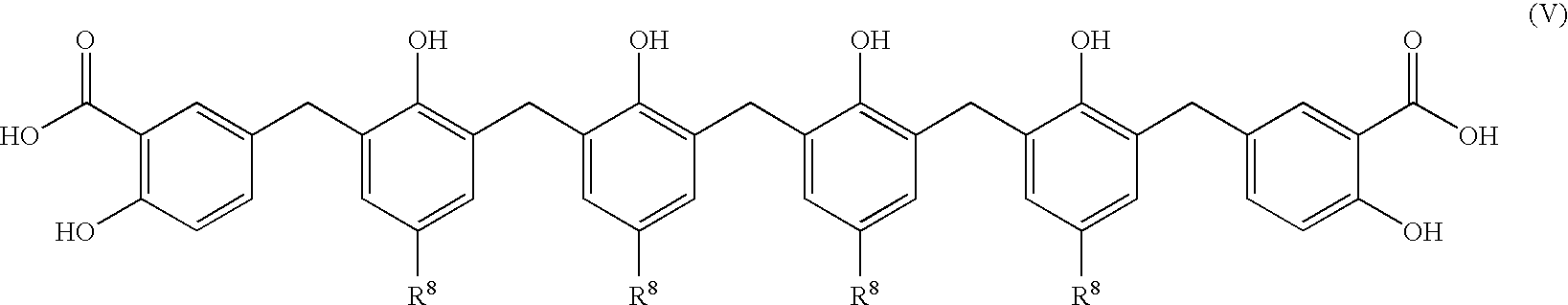

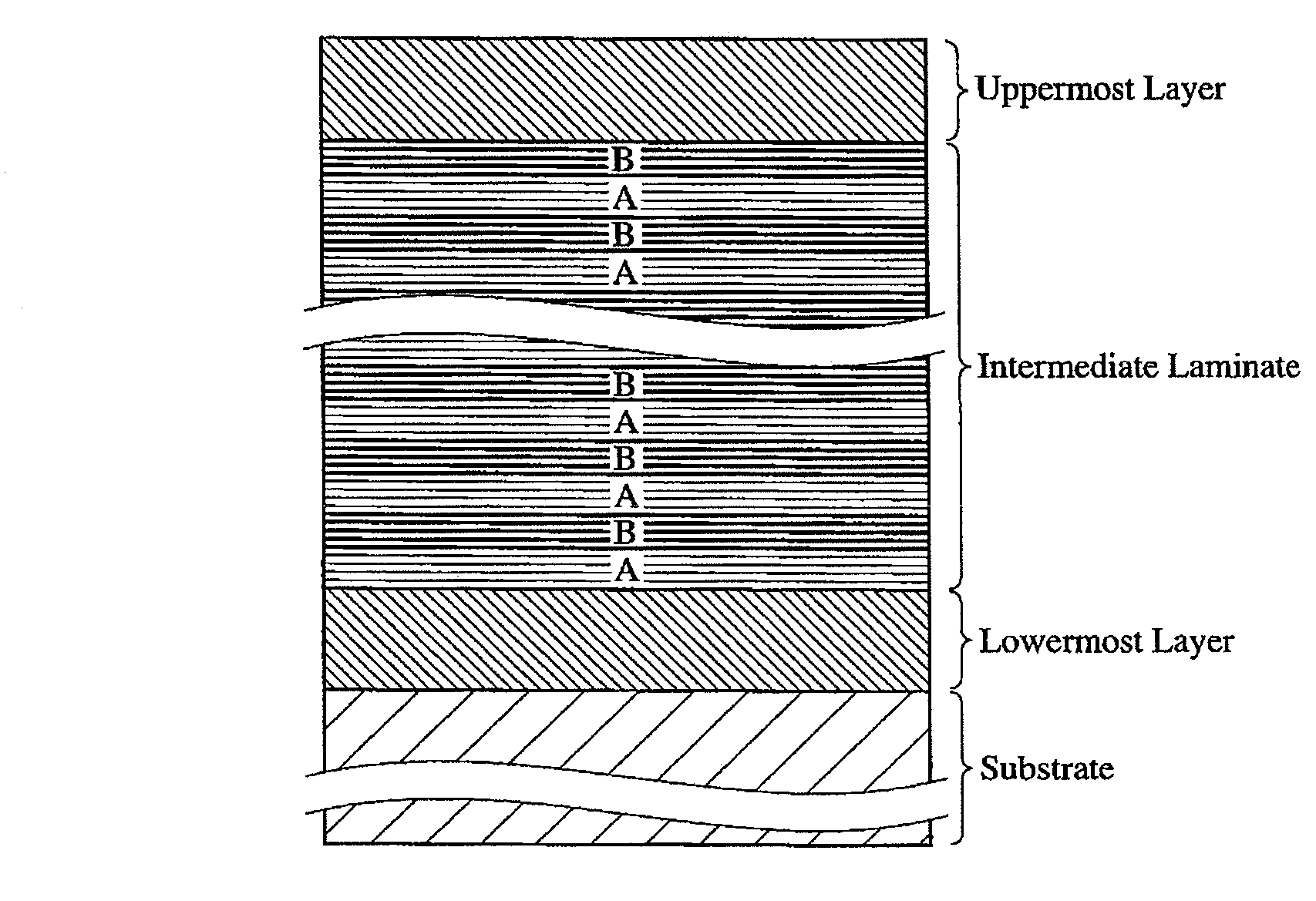

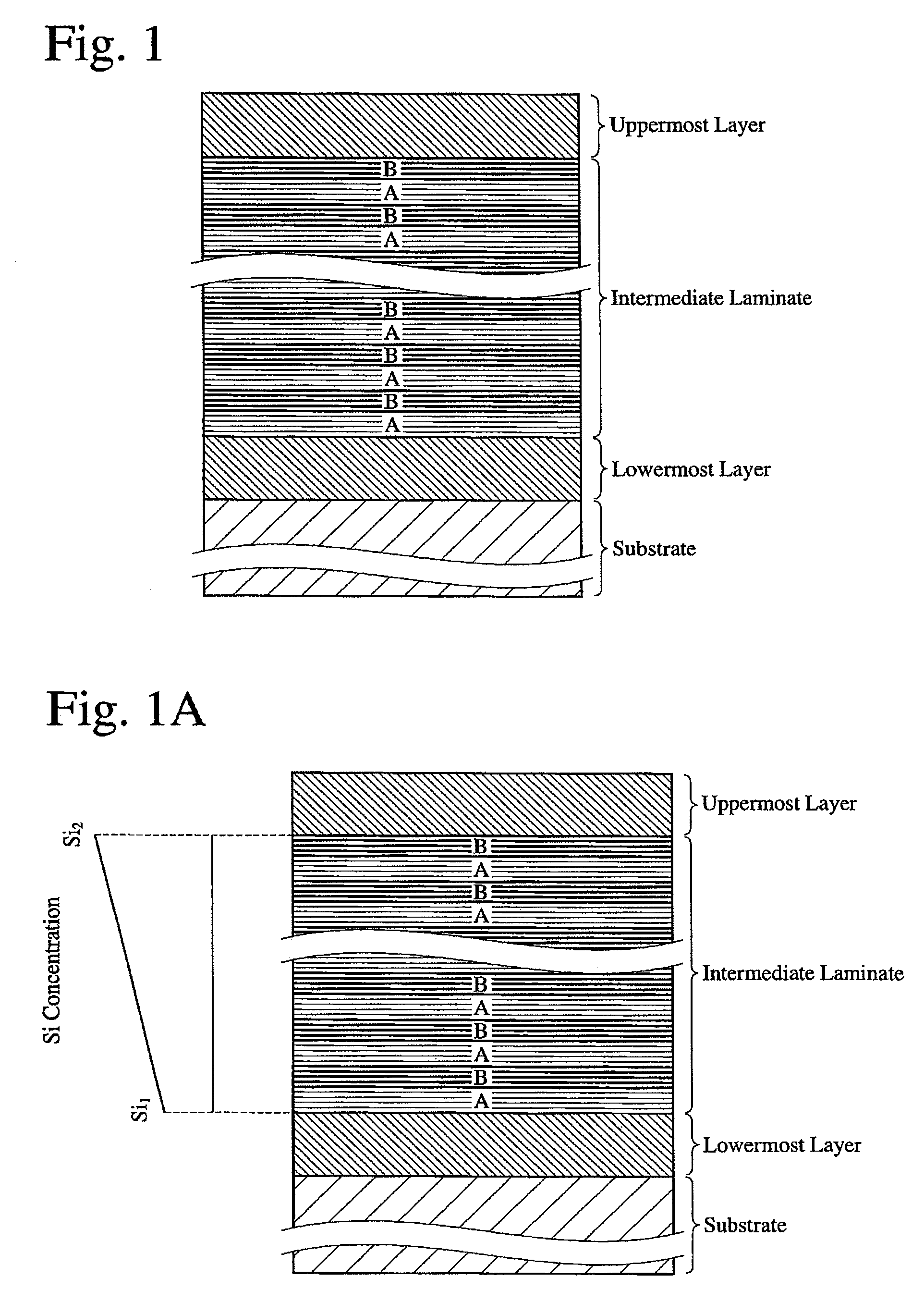

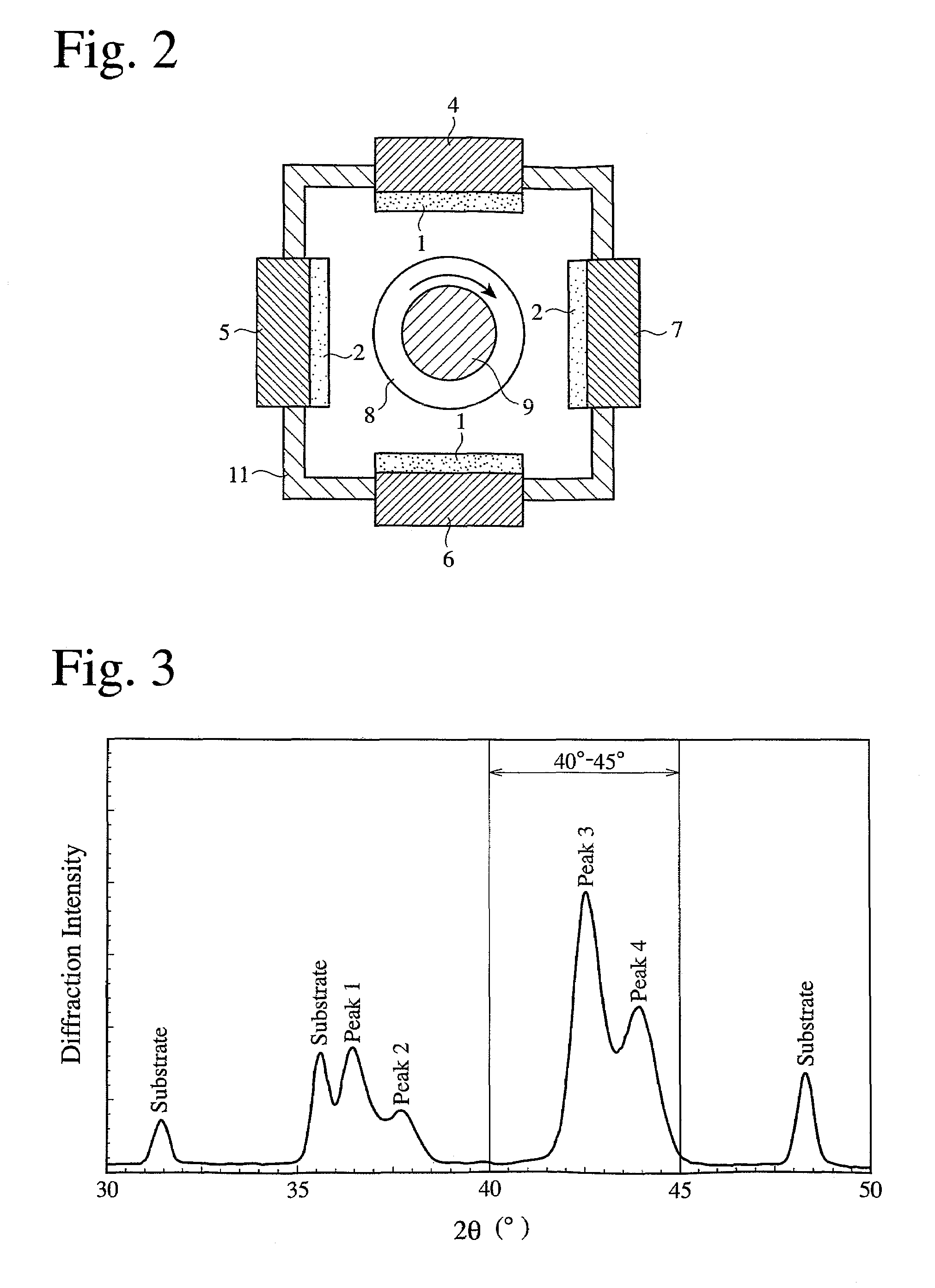

A hard-coated member comprising a hard coating comprising a lowermost layer, an intermediate laminate and an uppermost layer on a substrate, the intermediate laminate being constituted by alternately laminated layers A and layers B having different compositions, the layers A and the layers B being respectively made of at least one selected from the group consisting of nitrides, borides, carbides and oxides of metal components having compositions represented by the formula of AlWCrXTiYSiZ, wherein W, X, Y and Z respectively represent atomic % of Al, Cr, Ti and Si, W+X+Y+Z=100, and these combinations, the layers A meeting the condition of 70<=W+X<100, the layers B meeting the condition of 30<=Y<100, and the uppermost layer being made of at least one selected from the group consisting of nitrides, carbides, sulfides and borides of Ti or Ti and Si and these combinations, or at least one selected from the group consisting of nitrides, carbides, sulfides and borides of Cr or Cr and Si and these combinations.

Owner:HITACHI TOOL ENG LTD

Lithium iron phosphate anode material and its preparing method

InactiveCN1767238AImprove conductivityHigh tap densityElectrode manufacturing processesCalcium/strontium/barium compoundsBorideAlcohol

The invention relates to ferric phosphate lithium anode material and its preparing method, which relates to a cell anode material, especially to a ferric phosphate lithium anode material used in lithium ion cell second time. It provides a cell anode material and ití»s preparing method which can elevate the LiFePO4 conductivity and tap density at the same time. It is formed by ferric phosphate lithium and calcium boride (by weight rate): ferric phosphate lithium: calcium boride=100í† (1.01- 5.26). It first syntheses pure ferric phosphate lithium: it balls the ferrous salt, microcosmic salt and lithium salt by alcohol grease, heats the mixed material and uses inactive gas as preserving gas. It balls the synthesis ferric phosphate lithium anode and calcium boride, burns the mixed material and adds inactive gas as preserving gas to obtain the object product.

Owner:河南天科科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com