Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1936results about "Spinnerette packs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

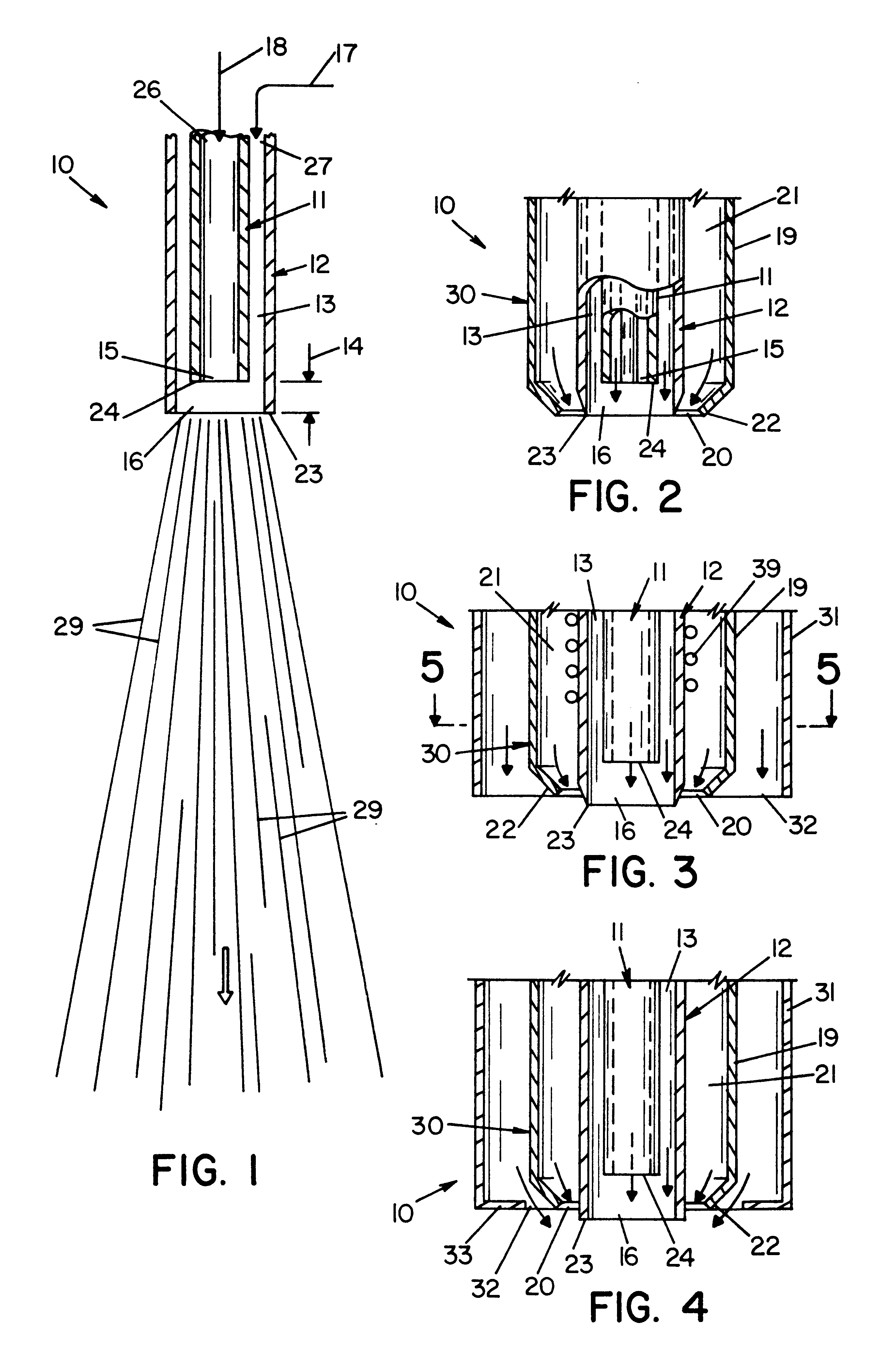

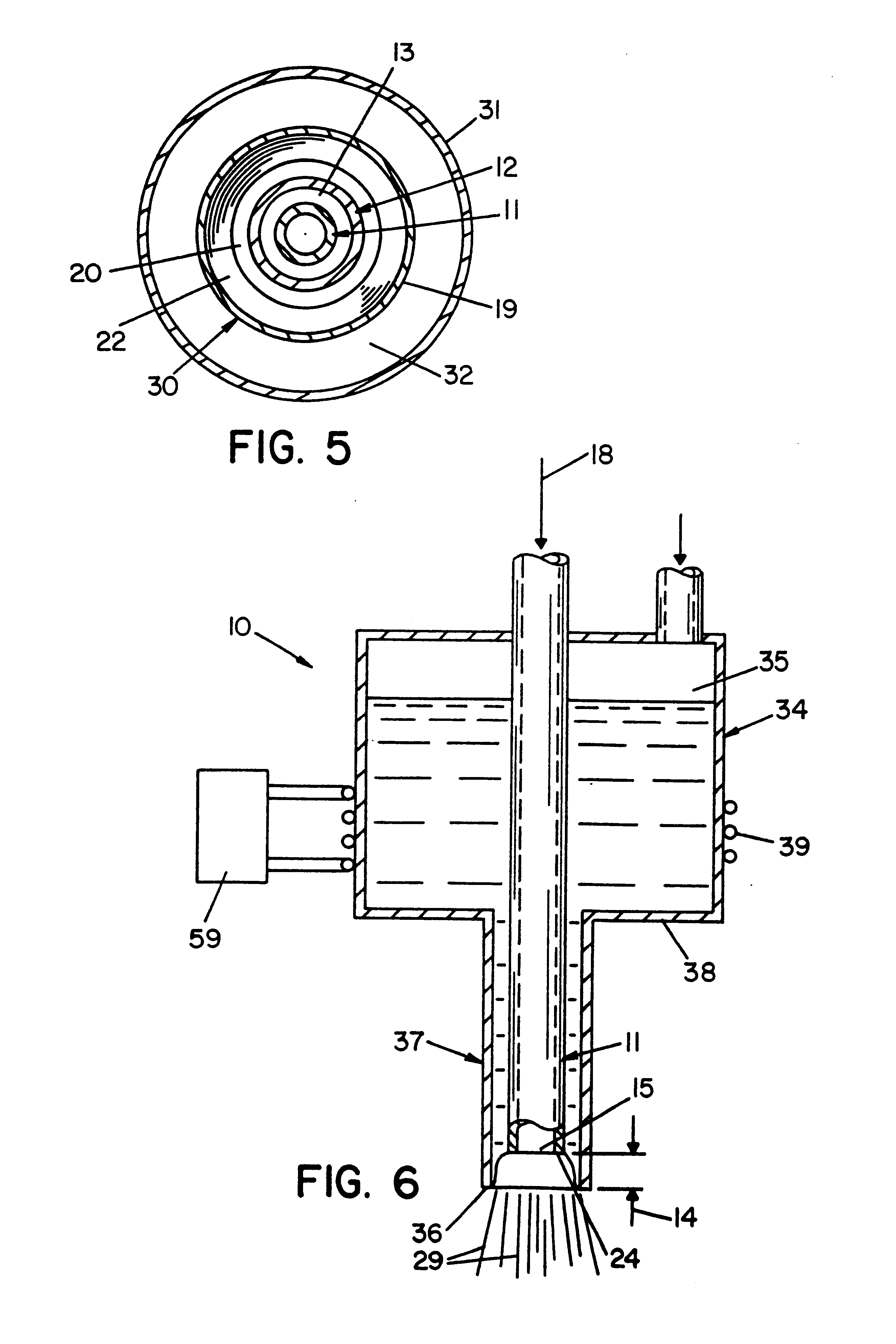

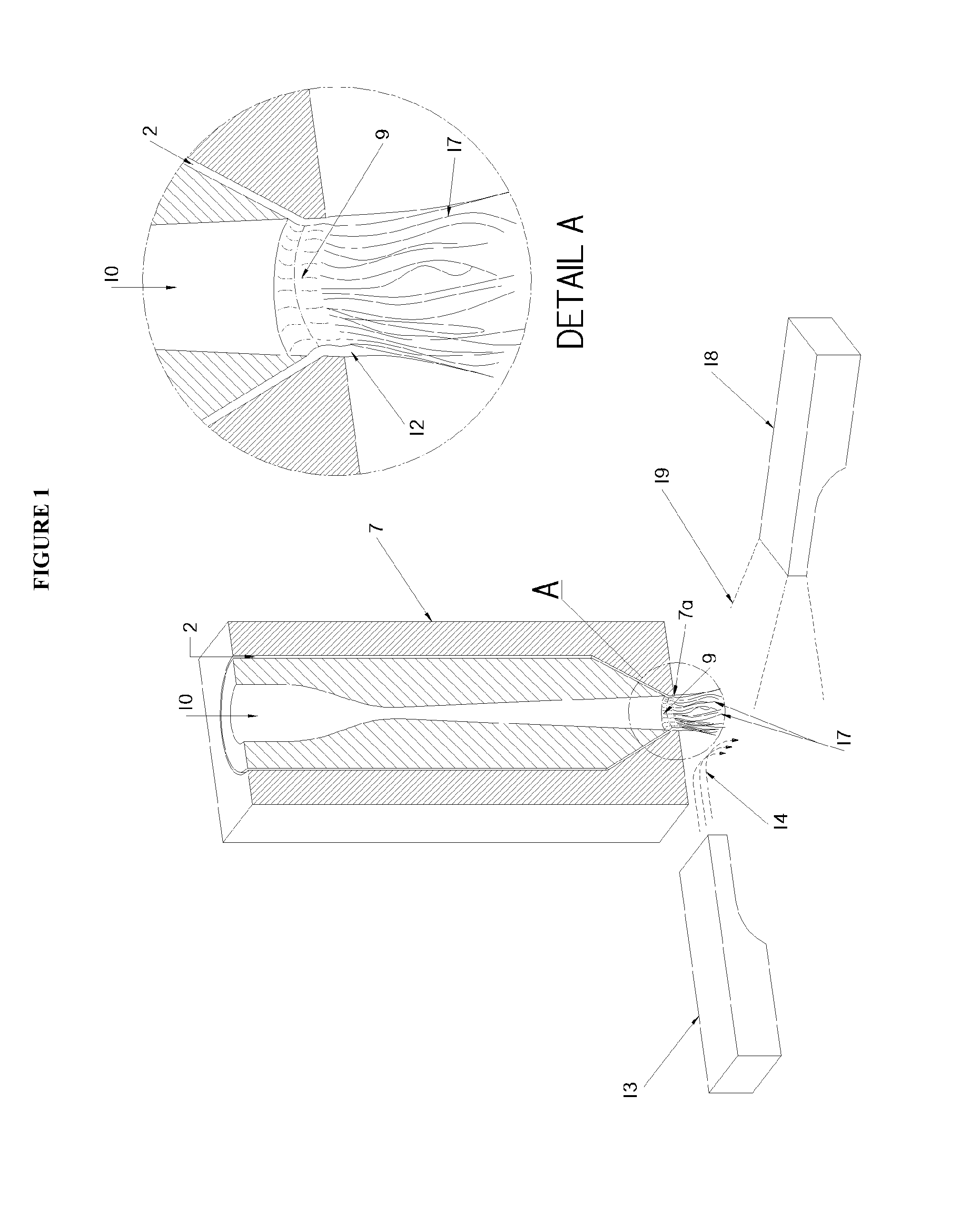

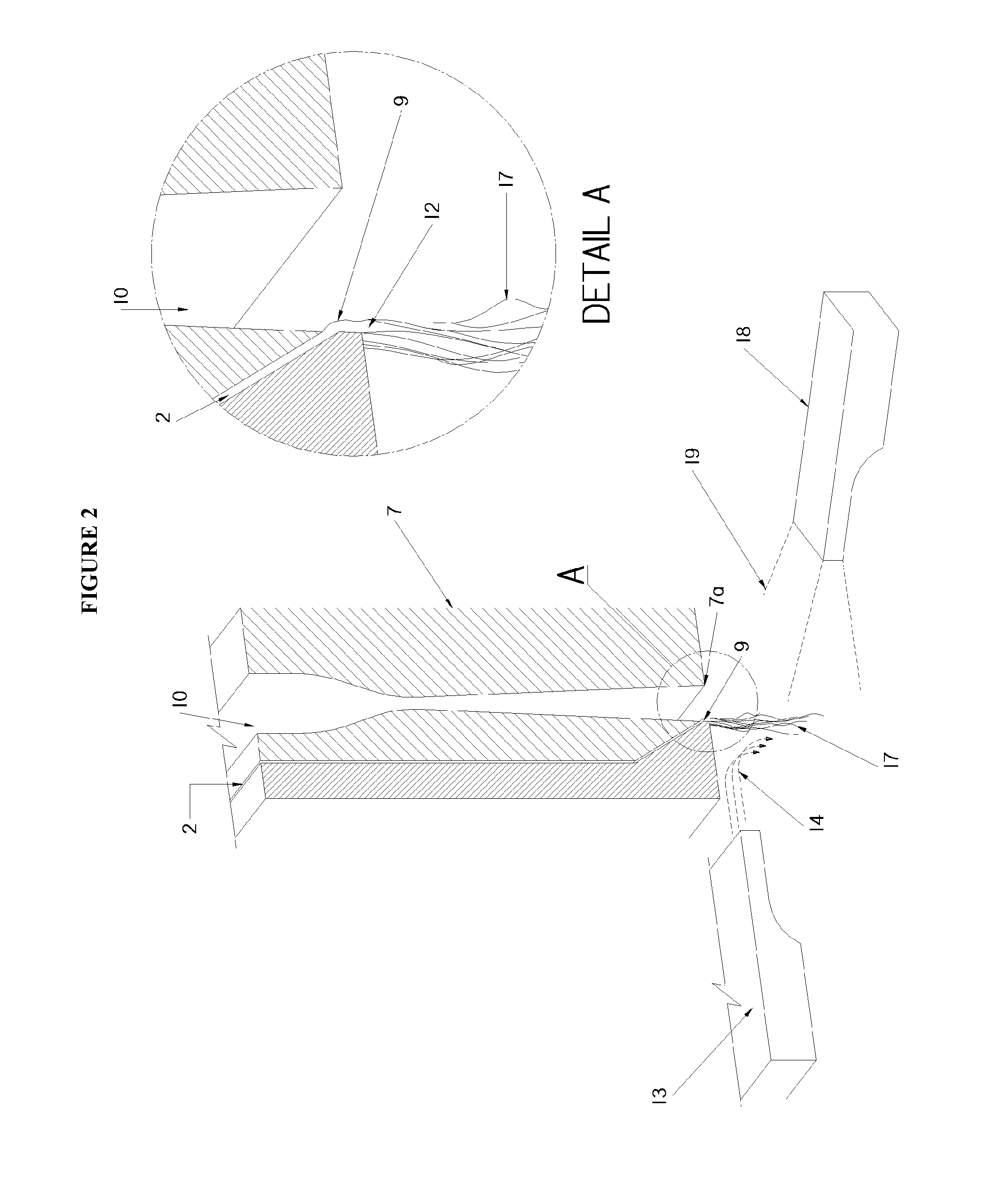

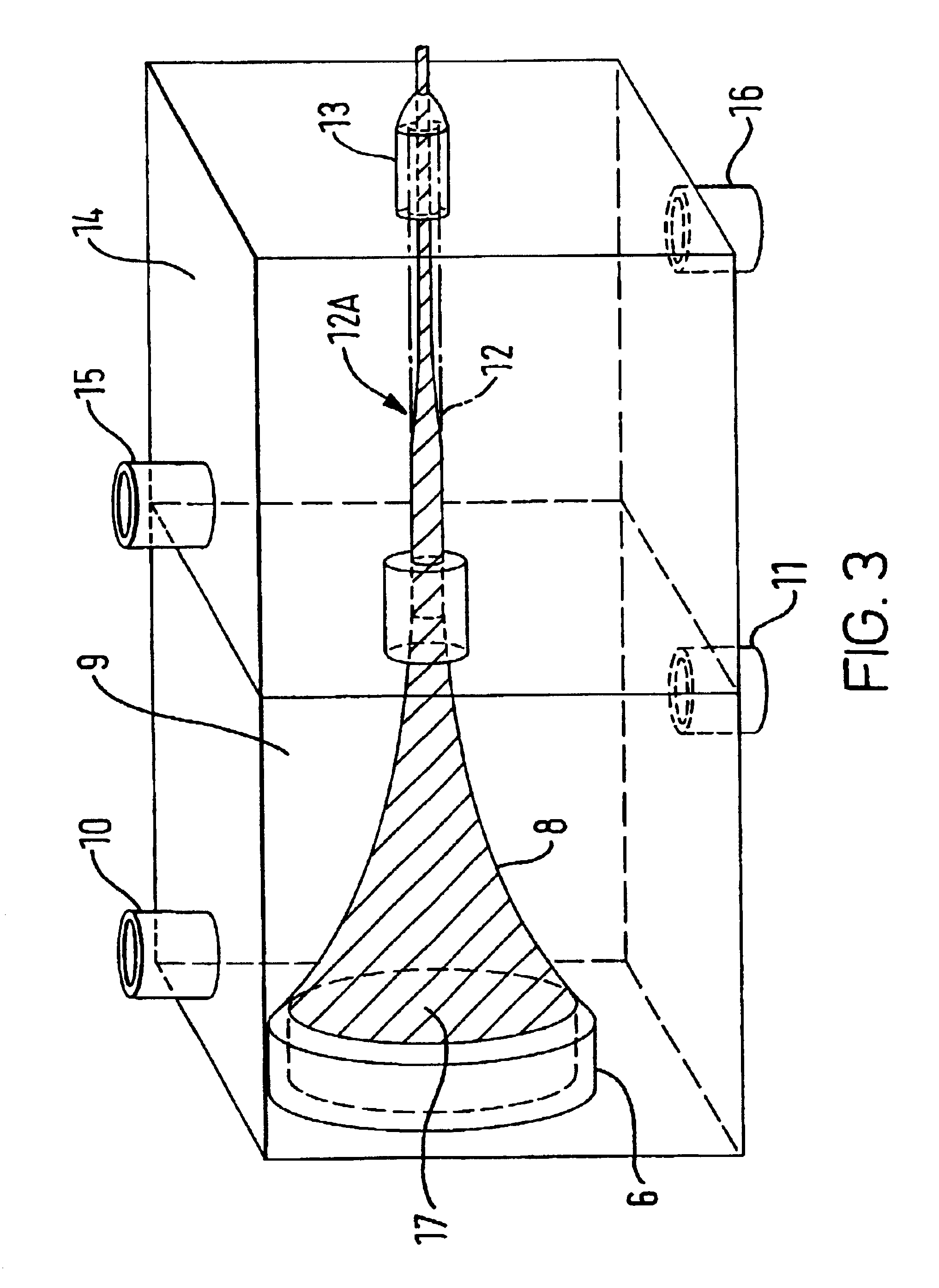

Process and apparatus for the production of nanofibers

A process for forming nanofibers comprising the steps of feeding a fiber-forming material into an annular column, the column having an exit orifice, directing the fiber-forming material into an gas jet space, thereby forming an annular film of fiber-forming material, the annular film having an inner circumference, simultaneously forcing gas through a gas column, which is concentrically positioned within the annular column, and into the gas jet space, thereby causing the gas to contact the inner circumference of the annular film, and ejects the fiber-forming material from the exit orifice of the annular column in the form of a plurality of strands of fiber-forming material that solidify and form nanofibers having a diameter up to about 3,000 nanometers.

Owner:THE UNIVERSITY OF AKRON

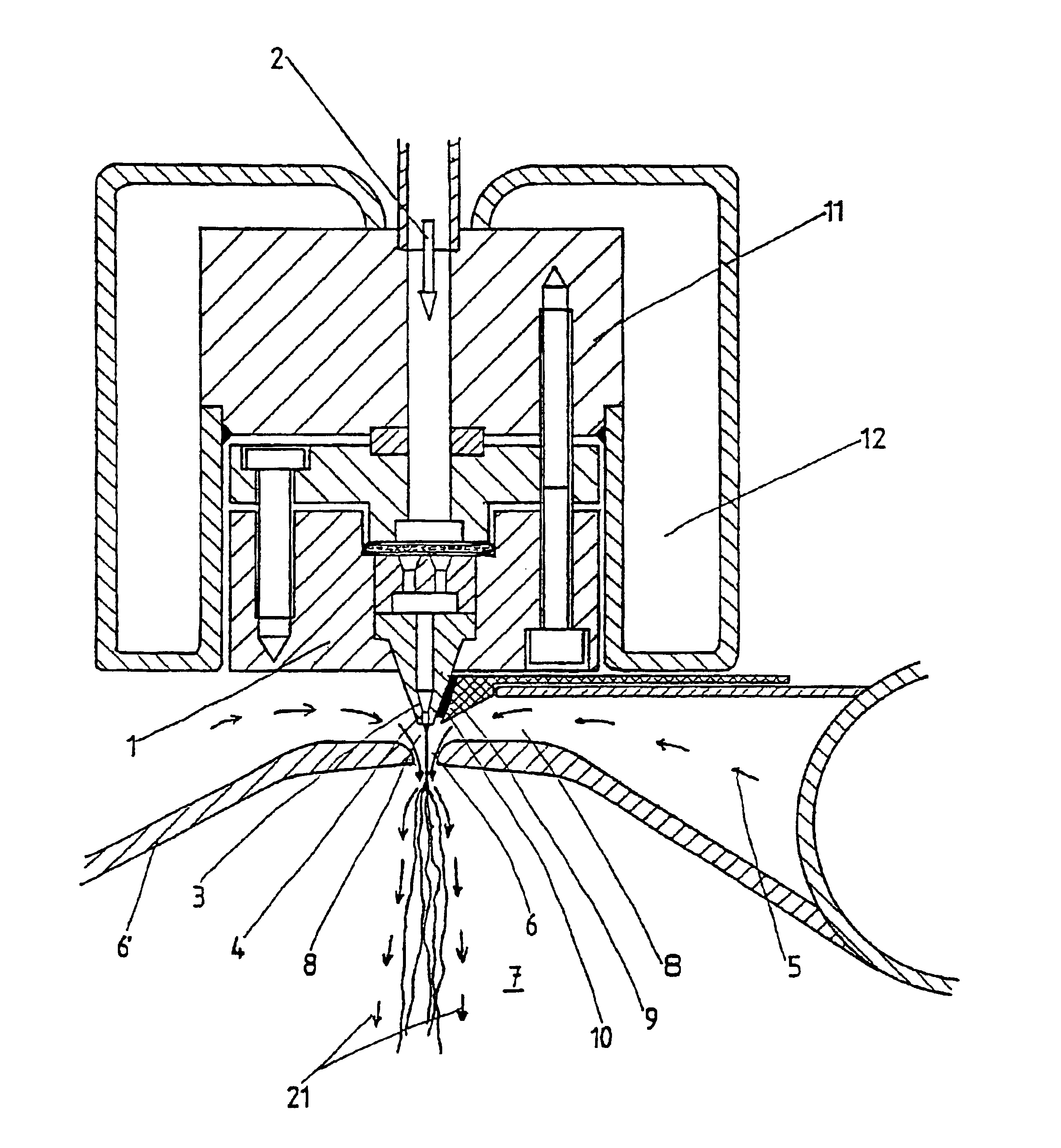

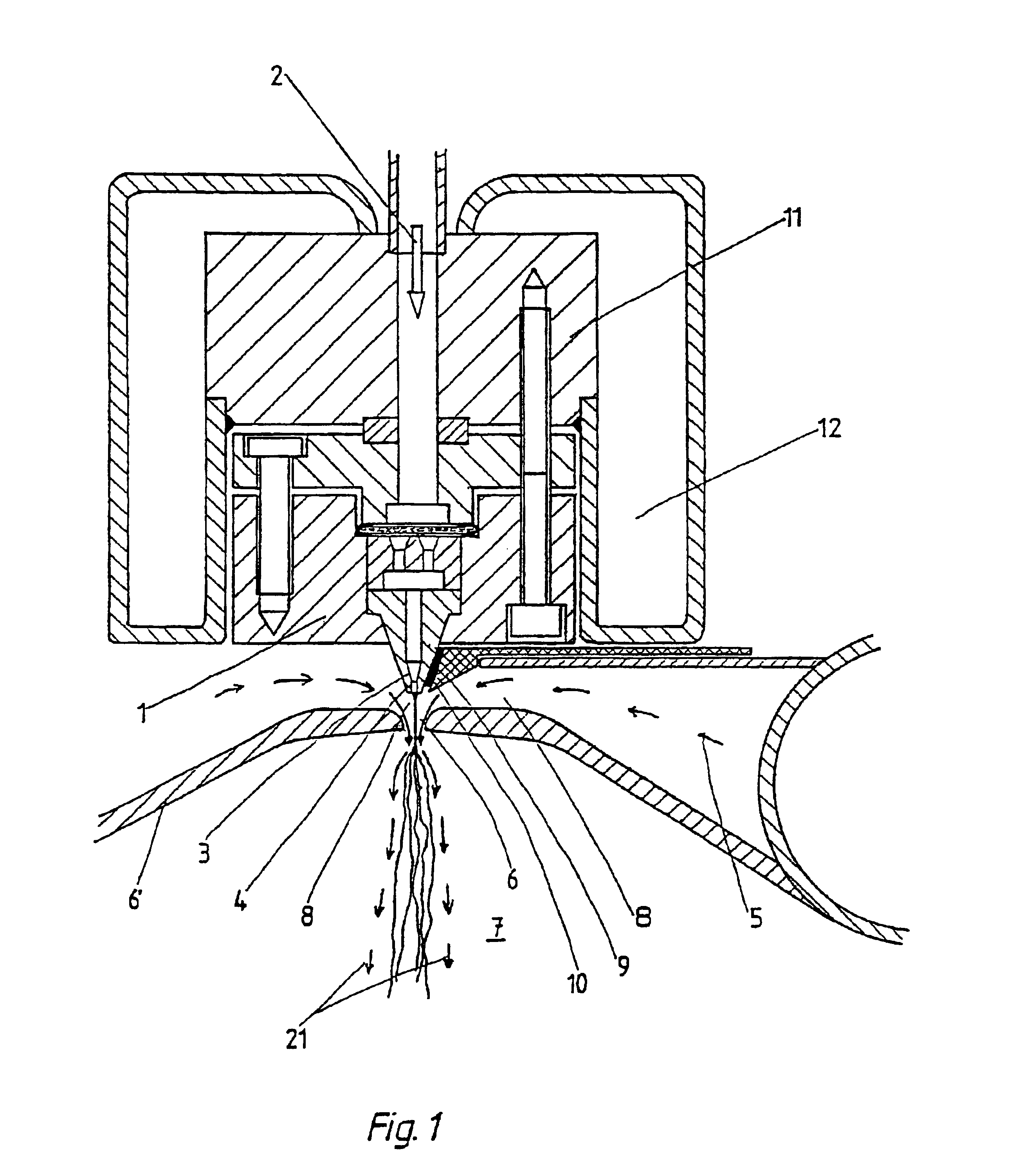

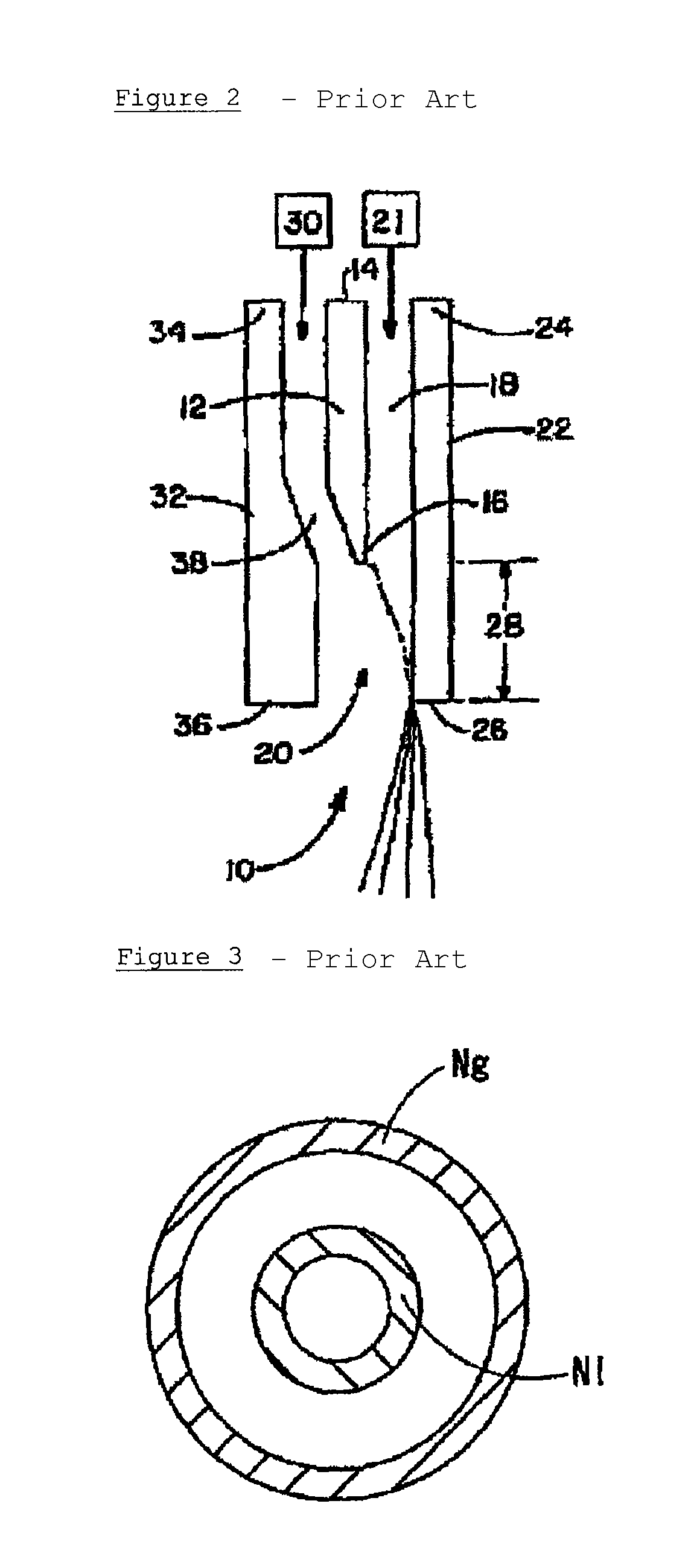

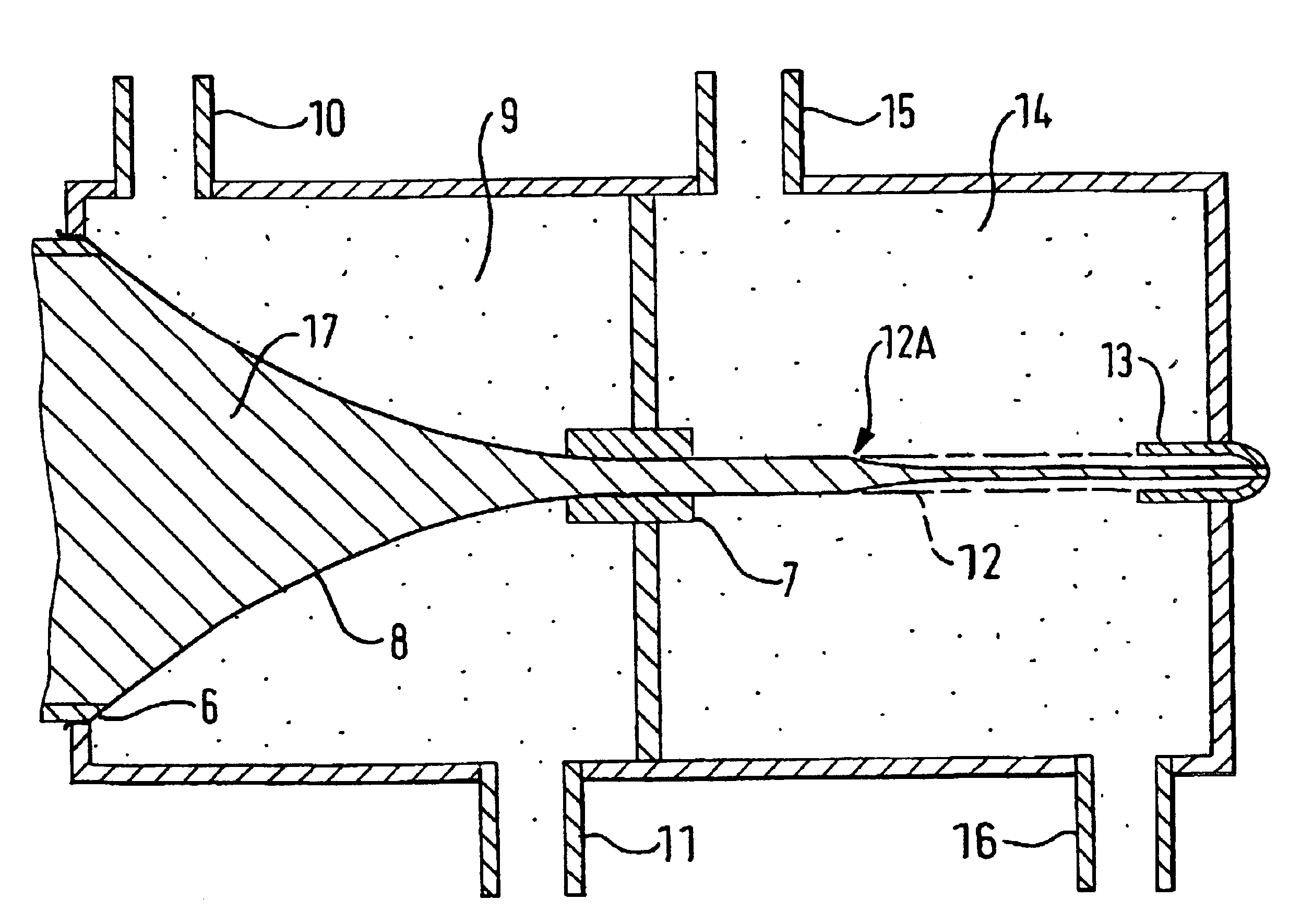

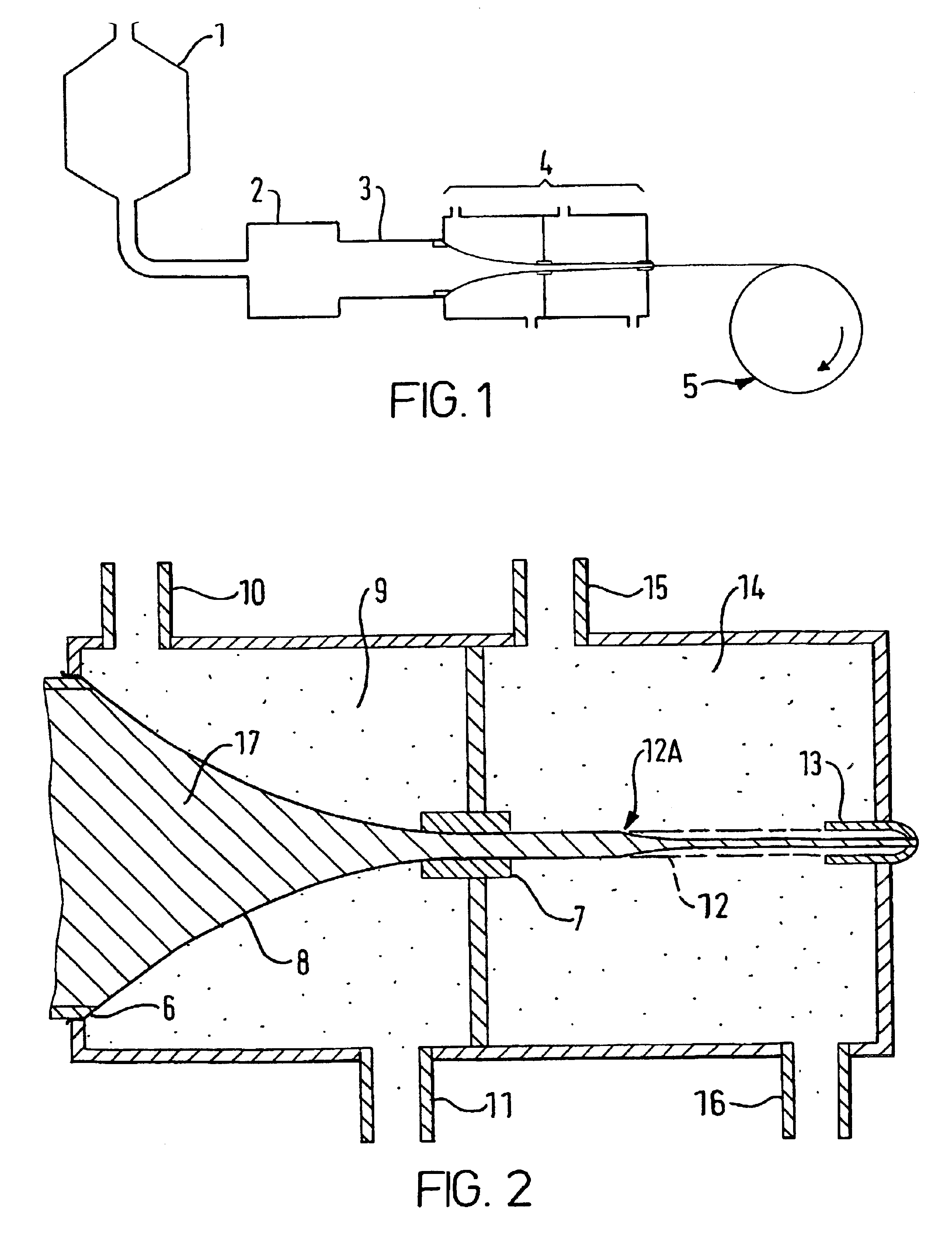

Method and device for the production of an essentially continous fine thread

InactiveUS6800226B1Simple and economical mannerReduced strengthSpinnerette packsMelt spinning methodsFine lineYarn

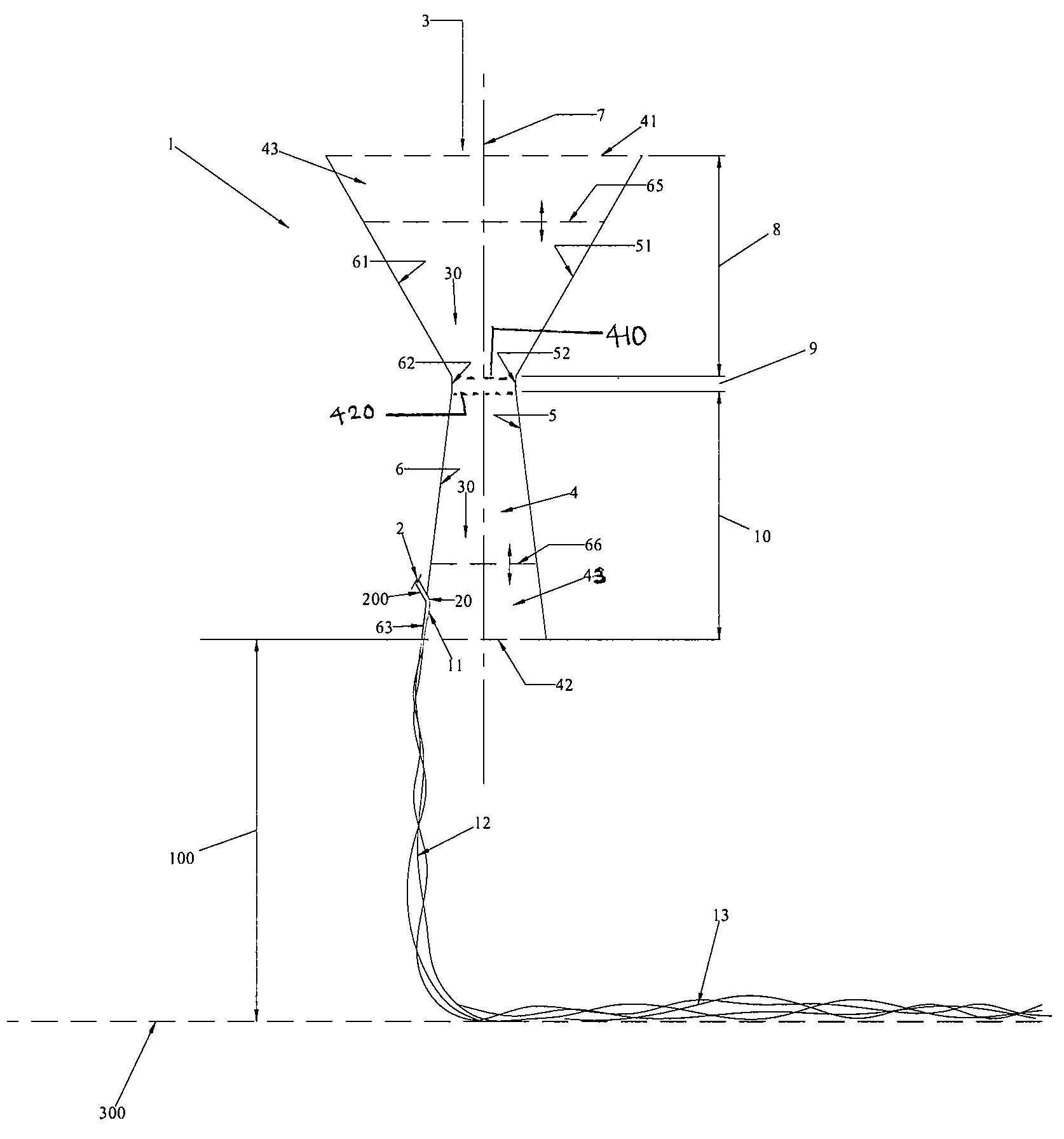

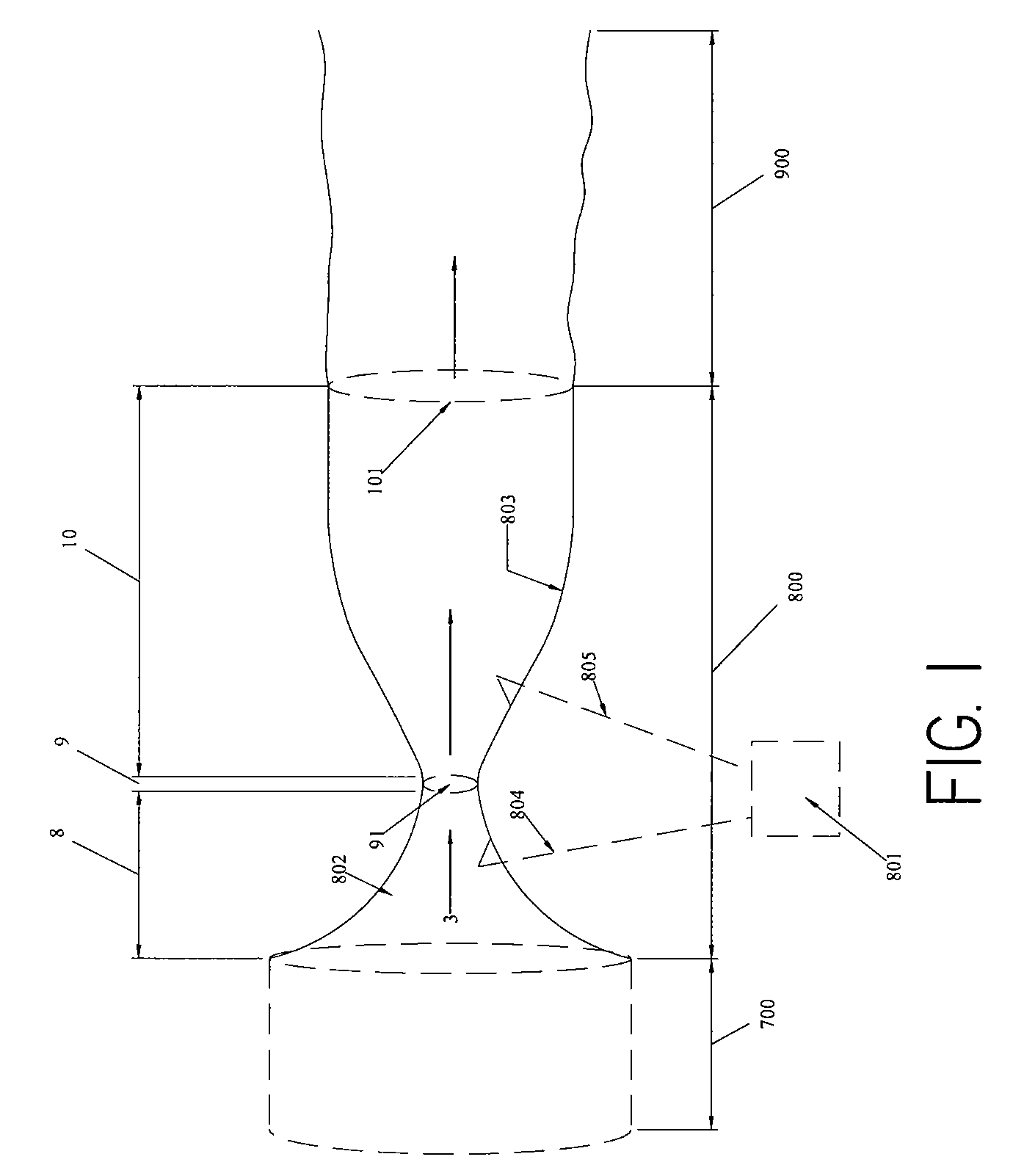

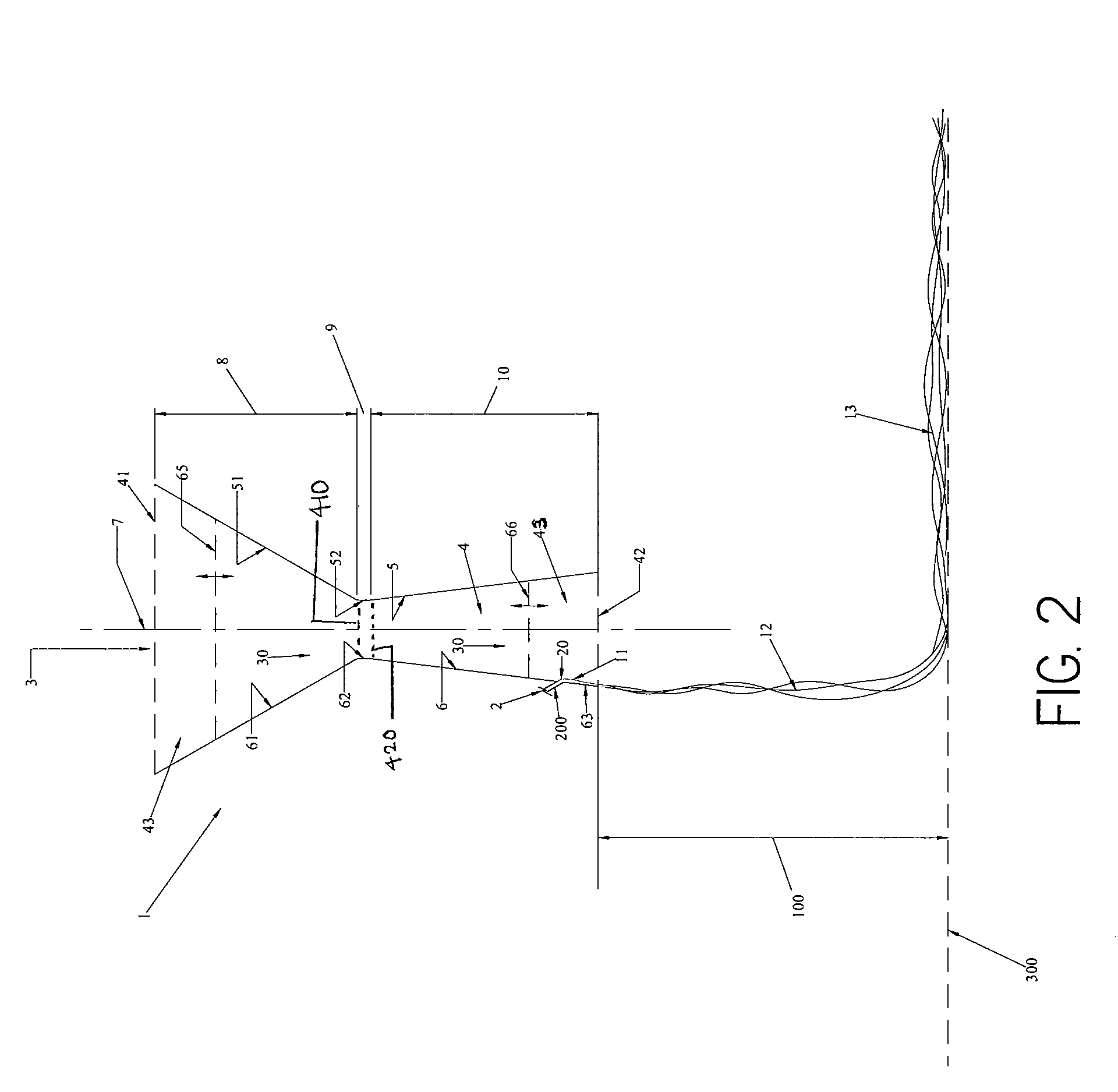

The invention relates to a method and a device for the production of essentially continuous fine threads made of meltable polymers. The polymer melt is spun from at least one spin hole (5) and the spun thread is attenuated using gas flows which are accelerated to achieve high speeds by means of a Laval nozzle (6). As a result of the specific geometry of the melt hole (4) and the position thereof in respect to the Laval nozzle (6), the temperature of the polymer melt, the throughout per spin hole and the pressures determining the velocity of the gas flow upstream and downstream from the Laval nozzle (6) are controlled in such a way that the thread reaches an internal hydrostatic pressure before solidifying, whereby said thread bursts into a plurality of fine threads.

Owner:GERKING LUDER

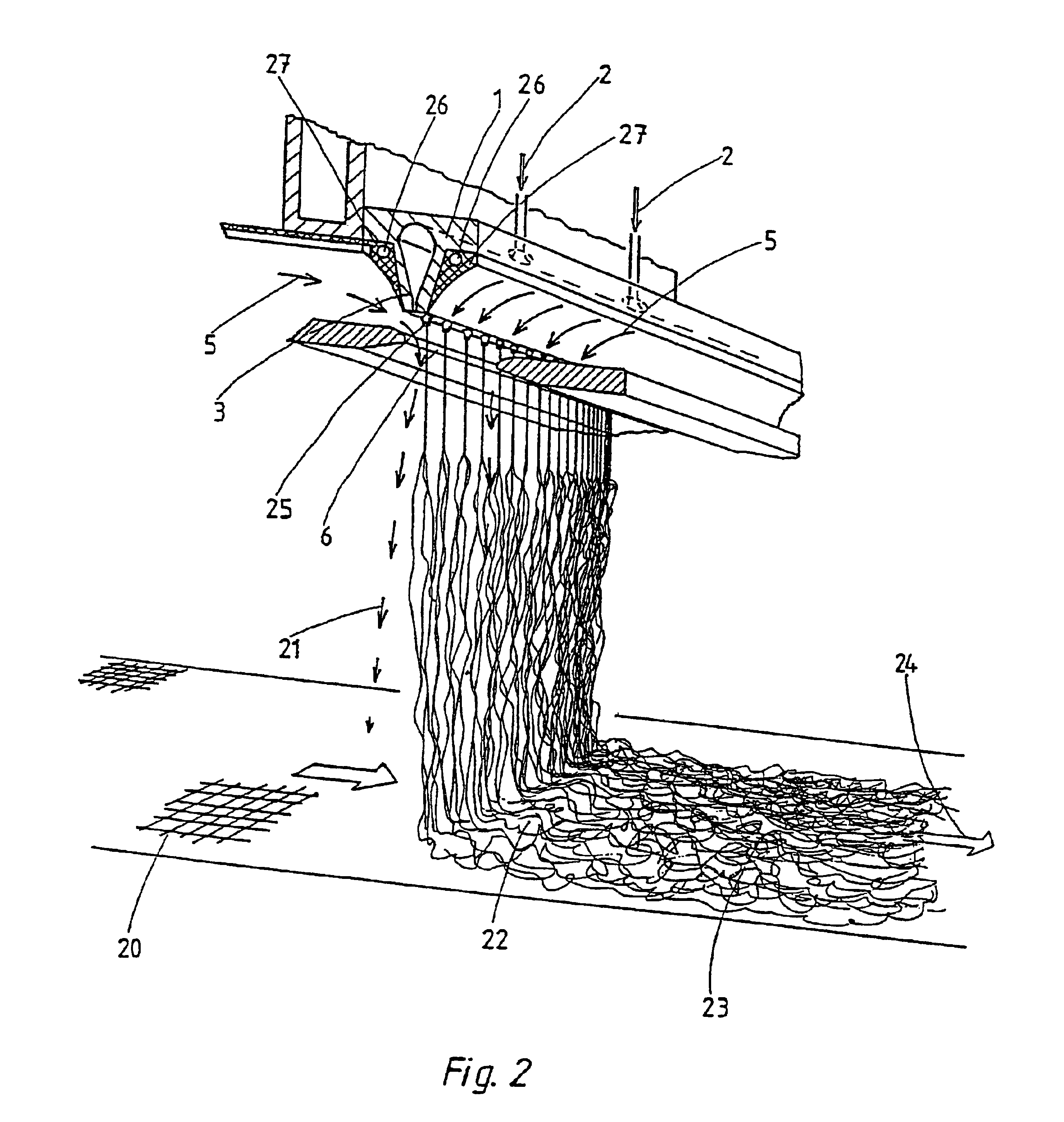

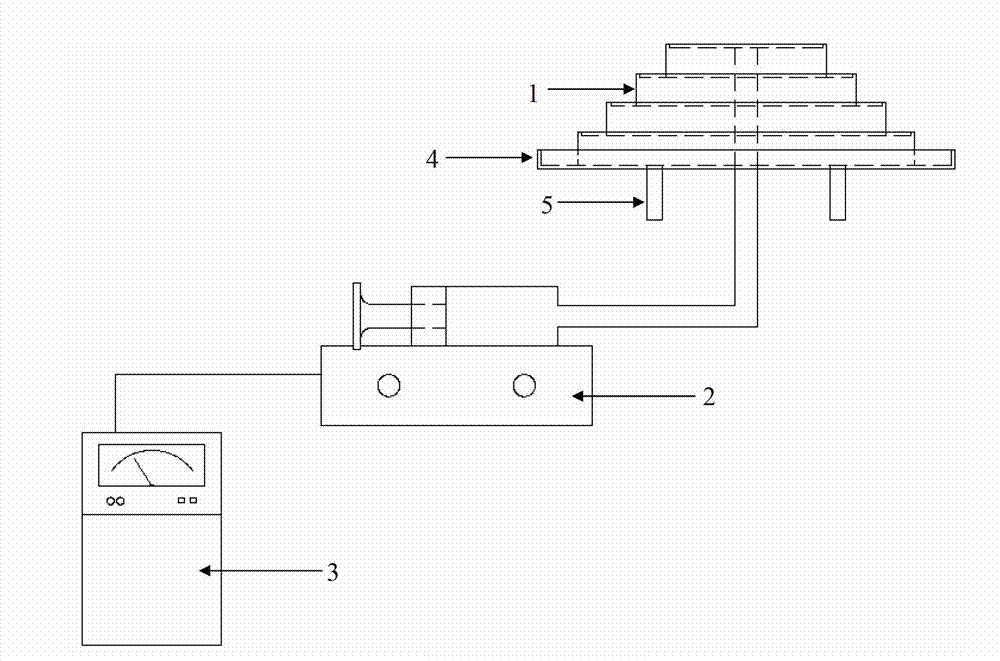

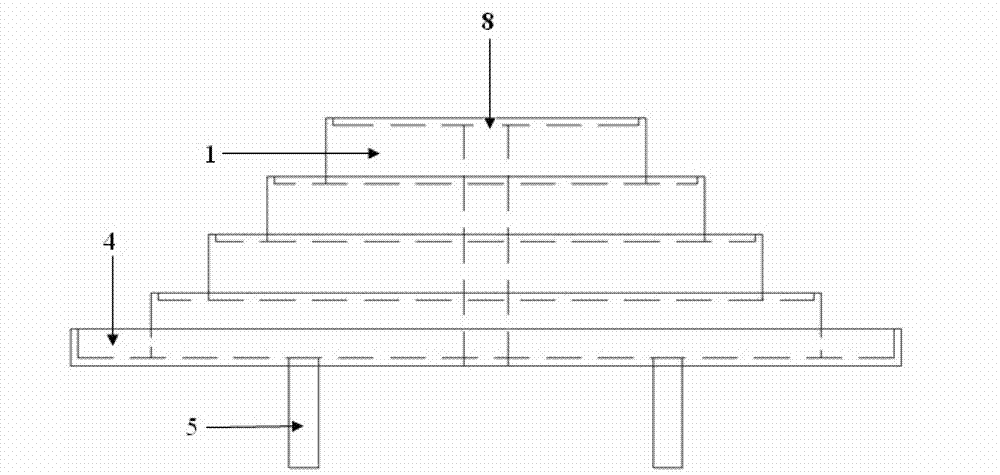

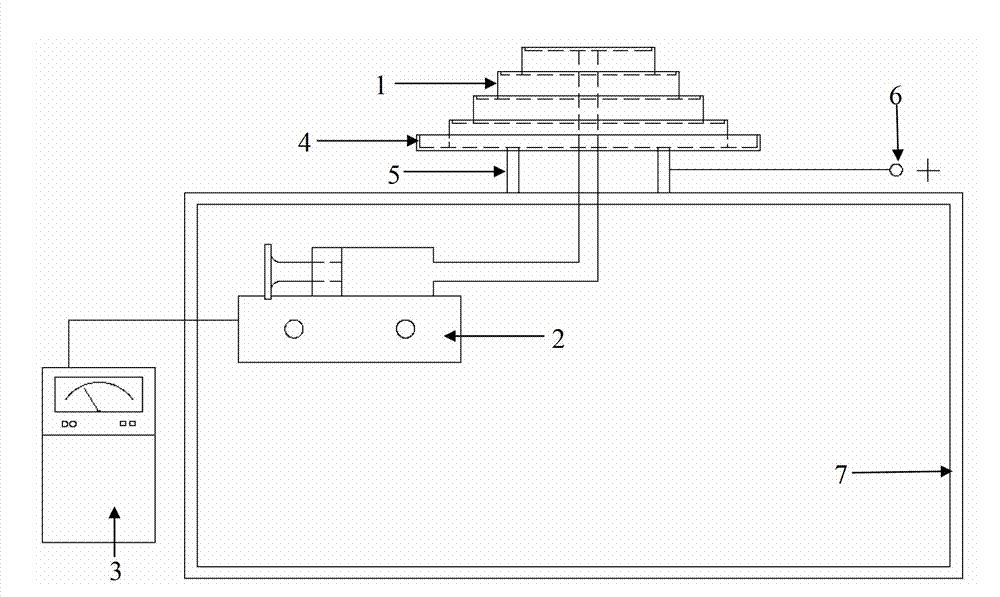

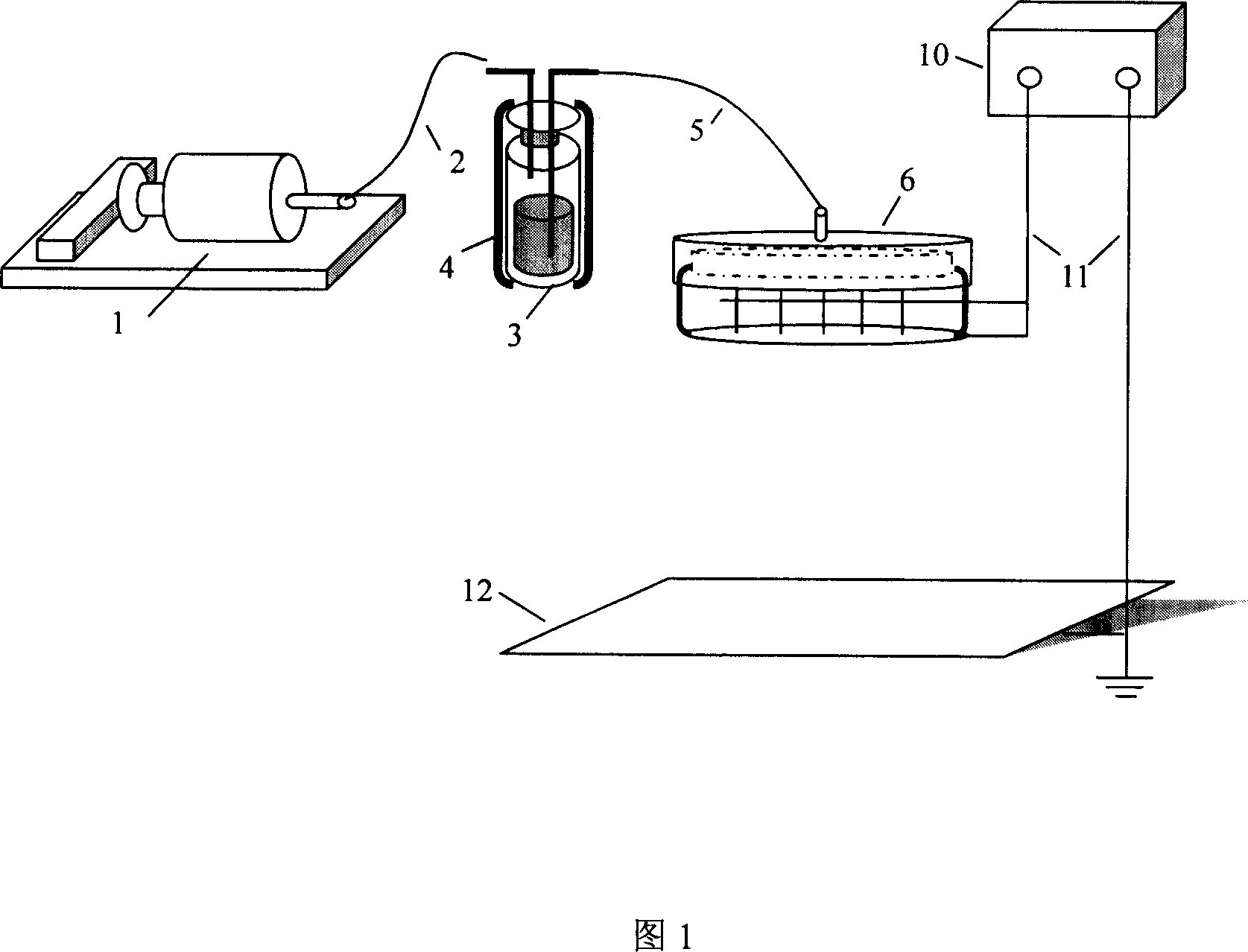

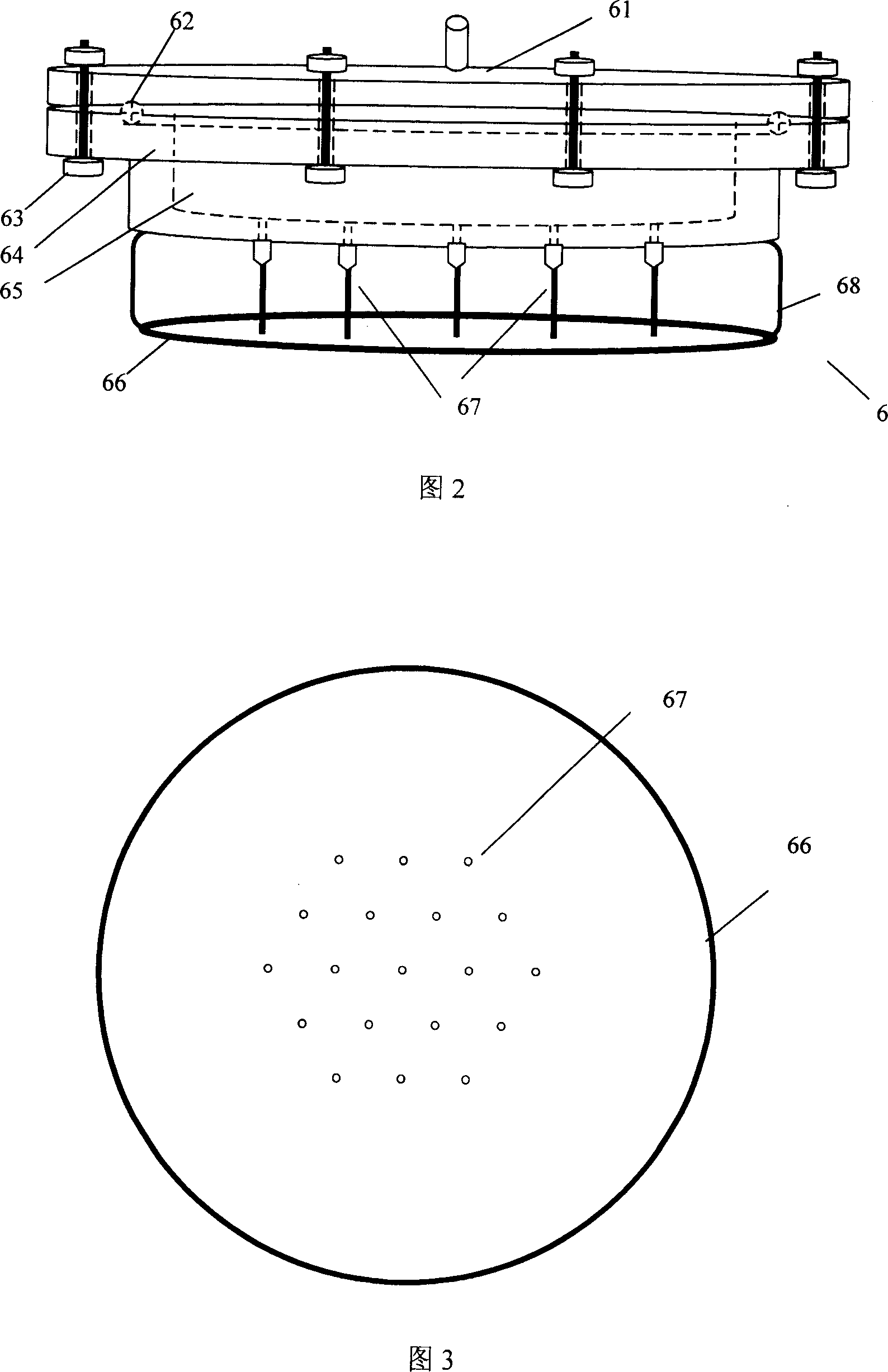

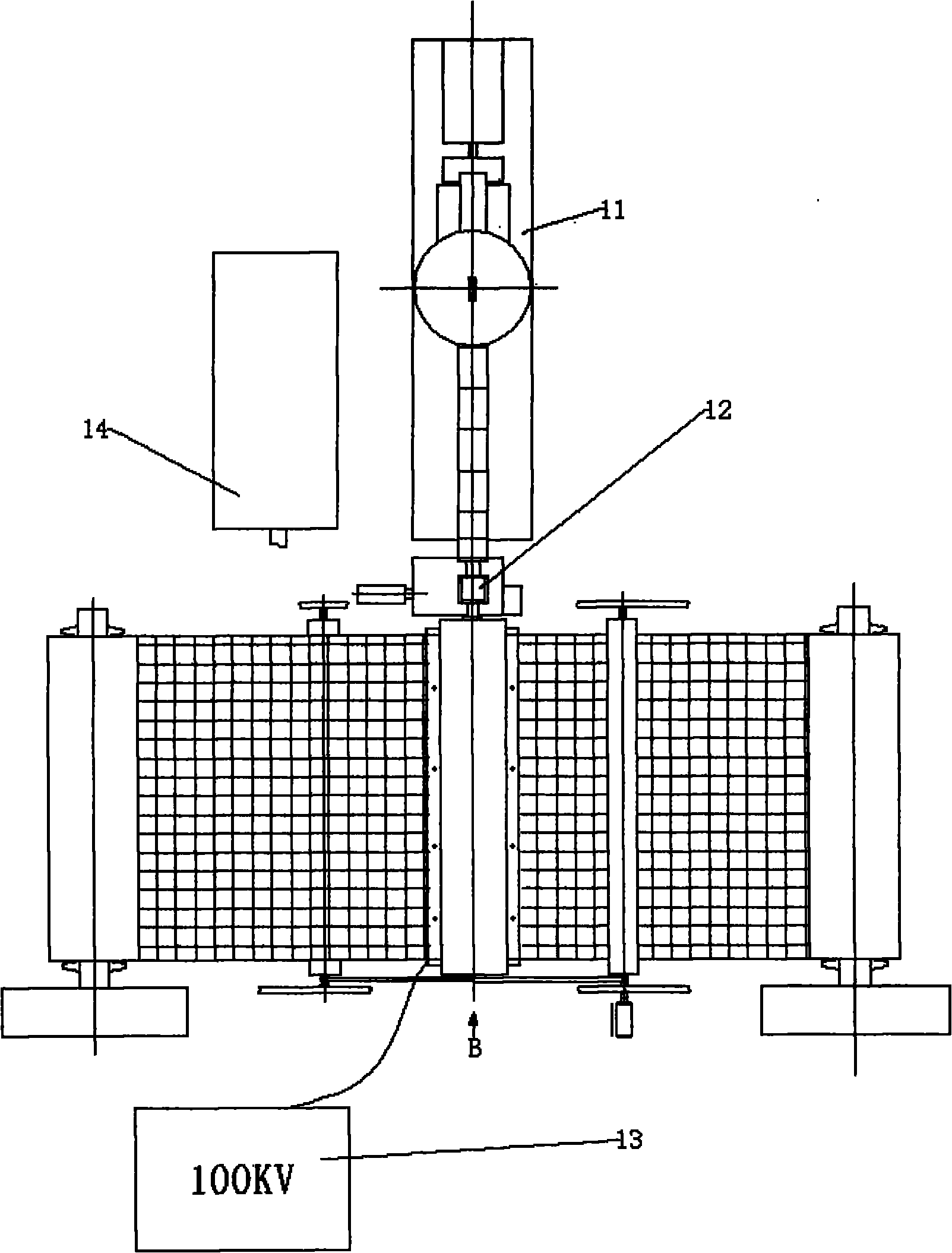

Jet type electrostatic spinning equipment capable of producing Nano fiber in bulk

InactiveCN101003916AThe need for large-scale productionNo frequent replacementSpinnerette packsFilament/thread formingFiberHigh volume manufacturing

Owner:DONGHUA UNIV

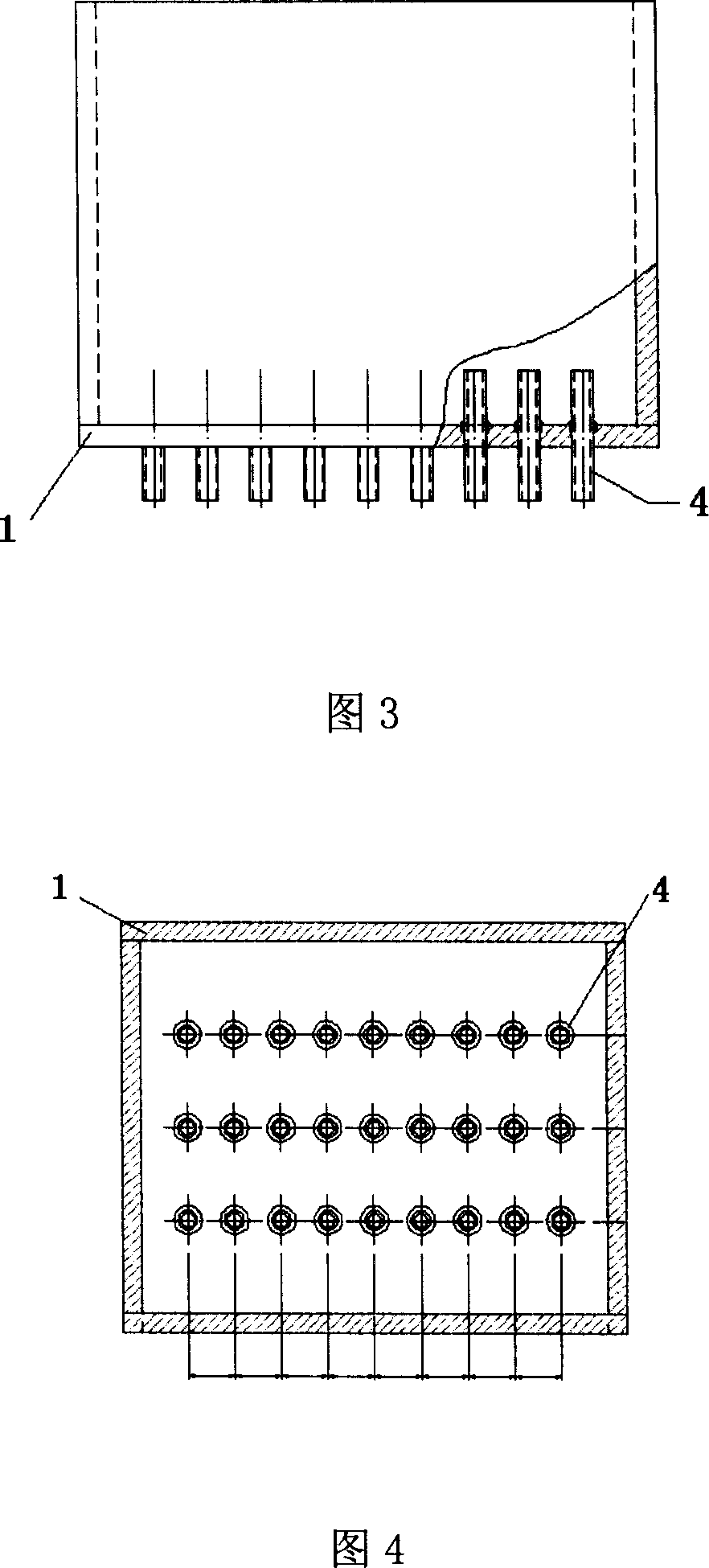

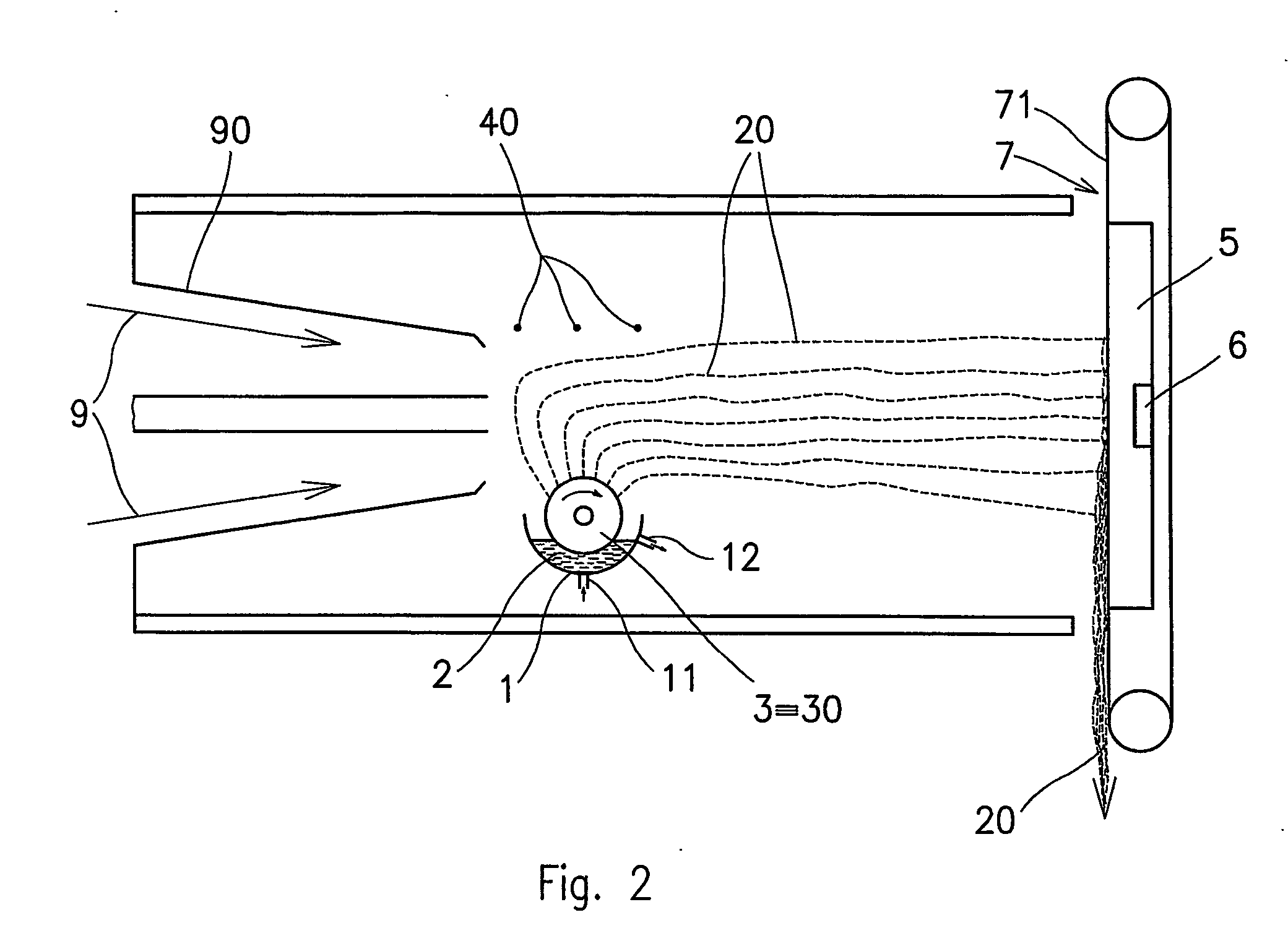

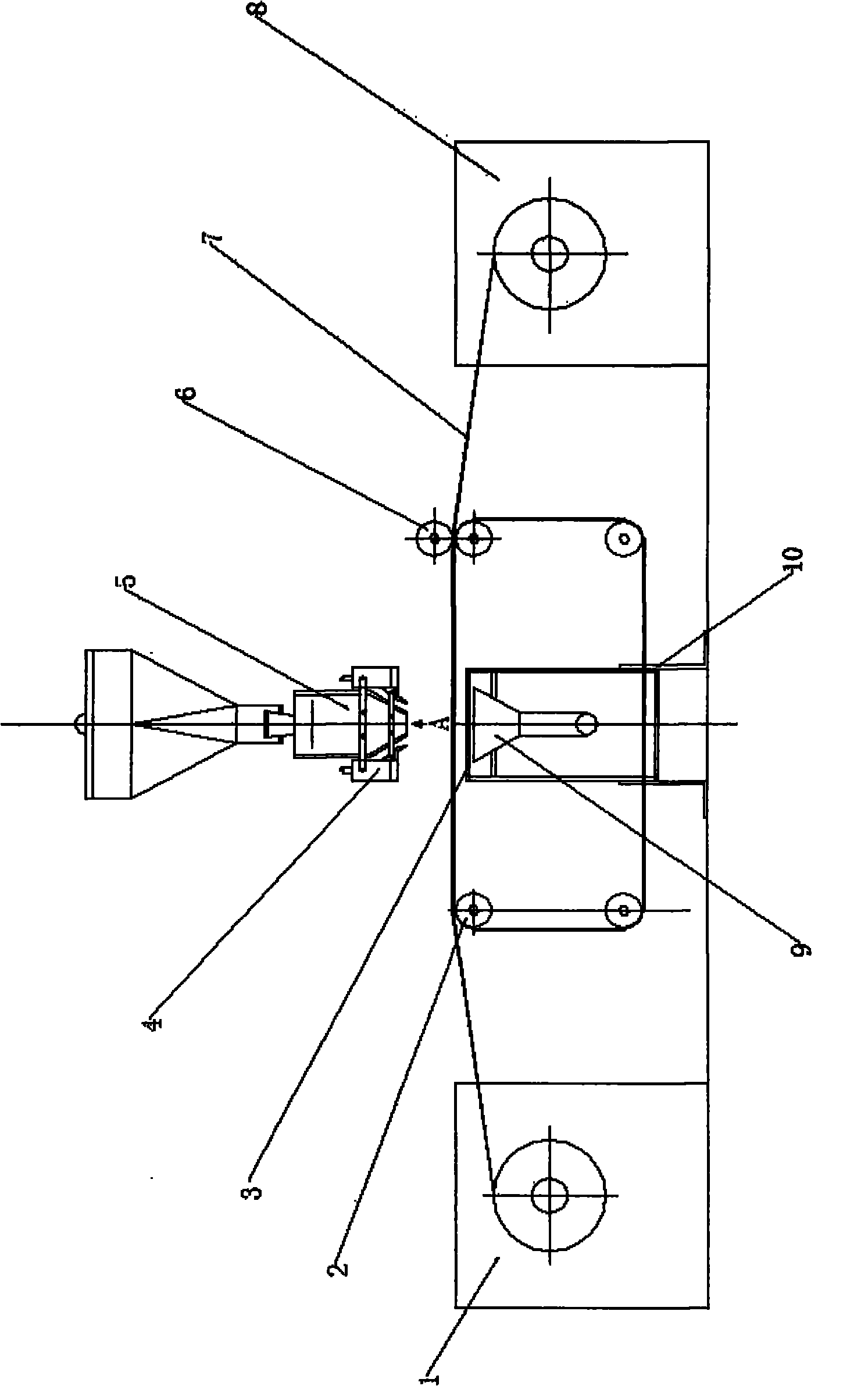

Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

ActiveUS7585437B2High quality and uniformity of layerSpinnerette packsNanotechnologyPotential differenceElectrospinning

A method of nanofibers production from a polymer solution uses electrostatic spinning in an electric field created by a potential difference between a charged electrode and a counter electrode. The polymer solution for spinning is supplied into the electric field using the surface of a rotating charged electrode. On a part of the circumference of the charged electrode near to the counter electrode, a spinning surface is created for attaining a high spinning capacity. In a device for carrying out the method, the charged electrode is pivoted and part of its circumference is immersed in the polymer solution. The free part of the circumference of the charged electrode is positioned opposite the counter electrode.

Owner:TECHNICKA UNIVEZITA V LIBERCI

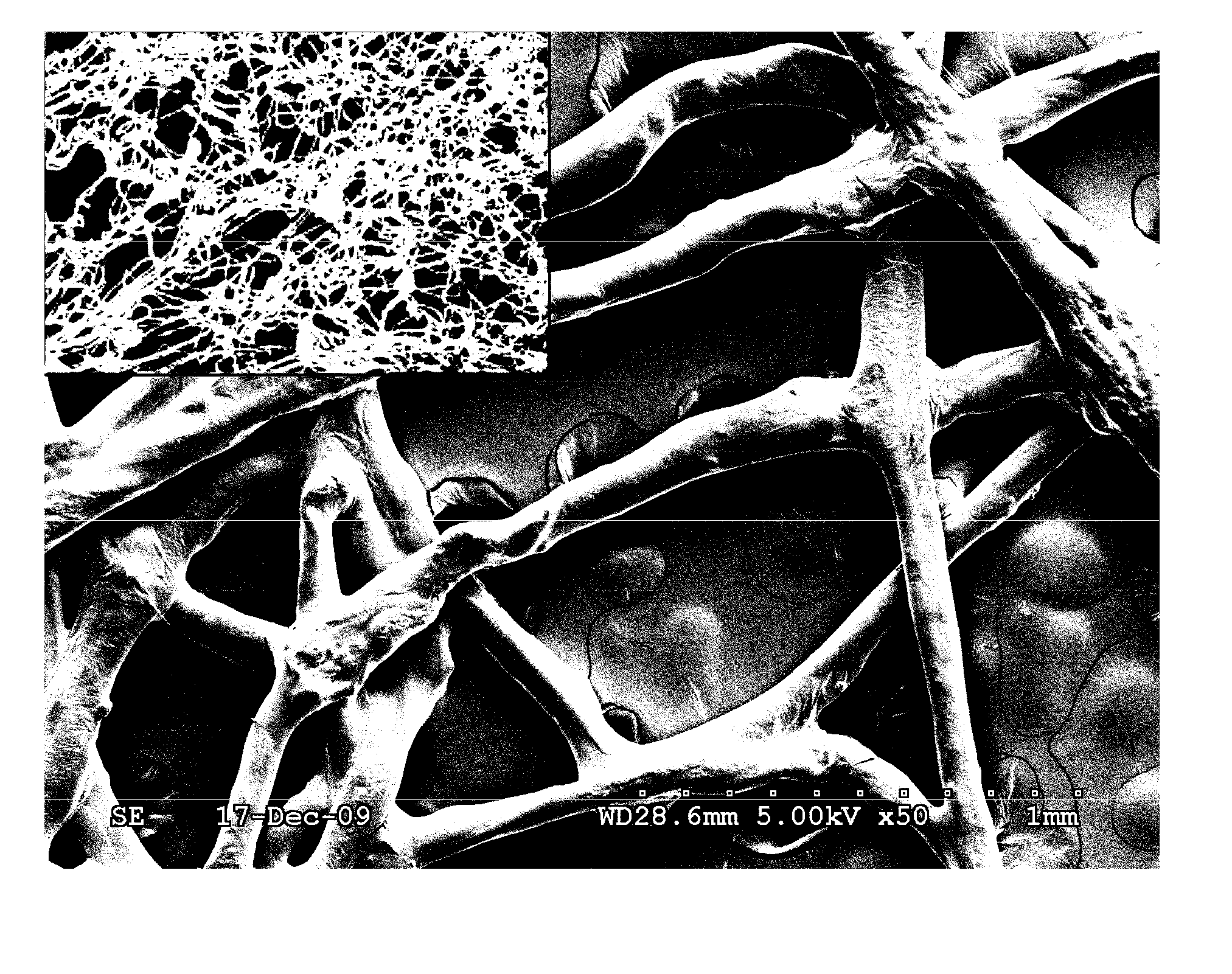

Process and apparatus for producing sub-micron fibers, and nonwovens and articles containing same

InactiveUS7666343B2Increase productionLower gas demandSpinnerette packsFilament/thread formingFiberPolymer science

A process and apparatus for producing sub-micron fibers, and more specifically a process and apparatus for effecting formation of sub-micron fibers by fibrillation of polymer films, and nonwoven materials and articles incorporating them.

Owner:AVINTIV SPECIALTY MATERIALS INC

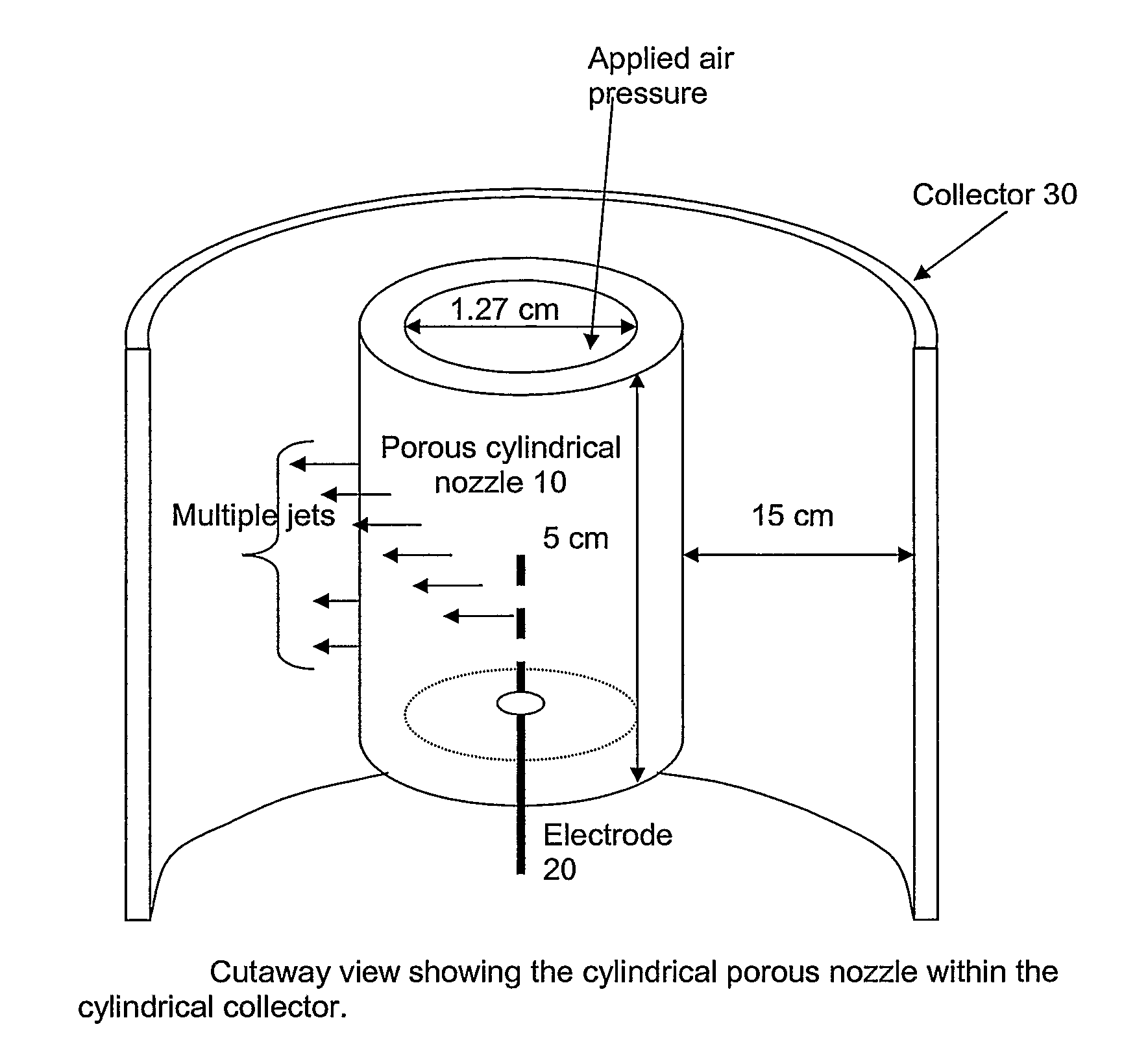

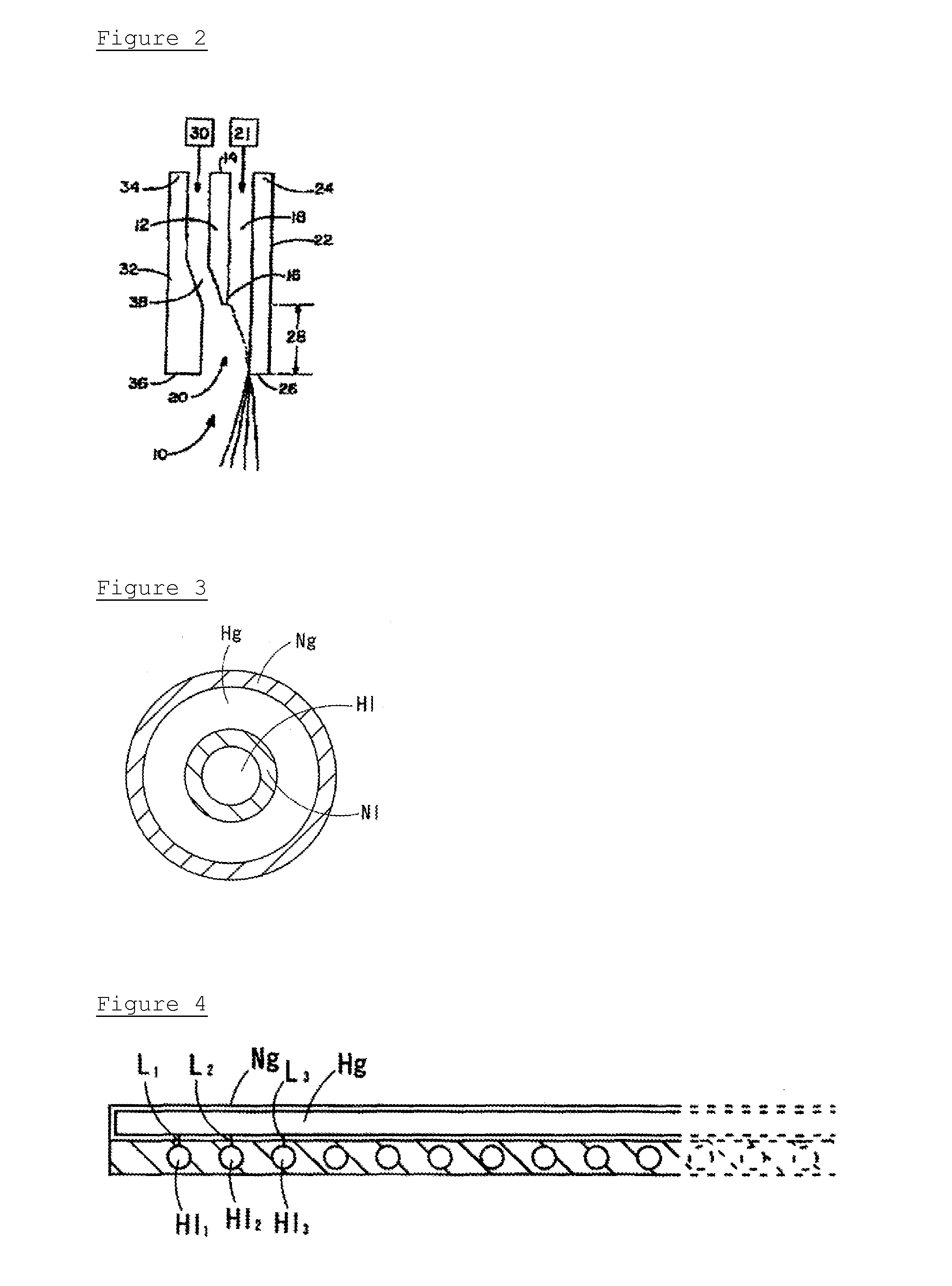

Apparatus for electro-blowing or blowing-assisted electro-spinning technology and process for post treatment of electrospun or electroblown membranes

InactiveUS20060049542A1Improve throughputElectric discharge heatingMouldsEngineeringMembrane configuration

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

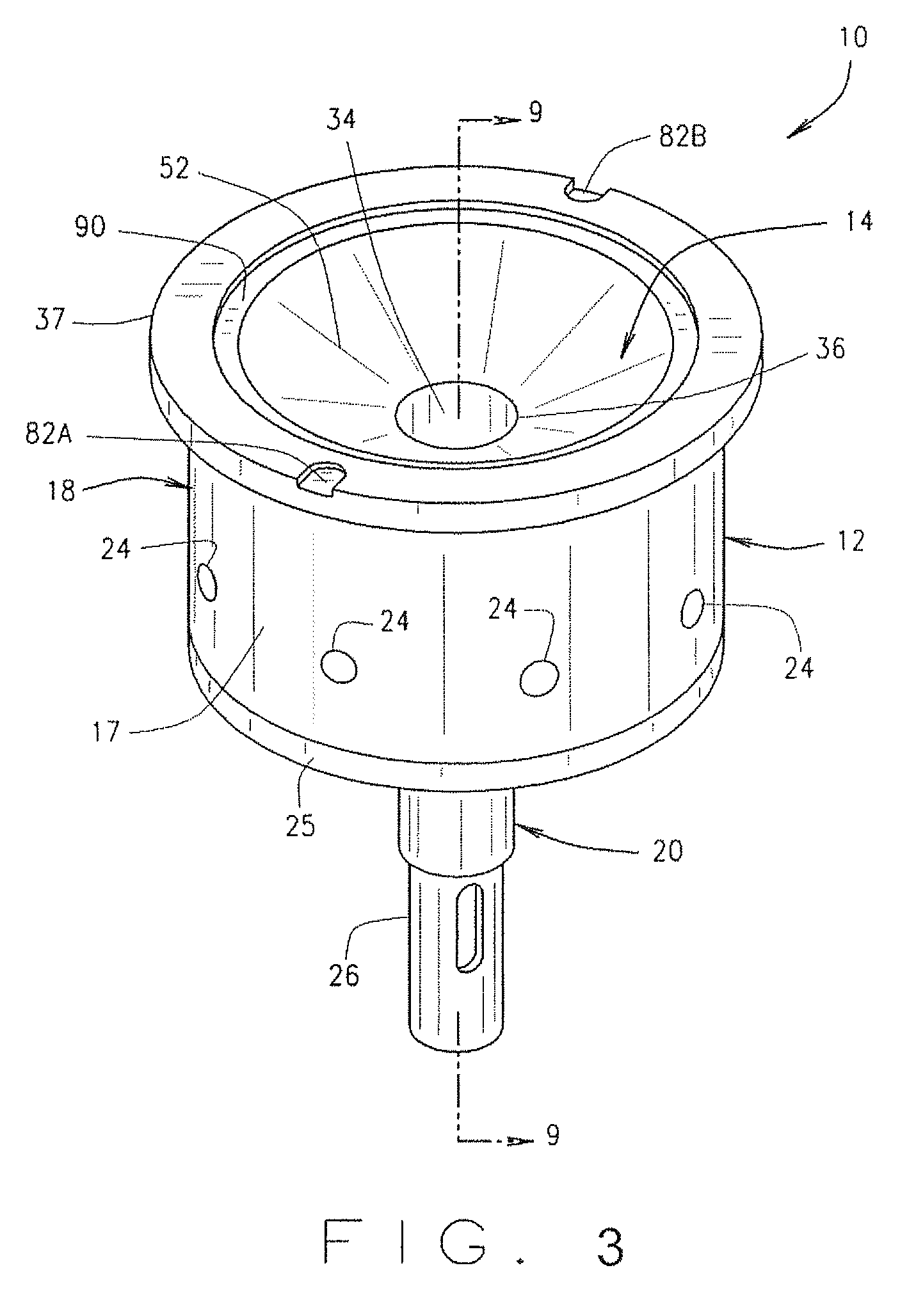

Umbrella-shaped electrostatic spinning sprayer and electrostatic spinning method

ActiveCN103088443AOvercoming easy blockageOvercome efficiencySpinnerette packsFilament/thread formingNumerical controlFiber

The invention relates to an umbrella-shaped electrostatic spinning sprayer and an electrostatic spinning method. The sprayer comprises an umbrella-shaped spinning nozzle, a numerical control type infusion device and a solution collecting groove, wherein the numerical control type infusion device mainly comprises a solution propeller and a controller; the middle of the umbrella-shaped spinning nozzle is provided with a cylindrical hollow portion, and an output end of the solution propeller is placed into the cylindrical hollow portion of the umbrella-shaped spinning nozzle; the controller controls flow velocity and flow of spinning solutions; and the solution collecting groove is placed in the bottom of the umbrella-shaped spinning nozzle. The electrostatic spinning method comprises that a binding post on the umbrella-shaped spinning nozzle is connected with a high-voltage positive electrode, conducting polymer solutions are continuously added to the umbrella-shaped spinning nozzle which is horizontally placed through the numerical control type infusion device, electrostatic spinning is started, collection is achieved through a collecting device, and nano-fibers are formed. The sprayer avoids blocking phenomena, and is easy to clean and good in stability; and the electrostatic spinning method improves production efficiency and the yield of electrostatic spinning.

Owner:DONGHUA UNIV

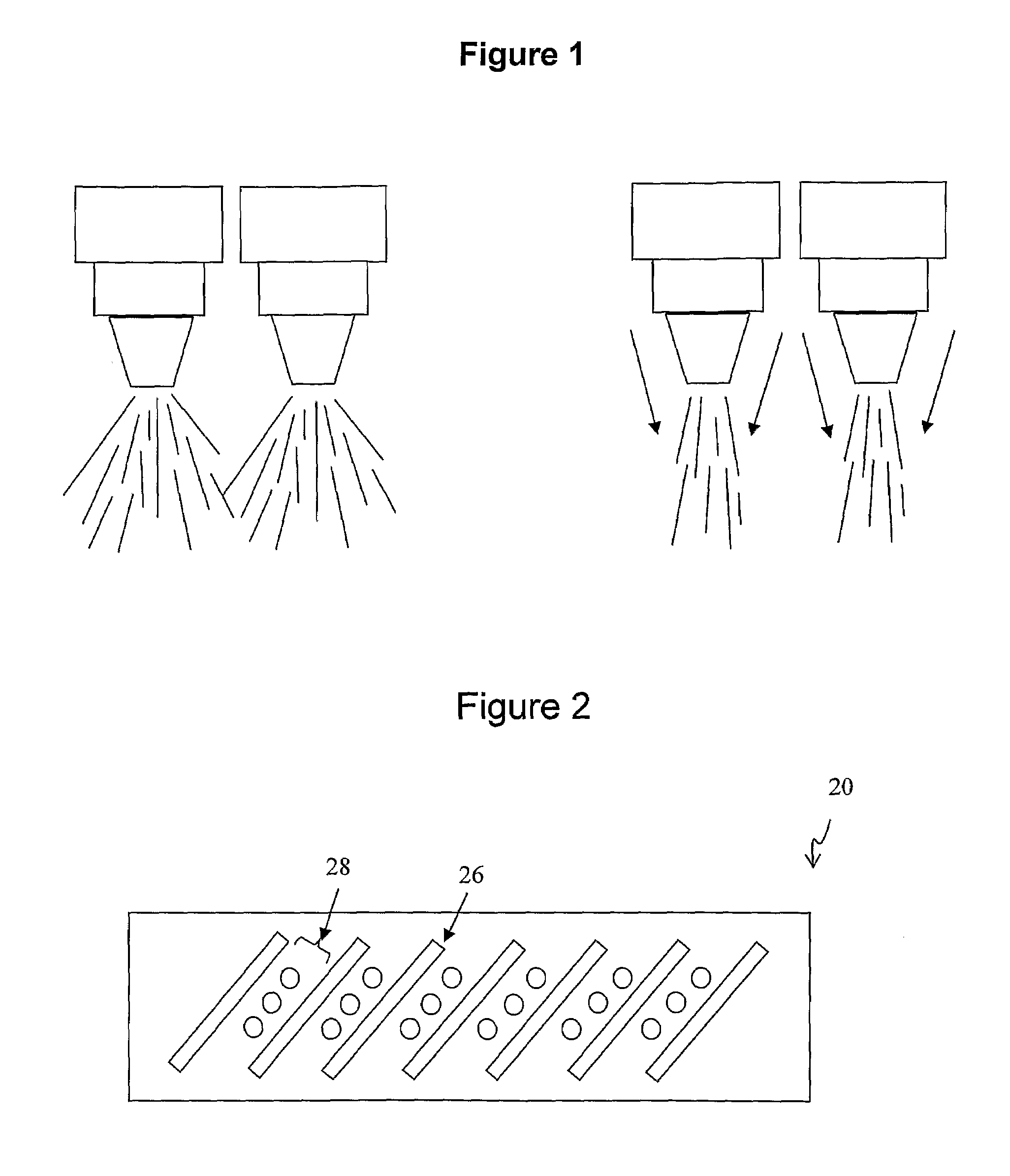

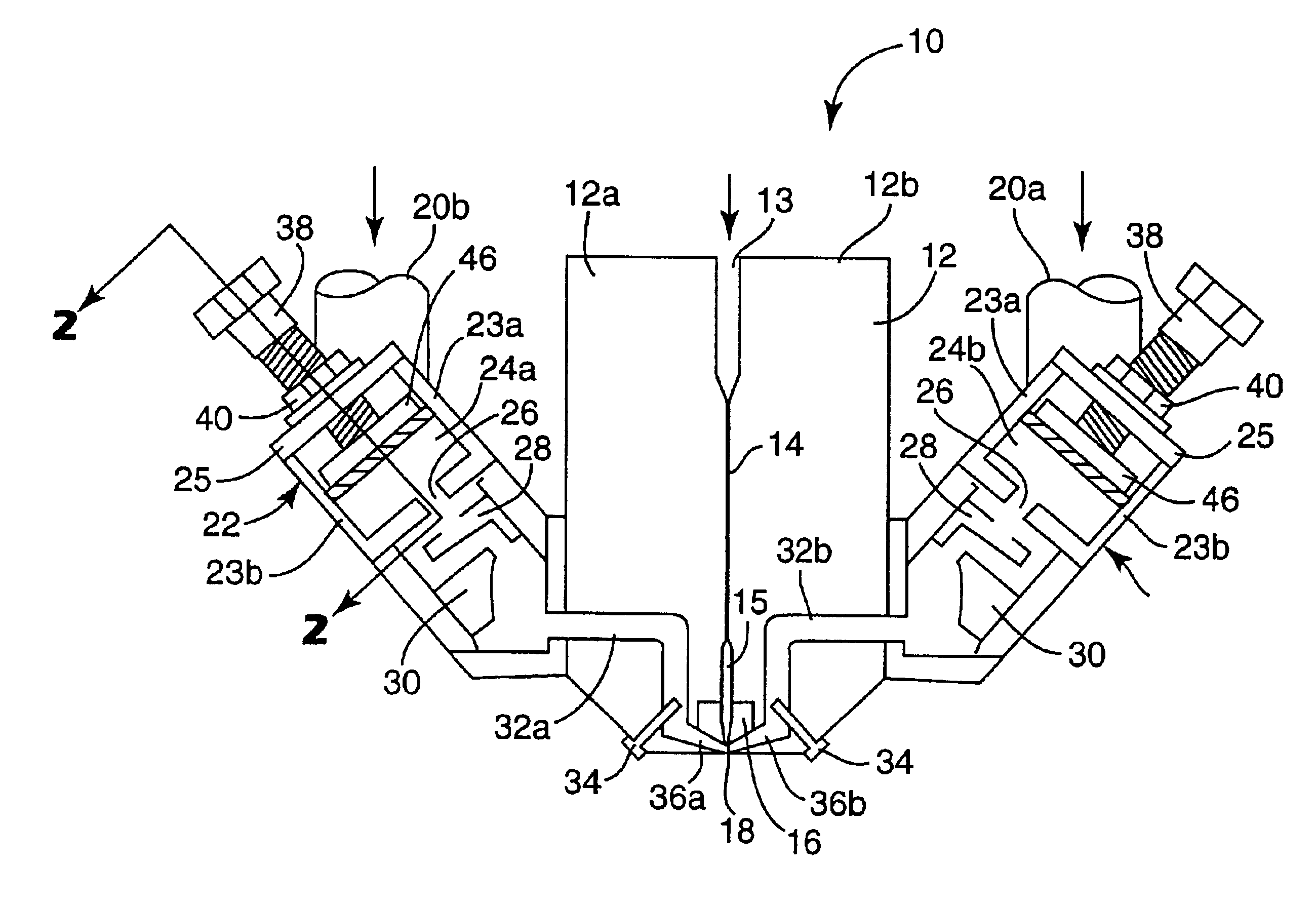

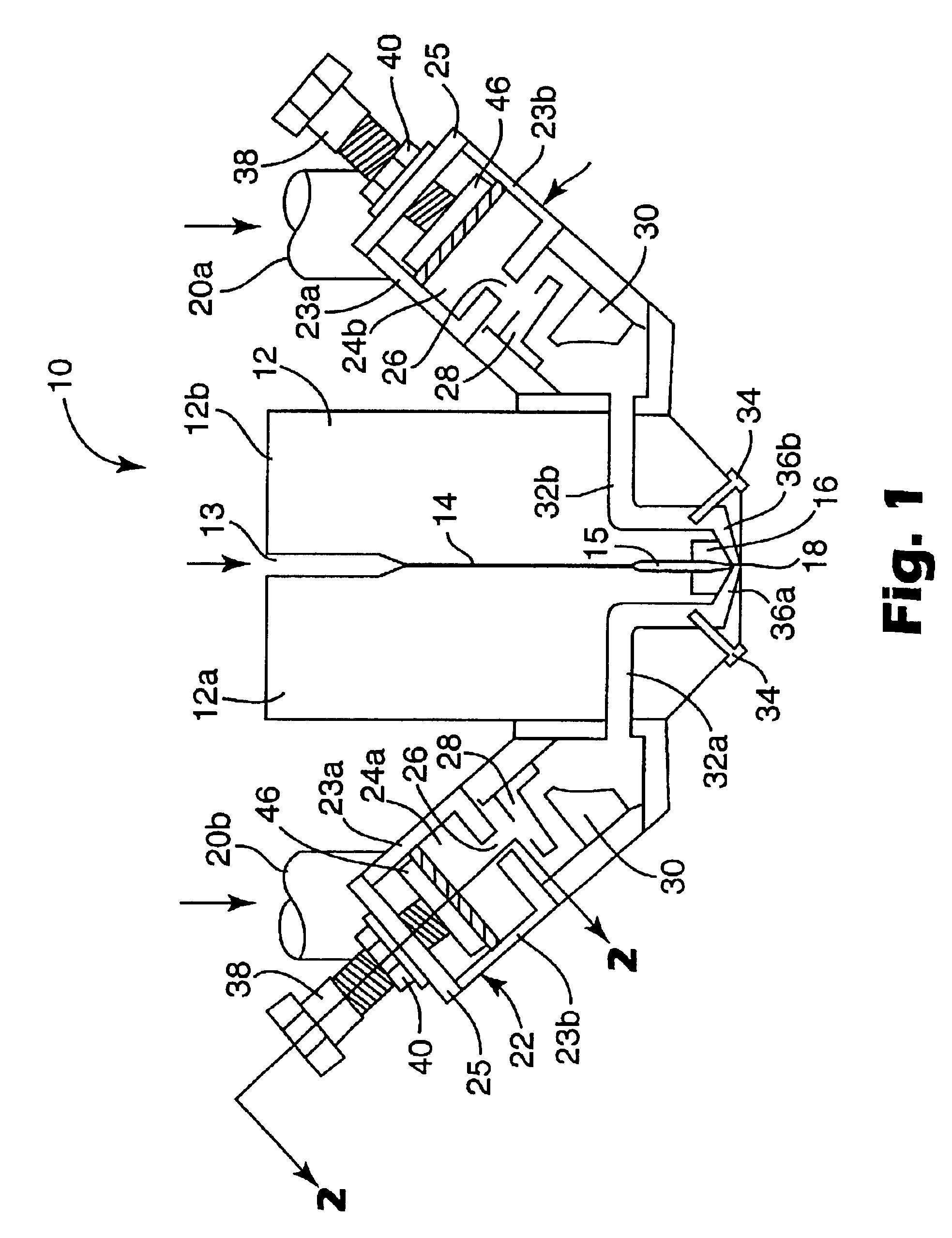

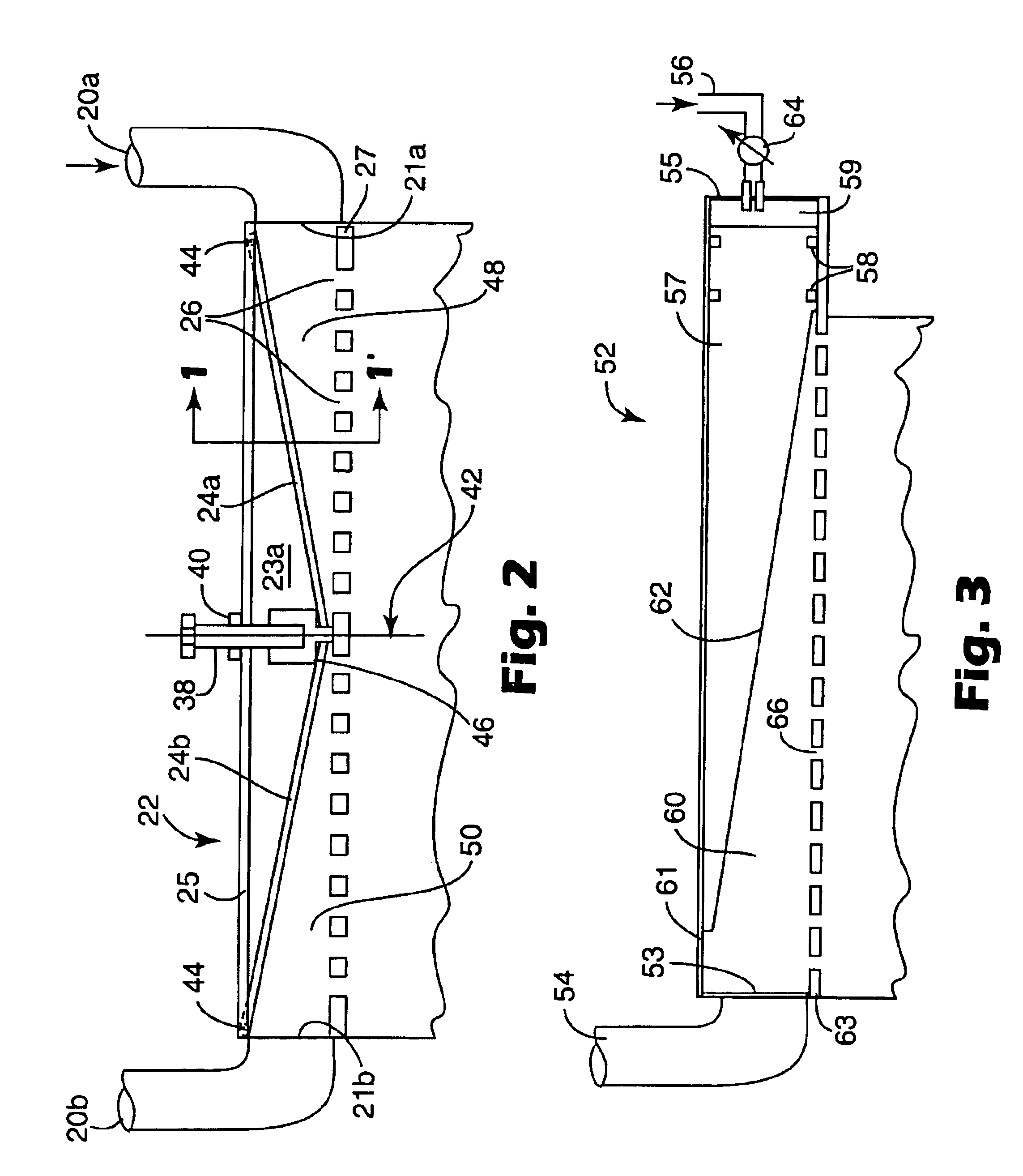

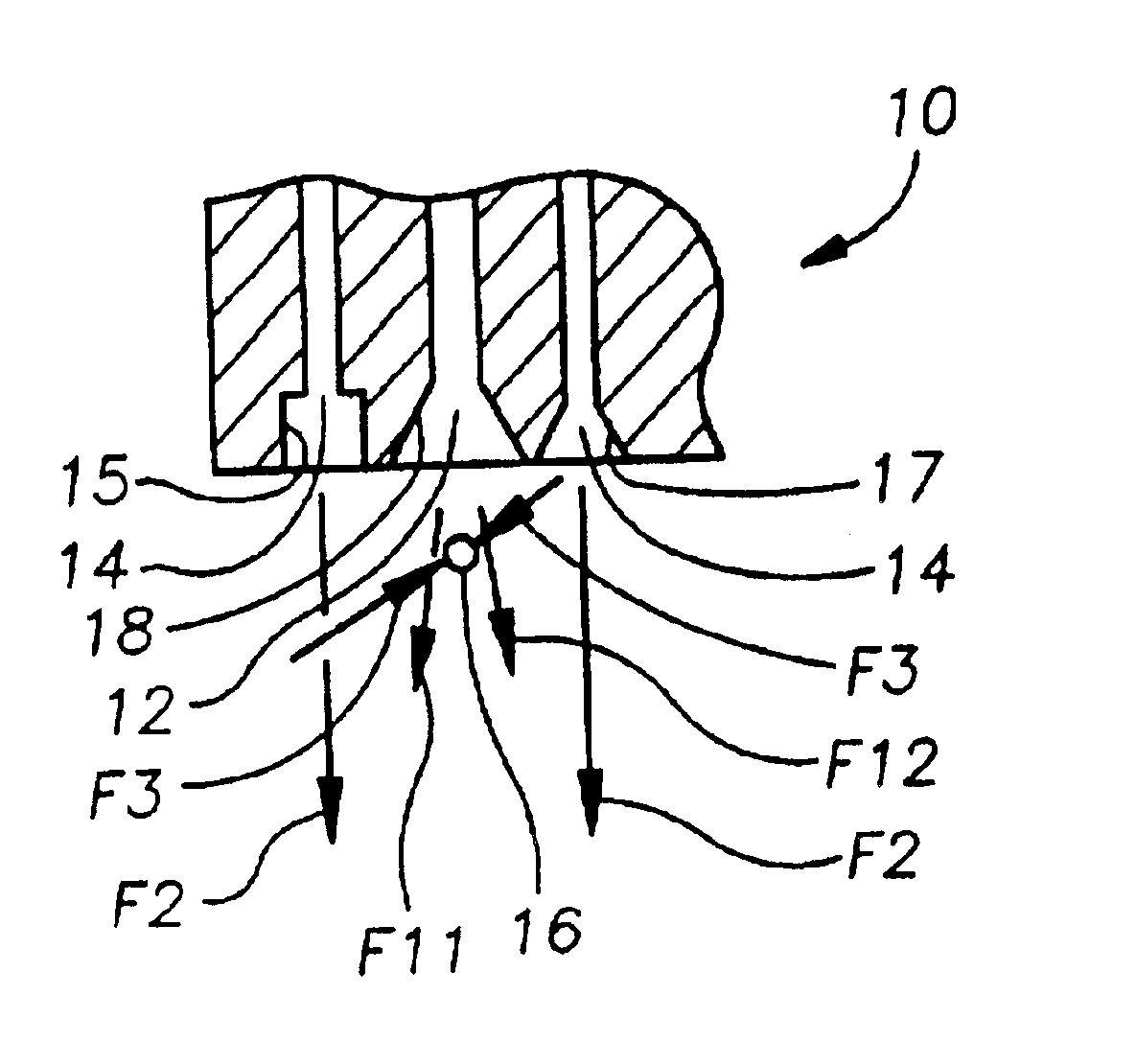

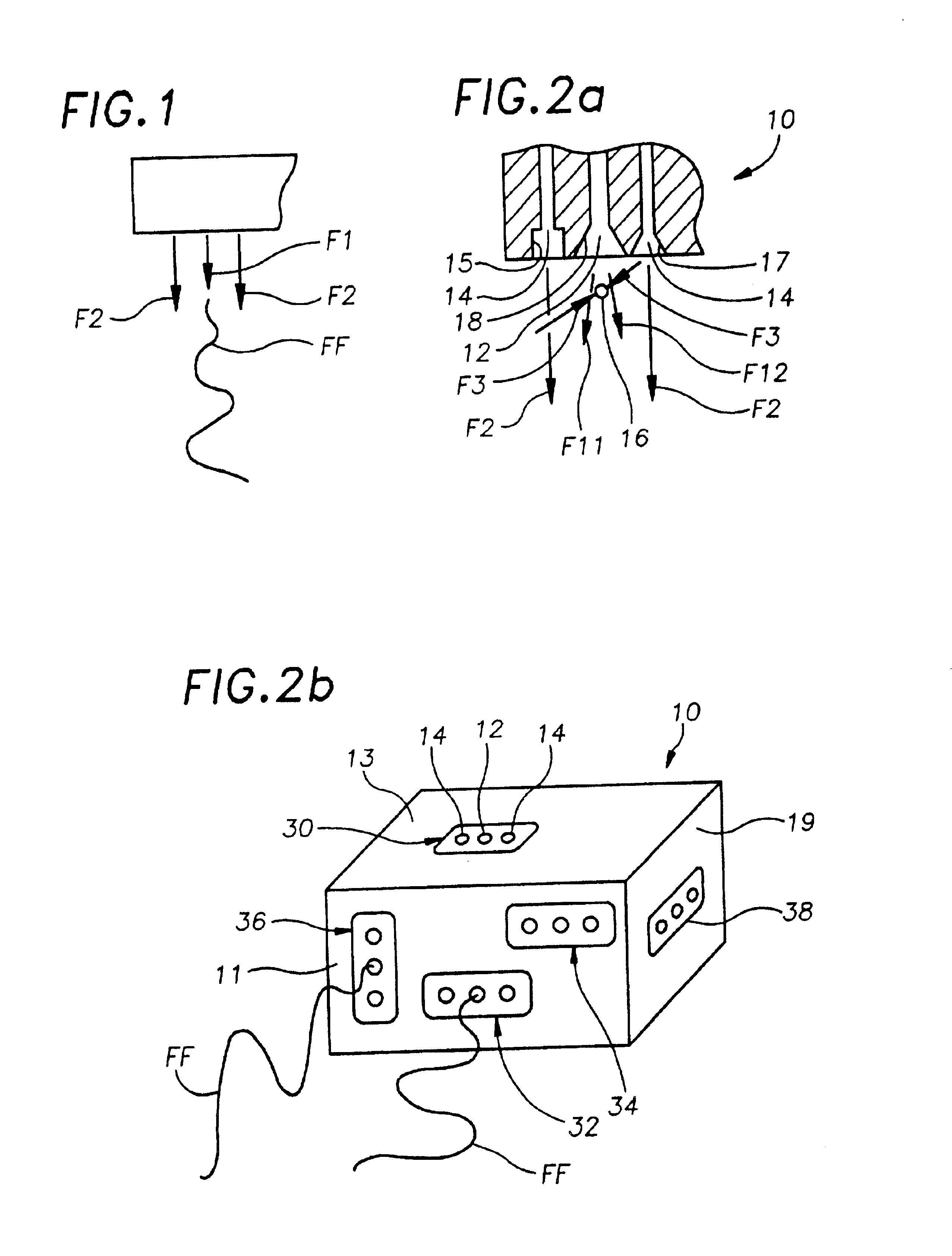

Process and apparatus for forming uniform nanofiber substrates

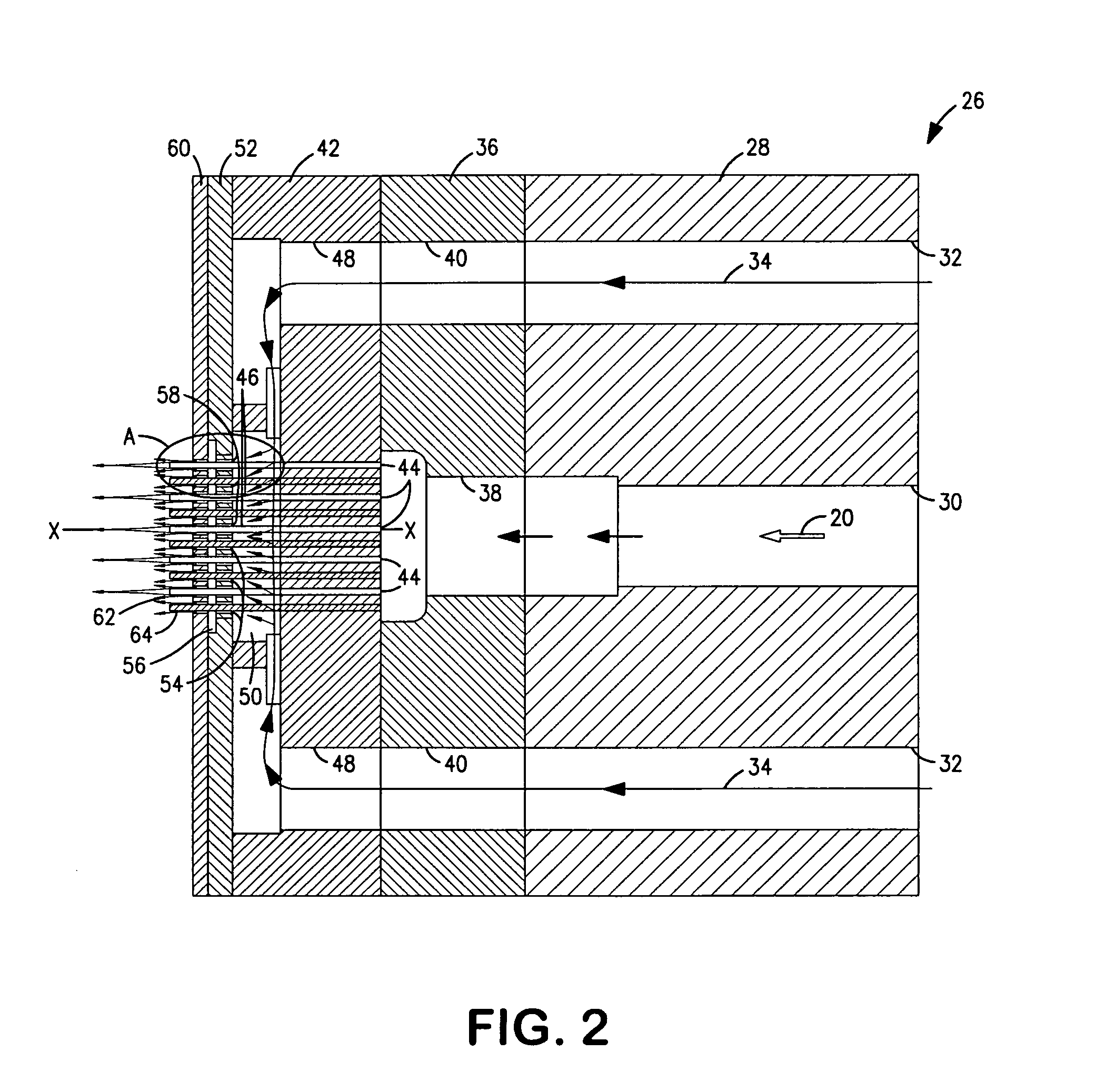

ActiveUS7628941B2Reduce distanceDiminish interaction and cominglingConfectioneryFilament/thread formingFiberNanofiber

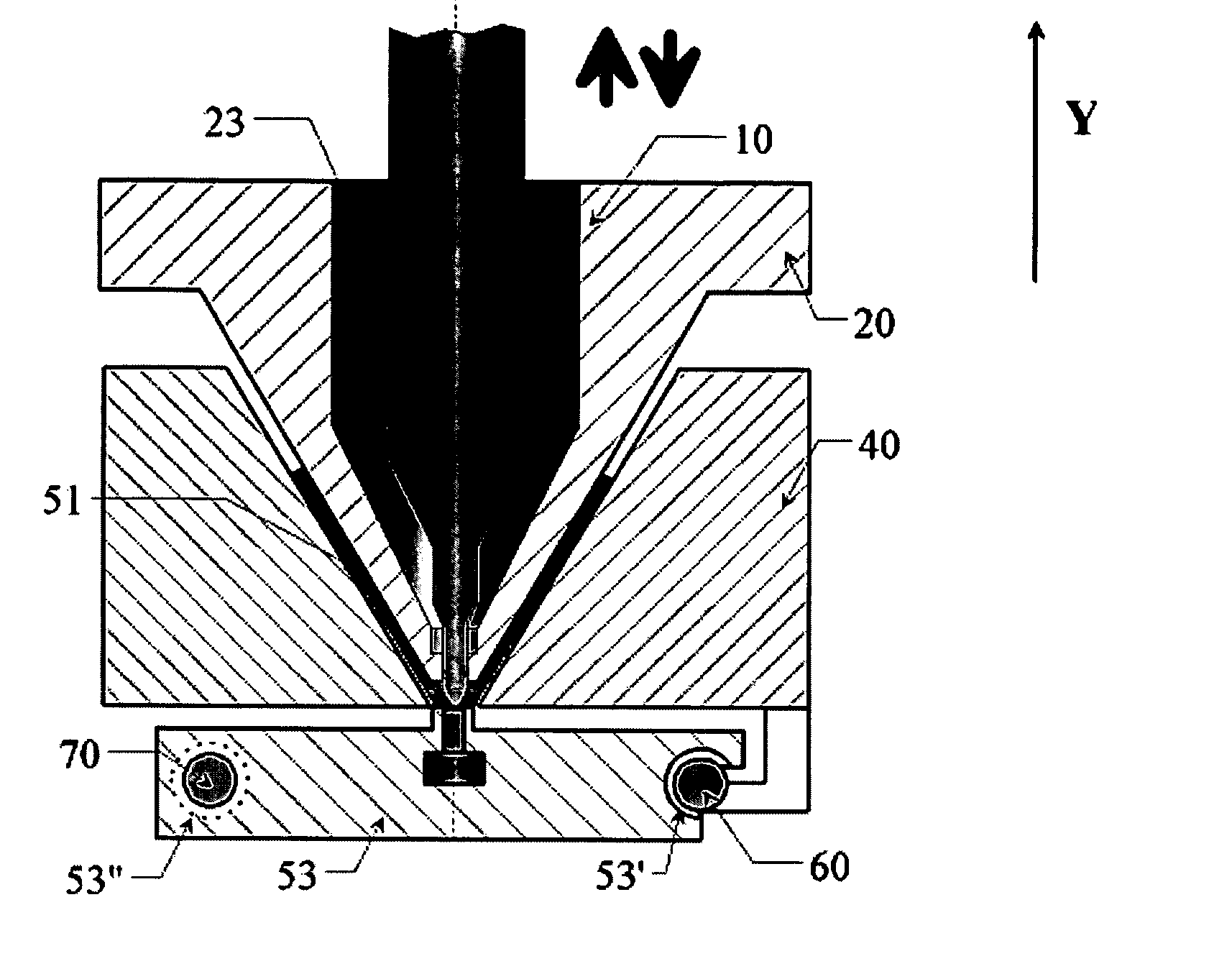

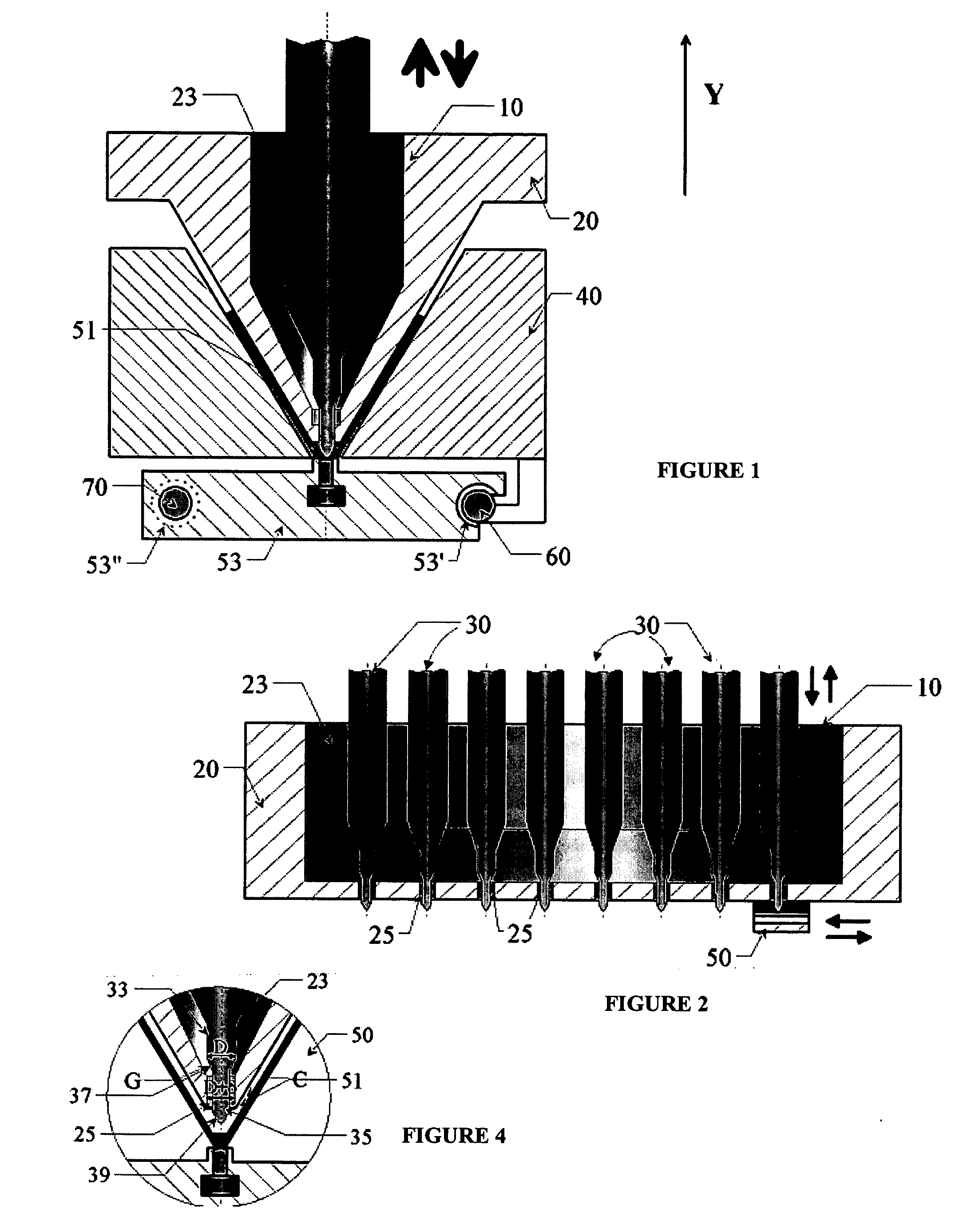

The present invention is directed to a method and apparatus for making nanofiber webs, wherein a source of process air is utilized to affect the spray pattern and quality of fibrillated material expressed from a die assembly including a multi-fluid opening. Appropriately, the aforementioned process air is defined herein as an alternate or ancillary air source apart from primary process air, which primary air is simultaneously supplied with the molten polymeric material to the fiber forming multi-fluid opening. The ancillary air source of the invention is further distinct from secondary air, which is also known in the art as quenching air. The ancillary air can be described as a continuous fluid curtain of shielding or shaping air.

Owner:AVINTIV SPECIALTY MATERIALS INC

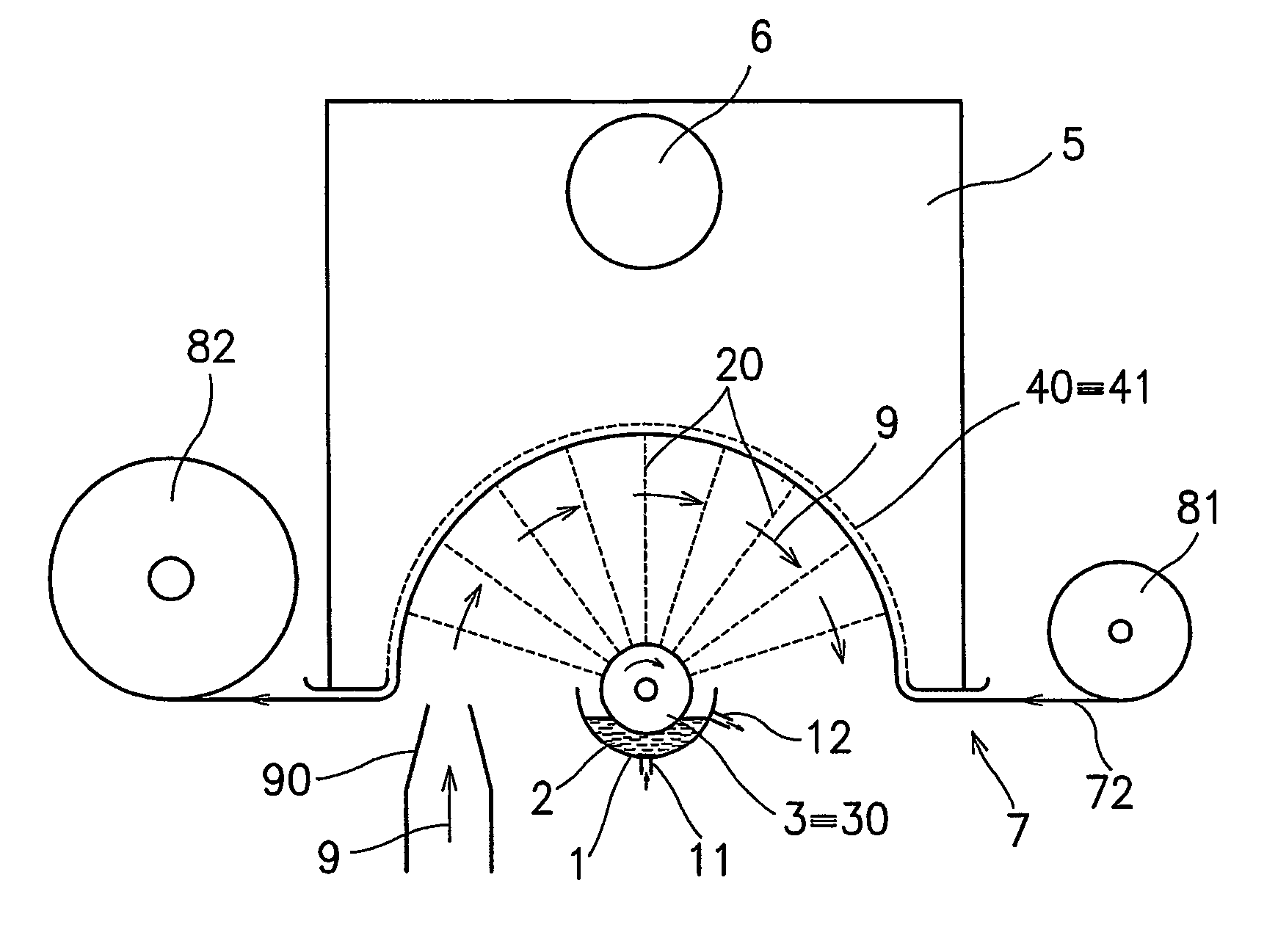

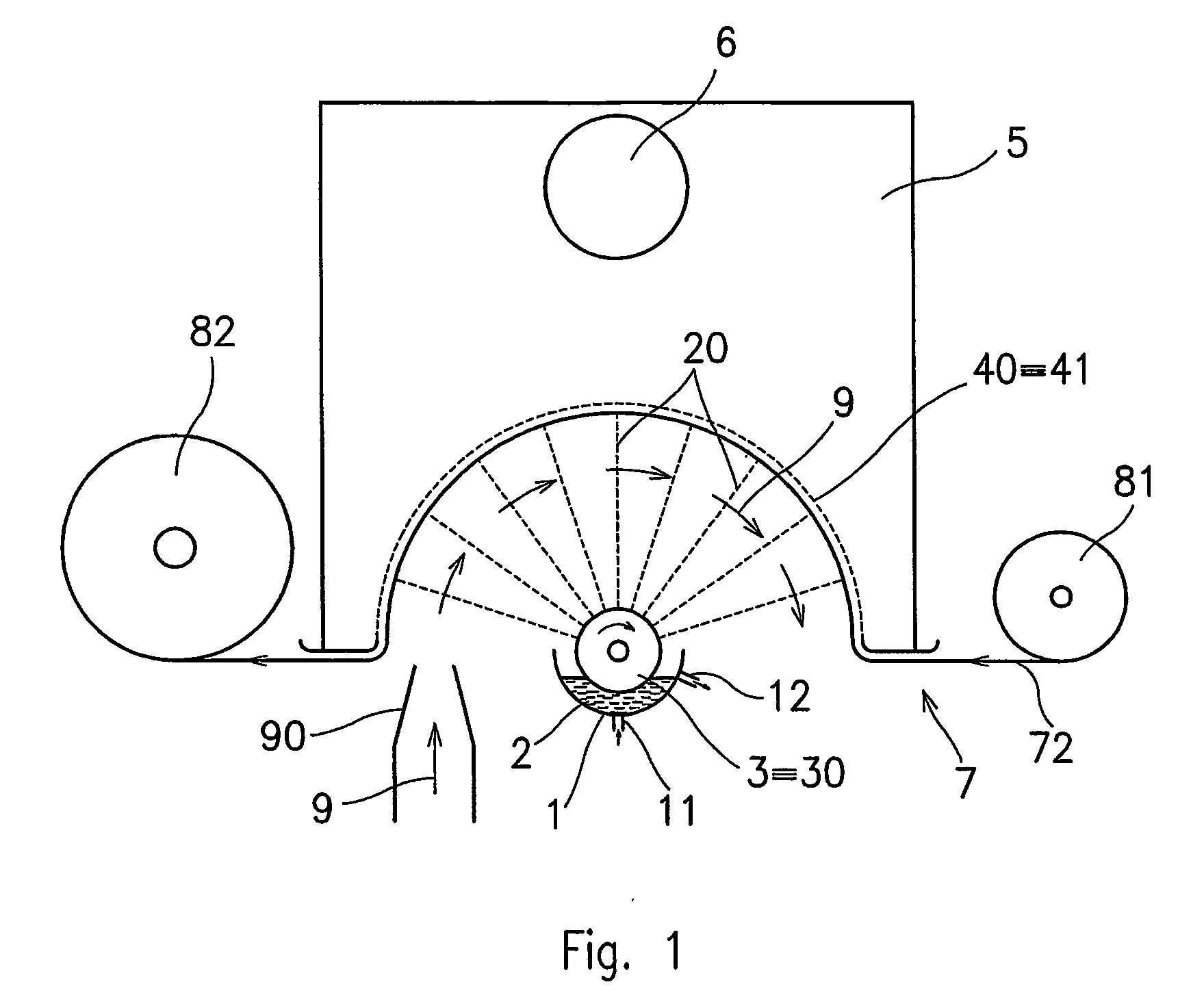

Method of nanofibres production from a polymer solution using electrostatic spinning and a device for carrying out the method

ActiveUS20060290031A1Quality improvementImprove uniformityElectric discharge heatingSpinnerette packsElectrospinningPotential difference

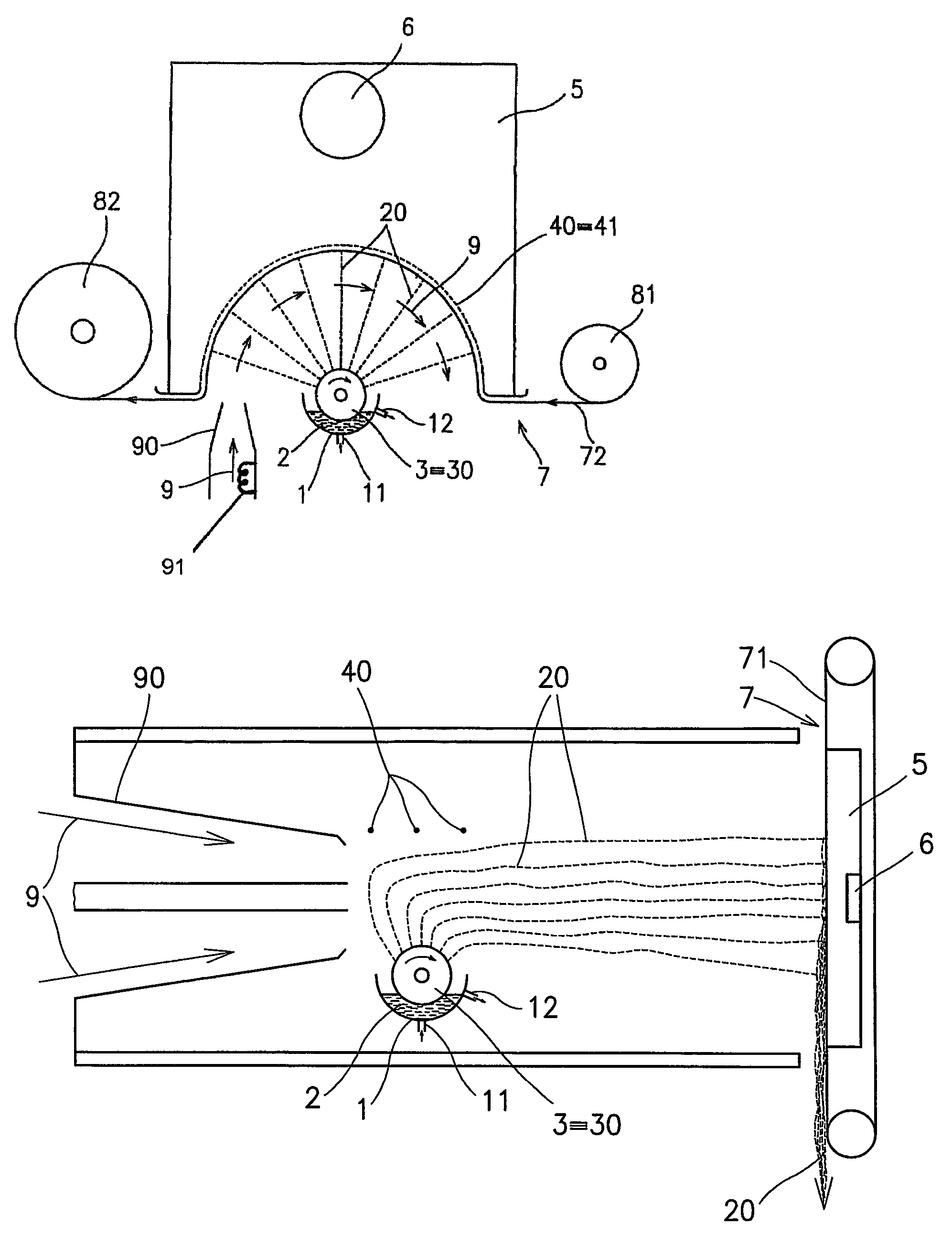

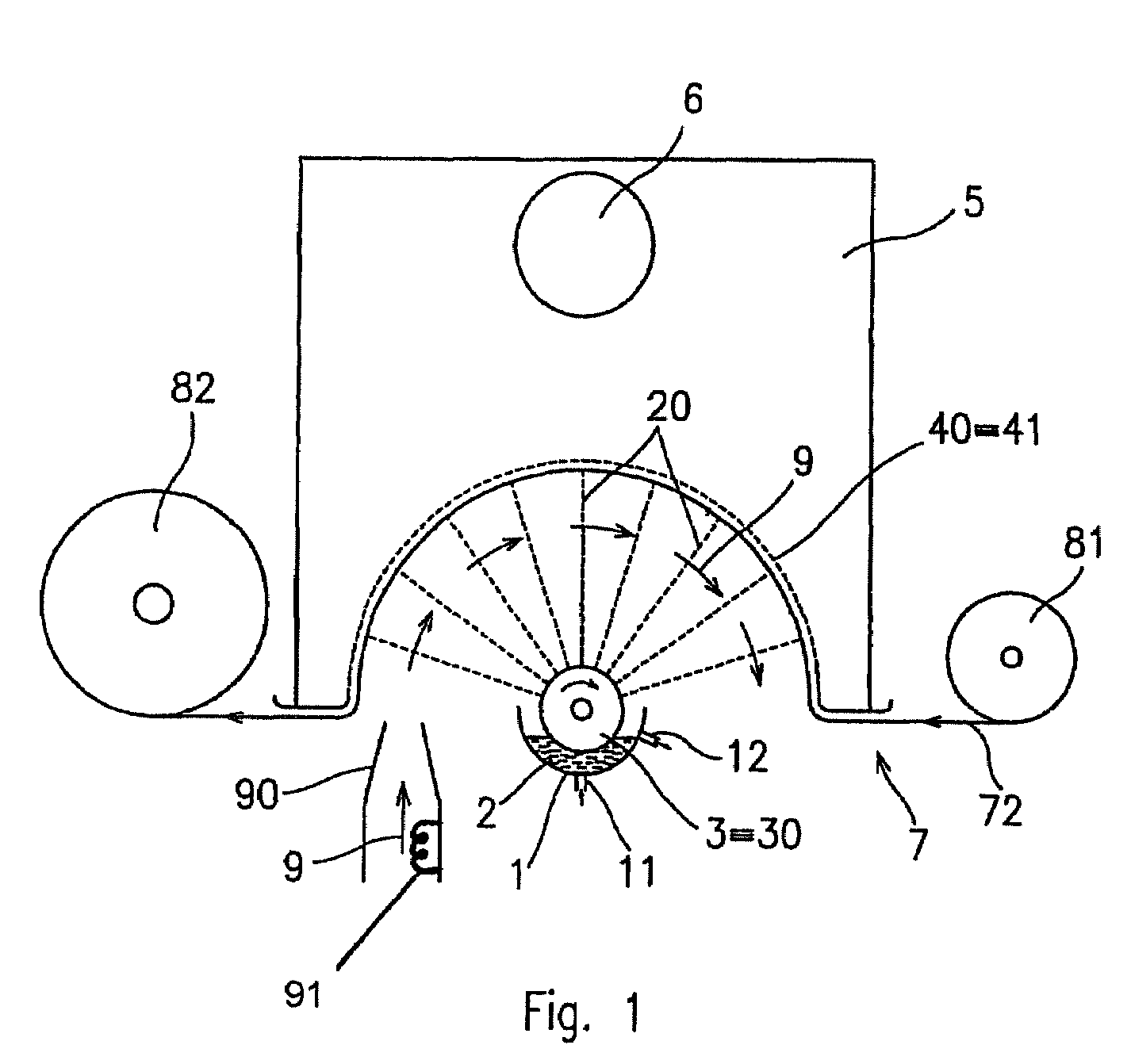

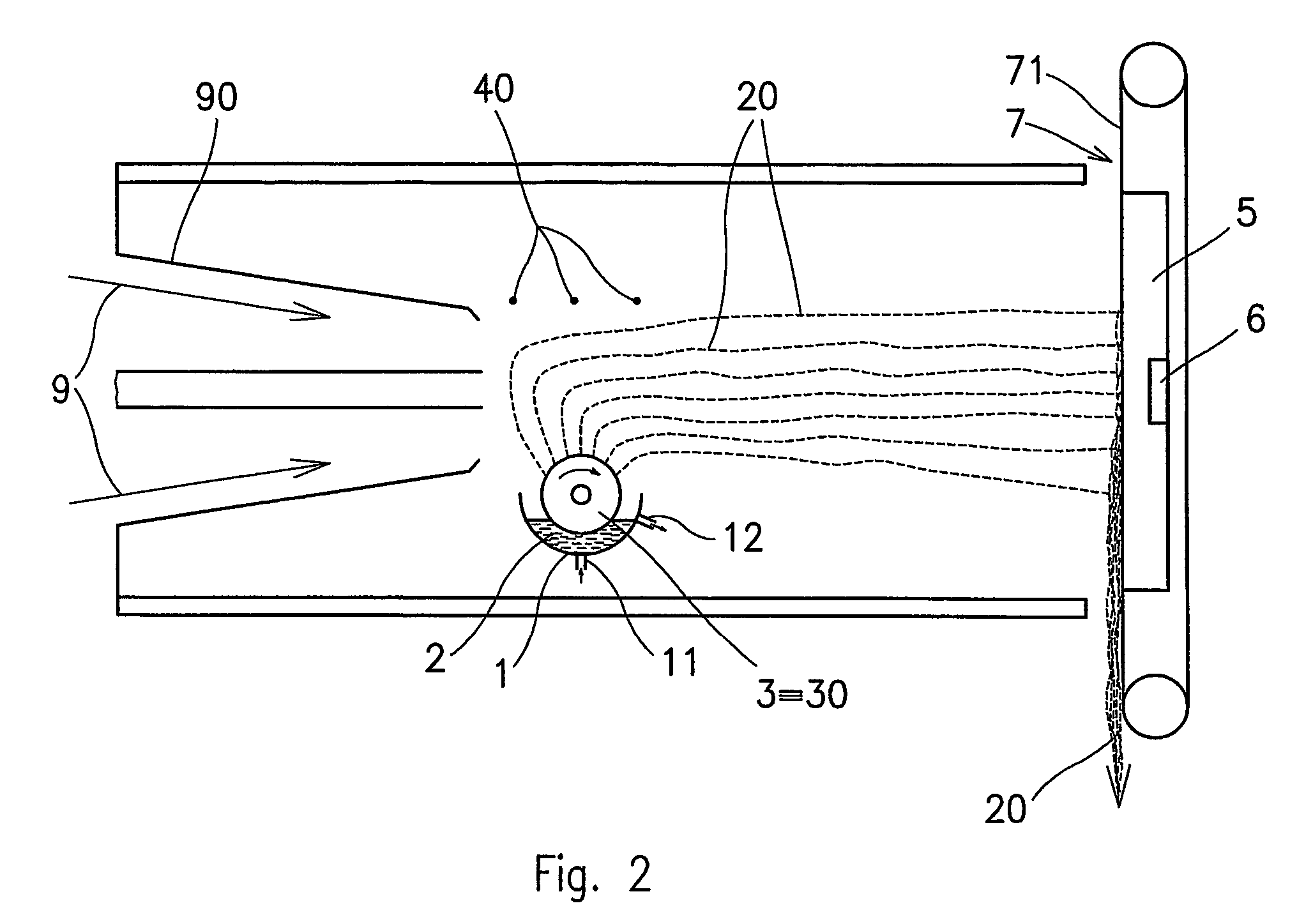

The invention relates to a method of nanofibres production from a polymer solution using electrostatic spinning in an electric field created by a potential difference between a charged electrode and a counter electrode. The polymer solution (2) is for spinning supplied into the electric field using the surface of the rotating charged electrode (30), while on a part of the circumference of the charged electrode (30) near to the counter electrode (40) is a spinning surface created, by which is a high spinning capacity reached. Further the invention relates to a device for carrying out the method, where the charged electrode (30) is pivoted and by its (bottom) part of its circumference it is immersed in the polymer solution (2), while against the free part of the circumference of the charged electrode (30) is positioned the counter electrode (40).

Owner:TECHNICKA UNIVEZITA V LIBERCI

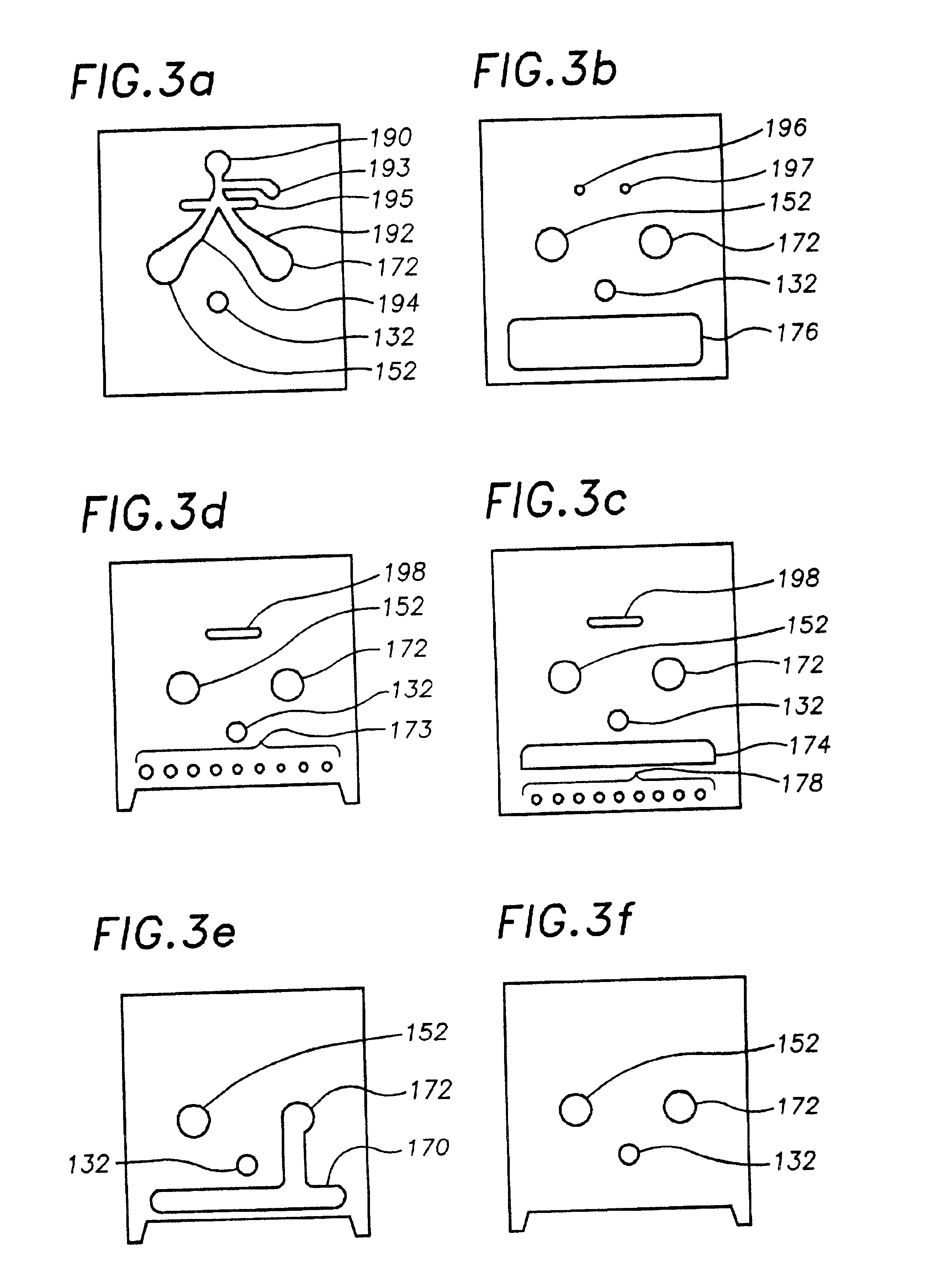

Attenuating fluid manifold for meltblowing die

InactiveUS6861025B2Quality improvementUniform physical propertiesSpinning head liquid feederConfectioneryDistribution characteristicEngineering

Melt blown nonwoven webs are formed by supplying attenuating fluid to a meltblowing die through an attenuating fluid distribution passage whose distribution characteristics can be changed while the die and manifold are assembled. By adjusting the distribution characteristics of the passage, the mass flow rate of attenuating fluid to channels in the meltblowing die and the temperature of the attenuating fluid at the die outlets can be made more uniform.

Owner:3M INNOVATIVE PROPERTIES CO

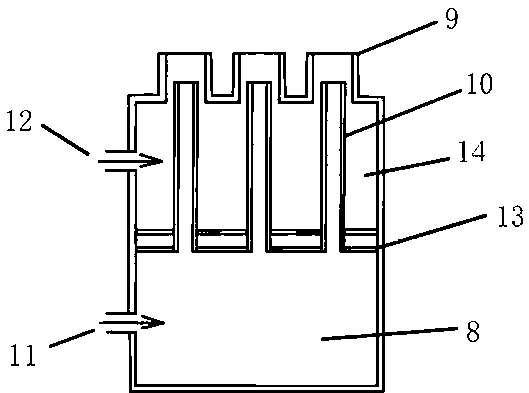

Meltblowing apparatus

InactiveUS6890167B1Reduce the amount requiredReduce air volumeLiquid surface applicatorsConfectioneryAdhesiveEngineering

A meltblowing apparatus for dispensing an adhesive through a plurality of first orifices of a die assembly fabricated from a plurality of laminated members to form a plurality of adhesive flows at a first velocity and dispensing air through a plurality of second orifices in the die assembly to form a plurality of air flows at a second velocity. The plurality of first and second orifices arranged in an alternating series so that each of the plurality of first orifices is flanked on substantially opposing sides by one of the plurality of second orifices, wherein the plurality of first and second orifices are oriented to direct non-convergently the plurality of adhesive flows and the plurality of air flows.

Owner:ILLINOIS TOOL WORKS INC

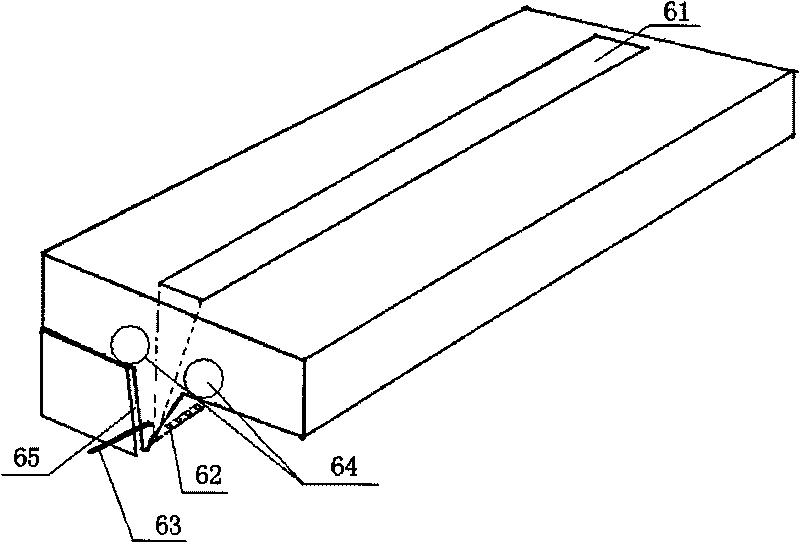

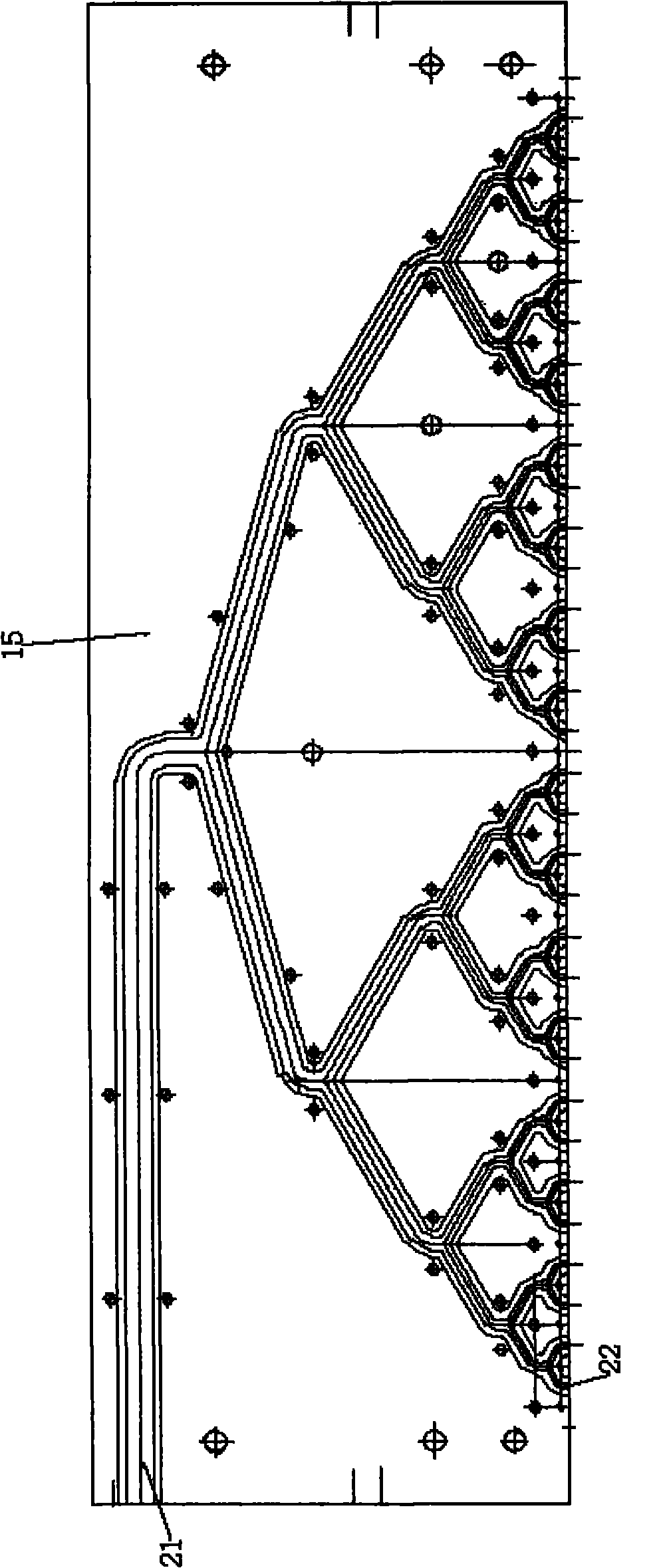

Saw tooth type needle-free electrostatic spinning device

ActiveCN102828259AAvoid cloggingAvoid cleaningSpinnerette packsArtificial thread manufacturing machinesNeedle freeElectrospinning

The invention discloses a saw tooth type needle-free electrostatic spinning device, which comprises a liquid supply system, a spinning system, a power supply system, a receiving system, a transmission system and a control system. The device is characterized in that the spinning system comprises a spinning manifold body, a spinning component and a center shaft; the exterior of the spinning manifold body has a horizontal cuboidal shape, and a horizontal cylindrical cavity is formed in the spinning manifold body; a main body of the center shaft is arranged in the cavity, and the two ends of the center shaft extend from the spinning manifold body, and are connected with the transmission system; the spinning component has an axially continuous or parallel thin rack structure, and points of a rack are outwards arranged on the center shaft, and can be driven by the center shaft to rotate; distances of 1 to 3mm are reserved between the points and the inner wall of the spinning manifold body; a liquid inlet pipe orifice of the spinning manifold body is communicated with a spinning metering pump of the liquid supply system, and an overflow port of the spinning manifold body is connected to a liquid storage device of the liquid supply system through a pipe, and is reserved between the bottom of the spinning component and the center shaft; and rectangular spinning openings are reserved in positions opposite to the highest parts of the spinning component on the upper surface of the spinning manifold body.

Owner:TIANJIN POLYTECHNIC UNIV

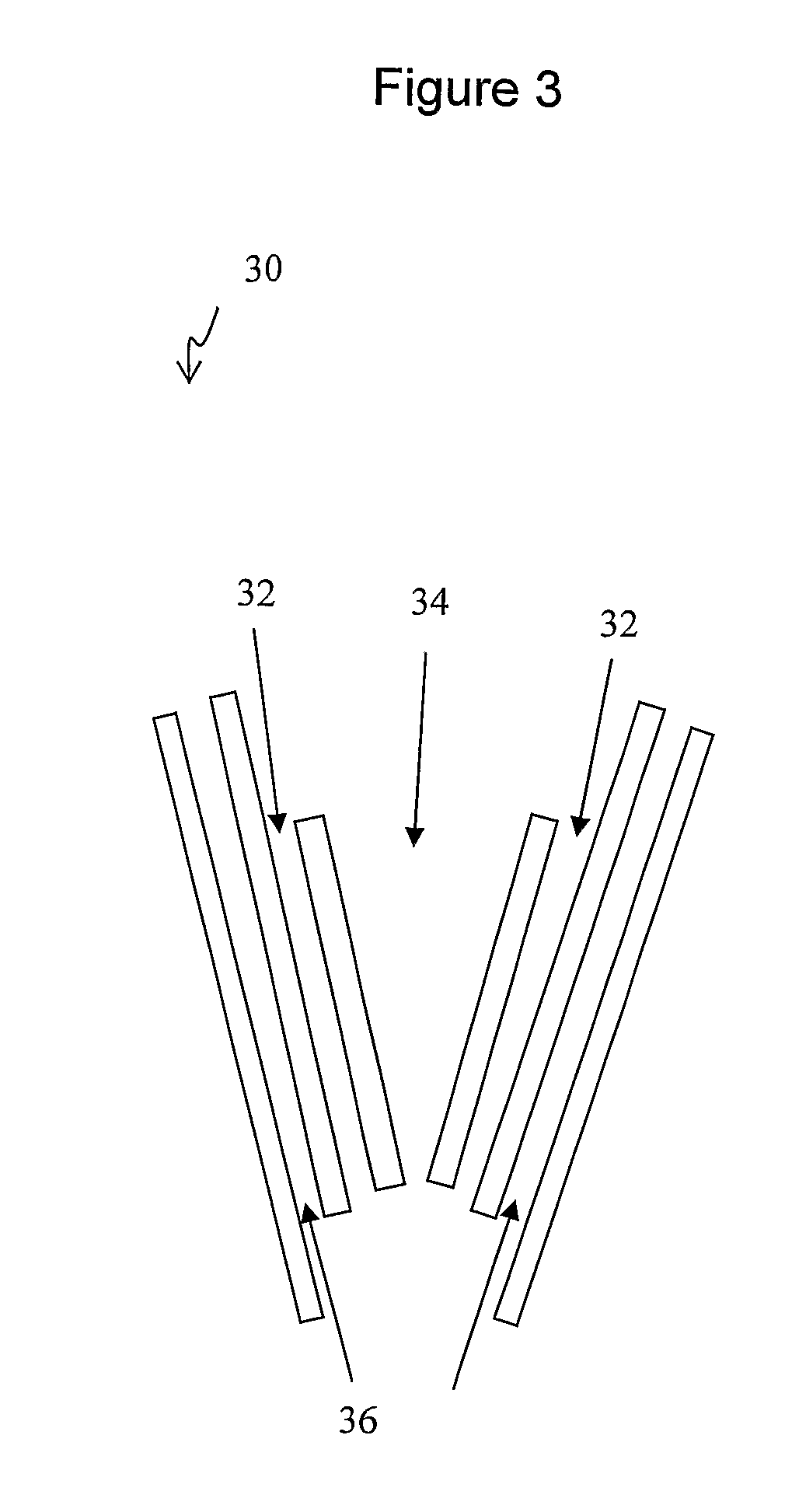

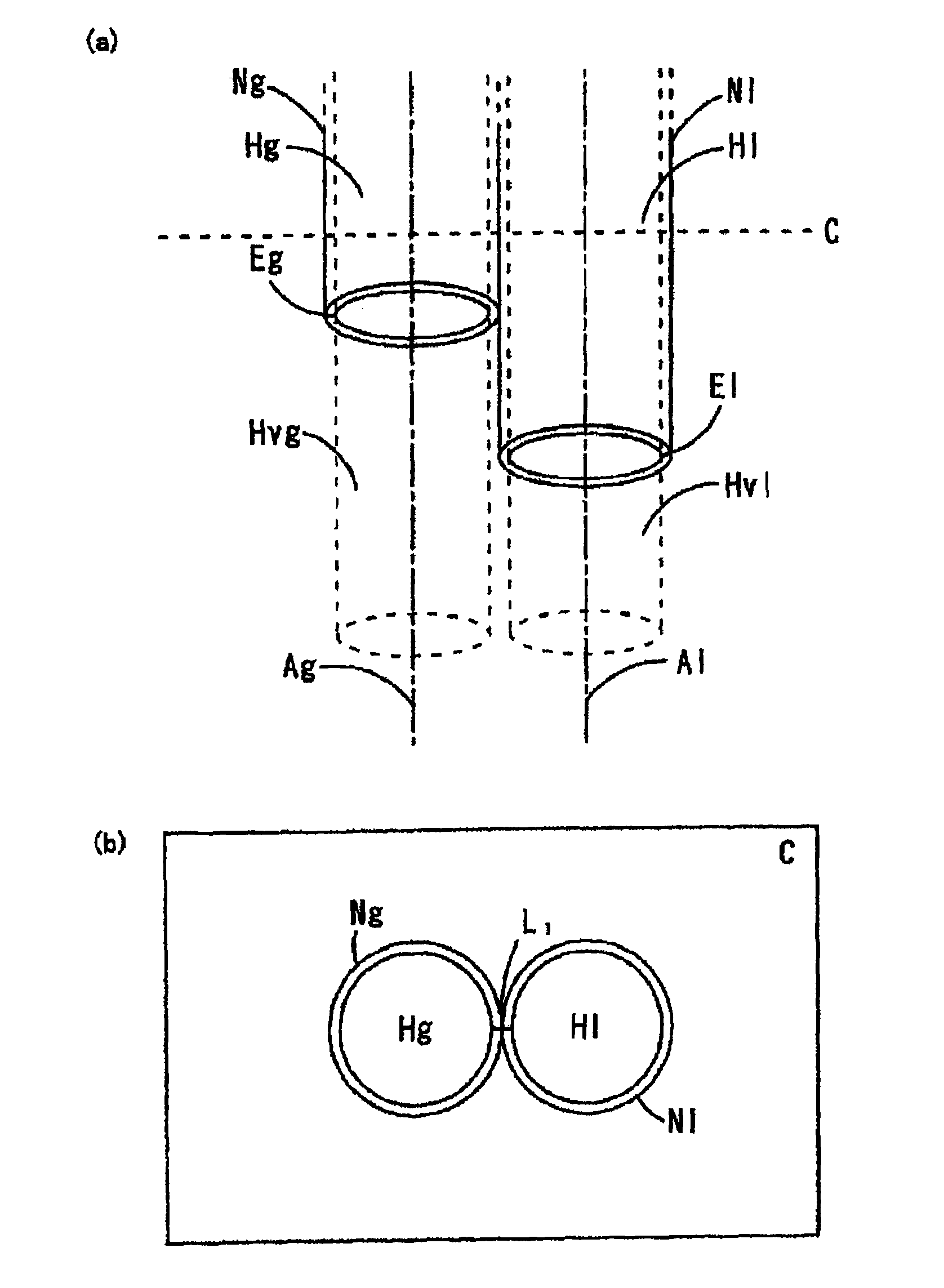

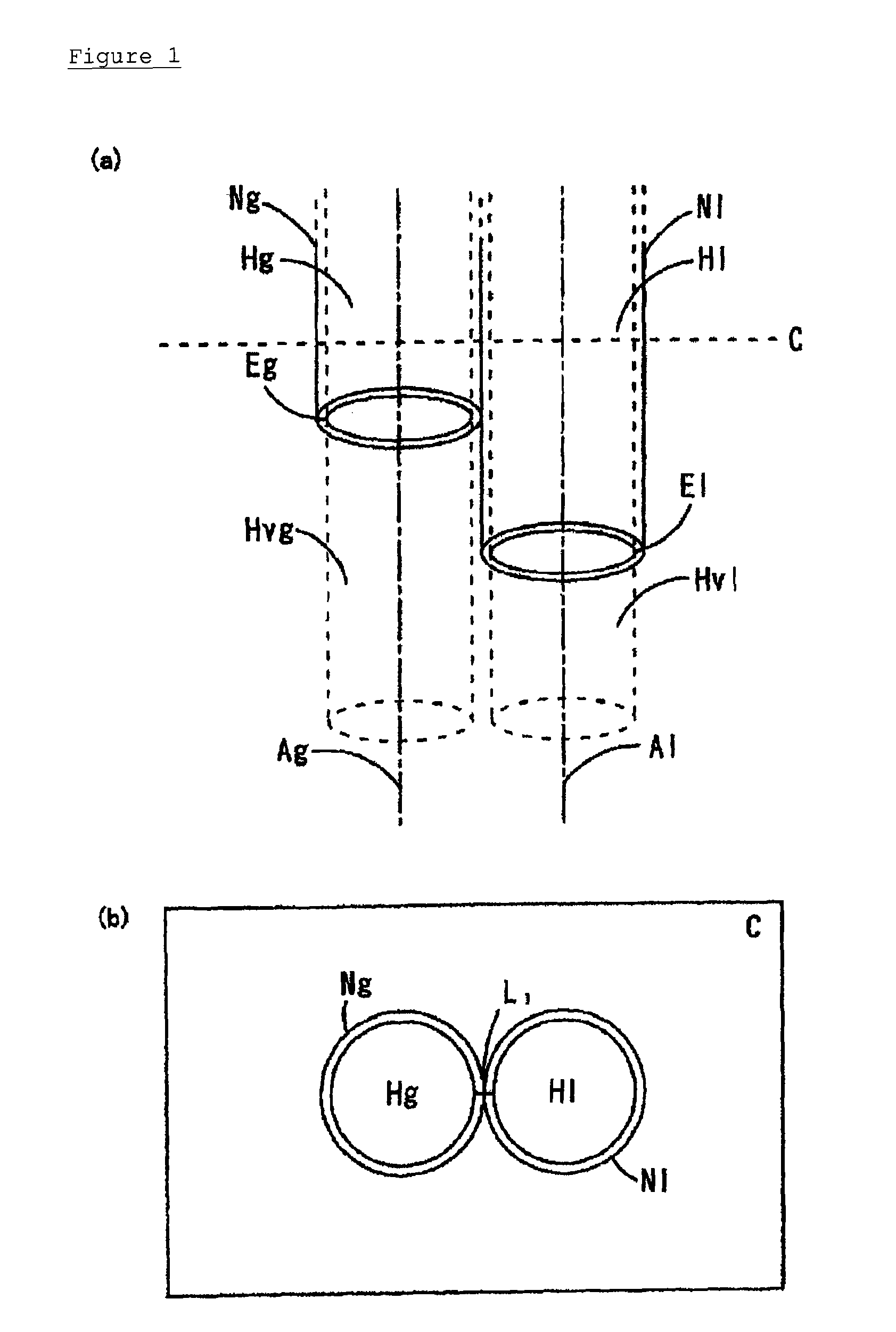

Fiber and nanofiber spinning apparatus

The present invention relates to a method and an apparatus for spinning fibers, or fiberizers, using a rotary fiber-making die system made up of thin plates, embodied by a housing fixture, configured and stacked to define slots, channels and / or grooves through which the material used to make the fibers will flow. The die system allows for the production of different size and types of fibers, including nanofibers having a diameter of less than 1 micron, and facilitates a variety of cost effective methods for extrusion. The use of plates means the dies can be manufactured cost effectively, with easier clean-outs, replacements and / or variations.

Owner:MEMPRO LTD

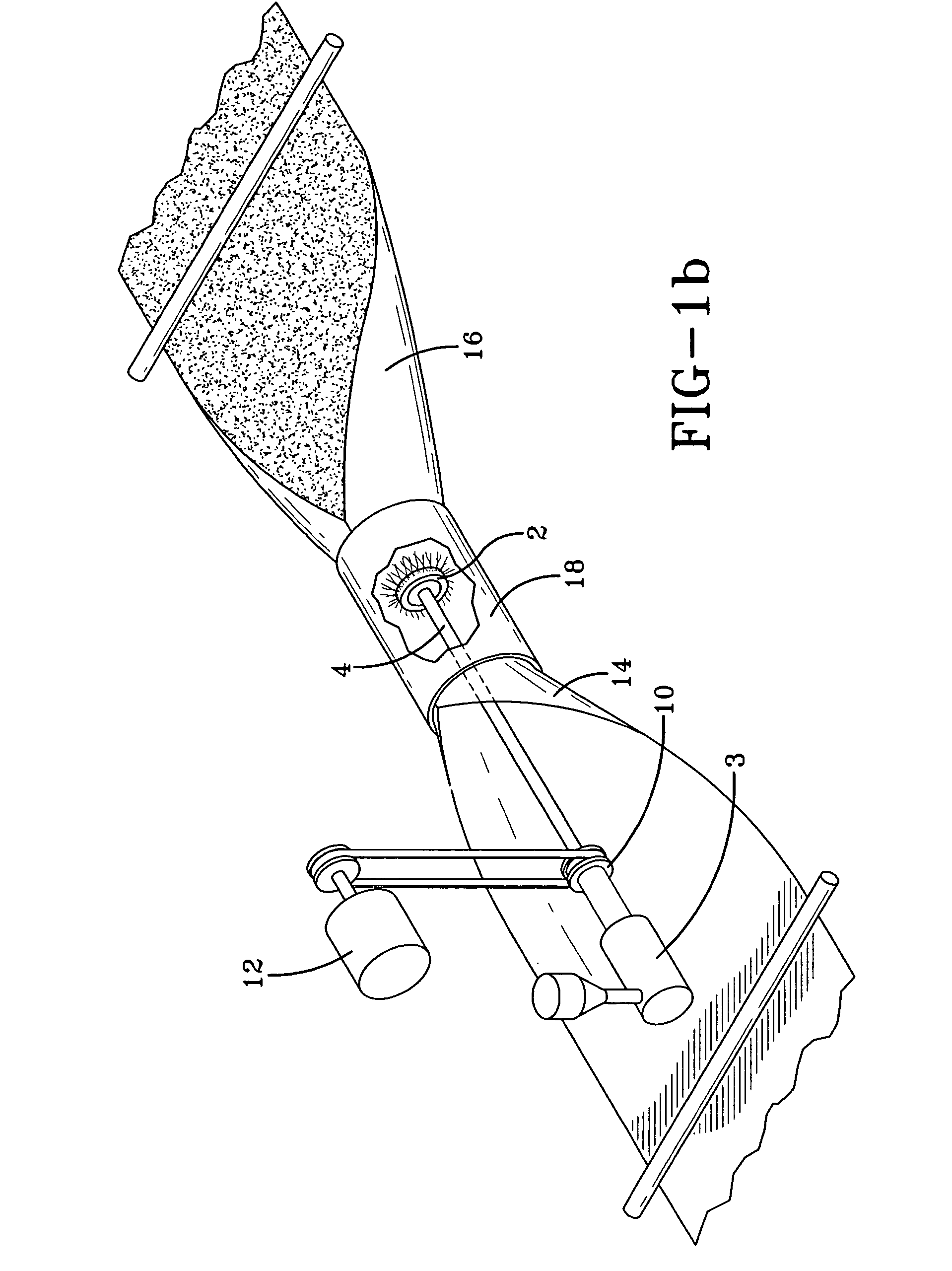

Method and device for producing electrospun fibers

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

Process of forming a non-woven cellulose web and a web produced by said process

ActiveUS20090258562A1Economical and efficientMonocomponent cellulose artificial filamentWoven fabricsCellulose fiberEngineering

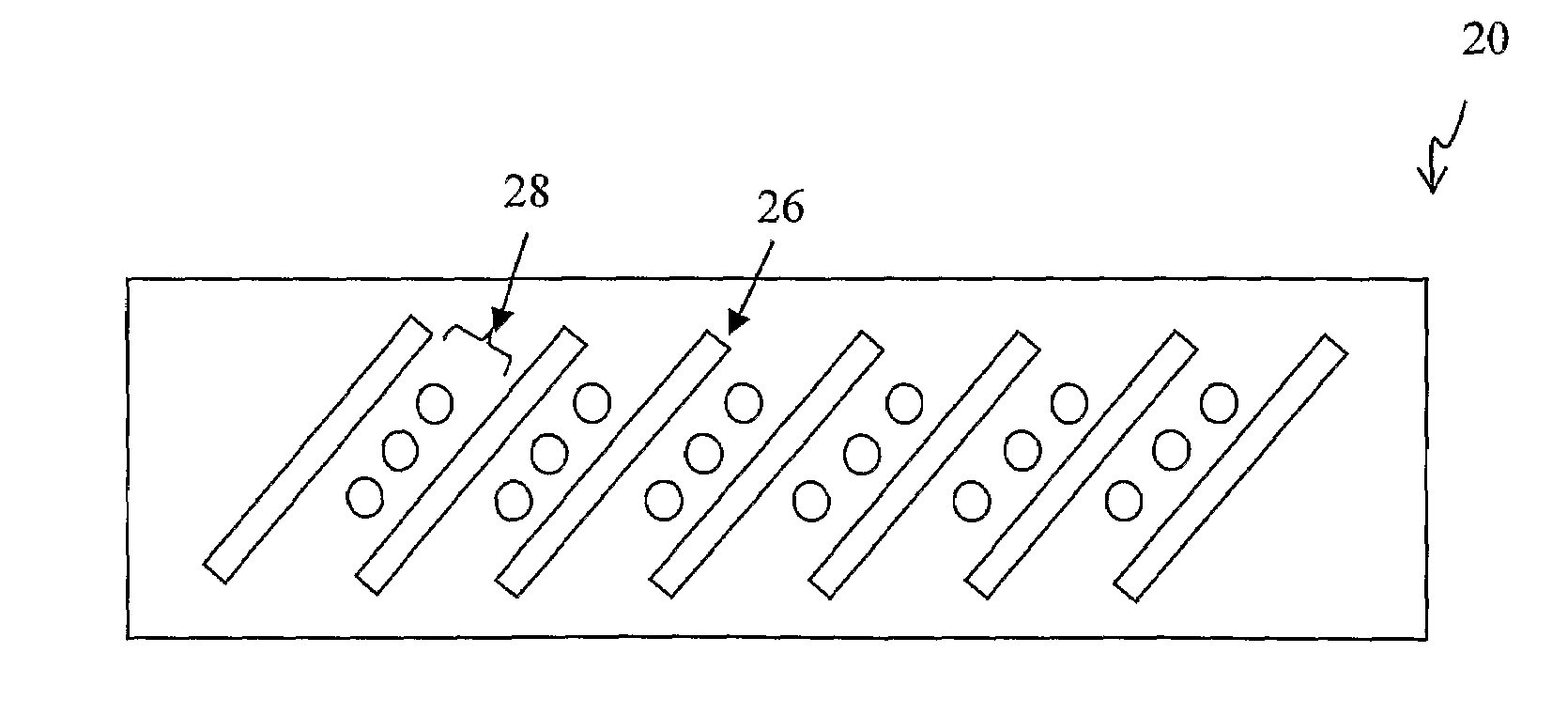

A process is disclosed of forming cellulose fibers. The process includes extruding an aqueous solution of cellulose and a solvent through a first member to form molten filaments. The first member has multiple rows of first and second openings with a nozzle positioned in each of the first openings. At least one of the nozzles in one row is staggered from at least one of the nozzles in an adjacent row. At least a portion of each of the molten filaments is shrouded in a pressurized gas emitted through each of the first openings. Each of the molten filaments is contacted with a liquid to remove some of the solvent and transform each of the molten filaments into a continuous solid fiber. The continuous solid fibers are then collected on a moving surface to form a non-woven cellulose web.

Owner:REIFENHAUSER GMBH & CO

Graphene conductive polyester fibers and preparation method thereof

ActiveCN104164707AOvercome cohesionOvercome uniformity issuesElectroconductive/antistatic filament manufactureSpinnerette packsPolyesterFiber

Owner:湖州市中磊化纤有限公司

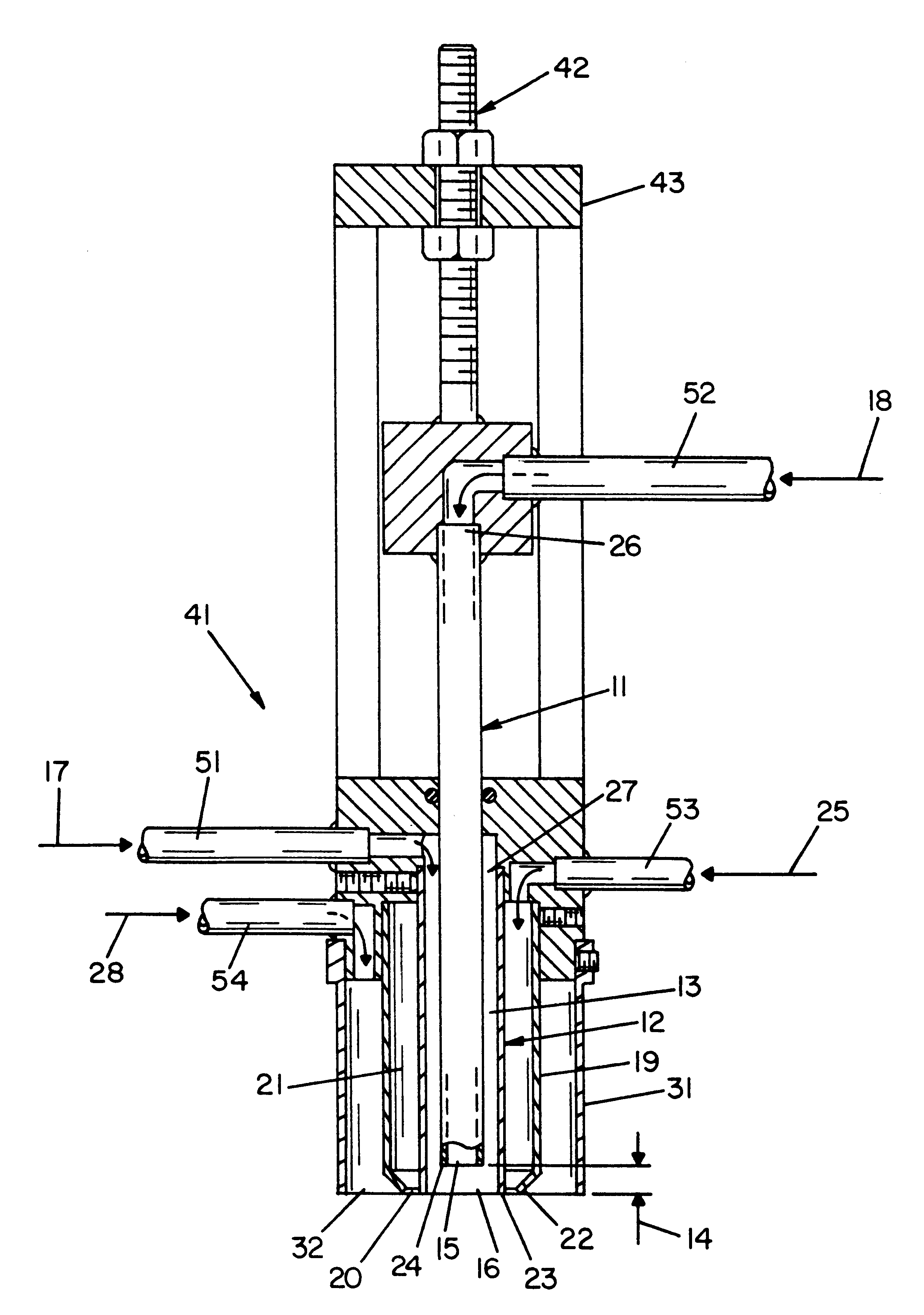

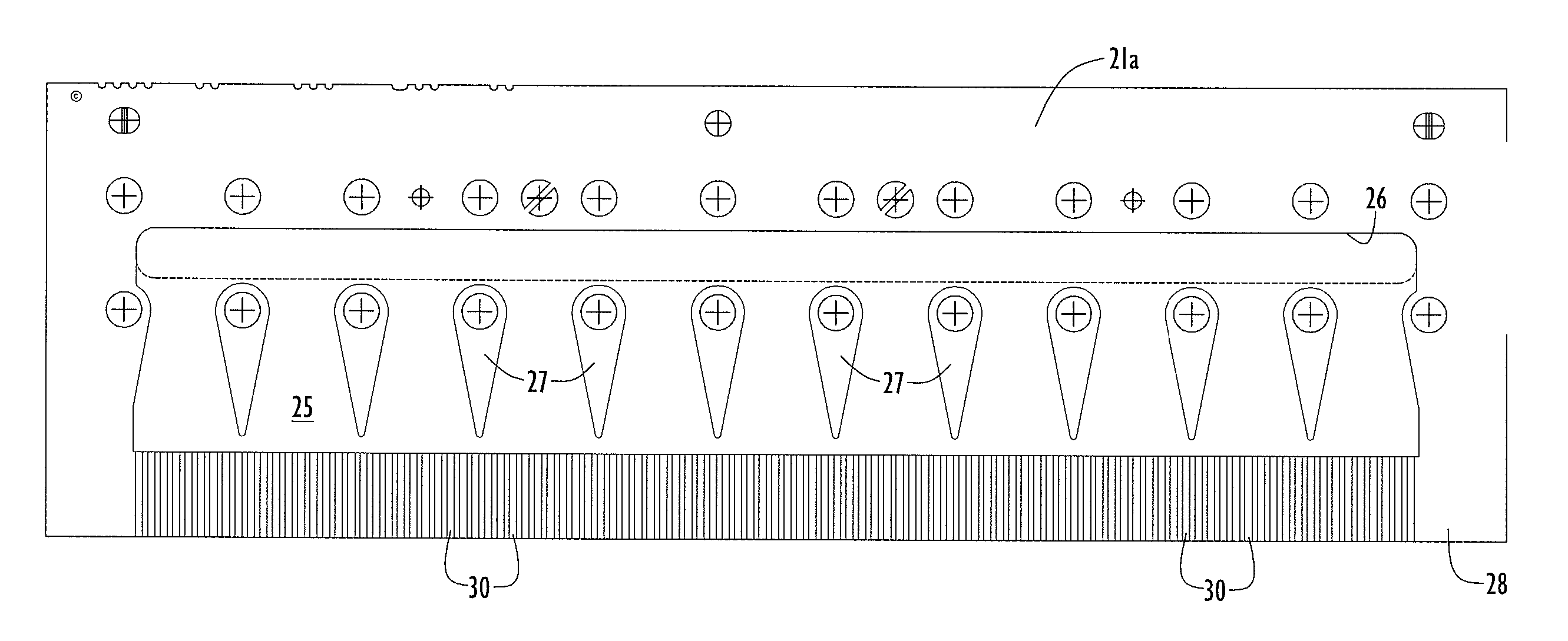

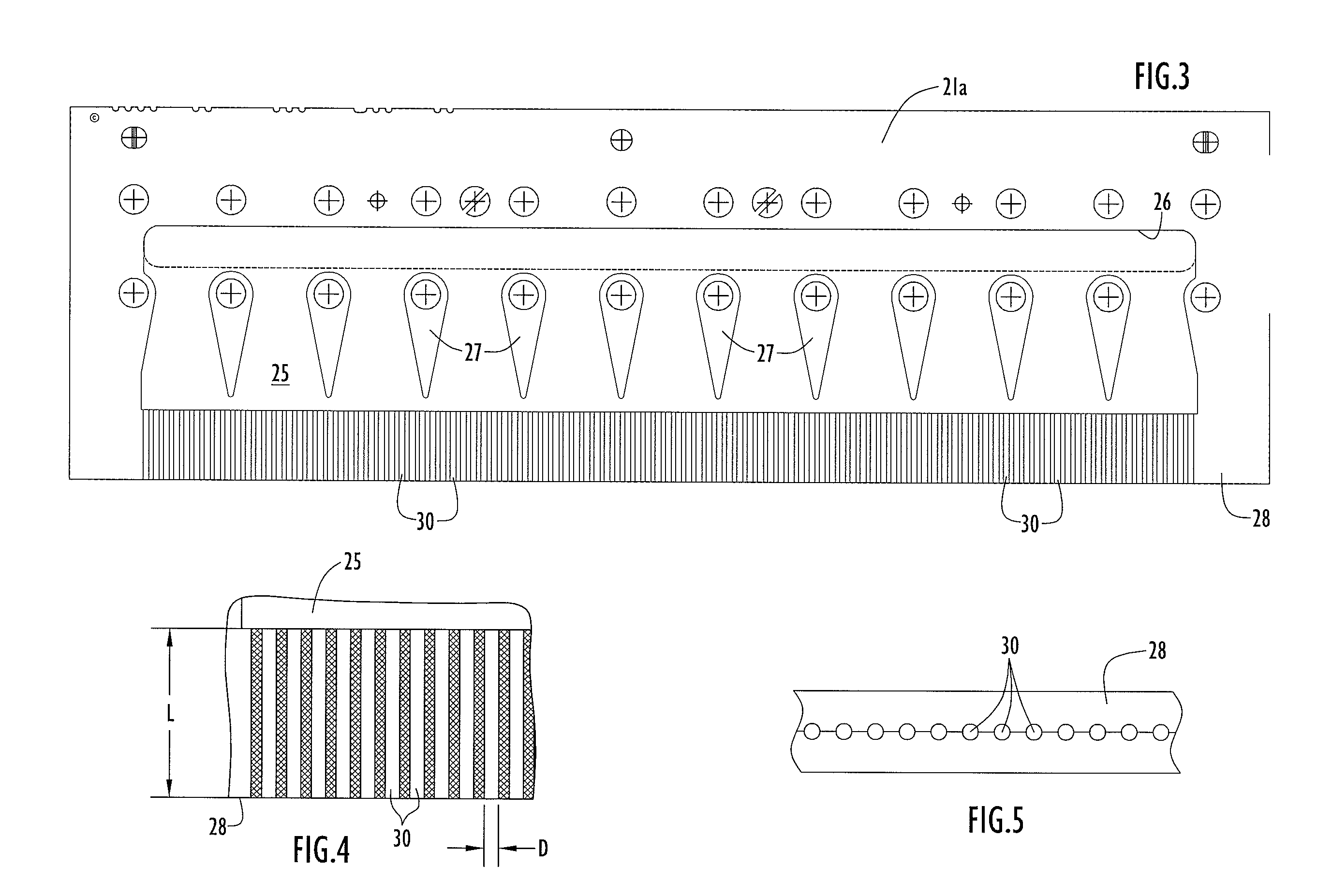

Method and apparatus for production of meltblown nanofibers

A method and apparatus for producing polymeric nanofibers utilizes a meltblown spinneret die having spin holes formed by grooves in plate(s) surface(s) of plate(s) where polymer exits at the plate(s) edge(s). The grooves are smaller than 0.005″ wide×0.004″ deep and have an L / D at least as large as 20:1. Flow rates of polymer through the apparatus are very low, on the order of 0.01 ghm or less. The method / apparatus produces may also be viewed as including A meltblown fabric having fibers mostly less than 0.5 microns in diameter is produced.

Owner:HILLS CO

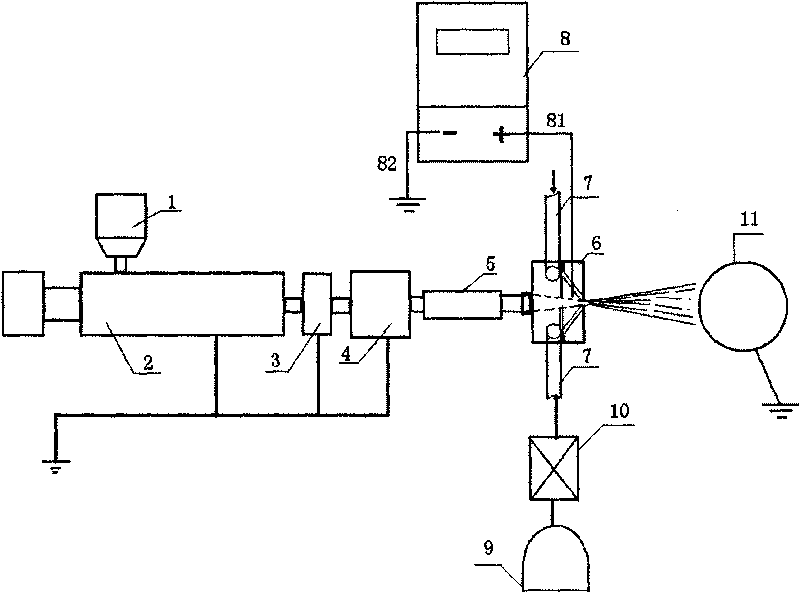

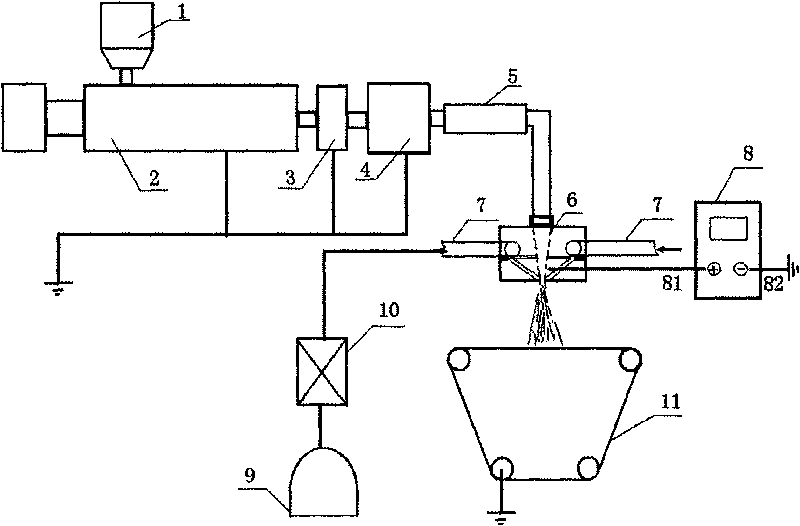

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

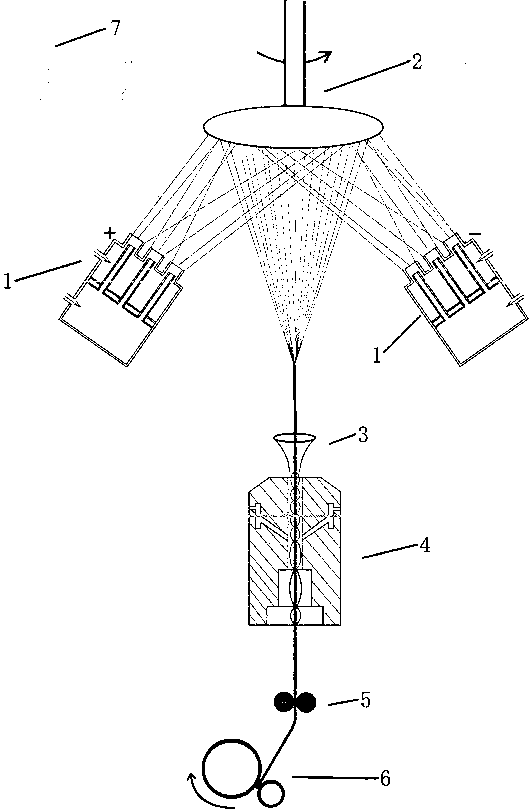

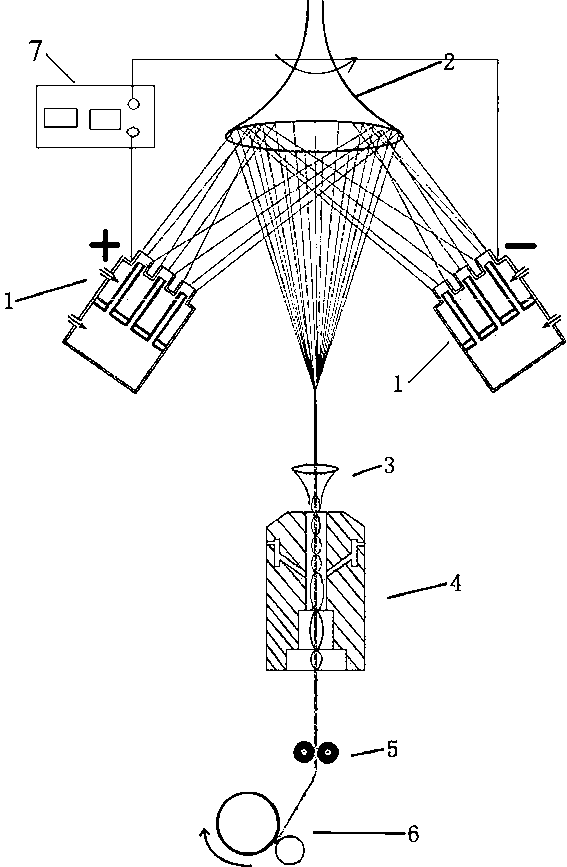

Jet yarn spinning device for electrostatic spun nano fiber and preparing method

InactiveCN102703998AIncrease productionReduce volatilitySpinnerette packsFilament/thread formingYarnNanofiber

The invention discloses a jet yarn spinning device for an electrostatic spun nano fiber, which includes a collecting device, wherein two thread jetting devices are arranged on the two sides of the collecting device and connected with a high-voltage electrostatic generator; a buncher is arranged below the collecting device; the two thread jetting devices are arranged between the collecting device and the buncher and symmetrically and oppositely arranged along the axis; a jet nozzle twister is arranged below the buncher; a delivery roller is arranged below the jet nozzle twister; a winding mechanism is arranged below the delivery roller; and the collecting device, the buncher, the jet nozzle twister and the delivery roller are arranged along the same axis from top to bottom. The electrostatic spun nano fiber spinning device integrates thread jetting, collecting, drawing, twisting and winding, and can continuously prepare the electrostatic spun nano fiber yarns. The nano fiber spinning method has simple process, high yarn yield, is suitable for multiple polymer yarn solutions, and realizes the continuous and scaled preparation of the nano fiber yarns.

Owner:ZHONGYUAN ENGINEERING COLLEGE

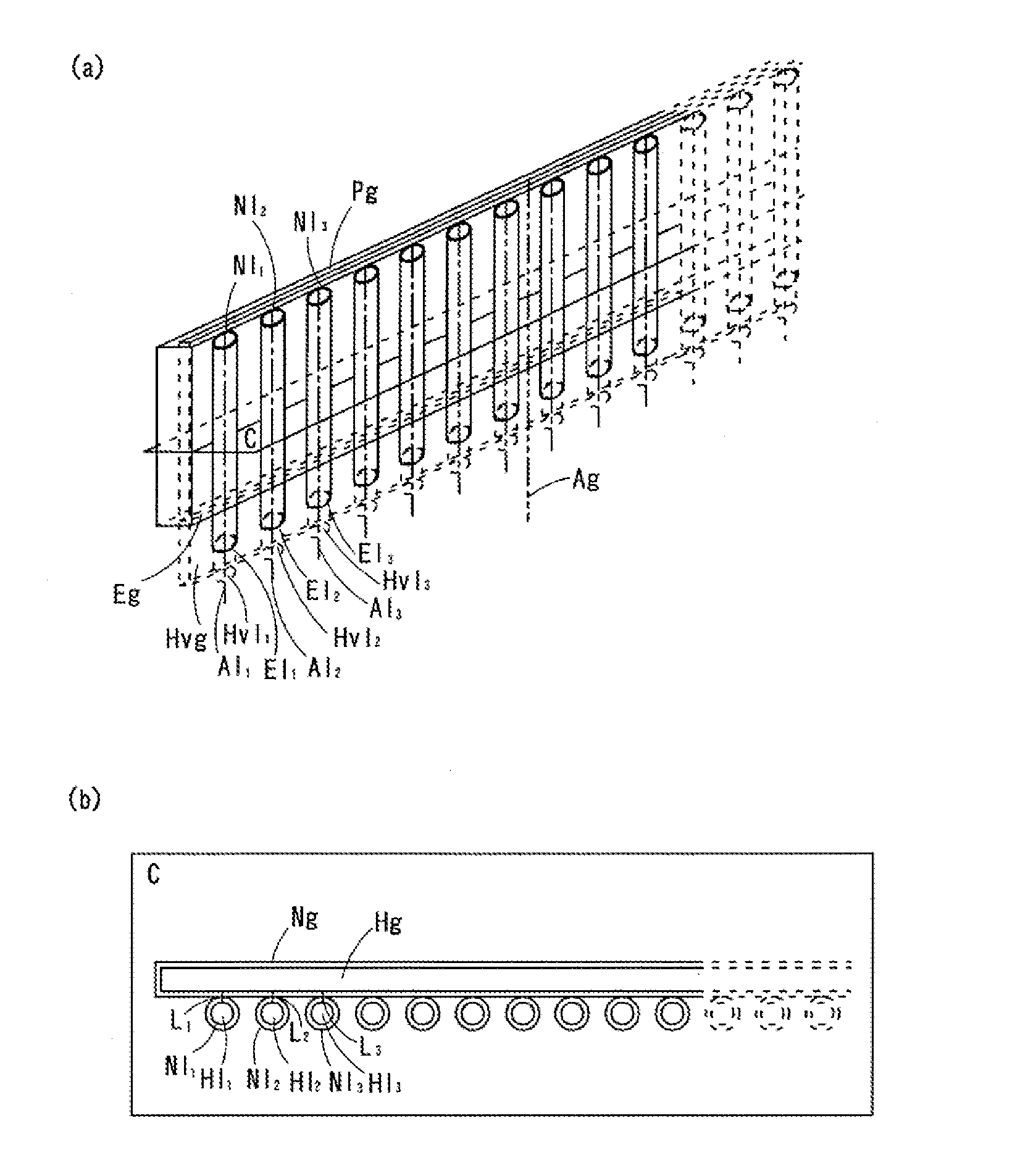

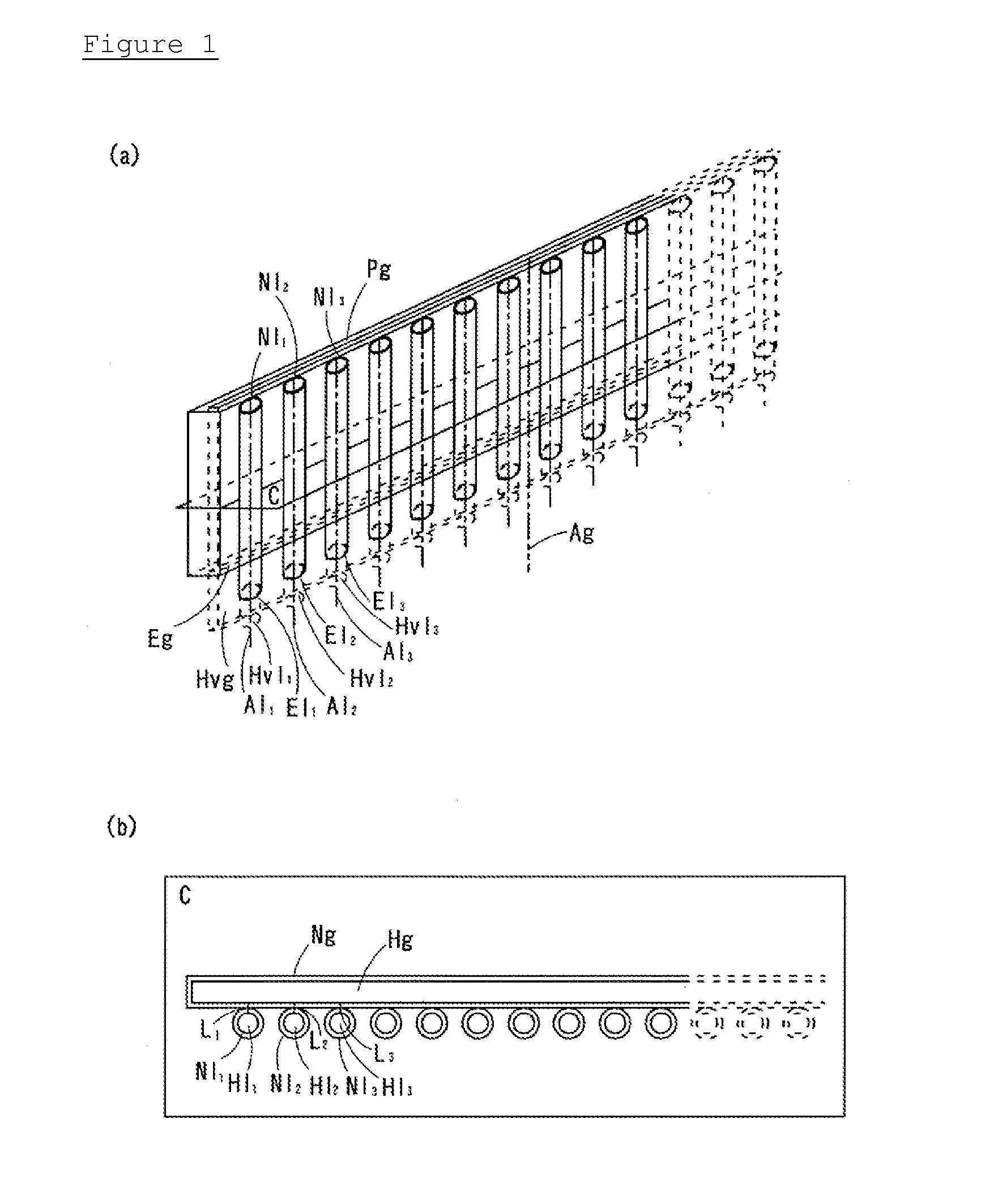

Spinning apparatus, and apparatus and process for manufacturing nonwoven fabric

Owner:JAPAN VILENE CO LTD

Apparatus and die cartridge assembly adapted for use therewith, and process for producing fibrous materials

Owner:AVINTIV SPECIALTY MATERIALS INC

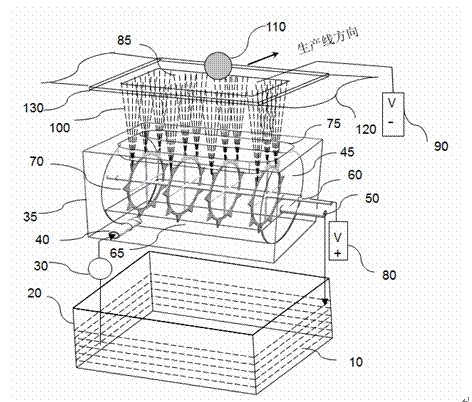

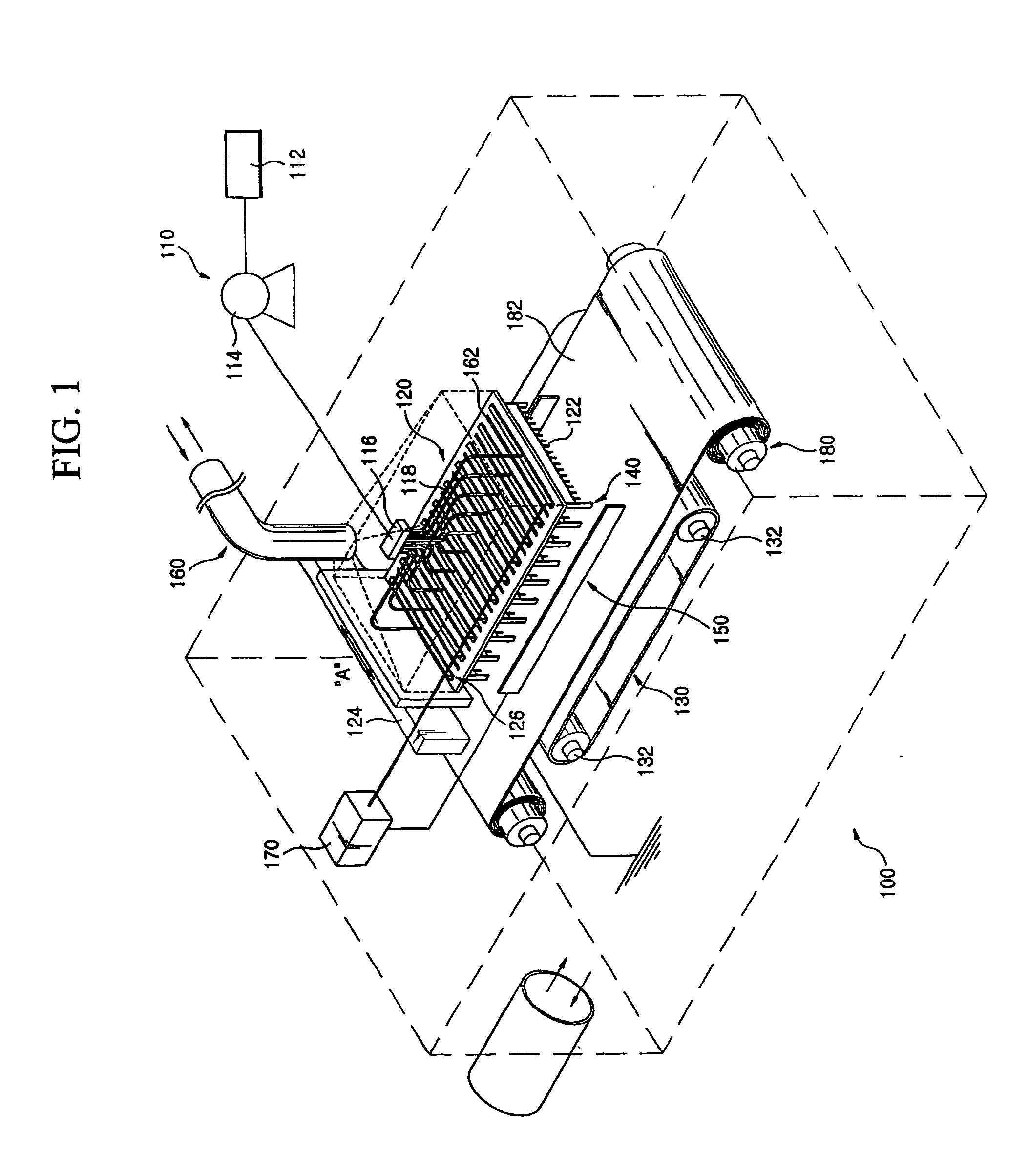

Apparatus for producing nanofiber utilizing electospinning and nozzle pack for the apparatus

The apparatus for producing a nanofiber includes a supply unit (110) for supplying melted polymer for fiber material, a spinning unit (122) having several radiation nozzles (122) to which first voltage having a polar is applied to discharge the polymer solution supplied from the supply unit in a filament form, a collector (130) spaced apart form the spinning nozzles in order to pile the filament from the spinning unit and applied to second voltage having opposite polar to the first voltage, and a control unit (140) applied to the first voltage having the same polar as the charged filament and extended from an end of the spinning nozzle toward the collector at least at both sides of the spinning unit in order to prevent repulsion and dispersion of the filament stream radiated from each spinning nozzle.

Owner:NANOPHIL

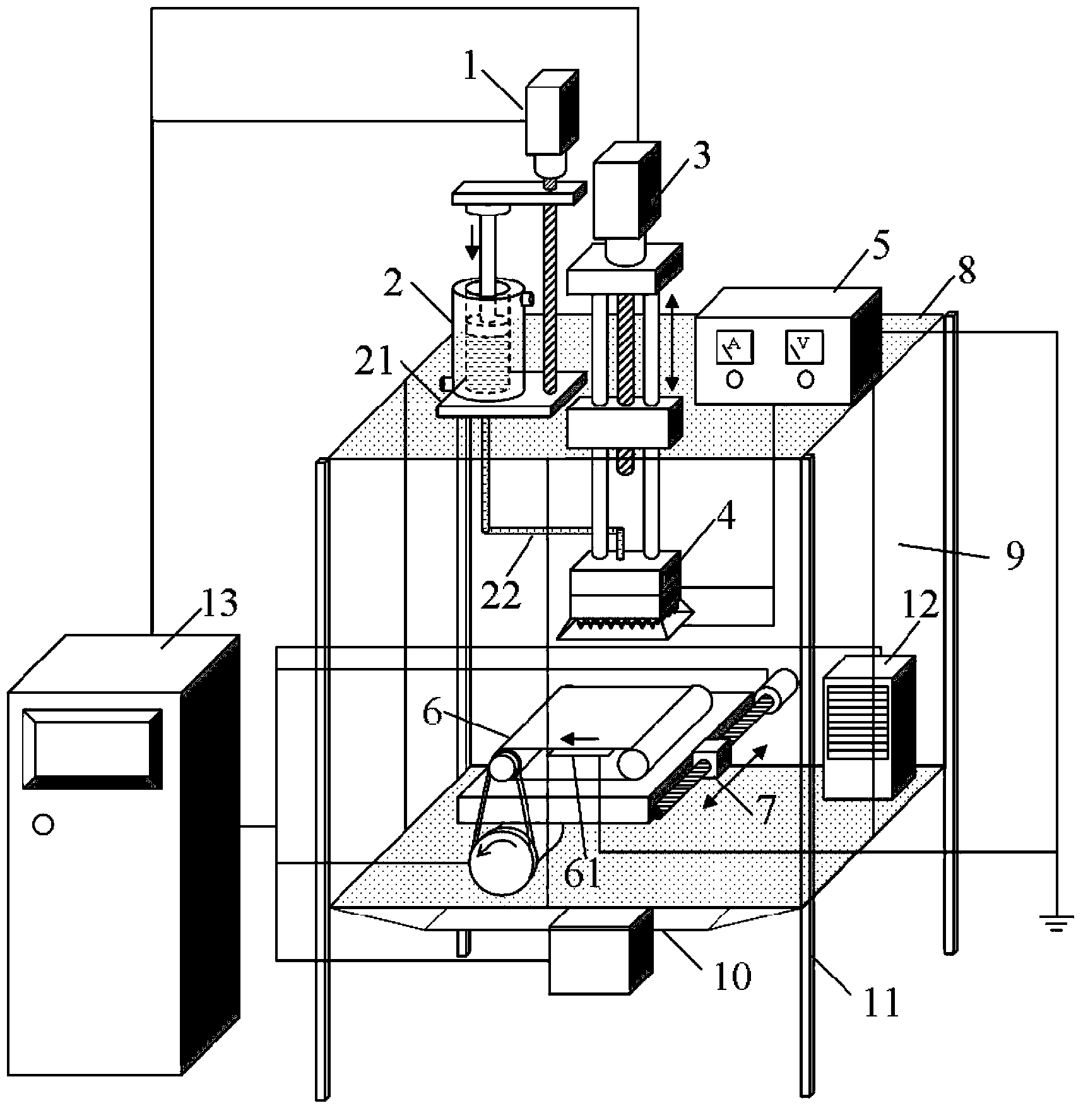

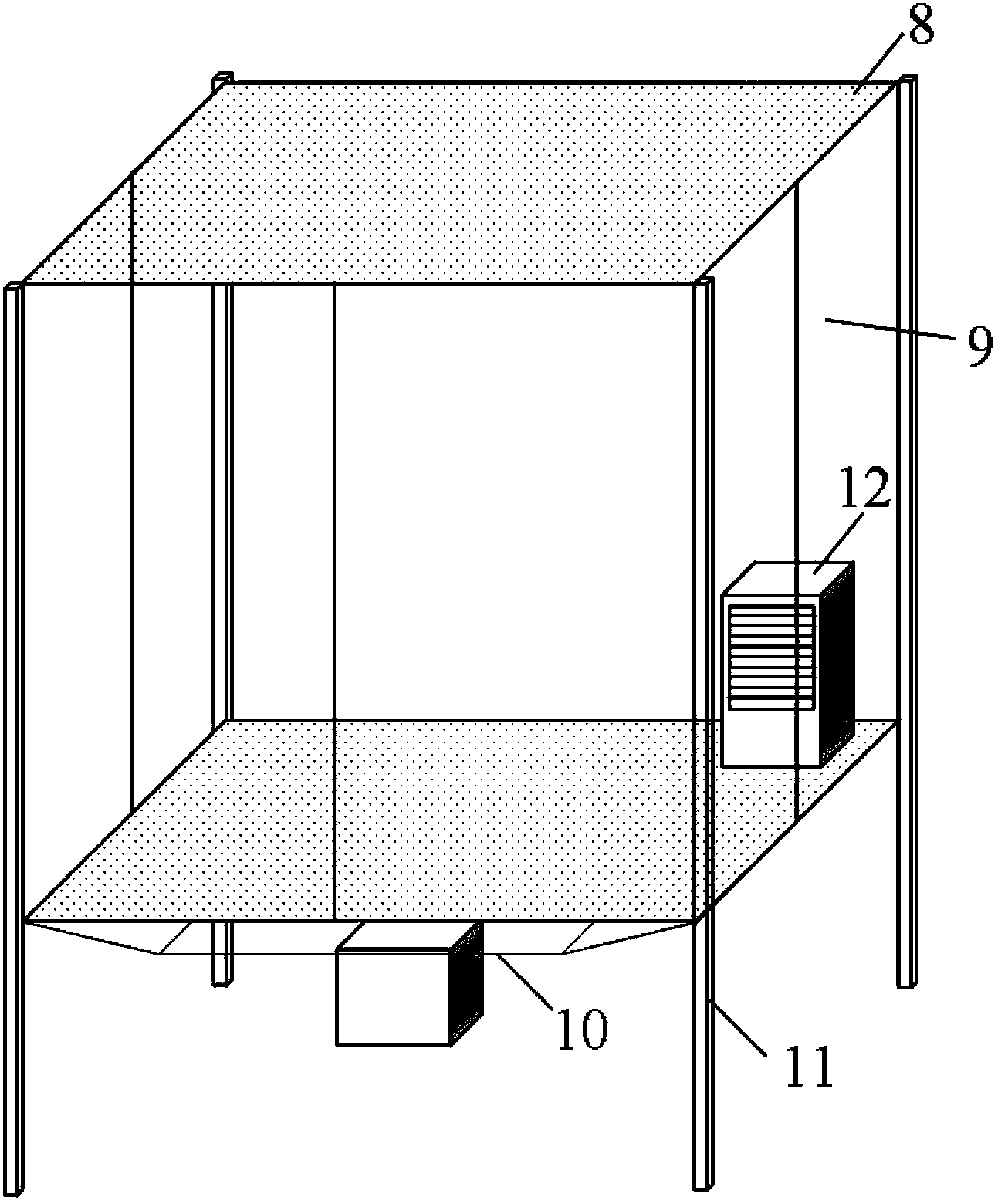

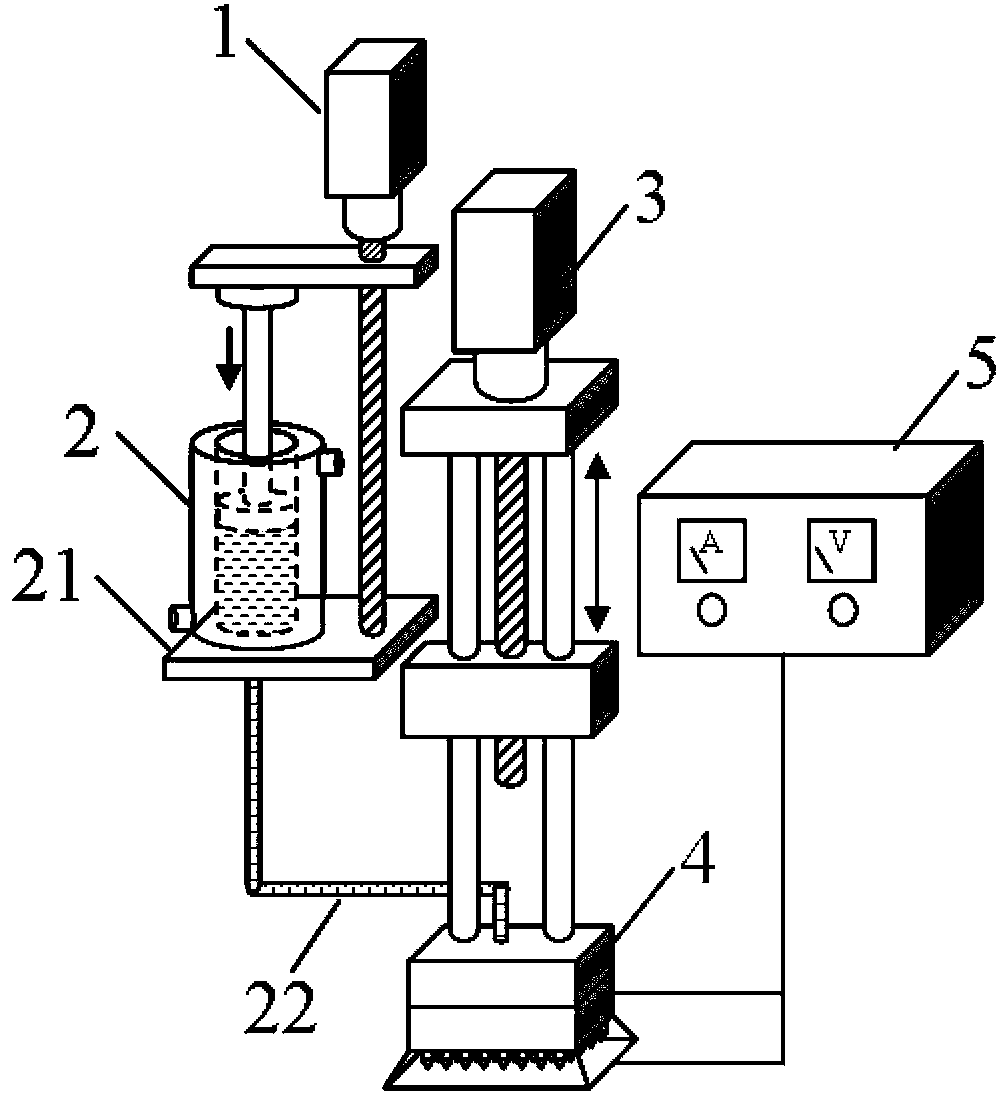

Multi-spraying-nozzle electrostatic spinning device with controllable spinning environment

InactiveCN103409818AControl impactImprove spinning efficiencySpinnerette packsFilament/thread formingFiberElectrospinning

The invention relates to a multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment. The multi-spraying-nozzle electrostatic spinning device comprises a spinning environment control unit, an electrostatic spinning unit and a spinning connecting unit. An air current stabilization cover is arranged on the top of a spinning box body; an air suction and solvent recovery device is arranged at the bottom of the spinning box body; a constant-temperature and constant-humidity system is arranged in the spinning box body; a spinning liquid material barrel, a micro spinning solvent propelling device, a material barrel fixing support and an electrostatic generator are installed on the top of the spinning box body; the spinning solvent in the material barrel enters a three-dimensional multi-spraying-nozzle spinneret plate through a tube; a spinneret plate lifting device penetrates through the air current stabilization cover and is connected with the three-dimensional multi-spraying-nozzle spinneret plate; a continuous fiber mat receiving device and a horizontal receiving surface moving device are arranged below the spinneret plate. Due to the multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment, an existing electrostatic spinning method is improved, the sealed spinning box body is additionally arranged to improve the electrostatic spinning environment, and accordingly requirements for temperature and humidity in the spinning process are satisfied; meanwhile, due to the adoption of the three-dimensional multi-spraying-nozzle spinneret plate, spinning efficiency is greatly improved and the multi-spraying-nozzle electrostatic spinning device with the controllable spinning environment can be applied to industrial production.

Owner:DONGHUA UNIV

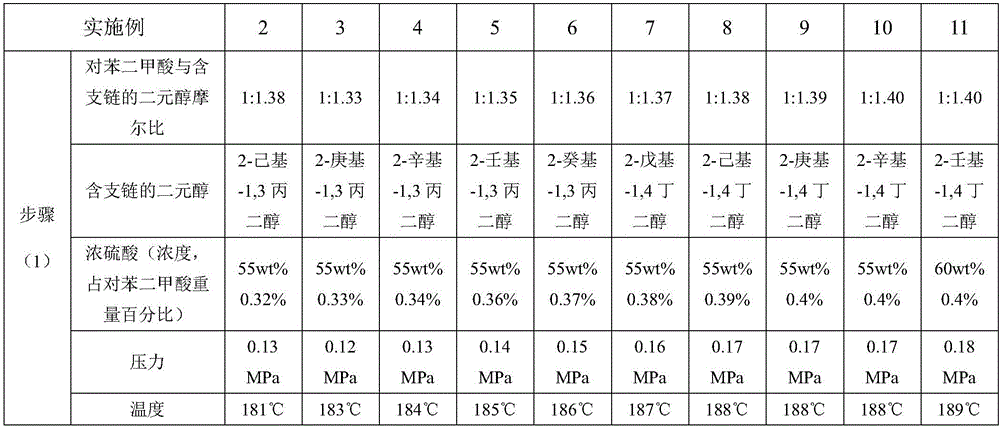

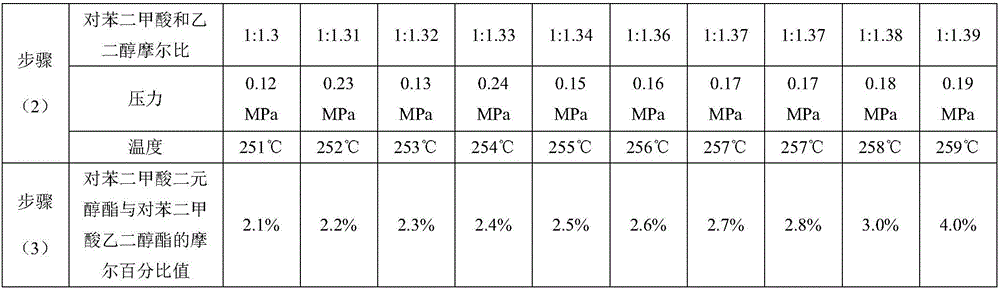

Polyester fibres and preparation method thereof

ActiveCN106367835AImprove dyeing effectEasy to processSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

Colored Structured Protein Products

InactiveUS20080254199A1Monocomponent protein artificial filamentConfectioneryProtein fiberColoring agents

The present invention provides a process for producing a colored structured protein product with protein fibers that are substantially aligned and the resultant product. Specifically, the plant protein is combined with a colorant and extruded, forming a colored structured protein product with protein fibers that are substantially aligned and the resultant product.

Owner:SOLAE LLC

Spinning apparatus, apparatus and process for manufacturing nonwoven fabric, and nonwoven fabric

InactiveUS20110130063A1Smooth rotationImprove productivitySpinnerette packsCeramic shaping apparatusProduction rateManufactured apparatus

Provided are a spinning apparatus capable of stably spinning fibers having a small fiber diameter with a high productivity, an apparatus comprising the same for manufacturing a nonwoven fabric, a process for manufacturing a nonwoven fabric using the nonwoven fabric manufacturing apparatus, and a nonwoven fabric produced by the process.The spinning apparatus of the present invention comprises one or more exits for extruding liquid, which are capable of extruding a spinning liquid, and one or more exits for ejecting gas, which extend linearly and are located upstream of each of the exits for extruding liquid and which are capable of ejecting a gas, wherein a shearing force by the gas and its accompanying airstream can be single-linearly exerted on the spinning liquid extruded. The apparatus of the present invention for manufacturing a nonwoven fabric comprises a fibers collection means as well as the spinning apparatus. The process of the present invention for manufacturing a nonwoven fabric is a process using the apparatus for manufacturing a nonwoven fabric. The nonwoven fabric of the present invention is a nonwoven fabric produced by the process.

Owner:NIPPON BAIRIIN

Dissolvable fibrous web structure article comprising active agents

InactiveUS20140329428A1Inorganic/elemental detergent compounding agentsCosmetic preparationsPersonal careFiber

The personal care compositions of the present invention are in the form of an Article comprising a dissolvable fibrous web structure. The fibers of the dissolvable fibrous web structure comprise a surfactant; a water soluble polymeric structurant; and a plasticizer. Additionally the ratio of the water soluble water soluble polymeric structurant to the active agent in the fiber is 3.5 or less.

Owner:THE PROCTER & GAMBLE COMPANY

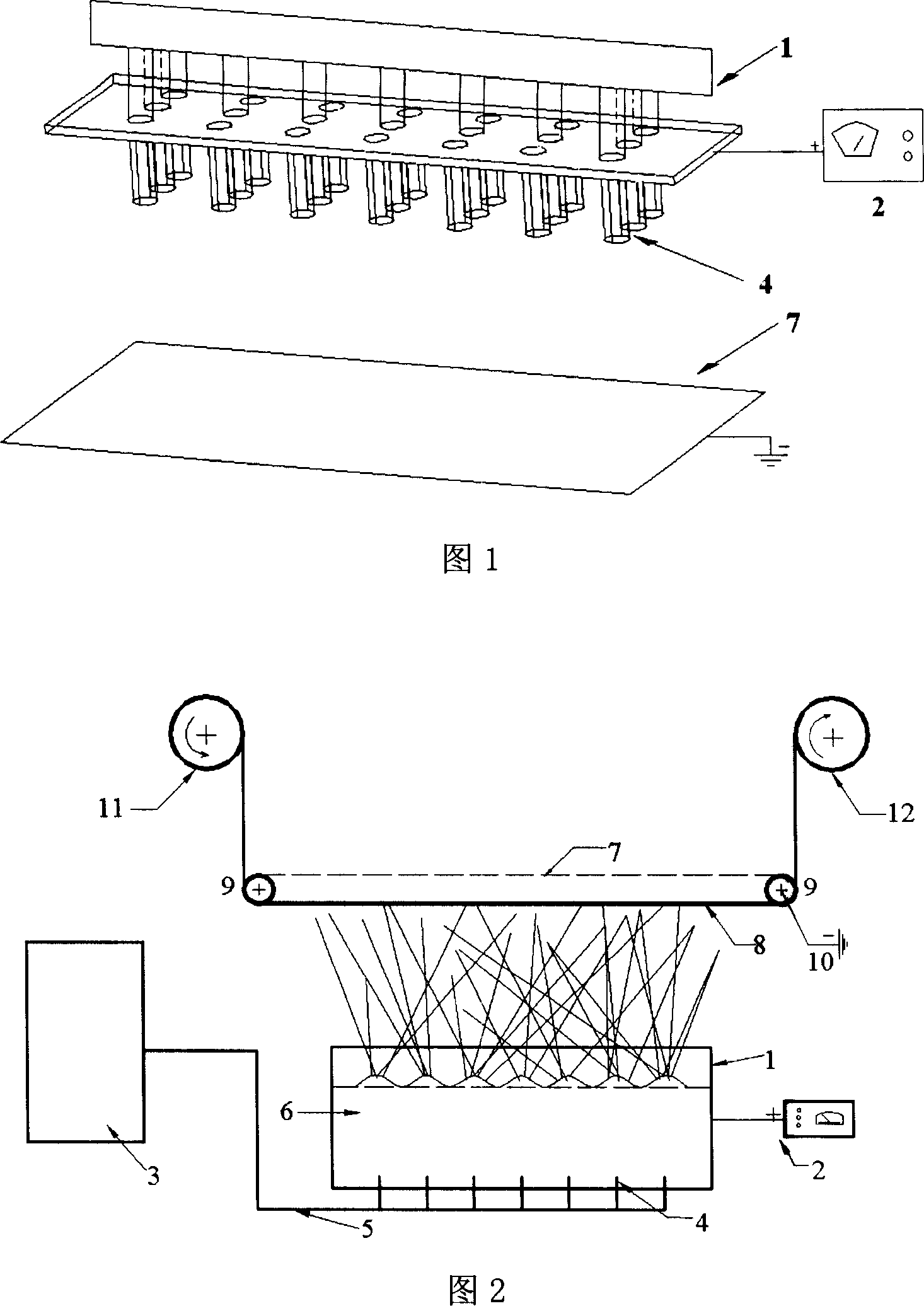

High-performance multineedle electrostatic spinning jet device

InactiveCN1962966AUniform thicknessReduce jet electrostatic repulsionSpinnerette packsFilament/thread formingFiberElectrospinning

The efficient multineedle electrostatic spinning sprinkling device includes constant pressure supplying system, spinnerette connected with the constant pressure supplying system, receiver electrode plate and electrostatic generator; said spinnerette is multineedle combined spinnerette, it includes spinnerette main body, cover and seal ring the two, the main body is provided with fluid cavity,the bottom of the main body is equipped with several metal nozzles, three adjacent metal nozzles are set up in regular triangle and the abduction of each circle of metal nozzles is in regular hexagon; insulated supporting parts are installed on the bottom of the main body, metal rings encompassing all metal nozzles are installed on the lower of said supporting parts, said metal rings and metal nozzles are connected with electrostatic generator directly. The invention achieves the goal of multi-needle injection simultaneously by improving the intensity of field of spinnerette, reduces the fluid jet electrostatic repulsion forces greatly caused by the small distance between the needles and makes the receiver can receive fiber in small range, so increases the efficiency in unit area and obtains carpet fiber with more uniform thickness.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Apparatus and method for forming materials

InactiveUS6858168B1Improves molecular orientationReduce pressure requirementsSpinnerette packsConfectioneryHydrogenSolid mass

An apparatus and method for forming liquid spinning solution into a solid formed product whereby the solution is passed through at least one tubular passage (17) having walls formed at least partly of semipermeable and / or porous material. The semipermeable and / or porous material allows parameters, such as the concentration of hydrogen ions, water, salts and low molecular weight, of the liquid spinning solution to be altered as the spinning solution passes through the tubular passage(s).

Owner:SPINOX LTD

Device for preparing non-woven fabric product continuously with electrostatic spinning method

ActiveCN101985793AEasy to processReduce processing costsSpinnerette packsFilament/thread formingTemperature controlElectrospinning

The invention relates to a device for preparing non-woven fabric products continuously with an electrostatic spinning method, belonging to the field of electrostatic spinning, and mainly comprising a melt body conveying device, a melt body metering pump, an electrostatic spinning die head, a die head temperature control device, a high-voltage static electricity generating device, a collecting device and a bracket, wherein the melt body conveying device is connected with an inlet of the melt body metering pump directly; an outlet of the melt body metering pump is connected with the electrostatic spinning die head; the die head temperature control device is arranged on the electrostatic spinning die head or distributed in the electrostatic spinning die head; the inner part of the electrostatic spinning die head is provided with a distributing passage; the distributing passage distributes a stream of melt body as a plurality of melt bodies uniformly; a spinneret plate of the terminal end of a plurality of the melt bodies is connected with a jet nozzle; the jet nozzle is not a single micro-hole but a hole-slot on a slit; and a passage of hot air is arranged at the outer part of the electrostatic spinning die head. According to the structure of the invention, the manufacturing difficulty of the electrostatic spinning die head is reduced greatly; the fiber diameter is much thinner than that of fiber manufactured by a melt blown method; the fiber quality is better; and modularization production is easy to realize.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com