Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2024results about "Electroconductive/antistatic filament manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

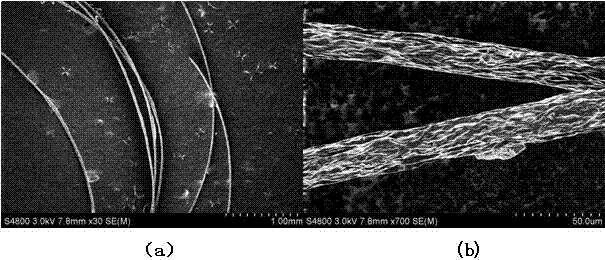

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

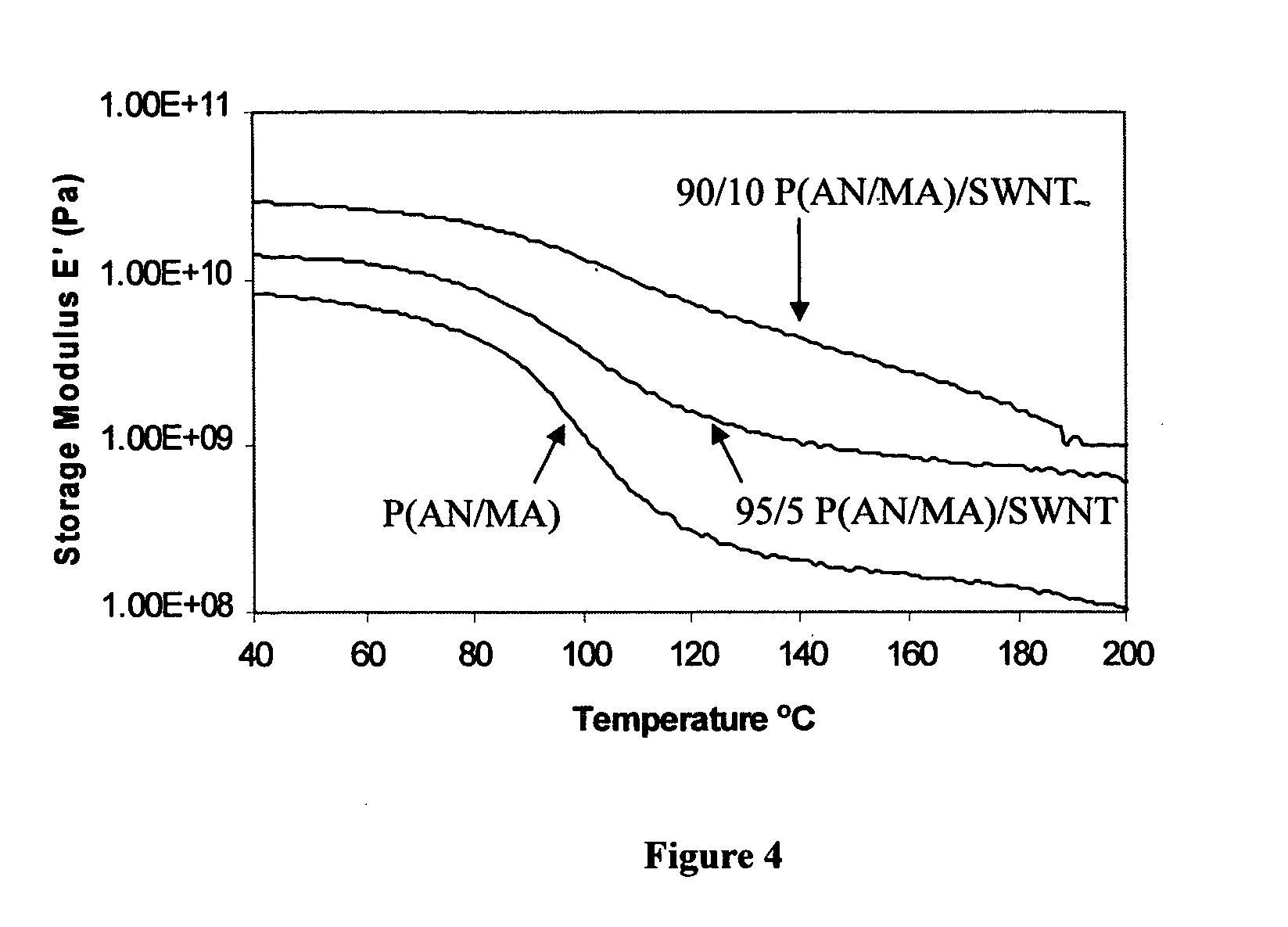

InactiveUS6852410B2Increased tensile modulusReduced thermal shrinkageMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

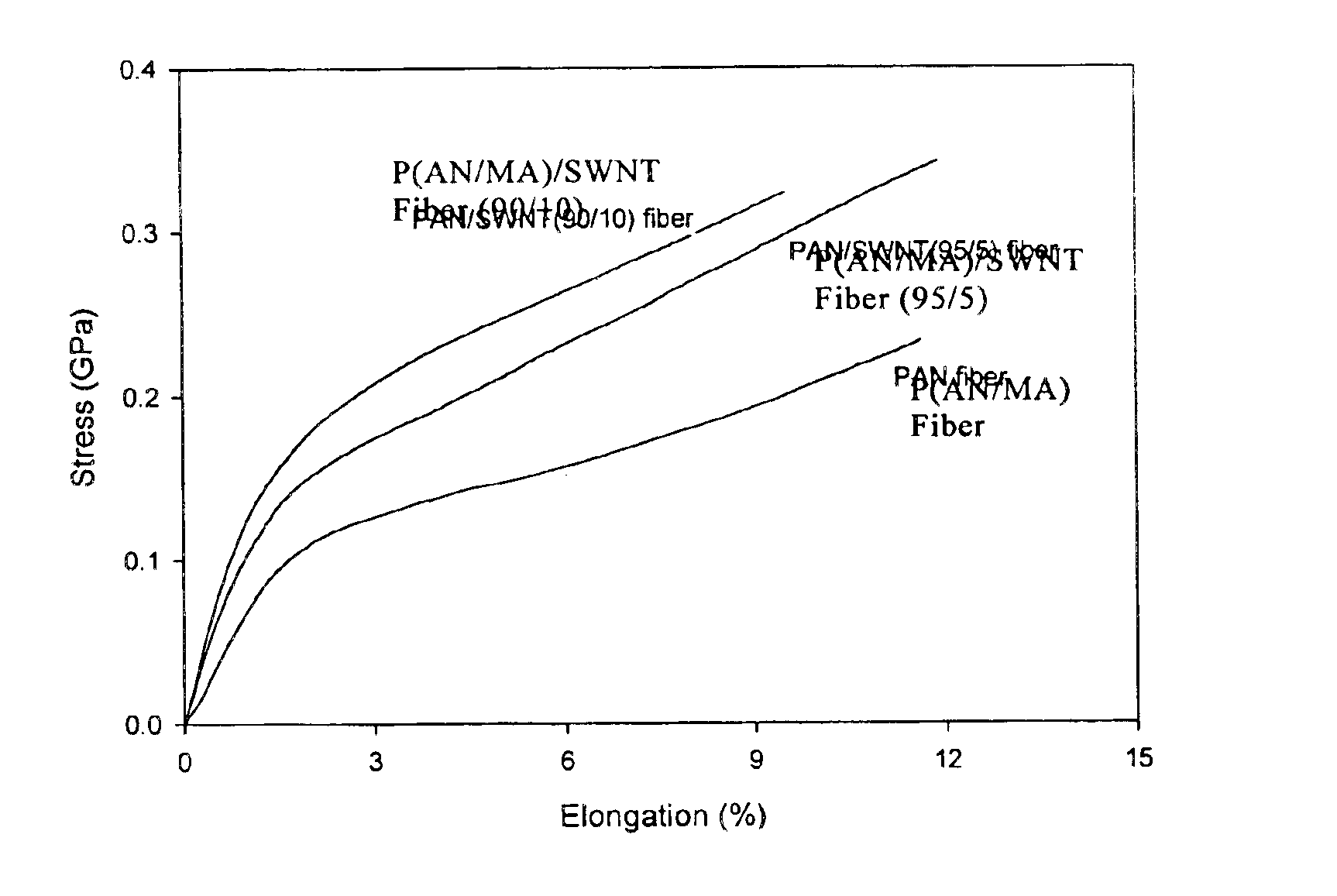

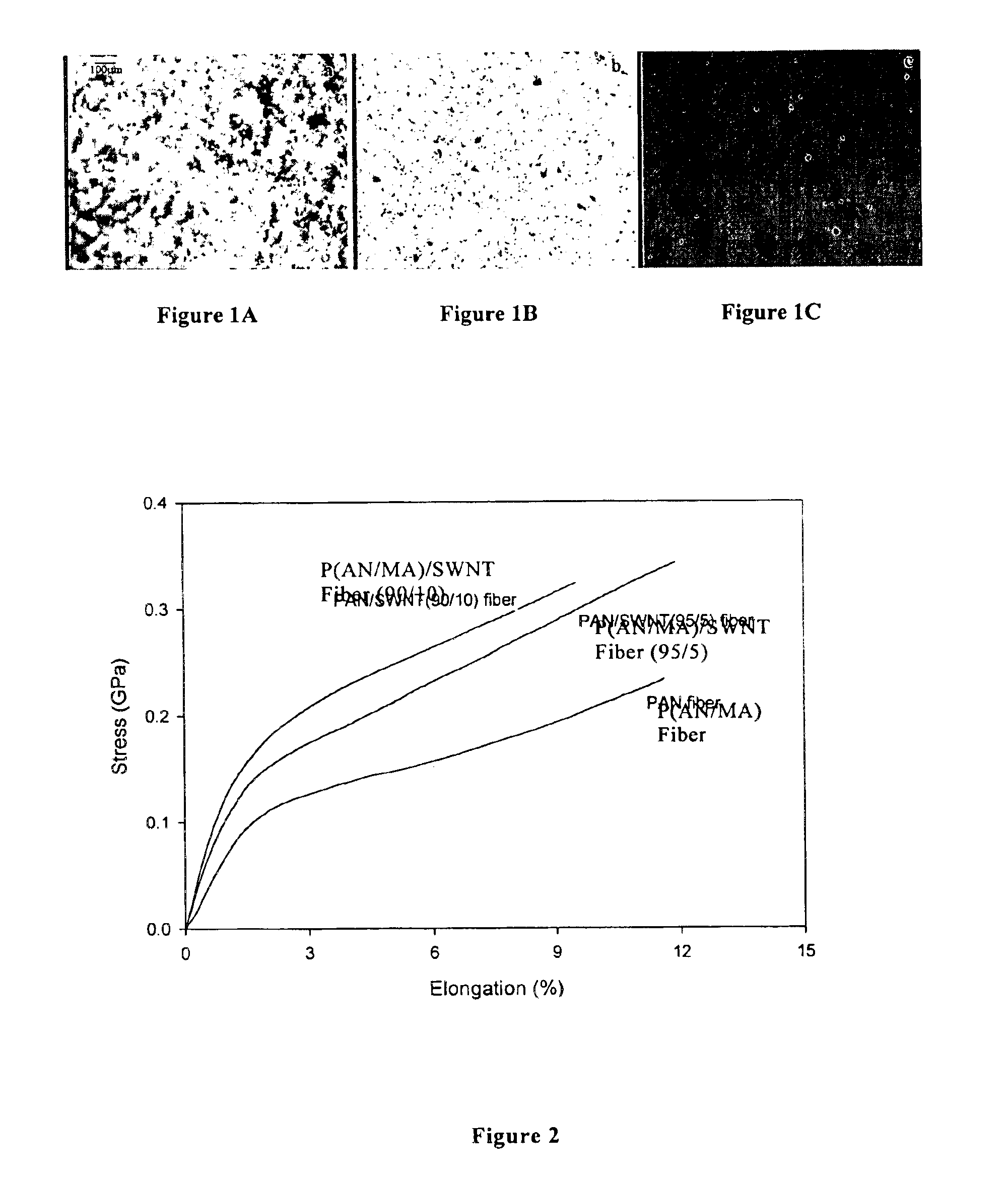

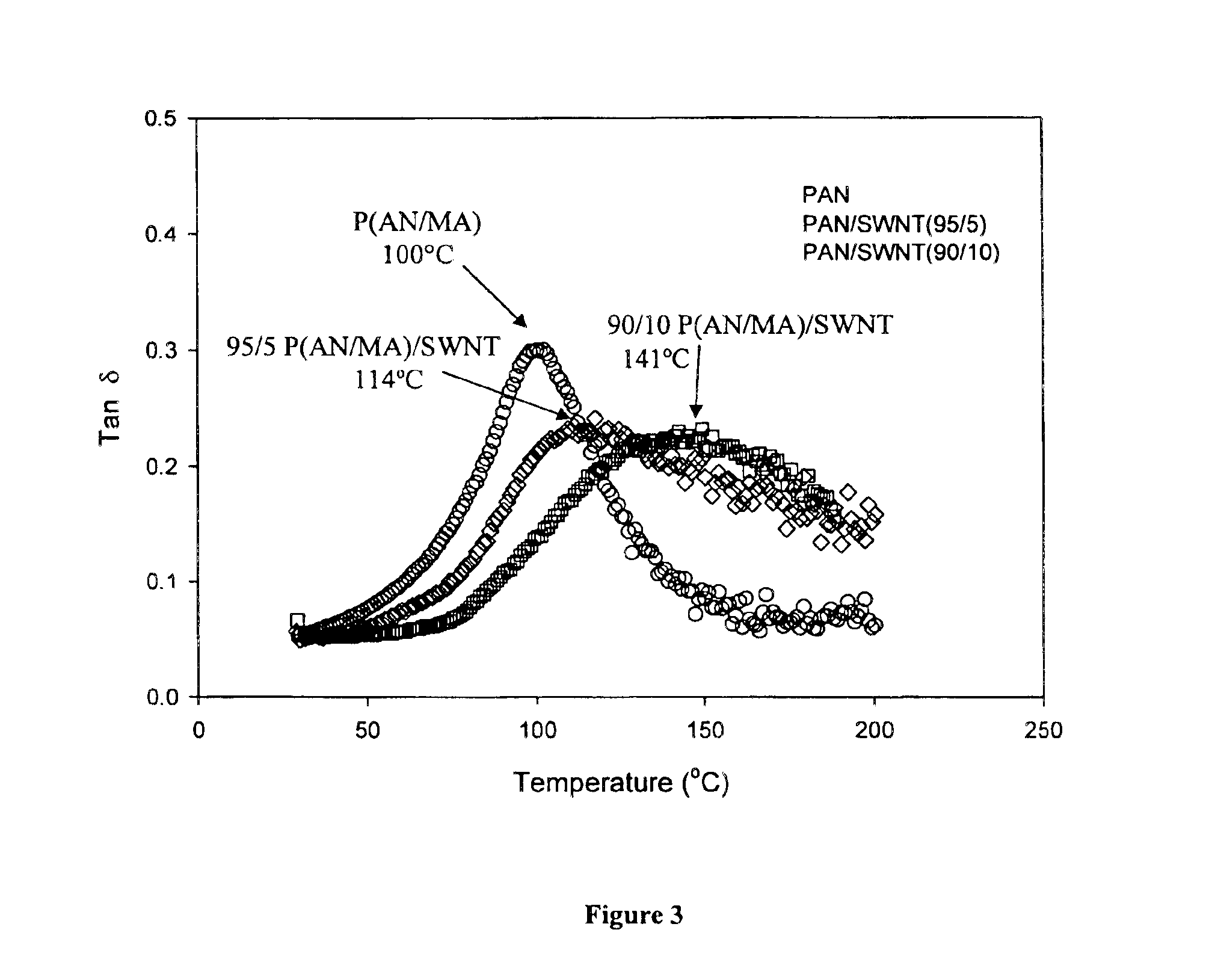

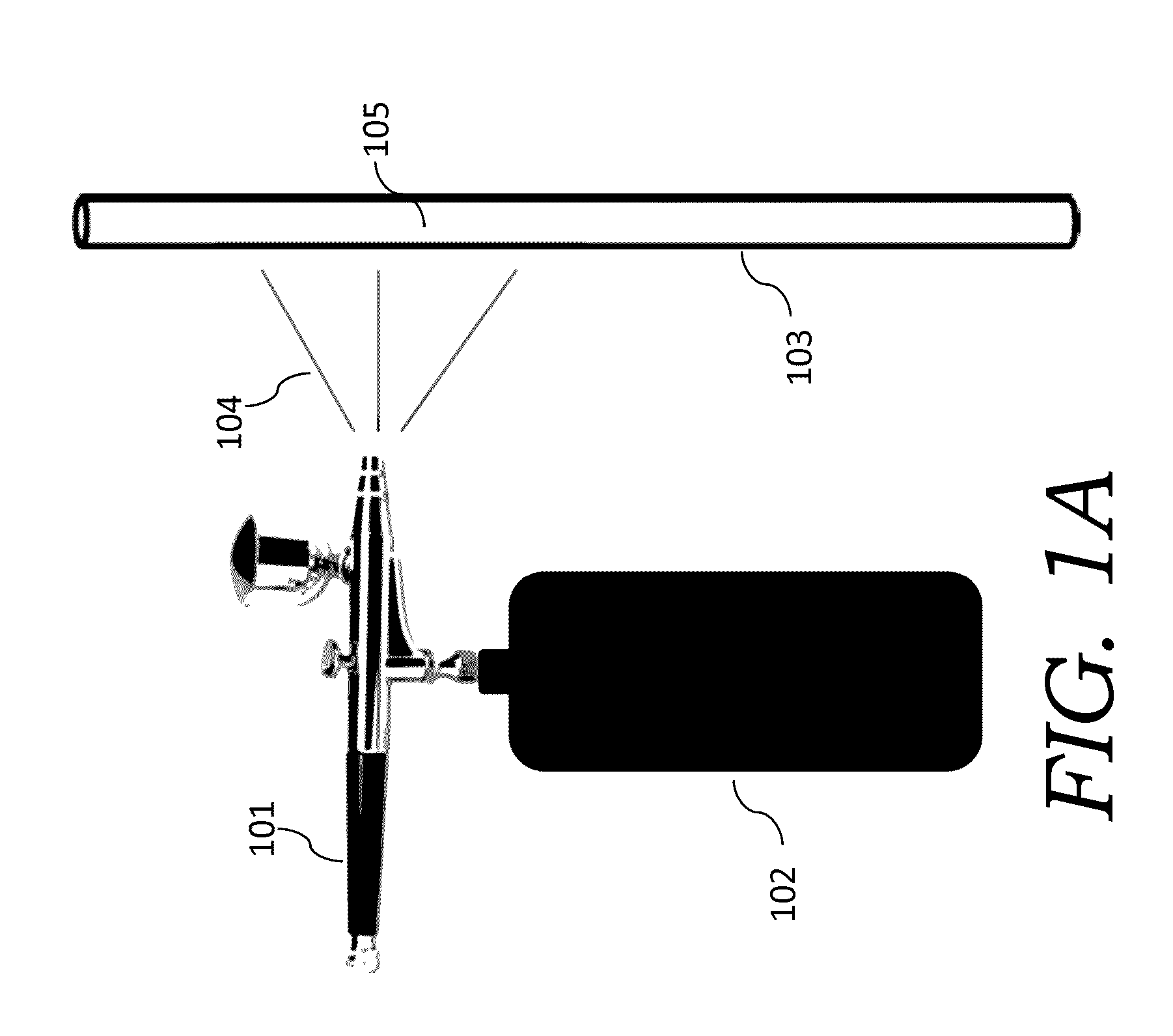

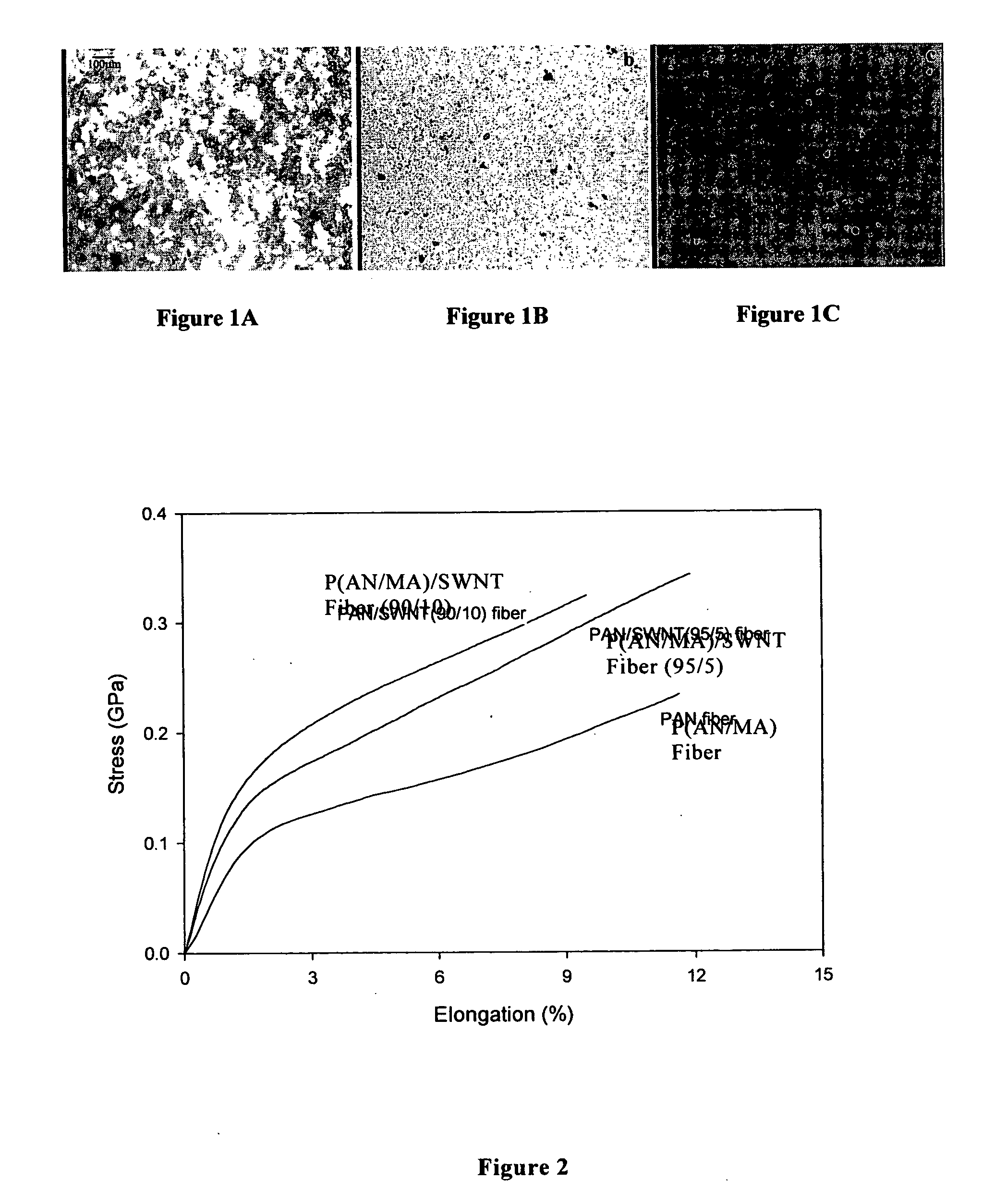

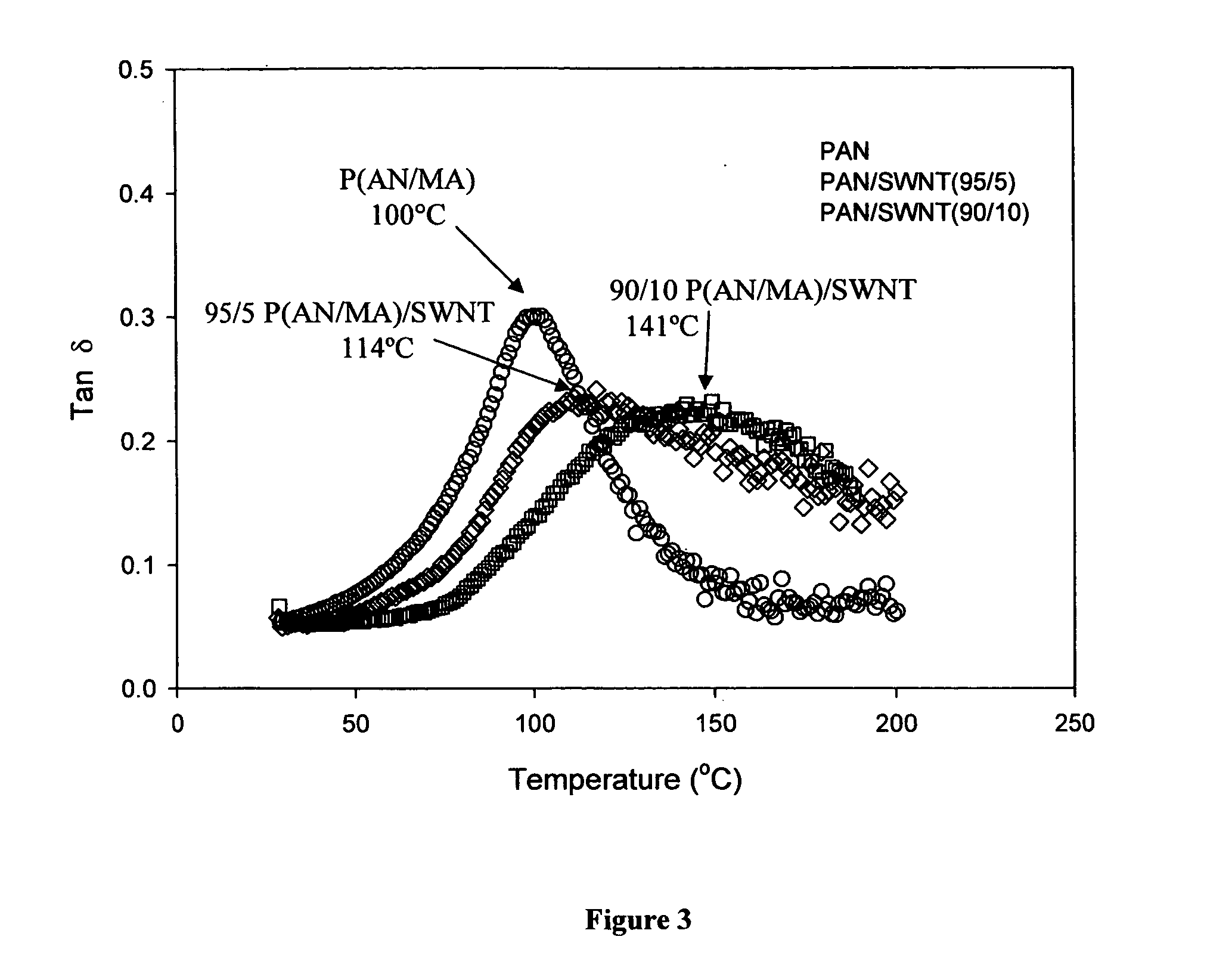

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

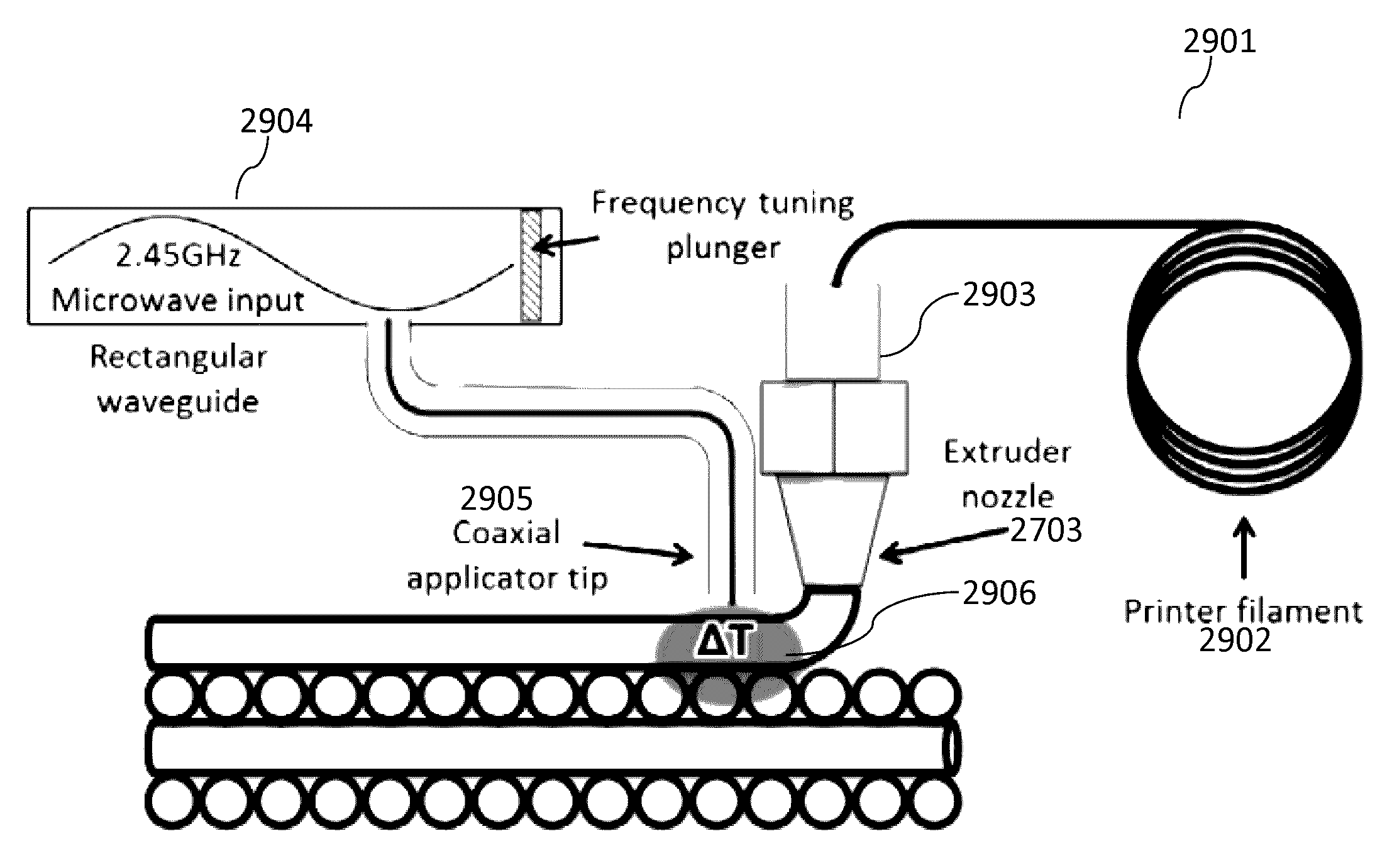

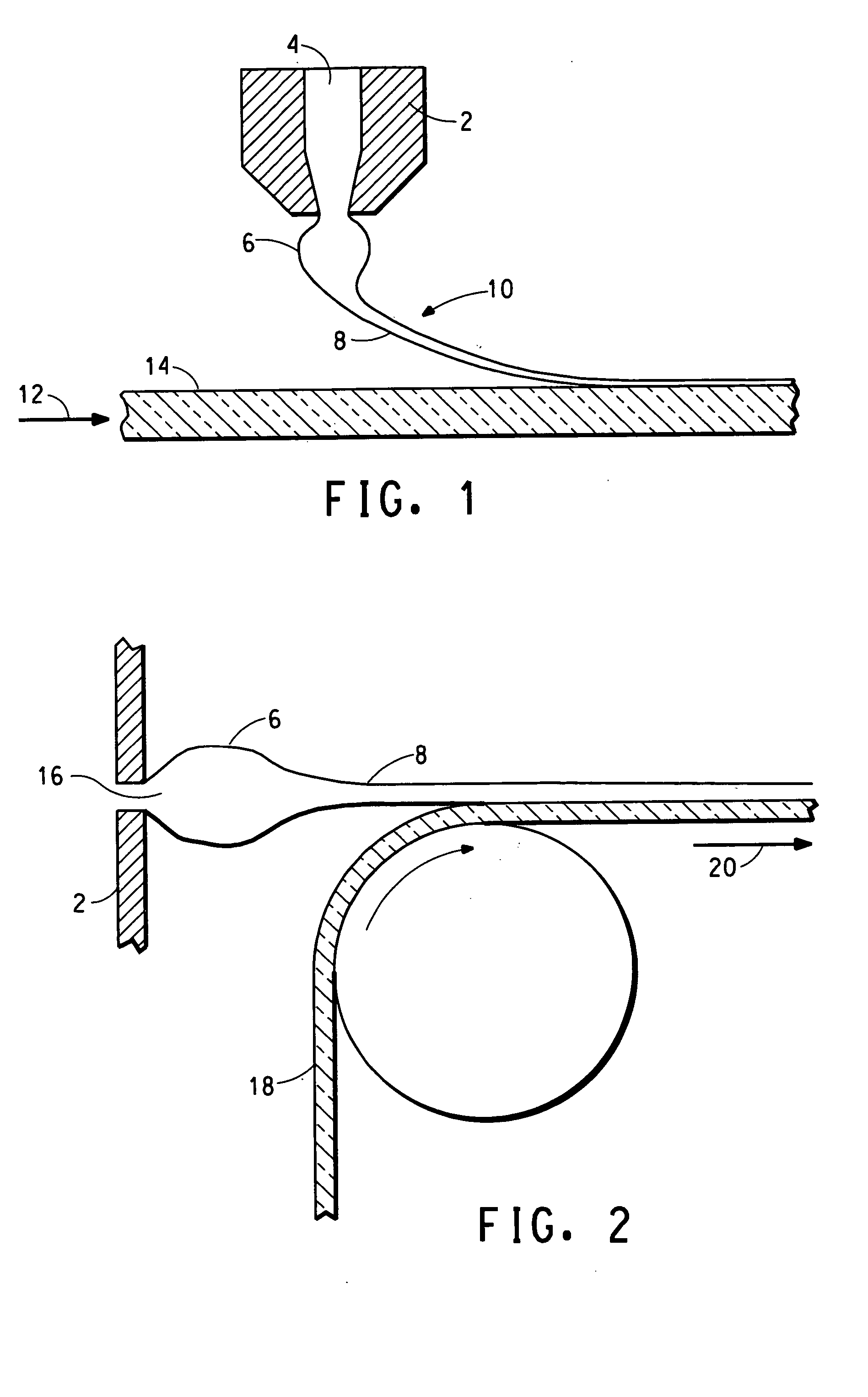

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS20050100501A1Good orientationIncrease modulusMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Polymeric fibers and articles made therefrom

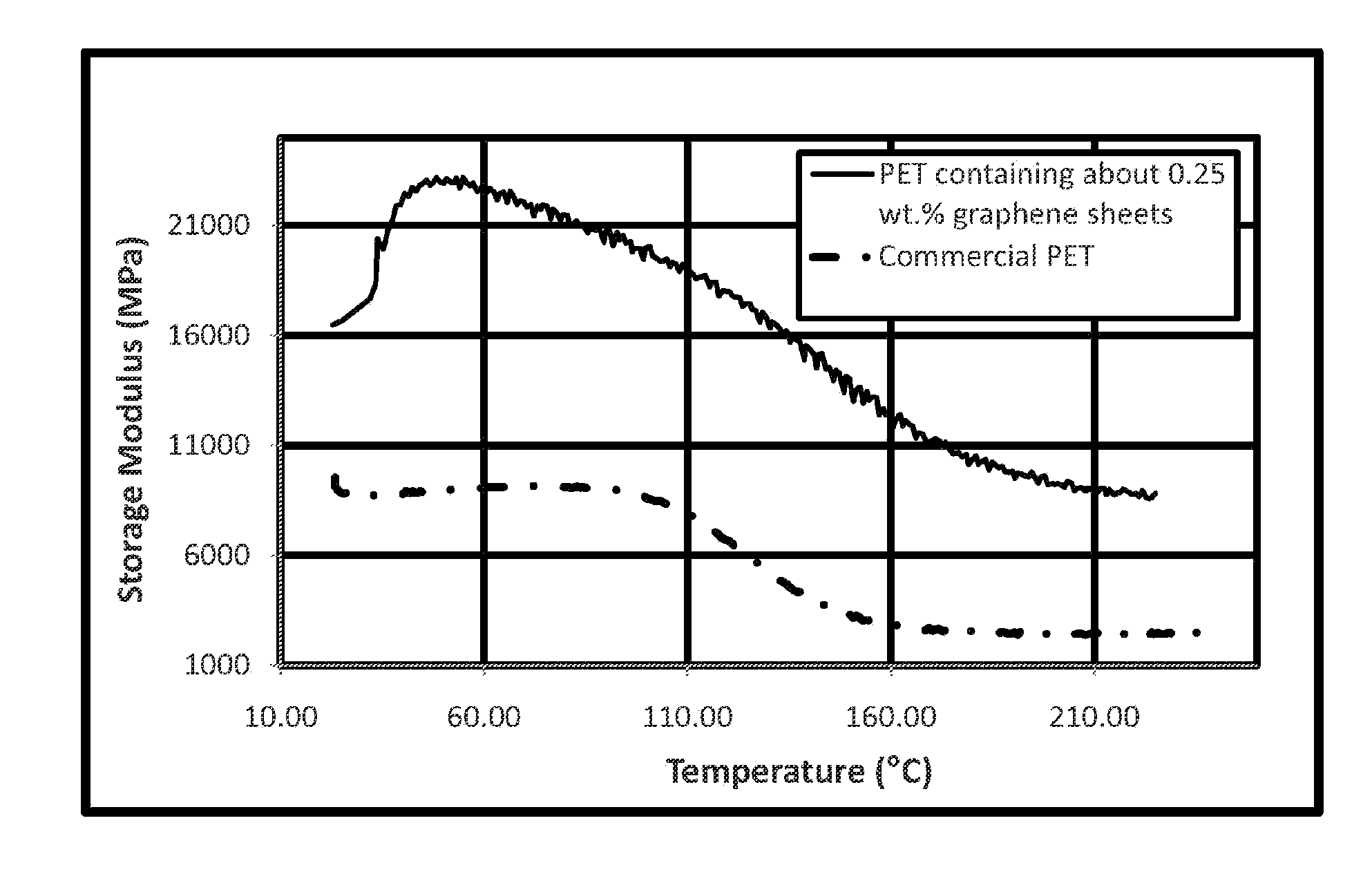

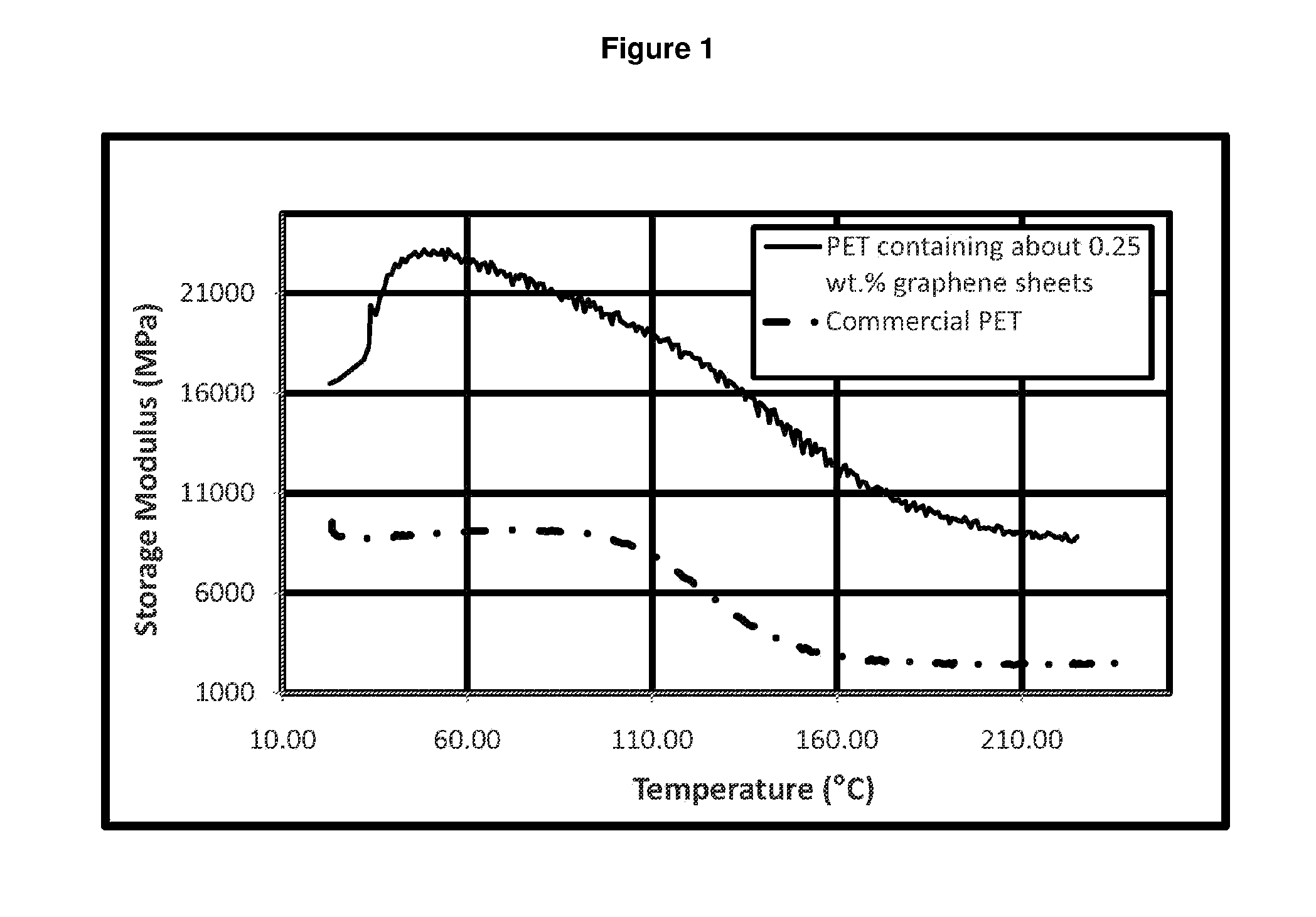

InactiveUS20120244333A1Electric discharge heatingMonocomponent cellulose artificial filamentPolyesterYarn

Fibers described herein comprise a composition including a polymer and graphene sheets. The fibers can be further formed into yarns, cords, and fabrics. The fibers can be in the form of polyamide, polyester, acrylic, acetate, modacrylic, spandex, lyocell fibers, and the like. Such fibers can take on a variety of forms, including, staple fibers, spun fibers, monofilaments, multifilaments, and the like.

Owner:VORBECK MATERIALS CORP +1

Spin-printing of electronic and display components

InactiveUS20050089679A1Electrolytic capacitorsFinal product manufactureDielectricElectrical conductor

The present invention is directed to a process for printing conductors, insulators, dielectrics, phosphors, emitters, and other elements that may be for electronics and display applications. The present invention also relates to viscoelastic compositions used in this printing process. The present invention further includes devices made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

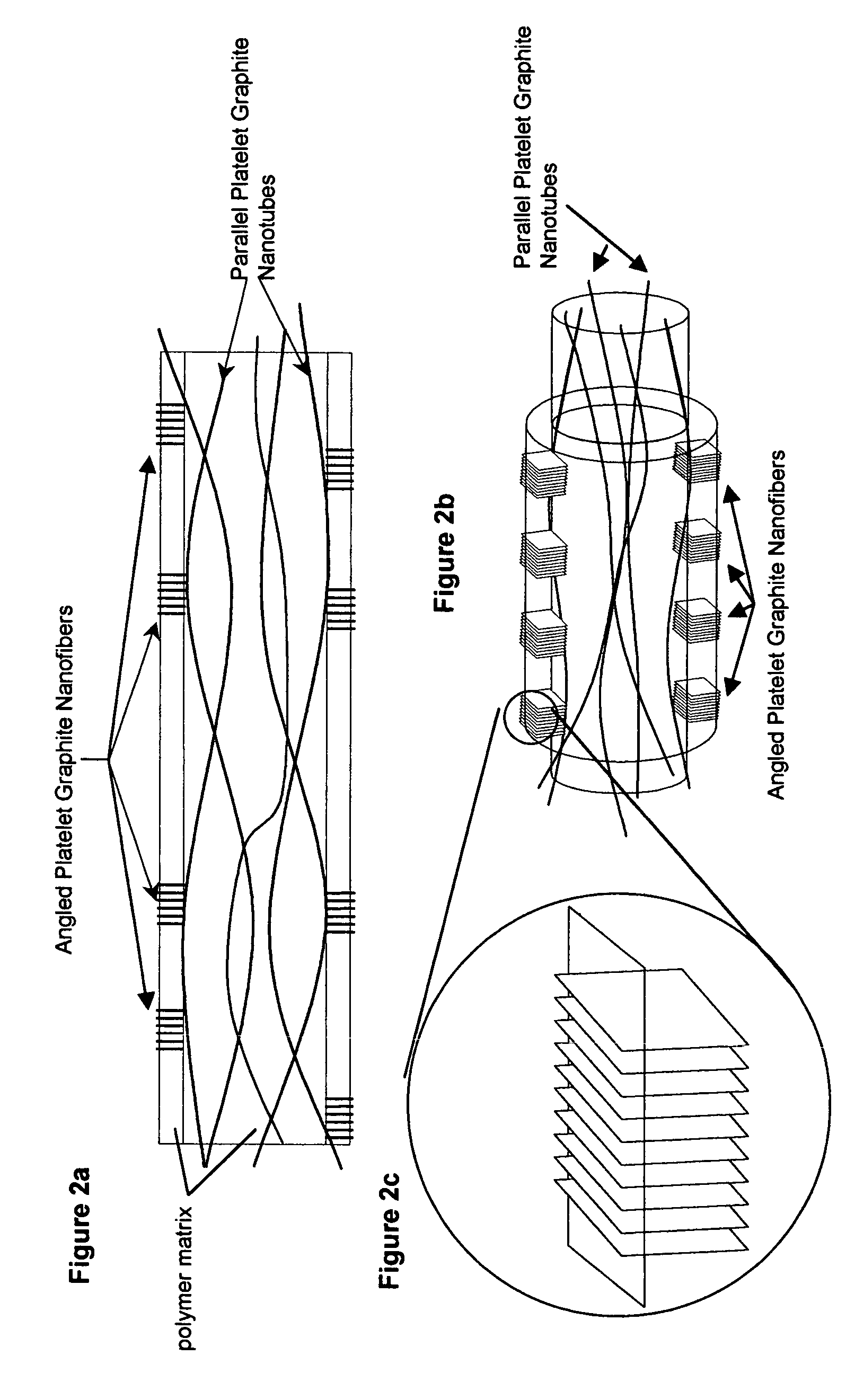

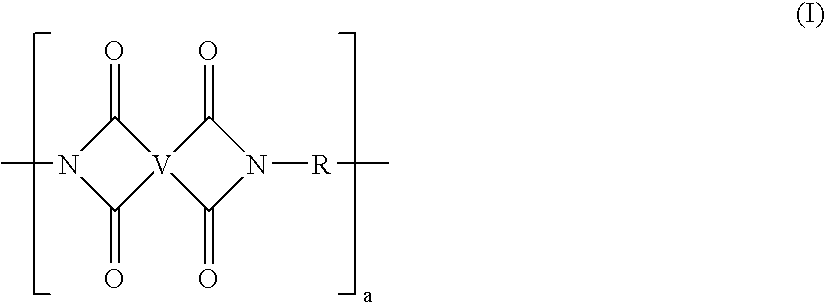

Multi-component conductive polymer structures and a method for producing same

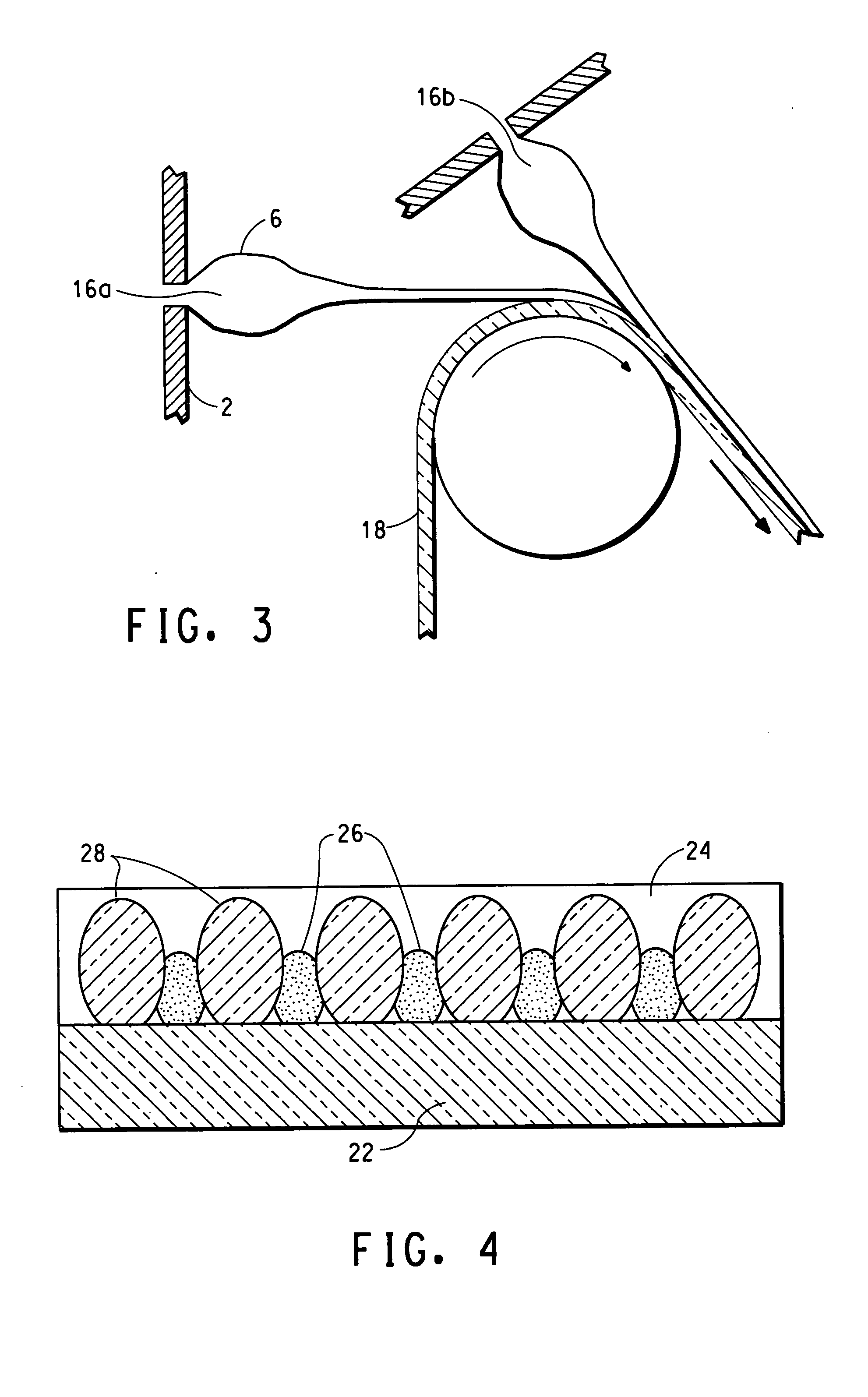

InactiveUS7238415B2Material nanotechnologyElectroconductive/antistatic filament manufacturePolymer scienceConductive polymer composite

Owner:CATALYTIC MATERIALS

Graphene conductive polyester fibers and preparation method thereof

ActiveCN104164707AOvercome cohesionOvercome uniformity issuesElectroconductive/antistatic filament manufactureSpinnerette packsPolyesterFiber

Owner:湖州市中磊化纤有限公司

Method for producing shaped bodies

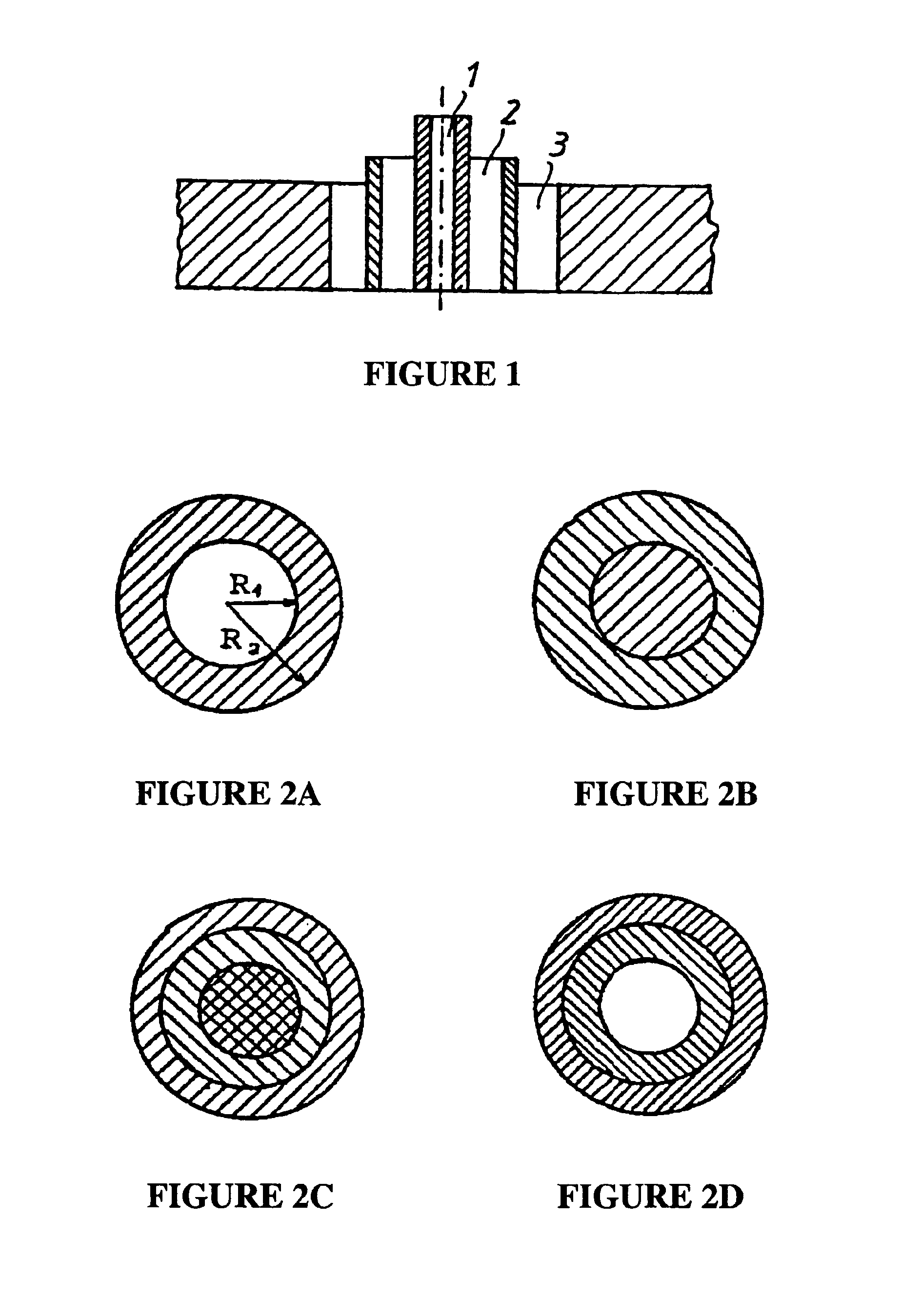

InactiveUS6881361B1Monocomponent cellulose artificial filamentConjugated cellulose/protein artificial filamentsPolyvinyl alcoholSolvent

The invention relates to a method for producing shaped bodies, especially threads or foils, from at least one polymer of the groups consisting of polysaccharide, polysaccharide derivative or polyvinyl alcohol by forming a solution of the polymer that contains an additive in a solvent containing amine-N-oxide, extruding the solution and precipitating the extrudate by contacting with a coagulant. The invention is characterized in that at least two polymeric solutions are formed. At least one of the two polymeric solutions contains one or more finely distributed additives and the at least two polymeric solutions are simultaneously extruded forming a combined extrudate.

Owner:OSTTHURINGISCHE MATERIALPRUFGES FUR TEXTIL & KUNSTE

Method for producing conducting fiber

InactiveCN101532190AImprove conductivityImprove wear resistanceElectroconductive/antistatic filament manufactureMelt spinning methodsFiberPolymer chemistry

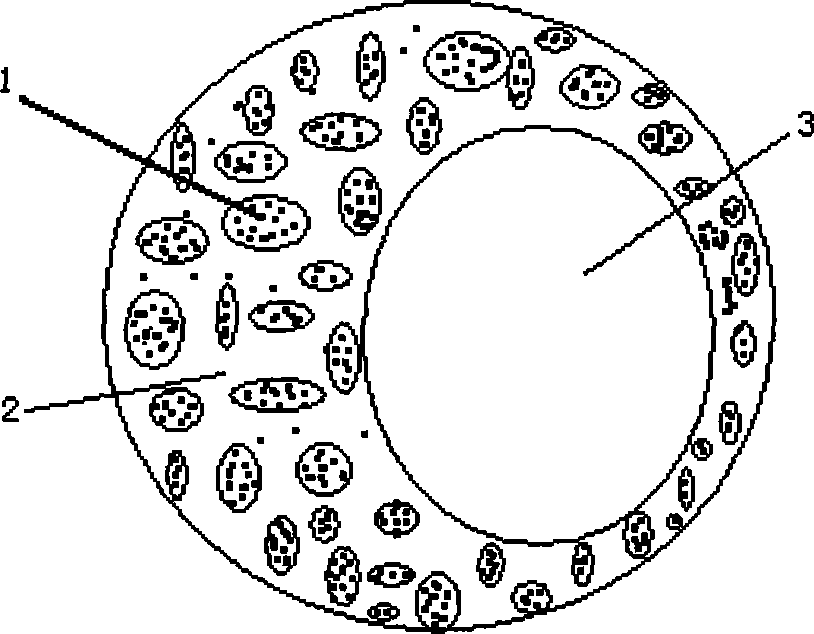

The invention relates to a method for producing conducting fiber, which comprises the following steps that: 1, a sea-island type conducting high polymer is prepared by using a high polymer containing conducting powder as an island phase and a high polymer incompatible with the island phase as a sea phase to blend; 2, a composite conducting fiber is prepared by performing bicomponent composite spinning by using the sea-island type conducting high polymer as a component and a linear high polymer compatible with the sea phase in the sea-island type conducting high polymer as another component, wherein the sea-island type conducting high polymer in proportion by weight is between 15 and 30 percent; 3, the content of the conducting powder in the composite fiber in proportion by weight is between 1.5 and 12 percent; and 4, the sea-island type conducting high polymer in the composite form of the bicomponent composite conducting fiber can be used as a cortex component, a core layer component, and the like.

Owner:WUXI AOLIN TEXTILE

Conductive filament

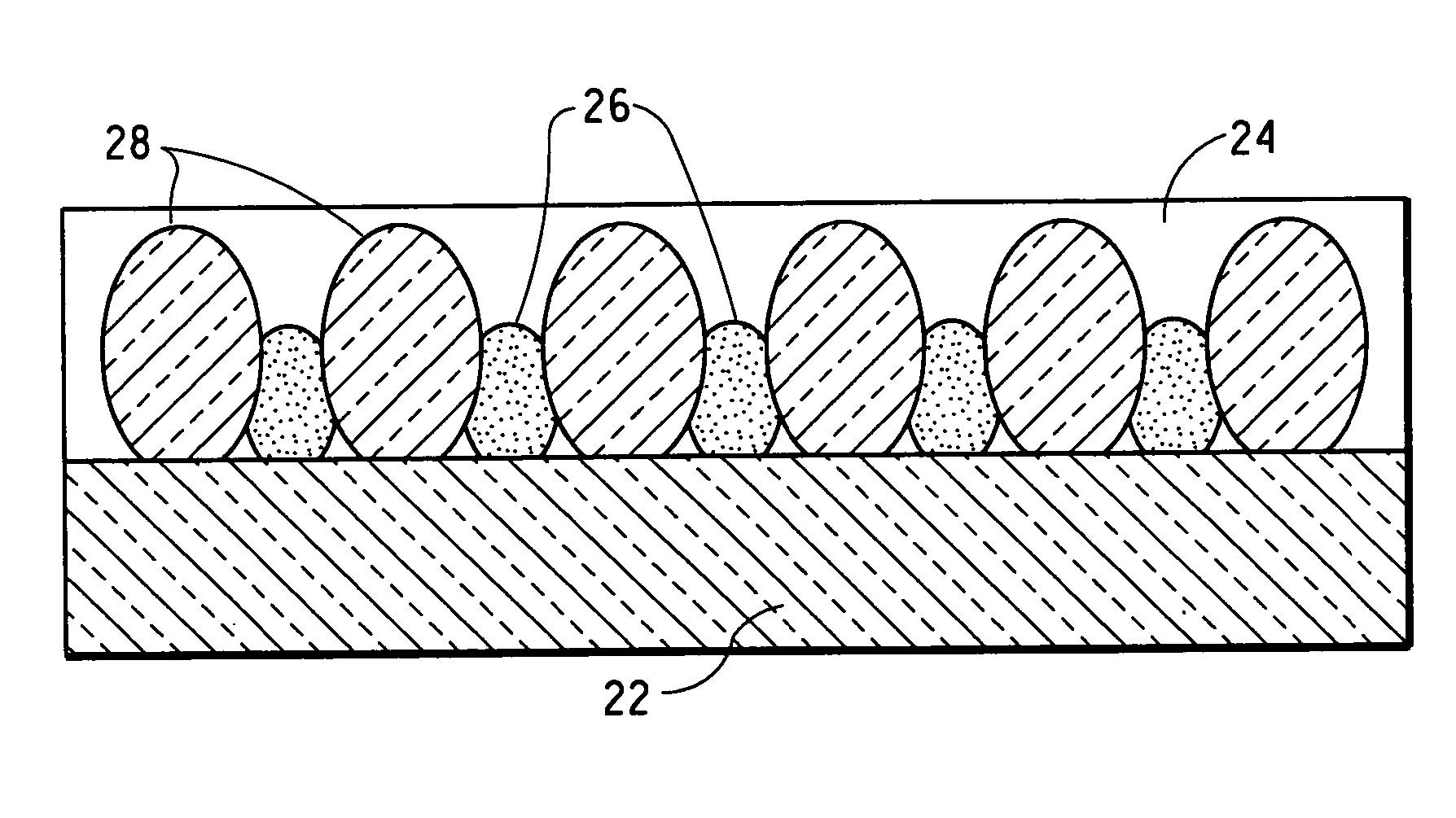

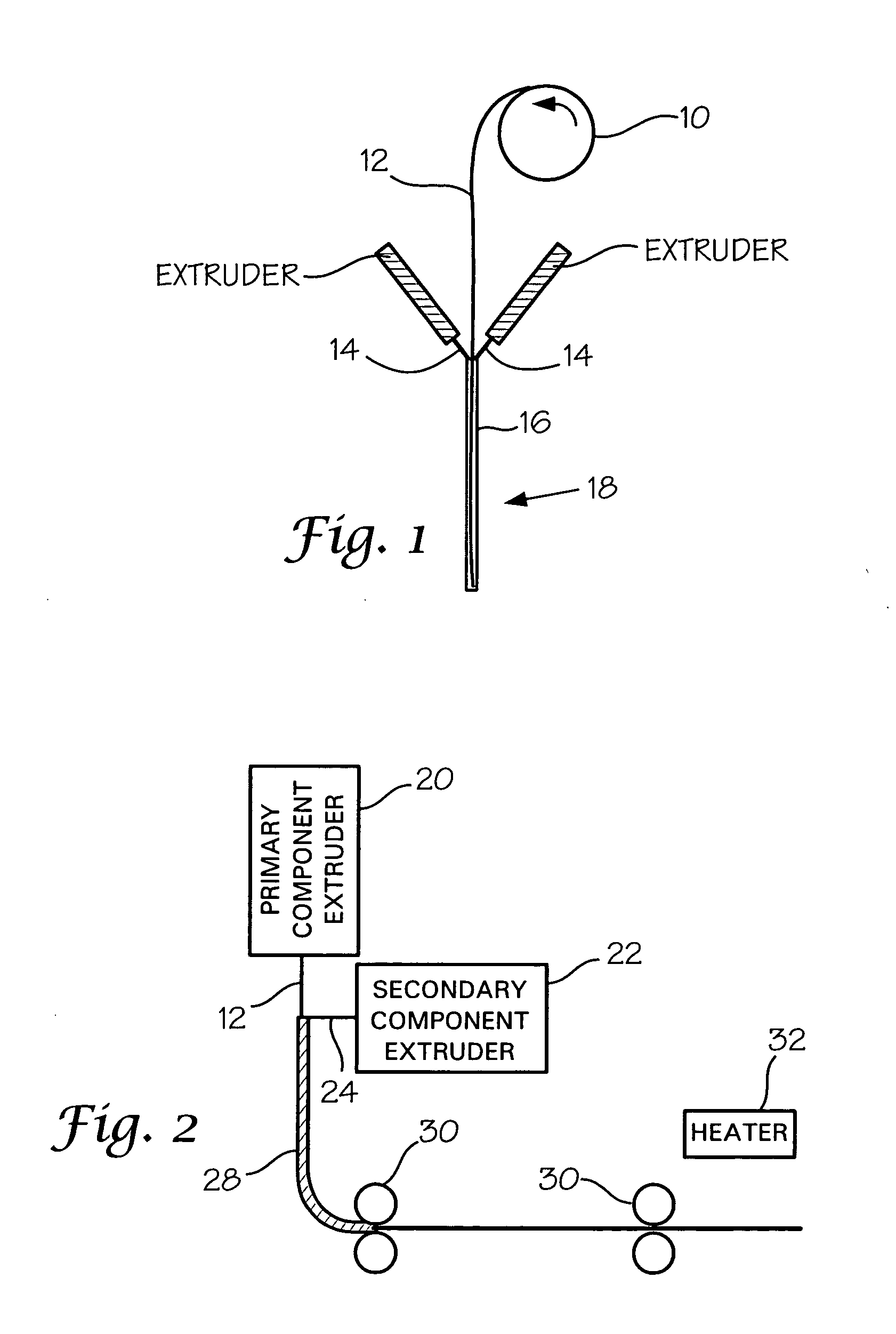

InactiveUS20050170177A1Material nanotechnologyElectroconductive/antistatic filament manufactureYarnSecondary component

A multi-component conductive yarn which includes a primary component and a secondary component. The primary component consists of at least one elongated filament formed of polymeric material while the secondary component consists of a blend of polymeric material and carbon nanotubes. The secondary component is bonded with the primary component along its length. The carbon nanotubes comprise up to 20% of the secondary component. The conductive yarn comprises no more than 10% carbon nanotubes.

Owner:TEIJIN MONOFILAMENT U S +1

Intrinsically conductive thermoplastic composition and compounding processing for making conductive fiber

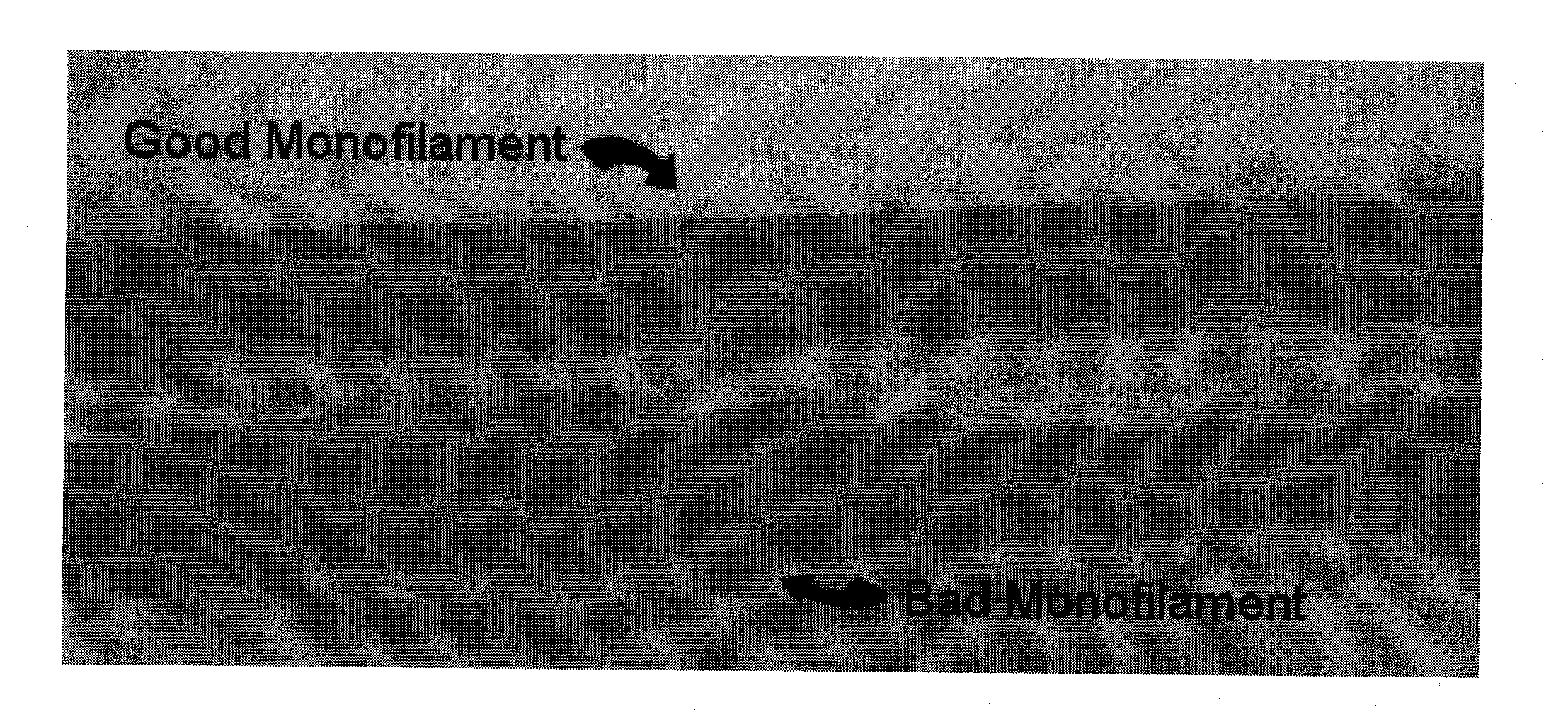

InactiveUS20080139065A1Effective static charge dissipationSafe dissipation of charge into the atmosphereElectroconductive/antistatic filament manufactureLayered productsFiberMaterials science

A conductive thermoplastic composition capable of forming conductive fibers including monofilaments, methods of making these compositions, and fibers including these compositions. The conductive thermoplastic compositions may be formed using any method capable of forming the compositions into fibers. The fibers are substantially smooth and / or are capable of being woven into fabrics or other articles to provide conductive properties to the fabric or article. These fibers provide effective static charge dissipation that may be imparted into applications such conveying belts or protective clothing for clean room operation.

Owner:SABIC INNOVATIVE PLASTICS IP BV

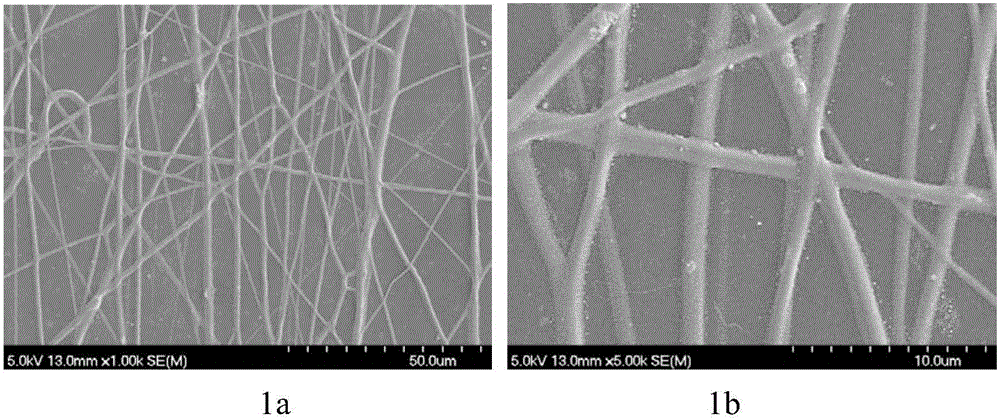

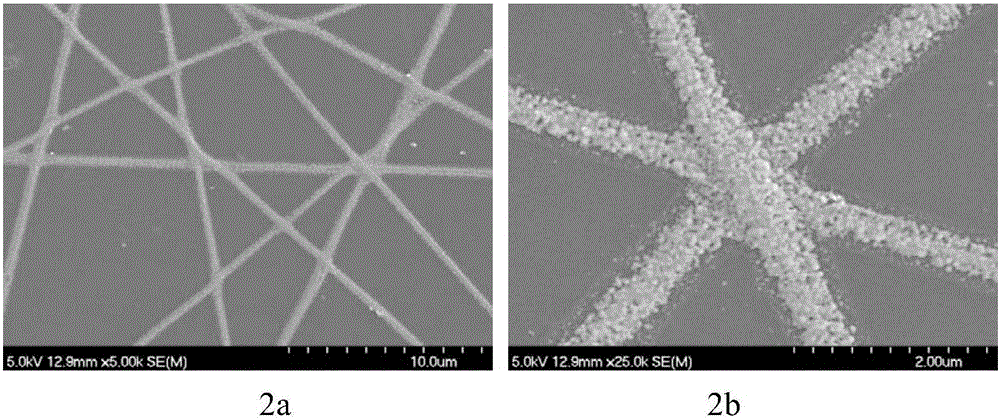

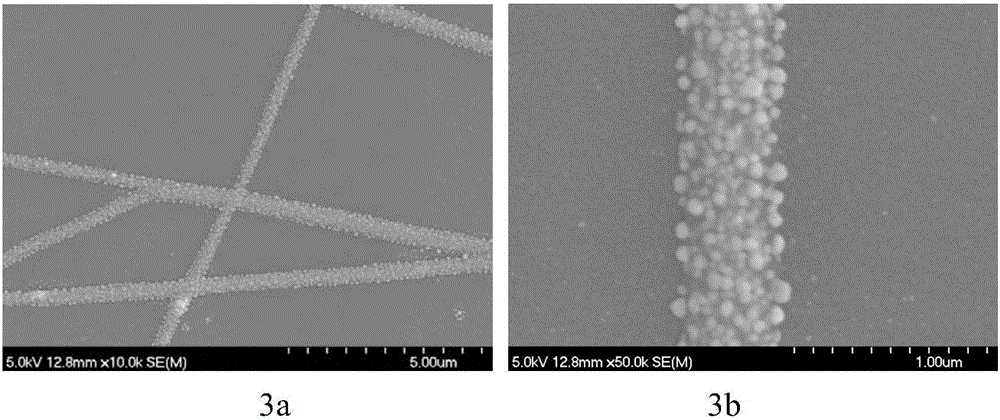

Conductive nanofiber and preparation method and application thereof

InactiveCN105696110AImprove conductivityLow costElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberResin matrix

The invention relates to a conductive nanofiber and a preparation method and application thereof. The conductive nanofiber is prepared from metal, a resin matrix and the like, wherein the metal is one or two of silver and copper or alloy of silver and copper. The conductive nanofiber is prepared through the electrospinning technique. The specific preparation method includes the steps that firstly, raw materials containing silver or / and copper and the resin matrix are prepared into a spinning solution, under the effect of a high-pressure electric field, a composite fiber is spun, and then the conductive nanofiber is prepared through heat treatment at low temperature. According to the provided conductive nanofiber and the preparation method thereof, the obtained conductive nanofiber has excellent conductivity and high length-diameter ratio, and can be used for preparing a conductive material of a transparent conductive electrode, and the application field is very wide.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

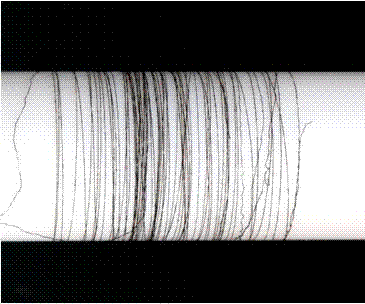

Preparation method of conductive high-strength graphene-reinforced polymer fiber

ActiveCN102828267ARaw materials are easy to getLow costElectroconductive/antistatic filament manufactureFiberPolymer dissolution

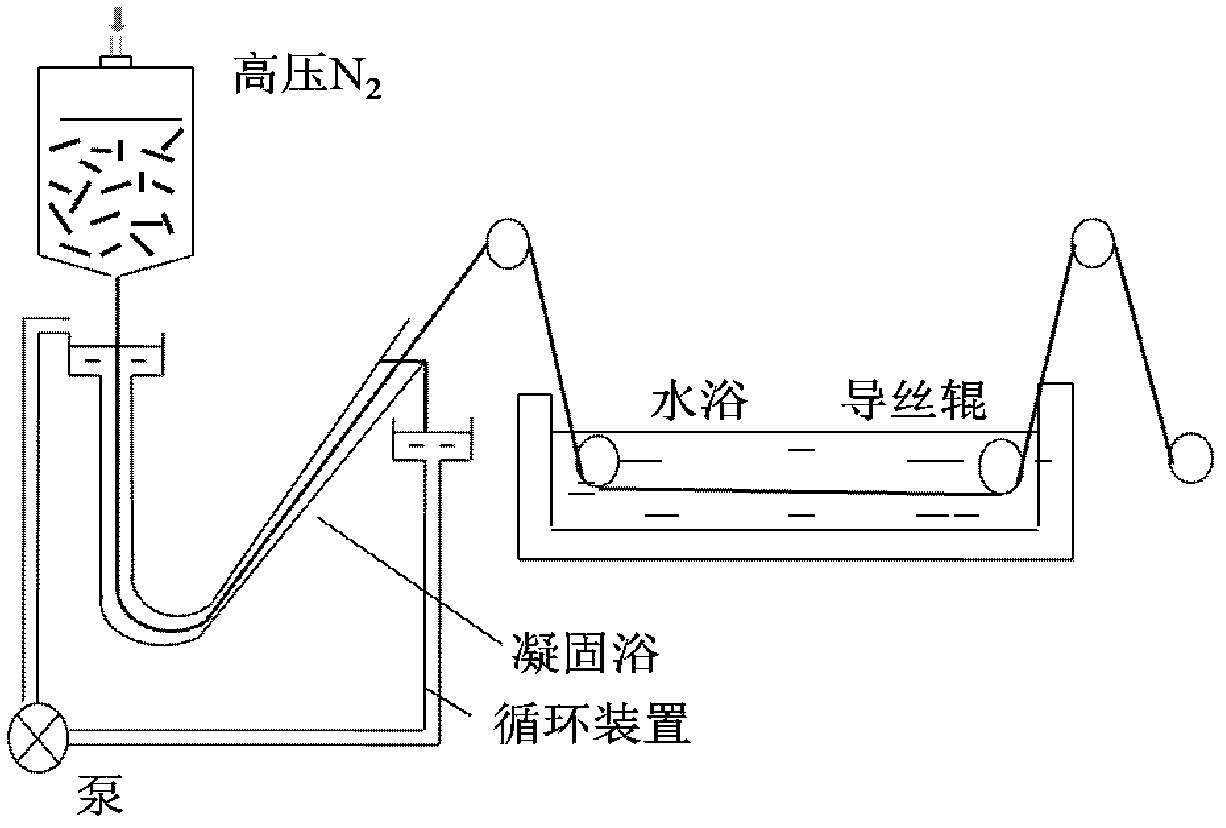

The invention discloses a preparation method of conductive high-strength graphene-reinforced polymer fiber, which comprises the following steps of: (1) dissolving a graphene oxide raw material in solvent, and carrying out ultrasonic treatment to obtain graphene oxide dispersion; (2) dissolving a polymer in solvent to obtain a polymer solution; and (3) adding the graphene oxide dispersion obtained in the step (1) to the polymer solution obtained in the step (2) under stirring, continuing stirring after complete addition, adding a reducing agent, centrifuging or carrying out rotary evaporation treatment, concentrating, transferring to a spinning device, continuously extruding from a spinning head at uniform speed, forming after entering a solidifying solution, and collecting to a roller to obtain continuous graphene-reinforced polymer fiber. The preparation method is simple and convenient, low in cost and multiple in used polymer variety, and is suitable for large-scale industrialized production; and the produced fiber has excellent mechanical property and better conductivity, and can be used for power transmission, antistatic textile, engineering material engineering material and other fields.

Owner:杭州德烯科技集团有限公司

Preparation method of carbon nanotubes/nano ATO (antimony tin oxide)/polypropylene electroconductive fibers

InactiveCN102409421AImprove fill factorImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentPolypropylene compositesOrganic solvent

The invention discloses a preparation method of carbon nanotubes / nano ATO (antimony tin oxide) / polypropylene electroconductive fibers. The preparation method comprises the following steps of: (1) mixing nano ATO and carbon nanotubes, placing in an organic solvent together with a dispersant, and carrying out surface treatment to obtain a double-component nano electroconductive agent; (2) mixing the double-component nano electroconductive agent with polypropylene slices, and carrying out melt blending and strip preparation and granulation with a screw extruder to obtain double-component nano electroconductive agent / polypropylene composite electroconductive slices; (3) carrying out melt spinning on the composite electroconductive slices to obtain carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers; and (4) stretching and shaping the carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers to obtain the carbon nanotubes / nano ATO / polypropylene electroconductive fibers. By using the preparation method, the filling factor of a filler is increased, the content of an electroconductive filler in the material is reduced, the electric conductivity of the material is improved, and the electric performance stability of the material is simultaneously improved; and the preparation method has low price and no special requirement on equipment, has a economicand simple process route, and is suitable for industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

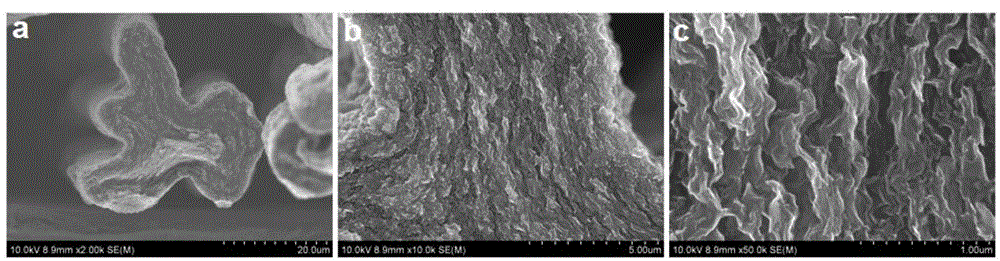

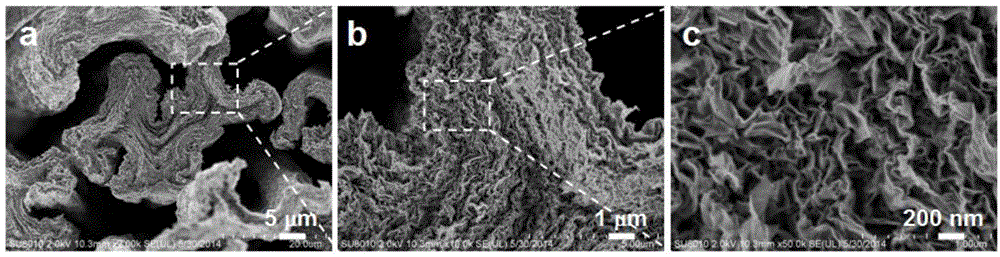

Water-soluble polymer/graphene composite fiber as well as preparation method and application thereof

ActiveCN104451925AHigh strengthImprove toughnessElectroconductive/antistatic filament manufactureElectrode carriers/collectorsFiberMicro structure

The invention relates to water-soluble polymer / graphene composite fiber as well as a preparation method and application thereof. The cross section of the fiber is special-shaped, the surface of the fiber is of an orientated micro-fiber-shaped structure, the strength of the fiber is greater than 100 MPa, the elongation at break is greater than 2%, and the conductivity of the fiber is greater than 0.1 S / cm. The preparation method comprises the following steps: preparing a composite spinning liquid, extruding into a coagulating bath for curing, drafting, leading out of the coagulating bath, drying, and coiling, thereby obtaining the water-soluble polymer / graphene composite fiber; and finally reducing by using a chemical or physical method, thereby obtaining the water-soluble polymer / graphene composite fiber. The cross section of the composite fiber provided by the invention is of a special-shaped structure, the surface of the fiber is of a rich groove micro structure, the strength and the toughness of the fiber are greatly improved when being compared with those of pure graphene fiber, and good conductivity is still maintained, so that the water-soluble polymer / graphene composite fiber has a wide application prospect in the fields such as anti-electrostatic and conductive fabrics, electromagnetic wave absorption and shielding fabrics, energy storage devices, sensors and water treatment.

Owner:DONGHUA UNIV

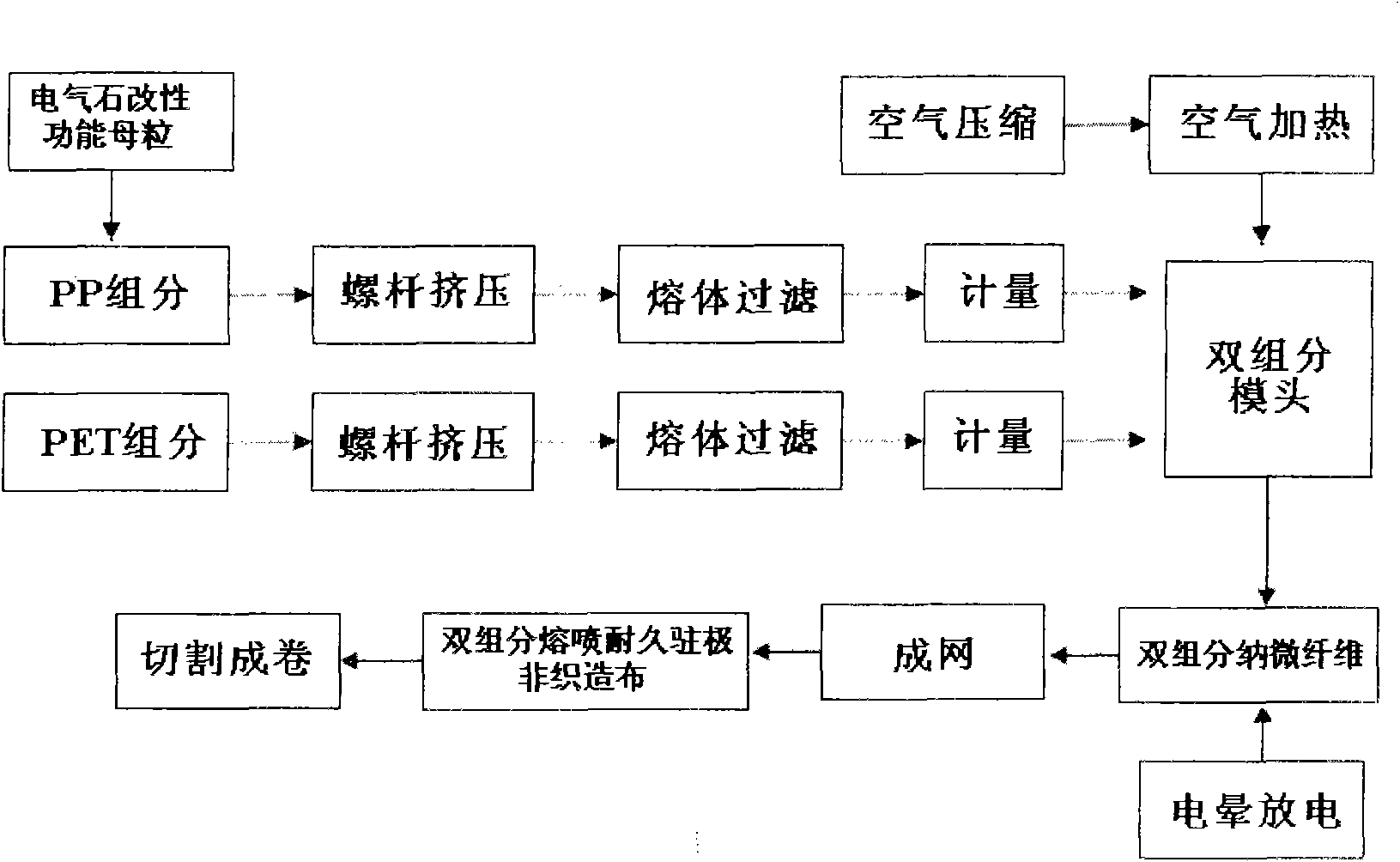

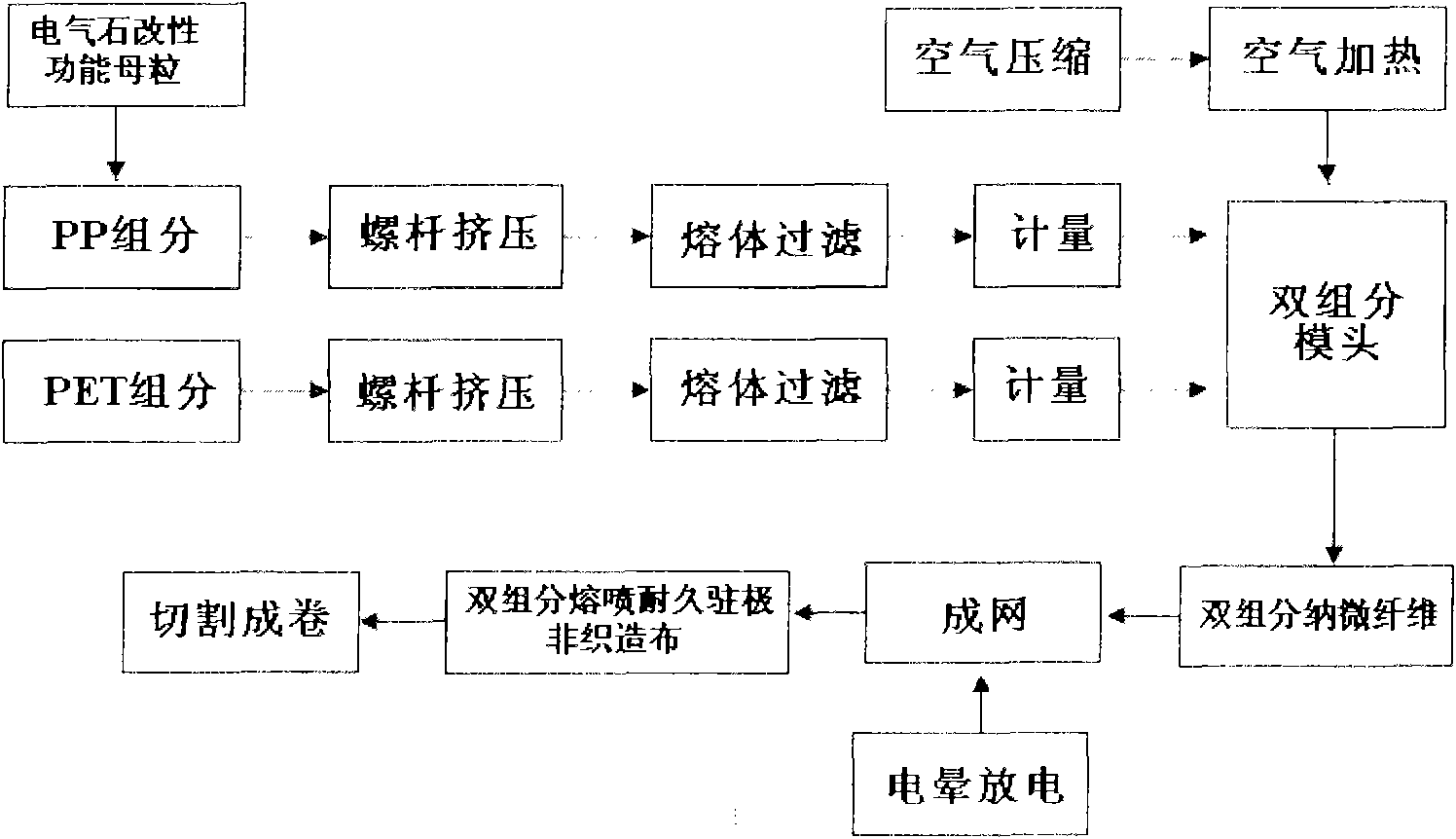

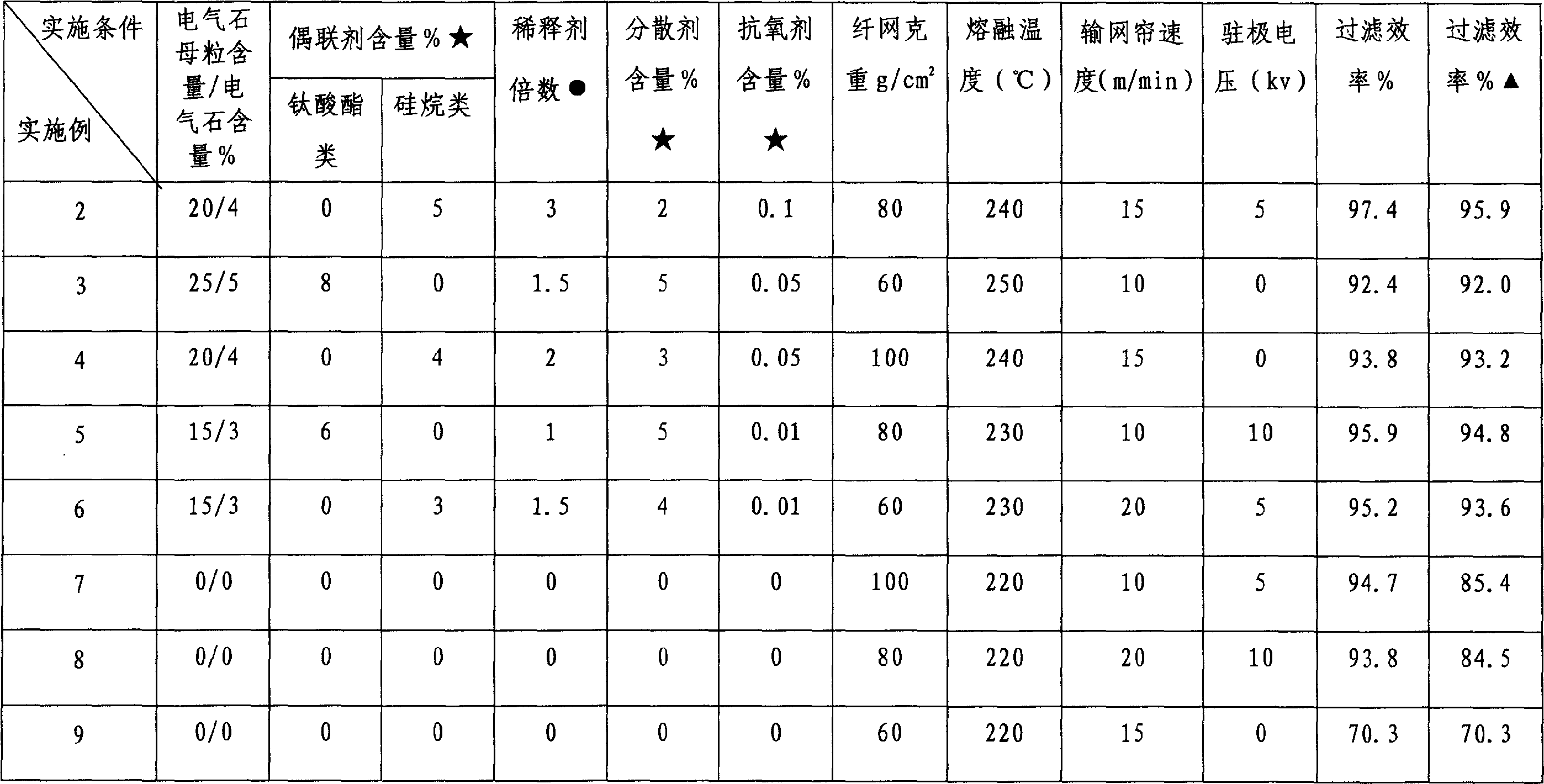

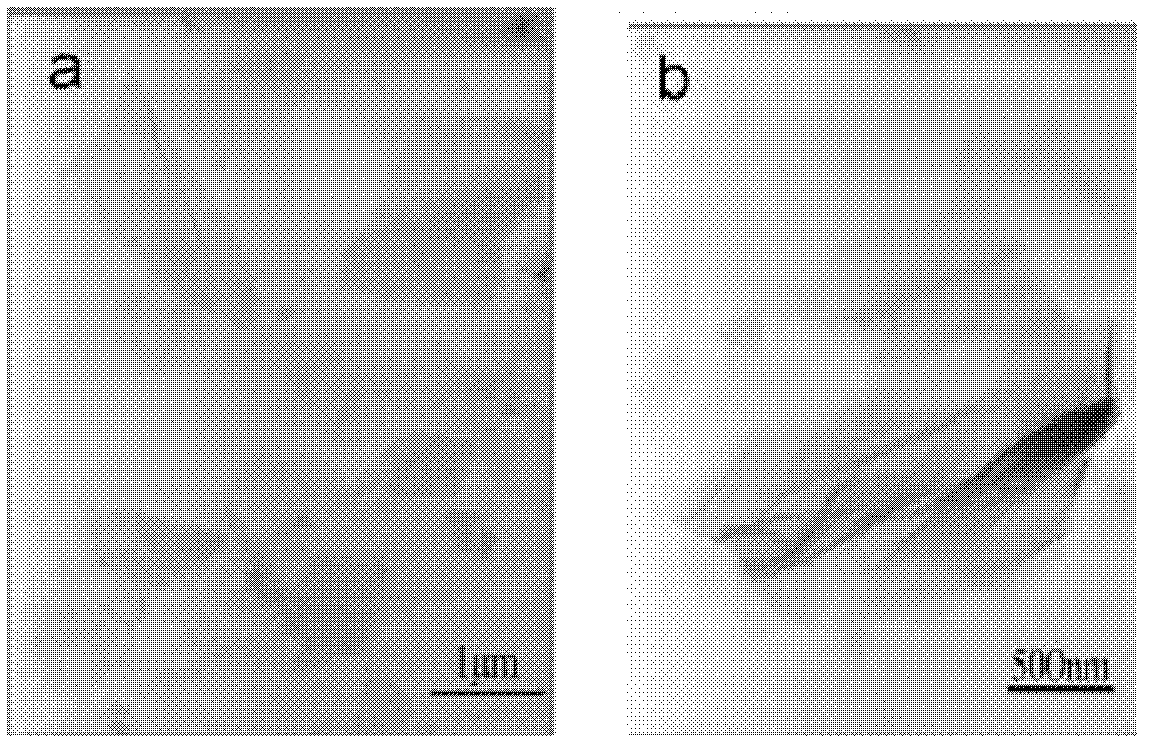

Double-component melt-blown durable electret non-woven fabric and manufacturing method thereof

InactiveCN101591837ASoft touchImprove breathabilityElectroconductive/antistatic filament manufactureArtificial filament physical treatmentFiltrationThermal insulation

The invention relates to a double-component melt-blown durable electret non-woven fabric and a manufacturing method thereof. The non-woven fabric consists of tourmaline modified polypropylene / polyethylene glycol adipate (tourmaline modified PP / PET) parallel double-component melt-blown nano microfiber; and the fiber has the following components in percentage by mass: 20 to 80 percent of tourmaline modified PP, and 80 to 20 percent of PET. The method for manufacturing the non-woven fabric adopts the components in percentage by mass and the process steps of: (1) performing drying pre-treatment on the PET first; (2) then preparing a double-component melt-blown non-woven fabric by tourmaline modified PP / PET melt-blown composite spinning technology; and (3) finally obtaining the double-component melt-blown durable electret non-woven fabric by performing high-voltage corona discharge electret treatment on the non-woven fabric. The non-woven fabric can be used for durable high-efficiency filtration materials, and can also be applied to thermal insulation materials, antibacterial medical materials, oil absorption materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Electret polypropylene melt-blown nonwovens and method for preparation

InactiveCN1544724AMature technologyWell mixedElectroconductive/antistatic filament manufactureFibre treatmentHigh humidityPolymer science

The invention relates to an electret polypropylene melt-spray nonwoven cloth and its making method, the components in weight percent: polypropylene 95-97%, and tourmaline 3-5% with average particle size not greater than 0.5mum; its making method: (1) uniformly mixing and fusing the tourmaline particles and the polypropylene slices to make particles; the assistants of making the tourmaline particles in weight percent: coupling agent 3-10%; dispersant 2-5% and chemical inhibitor 0.01-0.1%; (2) uniformly mixing, fusing and extruding the particles with the polypropylene slices, stretching under the high-speed hot air flow to make the product. The product has better adaptability to high temperature and high humidity environment, can be used in filtering liquid; the making method has the characters of simple technique, no special devices, easy industrialized implementation, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing polyacrylonitrile/carbon nano tube composite material by taking ionic liquid as solvent

InactiveCN101864015AEvenly dispersedHigh molecular weightElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentIn situ polymerizationCarbon nanotube

The invention relates to a method for preparing a polyacrylonitrile / carbon nano tube composite material by taking ionic liquid as a solvent. The method comprises the following steps of: dispersing carbon nano tubes to the ionic liquid; adding monomers and an initiator into the ionic liquid for polymerizing to obtain stock solution of the polyacrylonitrile / carbon nano tube composite material; and obtaining the polyacrylonitrile / carbon nano tube composite material by washing and drying the obtained stock solution. The polyacrylonitrile / carbon nano tube composite material is prepared into a polyacrylonitrile / carbon nano tube composite membrane by adopting a coating method or is prepared into polyacrylonitrile / carbon nano tube composite fibers by adopting a wet spinning process or a dry-jet wet spinning process. The adopted solvent ionic liquid can make the carbon nano tubes disperse uniformly, and has no volatility and environmental-friendliness. In the preparation method, an in-site polymerization method is adopted, so the preparation method is simple and convenient to operate. The composite material can be used in the fields such as the enhancement, the conductivity, the anti-static property, the electromagnetic shielding and the like of a material.

Owner:DONGHUA UNIV

Method for preparing graphene/polyimide composite fibers

InactiveCN102534858ASolve for uniformitySolve adhesivenessElectroconductive/antistatic filament manufactureWet spinning methodsFiberPolymer science

The invention relates to a method for preparing graphene / polyimide composite fibers. The method comprises the following steps of: (1) preparing graphene or graphene oxide; (2) preparing a graphene / polyamic acid spinning solution; and (3) preparing graphene / polyimide or graphene oxide / polyimide composite fibers. According to the method, through adopting stripped graphene layers as addition materials of polyimide fibers, the spinnability of the polyamic acid spinning solution is improved, the stability of the polyamic acid fibers is improved, the improvement on the performance of the fibers is facilitated, and thus, the polyimide fibers with excellent performance are prepared; and with the adoption of the method, the problem of difficulty in the spinning and the forming of the polyamic acid fibers is solved, the mechanical properties of the composite fibers is improved, meanwhile, the problems of uneven dispersion and interfacial adhesiveness of the graphene in a matrix polymer are solved.

Owner:DONGHUA UNIV

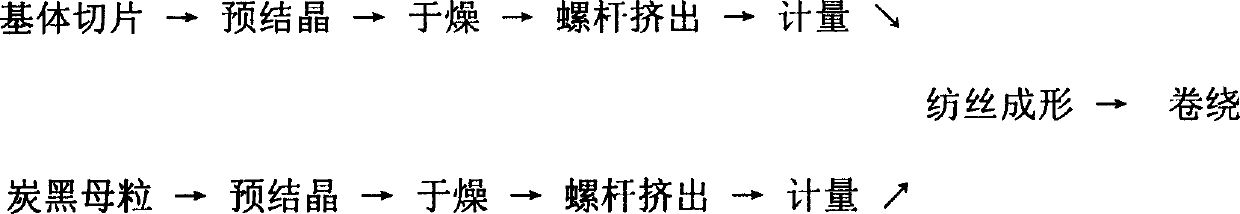

High-efficient conductive fibre and preparing method thereof

InactiveCN1584140AWith special effectsImprove conductivityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a kind of effective electric fibre. It contains: 5-9 %(w) electric charcoal parent-particle, 92-95%(w) PET polyester powder, and the electric parent-particle terylene, nitrile, or cotton fiber contains: 1-6%(w) selection-CT-928, 0 / 5-2%(w) 1010 and 0.5-2%(w) PLTP (antioxidant), 5-20%(w) dispersant-polyethene cere 2000 1-5%(w) magnesium stearic acid. The preparation method is: first, use electric charcoal as the electric component, and separate it evenly is polyester carrier by enwrap and disperse. Secondly produce the parent-particle by high-speed whisking, mix and extrude. Finally, use twin-screw to the filature and then obtain the electric fibre which has good peparative in ployester carrier. And the quality of spin is good. The invention has a low cost, high filature speed and good electric; the conductivity of one thread is 10000-1000000 ohm / cm.

Owner:浙江工程学院

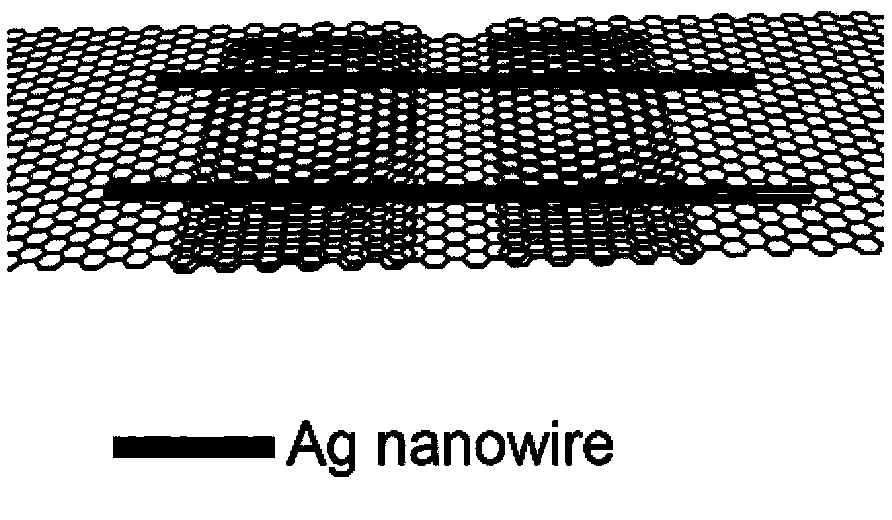

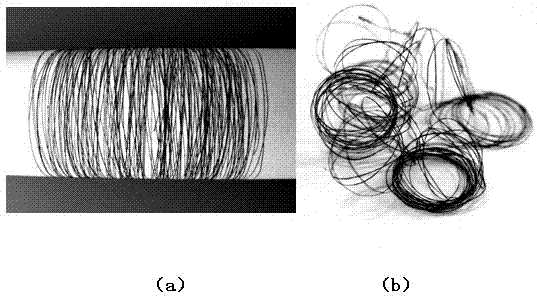

Graphene fiber and preparation method thereof

ActiveCN104099687AArranged in orderConvenient ArrangementElectroconductive/antistatic filament manufactureInorganic material artificial filamentsFiberDoped graphene

The invention discloses a graphene fiber and a preparation method thereof, wherein the graphene fiber is a composite fiber obtained by doping graphene fiber with metal nanowires, the composite fiber comprises the main components of graphene and the metal nanowires, wherein the mass ratio of the metal nanowires is 0.1% ~ 50%, the graphene is in lamellar morphology, and the metal nanowires and the graphene layers are parallelly and simultaneously arranged along the axial direction of the graphene fiber. The metal nanowire doped graphene fiber is a new high performance and multifunctional fiber material, by doping of the metal nanowires, fiber conductive rate is greatly improved, meanwhile the graphene fiber exhibits good tensile strength and excellent toughness, has the very strong potential application value in many fields such as use as lightweight flexible wires and the like.

Owner:HUAWEI TECH CO LTD +1

Preparation method for polymer-grafted graphene laminated fiber with electrical conductivity and high-strength

InactiveCN102926020ARaw materials are easy to getLow costElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolymer dissolution

The invention discloses a preparation method for a polymer-grafted graphene laminated fiber with electrical conductivity and high-strength. The preparation method comprises steps as follows: (1) dissolving graphene oxide raw materials into a solvent, and ultrasonically processing to obtain graphene oxide dispersing liquid; 2) dissolving the polymer into the solvent to obtain the polymer solution; 3) slowly adding the graphene oxide dispersing liquid into the polymer solution, and adding a reducing agent to reduce the graphene oxide into graphene; and 4) centrifugally processing to wash away free polymer to obtain polymer-grafted graphene sol, transferring the polymer-grafted graphene sol into a spinning device, continuously extruding the polymer-grafted graphene sol from a spinning head at a constant speed, forming in solidifying liquid, and then collecting the formed polymer-grafted graphene sol on a roller shaft, so as to obtain the continuous polymer-grafted graphene laminated fiber. The preparation method is simple and convenient, low in cost, rich in variety of used polymers, and suitable for massive industrial production; the produced fiber is excellent in mechanical performance, and higher in conductivity; and the produced fiber can be applied to fields of power transmission, anti-static textile, engineering material, etc.

Owner:ZHEJIANG UNIV

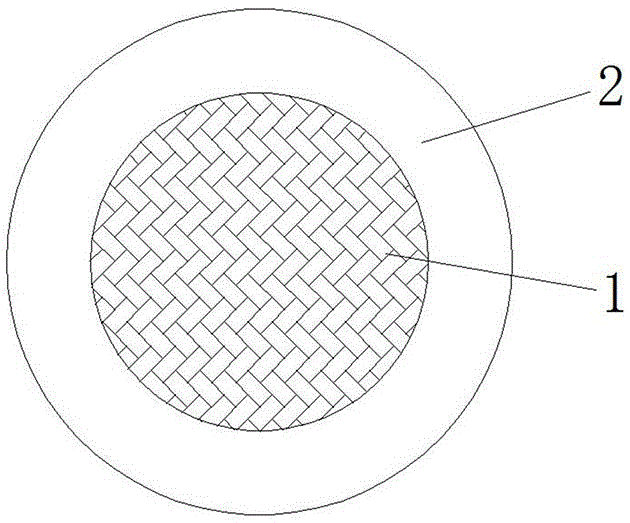

Multi-purpose sheath-core composite monofilament as well as production method and application thereof

InactiveCN106048777AElectroconductive/antistatic filament manufactureFlame-proof filament manufactureMosquito netPolypropylene

The invention relates to a multi-purpose sheath-core composite monofilament for weaving reticulated as well as a production method and application thereof, and belongs to the technical field of production of composite fibers. The multi-purpose sheath-core composite monofilament comprises a sheath layer and a core layer, wherein the sheath layer covers the core layer; the core layer is prepared from PP, TPU or TPEE; the sheath layer is prepared from PE, POE, TPU or TPEE; the melting point of the sheath layer is 120 to 170 DEG C; the melting point of the core layer is 150 to 210 DEG C; the content of the sheath layer is 30 to 70 percent; the content of the core layer is 70 to 30 percent. The multi-purpose sheath-core composite monofilament comprising two components can be applied to weaving of gauze, window screens, curtains, abat vents, light equalization cloth, anti-mosquito nets, anti-haze gauze, filter screen cloth, shoe screen cloth, and base materials of power transmission belts.

Owner:无锡盛烨特邦新材料科技有限公司

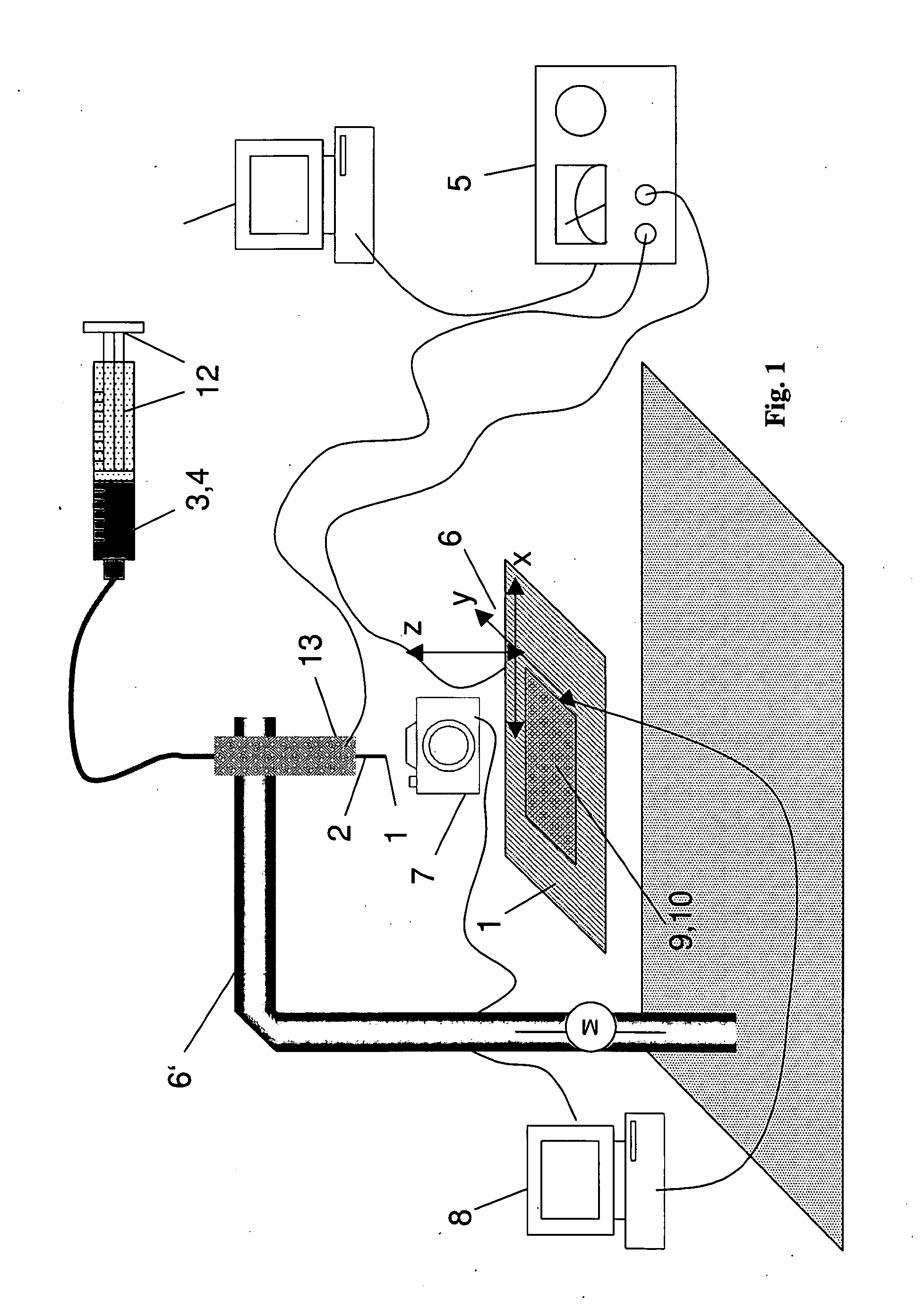

Apparatus and method for producing electrically conducting nanostructures by means of electrospinning

InactiveUS20090130301A1Electroconductive/antistatic filament manufactureElectric shock equipmentsElectrospinningEngineering

Apparatus and method for producing electrically conducting nanostructures by means of electrospinning, the apparatus having at least a substrate holder (1), a spinning capillary (2), connected to a reservoir (3) for a spinning liquid (4) and to an electrical voltage supply (5), an adjustable movement unit (6, 6′) for moving the spinning capillary (2) and / or the substrate holder (1) relative to one another, an optical measuring device (7) for monitoring the spinning procedure at the outlet of the spinning capillary (2), and a computer unit (8) for controlling the drive of the spinning capillary (2) relative to the substrate holder (1) in accordance with the spinning procedure.

Owner:BAYER MATERIALSCIENCE AG

Beam forming apparatus and method using interference power estimation in an array antenna system

InactiveUS20050259006A1Reduce implementation complexityEasy to useElectroconductive/antistatic filament manufactureShielding materialsFrequency spectrumTD-SCDMA

An apparatus and method are provided for simply estimating joint channel and Direction-of-Arrival (DOA) to efficiently estimate a channel impulse response associated with a spatially selective transmission channel occurring in a mobile radio channel, and performing efficient beam forming using the simplified joint channel and DOA estimation are provided. A receiver estimates the total interference power using power for each interference signal, estimates a spectral noise density, calculates steering vectors considering predetermined DOAs, and jointly calculates optimal weight vectors for each DOA of each user by applying the interference power and the spectral noise density to the steering vectors. The beam forming reduces implementation complexity of a TDD system such as a TD-SCDMA and increases beam forming efficiency in a mobile environment by efficiently using spatial diversity.

Owner:SAMSUNG ELECTRONICS CO LTD

Multifunctional high-performance carbon-based nanoparticle/sodium alginate composite fibers and preparation method thereof

ActiveCN104178845AEvenly dispersedHigh tensile strengthElectroconductive/antistatic filament manufactureAlginate artificial filamentsFiberSpinning

The invention discloses a preparation method of carbon-based nanoparticle / sodium alginate composite fibers. The method comprises the steps of firstly, preparing a sodium alginate water solution with a certain concentration; then, feeding graphene oxide into the solution, fully mixing, and carrying out ultrasonic dispersion to obtain a graphene oxide / sodium alginate water solution; feeding a certain quantity of carbon nano tubes into the solution, fully mixing, and carrying out the ultrasonic dispersion to obtain a carbon nano tube / graphene oxide / sodium alginate spinning solution with the good dispersion; filtering the spinning solution, defoaming, and carrying out solution spinning at the room temperature to prepare the carbon-based nanoparticle / sodium alginate composite fibers. According to the carbon-based nanoparticle / sodium alginate composite fibers prepared by adopting the method, the uniform dispersion and the formation of a network structure of carbon-based nanoparticles in the fibers can be realized, the effective orientation of the carbon-based nanoparticles in the fibers can be realized, and the tensile strength, the electrical conductivity and the degradability resistance of the fibers are improved; furthermore, the adsorbability of the fibers is effectively improved, so that the carbon-based nanoparticle / sodium alginate composite fibers can be used for absorbing heavy metal ions and dye in water solutions.

Owner:QINGDAO UNIV

Polyaniline/polyacrylonitrile composite conductive fibre and preparation process thereof

InactiveCN1450210AMeet the needs of industrial productionElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsOrganic sulfonic acidSulfonate

The present invention discloses a polyaniline / polyacrylonitrile composite conductive fibre and its preparation method. Its preparation method includes the following steps: firstly, preparing soluble polyaniline doped by organic sulfonic acid, then using solvent to dissolve the organic sulfonate of polyaniline and polyacrylonitrile; adopting wet spinning technology to press the mixed solution through spinning nozzle, and extruding the mixed solution into the coagulating bath, drawing and washing with water so as to obtain the invented composite conductive fibre. The electric conductivity of said fibre can be controlled in the range of 10(-7)-10(-1)(S / cm), and said fibre has good strength, generally it is 1.5CN / dtex-3.4 / detex, can be used for making electromagnetic shielding material and anti-static material.

Owner:DONGHUA UNIV

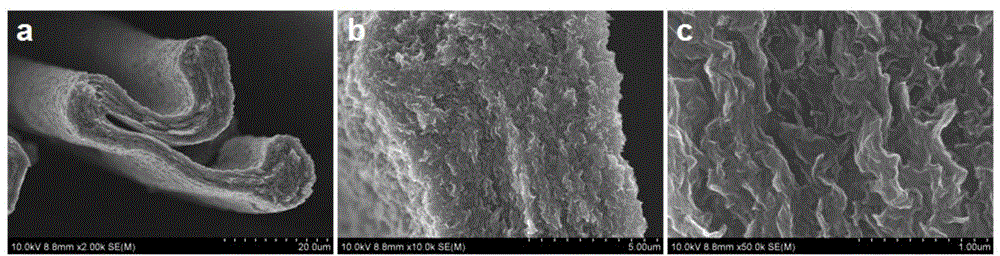

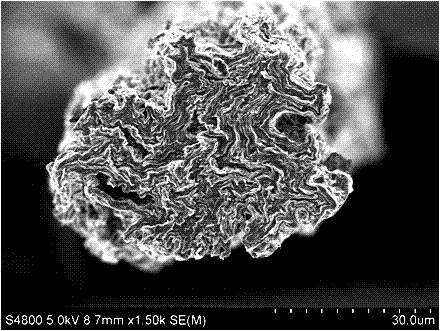

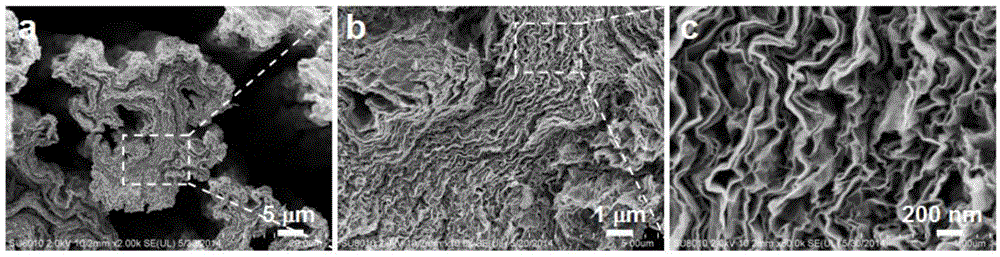

Nano conductive polymer/graphene composite fiber, and preparation method and application thereof

ActiveCN104790067AImprove toughnessAvoid brittle defectsElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberConductive polymer

The invention relates to a nano conductive polymer / graphene composite fiber, and a preparation method and application thereof. The section of the fiber is special; a graphene sheet is at a loose stacking state; enriched fold morphology is formed on the surface of the fiber; the average strength of the fiber is greater than 50 MPa; the average breaking elongation is greater than 2 percent; the average conductivity is greater than 1 S / cm. The method comprises the following steps: preparing conductive polymer / graphene oxide composite spinning solution; then extruding the solution into a coagulating bath and performing elongation and curing, and performing drying and winding on the obtained wet fiber, so as to obtain conductive polymer / graphene oxide composite fiber; finally performing reduction through a chemical or physical method so as to obtain the nano conductive polymer / graphene composite fiber. The nano conductive polymer / graphene composite fiber has the advantages that an adjustable special section structure is formed on the section of the composite fiber, rich microstructures are formed on the surface of the composite fiber, the problem that graphene sheet layers are closely stacked is overcome, the graphene fiber with pure toughness is greatly enhanced, and excellent conductivity of the graphene fiber is still kept, so that the composite fiber has a wide application prospect.

Owner:DONGHUA UNIV

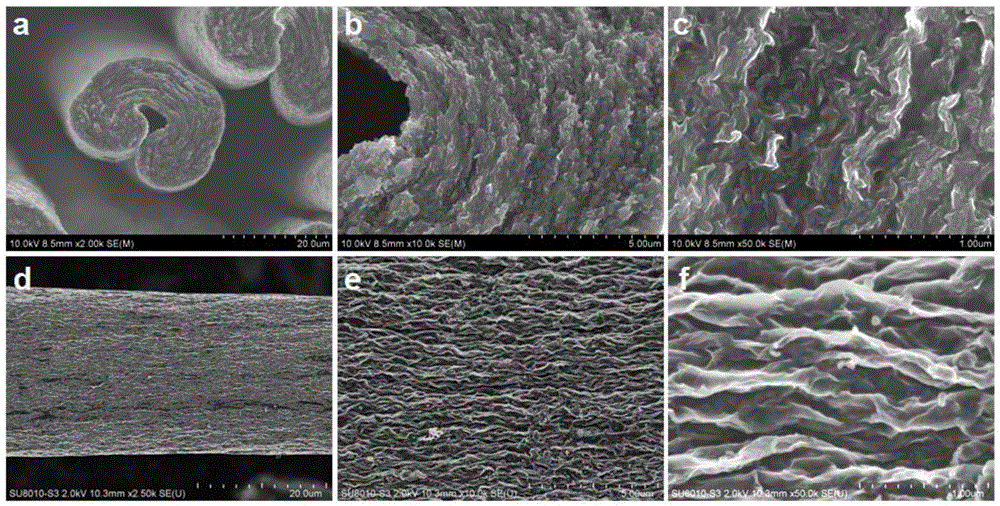

Polymer composite function fibers containing partial graphene, and preparation method thereof

ActiveCN105002595AIncrease productivityHigh strengthElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolyesterPolymer science

The present invention discloses a polymer composite function fibers containing partial graphene, and a preparation method thereof. The fibers comprise a component A and a component B, wherein the component A and the component B are combined in a partial exposing manner, side-by-side manner or skin-core manner, and 20-100% of the outer area of each fiber is the component B. The method comprises: crystallizing a polyester containing 0.1-1 wt% of partial reducing graphene and a polyester containing 4-20 wt% of a nanometer composite filler containing partial reducing graphene and TiO2, drying, carrying out melt composite spinning, and carrying out drawing and relaxation heat setting at a temperature of 80-160 DEG C, and reducing the partial graphene in the fibers to achieve the carbon / oxygen atom ratio of 9 / 1-15 / 1 through the reducing treatment. According to the present invention, the prepared fibers can be produced at the high spinning speed, and the production efficiency is high; and the fibers have characteristics of low single fineness, high strength and lower resistivity, meets the antistatic requirement, and further has characteristics of anti-bacterial property and flame retardant property so as to provide good application prospects.

Owner:NINGBO MYBABY BABY & CHILDREN PROD MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com