Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

332results about How to "Increase the tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

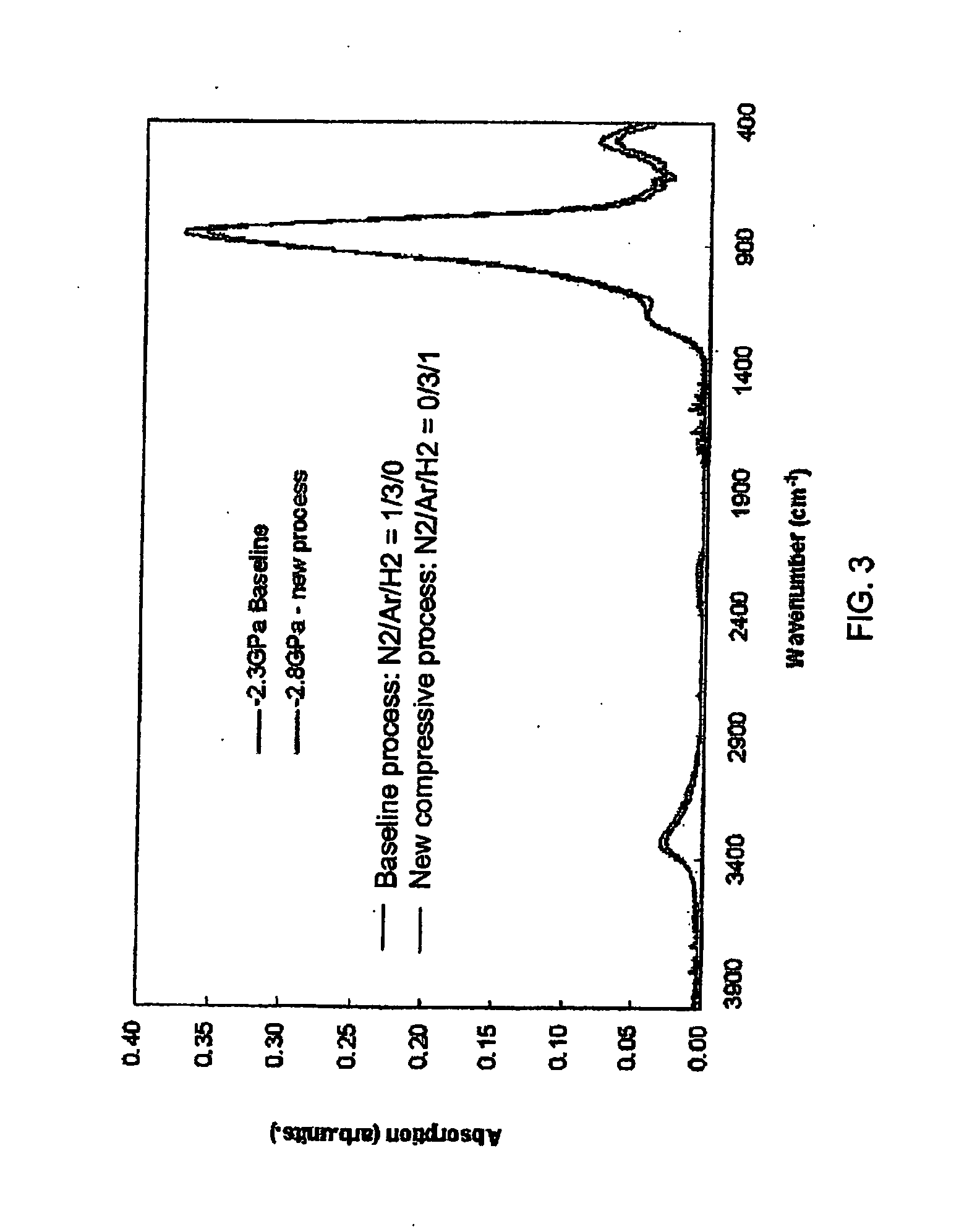

High stress nitride film and method for formation thereof

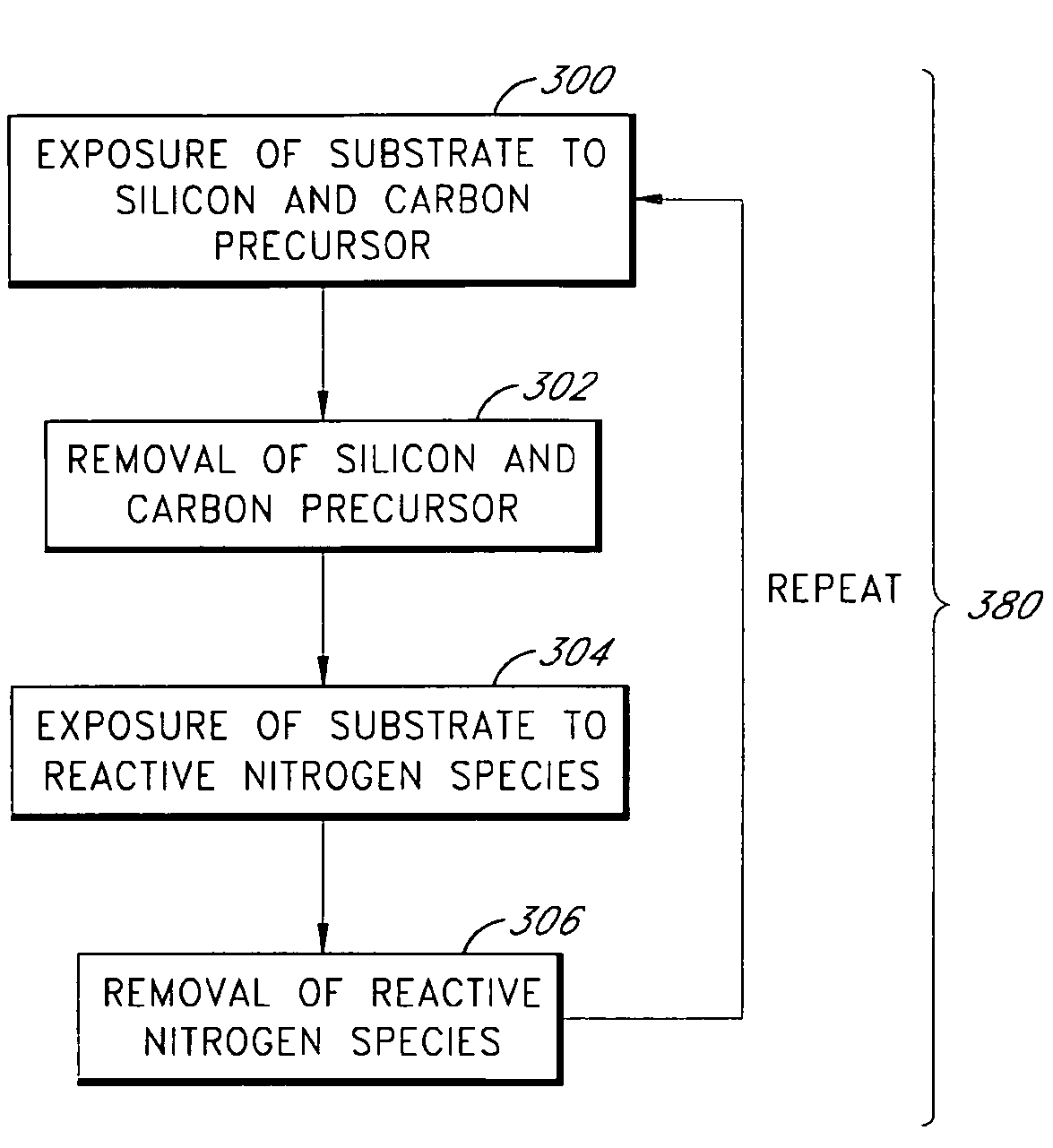

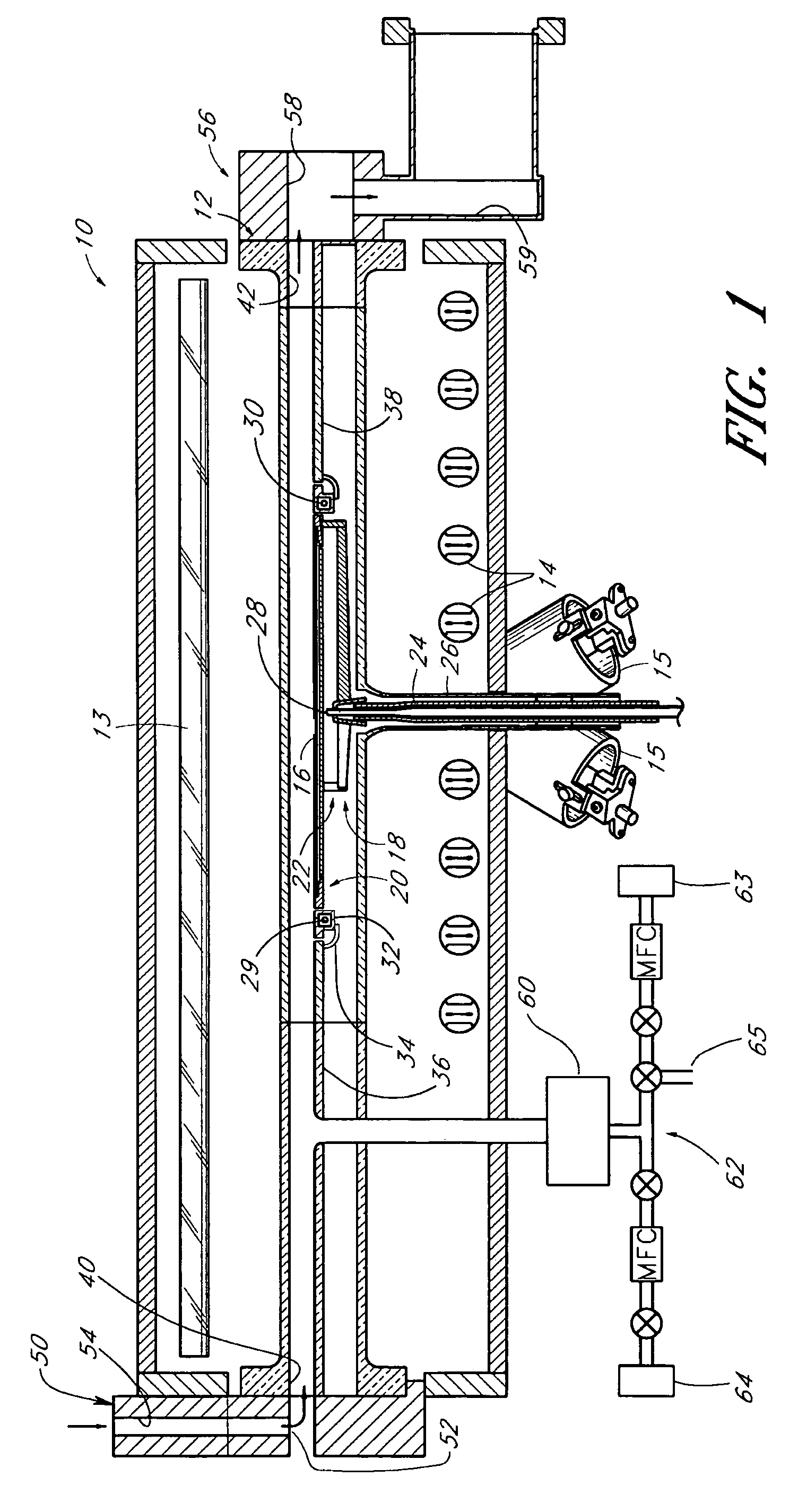

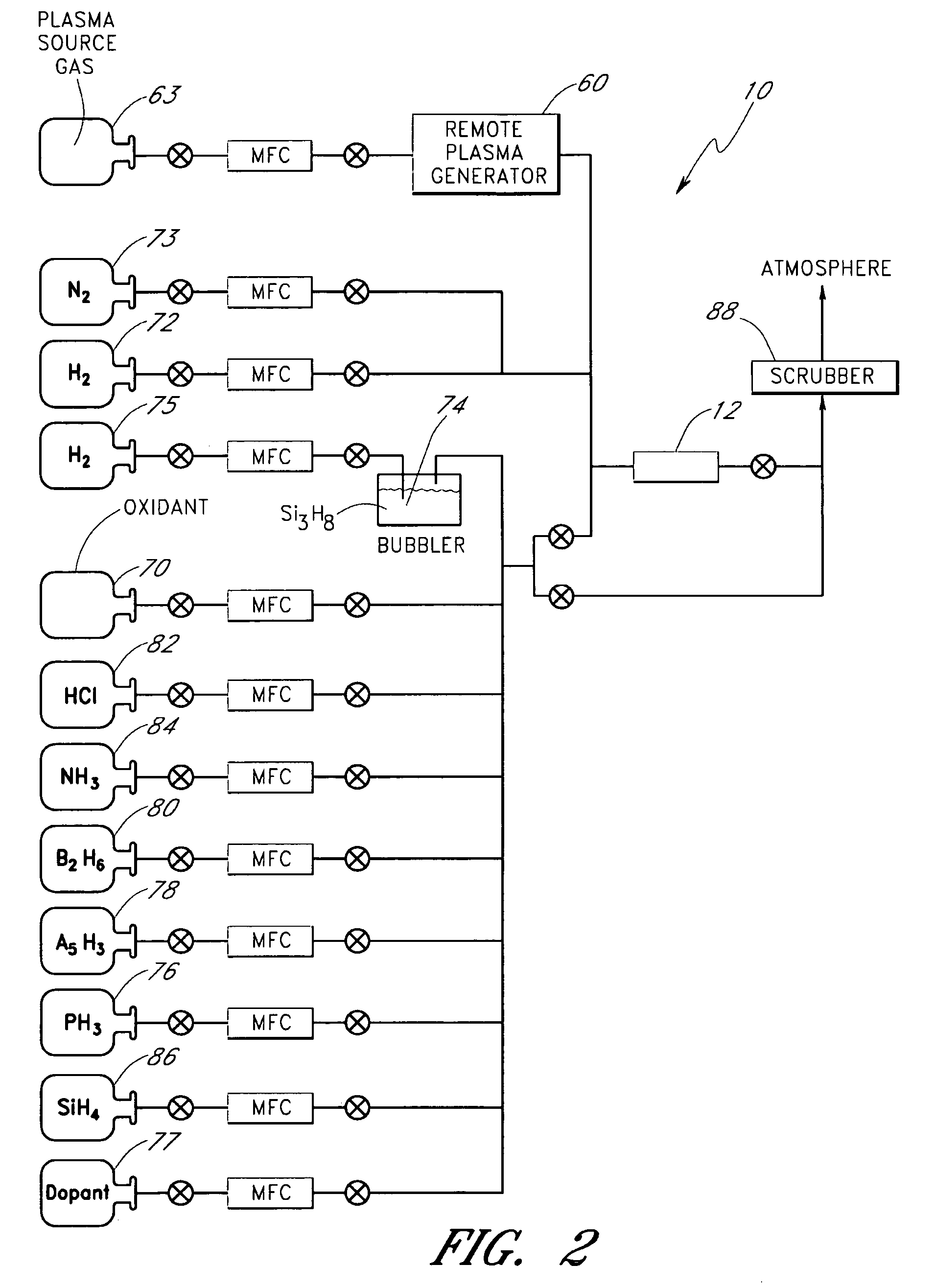

ActiveUS7629267B2Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

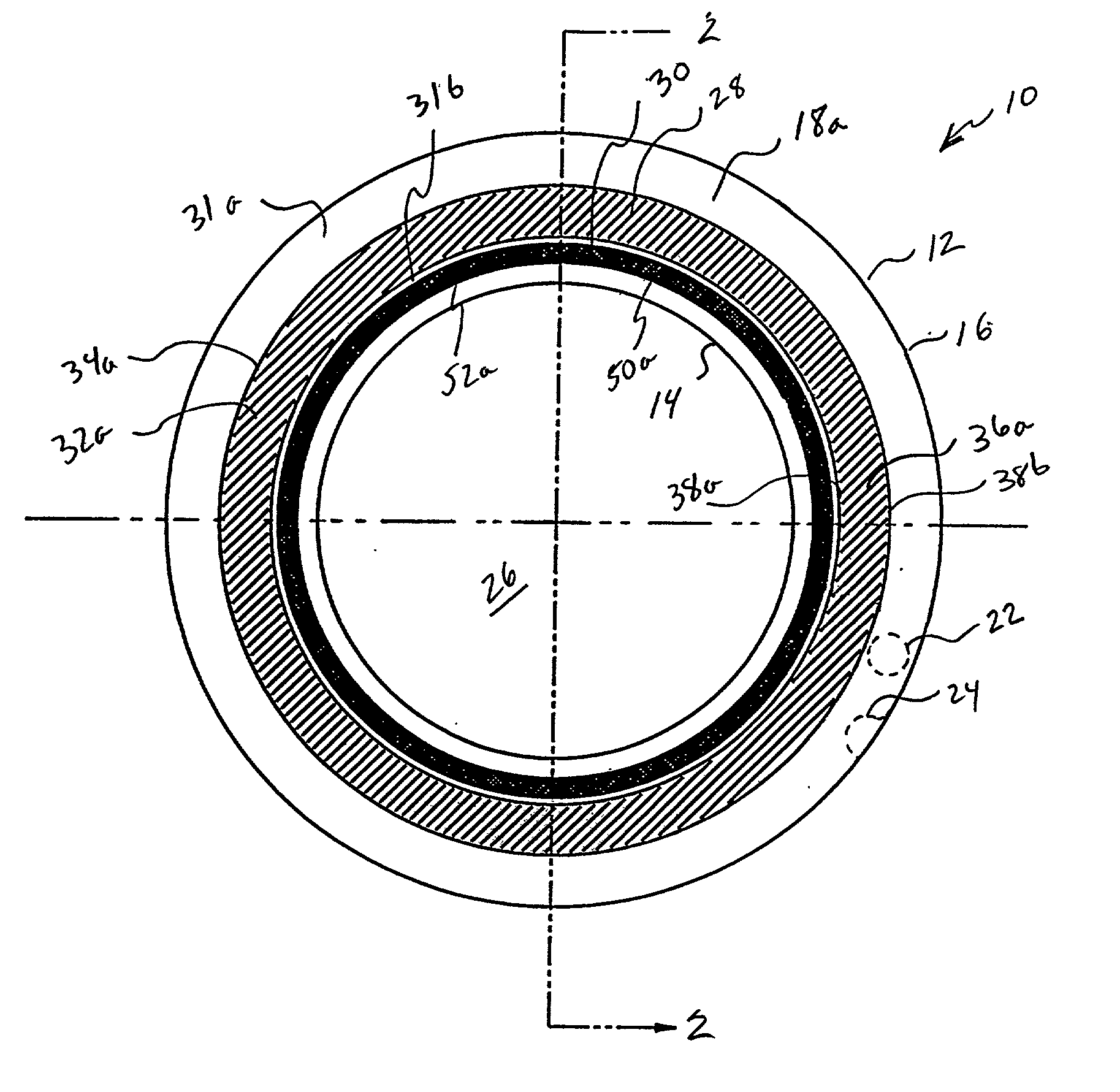

"flame resistant pipe flange gasket"

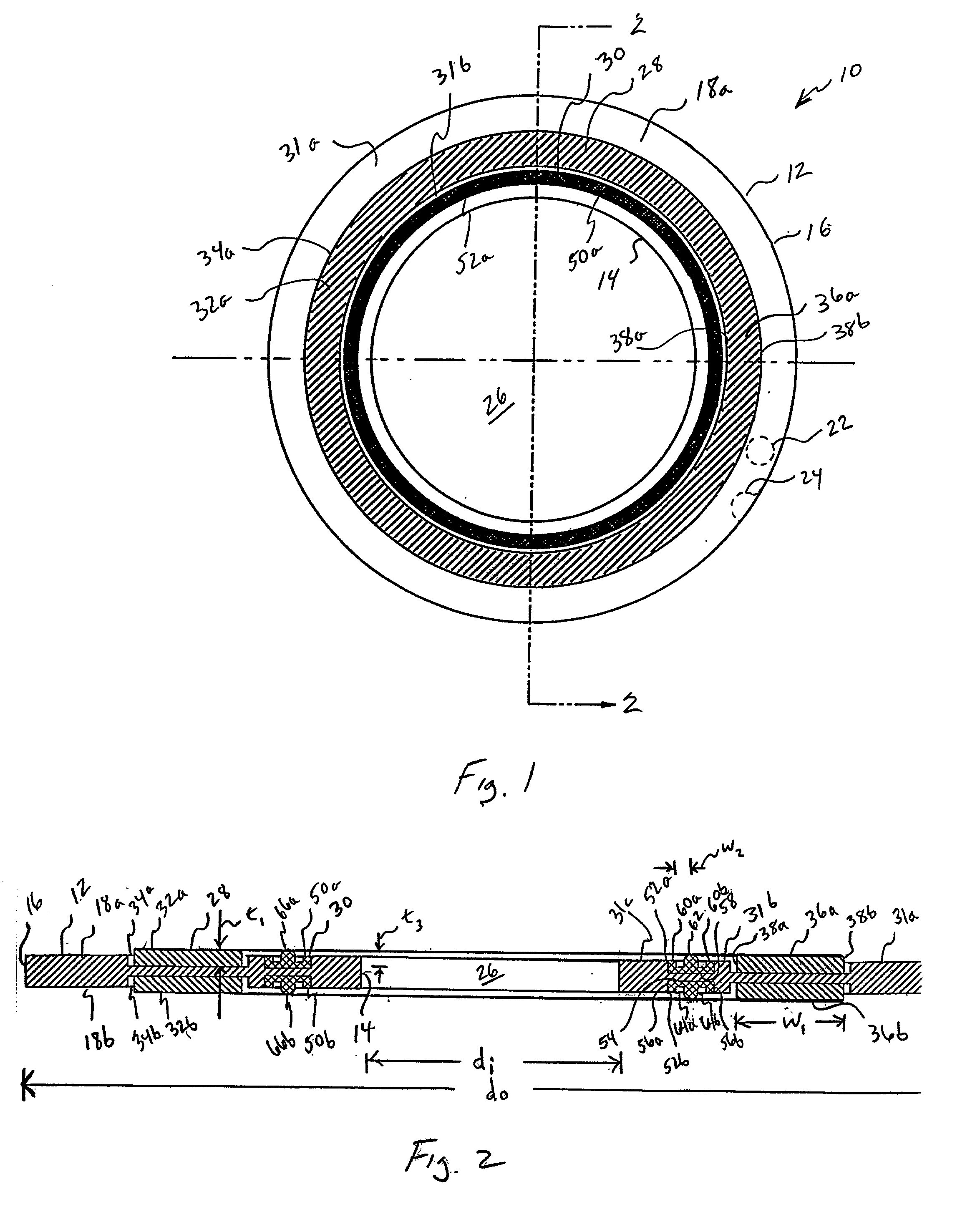

InactiveUS20020030326A1Increase the tensile stressMinimum of torque lossSleeve/socket jointsEngine sealsEngineeringFlange

A flame resistant gasket for interposition between the interface surfaces of a pair of mating pipe flanges. The gasket includes a metal retainer member having generally planar first and second surfaces with at least one aperture formed therethrough which is configured for generally coaxial registration with a fluid passageway defined through the pipe flanges. At least one generally annular, flame resistant outer seal member is supported on the retainer member as disposed coaxially with the aperture thereof a spaced-apart, radially outward distance therefrom. The outer seal member has oppositely-disposed first and second outer radial sealing surfaces for abutting contact with a corresponding one of the interfaces surfaces, and is compressible axially between the interface surfaces for effecting a first fluid-tight seal about the fluid passageway. At least one generally annular, elastomeric inner seal member optionally is attached to the retainer member as disposed coaxially with the aperture thereof radially inwardly of the outer seal member. The inner seal member has oppositely-disposed first and second inner radial sealing surfaces for abutting contact with a corresponding one of the interfaces surfaces, and is compressible axially between the interface surfaces for effecting a second fluid-tight seal about the fluid passageway.

Owner:PARKER HANNIFIN CORP

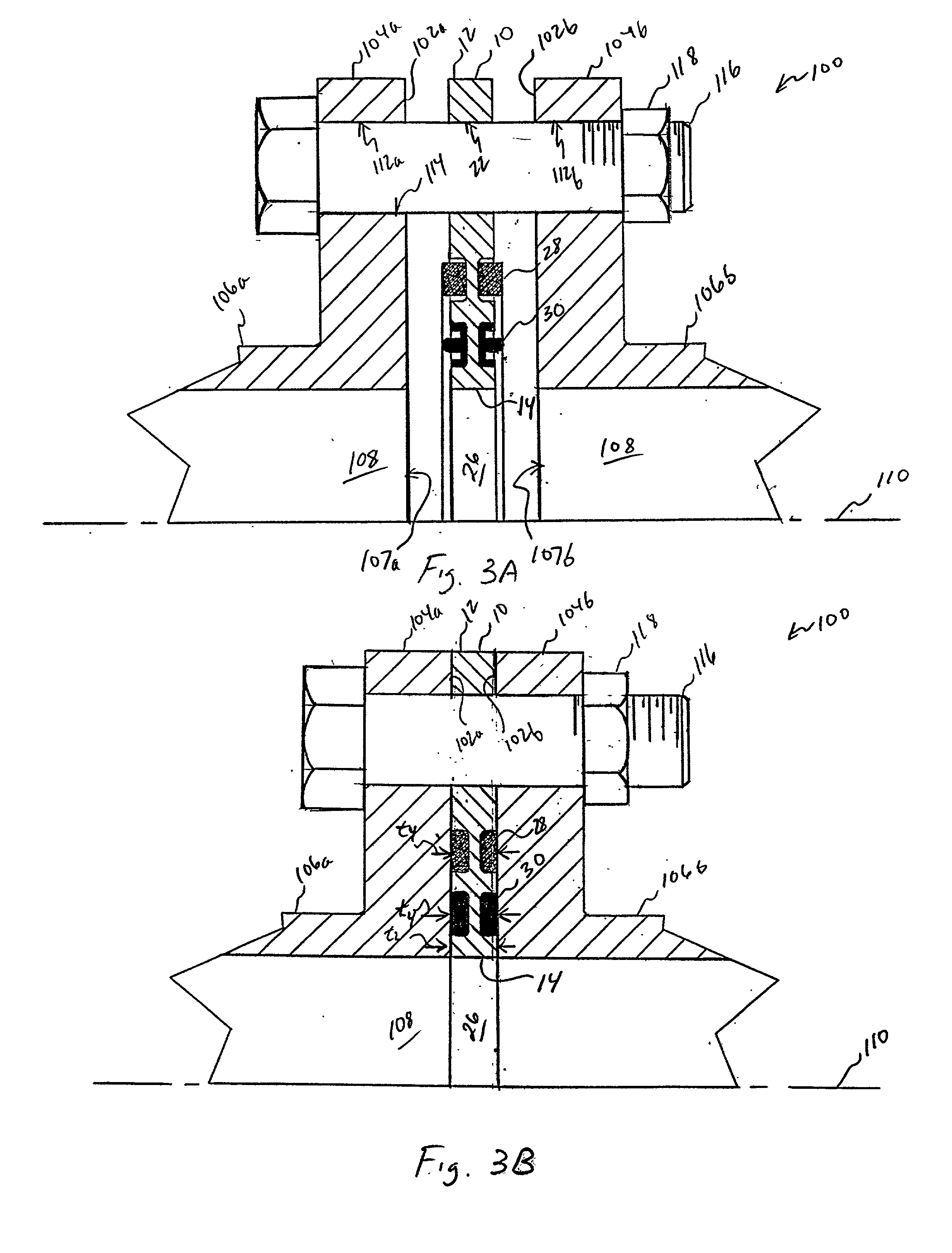

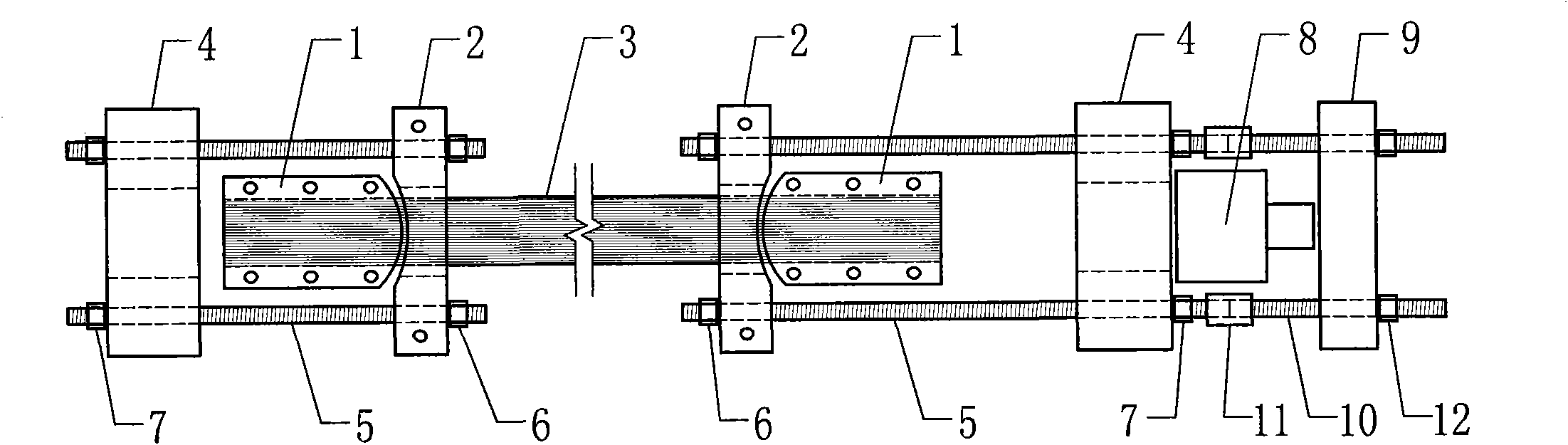

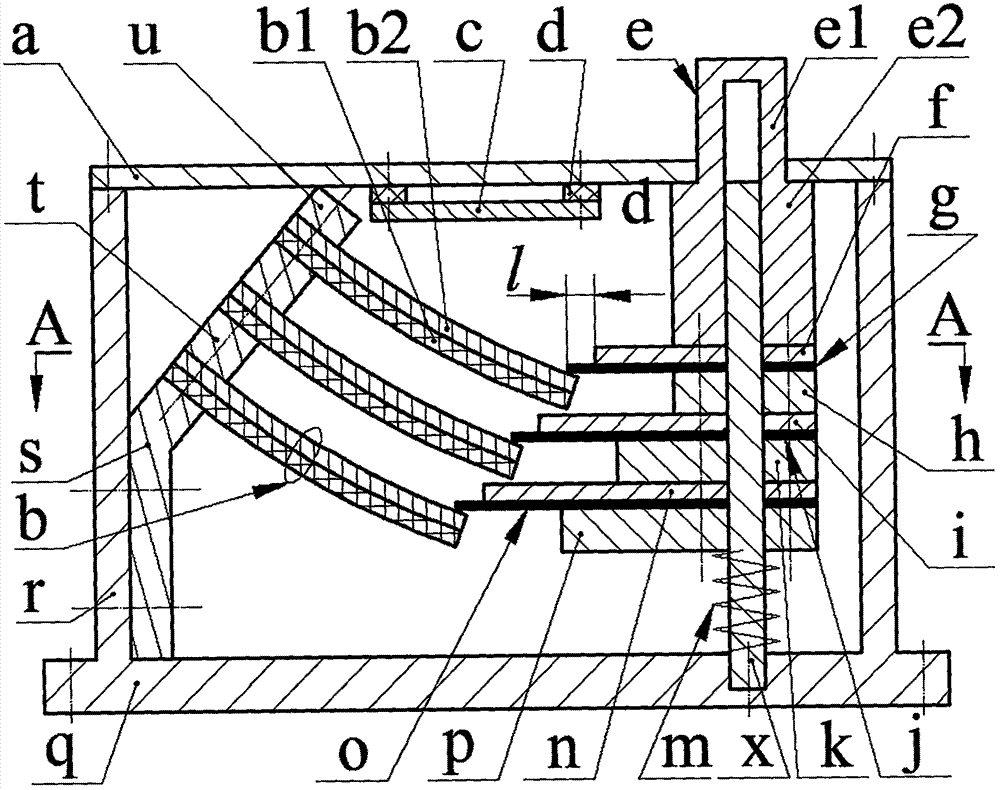

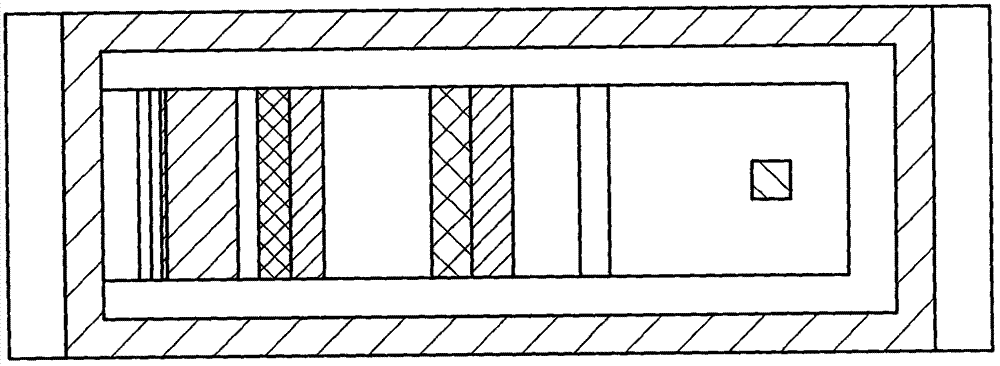

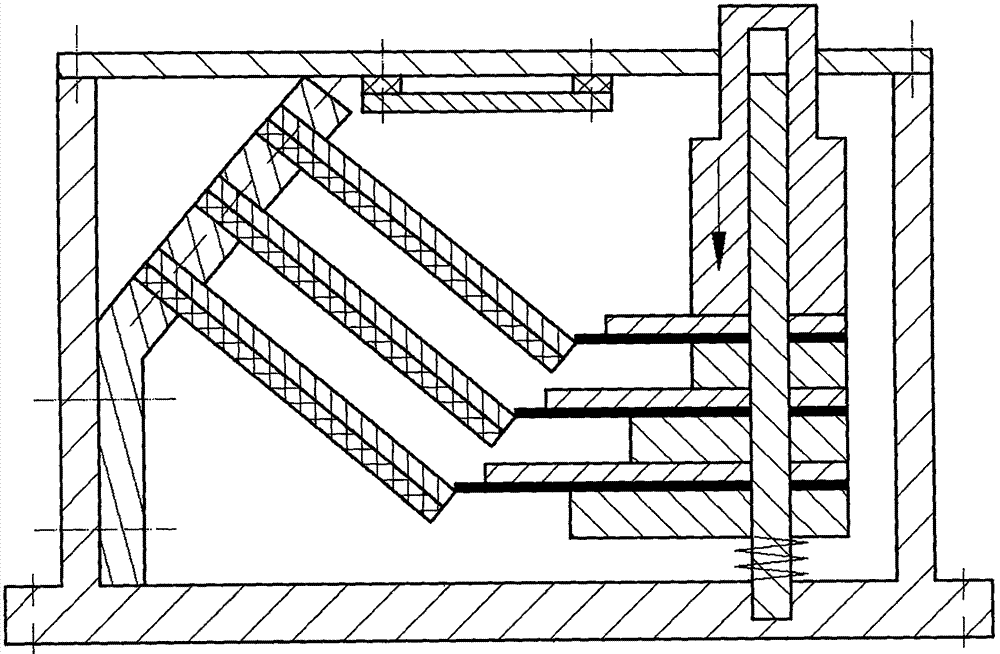

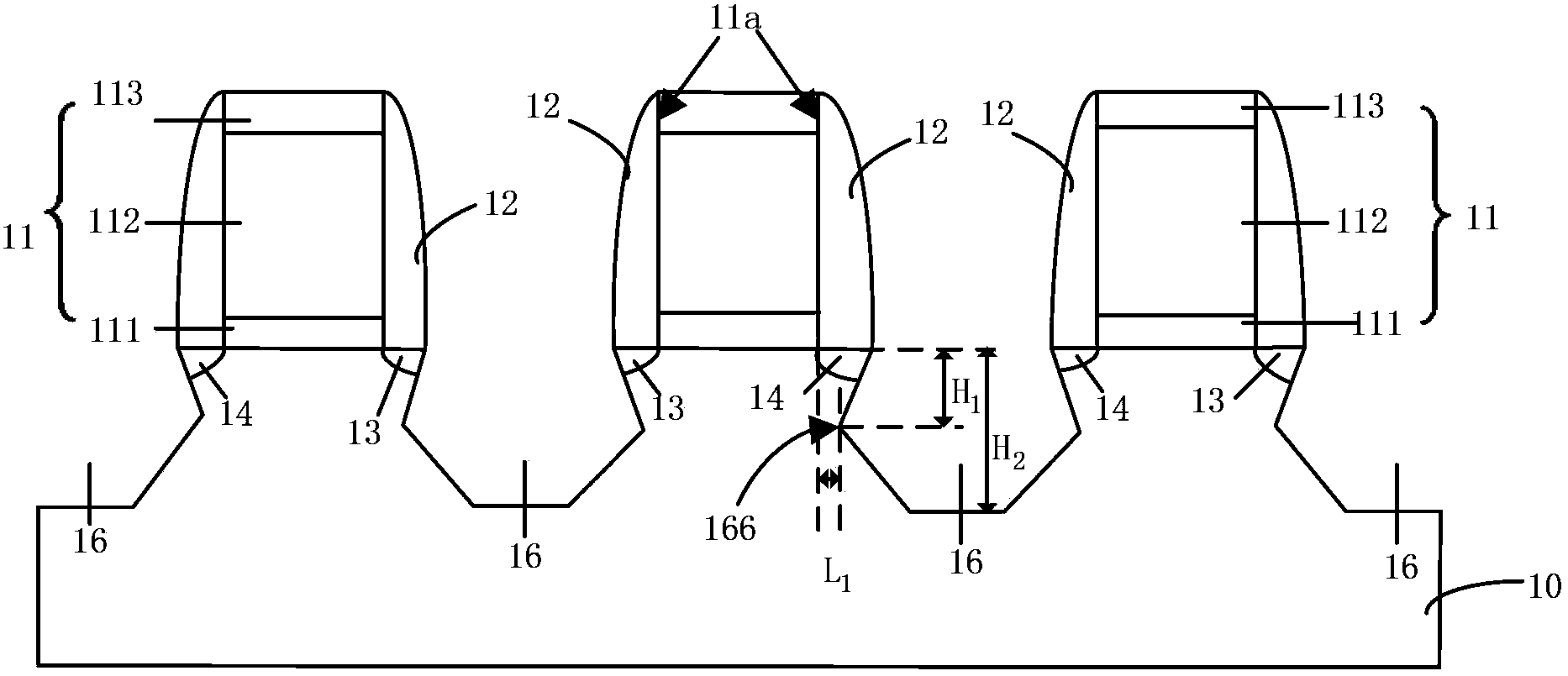

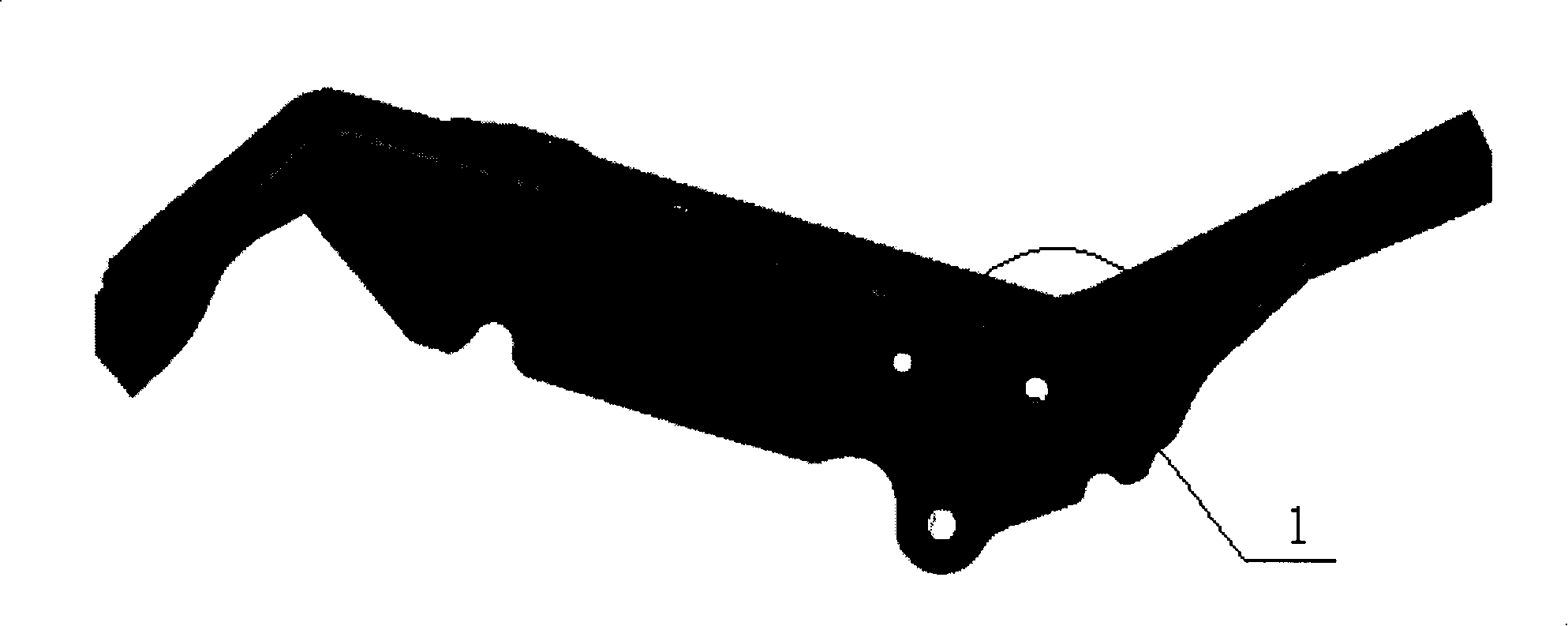

Articulated anchor and prestress tensioning method of high strength fibre composite sheet

ActiveCN101851985AGuaranteed automatic adjustmentGuaranteed uniformityBuilding reinforcementsBuilding material handlingFiberConcrete beams

An articulated anchor and a prestress tensioning method of high strength fibre composite sheet relate to an anchor holder used to perform prestress tensioning to the high strength fibre composite material of the enhancement or reinforcement engineering structure and a method thereof. The articulated anchor of the invention comprises an anchor head and a compression and locking device, and the articulated anchor is characterized in that the anchor head contains a raised head anchor and a concave block. The method of the invention is that the articulated anchor is used to clamp and anchor the two ends of FRP sheet, a jack is used to apply a tension on the concave block and the concave block pushes the raised head anchor to perform prestress tensioning to FRP sheet. The articulated anchor of the invention has simple structure, convenient installation and low cost; and the method of the invention is simple, intuitive and practical, and can ensure the tensioning uniformity of FRP sheet, made full use of the intensity of FRP sheet and effectively increase the bearing capacity of the engineering structure. The articulated anchor of the invention can be widely used to enhance or reinforce the large engineering structures such as bridges or buildings and especially to perform external prestressing reinforcement to longspan concrete beams, longspan concrete slabs and the like.

Owner:卓清

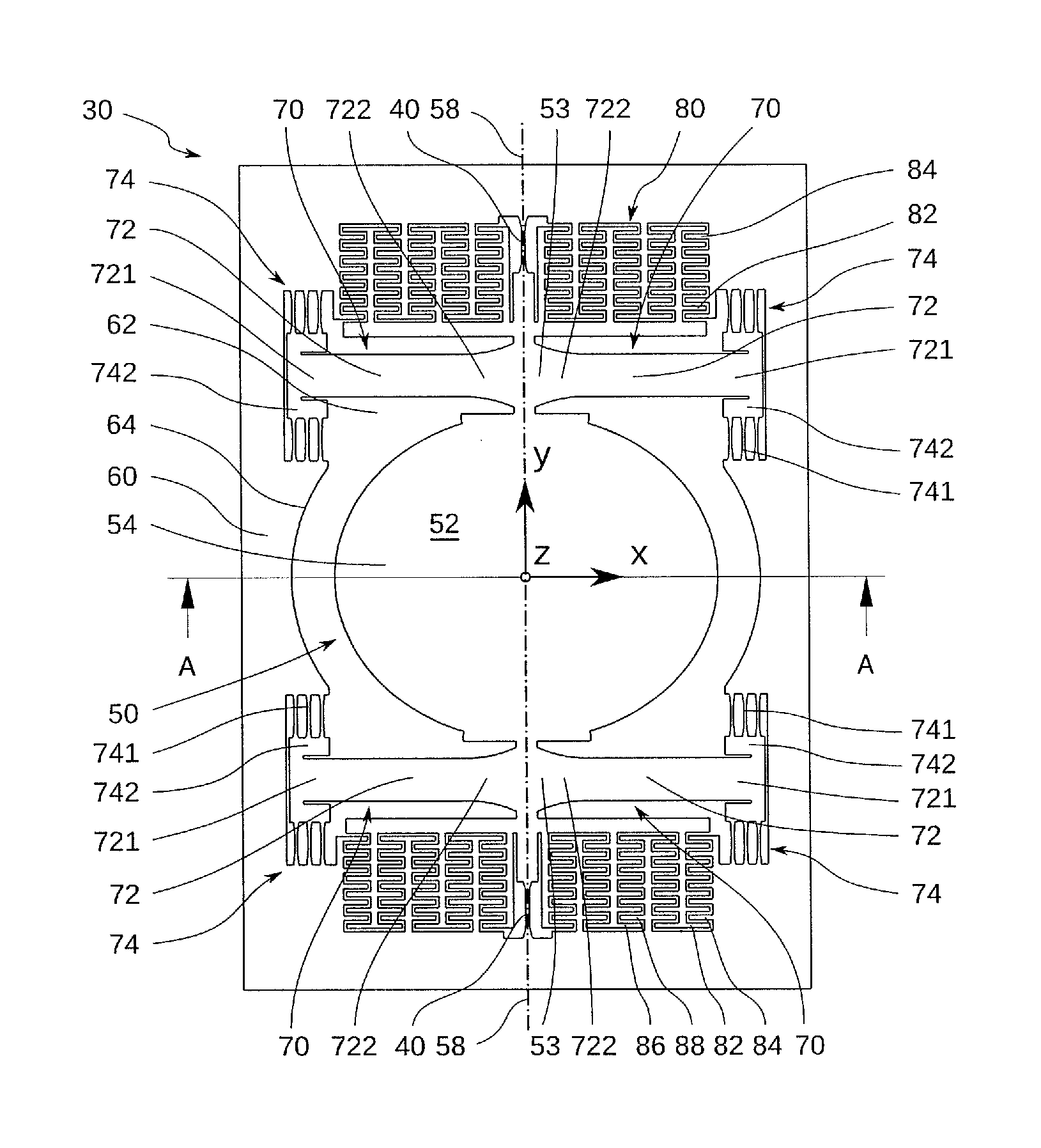

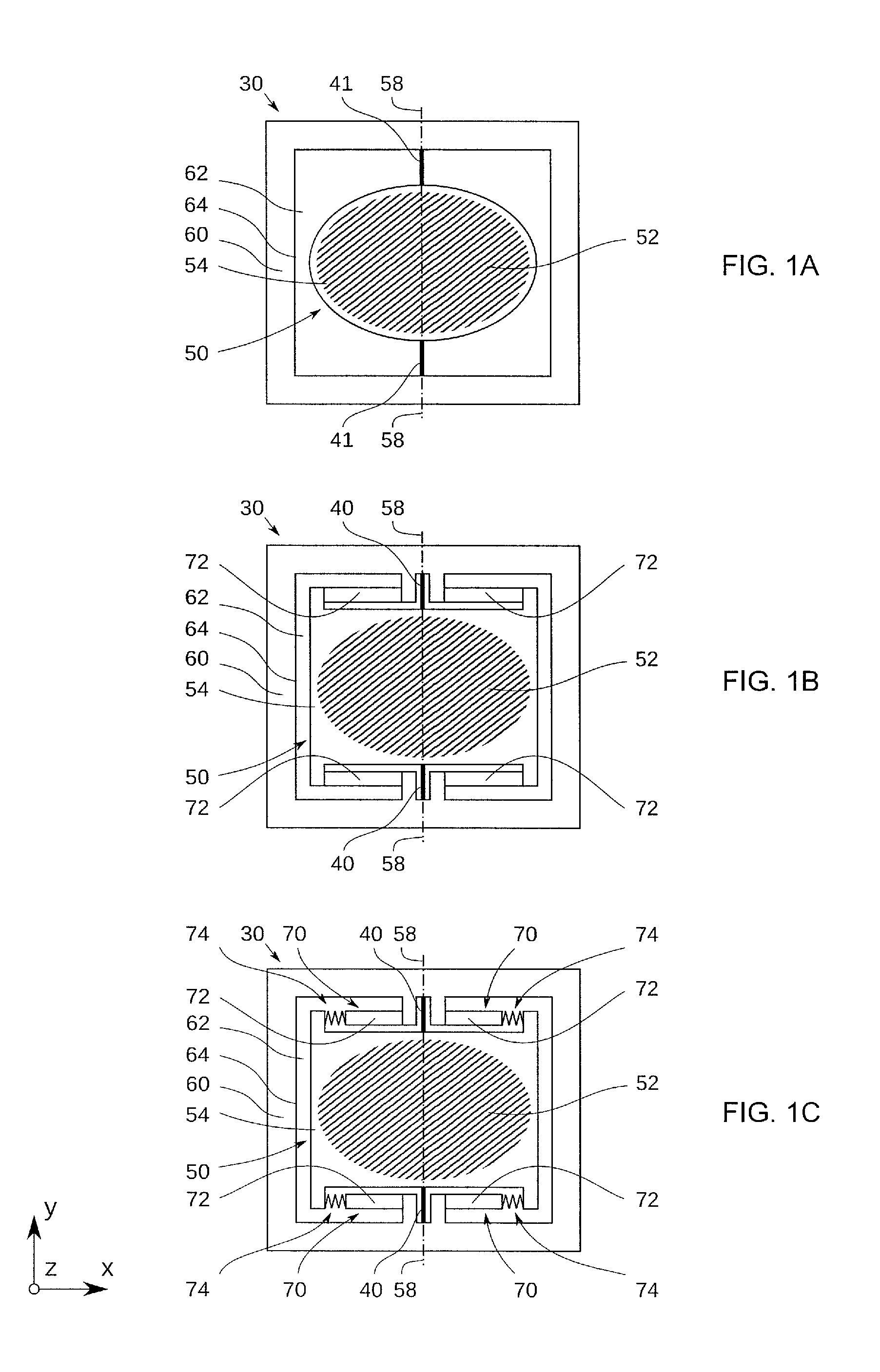

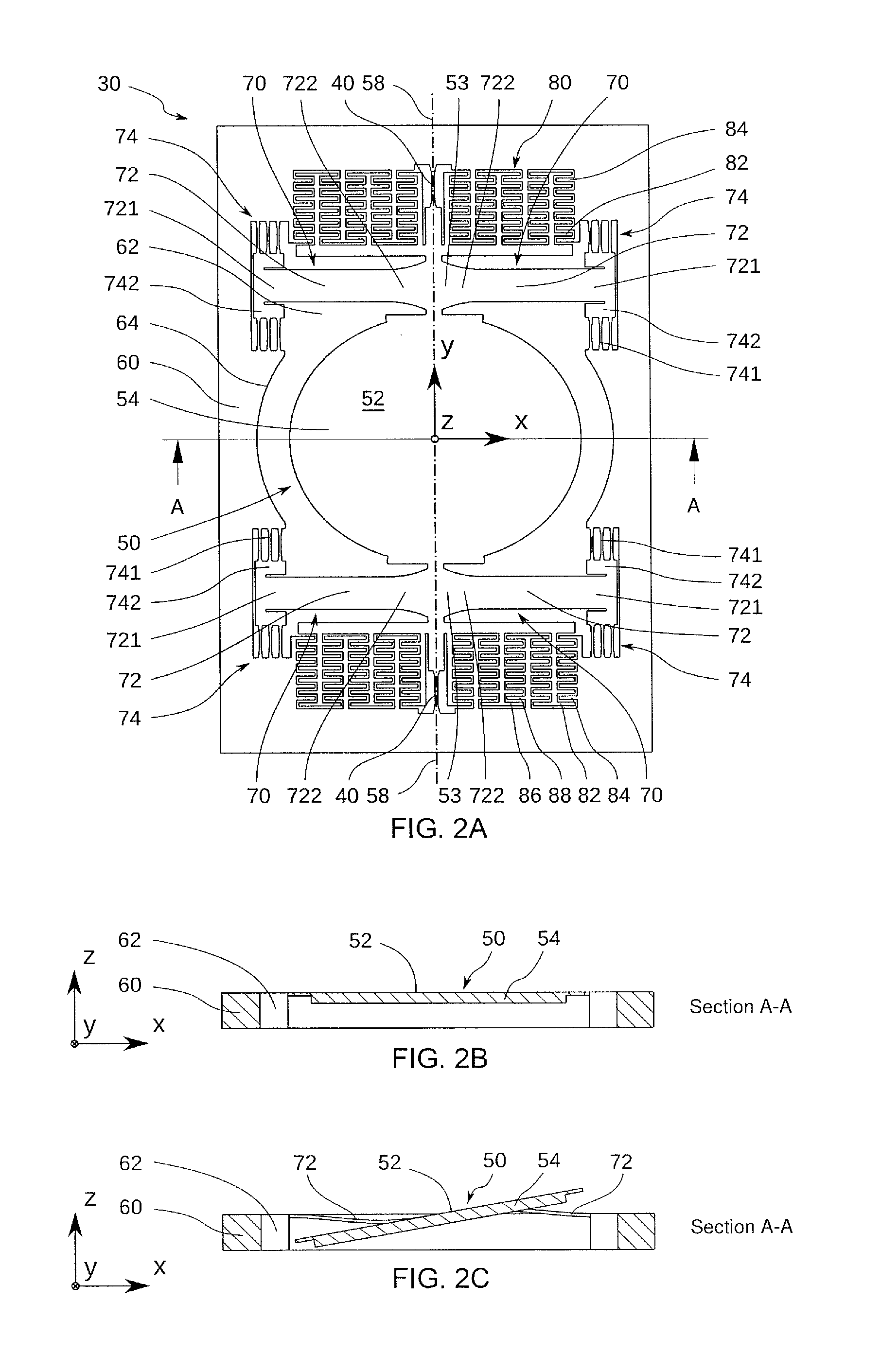

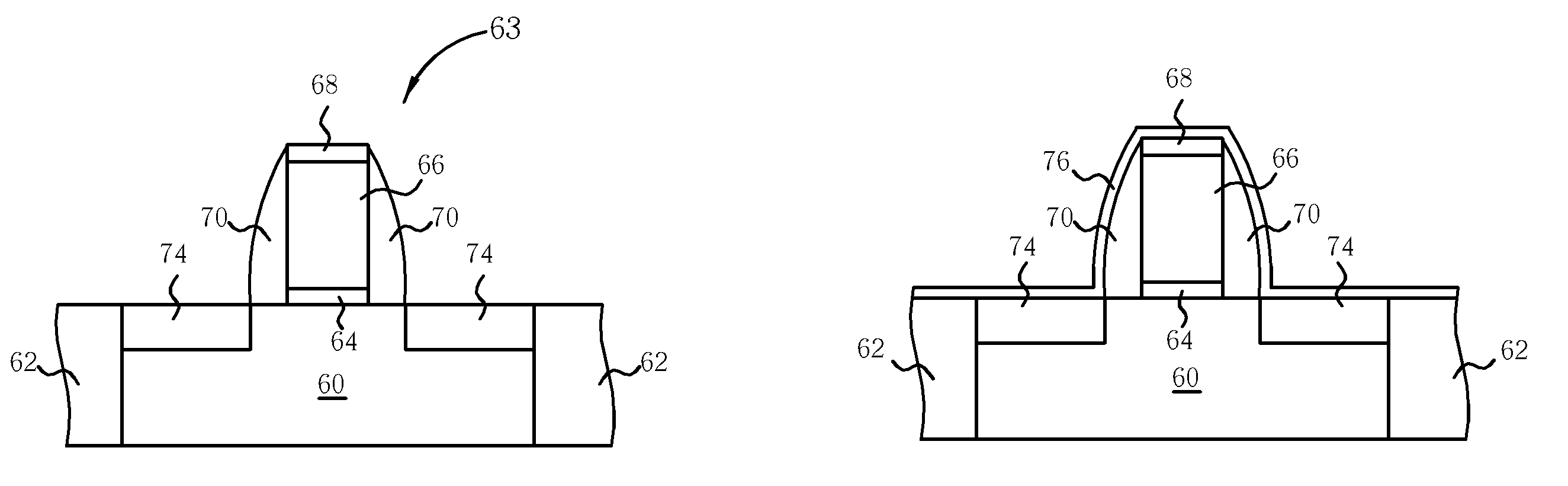

MEMS scanning micromirror

ActiveUS20140300942A1Negligible effectIncrease the tensile stressFlexible microstructural devicesOptical elementsEngineeringCantilever

A MEMS micromirror (30) is presented including a frame (60) with a mirror body (50) arranged therein. The mirror body (50) is rotatable around a rotation axis (58) extending in a plane (x-y) defined by the frame (60). The MEMS micromirror (30) further includes at least one cantilever beam assembly (70) having a longitudinal direction and extending within said plane. The MEMS micromirror (30) also includes vertical support beams (40) connected between the mirror body (50) and the frame (60) along the rotation axis (58). The at least one cantilever beam assembly (70) has a cantilever beam (72) with a first and a second end (721, 722) and a relief means (74) at the first end (721) allowing for a translation of the cantilever beam (72) at its first end (721) in said longitudinal direction. The first end (721) is coupled via the relief means (74) to the frame (60) and the second end (722) is fixed to the mirror body (50). The cantilever beam (72) has a thickness, perpendicular to a plane of the frame (60), that is smaller than its width, in the plane of the frame (60).

Owner:INNOLUCE

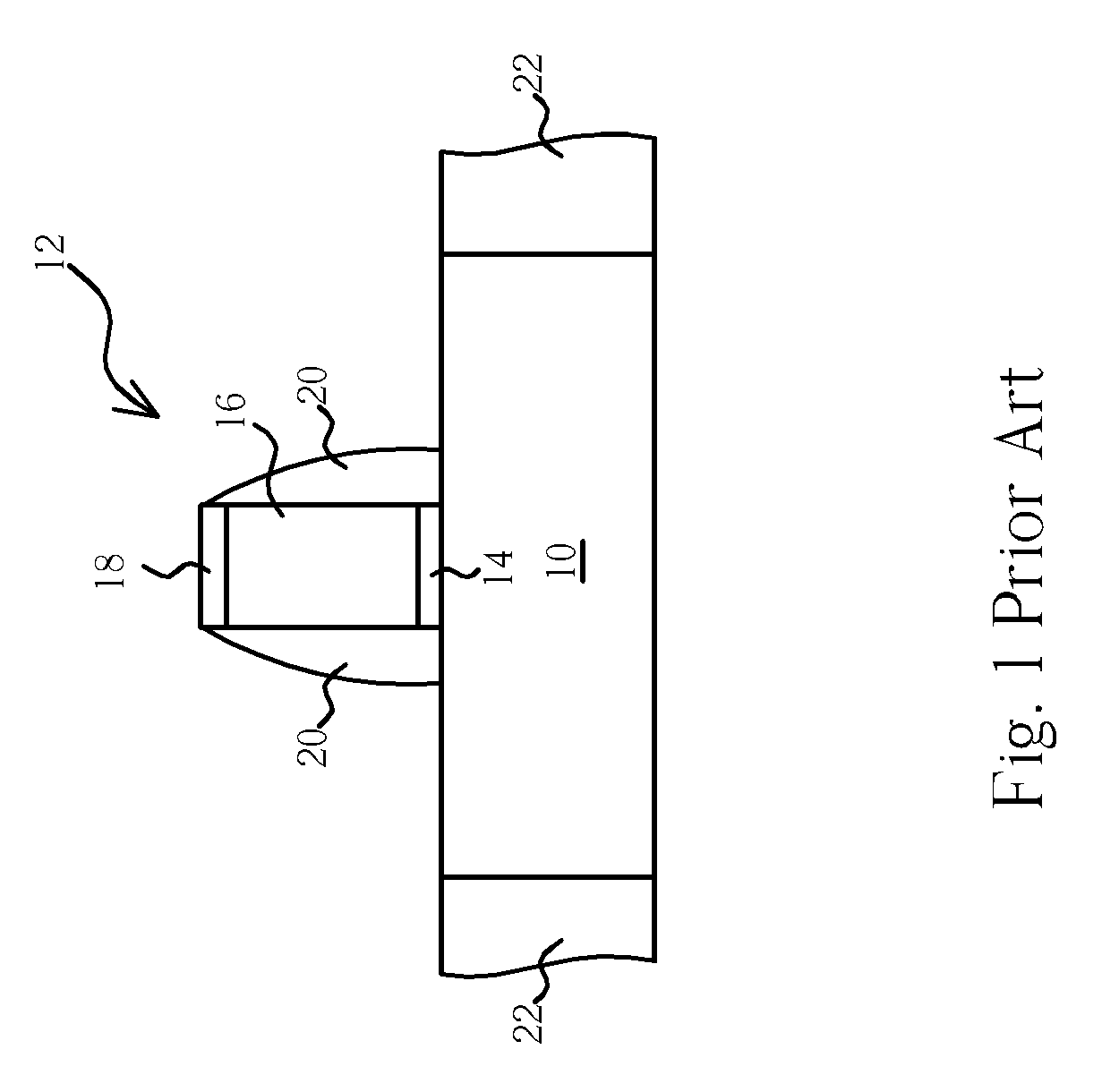

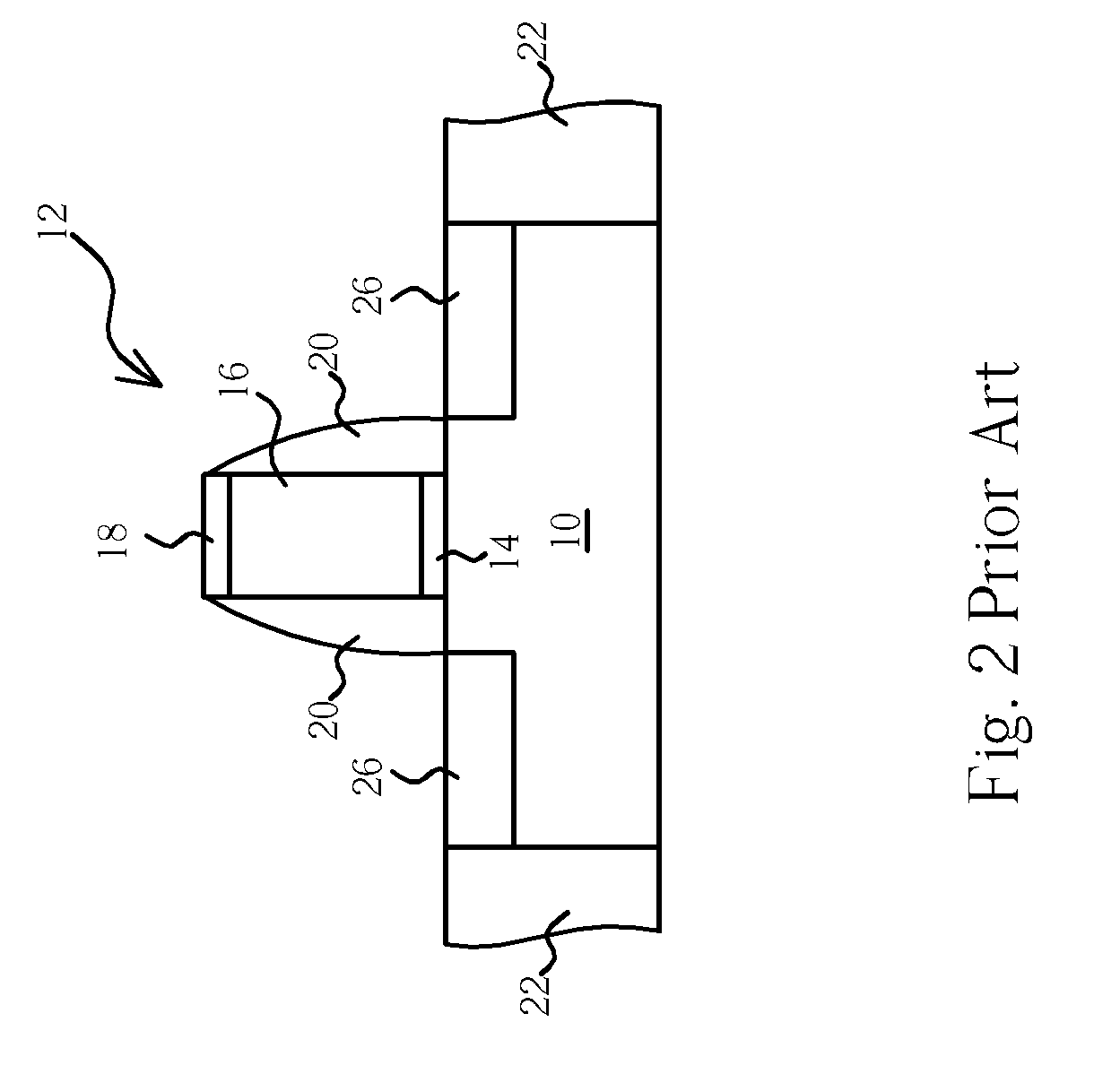

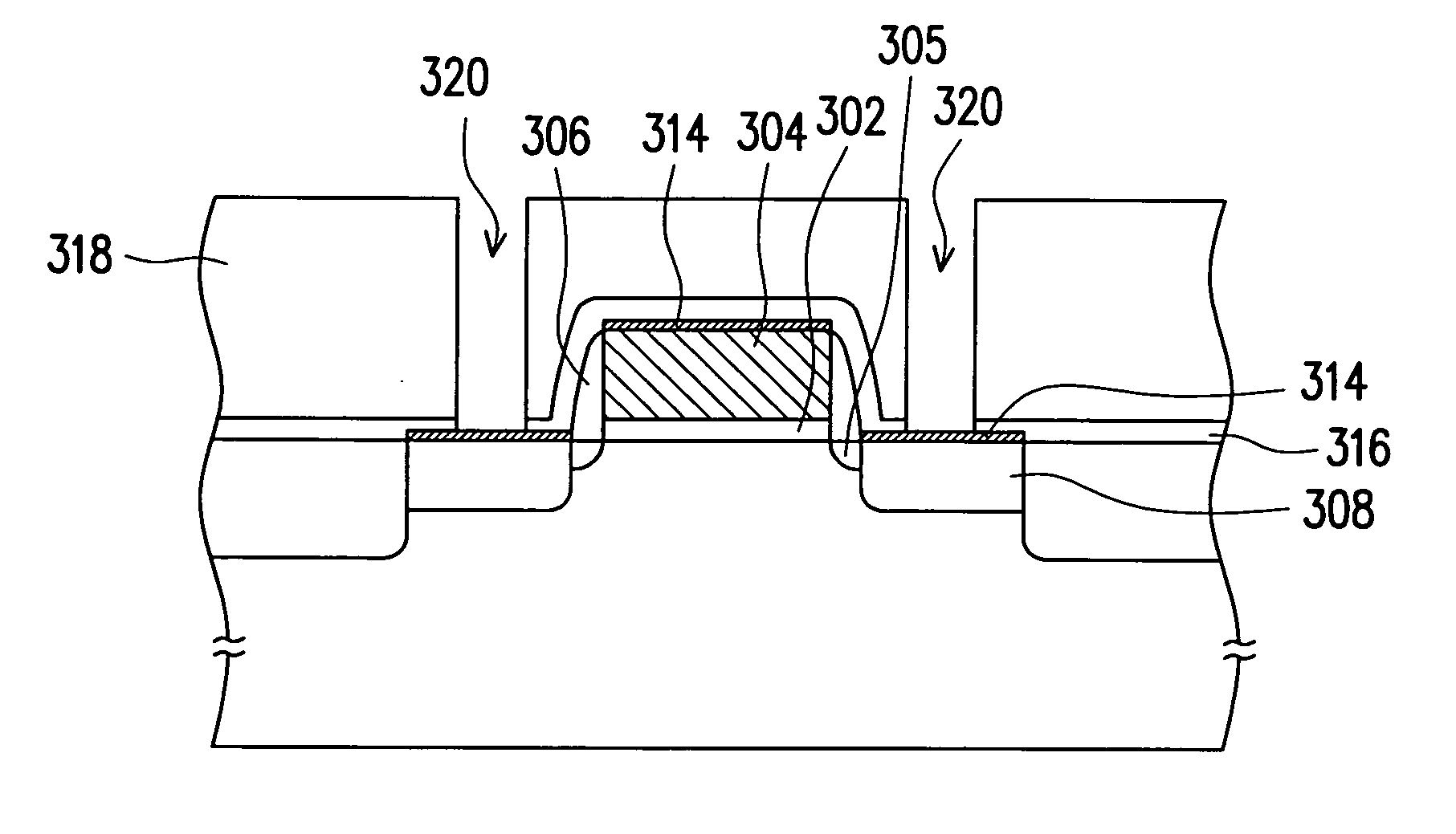

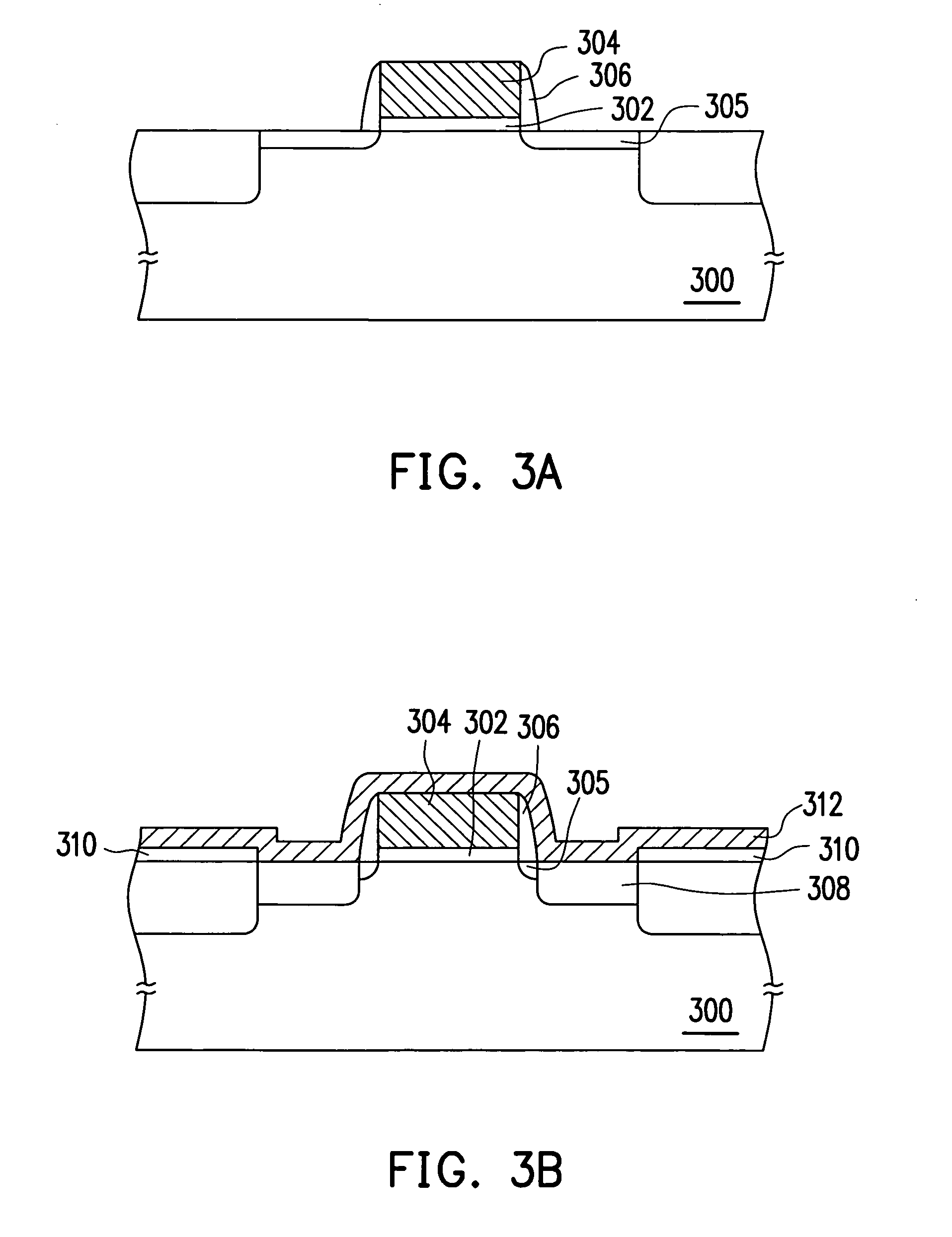

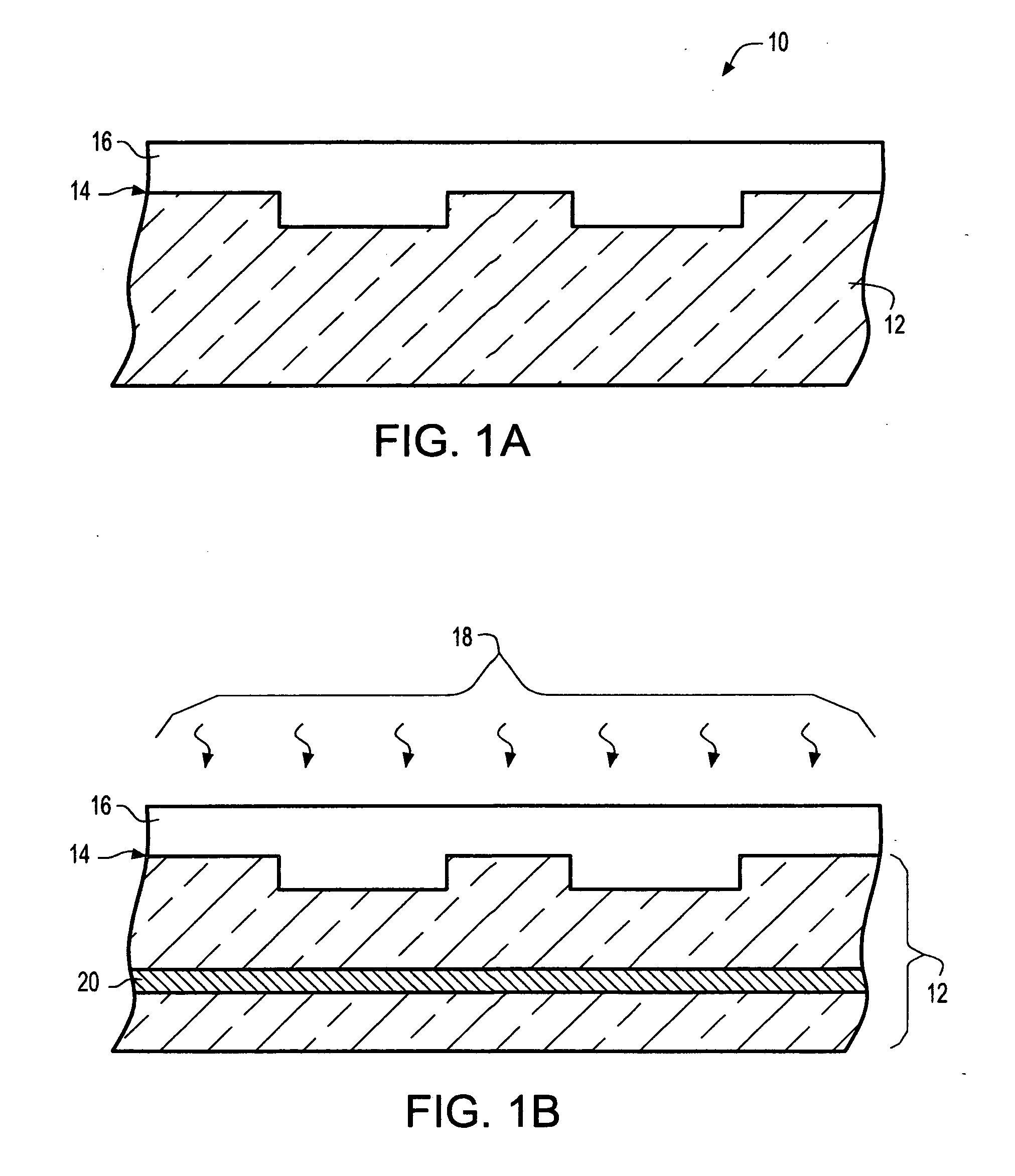

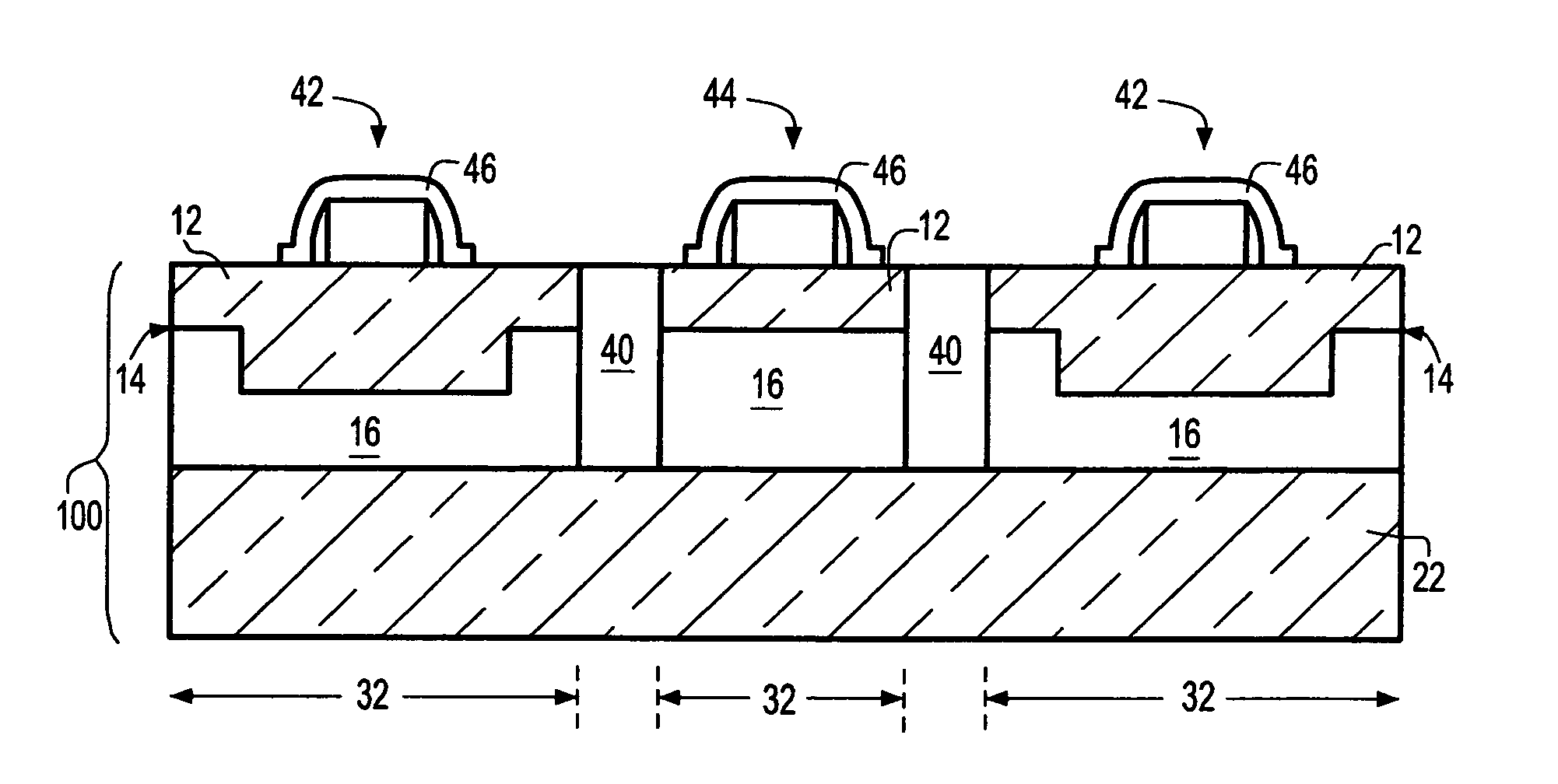

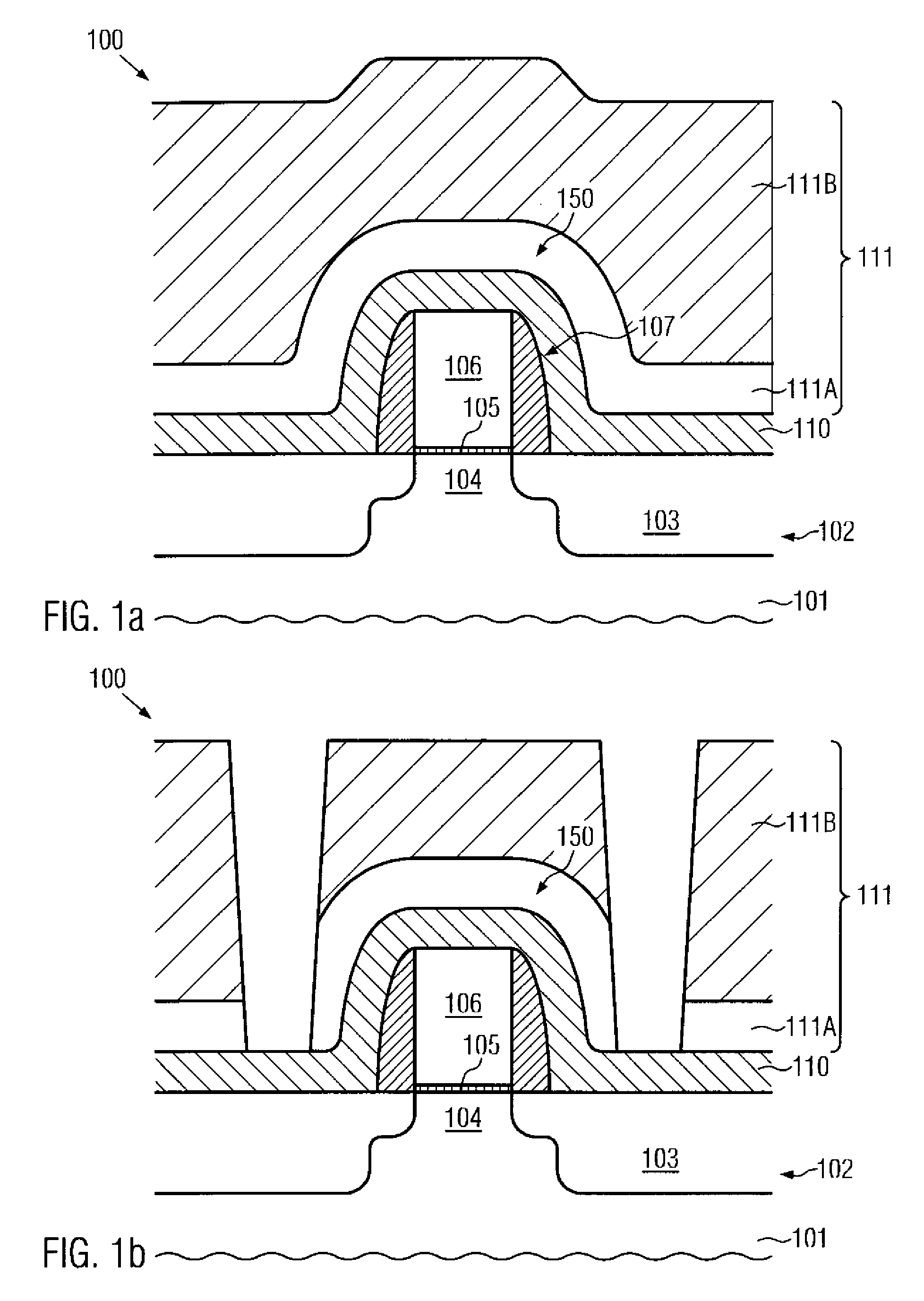

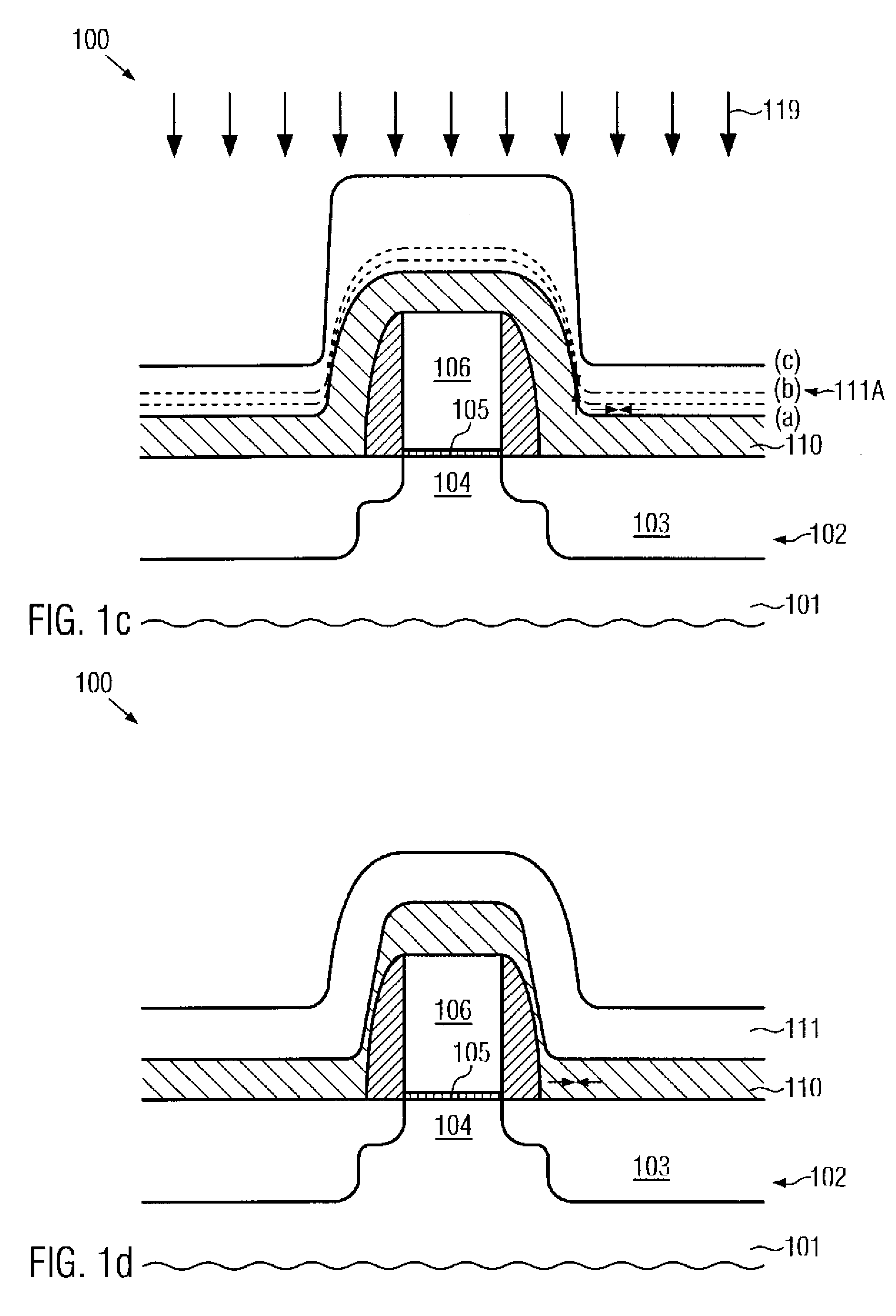

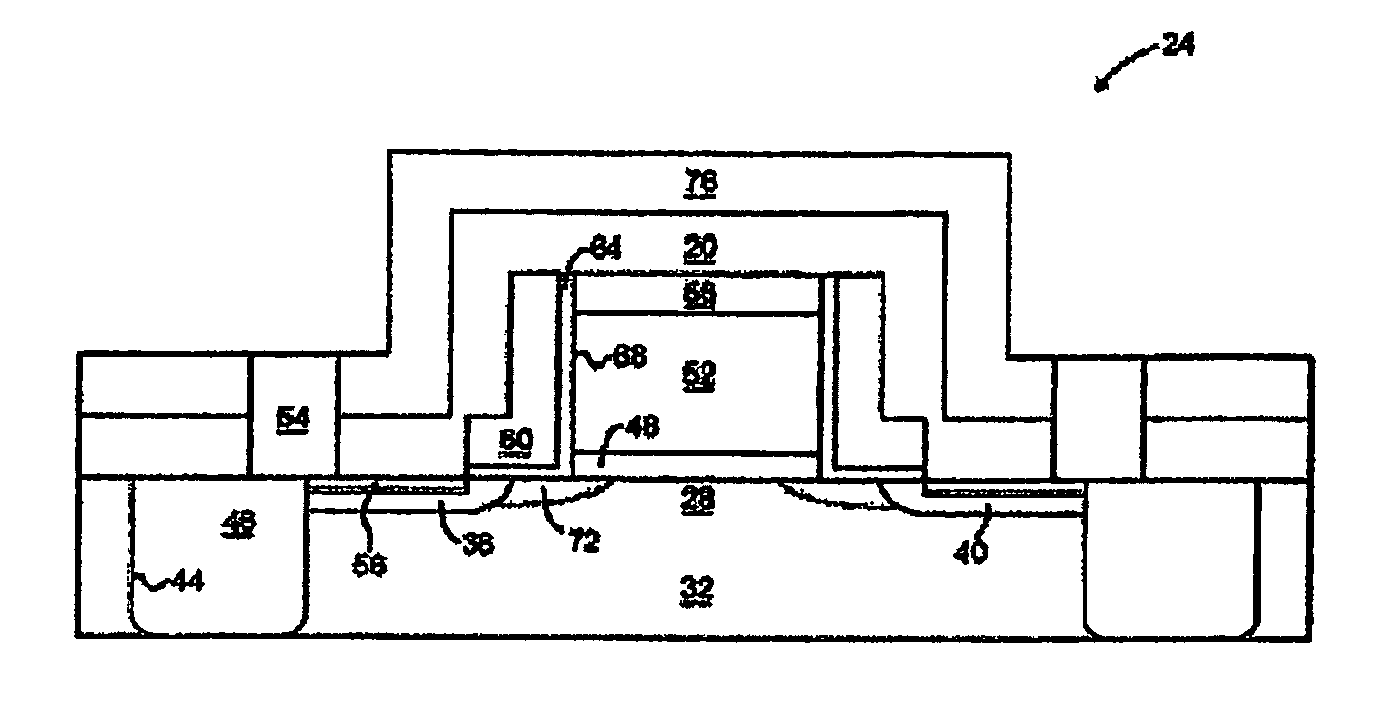

Method for fabricating high tensile stress film and strained-silicon transistors

InactiveUS20070105292A1Increase heightIncrease the tensile stressSemiconductor/solid-state device manufacturingSemiconductor devicesDeposition processSemiconductor

A method for fabricating high tensile stress film and strained-silicon transistors. First, a semiconductor substrate is provided and a gate, at least a spacer, and a source / drain region are formed on the semiconductor substrate. Next, n deposition processes are performed to form n layers of high tensile stress film over the surface of the gate and the source / drain region, in which each high tensile stress film is treated with a heat treatment process and n is greater than or equal to two.

Owner:UNITED MICROELECTRONICS CORP

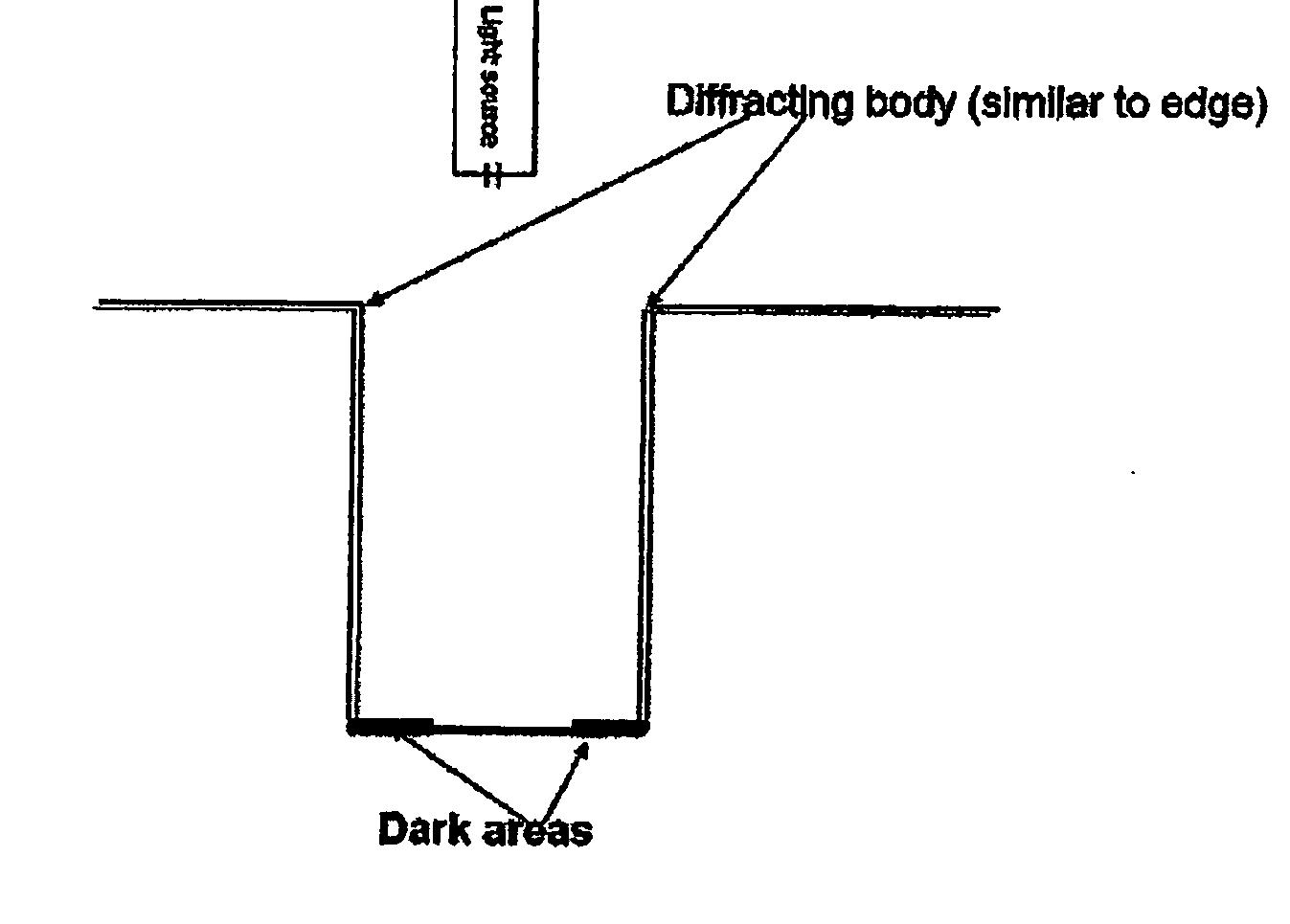

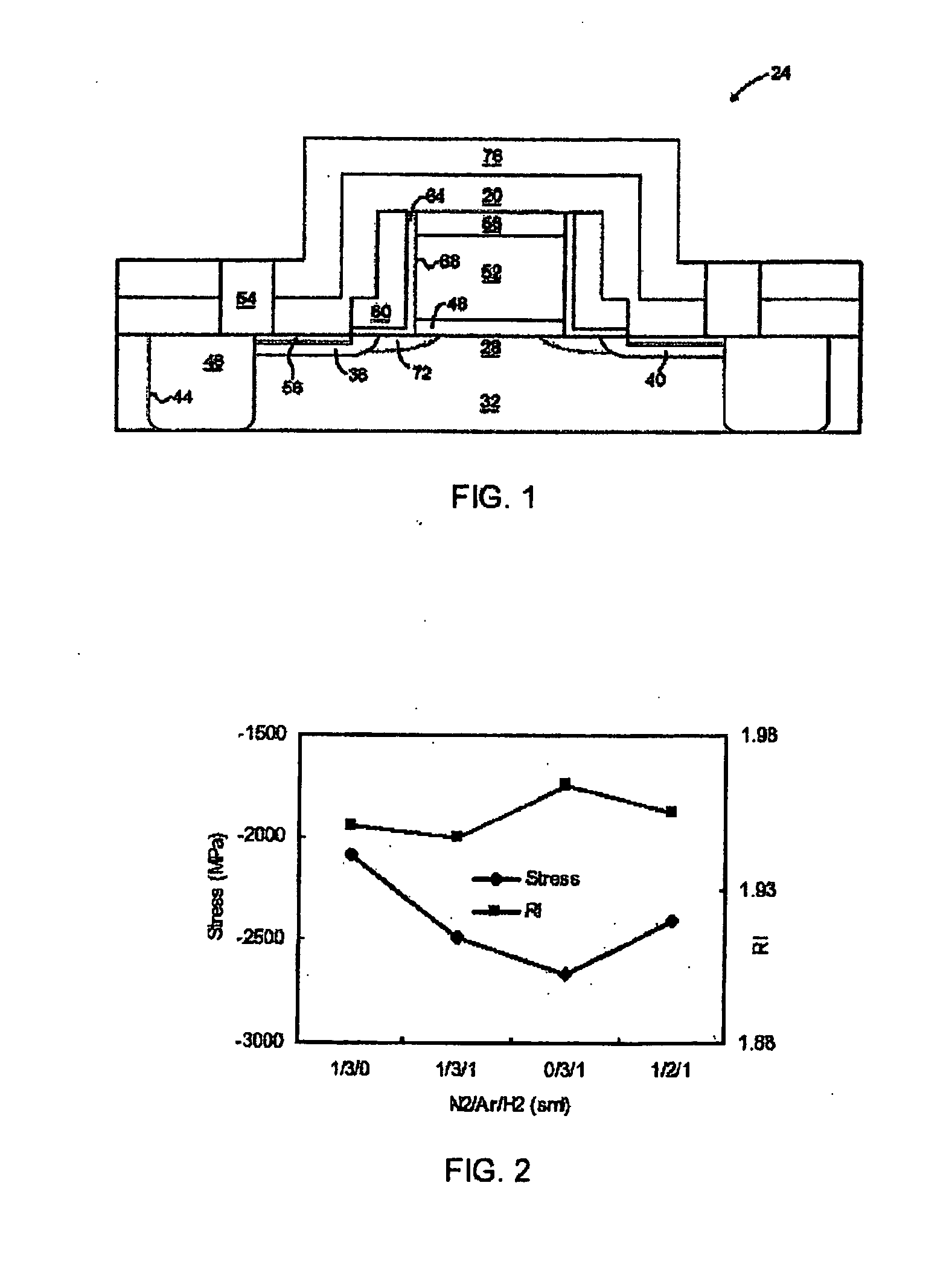

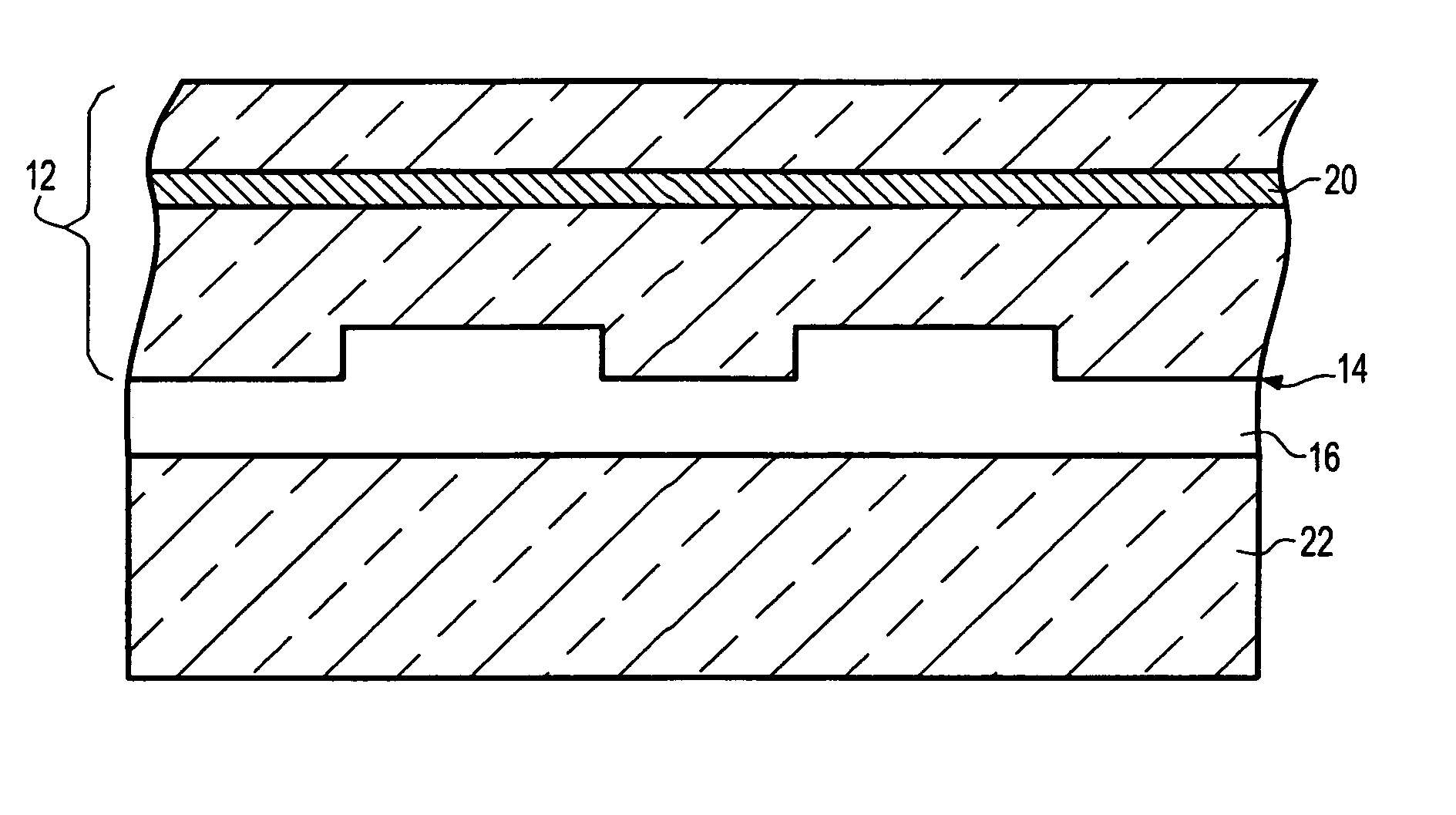

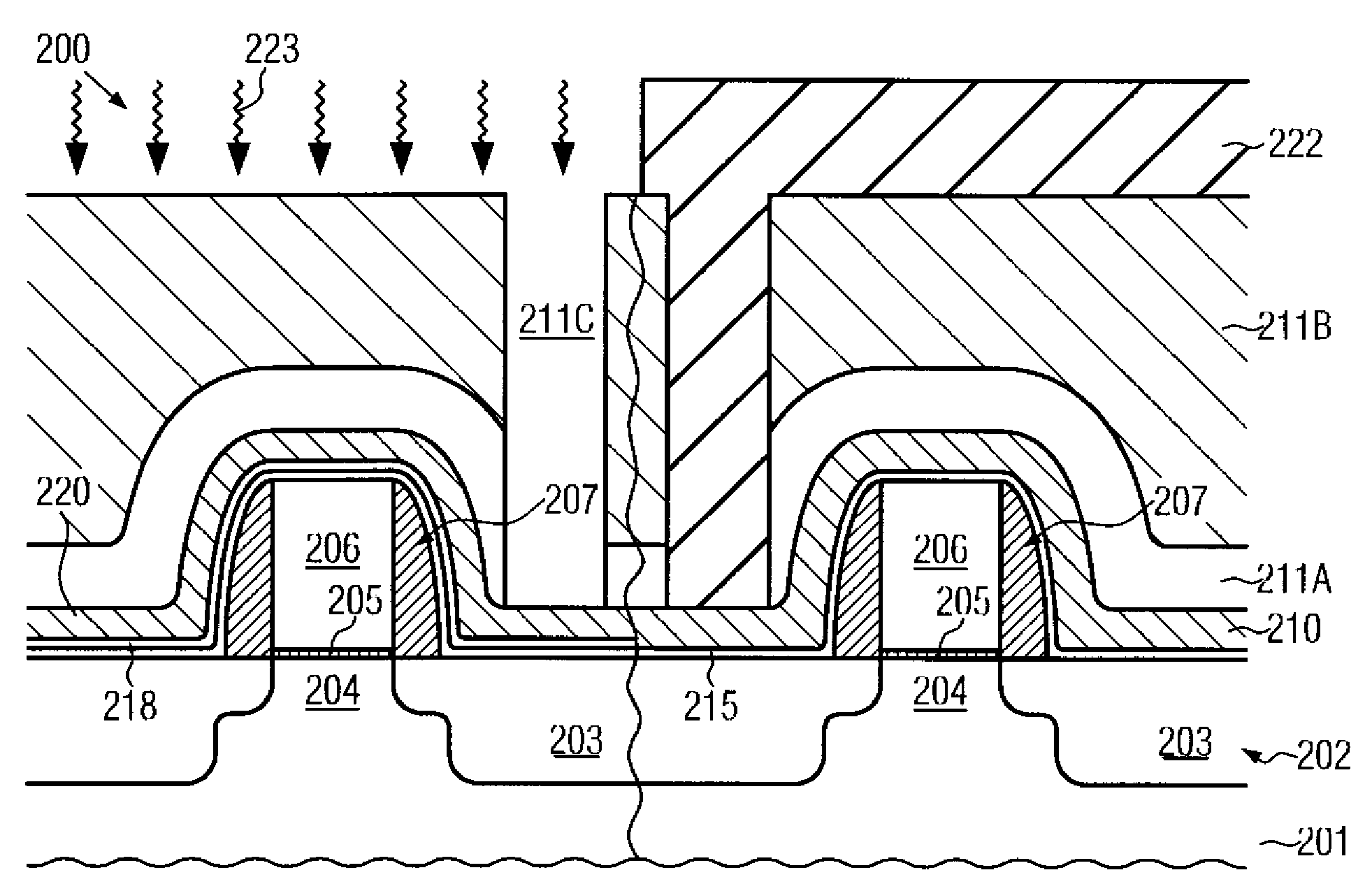

Integration process for fabricating stressed transistor structure

ActiveUS20060270217A1Enhance radiation curing efficiencyFilm stress is increasedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

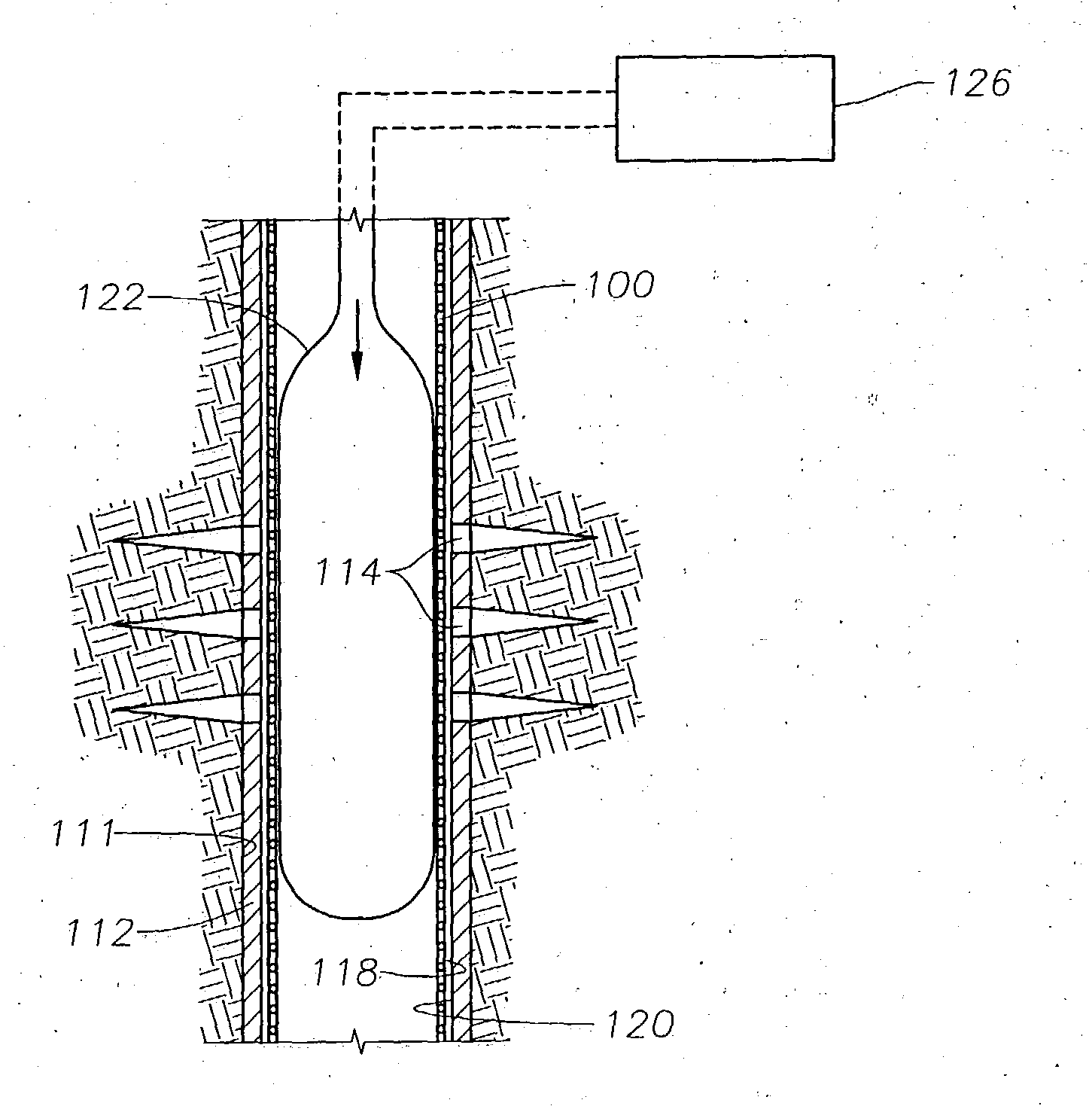

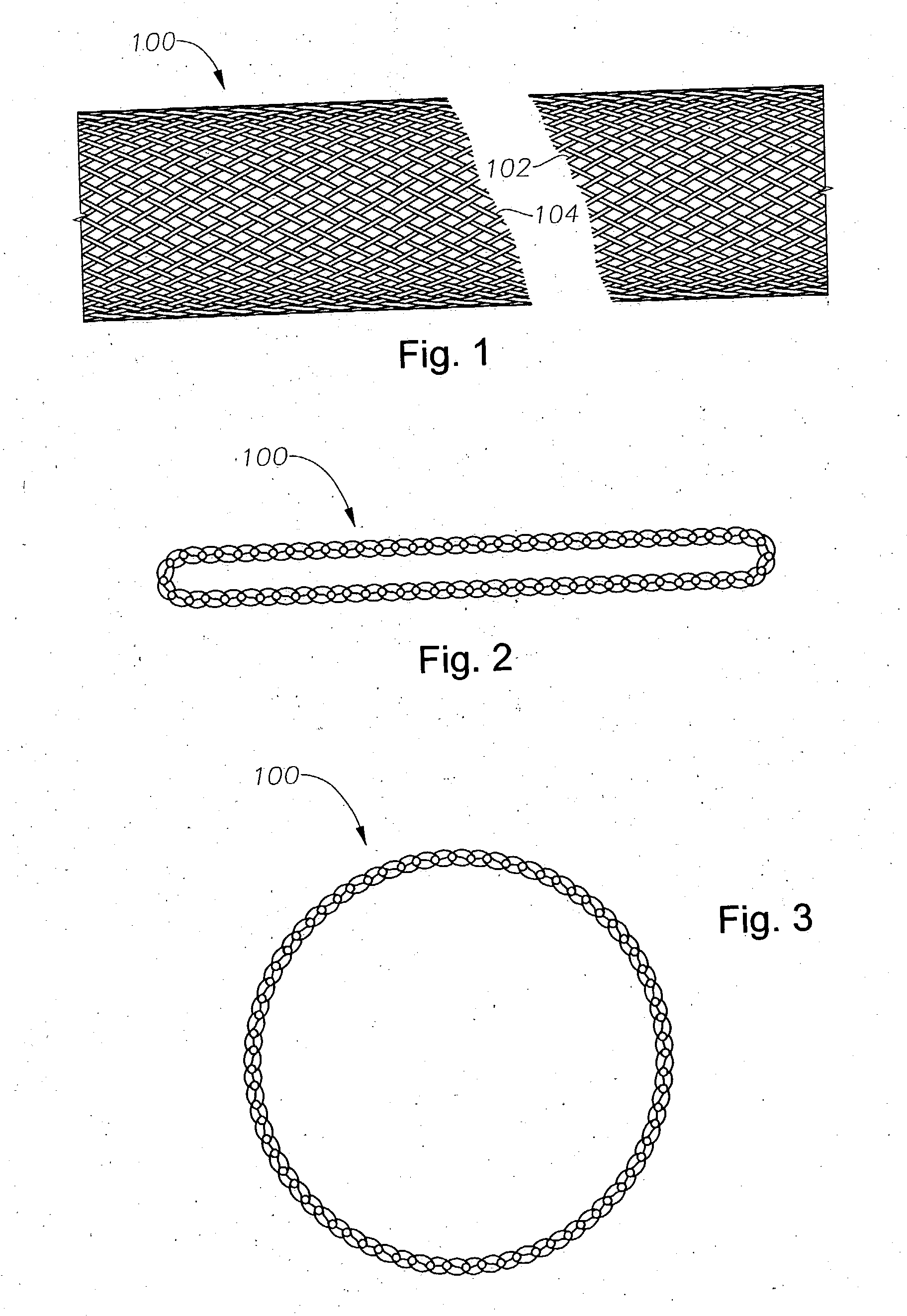

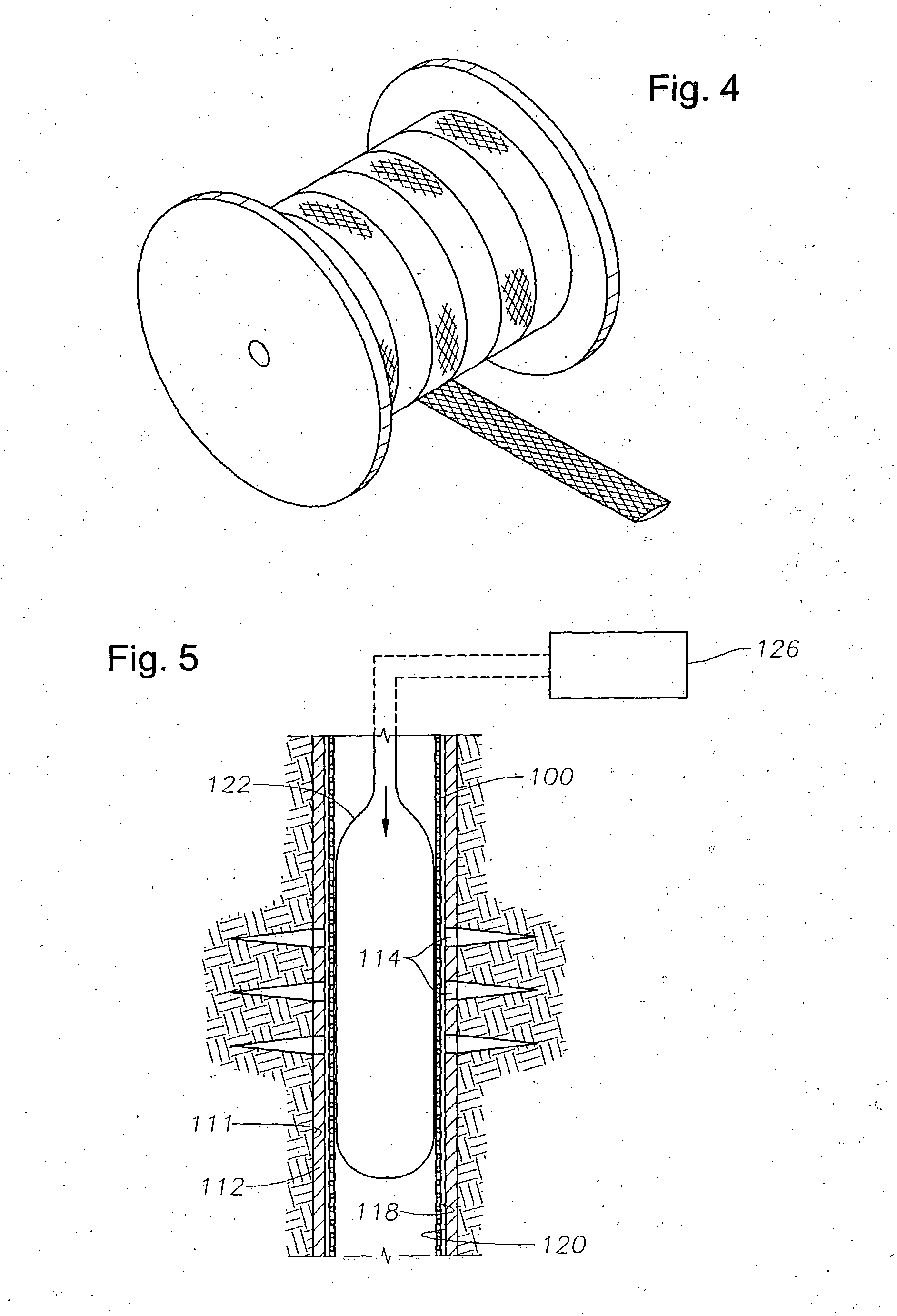

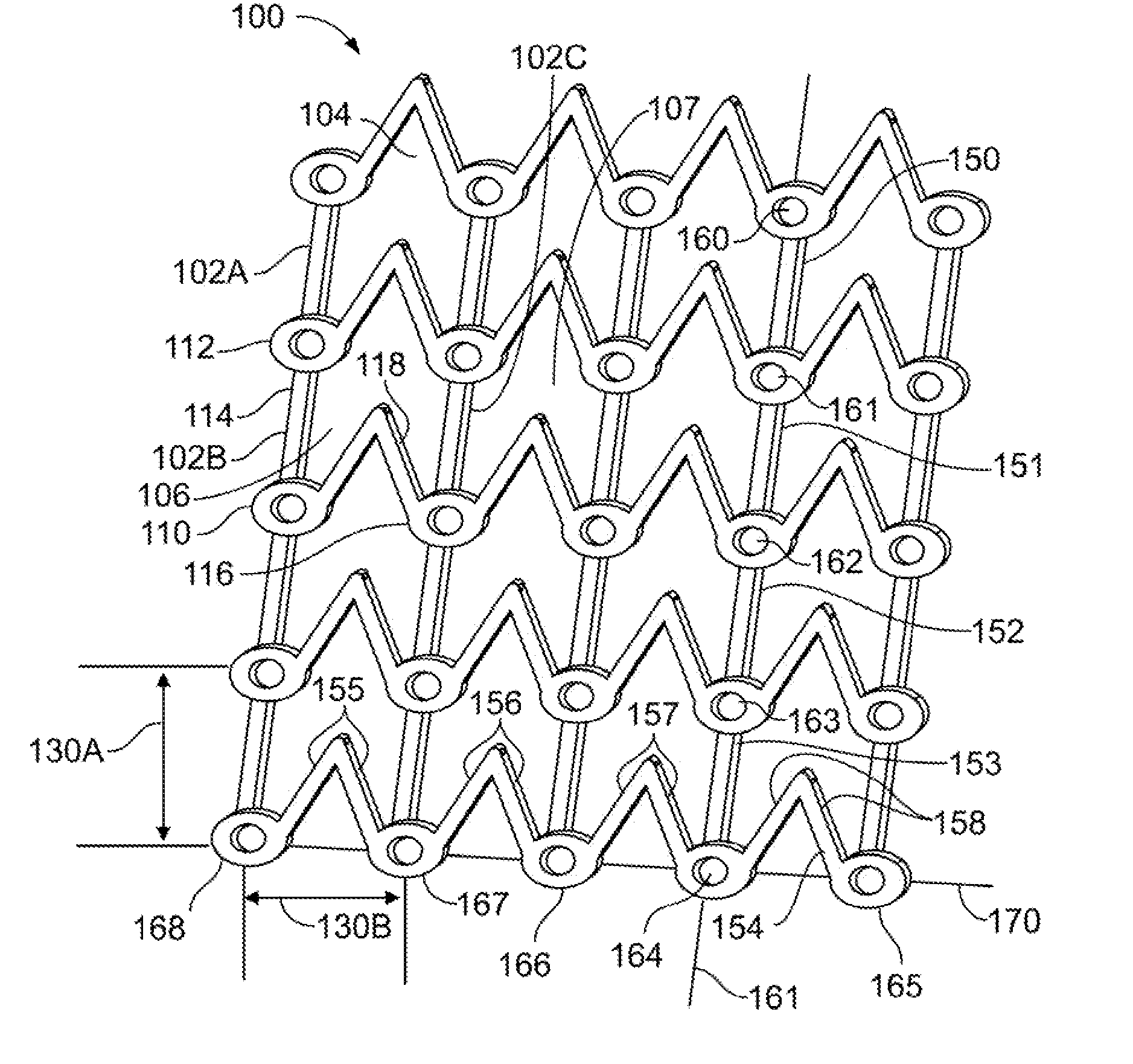

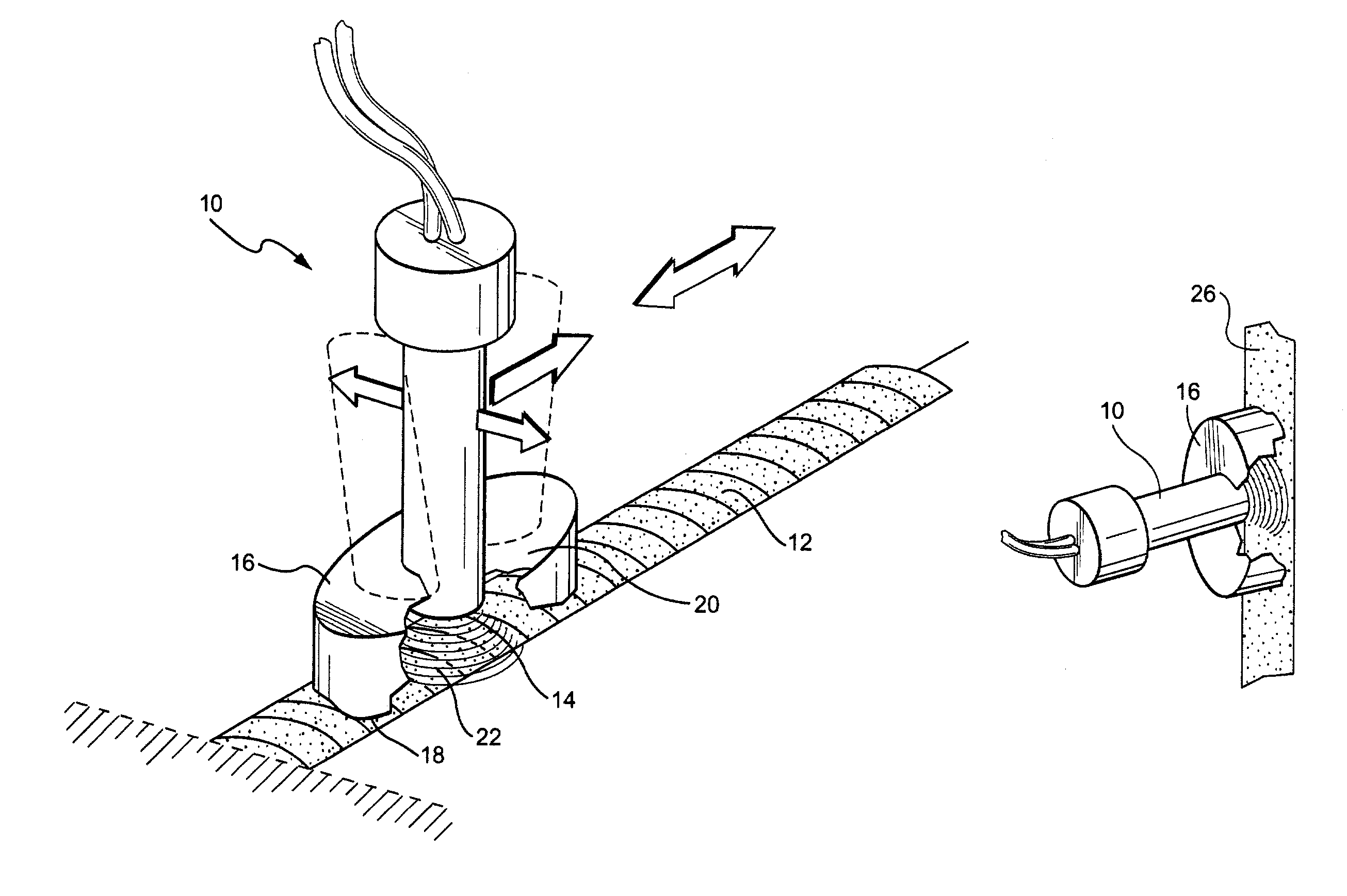

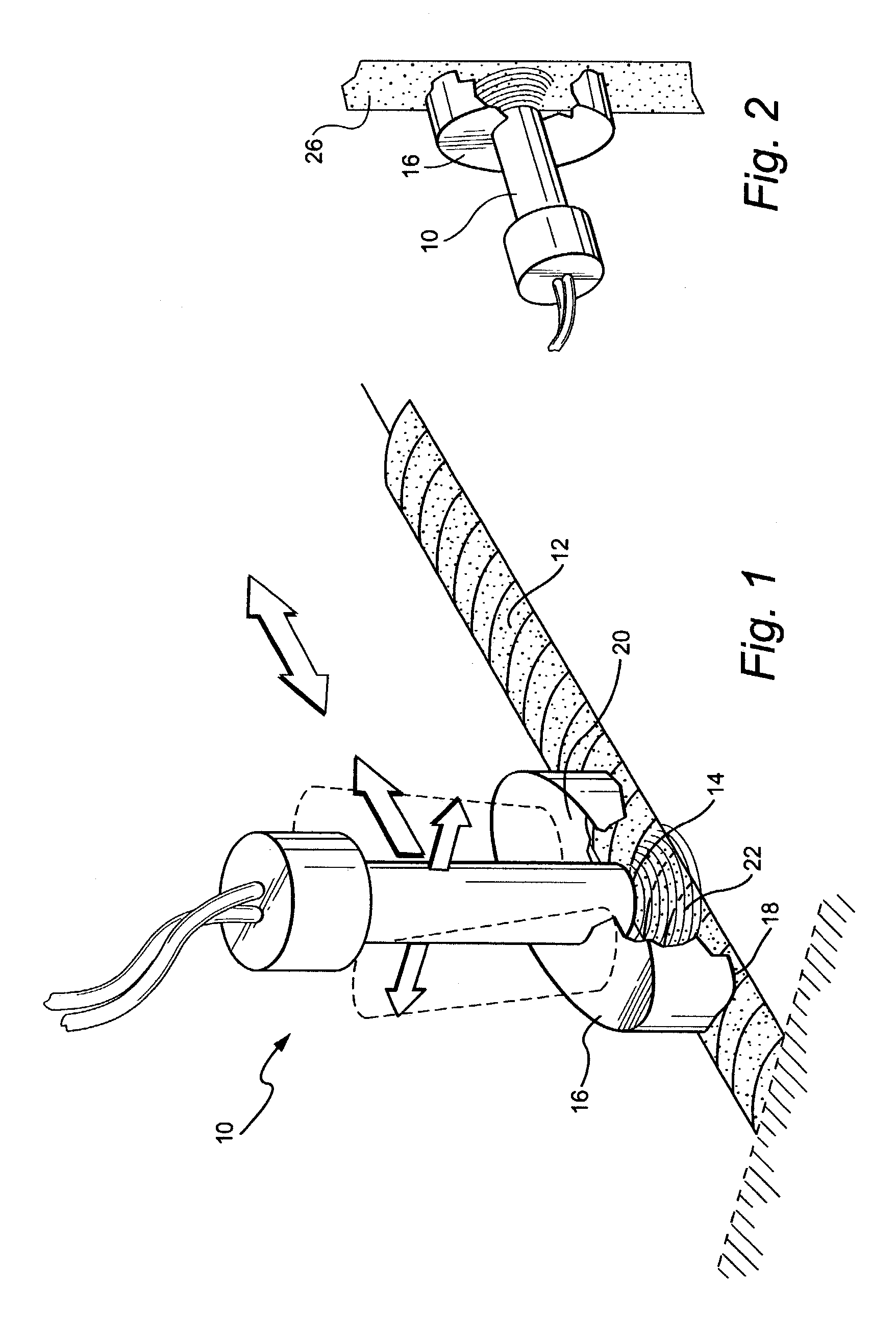

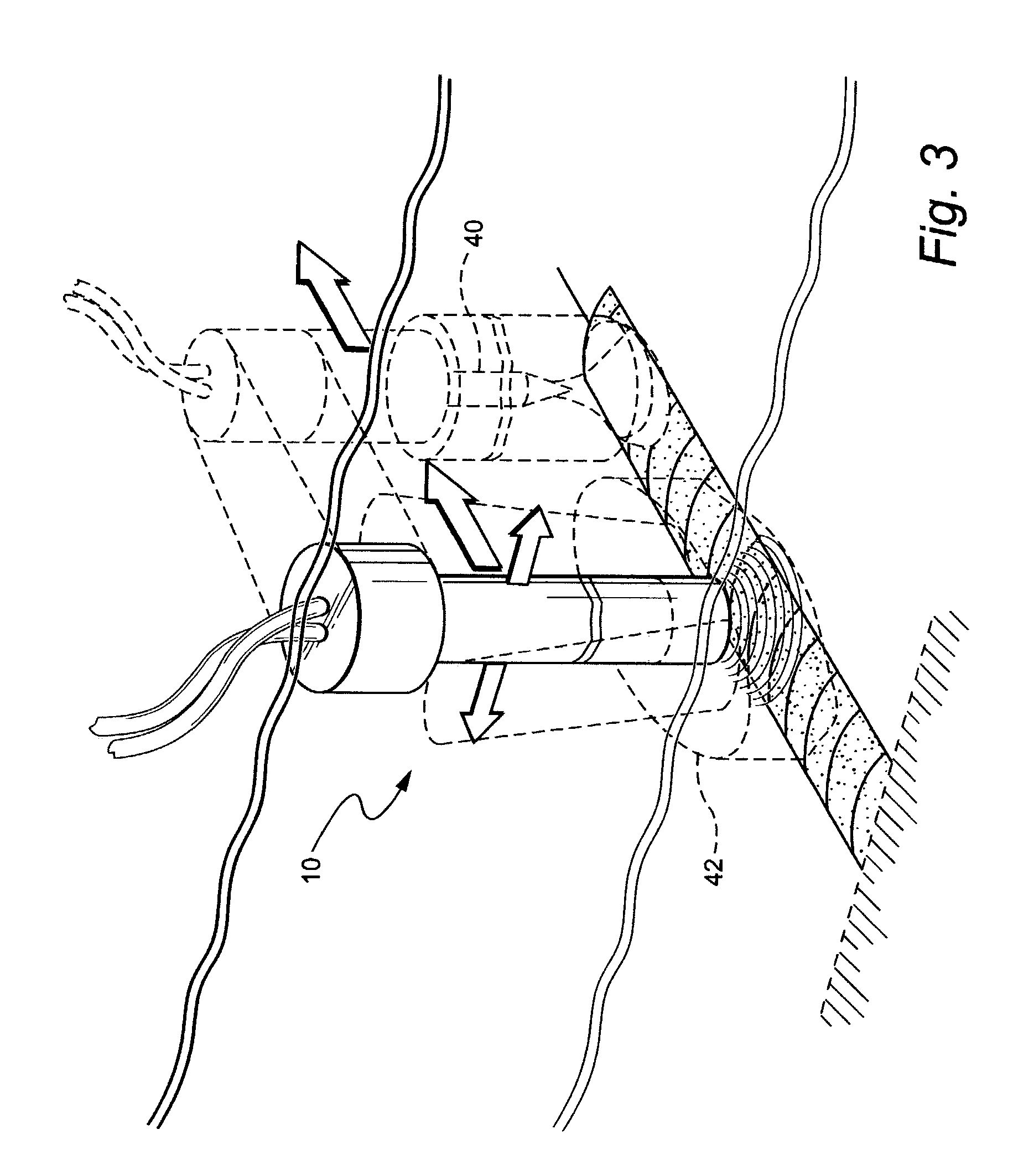

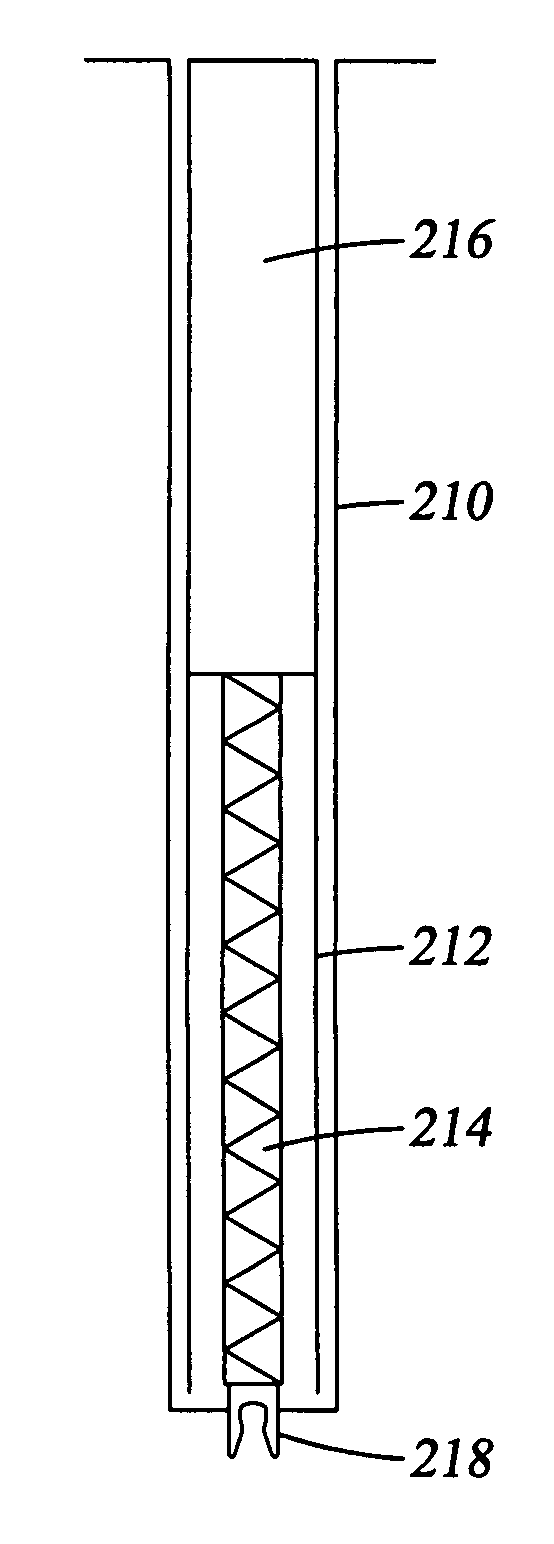

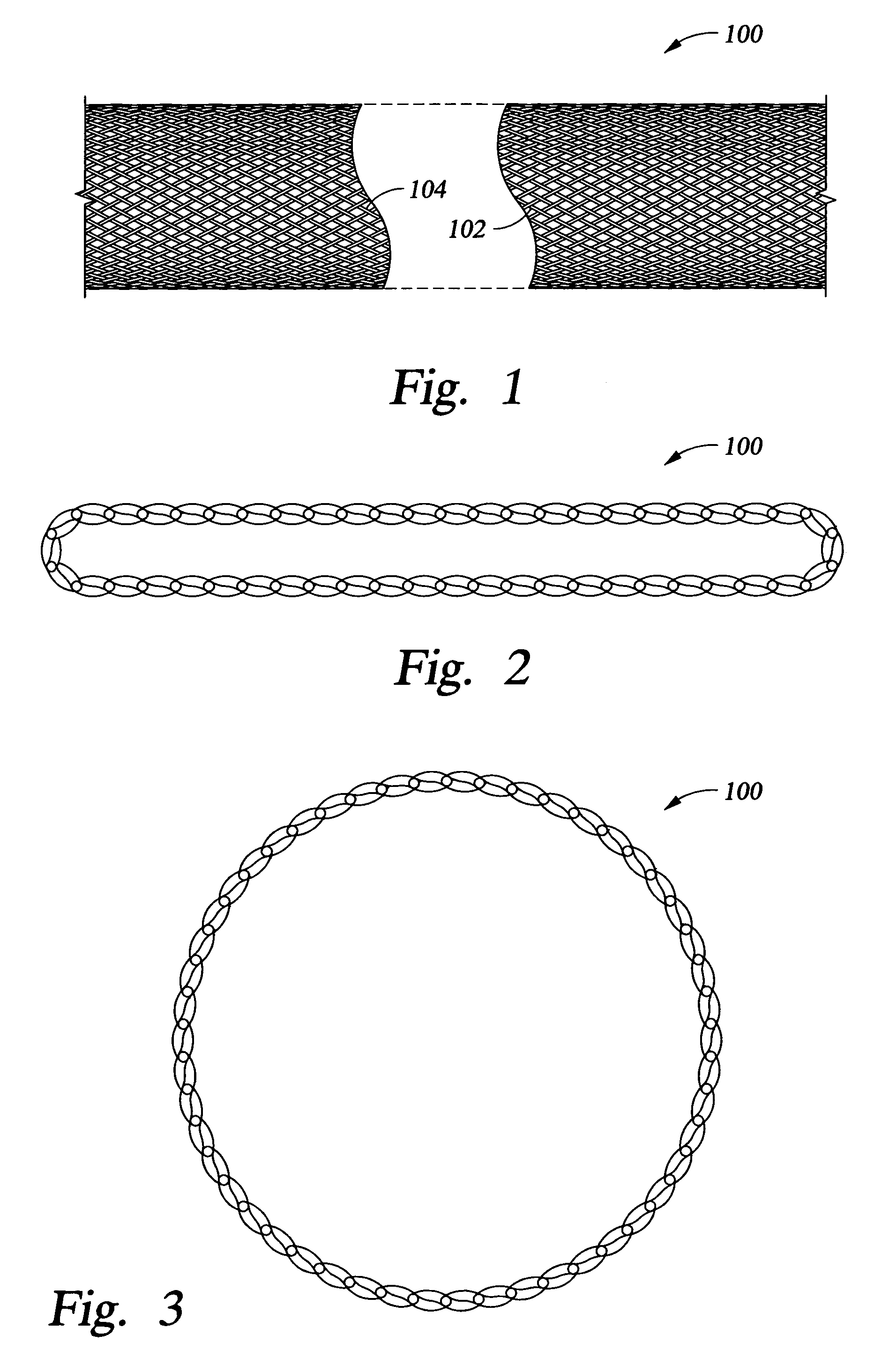

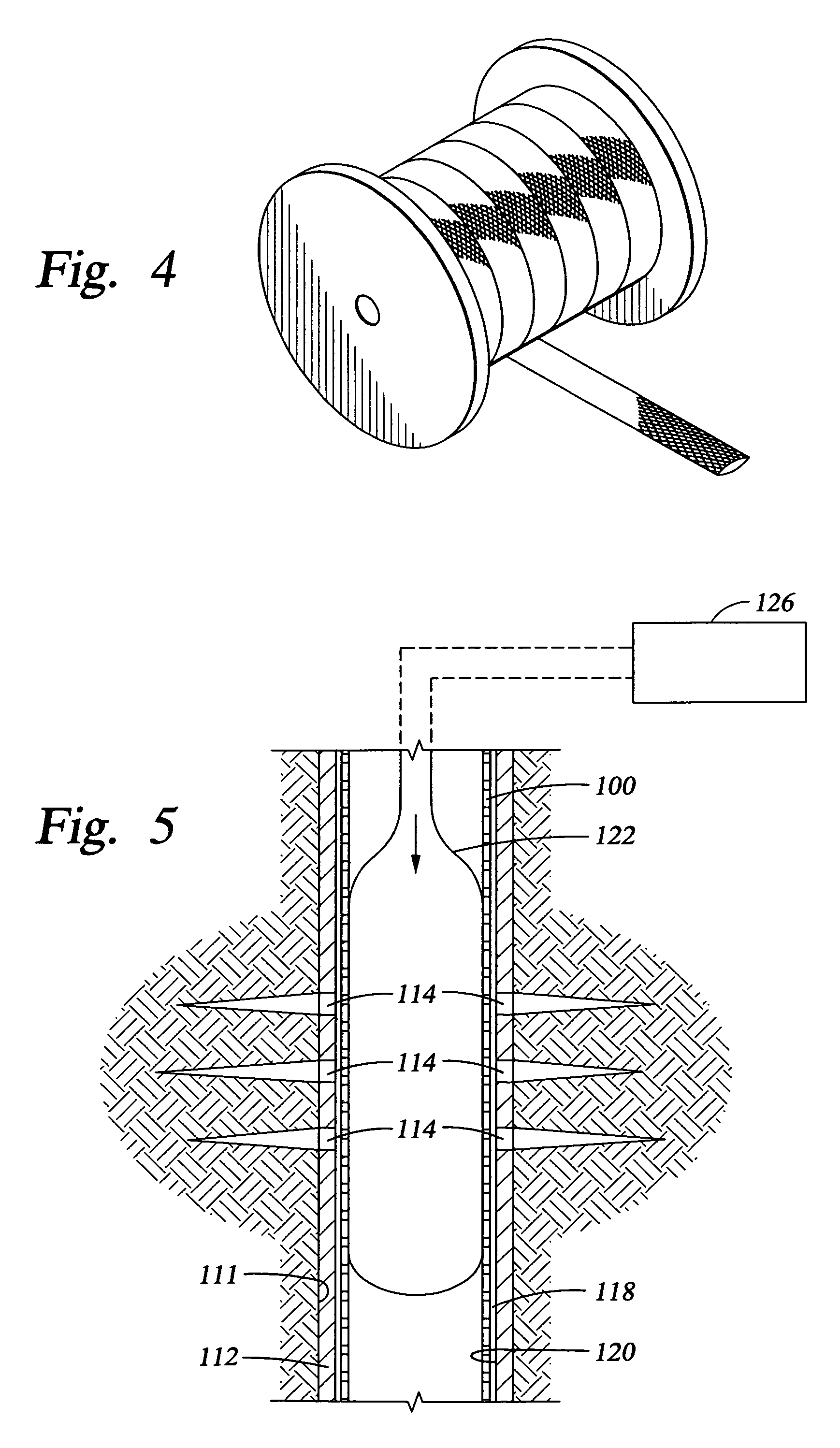

System and methods for placing a braided tubular sleeve in a well bore

Systems and methods for placing a tubular, braided sleeve in a well bore are provided. The sleeve is positioned within an interior of a carrier configured to hold the sleeve in an undeployed position, followed by lowering the carrier into the well bore. The sleeve may be used in conjunction with a curable resin that can be solidified to set the sleeve into a tubular cross section. After securing the sleeve to the well bore, the carrier may be moved away from the bottom of the well bore, deploying the sleeve and extending it along the contour of the well bore. The tubular sleeve may then be subsequently expanded in situ to increase its diameter. The curable resin can then cured to make the sleeve substantially rigid.

Owner:HALLIBURTON ENERGY SERVICES INC

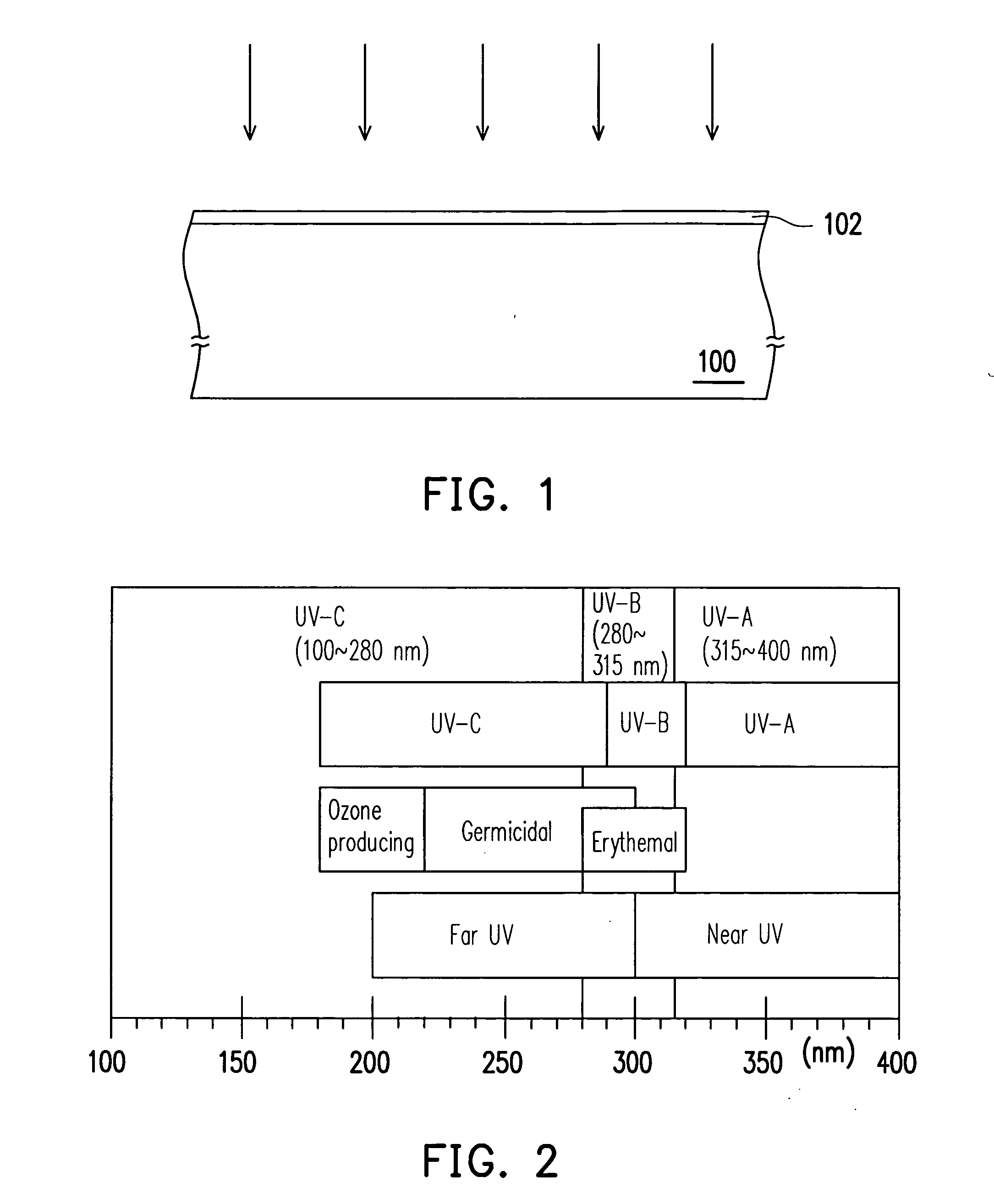

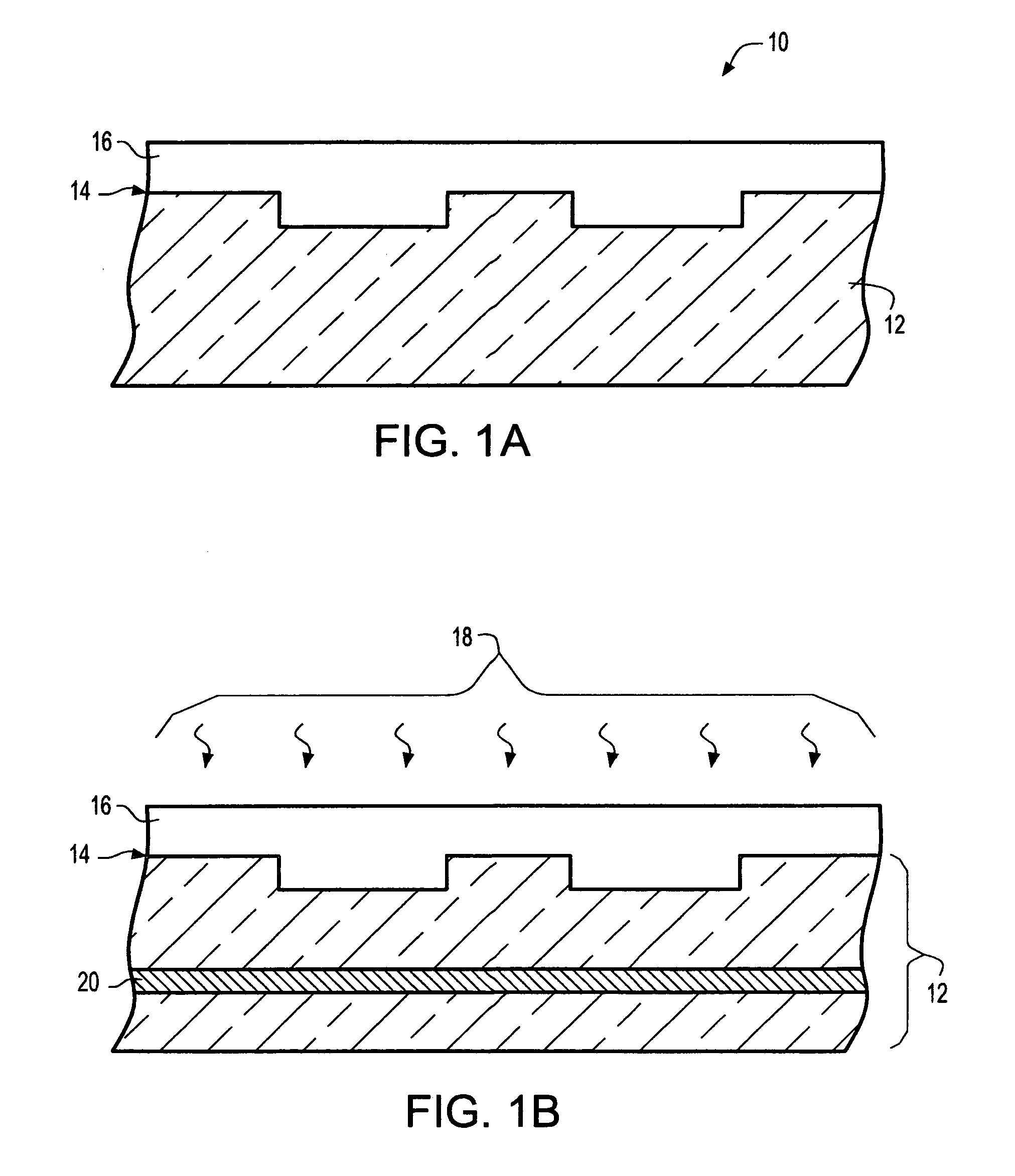

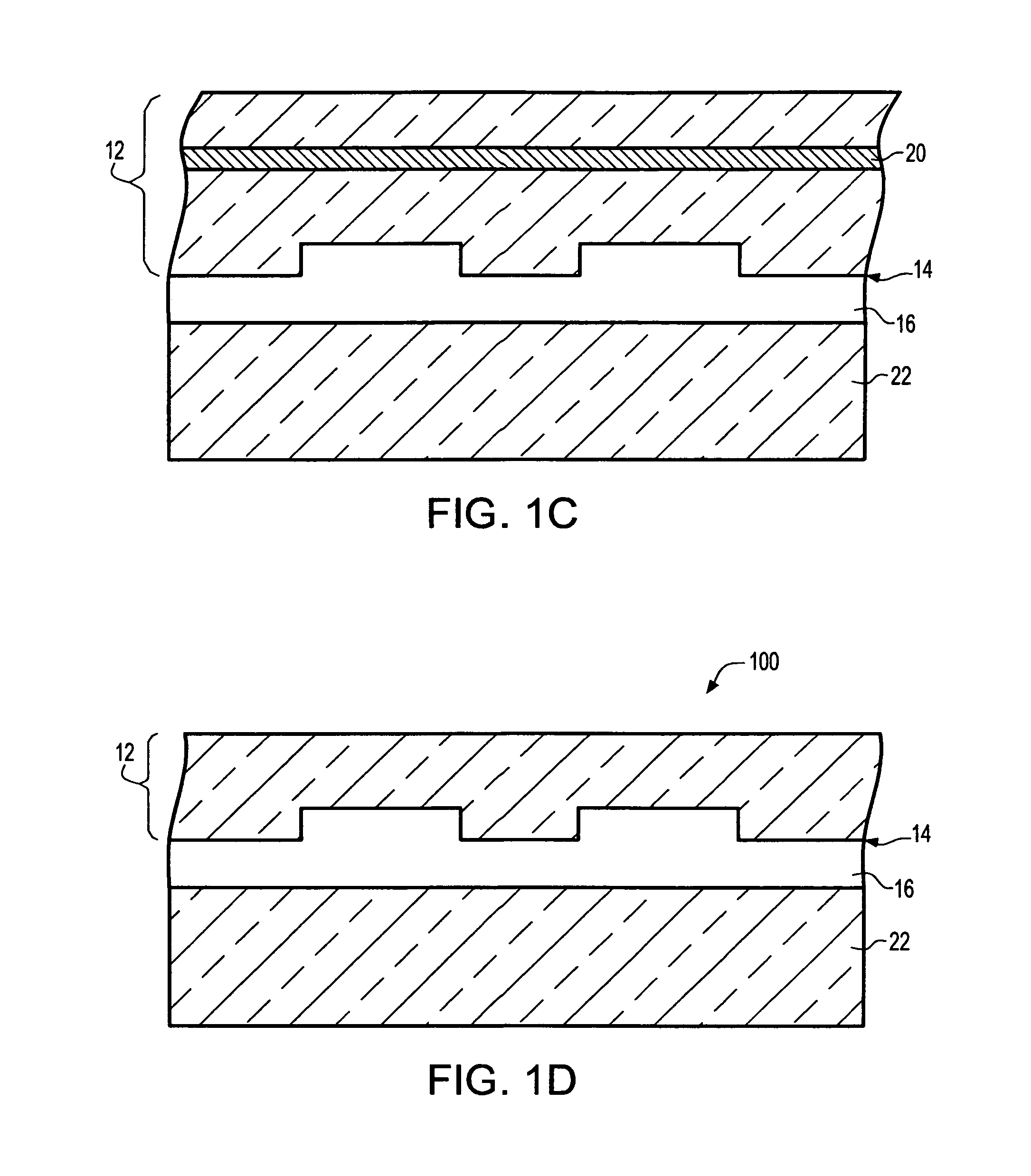

Method of fabricating silicon nitride layer and method of fabricating semiconductor device

ActiveUS20070066022A1Increase the tensile stressIncrease currentTransistorSemiconductor/solid-state device manufacturingUV curingDevice material

A method of fabricating a silicon nitride layer is described. First, a substrate is provided. Then, a silicon nitride layer is formed on the substrate. The silicon nitride layer is UV-cured in an atmosphere lower than the standard atmospheric pressure. Through the UV curing treatment, the tensile stress of the silicon nitride layer is increased.

Owner:UNITED MICROELECTRONICS CORP

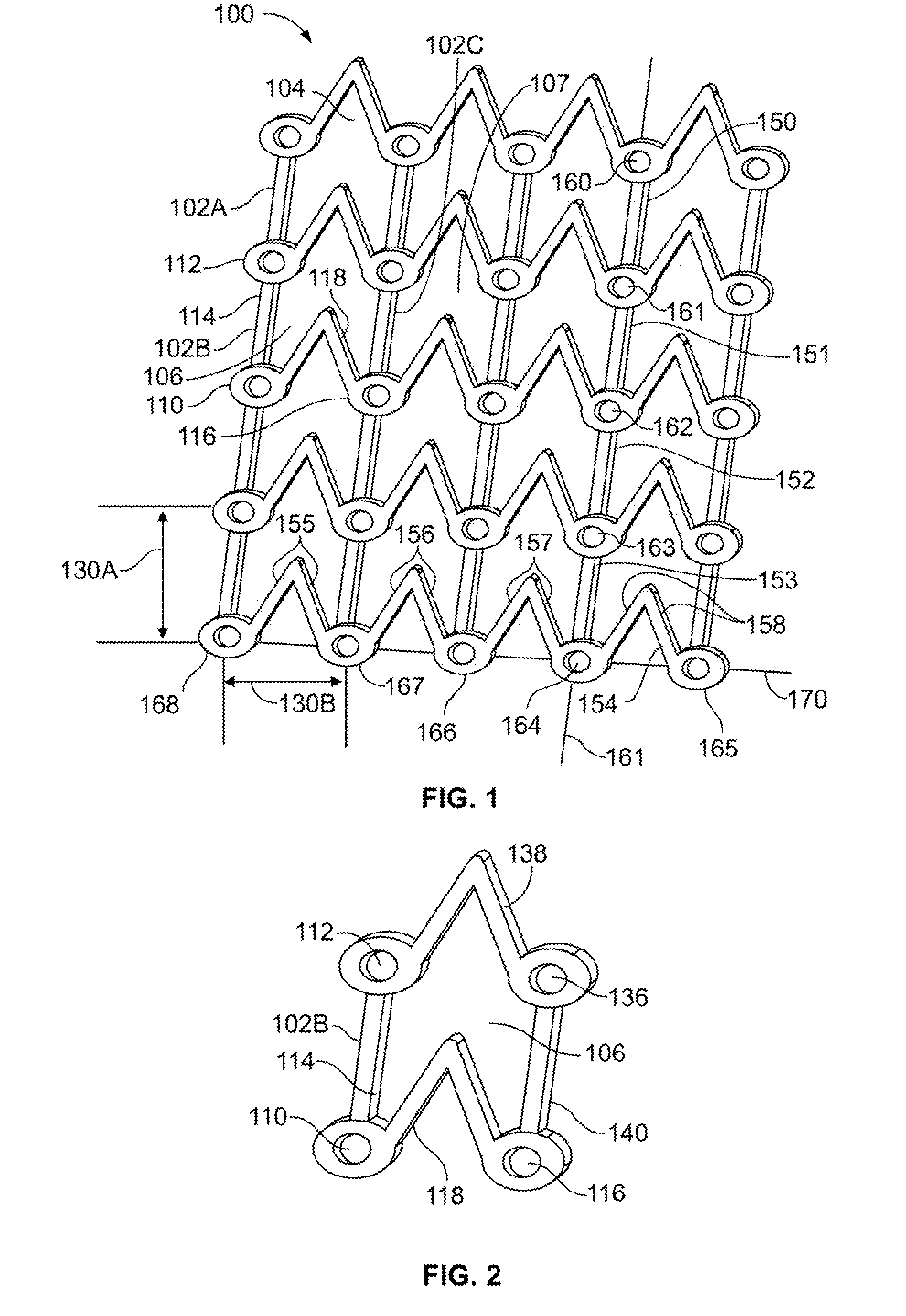

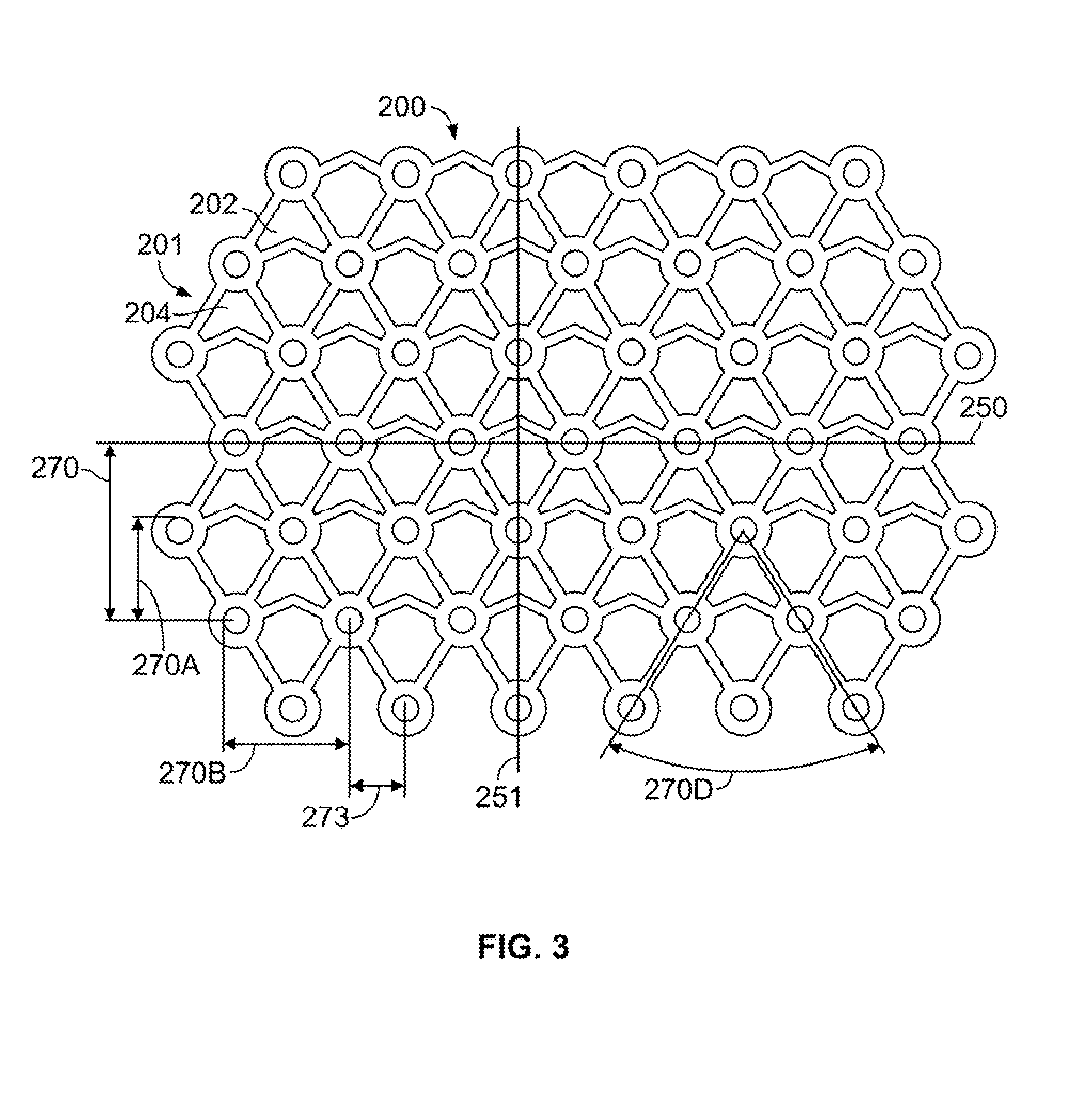

Low-Profile, High Tension Mesh Plate for Subcutaneous Fracture Fixation

A fixation device and method for the subcutaneous fixation of bone fragments. A fixation mesh is formed by the intersection of a plurality of linear legs that are interconnected in sagittal planes to form linear sagittal lines and a plurality of crimped legs that are interconnected in transverse planes to form transverse lines. The mesh resists expansive forces that are created in the linear sagittal lines and a compressive stress is created in the transverse lines when tensile loads are applied to the linear sagittal lines resulting in a device that minimizes the gap distance between bone fragments.

Owner:STC UNM

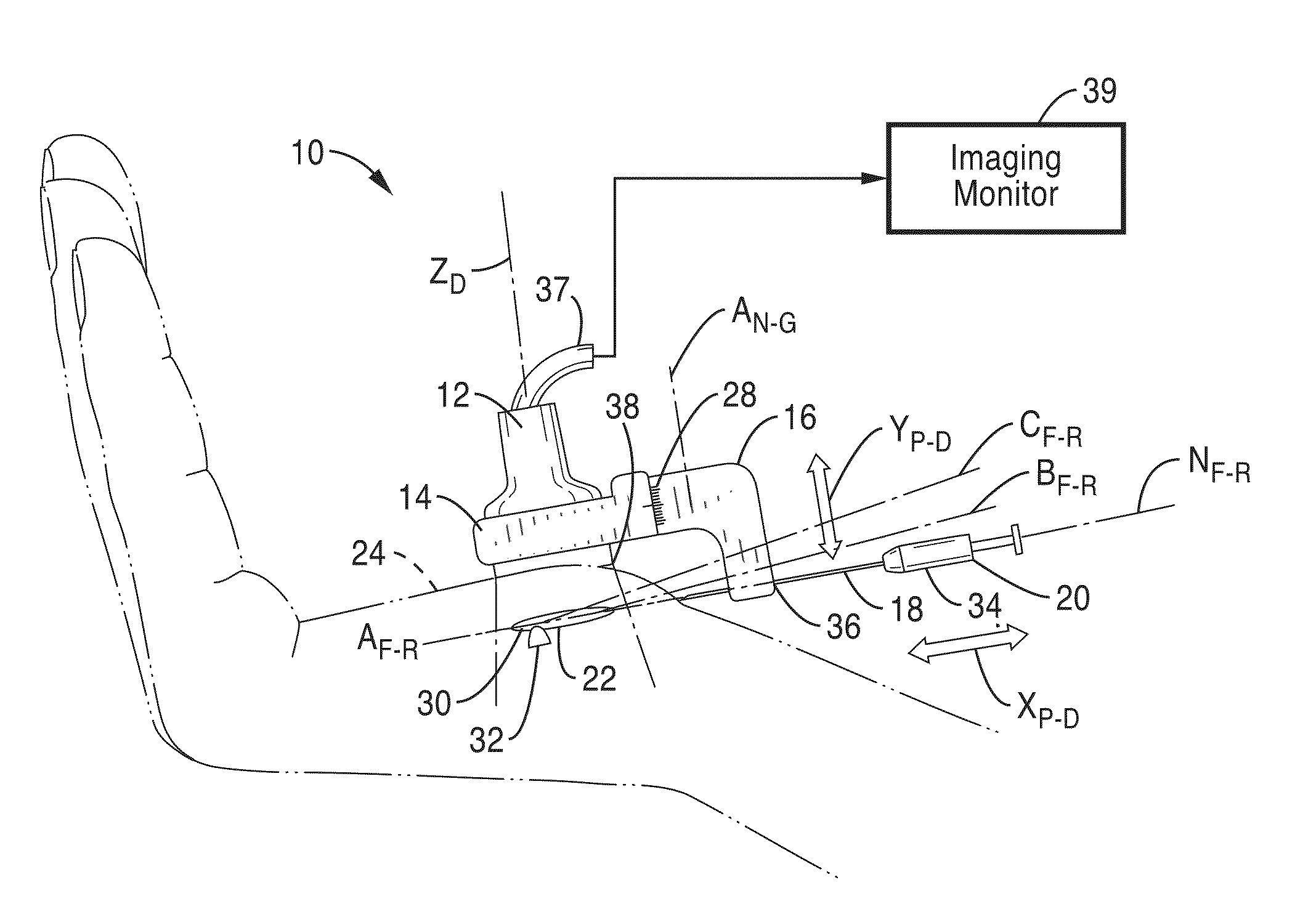

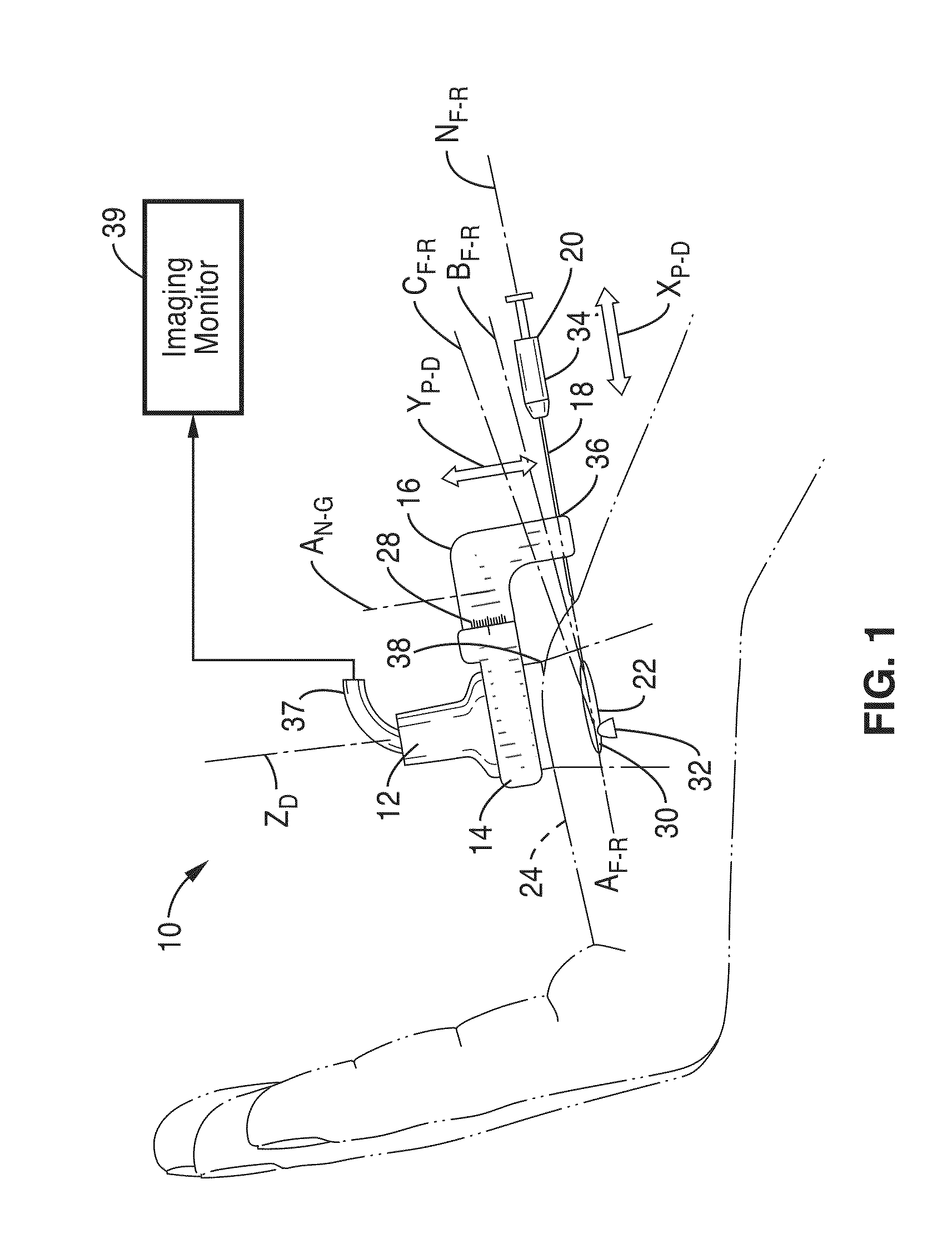

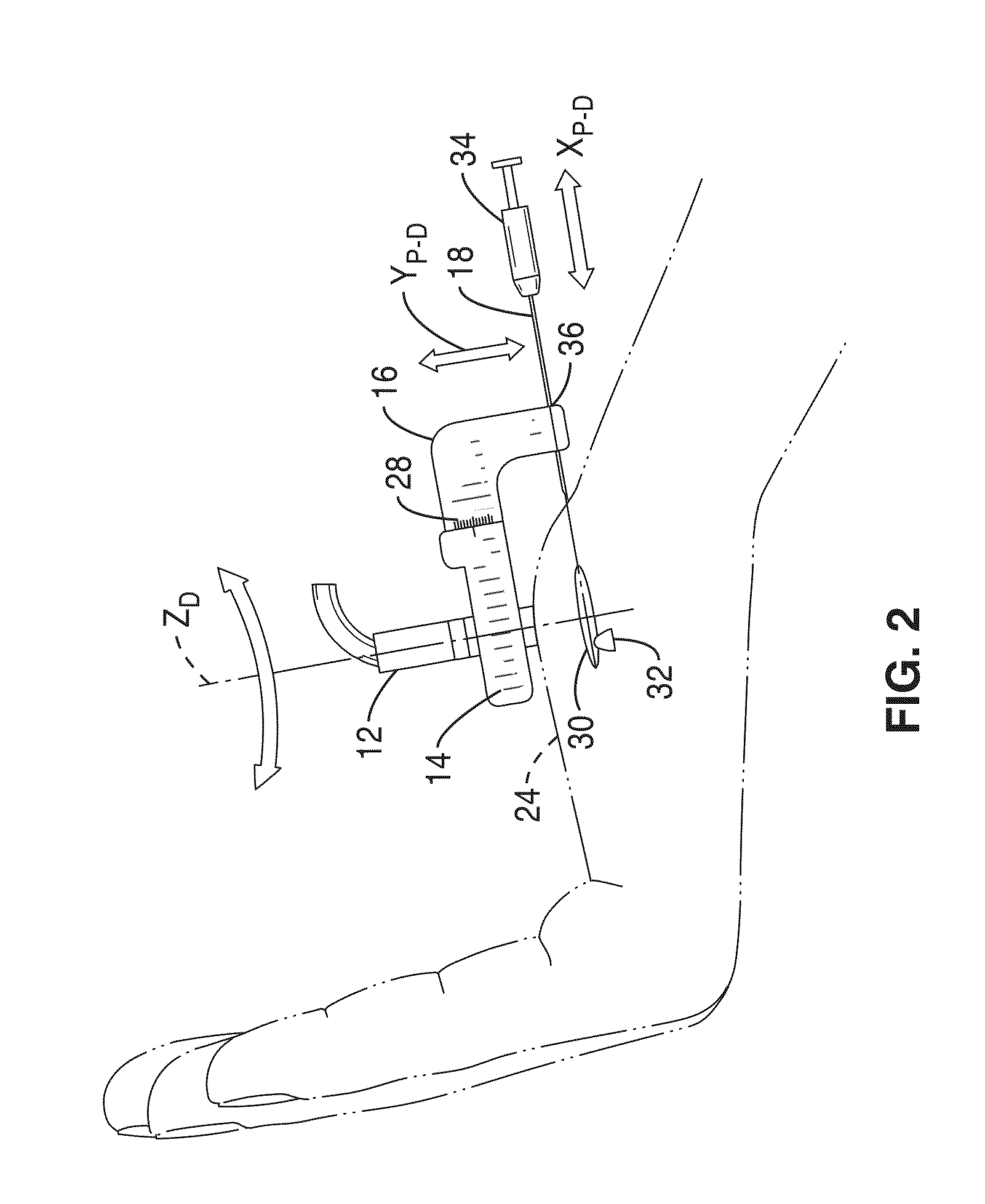

Treatment of carpal tunnel syndrome by injection of the flexor retinaculum

InactiveUS20100247513A1Altered stiffnessReduce pressureOrganic active ingredientsPeptide/protein ingredientsCTS - Carpal tunnel syndromeHand exercises

An apparatus and method for identifying the flexor retinaculum of the carpal tunnel, injecting an effective amount of an agent into at least a portion of flexor retinaculum or tissue adjacent thereto, wherein the agent is configured to weaken the flexor retinaculum. The system may further include means for increasing the tensile stress in the flexor retinaculum post-injection using hand exercises, thereby weakening its structural integrity and decreasing the pressure within the carpal tunnel that impairs median nerve function.

Owner:JOHN M AGEE & KAREN K AGEE TRUSTEES OF THE JOHN M AGEE TRUST

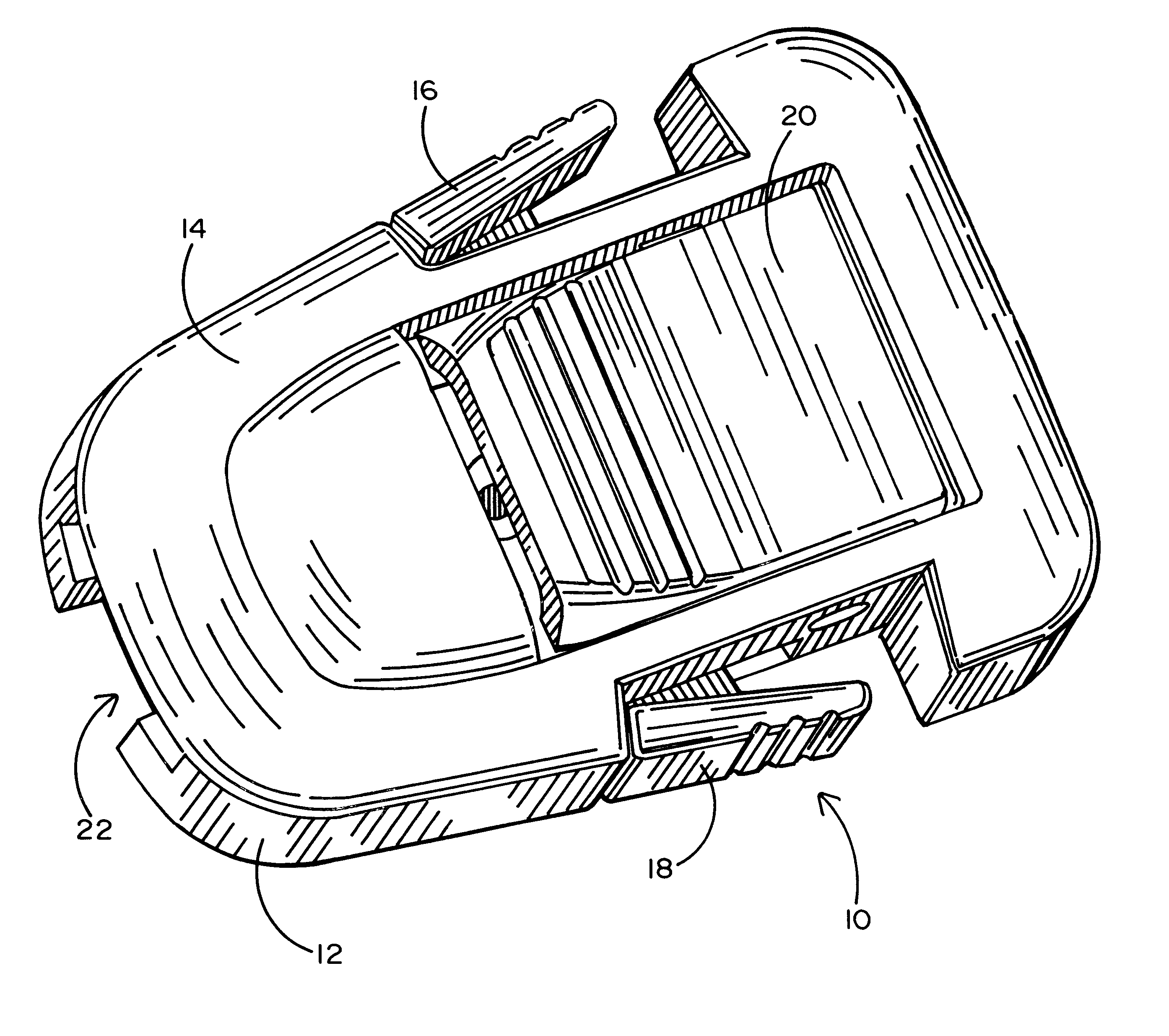

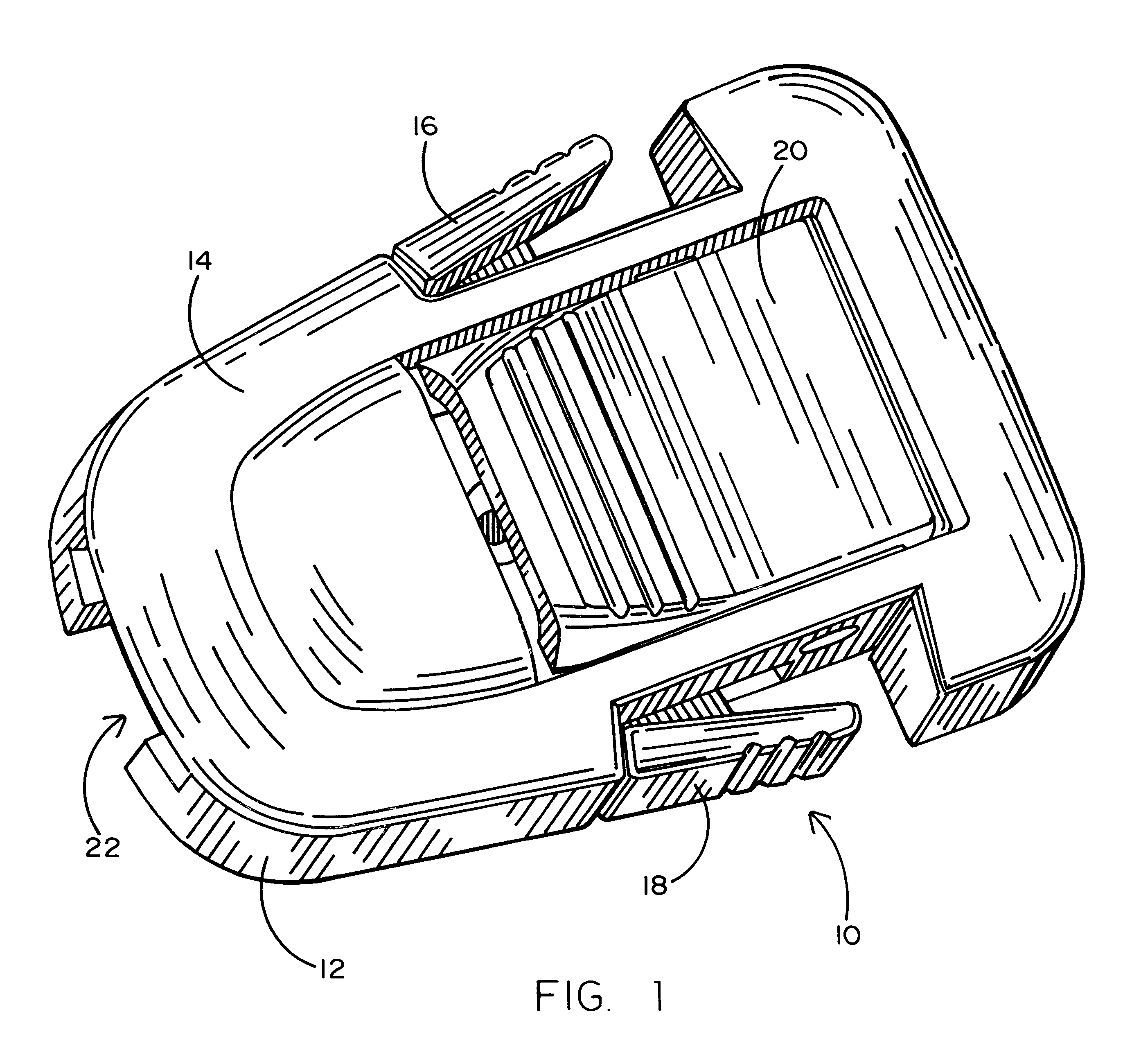

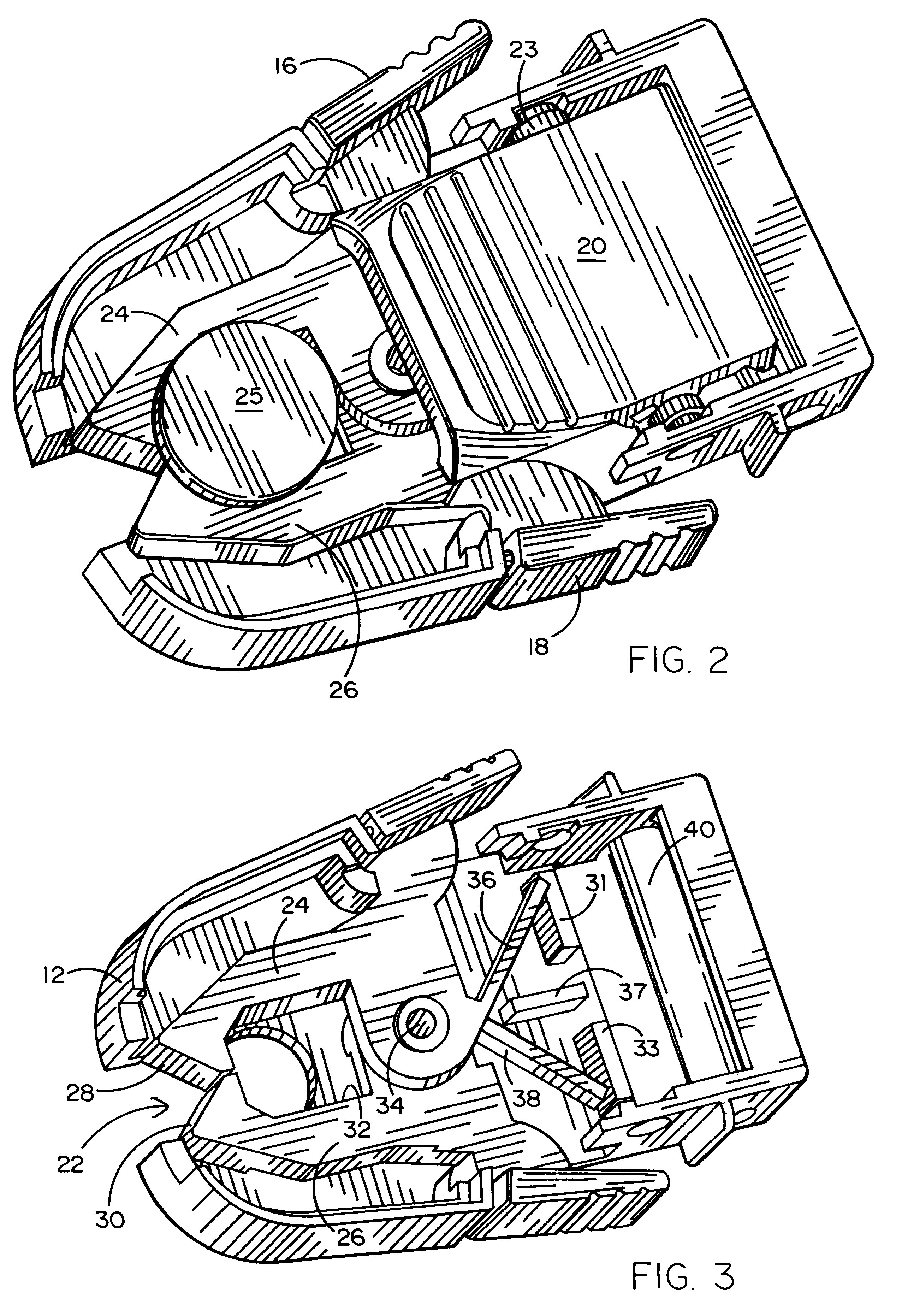

Strap connecting buckle

InactiveUS6463640B1Quick connectionQuick releaseSnap fastenersClothes buttonsEngineeringMechanical engineering

Owner:HUISH OUTDOORS

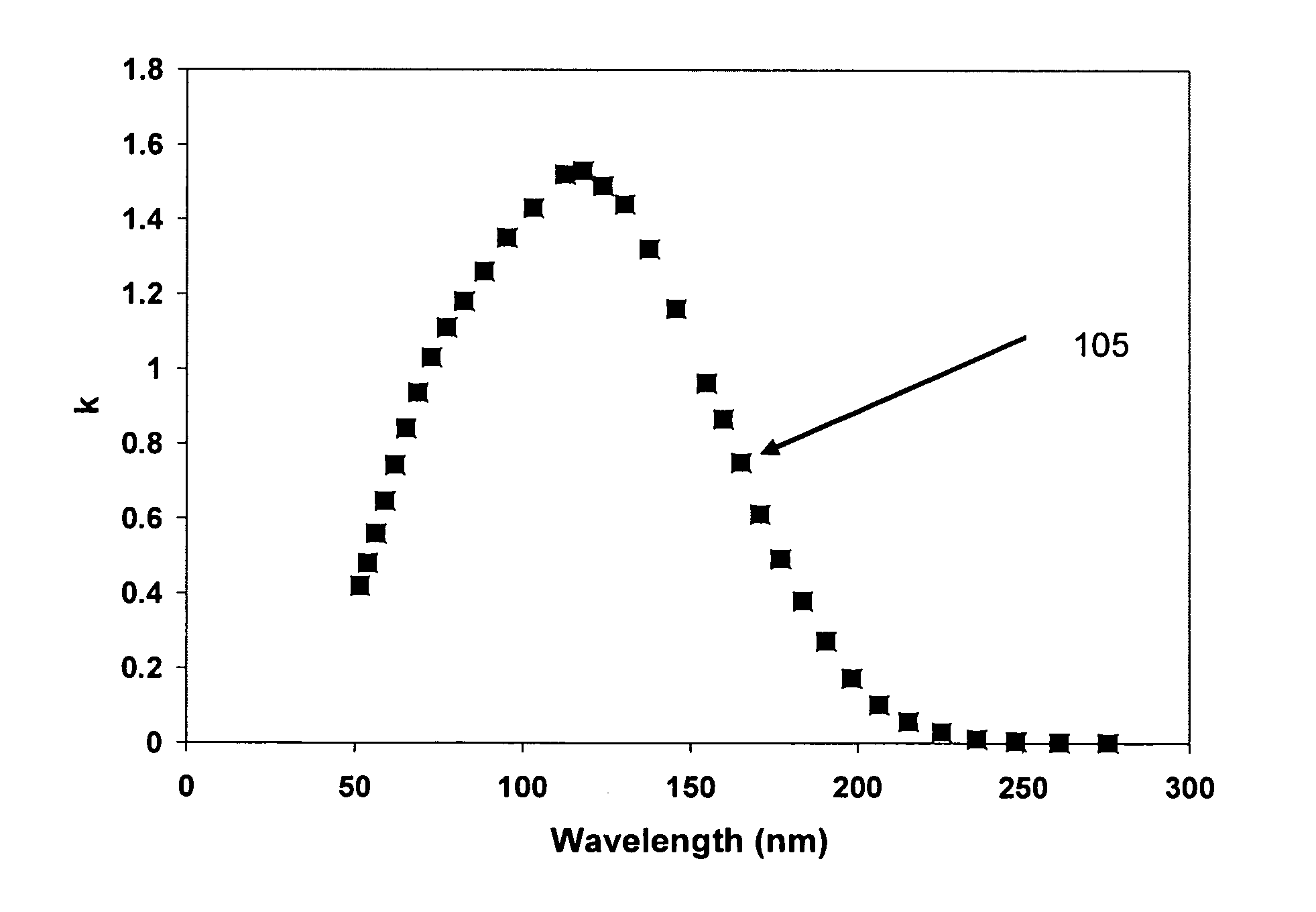

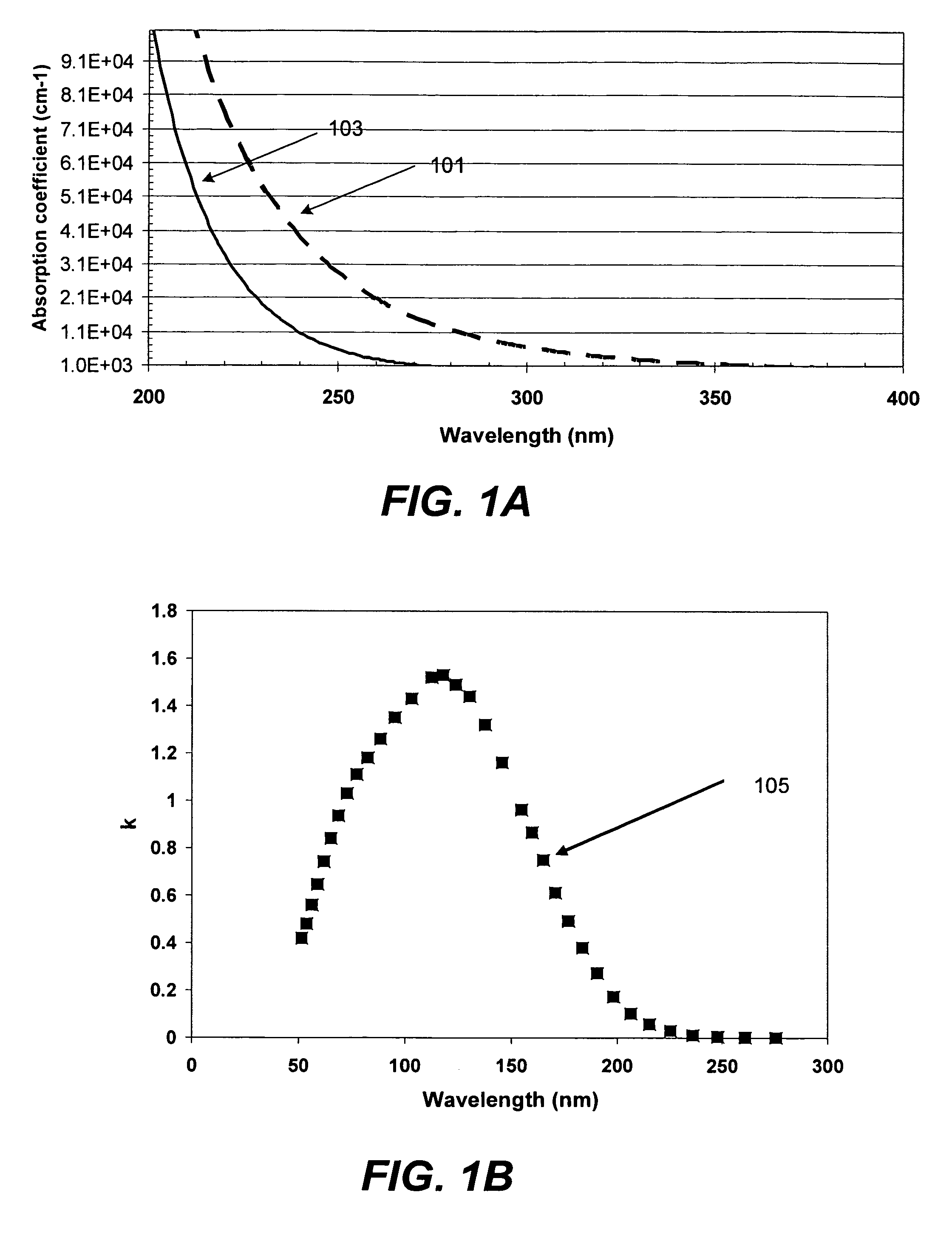

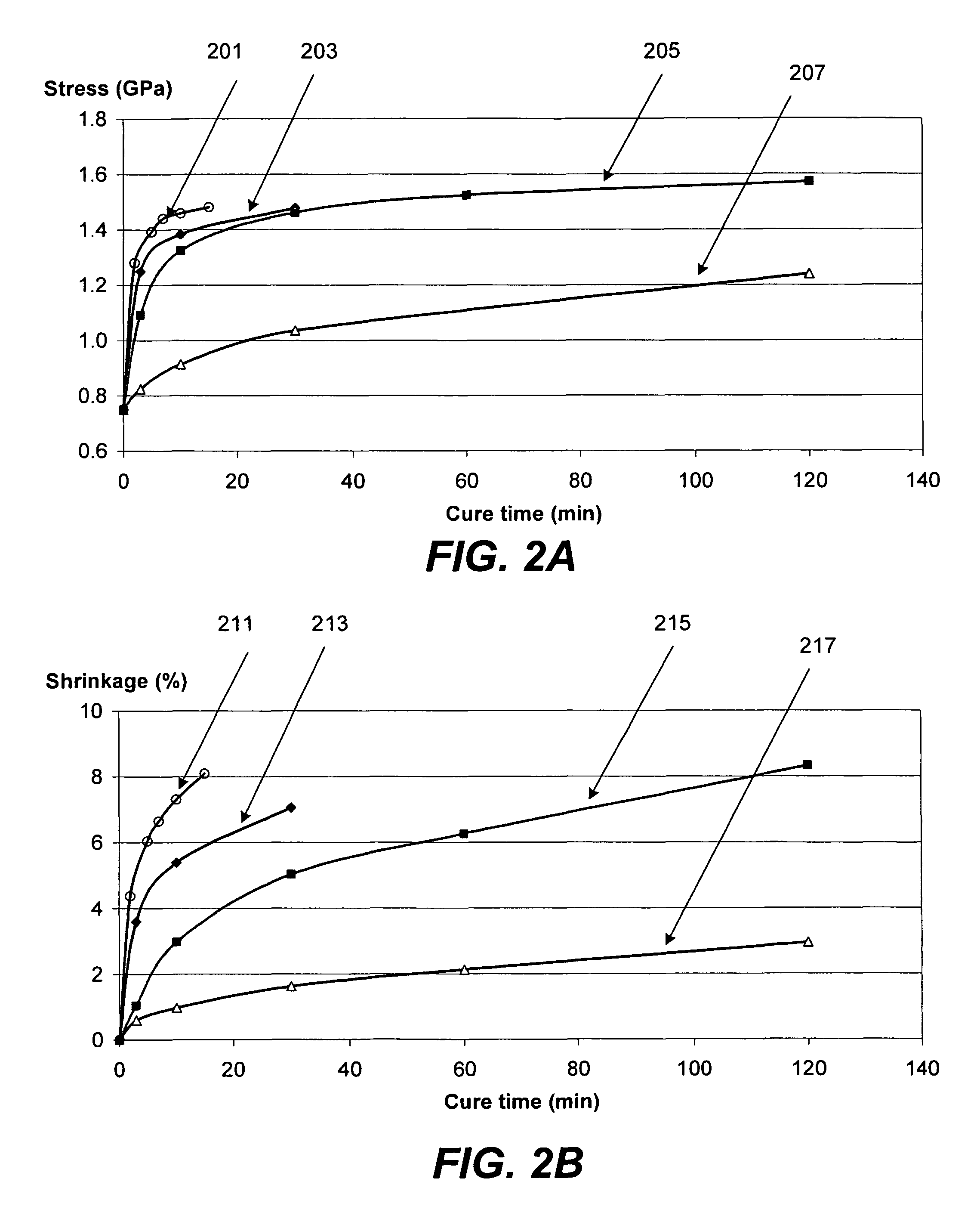

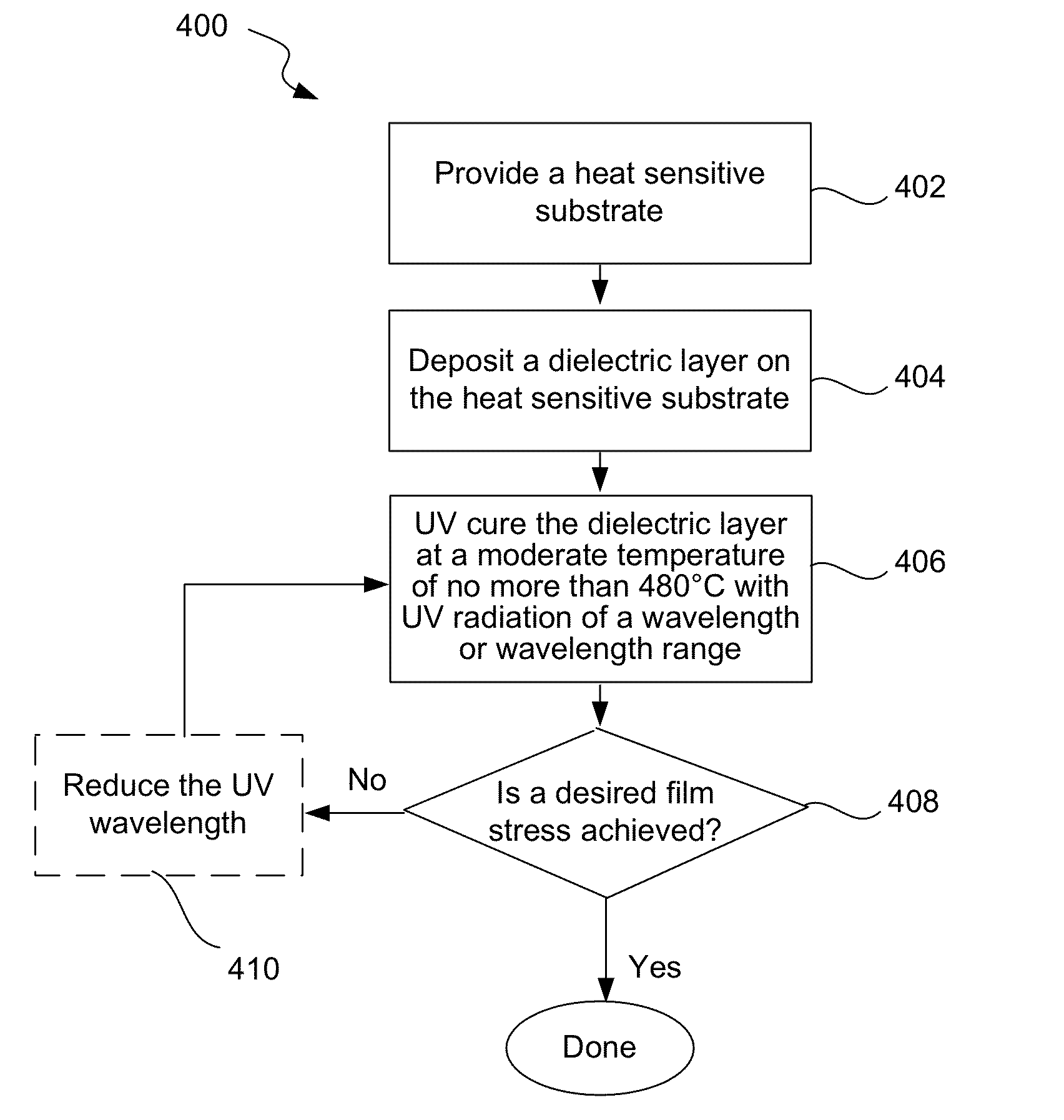

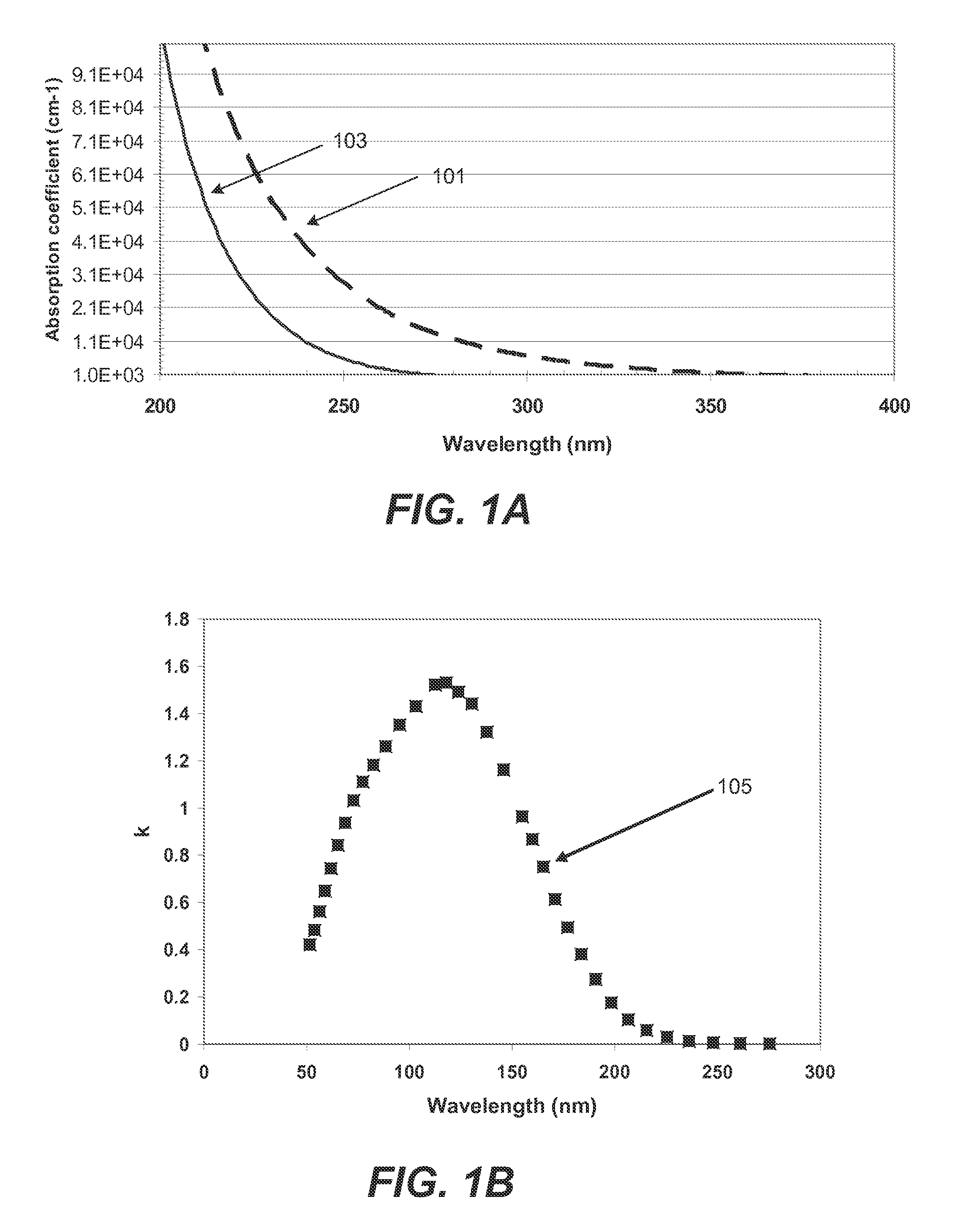

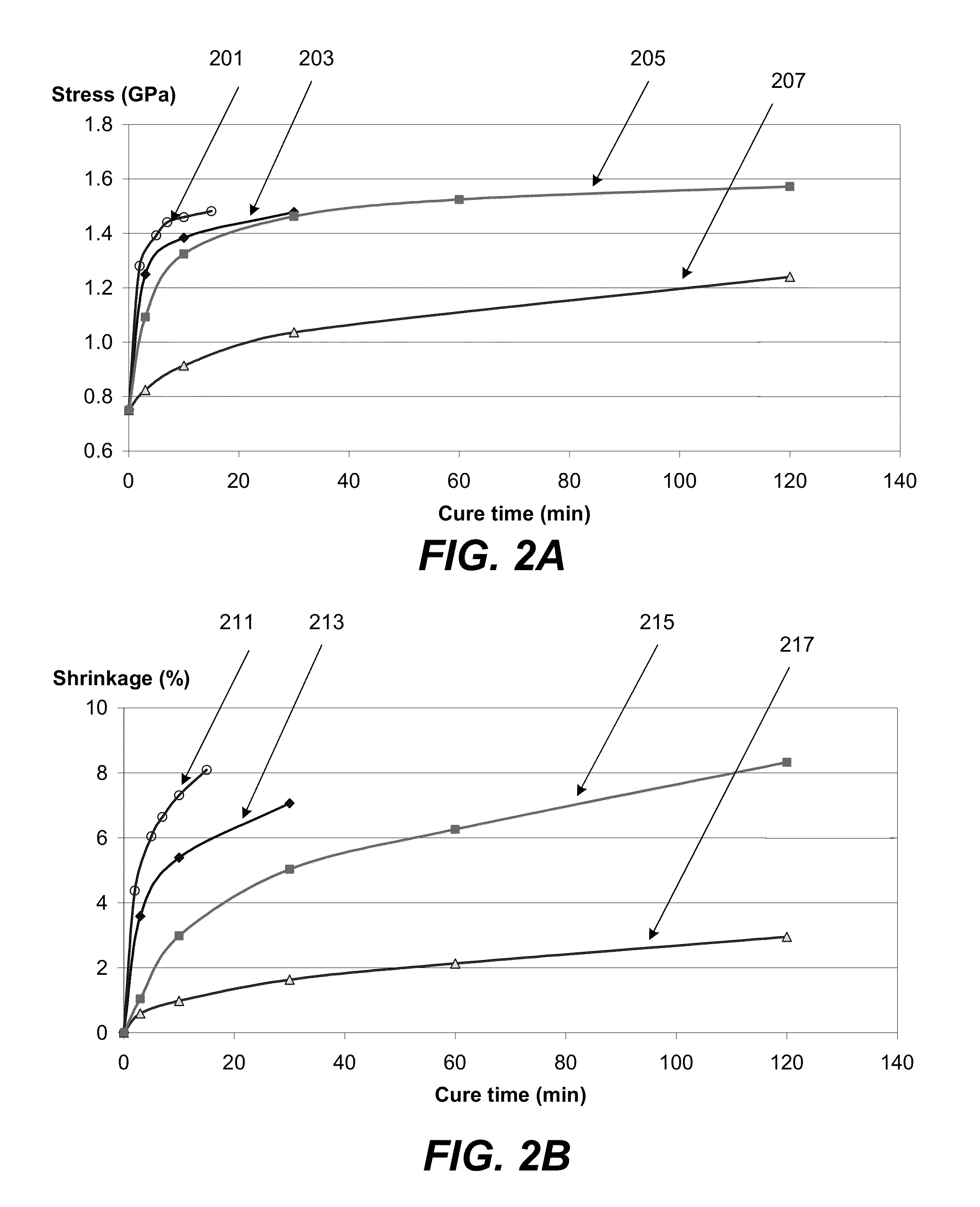

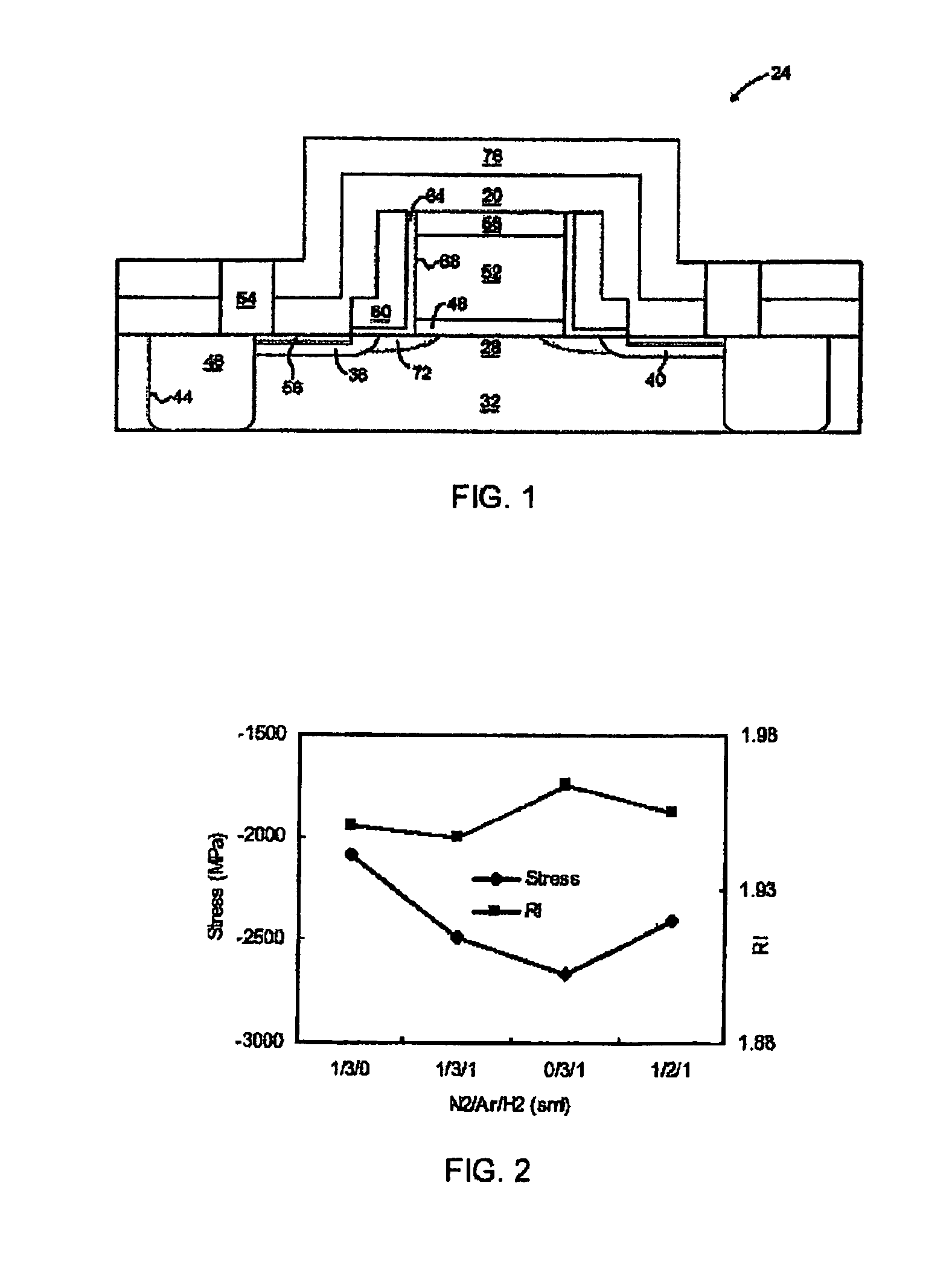

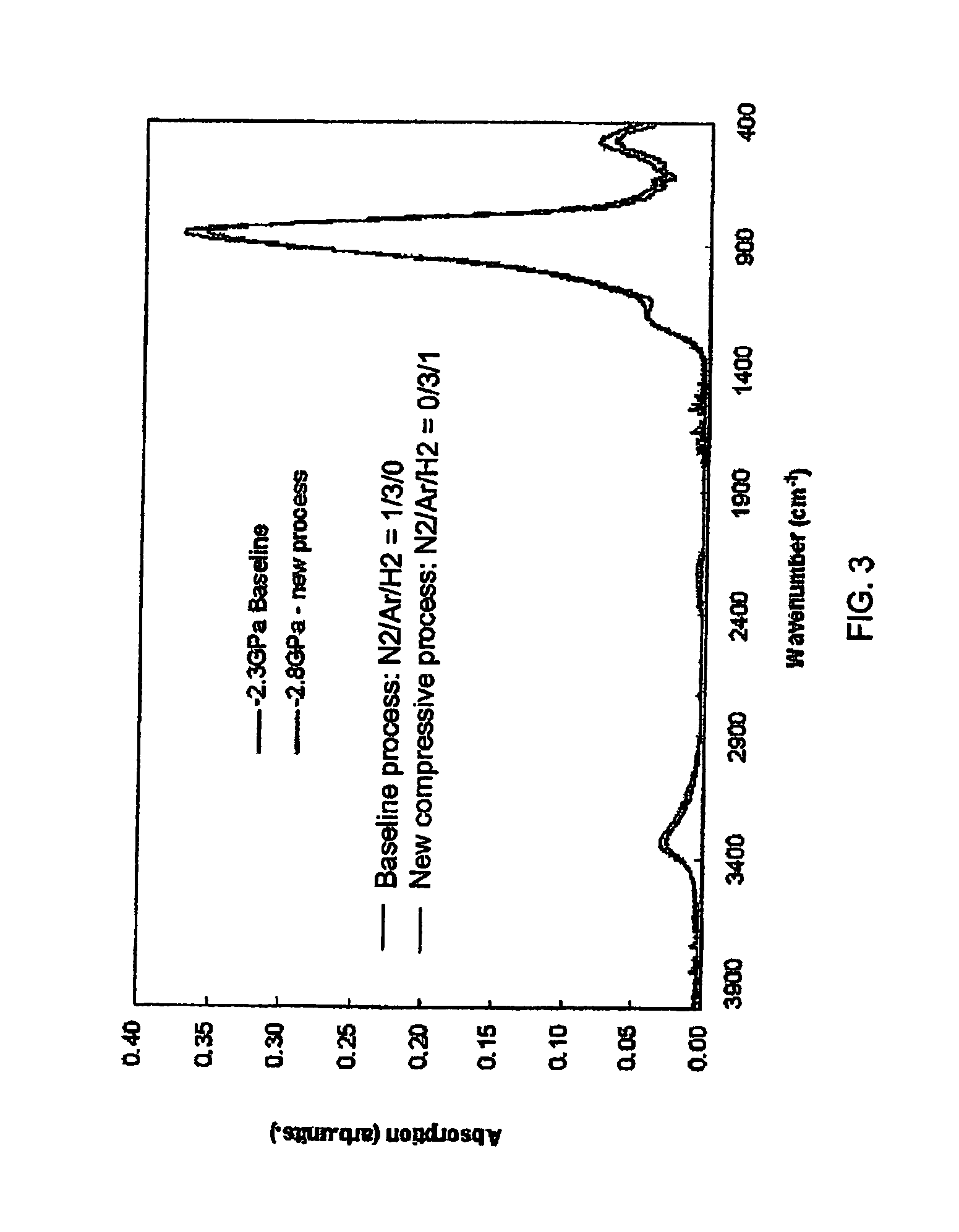

Cascaded cure approach to fabricate highly tensile silicon nitride films

ActiveUS8211510B1Minimizes shrinkage and film relaxationIncrease the tensile stressRadiation applicationsVacuum evaporation coatingUltravioletHeat sensitive

A highly tensile dielectric layer is generated on a heat sensitive substrate while not exceeding thermal budget constraints. Cascaded ultraviolet (UV) irradiation is used to produce highly tensile films to be used, for example, in strained NMOS transistor architectures. Successive UV radiation of equal or shorter wavelengths with variable intensity and duration selectively breaks bonds in the Si—N matrix and minimizes shrinkage and film relaxation. Higher tensile stress than a non-cascaded approach may be obtained.

Owner:NOVELLUS SYSTEMS

High performance field effect transistors on SOI substrate with stress-inducing material as buried insulator and methods

InactiveUS20060214225A1Enhance performanceHigh stressSemiconductor/solid-state device detailsSolid-state devicesStress inducedPerformance enhancement

The present invention provides a semiconductor structure that includes a high performance field effect transistor (FET) on a semiconductor-on-insulator (SOI) in which the insulator thereof is a stress-inducing material of a preselected geometry. Such a structure achieves performance enhancement from uniaxial stress, and the stress in the channel is not dependent on the layout design of the local contacts. In broad terms, the present invention relates to a semiconductor structure that comprises an upper semiconductor layer and a bottom semiconductor layer, wherein said upper semiconductor layer is separated from said bottom semiconductor layer in at least one region by a stress-inducing insulator having a preselected geometric shape, said stress-inducing insulator exerting a strain on the upper semiconductor layer.

Owner:GLOBALFOUNDRIES INC

Methods for altering residual stresses using mechanically induced liquid cavitation

InactiveUS6993948B2Altering residual tensile stressEffectively water-hammeringBurnishing machinesForging press detailsCavitationTransducer

A mechanical transducer induces liquid cavitation, causing pressure waves in a liquid which are applied against a metal surface to afford localized elastic and plastic tensile microstrain. The pressure waves alter the surface tensile stresses in the treated metal by reducing the tensile stresses or forming surface compressive stresses. A boot is provided about the operating face of the transducer for confining a liquid through which compression waves are generated and applied to the metal surface, the boot sealing about the transducer and the surface undergoing treatment.

Owner:GENERAL ELECTRIC CO

High performance field effect transistors on SOI substrate with stress-inducing material as buried insulator and methods

InactiveUS7388278B2Reduce parasitic capacitanceFast switching timeSemiconductor/solid-state device detailsSolid-state devicesStress inducedPerformance enhancement

The present invention provides a semiconductor structure that includes a high performance field effect transistor (FET) on a semiconductor-on-insulator (SOI) in which the insulator thereof is a stress-inducing material of a preselected geometry. Such a structure achieves performance enhancement from uniaxial stress, and the stress in the channel is not dependent on the layout design of the local contacts. In broad terms, the present invention relates to a semiconductor structure that comprises an upper semiconductor layer and a bottom semiconductor layer, wherein said upper semiconductor layer is separated from said bottom semiconductor layer in at least one region by a stress-inducing insulator having a preselected geometric shape, said stress-inducing insulator exerting a strain on the upper semiconductor layer.

Owner:GLOBALFOUNDRIES INC

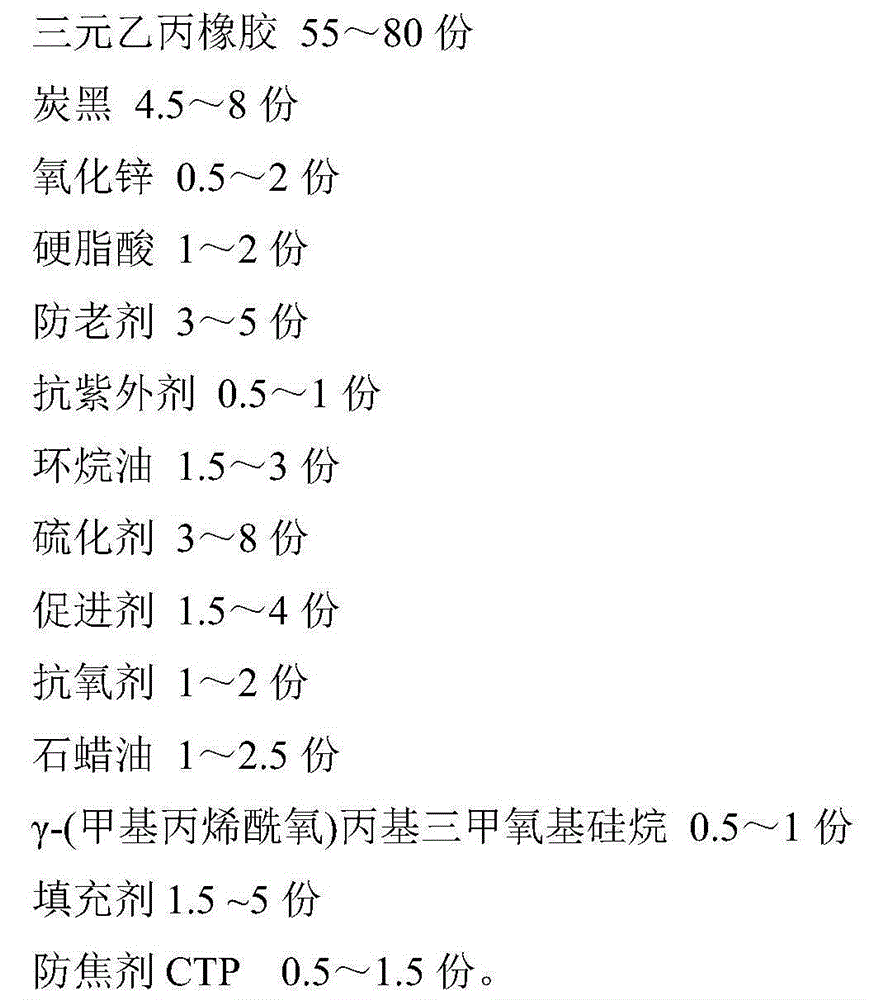

Automobile rubber sealing strip and preparation method thereof

The invention discloses an automobile rubber sealing strip and a preparation method thereof. The automobile rubber sealing strip comprises the following components in parts by weight: 55-80 parts of ethylene propylene diene monomer rubber, 4.5-8 parts of carbon black, 0.5-2 parts of zinc oxide, 1-2 parts of stearic acid, 3-5 parts of anti-aging agent, 0.5-1 part of ultraviolet-resistant agent, 1.5-3 parts of naphthenic oil, 3-8 parts of vulcanizing agent, 1.5-4 parts of accelerator, 1-2 parts of antioxidant, 1-2.5 parts of paraffin oil, 0.5-1 part of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-5 parts of filler and 0.5-1.5 parts of anti-scorching agent CTP. The automobile rubber sealing strip enhances the high temperature resistance, low temperature resistance, stability to light, ozone. oxygen and the like and other comprehensive properties of the product and improves the interface compatibility on the premise of keeping the original mechanical properties. The preparation method has the advantages of simple technique, short vulcanization time, lower energy consumption and lower production cost.

Owner:SUZHOU GOODTIME TECH DEV

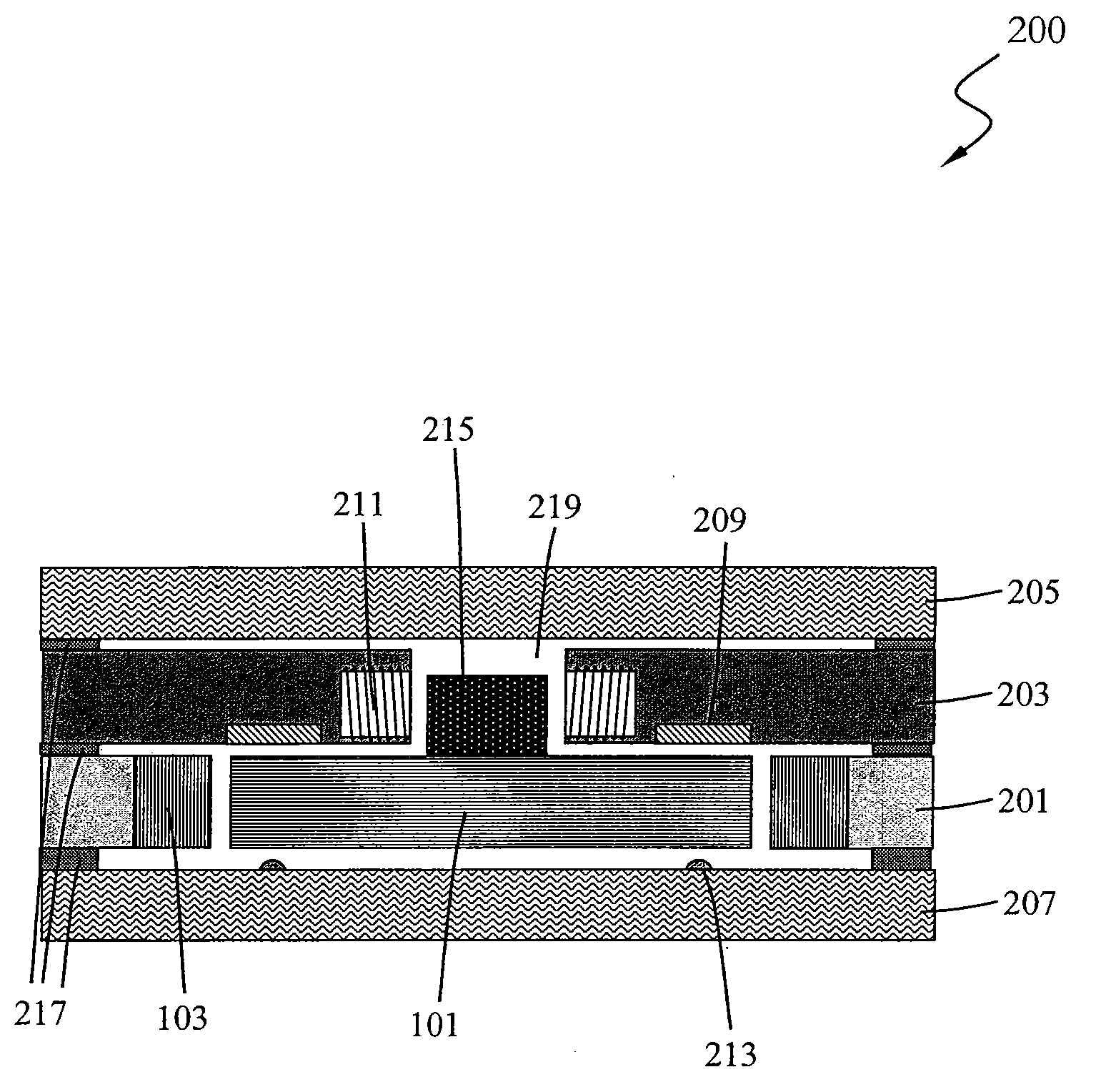

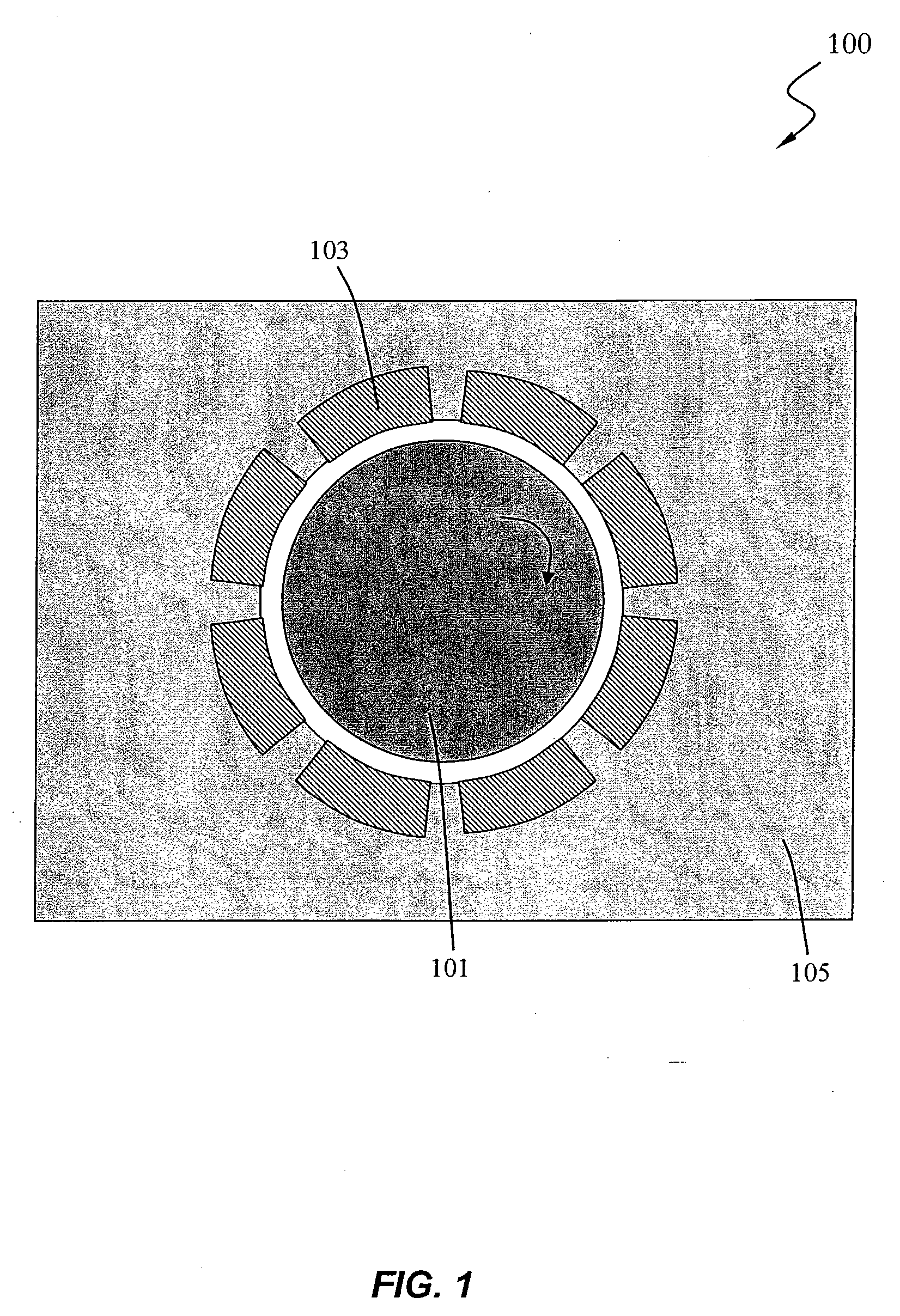

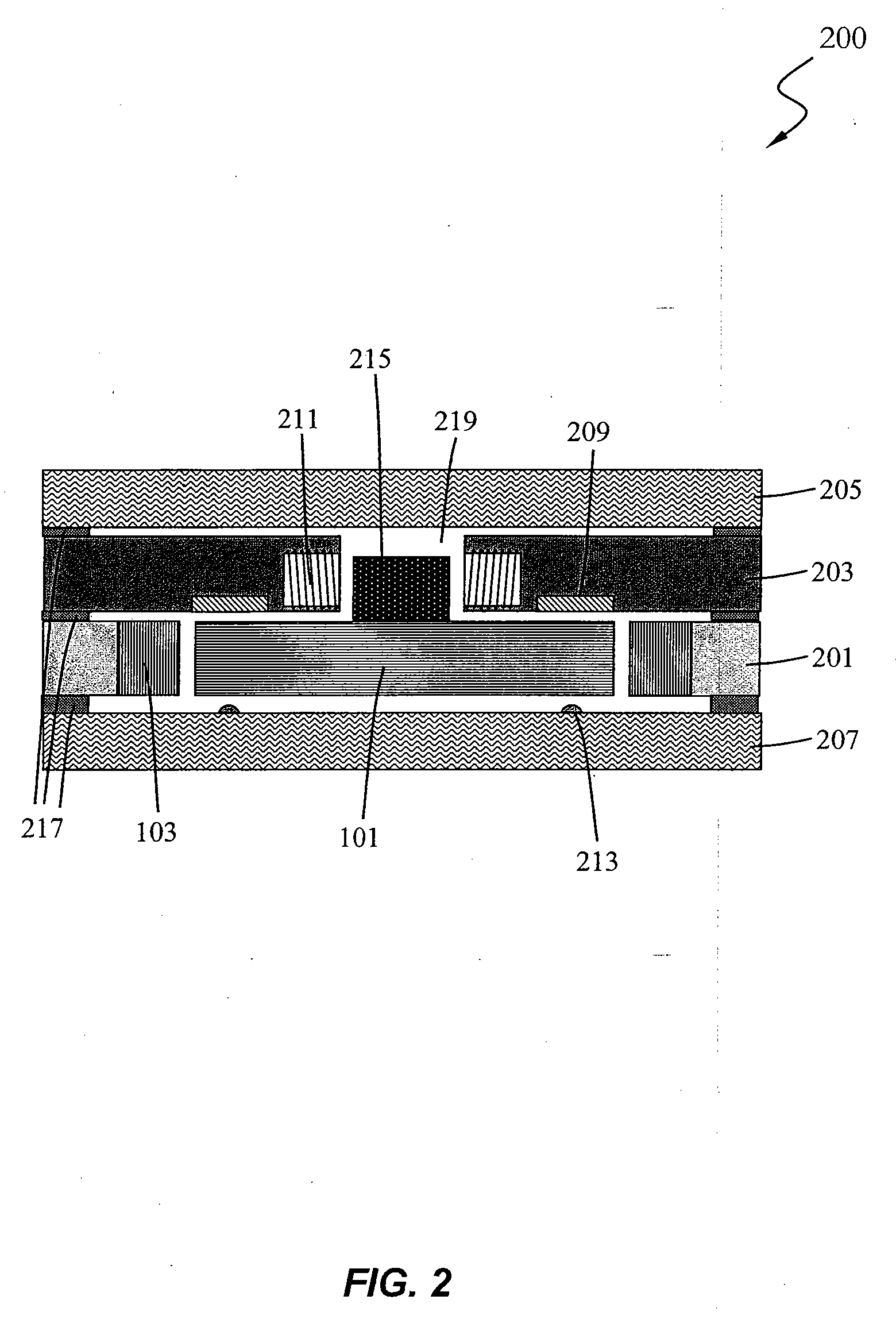

Method and Structure for Integrated Energy Storage Device

InactiveUS20070103009A1High tensile strengthHigh tensile stressMechanical energy handlingElectrostatic motorsFlywheel energy storage systemHigh energy

The present invention relates to a method and device for fabricating an integrated flywheel device using semiconductor materials and IC / MEMS processes. Single crystal silicon has high energy storage / weight ratio and no defects. Single crystal silicon flywheel can operate at much higher speed than conventional flywheel. The integrated silicon flywheel is operated by electrostatic motor and supported by electrostatic bearings, which consume much less power than magnetic actuation in conventional flywheel energy storage systems. The silicon flywheel device is fabricated by IC and MEMS processes to achieve high device integration and low manufacturing cost. For the integrated silicon flywheel, high vacuum can be achieved using hermetic bonding methods such as eutectic, fusion, glass frit, SOG, anodic, covalent, etc. To achieve larger energy capacity, an array of silicon flywheels is fabricated on one substrate. Multiple layers of flywheel energy storage devices are stacked.

Owner:YANG XIAO CHARLES

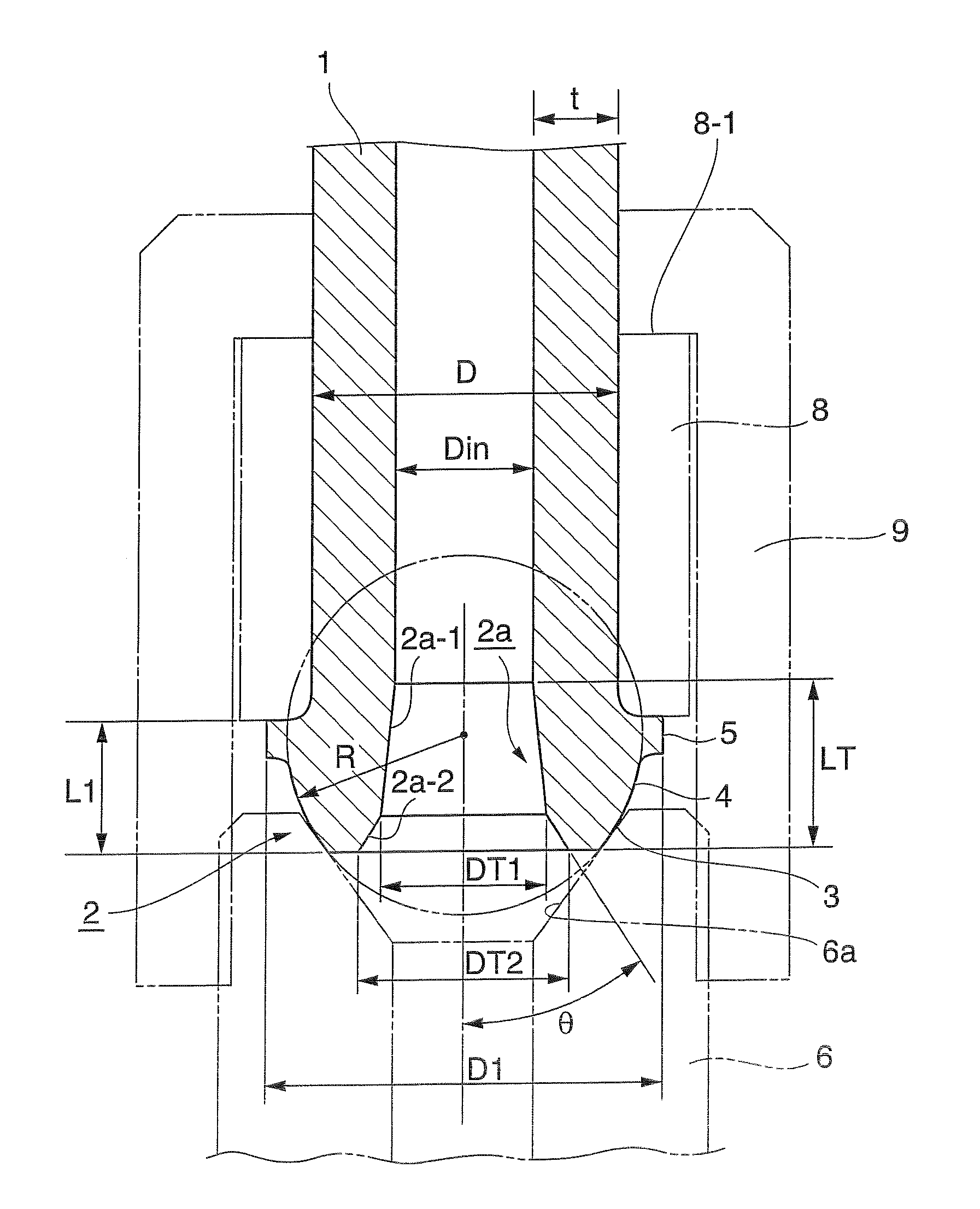

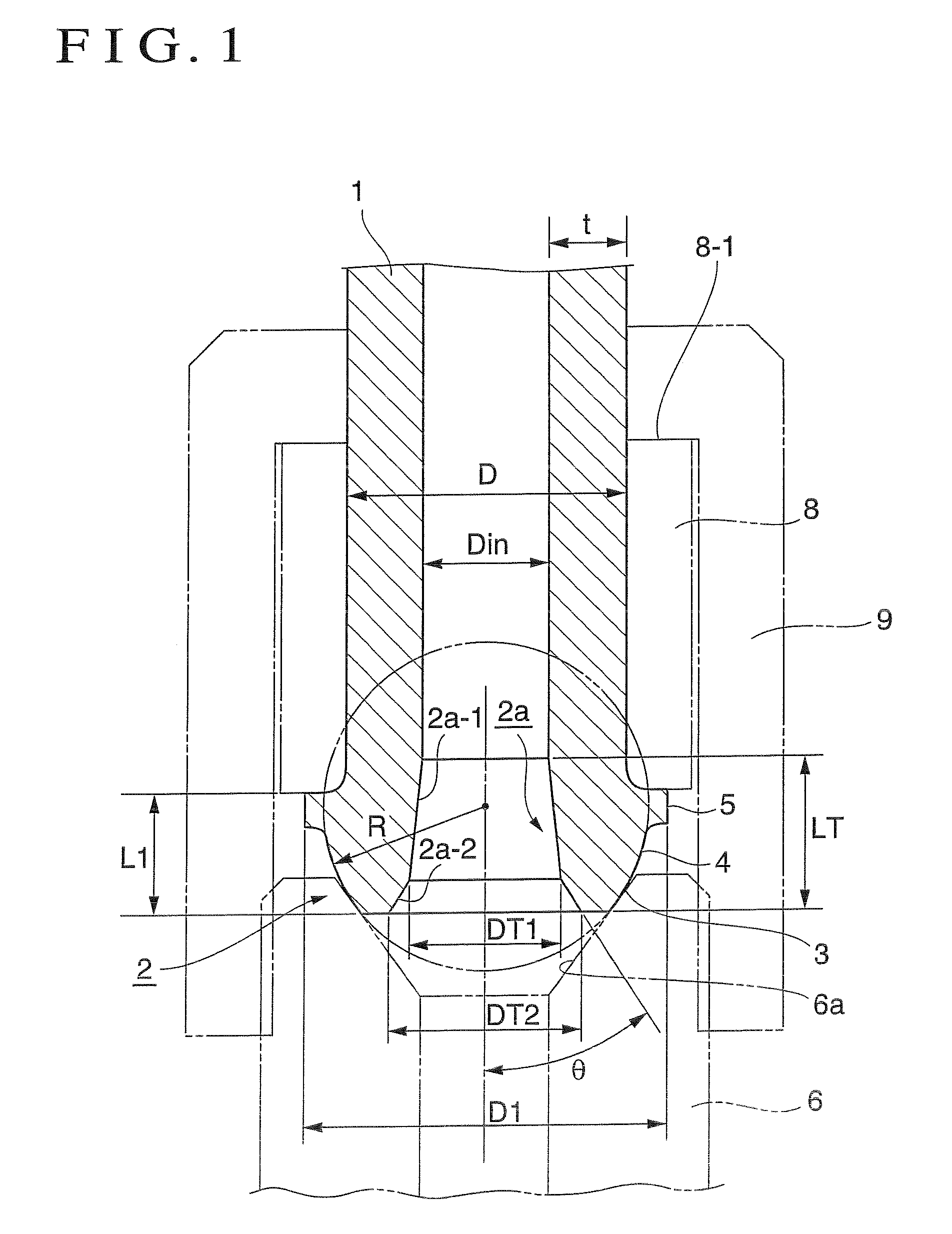

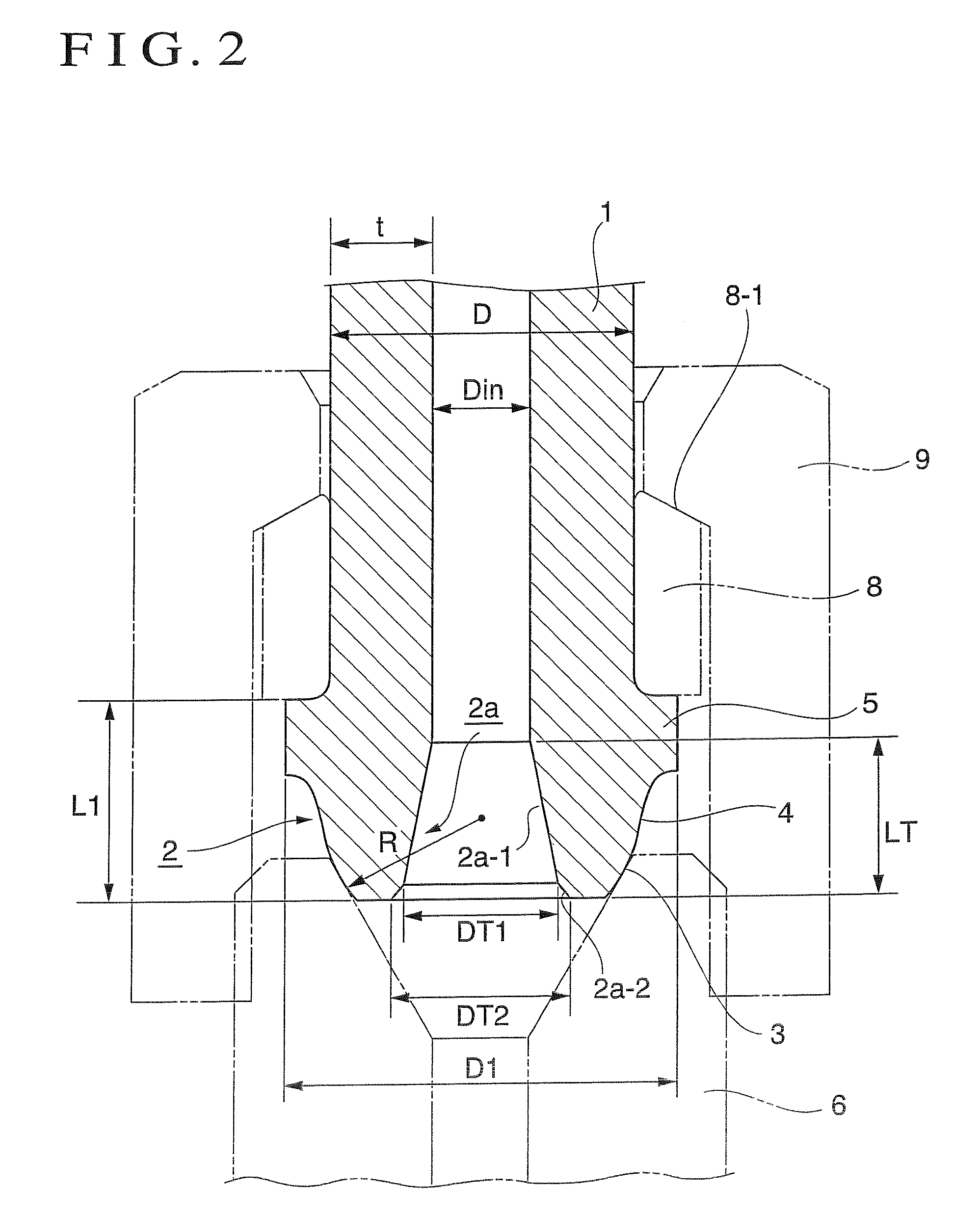

Connection head structure of high pressure fuel injection tube

ActiveUS7735473B2Improve sealingPrevent leakageJoints with sealing surfacesMachines/enginesCircular coneThick wall

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Systems and methods for placing a braided, tubular sleeve in a well bore

InactiveUS7082998B2Reduce forceReduce stressDrilling rodsFluid removalCombined useBiomedical engineering

Systems and methods for placing a tubular, braided sleeve in a well bore. The sleeve is positioned within an interior of a carrier configured to hold the sleeve in an undeployed position, followed by lowering the carrier into the well bore. The sleeve may be used in conjunction with a curable resin that can be solidified to set the sleeve into a tubular cross section. After securing the sleeve to the well bore, the carrier may be moved away from the bottom of the well bore, deploying the sleeve and extending it along the contour of the well bore. The tubular sleeve may then be subsequently expanded in situ to increase its diameter. The curable resin can then cured to make the sleeve substantially rigid.

Owner:HALLIBURTON ENERGY SERVICES INC

N-channel field effect transistor having a contact etch stop layer in combination with an interlayer dielectric sub-layer having the same type of intrinsic stress

InactiveUS20080054415A1Increase the tensile stressEfficient mechanismSemiconductor/solid-state device detailsSolid-state devicesStress conditionsEngineering

By forming a tensile silicon dioxide layer on the basis of a sub-atmospheric deposition technique, the strain-inducing mechanism of a tensile contact etch stop layer for N-channel transistors may be significantly improved. Consequently, for otherwise identical stress conditions, the performance of a respective N-channel transistor may be significantly enhanced.

Owner:GLOBALFOUNDRIES INC

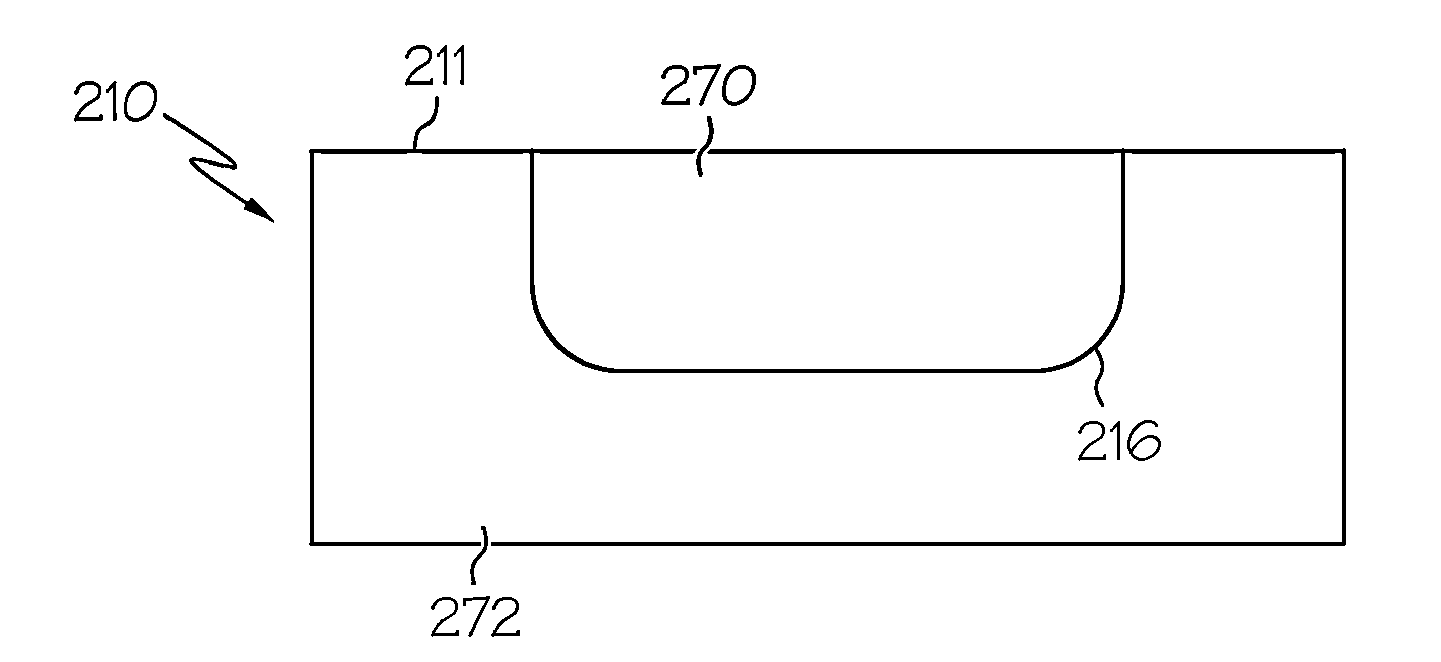

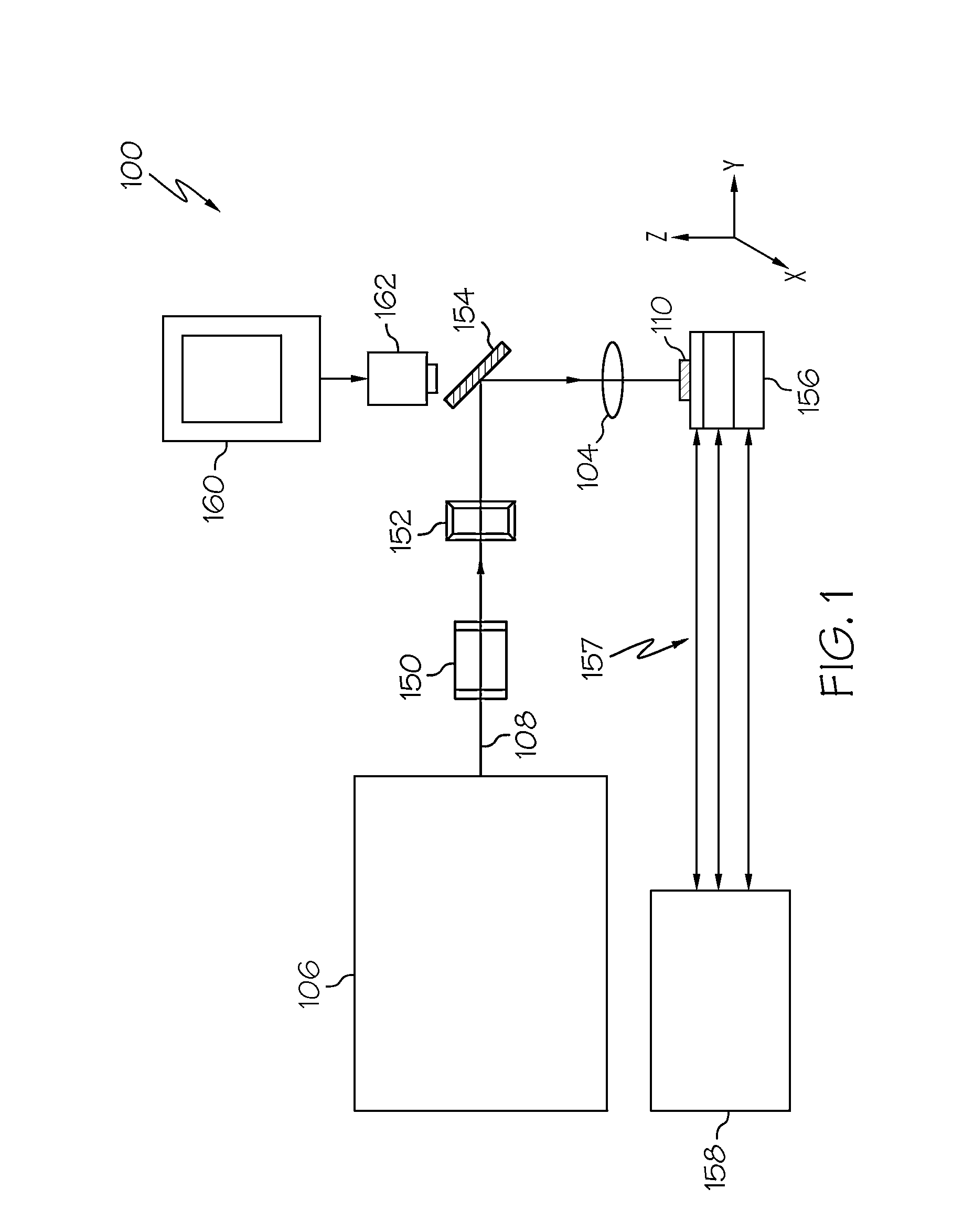

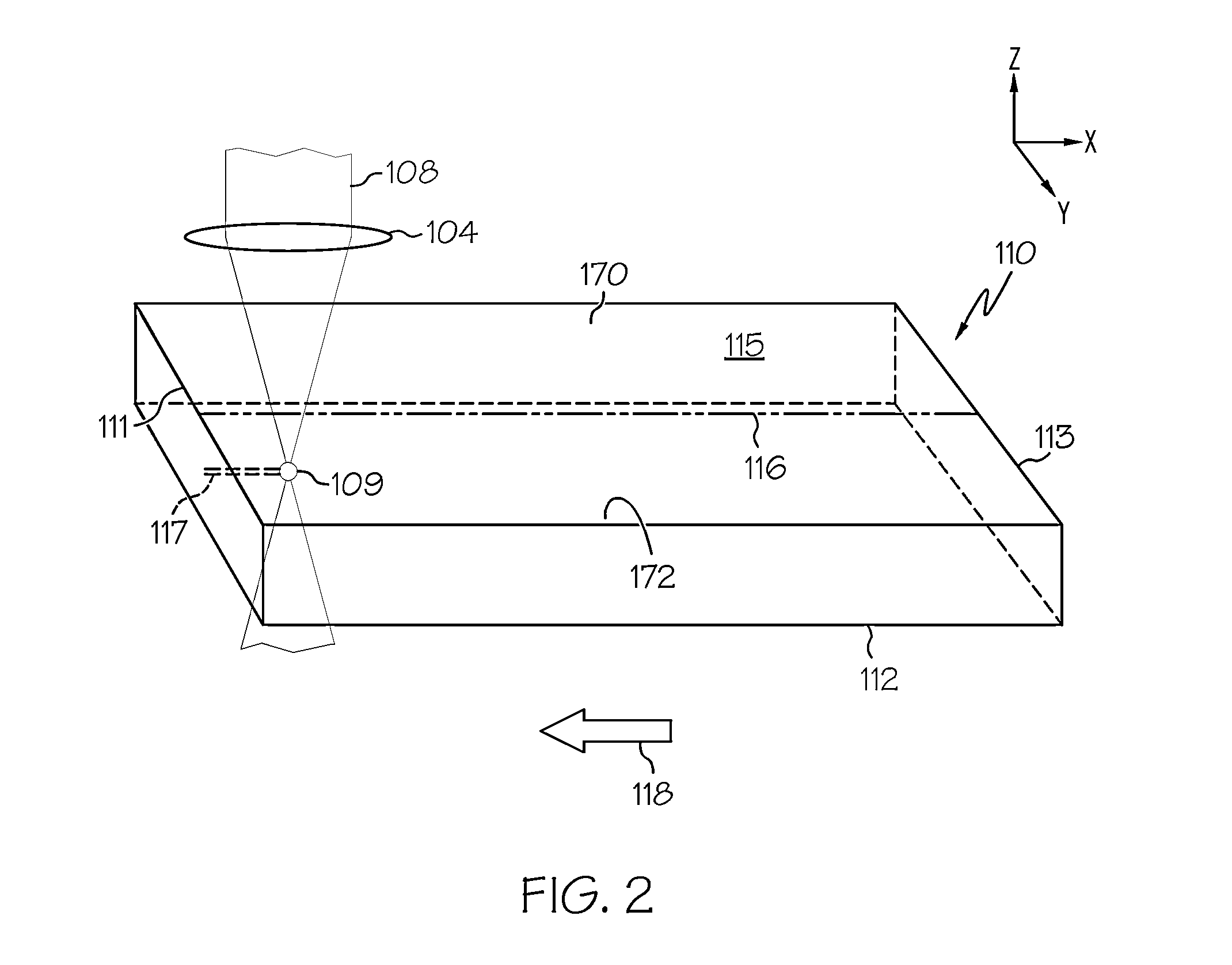

Methods for laser cutting articles from ion exchanged glass substrates

ActiveUS20130180665A2Increase the tensile stressGlass reforming apparatusGlass severing apparatusIon exchangeLaser cutting

A method of cutting an article (172) from a chemically strengthened glass substrate (110) includes generating a pulsed laser beam (108) from a laser source (106). The pulsed laser beam (108) may have a pulse duration of less than about 1000 fs and an output wavelength such that the chemically strengthened glass substrate (110) is substantially transparent to the pulsed laser beam (108). The pulsed laser beam (108) may be focused to form a beam waist (109) that is positioned in the same horizontal plane as an inner tensile region (124) of the chemically strengthened glass substrate (110). The beam waist (109) may be translated in a first pass along a cut line (116), wherein the beam waist (109) traverses an edge (111) of the chemically strengthened glass substrate. The beam waist (113) may then be translated in a second pass along the cut line (116) such that a crack (119) propagates from the edge (113) along the cut line (116) ahead of the translated beam waist (109) during the second pass.

Owner:CORNING INC

Cascaded cure approach to fabricate highly tensile silicon nitride films

InactiveUS8512818B1Minimizes shrinkage and film relaxationIncrease the tensile stressVacuum evaporation coatingPretreated surfacesUltravioletHeat sensitive

A highly tensile dielectric layer is generated on a heat sensitive substrate while not exceeding thermal budget constraints. Cascaded ultraviolet (UV) irradiation is used to produce highly tensile films to be used, for example, in strained NMOS transistor architectures. Successive UV radiation of equal or shorter wavelengths with variable intensity and duration selectively breaks bonds in the Si—N matrix and minimizes shrinkage and film relaxation. Higher tensile stress than a non-cascaded approach may be obtained.

Owner:NOVELLUS SYSTEMS

Piezoelectric hospital call signal generator

ActiveCN107332469ANo tensile stressIncrease the tensile stressPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsSignal generator

The invention relates to a piezoelectric hospital call signal generator and belongs to the technical field of a medical electronic product. The end portion of a side wall of a housing is connected with an upper cover having a through hole. The upper cover is provided with a circuit board through washers, and the circuit board is provided with an energy conversion circuit and a signal emission system. The side wall of the housing is connected with a vibrator base. The vibrator base is equipped with a group of piezoelectric vibrators through a press plate. The piezoelectric vibrators are separated by separator plates correspondingly. Each piezoelectric vibrator is in an arc structure formed by a substrate and a piezoelectric sheet, which are glued together, wherein the bending radius of the substrate is smaller than the bending radius of the piezoelectric sheet. A bottom wall of the housing is provided with a square sink groove, which is internally equipped with a guide bar. The guide bar is provided with a reset spring, a lower short rigid block, a lower flexible dial slice, a lower long rigid block, a middle short rigid block, a middle flexible dial slice, a middle long rigid block, an upper short rigid block, an upper flexible dial slice, an upper long rigid block and a button in sequence from the bottom up. A small end of the button passes through the through hole in the upper cover, and the upper surface of a big end of the button is abutted against the upper cover; and the bottom wall of the housing is connected to a sickbed.

Owner:ZHEJIANG NORMAL UNIVERSITY

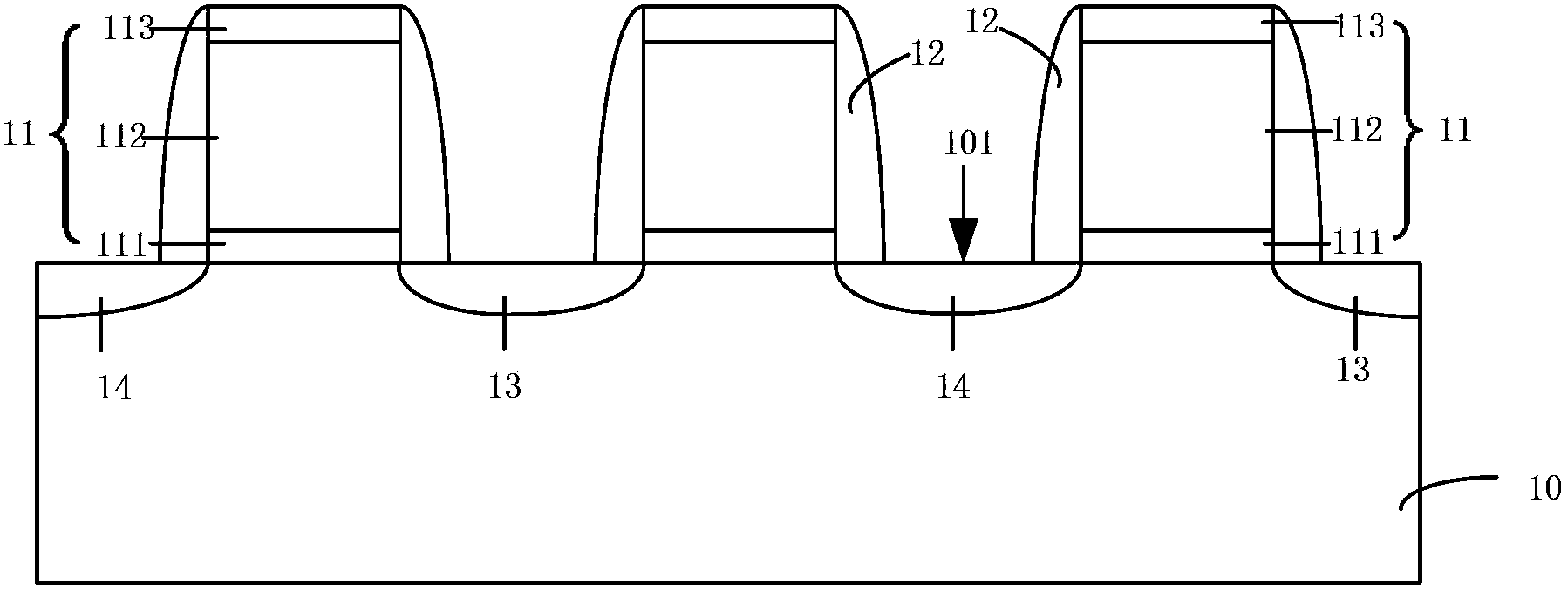

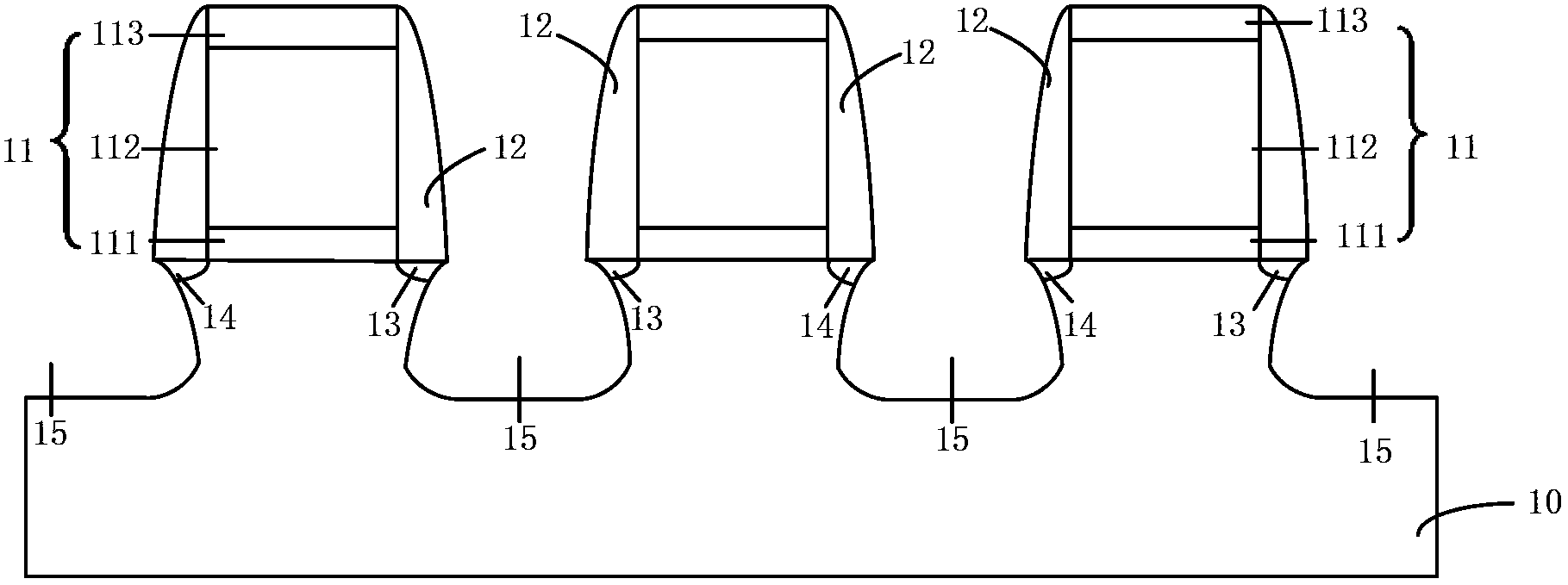

Manufacturing method for PMOS transistor and manufacturing method for NMOS transistor

ActiveCN104103515AIncrease compressive stressIncrease the tensile stressTransistorSemiconductor/solid-state device manufacturingEngineeringElectron

The invention provides a manufacturing method for a PMOS transistor and a manufacturing method for an NMOS transistor. According to the aforementioned manufacturing methods, multiple laminated sigma-shaped grooves (at least two), i.e. stepped sigma-shaped grooves, are formed in source electrode and drain electrode regions in a direction of being perpendicular to the surface of a silicon substrate. In the direction from the surface of the silicon substrate into the silicon substrate, the groove tip, which stretches into a channel, of each sigma-shaped groove presents to be away from the channel gradually. Then a) as for the PMOS transistor, silicon germanium material is filled in the stepped sigma-shaped grooves so that pressure stress is applied to the channel, b) and as for the NMOS transistor, silicon carbide material is filled in the stepped sigma-shaped grooves so that pulling stress is applied to the channel. Therefore, capacity of the stepped sigma-shaped grooves is larger, and more silicon germanium material or silicon carbide material can be accommodated. Correspondingly, pressure stress or pulling stress to the channel is increased so that migration rate of hole carriers or electron carriers is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Integration process for fabricating stressed transistor structure

ActiveUS7566655B2Defects are reducedIncrease compressive stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHigh stress

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

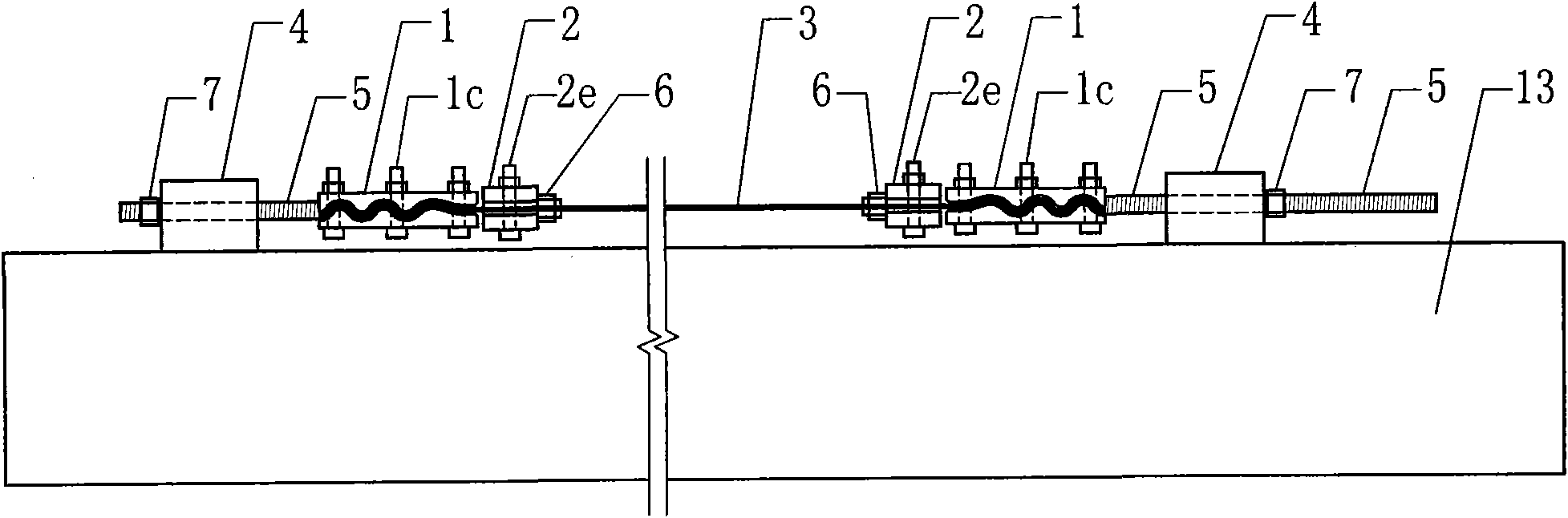

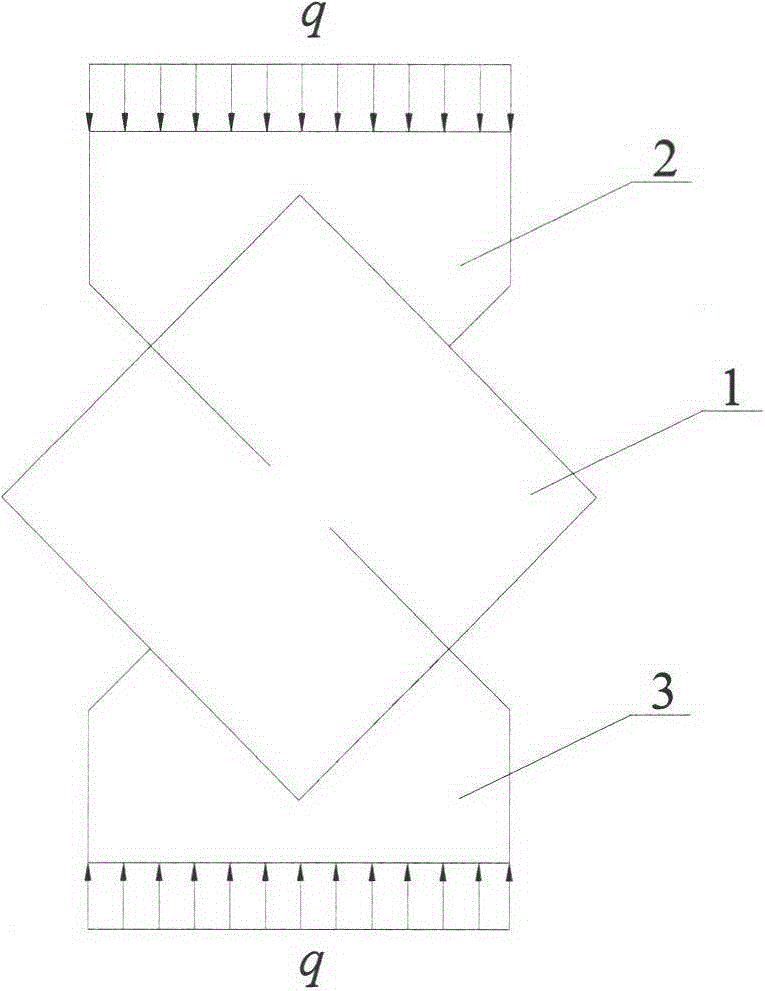

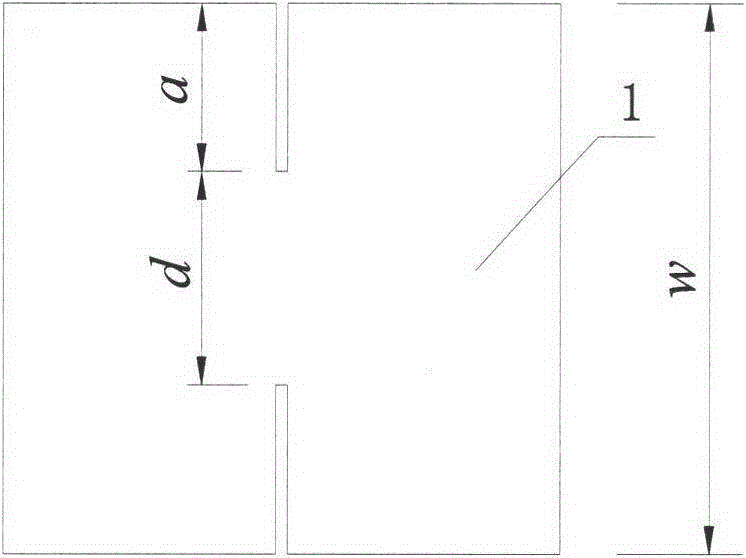

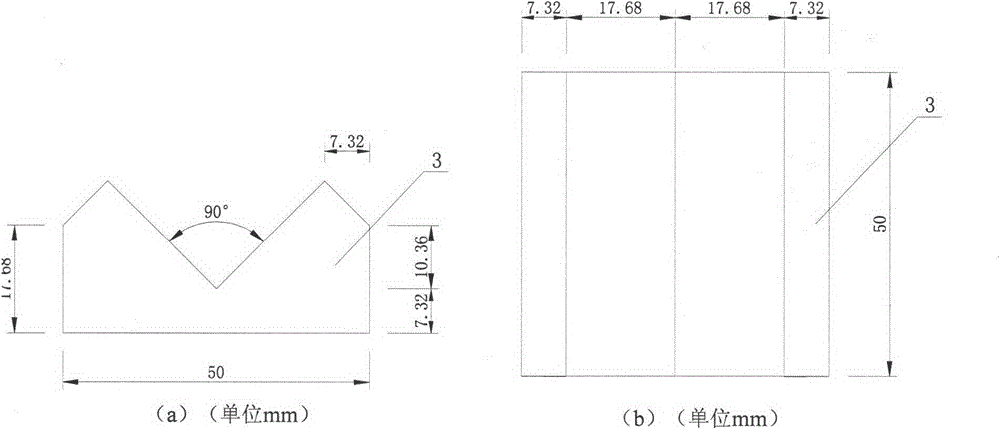

New rock II-type fracture toughness test method

InactiveCN104833590AEnables Mode II Fracture Toughness TestingIncrease the tensile stressPreparing sample for investigationMaterial strength using steady shearing forcesType fractureRock sample

The invention relates to a new rock II-type fracture toughness test method. According to the invention, on the basis of an original shear box test, by means of adjustments of the stress state of a loaded mould and arrangement of a sample to eliminate rotation tendency of the sample, generation of an excessive tensile stress on a crack tip is inhibited, thereby achieving rock II-type fracture toughness test. A test model includes a square rock sample and two steel loading moulds. Straight cracks are pre-formed on the middle parts of the two sides of the square rock sample, wherein the lengths and the widths of the two straight cracks are equal to each other. The two straight cracks are arranged symmetrically. The loading moulds can achieve 45-degree loading of the sample with a loading end surface being flat and smooth. The widths of two contact surfaces between the loading moulds and the square rock sample are both half of the side length of the sample. An upper end and a lower end of the whole system are subjected to a uniform load. The method enables processing of the rock sample and the loading moulds to be more convenient, is simplified in test process, ensures accuracy of test data, is suitable for the II-type fracture toughness test of various rocks, and provides basis for researching the II-type fracture of rocks and a problem of composite fracture mainly comprising II-type fracture.

Owner:吴礼舟

Method of fabricating strained-silicon transistors

ActiveUS20070111416A1High electron mobilityIncrease the tensile stressSemiconductor/solid-state device manufacturingSemiconductor devicesRapid thermal annealingSemiconductor

A method of fabricating strained-silicon transistors includes providing a semiconductor substrate, in which the semiconductor substrate includes a gate, at least a spacer, and a source / drain region; performing a first rapid thermal annealing (RTA) process; removing the spacer and forming a high tensile stress film over the surface of the gate and the source / drain region; and performing a second rapid thermal annealing process.

Owner:UNITED MICROELECTRONICS CORP

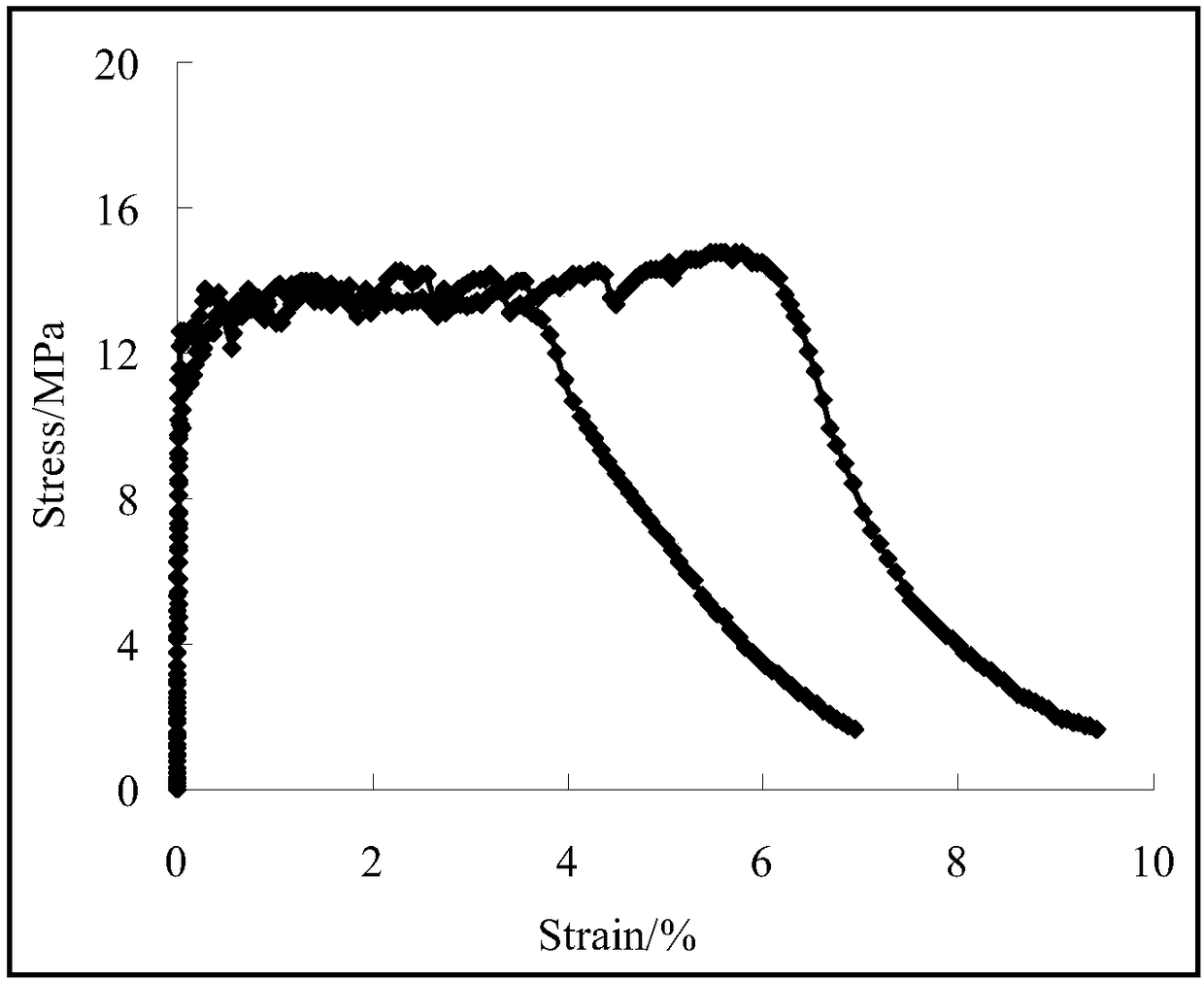

Hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material

The invention relates to a hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material which comprises the following ingredients in parts by weight: 700-1250 parts of 525 ordinary Portland cement, 200-300 parts of silica fume, 200-750 parts of mineral powder, 400-500 parts of quartz sand, 200-230 parts of water, 20-30 parts of a polycarboxylic acid high efficiency waterreducer, 5-20 parts of ultra-high molecular weight polyethylene fiber and 39-117 parts of ultrahigh-strength steel fiber. Compared with the prior art, the cement-based composite with maximum compressive strength of 200MPa, direct tension strength near 15MPa, tensile ductility near 10% and slump of greater than 180mm is obtained by mixed use of the ultra-high molecular weight polyethylene fiber and the steel fiber, and can be pumped and cast in place.

Owner:TONGJI UNIV

Method for eliminating plate shape component partial drape with dent area

InactiveCN101209470AEliminate wrinklesIncrease the tensile stressShaping toolsWrinkle skinEngineering

Owner:BYD CO LTD

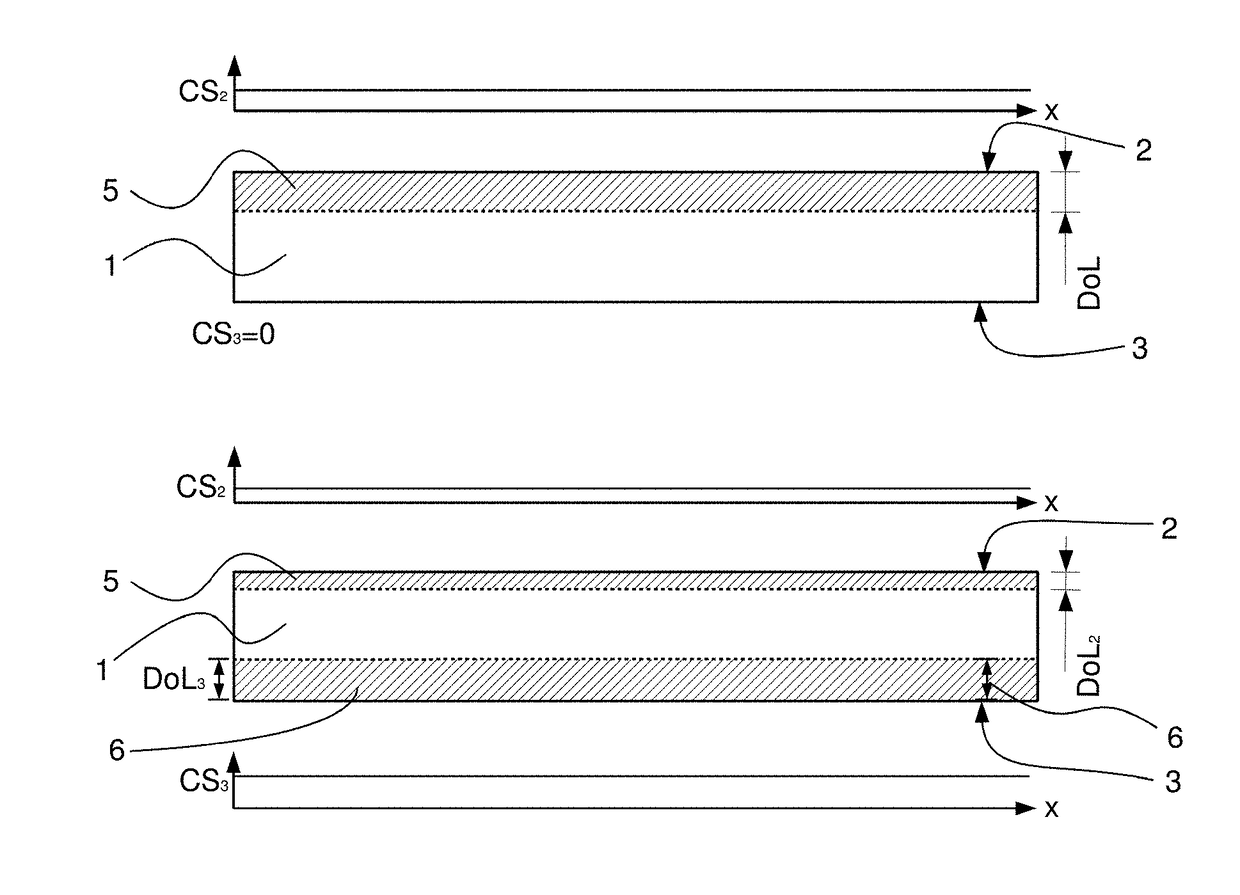

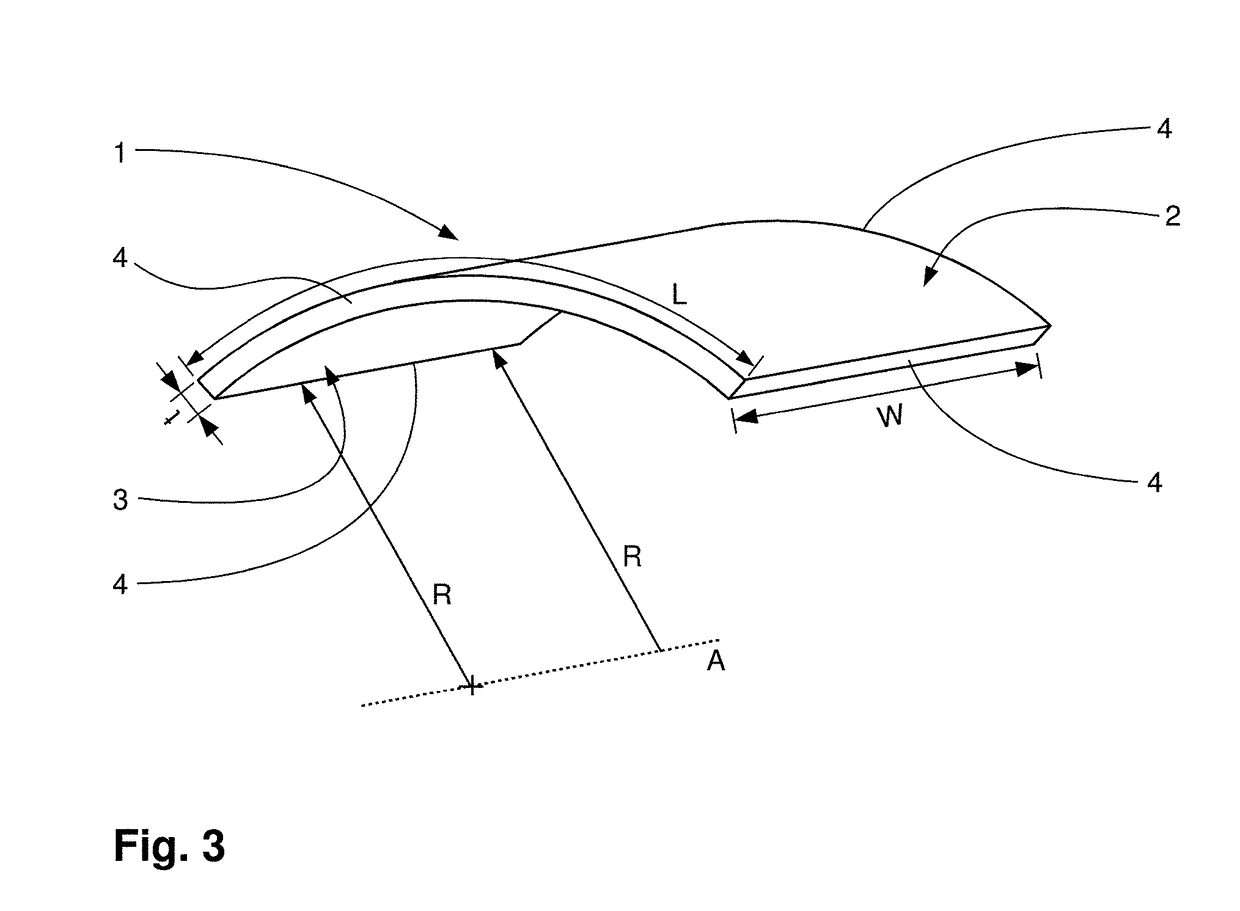

Shaped glass article and method for producing such a shaped glass article

ActiveUS20180009697A1Increase the tensile stressDecrease in fatigue lifetimeGlass/slag layered productsGlass reforming apparatusEngineering

A shaped glass article is provided that is ultrathin, has two surfaces and one or more edges joining the two surfaces, and a thickness between the two surfaces. The shaped ultrathin glass article has at least one curved area with a non-vanishing surface curvature with a minimal curvature radius R if no external forces are applied. A method for producing a shaped glass article is also provided that includes providing an ultrathin glass with two surfaces and one or more edges joining the two surfaces, having a thickness between the two surfaces and shaping the ultrathin glass to a shaped ultrathin glass article by forming at least one curved area having a non-vanishing surface curvature with a minimal curvature radius R if no external forces are applied to the shaped ultrathin glass article.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com