Method for eliminating plate shape component partial drape with dent area

A technology for areas and parts, applied in the field of eliminating wrinkling of drawn parts, can solve problems such as not very effective, more wrinkles in parts, and large mold wear, so as to achieve the effects of reducing waste, eliminating wrinkles, and reducing mold wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

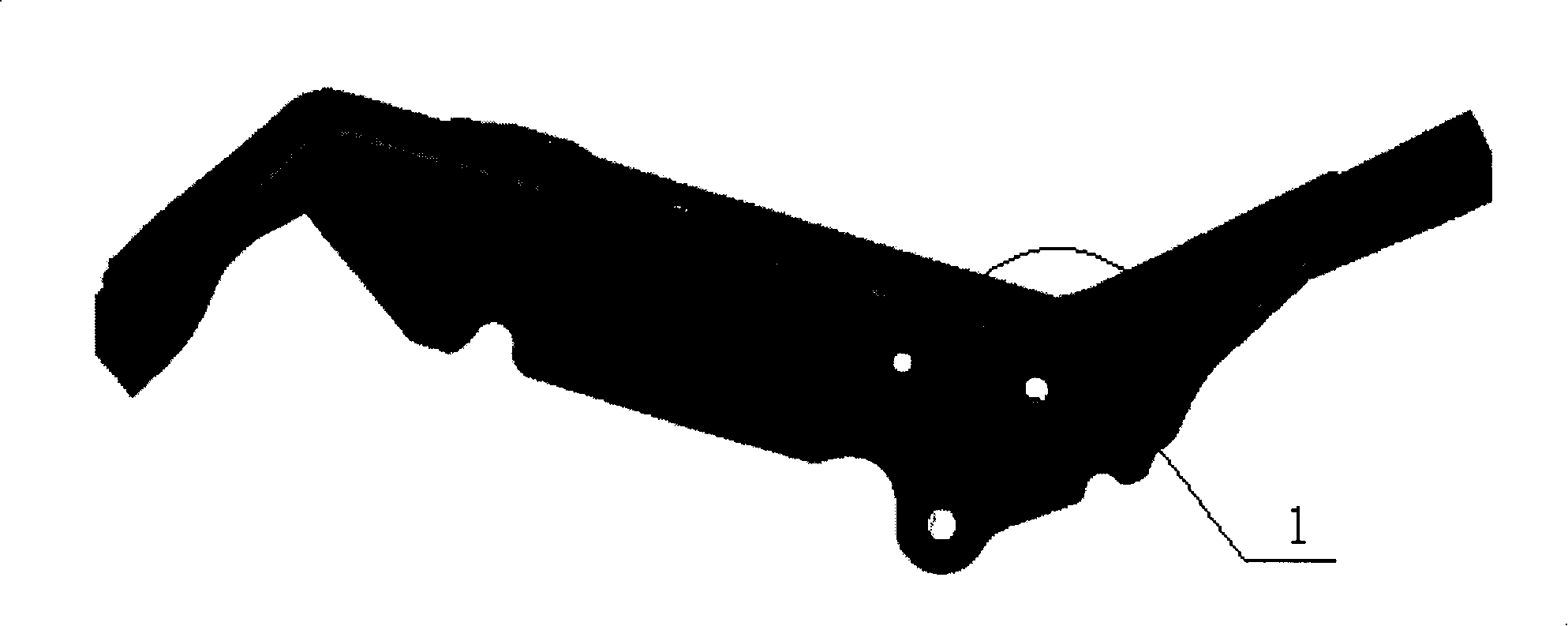

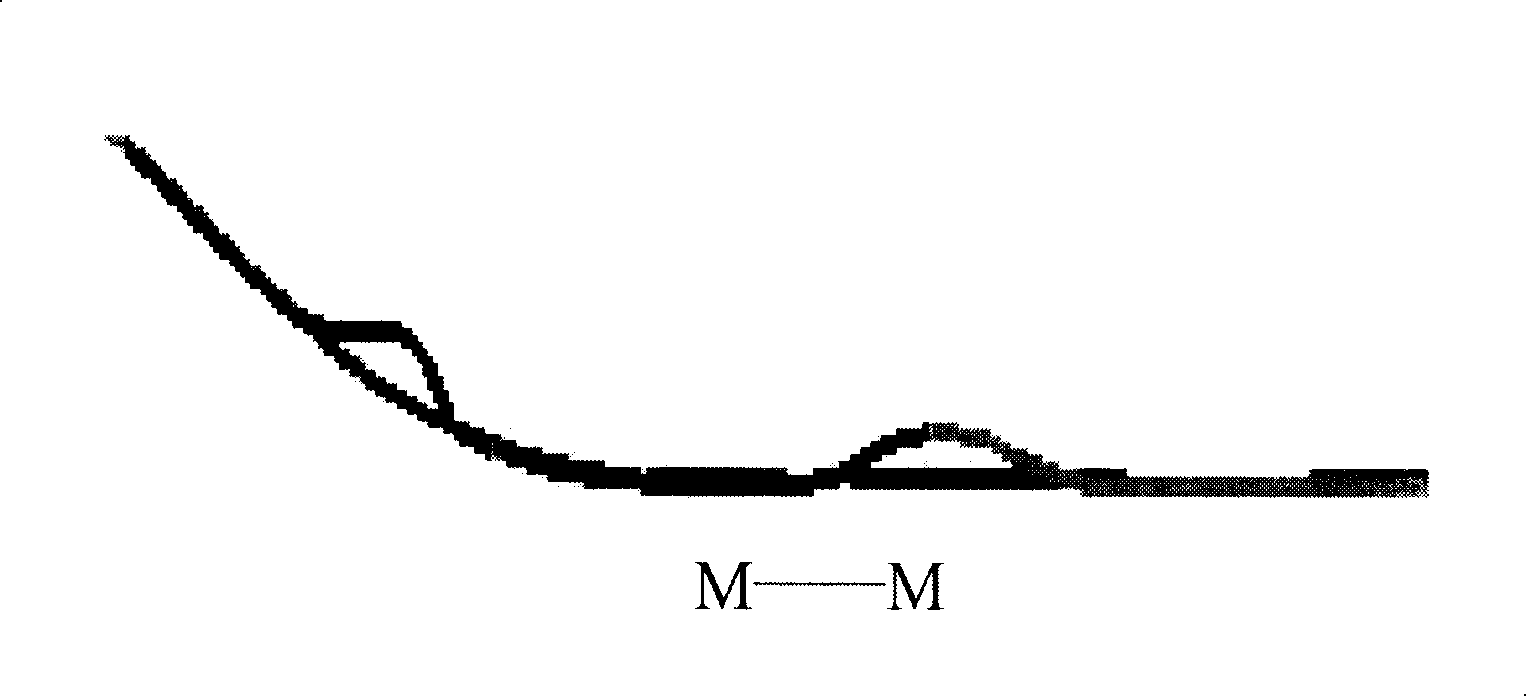

[0019] Such as figure 1 , figure 2 with image 3 As shown, the plate-like product with a concave area includes at least two surfaces that are not on the same plane, and the at least two surfaces that are not on the same plane are connected by the concave area 1. During the drawing forming process, the concave area 1 is prone to wrinkles . Such as Figure 5 As shown, the plate-shaped article with the recessed area 1 also includes two side faces 4, which are not on the same plane as at least two faces connected by the recessed area 1, and the two side faces 4 have different heights.

[0020] The prior art does not consider the specific shape of the plate-like product with the concave area, and the wrinkles of the concave area 1 where the two surfaces meet are produced in different time periods during the drawing process. The folds that ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com