Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1794results about "Cutting inserts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

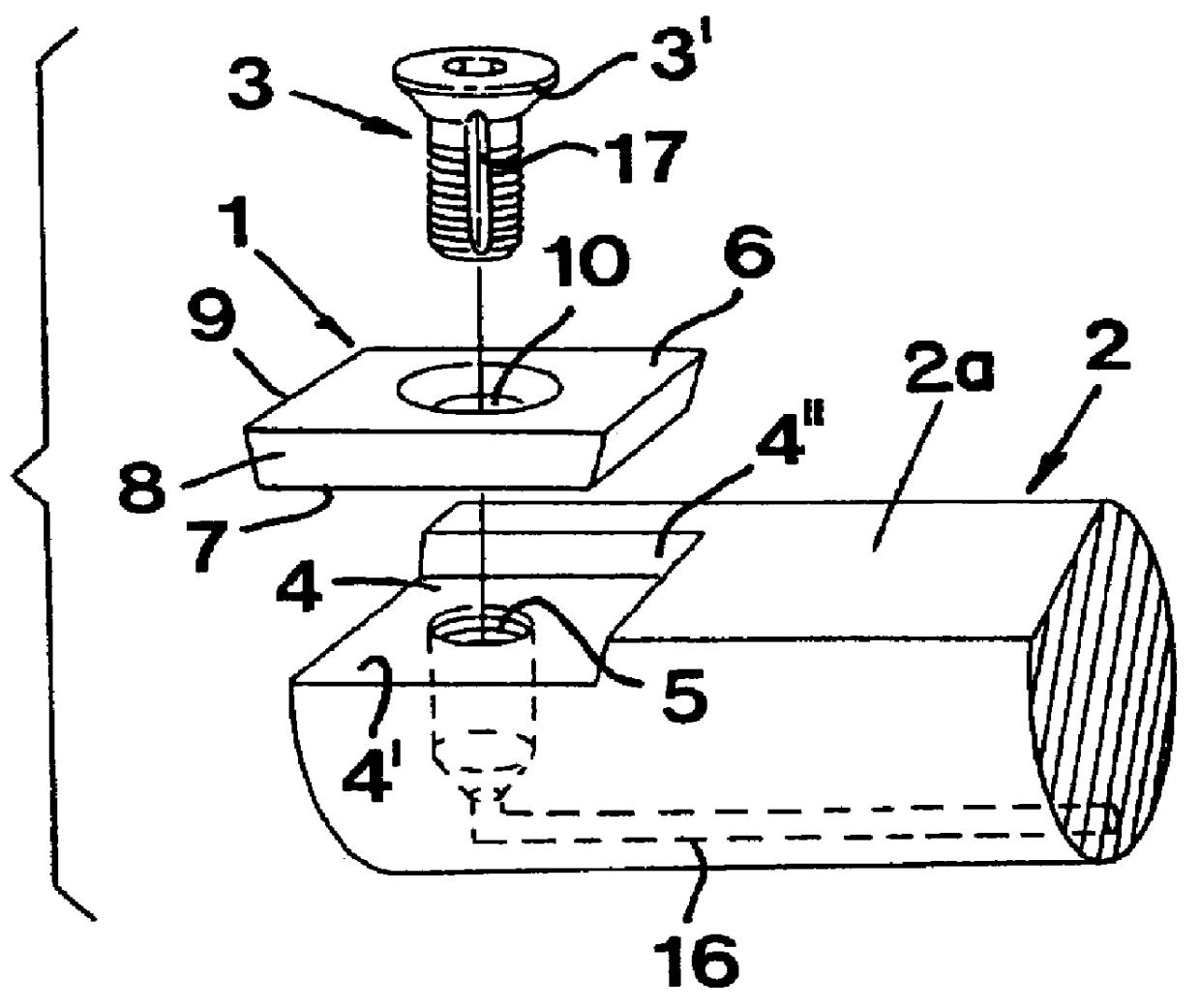

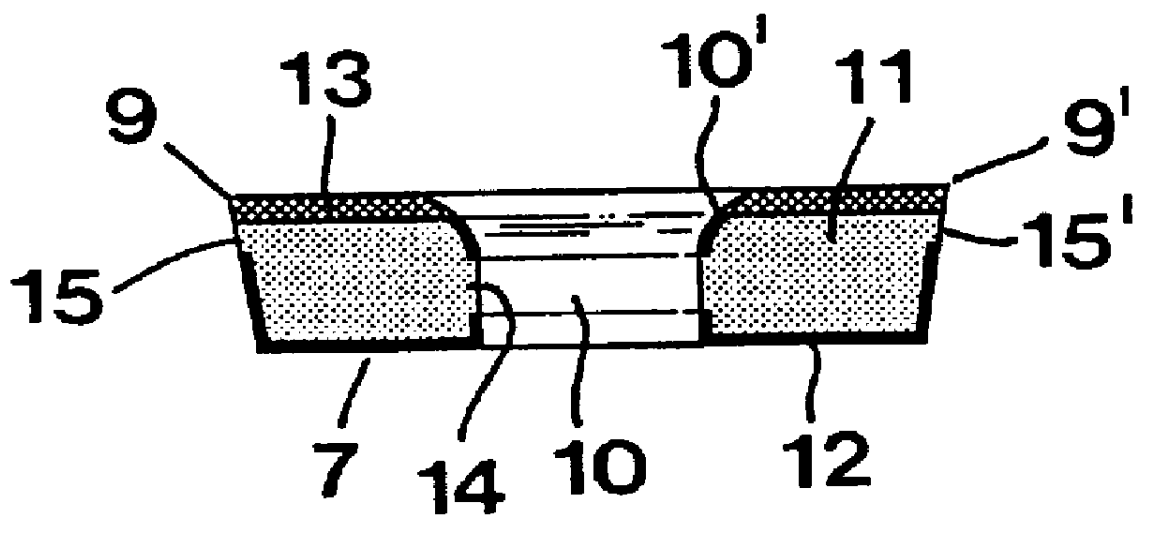

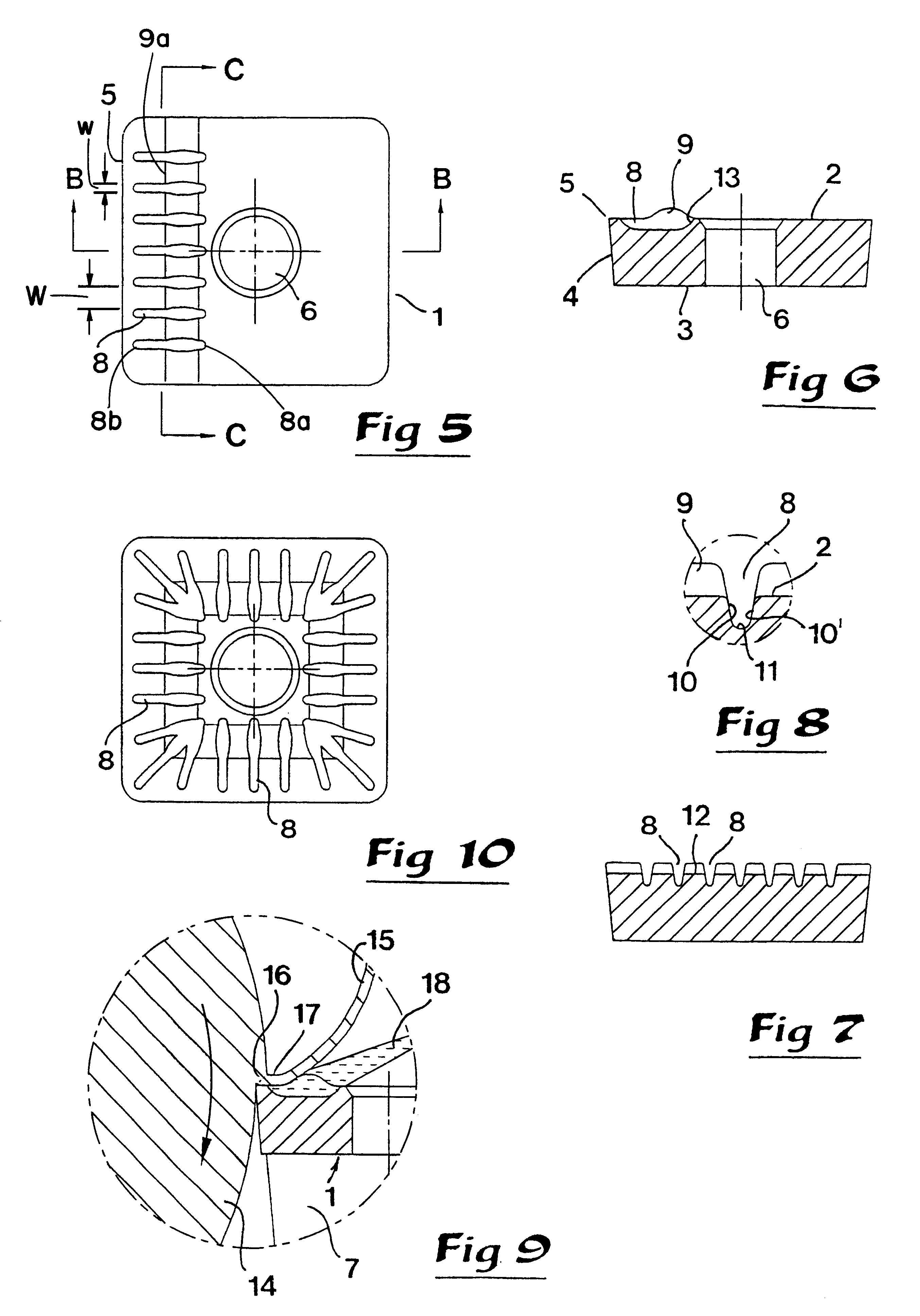

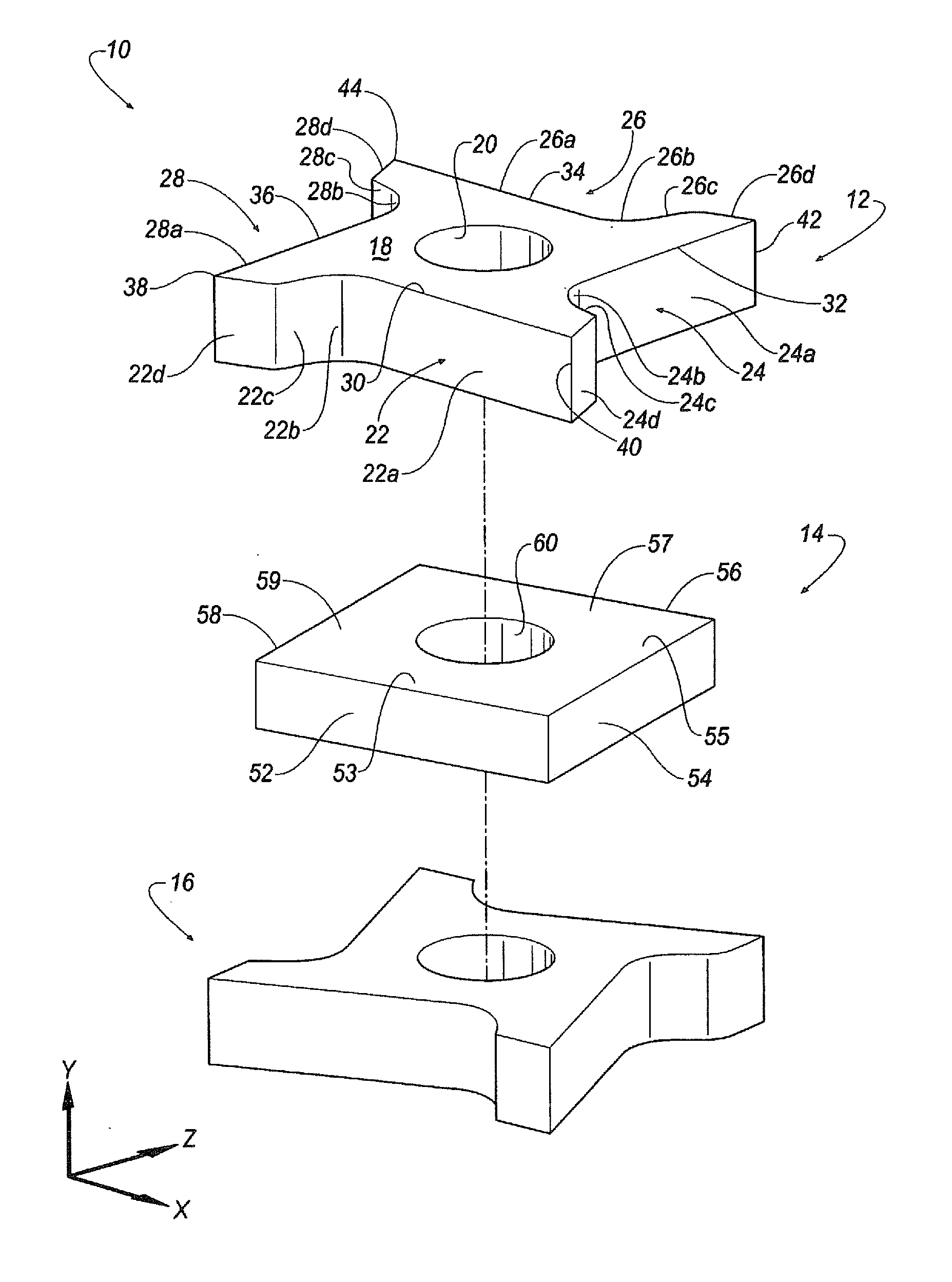

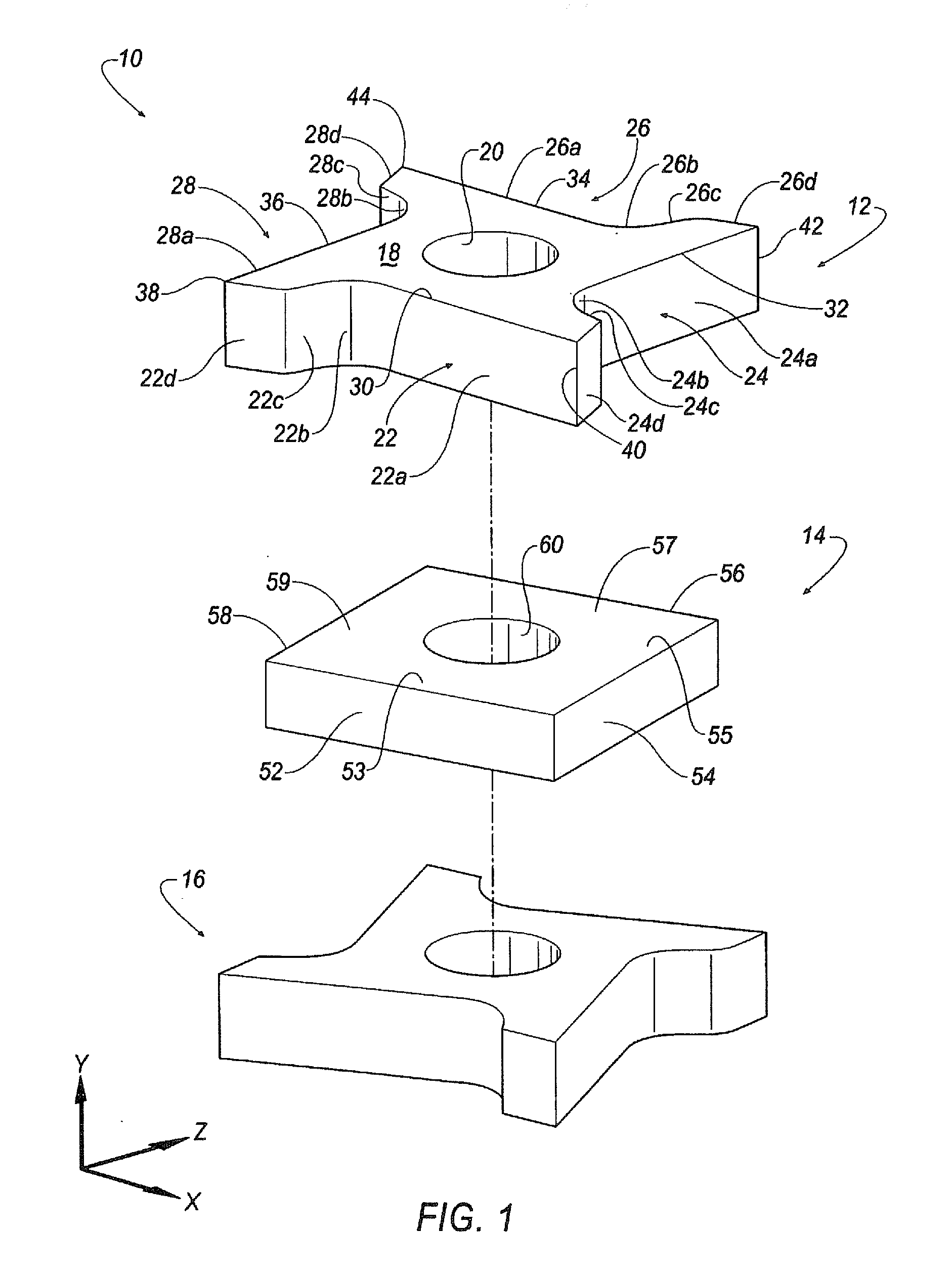

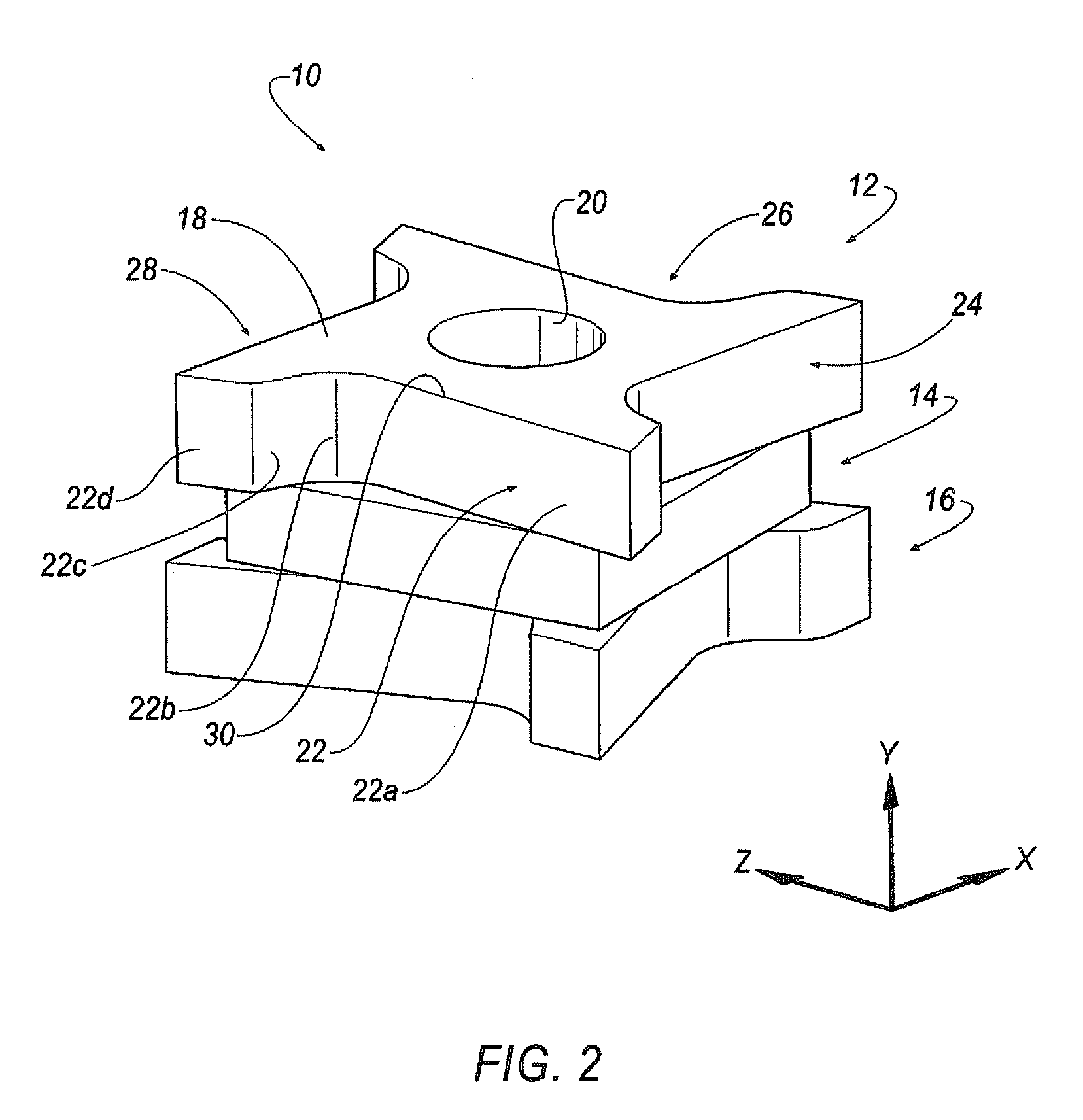

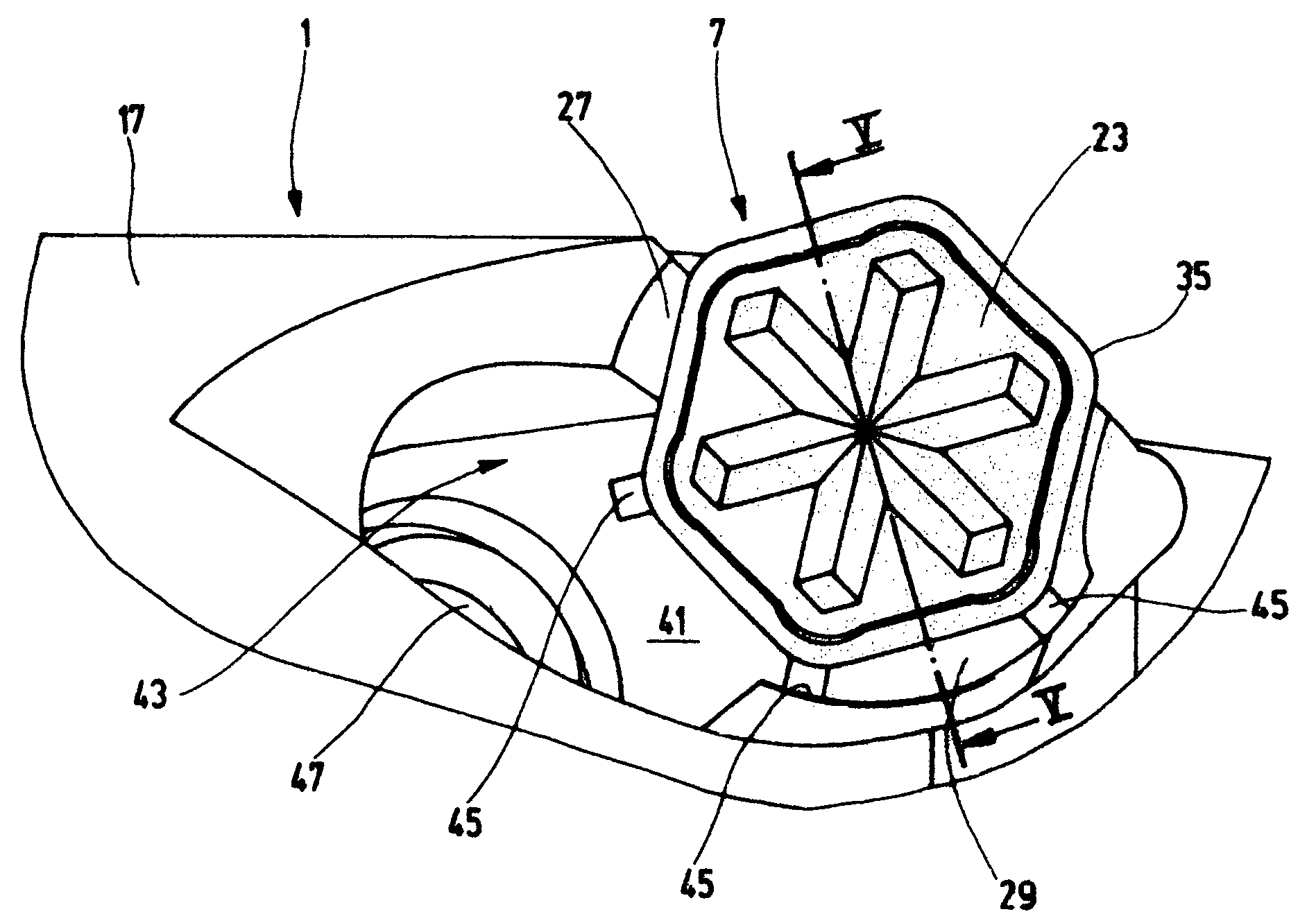

Tool coupling and method for coupling two tool parts

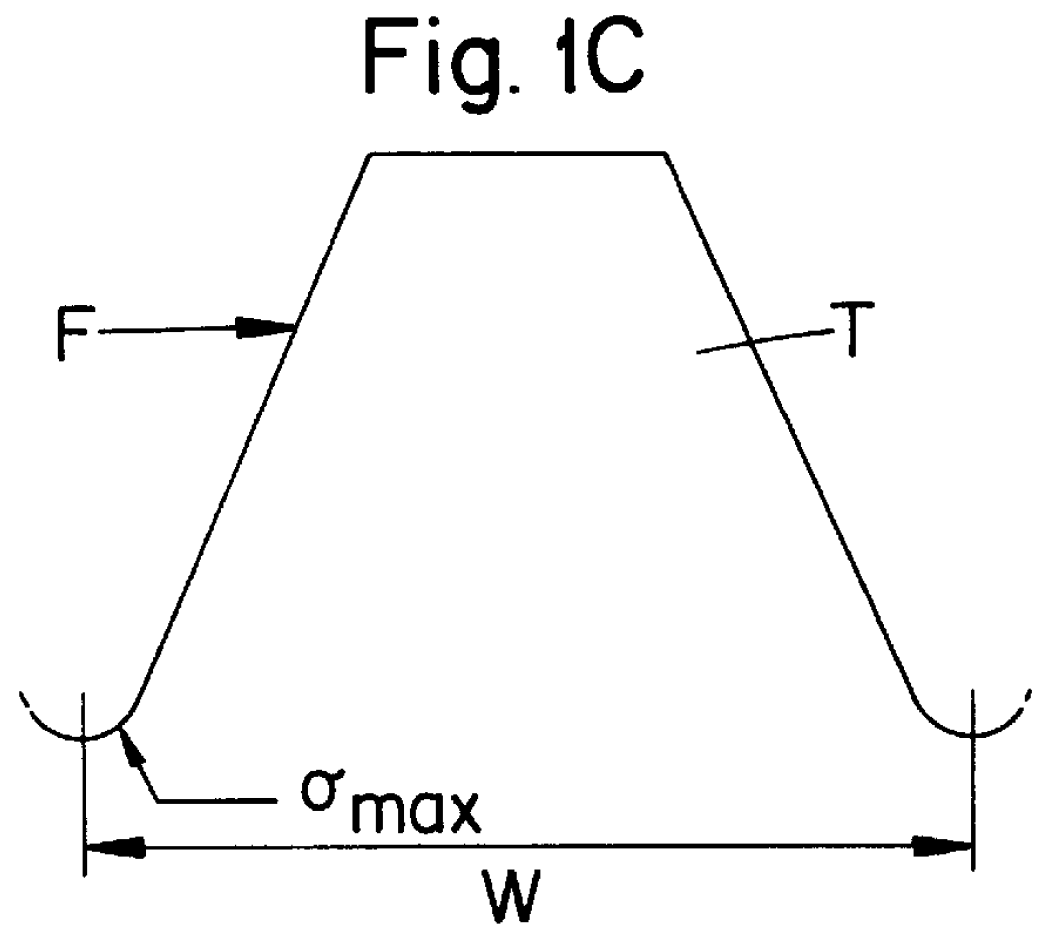

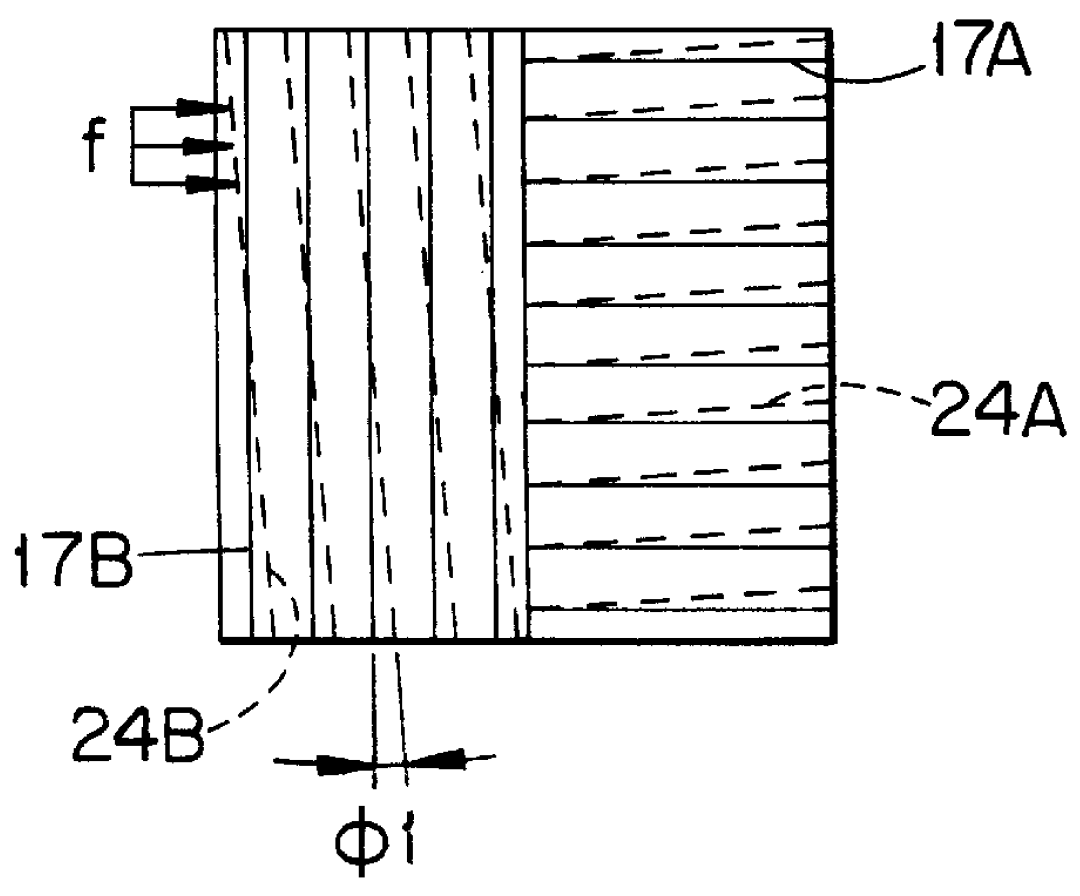

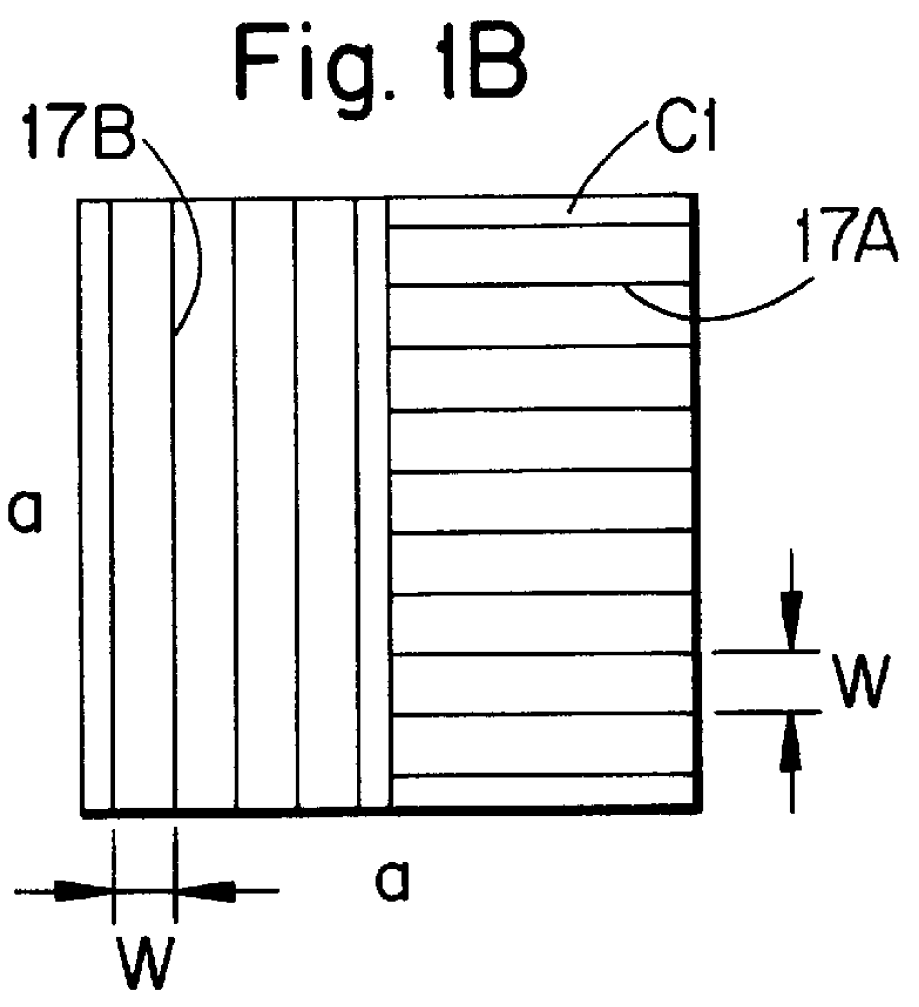

A tool includes a cutting head and a holder, wherein the cutting head and the holder form two cooperating surfaces that are pressed together. The surfaces possess rows of alternating parallel grooves and ridges for locking the surfaces to each other. Each of the surfaces has two rows of grooves, one row oriented 90 DEG relative to the other row. On one of the surfaces, some of the grooves of one row are in non-intersecting relationship with the grooves of the other row. On the other surface, the rows extend completely across one another, whereby the rows together form a waffle-like pattern. The cooperating surfaces allow at least four separate relative positions between the cutting head and holder.

Owner:SECO TOOLS AB

Chip forming cutting insert with internal cooling

InactiveUS6053669ADrawback can be obviatedEffective steeringCutting insertsTurning toolsEngineeringMachining

A cutting insert is cooled during chip removing machining of a workpiece by conducting cooling medium through a porous supporting body of the insert. The cooling medium enters the insert through an inlet formed therein at a location remote from a cutting edge of the insert and exits the insert through an outlet formed in the insert at a location proximate the cutting edge. The discharged cooling medium impinges on, and cools, the workpiece.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting insert with cooling channel

A cutting insert for chipforming machine has a tip face with a cutting edge. Grooves are formed in the top face and extend toward the cutting edge. Chip-deflecting projections extend upwardly from the top face and are situated in spaces formed between adjacent grooves. A jet of cooling fluid is directed toward inner ends of the grooves and travels between the projections and within the grooves toward the cutting edge.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

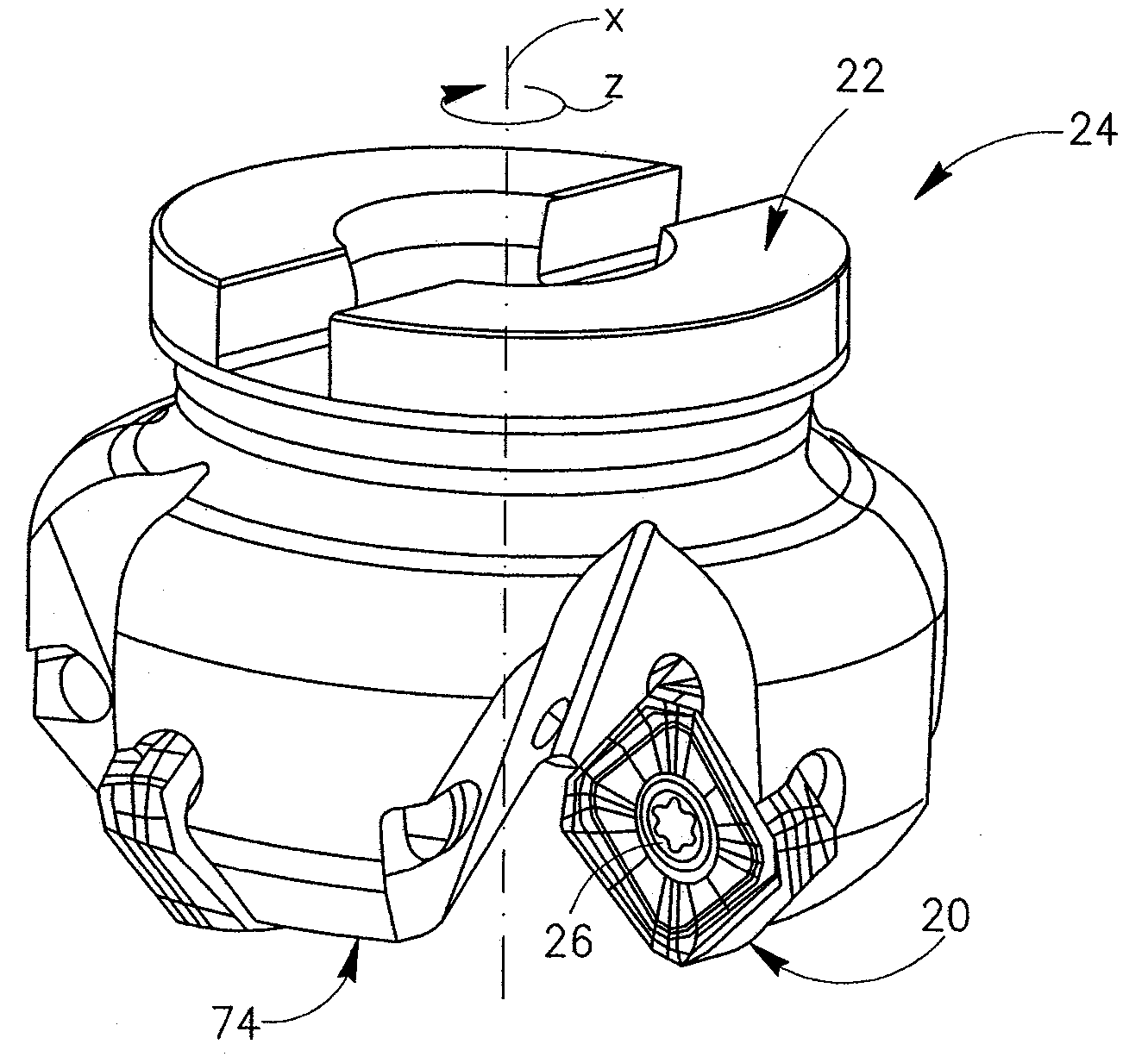

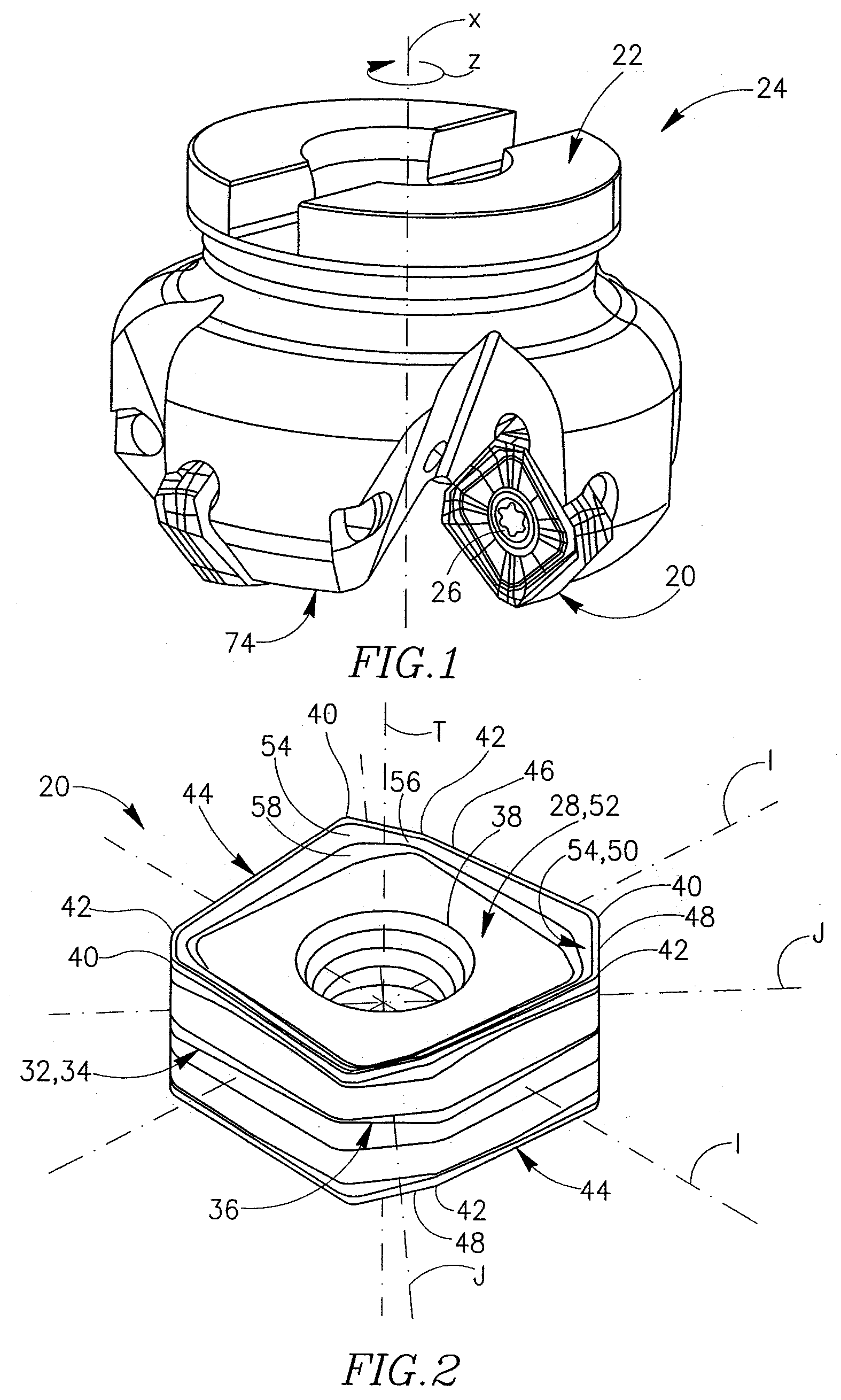

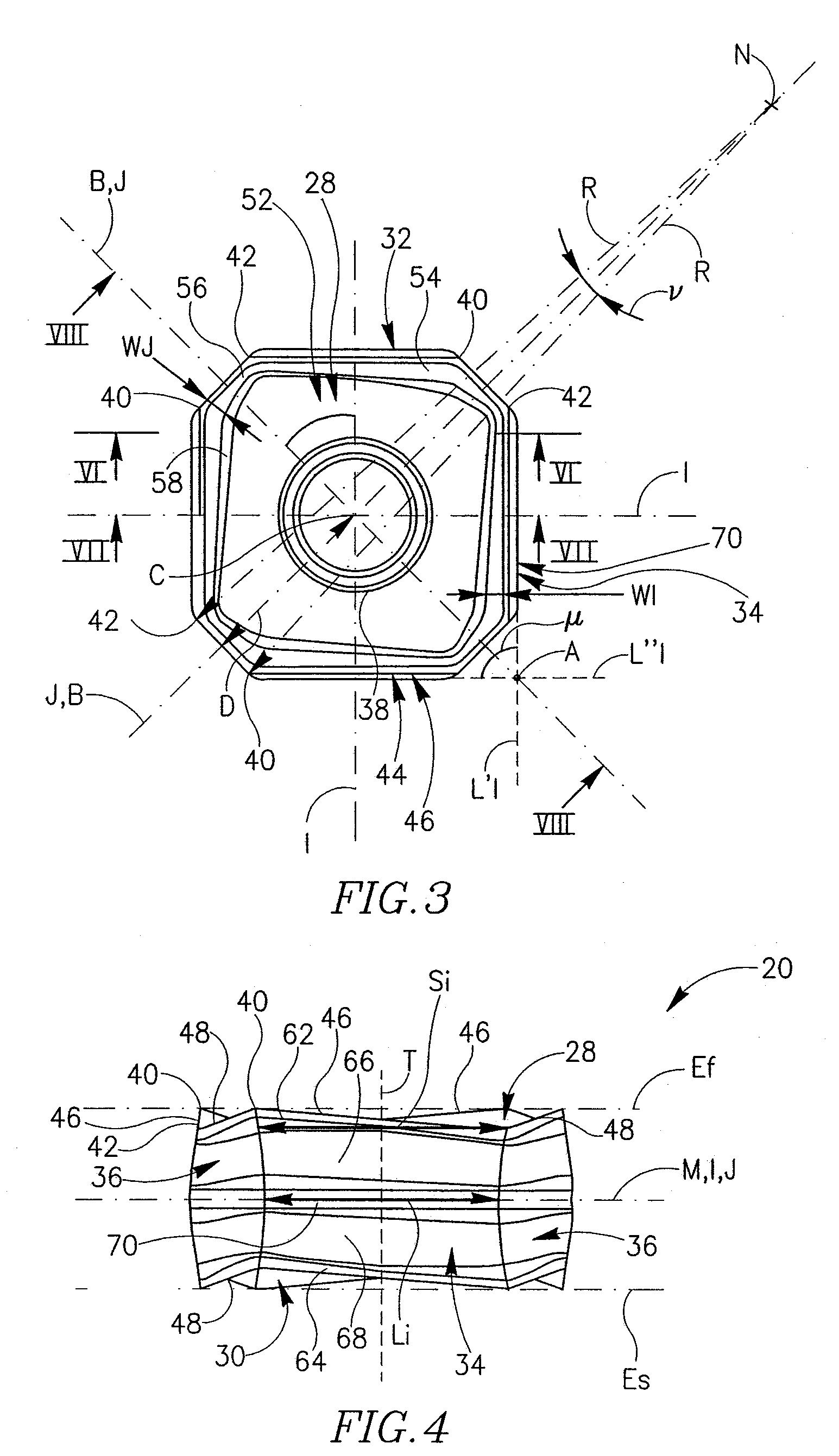

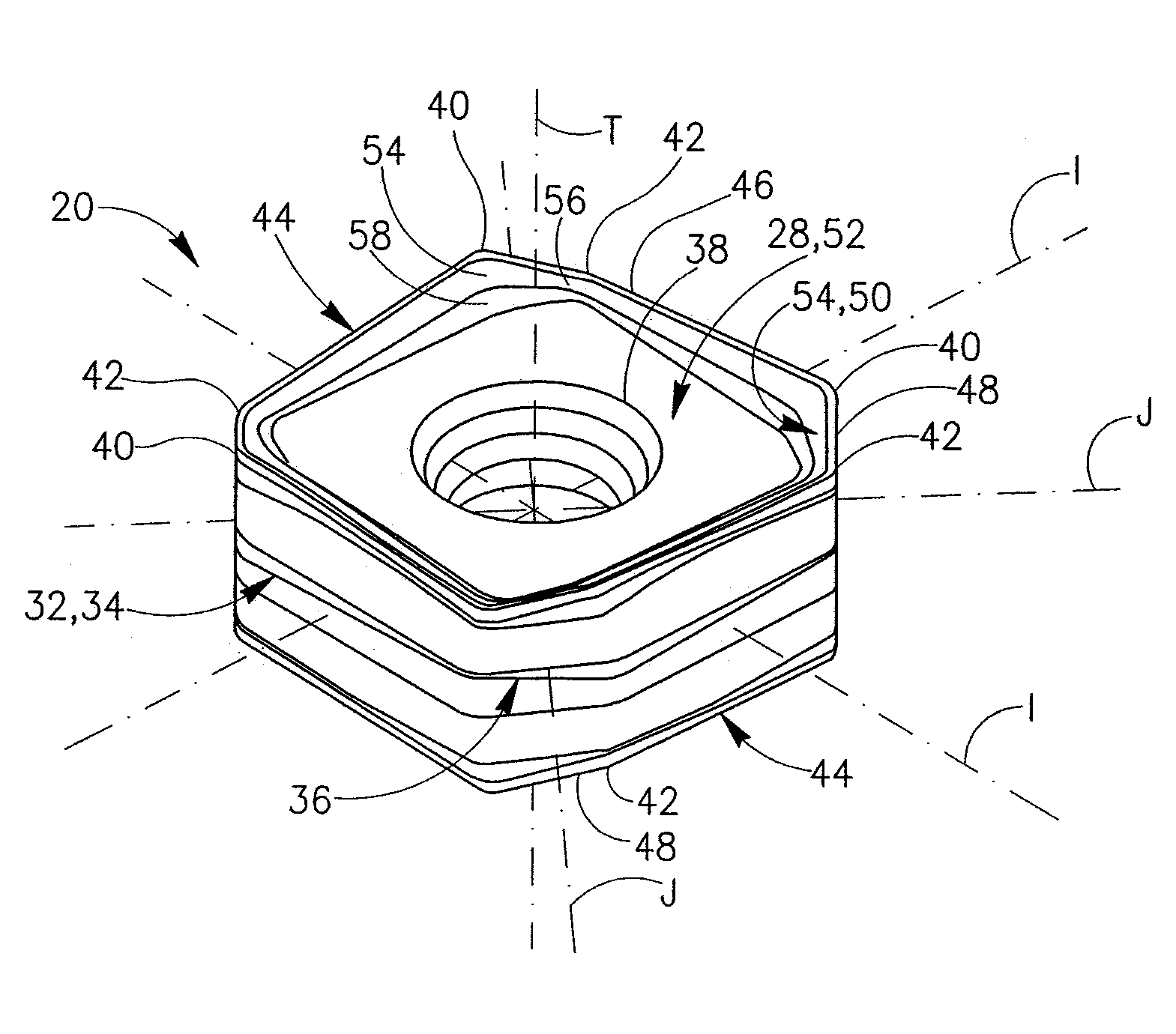

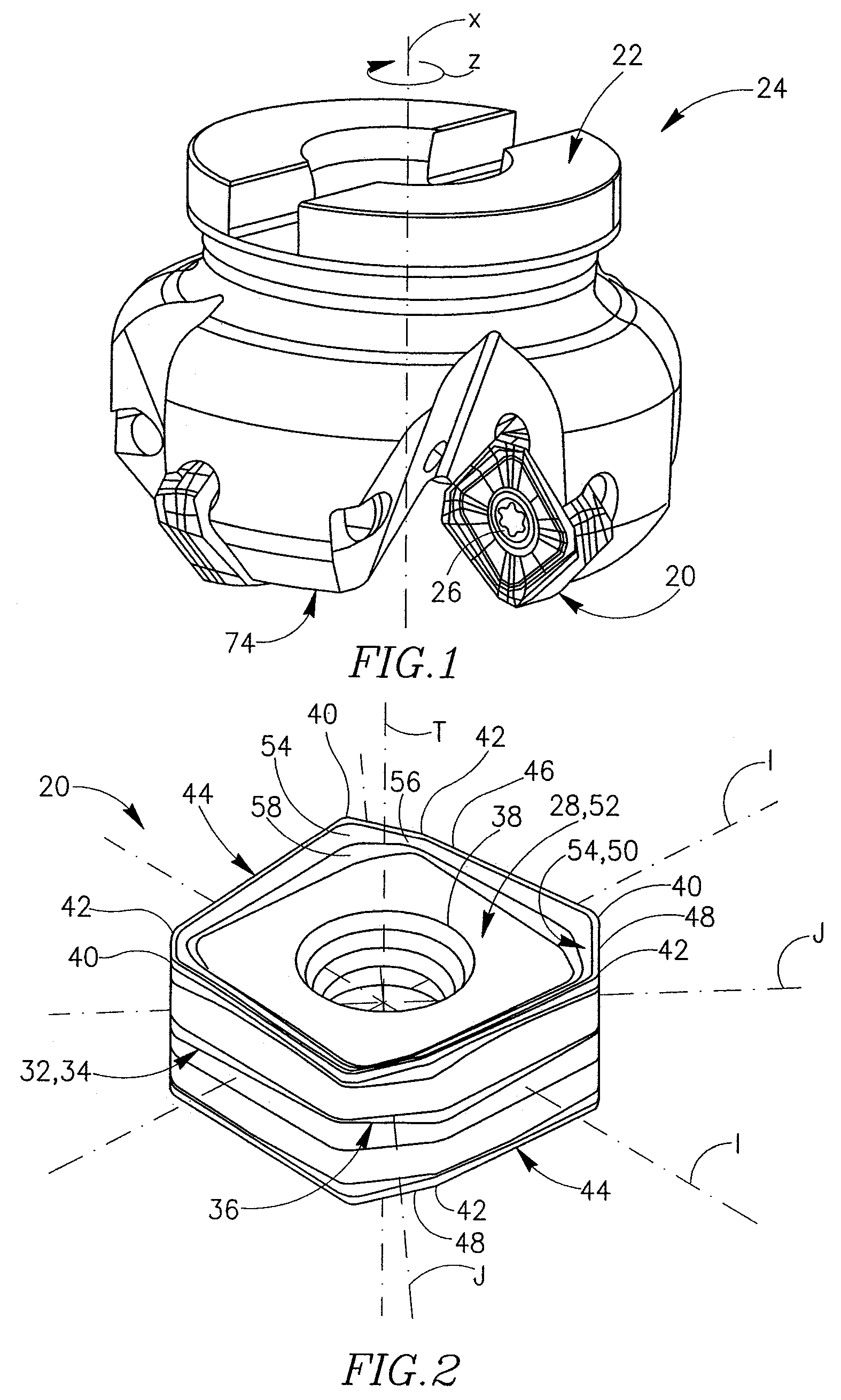

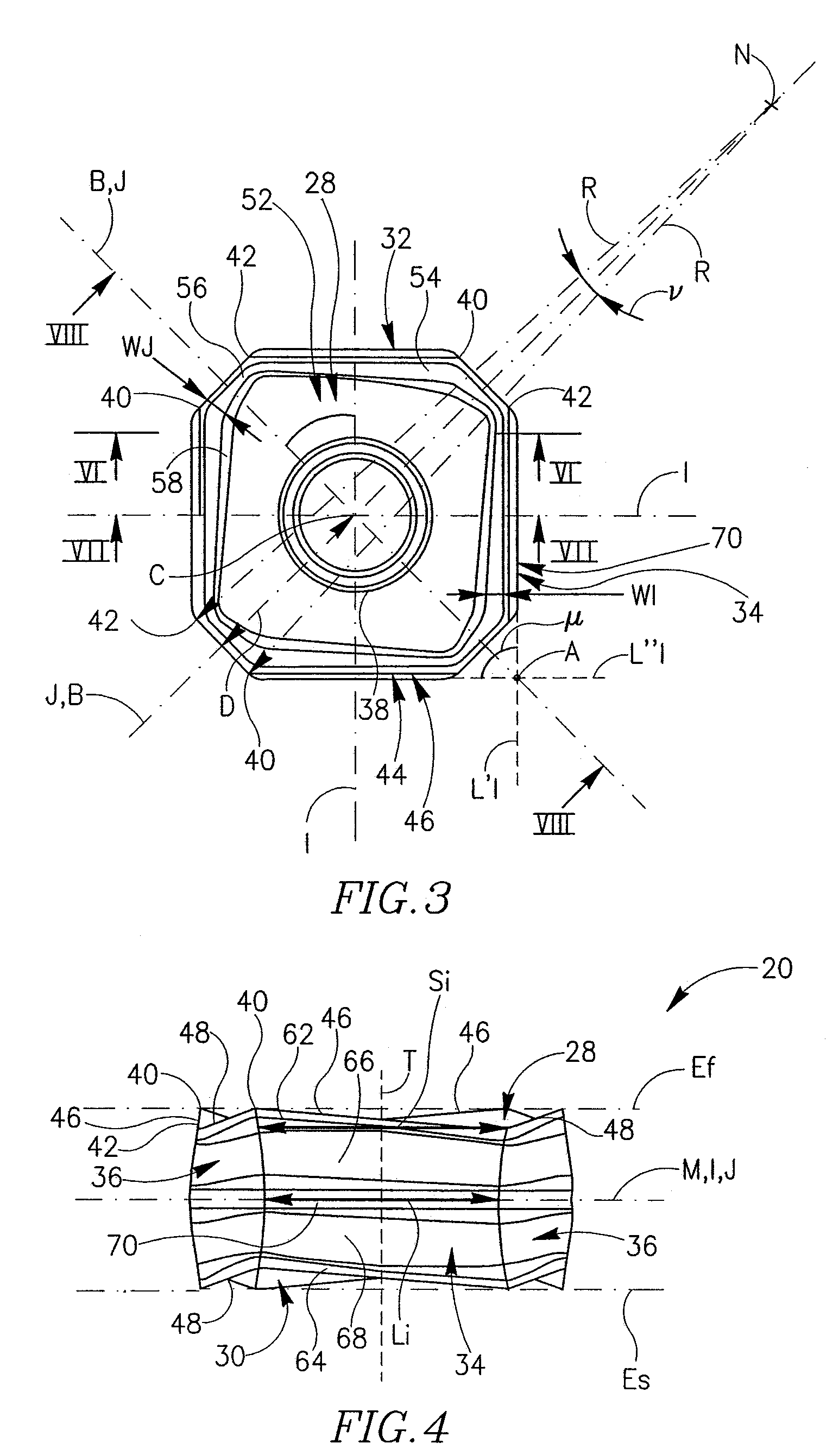

Cutting Insert Having Cylindrically Shaped Side Surface Portions

ActiveUS20070003384A1Reduced cutting performanceReduce the impactMilling cuttersCutting insertsRotational symmetryMedian plane

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

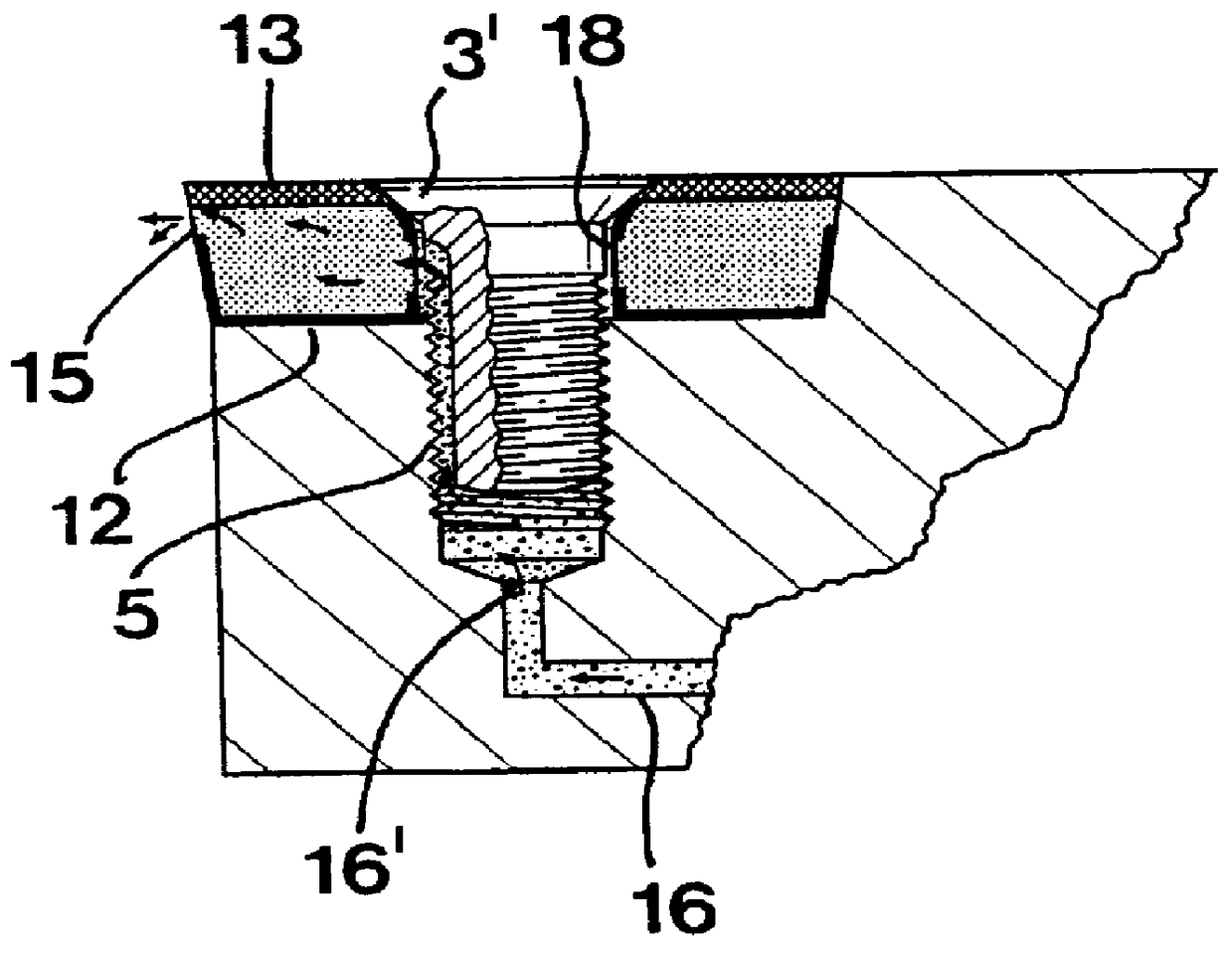

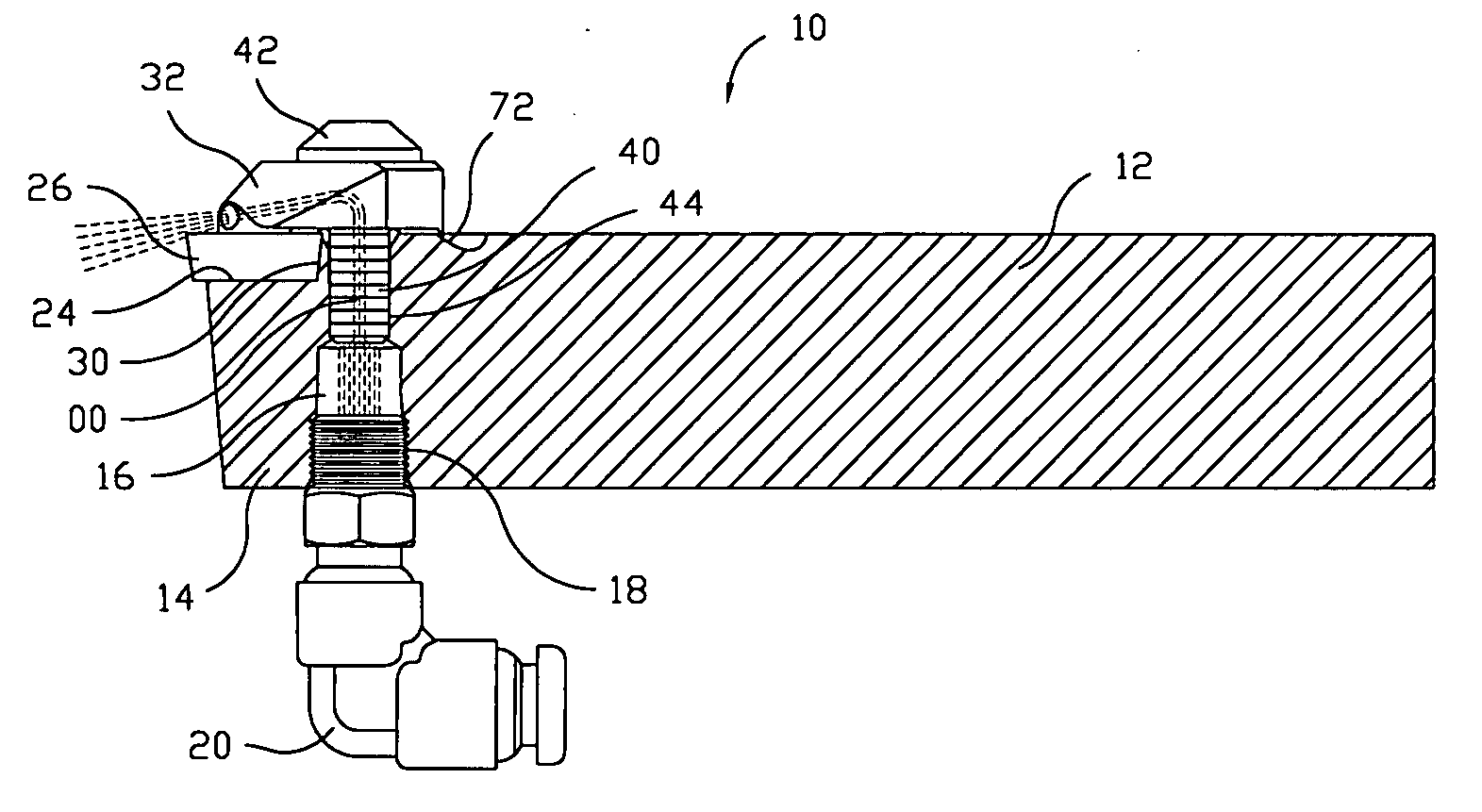

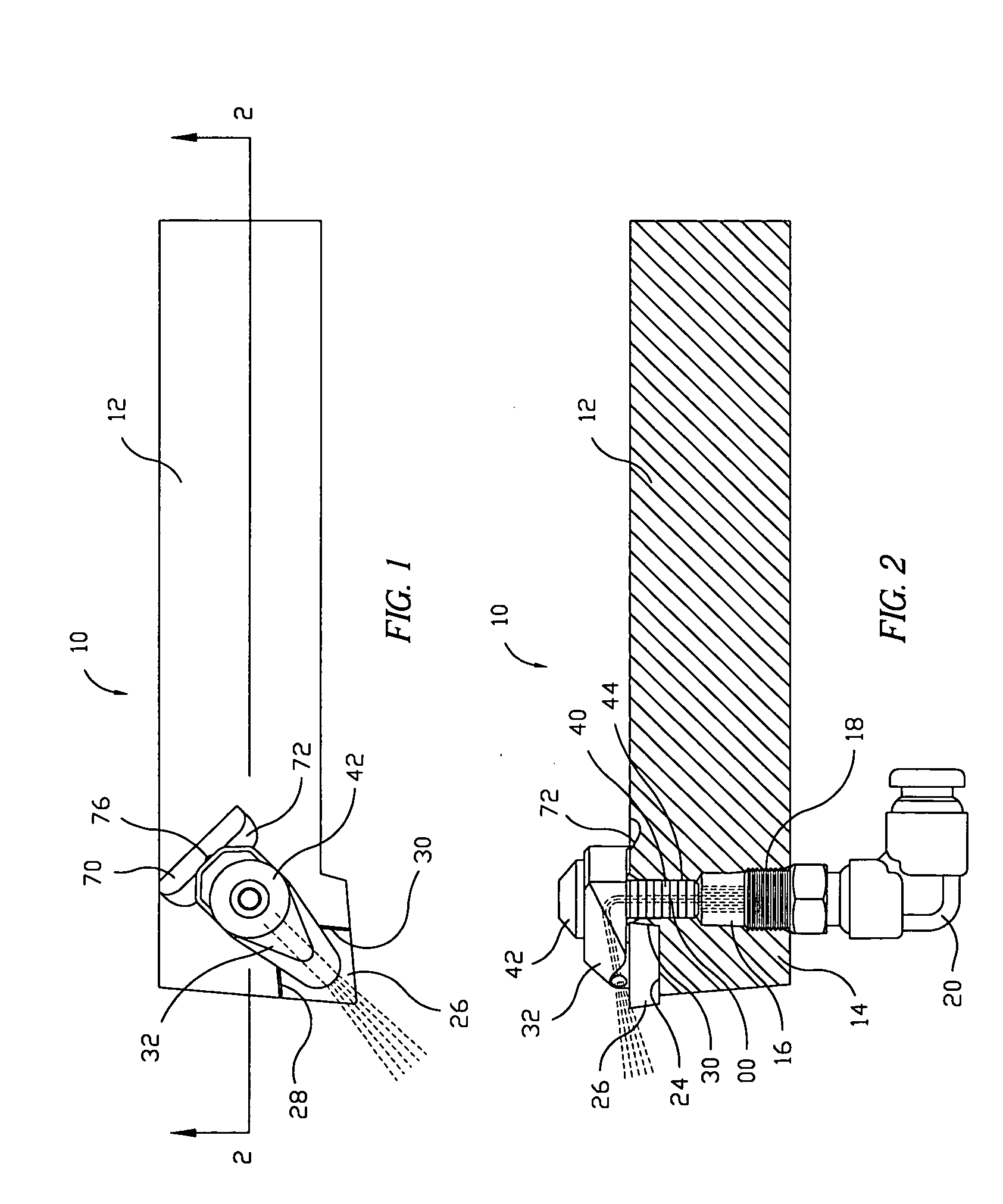

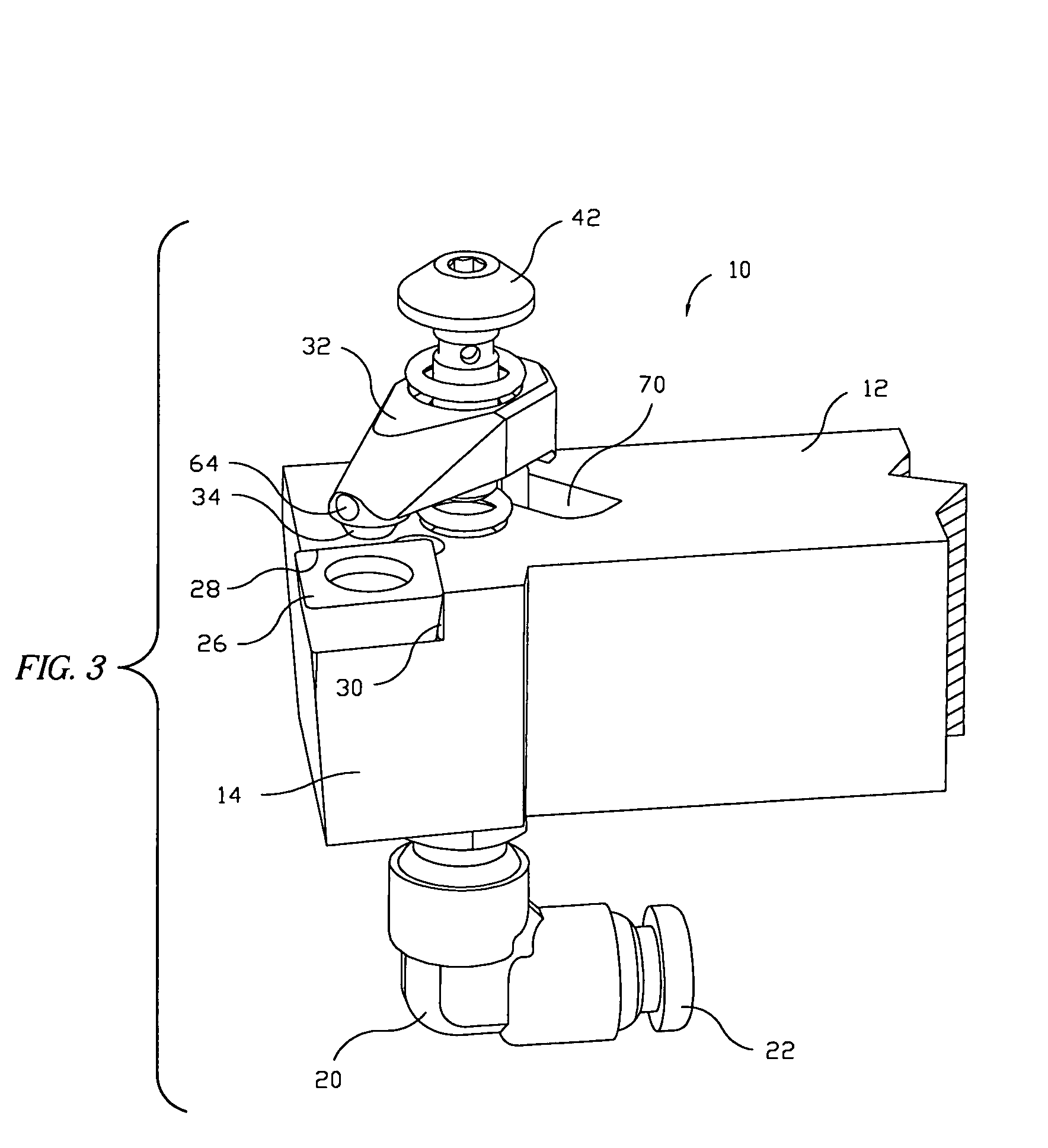

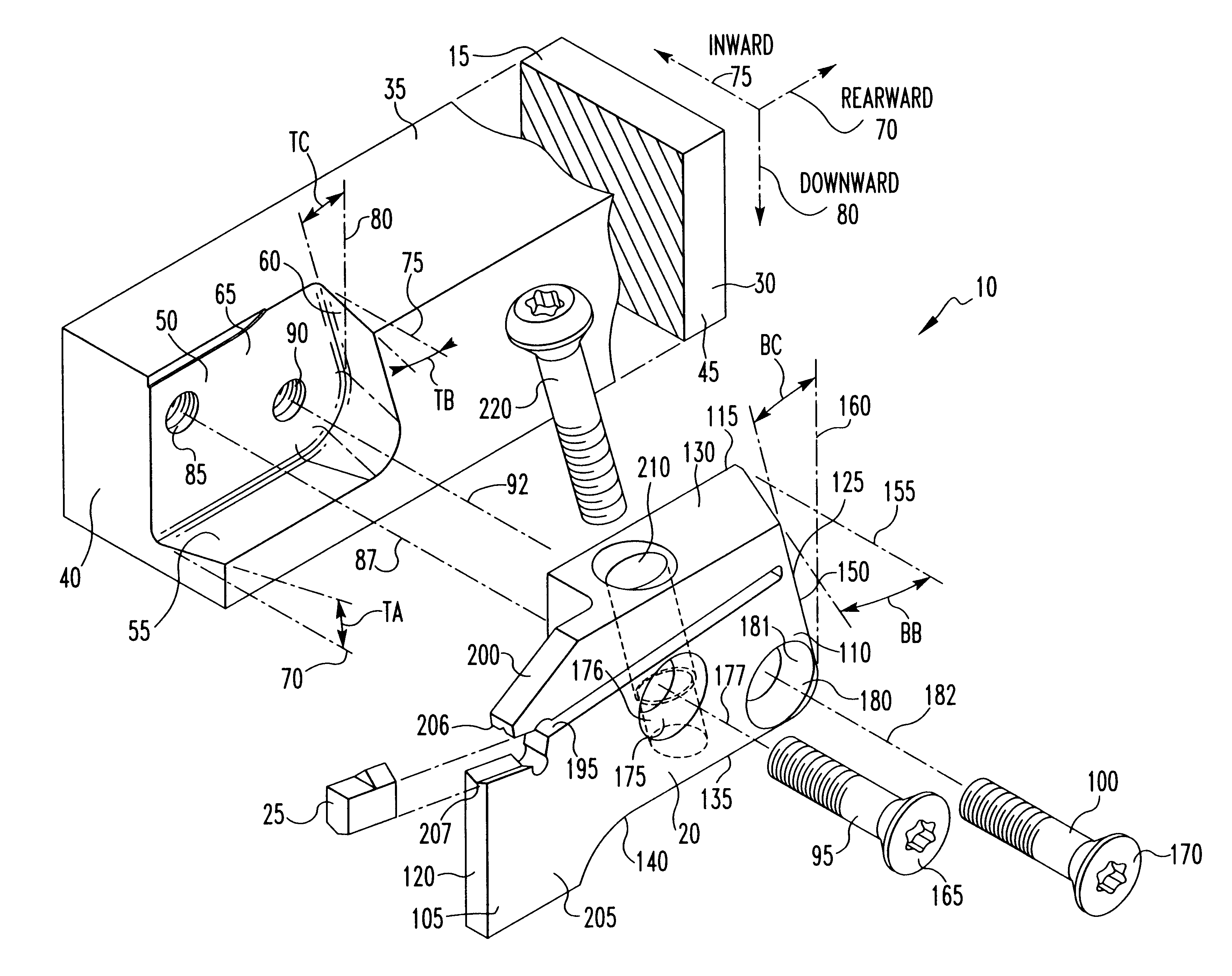

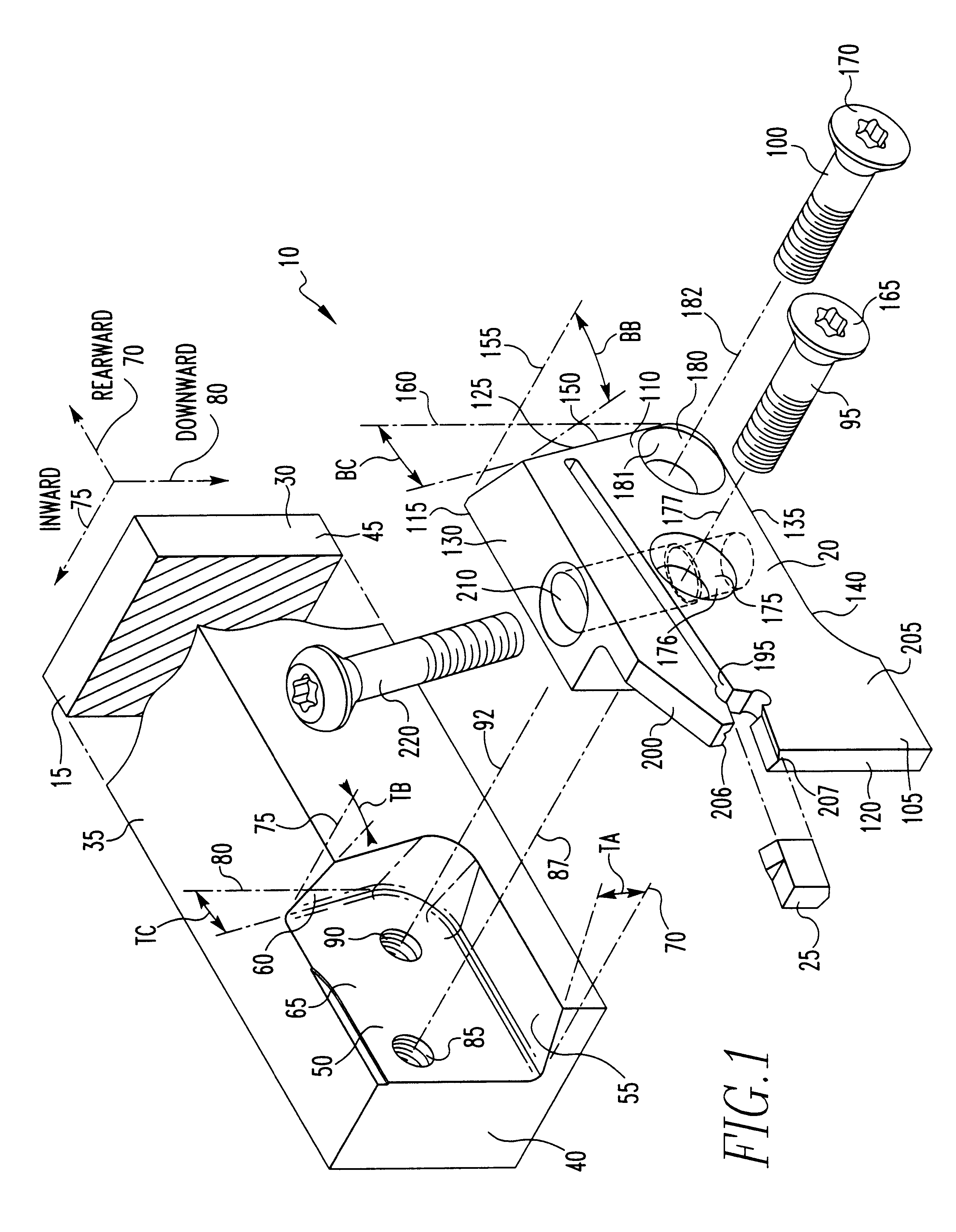

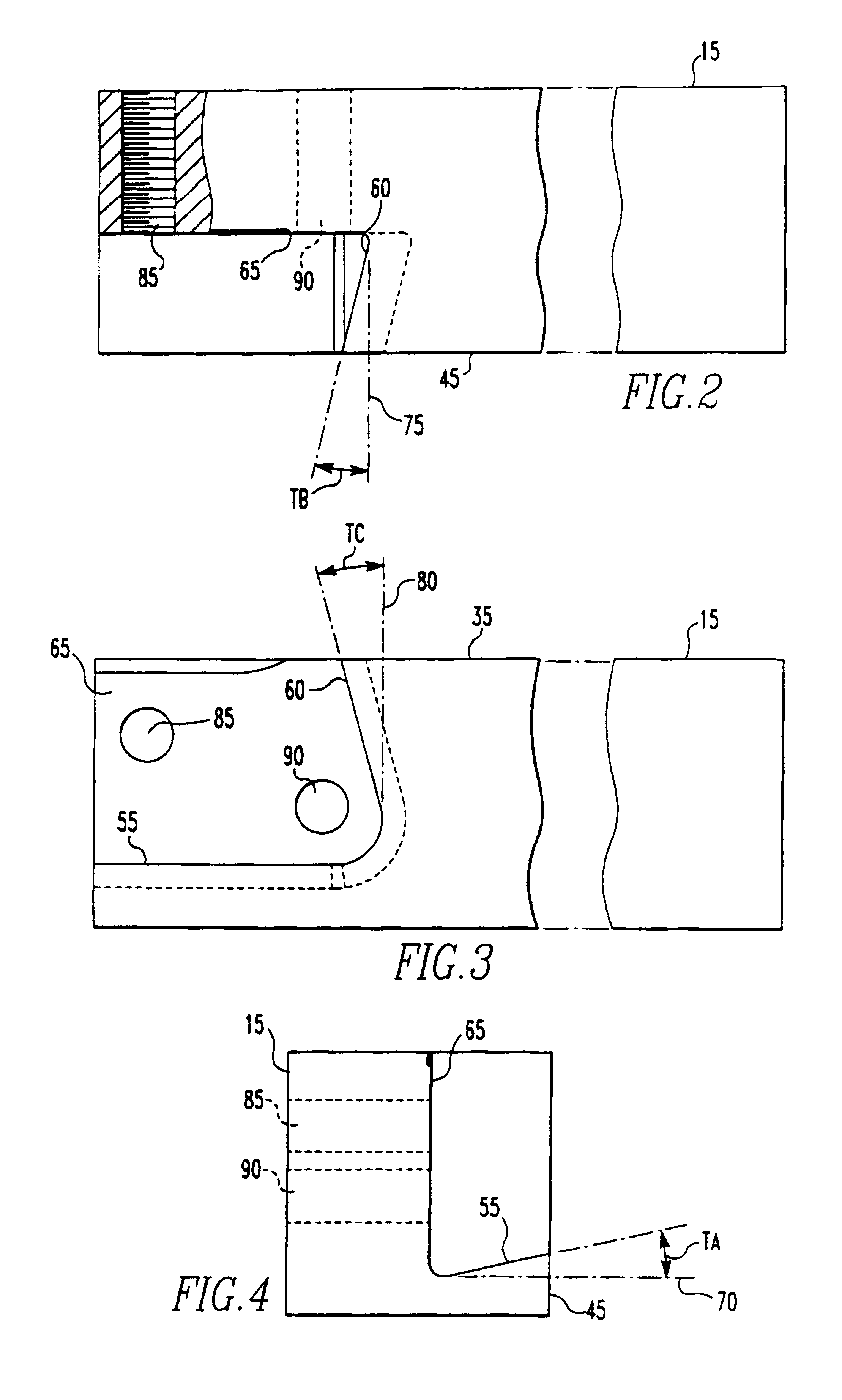

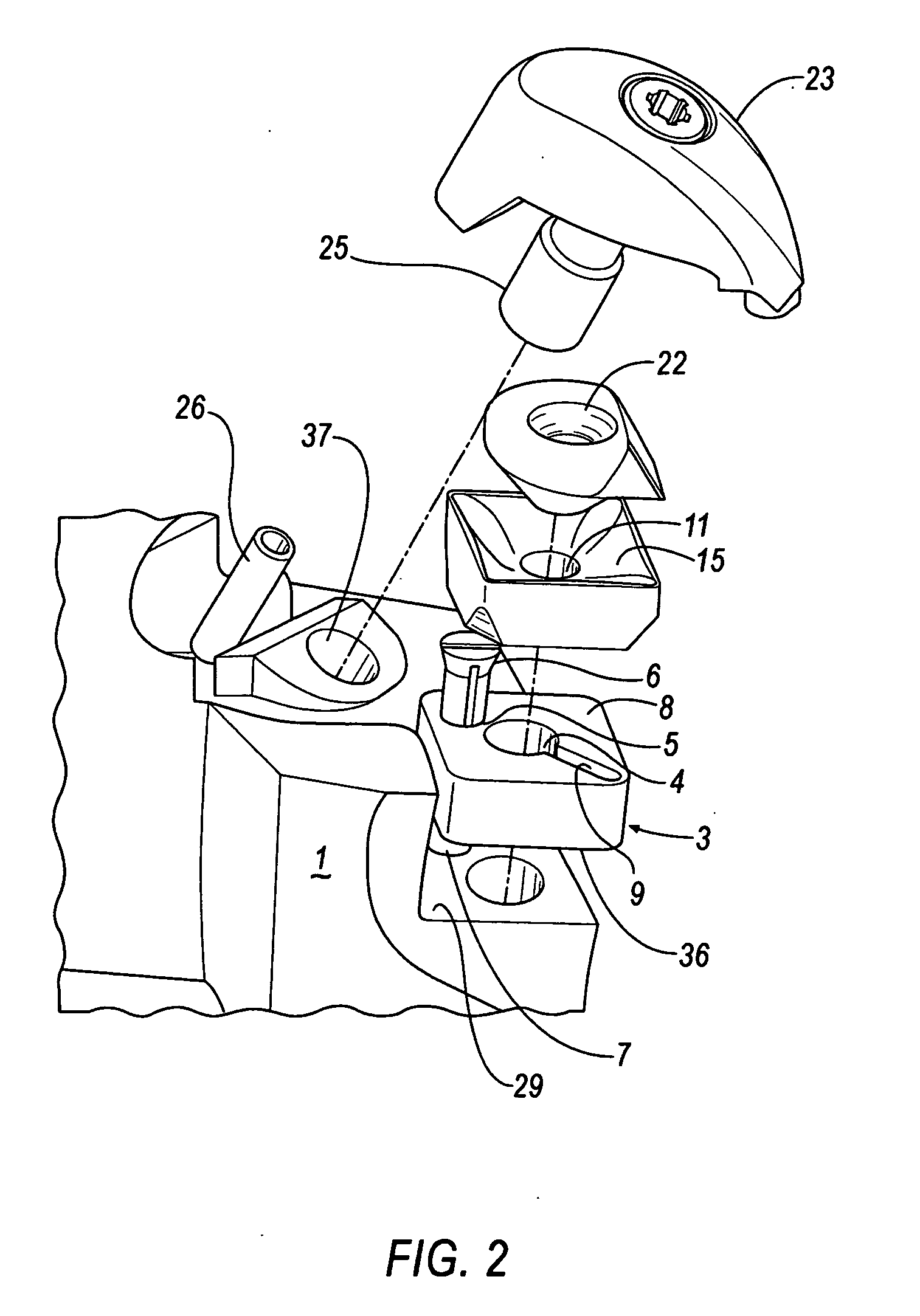

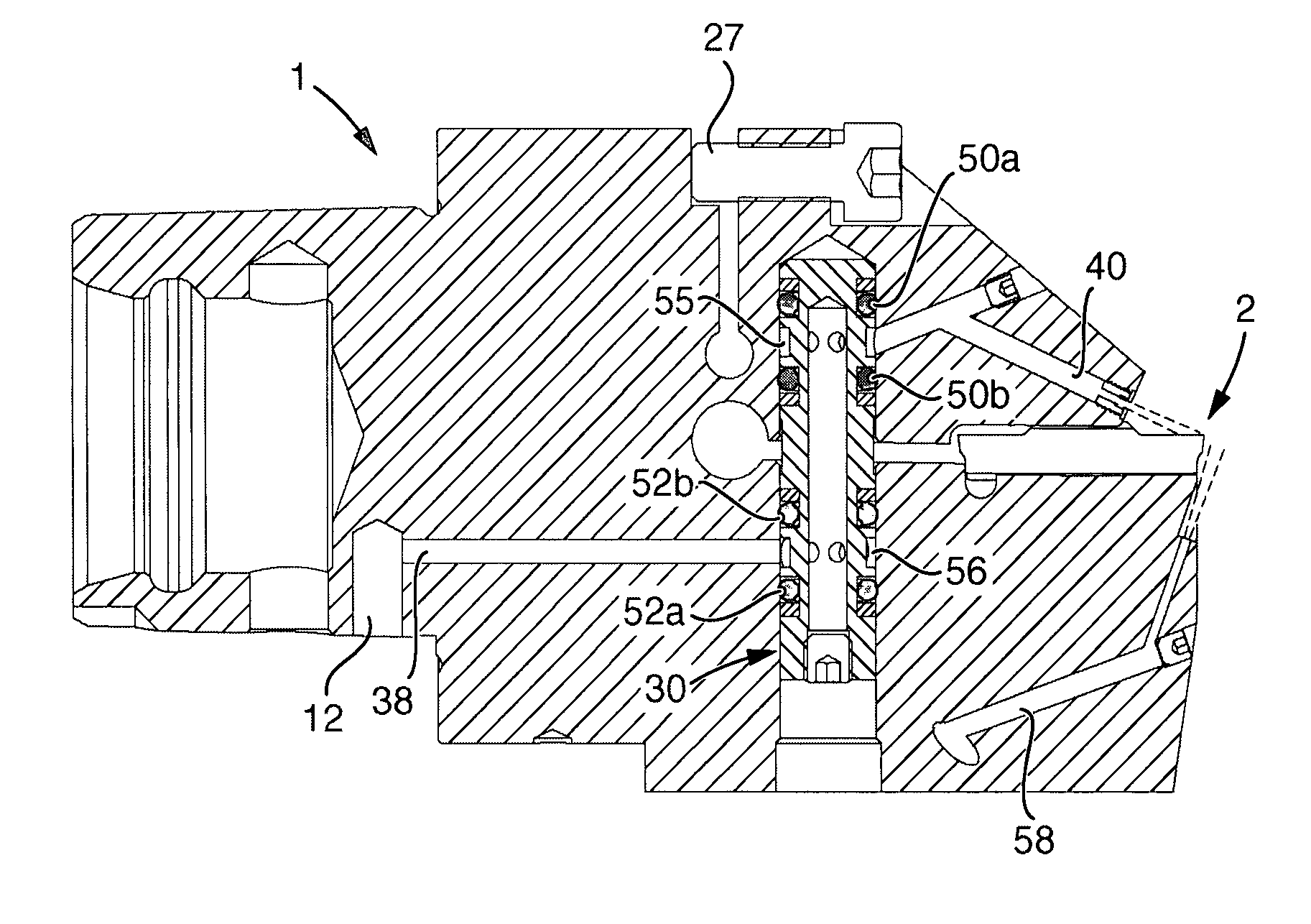

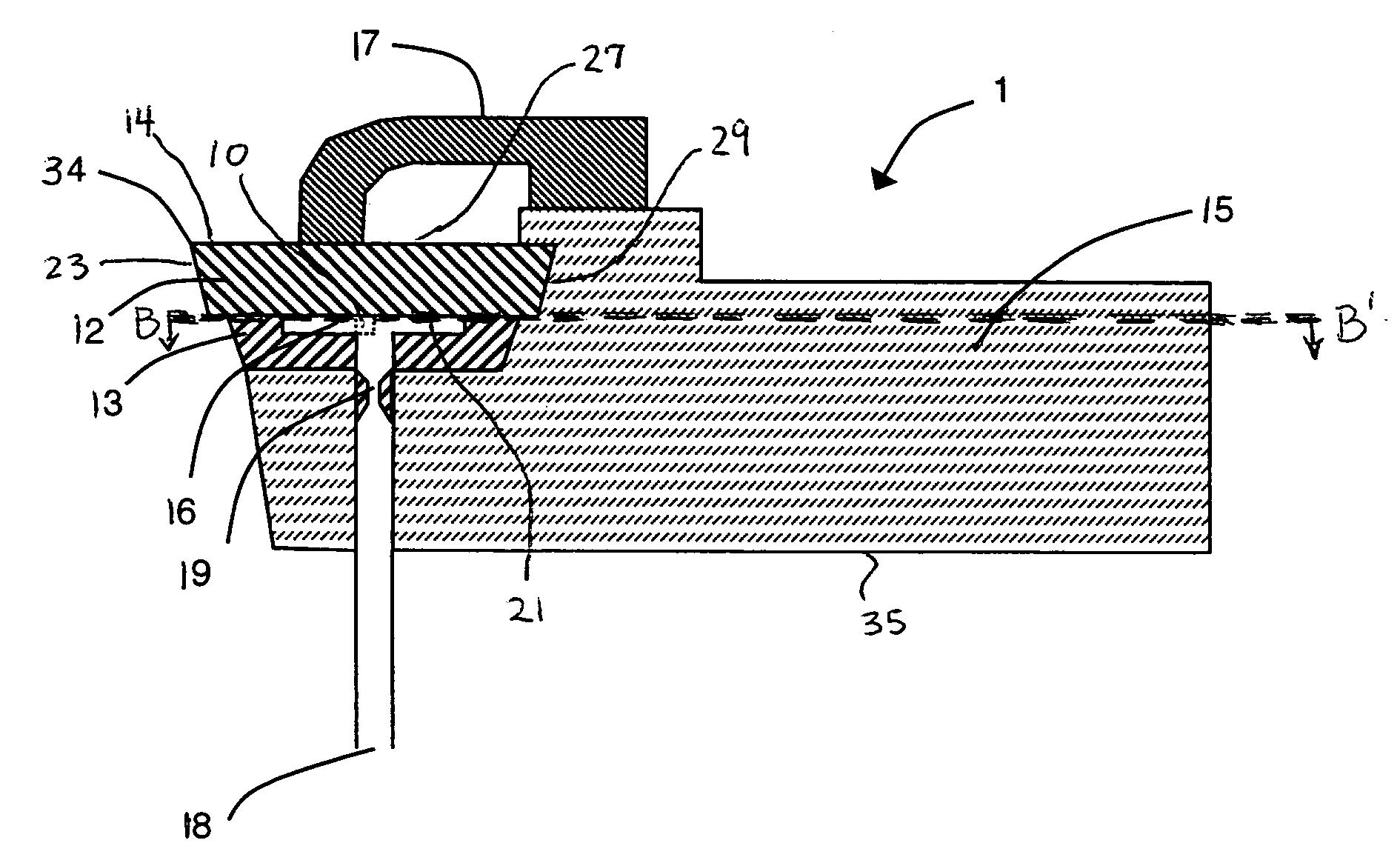

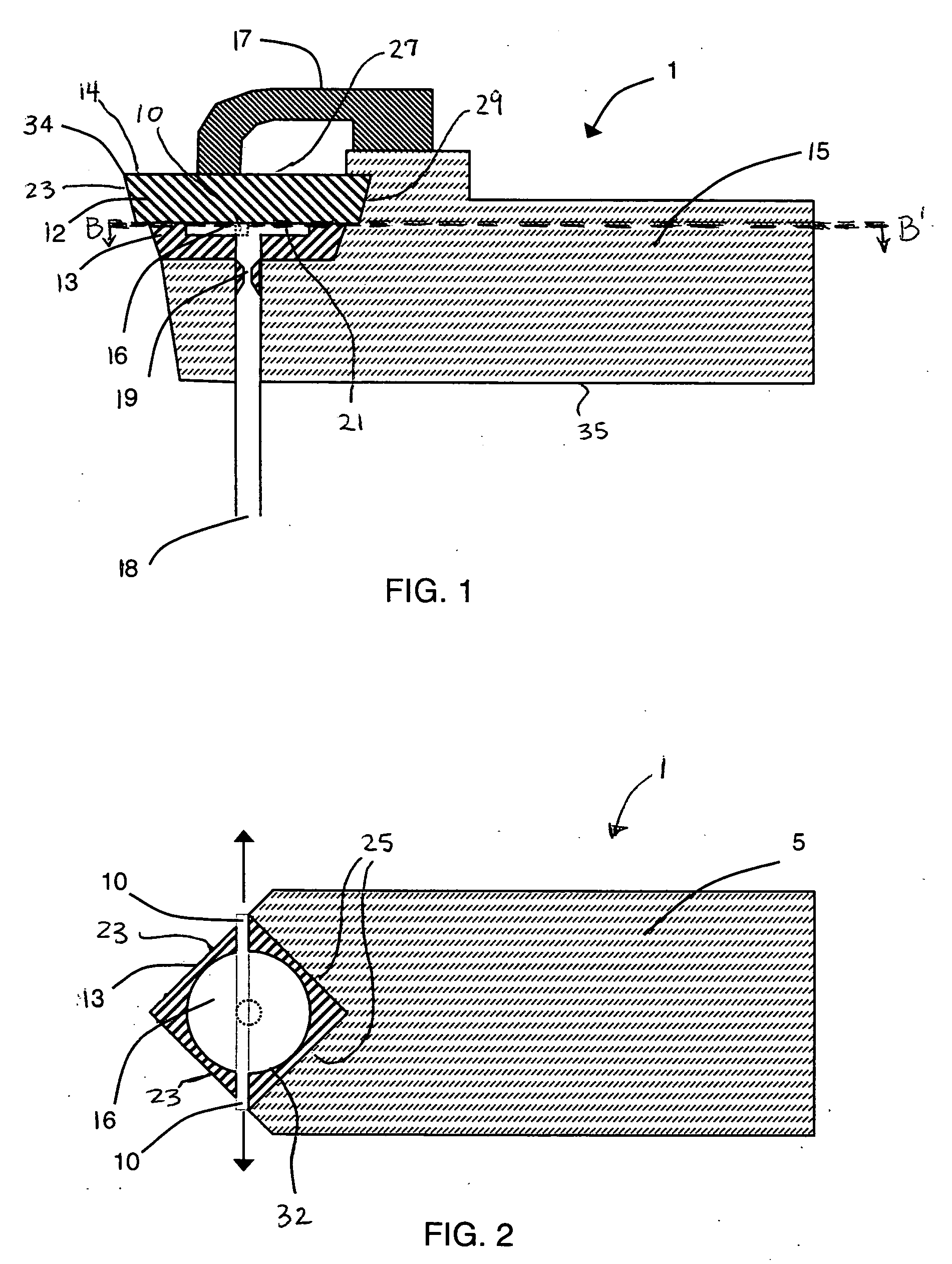

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

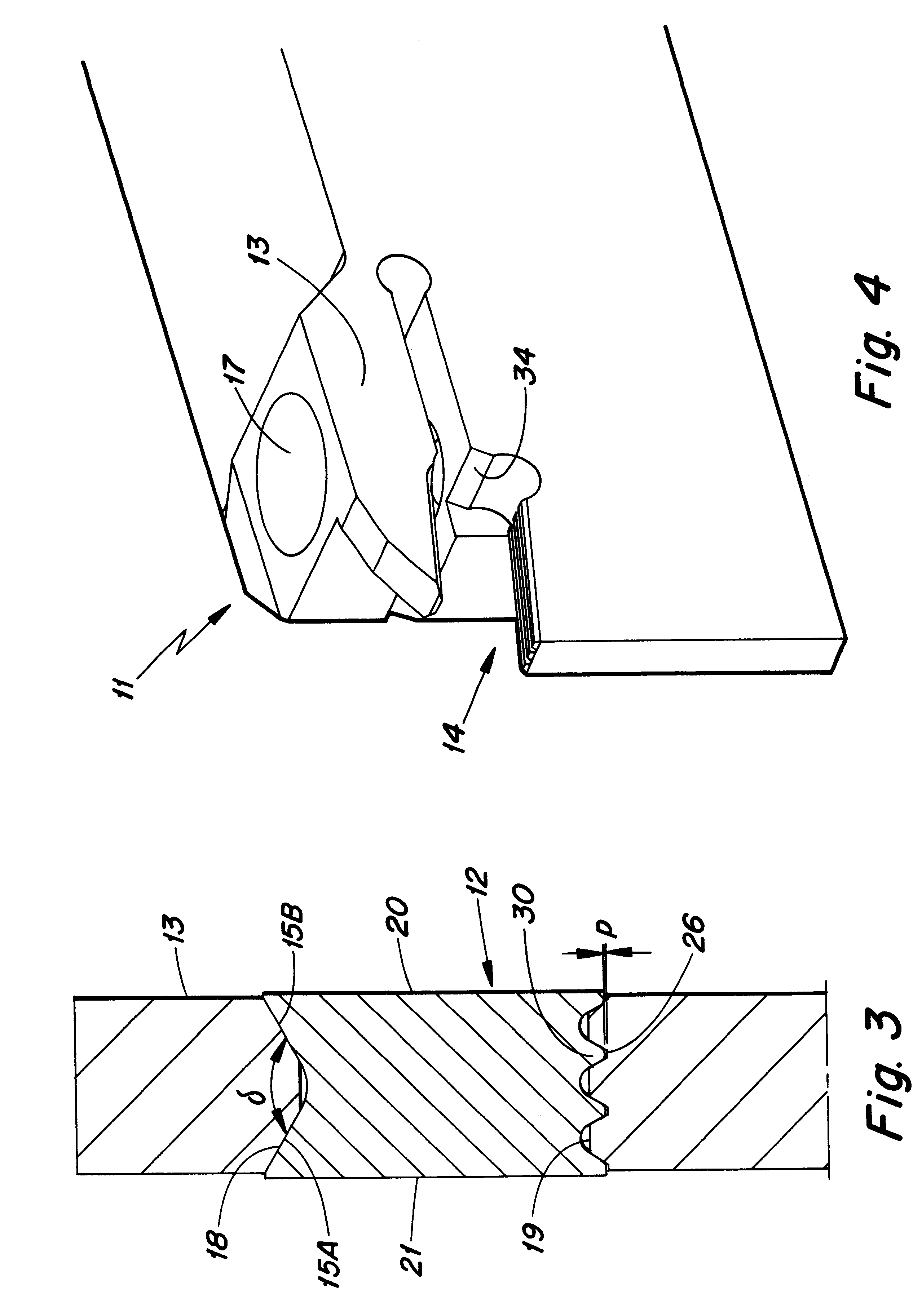

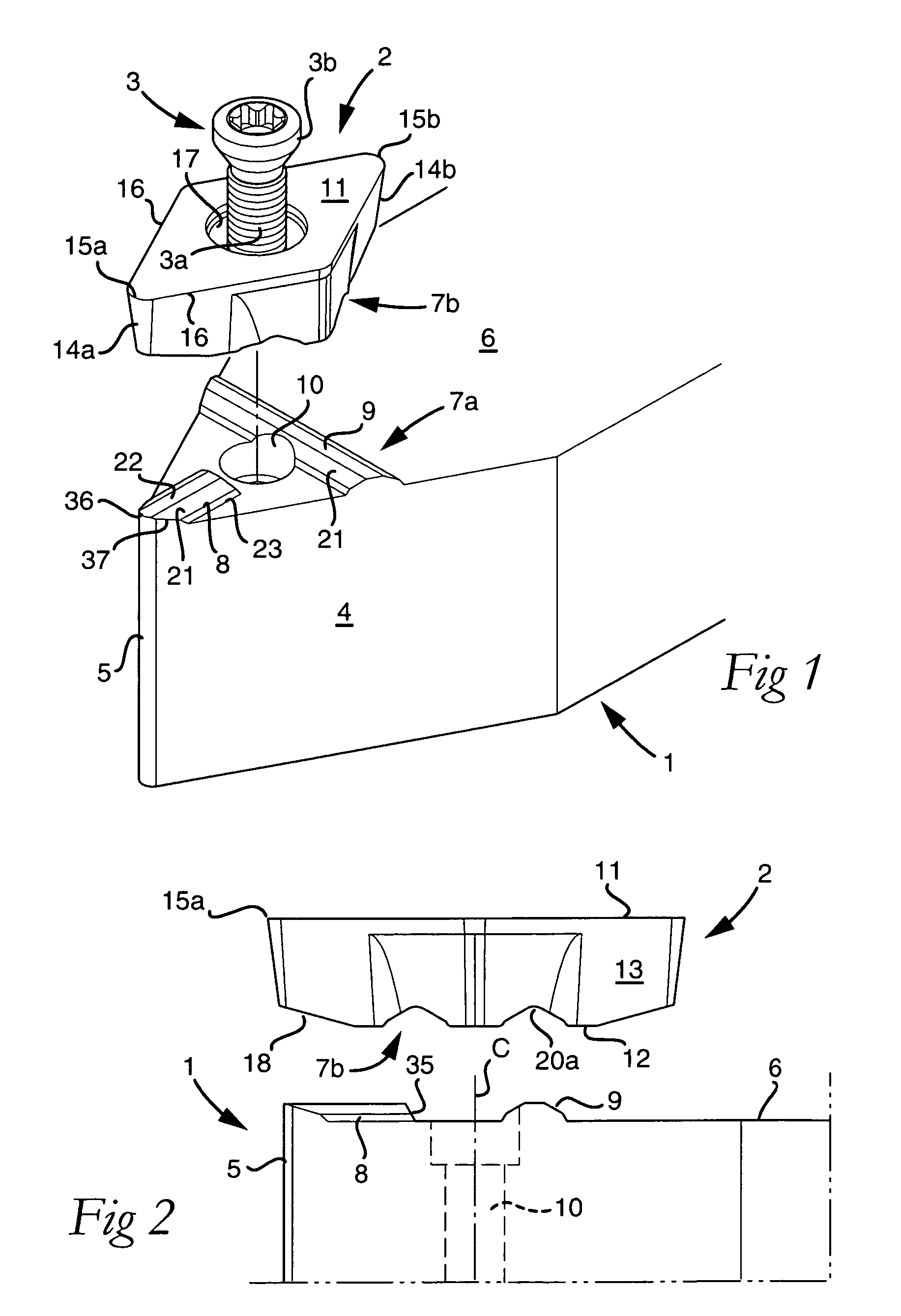

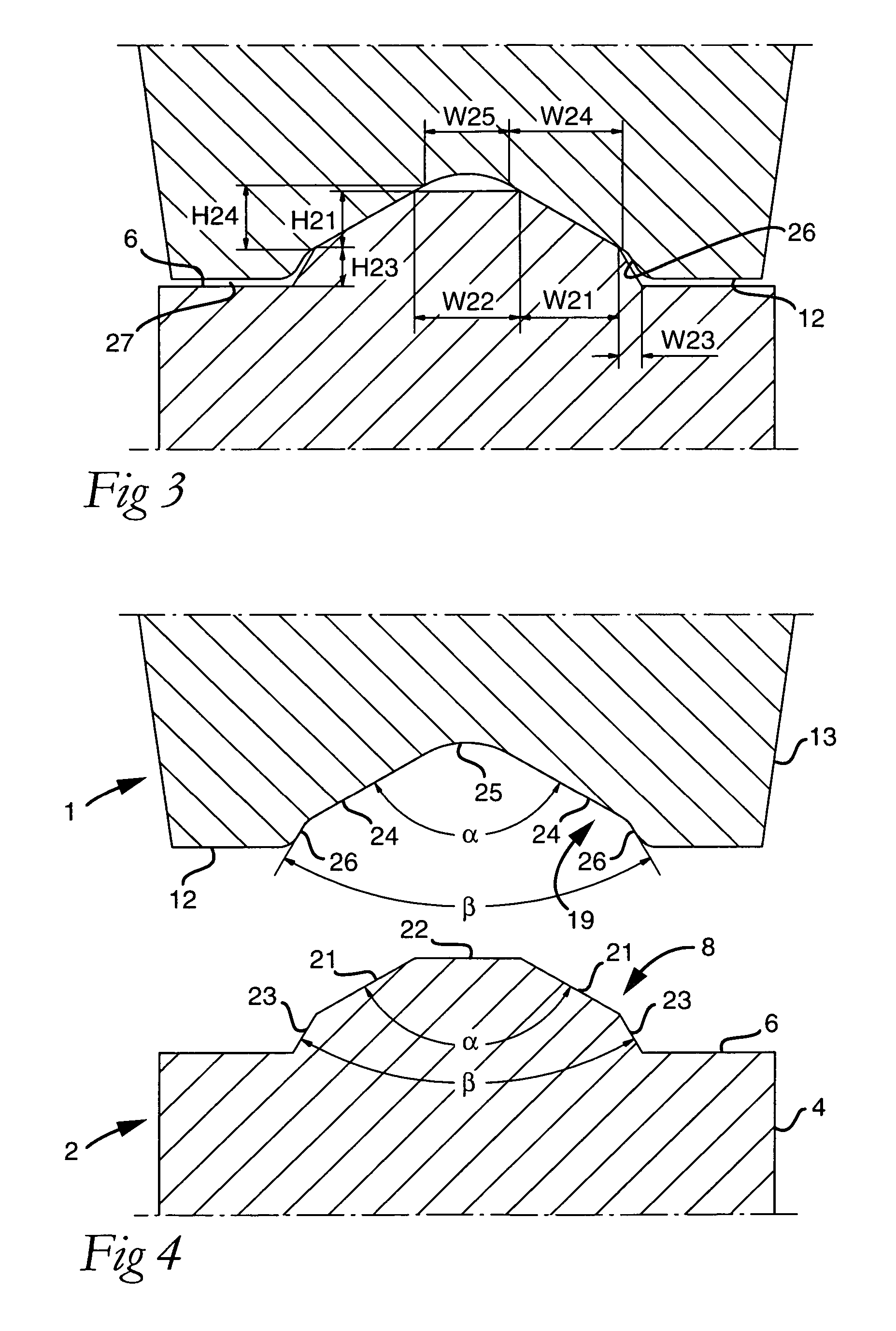

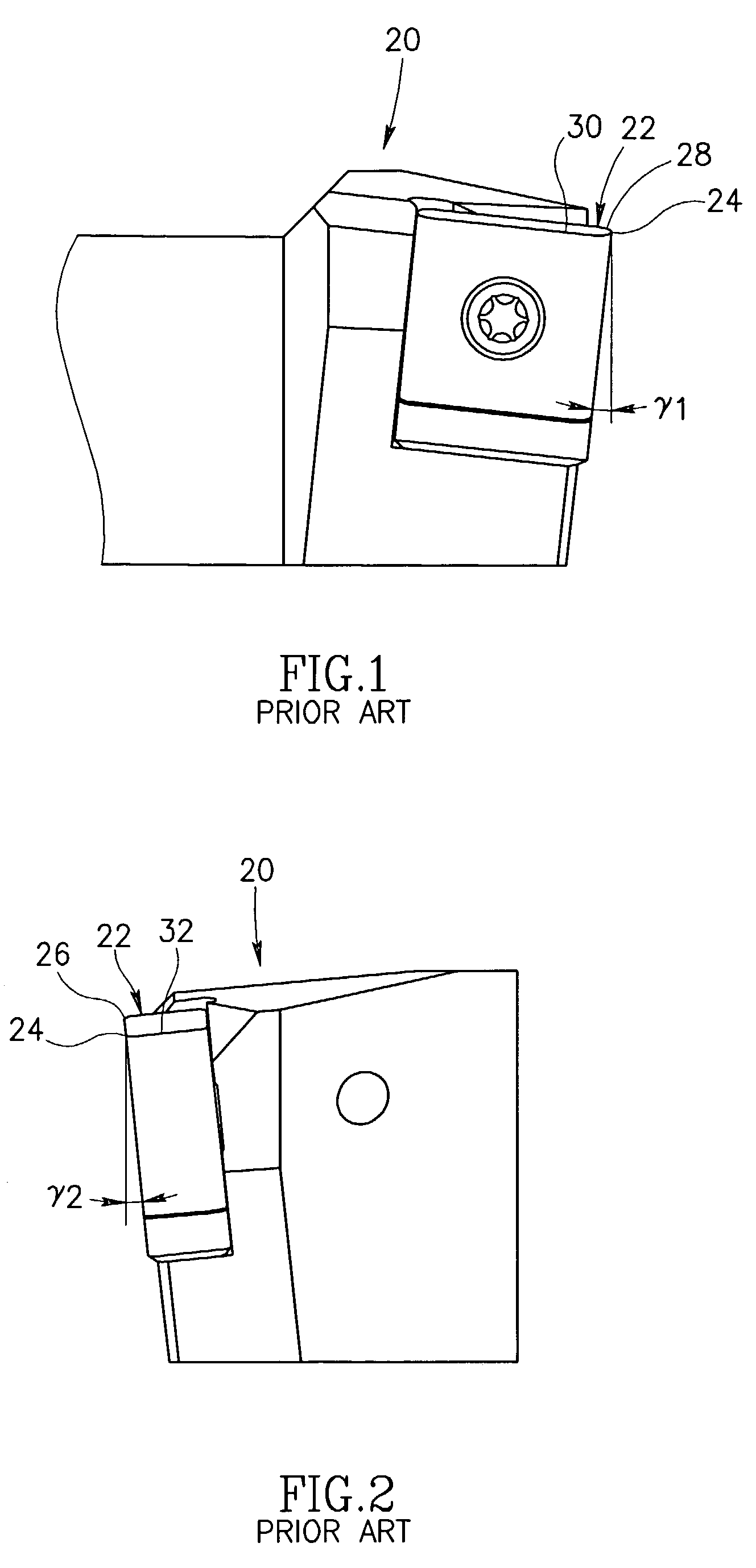

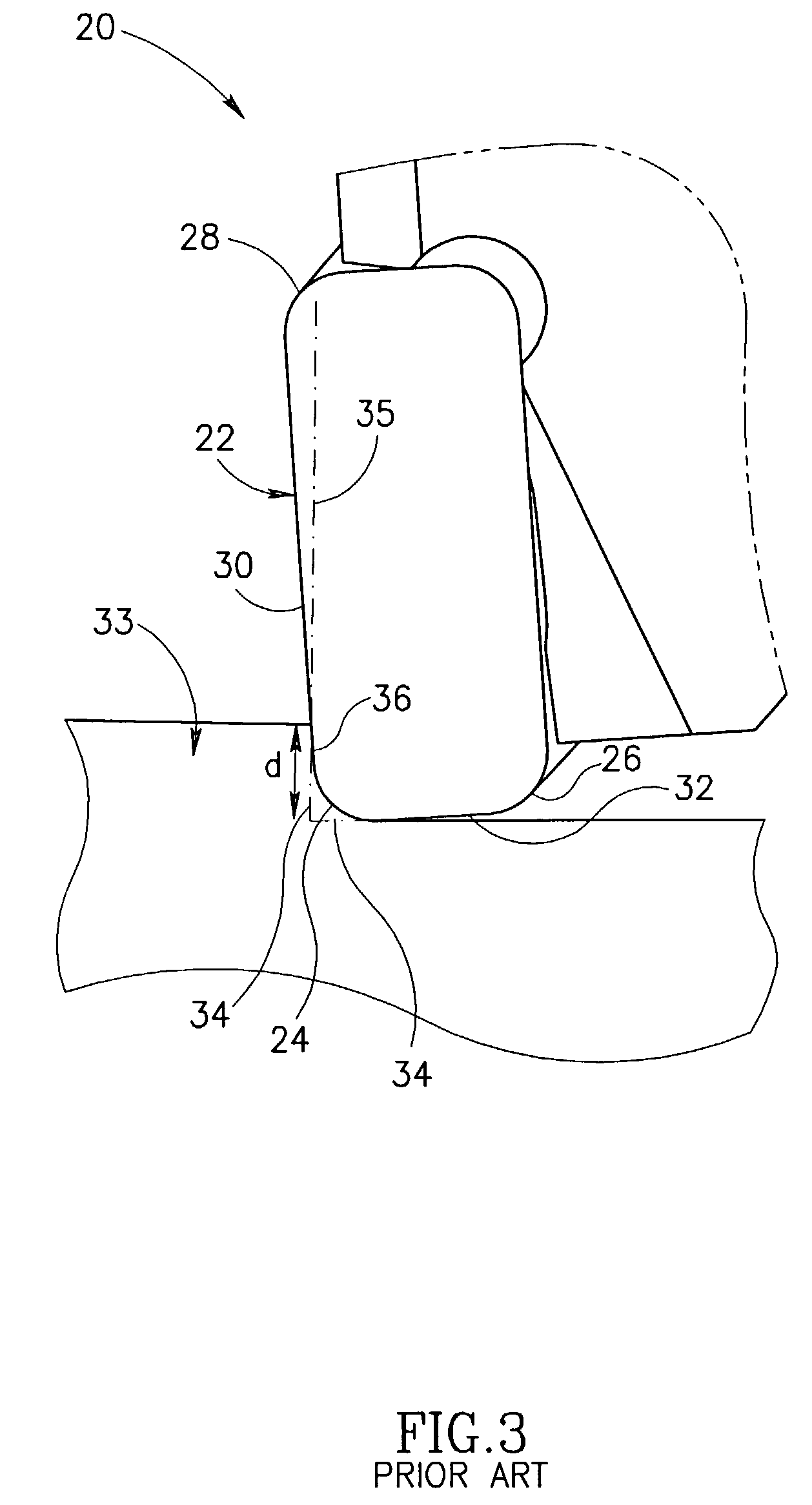

Tool and insert for chip removal machining

A tool for chip removing machining includes a holder and a cutting insert clamped within a pocket of the holder. The pocket has upper and lower sides, and the cutting insert comprises an upper surface and a lower surface. The upper side of the pocket and the upper surface of the cutting insert comprise first cooperating contact surfaces defining a first flank angle. The lower side of the pocket and the lower surface of the cutting insert comprise second cooperating contact surfaces which define a second flank angle. The first flank angle is larger than the second flank angle. The lower surface of the cutting insert and the lower side of the pocket form intermeshing projections and recesses which define the second contact surfaces.

Owner:SECO TOOLS AB

Indexable end-milling insert

ActiveUS20080304924A1Good chip formationWorn evenly and slowlyTransportation and packagingMilling cuttersEngineeringKnife blades

An indexable end-milling insert including an underside, an upperside and a plurality of cutting edges that are formed between the upperside and a number of clearance sides and that include a chip-removing main edge as well as a surface-wiping wiper edge. The cutting insert has a square basic shape and includes four main edges and four wiper edges that are countersunk to a lower level than the main edges. The wiper edge is included in a lip projecting in relation to a secondary clearance surface and has a tertiary clearance surface, which laterally transforms into a primary clearance surface. The primary clearance surface has a width that decreases from the two opposite ends thereof toward a section having a smallest width therebetween.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

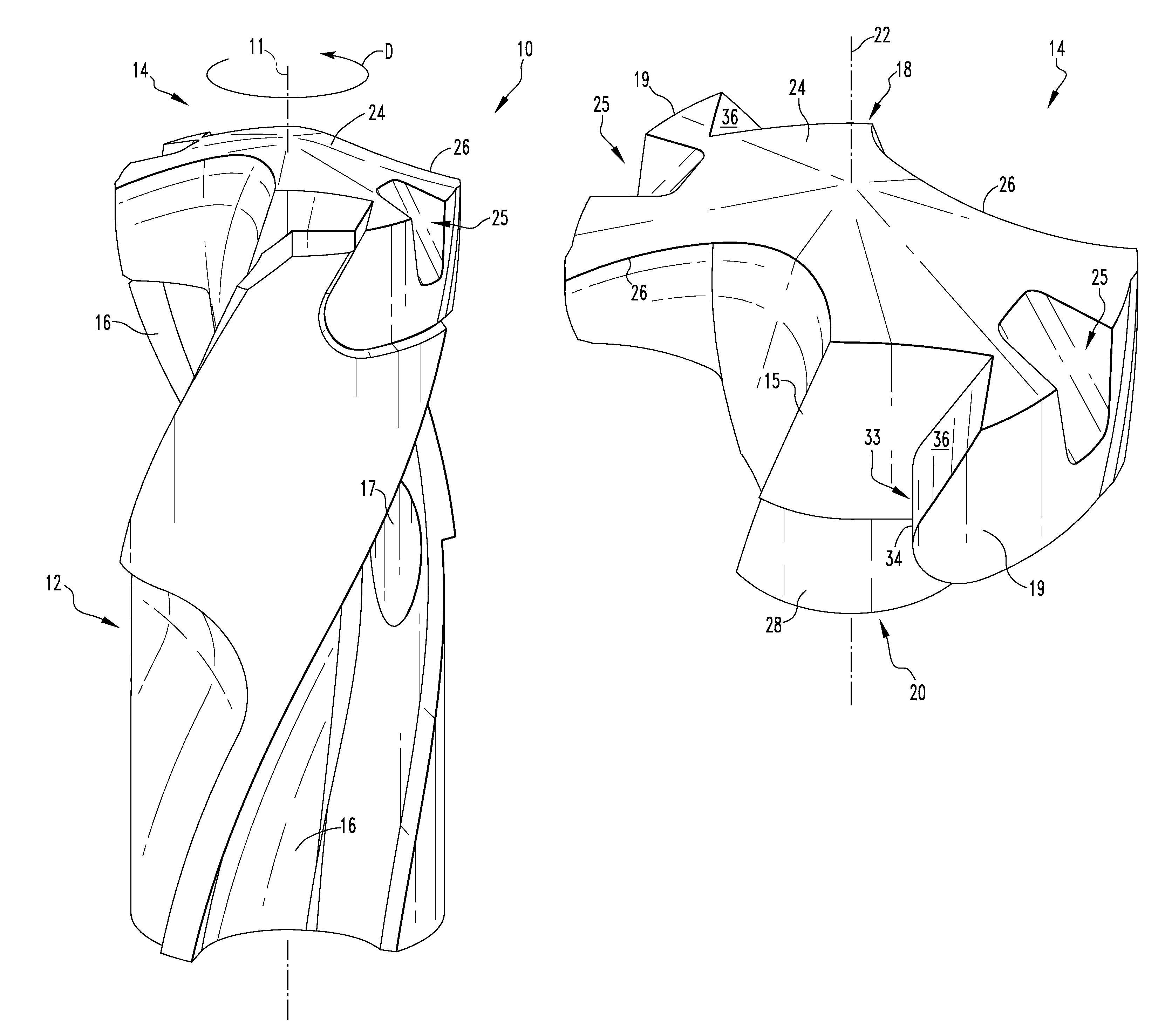

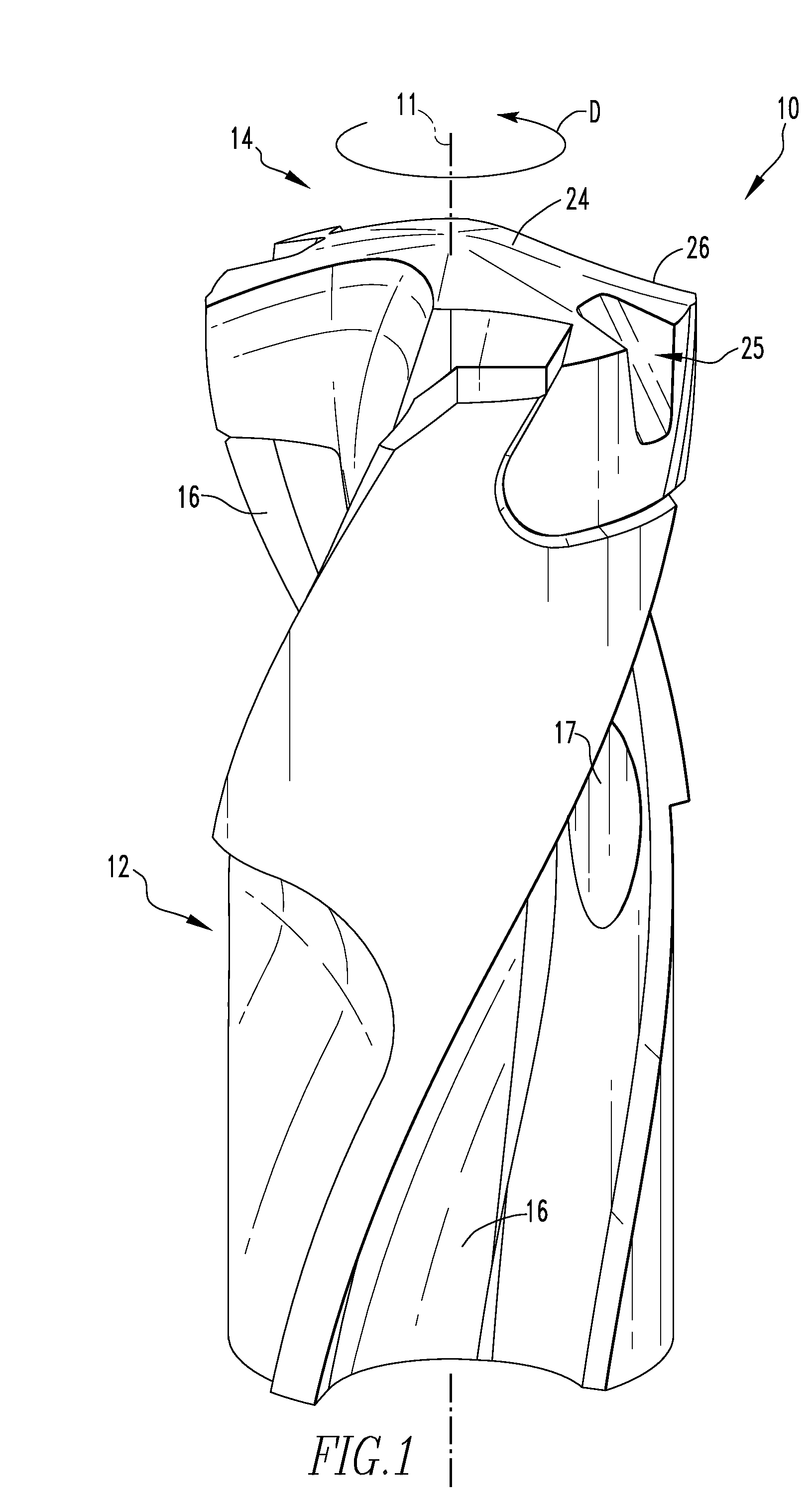

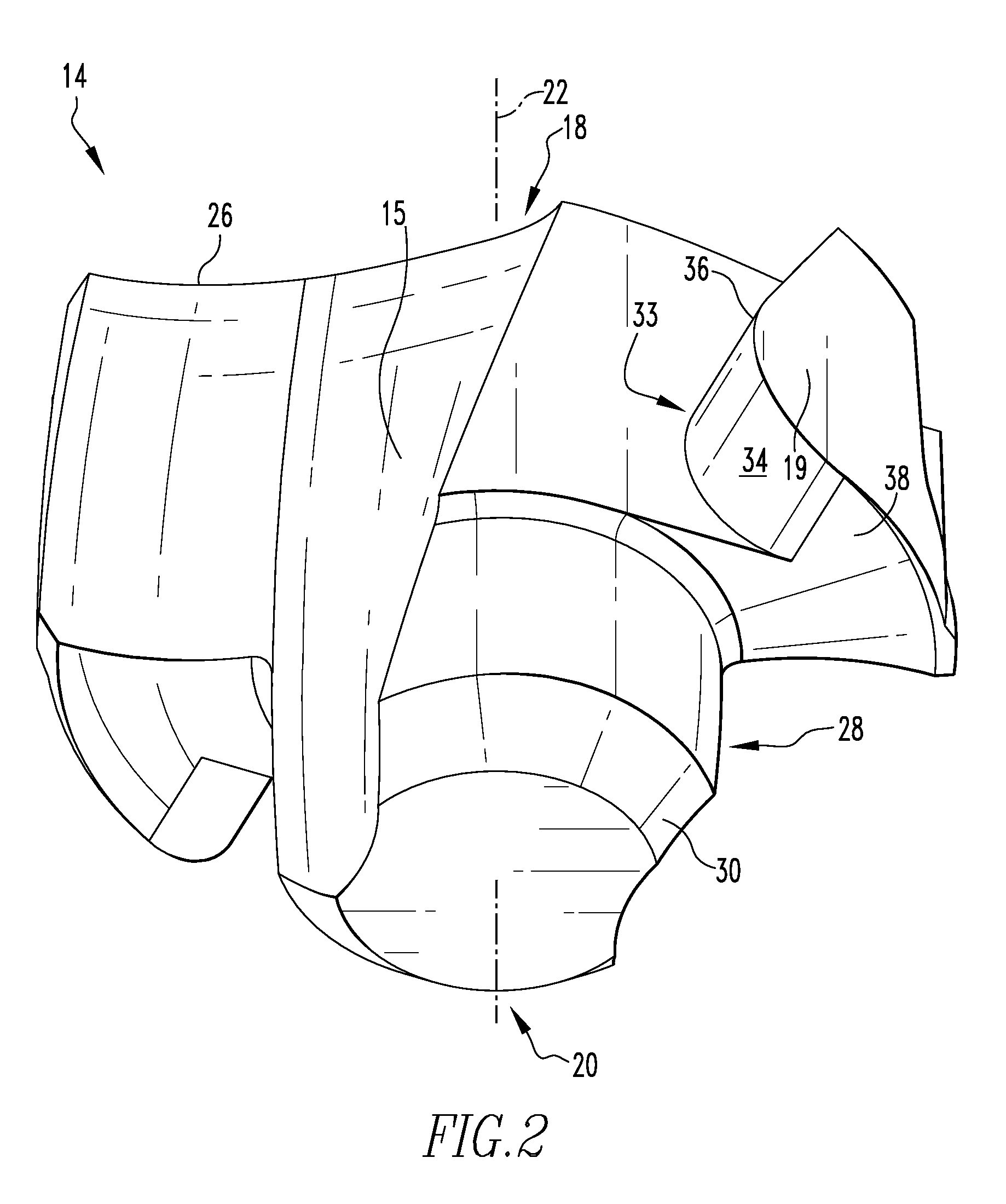

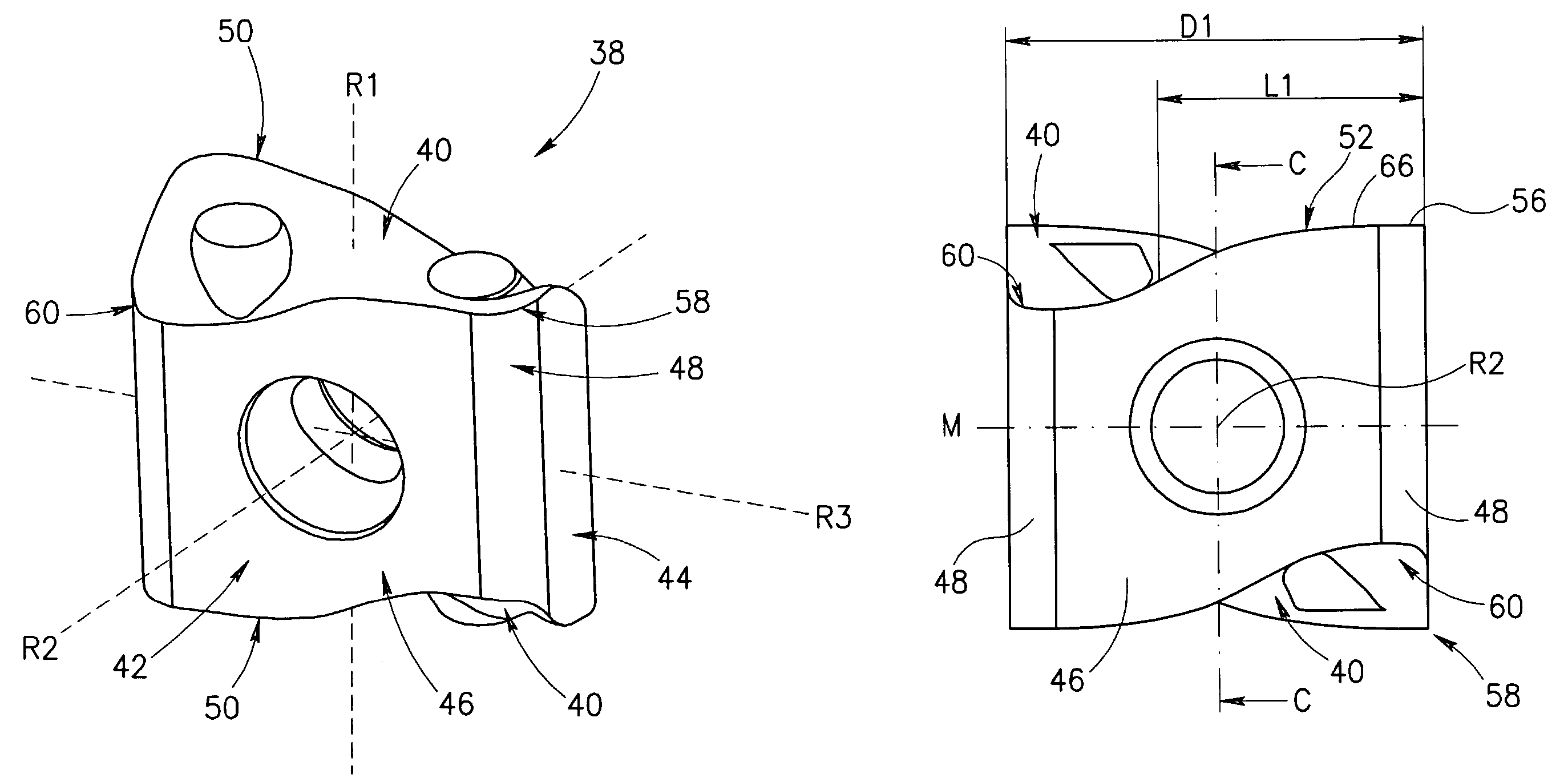

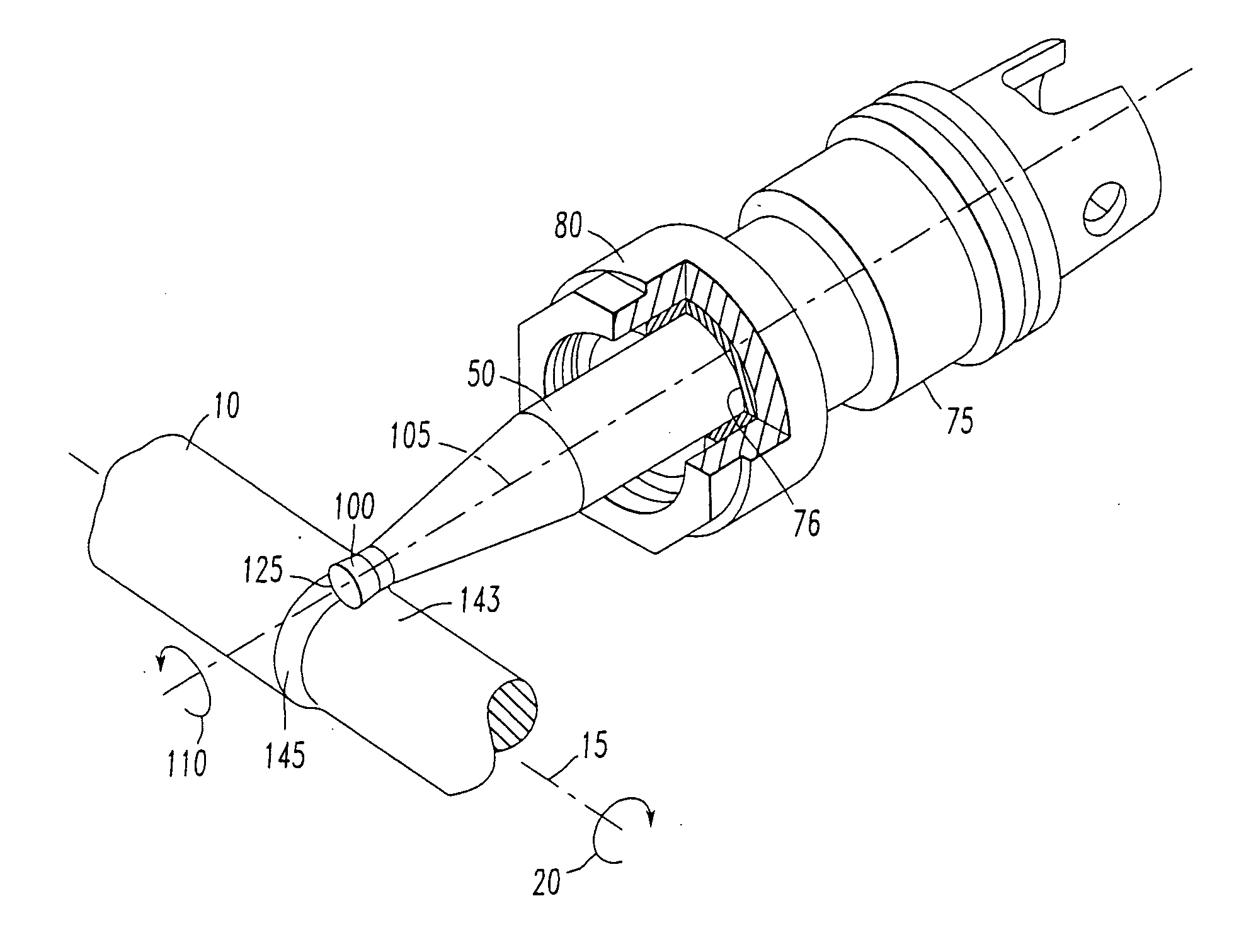

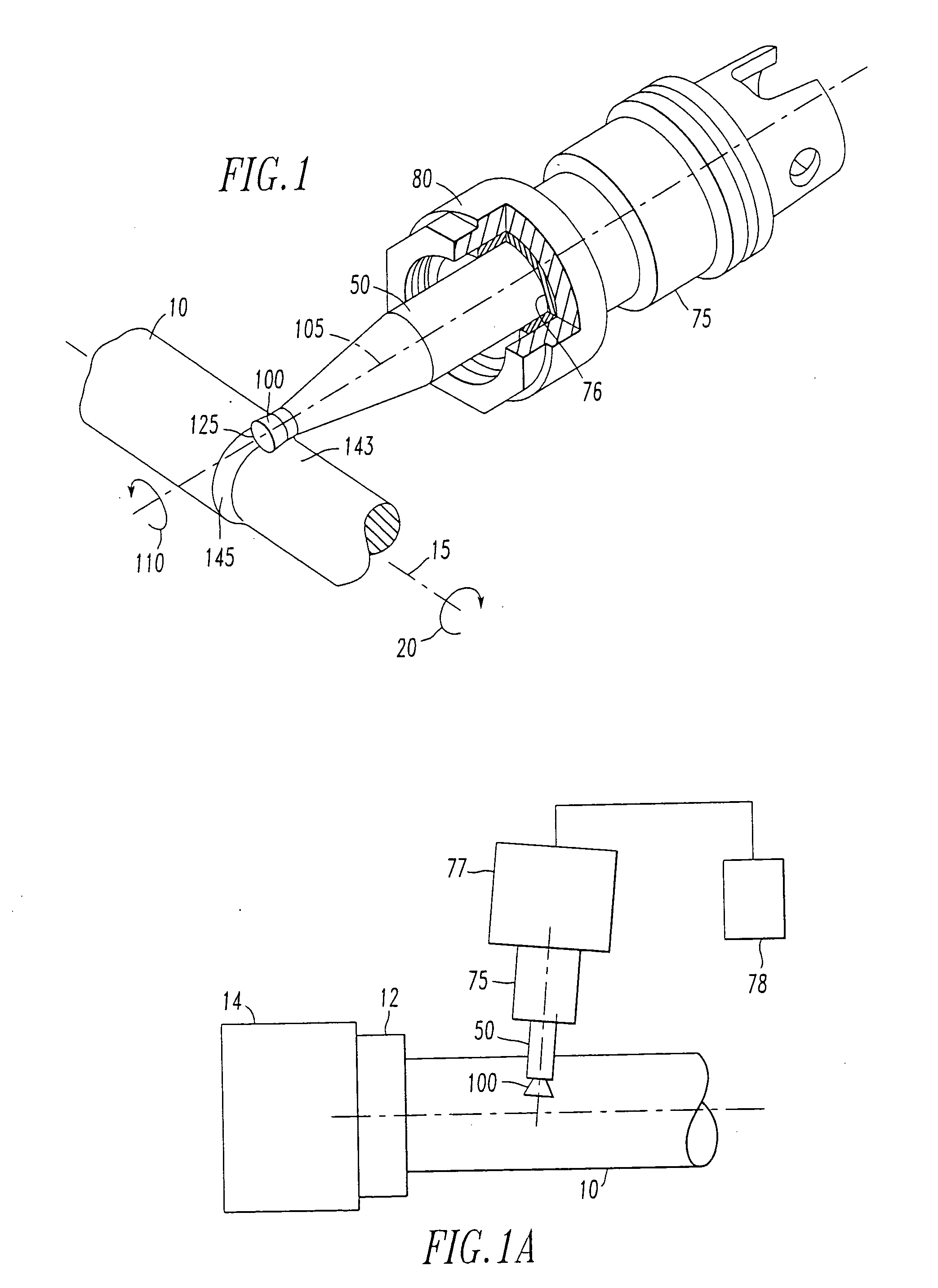

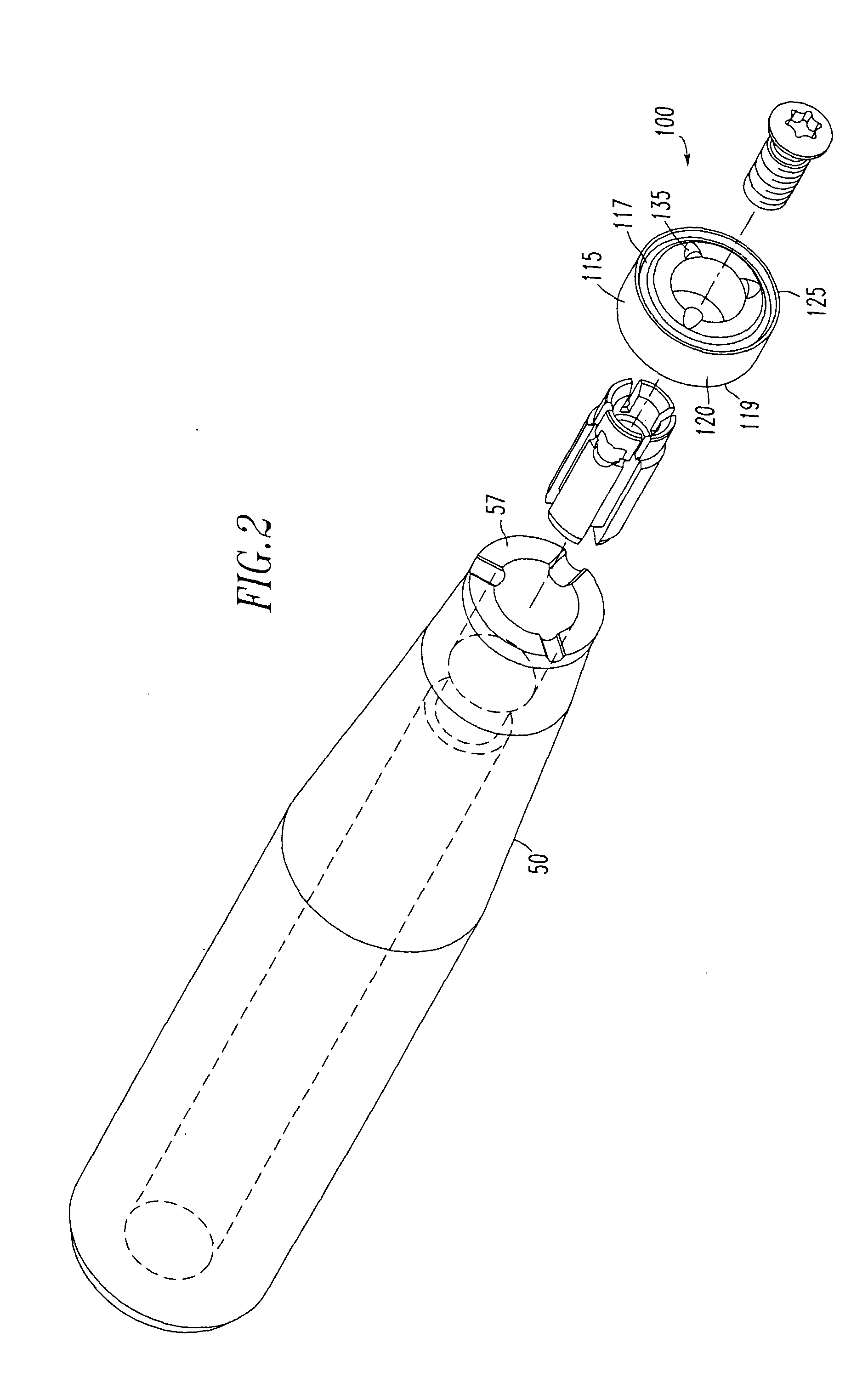

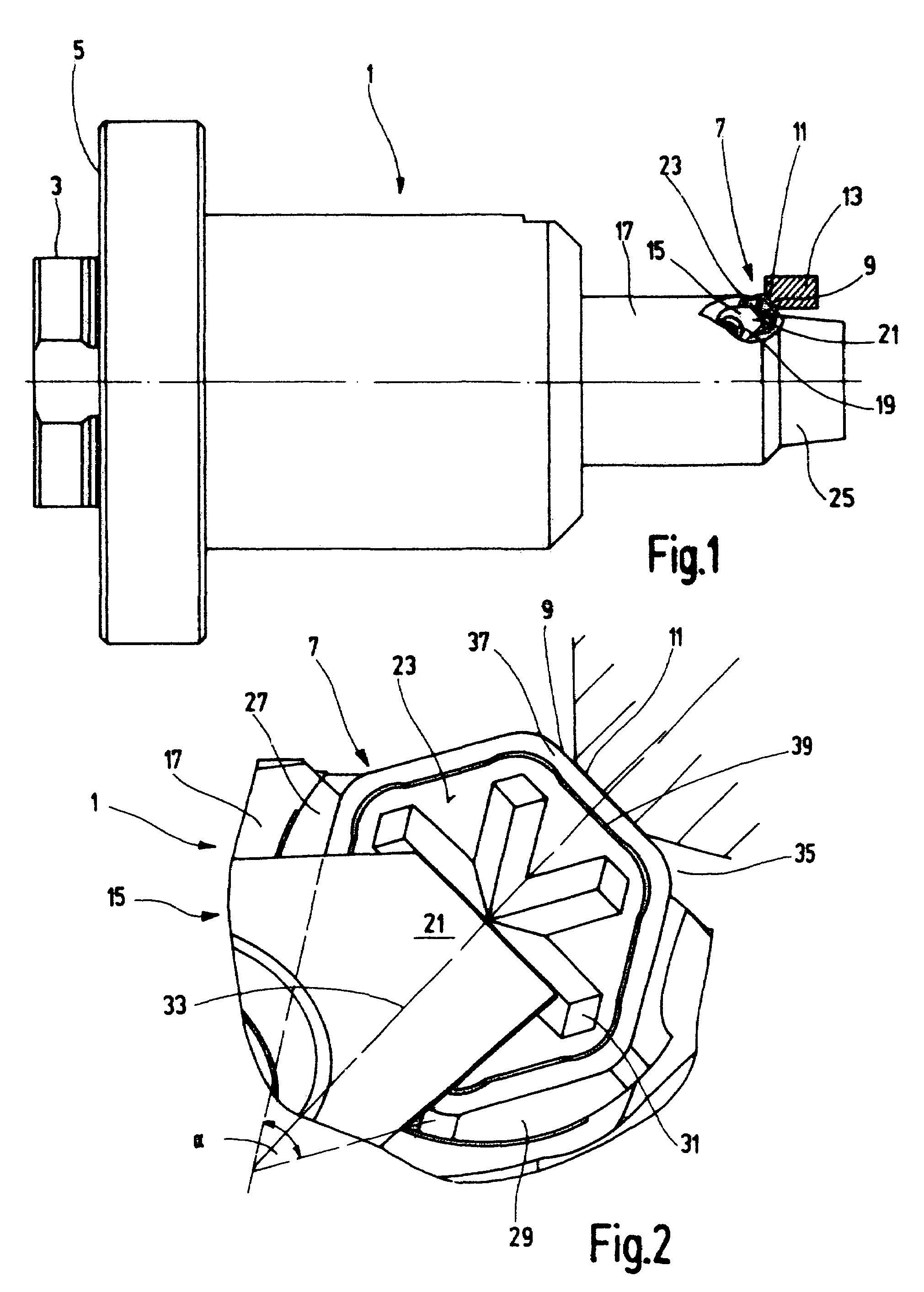

Rotary cutting tool assembly and cutting insert and tool shank therefor

A tool shank and a replaceable cutting insert are provided for a rotary cutting tool assembly. The tool shank has a drive surface including a central portion, a first portion of generally planar shape extending away from the central portion and a second portion of generally planar shape extending away from the central portion in a direction generally transverse to a central axis of the tool shank. The replaceable cutting insert has a driven surface including another central portion, a first portion of generally planar shape extending away from the other central portion and a second portion of generally planar shape extending away from the other central portion in a direction generally transverse to a central axis of the insert. The central portion of the driven surface has a curved surface transitioning between the first portion and the second portion of the driven surface. A portion of the driven surface of the replaceable cutting insert is engaged by a corresponding portion of the drive surface of the tool shank.

Owner:KENNAMETAL INC

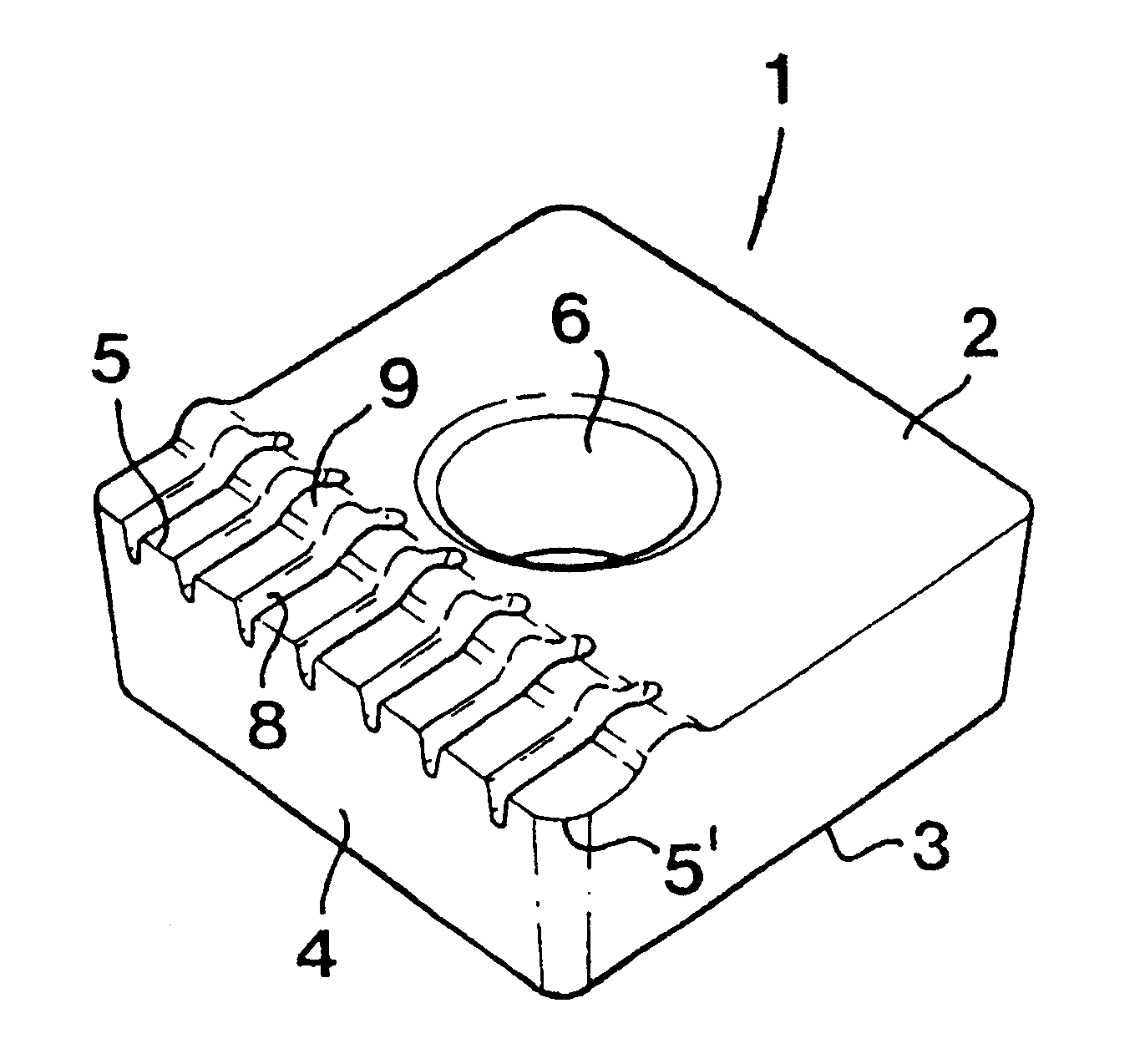

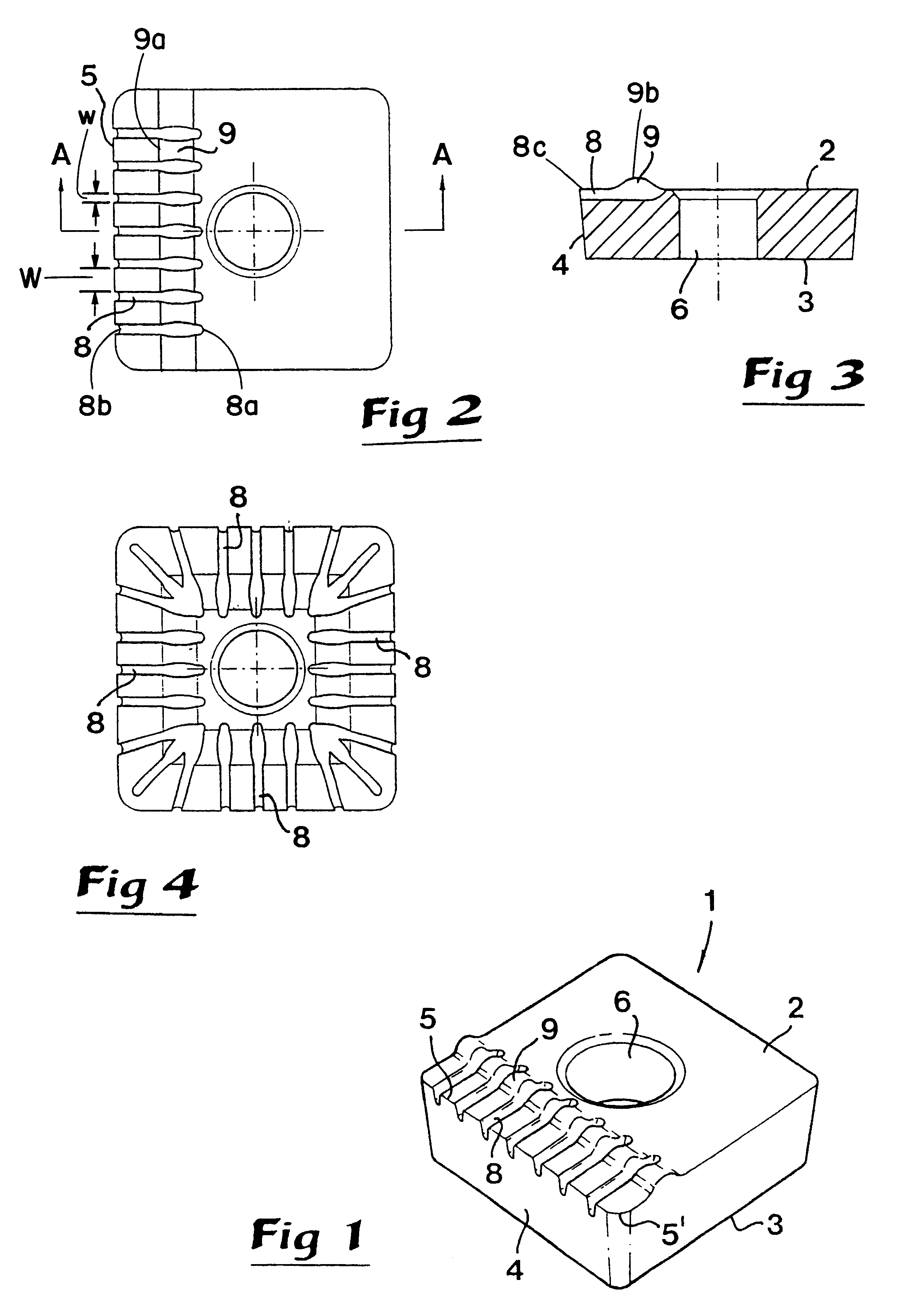

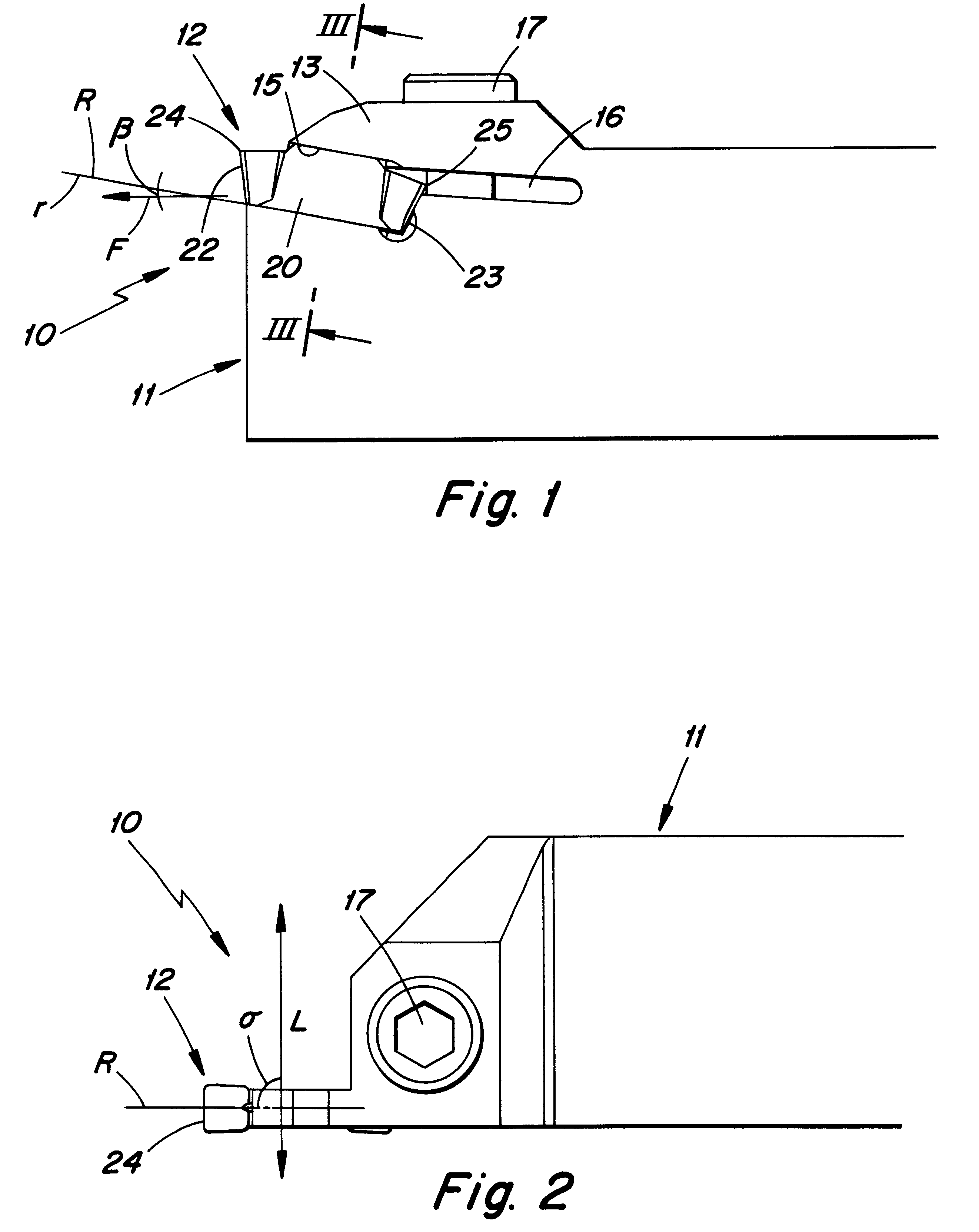

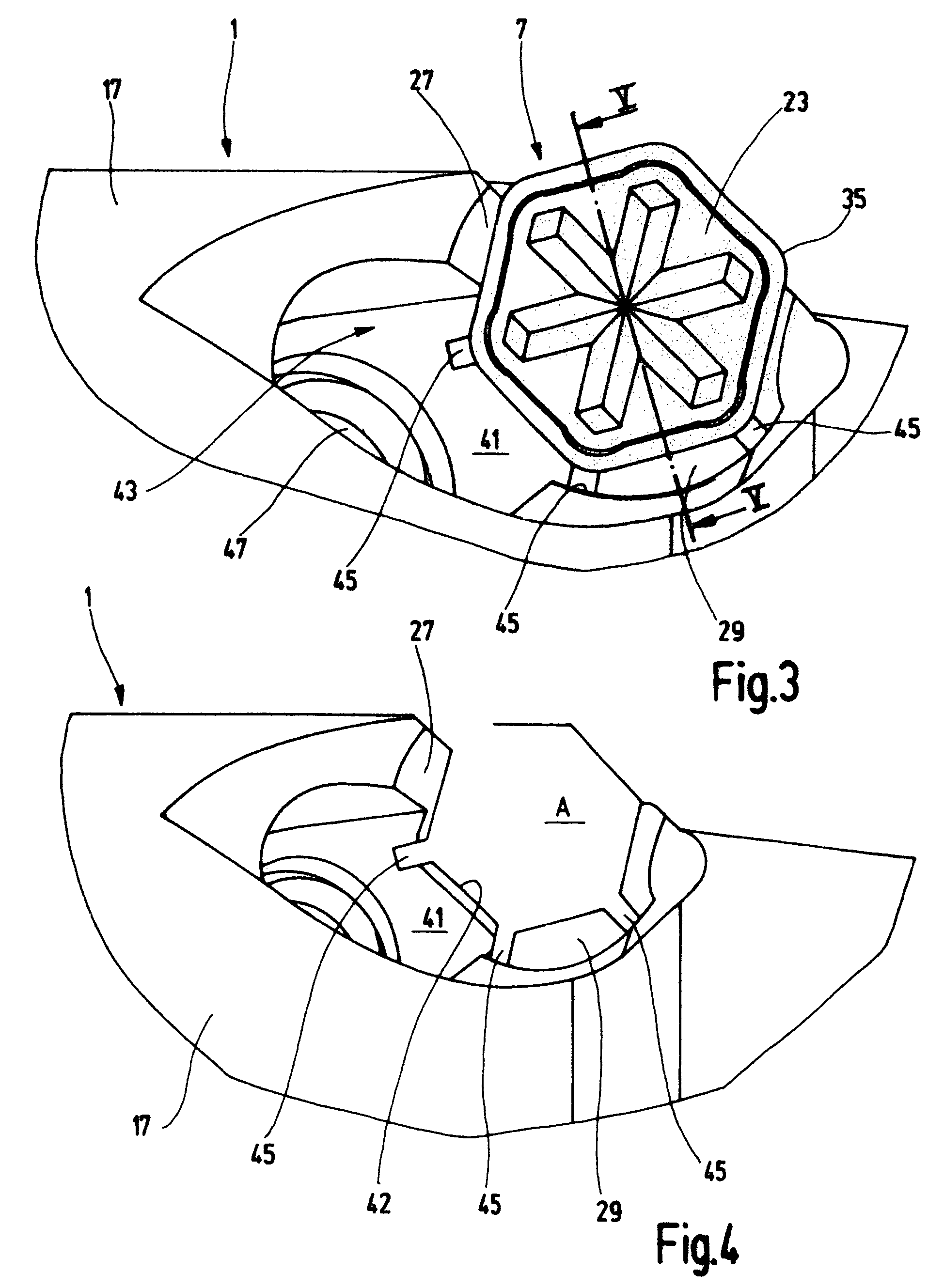

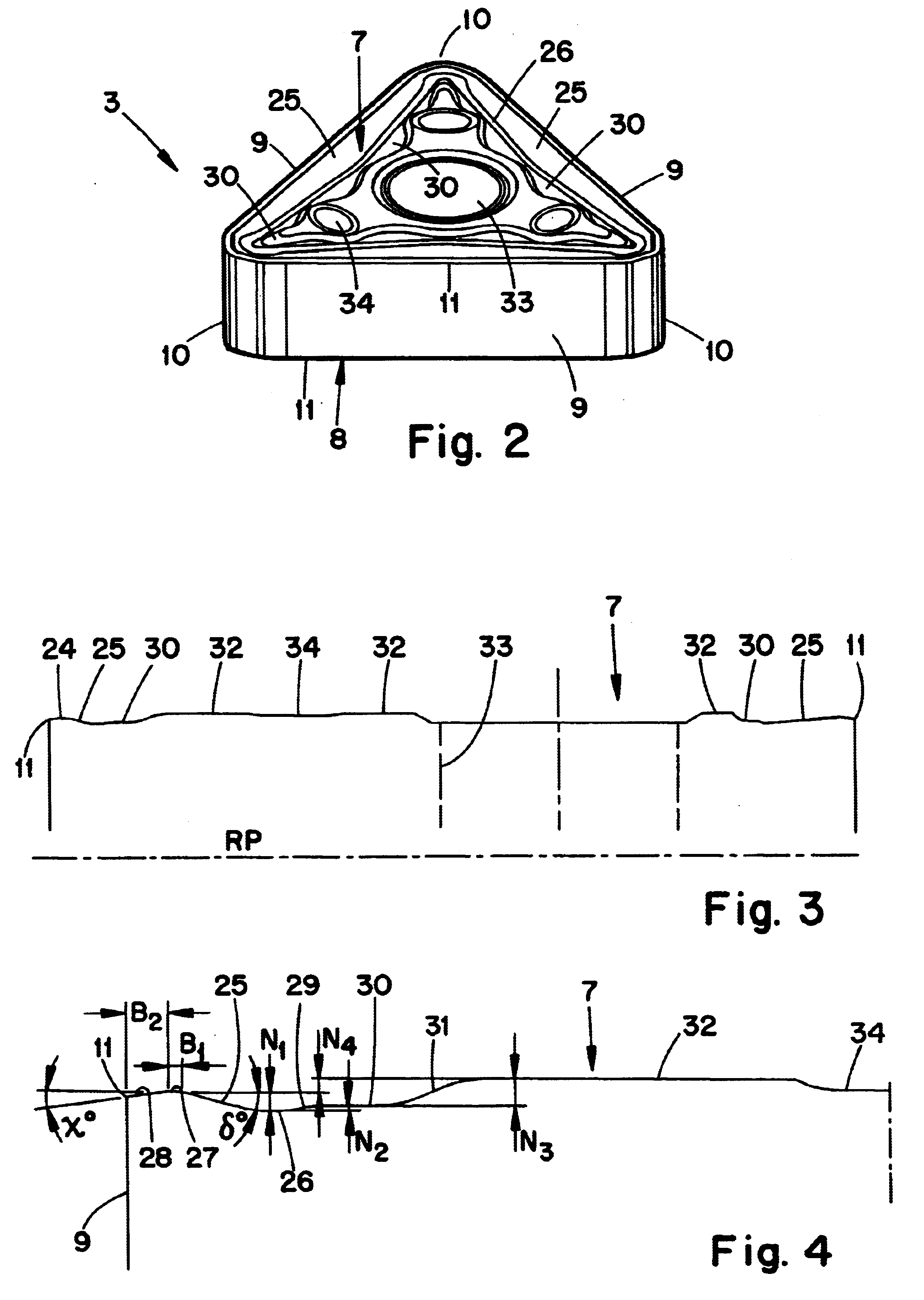

Cutting insert and a tool for chip removing machining, as well as an attachment for such tools

ActiveUS7387474B2Reduced dimensional accuracy requirementsMilling cuttersCutting insertsEngineeringKnife blades

A cutting insert having a front cutting edge and a connecting surface including male- and / or female-like engagement portions, in order to rigidly secure the cutting insert, a geometrically predetermined reference locus serving as a force-application spot for the clamping of the cutting insert. Simultaneously active engagement portions are of only two types—a first, elongate engagement portion, which is located between the front cutting edge and the reference locus, and a second, elongate engagement means, which is oriented at an angle to the first engagement portion and situated at a greater distance from the front cutting edge than the reference locus. In such a way, it is guaranteed that a tightening force always is applied to the cutting insert in a substantially triangular area, which is defined by the free ends of the engagement portions. Furthermore, a tool for chip removing machining, as well as an attachment, e.g., a shim plate, for such tools is provided.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

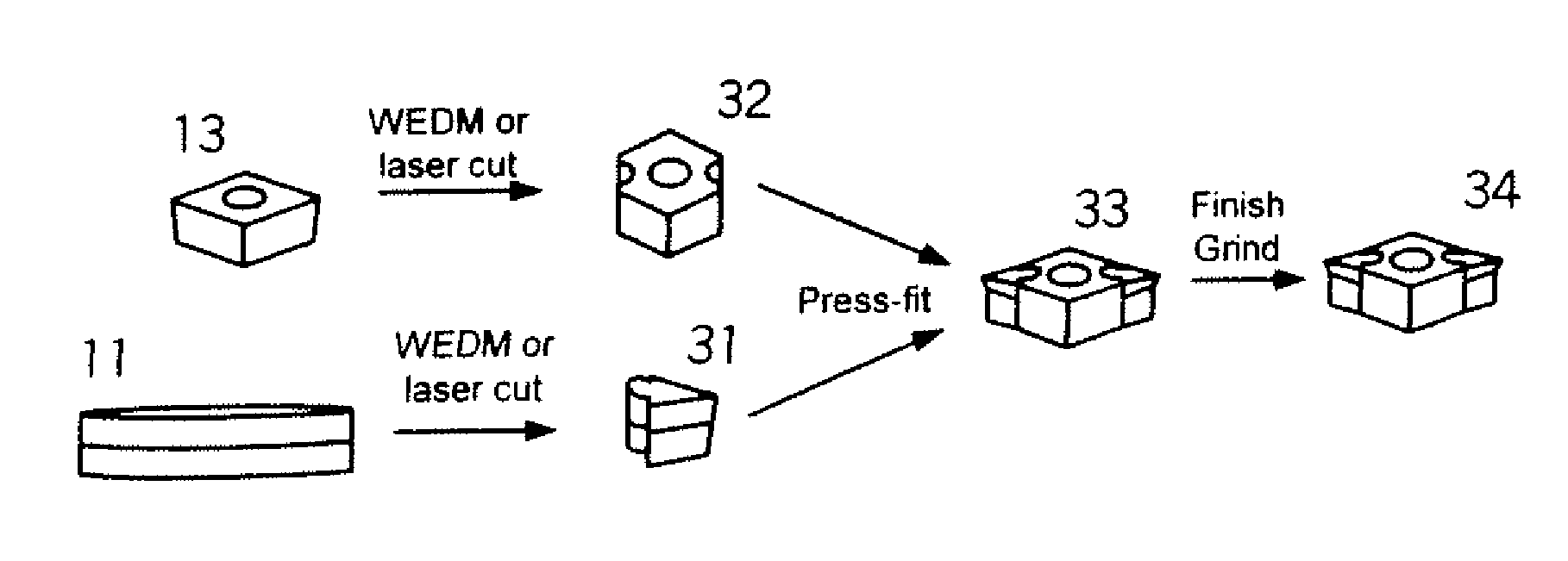

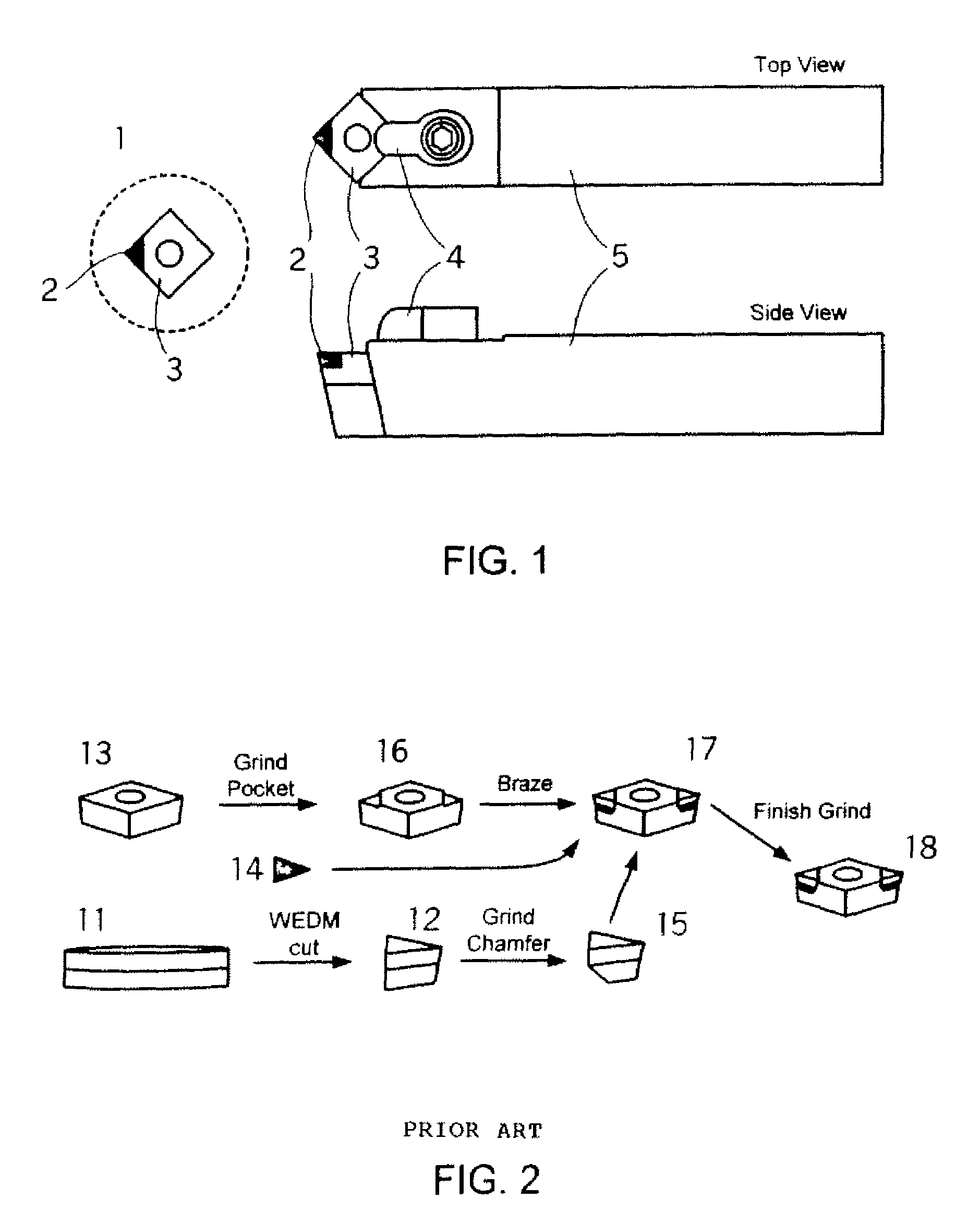

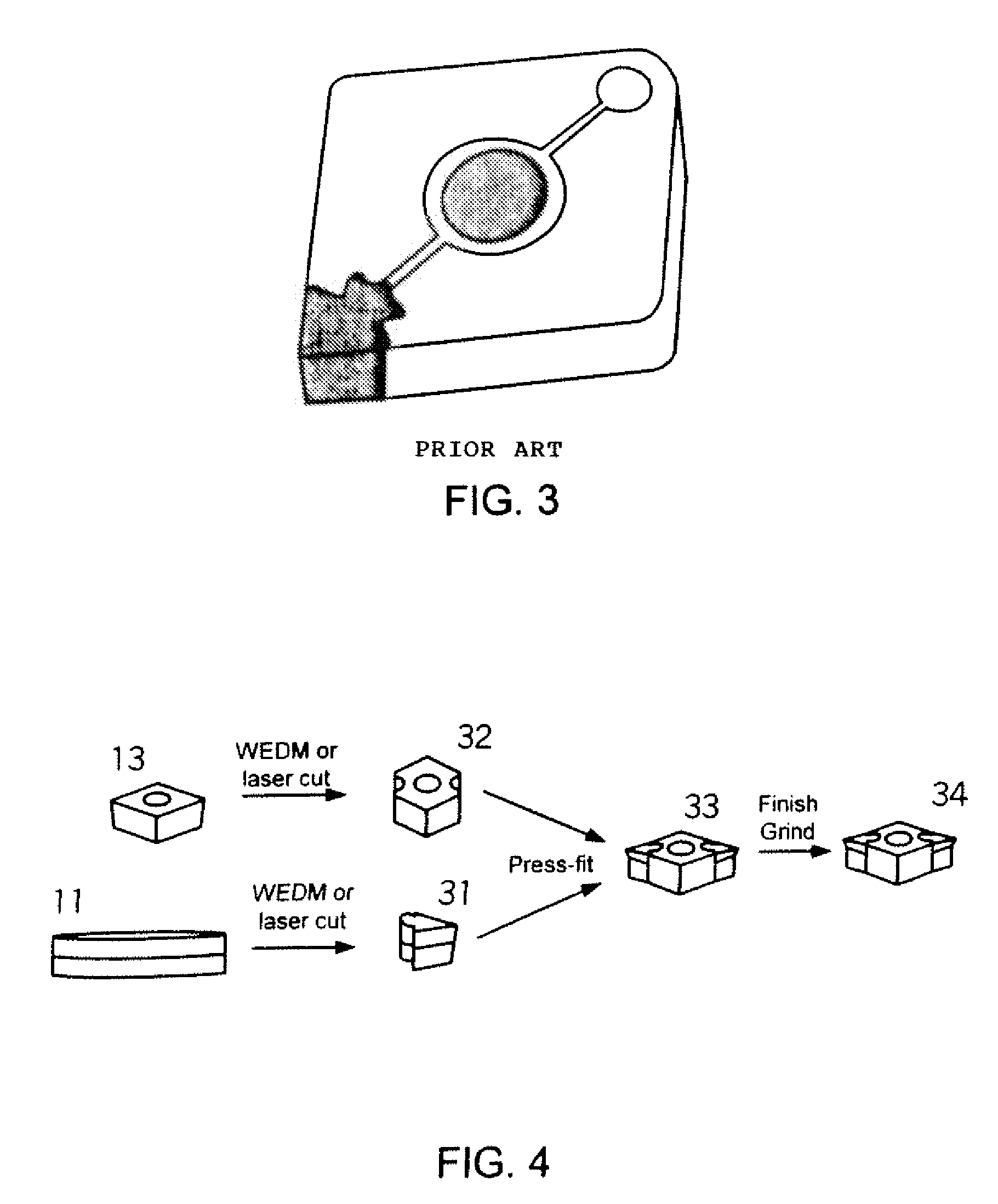

Cutting tool inserts and methods to manufacture

The present invention relates to cutting tool inserts. A cutting tool insert includes an abrasive tip of a hard material, an abrasive or superabrasive material. A cutting tool insert is bonded to an insert body by mechanical force. The mechanical forces are generated through deformation of mating geometric features on the abrasive tip and insert body.

Owner:DIAMOND INNOVATIONS INC

Tool for chip removing machining

A tool for chip-removing machining includes an insert holder and an insert that is mechanically connected with the holder via upper and lower interfaces. Each interface includes a pair of contact surfaces that extend at an obtuse angle relative to each other. Disposed centrally between one of those pairs of contact surfaces is a ridge, and disposed centrally between the other pair of contact surfaces there is a flute. Each of the recess and flute is defined by side surfaces that extend at an acute angle relative to each other. When the ridge engages the flute, a proper absorption of transverse forces acting upon the insert is guaranteed, whereby the insert is maintained essentially immovable in its position in order to guarantee a proper machining accuracy.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

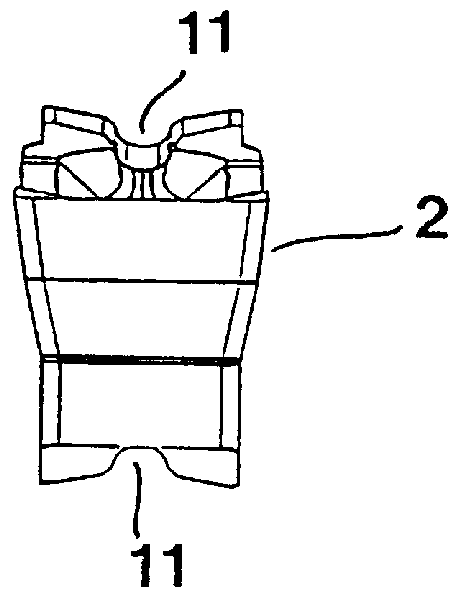

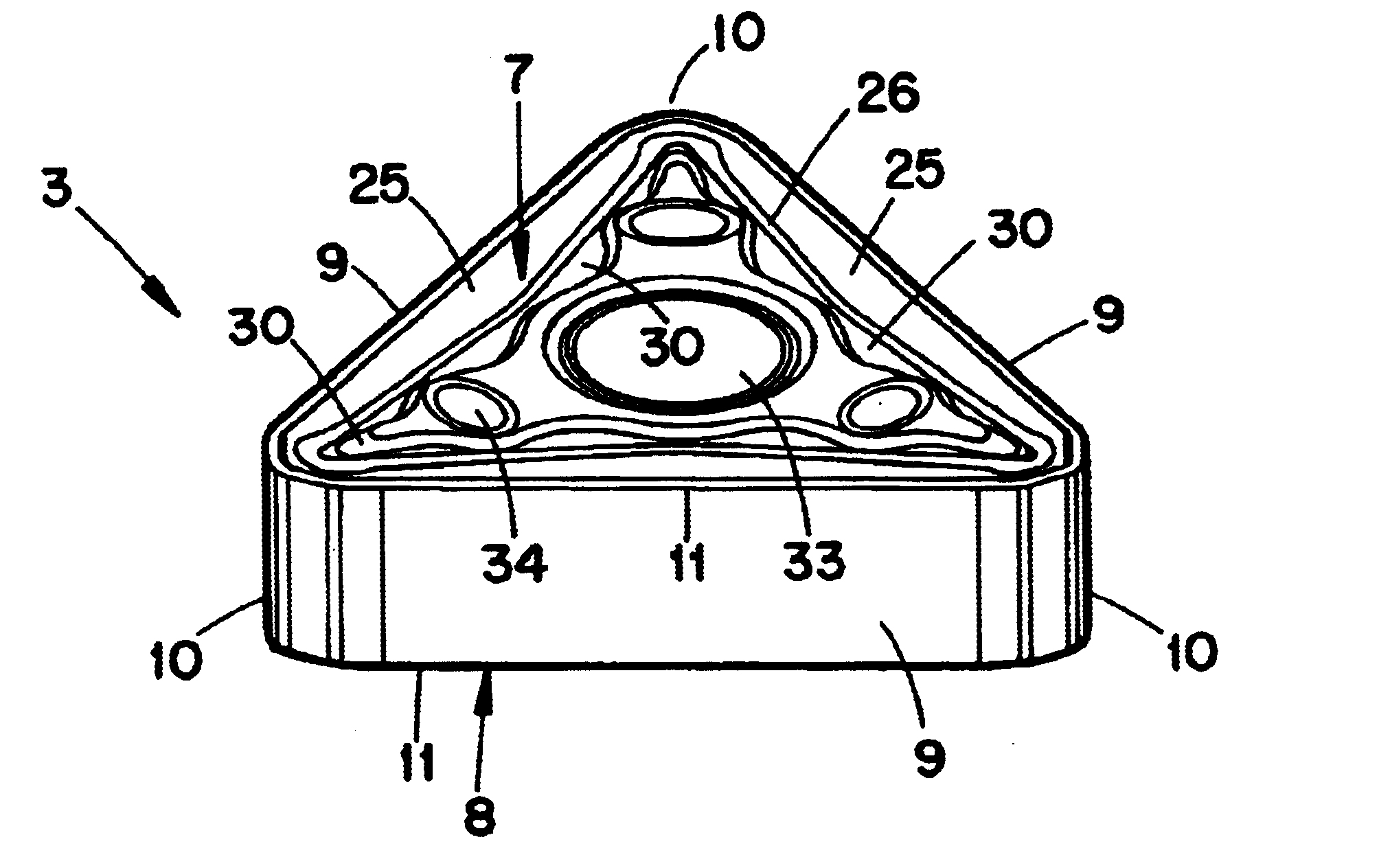

A cutting insert

ActiveUS20060228179A1Improve finenessLittle changeCutting insertsWorkpiecesEngineeringMechanical engineering

The present invention relates to a metal cutting insert that is primarily intended for turning operations. The cutting insert comprises an upper surface, a lower surface substantially parallel with said upper surface, and at least three side surfaces extending between said upper and lower surfaces. A transition between two adjacent side surfaces forms a rounded nose radius surface at a cutting insert corner. The cutting insert includes a peripheral land bridging the upper and side surfaces at least at the corner portion at a chamfer angle. An intersection of the land and the nose radius surface forms a nose cutting edge. The nose cutting edge is defined by at least one radius. The cutting corner includes at least one curved wiper edge. The chamfer angle in a cross-section at the nose cutting edge is larger than the chamfer angle in a cross-section a distance away from the nose cutting edge.

Owner:SECO TOOLS AB

Tangential cutting insert and insert holder

A tangential indexable cutting insert can be used for metal cutting processes in general and for radial and axial turning of a stepped square shoulder in particular. The cutting insert exhibits 180° rotational symmetry about three mutually perpendicular axes. The cutting insert has generally “S”-shaped cutting edges extending between raised and lowered corners. The cutting edges and side surfaces are concave in an end view of the cutting insert. The cutting insert enables radial and axial turning operations of a square shoulder with unlimited depth of cut.

Owner:ISCAR LTD

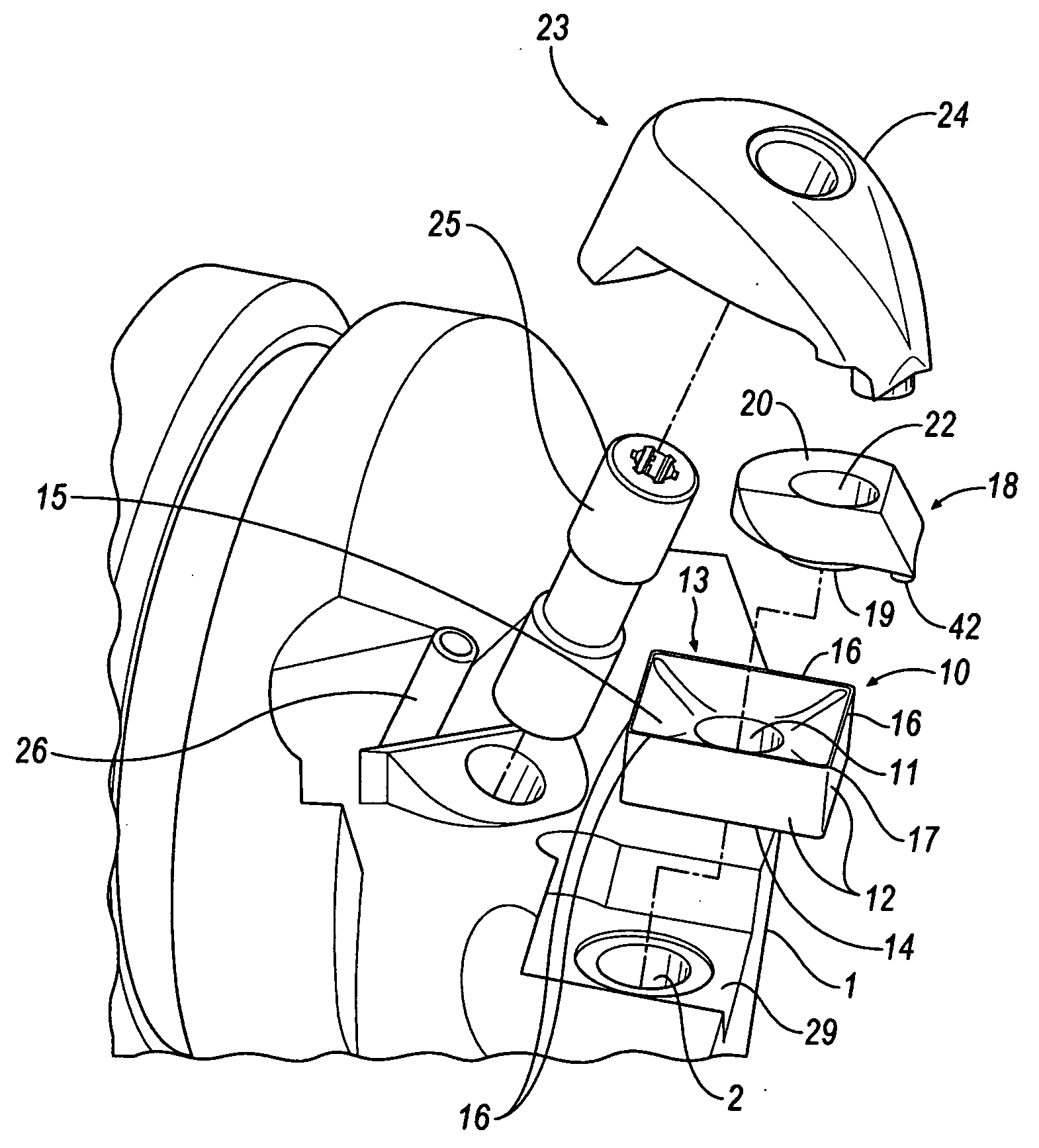

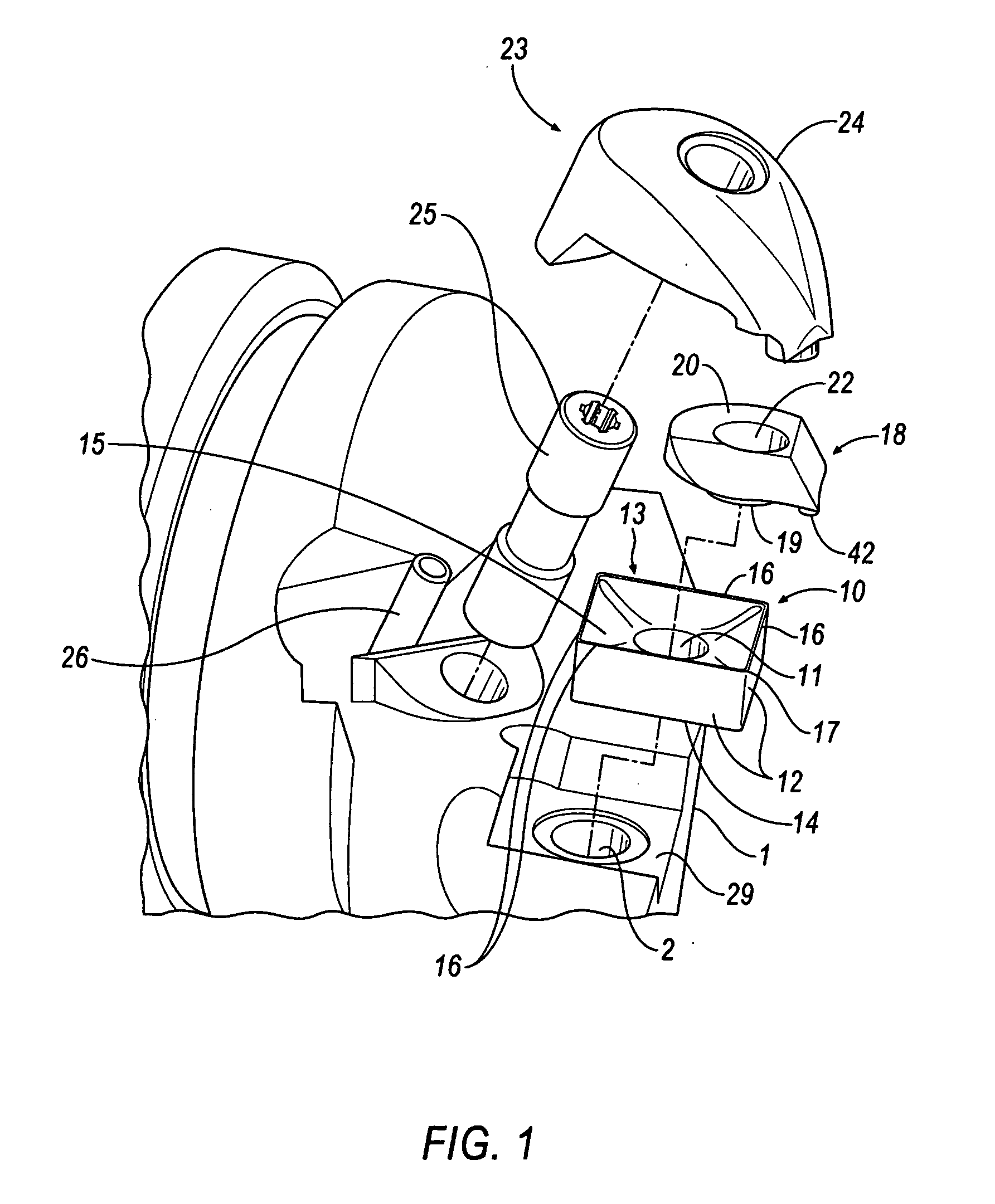

Metal cutting system for effective coolant delivery

A metal cutting system with a tool holder, a shim, an insert with a top depression, a top piece and a clamp. A rake face cooling channel for fluid delivery is formed between the top piece and the depression in the insert. A primary discharge slot at the end of the rake face cooling channel delivers fluid from below the cutting edge of the insert. A second cooling channel for delivery of fluid to the flank face is formed between the insert and the shim or is formed between the shim and the tool holder with a portion of the cooling channel passing through the shim.

Owner:KENNAMETAL INC

Indexable cutting insert with positive axial rake angle and multiple cutting edges

An indexable cutting insert includes a first component with an outer or top surface and side surfaces. A third component is mirror symmetric with respect to the first component about a vertical or y-axis of the cutting insert. A second component is disposed between the first and third components. Multiple cutting edges are defined at an intersection between the side surfaces and the top surface, wherein the cutting edges define a positive axial rake angle. In one embodiment, the first and third components are in the shape of a polygonal with a star appearance, and the second component is in the shape of a square. The first and third components are offset from one another by a first offset angle, while the second component is offset from the first and third components by a second offset angle to allow the cutting insert to be indexable.

Owner:KENNAMETAL INC

Tool for chip removing machining and a basic body therefor

In an embodiment, the invention provides a tool for chip removing machining, including a replaceable cutting insert and a basic body. The basic body includes a rear fixing part, a front supporting part having an insert seat, and a tightening part spaced apart from the front supporting part by a first gap and from the rear fixing part by a second gap. The tightening part is connected to the basic body via a joint around which the tightening part is pivoted to press the cutting insert against the insert seat by a front finger. The rear fixing part includes a first channel having an inlet and an outlet for feed of a fluid toward the cutting insert. The tightening part includes an internal, second channel that extends between an inlet and an outlet. A hollow coupling member extends between the tightening part and one of the rear fixing part and the front supporting part while bridging the respective gap to establish a fluid communication path between the outlet of the first channel and the inlet of the second channel.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

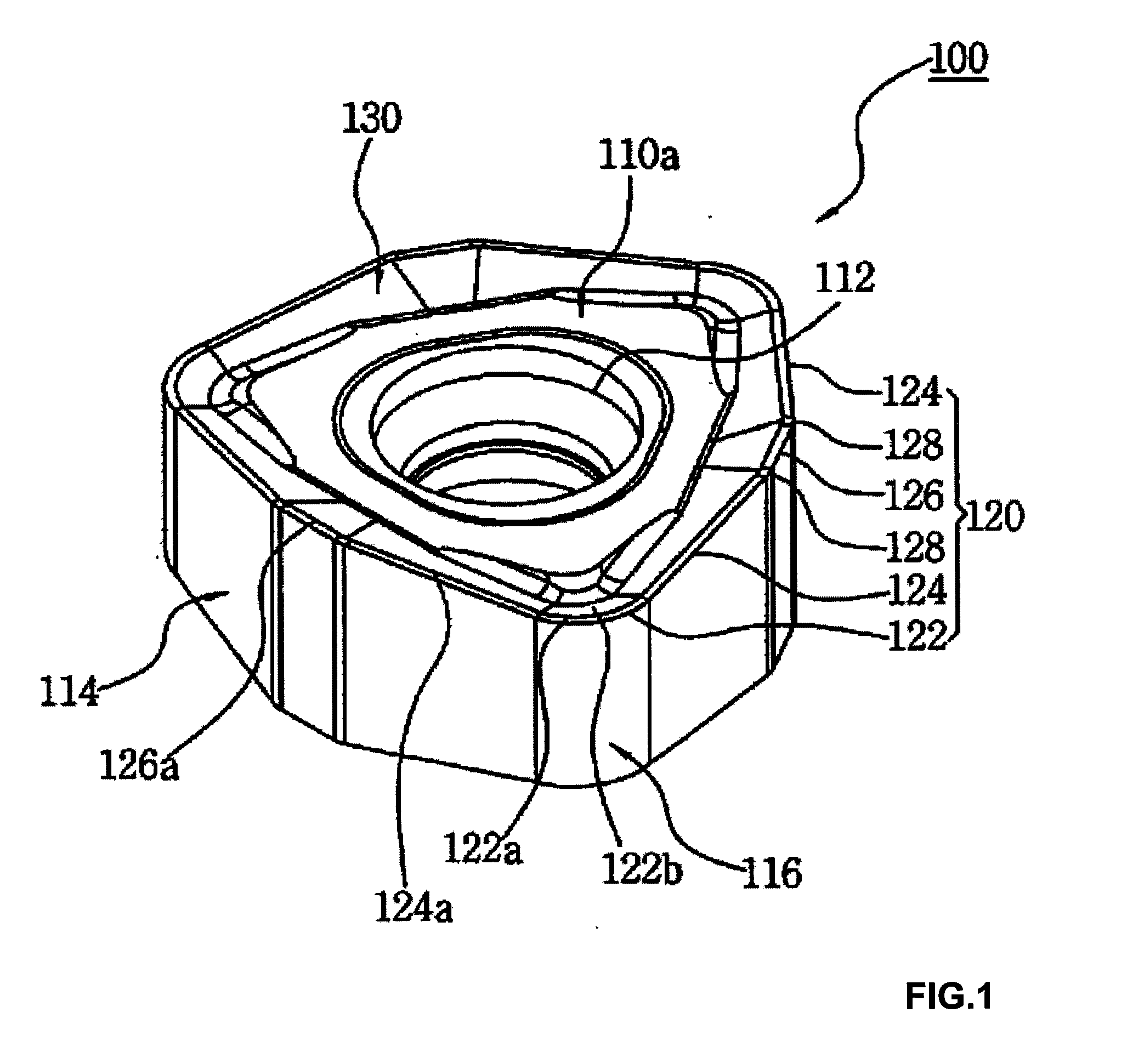

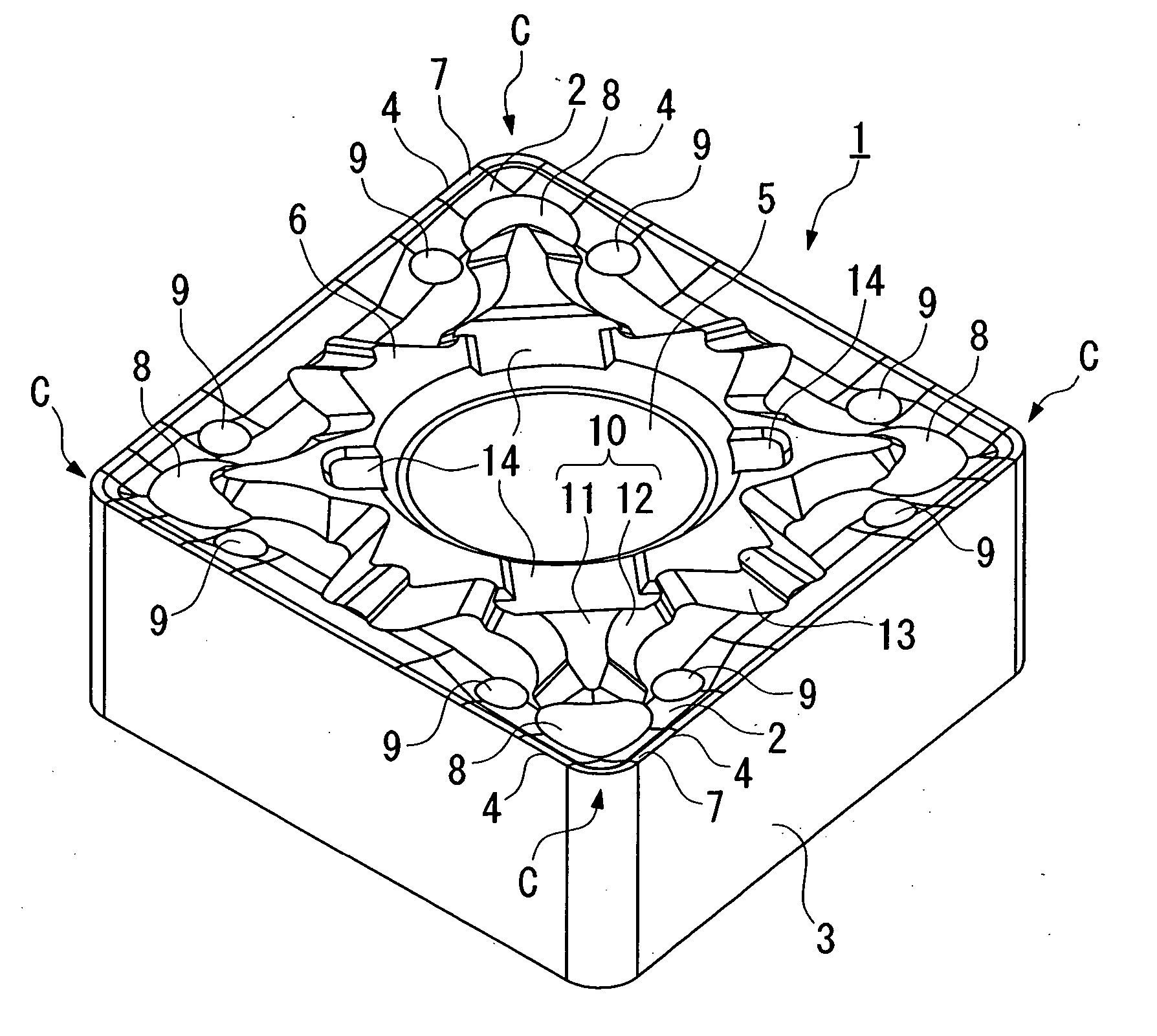

Cutting insert for high-efficient cutting

ActiveUS20100034602A1Increase stiffnessExtended service lifeMilling cuttersCutting insertsEngineeringMechanical engineering

A cutting insert for high-efficiency cutting is disclosed. The cutting insert includes an upper surface (110a), a lower surface (HOb), side surfaces (114) and corner side surfaces (116), which connect the side surfaces to each other. A circular opening is formed through the central portions of the upper and lower surfaces. In the cutting insert, cutting edges are formed by respective junctions between one of the upper and lower surfaces and the side surfaces and between one of the upper and lower surfaces and the corner side surfaces. The cutting edges comprise three corner cutting edges (122), six major cutting edges (124), which extend from opposite ends of the corner cutting edges towards the neighbor corner cutting edges, and three minor cutting edges (126), which are connected between the major cutting edges. Furthermore, the cutting edges may be formed on both the upper surface and the lower surface.

Owner:KORLOY

Method and apparatus for machining workpieces having interruptions

This invention is a method and apparatus for cutting a workpiece which may have interruptions, with a cutting insert having a cutting edge, where the cutting insert is held in a tool holder and is optionally supported by a shim. Coolant, which may contain liquid nitrogen, is introduced through a passageway to a cooling passage located near the cutting edge. The cooling passage may be located either under, behind, or under and behind the cutting edge. Coolant impacts the wall surfaces of the cooling passage near the cutting edge where it is partly evaporated thereby cooling the cutting insert.

Owner:AIR PROD & CHEM INC

Tool for chip removing machining as well as a solid indexable cutting insert and a solid basic body therefor

ActiveUS20100329800A1Reduce manufacturing costGood precisionMilling cuttersCutting insertsHardnessEngineering

A tool for chip removing machining, including a basic body having an insert seat, and an indexable cutting insert fixed in the seat. The insert includes an upperside, an underside, a pair of side contact surfaces, two cutting edges that individually extend along a chip surface included in one of the upperside and underside, at least two heads that are spaced-apart via an intermediate part and individually include a front portion having at least one cutting edge and a rear portion along which the pair of side contact surfaces are formed. The insert seat of the basic body includes a central hollow space, and a front cavity and at least one rear cavity in which the heads of the cutting insert are housed, the front cavity including a pair of side support surfaces against which the pair of side contact surfaces of the cutting insert are pressed when a tightening element pulls the head rearward toward the side support surfaces. The basic body is solid by being formed integrally of steel material. The seat is countersunk in the basic body such that the side support surfaces are integrated in the steel material. The cutting insert is formed integrally from a second, hard-wearing material having at least the same hardness as cemented carbide, the pair of side contact surfaces of the insert being integrated in the second material.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

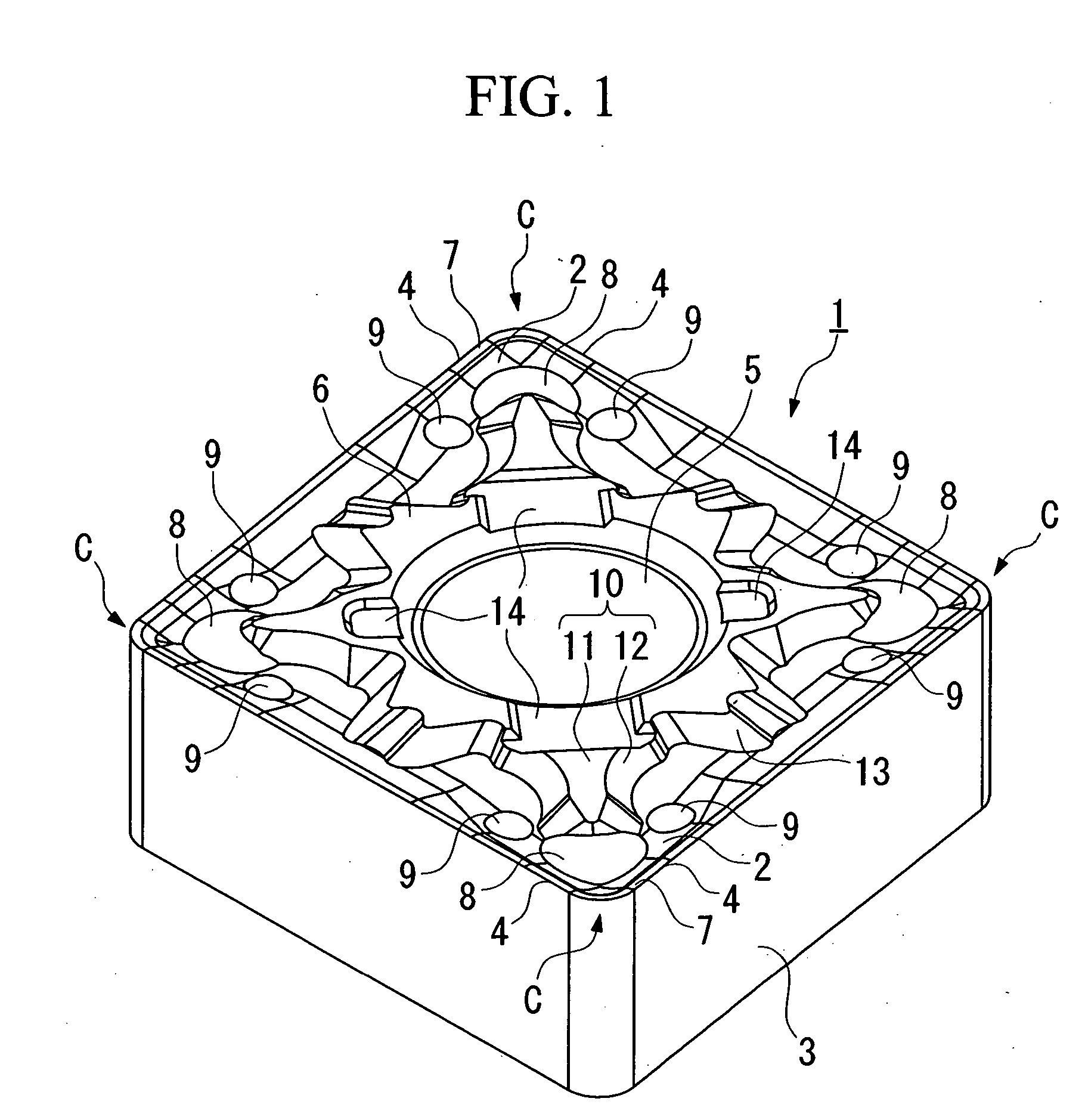

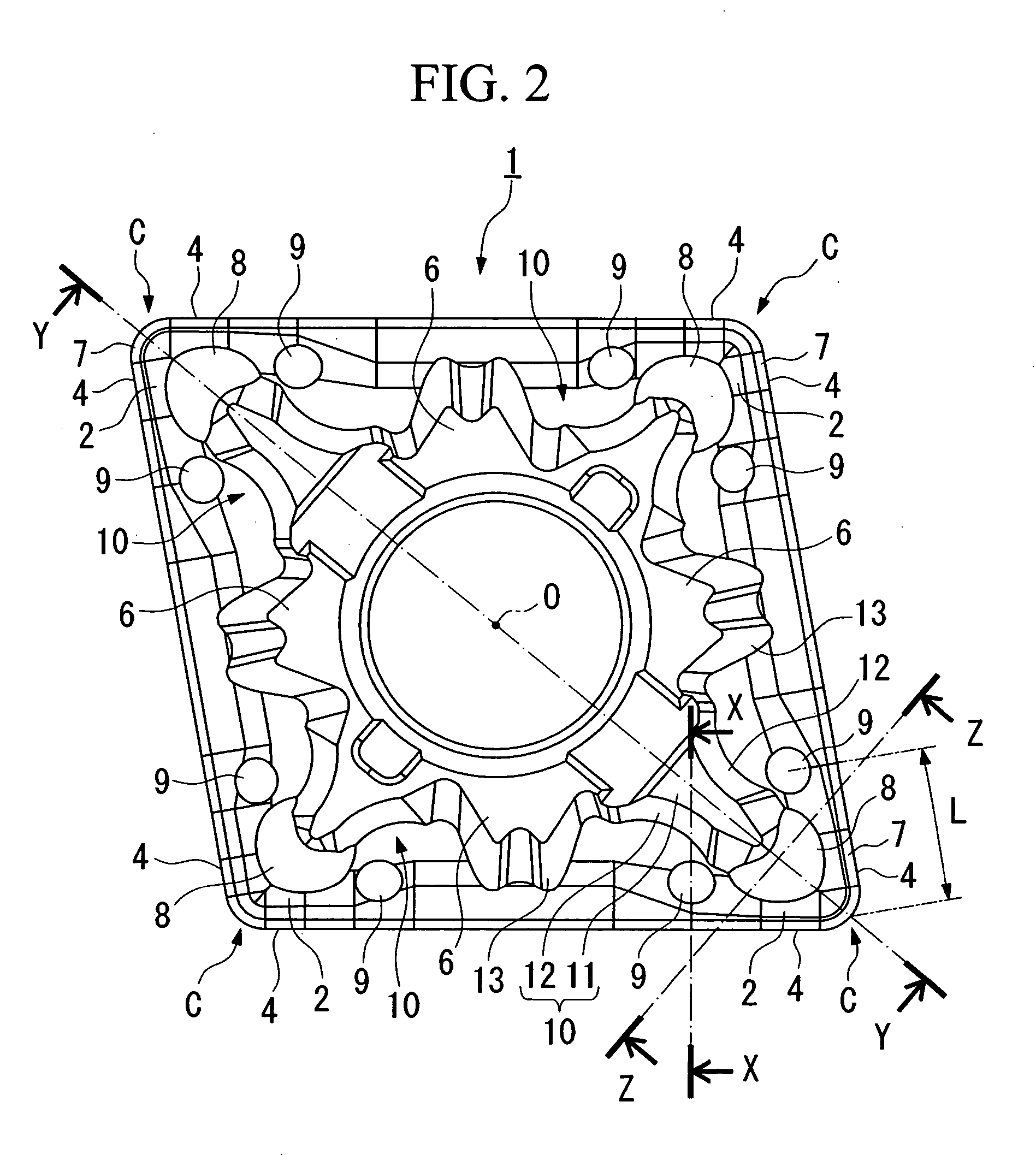

Cutting insert having cylindrically shaped side surface portions

ActiveUS7232279B2Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsEngineeringMechanical engineering

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

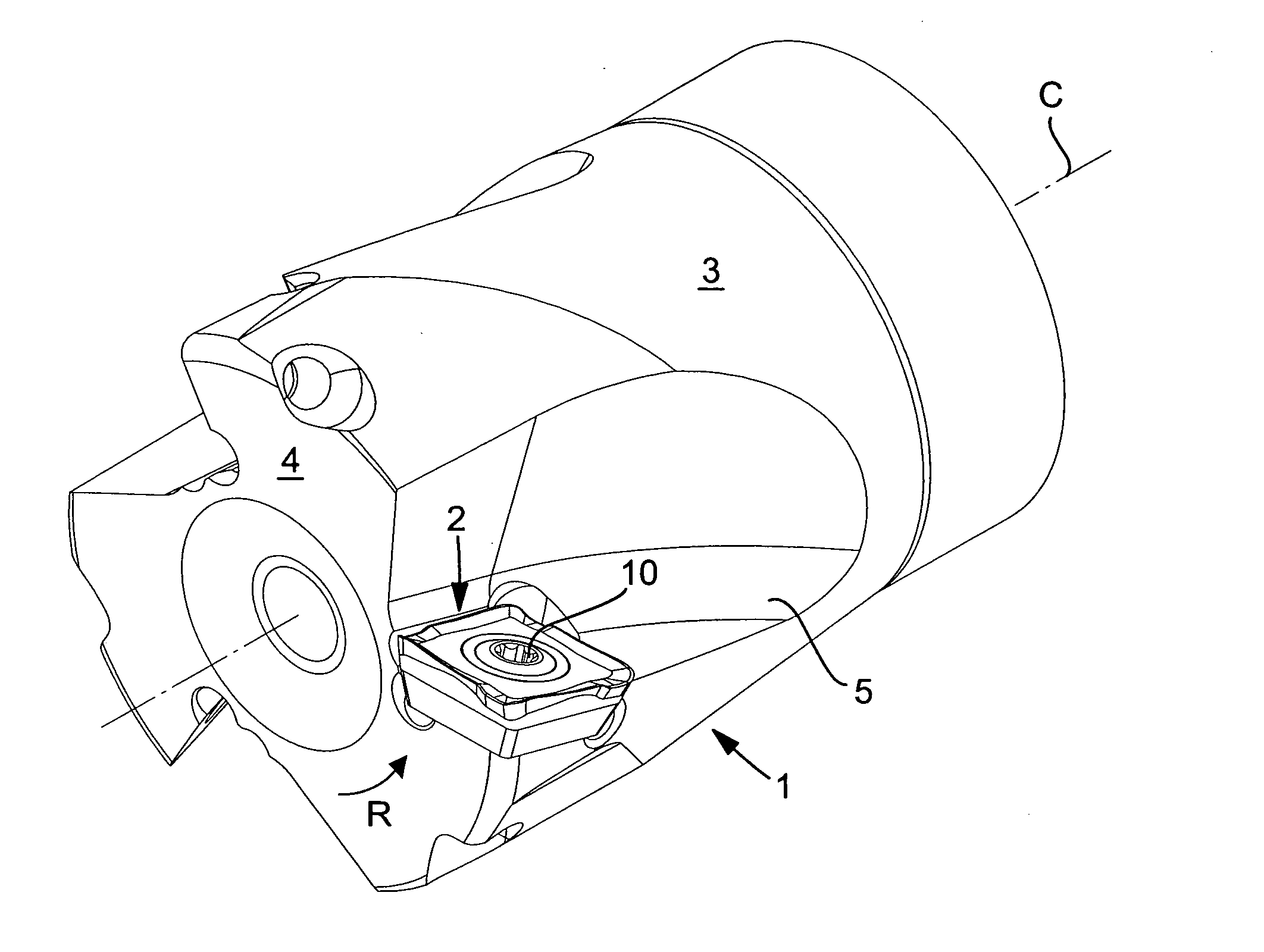

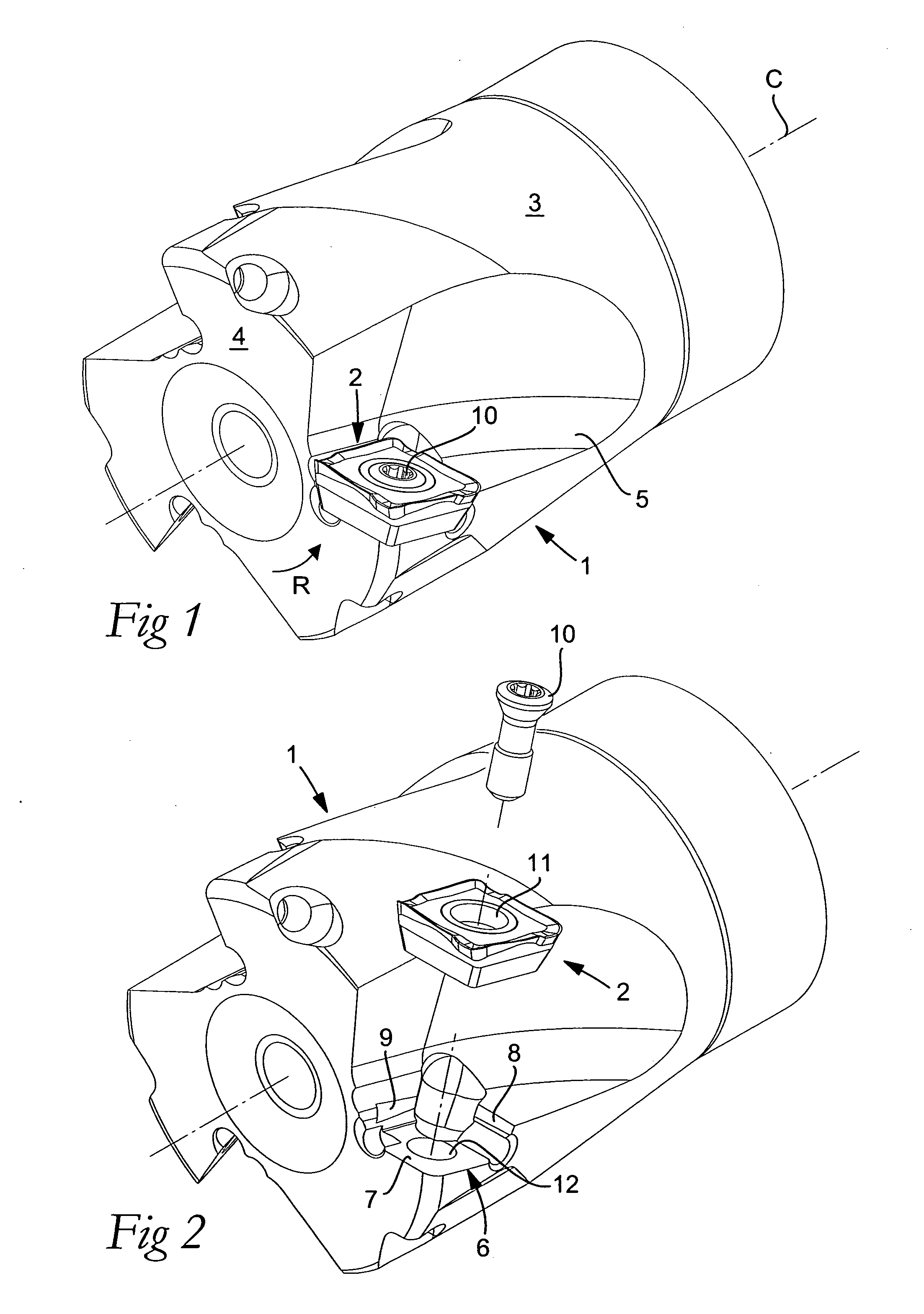

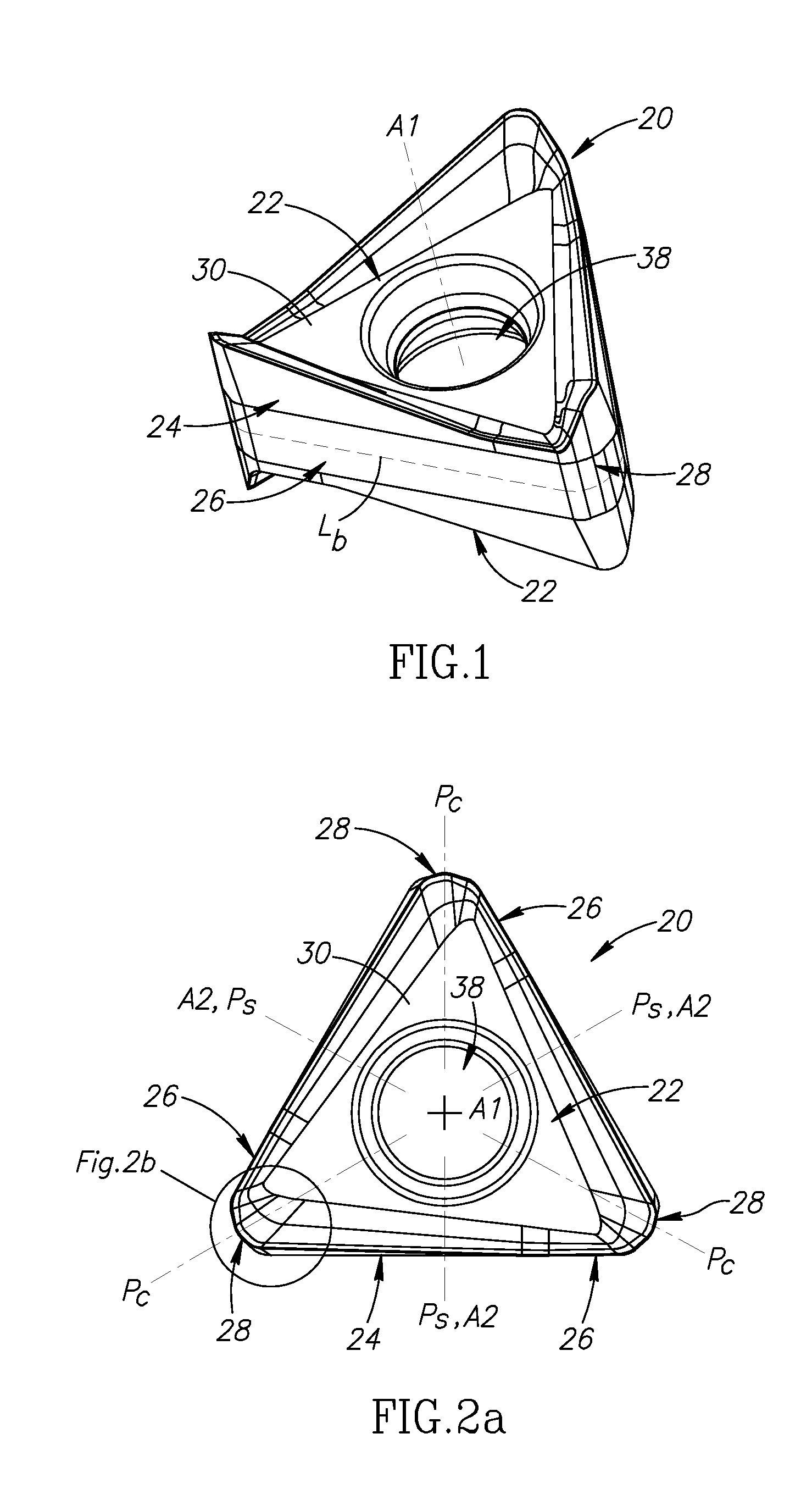

Rotary Cutting Tool and Reversible Cutting Insert Therefor

In a rotary cutting tool used for milling operations, a reversible indexable cutting insert is removably secured in a cutting body. The cutting insert has two opposing end surfaces interconnected by a continuous peripheral surface, including three side surfaces alternating with three corner surfaces. The side and corner surfaces intersect with both end surfaces at side and corner edges, respectively, with each side edge having a major cutting edge, and each corner edge having a corner and minor cutting edge. Each major and minor cutting edge slopes away from first and second end points, respectively, of its mutually associated corner cutting edge, towards a median plane. A first imaginary straight line extending perpendicular to the median plane and intersecting any one of the corner cutting edges at any point along its length except the second end point, passes through the median plane inside an insert boundary line.

Owner:ISCAR LTD

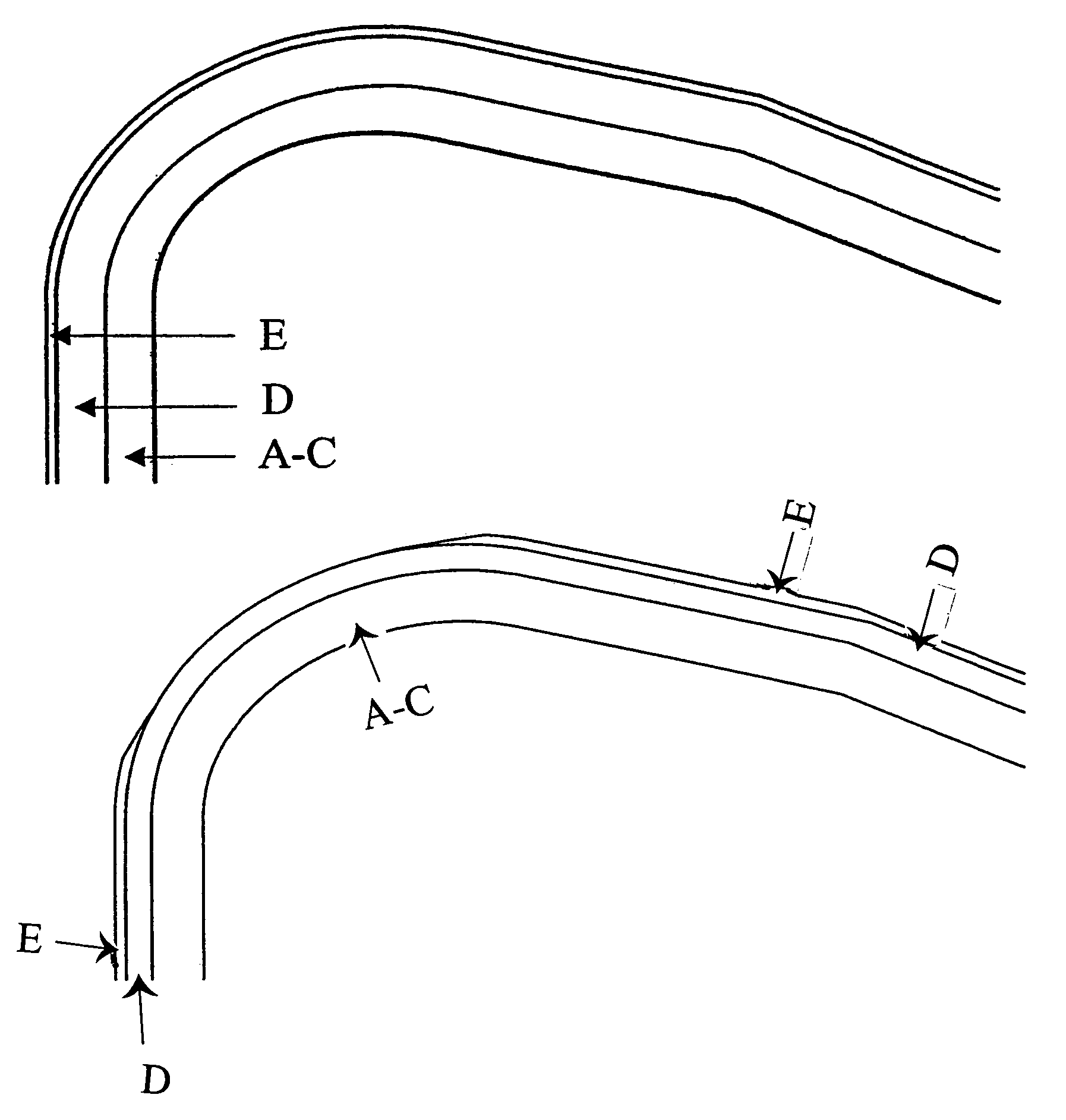

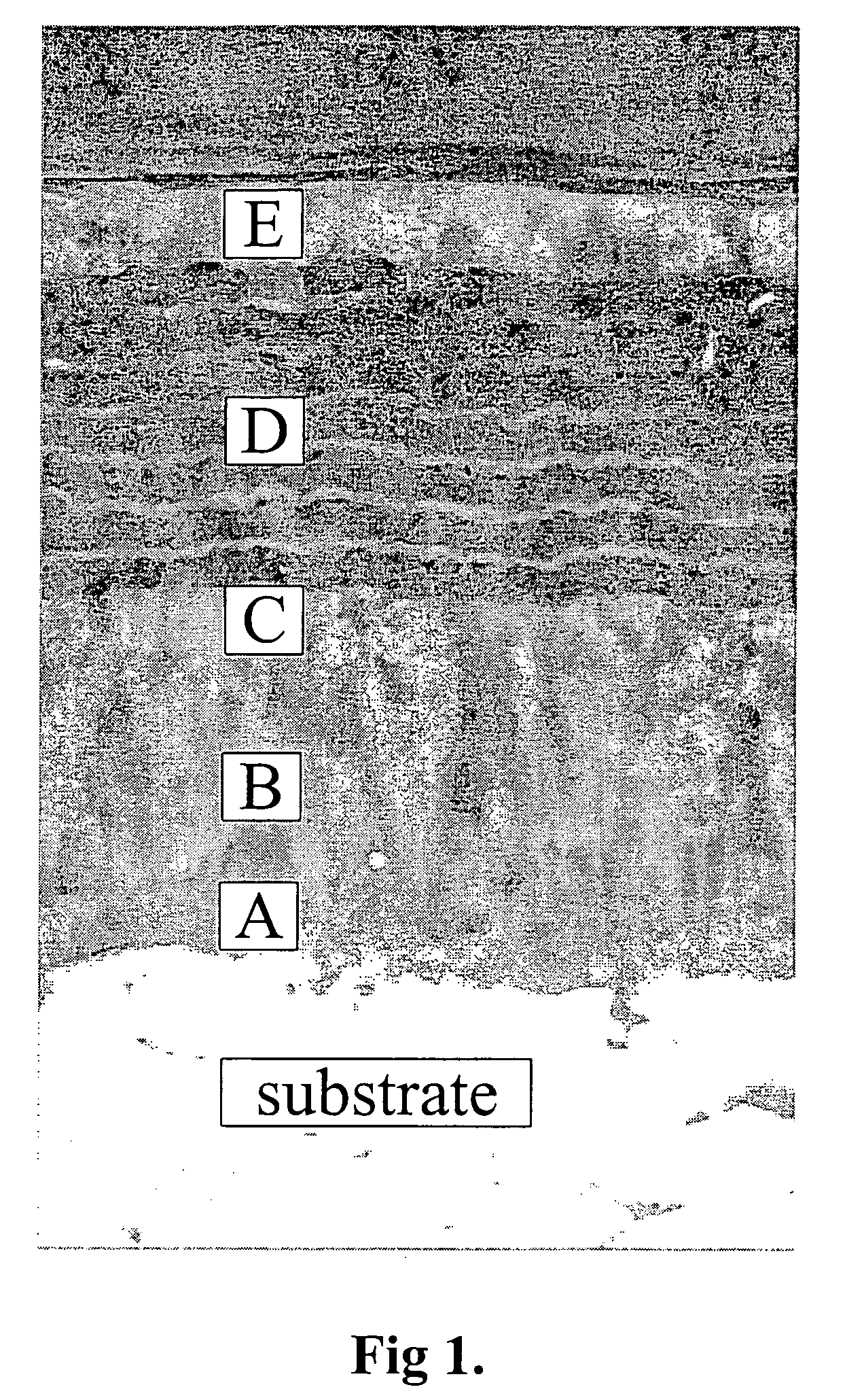

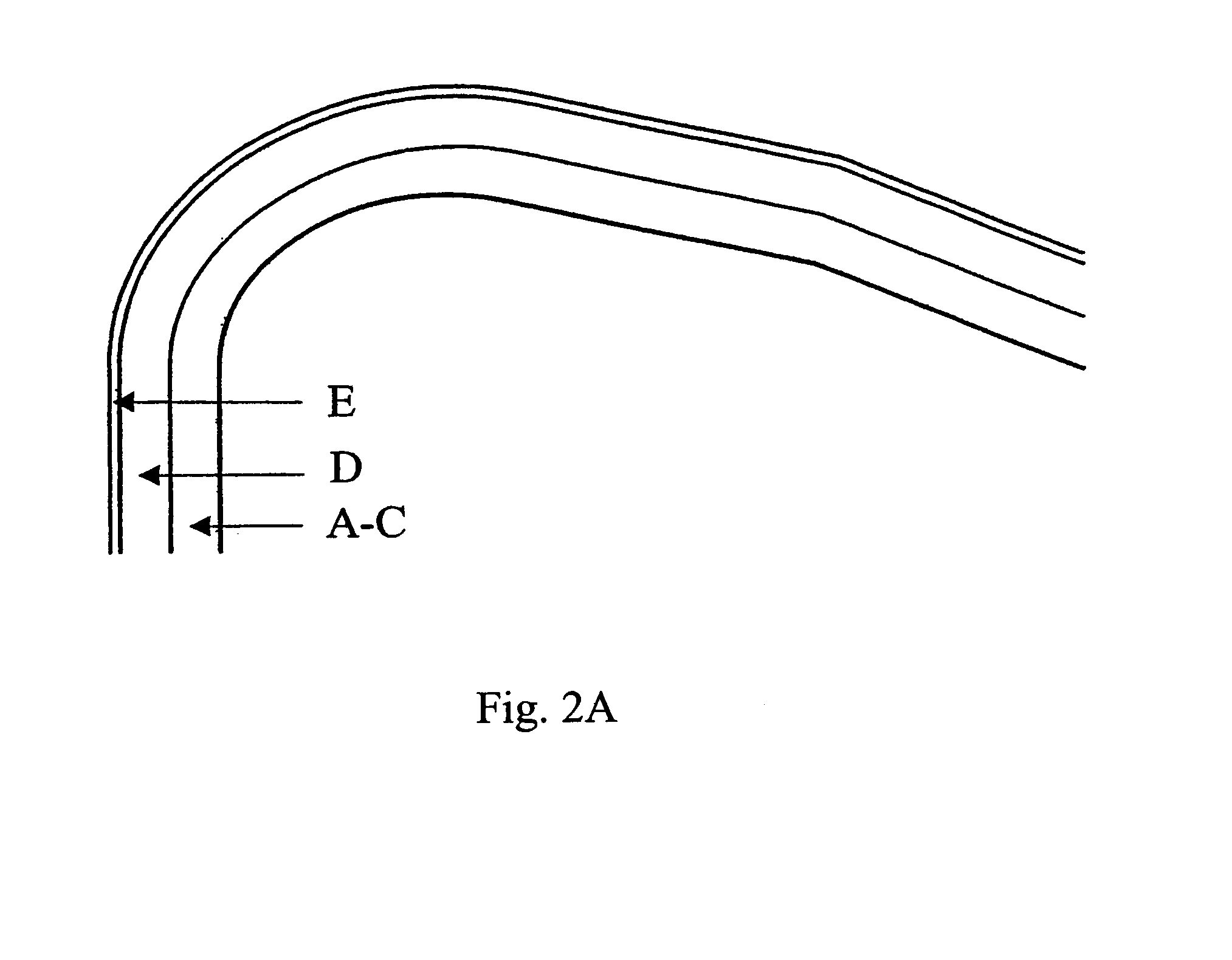

Coated cemented carbide insert

ActiveUS7153562B2Eliminate deficienciesImprove performancePigmenting treatmentCutting insertsAlloyCemented carbide

The present invention relates to a cutting tool insert particularly for turning of steel comprising a cemented carbide body, a coating with a post treatment witha first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of 0.7–4.5 μma second multilayer system consisting of a totally 5–31 alternating Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of <0.5 μm and the TiCxNyOz-layers 0.01–0.2 μm with a total thickness of the multilayer of 1.0–4.0 μm. The multilayer is exposed along the edge line and into the rake and flank face, at least 0.02 mm, from the edge line on the rake face, preferably the contact length of the chip at most 0.9 mm, and 0.02–0.20 mm on the flank face.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

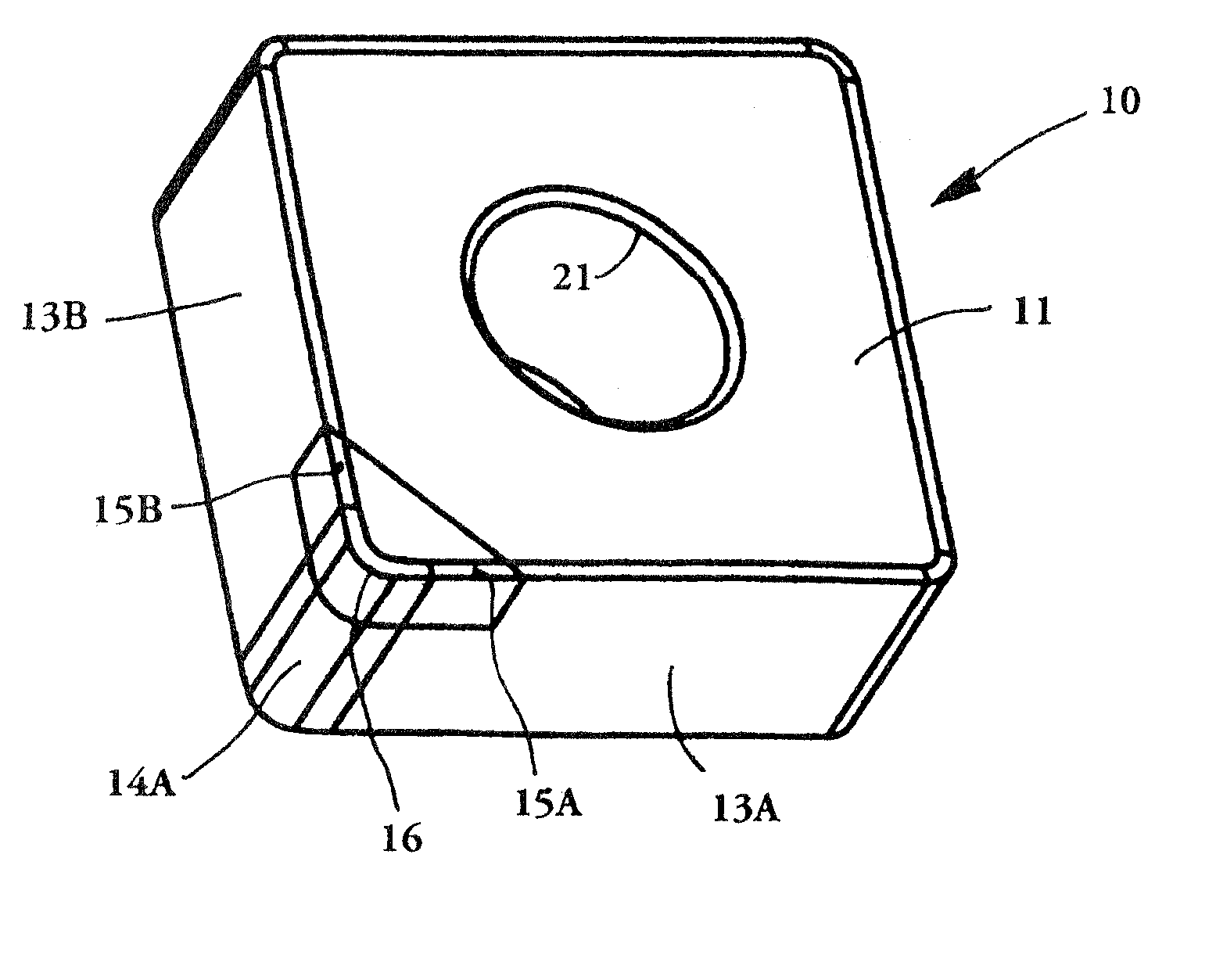

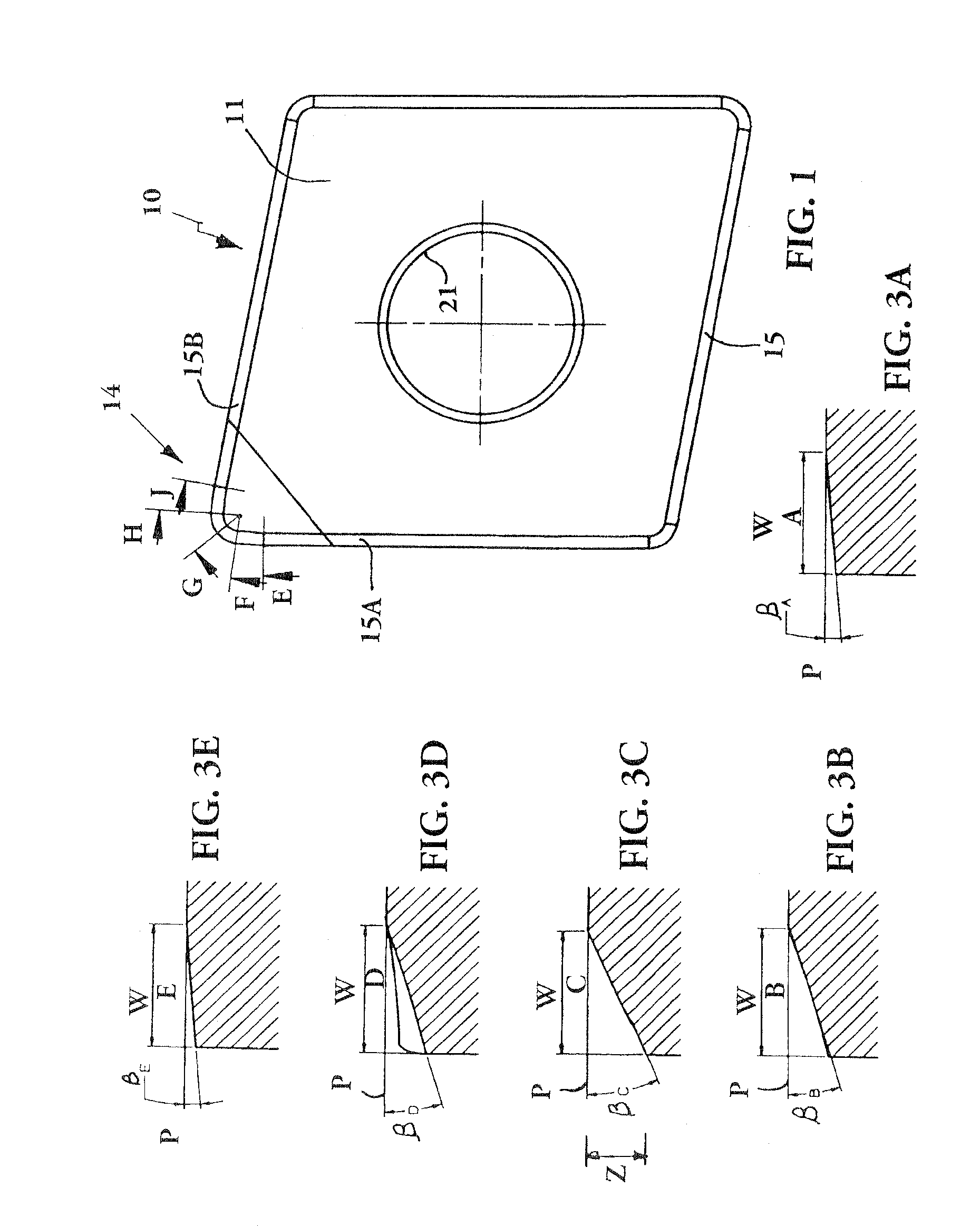

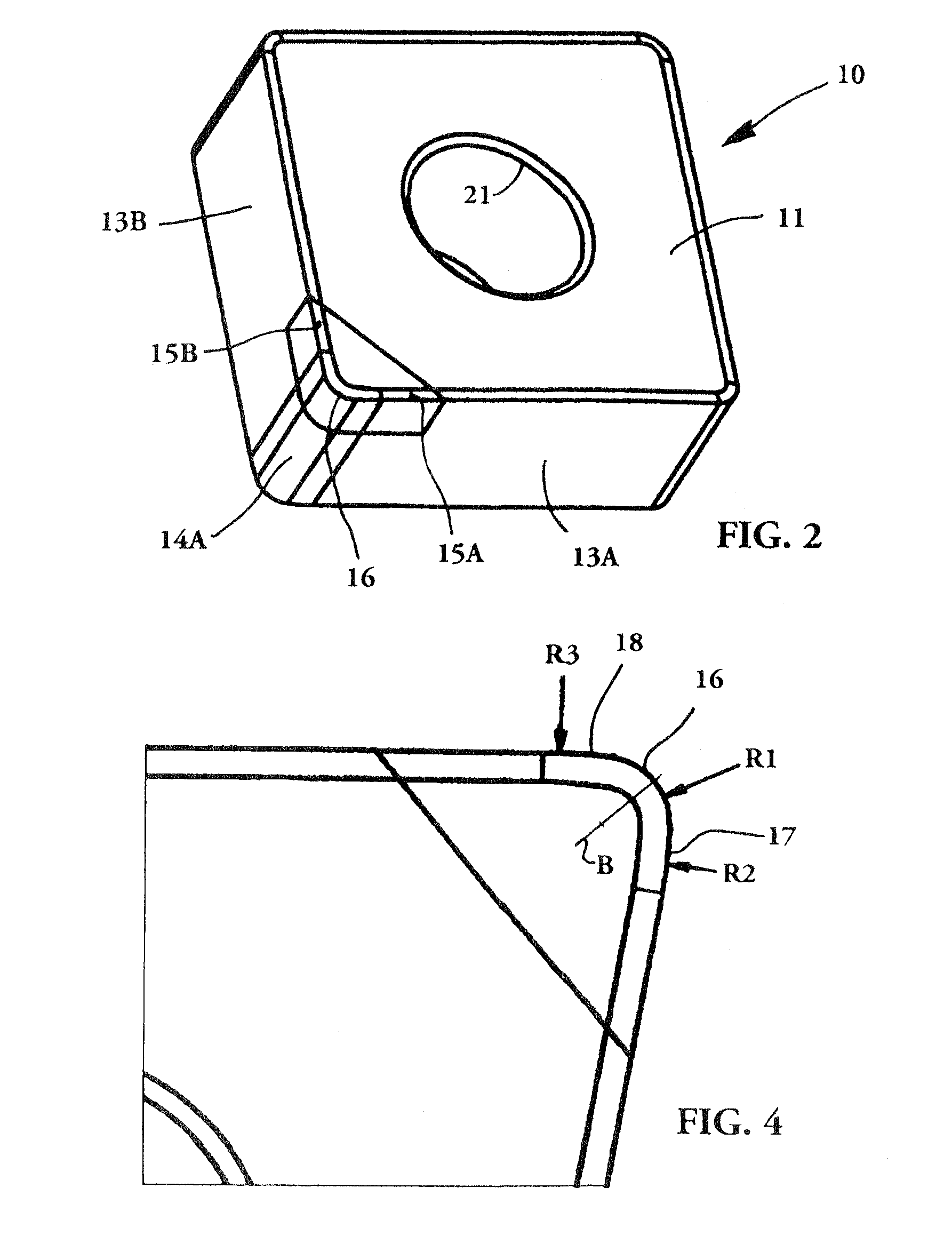

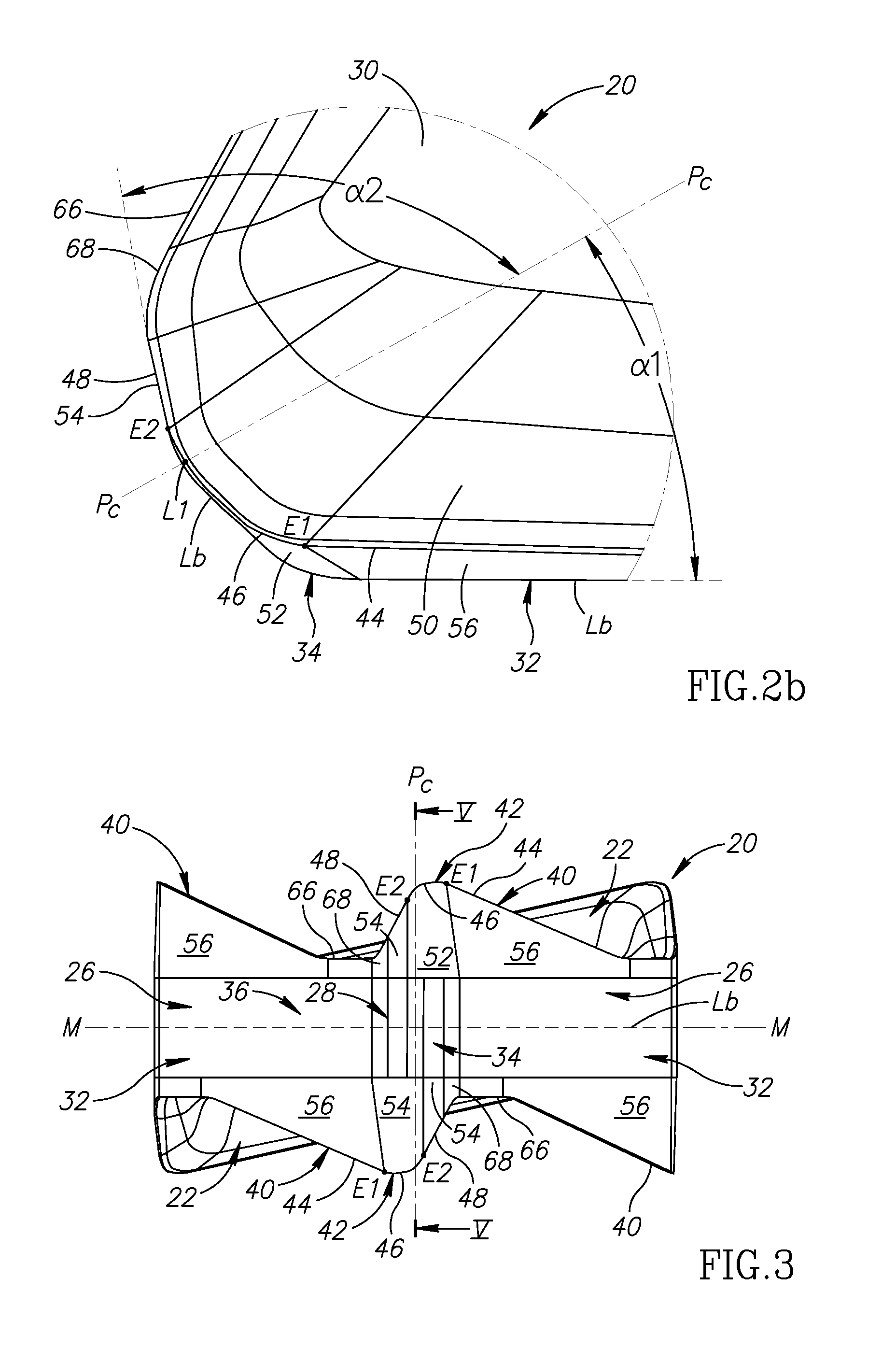

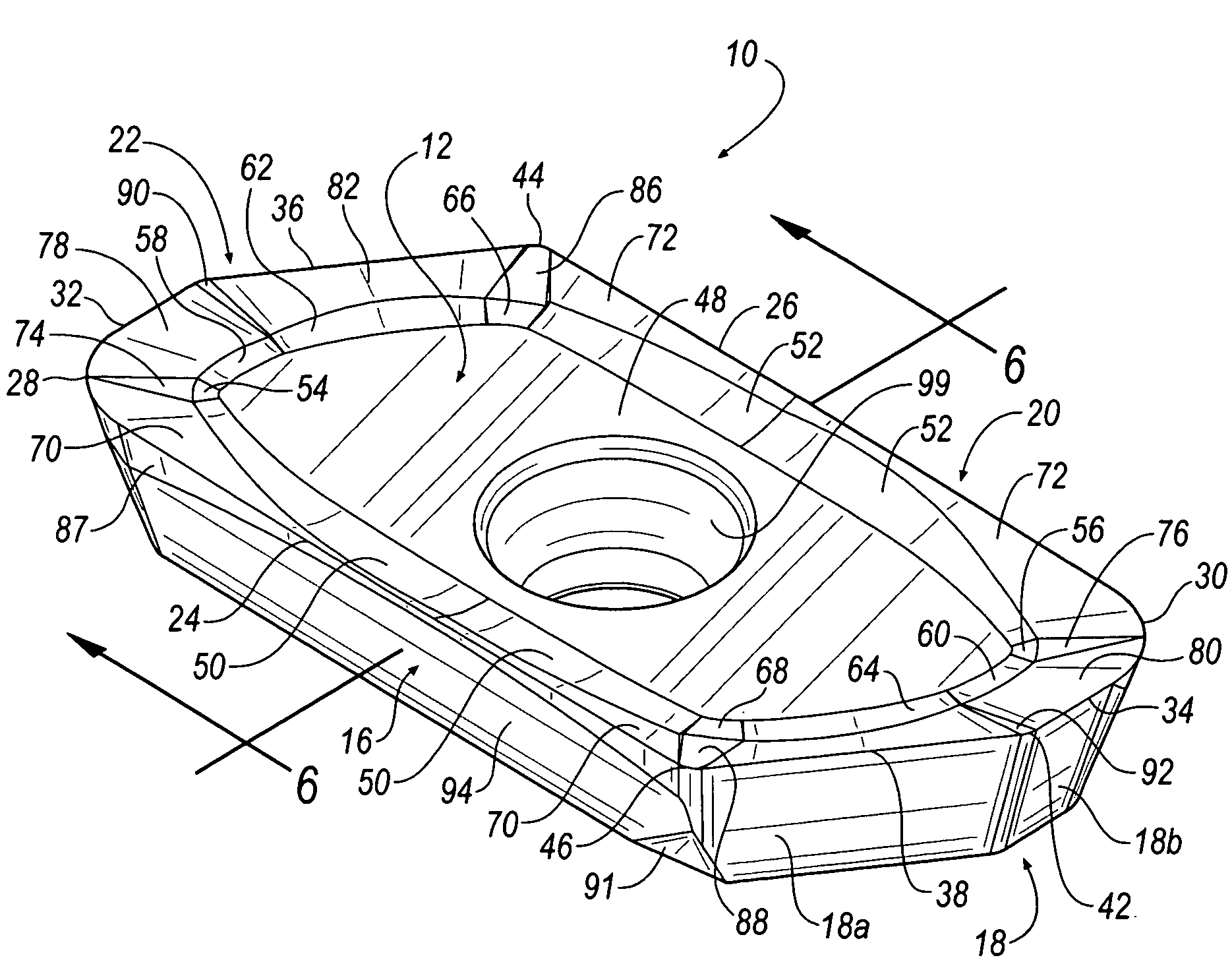

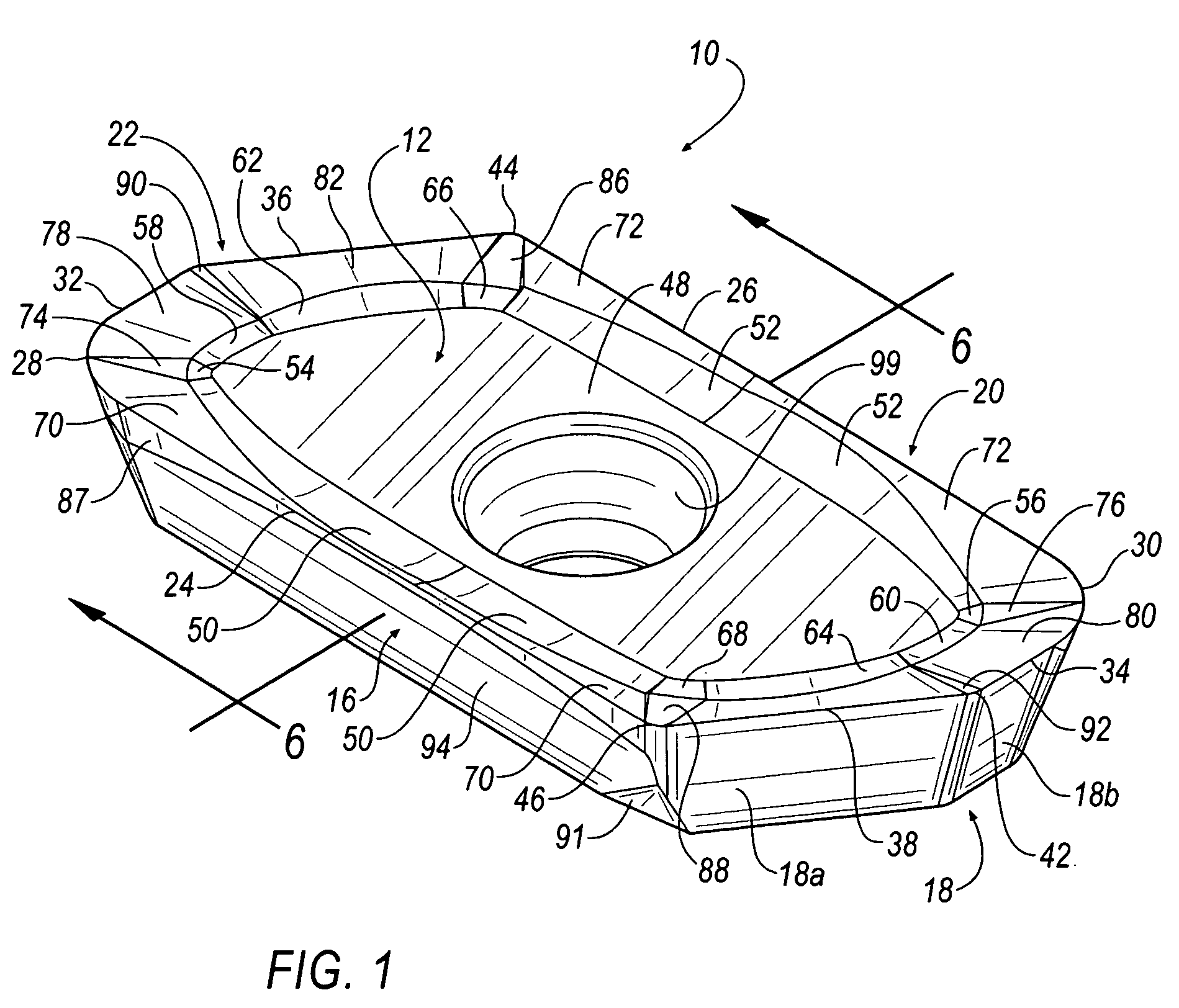

Cutting insert for high-speed milling cutter

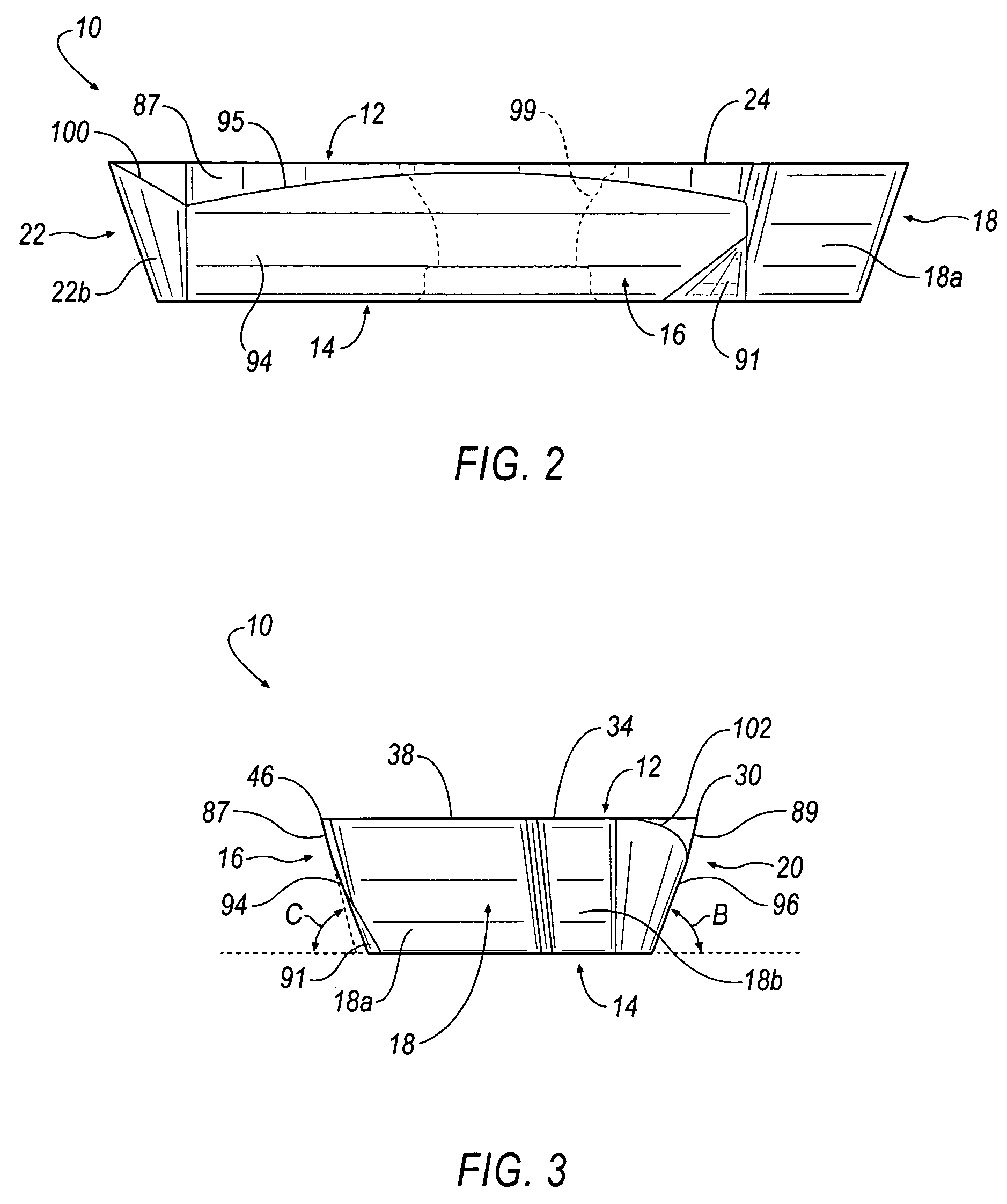

An indexable cutting insert (10) having a top surface (12) including a substantially planar central portion (48), a substantially planar bottom surface (14), and a plurality of side surfaces (16, 18, 20, 22). A long cutting edge (24, 26), a corner radius cutting edge (28, 30), a facet radius cutting edge (32, 34), and ramping cutting edge (36, 38) are defined at an intersection between the top surface (12) and one of the side surfaces (16, 18, 20, 22). A margin (87, 89) extends around a nose radius of the cutting insert (10) and blends into a flat surface (94, 96). A margin angle, C, formed by the margins (87, 89) is less than a seating angle, B, formed by the flat surfaces (94, 96). The top surface (12) includes a plurality of upward sloping radius blends (50, 52, 54, 56, 58, 60, 62, 64) extending between the substantially planar central portion (48) and a plurality of upward sloping rake faces (70, 72, 74, 76, 78, 80, 82, 84, 86, 88, 90, 92) extending between a respective radius blend and its respective cutting edge such that the rake face forms an angle, A, of between five and twenty-five degrees with respect to the central portion (48) of the top surface (12).

Owner:KENNAMETAL INC

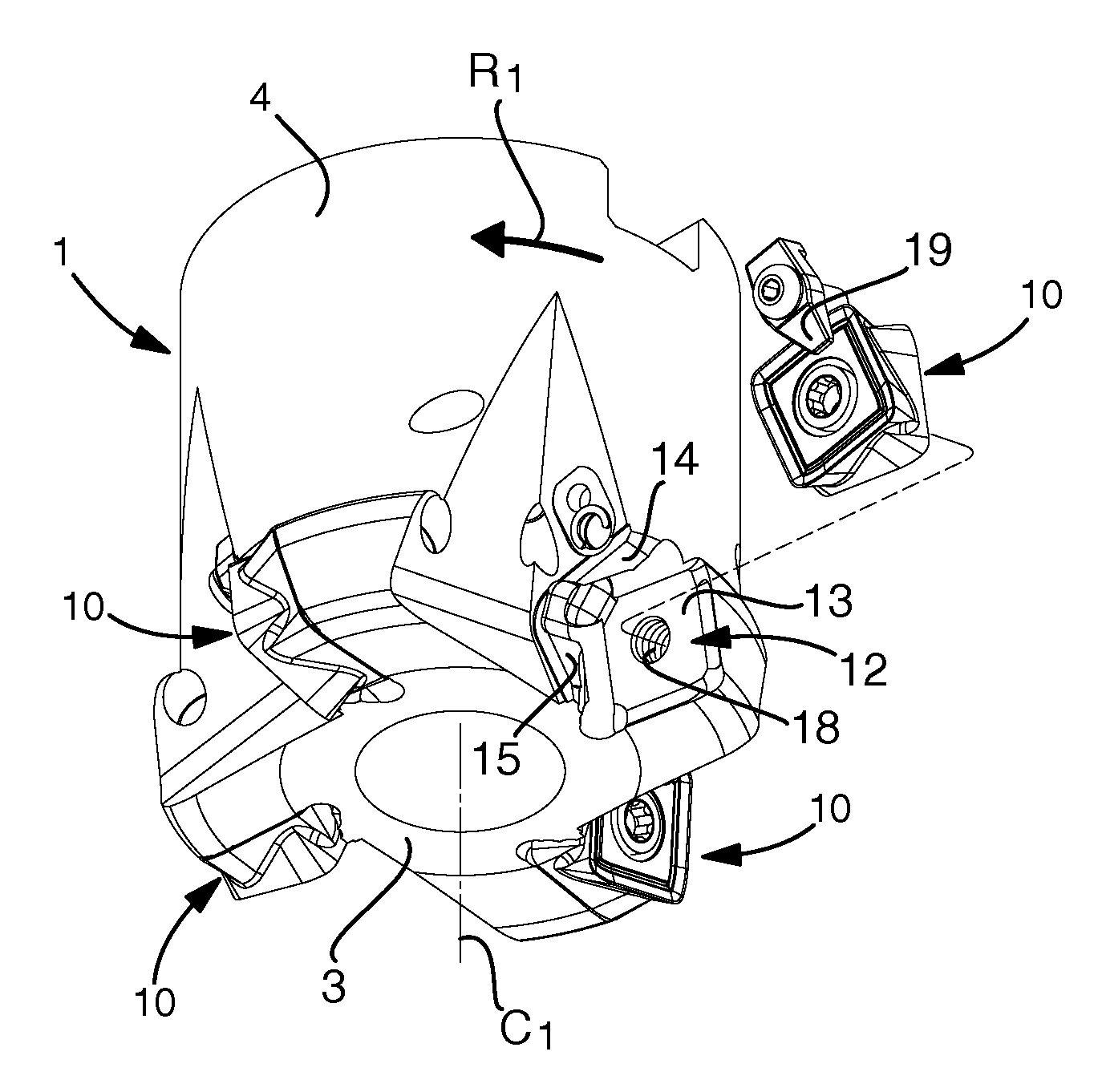

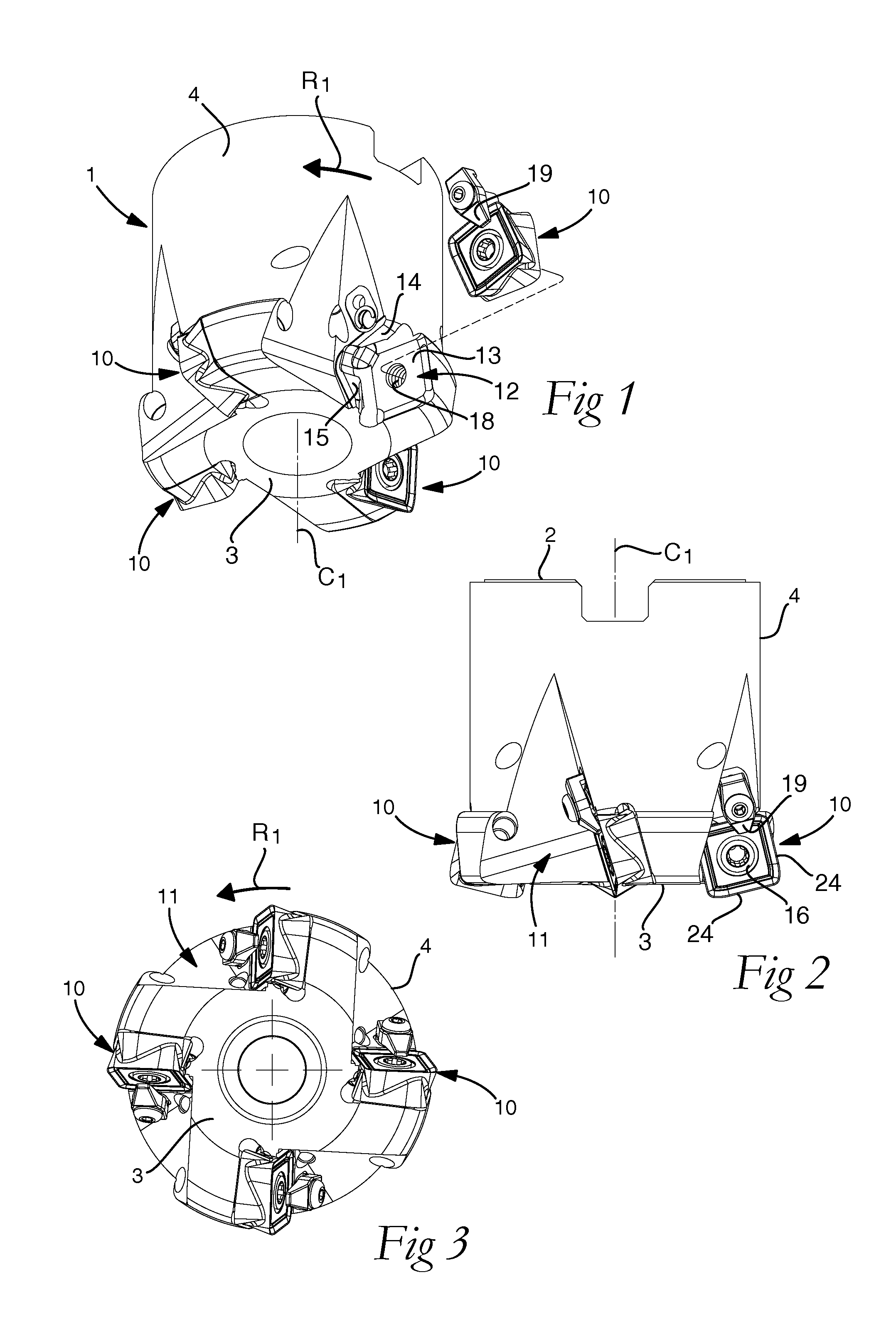

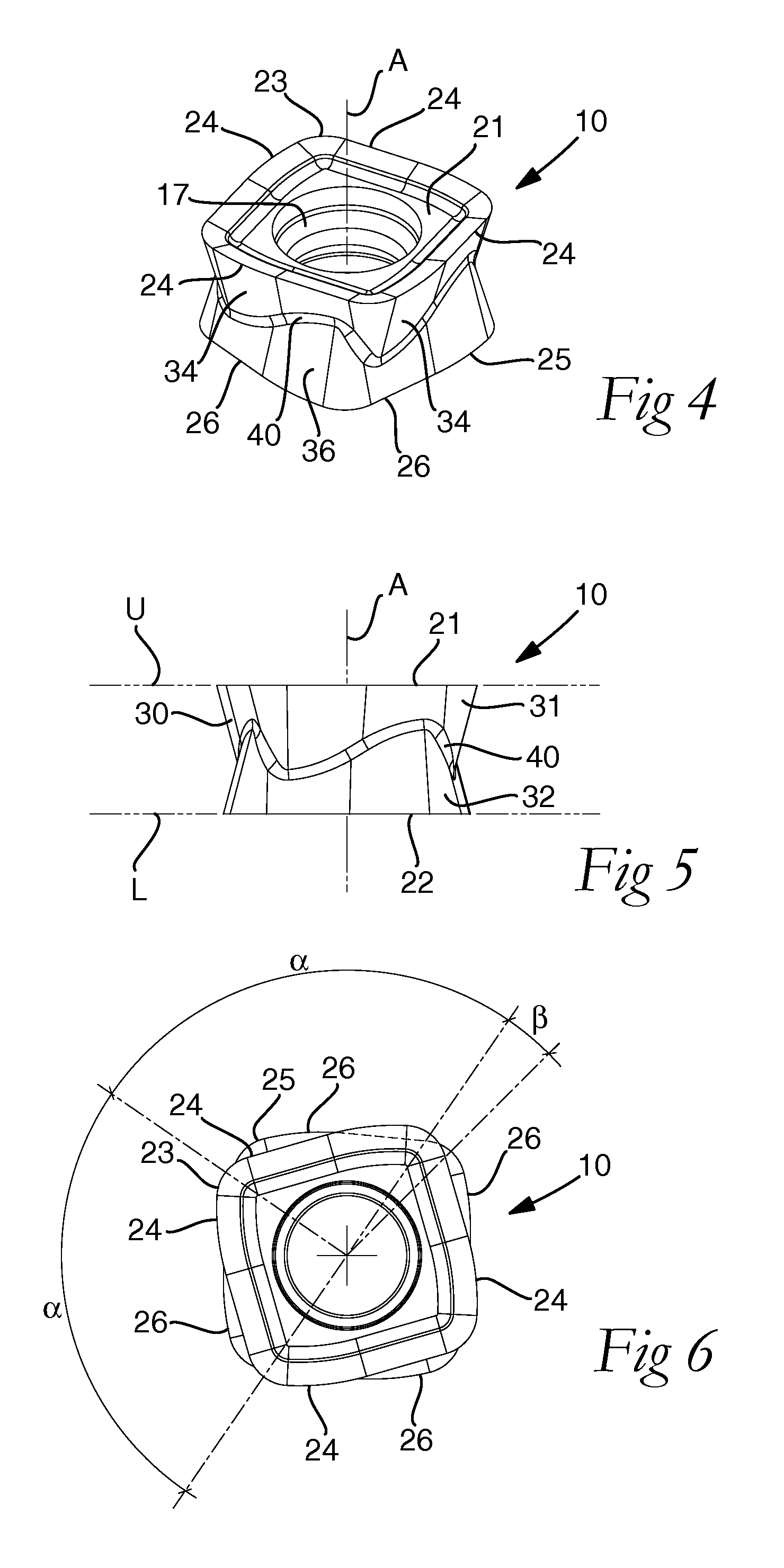

Cutting insert and a milling tool

A cutting insert for face milling and ramping includes an upper side defining an upper extension plane, a lower side defining a lower extension plane parallel with the upper extension plane, and an edge side extending around the cutting insert. A centre axis extends perpendicularly through the upper and lower extension planes. An upper cutting edge forms four upper cutting edge portions having an identical length corresponding to a determined angle with respect to the centre axis. A lower cutting edge forms four lower cutting edge portions (26), having an identical length corresponding to the determined angle with respect to the centre axis. Each upper cutting edge portion is displaced angularly with respect to the centre axis in relation to one of the lower cutting edge portions with a displacement angle being greater than zero and less than the determined angle.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

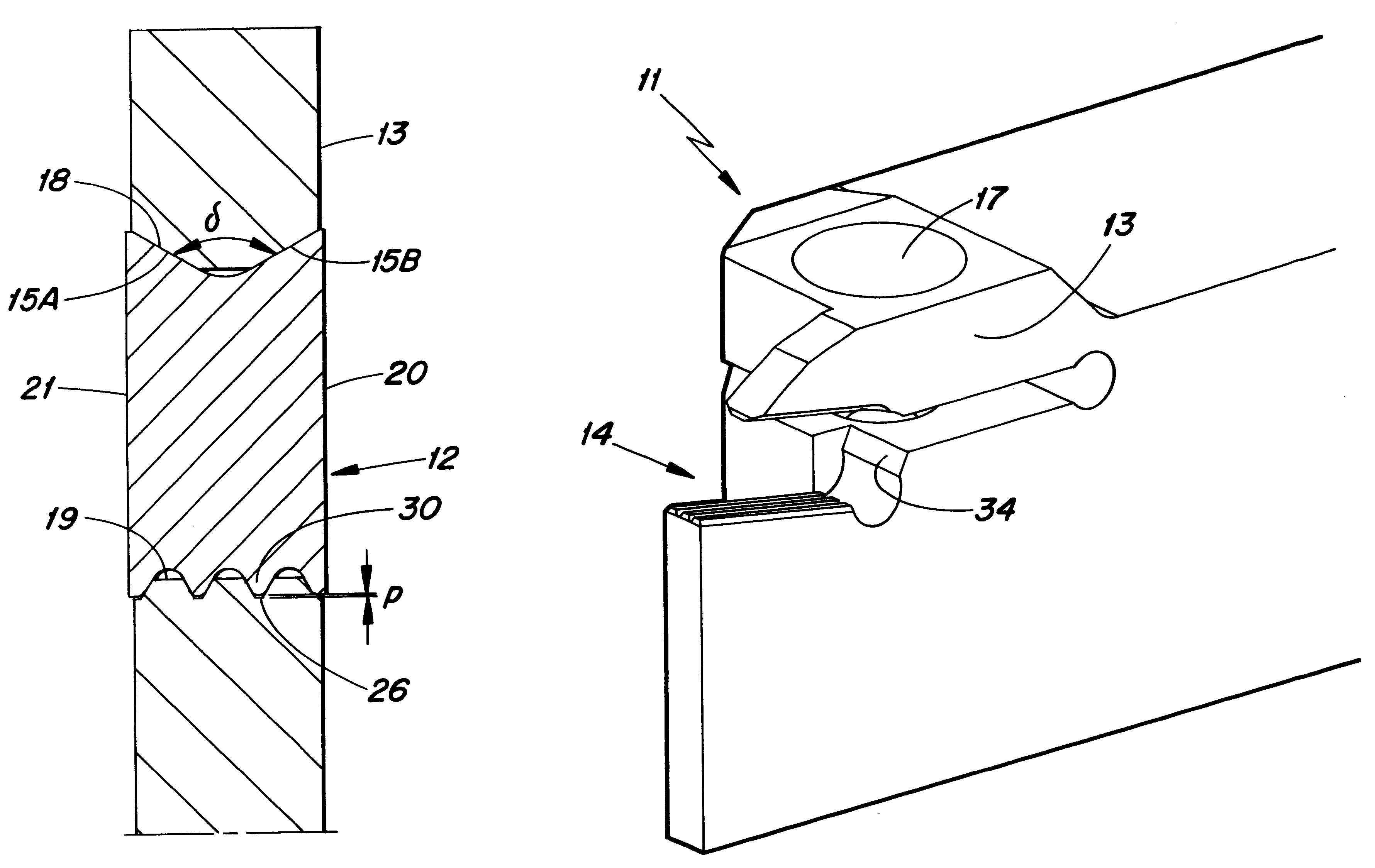

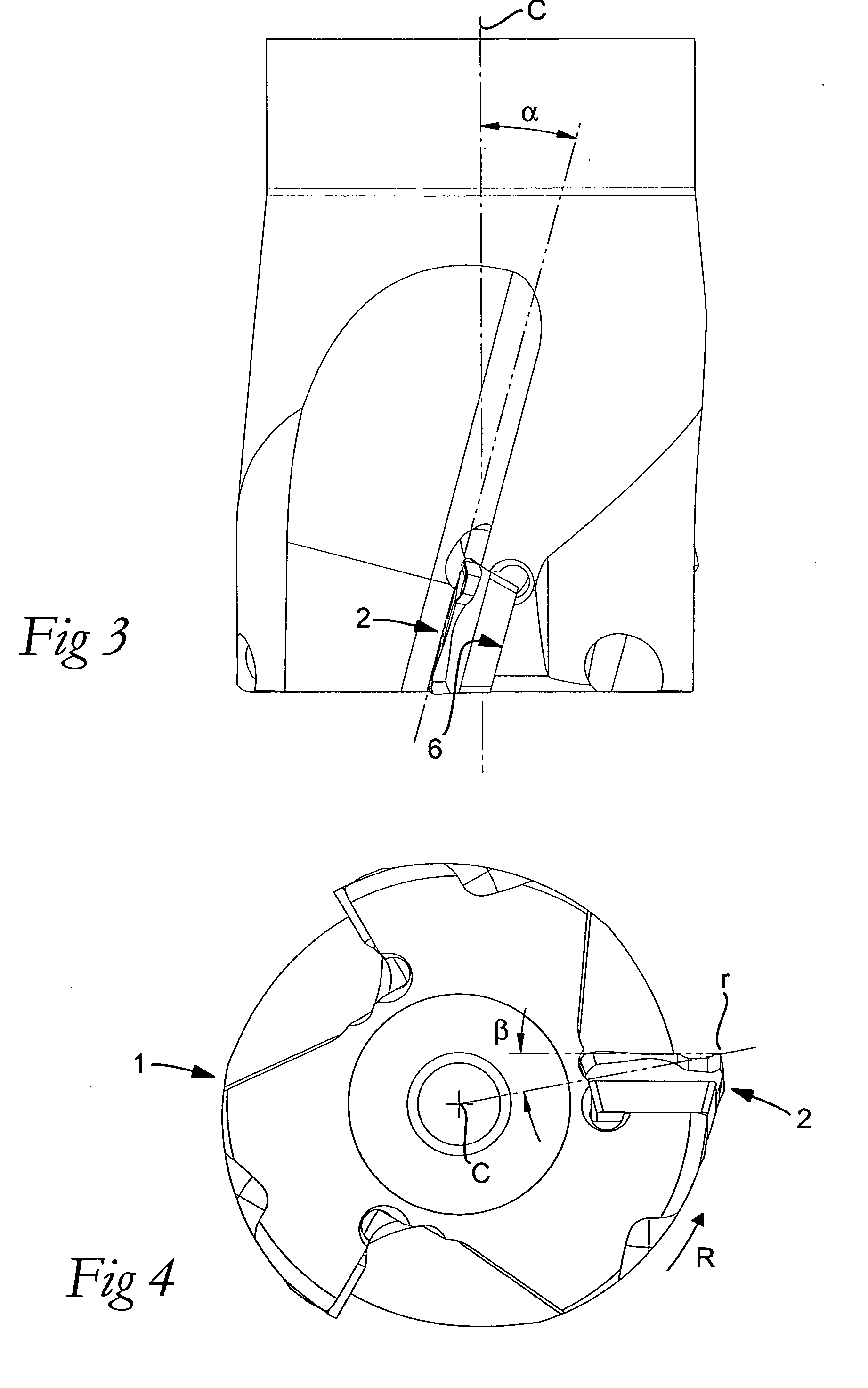

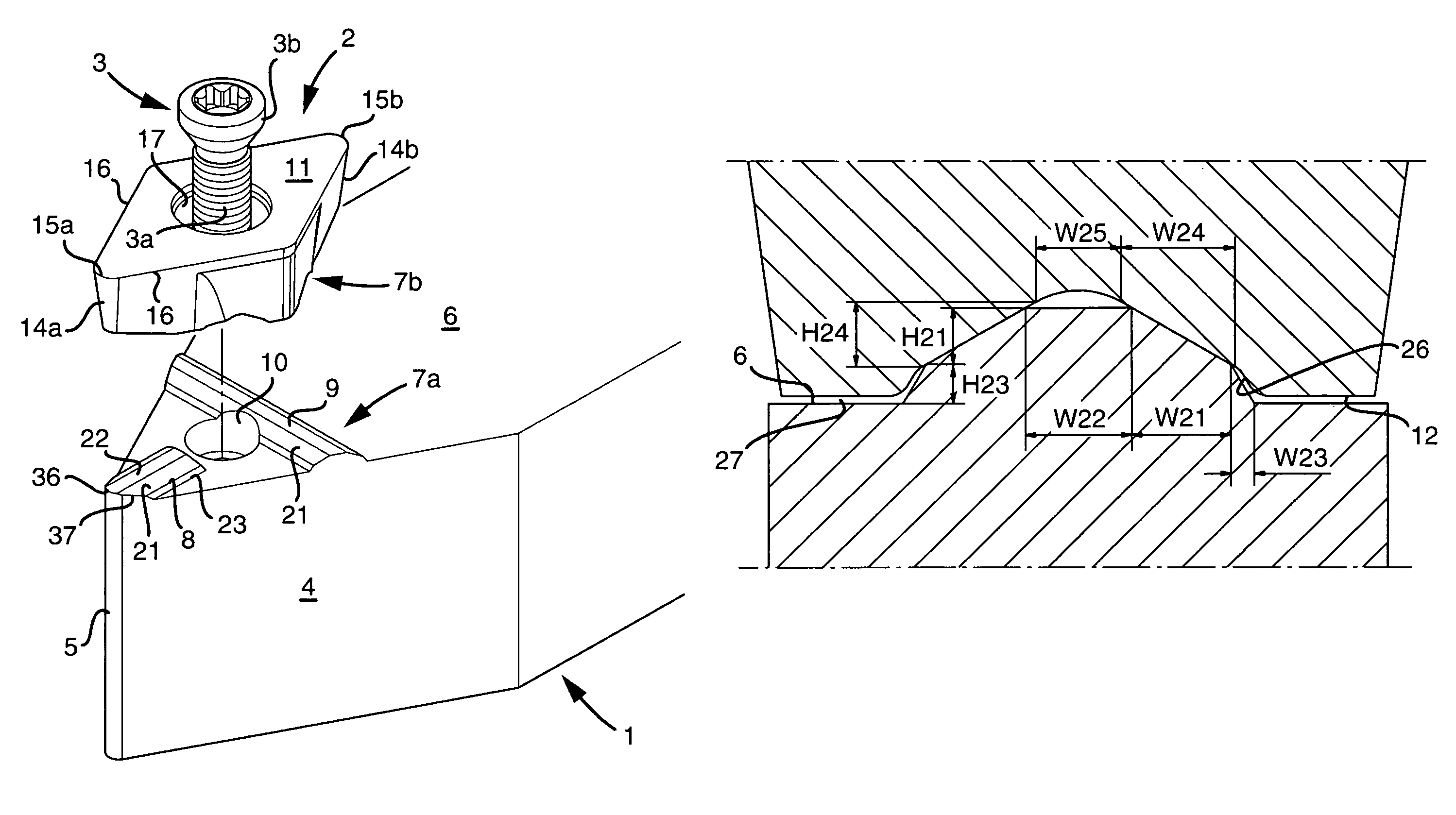

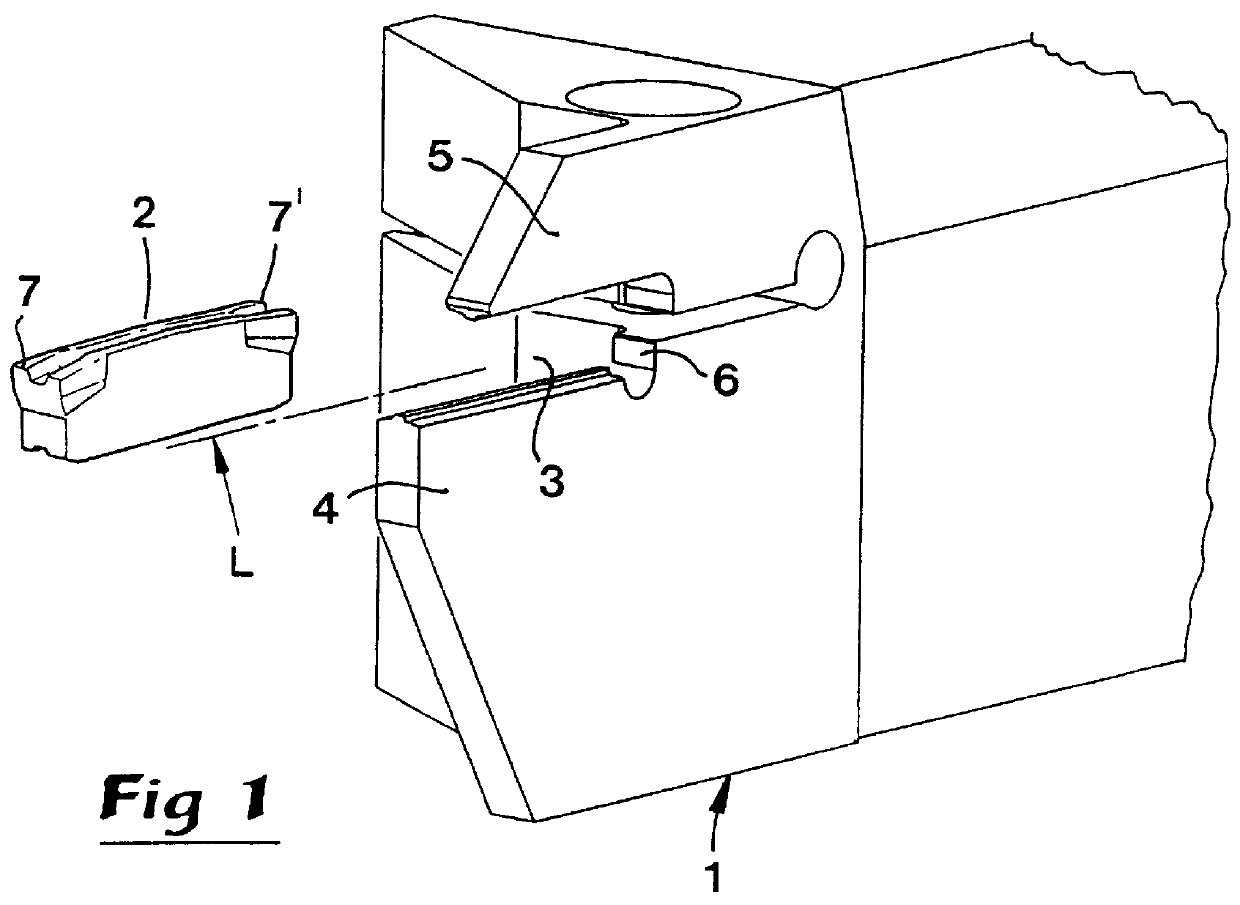

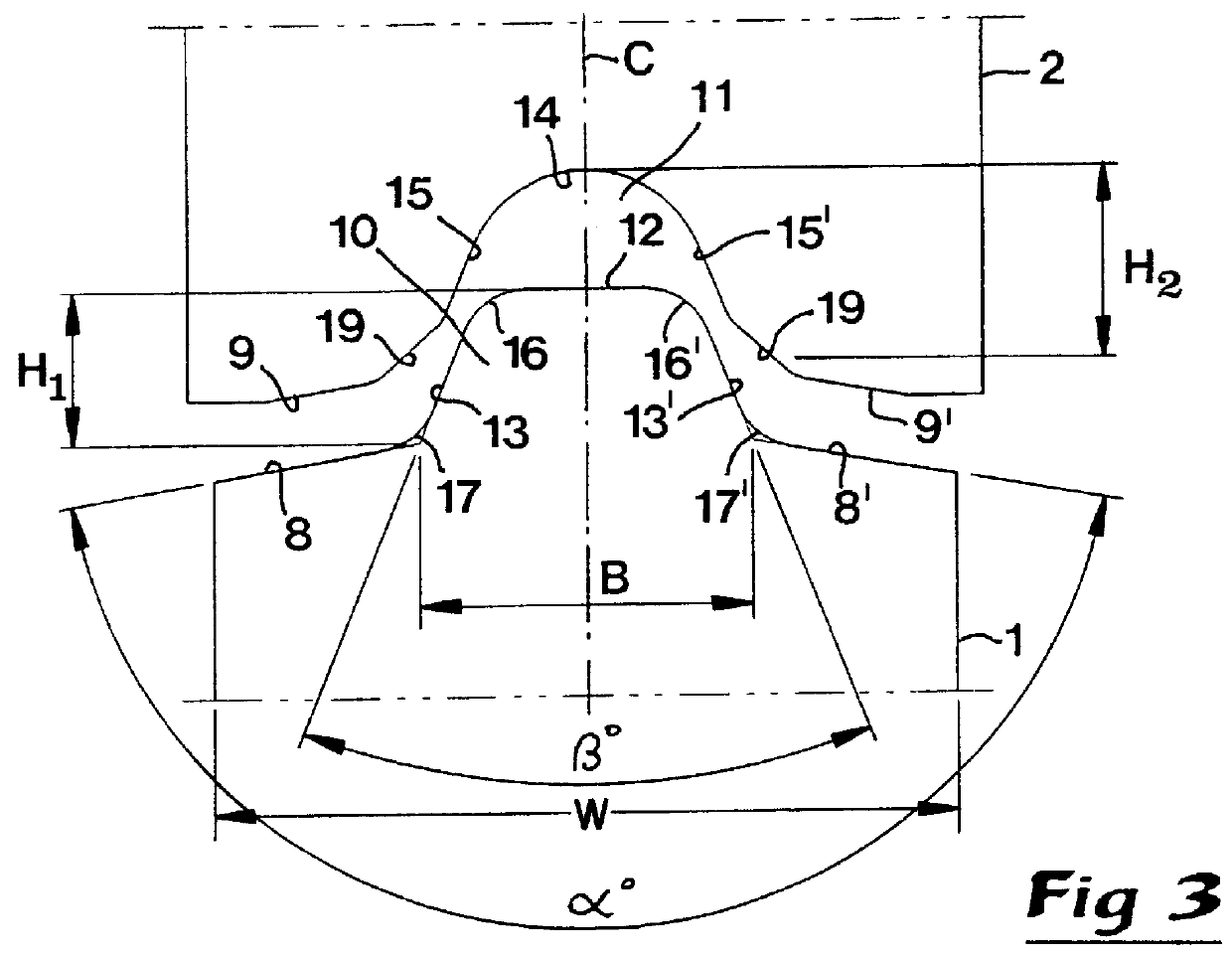

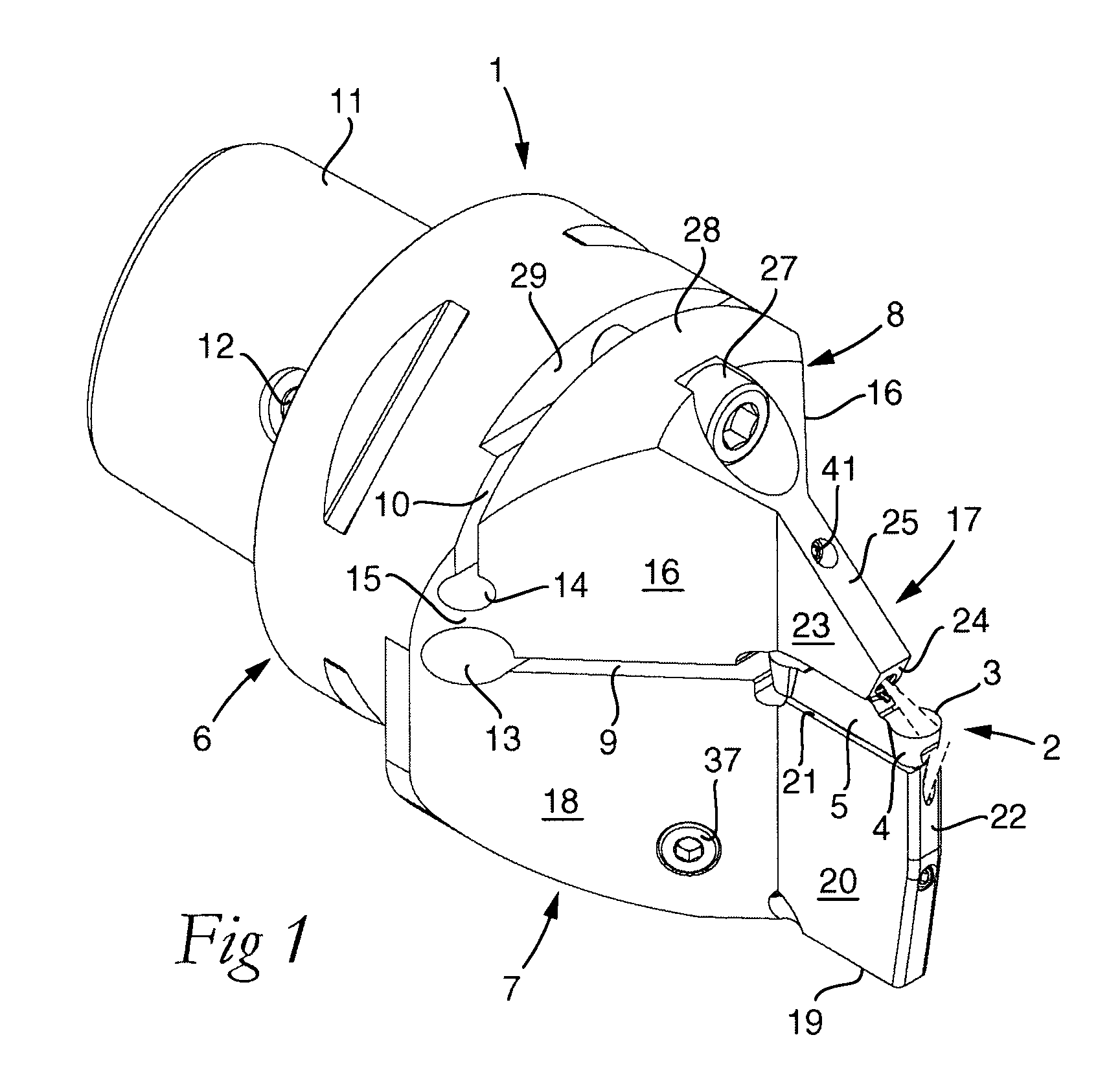

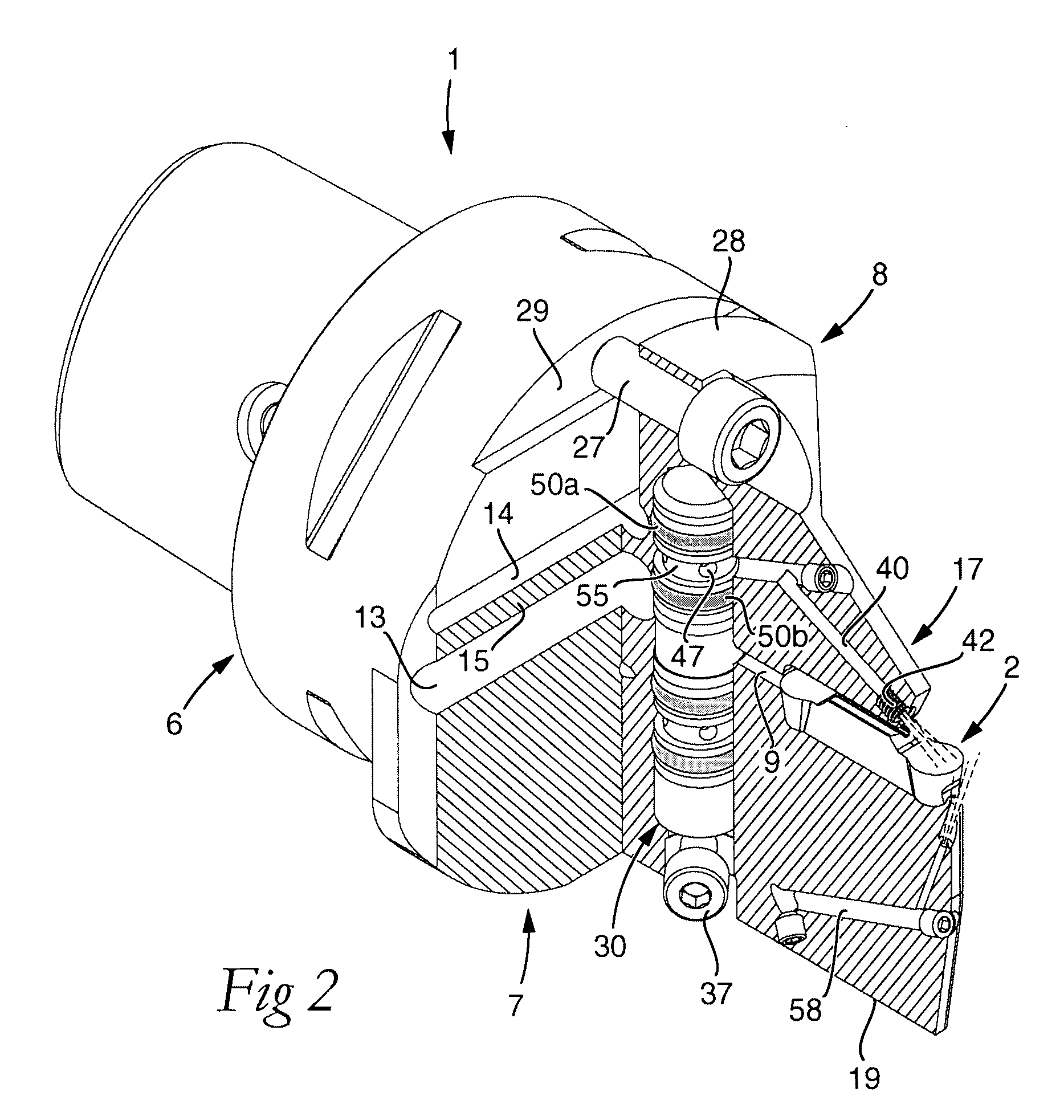

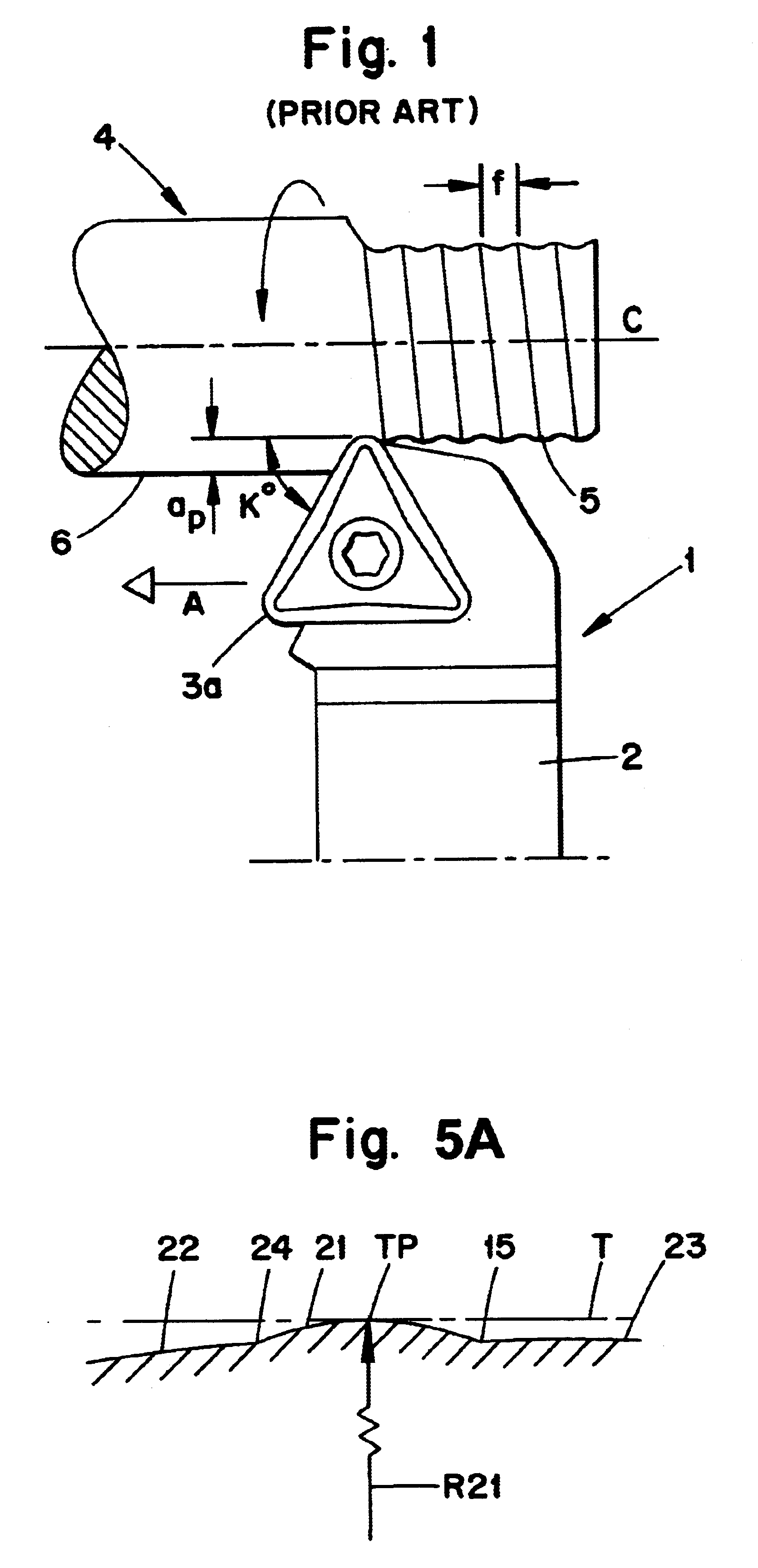

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

Cutting insert for chip removing machining

InactiveUS6715967B2Risk minimizationHigh surface finishCutting insertsTurning toolsEngineeringMachining

A cutting insert, intended for chip removing machining includes a cutting geometry surface having a cutting edge from which extends a primary chamfer that transforms into a chip removing surface. The chip removing surface is inclined in a inwards / downwards direction in order to permit sinking of a chip being formed, and transforms into a deflection surface arranged to initiate deflection of the chip from the cutting insert. The angle of inclination of the chip removing surface does not exceed 18°. The level difference in elevation between the primary chamfer and the chip deflection surface amounts to maximally 0.20 mm.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

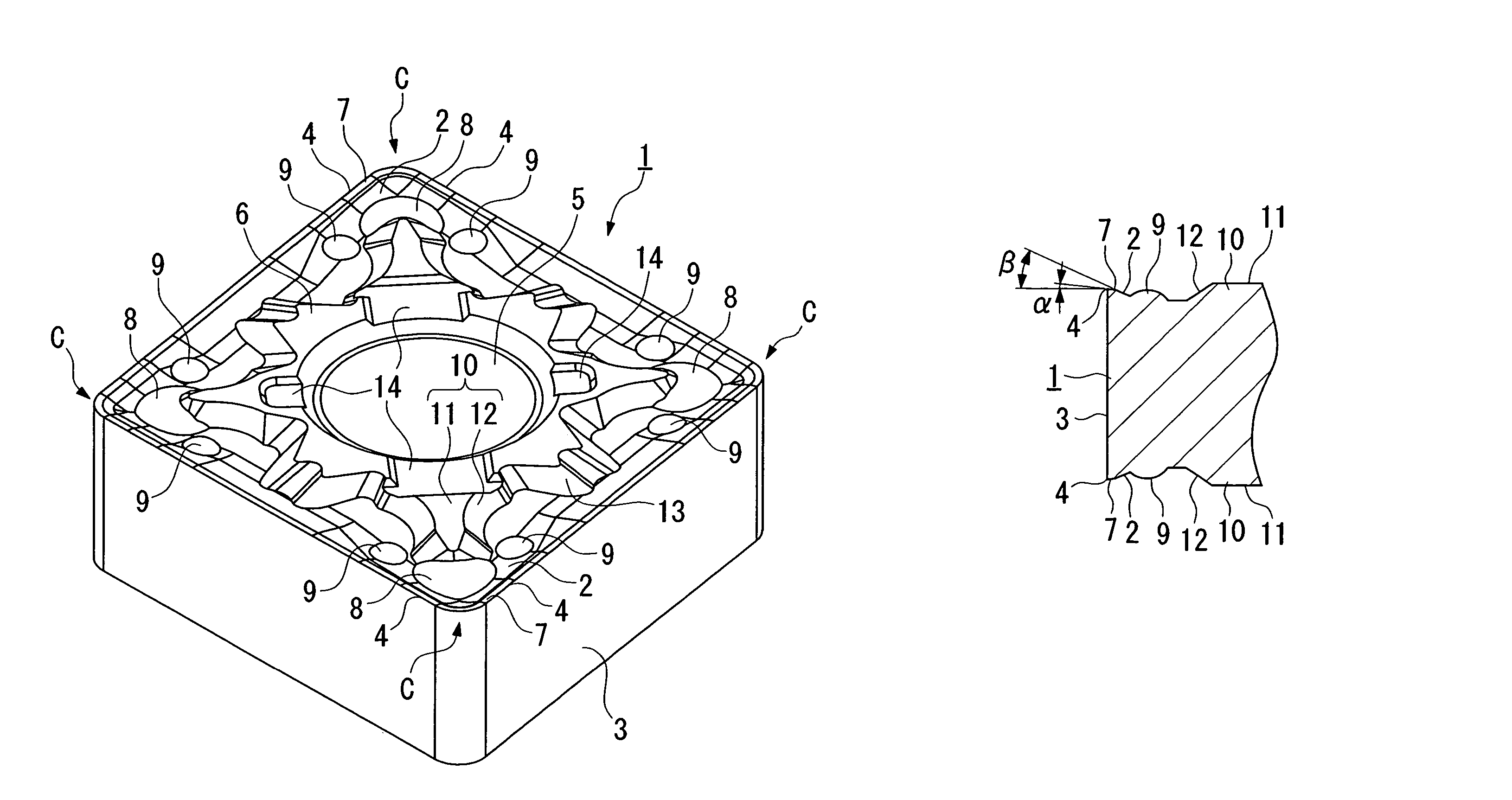

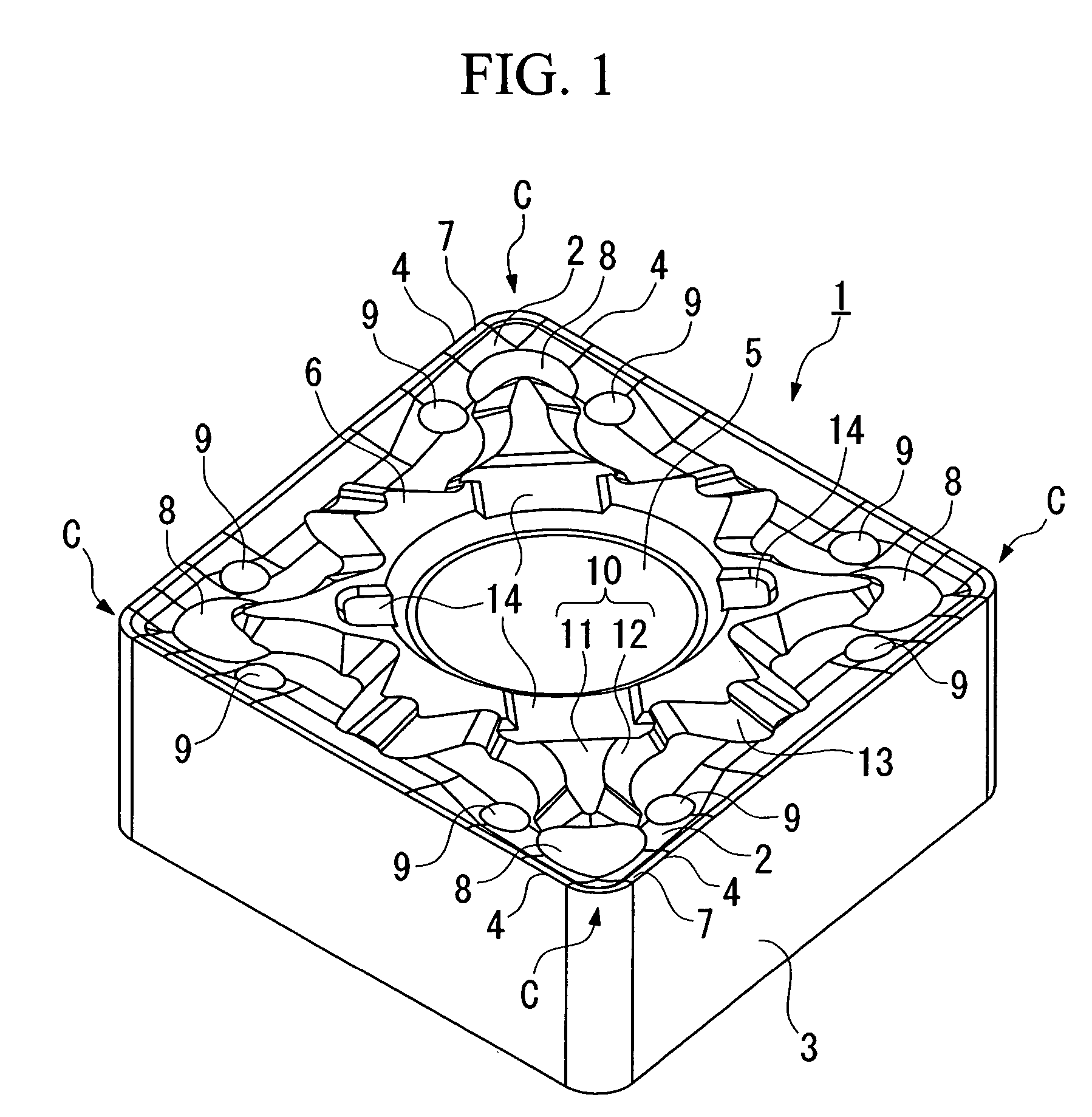

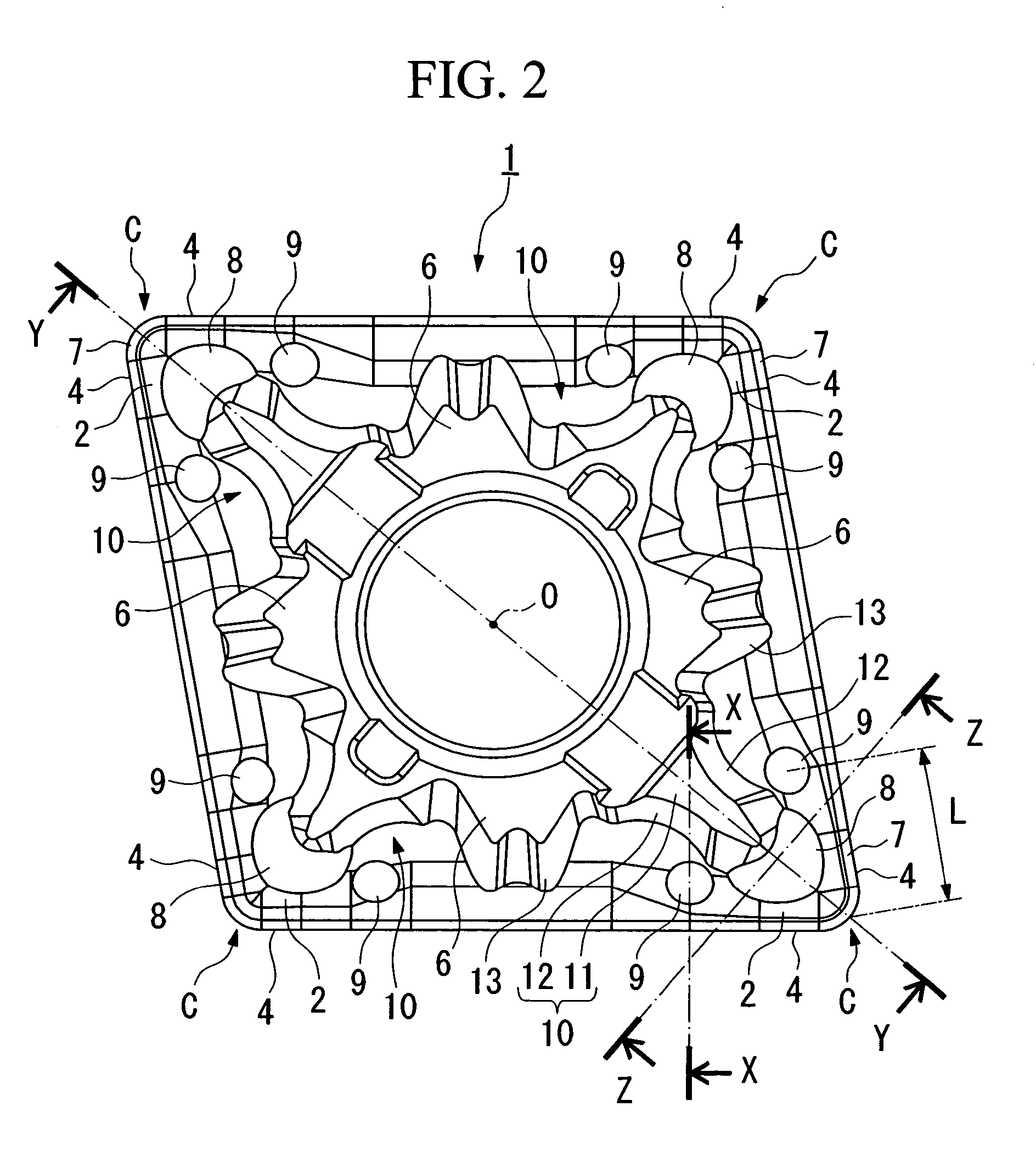

Throwaway tip

InactiveUS20050019111A1Reliable processing can be inhibitedSolve the broken effect is not goodCutting insertsTurning toolsConvex sideEngineering

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

Indexable insert

InactiveUS7182555B2Easily brokenReadily broken and processedCutting insertsTurning toolsEngineeringKnife blades

An object of the invention is to reliably control chip, particularly that produced in profiling. To achieve this, rake faces are formed on polygon faces of an insert in the form of a polygonal plate shape, and a pair of cutting edges extending respectively from corner parts of the polygon faces are formed on a ridge part of the polygon faces, and each of the rake faces is gradually inclined as it becomes farther away from the cutting edge, and a land formed along the cutting edge, is inclined so that it gradually sinks as it become farther away from the cutting edge at an angle of inclination smaller than a rake angle, and angles of inclination of these rake face and land are made smaller in the direction to separate from a tip of the corner part along the cutting edge, and a main convex being a convex spherical face shape is formed at intervals between the cutting edges, on the corner part C, and at least one pair of sub convexes being a convex spherical face shape is also formed respectively at positions away from this main convex, along the pair of cutting edges.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com