Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

315results about How to "Increase compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

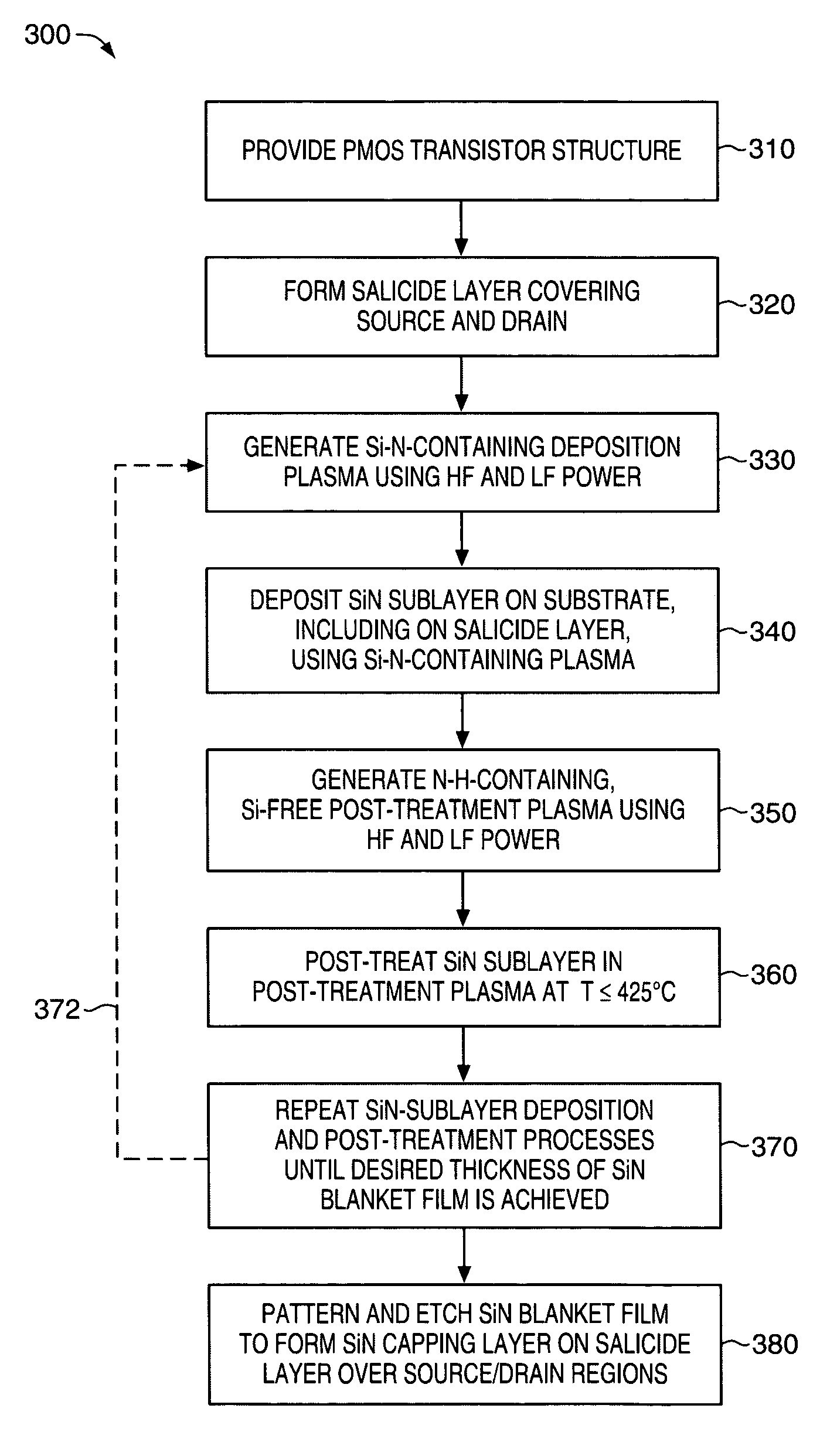

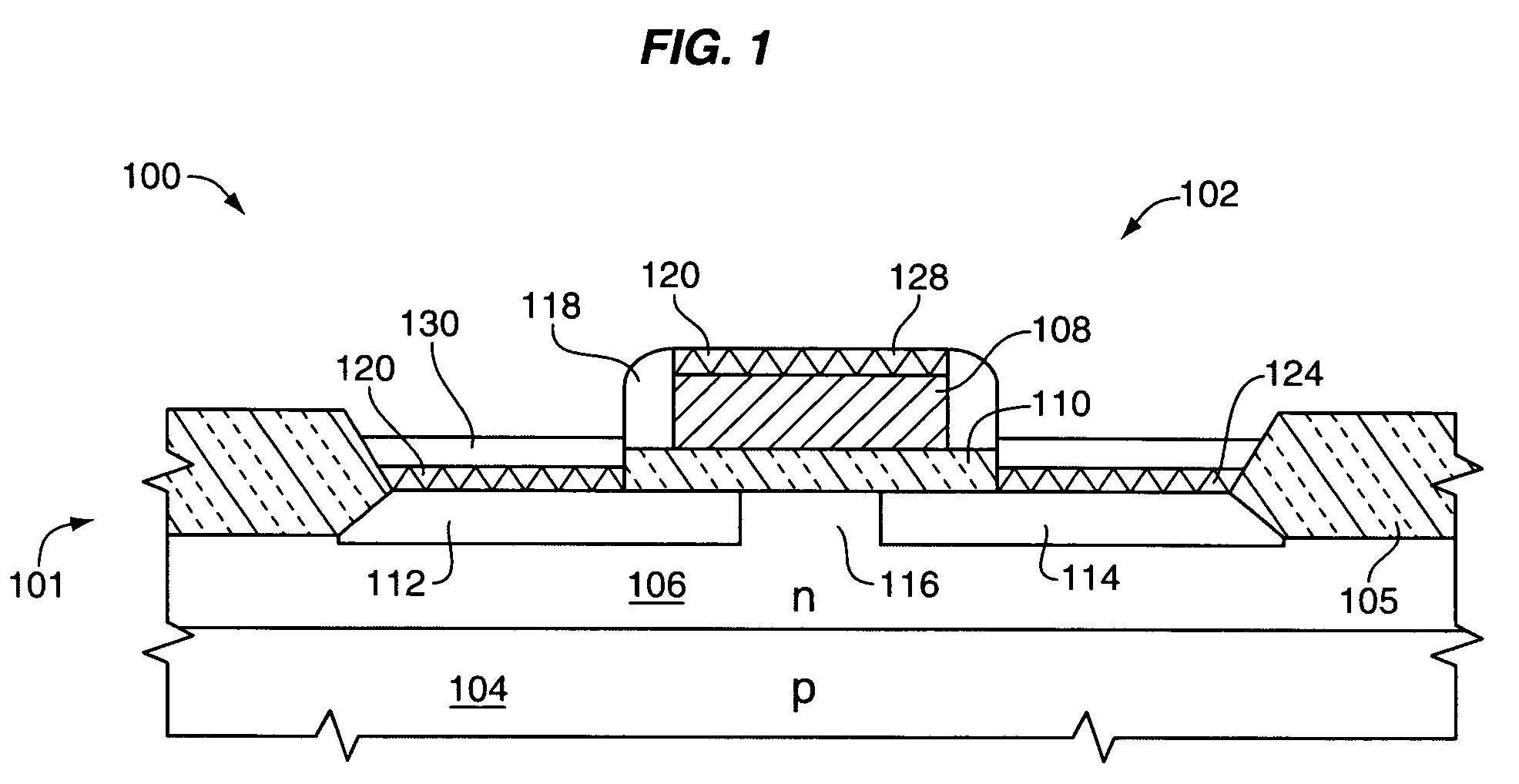

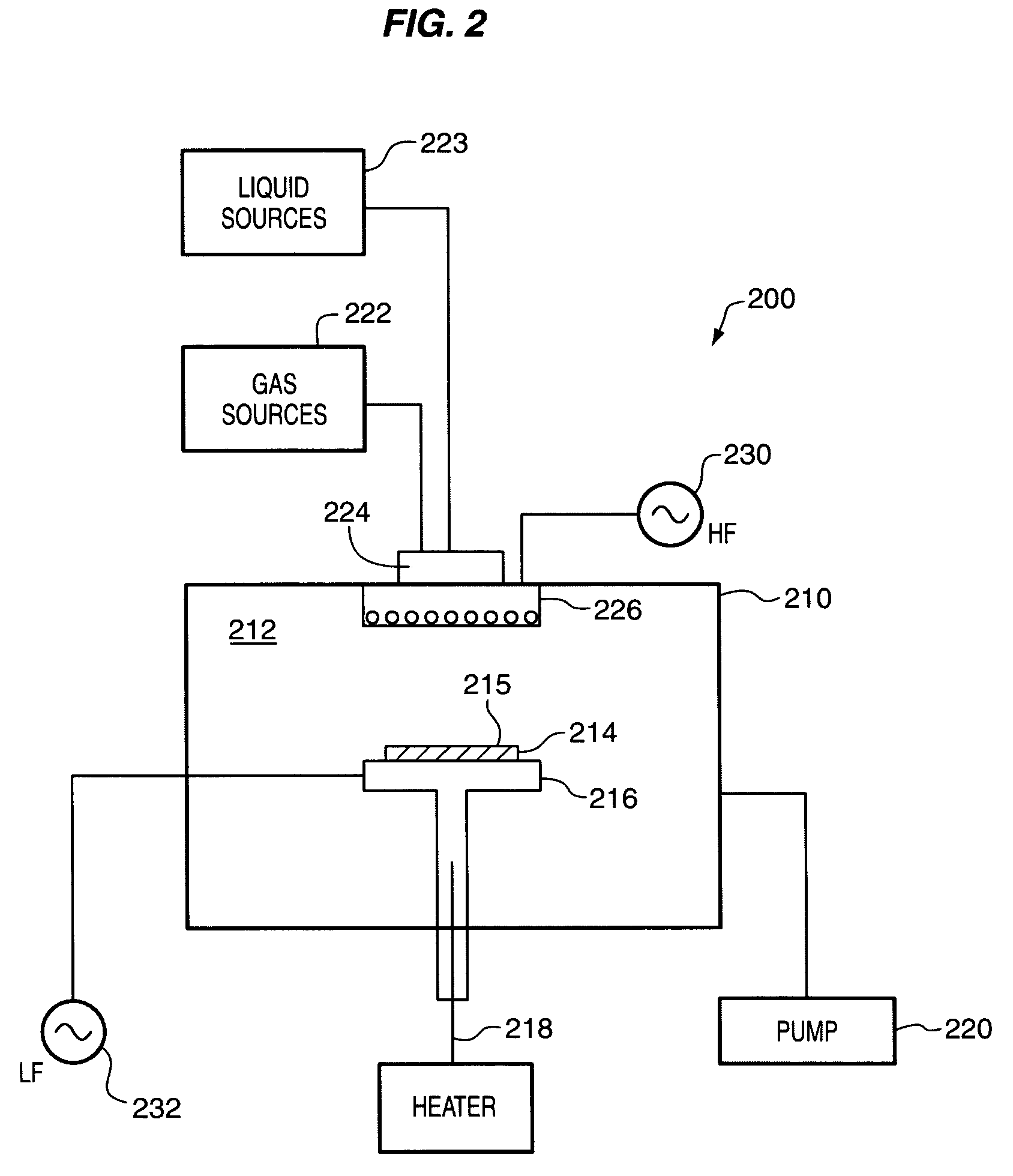

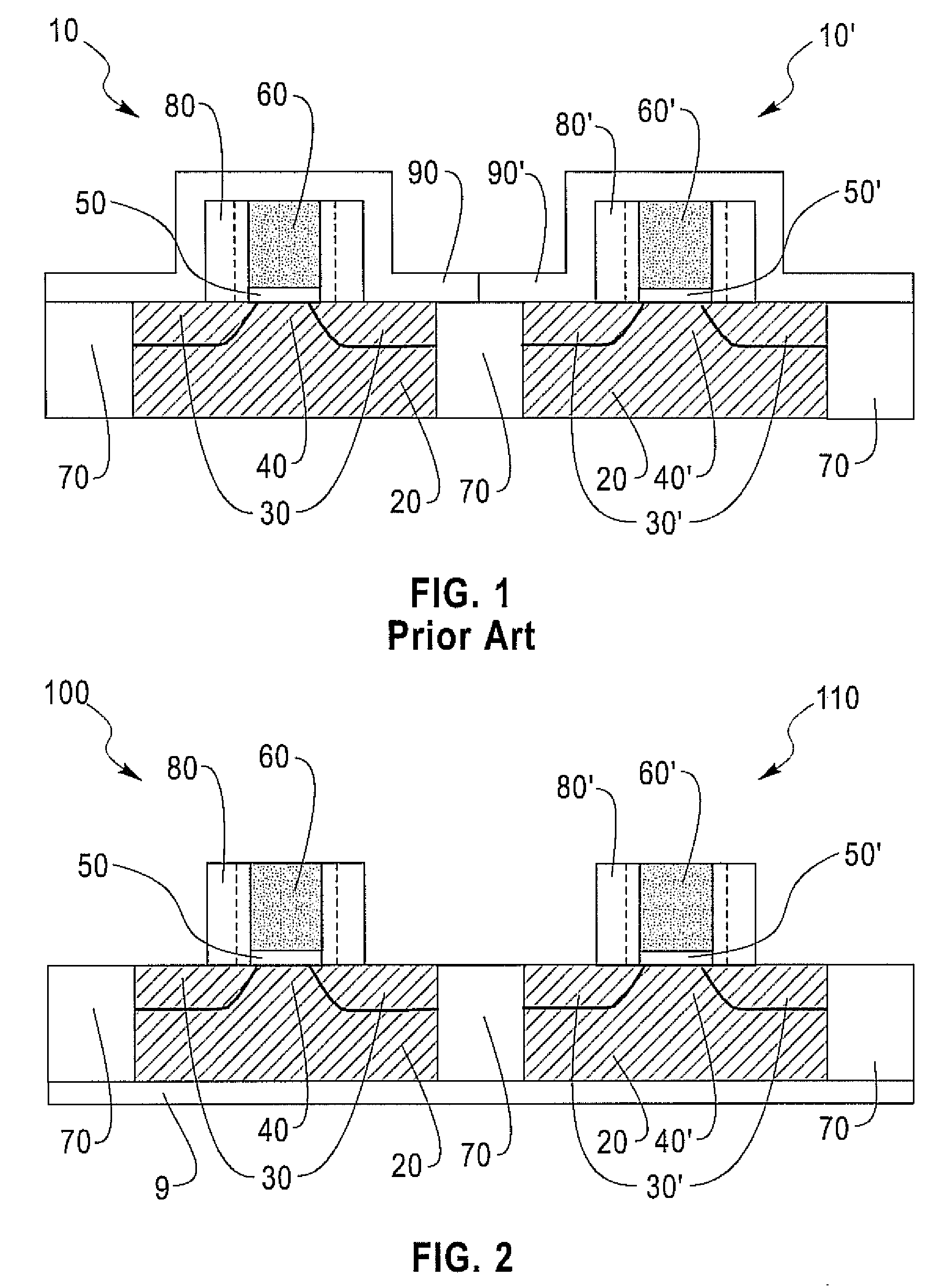

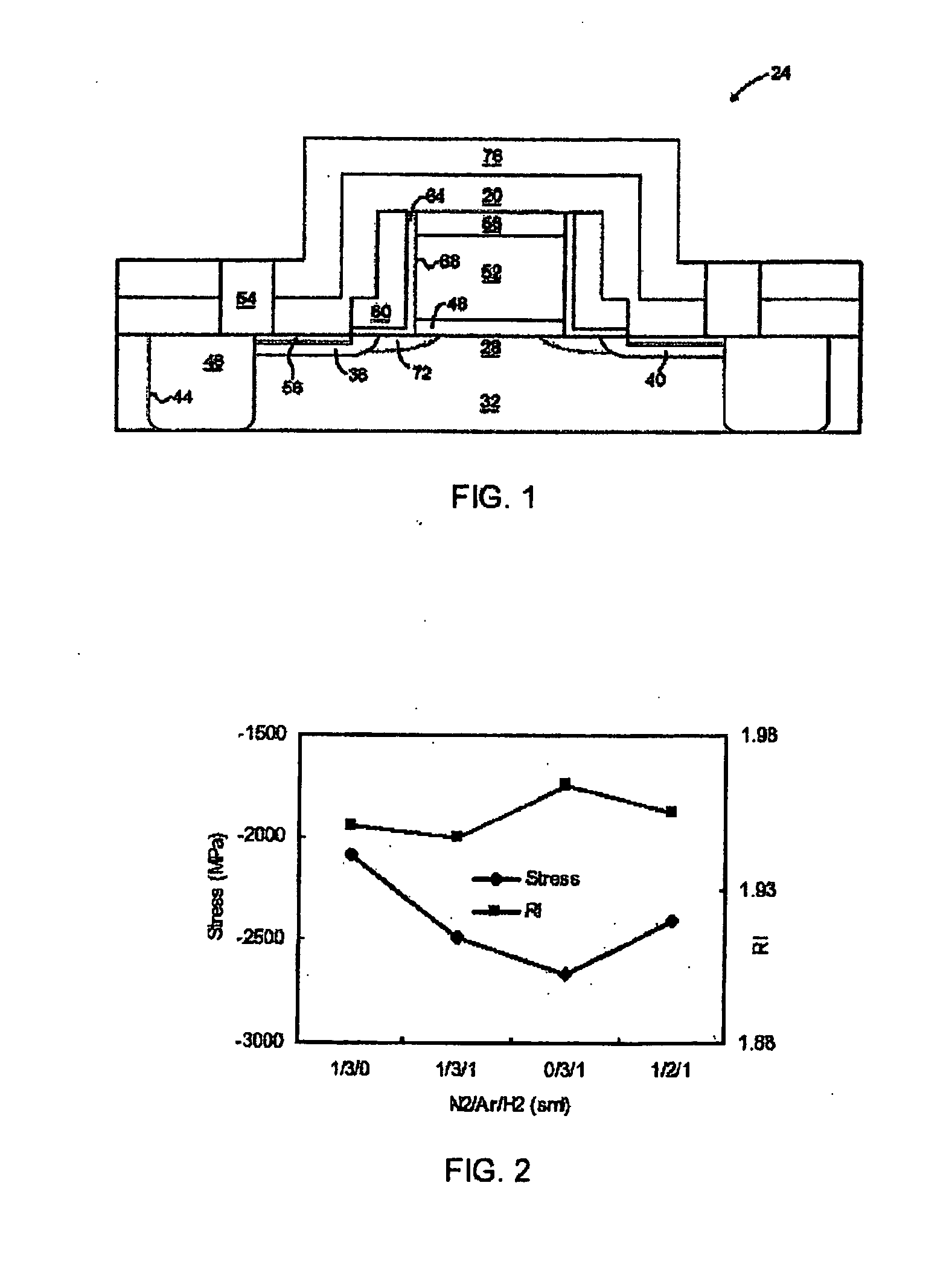

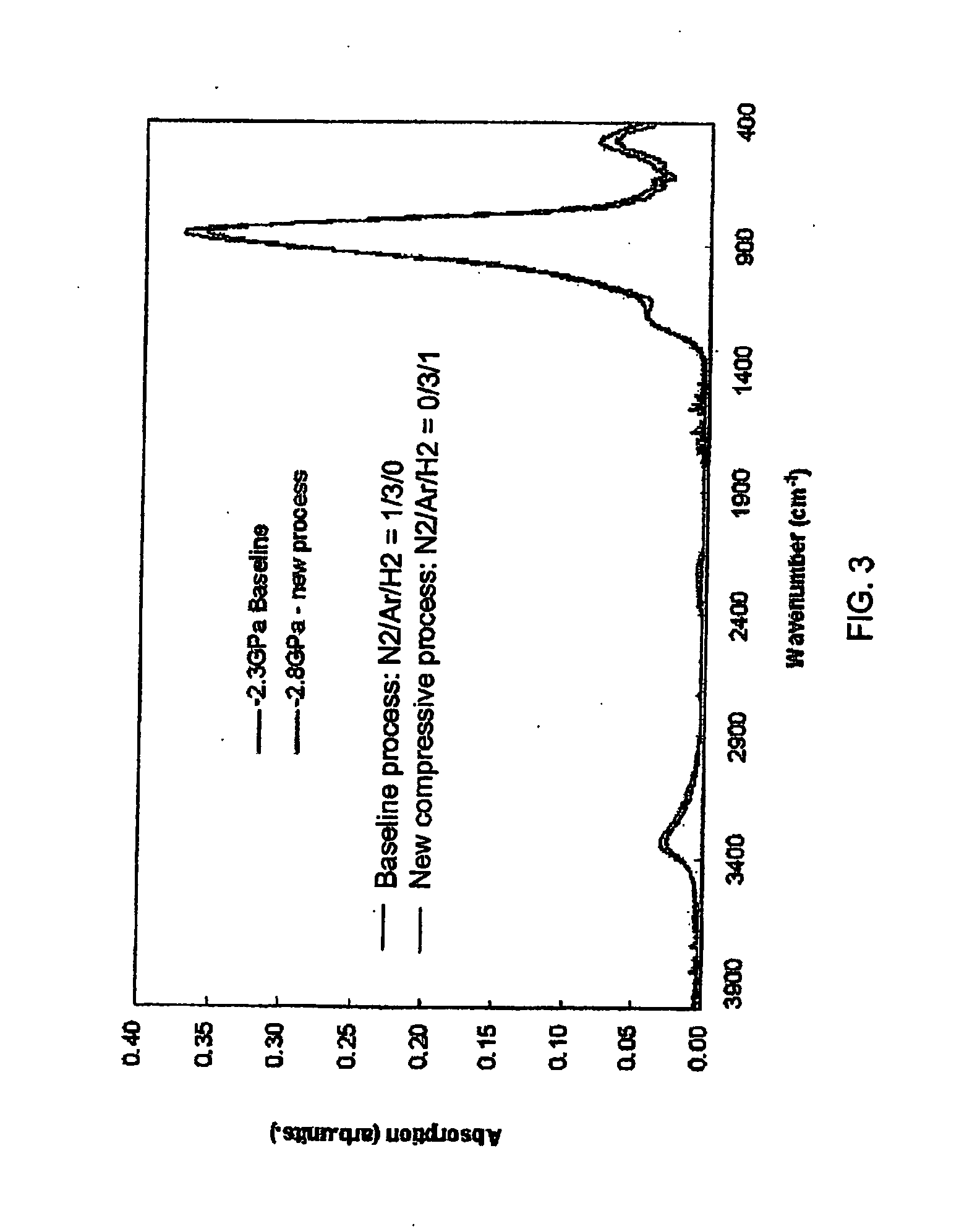

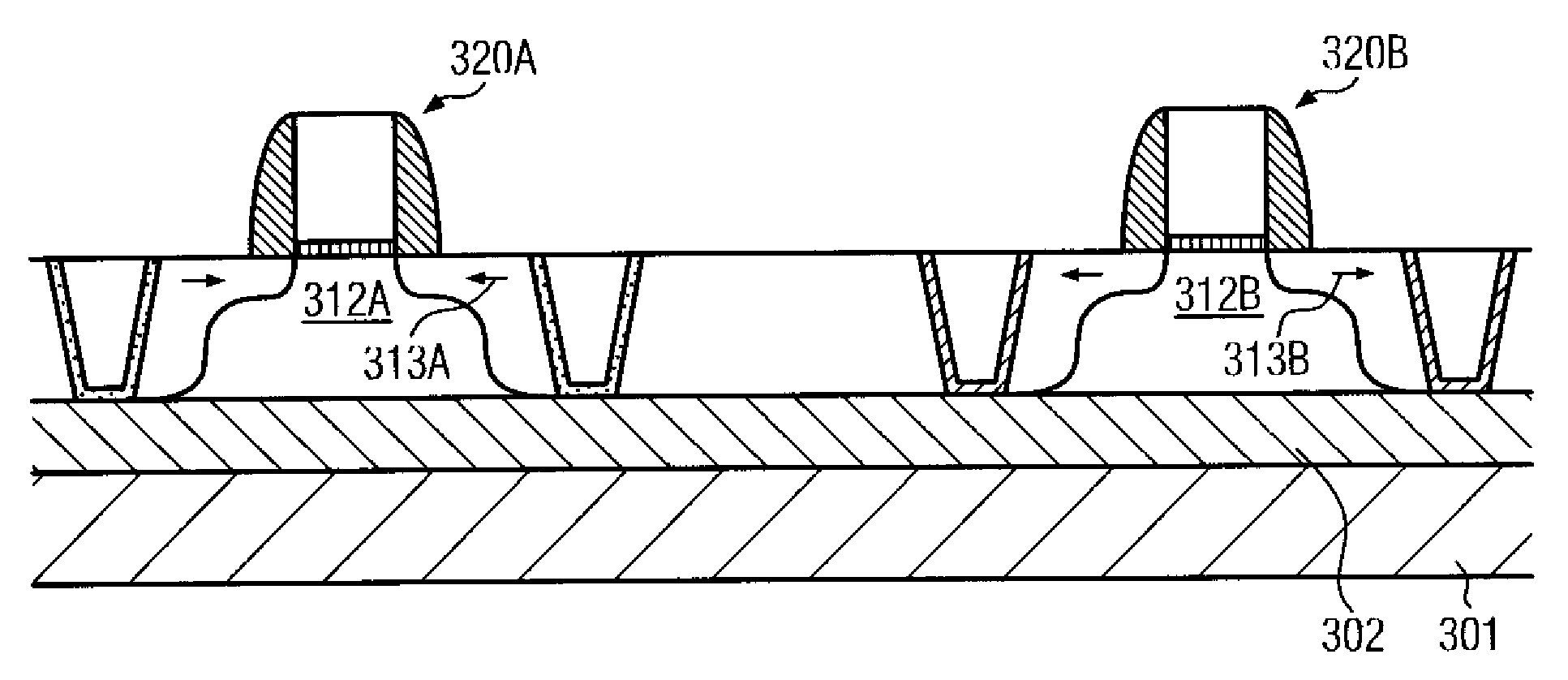

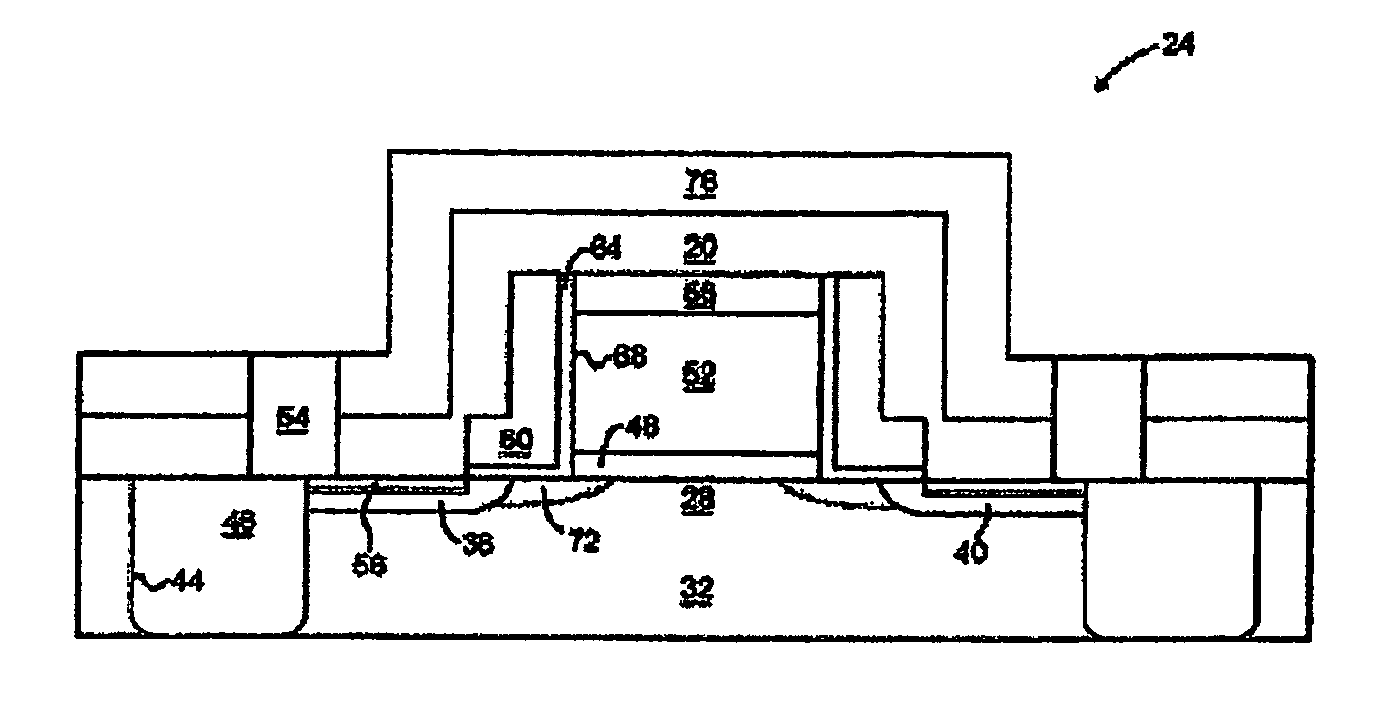

PMOS transistor with compressive dielectric capping layer

ActiveUS7214630B1Preserving material qualityImprove performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSalicideOxidation state

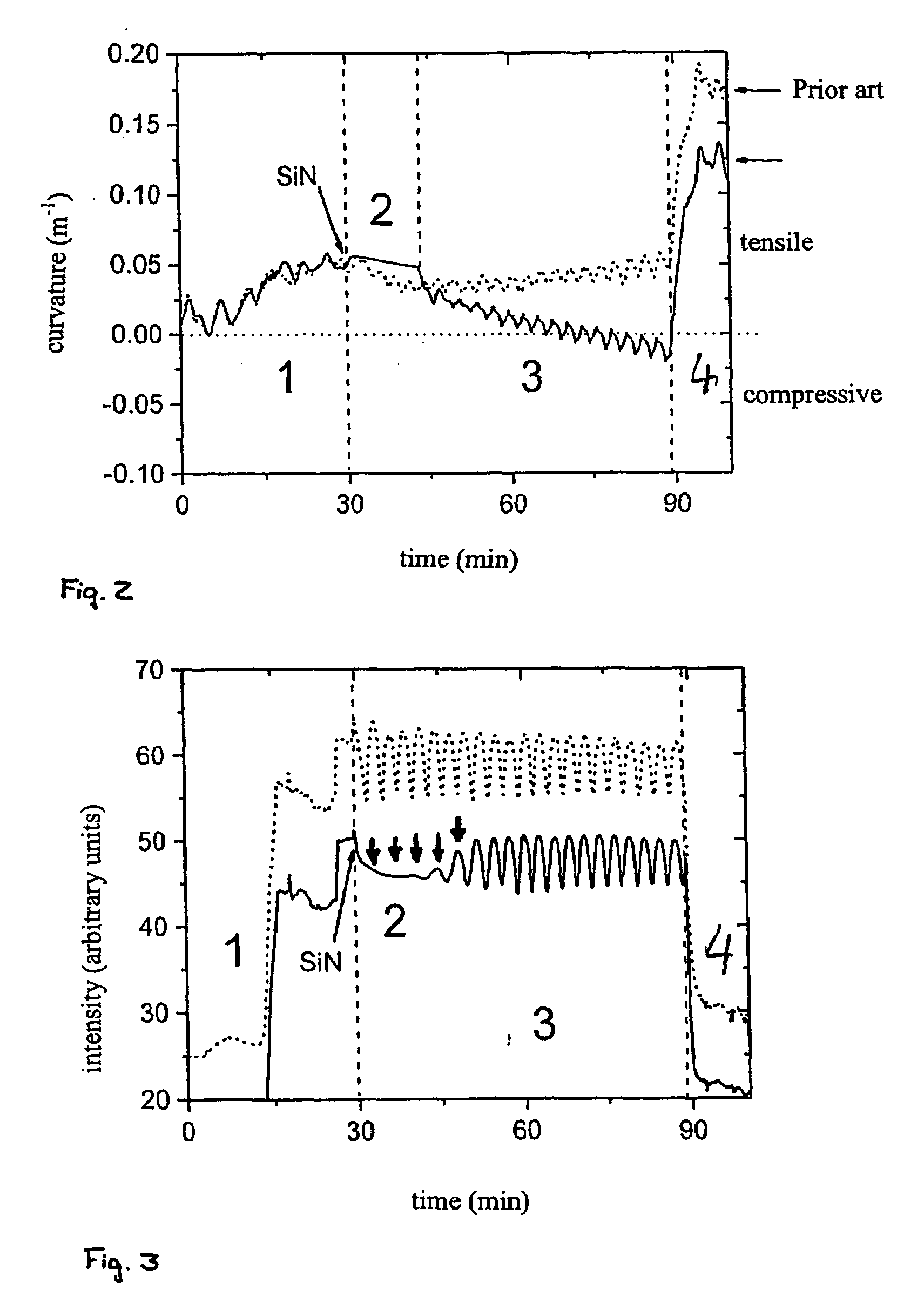

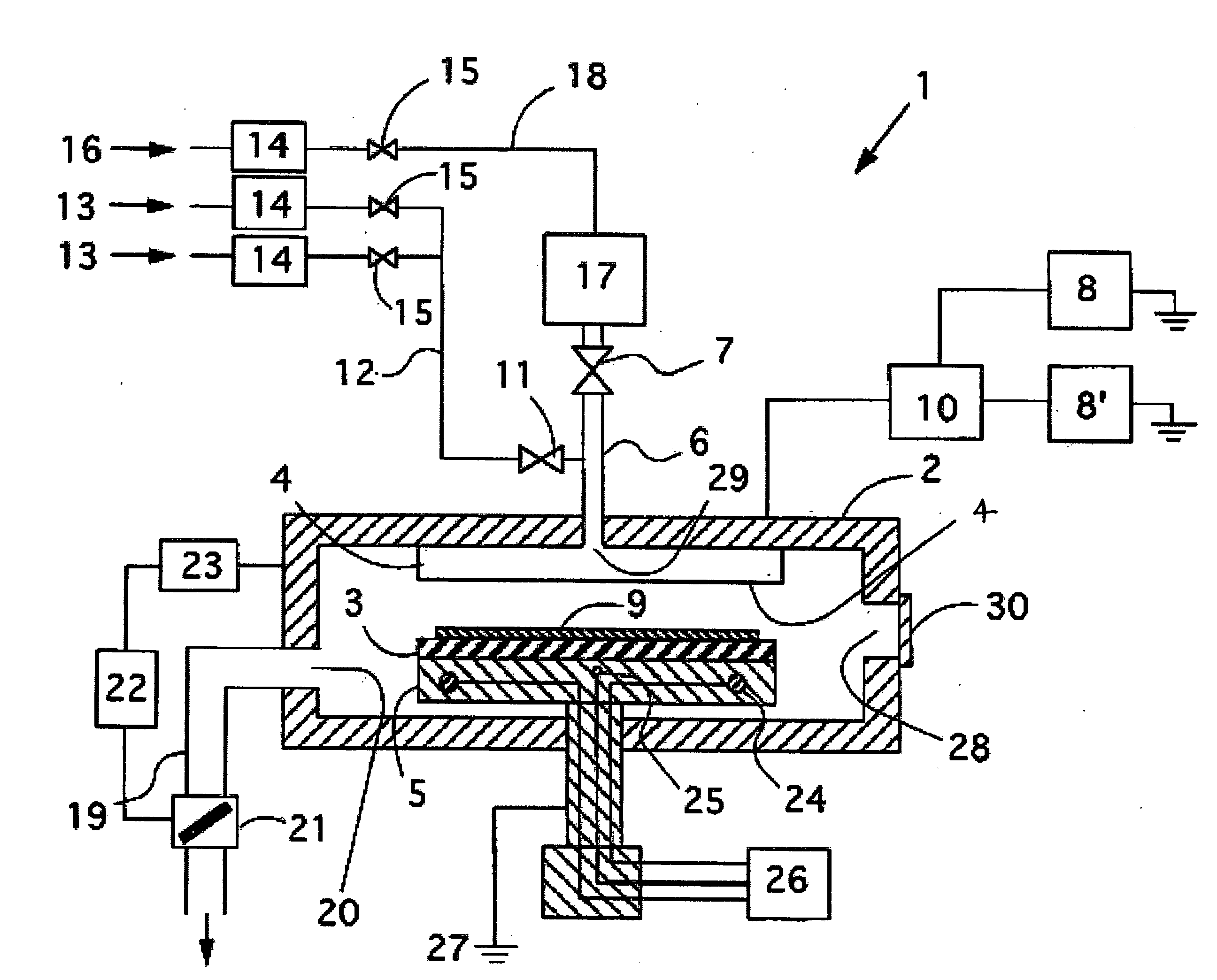

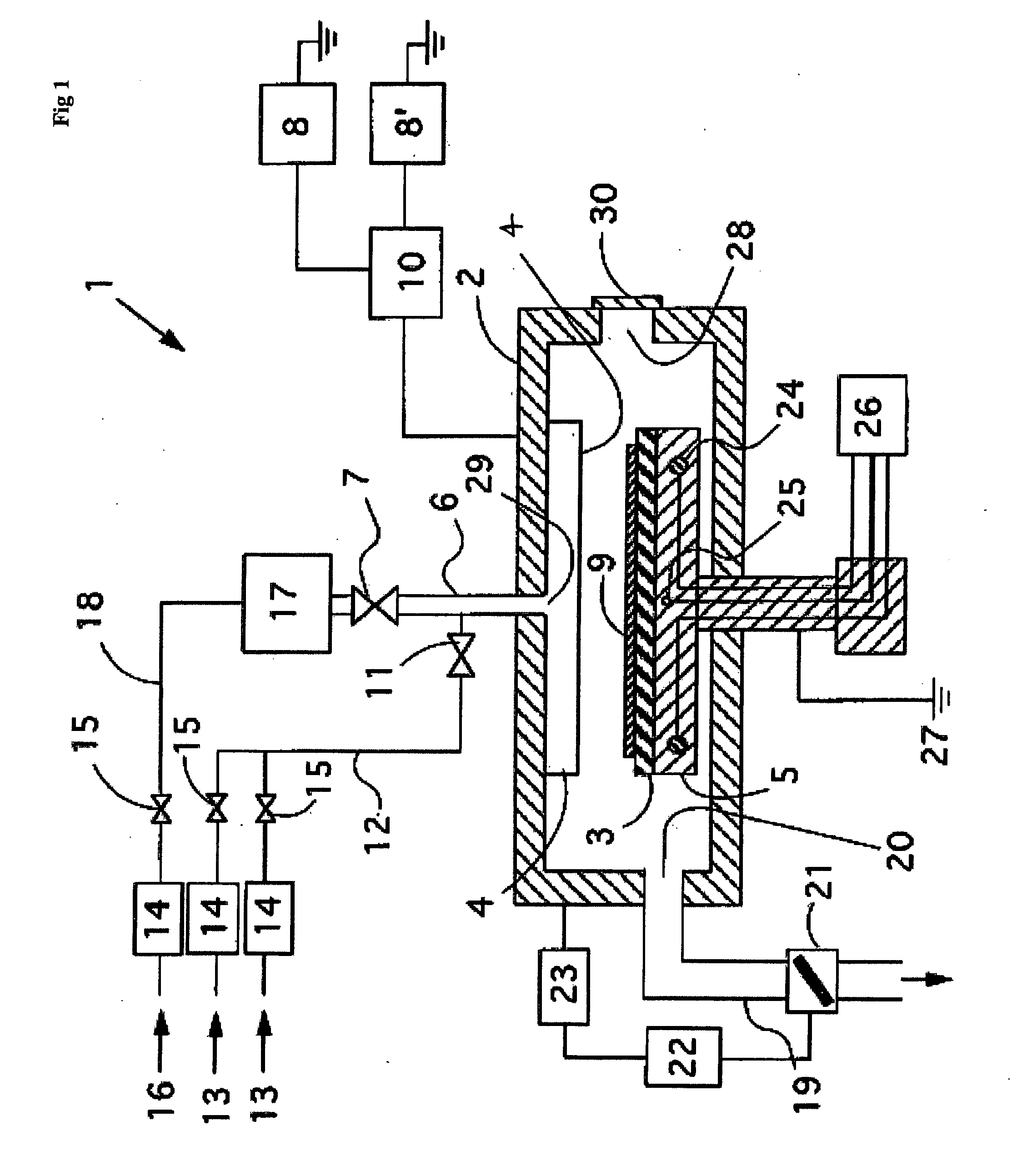

A salicide layer is deposited on the source / drain regions of a PMOS transistor. A dielectric capping layer having residual compressive stress is formed on the salicide layer by depositing a plurality of PECVD dielectric sublayers and plasma-treating each sublayer. Compressive stress from the dielectric capping layer is uniaxially transferred to the PMOS channel through the source-drain regions to create compressive strain in the PMOS channel. To form a compressive dielectric layer, a deposition reactant mixture containing A1 atoms and A2 atoms is provided in a vacuum chamber. Element A2 is more electronegative than element A1, and A1 atoms have a positive oxidation state and A2 atoms have a negative oxidation state when A1 atoms are bonded with A2 atoms. A deposition plasma is generated by applying HF and LF radio-frequency power to the deposition reactant mixture, and a sublayer of compressive dielectric material is deposited. A post-treatment plasma is generated by applying HF and LF radio-frequency power to a post-treatment gas that does not contain at least one of A1 atoms and A2 atoms. Compressive stress in the dielectric sublayer is increased by treating the sublayer in the post-treatment plasma. Processes of depositing a dielectric sublayer and post-treating the sublayer in plasma are repeated until a desired thickness is achieved. The resulting dielectric layer has residual compressive stress.

Owner:NOVELLUS SYSTEMS

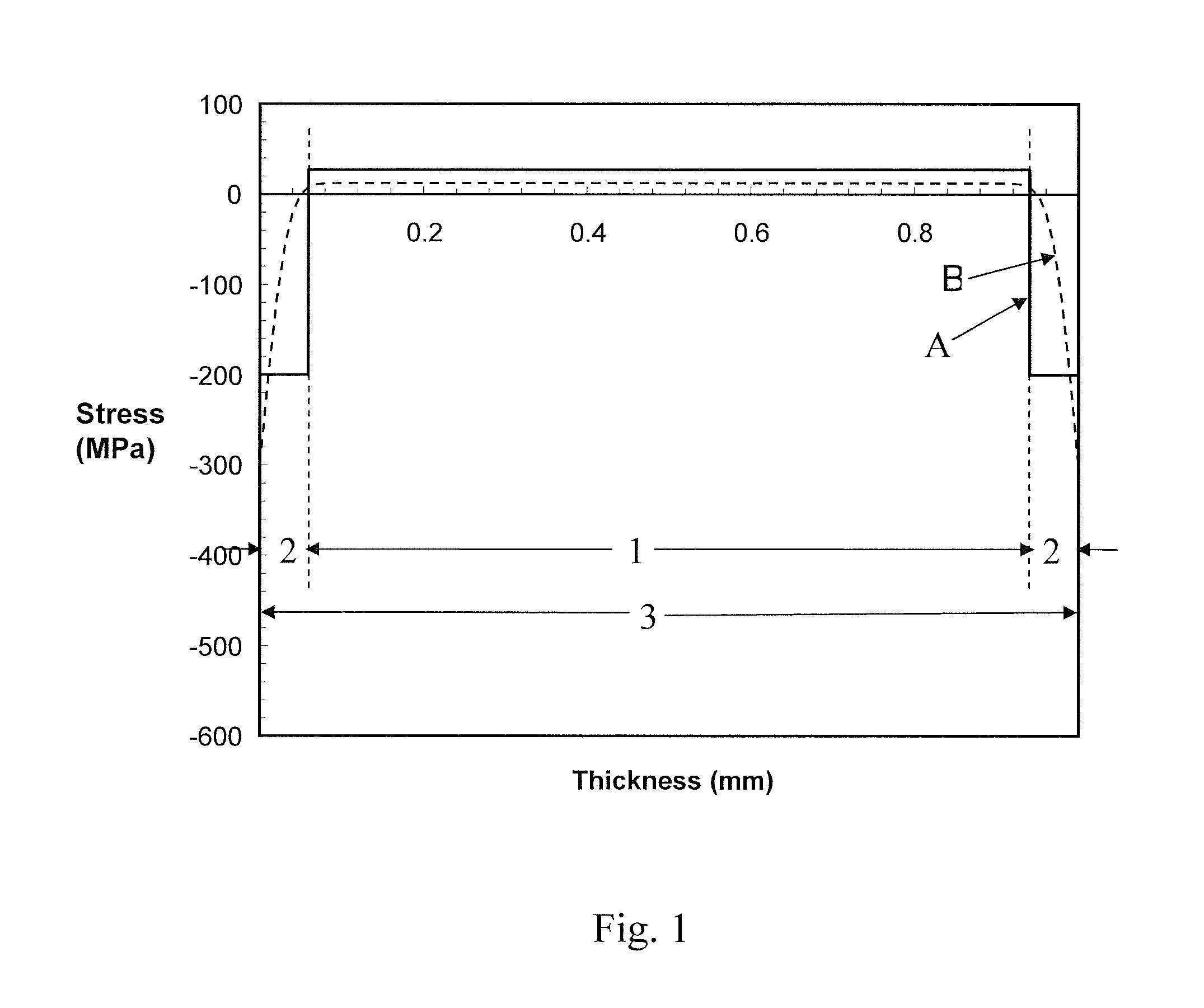

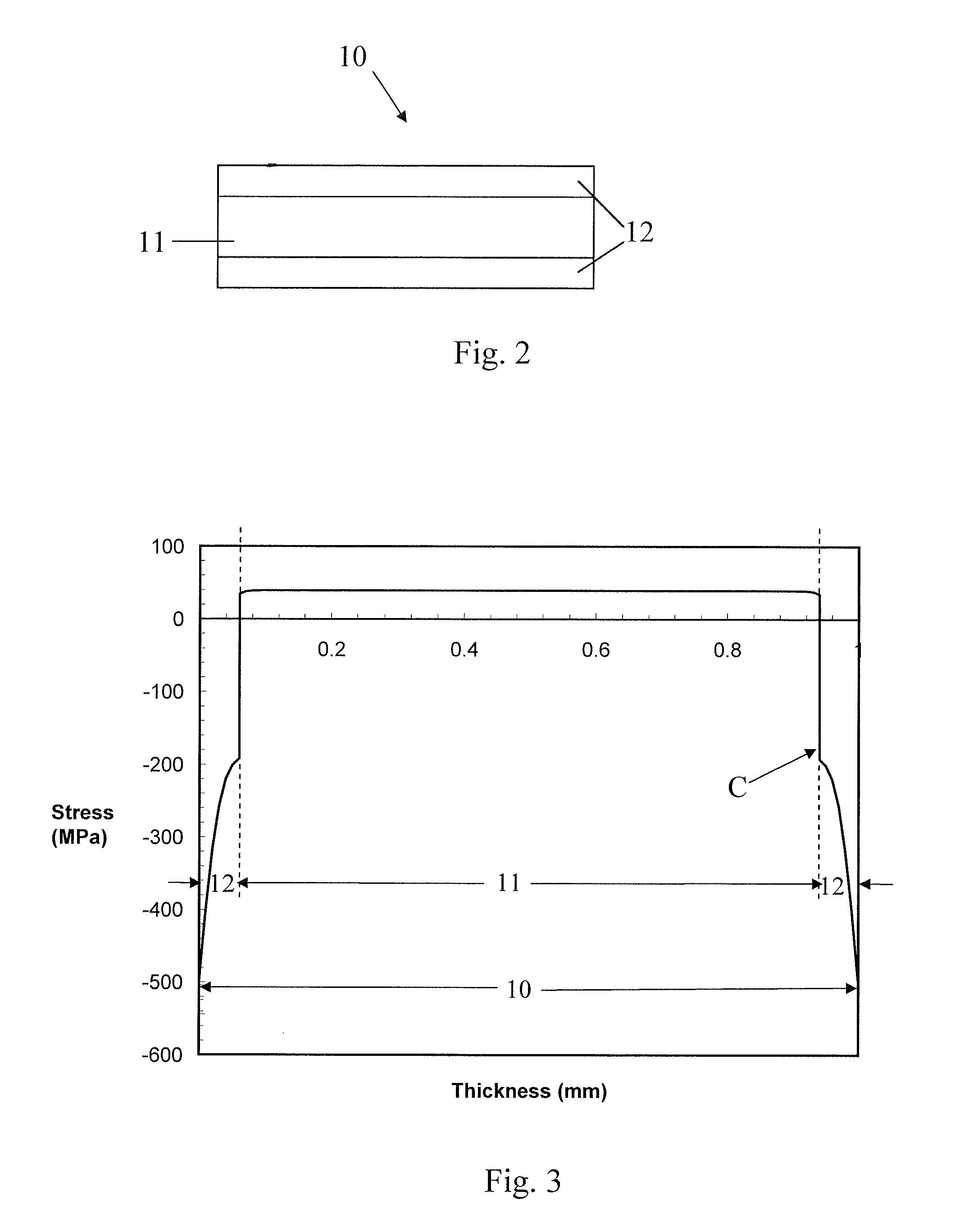

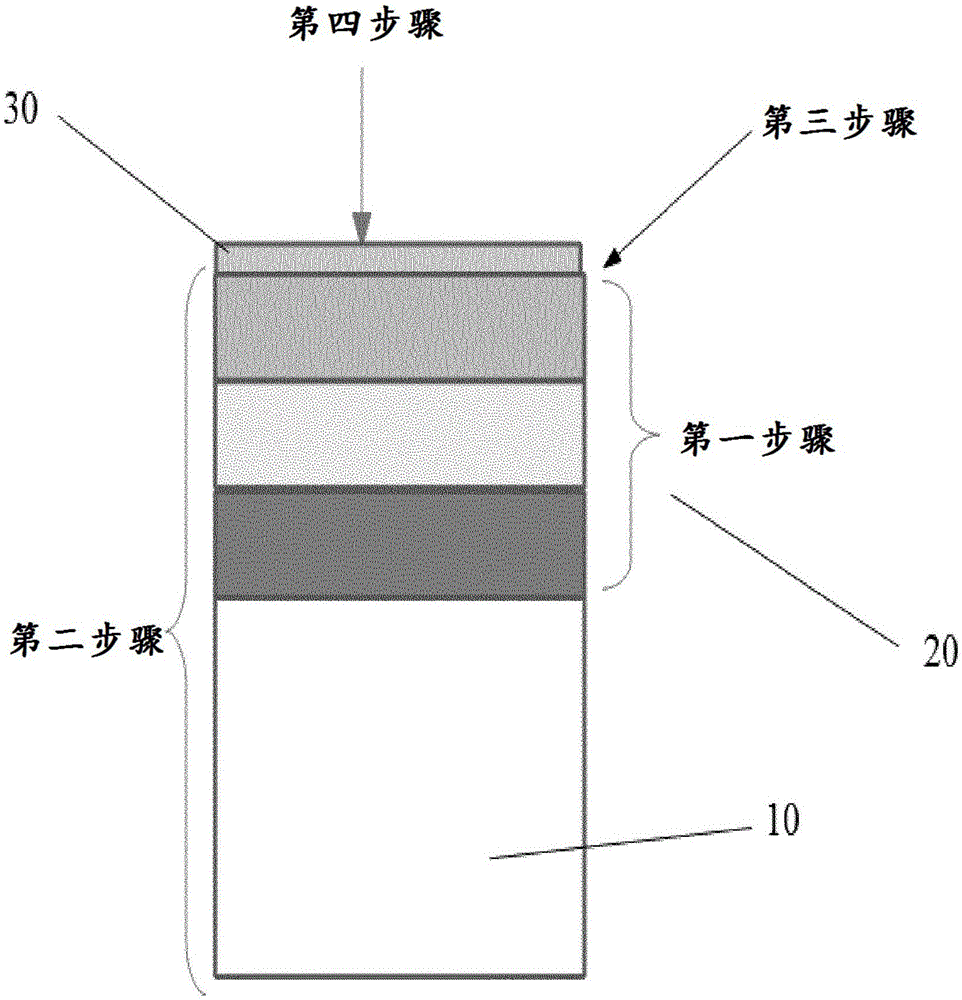

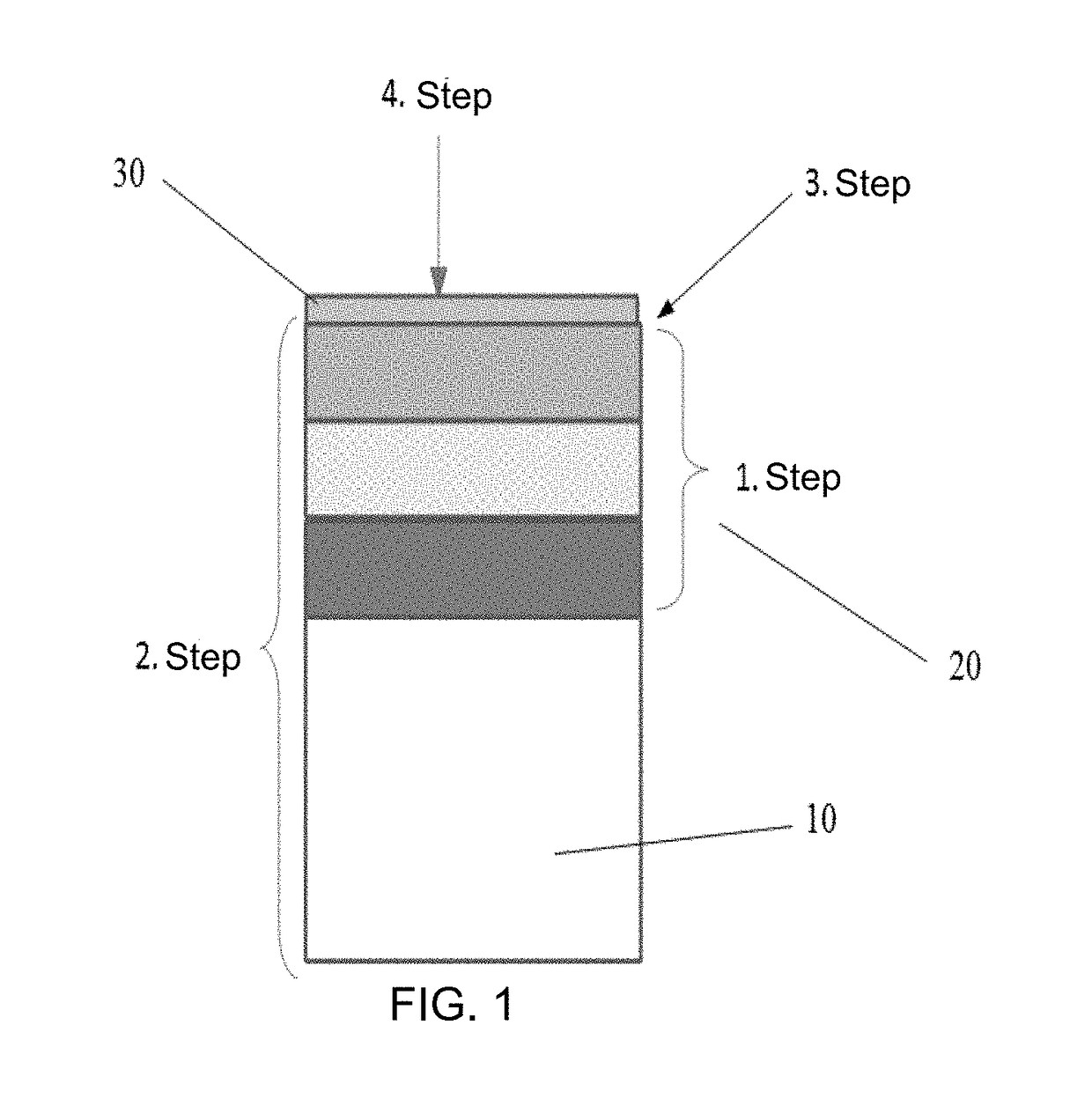

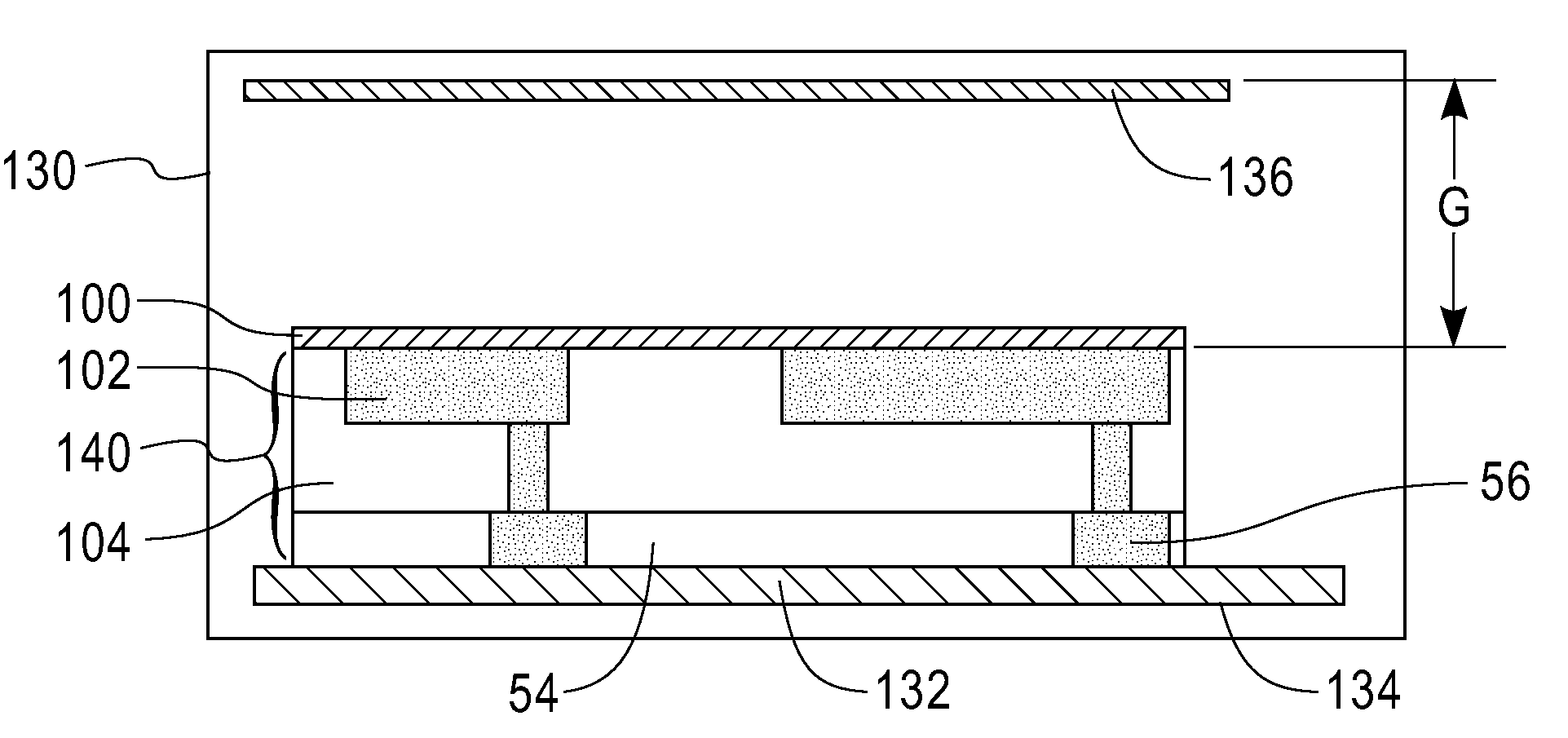

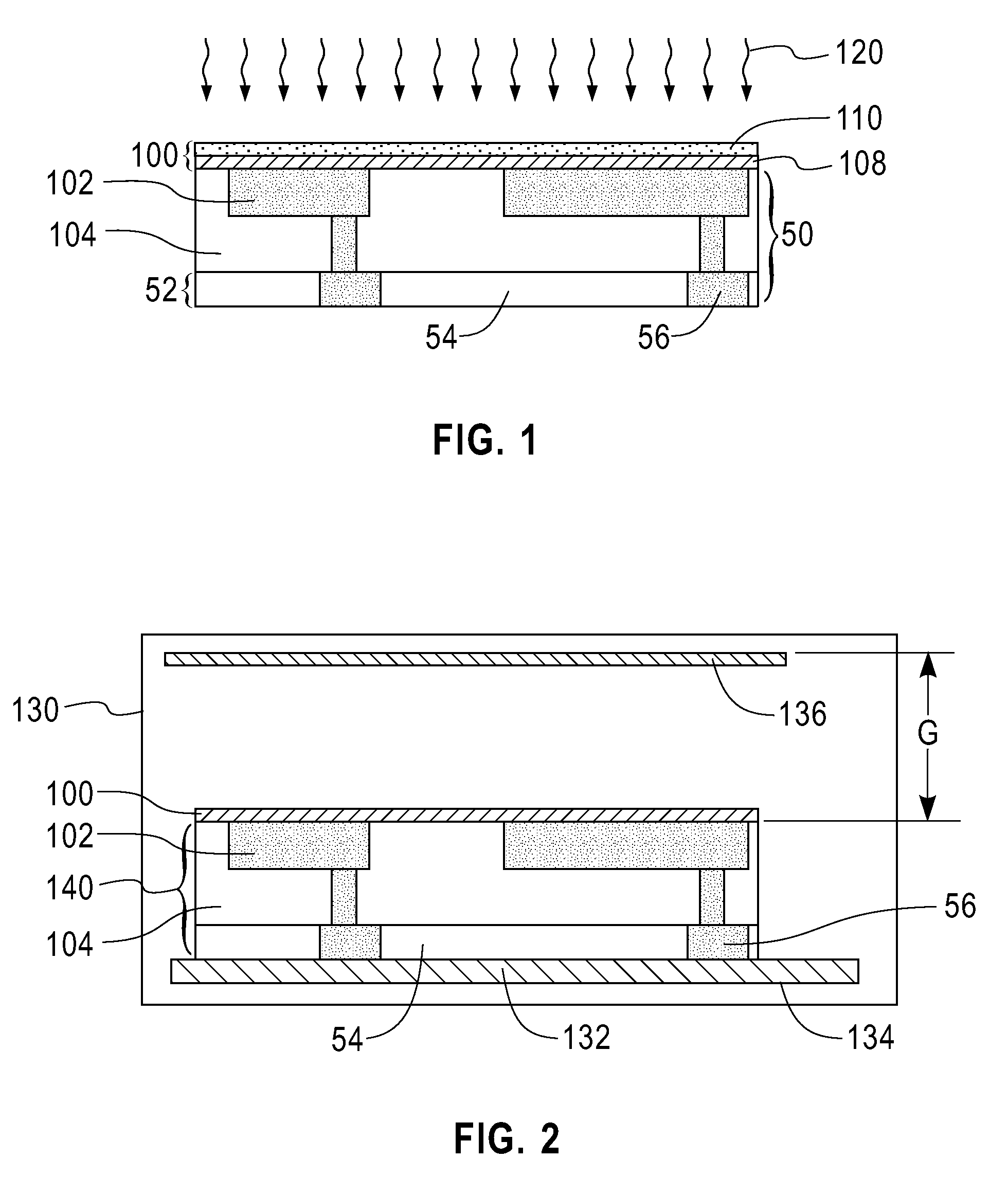

Laminated and ion-exchanged strengthened glass laminates

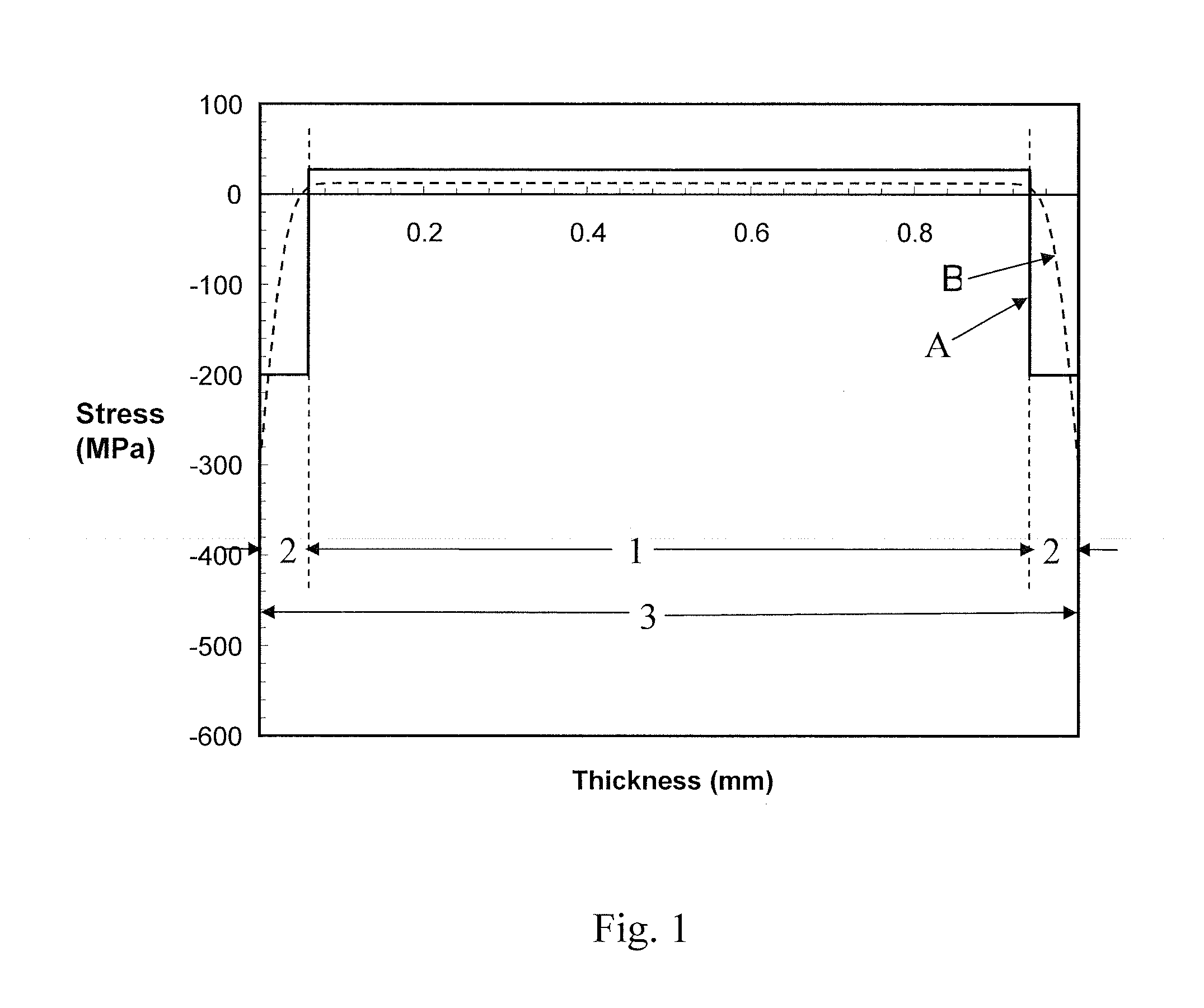

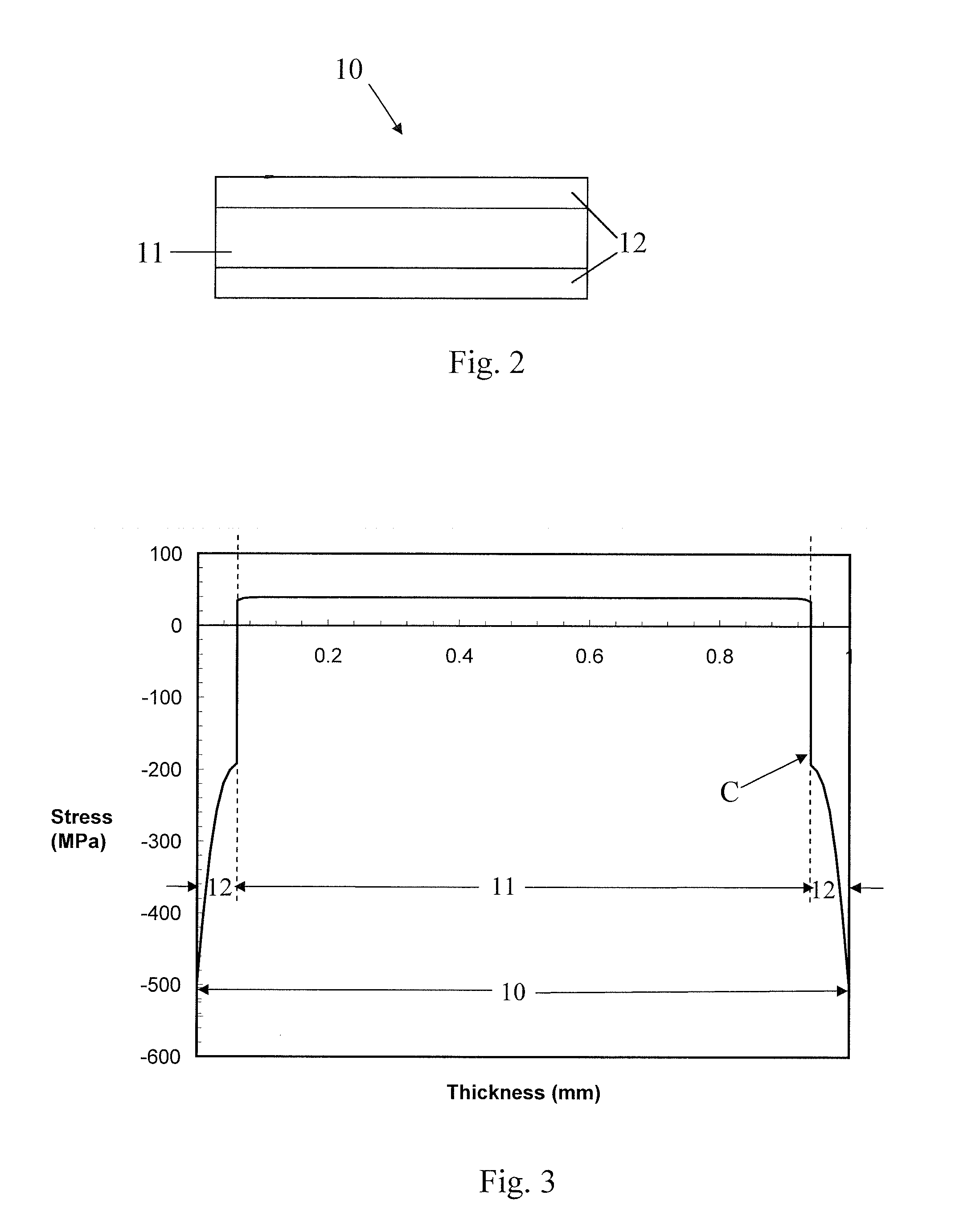

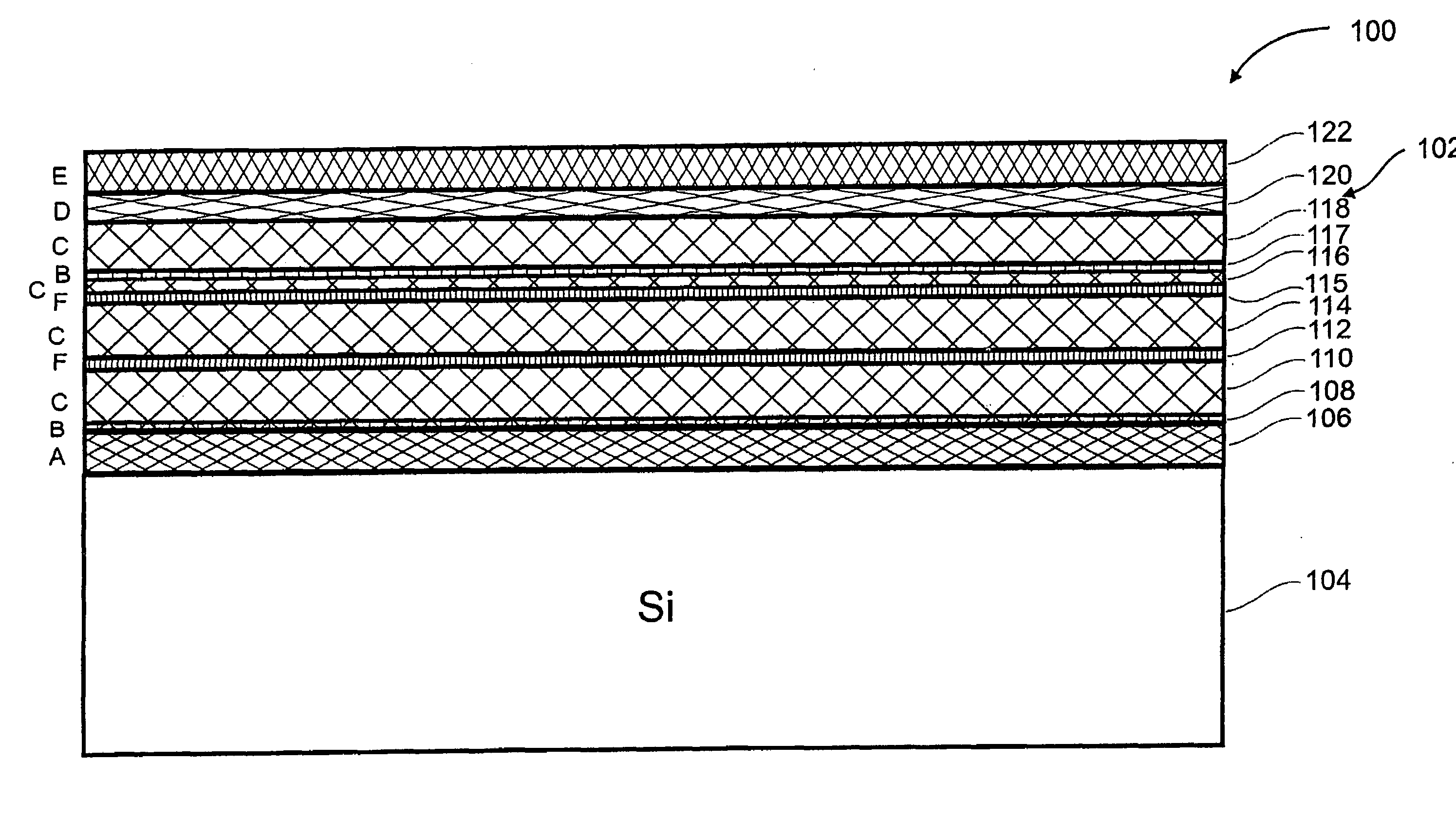

ActiveUS20140141217A1Increase compressive stressHigher depthGlass forming apparatusGlass/slag layered productsIonIon exchange

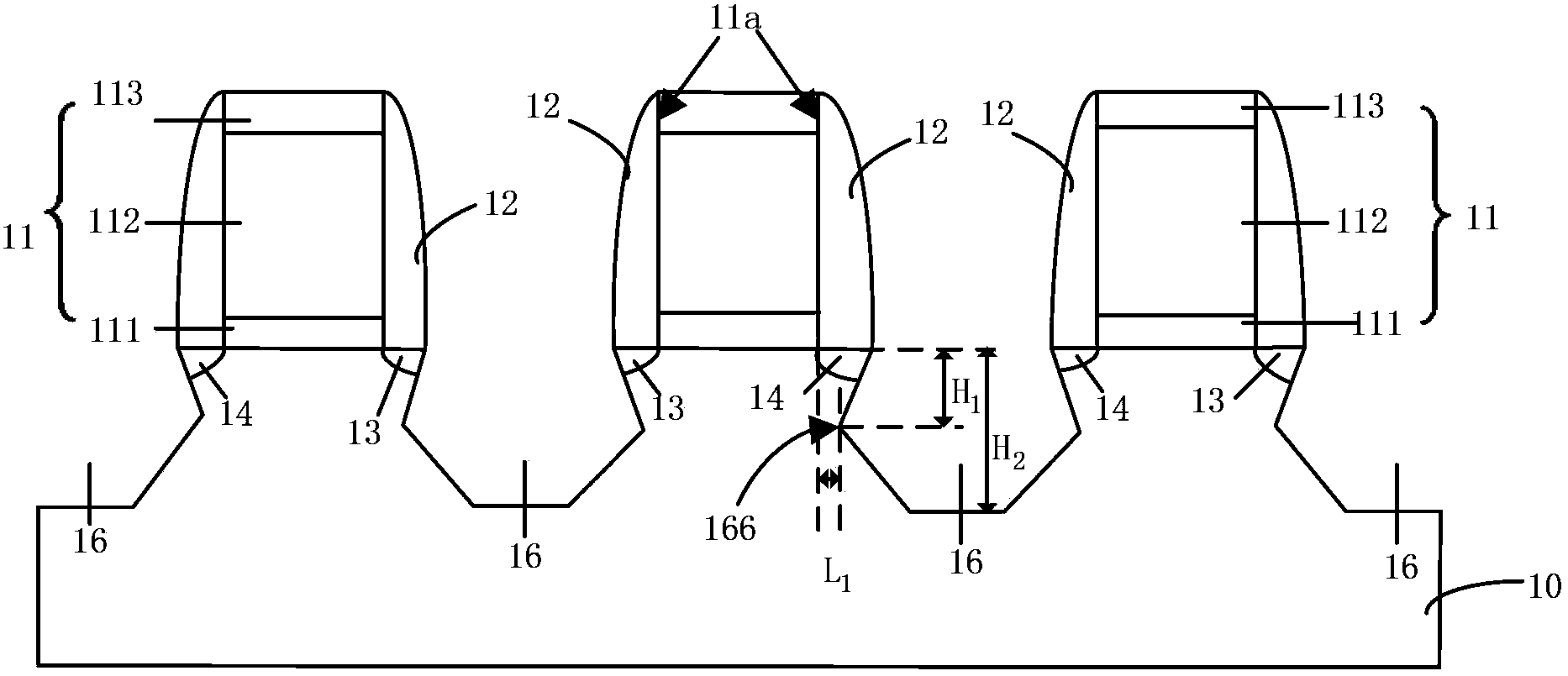

A method of making a glass sheet (10) comprises laminating a high CTE core glass (11) to a low CTE clad glass (12) at high temperatures and allowing the laminate (10) to cool creating compressive stress in the clad glass (12), and then ion exchanging the laminate (10) to increase the compressive stress in the outer near surface regions of the clad glass (12). The core glass (11) may include ions that exchange with ion in the clad glass (12) to increase the compressive stress in inner surface regions of the clad glass (12) adjacent to the clad glass / core glass interfaces. The glass laminate (10) may be formed and laminated using a fusion forming and laminating process and fusion formable and ion exchangeable glass compositions.

Owner:CORNING INC

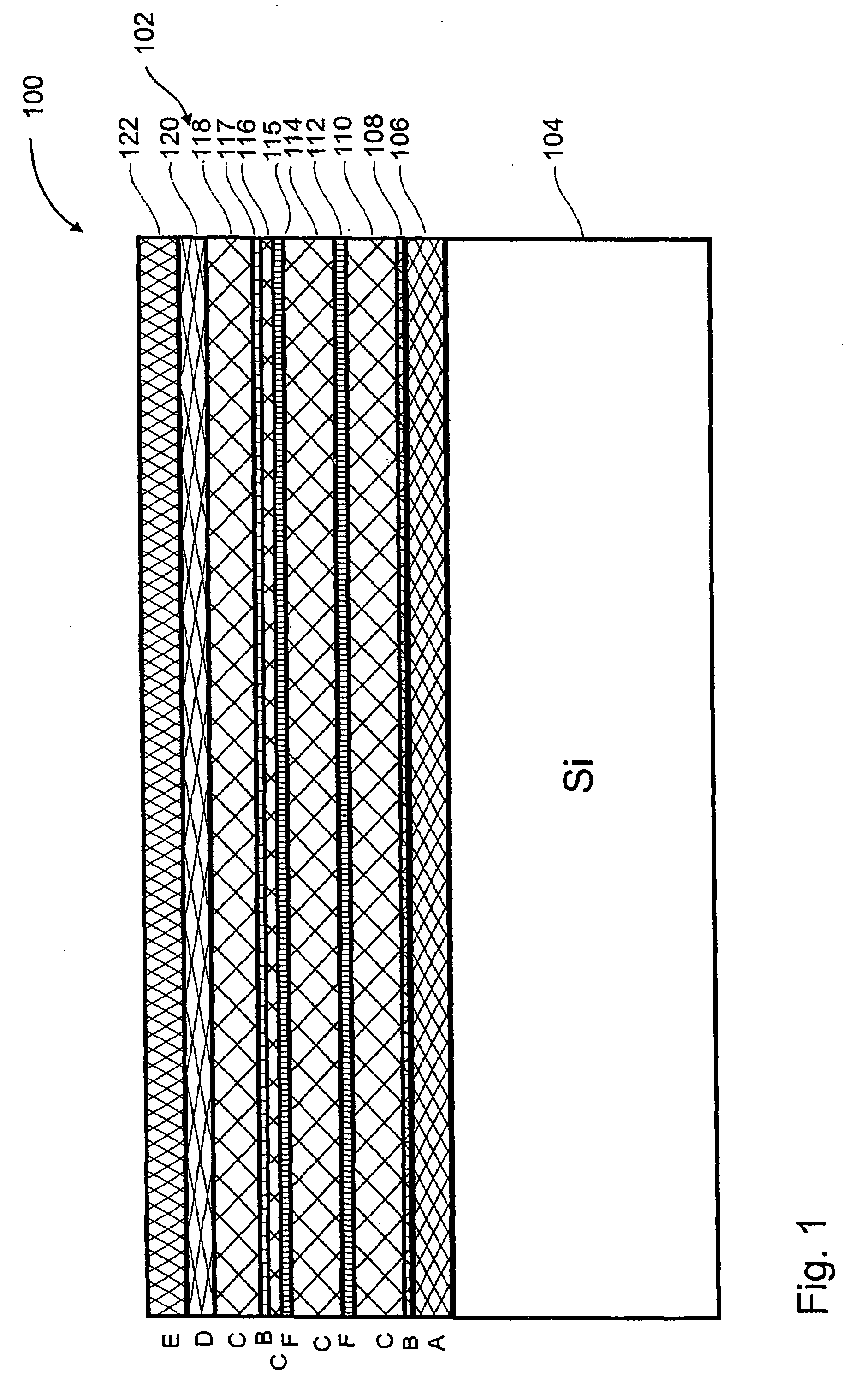

Nitride semiconductor component and process for its production

ActiveUS20070197004A1Cheap productionIncrease compressive stressSemiconductor/solid-state device manufacturingSemiconductor devicesLayer thicknessNucleation

The invention relates to a process for the production of a layer structure of a nitride semiconductor component on a silicon surface, comprising the steps:provision of a substrate that has a silicon surface;deposition of an aluminium-containing nitride nucleation layer on the silicon surface of the substrate;optional: deposition of an aluminium-containing nitride buffer layer on the nitride nucleation layer;deposition of a masking layer on the nitride nucleation layer or, if present, on the first nitride buffer layer;deposition of a gallium-containing first nitride semiconductor layer on the masking layer,wherein the masking layer is deposited in such a way that, in the deposition step of the first nitride semiconductor layer, initially separate crystallites grow that coalesce above a coalescence layer thickness and occupy an average surface area of at least 0.16 μm2 in a layer plane of the coalesced nitride semiconductor layer that is perpendicular to the growth direction.

Owner:AZUR SPACE SOLAR POWER +1

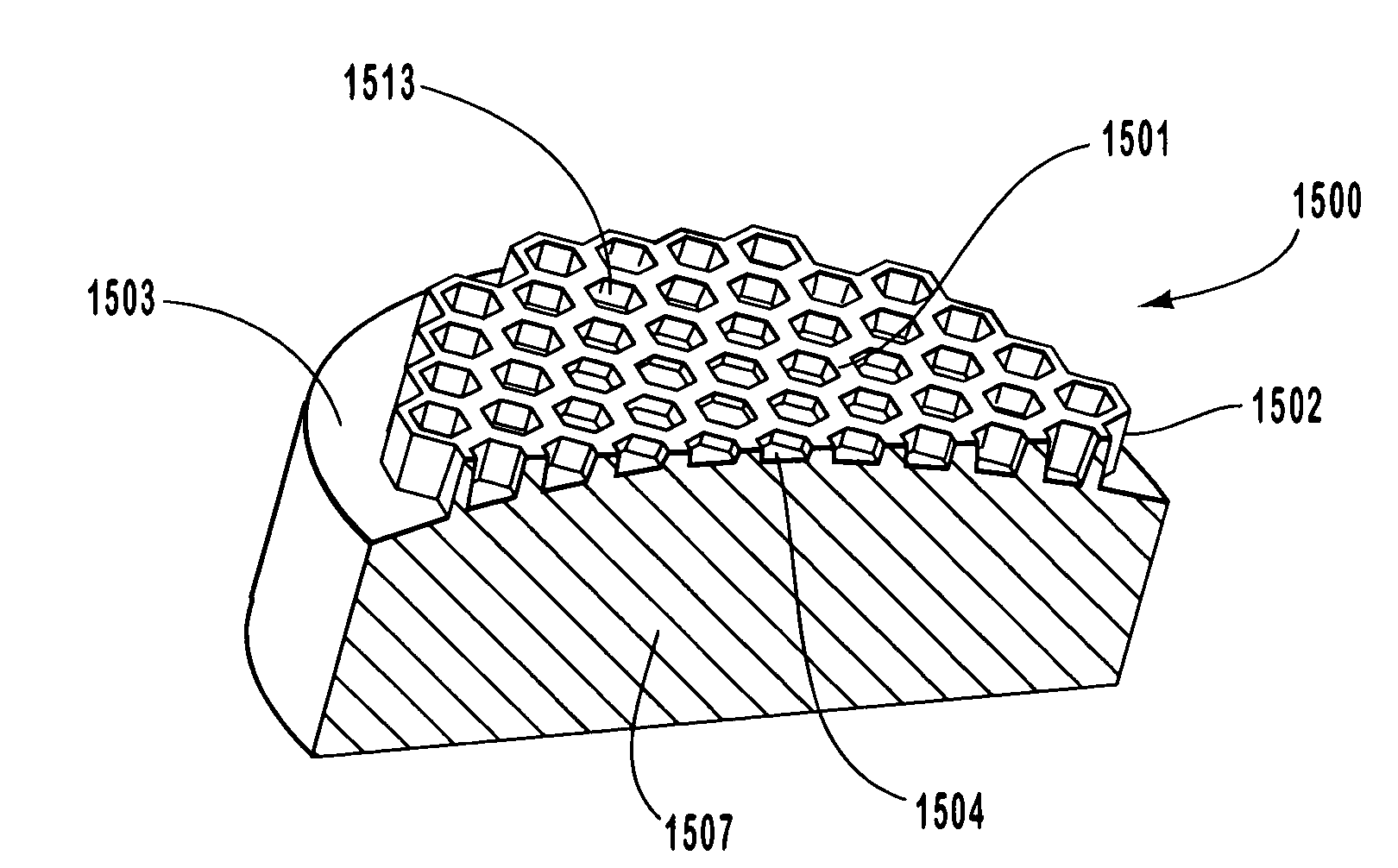

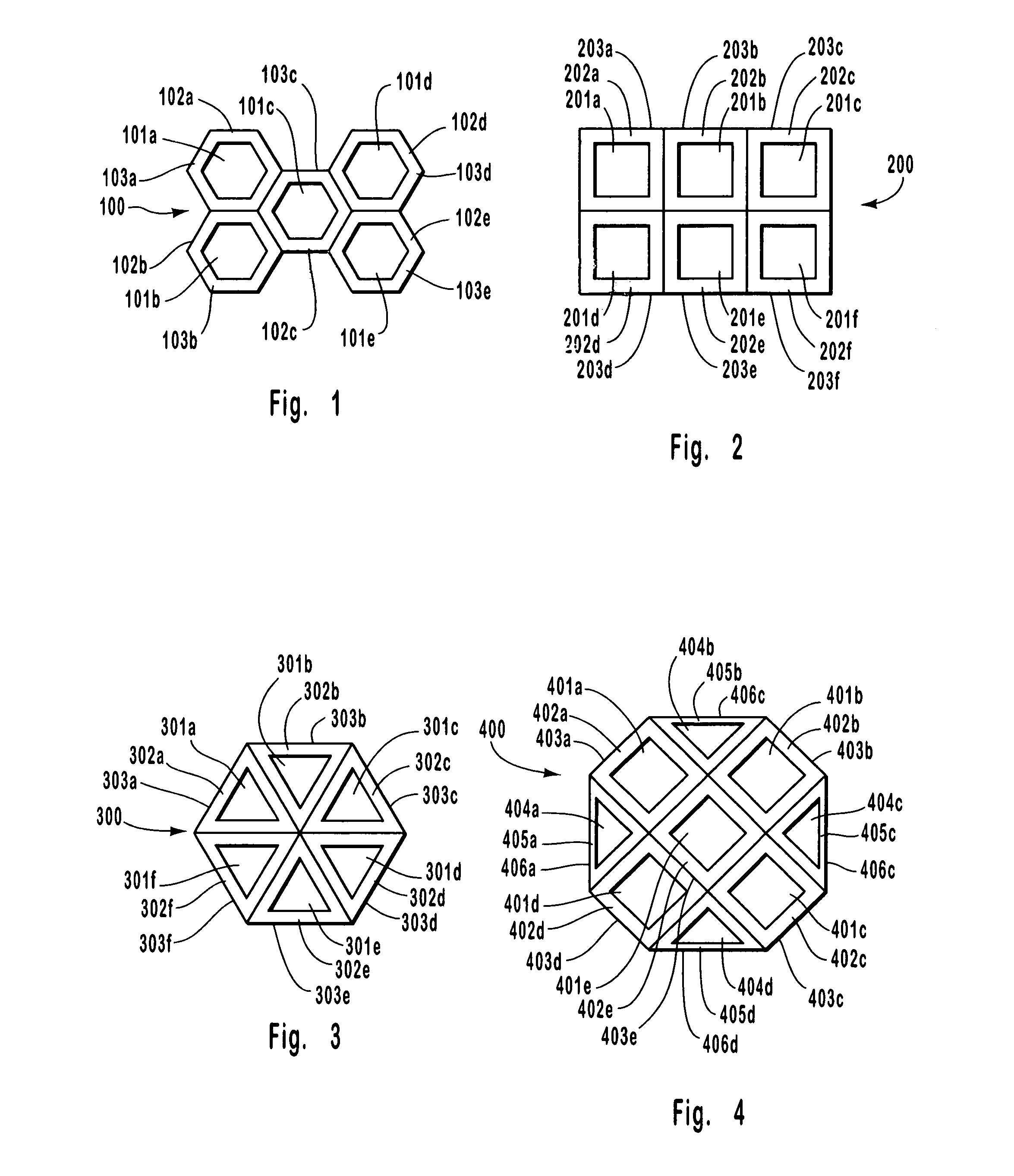

PDC interface incorporating a closed network of features

InactiveUS7108598B1Reduce workloadMinimize all harmful residual tensile stressPigmenting treatmentDrill bitsInterface designNetwork on

A superhard compact having an improved superabrasive-substrate interface region design for use in drilling bits, cutting tools and wire dies and the like. This compact is designed to provide an interface design to manipulate residual stresses to enhance the working the strength of the compact. The compact is provided with a network on interface features that share common walls to form cavities.

Owner:US SYNTHETIC CORP

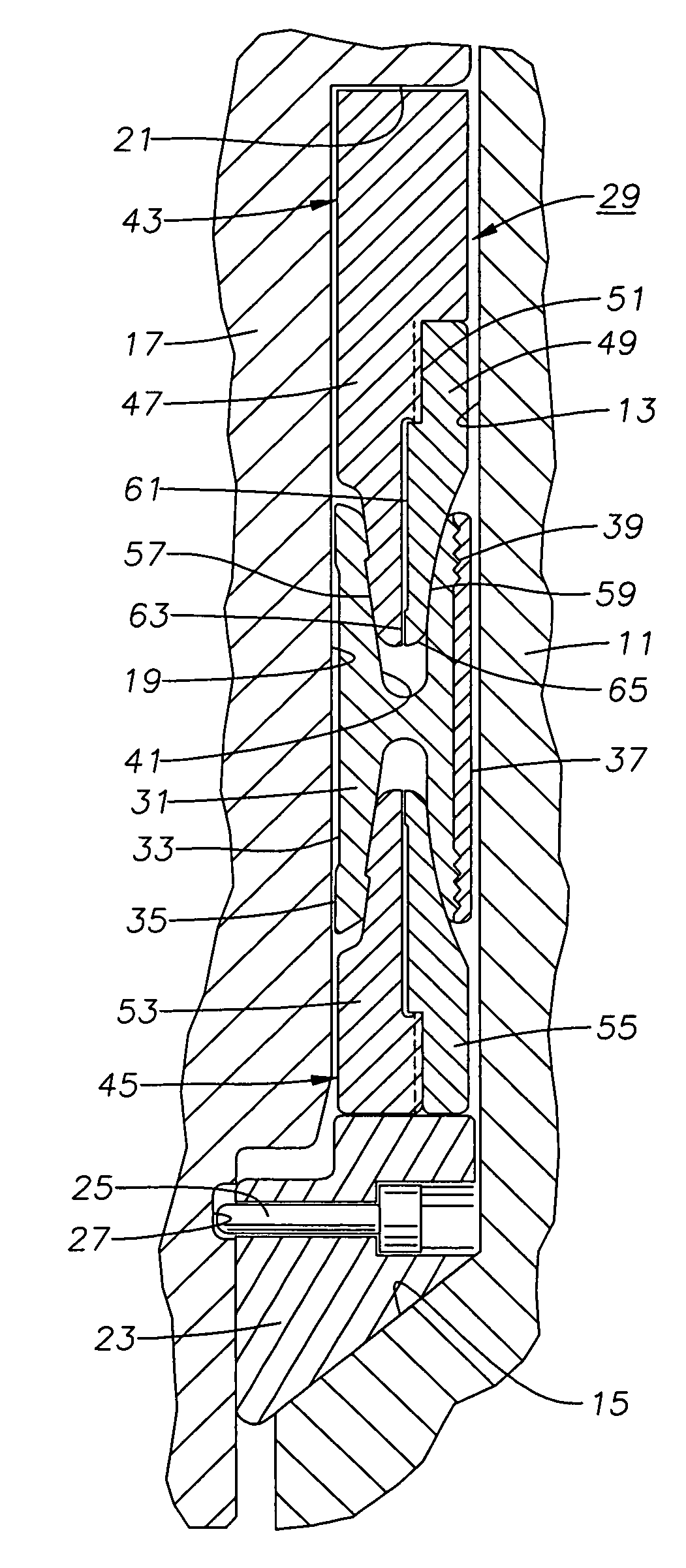

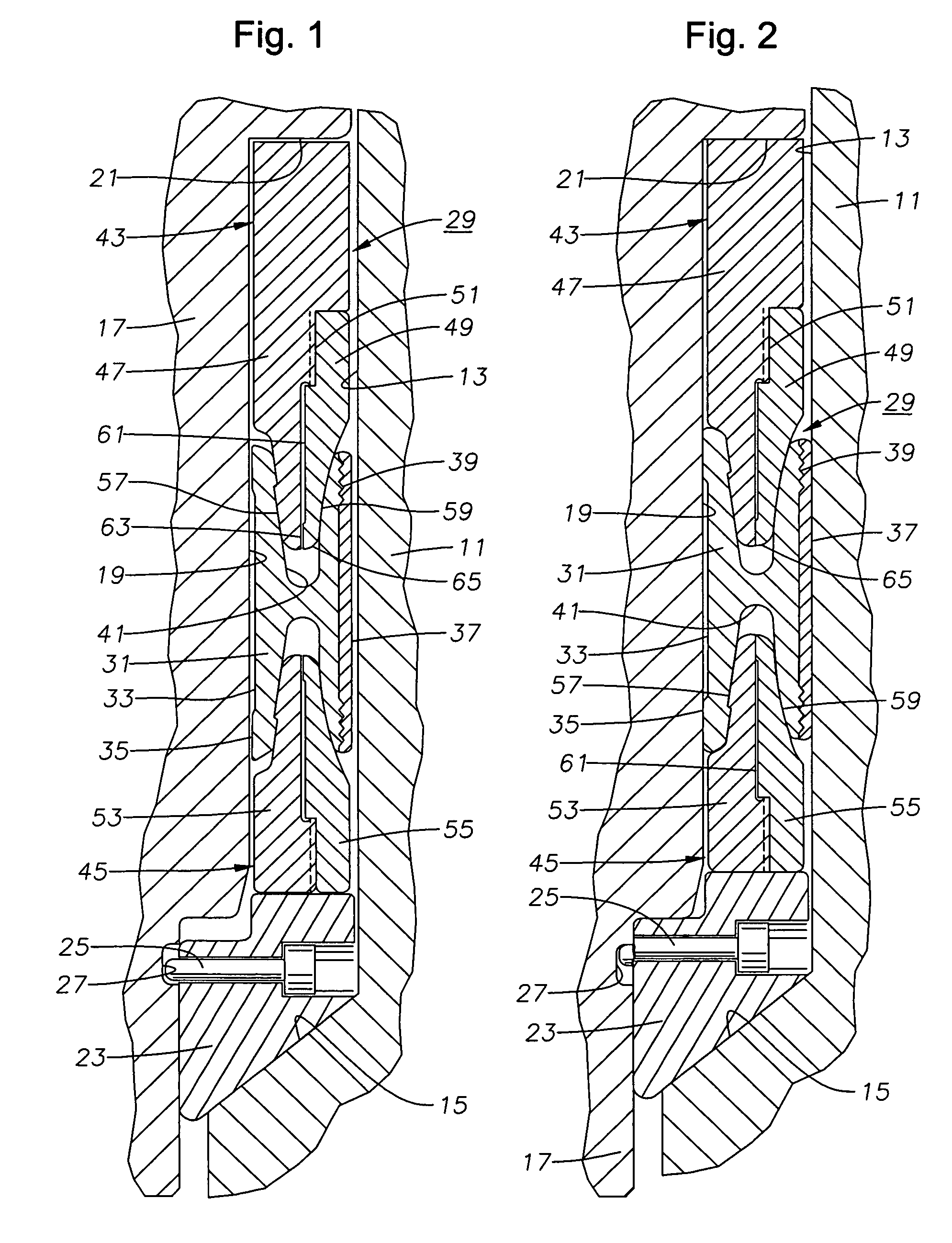

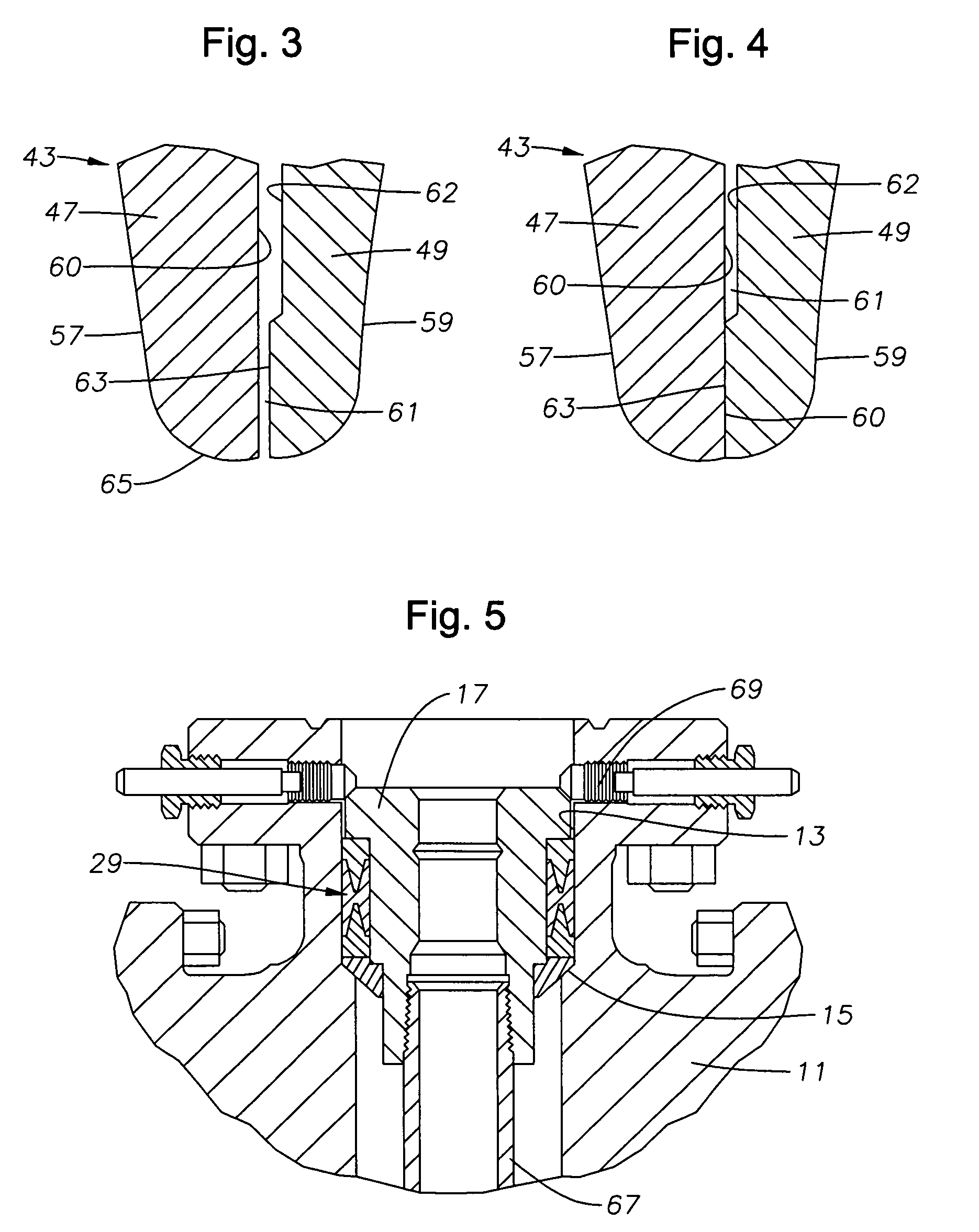

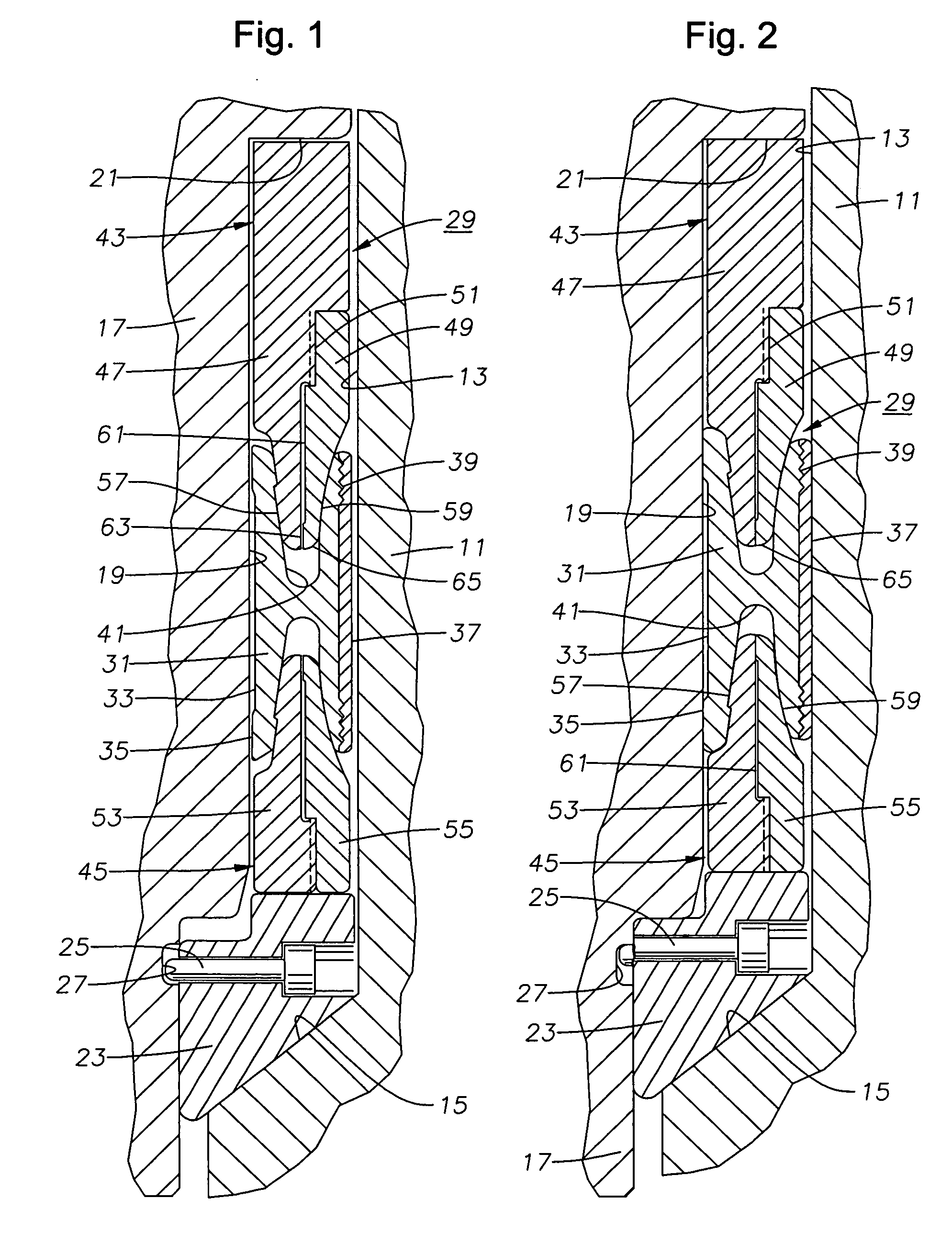

Flex-lock metal seal system for wellhead members

ActiveUS7559366B2Increase compressive stressAvoid insufficient thicknessEngine sealsDrilling rodsEngineeringMechanical engineering

A wellhead seal assembly forms a metal-to-metal seal between the inner and outer wellhead members. A metal seal ring has inner and outer conical walls separated by a tapered slot. An energizing ring has inner and outer annular members that are separated by an annular cavity. When the energizing ring is moved further into the slot, the cavity width decreases but remains to provide a preloaded radial force to the seal ring.

Owner:VETCO GRAY LLC

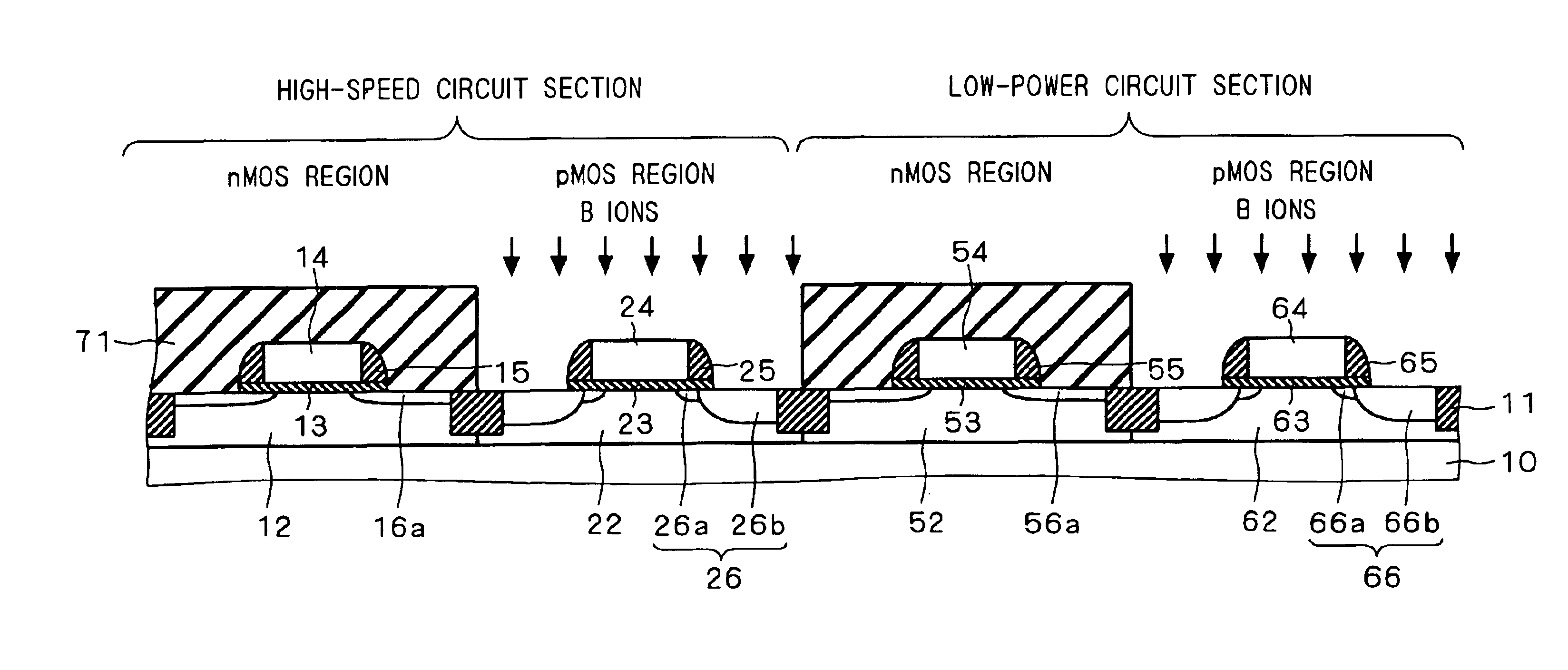

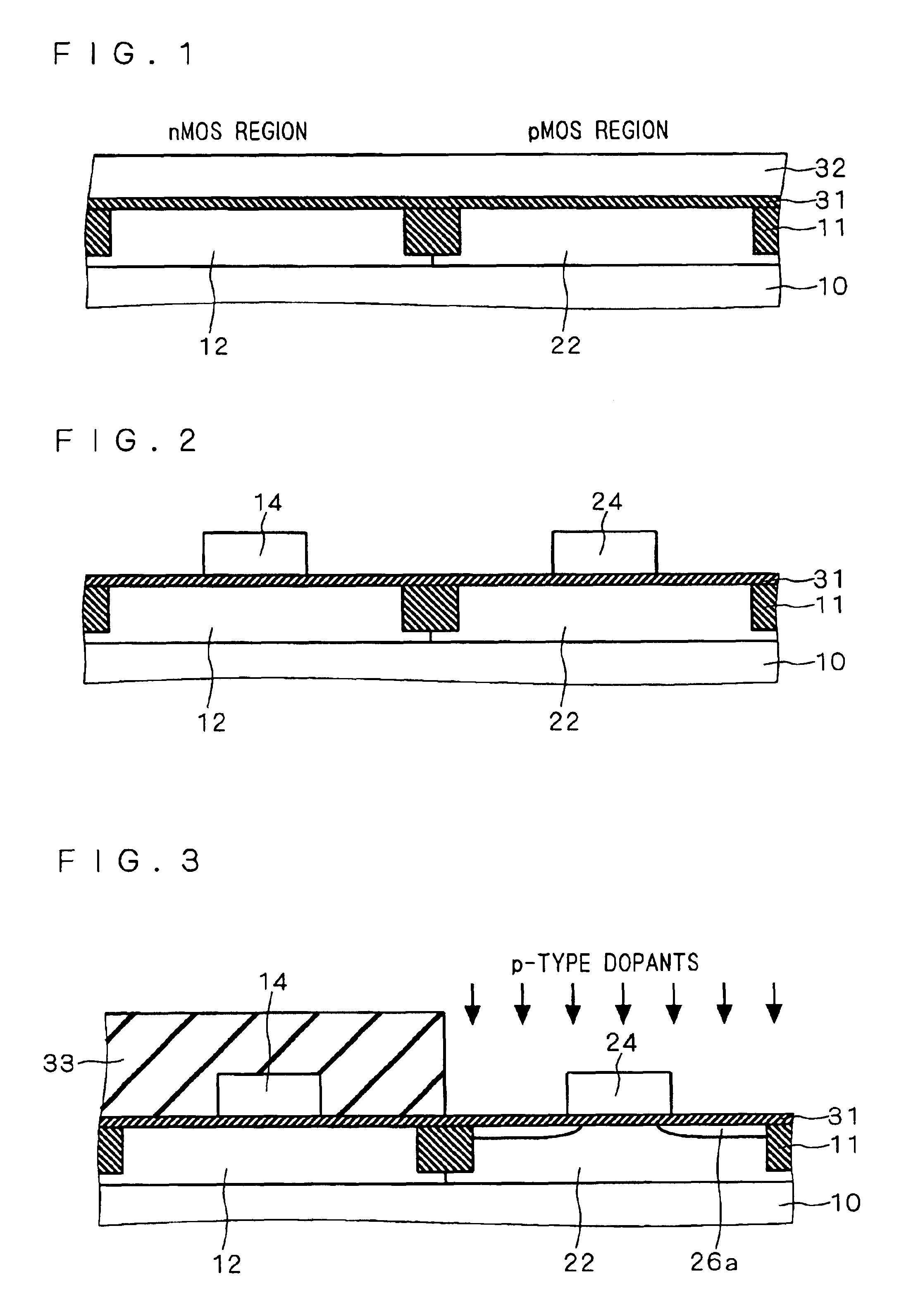

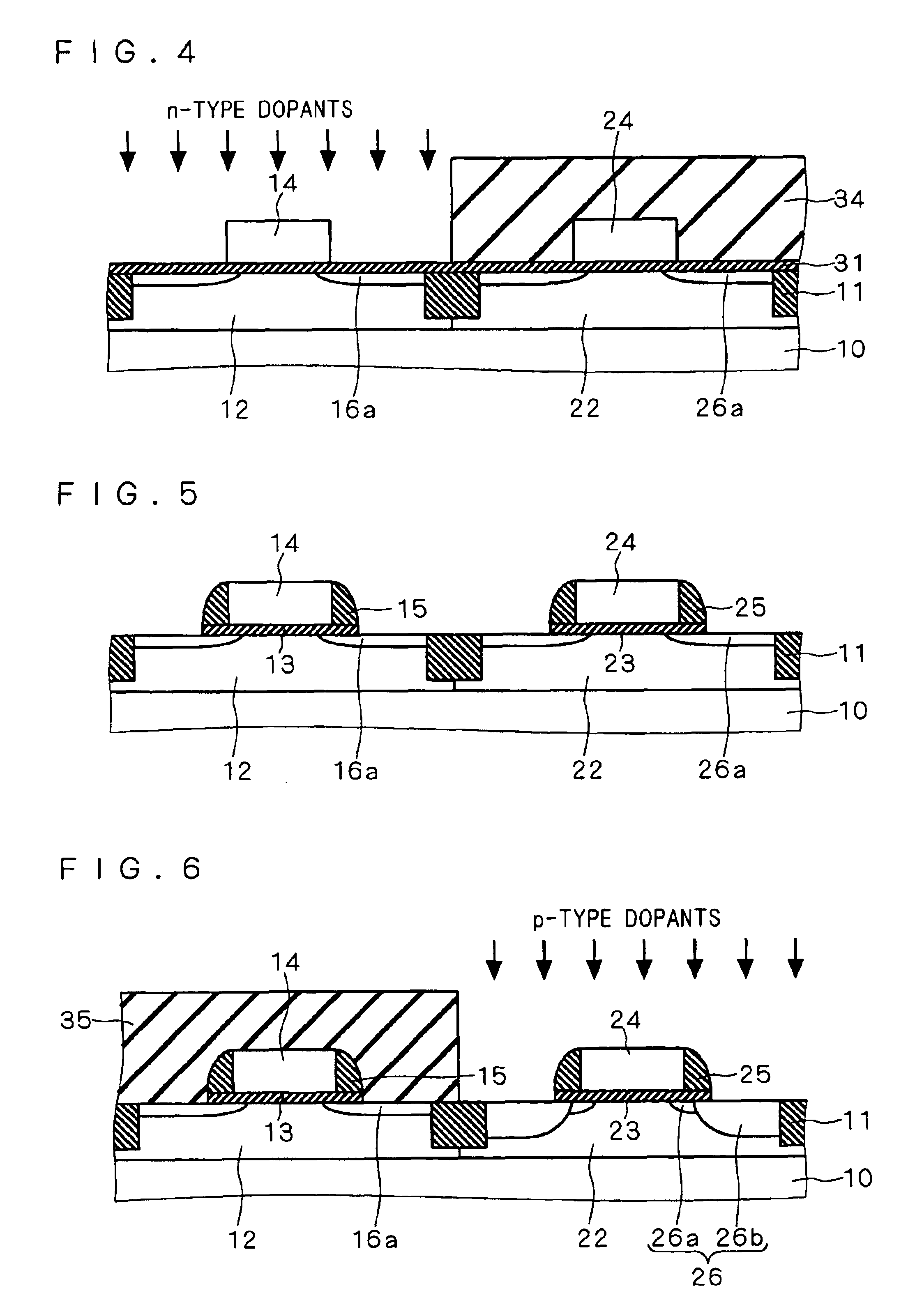

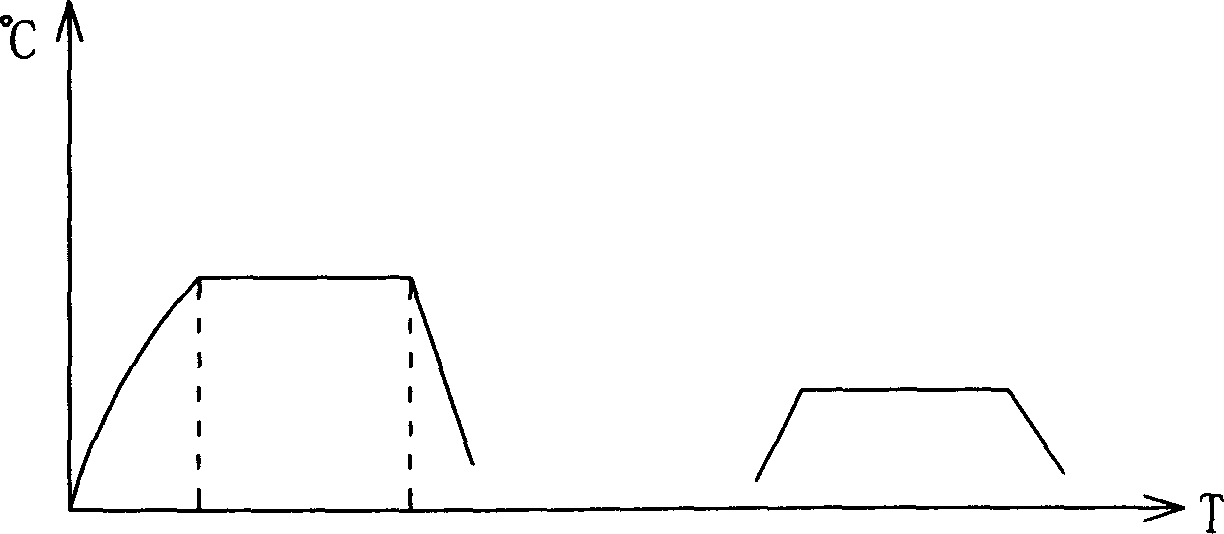

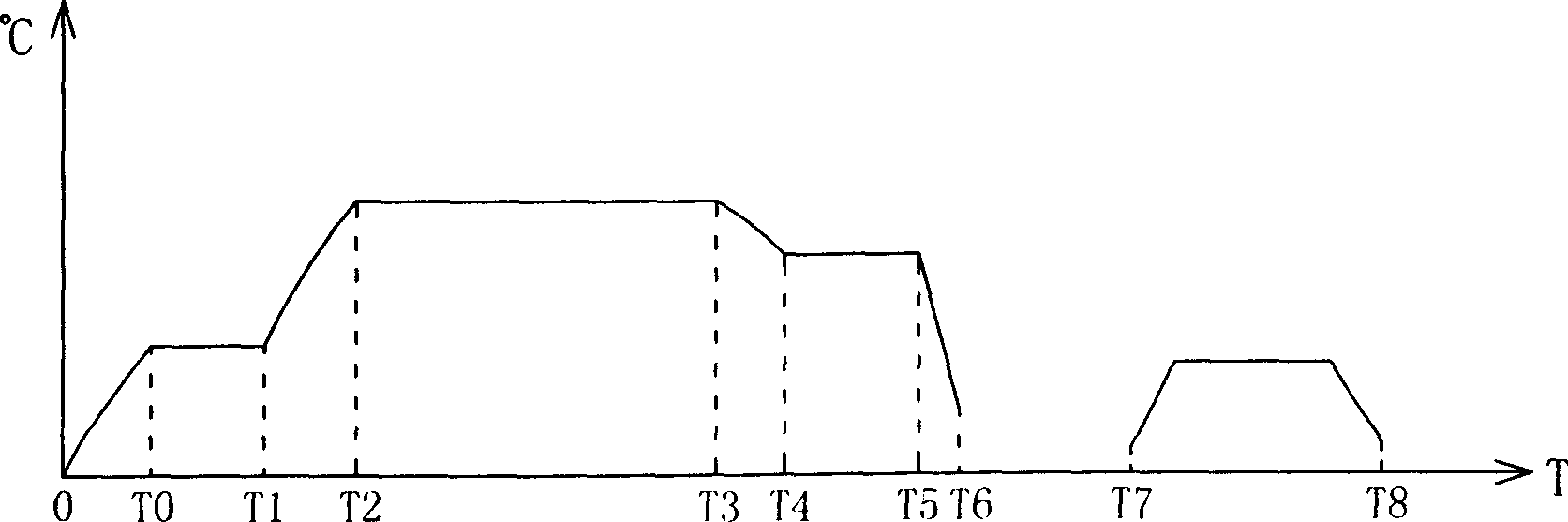

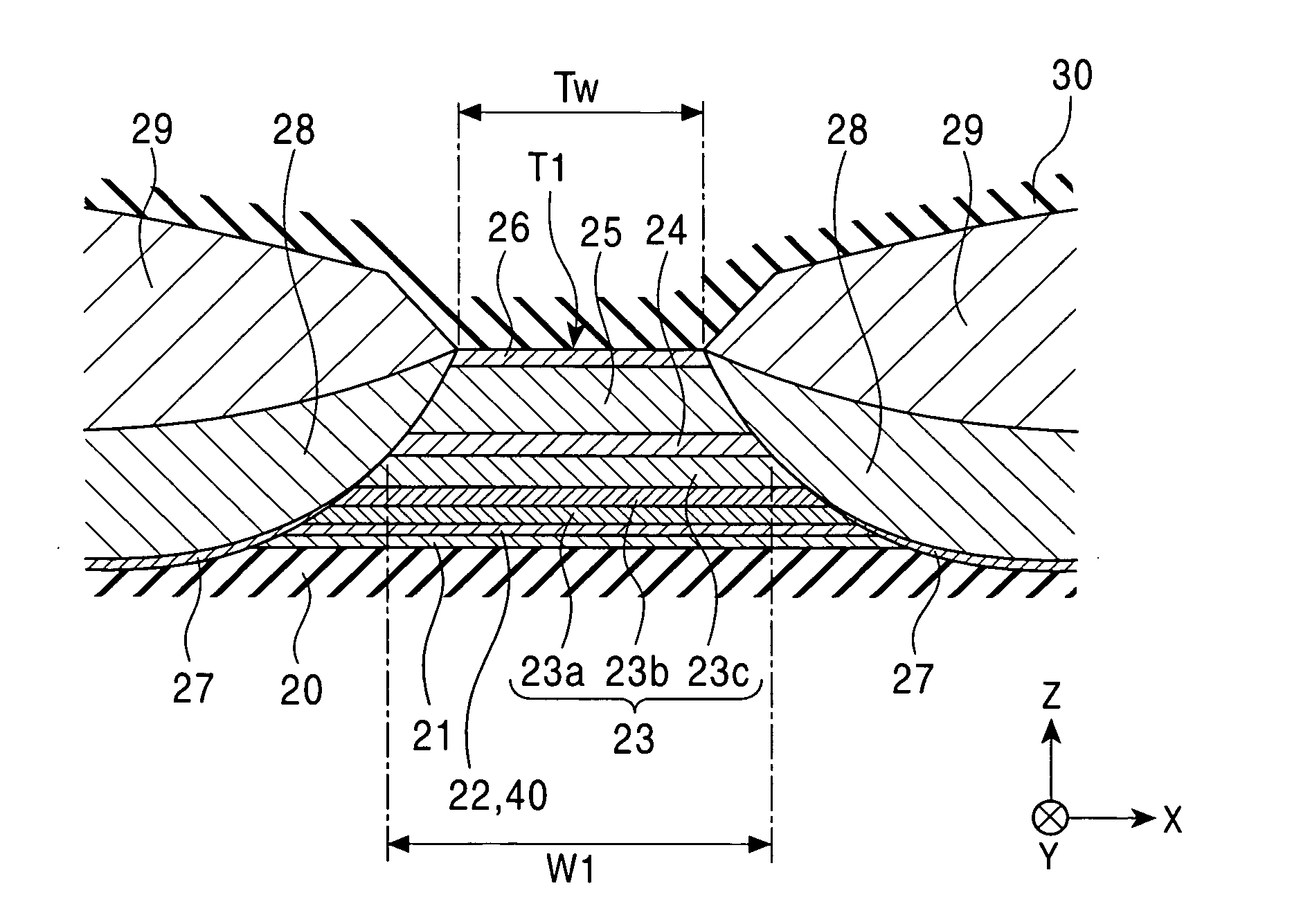

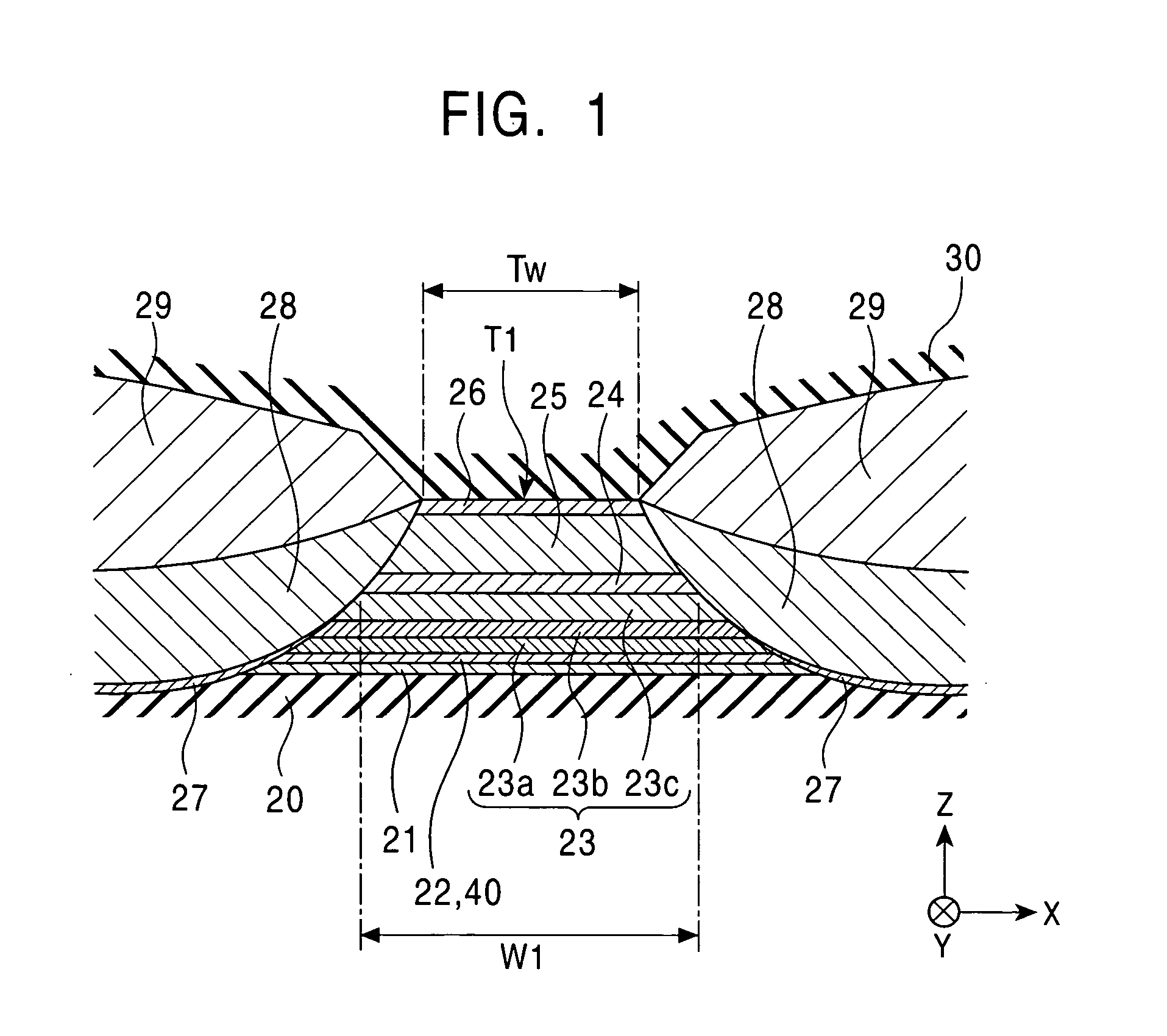

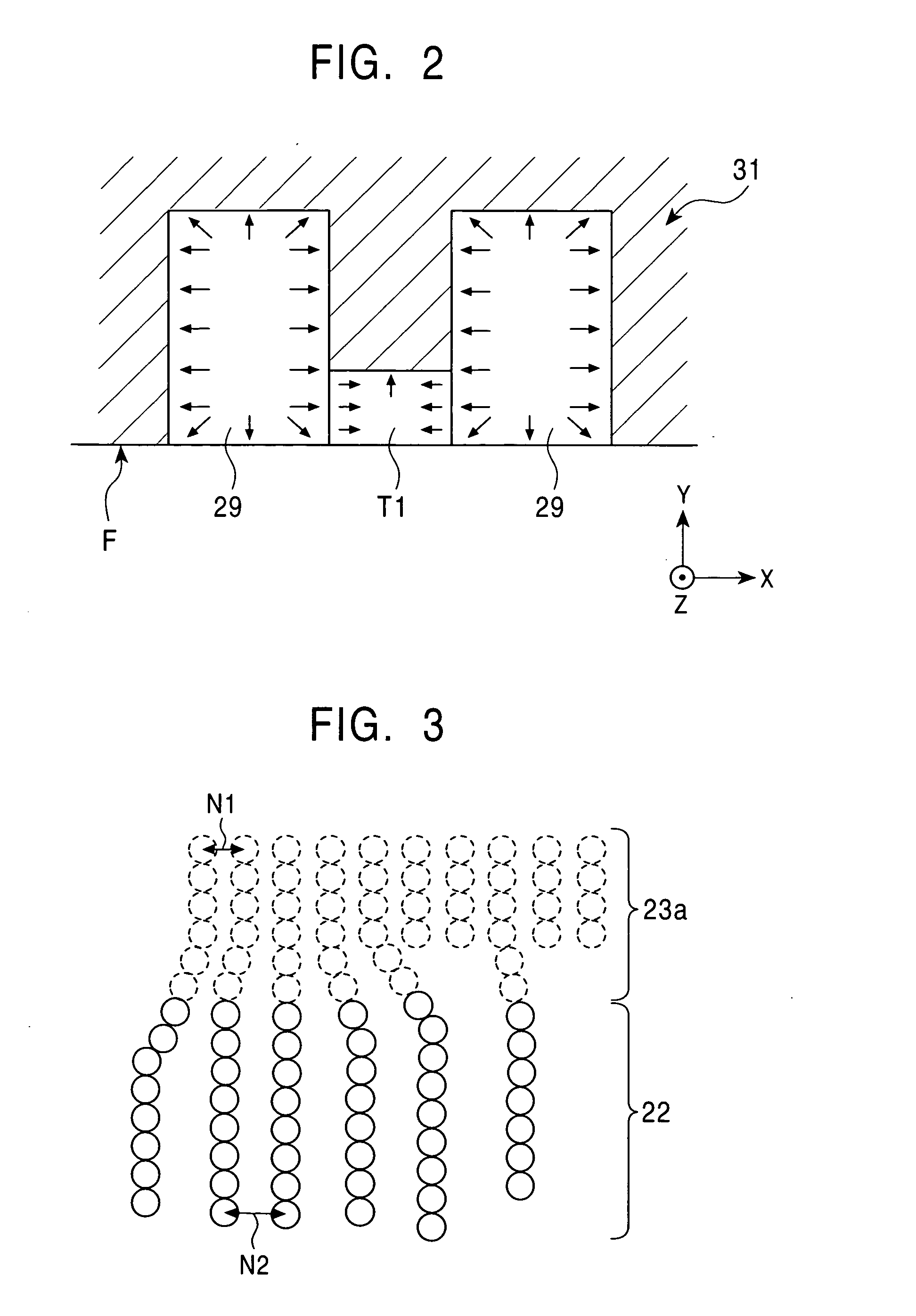

Semiconductor device including gate electrode for applying tensile stress to silicon substrate, and method of manufacturing the same

InactiveUS6906393B2High carrier mobilitySimplify manufacturing stepsTransistorSolid-state devicesMass numberCharge carrier mobility

A gate insulating film (13) and a gate electrode (14) of non-single crystalline silicon for forming an nMOS transistor are provided on a silicon substrate (10). Using the gate electrode (14) as a mask, n-type dopants having a relatively large mass number (70 or more) such as As ions or Sb ions are implanted, to form a source / drain region of the nMOS transistor, whereby the gate electrode (14) is amorphized. Subsequently, a silicon oxide film (40) is provided to cover the gate electrode (14), at a temperature which is less than the one at which recrystallization of the gate electrode (14) occurs. Thereafter, thermal processing is performed at a temperature of about 1000° C., whereby high compressive residual stress is exerted on the gate electrode (14), and high tensile stress is applied to a channel region under the gate electrode (14). As a result, carrier mobility of the nMOS transistor is enhanced.

Owner:RENESAS ELECTRONICS CORP

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

Laminated and ion-exchanged strengthened glass laminates

ActiveUS9522836B2Higher depthHigh stressGlass forming apparatusGlass/slag layered productsIon exchangeOptoelectronics

A method of making a glass sheet (10) comprises laminating a high CTE core glass (11) to a low CTE clad glass (12) at high temperatures and allowing the laminate (10) to cool creating compressive stress in the clad glass (12), and then ion exchanging the laminate (10) to increase the compressive stress in the outer near surface regions of the clad glass (12). The core glass (11) may include ions that exchange with ion in the clad glass (12) to increase the compressive stress in inner surface regions of the clad glass (12) adjacent to the clad glass / core glass interfaces. The glass laminate (10) may be formed and laminated using a fusion forming and laminating process and fusion formable and ion exchangeable glass compositions.

Owner:CORNING INC

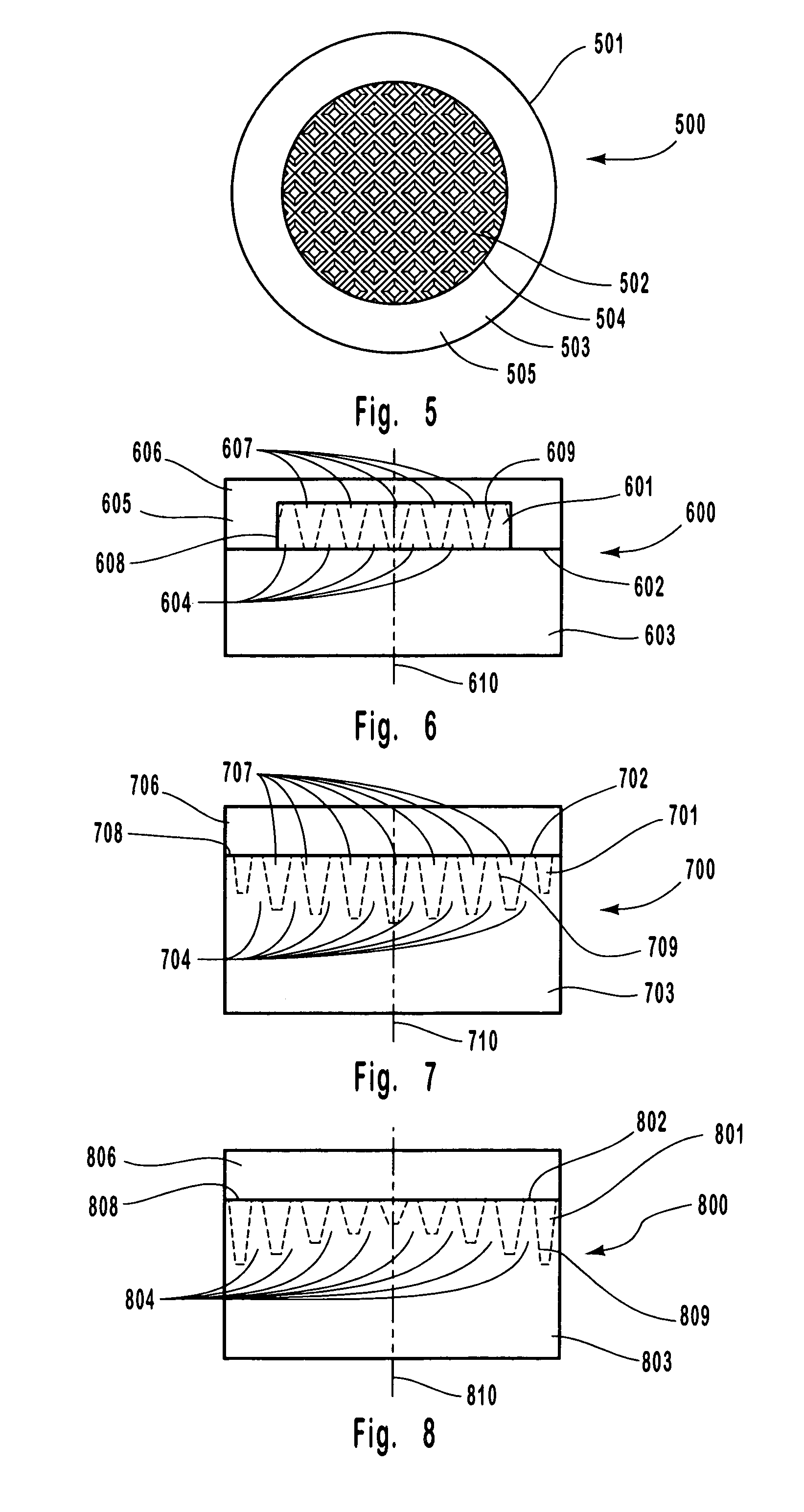

Field effect transistor using carbon based stress liner

InactiveUS20080303068A1Increase compressive stressTransistorSemiconductor/solid-state device manufacturingSemiconductor materialsHydrogen

A stress liner for use within a semiconductor structure that includes a field effect device has a dielectric constant less than about 7 and a compressive stress greater than about 5 GPa. The stress liner may be formed of a carbon based material, preferably a tetrahedral amorphous carbon (ta-C) material including at least about 60 atomic percent carbon and no greater than C about 40 atomic percent hydrogen. The carbon based material may be either a dielectric material, or given appropriate additional dielectric isolation structures, a semiconductor material. In particular, a ta-C stress liner may be formed using a filtered cathodic vacuum arc (FCVA) physical vapor deposition (PVD) method.

Owner:GLOBALFOUNDRIES INC

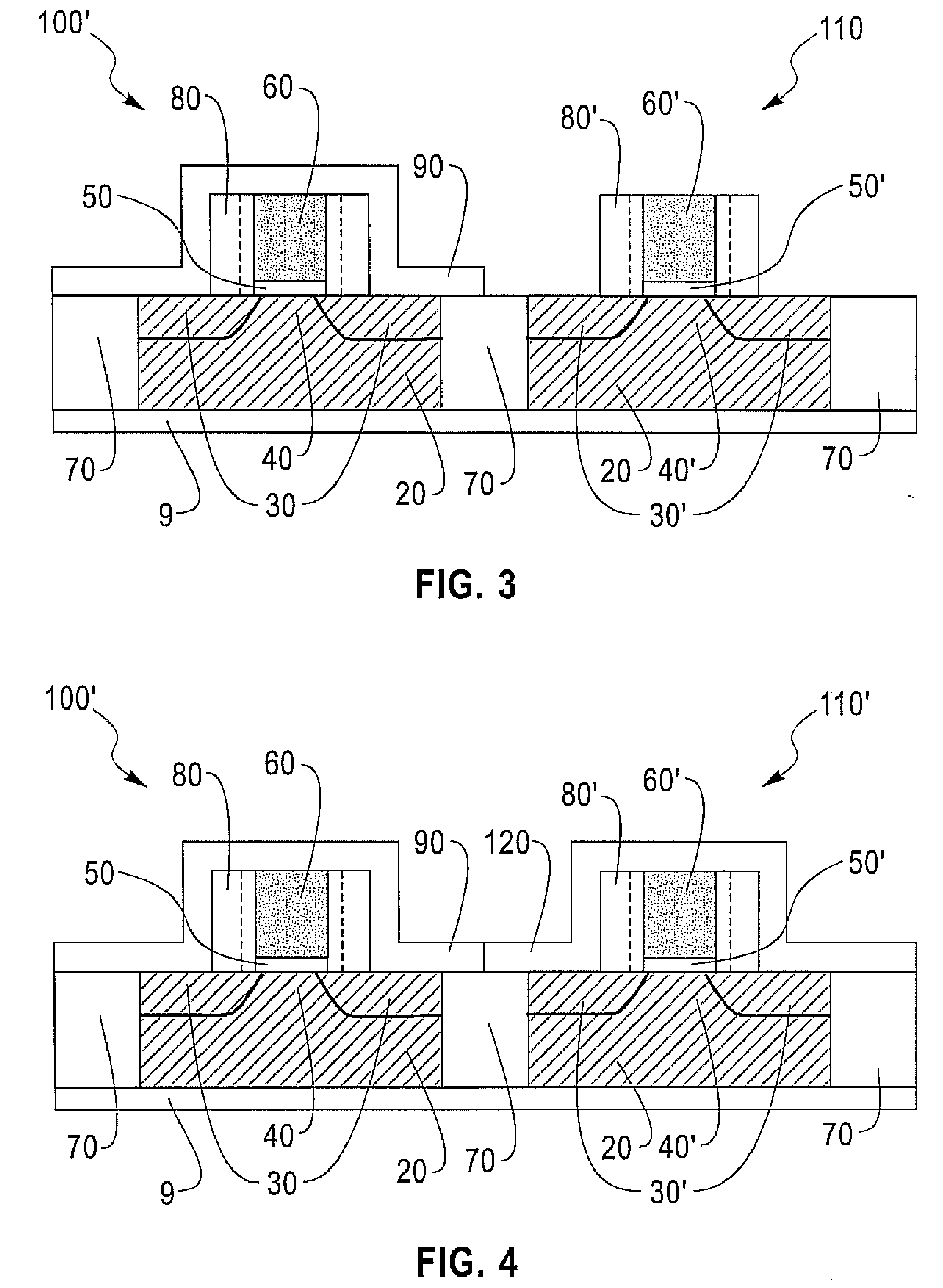

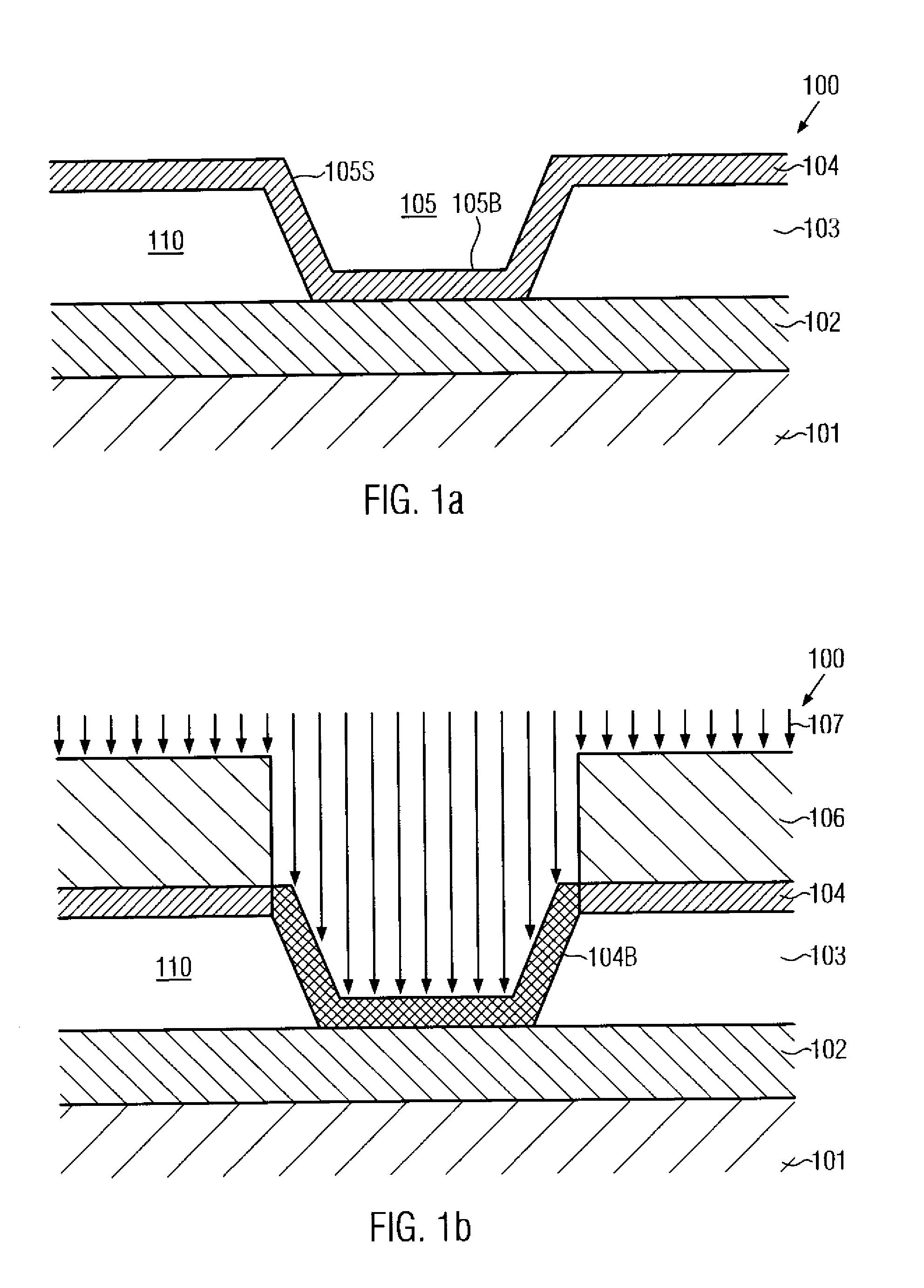

Integration process for fabricating stressed transistor structure

ActiveUS20060270217A1Enhance radiation curing efficiencyFilm stress is increasedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

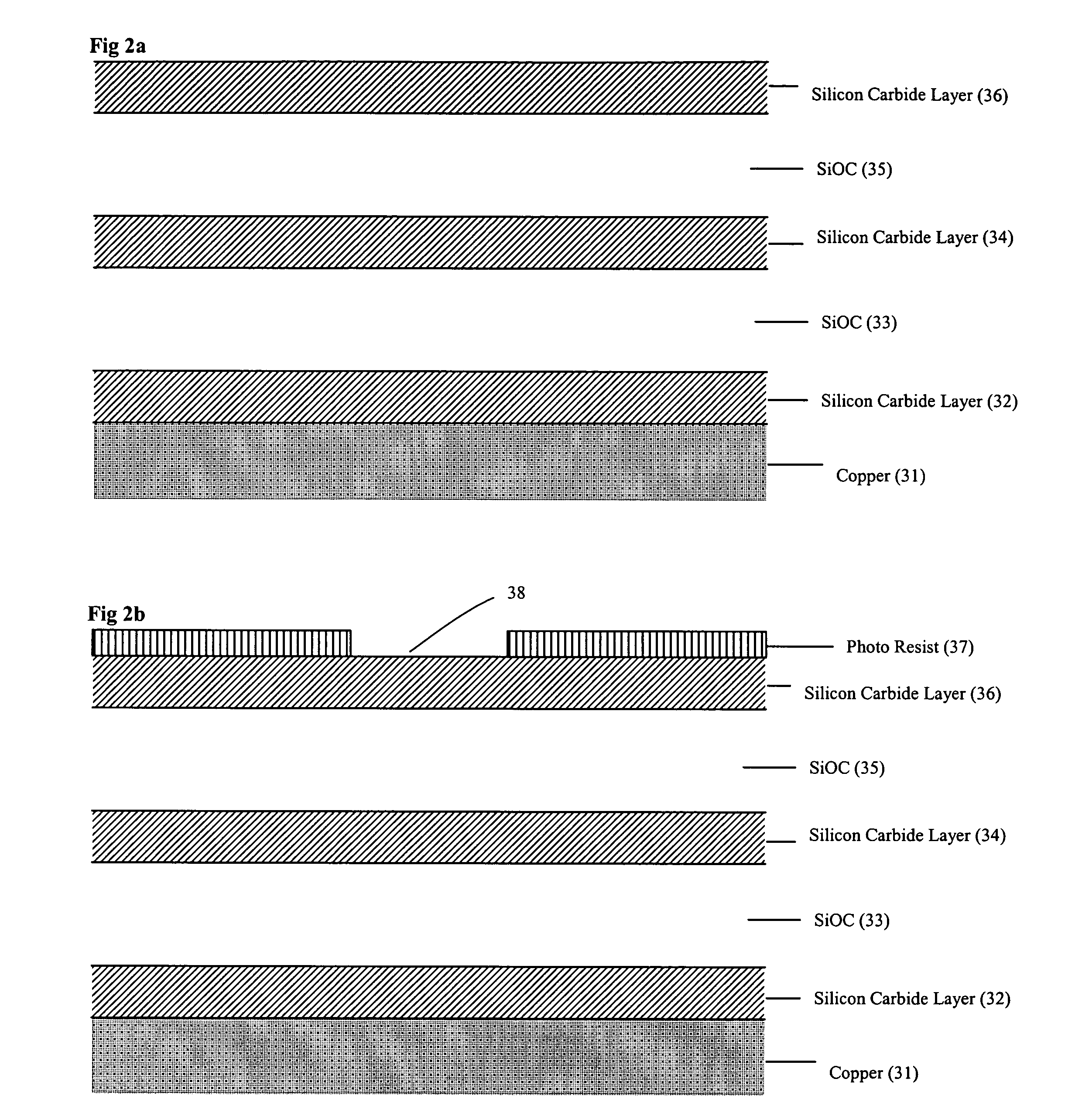

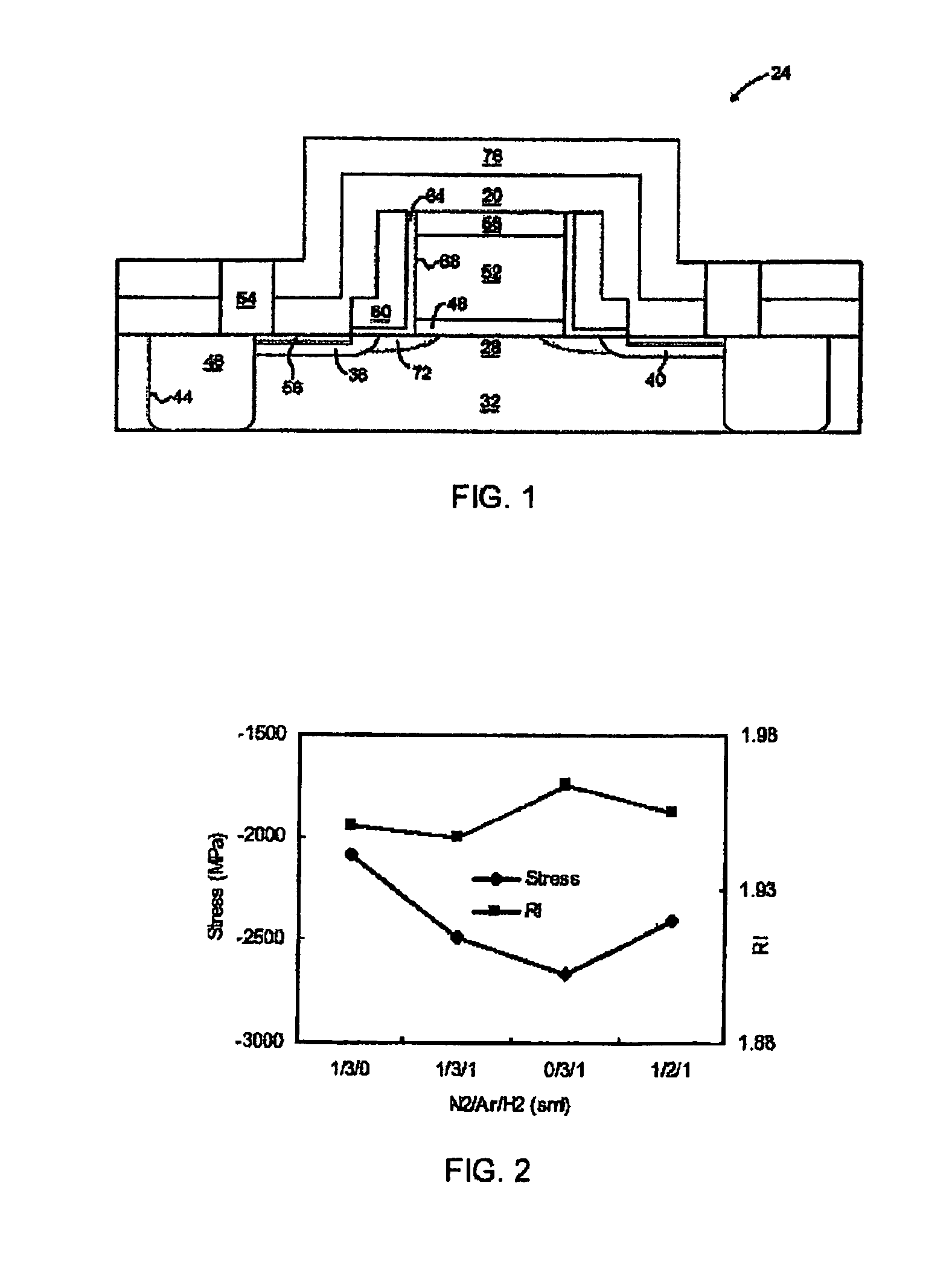

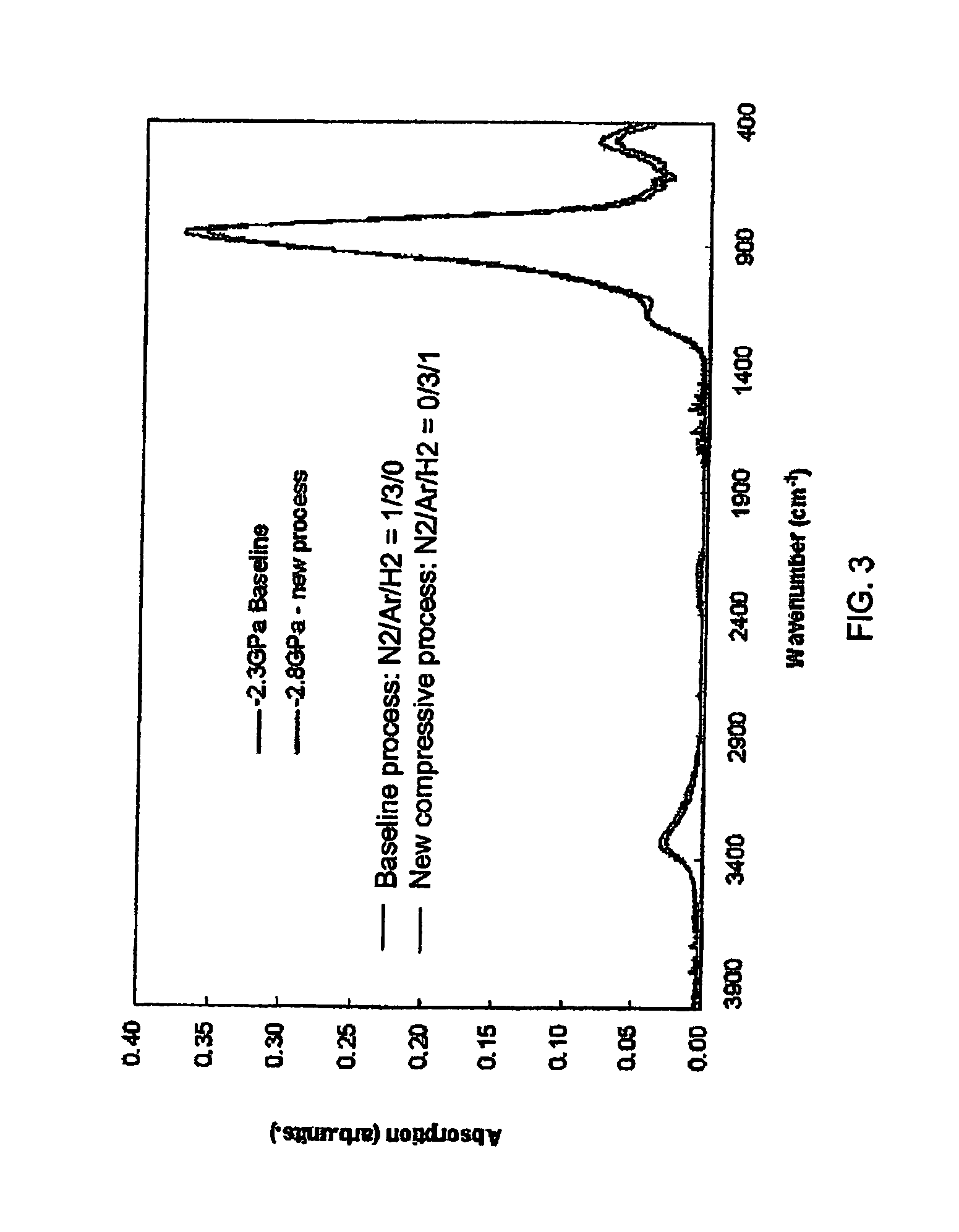

Method of forming silicon carbide films

ActiveUS20050009320A1Increase compressive stressReduce leakage currentSemiconductor/solid-state device detailsSolid-state devicesNitrogenReaction zone

To deposit silicon onto a substrate, there is introduced into a reaction zone a gas including source gases of silicon, carbon, nitrogen and an inert gas. An electric field is generated using low and high frequency RF power to produce a plasma discharge in the reaction zone to cause the deposition. The average power on the substrate is substantially constant. A ratio of low frequency RF power to total RF power is less than about 0.5.

Owner:ASM JAPAN

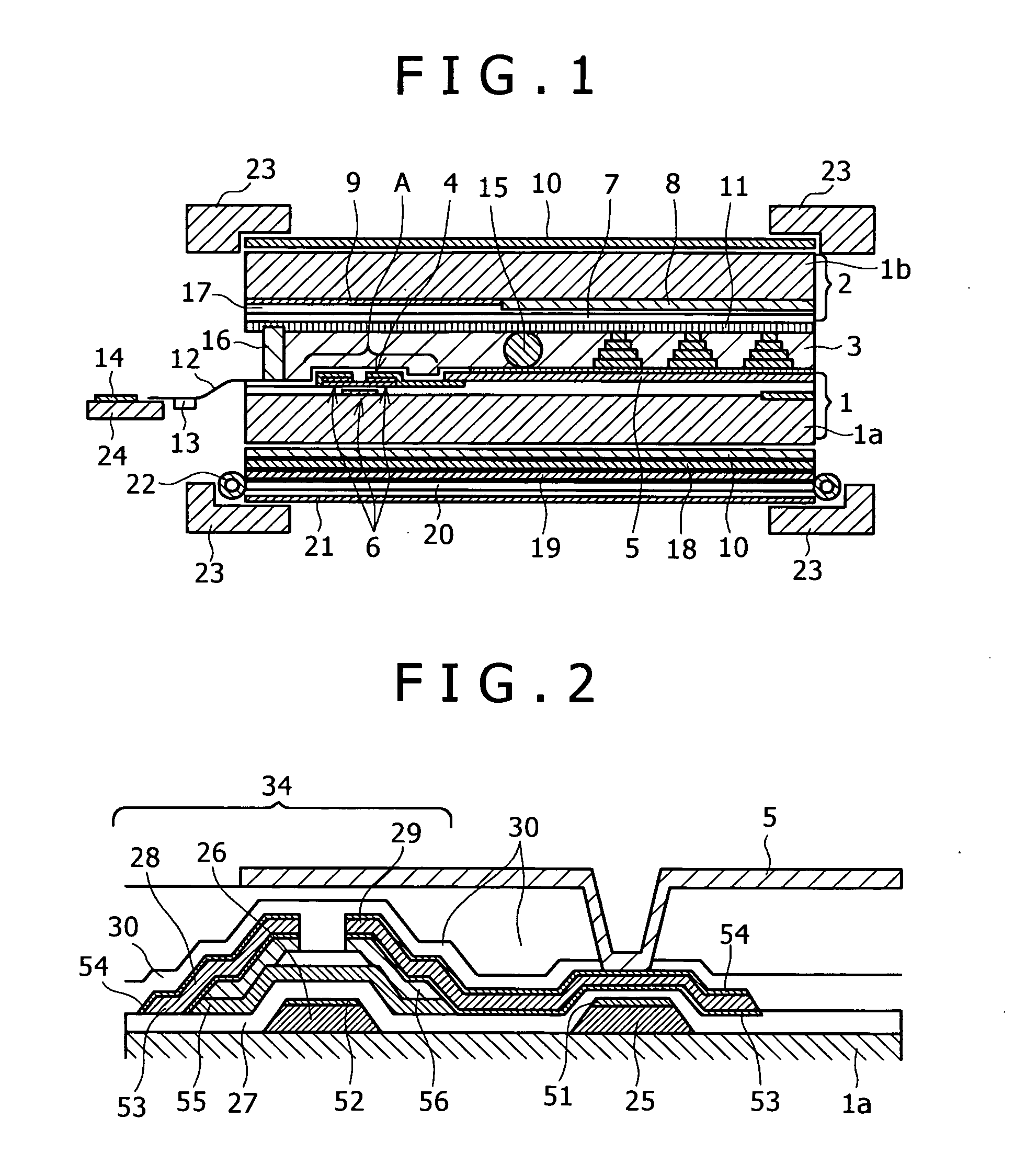

Al alloy film for display device,display device, and sputtering target

ActiveUS20100065847A1Excellent dry etching propertyIncrease production capacityCellsNon-insulated conductorsDisplay deviceAlloy

The present invention provides an Al alloy film for a display device, to be directly connected to a conductive oxide film on a substrate, the Al alloy film comprising Ge in an amount of 0.05 to 0.5 at %, and comprising Gd and / or La in a total amount of 0.05 to 0.45 at %, a display device using the same, and a sputtering target for the display device. For the Al alloy film of the present invention, even when a barrier metal is not provided, and a conductive oxide film and the Al alloy film are directly connected, the adhesion between the conductive oxide film and the Al alloy film is high, and the contact resistivity is low, and preferably, the dry etching property is also excellent.

Owner:KOBE STEEL LTD

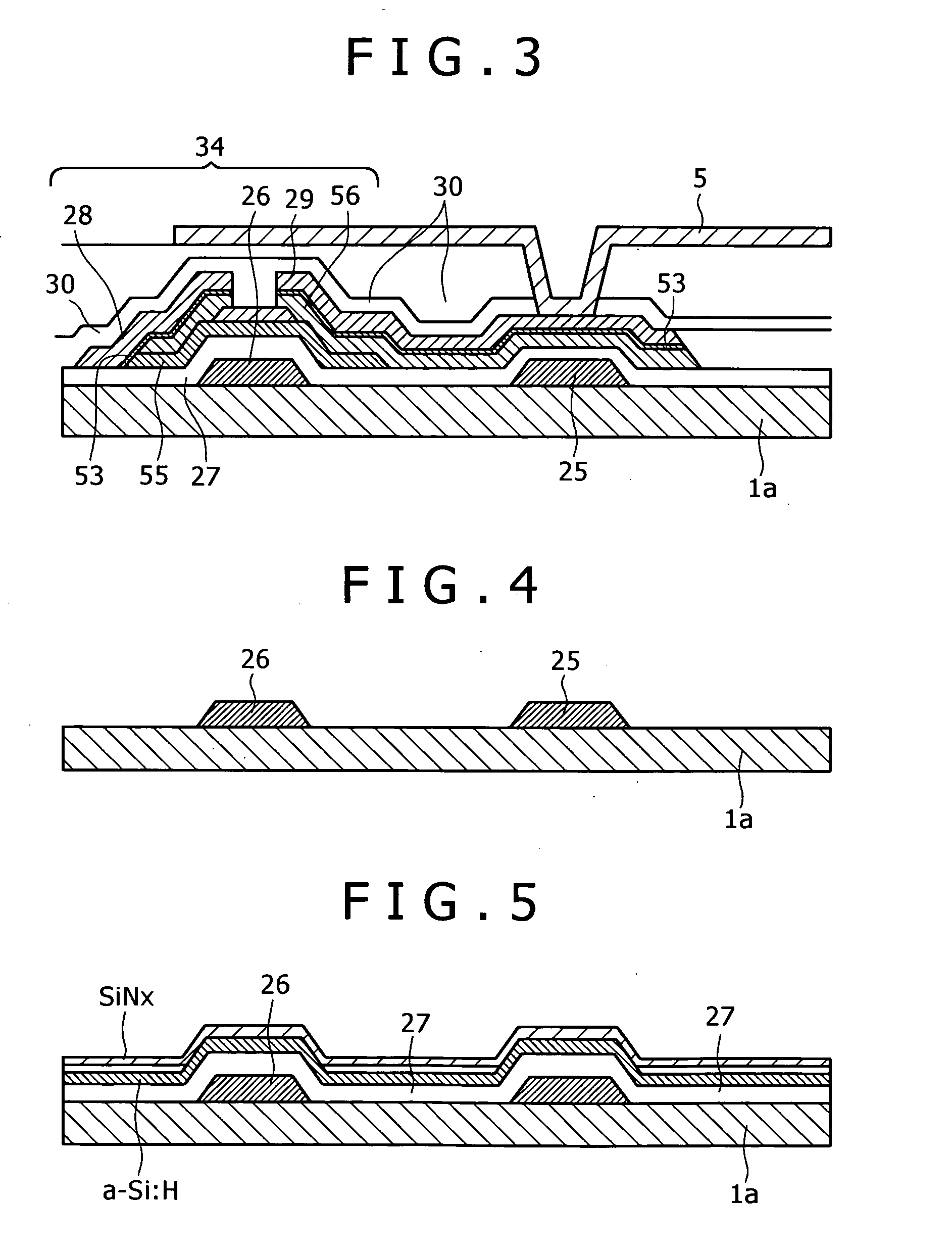

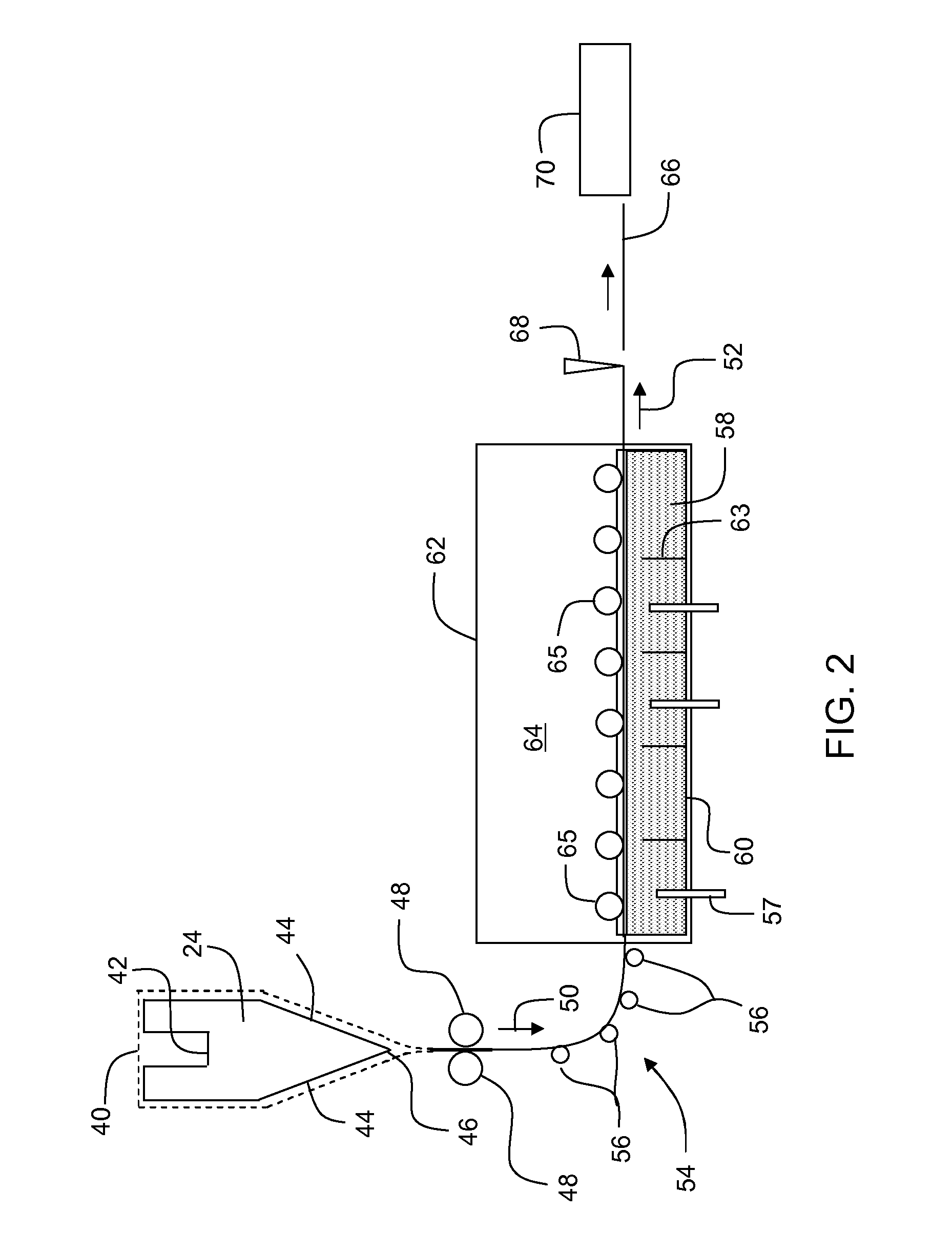

Apparatus and method for forming glass sheets

InactiveUS20130047671A1Increase compressive stressMore stressGlass drawing apparatusGlass forming apparatusGlass sheetMolten metal

Disclosed is a method of reducing the compaction of glass formed by a down draw process. The glass may be a glass sheet or a glass ribbon. Once the glass is formed, it is thermally treated on a molten metal bath for a time and at a temperature effective to reduce the fictive temperature of the glass below a predetermined level. In one embodiment, a glass ribbon is formed in a fusion process and the glass ribbon redirected onto a molten metal bath where the ribbon is thermally treated.

Owner:CORNING INC

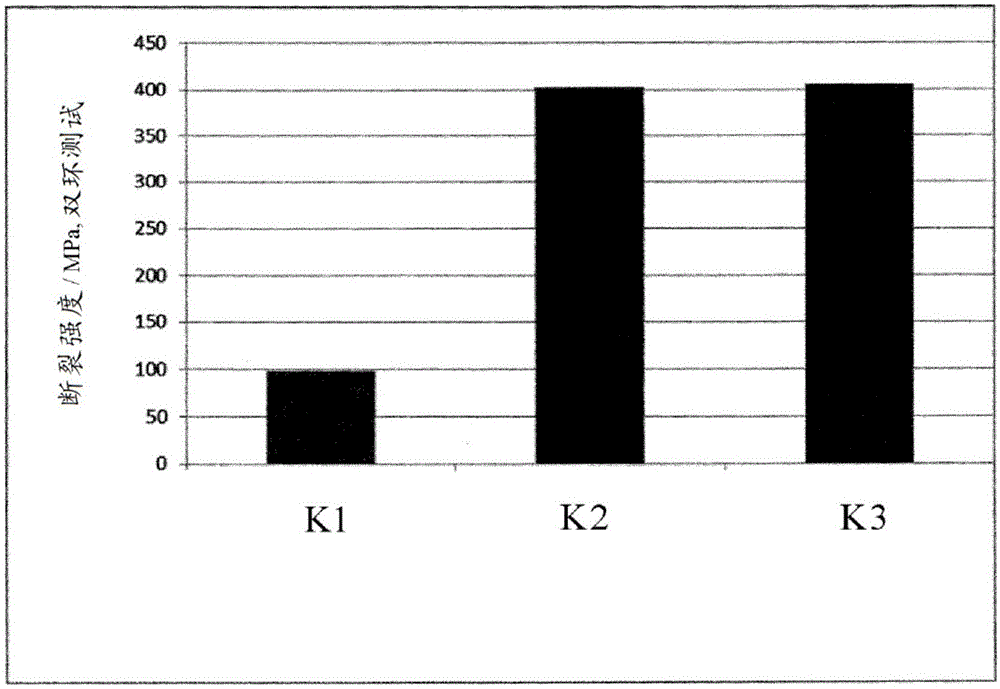

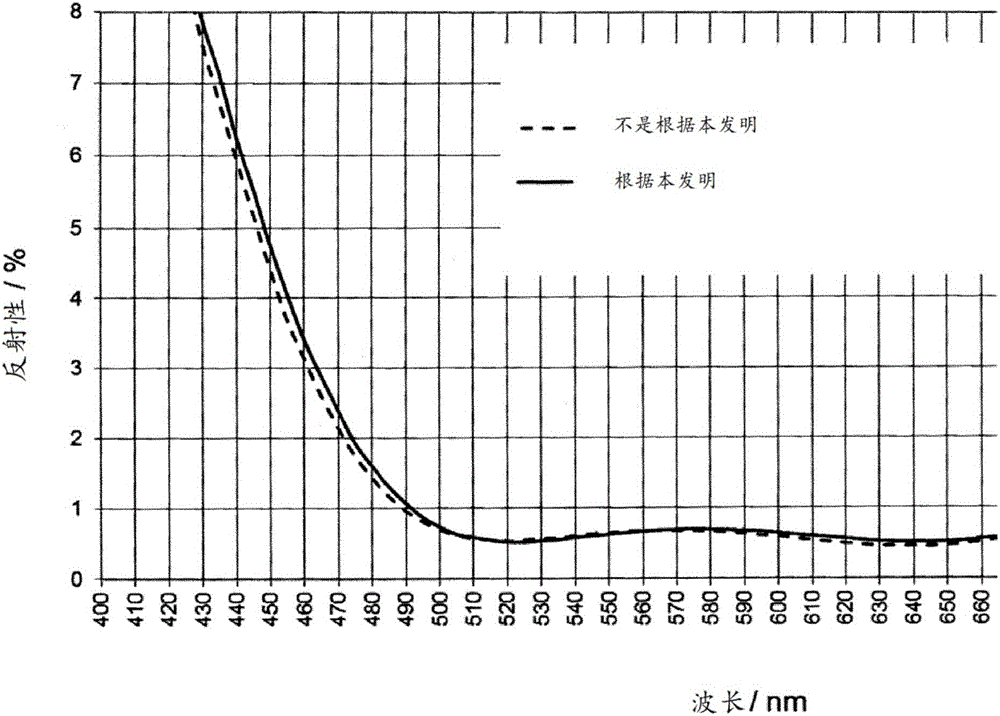

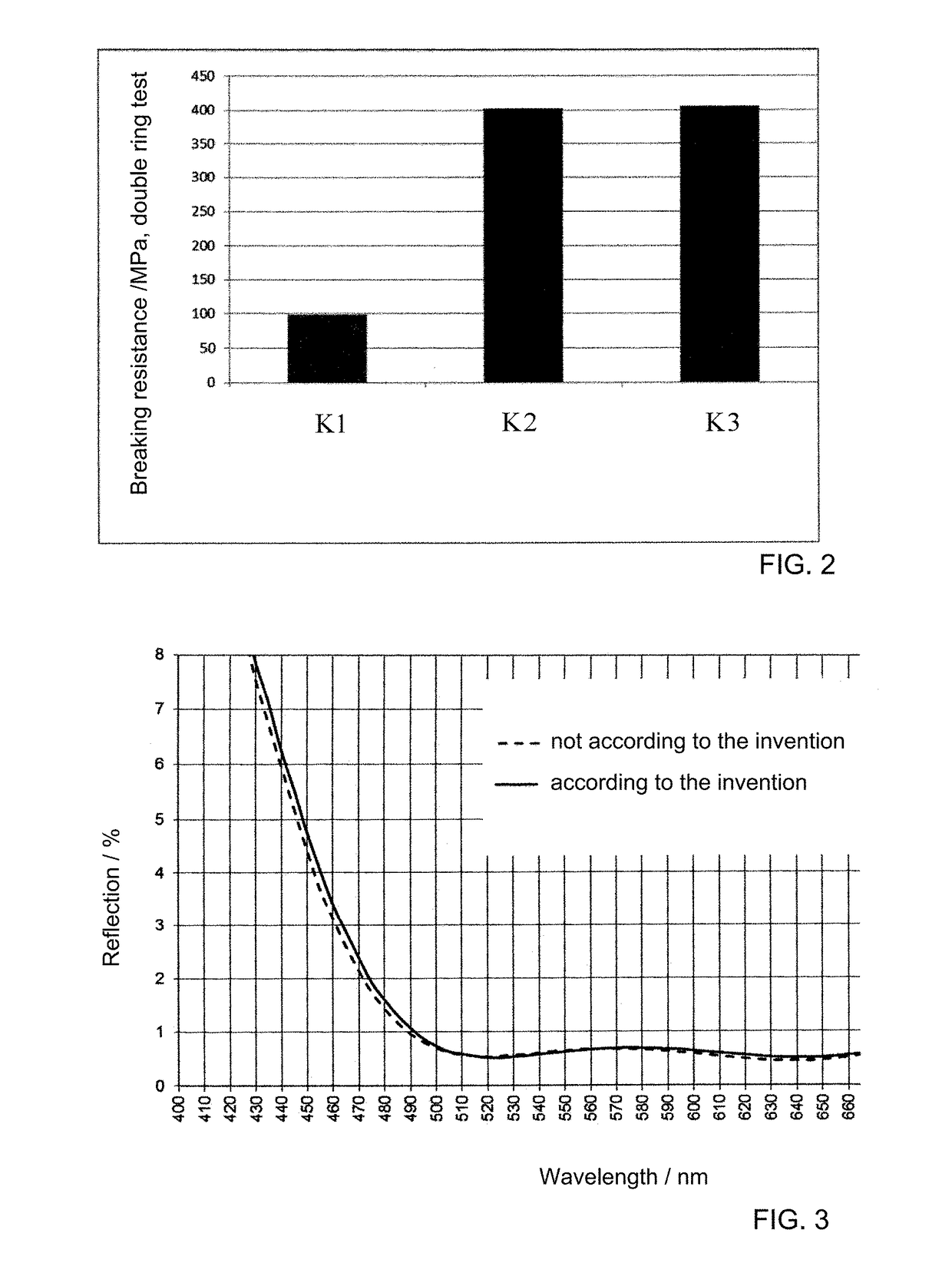

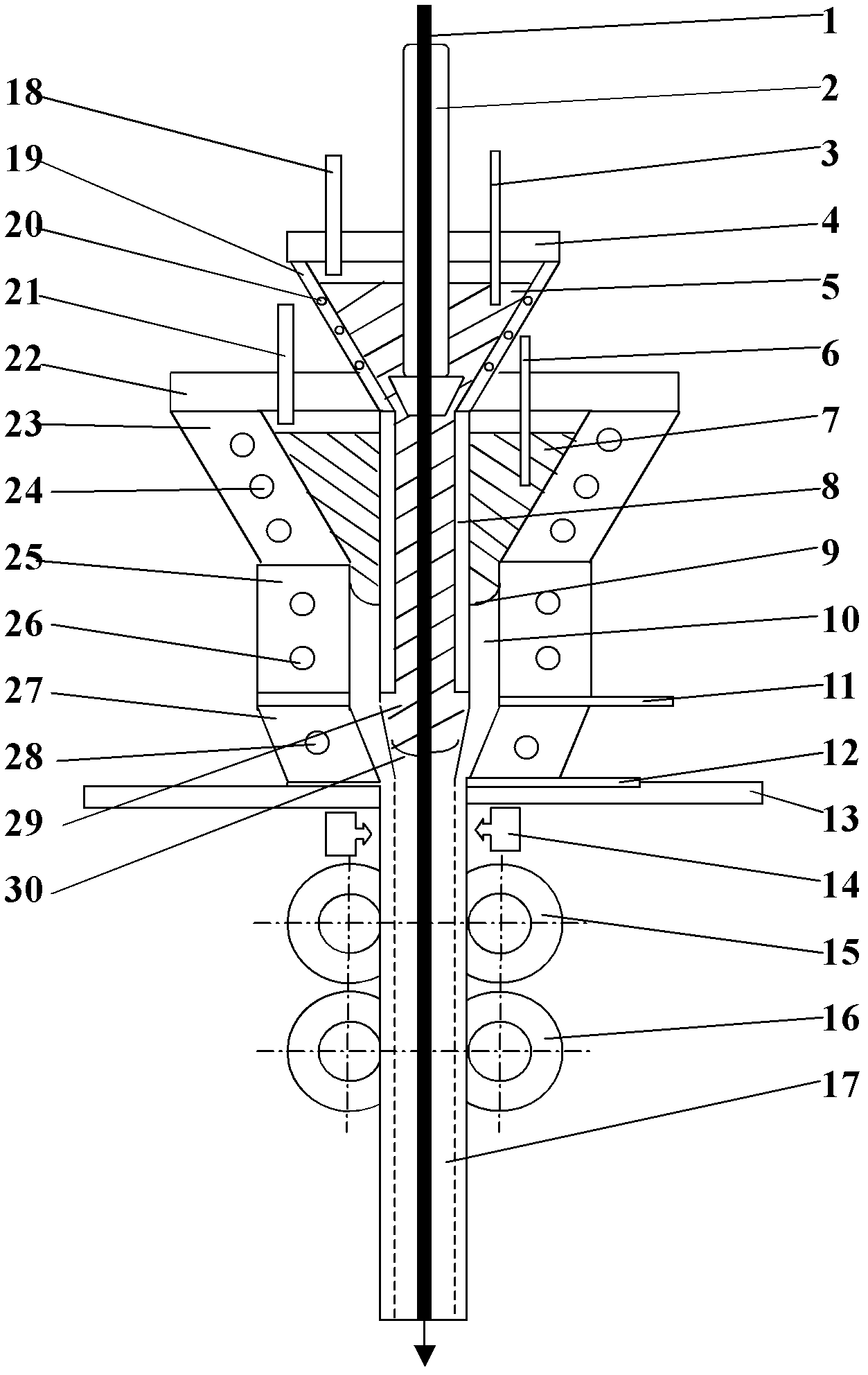

Method for producing a coated, chemically prestressed glass substrate having anti-fingerprint properties, and the produced glass substrate

InactiveCN106715352AIncrease compressive stressImprove long-term stabilityCoatingsIon exchangeBiological activation

The invention relates to a method for producing a coated, chemically prestressed glass substrate having anti-fingerprint properties, wherein the method comprises the following steps: applying at least one functional layer to a glass substrate; chemically prestressing the coated glass substrate by means of ion exchange, wherein existing smaller alkali metal ions are exchanged for larger alkali metal ions, and are enriched in the glass substrate and the at least one functional layer; activating the surface of the at least one functional layer, wherein, if more than one functional layer is present, the surface of the outermost or uppermost layer is activated, and the activating of the surface of the at least one functional layer is carried out using one of the described variations (1) to (8); and applying an amphiphobic coating to the at least one functional layer of the glass substrate, wherein, as a result of the activation process, the functional layer interacts with the amphiphobic coating. The glass substrate provides a unique combination of advantageous properties, such that, as well as anti-fingerprint properties and an increased scratch and breakage resistance, an improved durability of the amphiphobic coating is also achieved.

Owner:SCHOTT AG

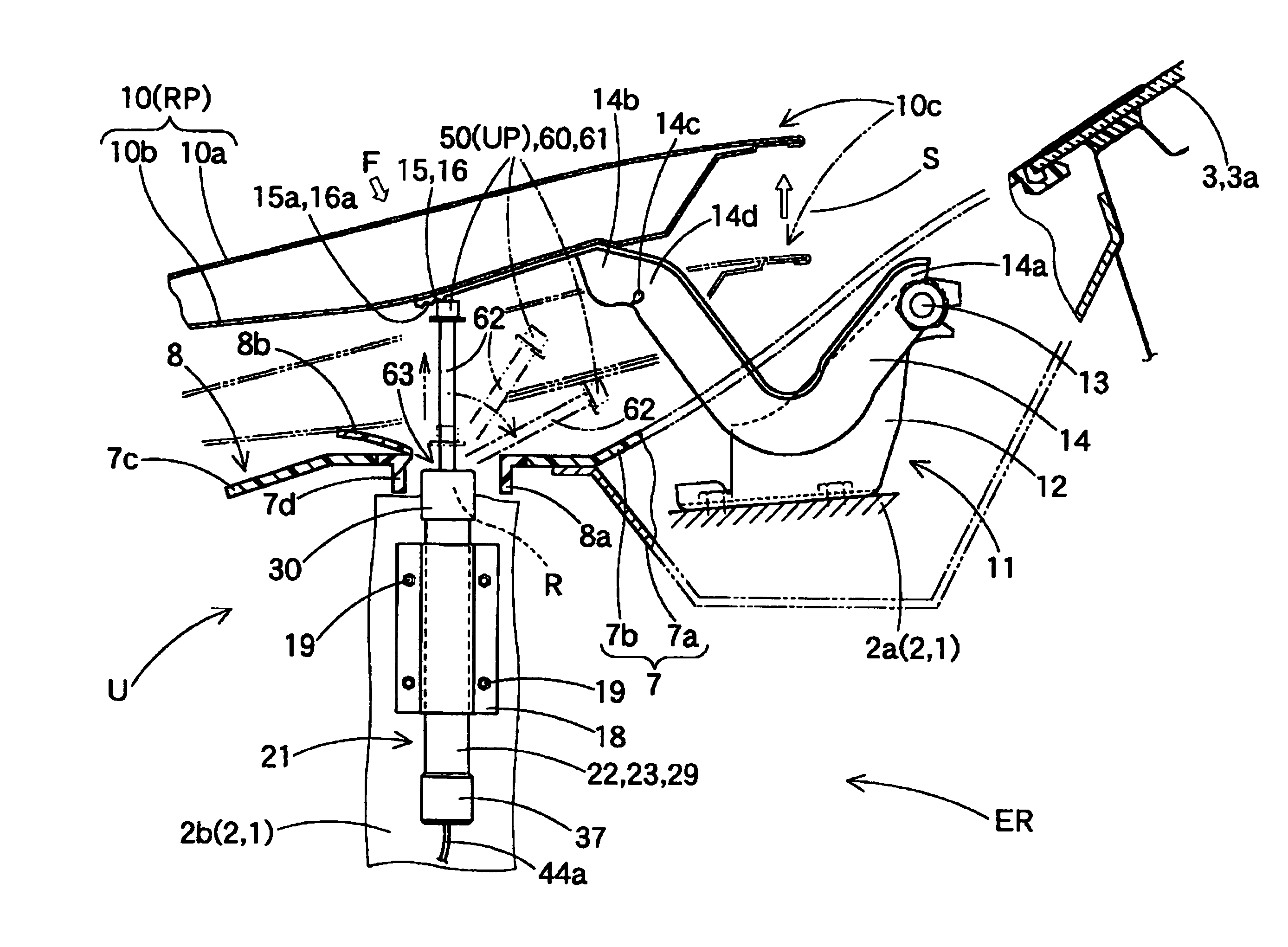

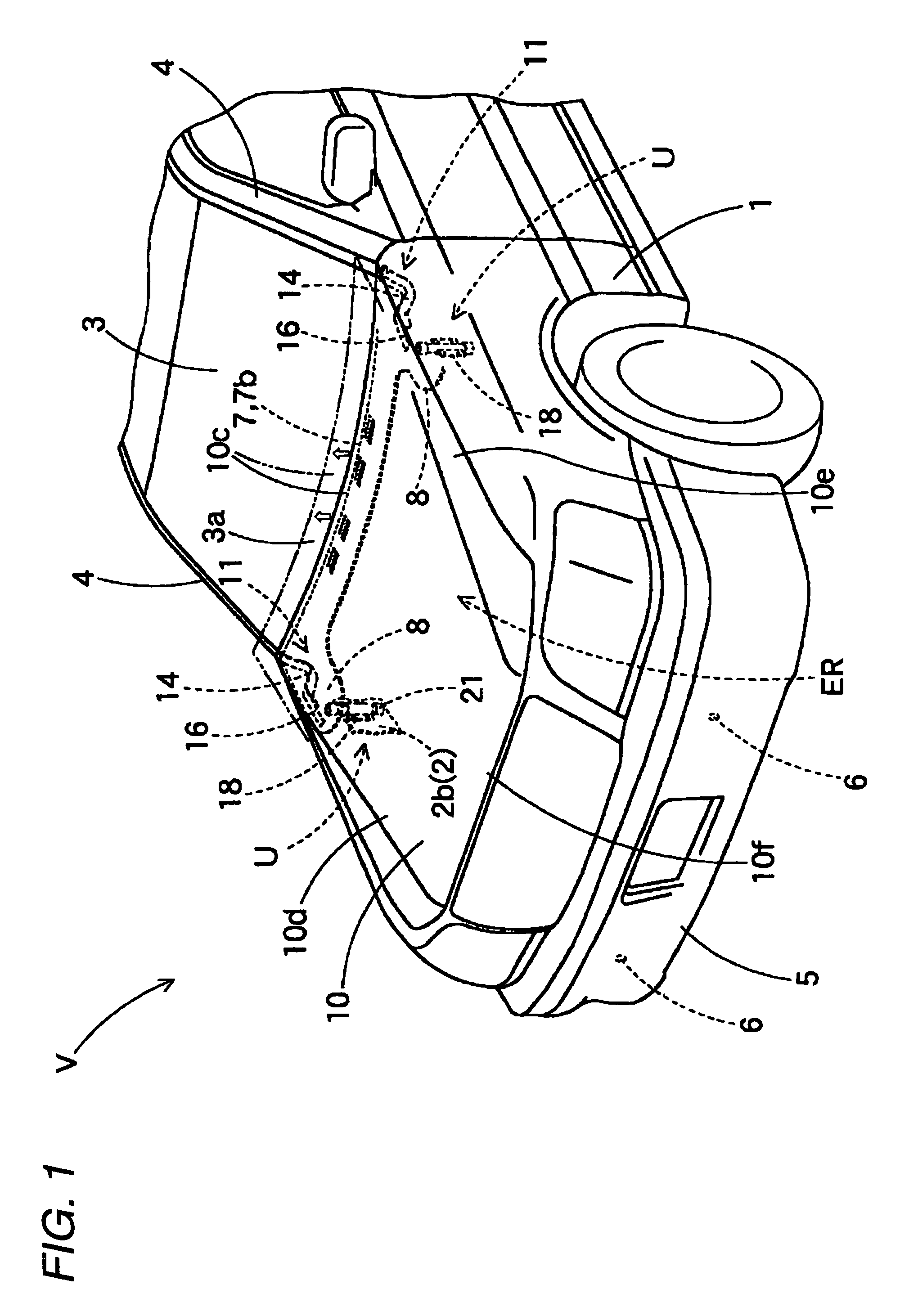

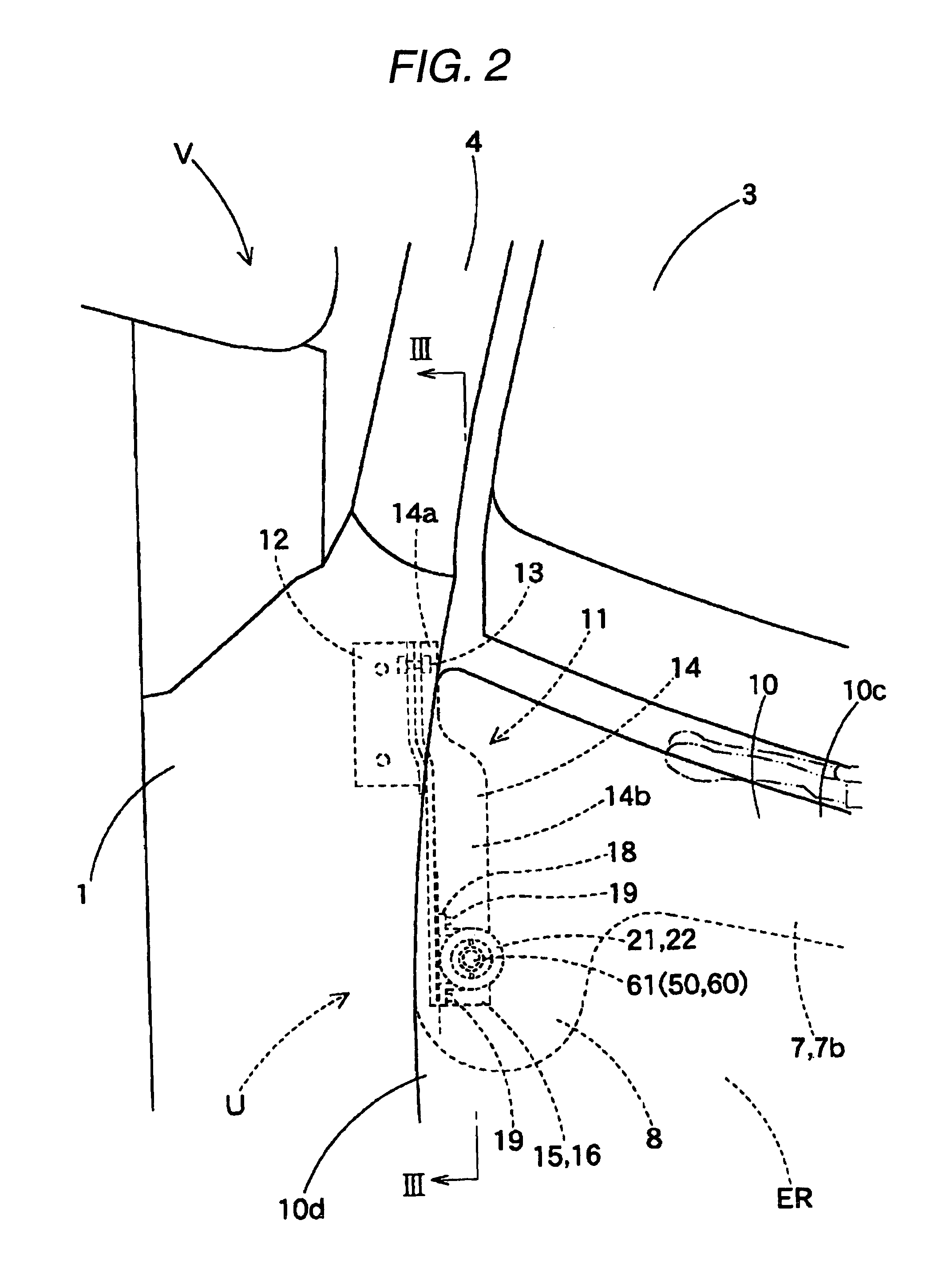

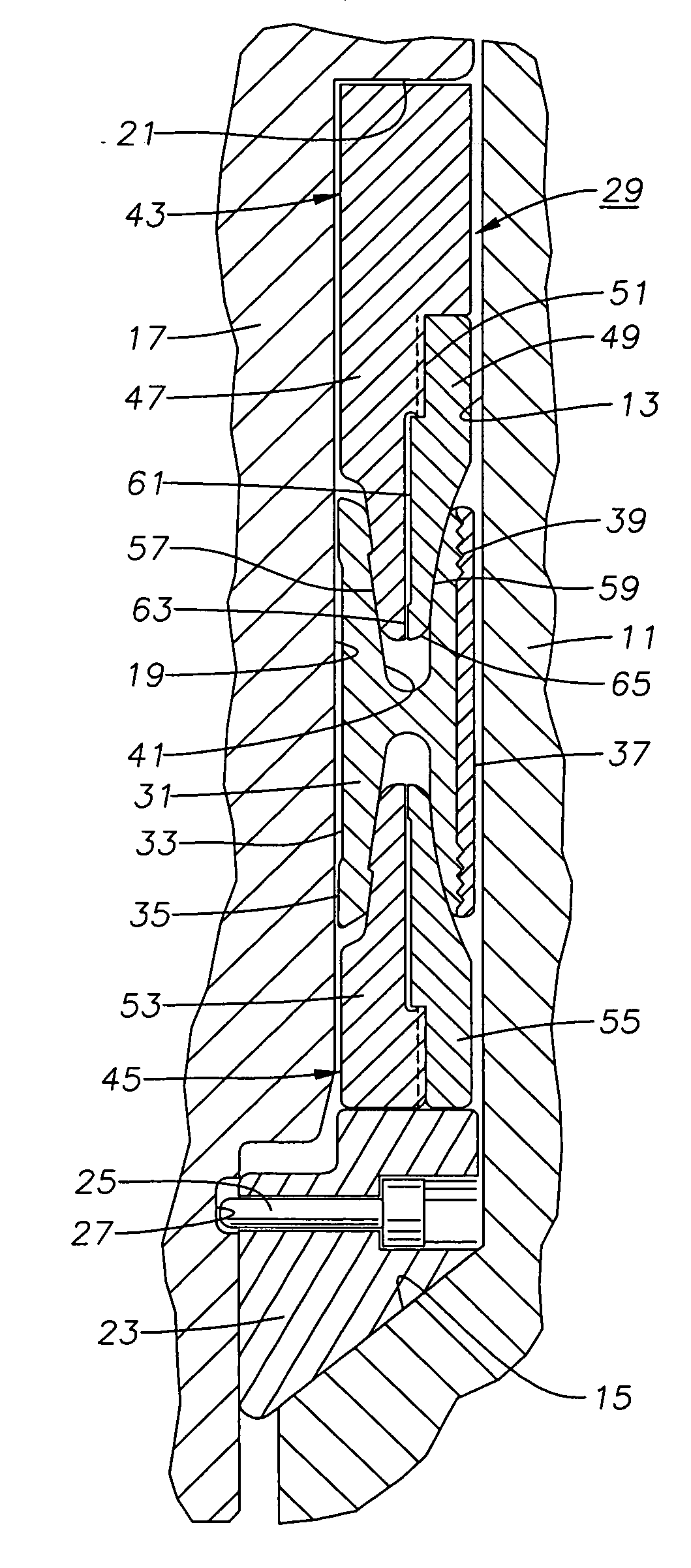

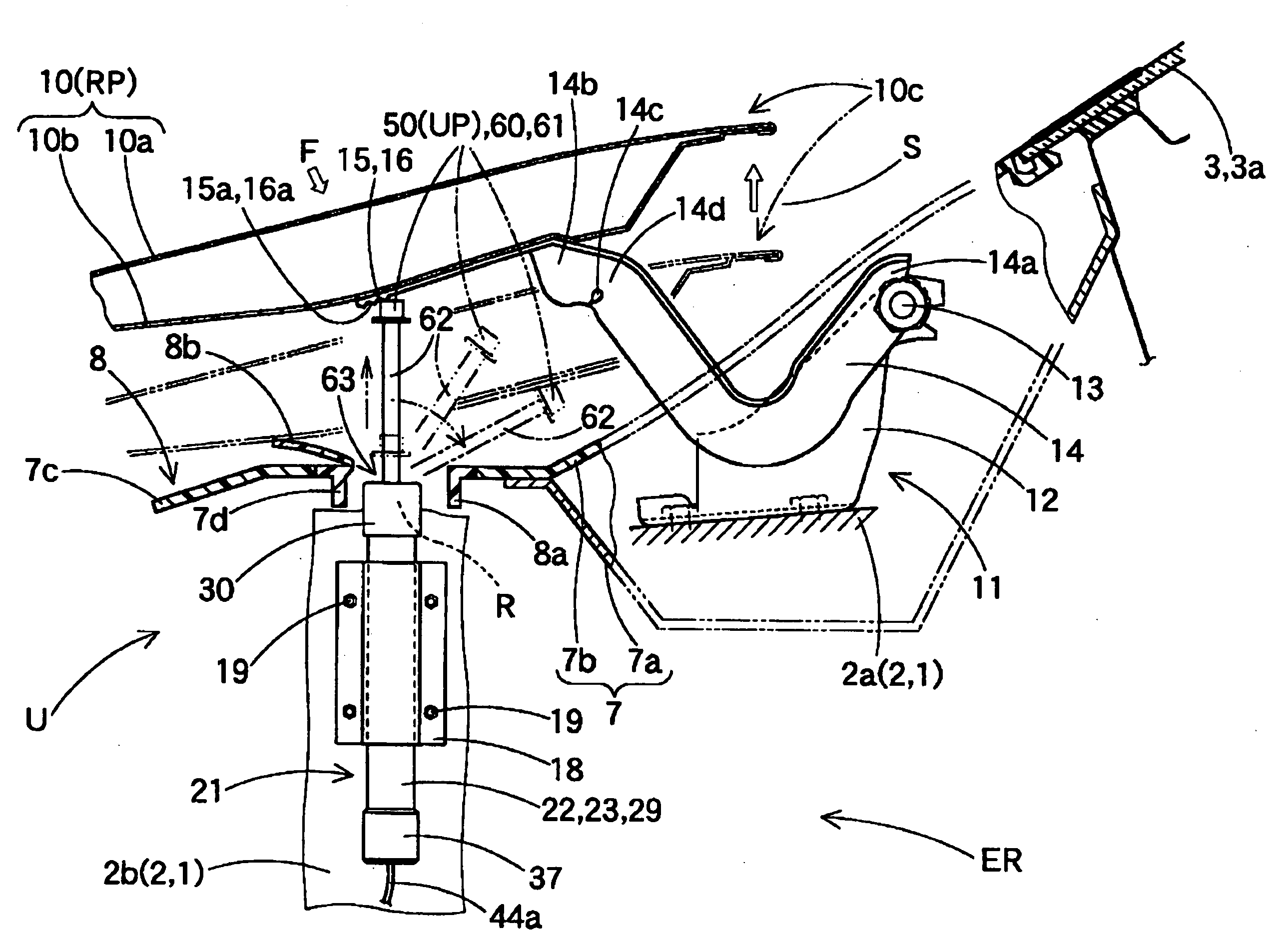

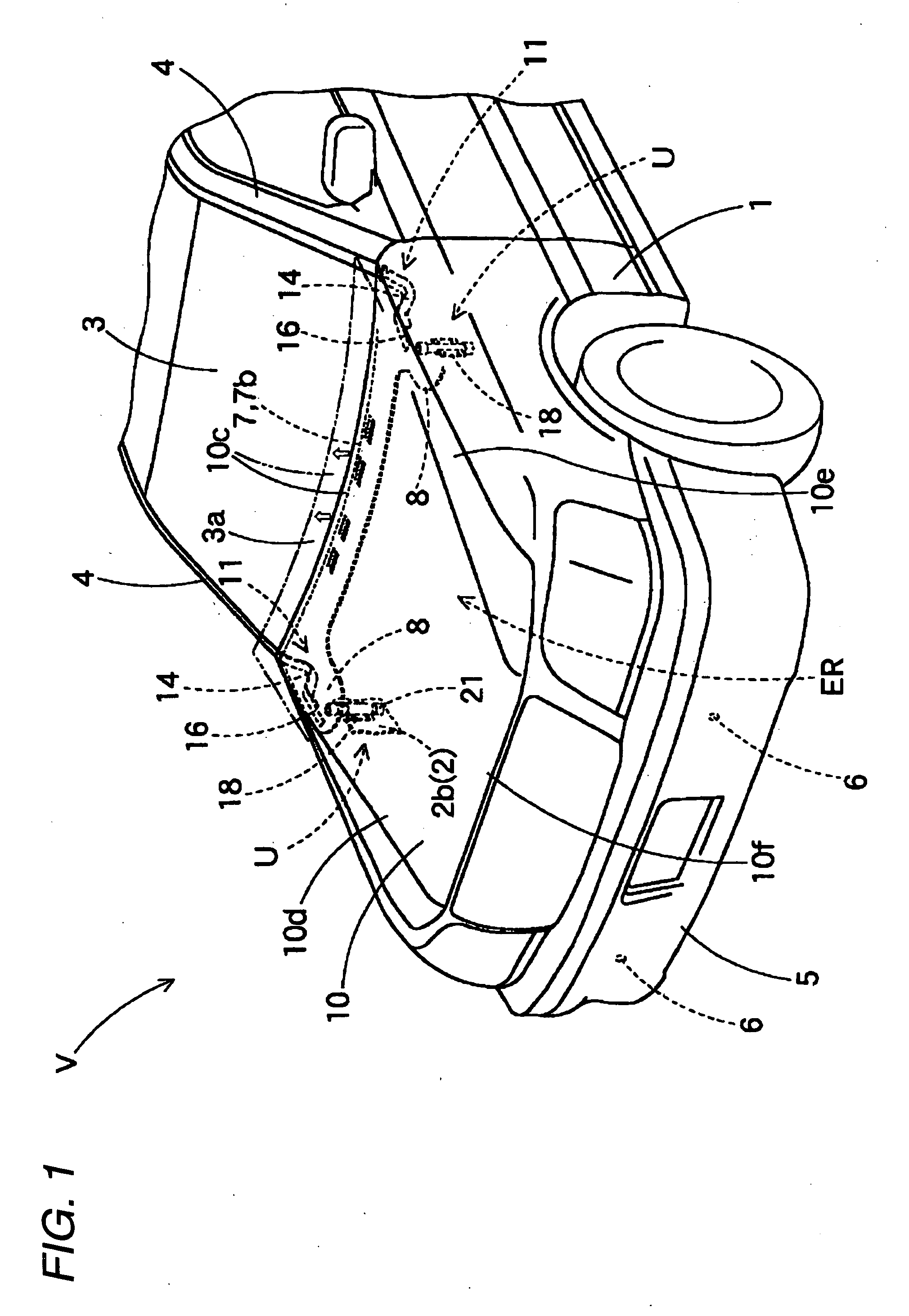

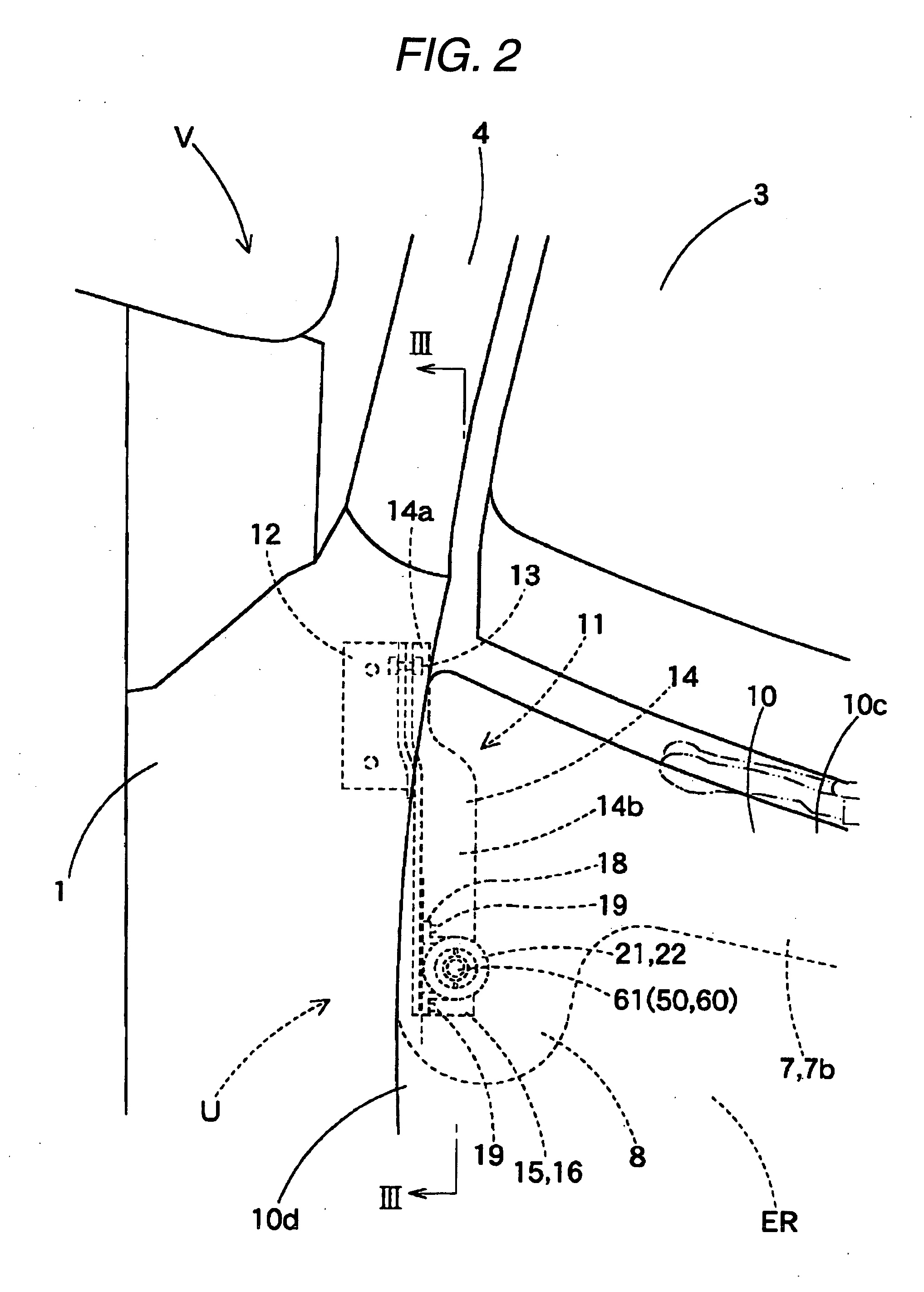

Actuator

ActiveUS7946376B2Suppress backward movementEasy to changePyrotechnical actuatorsPedestrian/occupant safety arrangementLocking mechanismEngineering

When activated, an actuator causes a piston rod in a cylinder to move forwards so as to support a receiving member for receiving an object to be protected. A lock mechanism for restricting a backward movement of the piston rod includes a lock ring which is accommodated in an accommodating groove on a piston portion and a locking stepped portion on the cylinder side. The locking stepped portion includes a locking and restricting surface and an outer circumferential restricting surface. A taper restricting surface in the accommodating groove on the piston portion is brought into abutment with an inner surface on a forward moving side of the lock ring which is being diametrically expanded as a result of the piston rod having moved forwards and is in abutment with the locking and restricting surface and the outer circumferential restricting surface of the locking stepped portion, whereby the backward movement of the piston rod is restricted by making use of the lock ring which is restricted in the locking stepped portion.

Owner:TOYODA GOSEI CO LTD

Flex-lock metal seal system for wellhead members

ActiveUS20080135229A1Increase compressive stressAvoid insufficient thicknessEngine sealsDrilling rodsEngineeringMechanical engineering

A wellhead seal assembly forms a metal-to-metal seal between the inner and outer wellhead members. A metal seal ring has inner and outer conical walls separated by a tapered slot. An energizing ring has inner and outer annular members that are separated by an annular cavity. When the energizing ring is moved further into the slot, the cavity width decreases but remains to provide a preloaded radial force to the seal ring.

Owner:VETCO GRAY LLC

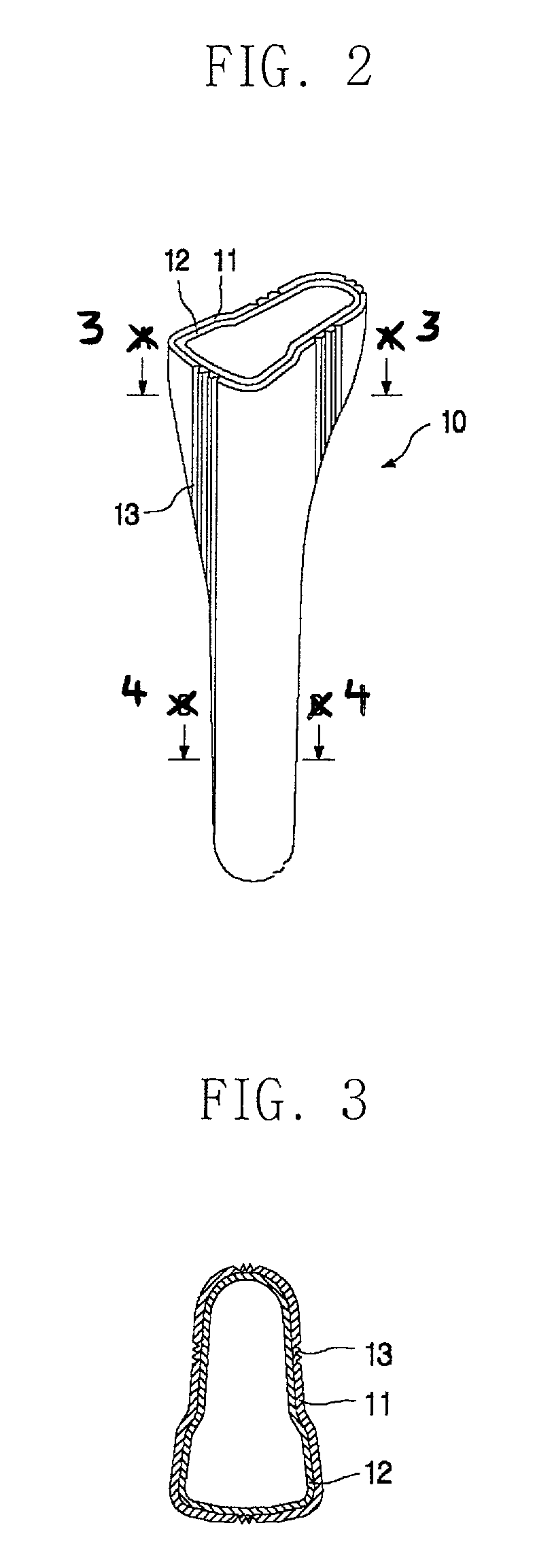

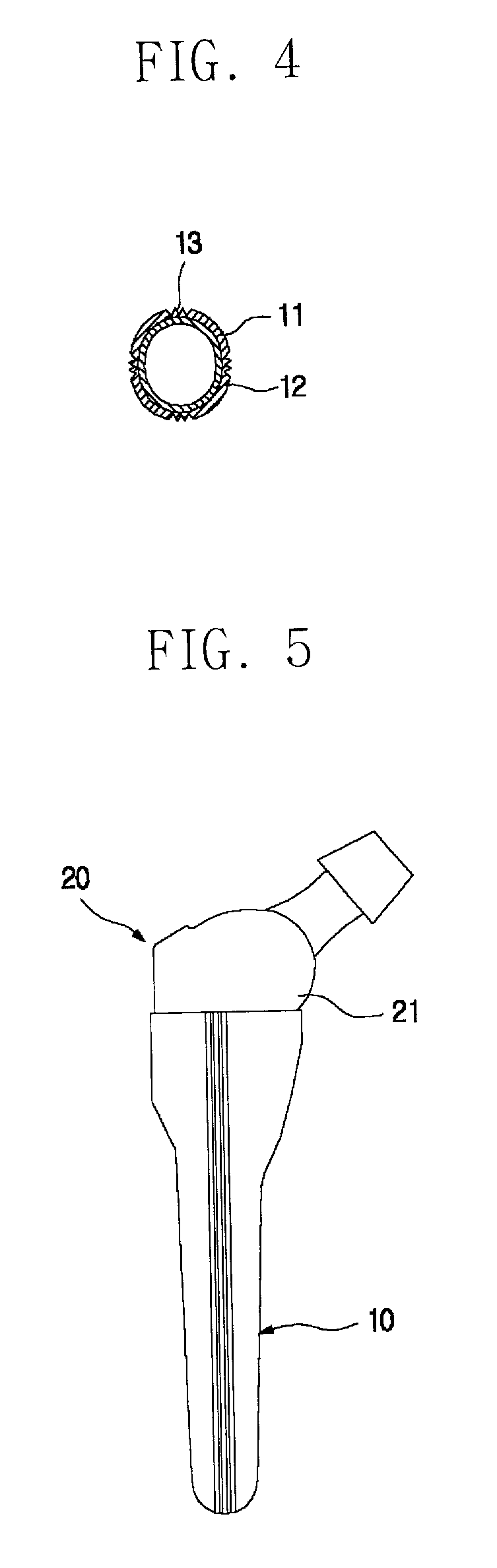

Cement jacket for a cemented artificial joint stem and artificial joint having the cement jacket

InactiveUS6524344B2Increase anchorageEasy dischargeBone implantJoint implantsHigh resistanceArtificial joints

Owner:KOREA ADVANCED INST OF SCI & TECH

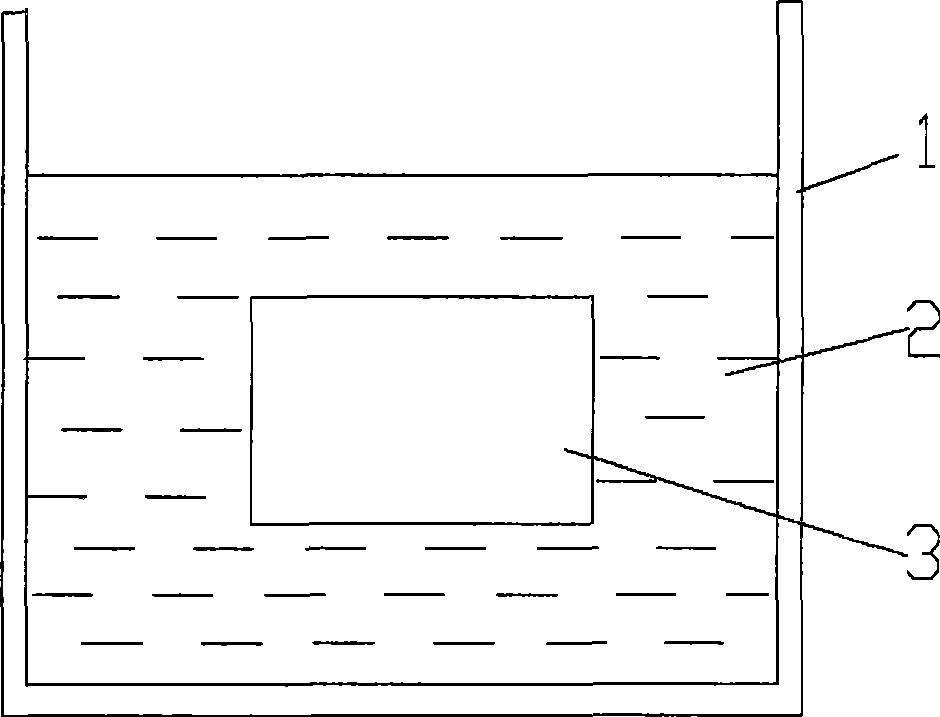

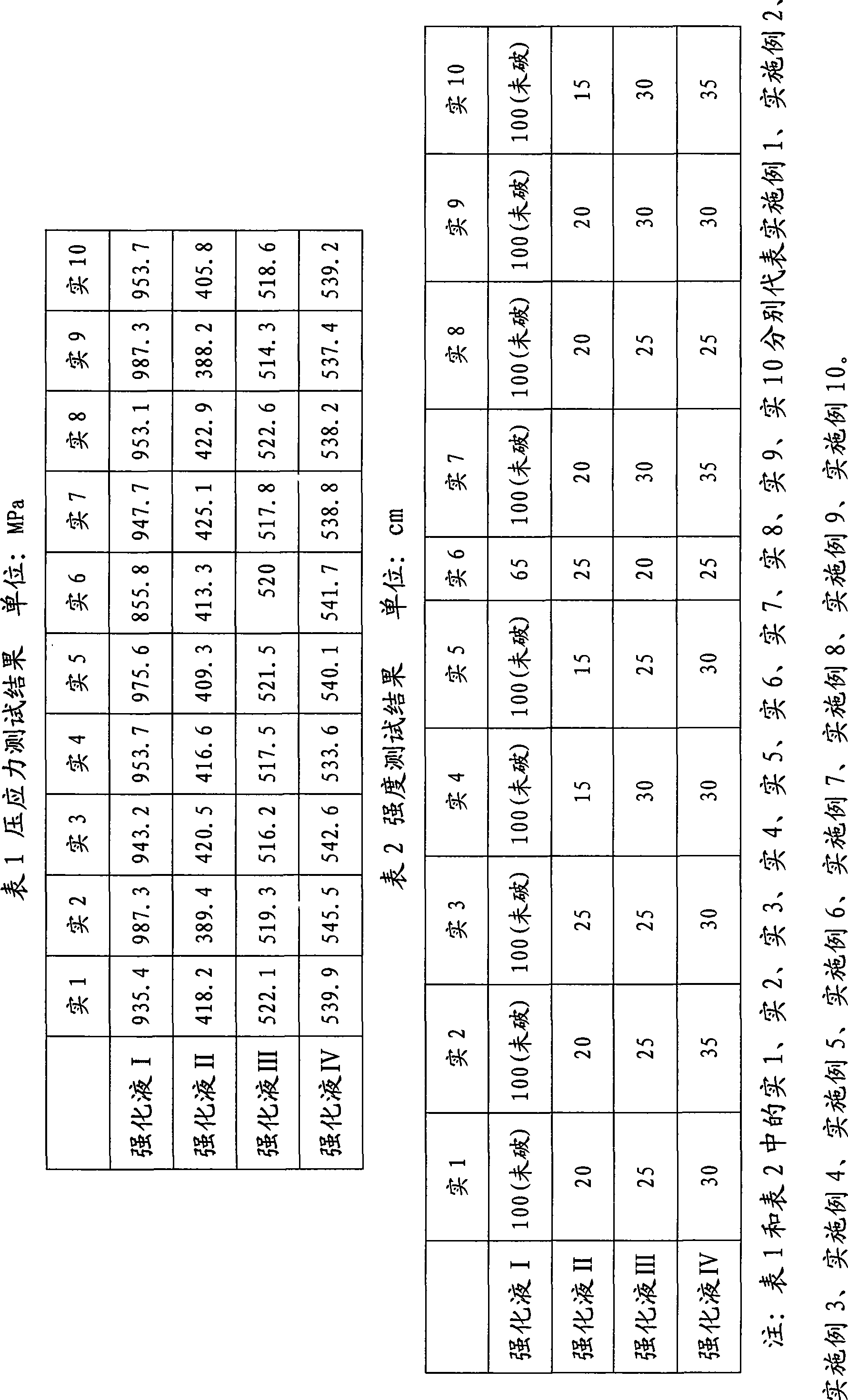

Catalyst for chemically enhancing glass and use thereof

The invention discloses a catalyst used for strengthening glass intensity, wherein, the catalyst comprises a first catalyst and a second catalyst. The first catalyst is added into molten salt, and first glass strengthening liquid is obtained. The second catalyst is added into the molten salt, and second glass strengthening liquid is obtained. Then the glass to be strengthened is put into the first glass strengthening liquid and the second glass strengthening liquid in sequence, and the strengthening process is completed. The catalyst of the invention can improve surface compressive stress and strength of the glass, as well as can prolong the service life of the glass. The invention pertains to the chemical strengthening field of the glass.

Owner:BYD CO LTD

Method for production of a coated, chemically prestressed glass substrate having Anti-fingerprint properties and produced glass substrate

The invention relates to a method for producing a coated, chemically prestressed glass substrate having anti-fingerprint properties. The method includes: applying at least one functional layer to a glass substrate; chemically prestressing the coated glass substrate by an ion exchange, where existing smaller alkali metal ions are exchanged for larger alkali metal ions, and are enriched in the glass substrate and the at least one functional layer; activating the surface of the at least one functional layer, where if more than one functional layer is present the surface of the outermost or uppermost layer is activated, the activating including one of several alternatives; and applying an amphiphobic coating to the at least one functional layer of the glass substrate, where, as a result of the activation process, the functional layer interacts with the amphiphobic coating.

Owner:SCHOTT AG

Method for mfg. high strength fireproof signle sheet cesium potash glass

ActiveCN1559942AImprove cooling effectIncrease compressive stressGlass tempering apparatusGlass productionSurface stressThermal spraying

The invention relates to a making process and method of a single piece of Cs-K fireproof glass, implemented by simultaneously making physical and chemical toughening in a horizontal toughening furnace, where the chemical toughening is implemented by hot-spraying a salt solution with specific components. The made product has surface stress not less than 140 MPa and not greater than 180 MPa and advantageous fire-proofing function, and overcomes the defects of grout fireproof glass in bad weatherability, easy foaming under ultraviolet irradiation, low strength, and unability of being used to outer walls of buildings.

Owner:甘肃金刚光伏股份有限公司

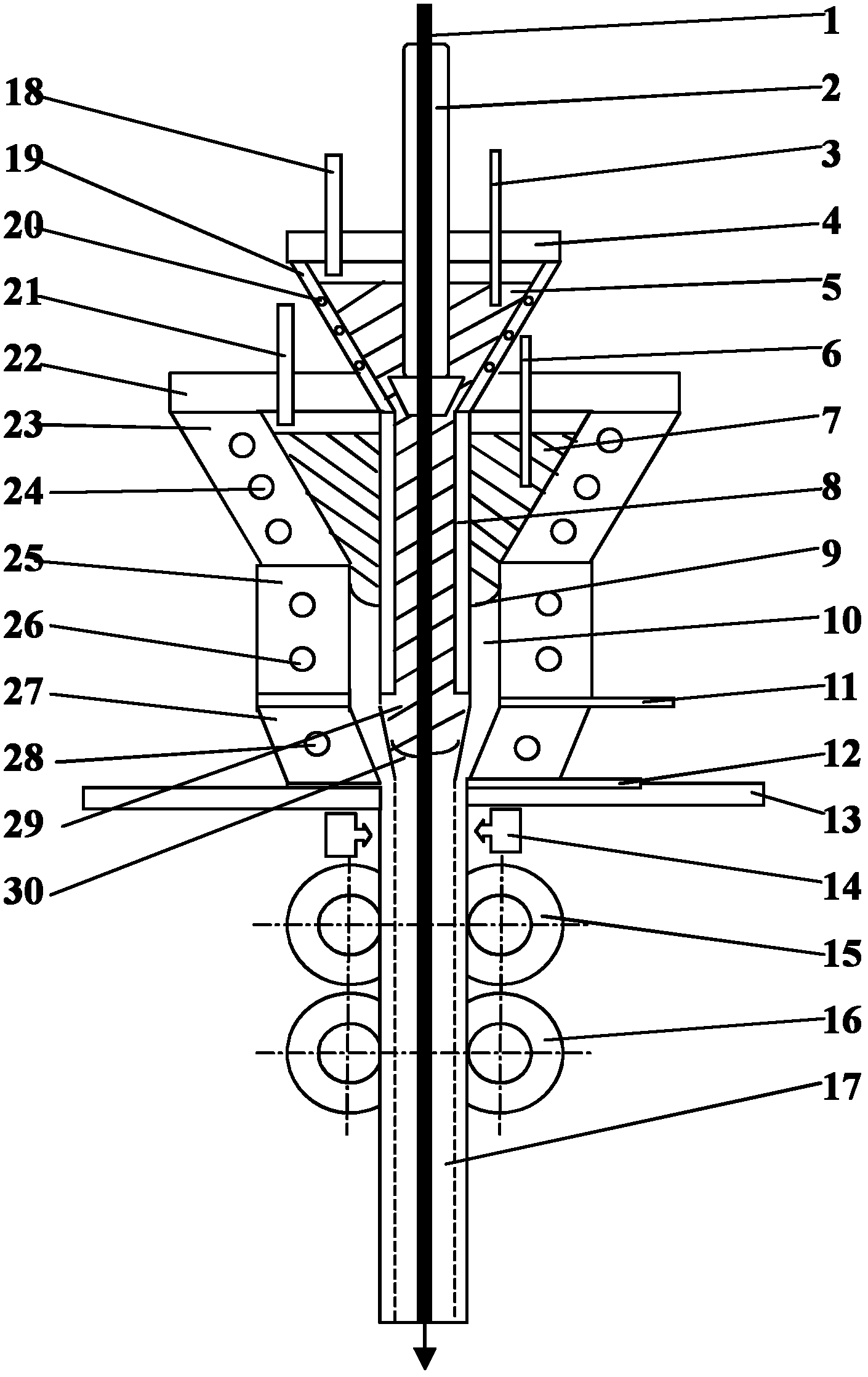

Pressure core-filling continuous casting equipment and process for double-metal-bag long carbon fiber composite material

The invention provides pressure core-filling continuous casting equipment and a process for a double-metal-bag long carbon fiber composite material. The continuous casting equipment is composed of an inner-layer metal plug rod, a carbon fiber guide pipe, an inner-layer metal thermodetector, an inner-layer metal pressurizing cover, an outer-layer metal thermodetector, a core filling pipe, an outer-layer metal pipe thermodetector, a composite interface pressurizing device, a heat-insulating and water-stopping plate, a secondary cooling device, a drawing roller, a finishing roller, an inner-layer metal liquid pressurizing pipe, an inner-layer metal temperature control furnace, an outer-layer metal liquid pressurizing pipe, an outer-layer metal pressurizing cover, an outer-layer metal liquid temperature control furnace, an outer-layer metal liquid temperature control crystallizer, a composite interface pressurizing device, a heating element and a temperature control element. Inner-layer metal is smelted and insulated in the inner-layer metal temperature control furnace and is filled into a condensed outer-layer metal pipe inner hole and one bundle of long carbon fibers through the core filling pipe, so as to be fused and condensed with the inner-layer metal and the carbon fibers to form a composite material. The speed of core-filling and continuous casting is controlled by the drawing roller and an outer-layer metal pipe casting blank is pressurized to be ejected out from the outer-layer metal liquid temperature control crystallizer.

Owner:UNIV OF SCI & TECH BEIJING

Actuator

ActiveUS20090266638A1Suppress backward movementEasy to deal withPyrotechnical actuatorsPedestrian/occupant safety arrangementLocking mechanismAbutment

When activated, an actuator causes a piston rod in a cylinder to move forwards so as to support a receiving member for receiving an object to be protected. A lock mechanism for restricting a backward movement of the piston rod includes a lock ring which is accommodated in an accommodating groove on a piston portion and a locking stepped portion on the cylinder side. The locking stepped portion includes a locking and restricting surface and an outer circumferential restricting surface. A taper restricting surface in the accommodating groove on the piston portion is brought into abutment with an inner surface on a forward moving side of the lock ring which is being diametrically expanded as a result of the piston rod having moved forwards and is in abutment with the locking and restricting surface and the outer circumferential restricting surface of the locking stepped portion, whereby the backward movement of the piston rod is restricted by making use of the lock ring which is restricted in the locking stepped portion.

Owner:TOYODA GOSEI CO LTD

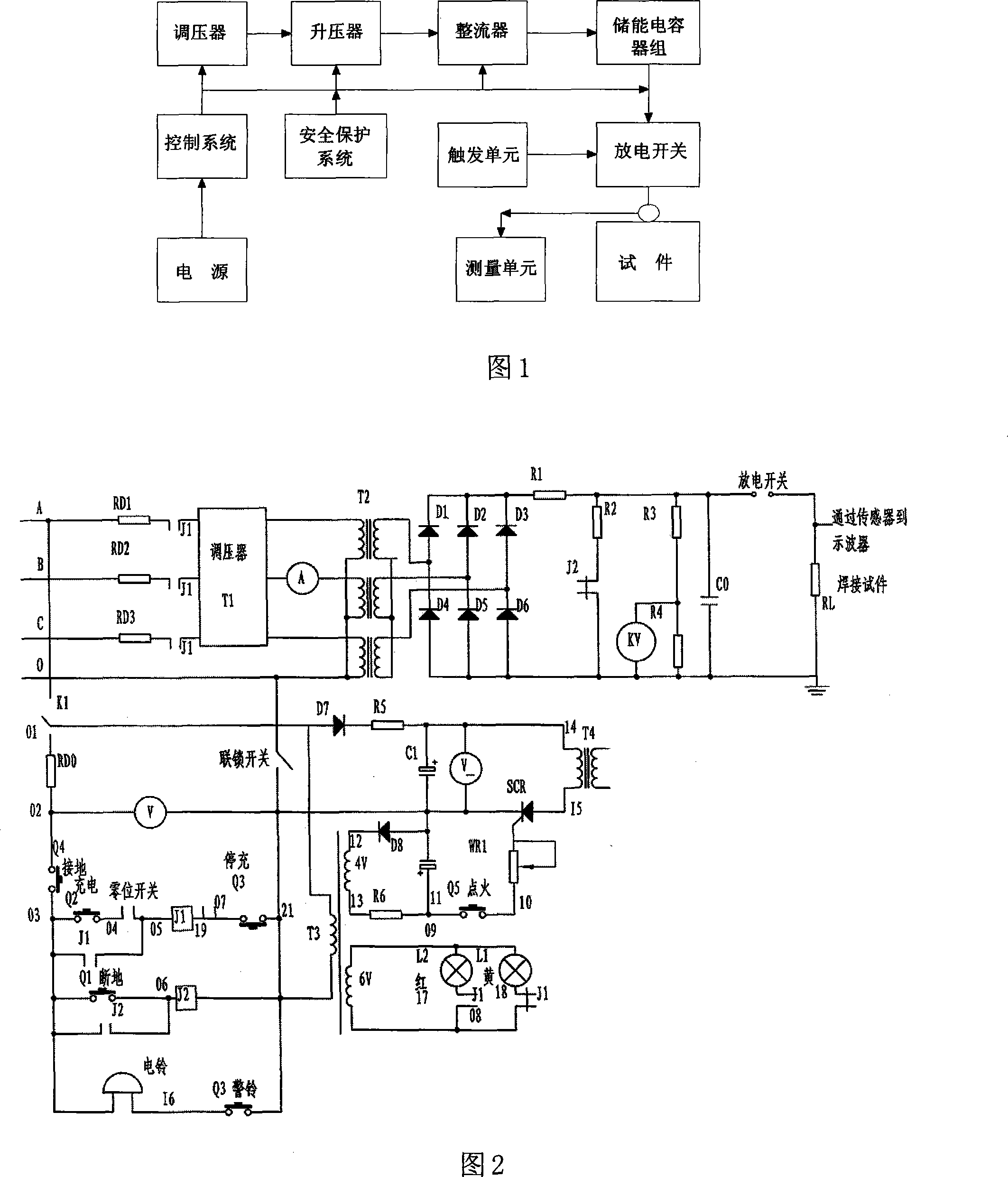

Electromagnetic thermal effect welding seam crack arresting and soldering structure strengthening device

InactiveCN101215630AInhibition of cracking tendencyImprove the extension functionHigh pressure pulseVoltage

The invention discloses an electromagnetic thermal effect weld metal crack arrest and welded structure strengthening device, which comprises a boost pressure rectification unit, a high pressure energy storage unit and a pulse discharge unit, wherein two outputted terminals of pulse discharge unit are connected with components of the welded structure through fasteners. The welded structure weld metal cracking and structure strengthening are realized through adopting the method of instant high pressure pulse discharge, the surface of an electrode is tightly applied with the surface of welded structure and a crossing type positive electrode and negative electrode is formed towards a weld seam when the electrode is fixed on the components of the welded structure through a fastener, and basic parameters such as discharge voltage and discharge time and the like are analyzed and determined through applying numerical modeling or theoretical analysis. The electromagnetic thermal effect weld metal micro-crack arrest and strengthening prevents the development of the micro-crack, realizes the ultra-fining of structures around the weld seam, removes residual stress in the weld seam, thereby achieving the purpose of strengthening and toughening of the welded structure. The invention simultaneously does not change the structure and property of a body without crack welded structure, and has the advantages of simple application method, instant finish, low cost and on-line strengthening repair and the like.

Owner:YANSHAN UNIV

Advanced multilayer dielectric cap with improved mechanical and electrical properties

InactiveUS7737052B2Improve antioxidant capacityImprove mechanical stabilitySemiconductor/solid-state device detailsSolid-state devicesDielectricMechanical stability

A dielectric cap, interconnect structure containing the same and related methods are disclosed. The inventive dielectric cap includes a multilayered dielectric material stack wherein at least one layer of the stack has good oxidation resistance, Cu diffusion and / or substantially higher mechanical stability during a post-deposition curing treatment, and including Si—N bonds at the interface of a conductive material such as, for example, Cu. The dielectric cap exhibits a high compressive stress and high modulus and is still remain compressive stress under post-deposition curing treatments for, for example: copper low k back-end-of-line (BEOL) nanoelectronic devices, leading to less film and device cracking and improved reliability.

Owner:ADVANCED MICRO DEVICES INC +2

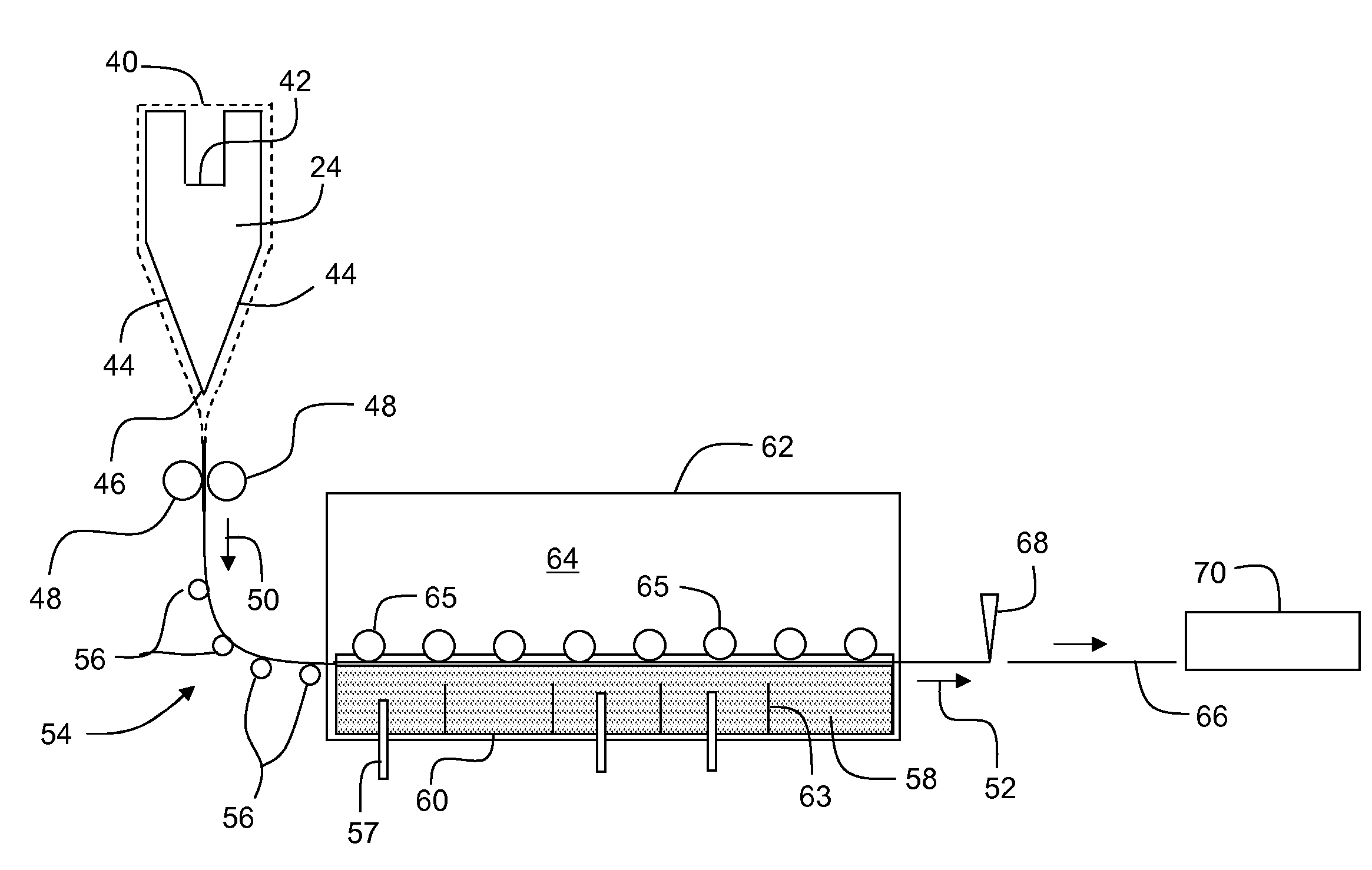

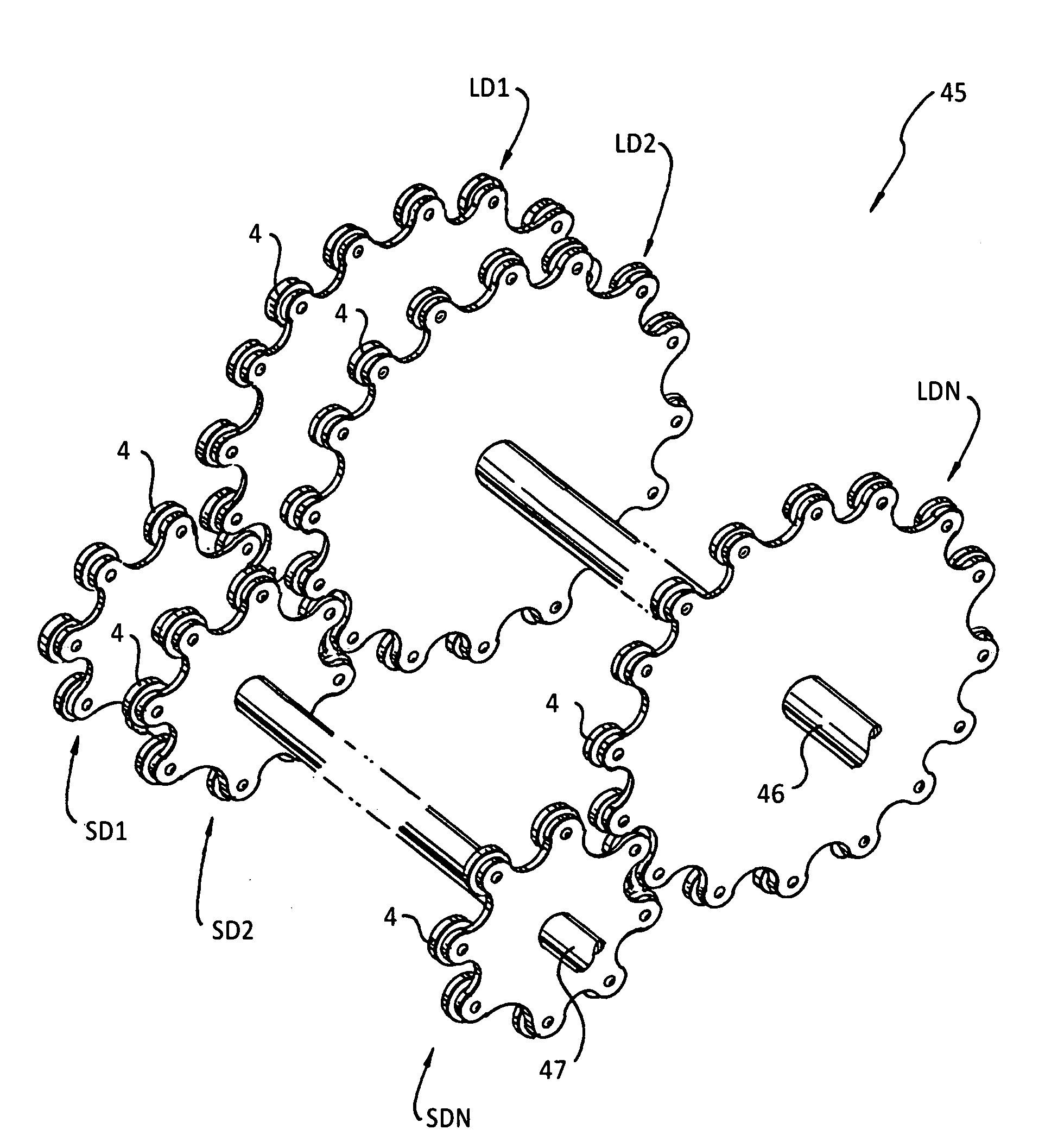

Bearing tooth gears for wind turbine applications

InactiveUS20090048051A1Reduce maintenance costsReduce replacement costsEngine fuctionsToothed gearingsGear driveDrive shaft

A horizontal axis wind turbine includes a vertically extending tower 117 having a rotatable long shaft 121. A bottom end of the long shaft drives an electric generator 122 and a top end of the long shaft is connected to a power output gear assembly of a bearing tooth angle drive 120. The power output gear assembly is engaged with a power input gear in the bearing tooth angle drive 120. The power input gear is connected by a drive shaft 86 through a preferably planetary gear drive 119 to blades 106 of a wind turbine to receive power from the wind turbine and to deliver torque to the long shaft 121 to drive the generator 122. The planetary gear teeth preferably have flat surfaces providing contact with related gear teeth.

Owner:KOLEOGLOU ALEX

Technique for forming an isolation trench as a stress source for strain engineering

InactiveUS20070155121A1Increase compressive stressEfficient stress engineeringSemiconductor/solid-state device detailsSolid-state devicesIon bombardmentEngineering

By forming a non-oxidizable liner in an isolation trench and selectively modifying the liner within the isolation trench, the stress characteristics of the isolation trench may be adjusted. In one embodiment, a high compressive stress may be obtained by treating the liner with an ion bombardment and subsequently exposing the device to an oxidizing ambient at elevated temperatures, thereby incorporating silicon dioxide into the non-oxidizable material. Hence, an increased compressive stress may be generated within the non-oxidizable layer.

Owner:GLOBALFOUNDRIES INC

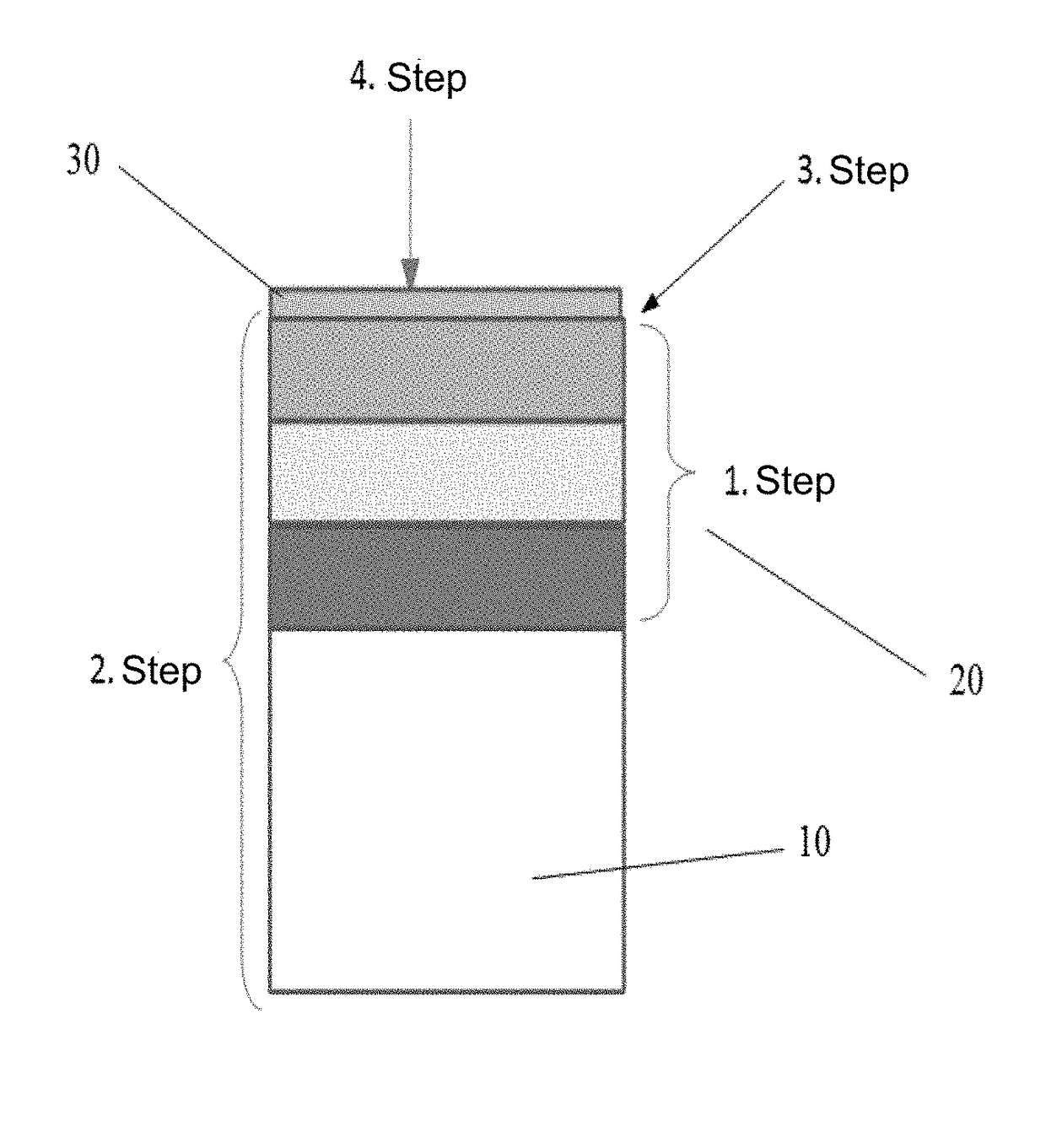

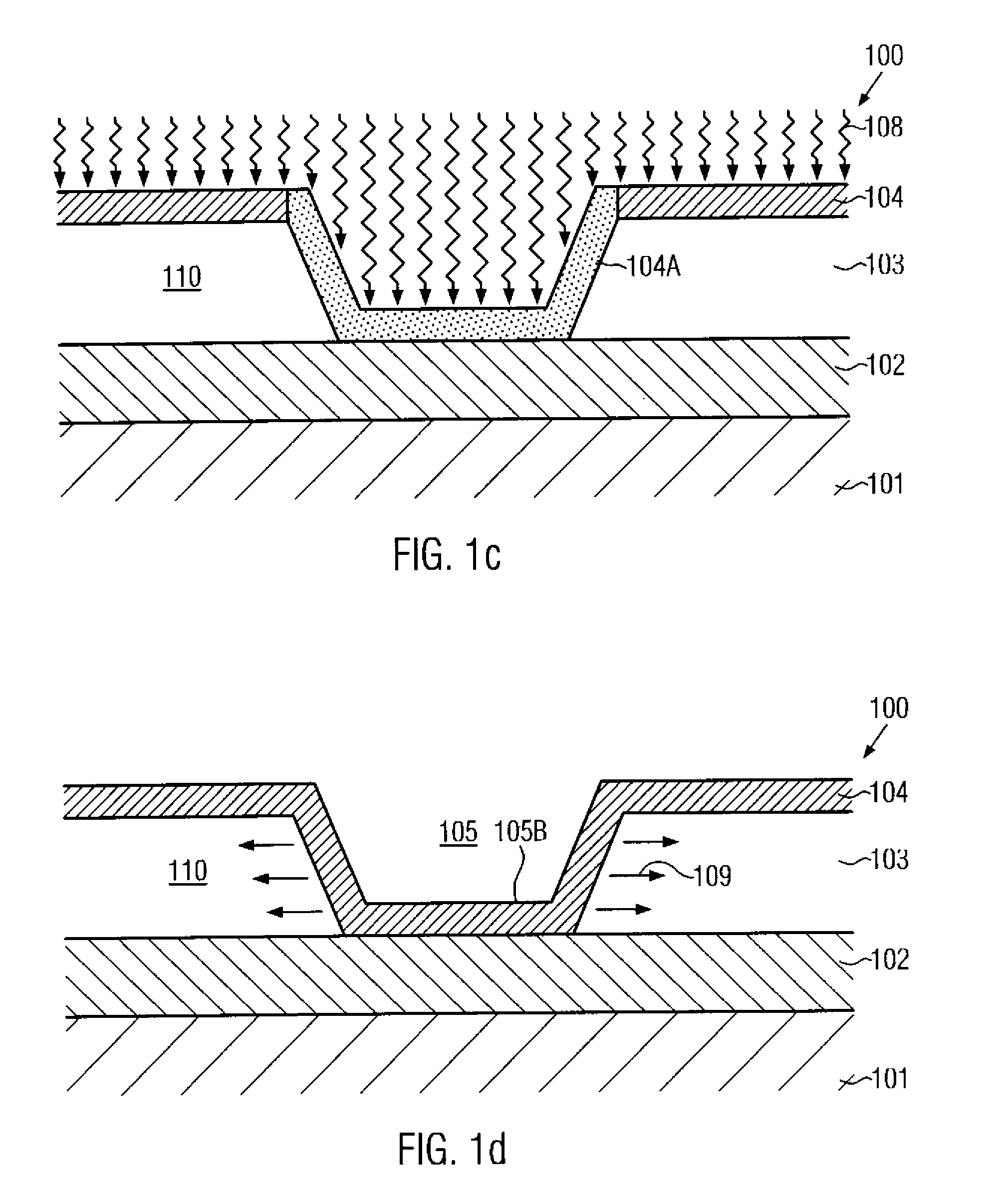

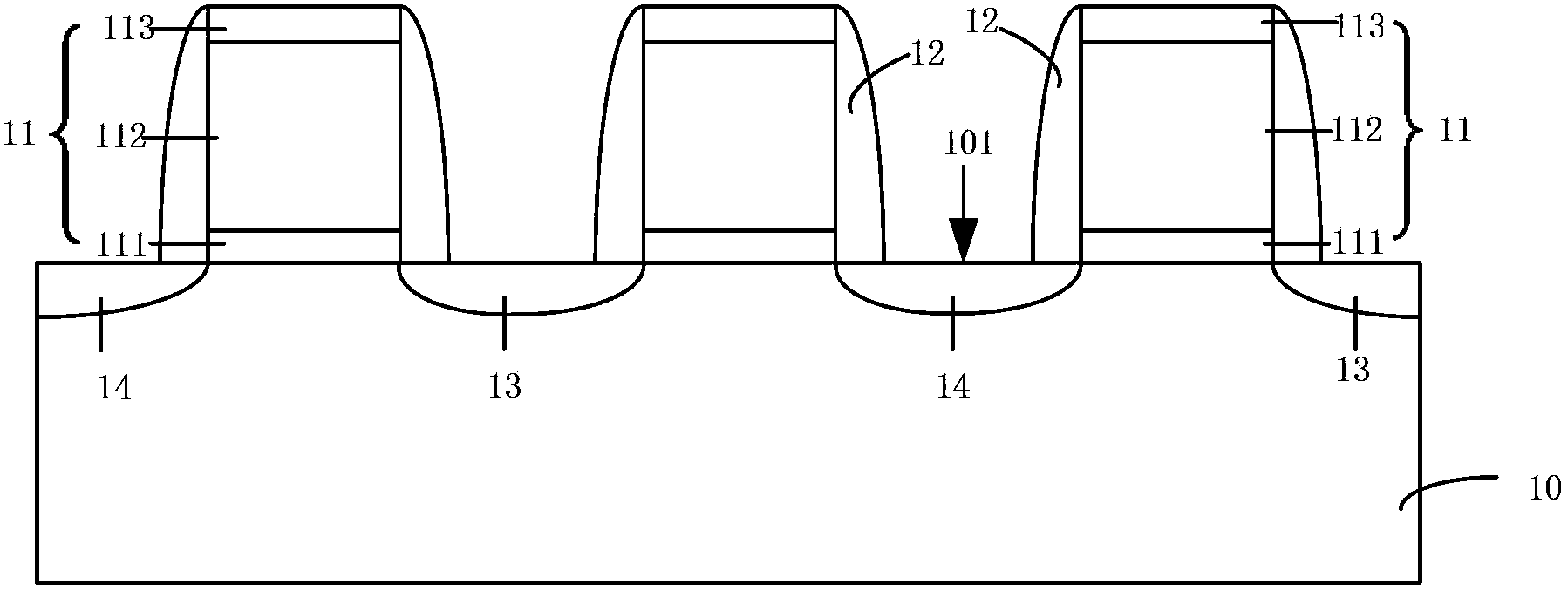

Manufacturing method for PMOS transistor and manufacturing method for NMOS transistor

ActiveCN104103515AIncrease compressive stressIncrease the tensile stressTransistorSemiconductor/solid-state device manufacturingEngineeringElectron

The invention provides a manufacturing method for a PMOS transistor and a manufacturing method for an NMOS transistor. According to the aforementioned manufacturing methods, multiple laminated sigma-shaped grooves (at least two), i.e. stepped sigma-shaped grooves, are formed in source electrode and drain electrode regions in a direction of being perpendicular to the surface of a silicon substrate. In the direction from the surface of the silicon substrate into the silicon substrate, the groove tip, which stretches into a channel, of each sigma-shaped groove presents to be away from the channel gradually. Then a) as for the PMOS transistor, silicon germanium material is filled in the stepped sigma-shaped grooves so that pressure stress is applied to the channel, b) and as for the NMOS transistor, silicon carbide material is filled in the stepped sigma-shaped grooves so that pulling stress is applied to the channel. Therefore, capacity of the stepped sigma-shaped grooves is larger, and more silicon germanium material or silicon carbide material can be accommodated. Correspondingly, pressure stress or pulling stress to the channel is increased so that migration rate of hole carriers or electron carriers is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Spin-valve magnetoresistive element having fixed magnetic layer of epitaxal laminate including magnetic layer and nonmagnetic layer

InactiveUS20050018363A1Easy to controlShunt loss can be decreasedElectrical transducersNanomagnetismCrystal structureMagnetic reluctance

Owner:TDK CORPARATION

Integration process for fabricating stressed transistor structure

ActiveUS7566655B2Defects are reducedIncrease compressive stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHigh stress

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

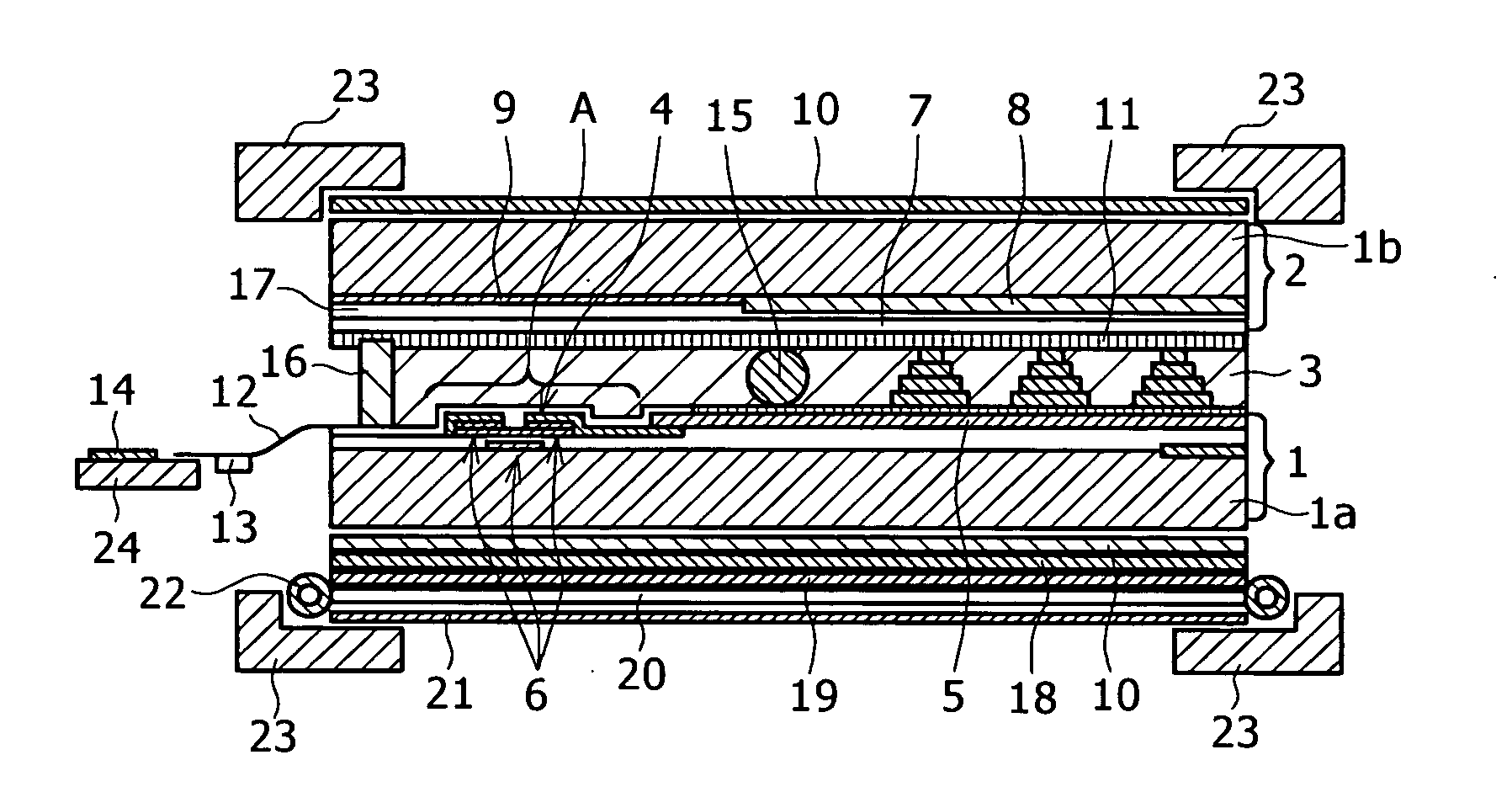

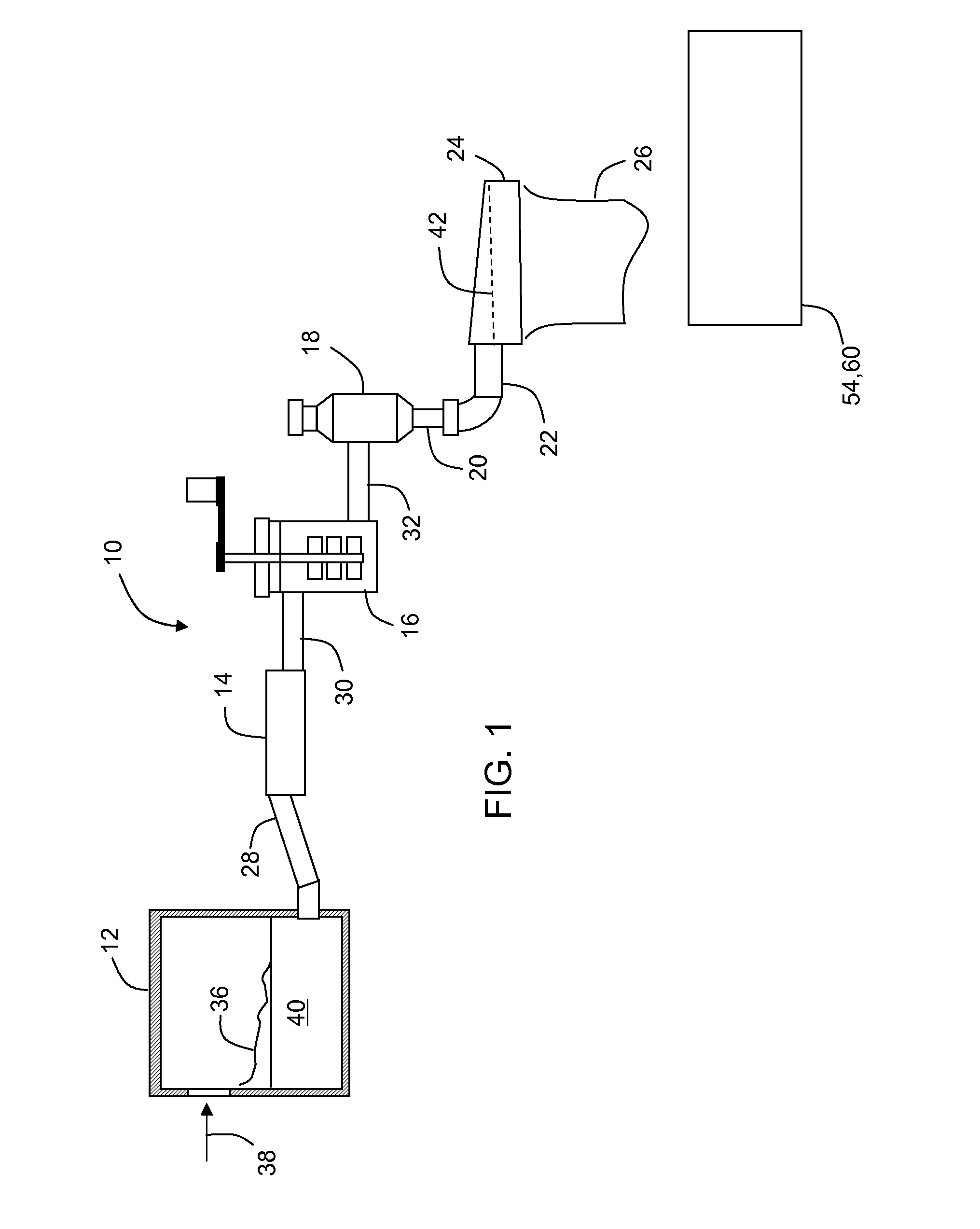

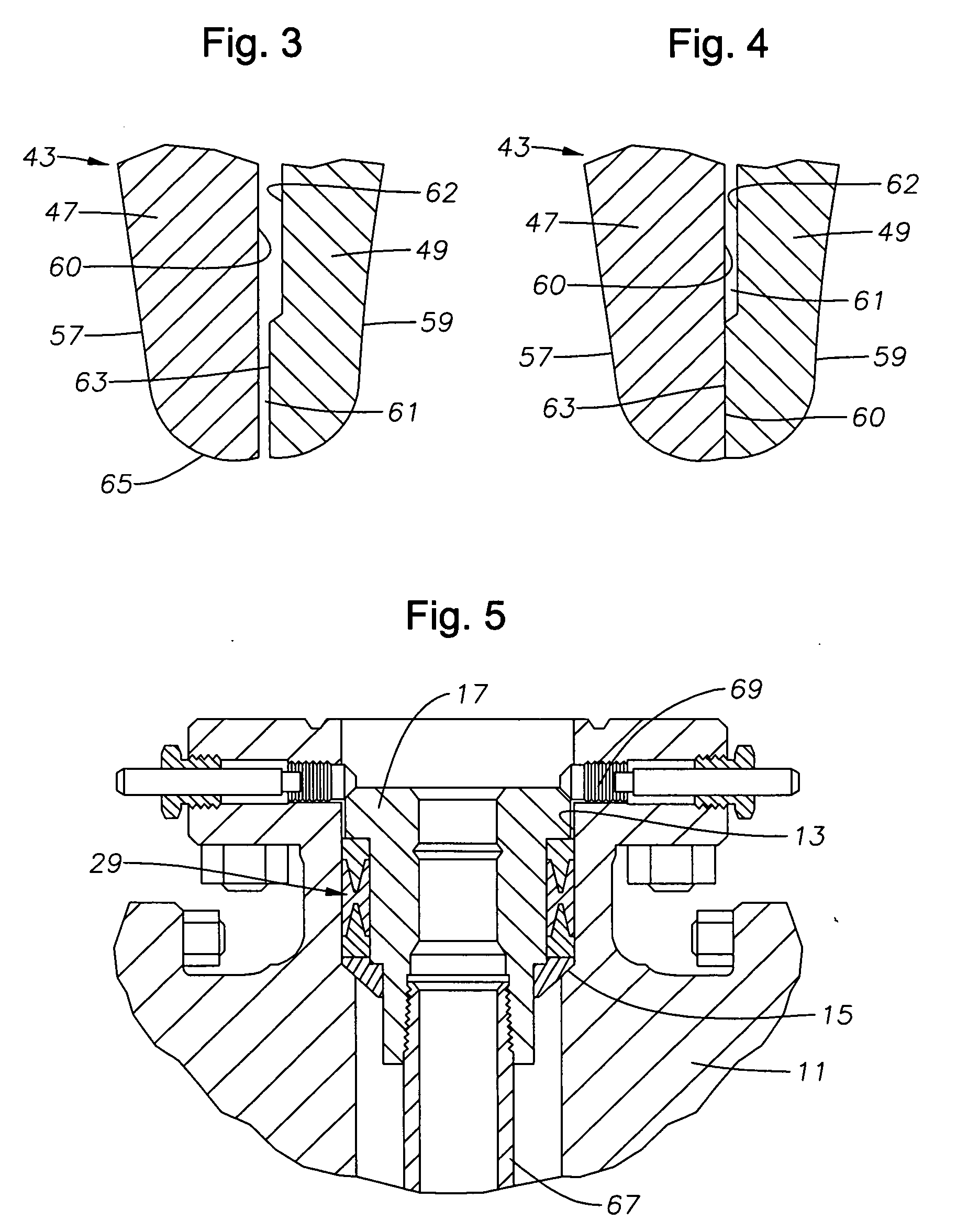

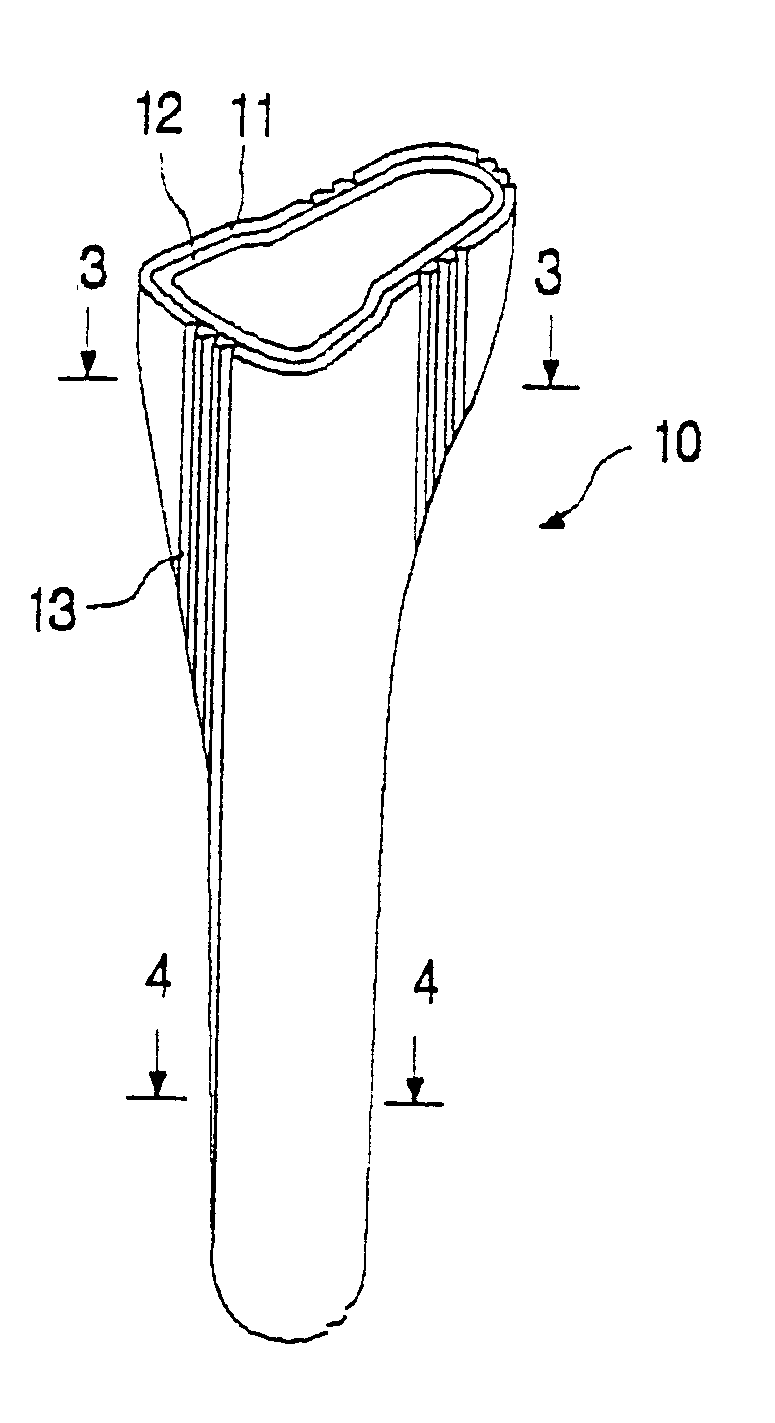

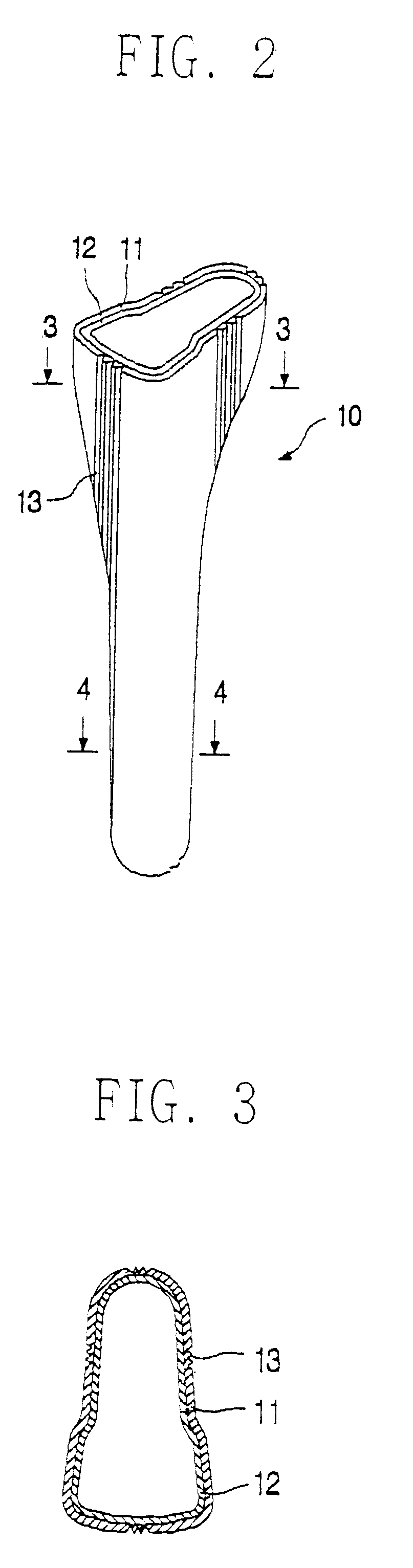

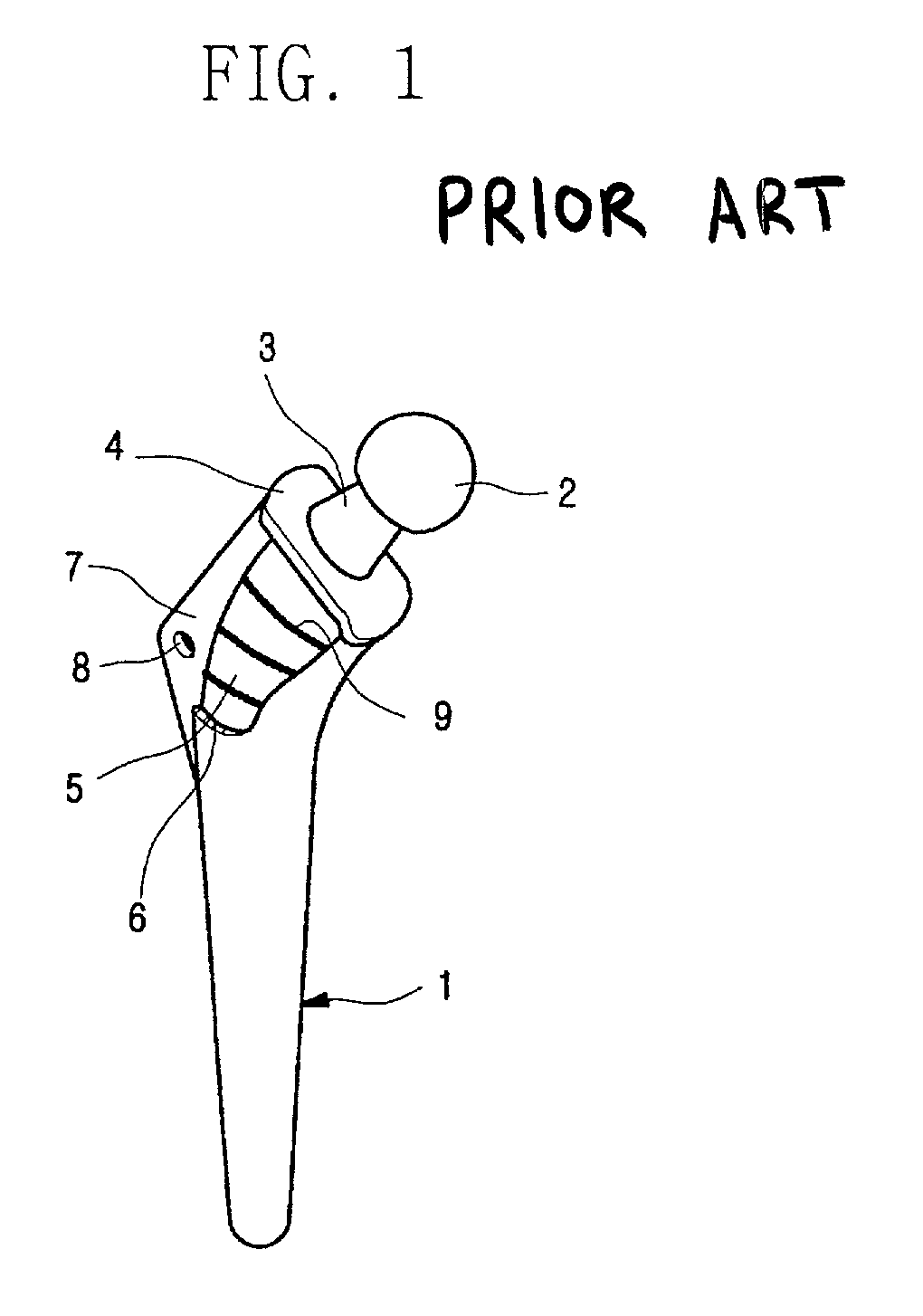

Cement jacket for a cemented artificial joint stem and artificial joint having the cement jacket

InactiveUS20010014828A1Increase anchorageEasy dischargeBone implantJoint implantsHigh resistanceFiber

The present invention relates to a cement jacket for a cemented artificial joint stem, wherein shear force detrimental to the service life of an artificial joint can be markedly reduced while the compressive force beneficial for the strengthening of the bone is significantly increased and stress shielding phenomena which makes the bone resorbed can also be markedly relieved, due to the construction of the cement jacket which can be fixed within the bone canal and can enclose the surface of the stem so as to allow for the artificial joint stem to slide vertically relative to the bone, and wherein the osteolysis of a femur due to the infiltration of wear particle can be minimized by curbing the gap formation between the femur and the stem. According to the invention, there is provided a cement jacket 10 for an artificial joint stem 21 for enclosing at least a part of the cemented artificial joint which is inserted longitudinally in the opening formed in the bone canal of a human body. The cement jacket 10 may be made of all cement, or the inner surface of said jacket of cement is coated with a plastic film 12 having a high resistance to abrasion. The cement jacket itself could be reinforced by imbedded wire or fiber. And preferably the outer surface of said cement jacket 10 is formed with discharging paths 13 in the longitudinal direction, so that excessive cement paste poured into the bone canal previously for the surgical purpose can be easily discharged upward at the time of inserting the jacket. (FIG. 2).

Owner:KOREA ADVANCED INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com