Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

a technology of fused filament and diffusive bonding, which is applied in the direction of additive manufacturing processes, manufacturing tools, transportation and packaging, etc., can solve the problems of reduced mechanical properties and incomplete welding of beads, and achieve the effect of enhancing the interbead diffusive bonding of fused filament fabricated parts, increasing interbead bond strength, and reducing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

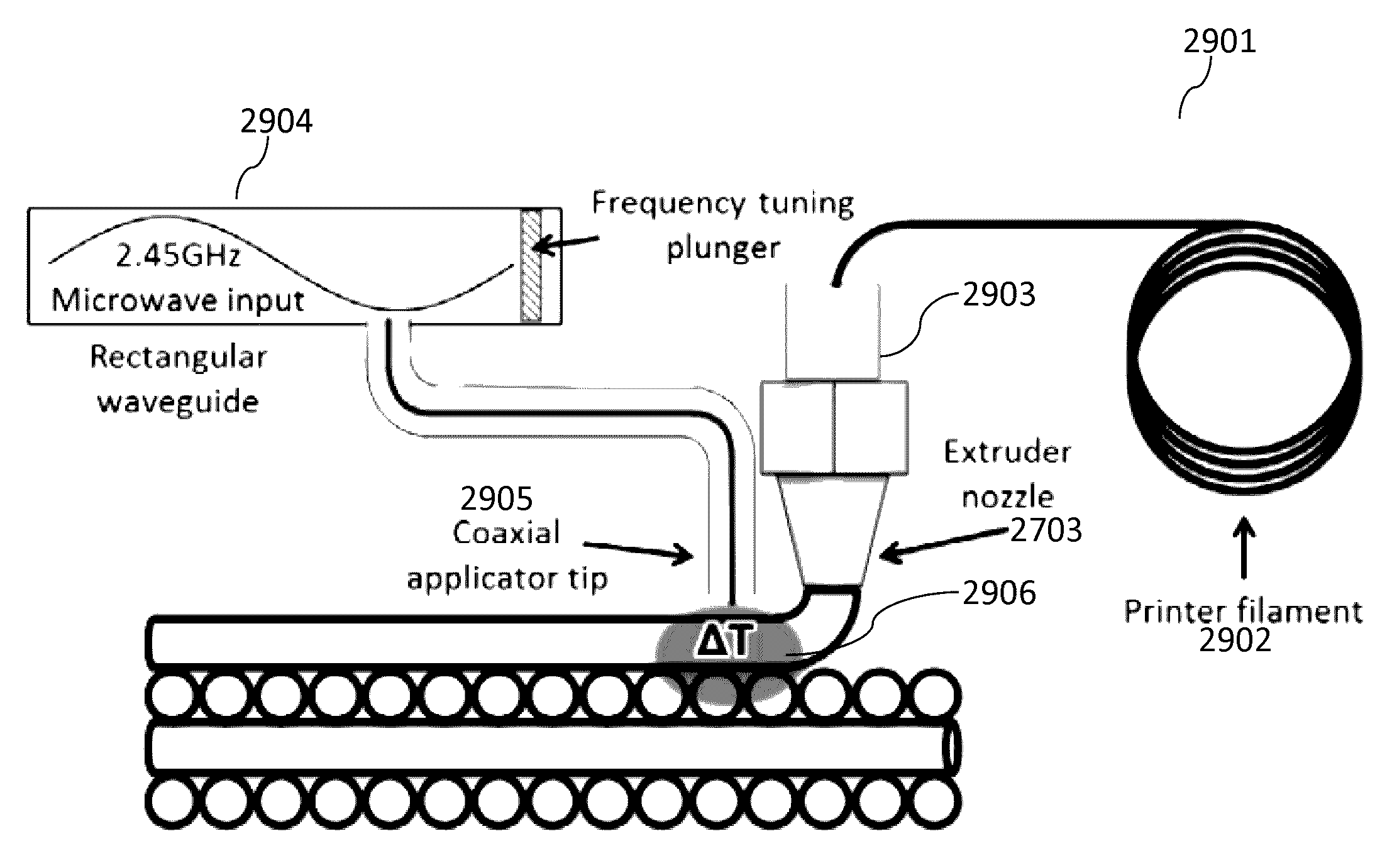

[0086]The present invention embodies a technique for incorporating microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface (or throughout the volume) of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. In embodiments of the present invention, additive manufacturing techniques, in which successive layers are laid down additively into the desired shape, are utilized by 3D printers to manufacture thermoplastic parts. These 3D printers can print intricate product designs much faster than regular machining techniques; however, the strength of the final part may be compromised when compared to parts produced through conventional machining methods. A treatment process of the present invention is used to address the compromise of the strength of the produced part as compared to parts produced through conventional machining methods. The treatment pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com