Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

987results about "Lathes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

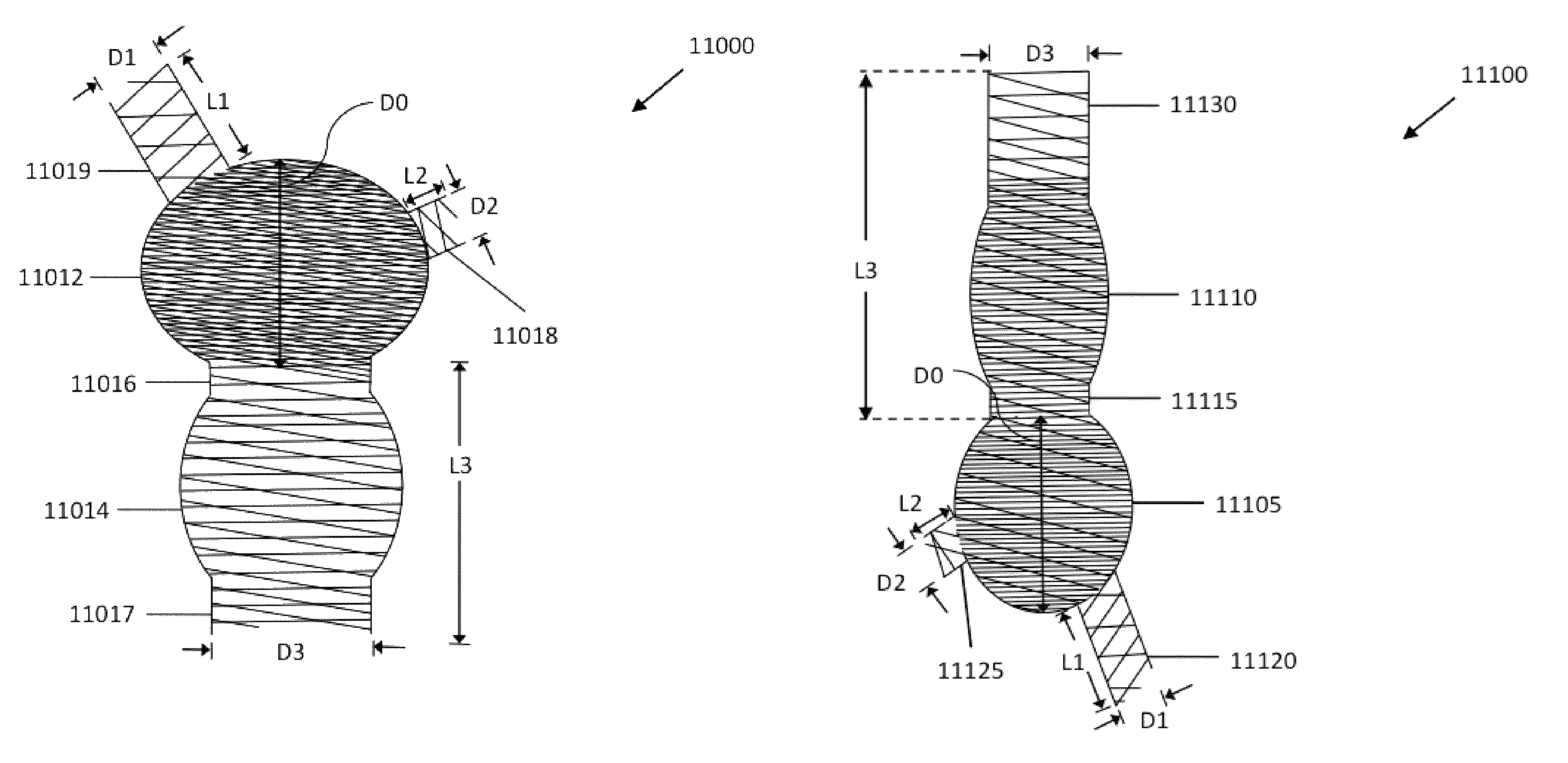

Flow diverting devices

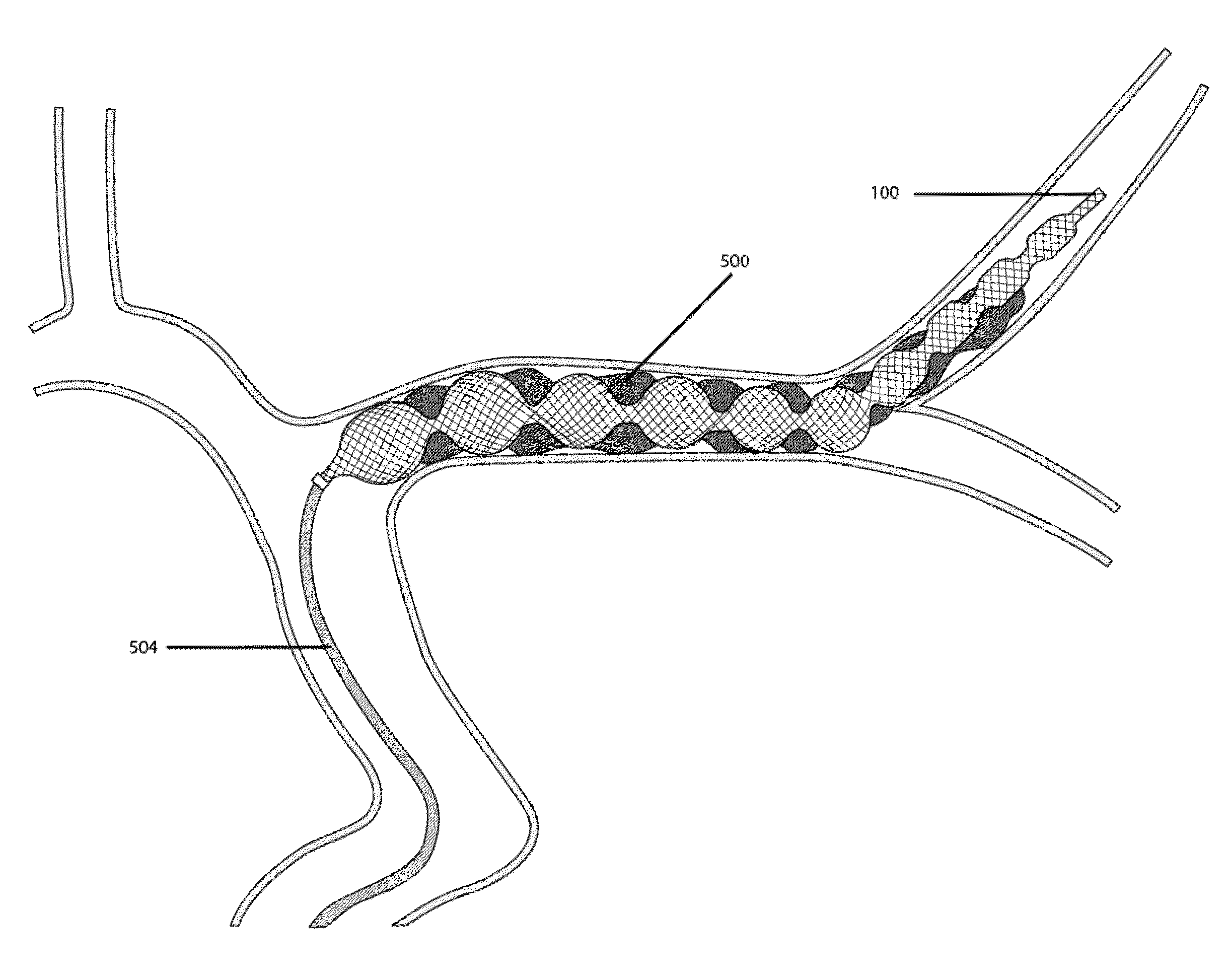

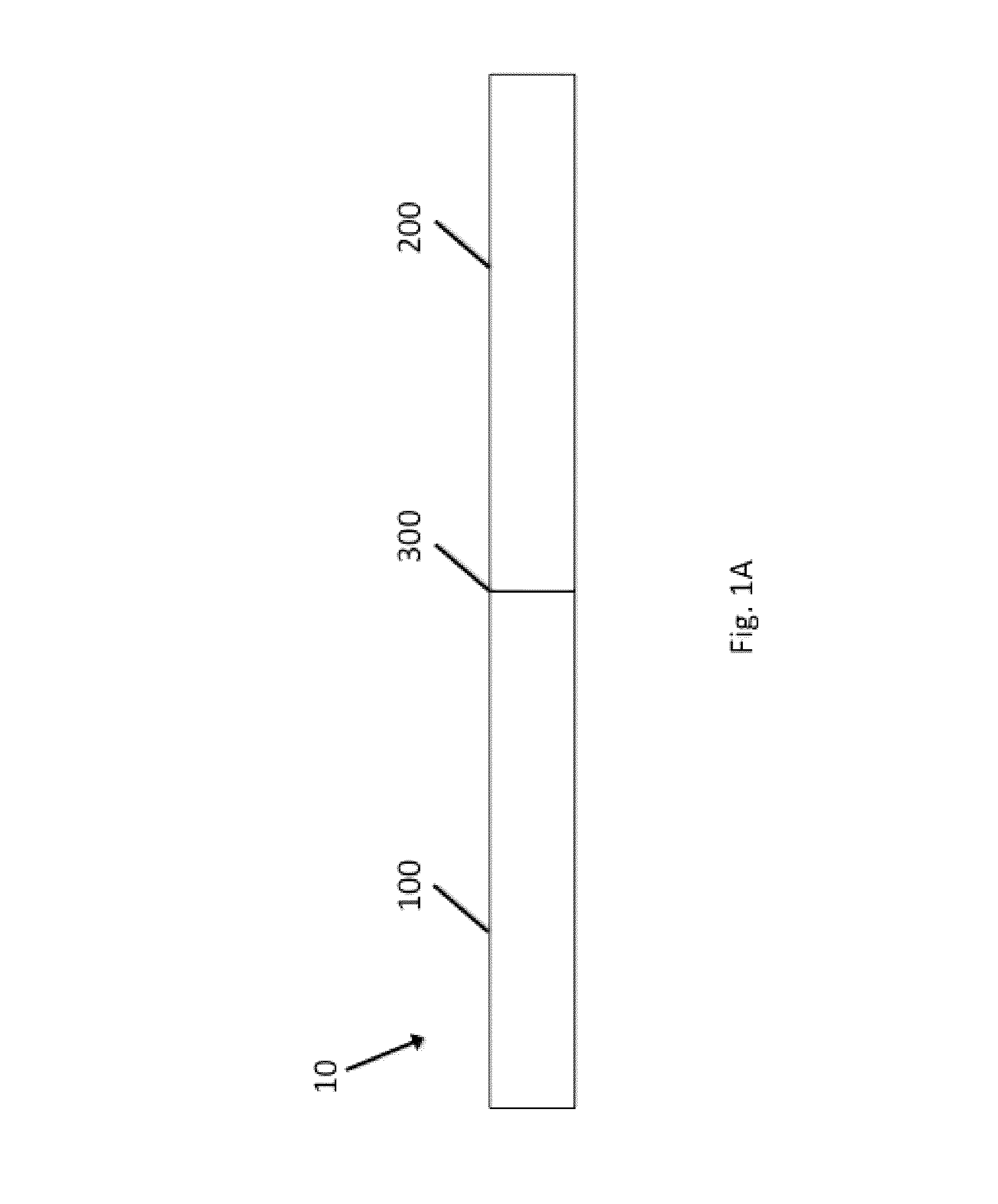

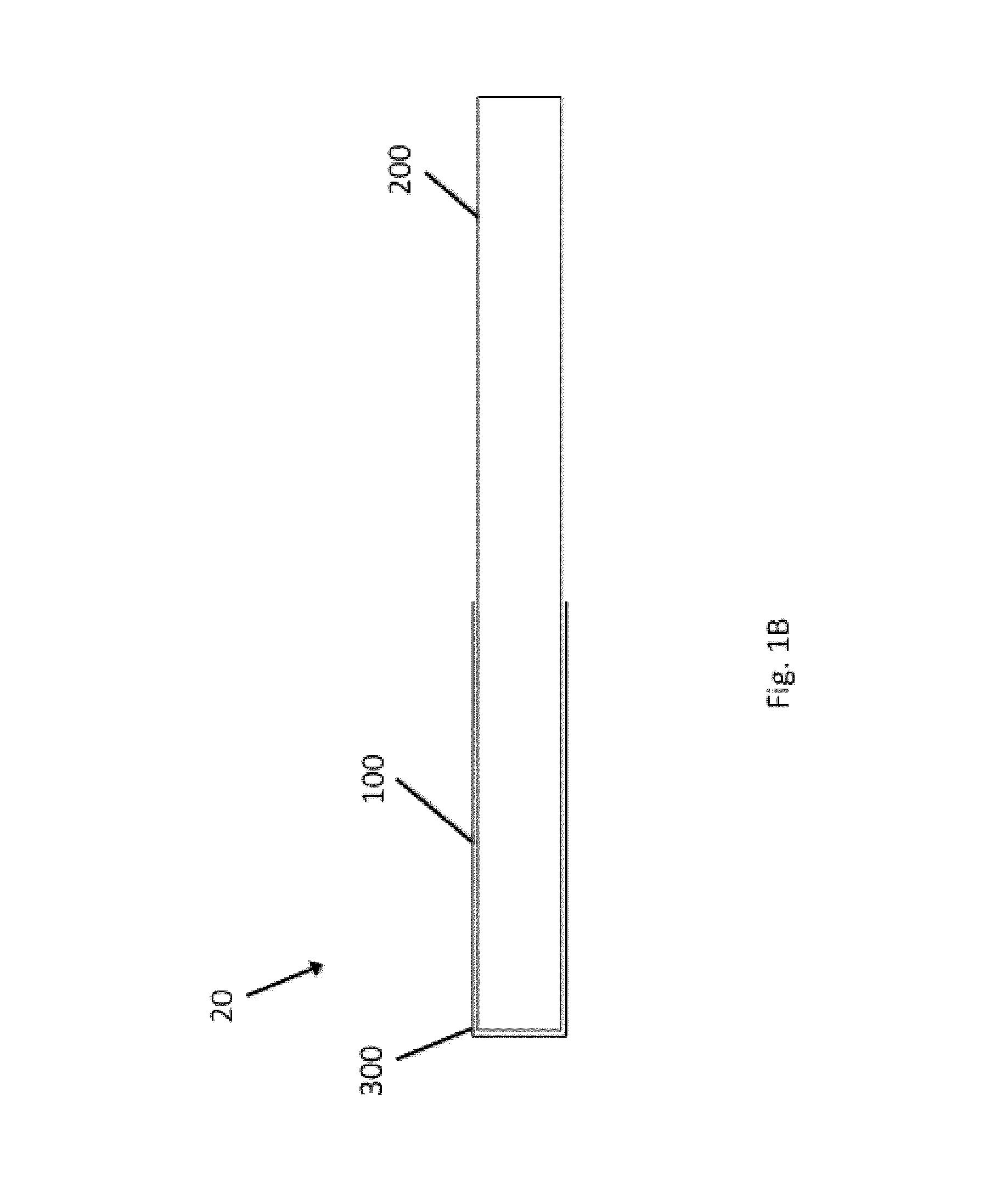

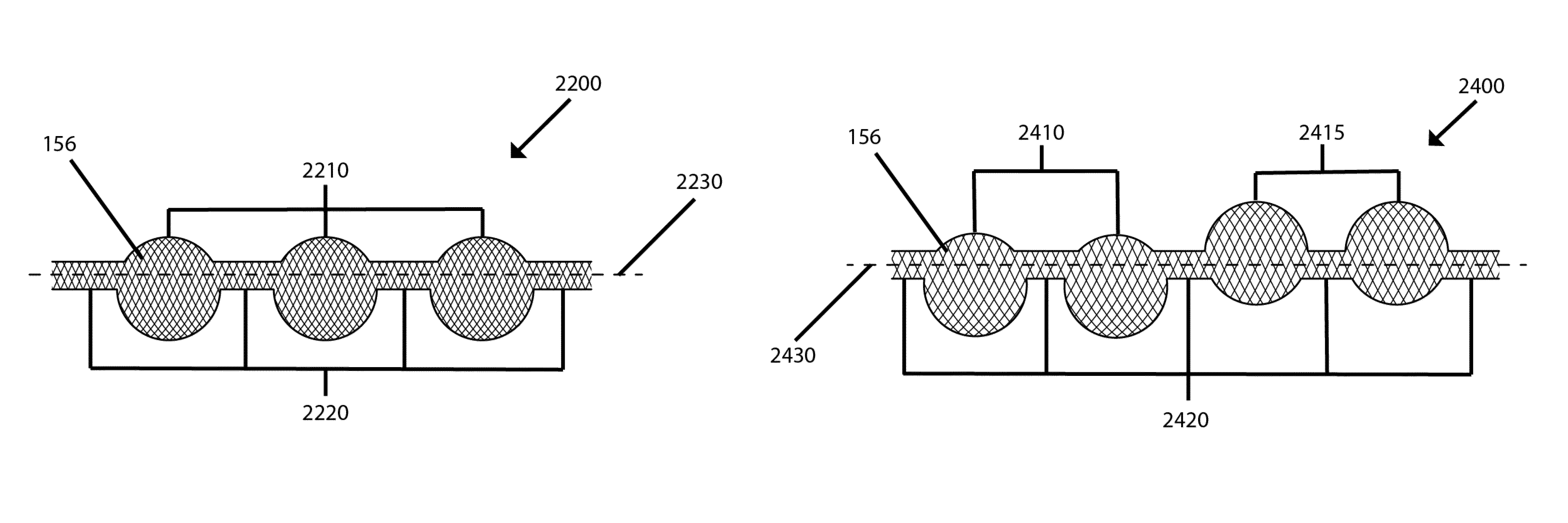

ActiveUS8715317B1Effectively and efficiently capturingIncrease awarenessLathesOrnamental textile articlesLaser cuttingBlood vessel

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measureable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

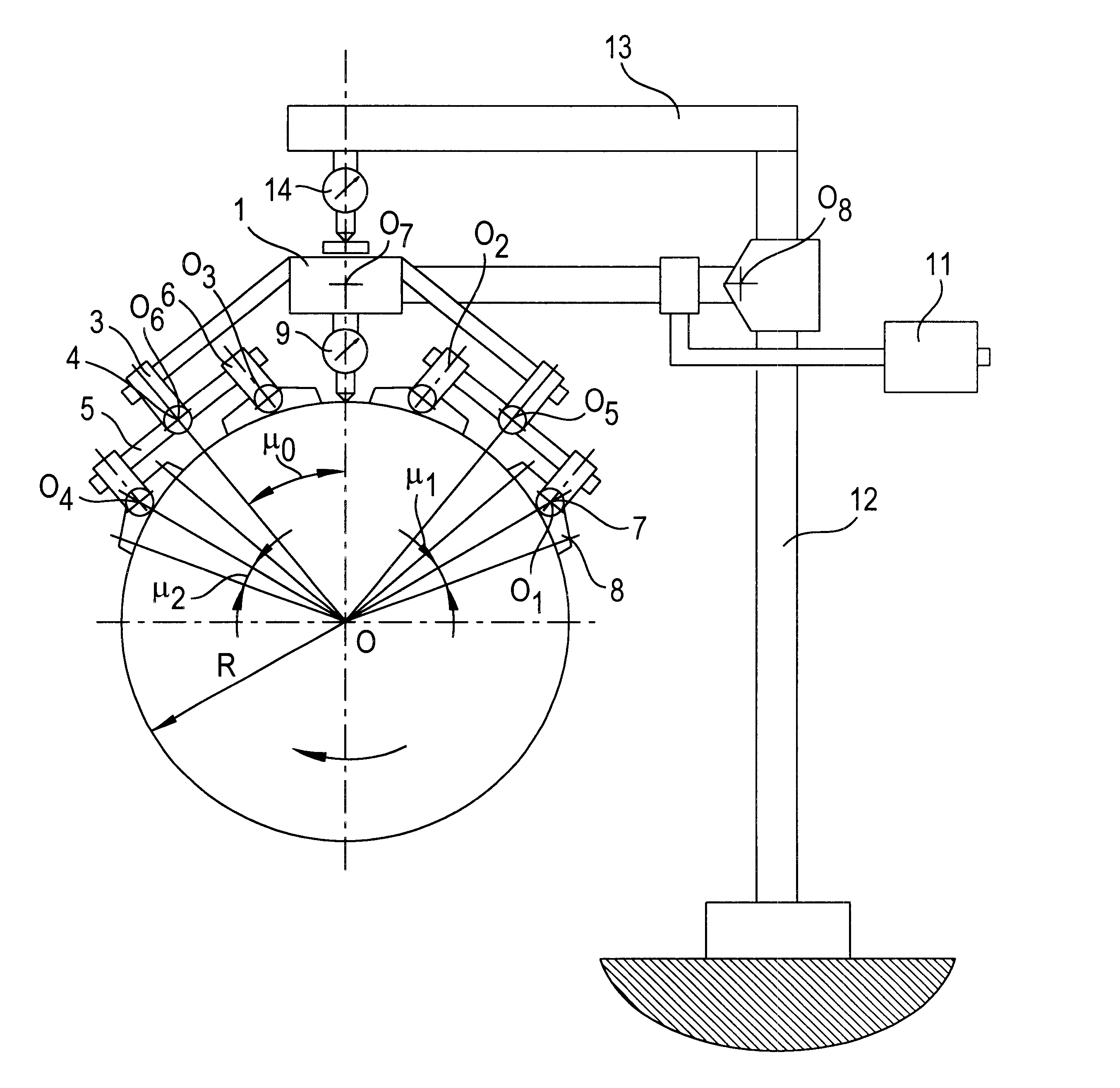

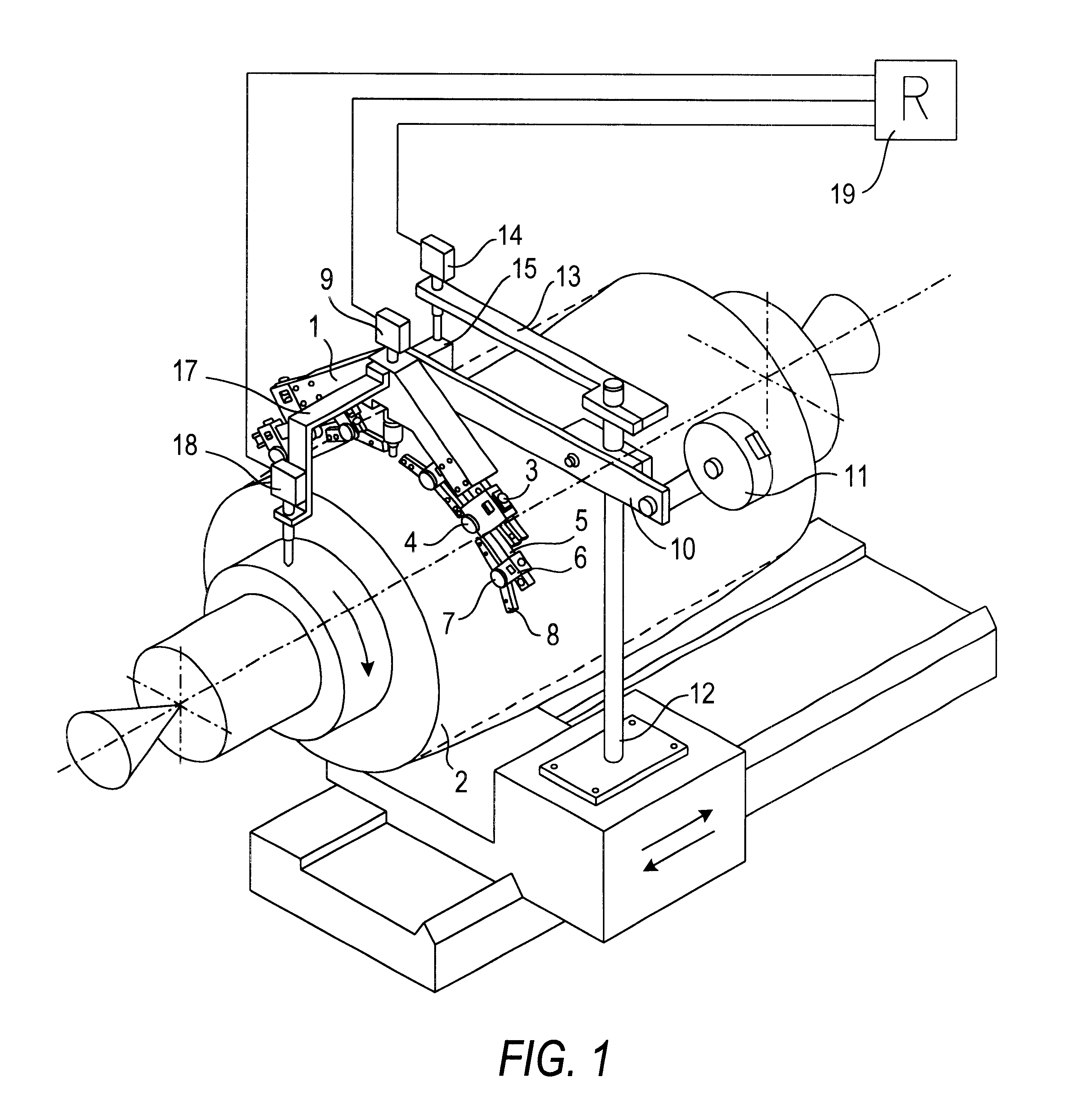

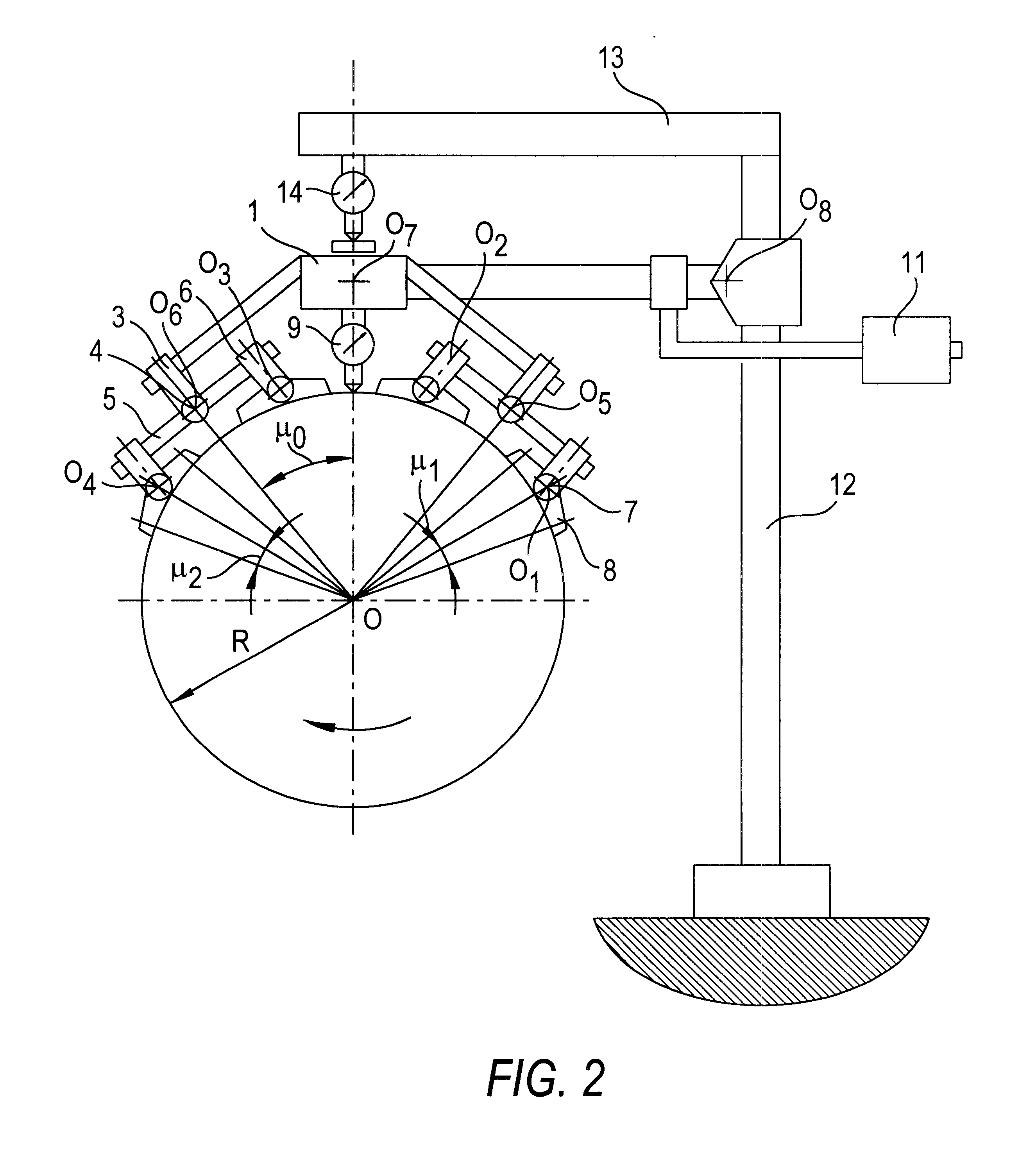

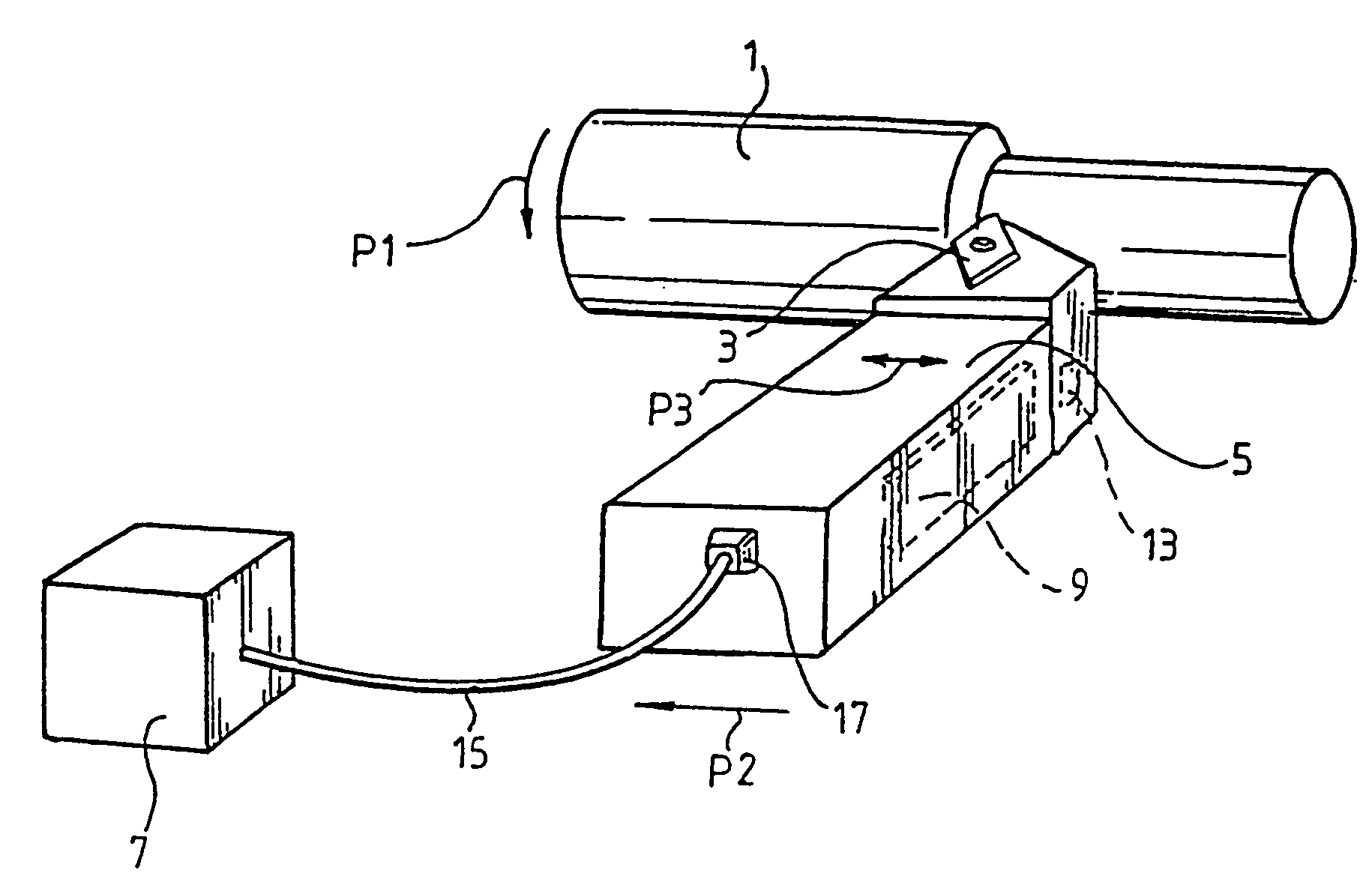

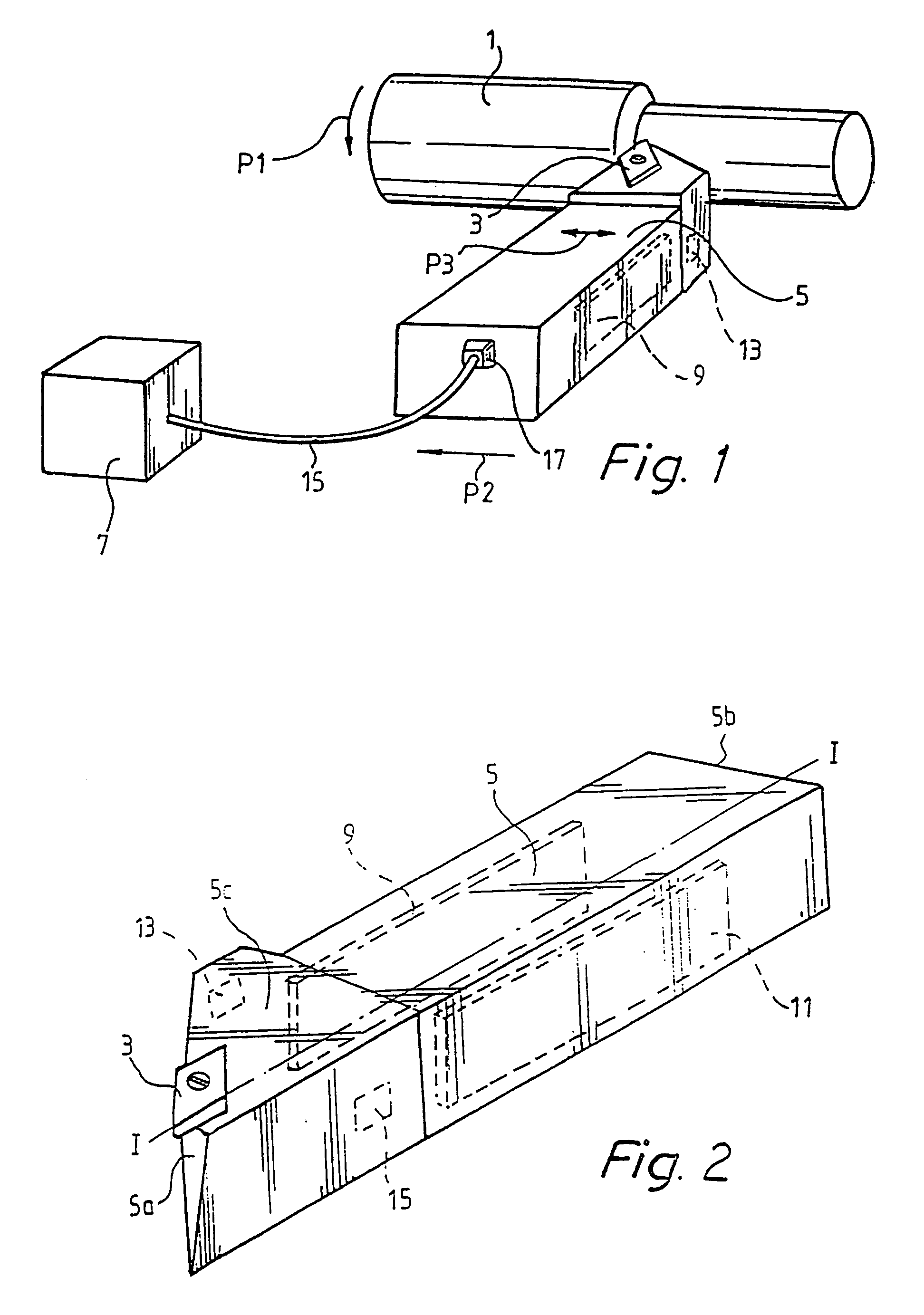

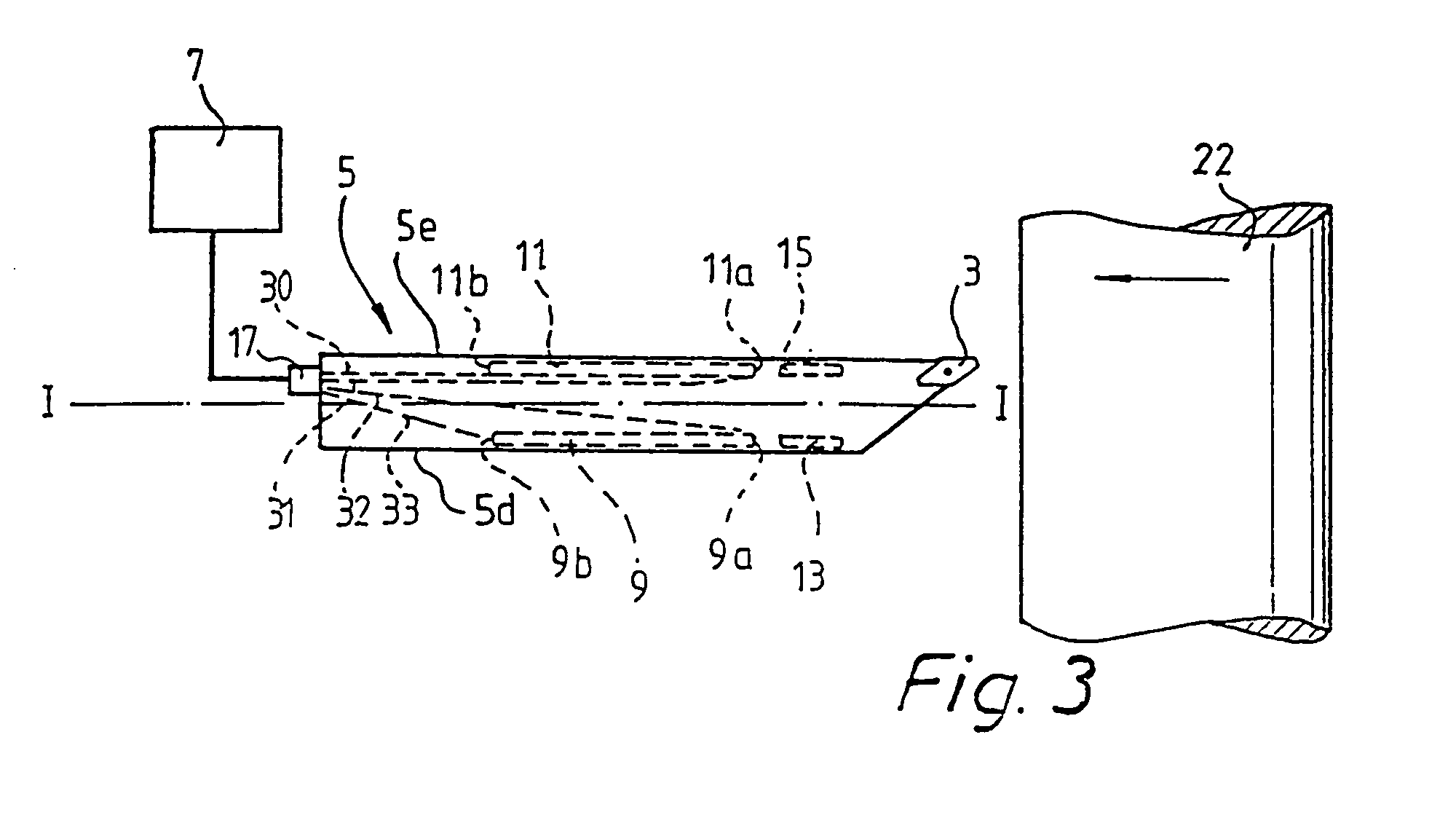

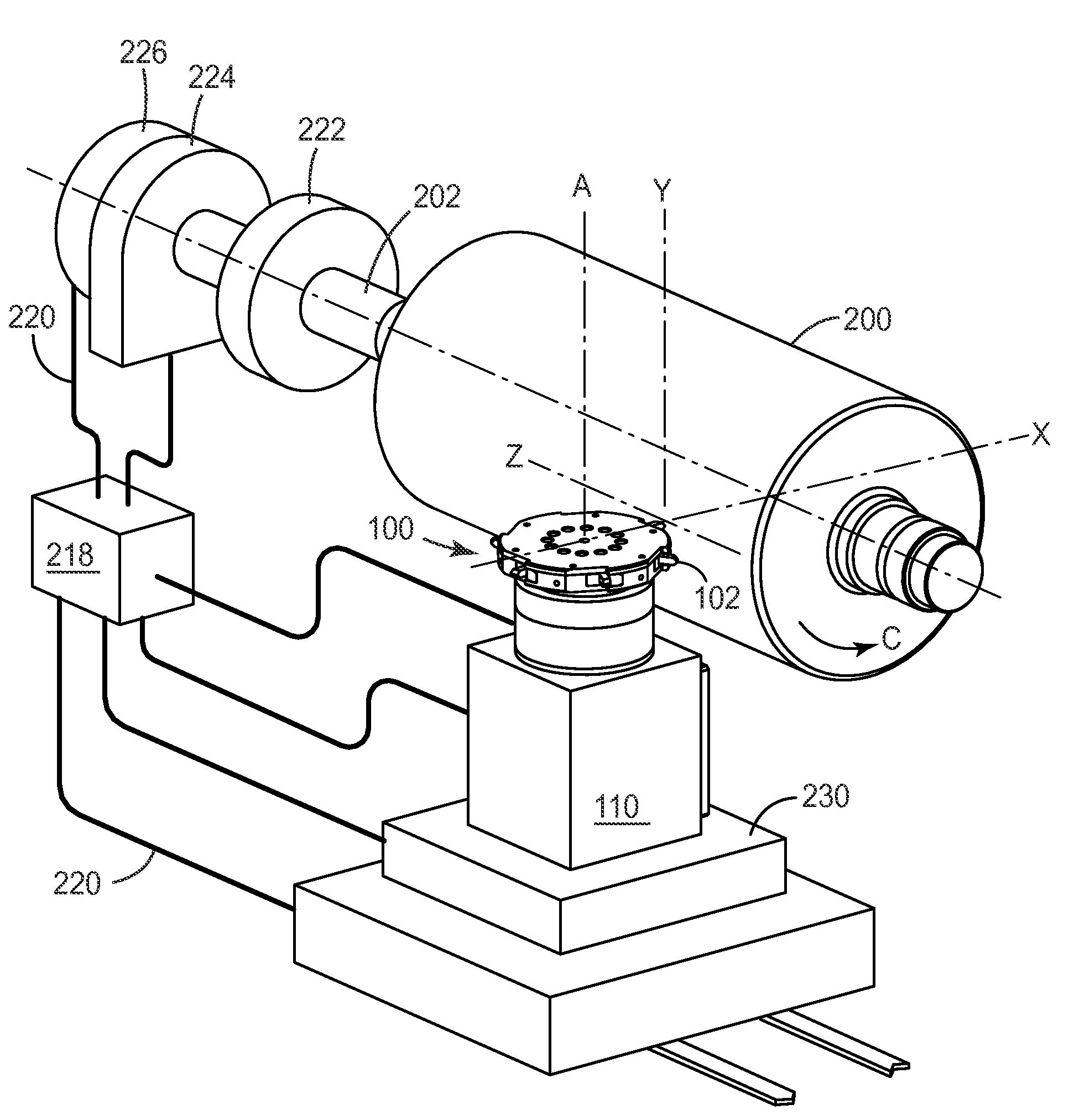

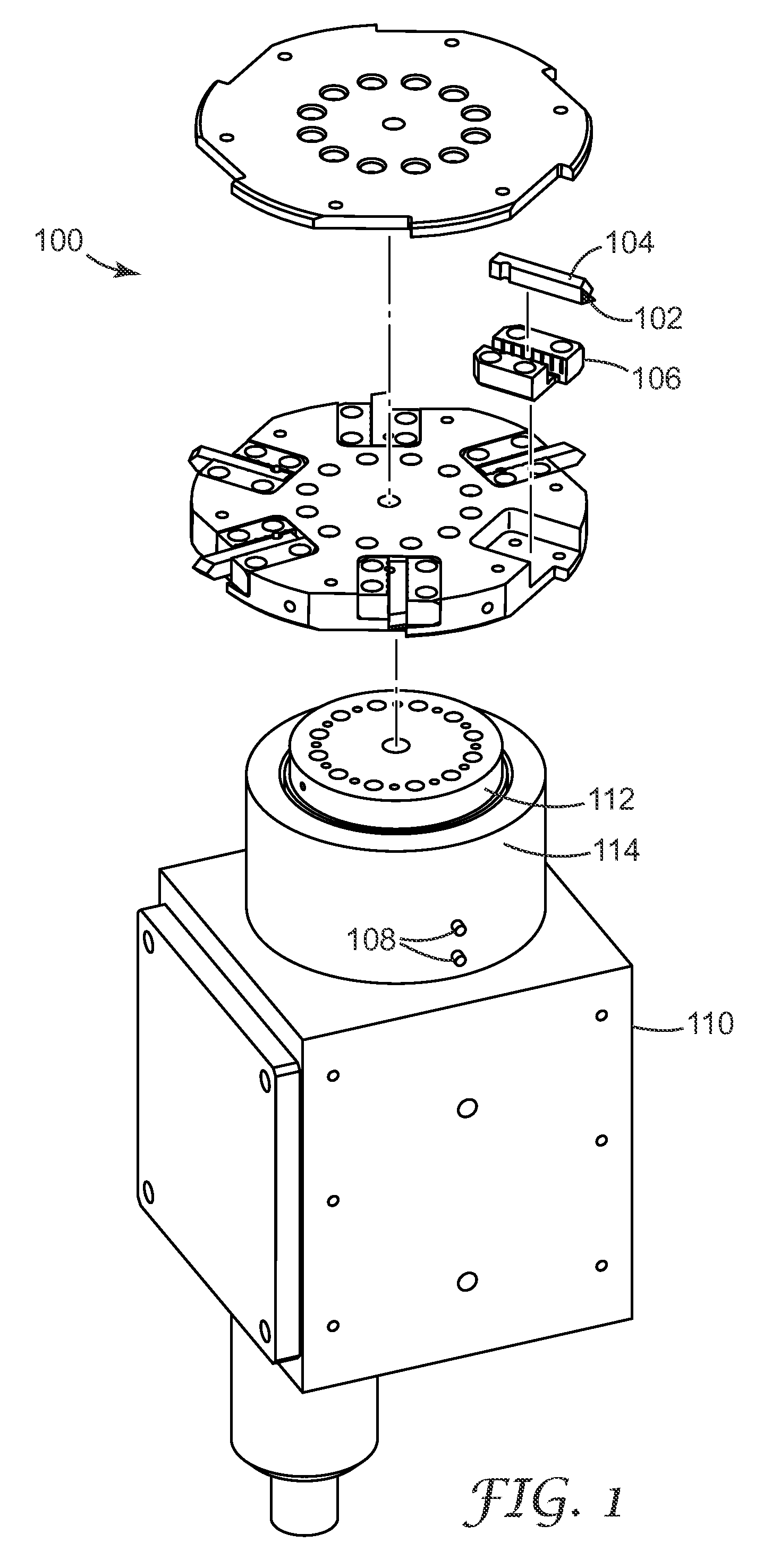

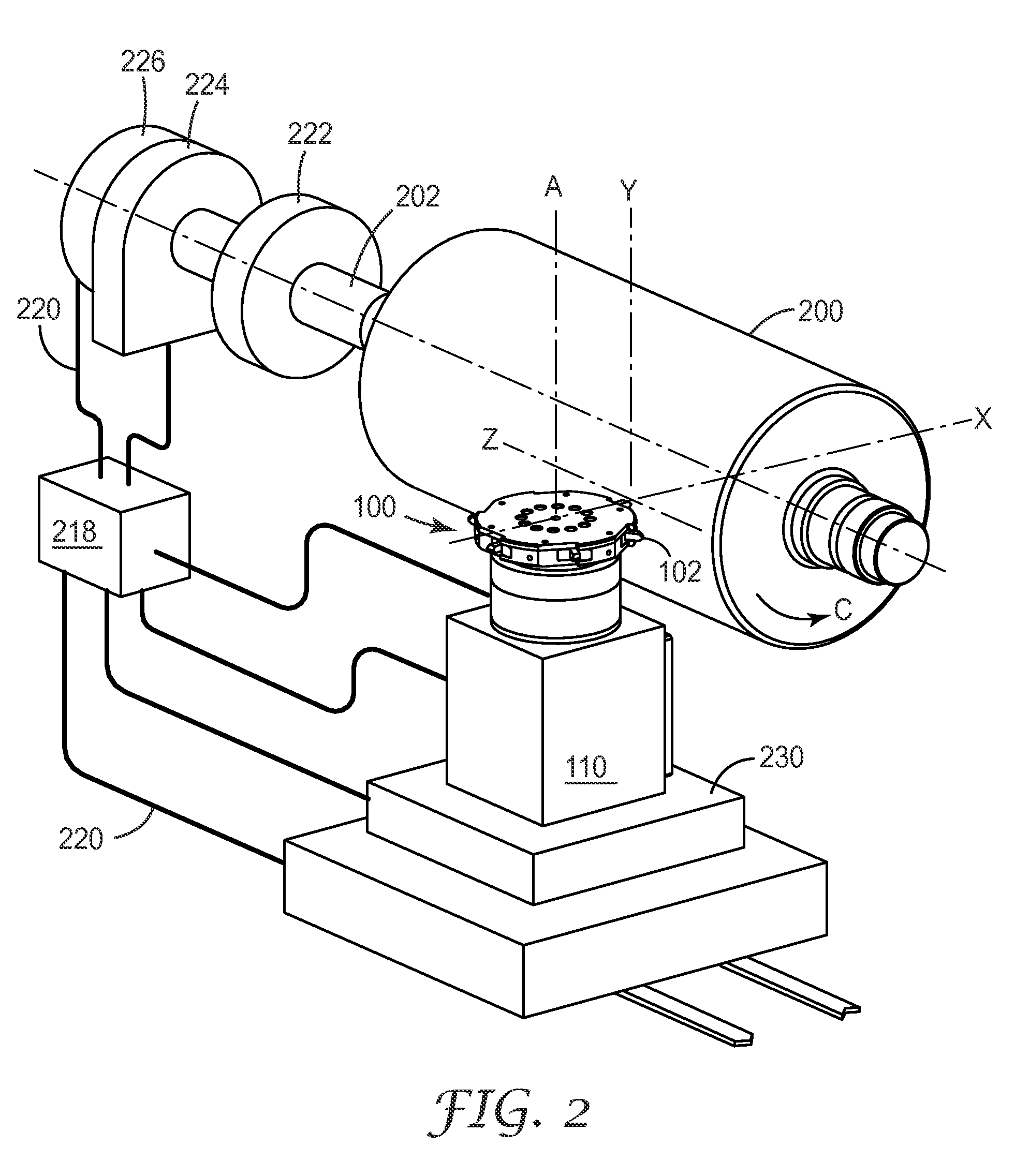

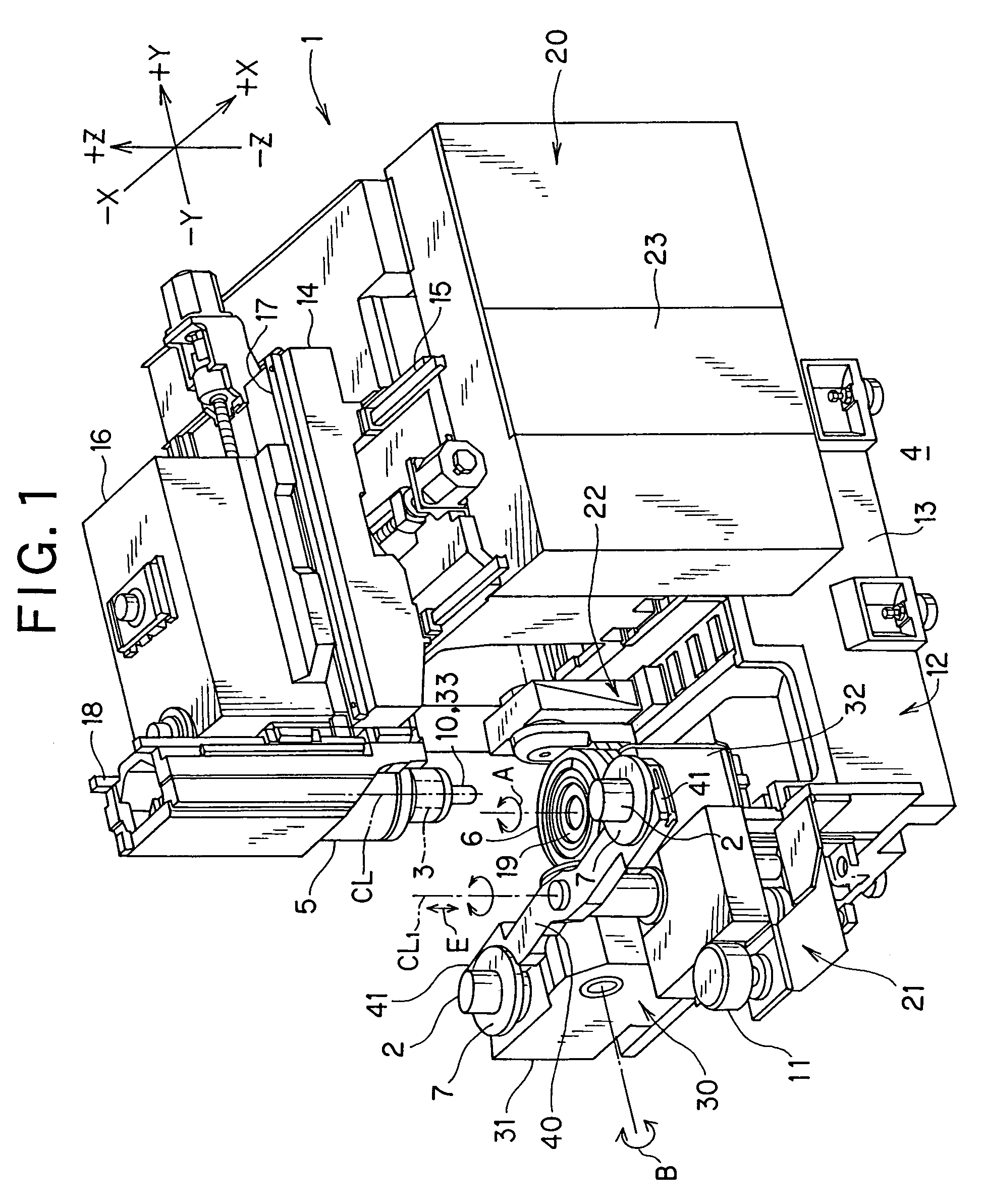

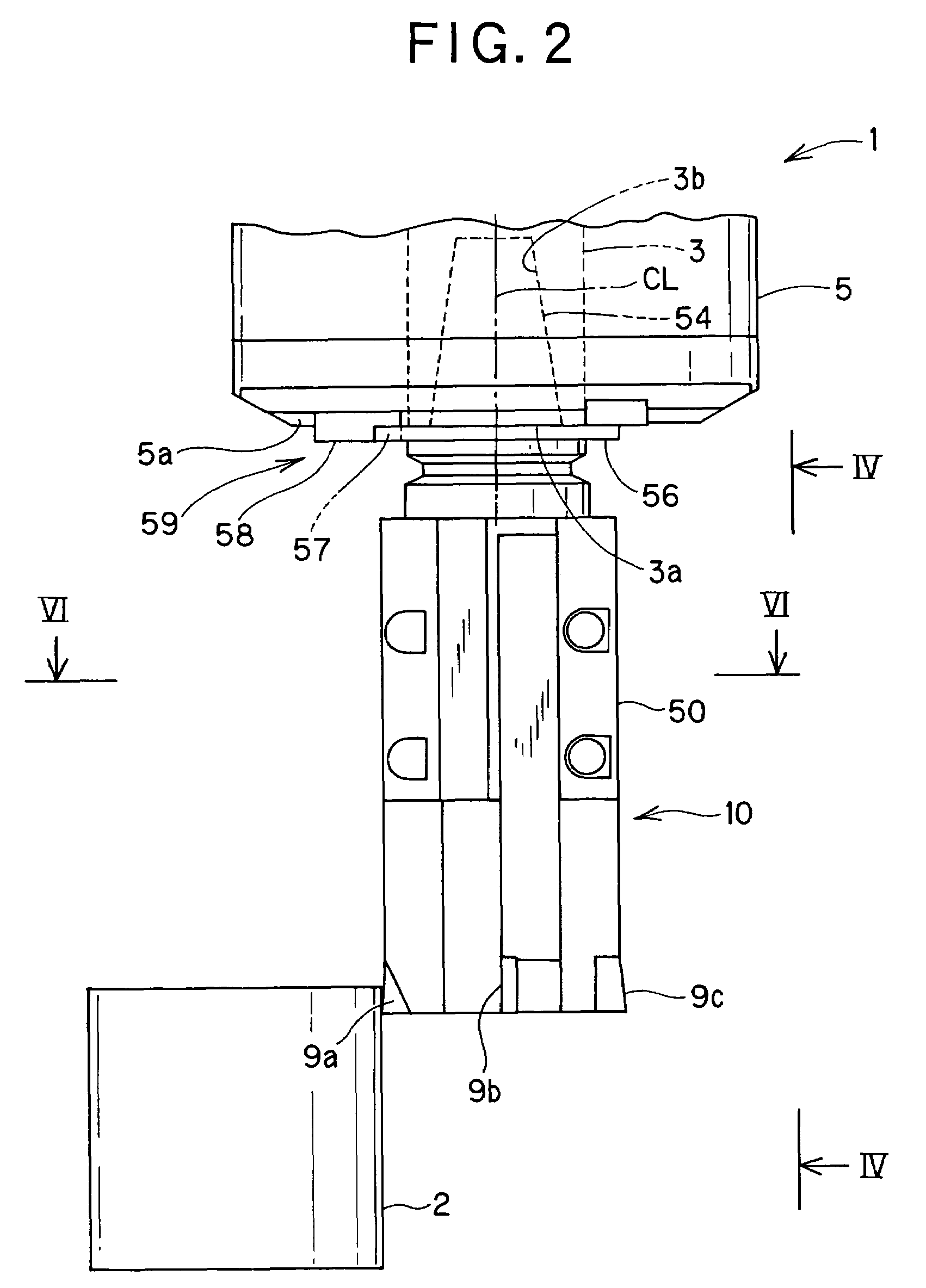

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

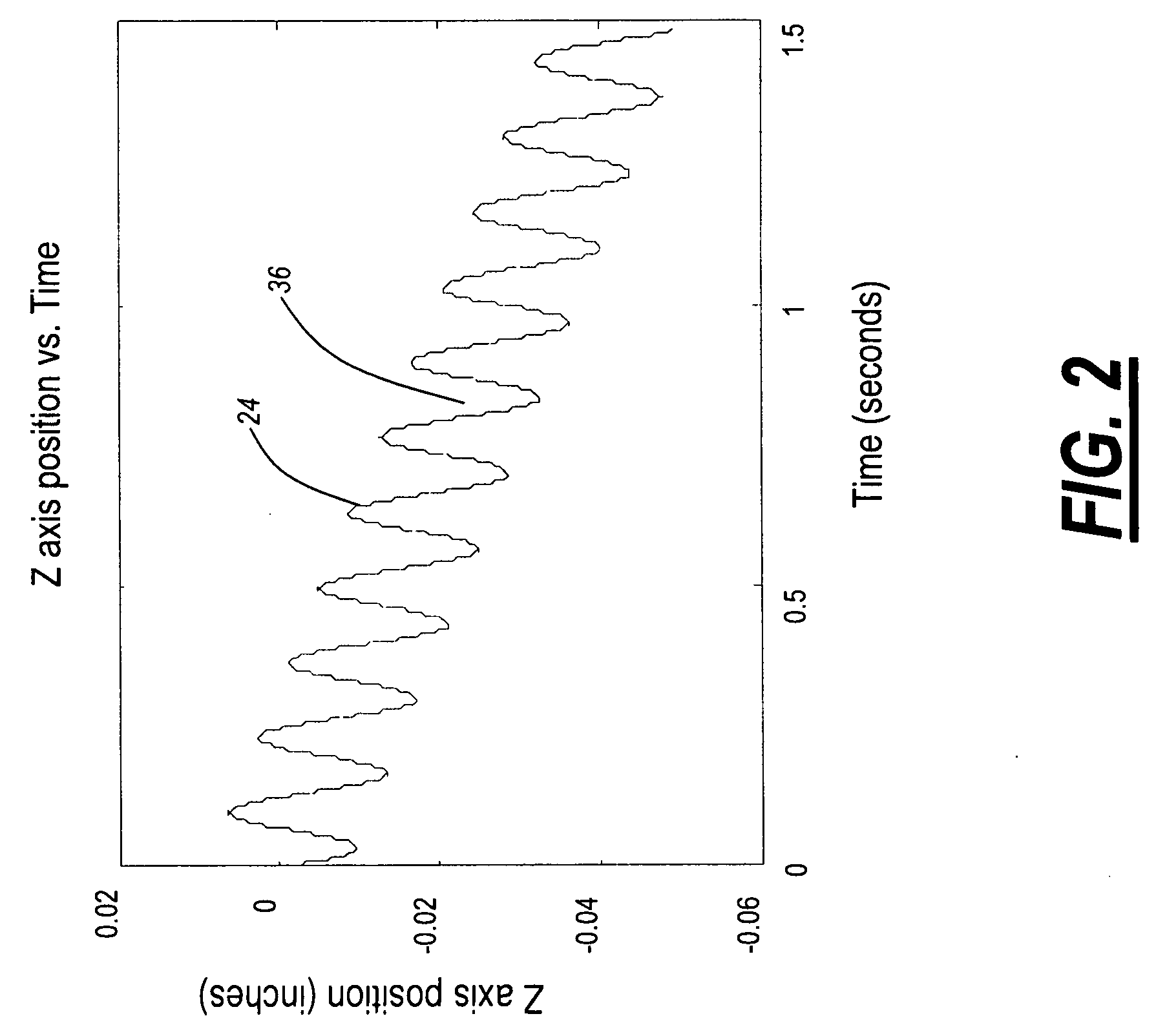

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

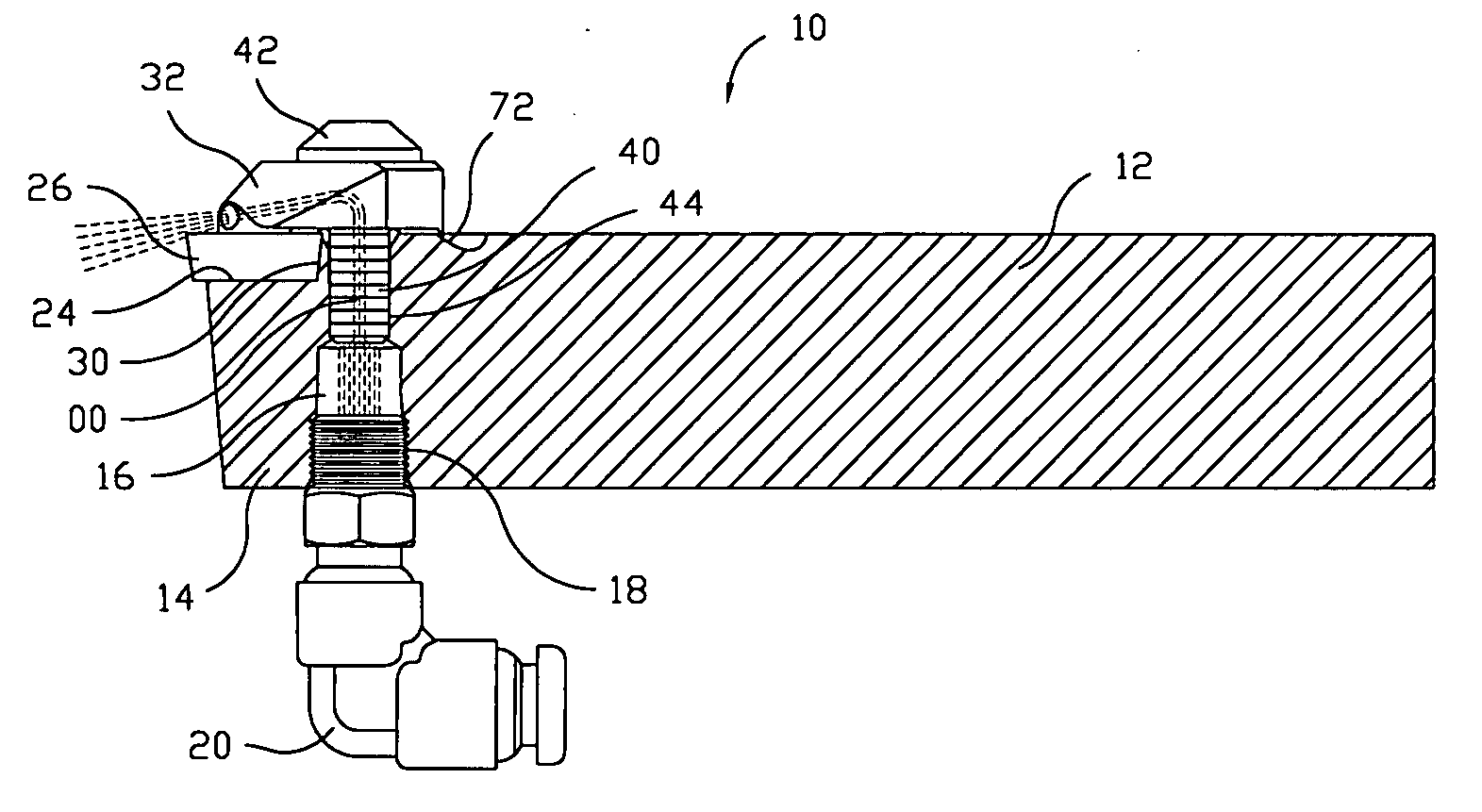

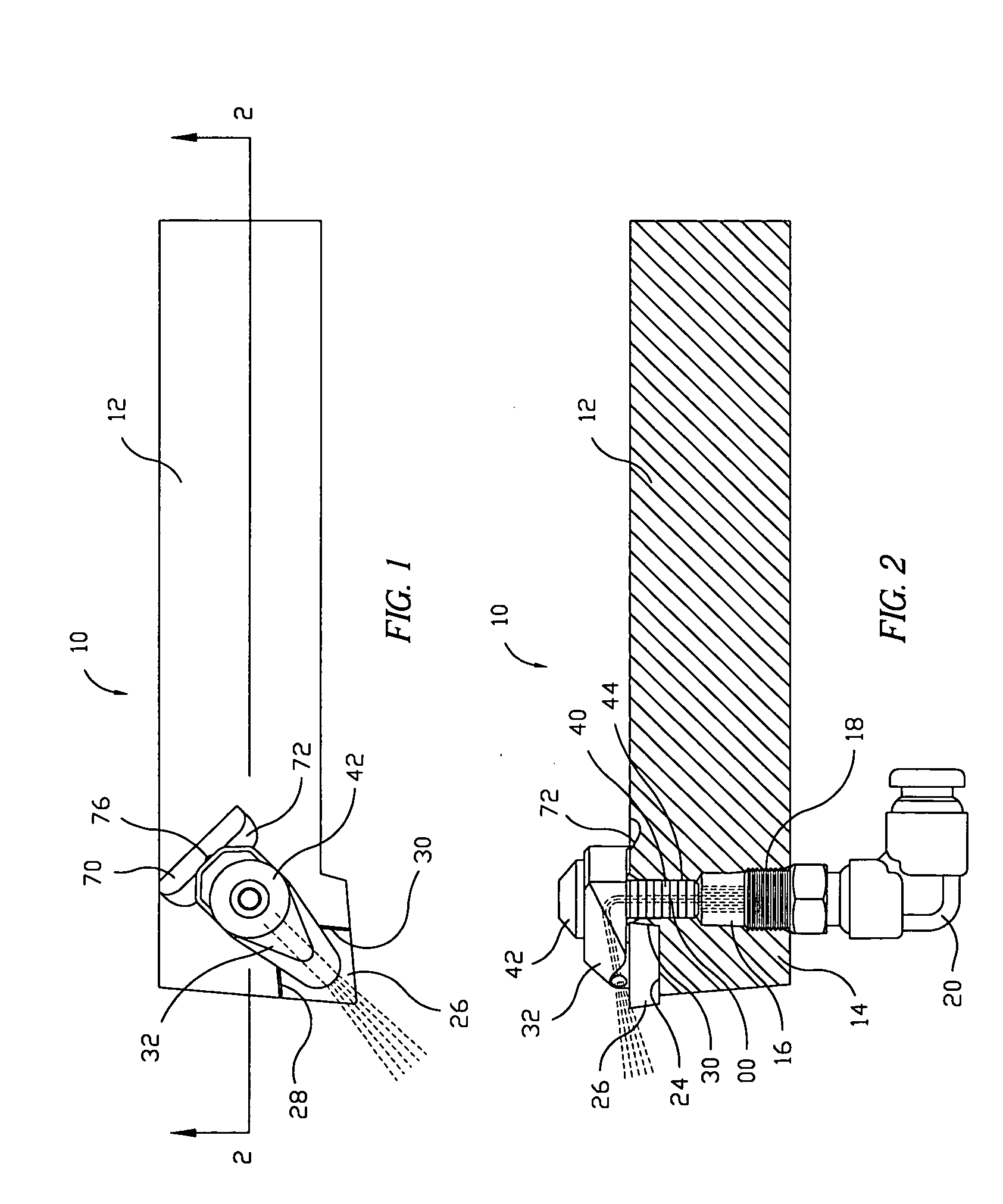

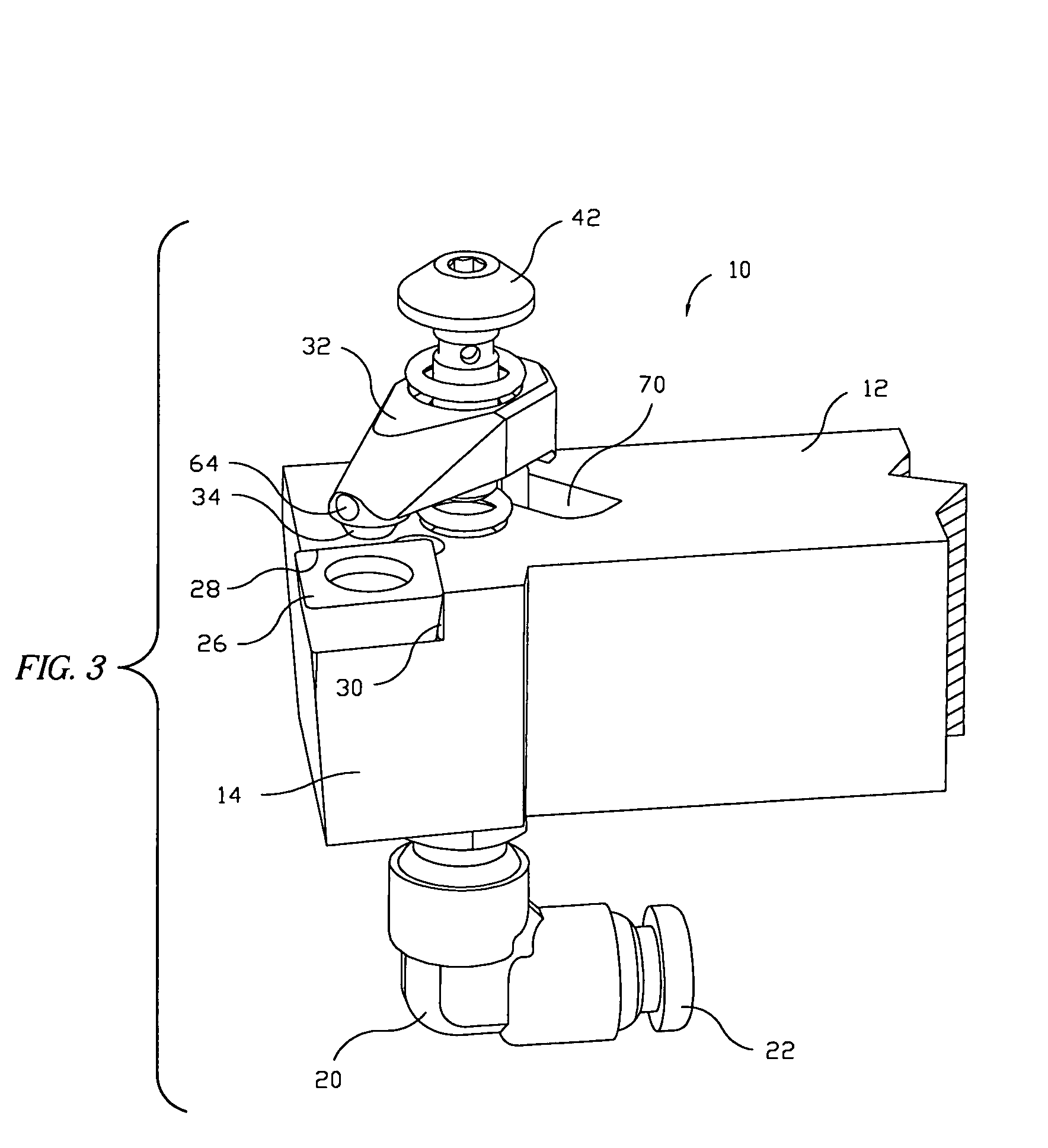

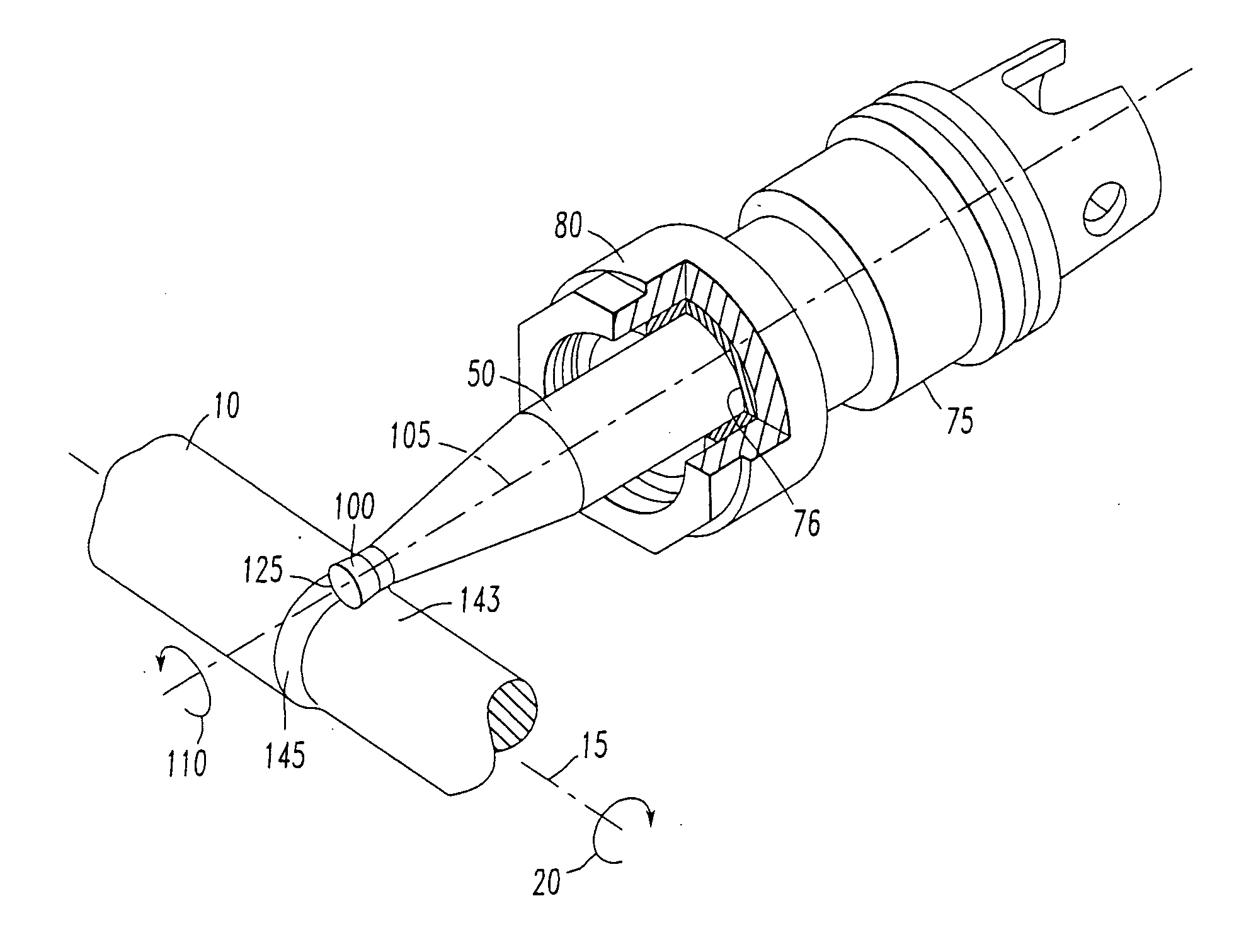

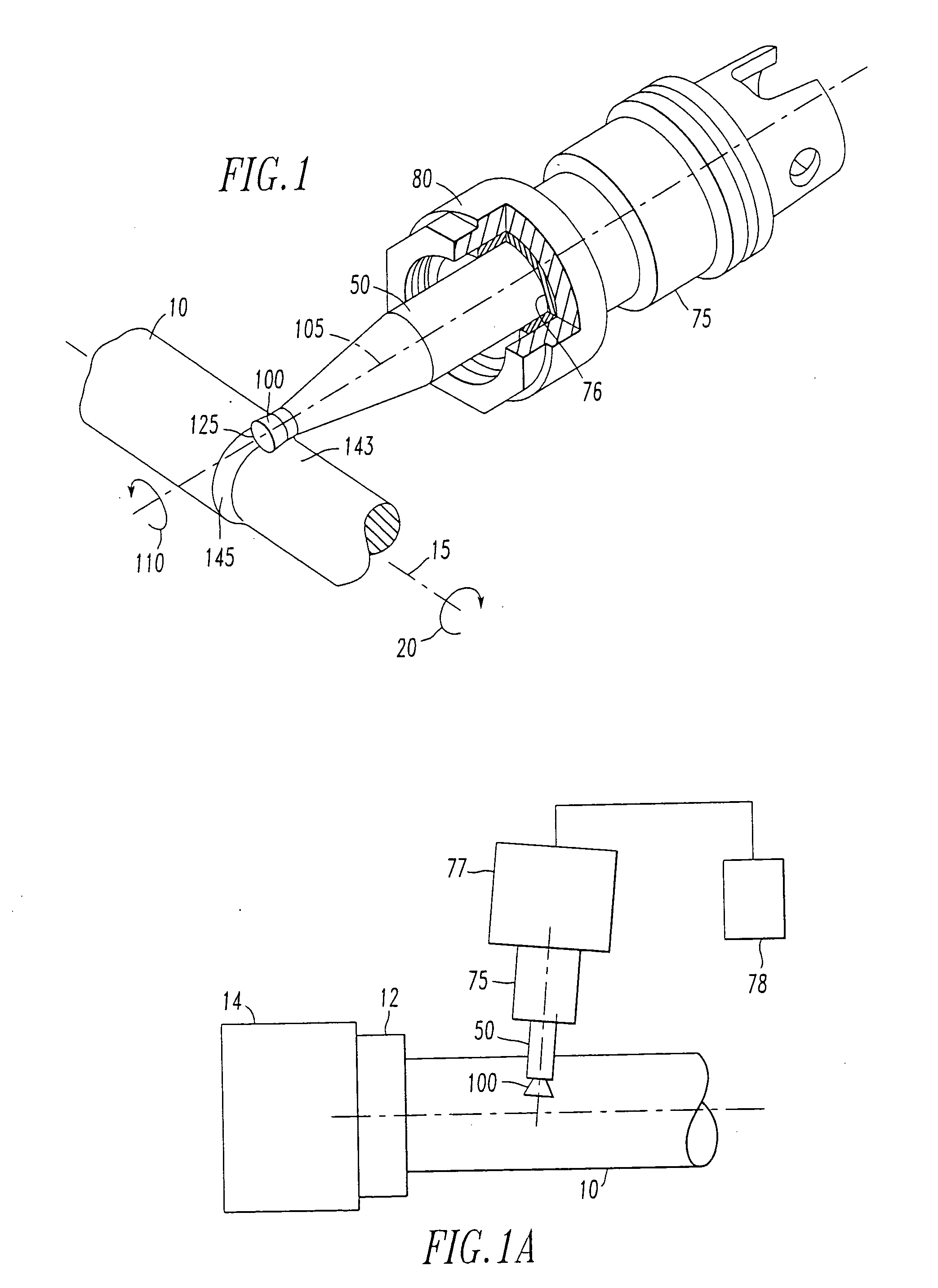

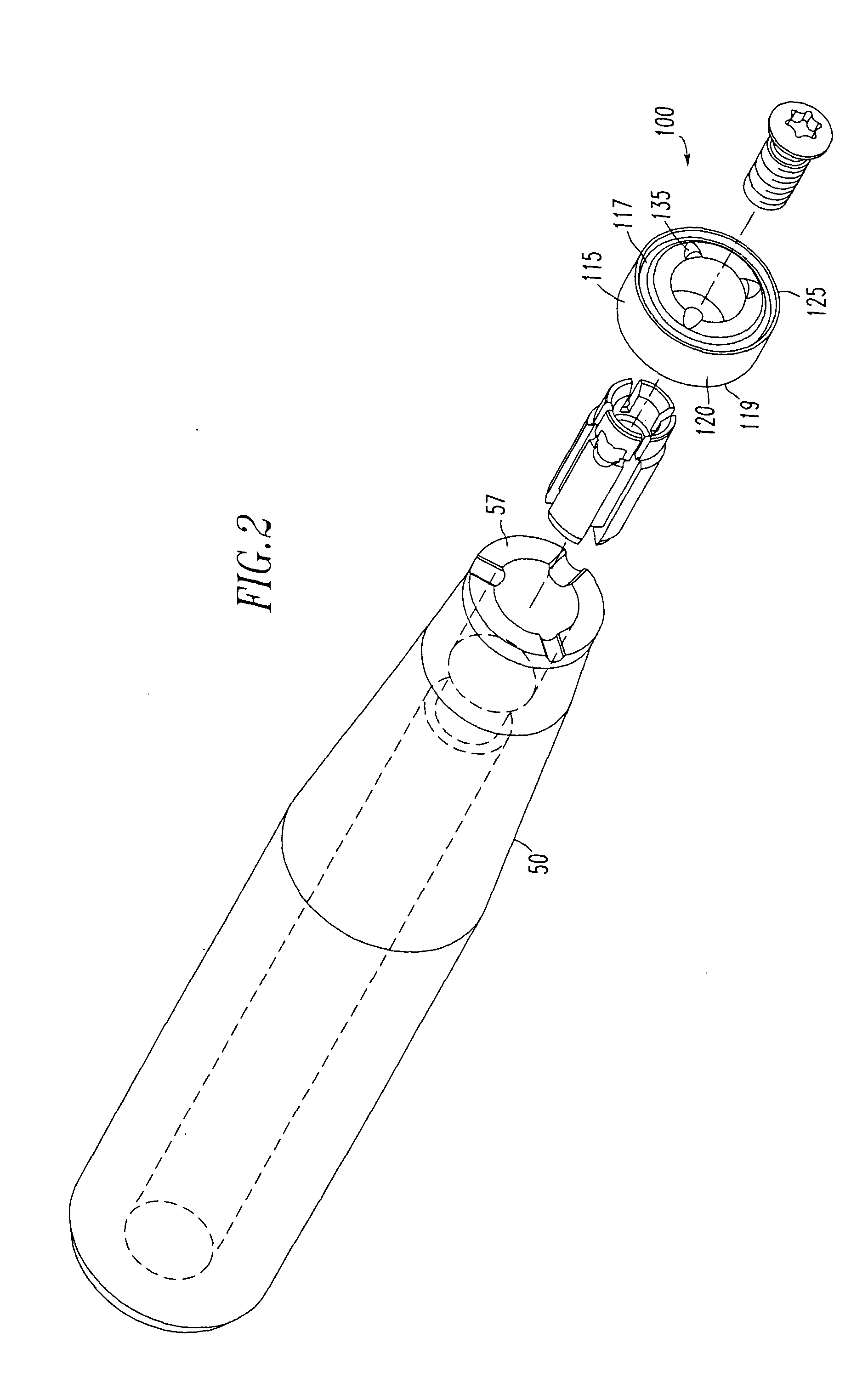

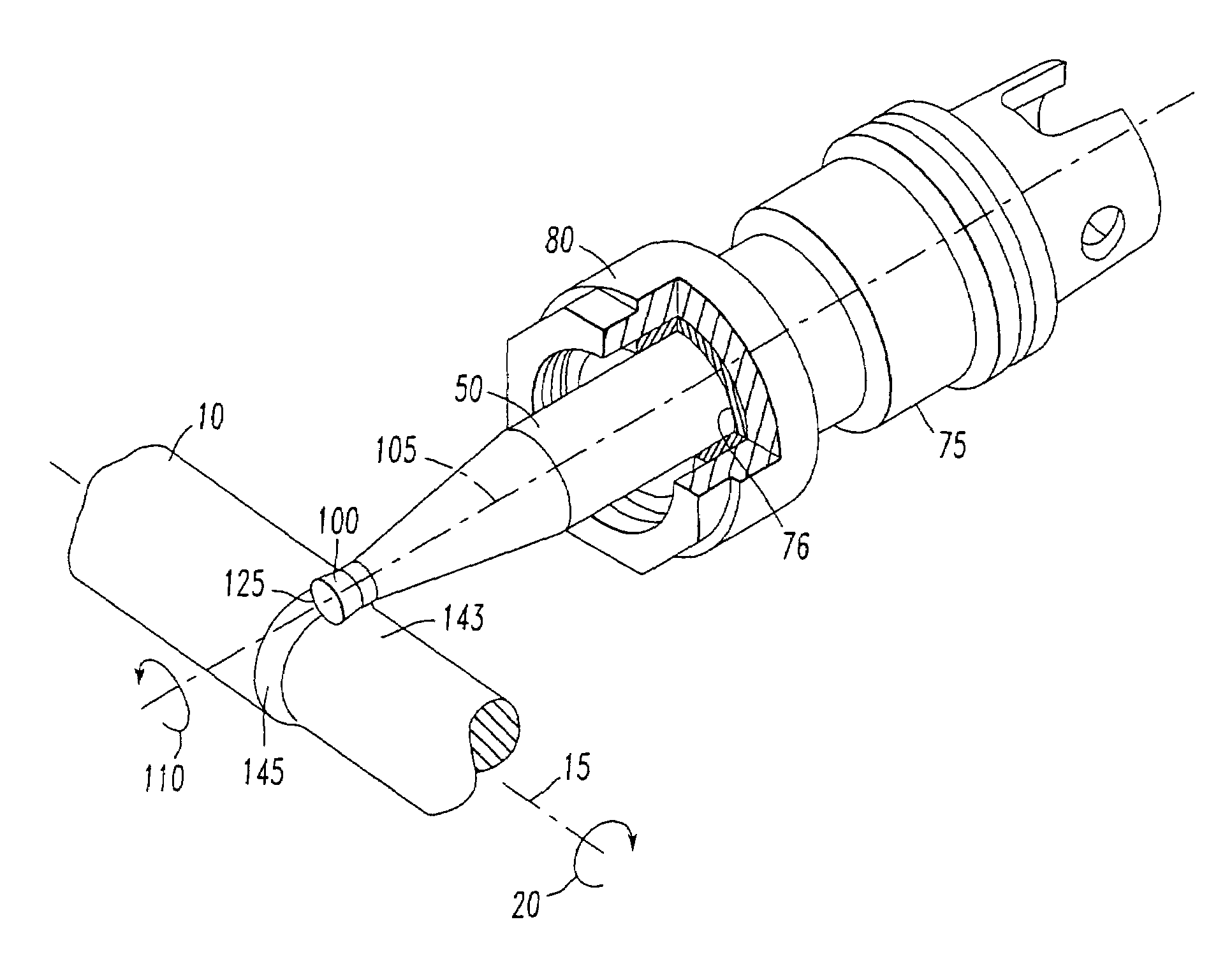

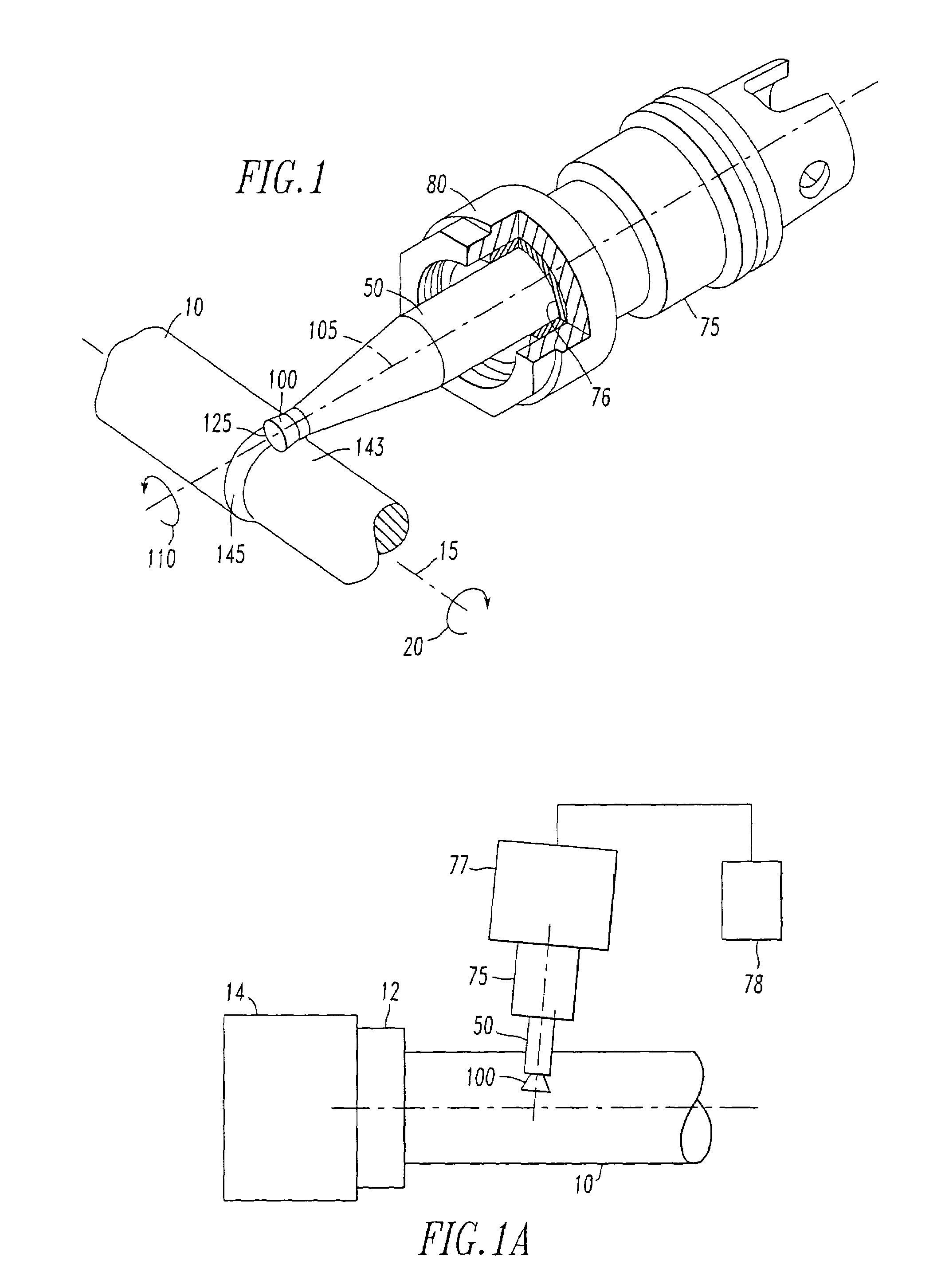

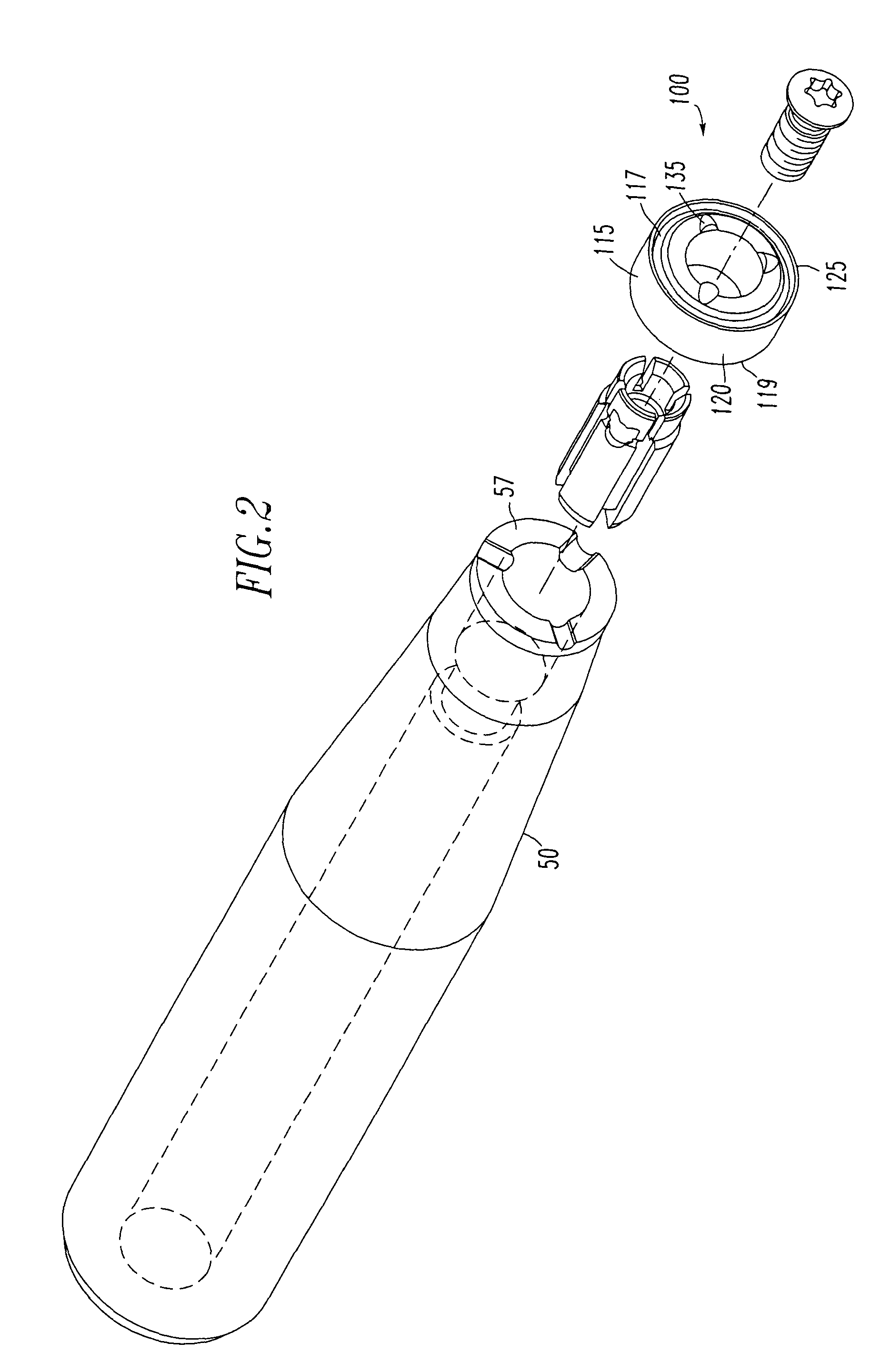

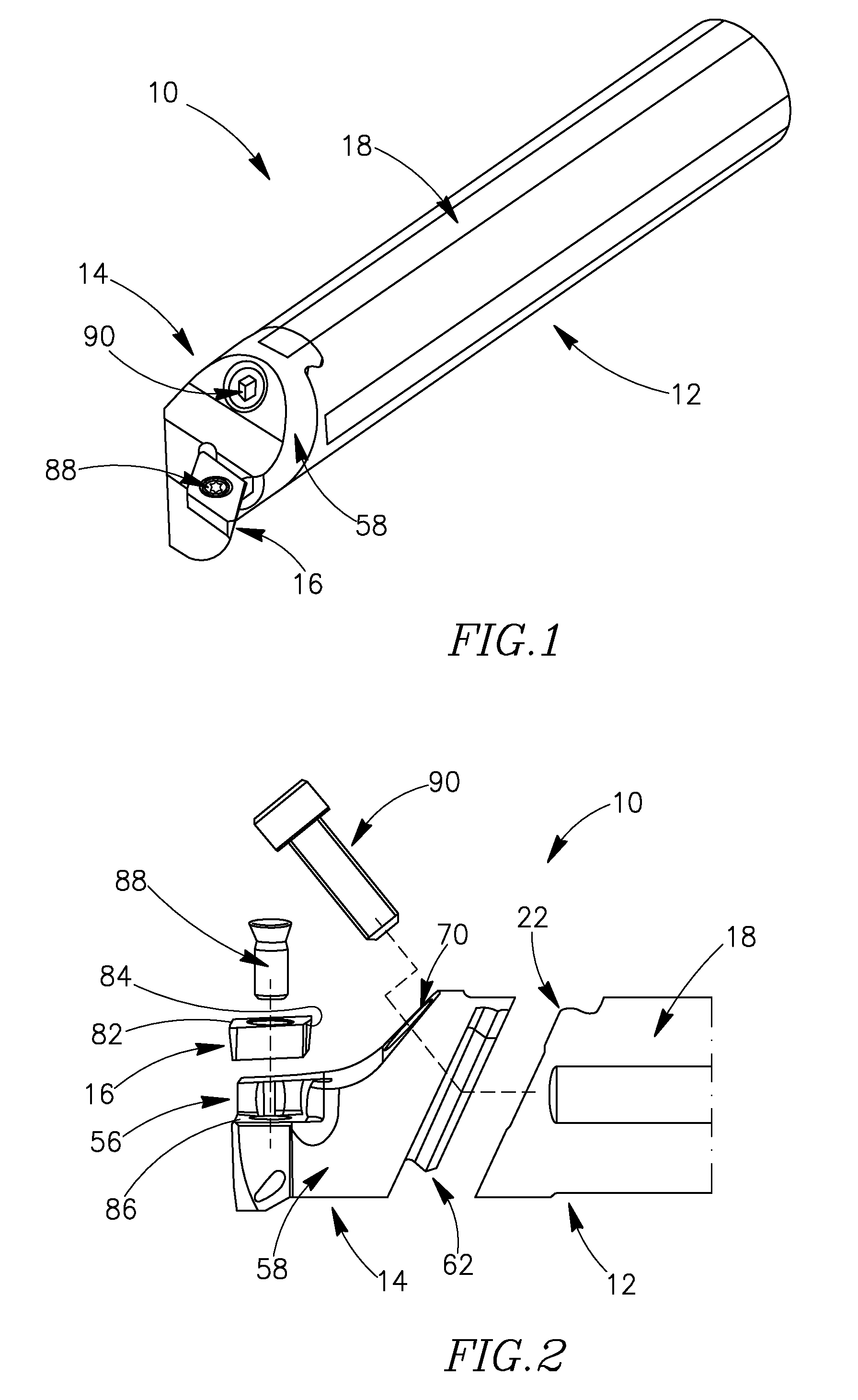

Machine tool holder having internal coolant supply and cutter retaining and coolant distribution cutter insert retaining clamp assembly

InactiveUS20070283794A1Minimizes heat induced wear and deteriorationExtended service lifeLathesCutting insertsCooling fluidMachine tool

A boring bar has a shank having a cutter support head at one end. A flow passage extends to the cutter support head and intersects a transverse flow passage that is defined in part by a clamp screw passage of the head. A metal cutting insert is clamped to the cutter support head by a clamp that is secured by a clamp screw being threaded into the clamp screw passage. The clamp screw defines an internal or external passage that communicates with the internal coolant fluid passage and completes a coolant distribution circuit. The clamp defines an internal coolant fluid passage having a discharge opening located and oriented to direct a jet of coolant fluid onto the metal cutting insert immediately at the site of cutting engagement within the rotating workpiece. The cutter support head also has a passage and chip removal jet nozzle that orients a jet of coolant fluid adjacent the cutter insert for remove metal chips during machining.

Owner:GIANNETTI ENRICO R

Vascular treatment measurement methods

ActiveUS8715314B1Increase awarenessLathesOrnamental textile articlesLaser cuttingBiomedical engineering

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measureable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

Offset vascular treatment devices

ActiveUS8715316B1Effectively and efficiently capturingIncrease awarenessLathesOrnamental textile articlesMedicineLaser cutting

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measurable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

Vascular treatment devices and methods

ActiveUS20150374483A1Effectively and efficiently capturingReduce riskLathesMedical devicesX-rayLaser cutting

Vascular treatment devices and methods include a woven structure including a plurality of bulbs that may be self-expanding, a hypotube, for example including interspersed patterns of longitudinally spaced rows of kerfs, and a bonding zone between the woven structure and the hypotube. The woven structure may include patterns of radiopaque filaments measureable under x-ray. Structures may be heat treated to include various shapes at different temperatures. The woven structure may be deployable to implant in a vessel. A catheter may include a hypotube including interspersed patterns of longitudinally spaced rows of kerfs and optionally a balloon. Laser cutting systems may include fluid flow systems.

Owner:INSERA THERAPEUTICS

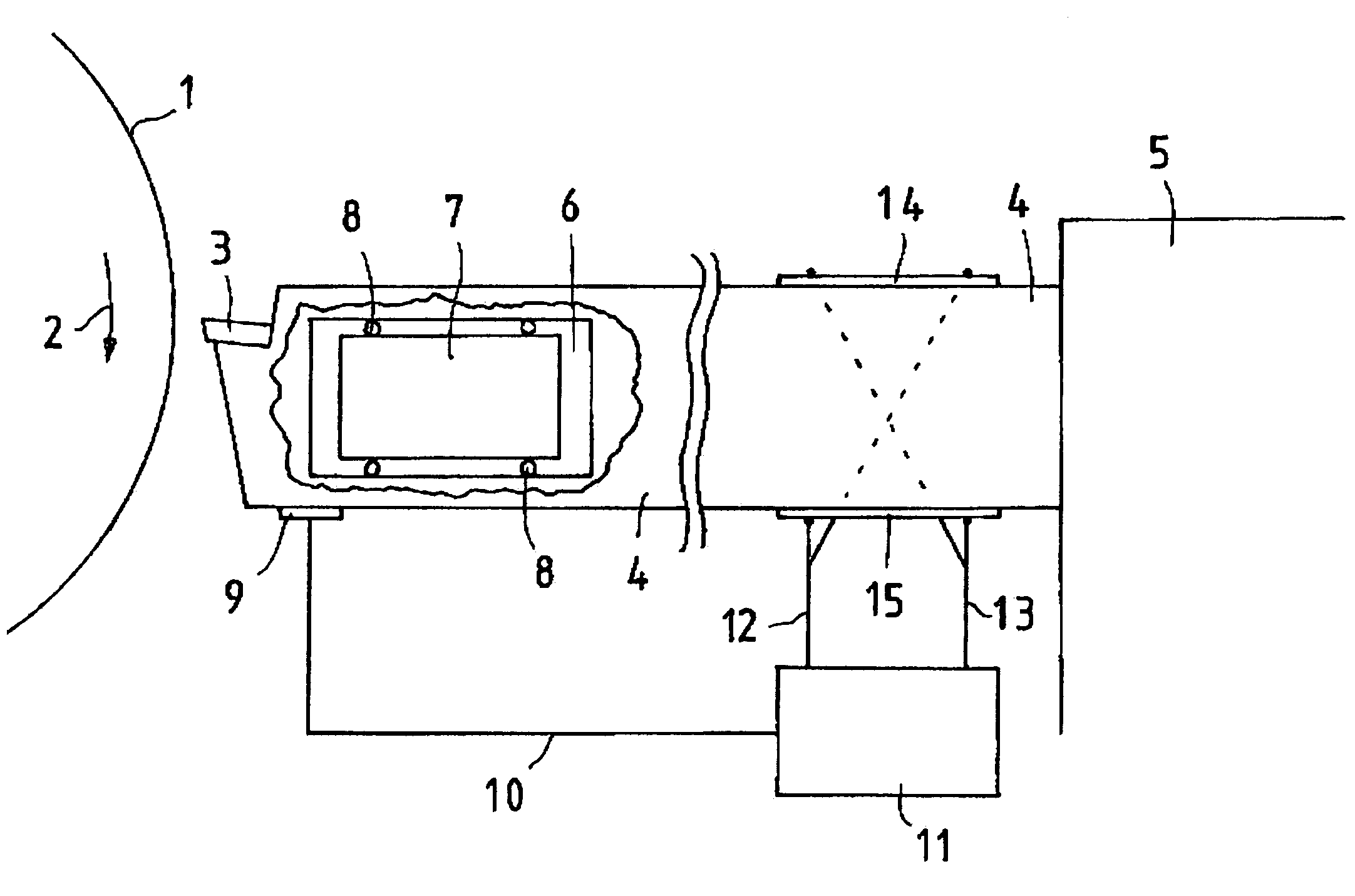

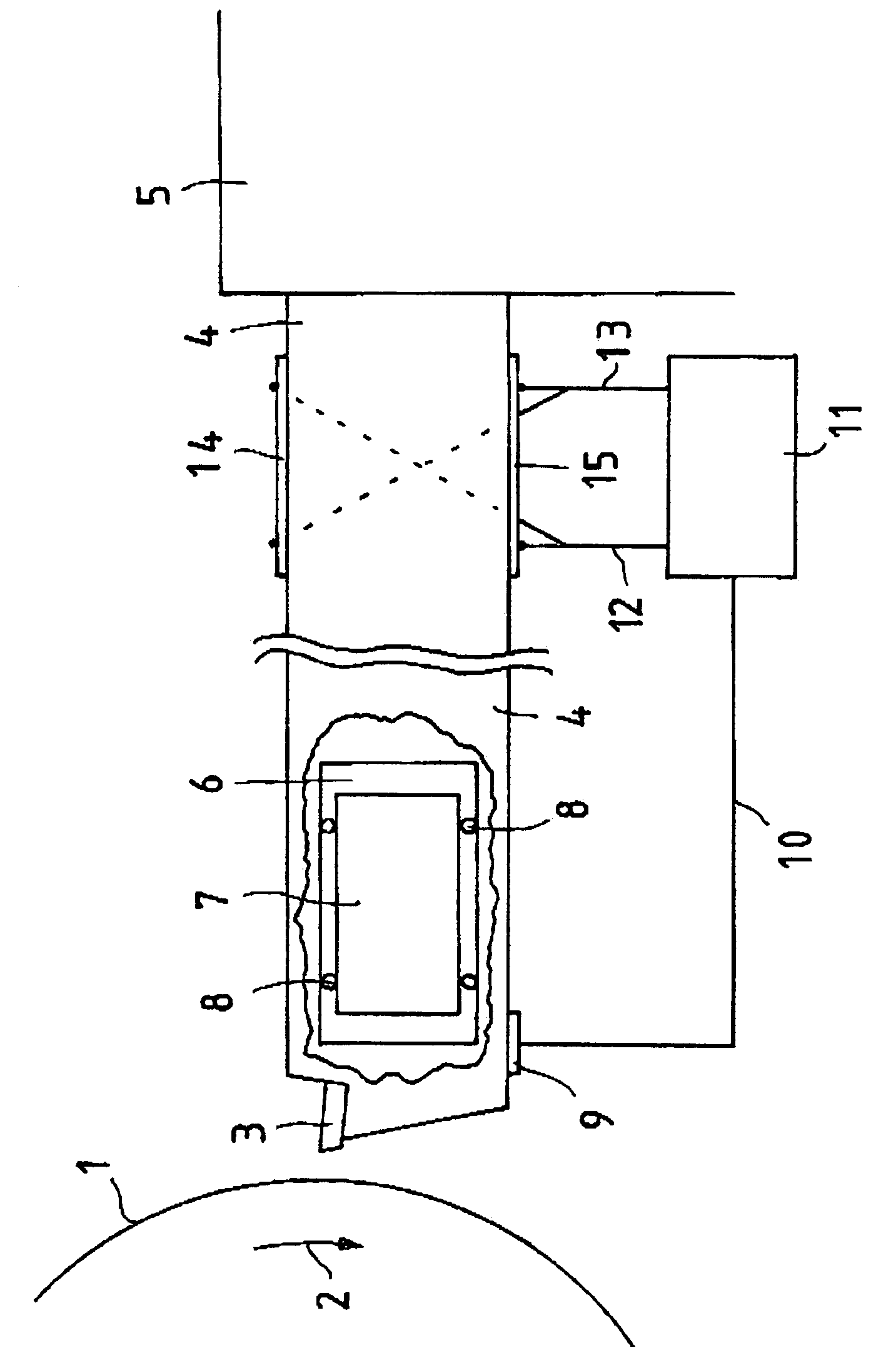

Device and a method for preventing or reducing vibrations in a cutting tool

An arrangement for reducing vibrations in a tool holder (4) with a cutting tool (3) and has a vibration sensor on the tool holder (4) that is connected to a guide unit (11). The tool holder (4) has further two piezo-electric actuators 14 and 15.Under the influence of the vibration sensor (9), the guide unit (11) provides an electric alternating current that is actively guided over time so that the actuators movably affect the tool holder (4) to reduce the vibrations in this. To also be able to dampen transients in the tool holder (4) this is movably connected with a passive dampening arrangement that is independent of the guide unit (11) and that is based on the principle of a springing (8) suspended mass (7). The invention also relates to a method for reducing vibrations. The vibrations in the tool holder are sensed and a corresponding signal is provided to a guide unit that over time provides actively guided signals to the actuators. The tool holder is also passively influenced by a dampening arrangement that is independent of the guide unit.

Owner:CLAESSON INGVAR +4

Method and device for controlling a turning operation

InactiveUS6925915B1Improve surface smoothnessLathesAutomatic/semiautomatic turning machinesControl systemActuator

A device increases the surface smoothness of a turned surface. The device comprising a control system with a control unit and an actuator connectible to the control unit and connectible with a tool holder. The actuator in adapted to impart a vibrating motion in the lateral direction to the tool holder. A method will also increase the surface smoothness of a turned surface, comprising the step of controlling the vibrations of the tool holder during turning. The method also comprises the step of imparting a vibrating motion in the lateral direction to the tool holder. Moreover, a turning lathe and a turning tool holder which like the device are designed to generate vibrating motion in the lateral direction.

Owner:STAFFANSBODA CIE

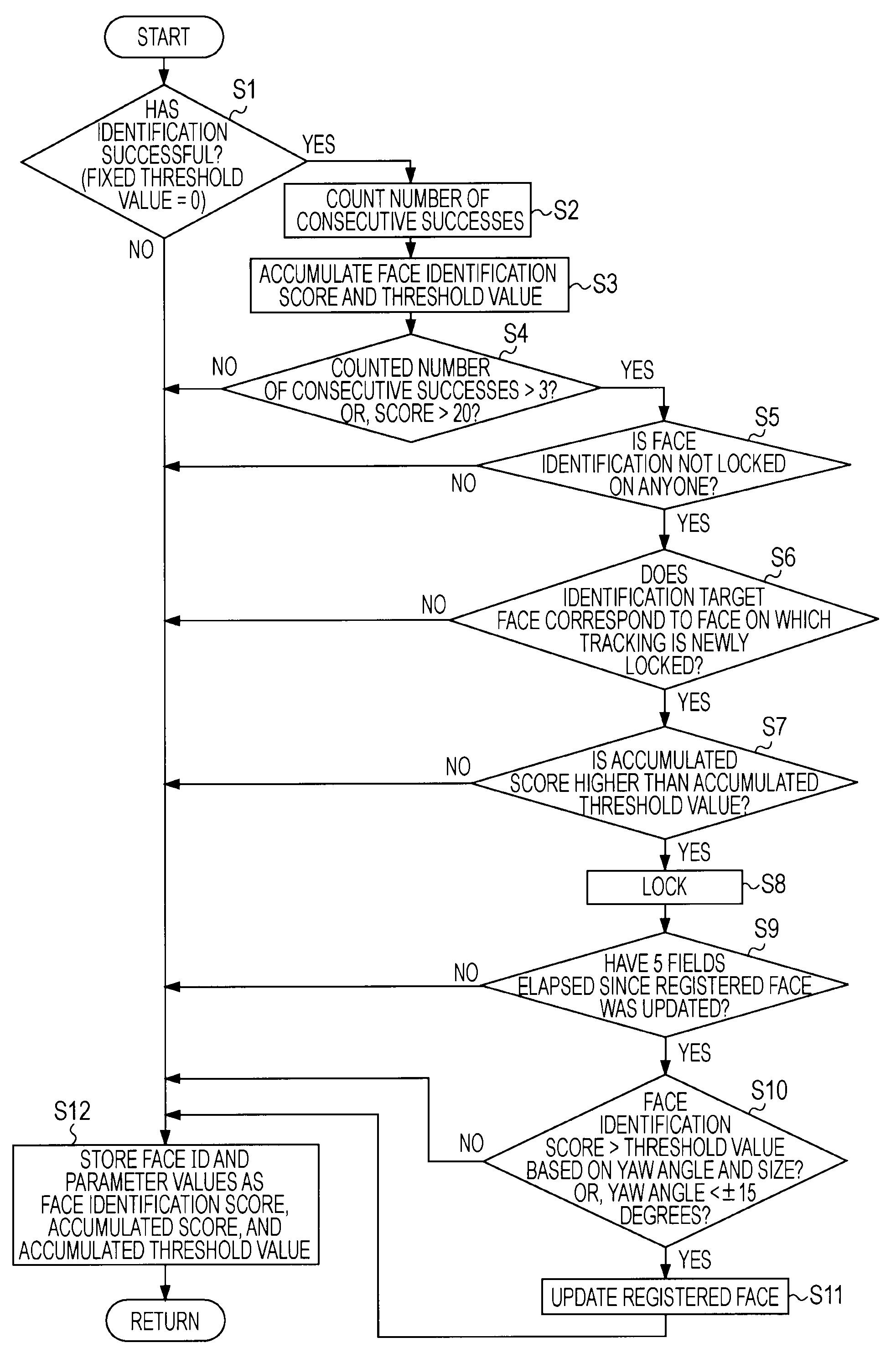

Apparatus and method for face recognition and computer program

InactiveUS20080247611A1Continuously face recognitionStably identifying the sameLathesCharacter and pattern recognitionFace detectionPattern recognition

Disclosed is a face recognition apparatus for previously registering a face image of a person, receiving a moving image in which face identification is intended to be performed, and performing face recognition in the received moving image. The apparatus includes the following elements. A face registration unit registers the face of a person as an image. A face detection unit detects a face in a frame of an input moving image. A face tracking unit tracks the detected face in frames of the input moving image. A face identification unit compares the detected face, which is being tracked by the face tracking unit, with the registered face registered in the face registration unit to identify the face. A stabilization unit stabilizes the result of face identification by the face identification unit.

Owner:SONY CORP

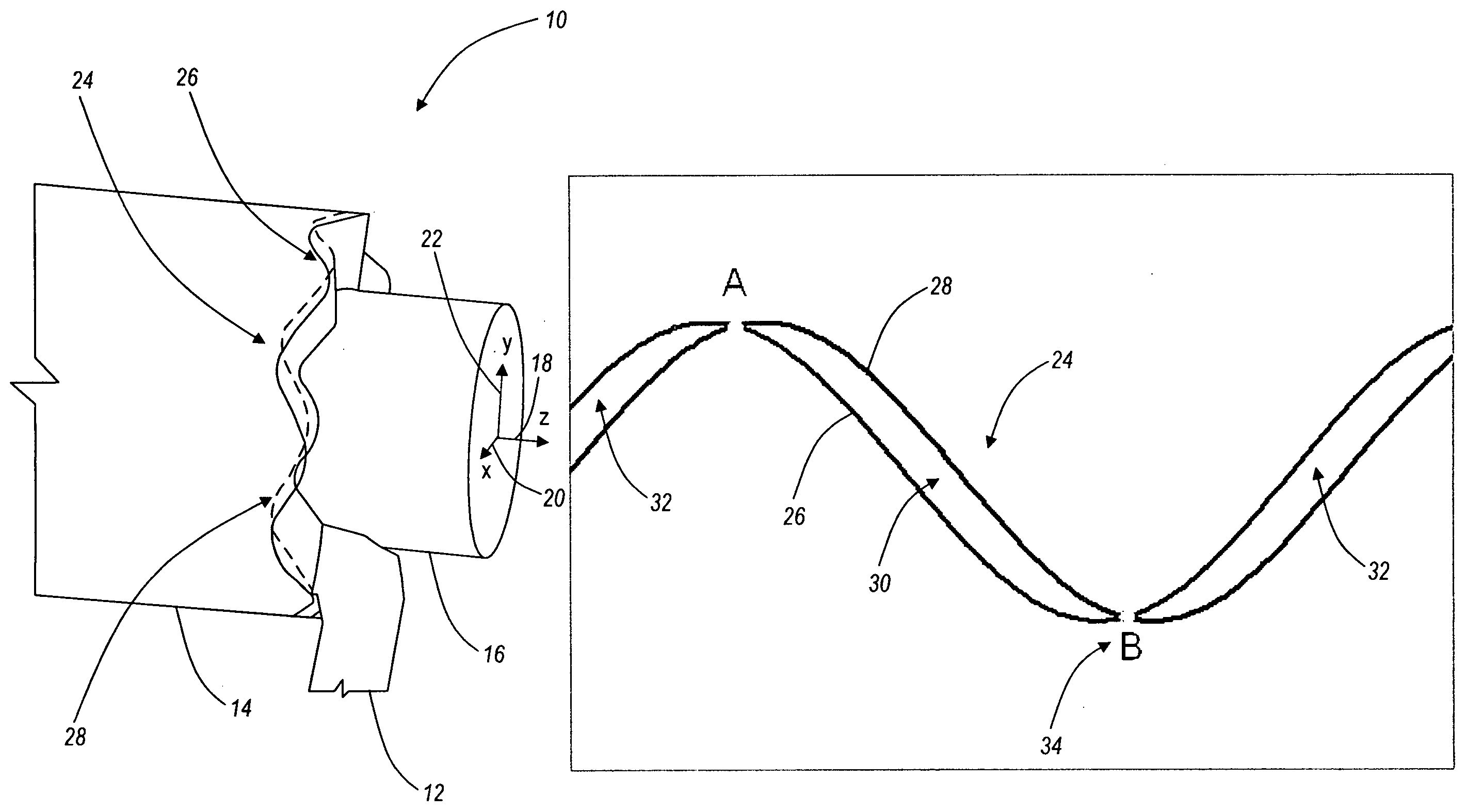

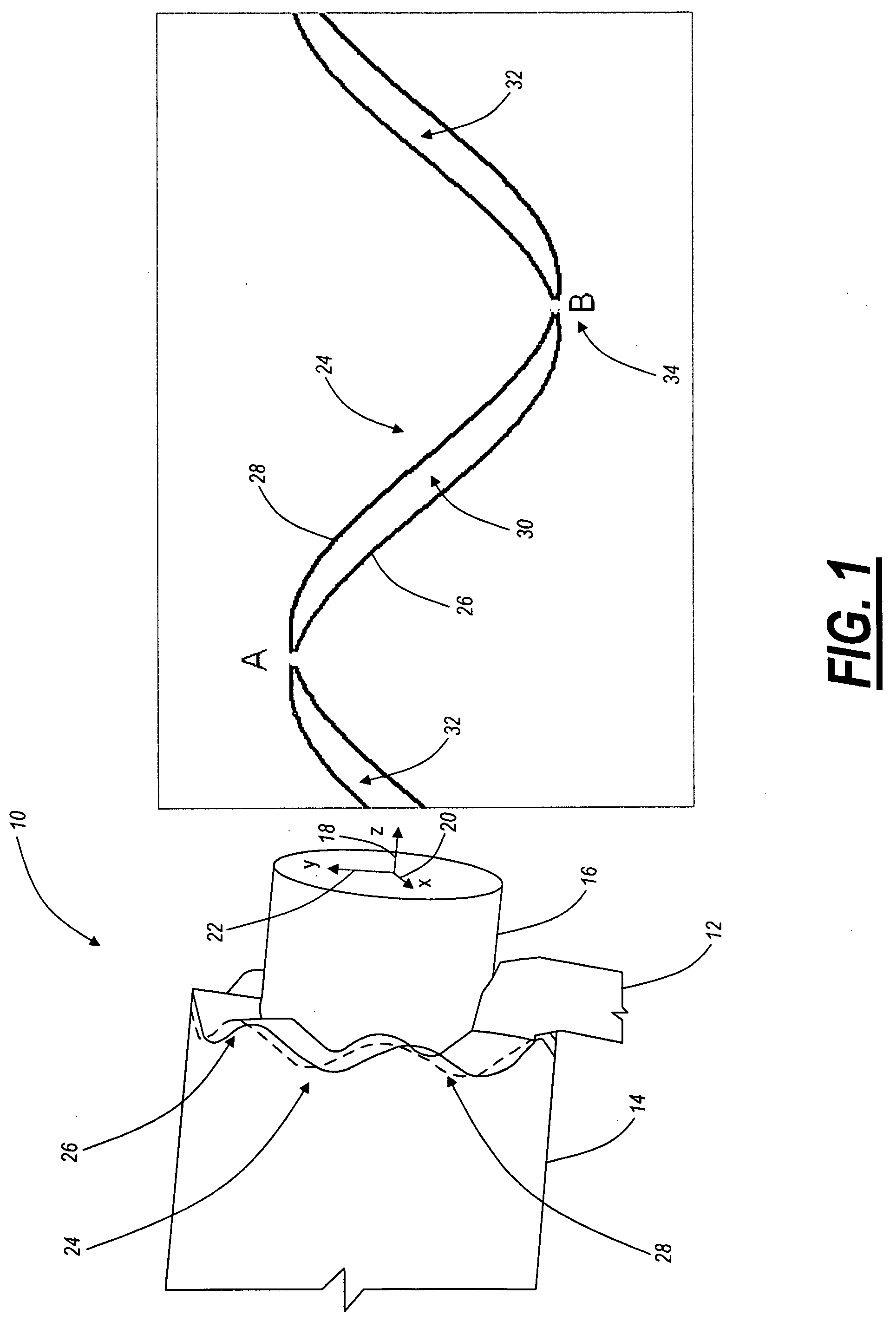

Fly-cutting system and method, and related tooling and articles

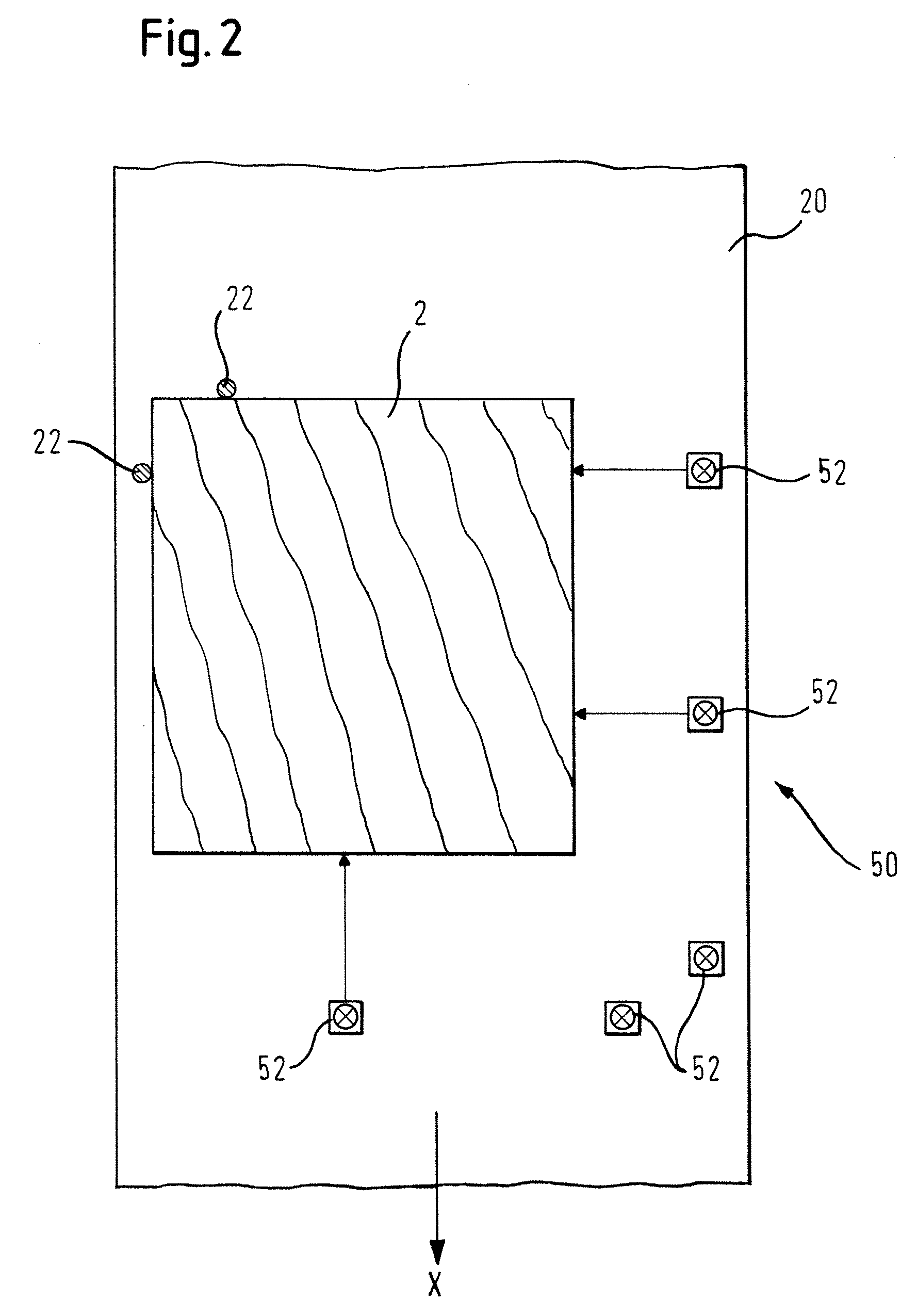

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

Slotted catheters

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measurable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

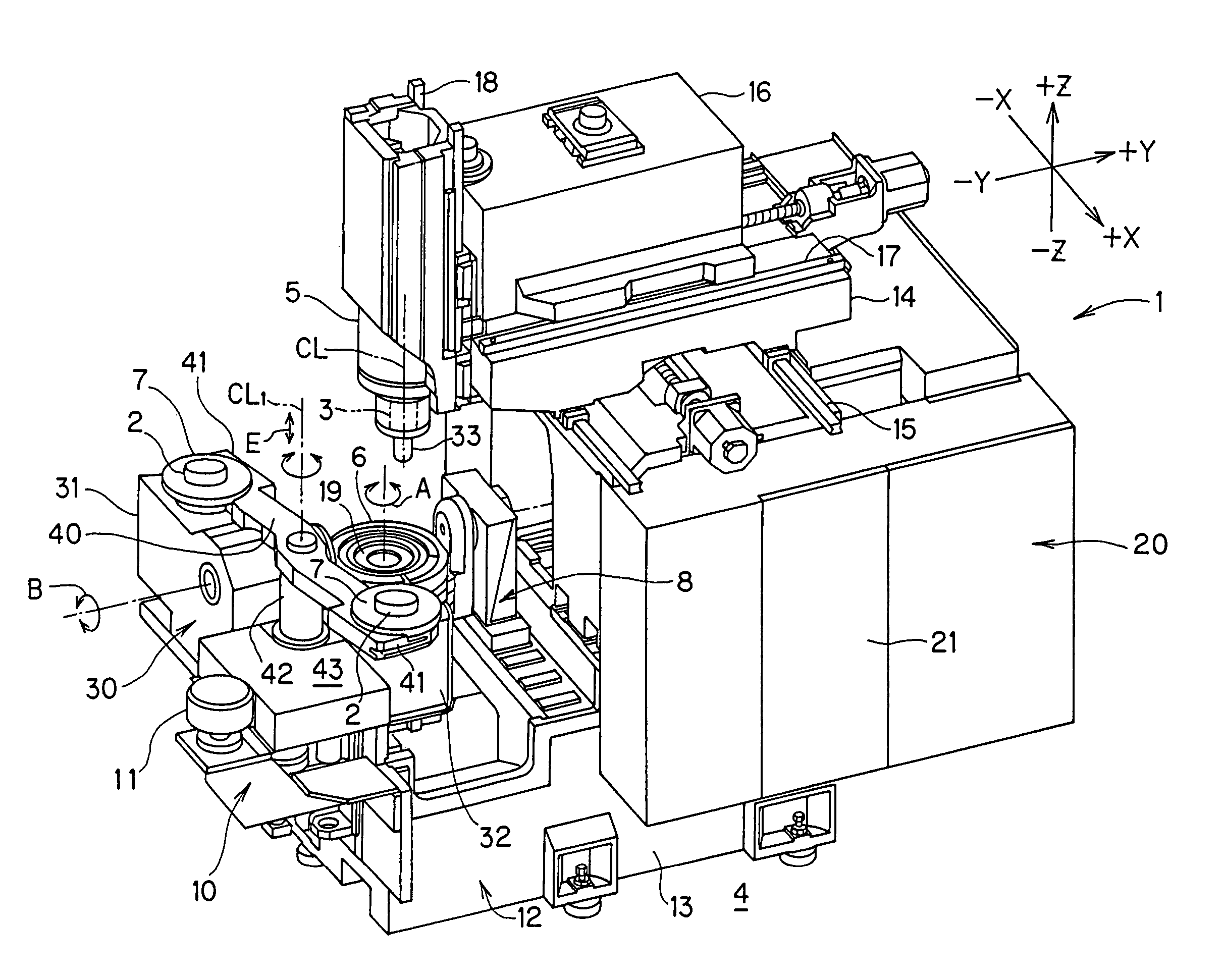

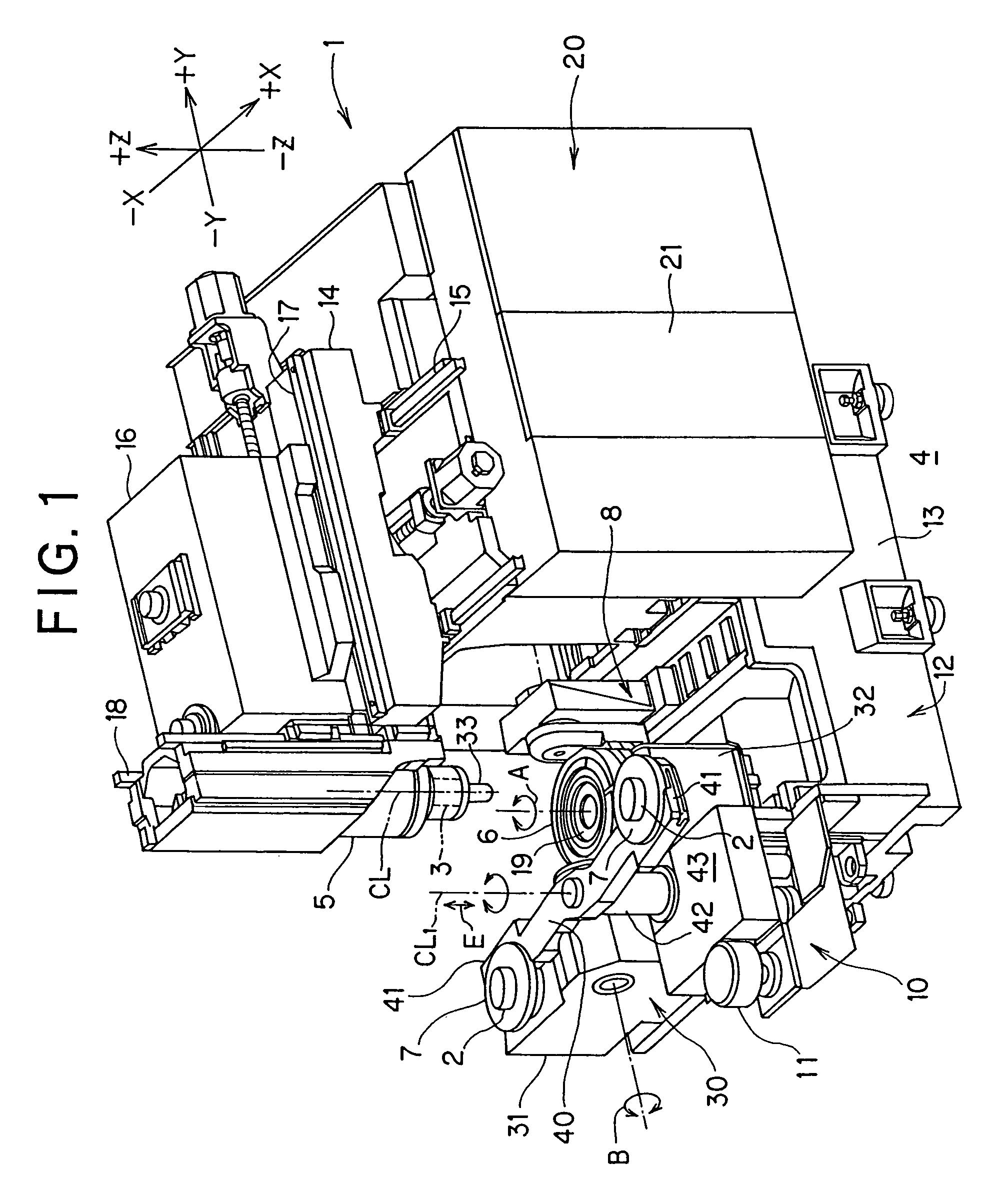

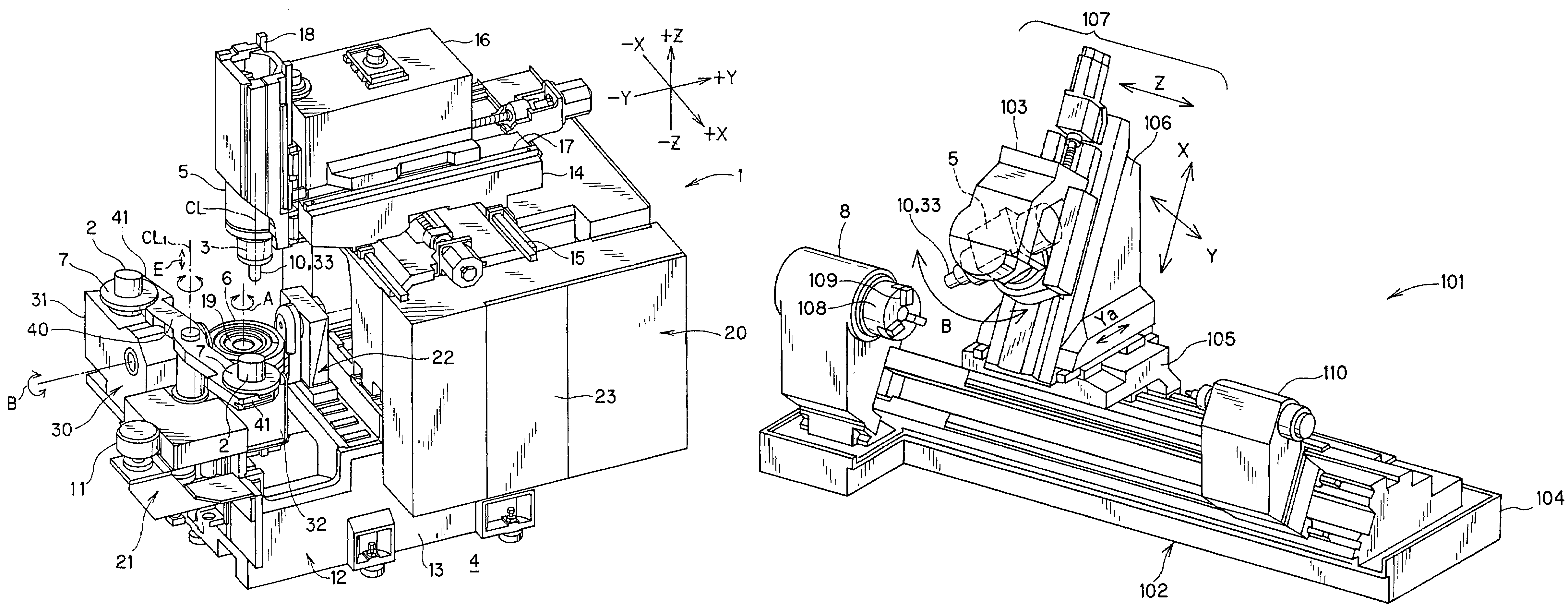

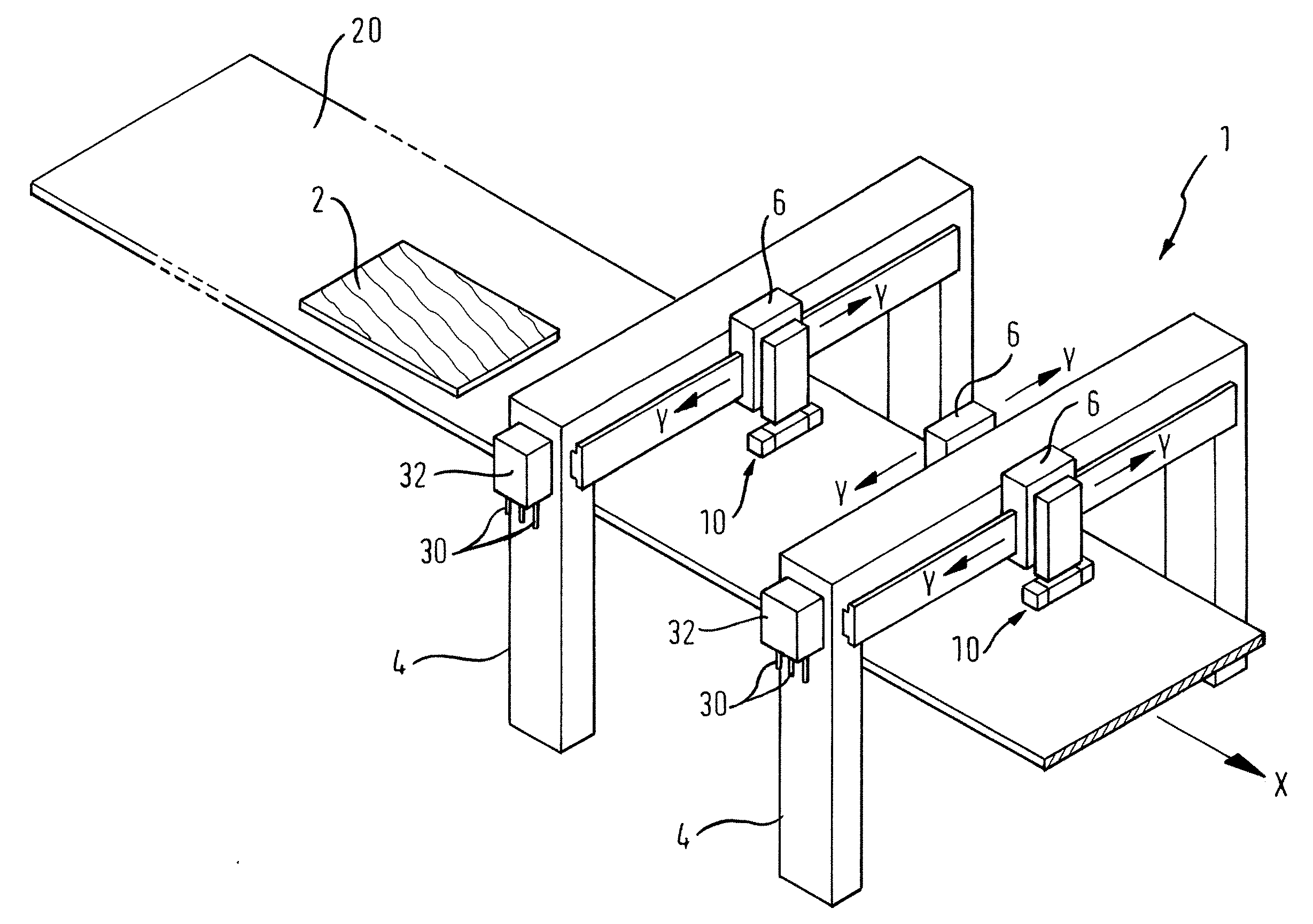

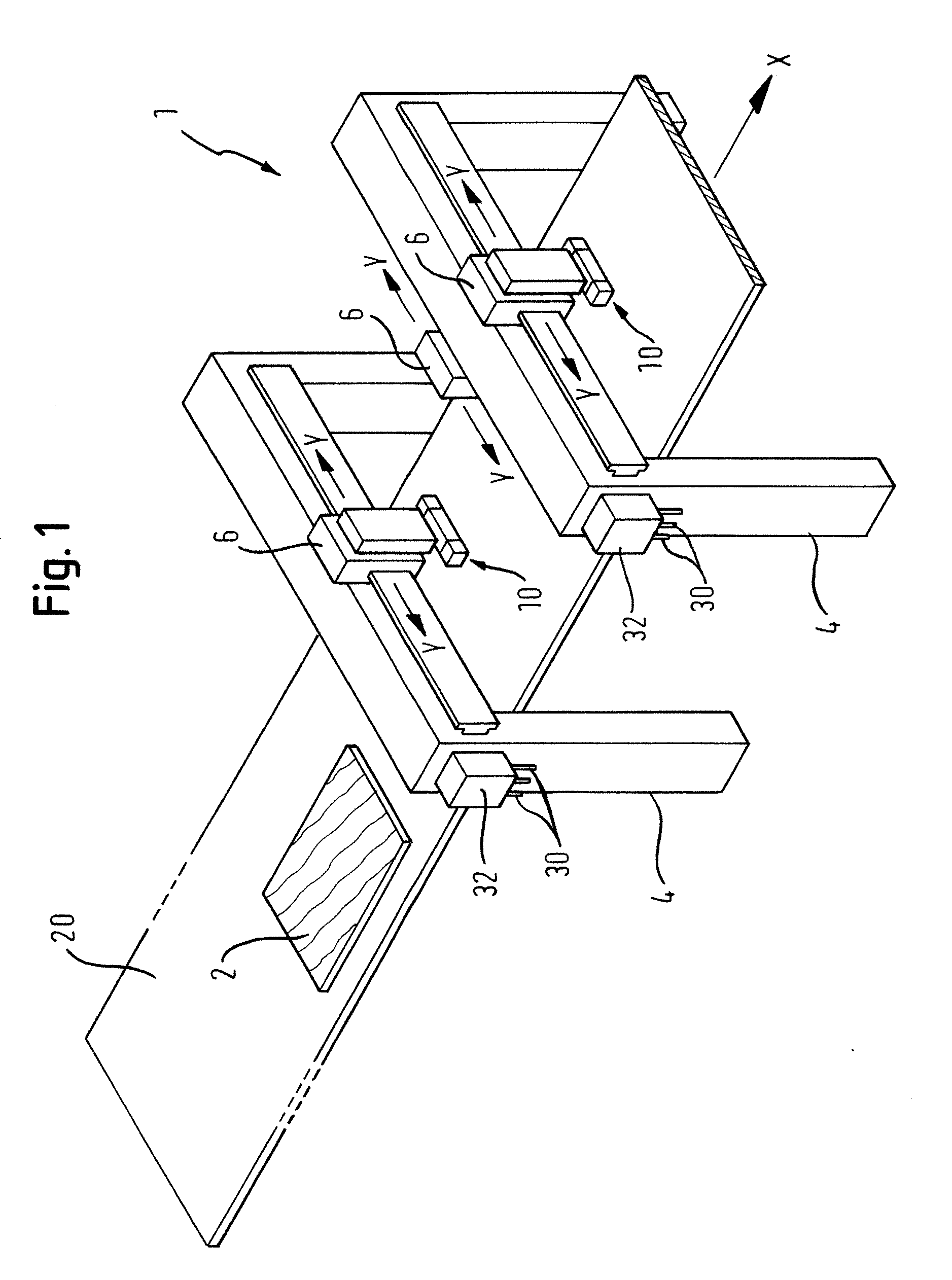

Machine tool and pallet changer for machine tool

InactiveUS7013544B2No longer be changedSimple and compact structureLathesAutomatic/semiautomatic turning machinesTransverse axisMachine tool

An APC is provided in a five-axis controlling vertical machining center. A spindle head is movable in three mutually transverse axes directions to a workpiece. A table disposed below swings to be positioned and is directed upwardly and indexed. A pallet setup base is provided outside a machining area. A pallet change arm has pallet grip portions for gripping and releasing the pallets. The arm makes a swivel motion and makes an ascending and descending motion. Thus, the pallet is transferred between the table and the pallet setup base and is received and discharged to the table and the pallet setup base.

Owner:MORI SEIKI HITECH

Variably-shaped vascular devices

Owner:INSERA THERAPEUTICS

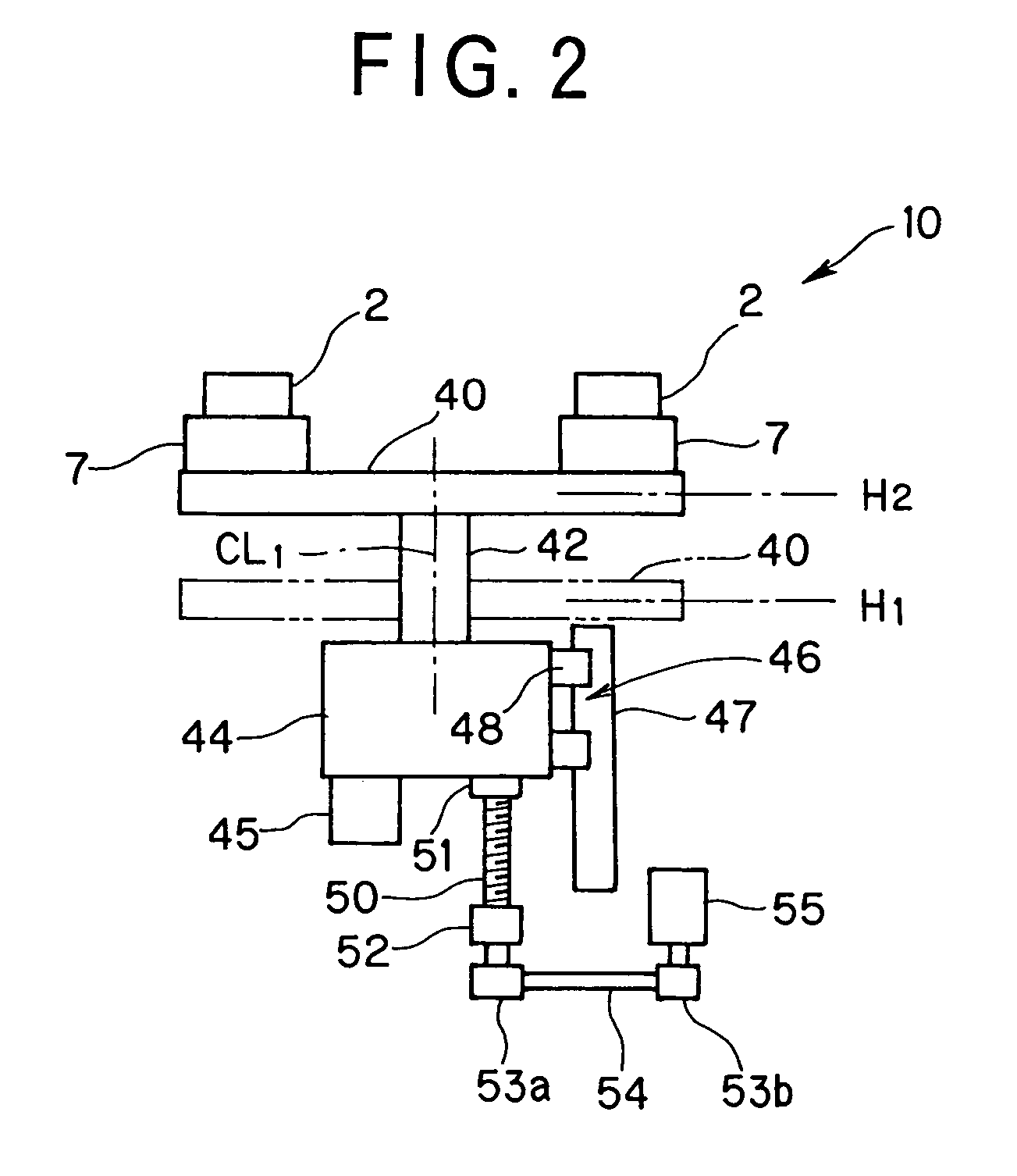

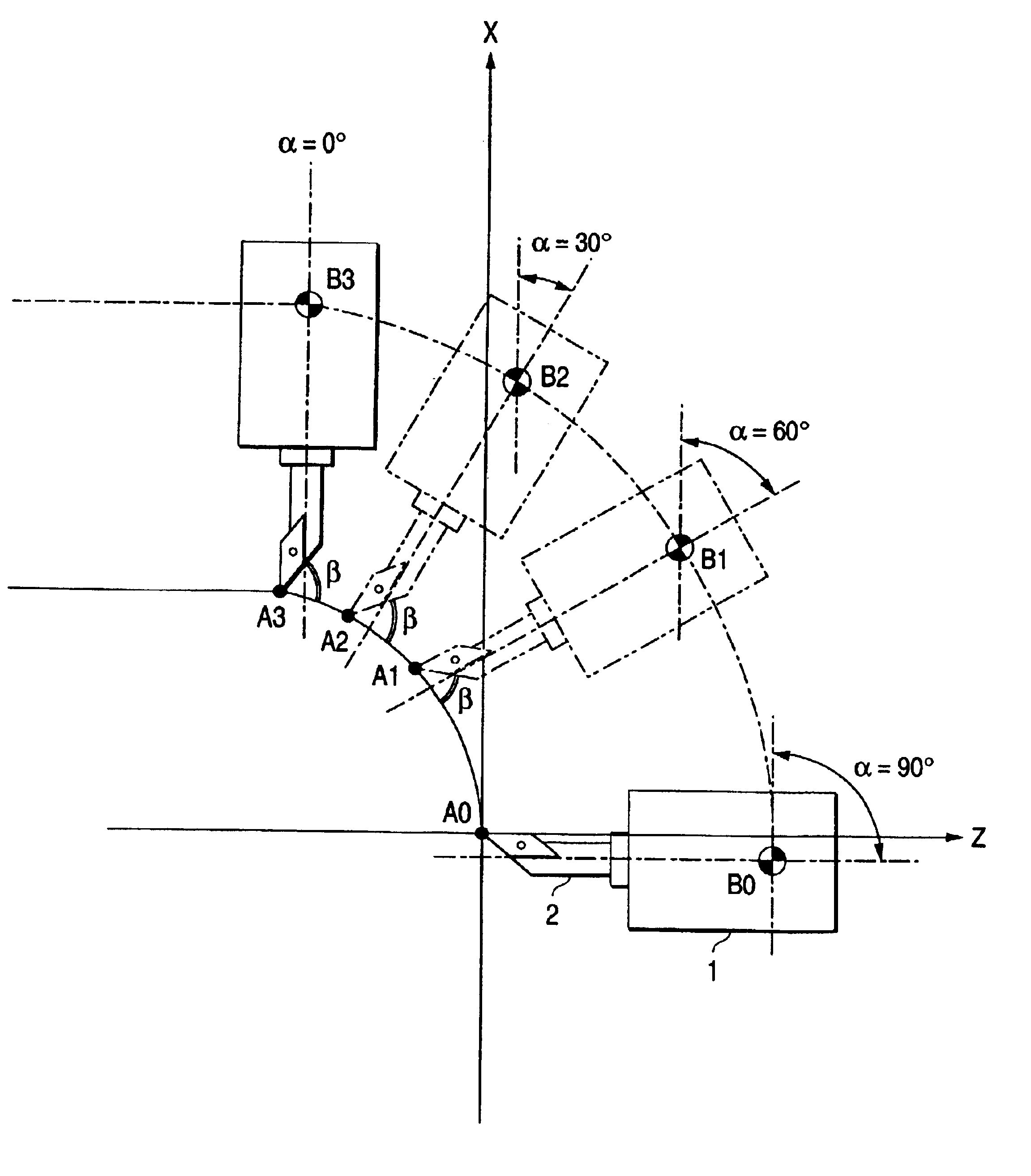

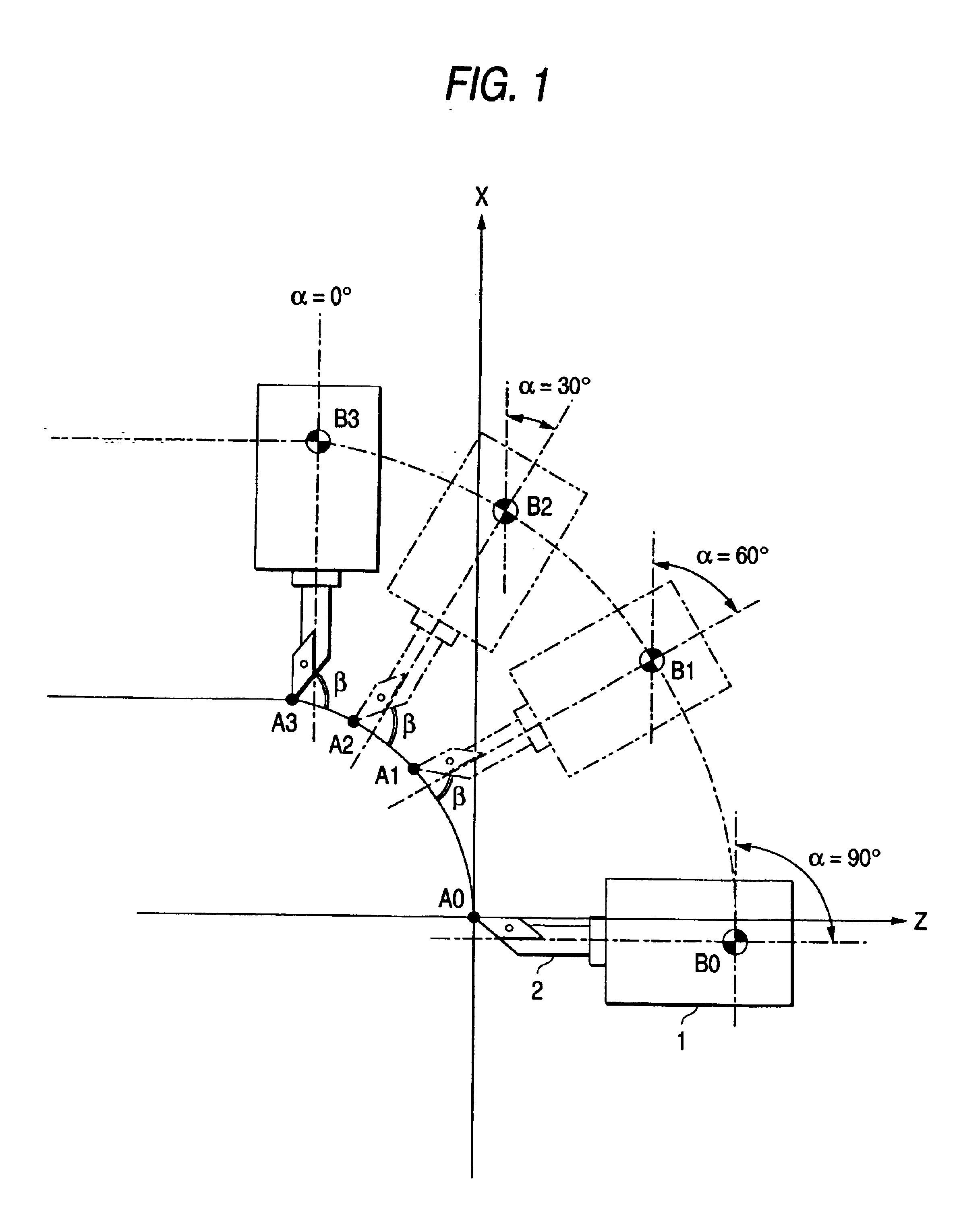

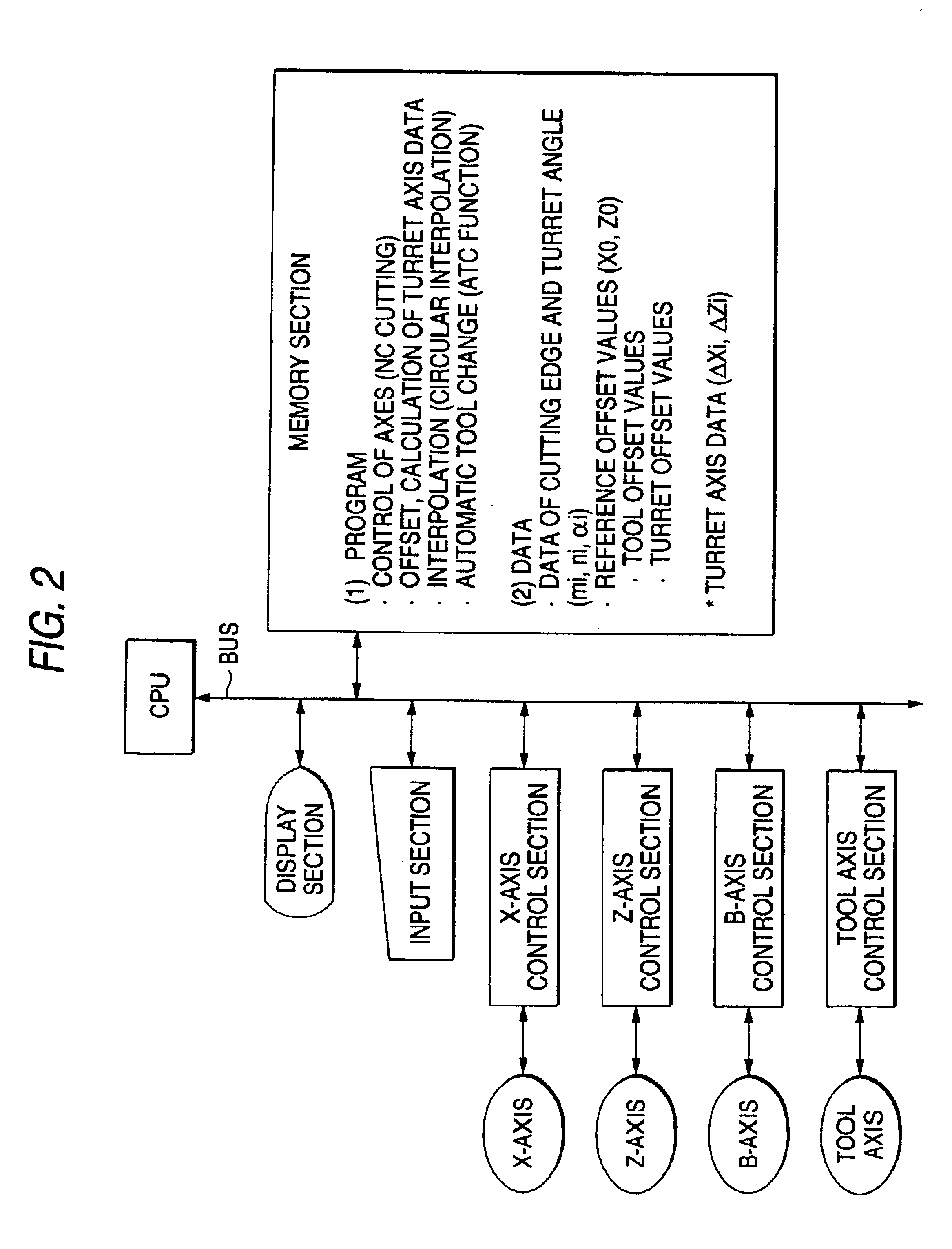

Control apparatus for cutting machine, cutting machine and cutting method

InactiveUS6842664B2Easy to calculateEasy to performLathesProgramme controlNumerical controlEngineering

This invention relates to a control apparatus for numerical control in a cutting machine having a turret which can be rotated to arbitrary positions, and characterized by including means for obtaining turret axis data (ΔX, ΔZ) from reference offset values (X0, Z0) corresponding to a length from a cutting edge to a turret axis B, turret angle data α, and cutting edge data (m, n), and moving the turret on the basis of these turret axis data (ΔX, ΔZ) to perform a cutting.

Owner:DMG MORI SEIKI CO LTD

Toothed tool coupling for rotating a rotary tool

A driven tool includes a driven part which is rotatably driven by a drive part. The driven part and the drive part are coaxially arranged one inside of the other. The drive part and the driven part are conical as viewed in a longitudinal section plane containing the axis. The driven part includes driven teeth projecting generally radially with respect to the axis and received in respective radially-open recesses formed in the drive part. Each of the driven teeth makes contact with a wall of the respective recess at first and second contact places which are respectively situated on opposite sides of a generally radial line of symmetry of the driven tooth. The contact places are operable to transmit a drive force from the drive part to the driven part in respective directions of rotation. A driving angle in the range of -5° to +45° is formed at each contact place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

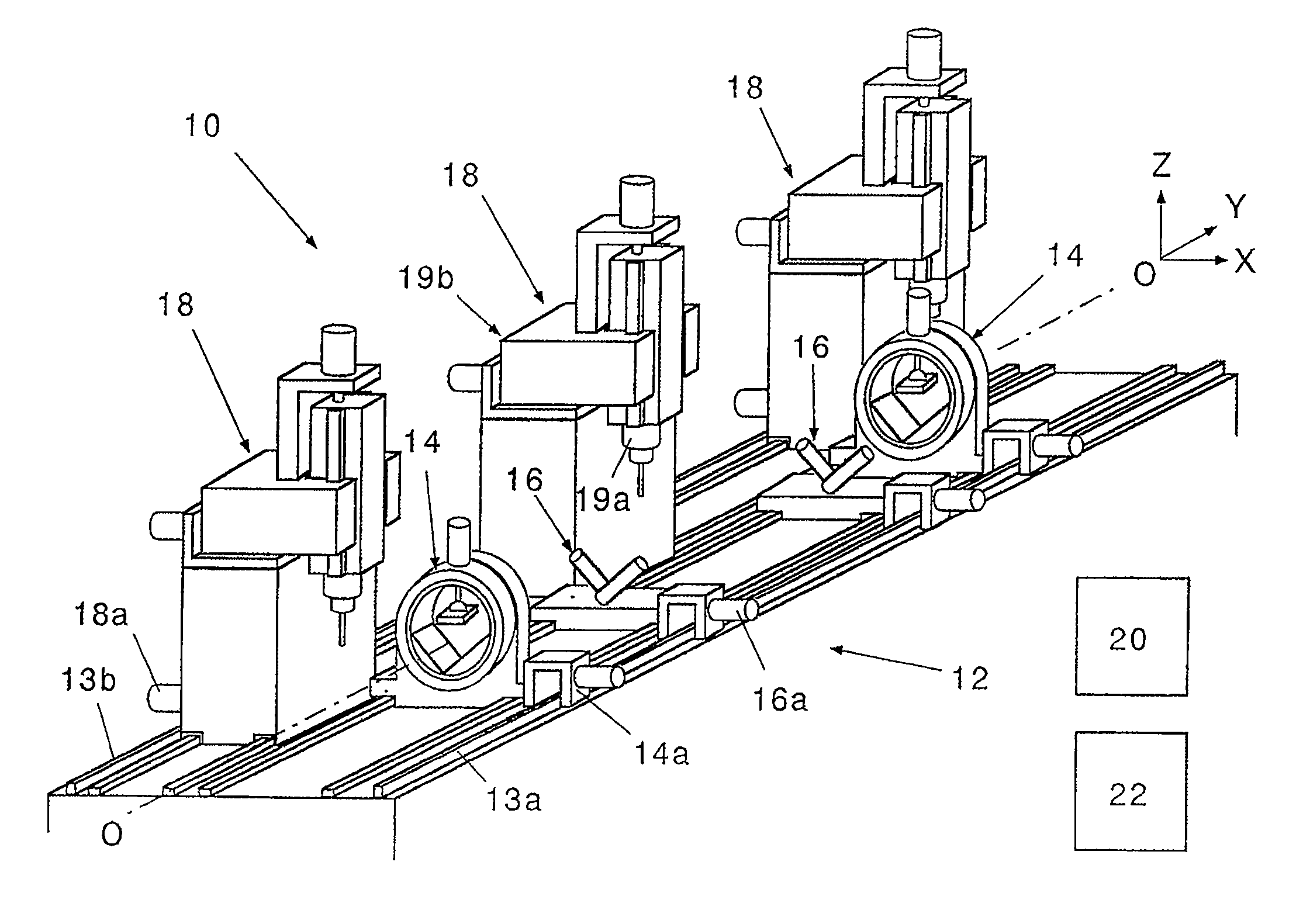

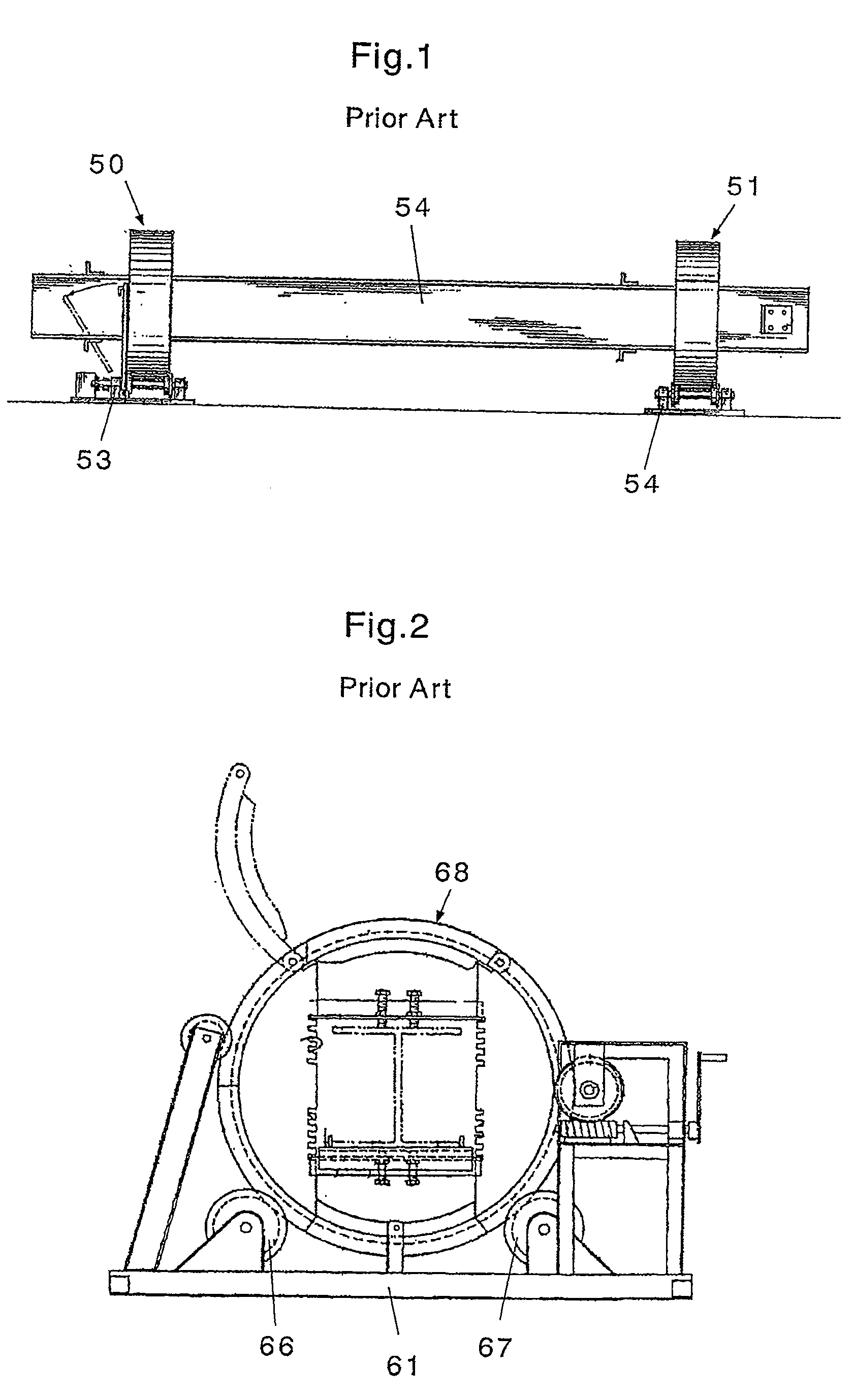

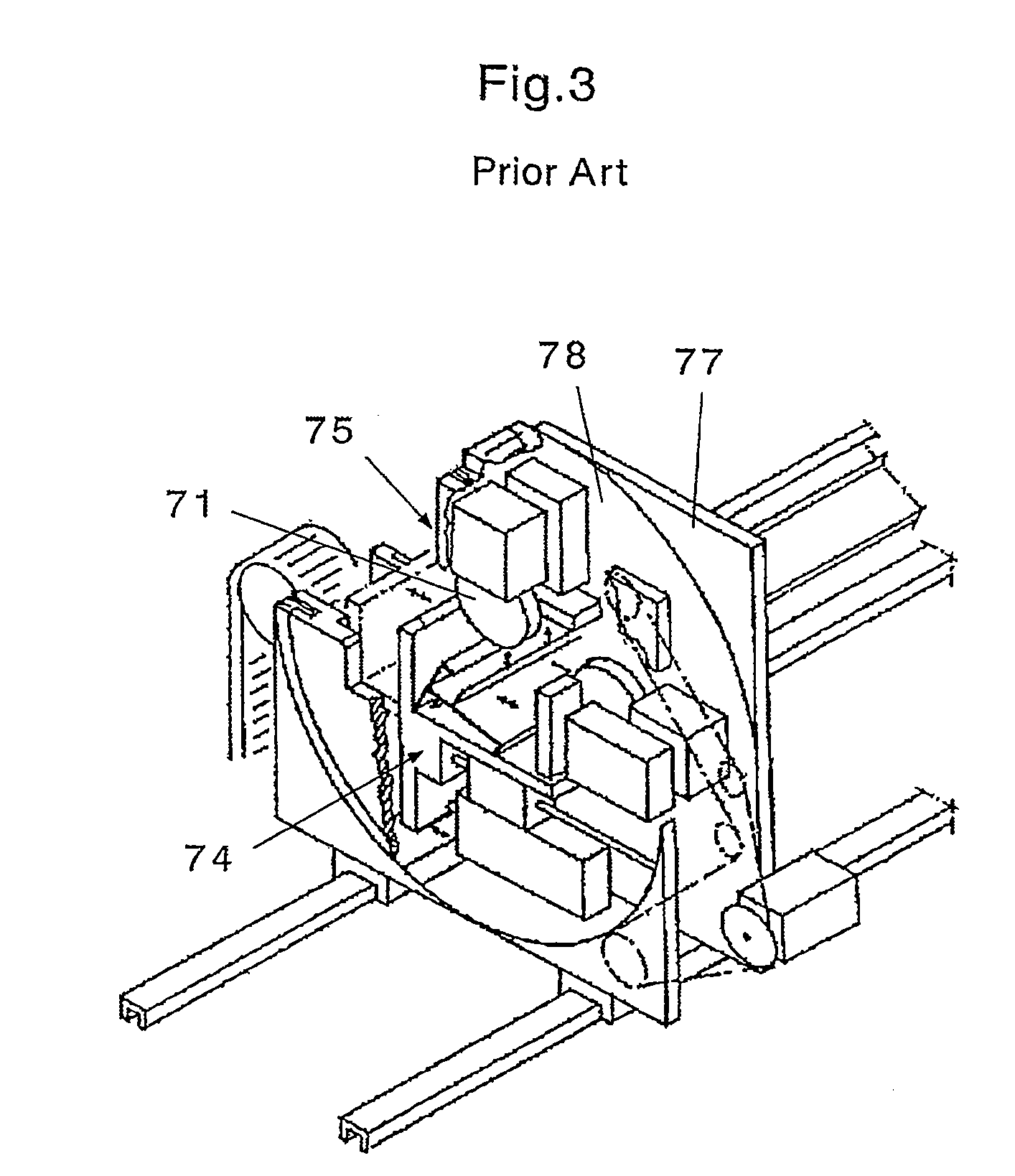

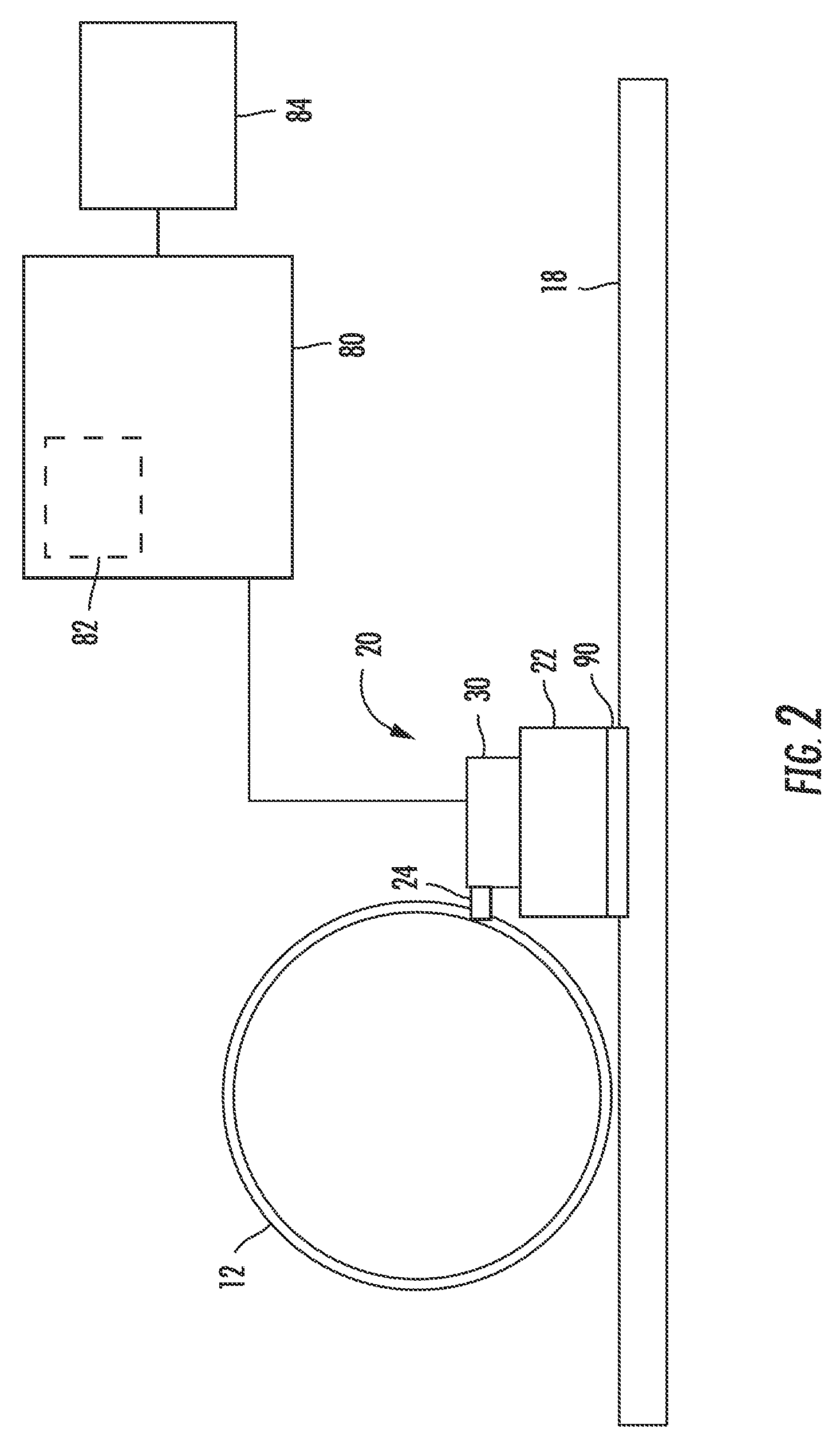

Apparatus and method for machining long workpiece

There are provided a base frame 12 positioned below a horizontal axis O; a pair of clamp units 14 positioned at the two ends above the base frame; a pair of support units 16 that horizontally support the long workpiece in two locations, and that are capable of moving vertically; and machining units 18 that are capable of machining the long workpiece. The two clamp units 14 are capable of moving from the outside toward the inside, which support the long workpiece in two locations, and rotate around the horizontal axis O in synchronization with each other.

Owner:IMAX CO LTD

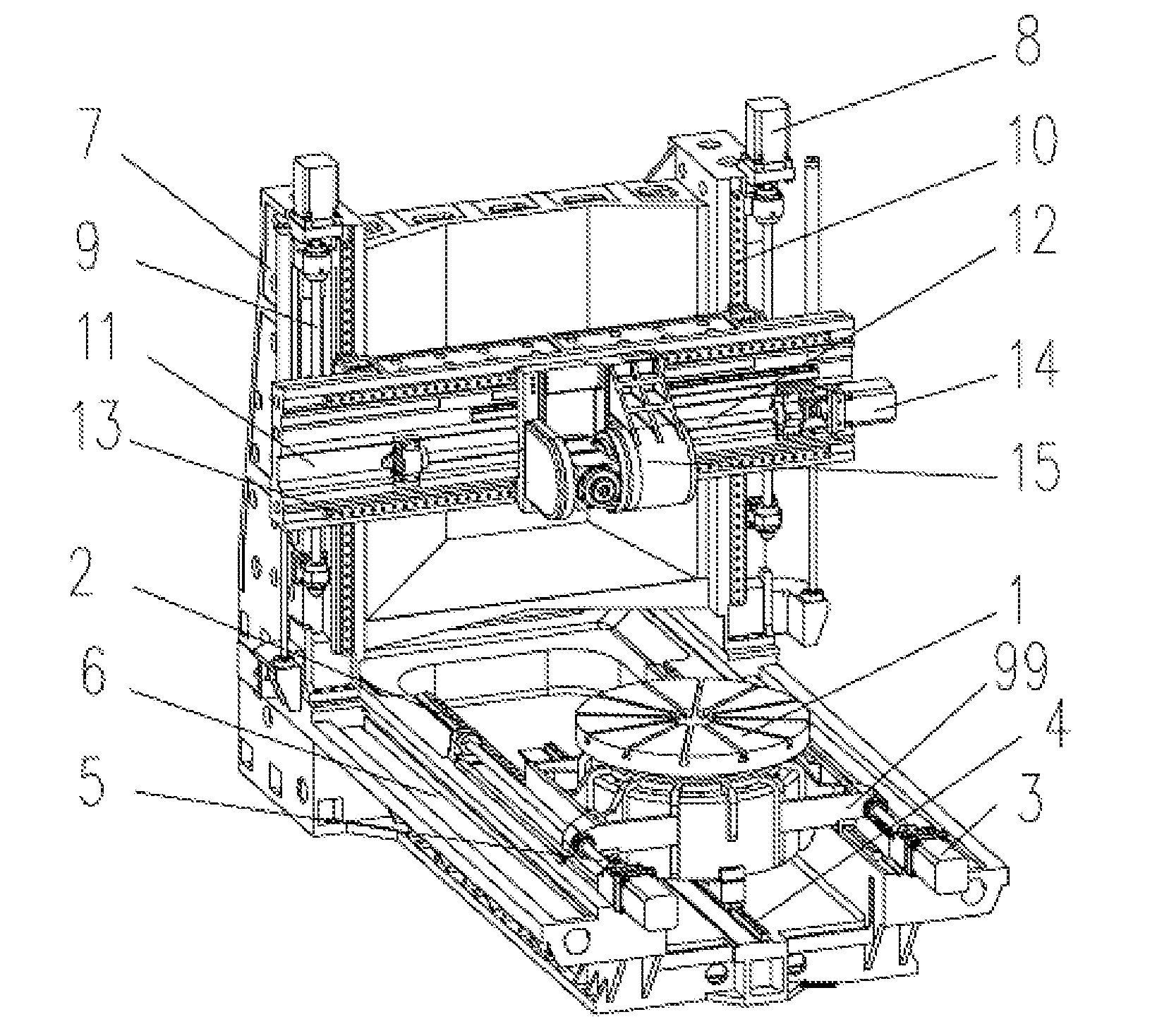

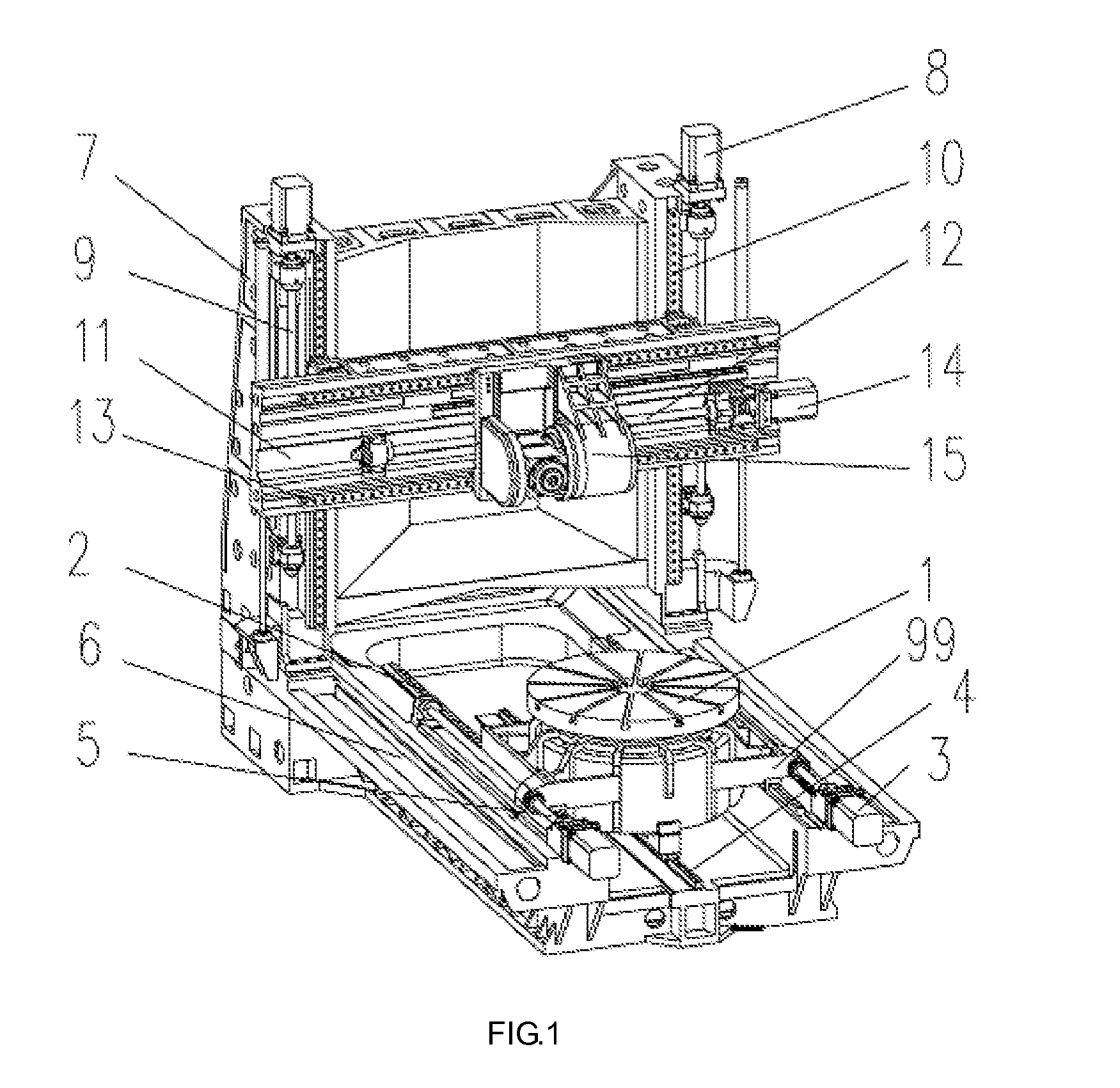

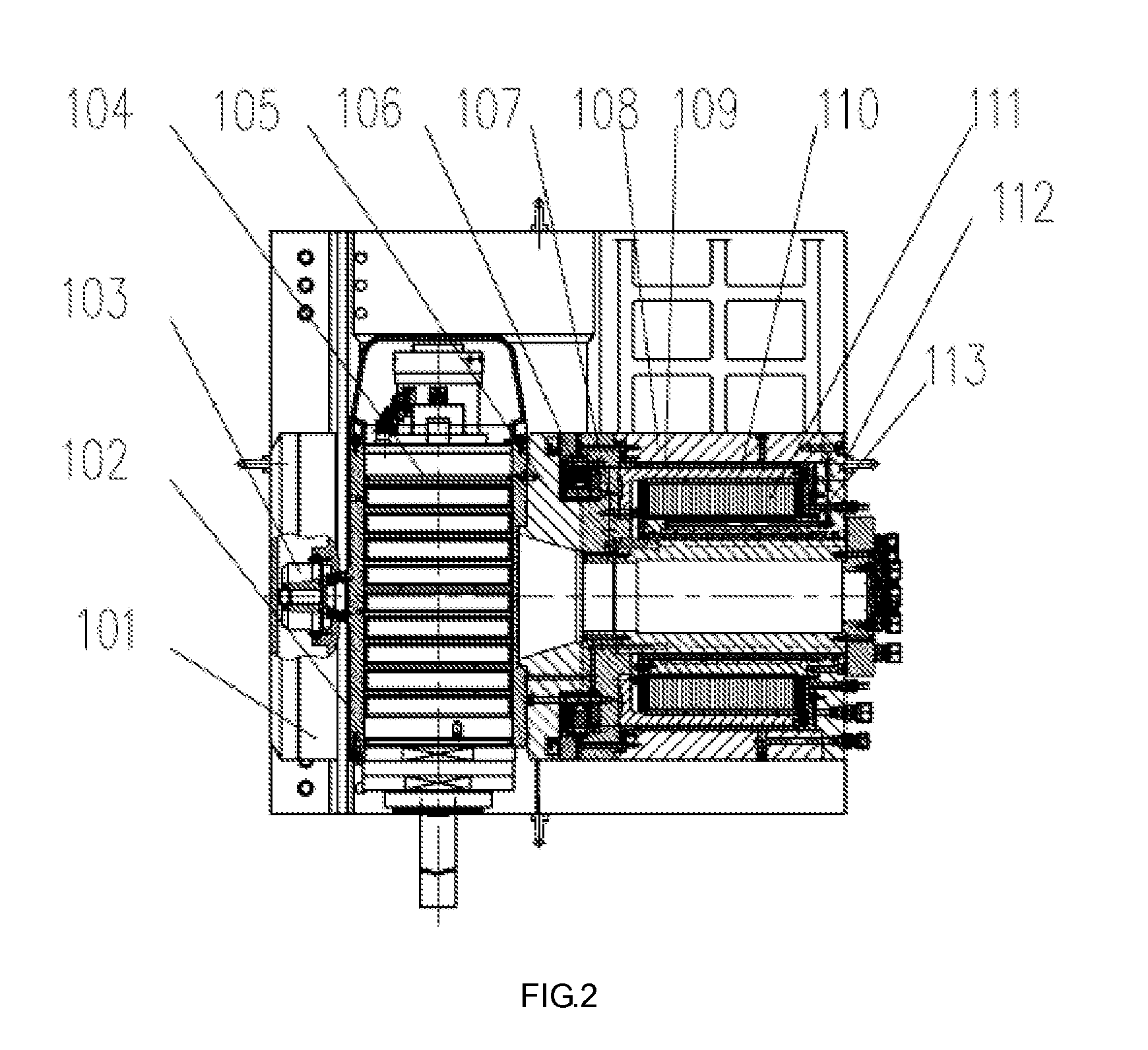

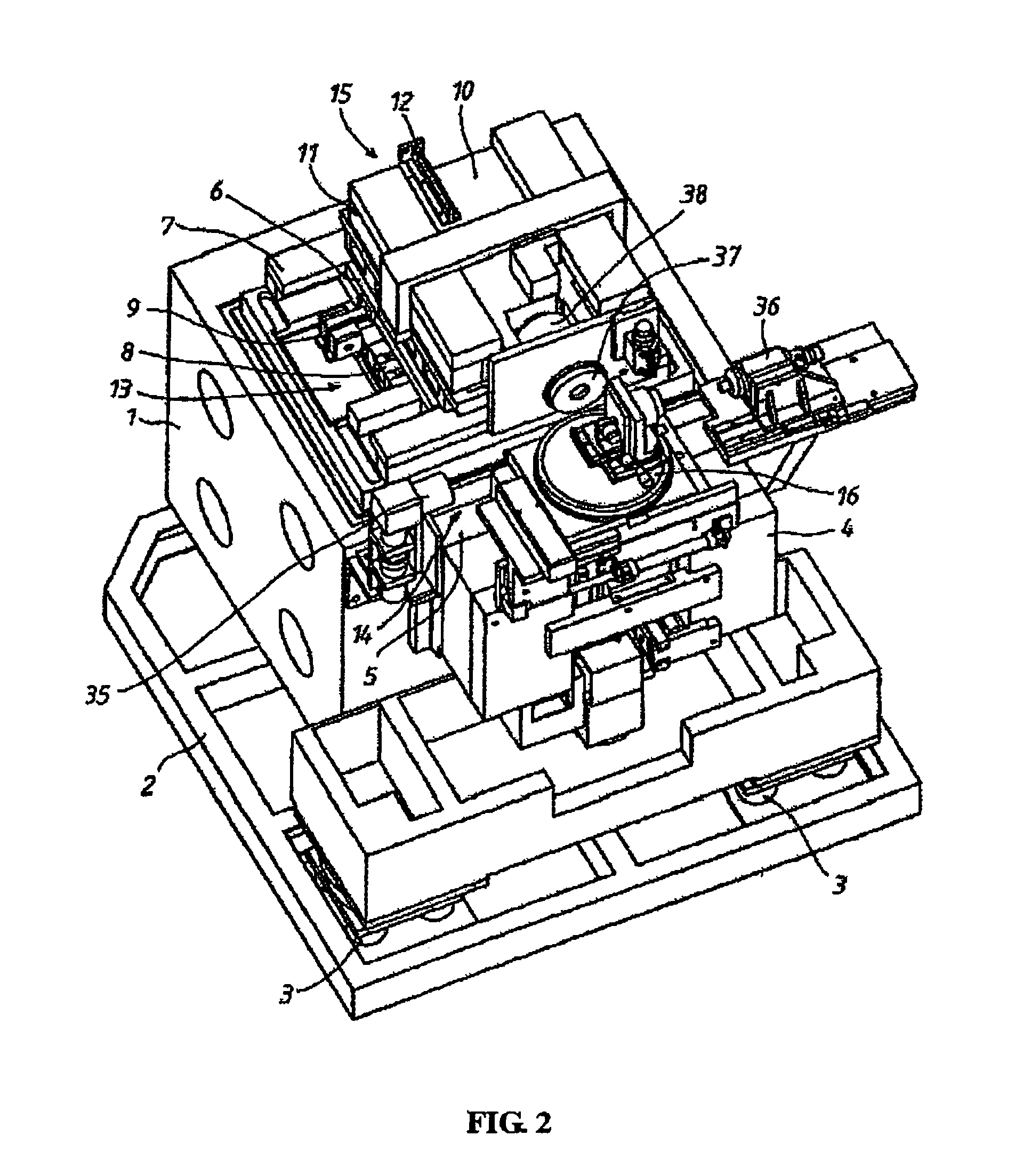

Vertical turning-milling complex machining center

ActiveUS20120210551A1Avoid vibrationDeformation MinimizationLathesAutomatic/semiautomatic turning machinesReciprocating motionTorque motor

A vertical turning-milling complex machining center comprises a horizontally-arranged bed body (6) and a vertically-arranged column (7). The bed body (6) is provided with an X-axis lateral supporting linear track (2) and an X-axis guide screw (5). The bed body (6) is also provided with a uniaxial rotating table (1) which can reciprocate and is driven directly by a first external rotor torque motor. The column (7) is vertically provided with a Z-axis lateral supporting linear track (10), a Z-axis guide screw (9) and a crossbeam (11) that reciprocates up and down. The crossbeam (11) is provided with a transverse Y-axis linear track (13), a Y-axis guide screw (12) and a single-pendulum milling head seat frame that can reciprocate along the Y-axis guide screw (12). The single-pendulum milling head is driven directly by a second external rotor torque motor. The vertical turning-milling complex machining center uses direct-drive technology applied to a B-axis and a C-axis, the motor torque is greatly increased and functional parts can stably operate, therefore the integral rigidity and stability of the machining center are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

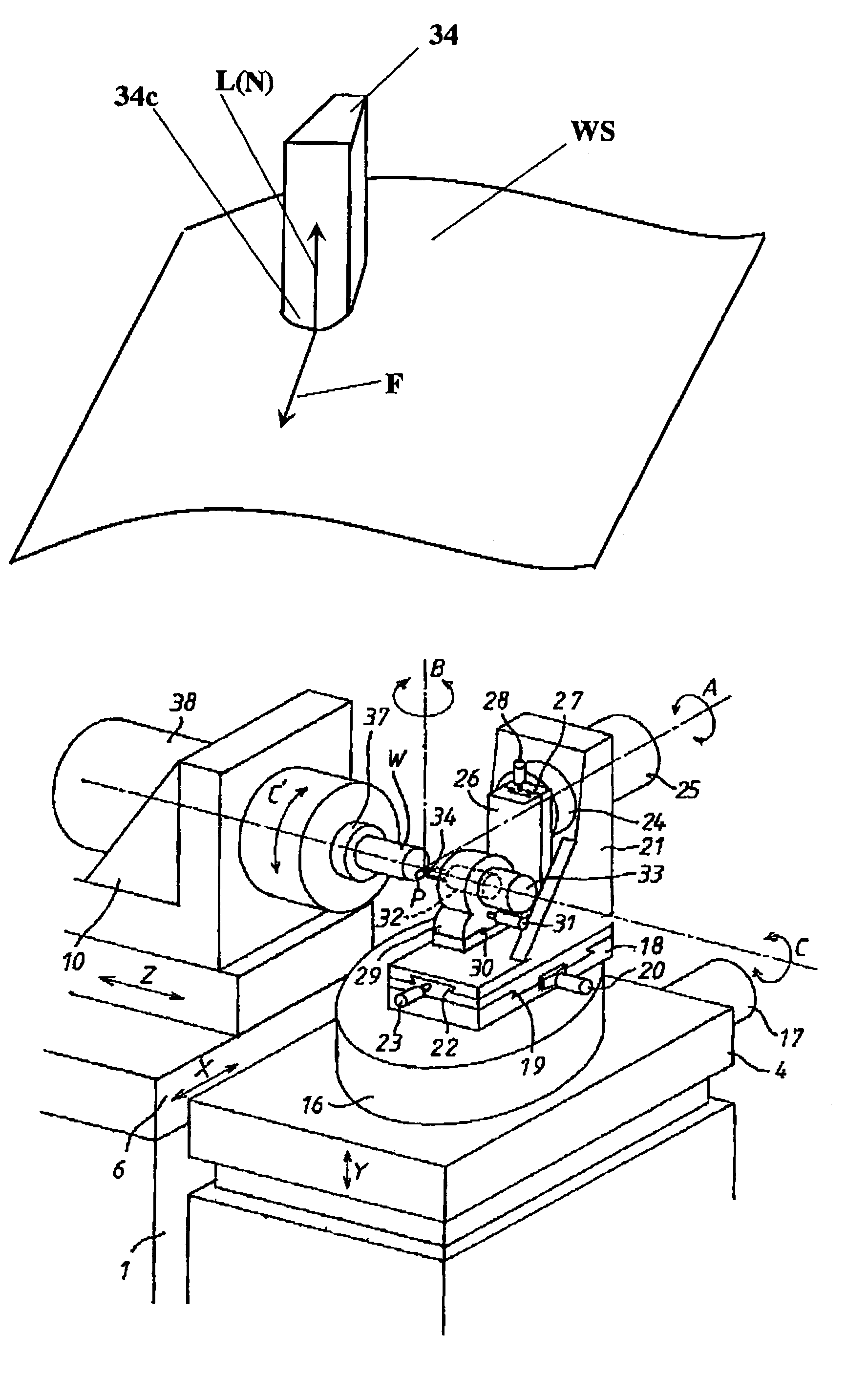

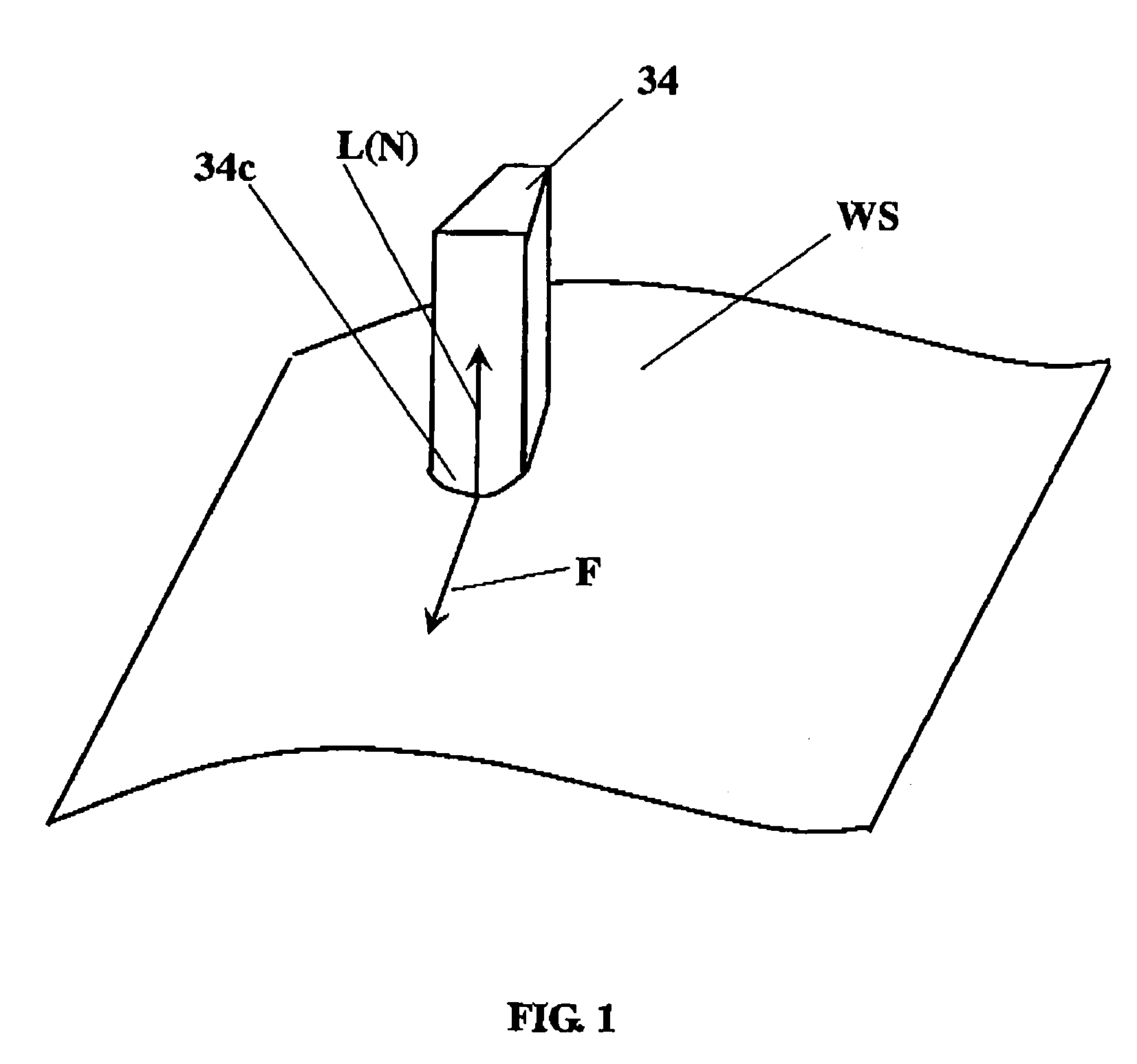

Hale-machining method and apparatus

InactiveUS7089836B2Easy to prepareHigh geometric accuracyLathesAutomatic/semiautomatic turning machinesRotary stageRotational axis

It is one object of a hale-machining method and apparatus thereof according to the present invention to achieve an easy preparation of an NC machining program and perform a high geometrical accuracy in the predetermined three-dimensional free curved surface.A haling tool 34 is set on a tool holder 32 in such a manner that a cutting point P of the haling tool 34 is substantially coincided with an intersection of a first rotating axis B, a second rotating axis A and a third rotating axis C. A rotary table 16 and a rotary base 24 are rotated in such a manner that a tool axis direction of said haling tool is substantially coincided with a normal direction of said machined surface. A tool holder 32 is rotated in such a manner that a front rake surface of the haling tool 34 is substantially directed in perpendicular to a feeding direction of said haling tool 34. A workpiece table holding a workpiece and the tool holder are relatively moved along a machined surface of said workpiece in three perpendicular axes including an axis parallel to said first rotating axis.

Owner:TOYODA MASCH WORKS LTD

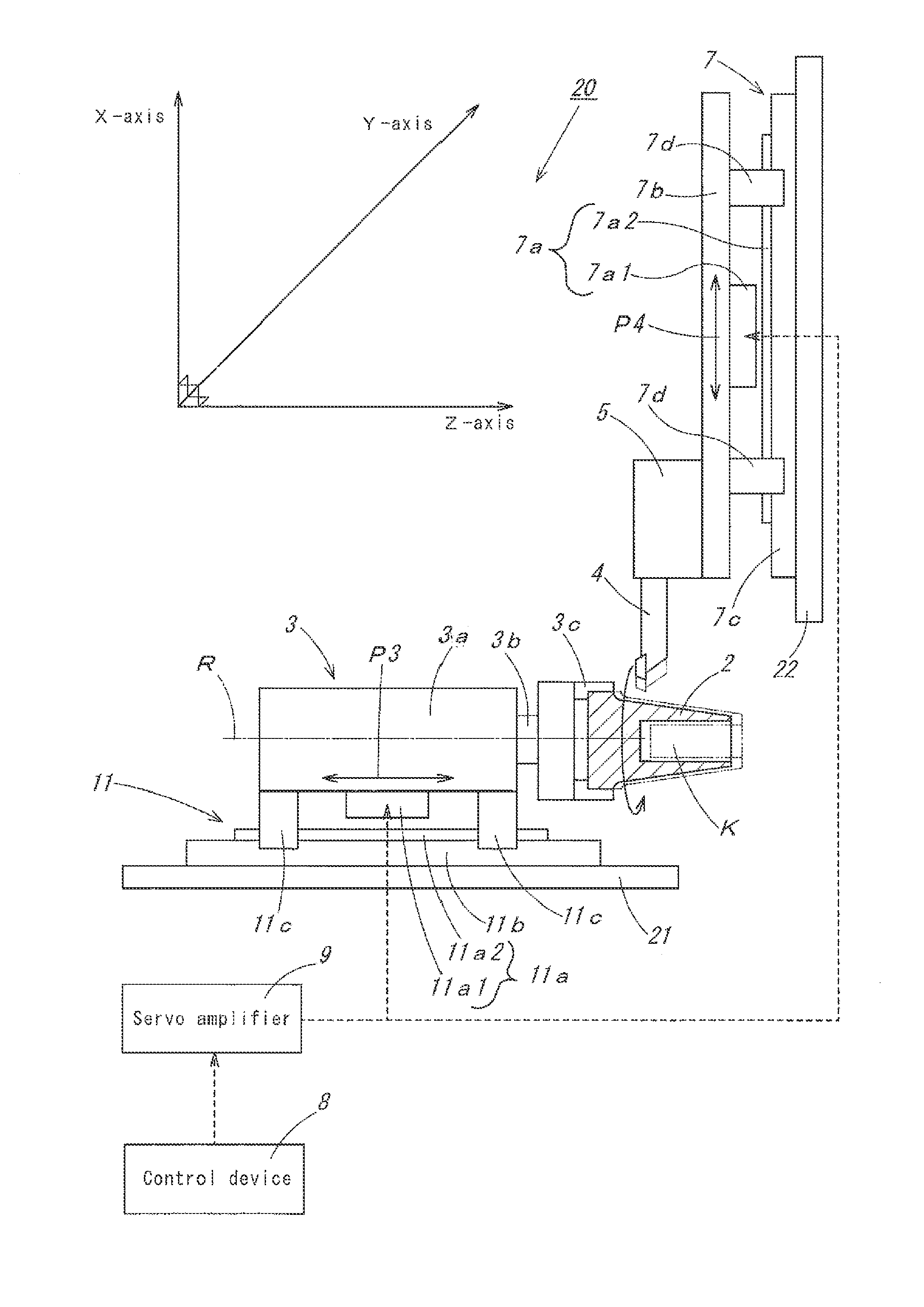

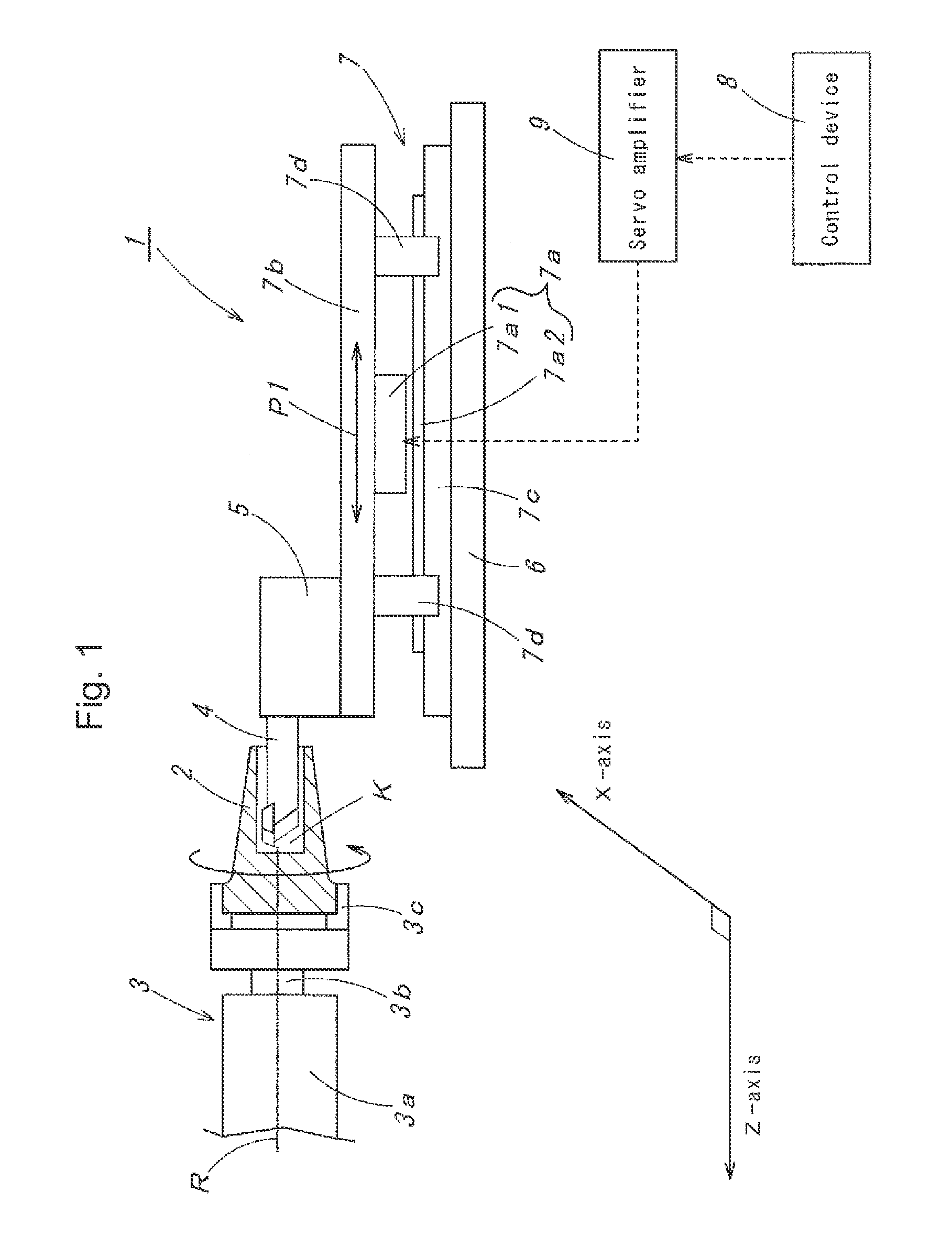

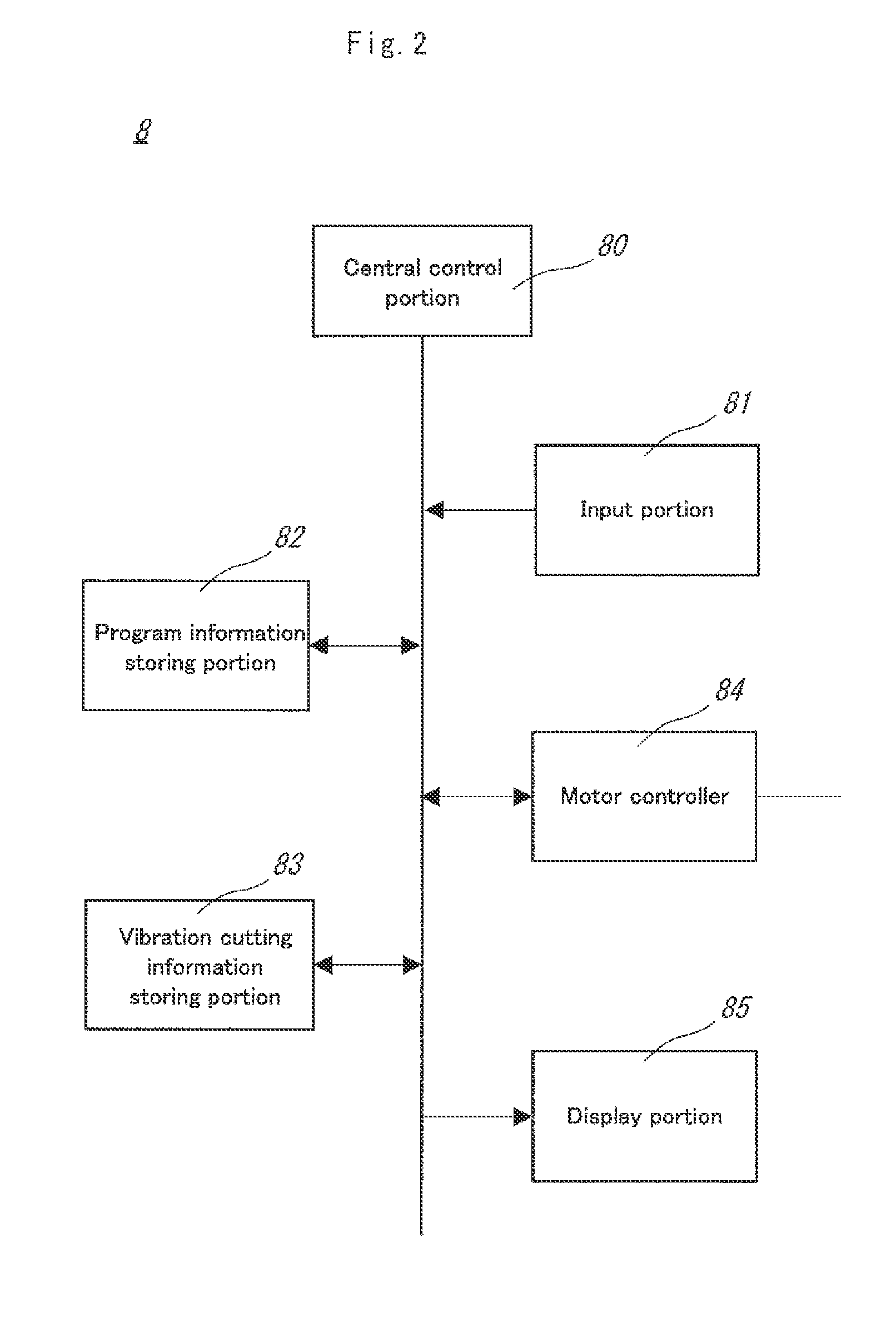

Machine Tool

ActiveUS20140102268A1Improve vibrationReduce vibrationProgramme controlLathesMachine toolTool holder

A machine tool for machining a workpiece is provided with a cutting tool holder for holding a cutting tool and a rotation mechanism for holding the workpiece. One or both of the cutting tool holder and the rotation mechanism are movable on multiple axes so that the cutting tool is movable relative to the workpiece in multiple axial directions. A control device is provided for controlling the movement of one or both of the cutting tool holder and the rotation mechanism to synchronously vibrate the workpiece and the cutting tool relative to each other at a low frequency in multiple axial directions.

Owner:CITIZEN WATCH CO LTD

Methods and apparatus for image transfer to non-planar surfaces

A method and apparatus for imprinting high quality images on non-planar surfaces, including the surfaces of various types of three-dimensional articles, such as baseball bats, formed from a number of different types of materials. In the preferred method of the invention, the non-planar surfaces of the three-dimensional articles are printed using a uniquely modified ink jet image transfer technique. The apparatus of the invention includes a modified ink jet printer coupled with a novel article positioning apparatus which functions to controllably rotate the article to be imprinted and to maintain the longitudinal axis of the article within a plane substantially parallel to and spaced apart from the plane within which the ink jet nozzles of the ink jet printer travel.

Owner:JETSYST

Multi-axis turning center and turning method

InactiveUS7506423B2Improve rigidityLathesAutomatic/semiautomatic turning machinesTransverse axisMulti axis

A multi-axis turning center has a spindle head, a spindle rotatably supported by the spindle head, and a table or a headstock for gripping and rotating a workpiece thereon. The table or the headstock is disposed in confronting relation to the spindle. The spindle head is relatively movable in the three mutually transverse axes directions to the workpiece gripped and rotated by the table or the headstock. A multi-point turning tool is mounted on the spindle and having a plurality of tips, for turning the workpiece gripped and supported by the table or the headstock. The spindle head is movable to translate the multi-point turning tool to one of positions around the workpiece, and the tips are selectively used depending on the one of the positions to turn the workpiece.

Owner:DMG MORI CO LTD

Device For Refining Workpieces

InactiveUS20090120249A1Easy to insertSimple designLathesTailstocks/centresRelative motionEngineering

The invention relates to a device for refining workpieces, which preferably consist at least partially of wood, wood materials or the like, having an ink-jet printing means having a plurality of nozzles from which drops of ink can be expelled, a workpiece carrier means for carrying the workpiece to be patterned, a conveyor device for bringing about a relative movement between the workpiece to be refined and the printing means. The device according to the invention is characterised in that it further has at least one machining means for machining the workpiece.

Owner:HOMAG HOLZBEARBEITUNGSSYST

Cutting Tool Assembly and Tool Holder Therefor

A cutting tool assembly for boring and internal grooving operations includes a tool head having a removably secured cutting insert at a forward insert receiving end and a rear mating end with a male or female type tool holder coupler in the form of an engagement protrusion or cutting holder receiving pocket. The tool head is fixed to a tool holder with a front mating end having a female or male tool head coupler in the form of a tool head receiving pocket or engagement protrusion. Following assembly, at least three abutting wall surfaces and an adjacent support surface of the tool holder coupler are in contact with at least three non-coplanar abutment surfaces and an adjacent supporting surface of the tool head coupler, respectively, and a fastening screw member extends through a through bore in the tool holder coupler engaging a threaded screw bore in the tool head coupler.

Owner:ISCAR LTD

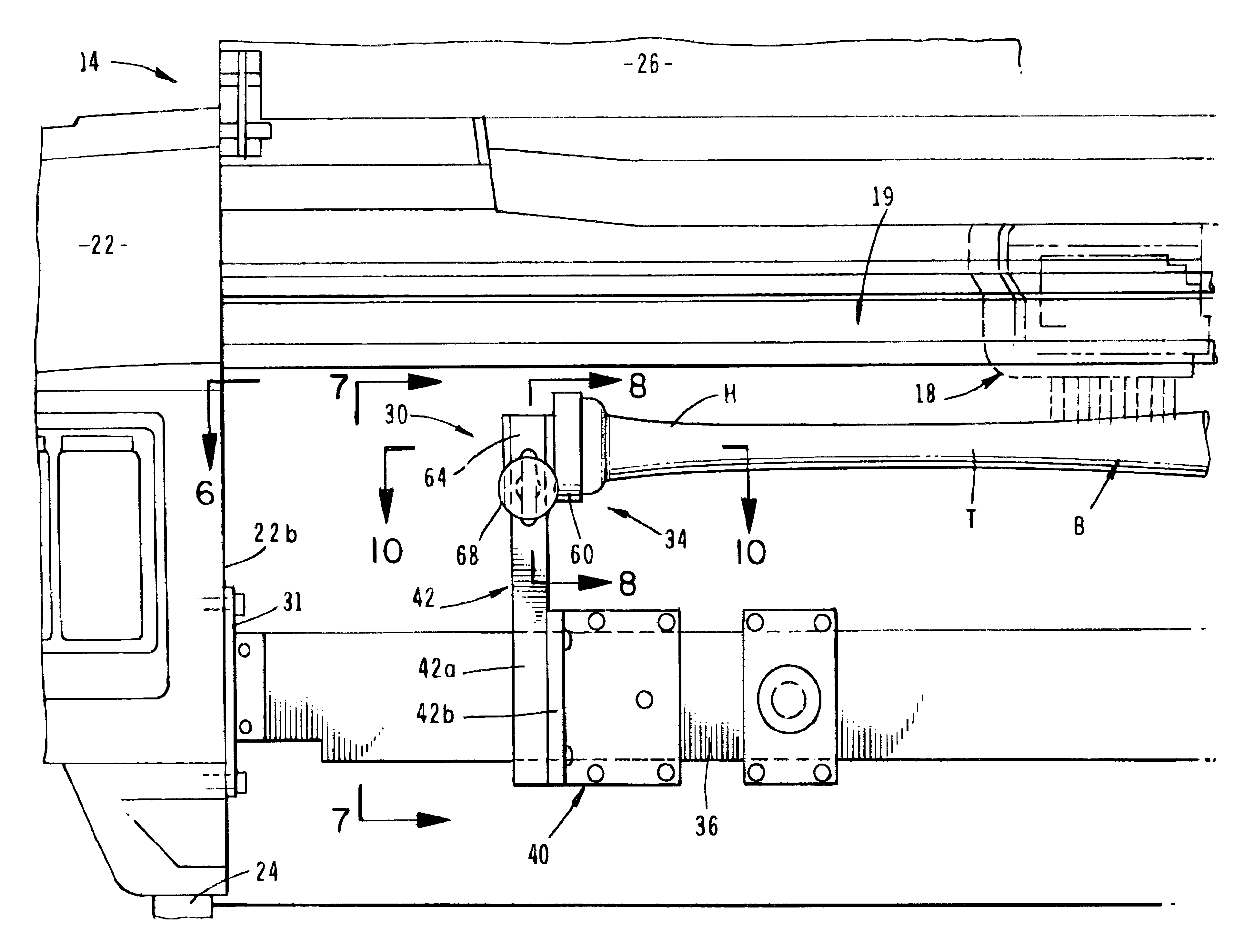

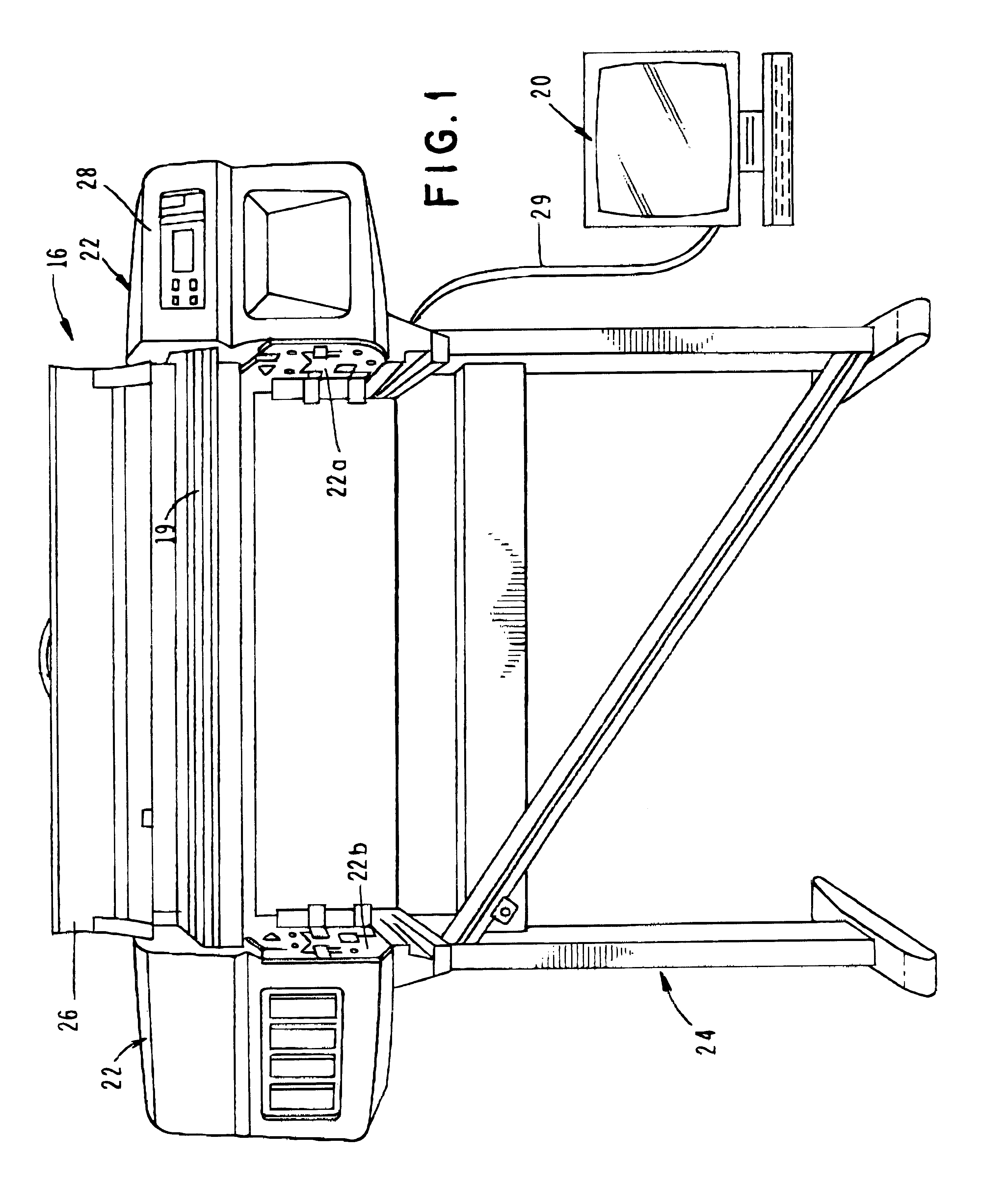

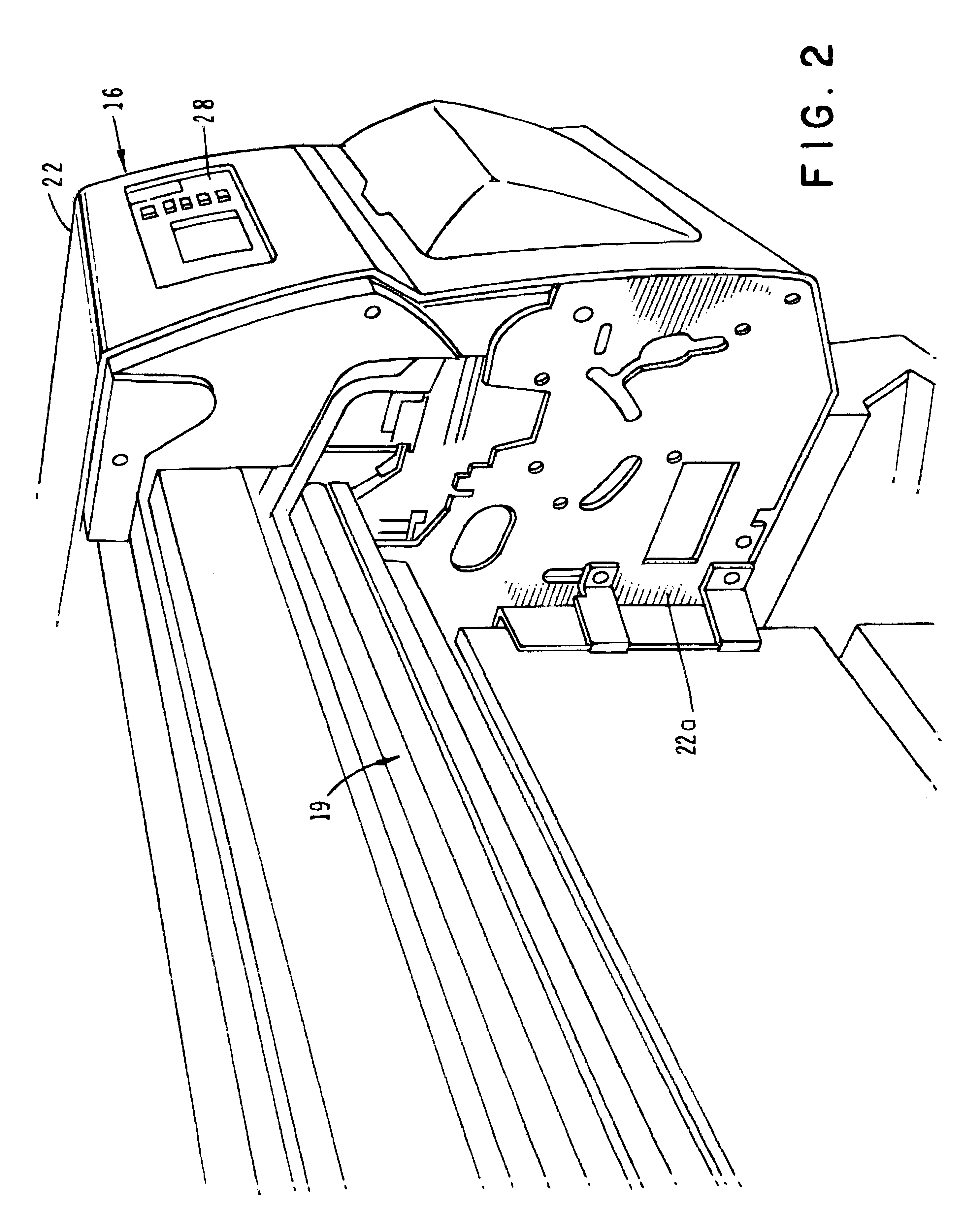

Wheel lathe for box cars

One embodiment of the invention relates to an apparatus for configuring a wheel associated with a train. The apparatus comprises a tool configured to engage the wheel; a compound slide system for positioning the cutting tool in at least two axes; and a computer control coupled to control the compound slide system. The compound slide system is controlled so that the wheel is configured in accordance with a profile.

Owner:HJR REAL ESTATE MANAGEMENT LLC

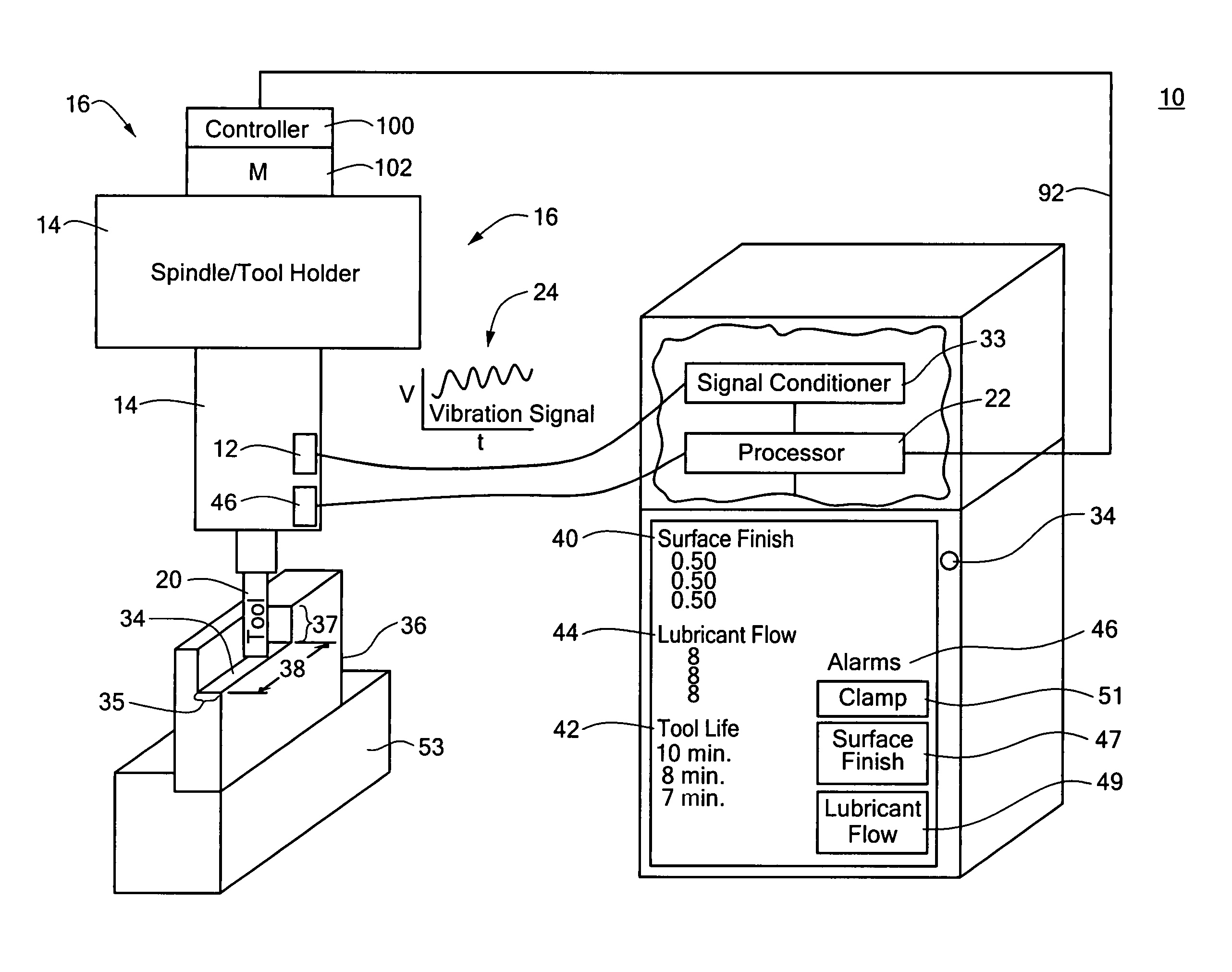

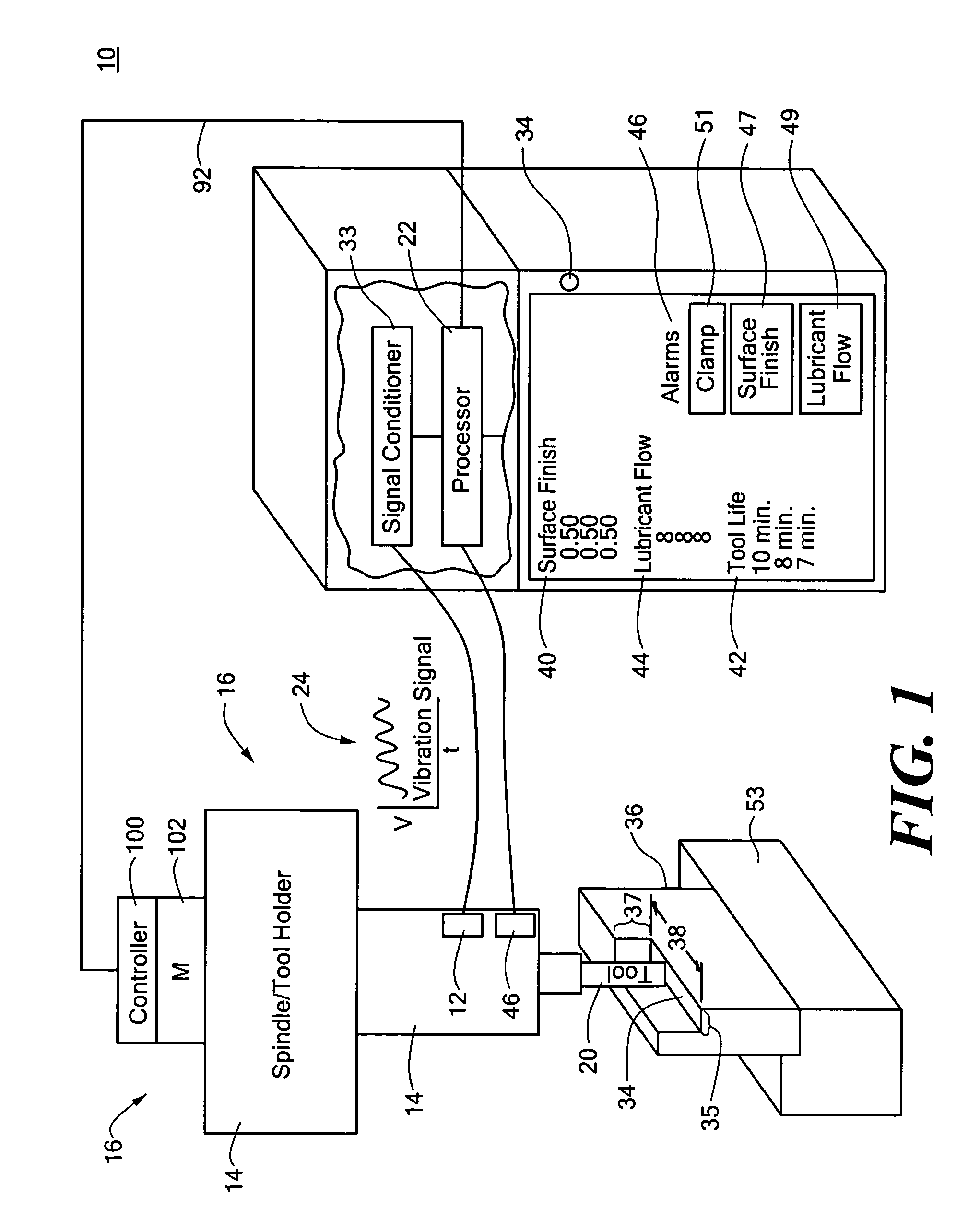

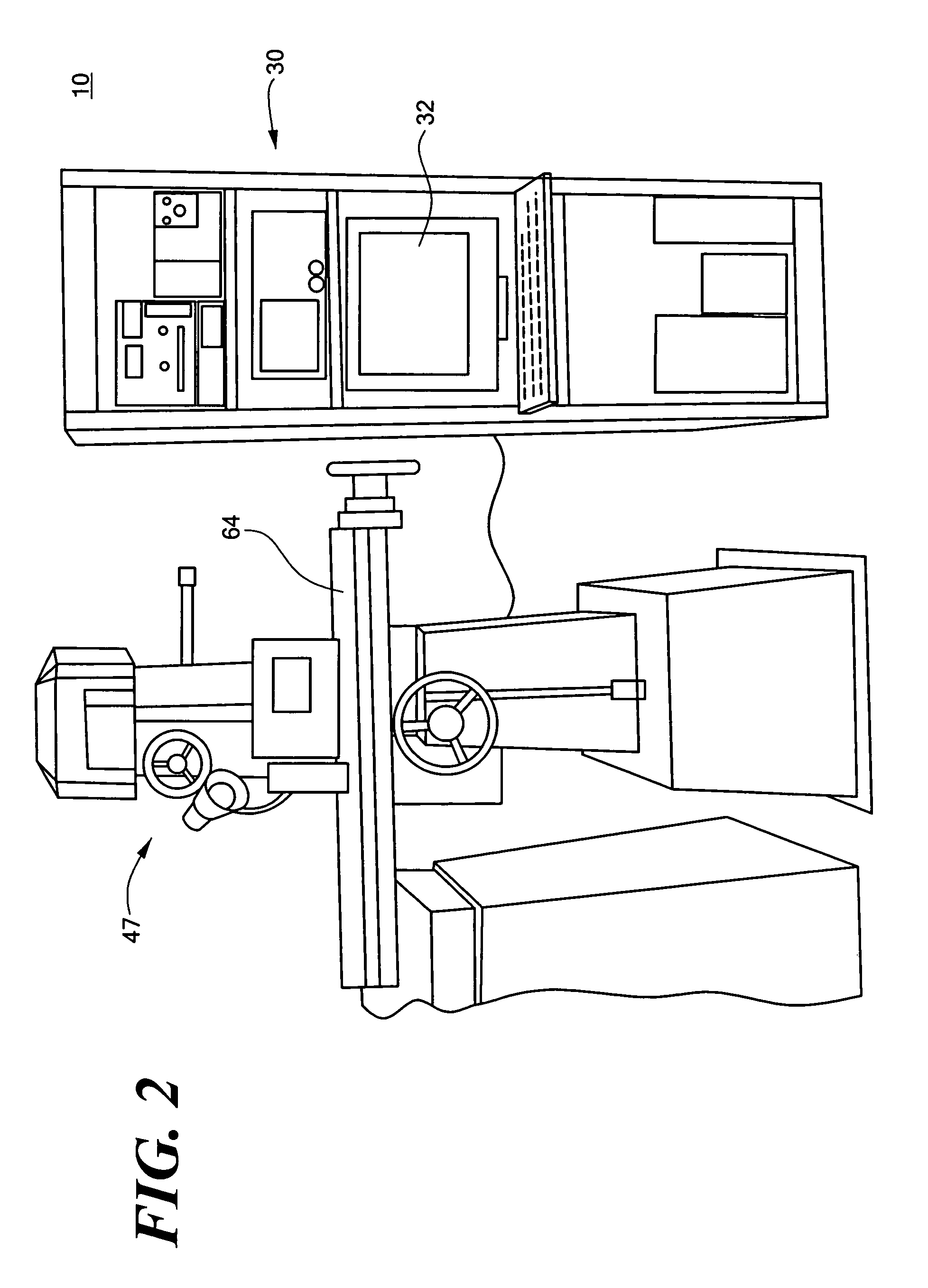

Dynamical instrument for machining

InactiveUS7341410B2Improve operational capabilitiesAccurate surface finishLathesVibration measurement in solidsEngineeringMachining

A dynamical instrument for machining comprising a sensor responsive to a non-rotating part of a machine proximate the tool of the machine for outputting a vibration signal, and a processor responsive to the sensor output configured to calculate a plurality of signature quantities which characterize the dynamics of the vibration signal and correlate the signature quantities to detect parameters associated with the operation of the machine.

Owner:FOSTER-MILLER

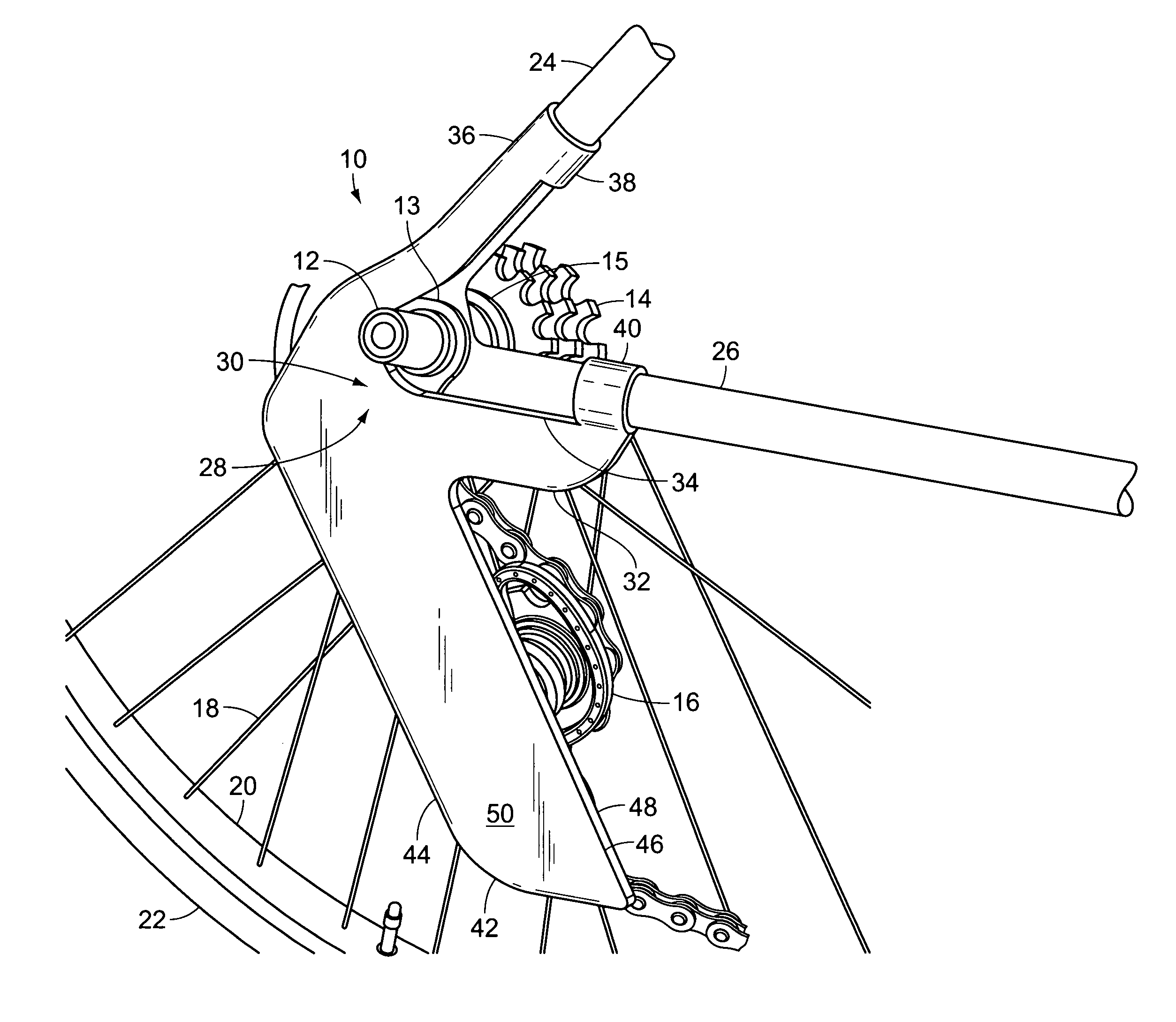

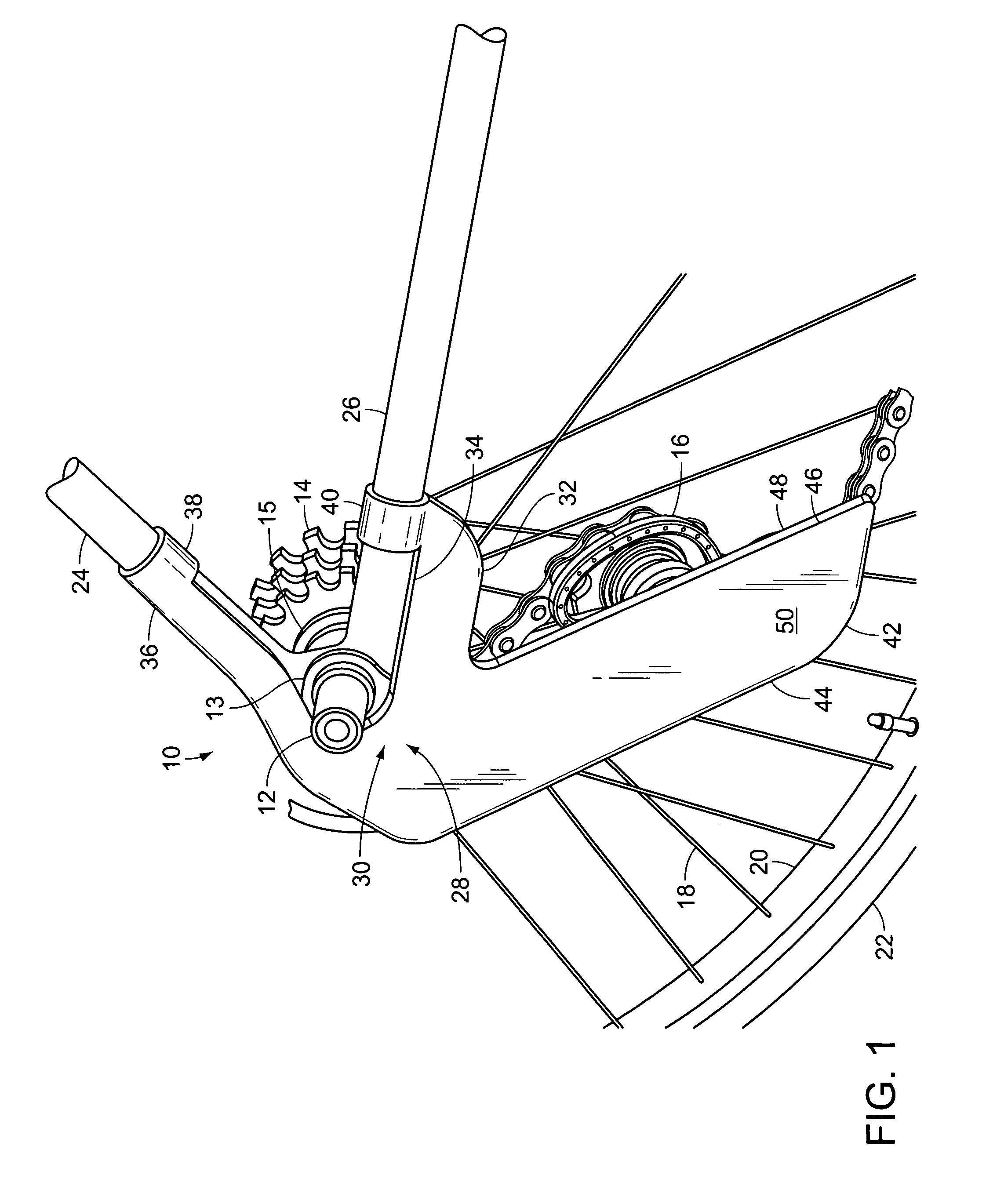

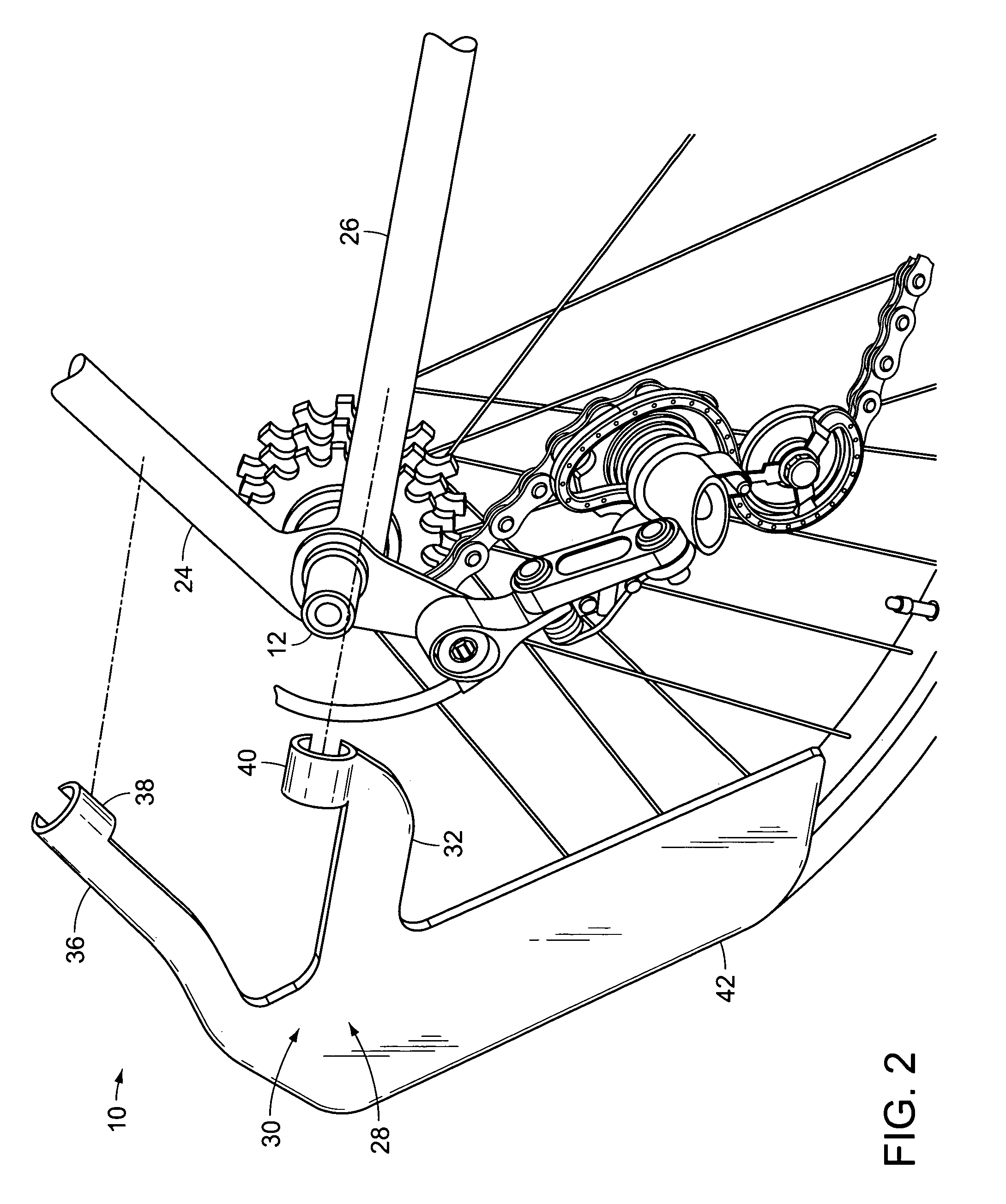

Rear derailleur guard

InactiveUS7066857B1Improve efficiencyAttach and detachLathesGearboxesStructural engineeringEngineering

Owner:DEROSA UMBERTO

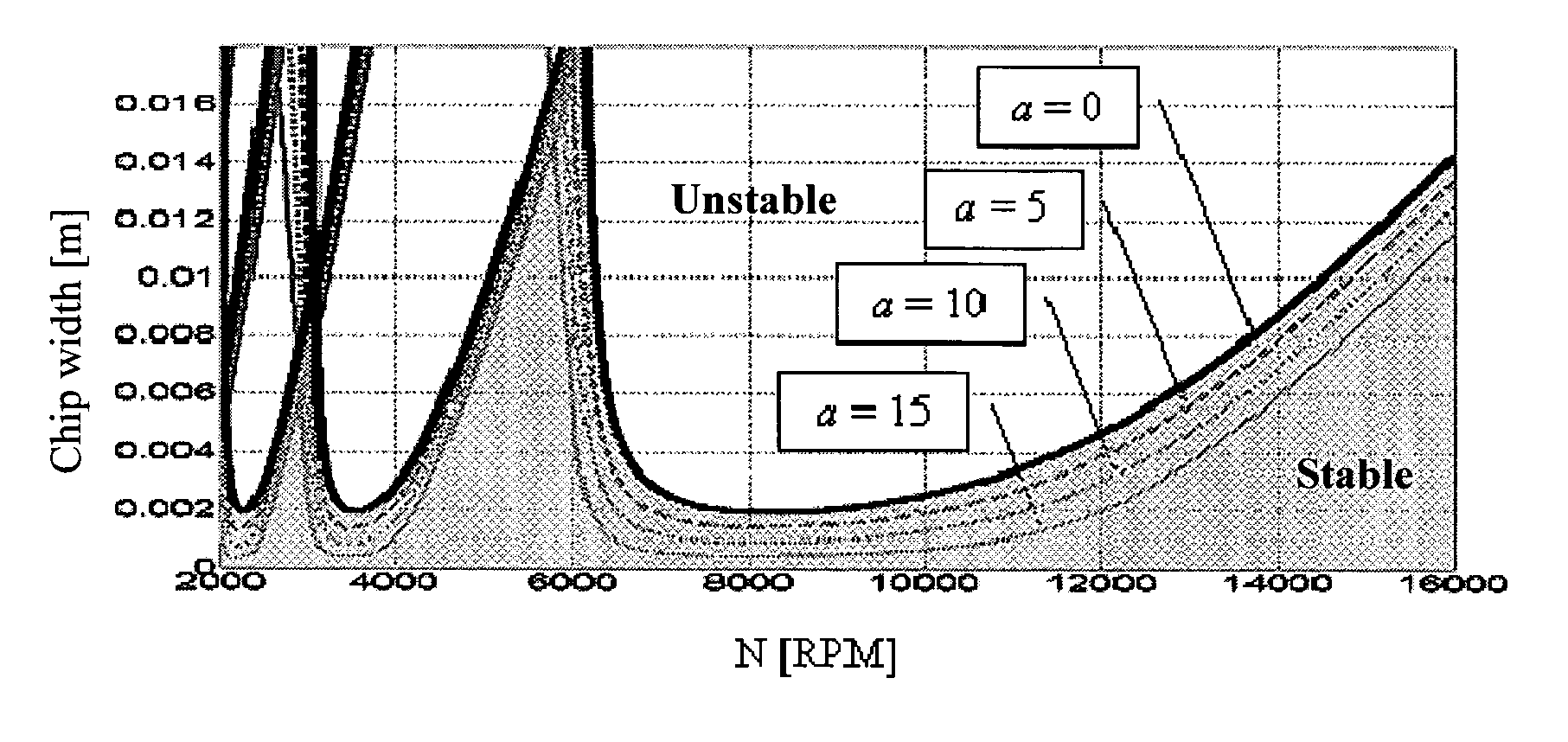

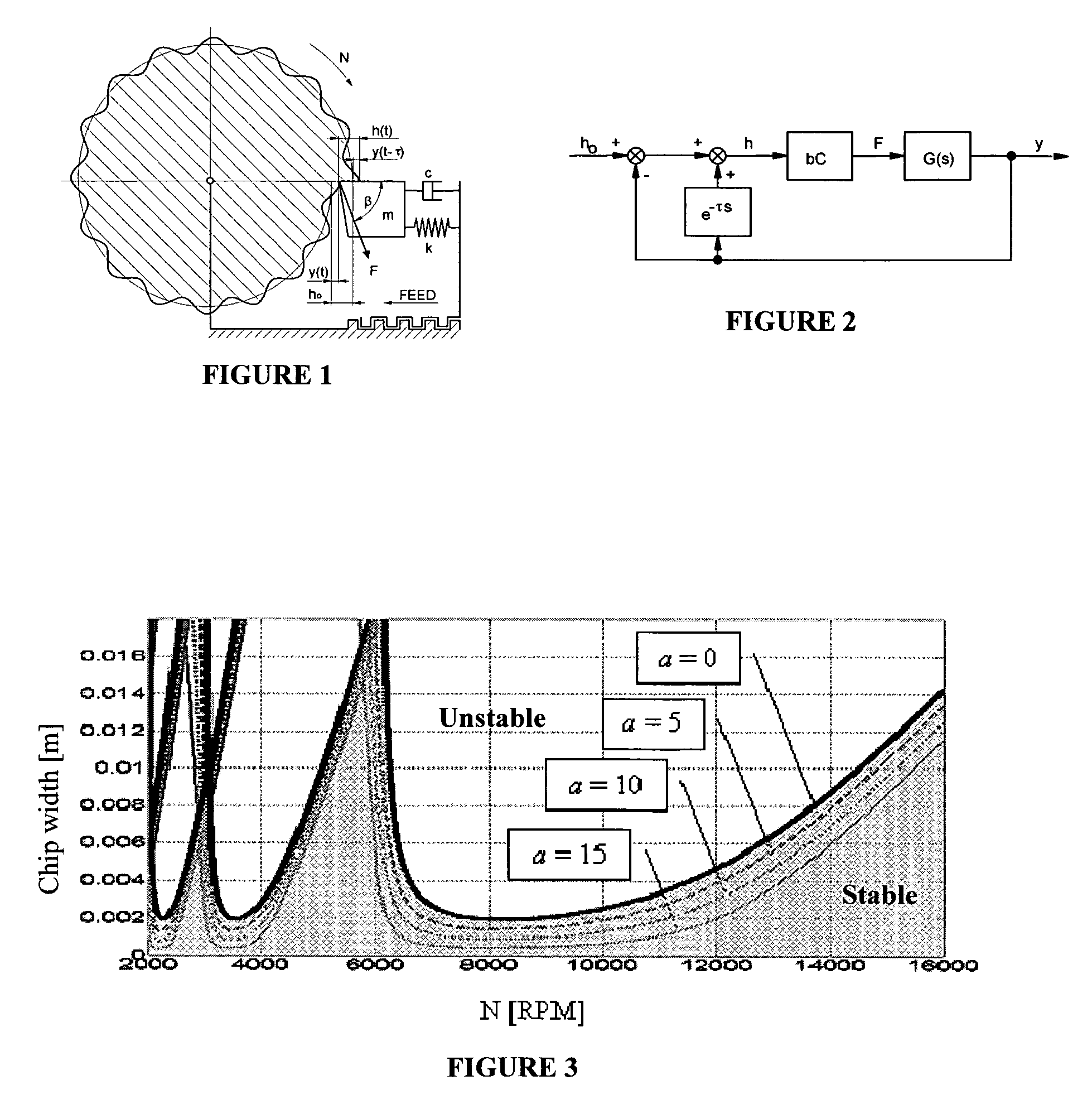

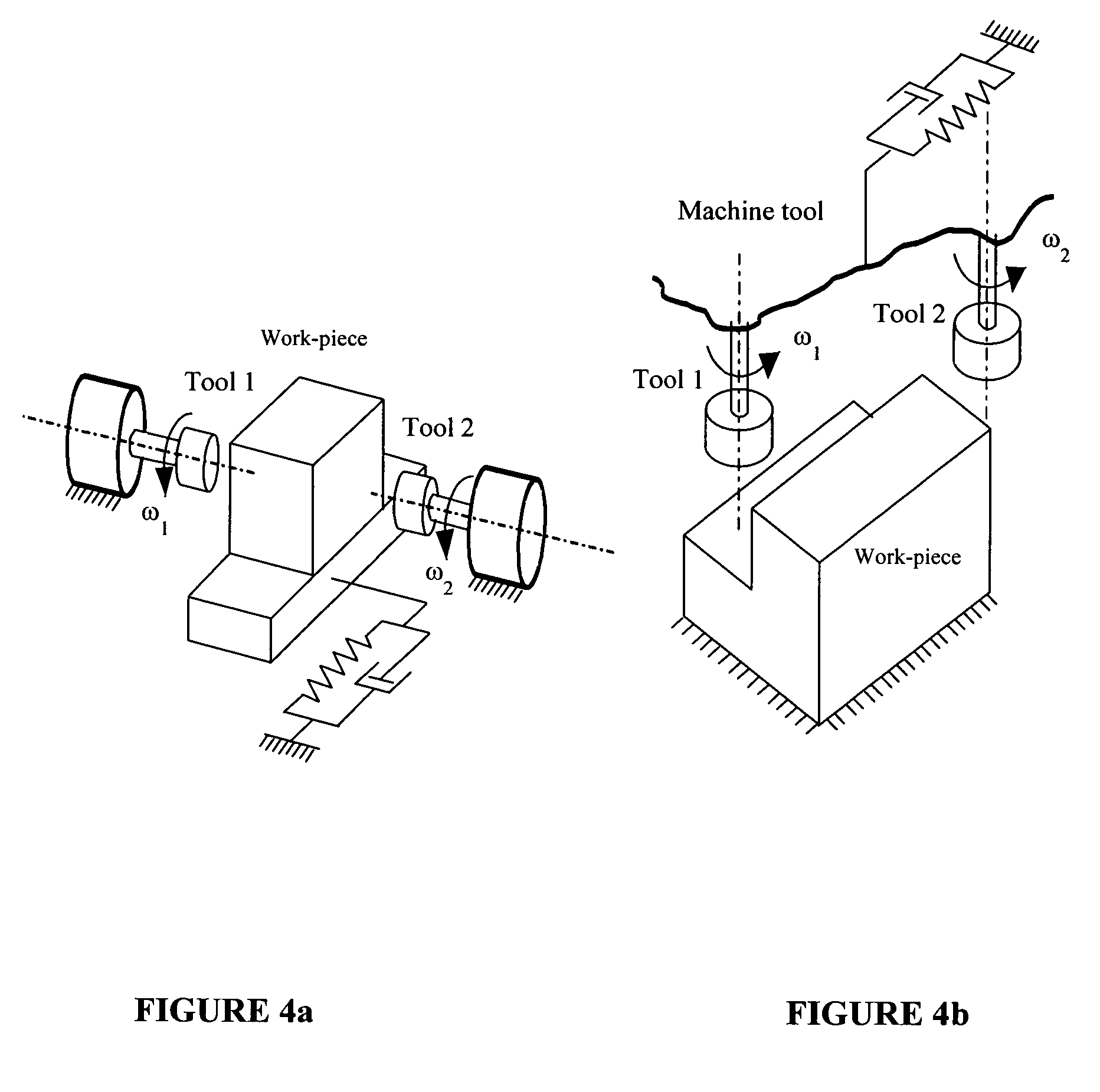

System and method for chatter stability prediction and control in simultaneous machining applications

InactiveUS20060271231A1Reducing and controlling machine tool chatterReduce controlProgramme controlLathesMilling cutterMachined surface

Systems and methods are provided for use in assessing the stability of simultaneous machining (SM) dynamics (which is also known as parallel machining). In SM, multiple cutters, which are generally driven by multiple spindles at different speeds, operate on the same work-piece. In an alternative implementation of SM, single milling cutters with non-uniformly distributed cutter flutes operate on a work-piece. When SM is optimized in the sense of maximizing the rate of metal removal constrained with or by the machined surface quality, “chatter instability” phenomenon appears. The present disclosure declares the complete stability picture of SM chatter within a mathematical framework of multiple time-delay systems (MTDS). A cluster treatment of characteristic roots (CTCR) procedure determines the regions of stability completely in the domain of the spindle speeds for varying chip thickness, thereby replicating the well-known “stability lobes” concept of STM for simultaneous machining.

Owner:UNIV OF CONNECTICUT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com