Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1006results about How to "Control quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

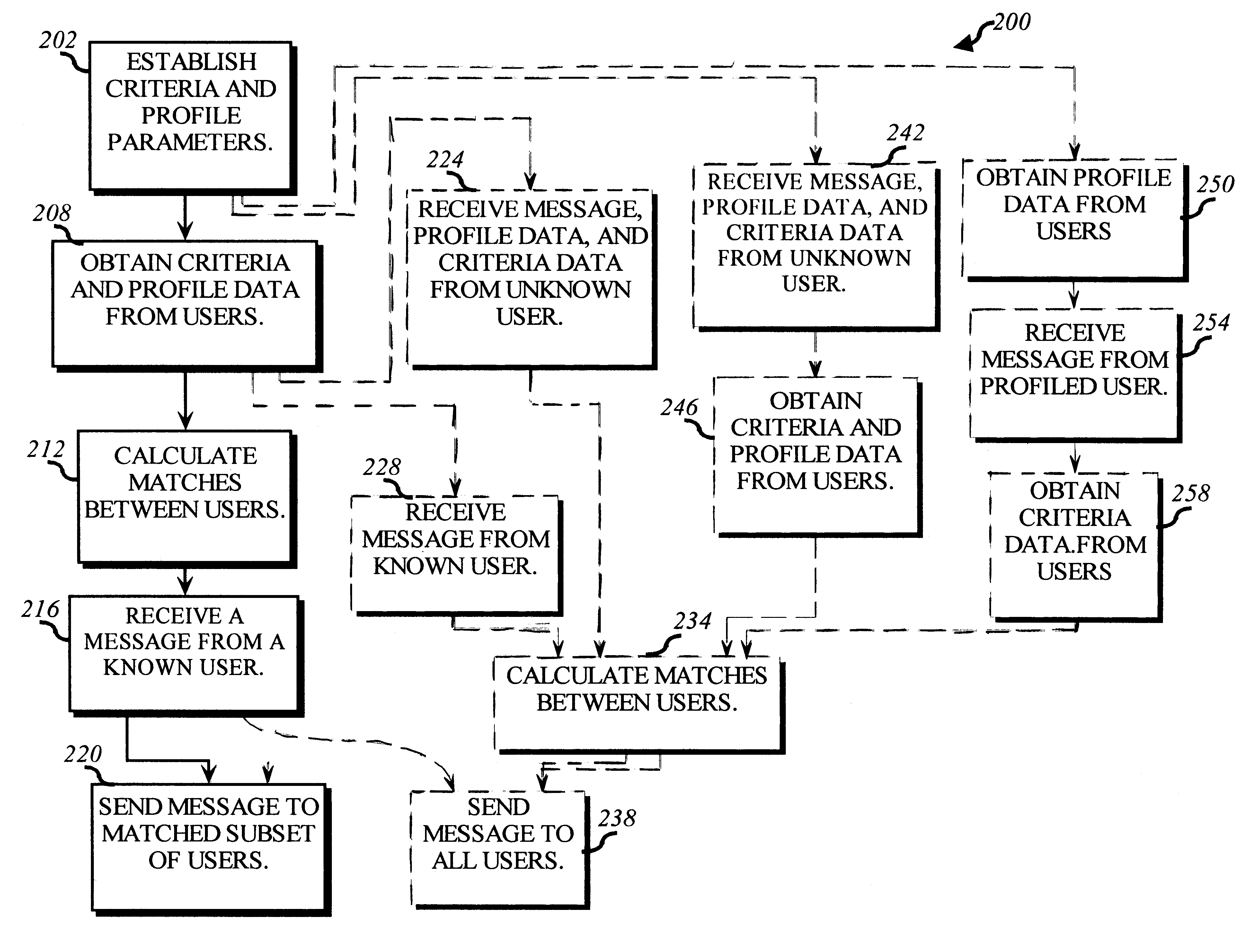

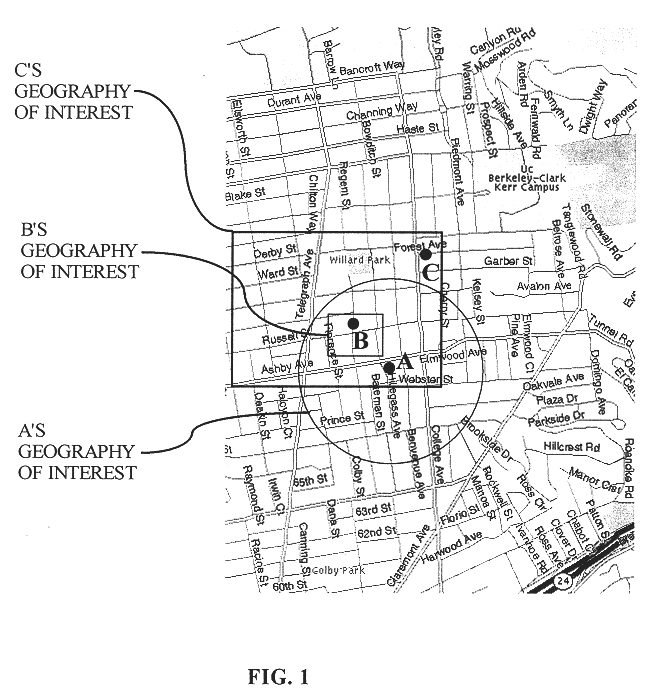

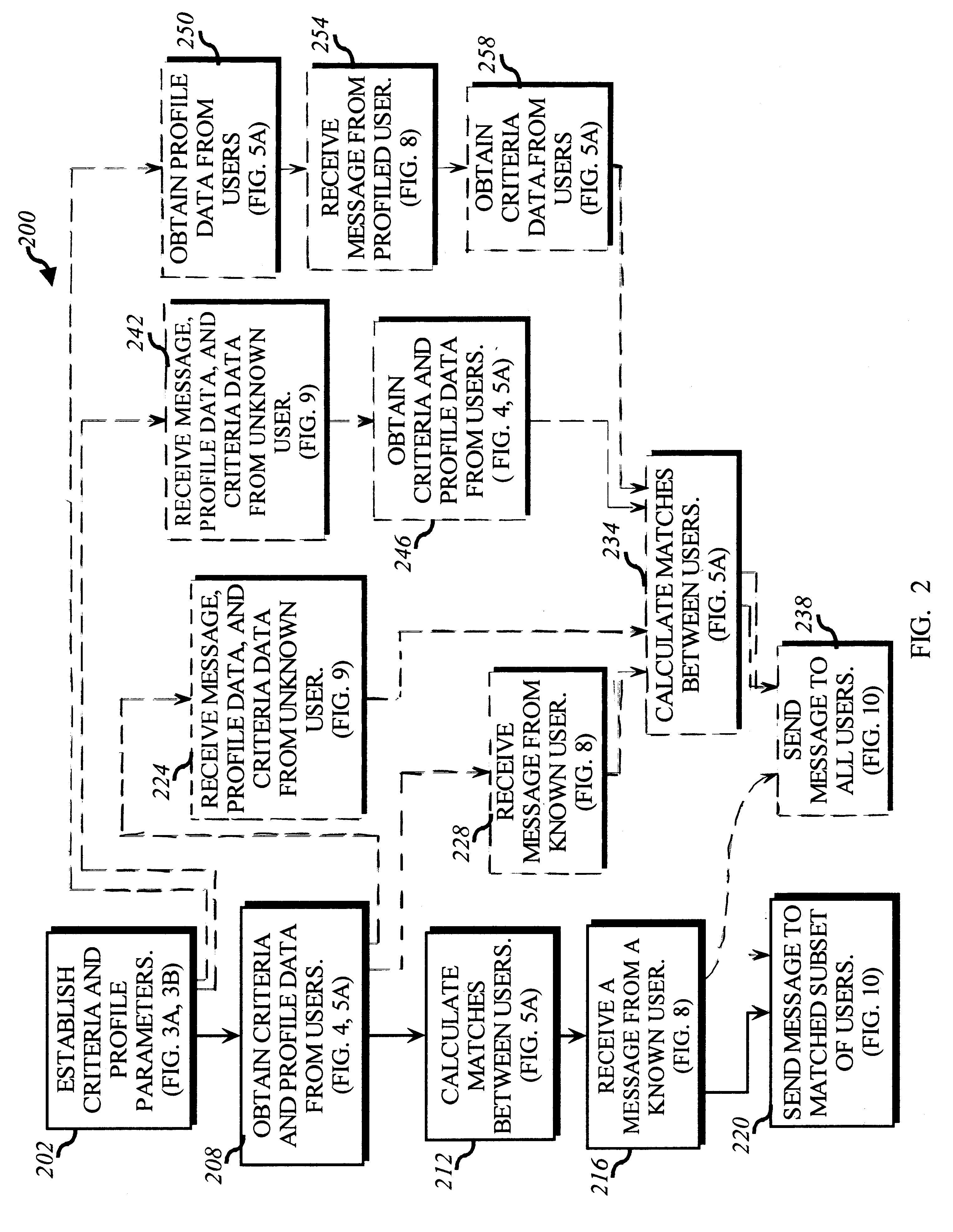

Dynamically matching users for group communications based on a threshold degree of matching of sender and recipient predetermined acceptance criteria

InactiveUS6480885B1Quality of communicationReduce in quantitySpecial service provision for substationMultiprogramming arrangementsPersonalizationWeb service

A method for enabling users to exchange group electronic mail by establishing individual profiles and criteria, for determining personalized subsets within a group. Users establish subscriptions to an electronic mailing list by specifying user profile data and acceptance criteria data to screen other users. When a user subscribes, a web server establishes and stores an individualized recipient list including each matching subscriber and their degree of one-way or mutual match with the user. When the user then sends a message to the mailing list, an email server retrieves 100% her matches and then optionally filters her recipient list down to a message distribution list using each recipient's message criteria. The message is then distributed to matching users. Additionally, email archives and information contributions from users are stored in a database. A web server creates an individualized set of web pages for a user from the database, containing contributions only from users in his recipient list. In other embodiments, users apply one-way or mutual criteria matching and message profile criteria to other group forums, such as web-based discussion boards, chat, online clubs, USENET newsgroups, voicemail, instant messaging, web browsing side channel communities, and online gaming rendezvous.

Owner:TUMBLEWEED HLDG LLC

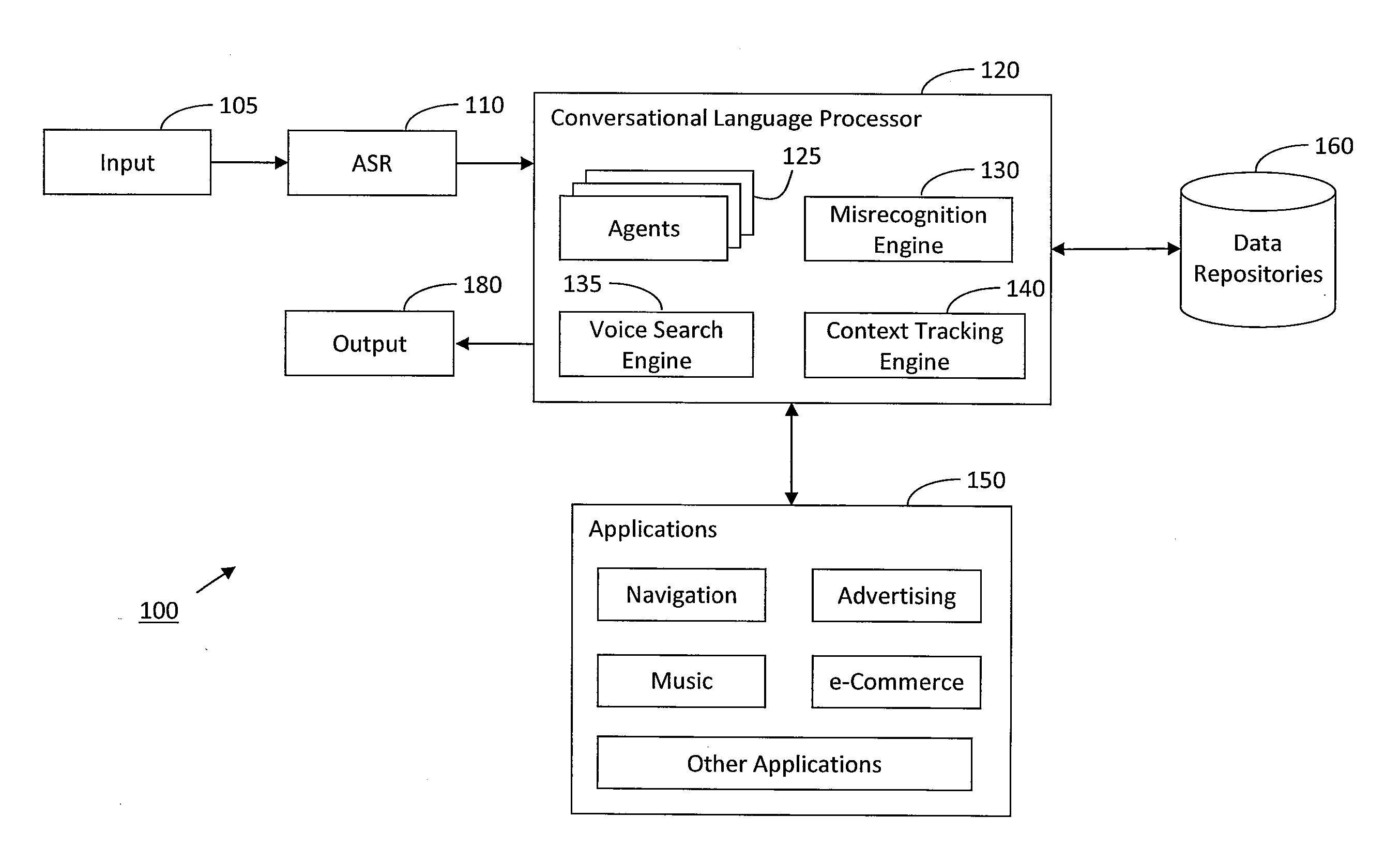

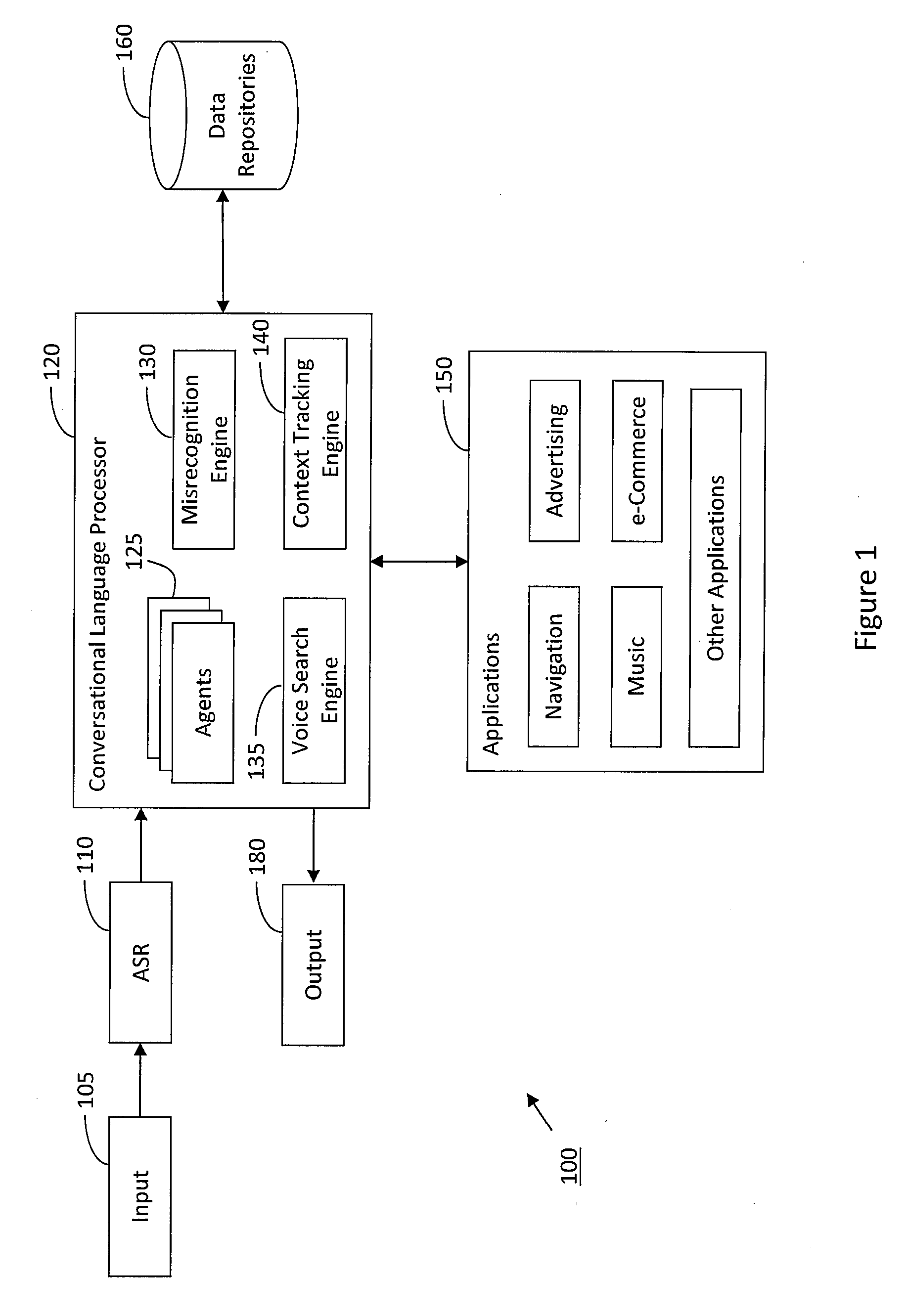

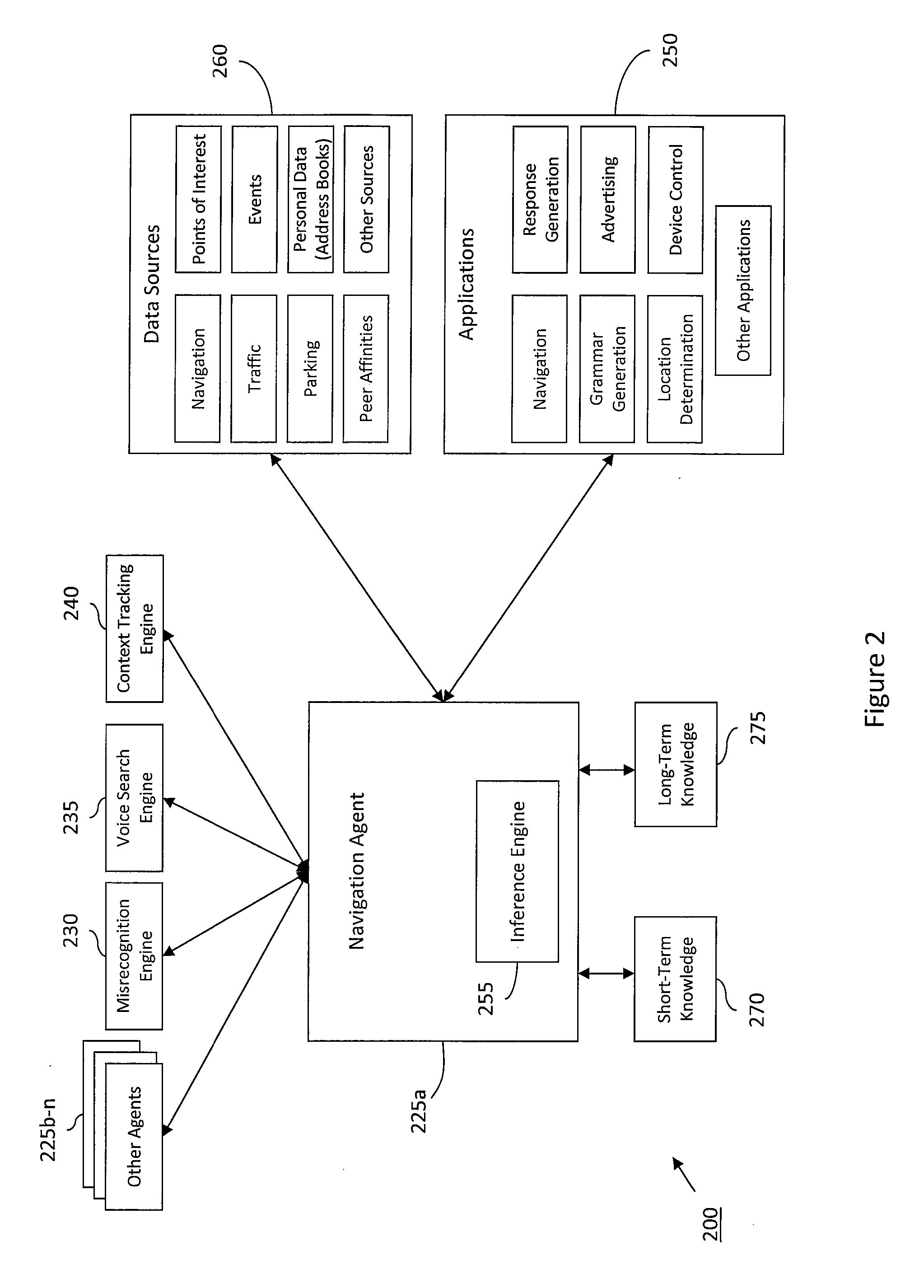

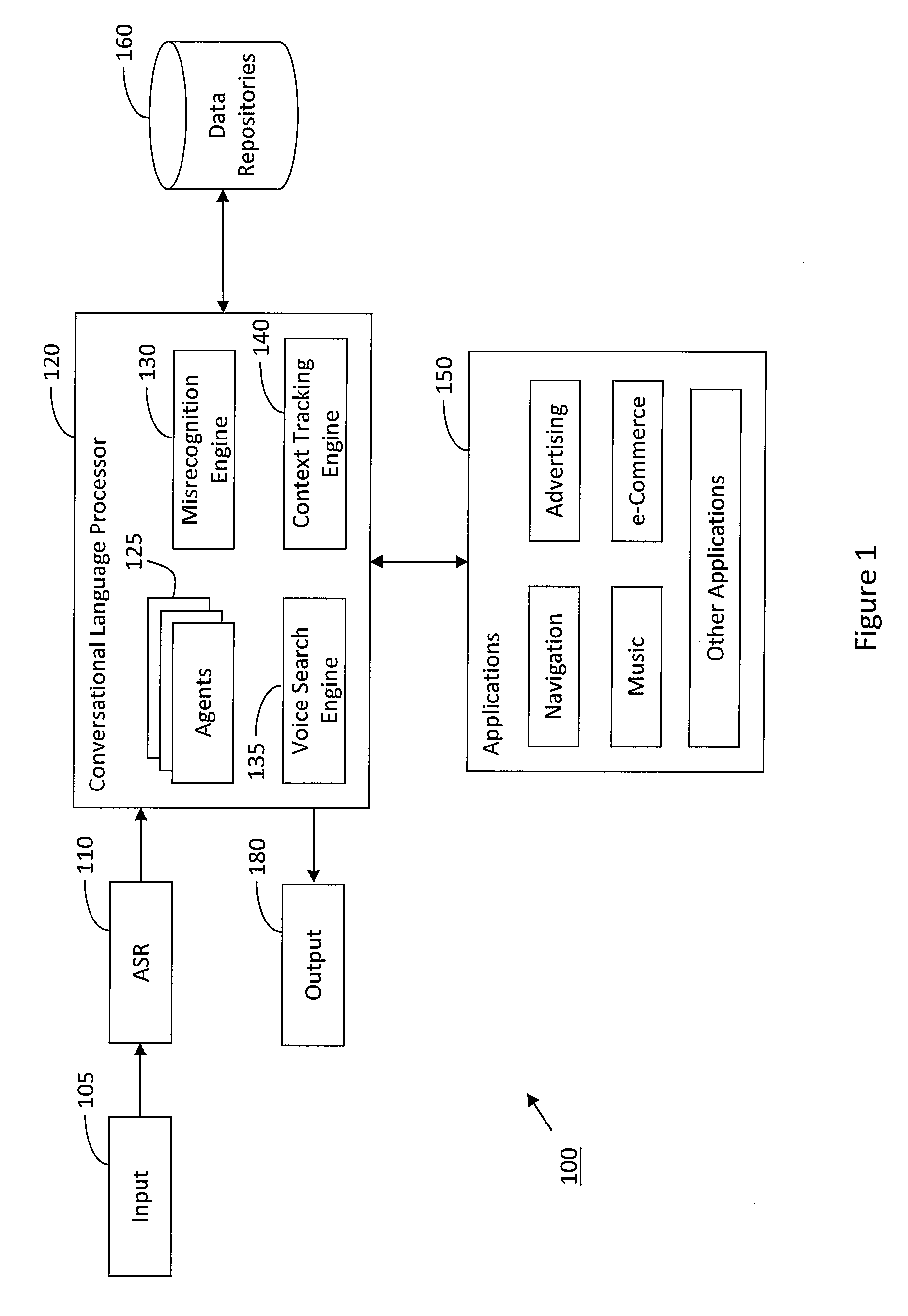

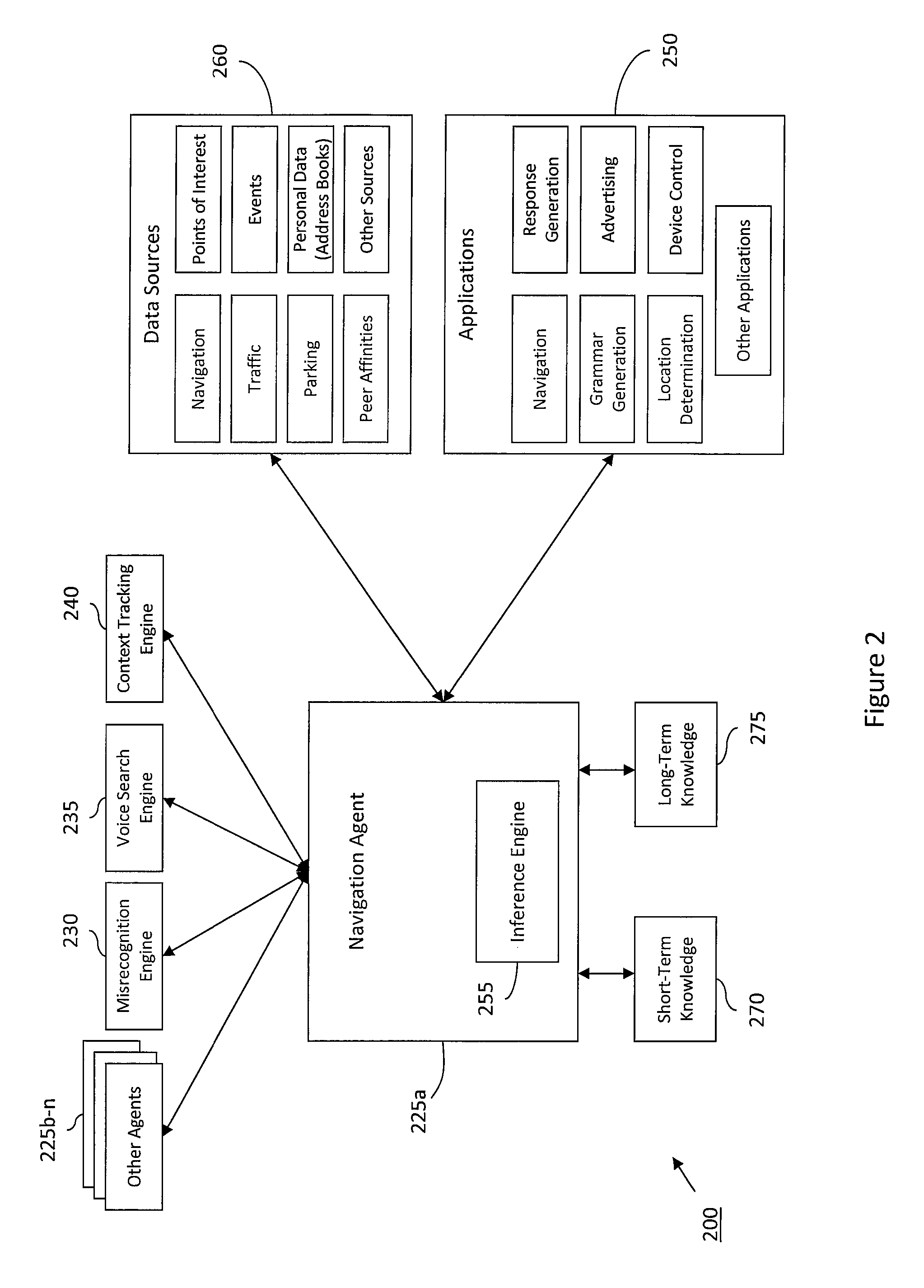

System and method for providing a natural language voice user interface in an integrated voice navigation services environment

ActiveUS20090150156A1Reduce in quantityIncrease volumeNavigation instrumentsSpeech recognitionSpeech soundMarine navigation

A conversational, natural language voice user interface may provide an integrated voice navigation services environment. The voice user interface may enable a user to make natural language requests relating to various navigation services, and further, may interact with the user in a cooperative, conversational dialogue to resolve the requests. Through dynamic awareness of context, available sources of information, domain knowledge, user behavior and preferences, and external systems and devices, among other things, the voice user interface may provide an integrated environment in which the user can speak conversationally, using natural language, to issue queries, commands, or other requests relating to the navigation services provided in the environment.

Owner:VOICEBOX TECH INC

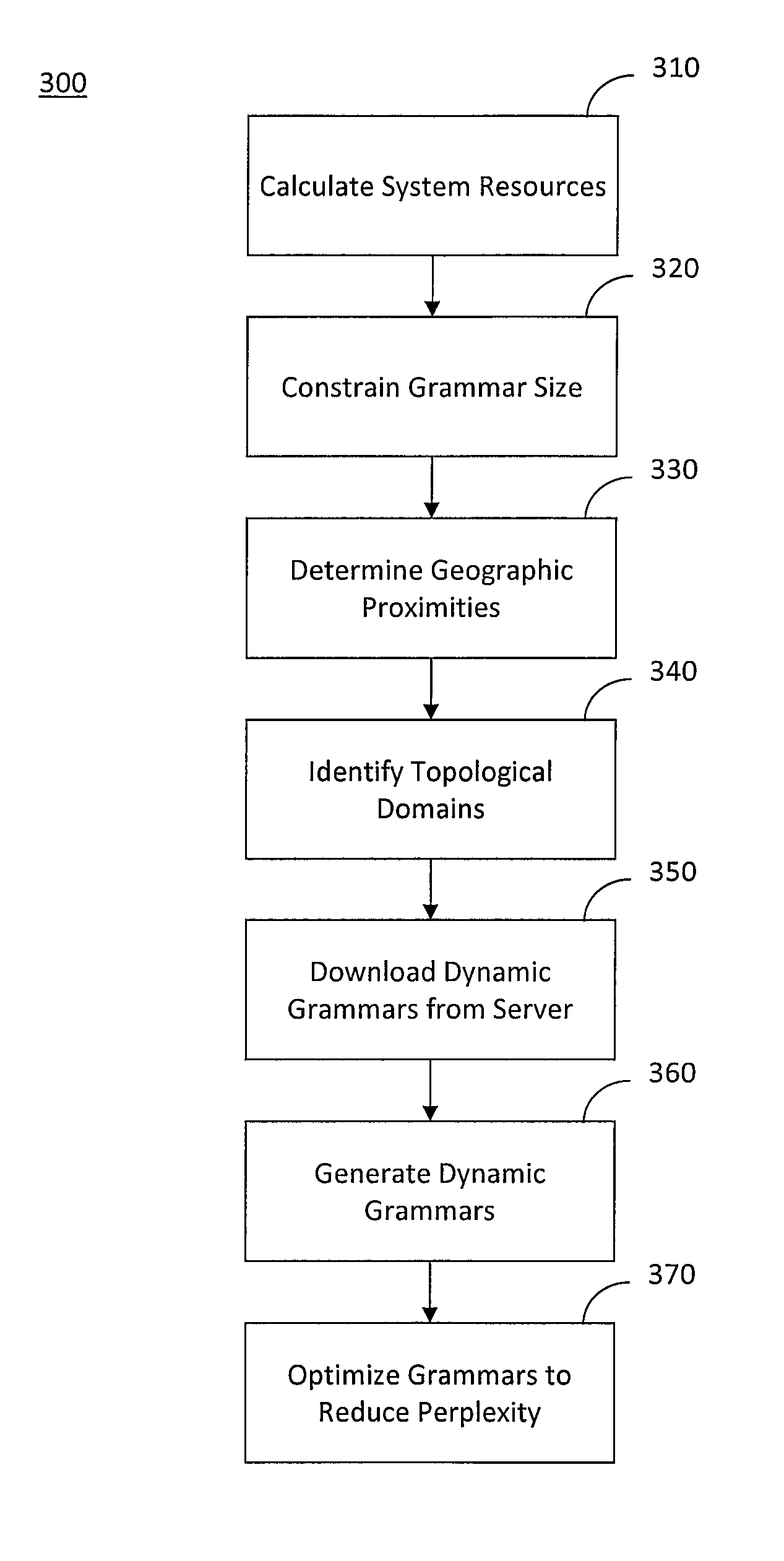

System and method for providing a natural language voice user interface in an integrated voice navigation services environment

ActiveUS8140335B2Efficient loadingAvoid processing bottlenecksNavigation instrumentsSpeech recognitionSpeech soundMarine navigation

A conversational, natural language voice user interface may provide an integrated voice navigation services environment. The voice user interface may enable a user to make natural language requests relating to various navigation services, and further, may interact with the user in a cooperative, conversational dialogue to resolve the requests. Through dynamic awareness of context, available sources of information, domain knowledge, user behavior and preferences, and external systems and devices, among other things, the voice user interface may provide an integrated environment in which the user can speak conversationally, using natural language, to issue queries, commands, or other requests relating to the navigation services provided in the environment.

Owner:VOICEBOX TECH INC

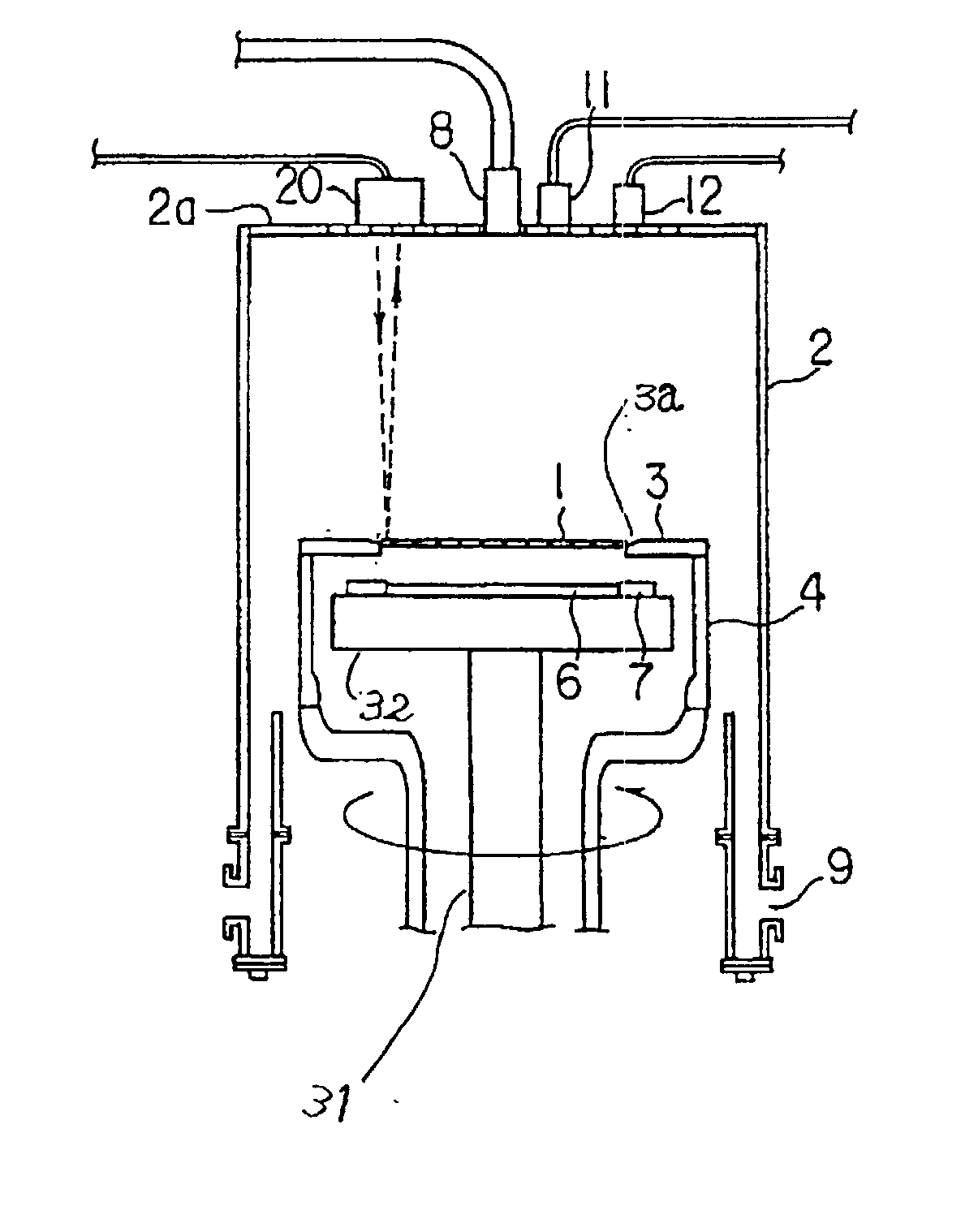

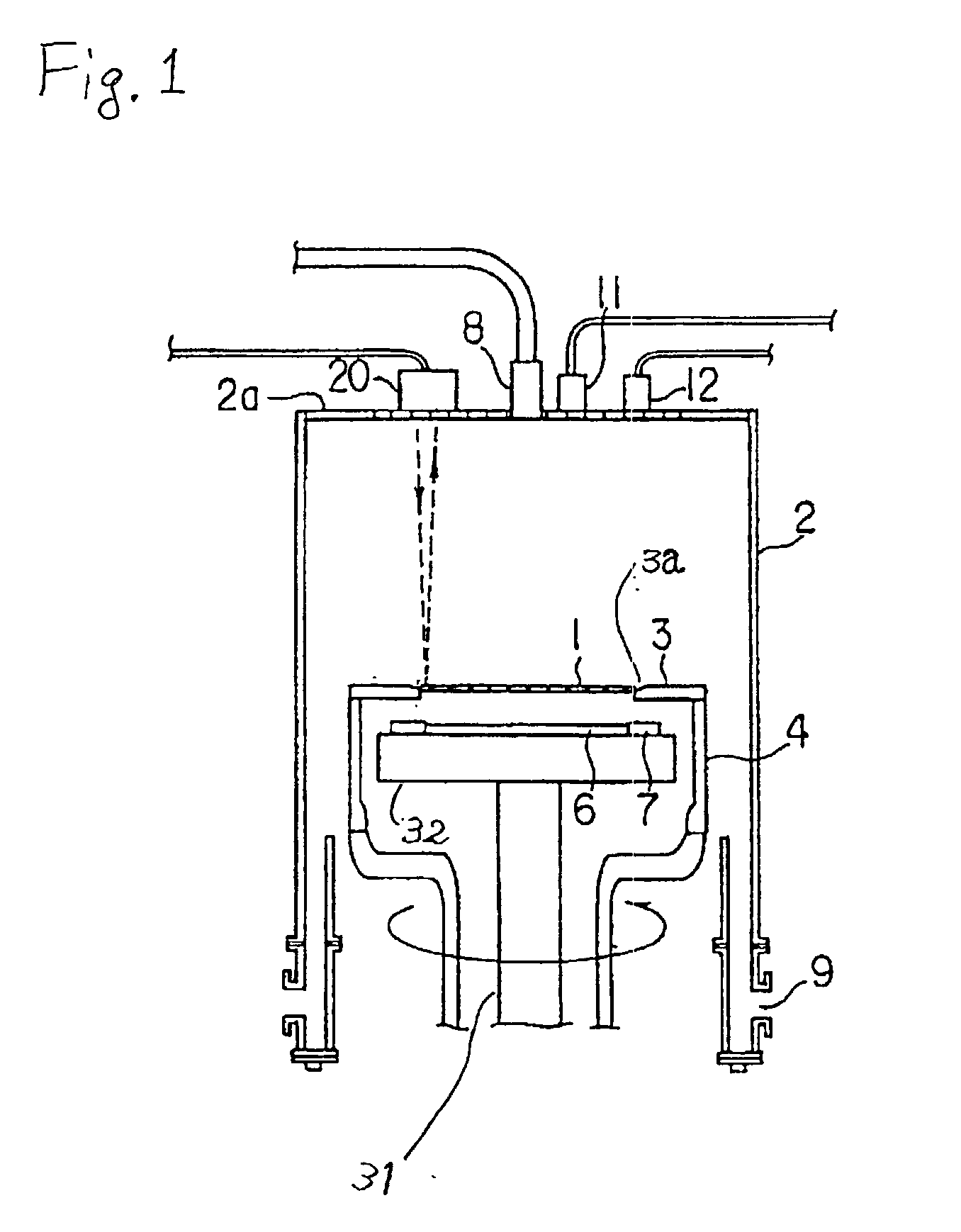

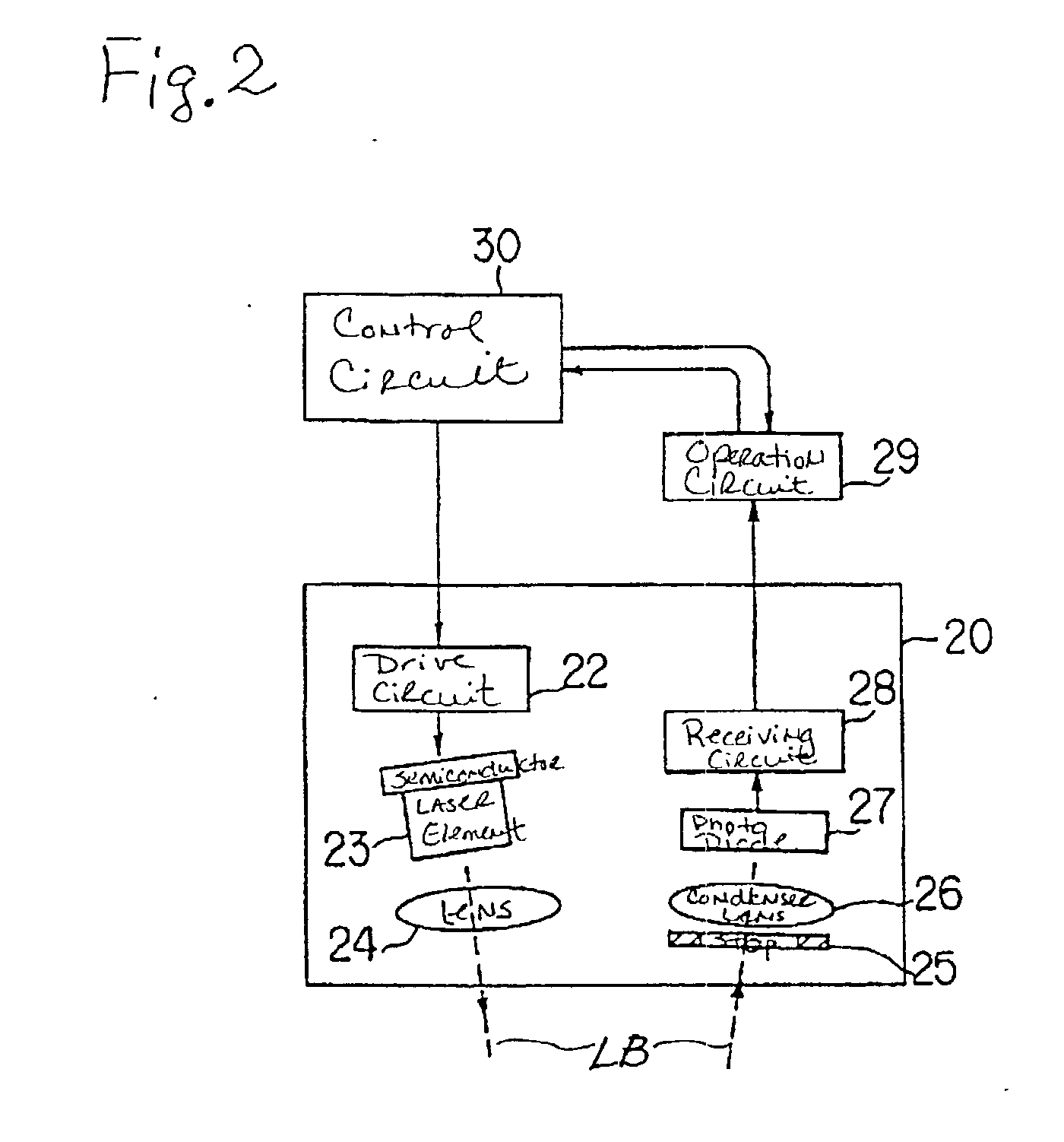

Method and apparatus for detecting a wafer's posture on a susceptor

InactiveUS20030042419A1Improve accuracyControl quantityRadiation pyrometryMaterial analysis by optical meansWaferingSusceptor

An apparatus used for an epitaxial vapor growing arrangement and for detecting whether a wafer is properly seated within a susceptor contained therein. The apparatus includes a semiconductor laser element that generates a laser beam which irradiates the wafer's surface. The apparatus, further, includes a combination of a stop mechanism, a condenser lens and a photo diode, which detects the laser beam reflected from the wafer surface and an operation circuit, which determines the wafer's posture on the susceptor. During operation, the reflected laser beam focuses on a receiving surface of the photo diode through the condenser lens. The operation circuit then compares the output signal from the photo diode with a preset reference value for discriminating the slope of the wafer.

Owner:TOSHIBA MASCH CO LTD

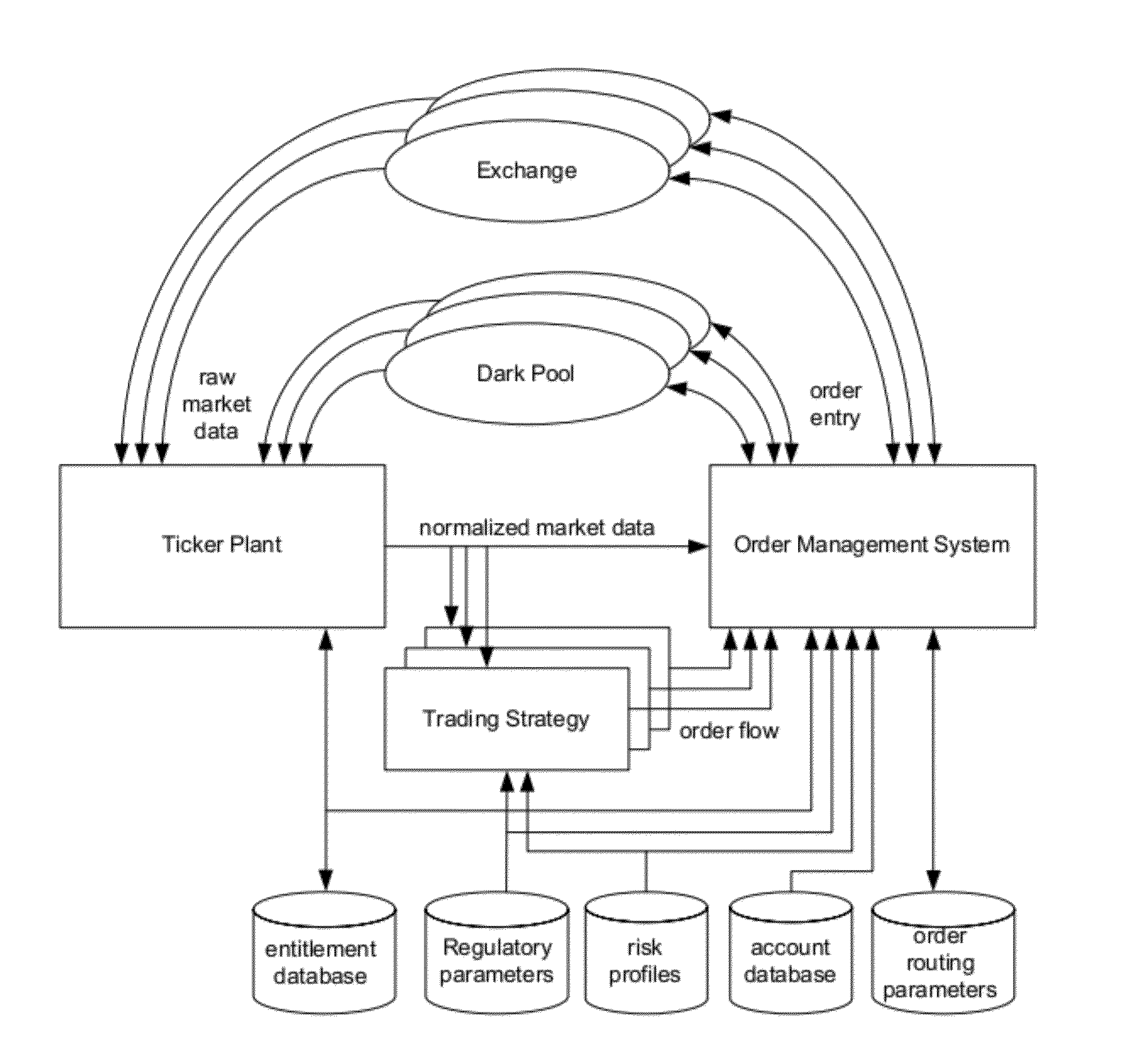

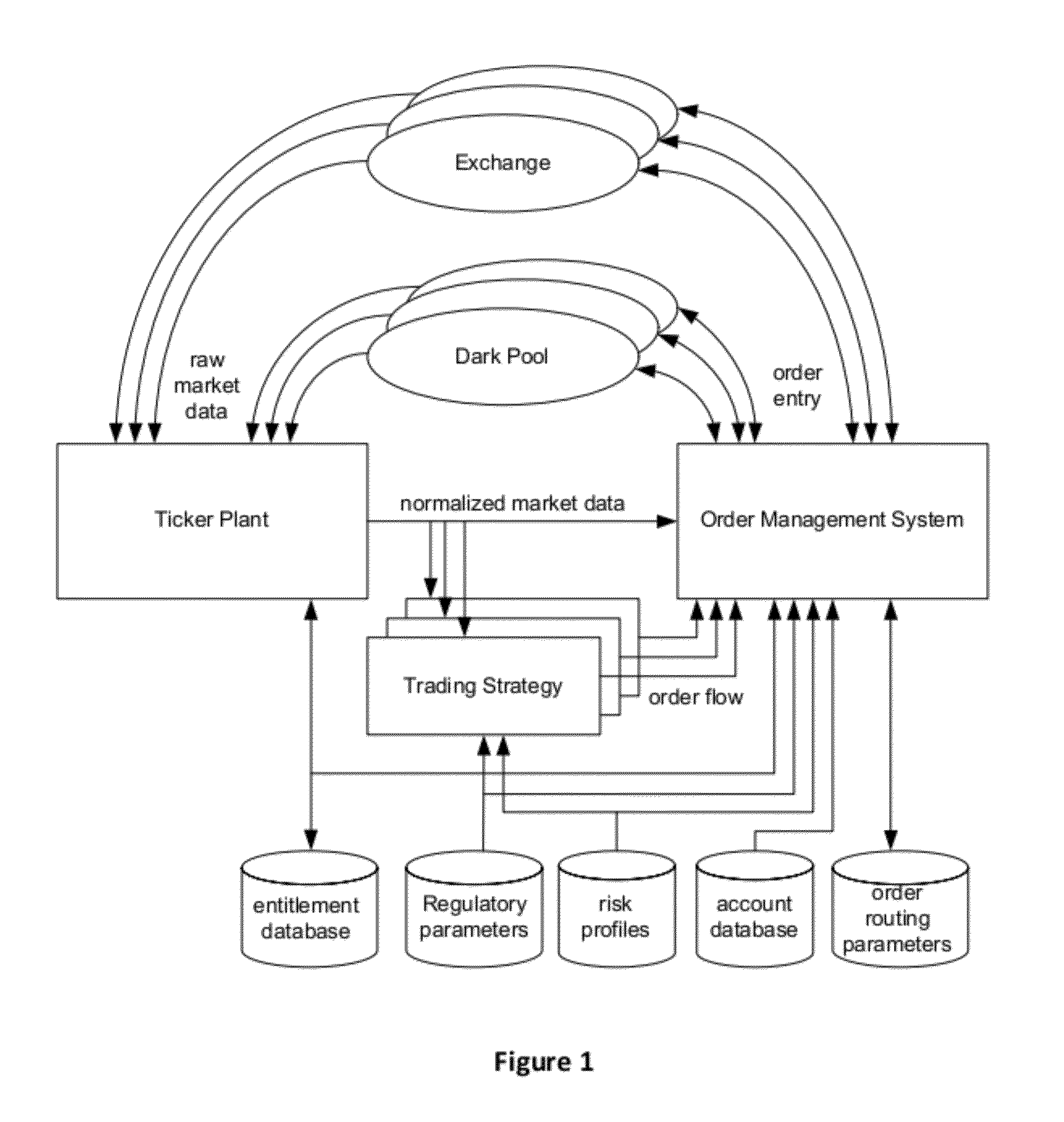

Method and Apparatus for Managing Orders in Financial Markets

ActiveUS20120246052A1Reduce and eliminate opportunityLimited opportunityFinanceLatency (engineering)Engineering

An integrated order management engine is disclosed that reduces the latency associated with managing multiple orders to buy or sell a plurality of financial instruments. Also disclosed is an integrated trading platform that provides low latency communications between various platform components. Such an integrated trading platform may include a trading strategy offload engine.

Owner:EXEGY INC

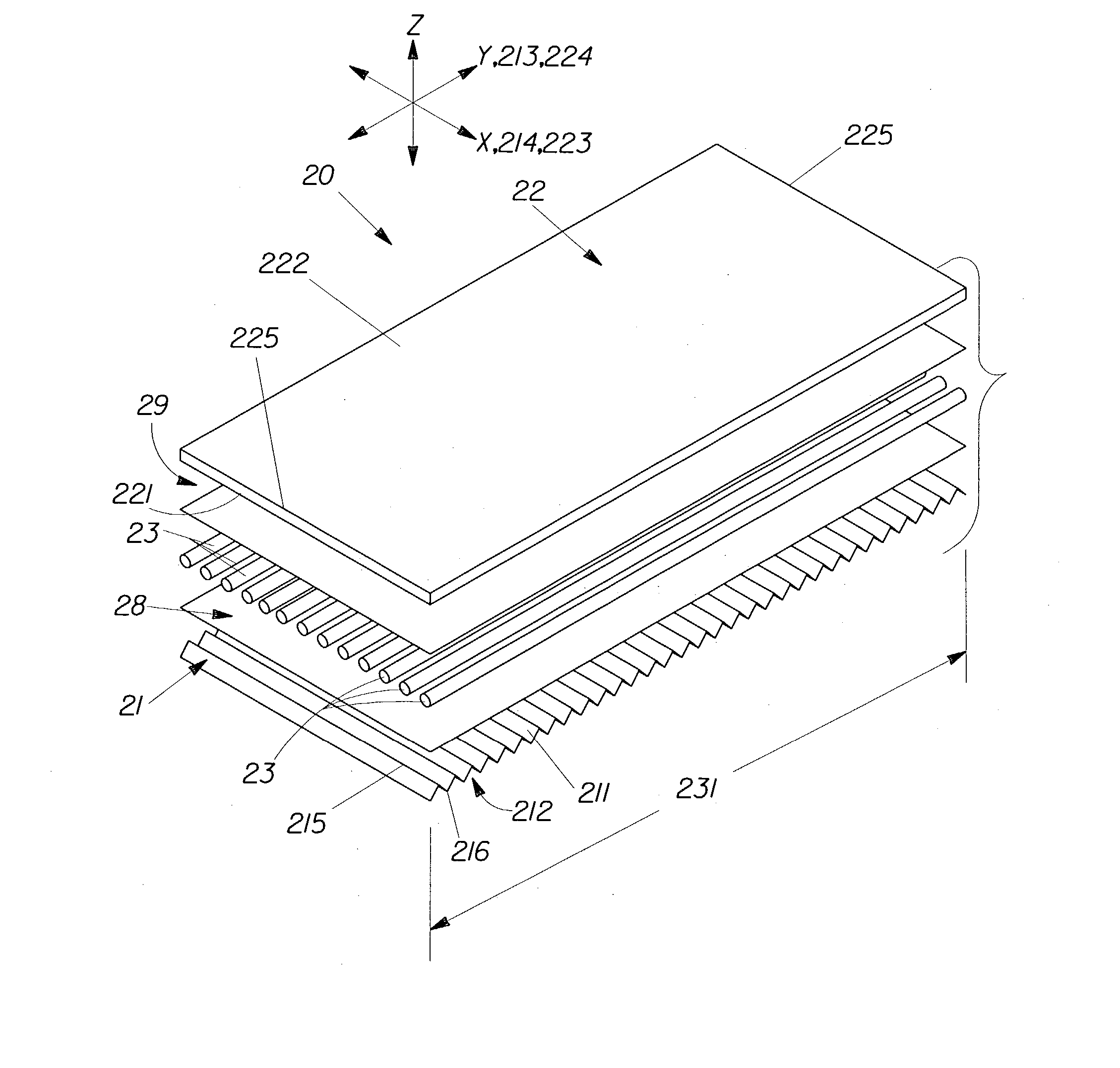

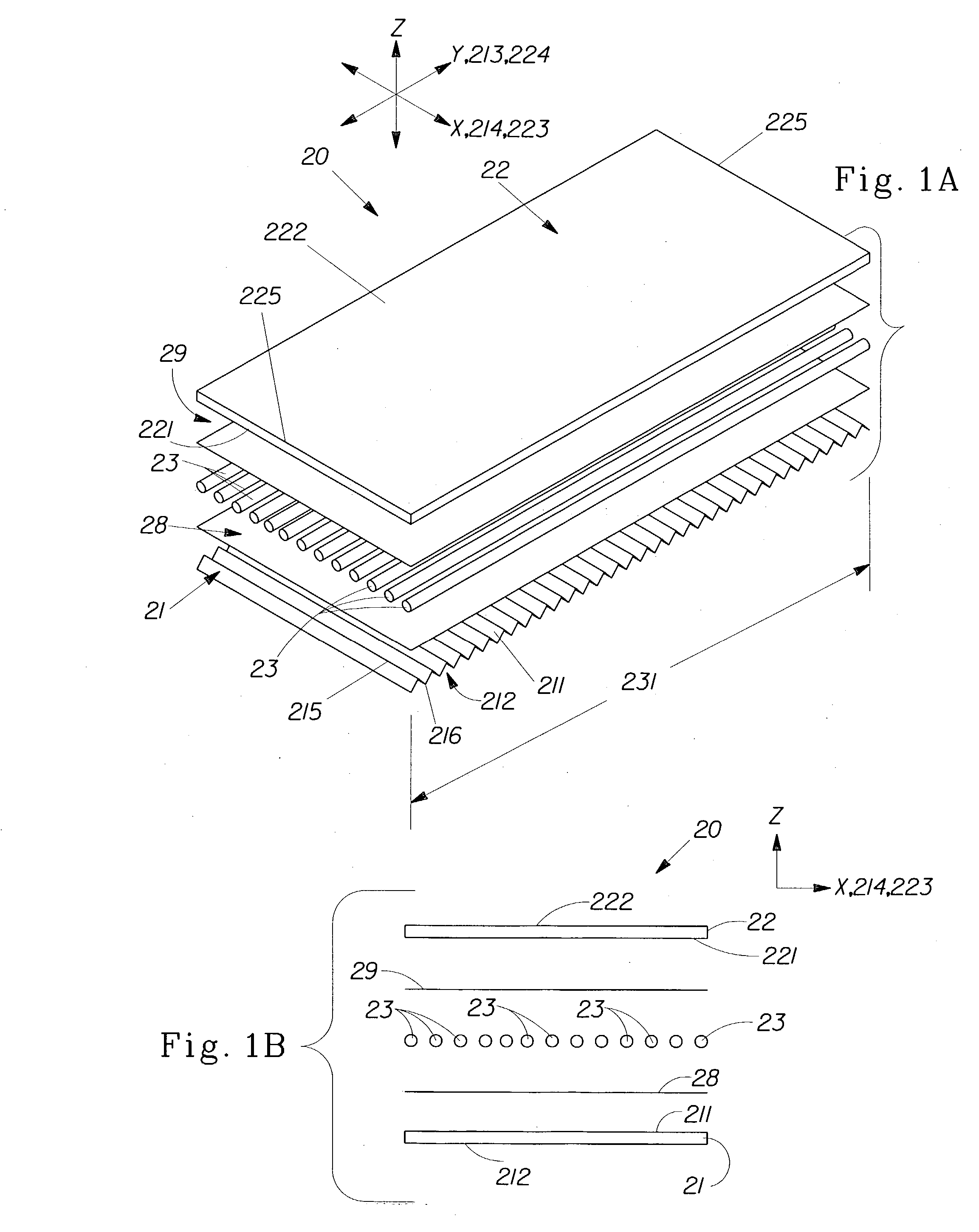

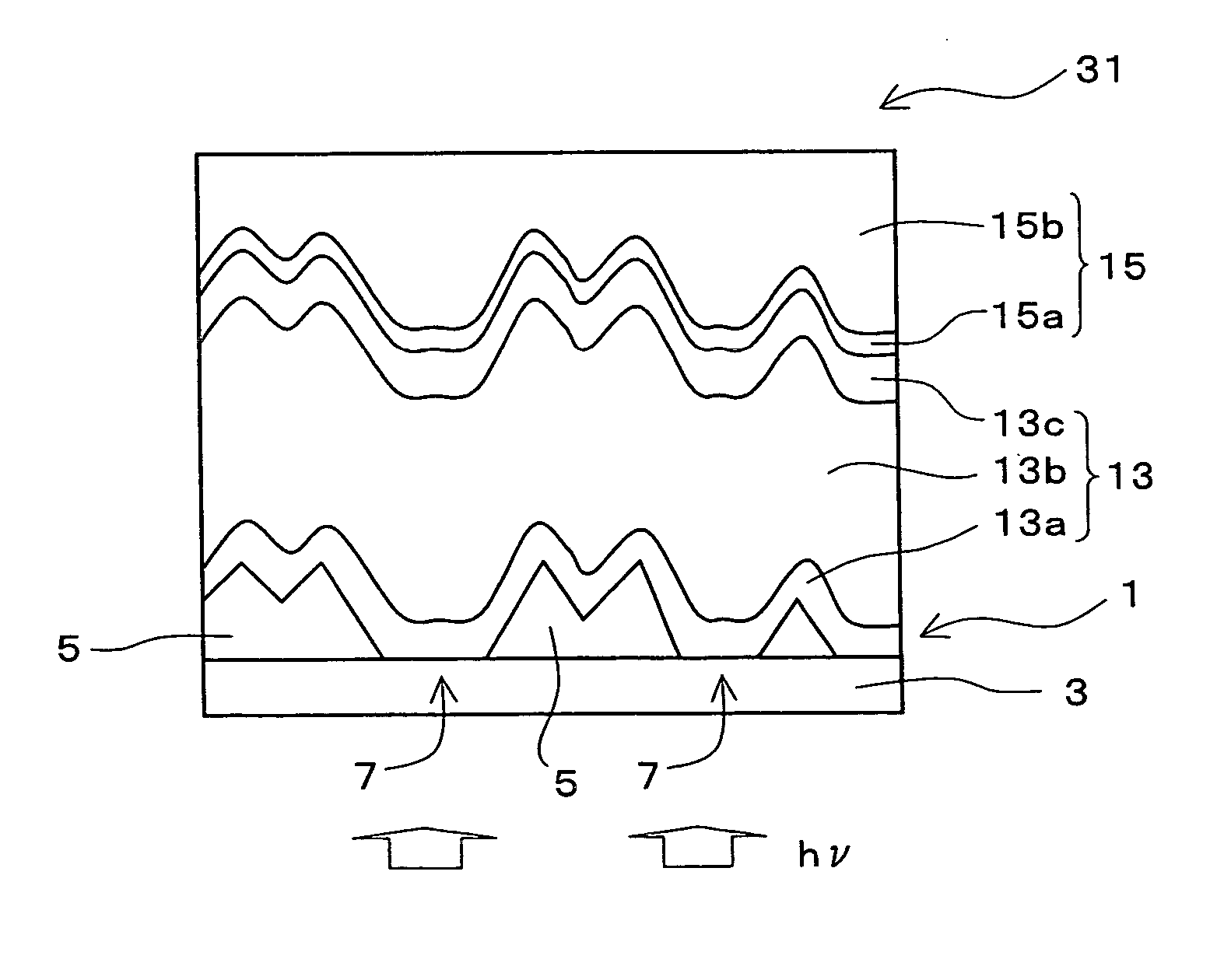

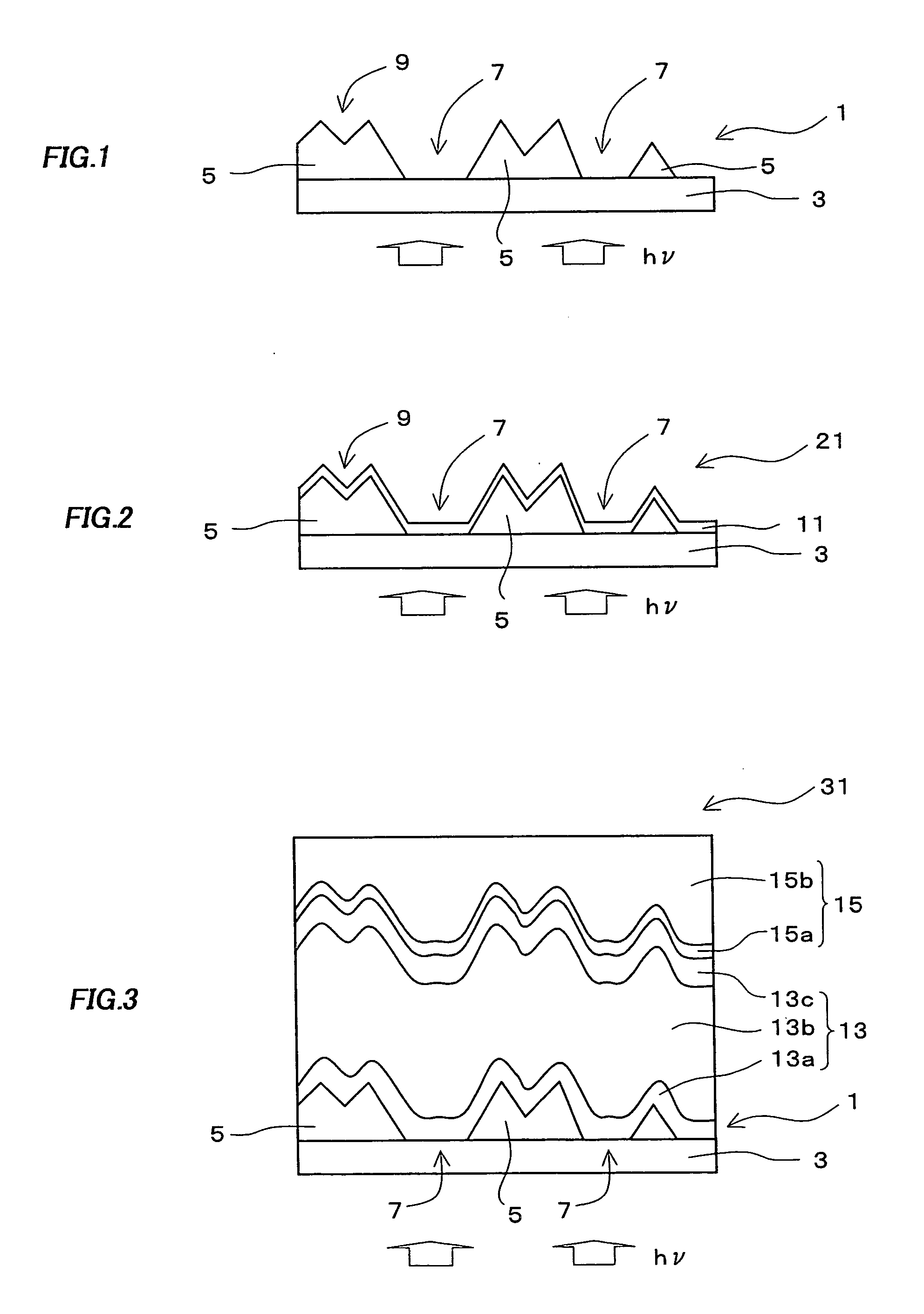

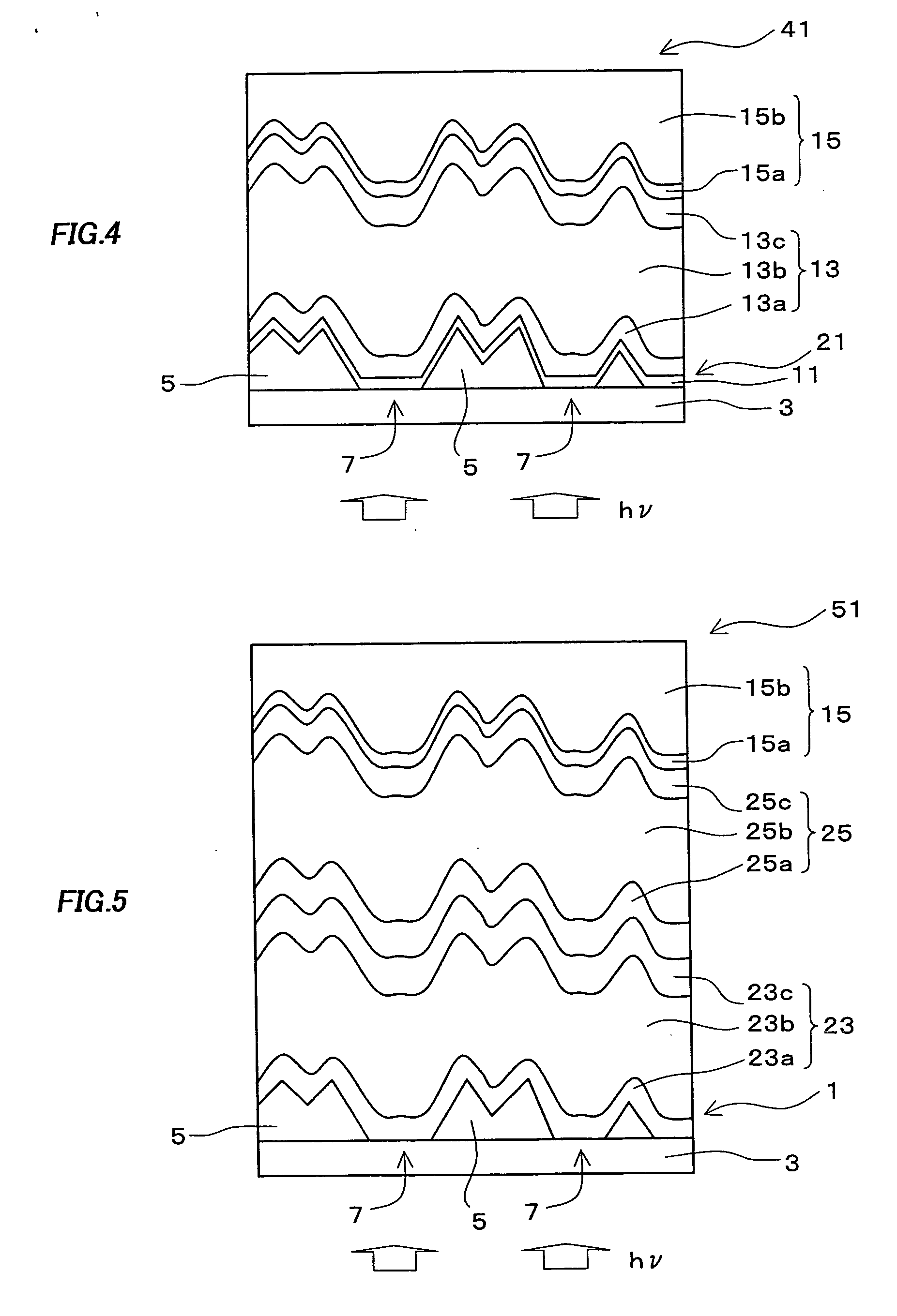

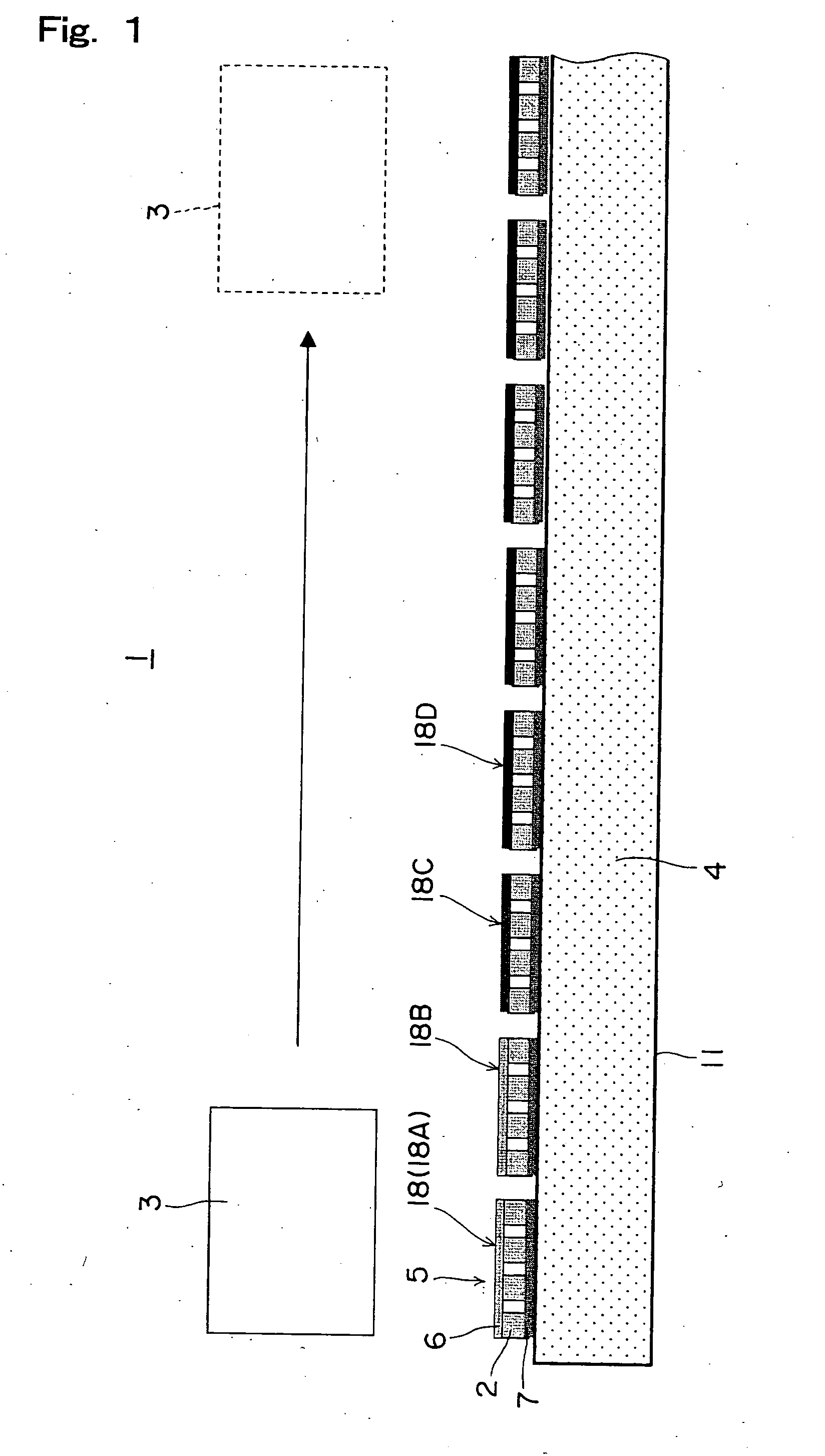

Substrate for photoelectric conversion device, photoelectric conversion device, and stacked photoelectric conversion device

InactiveUS20070151596A1High light transmittanceSpeed up the conversion processPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversion

A substrate 1 for a photoelectric conversion device includes a first transparent conductive layer 5 formed on at least a part of the surface region of a transparent substrate 3, the first transparent conductive layer 5 having at least an opening portion 7 exposing the substrate 3.

Owner:SHARP KK

Antimicrobial articles

InactiveUS20050249791A1Promote migrationEliminate the problemBiocideAdhesive dressingsWound dressingSurgical tape

An antimicrobial article is disclosed comprising a layer of a thermoplastic polymer, and an adhesive layer having a antimicrobial agent dispersed therein. The antimicrobial article is useful, for example, surgical tapes, surgical drapes and wound dressings, and as disposable surfaces for food preparation and handling.

Owner:3M INNOVATIVE PROPERTIES CO

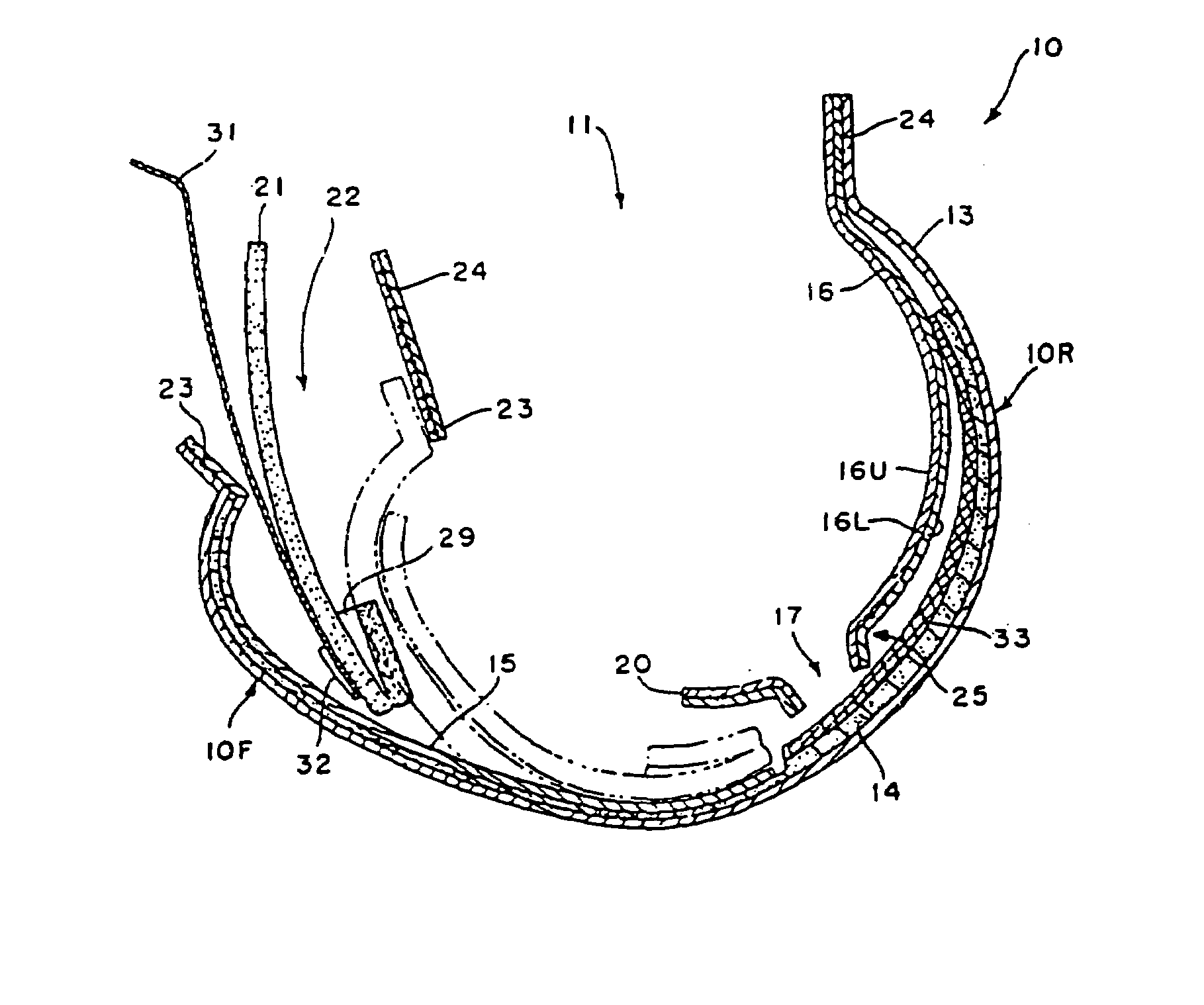

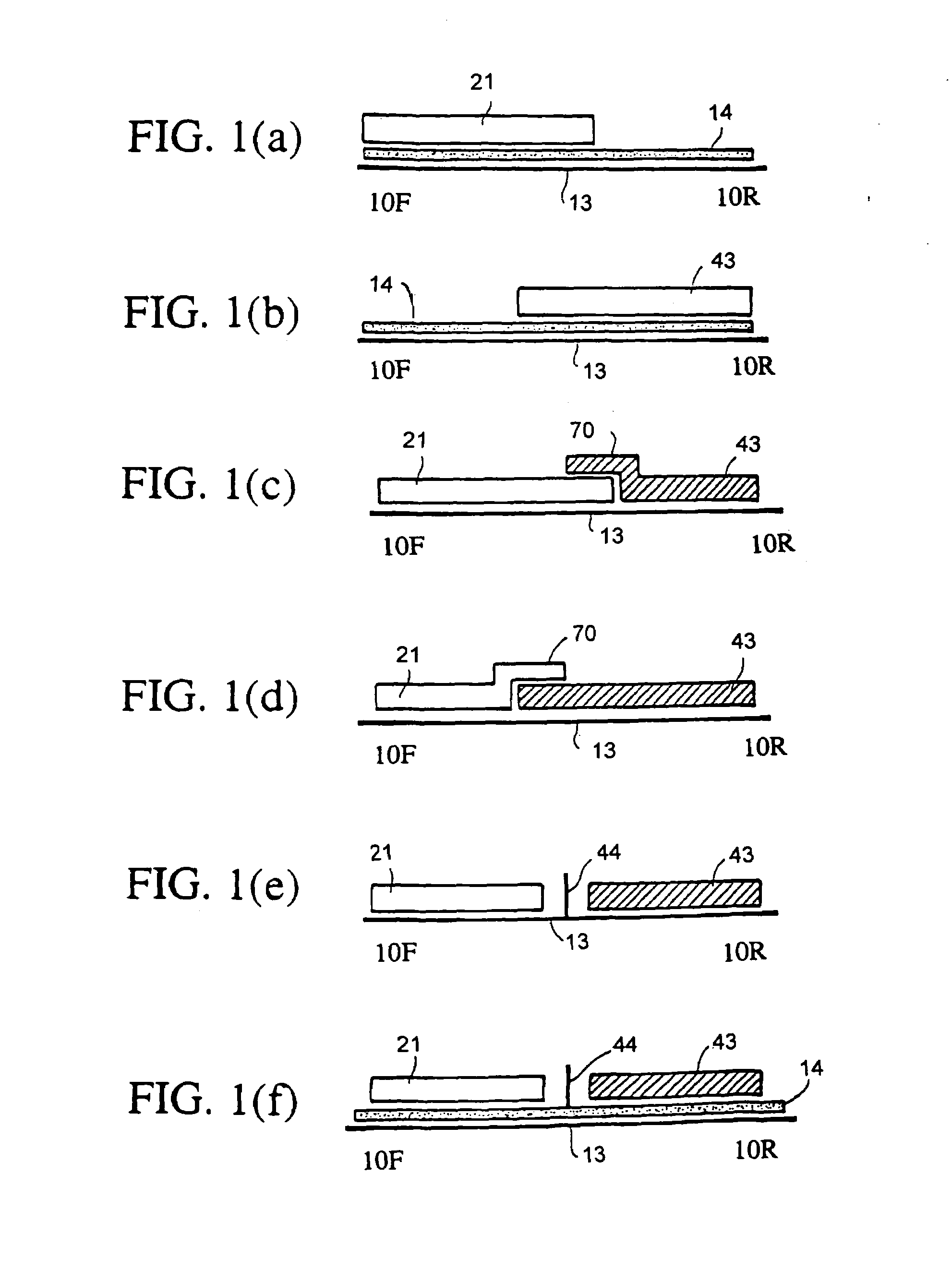

Absorptive product having removable absorbers

An absorptive product comprising a front region, a rear region, a crotch region, a waist opening, a pair of leg openings, and a liquid-impermeable back sheet. Disposed interiorly of the back sheet are a front absorber and a rear absorber. An access port is provided for taking out and / or replacing at least one of these absorbers.

Owner:PROCTER & GAMBLE CO

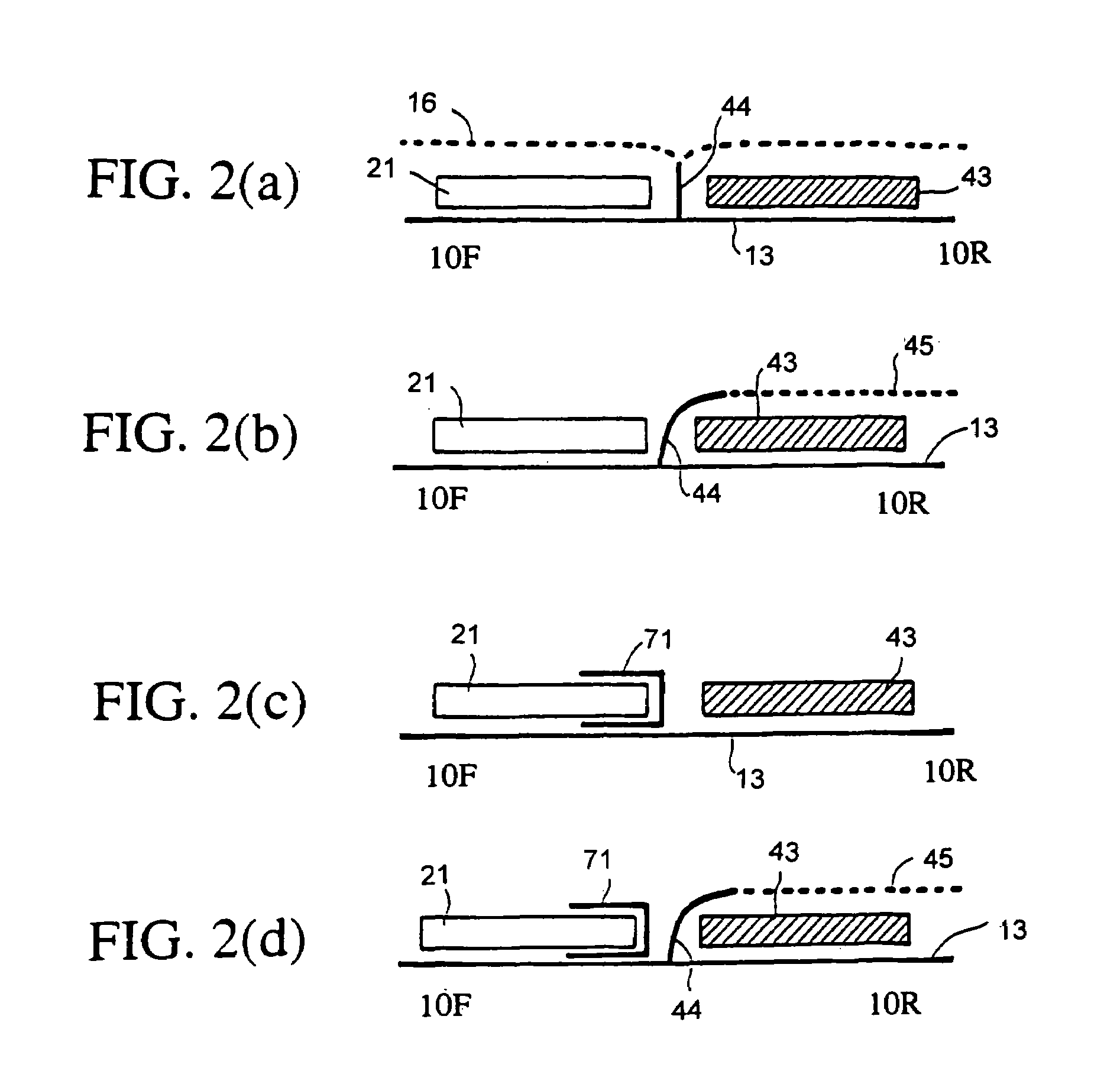

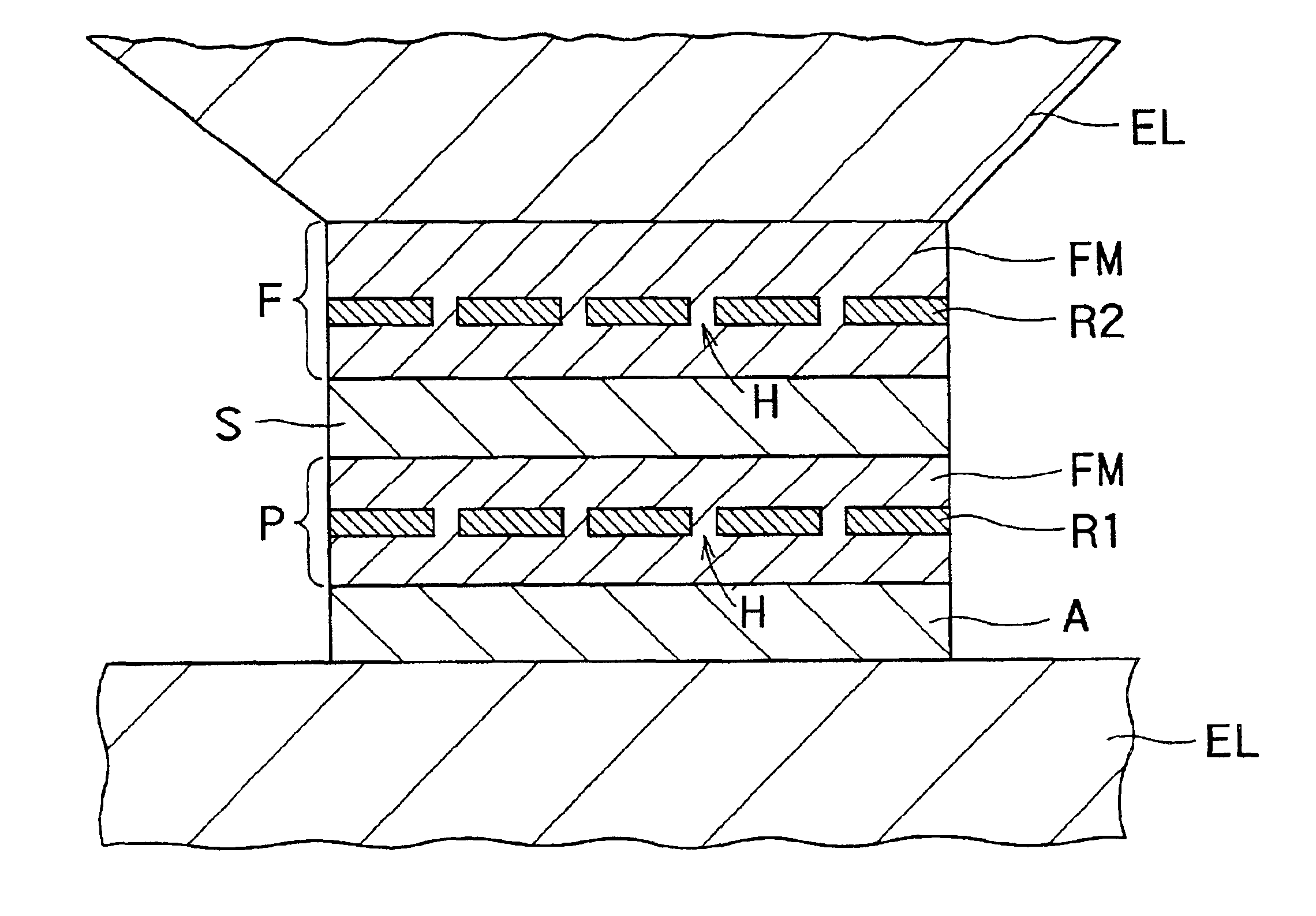

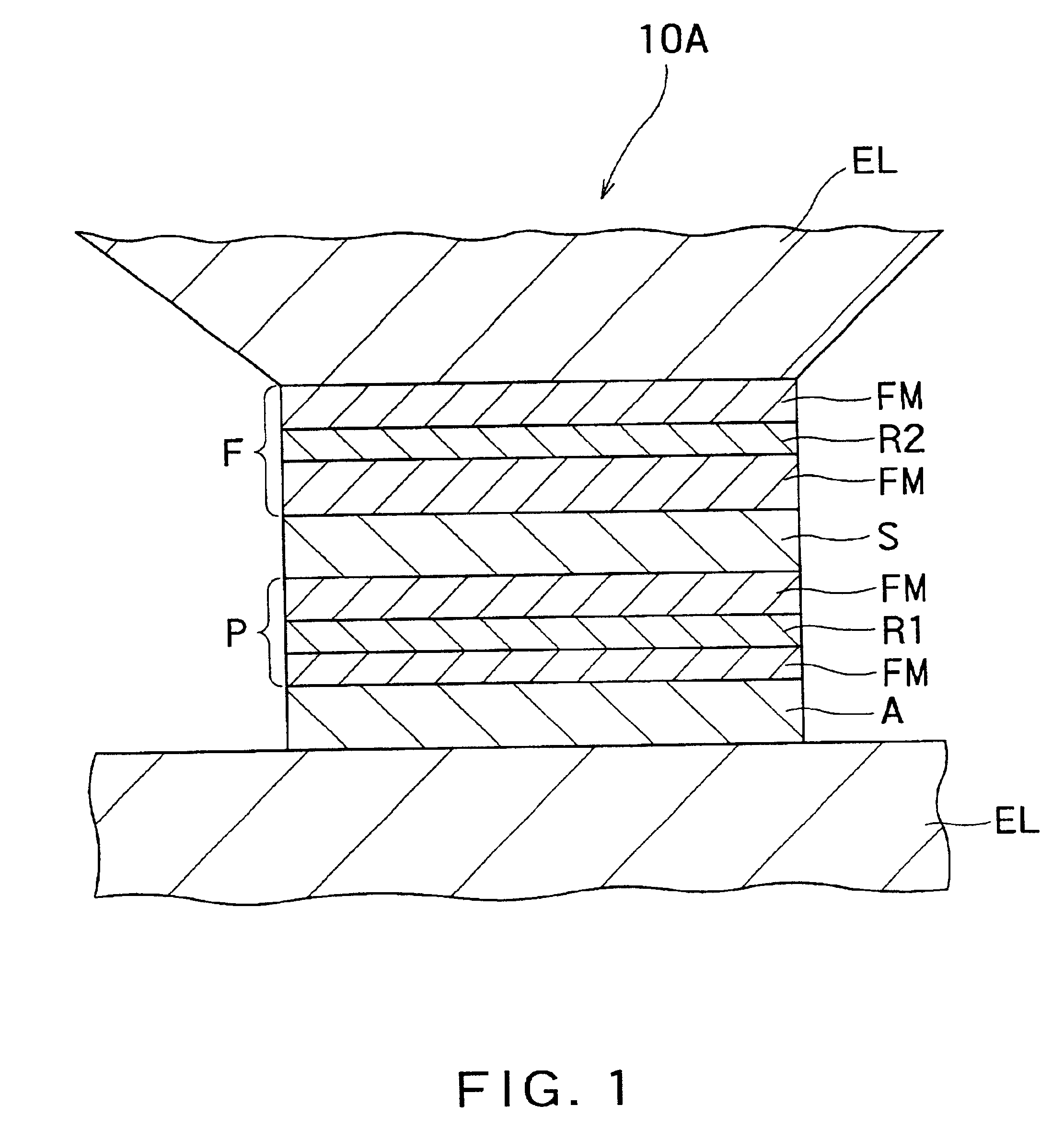

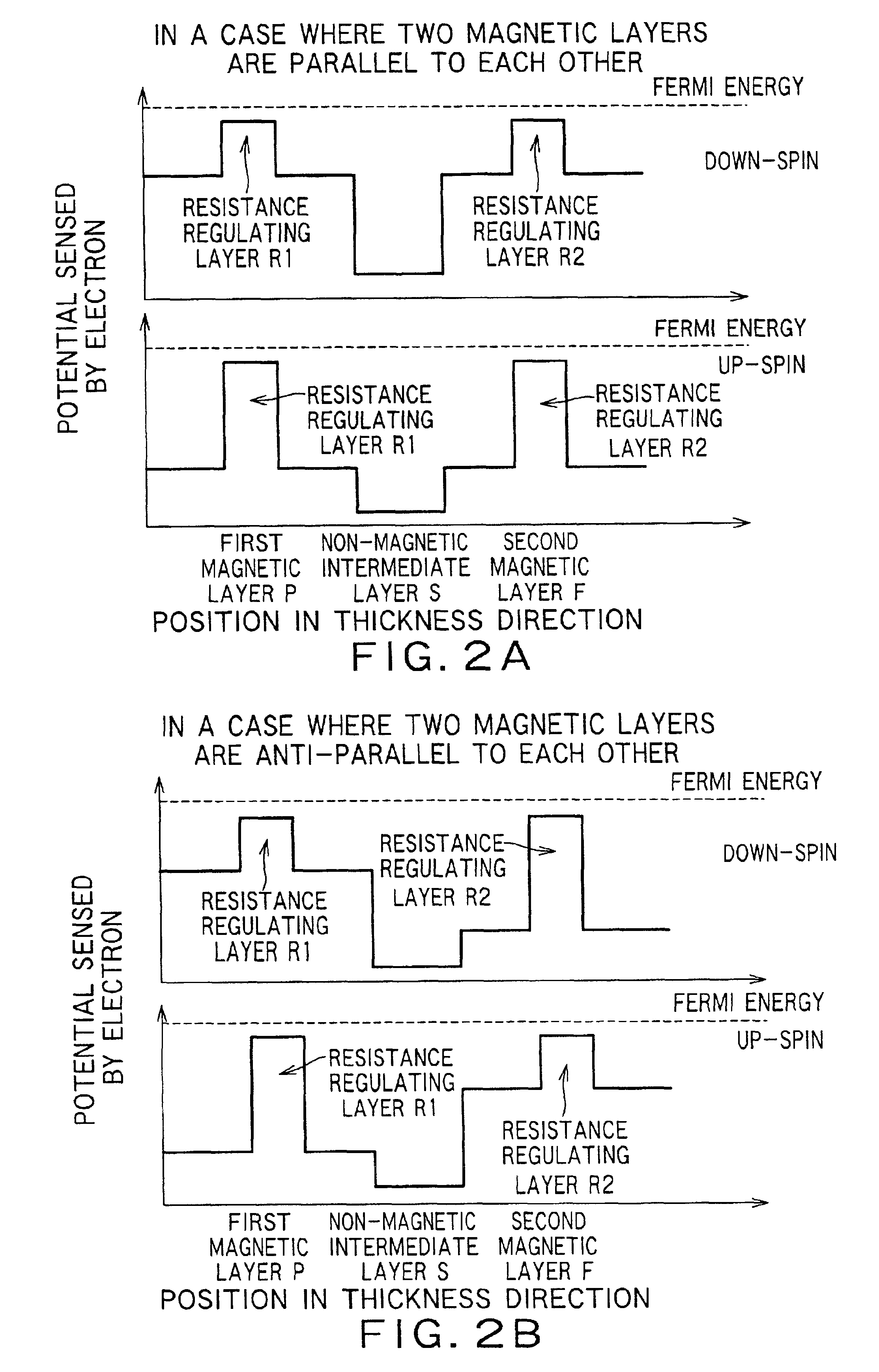

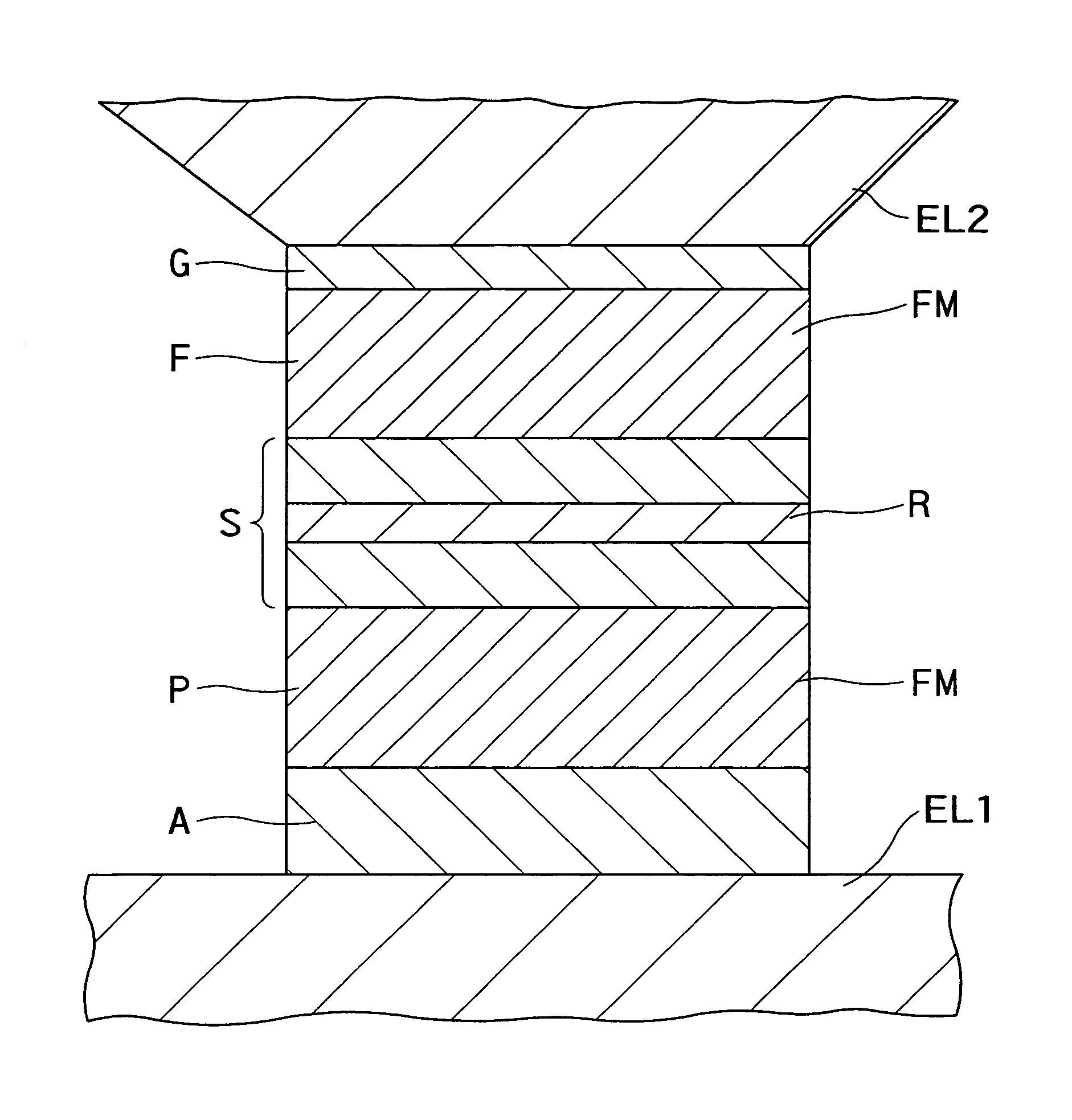

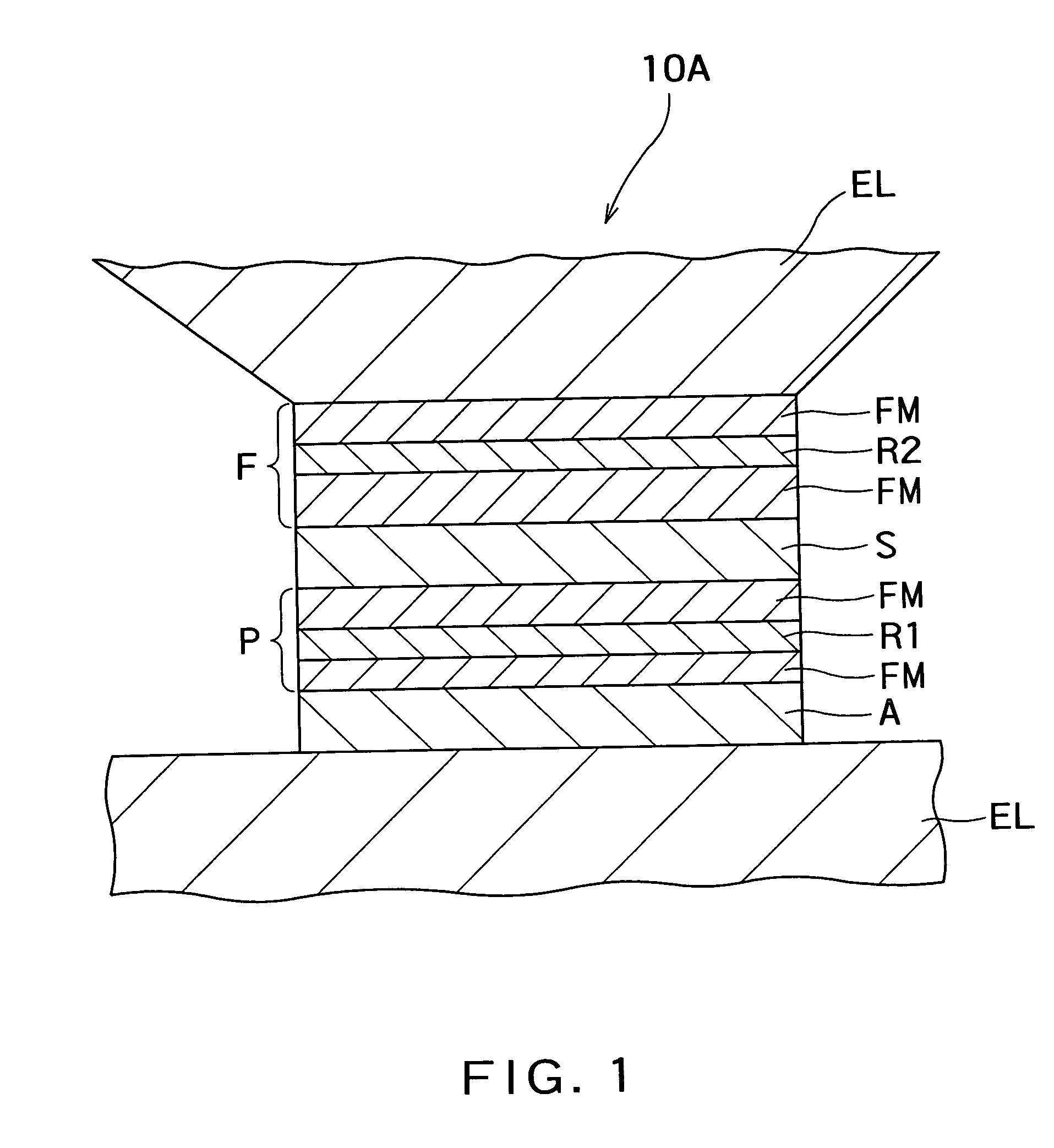

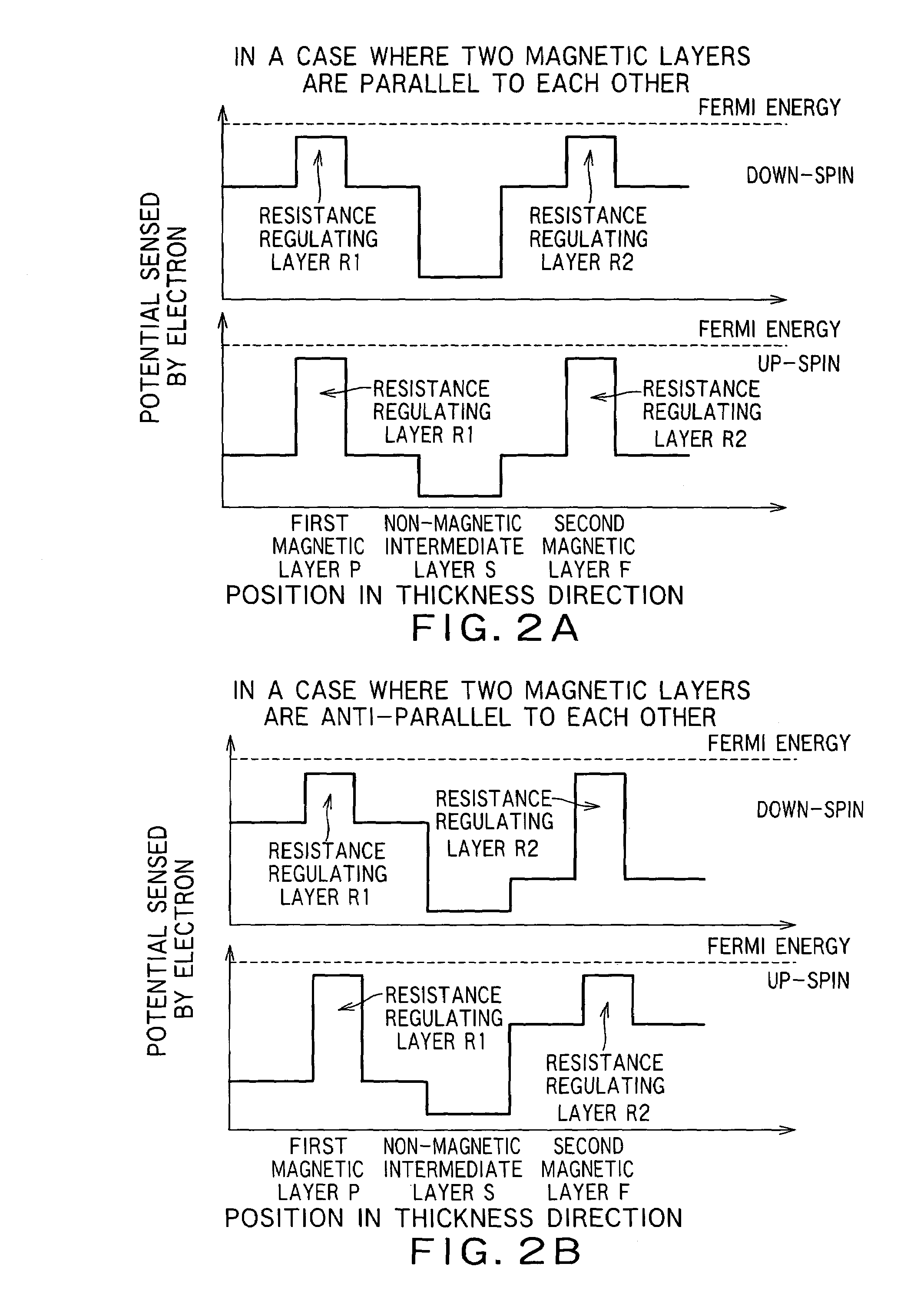

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS6937446B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

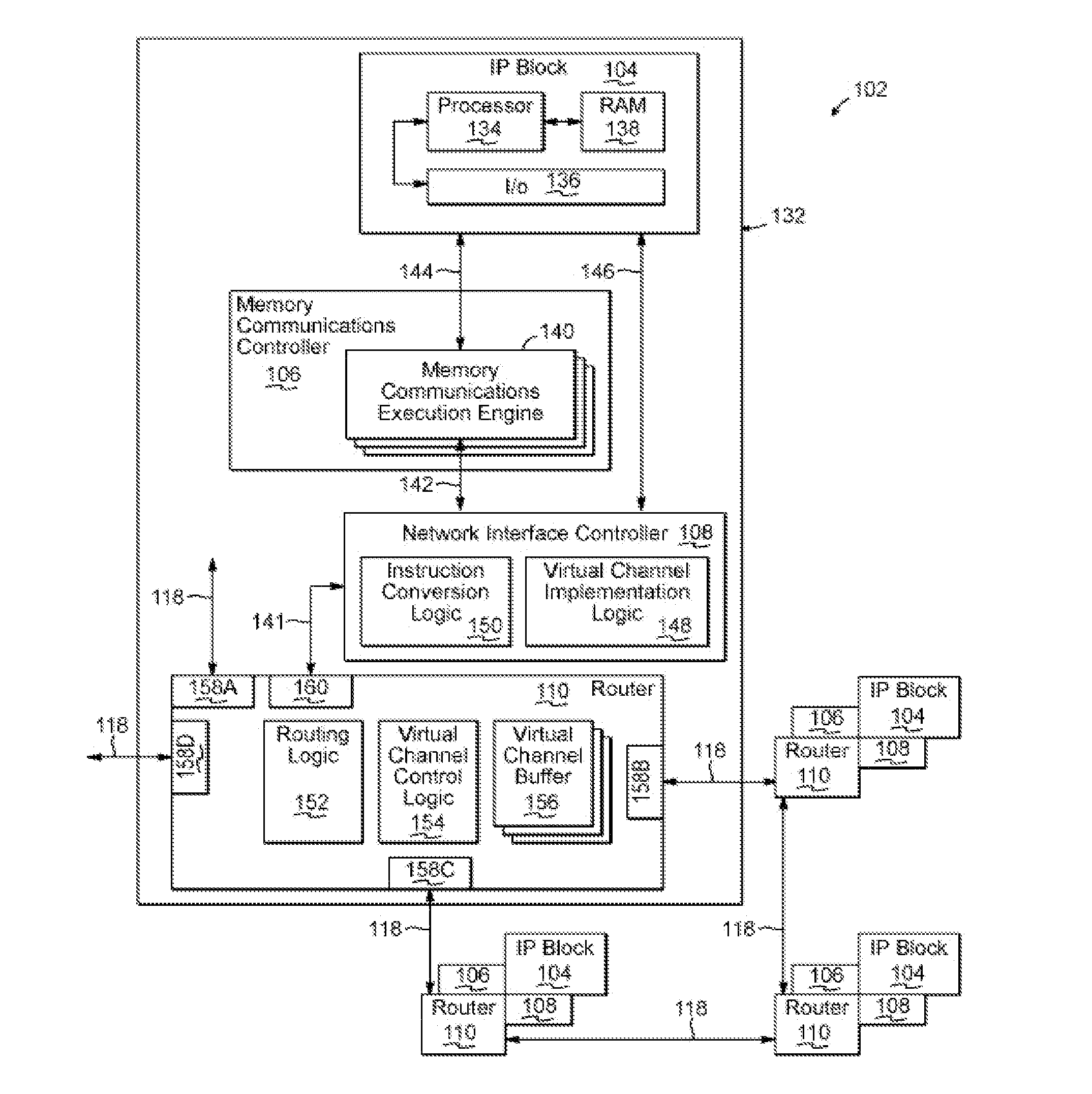

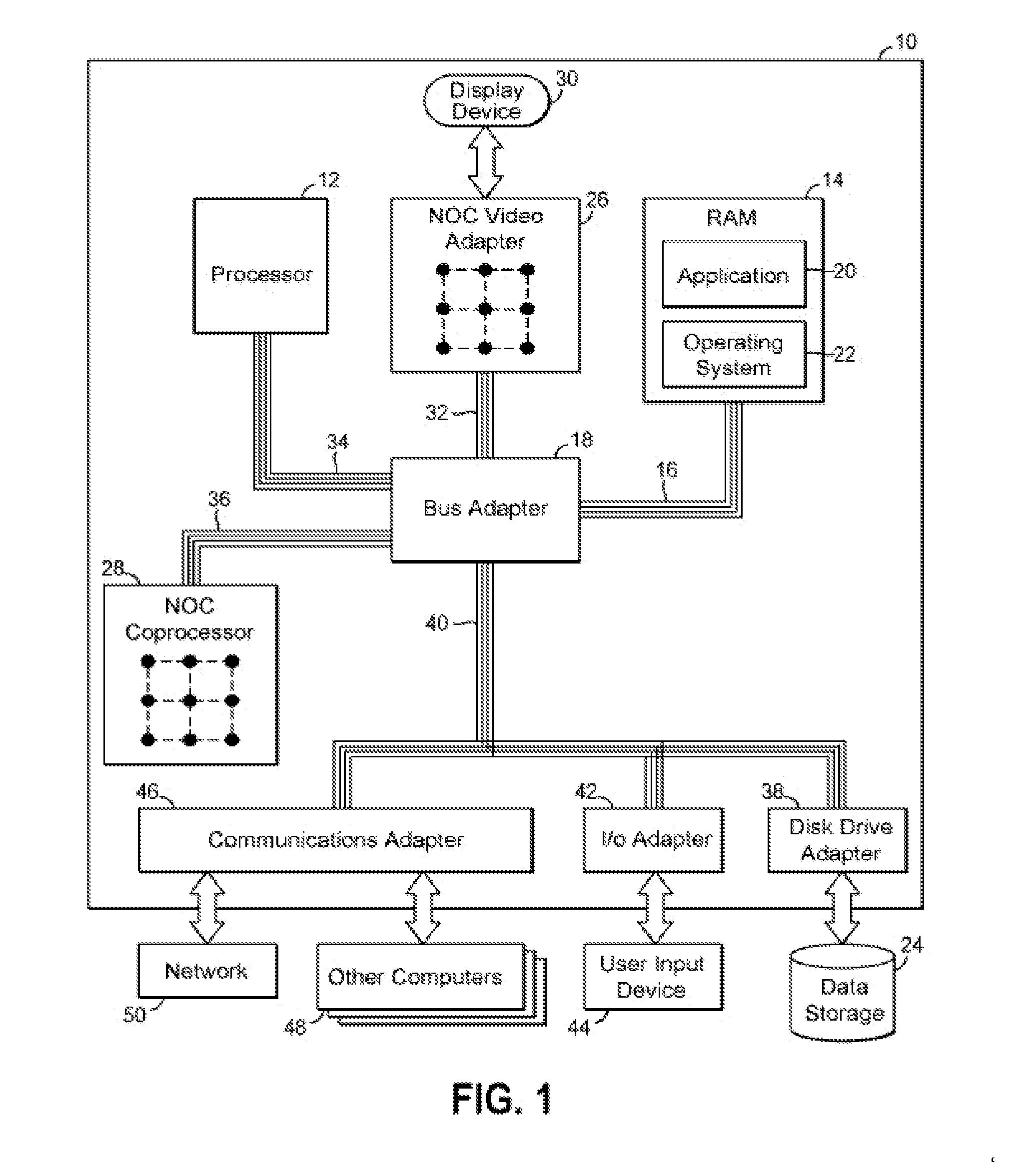

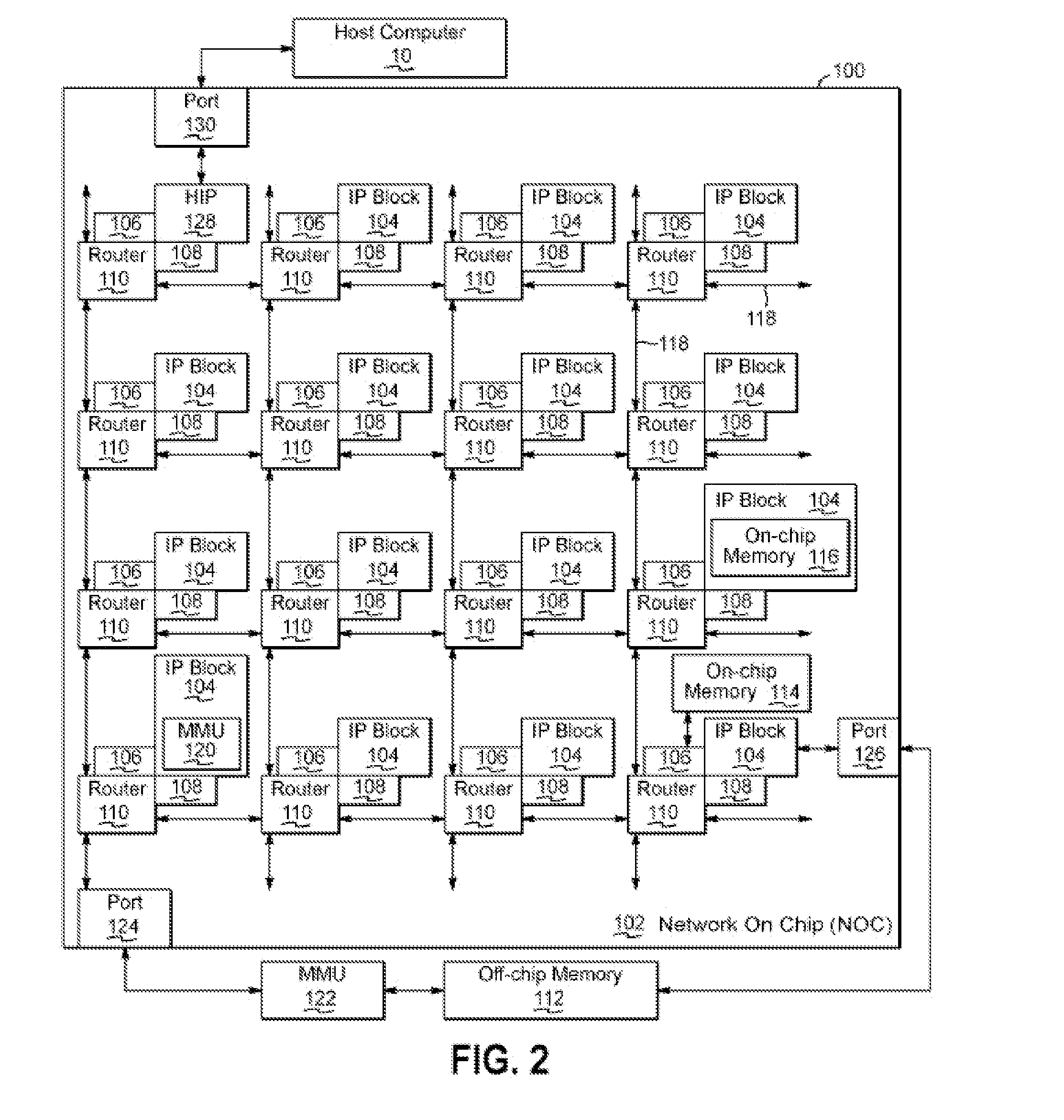

Shared receive queue allocation for network on a chip communication

InactiveUS20150081941A1Control quantityData switching networksElectric digital data processingDistributed computingReceipt

A circuit arrangement, method, and program product for communicating data in a processing architecture comprising a plurality of interconnected IP blocks. Transmitting IP blocks may transmit messages to a shared receive queue for a first IP block. Receipt of the messages at the shared receive queue may be controlled based on receive credits allocated to each transmitting IP block. The allocation of receive credits for each transmitting IP block may dynamically managed such that the allocation of receive credits may be dynamically adjusted for each transmitting IP block based at least in part on message traffic associated with each transmitting IP block and / or a priority associated with each transmitting IP block.

Owner:IBM CORP

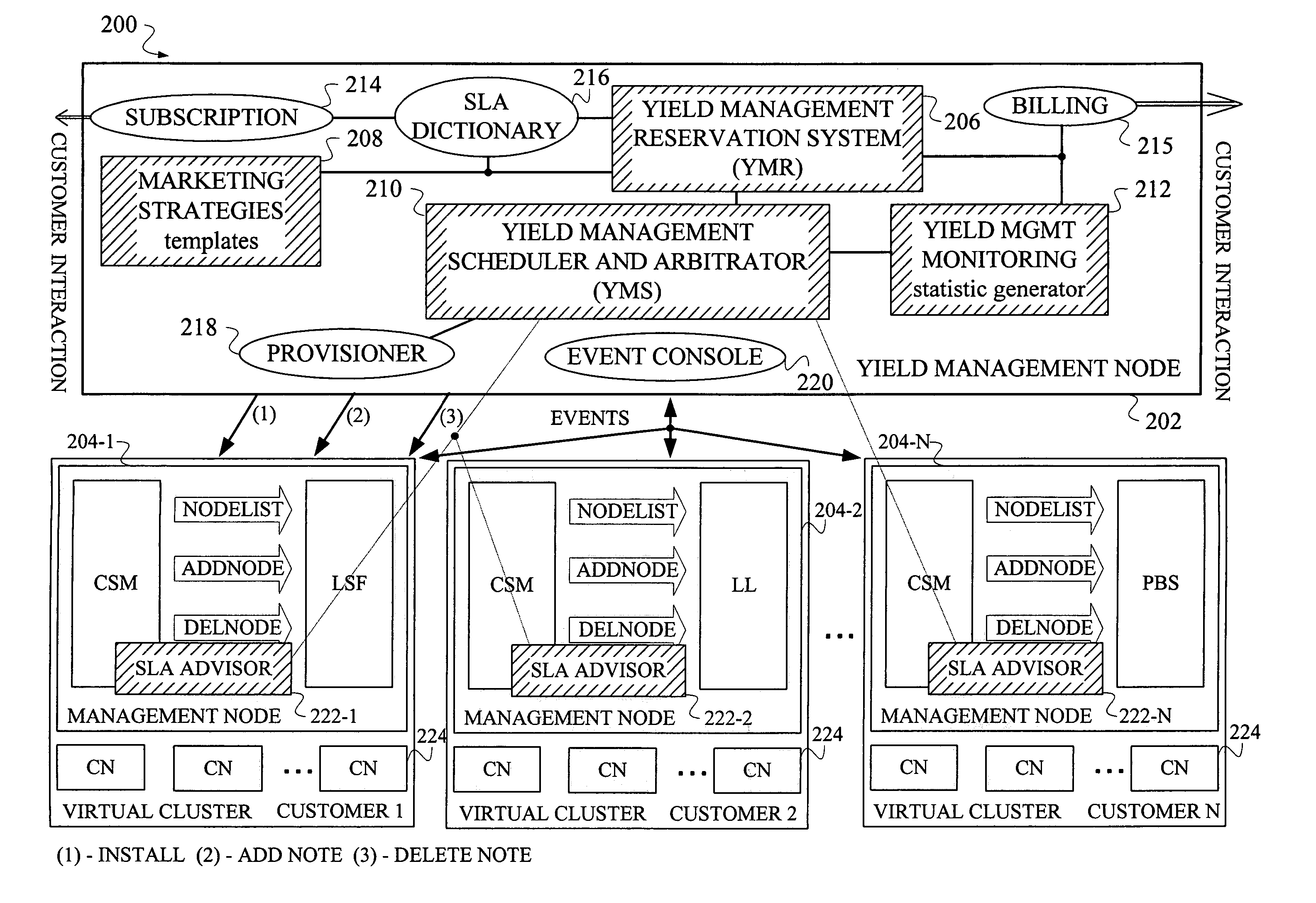

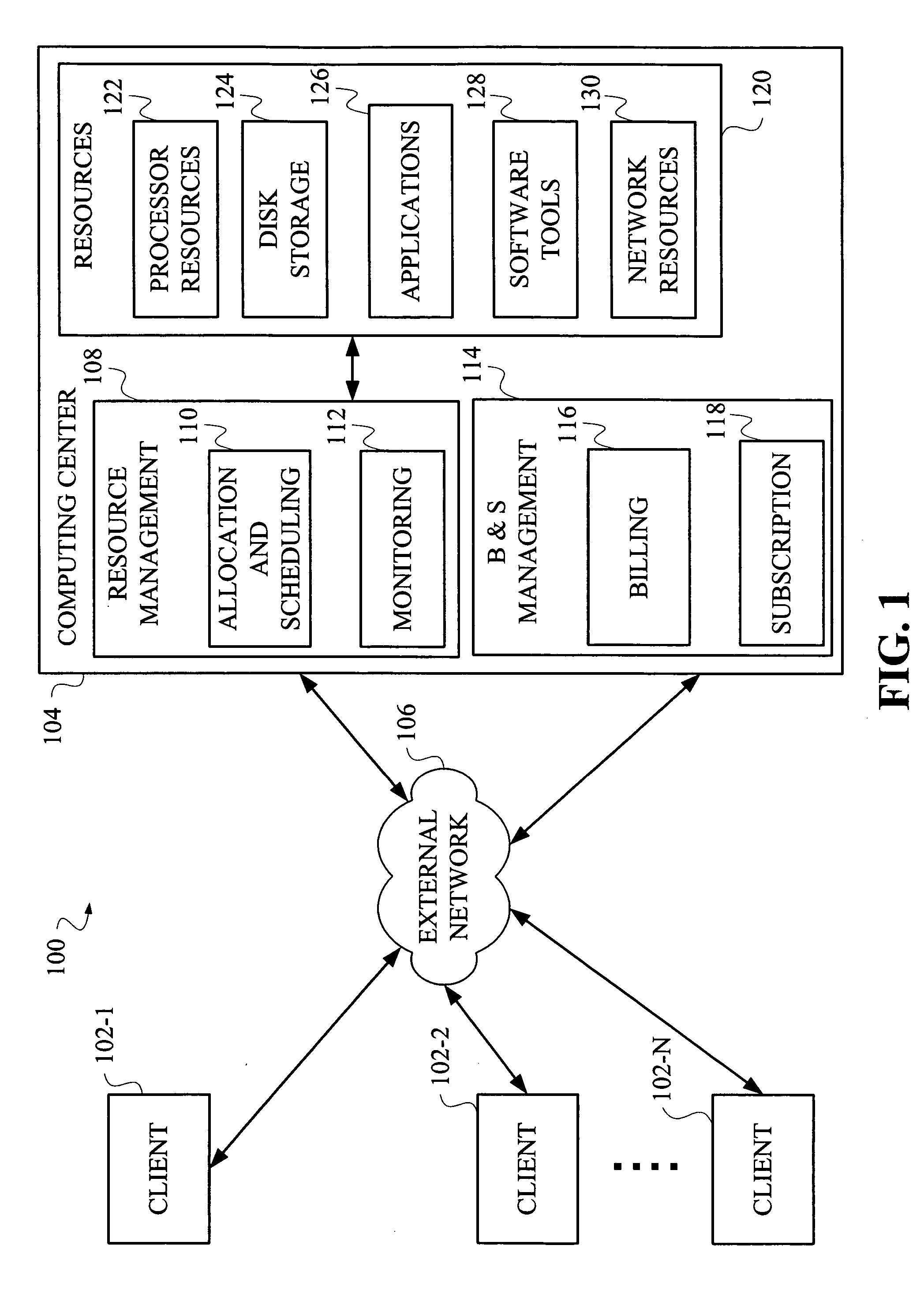

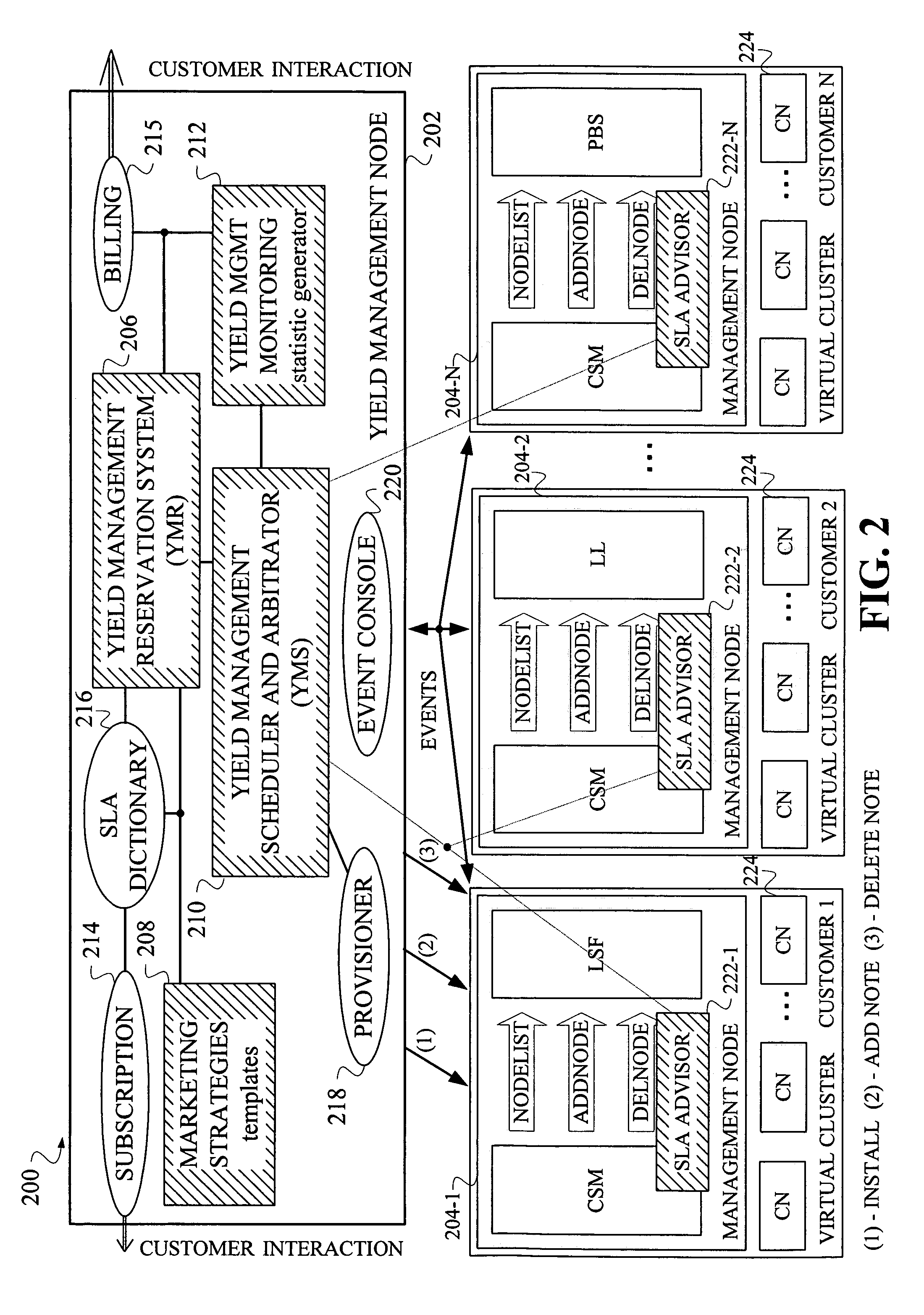

On-demand utility services utilizing yield management

InactiveUS20060117317A1Control quantityOptimize quantityReservationsForecastingResource managementOn demand

Techniques for provision of on-demand utility services utilizing a yield management framework are disclosed. For example, in one illustrative aspect of the invention, a system for managing one or more computing resources associated with a computing center comprises: (i) a resource management subsystem for managing the one or more computing resources associated with the computing center, wherein the computing center is able to provide one or more computing services in response to one or more customer demands; and (ii) a yield management subsystem coupled to the resource management subsystem, wherein the yield management subsystem optimizes provision of the one or more computing services in accordance with the resource management subsystem and the one or more computing resources.

Owner:IBM CORP

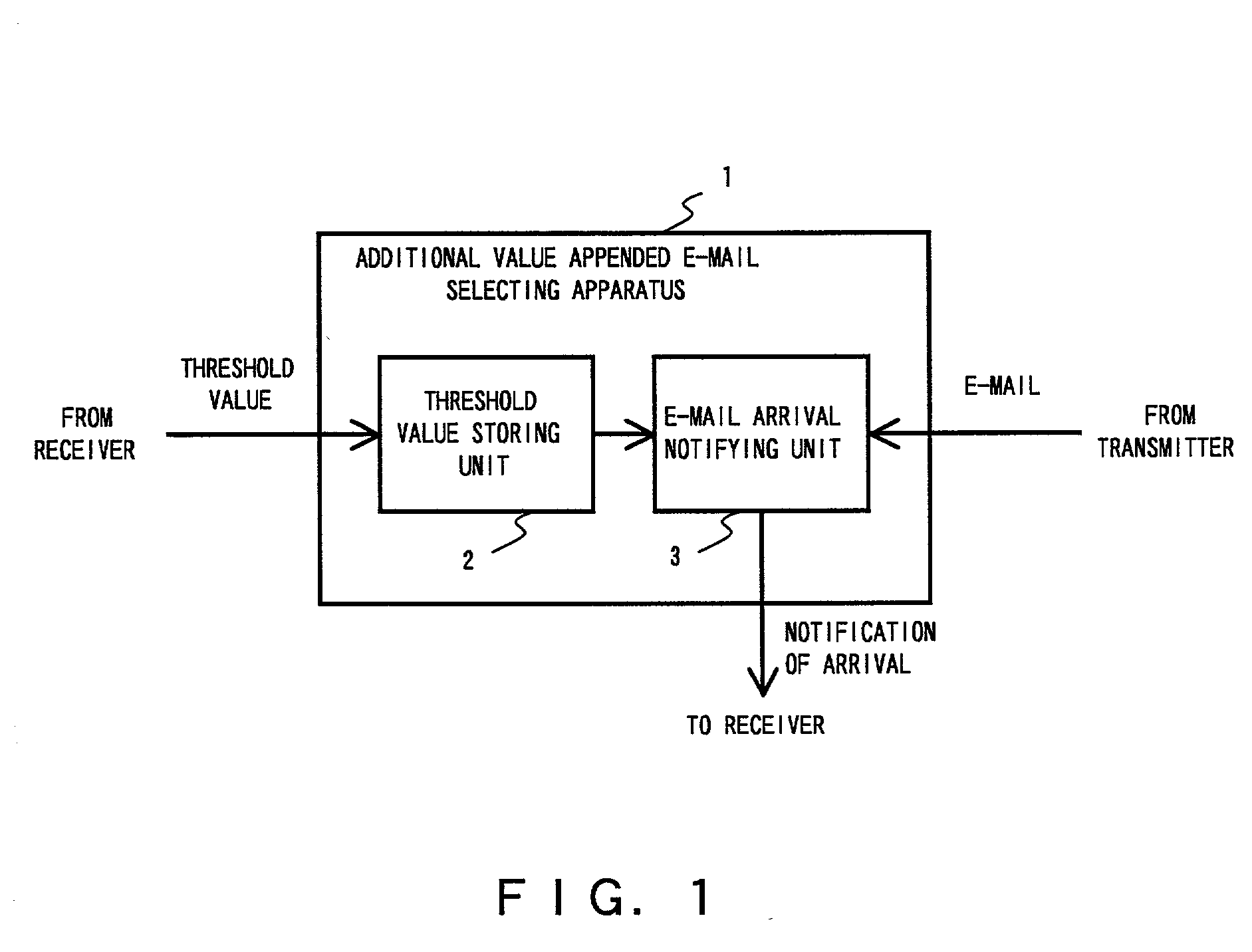

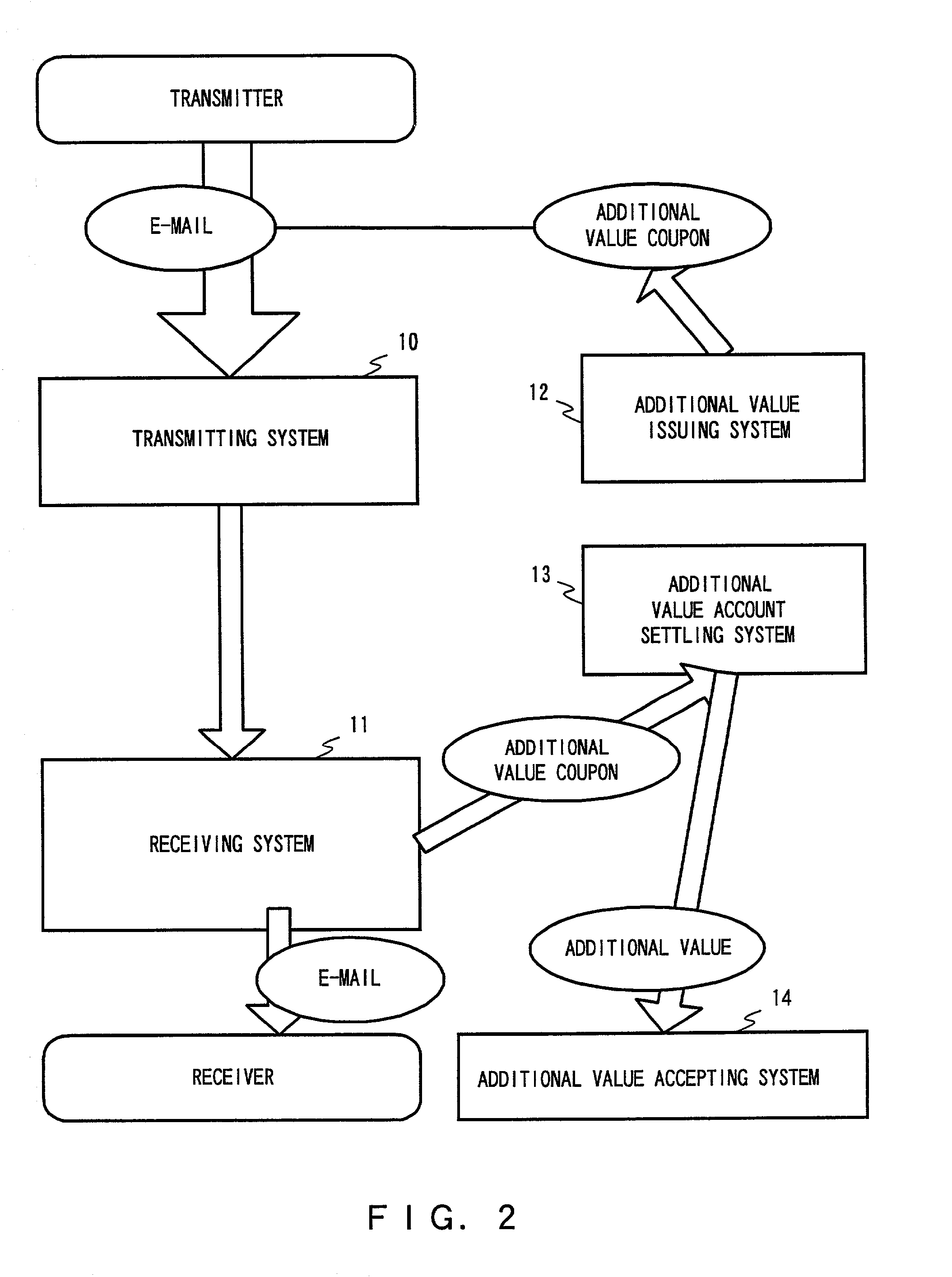

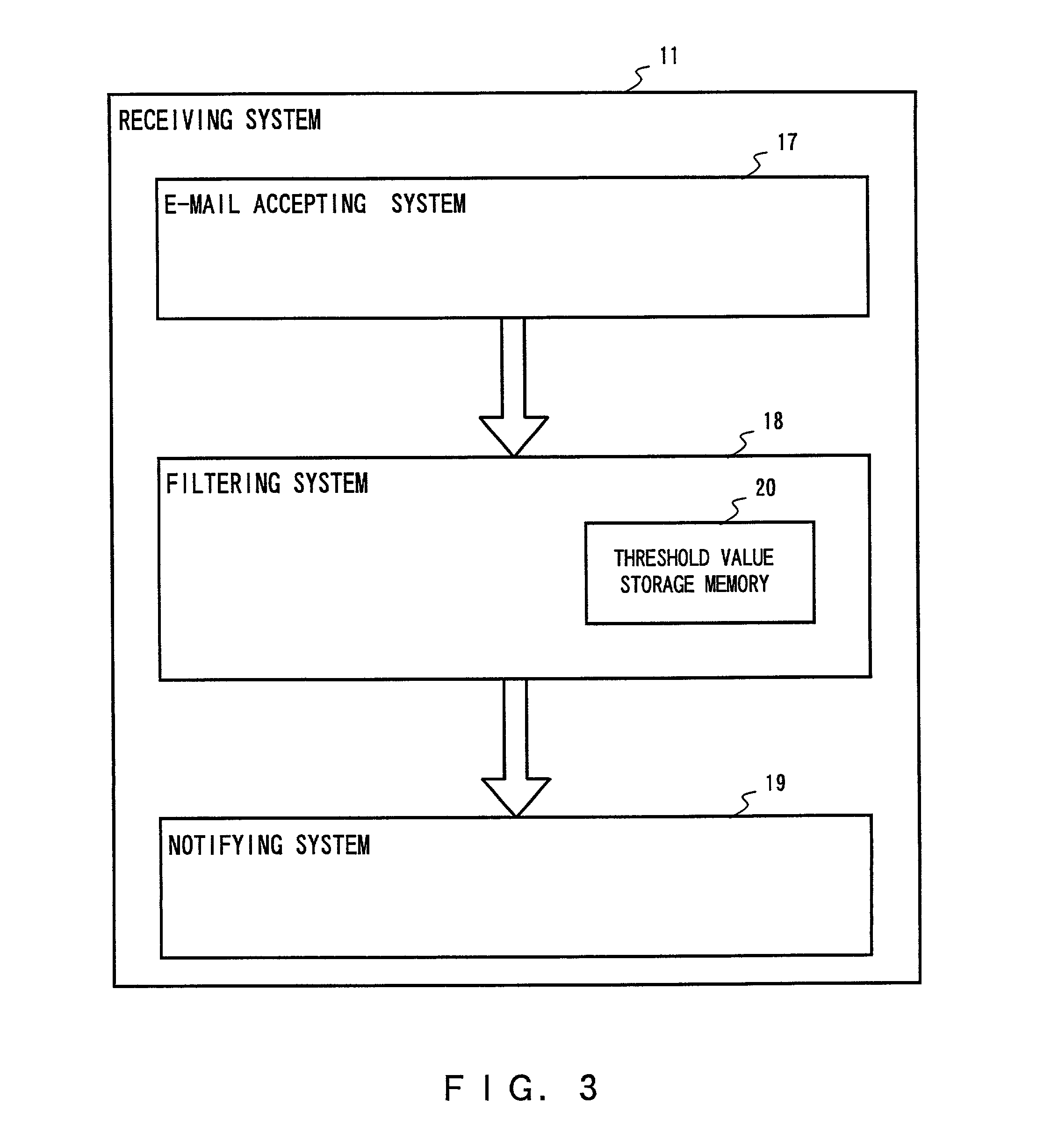

Additional value appended e-mail selecting apparatus, transmitting apparatus, transmitting/receiving system and methods of selecting and transmitting/receiving the same

InactiveUS20010032247A1Quality improvementControl quantityMultiple digital computer combinationsOffice automationNotification ReceiverValue set

There are provided a threshold value storing unit for storing a threshold value set by a receiver for an additional value which becomes effective for the receiver when the receiver reads a piece of E-mail and an E-mail arrival notifying unit for, when the additional value which is appended to the the E-mail transmitted from a transmitter side exceeds the threshold value stored in the threshold value storing unit, notifying the receiver of the arrival of the E-mail so as to select the E-mail to which the additional value exceeding the threshold value is appended in order to induce the receiver to read the E-mail, by which it becomes possible for the E-mail receiver to select an appropriate piece of E-mail and it becomes possible for the transmitter to induce the receiver to select and read an advertisement or the like from among many pieces of E-mail.

Owner:FUJITSU LTD

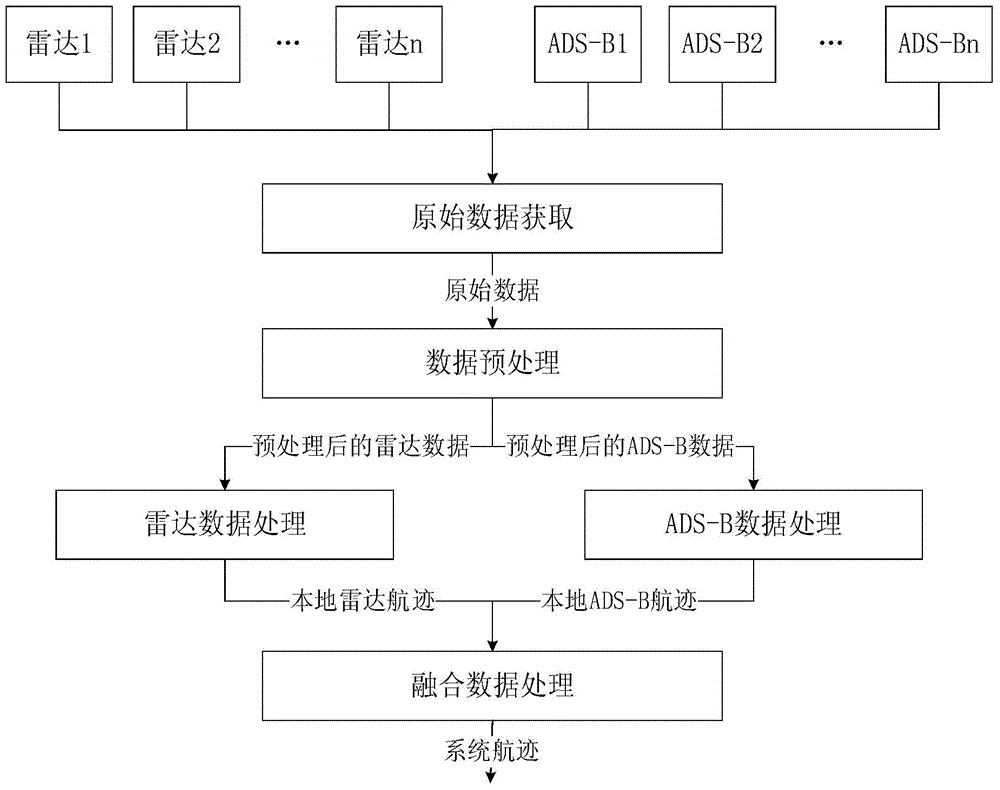

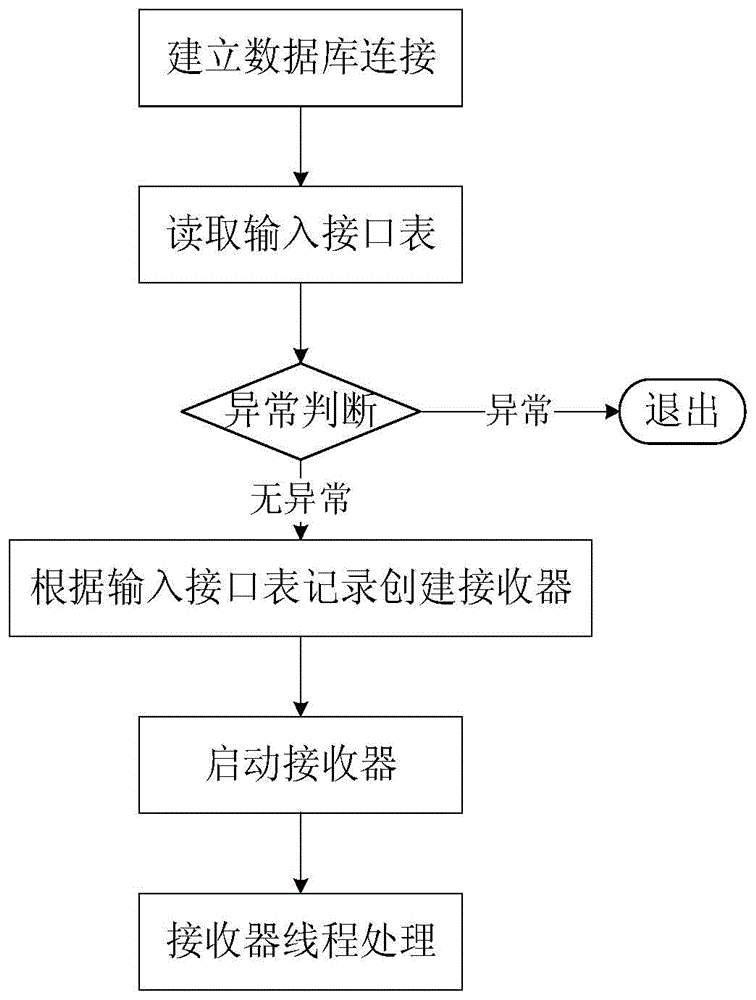

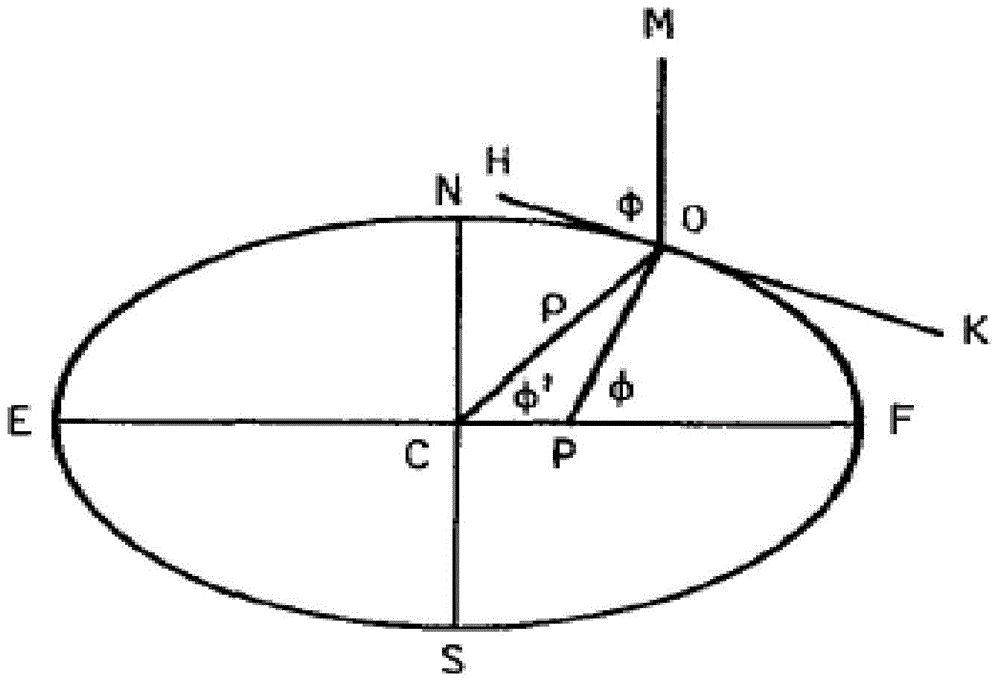

Multi-surveillance-source flying target parallel track processing method

ActiveCN104808197AMeet the requirements of real-time processingControl quantityRadio wave reradiation/reflectionData processing systemHigh availability

The invention discloses a multi-surveillance-source flying target parallel track processing method. The method includes the steps: multi-surveillance-source data receiving; multi-surveillance-source data analysis; radar data processing; ADS-B (automatic dependent surveillance-broadcast) data processing; multi-surveillance-source data fusion. Surveillance of quality of data accessing to radar is realized by monitoring and analyzing quality of radar signals. In addition, real-time receive processing of the radar data is realized by means of multithreading, high safety, high reliability and high usability of a data processing system can be further guaranteed, and accuracy and quickness in track processing of flying targets in different data types from different surveillance sources can be realized.

Owner:四川九洲空管科技有限责任公司

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS7046489B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

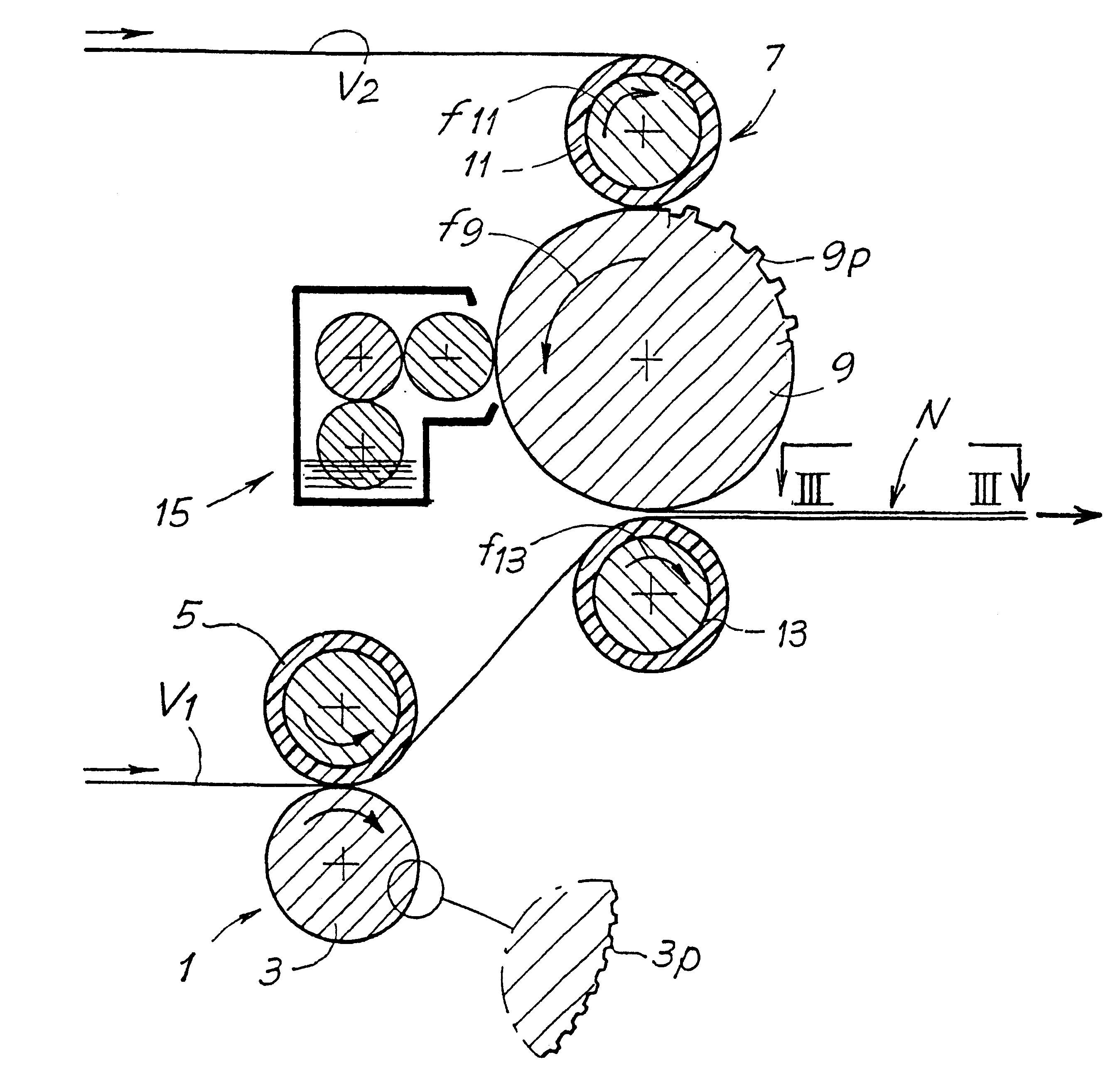

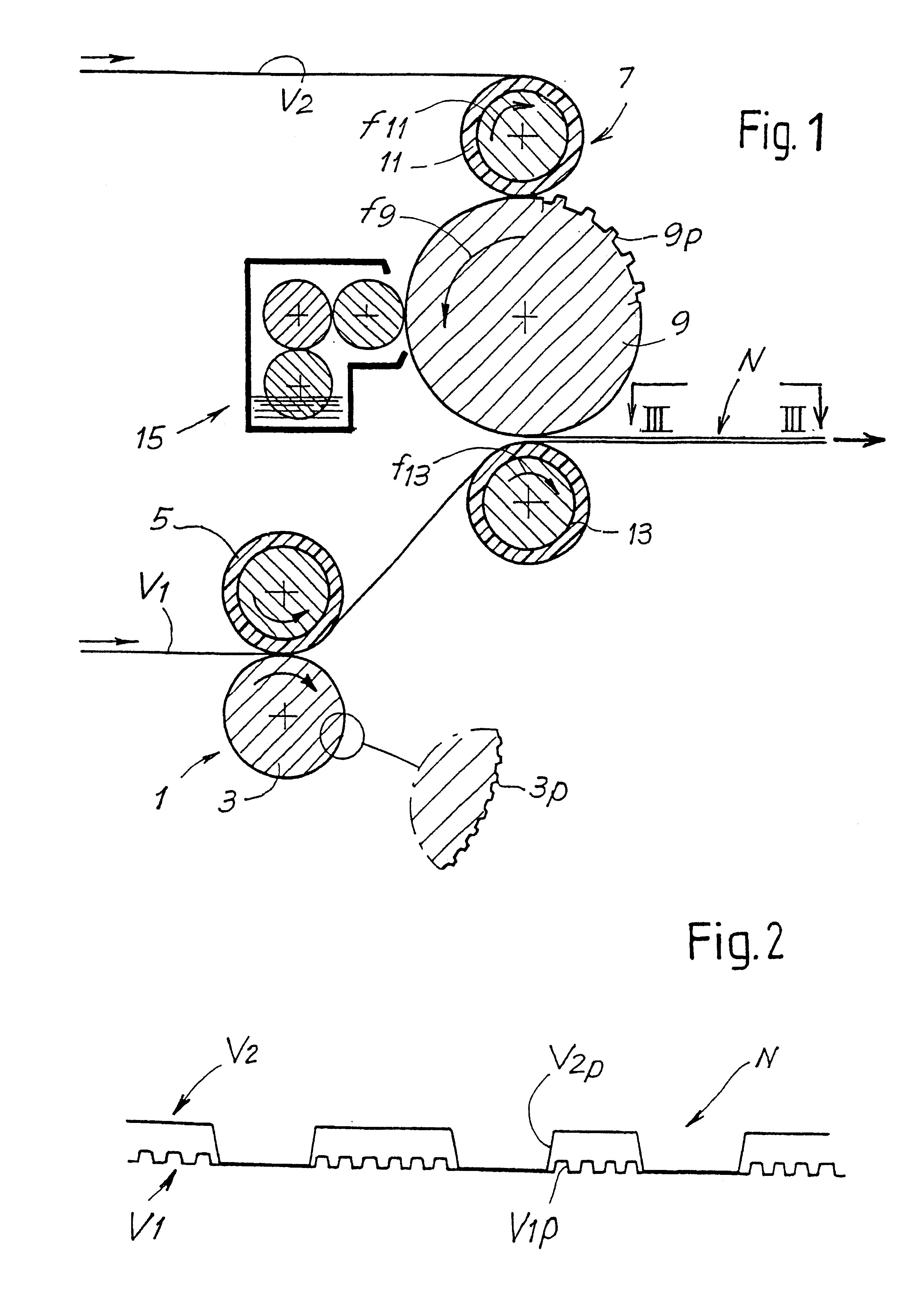

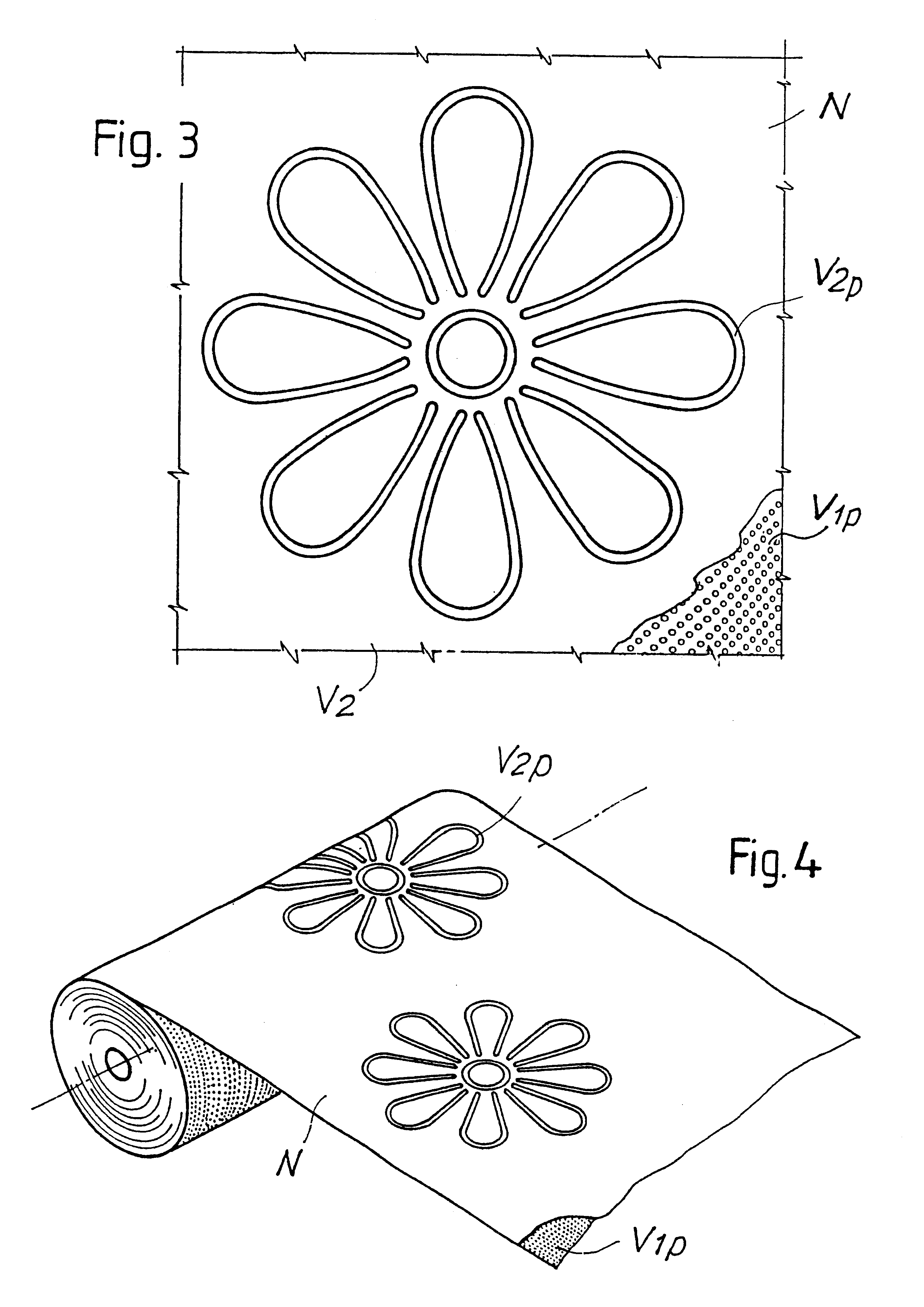

Device for the production of multi-ply web material with different size and density patterns on different plies

InactiveUS6681826B1Quality improvementIncrease volumeMechanical working/deformationHigh densityAdhesive

The embossing device comprises in combination: a first embossing unit (1) with a first embossing cylinder (3) provided with a first set of points (3P) and interacting with a first pressure cylinder (5) for forming, on a first ply (V1), a first set of protuberances (V1p) having small sizes and a high density; a second embossing unit (7) with a second embossing cylinder (9) provided with a second set of points (9P) and interacting with a second pressure cylinder (11) and a laminating cylinder (13), for forming, on a second ply (V2), a second set of protuberances (V2p) having larger sizes and a lower density than the protuberances of the first set; an adhesive dispenser (15) for applying an adhesive to one of said plies before lamination.

Owner:FABIO PERINI SPA

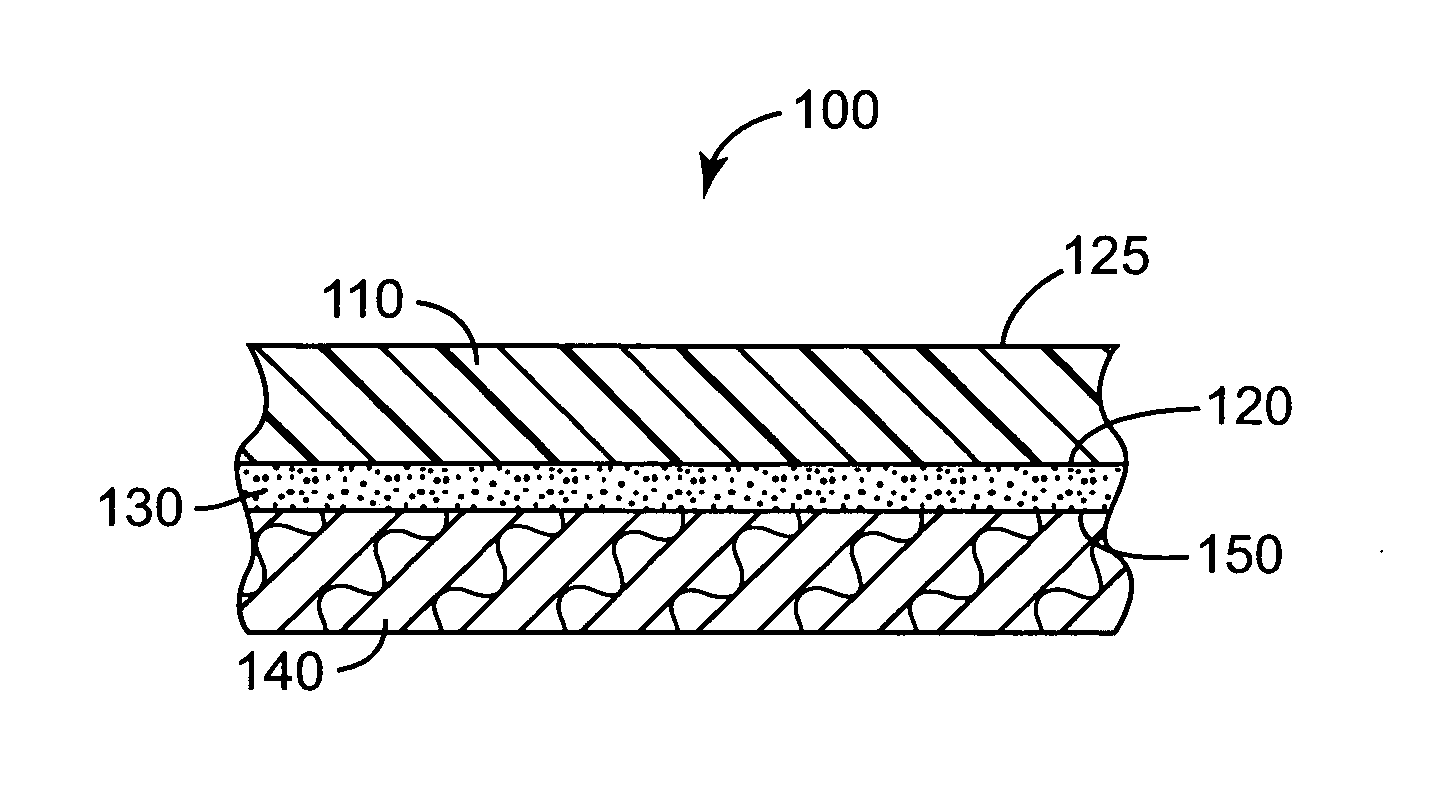

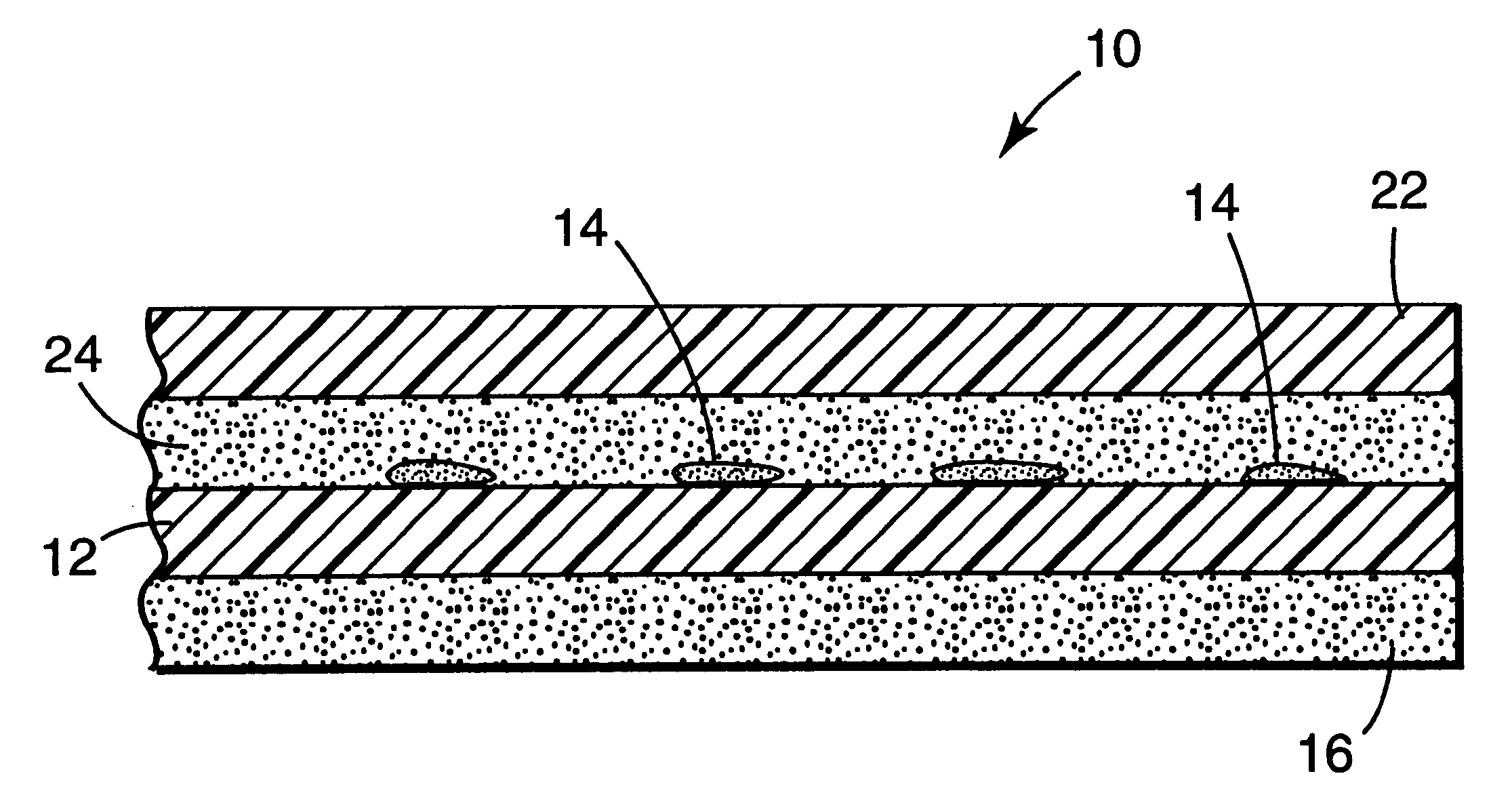

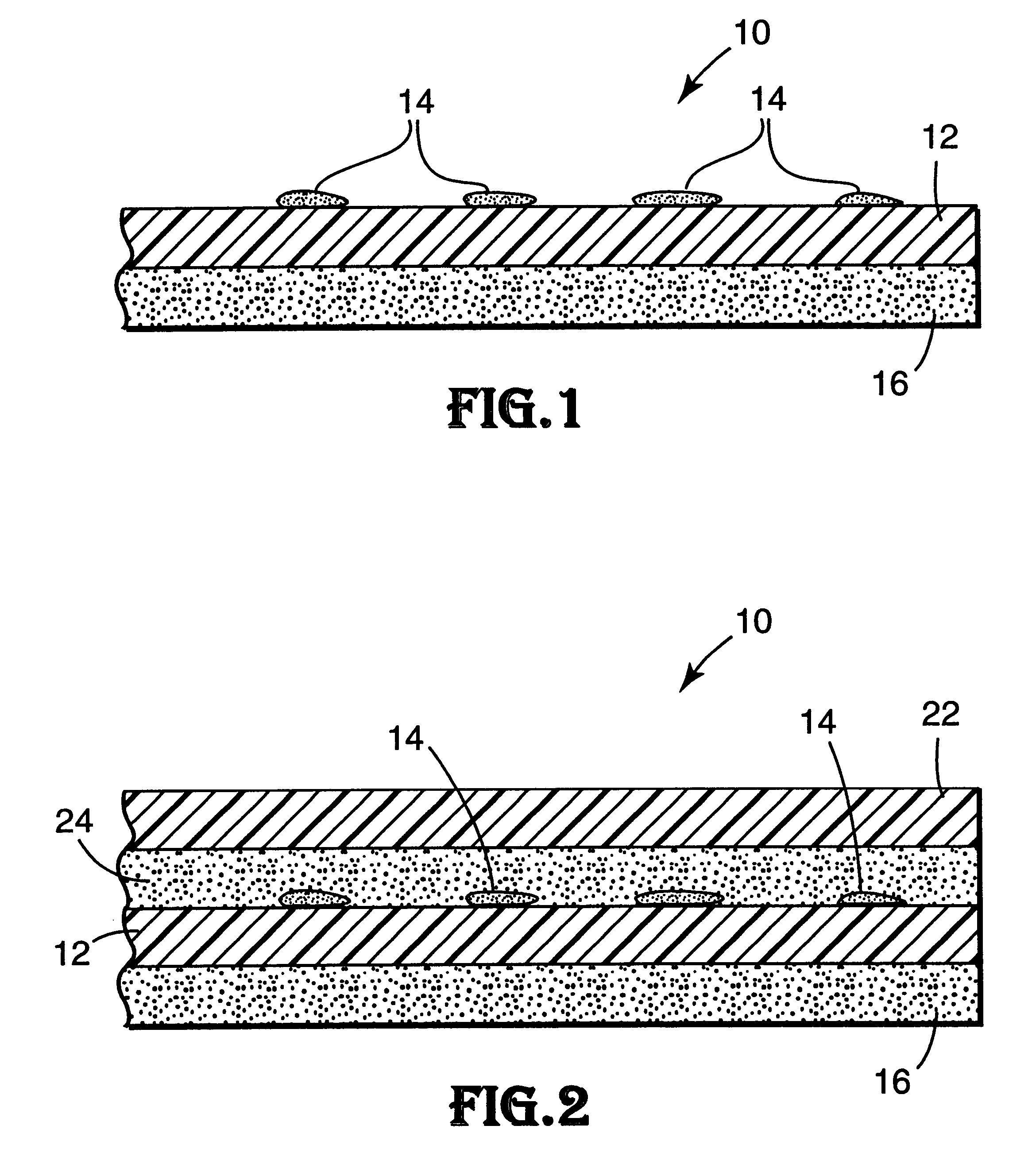

Method of stabilizing films or membranes using adhesive as a reservoir

InactiveUS6221198B1Provide protectionList to growEster polymer adhesivesDomestic articlesEnvironmental effectAdhesive

Environmental stabilizing agents are stored in an adhesive adjoining, directly or indirectly, a film or membrane that requires protection from the environment. Such stabilizing agents include ultra-violet protectors and anti-oxidants. Migration of such environmental stabilizing agents from an adhesive to a film or membrane permits the use of new and different materials for such films and membranes because their method of manufacture no longer needs to accommodate the heat and processing sensitivities of the stabilizing agents.

Owner:3M CO +1

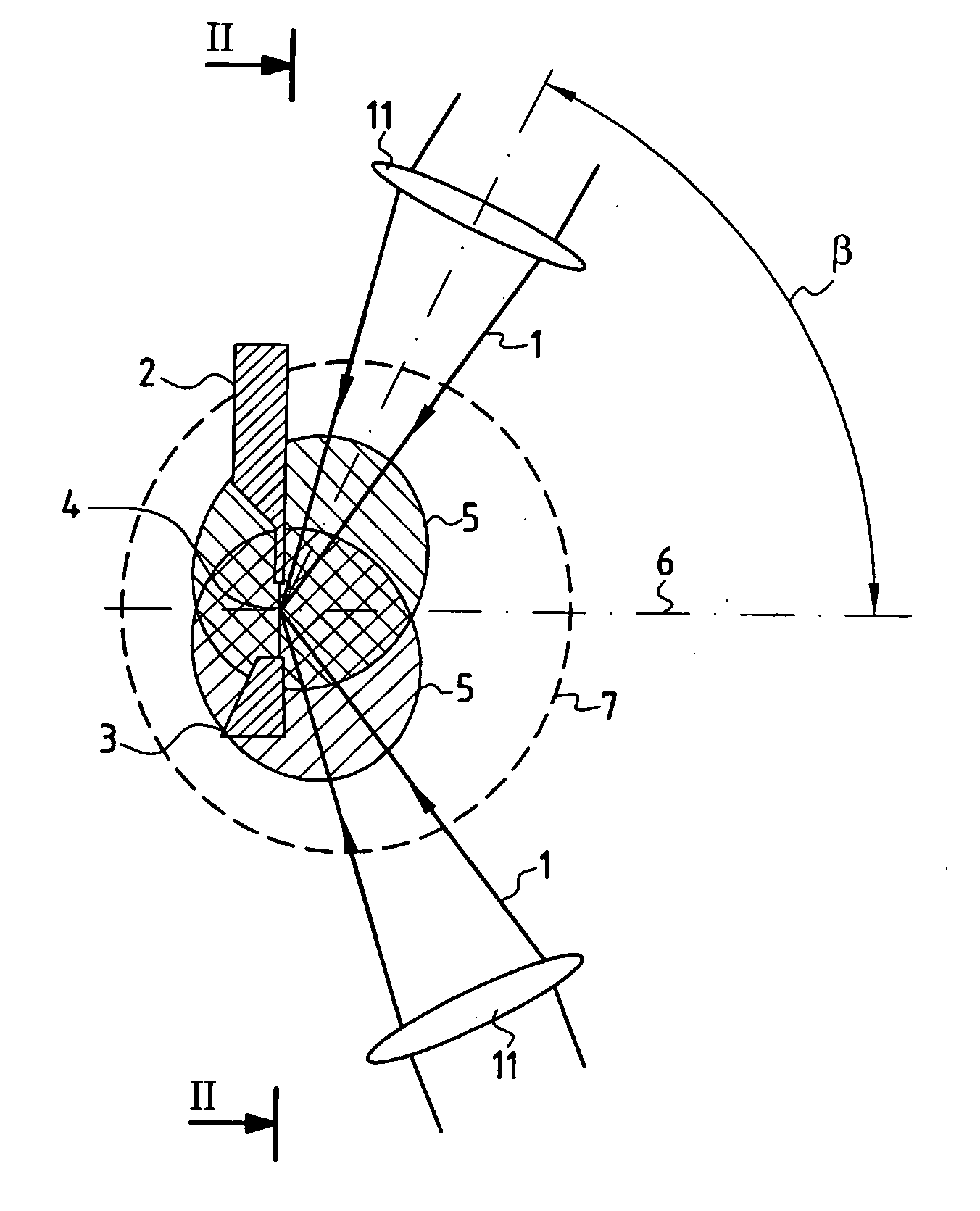

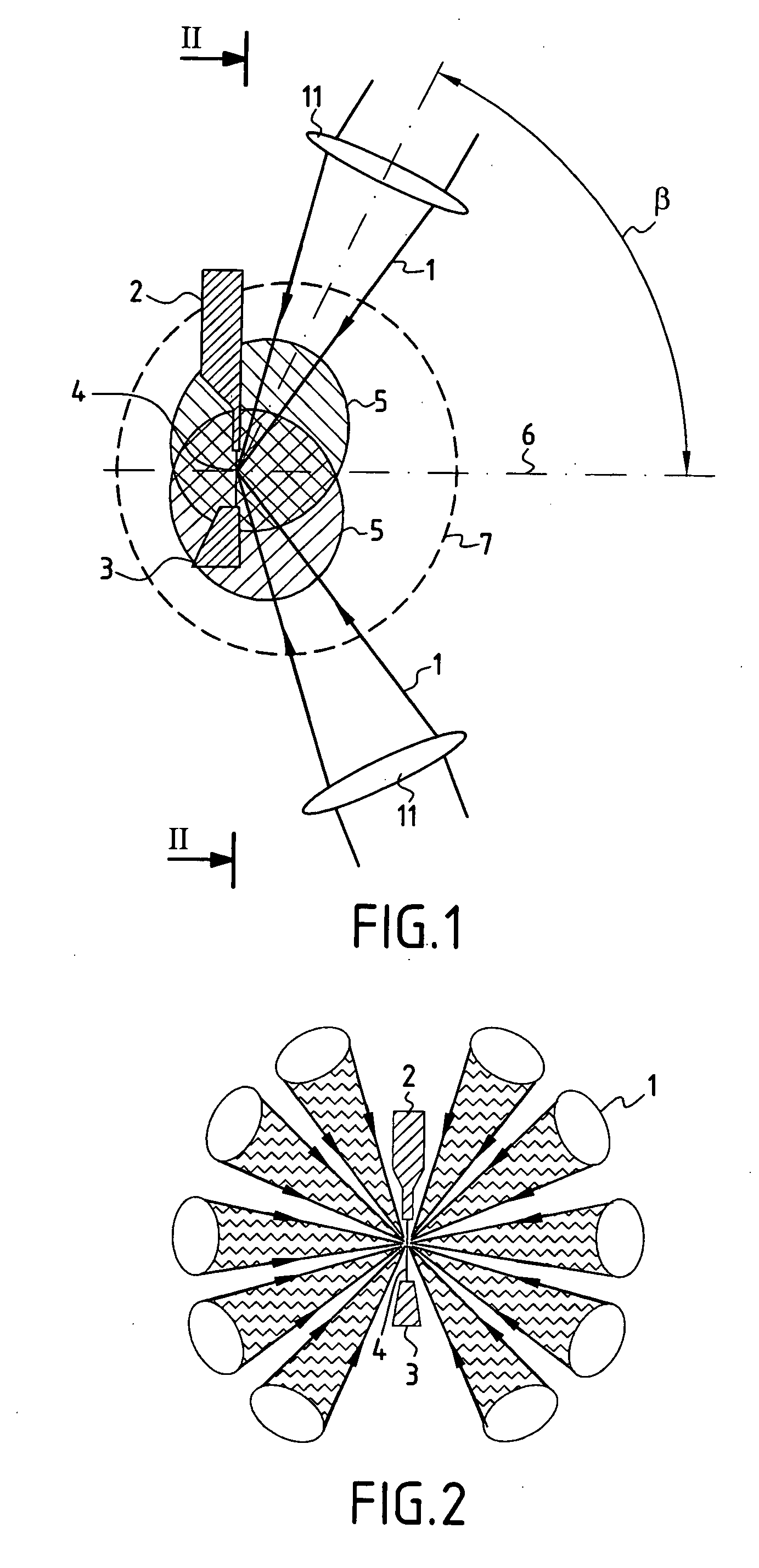

Apparatus for generating light in the extreme ultraviolet and use in a light source for extreme ultraviolet lithography

InactiveUS20060039435A1Increase powerIncrease laser powerNanoinformaticsPhotometryLithographic artistUltraviolet

The device comprises a device (2) for creating an essentially linear target (4) in an evacuated space where laser beams (1) are focused, the target being suitable for interacting with the focused laser beams (1) to emit a plasma emitting radiation in the extreme ultraviolet. A receiver device (3) receives the target (4) after it has interacted with the focused laser beams (1), and a collector device (110) collects the EUV radiation emitted by the target (4). The focusing elements (11) for focusing the laser beams on the target (4) are arranged in such a manner that the laser beams (1) are focused on the target (4) laterally, being situated in a common half-space relative to the target (4) and being inclined at a determined angle lying in the range about 60° to about 90° relative to a mean collection axis (6) perpendicular to the target (4). The collector device (110) is disposed symmetrically about the mean collection axis (6) in the half-space containing the laser beams (1) focused on the target (4) and inside a conical space (8) centered on the mean collection axis (6) with a vertex situated at the target (4) and a half-angle at the vertex that is less than the angle of inclination of the focused laser beams (1) relative to the mean collection axis (6). The device is suitable for use as a source for EUV radiation in lithography for fabricating integrated circuits.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

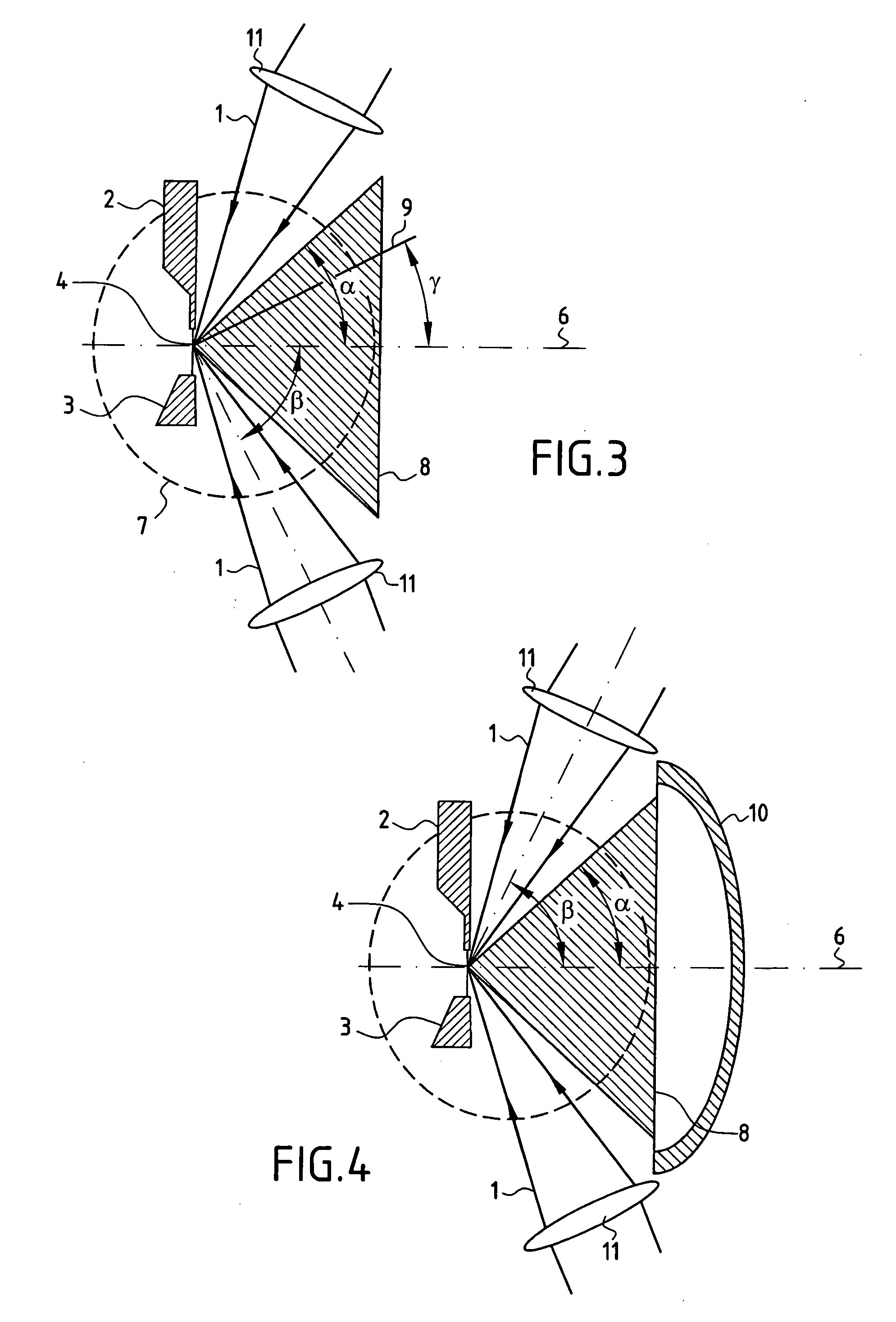

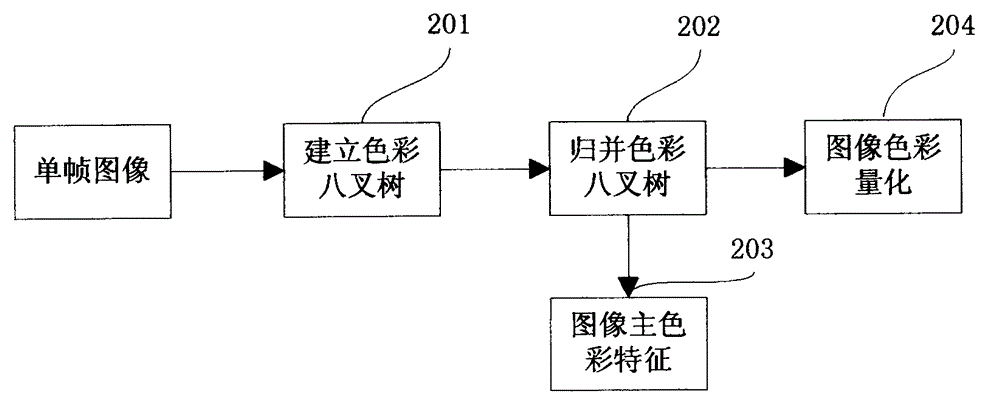

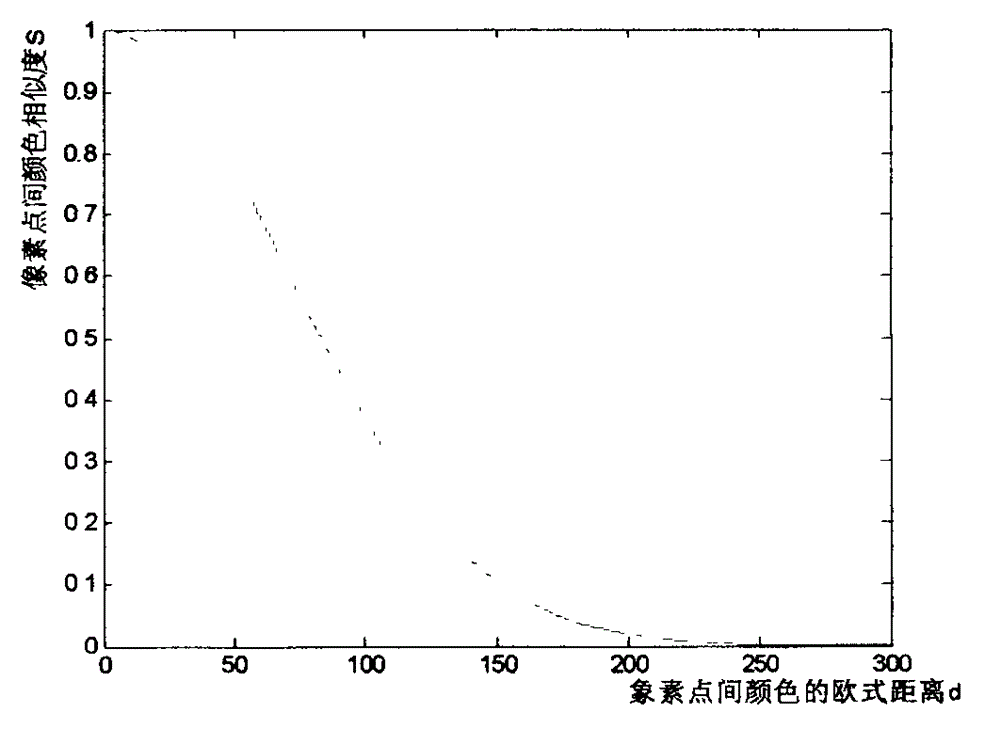

Video key frame extraction method based on color quantization and clusters

InactiveCN103065153ALow type dependencyAvoid redundant selectionCharacter and pattern recognitionTelevision systemsCanonical quantizationFrame difference

The invention discloses a video key frame extraction method based on color quantization and clusters. The method comprises the steps of loading video data flow; conducting single frame scanning on video flow; conducting the color quantization on obtained frame images, and extracting main color features of the frame images going through quantization; calculating similarity of adjacent frames so as to obtain adjacent frame difference; conducting shot boundary detection according to the adjacent frame difference; conducting shot classification on intersected shots and extracting a representative frame of each shot; and conducting compression clustering on the sequence of the representative frames so as to obtain a key frame sequence. According to the method, the color quantization is conducted on the single frame images so that main color of the images is extracted, frame difference calculation is conducted through the cluster feature similarity calculation method based on color features of the clusters so that the shot boundary detection is realized, and finally clustering according to the compression ratio is conducted on the extracted representative frames. Due to the fact that he whole process is low in dependency on video formats and types, the method has good universality and adaptability, is simple in calculation and low in space consumption, and can effectively avoid the phenomenon of key frame selection redundancy, control the number and quality of the key frames, and realize control of the video compression ratio.

Owner:SOUTHWEAT UNIV OF SCI & TECH

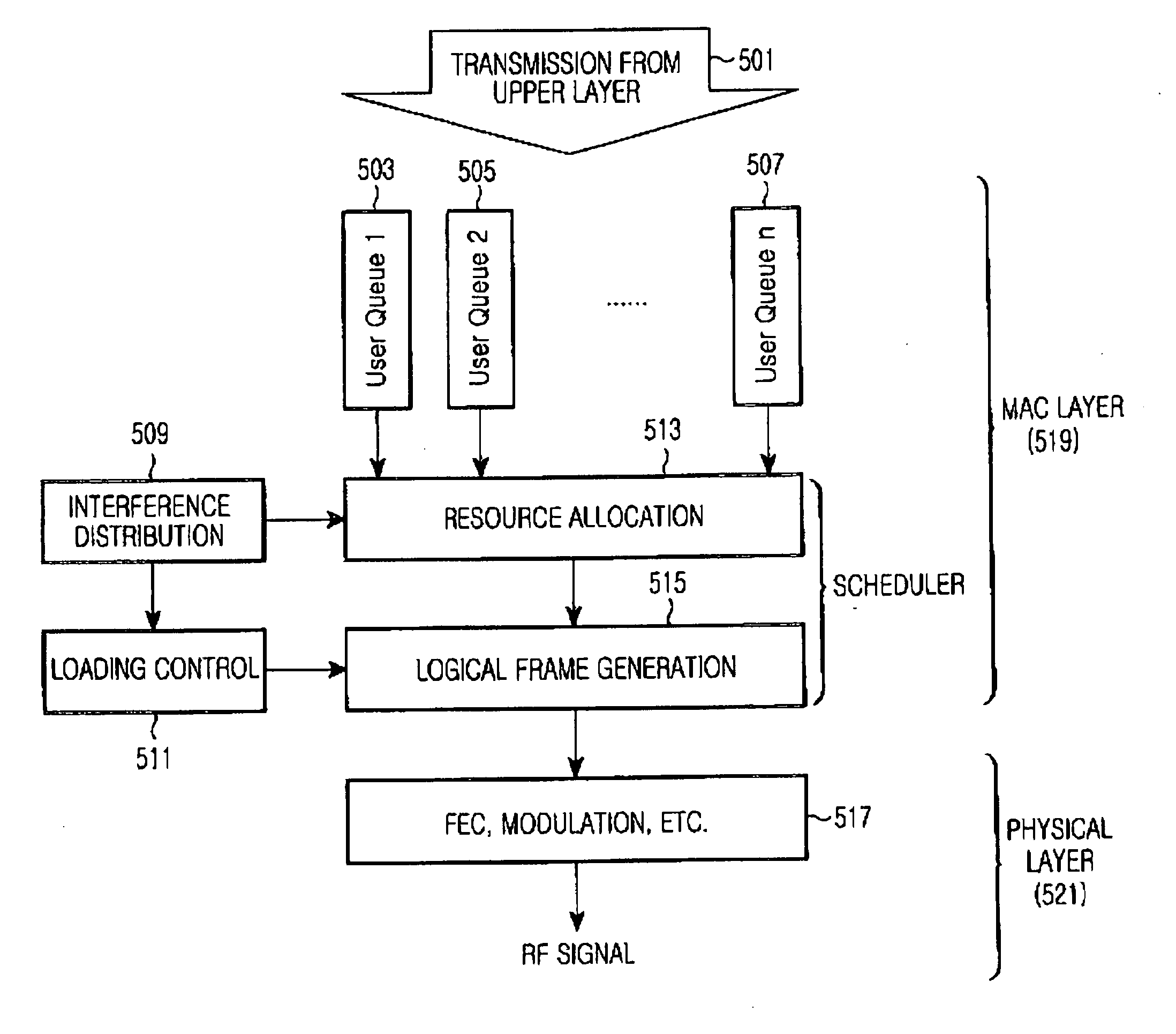

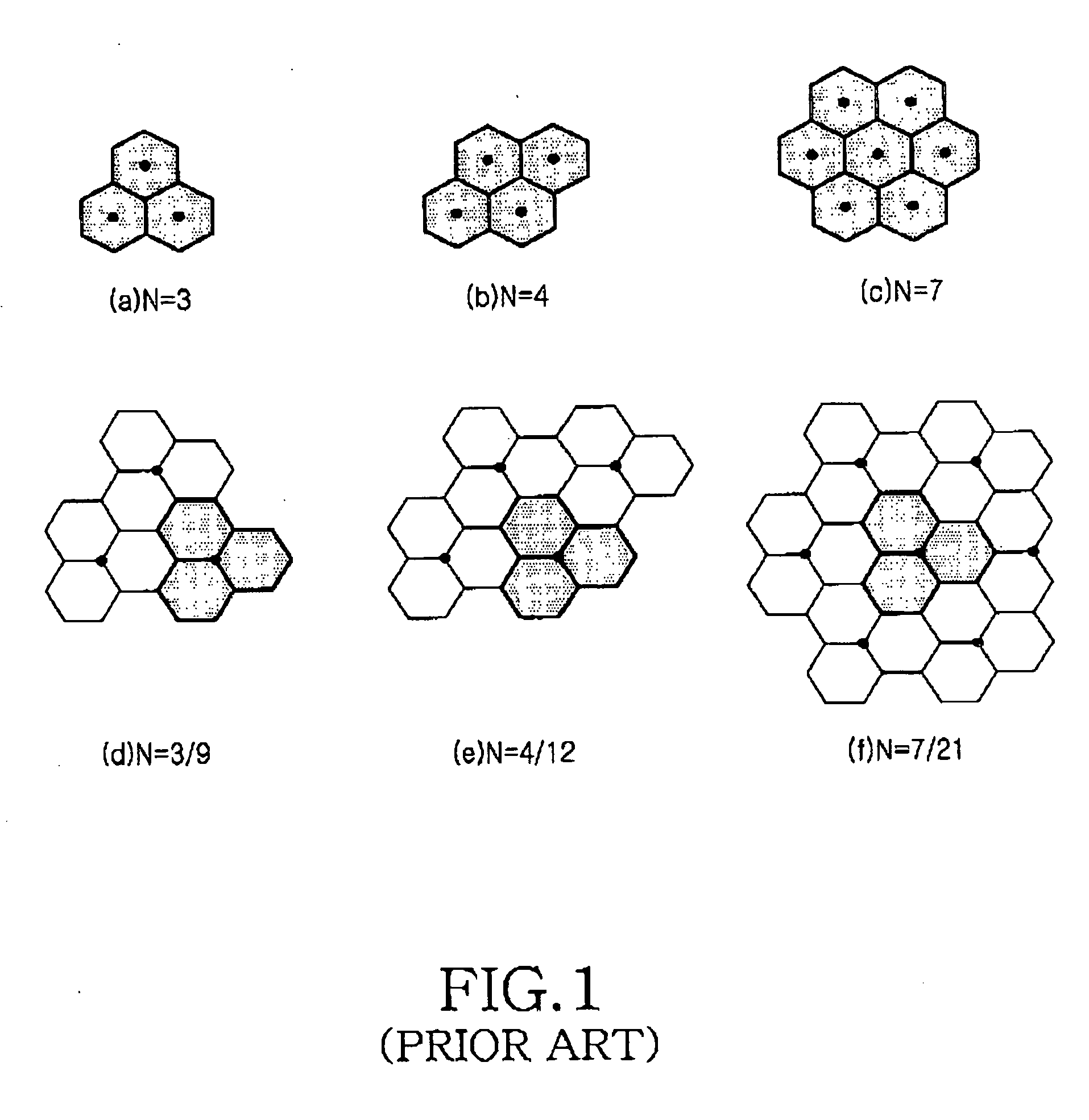

Method for increasing network throughput of cellular wireless packet network by loading control

InactiveUS20050074030A1Improve system efficiencyImprove system performanceTime-division multiplexBroadcast service distributionMobile stationThroughput

A method for increasing a network throughput of a cellular wireless packet network by controlling loading on a transmission frame in a cellular wireless packet network. In the method, transmission data are mapped to a transmission frame to be transmitted in a cellular wireless packet network in which a plurality of base stations and a plurality of mobile stations transmit packet data to each other. The method includes the steps of: dividing the transmission frame into a plurality of transmission groups each of which includes at least one slot; and constructing the transmission frame by allocating data with different loadings to the divided transmission groups.

Owner:SAMSUNG ELECTRONICS CO LTD

Production of 3,4-dichloroaniline catalyst with 3,4-mirbane oil dichloride hydrogenation

InactiveCN1817455AEasy to makeQuality is not affectedOrganic compound preparationCatalyst activation/preparationActivated carbonHalogen

A catalyst for preparing 3,4-dichlorophenylamine from 3,4-dichloronitrobenzene by hydrogenating is prepared through immersing activated carbon in the aqueous solution of potassium (or sodium) halide, washing until no halogen ions, immersing it in the aqueous solution of H2PdCl4, regulating pH value, filtering, washing filtered cake, reducing to obtain neutral product, and drying. It has high catalytic activity and selectivity.

Owner:ZHEJIANG UNIV OF TECH

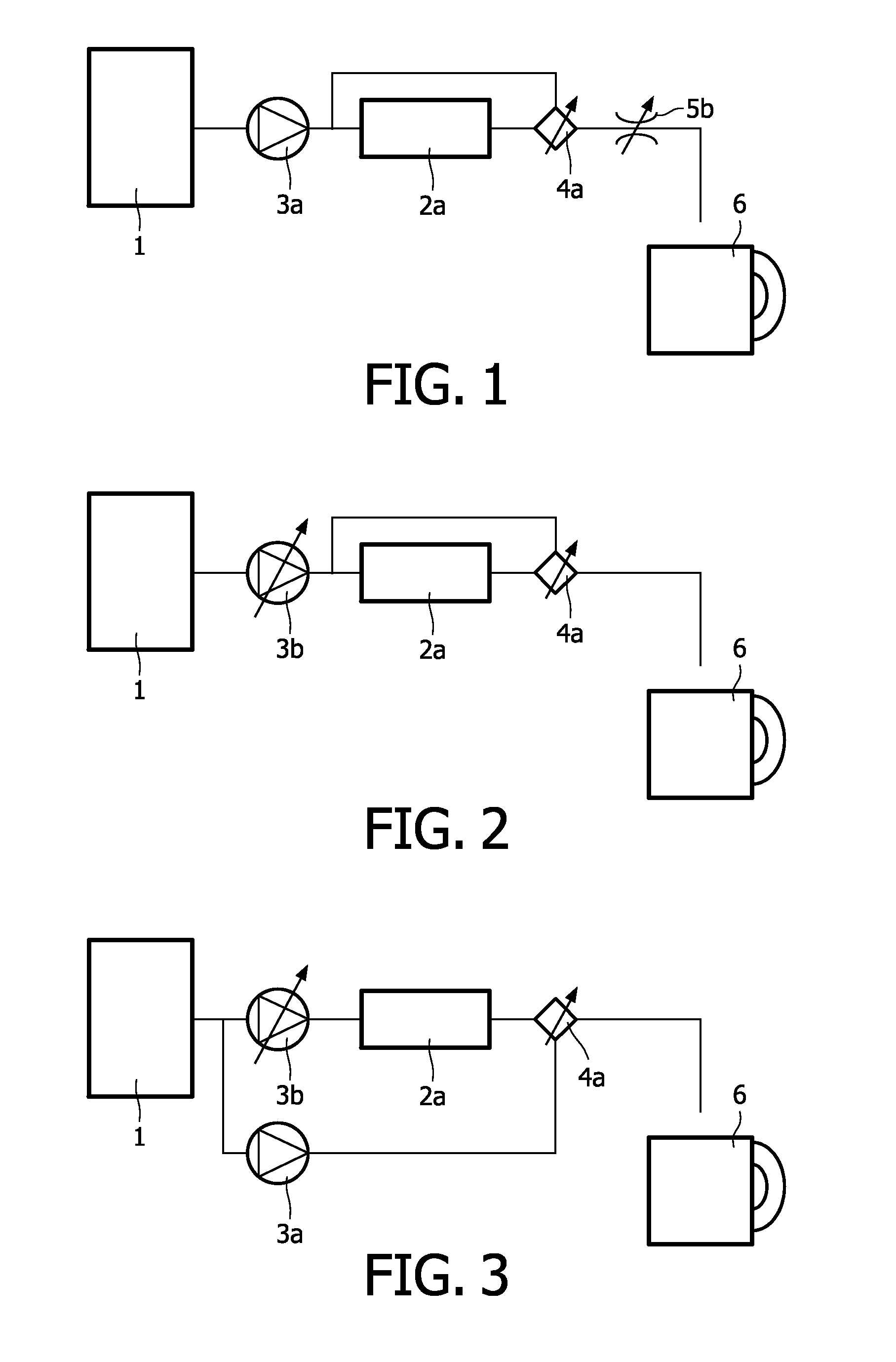

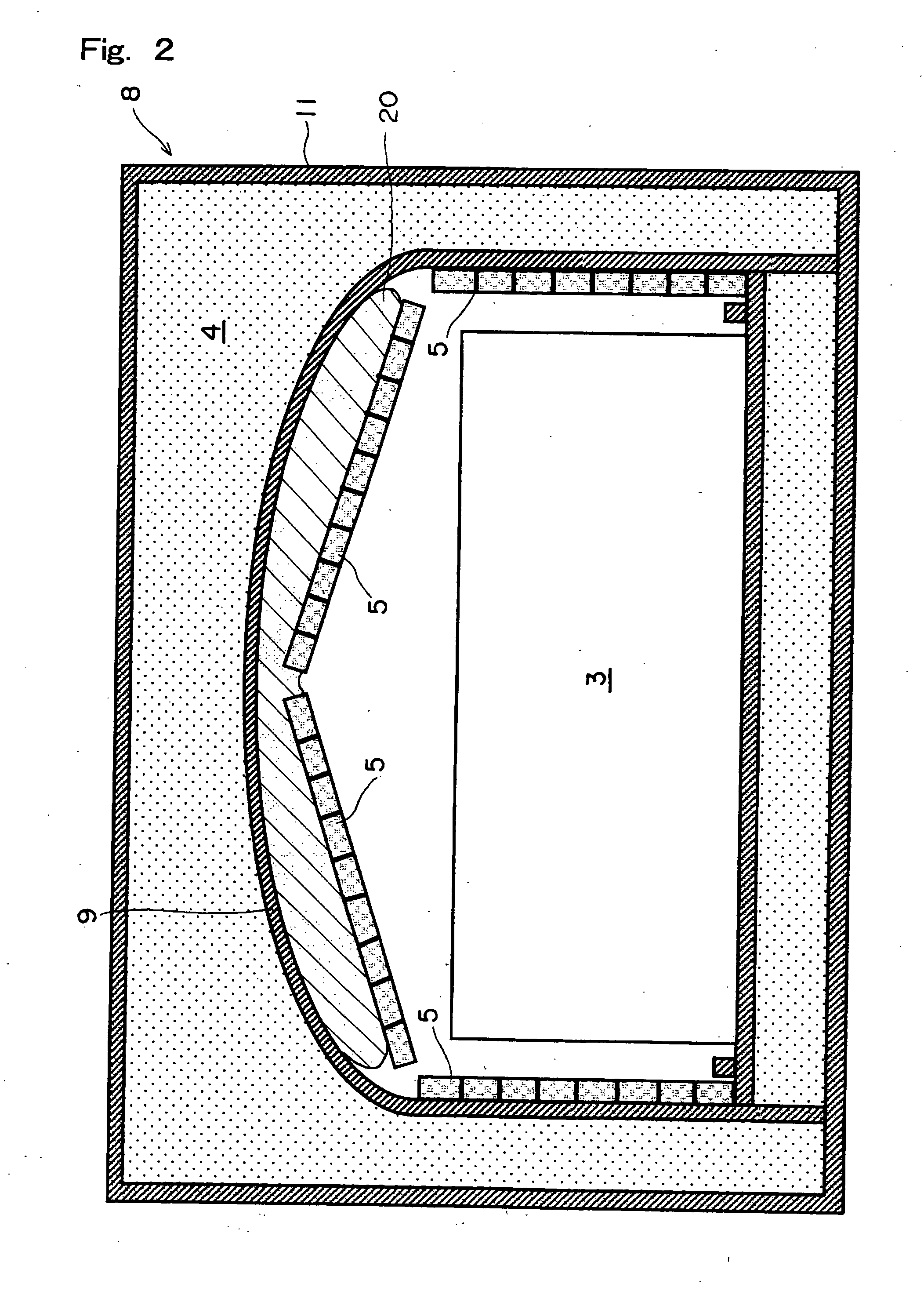

Thermoelectric Conversion System and of Increasing Efficiency of Thermoelectric Conversion System

InactiveUS20080023056A1Control quantityKeep soundnessThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEmissivityTemperature difference

The present invention relates to a thermoelectric conversion system for receiving heat by radiation from a heat source and an efficiency improving method of the thermoelectric conversion system, the system including at least one thermoelectric conversion module 5 having at least a pair of thermoelectric elements 2, a heat receiving zone 6 placed not to contact a heat source 3 for receiving heat by radiation from the heat source 3 and a radiating zone 7 positioned on an opposite side to the heat receiving zone 6 and cooled by a coolant 4, generating electric power by a temperature difference between the heat receiving zone 6 and the radiating zone 7, a continuous or divided heat receiving surface 18 formed by one or a plurality of surfaces facing the heat source 3 of the heat receiving zone 6, and each of the heat receiving surface 18 is given a different quantity of heat from the heat source 3, the system comprising the heat receiving surface 18 has a plurality of different emissivities according to the quantity of heat received from the heat source 3.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

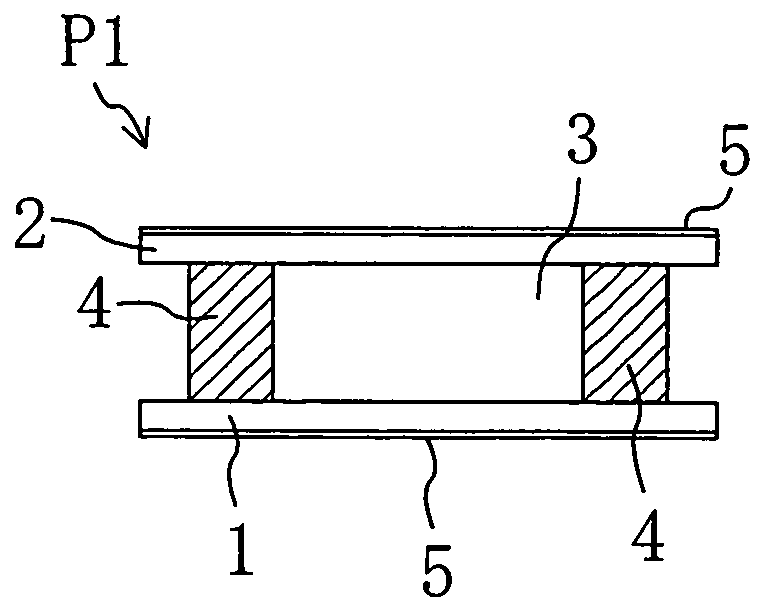

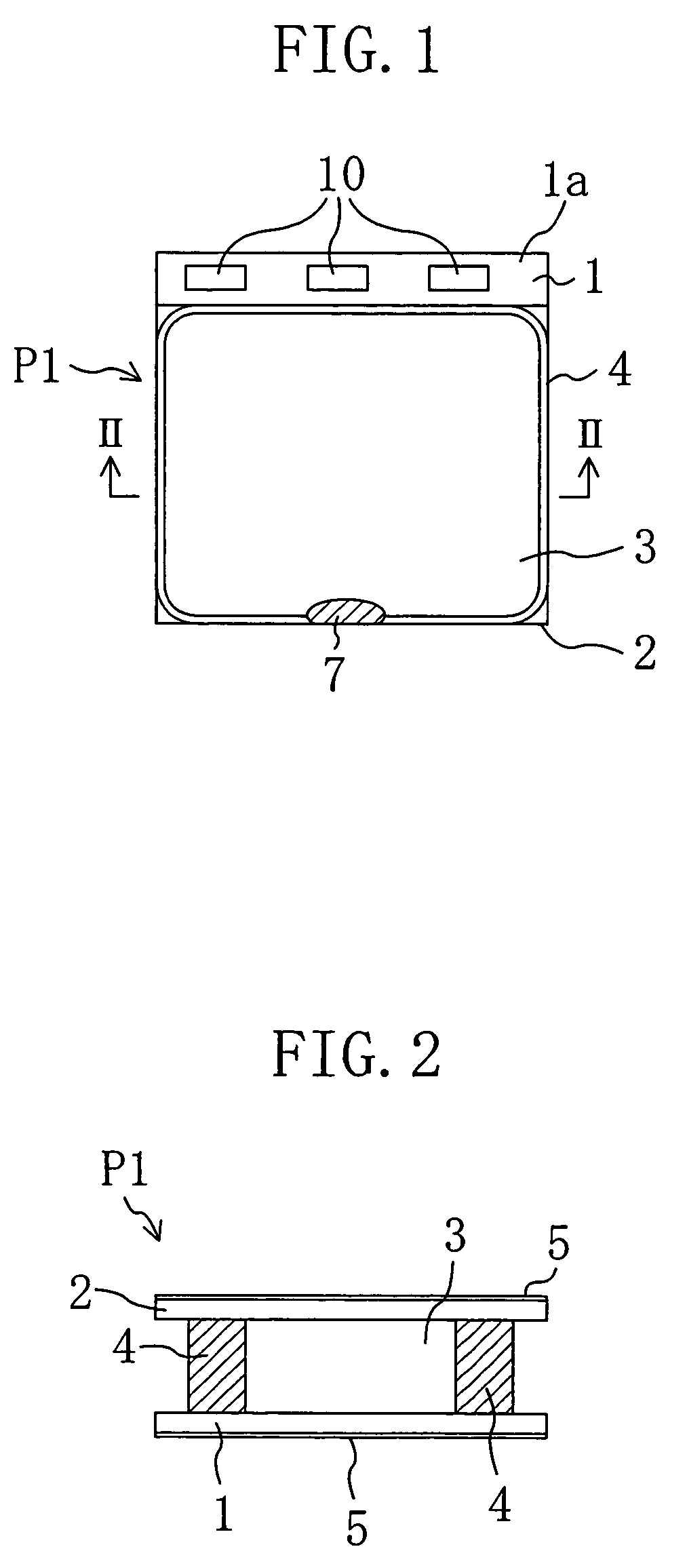

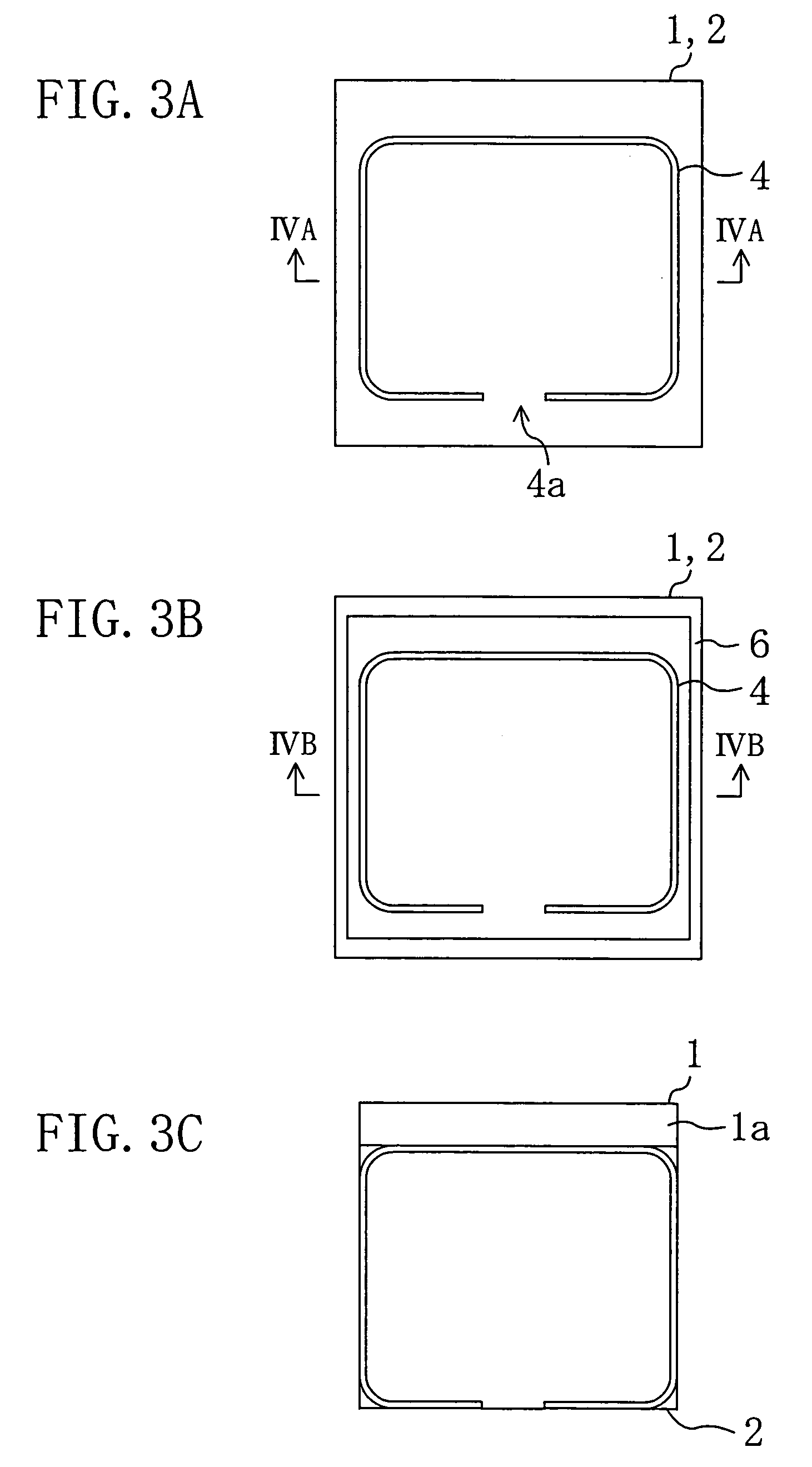

Display panel and method for fabricating the same

InactiveUS7359021B2High mechanical strengthSufficient strength against external stressSolid-state devicesSemiconductor/solid-state device manufacturingComposite materialSurface plate

Owner:SHARP KK

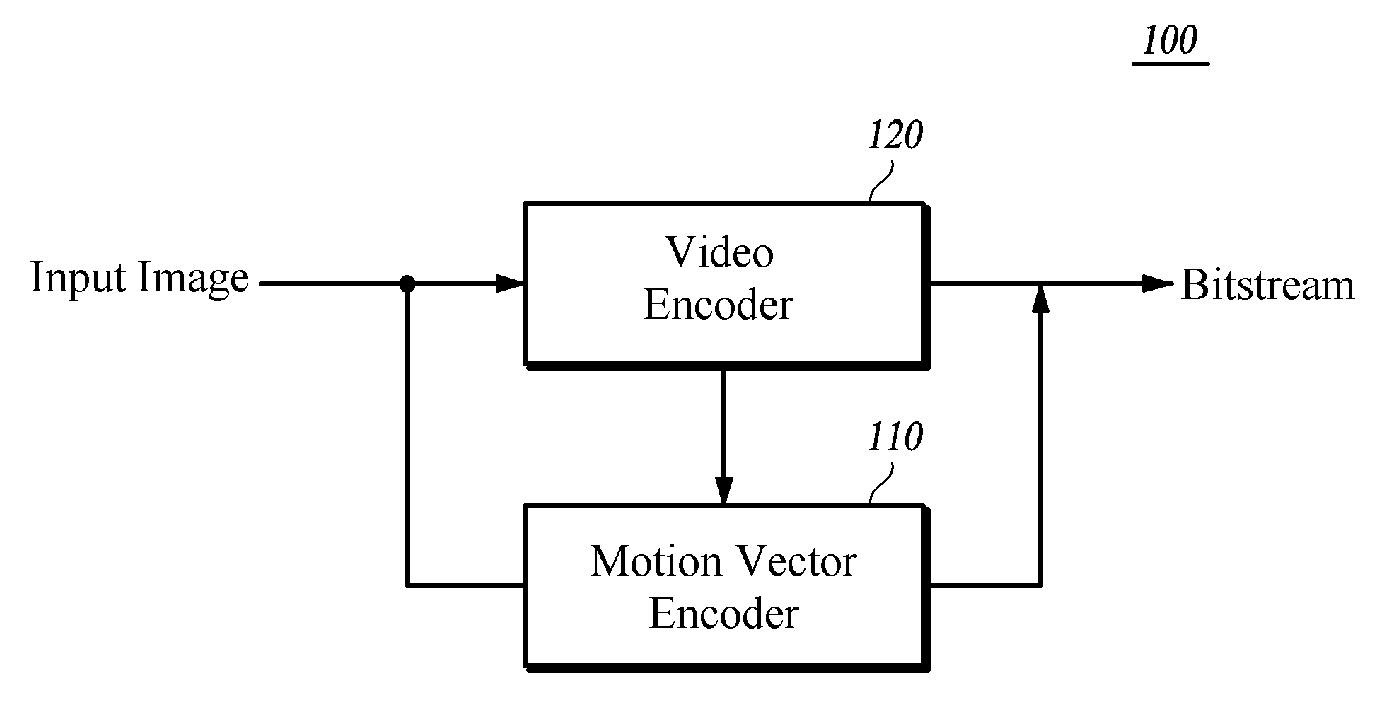

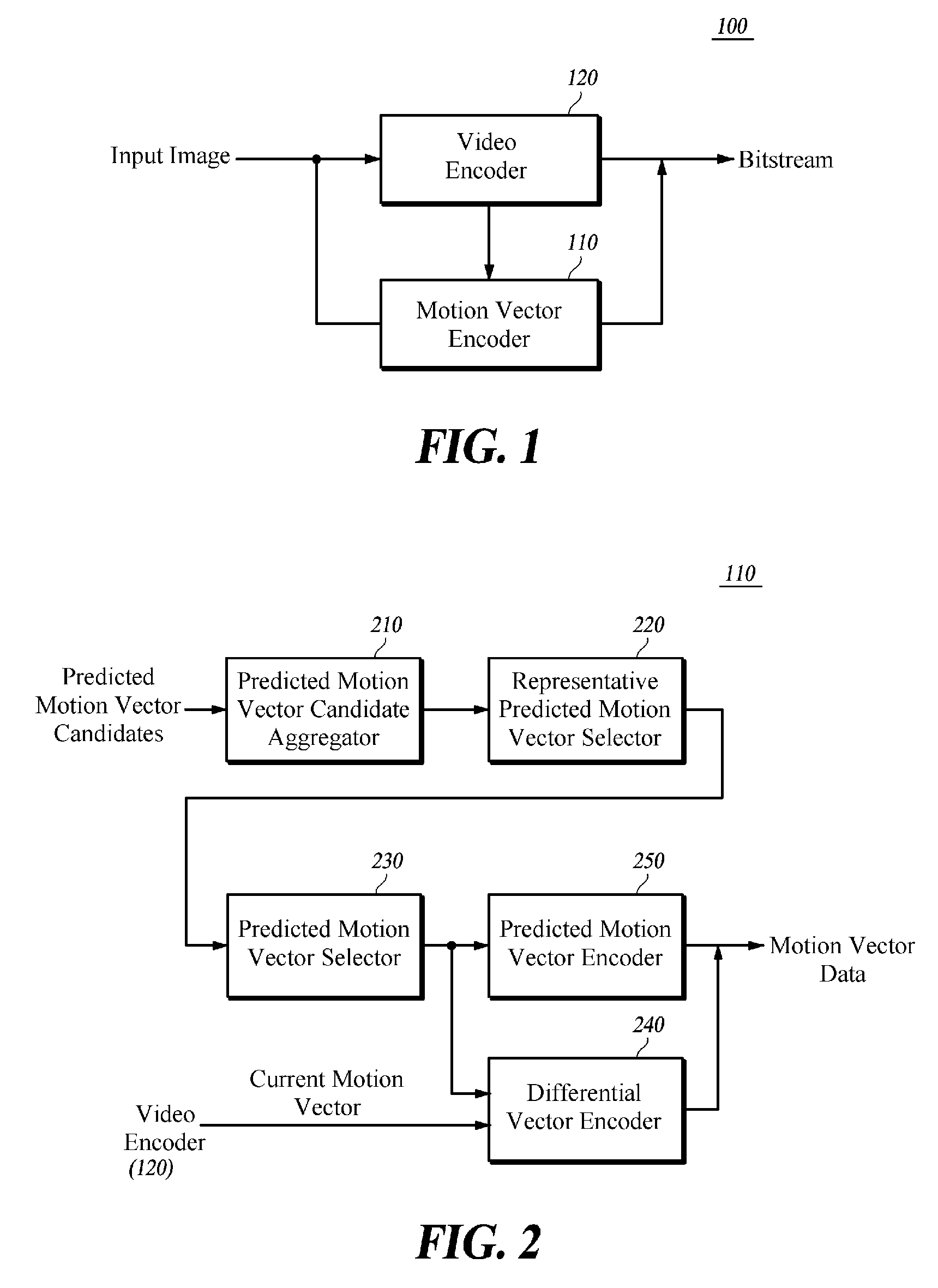

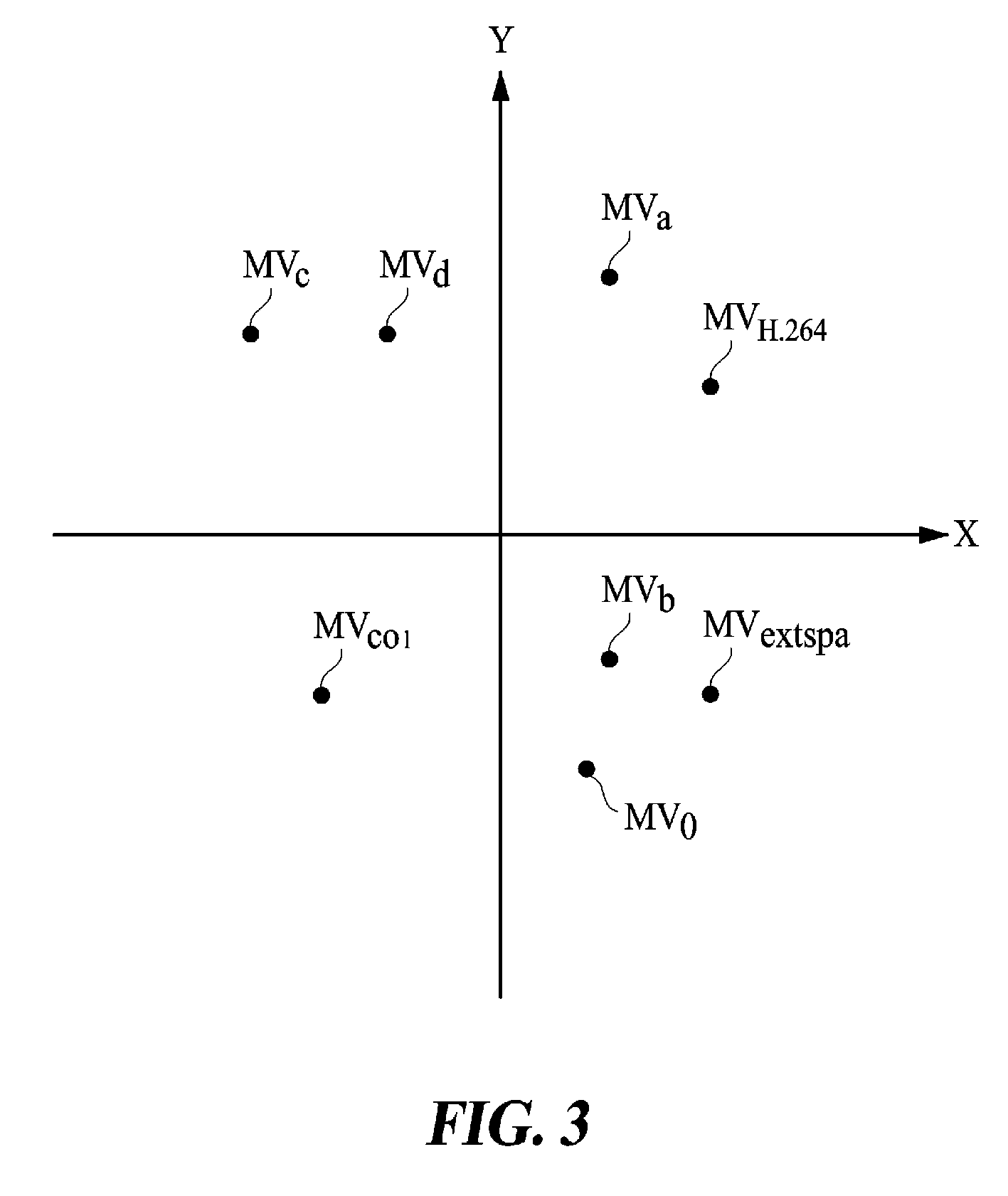

Method and apparatus for motion vector encoding/decoding using spatial division, and method and apparatus for image encoding/decoding using same

ActiveUS20120275522A1Improve efficiencyEasy to compressColor television with pulse code modulationColor television with bandwidth reductionMotion vectorSide information

The present disclosure relates to a method and apparatus for motion vector encoding / decoding using spatial division, and to a method and apparatus for image encoding / decoding using same, wherein the motion vector encoding method includes: aggregating predicted motion vector candidates of a current block into a plurality of groups; selecting representative predicted motion vectors for respective groups by selecting one of aggregated predicted motion vector candidates within the respective groups as representative predicted motion vector; selecting single representative predicted motion vector from the representative predicted motion vectors for the respective groups as a predicted motion vector; and encoding a differential vector representing difference between a current motion vector of the current block and a selected predicted motion vector. The disclosure suppresses an increase in bit rate caused by encoding side information for indicating which predictor motion vector is selected while is reducing the size of the differential vector to be encoded.

Owner:SK TELECOM CO LTD

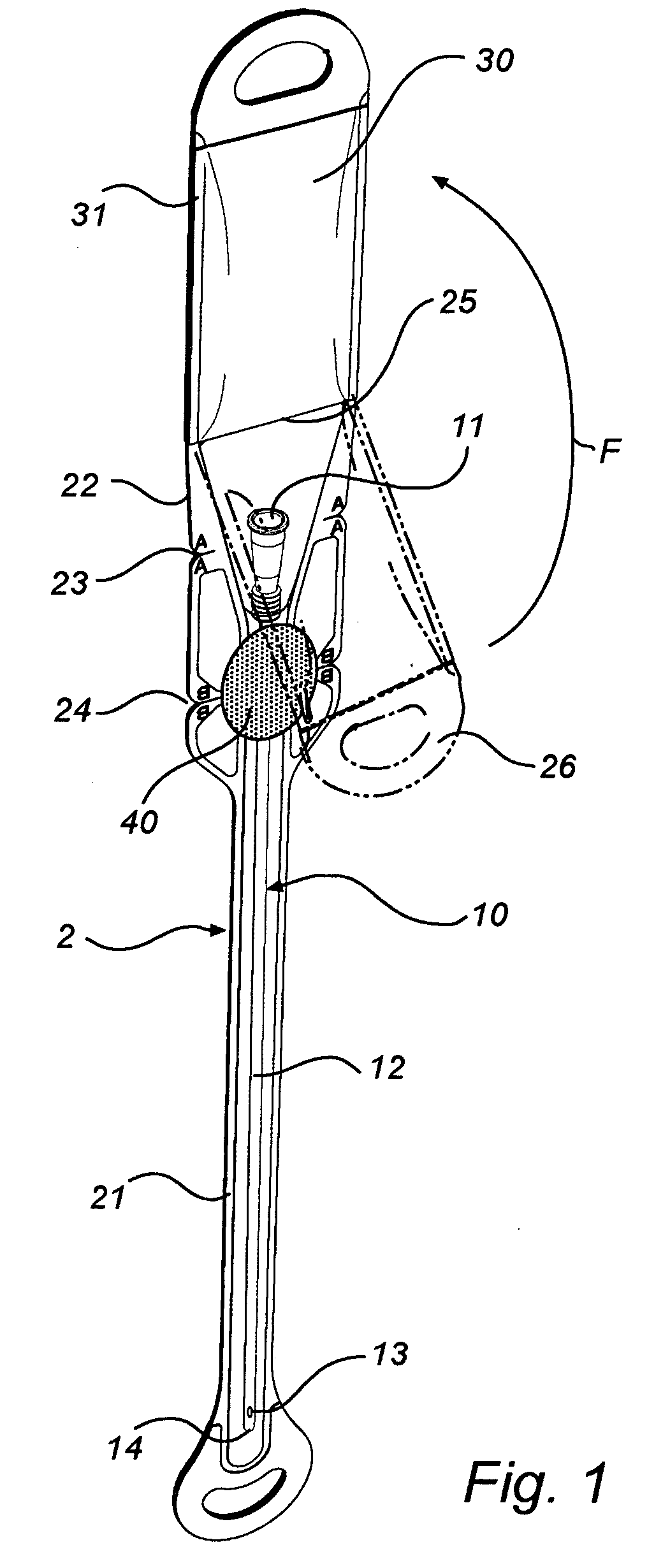

Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure

InactiveCN103462729APrecise control over distributionPrecise Control of ConnectivityBone implantCorrosionAdhesion process

The invention relates to a preparation method of a bionic artificial bone with a multistage [micrometer / nanometer] pore structure. The method is characterized by the following steps of: realizing 150-800 mum gradient through pores by selective laser sintering (the diameter of the light spot is micrometer scale); mixing and performing oxygenolysis on a small amount of high polymer microballoons in the sintering process to form 10-100 mum random spherical pores; finally obtaining the bionic artificial bone which has an three-dimensional hierarchical pore structure similar to that of a natural bone by a method of obtaining irregular pores in tens of nanometer surfaces by a corrosion process. In the invention, according to the requirement of an implanting position, the distribution, connectivity and the like of the gradient through pore can be accurately controlled by adjusting sintering process parameters; the shape, size and the like of the spherical pores can be controlled by precisely controlling the furnace temperature curve and high polymer particle properties; the size, quantity and the like of the nanometer pores can be controlled by controlling the corrosion liquid concentration and corrosion time. The preparation method disclosed by the invention has an important significance in creating a microenvironment beneficial to cell adhesion, proliferation and function exertion, improving forming of new bones, and increasing healing of bones.

Owner:CENT SOUTH UNIV

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

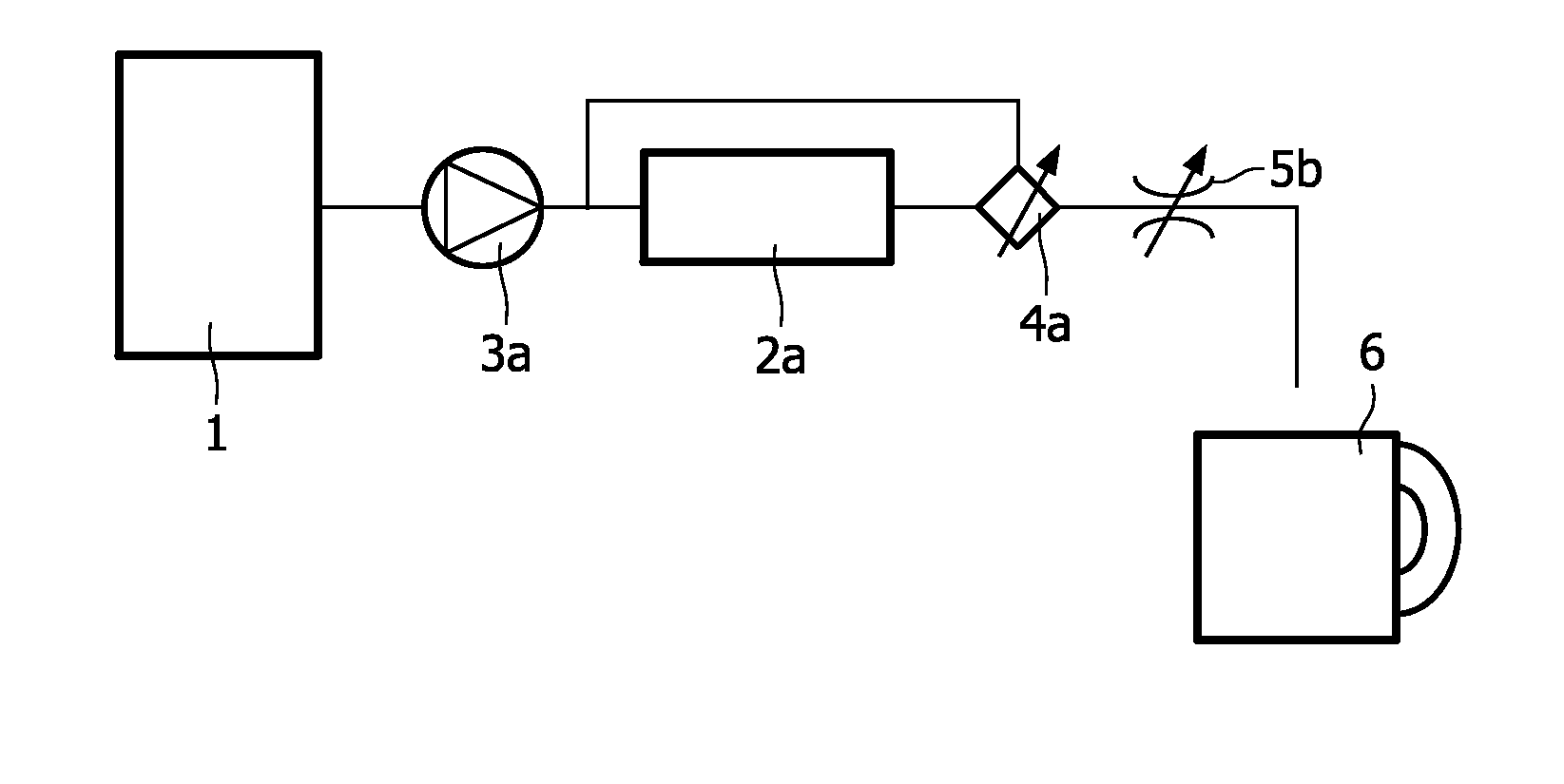

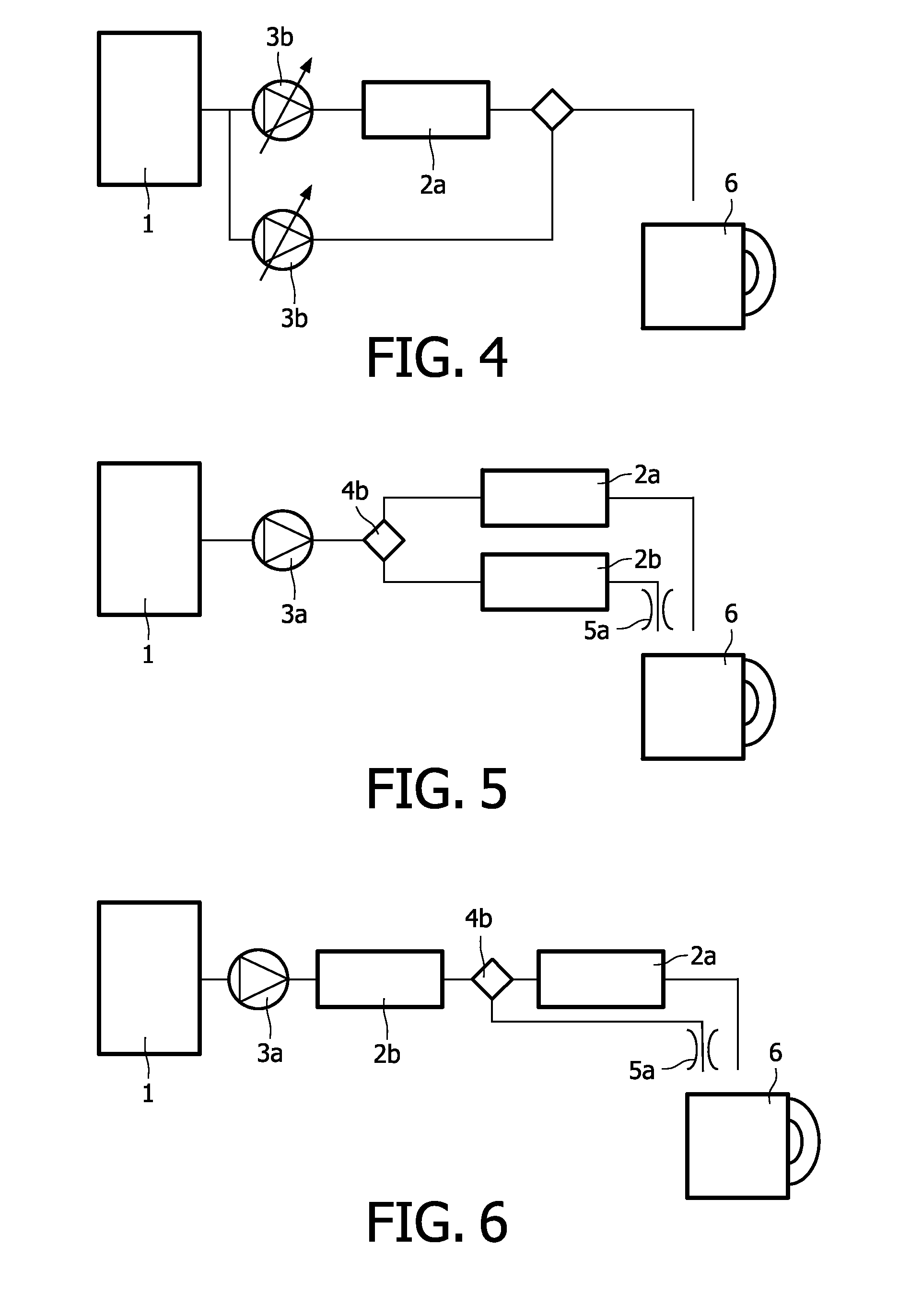

Method and appliance for making ice coffee

InactiveUS20100266740A1Nice tasteReduce extraction timeFrozen sweetsBeverage vesselsAmbient pressureEngineering

A method for making ice coffee comprises the following steps: extracting coffee by using water at a temperature that is in a range of 35° C. to 55° C., at a normal brewing pressure that is in a range of ambient pressure to 1.5 bar, and at an extraction time that is shorter than 60 seconds, and supplying a quantity of ice to the beverage which is obtained as a result of this extraction process, in order to get the ice coffee at a temperature at which it is ready to drink. An appliance for carrying out the method may also be adapted to make hot coffee, so that a user may choose which type of coffee he / she would like to receive from the appliance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

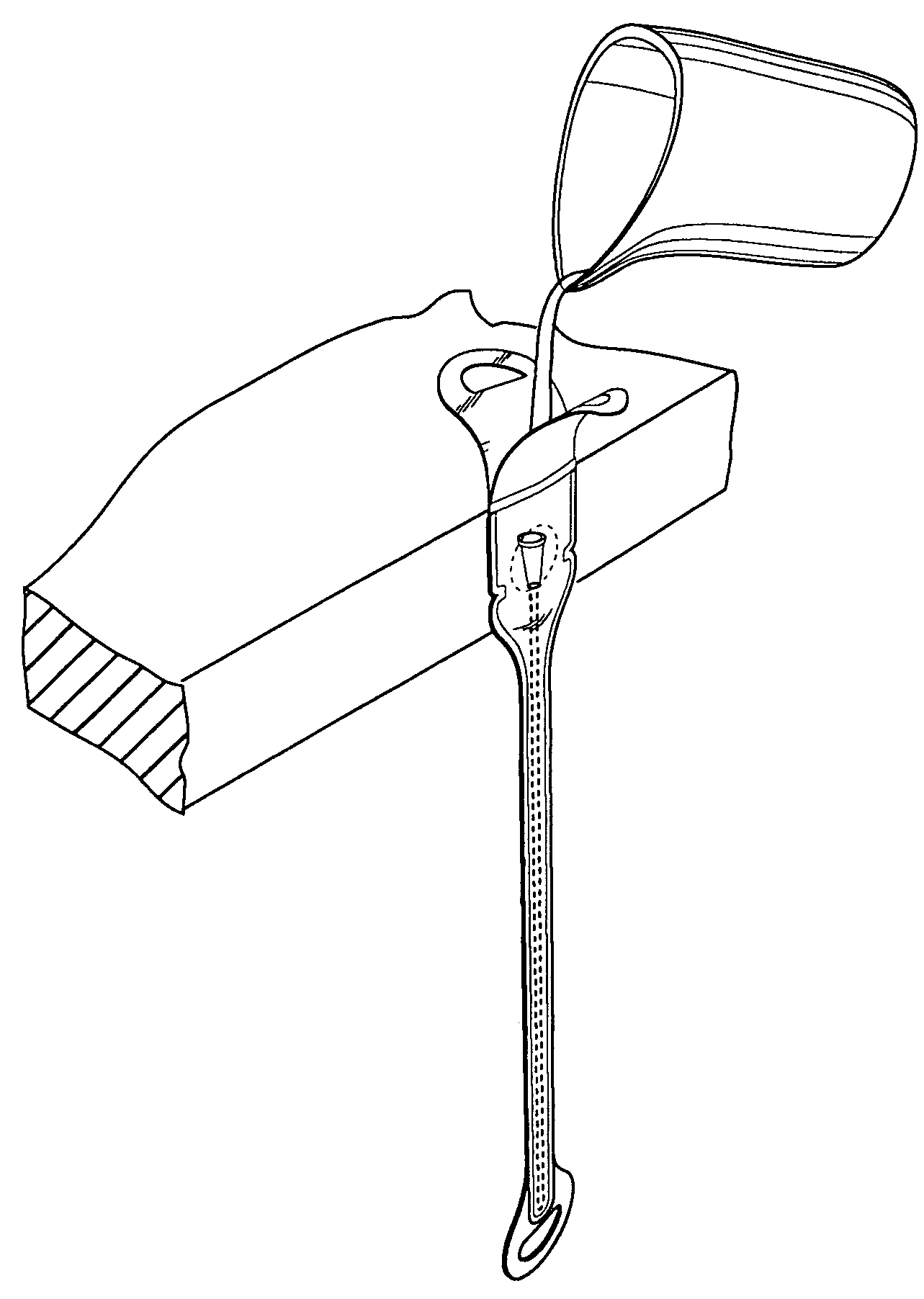

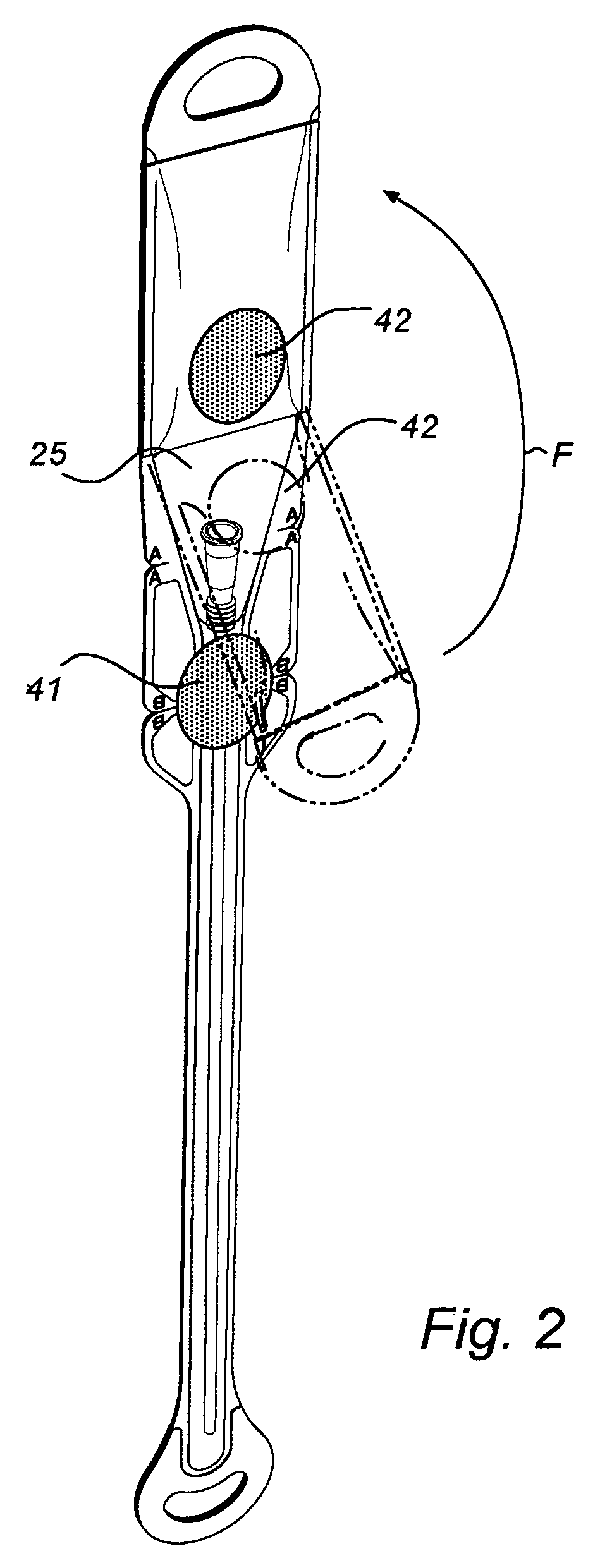

Folded Catheter Assembly With Adhesive Grip

ActiveUS20080200907A1Widely distributedImprove usabilityDispensing apparatusDiagnosticsGuide tubeBiomedical engineering

A catheter assembly is disclosed comprising a catheter and a receptacle enclosing said catheter. The receptacle has a first part and a second part, which parts are foldable over each other. Further, at least one sticky adhesive area is arranged on the surface of one of the parts of the receptacle in such a way that the sticky adhesive area is covered by the other part when the receptacle is in a folded disposition, and exposed to the environment when the receptacle is in an unfolded disposition.

Owner:ASTRA TECH SE

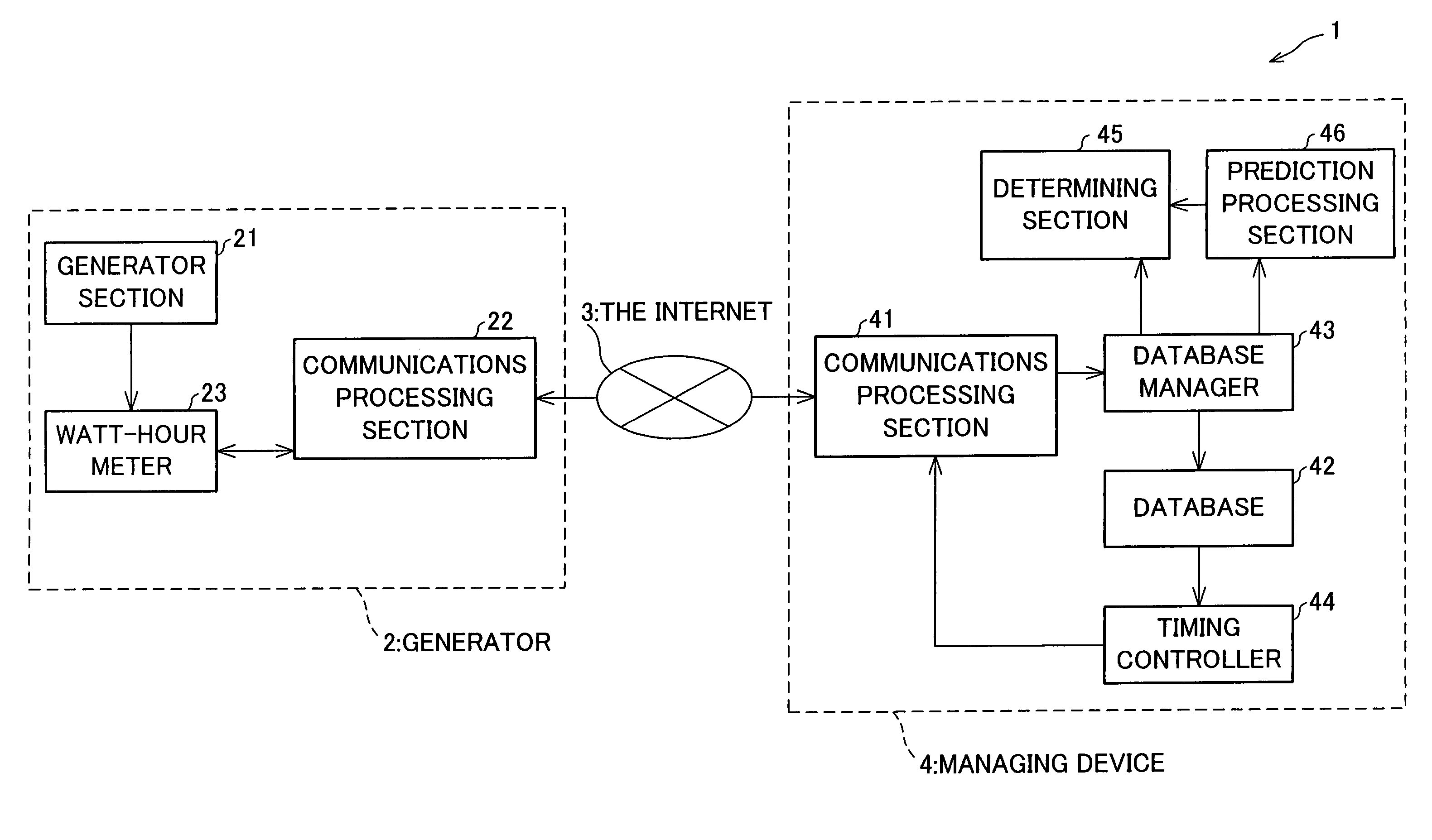

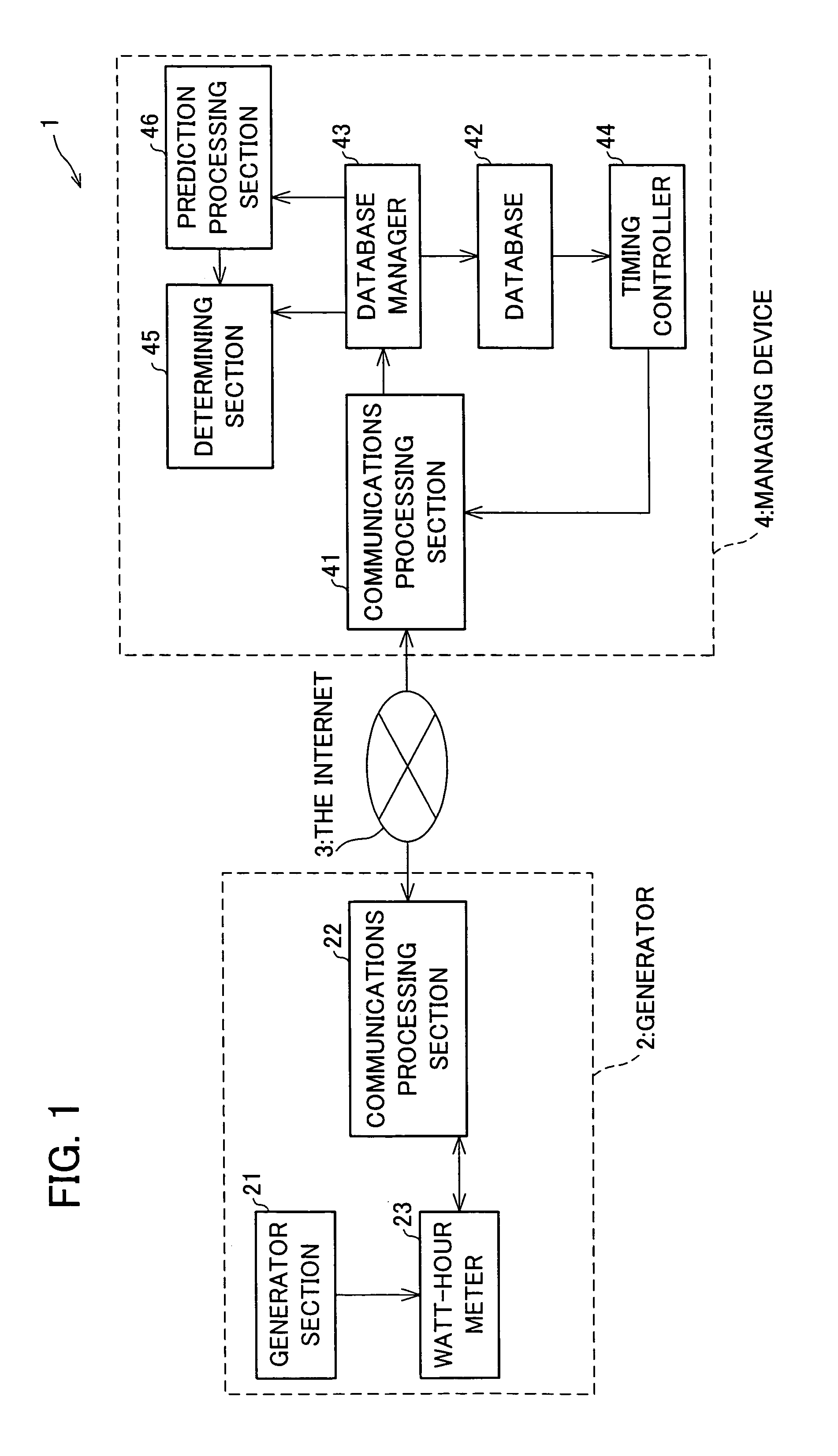

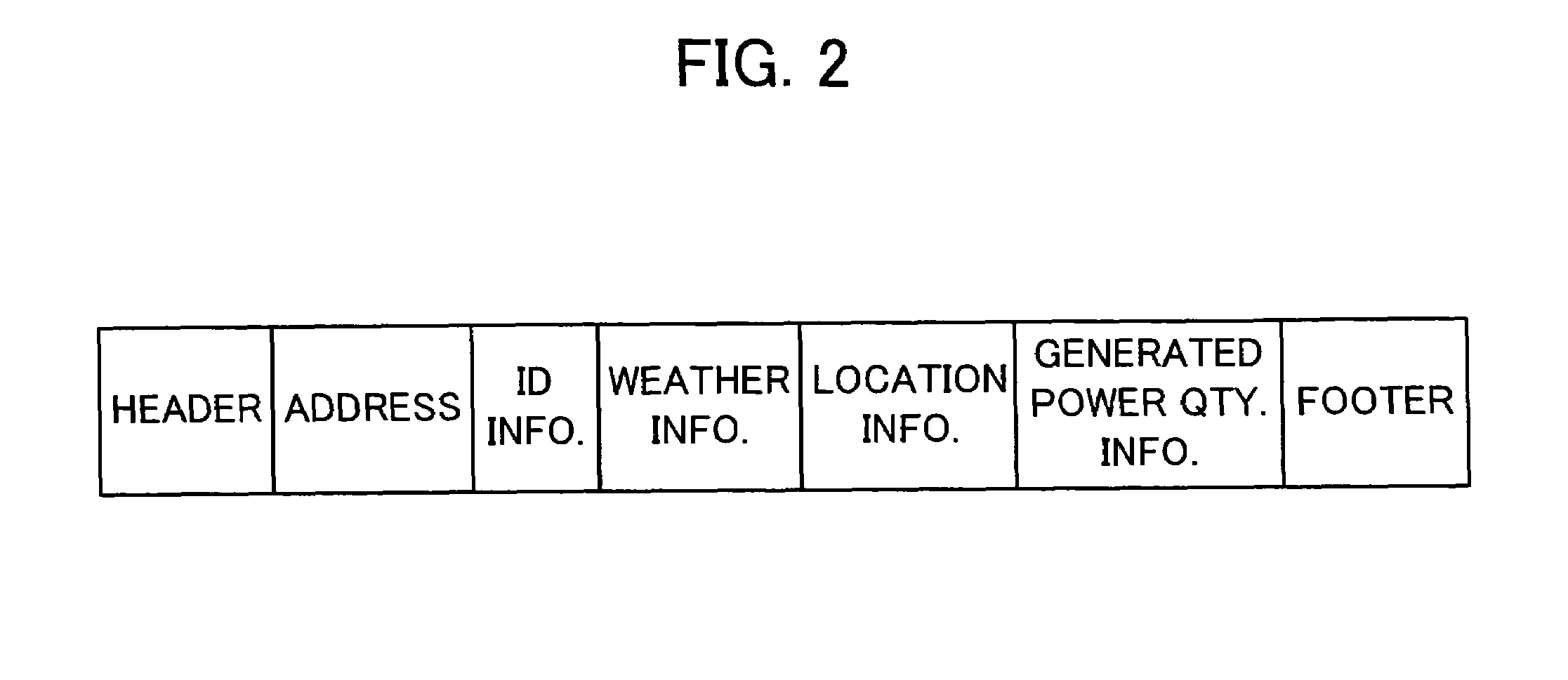

Method of managing electric power generator, managing device, electric power generator, communications device, computer program therefor, and managing system for electric power generator

ActiveUS7133787B2Decreases its power generation capabilityQuickly takenElectric signal transmission systemsLevel controlThe InternetDatabase manager

A communications processing section in a managing device transmits a request for a transmission of generated power quantity information via the Internet to an electric power generator to be managed. A database manager in the managing device stores the generated power quantity information transmitted back from the electric power generator into a database. A timing controller in the managing device controls so that the number of electric power generators to which a transmission request is being transmitted does not exceed a predetermined value.

Owner:SHARP KK

Sbsorptive product having removable absorbers

InactiveUS20030220623A1Easy disposalMinimizes problemBaby linensTamponsEngineeringMechanical engineering

An absorptive product comprising a front part, a rear part, an inside leg part, a waist opening, a pair of leg circumference openings, and a liquid-impermeable back sheet, wherein disposed on the inner side of the back sheet are a urinal front absorber and a feces rear absorber, with a take-out port formed for taking out these absorbers.

Owner:THE PROCTER & GAMBLE COMPANY

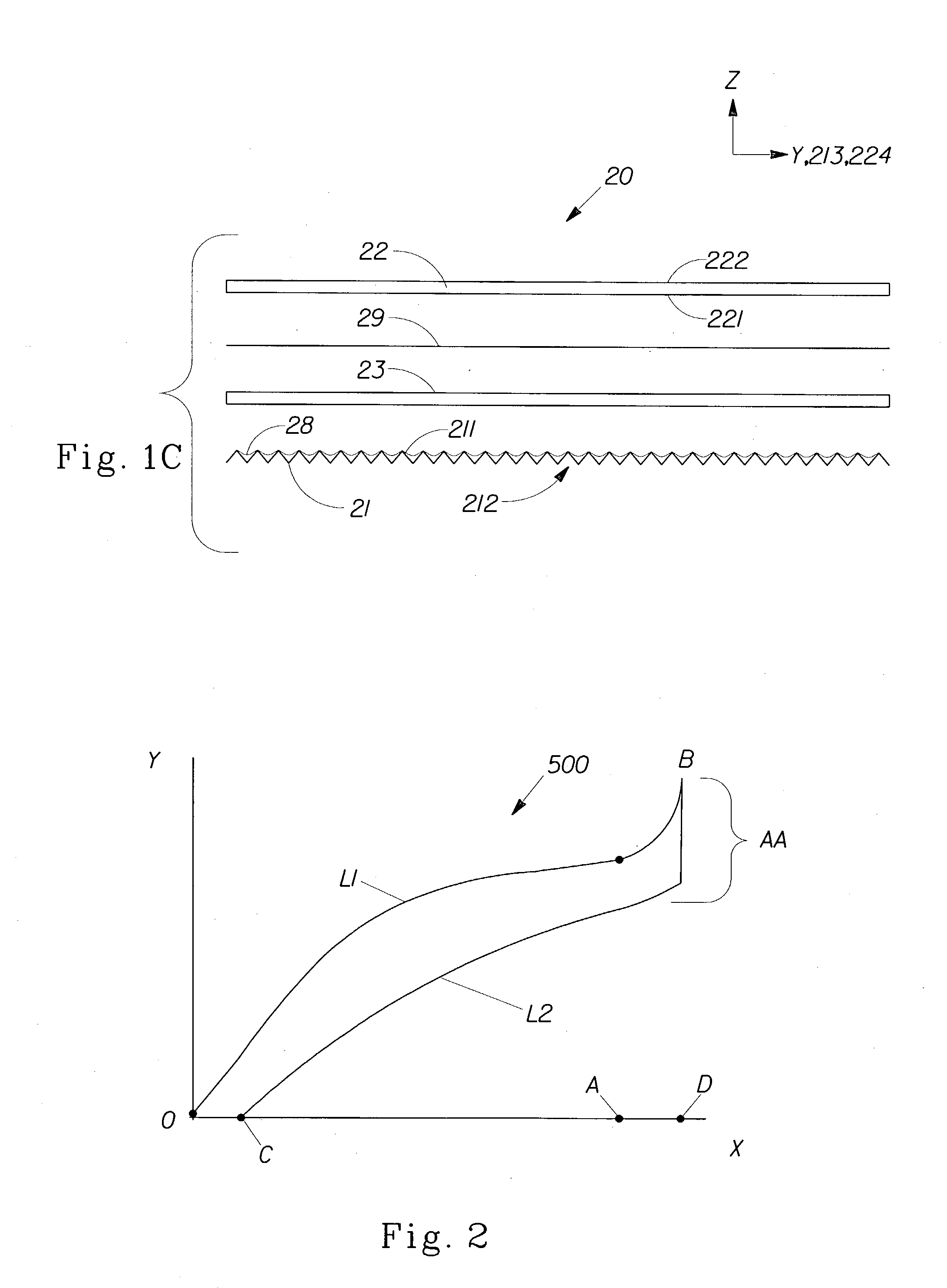

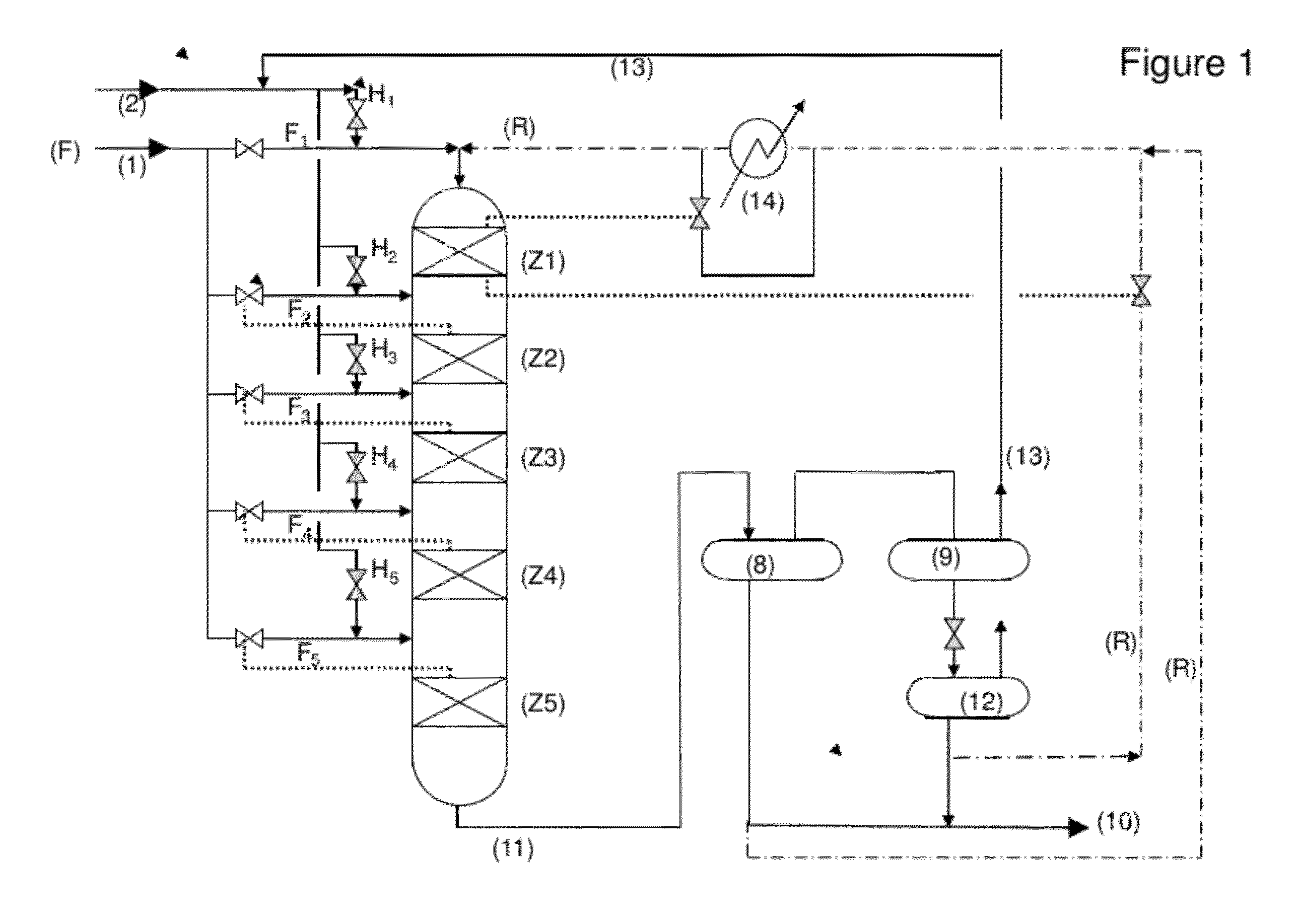

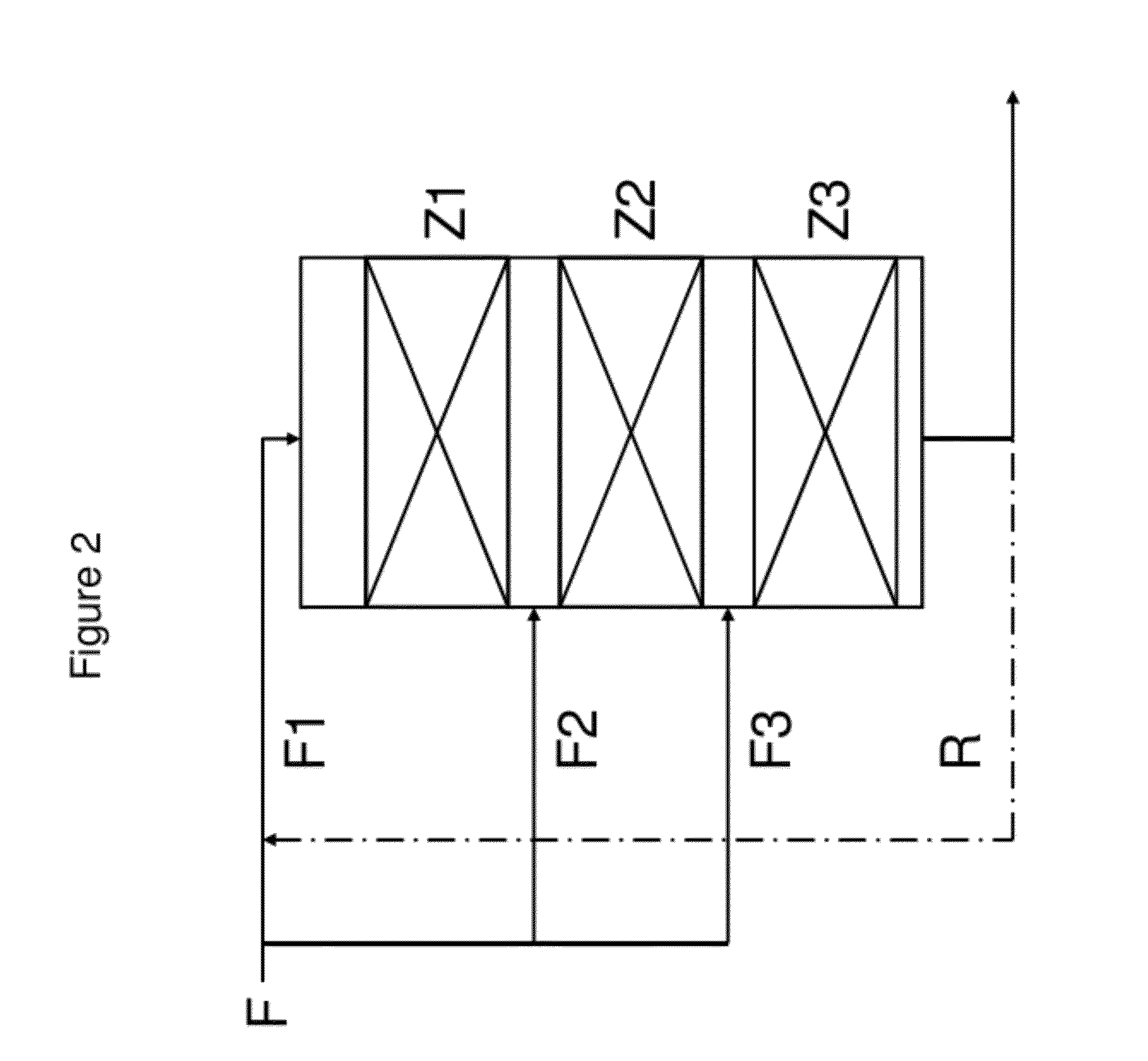

Production of paraffinic fuels from renewable materials using a continuous hydrotreatment process

ActiveUS20120165581A1Promote reactionIncrease temperature profileHydrocarbon purification/separationBiofuelsChemistryAlkane

The invention concerns a process for hydrotreating a feed originating from renewable sources such as vegetable oils to produce paraffinic hydrocarbons in the presence of hydrogen in excess over the theoretical hydrogen consumption and under hydrotreatment conditions in a fixed bed reactor having a plurality of catalytic zones disposed in series and comprising a hydrotreatment catalyst. The total feed flow is divided into a certain number of different part flows equal to the number of catalytic zones in the reactor; the various part flows are injected into the successive catalytic zones in increasing proportions to produce an effluent comprising paraffinic hydrocarbons. The effluent undergoes a separation step in order to separate a gas fraction and a liquid fraction containing the paraffinic hydrocarbons. At least a portion of said liquid fraction is recycled to the first catalytic zone so that the weight ratio between said recycle and the part flow introduced into the first catalytic zone is 10 or more.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200011.PNG)

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200012.PNG)

![Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure Preparation method of bionic artificial bone with multistage [micrometer/nanometer] pore structure](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/031953b7-3dc4-47ad-a8f2-372d94761e6e/HSA00000729923200013.PNG)