Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10101results about "Milling equipment details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

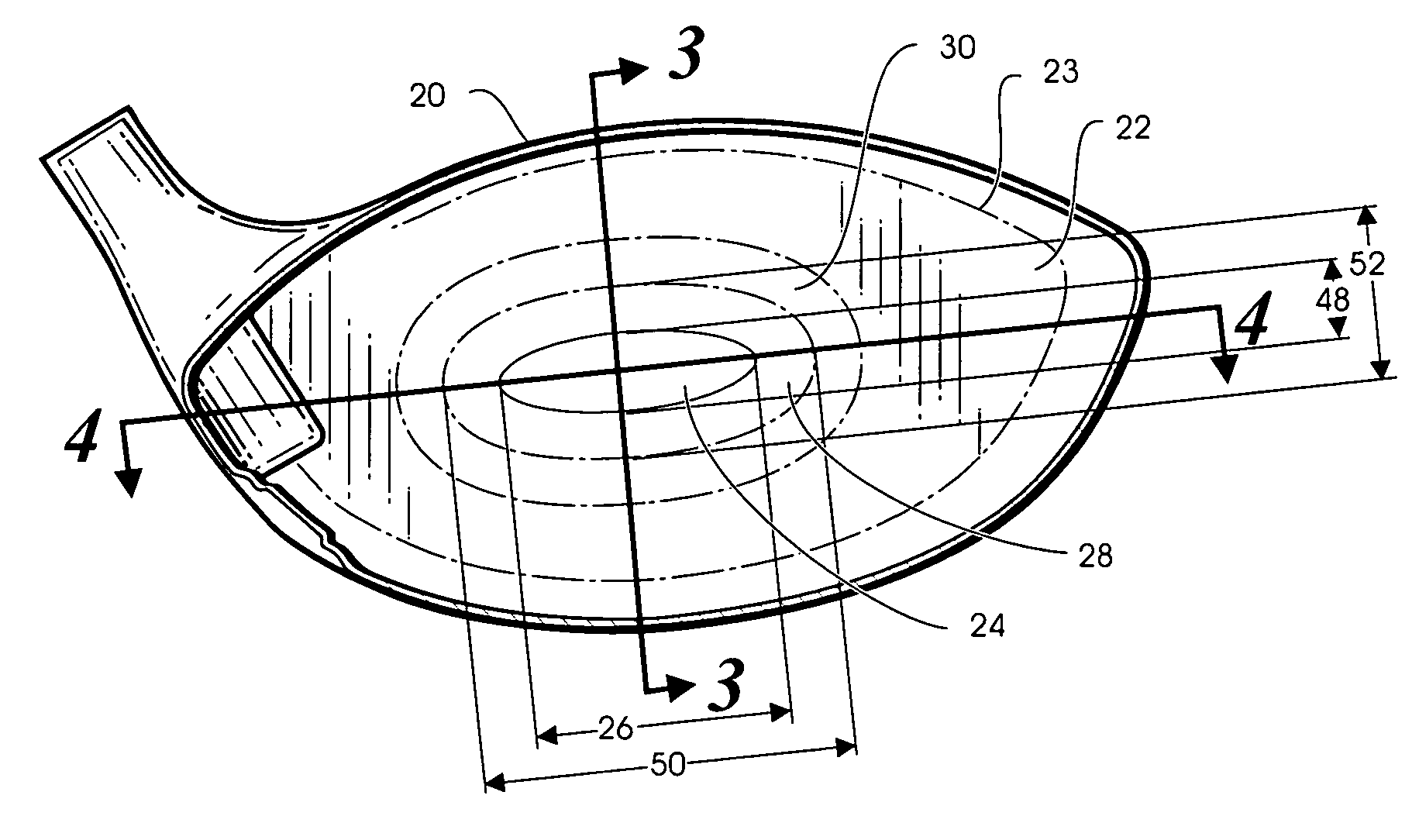

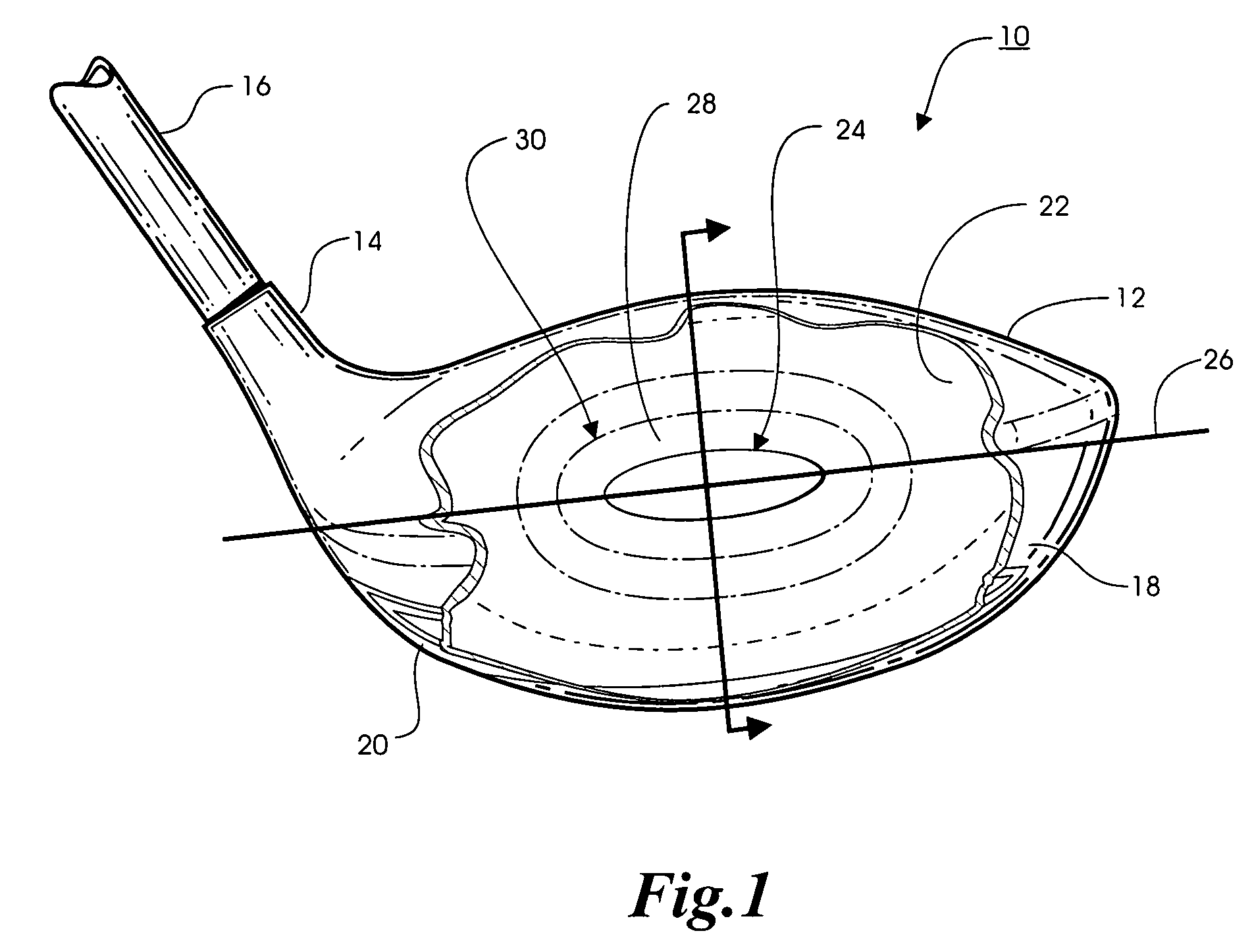

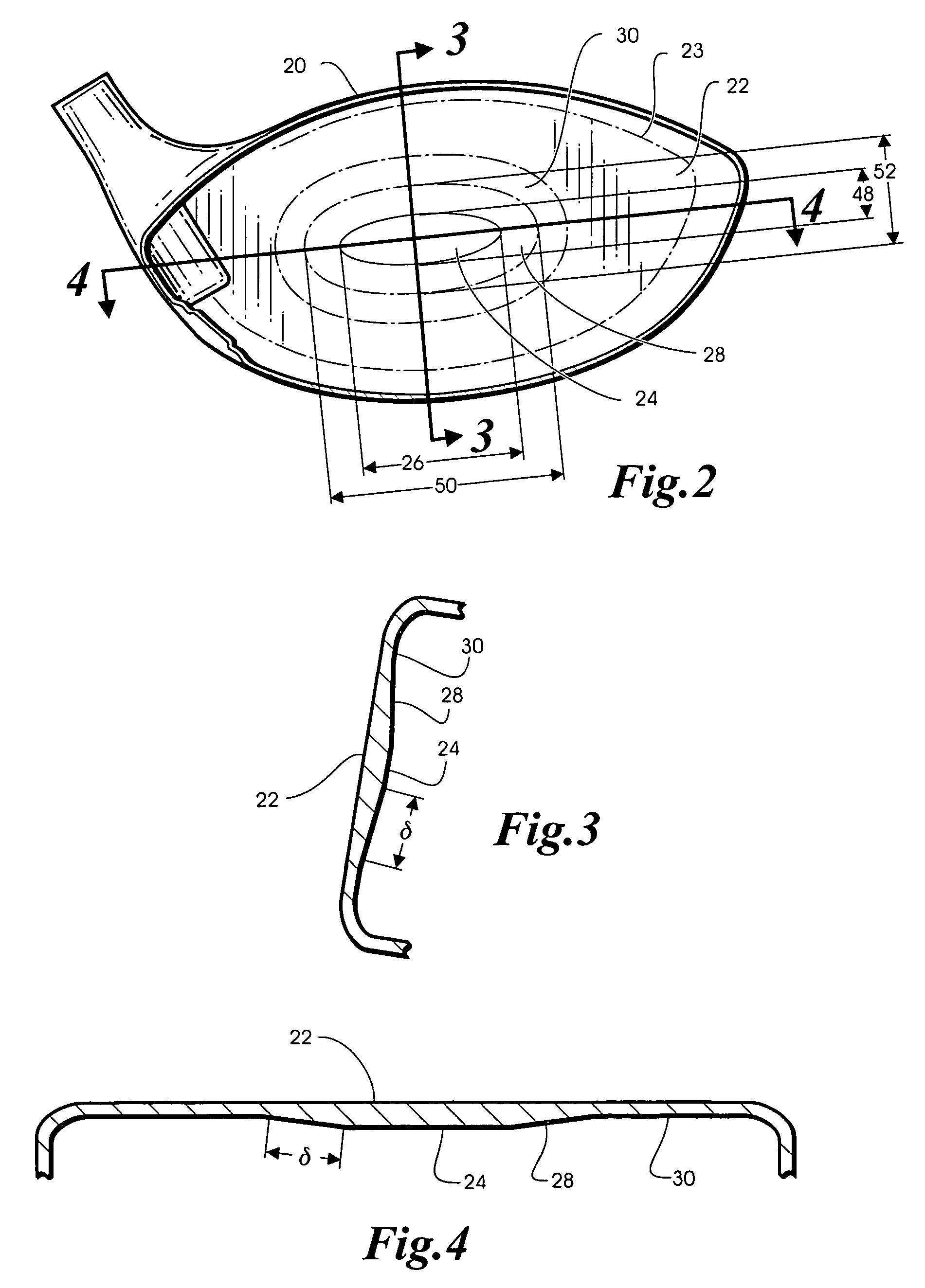

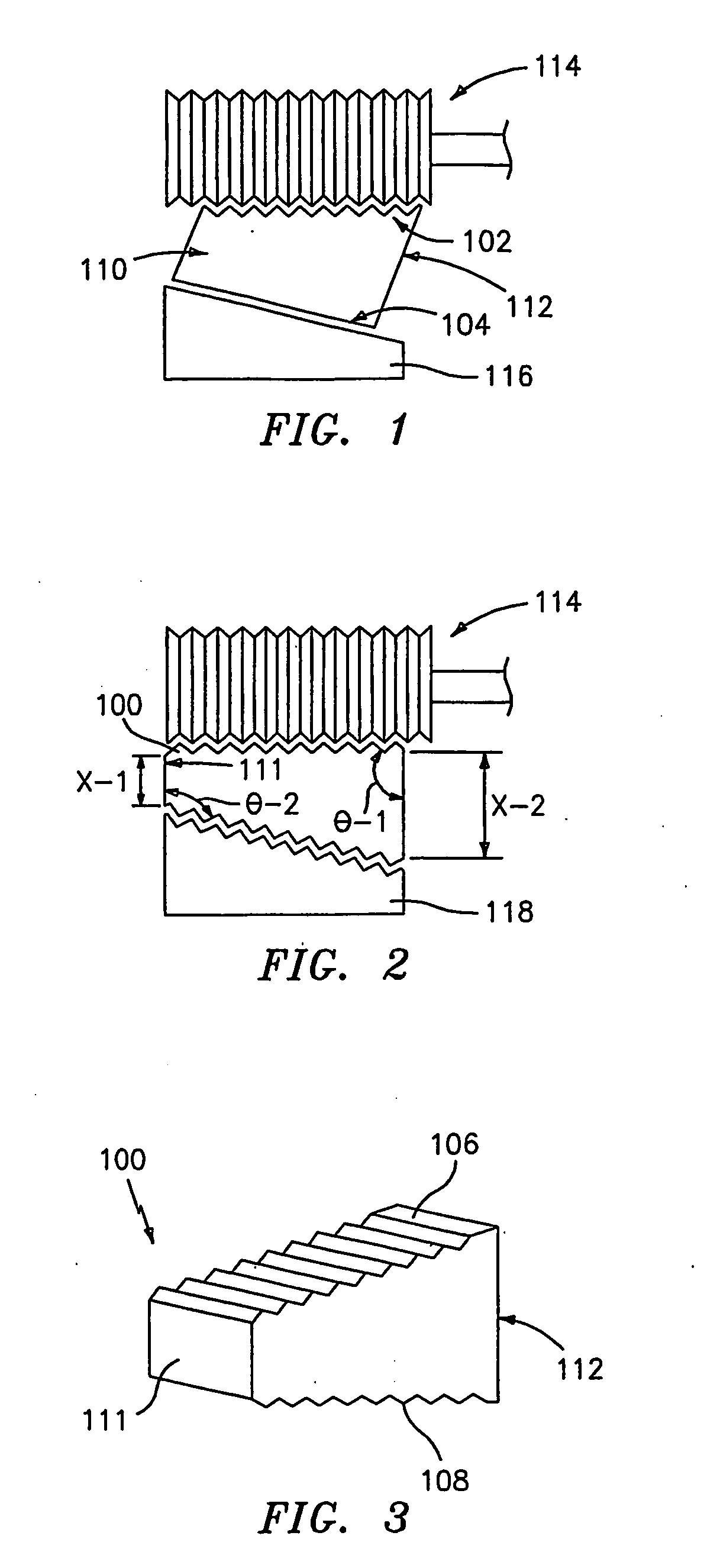

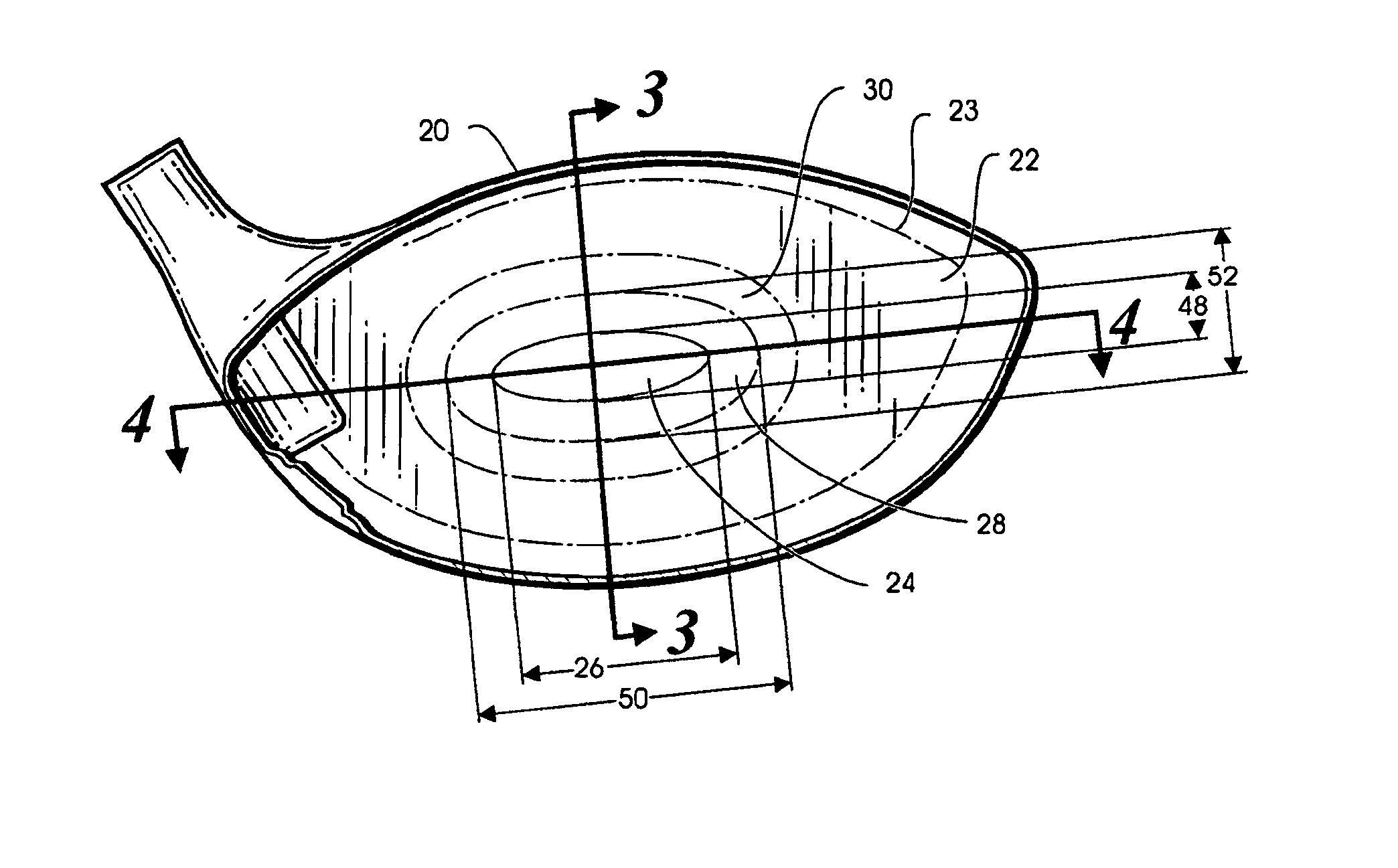

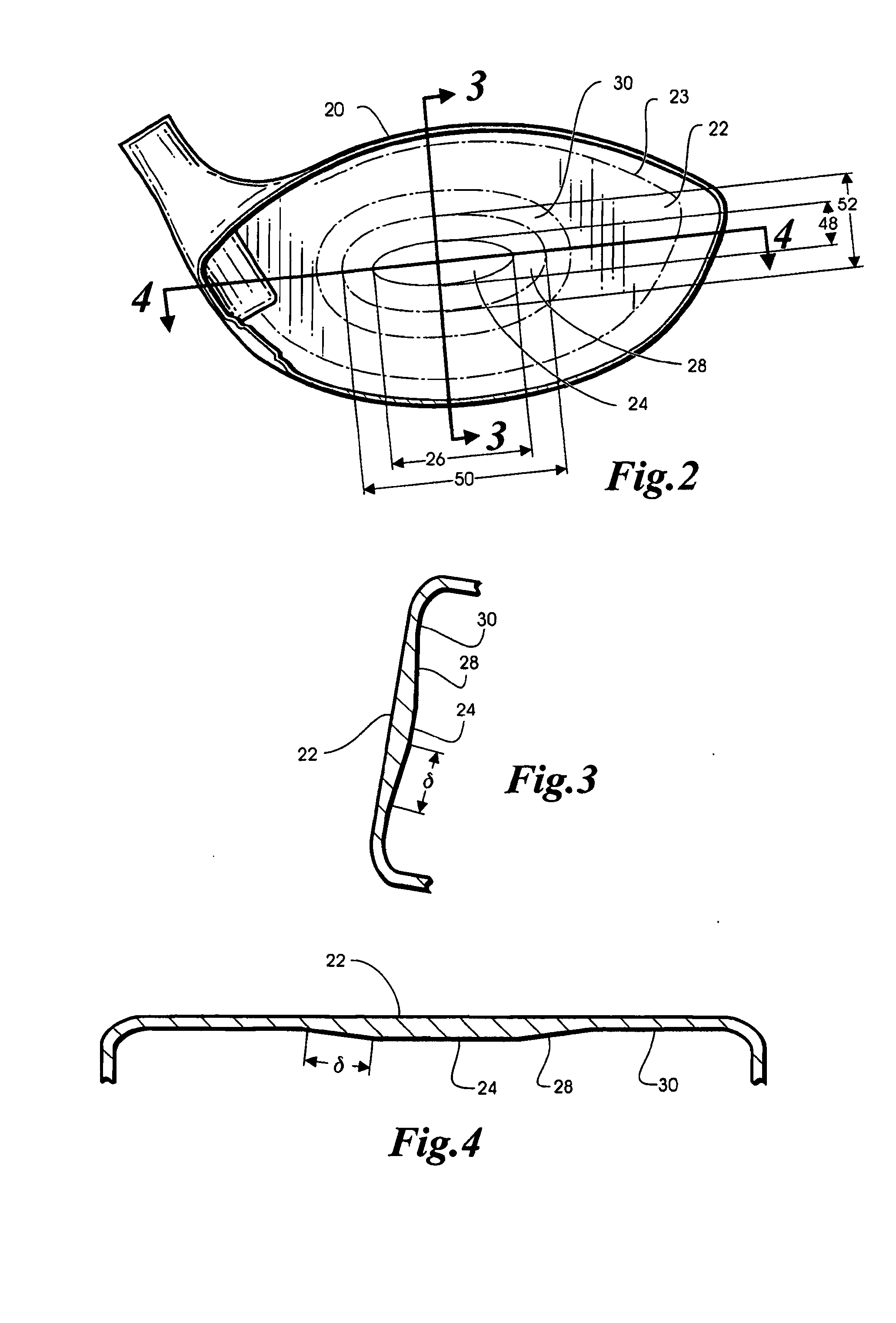

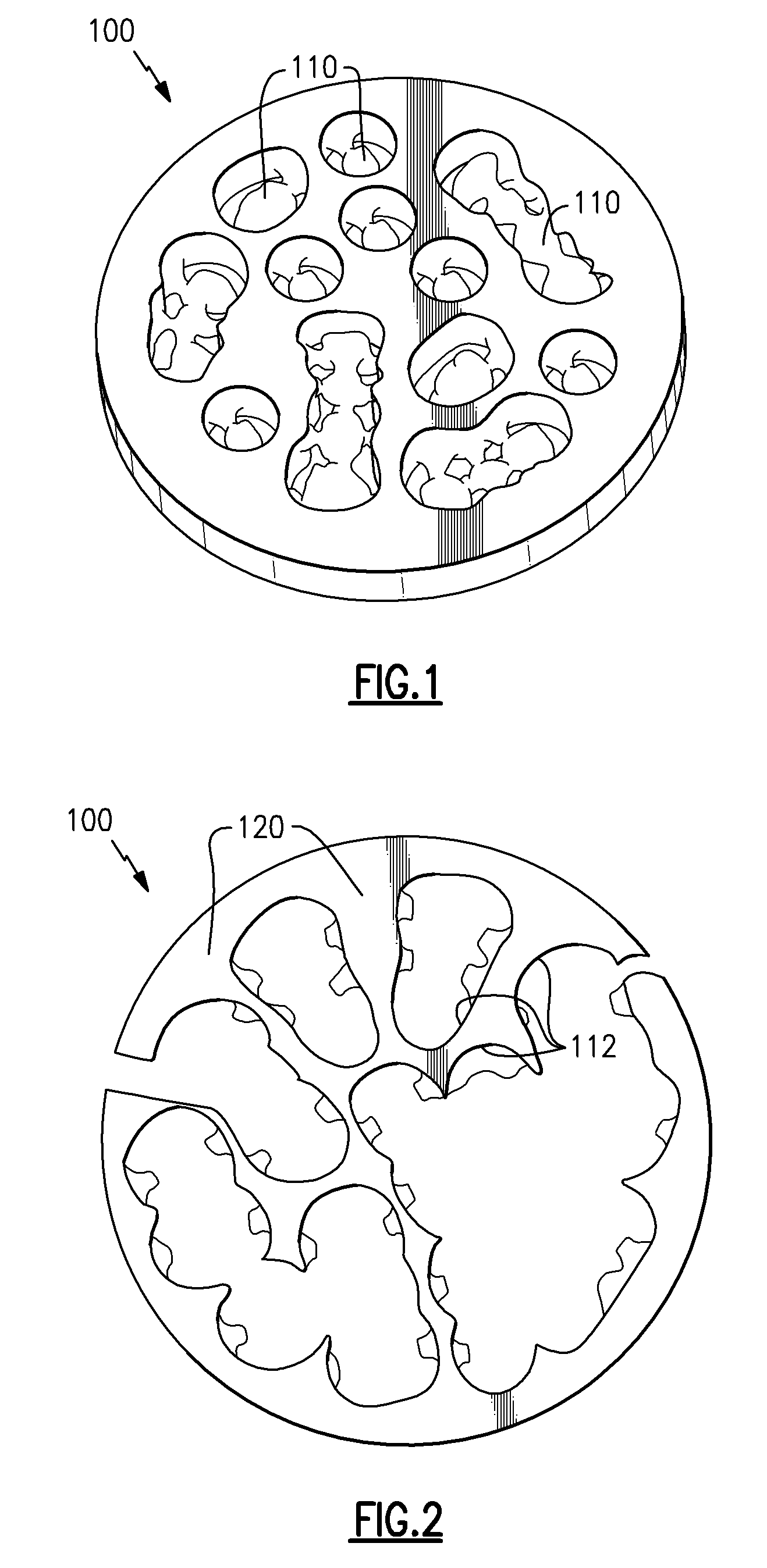

Method of manufacturing a face plate for a golf club head

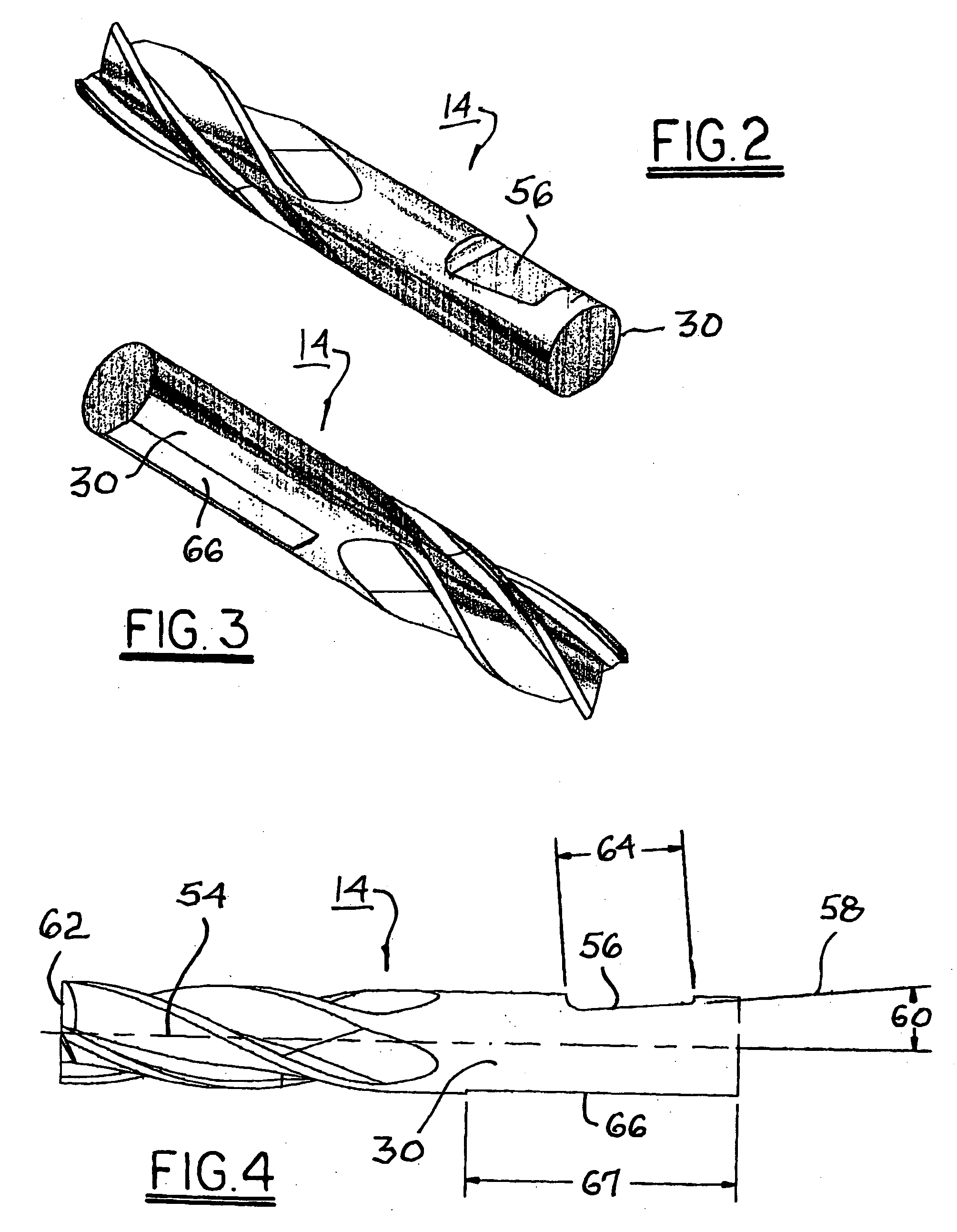

ActiveUS7347794B2Improve uniformitySignificant timeMilling equipment detailsShaping cuttersEngineeringGolf Ball

A golf club is manufactured by machining away a portion of the rear surface of a club face blank to form an elliptical central thickened region that tapers through a transition region to a thinner peripheral region. The elliptical central thickened region, transition region and the portion of the peripheral region surrounding the raised portion are formed in a single elliptical pass with a special cutting tool. The cutting tool, or “form cutter” has a conical lateral cutting surface, which forms the sloped transition region and the peripheral region surrounding it in a single operation.

Owner:KARSTEN MFG CORP

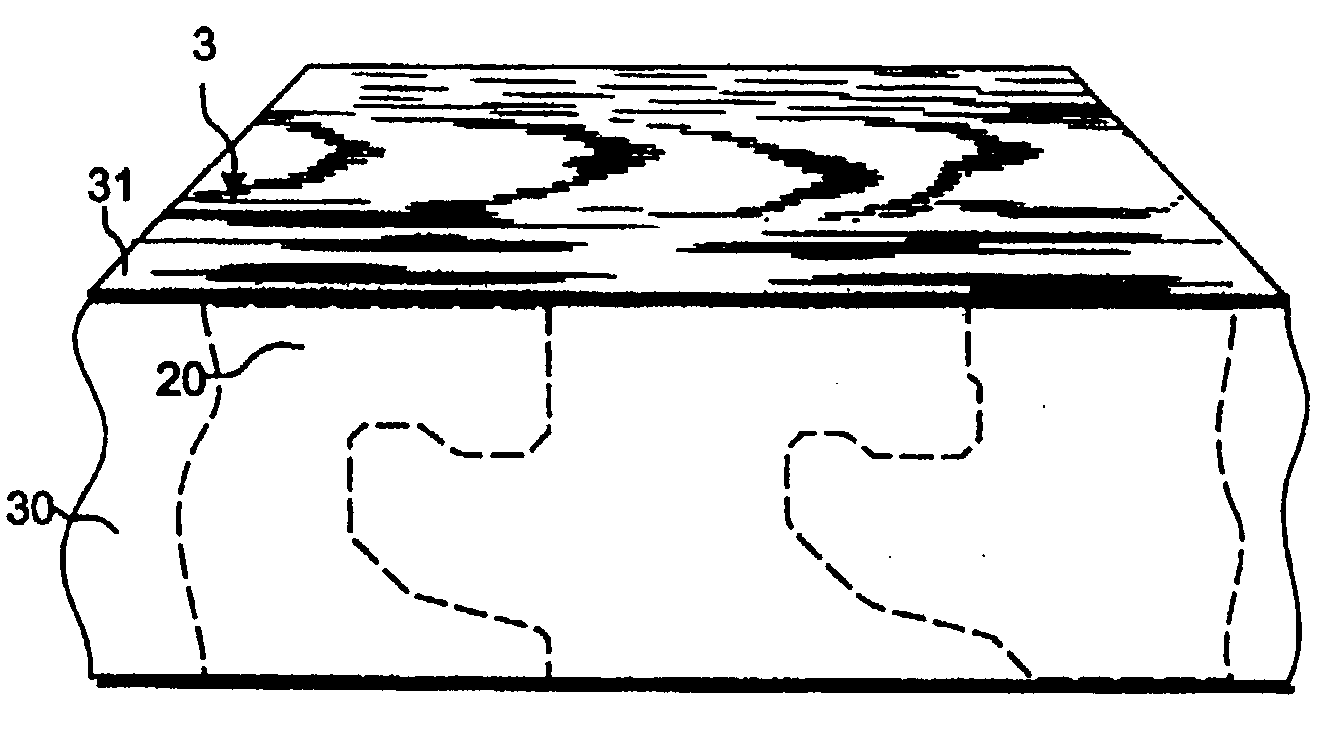

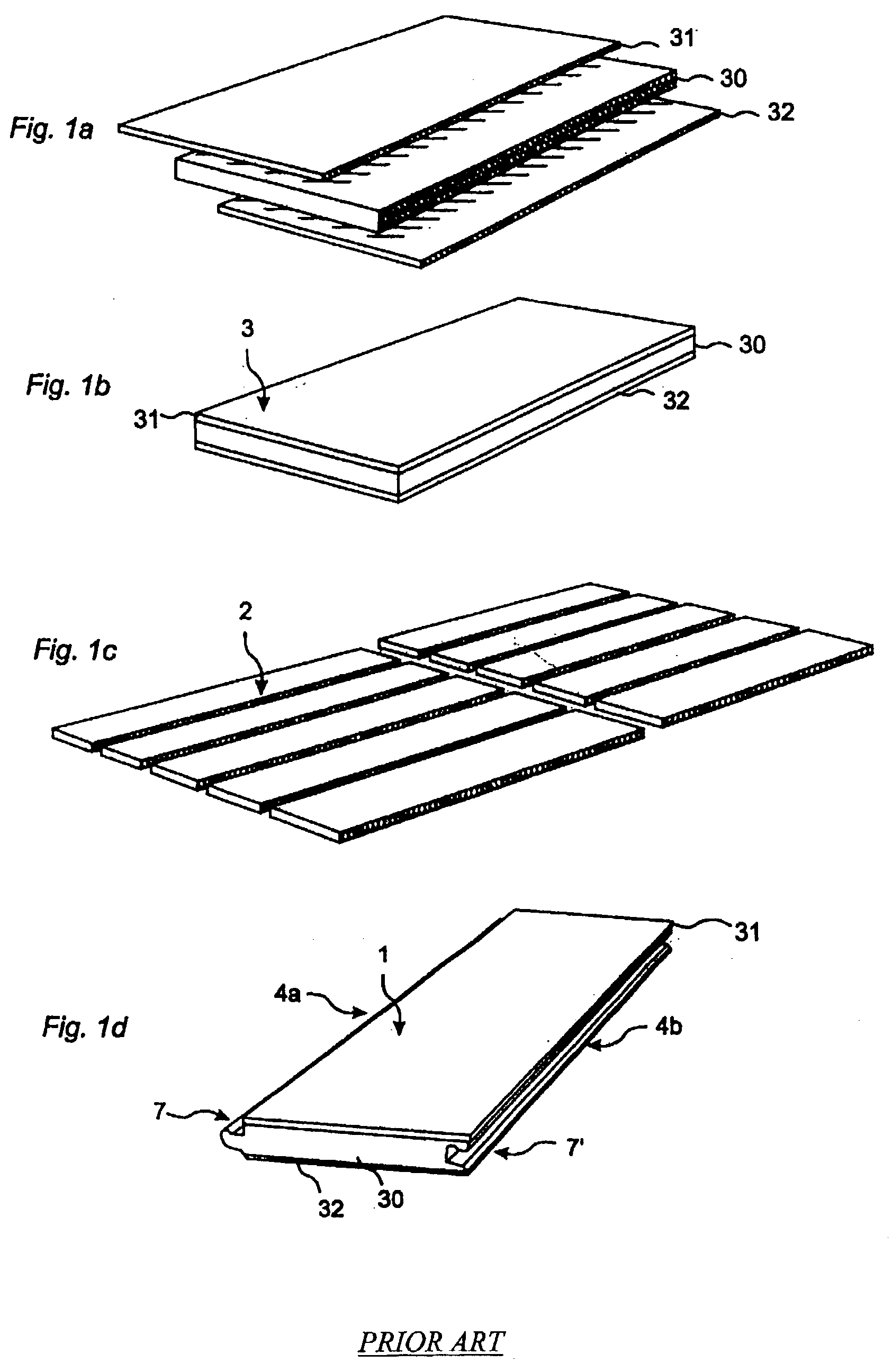

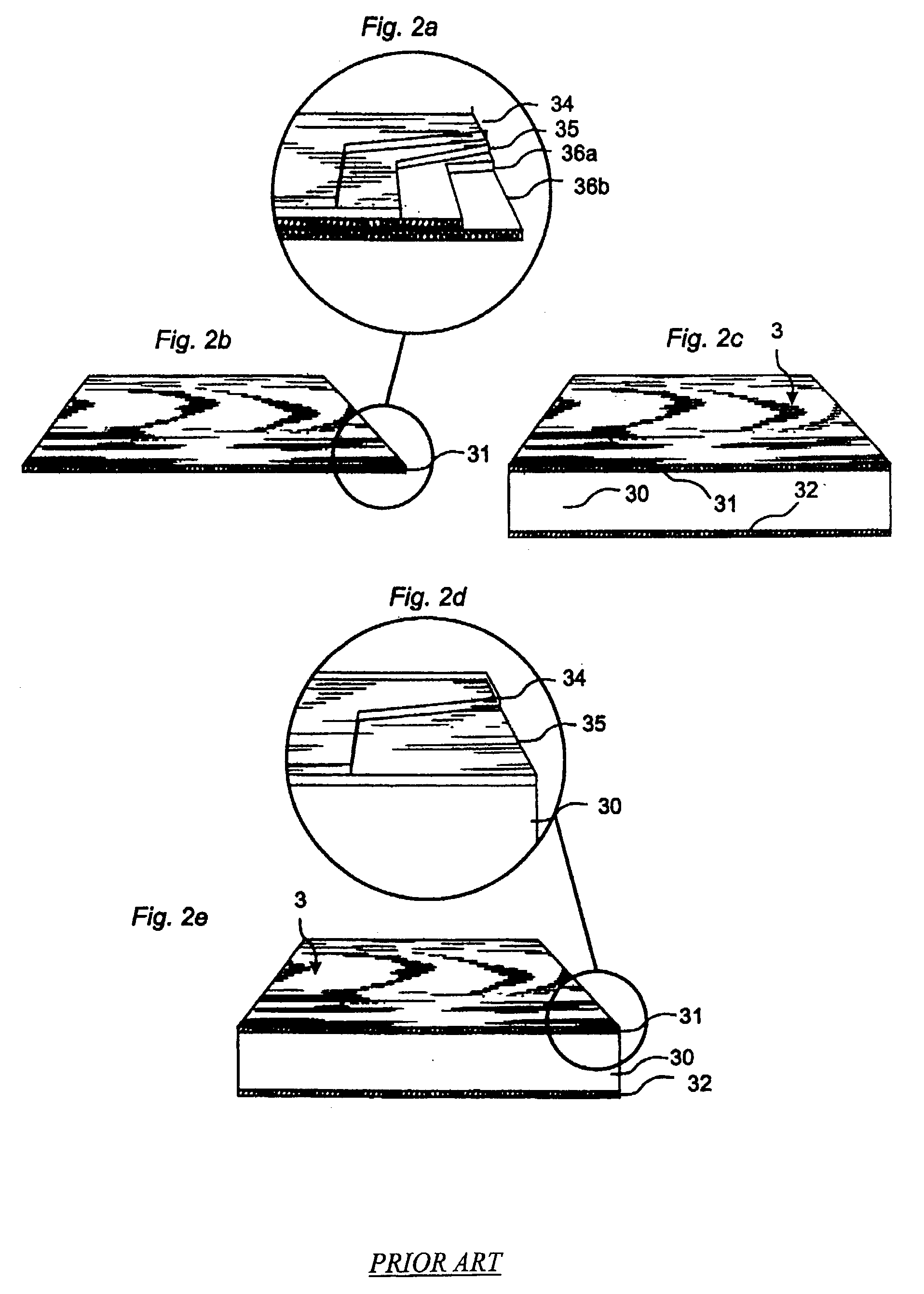

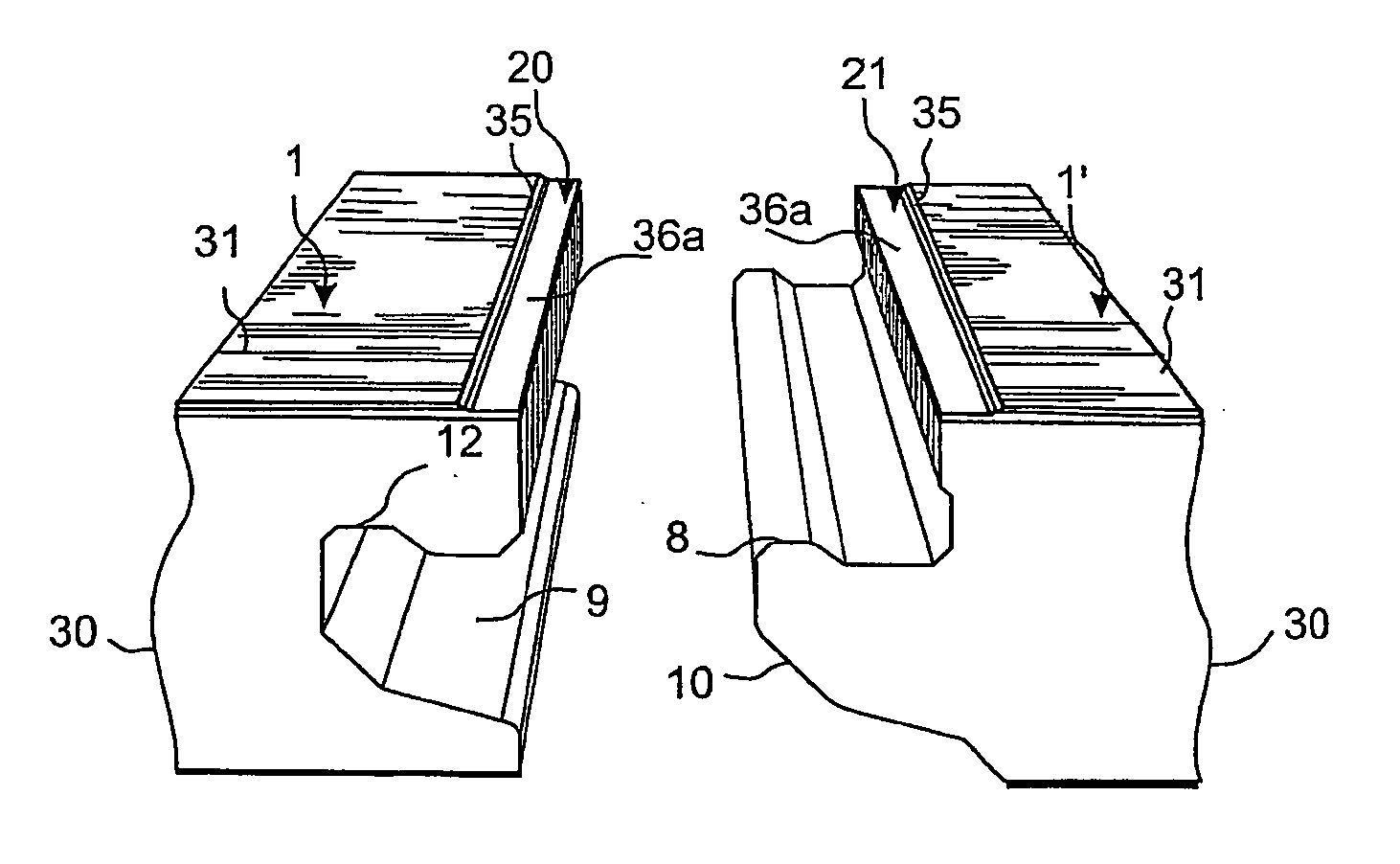

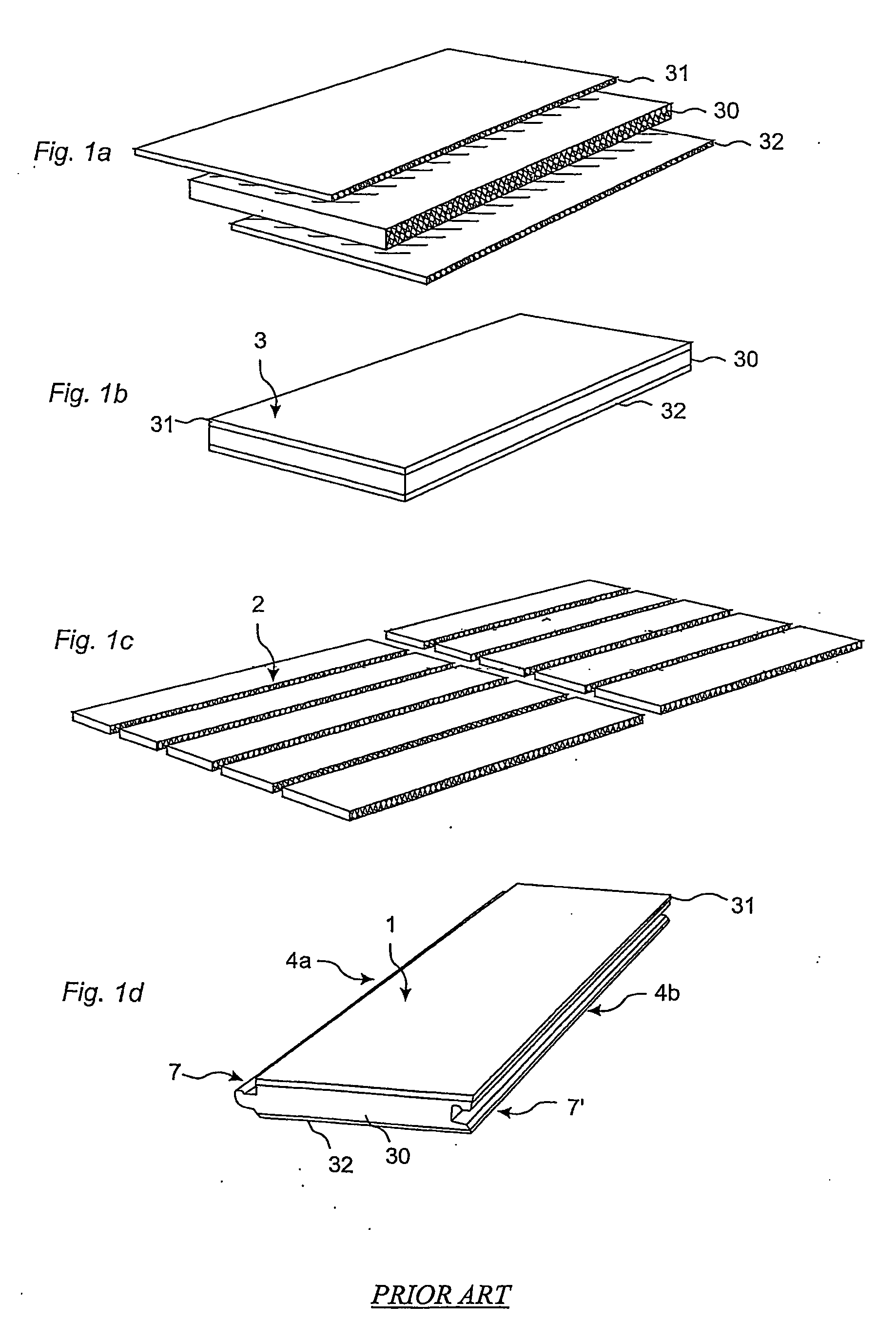

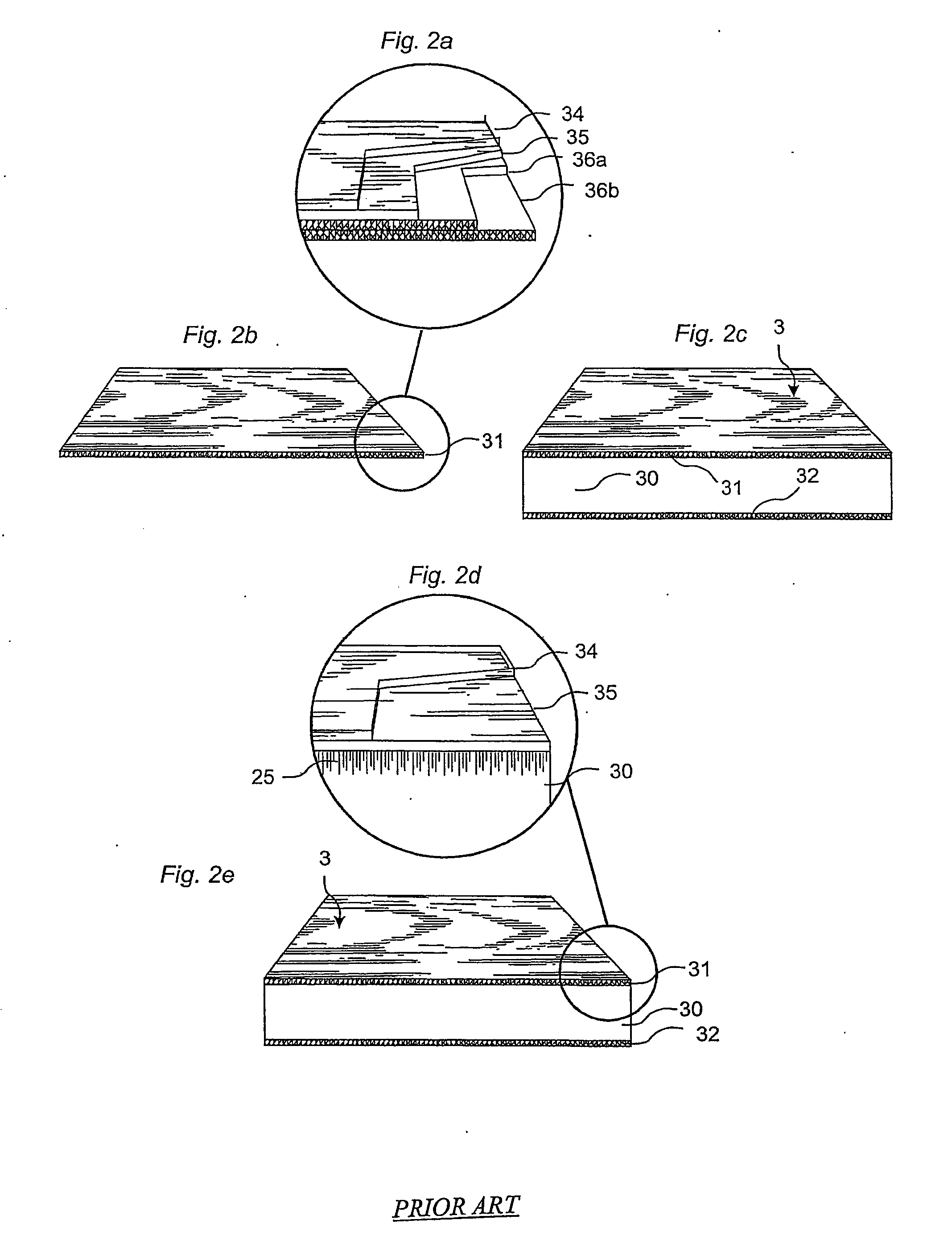

Floorboards with decorative grooves

InactiveUS20040035078A1Provides appearance and durabilityNatural appearanceCovering/liningsTongue/grooves making apparatusSurface layerEngineering

Floorboards consisting of a core and a surface layer with decorative joint edge portions which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

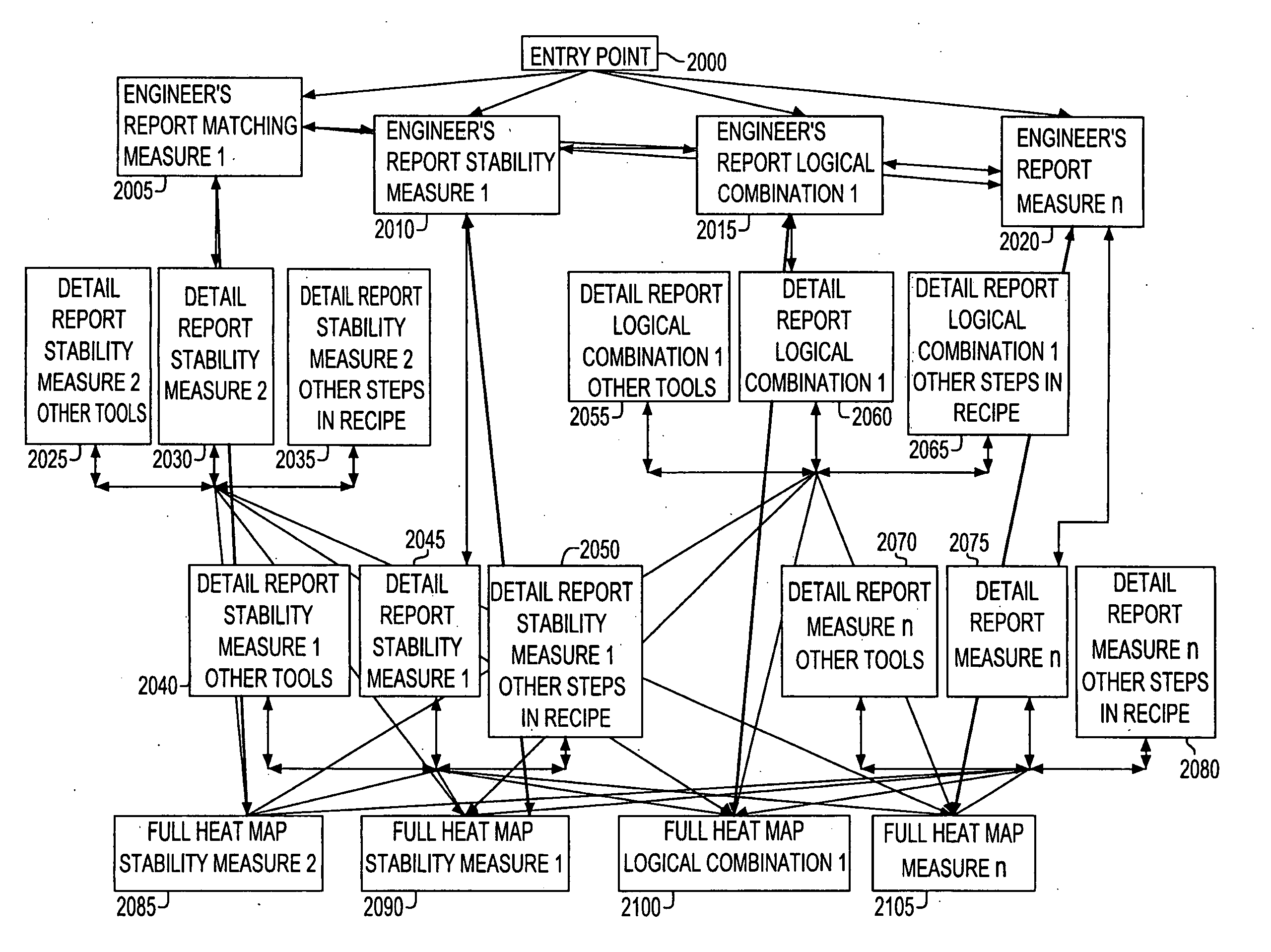

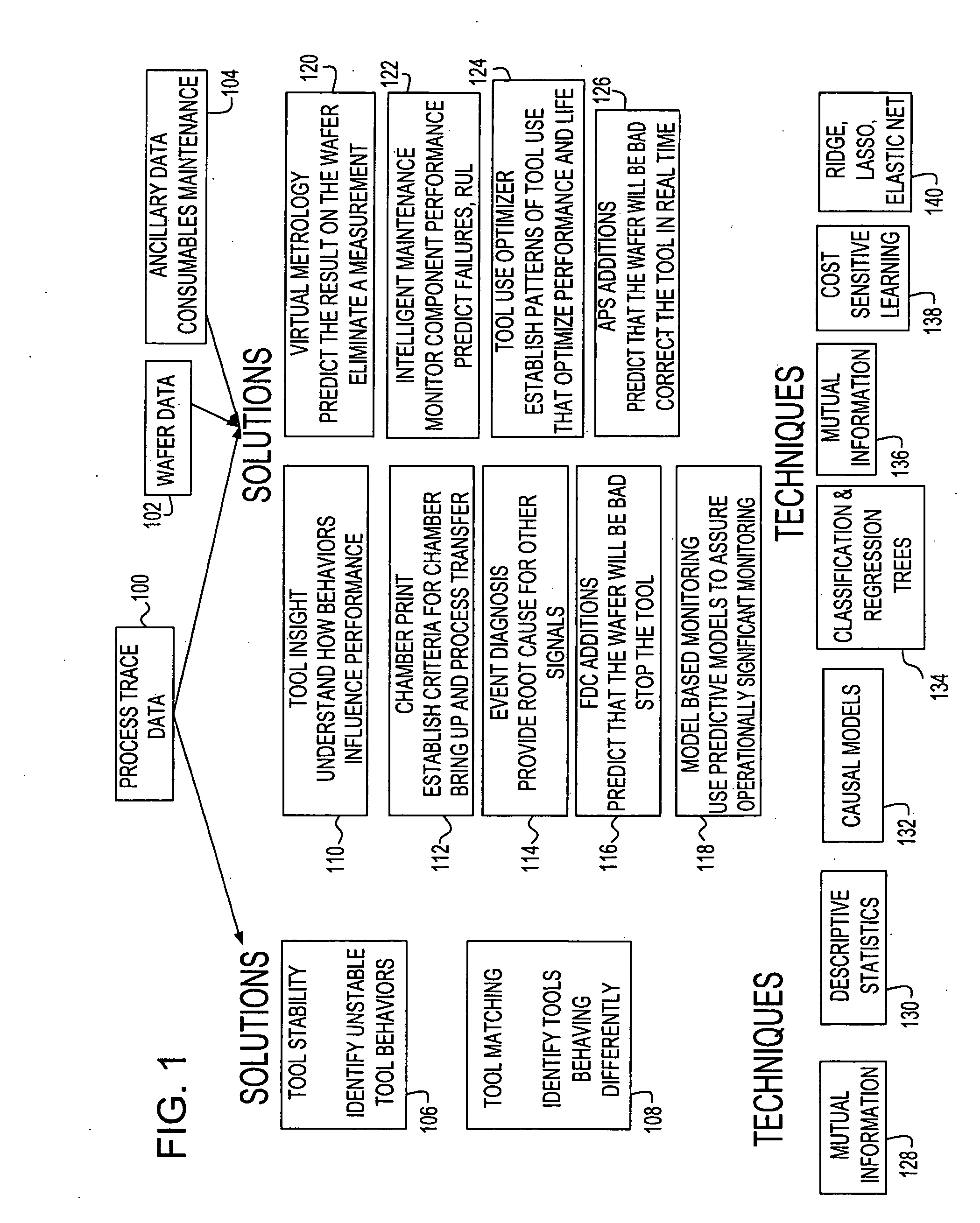

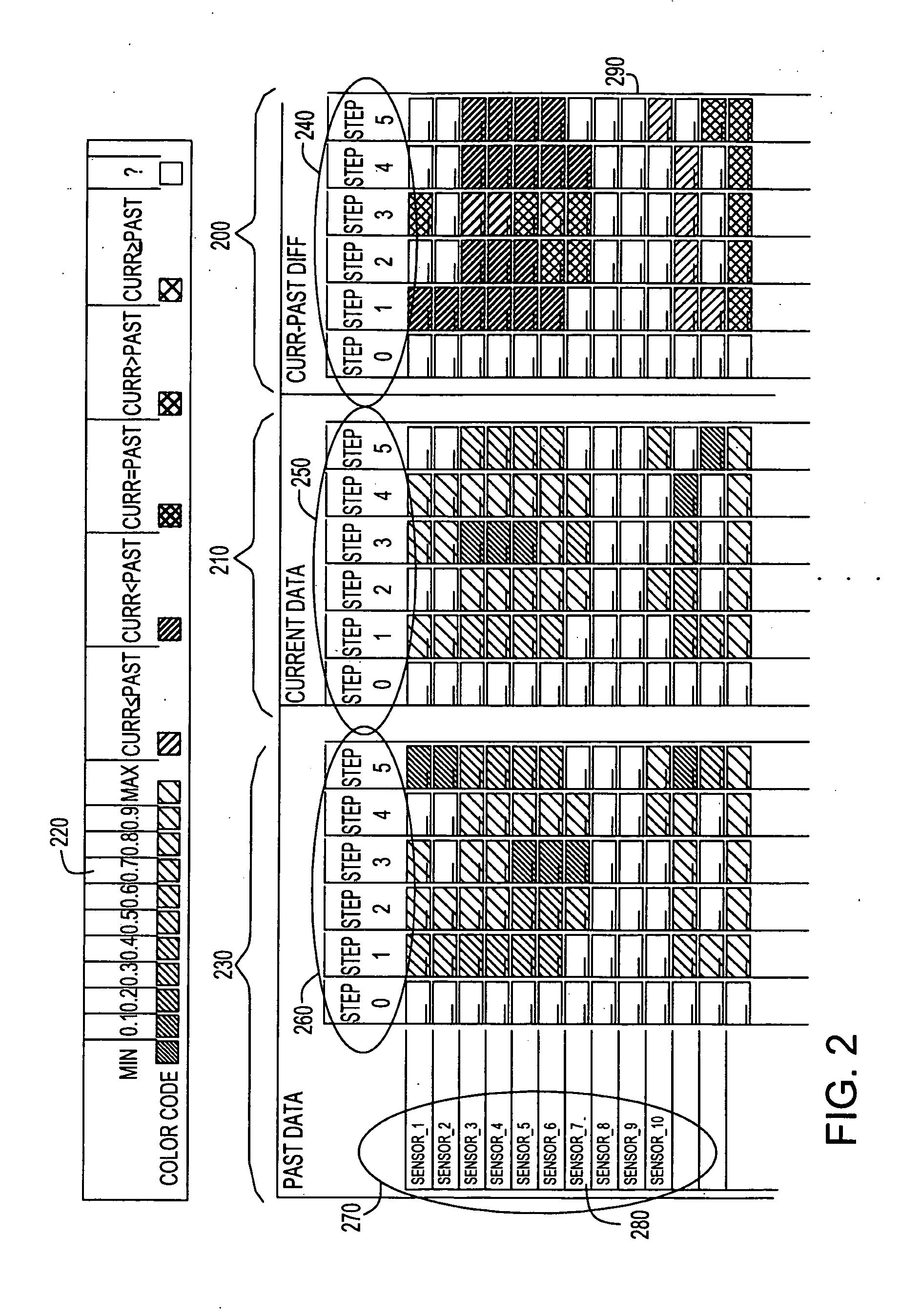

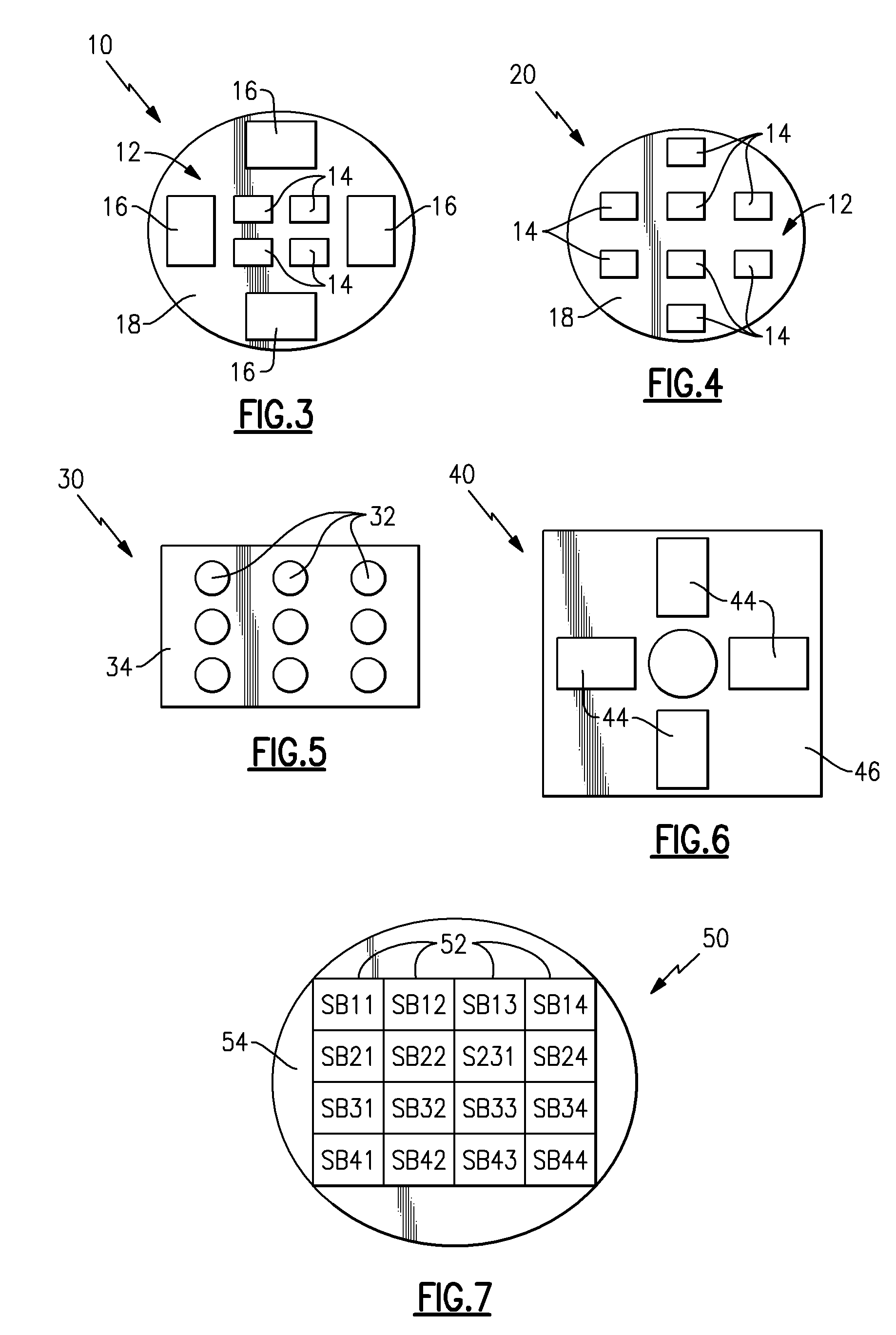

Method and system for evaluating a machine tool operating characteristics

A method and system for evaluating a performance of a semiconductor manufacturing tool while manufacturing microelectronic devices are disclosed. At least one report is generated based on executions of at least one statistical test. The report includes at least one heat map having rows that correspond to sensors, columns that correspond to trace data obtained during recipe steps, and cells at the intersection of the rows and the columns. At least one sensor in the tool obtains trace data of a recipe step while manufacturing at least one microelectronic device. A computing device analyzes the obtained trace data to determine a level of operational significance found in the data and assigns a score to the trace data that indicates a level of operational significance. Then, the computing device places the score in a corresponding cell of the heat map. A user uses the cell for evaluating the tool performance.

Owner:GLOBALFOUNDRIES INC

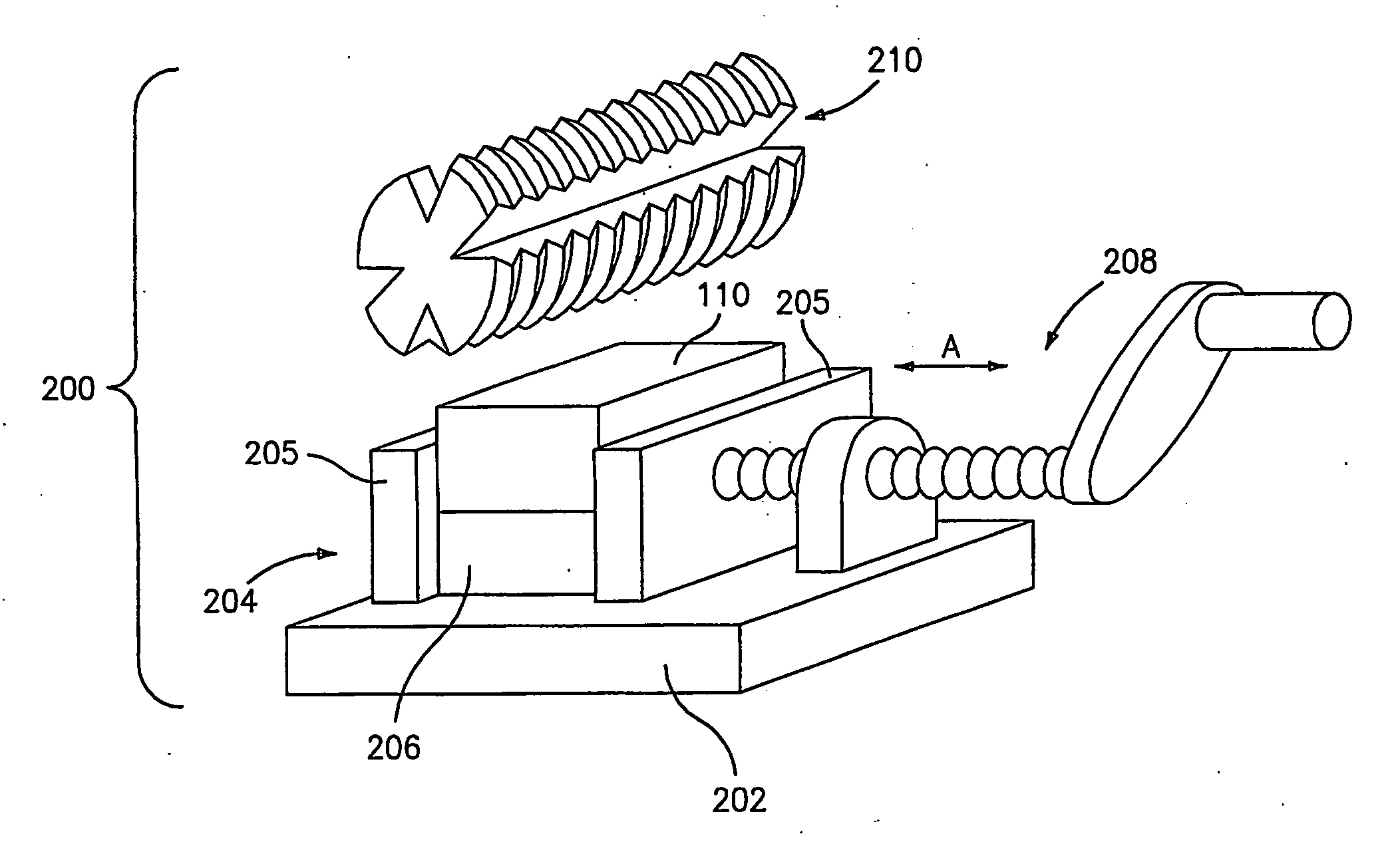

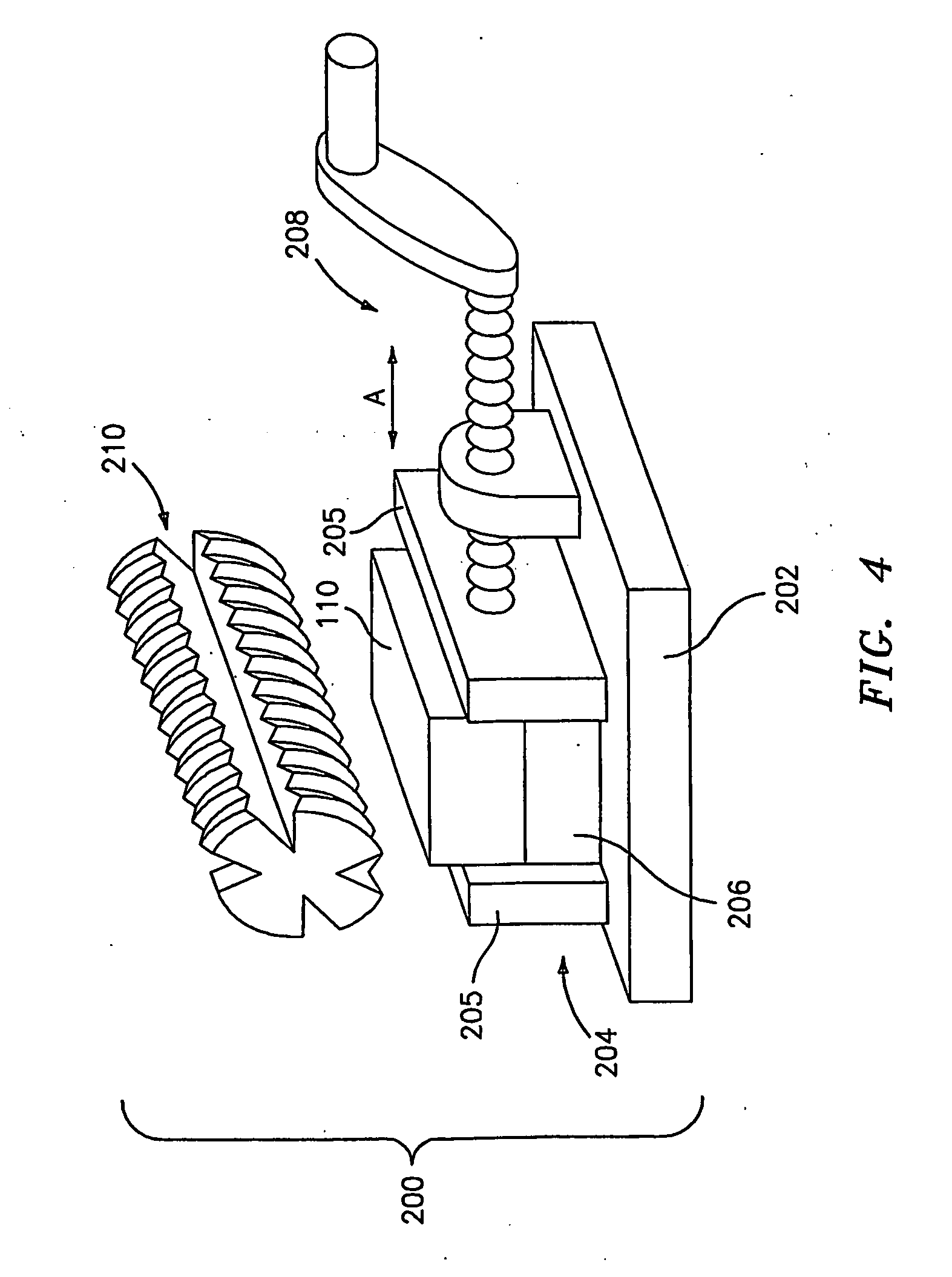

Method and apparatus for machining a surgical implant

InactiveUS20050244239A1Permit adjustment of overall mechanical propertyReduced strengthBone implantMilling cuttersEngineeringBiomedical engineering

A method is provided for machining a customized surgical implant in the operating room provided. Apparatus and a kit for carrying out the method are also provided.

Owner:OSTEOTECH

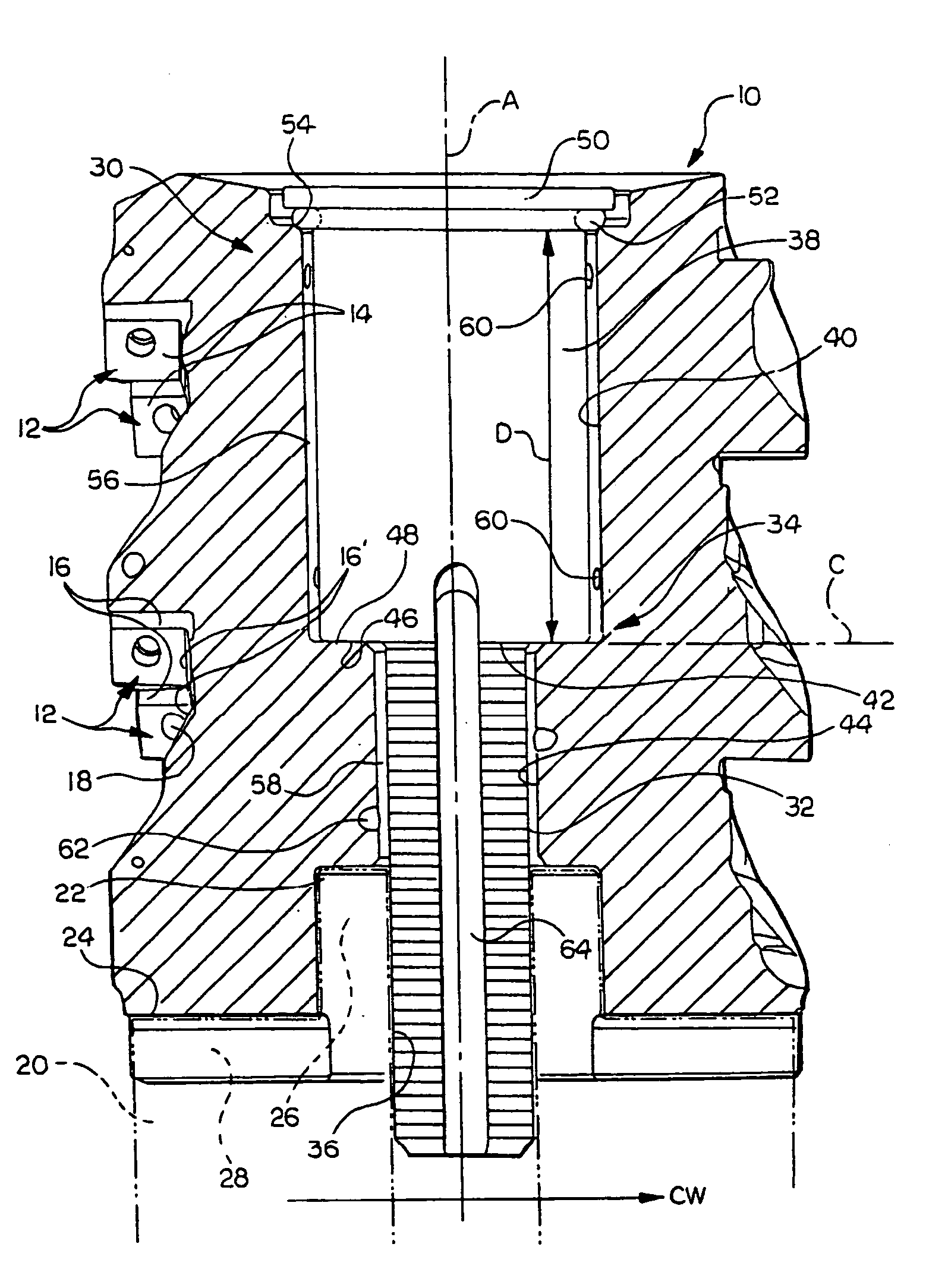

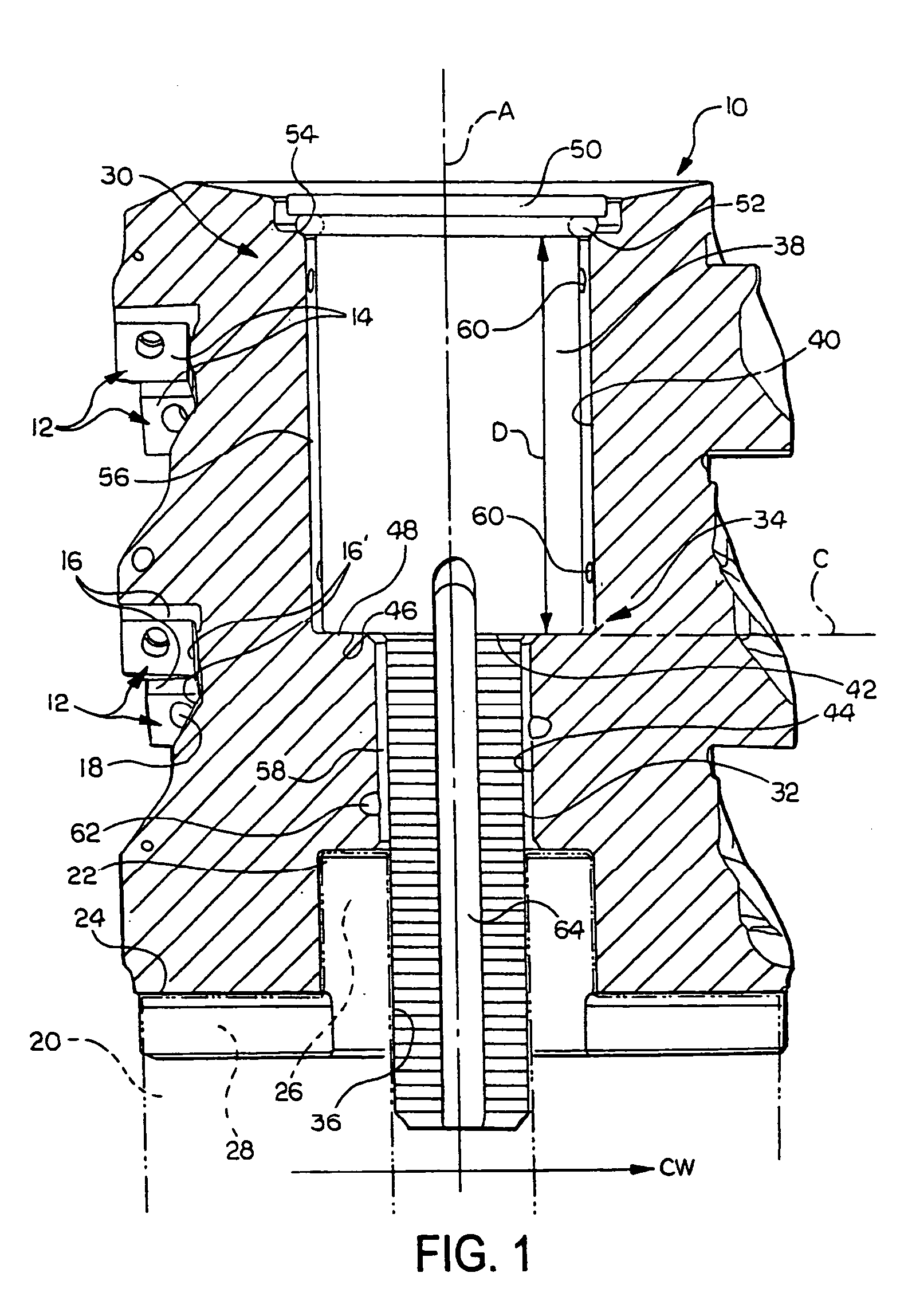

Method of manufacturing a golf club face

InactiveUS20080004133A1Improve uniformitySignificant timeMilling equipment detailsShaping cuttersEngineeringGolf Ball

Embodiments of methods of manufacturing a face plate for a golf cub are generally described herein. In one exemplary embodiment, a method for manufacturing a golf club face plate comprises: providing a face plate material, and milling the face plate material in an elliptical pattern to form a central region comprising, a first elliptical outer edge and a transition region extending from the first elliptical outer edge to a second elliptical outer edge. In this exemplary embodiment, each point along the second elliptical outer edge is displaced outward from the first elliptical outer edge by a predetermined distance. Other embodiments herein may be described and claimed.

Owner:KARSTEN MFG CORP

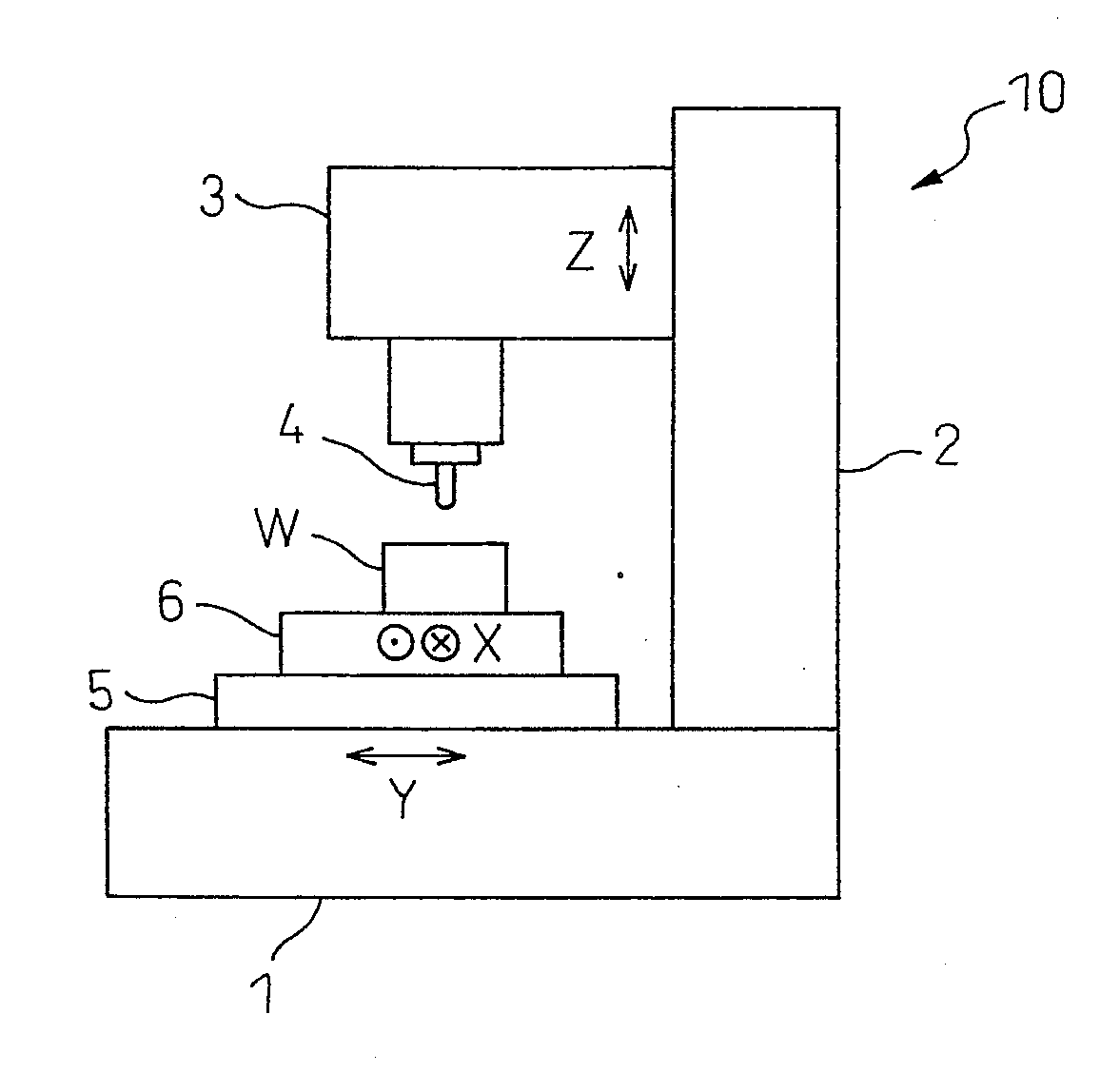

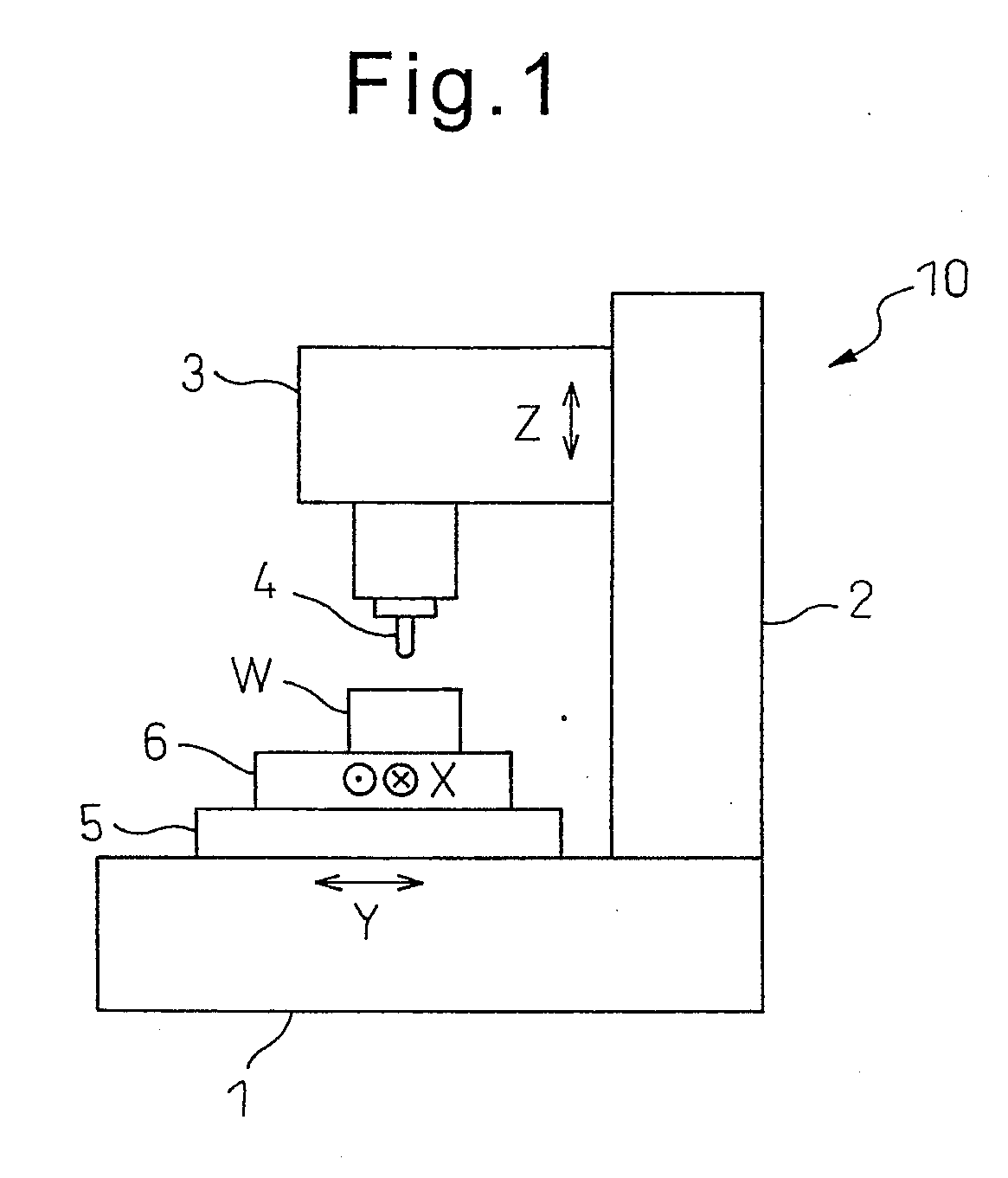

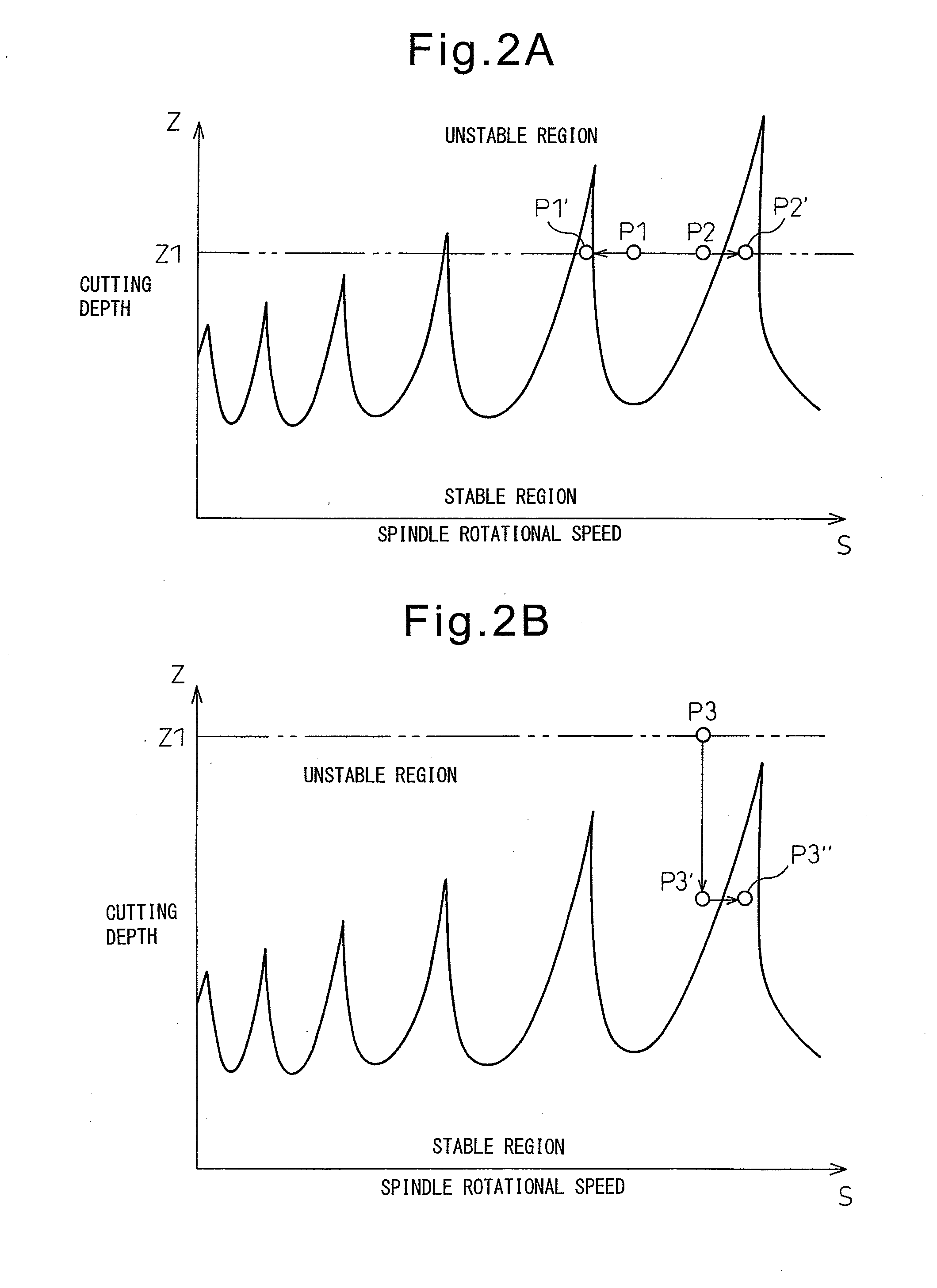

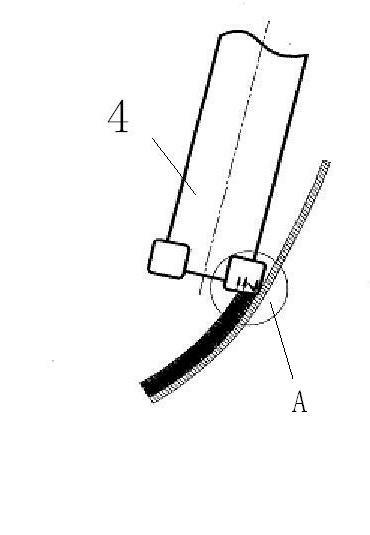

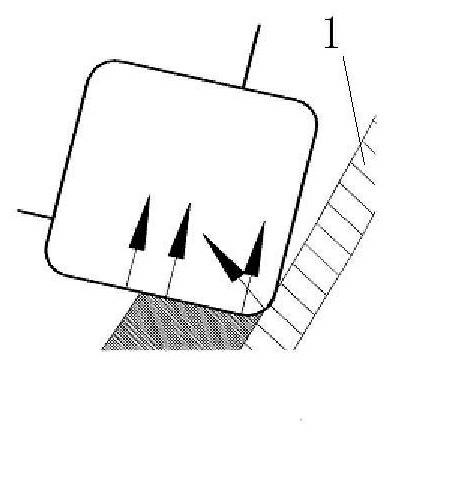

Chatter vibration detection method, chatter viberation avoidance method, and machine tool

A chatter vibration detection method includes acquiring vibration data of a tool (4) at a time of machining a workpiece at a predetermined sampling period (Δt), calculating an autocorrelation coefficient (Rxx′) corresponding to a time required for a cutting edge (4a, 4b) to contact the workpiece (W) several times based on acquired time series vibration data and calculating a period (Tx) of characteristics of the calculated autocorrelation coefficient (Rxx′), and deciding that chatter vibration occurs when a contact period (T1) at which the cutting edge (4a, 4b) contacts the workpiece (W) is not an integral multiple of the calculated period (Tx).

Owner:MAKINO MILLING MASCH CO LTD

Floorboards with decorative grooves

ActiveUS20060048474A1Rational and cost-efficientEasy to cleanTongue/grooves making apparatusWallsSurface layerEngineering

Floorboards are shown, which consist of a core and a surface layer and are provided with decorative joint edges which are formed by removing the surface layer.

Owner:VÄLINGE INNOVATION AB

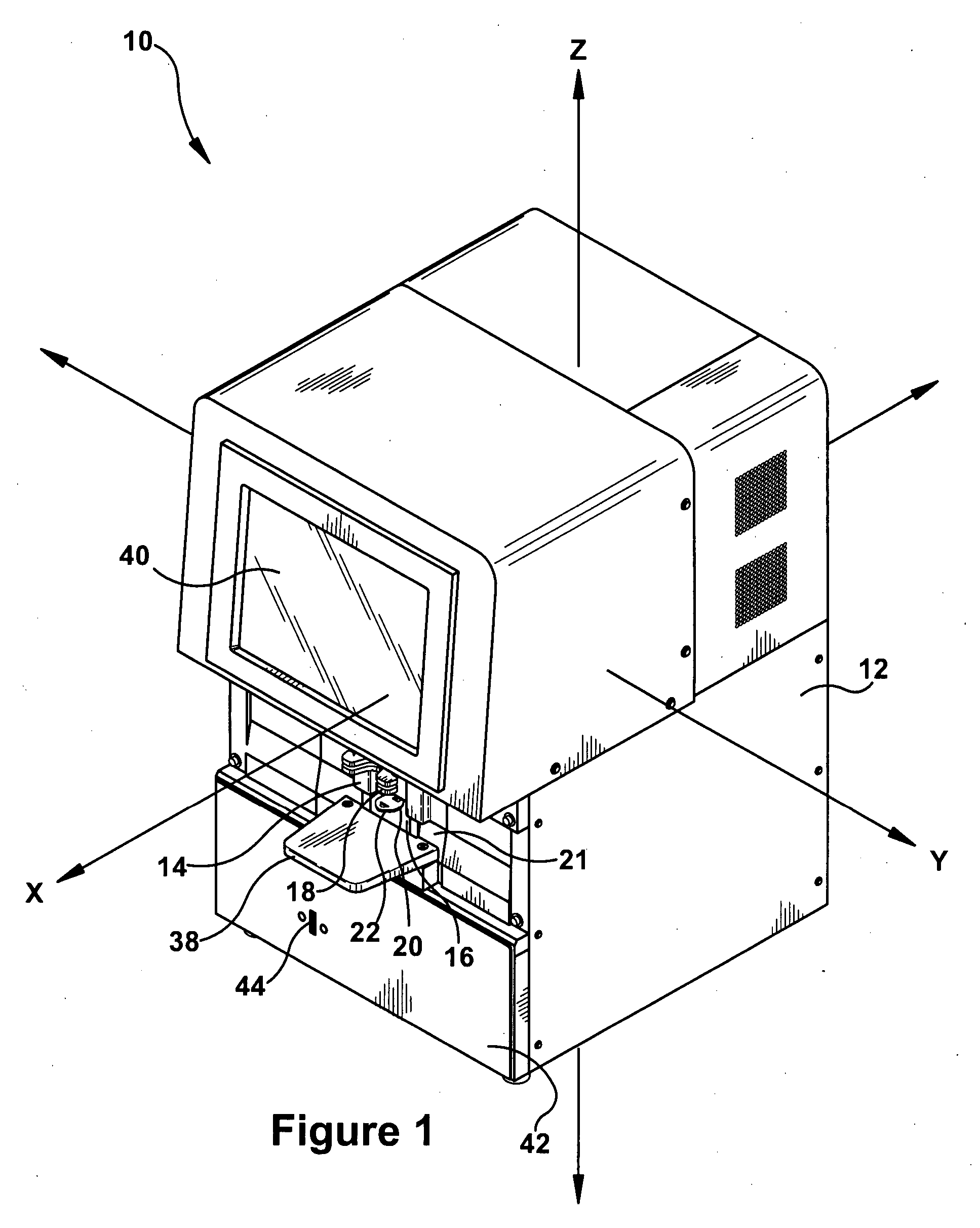

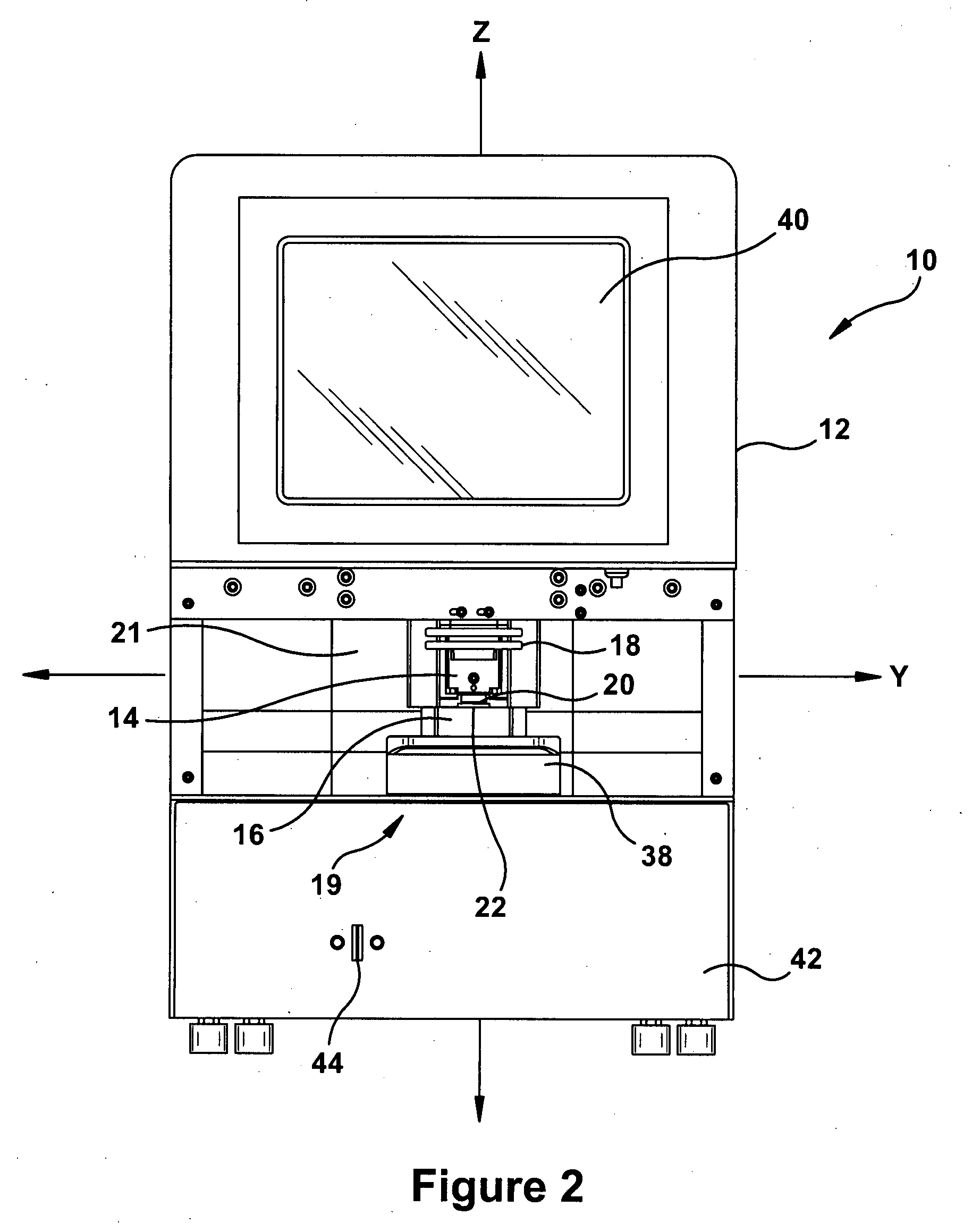

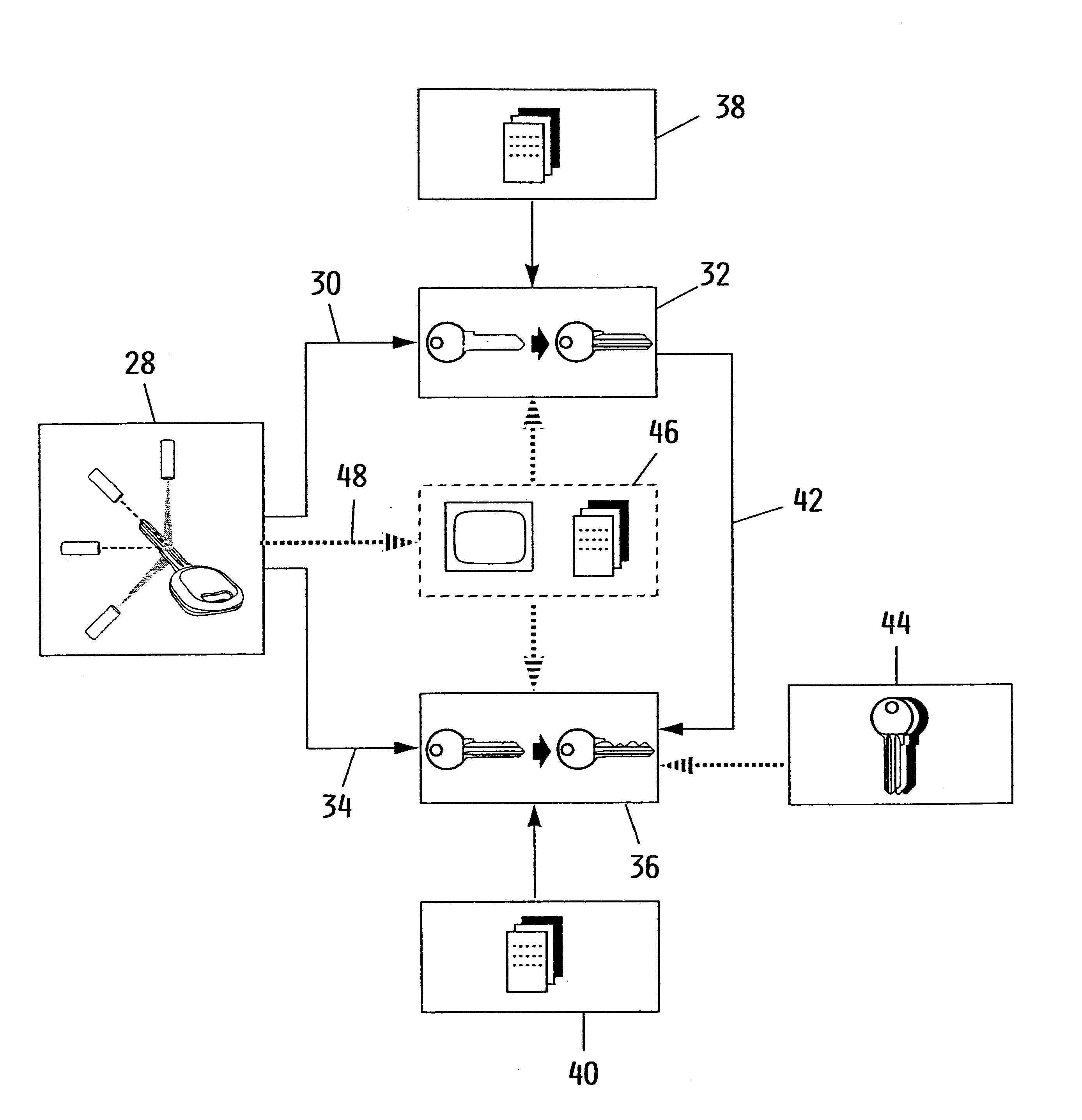

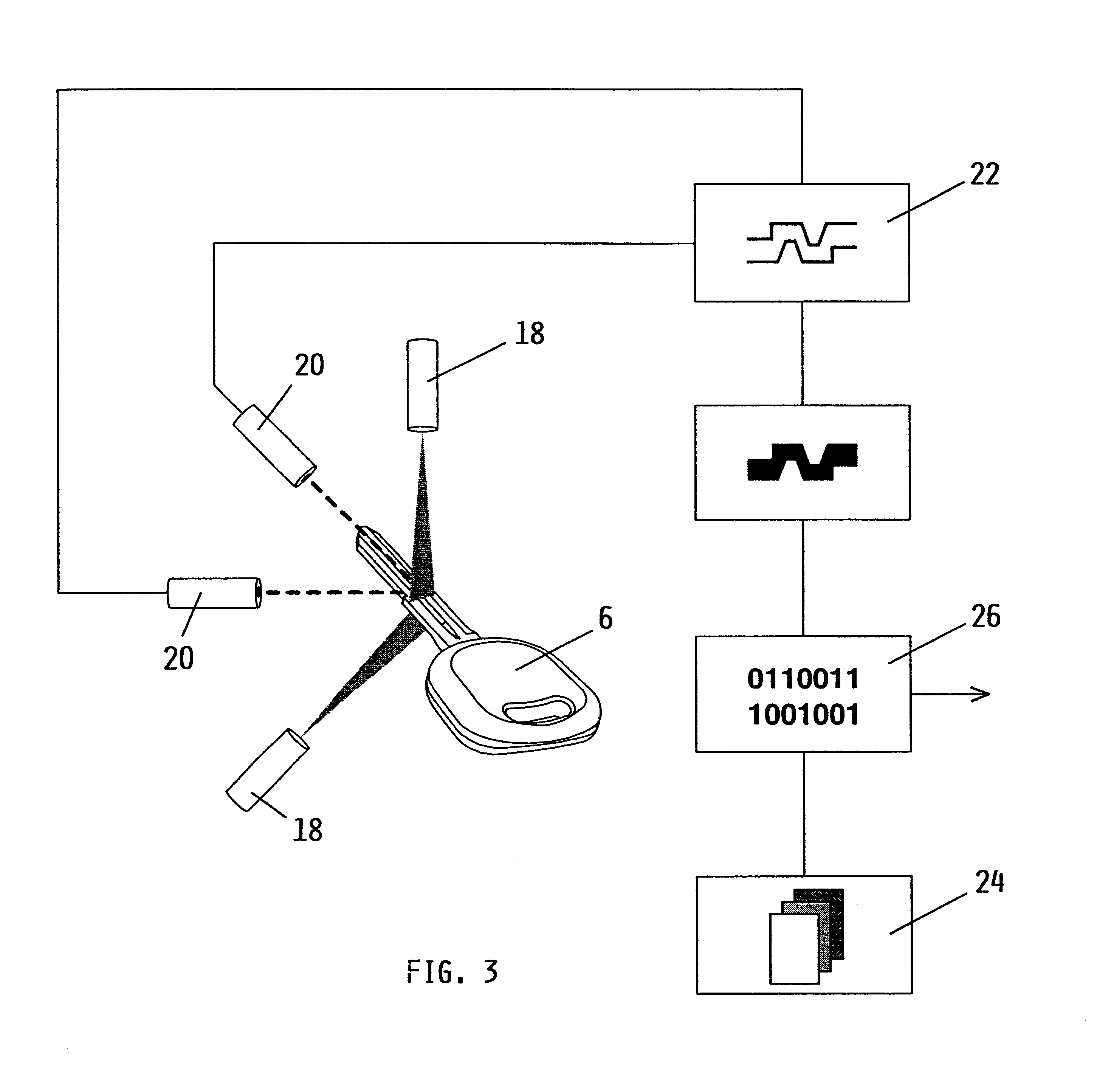

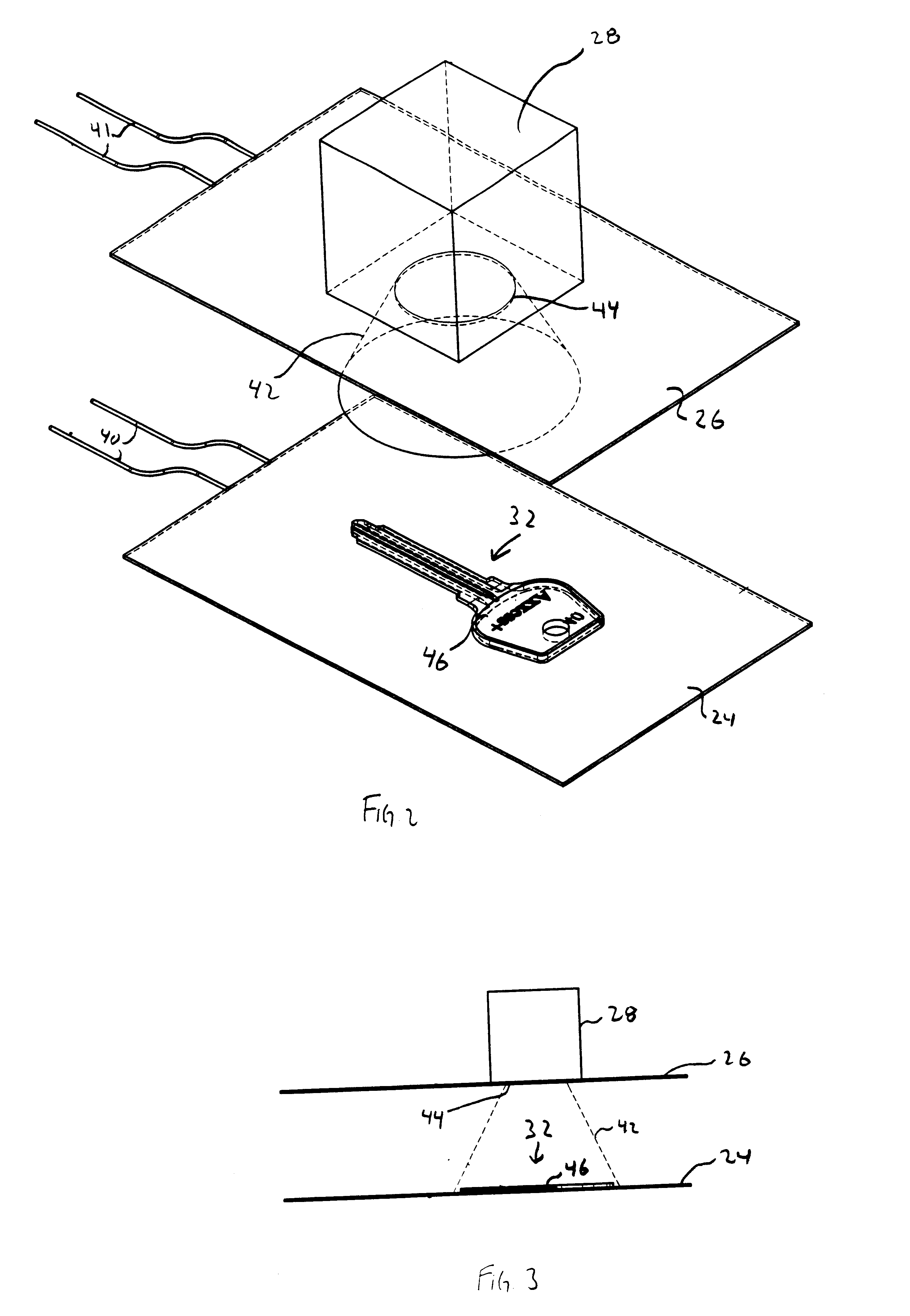

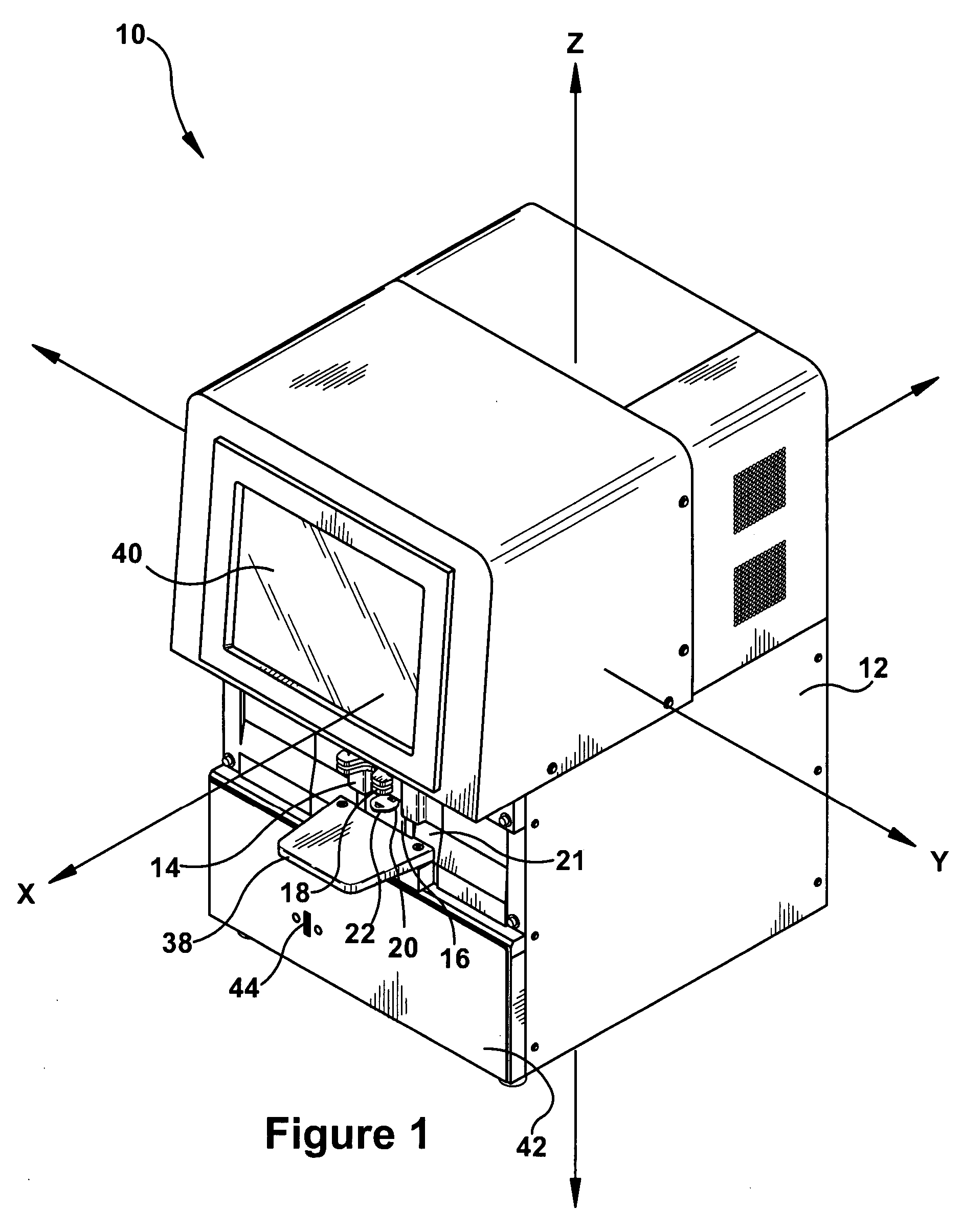

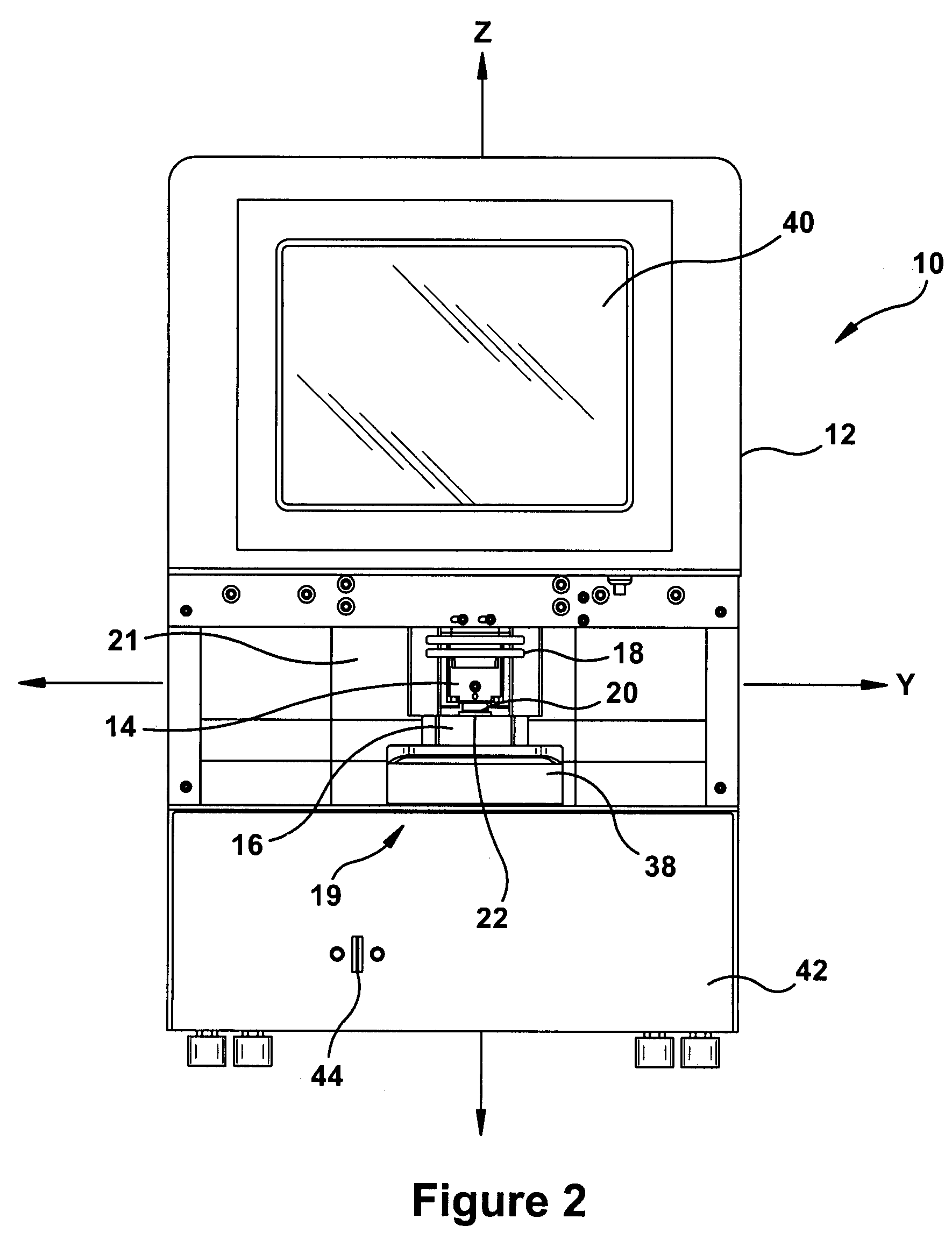

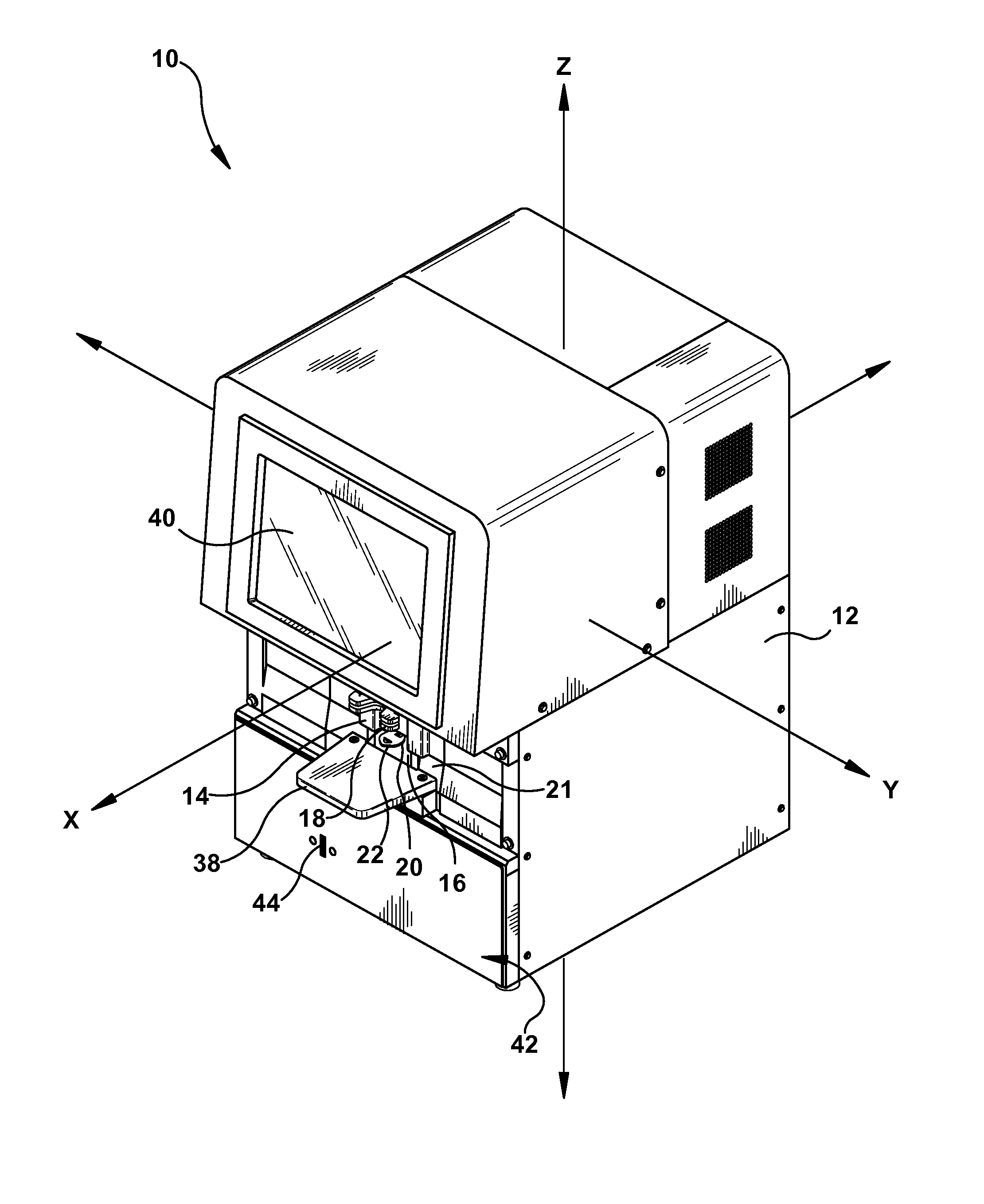

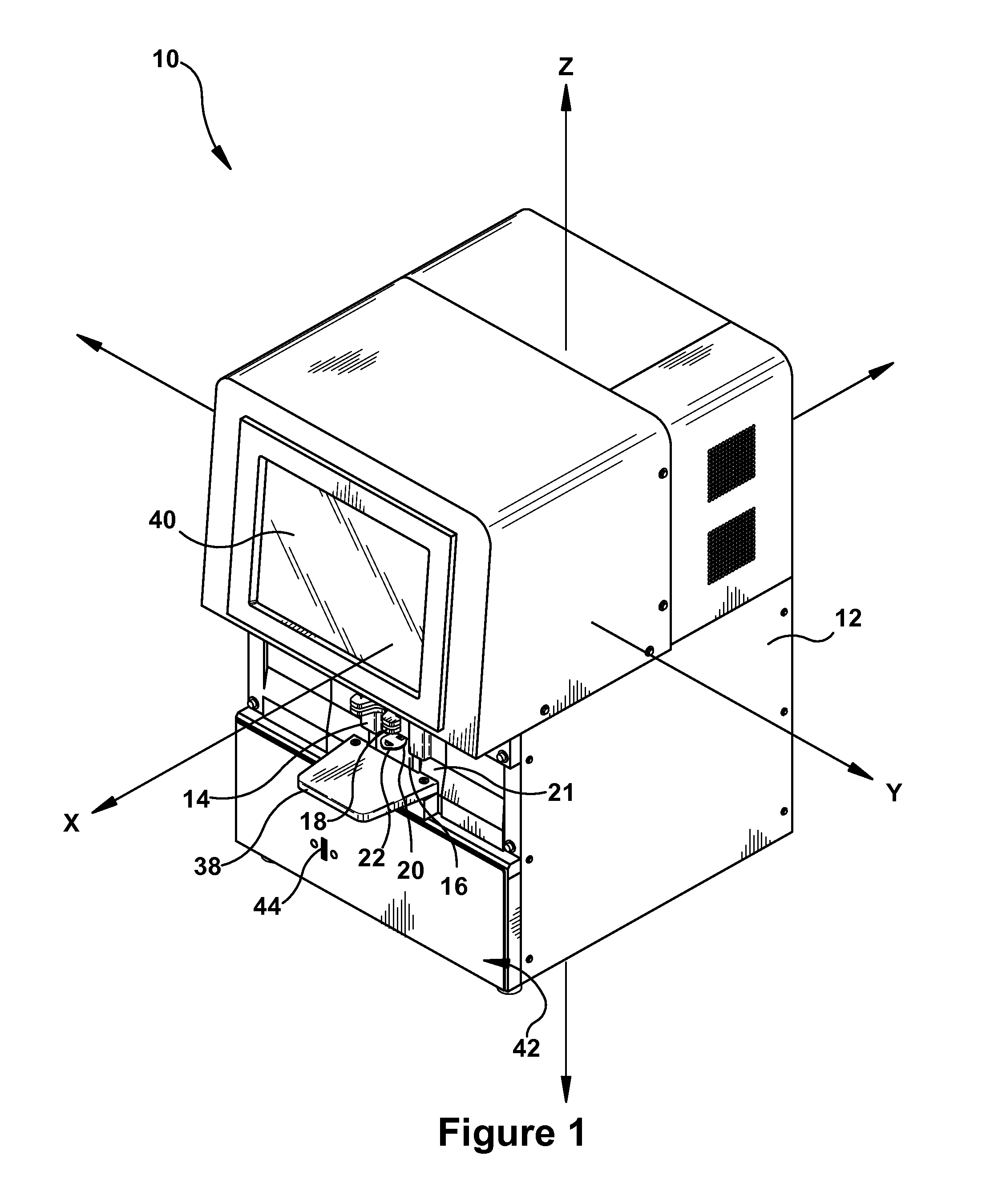

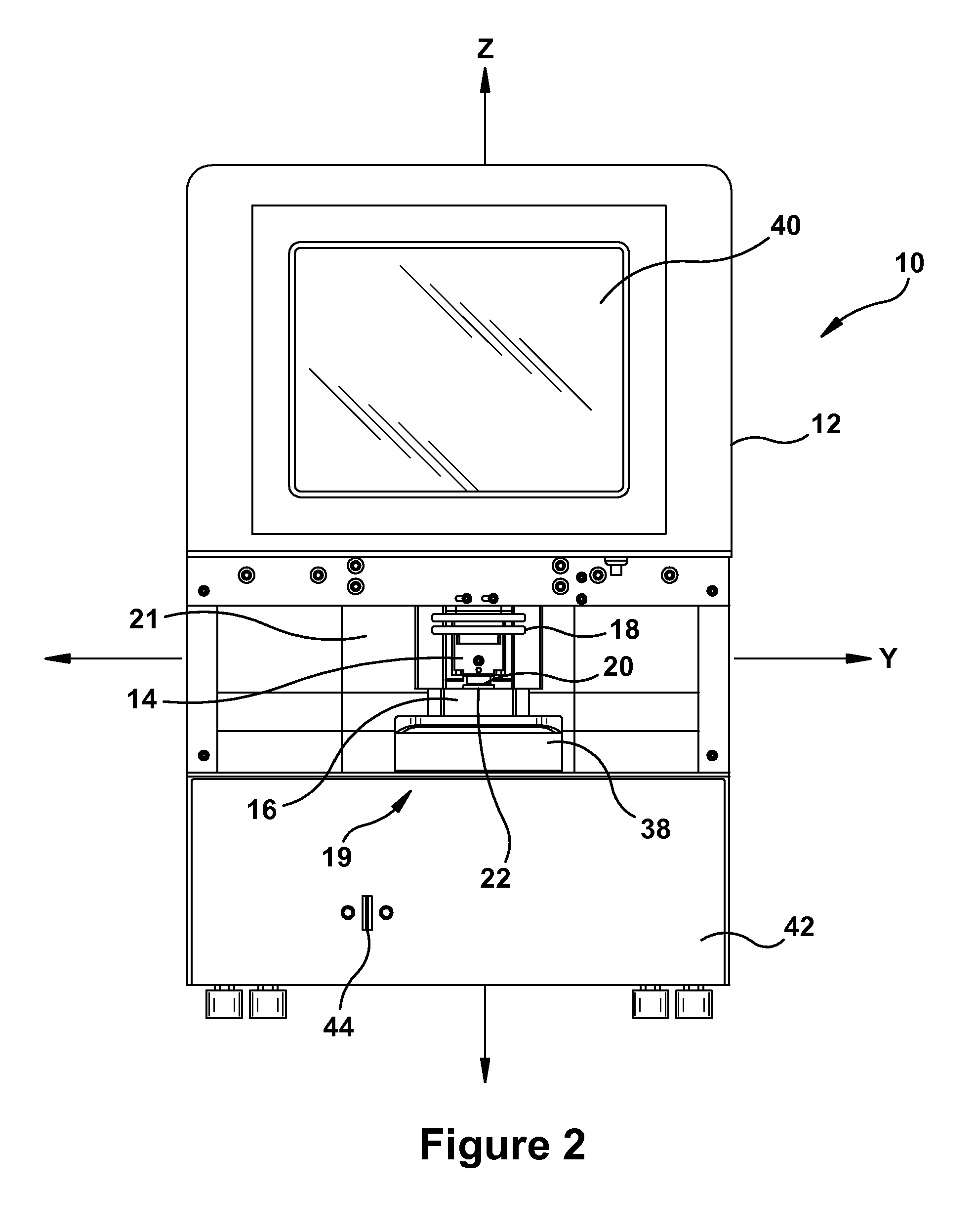

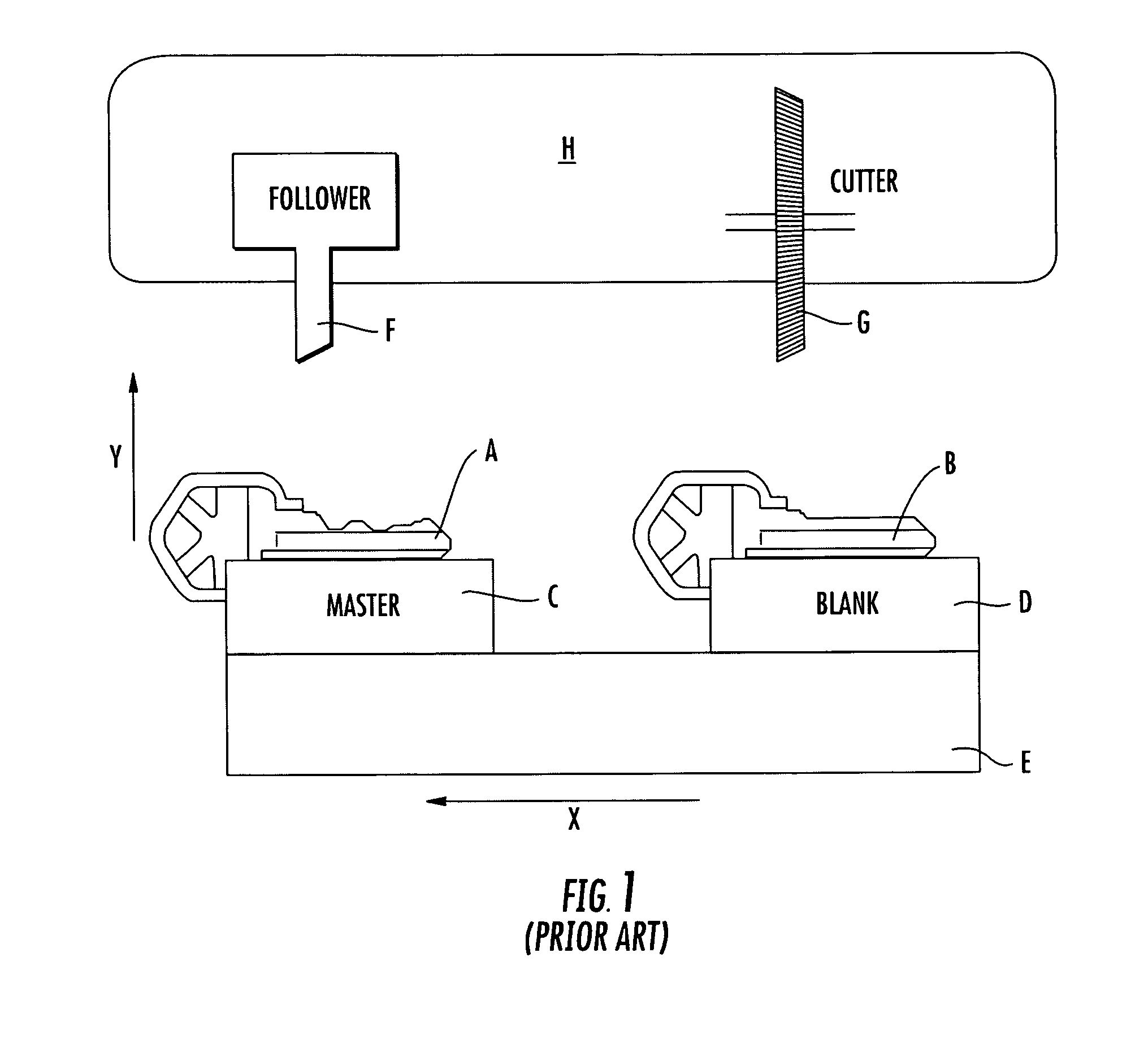

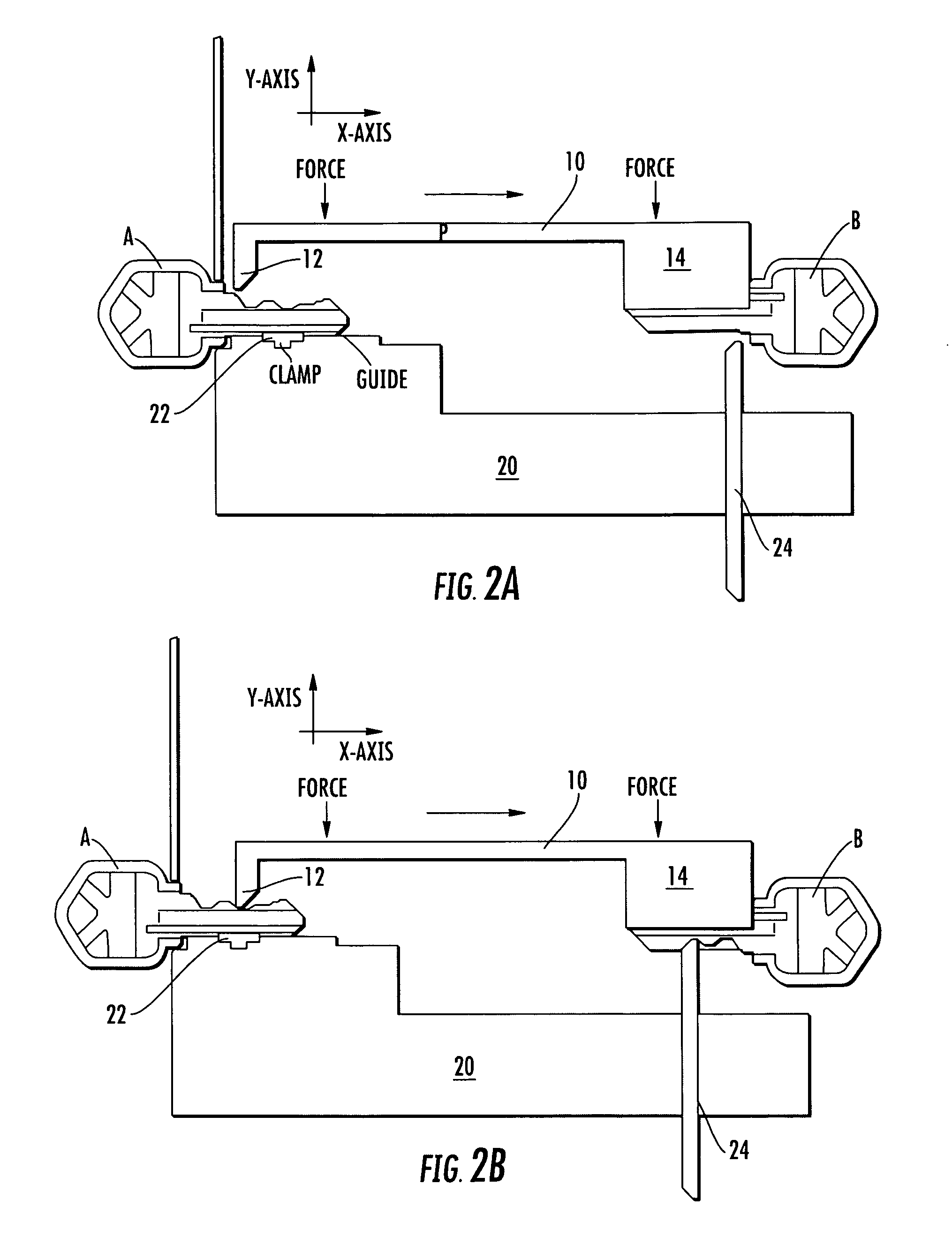

Key duplication machine

Apparatus, methods, and other embodiments associated with a key duplication machine are described. In one embodiment, an assembly for duplicating a master key includes an optical imaging device, a logic, a clamping assembly, and a cutting member. The optical imaging device is capable of capturing an optical image of at least a portion of the master key. The logic is capable of determining a key pattern of the master key from the optical image of the master key. The clamping assembly is capable of clamping a key blank and the cutting member is capable of cutting a key pattern into said key blank.

Owner:HY KO PRODS

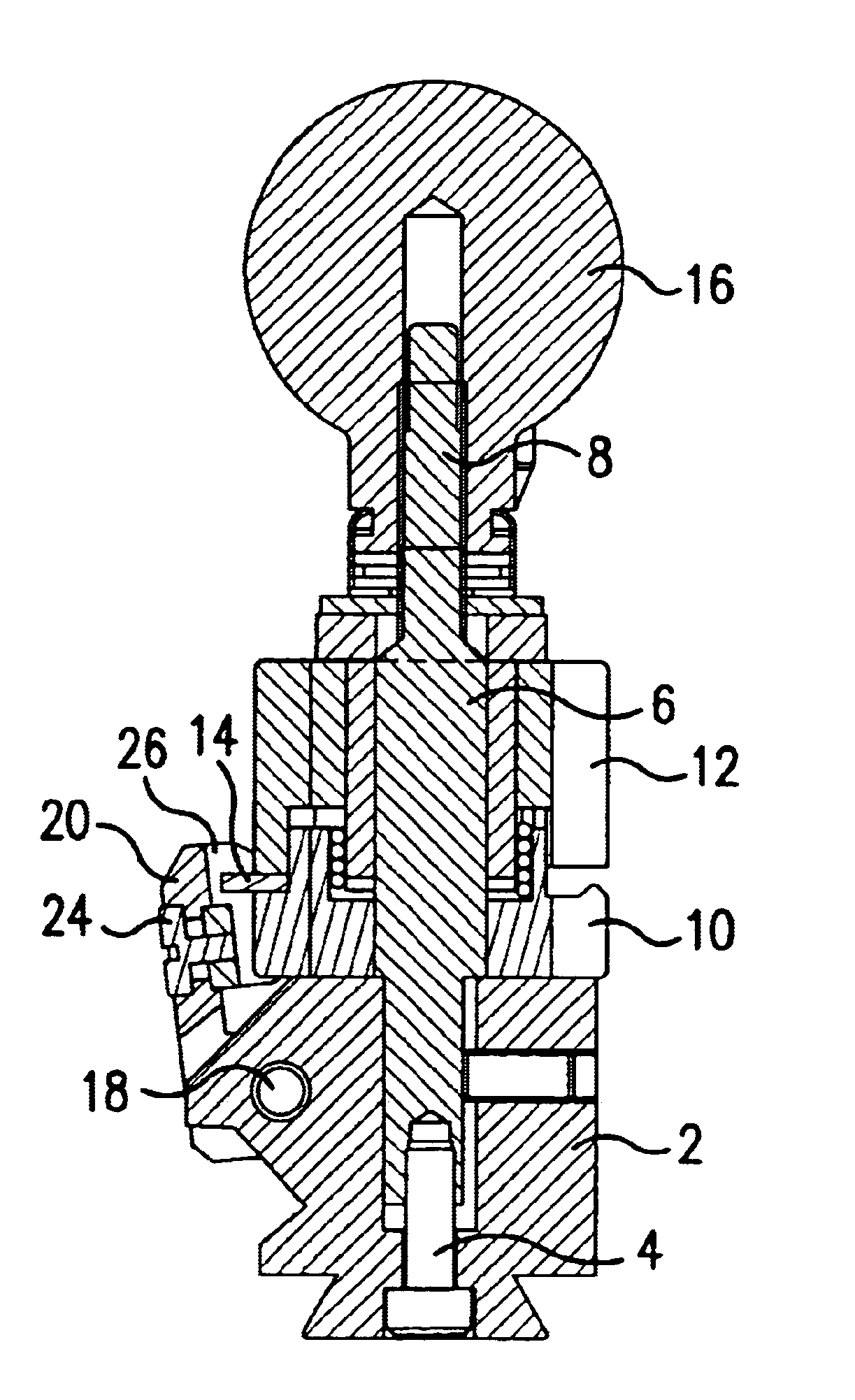

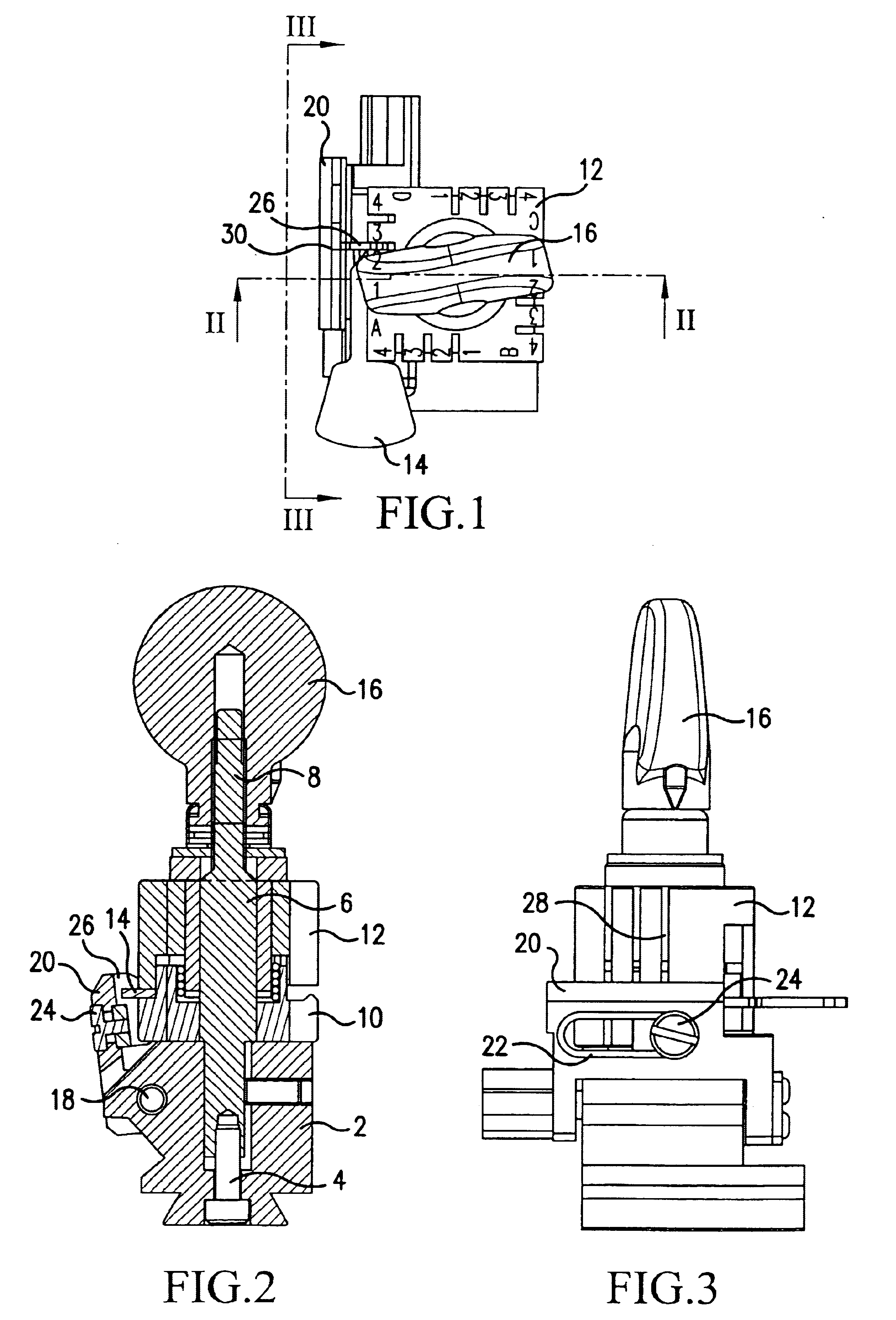

Method to identify a key profile, machine to implement the method and apparatus for the duplication of keys utilizing the machine

A method to identify a key profile, comprising:illuminating with two laminar beams emitted by two laser light sources said two sides of said shank of a key driven to move axially relative to said beams,reading with two video cameras, fixed relative to said sources and having their optical axis inclined to said planes in which said light beams lie, said two light profiles formed by said laminar beams striking said two surfaces of said shank of said keys,digitizing said optical images read in this manner, to obtain two sequences of signals representative of said profiles of said two lateral surface portions of said key, as instantaneously illuminated by said laminar beams and read by said video cameras,reconstructing from said signals, by means of a processor unit, a signal representative of the entire key profile, andcomparing said thus reconstructed signal with said signal representative of profiles stored in said processor unit to obtain data identifying said profile of said read key.

Owner:SILCA SPA

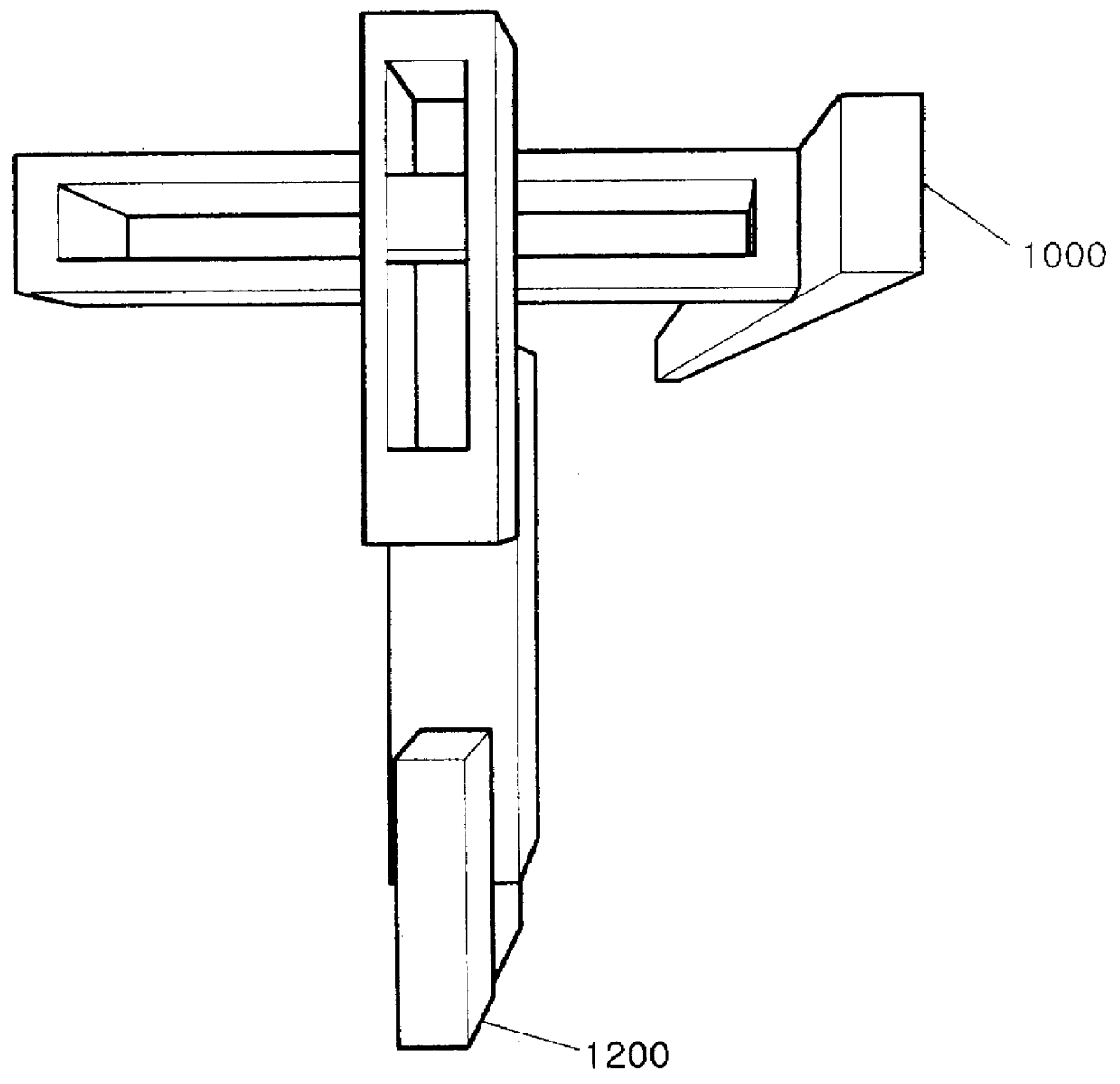

Parallel mechanism for multi-machining type machining center

InactiveUS6135683AImprove robustnessMeasurement/indication equipmentsPlaning/slotting machinesActuatorMachining

A six-degree-of-freedom parallel mechanism is provided for expanding a grade of a spindle. The parallel mechanism has a spindle that turns round a workpiece at a tilting angle of 90 DEG in a workspace, to thereby allow a machining for both vertical and horizontal planes of the workpiece, and a vertical turning process, by a single machining center. A six-axis multi-machining type machining center embodying the parallel mechanism of the present invention is also disclosed. An over-actuated multi-machining type machining center further including over-actuated actuators is presented to solve a problem of driving joints' singularity caused by the parallel mechanism.

Owner:SEOUL NAT UNIV R&DB FOUND

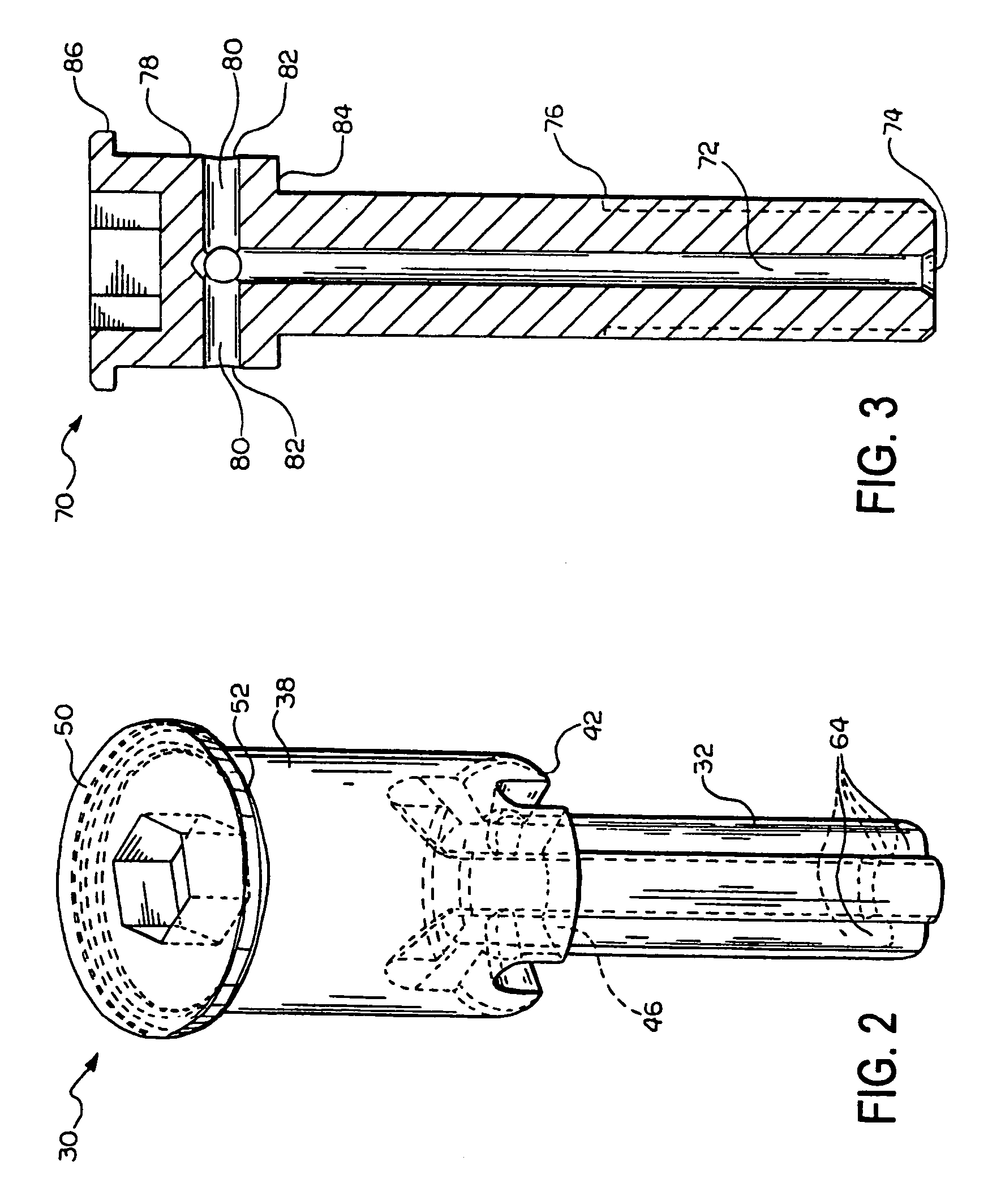

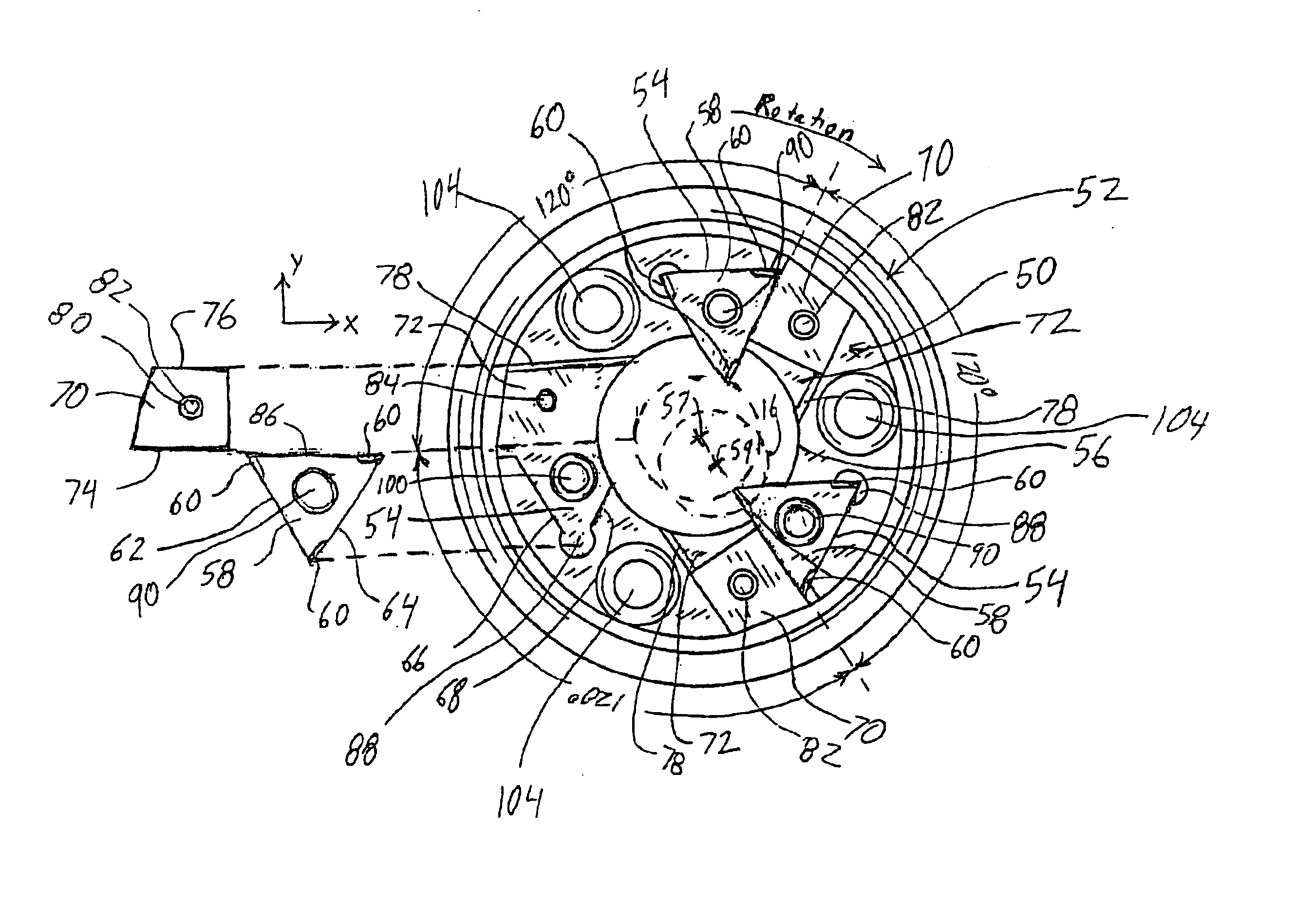

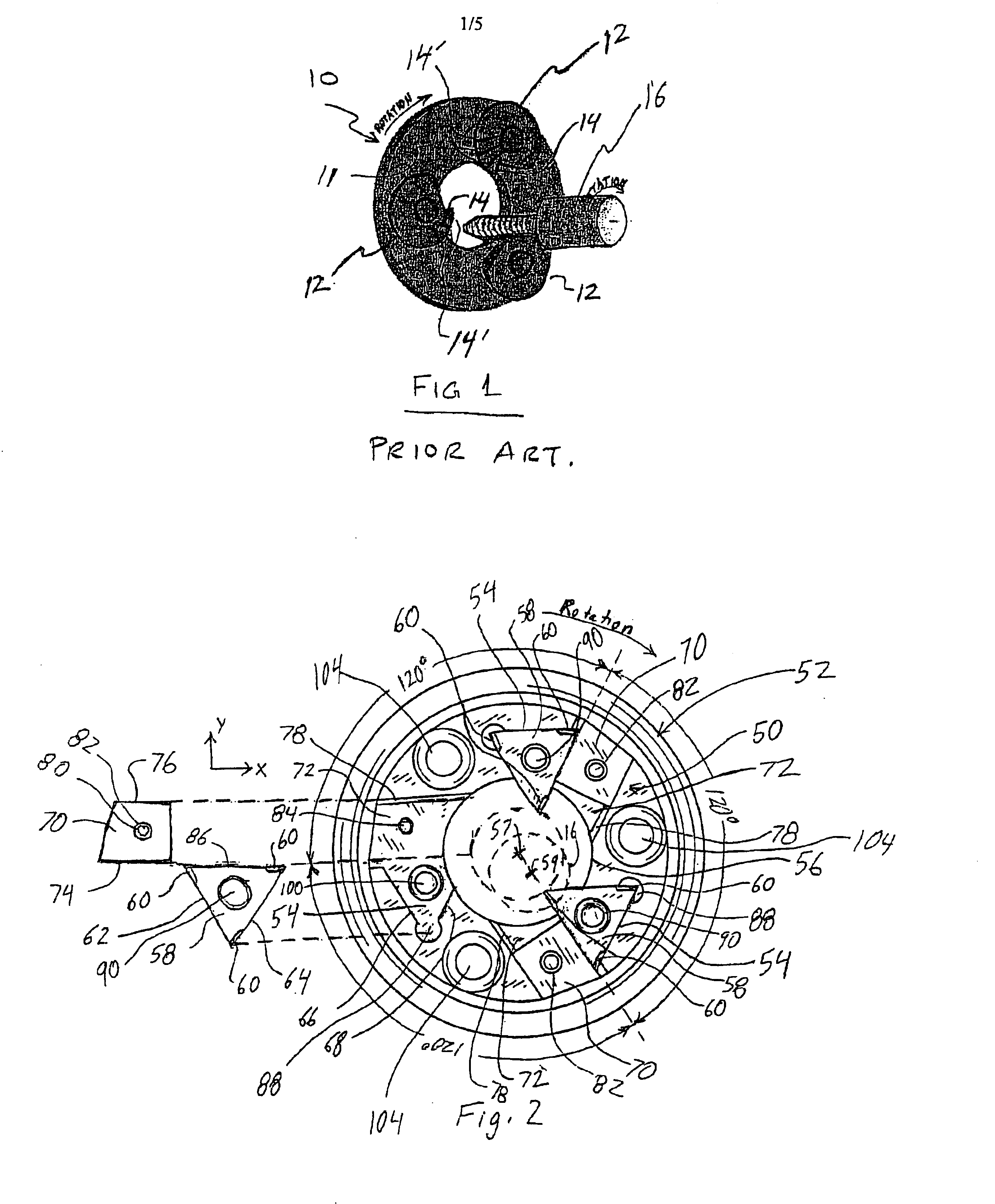

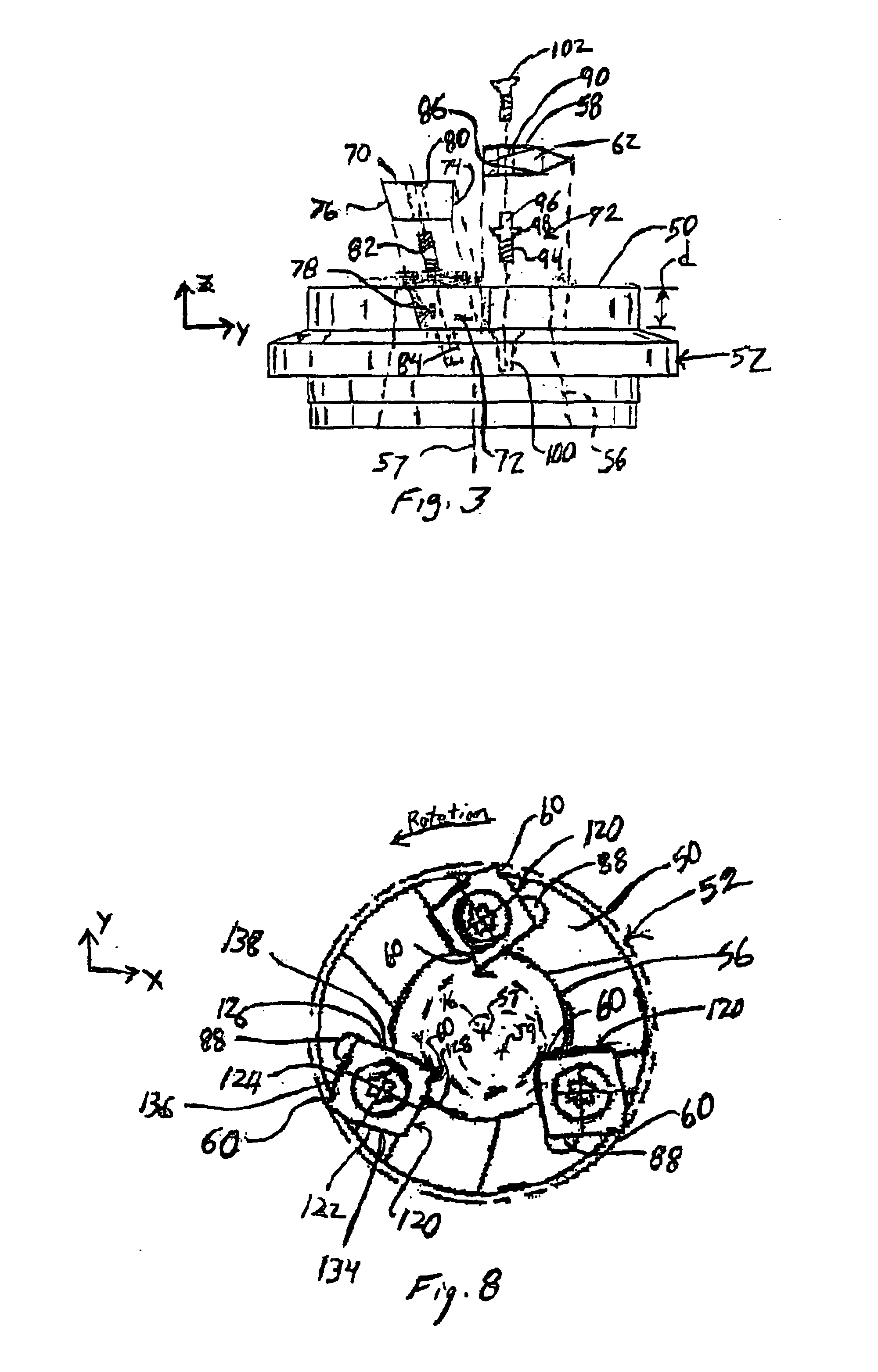

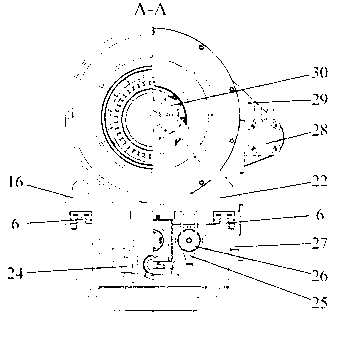

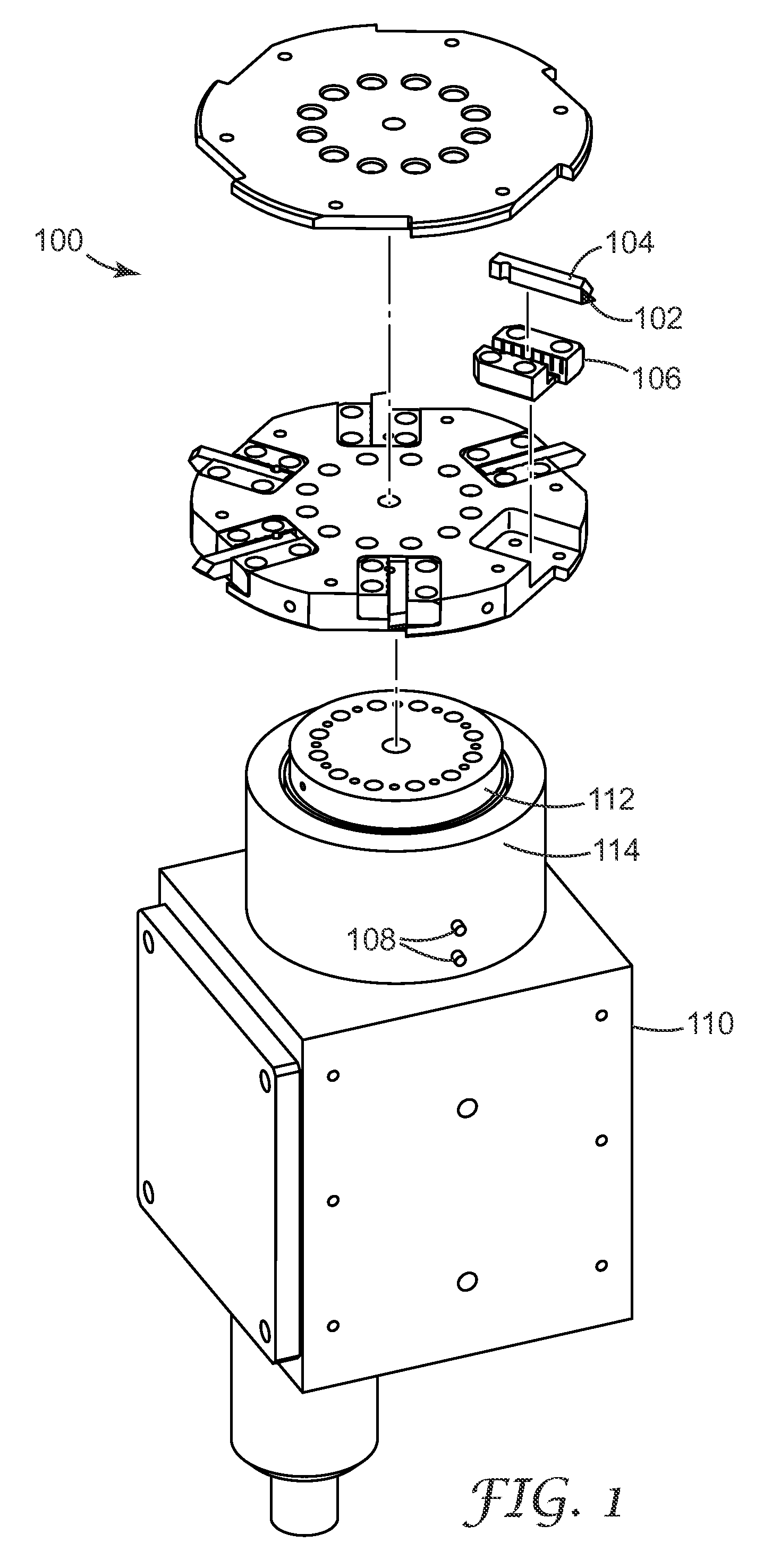

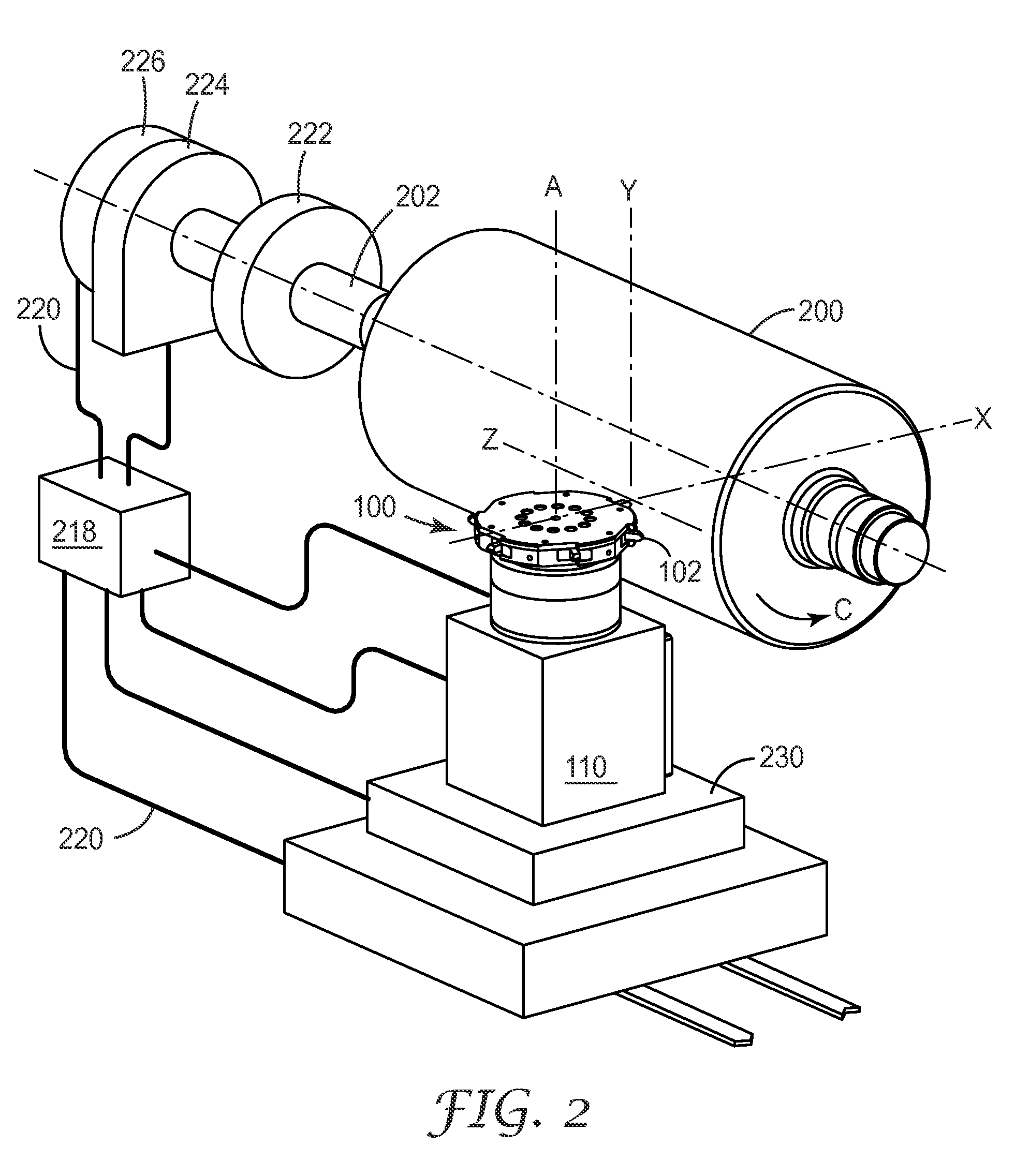

Milling head for thread whirling

A milling head for thread whirling, the milling head includes a plurality of cutting elements evenly disposed around a center hole, each cutting element in the plurality of cutting elements includes at least two cutting surfaces formed thereon. Any one of the at least two cutting surfaces is selectable to extend within the center hole for contacting a work-piece. Each cutting element in the plurality of cutting elements is disposed in a recess formed in a face of the milling head, with each recess defining at least two walls. Each of the at least two walls contacts a side of the cutting element to align the cutting element in a predetermined relationship with respect to the milling head. In one embodiment, the plurality of cutting elements include first and second sets of cutting elements. The first set of cutting elements is evenly disposed around the center hole and contact the work-piece to produce a thread form on the work-piece. The second set of cutting elements is evenly disposed around the center hole and contacts the work-piece to remove material proximate the outside diameter of the work-piece.

Owner:REM SALES

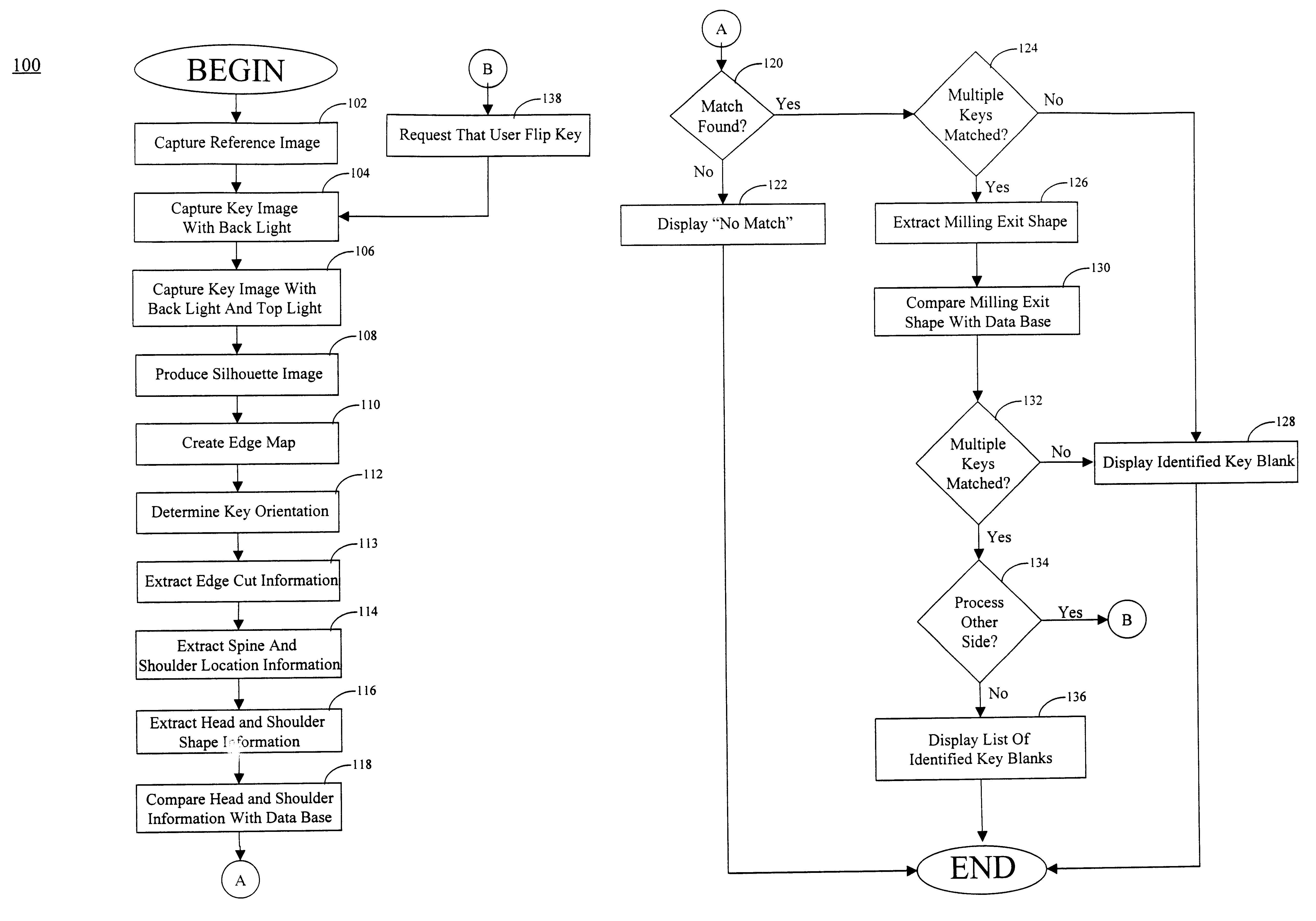

Key identification system

A system for identifying the key blank corresponding to a master key is provided. The system includes a first luminous surface and a second luminous surface. The second luminous surface is disposed opposite the first luminous surface such that the master key is disposable therebetween. The first and second luminous surfaces are operable to generate an image of the master key. A receiver is provided to capture the image of the master key. The system also includes a control having a memory that stores information on a plurality of key blanks. The control is operable to identify the key blank corresponding to the master key based on the image captured by the receiver.

Owner:THE HILLMAN GRP INC

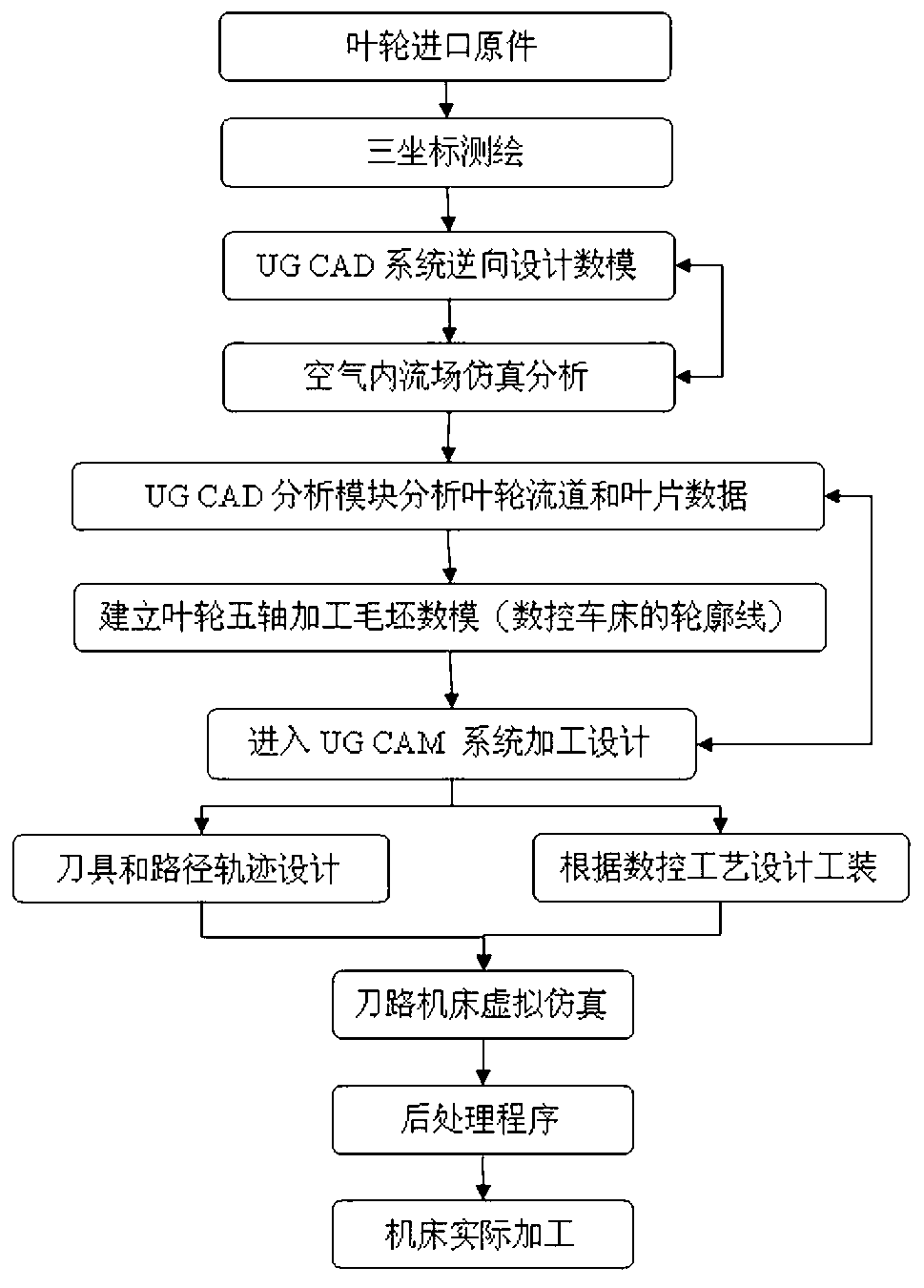

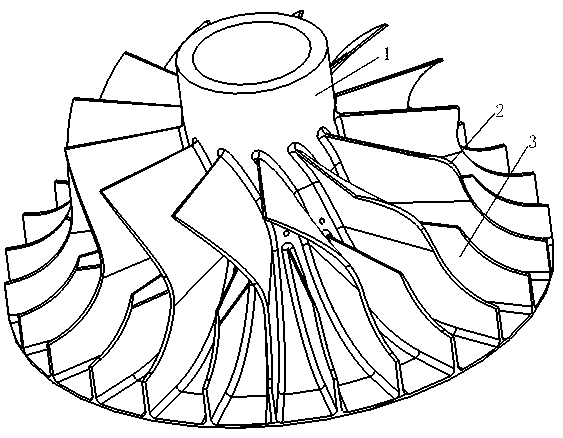

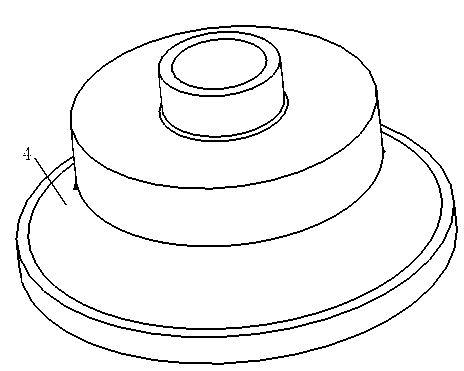

Integral impeller 5-axis machining method based on UG NX system platform

The invention discloses an integral impeller 5-axis machining method based on a UG NX system platform and relates to a technical scheme of a 5-axis numerical control processing technology for an integral impeller researched and developed under a UGNX 7.5 computer-aided design (CAD) system platform. The method comprises using a reversal design technique under the UGNX 7.5 CAD system platform to obtain compressor wheel digifax; acquiring corresponding data from the digifax to establish blank digifax on the digifax according to numerical control technology requirements; selecting a machine tool: using a 5-axis linkage machining center; selecting a cutter according to the geometrical shape and machining materials of an impeller and selecting the cutter with a diameter as large as possible as long as the passage dimension allows; and setting the impeller machining track: UGNX, selecting an appropriate machining method and selecting allowances for rough and finish machining, outputting 5-axis machining center machine tool machining codes for being called by the 5-axis linkage machining center.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

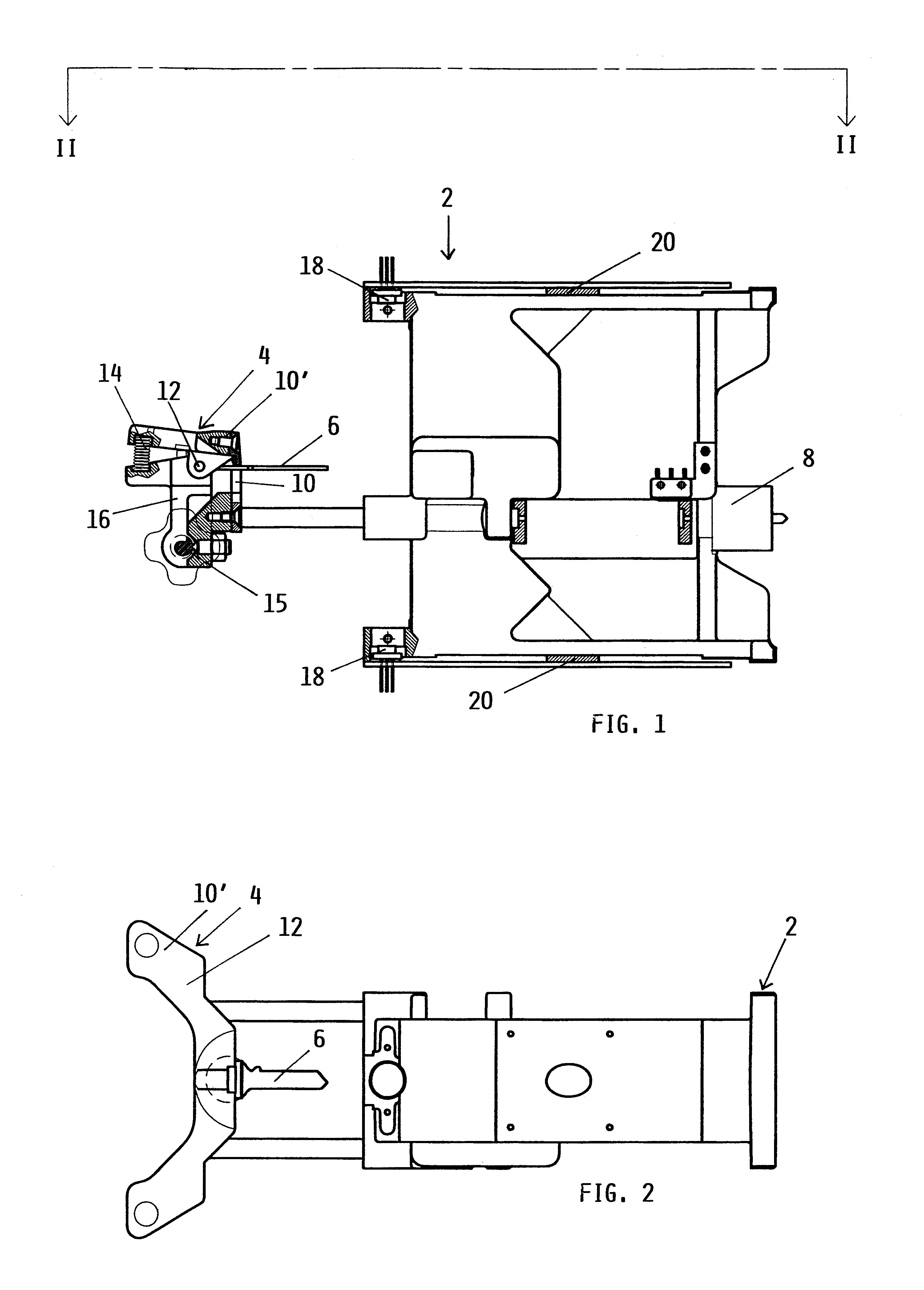

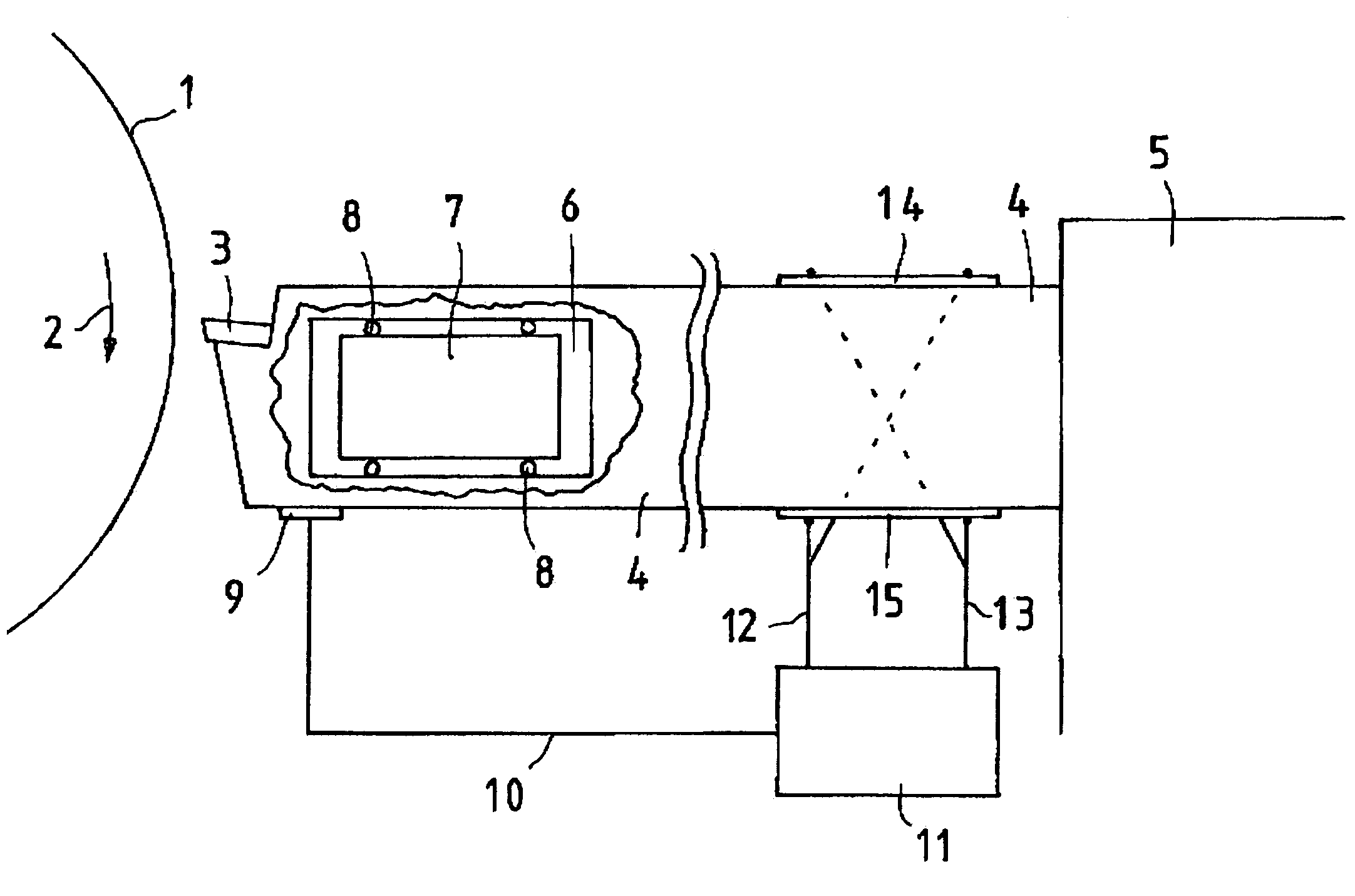

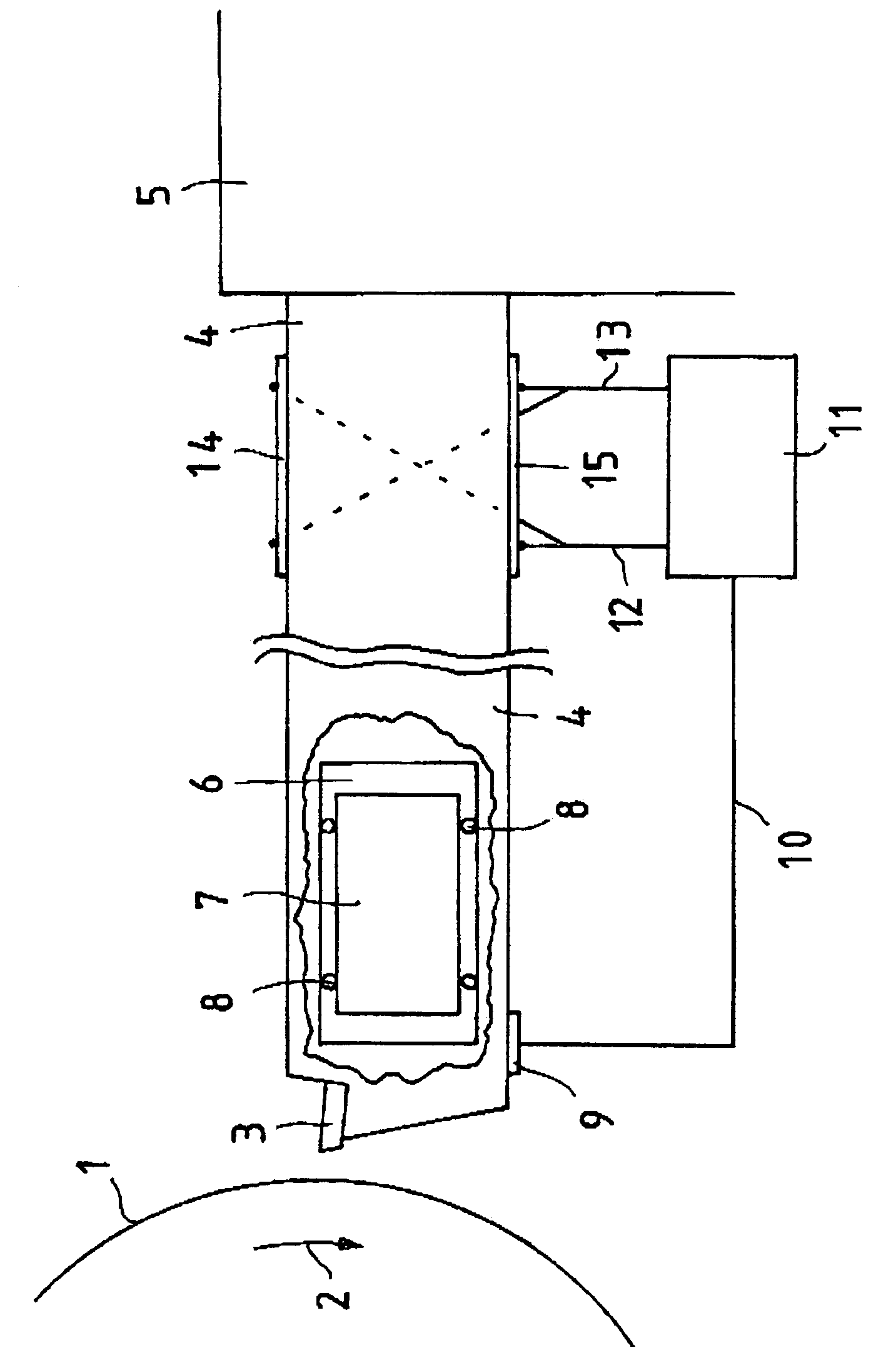

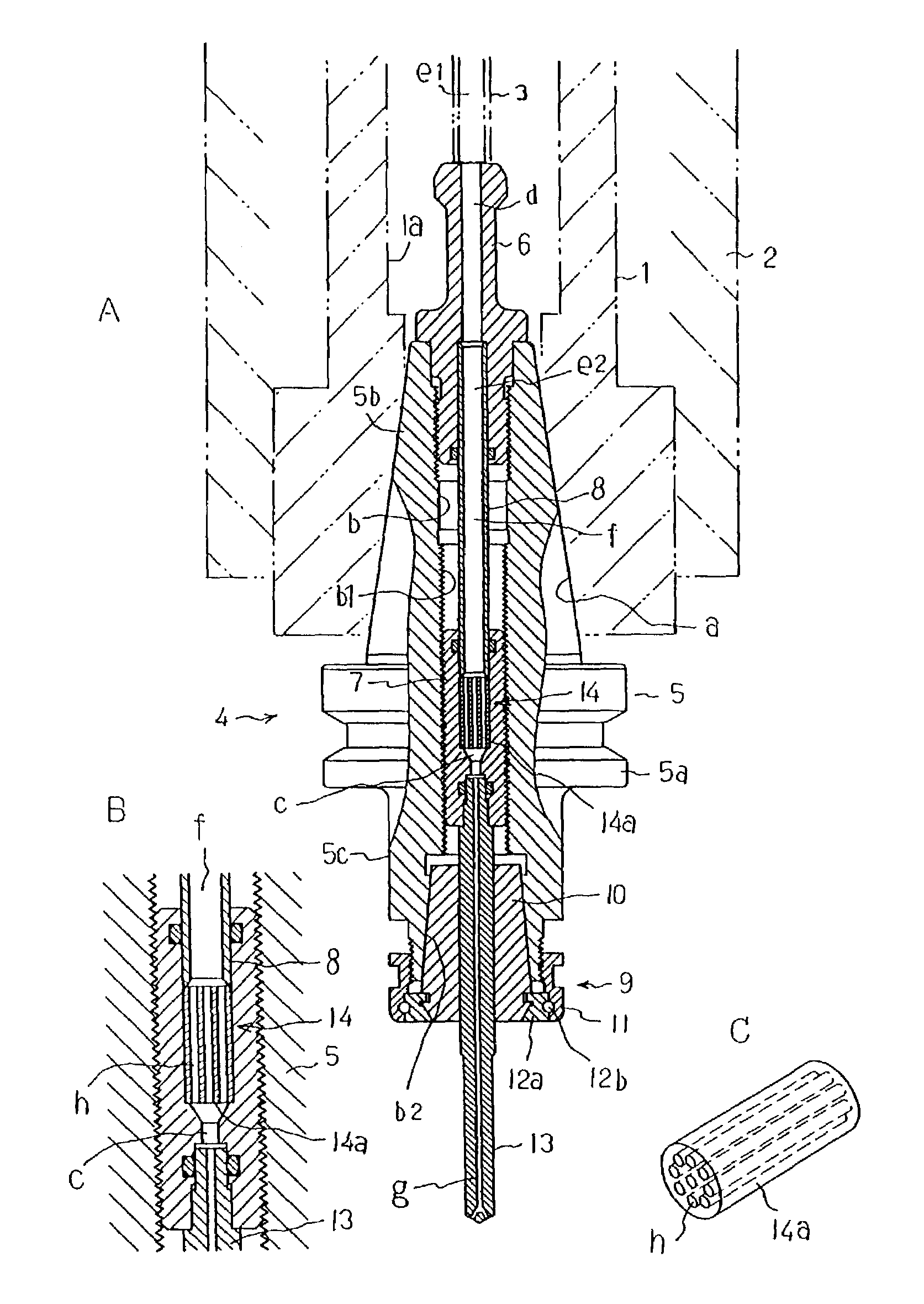

Device and a method for preventing or reducing vibrations in a cutting tool

An arrangement for reducing vibrations in a tool holder (4) with a cutting tool (3) and has a vibration sensor on the tool holder (4) that is connected to a guide unit (11). The tool holder (4) has further two piezo-electric actuators 14 and 15.Under the influence of the vibration sensor (9), the guide unit (11) provides an electric alternating current that is actively guided over time so that the actuators movably affect the tool holder (4) to reduce the vibrations in this. To also be able to dampen transients in the tool holder (4) this is movably connected with a passive dampening arrangement that is independent of the guide unit (11) and that is based on the principle of a springing (8) suspended mass (7). The invention also relates to a method for reducing vibrations. The vibrations in the tool holder are sensed and a corresponding signal is provided to a guide unit that over time provides actively guided signals to the actuators. The tool holder is also passively influenced by a dampening arrangement that is independent of the guide unit.

Owner:CLAESSON INGVAR +4

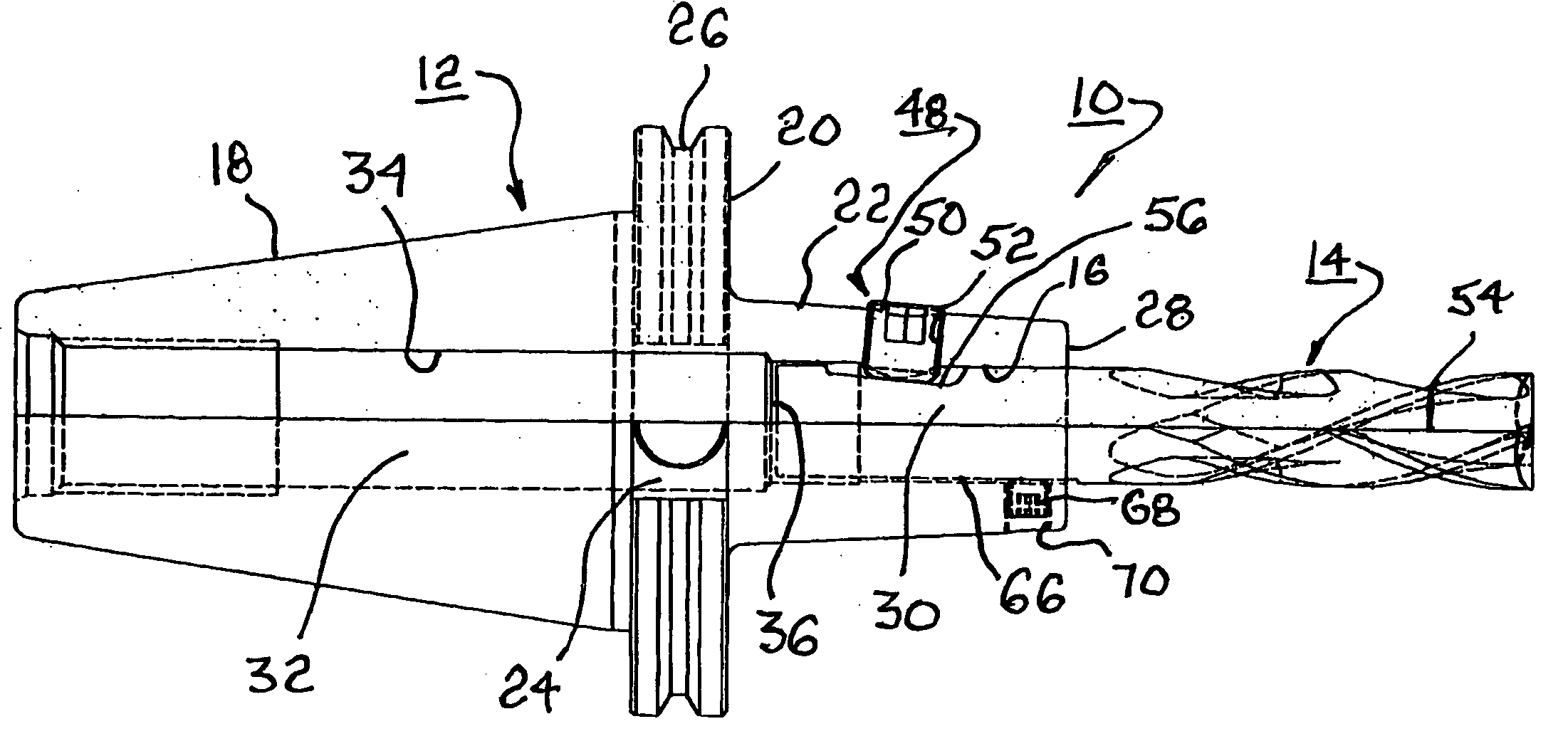

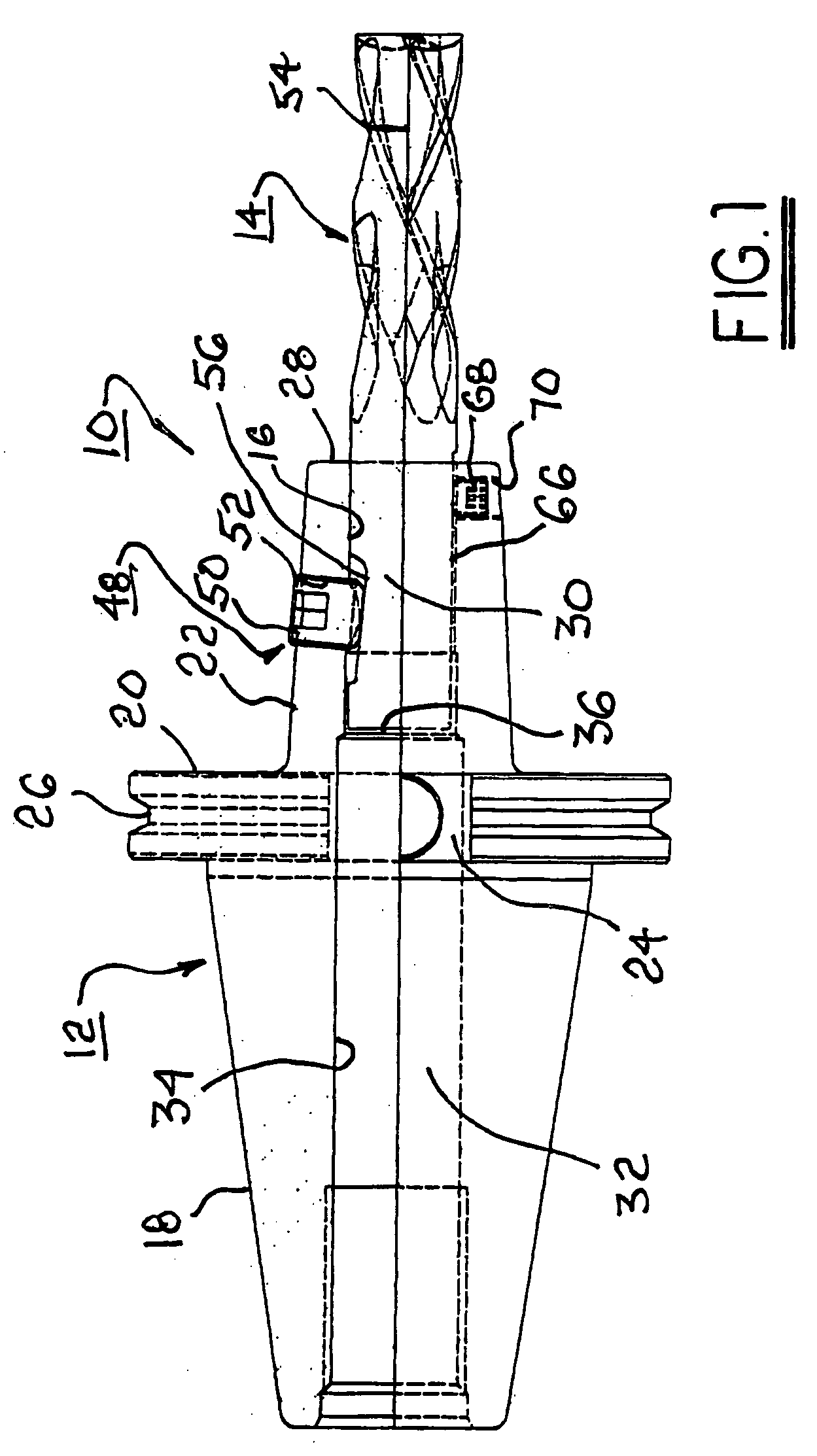

System for mounting a machine tool in a tool holder

InactiveUS20050238451A1Accurate centerAvoid turningSleeve/socket jointsTransportation and packagingSet screwEngineering

A system for mounting a tool in a tool holder combining a means for high-precision centering of the tool and a means for positive restraint of the tool from rotation within the tool holder. The tool holder includes a cylindrical aperture having a diameter slightly less than the diameter of the shank of a cylindrical tool. The tool is installed into the tool holder by heating the tool holder to a temperature sufficient to increase the pocket diameter sufficiently to accept the tool shank. In a first shrink-fit embodiment, the tool shank is further provided with an angular flat for engagement with a set screw to prevent the tool from being turned in the holder in use. In a second shrink-fit embodiment, a groove extending partially around the tool receives a tangential pin through a passage in the tool holder. The tool is rotated in the holder until the pin binds in the groove, thus preventing any further rotation of the tool in the holder during use.

Owner:PARLEC

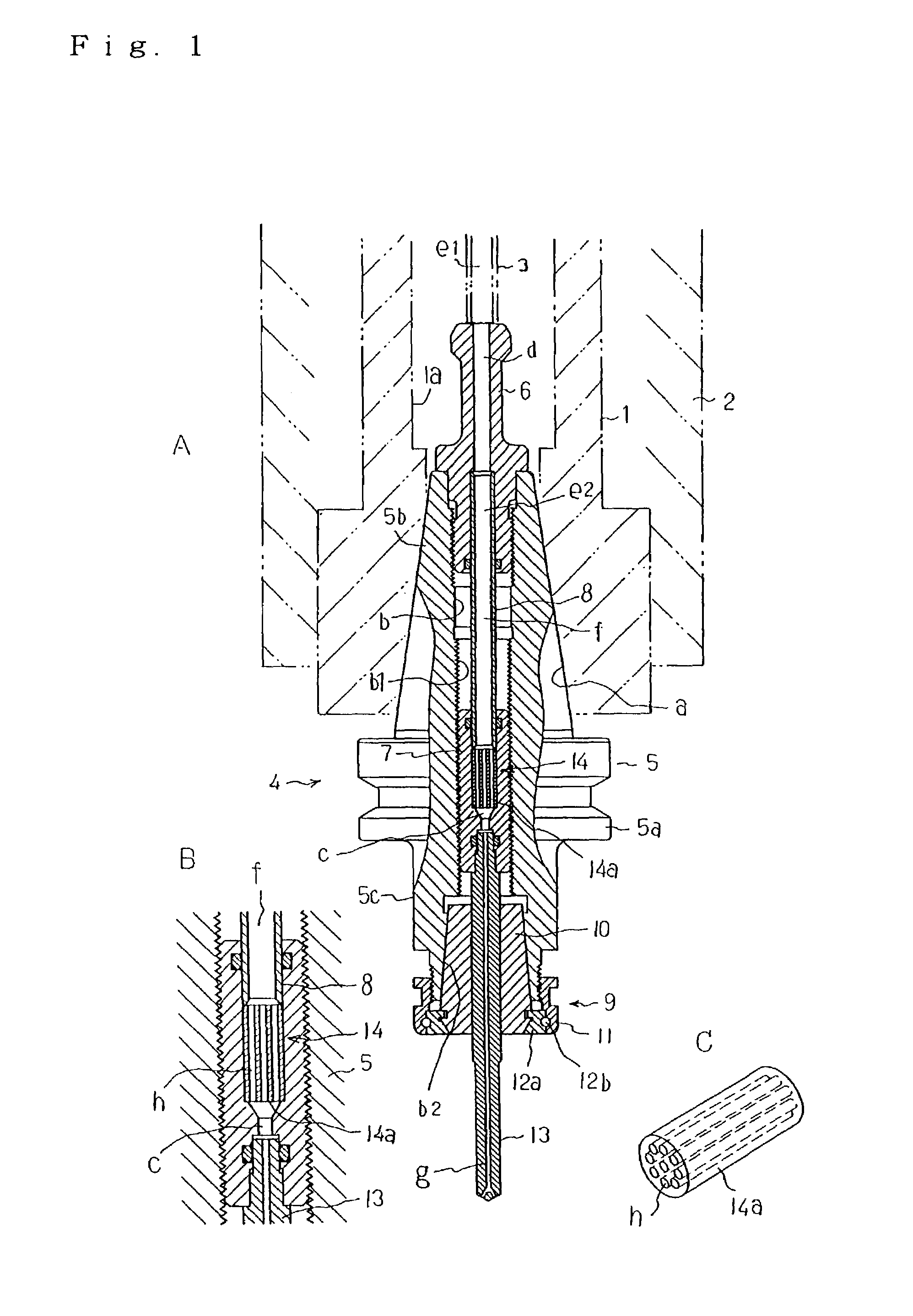

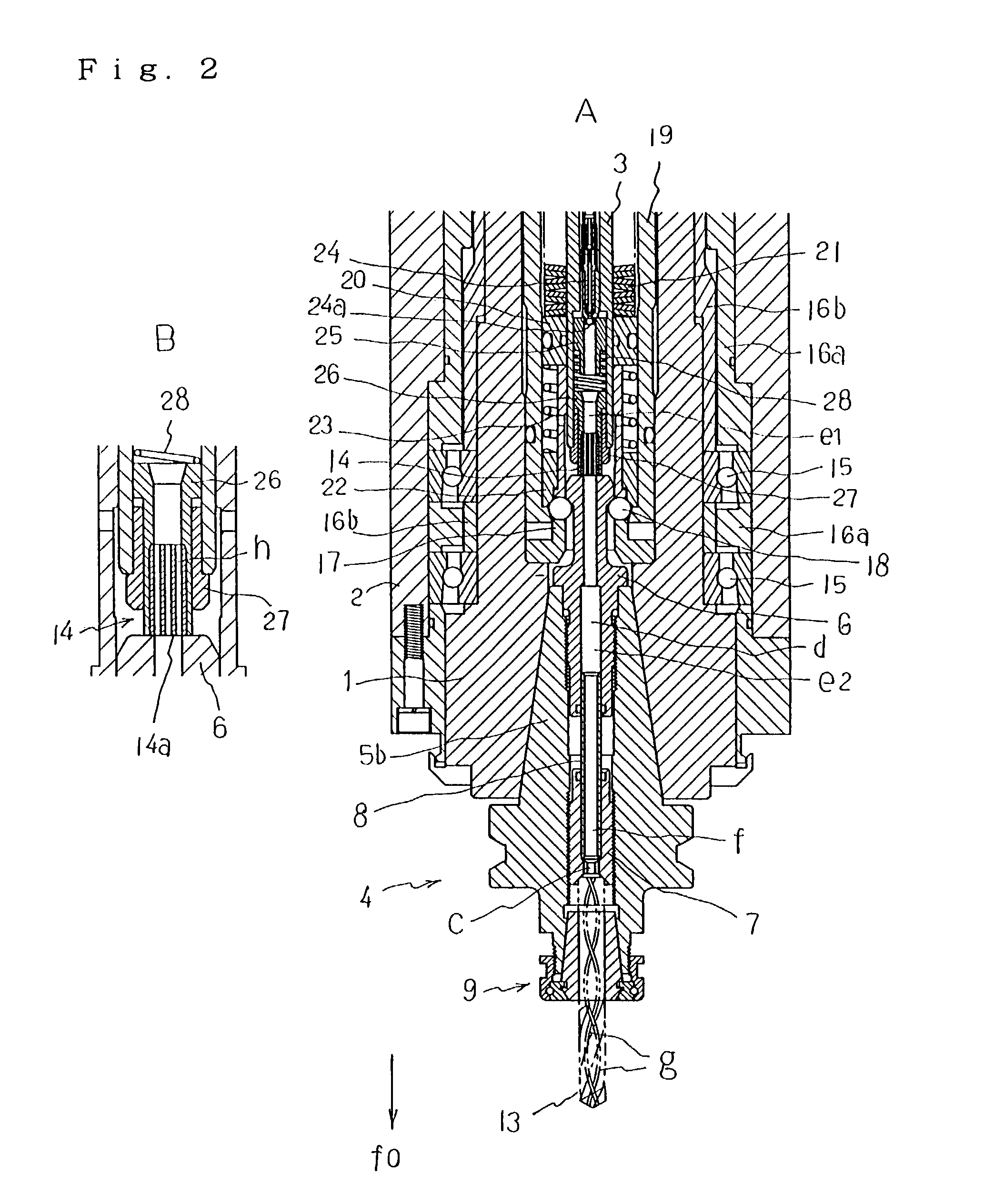

Cutting fluid device for a spindle of a machine tool

InactiveUS7048481B2Easy to producePrevent liquefactionTransportation and packagingMulti-purpose machinesMachine toolCutting fluid

A spindle device of a machine tool, which can prevent the liquefaction of atomized cutting fluid in atomized cutting fluid passage downstream of a straightening unit 14, enhance a responsiveness to an ejecting start or stop instruction, and prevent a waste of cutting fluid. The spindle device for a machine tool has atomized cutting liquid passage (e1, e2) each having a single-shape passage section and formed inside the device ranging from the spindle 1 to the tip end of a cutting tool 13 mounted thereto in one piece, and is operated so as to eject atomized cutting tool 13 via the atomized cutting fluid passages (e1, e2), wherein a straightening unit 14 formed with a plurality of small-diameter passages h are provided in the middle of the cutting liquid passages (e1, e2).

Owner:HORKOS

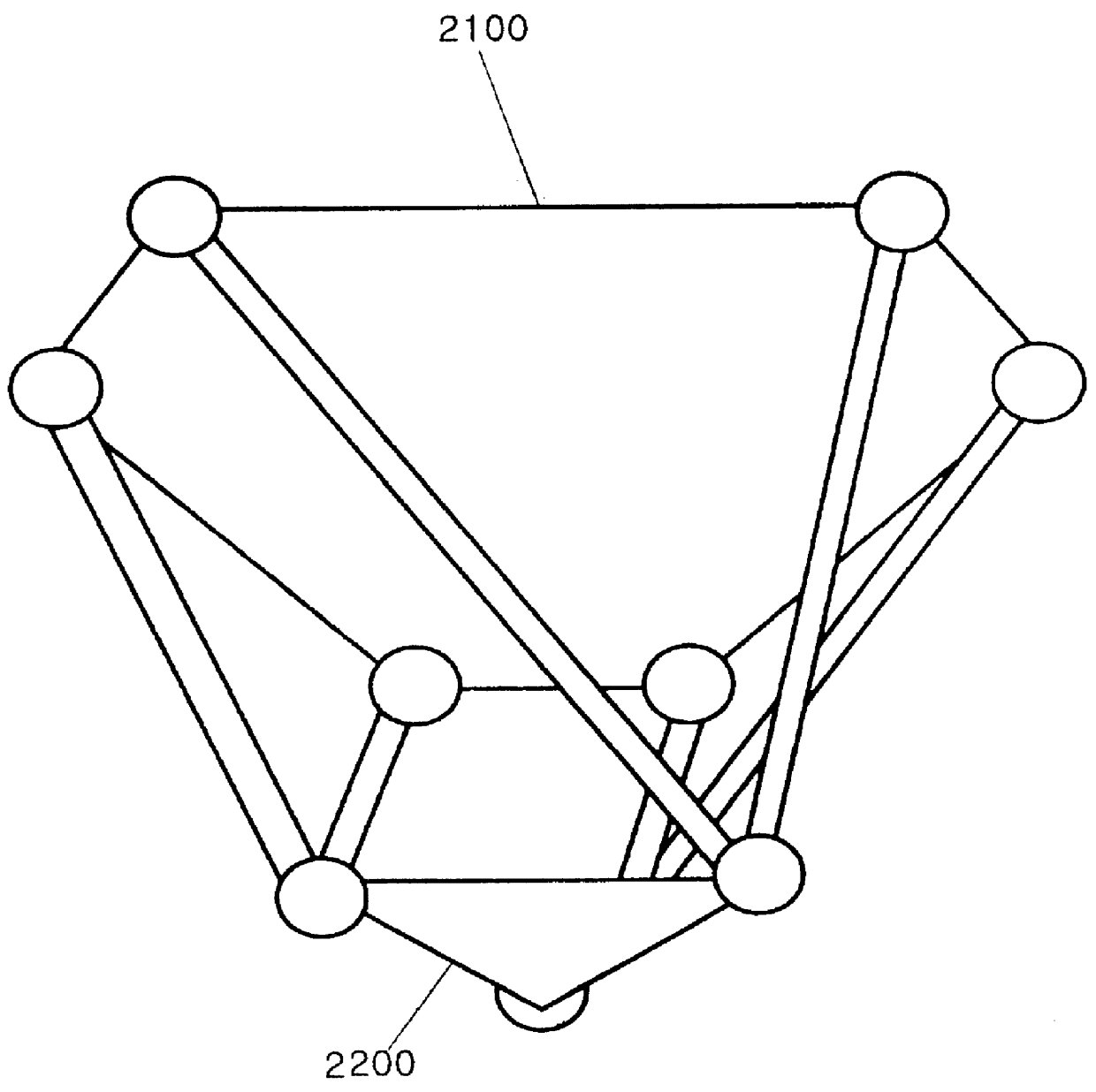

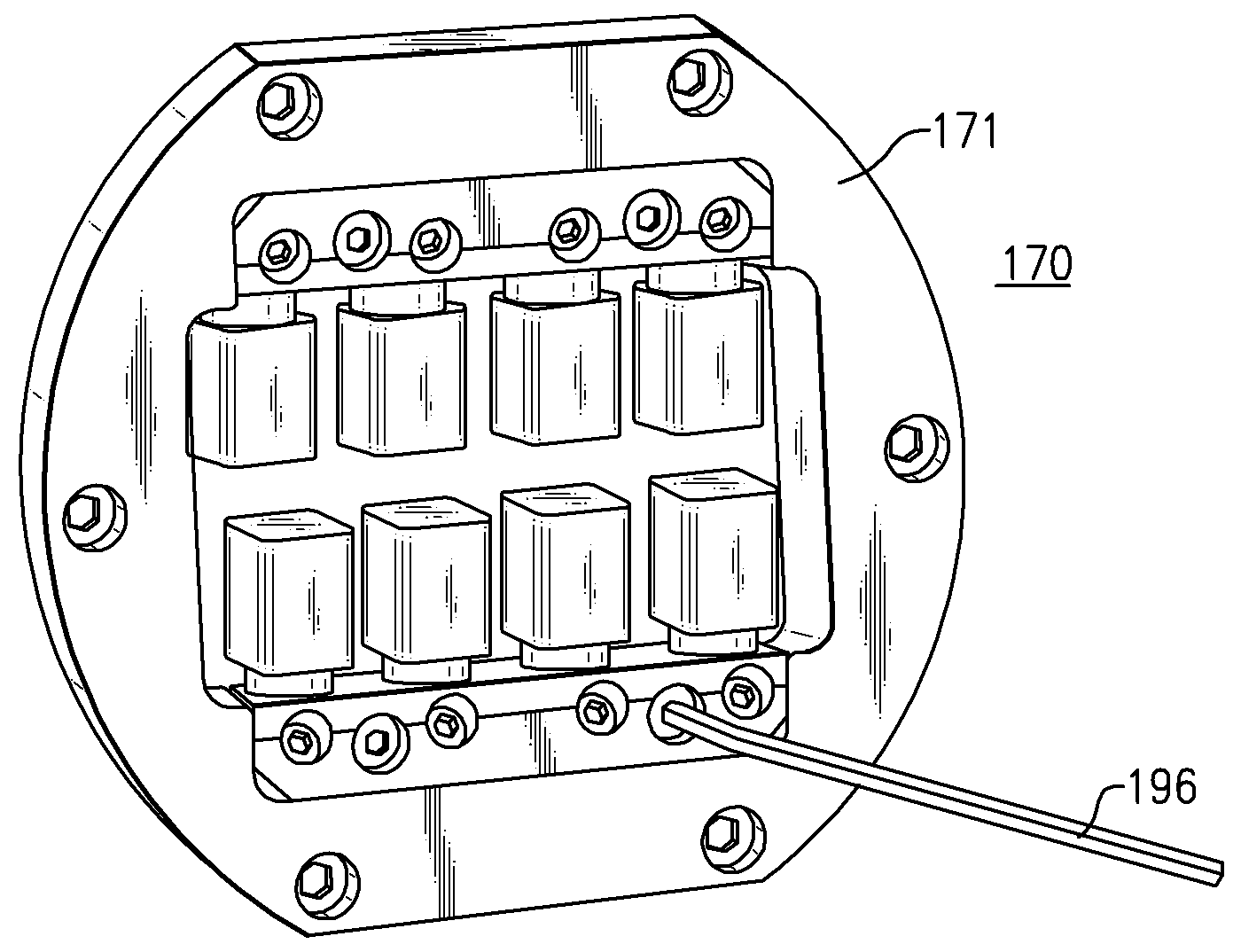

Addressable matrices/cluster blanks for dental cad/cam systems and optimization thereof

ActiveUS20090130634A1Maximum interchangabilityMaximum flexibilityDwelling equipmentDental toolsEngineering

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

Five-axis linkage variable-axis plunge milling numerically controlled processing method for blade part of integral impeller

InactiveCN102085576ASolve the technical problems of low removal efficiencyImprove processing efficiencyAutomatic control devicesFeeding apparatusImpellerStress conditions

The invention discloses a five-axis linkage variable-axis plunge milling numerically controlled processing method for a blade part of an integral impeller. The method comprises the following steps: 1) dividing a spatial free-form surface to be processed of a part into multiple areas to be processed; 2) analyzing the stress conditions in a tooling process; 3) selecting a proper plunge milling cutter; 4) planning a processing route; 5) generating a track of a numerically controlled cutter; 6) simulating by utilizing a numerically controlled program; 7) editing the numerically controlled program; and 8) processing the part. The method is characterized in that by adopting a five-axis linkage variable-axis plunge milling manner, the processing efficiency of removing large margin by virtue of rough grooving of the integral impeller is improved, and the processing problem that finishing process with a ball cutter is required as the residual margin on a blade surface is not uniform after the plunge milling of a fixed axle of the free-form surface is solved; and the method disclosed by the invention can be applied to the five-axis numerically controlled milling processing needing to remove large-margin parts of the complicated free-form surface structures such as axial-flow type integral impellers, integral blade rings and the like as well as to the multi-axis numerically controlled milling processing of the parts of simple free-form surface structures such as centrifugal type integral impellers, mould processing and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

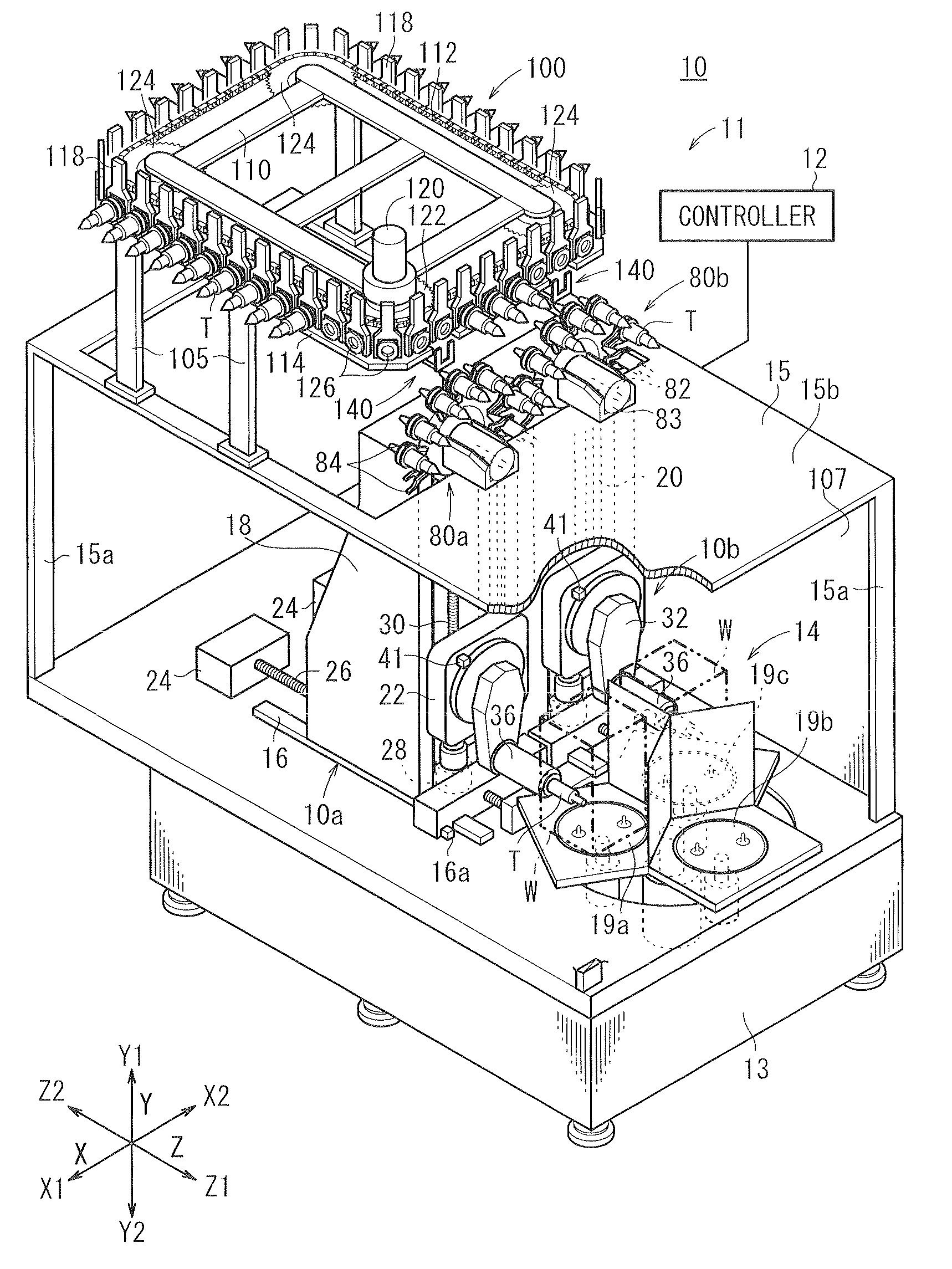

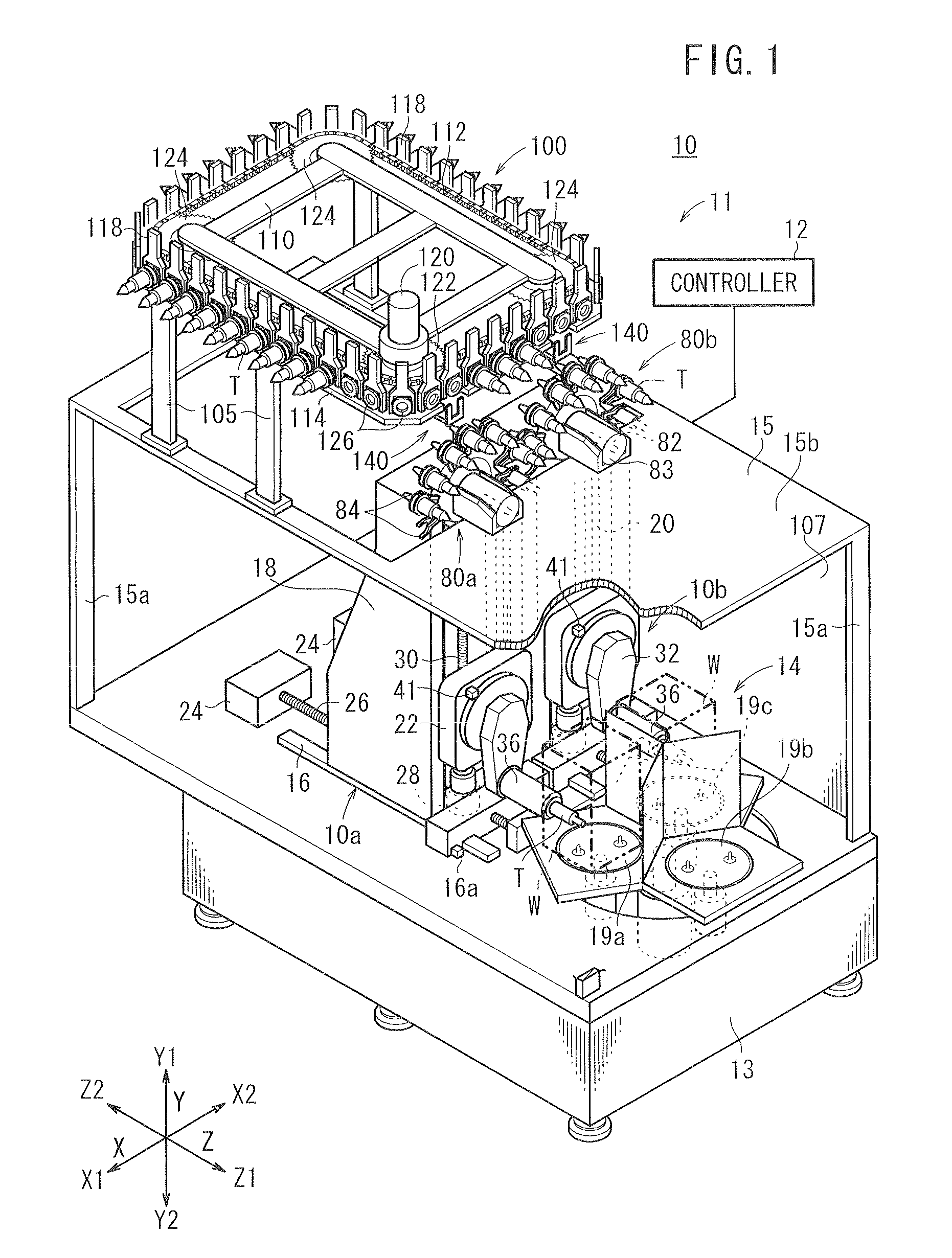

Tool stocker, machine tool system, and tool damage detecting apparatus

ActiveUS20100145498A1Easy and stable transferSmooth transferAttachable milling devicesMilling machinesTransfer mechanismMachine tool

A tool stocker includes main stockers for holding a plurality of tools detachably mounted on a main spindle for machining a workpiece, an auxiliary stocker for holding and transferring tools to and from the main stockers, and a tool transfer mechanism for transferring tools between the main stockers and the auxiliary stocker. The auxiliary stocker includes a plurality of tool pods for removably supporting the tools therein, a rail in sliding engagement with outer surfaces of the tool pods, a chain for moving the tool pods in sliding engagement with the rail, and a motor for actuating the chain. The rail has a recess defined therein in alignment with the tool transfer mechanism, such that the tools transferred by the tool transfer mechanism pass through the recess.

Owner:HONDA MOTOR CO LTD

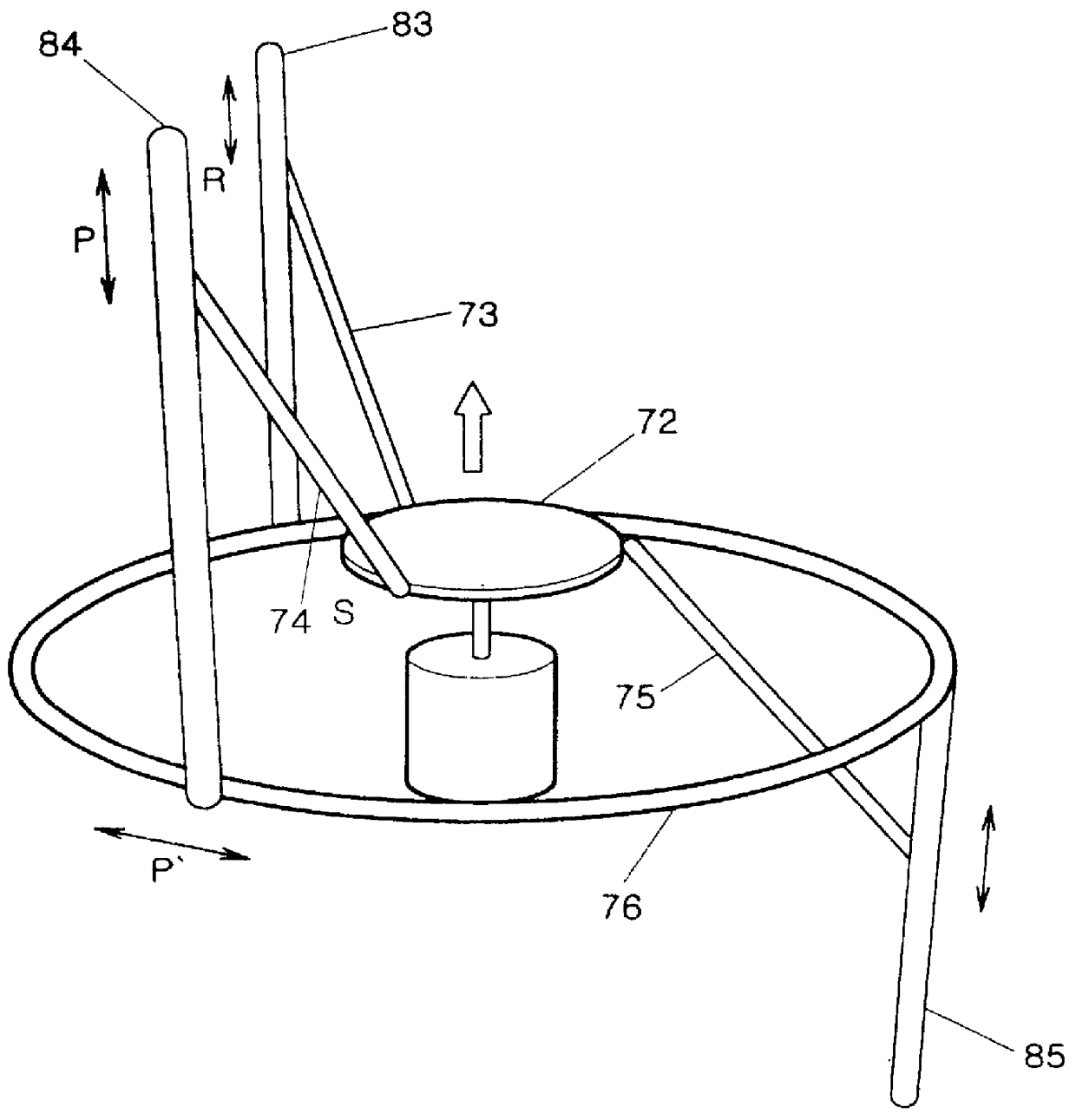

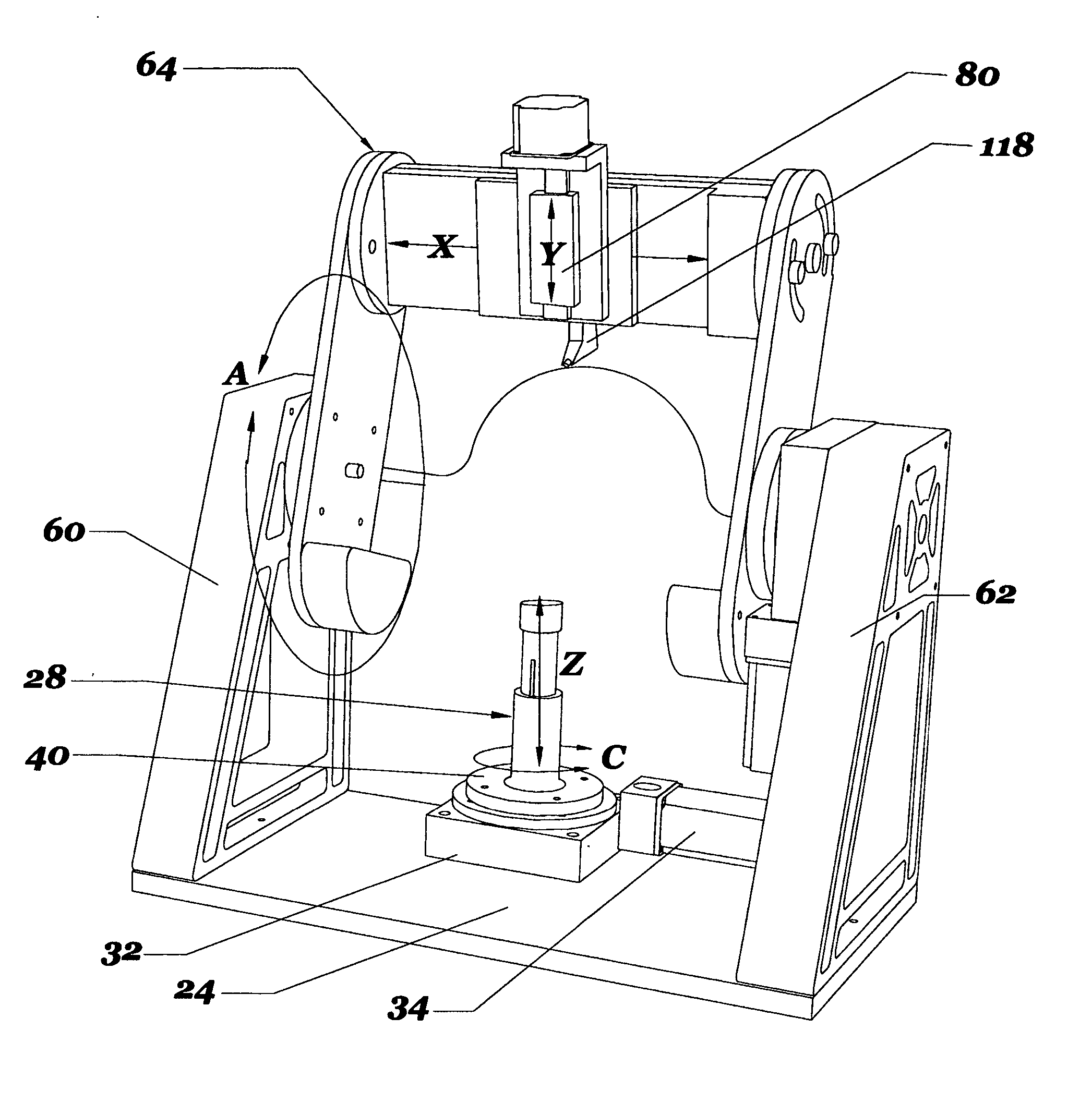

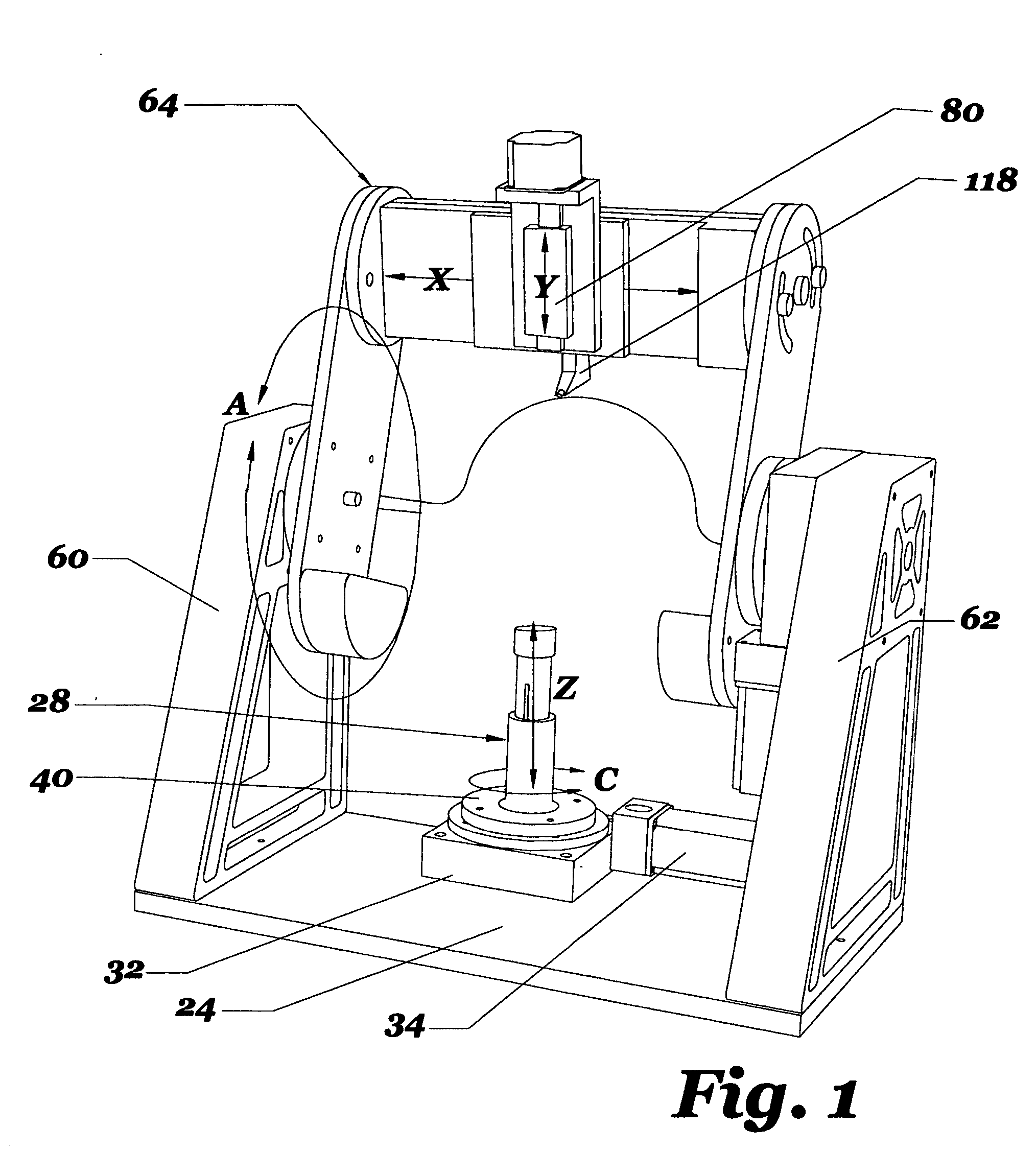

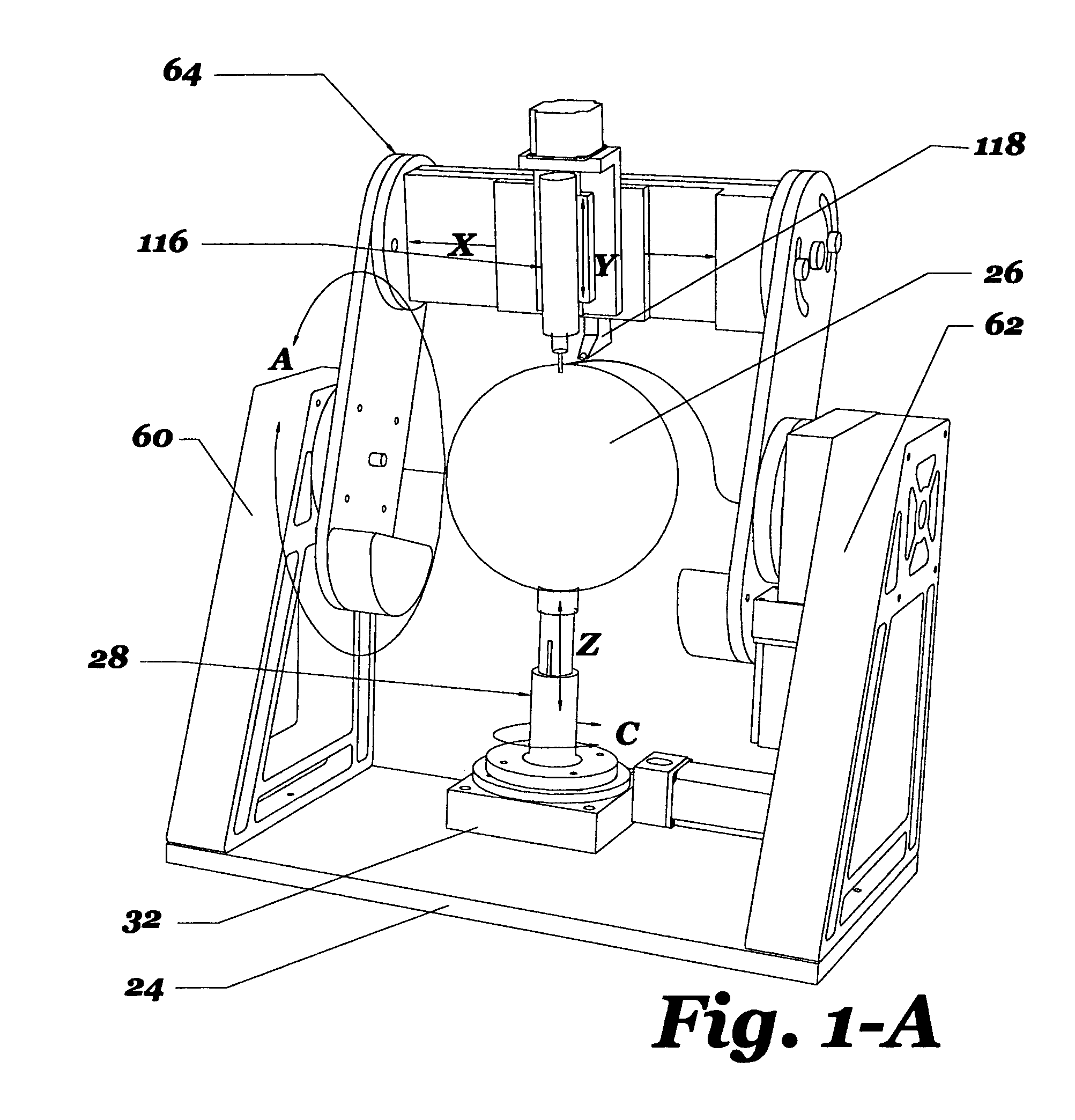

Multi-axis, processor-controlled, toolhead positioner

InactiveUS20060242818A1Programme-controlled manipulatorPlaning/slotting machinesRotational axisEngineering

A multi-axis, computerized numerically-controlled (CNC) toolhead positioning device with six degrees of freedom of movement while utilizing only five axes of movement, comprising a rotating workpiece mount assembly (28) and a rotating gantry (64) with a mounted toolhead assembly base (80). Perpendicular rotational axes about a mounted workpiece (26) provide the capability to perform specific toolhead operations on the arcuate surface of the workpiece (26), subject to the type of mounted toolhead assembly. The computer (120) uses CNC software to integrate operator instructions, machining operations, and the sequence of operations into an automatic and coherent machining package.

Owner:PRECISION SPHERICAL

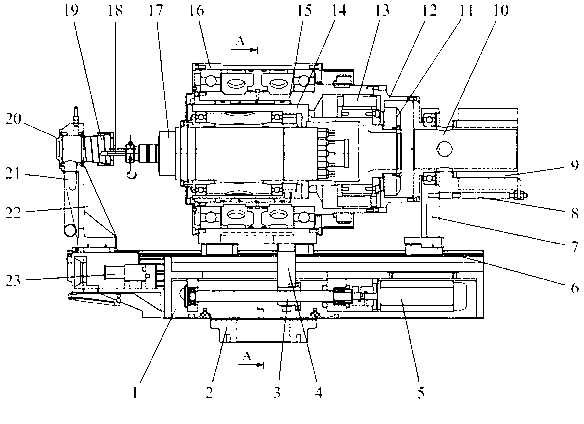

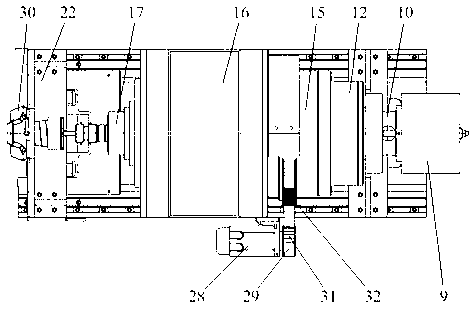

Device and method of automatic helical milling of hole

ActiveCN102794491AEasy to controlHigh control precisionAutomatic control devicesMeasurement/indication equipmentsNumerical controlGrating

The invention discloses a device and a method for automatic helical milling of a hole. The device comprises a base, a spindle slide base, an outer eccentric sleeve, an inner eccentric sleeve, a torque motor, a circular grating, an electric spindle, a presser foot, an industrial camera, a linear grating, four laser distance sensors, a servo motor, a ball screw assembly, a synchronous belt and the like, wherein axes of inner and outer contours of the inner and outer eccentric sleeves have offsets; the inner eccentric sleeve is installed in the outer eccentric sleeve; and the axis of the inner contour of the outer eccentric sleeve and the axis of the outer contour of the inner eccentric sleeve are coincident. The device and the method have the advantages that the tool radial offset is realized through control of a relative rotation angle between the inner eccentric sleeve and the outer eccentric sleeve; in spindle feeding, a double-grating feedback technology is adopted so that dimple depth accuracy is guaranteed; and a preset hole position on a workpiece is detected by the industrial camera and a normal vector of the preset hole position is detected by the four laser distance sensors and the industrial camera and the four laser distance sensors cooperate with automatic numerically-controlled devices such as an industrial robot, a numerically-controlled machine tool and the like and thus high-precision and high-efficiency automatic hole milling is realized.

Owner:ZHEJIANG UNIV

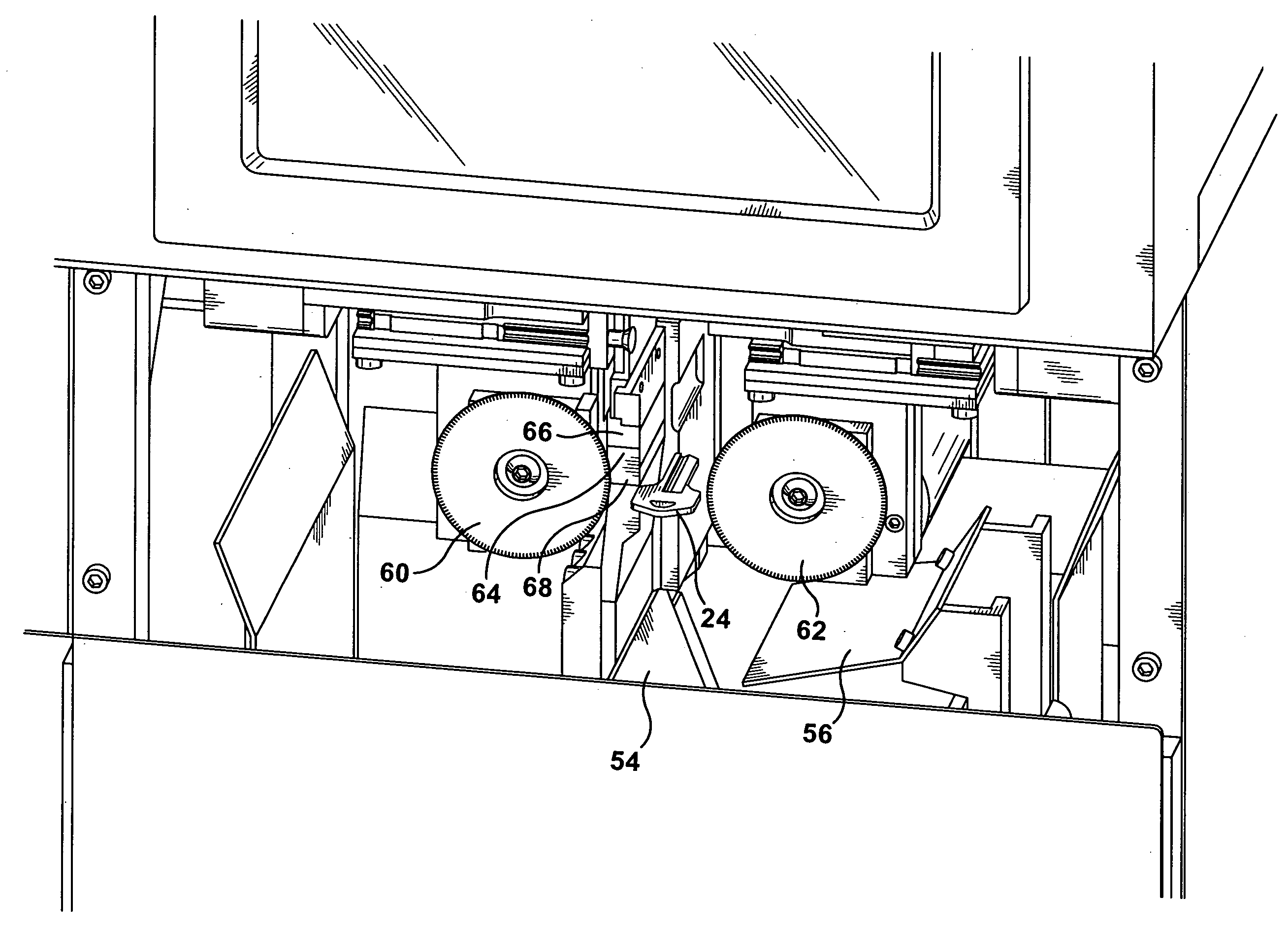

Key duplication machine

Apparatus, methods, and other embodiments associated with a key duplication machine are described. In one embodiment, an assembly for duplicating a master key includes an optical imaging device, a logic, a clamping assembly, and a cutting member. The optical imaging device is capable of capturing an optical image of at least a portion of the master key. The logic is capable of determining a key pattern of the master key from the optical image of the master key. The clamping assembly is capable of clamping a key blank and the cutting member is capable of cutting a key pattern into said key blank.

Owner:HY KO PRODS

Key duplication machine

Apparatus, methods, and other embodiments associated with a key duplication machine are described. In one embodiment, an assembly for duplicating a master key includes an optical imaging device, a logic, a clamping assembly, and a cutting member. The optical imaging device is capable of capturing an optical image of at least a portion of the master key. The logic is capable of determining a key pattern of the master key from the optical image of the master key. The clamping assembly is capable of clamping a key blank and the cutting member is capable of cutting a key pattern into said key blank.

Owner:HY KO PRODS

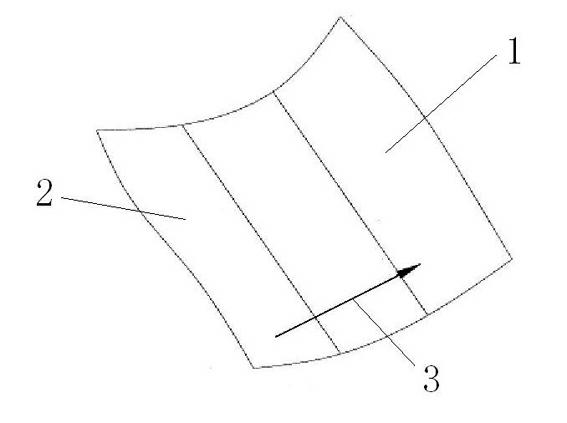

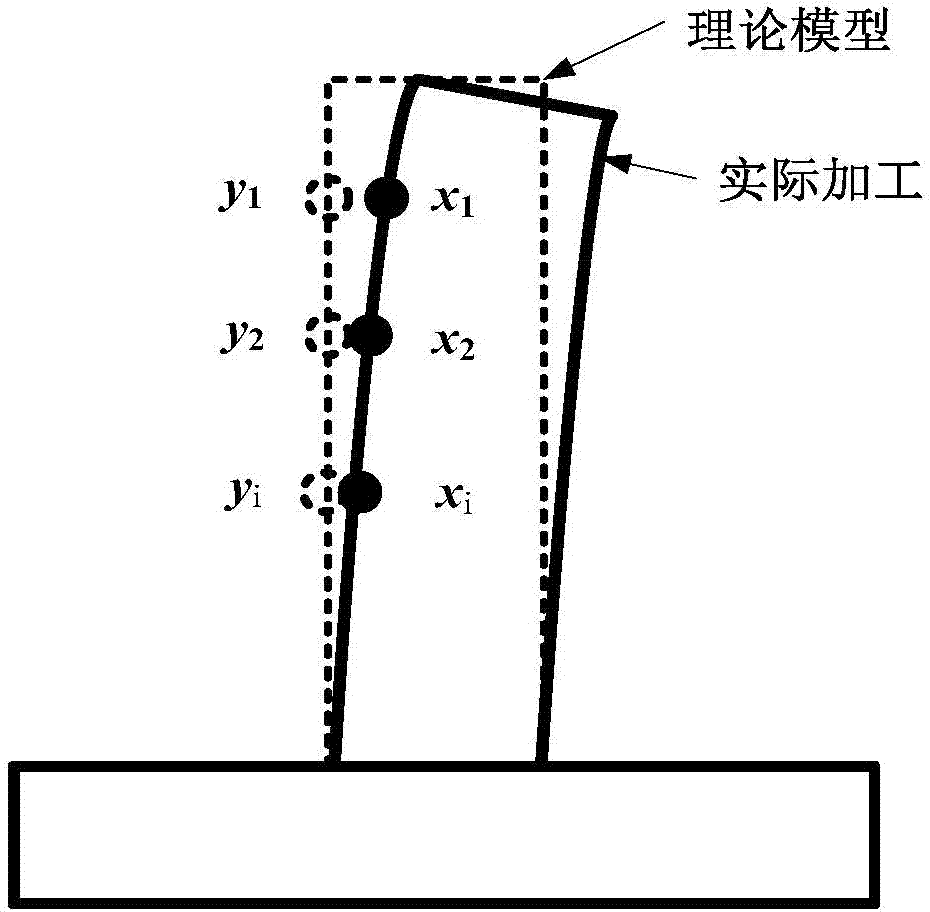

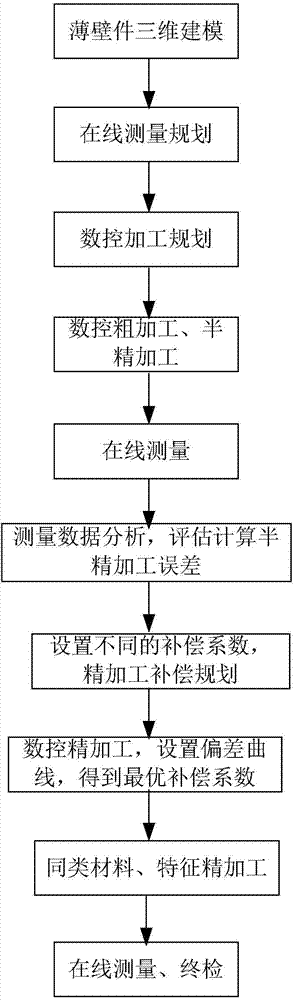

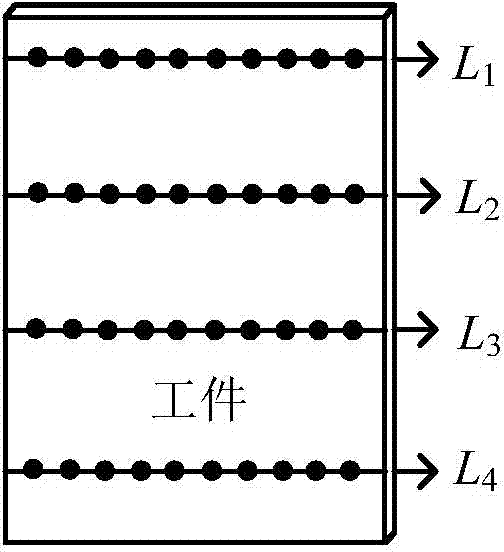

Online milling deformation measurement and complementation machining method for thin-walled part

ActiveCN104759942AAvoid insufficient boundary conditionsGood compensationGeometric CADMachine tool componentsNumerical controlMeasurement point

The invention discloses an online milling deformation measurement and complementation machining method for a thin-walled part. The online milling deformation measurement and complementation machining method for the thin-walled part comprises the steps that 1, a three-dimensional model of the thin-walled part is established, and a numerical control code is obtained; 2, measurement point locations are extracted from the three-dimensional model; 3, based on the model, a measurement path is planned; 4, rough machining and semi-precise machining are conducted on a workpiece blank; 5, online measurement is conducted, and the coordinate values of all the planed measurement point locations are obtained; 6, the obtained coordinate values of the planed measurement point locations are compared with those of the corresponding point locations on the three-dimensional model of the thin-walled part, and the difference between the coordinates of each point location of the actually machined workpiece and those of the corresponding point location on the three-dimensional model is calculated; 7, according to the machining differences, a complementation factor optimal machining path is generated according to the machining differences, precise machining is conducted according to the path, and then the final deformation deviation and the compensation values are obtained. By the adoption of the online milling deformation measurement and complementation machining method, semi-precise machining and precise machining are adopted, the identical machining parameters are adopted by the semi-precise machining and the precise machining, and the best precise machining compensation effect of the thin-walled parts which are made of the same materials and have the same characteristics can be achieved to the greatest extent through only one group of tests.

Owner:HUAZHONG UNIV OF SCI & TECH

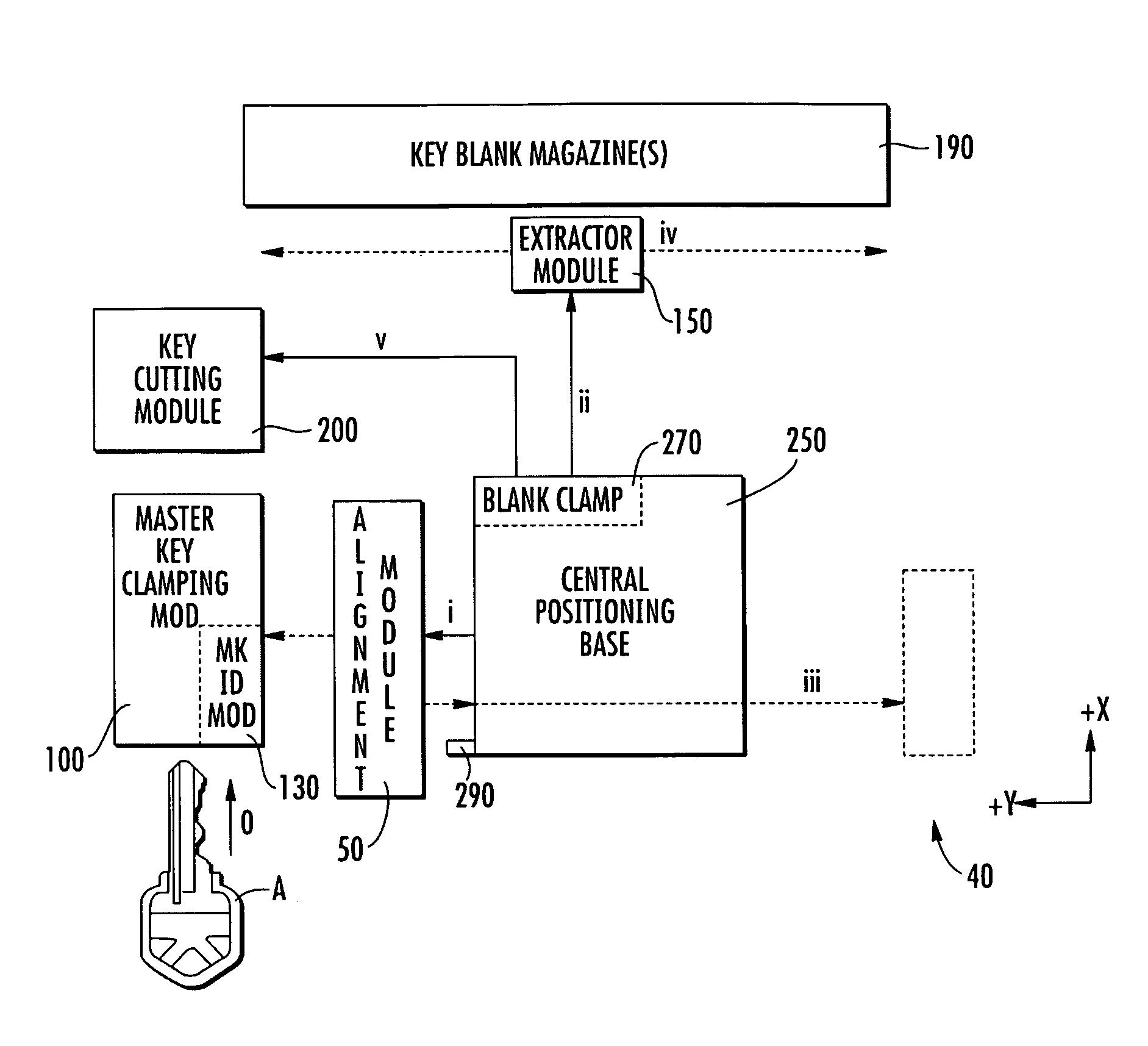

Fully automatic key duplicating machine with automatic key model identification system

ActiveUS20080145163A1Reduce the required powerIncrease powerAutomatic/semiautomatic turning machinesMeasurement devicesComputer moduleMaster key

A fully automatic key duplicating machine. A master key alignment module is movably disposed into and out of proximity with a master key clamping module, the master key being aligned by the alignment module within the master key clamping module. A master key identification module is disposed in fixed relation to the master key clamping module and identifies a type of key secured in the master key clamping module. A central positioning base is provided automatically movable into and out of engagement with the key cutting module and optionally the alignment module, adapted to move the master key alignment module into proximity with the master key clamping module and adapted to secure a key blank to be cut at the key cutting module in accordance with the tooth pattern of a clamped master key.

Owner:THE HILLMAN GRP INC

Clamp for a key duplicating machine

Owner:SILCA SPA

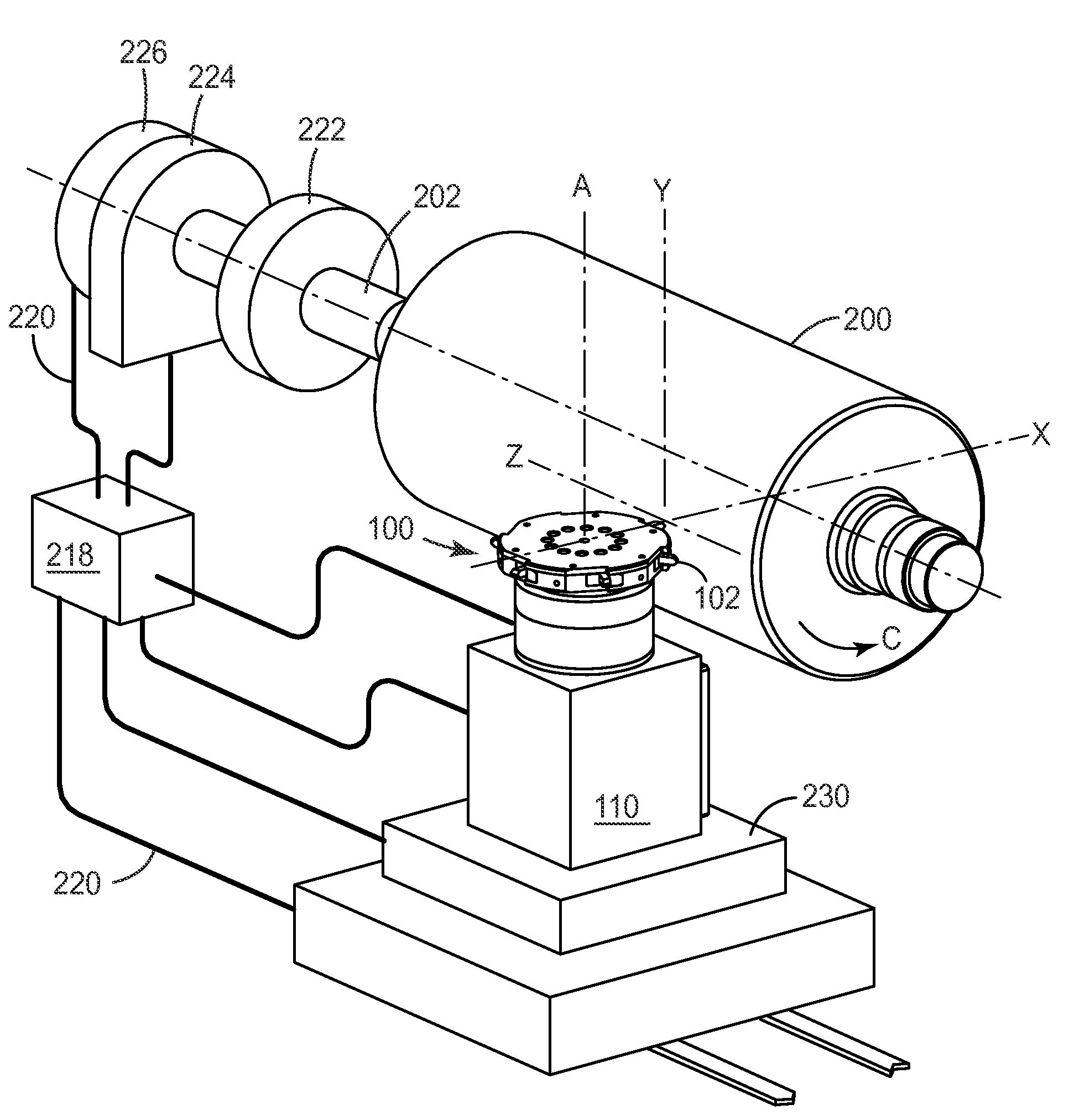

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

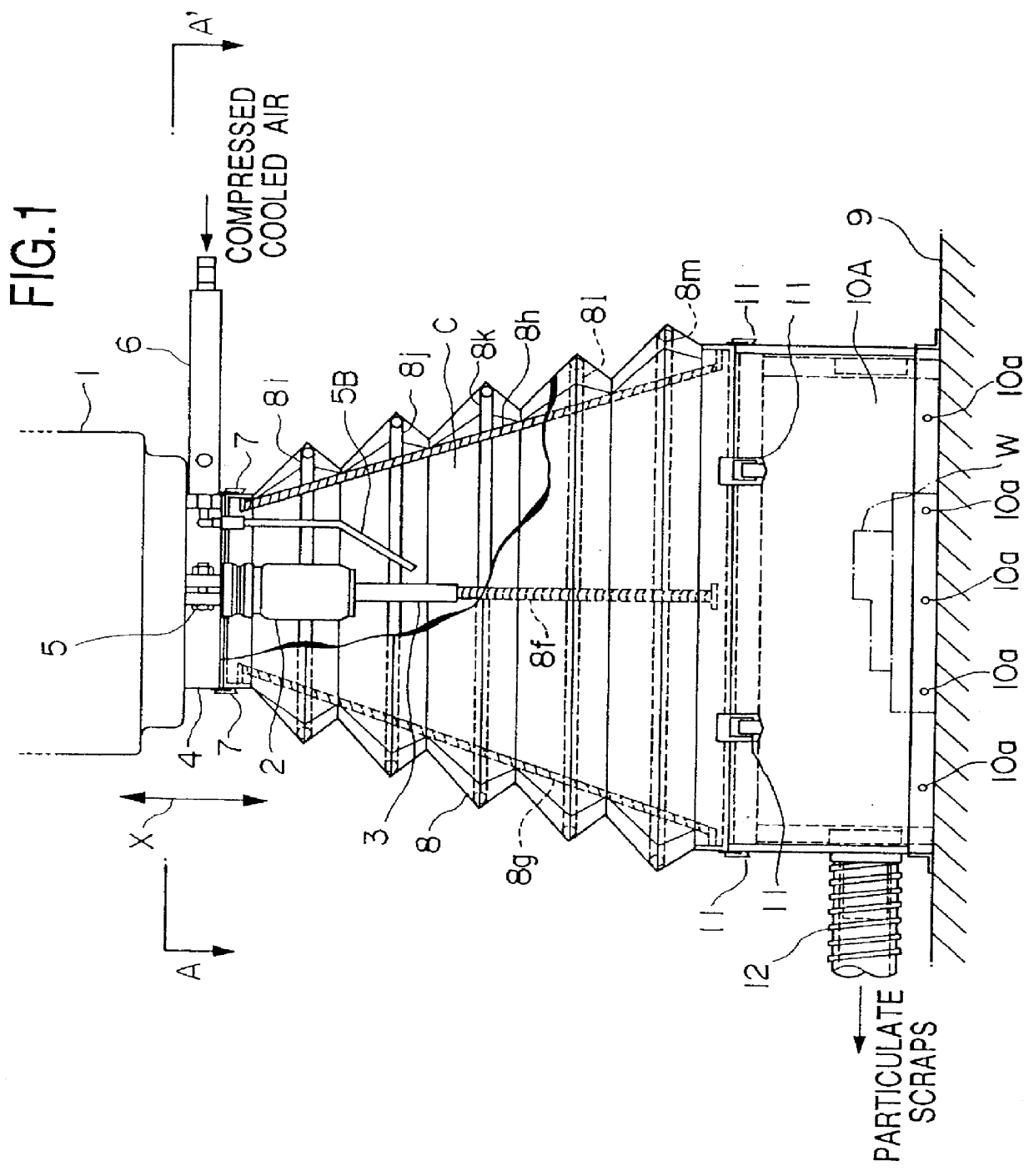

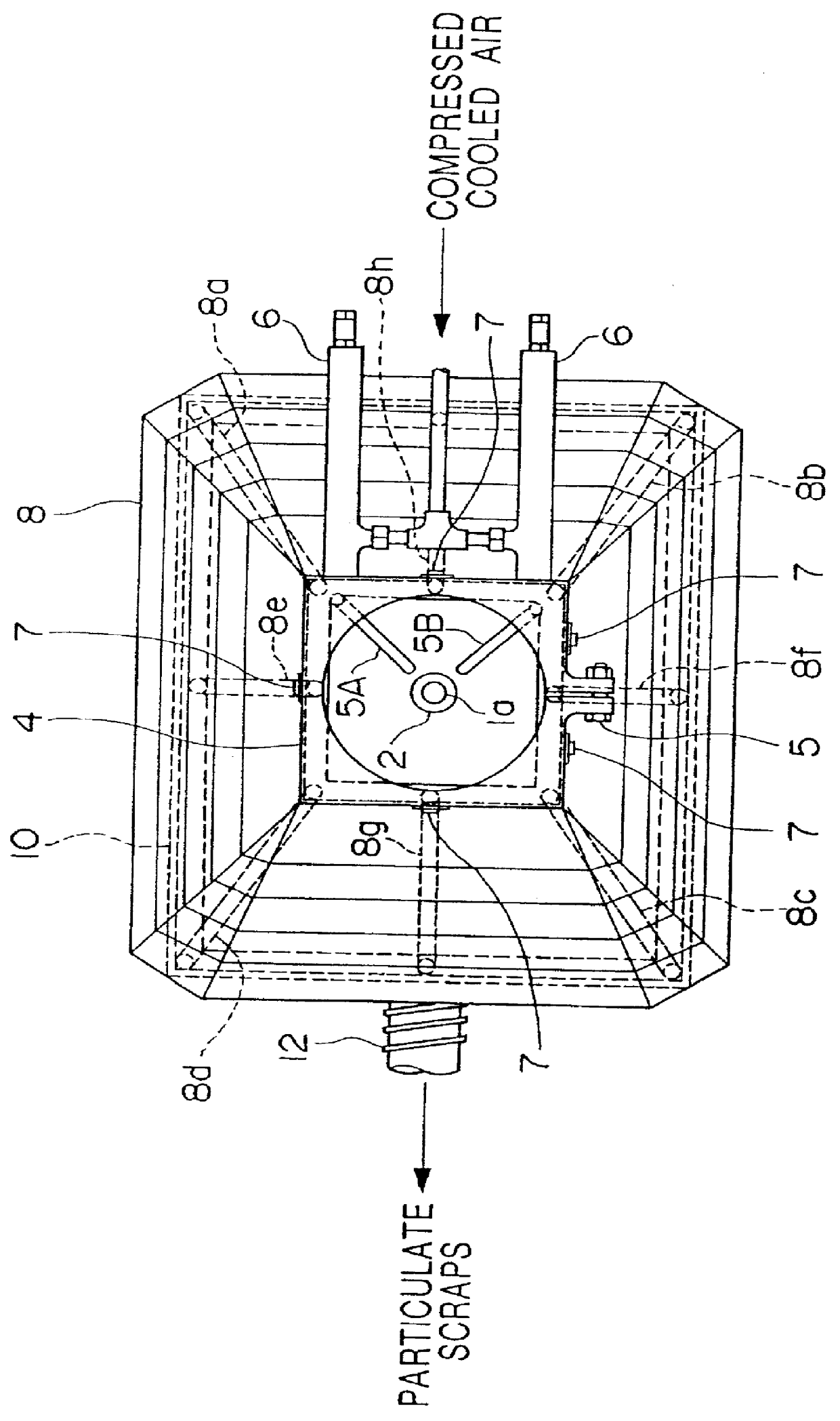

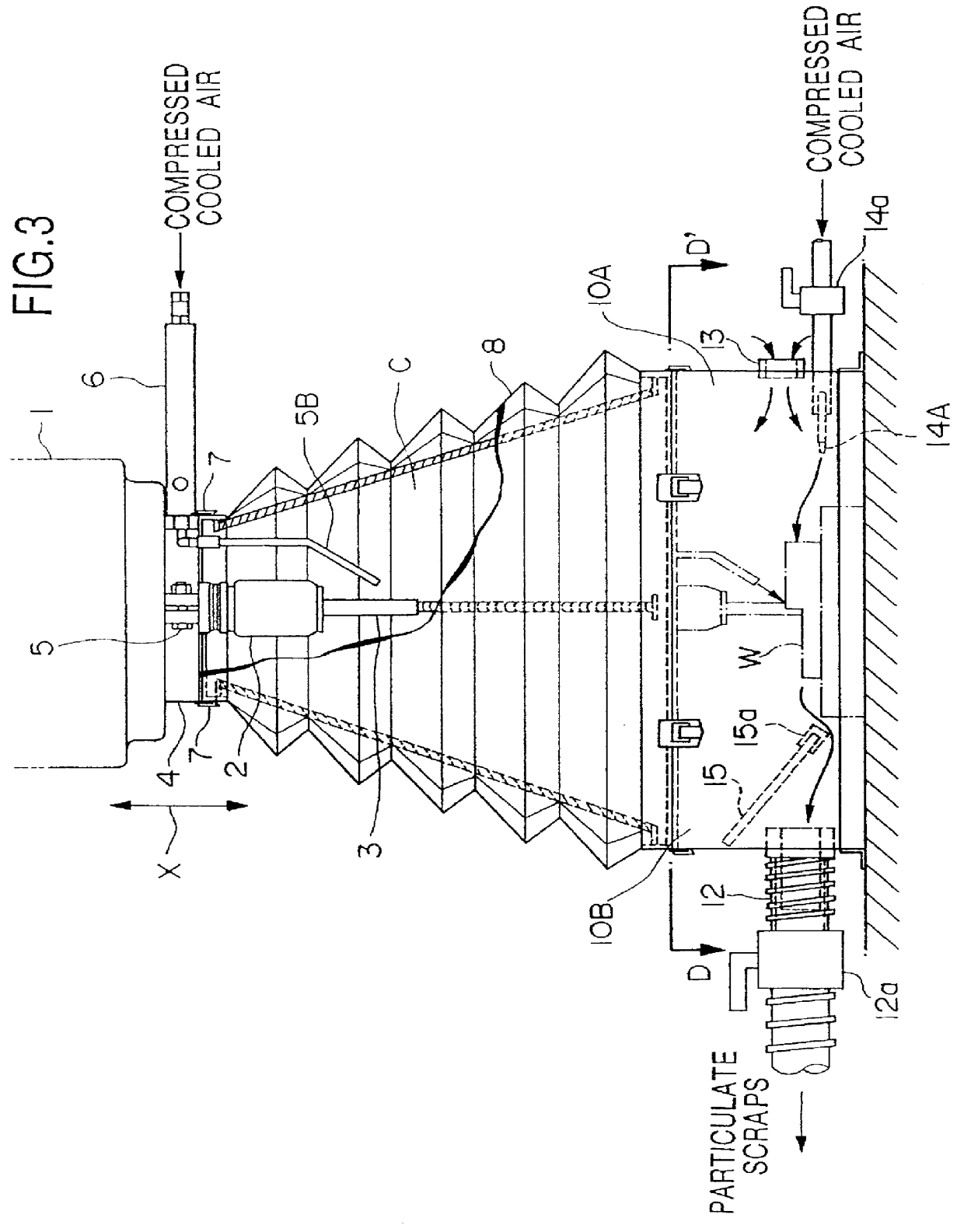

Machine tool

PCT No. PCT / JP97 / 02496 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Jul. 18, 1997 PCT Pub. No. WO98 / 03302 PCT Pub. Date Jan. 29, 1998In order to process a solid processed object with a simple construction, and to process a solid and flat work while effectively collecting particulate scraps, in a machine tool for processing work in which a working table on which the work is mounted and a spindle in which a cutter is installed move relatively to each other, a bellow which telescopes freely is provided, one open end of which connects to the spindle head so as to surround the spindle, and the other open end of which connects to a working table in such a manner as to surround the work.

Owner:TOKO KABUSHIKI KAISHA

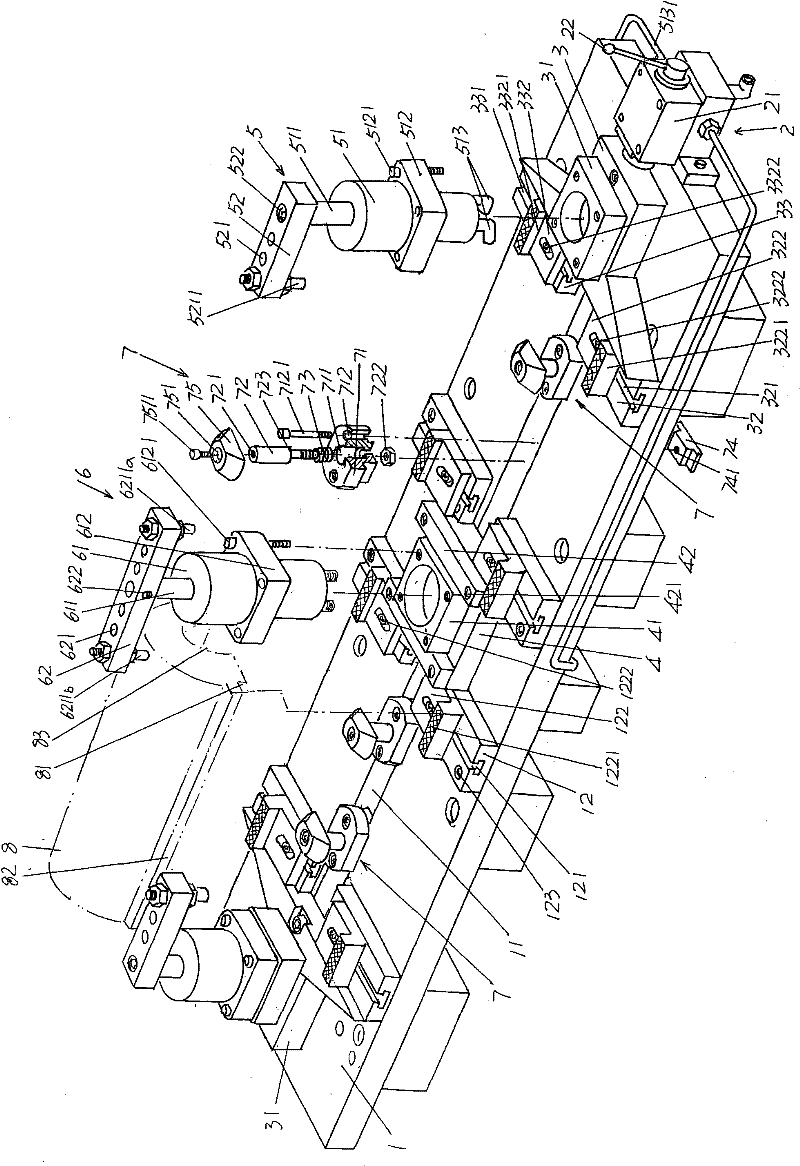

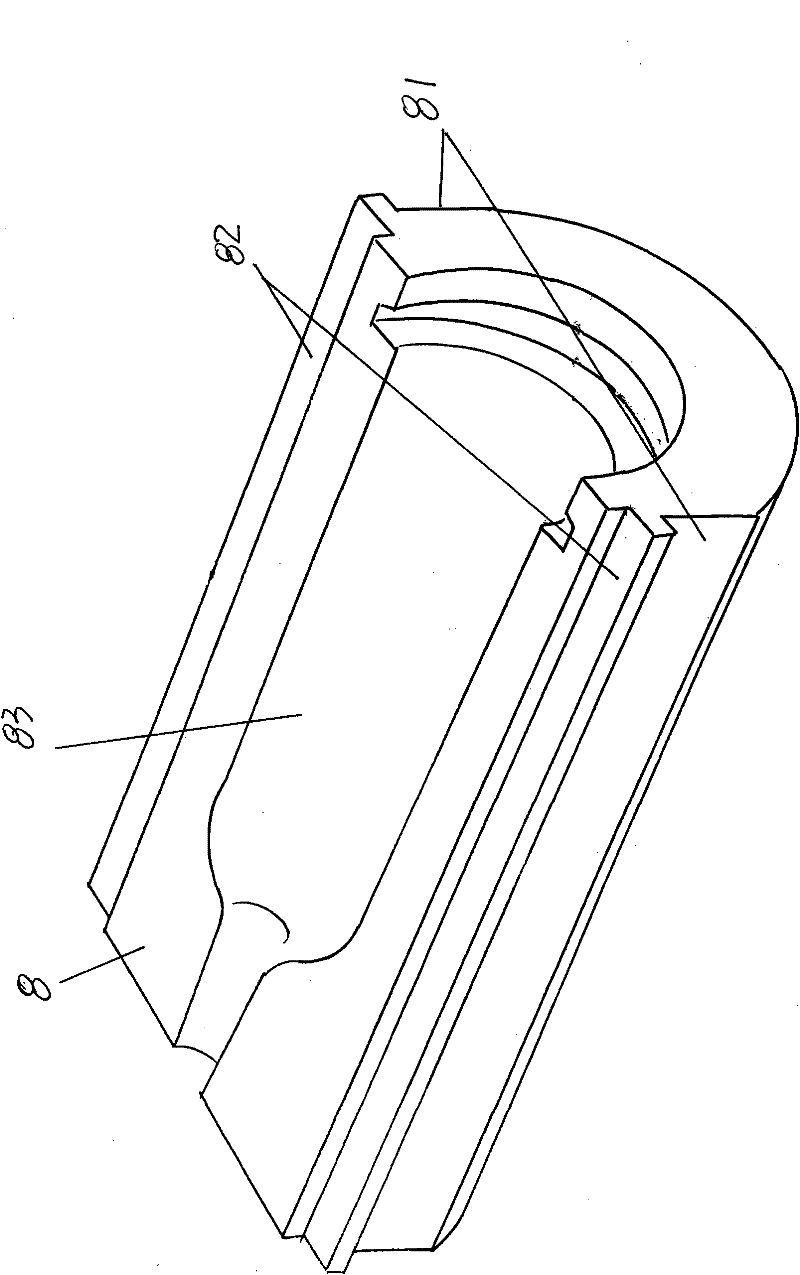

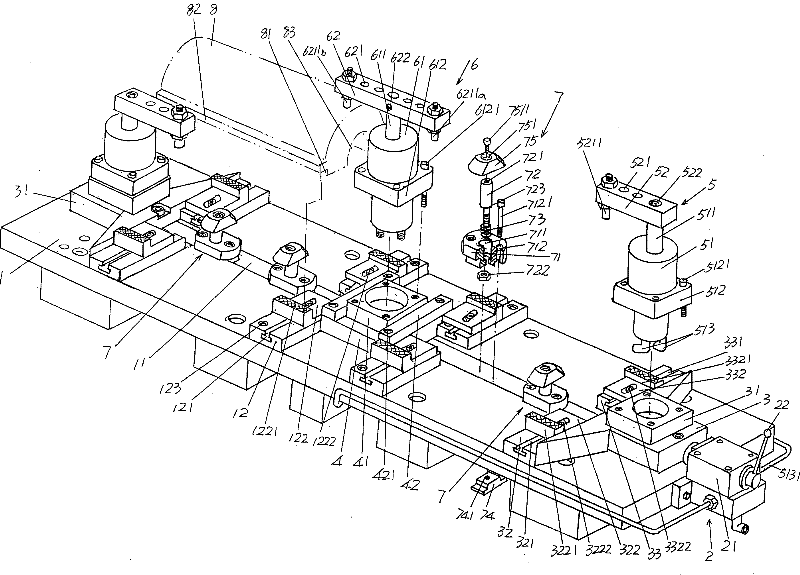

Clamp structure for milling positioning reference plane on glass die blank

ActiveCN101898311BGuaranteed thicknessAvoid damageMilling equipment detailsPositioning apparatusEngineeringMechanical engineering

The invention provides a clamp structure for milling a positioning reference plane on a glass die blank and belongs to an auxiliary facility for processing a glass die. The structure comprises a base, an acting cylinder control device, at least one adjusting seat, a fixed seat, a first die blank back side pressing device, a second die blank back side pressing device and at least one pair of die blank die cavity supporting devices, wherein a reference seat adjusting groove which is penetrated from one end to the other end is formed at a middle position in the width direction of the base; the acting cylinder control device is fixed at one end of the base; the at least one adjusting seat is arranged on the base and in sliding fit with the reference seat adjusting groove; the fixed seat is fixedly arranged on the base and corresponds to the adjusting seat; the first die blank back side pressing device is arranged on the adjusting seat and connected with the acting cylinder control device;the second die blank back side pressing device is arranged on the fixed seat and connected with the acting cylinder control device; and the at least one pair of die blank die cavity supporting devices is arranged on the reference seat adjusting groove in a sliding way and positioned between the adjusting seat and the fixed seat. The structure has the advantages of guaranteeing the accuracy of subsequent processing and ensuring the thickness of a high-quality compact layer of the die cavity.

Owner:CHANGSHU JIANHUA MOLD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com