Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4388results about "Nanomagnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

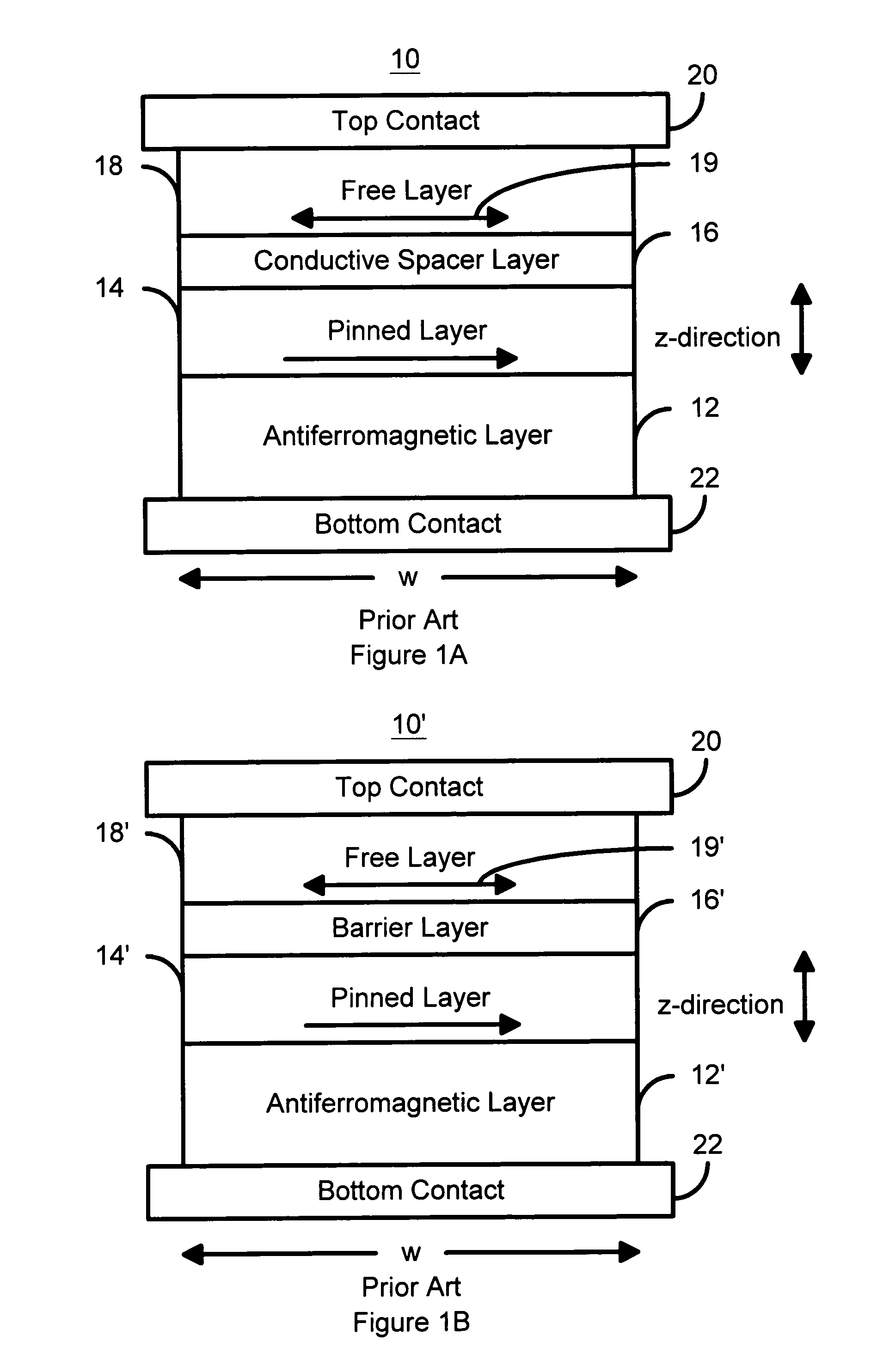

Current-induced magnetic switching device and memory including the same

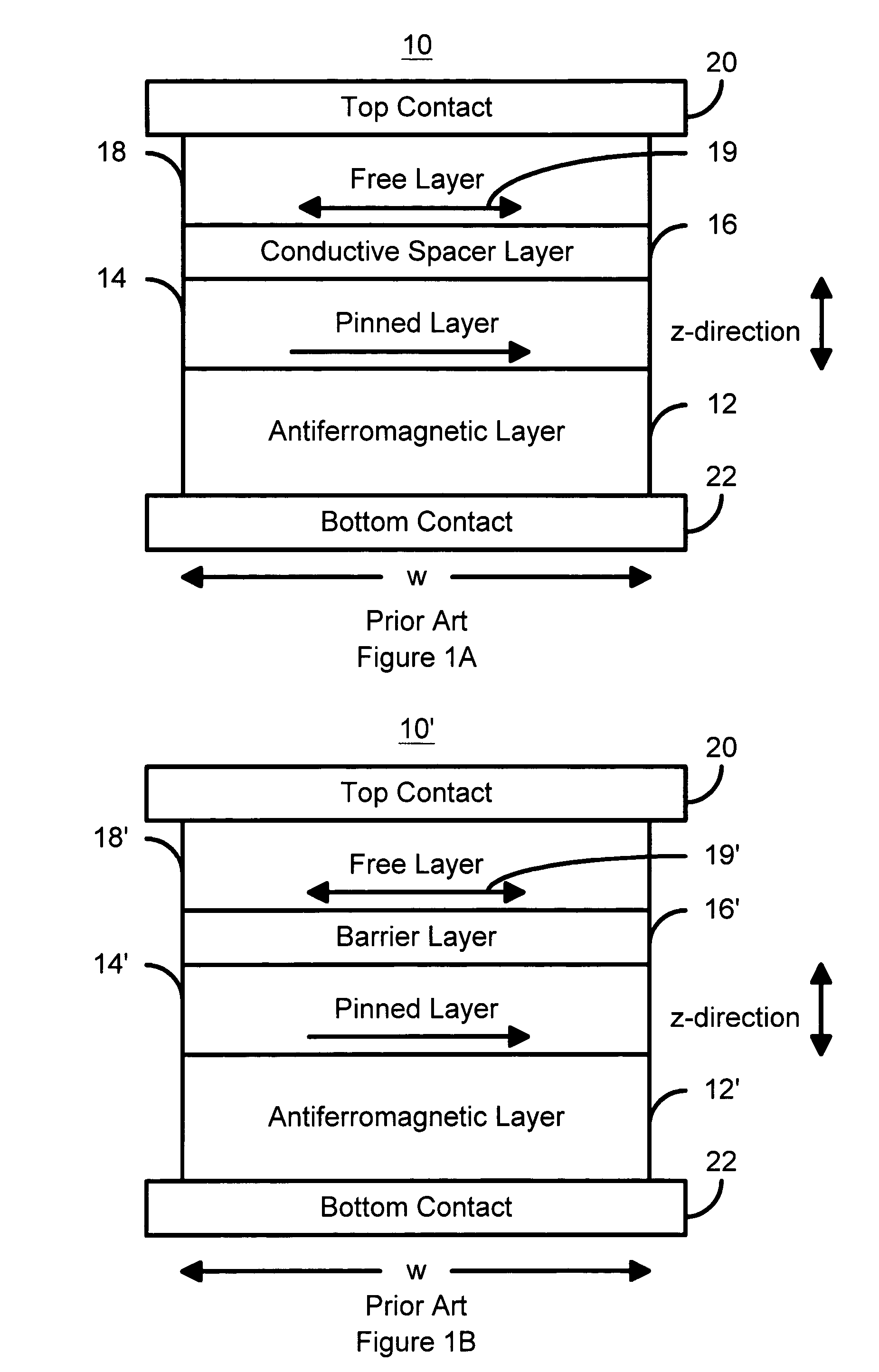

InactiveUS6256223B1High bulk densitySimpler driving circuitsNanomagnetismMagnetic-field-controlled resistorsNanoparticleConduction band

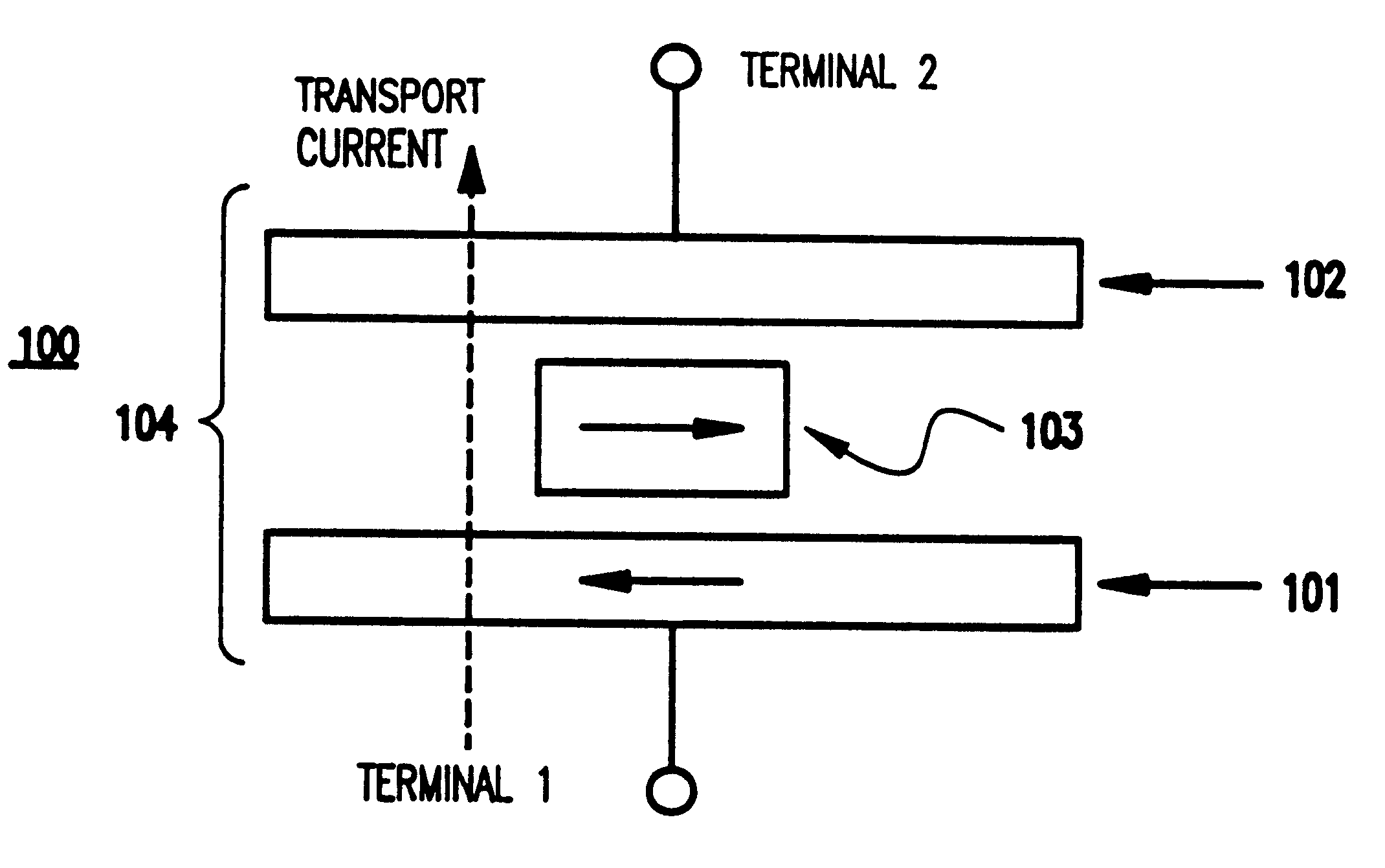

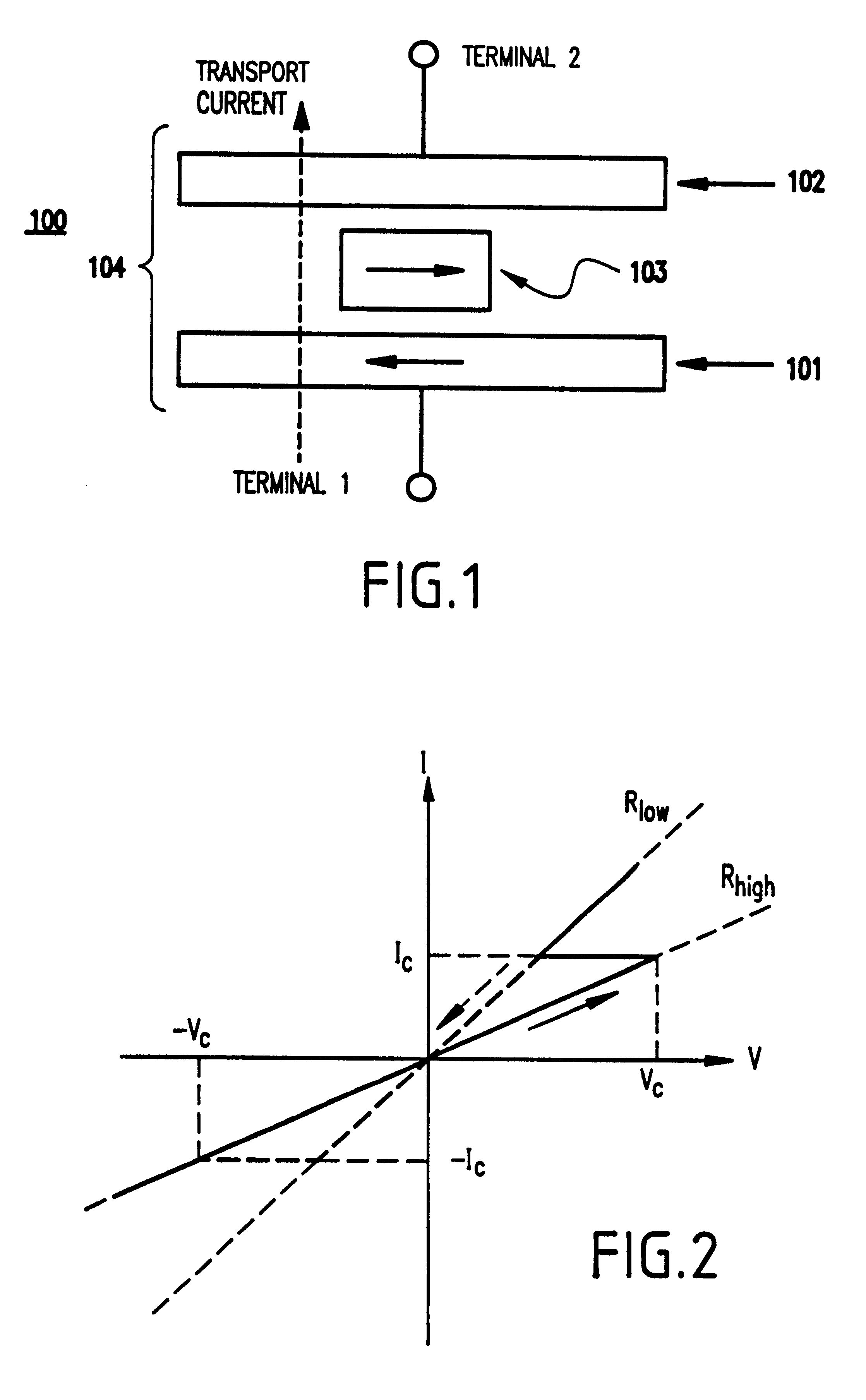

A magnetic switching device, includes a first electrode, a second electrode, and a nanoparticle having a magnetic moment and being disposed between the first and second electrodes. At least one of the first electrode and the second electrode includes a magnetic material which has a net spin polarization in its conduction band for injecting, into the nanoparticle, an electrical current including a net spin polarization for overcoming the magnetic moment of the nanoparticle upon selection of a predetermined magnitude for the electrical current.

Owner:INT BUSINESS MASCH CORP

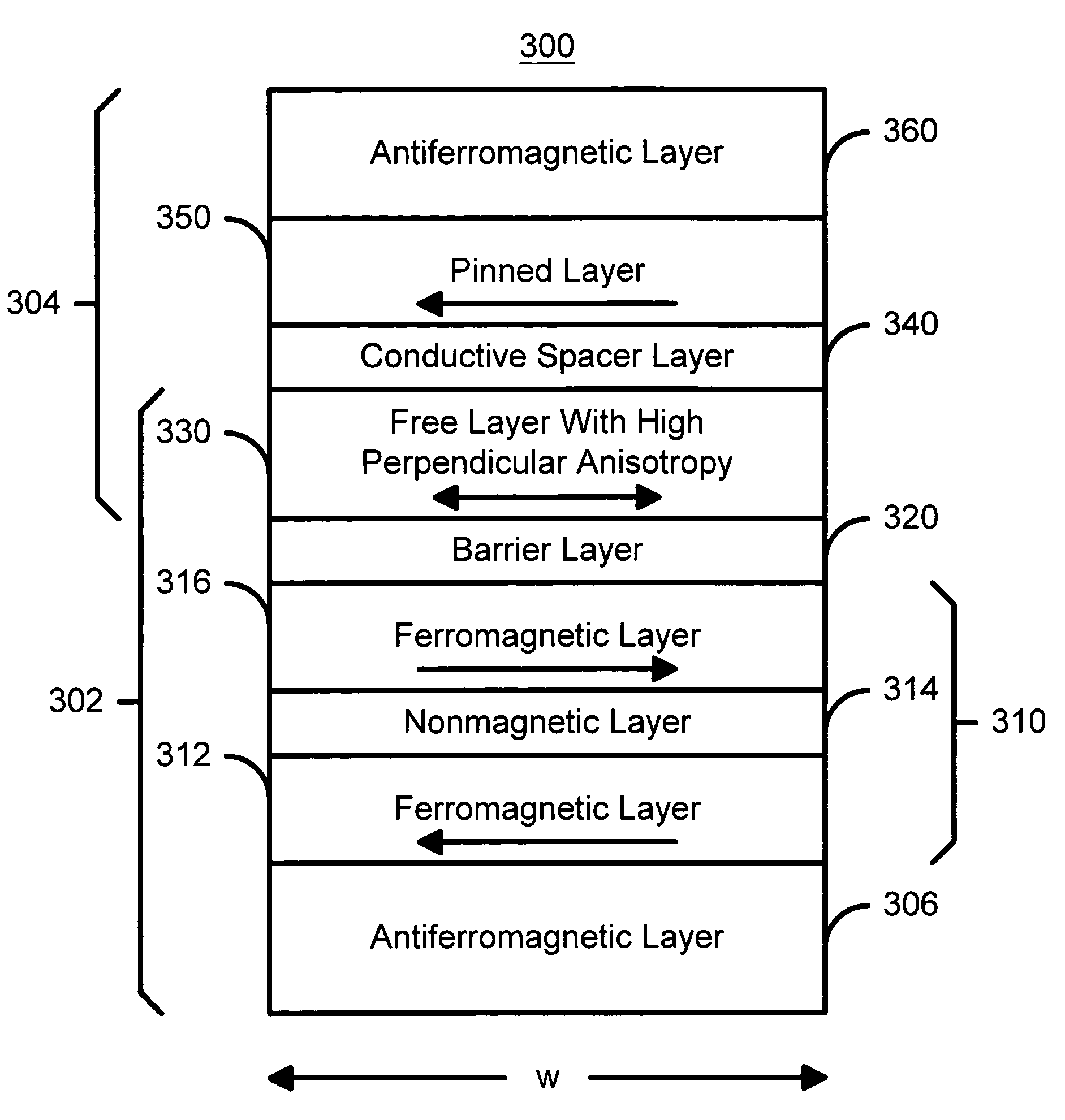

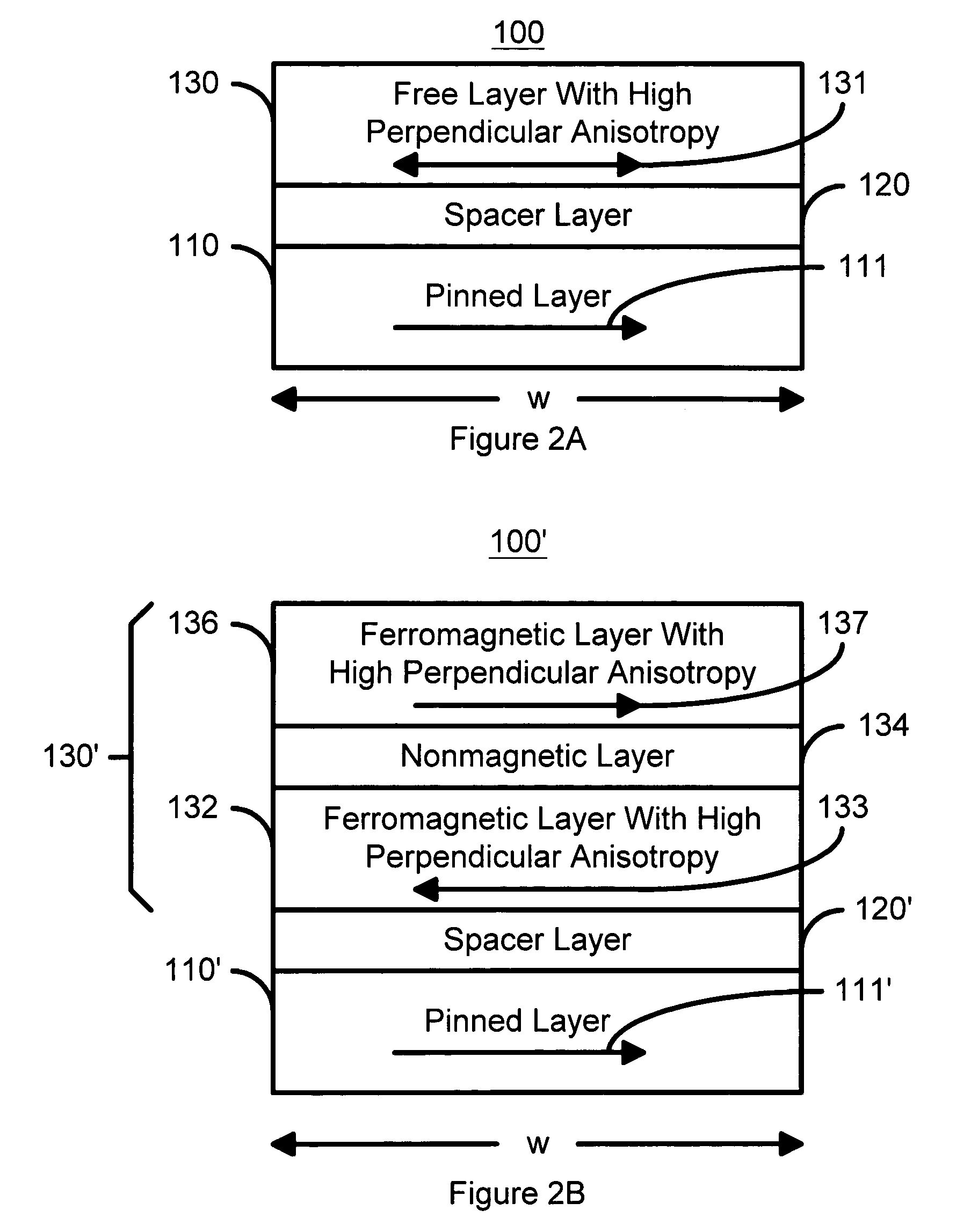

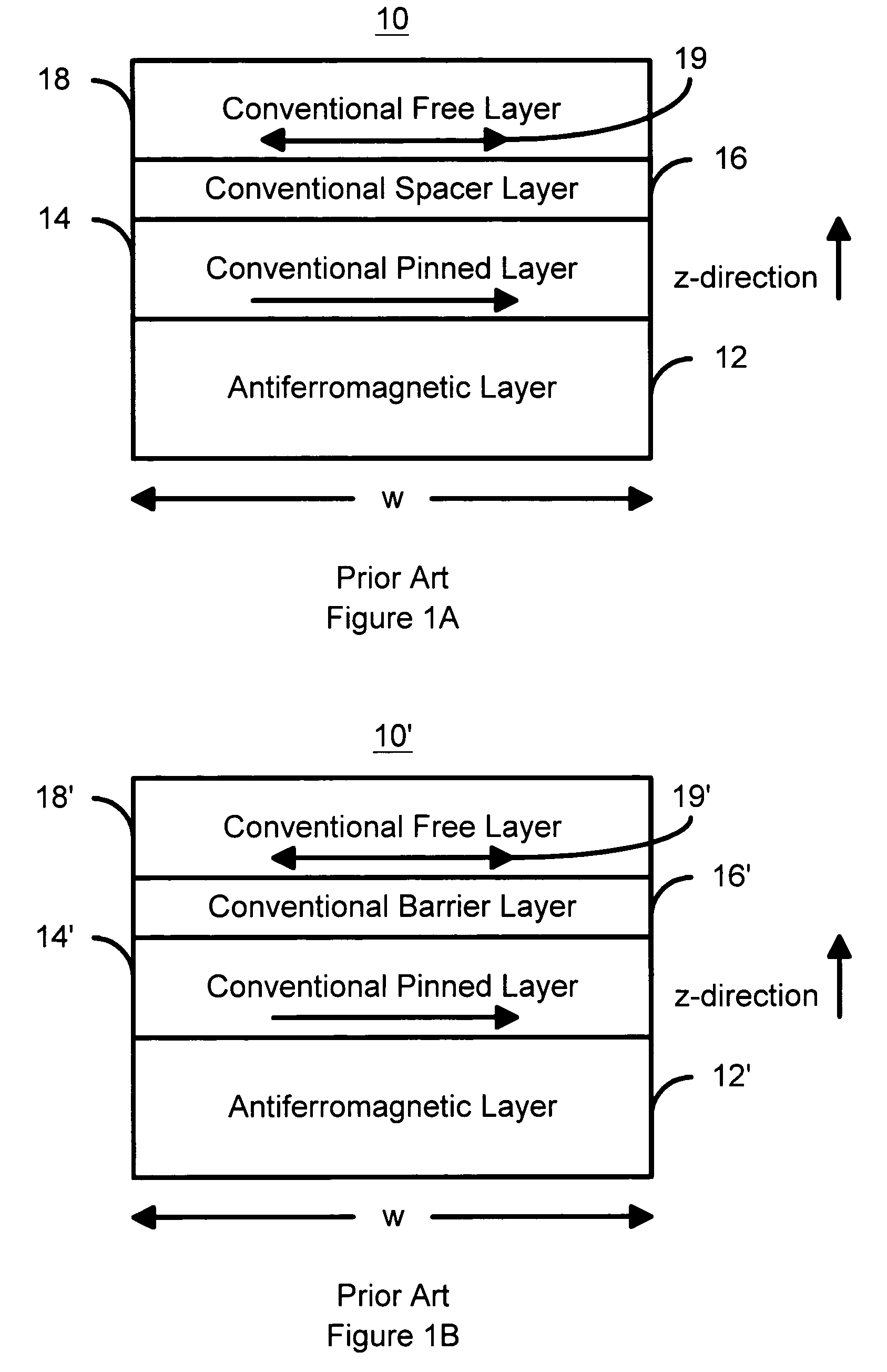

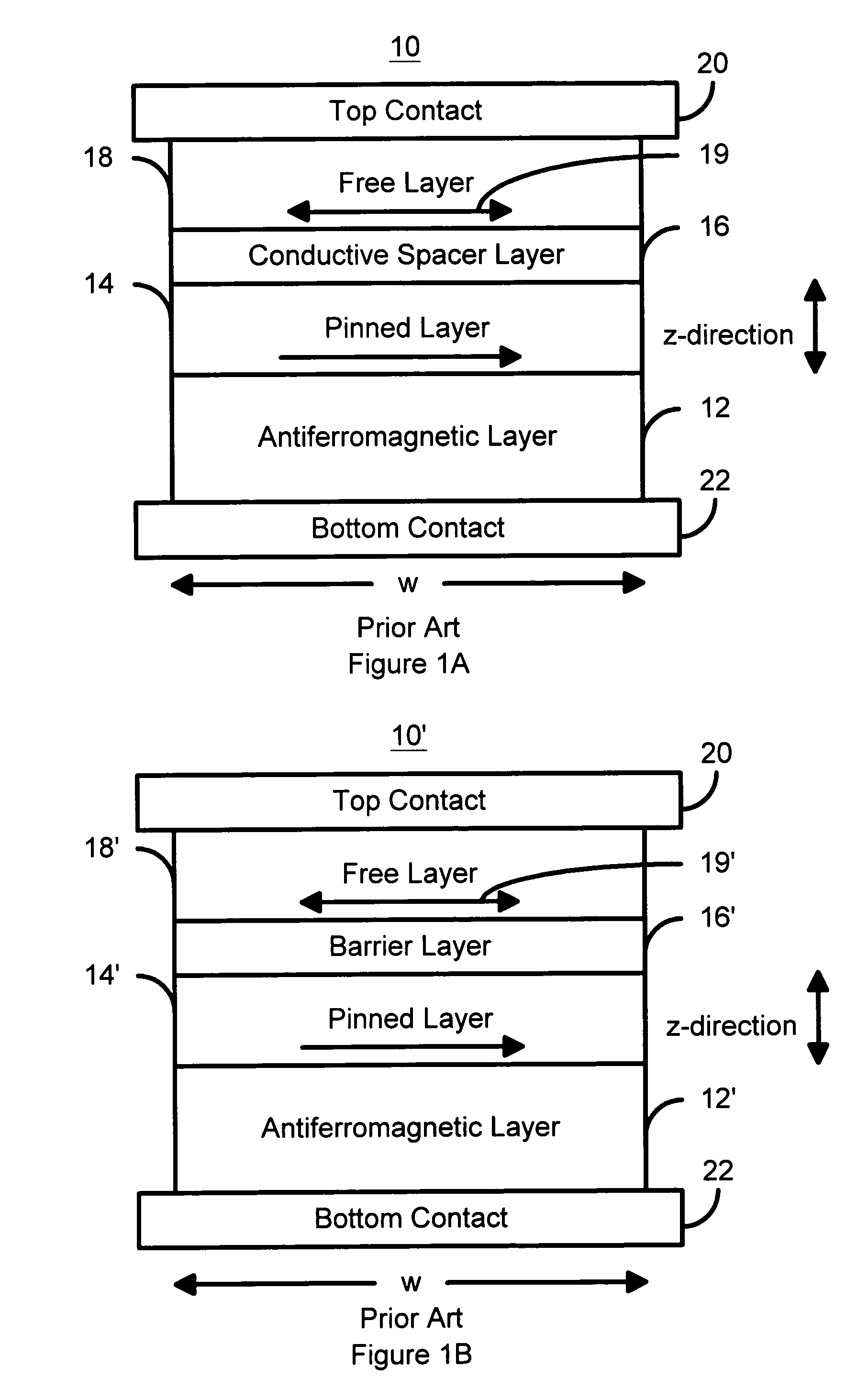

Spin transfer magnetic element with free layers having high perpendicular anisotropy and in-plane equilibrium magnetization

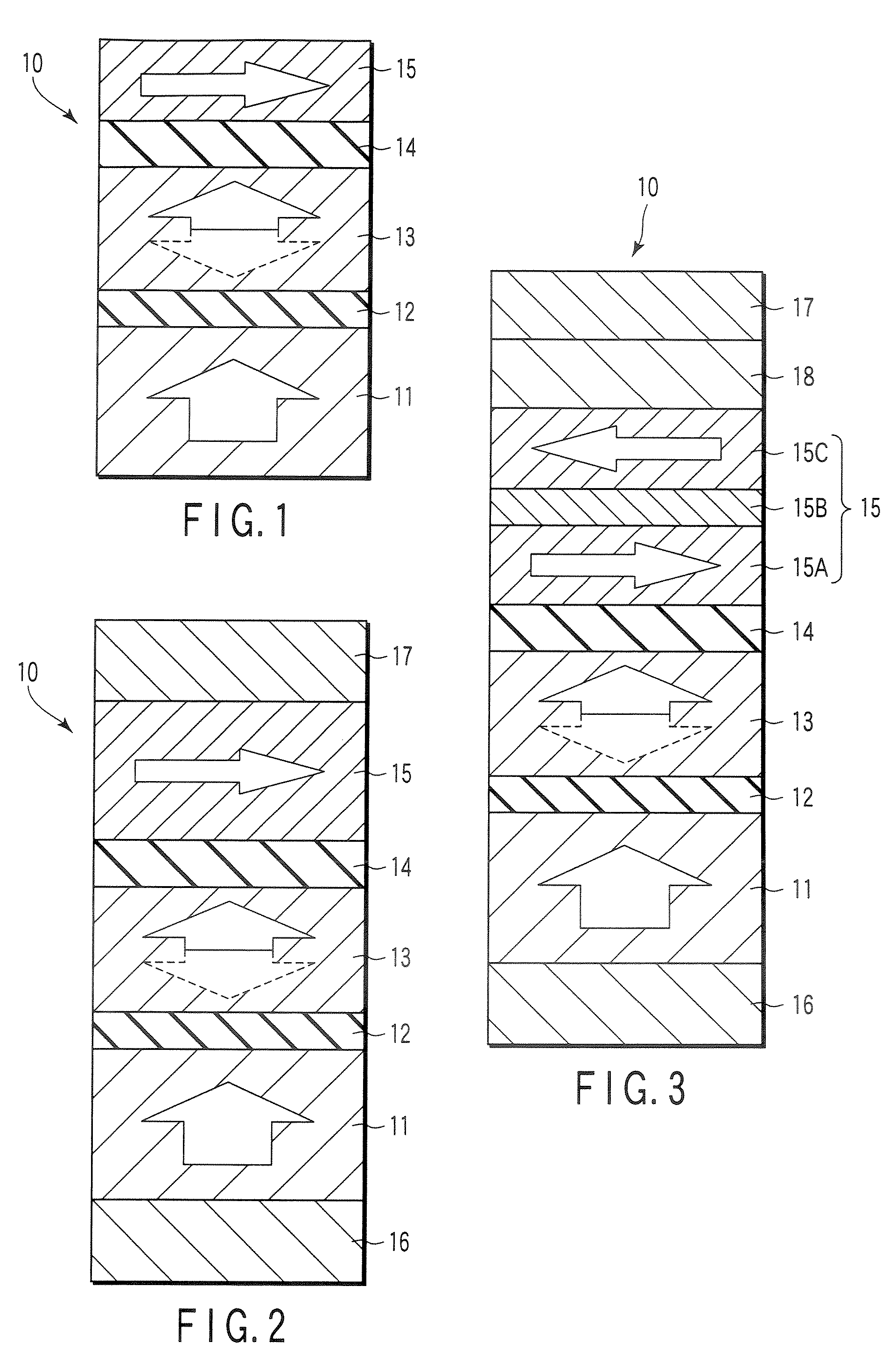

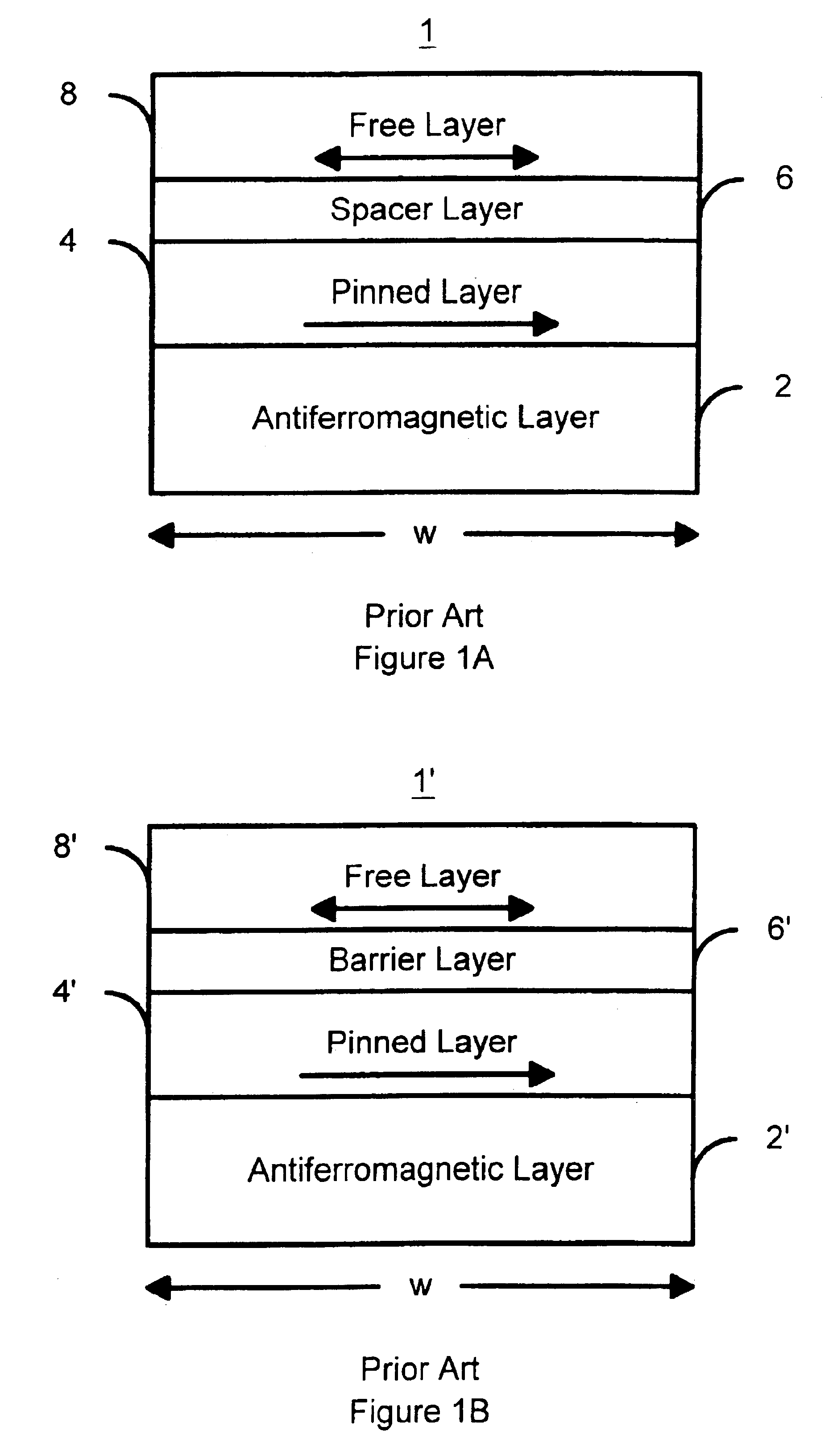

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. At least one free layer has a high perpendicular anisotropy. The high perpendicular anisotropy has a perpendicular anisotropy energy that is at least twenty and less than one hundred percent of the out-of-plane demagnetization energy.

Owner:SAMSUNG SEMICON

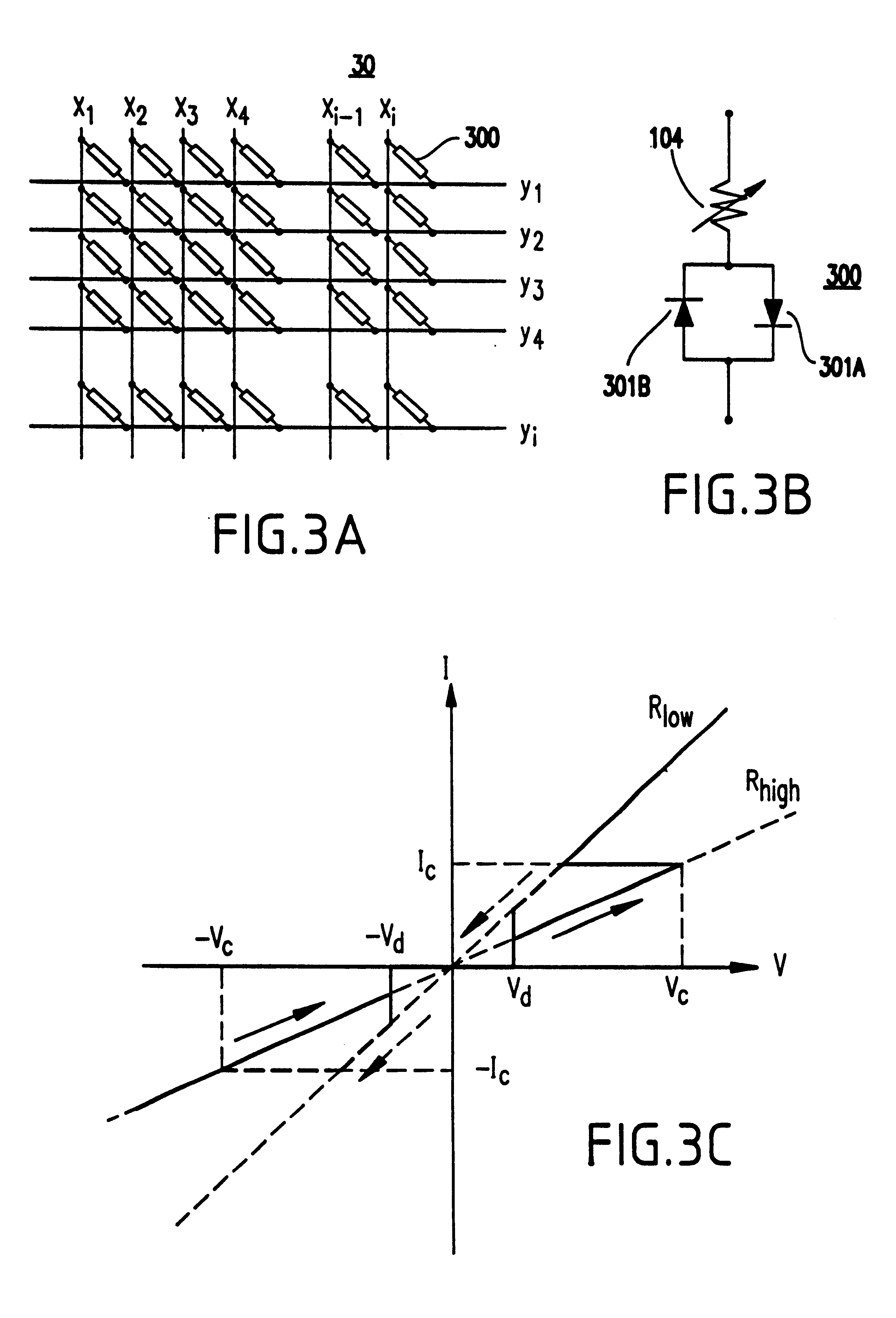

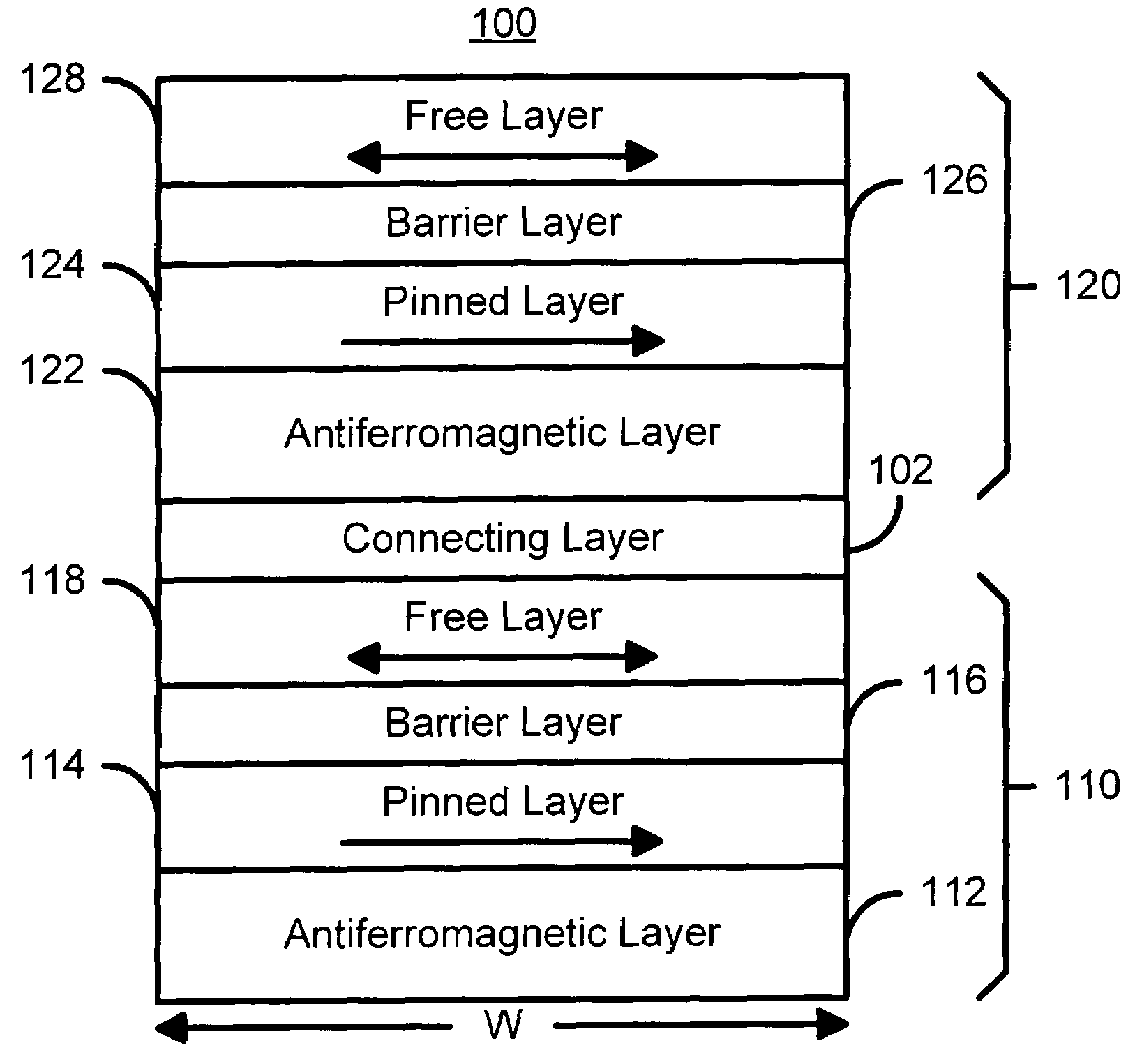

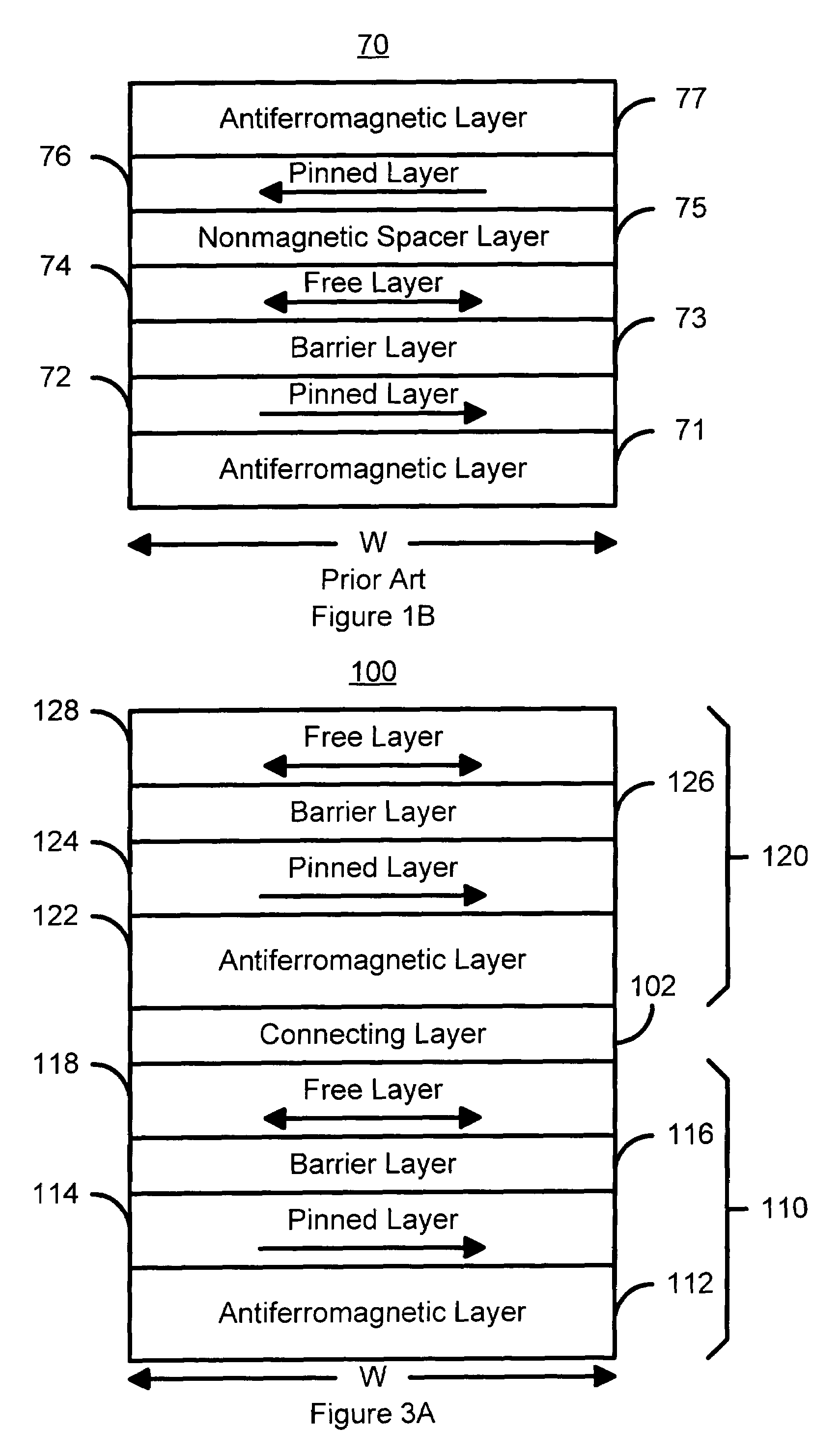

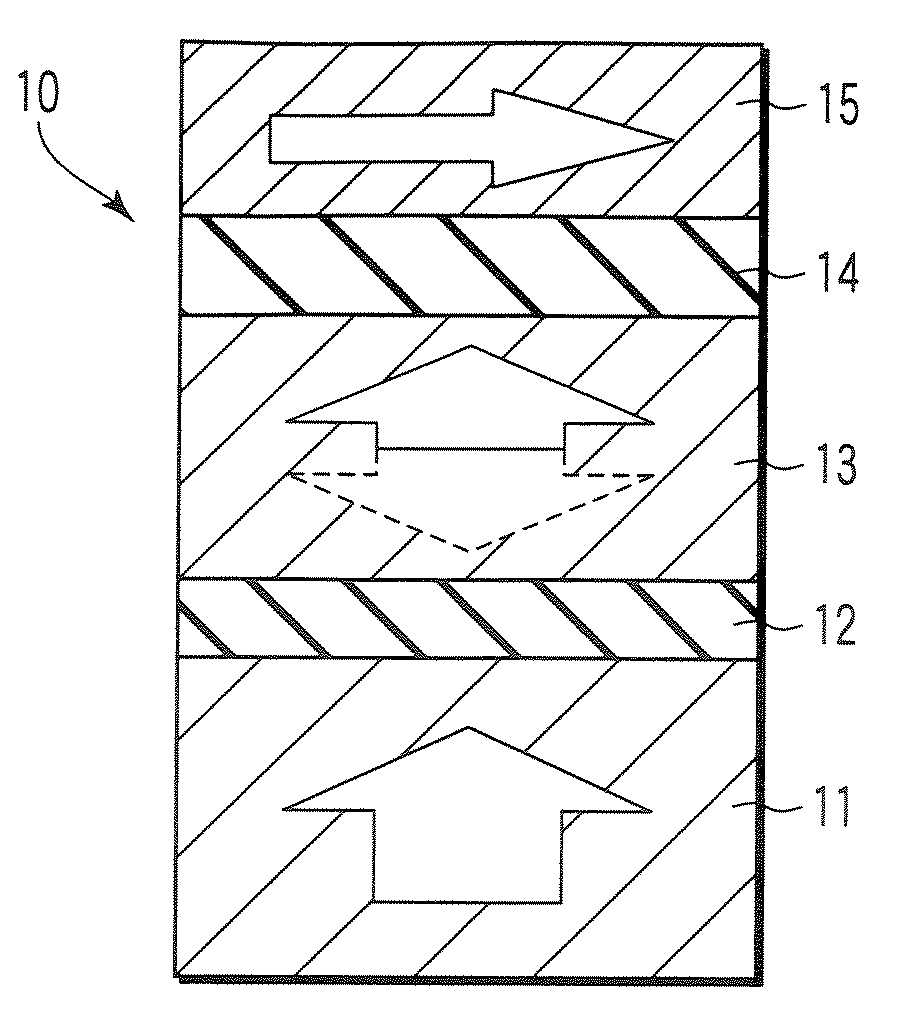

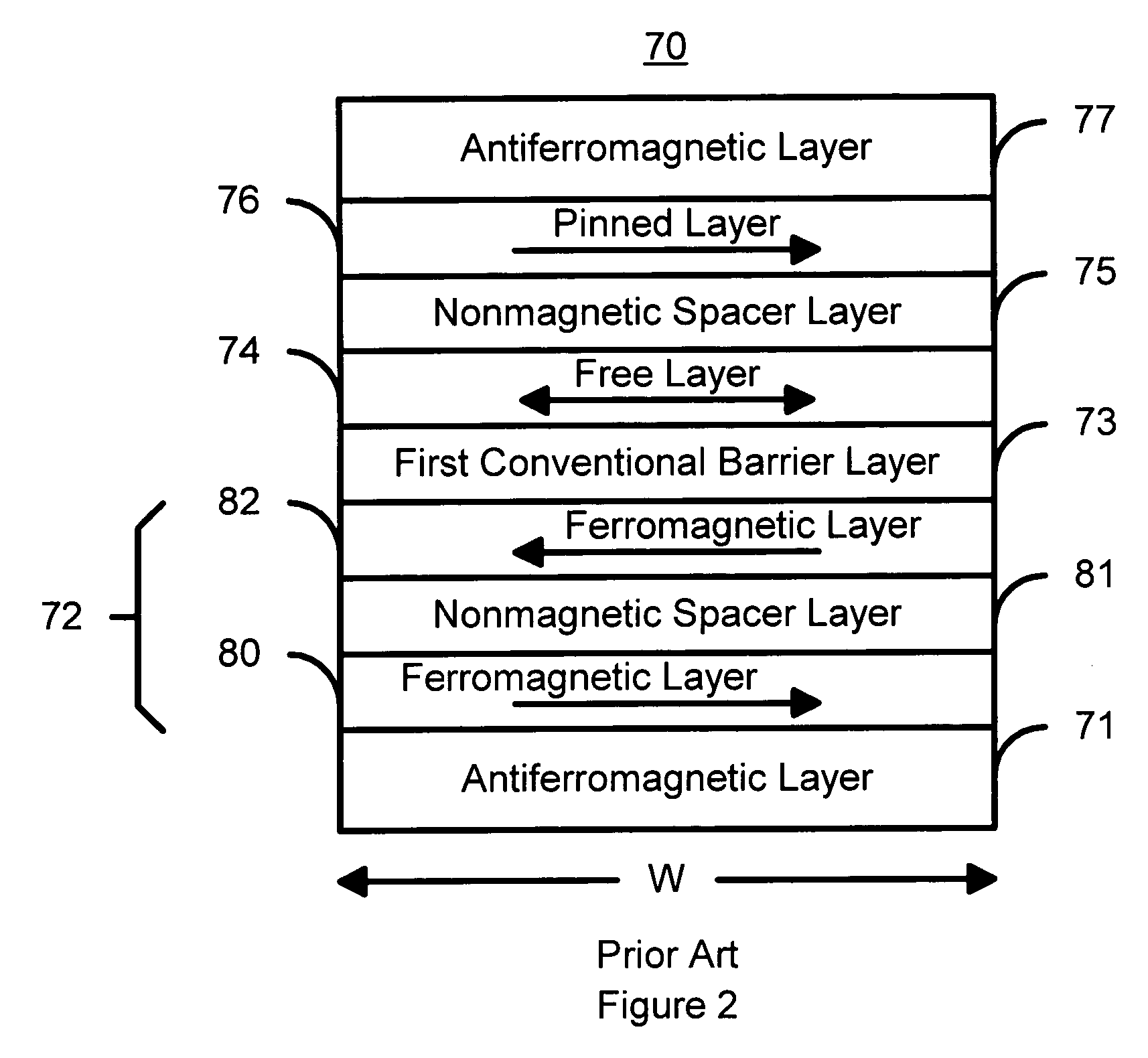

Magnetic memory element utilizing spin transfer switching and storing multiple bits

A method and system for providing a magnetic element capable of storing multiple bits is disclosed. The method and system include providing first pinned layer, a first nonmagnetic layer, a first free layer, a connecting layer, a second pinned layer, a second nonmagetic layer and a second free layer. The first pinned layer is ferromagnetic and has a first pinned layer magnetization pinned in a first direction. The first nonmagnetic layer resides between the first pinned layer and the first free layer. The first free layer being ferromagnetic and has a first free layer magnetization. The second pinned layer is ferromagnetic and has a second pinned layer magnetization pinned in a second direction. The connecting layer resides between the second pinned layer and the first free layer. The second nonmagnetic layer resides between the second pinned layer and the second free layer. The second free layer being ferromagnetic and having a second free layer magnetization. The magnetic element is configured to allow the first free layer magnetization and the second free layer magnetization to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

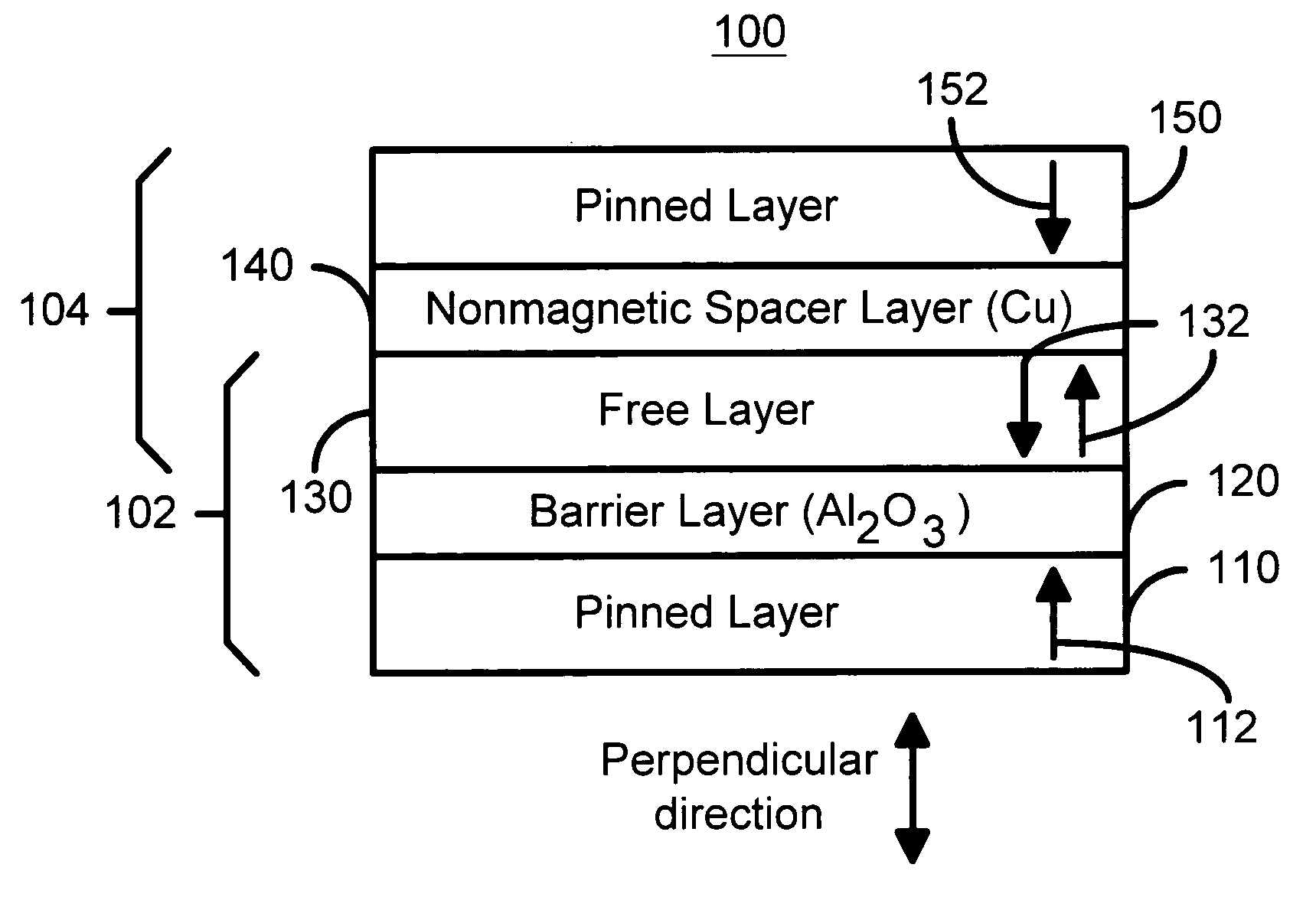

Perpendicular magnetization magnetic element utilizing spin transfer

ActiveUS6967863B2Reduce currentNanomagnetismMagnetic measurementsPerpendicular magnetizationMagnetic memory

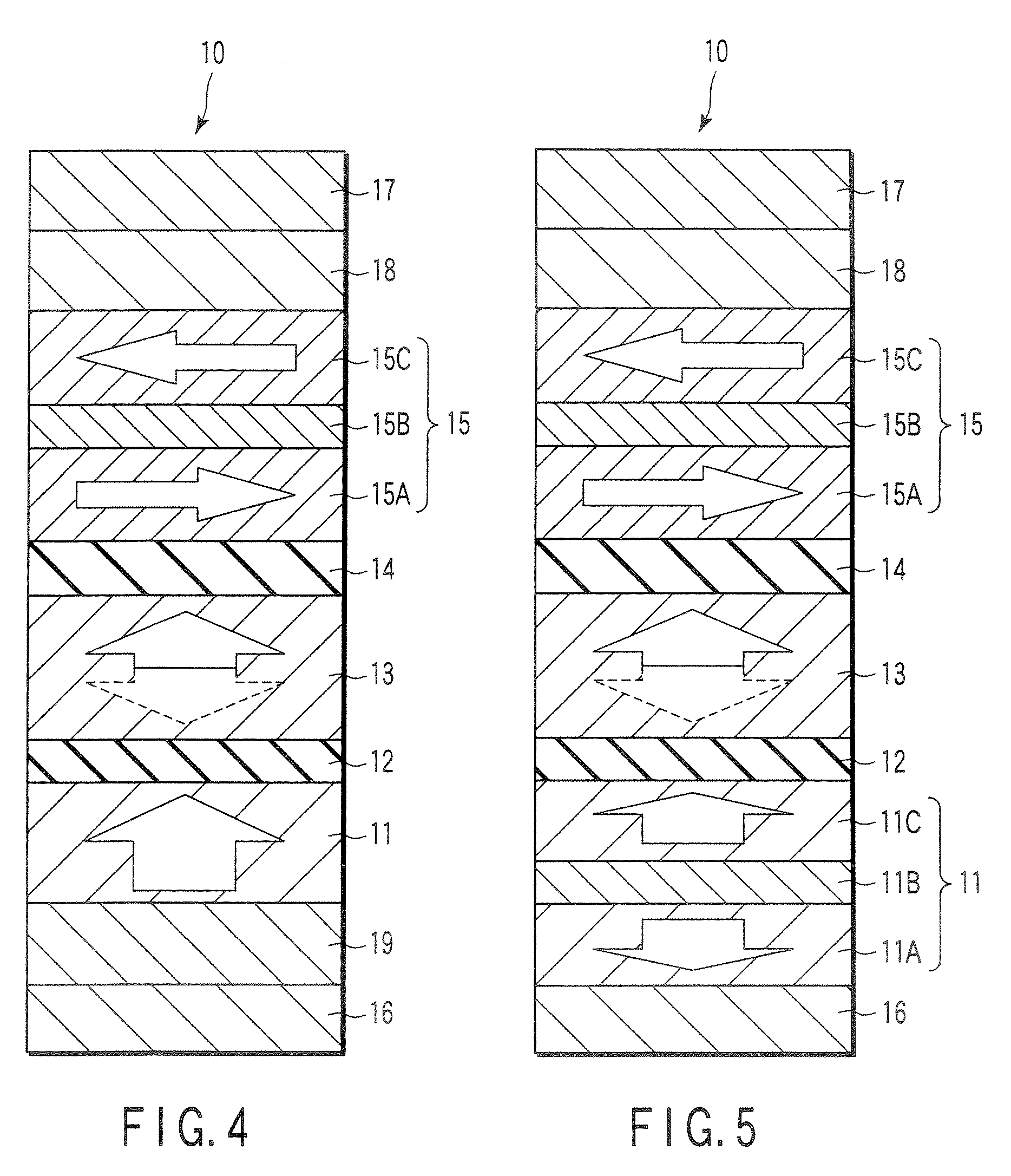

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The method and system include providing a first pinned layer, a barrier layer, a free layer, a conductive nonmagnetic spacer layer, and a second pinned layer. Each pinned layer has a pinned layer easy axis. At least a portion of the pinned layer easy axis is in a perpendicular direction. The barrier layer resides between the first pinned layer and the free layer. The spacer layer is between the free layer and the second pinned layer. The free layer has a free layer easy axis, at least a portion of which is in the perpendicular direction. The magnetic element is also configured to allow the free layer to be switched due to spin transfer effect when a write current is passed through the magnetic element. Because of the perpendicular magnetization(s), the writing current for spin transfer may be significantly reduced.

Owner:SAMSUNG SEMICON

Thermally stable magnetic elements utilizing spin transfer and an MRAM device using the magnetic element

InactiveUS6838740B2Improve performanceImprove thermal stabilityTransistorNanomagnetismAntiferromagnetic couplingMagnetic memory

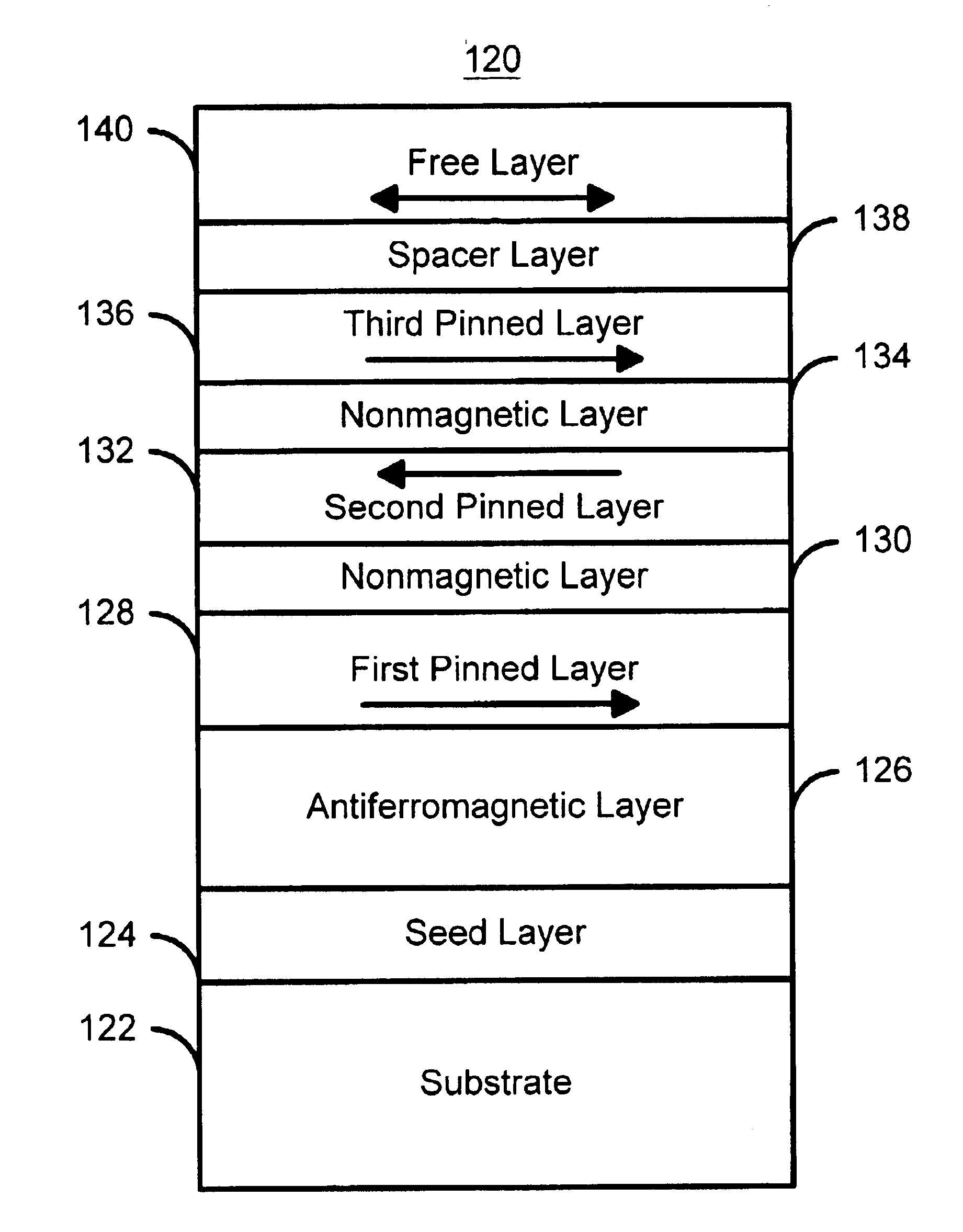

A method and system for providing a magnetic element capable of being written using spin-transfer effect while being thermally stable and a magnetic memory using the magnetic element are disclosed. The magnetic element includes a first, second and third pinned layers, first and second nonmagnetic layers, a free layer and a nonmagnetic spacer layers. The first, second and third pinned layers are ferromagnetic and have first, second and third magnetizations pinned in first, second and third directions. The first and second nonmagnetic layers include first and second diffusion barriers, respectively. The first and second nonmagnetic layers are between the first and second pinned layers and the second and third pinned layers, respectively. The first and second pinned layers and the second and third pinned layers are antiferromagnetically coupled. The nonmagnetic spacer layer is conductive and resides between the free layer and the third pinned layer. In addition, performance can be further improved by doping Co containing ferromagnetic layers with Cr and / or Pt.

Owner:SAMSUNG SEMICON

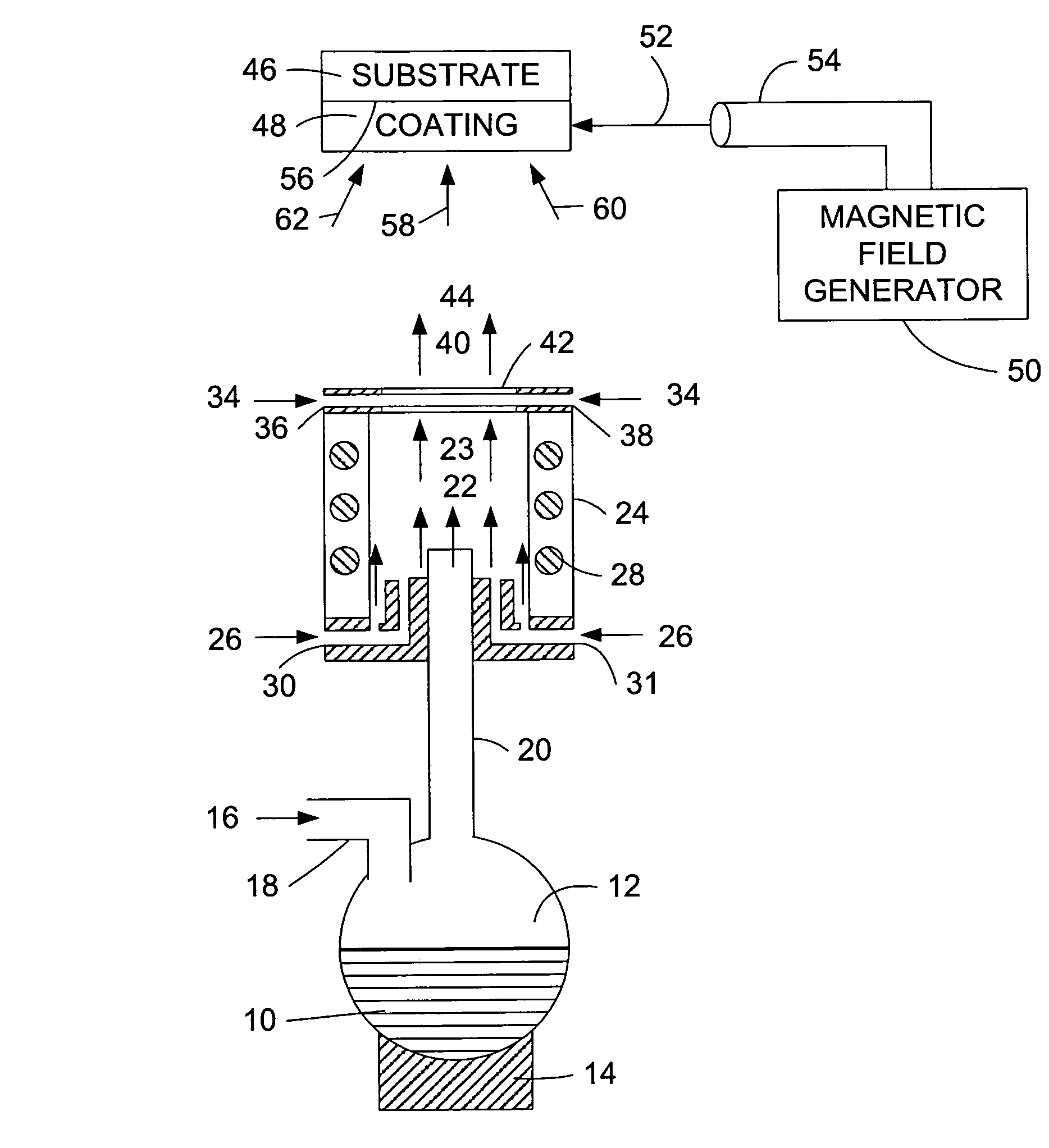

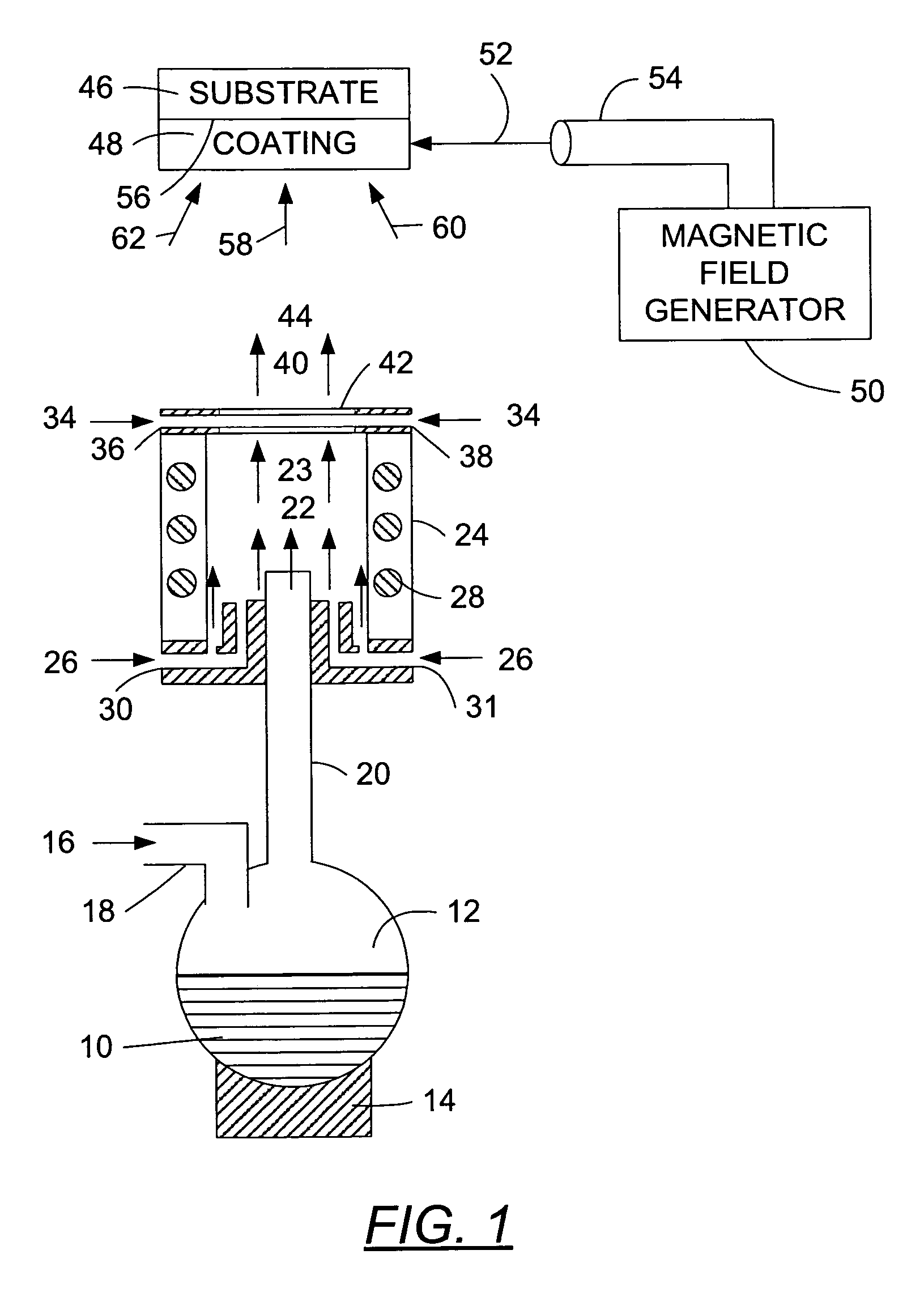

Medical device with low magnetic susceptibility

InactiveUS20050079132A1Batteries circuit arrangementsElectrotherapyMagnetic susceptibilityCoherence length

An assembly with a substrate, nanomagnetic material and magetoresistive material. The nanomagnetic material has a saturation magentization of from about 2 to about 3000 electromagnetic units per cubic centimeter; and it contains nanomagnetic particles with an average particle size of less than about 100 nanometers. The average coherence length between adjacent nanomagnetic particles is less than 100 nanometers.

Owner:BIOPHAN TECH

Current switched magnetoresistive memory cell

InactiveUS6744086B2Weakening rangeNanomagnetismSemiconductor/solid-state device manufacturingDigital memoryConduction electron

A ferromagnetic thin-film based digital memory cell with a memory film of an anisotropic ferromagnetic material and with a source layer positioned on one side thereof so that a majority of conduction electrons passing therefrom have a selected spin orientation to be capable of reorienting the magnetization of the film. A disruption layer is positioned on the other side of the memory film so that conduction electrons spins passing therefrom are substantially random in orientation. The magnitude of currents needed to operate the cell can be reduced using coincident thermal pulses to raise the cell temperature.

Owner:NVE CORP

Magnetic tunneling junction configuration and a method for making the same

InactiveUS6897532B1Reduce the temperatureAvoid depositionTransistorNanomagnetismEngineeringGobio gobio obtusirostris

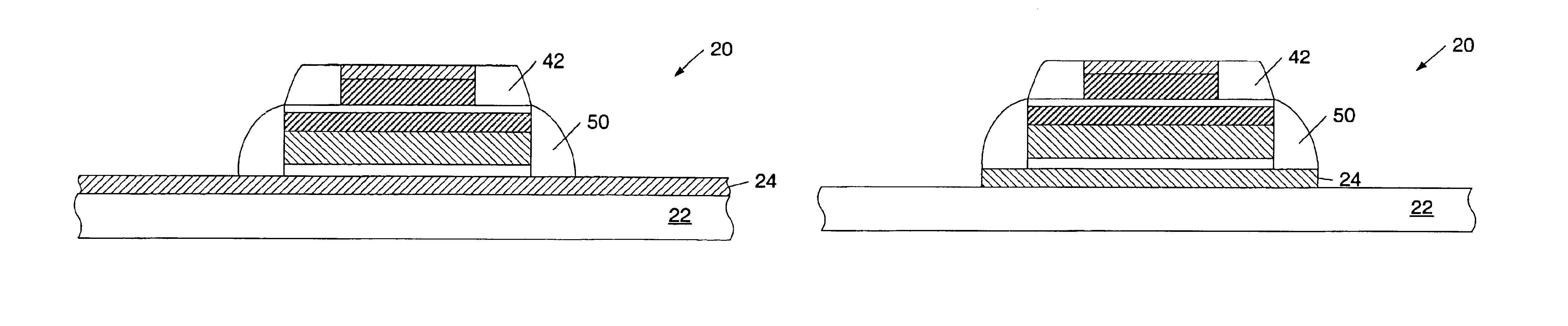

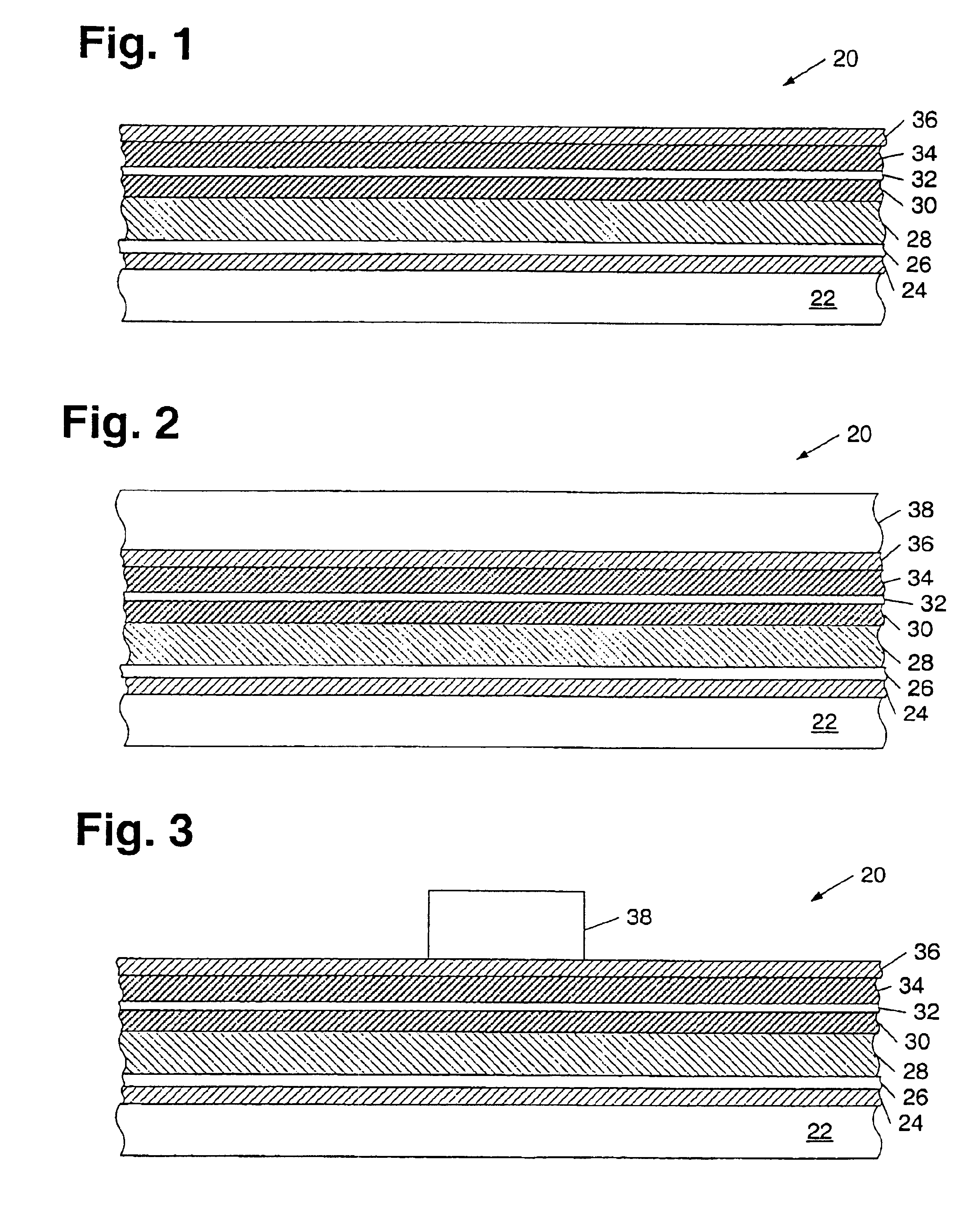

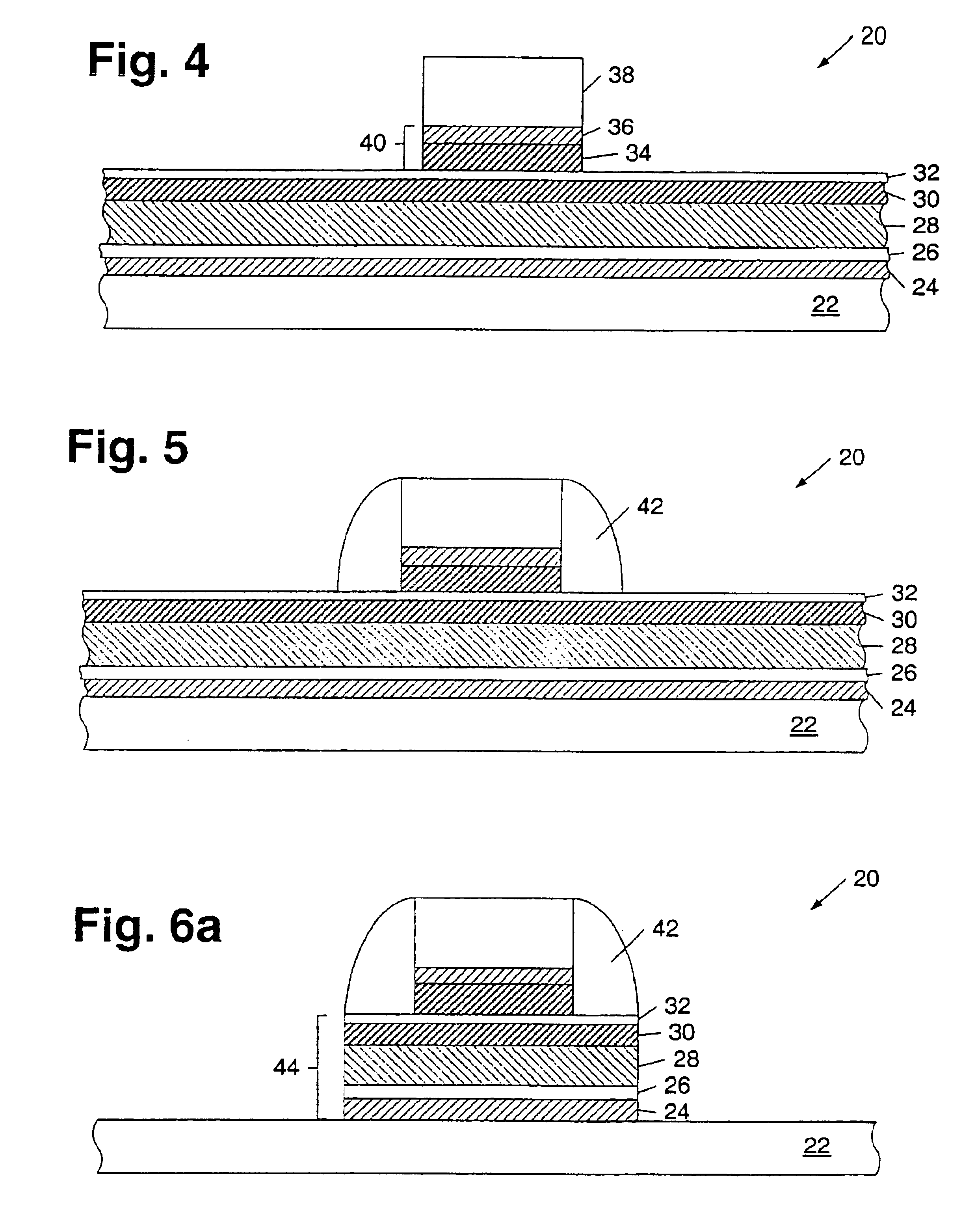

A method for forming a magnetic tunneling junction (MJT) is provided. In some embodiments, the method may include patterning one or more magnetic layers to form an upper portion of a MTJ. The method may further include patterning one or more additional layers to form a lower portion of the MTJ. In some cases, the lower portion may include a tunneling layer of the MTJ having a width greater than the upper portion. In addition, in some embodiments the method may further include patterning an electrode below the lower portion. In some cases, the electrode may include a lowermost layer with a thickness equal to or less than approximately 100 angstroms. In addition or alternatively, the electrode may have a width greater than the width of the tunneling layer. In yet other embodiments, the method may include forming spacers along the sidewalls of the upper and / or lower portions.

Owner:CENT NAT DE LA RECHERCHE SCI

Magnetoresistive element

A magnetoresistive element which records information by supplying spin-polarized electrons to a magnetic material, includes a first pinned layer which is made of a magnetic material and has a first magnetization directed in a direction perpendicular to a film surface, a free layer which is made of a magnetic material and has a second magnetization directed in the direction perpendicular to the film surface, the direction of the second magnetization reversing by the spin-polarized electrons, and a first nonmagnetic layer which is provided between the first pinned layer and the free layer. A saturation magnetization Ms of the free layer satisfies a relationship 0≧Ms<√{square root over ( )}{Jw / (6nAt)}. Jw is a write current density, t is a thickness of the free layer, A is a constant.

Owner:KIOXIA CORP

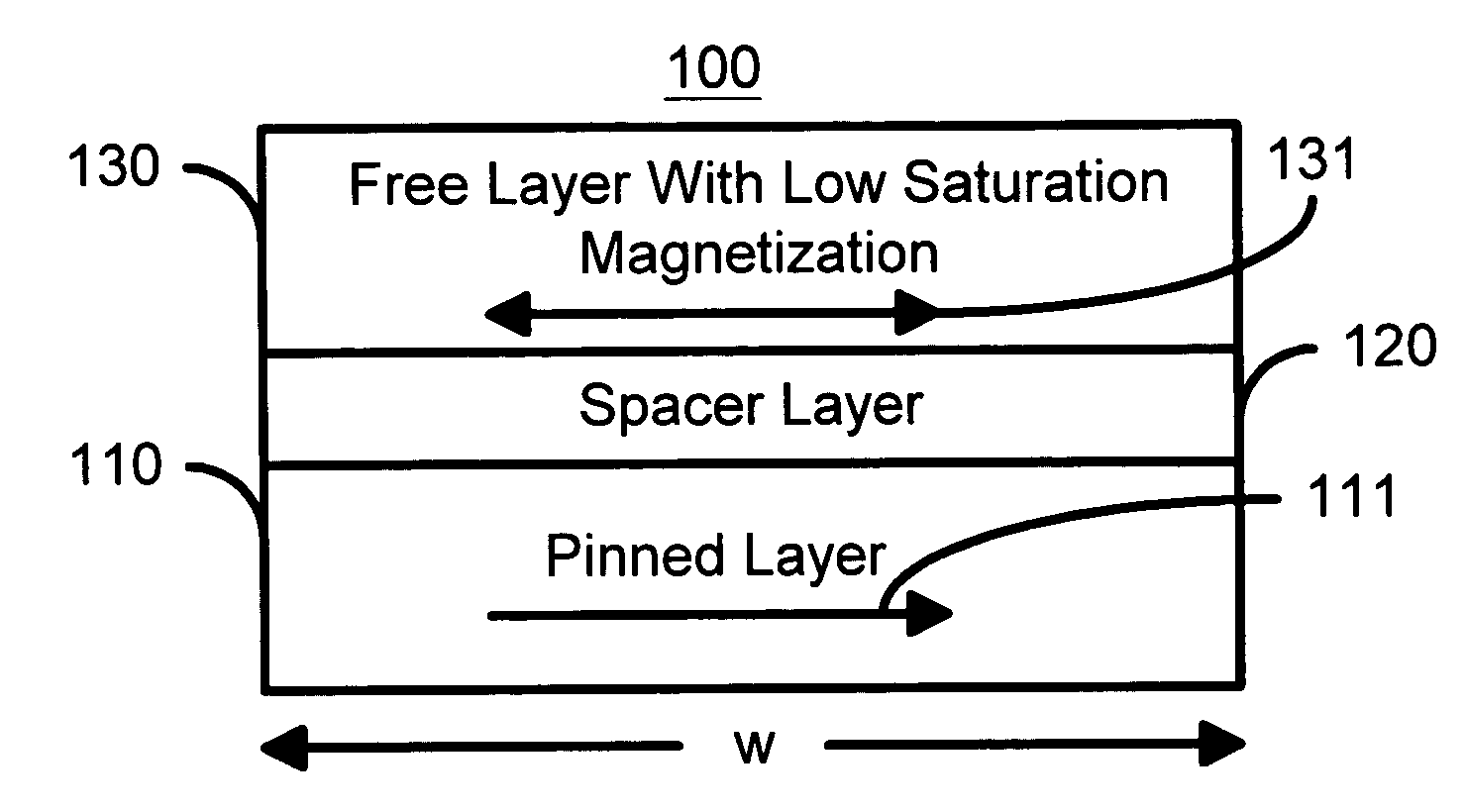

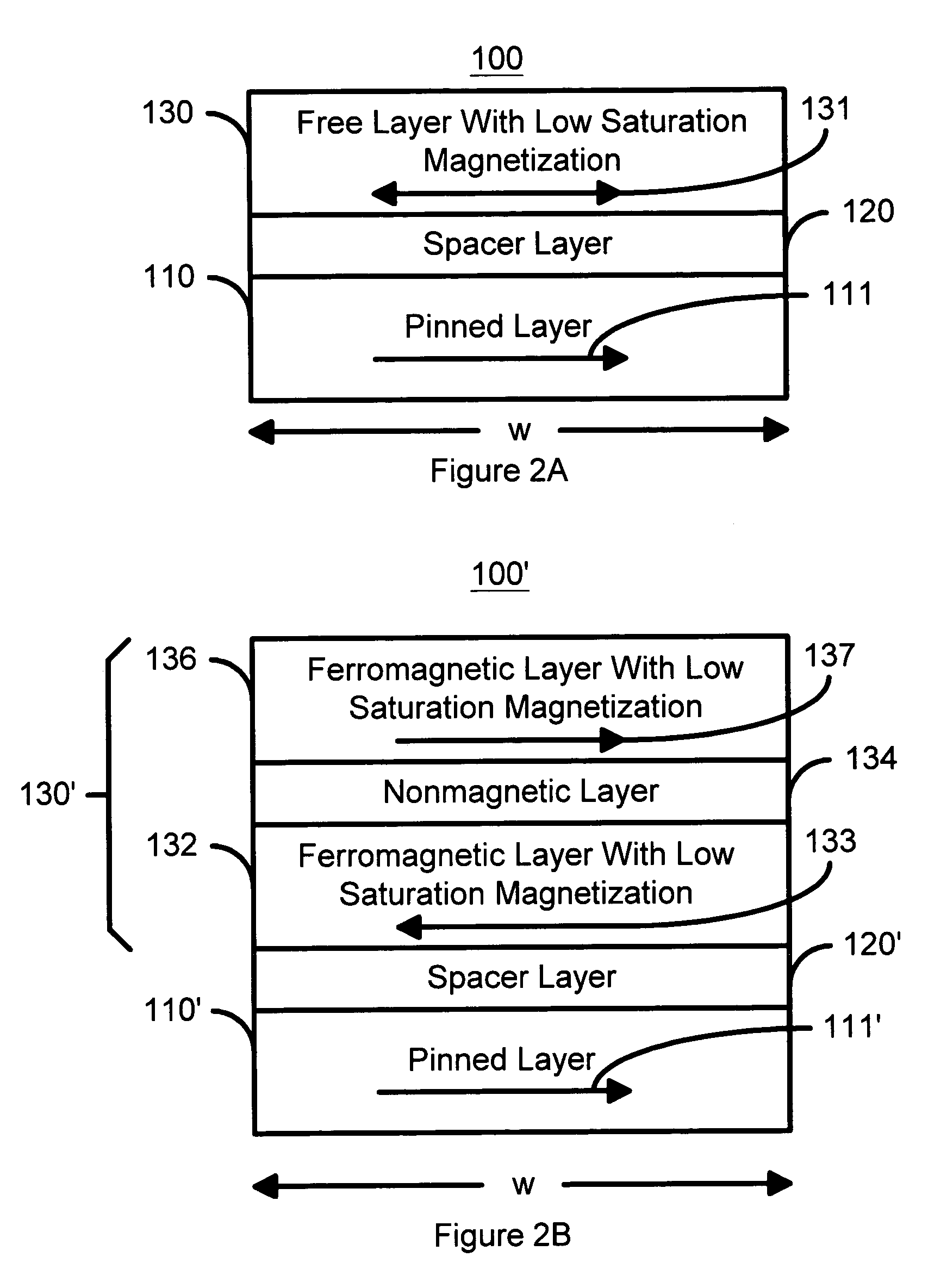

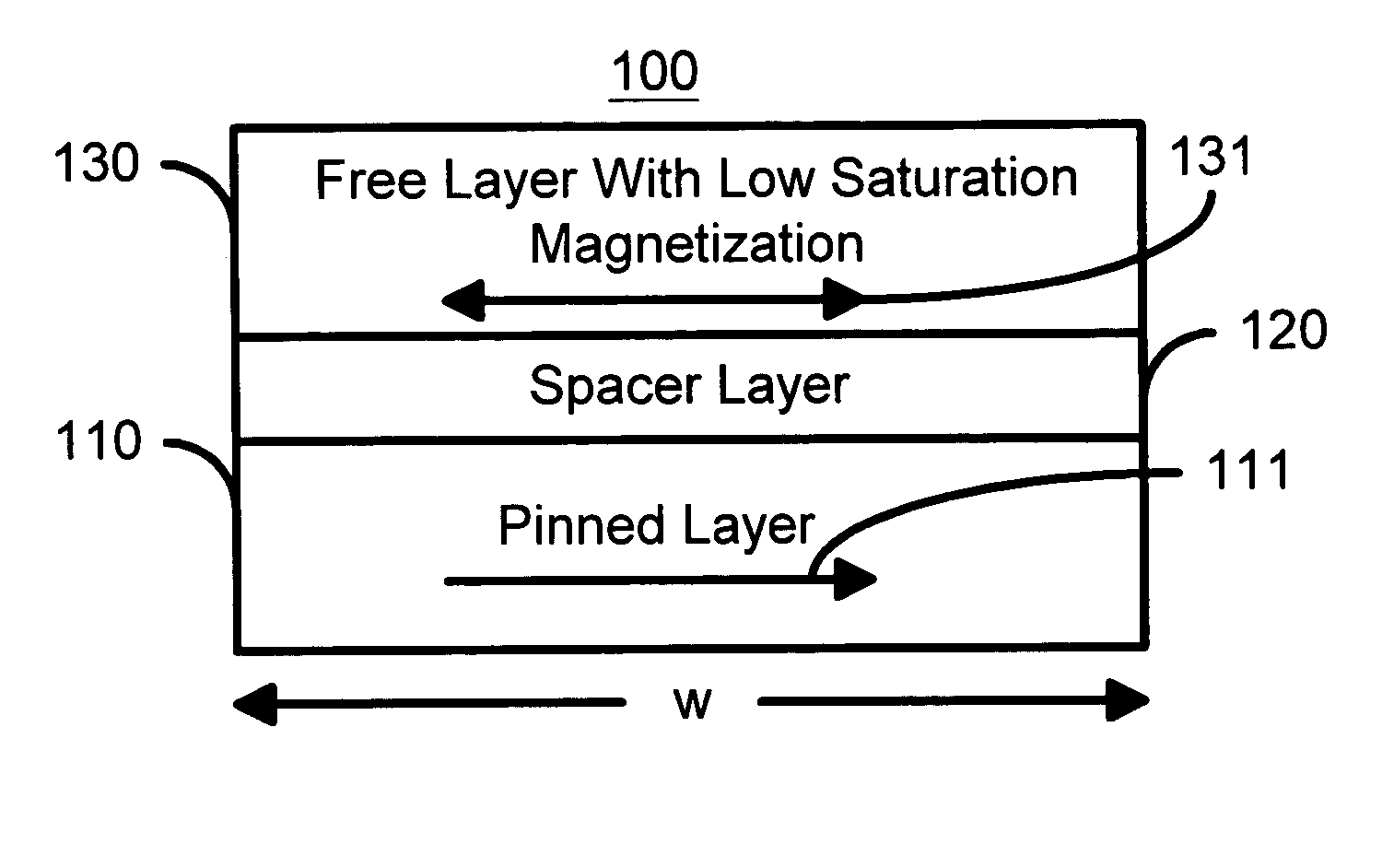

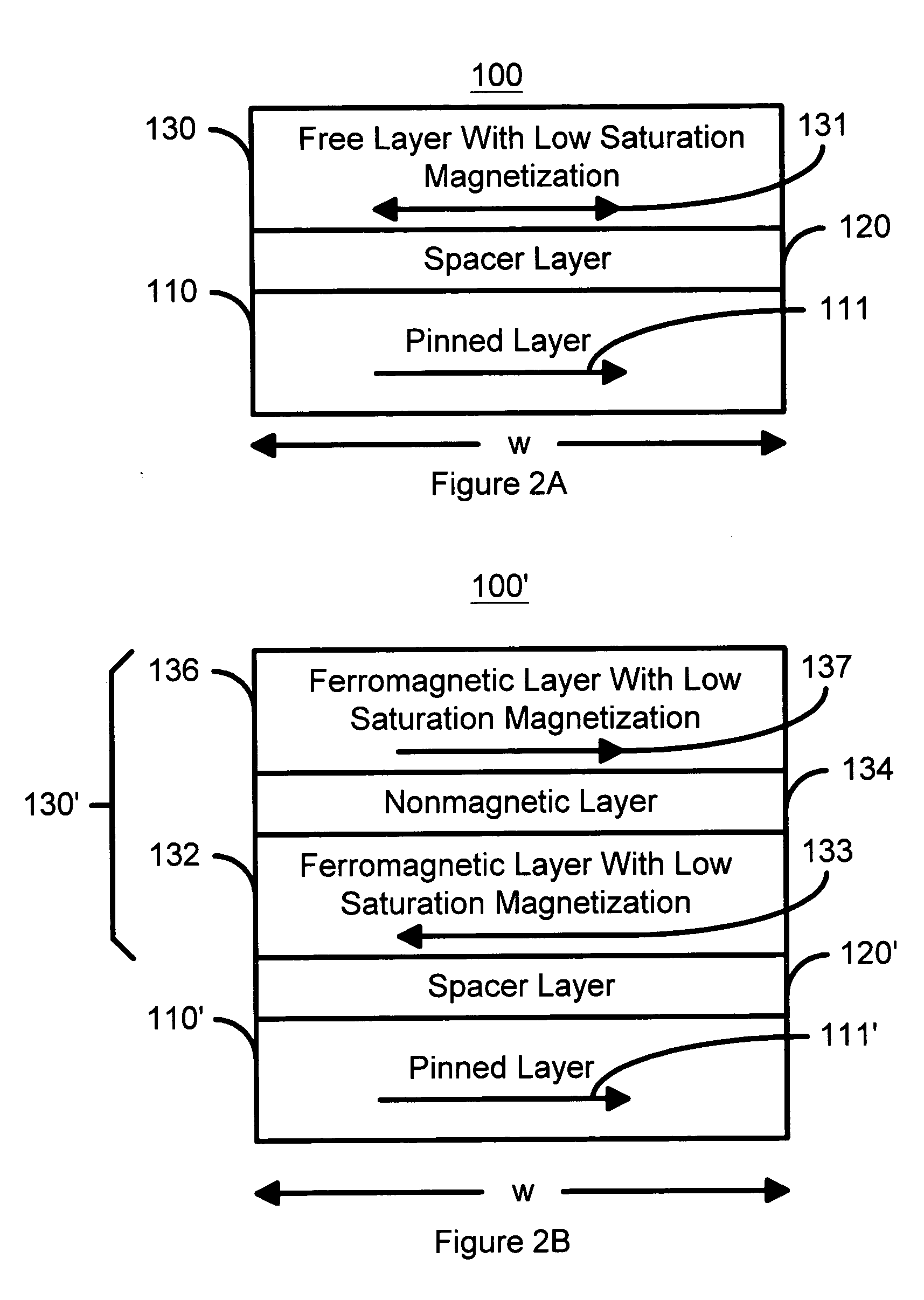

Spin transfer magnetic element having low saturation magnetization free layers

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

Protective assembly

An assembly for protecting biological tissue from the effects of heating. The assembly contains a conductor in contact with the biological tissue and forming an electrical circuit comprising the biological tissue. The assembly contains a device for modifying the impedance of the electrical circuit such that, at a frequency of from about 10 megahertz to about 150 megahertz, such impedance is at least about 0.5 ohms per centimeter of length of said conductor. The assembly also contains a device for limiting the flow of current through the biological tissue such that, when the assembly is exposed to an alternating current electromagnetic field at a frequency of 64 megahertz and a magnetic field strength of 1.5 Tesla for 15 minutes, the temperature of the biological tissue does not exceed 42 degrees Celsius.

Owner:BIOPHAN TECH

Spin transfer magnetic element having low saturation magnetization free layers

ActiveUS20050184839A1Current densityNanostructure applicationNanomagnetismMagnetic memoryNon magnetic

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, nonmagnetic spacer, and free layers. The spacer layer resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The magnetic element may also include a barrier layer, a second pinned layer. Alternatively, second pinned and second spacer layers and a second free layer magnetostatically coupled to the free layer are included. In one aspect, the free layer(s) include ferromagnetic material(s) diluted with nonmagnetic material(s) and / or ferrimagnetically doped to provide low saturation magnetization(s).

Owner:SAMSUNG SEMICON

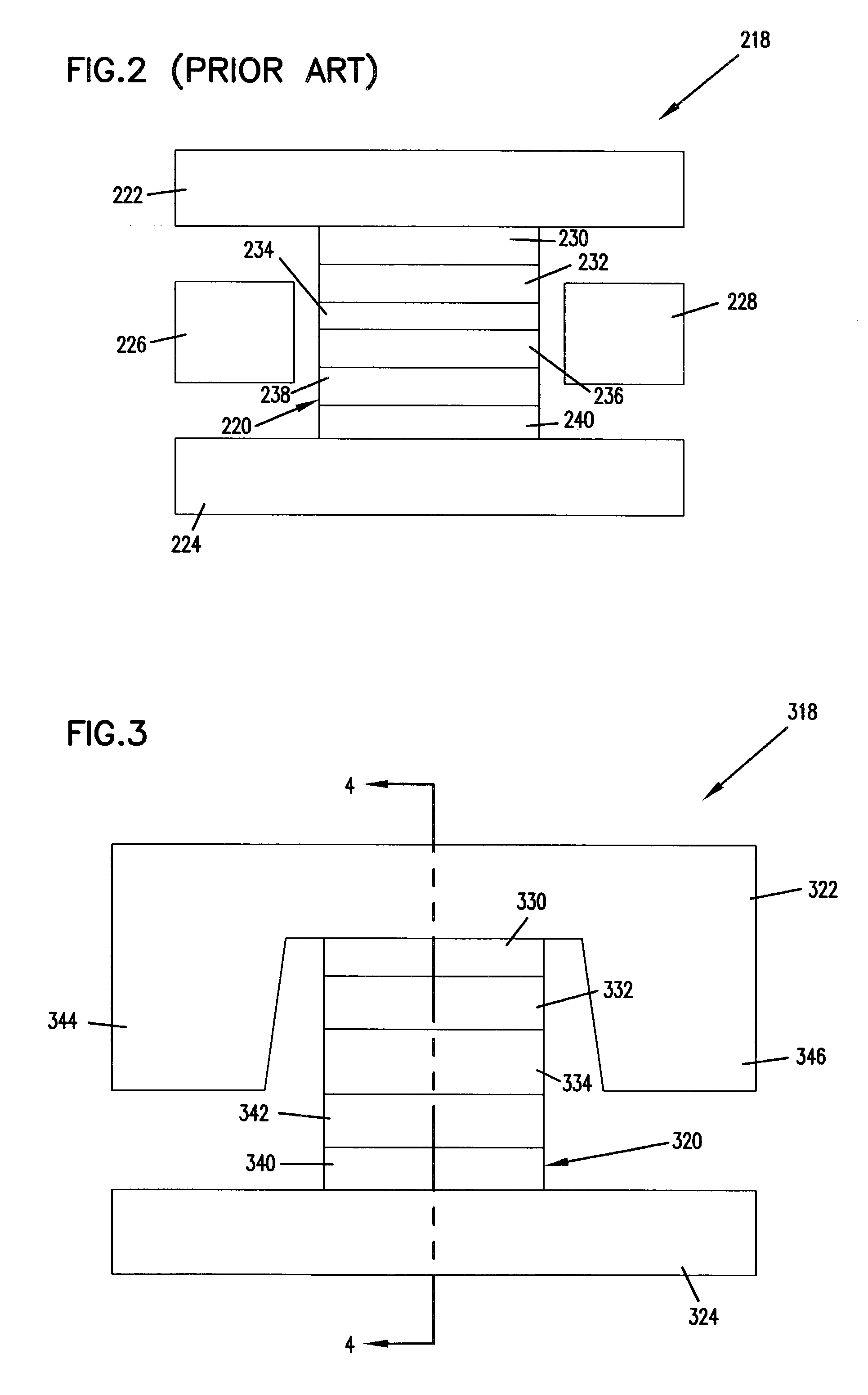

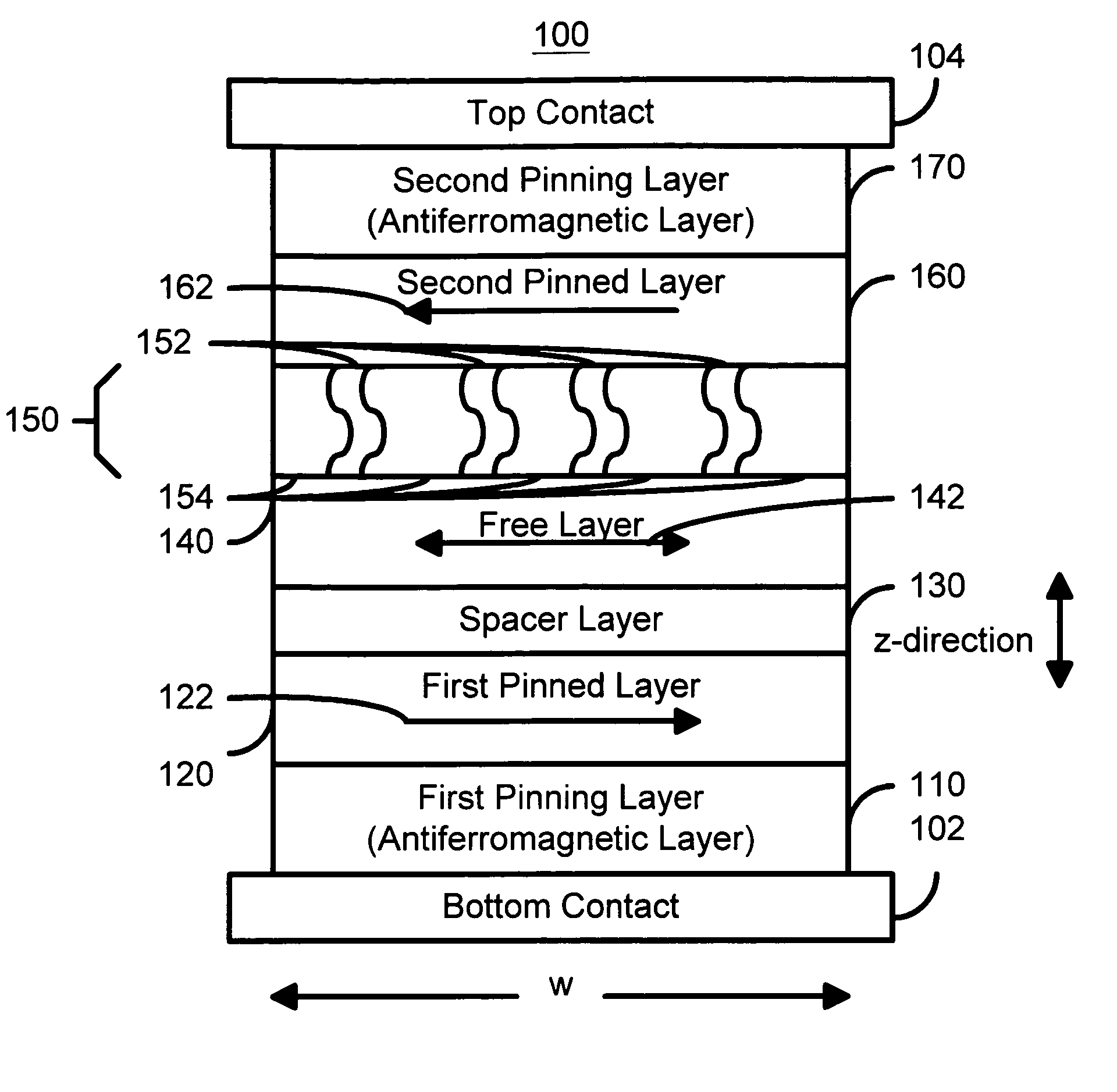

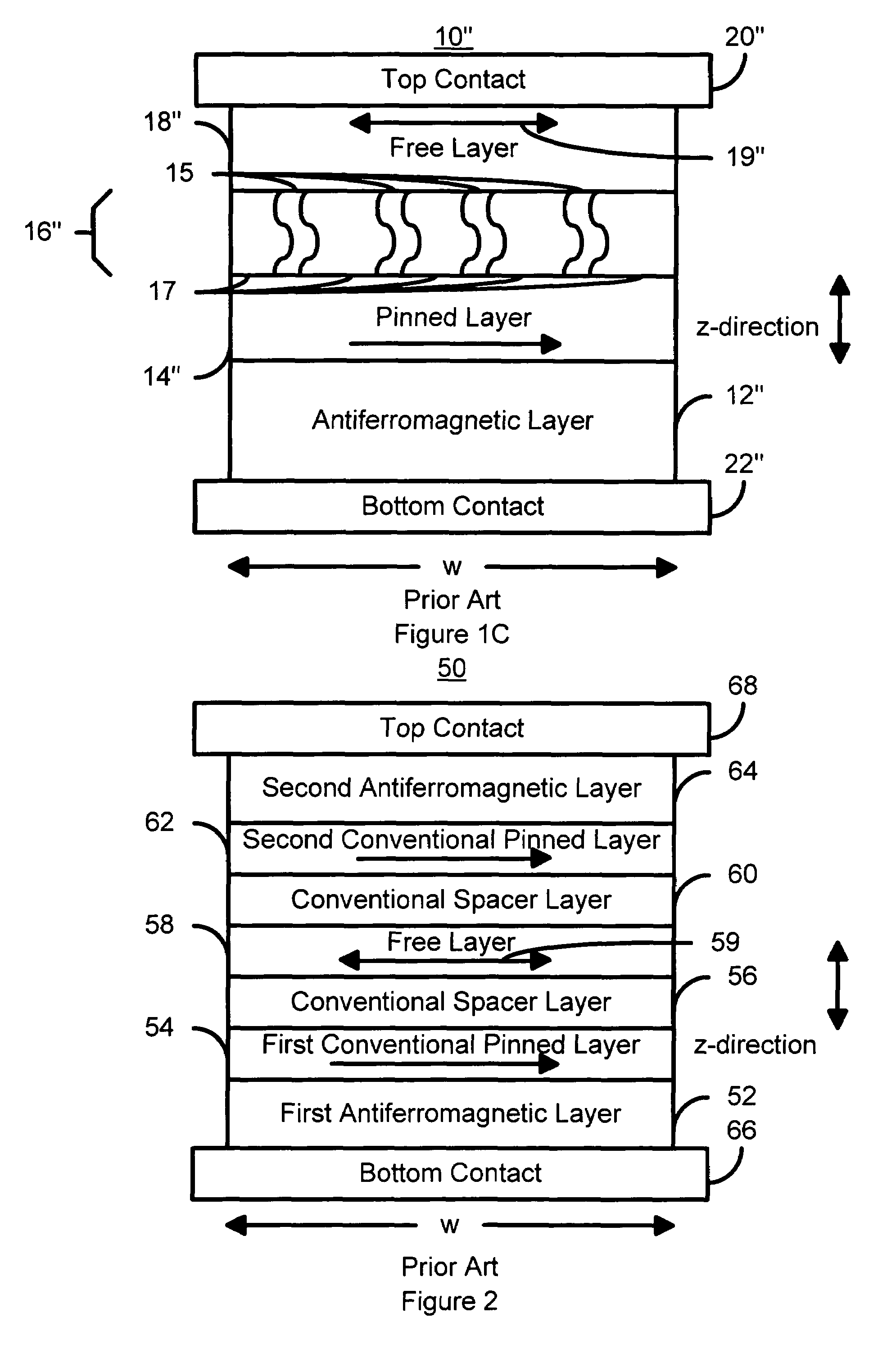

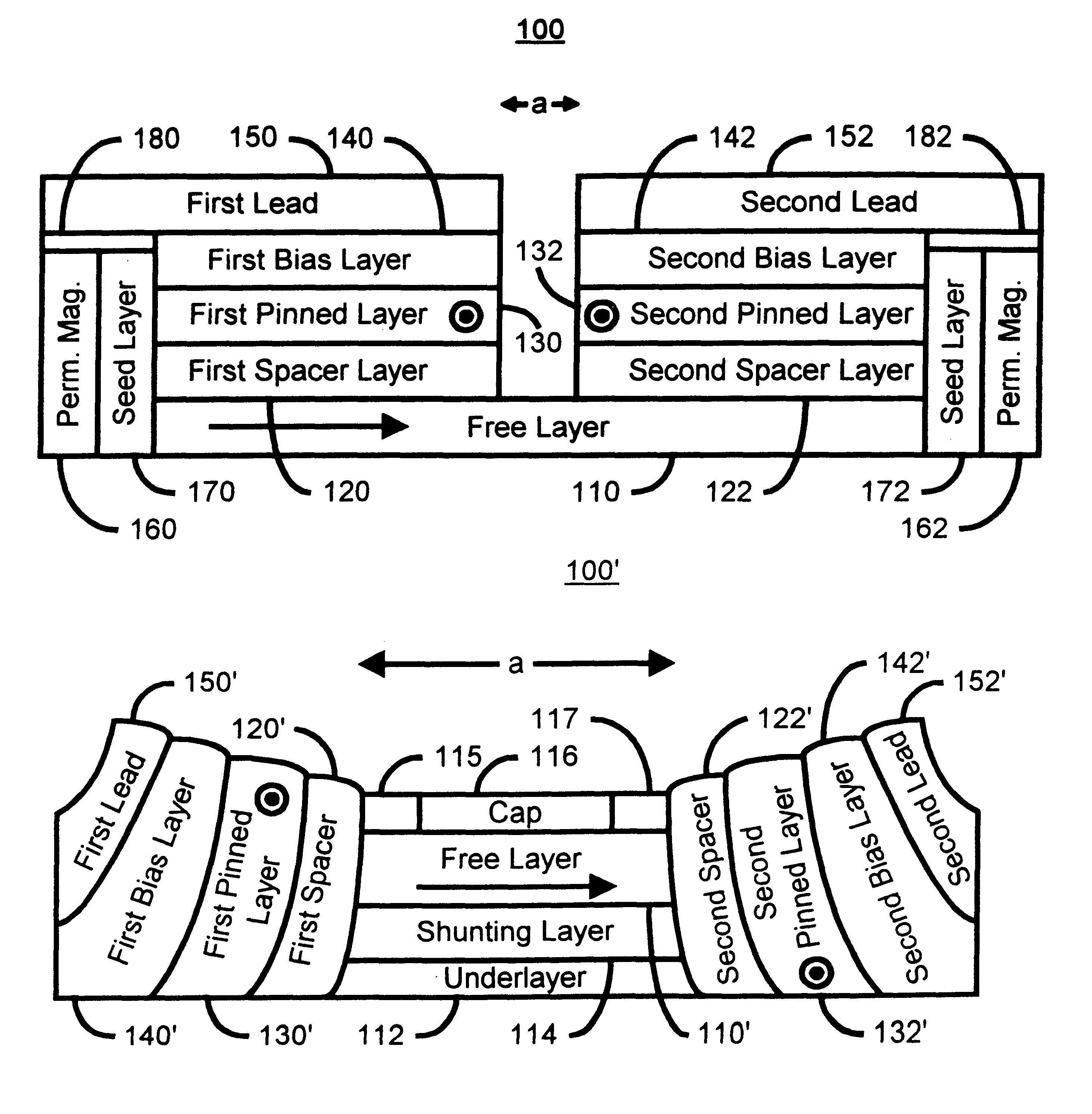

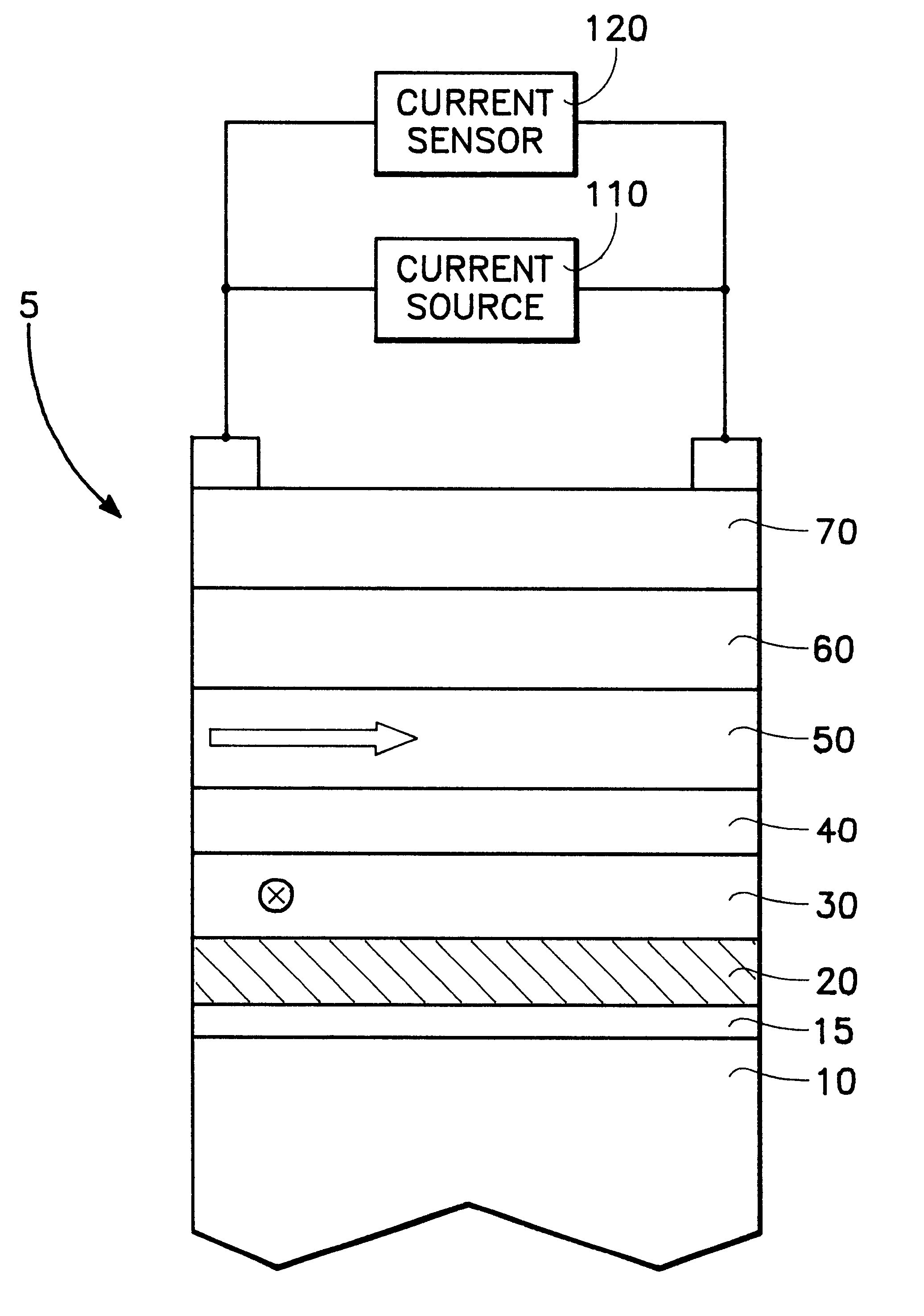

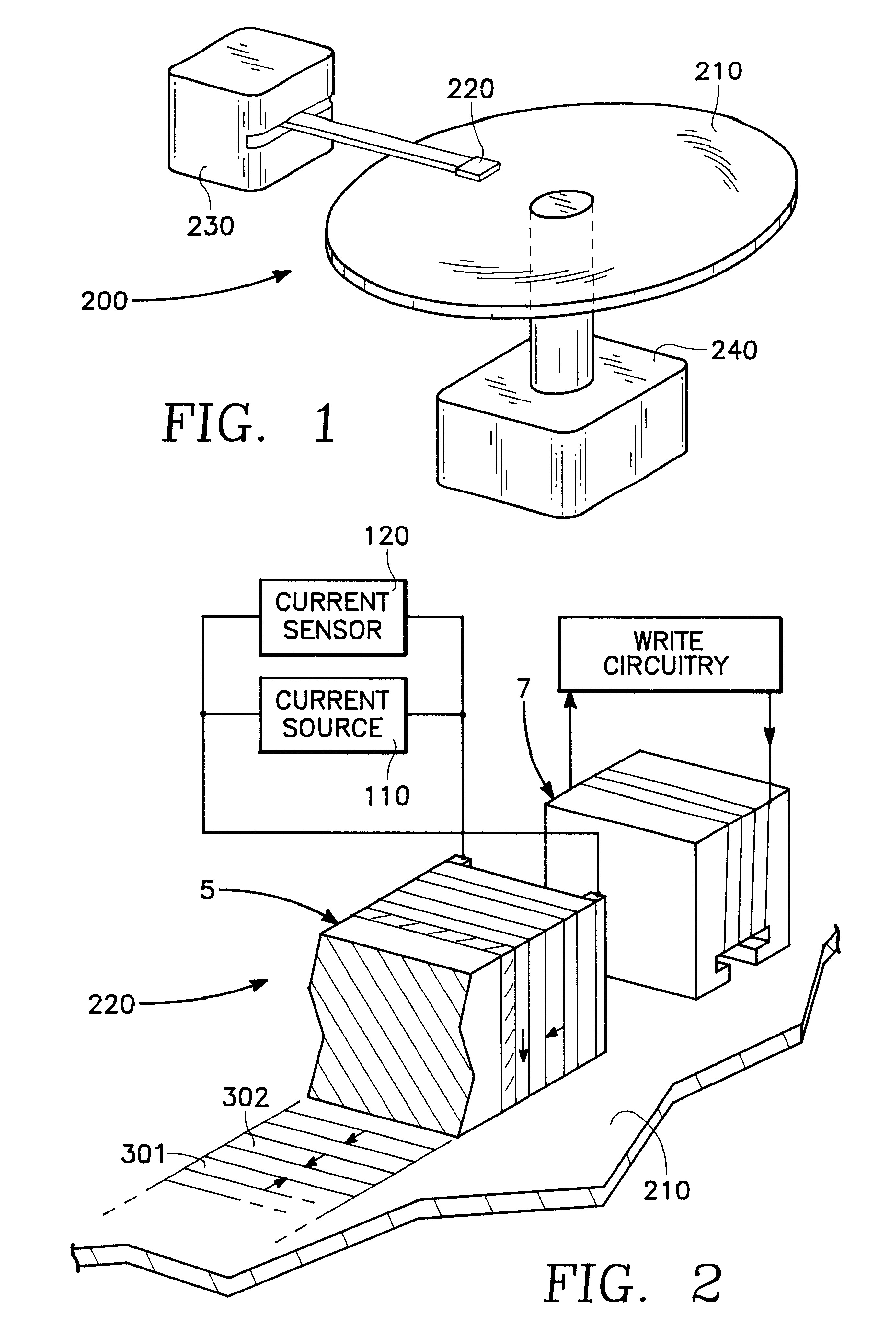

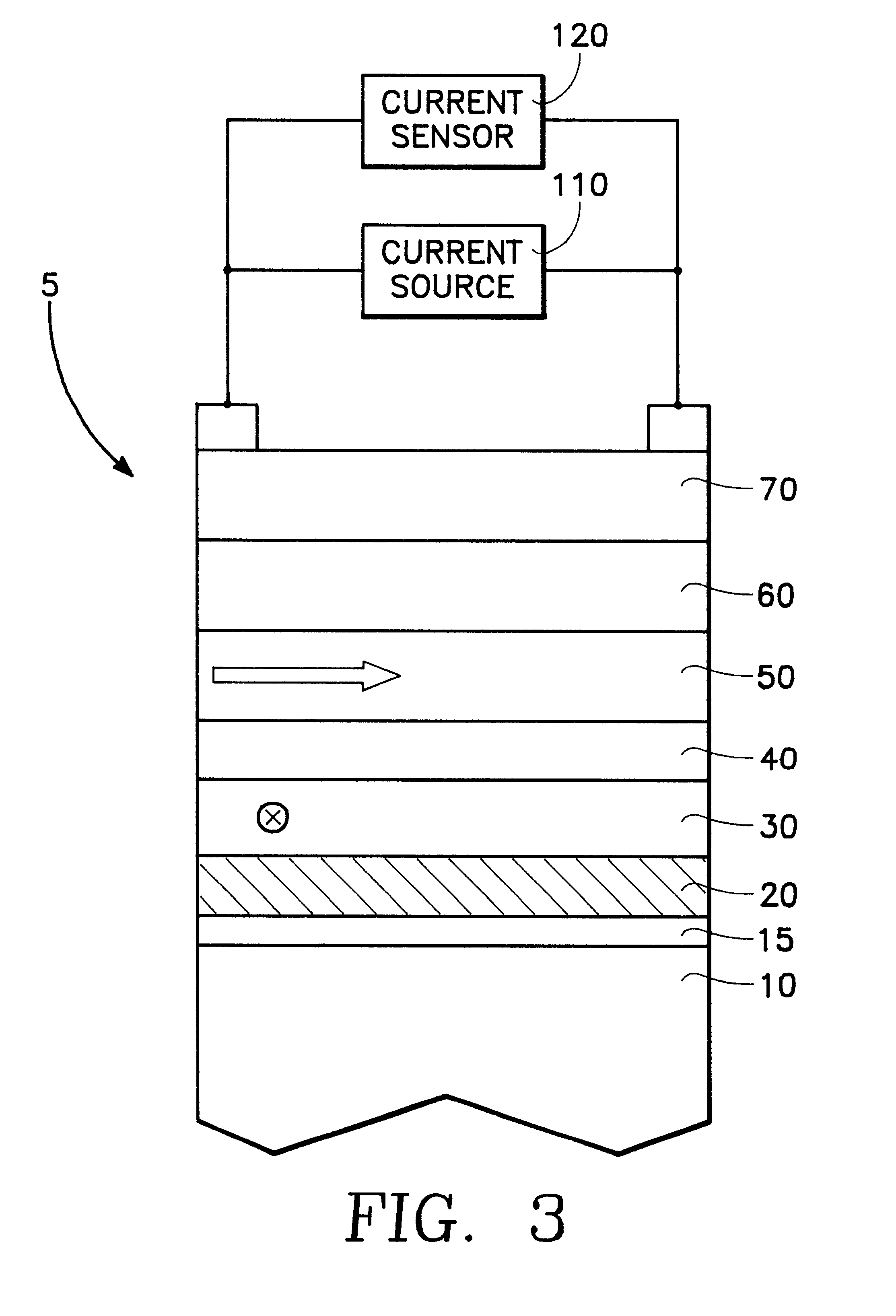

Structure to achieve sensitivity and linear density in tunneling GMR heads using orthogonal magnetic alignments

ActiveUS7035062B1Increase linear densityHigh sensitivityNanomagnetismNanoinformaticsMagnetic reluctanceMagnetization

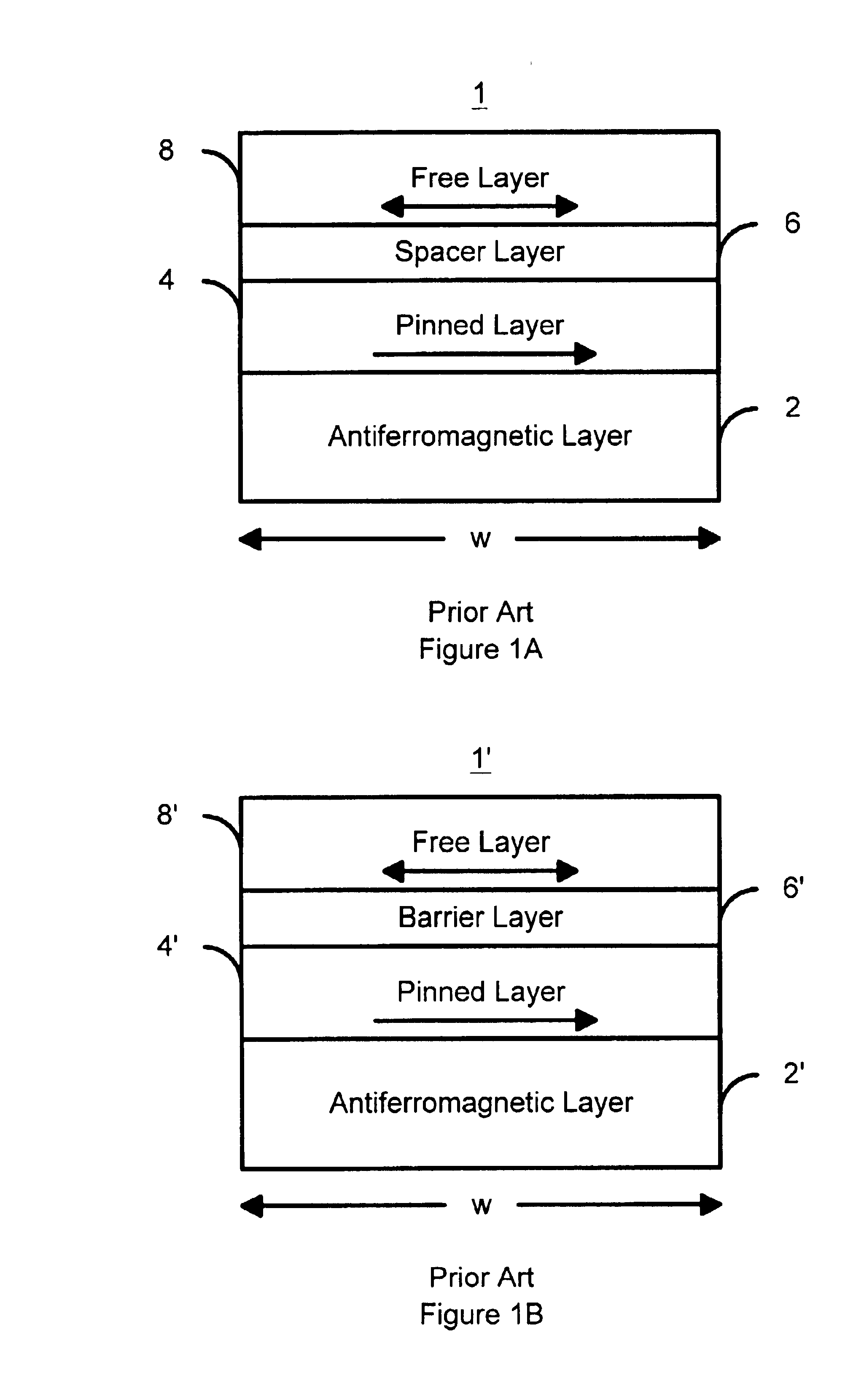

The present invention provides a tunneling magneto-resistive read sensor structure that improves sensitivity and linear density of the sensor structure. The sensor includes first and second electrodes and a stack positioned between the electrodes. The stack includes first and second free layers with magnetization orientations that are biased relative to each other. A tunneling barrier (insulating layer) or non-magnetic metal spacer is positioned between the first and second free layers. A sense current is passed between the first and second free layers of the stack. The amount of current passing through the first and second free layer changes based upon the orientation of the first and second free layers relative to each other.

Owner:SEAGATE TECH LLC

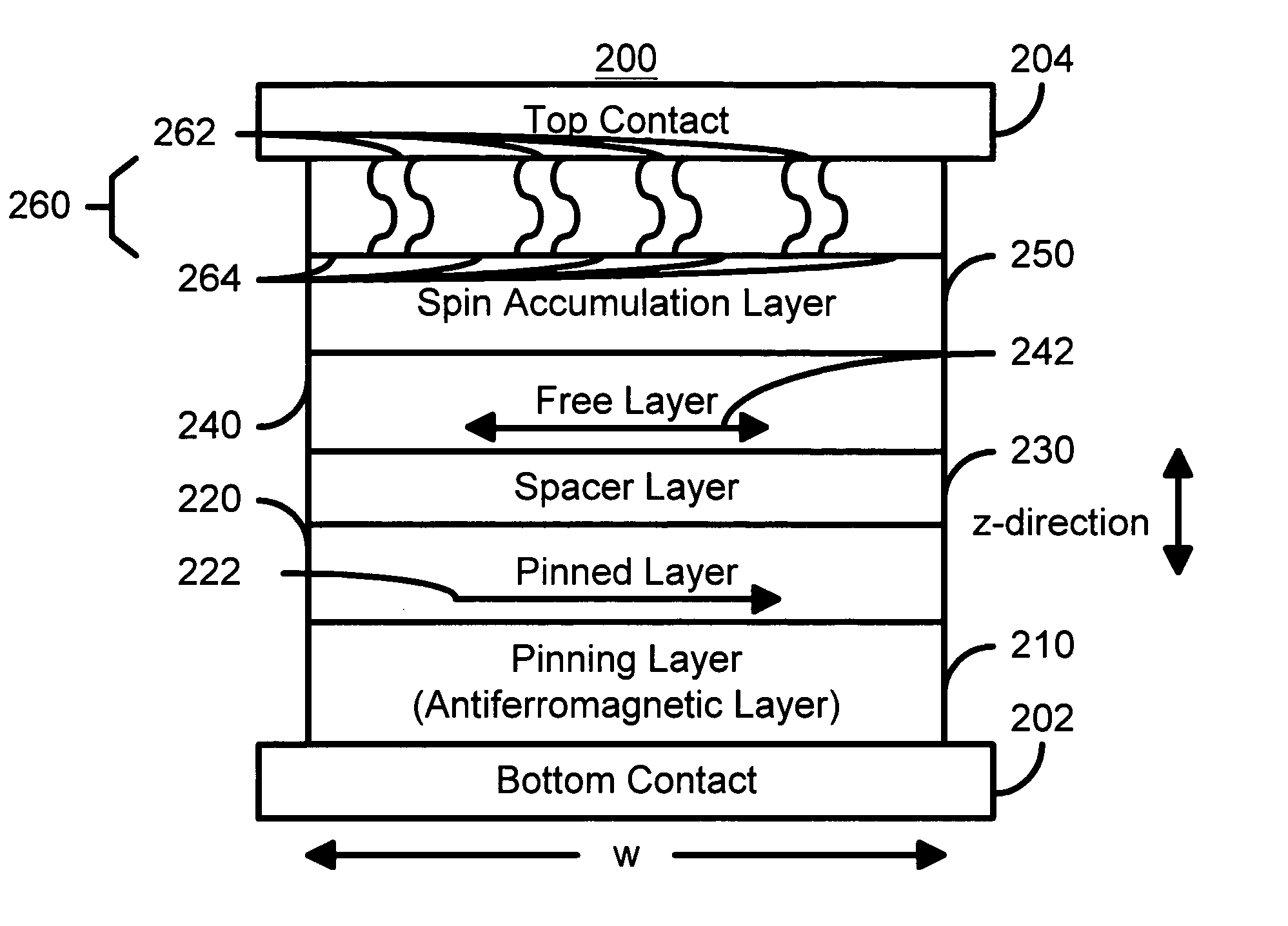

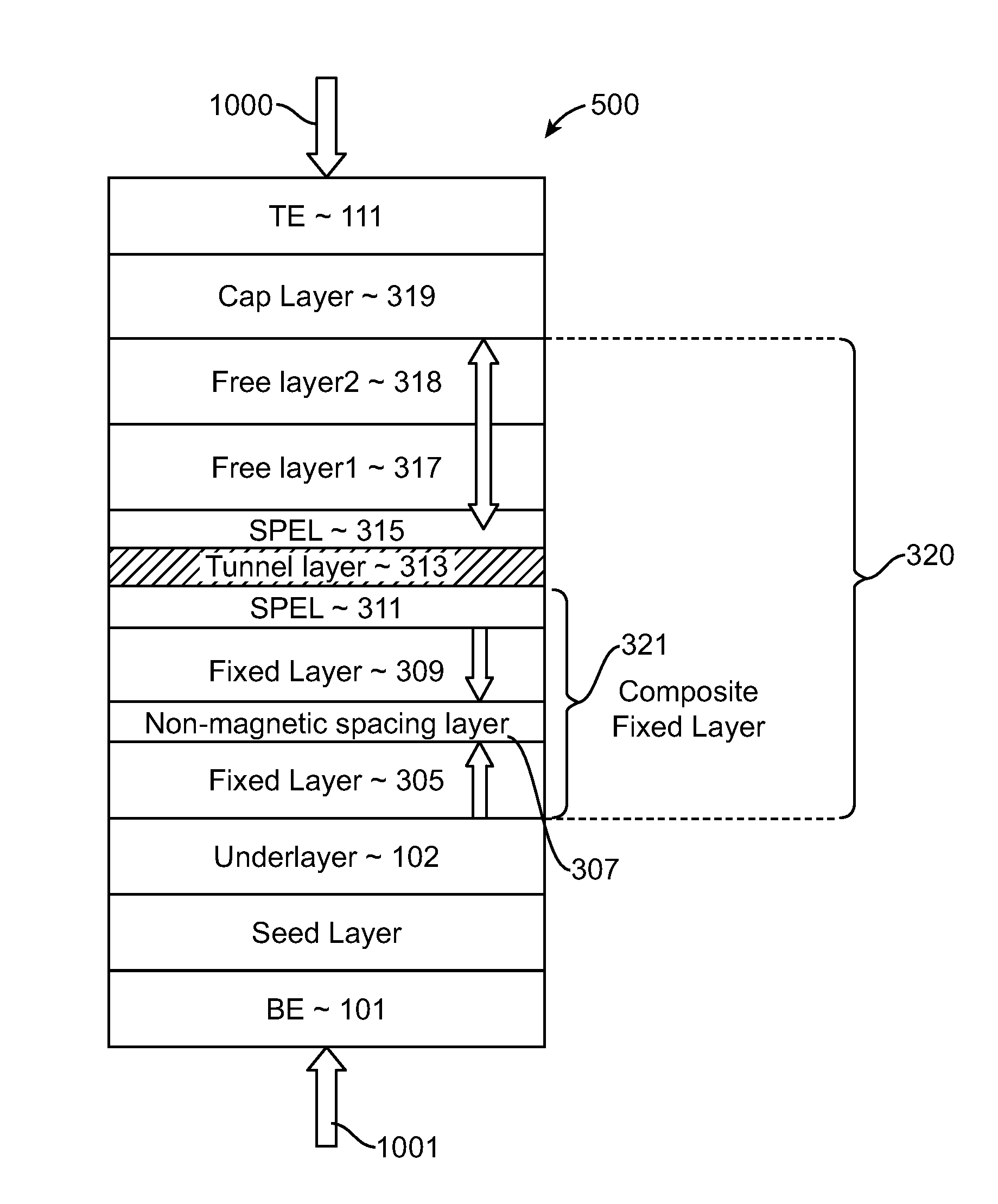

Spin barrier enhanced magnetoresistance effect element and magnetic memory using the same

ActiveUS7088609B2Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, spacer, free, and spin barrier layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer layer and the spin barrier layer. The spin barrier layer is configured to reduce an outer surface contribution to a damping constant of the free layer. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity, preferably being metallic, and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

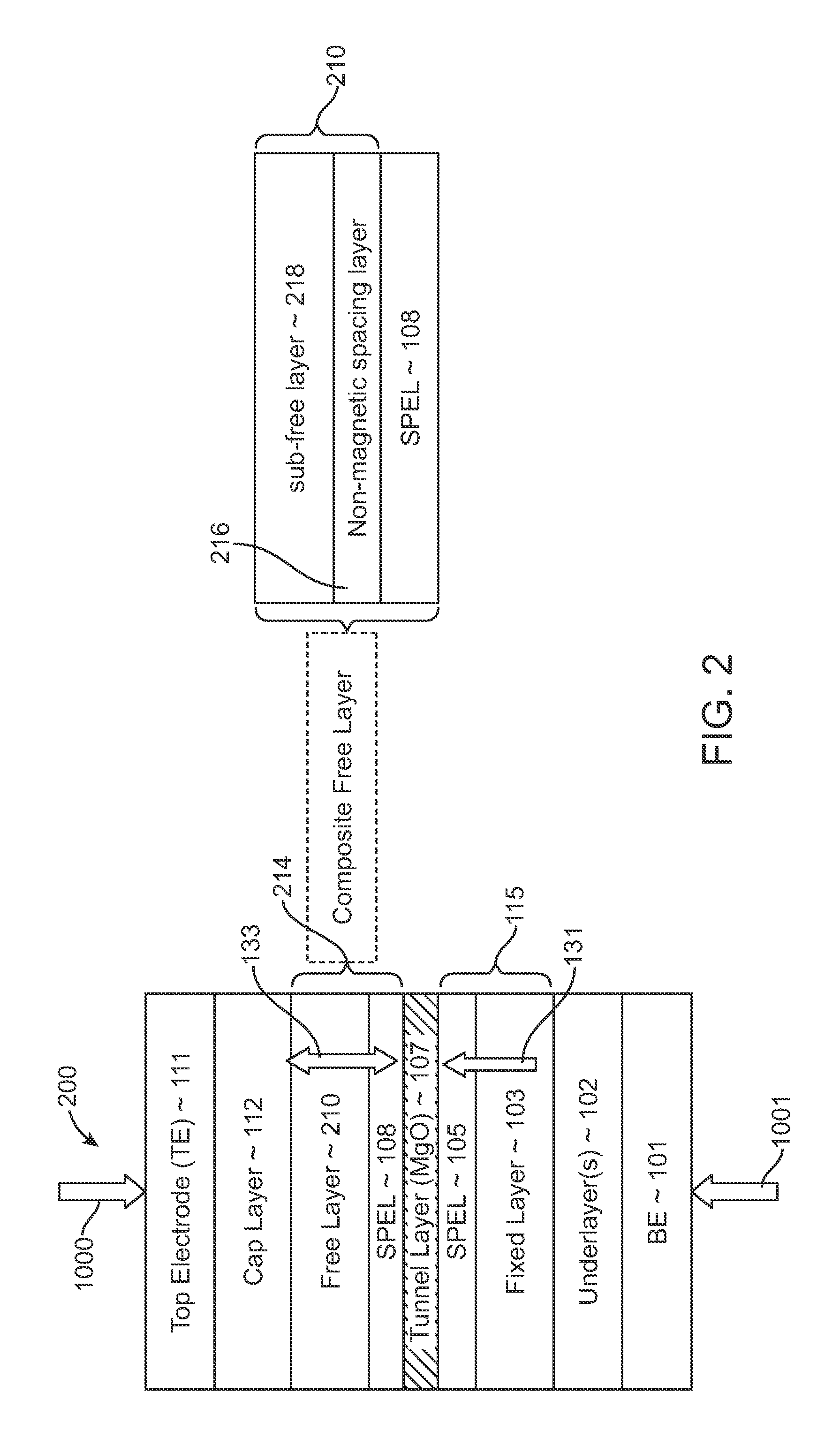

Spin-transfer torque magnetic random access memory having magnetic tunnel junction with perpendicular magnetic anisotropy

A spin-torque transfer memory random access memory (STTMRAM) element includes a fixed layer formed on top of a substrate and a a tunnel layer formed upon the fixed layer and a composite free layer formed upon the tunnel barrier layer and made of an iron platinum alloy with at least one of X or Y material, X being from a group consisting of: boron (B), phosphorous (P), carbon (C), and nitride (N) and Y being from a group consisting of: tantalum (Ta), titanium (Ti), niobium (Nb), zirconium (Zr), tungsten (W), silicon (Si), copper (Cu), silver (Ag), aluminum (Al), chromium (Cr), tin (Sn), lead (Pb), antimony (Sb), hafnium (Hf) and bismuth (Bi), molybdenum (Mo) or rhodium (Ru), the magnetization direction of each of the composite free layer and fixed layer being substantially perpendicular to the plane of the substrate.

Owner:AVALANCHE TECH

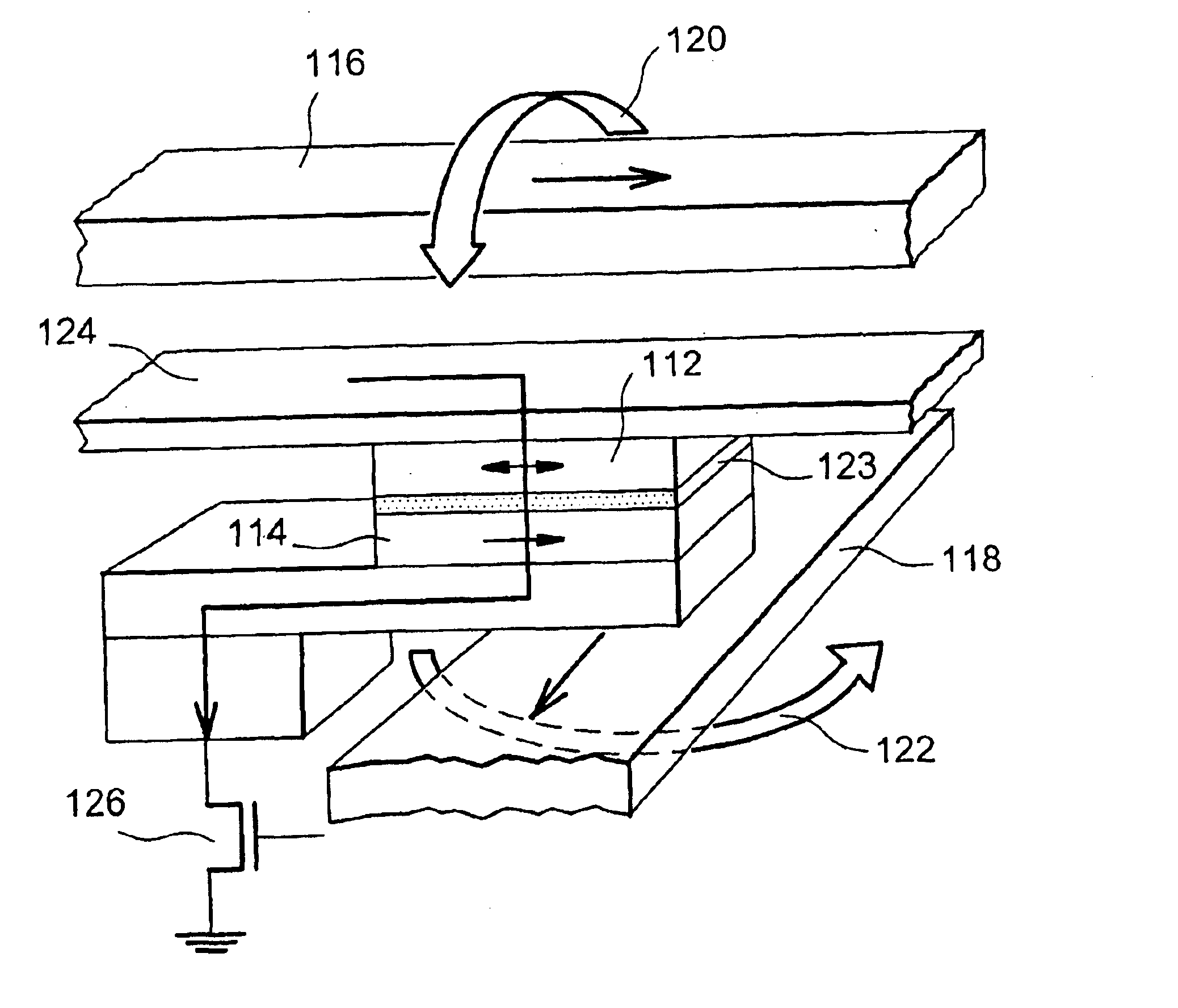

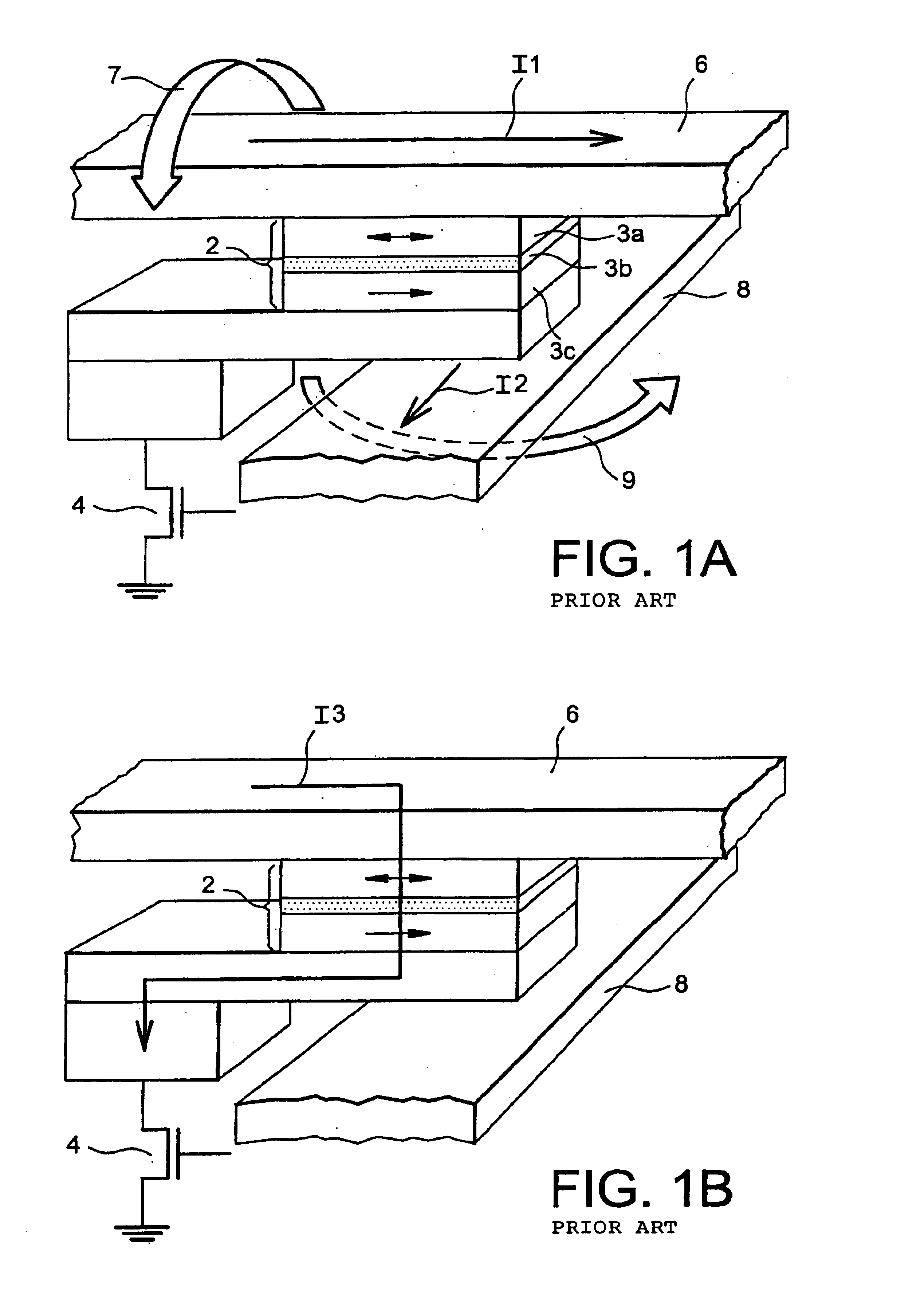

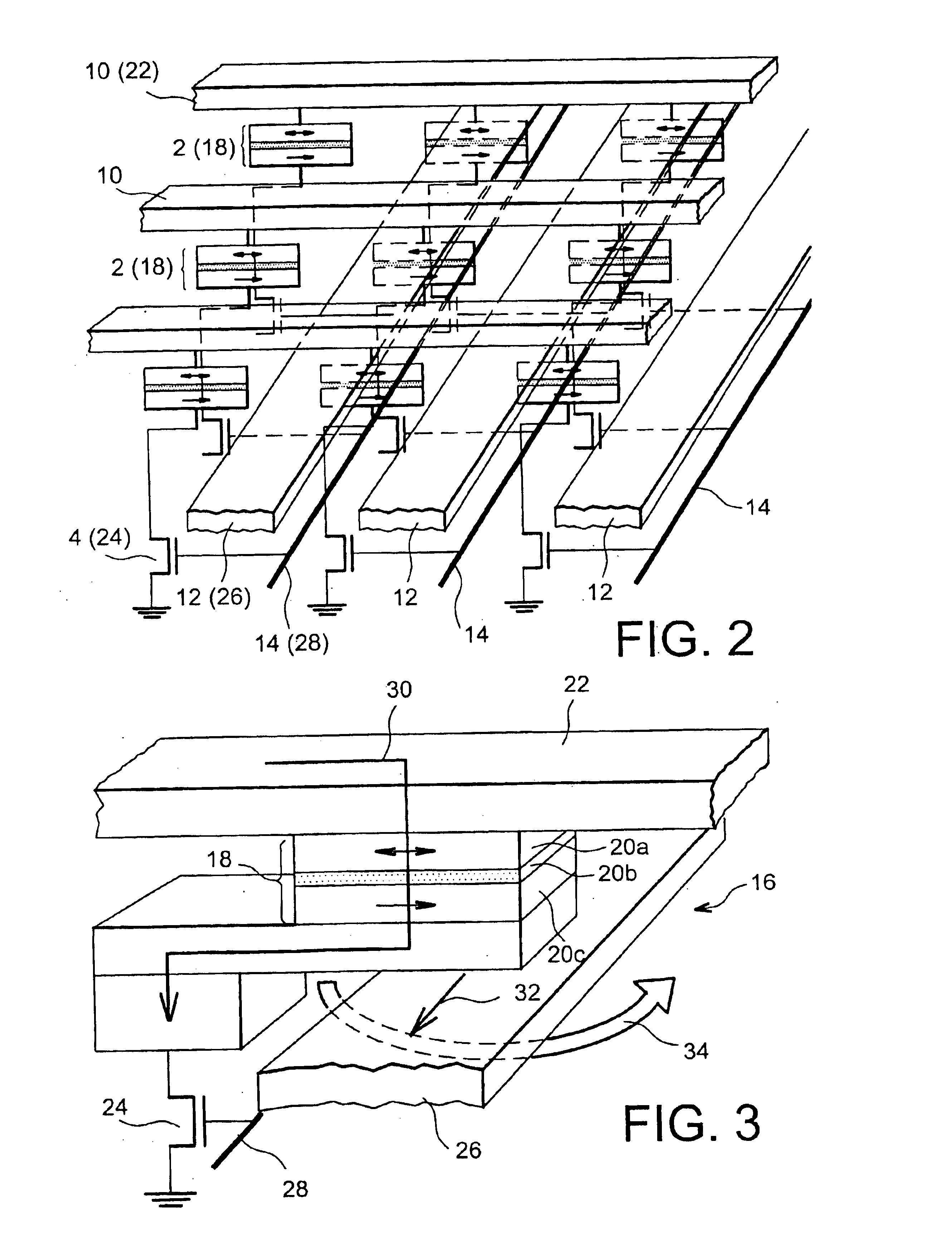

Magnetic tunnel junction magnetic device, memory and writing and reading methods using said device

InactiveUS6950335B2Good reproducibilityEliminate errorsNanomagnetismMagnetic-field-controlled resistorsMagnetizationSemiconductor

Magnetic tunnel junction magnetic device (16) for writing and reading uses a reference layer (20c) and a storage layer (20a) separated by a semiconductor or insulating layer (20b). The blocking temperature of the magnetisation of the storage layer is less than that of the reference layer. The storage layer is heated (22, 24) above the blocking temperature of its magnetisation. A magnetic field (34) is applied (26) to it orientating its magnetization with respect to that of the reference layer without modifying the orientation of the reference layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

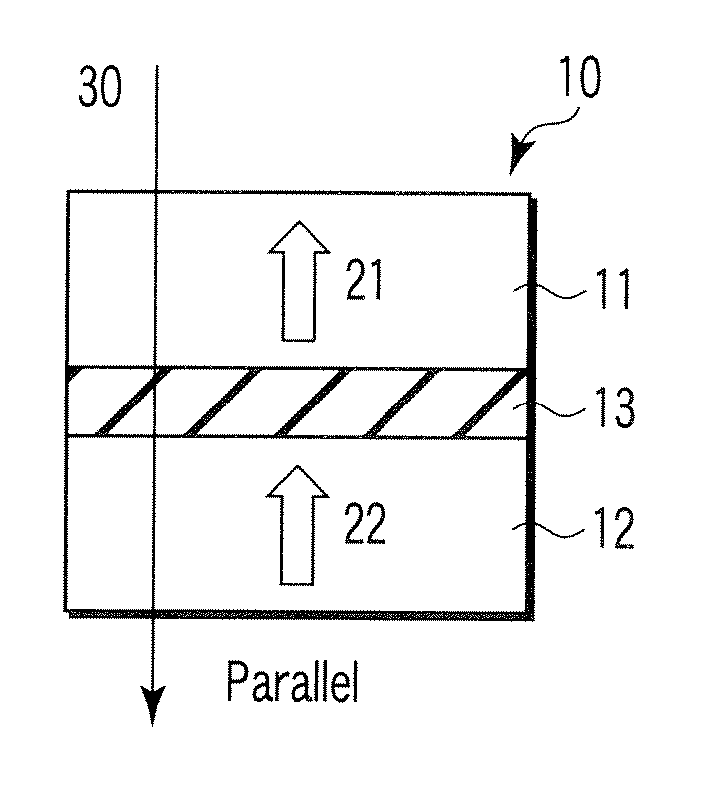

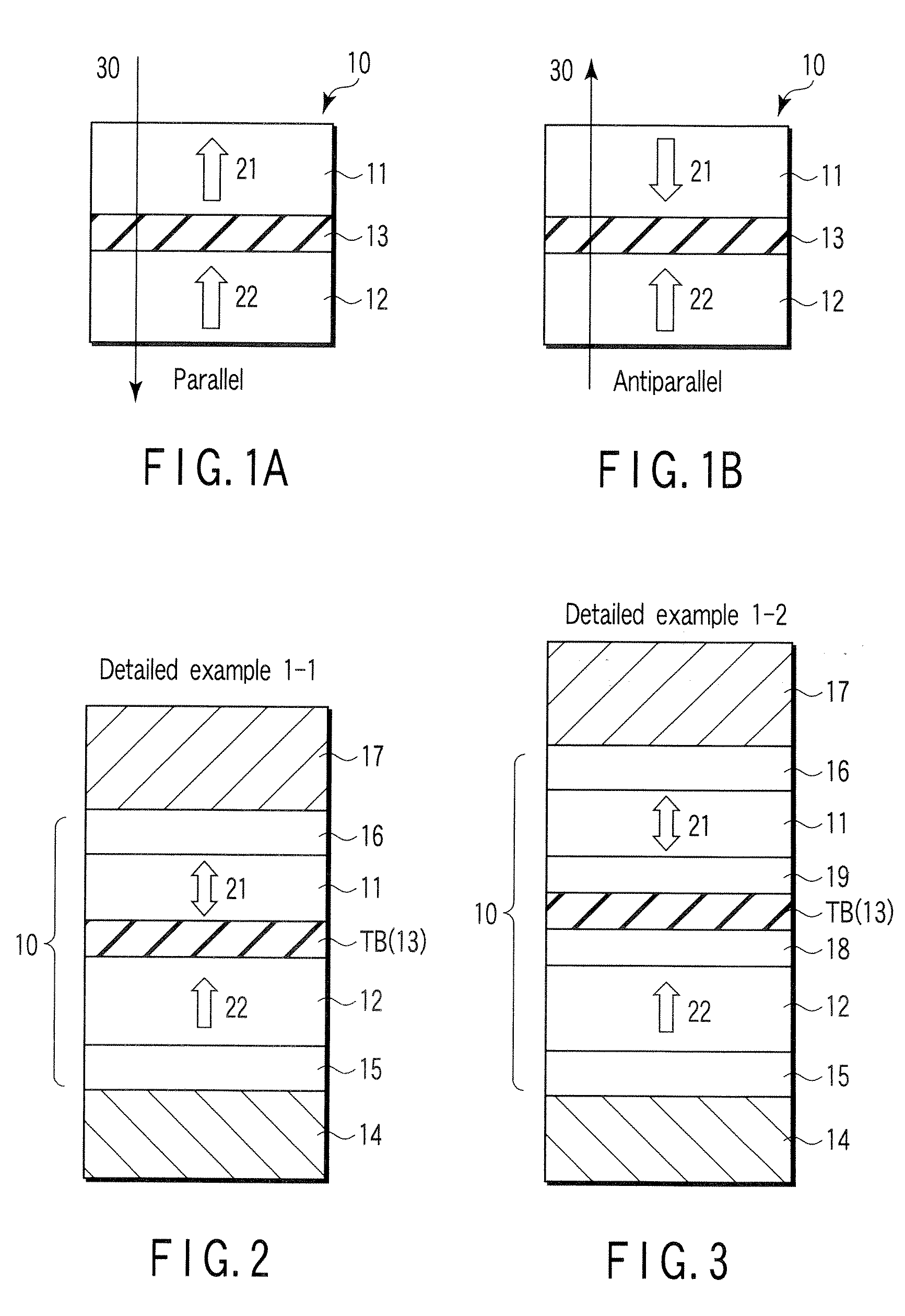

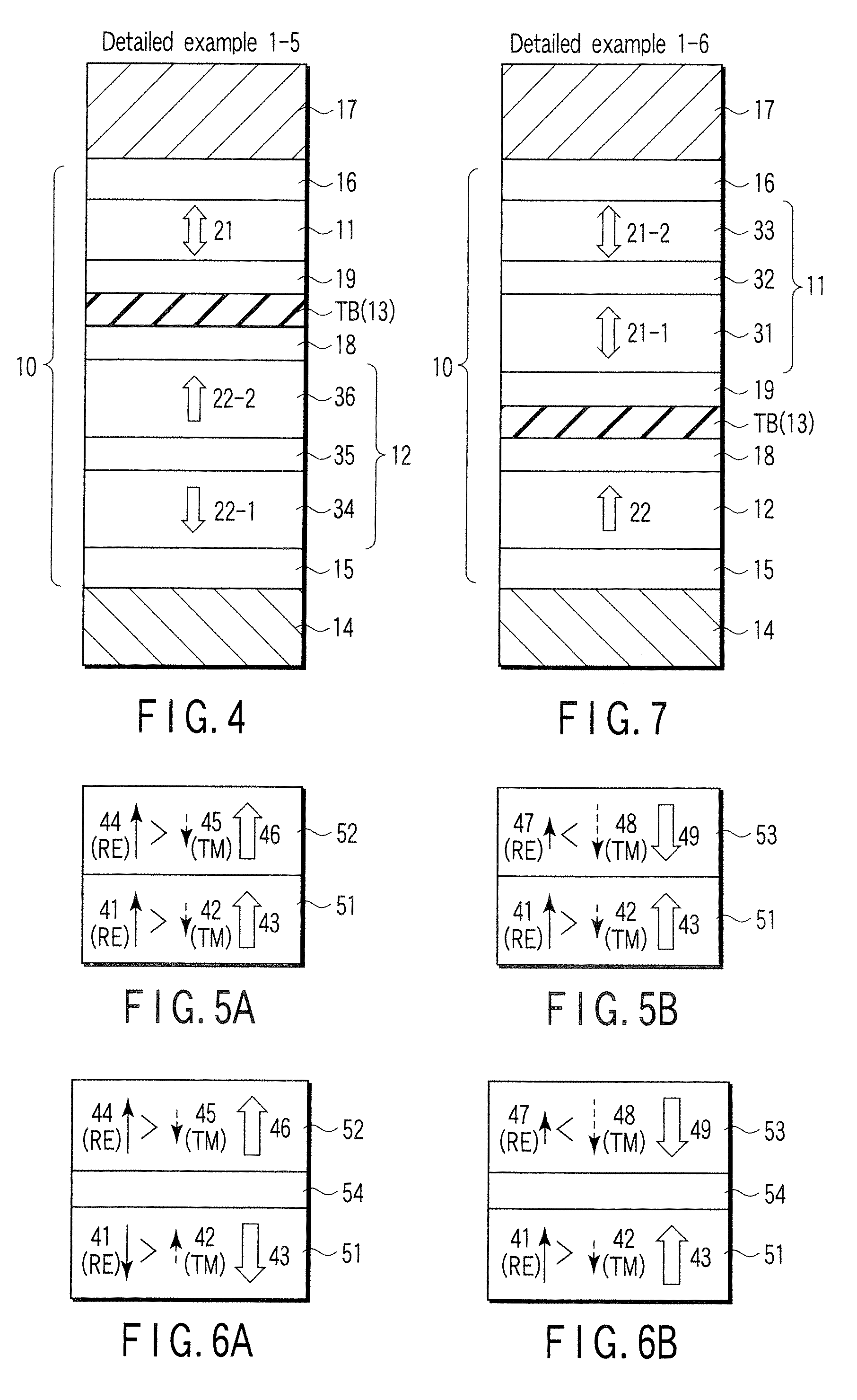

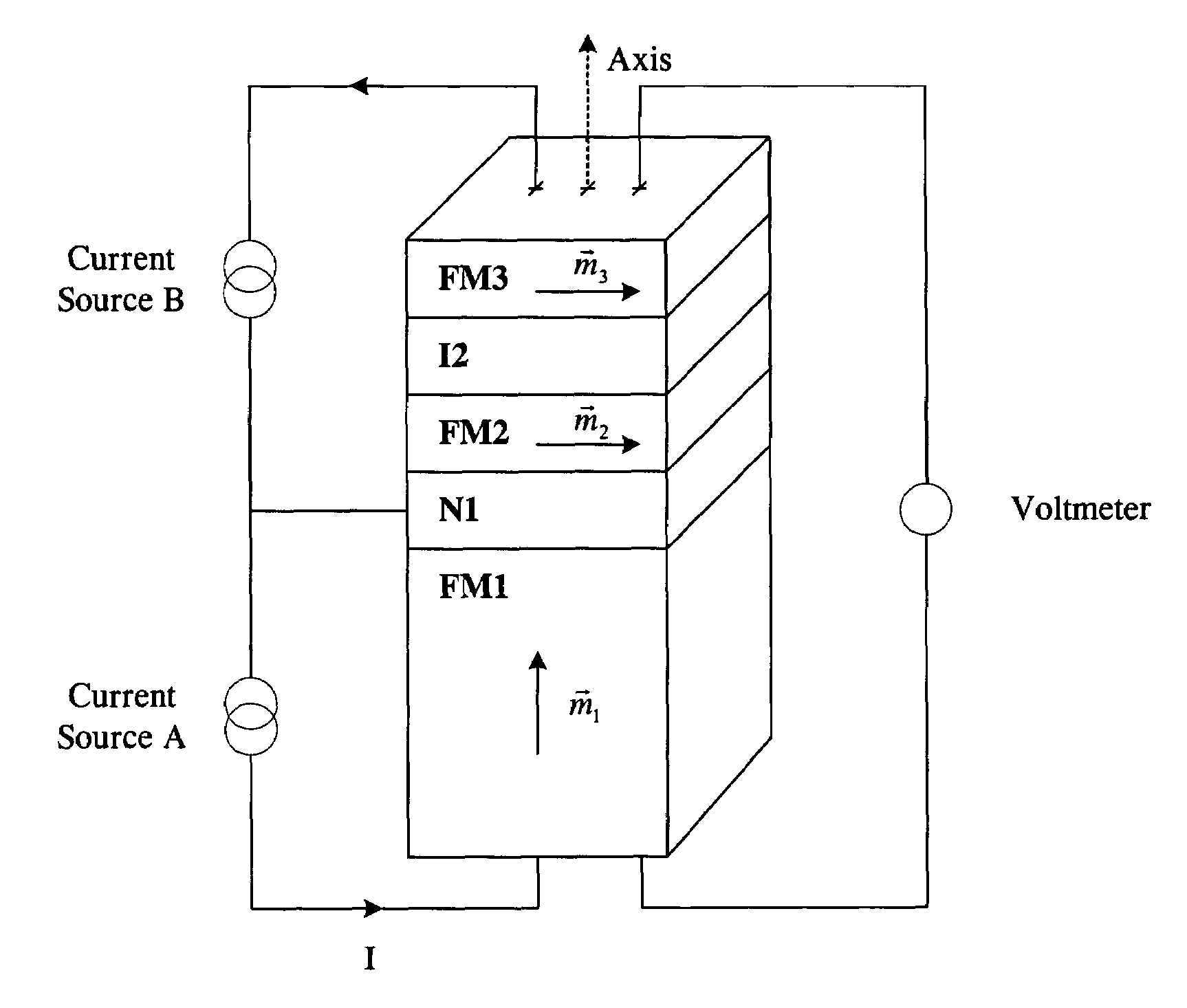

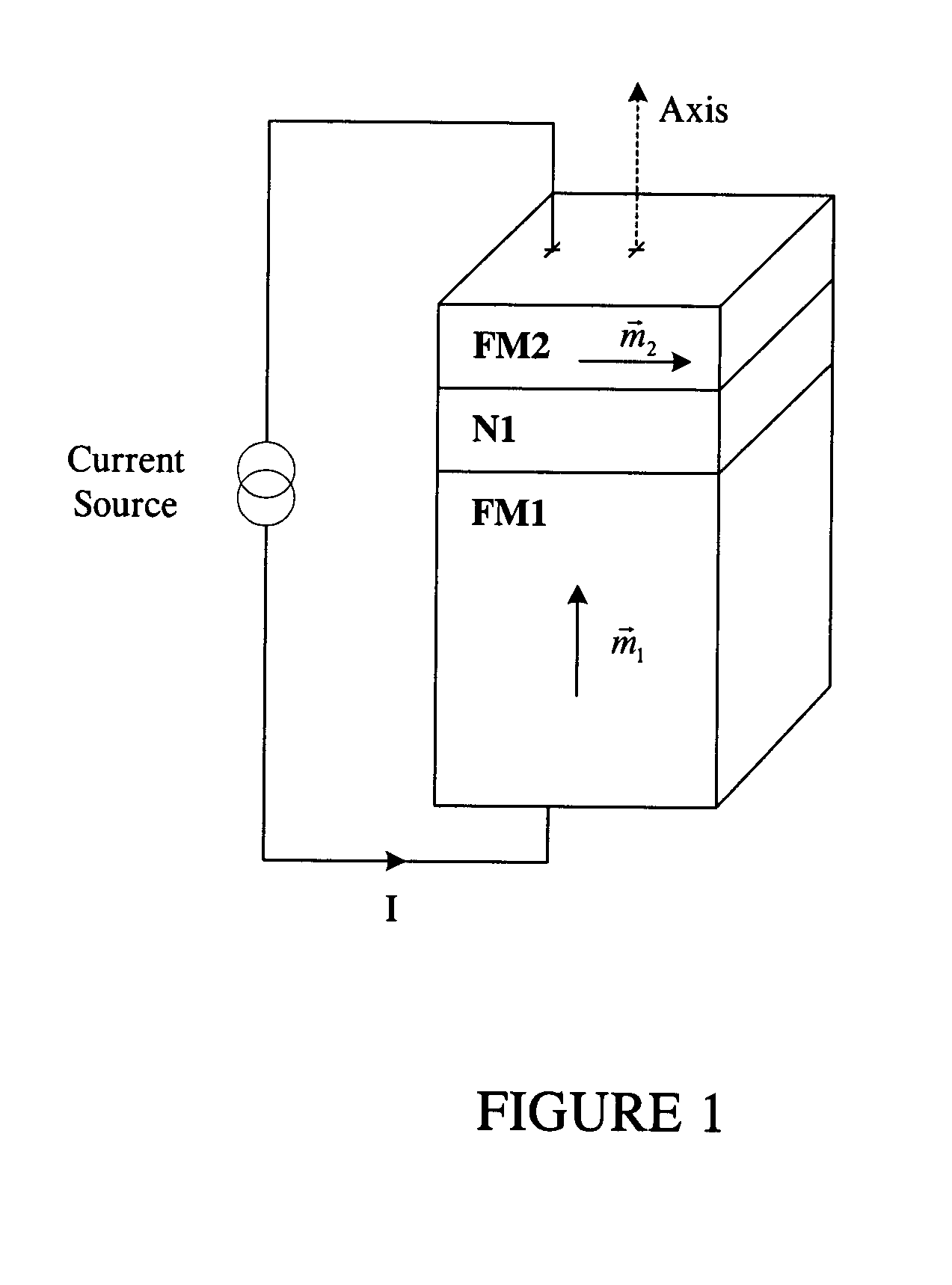

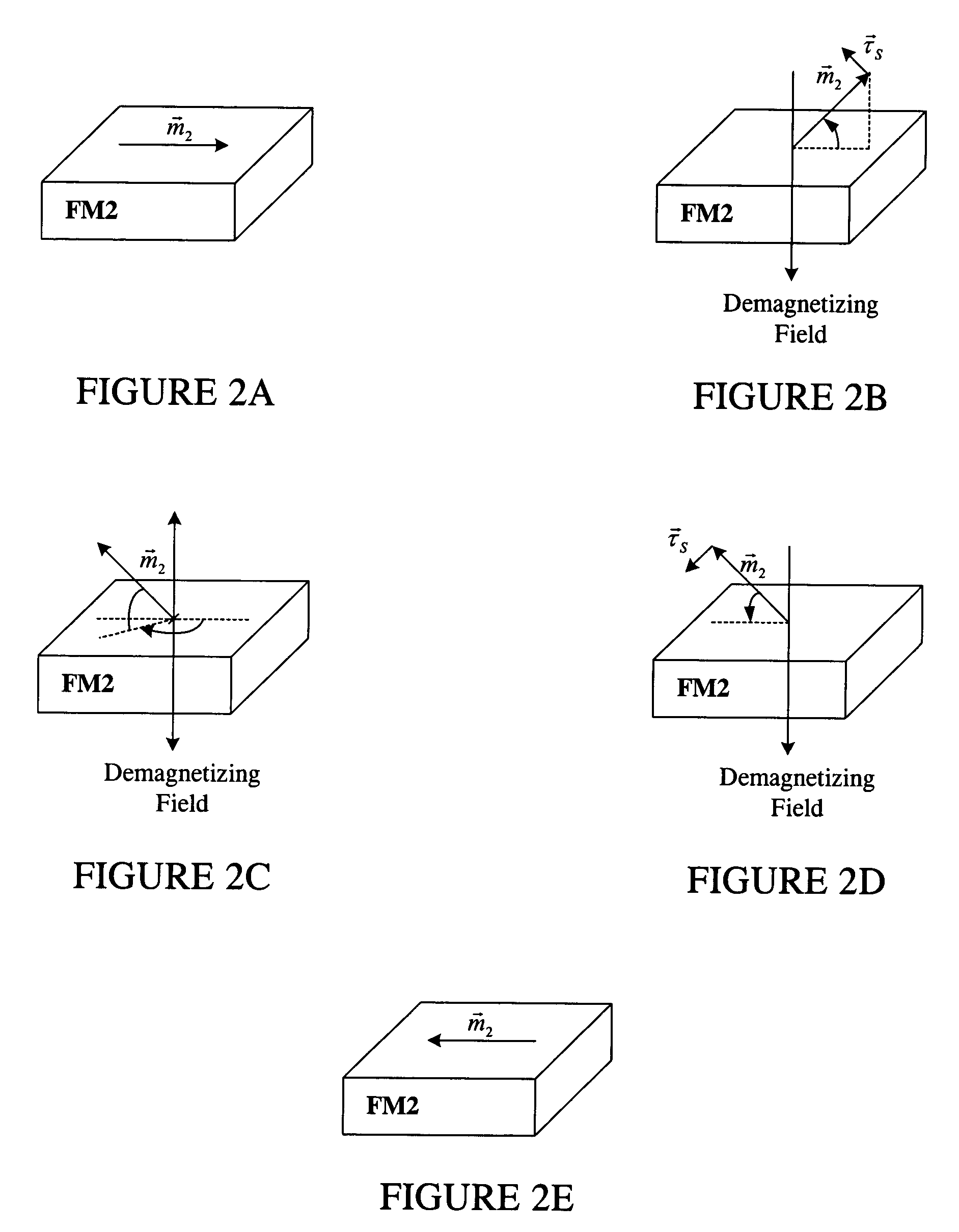

High speed low power magnetic devices based on current induced spin-momentum transfer

InactiveUS6980469B2Operational advantageReduce the required powerNanomagnetismNanoinformaticsMagnetic memoryMagnetization

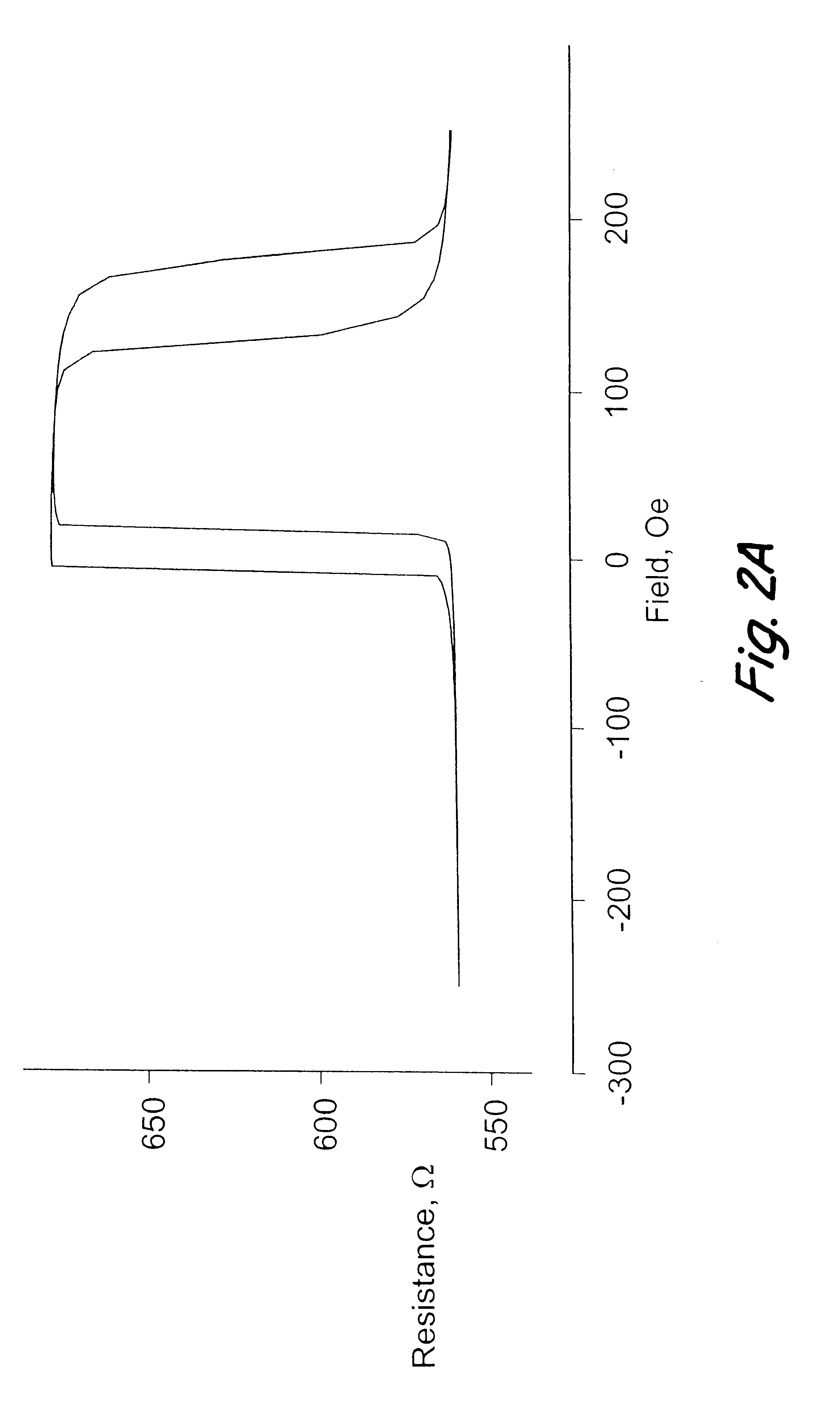

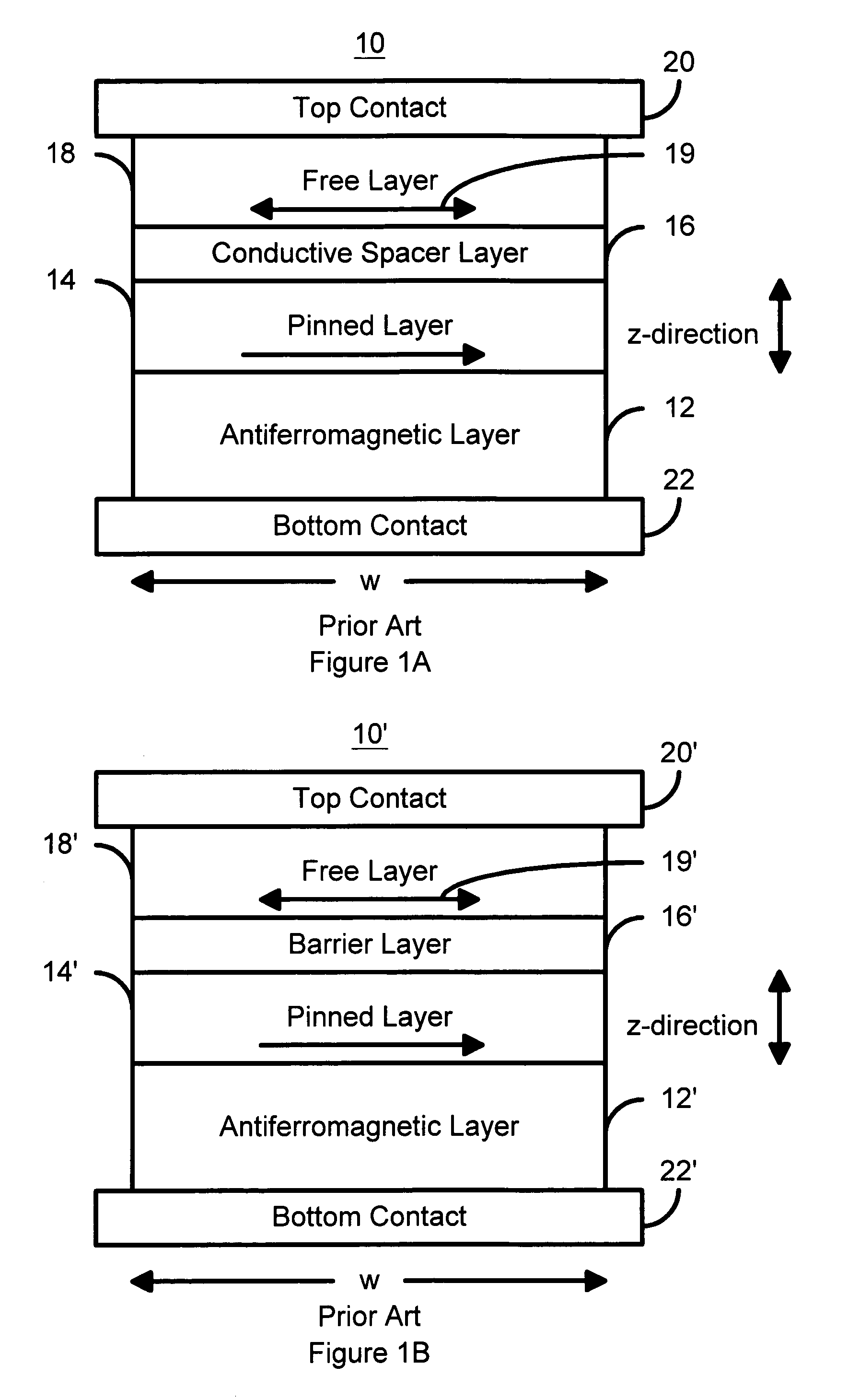

The present invention generally relates to the field of magnetic devices for memory cells that can serve as non-volatile memory. More specifically, the present invention describes a high speed and low power method by which a spin polarized electrical current can be used to control and switch the magnetization direction of a magnetic region in such a device. The magnetic device comprises a pinned magnetic layer with a fixed magnetization direction, a free magnetic layer with a free magnetization direction, and a read-out magnetic layer with a fixed magnetization direction. The pinned magnetic layer and the free magnetic layer are separated by a non-magnetic layer, and the free magnetic layer and the read-out magnetic layer are separated by another non-magnetic layer. The magnetization directions of the pinned and free layers generally do not point along the same axis. The non-magnetic layers minimize the magnetic interaction between the magnetic layers. A current is applied to the device to induce a torque that alters the magnetic state of the device so that it can act as a magnetic memory for writing information. The resistance, which depends on the magnetic state of the device, is measured to thereby read out the information stored in the device.

Owner:NEW YORK UNIV

Magnetoresistive element and magnetic memory

InactiveUS20070297220A1Easily magnetizedNanomagnetismMagnetic-field-controlled resistorsIn planeInter layer

A magnetoresistive includes a first magnetic reference layer having a fixed magnetization direction, a magnetic free layer having a magnetization direction which is changeable by being supplied with spin polarized electrons, a second magnetic reference layer having a fixed magnetization direction, a first intermediate layer provided between the first magnetic reference layer and the magnetic free layer, and a second intermediate layer provided between the magnetic free layer and the second magnetic reference layer. The magnetic free layer and the first magnetic reference layer have directions of easy magnetization perpendicular or parallel to an in-plane direction. The first magnetic reference layer and the second magnetic reference layer have directions of easy magnetization perpendicular to each other.

Owner:KK TOSHIBA

Spin barrier enhanced dual magnetoresistance effect element and magnetic memory using the same

ActiveUS7057921B2Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes first pinned, spacer, free, spin barrier, and second pinned layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer and spin barrier layers. The spin barrier layer is between the free and second pinned layers. The spin barrier layer is configured to reduce an outer surface contribution to the free layer damping constant. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

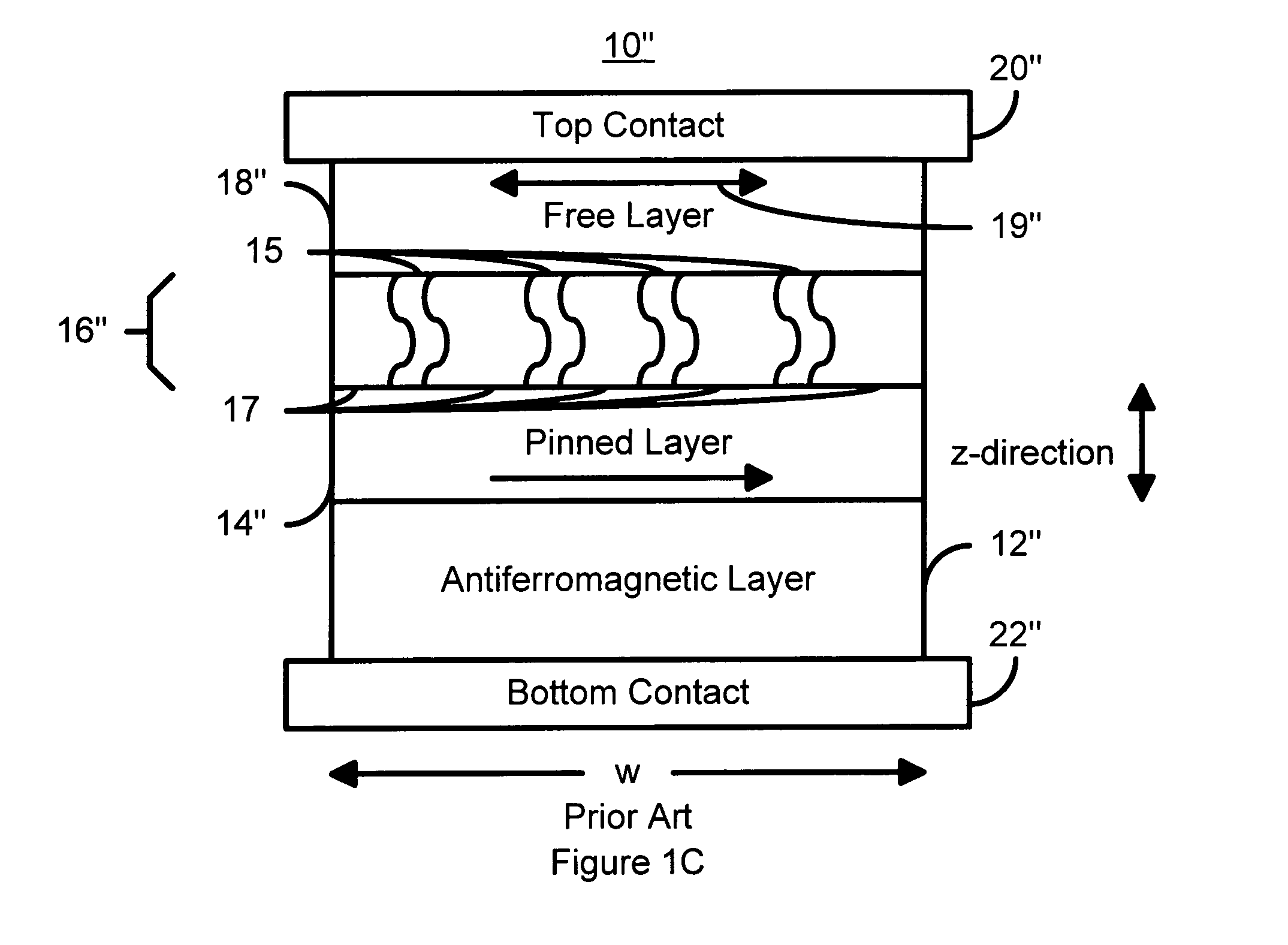

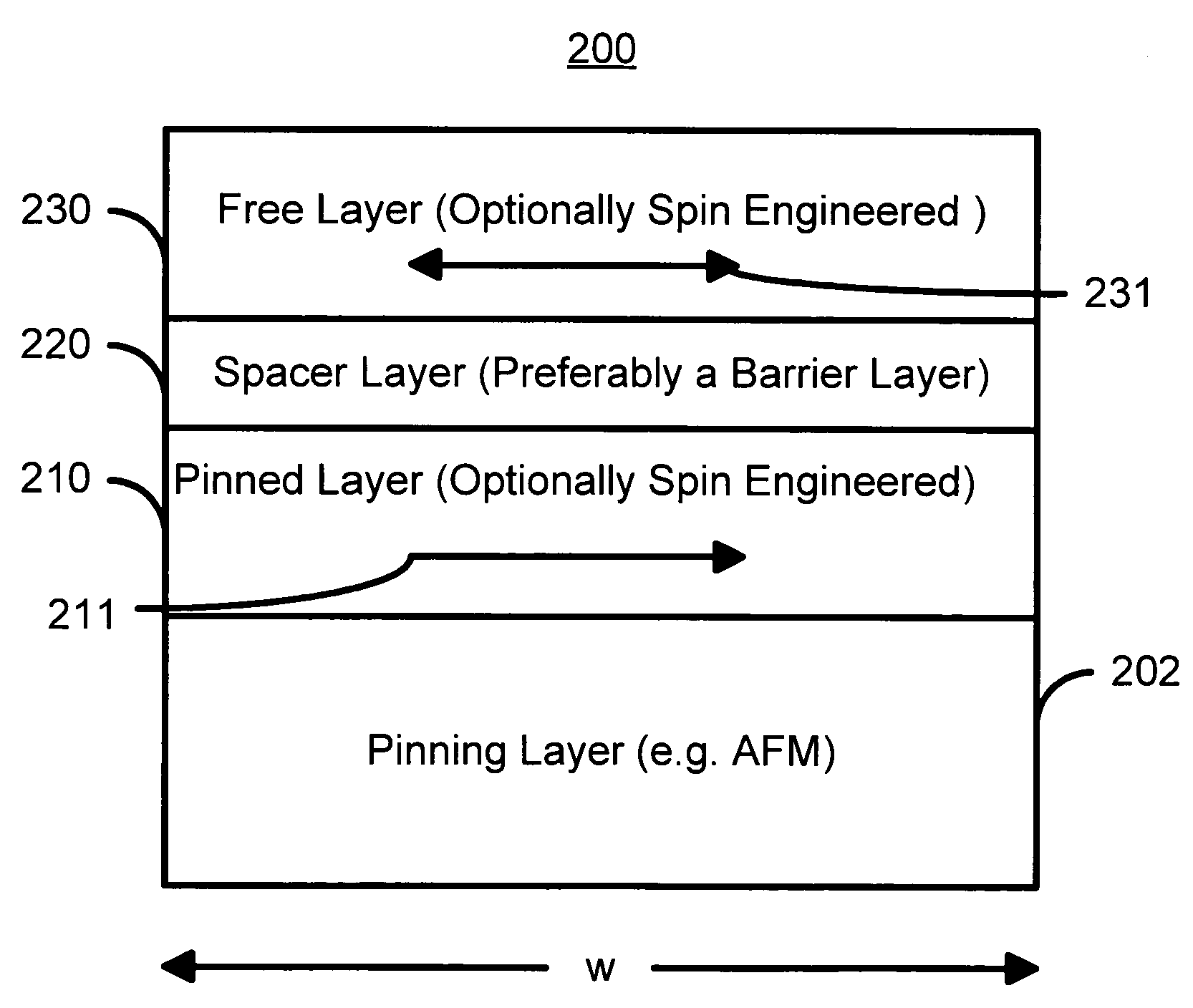

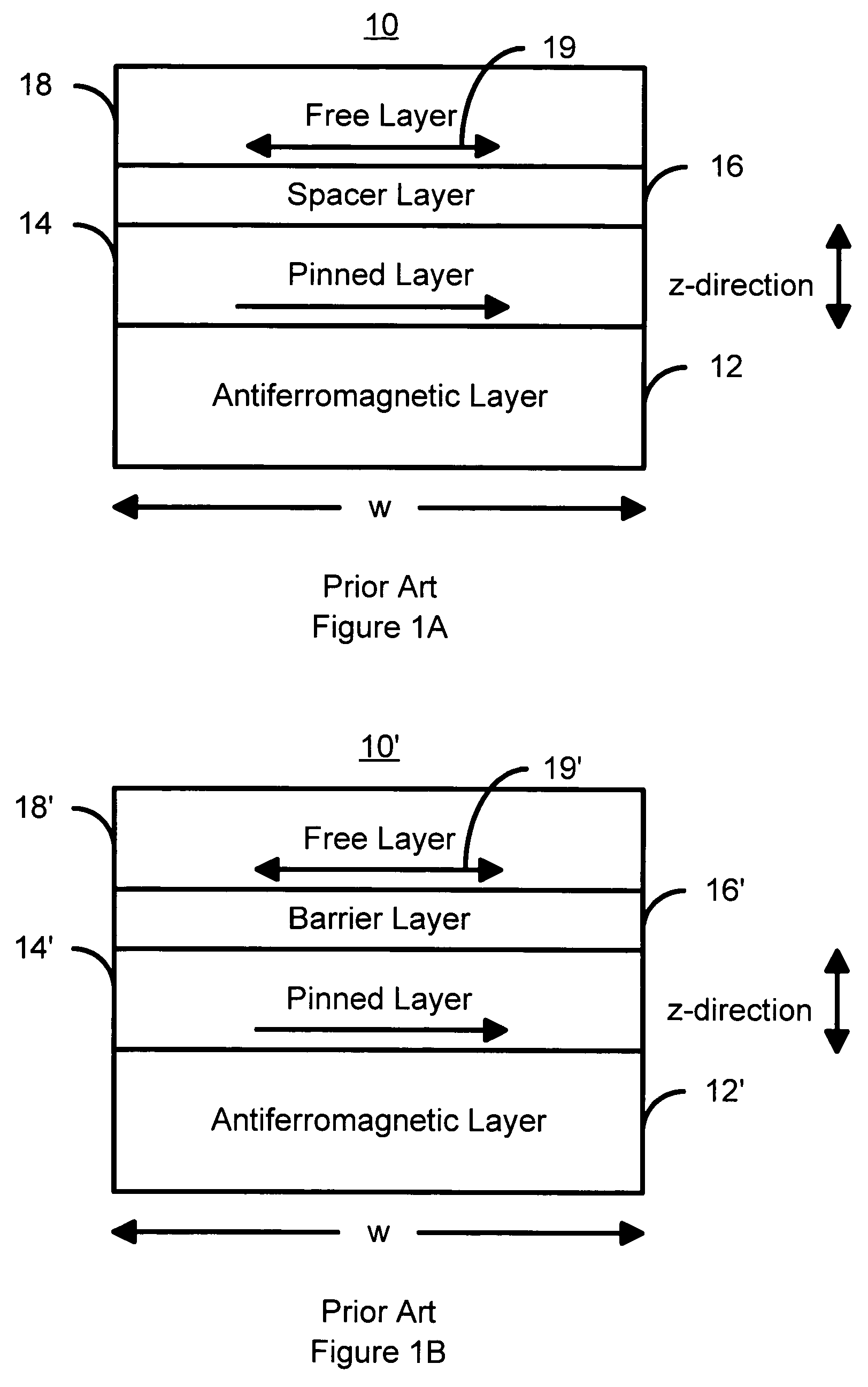

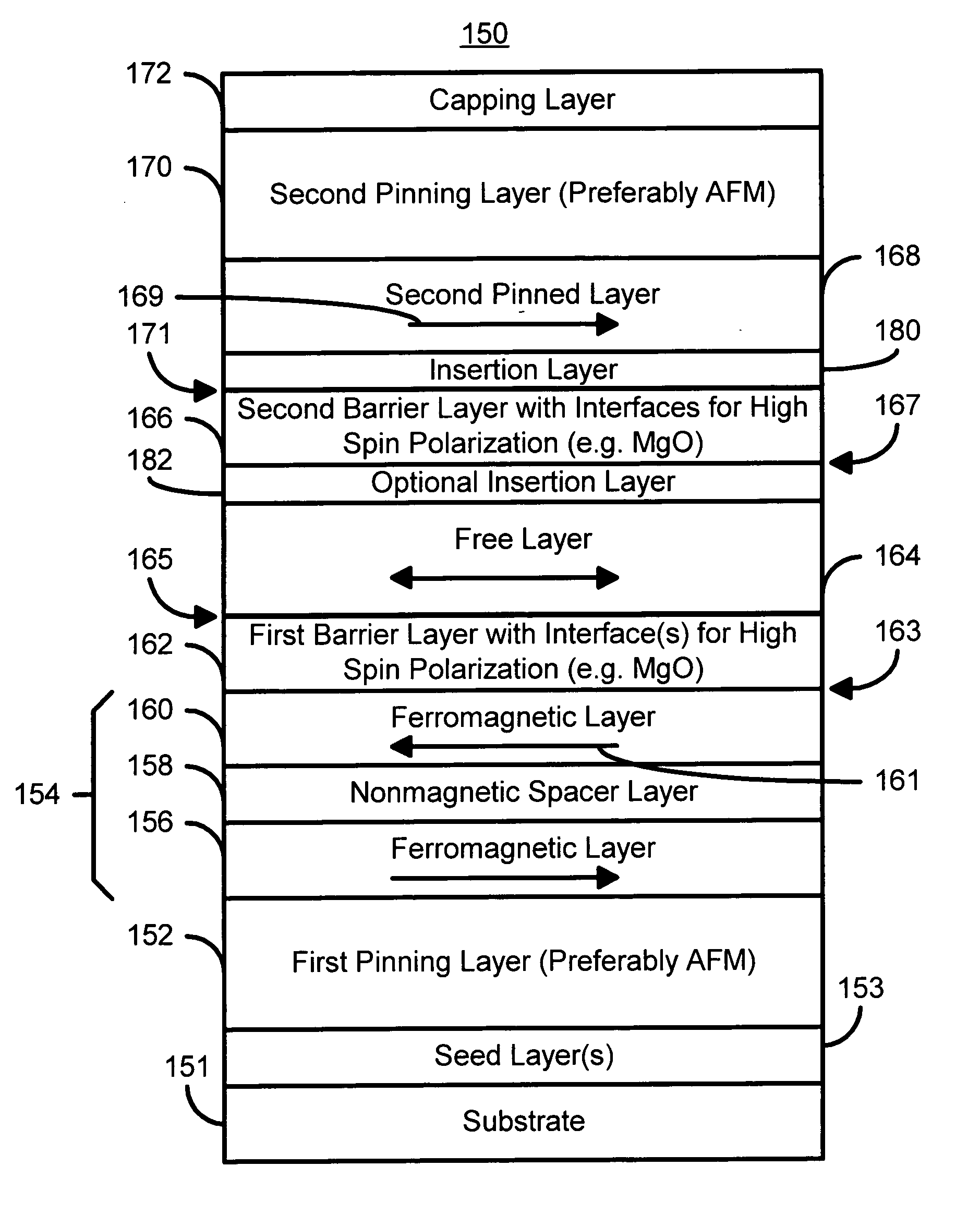

Magnetic elements with spin engineered insertion layers and MRAM devices using the magnetic elements

ActiveUS7369427B2Lower average currentReduce consumptionNanomagnetismGalvano-magnetic material selectionSpinsSpin transfer

A method and system include providing a pinned layer, a free layer, and a spacer layer between the pinned and free layers. The spacer layer is nonmagnetic. The magnetic element is configured to allow the free layer to be switched due to spin transfer when a write current is passed through the magnetic element. In one aspect, the method and system include providing a spin engineered layer adjacent to the free layer. The spin engineered layer is configured to more strongly scatter majority electrons than minority electrons. In another aspect, at least one of the pinned, free, and spacer layers is a spin engineered layer having an internal spin engineered layer configured to more strongly scatter majority electrons than minority electrons. In this aspect, the magnetic element may include another pinned layer and a barrier layer between the free and pinned layers.

Owner:SAMSUNG SEMICON

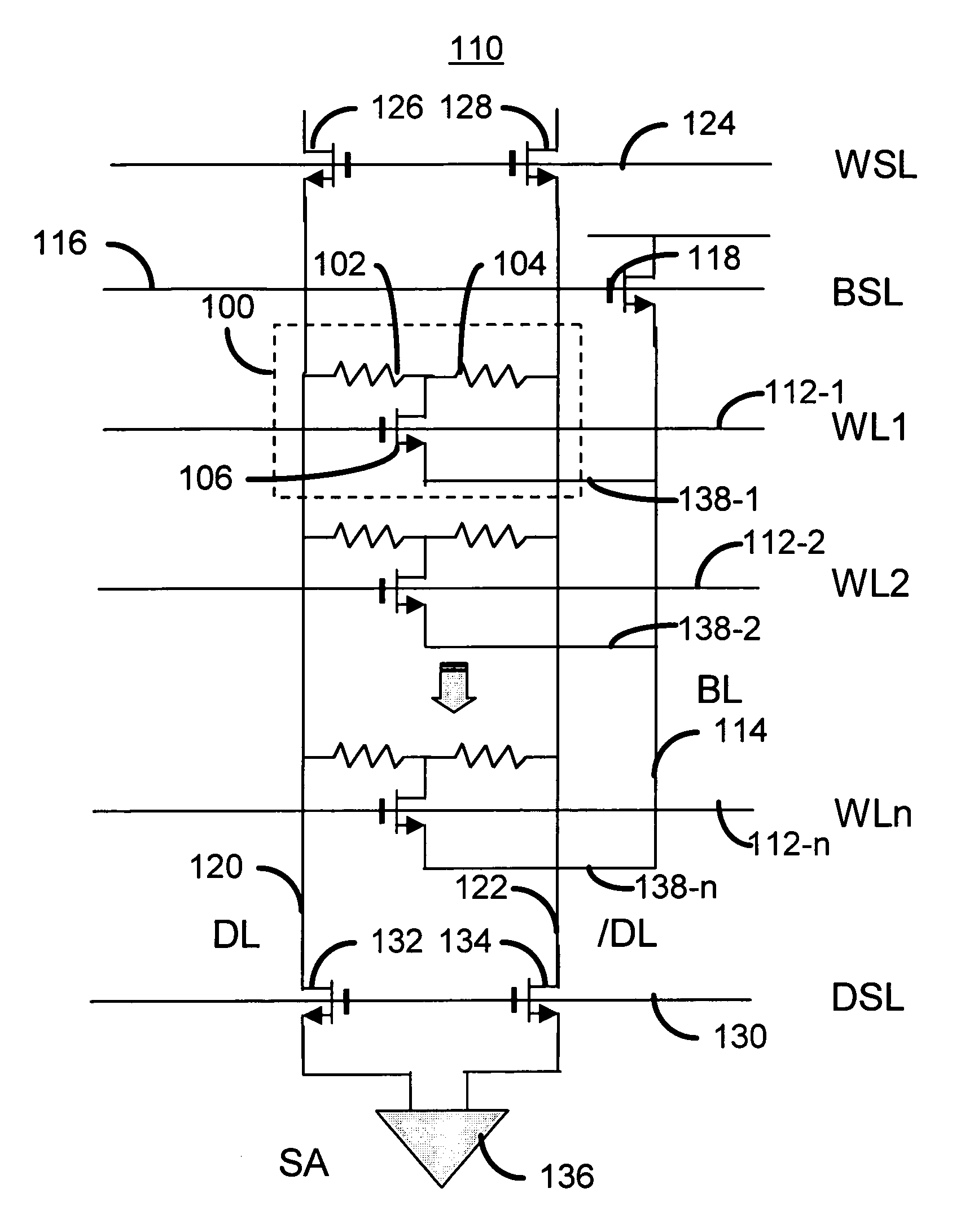

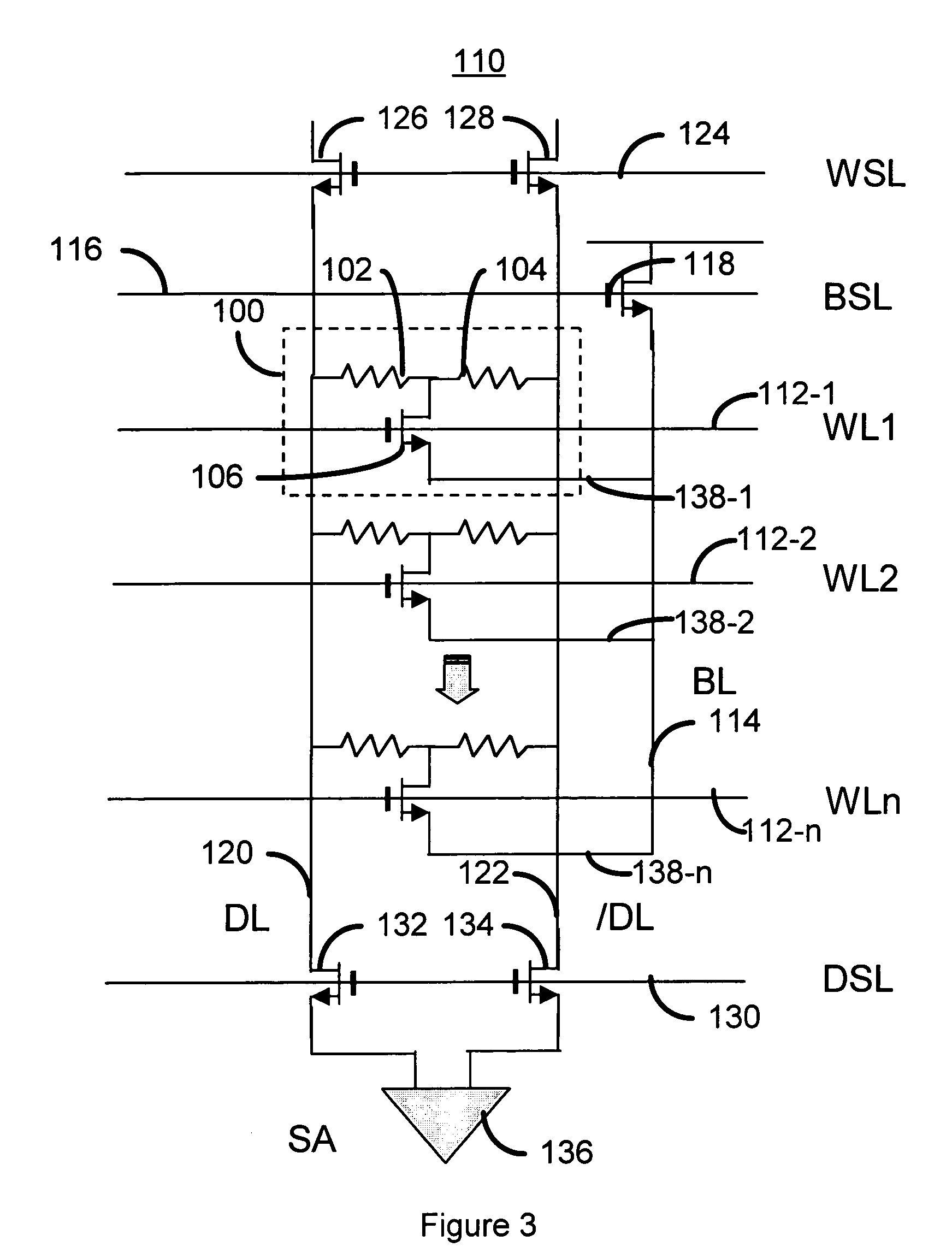

Spin-current switched magnetic memory element suitable for circuit integration and method of fabricating the memory element

A magnetic memory element switchable by current injection includes a plurality of magnetic layers, at least one of the plurality of magnetic layers having a perpendicular magnetic anisotropy component and including a current-switchable magnetic moment, and at least one barrier layer formed adjacent to the plurality of magnetic layers (e.g., between two of the magnetic layers). The memory element has the switching threshold current and device impedance suitable for integration with complementary metal oxide semiconductor (CMOS) integrated circuits.

Owner:GLOBALFOUNDRIES US INC

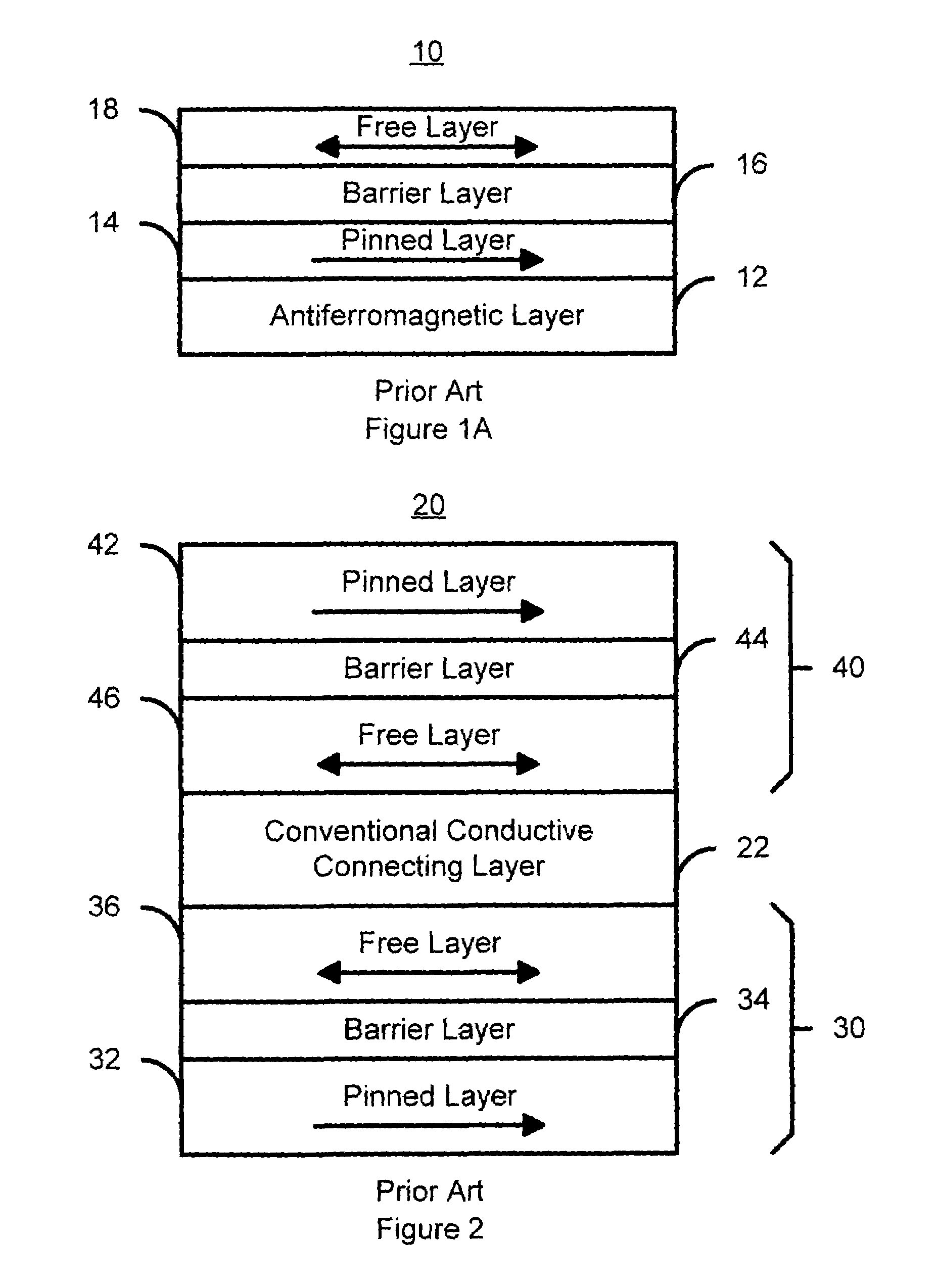

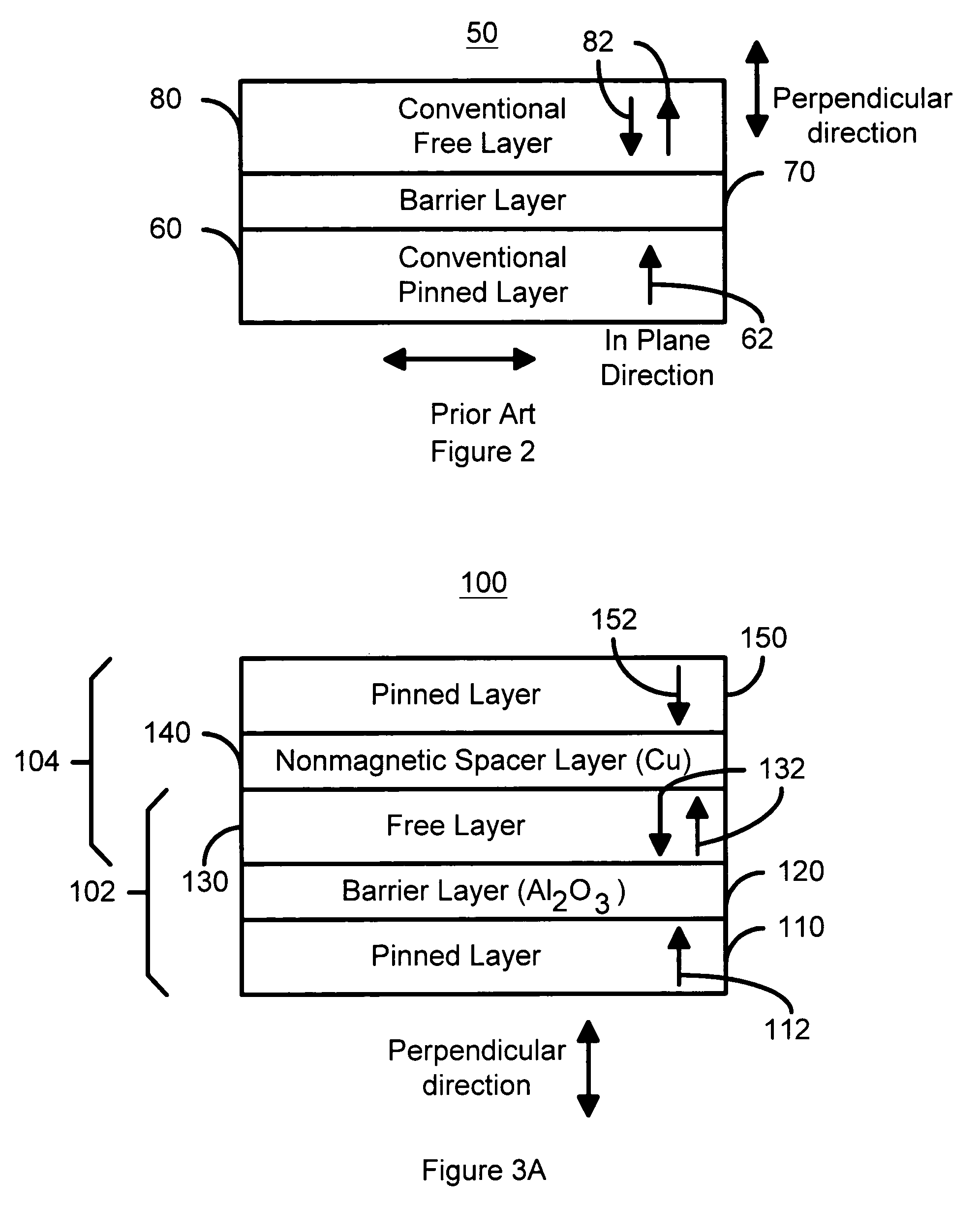

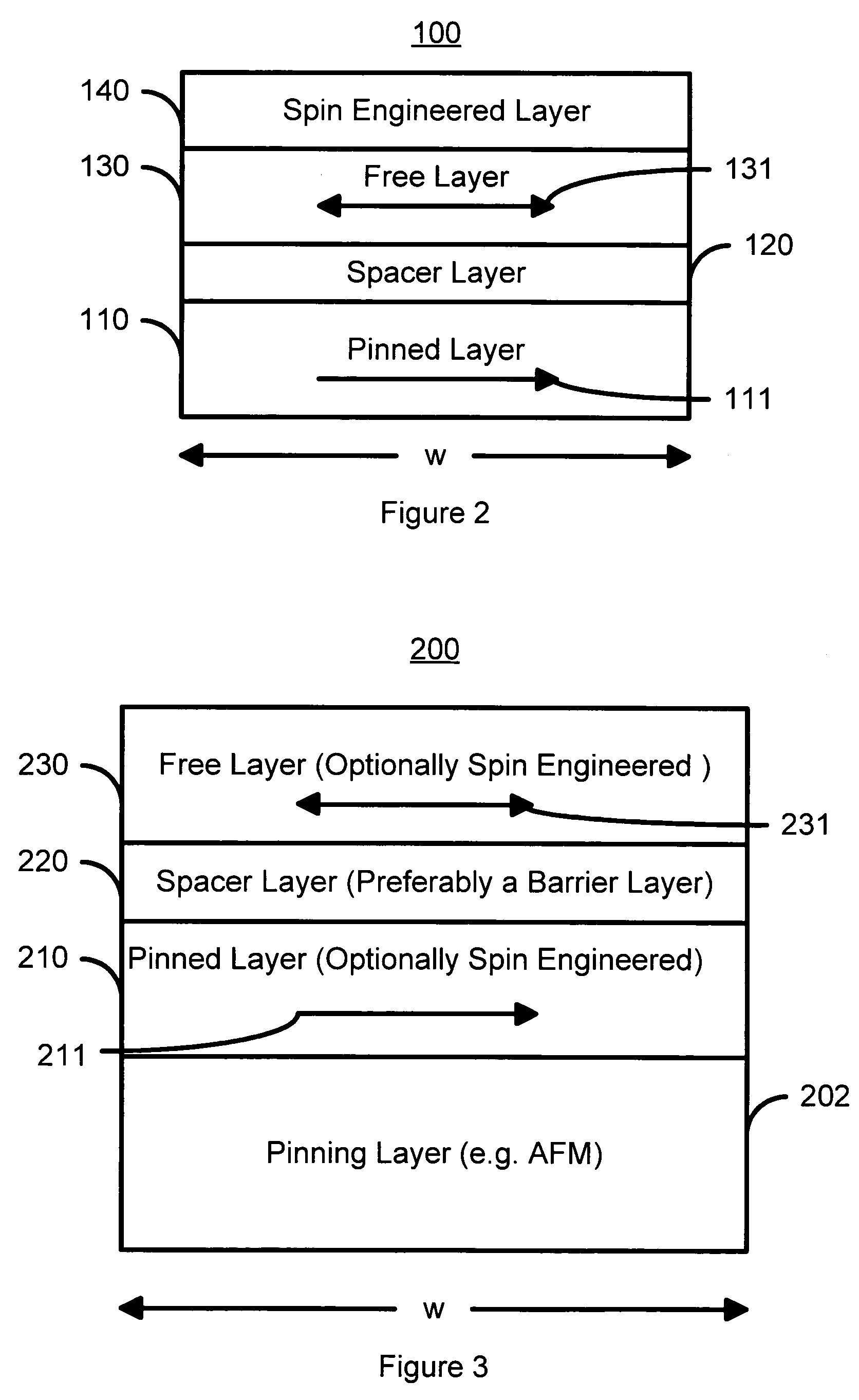

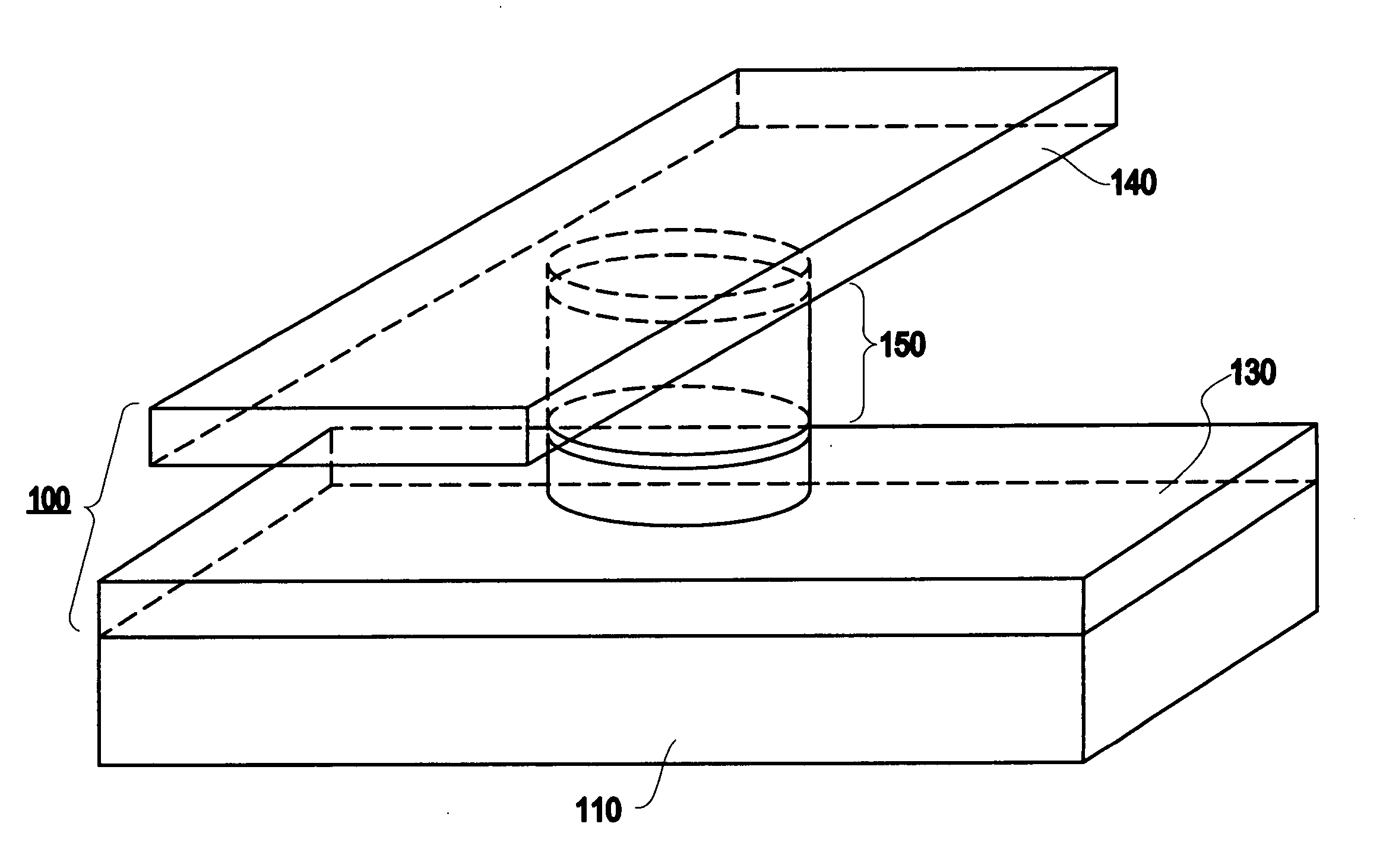

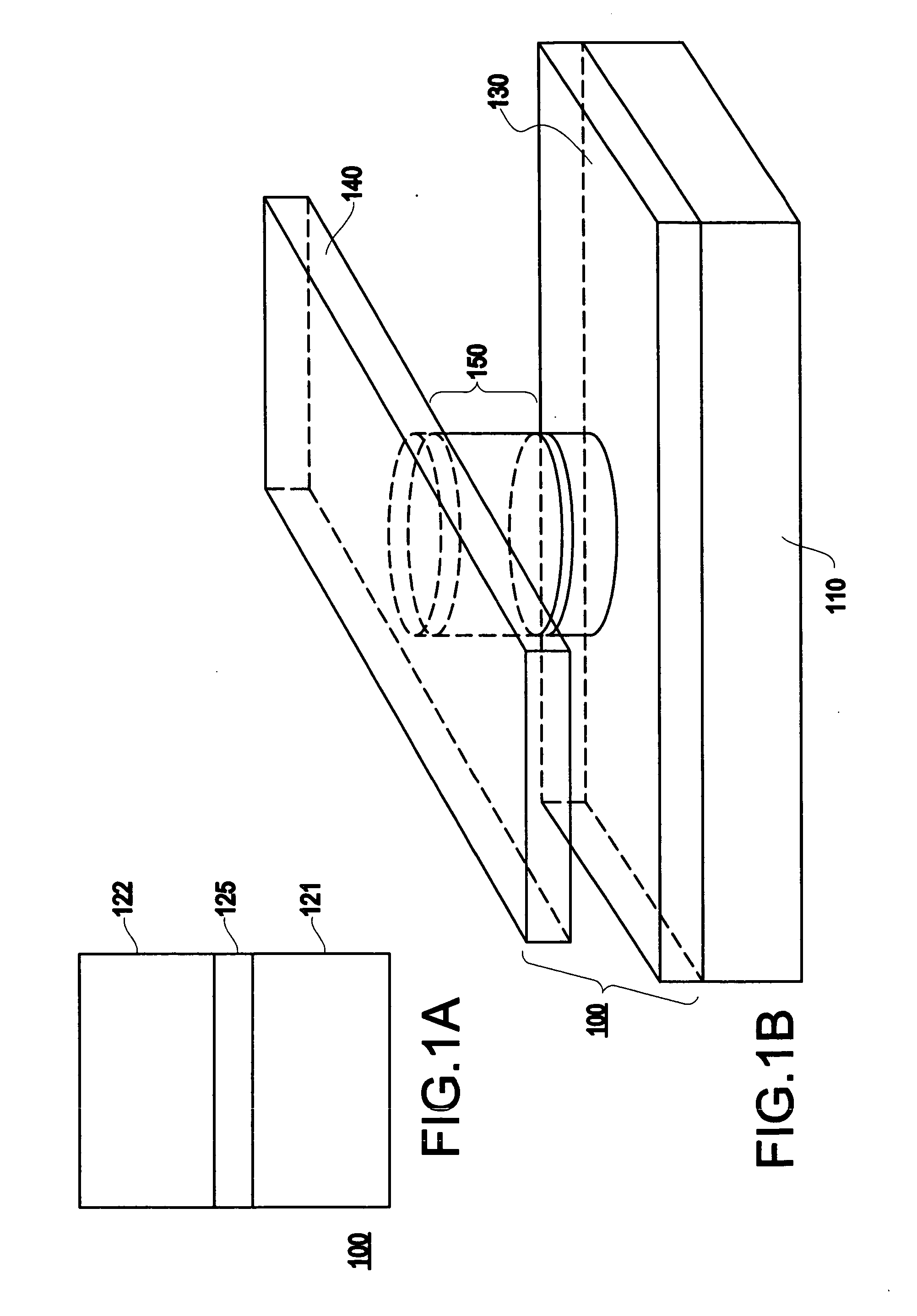

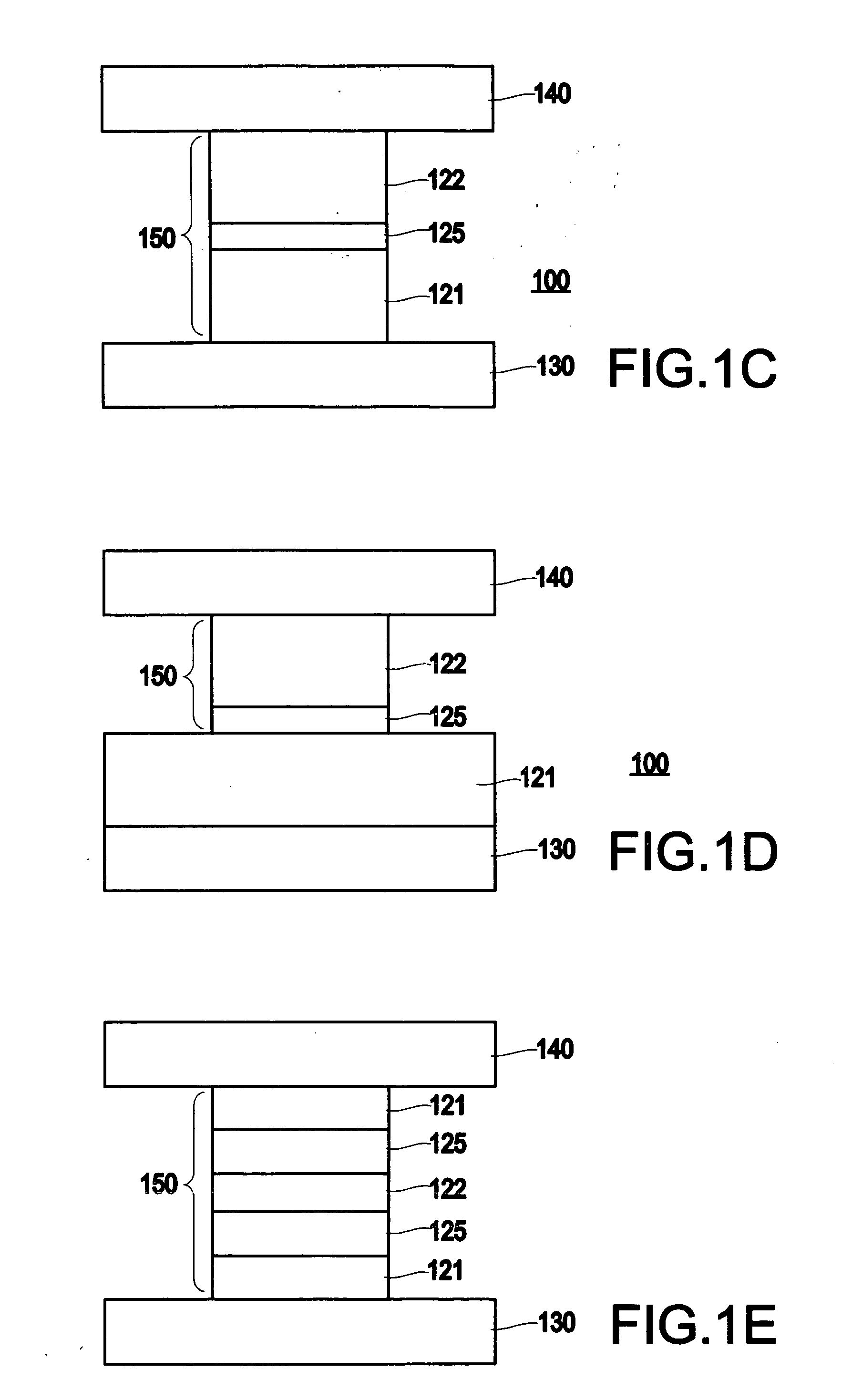

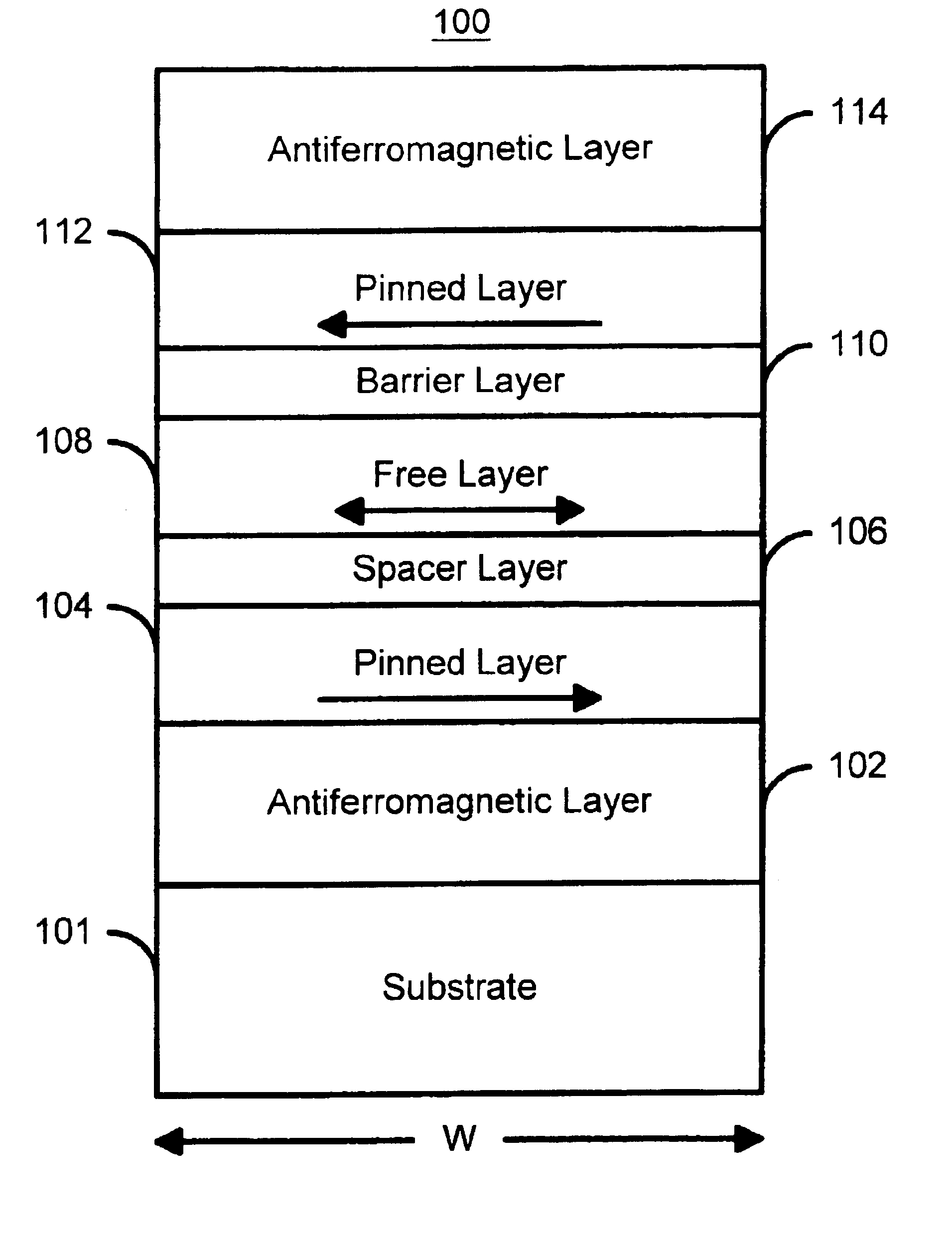

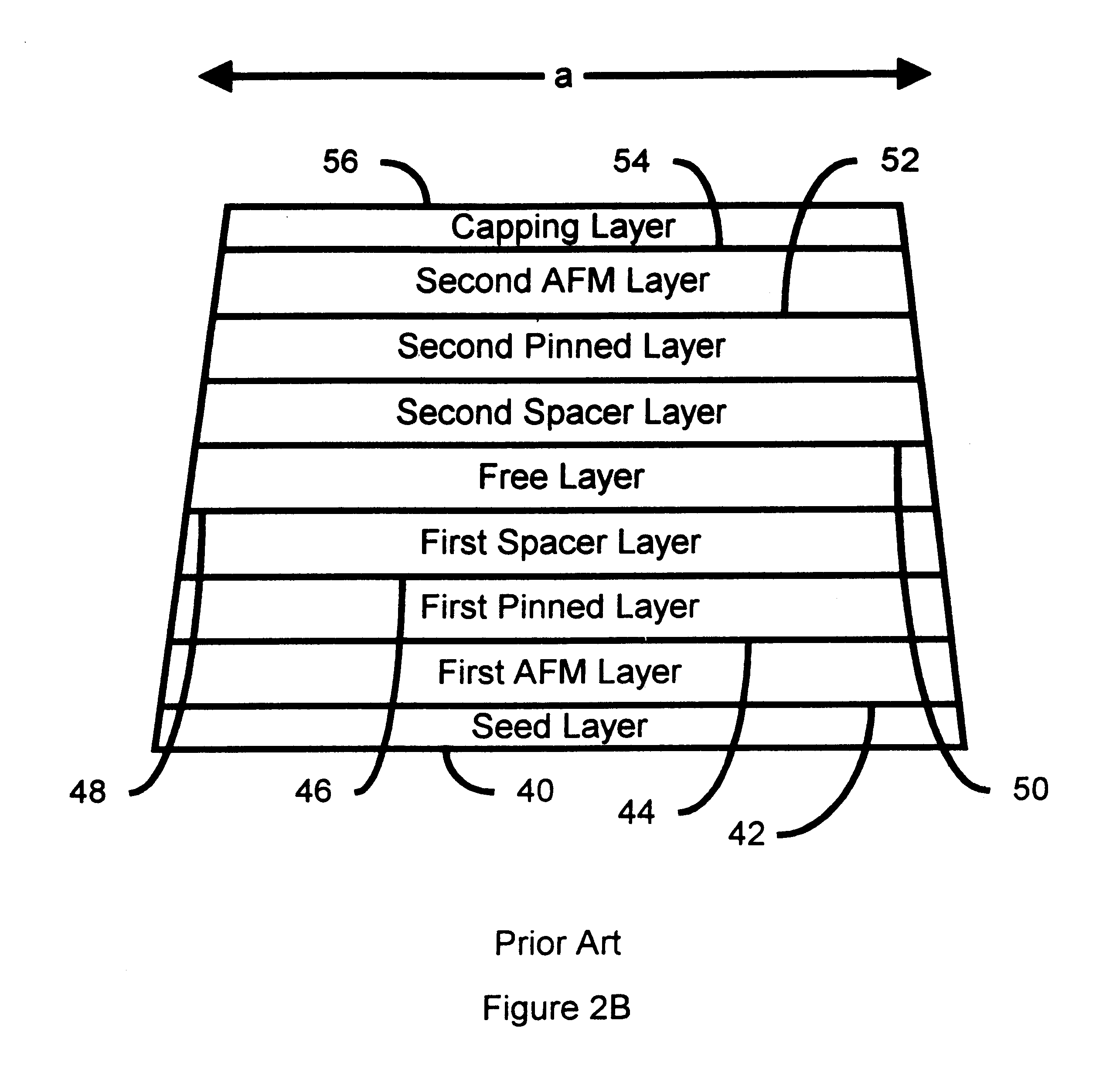

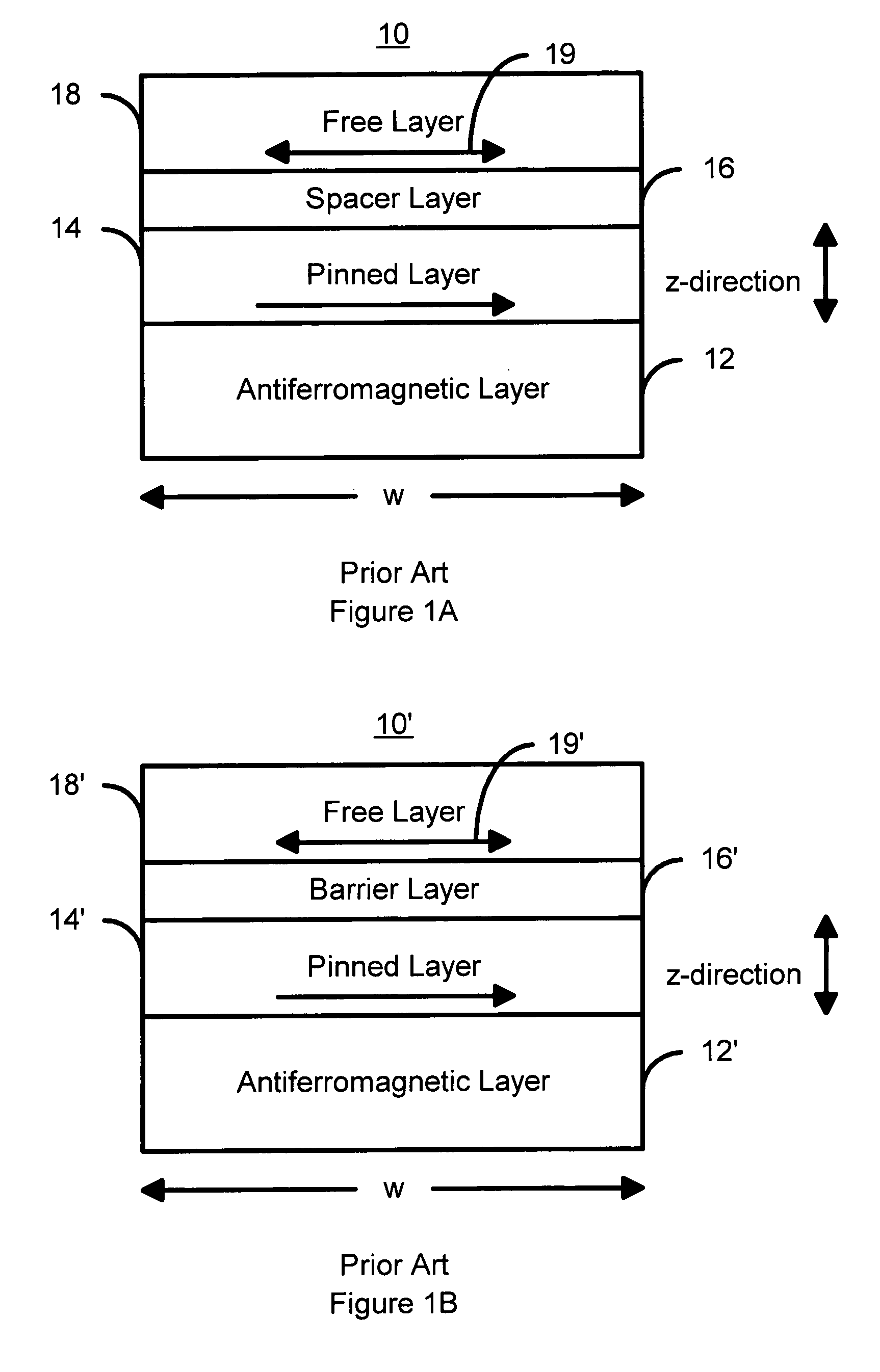

Magnetic element utilizing spin transfer and an MRAM device using the magnetic element

InactiveUS6920063B2Efficient and localized phenomenonEnhanced output signalNanostructure applicationNanomagnetismMagnetic memorySpin transfer

A method and system for providing a magnetic element capable of being written using spin-transfer effect while generating a high output signal and a magnetic memory using the magnetic element are disclosed. The magnetic element includes a first ferromagnetic pinned layer, a nonmagnetic spacer layer, a ferromagnetic free layer, an insulating barrier layer and a second ferromagnetic pinned layer. The pinned layer has a magnetization pinned in a first direction. The nonmagnetic spacer layer is conductive and is between the first pinned layer and the free layer. The barrier layer resides between the free layer and the second pinned layer and is an insulator having a thickness allowing electron tunneling through the barrier layer. The second pinned layer has a magnetization pinned in a second direction. The magnetic element is configured to allow the magnetization of the free layer to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

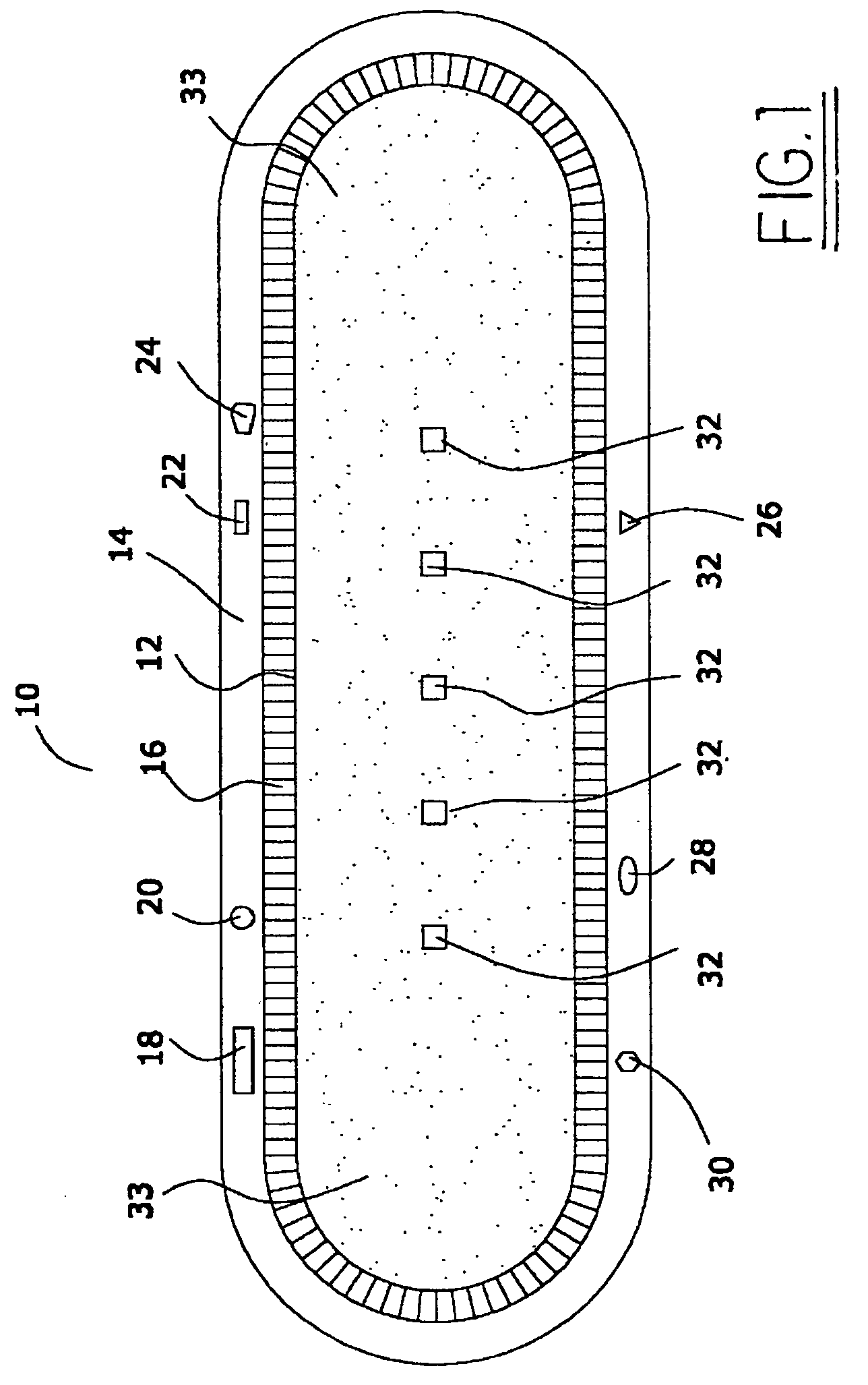

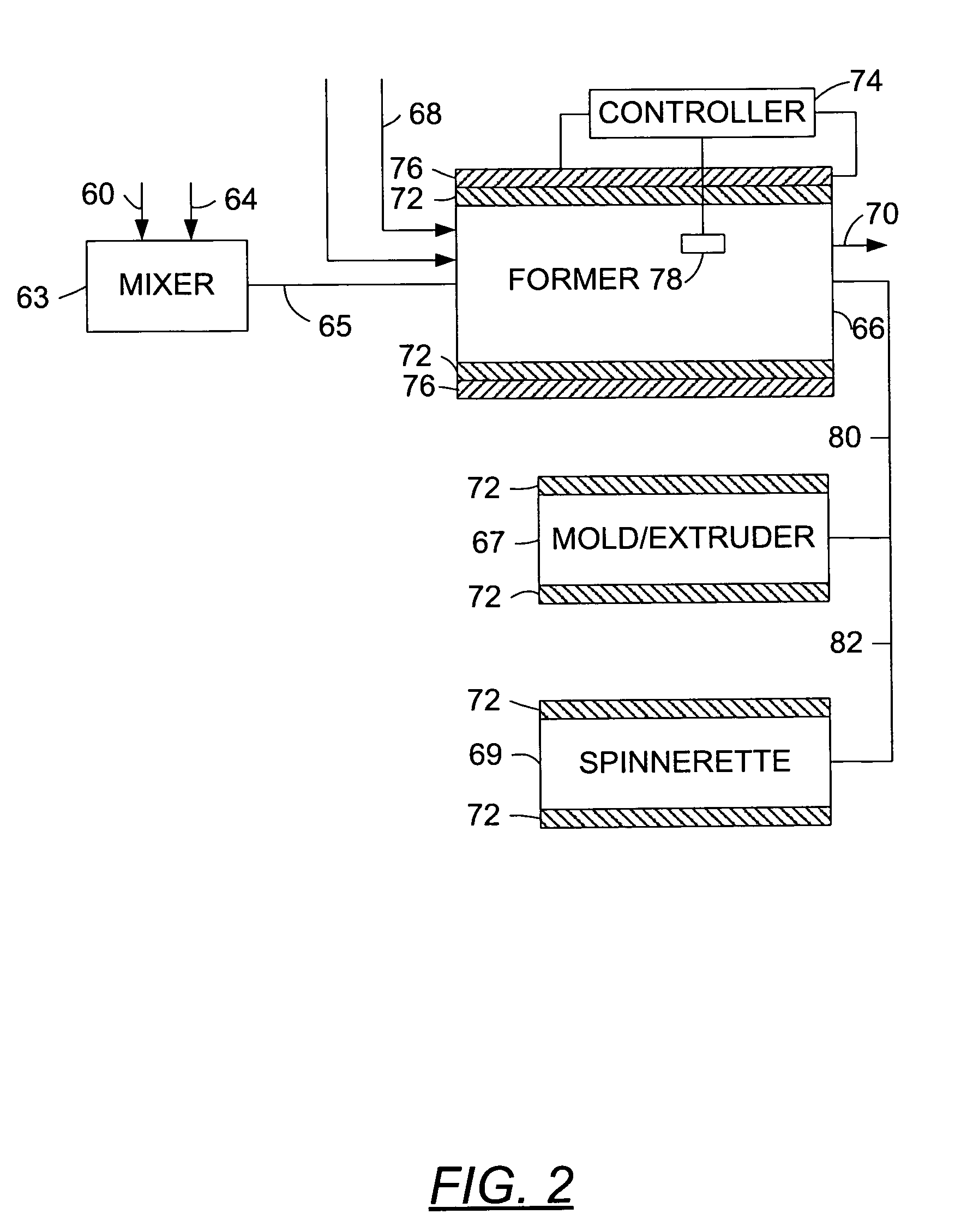

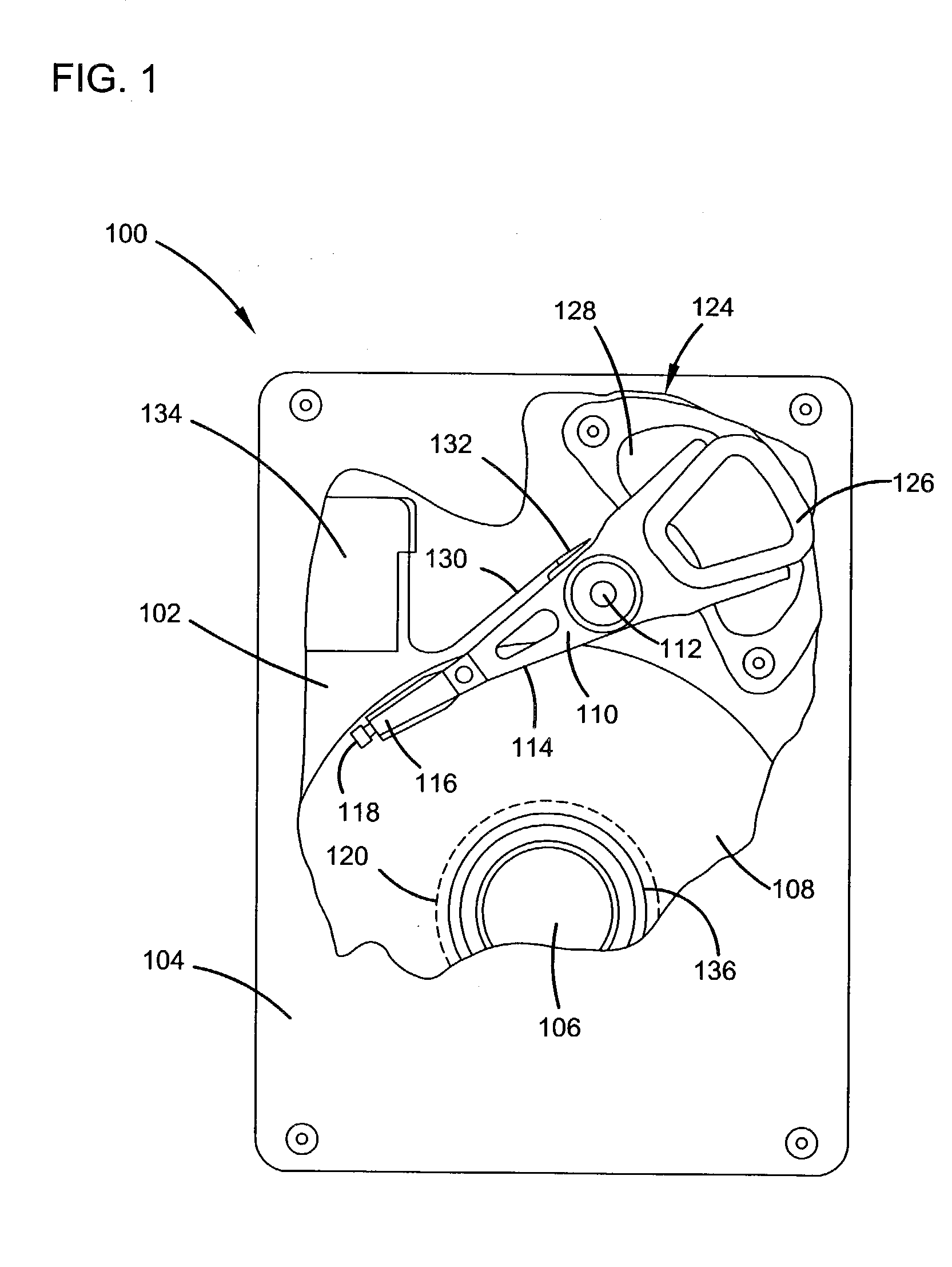

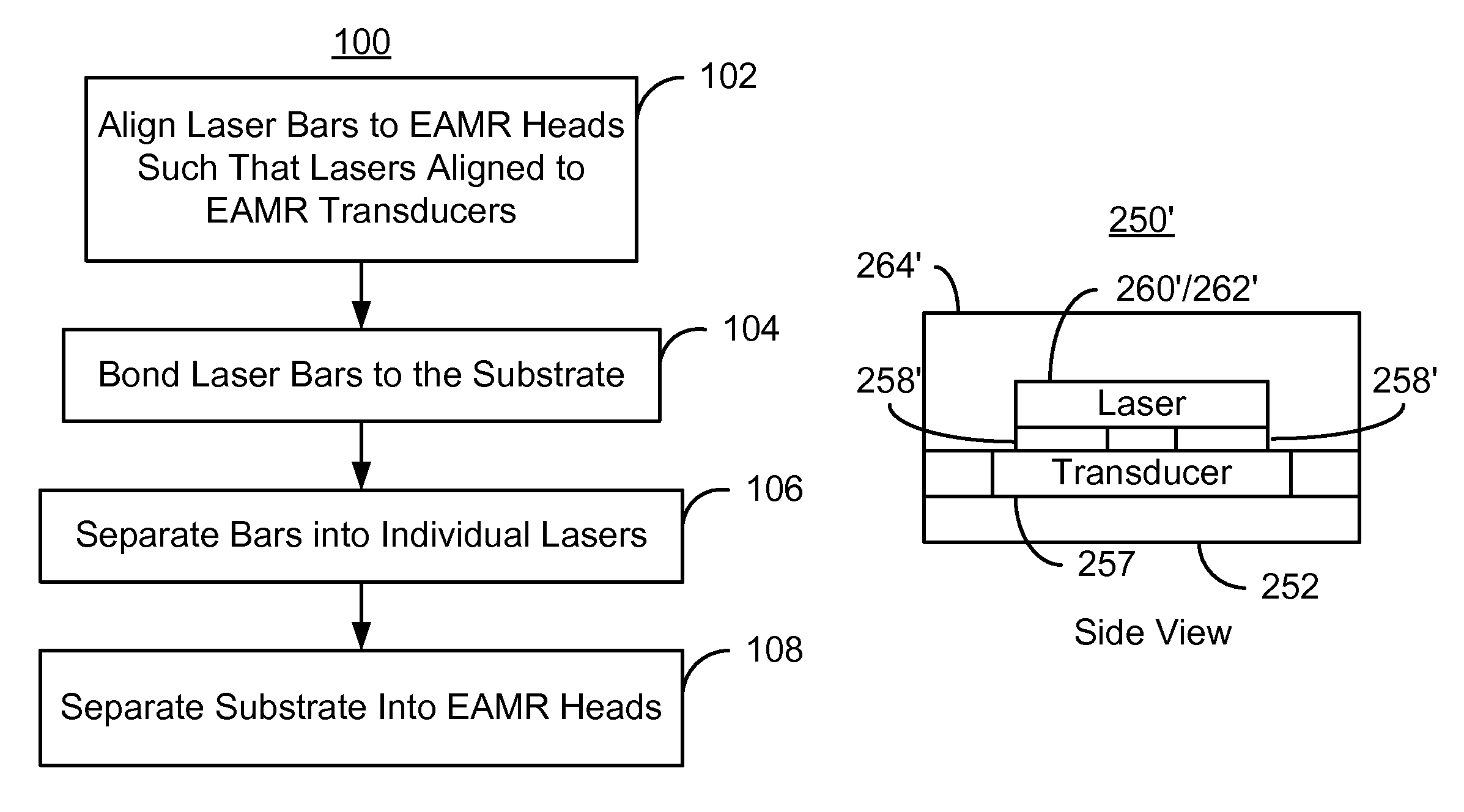

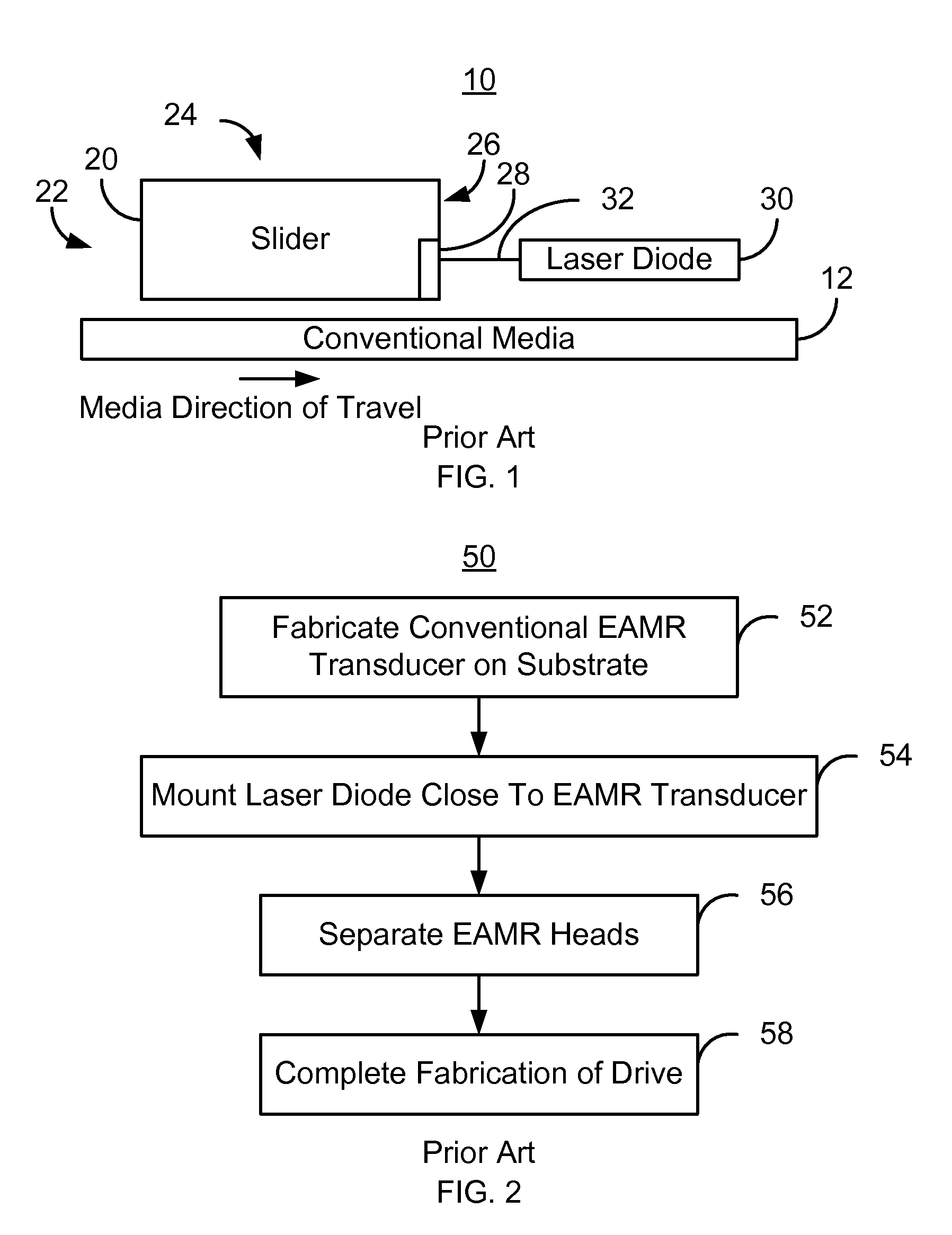

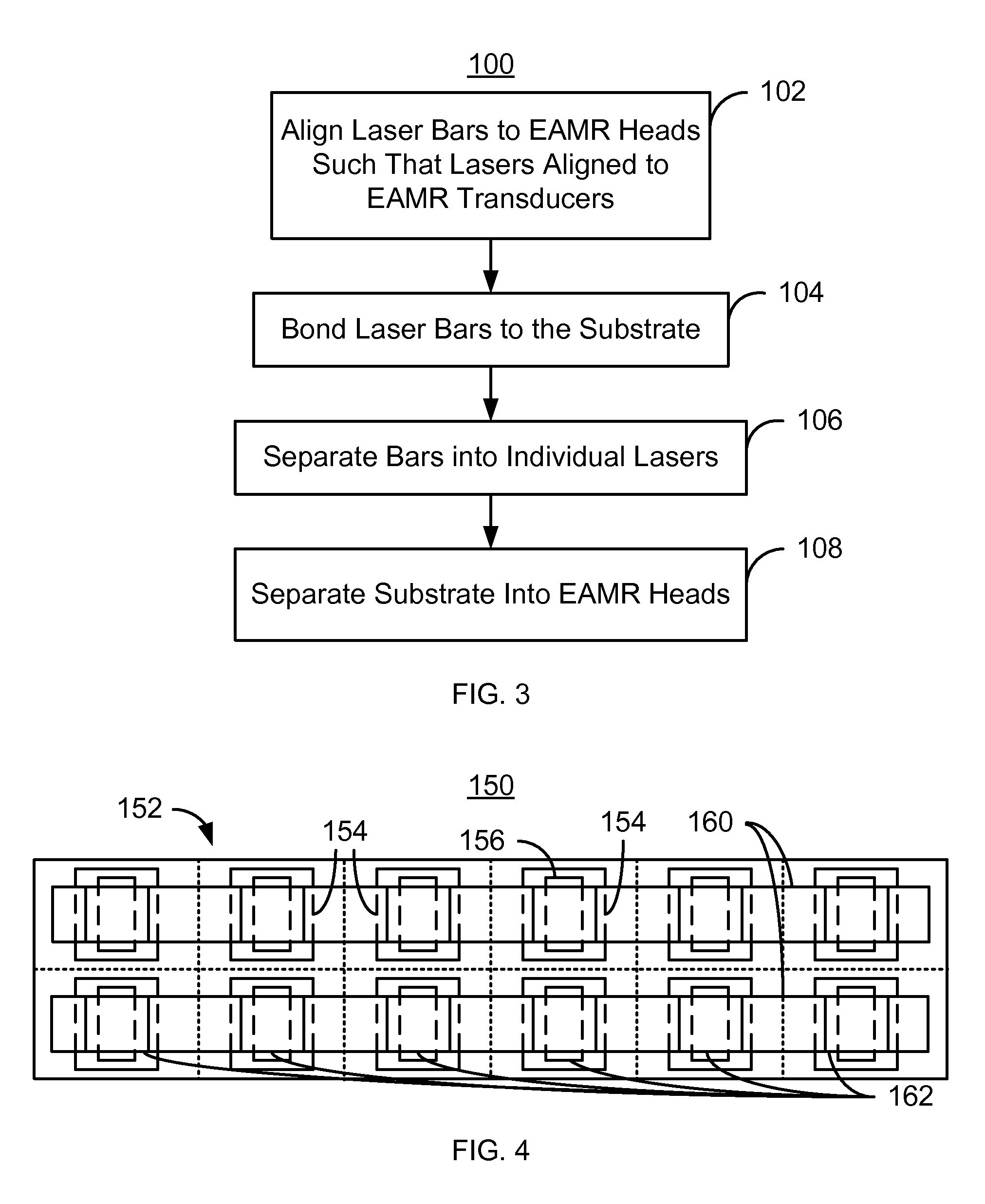

Method and system for mounting lasers on energy assisted magnetic recording heads

A method and system for providing energy assisted magnetic recording (EAMR) heads including EAMR transducers are described. The method and system include aligning a laser bar to the EAMR heads on a substrate. The laser bar includes lasers in locations corresponding to a portion of the EAMR transducers. The method and system also include bonding the laser bar to the substrate and removing a portion of the laser bar to separate the plurality of lasers. The substrate is separated into the EAMR heads.

Owner:WESTERN DIGITAL TECH INC

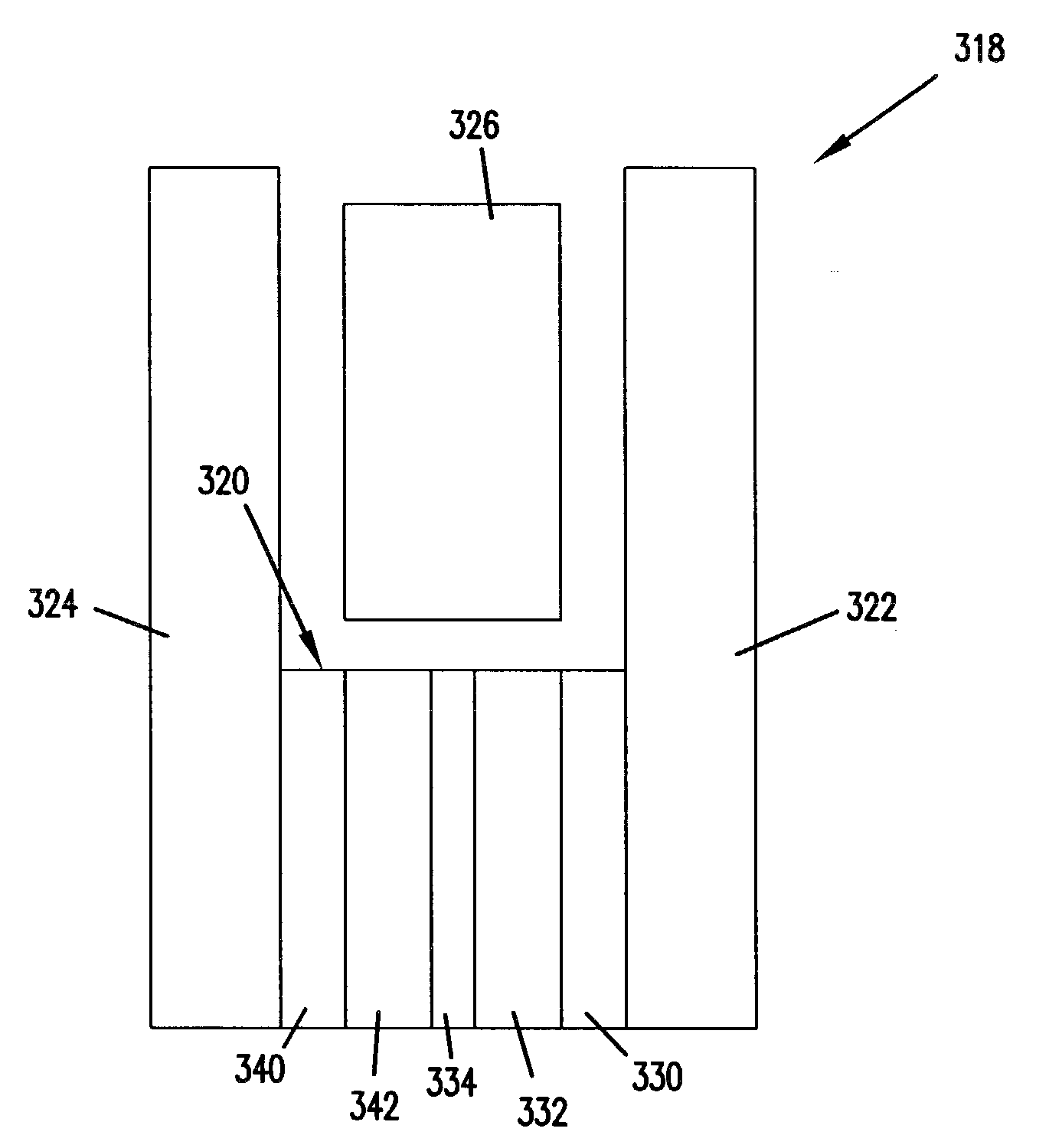

Method and system for providing a dual spin filter

Owner:WESTERN DIGITAL TECH INC

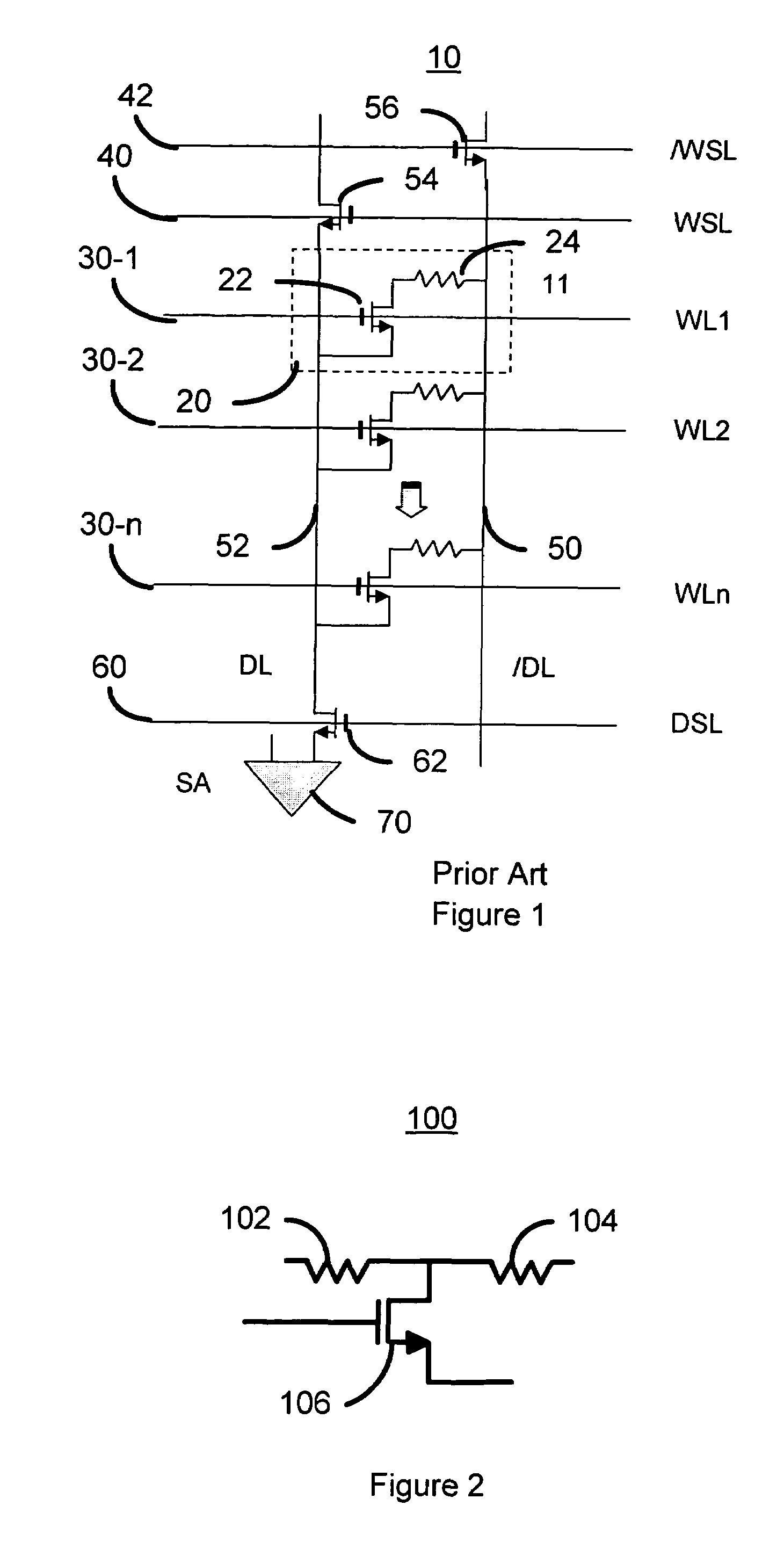

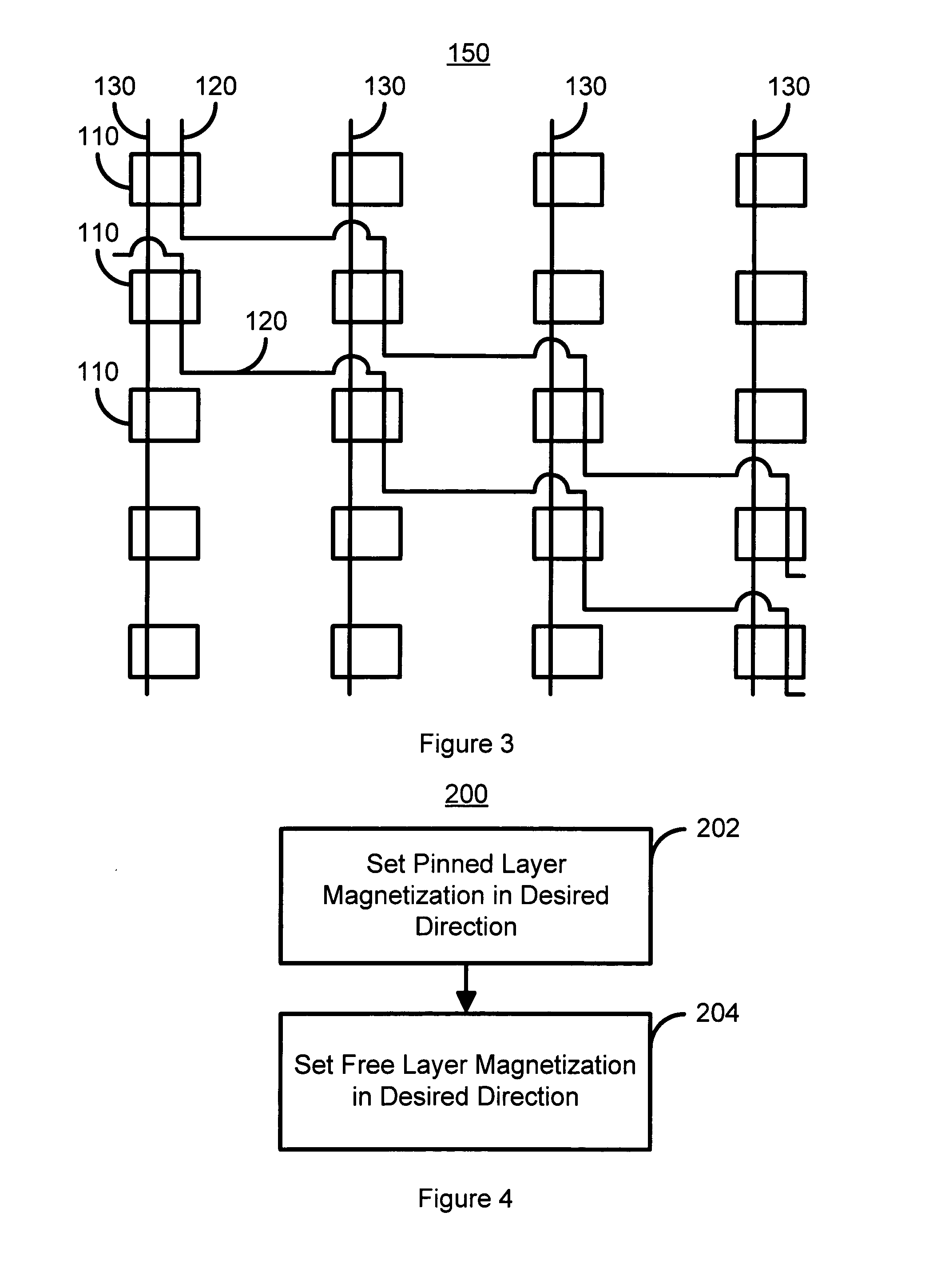

Fast magnetic memory devices utilizing spin transfer and magnetic elements used therein

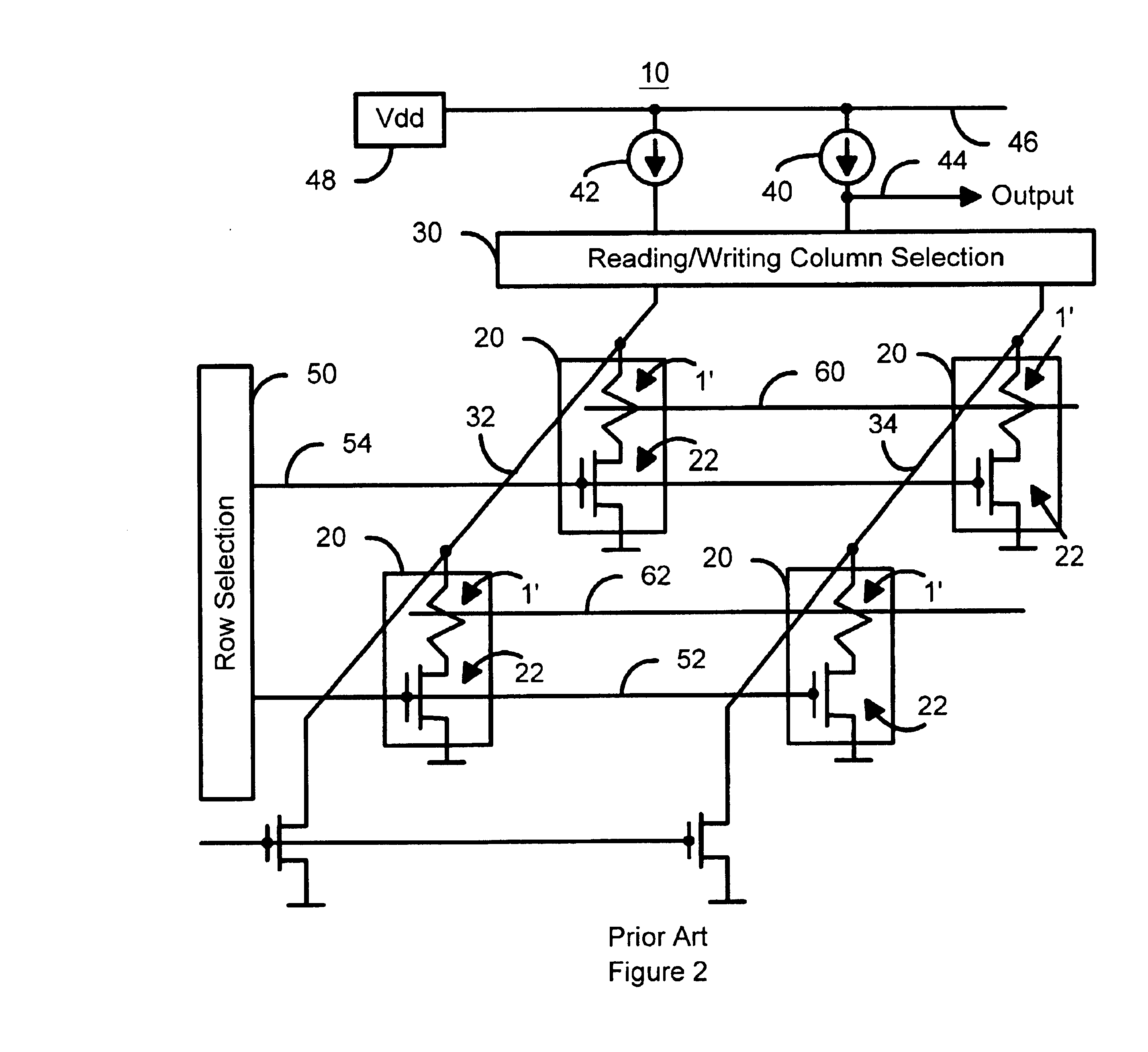

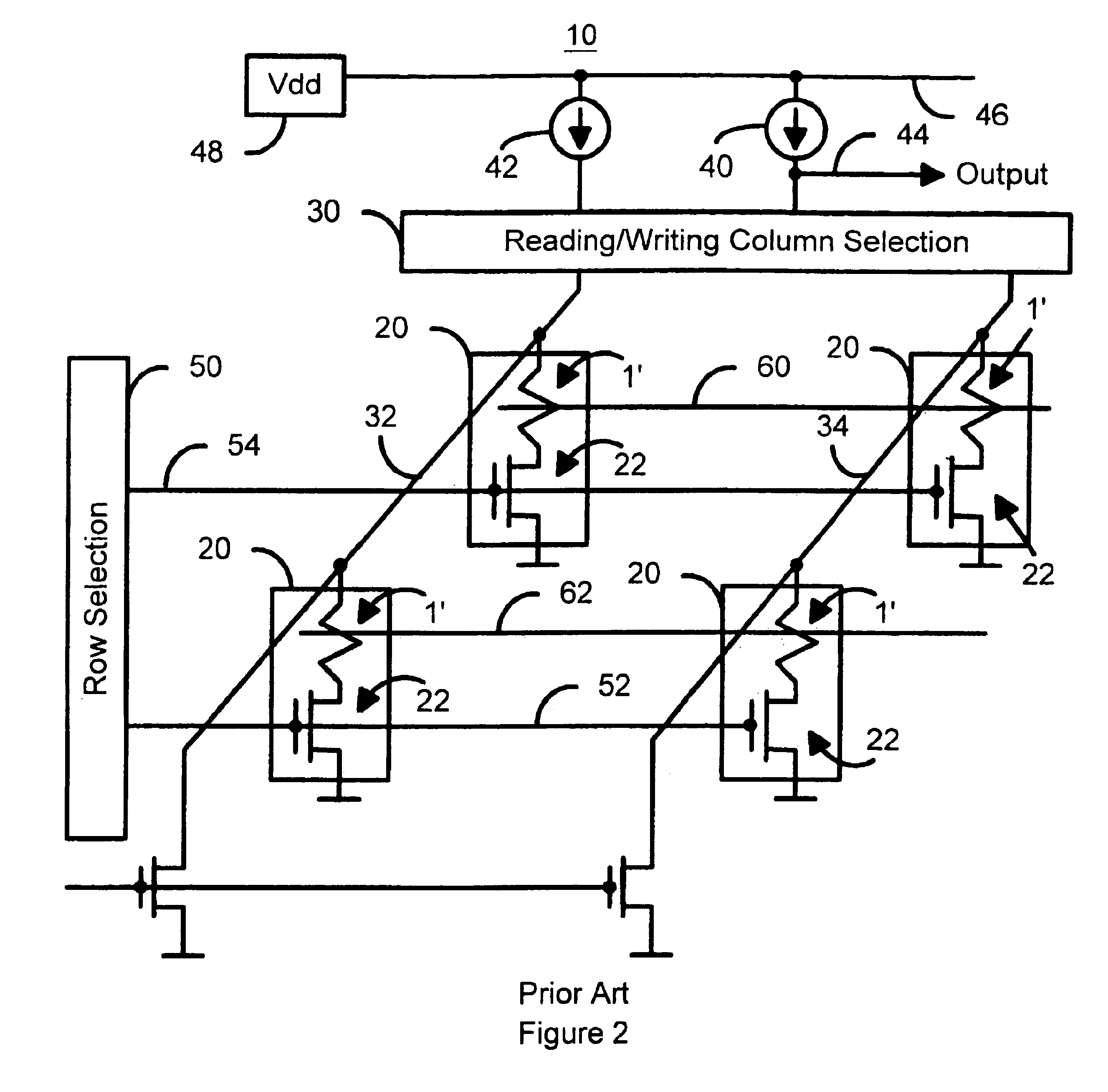

A method and system for providing a magnetic memory is described. The method and system include providing a plurality of magnetic storage cells, a plurality of word lines, and a plurality of bit lines. Each of the plurality of magnetic storage cells includes a plurality of magnetic elements and at least one selection transistor. Each of the plurality of magnetic elements is capable of being programmed using spin transfer induced switching by a write current driven through the magnetic element. Each of the plurality of magnetic elements has a first end and a second end. The at least one selection transistor is coupled to the first end of each of the plurality of magnetic elements. The plurality of word lines is coupled with the plurality of selection transistors and selectively enables a portion of the plurality of selection transistors.

Owner:SAMSUNG SEMICON

Water soluble metal and semiconductor nanoparticle complexes

The invention provides a water soluble complex comprising an inner core of a metal or semi-conductor nanoparticle. The nanoparticle is coated with a hydrophobic ligand, which is encapsulated in a micelle. In an aqueous medium, the micelle comprises a hydrophilic shell and a hydrophobic core, the hydrophilic shell comprising a plurality of hydrophilic moieties, the hydrophobic core comprising a plurality of hydrophobic moieties, each hydrophobic moiety comprising at least one chain, each chain comprising a minimum of 8 atoms; wherein the total number of atoms in all chains for each moiety comprises at least 24 atoms. The micelle has a minimum average diameter of approximately 5 nm and a maximum average diameter of approximately 45 nm.

Owner:THE ROCKEFELLER UNIV

MTJ elements with high spin polarization layers configured for spin-transfer switching and spintronics devices using the magnetic elements

ActiveUS20060141640A1Write currentEnhanced signalNanomagnetismMagnetic-field-controlled resistorsSpin transferSpin polarization

A method and system for providing a magnetic element are disclosed. The method and system include providing first and second pinned layers, a free layer, and first and second barrier layers between the first and second pinned layers, respectively, and the free layer. The first barrier layer is preferably crystalline MgO, which is insulating, and configured to allow tunneling through the first barrier layer. Furthermore, the first barrier layer has an interface with another layer, such as the free layer or the first pinned layer. The interface has a structure that provides a high spin polarization of at least fifty percent and preferably over eighty percent. The second barrier layer is insulating and configured to allow tunneling through the second barrier layer. The magnetic element is configured to allow the free layer to be switched due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

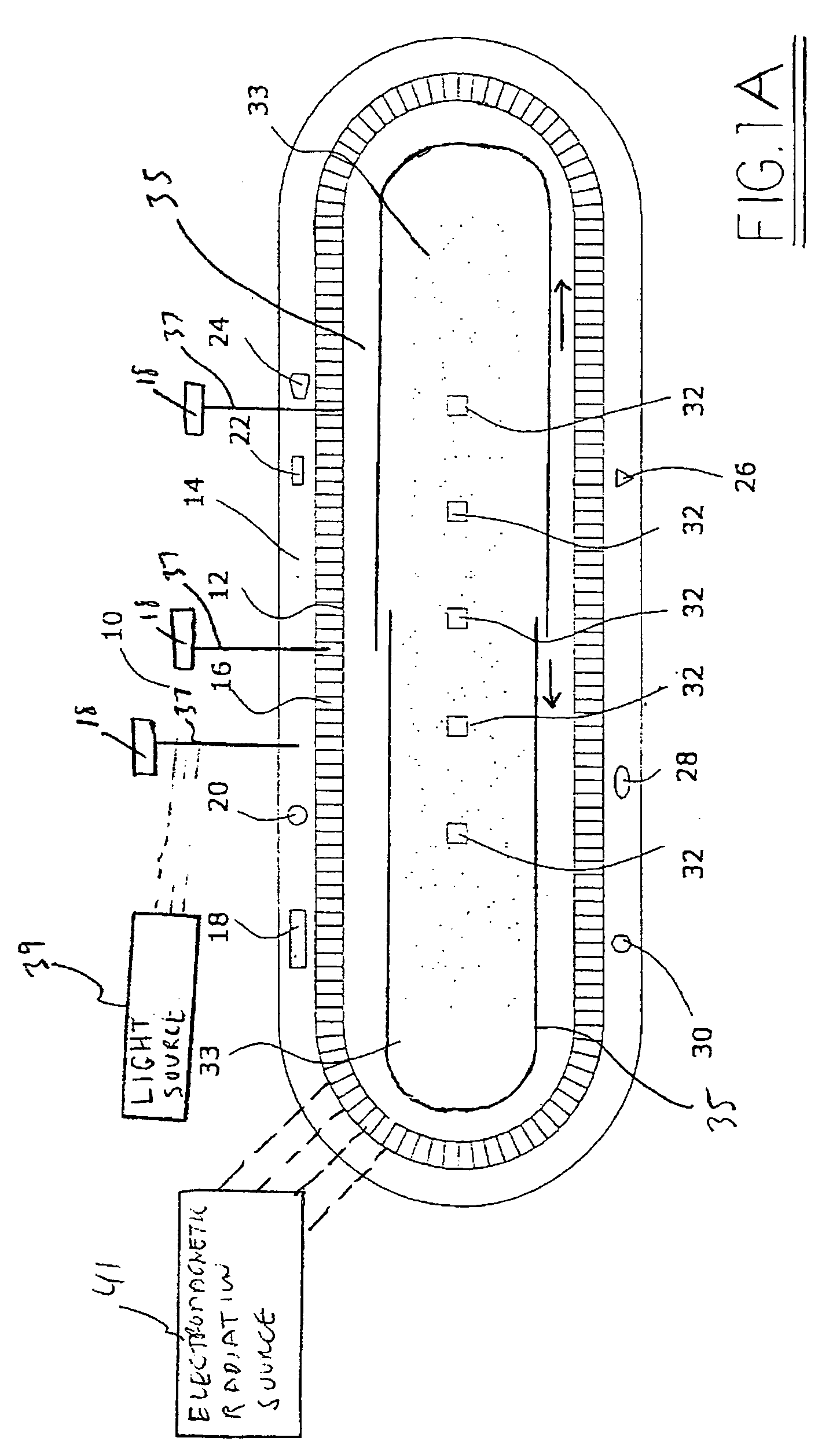

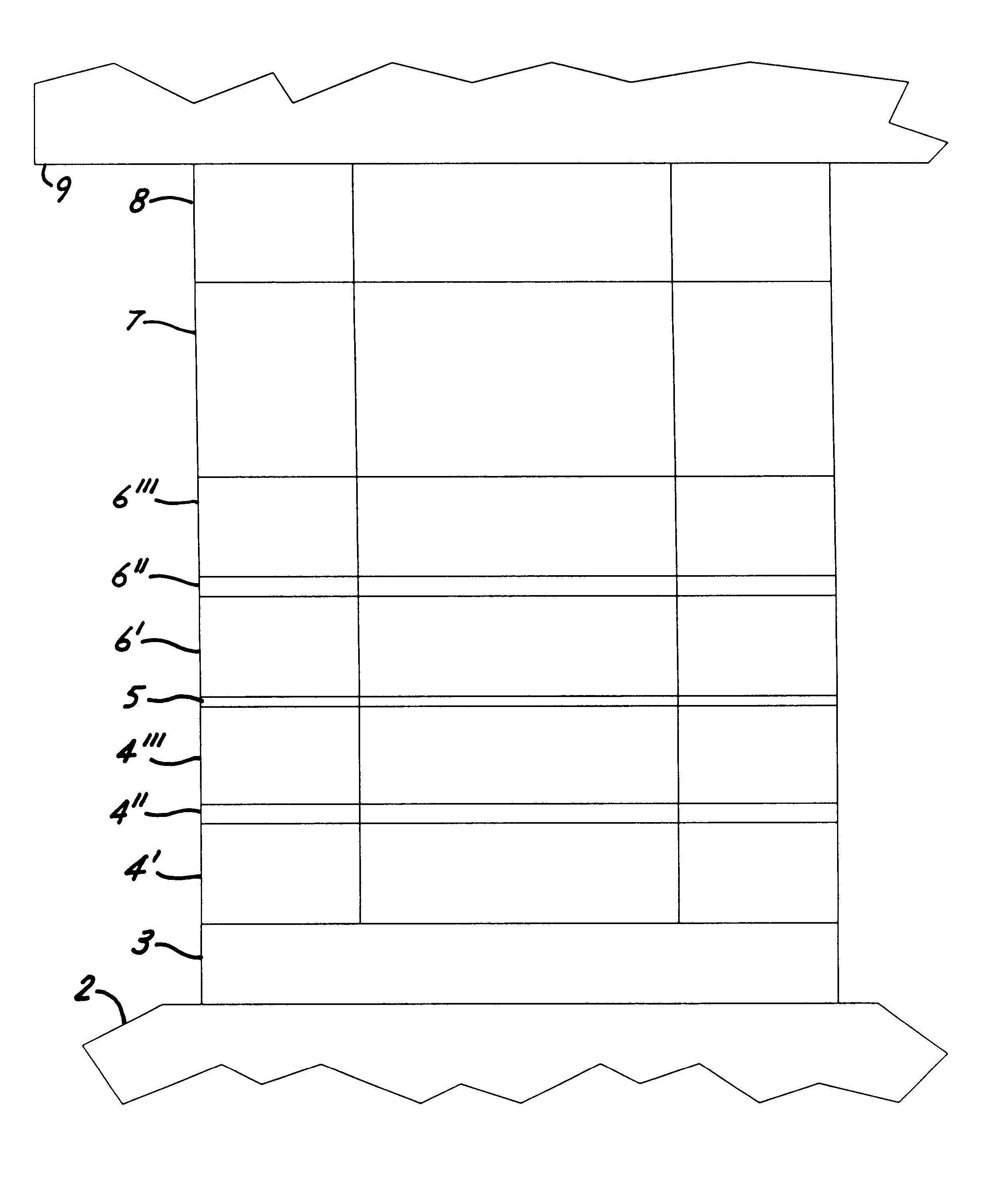

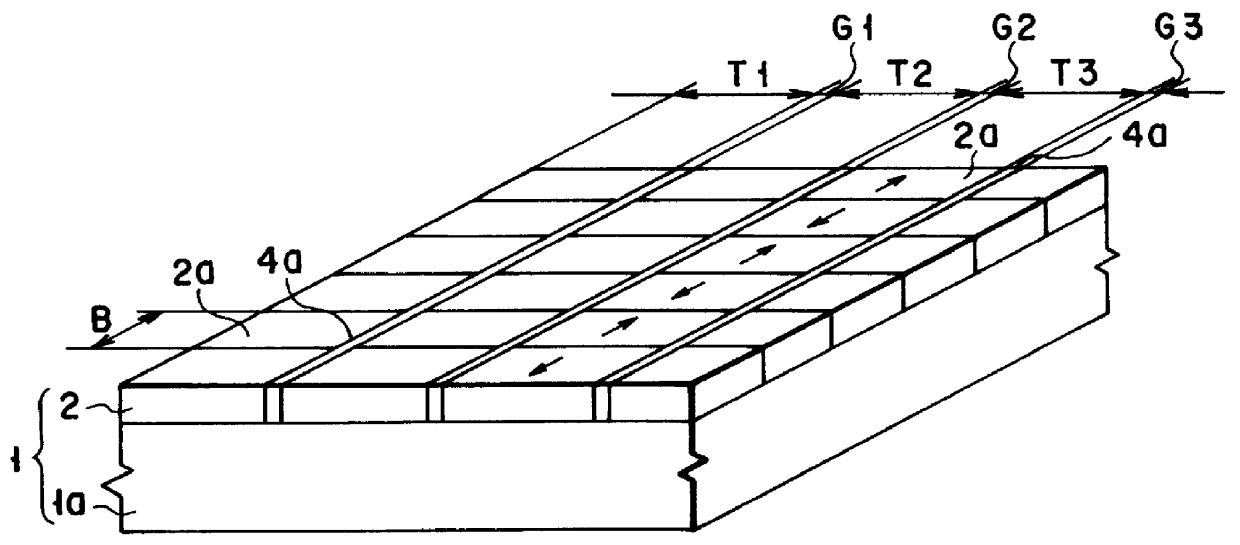

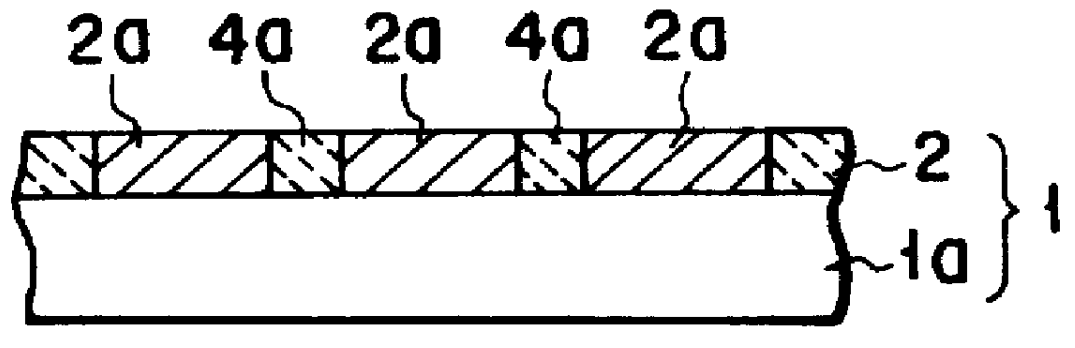

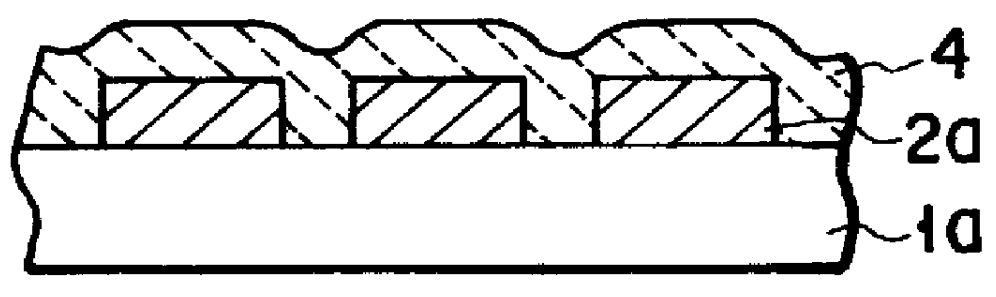

Magnetic disk with a guard band arrangement

A magnetic disk including a substrate, a recording track section which is made of a magnetic member for recording and reproducing information magnetically and is provided on the substrate, and a guard band member which is provided between the recording track sections adjacent to each other so that they are substantially continued in a track direction and is harder than the magnetic member and is made of a non-magnetic material. Moreover, the magnetic member is not provided or magnetic members with a different thickness from the magnetic member forming the recording track section is provided on a lower area of the guard band member.

Owner:KK TOSHIBA

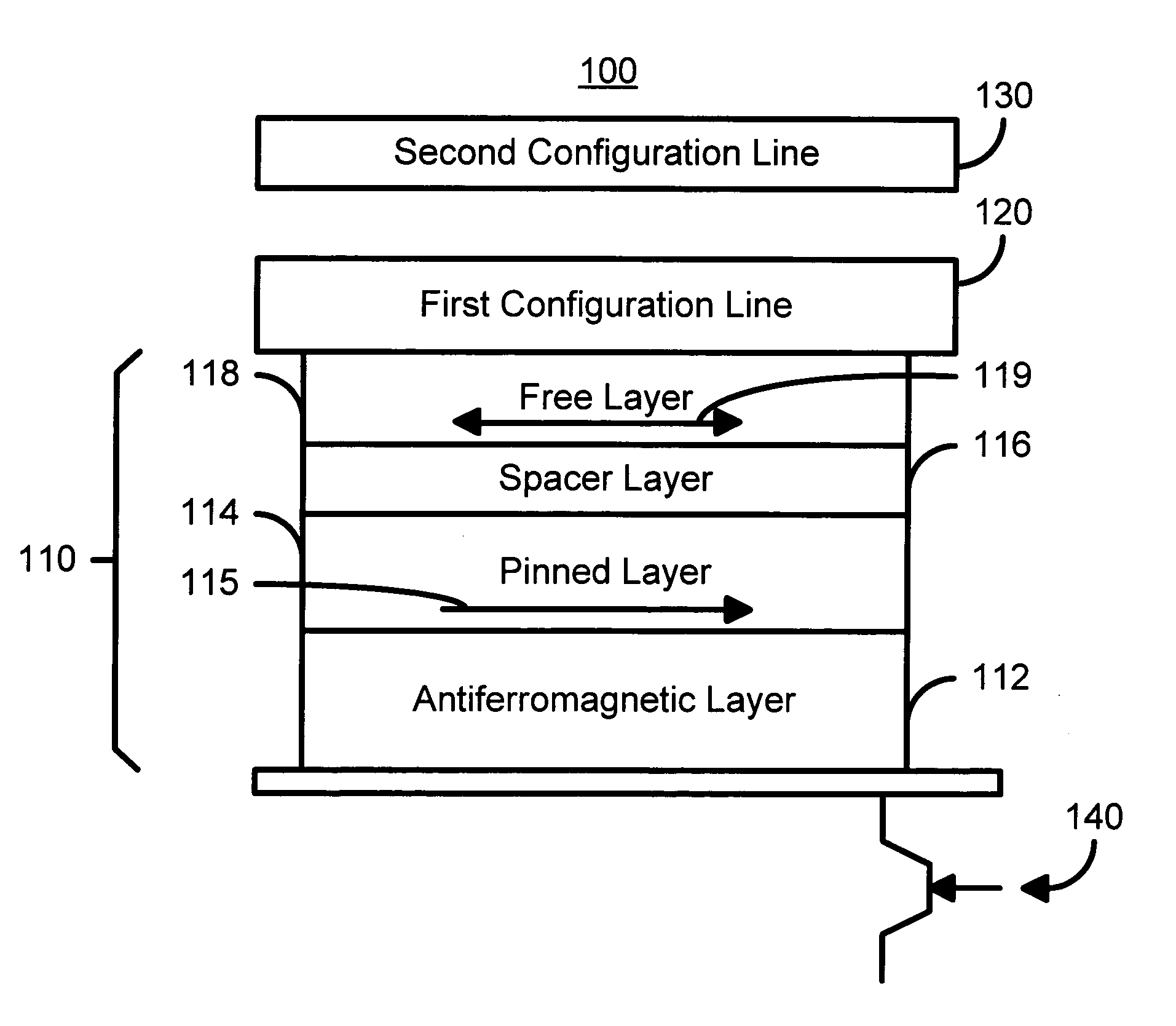

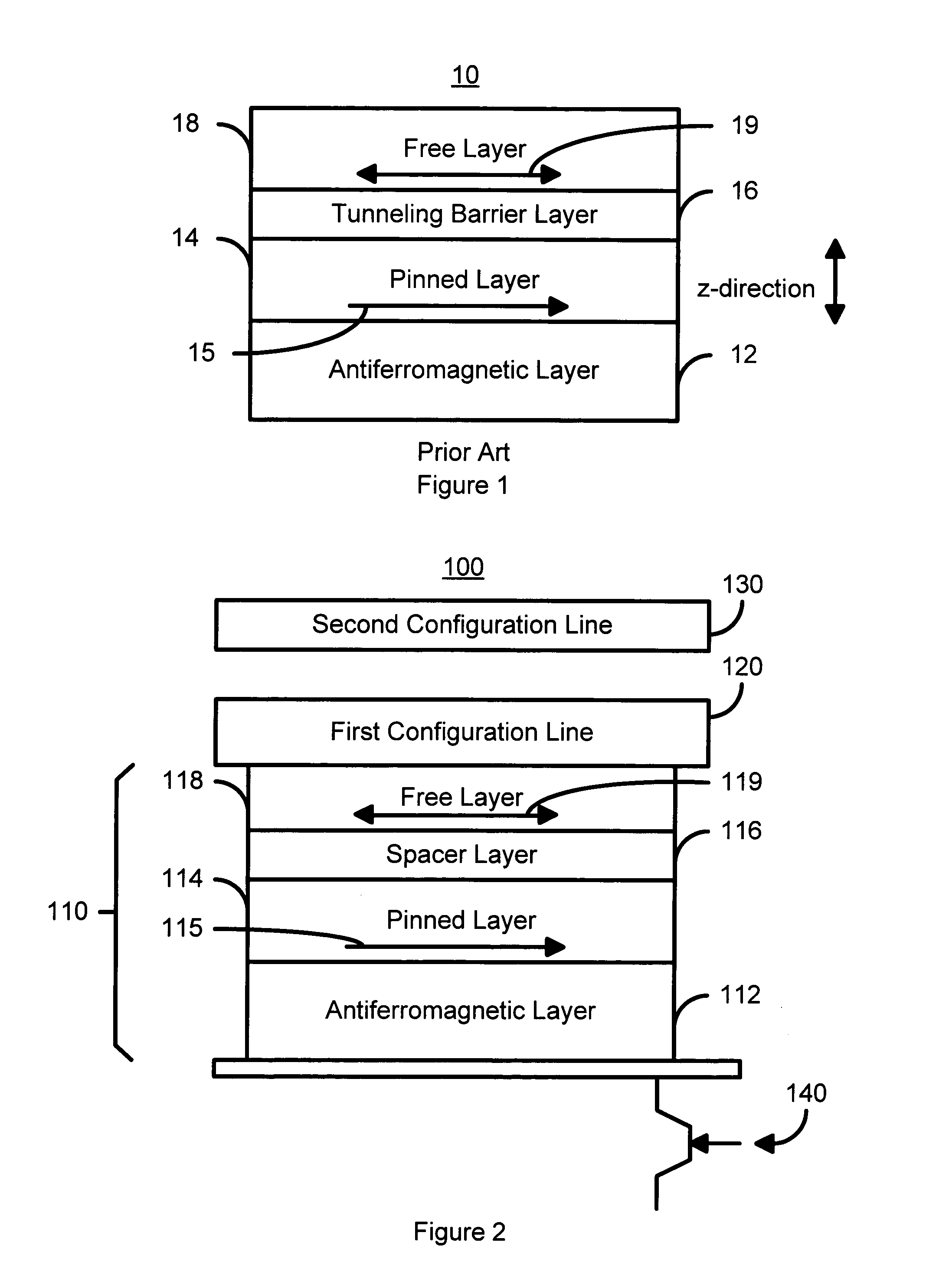

Re-configurable logic elements using heat assisted magnetic tunneling elements

A magnetic logic cell includes a magnetic element having a pinned layer, a free layer, and a spacer layer. The pinned and free layers have pinned and free layer magnetizations. The spacer layer resides between the pinned and free layers. In one aspect, the magnetic logic cell includes a first configuration line that is electrically connected to the magnetic element and carries a first current and a second configuration line electrically that is insulated from the magnetic element and the first configuration line and carries a second current. The first or second current alone cannot switch the free layer magnetization. The first and second currents together can switch the free layer magnetization. When the first current is driven through the magnetic element and the second current is provided, the combination sets the pinned layer magnetization direction. In one aspect, the pinned layer magnetization is set by heating the AFM layer to approximately at or above the blocking temperature. In order to configure the logic cell, an initial direction for the free layer magnetization is also set.

Owner:SAMSUNG SEMICON

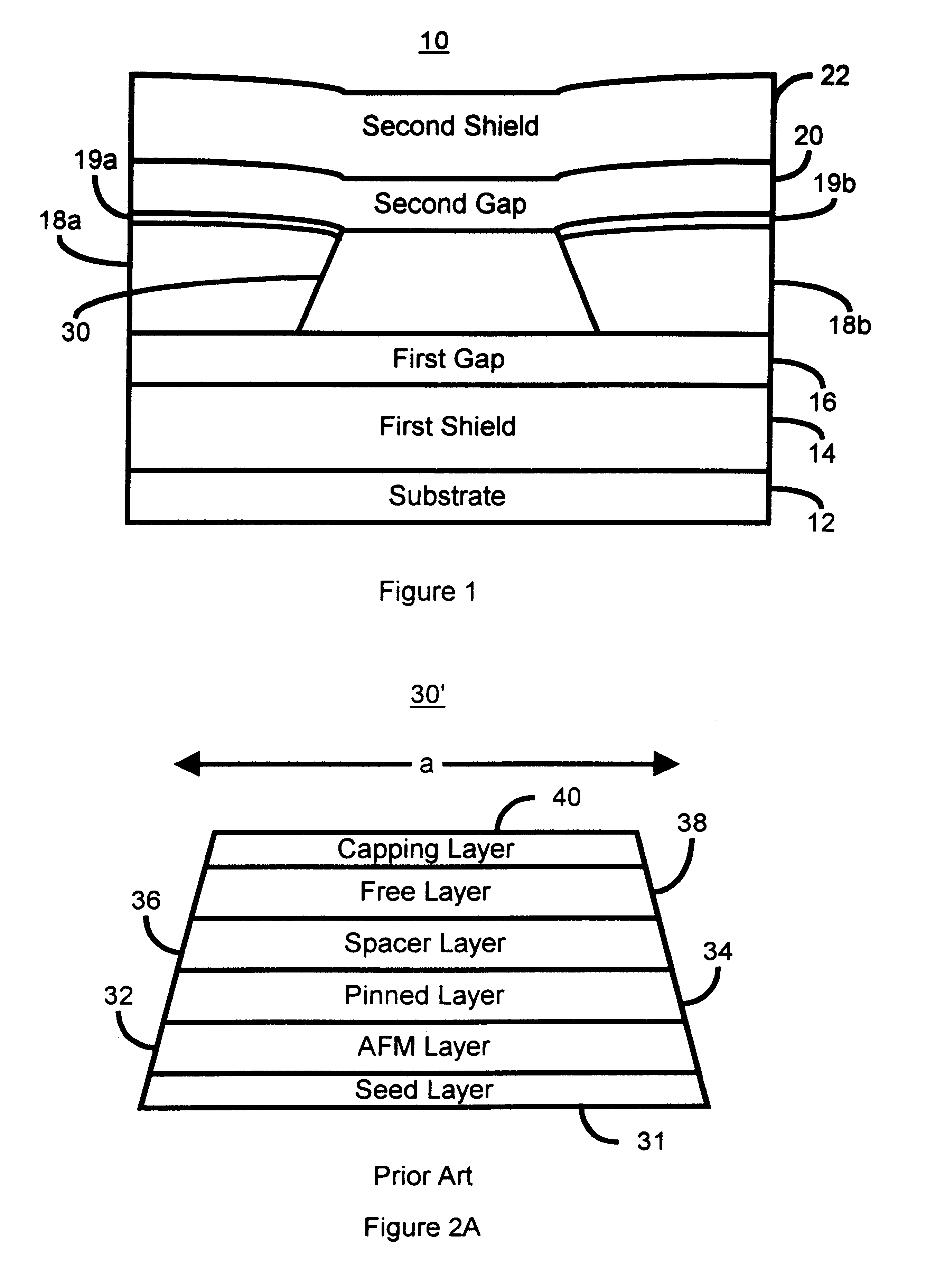

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com