Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

656 results about "Linear density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear density is the measure of a quantity of any characteristic value per unit of length. Linear mass density (titer in textile engineering, the amount of mass per unit length) and linear charge density (the amount of electric charge per unit length) are two common examples used in science and engineering. The term linear density is most often used when describing the characteristics of one-dimensional objects, although linear density can also be used to describe the density of a three-dimensional quantity along one particular dimension.

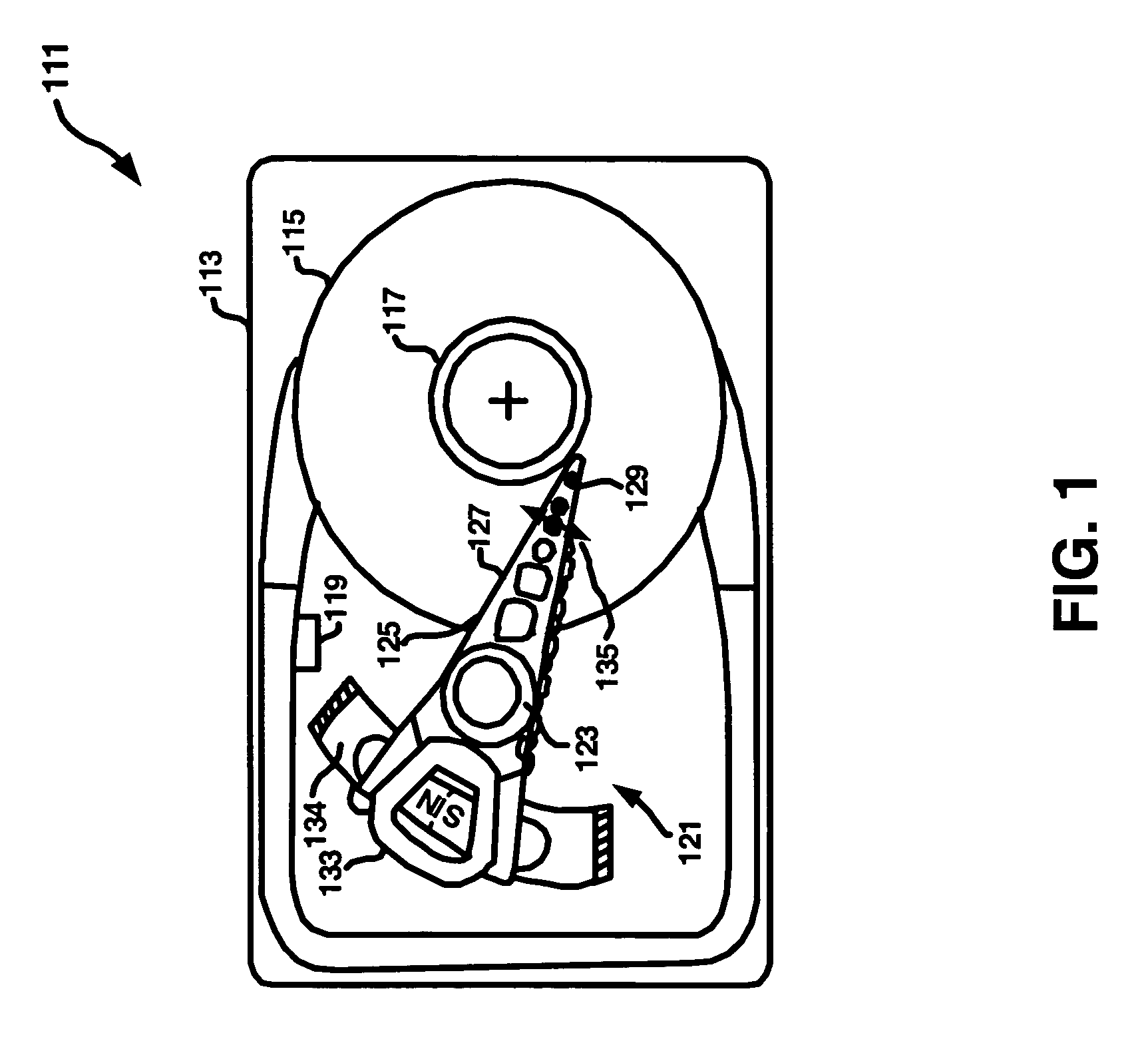

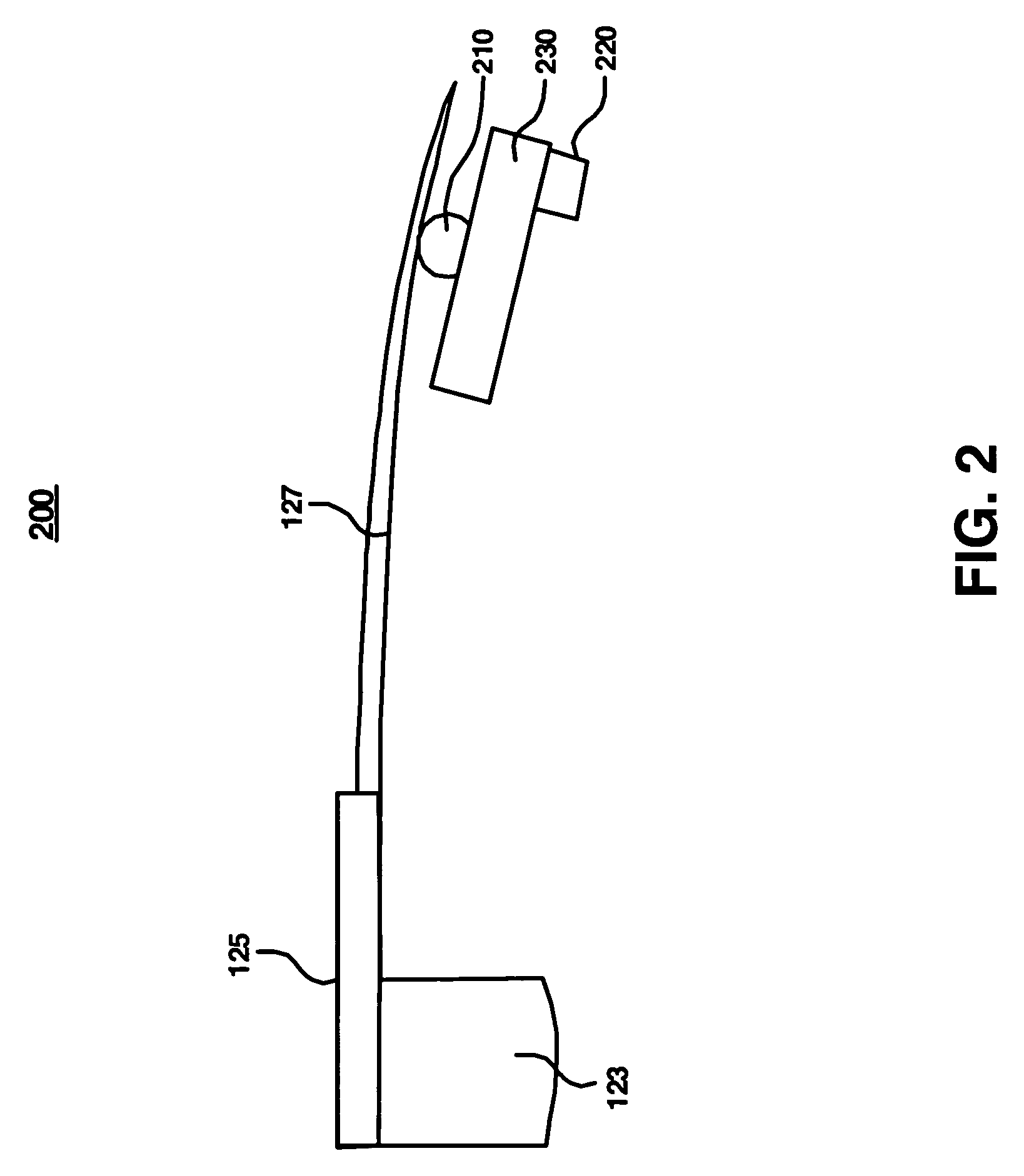

Structure to achieve sensitivity and linear density in tunneling GMR heads using orthogonal magnetic alignments

ActiveUS7035062B1Increase linear densityHigh sensitivityNanomagnetismNanoinformaticsMagnetic reluctanceMagnetization

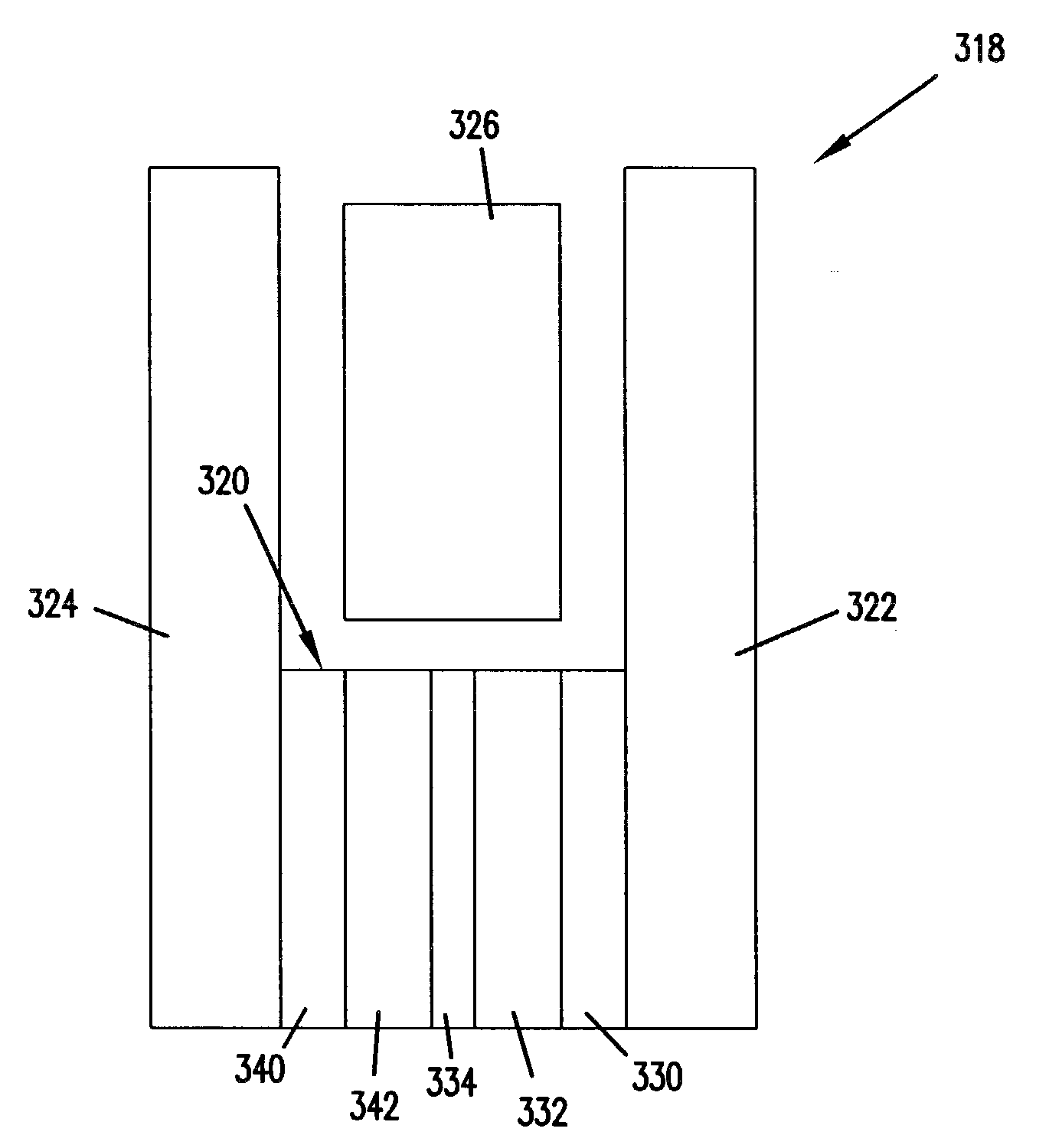

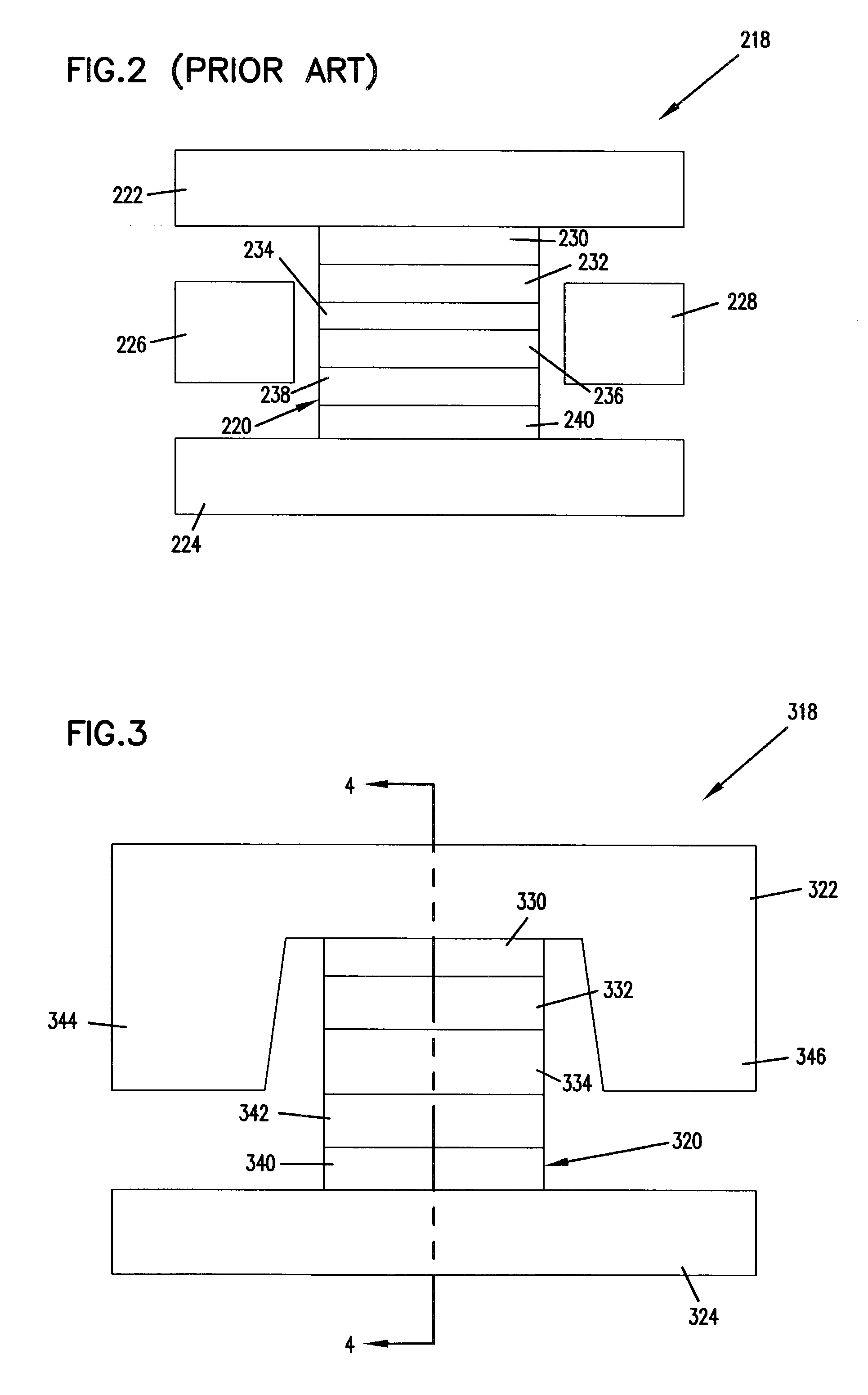

The present invention provides a tunneling magneto-resistive read sensor structure that improves sensitivity and linear density of the sensor structure. The sensor includes first and second electrodes and a stack positioned between the electrodes. The stack includes first and second free layers with magnetization orientations that are biased relative to each other. A tunneling barrier (insulating layer) or non-magnetic metal spacer is positioned between the first and second free layers. A sense current is passed between the first and second free layers of the stack. The amount of current passing through the first and second free layer changes based upon the orientation of the first and second free layers relative to each other.

Owner:SEAGATE TECH LLC

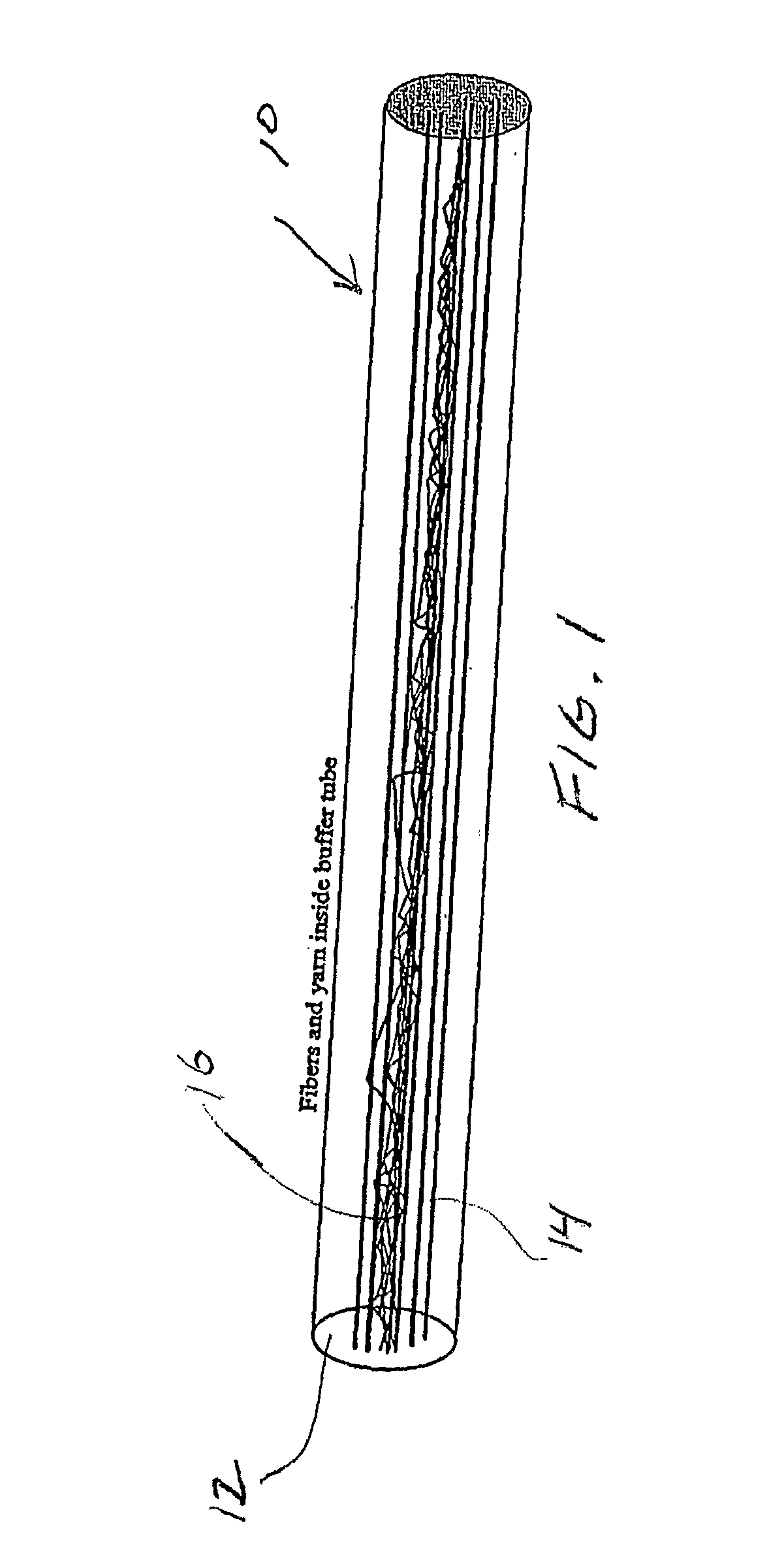

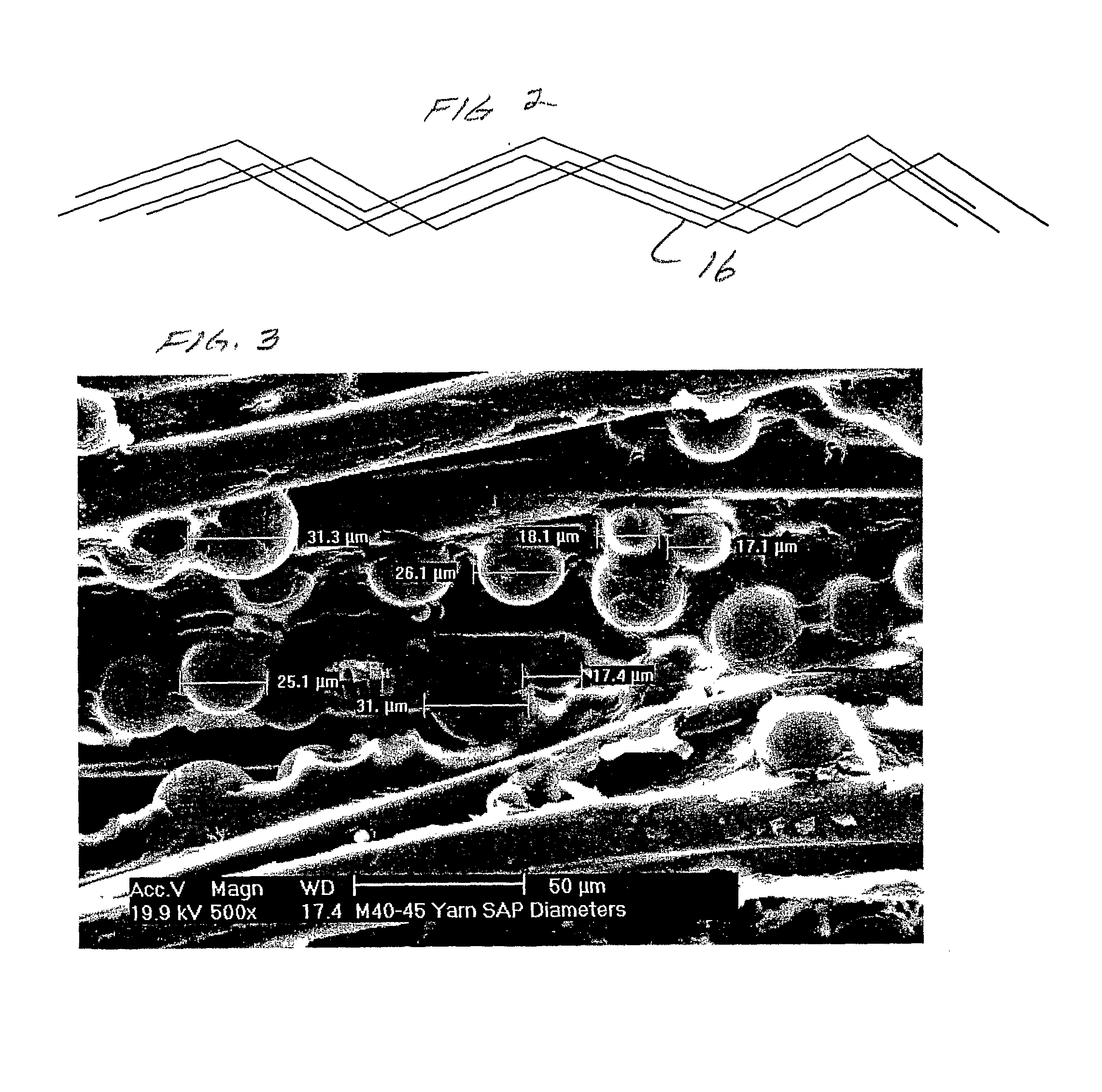

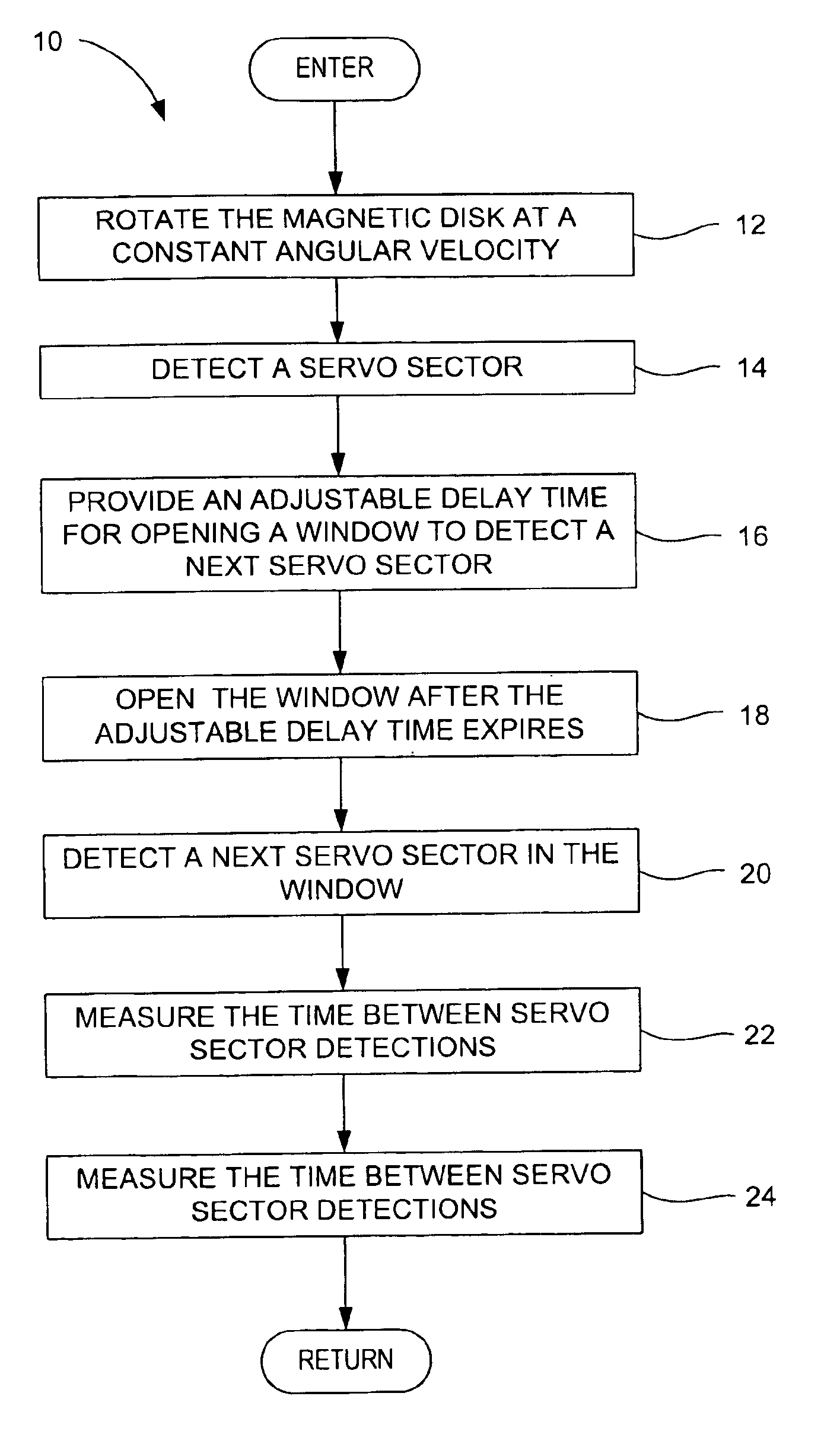

Grease-Free Buffer Optical Fiber Buffer Tube Construction Utilizing a Water-Swellable, Texturized Yarn

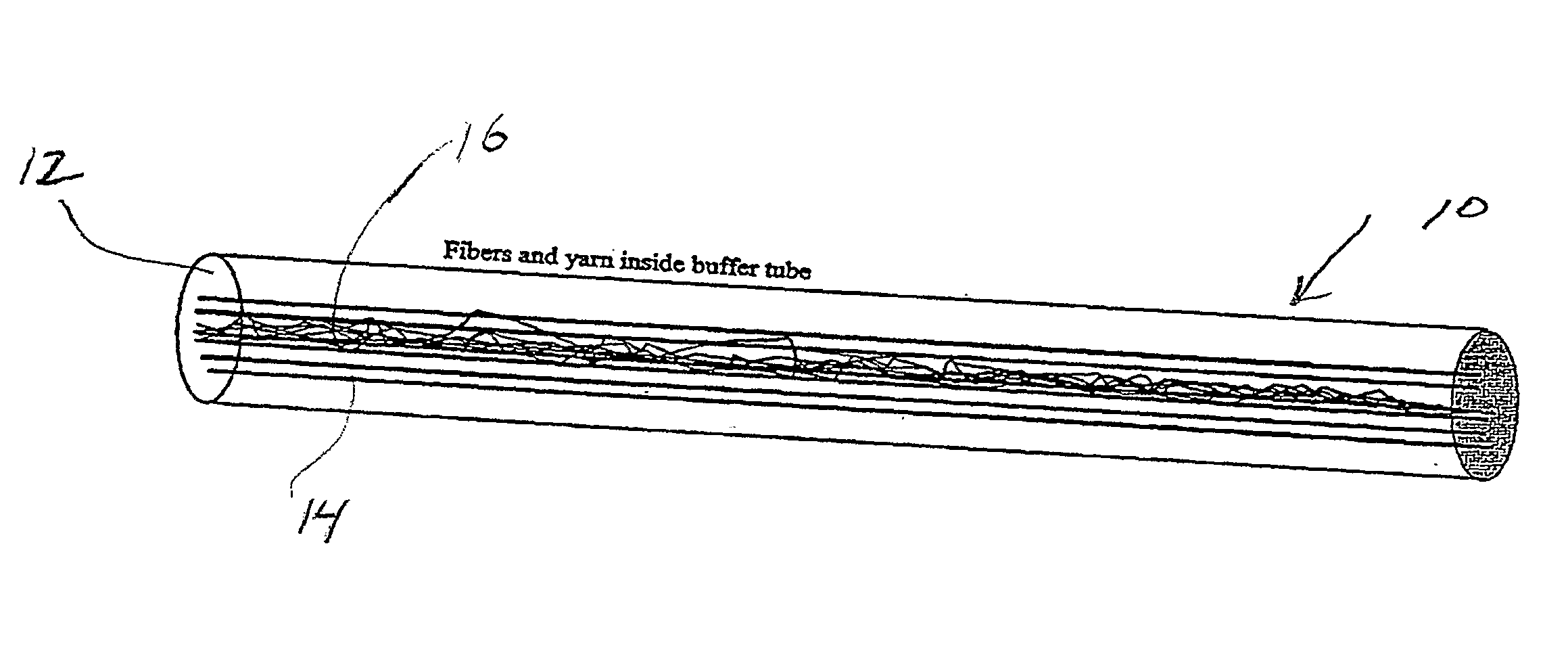

A buffered optical fiber arrangement that includes a buffer tube in which is provided optical fibers and a texturized yarn coated with a water-swellable material. The filament diameter of the yarn used in the present invention may be between about 5 microns and about 100 microns, more preferably between about 10 and about 60 microns, still more preferably between about 20 and about 40 microns. The linear density, or denier in grams per 9000 meters, of the base yarn may be between about 100 and 1000, more preferably between about 200 and 600, or still more preferably between about 250 and 350. The degree of decrease in length (the "degree of texturizing") between the perfectly straight filaments before texturizing and the texturized filament may be between 1 percent and 90 percent, more preferably between about 2 percent and 50 percent, or still more preferably between about 5 percent and 25 percent.

Owner:DRAKA COMTEQ BV

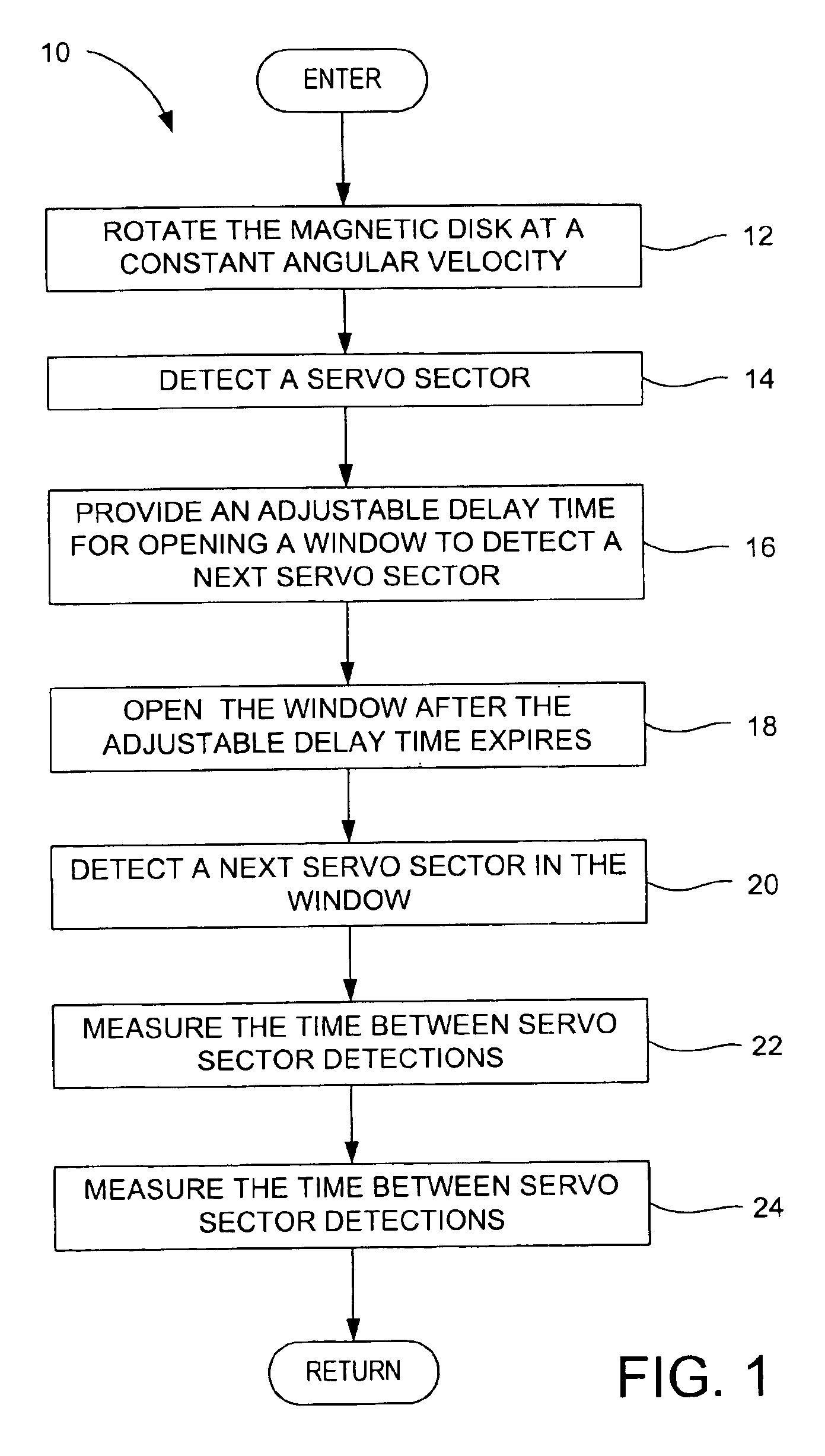

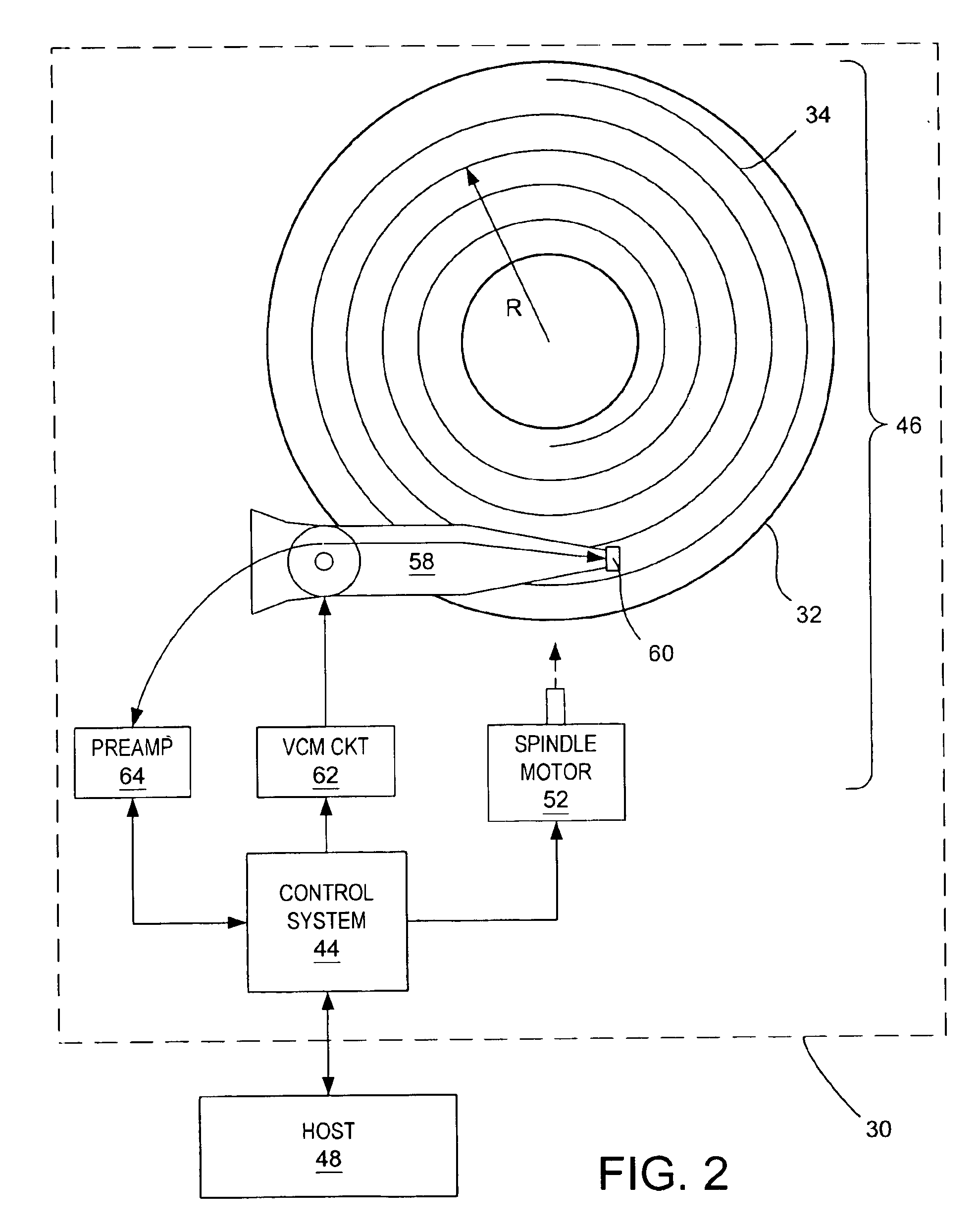

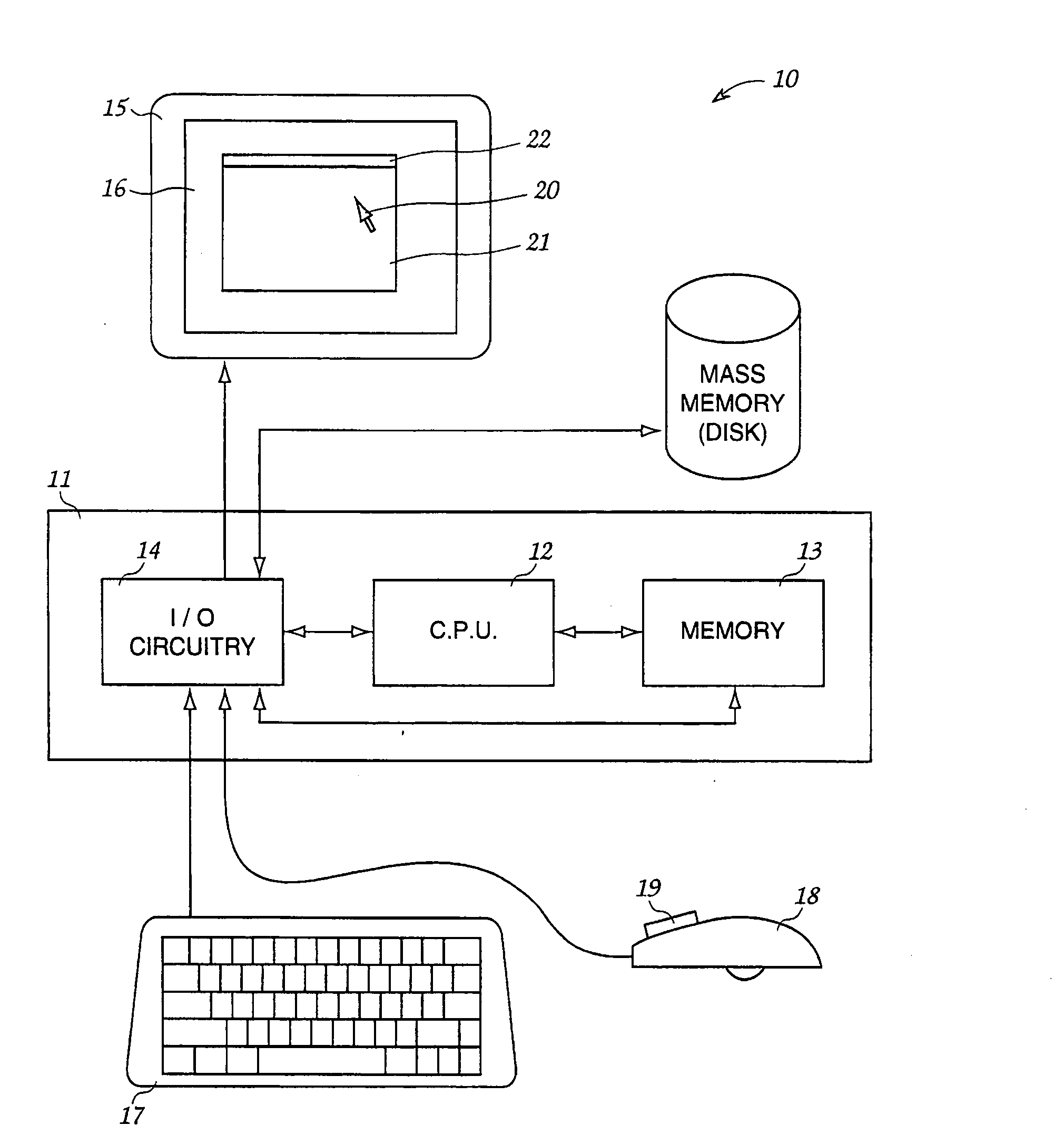

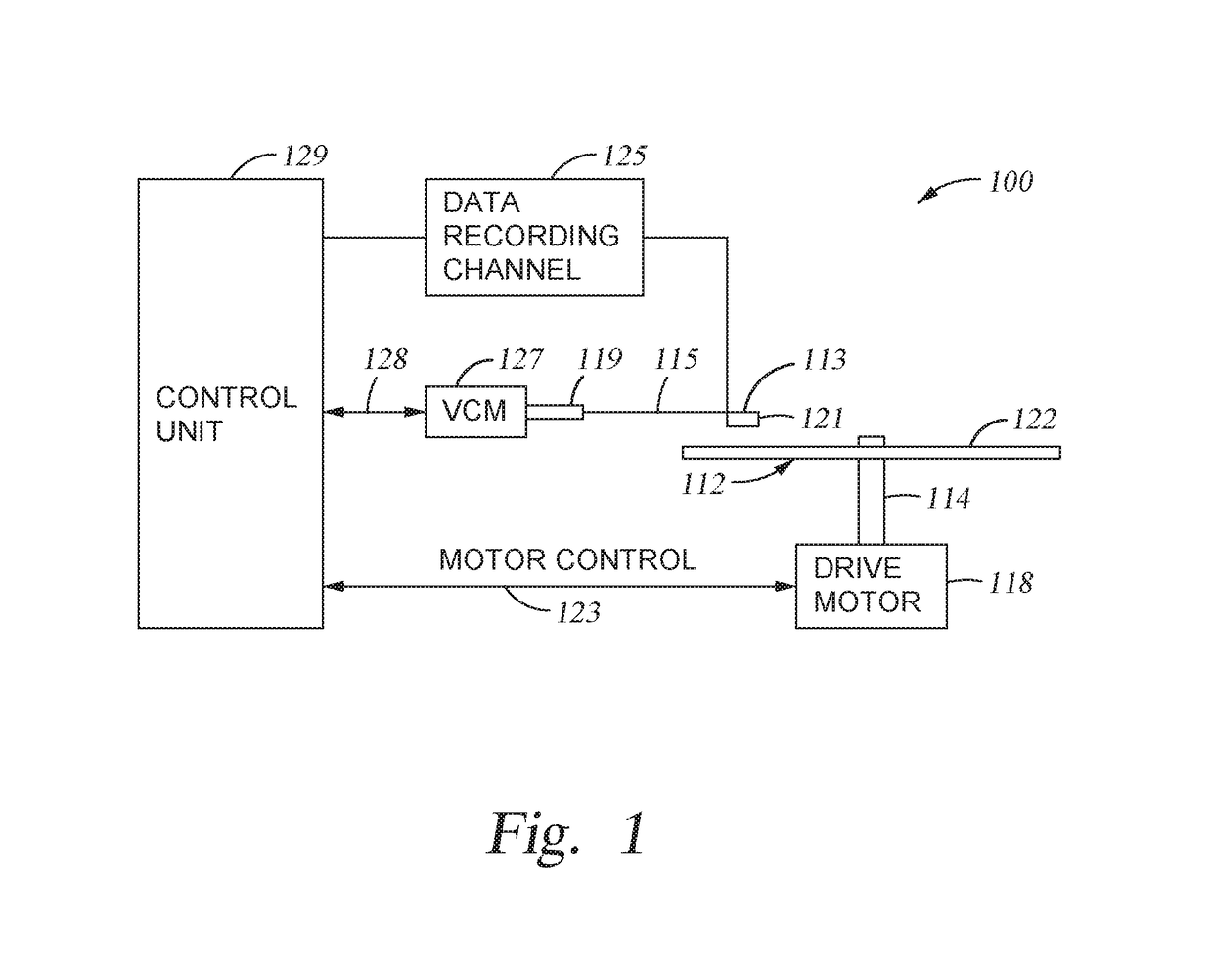

Method for adjusting a delay time for opening a servo sector detection window in a disk drive having a spiral track

InactiveUS6920004B1Disc-shaped record carriersRecord information storageLinear densityControl theory

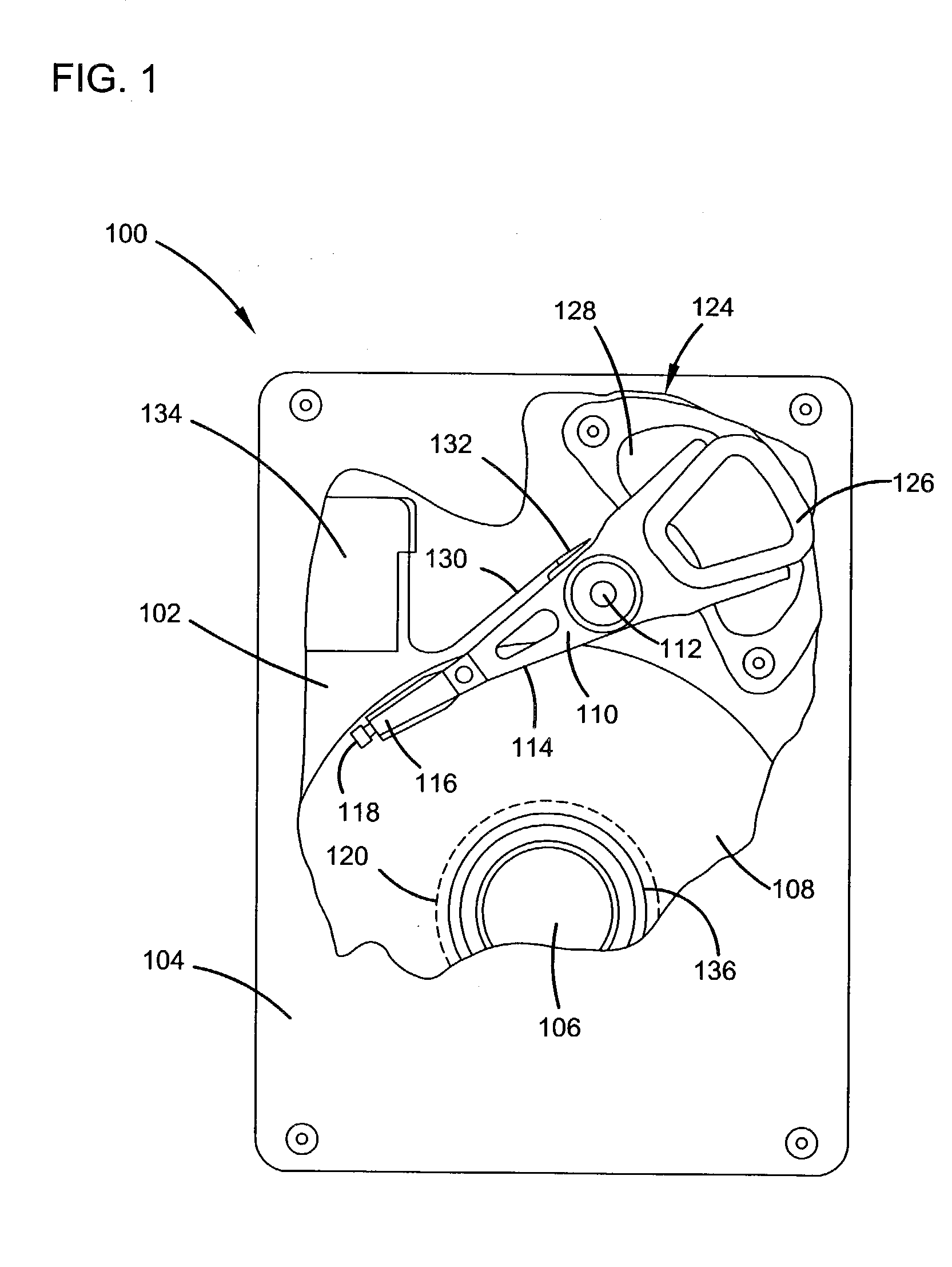

The present invention may be embodied in a method for adjusting a servo sector detection delay time between detection windows in a disk drive. The disk drive includes a magnetic disk with a spiral track having contiguous storage segments. Each storage segment has a servo sector and a predetermined number of uniformly-sized data sectors. The storage segments are written at a relatively constant linear density along the spiral track. In the method, the magnetic disk is rotated at a constant angular velocity. A servo sector is detected. An adjustable delay time is provided for opening a window to detect a next servo sector. The window is opened after the adjustable delay time expires. A next servo sector is detected in the window. A time between the servo sector detections is measured and the adjustable delay time is adjusted based on the measured time.

Owner:WESTERN DIGITAL TECH INC

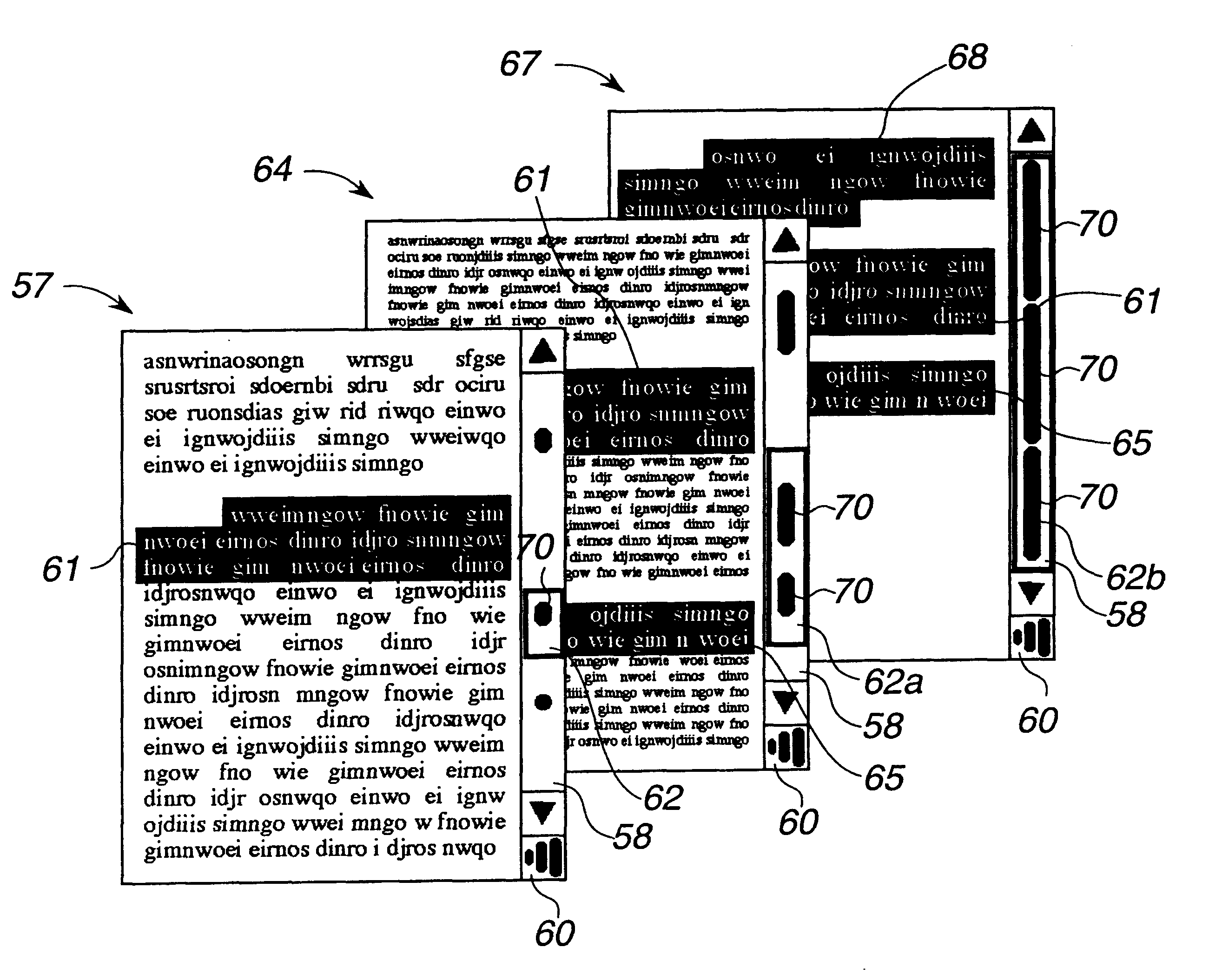

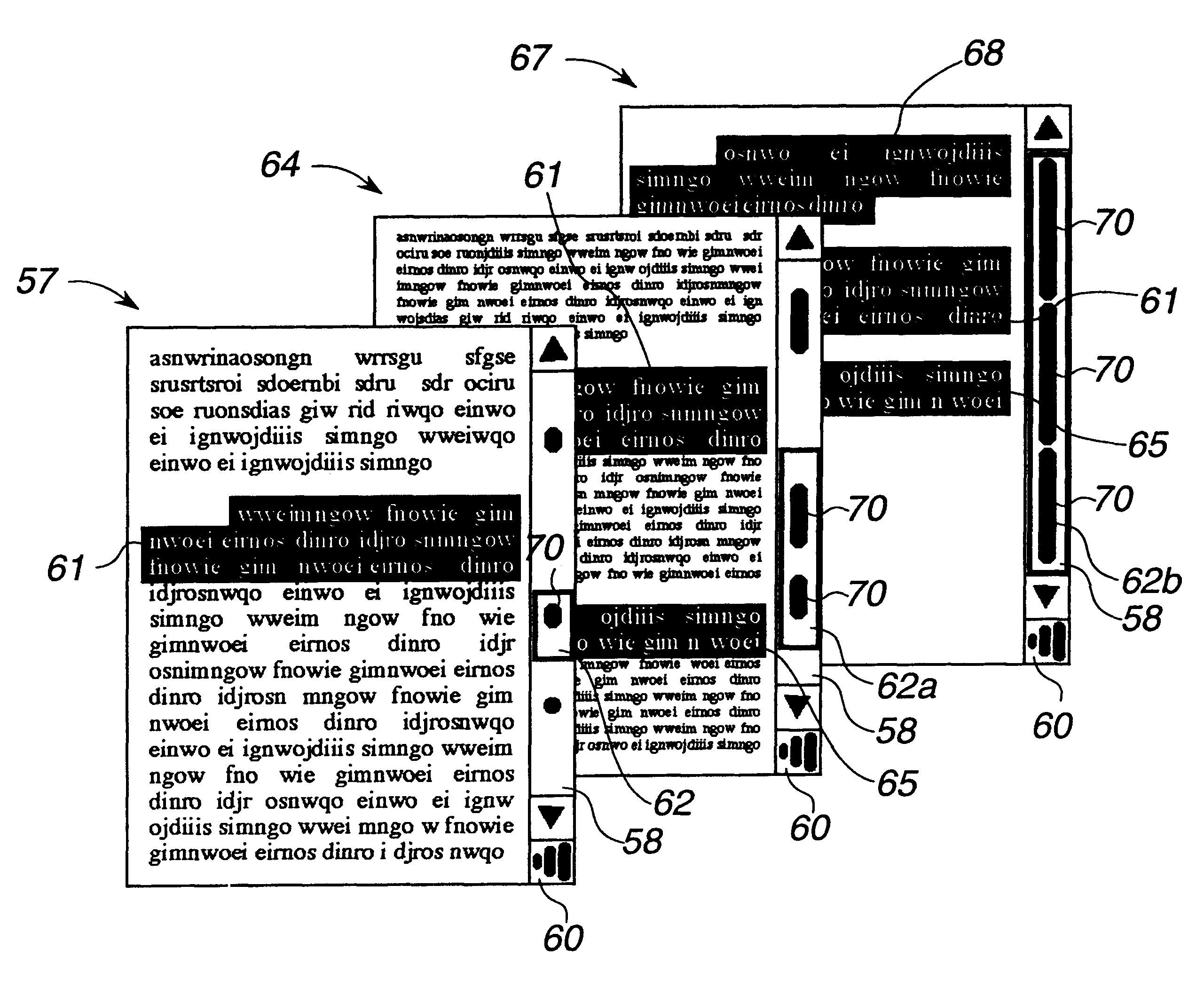

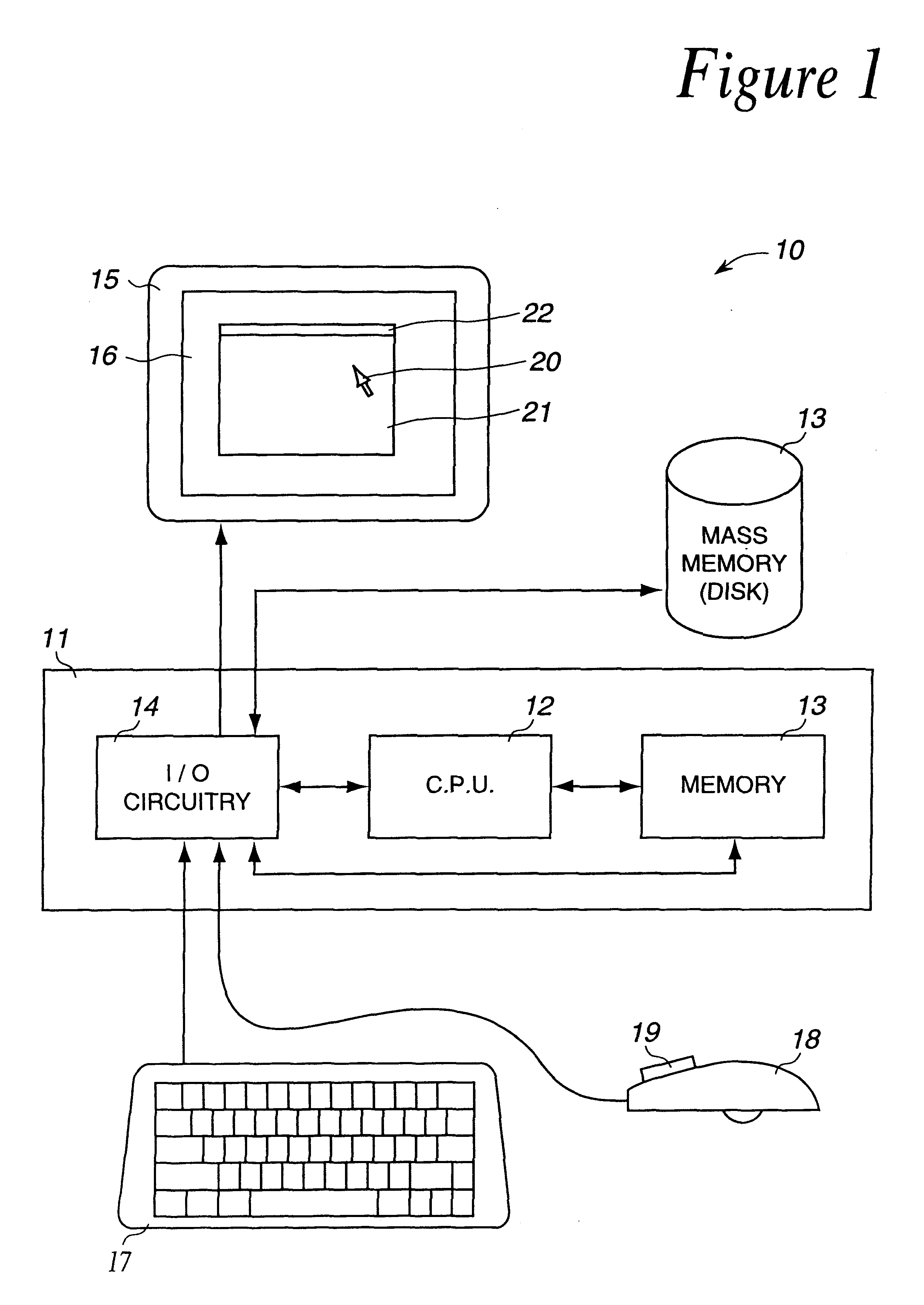

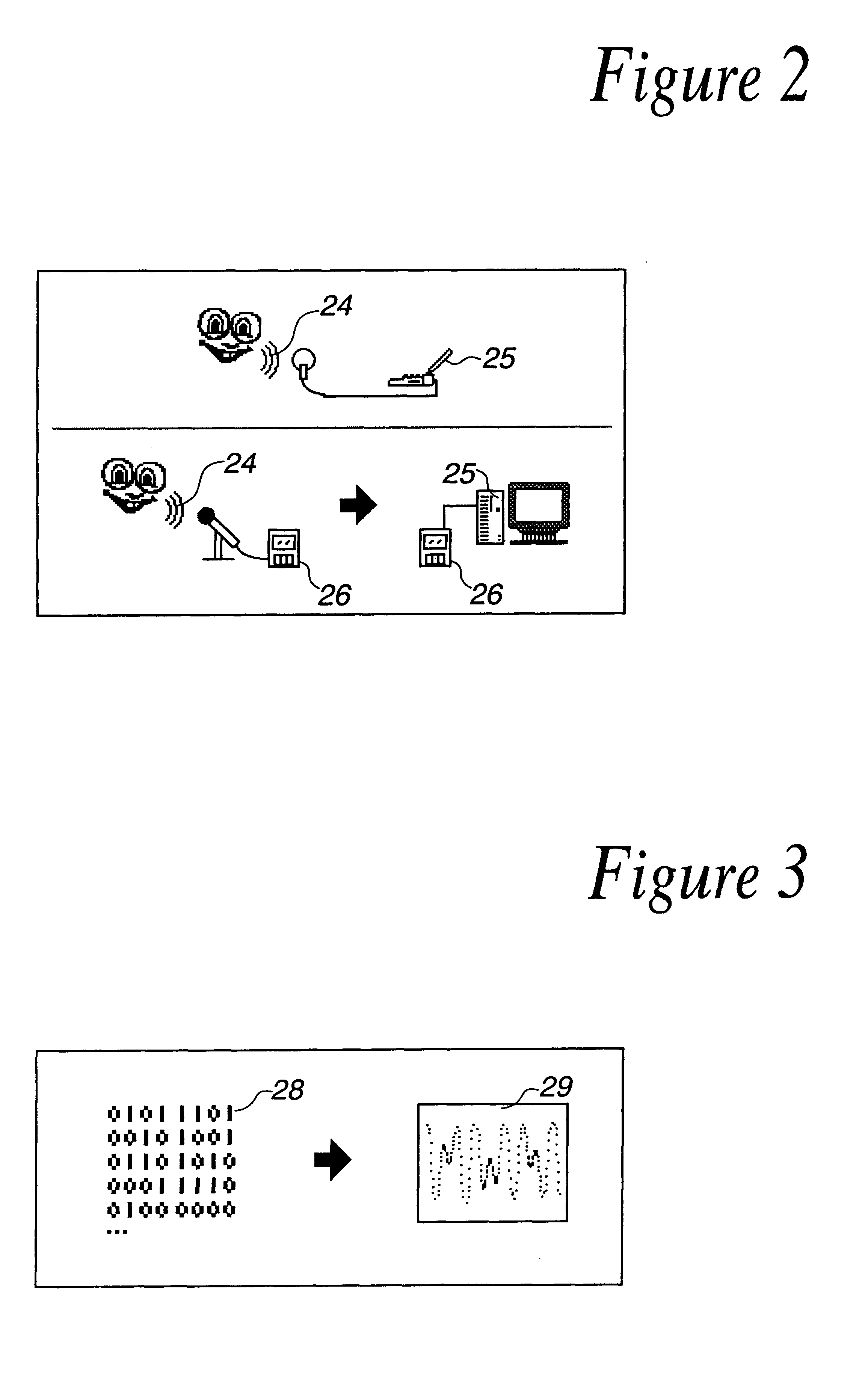

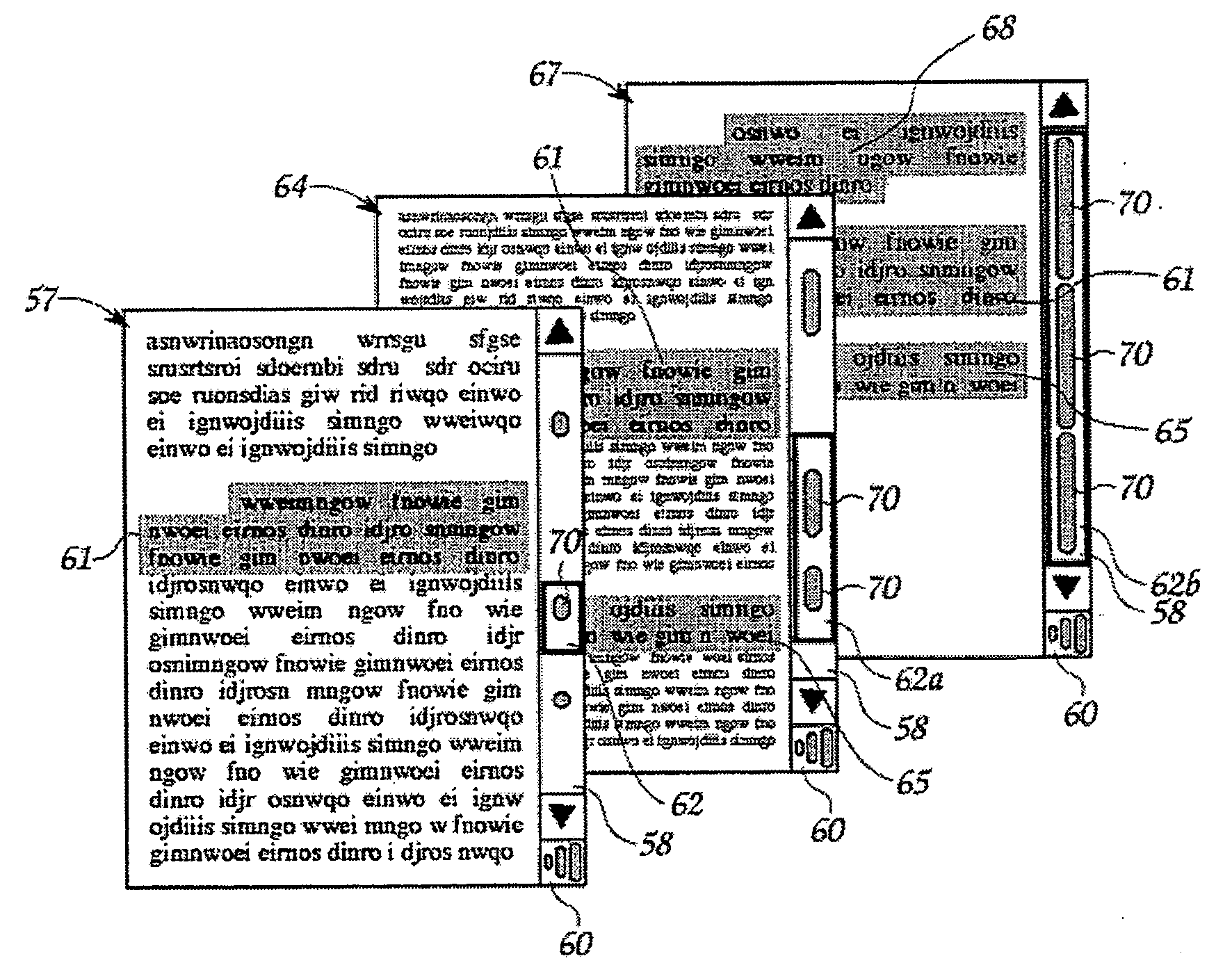

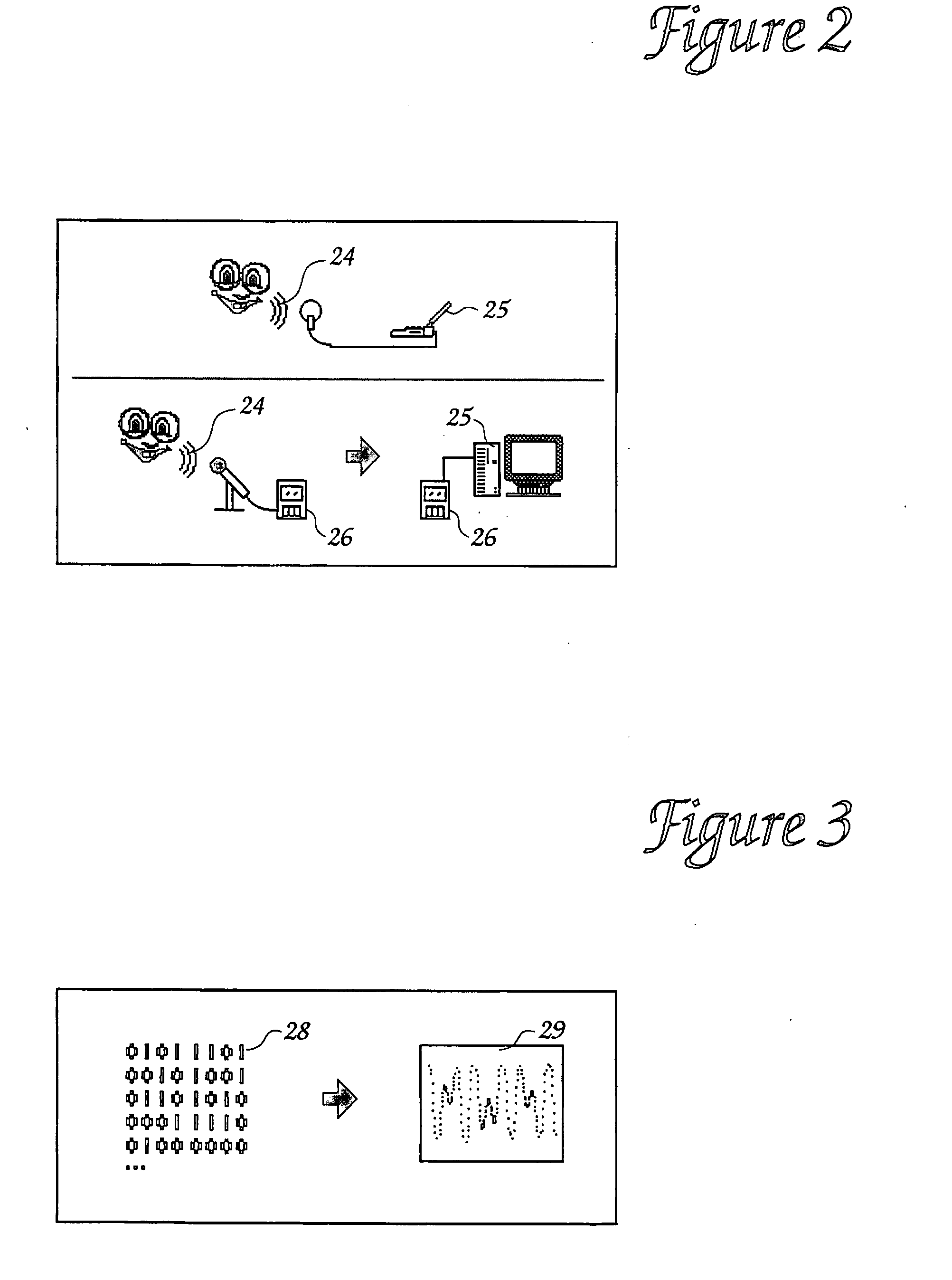

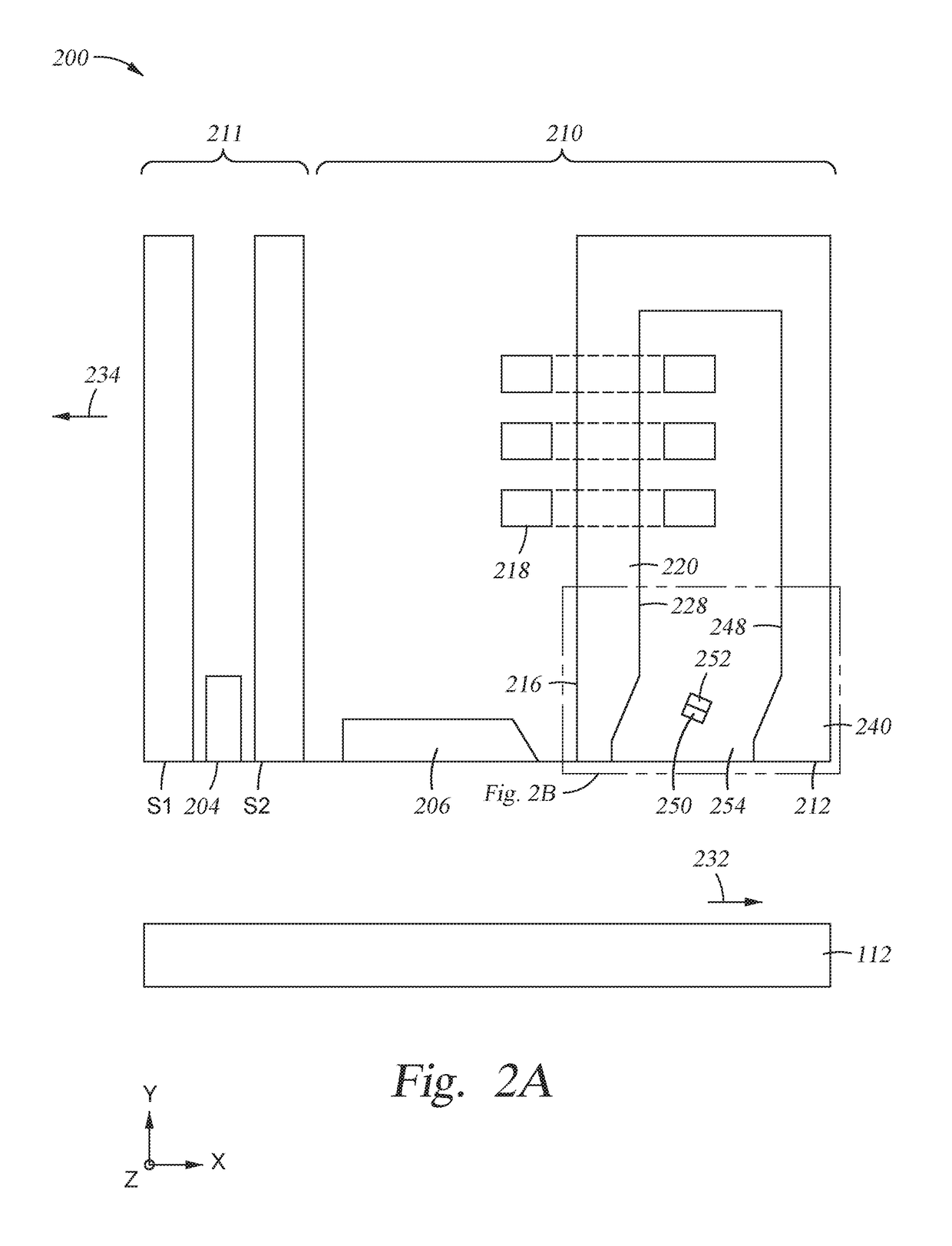

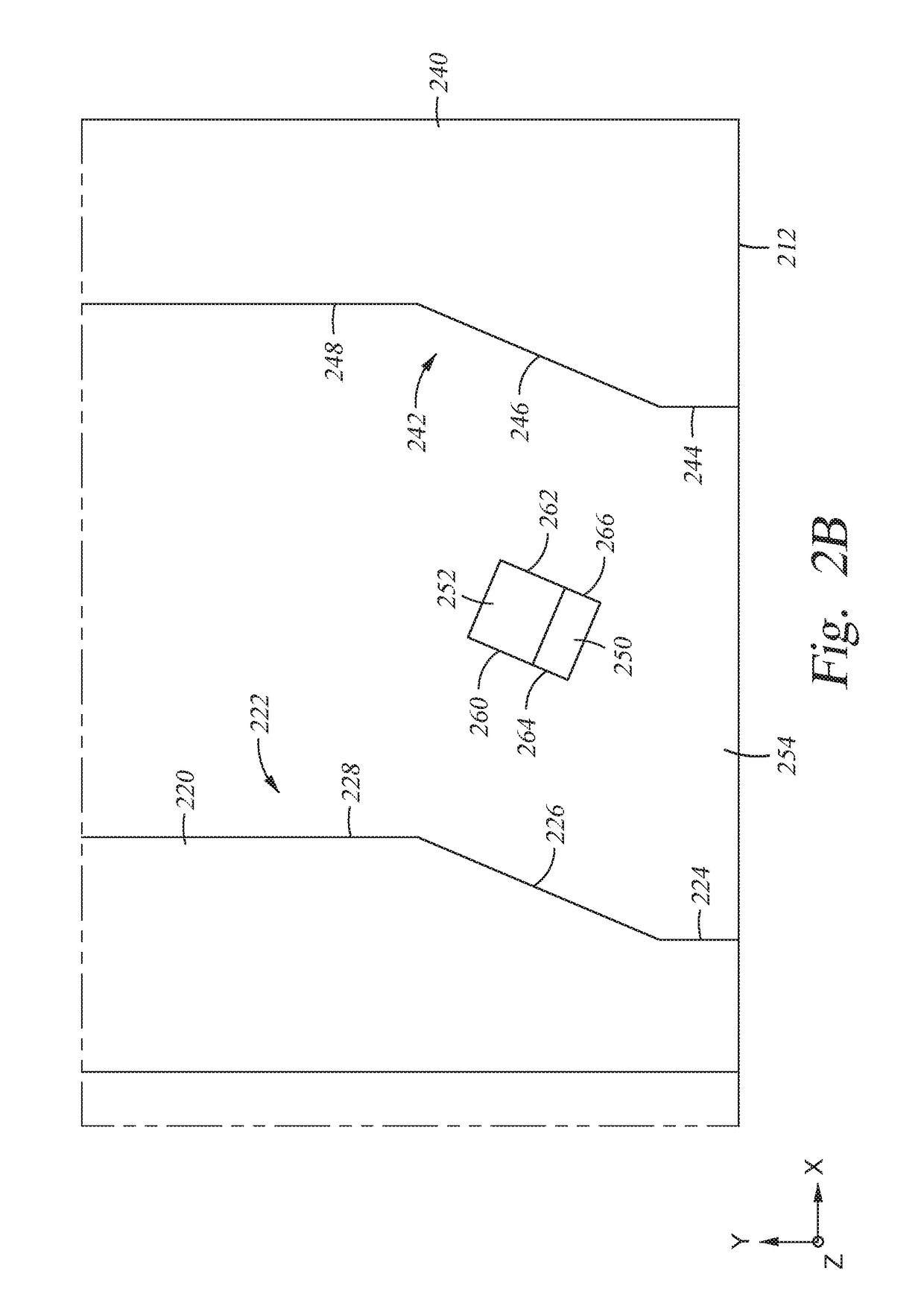

Computer user interface with non-salience deemphasis

InactiveUS6219052B1Quick navigationIncrease the number ofData processing applicationsCathode-ray tube indicatorsGraphicsDocumentation procedure

Owner:MONKEYMEDIA

Computer user interface with non-salience deemphasis

InactiveUS6215491B1Quick navigationData processing applicationsCathode-ray tube indicatorsGraphicsDocumentation procedure

A relativity controller is a scroll bar / window combination that provides a way to see data in relation to both the context of its wholeness and the salience of its contents. To accomplish this, the linear density or other appearance of the scroll bar (acting as a ruler or scale) varies with the density of the document salience (as indicated by different kinds of annotations or marks). It also provides a way to zoom between perspectives. This is usable on many different data types: including sound, video, graphics, calendars and word processors.

Owner:MONKEYMEDIA

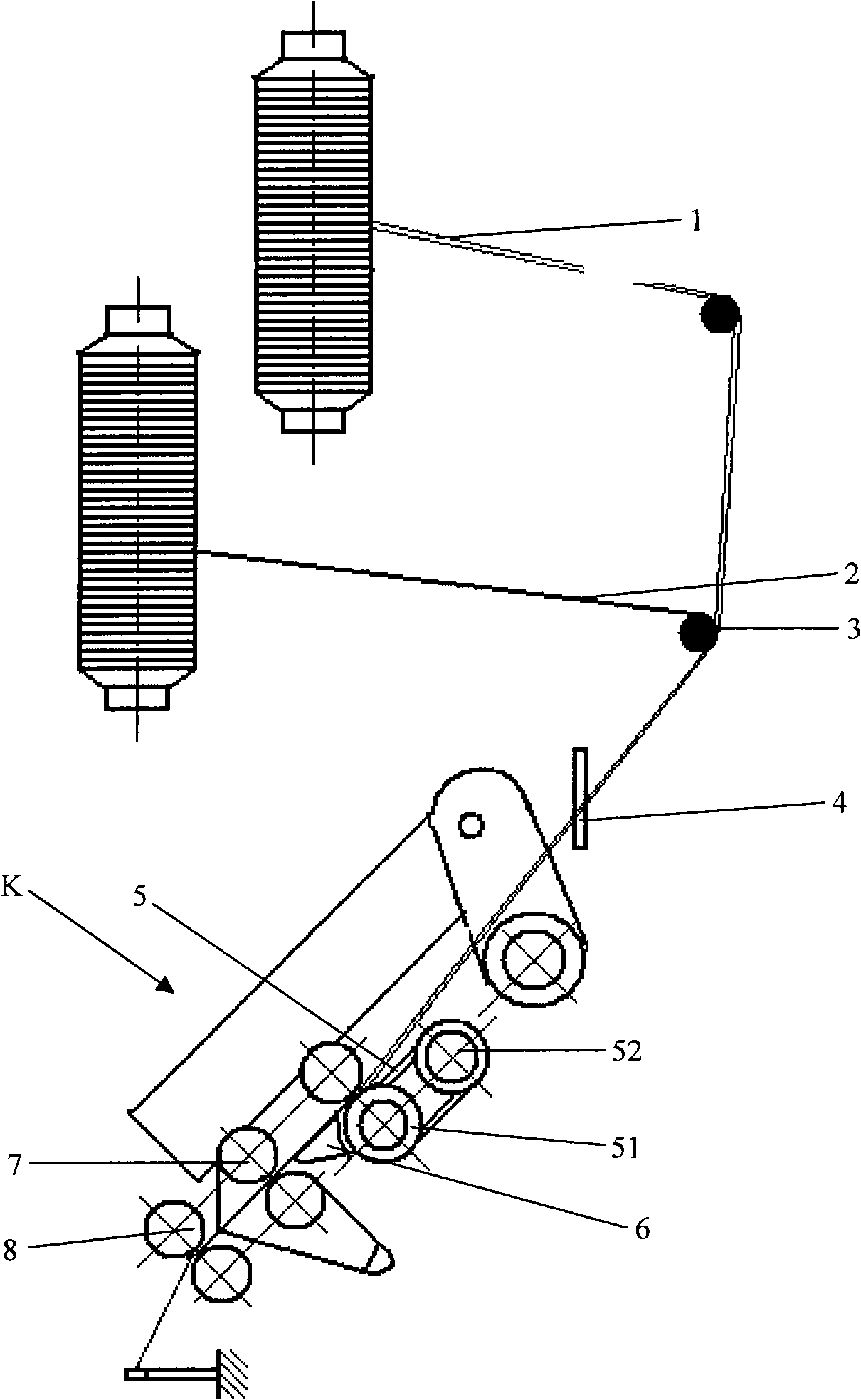

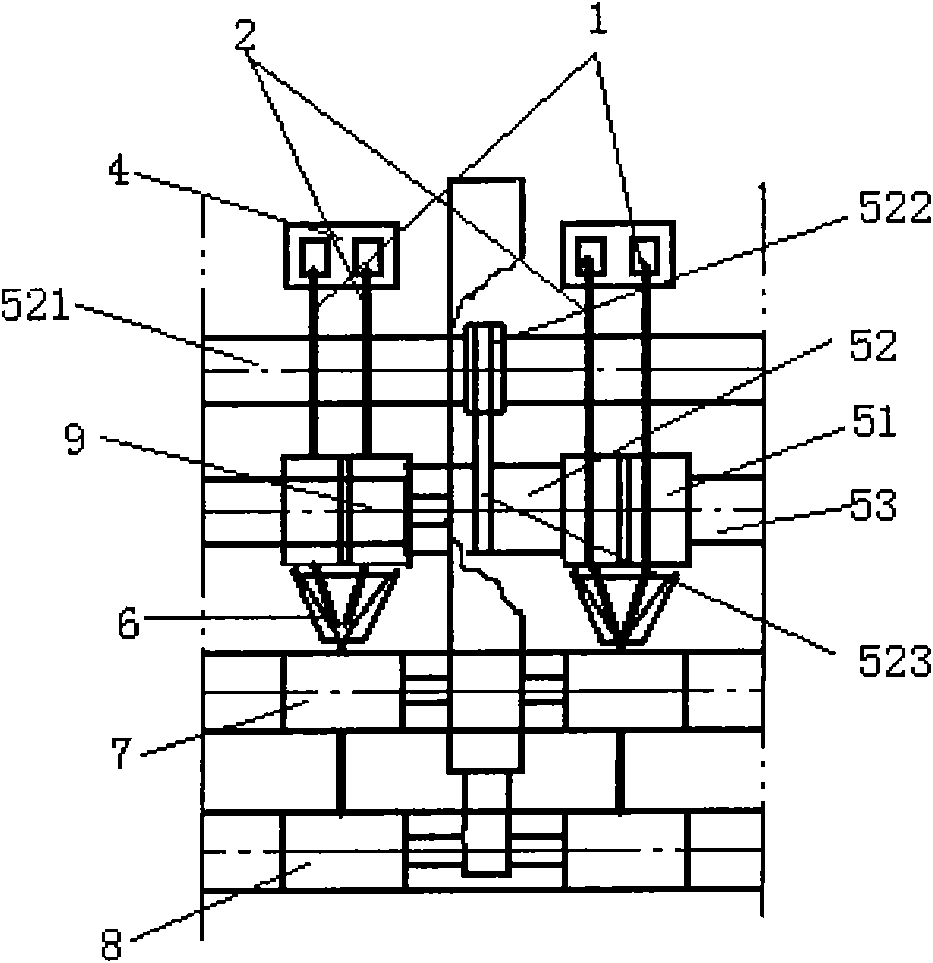

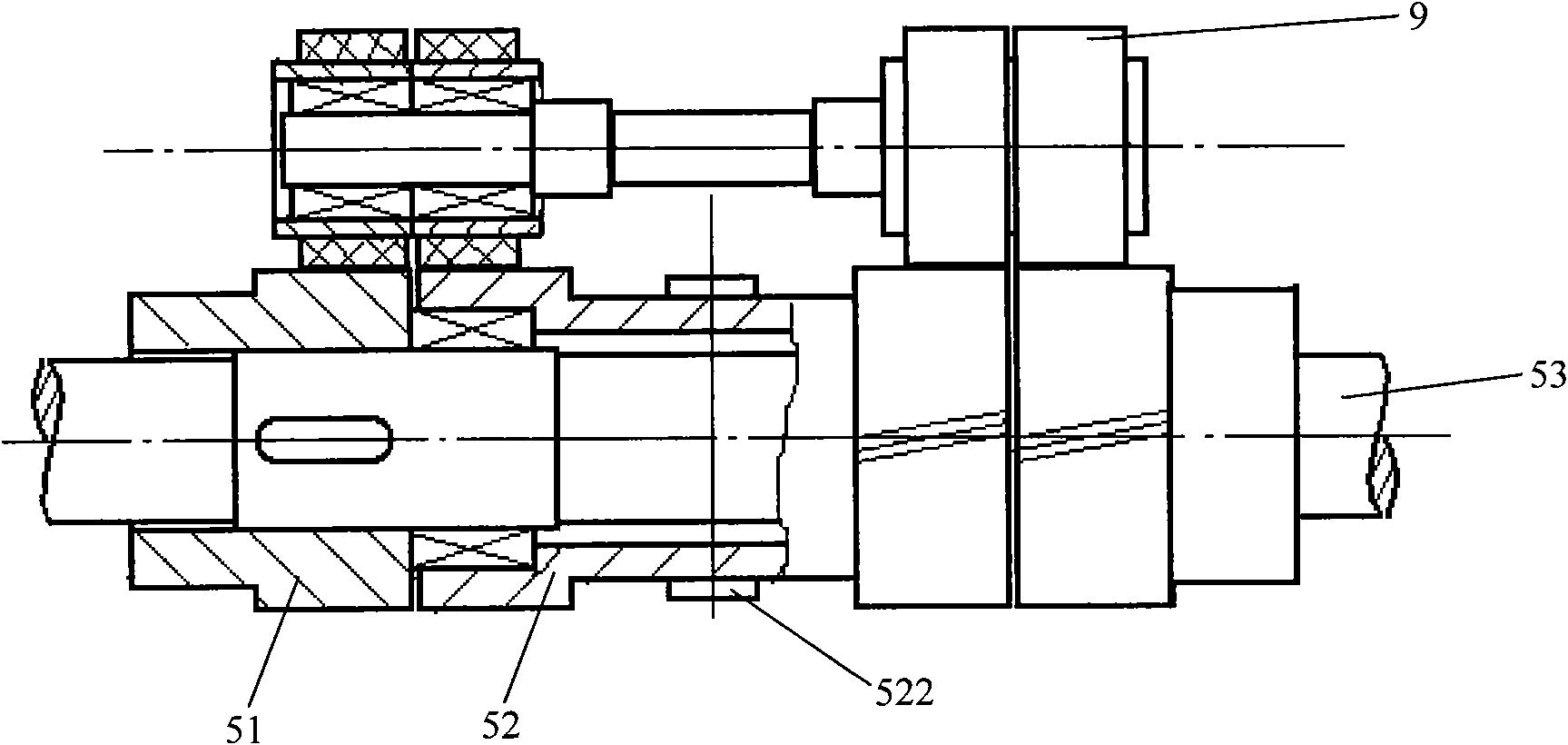

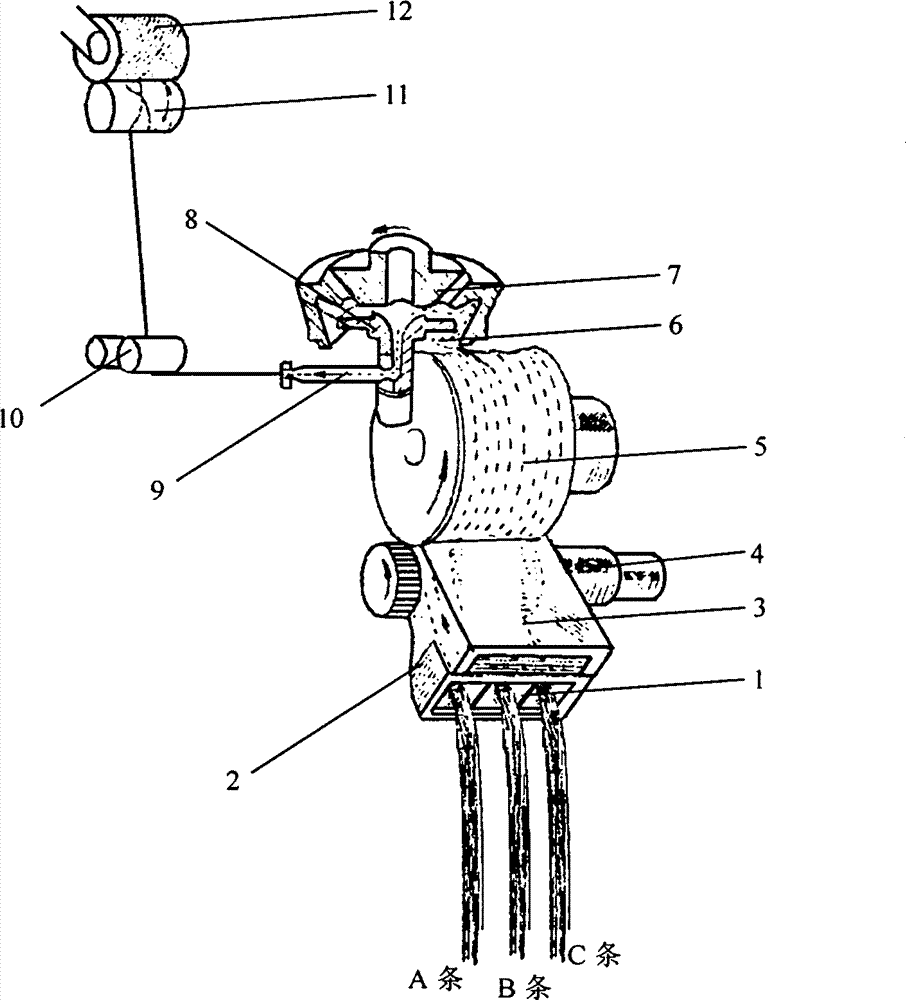

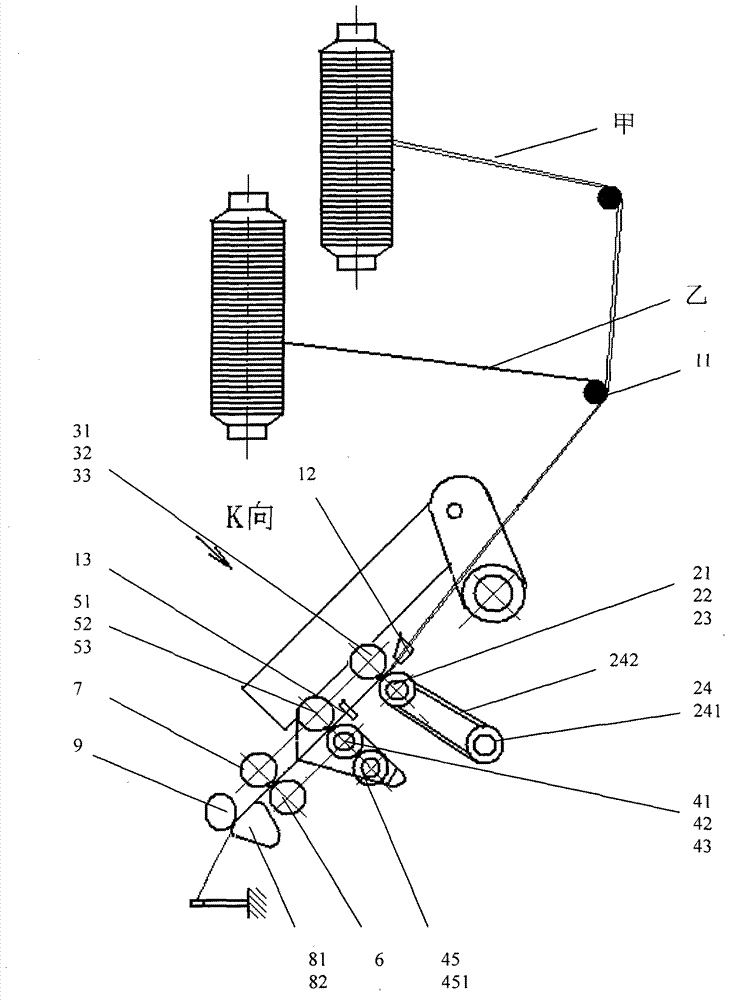

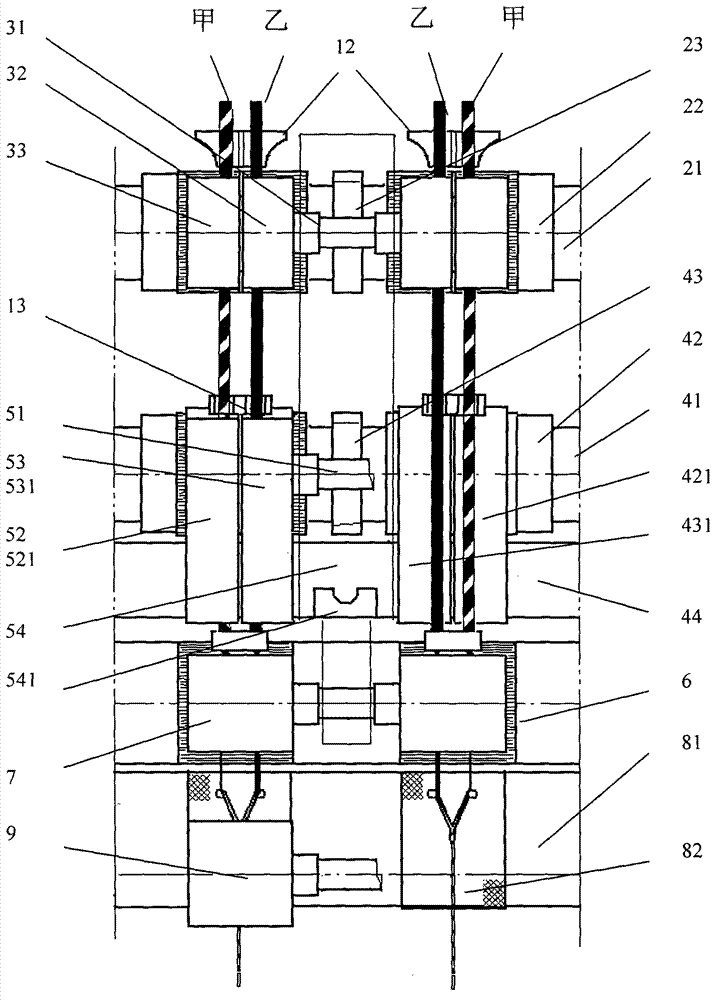

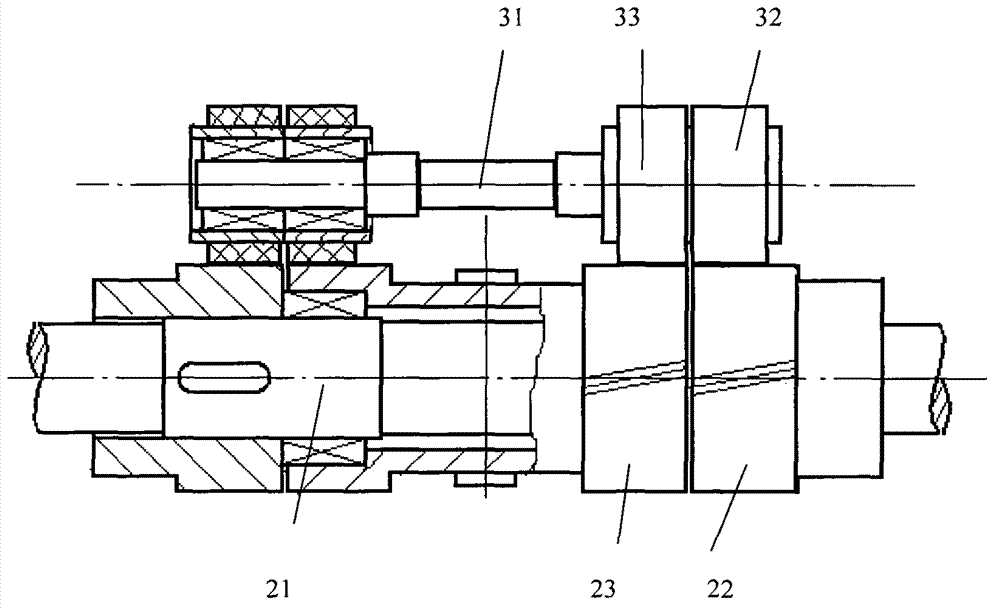

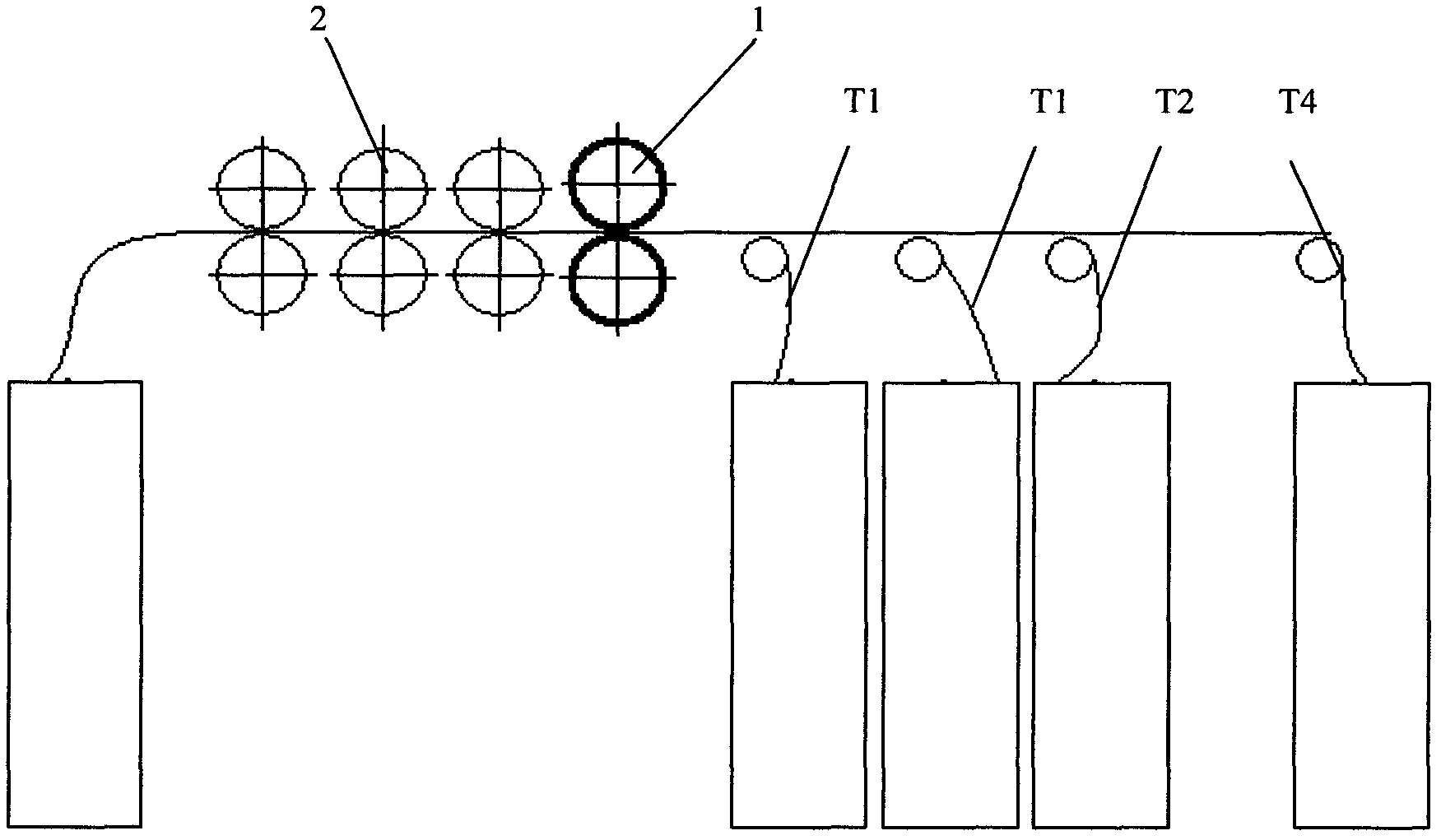

Ring spinning method and device of equi-linear density space dyed yarn

The invention relates to ring spinning method and device of equi-linear density space dyed yarn. The method comprises the following steps of: respectively feeding a fiber strip group (A) with the linear density tex T(A) and a fiber strip group (B) with the linear density tex T(B) into a fixed rear roller and a loop rear roller on a rear roller shaft through yarn guiding rods and grids; and feeding the fiber strip group (A) and the fiber strip group (B) with constant feeding quantity sum into a rear drawing region in any period of time under the process requirement that the feeding speeds of the fiber strip group (A) and the fiber strip group (B) vary with stages by adopting a speed coupling uniform feeding control method. After the strip collection of a strip collector, fiber strips are fed into a middle roller in different drawing ratios, converged in a front drawing region of a spinning machine, drawn and output by a front roller and twisted into equi-linear density space dyed yarn.

Owner:陈伟雄

Rotor spinning melange yarn forming method and device and product

The invention discloses a rotor spinning melange yarn forming method and device and product. On a rotor spinning machine, two or more fiber strips enter a feeding mechanism through a striping gate and a horn mouth, the feeding mechanism contains at least two independently controlled feeding rollers and can control the independent feeding of at least two fiber strips, different fiber strips are of different colors, or of different color combinations, or of different fiber components, the feeding speed of each fiber strip is controllable, the feeding can be conducted at different time sections, and the feeding speeds of all the fiber strips are independently changeable or simultaneously changeable; through the implement of continuous constant-speed feeding or segmentation variable speed feeding of different fiber strips, continuous constant feeding or segmentation variable feeding of the fiber strips is controlled; the fed fiber strips break away from a combing roller, are transferred to a delivery pipe, and then enter a spinning cup depending on the centrifugal force of the combing roller and the action of added air flow after the opening and carding actions of the combing roller; single fibers of different components are mixed, condensed and twisted in the spinning cup to form rotor spinning melange yarn blended by monochrome or polychromatic fiber, or with segmentation color effect, uniform linear density or changing linear density.

Owner:JIAXING UNIV

Manufacturing method of high-strength, high-modulus and low-shrinkage polyester industrial yarn

ActiveCN102797054AGuaranteed positionAvoid stretching unevenlyFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

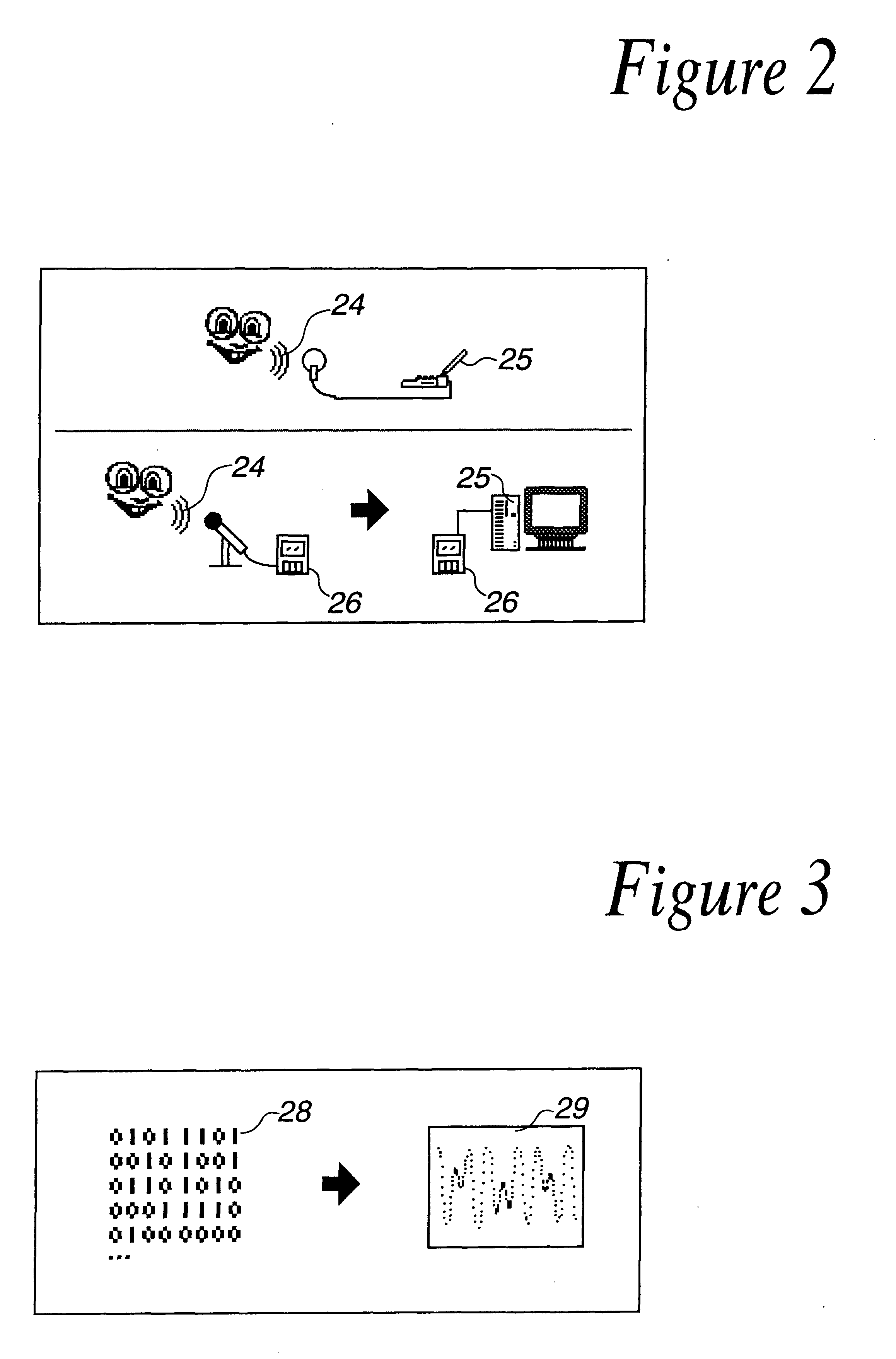

Computer user interface for audio and/or video auto-summarization

InactiveUS20080158261A1Good navigationImprove visualizationRecord information storageUsing detectable carrier informationGraphicsDocumentation procedure

A relativity controller is a scroll bar / window combination that provides a way to see data in relation to both the context of its wholeness and the salience of its contents. To accomplish this, the linear density or other appearance of the scroll bar (acting as a ruler or scale) varies with the density of the document salience (as indicated by different kinds of annotations or marks). It also provides a way to zoom between perspectives. This is usable on many different data types: including sound, video, graphics, calendars and word processors.

Owner:MONKEYMEDIA

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

Flexible spike/ballistic penetration-resistant articles

ActiveUS20050003727A1Improve performanceImprove ballistic performanceProtective equipmentProtective fabricsYarnEngineering

An article is disclosed to protect a wearer from spike and ballistic threats that is made from a spike resistant panel and a ballistic resistant panel. Each panel is made from flexible fabric layers. The fabrics in the spike resistant panel are made from first yarns having a linear density of from 50 to 600, with a plurality of filaments. There are 40 to 100 first yarns per inch in both the warp and fill directions. The fabrics in the ballistic resistant panel are made from second yarns having a linear density of from 100 to no more than 840 denier with a plurality of filaments, which provide from 20,000,000 to no more than 90,000,000 filament crossovers per square inch. There are 5 to less than 40 second yarns per inch in both the warp and fill directions

Owner:DUPONT SAFETY & CONSTR INC

Polyester filament woven fabric for air bags

InactiveUS20060252322A1Pedestrian/occupant safety arrangementSynthetic resin layered productsEngineeringFabric structure

A polyester plain weave fabric construction wherein said fabric has a basis weight of between 150 to 300 g / m2 with tongue tear strength equal to or better than nylon fabrics of the same construction and weight. The present invention relates to both coated and uncoated polyester filament woven fabric. The uncoated fabric is useful for industrial purposes wherein the fabric has a warp tongue tear resistance of at least 0.75 N / g / m2, when the fabric basis weight is between 150 to 300 g / m2 The preferred uncoated polyester filament yarn has a linear density of between about 200 to about 800 dtex, a tenacity of at least 65 cN / tex, a tensile index of at least 350. The fabrics can be coated with chloroprene, neoprene, polyurethane, silicone or other organic coatings to reduce air permeability. The fabric of the present invention may also be constructed with the warp and / or filling yarn having an aspect ratio between 1.2 and 6.

Owner:INV PERFORMANCE MATERIALS LLC +1

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

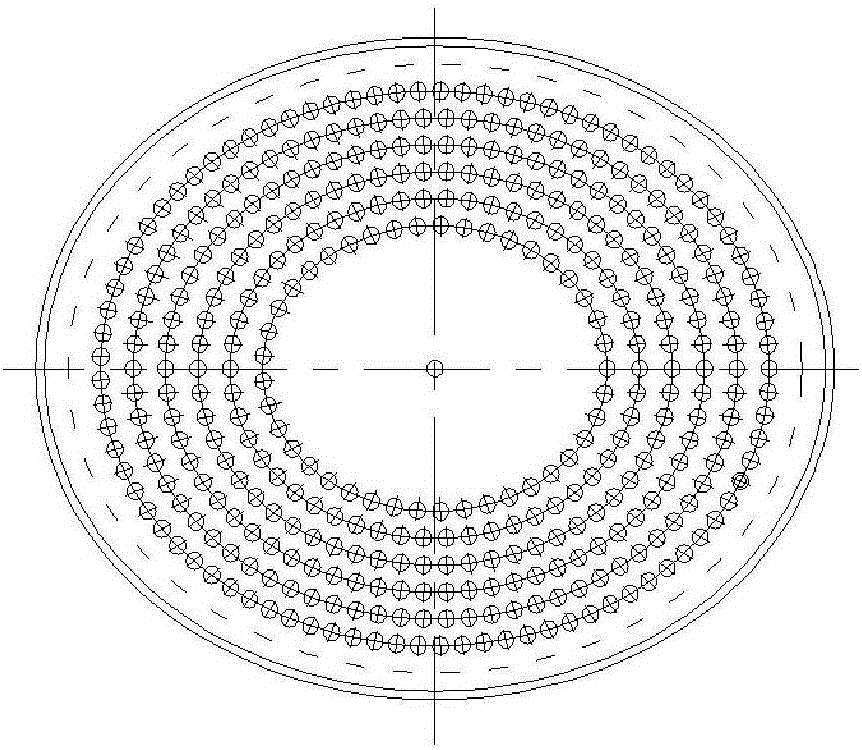

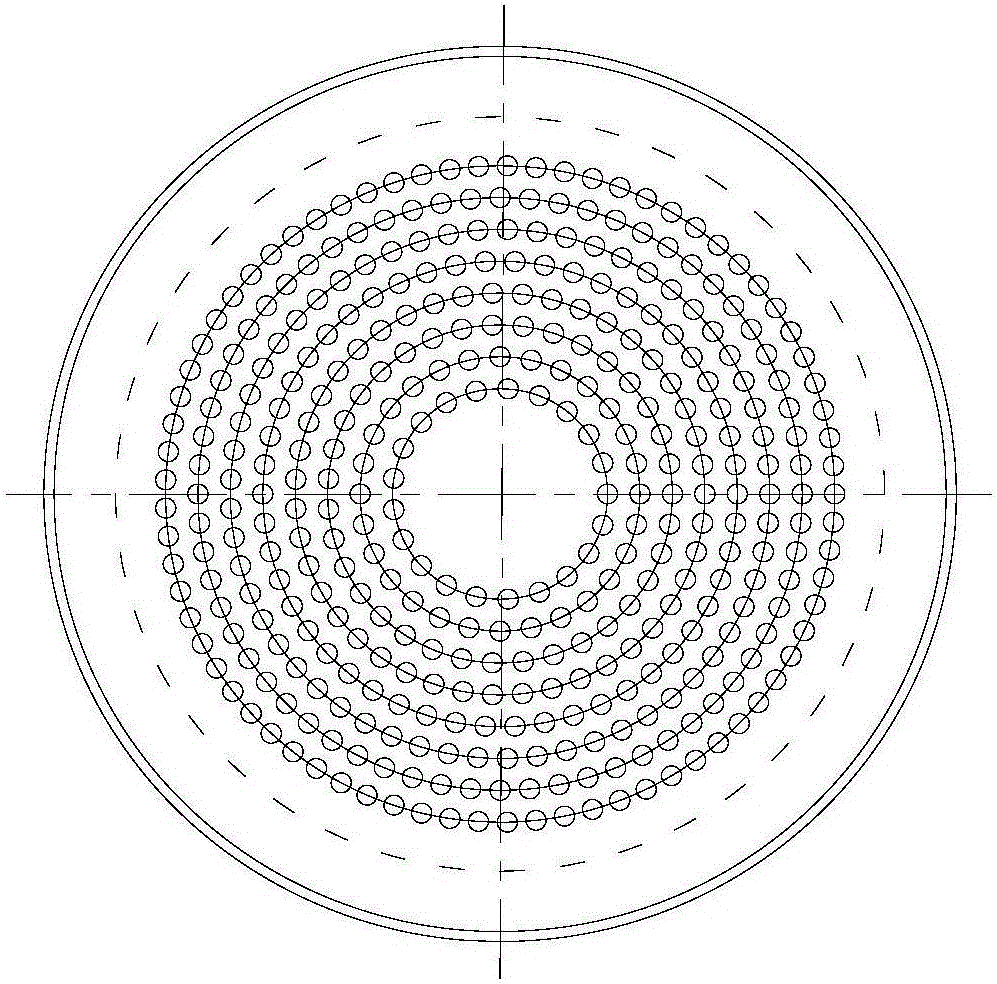

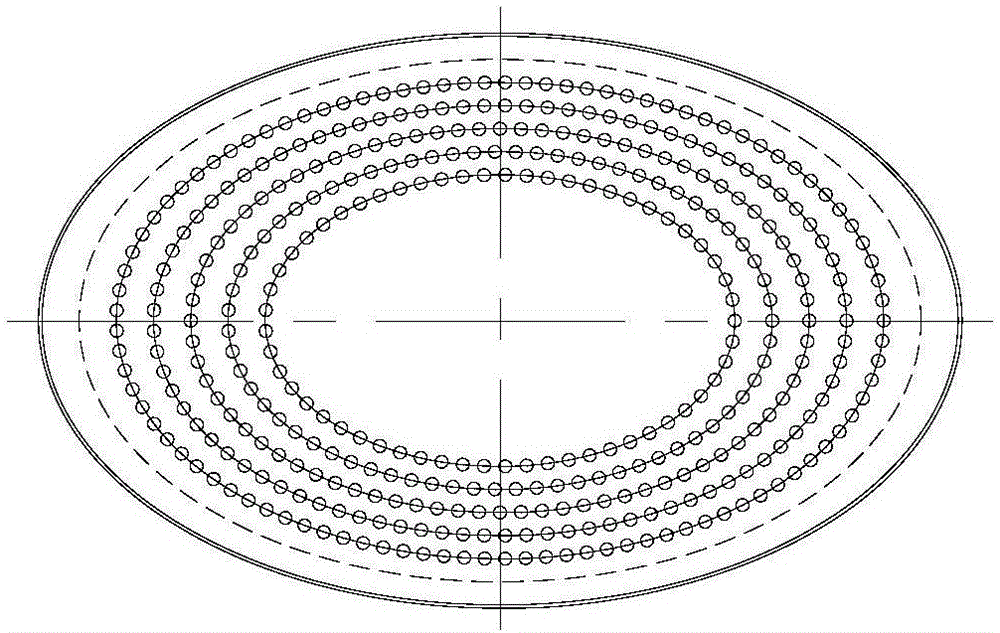

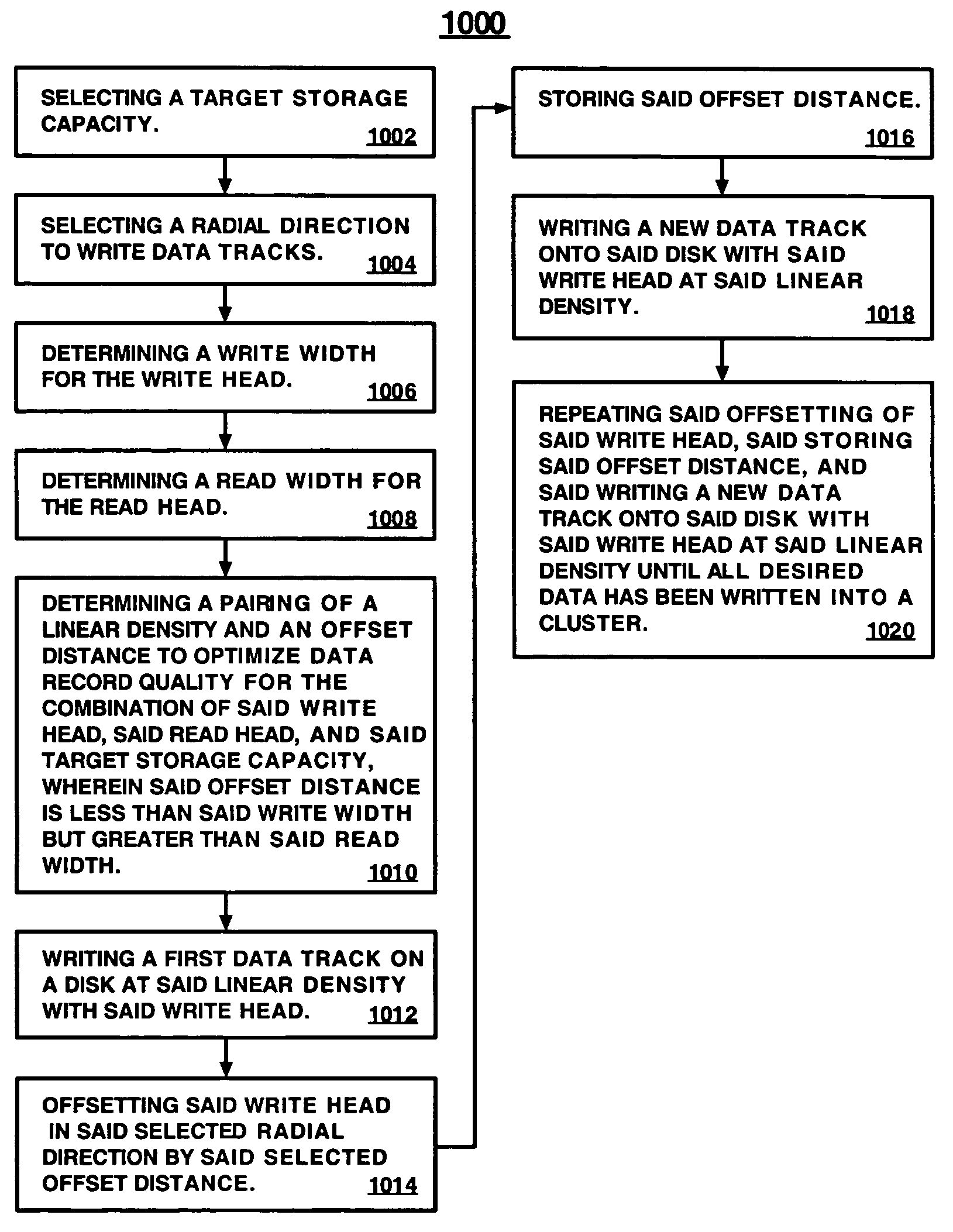

Method and apparatus for optimizing record quality with varying track and linear density by allowing overlapping data tracks

InactiveUS7133241B2Driving/moving recording headsRecord information storageTrack densityOffset distance

A method and apparatus for optimizing data record quality on a disk for a pair of read and write heads, in which the write head is bigger, by adaptively varying linear and track density of overlapping recorded tracks to achieve a target storage capacity. In the method, target storage capacity and radial writing direction are selected. Read and write widths of heads are determined. A linear density and offset distance pairing for optimizing record quality at target storage capacity is determined, wherein offset distance is less than write width but greater than read width. The write head writes a track at the linear density, is offset in the radial direction by the offset distance, and the offset distance is stored. The write head writes a new track at the linear density. Offsetting, storing offset, and writing a new track are repeated until desired data is written into a cluster.

Owner:WESTERN DIGITAL TECH INC

Computer uswer interface for calendar auto-summerization

InactiveUS20080216011A1Good navigationImprove visualizationData processing applicationsInput/output processes for data processingGraphicsDocumentation procedure

A relativity controller is a scroll bar / window combination that provides a way to see data in relation to both the context of its wholeness and the salience of its contents. To accomplish this, the linear density or other appearance of the scroll bar (acting as a ruler or scale) varies with the density of the document salience (as indicated by different kinds of annotations or marks). It also provides a way to zoom between perspectives. This is usable on many different data types: including sound, video, graphics, calendars and word processors.

Owner:MONKEYMEDIA

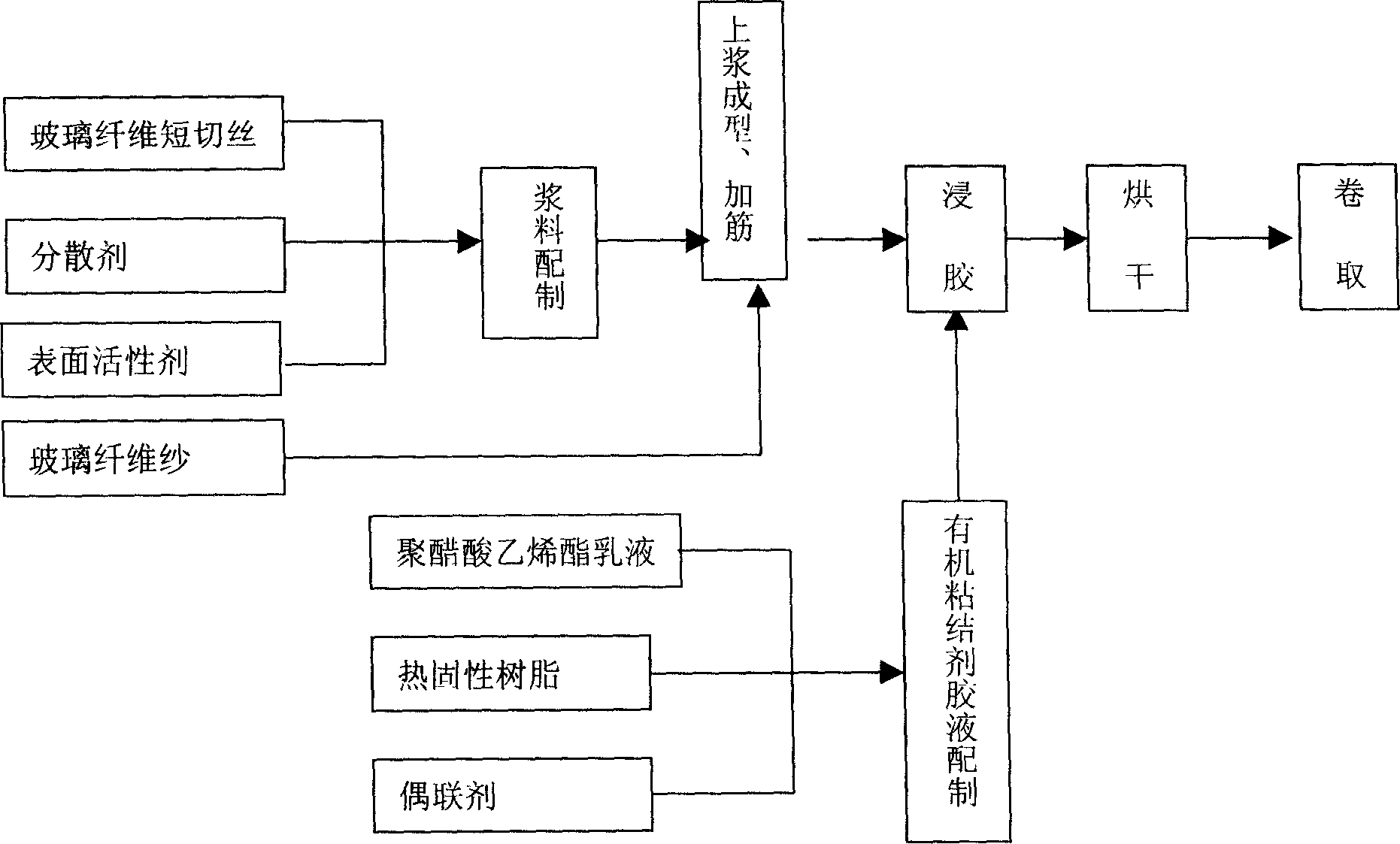

Glass fiber thin felt for waterproof coiled material tyre base and preparation method thereof

The invention provides a thin felt with glass fiber for waterproofing fetus basis and the manufacturing method, comprising short-cut silk of glass fiber, yarn of glass fiber, dispersant, surfactant and organic binder. The short-cut silk of glass fiber is middle-alkali or non-alkali, the diameter is 12-13 mum and the length is 10-18mm. The yarn of glass fiber is non-alkali the linear density is 60-70Tex. The dispersant is thickener belonging to cellulose acetate. The surfactant is quaternary ammonium cationic surfactants. The organic binder is the mixture of thermosetting resin, KH560 coupling agent and water. Said thin felt with glass fiber is produced by wet technology, which comprises producing stock, preparing slurry, adding reinforced rib yarn for sizing forming, dipping and drying so on. The felt is provided with even thickness, high intensity, no-deformation under high temperature, and high hole ratio. The waterproofing rolling-material produced by the felt as the fetus basis is provided with corrosion resistance, good waterproofness, high intensity and good weather resistance so on.

Owner:樊福定

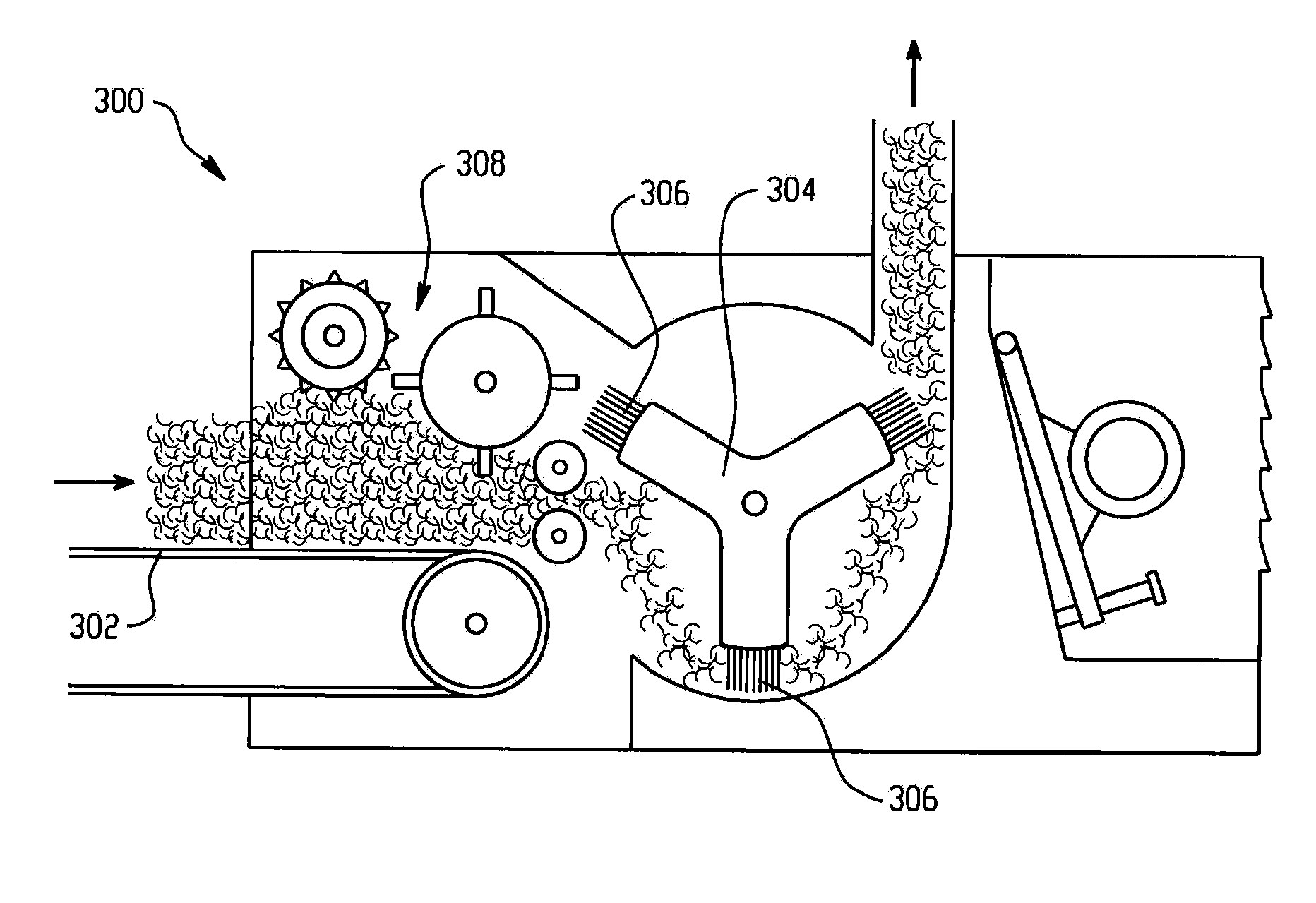

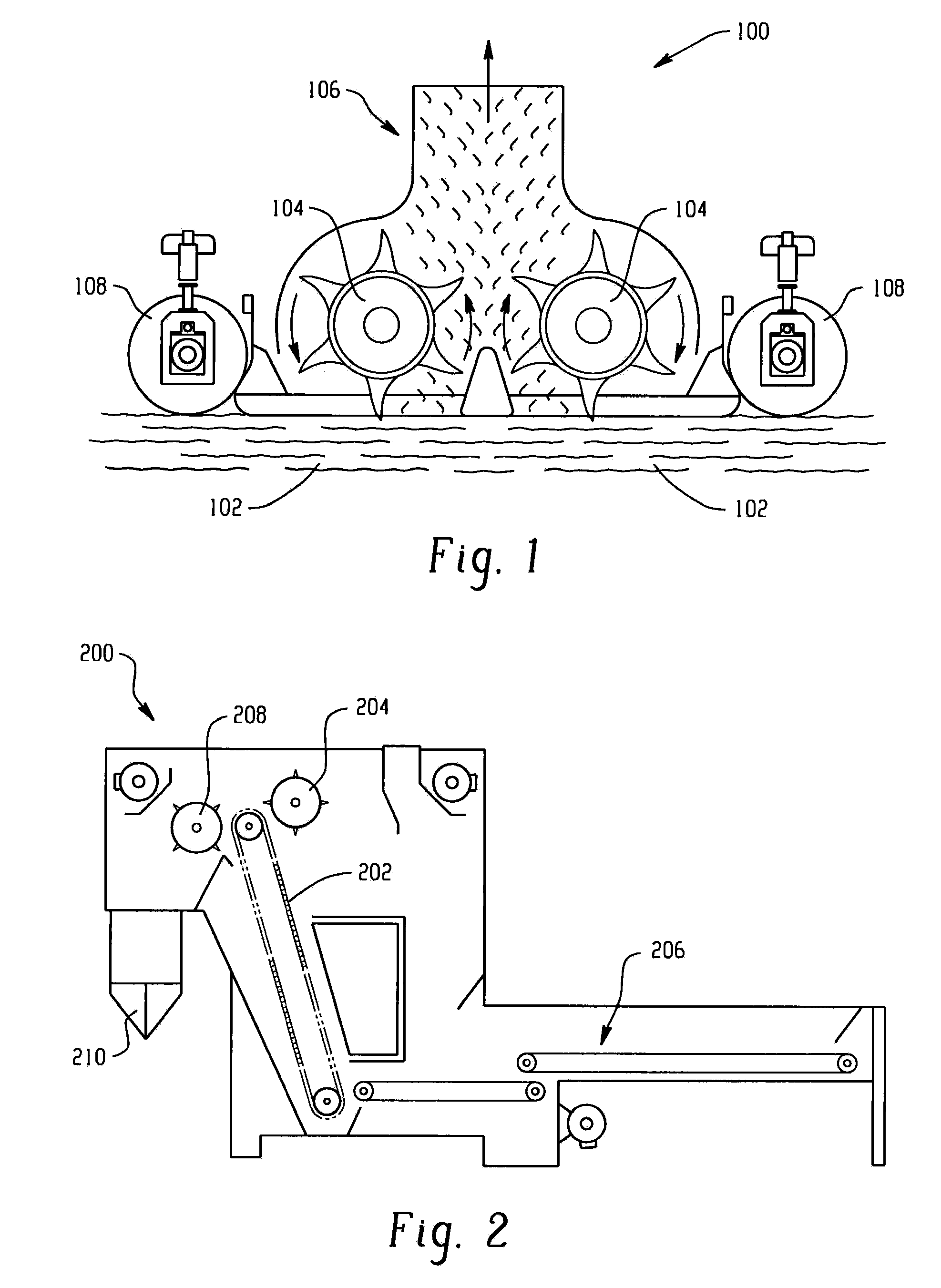

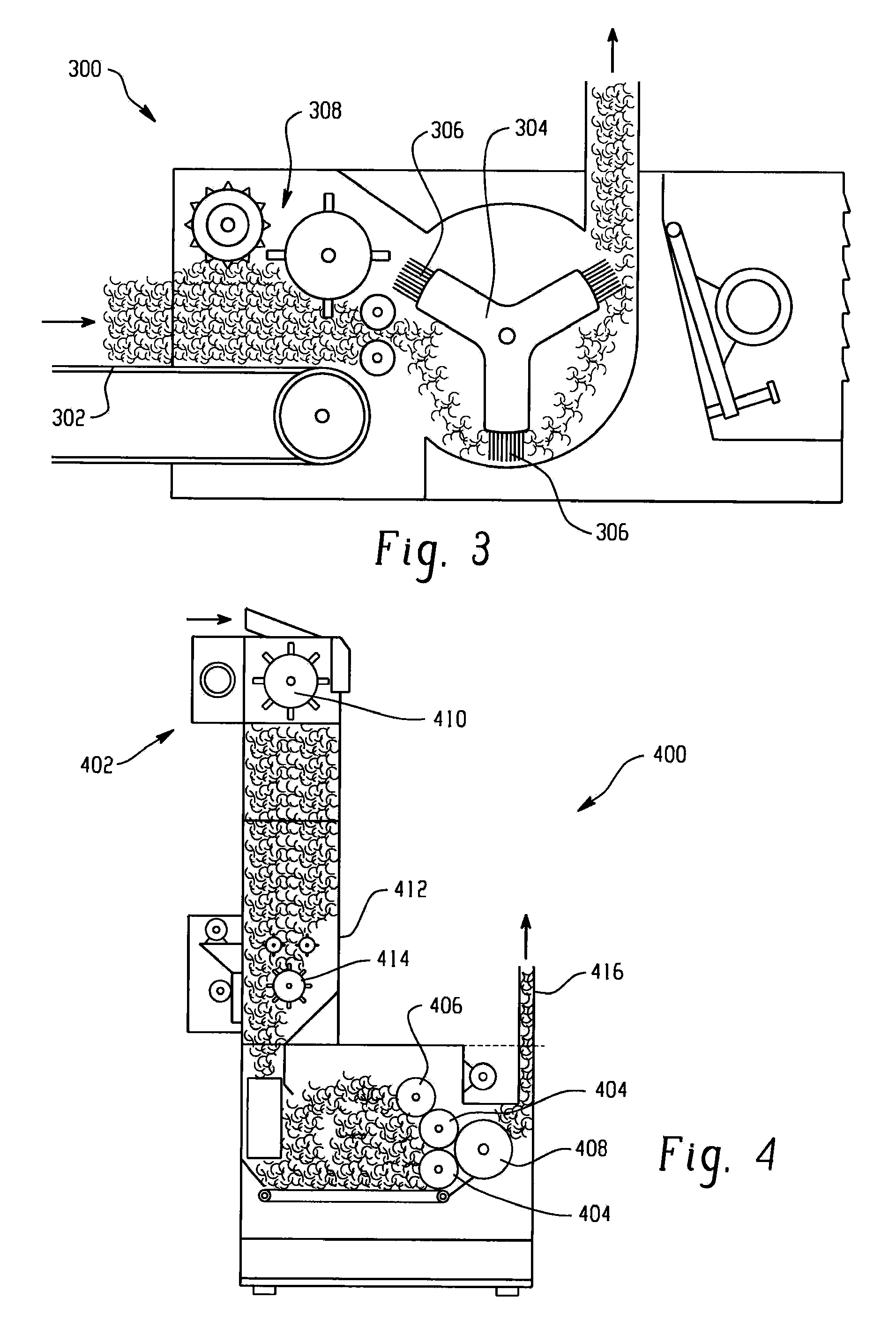

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

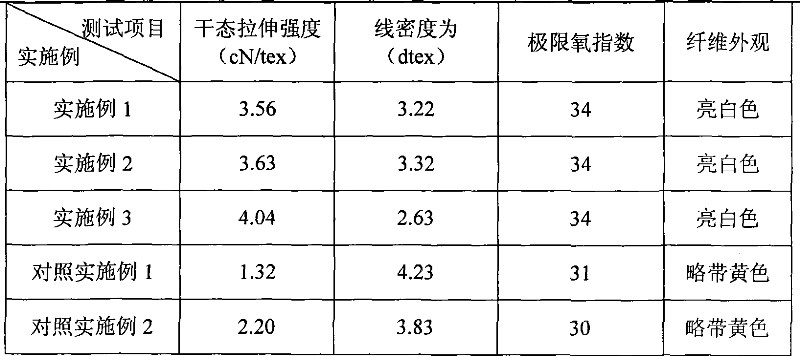

Preparation method of flame-proof sea silk new material

ActiveCN101037814AIntrinsically flame retardantHas flame retardant propertiesAlginate artificial filamentsWet spinning methodsFiberPolymer science

This invention disclosed a method of produce new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reaches to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blended. This invention disclosed a method of produce a new material of flame retardant alginate fiber: make sure the proportion of G chain segment and M chain segment which in the molecular structure is 1:1 - 1:3, the potassium alginate's weight percent of solute is 4-7% or the mixture of potassium alginate and sodium alginate be fully predissolved and dissolved and after adjustment viscosity, filter and defoamed by sodium hypochlorite or hydrogen peroxide, produce alginate fiber material by solution spinning at room temperature, the draft proportion of fiber is 120-300%. The limited oxygen index of the fiber reached to 34, the fiber's tensile strength is more than 3.5cN / tex, the linear density is 2.2-3.5 dtex. The fiber produced by this method is flame retardant, high strength of fracture and bio-degradable, and so on, so which can be used to produce flame retardant textiles by pure spinning or blending.

Owner:QINGDAO UNIV

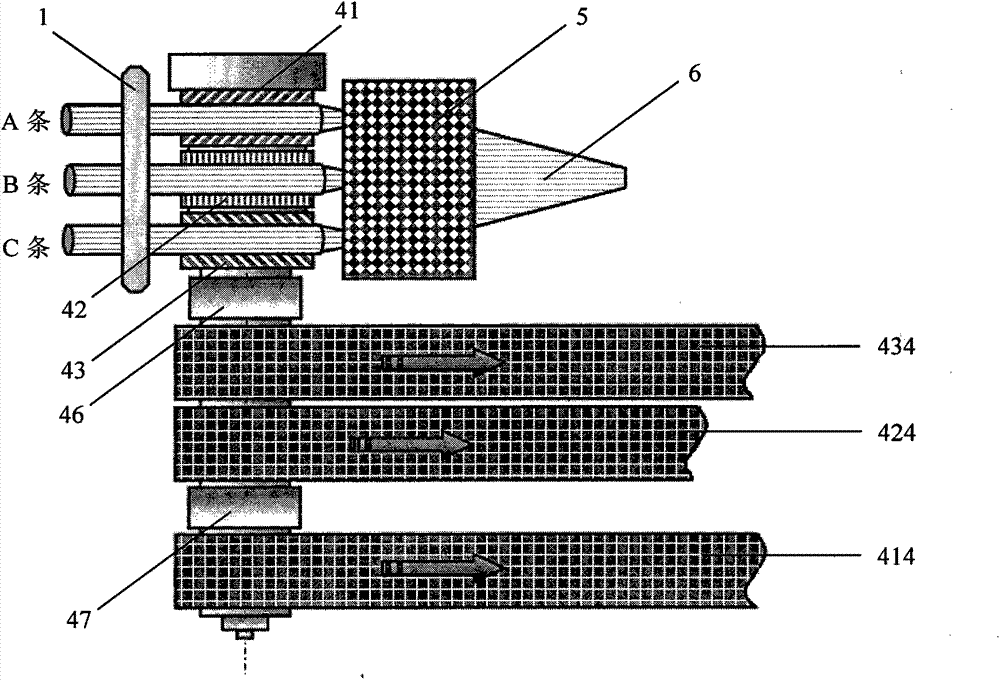

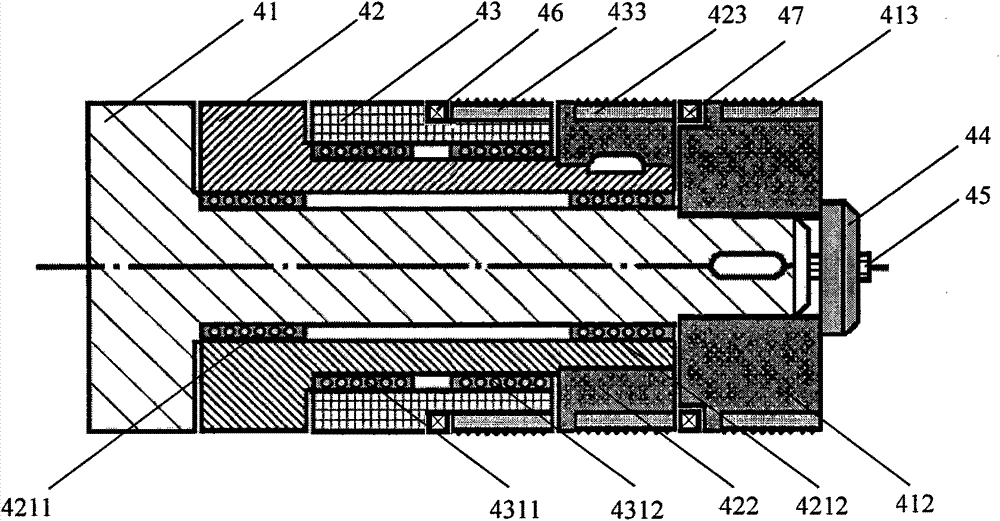

Method for spinning segment color yarn by front area segmentation and drawing mechanism

The invention discloses a method for spinning segment color yarn by front area segmentation and a drawing mechanism. The method comprises the following steps of: drawing and feeding a group A and a group B of fiber whiskers of which the linear density tex is Ta and Tb by a rear fixed roller and a rear loose roller which are arranged on the same rear roller shaft into a rear drawing area respectively, and keeping the drawing multiples of the rear area constant and the same, wherein in a front drawing area, the two groups of fibers are different in feeding speed and drawing multiple, and variable in segmentation; outputting by a front roller, adsorbing the group A and the group B of the drawn fiber whiskers to a mesh ring which is sleeved on a negative pressure special-shaped pipe; guiding and conveying by the mesh ring; allowing the fibers to pass through a Y-shaped or V-shaped air groove on the surface of the negative pressure special-shaped pipe; gathering and combining under the air flow adsorption action at the Y-shaped or V-shaped groove; and outputting and twisting by a yarn guide rubber roller to form fine yarn of which combination of different lengths and component ratios or combination of different colors are distributed in the length direction of the yarn.

Owner:陈伟雄

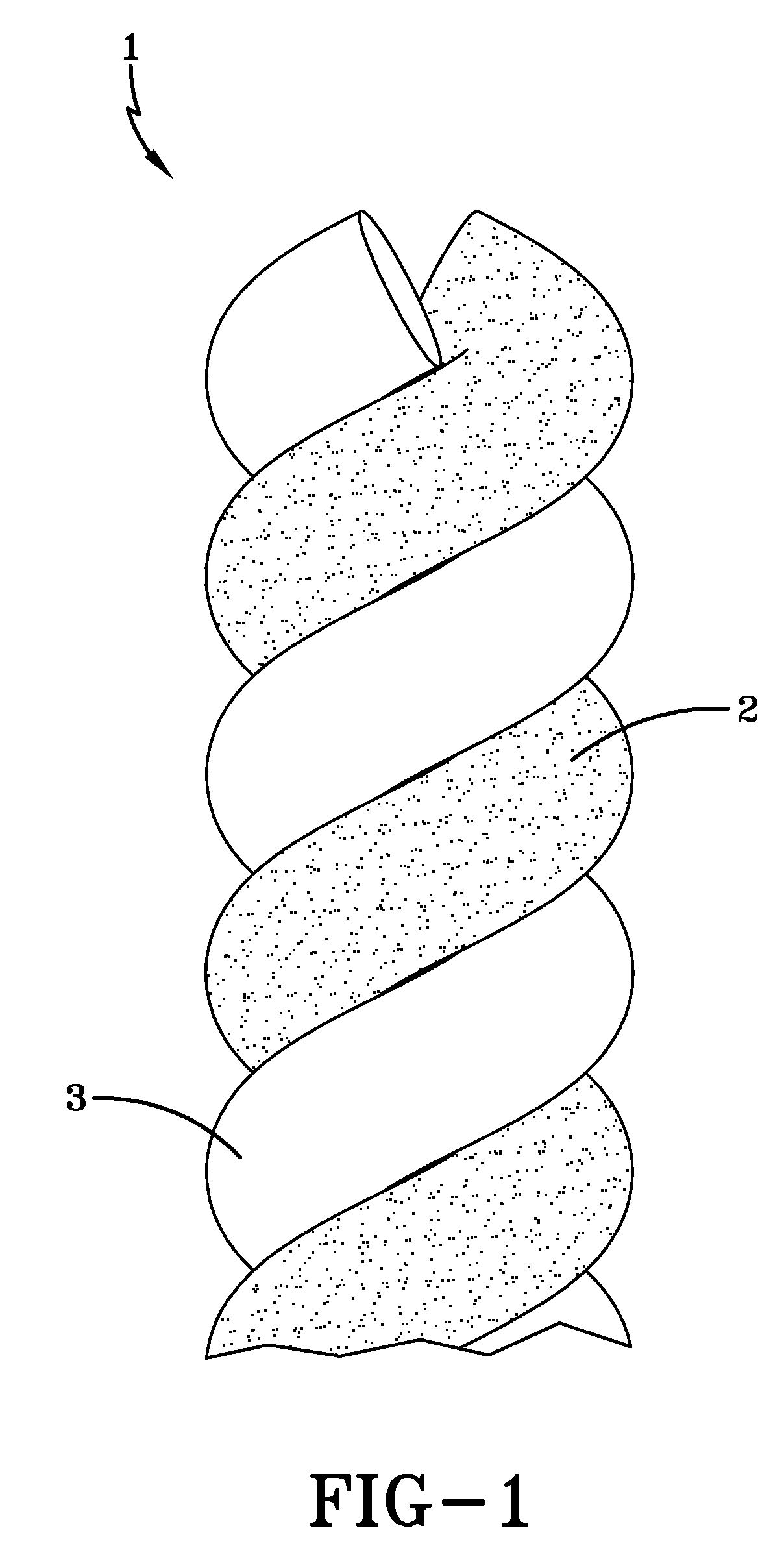

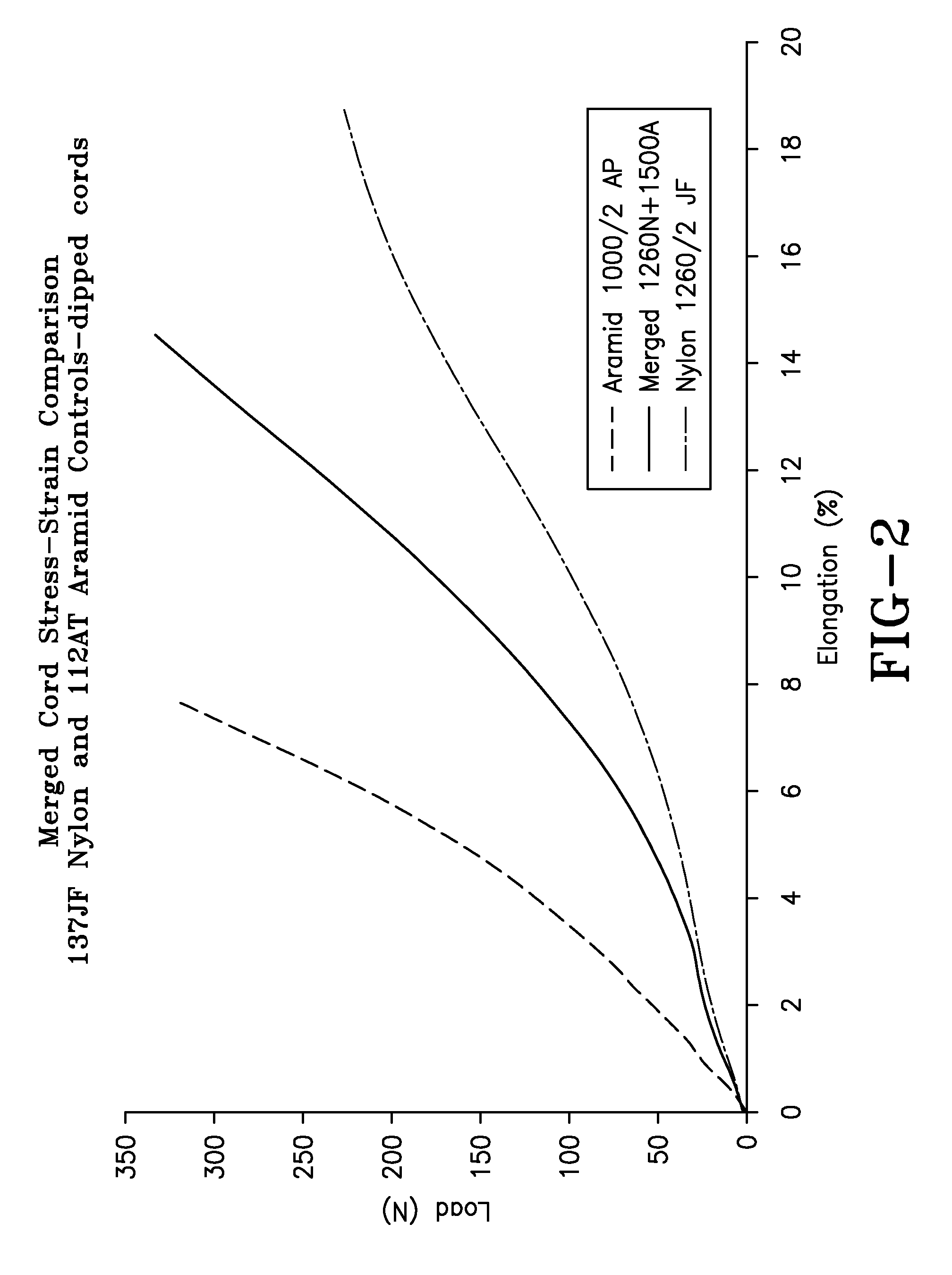

Tire cord reinforcement

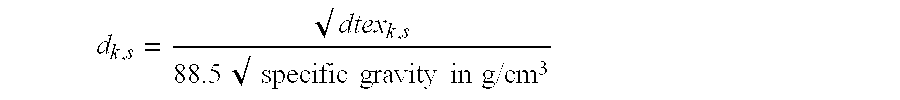

A composite cable is disclosed suitable for use as a reinforcement in an aircraft tire. The cable is formed of an aramid yarn and a nylon yarn cabled together, wherein the aramid yarn has a linear density in the range of about 220 to about 3300 dtex, and the nylon yarn has a linear density in the range of about 220 to about 2100 dtex.

Owner:BALDWIN JR DONALD WILLIAM +2

Anti-wear polyvinyl alcohol aldehyde acetal fiber and its preparing method and use

ActiveCN1900388AImprove spinnabilitySpinning head change rate is lowMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberPolymer science

The present invention refers to wearability vinylon and preparation method and application. It is composed of 100 part by weight polyvinyl alcohol with degree of polymerization 1500-3000, alcoholysis degree 92-99 mol per cent, additive 2-6 part by weight, water 400-900 part by weight, adding to dissolution kettle, at temperature 90-120 degree centigrade, pressure 0.02-0.17 MPa, dissolution 6-10 hr, through filtering and debubbling to make spinning raw liquor; utilizing wet spinning, drawing-heat treating, aldehyde concentration 20-80 g / L, acid concentration 20-300 g / L, temperature 50-90 degree centigrade acetalation processing, to make wearability vinylon with linear density being 1.0-10 dtex, rupture strength 7-11 CN / dtex, elongation at break 10-30 per cent, softening temperature in water 110-120 degree centigrade, number of crimp 3.0-5.0 piece / 25 mm. Said short fiber pure spinning or mixed spinning with other fiber to make different count yarn, fabric used as tent gabe, Knapsack or training garment etc.

Owner:SOLDIER SYST RES CENT MILITARY SUPPLY EQUIP INST GENERAL LOGISTICS DEPT PLA +2

Penetration resistant fabric

A laminated fabric for penetration resistant e.g. ballistic applications. The fabric comprising a fabric of penetration resistant yarns having a linear density in the range from 100 to 700 dtex, said yarns being woven in a satin weave. The woven fabric is coated on at least one-side with a polymeric material in a micro-lamination process, the coating material being from 0.5 to 20%

Owner:TEIJIN TWARON GMBH

Areal density capability improvement with spin-orbit torque based structures surrounding main pole tip

ActiveUS10157632B1High track densityImproves write-abilityHeads using thin filmsRecord information storageTrack densityMagnetic media

The present disclosure generally relates to data storage devices, and more specifically, to a magnetic media drive employing a magnetic recording head. The head includes a main pole, a heavy metal structure surrounding at least a portion of the main pole at a media facing surface (MFS), and two magnetic structures sandwiching the heavy metal structure. Spin-orbit torque (SOT) is generated from the heavy metal structure, inducing magnetization switching (or precession) in the magnetic structures. The SOT reduces the magnetic flux shunting from the main pole to the trailing shield, and the magnetization switching sharpens the write field profile in the cross-track direction. The SOT based head with the magnetic structures sandwiching the heavy metal structure increases both track density (tracks per inch) and linear density (bit per inch), which in turn increases the areal density capability (ADC), which is the product of tracks per inch and bit per inch.

Owner:WESTERN DIGITAL TECH INC

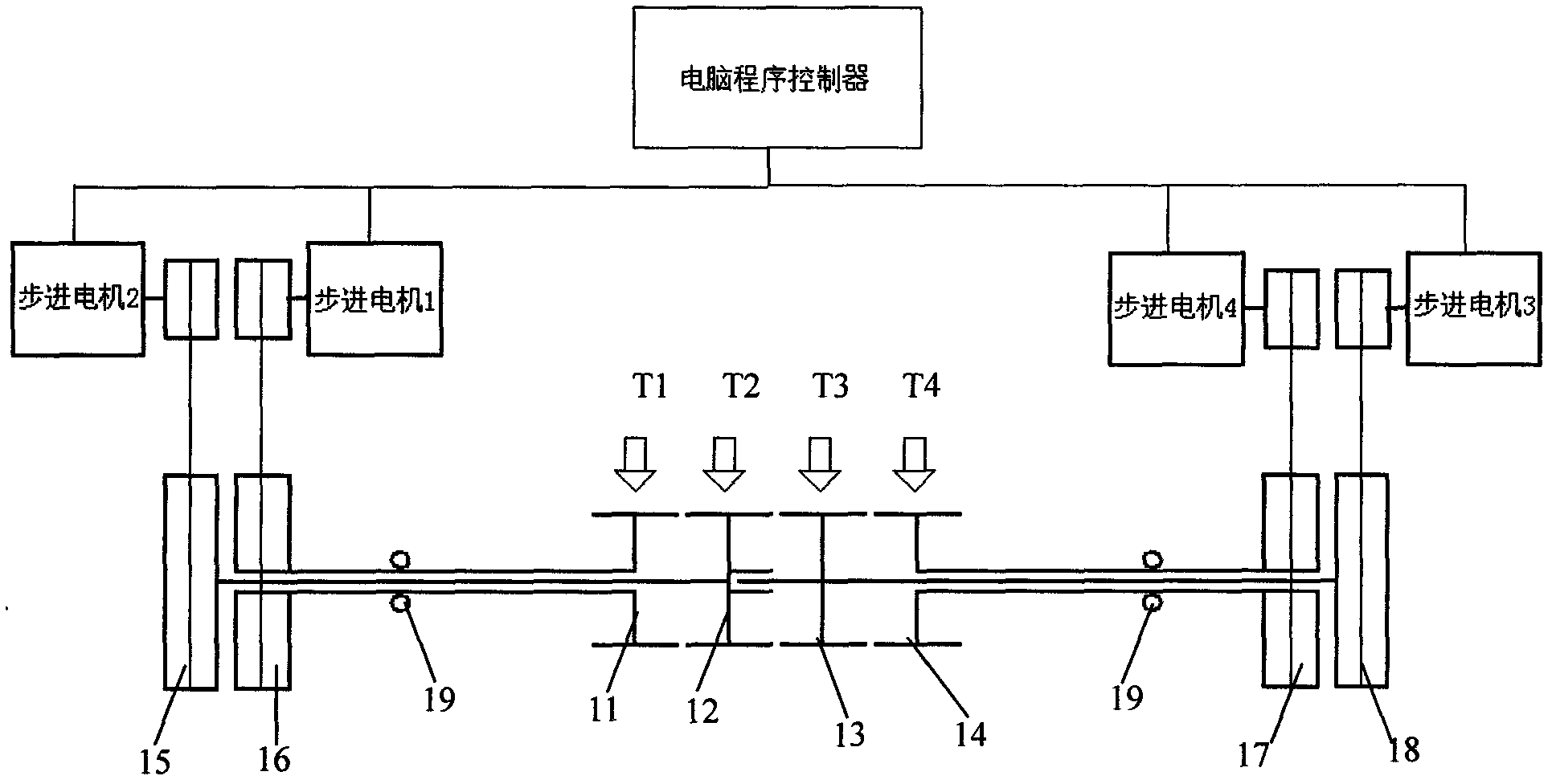

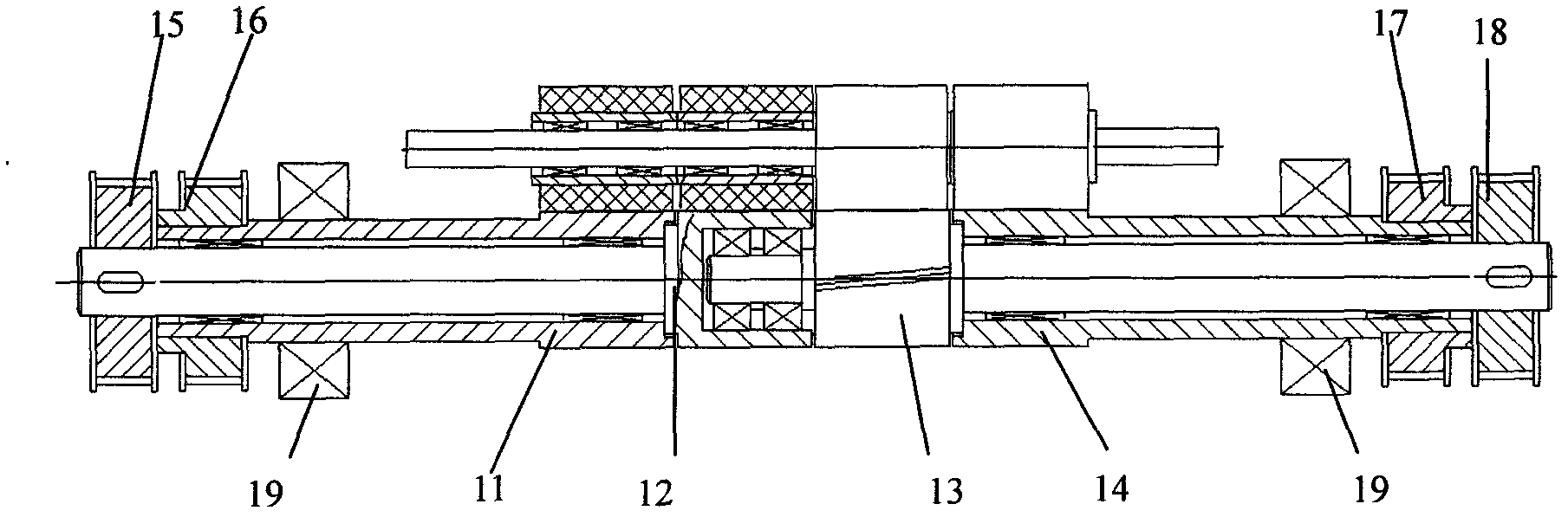

Method and device for drawing segmented colored cotton or segmented wool with equal linear density

A method for drawing colored cotton or colored wool with equal linear density, through segmental, synchronous, and equal speed coupling control methods, using a computer program controller to control the speed of coaxial combined rollers, which can be very easy to program the process , to achieve the same amount of sliver or woolen sliver fed at any time, and different feeding ratios in different periods, to achieve different colors and irregular combinations in the cross-section and length direction, and to maintain sliver or woolen sliver evenness of dryness.

Owner:JIAXING UNIV

Carbon fiber continuous fiber reinforcing polyether-ether-ketone matrix composite material and preparing method thereof

ActiveCN107245810AGood dispersionImprove mechanical propertiesMelt spinning methodsNon-woven fabricsCarbon fibersCarding

The invention discloses a carbon fiber continuous fiber reinforcing polyether-ether-ketone matrix composite material and a preparing method thereof, and belongs to the technical field of thermoplastic composite materials. The preparing method comprises the first step of adopting a spinning-grade polyether-ether-ketone special material to prepare polyether-ether-ketone multifilament with the linear density being 12-380D / 12F through a melt spinning method; the second step of chopping the polyether-ether-ketone multifilament into 30-80 mm through a fiber cut-off machine to obtain polyether-ether-ketone continuous fiber, and chopping the carbon fiber into 20-70mm to obtain carbon fiber continuous fiber; the third step of conducting mixing, carding, lapping, needling on the polyether-ether-ketone PEEK continuous fiber and carbon fiber CF continuous fiber according to the mass ratio of 50%-70% to 50%-30% to prepare a CF / PEEK compound needled felt prefabricated part; the fourth step of conducting hot-pressing, exhausting, cooling and demolding on the obtained CF / PEEK compound needled felt prefabricated part on a vacuum hot-pressing machine to obtain the carbon fiber continuous fiber reinforcing polyether-ether-ketone matrix composite material. No solvent is involved in the process, the carbon fiber continuous fiber reinforcing polyether-ether-ketone matrix composite material does not pollute the environment, the technology is short in process, the prepared composite material is higher in intensity, the material aspect ratio of strength is lowered.

Owner:JILIN UNIV

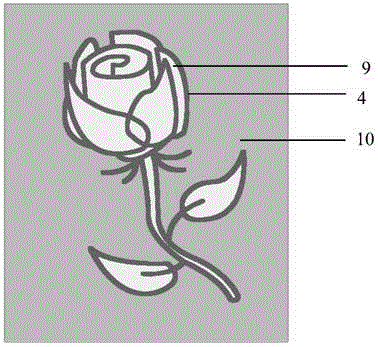

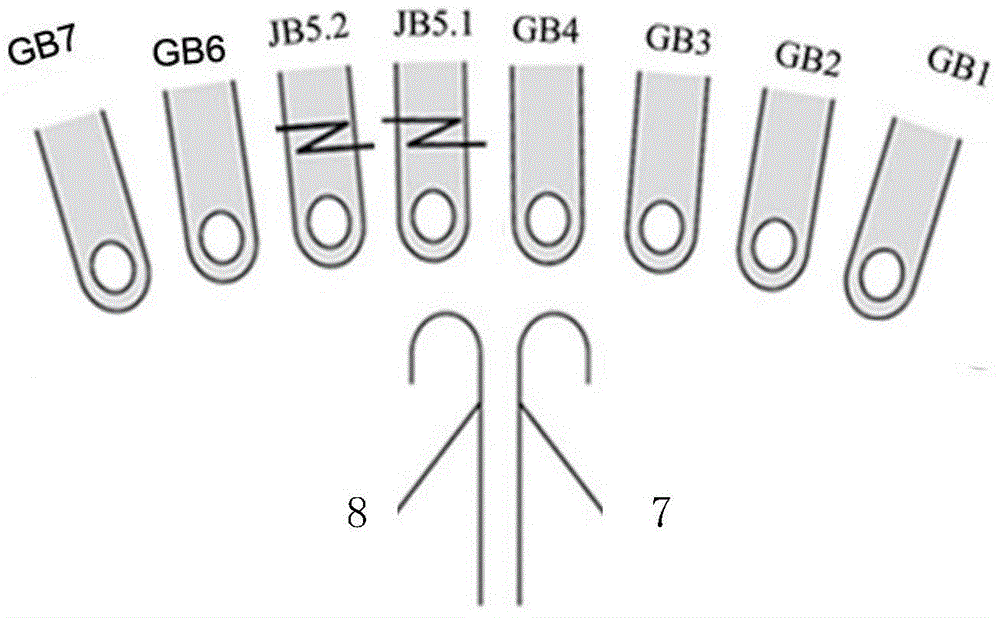

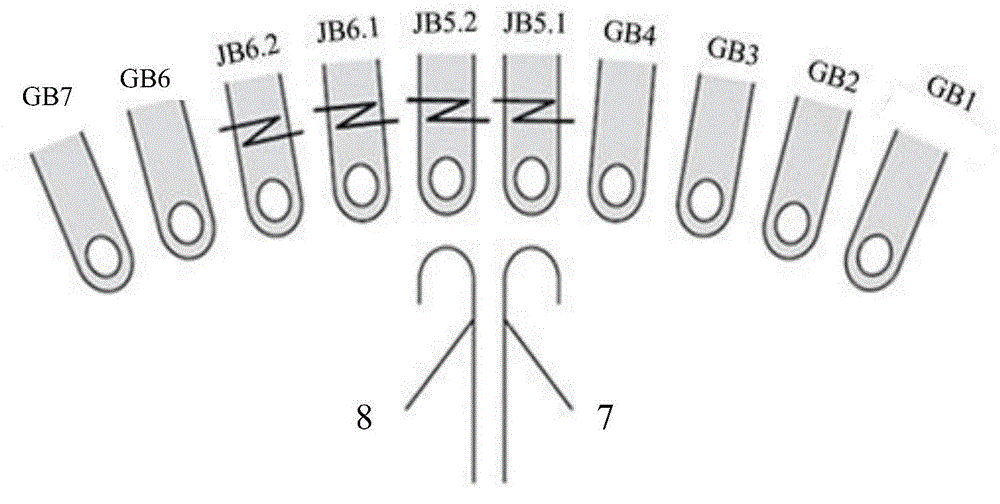

Method for producing elastic jacquard spacer fabric by a double-needle-bar warp knitting machine

InactiveCN104153114AIncrease elasticityComfortable to takeFlat warp knitting machinesSurface layerEngineering

The invention discloses a method for producing elastic jacquard spacer fabric by a double-needle-bar warp knitting machine. The method includes that a spacing yarn guide bar and a jacquard guide bar are arranged in the middle; ground bars are arranged on the outer sides of the spacing yarn guide bar and the jacquard guide bar; elastic guide bars are arranged on the outer sides of the ground bars; according to different purposes of the to-be-produced spacer fabric, the distance between warp knitting machine needle bars is configured correspondingly; yarns include spacing yarns, jacquard yarns, surface yarns and elastic yarns, and according to difference of surface structures of the spacer fabric, the surface yarns and the elastic yarns with corresponding linear density are selected; the jacquard surface is designed through CAD (computer-added design) software; the surface yarns and the elastic yarns are matched to be knitted into the upper surface layer and the lower surface layer of the spacer fabric, the jacquard yarns are knitted on the surface of the spacer fabric to form single-color or double-color jacquard effect according to design in the step (4), and the spacing yarns are knitted into a middle spacer layer of the spacer fabric. The elastic jacquard spacer fabric produced by the method is good in elasticity and has single-color or double-color jacquard effect.

Owner:JIANGNAN UNIV

Manufacturing method for high-strength low-elongation type dacron industrial yarn

ActiveCN102787378AReduce cooling rateReduce solidification point downshiftArtificial thread manufacturing machinesMelt spinning methodsYarnDry heat

The invention relates to a manufacturing method for high-strength low-elongation type dacron industrial yarn. The manufacturing method comprises compress flows of hyper-viscous melting of a dacron raw material, metering, yarn spraying, cooling, oiling, drawing, heat setting and winding forming. An adopted dacron slice is a hyper-viscous slice obtained by solid phase tackifying. A cooling device sequentially comprises slow cooling, pre-cooling, windless region cooling and air-blowing cooling, wherein the pre-cooling is initiative outer ring pre-cooling and refers to enabling hot air to be conveyed and flow through an initiative outer ring device so as to cool yarn strips. The initiative outer ring device is a hollow annular belt, the air passing area ratio of the initiative outer ring device is 20-50%, and the height is 30-80mm. The temperature of the hot air is 60-80 DEG C, the humidity is 60-80%, and the conveying speed is 0.2-0.8m / s. The obtained dacron filament has the advantages of being high in breaking strength, low in breaking elongation and linear density deviation rate and reasonable in dry heat shrinkage rate, and can meet the application requirements well.

Owner:JIANGSU HENGLI CHEM FIBER

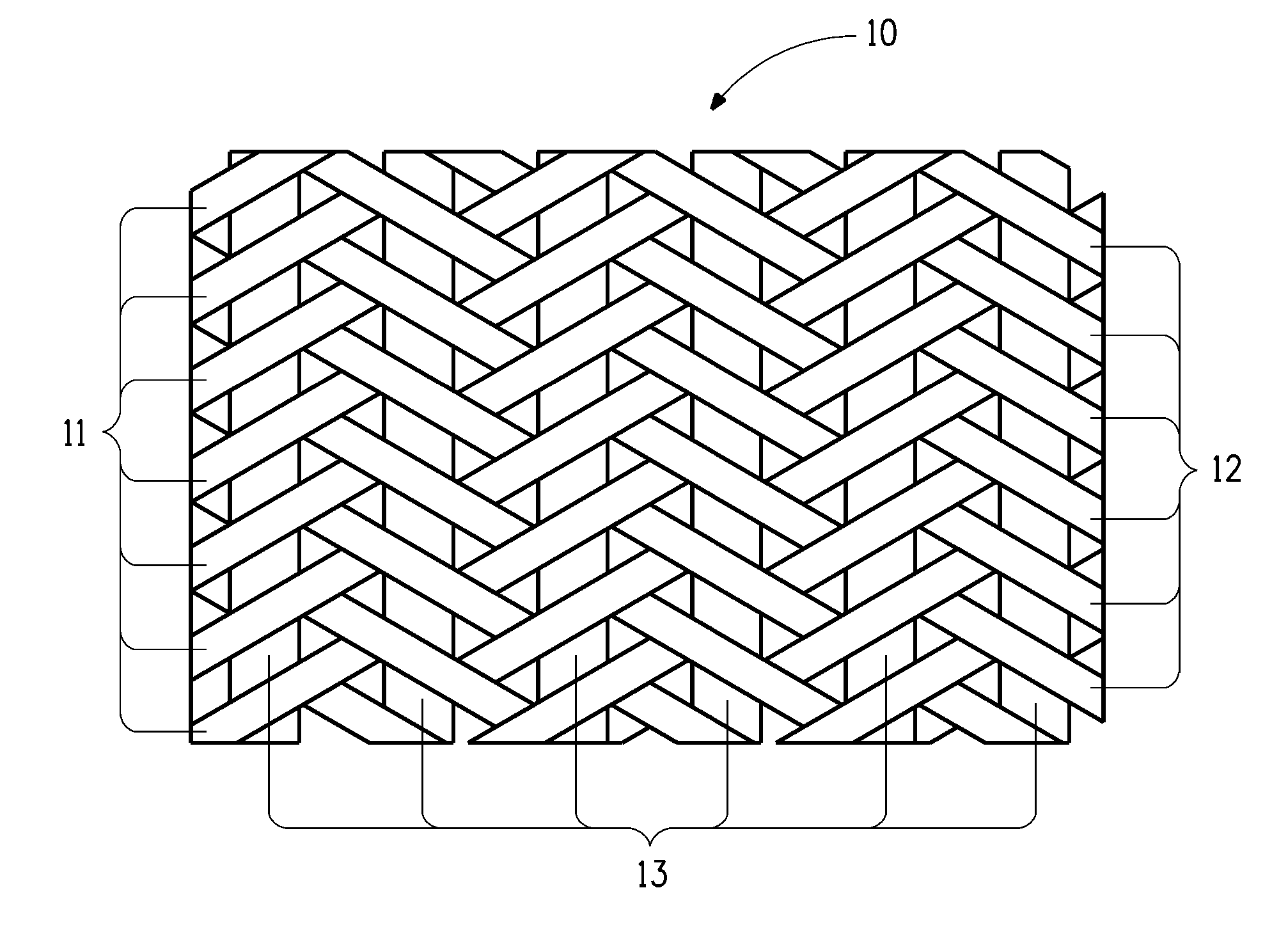

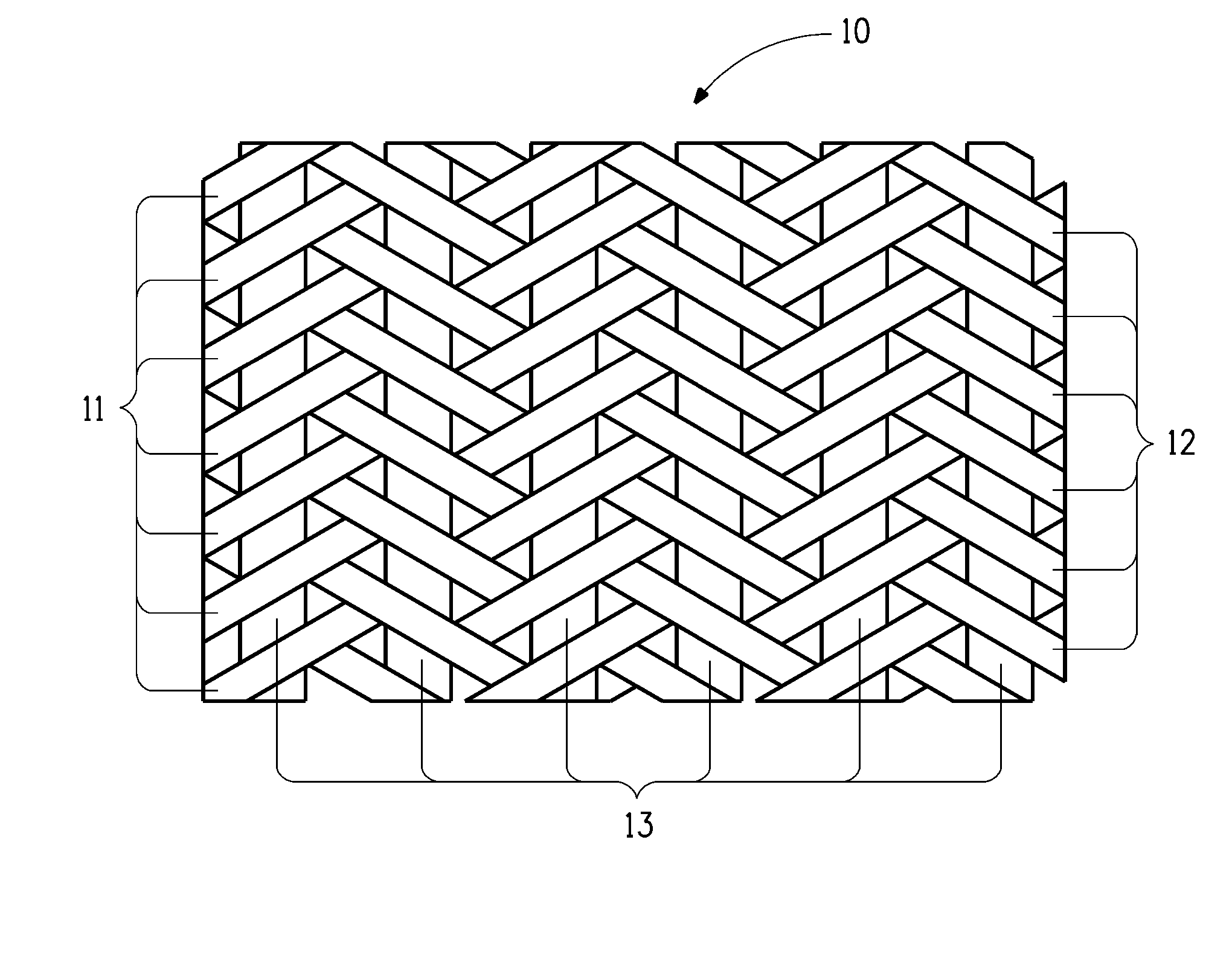

Triaxial braid fabric architectures for improved soft body armor ballistic impact performance

A fabric comprising a first plurality of yarns, a second plurality of yarns and a third plurality of yarns wherein the first, second and third pluralities of yarns have a yarn orientation that is different from each other. The third plurality of yarns is oriented in an axial direction. The second plurality of yarns is interwoven with the first plurality of yarns. The third plurality of yarns have no crimp. The yarns of the second plurality of yarns have an average linear density greater than or equal to the average linear density of the yarns of the first plurality of yarns and the yarns of the third plurality of yarns have an average linear density greater than the average linear density of the yarns of the second plurality of yarns and less than three times the average linear density of the yarns of the first plurality of yarns.

Owner:DUPONT SAFETY & CONSTR INC

Multe-component hemp blended spinning products and textile technology thereof

InactiveCN1483873AAnti-mold and antibacterialMoisture-absorbing and breathableWoven fabricsYarnFiberPolyester

The present invention relates to a multicomposition hemp blended spinning products and its technology. It is made from four fibres of hemp, yak cashmere, polyester fiber and modal as raw material, and its linear density is 9.7-200 tex, and its total compactness is 30%-99.5%. Its spinning technology includes the following steps: hemp and yak cashmere, dressing (A1860), pre-drawing (A272F) model and polyester fibre, dressing (FA201A), pre-drawing (FA304) mixed drawing first pass, mixed drawing second pass, roving (FA401), spinning (P7501), coning, warping, sizing, weaving and fabric finishing.

Owner:山西绿洲纺织有限责任公司

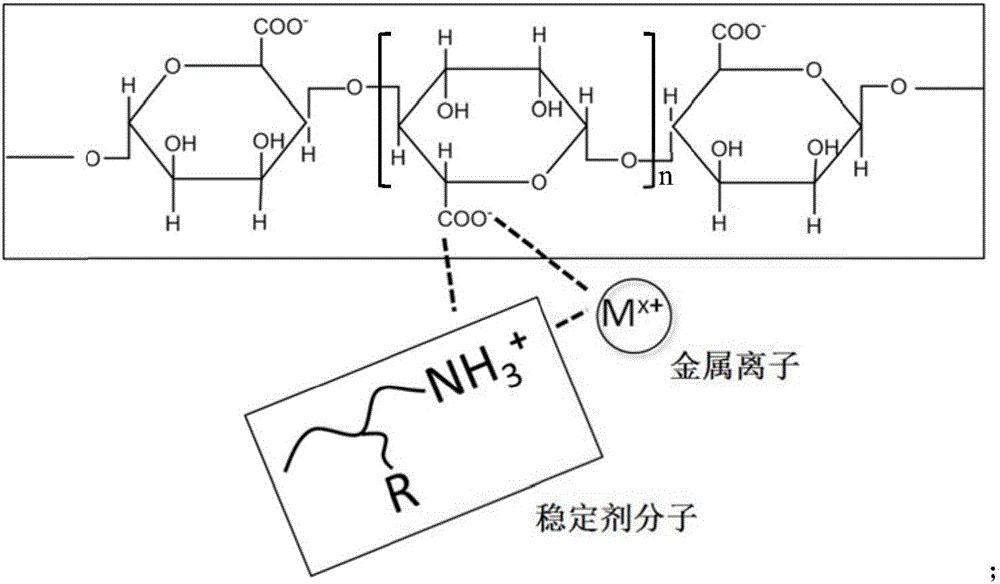

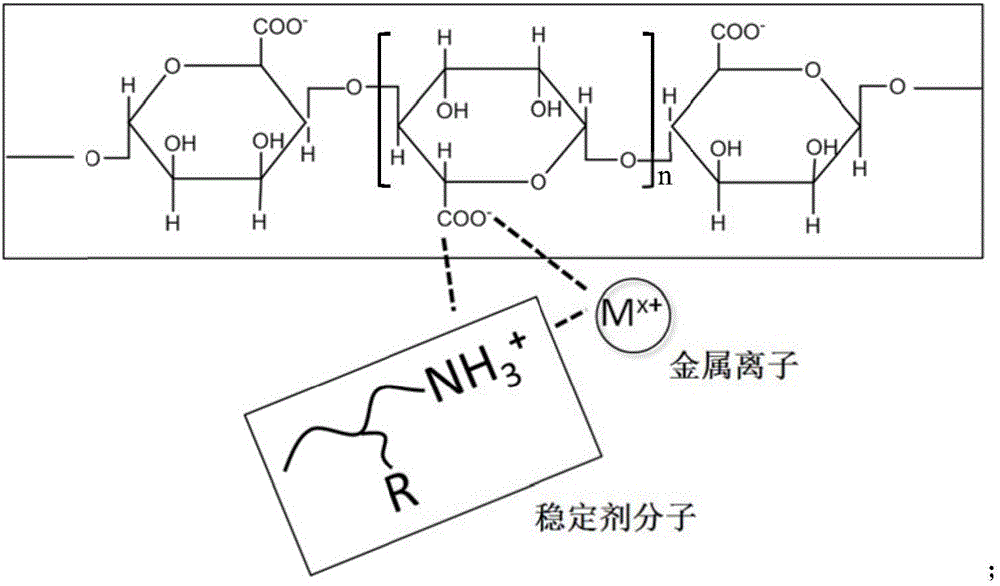

Sodium alga acid flame retardant fibers loaded with metal ions and manufacture method thereof

ActiveCN105821523AHigh breaking strengthBiodegradableFlame-proof filament manufactureAlginate artificial filamentsFiberBreaking strength

The invention provides sodium alga acid flame retardant fibers loaded with metal ions and a preparation method thereof. The sodium alga acid flame retardant fibers are prepared by the following steps: dissolving a water soluble sodium alga acid hybrid material loaded with metal ions in water to prepare a spinning solution, and performing a wet spinning process, wherein the water soluble sodium alga acid hybrid material loaded with metal ions is composed of sodium alga acid, stabilizer molecules and the metal ions with flame retardant effect. The fibers produced by the method disclosed by the invention have the characteristics of high flame retardant property and high breaking strength. The limit oxygen index of the fibers can be 34% and above, the tensile strength of the fibers is higher than 3.5cN / tex, and the linear density is 2.2-3.5dtex.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com