Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4886 results about "Cutting tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the context of machining, a cutting tool or cutter is any tool that is used to remove material from the work piece by means of shear deformation. Cutting may be accomplished by single-point or multipoint tools. Single-point tools are used in turning, shaping, planing and similar operations, and remove material by means of one cutting edge. Milling and drilling tools are often multipoint tools. It is a body having teeth or cutting edges on it. Grinding tools are also multipoint tools. Each grain of abrasive functions as a microscopic single-point cutting edge (although of high negative rake angle), and shears a tiny chip.

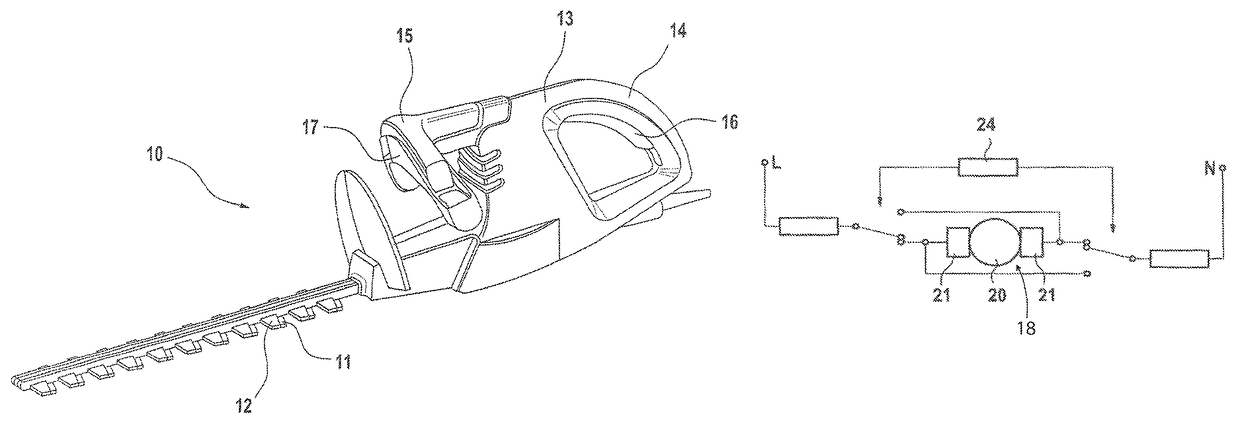

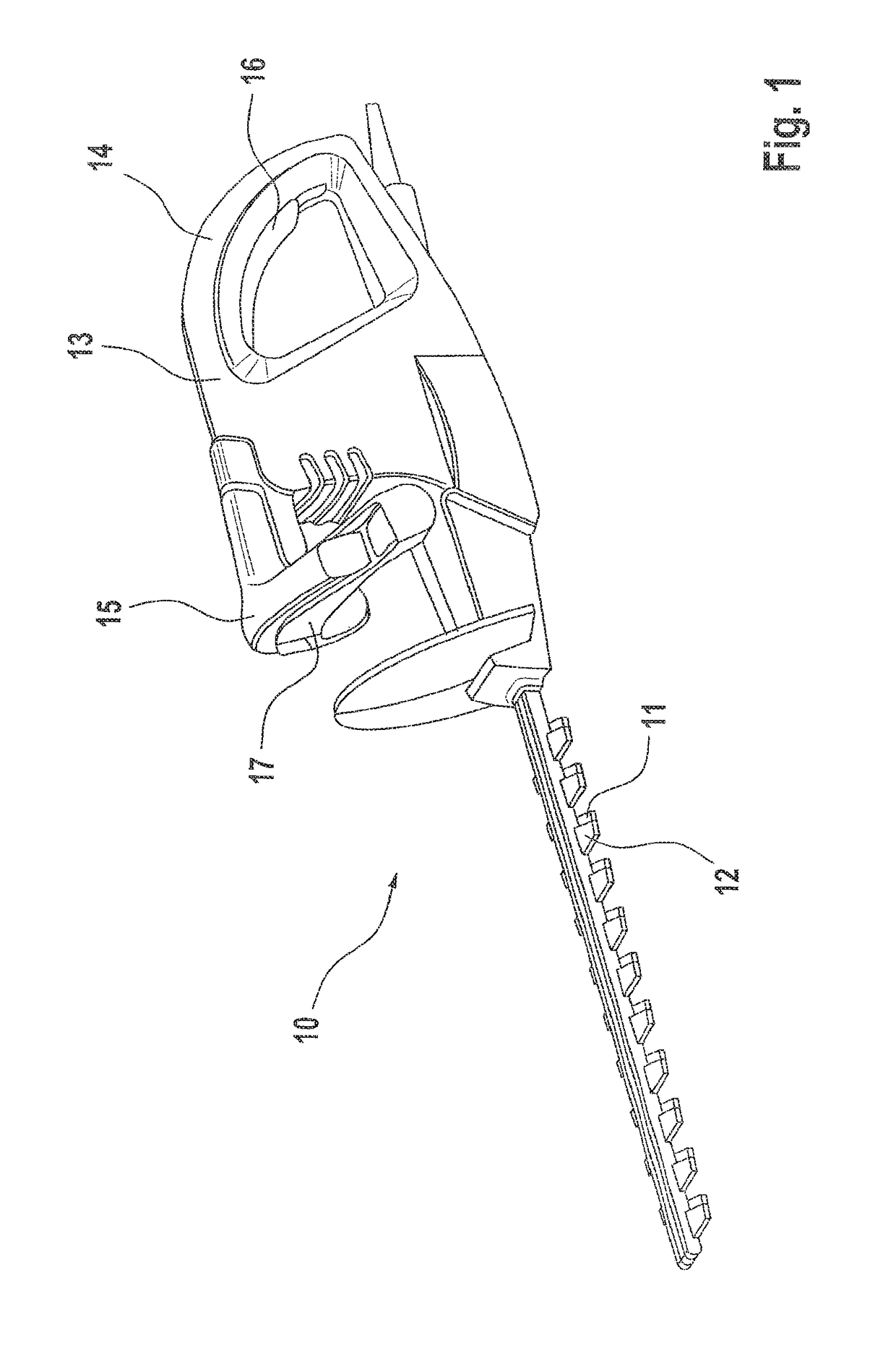

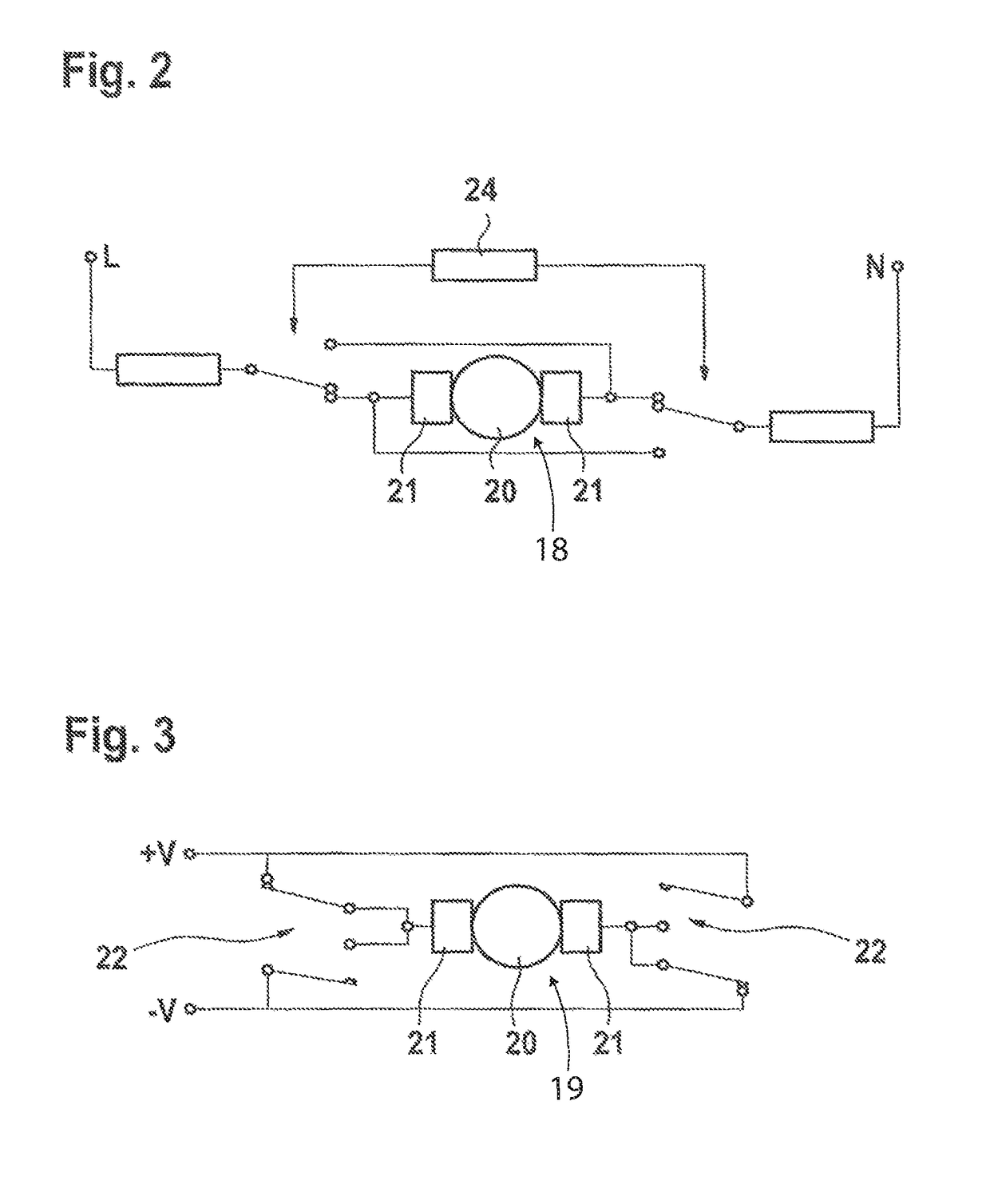

Reciprocating cutting tool

The present invention relates to cutting tools, in particular, to control systems for cutters such as vegetation cutters, especially hedge cutters or trimmers (10). Hedge cutters (10) frequently suffer in use from a problem of blocked cutting blades when they encounter a twig or branch whose size or density exceeds the capacity of the blades. We describe a vegetation cutting apparatus (10) having a plurality of cutting blades (11,12), at least one of which blades (11,12) is drivable by an electric motor. At least one driven blade (11,12) is movable between two predefined points of maximum travel. The apparatus (10) includes a control mechanism which causes a change of direction in the movement of the at least one movable blade at a point intermediate the points of maximum travel in response to an event sensed by the control mechanism.

Owner:ROBERT BOSCH GMBH

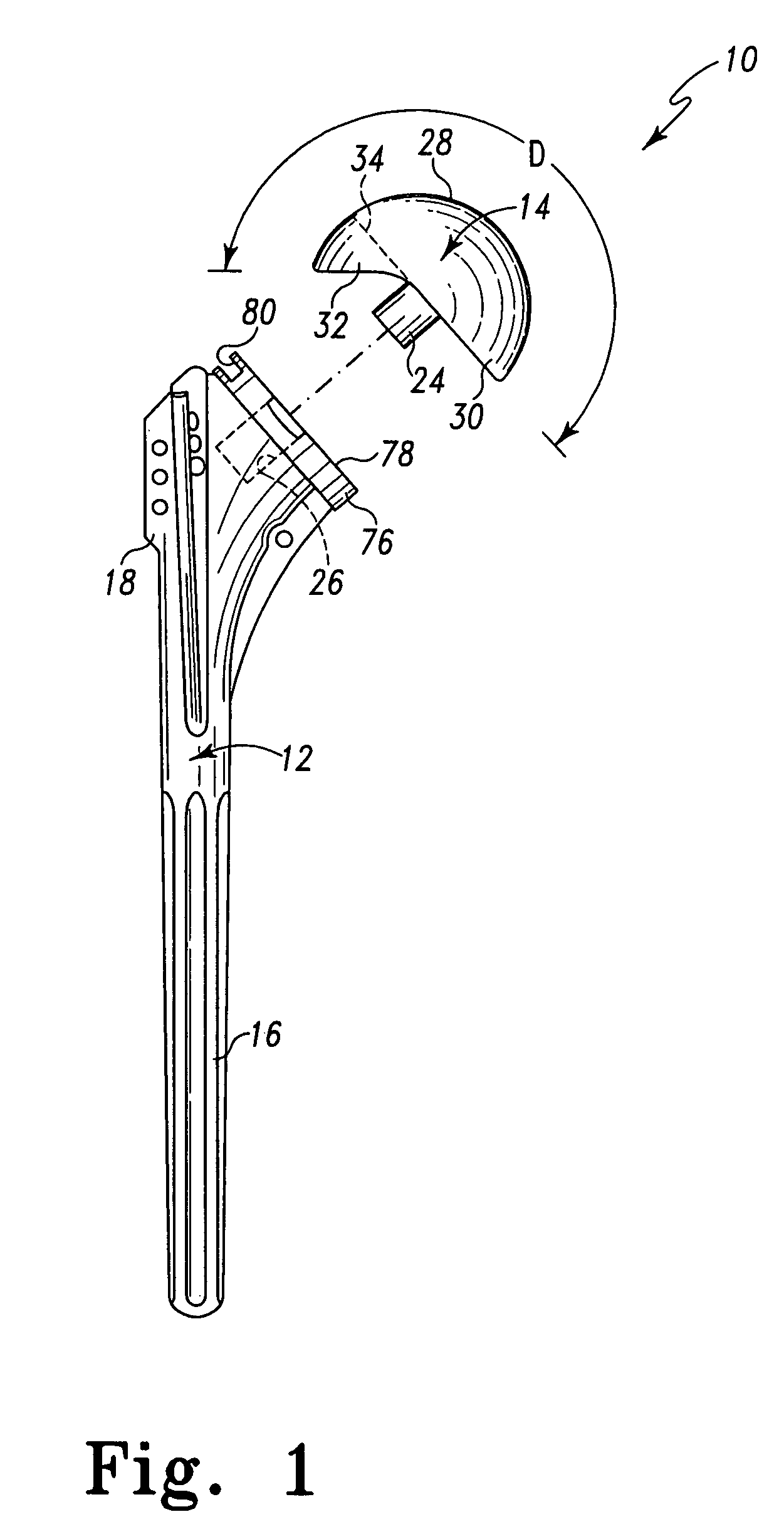

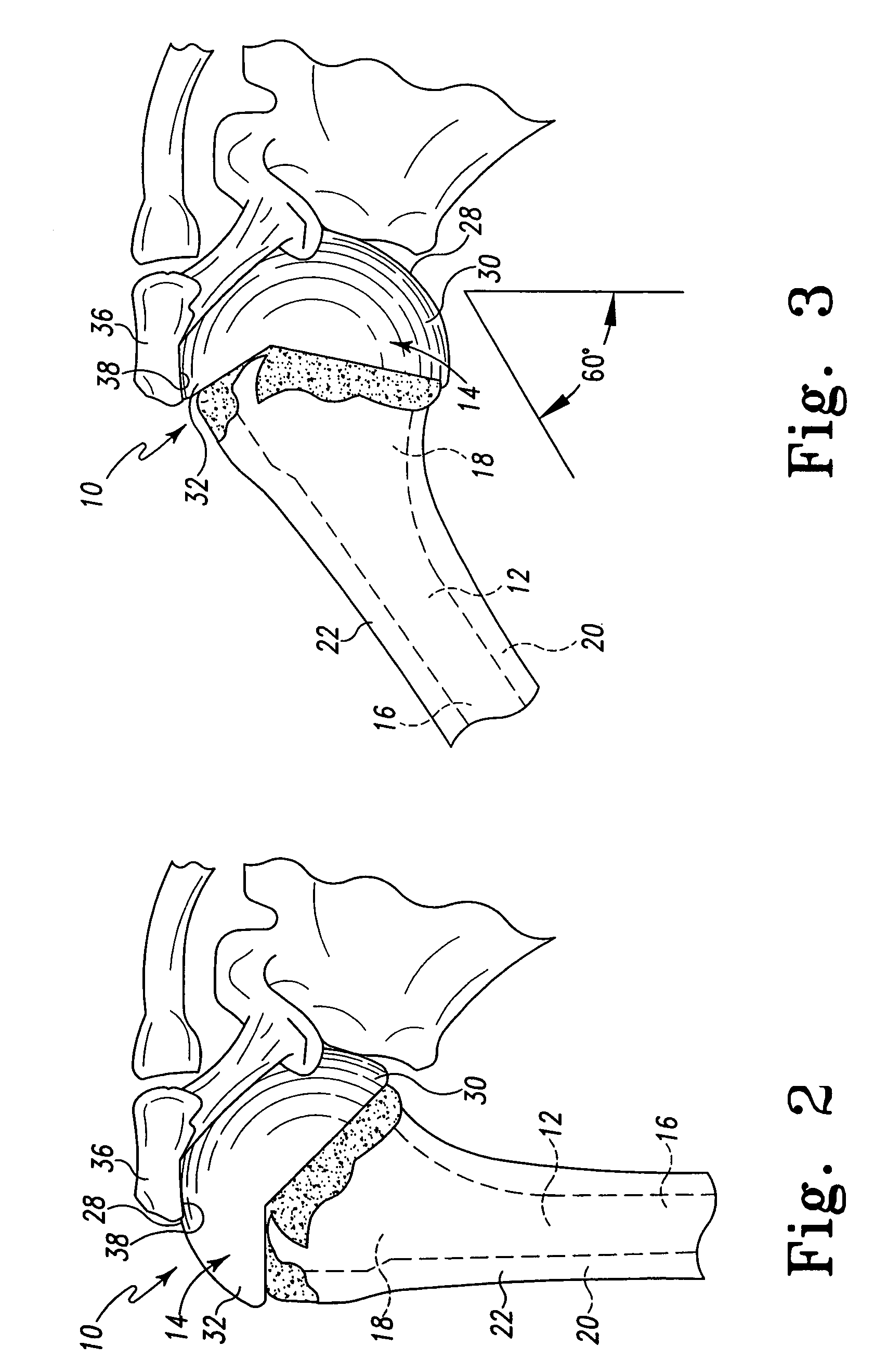

Bone resection apparatus

Owner:DEPUY PROD INC

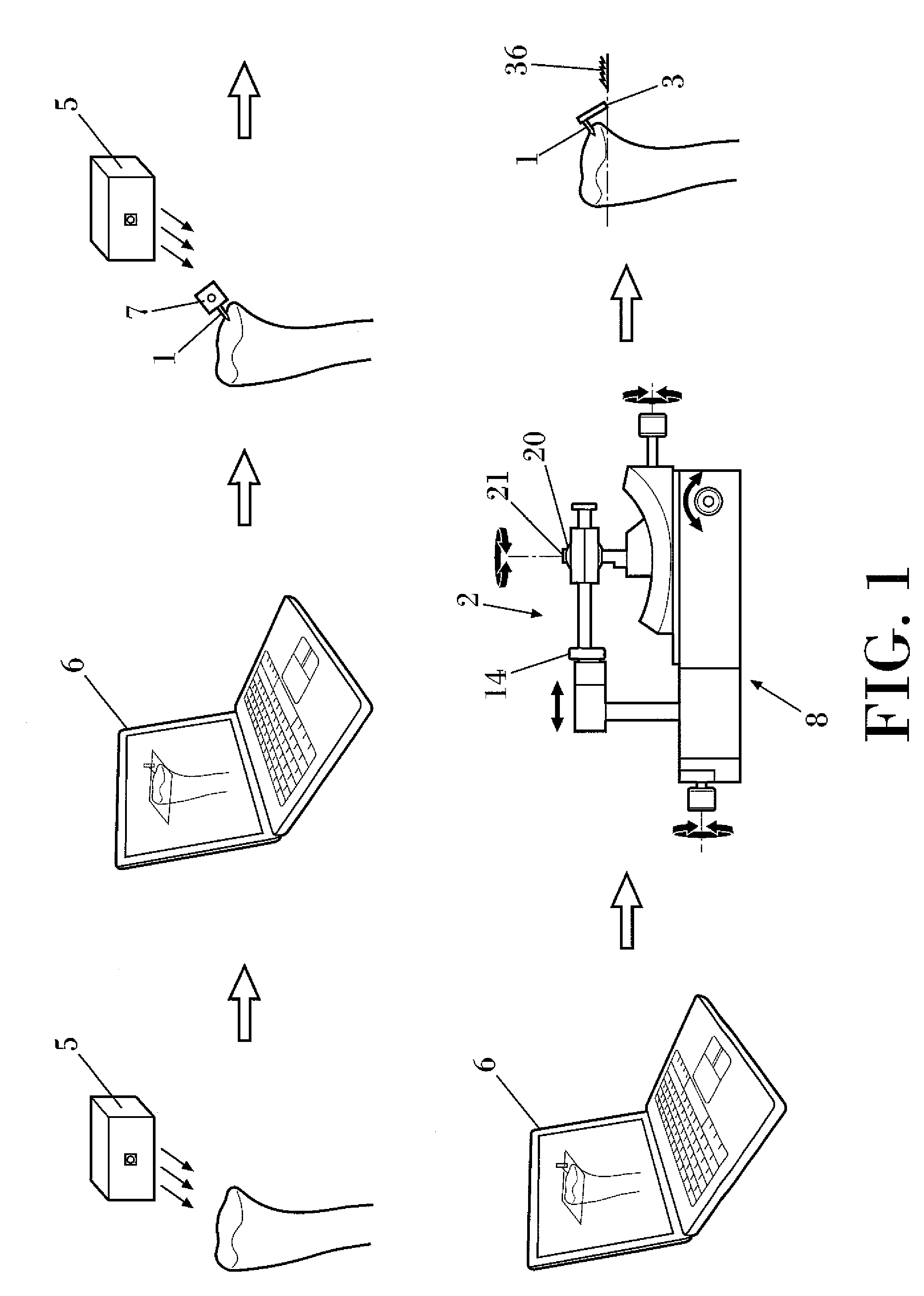

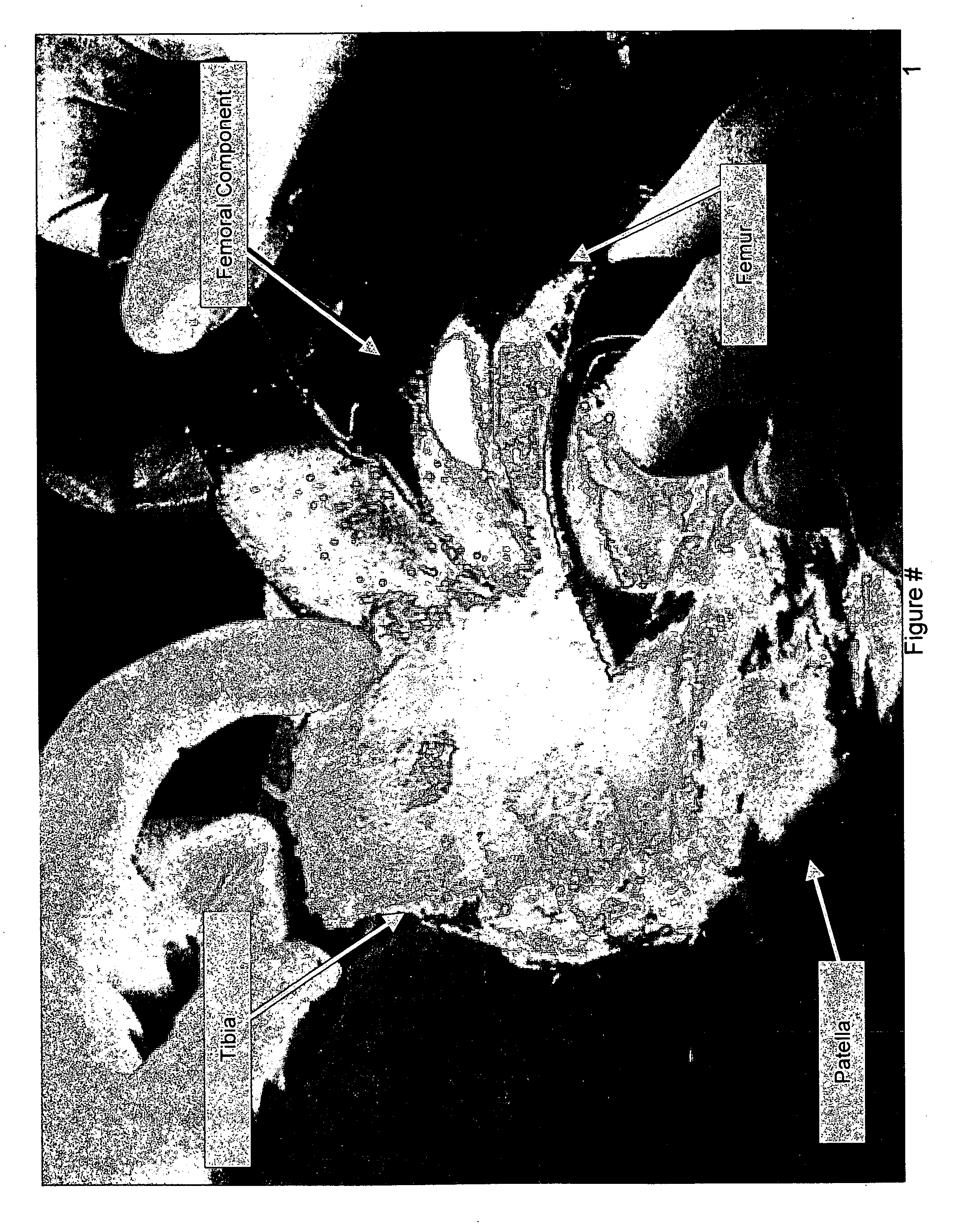

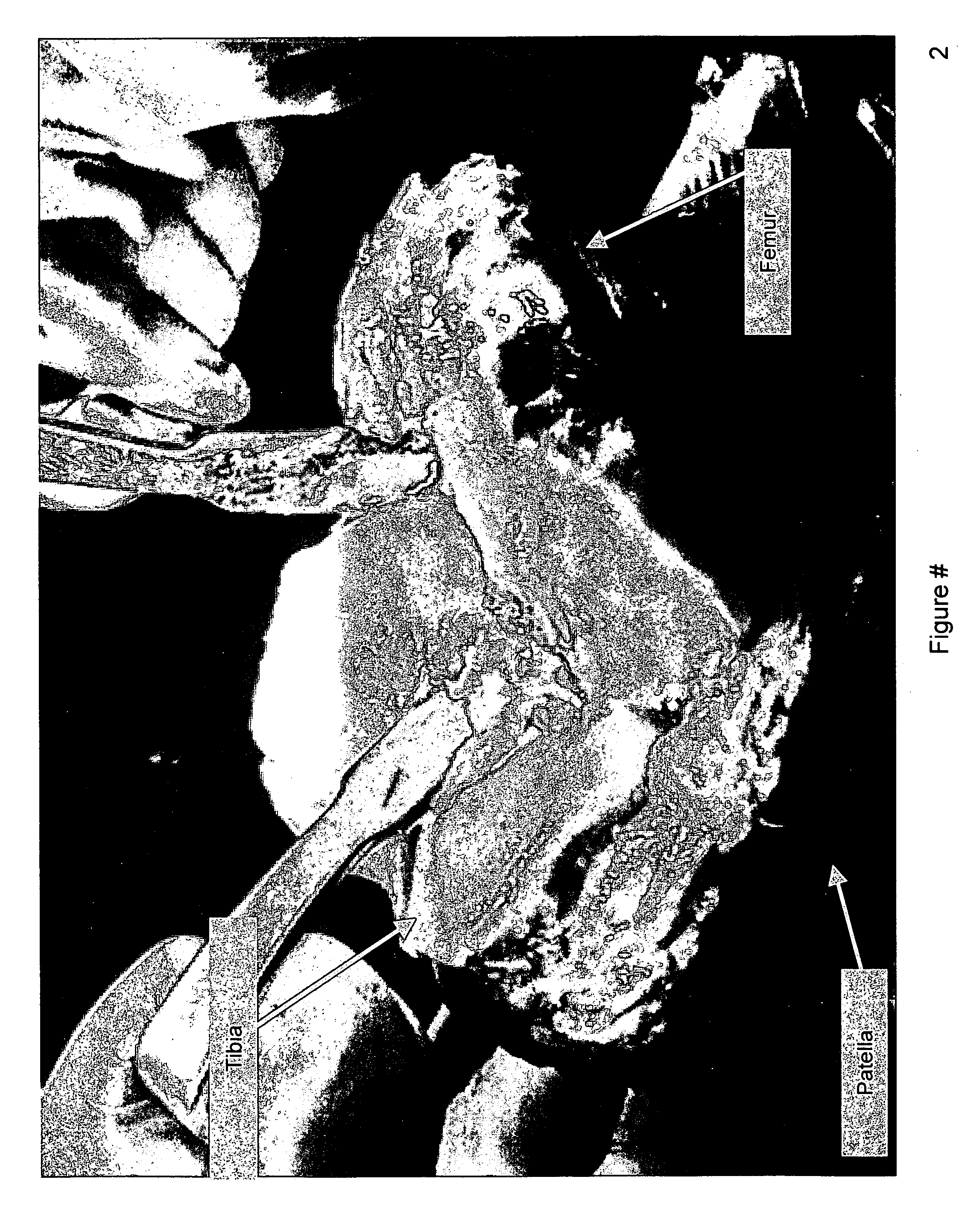

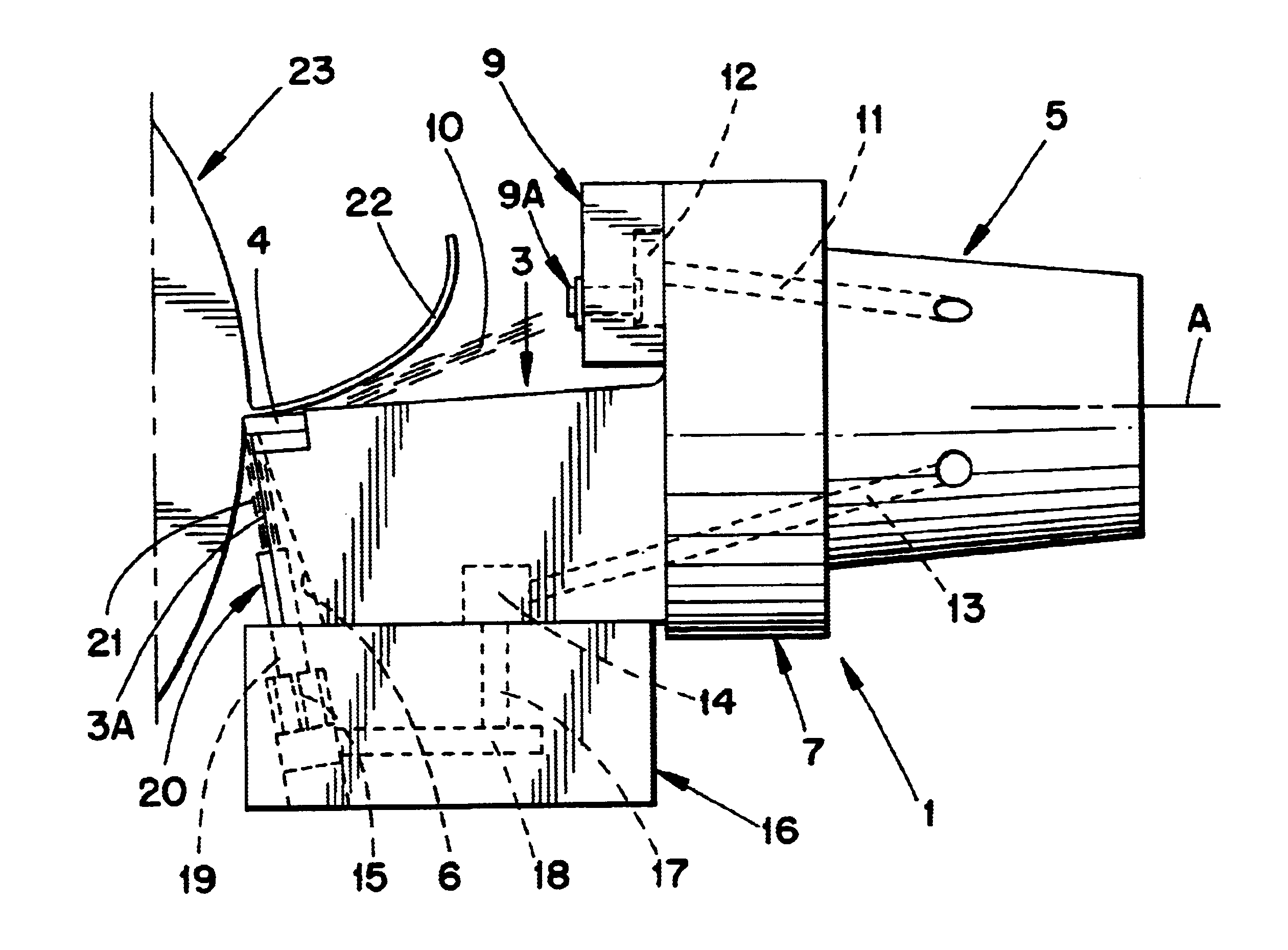

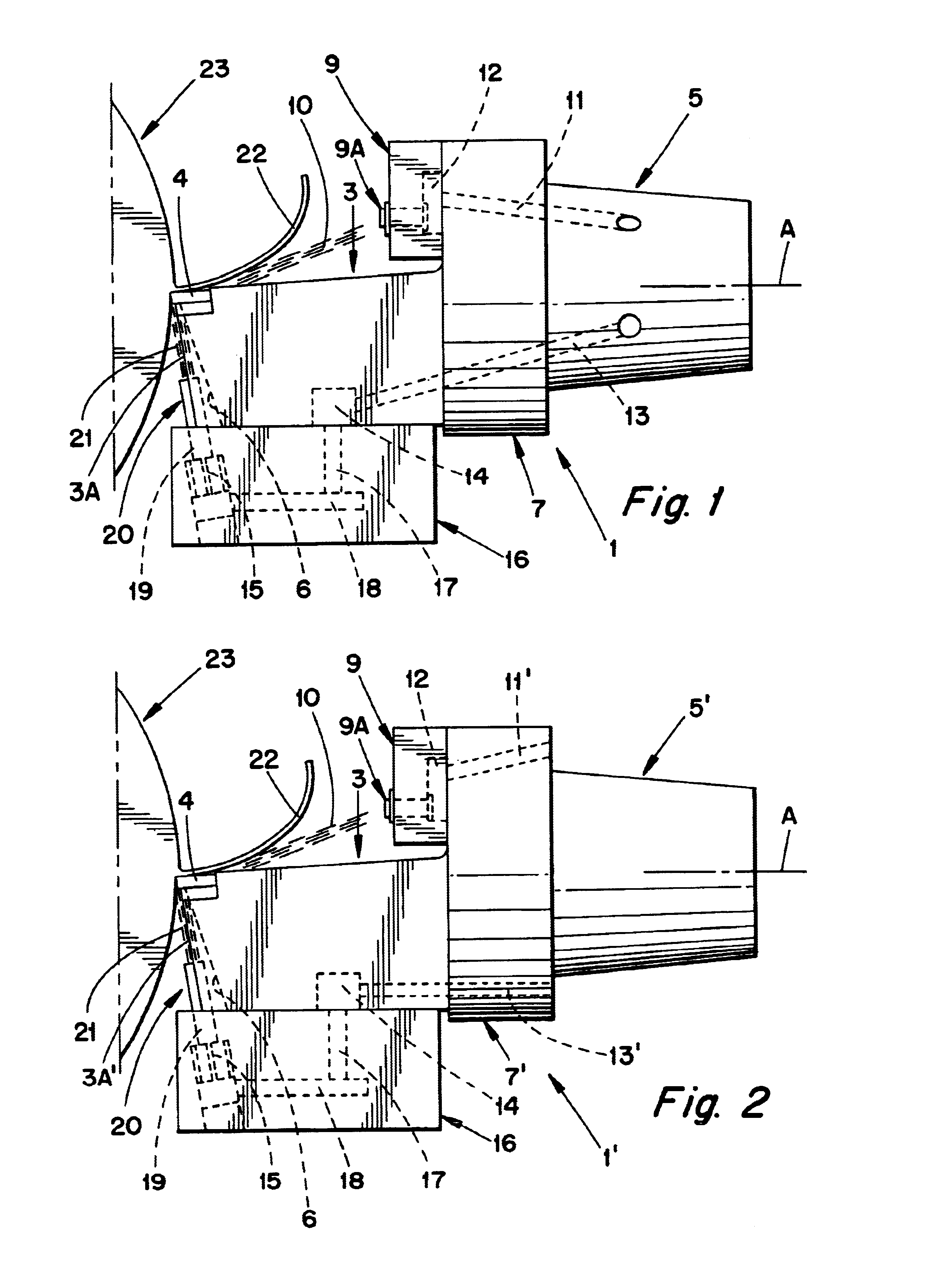

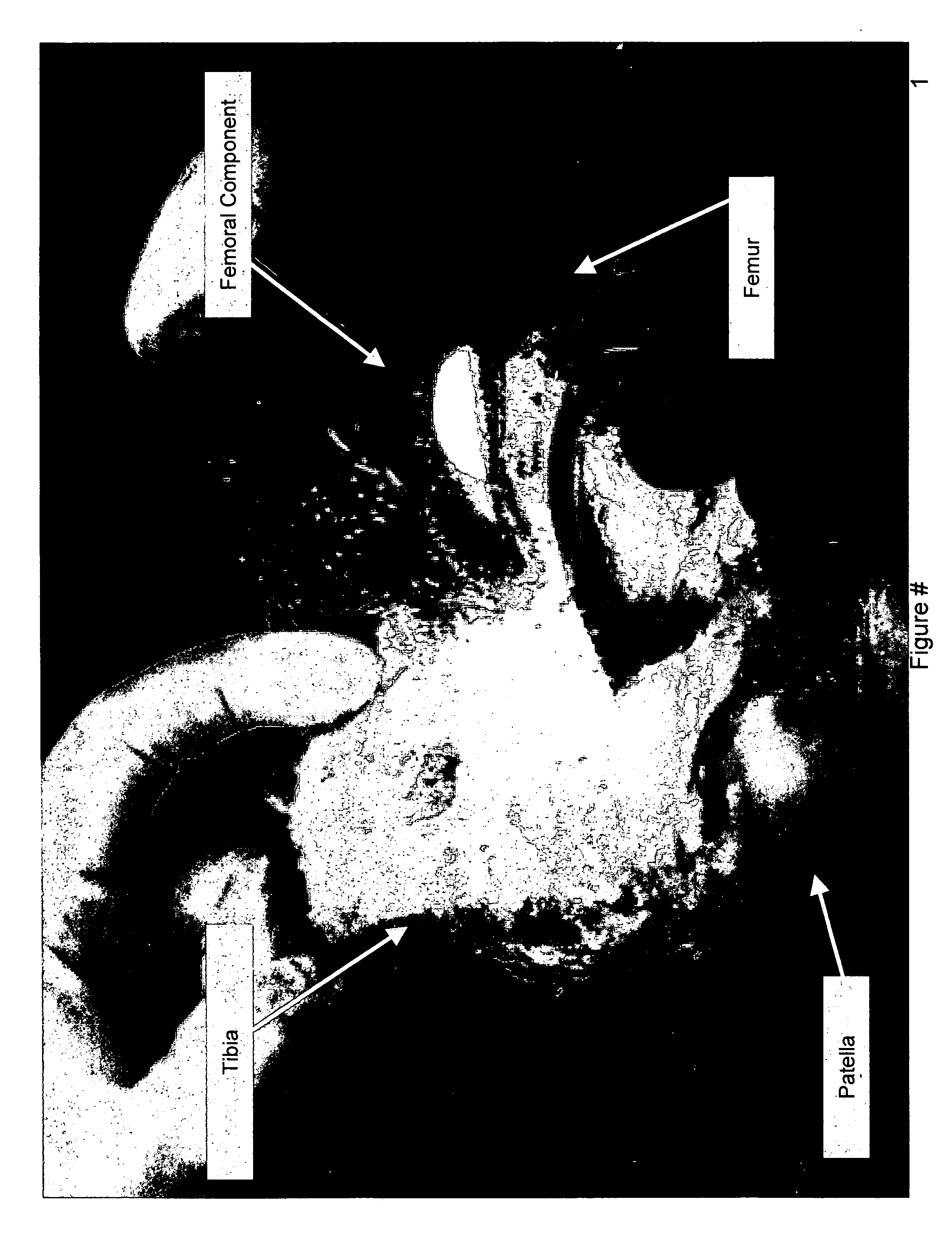

Tibial plateau and/or femoral condyle resection system for prosthesis implantation

According to the invention, the system enables a preoperative study to be carried out wherein the tibia and / or femur is modelled on a computer (6) in 3D, the ideal cutting plane is defined and the position of the resection instruments (1, 2, 3) used to cut the bone is modelled. Additionally, according to the invention, the system enables redefinition of the ideal cutting plane and the positioning and orientation of the resection instruments (1, 2, 3) on the tibia and / or femur, in such a manner that the plane of the slot (4) of the cutting guide (3) through which the cutting tool is introduced coincides with the ideal cutting plane.

Owner:TRAIBER

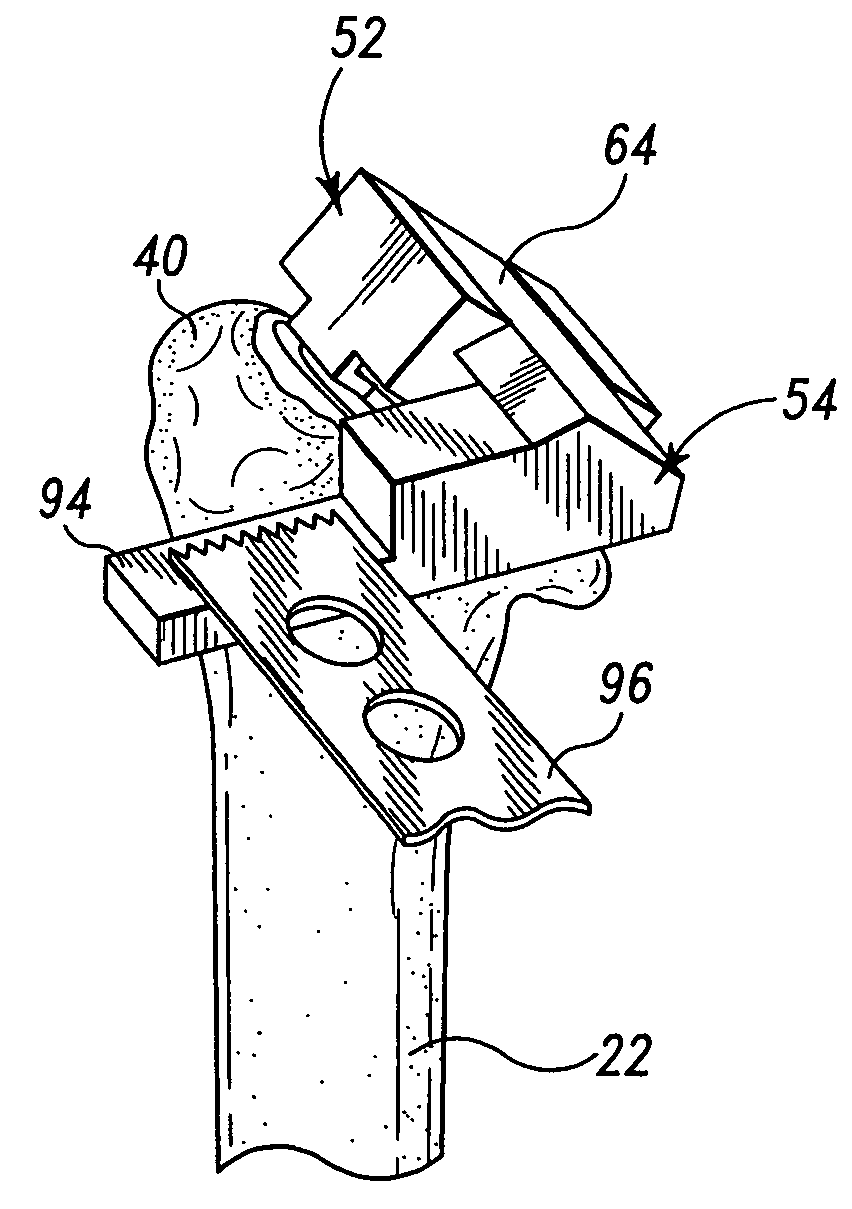

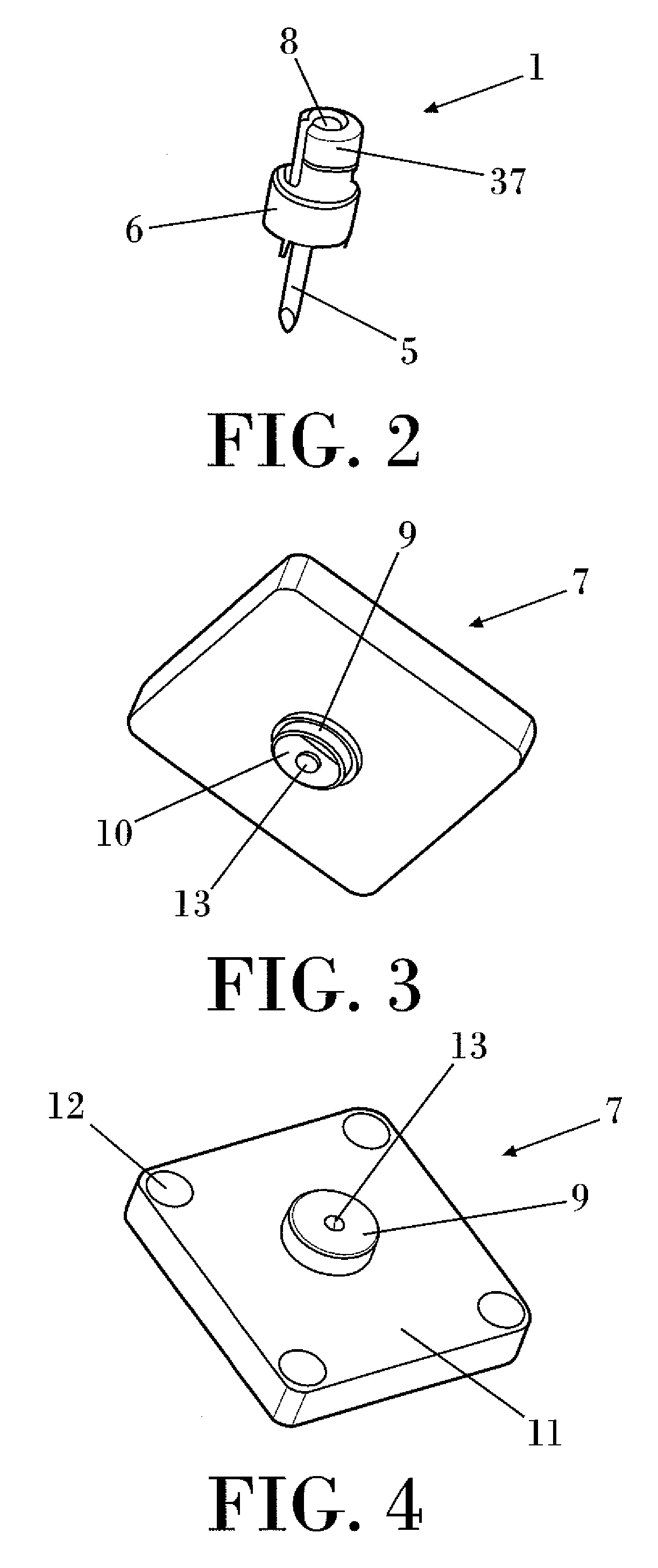

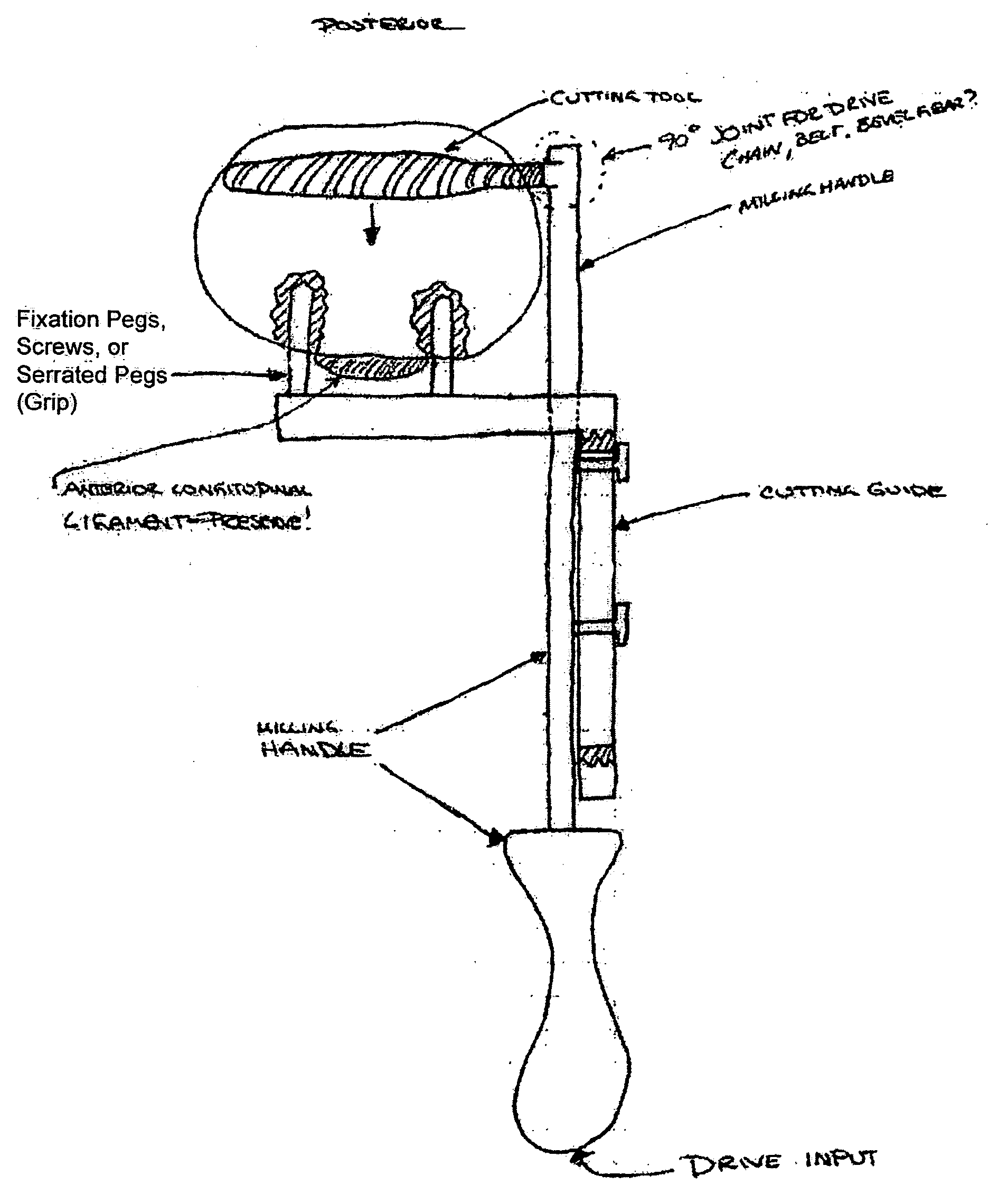

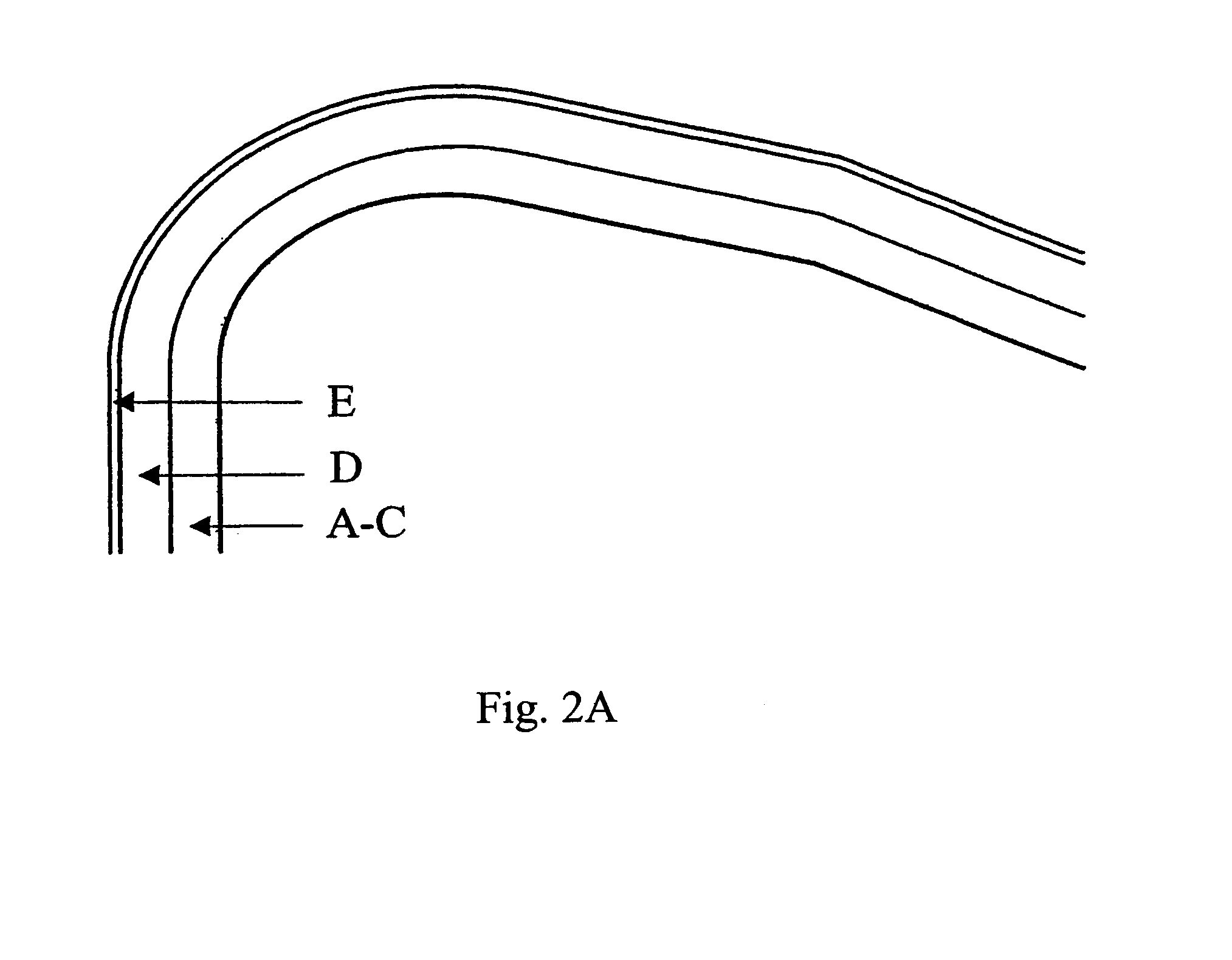

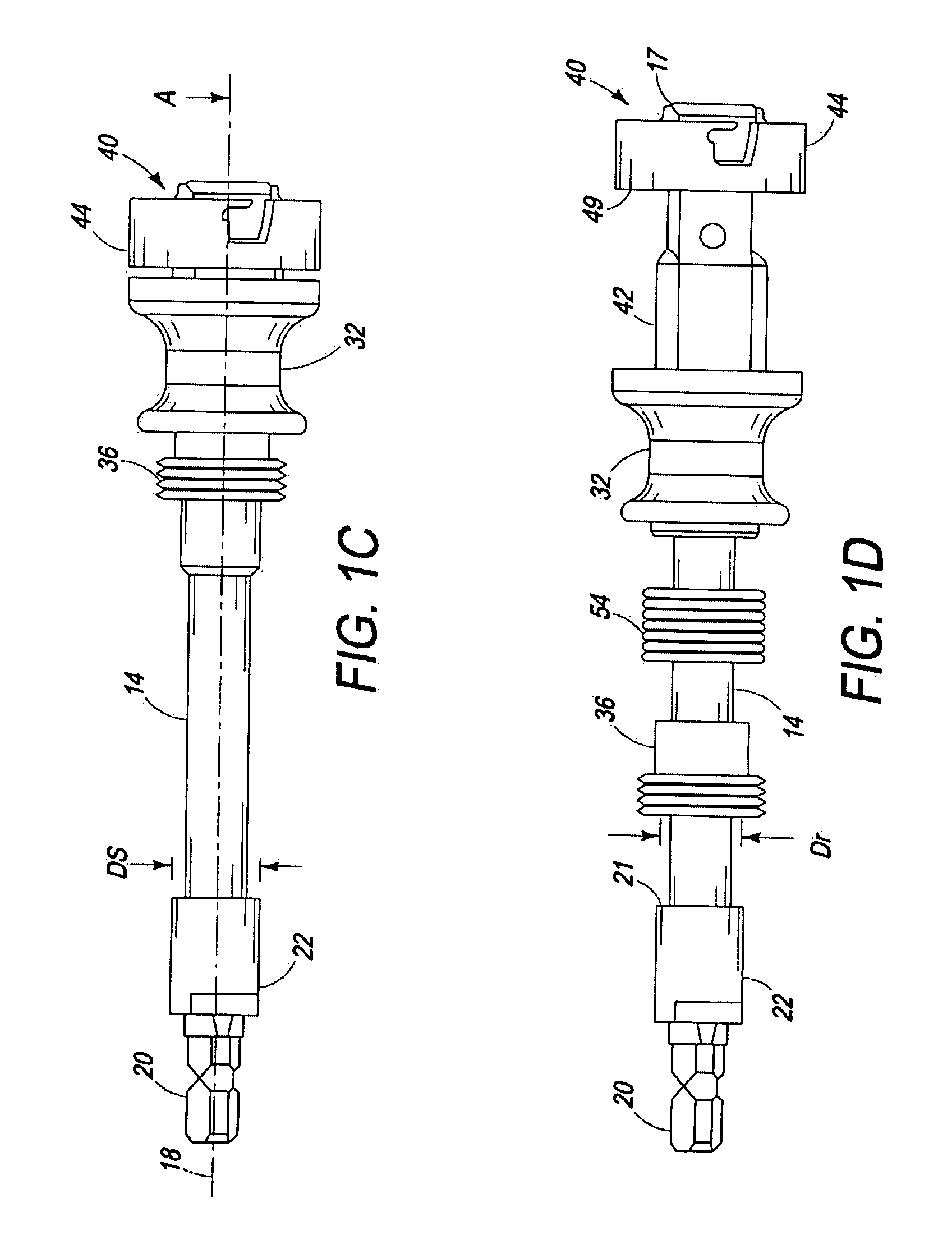

Methods and apparatus for improved cutting tools for resection

ActiveUS20060015109A1Facilitating intraoperativeFacilitating postoperative efficacyJoint implantsNon-surgical orthopedic devicesTibiaSacroiliac joint

A cutting tool is provided with an arcuate cutting blade that preferably engages a guide tool to create a curved resected surface during an arthorplasty procedure. In one embodiment, a depth of the cutting blade is sufficient to permit the simultaneous creation of resected surfaces on two bones that articulate, such as both the femor and the tibia for a given condyle, without the need to reposition the guide or the leg. In another embodiment, a cutting member has a generally rectangular cross-section along a longitudinal axis with a first and second surface having cutting teeth defined thereon and a third and fourth surface adapted to interface with a cutting guide positioned proximate the bone. In this embodiment, the cutting tool can resect the bone in two different directions without reorienting the cutting member.

Owner:BIOMET MFG CORP

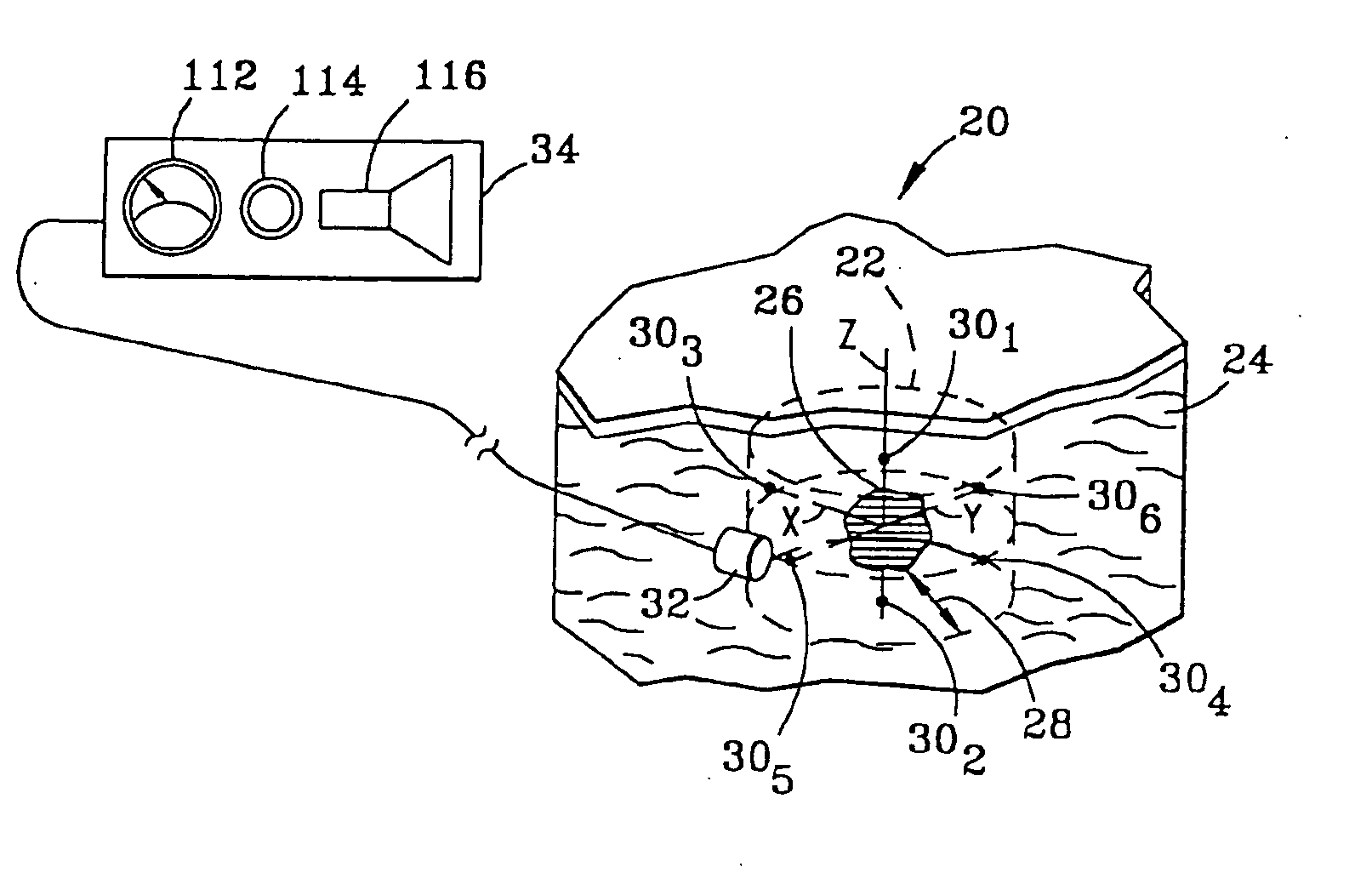

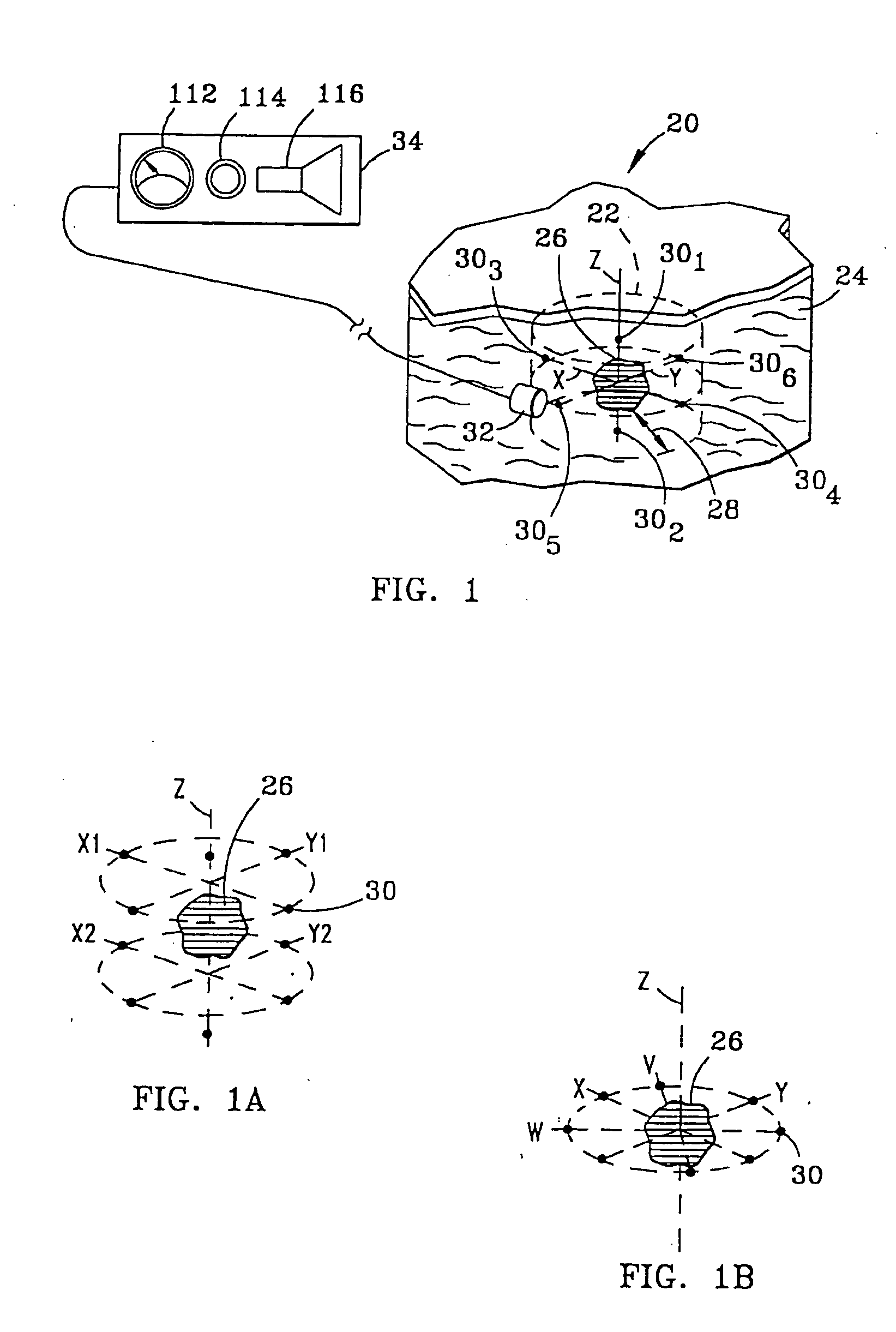

System and method for bracketing and removing tissue

Owner:VARIAN MEDICAL SYSTEMS

Chip removing machining of a workpiece while applying high pressure cooling liquid

The chip removing machining of a workpiece is performed by a cutting tool which includes a cutting insert. In order to cool the cutting insert, one or more over-cooling nozzles is arranged for directing a jet of cooling liquid downwardly toward a contact area between the workpiece and a chip surface of the cutting insert. A sub-cooling nozzle is arranged for directing a jet of cooling liquid upwardly toward a contact area between the workpiece and a flank surface of the cutting insert. A jet of cooling liquid can be emitted from only the over-cooling nozzle, or from only the sub-cooling nozzle, or from both of those nozzles simultaneously.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

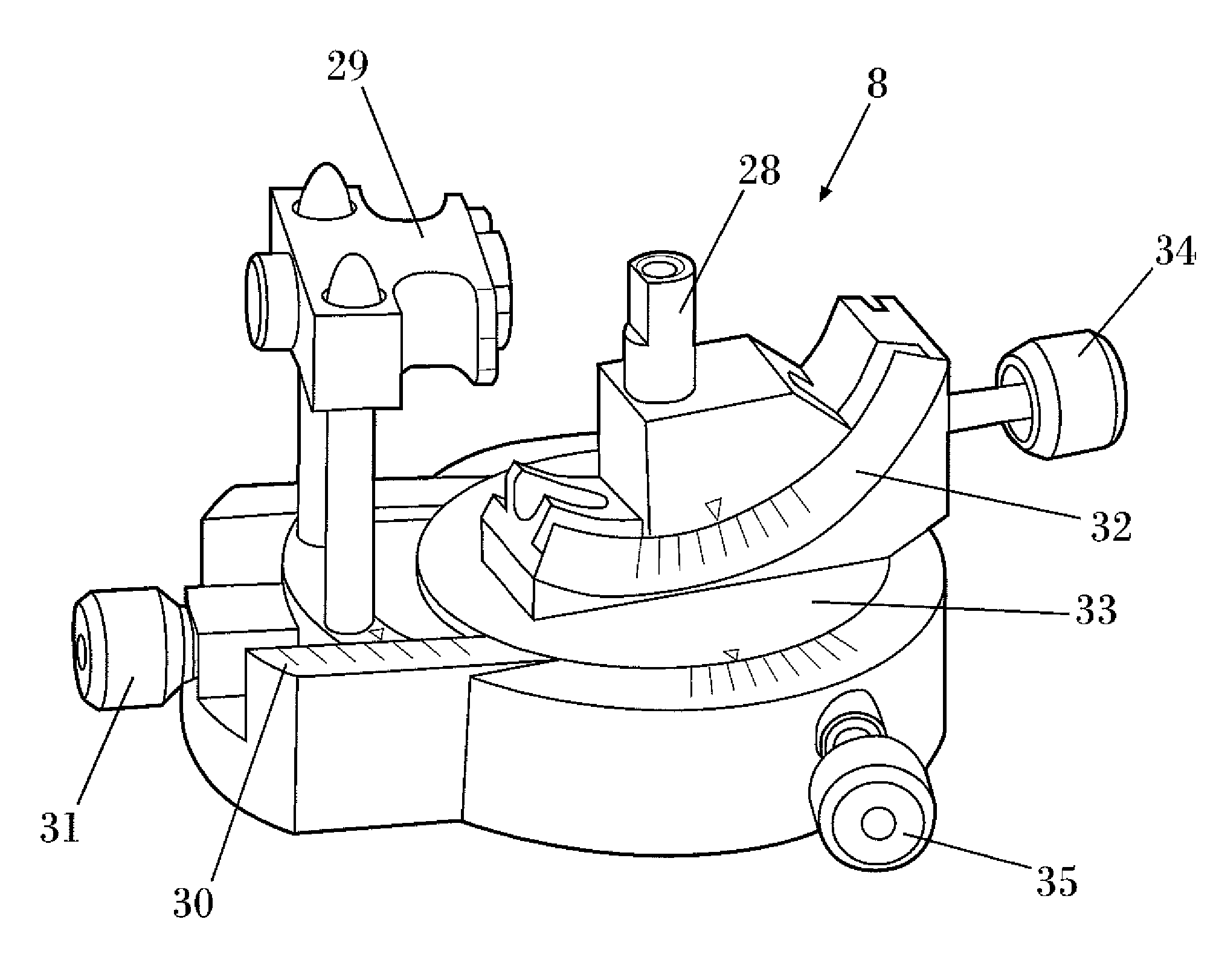

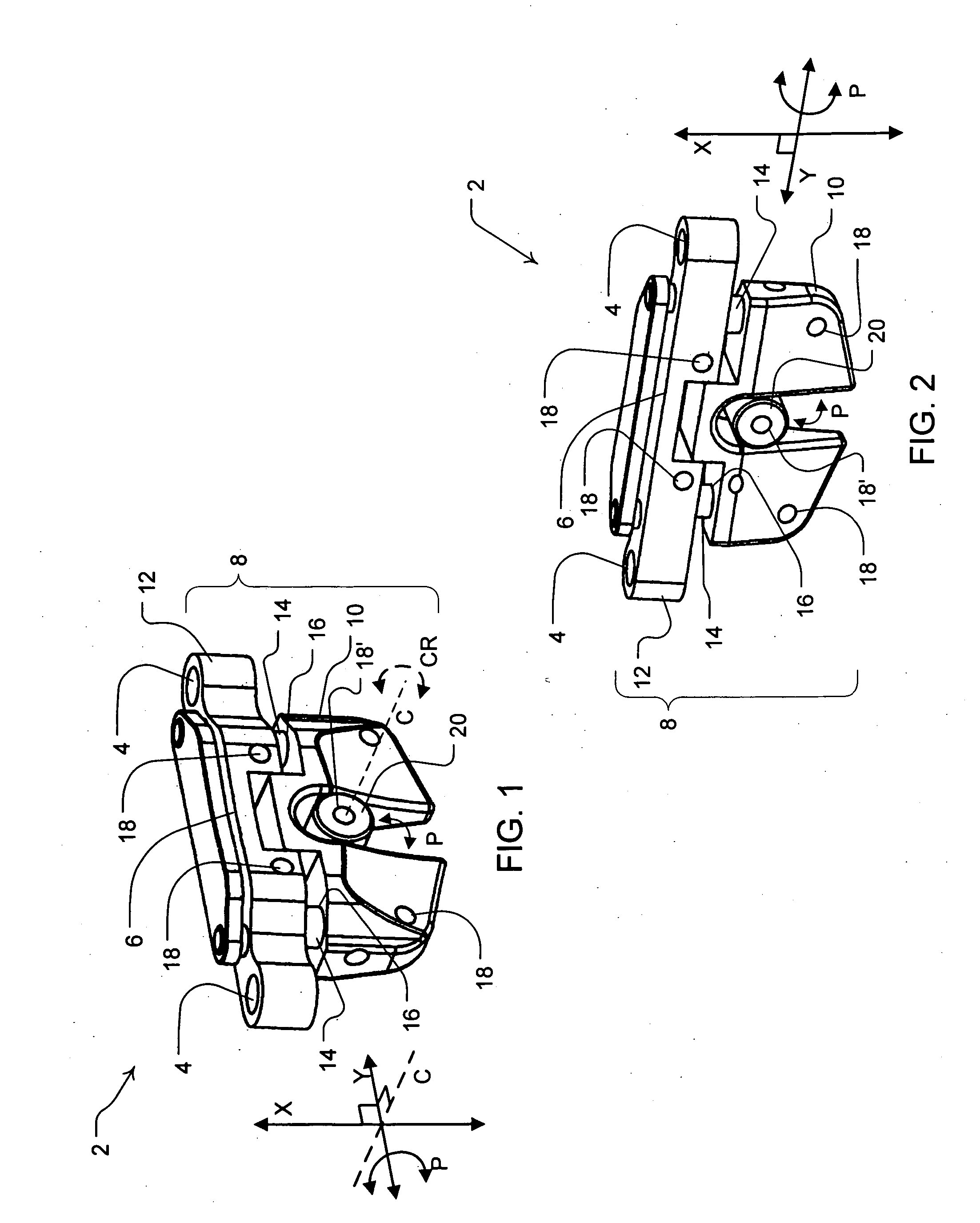

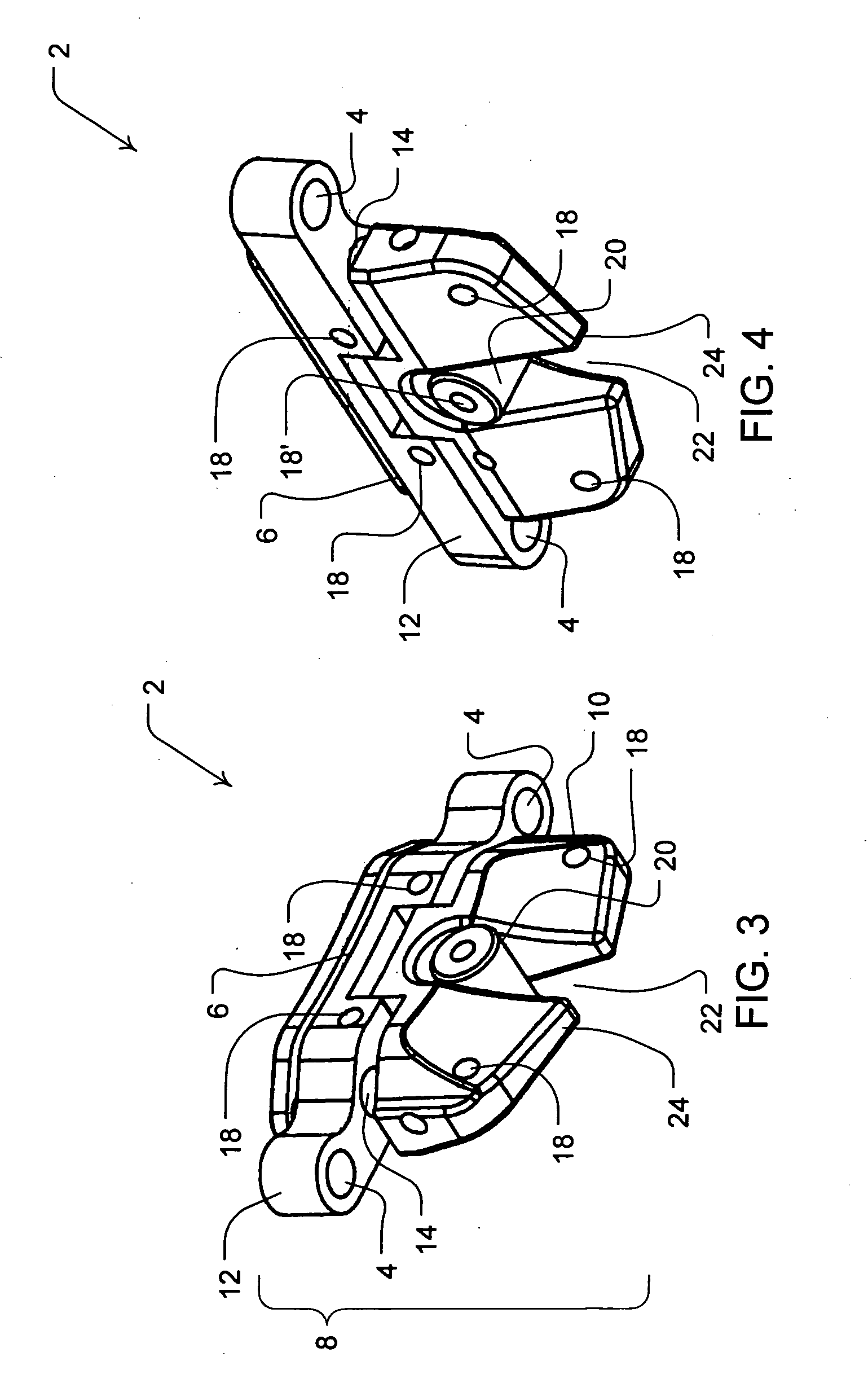

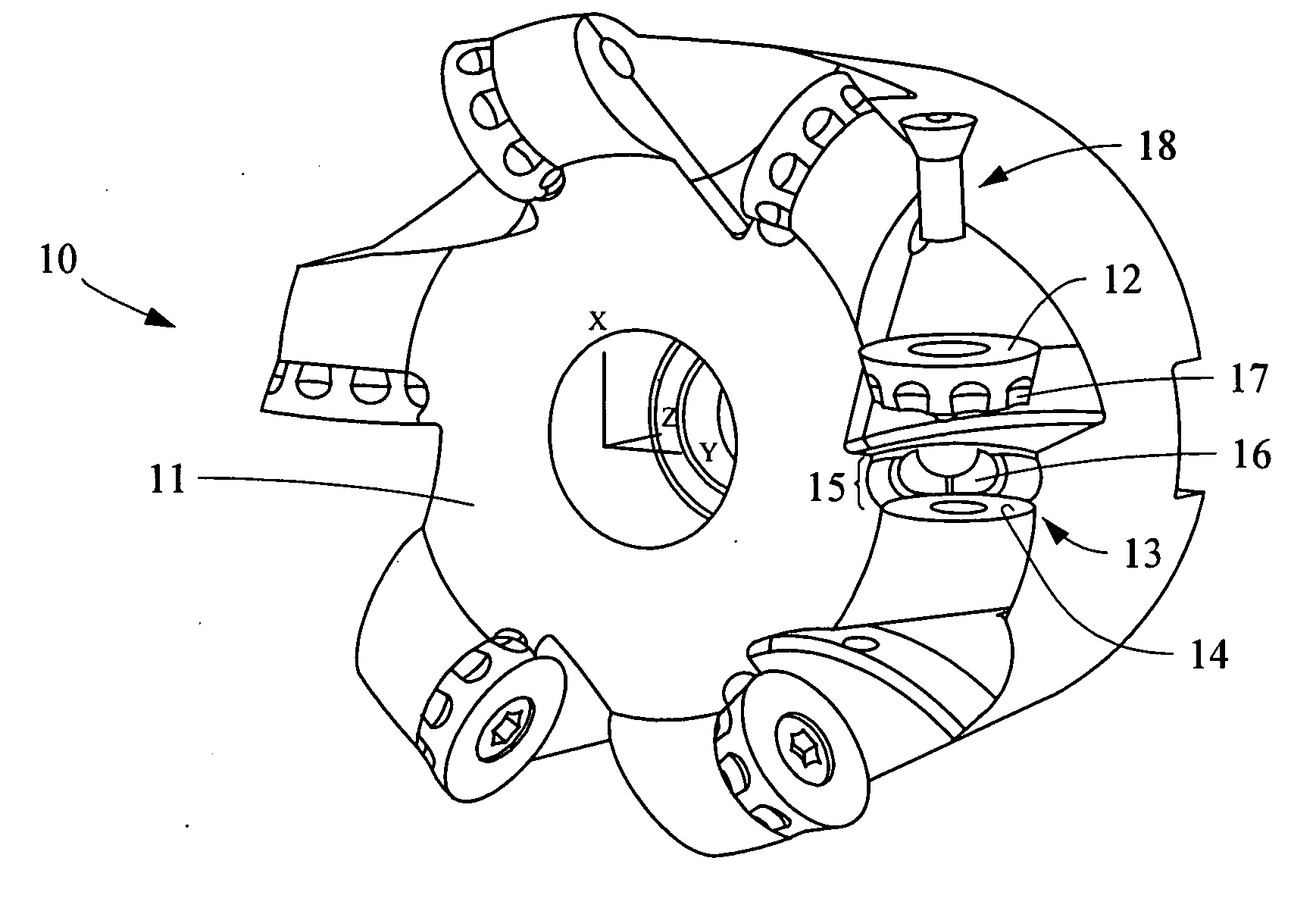

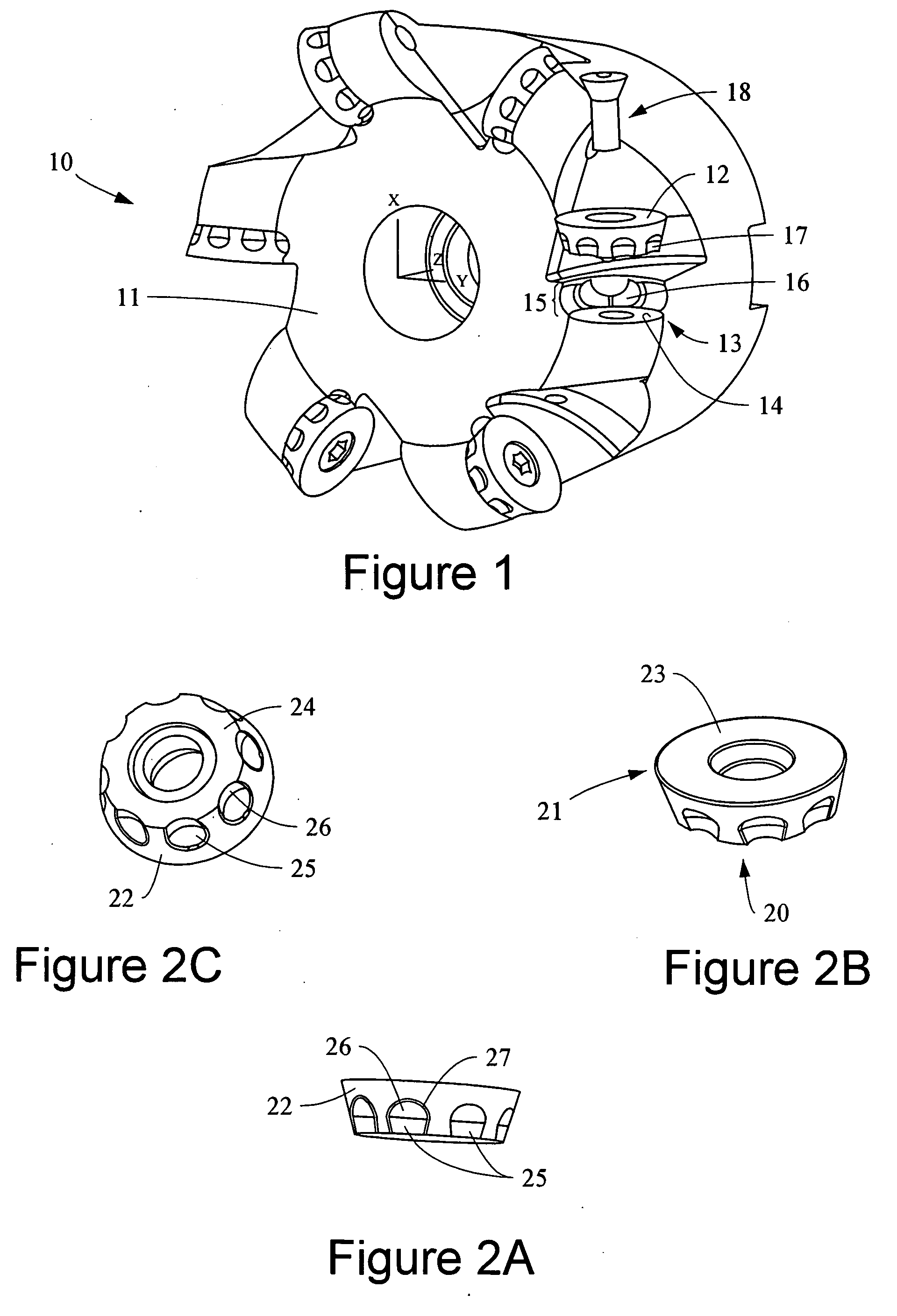

Methods and apparatus for pivotable guide surfaces for arthroplasty

InactiveUS20060015115A1Good reproducibilityOutstanding of economicJoint implantsKnee jointsEngineeringTarsal Joint

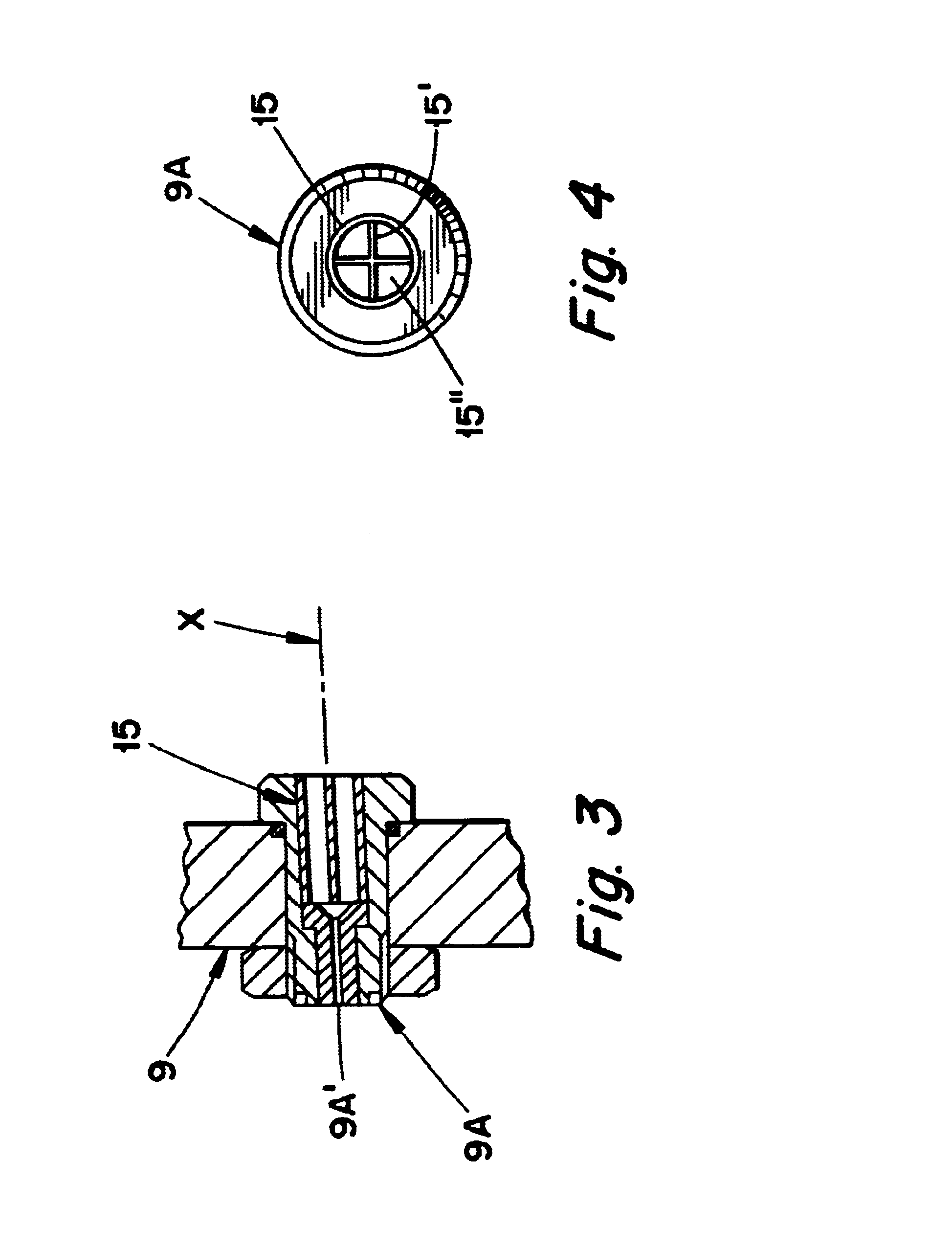

Cutting guides, cutting tools, and soft tissue management techniques permit the use of pivoting guide surfaces to facilitate in controlling the sweep or arc of a cutting tool used in connection with resection and arthroplasty procedures. In accordance with one embodiment, a guide structure is provided with one or more guide pivot aperture(s) and one or more guide pivot reference surface(s) that mate with a bushing assembly controlling a cutting tool. The bushing assembly possesses a bushing reference plan which mates with the pivot reference surface(s) of the guide structure and a bushing pivot pin which mates with the guide pivot aperture(s) of the guide structure. In one embodiment, a bushing guide lumen is operably coupled to the guide structure for articulated and / or axial guidance of the cutting tool.

Owner:PUGET BIOVENTURES

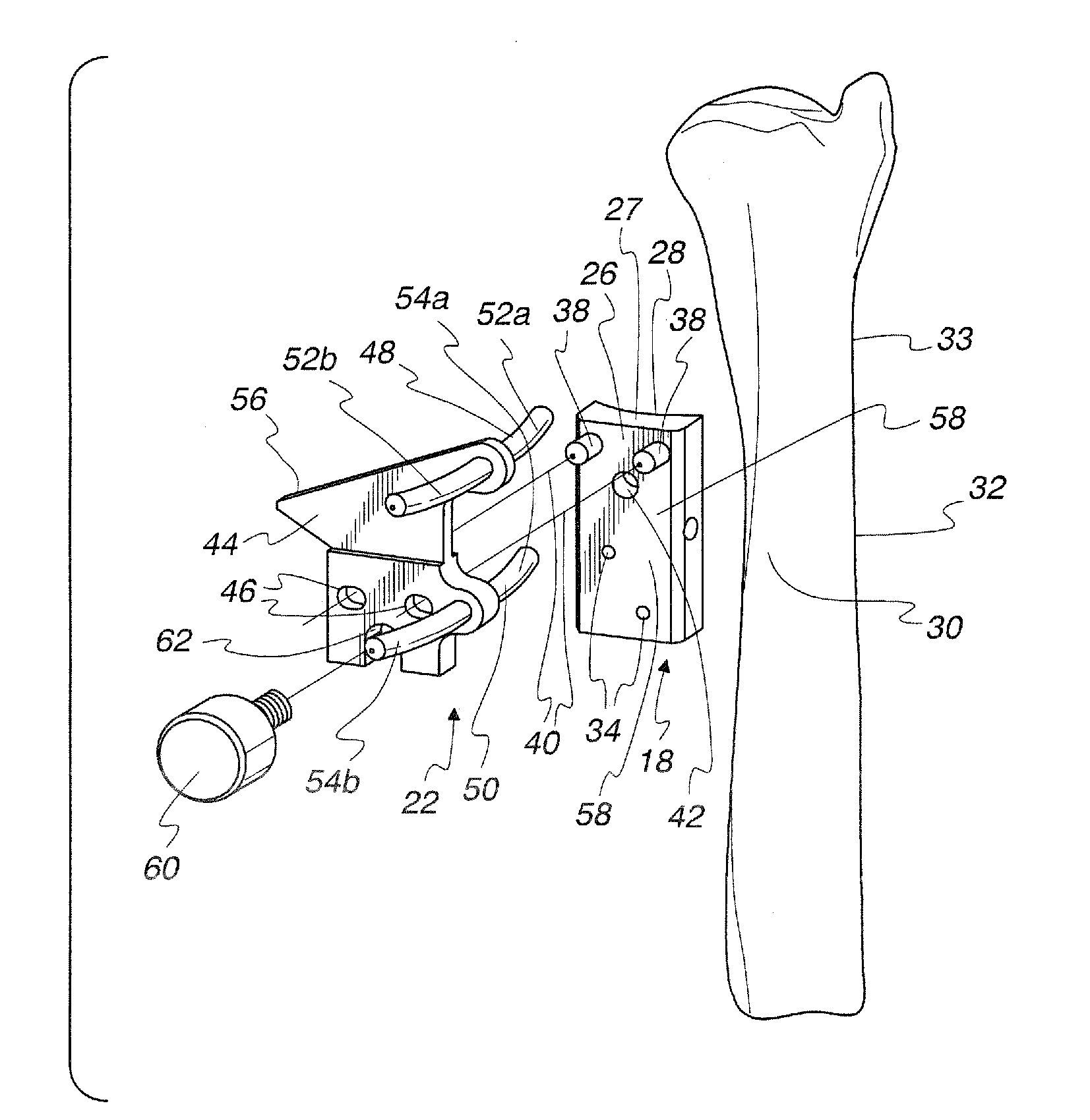

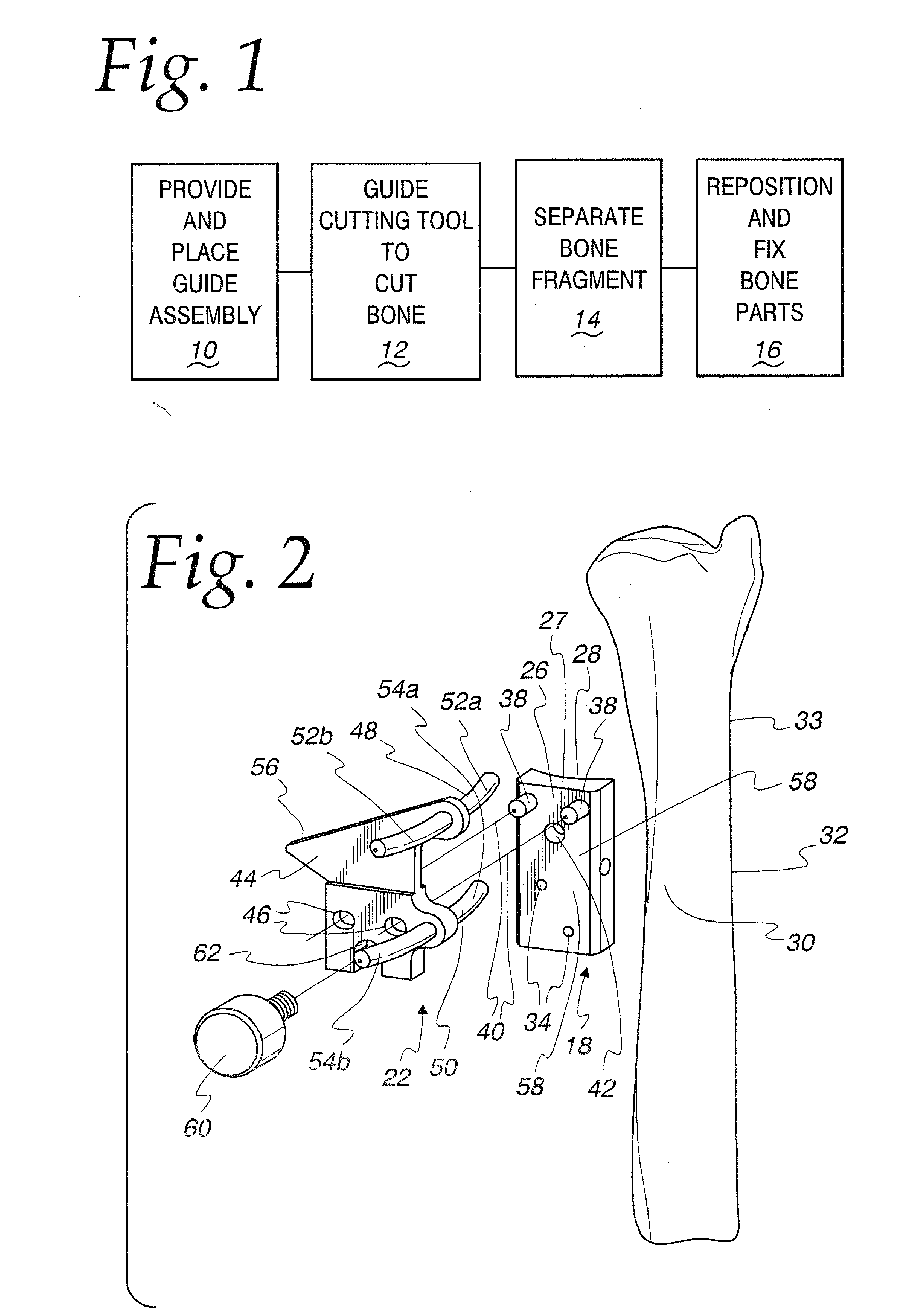

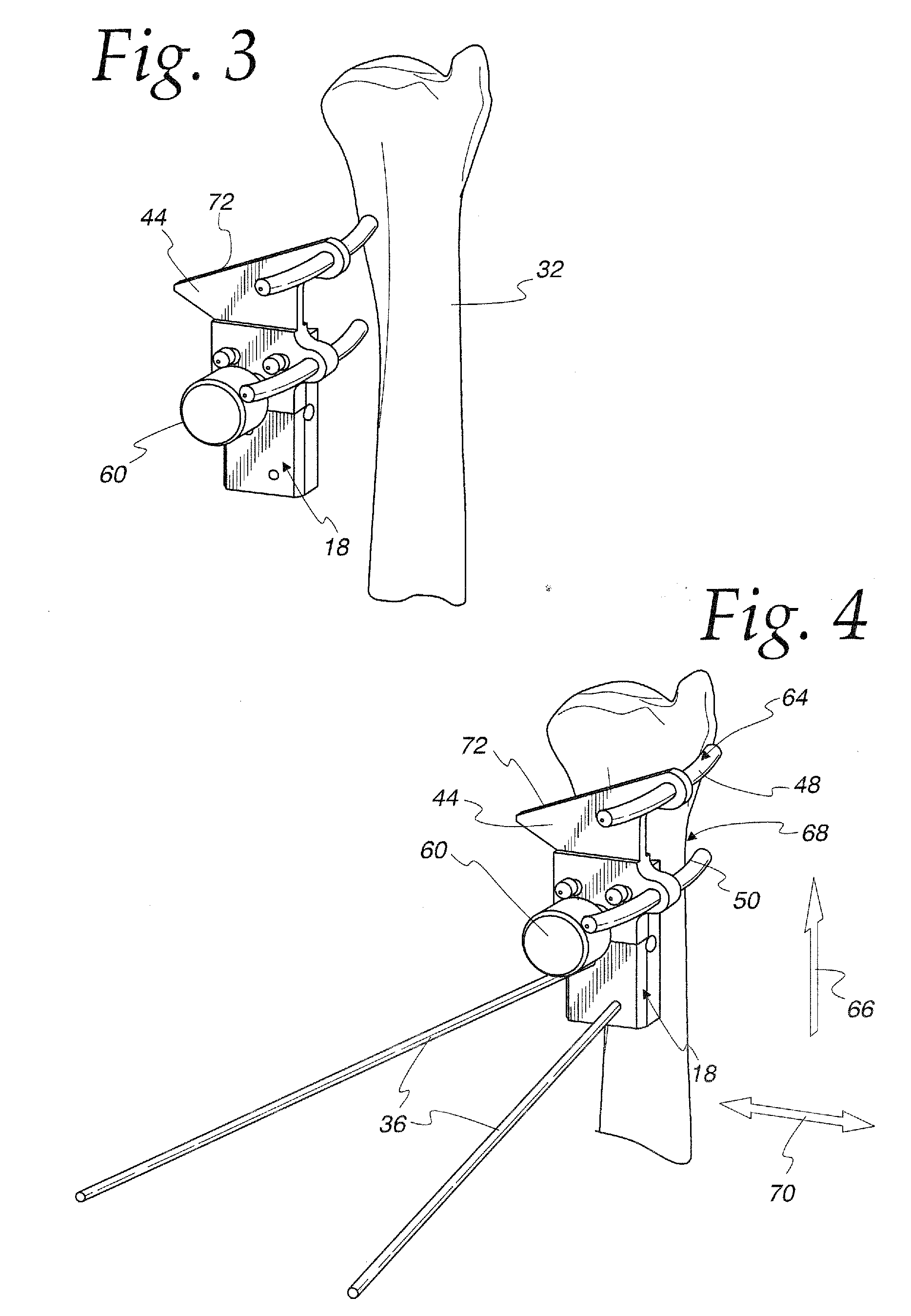

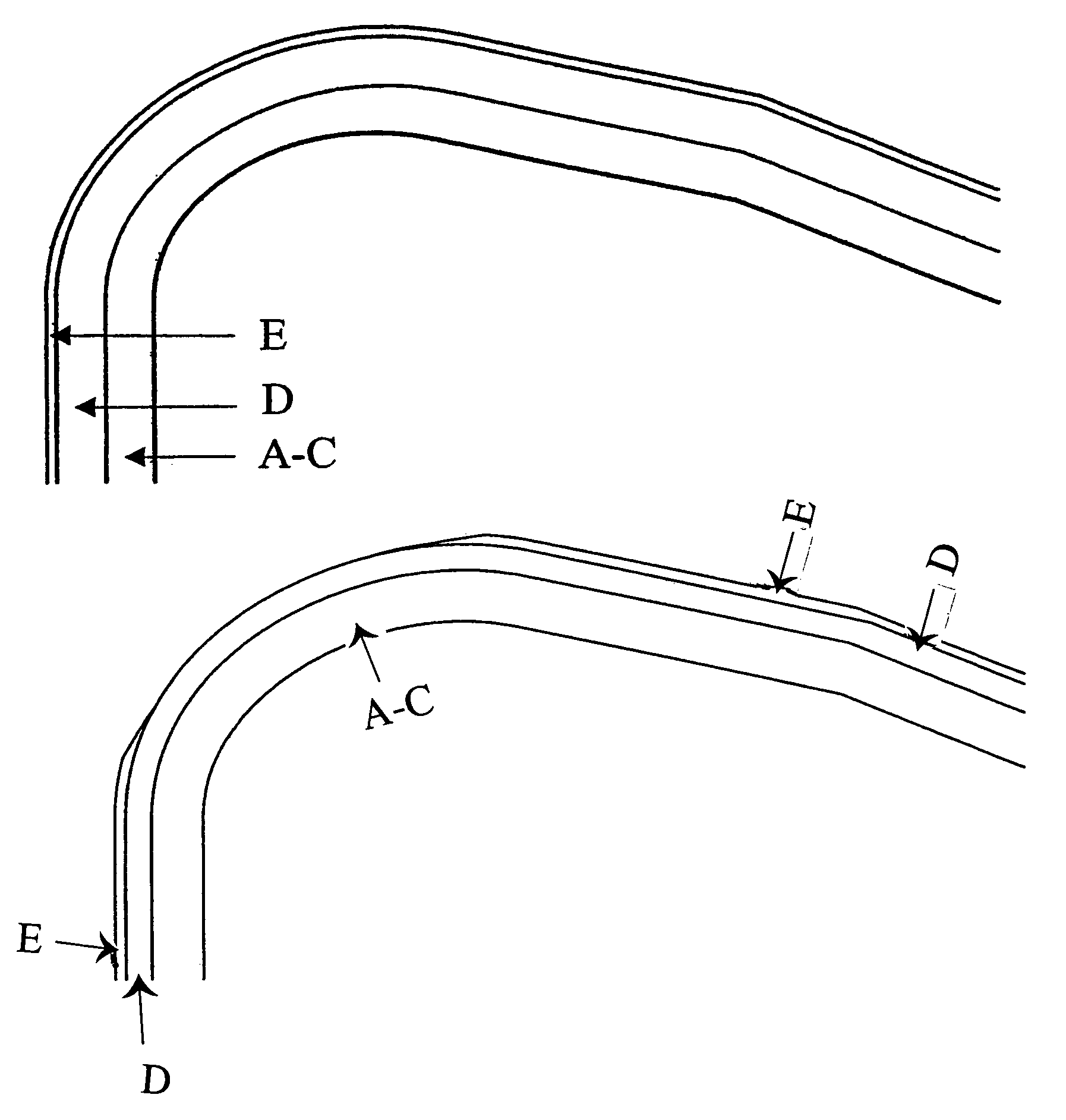

Method of performing osteotomy

InactiveUS20120130383A1Easy to separateEasy to removeNon-surgical orthopedic devicesSurgical sawsEngineeringOsteotomy

A method of performing an osteotomy including the steps of: providing a guide assembly; placing the guide assembly in operative relationship to a bone to be cut so that the guide assembly defines first and second guide edges that are in fixed relationship to each other to each guide movement of a cutting tool; guiding the cutting tool along each of the first and second guide edges to produce first and second cut lines in the bone to facilitate separation of a fragment of the bone from between first and second bone surfaces formed respectively at the first and second cut lines; separating the bone fragment so that a gap with a first width is formed between the first and second bone surfaces; and changing the width of the gap to be less than the first width.

Owner:TRIMED

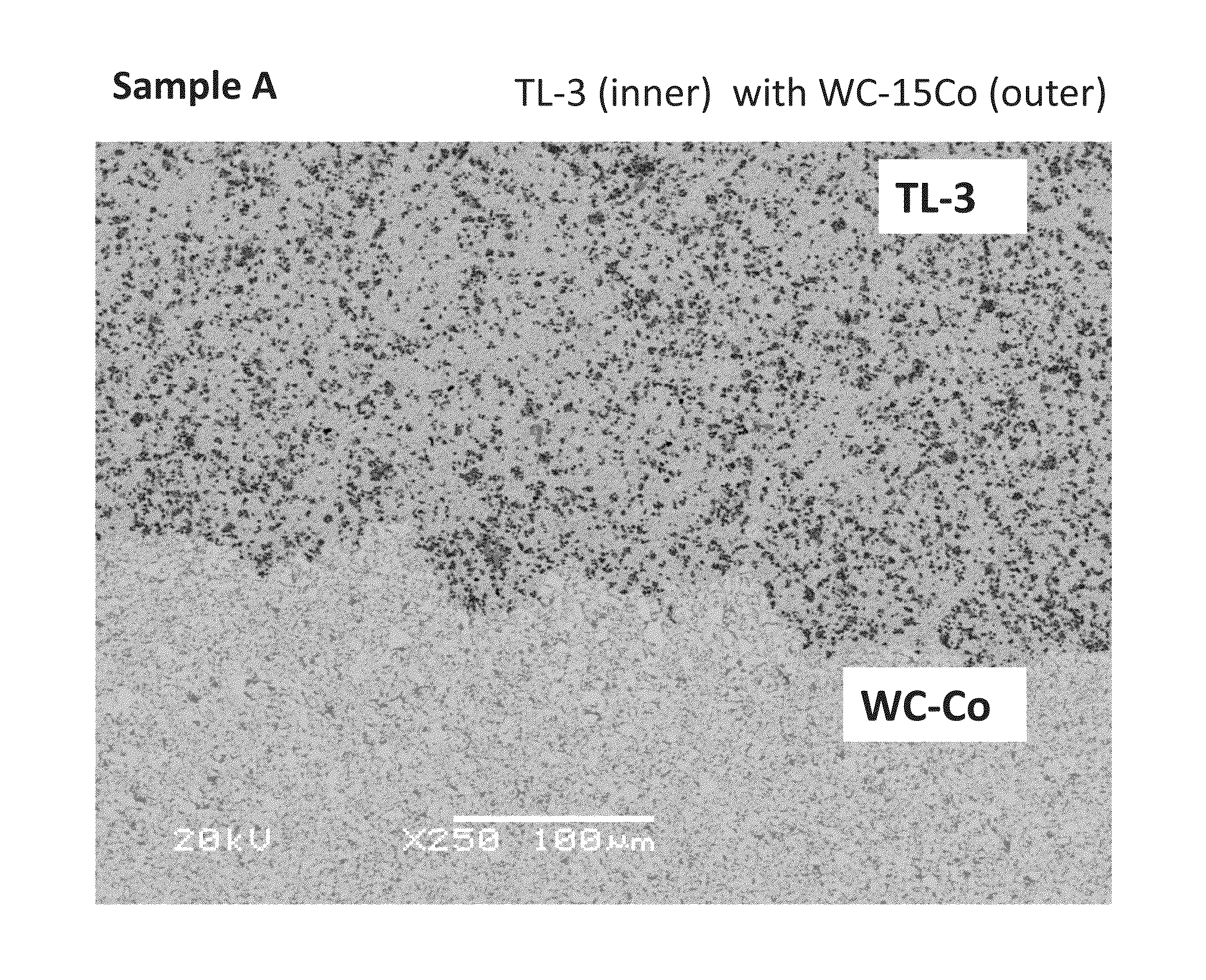

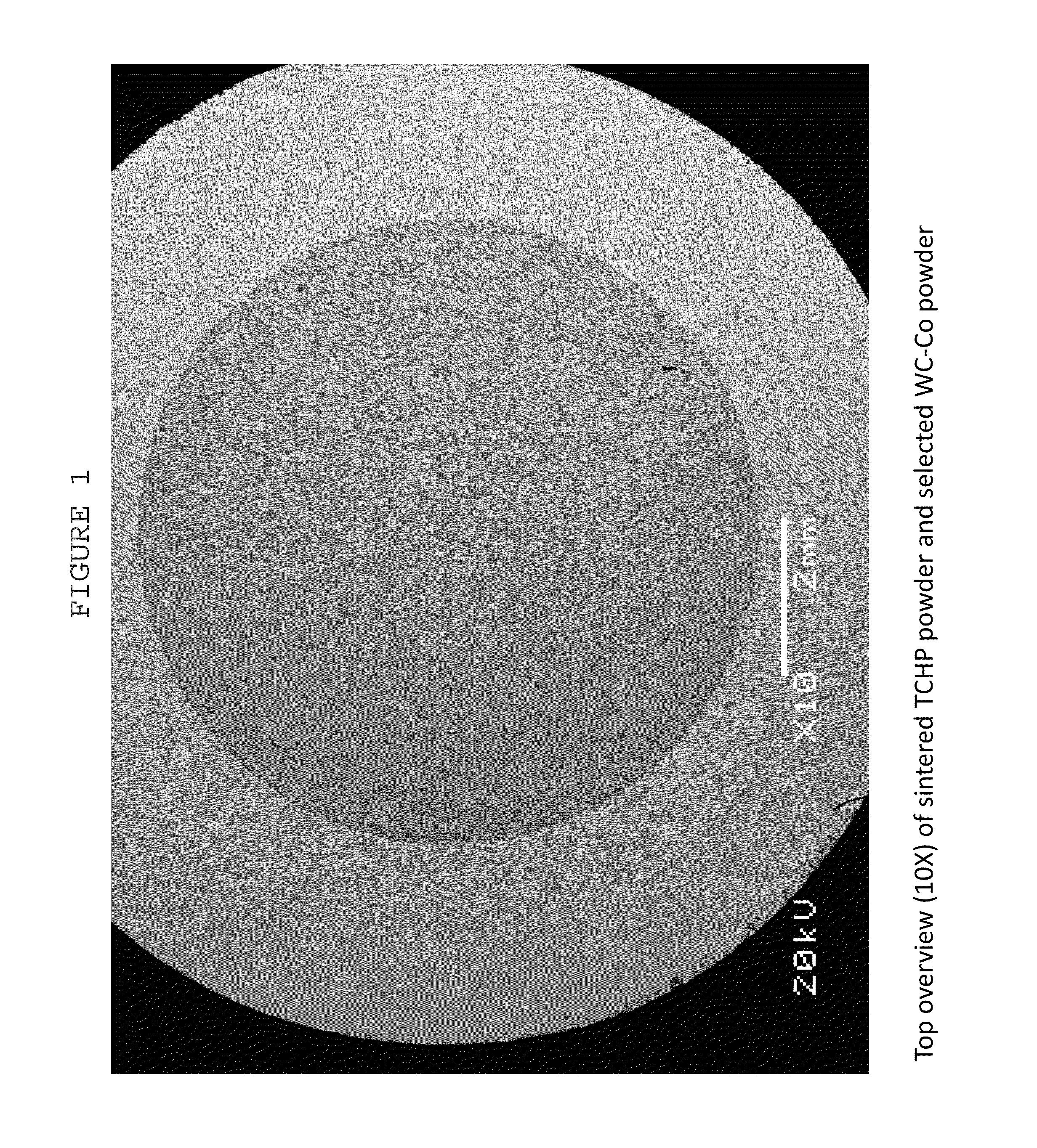

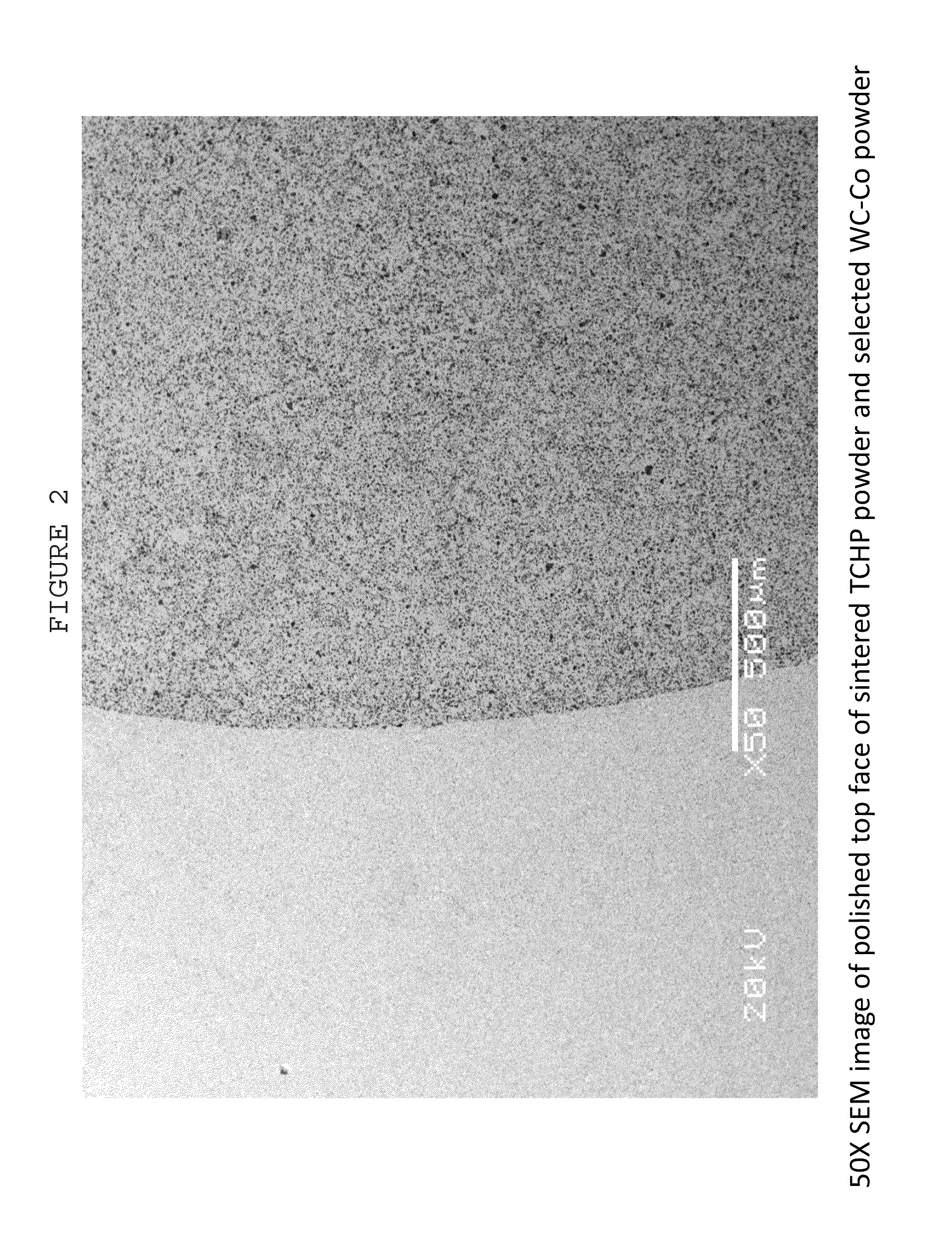

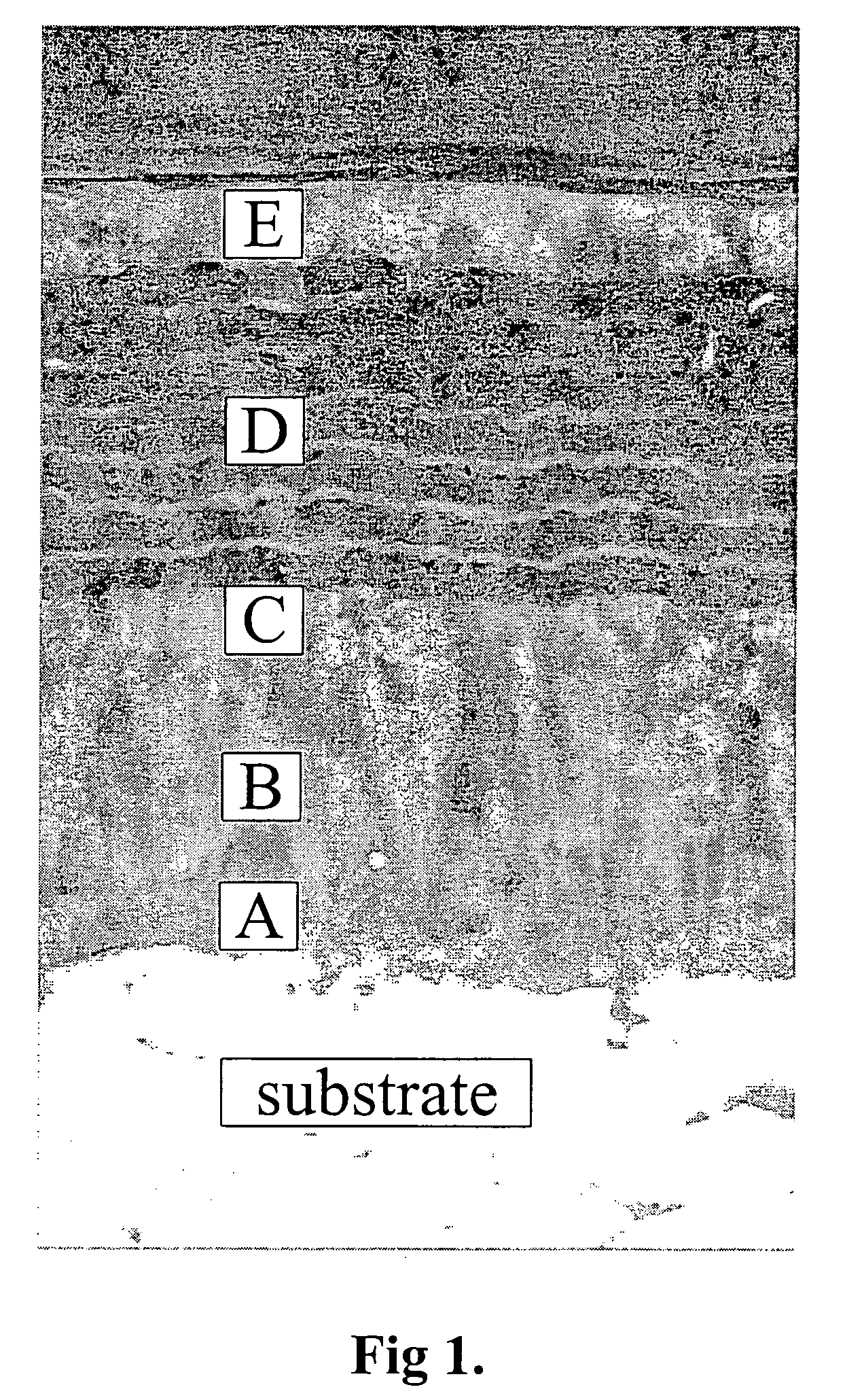

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

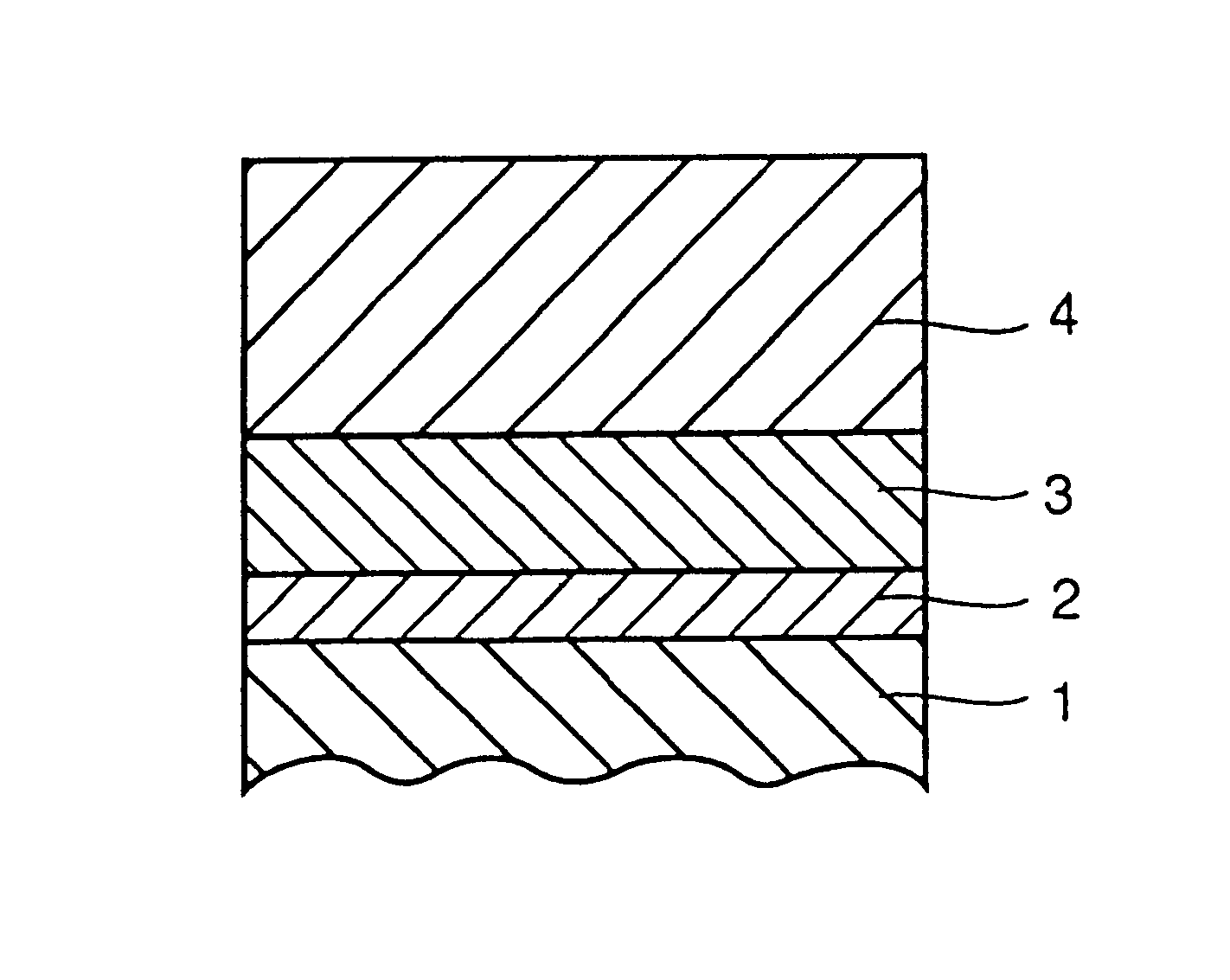

Coated hard metal material

InactiveUS6183846B1Increase speedImprove efficiencyPigmenting treatmentOther chemical processesCemented carbideCermet

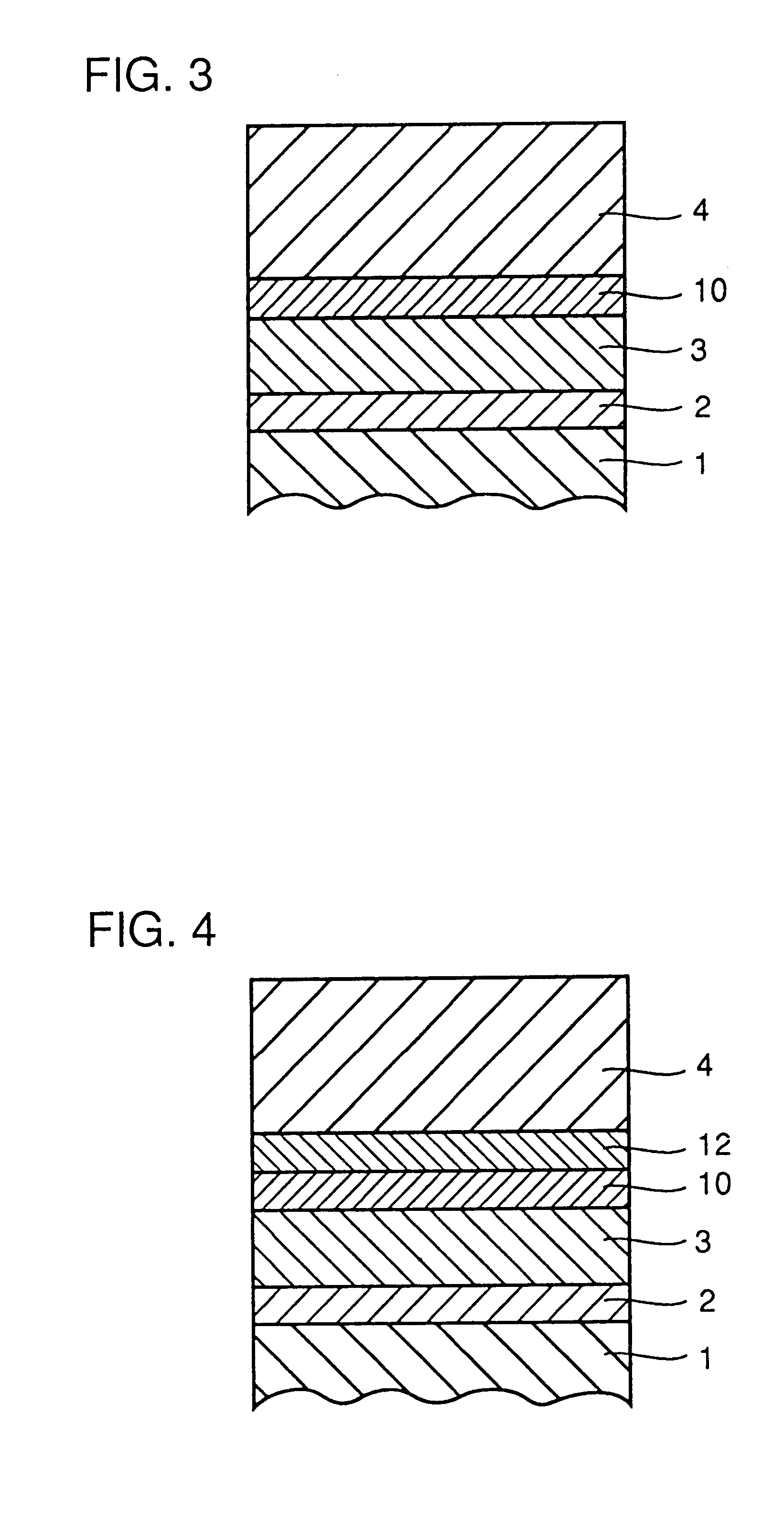

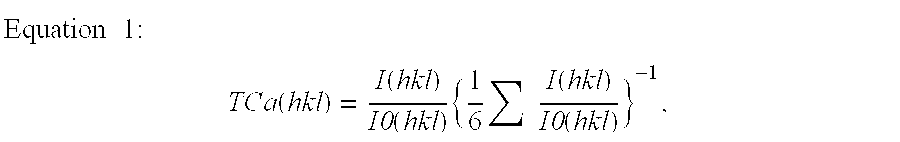

A coated hard metal for a cutting tool is excellent in wear resistance and chipping resistance. The coated hard metal includes a hard coating layer on a surface of a base material of cemented carbide or cermet. The hard coating layer includes an inner layer (2) on the base material (1), an intermediate layer (3) on the inner layer (2) and an outer layer (4) on the intermediate layer (3). The inner layer (2) consists of a carbide, a nitride, a carbo-nitride, a carbo-oxide, a carbonitrogen oxide or a boronitride of Ti. The intermediate layer (3) consists of Al2O3 or ZrO2. The outer layer (4) consists of a carbide, a nitride, a carbo-nitride, a carbo-oxide, a carbonitrogen oxide or a boronitride of Ti. The thickness of the inner layer (2) is 0.1 to 5 mum, the thickness of the intermediate layer (3) is 5 to 50 mum in the case of it being an Al2O3 layer and 0.5 to 20 mum in the case of it being a ZrO2 layer, and the thickness of the outer layer (4) is 5 to 100 mum.

Owner:SUMITOMO ELECTRIC IND LTD

Coated cemented carbide cutting tool

InactiveUS6293739B1Extended service lifeImproving flaking resistance of coating layerLayered productsTurning toolsCrystal structureAlloy

The invention is to prolong the life time of tools dramatically by (1) considerably improving the flaking resistance of the coating layer at the time of cutting, (2) increasing the wear resistance and crater resistance of the coating layer itself, and (3) enhancing the breakage strength of the coating layer in comparison with the conventional coating cutting tools. In order to achieve the object, the coated cemented carbide of the invention has the following structure in the coating layer on the surface of the cemented carbides: The outer layer has an Al2O3 layer practically having an alpha-type crystal structure. The Al2O3 layer has a region where alpha-type and kappa-type crystal grains coexist in the first row of the crystal grains that grow on the inner layer. In addition to that, the crystal grains of alpha-Al2O3 in the region include no pores.

Owner:SUMITOMO ELECTRIC IND LTD

Vacuum shroud for use with drilling tools

InactiveUS20090181606A1Improve sealingSecurely holdMaintainance and safety accessoriesGrinding/polishing safety devicesEngineeringMechanical engineering

Owner:DUSTLESS DEPOT

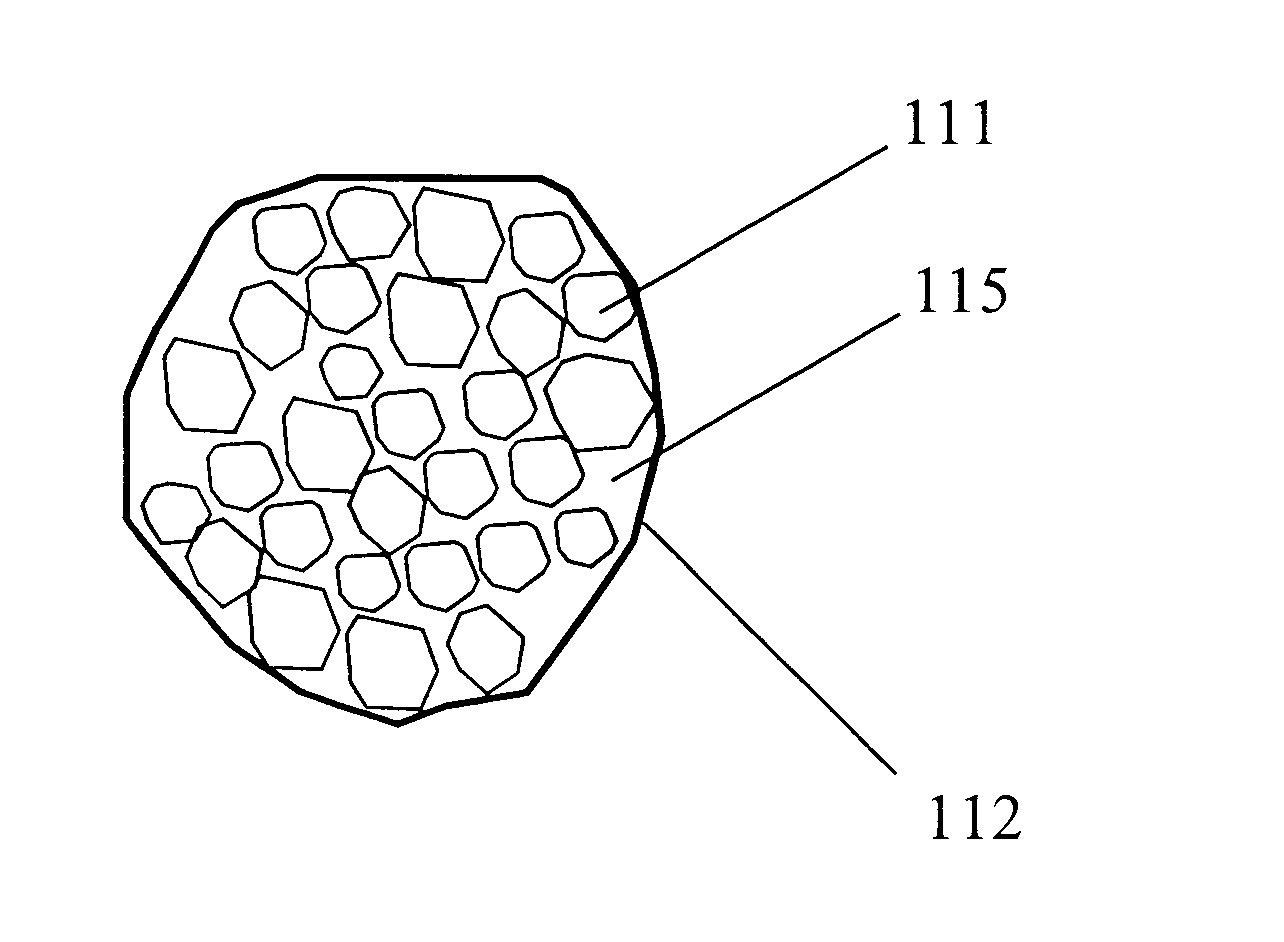

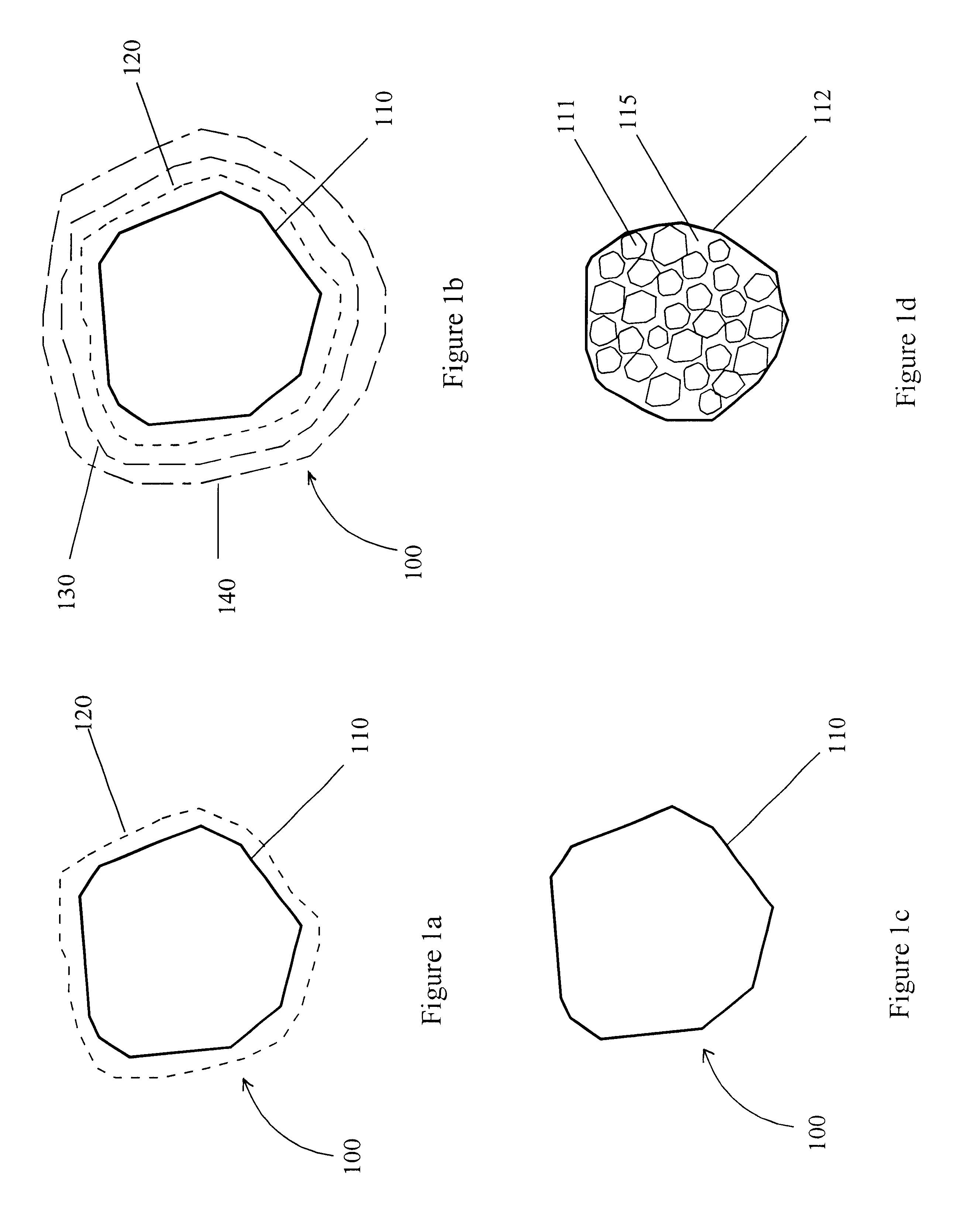

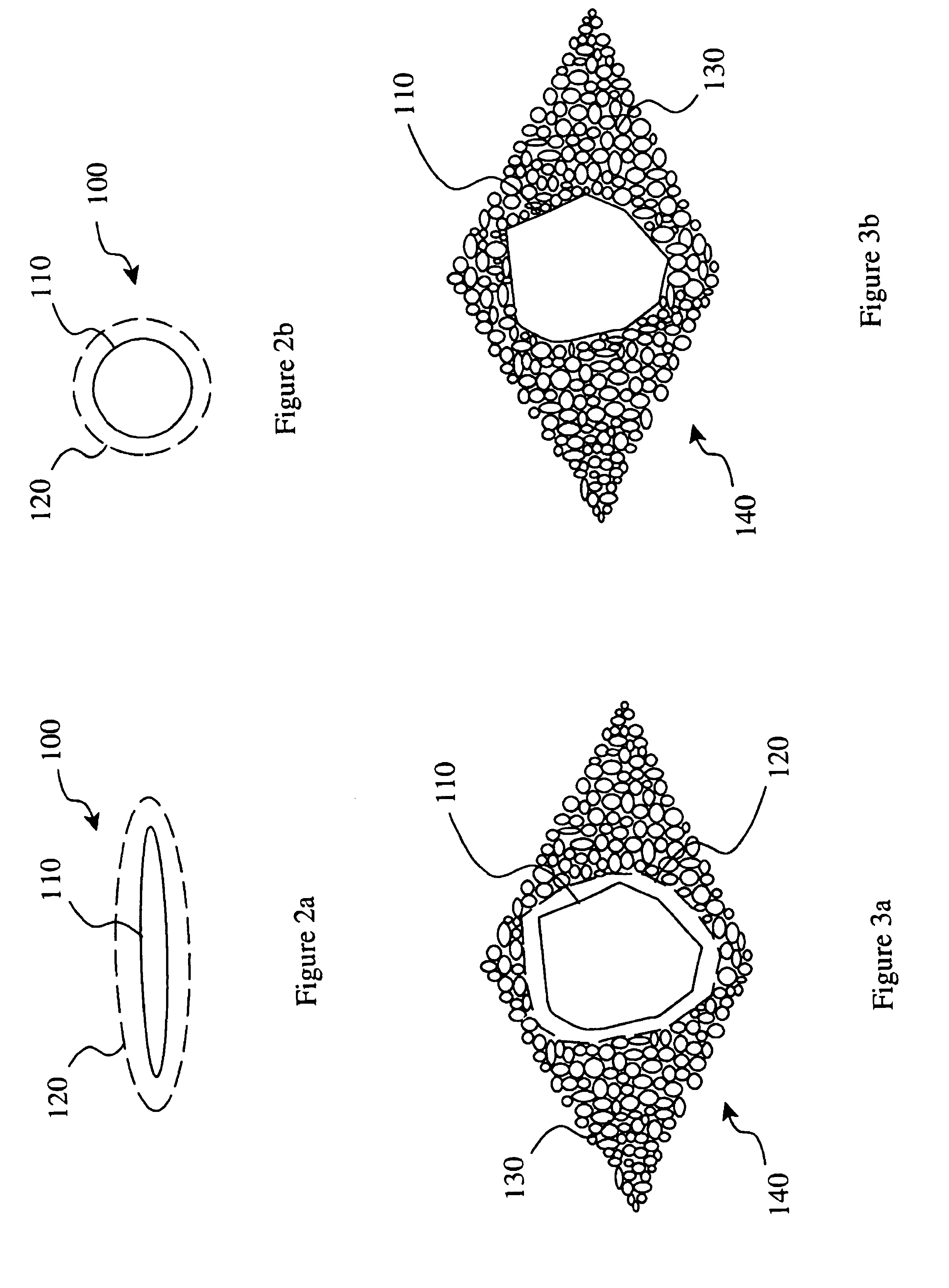

Self-grown monopoly compact grit

InactiveUS6616725B2Strong and more resilientProduced cost-effectivelyPigmenting treatmentOther chemical processesBoron nitrideSolvent

A self-grown monopoly compact grit and high pressure, high temperature process for preparing the same. The high pressure, high temperature sintered / synthesized monopoly compact grit is used in various industrial tools such as saw blades, grinding wheels, cutting tools and drill bits. Further, the monopoly compact grit of the present invention is produced from a seed of a mono-crystal of diamond or cubic boron nitride surrounded by either a self-grown crystal layer or an integrally bonded poly-crystalline sintered compact layer. The self-grown crystal layer is a new grown crystal structure where the seed crystal grows into a new phase through a normal diamond or cubic boron nitride synthesis process in the presence of a catalyst metal solvent. The compact layer is composed of about 50 to about 90 volume percent of diamond or cubic boron nitride, a typical binder material, which is a catalyst for crystal-to-crystal bonding, and a cementing agent which is a binding agent capable of forming stable carbide and nitride bonds.

Owner:CHO HYUN SAM +2

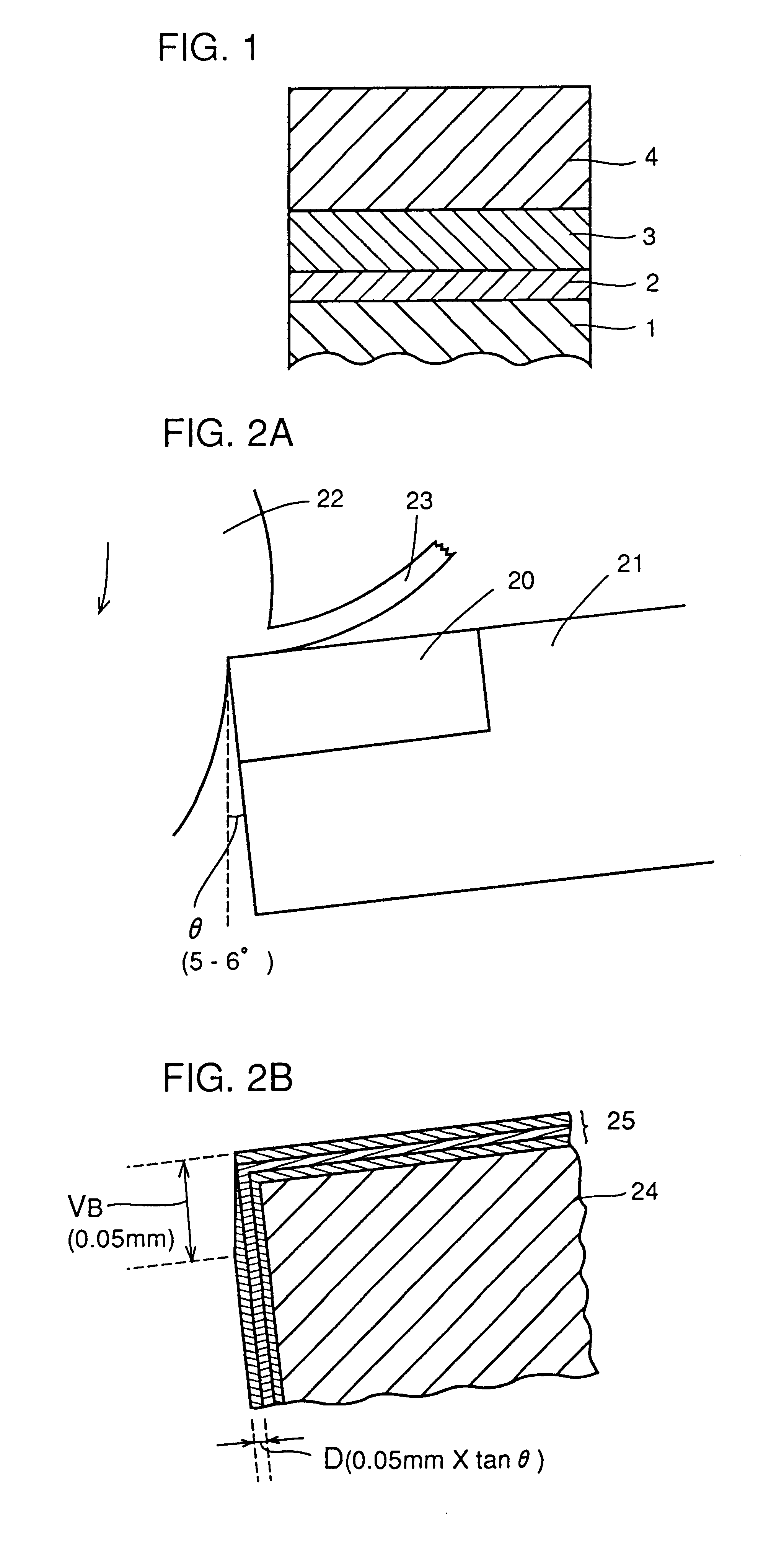

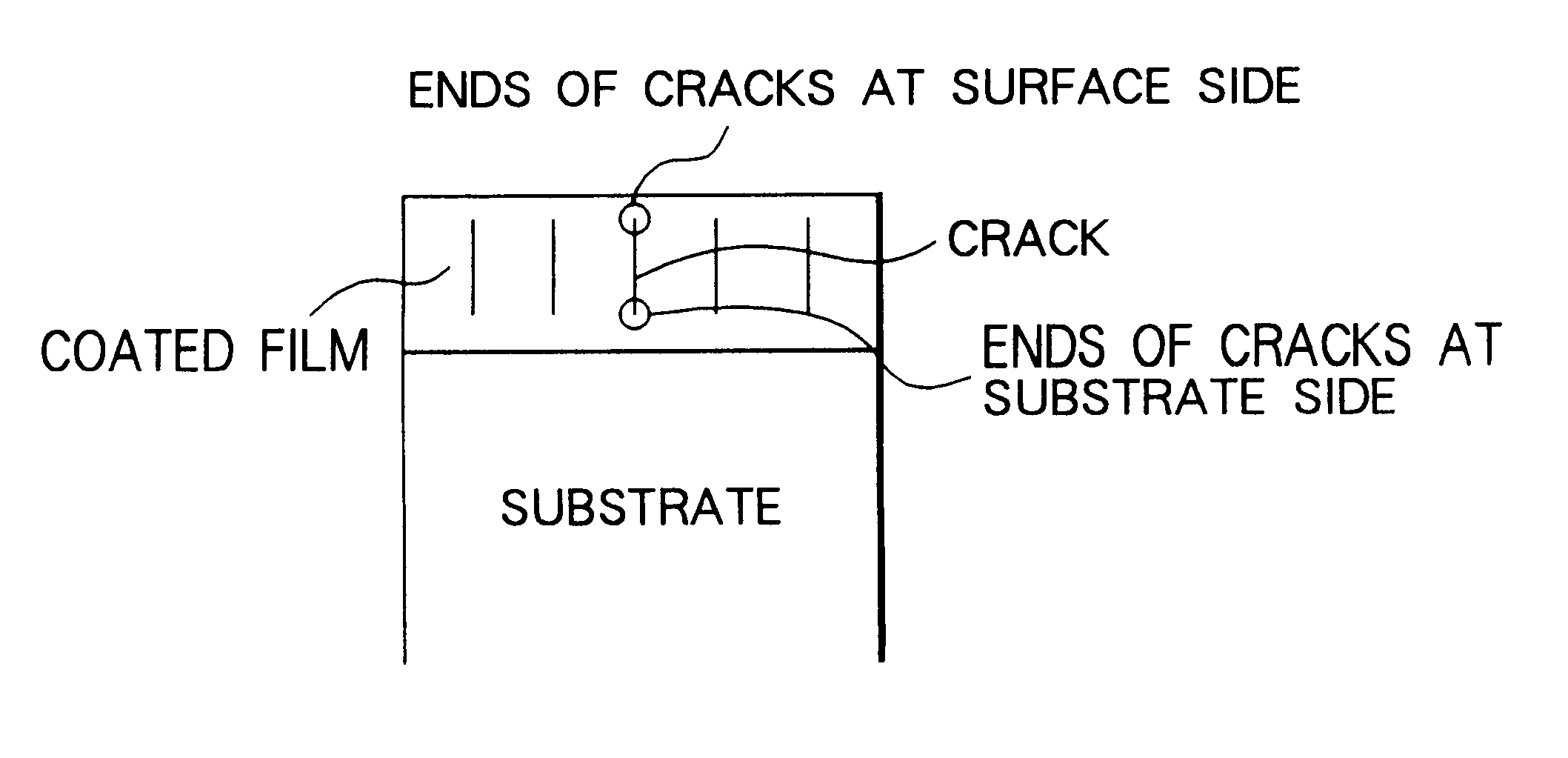

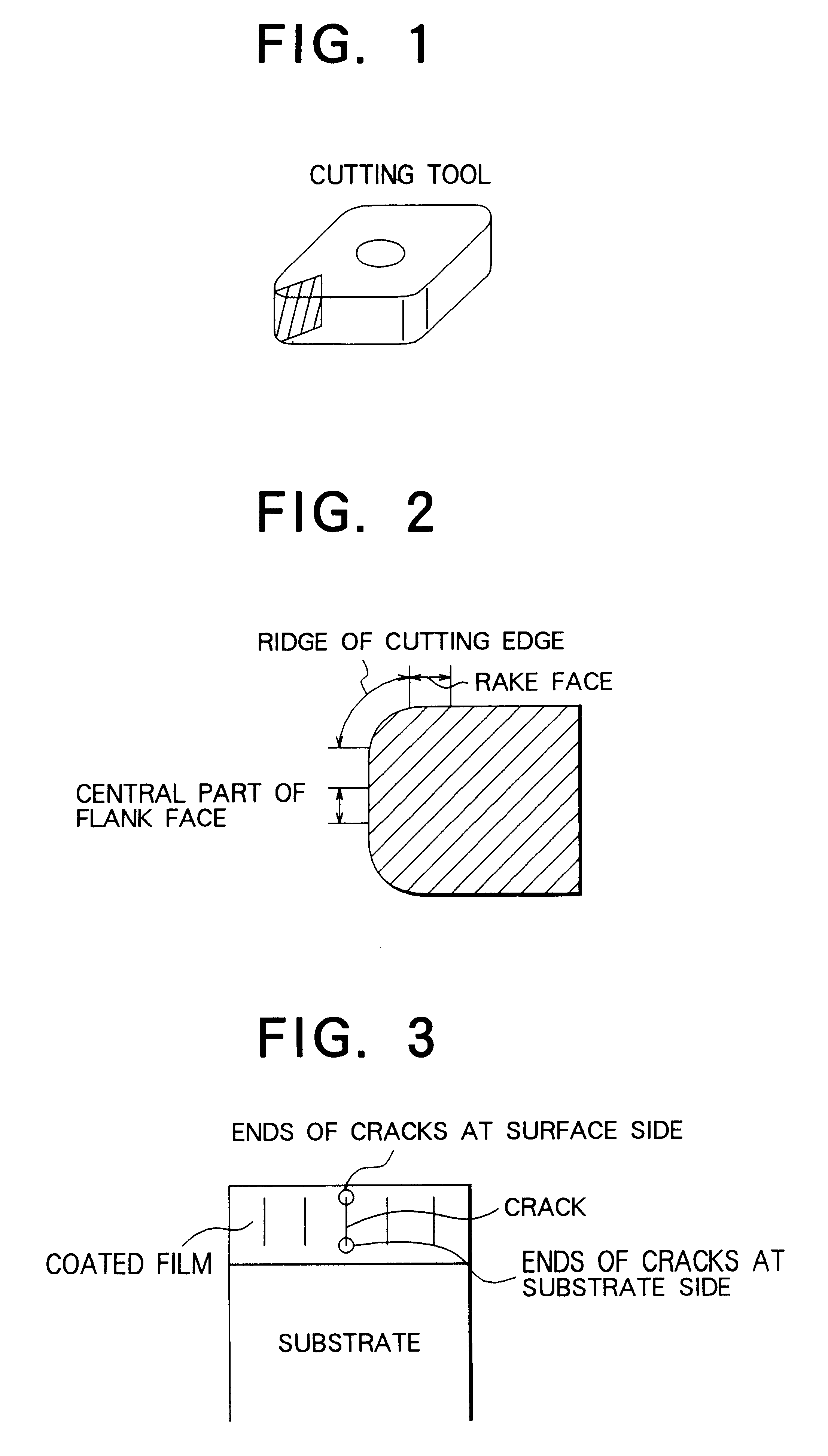

Coated tool of cemented carbide

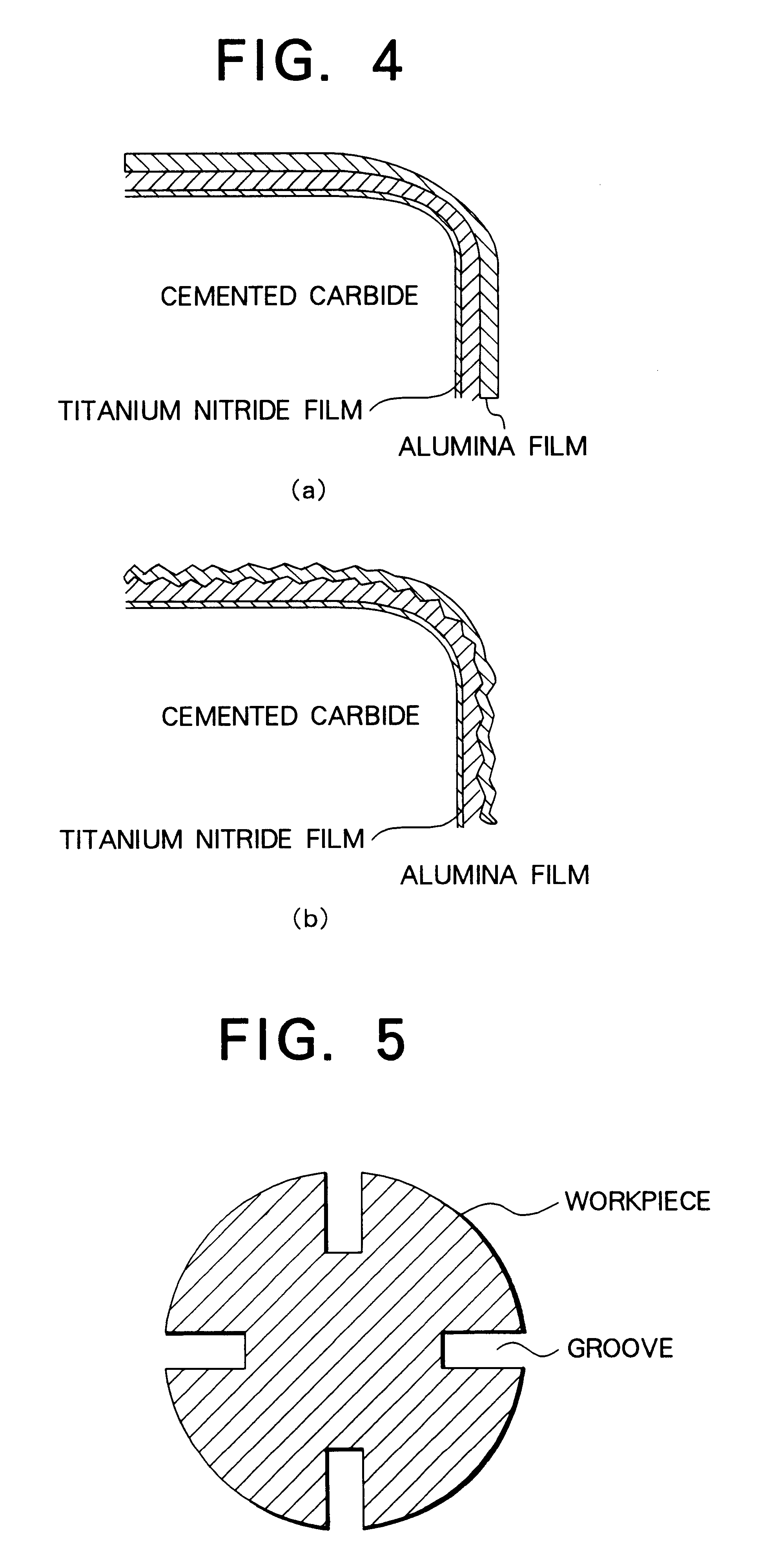

InactiveUS6187421B1Improve propertiesImprove tool lifePigmenting treatmentOther chemical processesCoated membraneCarbide coating

The principal object of the present invention is to provide a coated cemented carbide tool whose both properties of breakage resistance and wear resistance are improved and whose life is lengthened.The present invention has been made to achieve this object and is related with a coated cemented carbide cutting tool comprising a substrate consisting of a matrix of WC and a binder phase of an iron group metal and a plurality of coated layers provided on a surface of the substrate, in which (a) an innermost layer, adjacent to the substrate, of the coated layers consists essentially of titanium nitride having a thickness of 0.1 to 3 mum, (b) on a mirror-polished cross-sectional microstructure of the said tool, an average crack interval in the coated film on a ridge of a cutting edge and / or rake face is smaller than an average crack interval in the coated layer on a flank face, (c) at least 50% of the cracks in the coated film on the said ridge of the cutting edge and / or rake face have ends of the cracks in the said innermost titanium nitride layer, in a layer above the titanium nitride layer or in an interface between these layers and (d) an average crack length in the coated film on the said ridge of the cutting edge and / or rake face is shorter than an average film thickness on the flank face.According to the present invention, quantitatively specifying the crack intervals and positions of the ends of the cracks in the coated layer results in excellent breakage resistance as well as wear resistance.

Owner:SUMITOMO ELECTRIC IND LTD

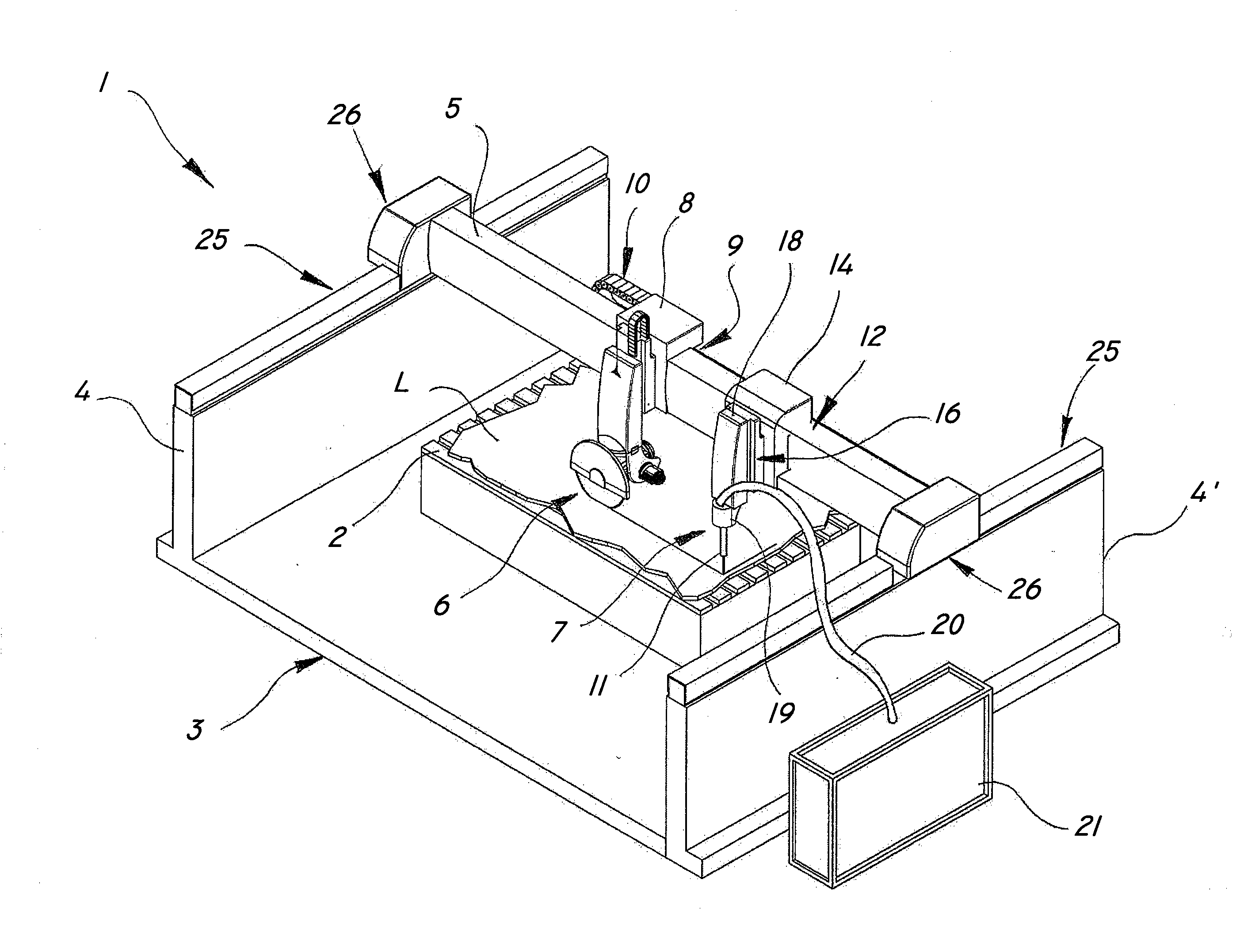

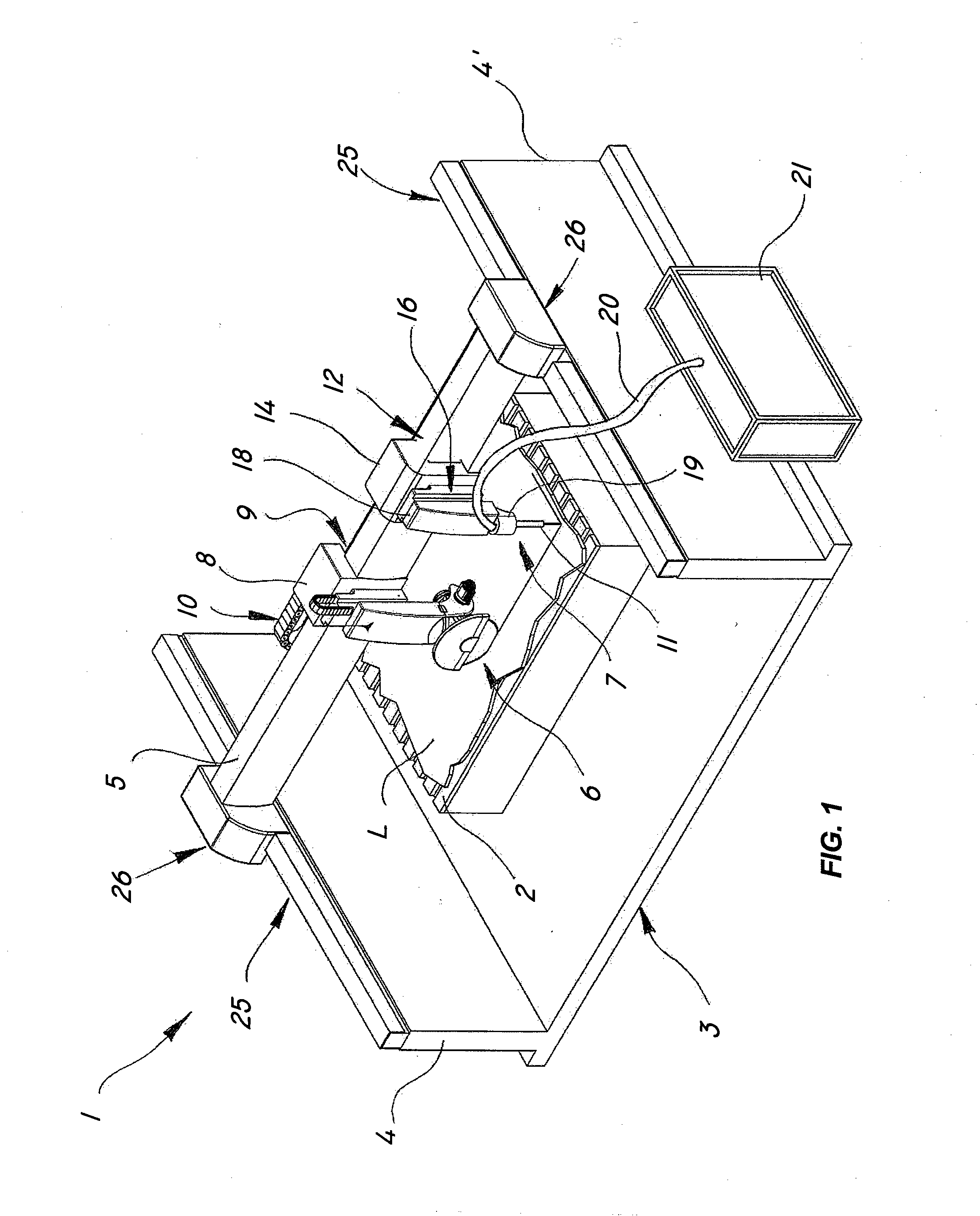

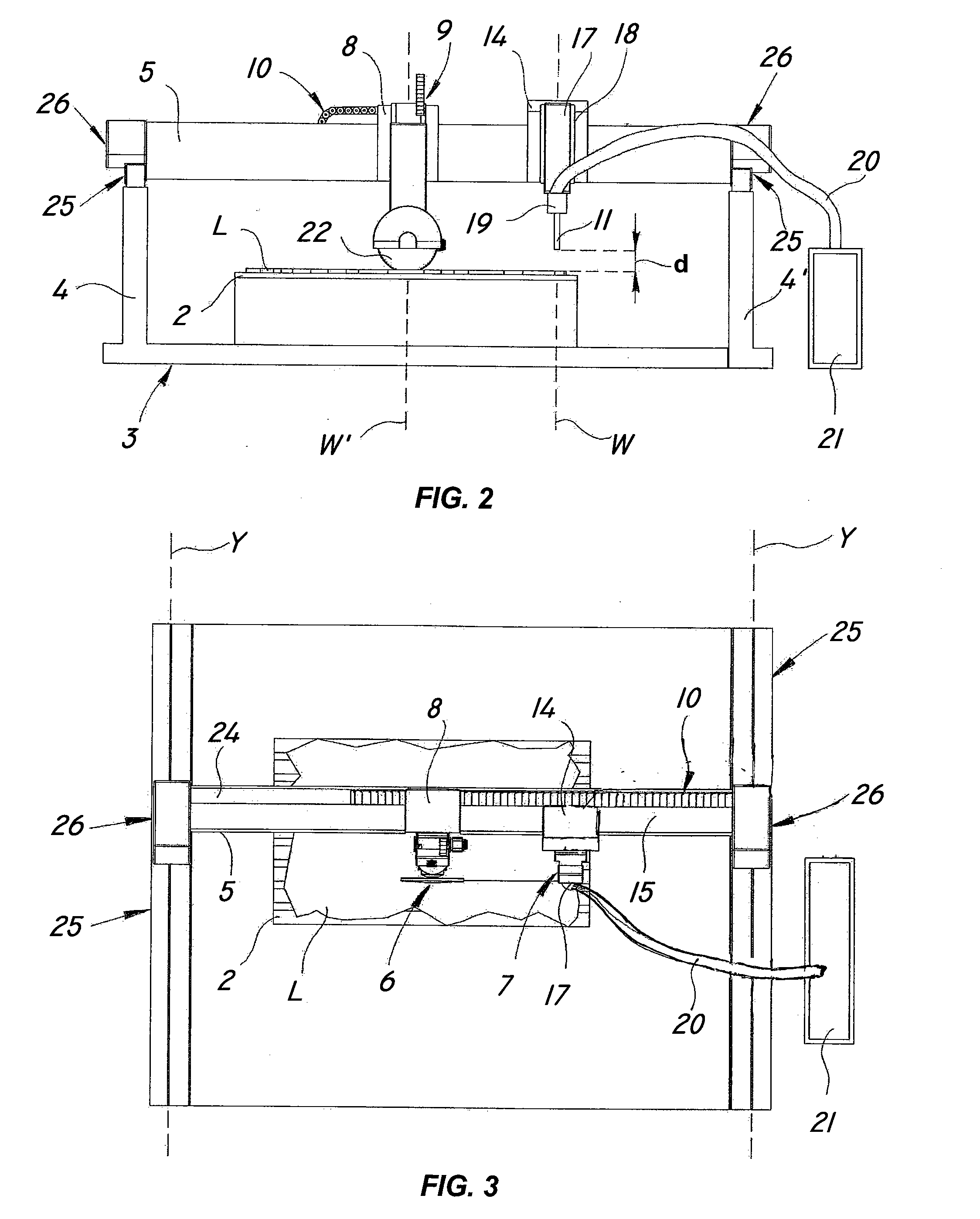

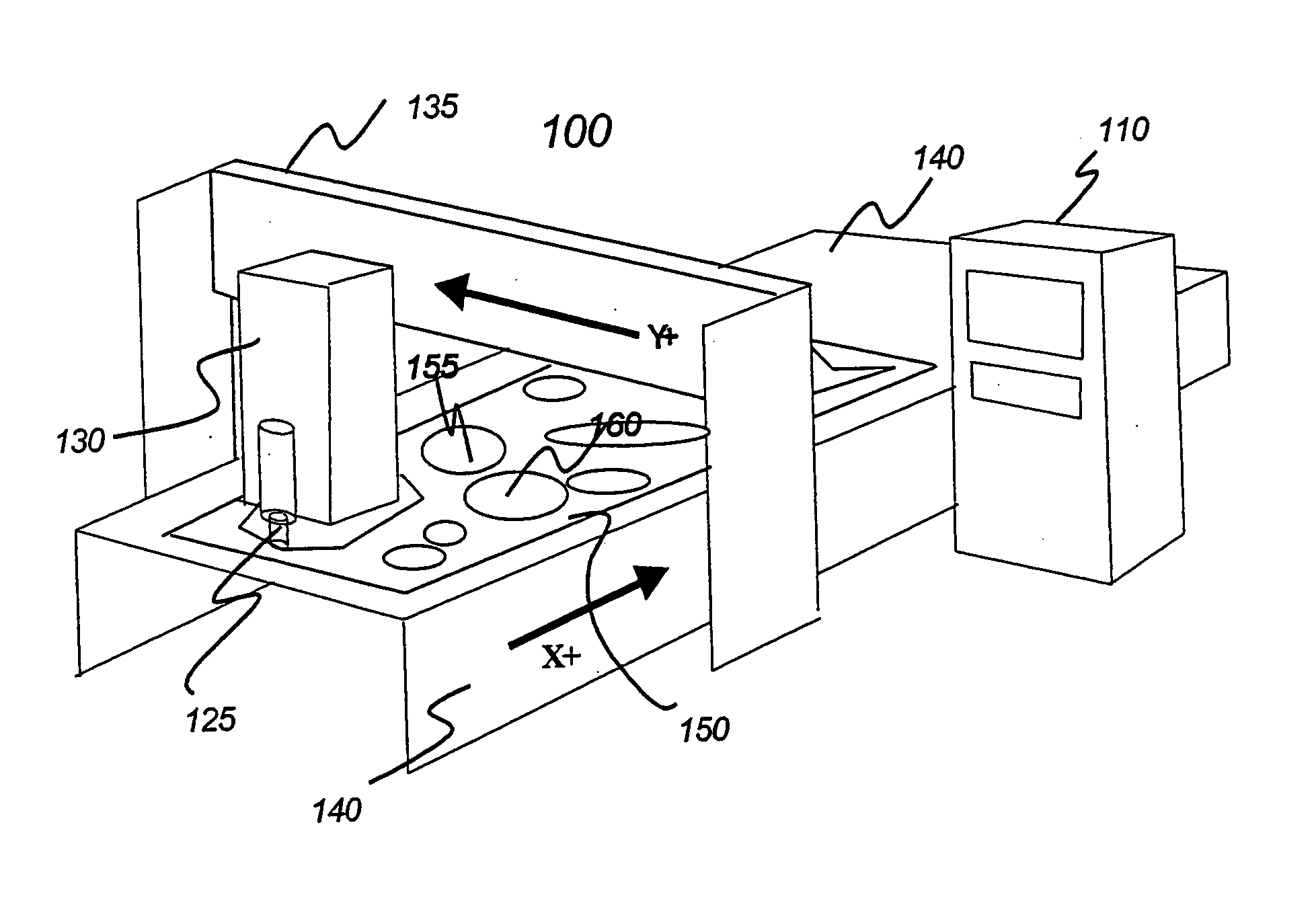

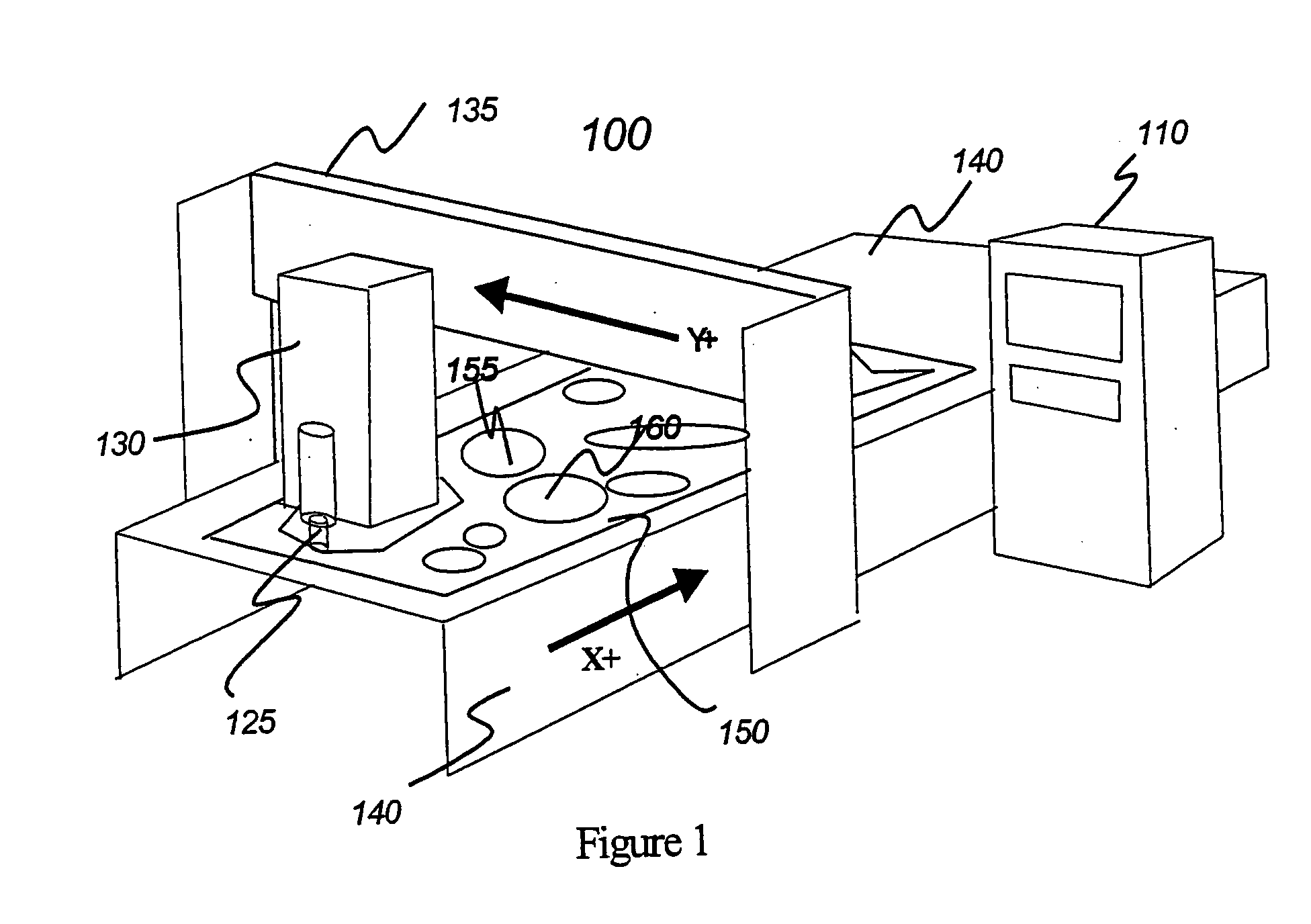

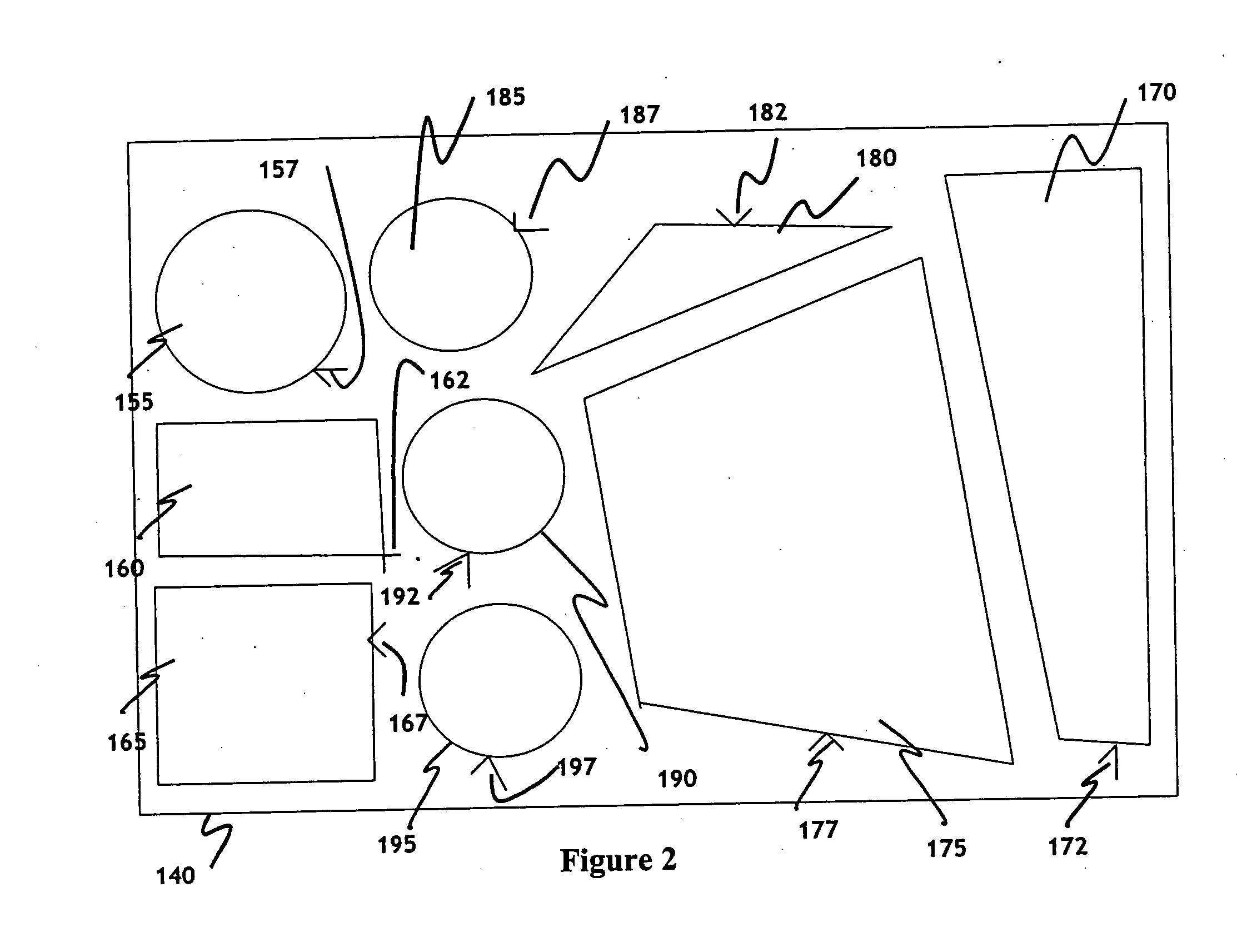

Multiple-tool machine for combined cutting of slabs of hard material

InactiveUS20080110311A1Improve efficiencyCost effectiveMetal sawing devicesGuide fencesClassical mechanicsStringer

The present invention relates to processing of hard materials, and more particularly relates to a multiple-tool machine for the combined cutting of slabs of hard materials such as stone, marble, granite, concrete, wood, metal, glass and the like. One embodiment of the present invention includes a support surface for receiving a slab; a load-bearing frame with a longitudinal beam extending over the support surface; a first disk blade cutting tool mounted on a first slide and movable along a first guide connected to the beam; a first motion imparting device for moving the first slide; a second cutting tool with a nozzle for high-pressure waterjet cutting, which is mounted in sliding relationship to a second guide coupled to the beam; and a second motion imparting device, other than the first motion imparting device, for translating the second cutting tool independently of the first cutting tool.

Owner:SIMEC SPA

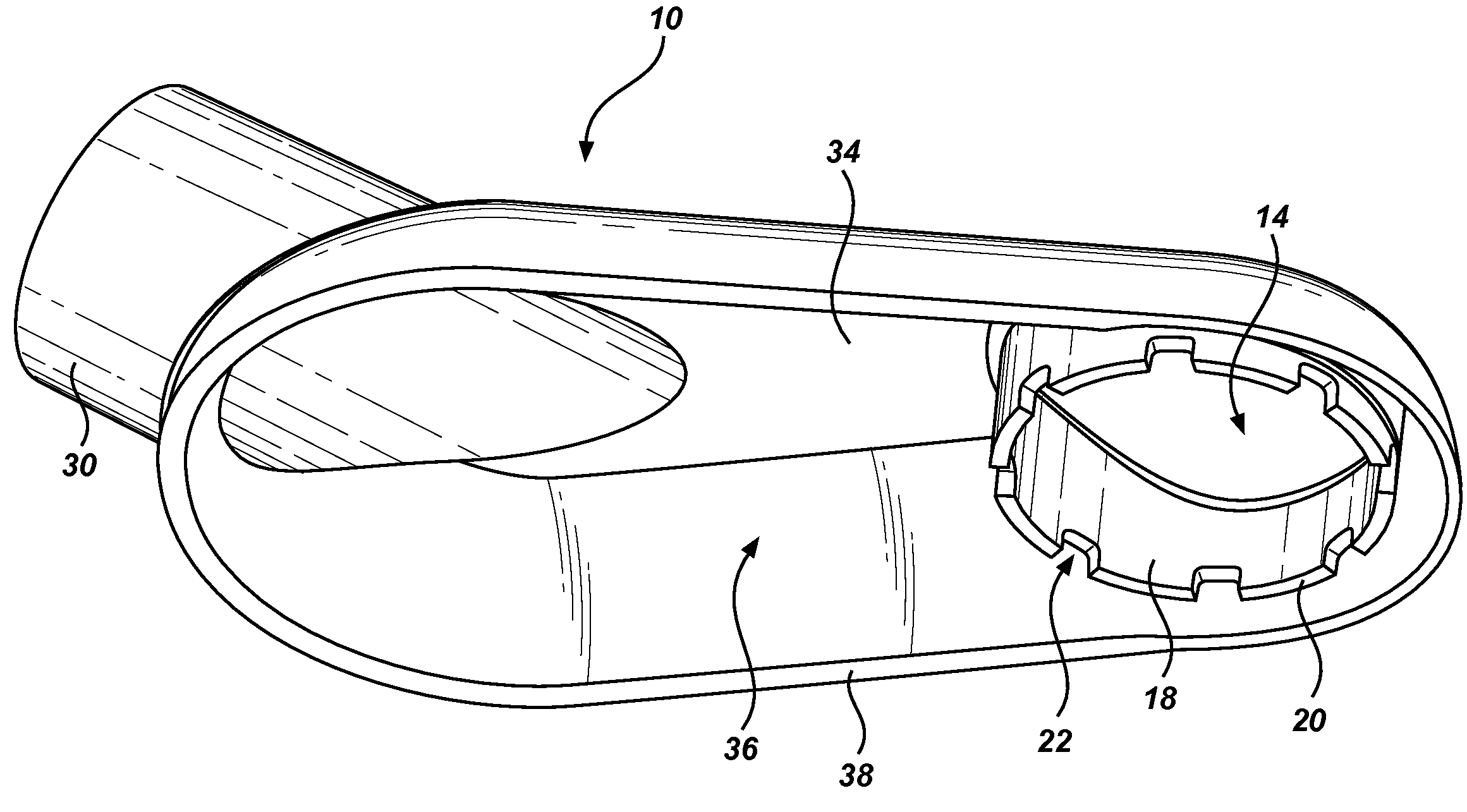

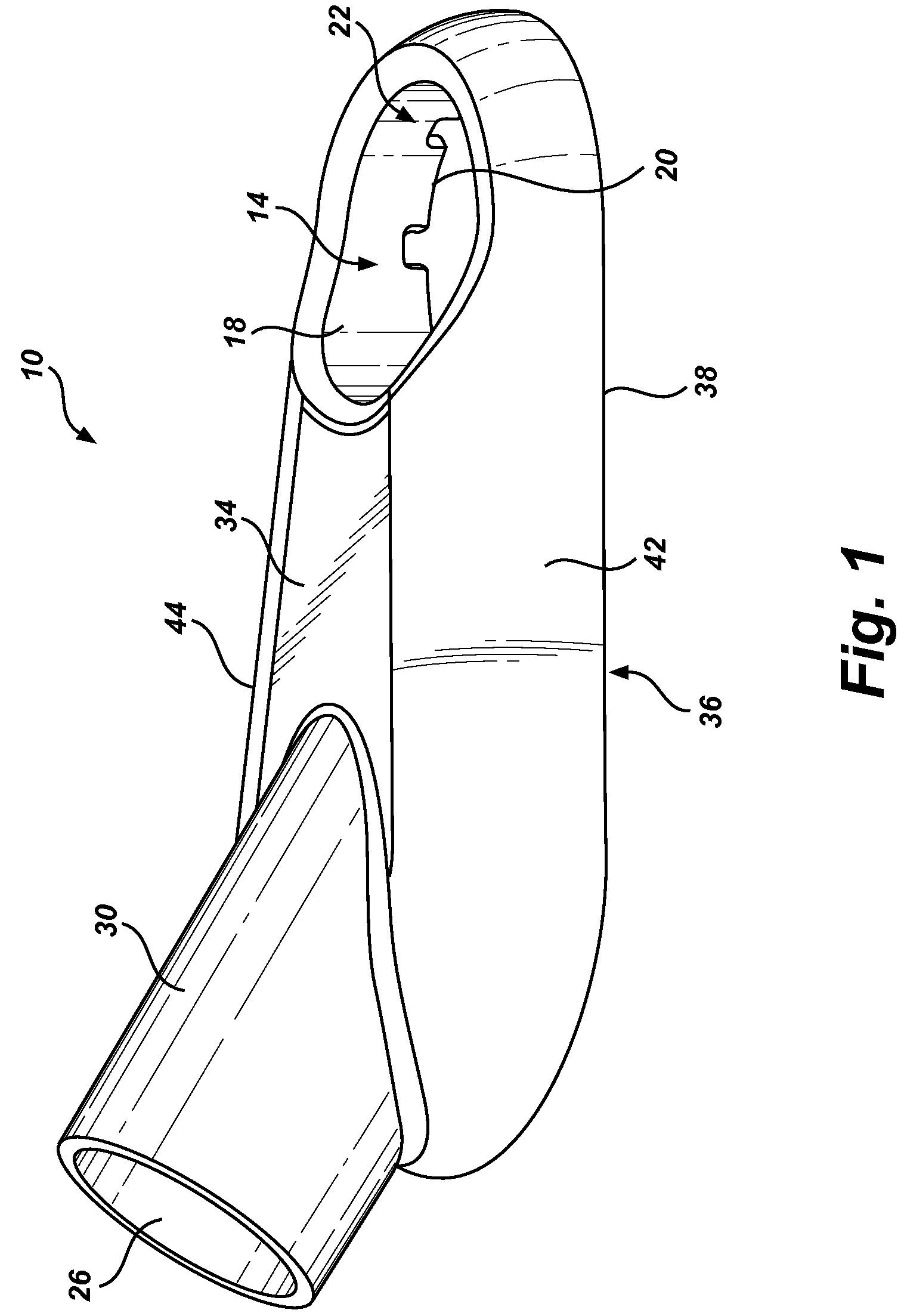

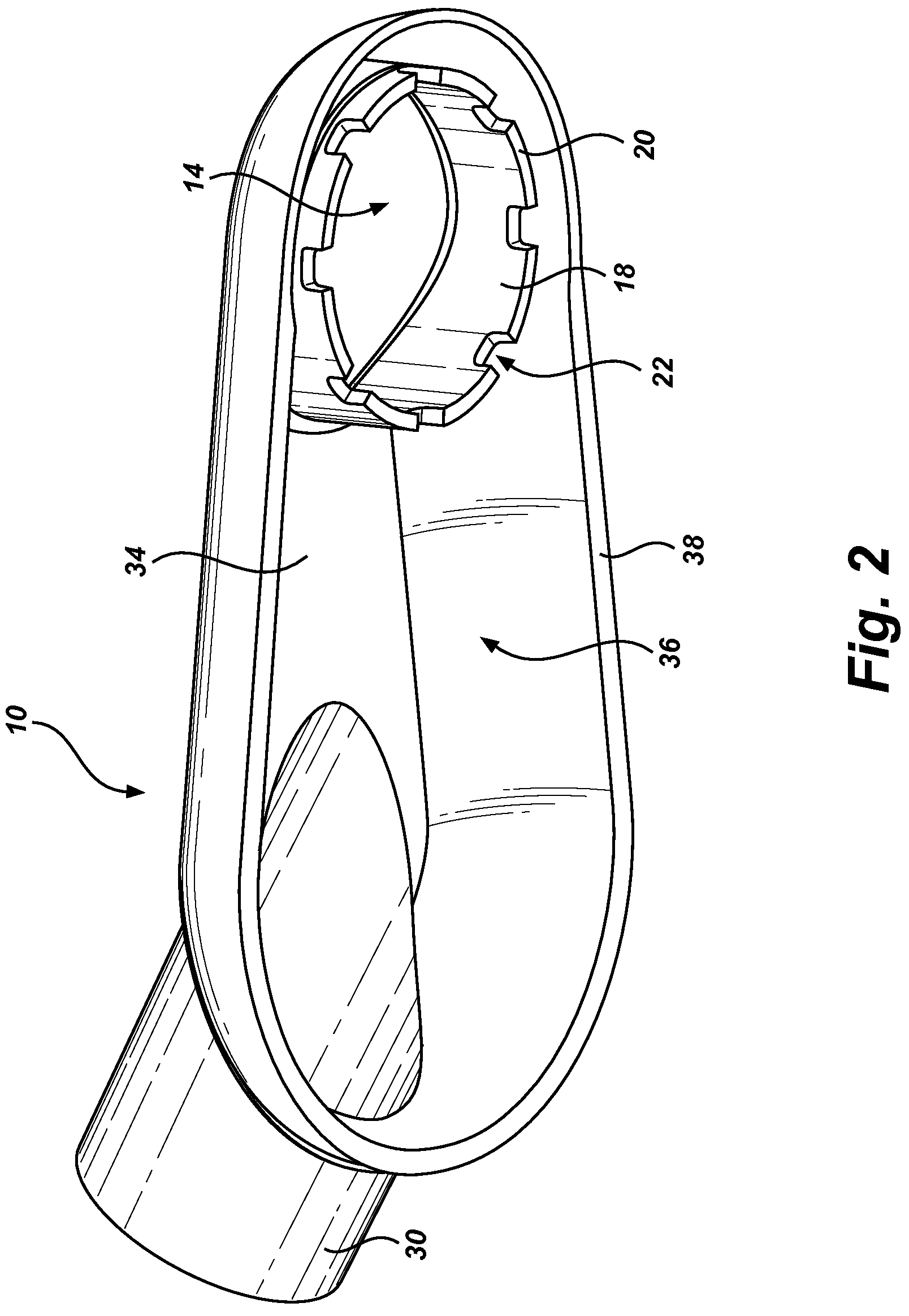

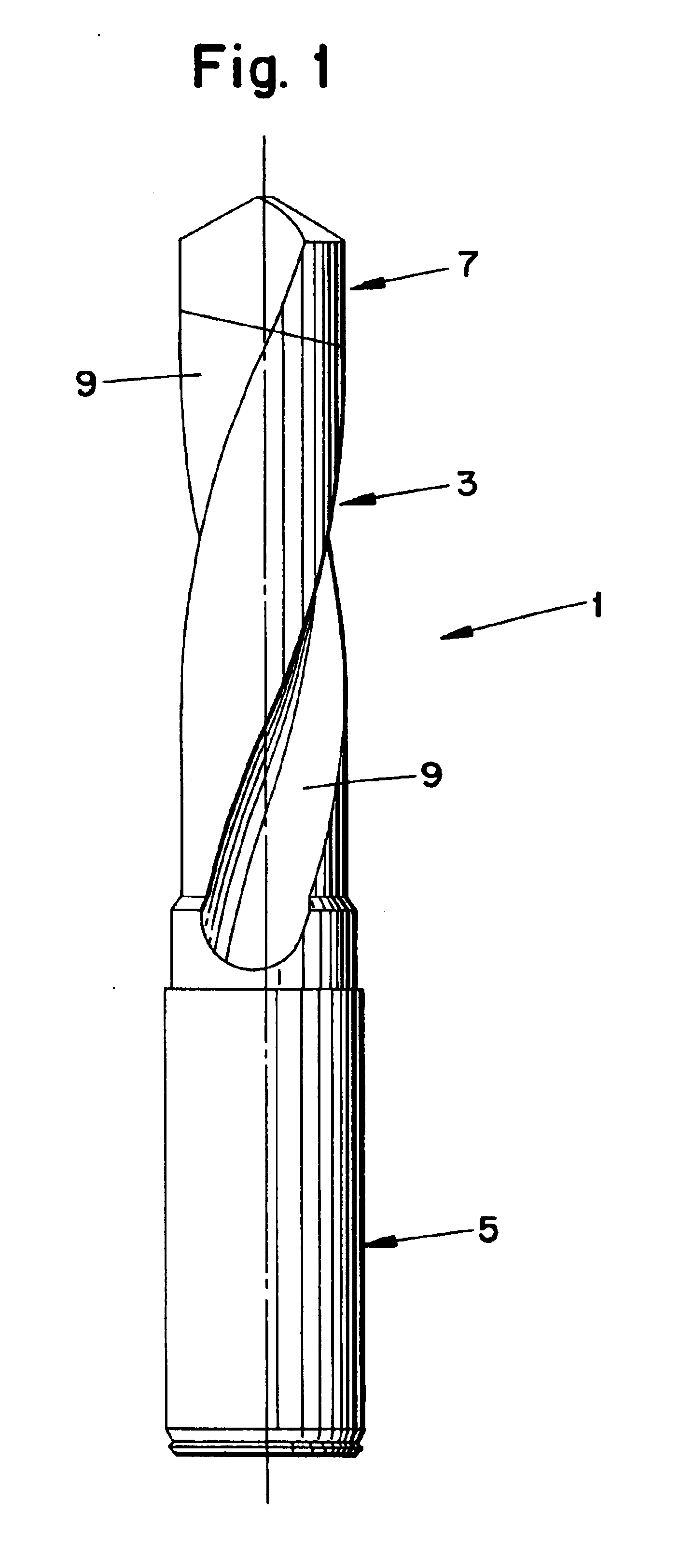

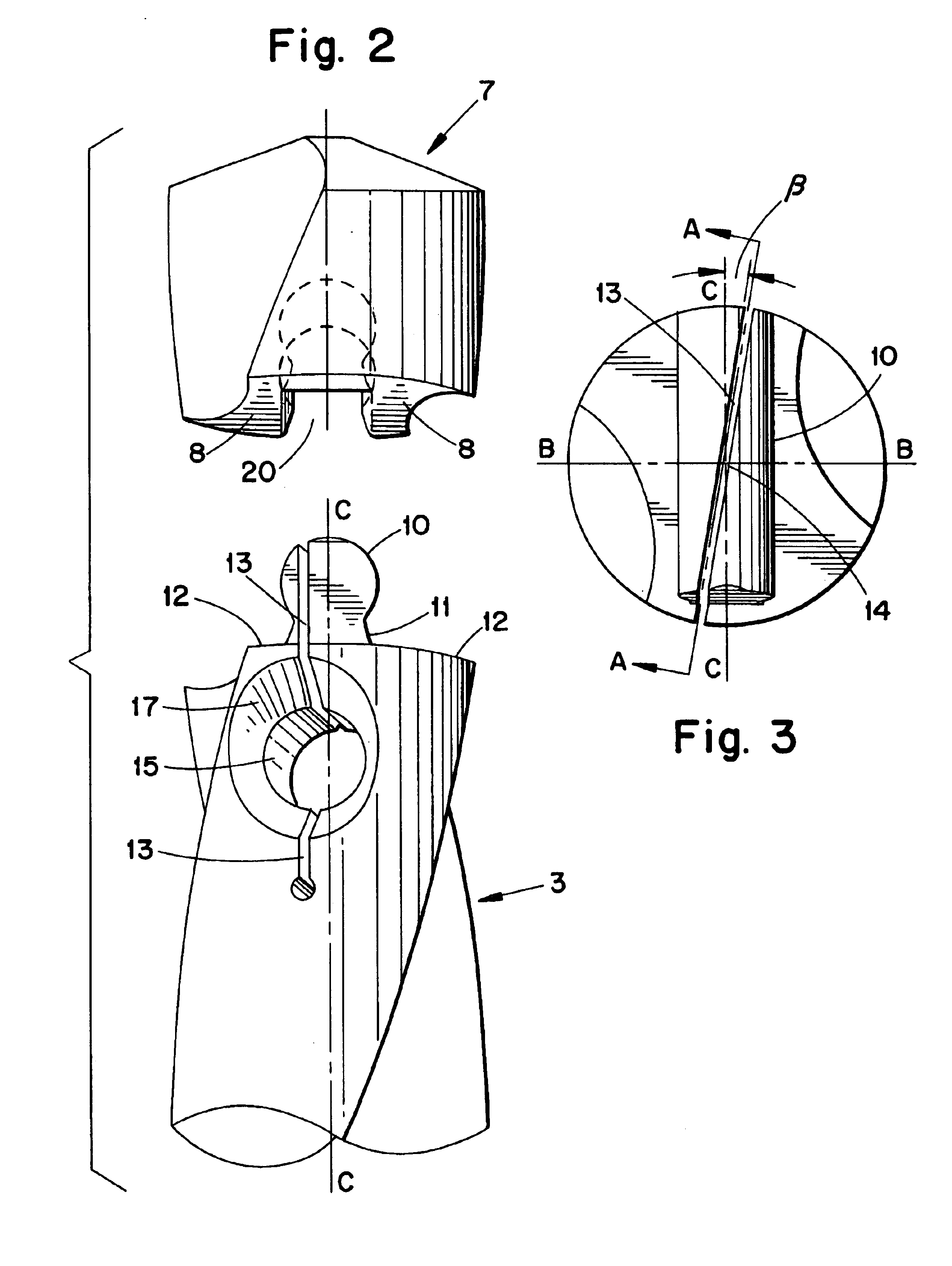

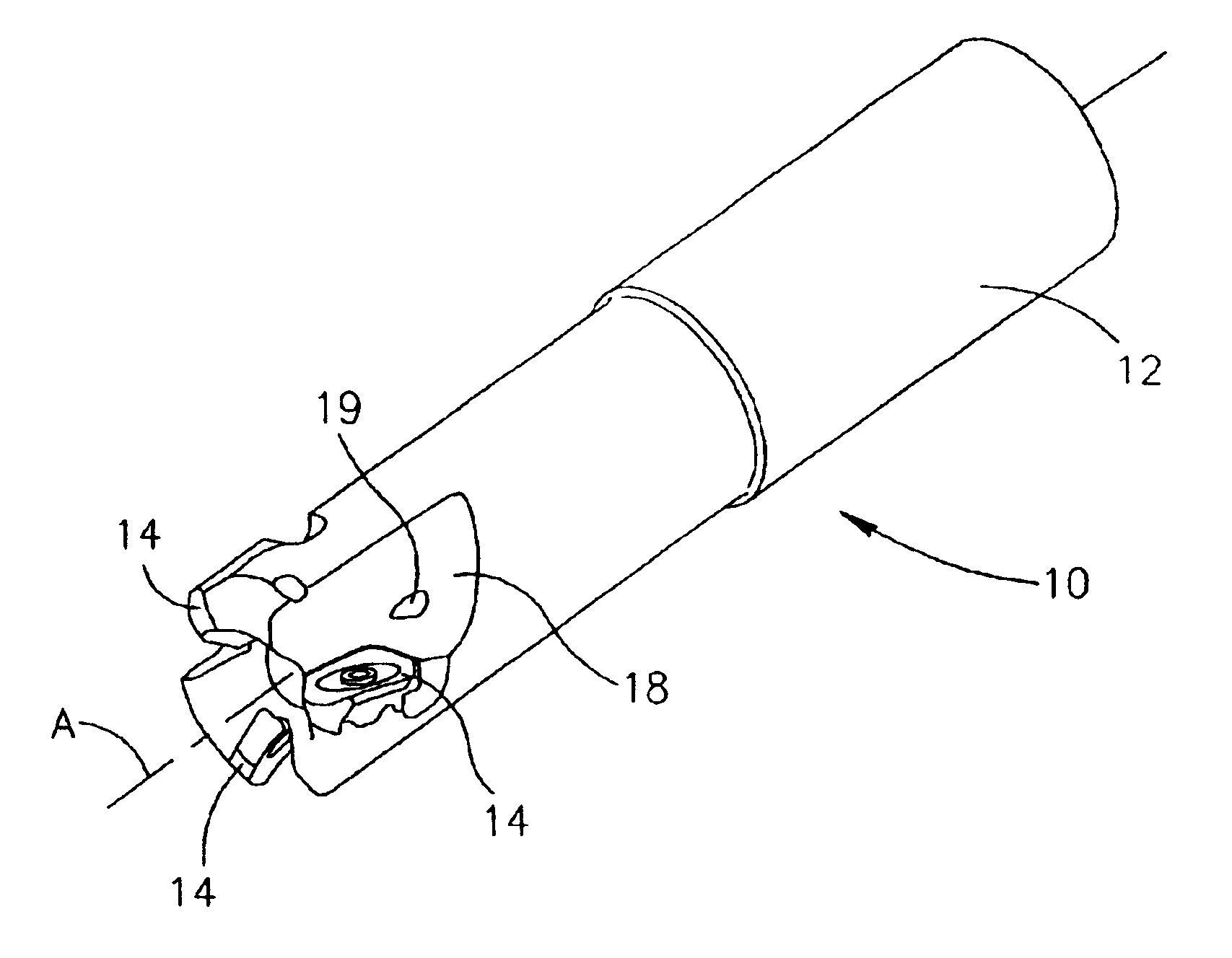

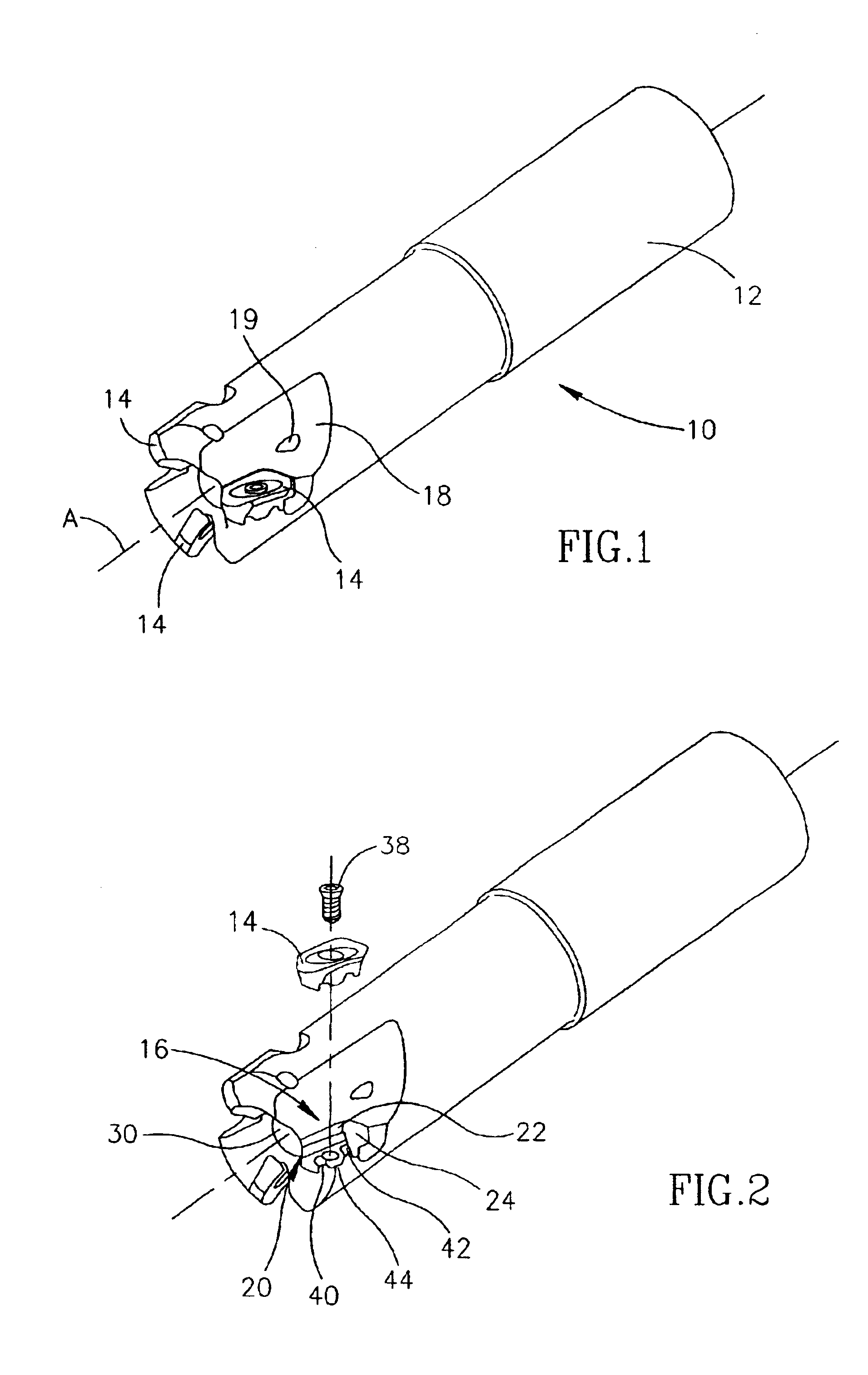

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

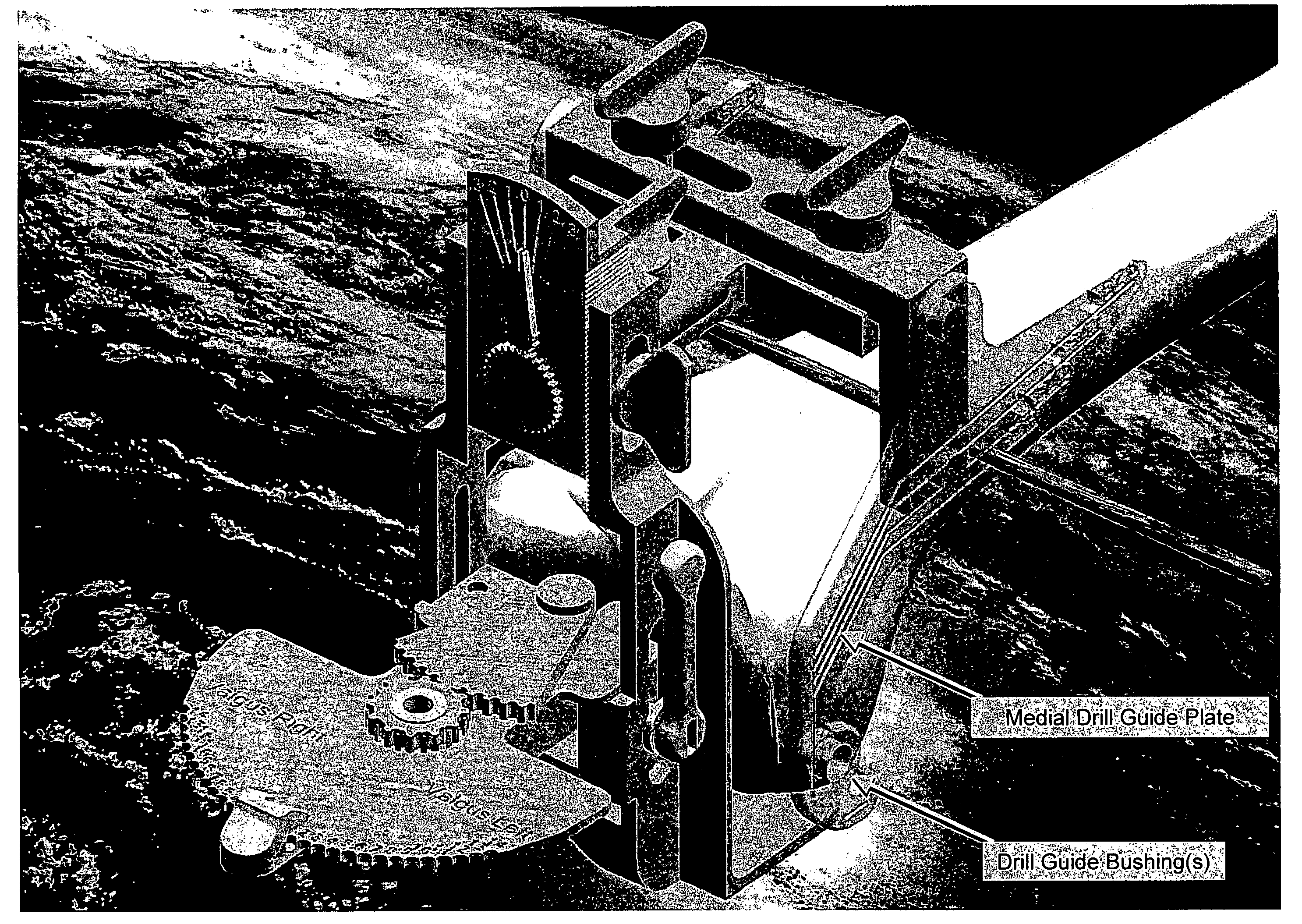

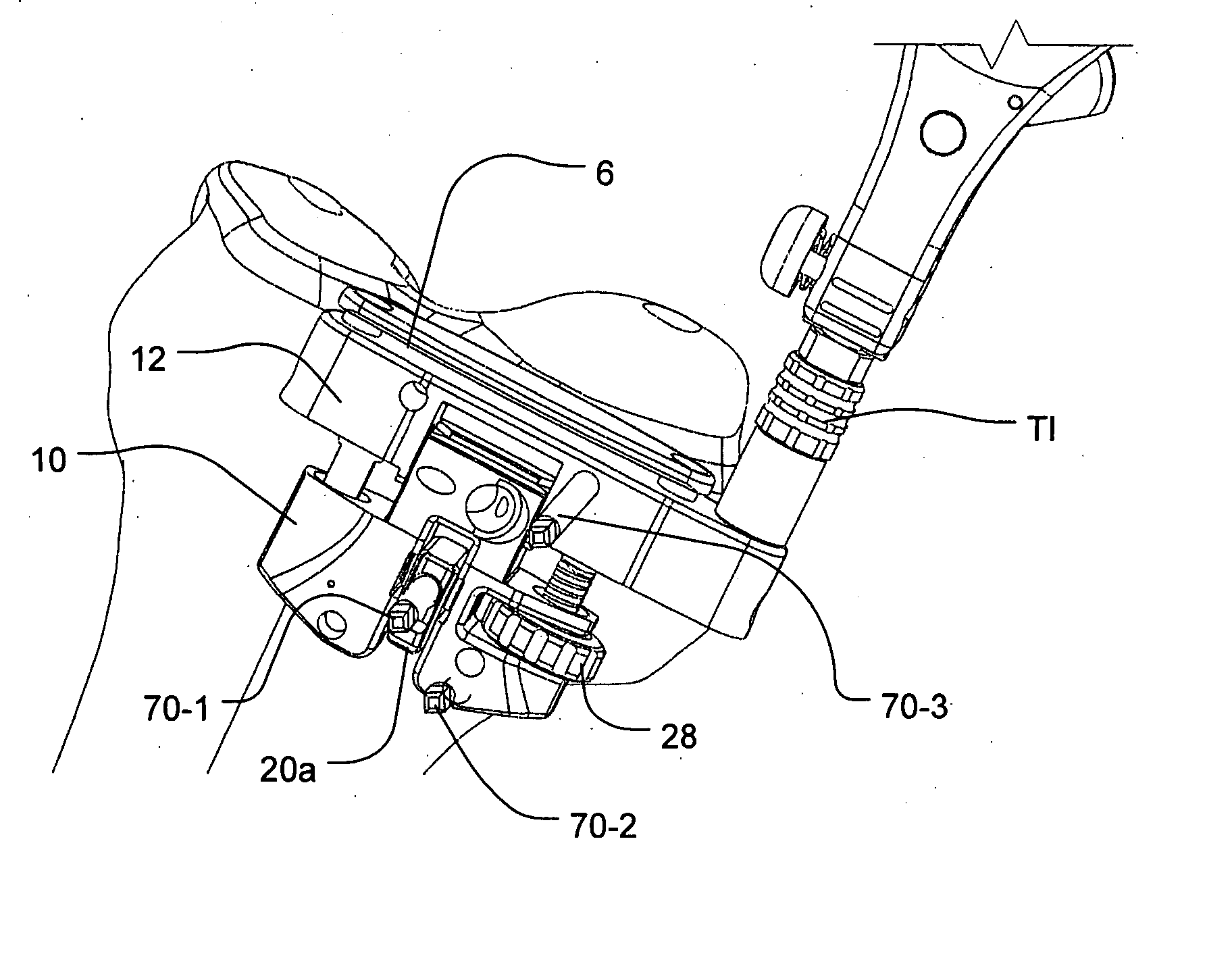

Navigated drill guided resection block

A bone cutting guide block has a cutting tool guide surface and a navigation mount for a navigation tracker component for computer aided positioning of the guide for a resection procedure. In various embodiments, the guide includes a rotation means. Preferably, a swivel with a pivot apparatus is provided to limit rotation to permit controlled flexion-extension angle about the pivot with respect to the cutting guide surface. A fixing member through the swivel permits for varus-valgus adjustment of the guide surface. Optionally, a positioning actuator and / or biased resistance actuator implements more regulated flexion-extension angle adjustment with the swivel. Various traversing mechanisms, such as a threaded wheel or pivoted cam tool permit controlled proximal-distal adjustment of the cutting guide surface.

Owner:HOWMEDICA OSTEONICS CORP

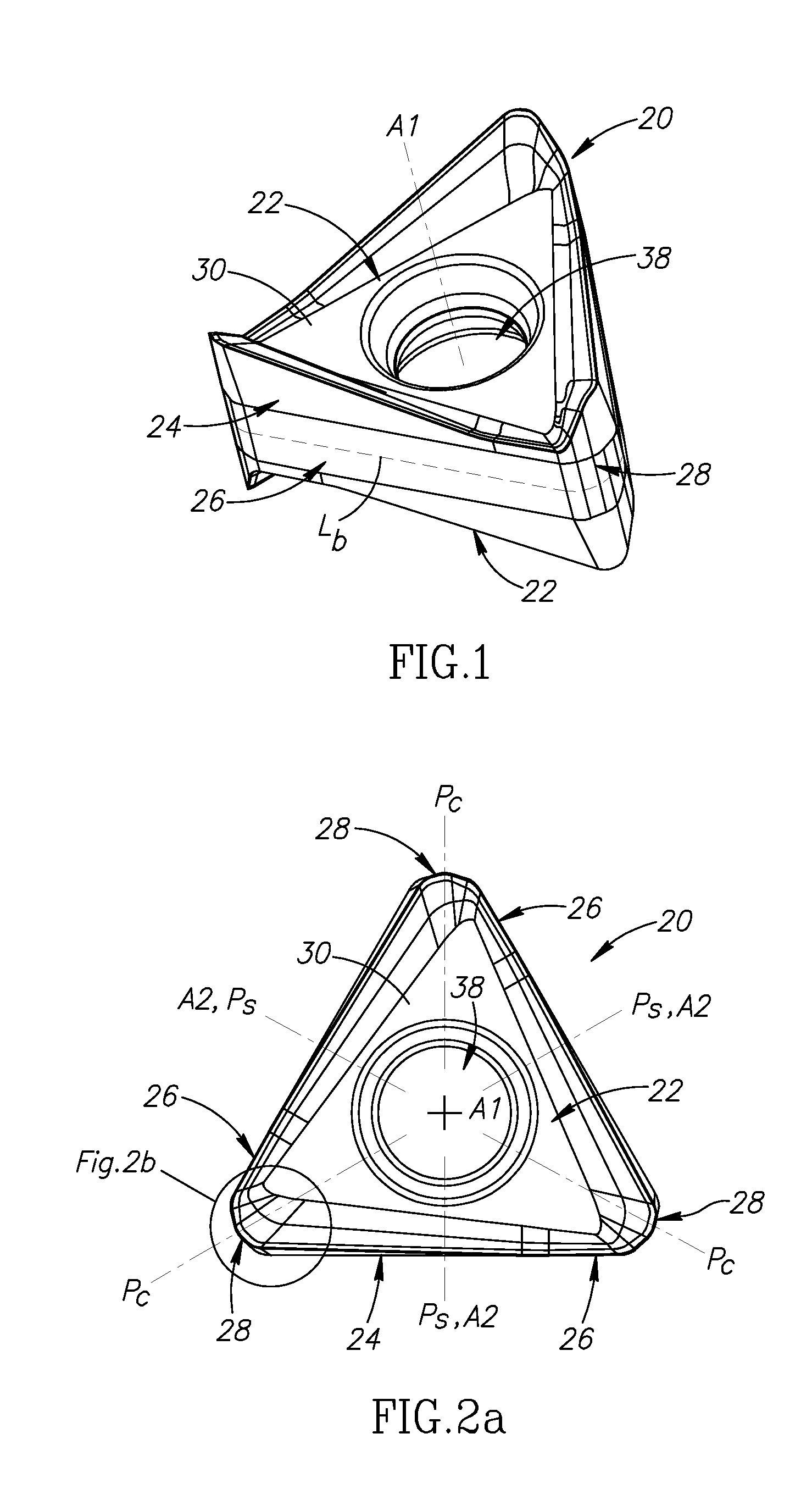

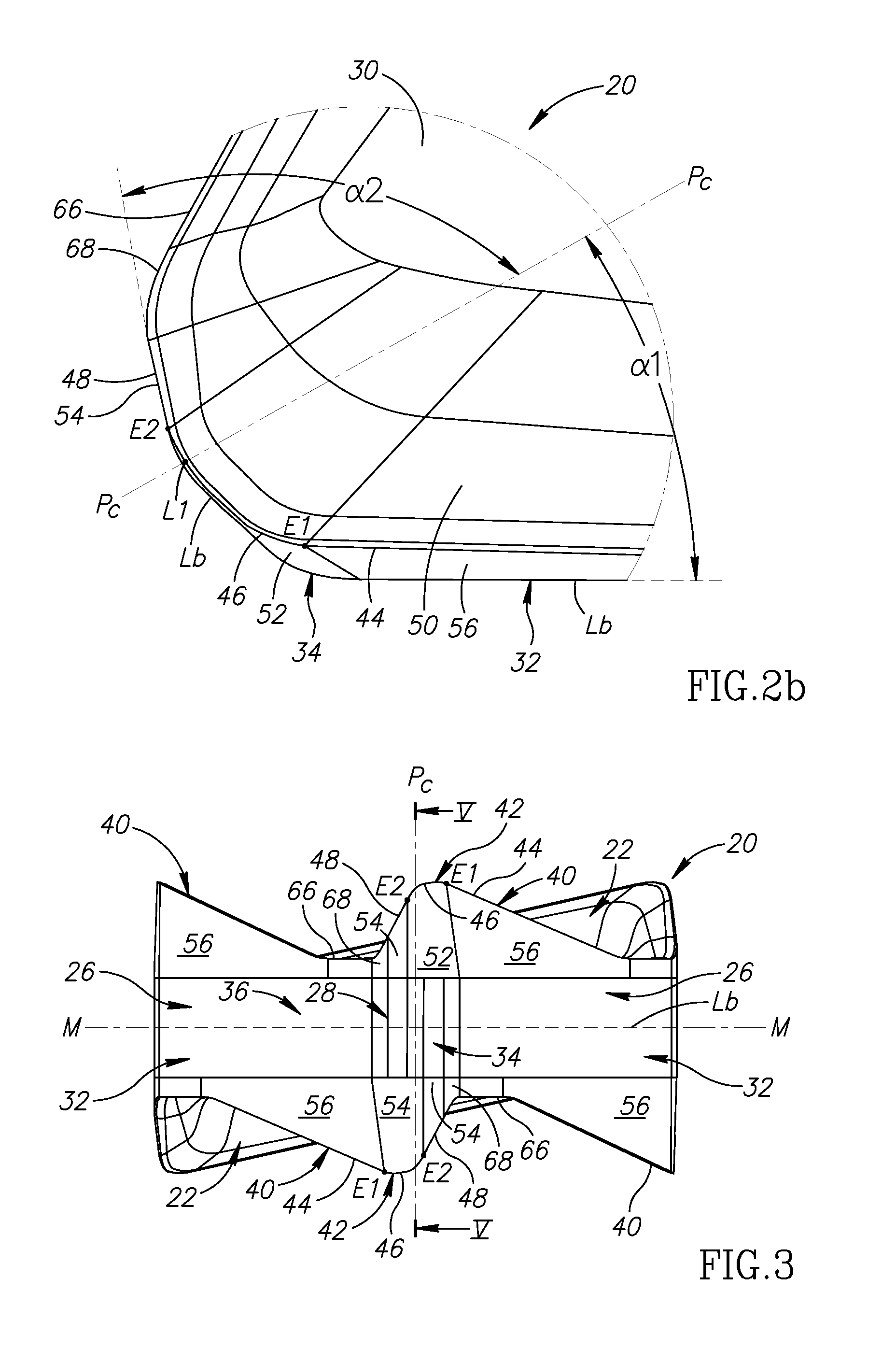

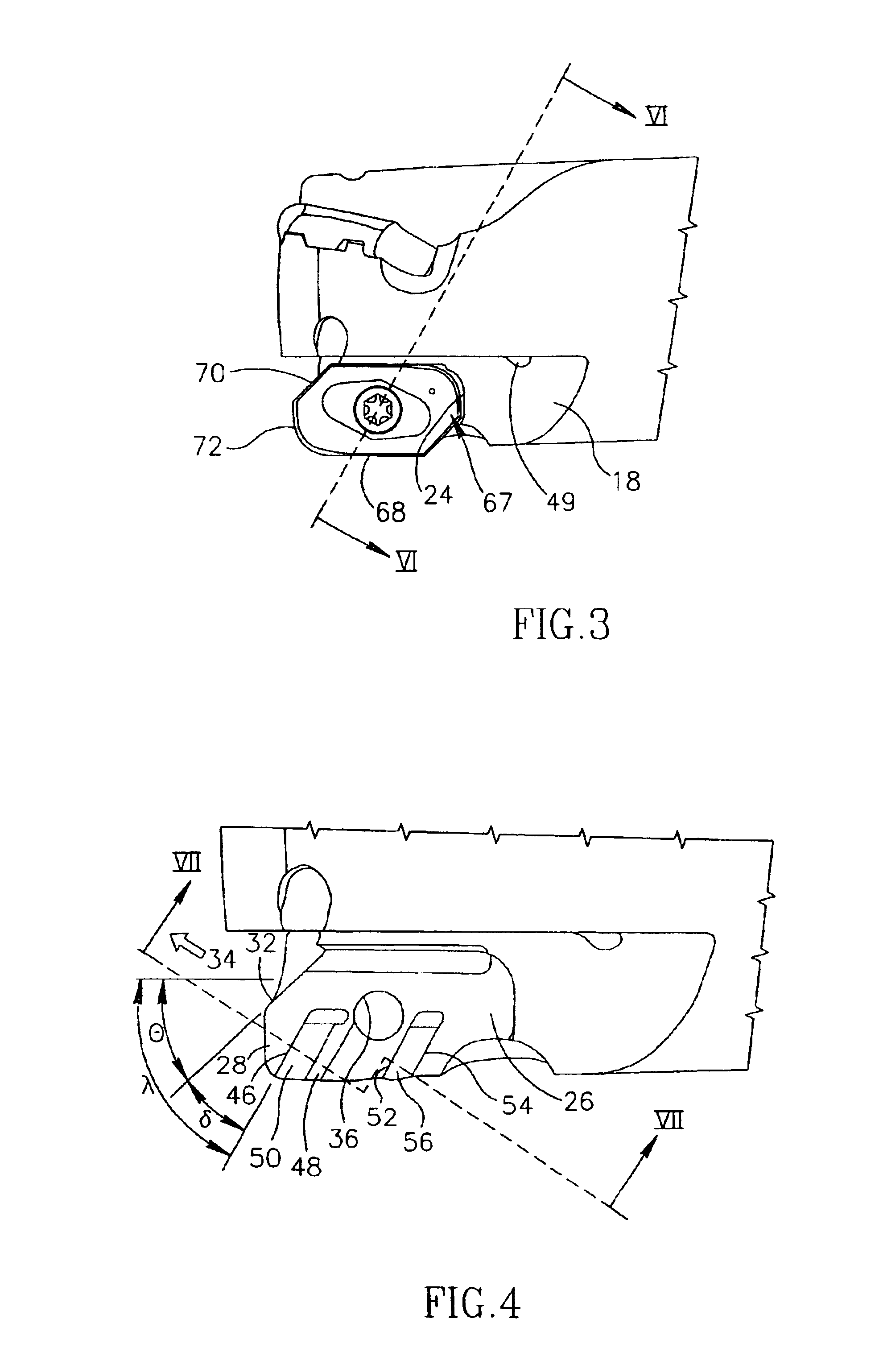

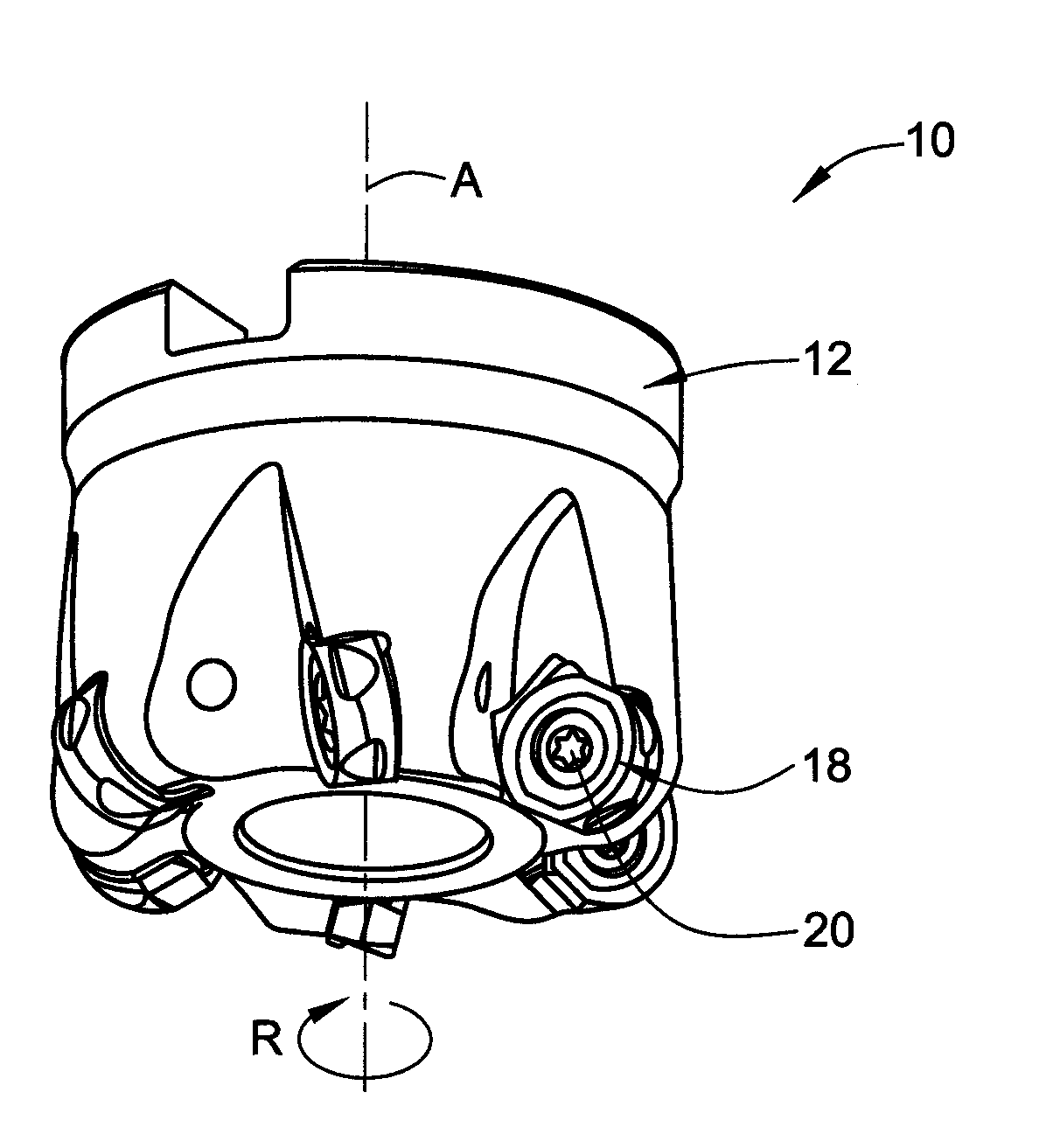

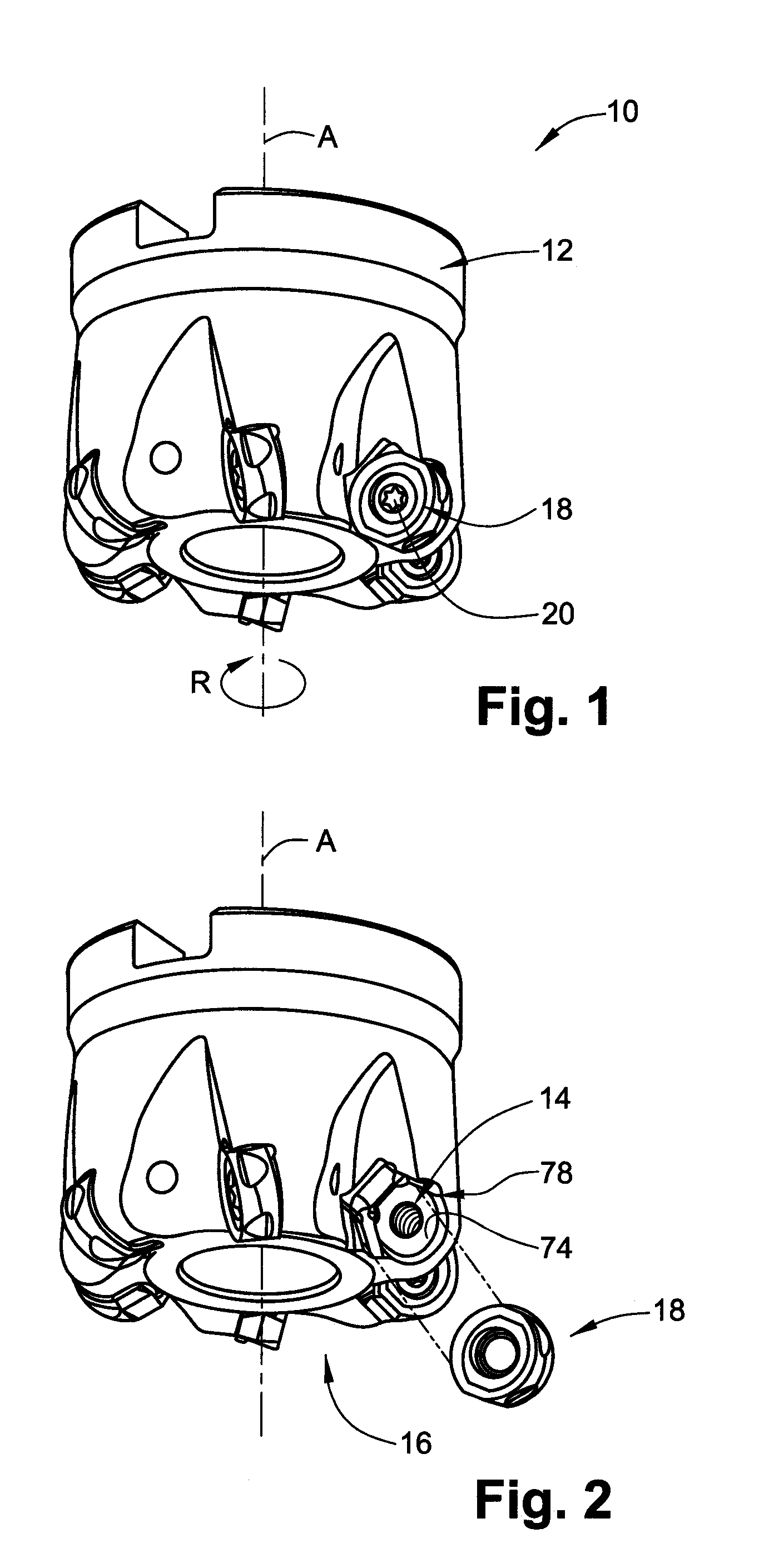

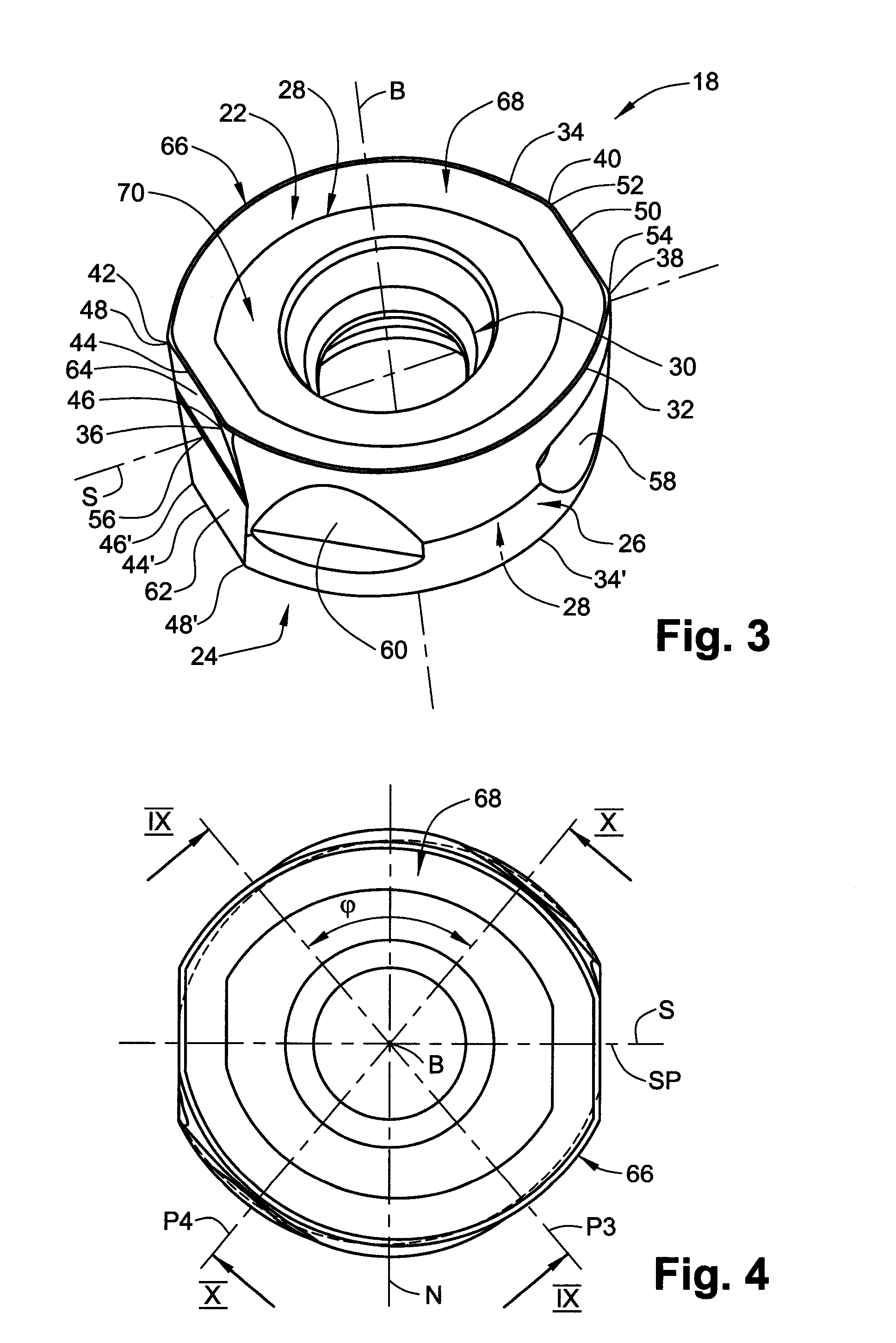

Rotary Cutting Tool and Reversible Cutting Insert Therefor

In a rotary cutting tool used for milling operations, a reversible indexable cutting insert is removably secured in a cutting body. The cutting insert has two opposing end surfaces interconnected by a continuous peripheral surface, including three side surfaces alternating with three corner surfaces. The side and corner surfaces intersect with both end surfaces at side and corner edges, respectively, with each side edge having a major cutting edge, and each corner edge having a corner and minor cutting edge. Each major and minor cutting edge slopes away from first and second end points, respectively, of its mutually associated corner cutting edge, towards a median plane. A first imaginary straight line extending perpendicular to the median plane and intersecting any one of the corner cutting edges at any point along its length except the second end point, passes through the median plane inside an insert boundary line.

Owner:ISCAR LTD

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

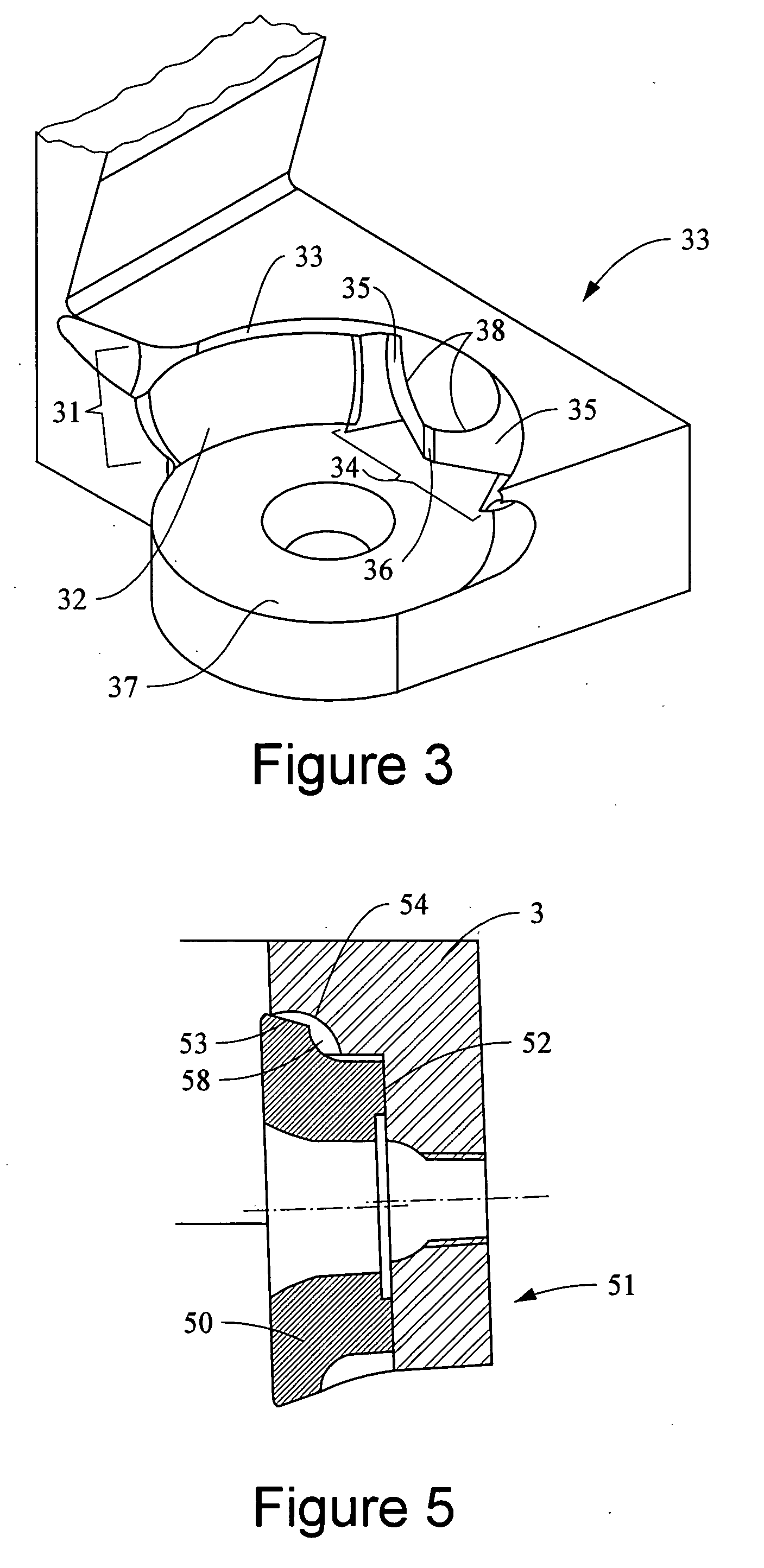

Antirotation tool holder and cutting insert

The present invention relates to embodiments of a cutting tool holder having at least one insert pocket, wherein at least one insert pocket comprises a side surface and at least one antirotation stop protruding from the side surface. The antirotation stop may comprise at least two substantially planar surfaces. In certain embodiments, the cutting tool holder may have a pocket which comprises a bottom surface and an antirotation stop having three substantially planar surfaces that are substantially perpendicular to the bottom surface. The antirotation stop may be integral to the tool holder or may be produced separately and attached, either permanently or temporarily, to the tool holder. Embodiments may further comprise additional antirotation stops if desired by the machining application. In one embodiment, the cutting tool holder includes an insert pocket in the tool holder and at least one antirotation stop protruding from at least one of a side wall and the bottom surface of the insert pocket, wherein the antirotation stop comprises at least two substantially planar surfaces. A cutting insert may be secured in the tool holder, wherein the cutting insert has a recess having a shape that is non-complementary to the shape of the antirotation stop and may be made from tungsten based carbide or cermet.

Owner:KENNAMETAL INC

Cutting tool and cutting insert therefor

A cutting tool has an insert holder provided with an insert receiving pocket and at least one cutting insert mounted therein. The insert receiving pocket has a longitudinally extending inner wall, a rear wall adjacent the inner wall and a lower wall adjacent the inner wall and the rear wall. A front end of the lower wall protrudes forwardly with respect to a central portion of the insert holder. A front protrusion rises upwardly from the lower wall and extends inwardly and rearwardly from a periphery of the insert holder. The front protrusion has a front surface perpendicular to the lower wall. A groove formed in the bottom surface of the cutting insert has a distal side wall perpendicular to the bottom surface. When assembled, a radial abutment surface of the cutting insert abuts a radial abutment surface of the insert receiving pocket, the front surface of the front protrusion abuts the front distal side wall of the groove and a rear portion of the one cutting insert is spaced from the rear wall of the insert receiving pocket.

Owner:ISCAR LTD

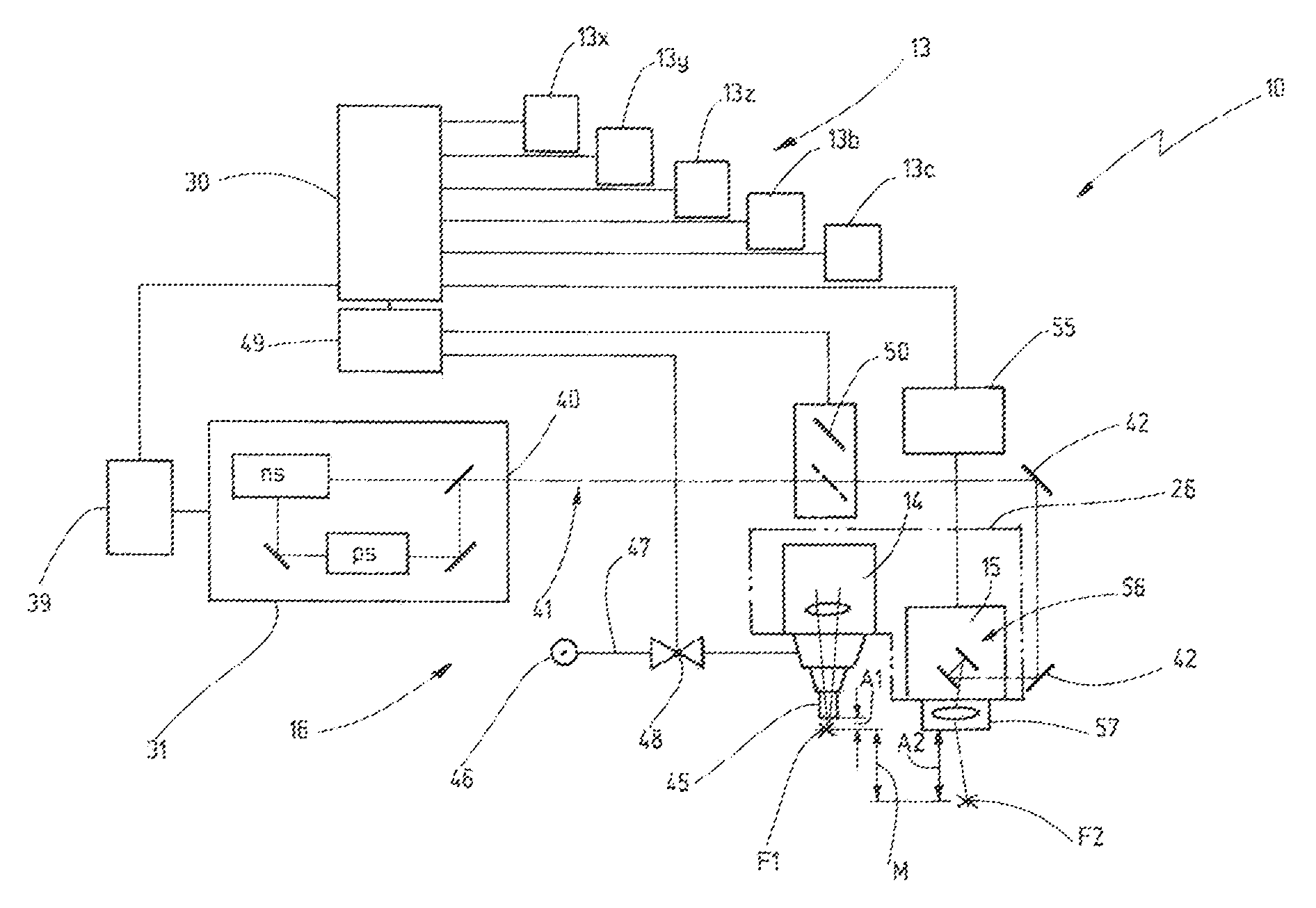

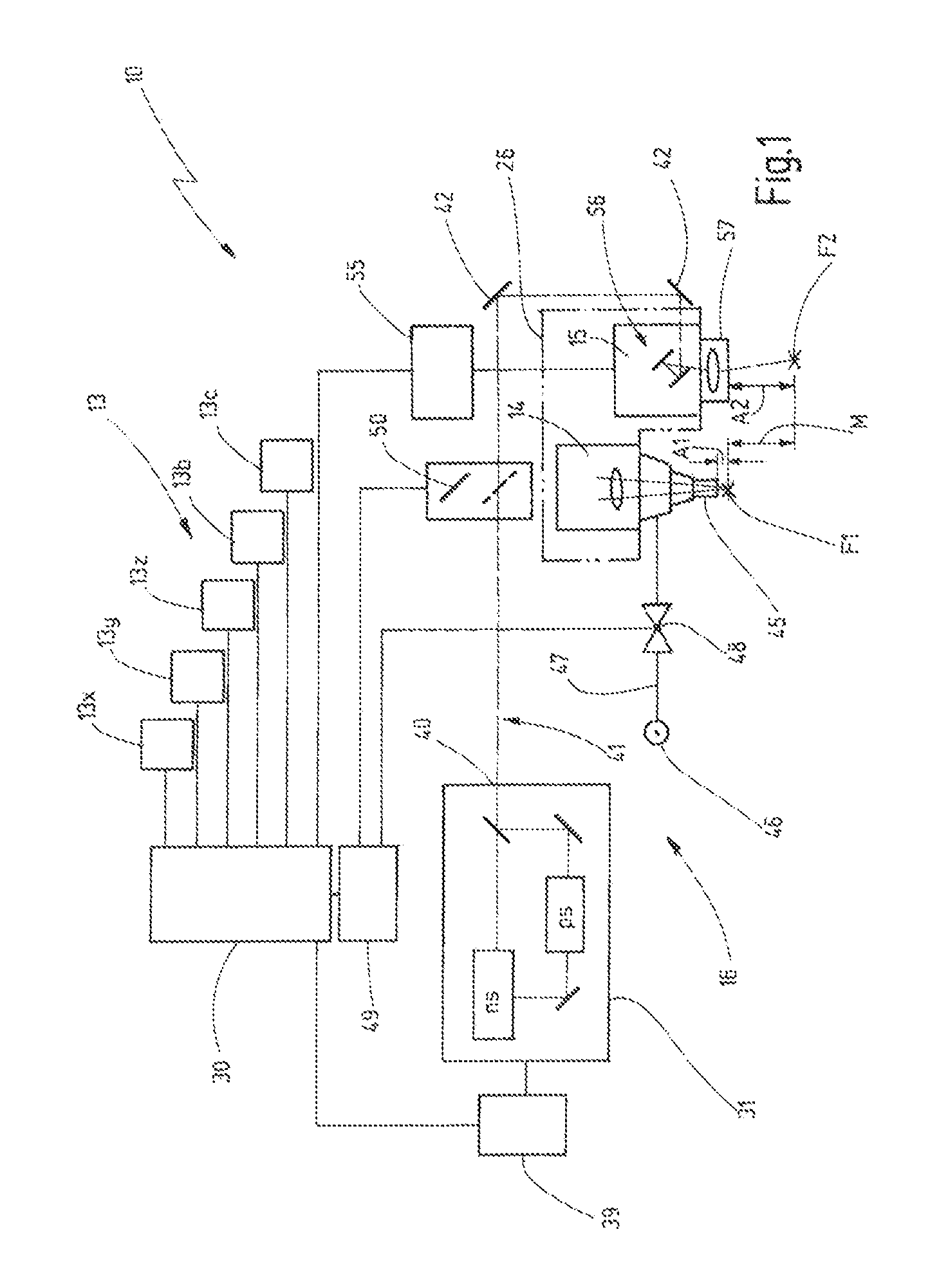

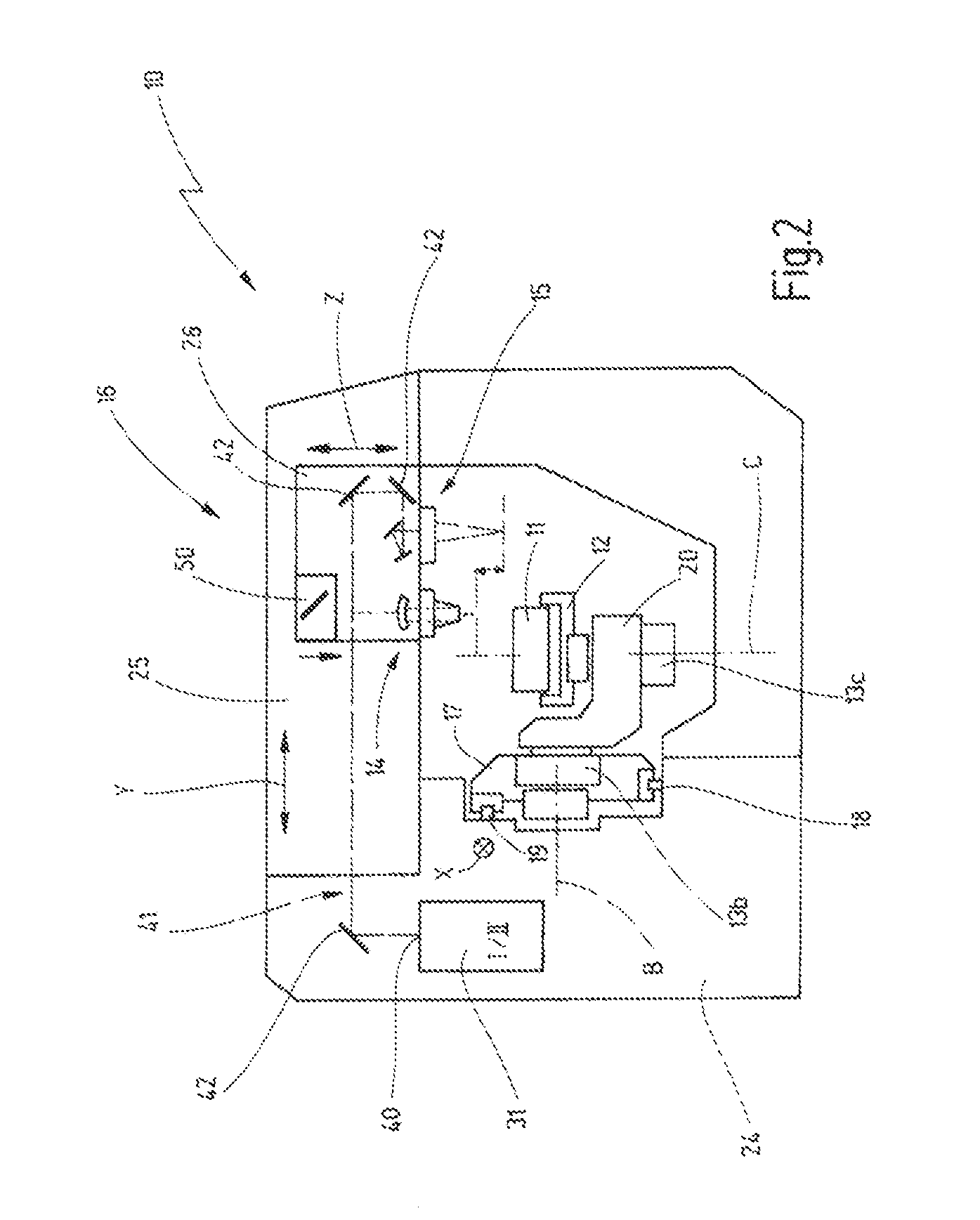

Laser machining apparatus with switchable laser system and laser machining method

ActiveUS8916798B2Quality improvementIncrease machine speedMetal working apparatusLaser beam welding apparatusNanosecondLaser processing

A laser machining apparatus and method for producing from a workpiece a rotating cutting tool having a cutting edge and a flank. The laser machining apparatus works in two different operating modes. In the first operating mode, a first laser head is used for machining the workpiece at high advance speeds of the workpiece relative to the first laser head to form a rough desired contour with pulses having a duration in the nanosecond range resulting in laser melt cutting. Subsequently, the laser machining apparatus is operated in the second operating mode generating laser pulses with having a pulse duration in the picosecond range. In the second operating mode, a second laser head is activated by means of an optical scanner system and directs the laser pulses onto a two-dimensional pulse area on the surface of the workpiece, the material removal is accomplished by laser ablation.

Owner:FRITZ STUDER AG

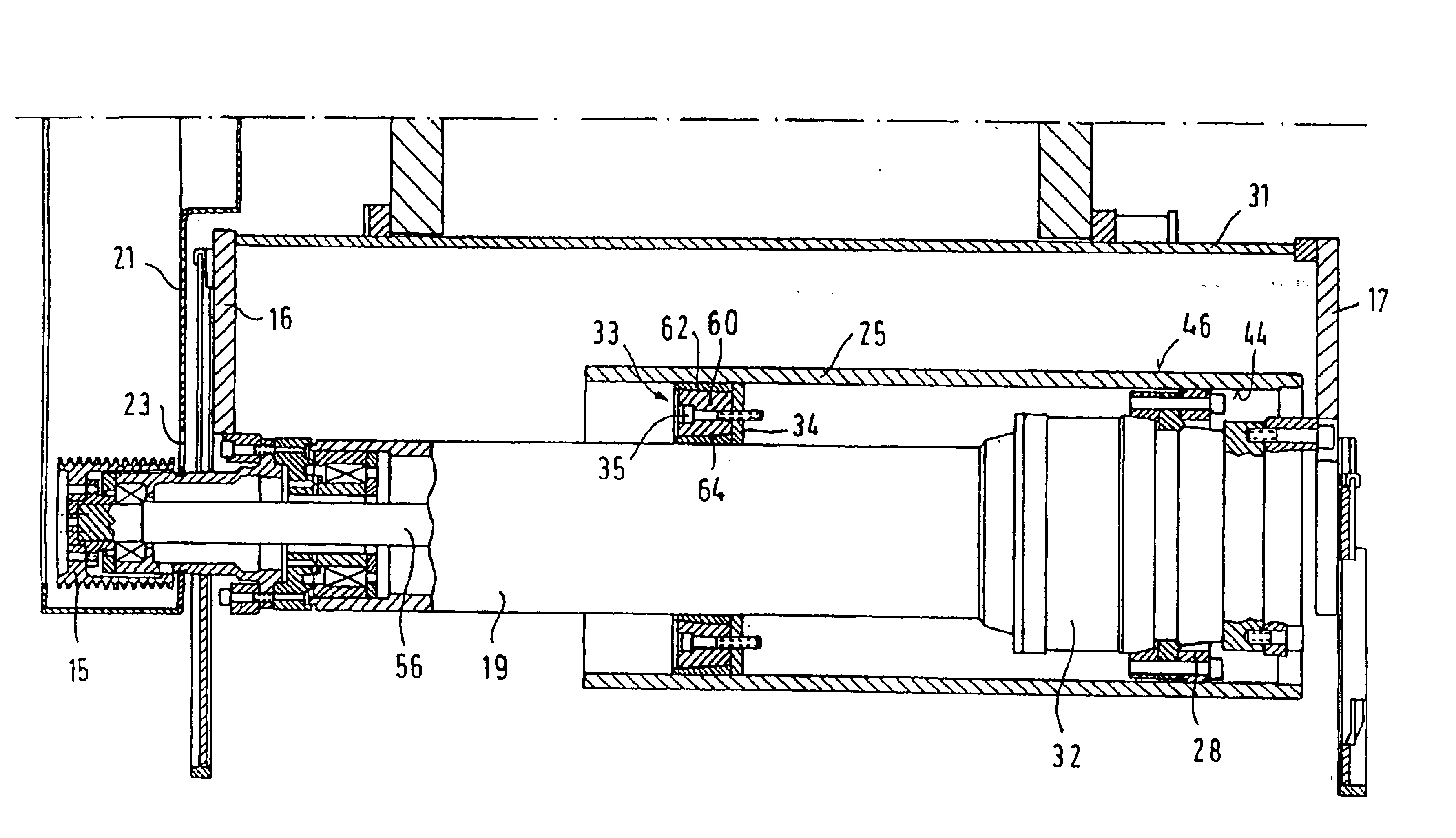

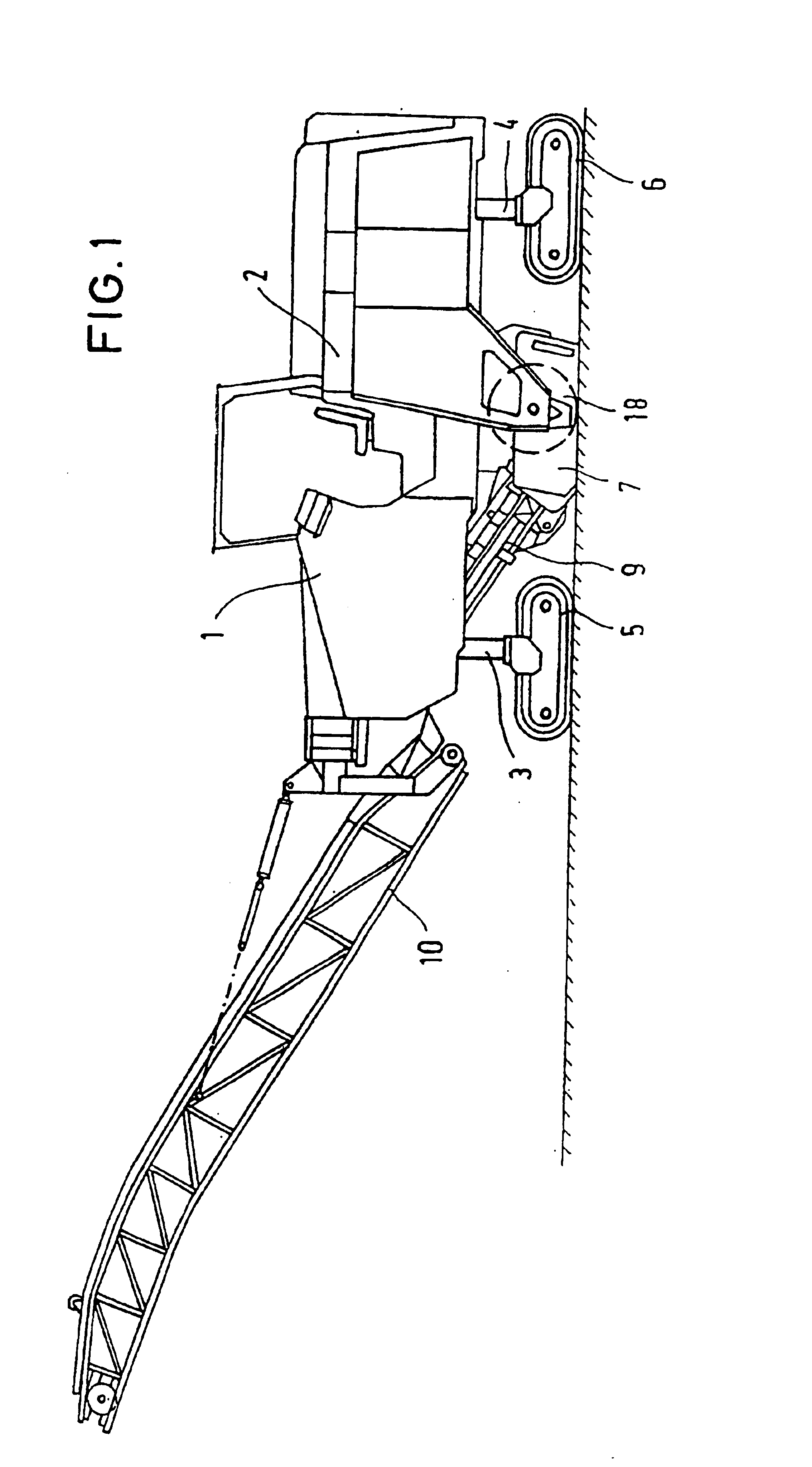

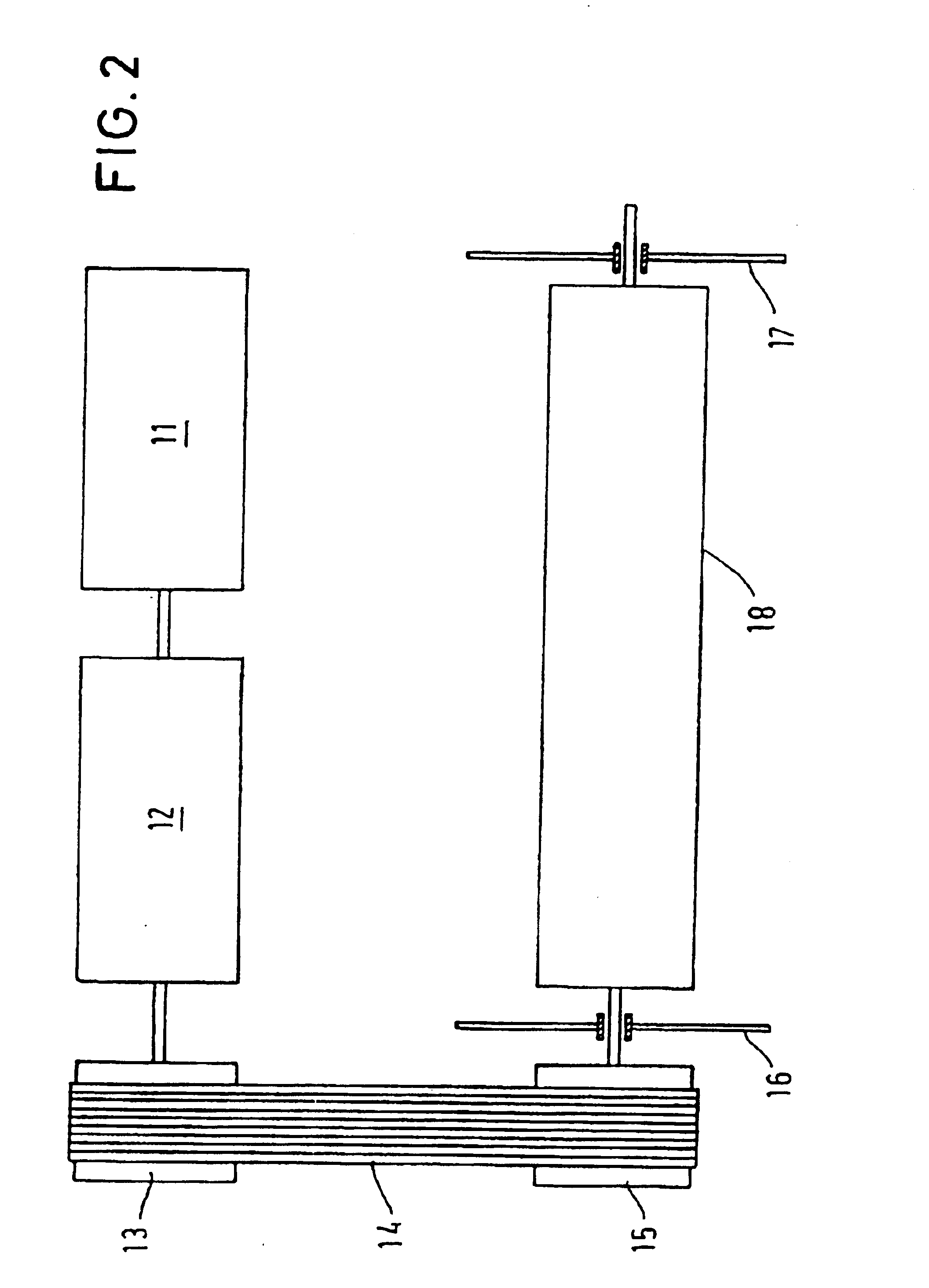

Construction machine and milling roller

InactiveUS6877818B1Quick exchangeEasy to operateMechanical machines/dredgersTilling equipmentsEngineeringMachine

In a construction machine comprising a machine frame (2) having a milling roller (18) arranged for rotation therein, the milling roller (18) comprising a roller base body (19) driven by a milling roller drive device (11 to 15) via a transmission unit (32), and a milling tube (25) to be coaxially mounted on the roller base body (19) and to be attached in a manner allowing exchange thereof, with the milling tube (25) carrying cutting tools on its outer surface (46), it is provided that the milling tube (25) comprises fastening elements (28), radially projecting from the inner surface (44), by which the milling tube (25) can be mounted in a rotationally fixed manner to the roller base body (19) or to a member connected to the roller base body (19).

Owner:WIRTGEN GMBH

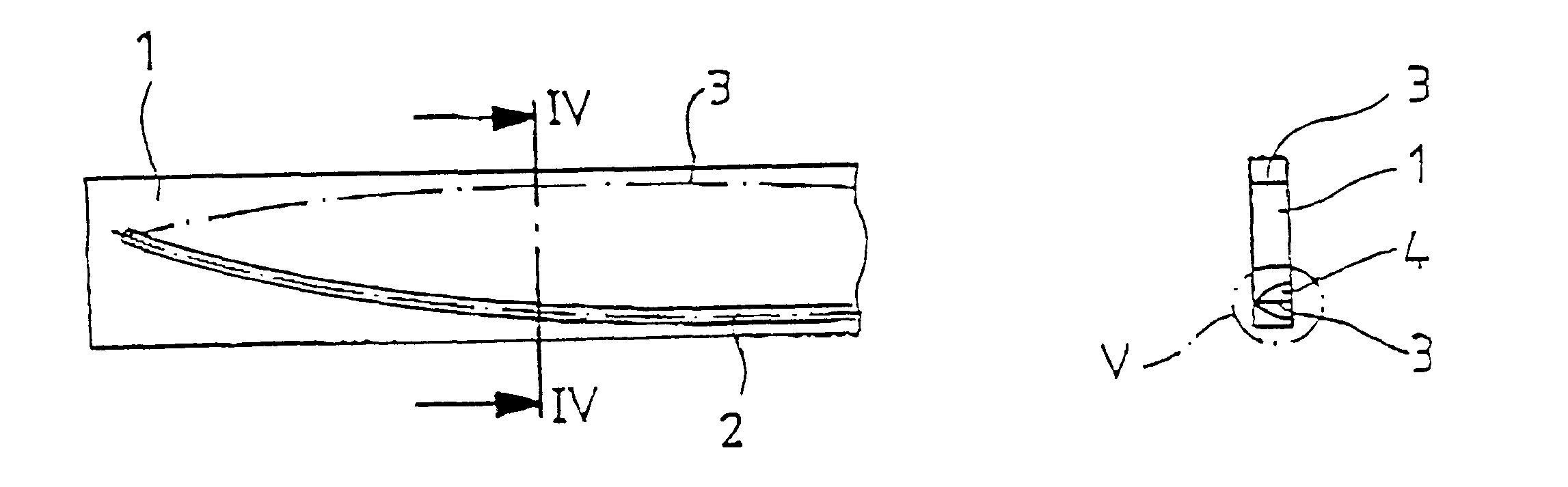

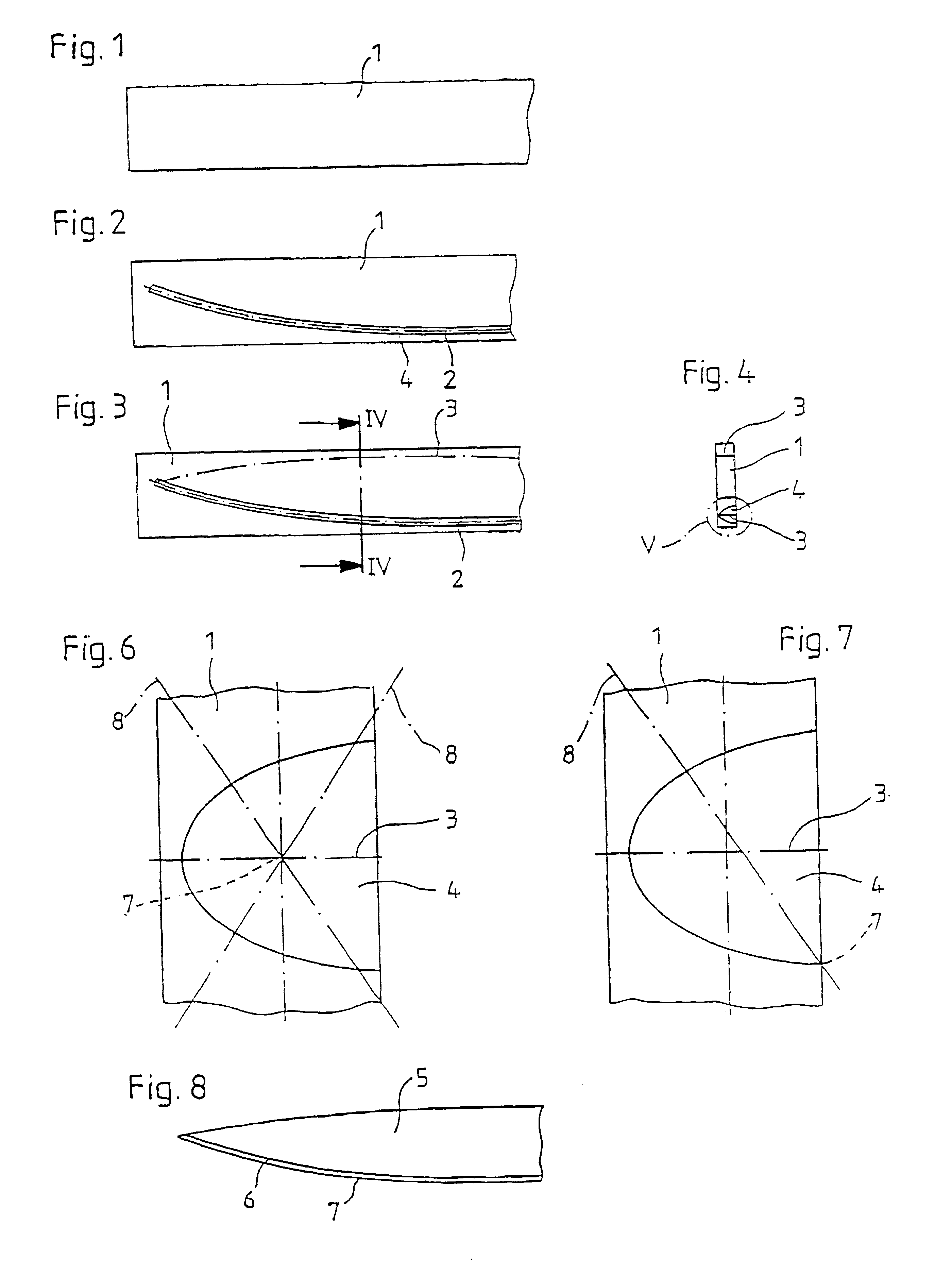

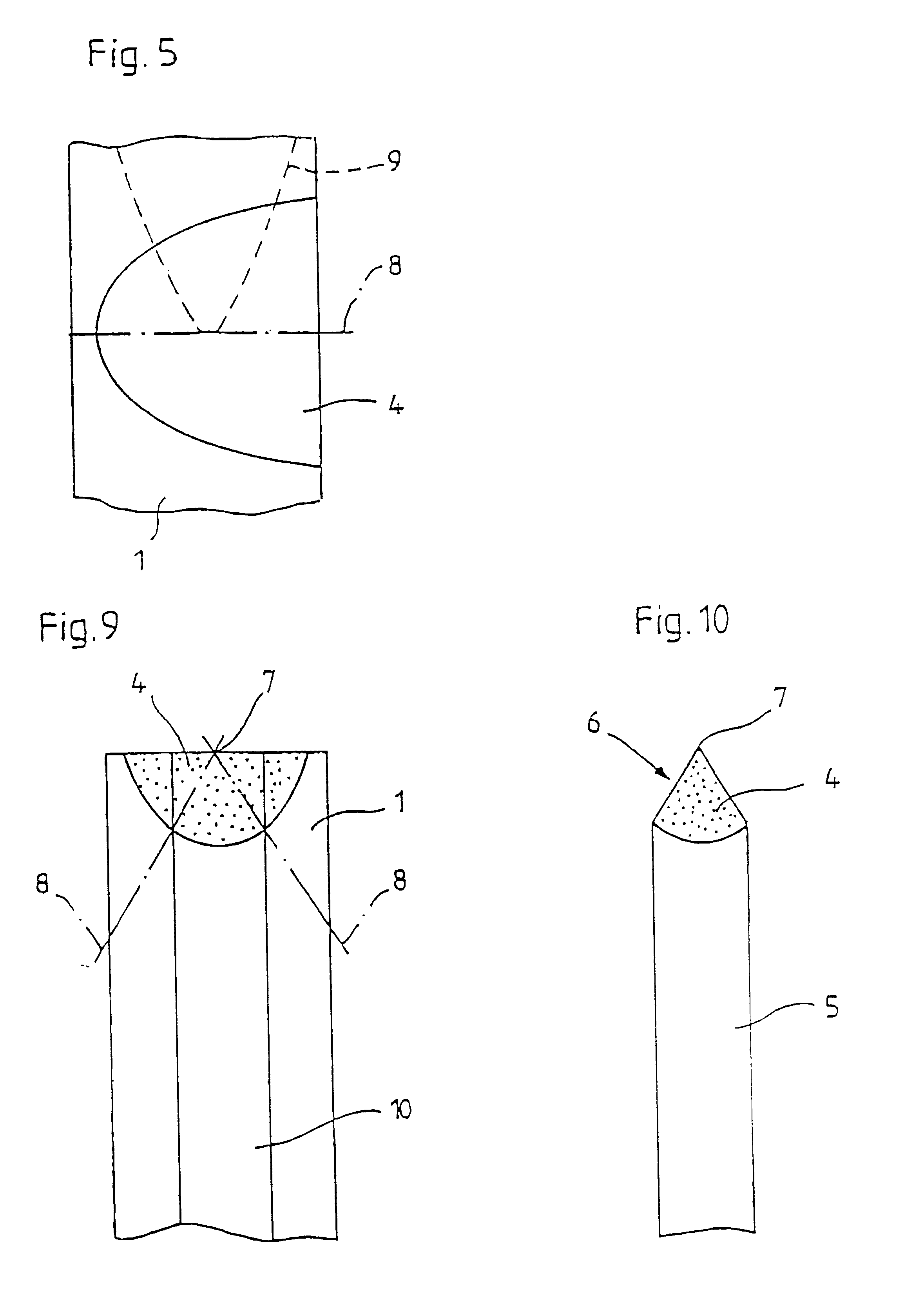

Process for manufacturing a blade of a cutting tool and product manufactured therewith

A method for manufacturing a blade of a cutting tool, in particular, a knife. In order to create a process with which influence is to be exerted in a targeted manner on the technological material properties of the blade and material chipping to be avoided, as well as permitting economical manufacturing, a process is carried out by treating a blade base material with a laser in a first process step along a curve contour determined by the final edge of the blade and, in a second process step, the edge of the blade is formed, in particular, cut to shape, along the curve contour determined by the final blade form inside the laser-treated area, or the blade base material is machined in a first process step by punching or trimming to form the final edge, subsequently the laser treatment is performed in a second process step on the narrow side forming the final edge and finally, in a third process step, the blade is formed, in particular, ground, inside the laser-treated area.

Owner:ZWILLING J A HENCKELS

Cutting Tool and Round Double Sided Cutting Insert Therefor

A cutting insert for retention in a rotating cutting tool having an axis of rotation has two opposing end surfaces and a peripheral surface extending therebetween, each end surface having a mutual first axis of symmetry passing through the end surfaces about which each end surface has N-fold rotational symmetry for some value of N where N is chosen from the group consisting of 2, 3 and 4. A peripheral cutting edge is formed at the junction between each end surface and the peripheral surface, the peripheral cutting edge having N curved cutting edges merging with N straight cutting edges which extend between the curved cutting edges at extremities thereof. The curved cutting edges of the two end surfaces are not aligned in an end view of the cutting insert along the first axis of symmetry.

Owner:ISCAR LTD

Cutting Insert, Cutting Tool, and Method of Cutting Workpiece Using the Same

ActiveUS20110135407A1Reduce cutting resistanceImprove fracture resistanceTransportation and packagingMilling cuttersEngineeringLower face

A cutting insert of the present invention includes a side face having an upper concave portion which is located between an upper face and a lower face and extends up to the upper face, and a plurality of divided upper cutting edges which are located at the intersection of the upper face and the side face, and are divided by the upper concave portion. Each of these divided upper cutting edges includes a first end and a second end, and is inclined being closer to the lower face from the first end toward the second end. The plurality of divided upper cutting edges include a first divided upper cutting edge and a second divided upper cutting edge adjacent to each other. When viewed from side, the first end of the second divided upper cutting edge is located above the intersection of an extension line of the first divided upper cutting edge, and a line which passes through the first end of the second divided upper cutting edge and is parallel to the central axis of the cutting insert, and is located at the same position as the second end of the first divided upper cutting edge, or located therebelow. A cutting tool including the cutting insert, and a method of cutting a workpiece by using the cutting tool are also provided.

Owner:KYOCERA CORP

Coated cutting tool and method for producing the same

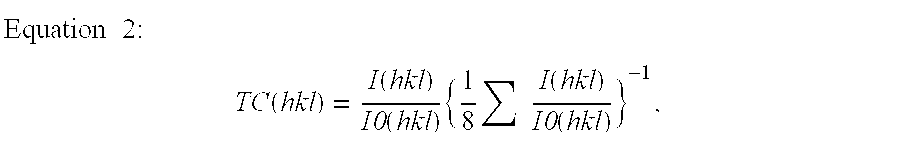

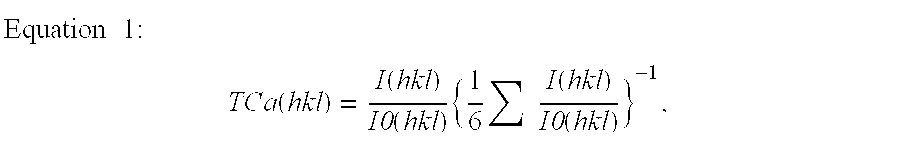

ActiveUS20080057280A1Improve fracture resistanceReduce machining accuracyPigmenting treatmentOther chemical processesX-rayWear resistance

Provided are a coated cutting tool having excellent wear resistance and excellent resistance to chipping as well as excellent fracture resistance such that the coated cutting tool is unlikely to cause backward movement of the tool edge position due to wear or chipping, and a method for producing the same.A coated cutting tool comprising a base material having a surface coated with a coating film, wherein the coating film comprises at least one layer comprised of a TiCN columnar crystal film, wherein the TiCN columnar crystal film has an average grain size of 0.05 to 0.5 μm, as measured in the direction parallel to the surface of the base material, and exhibits an X-ray diffraction pattern having a peak at a diffraction angle 2θ in the range of from 121.5 to 122.6° wherein the peak is ascribed to the (422) crystal facet of the TiCN columnar crystal as measured using CuKα radiation.

Owner:TUNGALOY CORP

Method and system for eliminating external piercing in NC cutting of nested parts

ActiveUS20050172764A1Programme controlWelding/cutting auxillary devicesEngineeringManufacturing engineering

This invention pertains to machinery and methods for cutting a workpiece utilizing a cutting tool into at least two parts having prescribed shapes from a metal plate comprising the steps of: identifying each of the parts by one or more contour lines; cutting a workpiece along one of the identifying contour lines into one of the parts; creating at least one path diversion, wherein the diversion has an associated bounded region or opportunity; cutting the workpiece along a contour line associated with the opportunity; resuming the cutting of the part along the identifying contour line with minimal damage to the part being cut; finishing the cutting of the part and then moving the cutting tool to the opportunity and thence to an associated adjacent identifying contour line and then repeating the process until all parts have been manufactured.

Owner:FAGAN MATTHEW

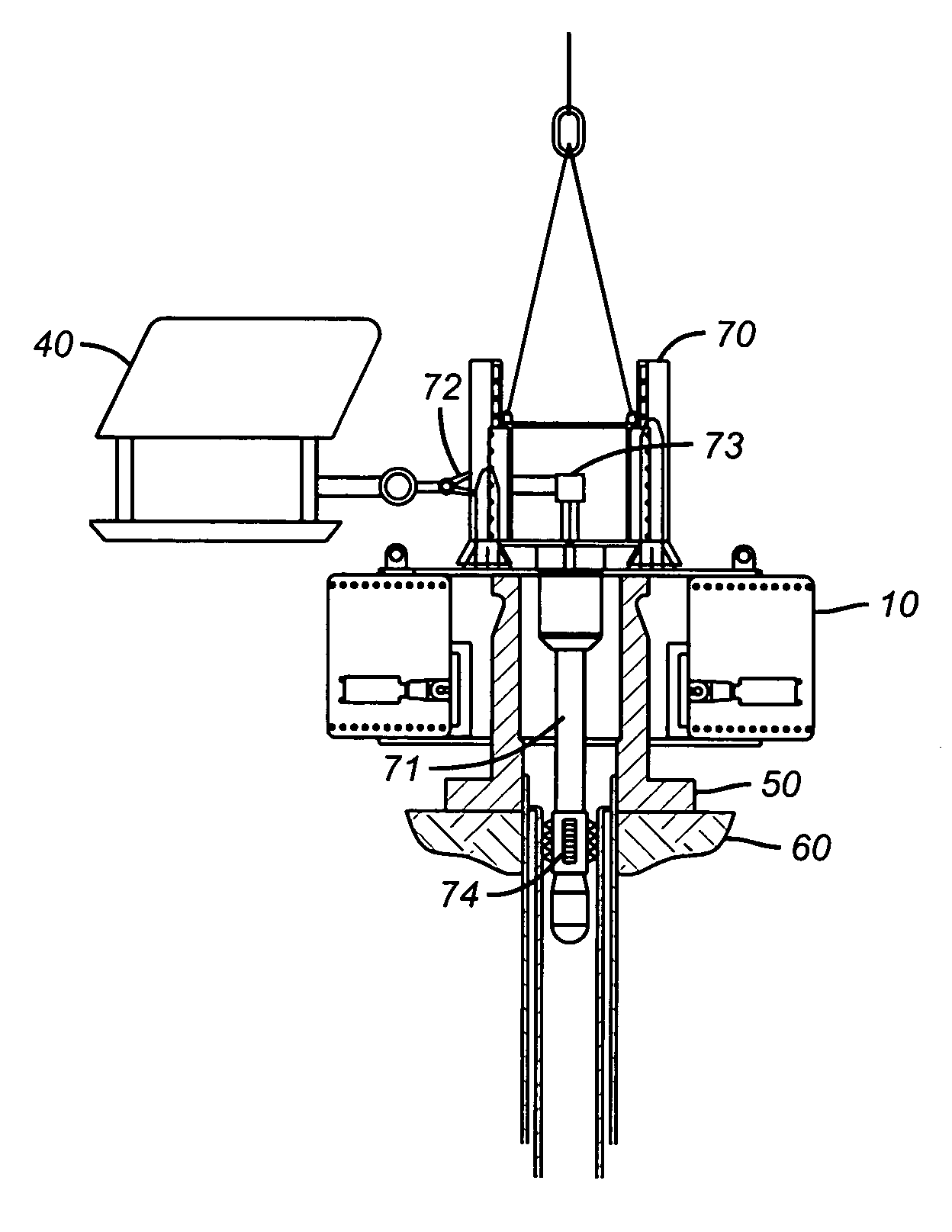

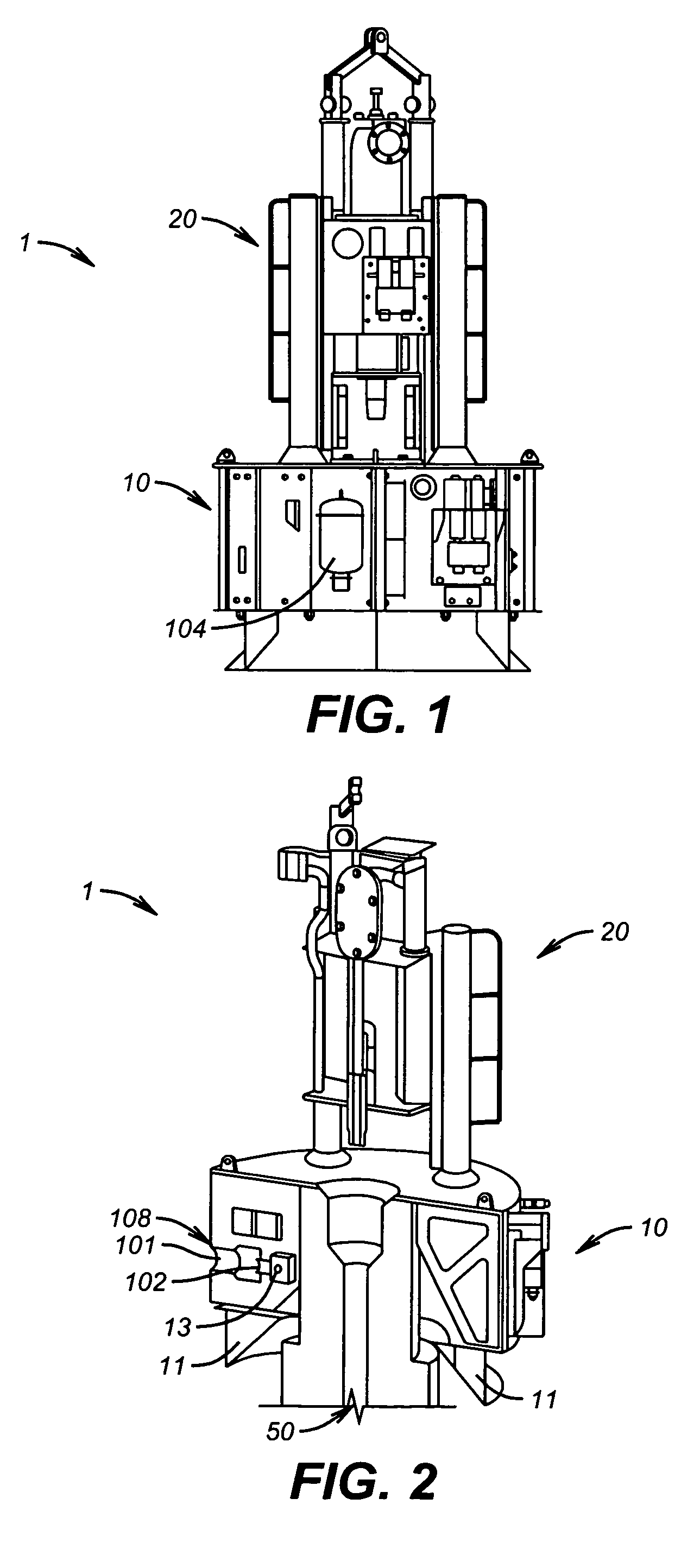

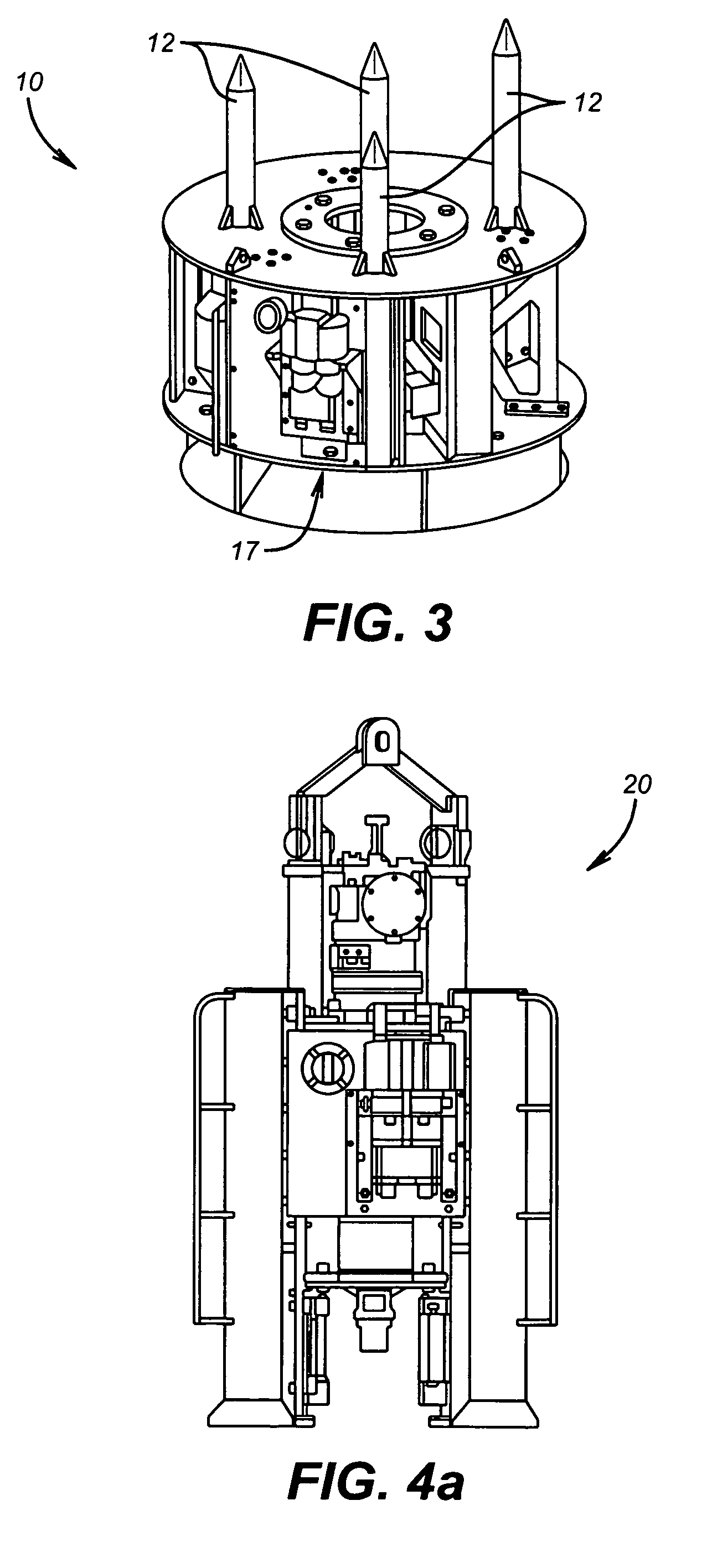

Casing cutter

A subsea well casing cutting tool for use as part of a well abandonment procedure, the casing cutting tool deployable from a vessel located at a water surface, where in certain embodiments the casing cutting tool comprises a casing gripper; a rotary cutter drive assembly; a rotary cutter; a rotating fluid union that allows high volume water to be fed to the rotating cutting assembly below the drive motor for purposes of extending the cutting blades; and a third party casing hanger removal tool wherein the casing cutting drive assembly forms an interface between the third party rotary casing cutter, an existing subsea casing, and a work class ROV. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:OCEANEERING INTERNATIONAL

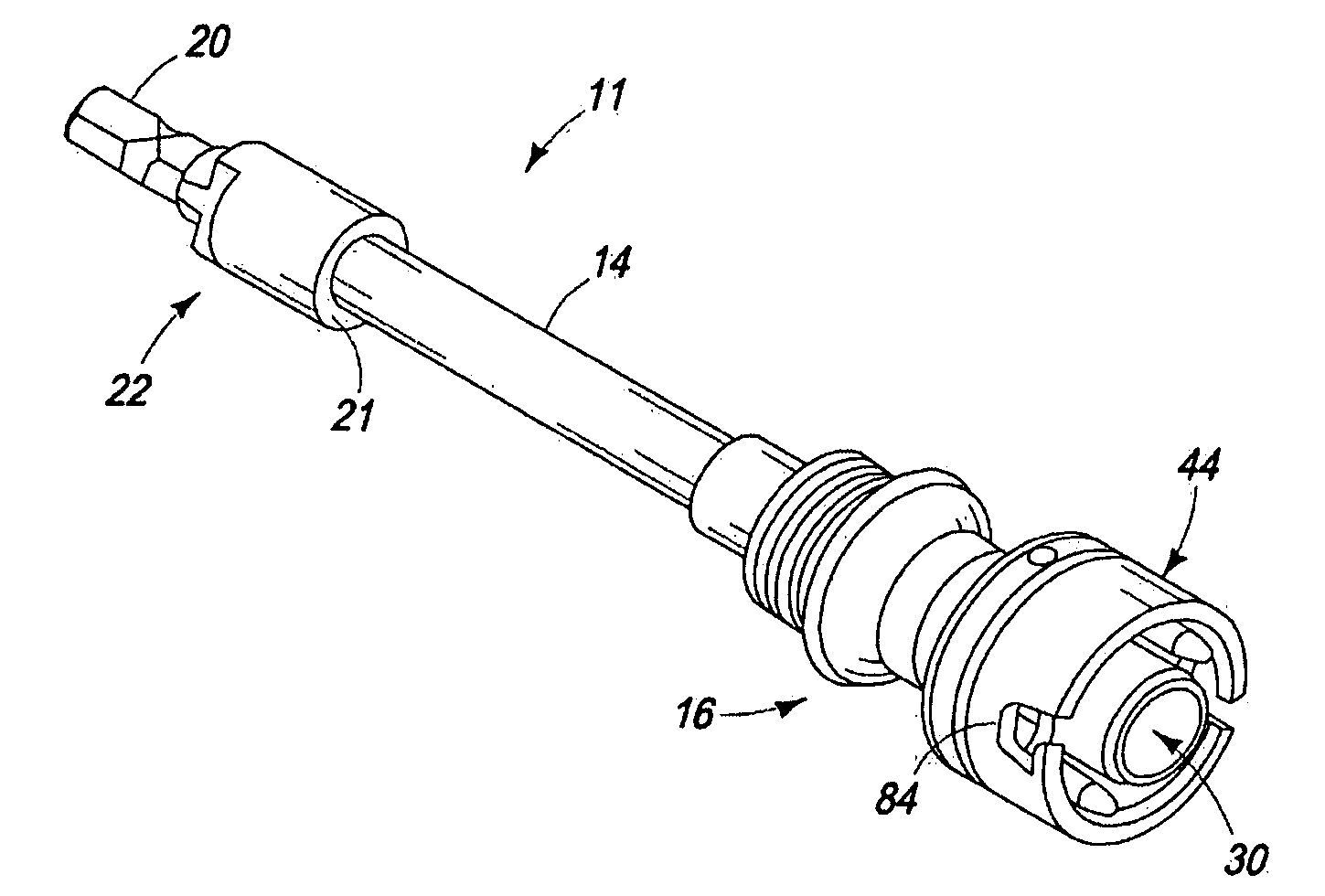

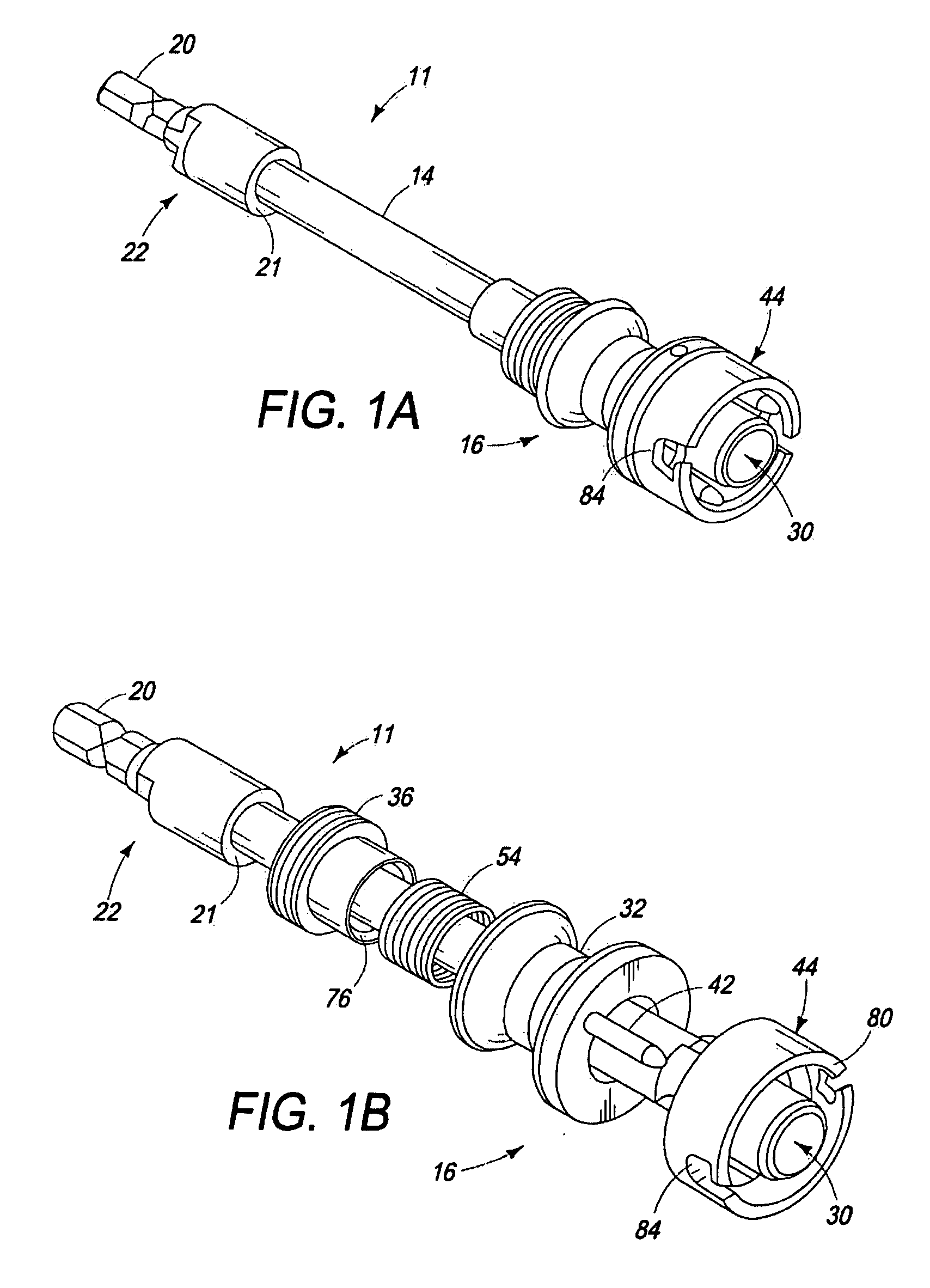

Holder for a surgical reamer and single use, flat reamer

ActiveUS20080195101A1Easy to sterilizeQuick disassemblyDiagnosticsSurgical needlesCouplingLocking mechanism

Disclosed is a surgical tool holder 11 adapted to connect to a disposable cutting tool 12, and the surgical instrument 10 combination. The tool holder 11 has a shank 14 with a quick tool coupling 24 at one end 16 and a drive adaptor 20 at a second end 22. The coupling assembly 24 has a coupling interface 40 for holding the tool 12, and has a debris reservoir 44. A locking mechanism 26 is engageable with the shank 14 by a lock interface 95 that holds the coupling assembly in functional assembly, and when unlocked allows component parts of the coupling assembly to be separated for cleaning and sterilization. The surgical tool 12 has a flat base 104 and complementary fittings 114 adapted to be received by the holder's coupling interface. The combination of the flat base 104 with the reservoir 44 defines a relatively enclosed collection space 46 to receive cutting debris from the tool 12 while the holder 11 and tool 12 are coupled together.

Owner:VIANT AS&O HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com