Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

286 results about "Median plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The median plane also called a mid-sagittal plane is used to describe the sagittal plane as it bisects the body vertically through the midline marked by the navel, dividing the body exactly in left and right side. The term parasagittal plane is used to refer to any plane parallel to the sagittal and median plane.

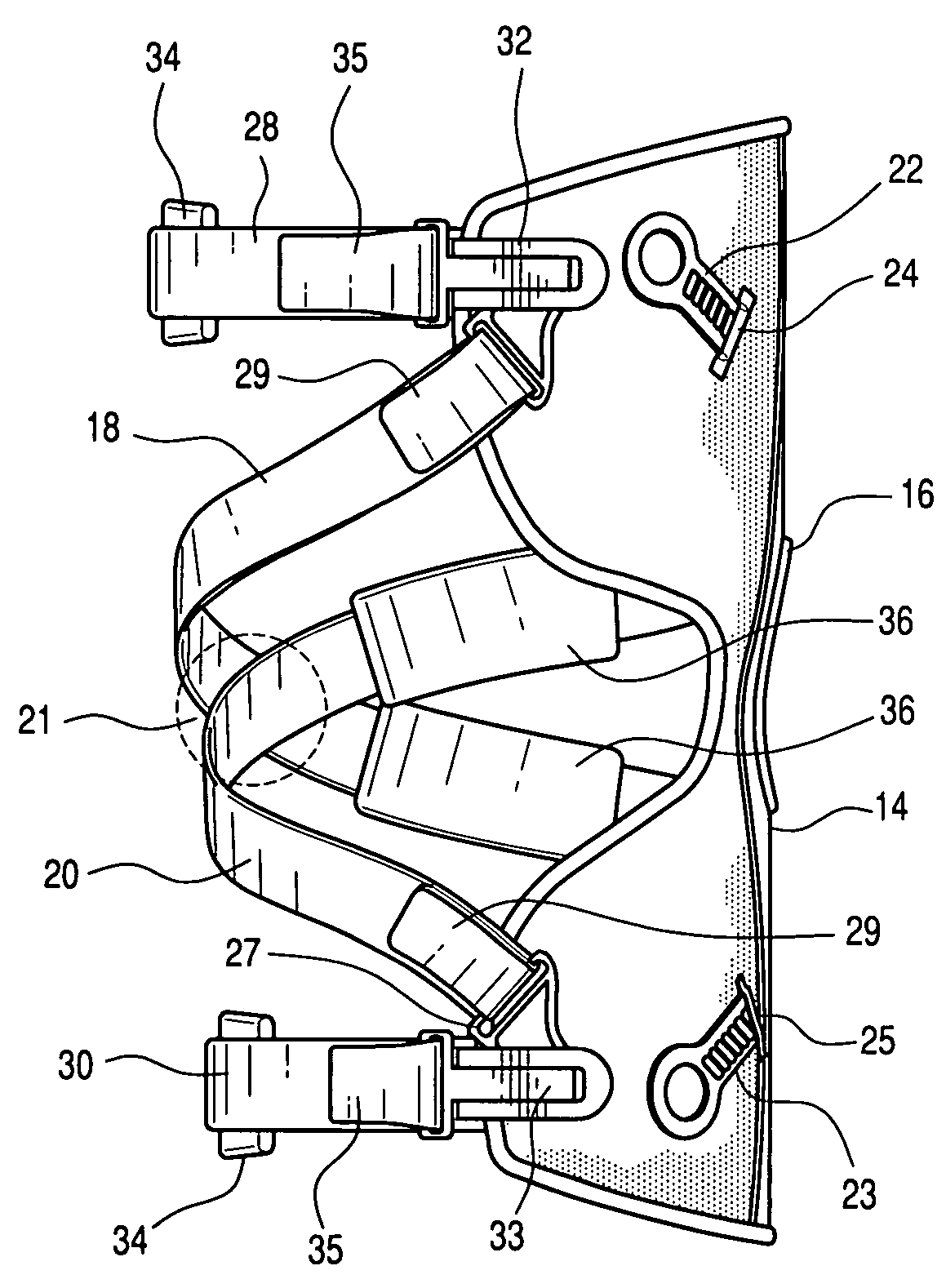

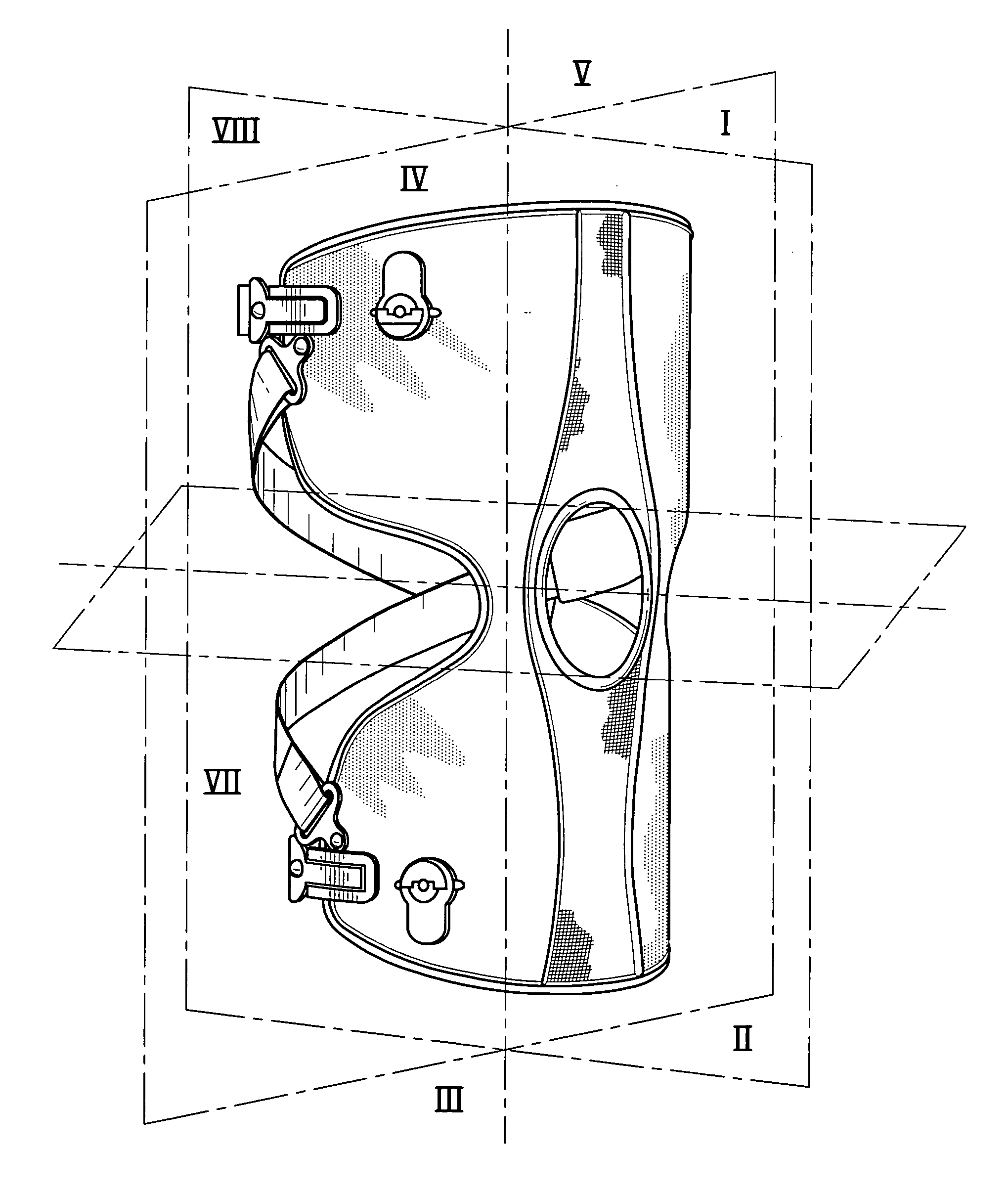

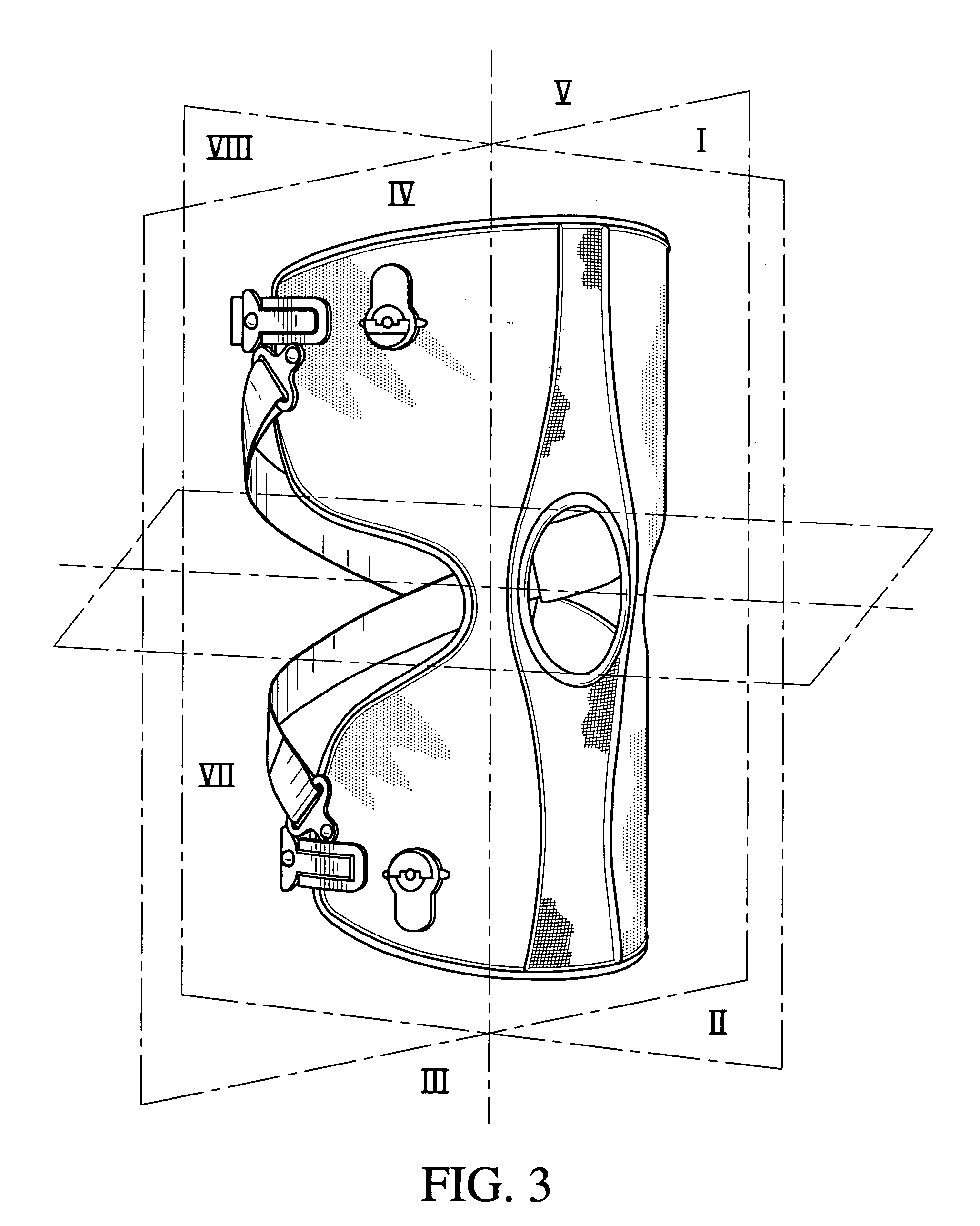

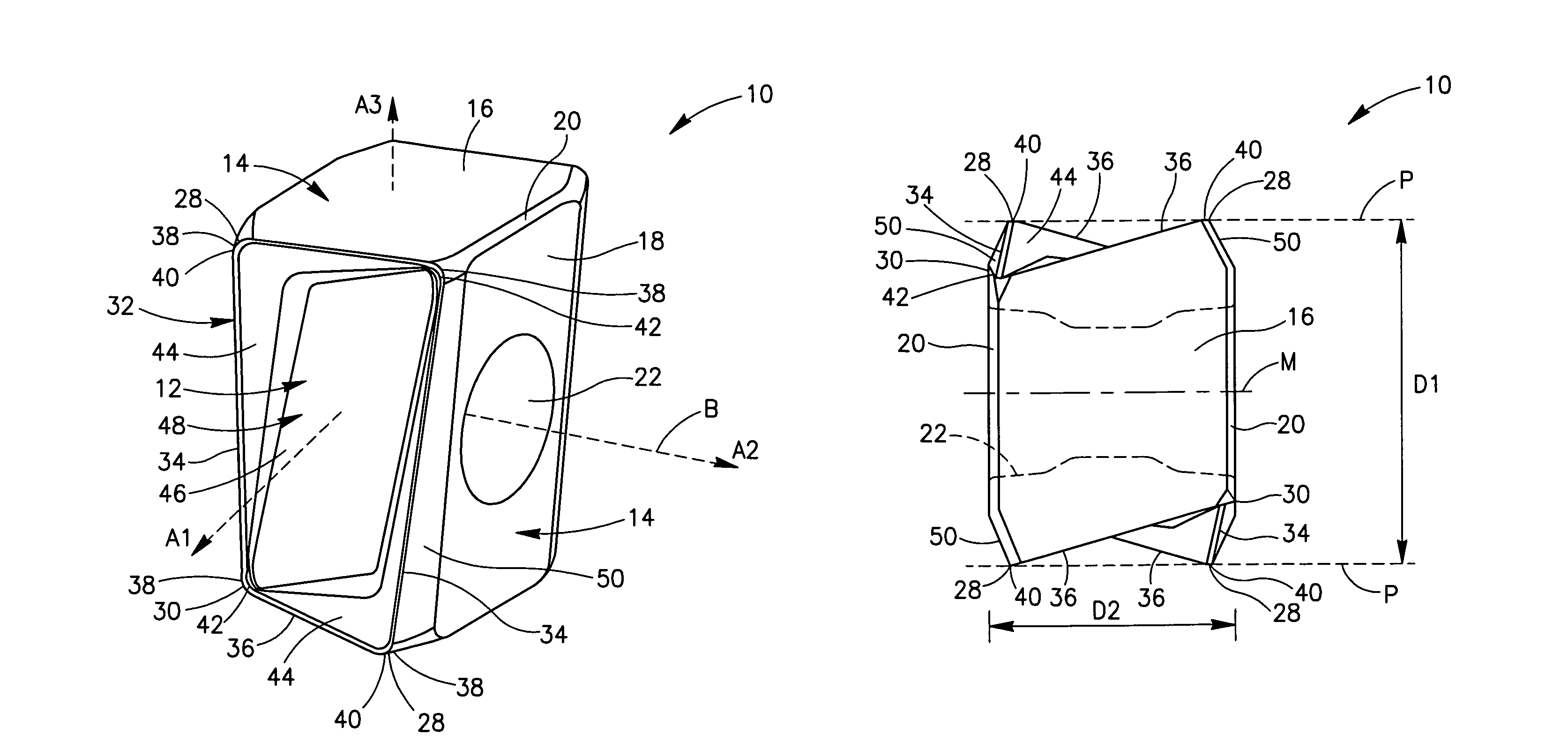

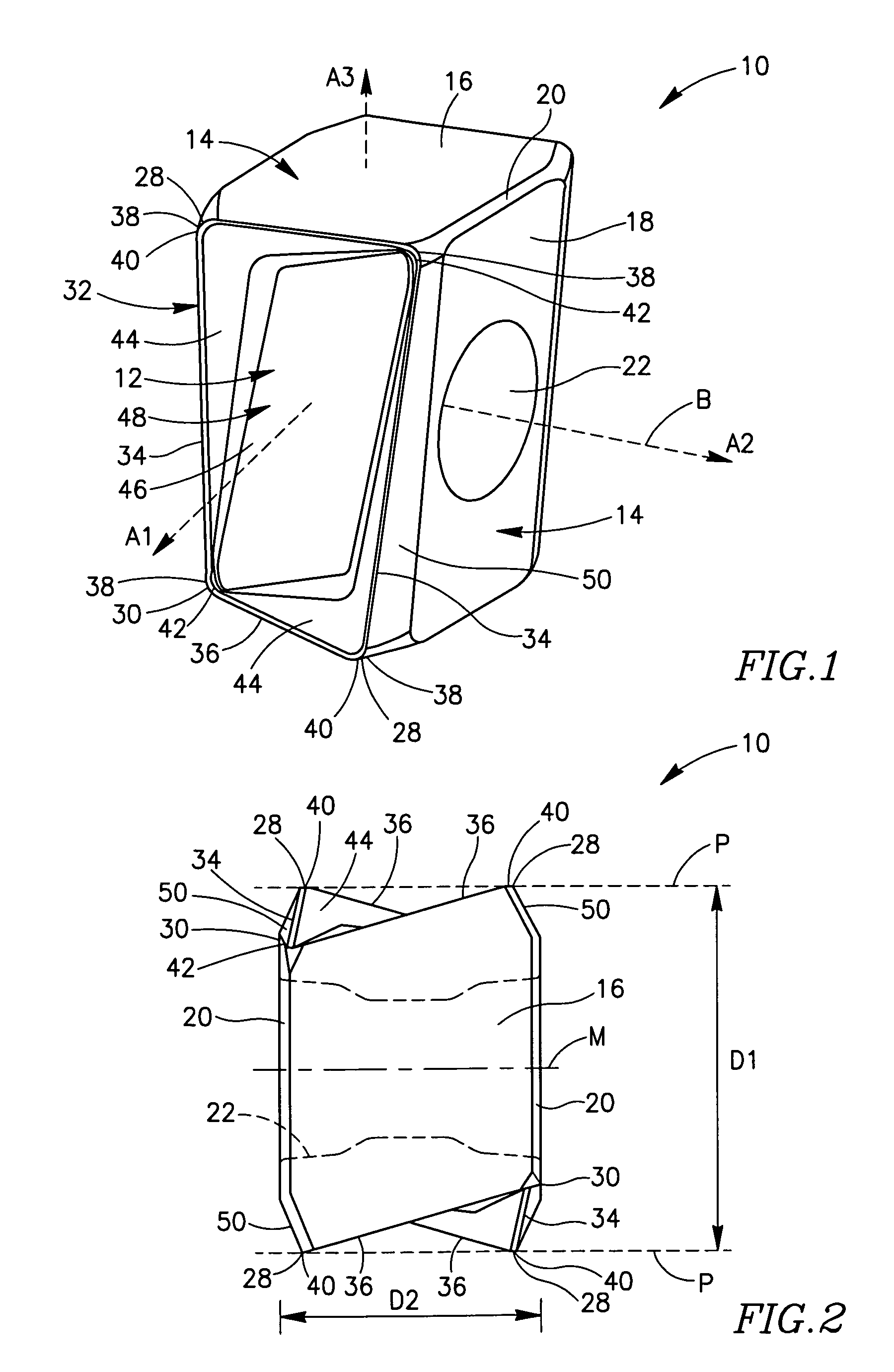

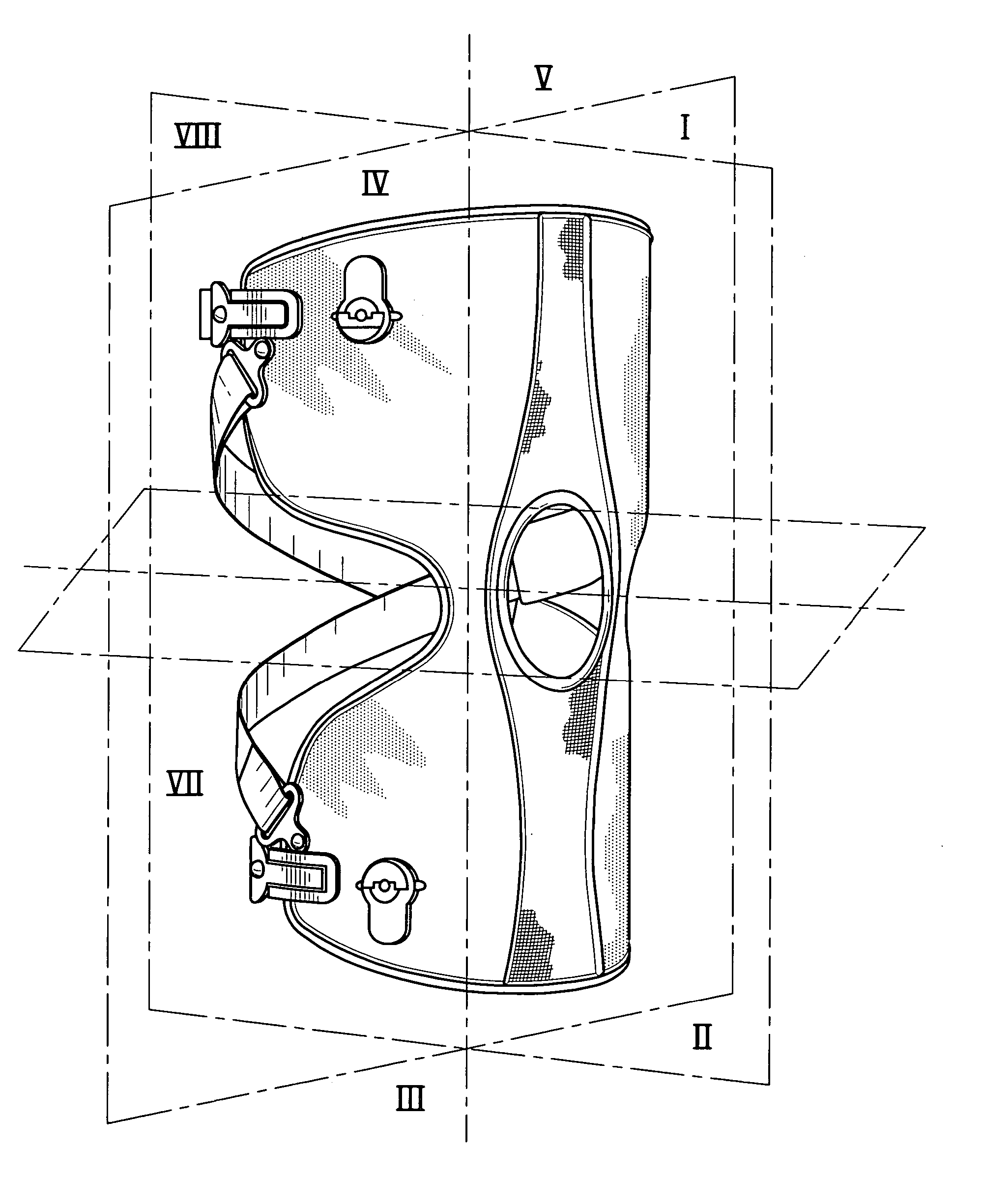

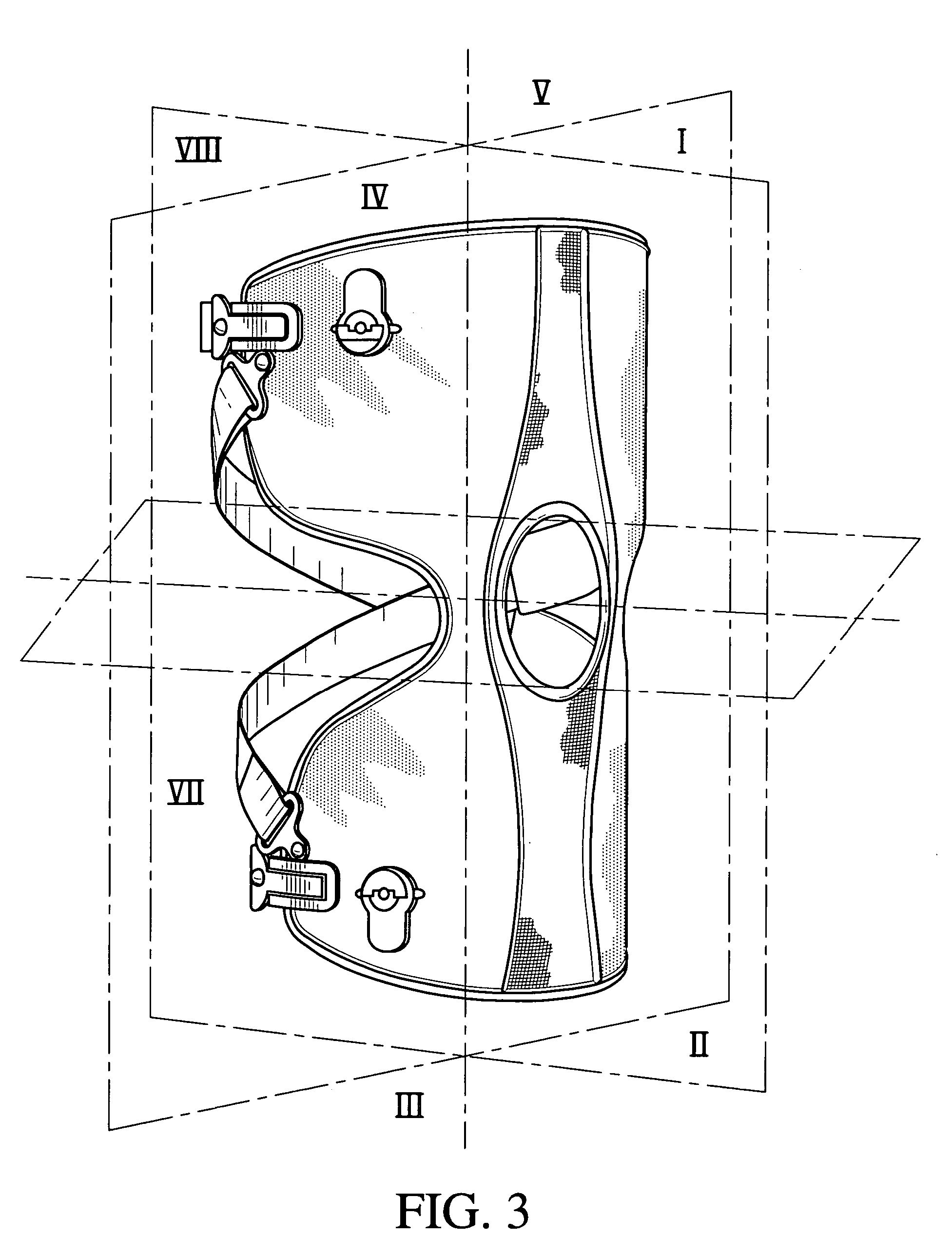

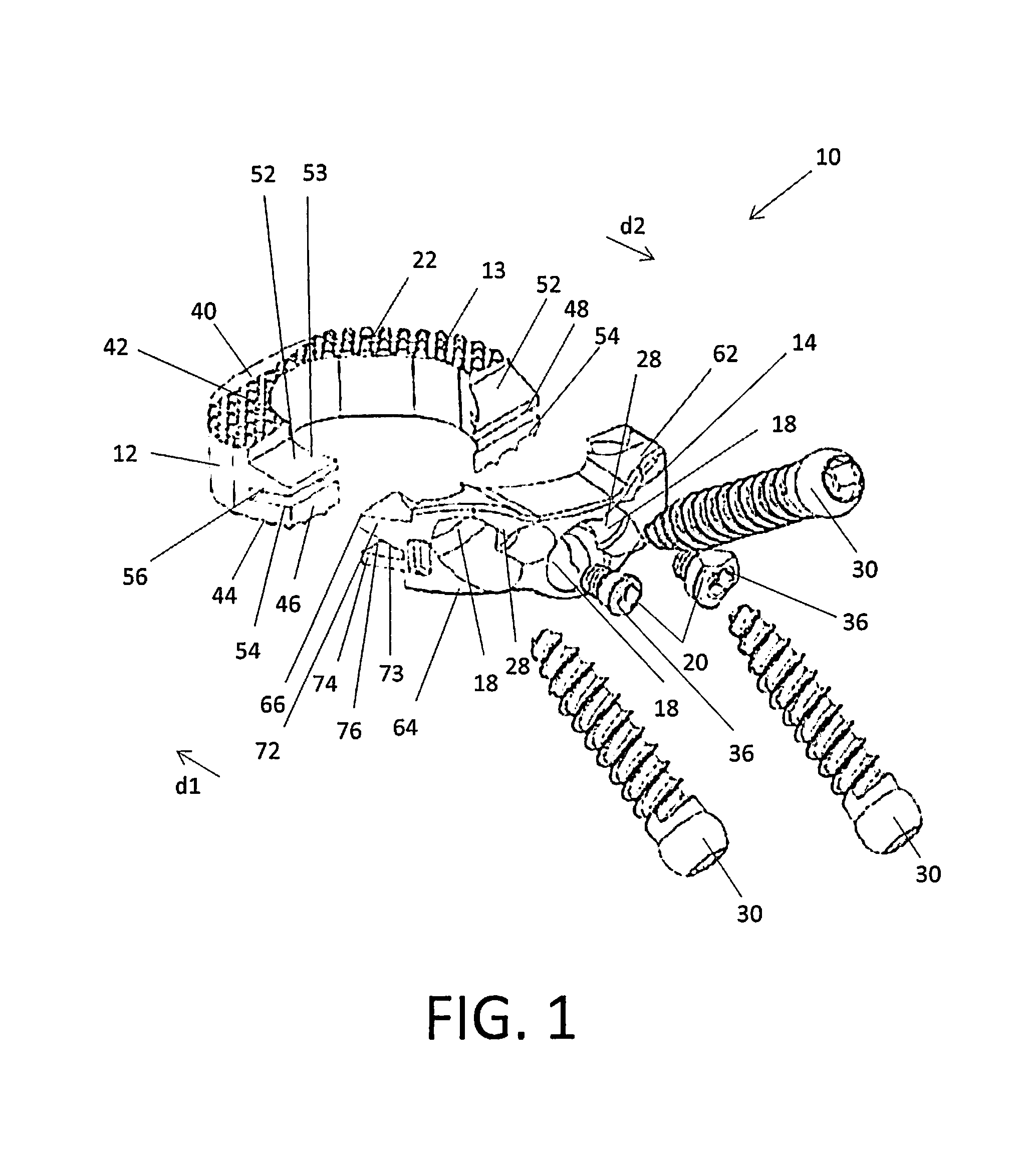

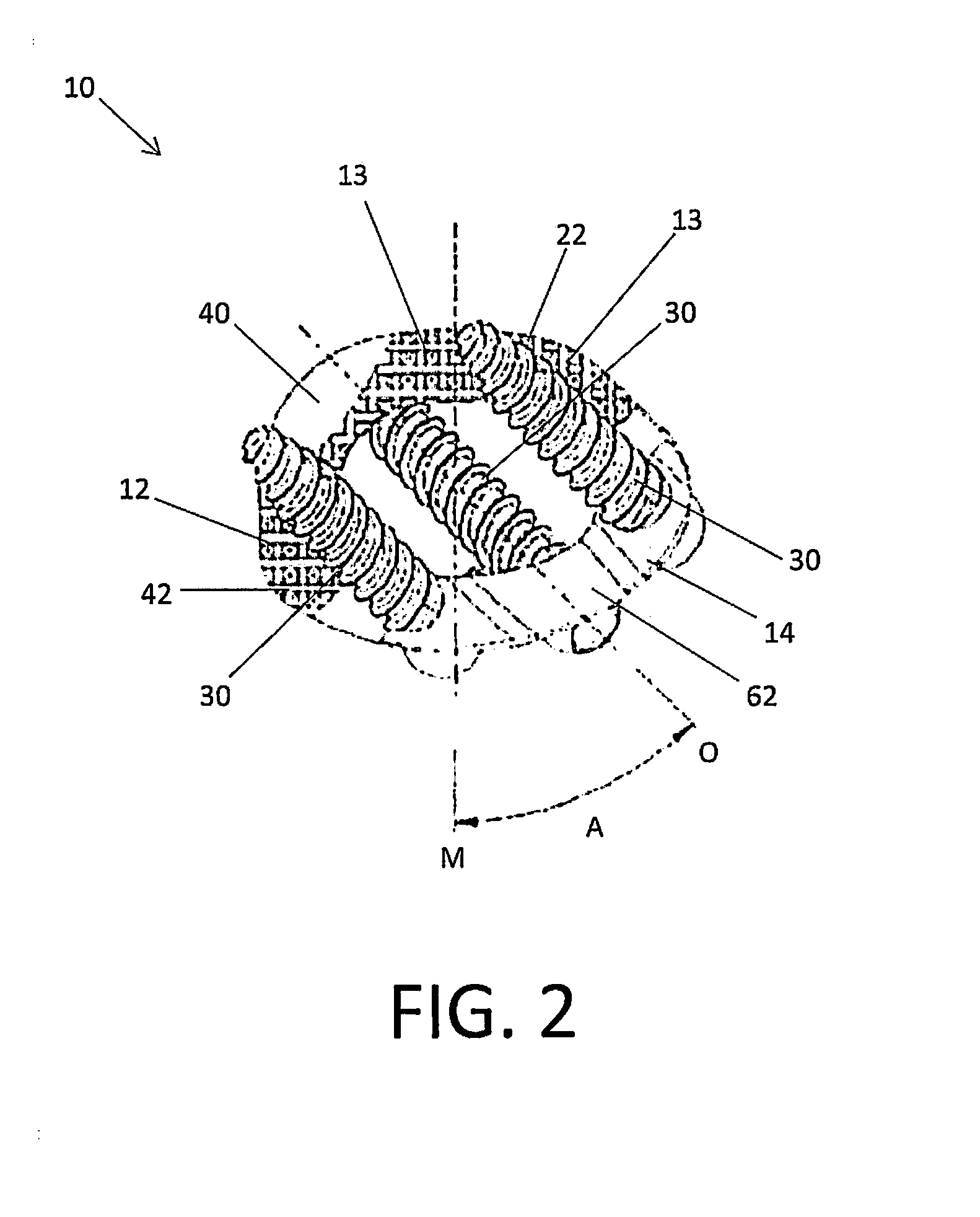

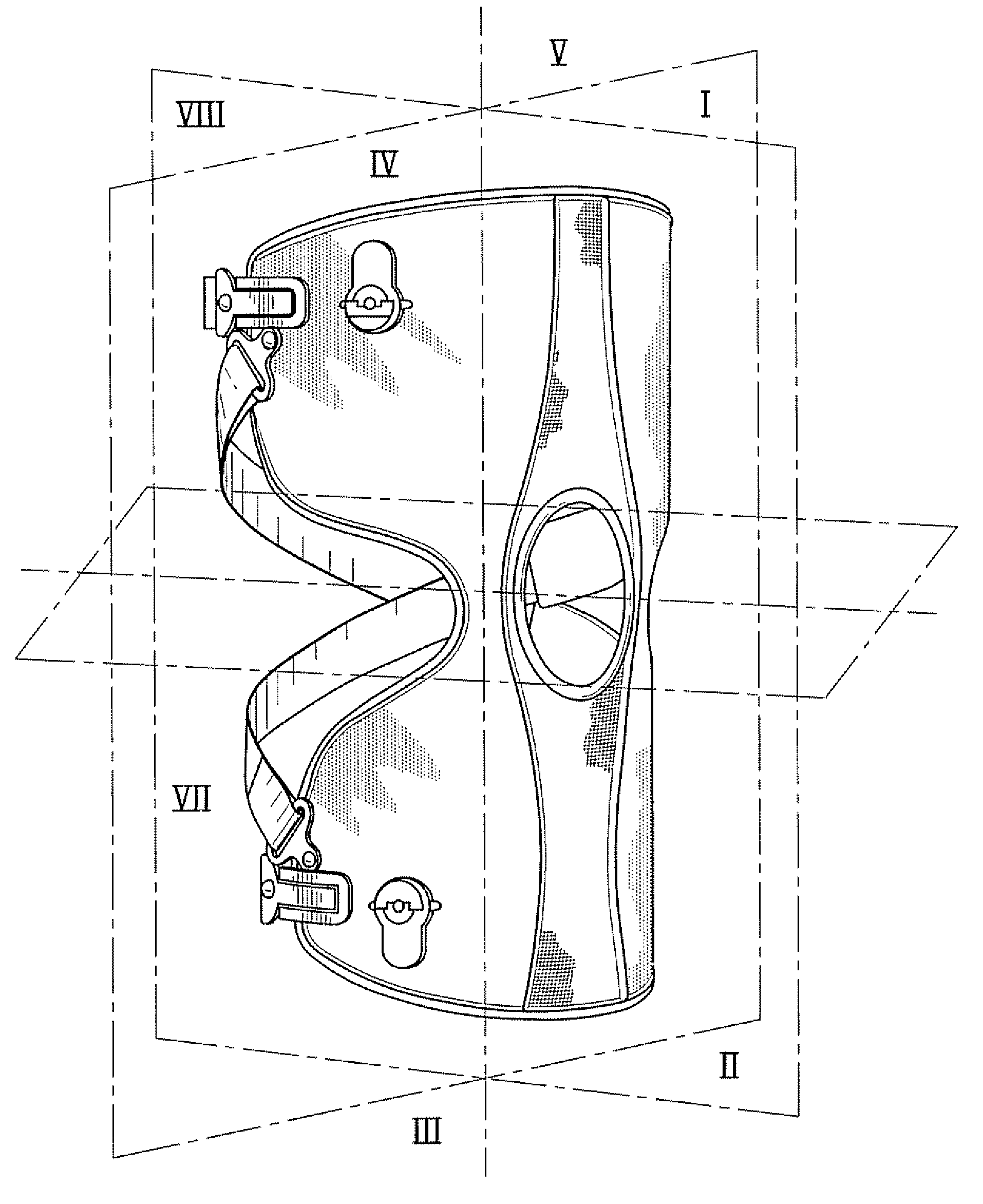

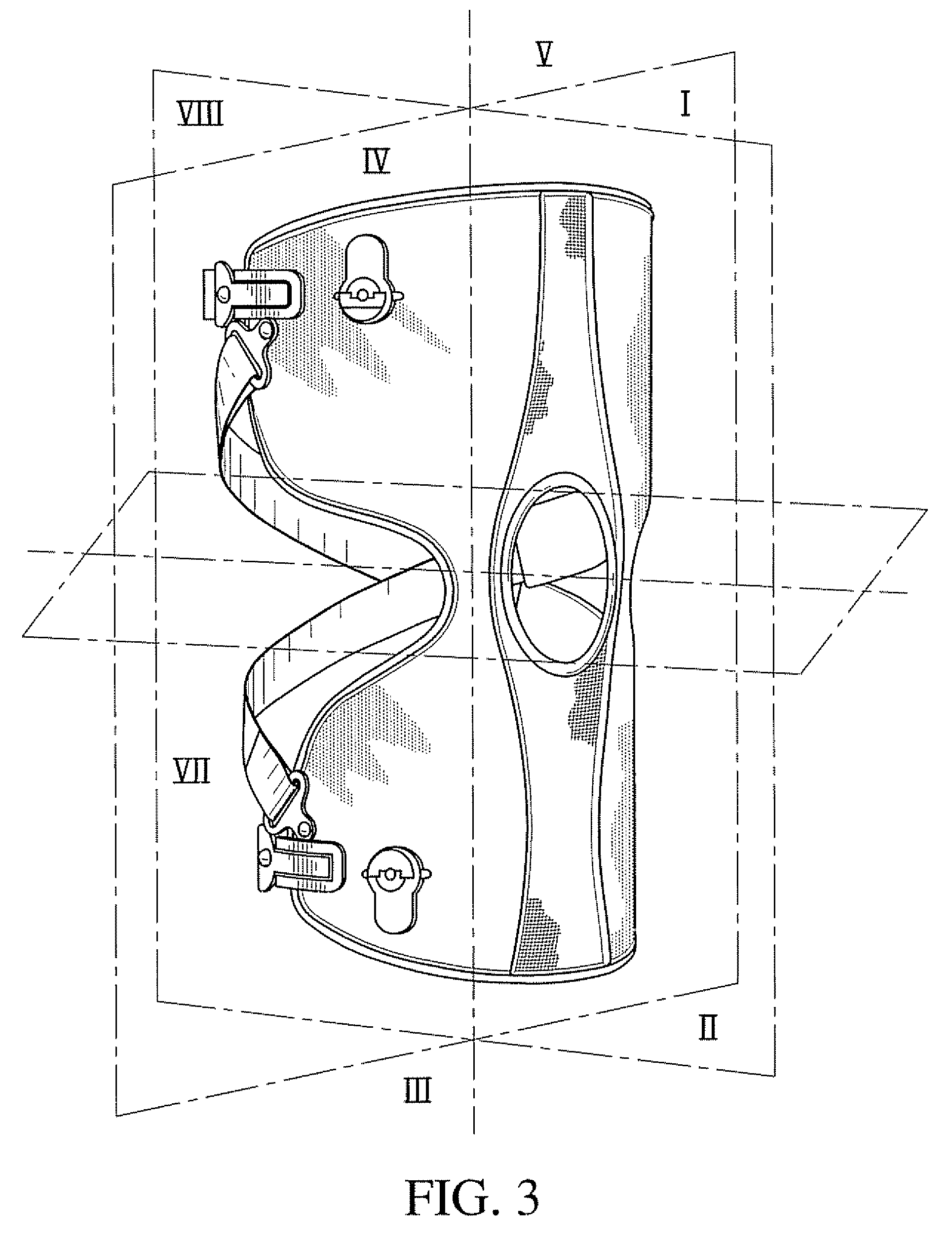

Knee brace and method for securing the same

ActiveUS7597675B2Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesPhysical medicine and rehabilitationKnee braces

Owner:KAUPTHING BANK

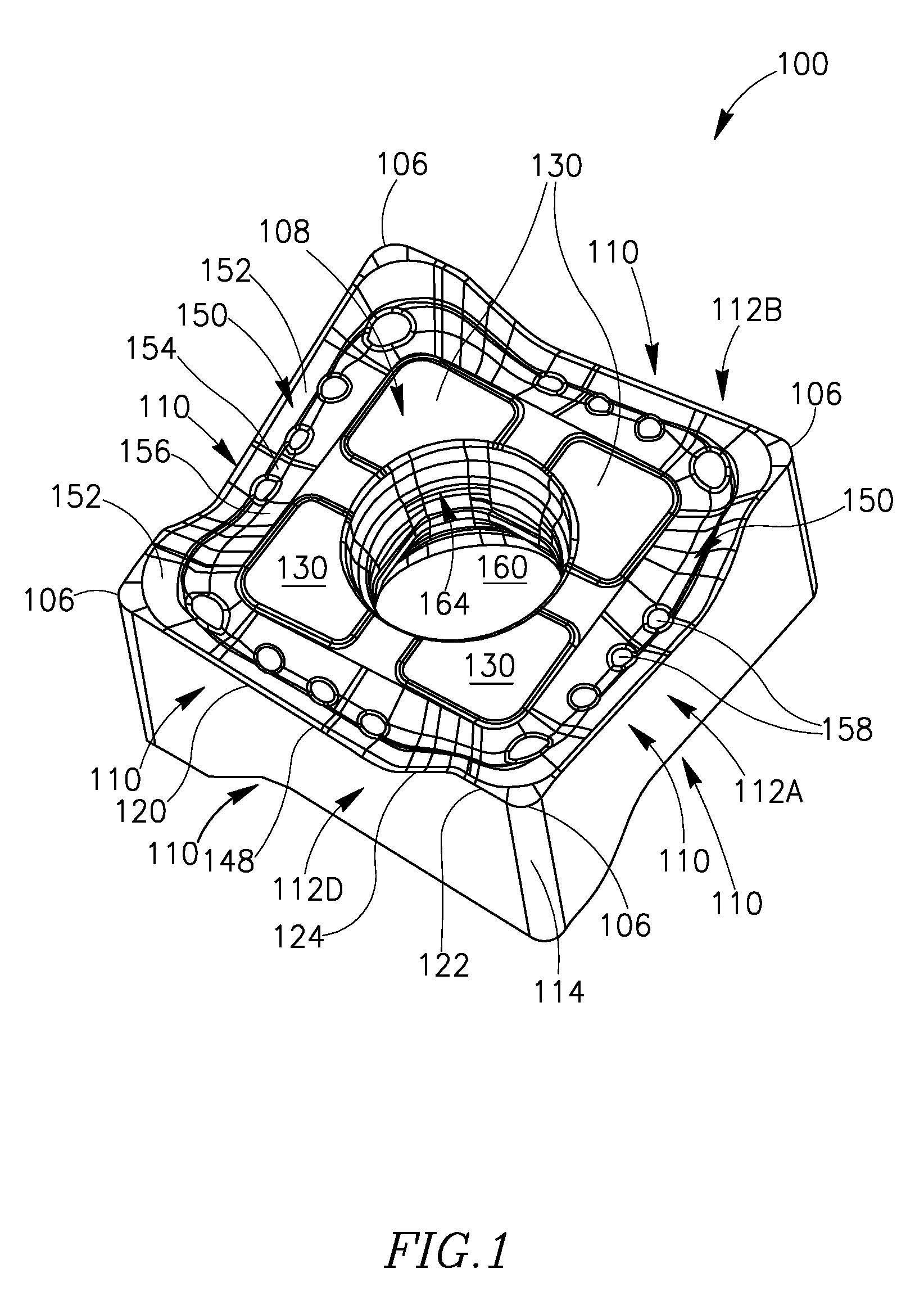

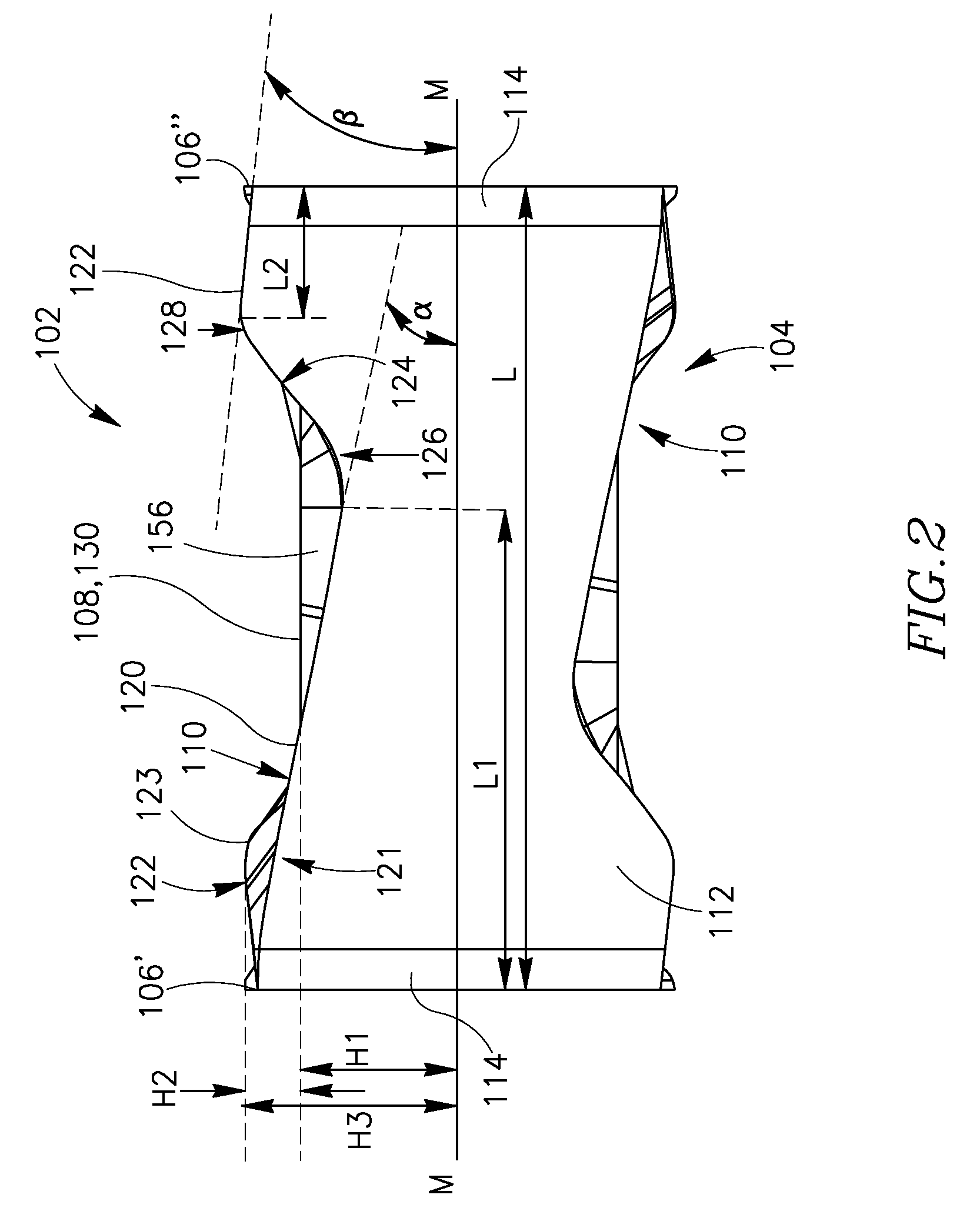

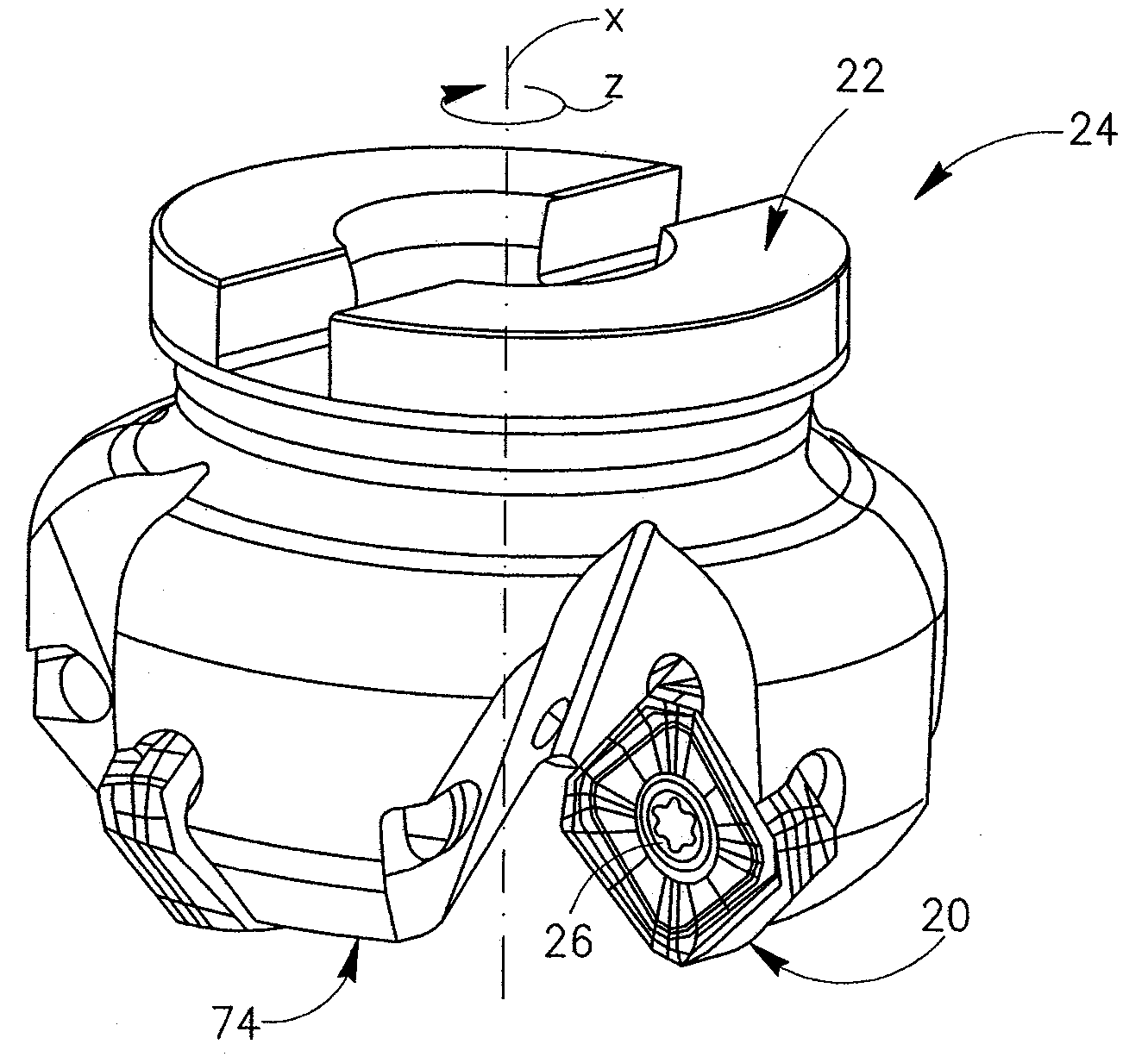

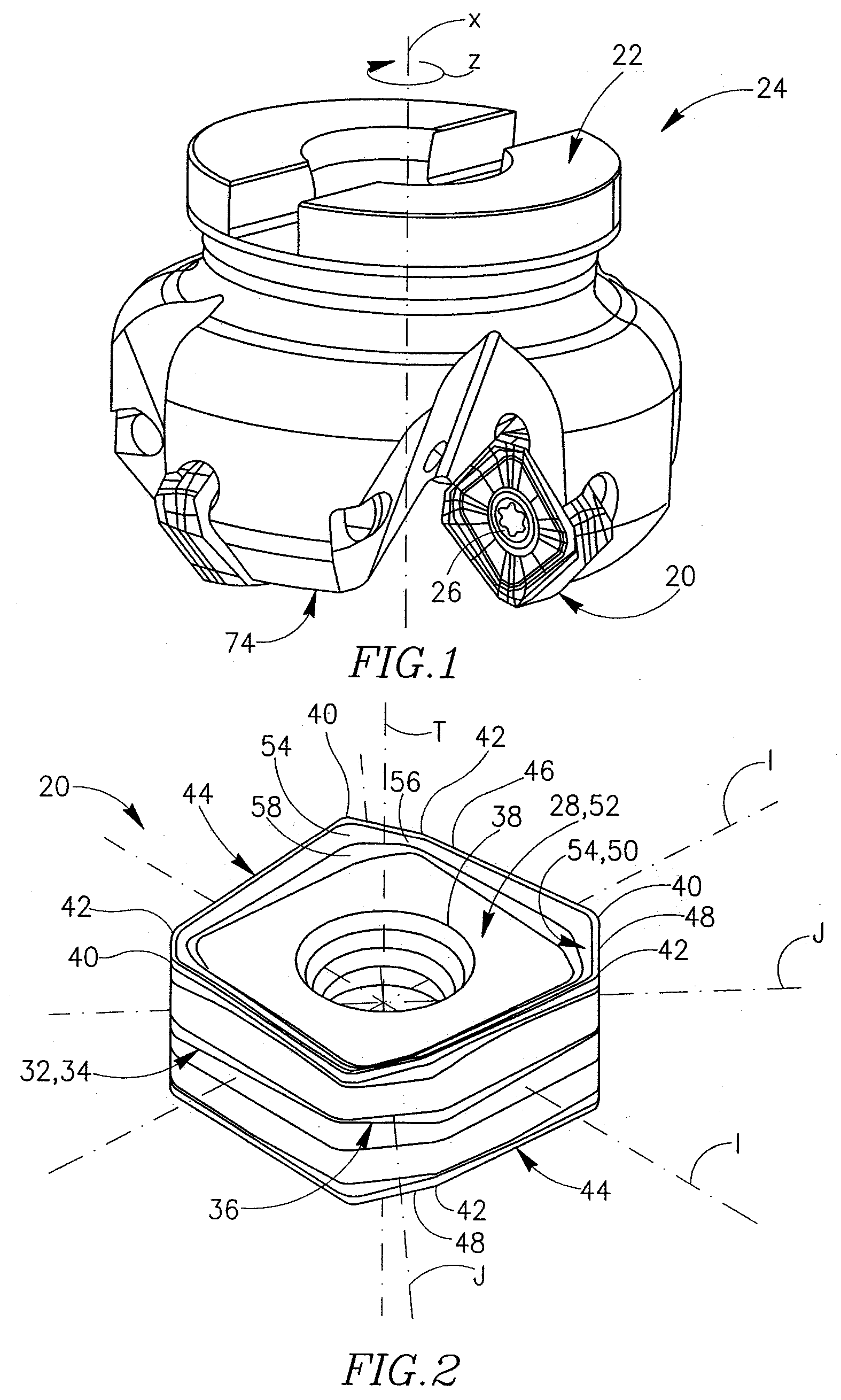

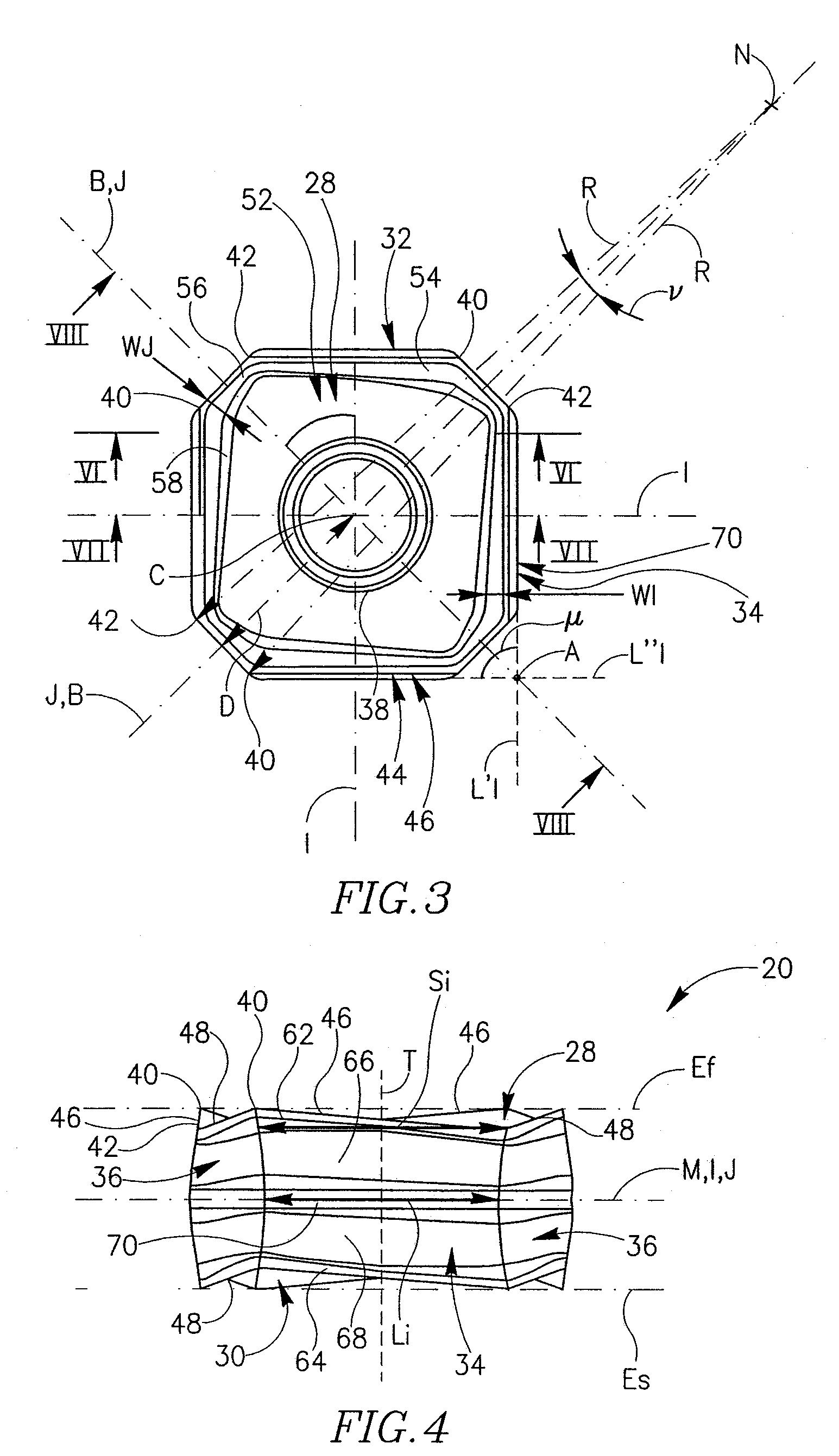

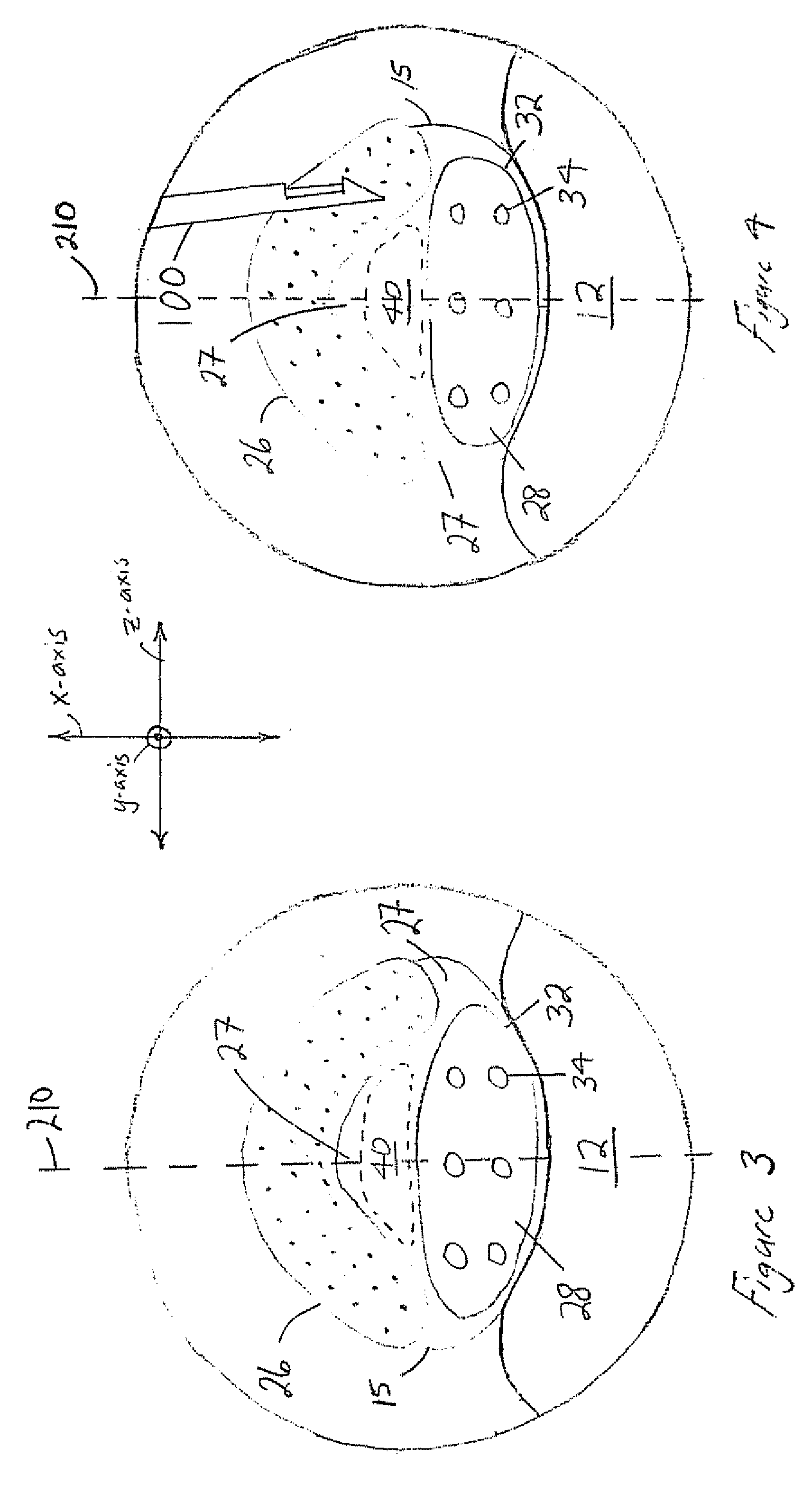

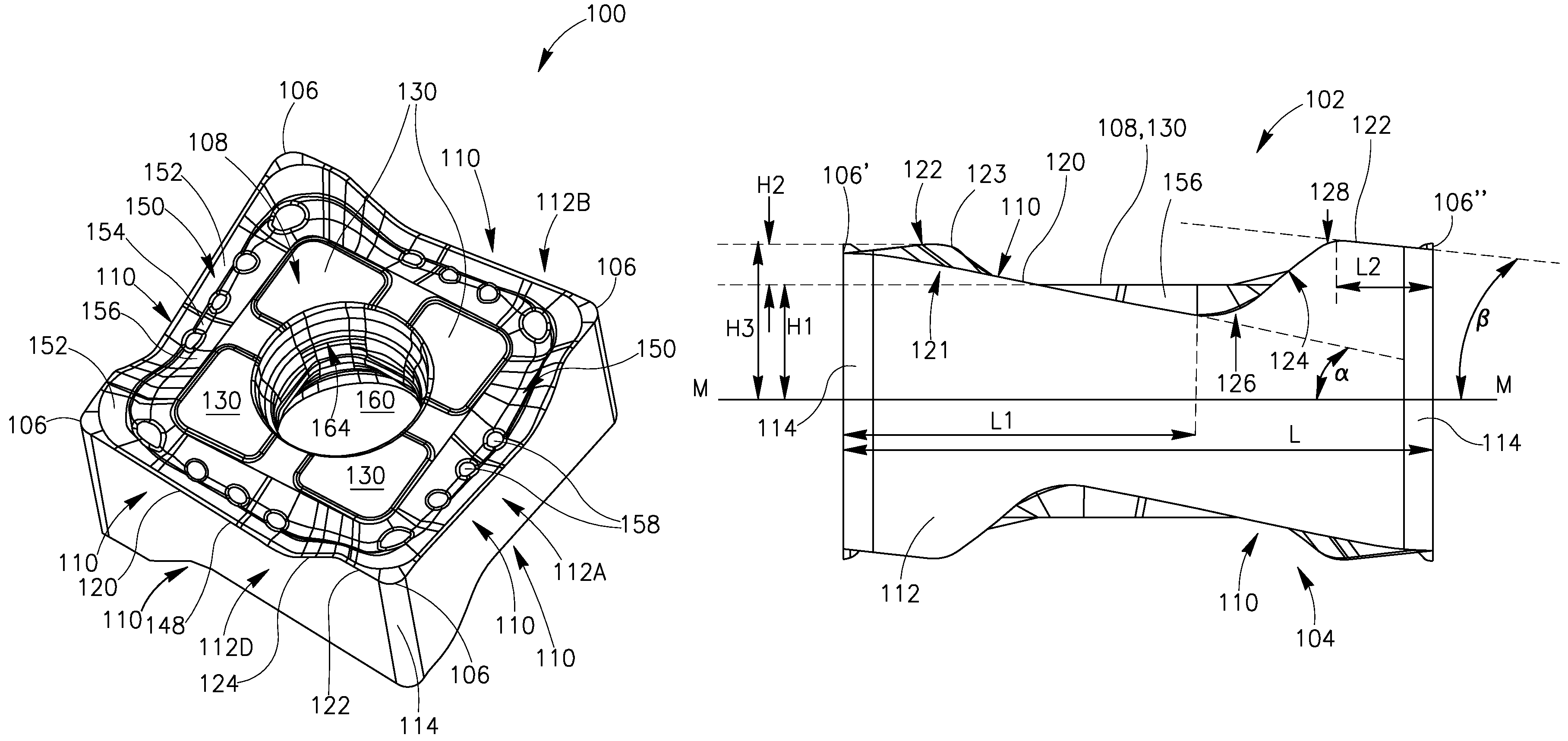

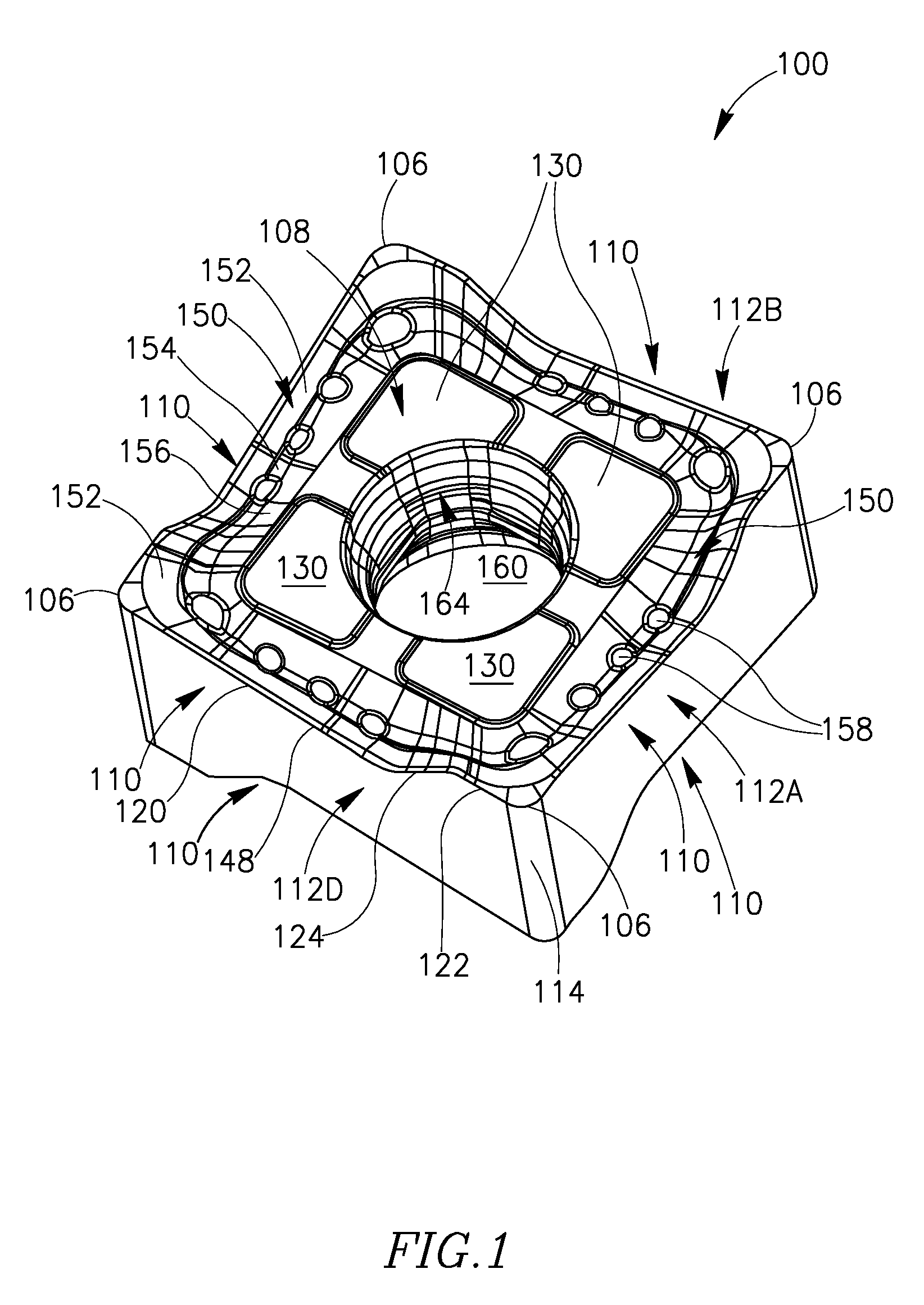

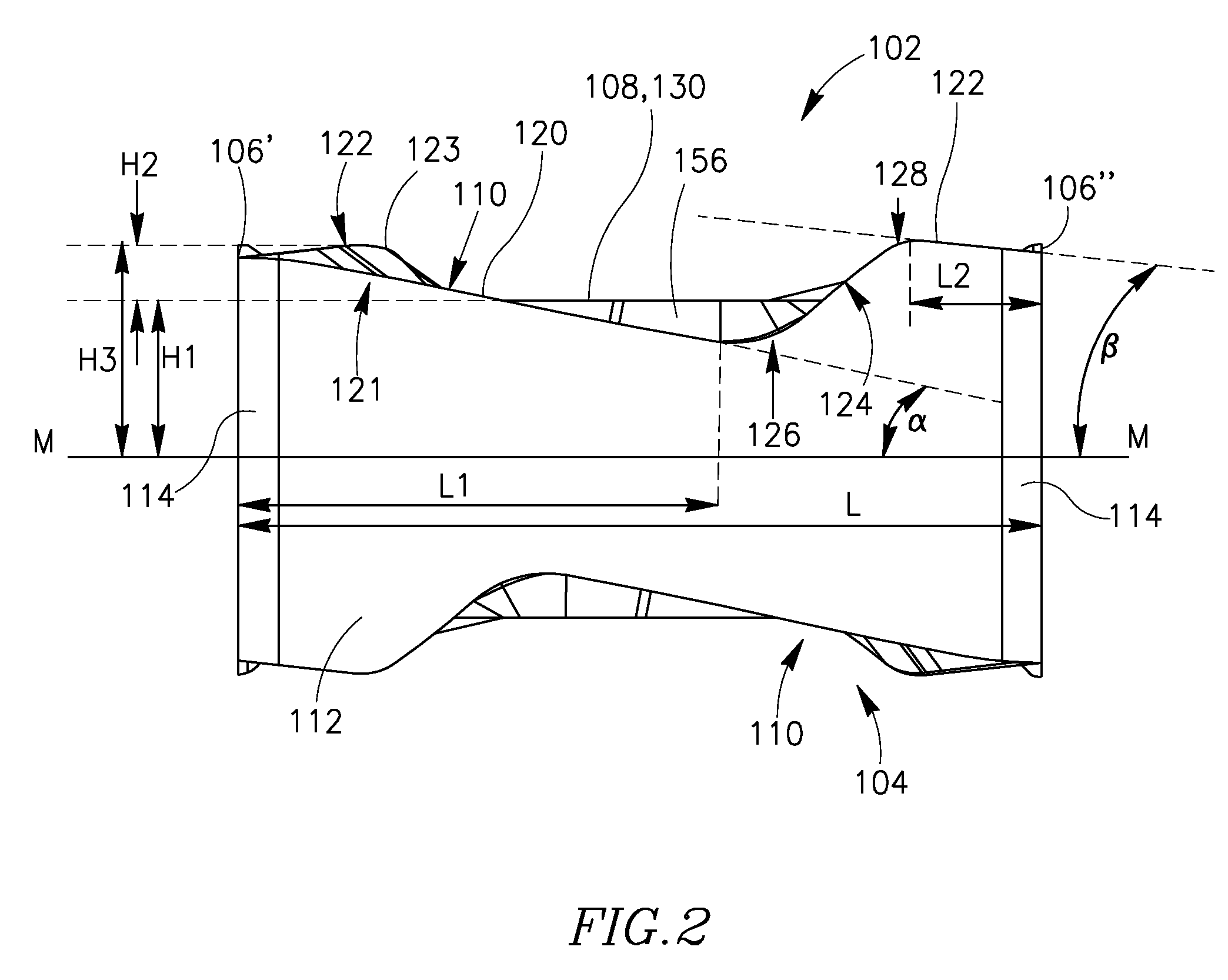

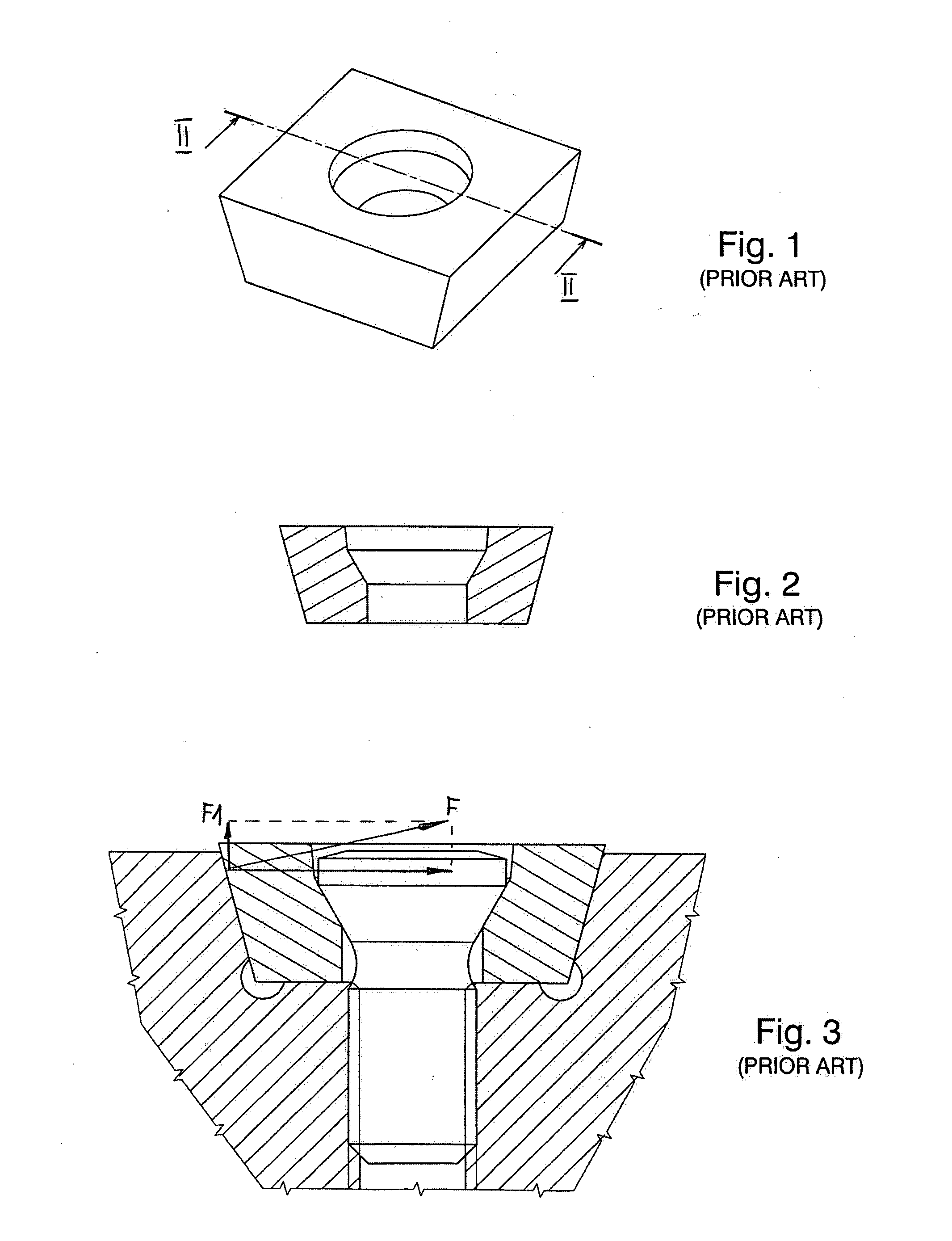

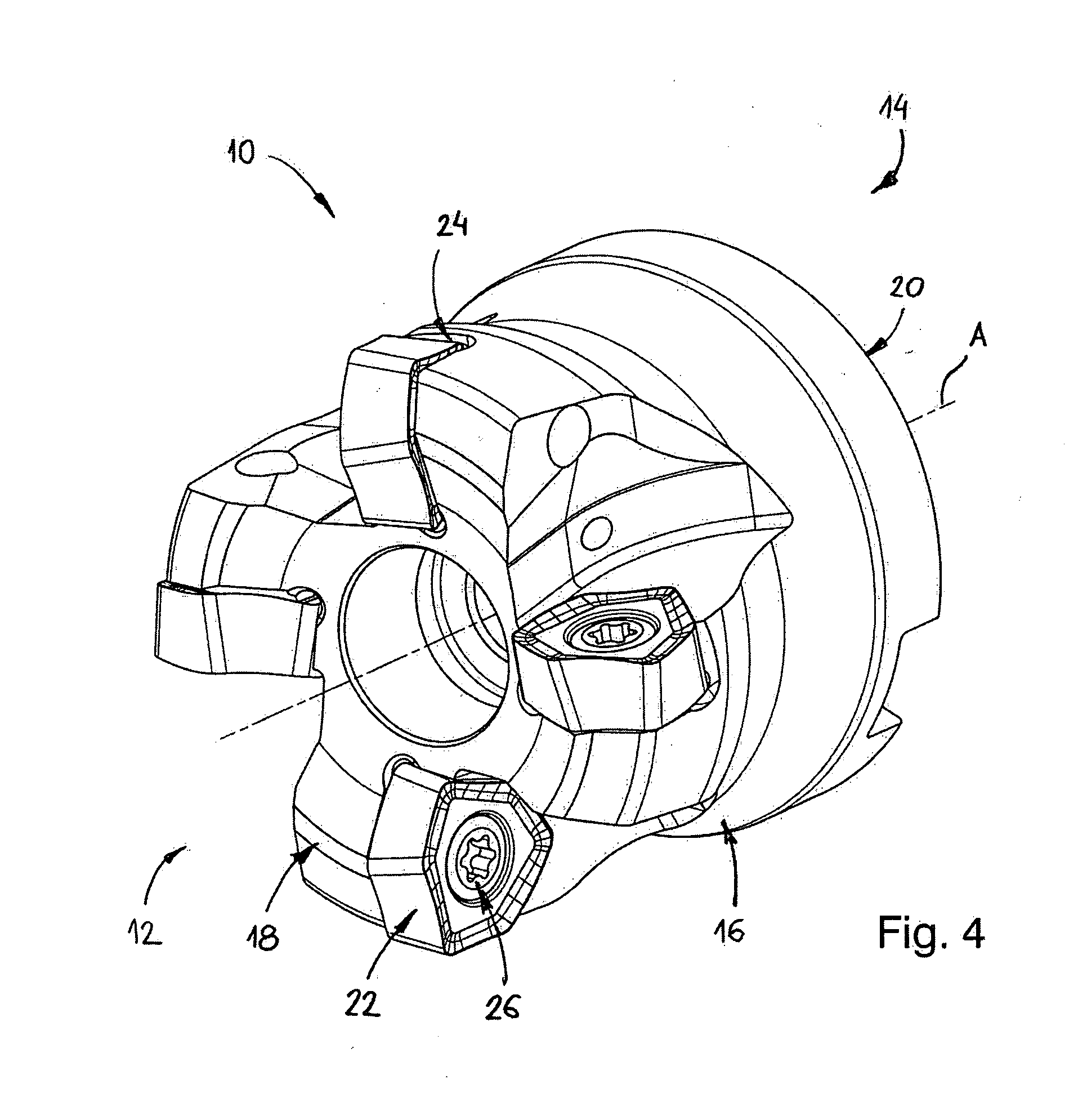

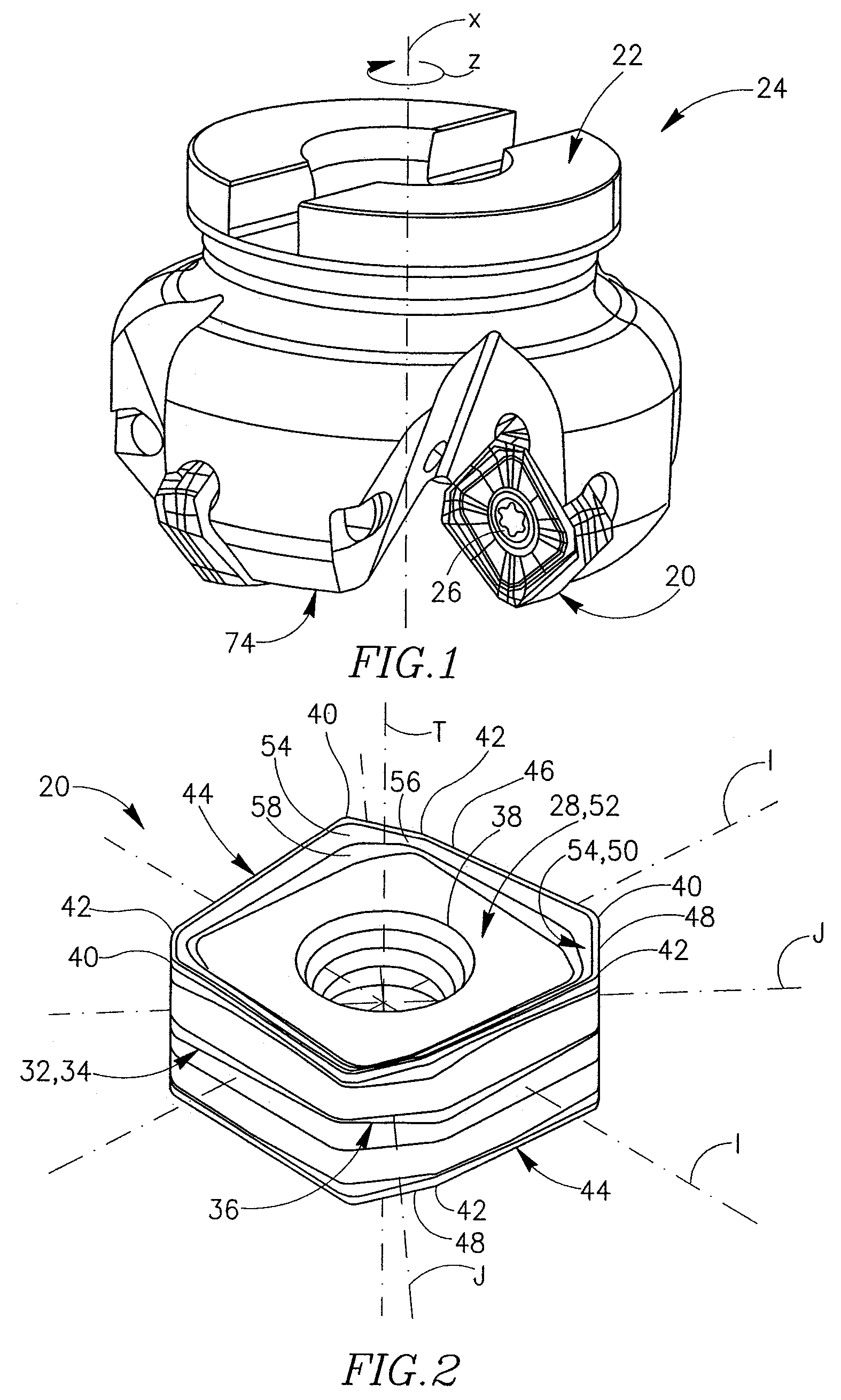

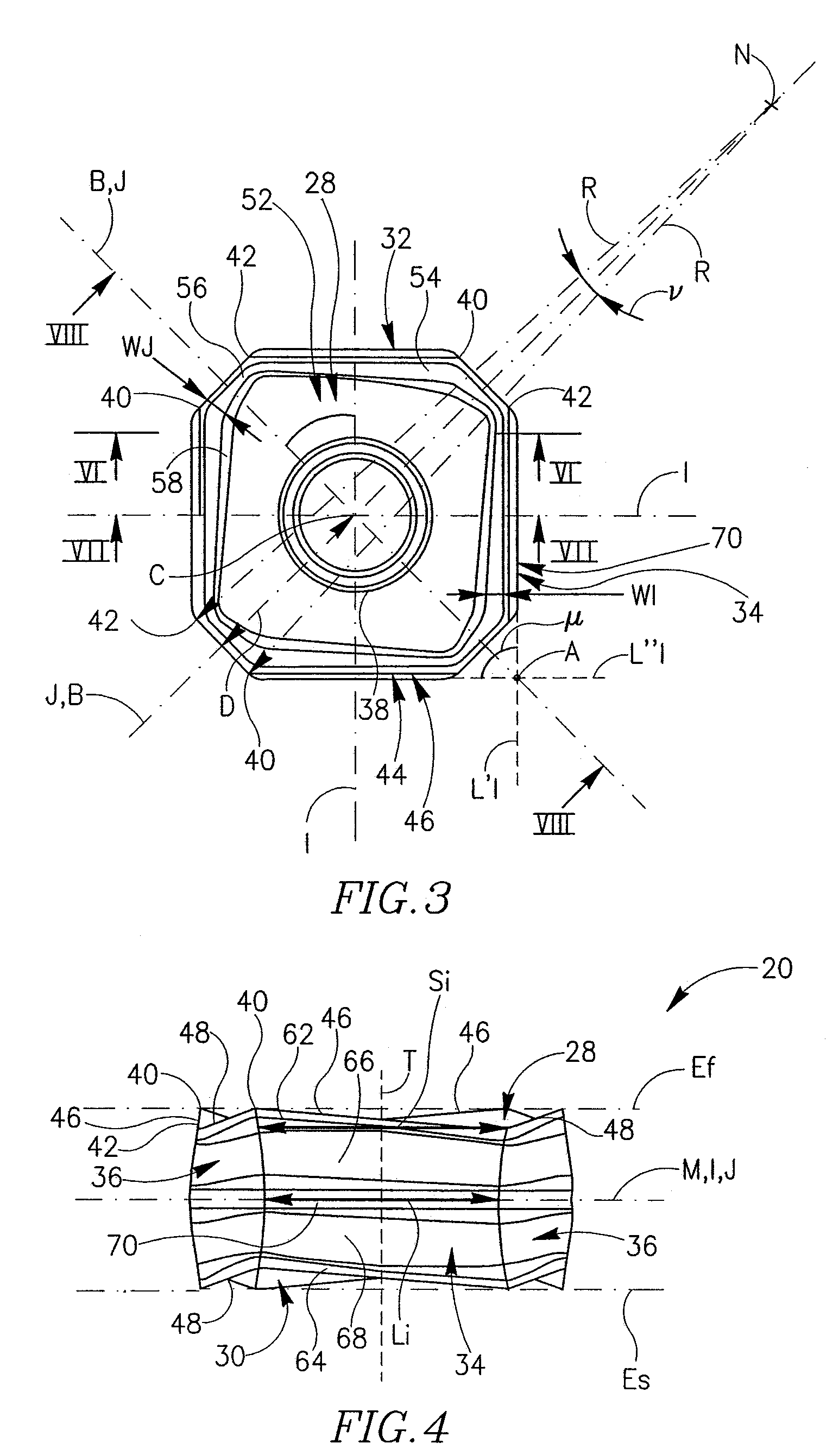

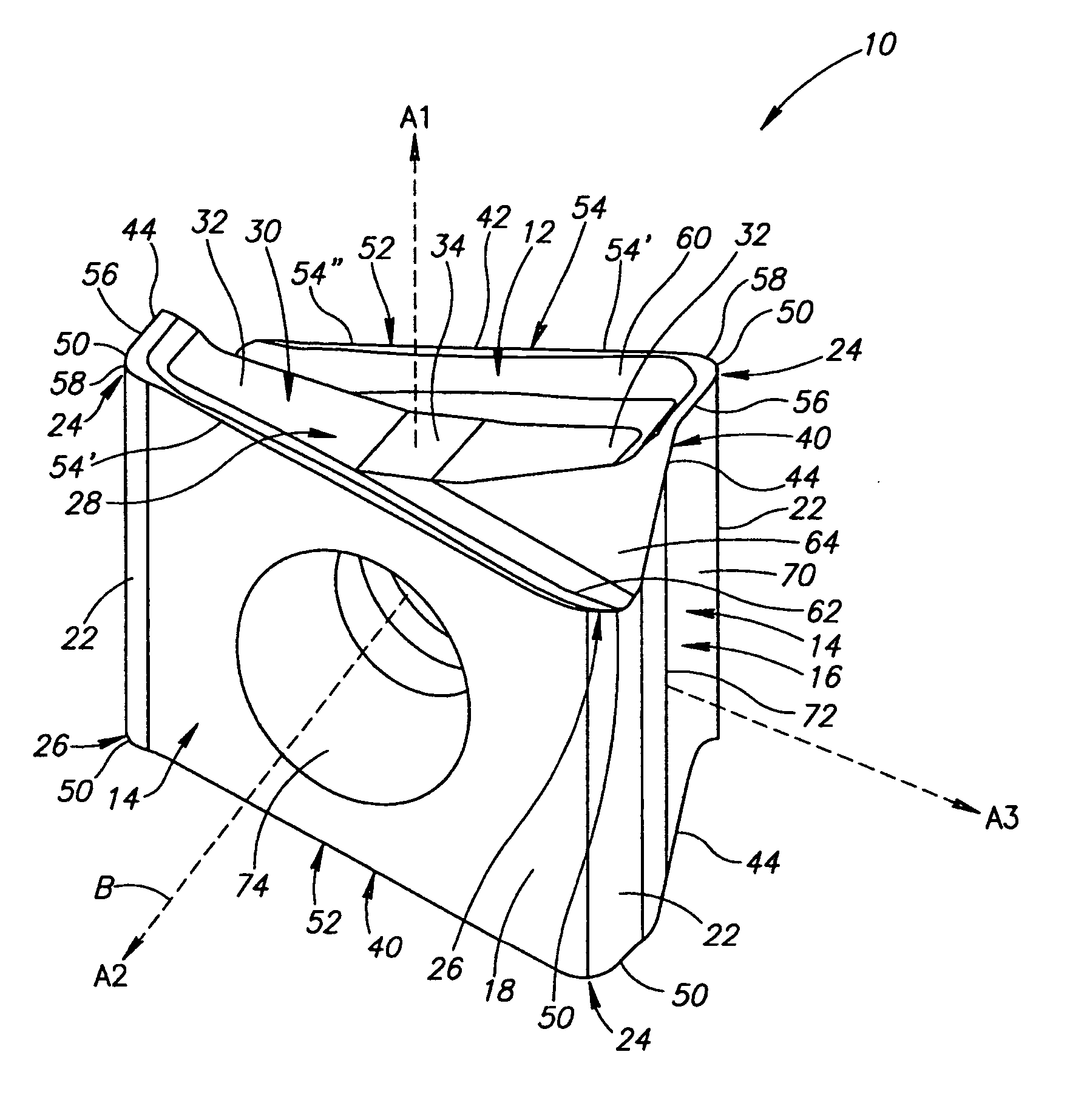

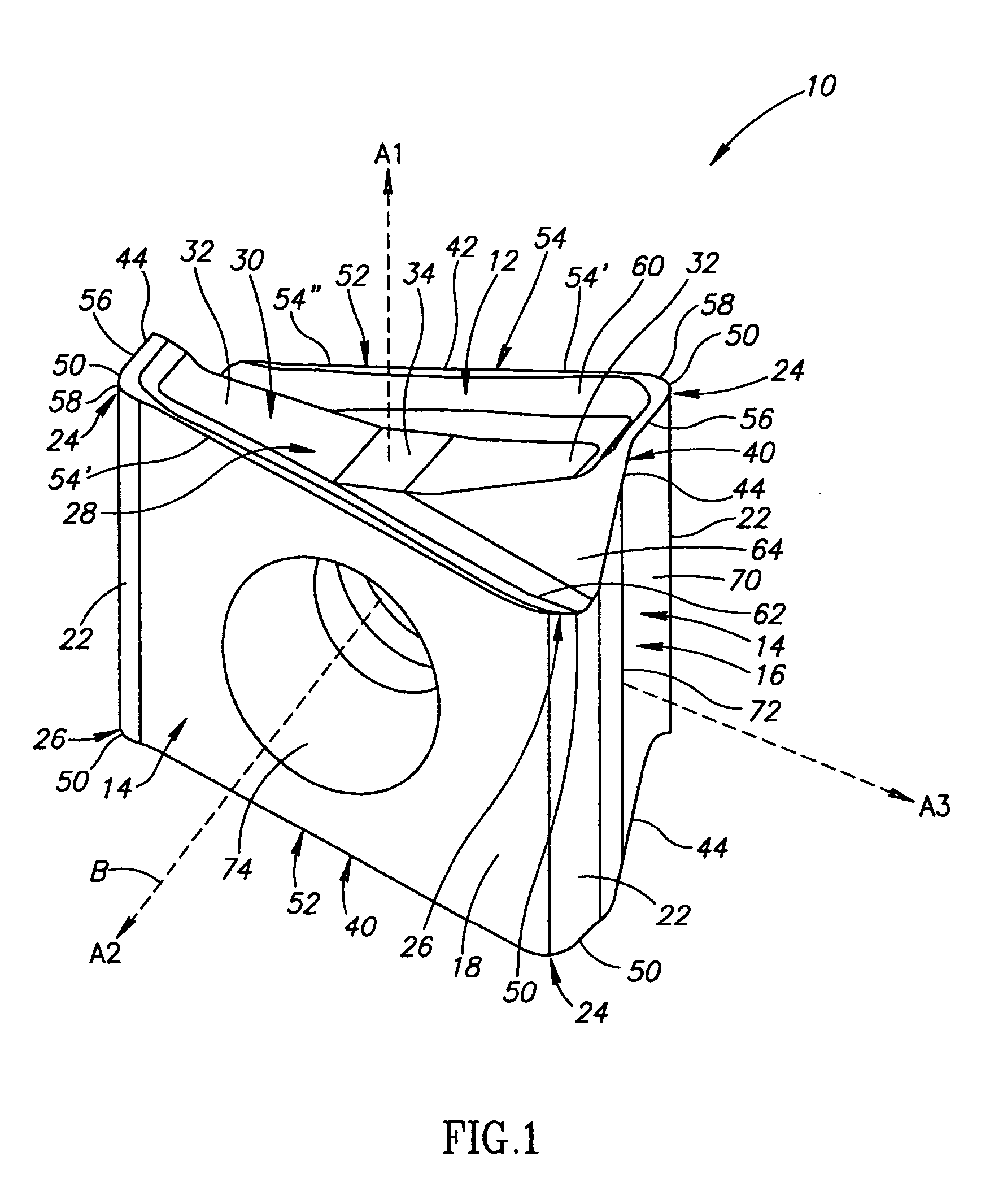

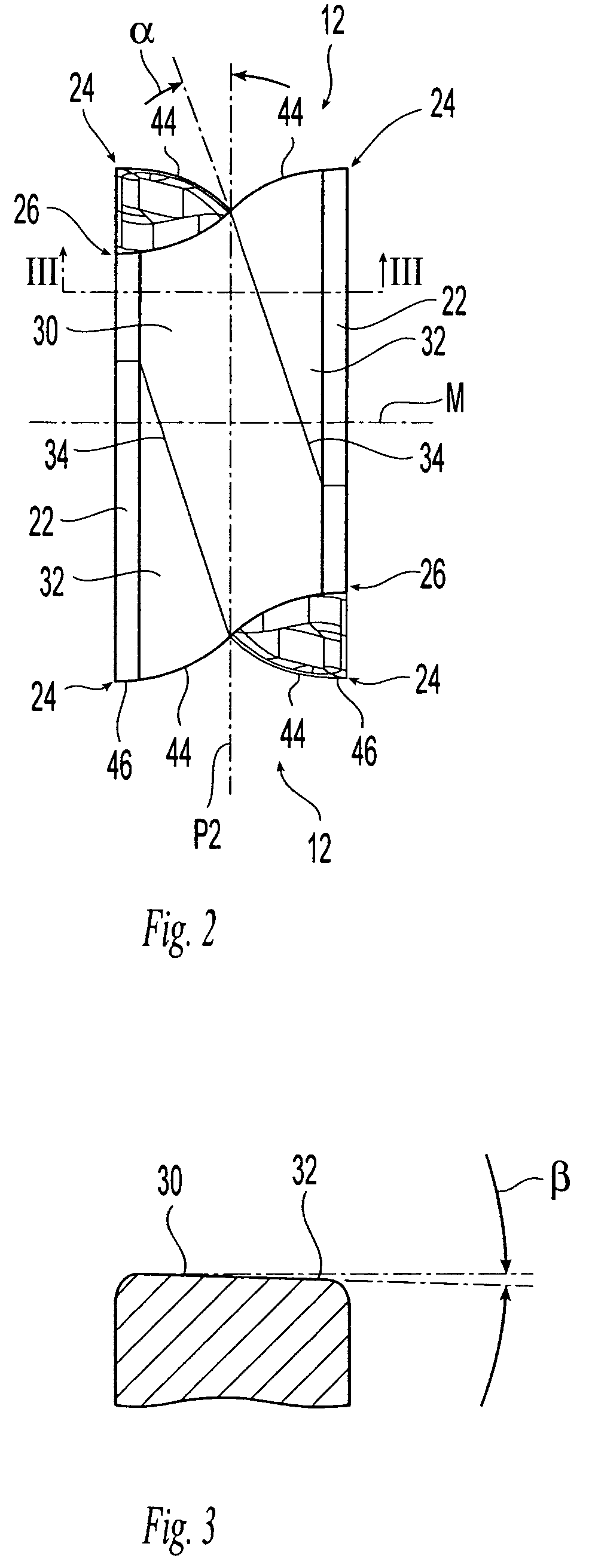

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

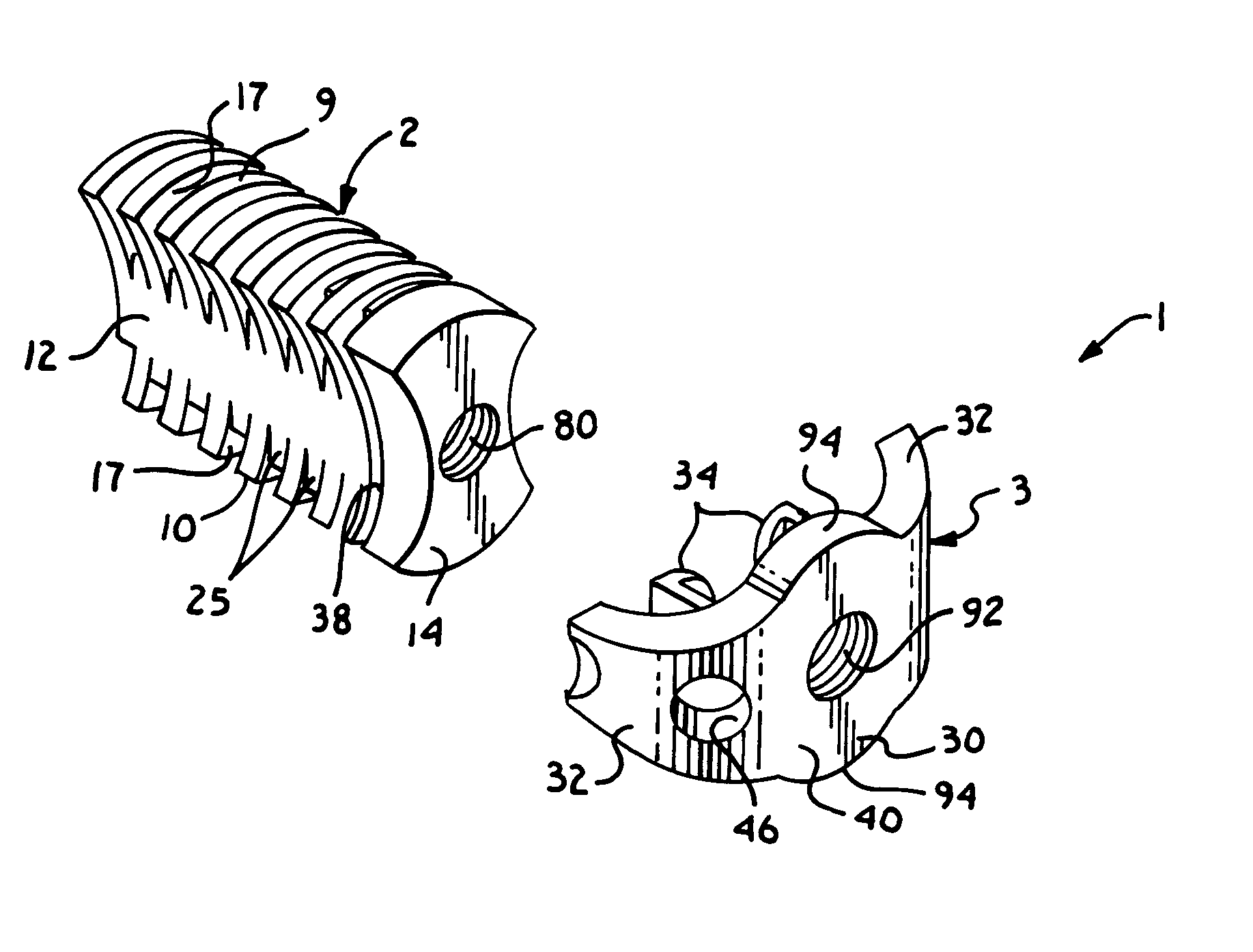

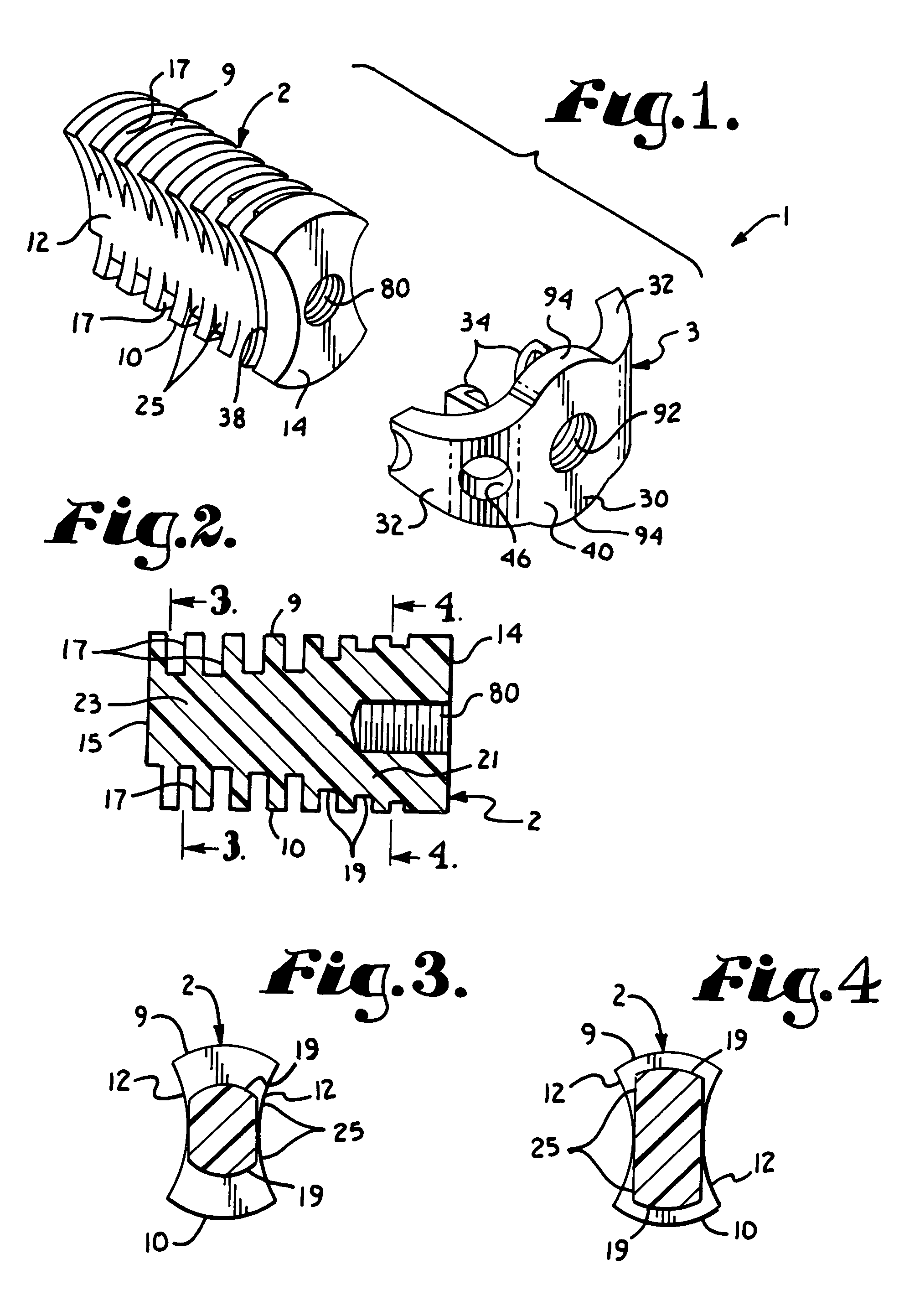

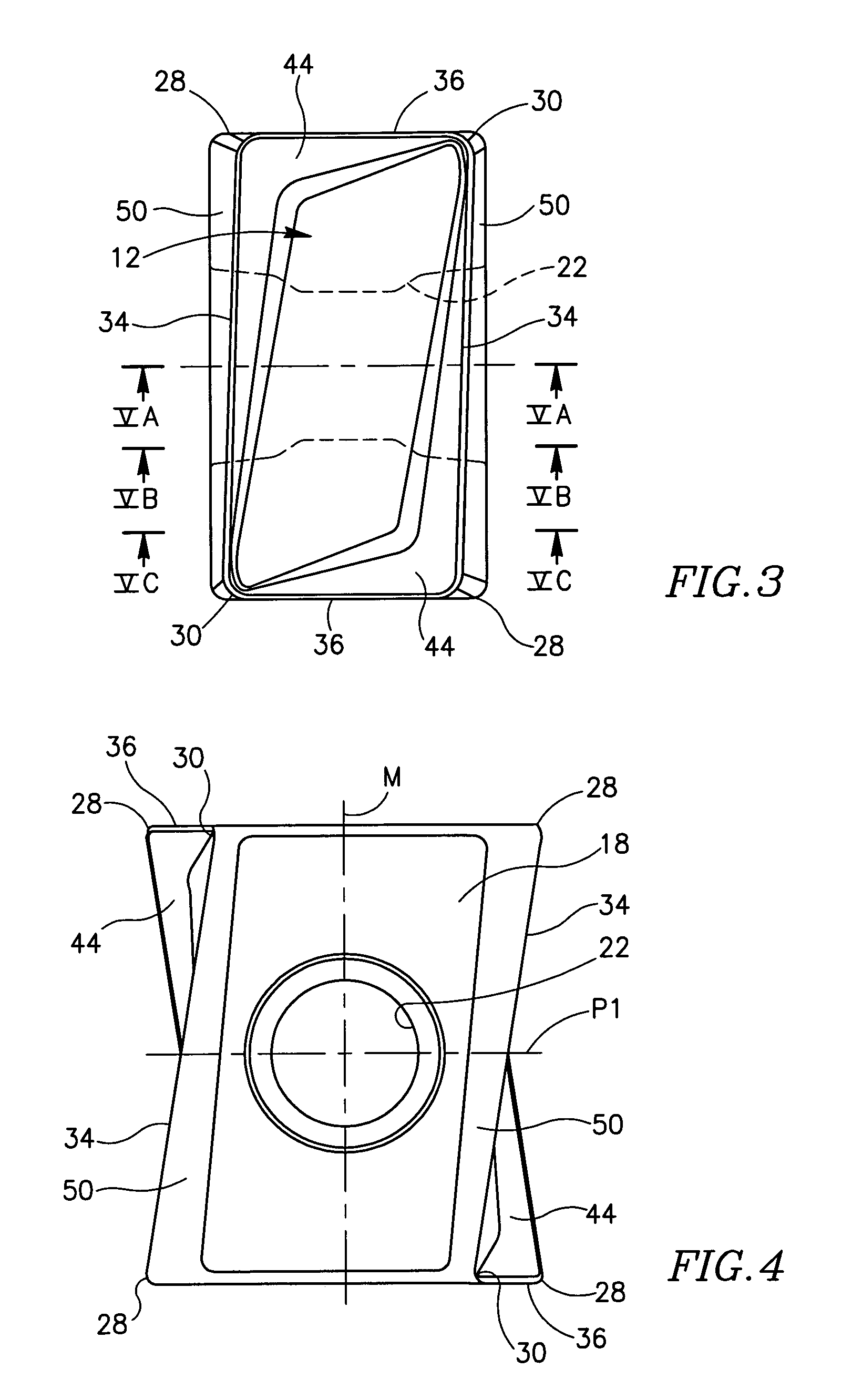

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

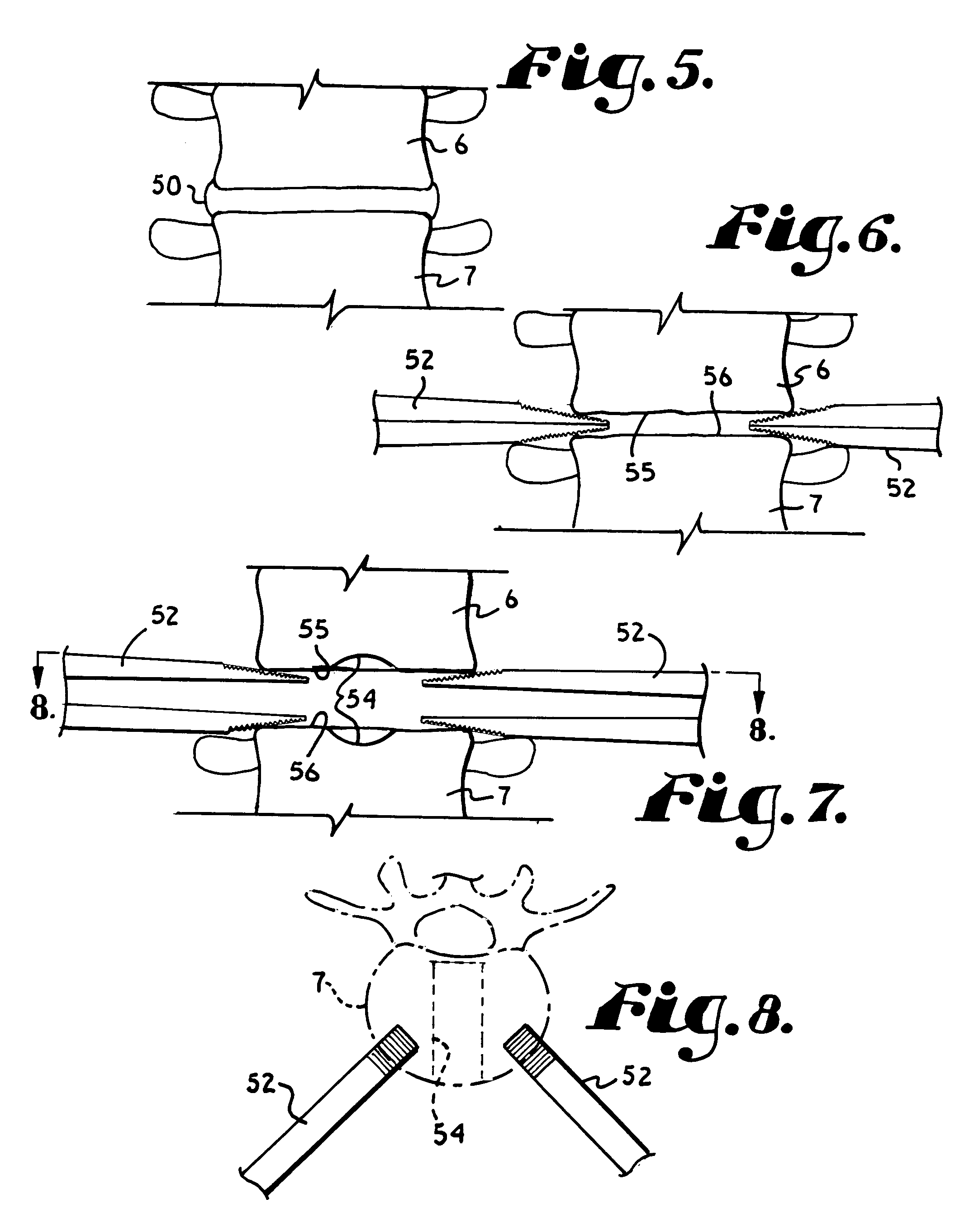

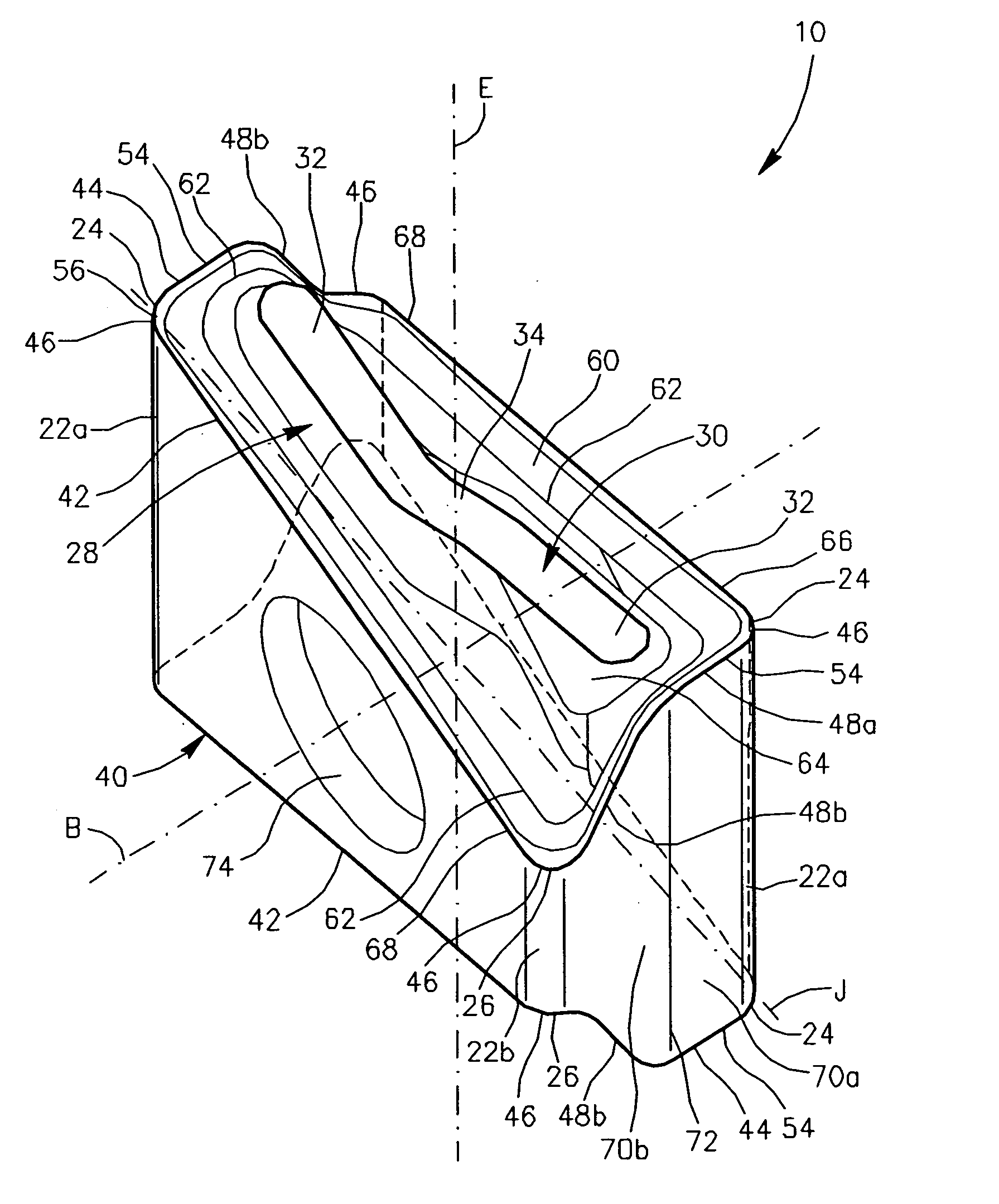

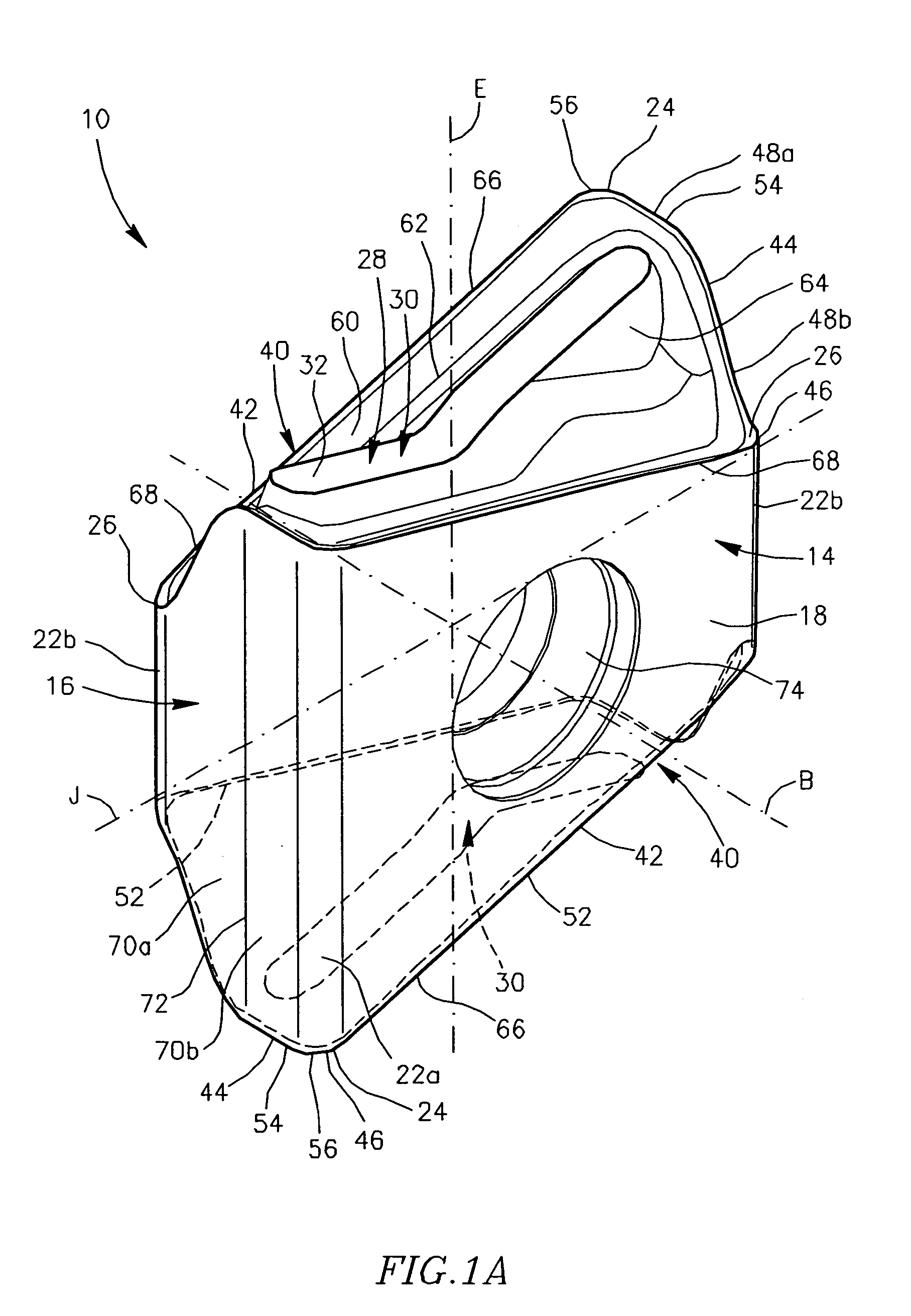

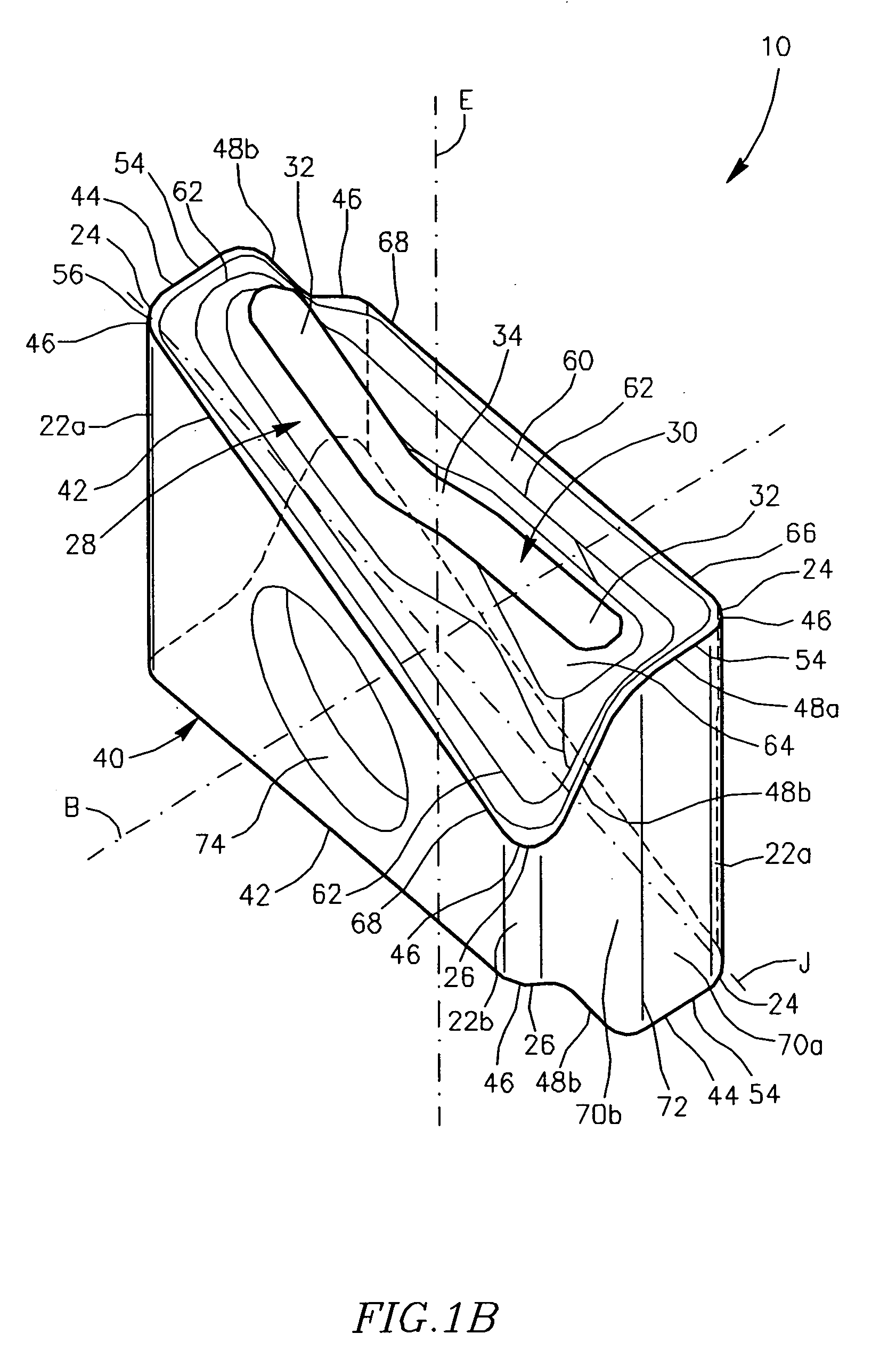

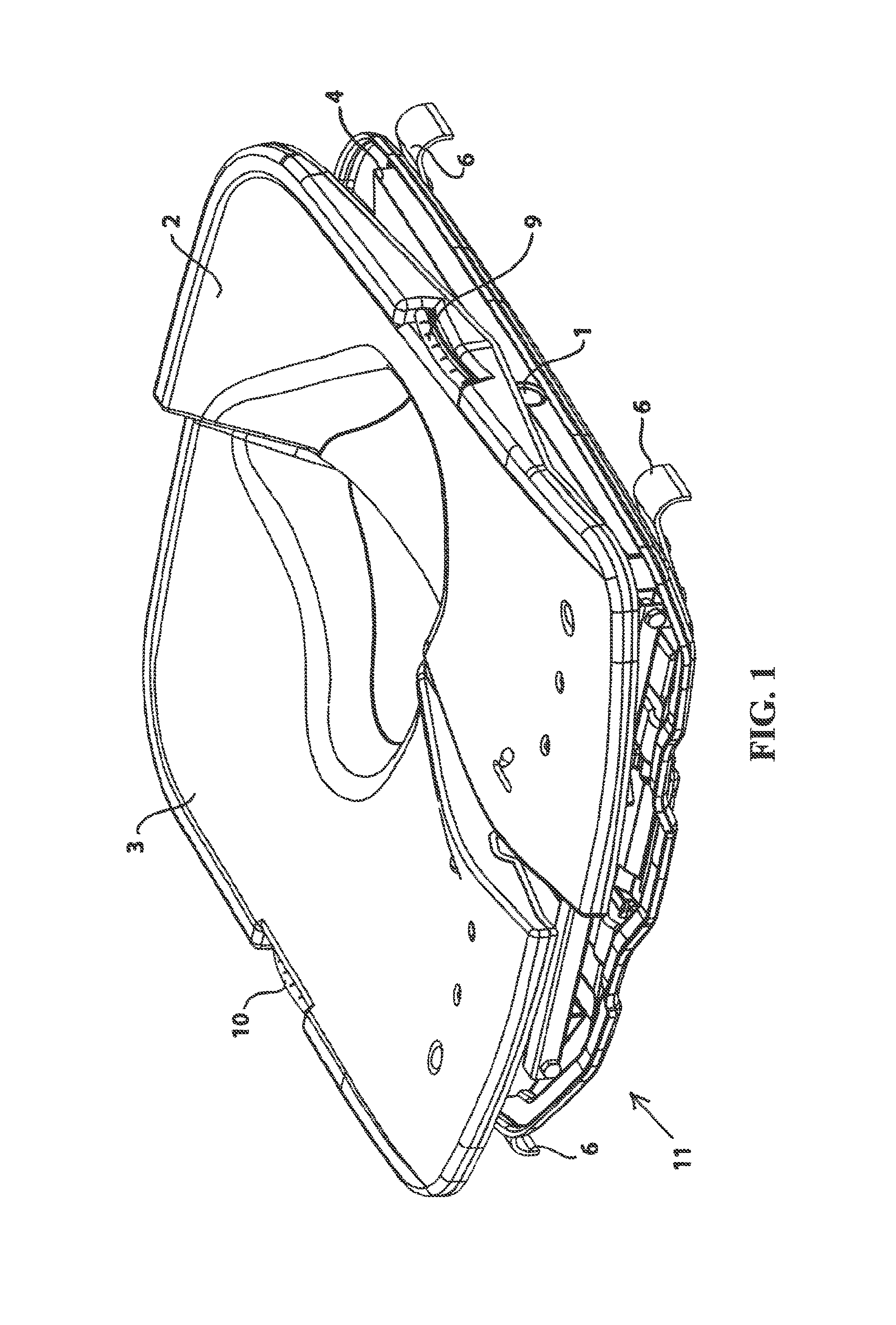

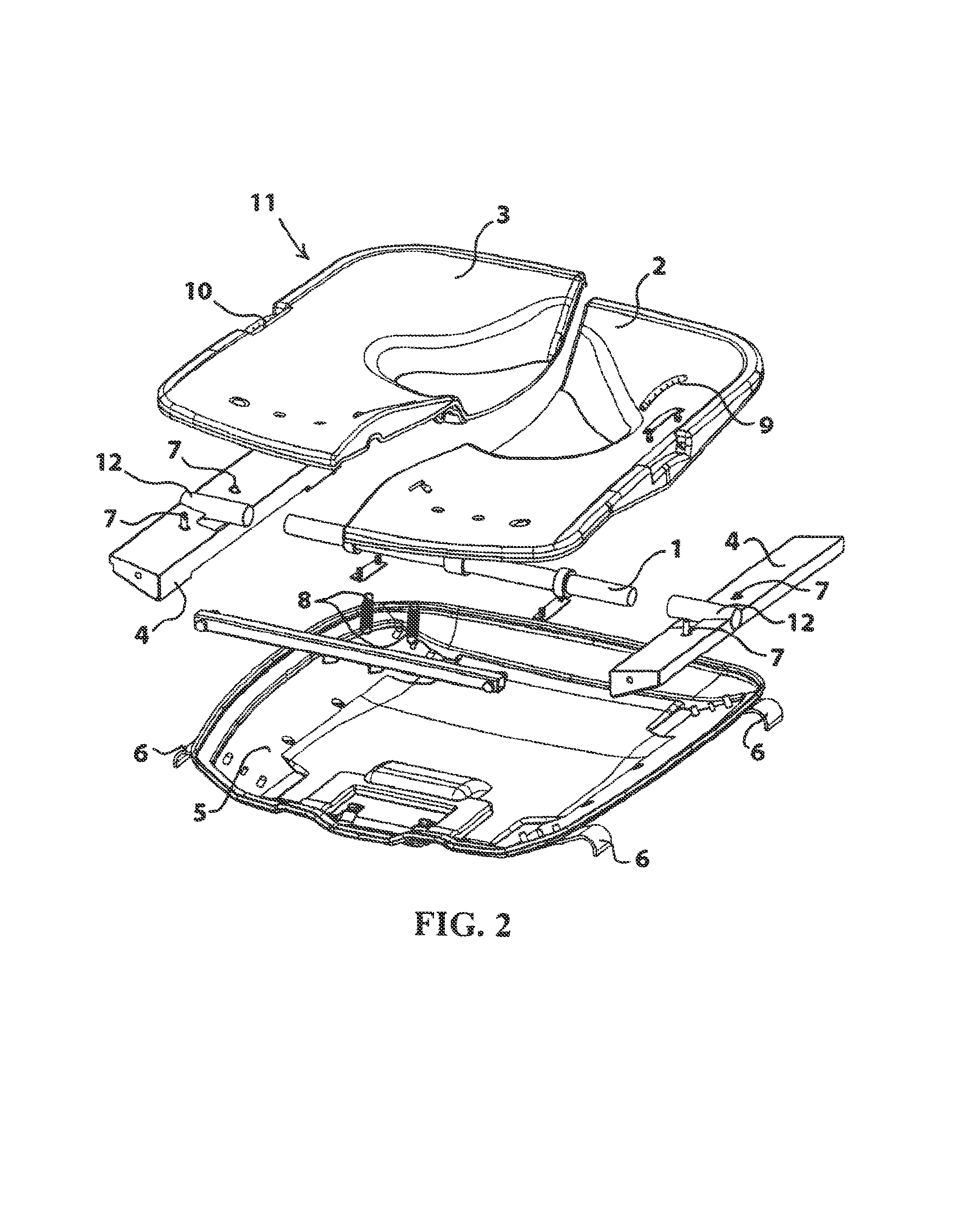

Knee brace and method for securing the same

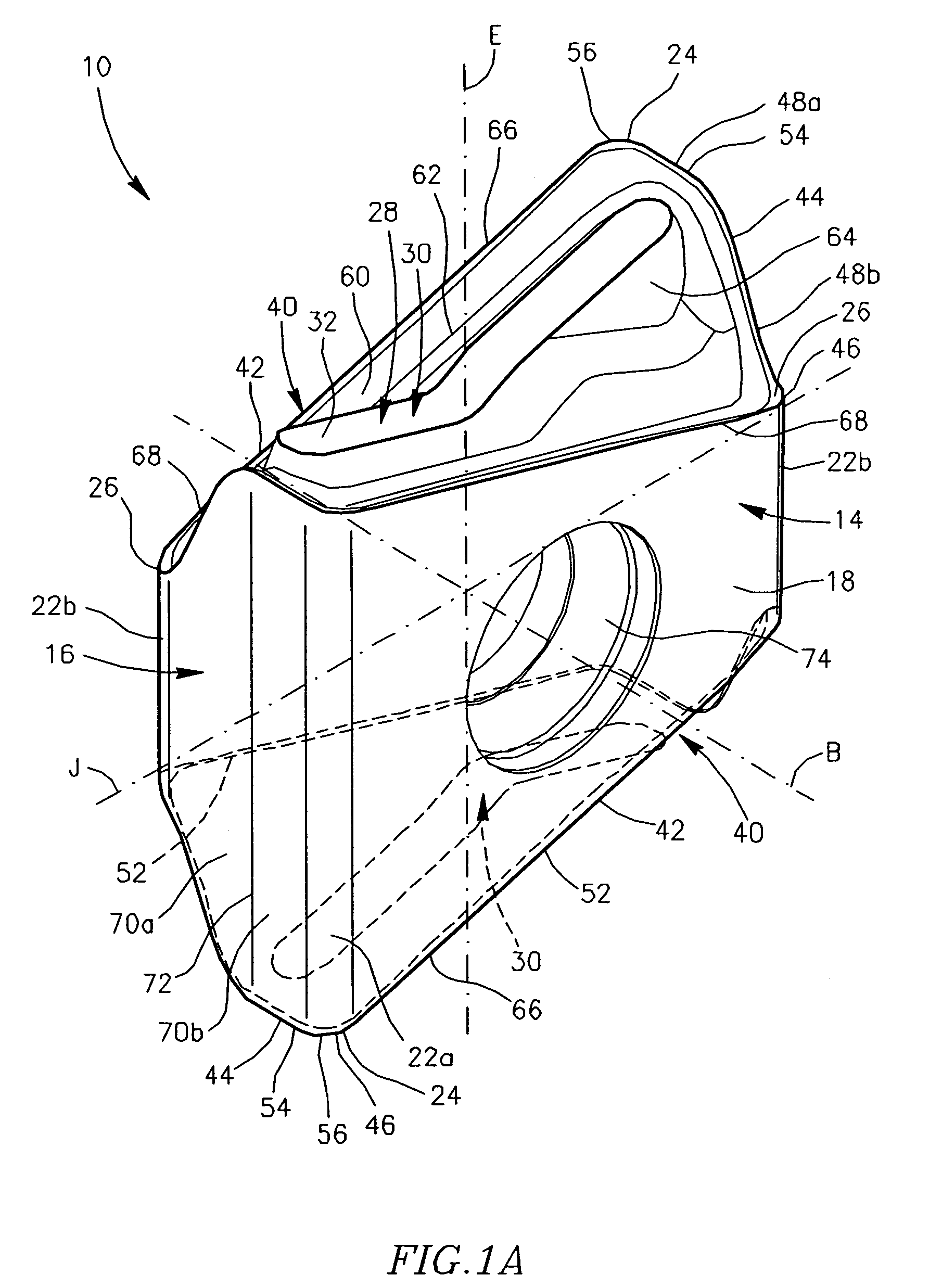

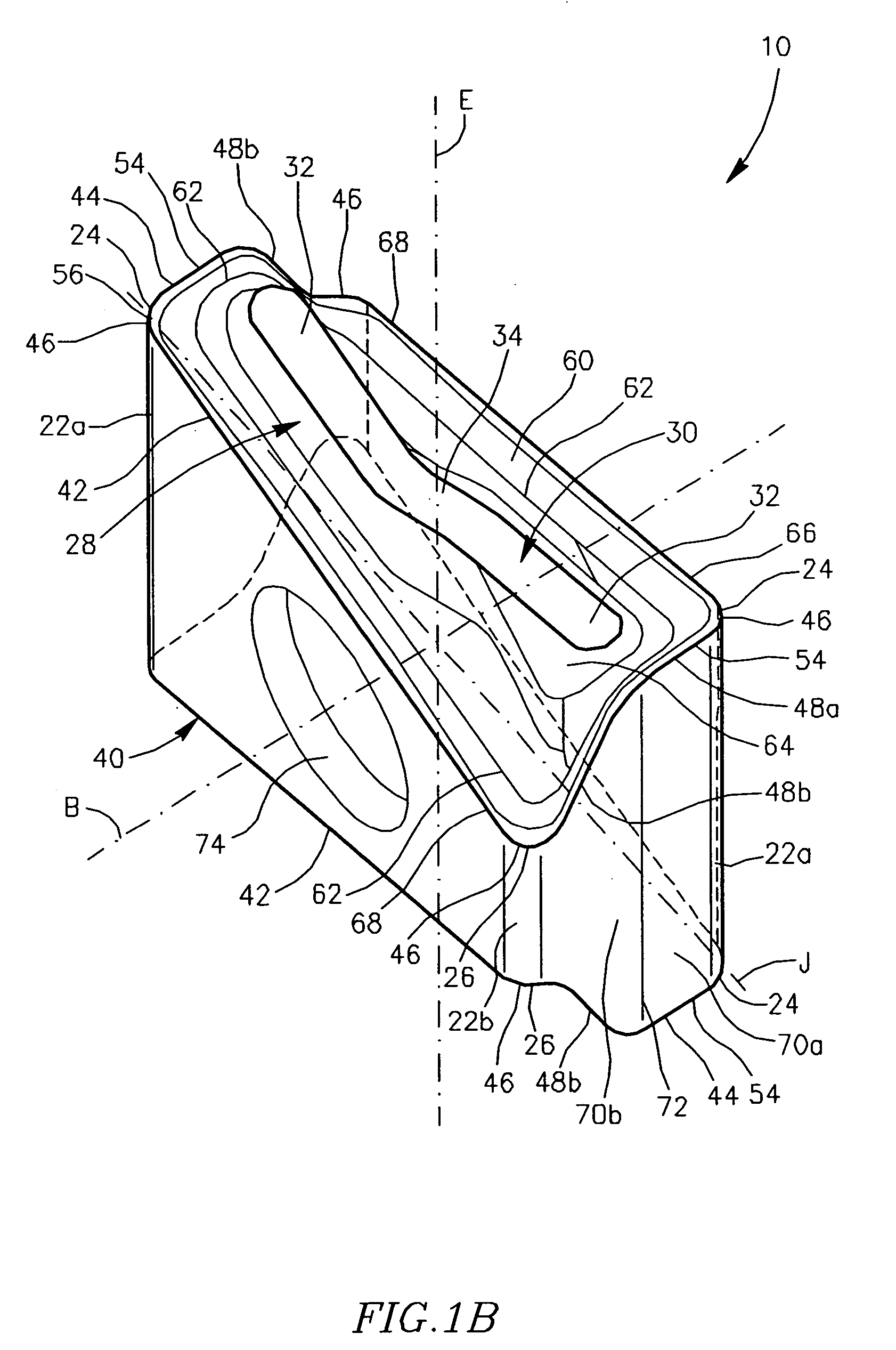

ActiveUS20060135901A1Reduce the impactMinimizing rotational forceNon-surgical orthopedic devicesMedian planeKnee braces

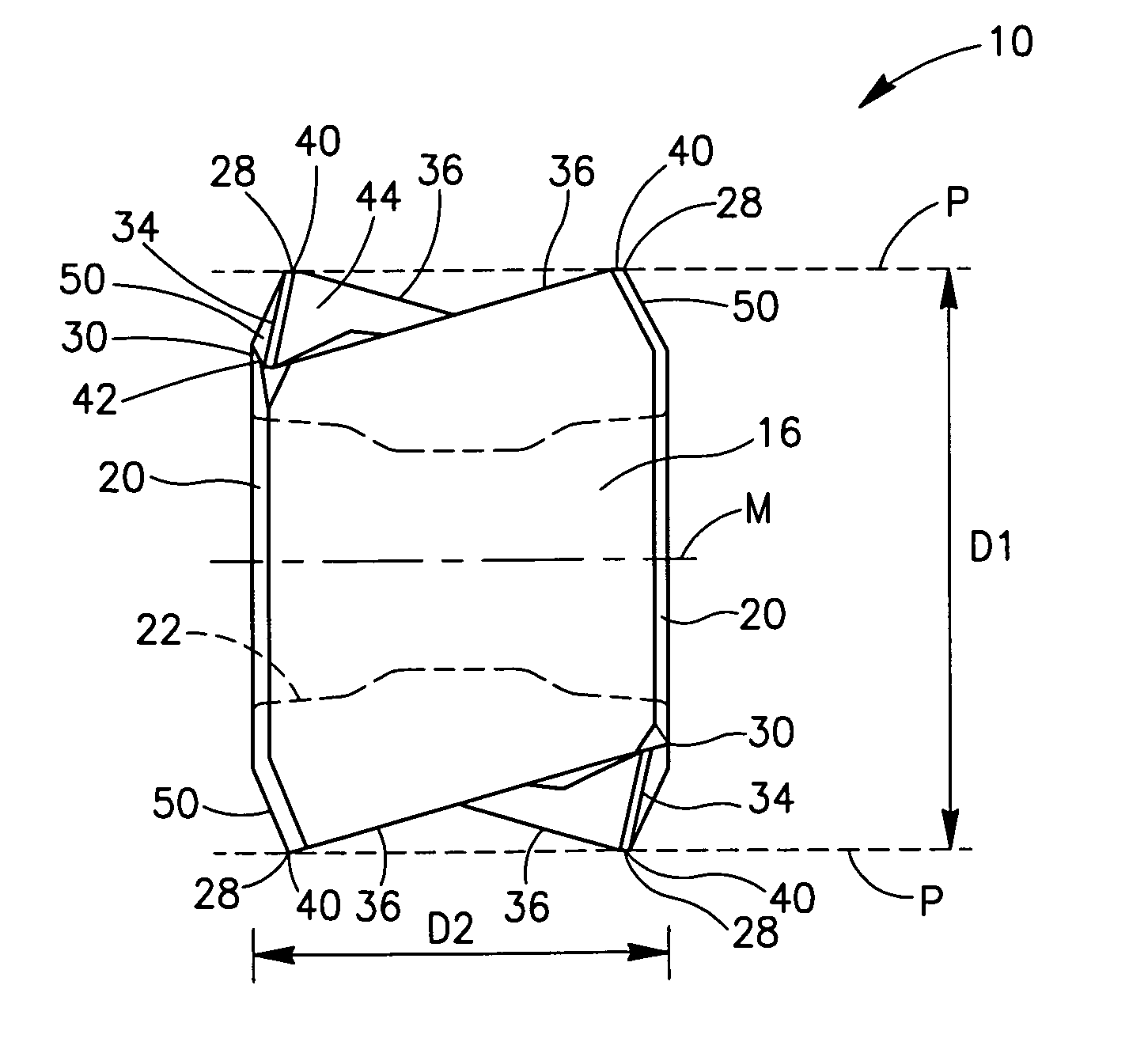

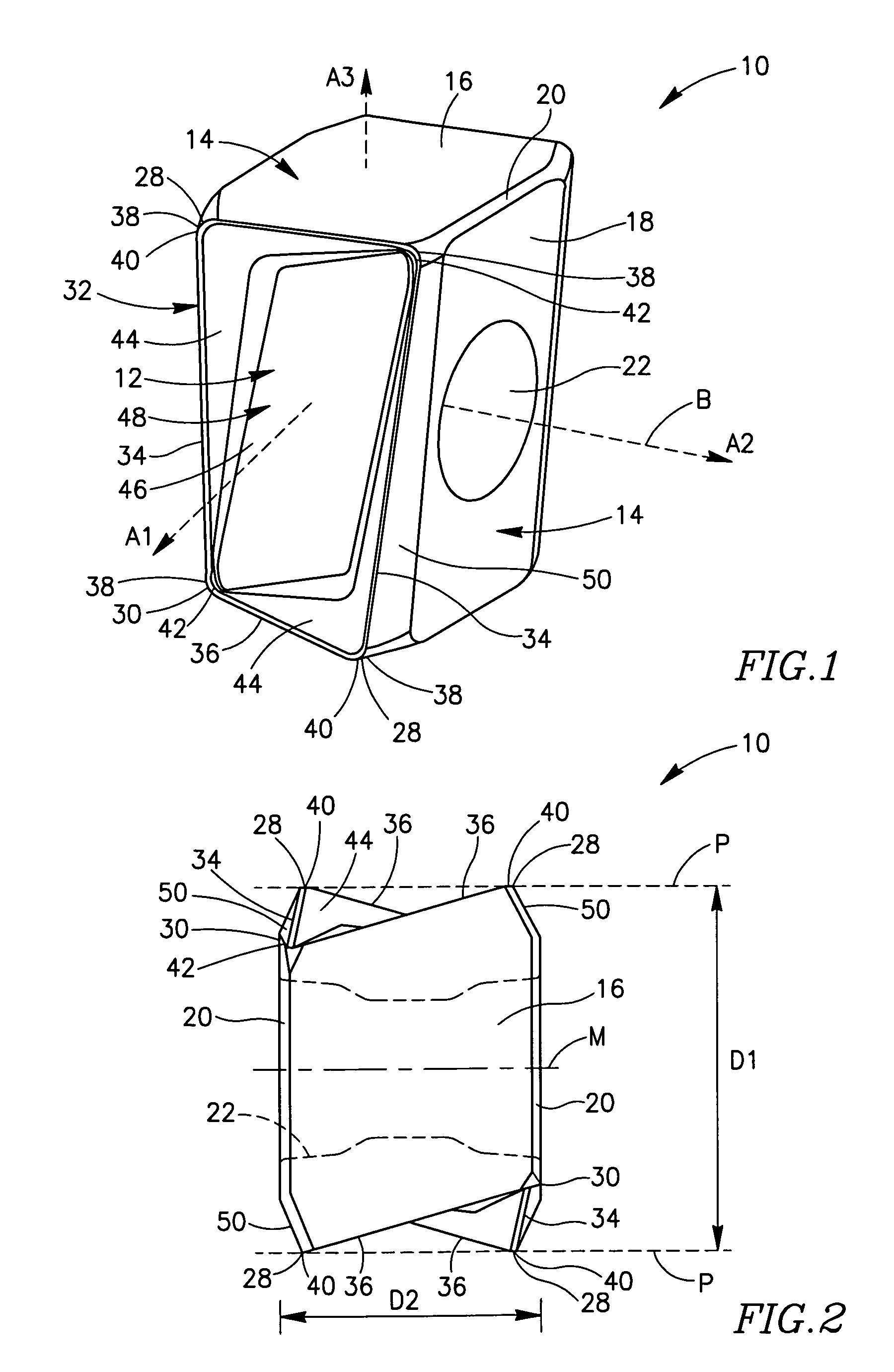

A knee brace divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace having a frame, and at least one cross strap that is connected to the frame and extends across over at least a portion of the first and second brace sides. The at least one cross strap is arranged obliquely relative to the median plane. The brace also includes a tightening mechanism that is connected to the frame and is configured to incrementally tension the at least one cross strap at predefined settings and to release tension on the at least one cross strap. A first end of the at least one cross strap engages the tightening mechanism. A dosage meter is connected to the frame, and includes an indication feature representing tension settings of the at least one cross strap.

Owner:KAUPTHING BANK

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

Cutting Insert Having Cylindrically Shaped Side Surface Portions

ActiveUS20070003384A1Reduced cutting performanceReduce the impactMilling cuttersCutting insertsRotational symmetryMedian plane

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

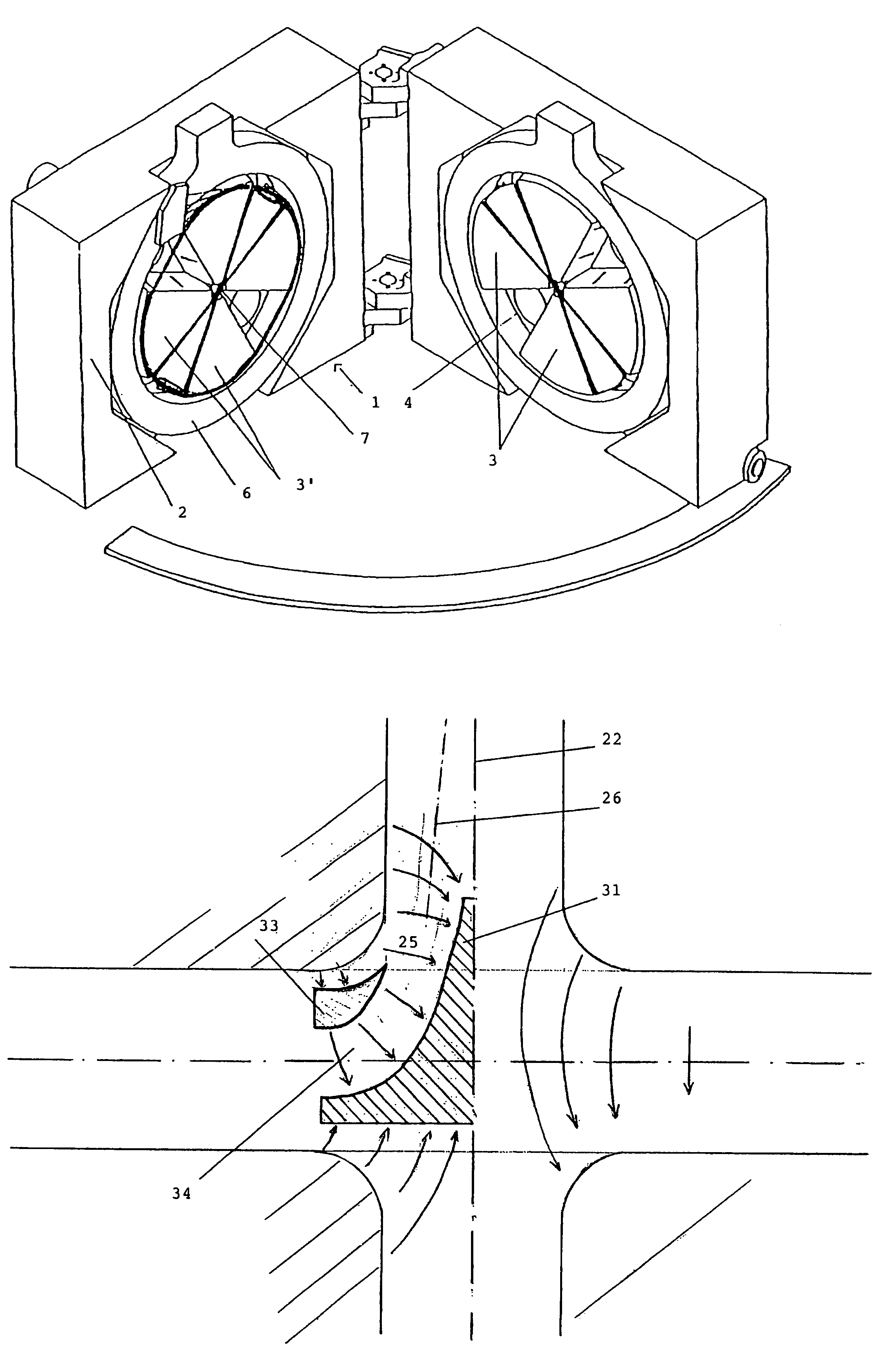

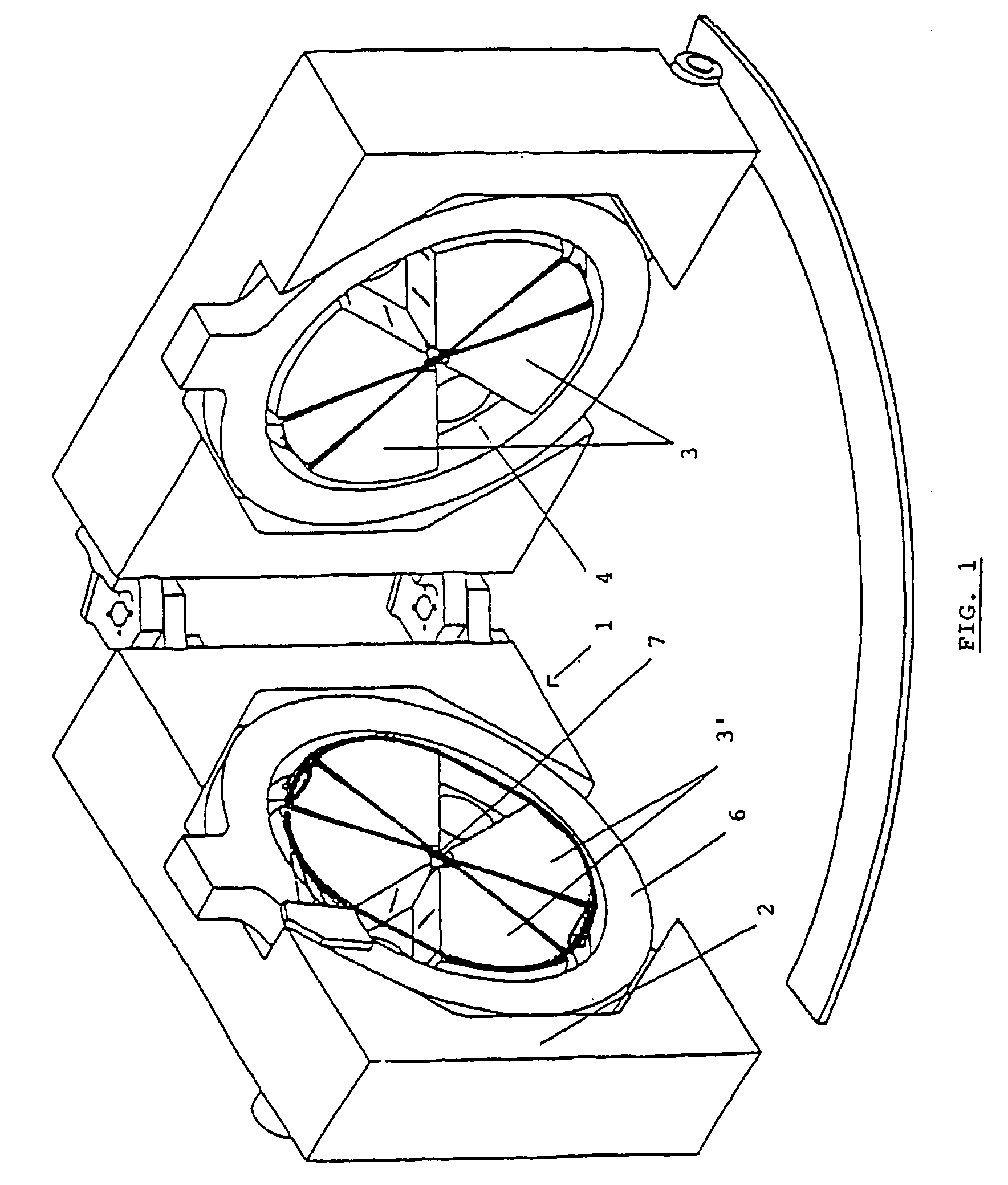

Cyclotron equipped with novel particle beam deflecting means

The invention concerns a cyclotron for accelerating a charged particle beam circulating in the median plane essentially in the form of two poles inducing a magnetic field and having a so-called axial injector, that is an injector arranged outside the cyclotron substantially along the main axis of the cyclotron and hence perpendicular to the median plane thereof and which is combined with deflecting means which enable the particle beam to be deflected until it is positioned in the median plane. The invention is characterized in that the deflecting means consist of a magnetic deflector.

Owner:ION BEAM APPL

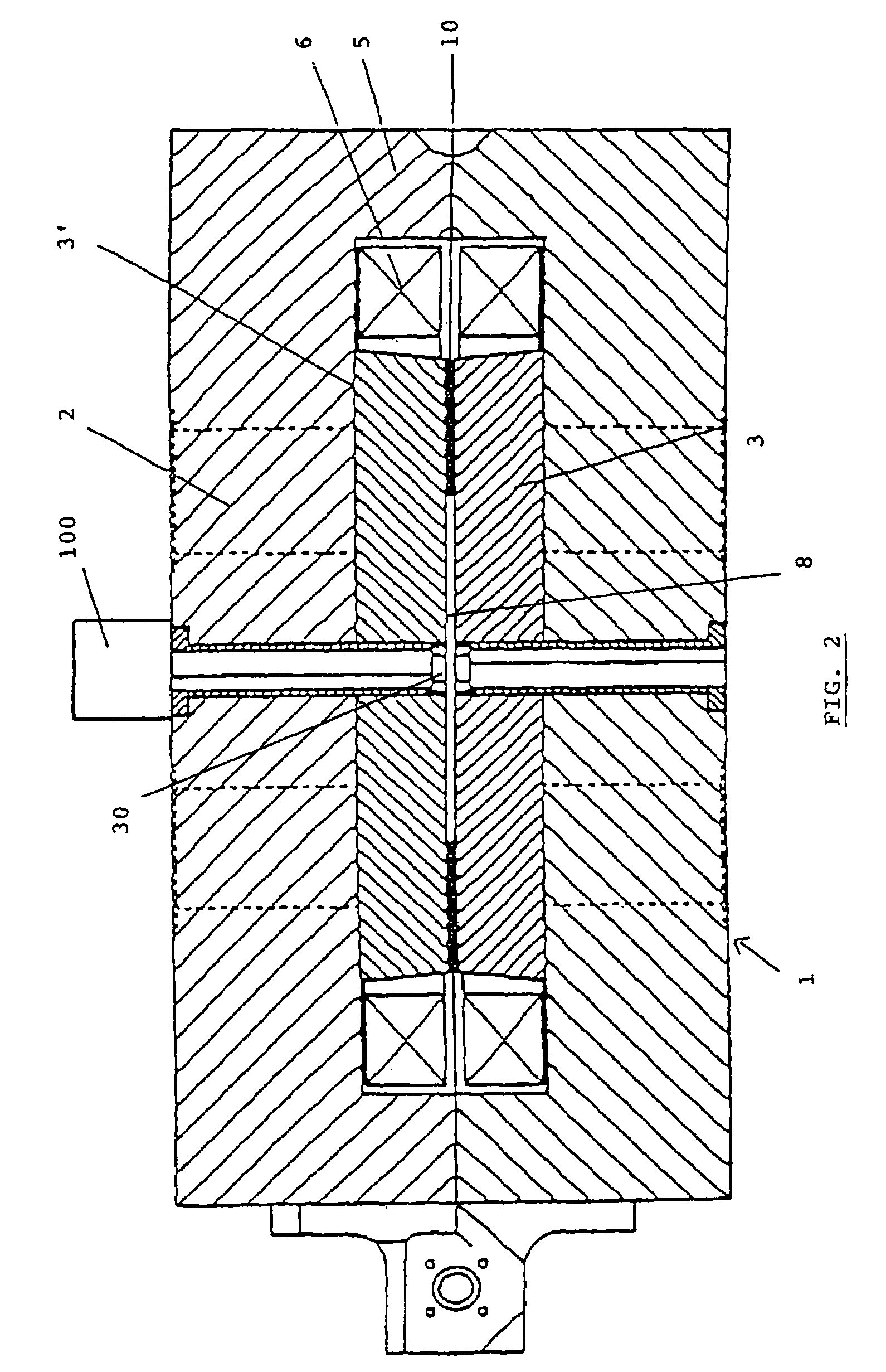

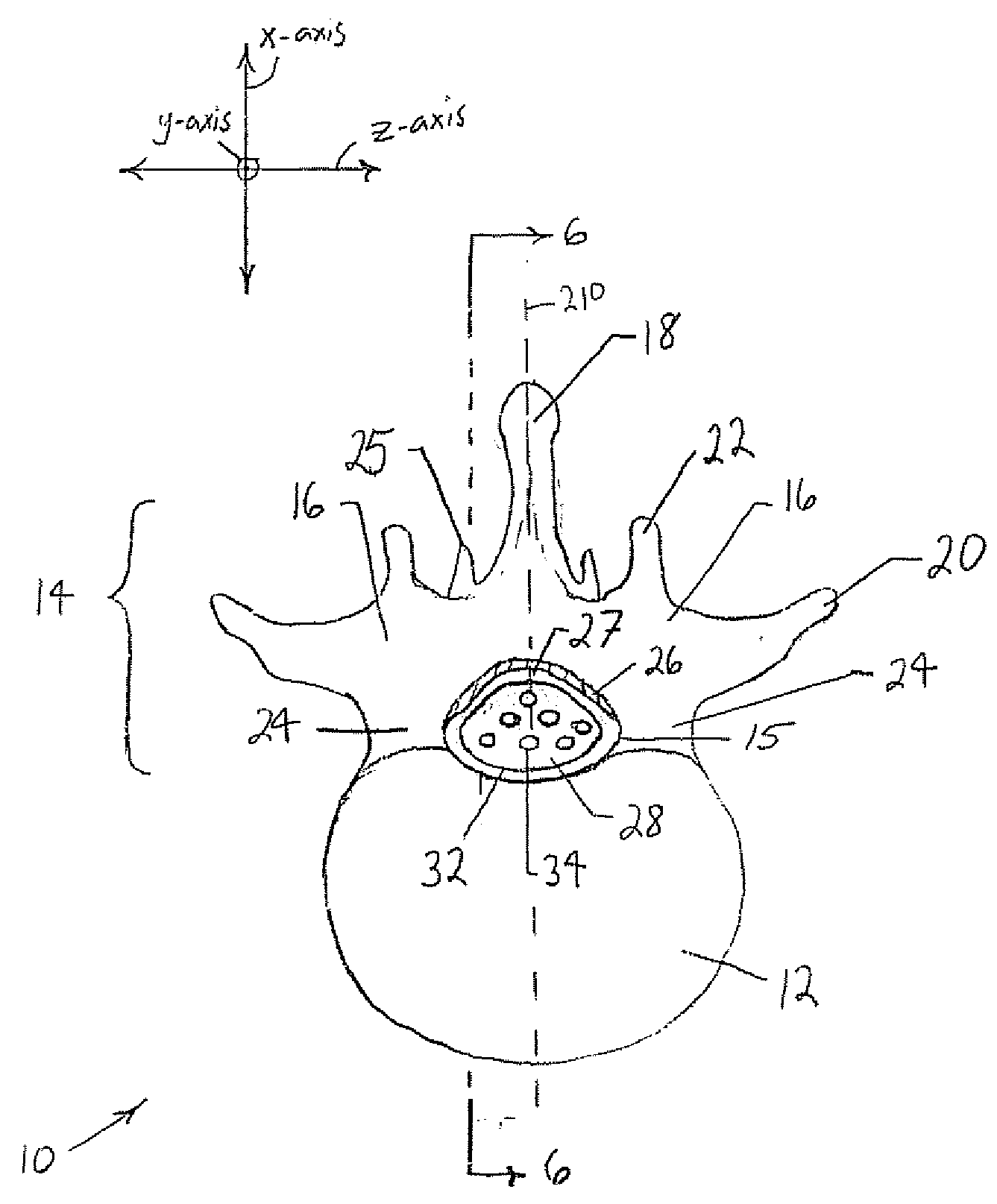

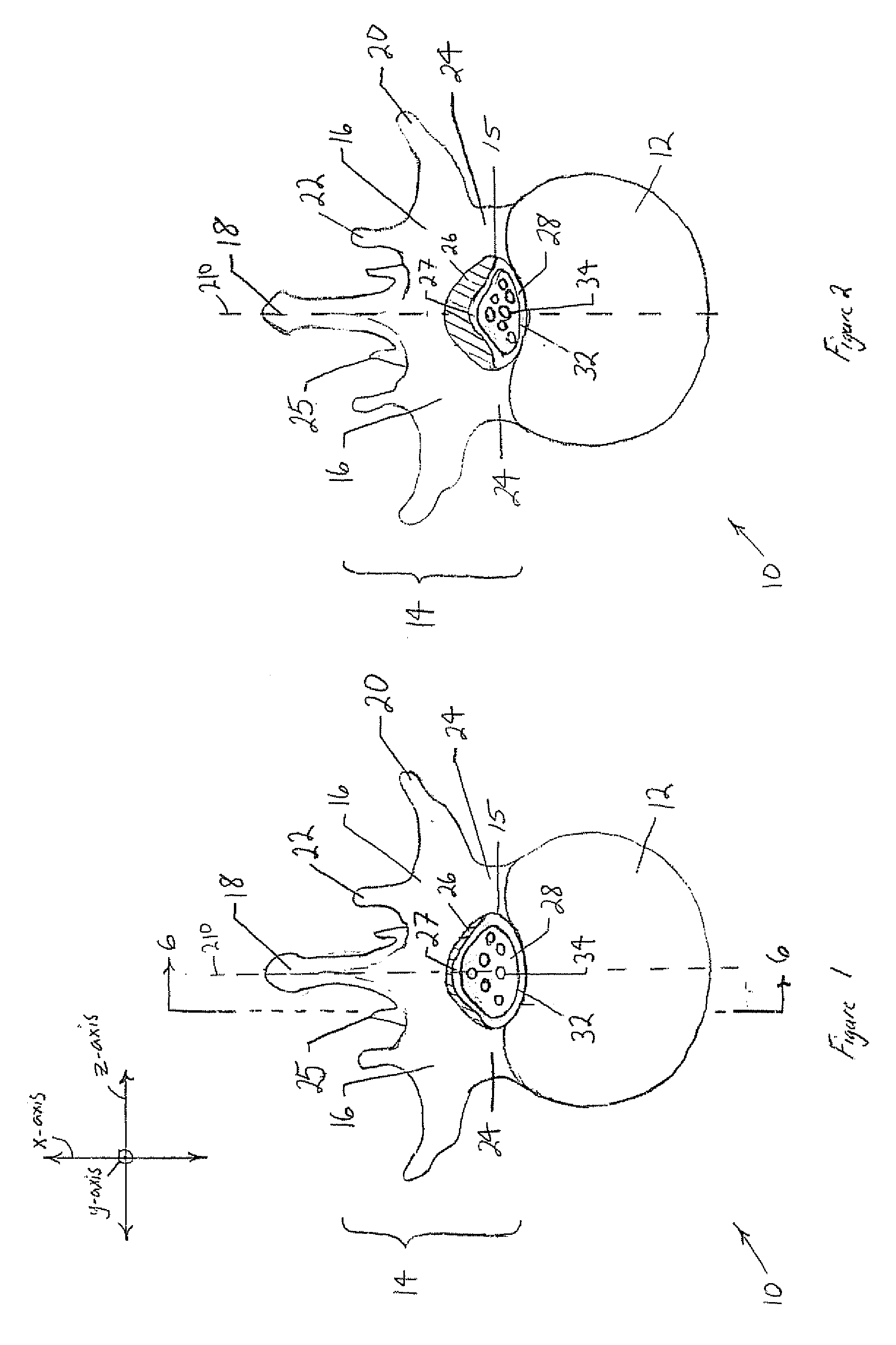

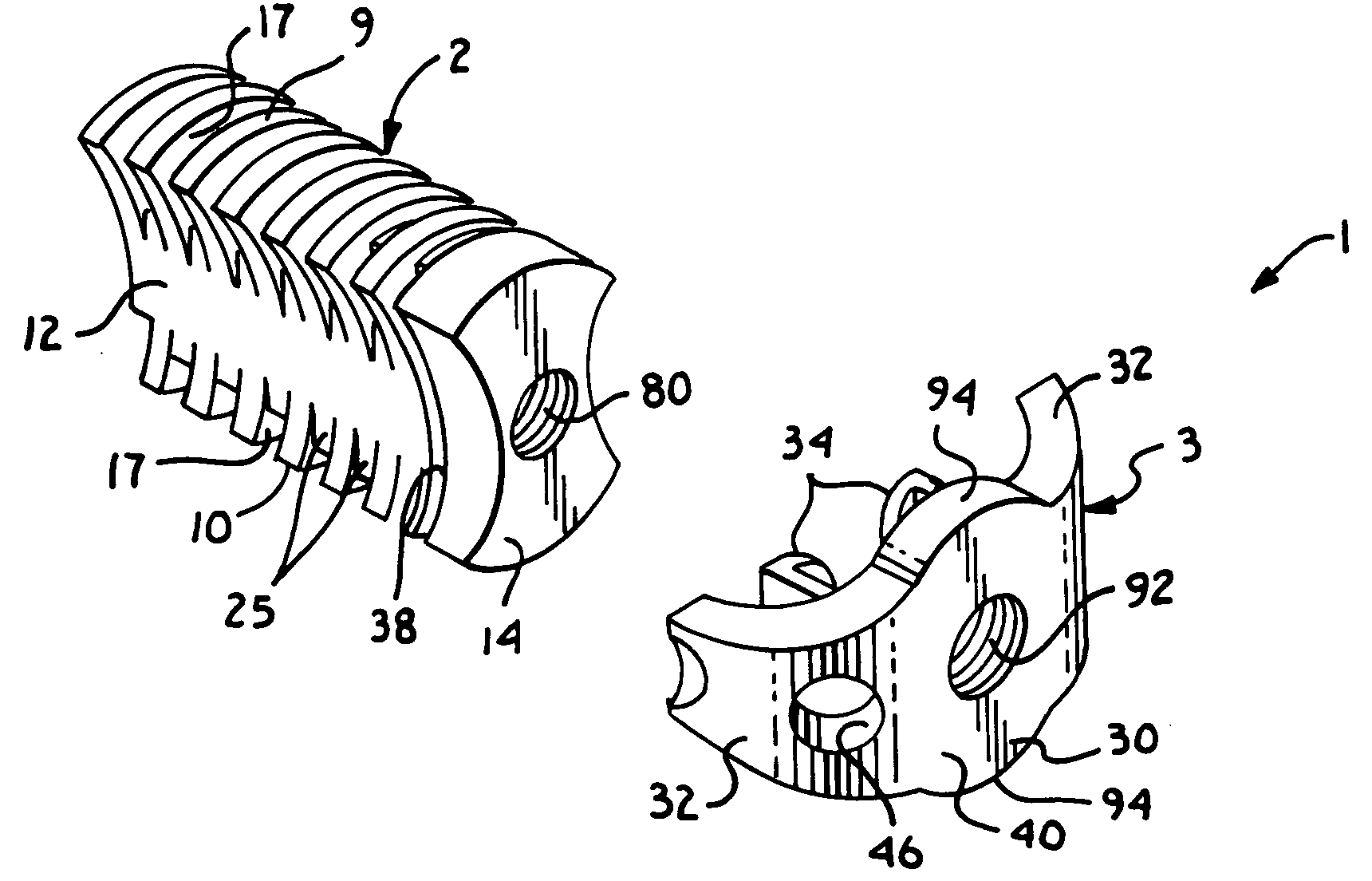

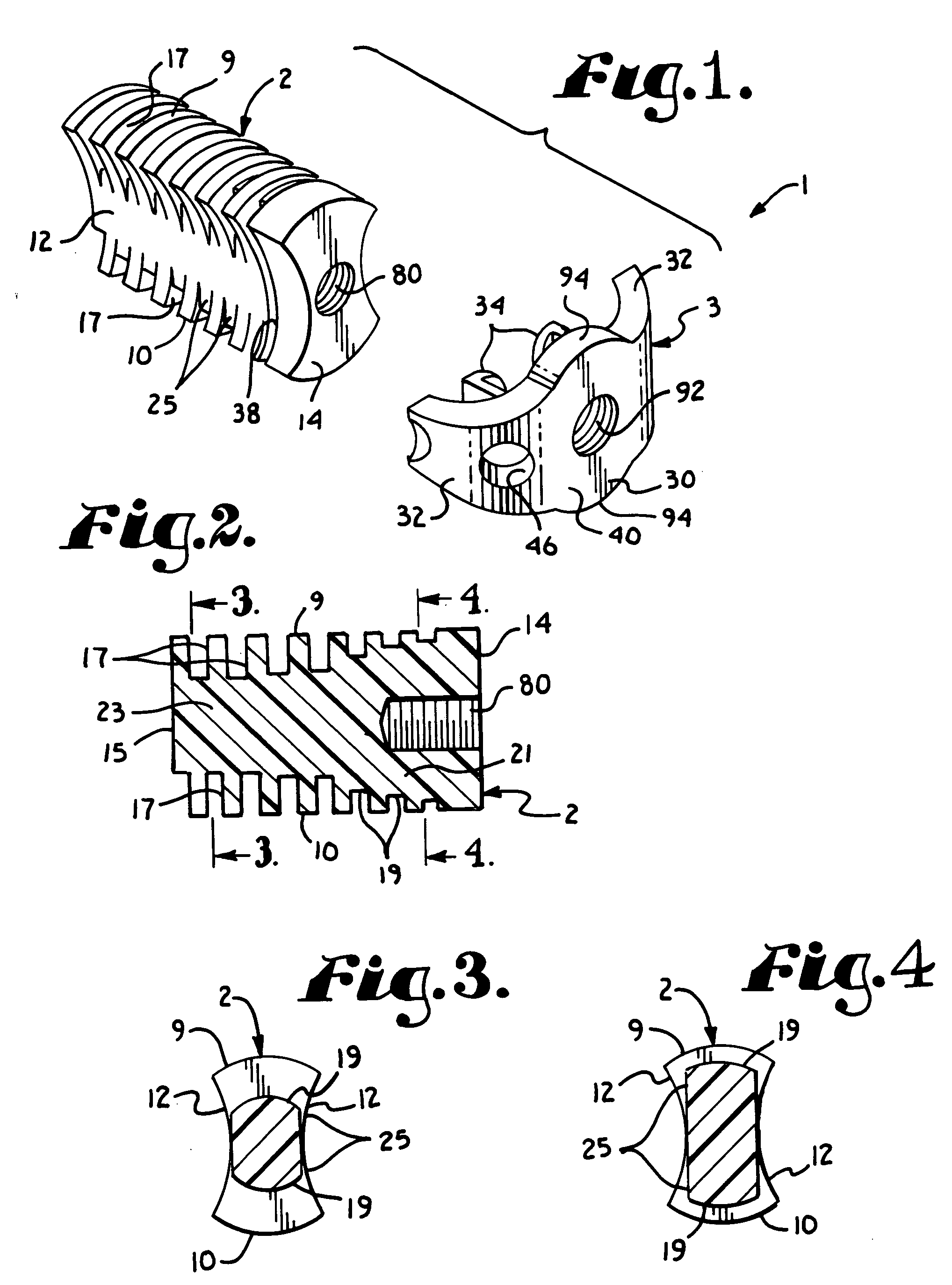

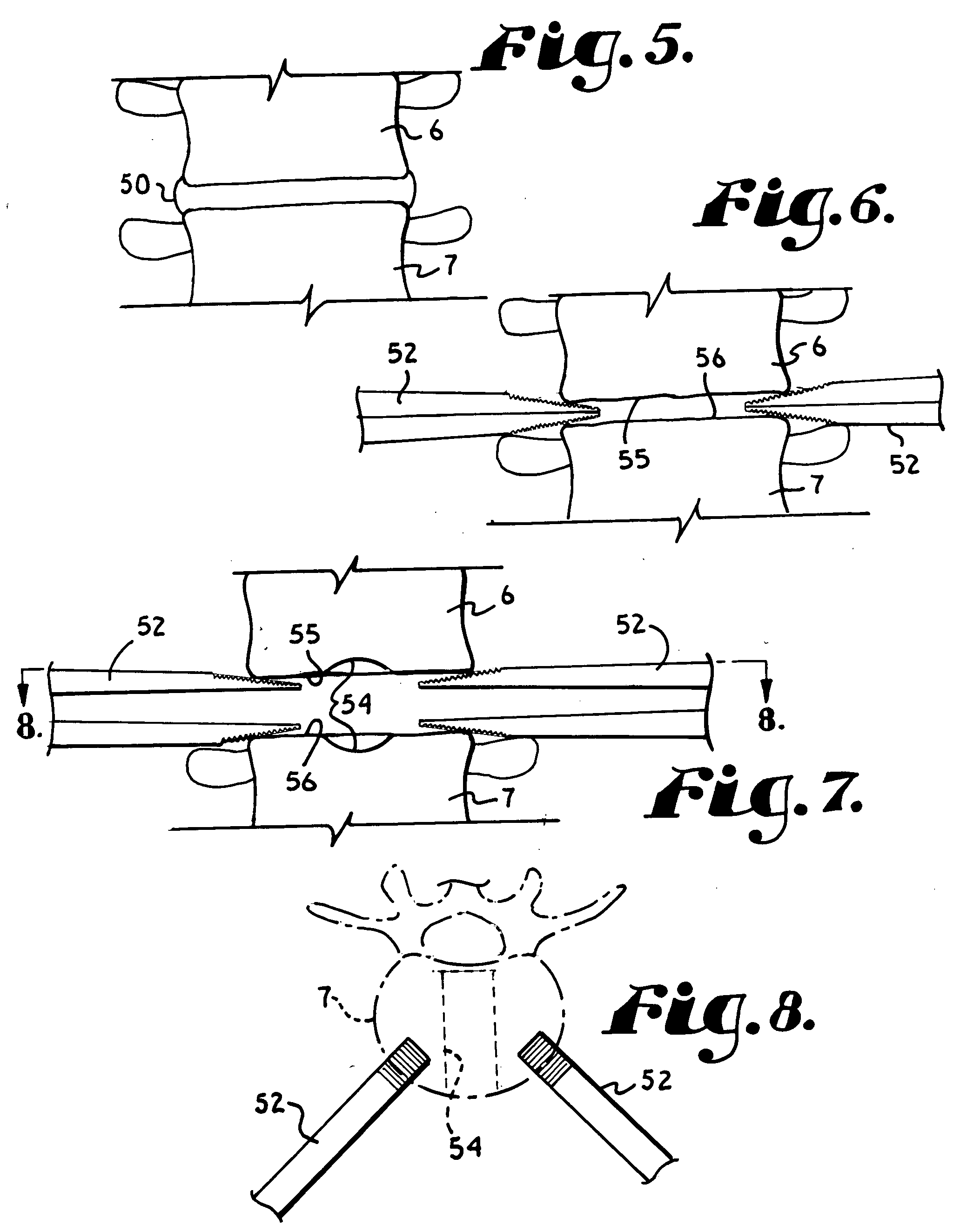

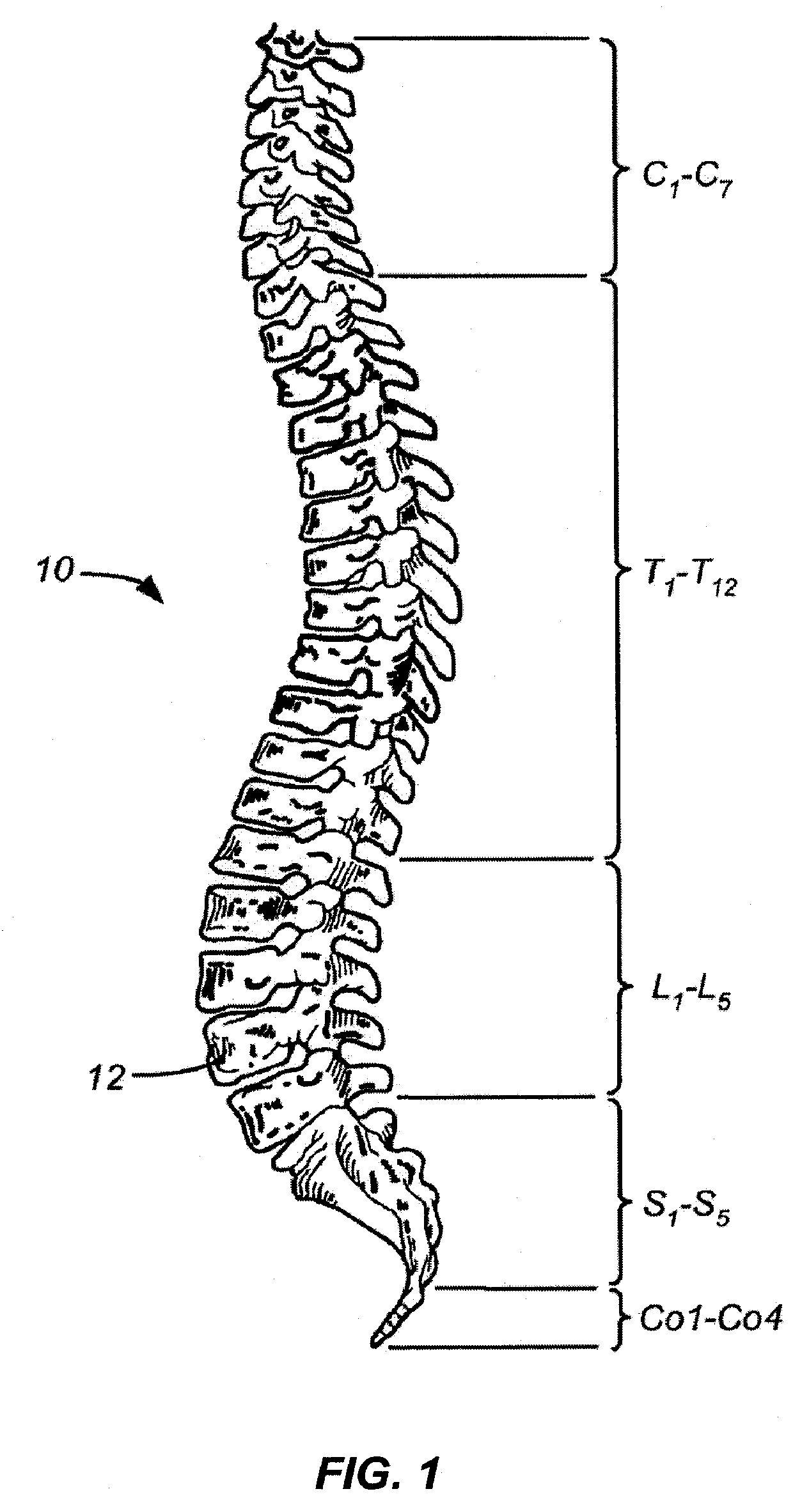

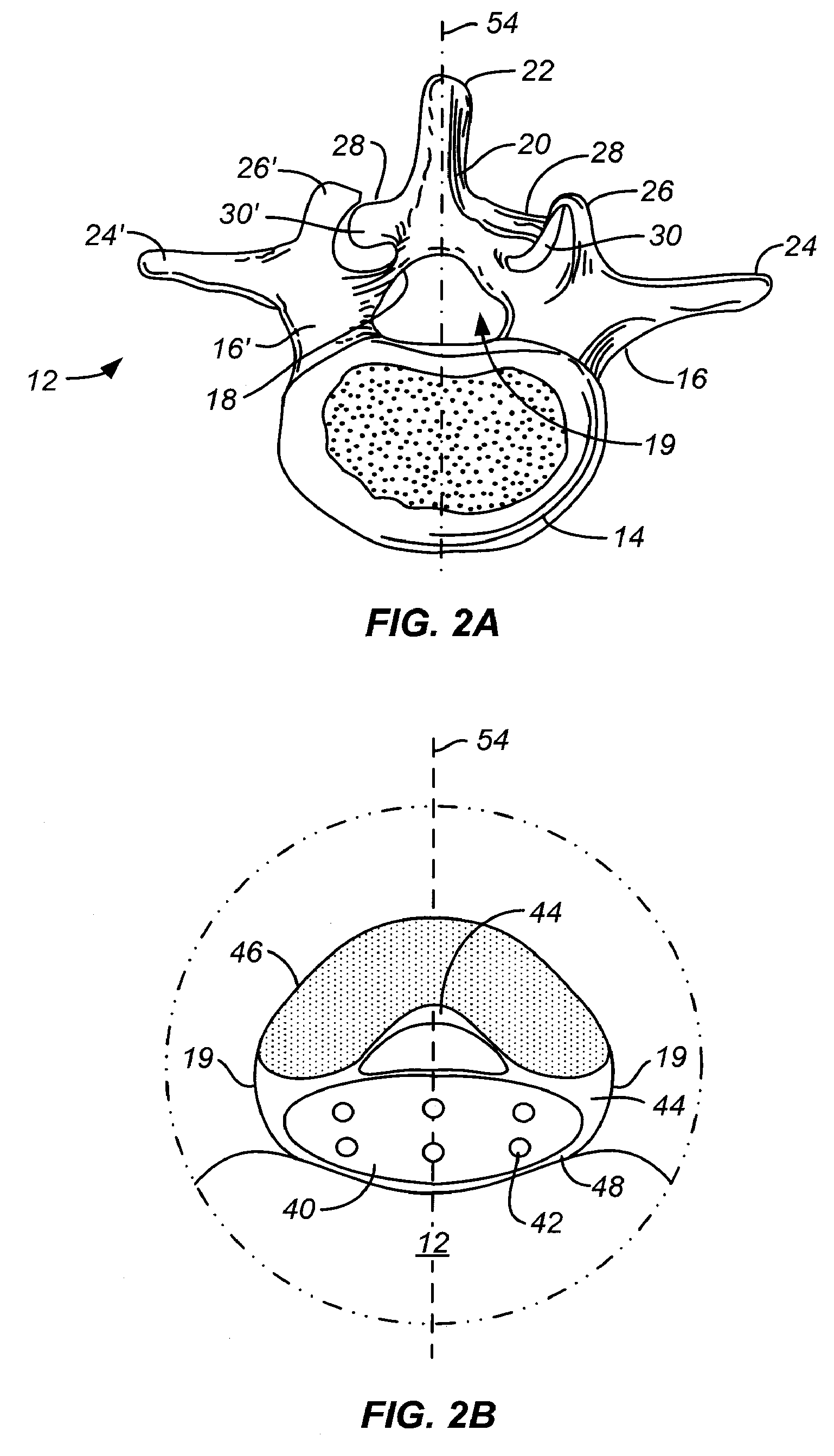

Threaded center line cage with winged end gap

A threaded center line cage assembly includes a cylindrical intervertebral spacer member to which is attached a winged end cap. The spacer member is implanted along a center line or median plane between a pair of adjacent vertebrae to engage inner regions of mutually facing surfaces of the vertebrae. The end cap engages edge regions of the vertebrae to provide lateral support thereto, in cooperation with the spacer member. The spacer member is provided with threads having roots which vary in a conically diminishing manner in a posterior direction and then become constant to form an effectively funnel shaped profile to the thread roots. The funnel shaped profile of the roots tends to promote a desired lordosis between the adjacent vertebrae.

Owner:WARSAW ORTHOPEDIC INC

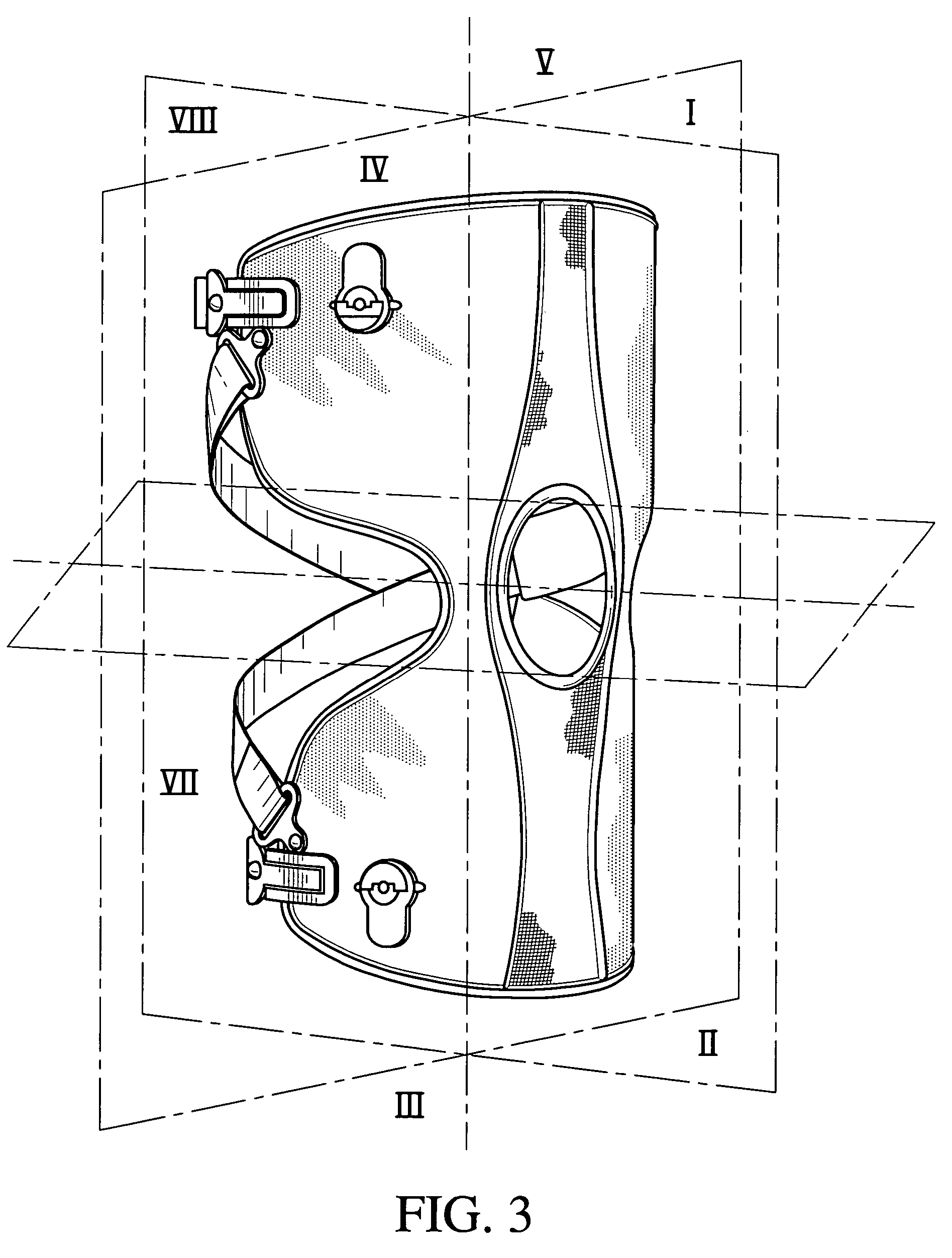

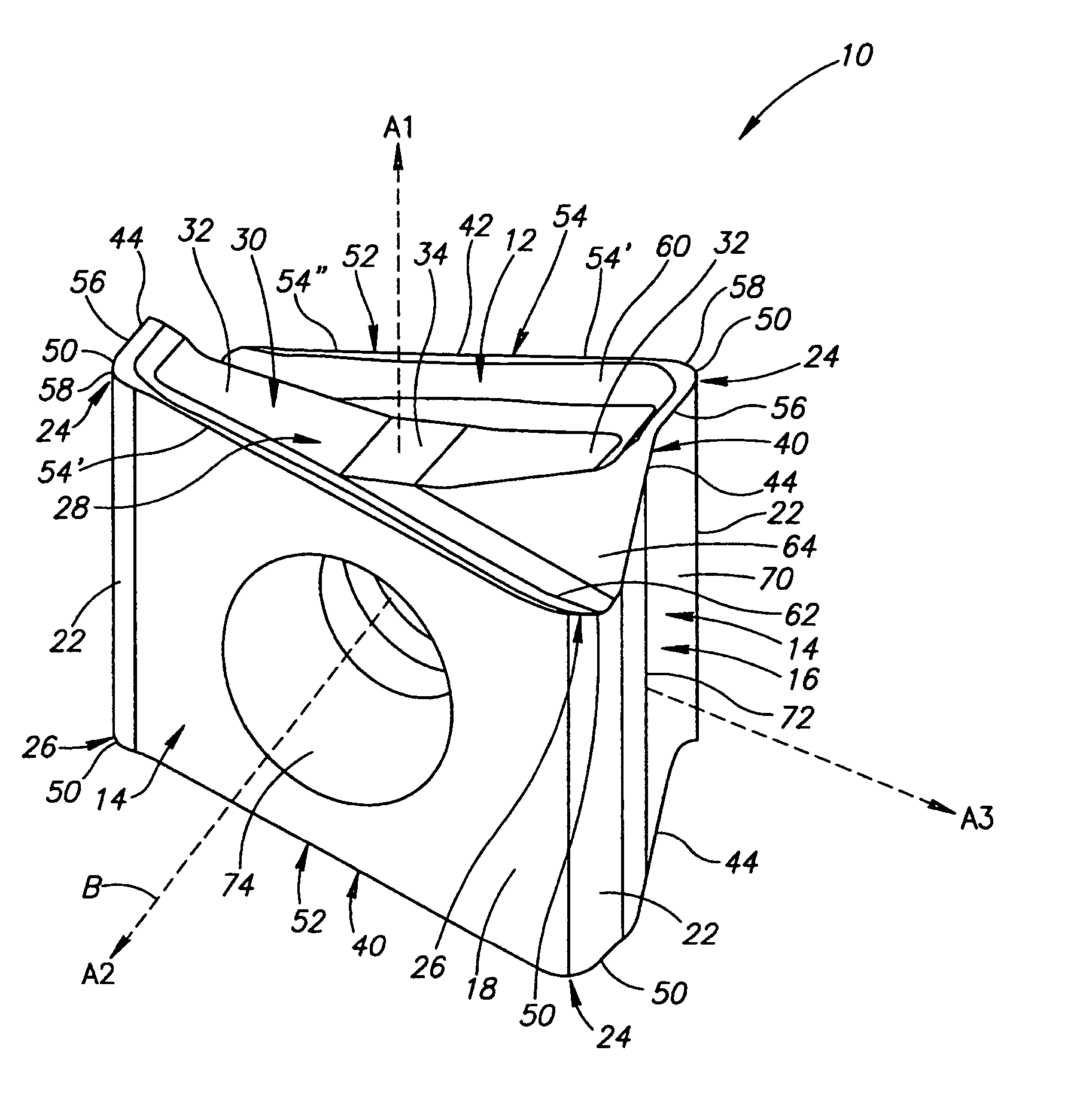

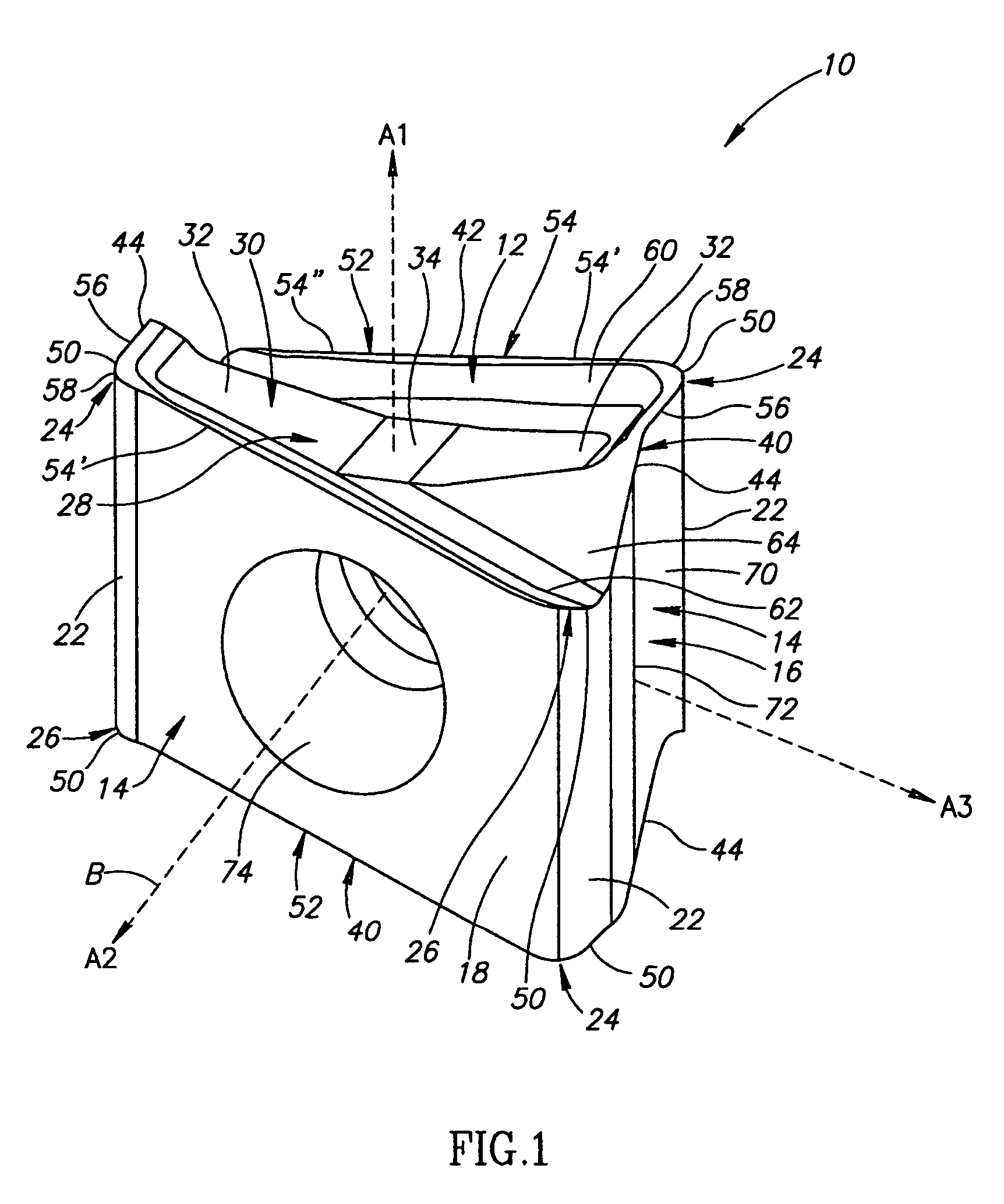

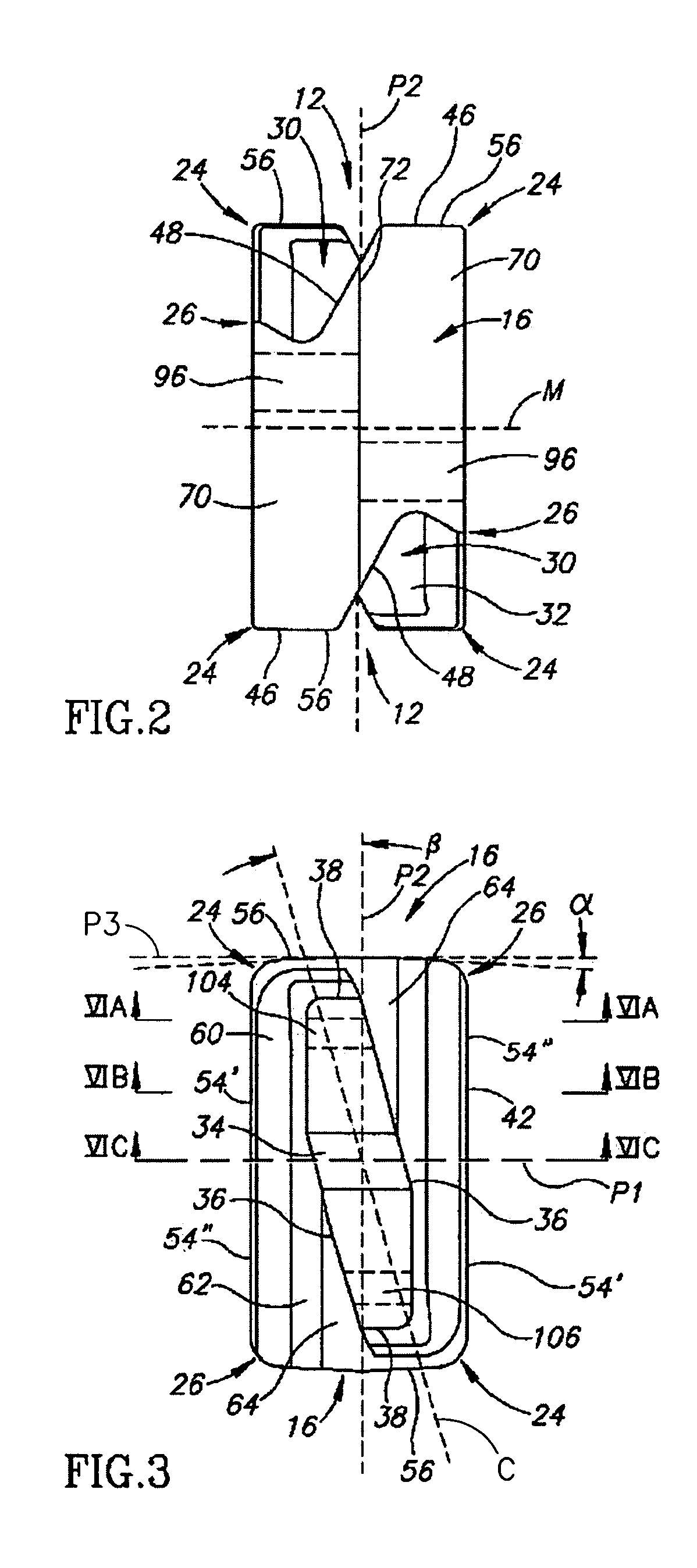

Knee brace and method for securing the same

ActiveUS20060135900A1Reduce impactMinimizing rotational forceNon-surgical orthopedic devicesKnee bracesMedian plane

A knee brace that is divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace includes a ventilated, flexible proximal shell generally extending between the first and second sides on the anterior side of the brace, and a flexible distal shell connected to the proximal shell and generally extending across the first and second sides on the anterior side of the brace. The distal shell has an extension segment extending from one of the first and second sides to the posterior side of the brace. The proximal and distal shells include suitable openings and slots for attaching brackets and mechanical devices. The proximal and distal shells each include a body portion and a compliant edge. The compliant edges are formed from flexible resilient material that is configured to extend beyond the outer perimeter of the body portion of each the proximal and distal shells.

Owner:KAUPTHING BANK

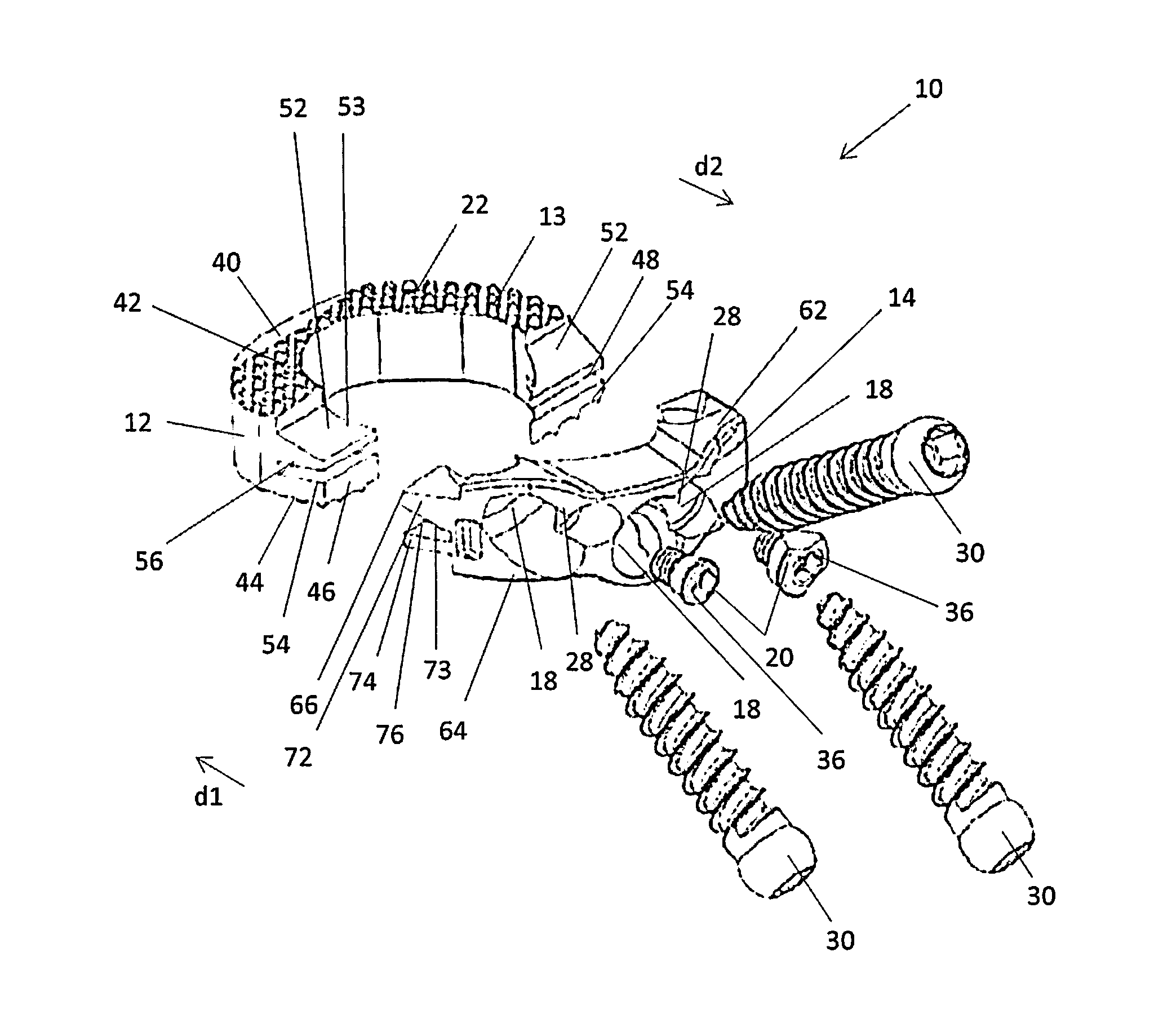

Interbody Standalone Intervertebral Implant

ActiveUS20140277497A1Vascular anatomy of the patient may be avoidedSpinal implantsSpinal cageCorpectomy

Stand-alone interbody fusion devices and corpectomy devices suitable for use with an oblique implantation. The stand-alone interbody fusion devices may include a spacer having a substantially U-shaped body and a plate coupled to the spacer. The overall shape of the implant is asymmetrical such that a median plane, an oblique plane, or both planes divide the spacer and the plate into two asymmetrical halves. The implants are shaped and configured to allow for an oblique or anterolateral approach to the spine or an oblique corpectomy.

Owner:GLOBUS MEDICAL INC

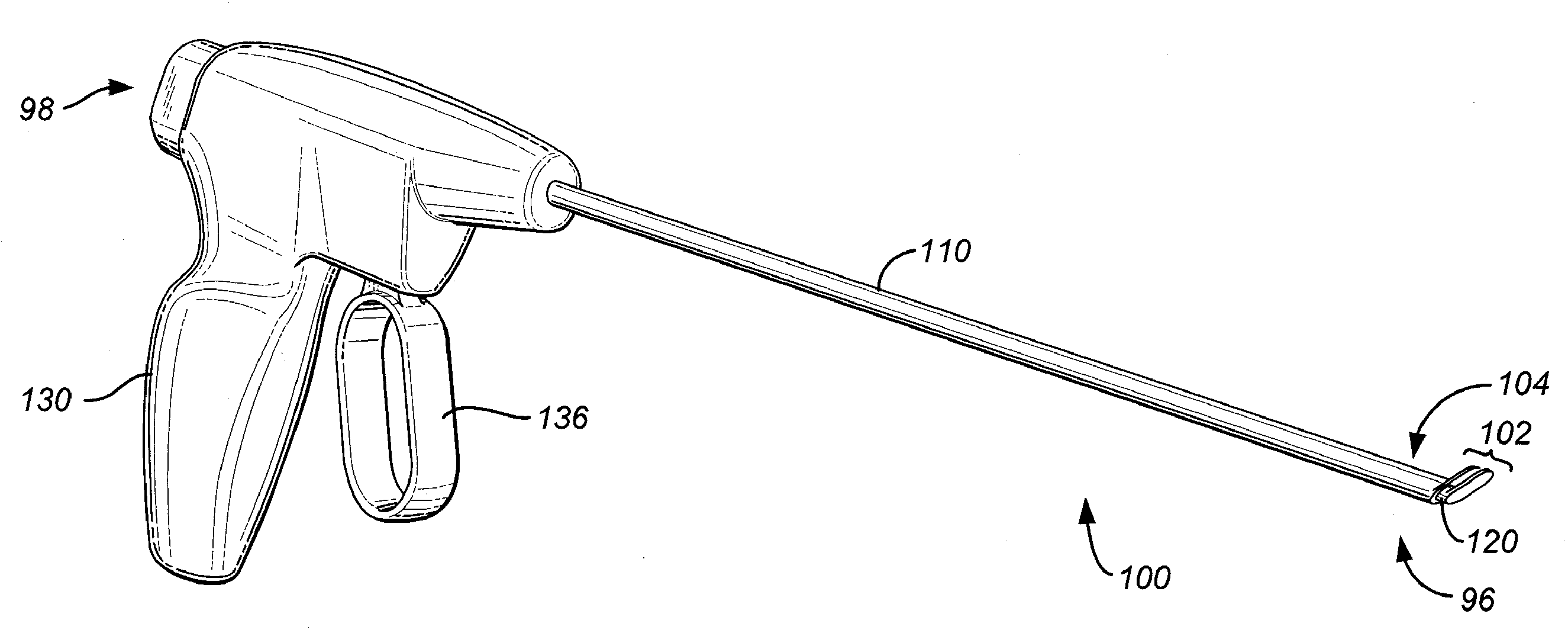

Ipsilateral Approach to Minimally Invasive Ligament Decompression Procedure

A method for treating stenosis in a spine of a patient having a median plane, wherein the spine includes a spinal canal having a posterior surface, a dural sac and an epidural space between the posterior surface and dural sac, the location of the stenosis determining a region of interest in the spine. In an embodiment the method comprises the steps of a) generating at least one view of a portion of the spinal canal in the region of interest; b) compressing the dural sac in the region of interest by injecting a fluid to form a safety zone and establish a working zone in the region of interest, the safety zone lying between the working zone and the dural sac; c) percutaneously accessing the epidural space in the region of interest on a first side of the median plane; d) inserting a tissue removal tool into tissue in the working zone on the first side of the median plane; e) using the tissue removal tool to percutaneously reduce the stenosis on the first side of the median plane; and f utilizing the at least one view to position the tissue removal too during at least a part of step d) and at least part of step e)

Owner:VERTOS MEDICAL

Knee brace and method for securing the same

ActiveUS20090124948A1Reduce impactMinimizing rotational forceFeet bandagesNon-surgical orthopedic devicesPhysical medicine and rehabilitationDistal portion

A knee brace divided into anterior and posterior sides by a frontal plane, and having first and second sides divided by a median plane. The knee brace including a frame having proximal and distal portions, a stability strap having first and second ends respectively connected to first and second sides on the proximal frame portion along the posterior side thereof, and a cross strap having a first end connected to the first side of the proximal and a second end connected to the distal frame portions. A bracket assembly having a buckle connects the stability and cross straps to the frame. A sleeve is provided which covers the frame and upon which the bracket assembly rests.

Owner:OSSUR HF

Cutting insert for a milling cutter

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

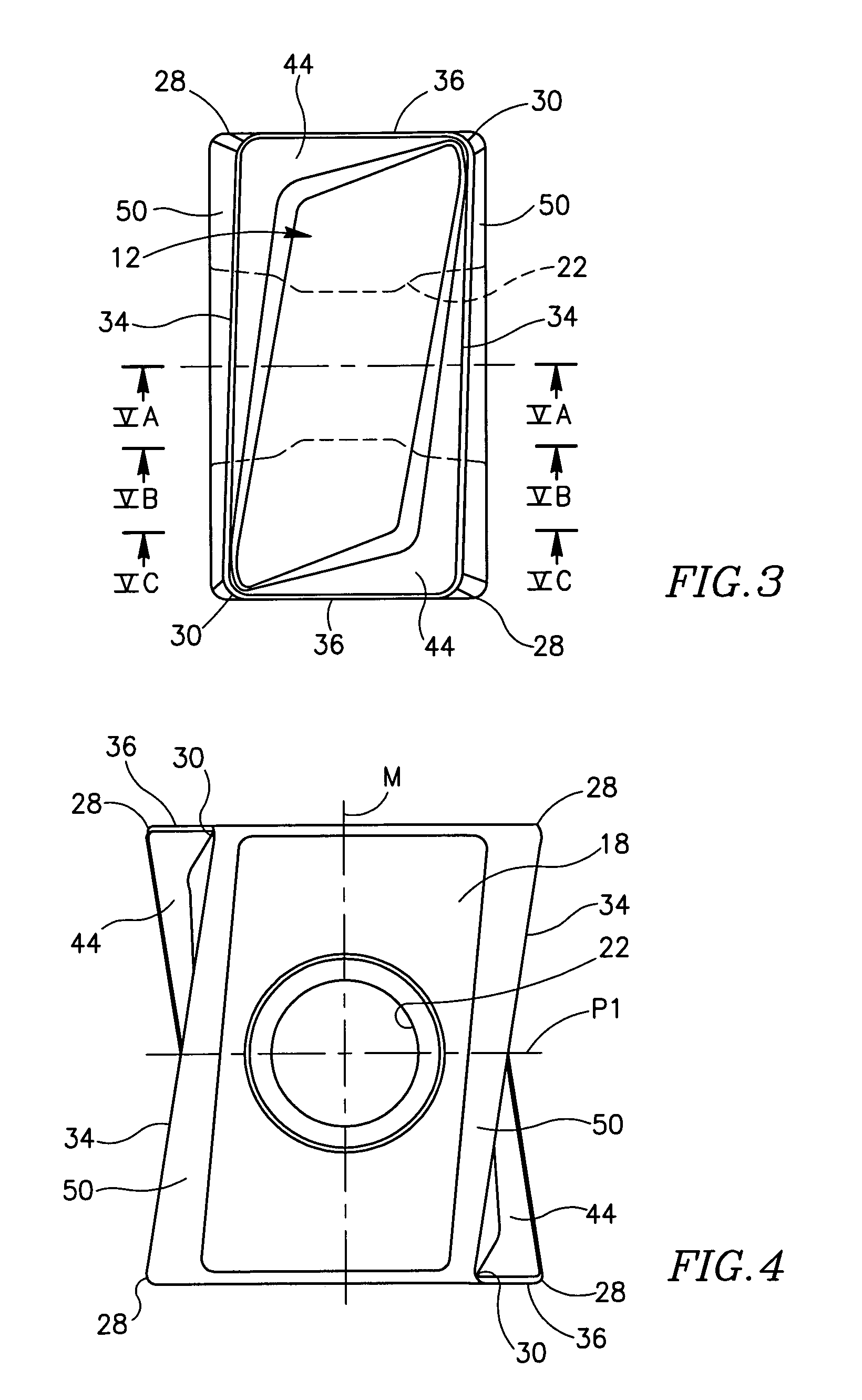

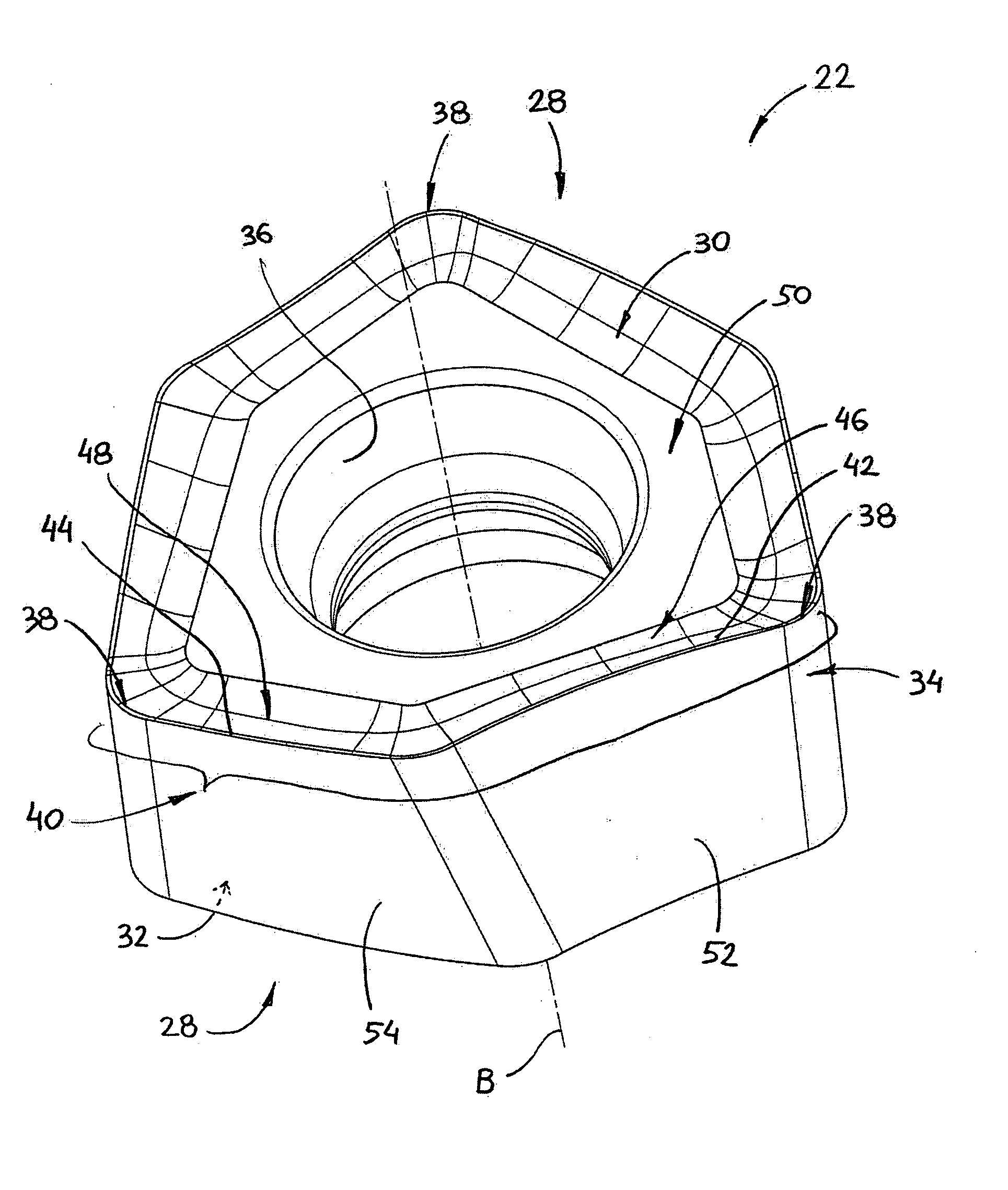

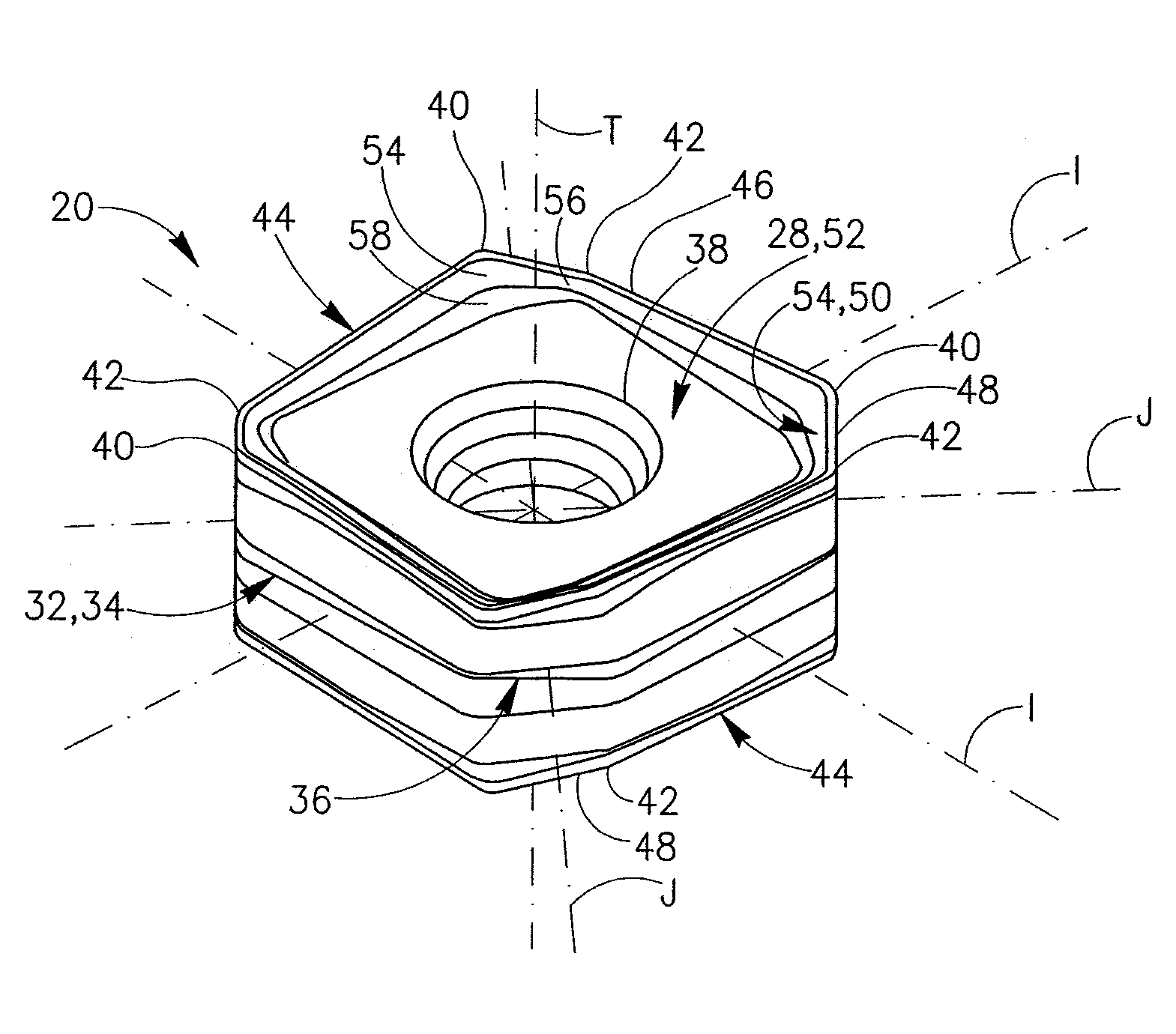

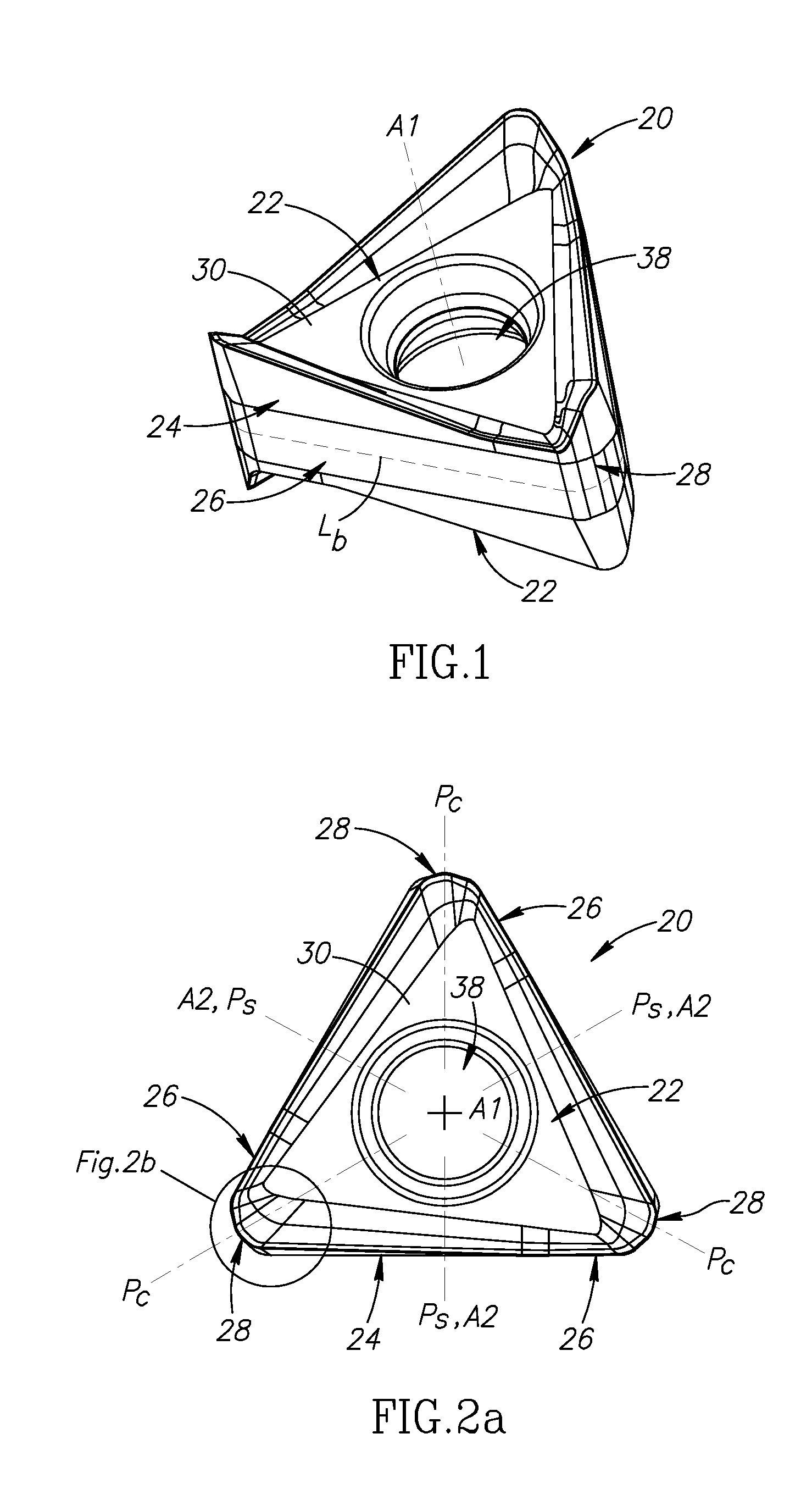

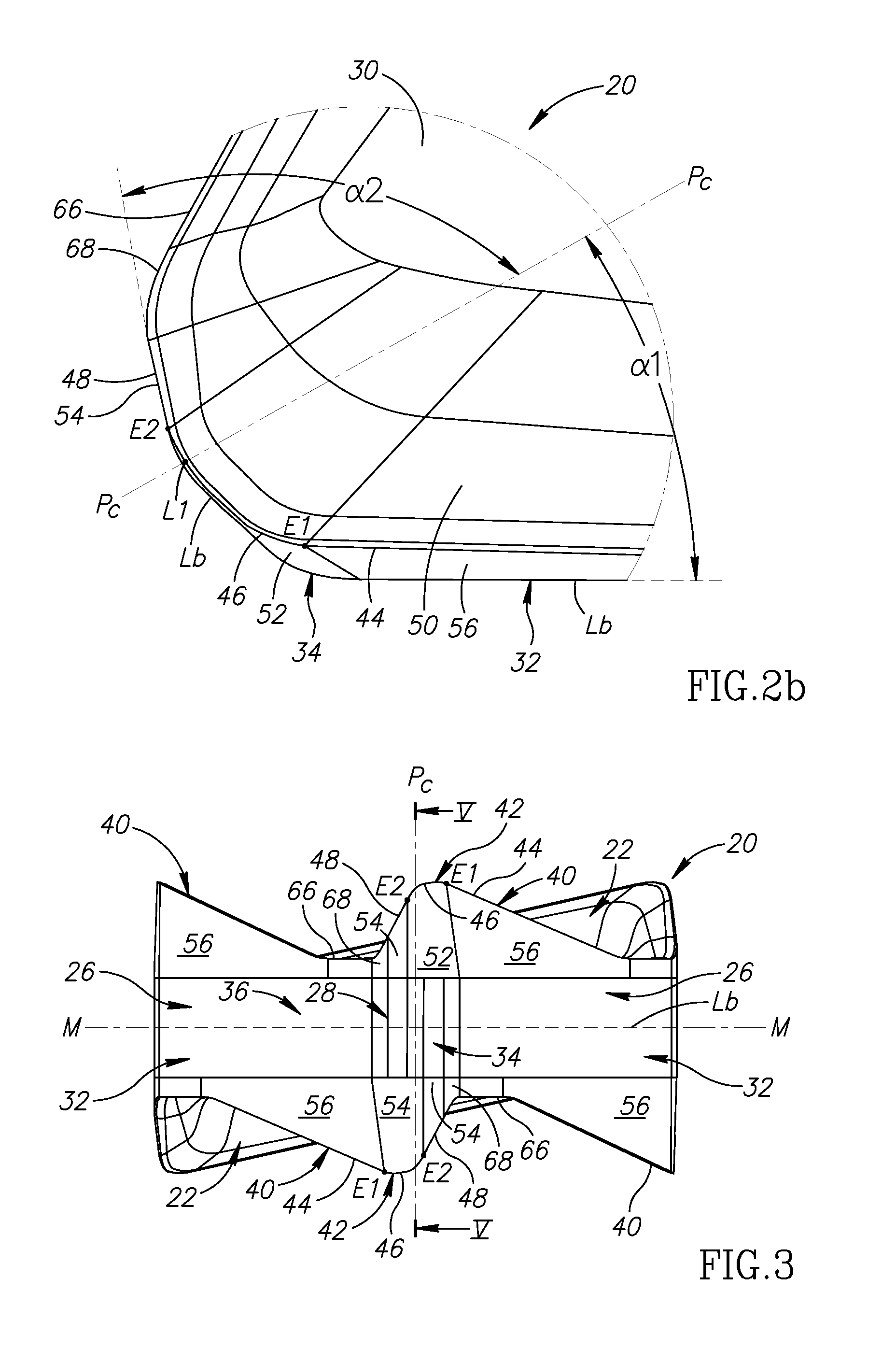

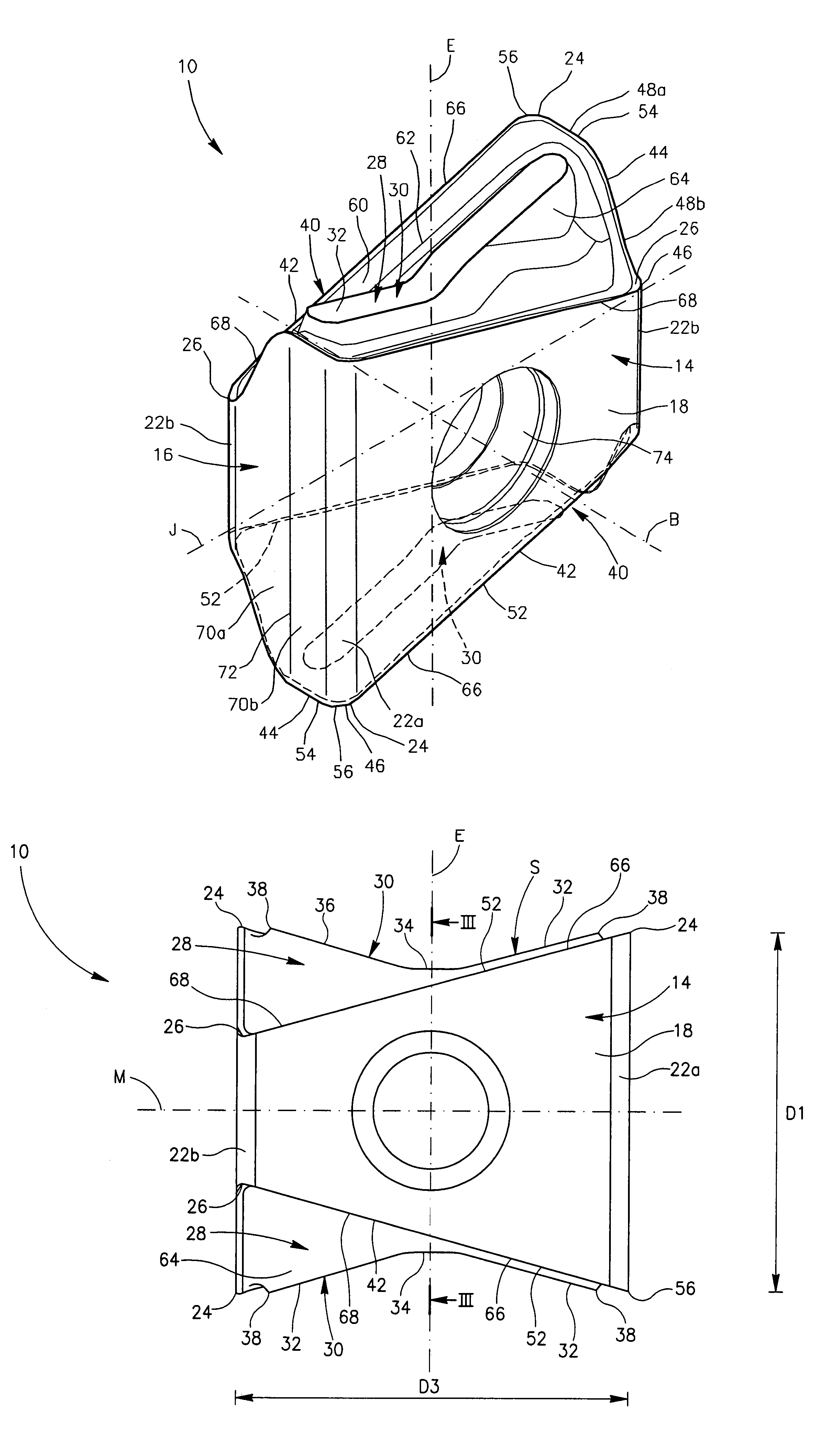

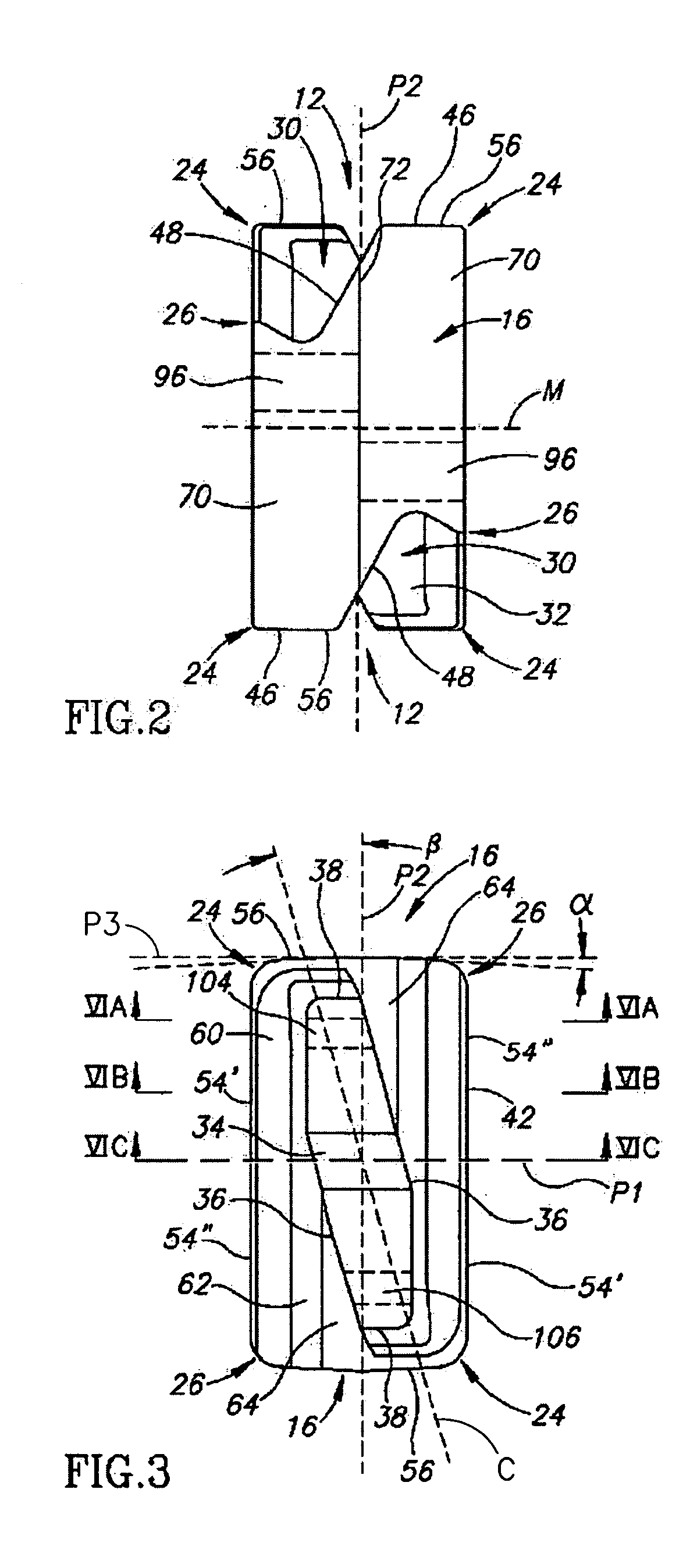

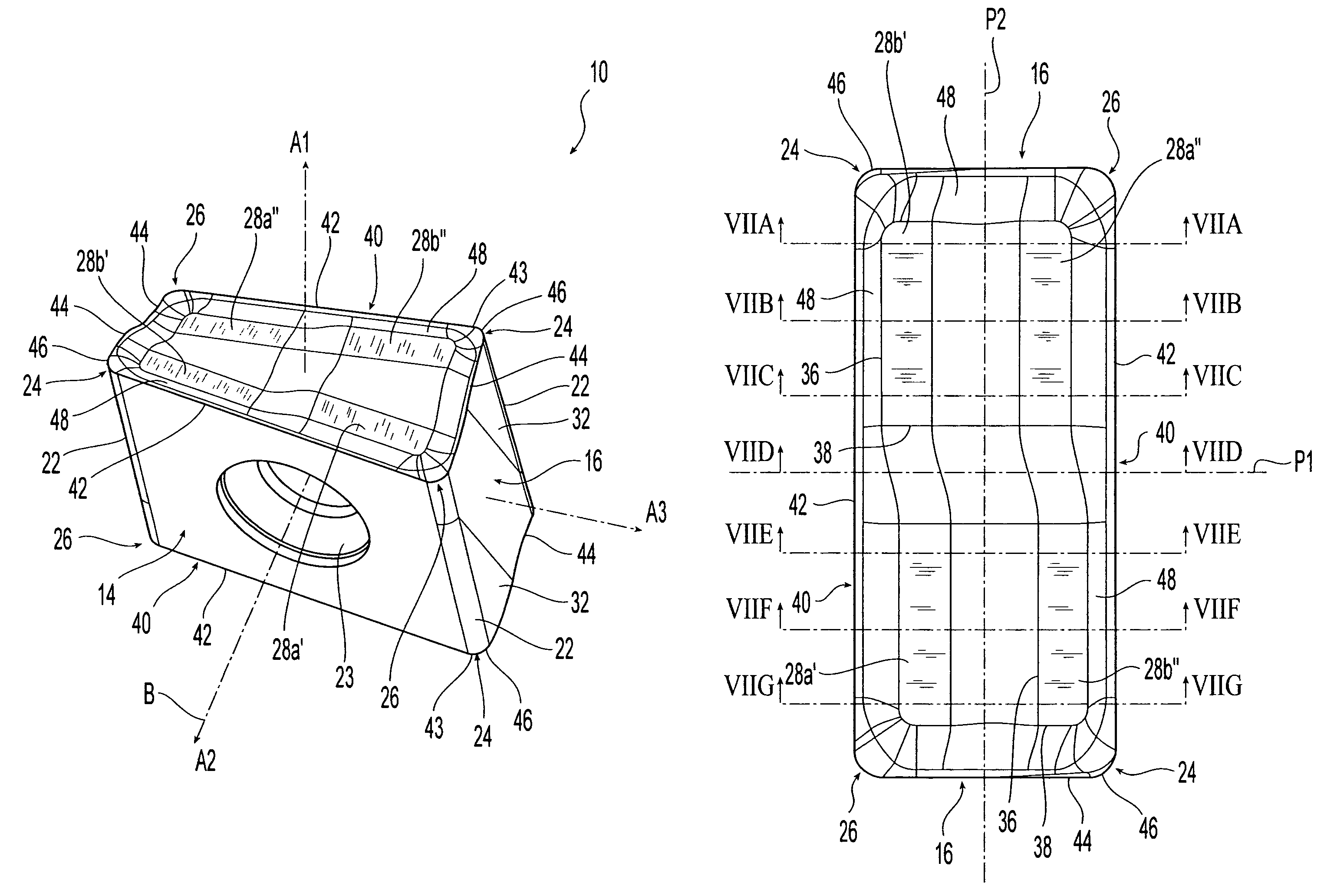

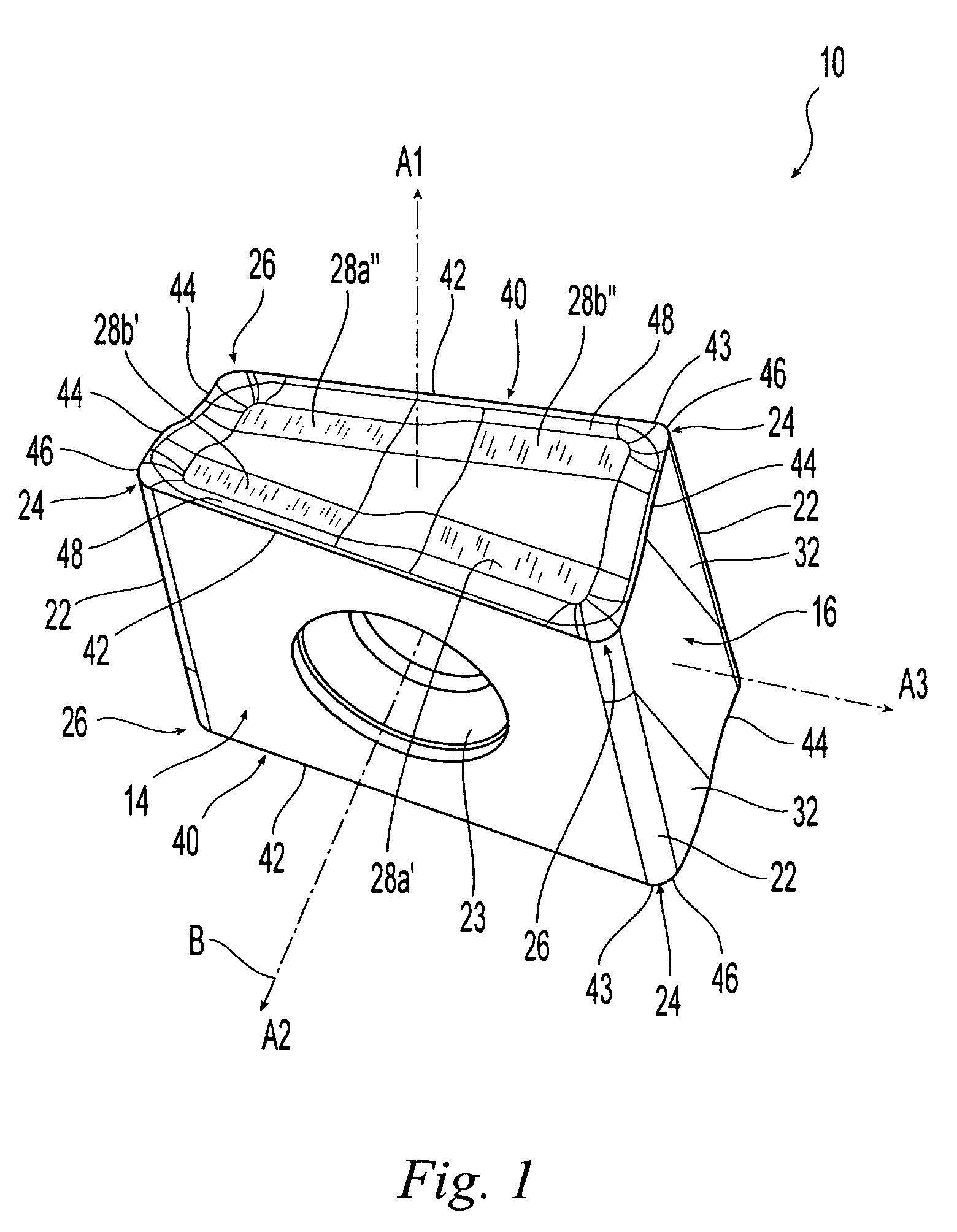

Cutting Insert

ActiveUS20100080662A1High operating requirementsMilling cuttersShaping cuttersAcute angleMechanical engineering

A cutting insert has a trigonal shape. The cutting insert has a peripheral surface that extends between two opposing identical end surfaces. A median plane (M) bisects the cutting insert between the end surfaces. A through bore extends between the end surfaces. A cutting edge, formed at the intersection of each end surface with the peripheral surface, is divided into three identical cutting sections. Each cutting section is located between two vertexes of the trigonal shape. Each cutting section has a convex primary cutting edge and a concave secondary cutting edge that merge together. An insert tangential abutment surface is located between the cutting edge and the through bore. A primary relief surface forms an insert internal obtuse angle with a first reference plane (P1). A secondary relief surface forms an insert internal acute angle with a second reference plane (P2).

Owner:ISCAR LTD

Threaded center line cage with funnel shaped profile

InactiveUS20050065605A1Minimize alterationReduce volumeBone implantJoint implantsEngineeringScrew thread

A threaded center line cage assembly includes a cylindrical intervertebral spacer member to which is attached a winged end cap. The spacer member is implanted along a center line or median plane between a pair of adjacent vertebrae to engage inner regions of mutually facing surfaces of the vertebrae. The end cap engages edge regions of the vertebrae to provide lateral support thereto, in cooperation with the spacer member. The spacer member is provided with threads having roots which vary in a conically diminishing manner in a posterior direction and then become constant to form an effectively funnel shaped profile to the thread roots. The funnel shaped profile of the roots tends to promote a desired lordosis between the adjacent vertebrae.

Owner:JACKSON

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally isosceles trapezoidal shape and two identical opposing minor side surfaces extending between them is disclosed. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to a median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

Cutting insert having cylindrically shaped side surface portions

ActiveUS7232279B2Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsEngineeringMechanical engineering

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

Rotary Cutting Tool and Reversible Cutting Insert Therefor

In a rotary cutting tool used for milling operations, a reversible indexable cutting insert is removably secured in a cutting body. The cutting insert has two opposing end surfaces interconnected by a continuous peripheral surface, including three side surfaces alternating with three corner surfaces. The side and corner surfaces intersect with both end surfaces at side and corner edges, respectively, with each side edge having a major cutting edge, and each corner edge having a corner and minor cutting edge. Each major and minor cutting edge slopes away from first and second end points, respectively, of its mutually associated corner cutting edge, towards a median plane. A first imaginary straight line extending perpendicular to the median plane and intersecting any one of the corner cutting edges at any point along its length except the second end point, passes through the median plane inside an insert boundary line.

Owner:ISCAR LTD

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally parallelogrammatic shape and two identical opposing minor side surfaces extending between them. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to the median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally isosceles trapezoidal shape and two identical opposing minor side surfaces extending between them is disclosed. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to a median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

Percutaneous Devices for Separating Tissue, Kits and Methods of Using the Same

The disclosure describes devices for separating a first tissue from a second tissue at a surgical site, comprising, a hollow body having a distal end and a proximal end, wherein the distal end further comprises an upper separation member extendable laterally from hollow body at a first angle; an inner member slidably disposed within the hollow body, wherein the distal end of the inner member has a lower separation member extendable laterally from inner member at a second angle, wherein the upper separation member and the lower separation member have a first configuration and a second configuration into a tissue in the working zone on the first lateral side of the median plane. Additionally, methods for using the device and kits containing the device are disclosed.

Owner:VERTOS MEDICAL

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally parallelogrammatic shape and two identical opposing minor side surfaces extending between them. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to the median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

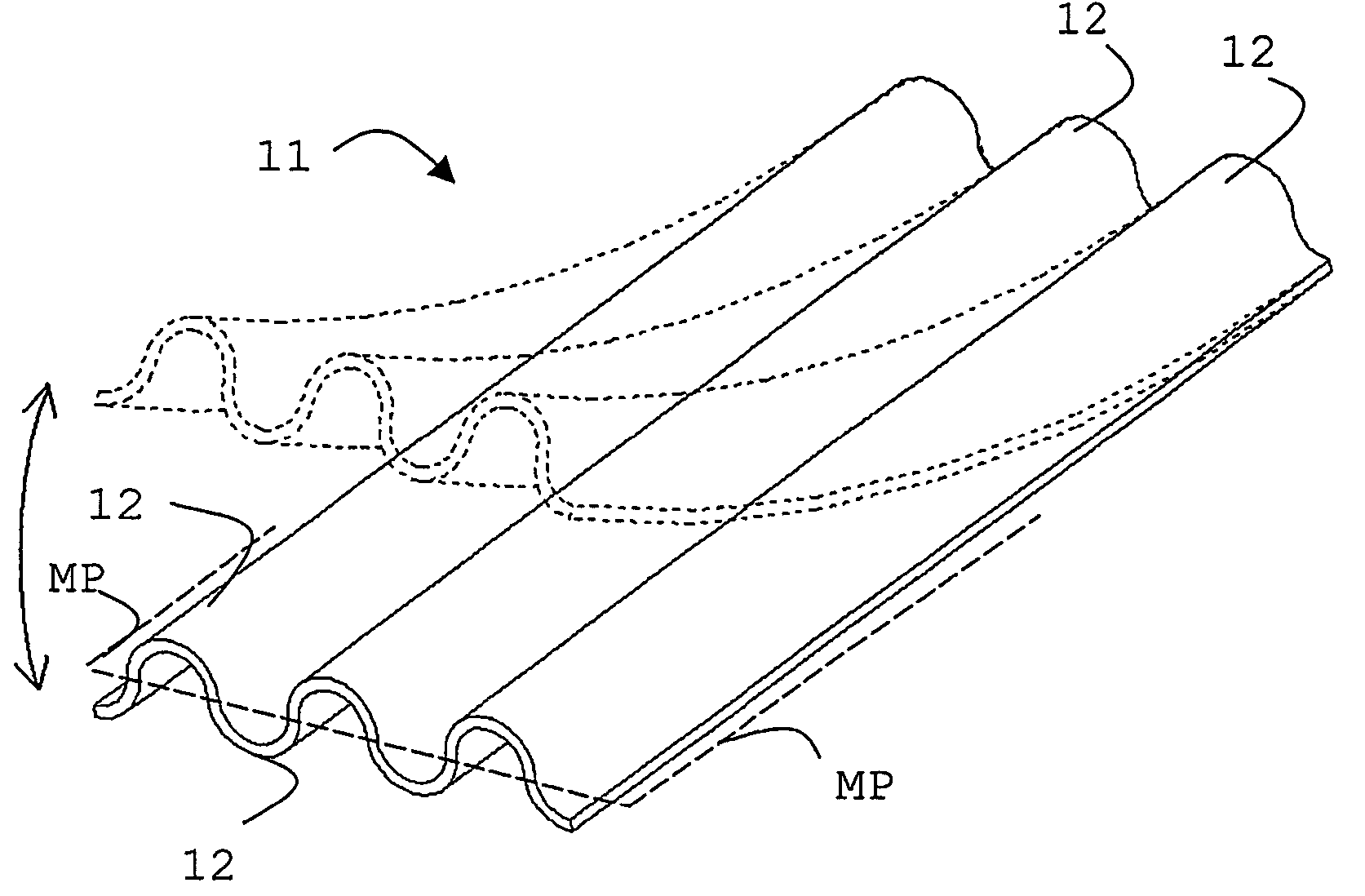

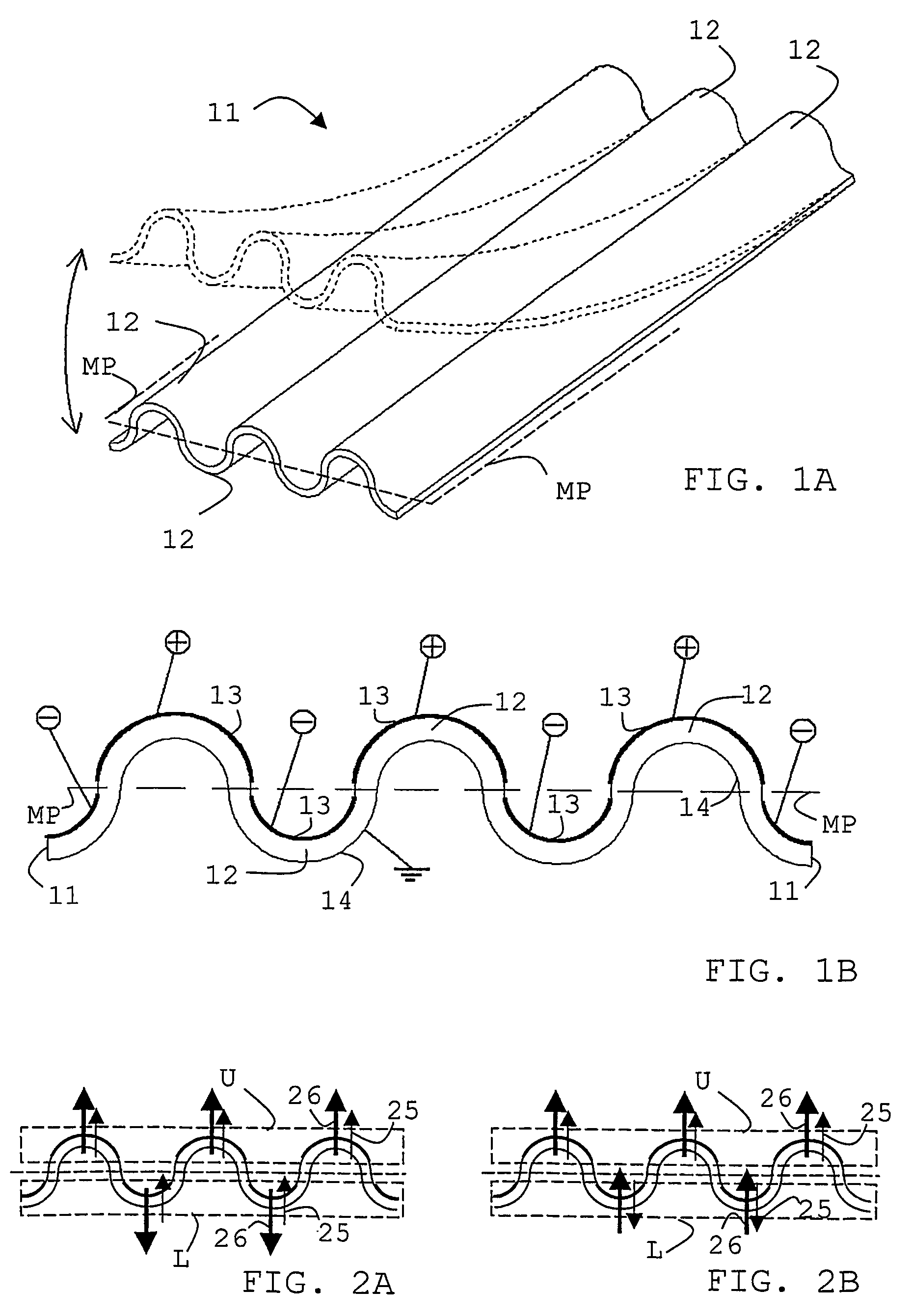

Piezoelectric structures

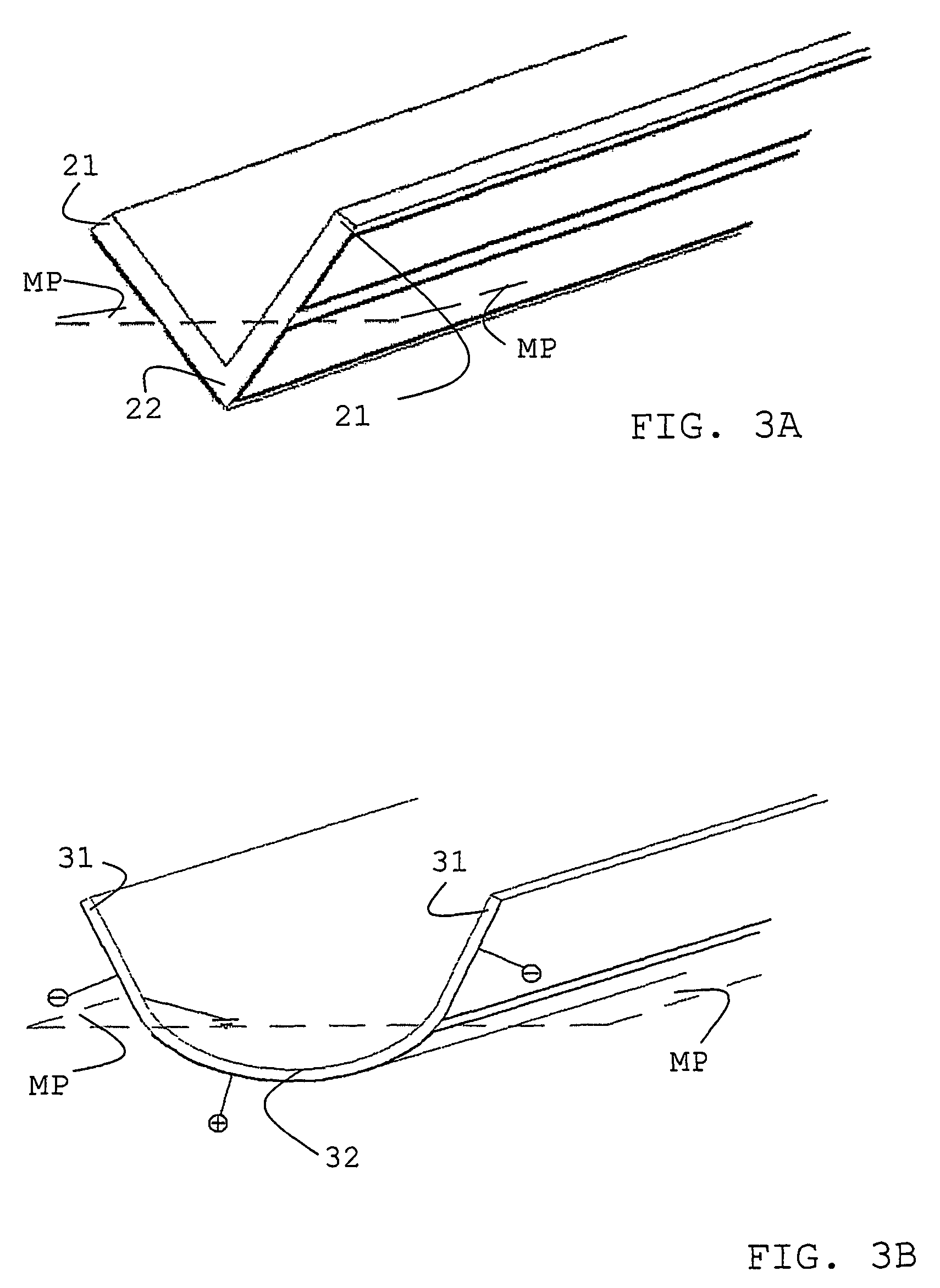

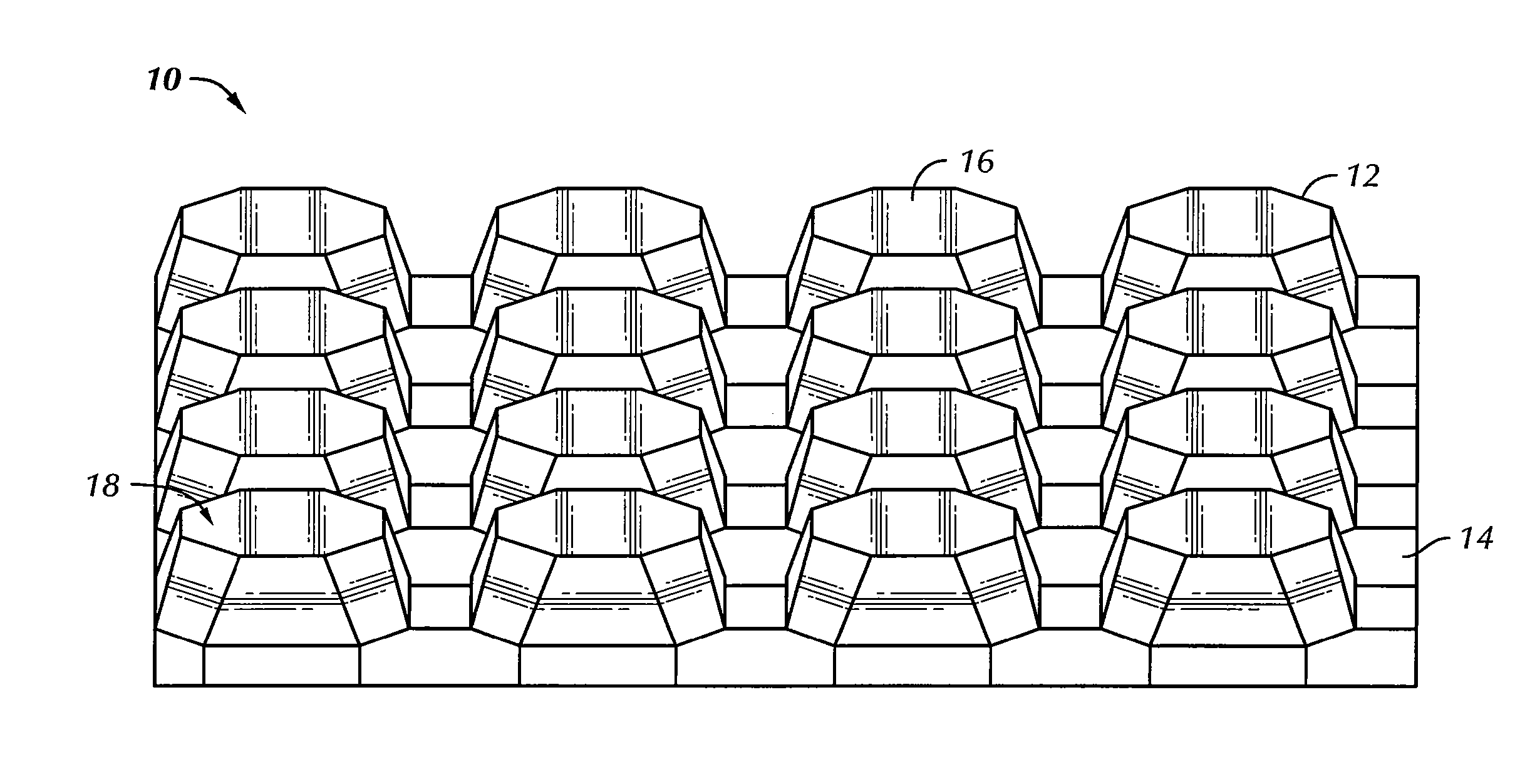

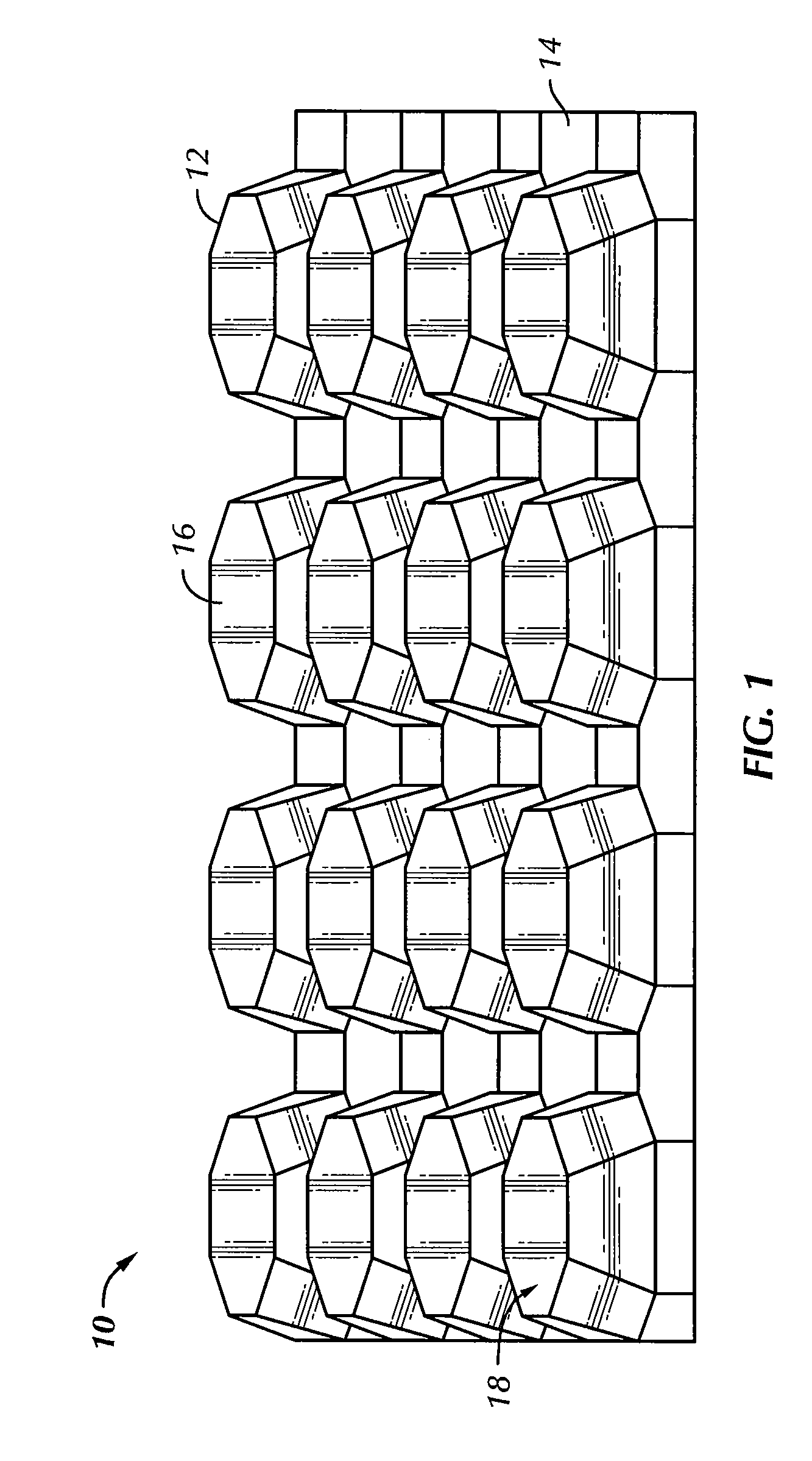

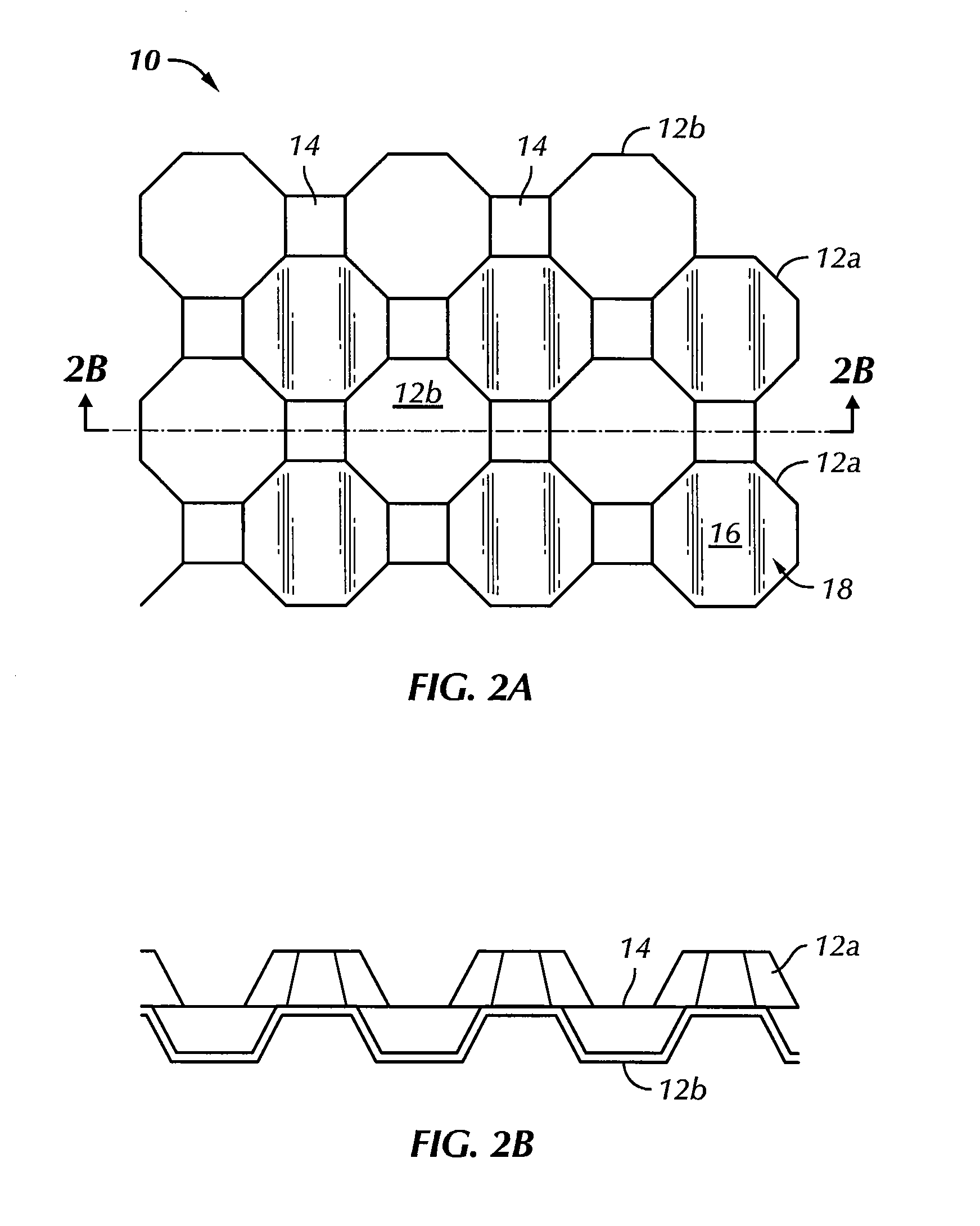

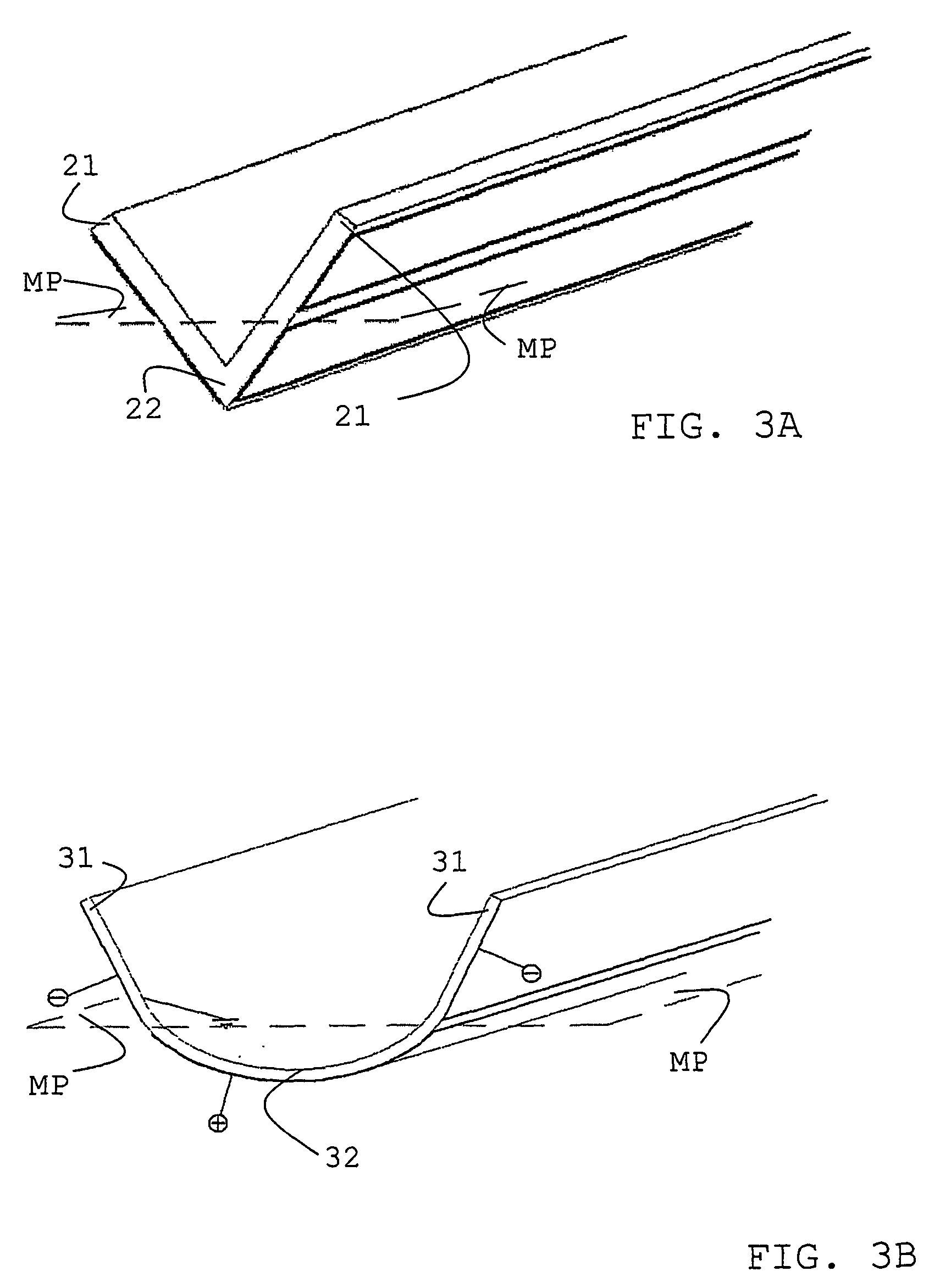

Formed core sandwich structure and method and system for making same

InactiveUS20070243408A1Easy and economical to manufactureEnhanced capillary actionPrinted circuit assemblingSoldering apparatusEngineeringMetal sheet

A method and apparatus for producing a metal core sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed metal core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be brazed or bonded with corresponding external metal sheets on both sides of the formed metal core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger brazing or bonding joints to be formed between the metal core and the external metal sheets by facilitating improved capillary action by the metal core during the brazing or bonding process.

Owner:CELLTECH METALS INC

Tangential cutting insert and milling cutter

A tangential milling cutting insert has two identical opposing end surfaces with two identical opposing major side surfaces of a generally parallelogrammatic shape and two identical opposing minor side surfaces extending between them. An ambidextrous tangential cutting insert has two non-identical end surfaces and two opposing major side surfaces of a generally trapezoidal nature. In either cutting insert, each end surface has a peripheral cutting edge and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface comprises four separate planar regions arranged in pairs, the planar regions do not protrude relative to the surrounding end surface and the two planar regions of a given pair of planar regions slope in opposite directions with respect to a median plane of the cutting insert.

Owner:THE INGERSOLL CUTTING TOOL CO

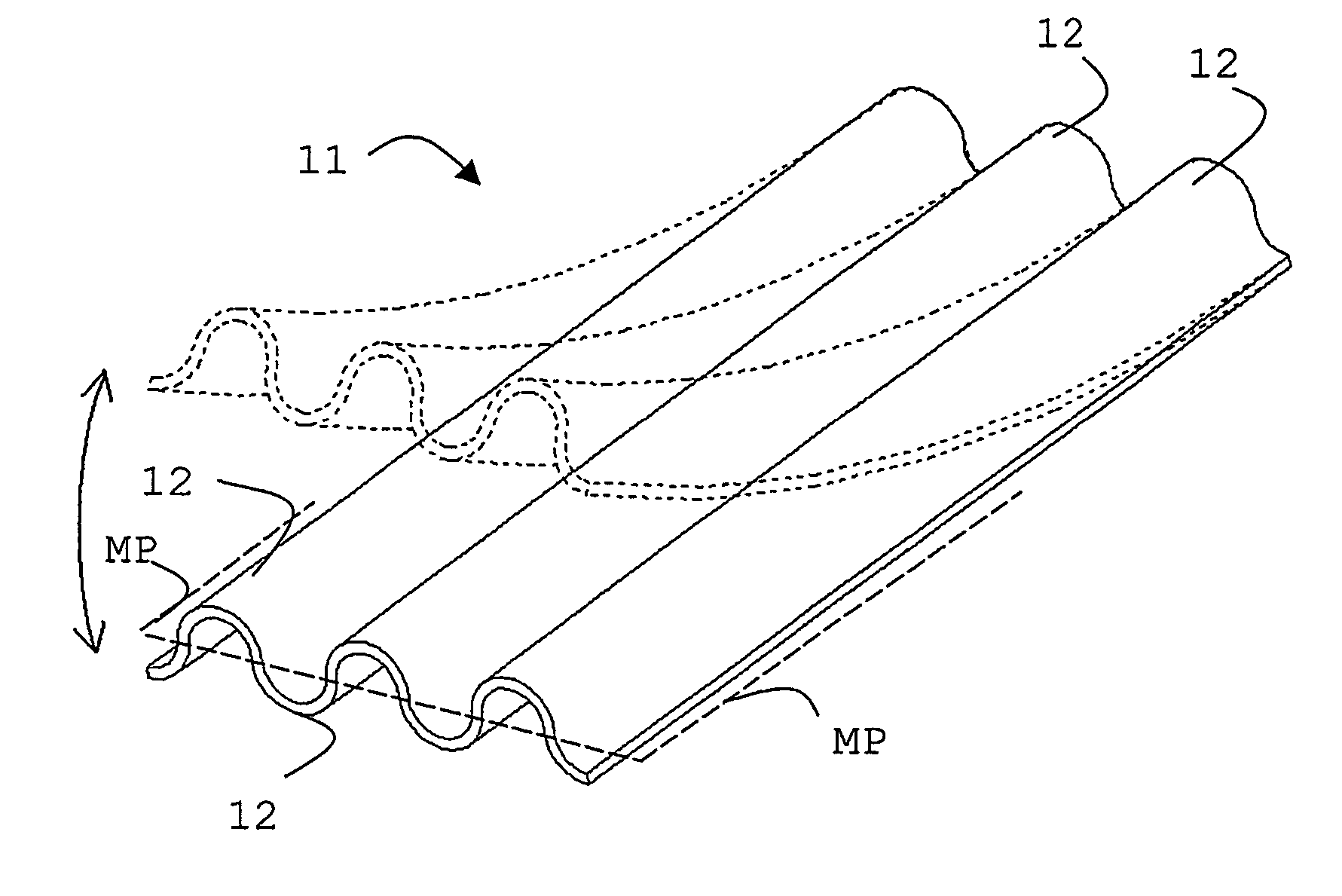

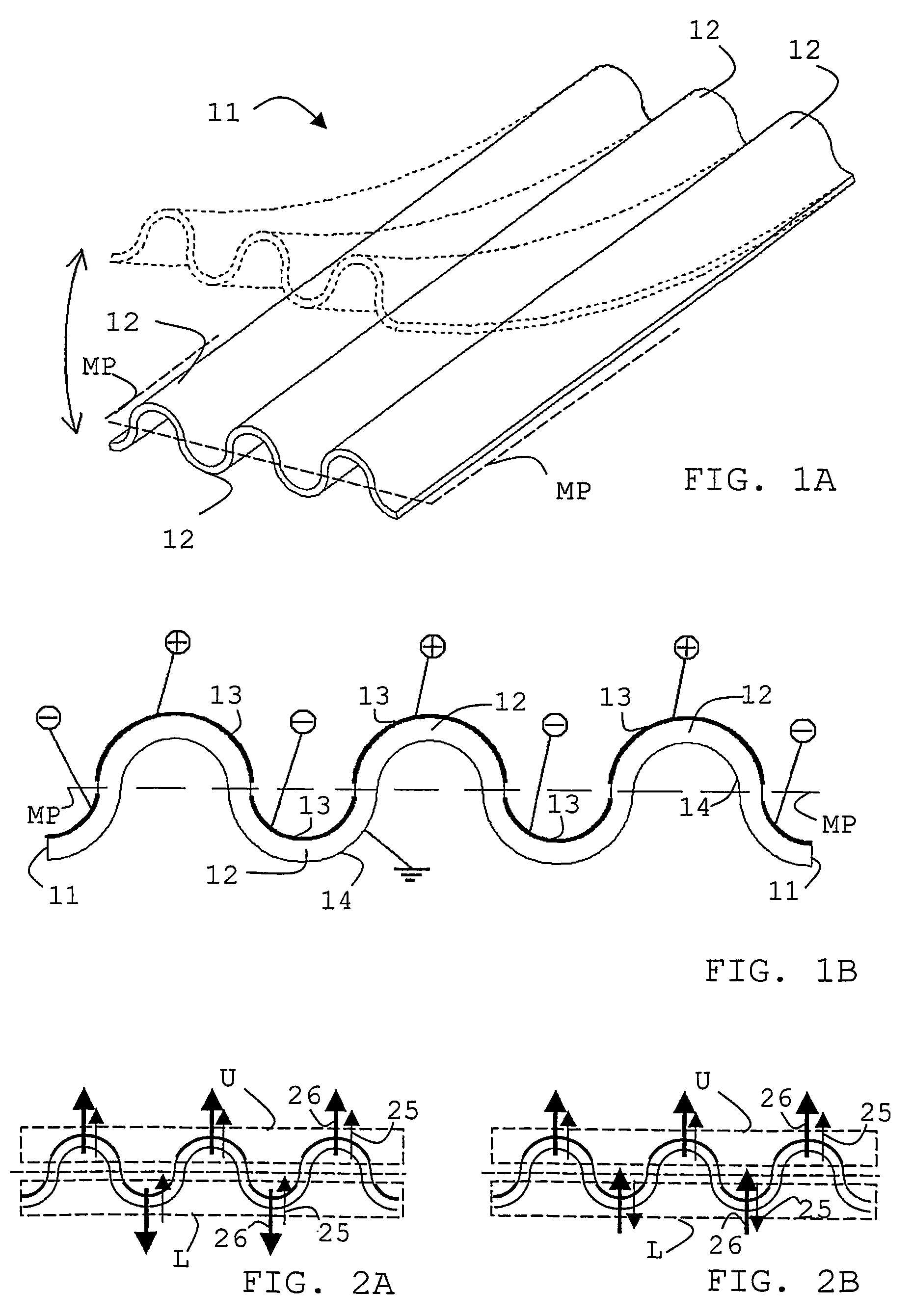

Piezoelectric structures

InactiveUS20050040736A1Overcome limitationsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringMono layer

An equivalent to the spatial separation either side of a nominal median plane that is inherent in a bimorph (with one piezoelectric layer on one side, and the second on the other side of the plane) is attained by structurally shaping the cross-section of a simple, single piezoelectric layer (11) such that it has a multiplicity of piezoelectric portions arranged in two generally-planar groups one either side of a median plane, so that any dimension change undergone by a portion on one side of that plane will tend to bend the whole device in the opposite direction to the same sense dimension change undergone by a portion on the other side of that plane. The simple, single layer acts as though it were a bimorph if elongate and beam-like, bending along its length, one end moving up / down, or back / forth, relative to the other but with any need for an internal, electrode.

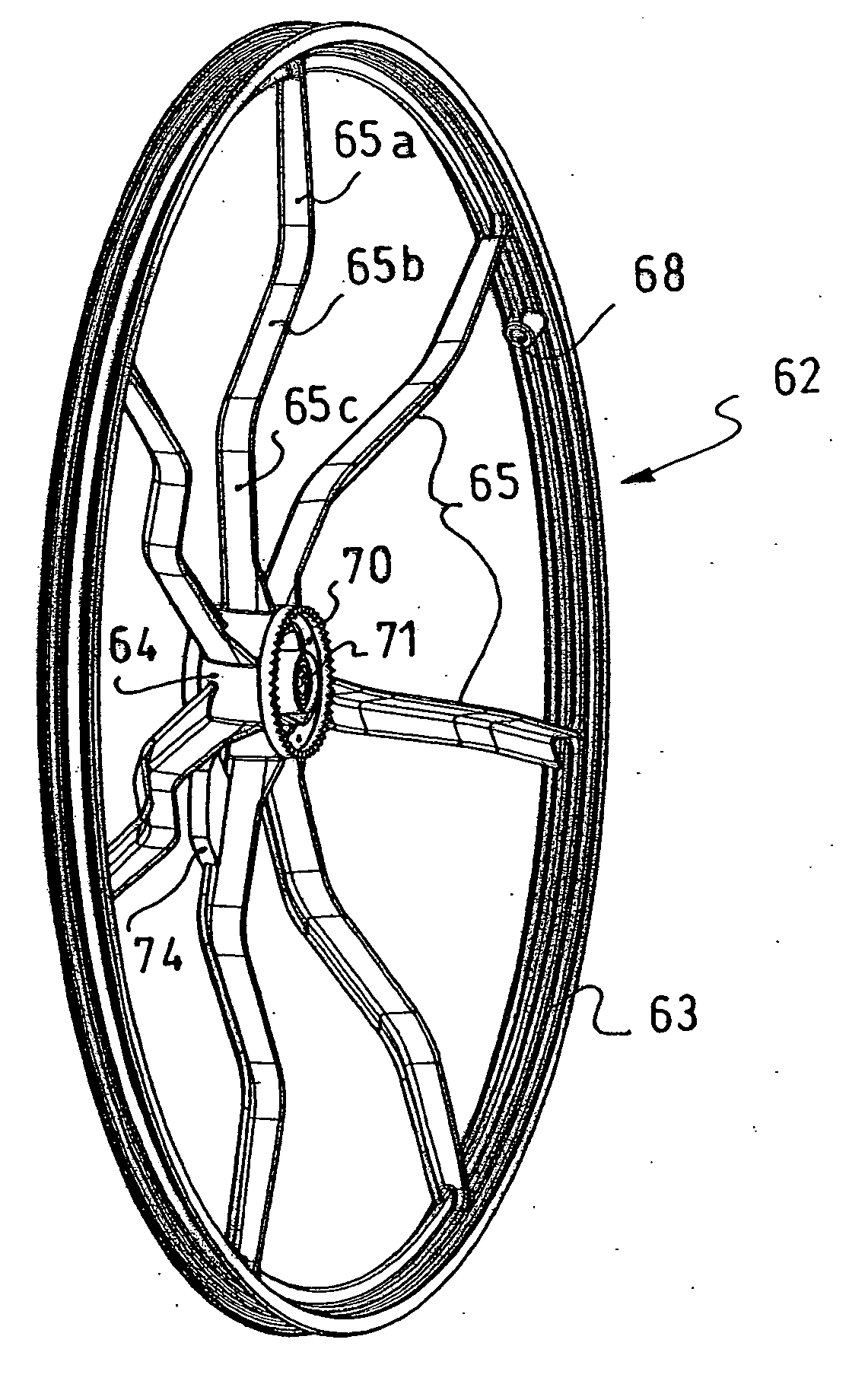

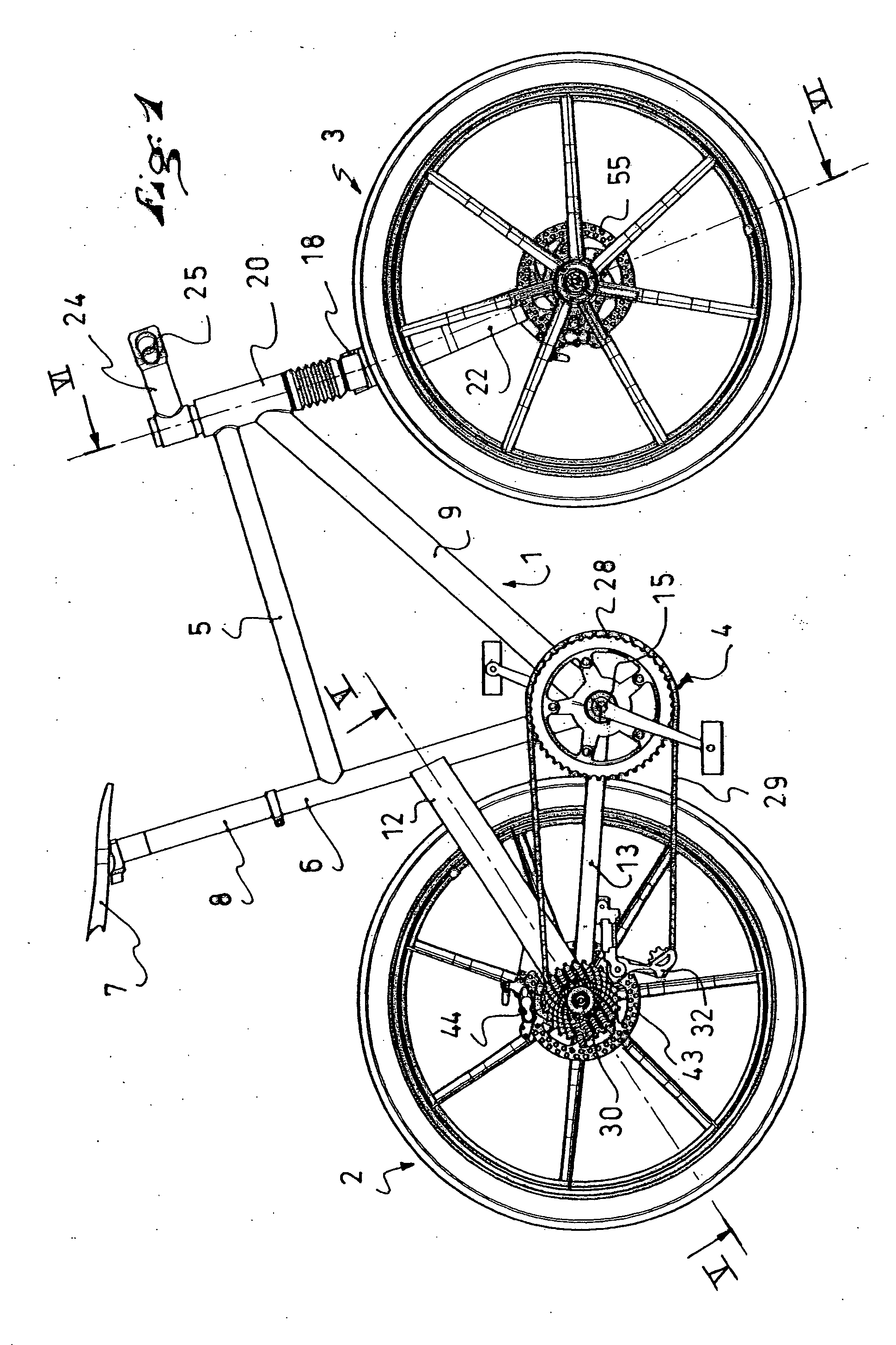

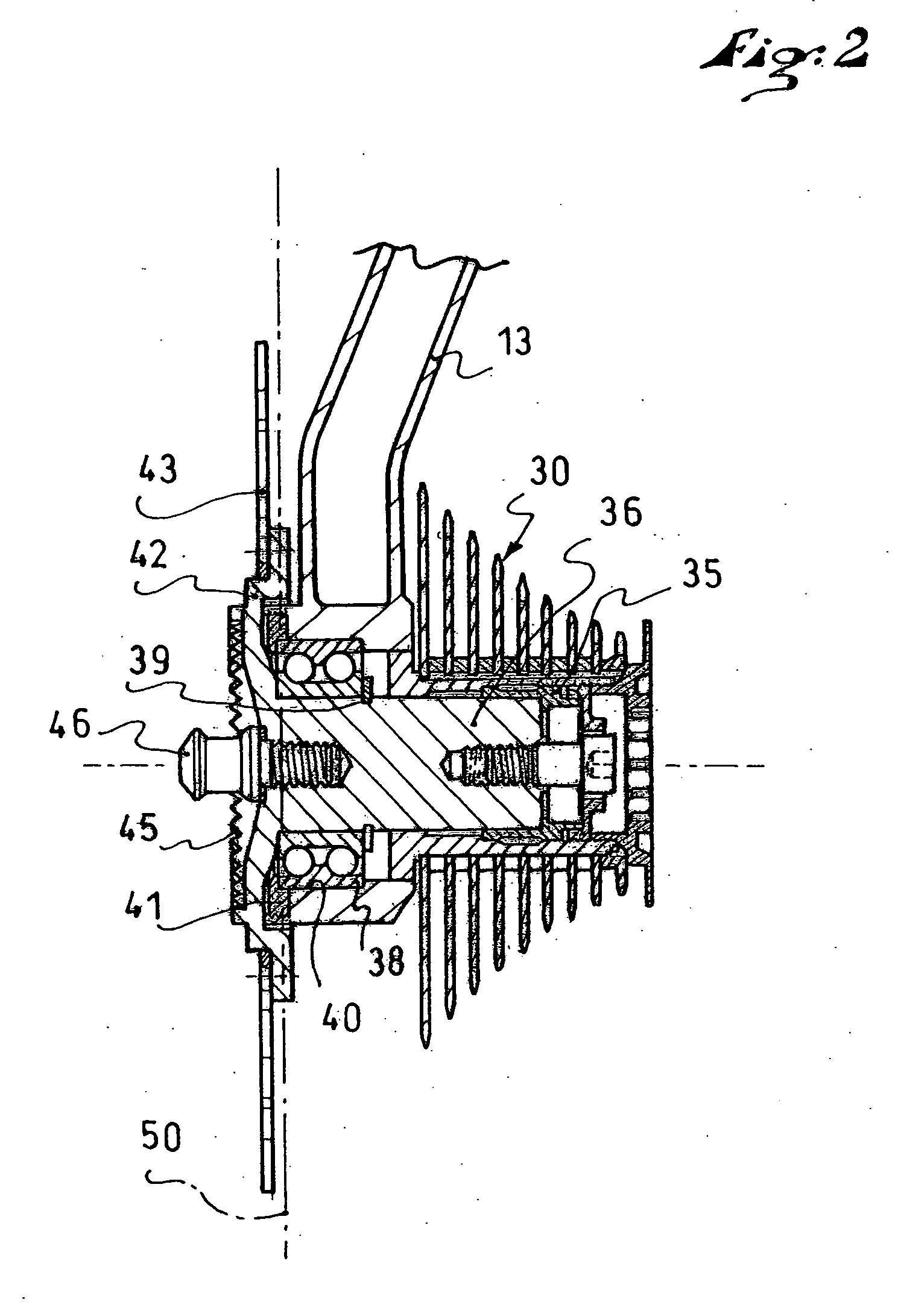

Wheel and a bicycle equipped with such wheel

InactiveUS20060108858A1Improve compromiseEasy to useHubsMechanical vibrations separationVehicle frameMedian plane

A bicycle that includes front and rear single-arm forks enabling the front and rear wheels to be mounted and demounted from the frame of the bicycle without necessitating the removal or repositioning of a transmission element, such as a chain, or the brake, if the bicycle is so equipped, each of the wheels including at least one flexibly and compressively rigid element connecting the central hub and the rim, such elements being asymmetrical with respect to a radial median plane defined by the rim, so that the hubs of the wheels are axially off-centered in relation to the radial median plane of the rim, while the radial median plane of the rims coincides with the general median plane of the frame. The invention is also directed to the wheel of the bicycle.

Owner:SALOMON SA

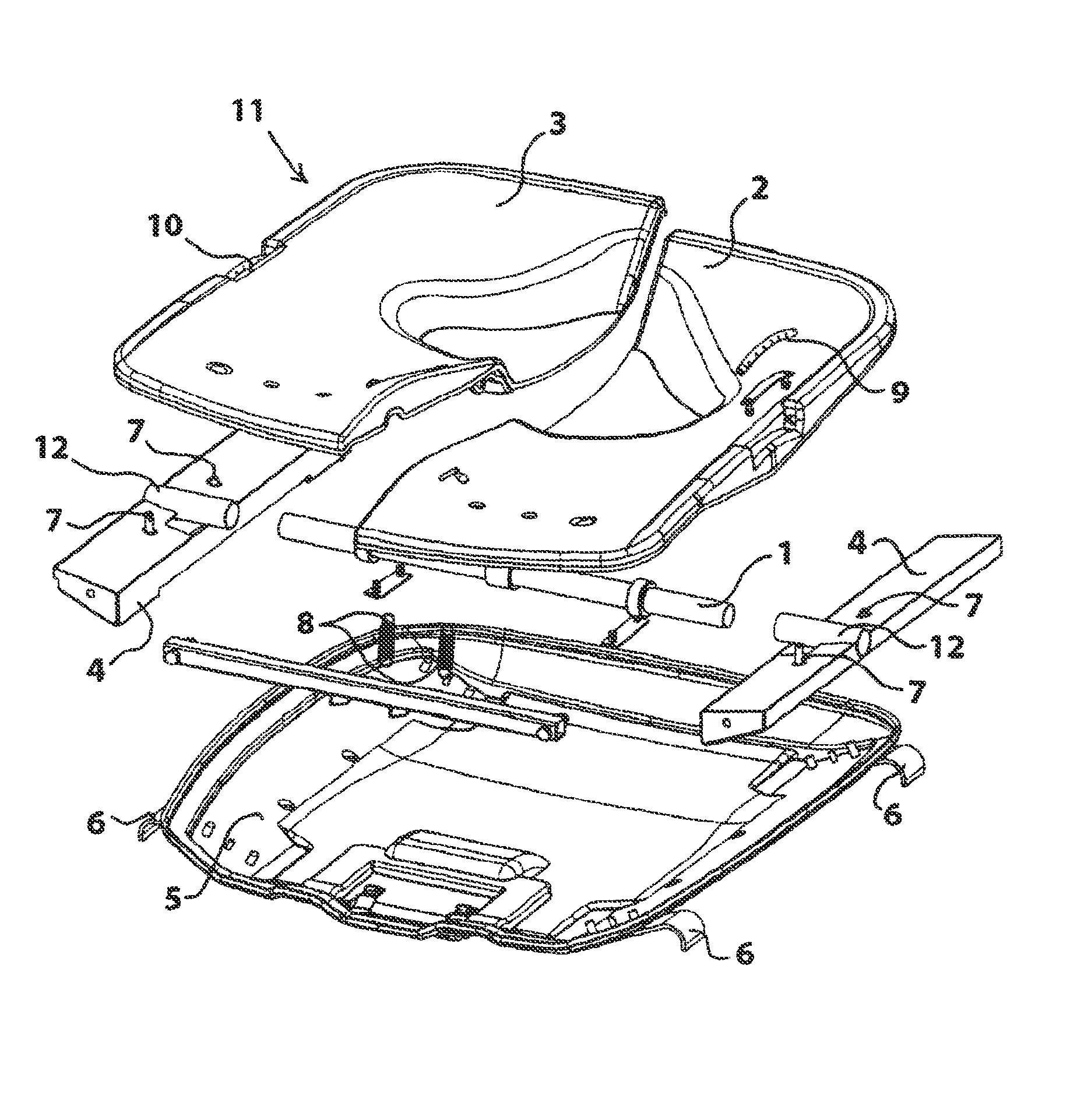

Pivotable seat

A seat for supporting the bottom area of a seated person, which seat is intended and adapted to form part of an article of seating furniture, such as a chair or a couch, a seat for a means of transport such as a car, a bus or an aircraft, or a wheelchair, has the feature that the seat consists of two parts, i.e. a left-hand seat part and a right-hand seat part, which seat parts are separated from each other along the nominal median plane of a user, each of the seat parts is pivotable around a pivot zone extending at least roughly perpendicularly of said median plane; and the projected position of the pivot zone lies in front of the tubera.

Owner:PR SELLA

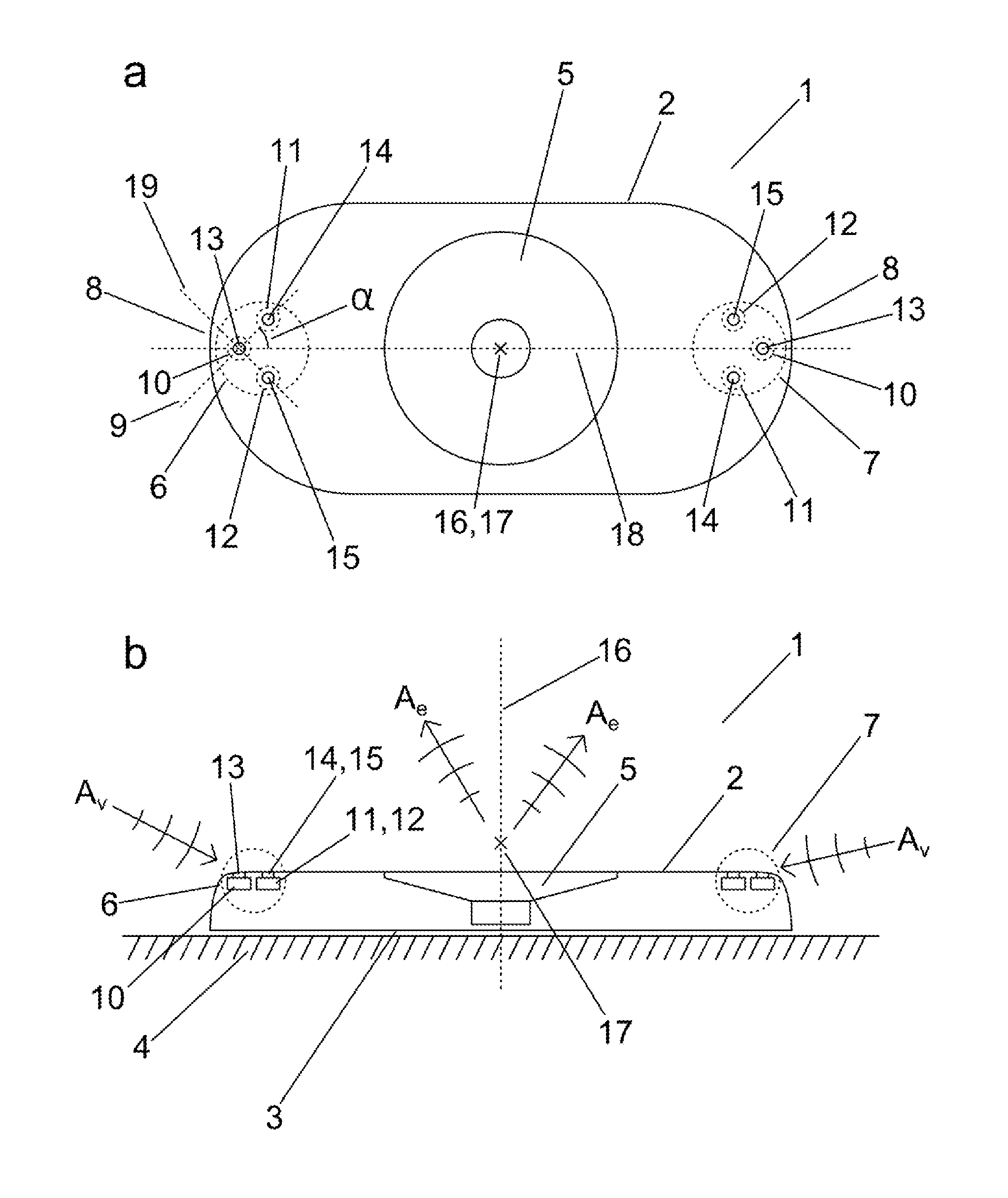

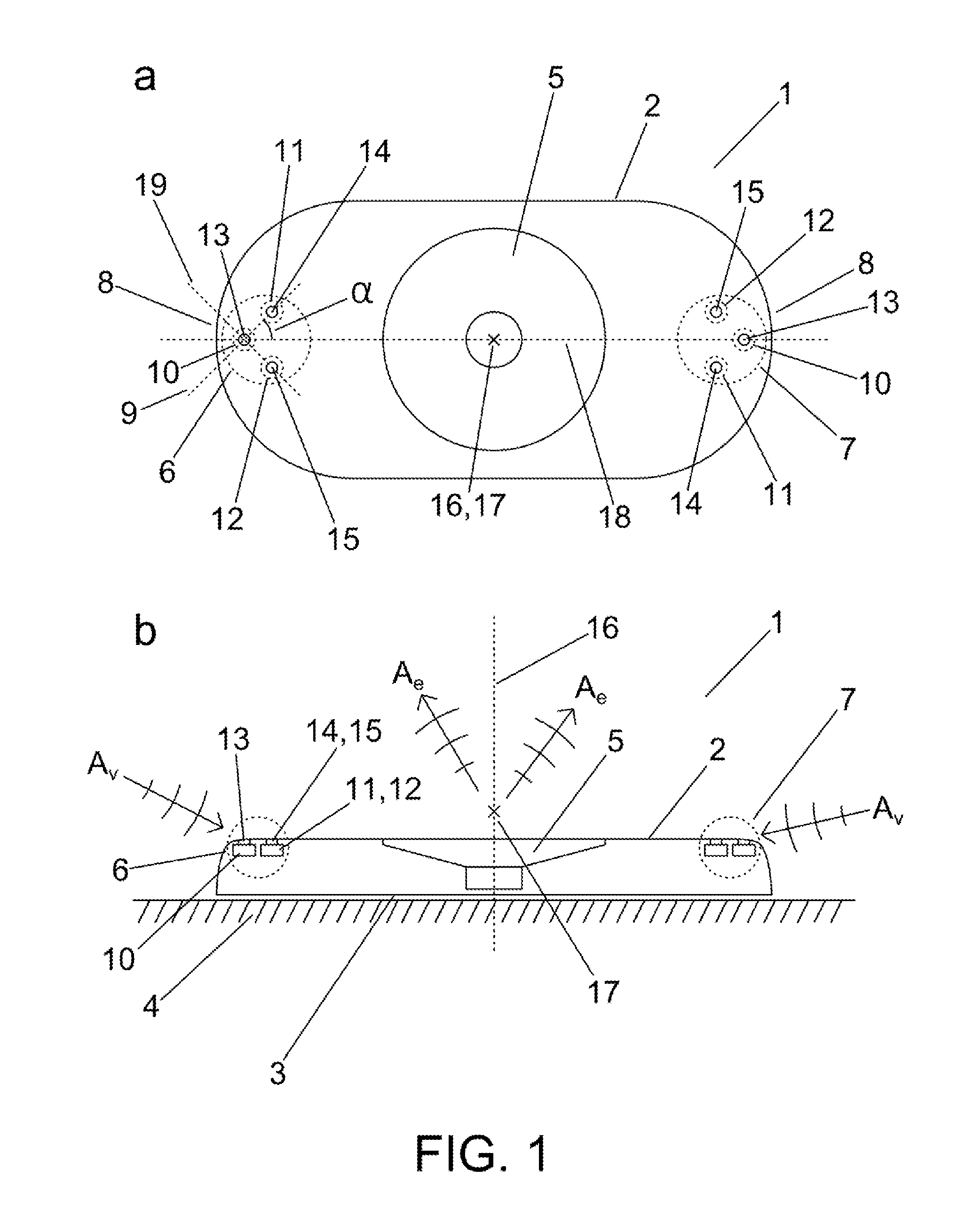

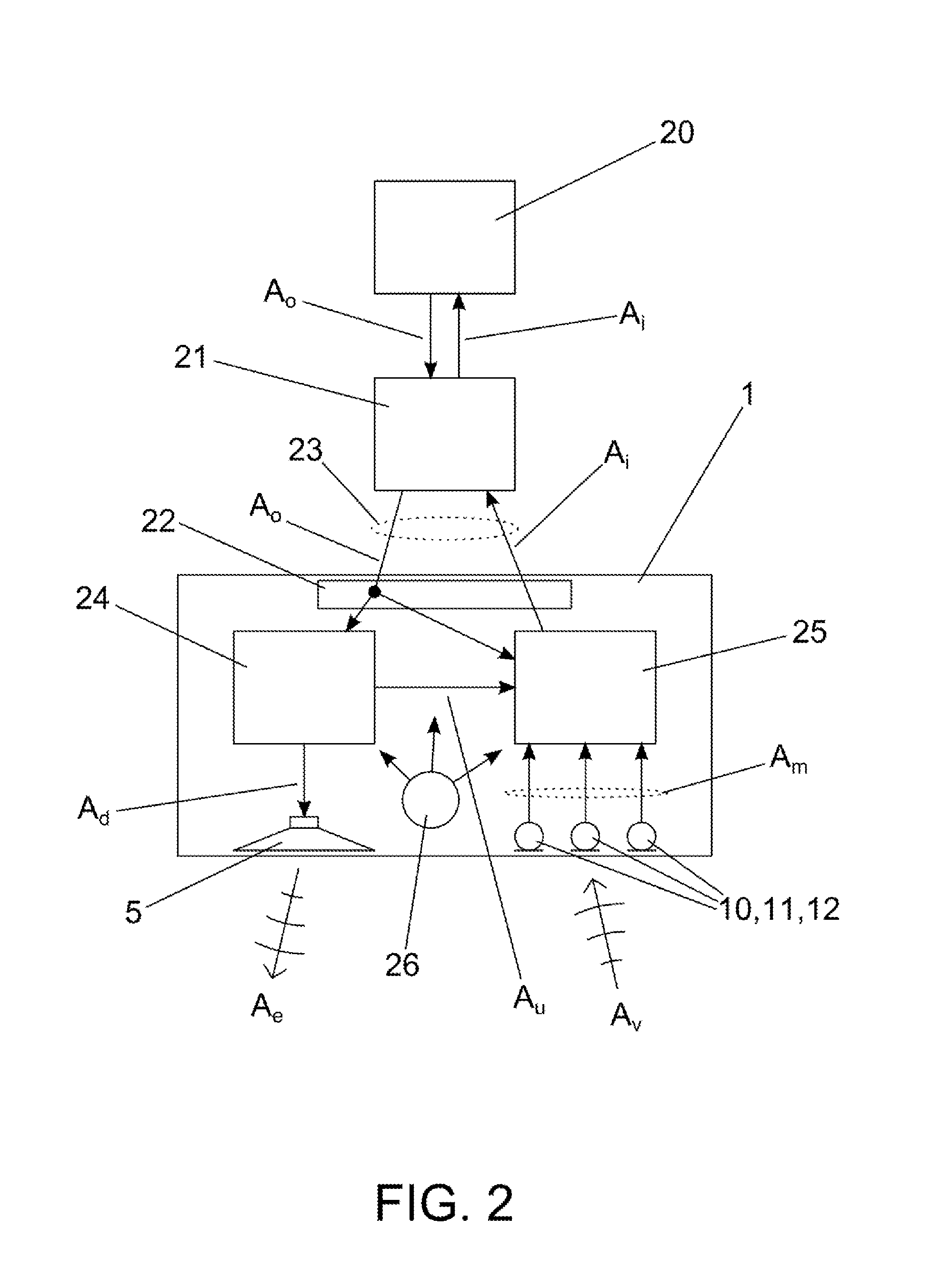

Desktop speakerphone

ActiveUS9479627B1Reduce manufacturing costHigh-quality soundInterconnection arrangementsSubstation speech amplifiersEngineeringMicrophone signal

The present invention relates to a desktop speakerphone constructed to make the desktop speakerphone less space-consuming while having improved audio qualities. The desktop speakerphone preferably has two microphone clusters 6, 7 mounted at the upper side of the housing 2 closer towards respective longitudinal ends 8 of the latter, so that each microphone cluster 6, 7 can receive voice sound Av from one or more of the users. Each microphone cluster 6, 7 preferably comprises three pressure microphones 10, 11, 12. Furthermore, within each microphone cluster 6, 7, the second and third sound inlets 14, 15 are preferably arranged symmetrically on opposite sides of the respective median plane 18. Within each microphone cluster 6, 7, the relative arrangement of the three sound inlets 13, 14, 15 defines a respective microphone axis 9, 19 for each of the microphone pairs 10, 11, 10, 12. The microphone axis 9 of the first microphone pair 10, 11 extends through the first and the second sound inlet 13, 14, while the microphone axis 19 of the second microphone pair 10, 12 extends through the first and the third sound inlet 13, 15. The microphones are connected to multiple array processors, each configured to provide an array signal in dependence on two or more of the multiple microphone signals. First and second array processor configured to provide array signals in dependence on microphone signals.

Owner:GN AUDIO AS

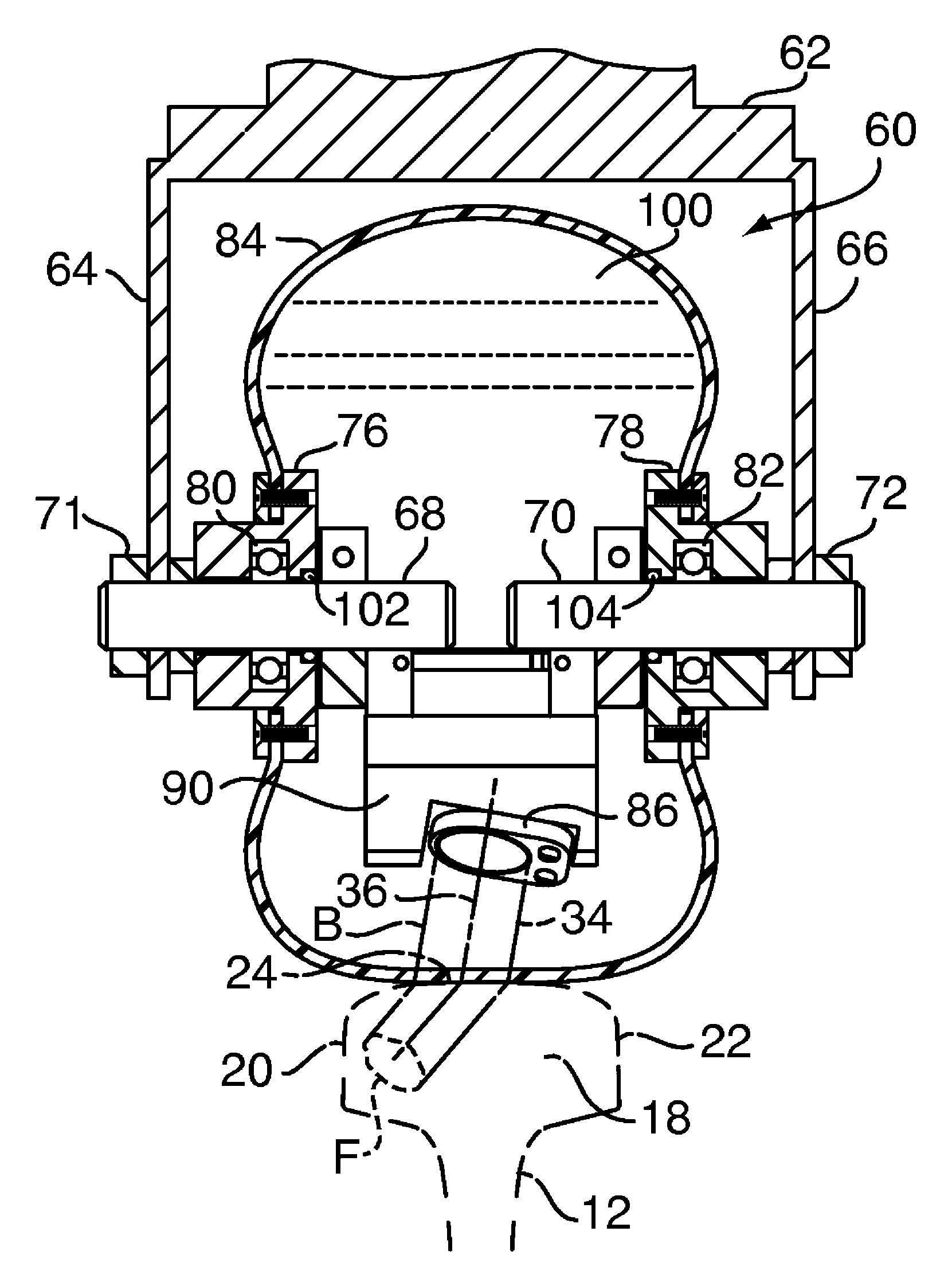

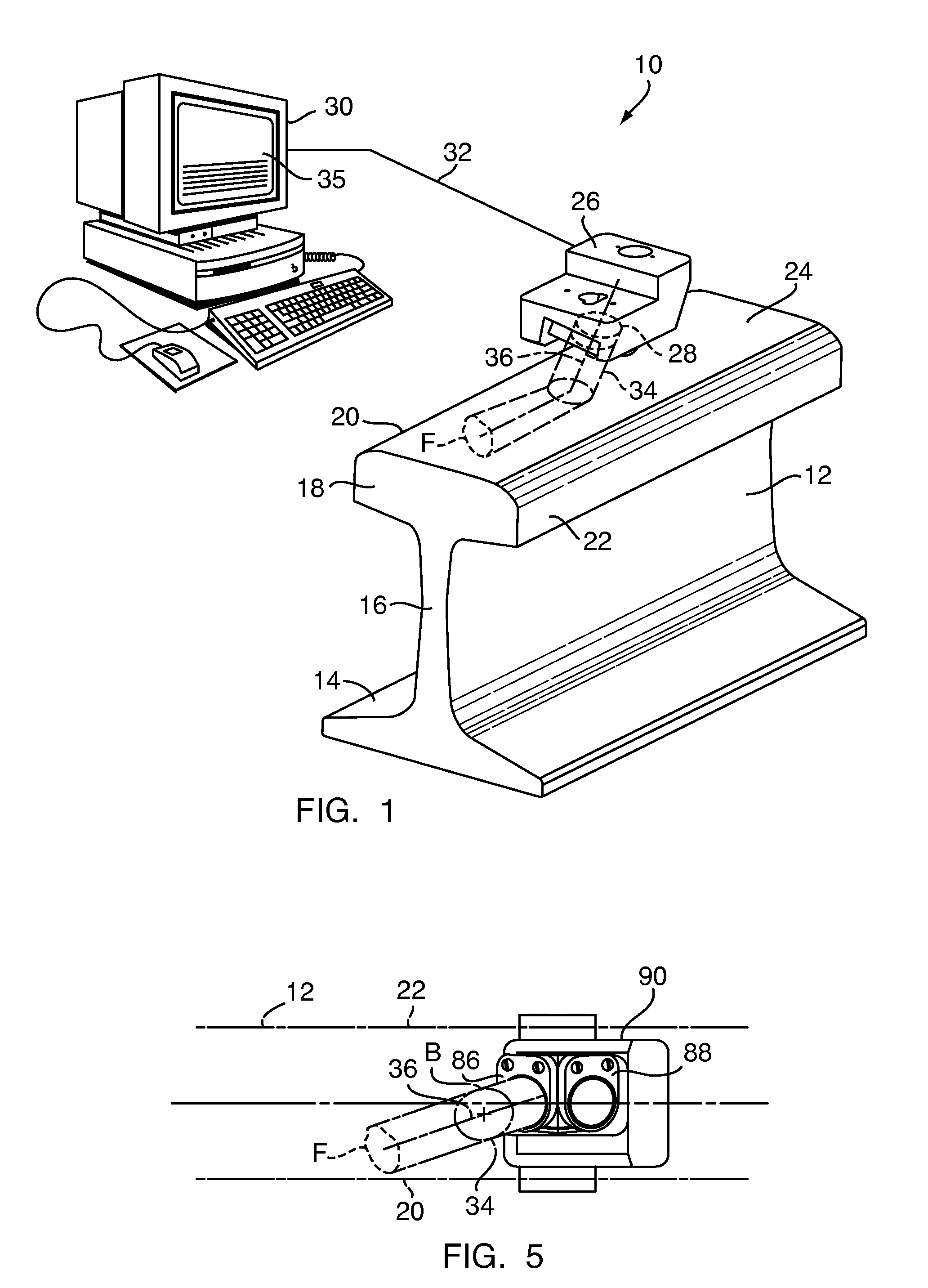

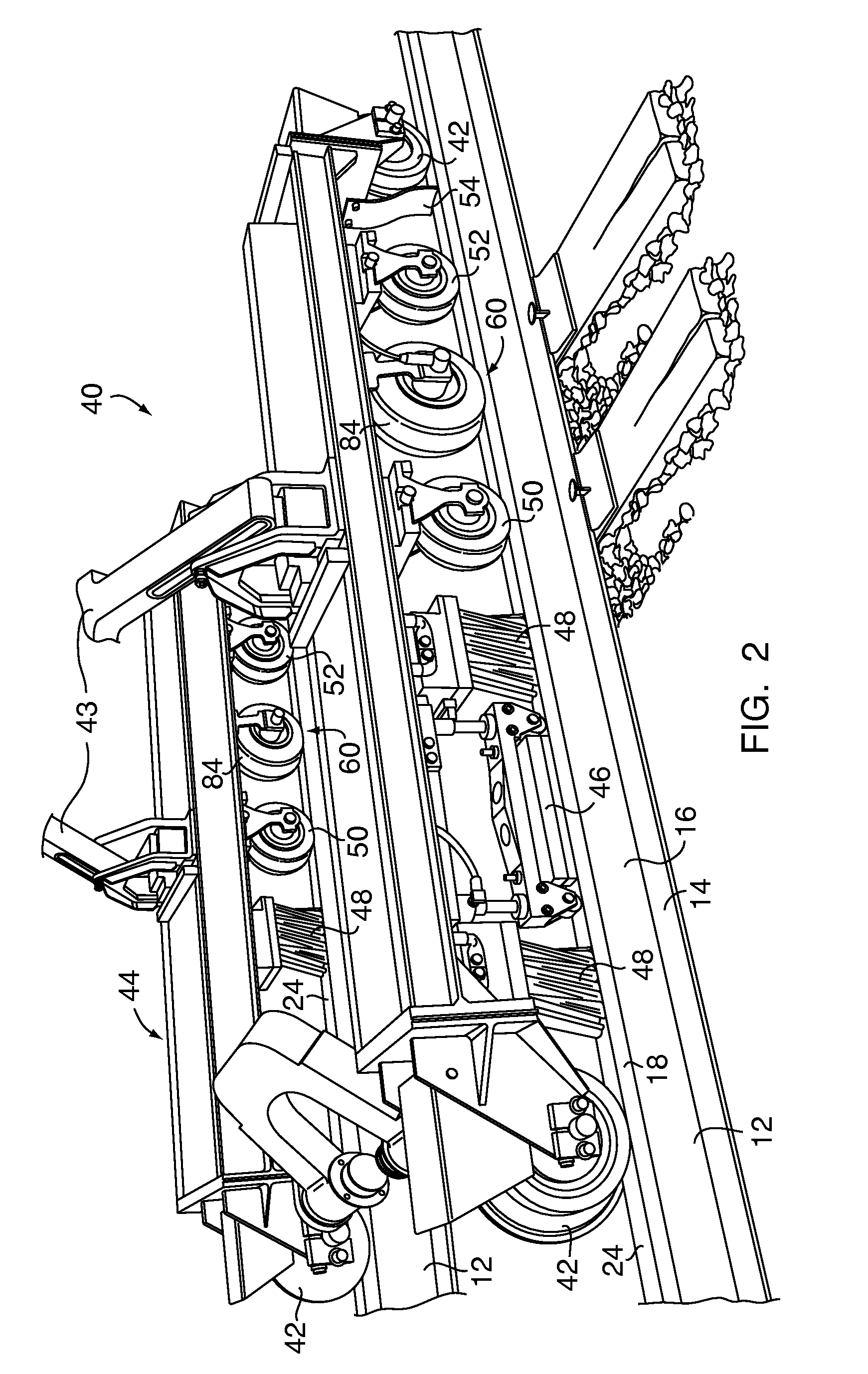

Method of and an apparatus for in situ ultrasonic rail inspection of a railroad rail

ActiveUS7849748B2Analysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementRail inspectionUltrasonic beam

An ultrasonic railroad rail inspection system, apparatus and method for in situ rail inspection including a wheel assembly containing a fluid-filled tire and an ultrasonic transducer mounted within the wheel assembly. The transducer is supported in the tire such that the ultrasonic beam generated by the transducer has a beam axis that intersects a head of a railroad rail at a position offset from the longitudinal median plane of the rail to the side of the head penetrated by the ultrasonic beam. The ultrasonic beam is reflected by flaws in the rail in the form of echoes. The echoes return to the transducer identifying the location of flaws.

Owner:SPERRY RAIL HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com