Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31536 results about "Numerical control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (drills, boring tools, lathes) and 3D printers by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following a coded programmed instruction and without a manual operator.

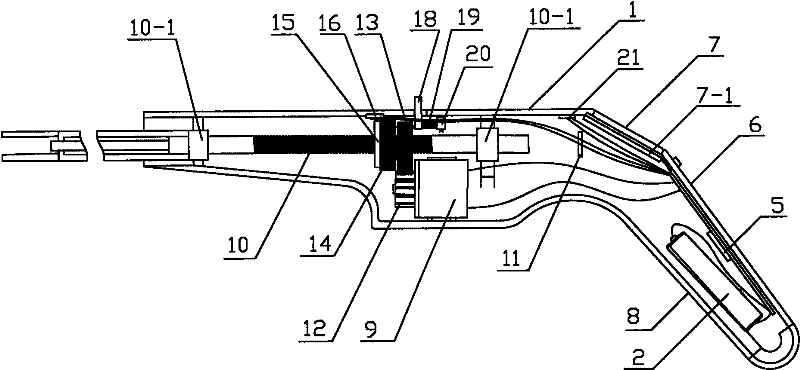

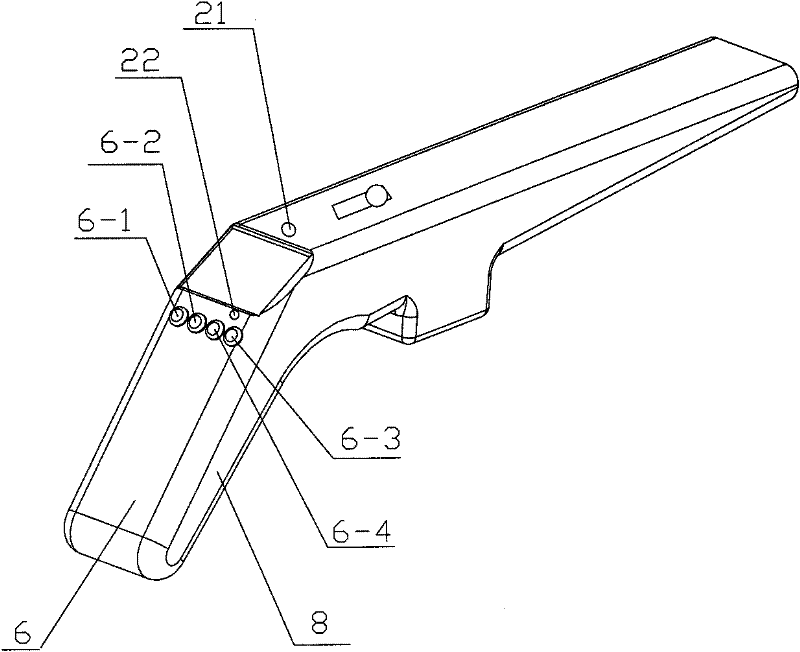

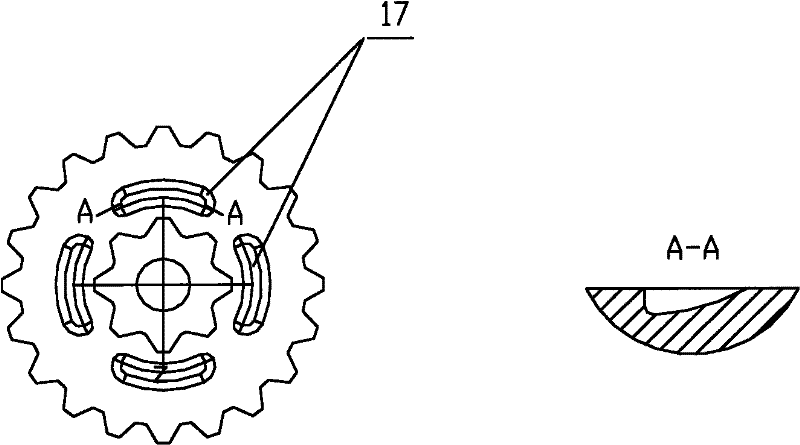

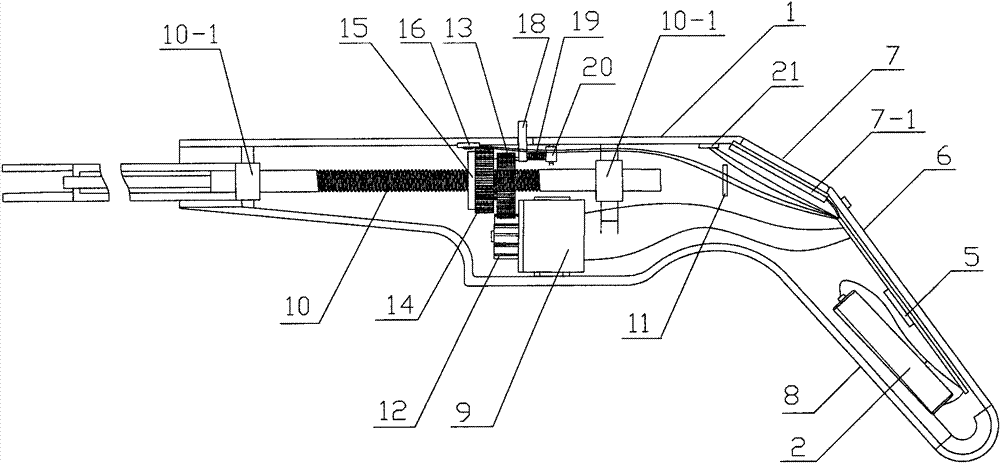

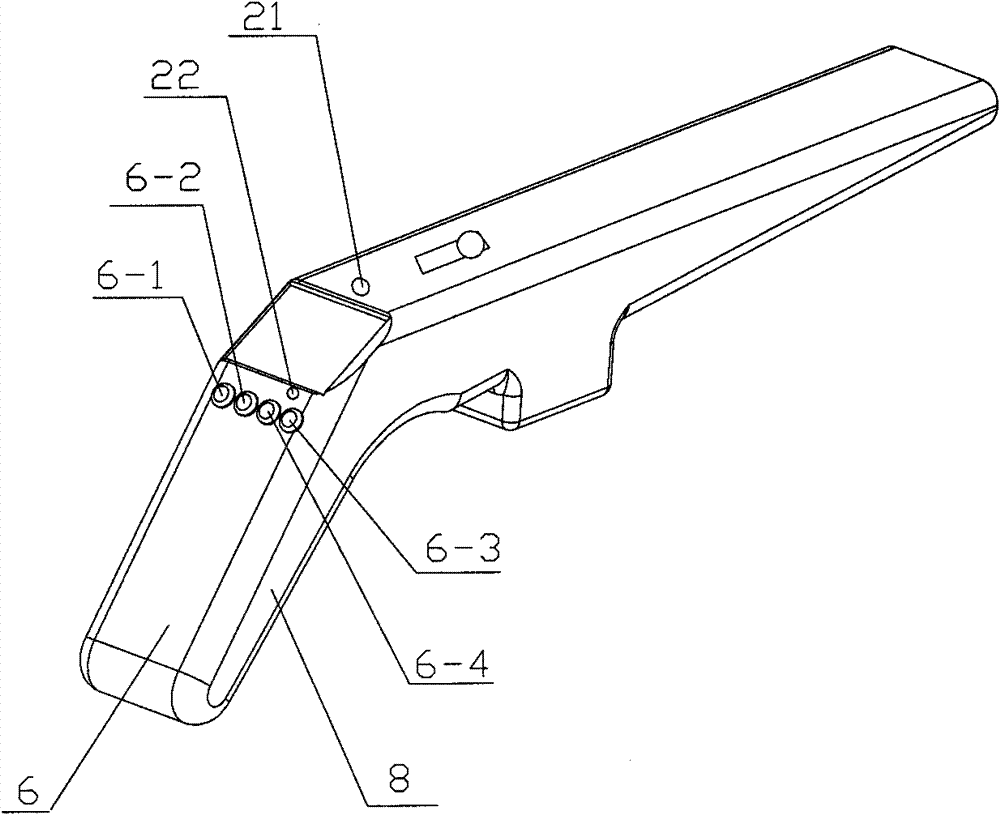

Numerically controlled surgical stapling apparatus

ActiveCN102228387AAccurate operationOperational securityNumerical controlSurgical staplesElectricityMemory chip

The invention relates to a numerically controlled surgical stapling apparatus comprising a clamping assembly, a housing and a main body assembly arranged in the housing. An electric driving device is arranged in the main body assembly. The stapling apparatus is characterized by further comprising a numerical control device which comprises a control board, a display screen and a sensing device, wherein at least one memory chip and a control chip are arranged on the control board; and the display screen is capable of displaying the values of operation parameters and clock information. The electric driving device is capable of receiving a signal produced by the numerical control device and drives a nail magazine to move toward a nail anvil until a predetermined closing gap, and further causes a suturing nail to reach a predetermined forming height after firing the suturing nail. The numerically controlled surgical stapling apparatus provided in the invention is capable of performing accurate and safe control on the transmission steps and the operation actions and also of clearly displaying the operation parameters so that a doctor can know the whole surgery process; therefore, human-machine conversation is made possible.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Numerically controlled surgical stapling apparatus

ActiveCN102228387BAccurate operationOperational securitySurgical staplesNumerical controlMemory chipElectricity

The invention relates to a numerically controlled surgical stapling apparatus comprising a clamping assembly, a housing and a main body assembly arranged in the housing. An electric driving device is arranged in the main body assembly. The stapling apparatus is characterized by further comprising a numerical control device which comprises a control board, a display screen and a sensing device, wherein at least one memory chip and a control chip are arranged on the control board; and the display screen is capable of displaying the values of operation parameters and clock information. The electric driving device is capable of receiving a signal produced by the numerical control device and drives a nail magazine to move toward a nail anvil until a predetermined closing gap, and further causes a suturing nail to reach a predetermined forming height after firing the suturing nail. The numerically controlled surgical stapling apparatus provided in the invention is capable of performing accurate and safe control on the transmission steps and the operation actions and also of clearly displaying the operation parameters so that a doctor can know the whole surgery process; therefore, human-machine conversation is made possible.

Owner:B J ZH F PANTHER MEDICAL EQUIP

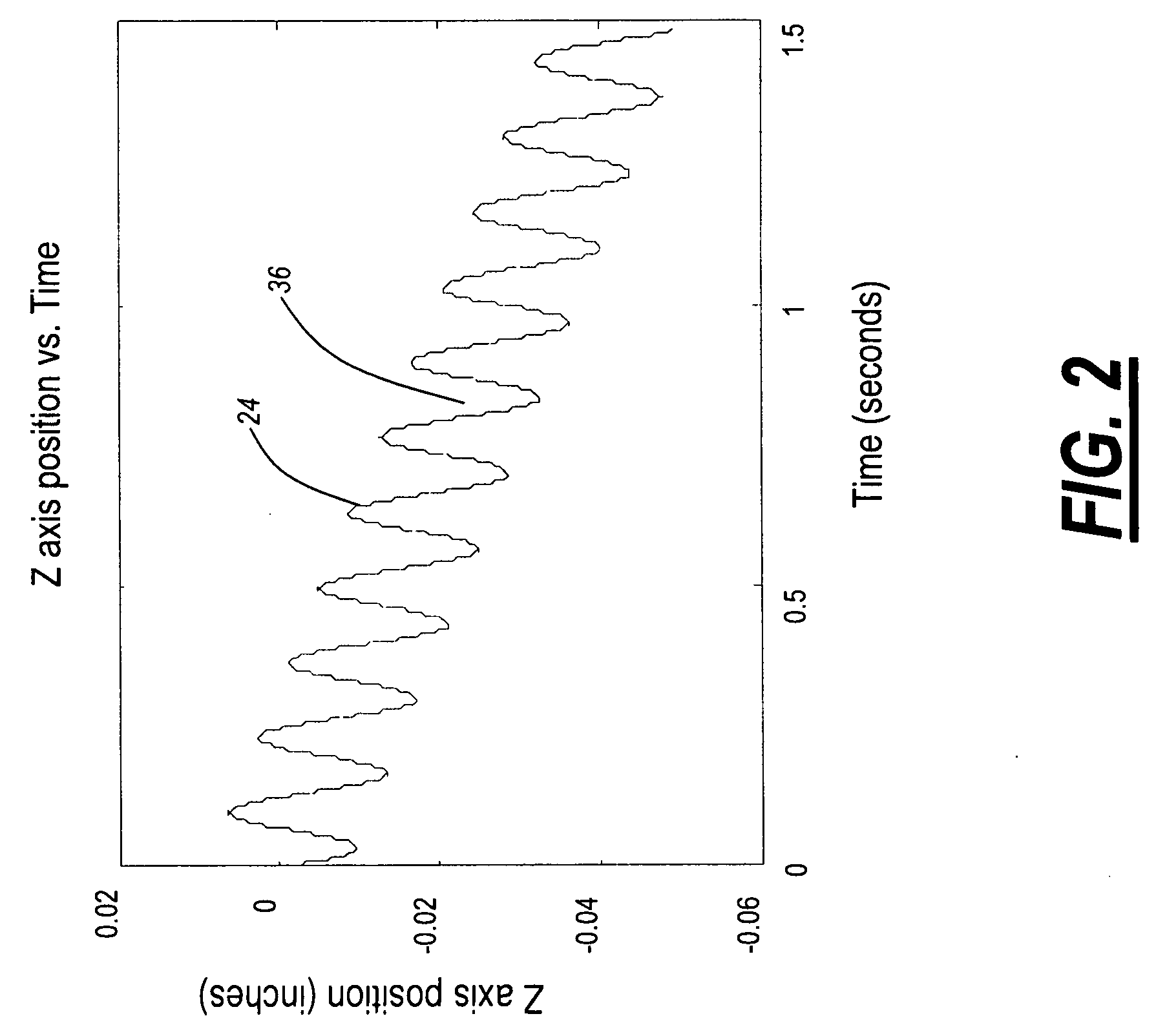

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

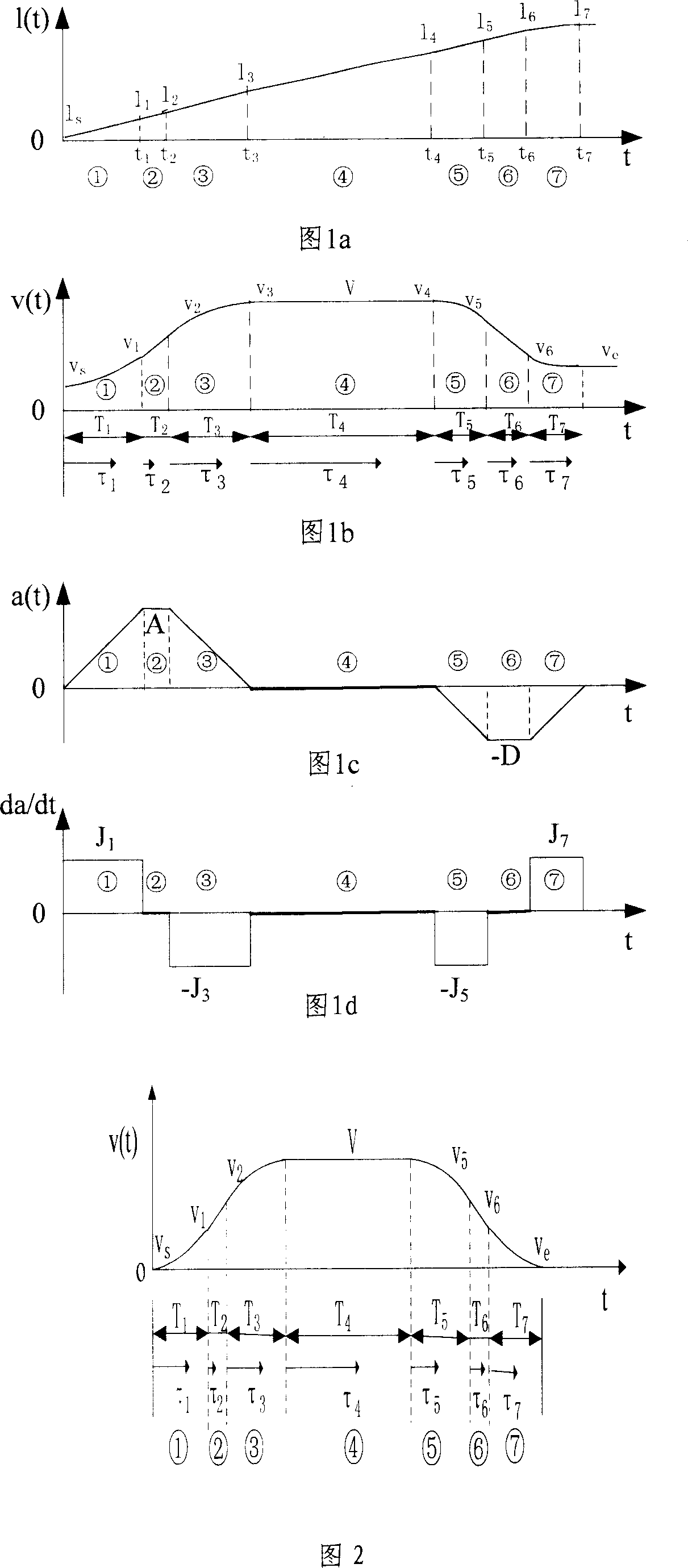

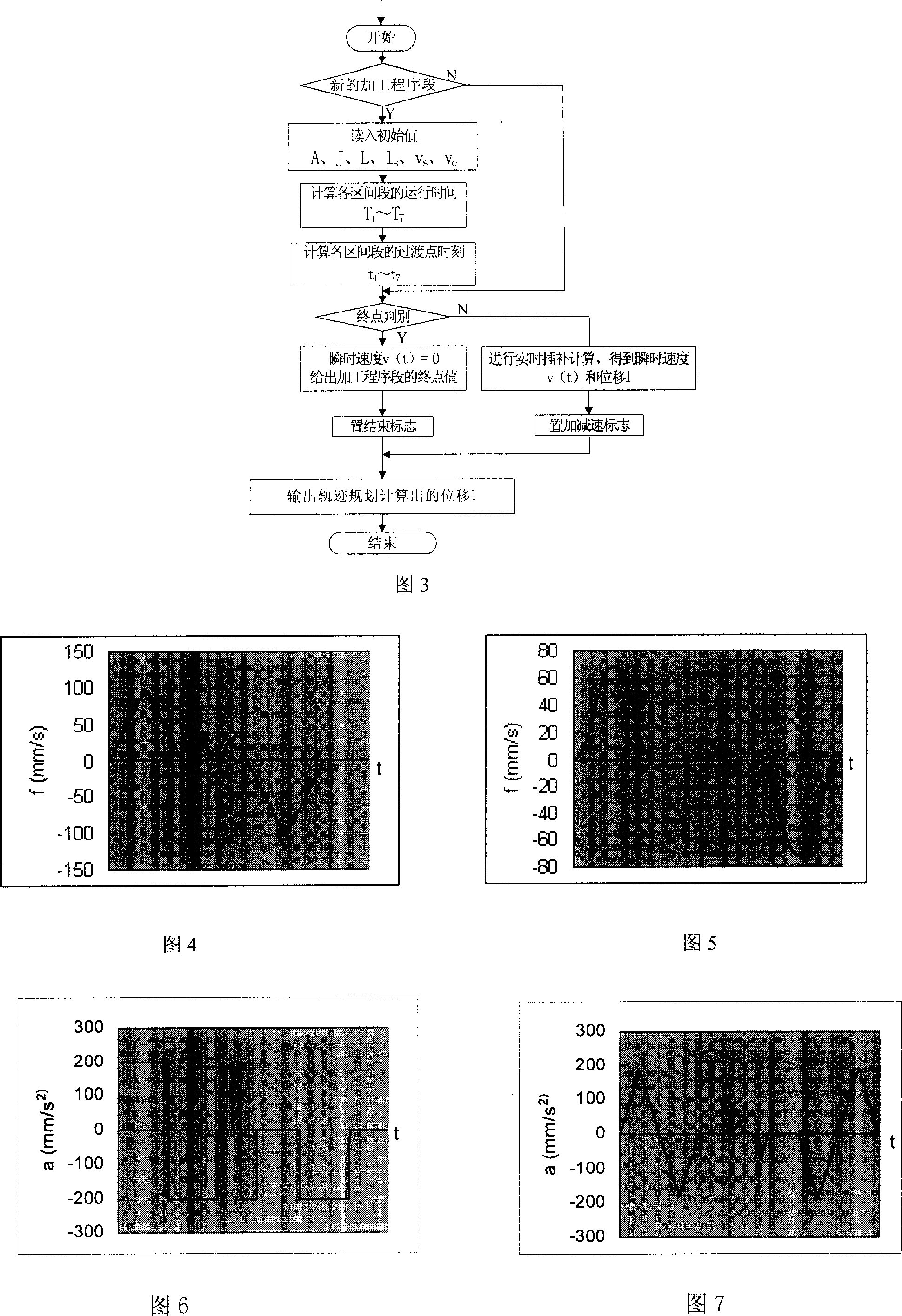

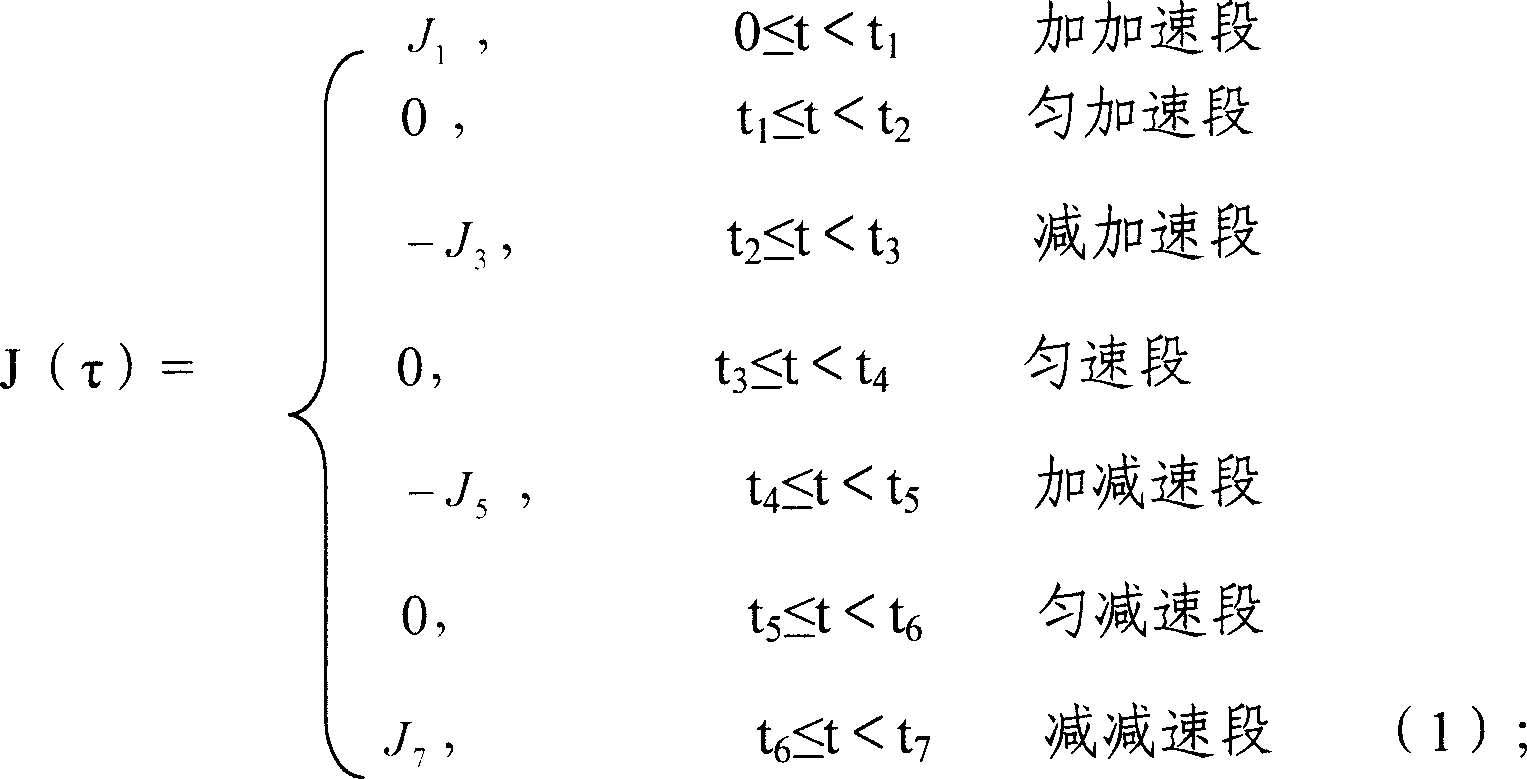

Speed control method used for numerical control machine

InactiveCN1971457AReduce shockImprove smoothnessComputer controlSimulator controlNumerical controlControl theory

The invention discloses acceleration and deceleration controlling means used in numerical control machine, the concept of 'add-acceleration' is introduced against the dynamic property of the controlled member, the add-acceleration is constant in stage of acceleration and deceleration, the two physical quantities of acceleration and add-acceleration are setting; the segmented handling method of add-accelerating sections, uniform accelerating sections, decelerated accelerating sections, uniform speed sections, add-decelerating sections, uniformly-retarded sections and decelerated deceleration sections is adopted, after the interval discrimination, the real-time interpolating calculation in every interval is exceeded based on the integral relation between the add-acceleration, acceleration, speed and displacement, the S type velocity curve is formed to realize the flexible acceleration and deceleration control; the destination discrimination process is proceeded before the interpolating calculation can increase the machining precision of the acceleration and deceleration control. The method is simple, the impact is small, the speed is smooth, the machining precision is high and the flexible control can be realized.

Owner:中国科学院沈阳计算技术研究所有限公司 +1

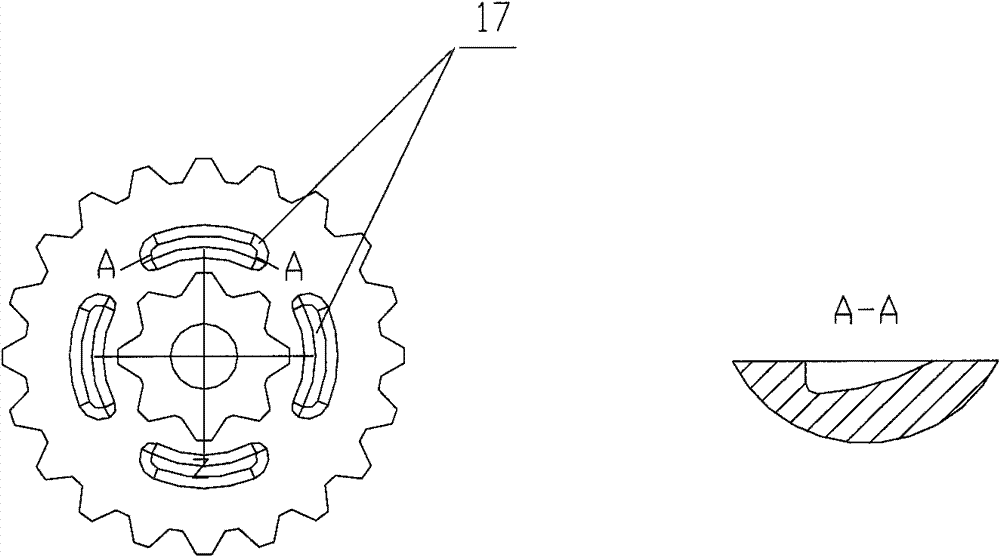

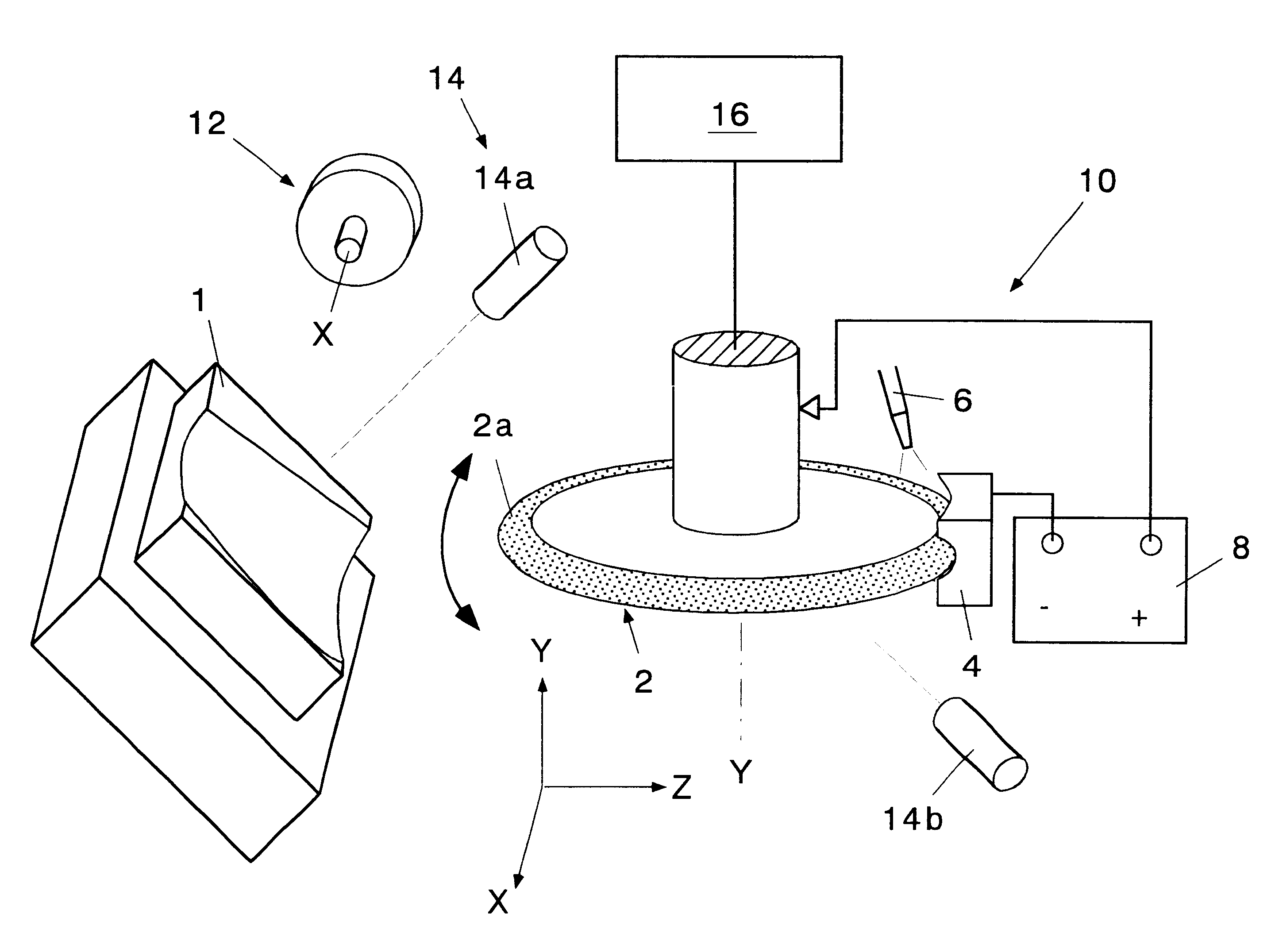

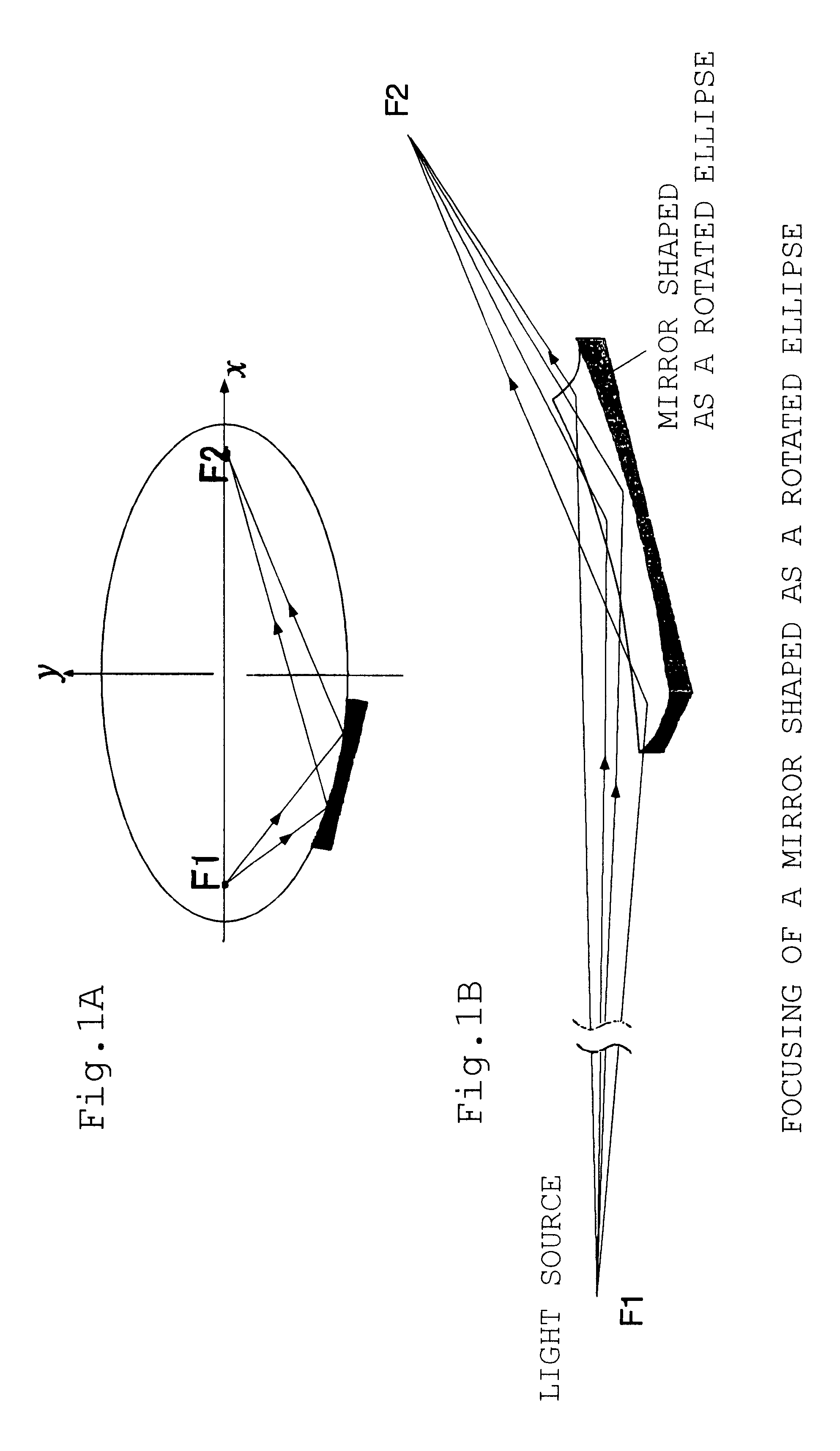

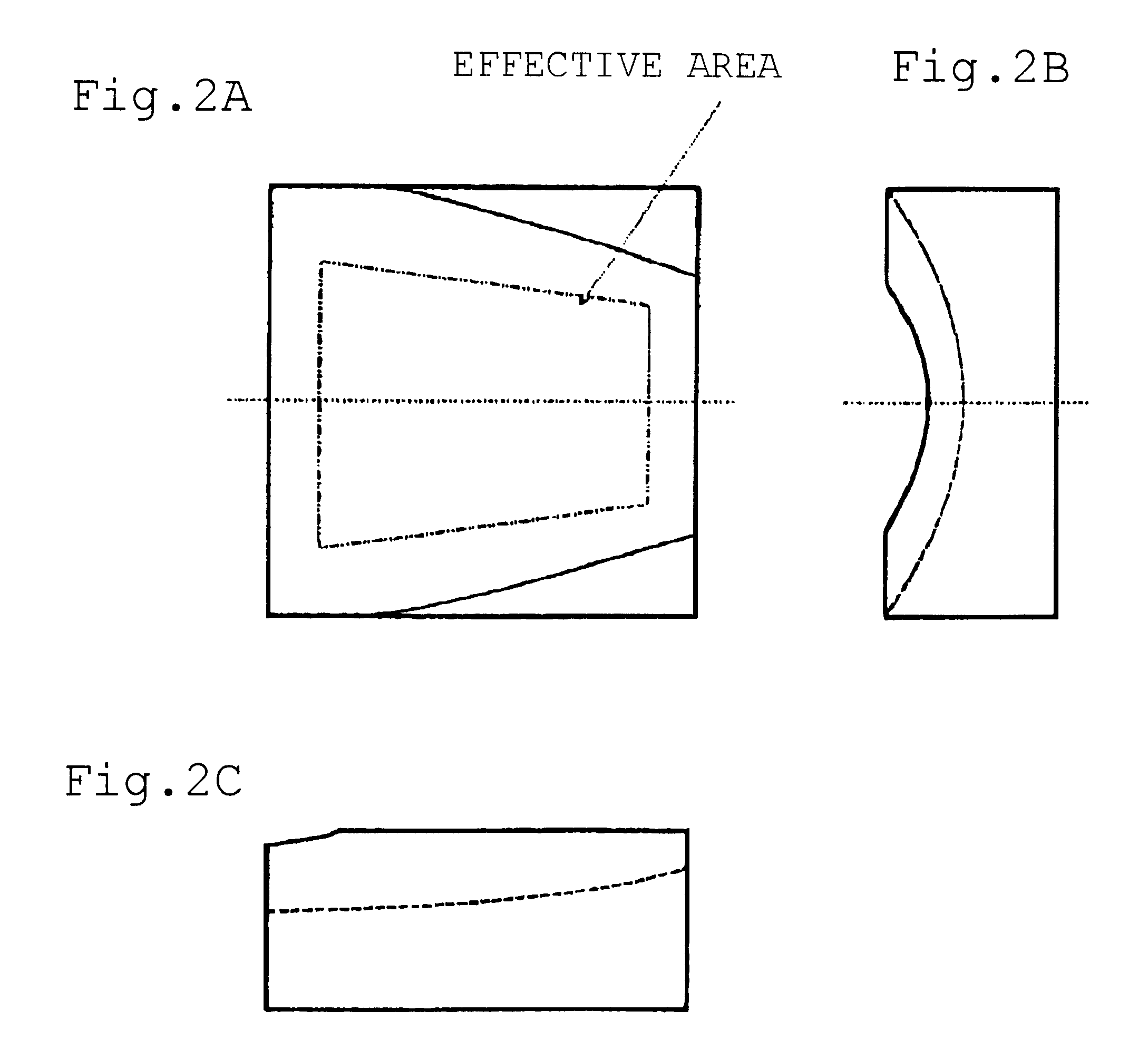

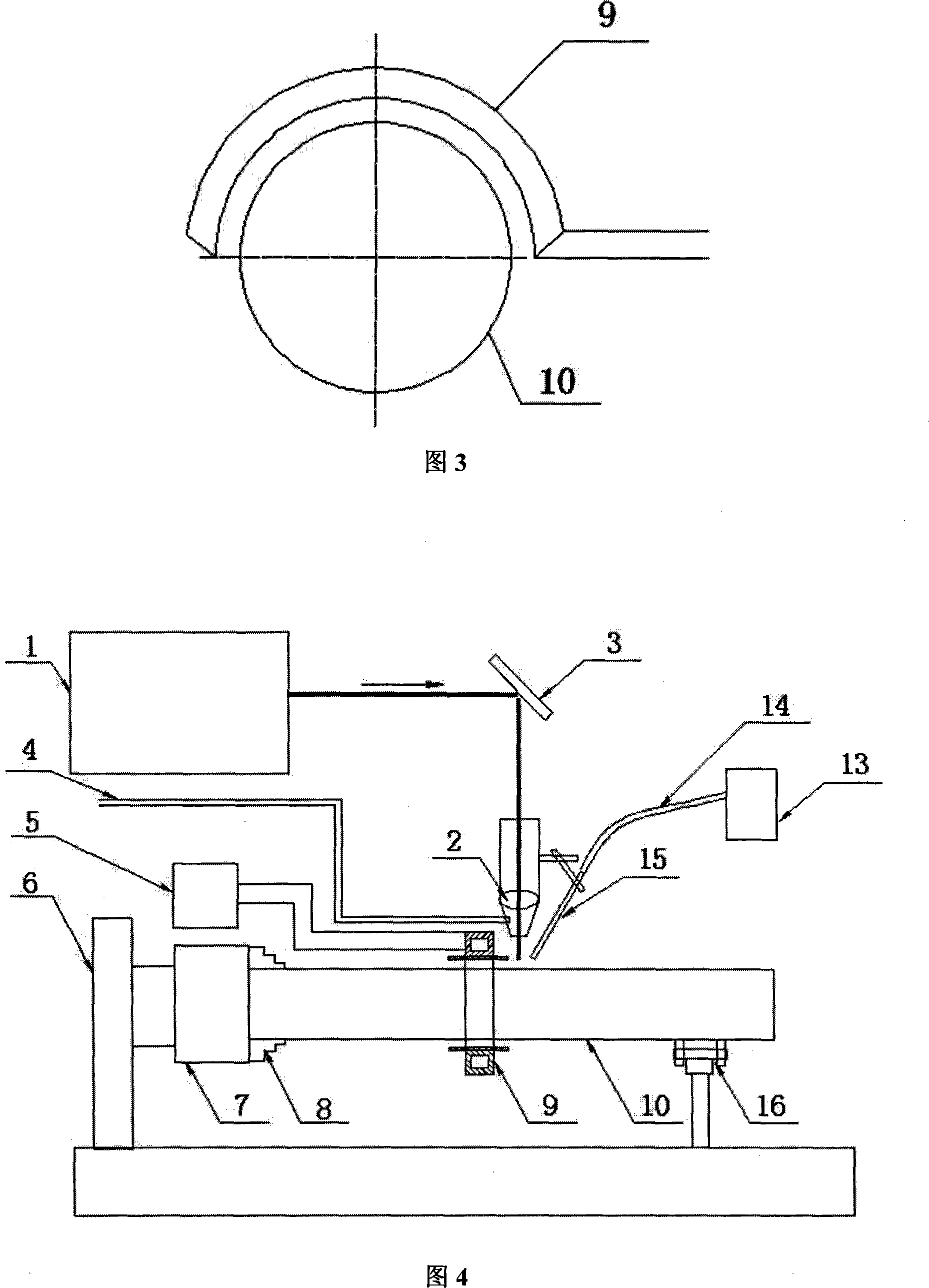

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

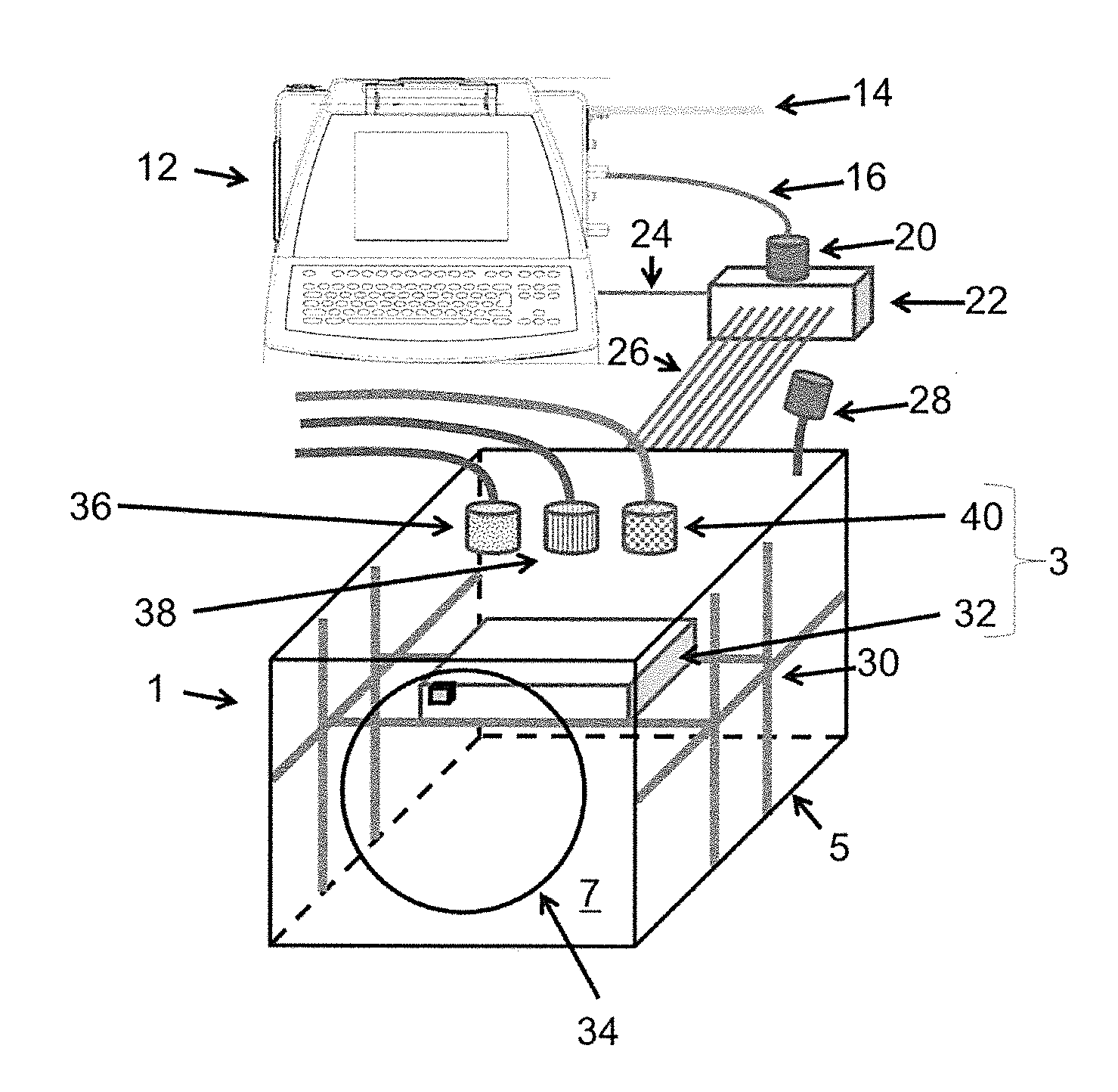

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

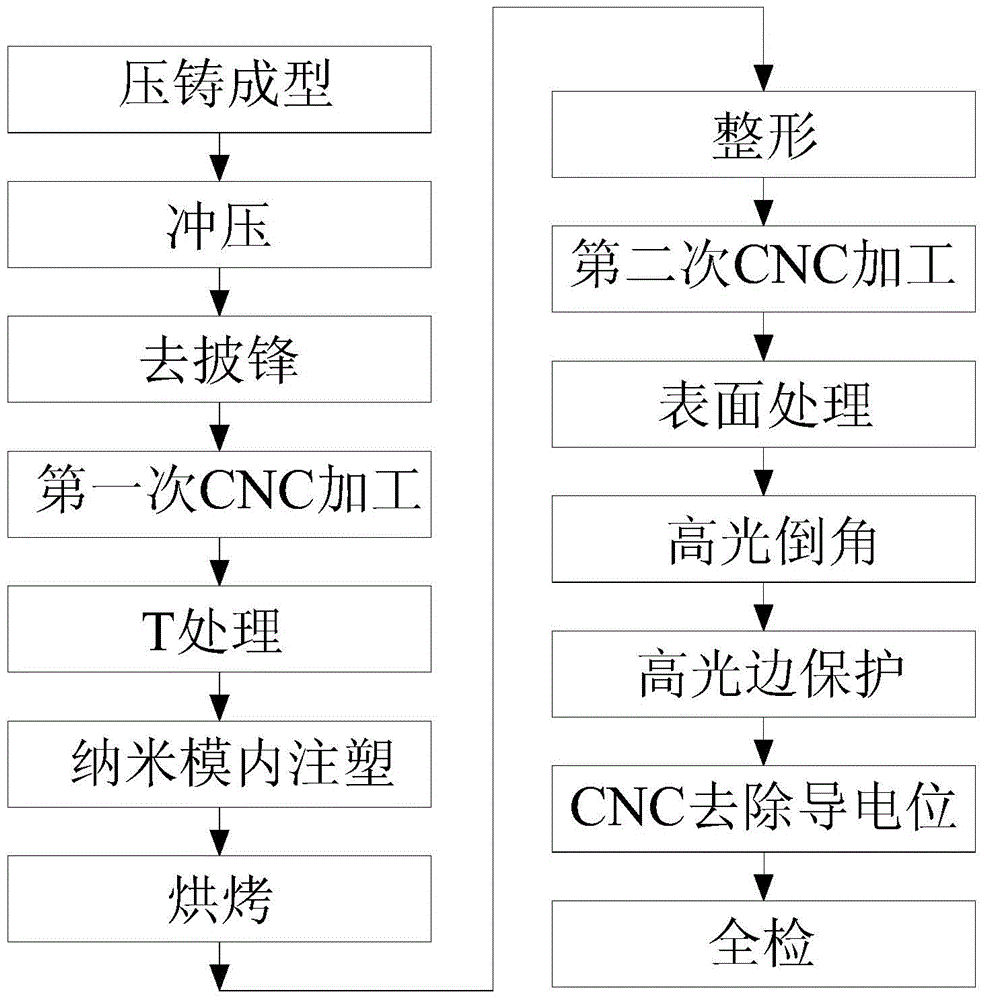

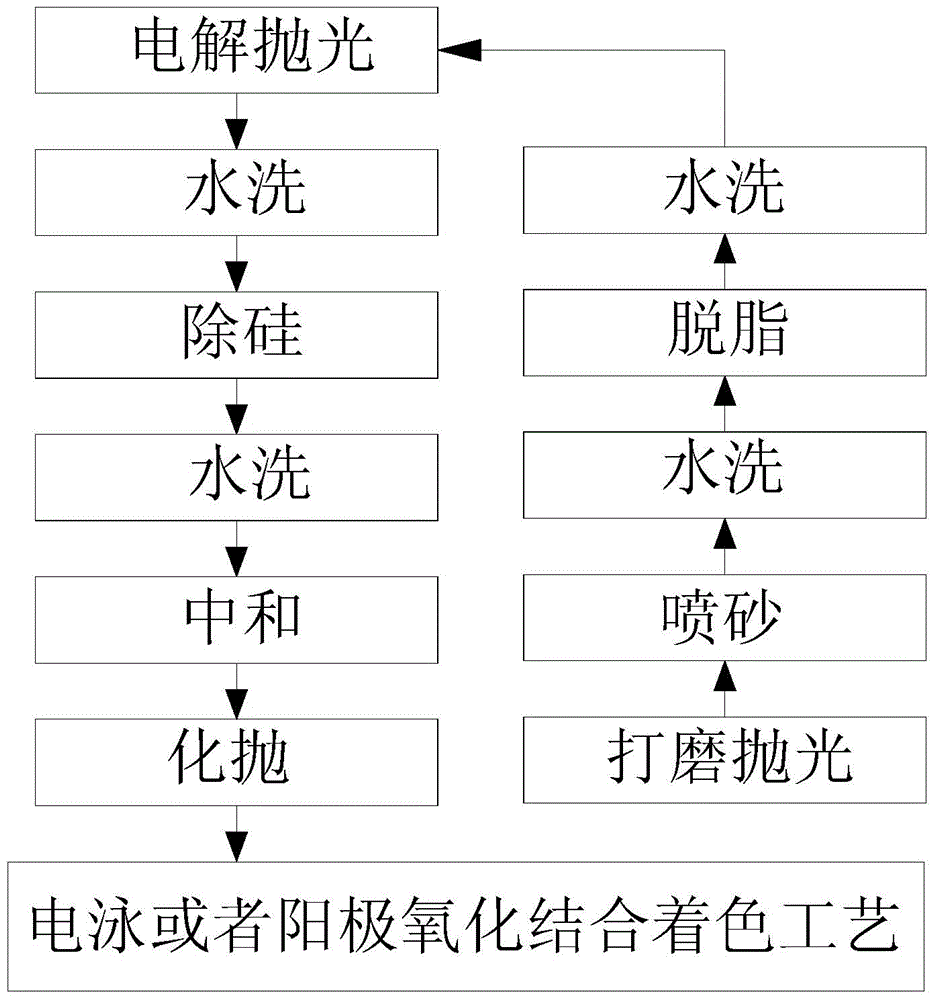

Processing technique of cellphone shell with metal luster

ActiveCN104607884AGuaranteed StrengthReduce processing costsCoatingsNumerical controlAbrasive blasting

The invention provides a processing technique of a cellphone shell with metal luster. The processing technique includes the steps of S1, performing compression molding; S2, performing stamping; S3, performing primary CNC (computer numerical control) machining; S4, performing T treatment; S5, performing injection molding in a nano mold; S6, performing secondary CNC machining; S7, performing surface treatment, to be specific, performing a, polishing, b, shot-blasting, c, degreasing, d, washing, e, electrolytic polishing, f, washing, g, silicon removal aiming to decrease silicon content of the polished surface of the cellphone shell, h, neutralizing, i, chemical polishing, and j, electrophoresis or combination of anodic oxidation and coloring, aiming to impart metal luster to the polished surface of the cellphone shell. The compete cellphone shell is made through the steps S1 to S6, the silicon content of the polished surface of the cellphone shell is processed, the cellphone shell never produces compounds of intervals such as Al-Mg-Si-Fe during following anodic oxidation, defects such as oxide film darkening, bluing or milky-whiting are avoided, and the metal-lustered cellphone shell is manufactured through the complete process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

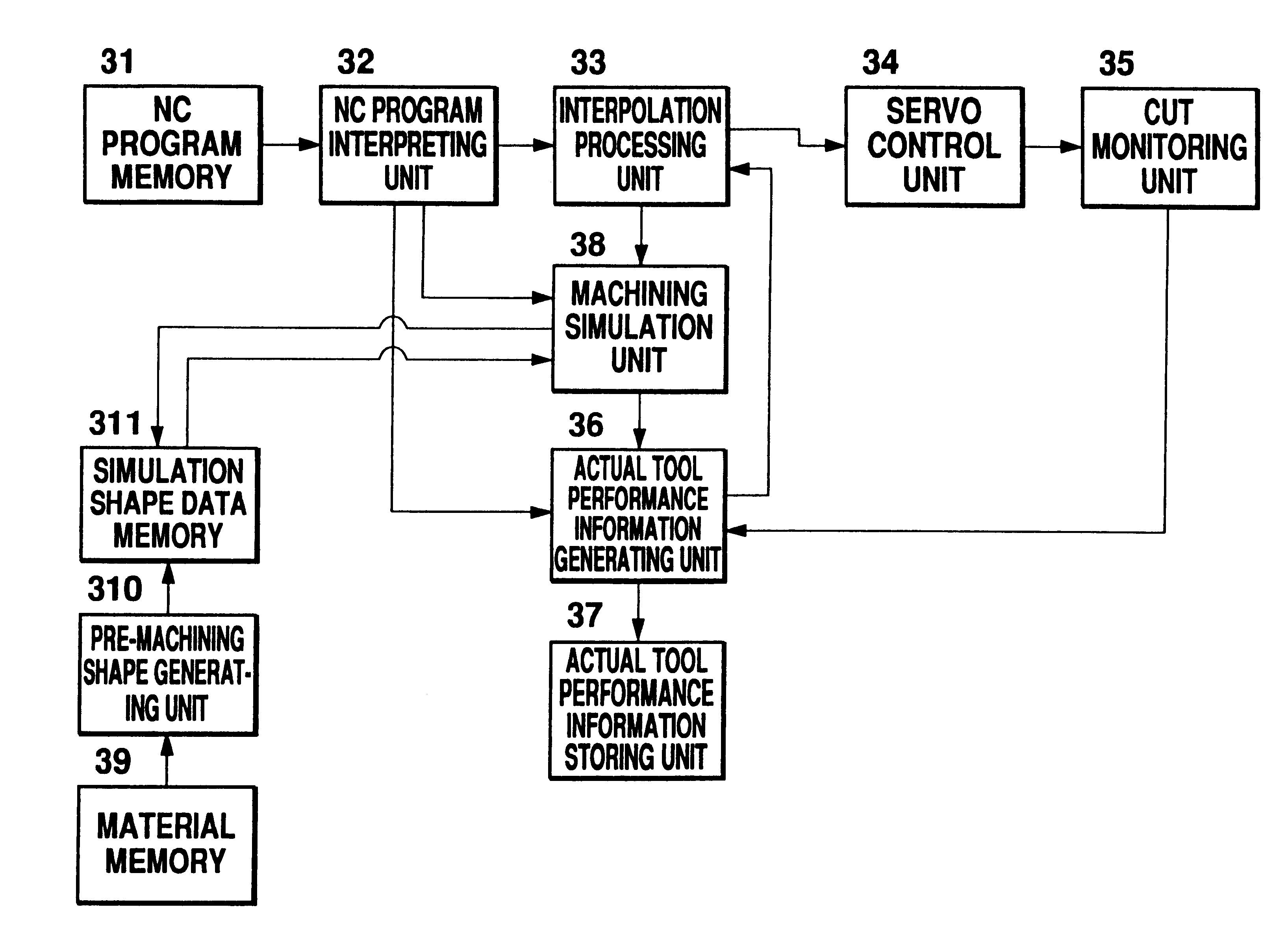

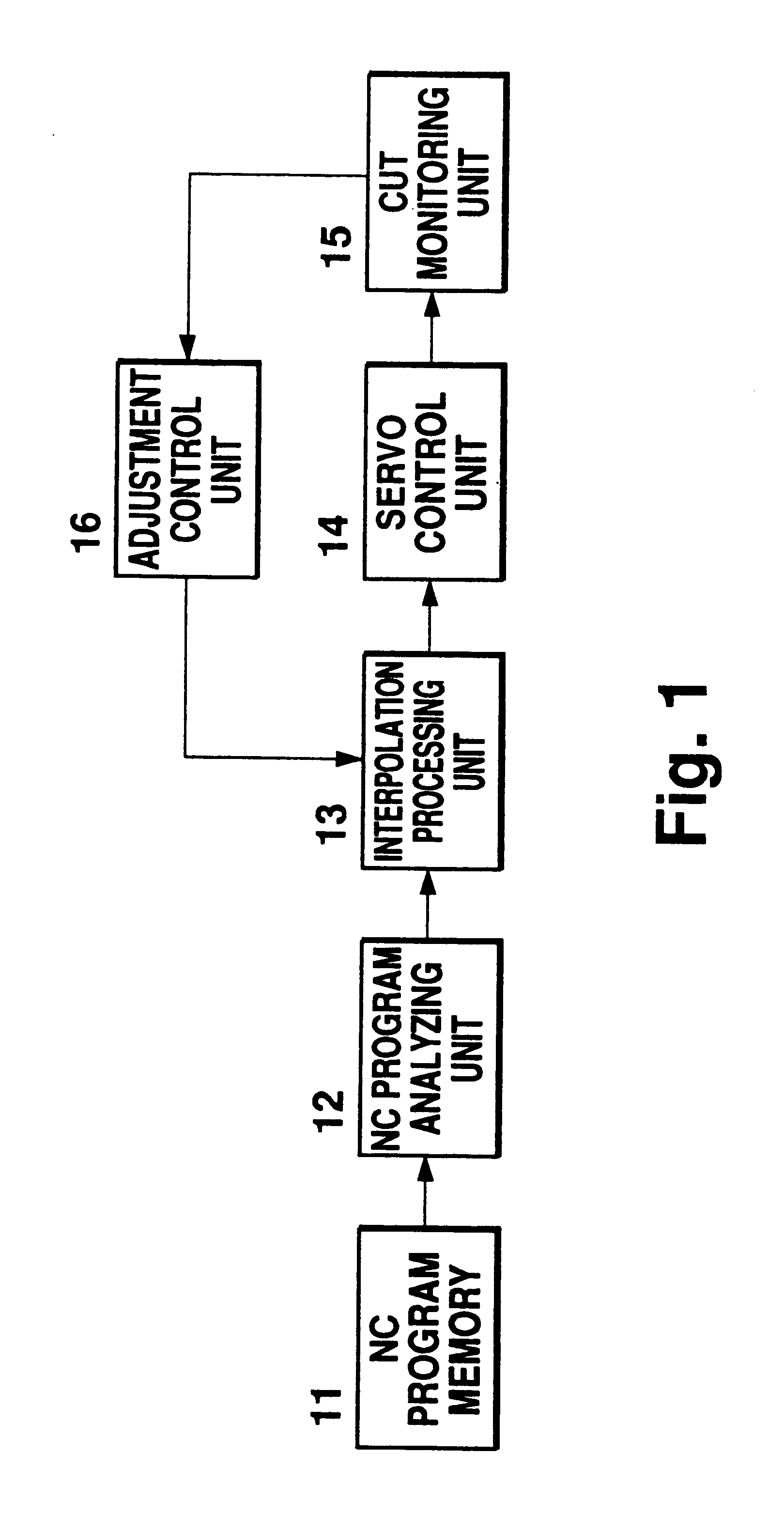

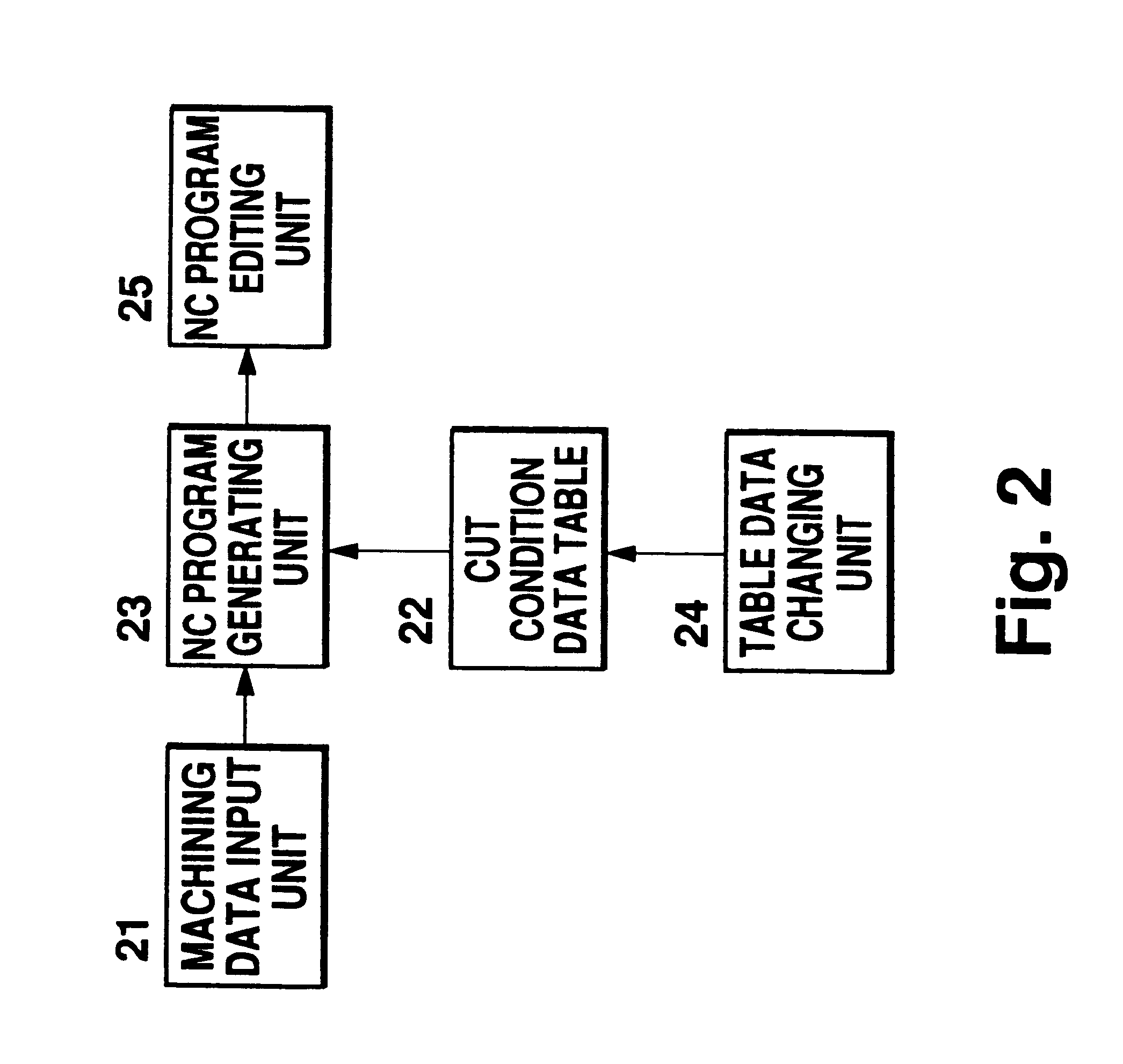

Apparatus for generating a numerical control command according to cut resistance value and cut torque value of machining simulation

InactiveUS6266572B1Solution to short lifeImprove wear resistanceProgramme controlAutomatic control devicesNumerical controlMachine simulation

A method of simulation of NC machining, wherein machining simulation is carried out according to blank shape data, tool shape data and an NC program to modify the NC program or interpolation data by feedforward control so that optimum cutting conditions can be obtained. The simulation result can be used for correcting the NC program and the interpolation data at the next stage. Further, a record of tools used can be generated on the basis of this simulation result.

Owner:OKUMA CORP +3

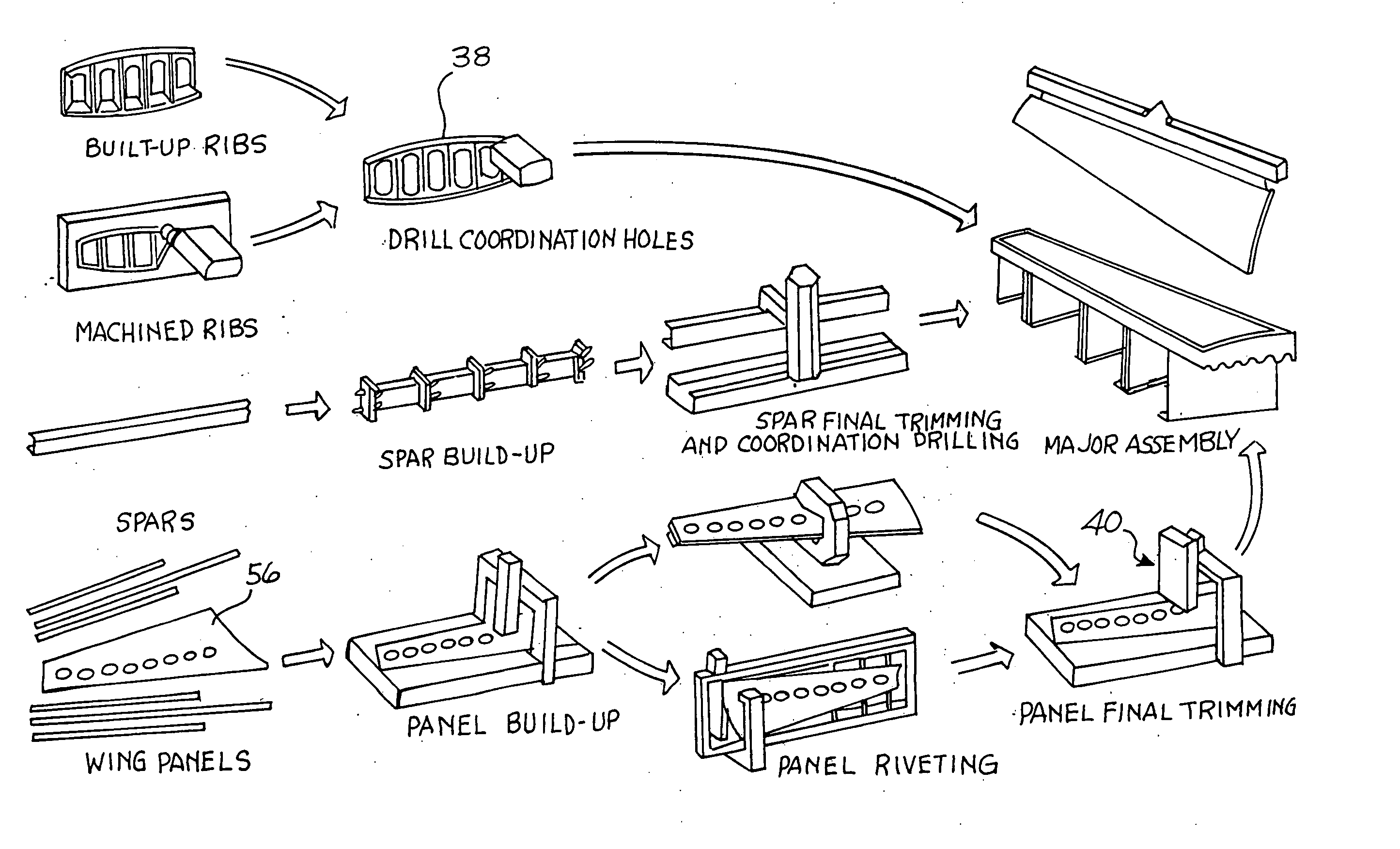

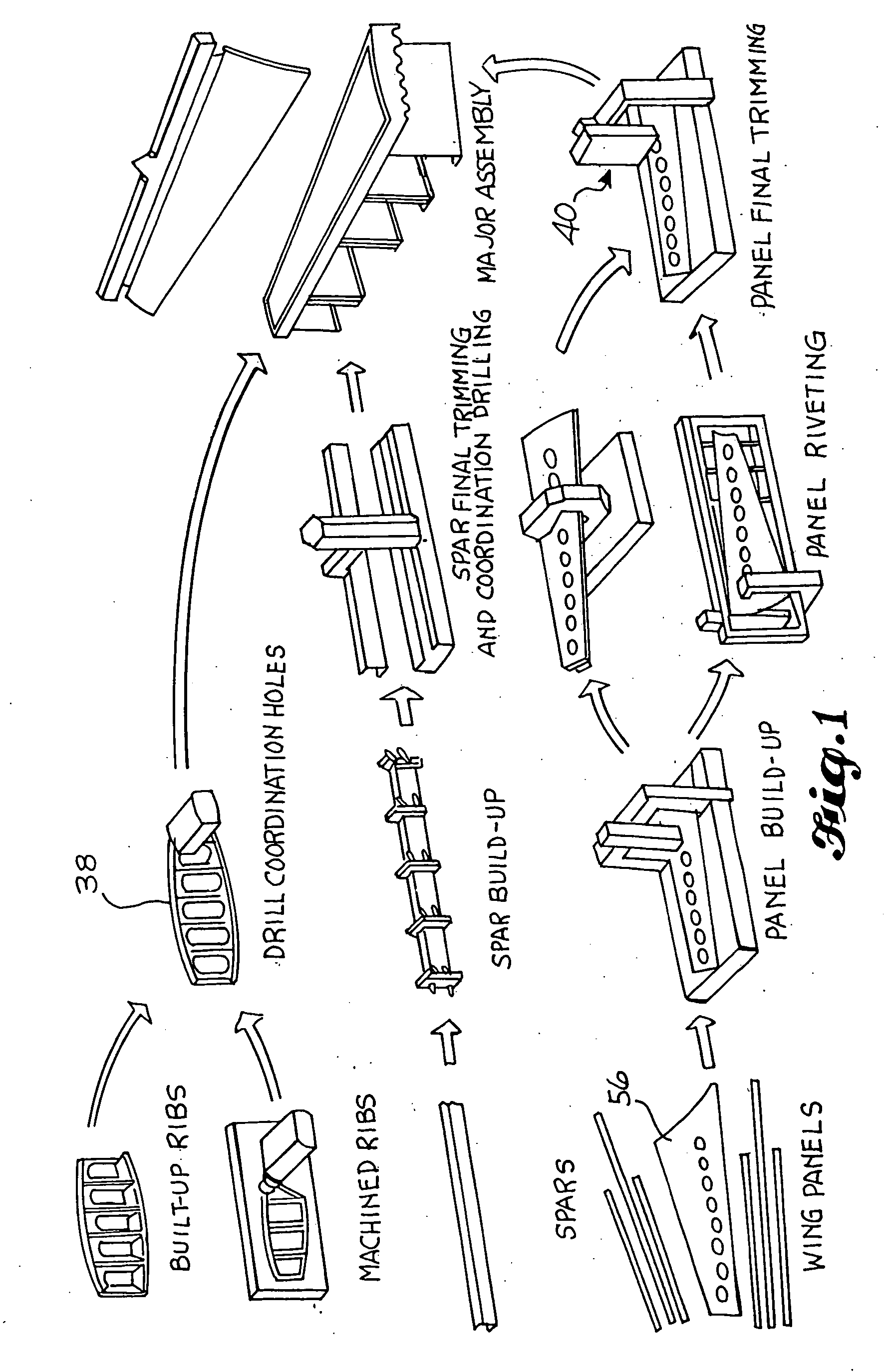

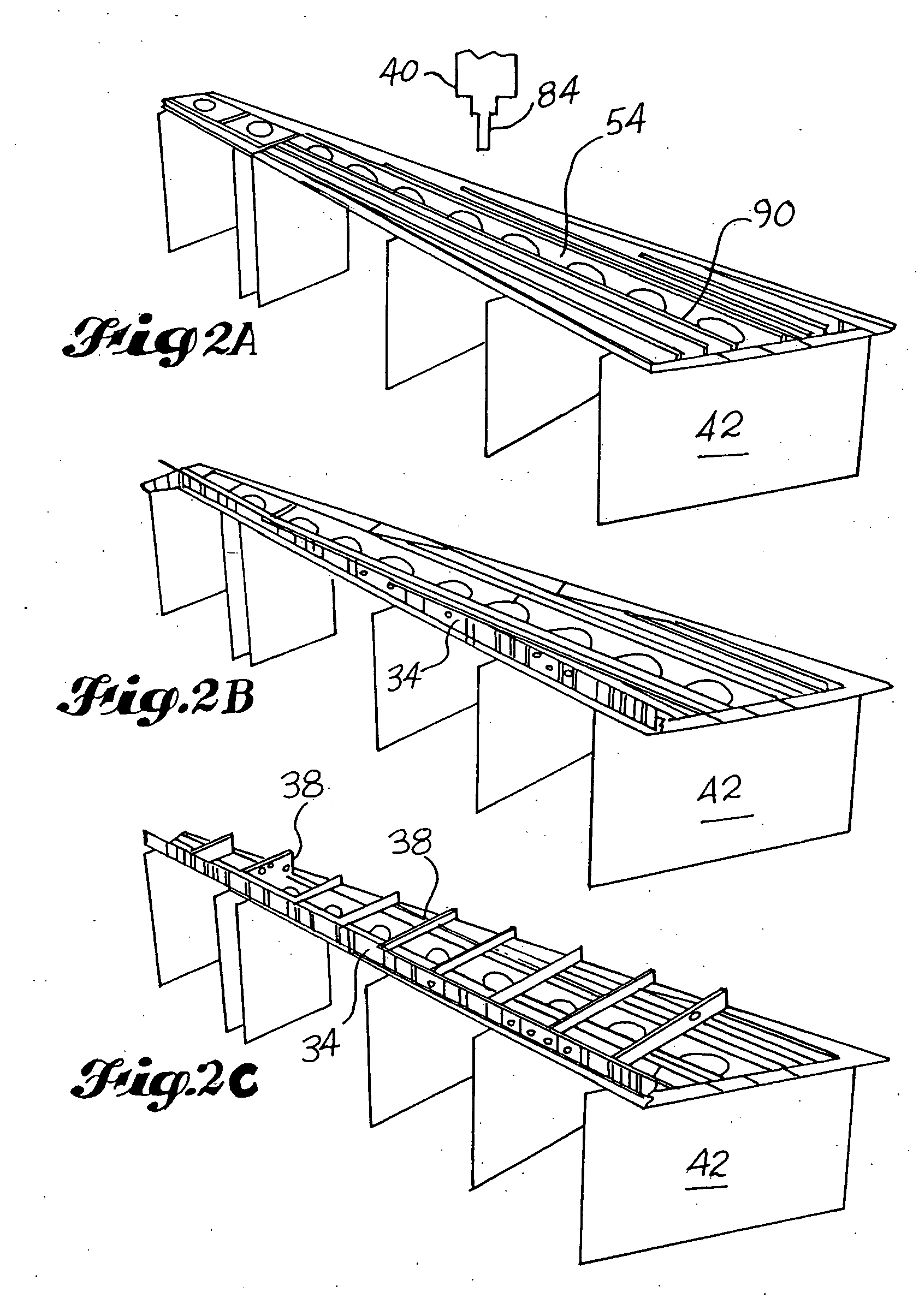

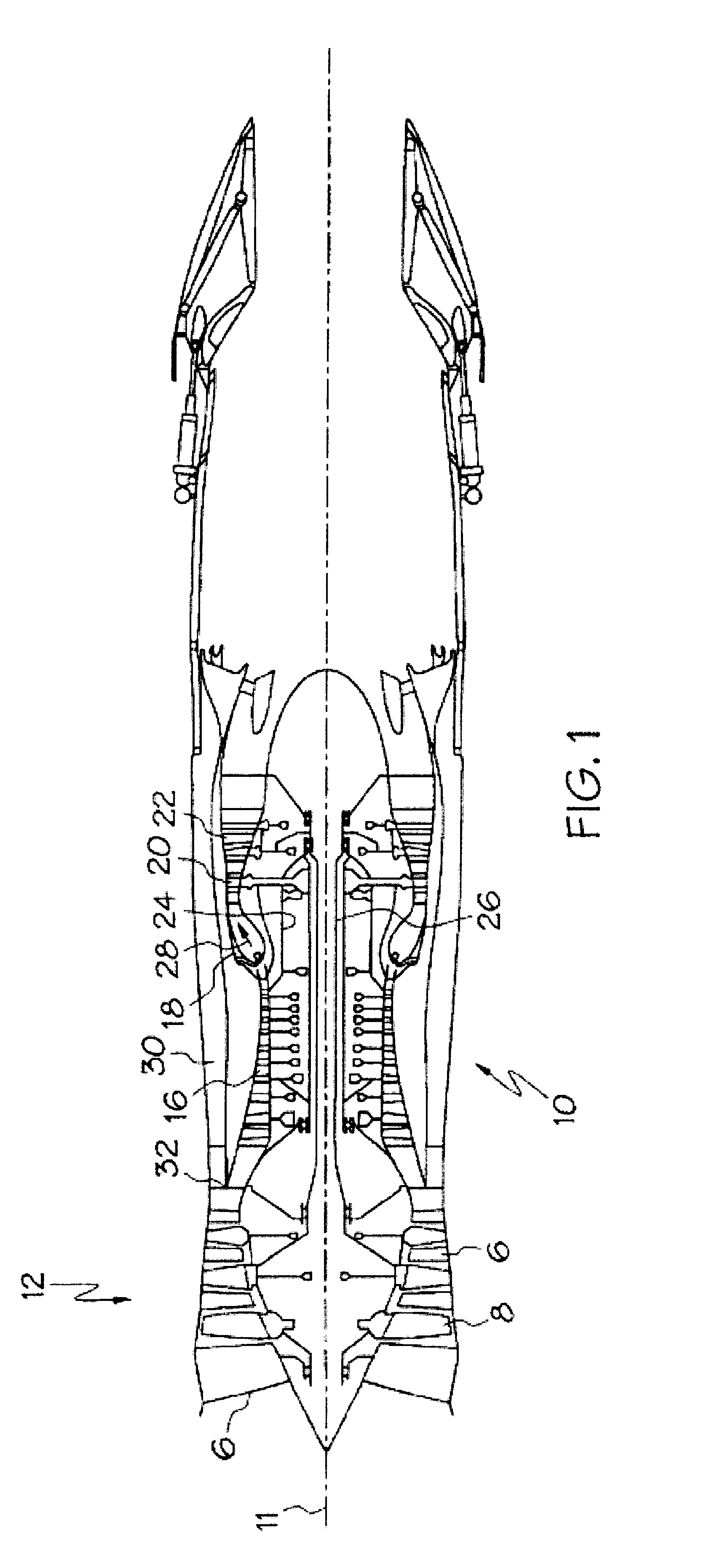

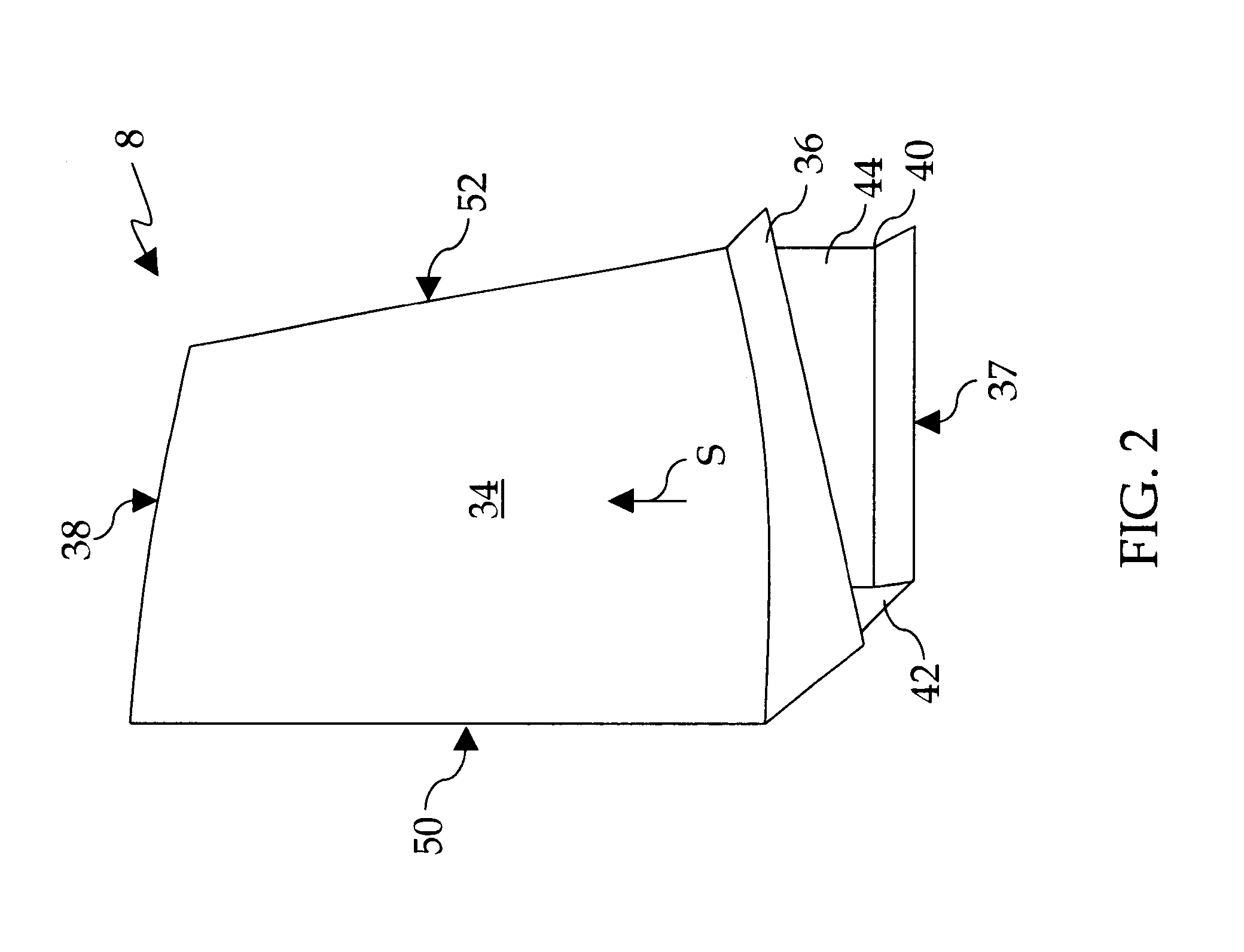

Determinant wing assembly

InactiveUS20050116105A1Accurate locationEasy to manufactureAircraft stabilisationWingsNumerical controlMachine tool

A method and apparatus for manufacturing wings includes a fixture that holds wing panels for drilling and edge trimming by accurate numerically controlled machine tools using original numerical part definition records, utilizing spatial relationships between key features of detail parts or subassemblies as represented by coordination features machined into the parts and subassemblies, thereby making the parts and subassemblies intrinsically determinant of the dimensions and contour of the wing. Spars are attached to the wing panel using the coordination holes to locate the spars accurately on the panel in accordance with the original engineering design, and in-spar ribs are attached to rib posts on the spar using accurately drilled coordination holes in the ends of the rib and in the rib post. The wing contour is determined by the configuration of the spars and ribs rather than by any conventional hard tooling which determines the wing contour in conventional processes.

Owner:THE BOEING CO

Method for measuring geometric error parameter value of rotary oscillation axis of five-axis linkage numerical control machine tool

The invention discloses a method for measuring a geometric error parameter value of a rotary oscillation axis of a five-axis linkage numerical control machine tool. The method comprises the following steps of: measuring displacement errors of X, Y and Z directions on at least three positions under different rotating angles of the rotary oscillation axis respectively by using a ballbar, wherein translation axis linkage coordinates provided by a revolving tool central point (RTCP) cutter central point movement control function of a five-axis machine tool serve as measurement datum; and performing data processing according to the displacement errors to identify and calculate the geometric error of each rotating angle of the rotary oscillation axis. The rotary oscillation axis is measured independently by the method, so the geometric error value of the five-axis linkage numerical control machine tools of various structures at each rotary oscillation angles can be obtained. The method is not limited by the structures of the machine tools, is convenient to arrange and has high measuring precision.

Owner:成都天佑创软科技有限公司

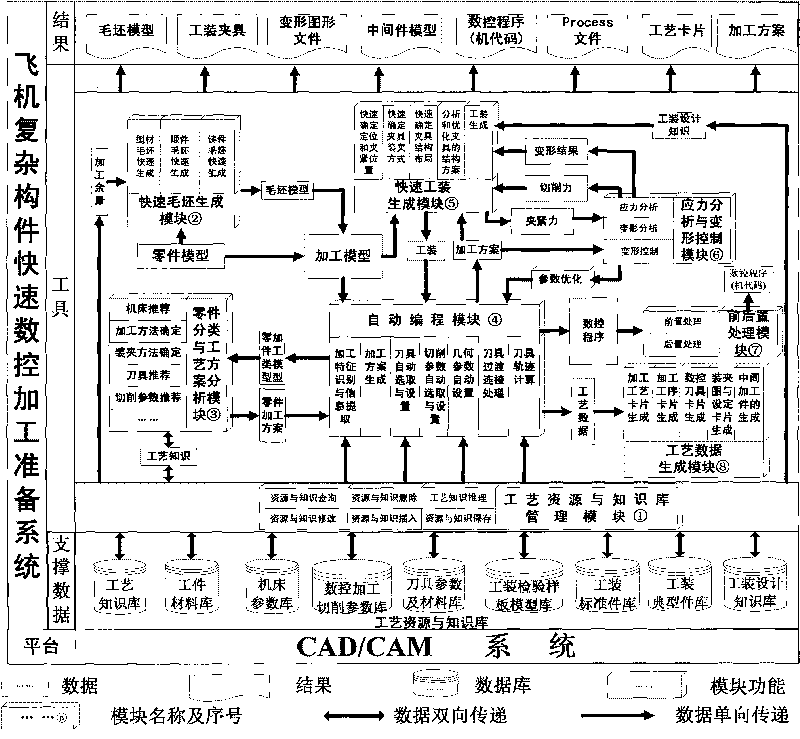

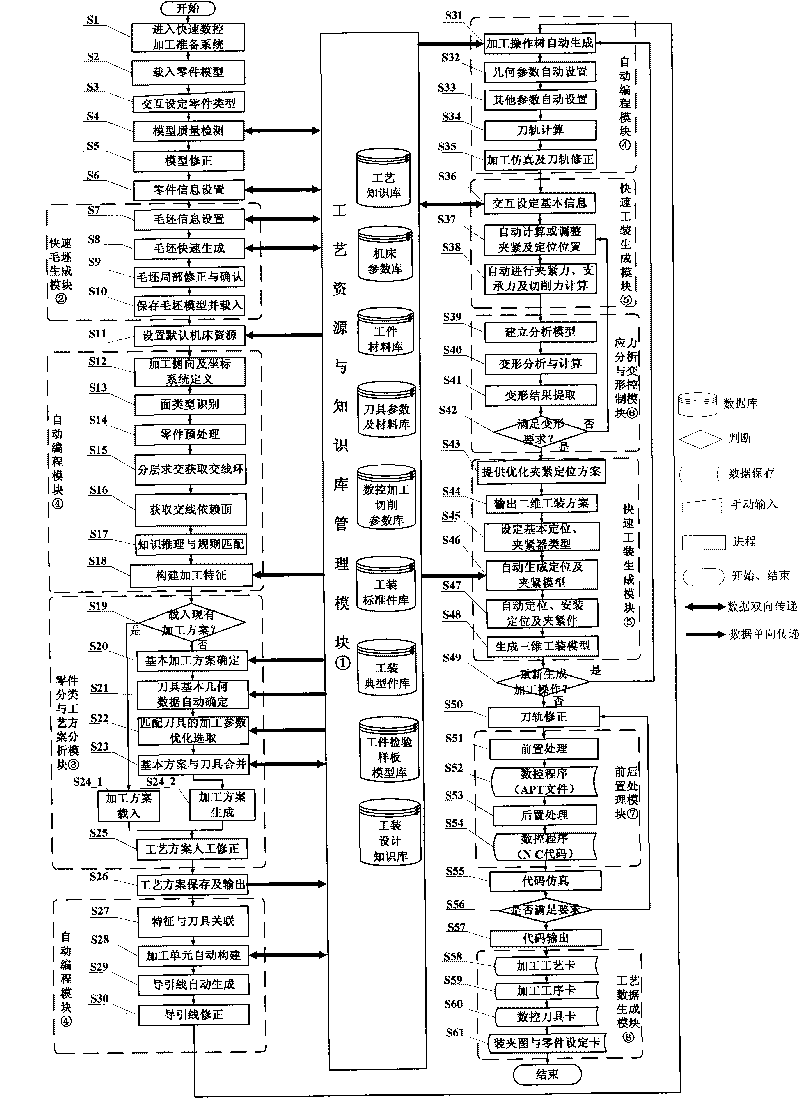

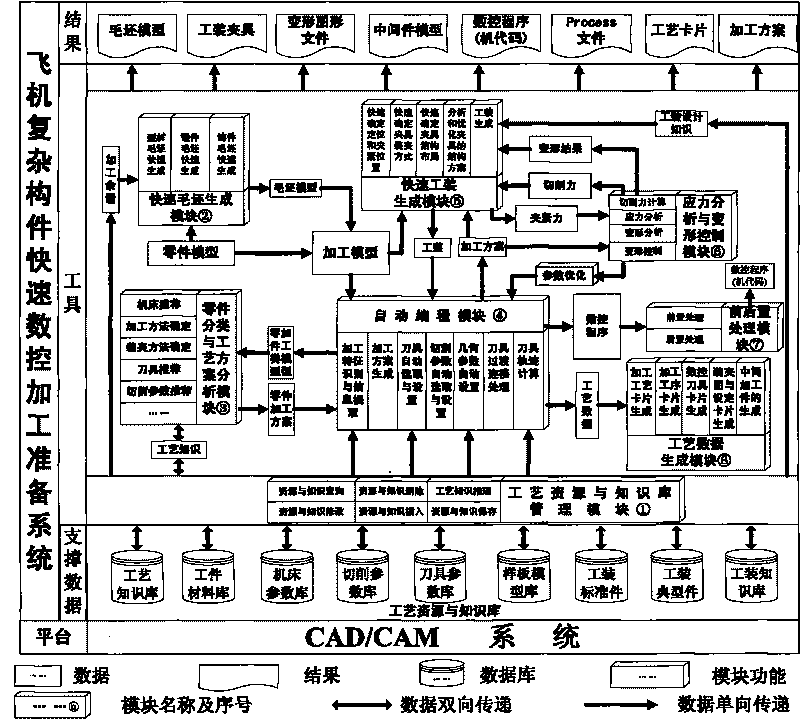

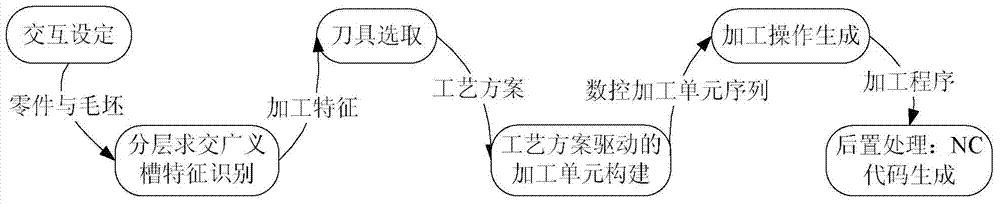

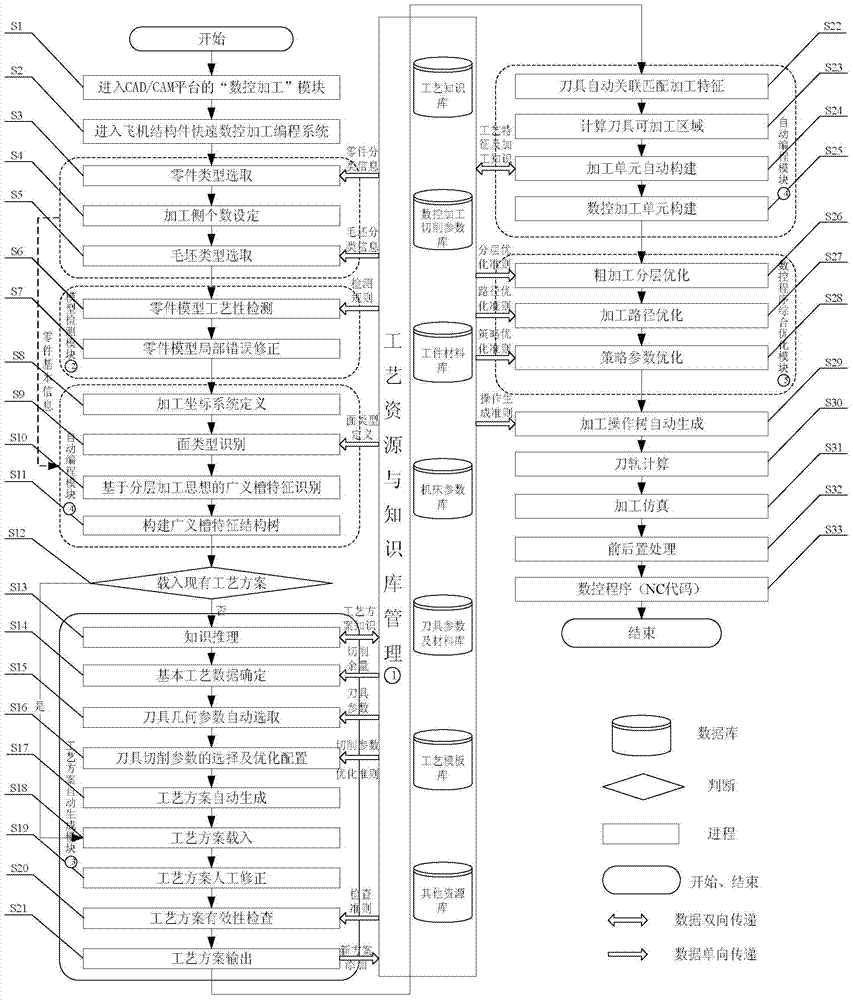

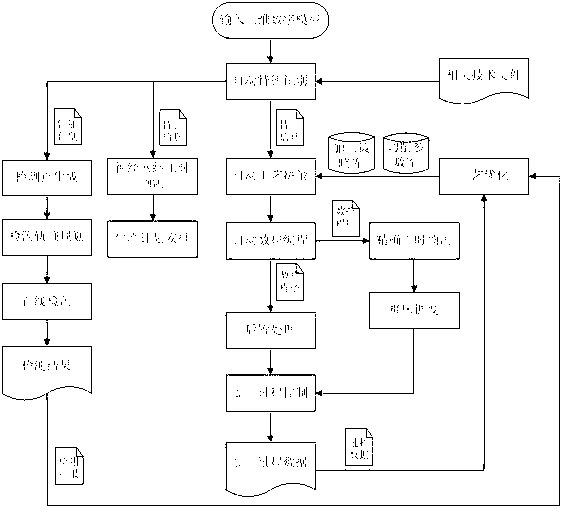

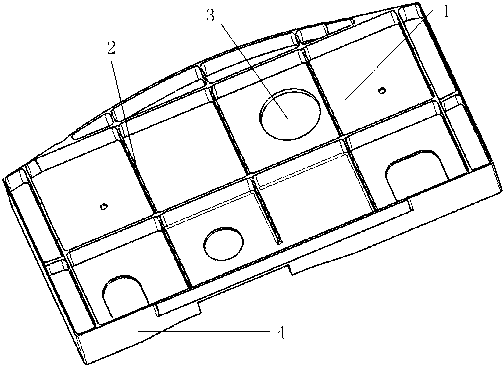

Preparation system of quick numerical control machining of complex parts of airplane and method

InactiveCN101763068ASolve problems such as unreasonable designIncrease specializationProgramme controlComputer controlNumerical controlProcess module

The invention discloses a preparation system of quick numerical control machining of complex parts of an airplane and a method. The system takes the existing CAD / CAM system as a platform, and comprises a technology resource and knowledge base management module, a quick blank generation module, a part classification and technical scheme analysis module, an automatic programming module, a quick tool generation module, a strain analysis and deformation control module, a front and rear process module and a technology data generation module. The system is built on the basis of a three-dimensional numeric part model, systematically and exactly embodies a specialized flow path for supporting the numerical control machining technology preparing and the programming of the complex parts of the airplane, can greatly reduce man-machine interaction operation required by preparing technology and programming, effectively solves the problems of the unstable programmed procedure and the unreasonable scheme design of the machining technology caused by the lack of the experience of process operators, and the like, can effectively control the deformation quantity during and after machining the parts, can obviously improve the efficiency and the quality of the numerical control machining preparing and the programming, and improves the professional level and the intelligence level of the CAD / CAM system.

Owner:SHENYANG AIRCRAFT CORP +1

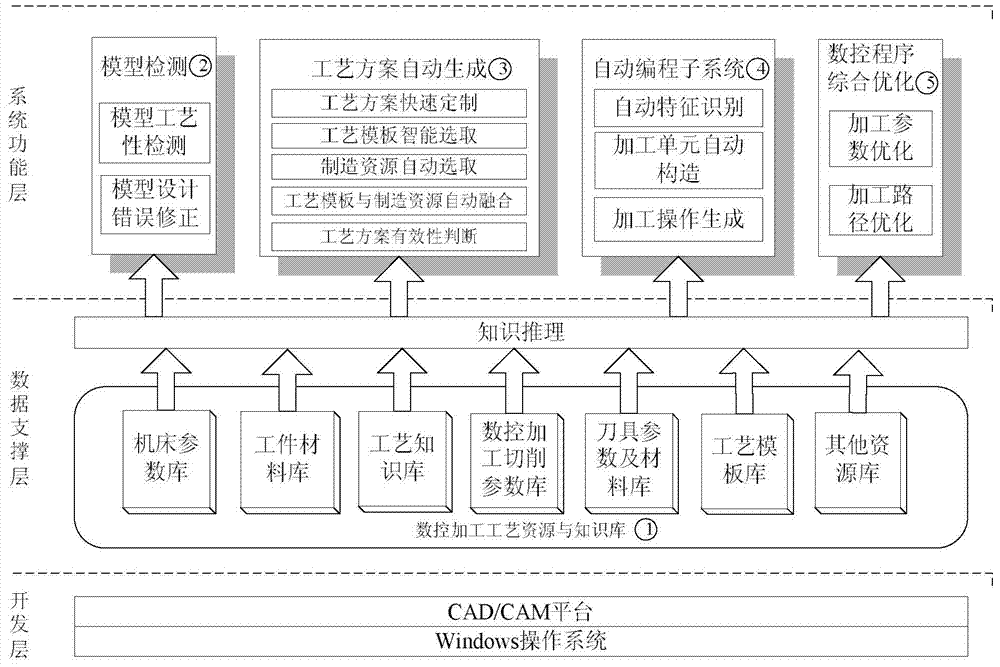

Intelligent numerical control machining programming system and intelligent numerical control machining programming method for aircraft structural parts

ActiveCN103699055AReasonableHigh automatic generation efficiencyProgramme controlComputer controlNumerical controlHuman–computer interaction

The invention relates to an intelligent numerical control machining programming system and an intelligent numerical control machining programming method for aircraft structural parts. According to the system, an existing CAD / CAM (Computer-Aided Design / Computer-Aided Manufacturing) system is taken as a platform; the system comprises a model detection module, a process scheme automatic generation module, a process resource and knowledge base management model, an automatic programming subsystem module and a numerical control program intelligent optimization module. The system is established on the basis of a three-dimensional model, the numerical control machining programming specialization process of the aircraft structural parts is relatively systematically and accurately reflected and supported, the man-machine interaction operation required in the technological preparation and programming process can be greatly reduced, the problems of unstable program, long programming period and the like caused by interactive programming based on universal platform and artificial experience are effectively solved, the numerical control machining preparation and programming efficiency and quality can be obviously improved, and the specialization level and the intelligence level of the CAD / CAM system are promoted.

Owner:SHENYANG AIRCRAFT CORP

Position control apparatus and method of the same, numerical control program preparation apparatus and method of the same, and methods of controlling numerical control machine tool

InactiveUS6097168AEasy to controlPrecise positioningProgramme-controlled manipulatorComputer controlNumerical controlTarget setting

Owner:TOSHIBA MASCH CO LTD

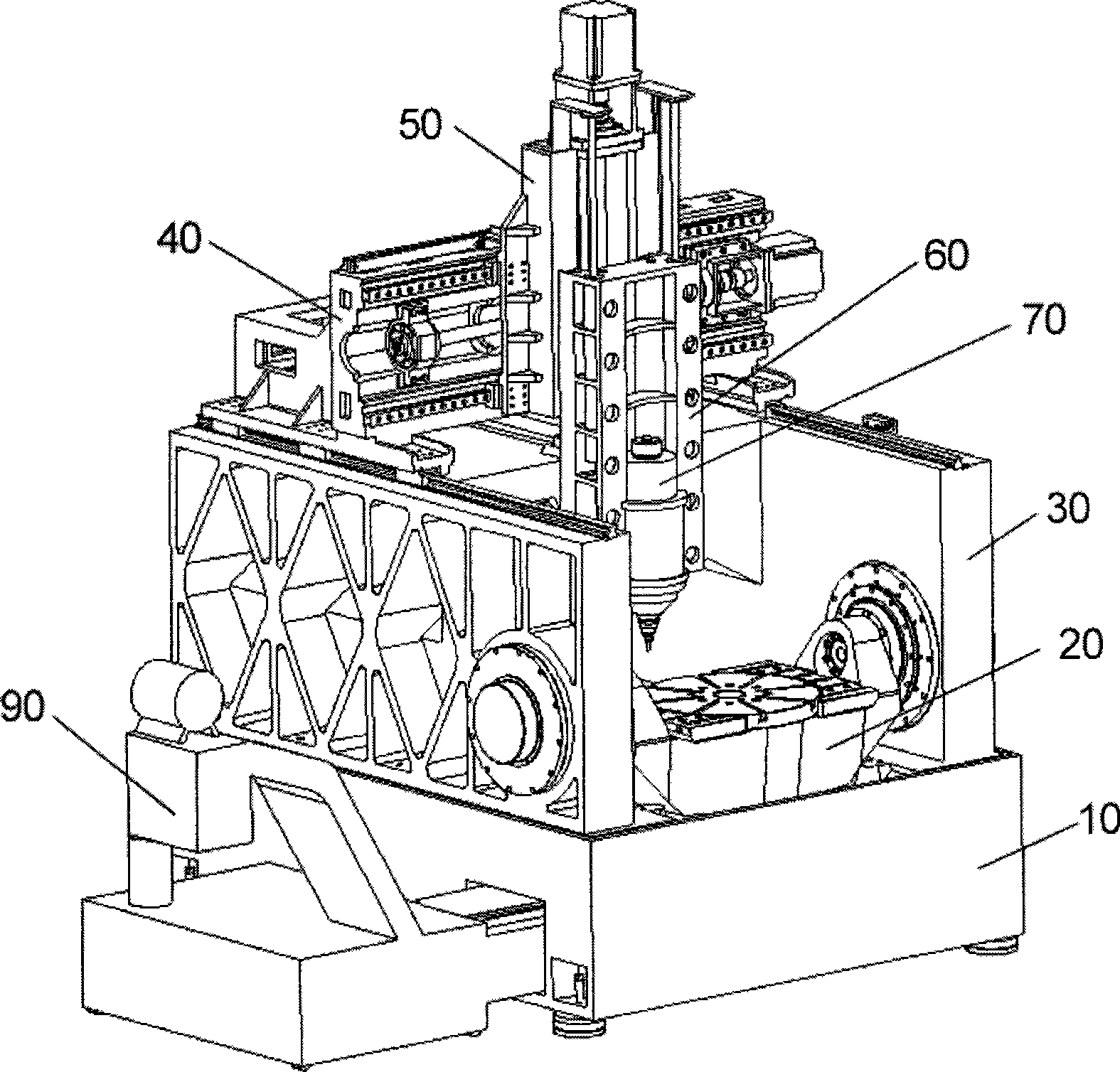

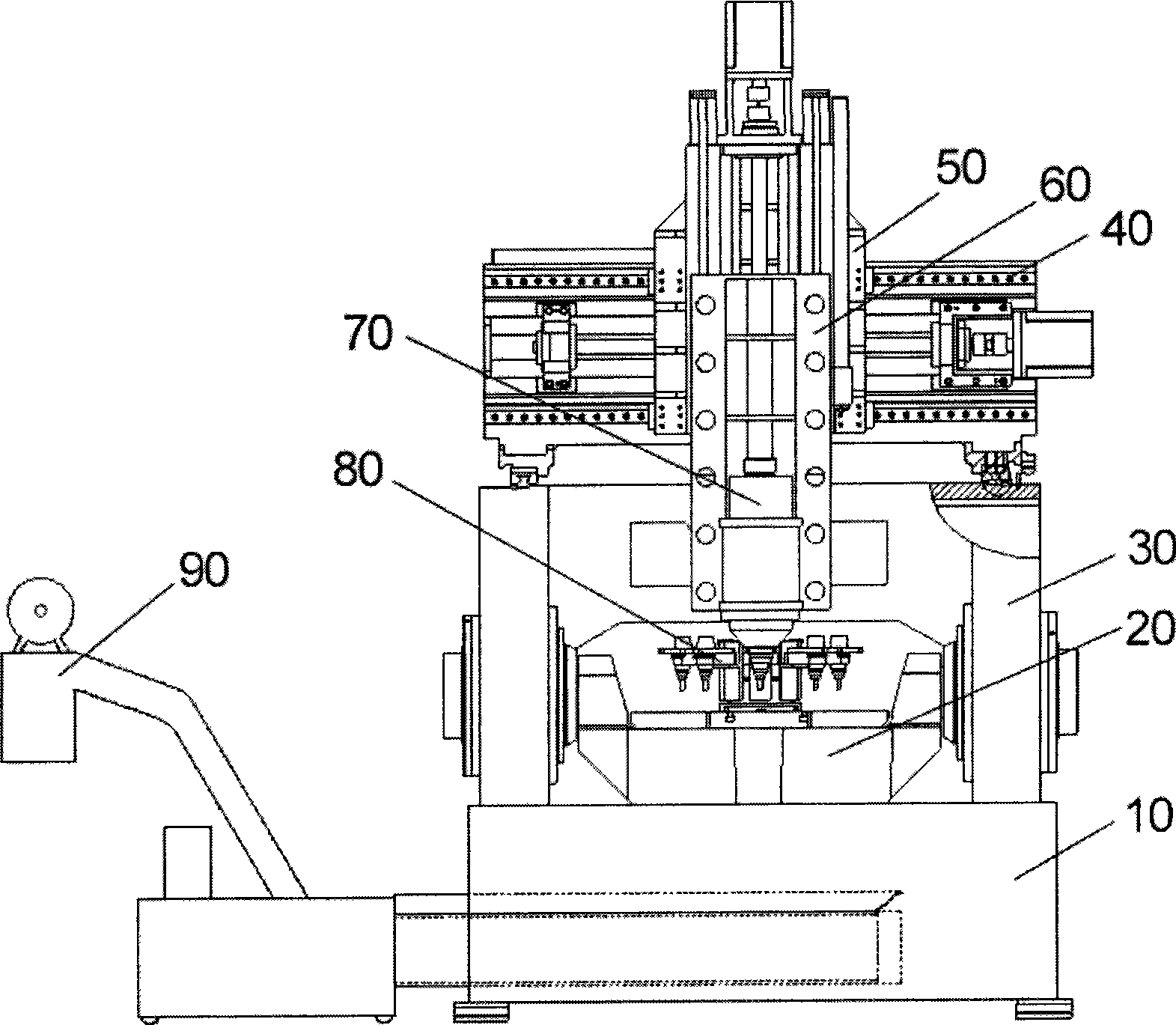

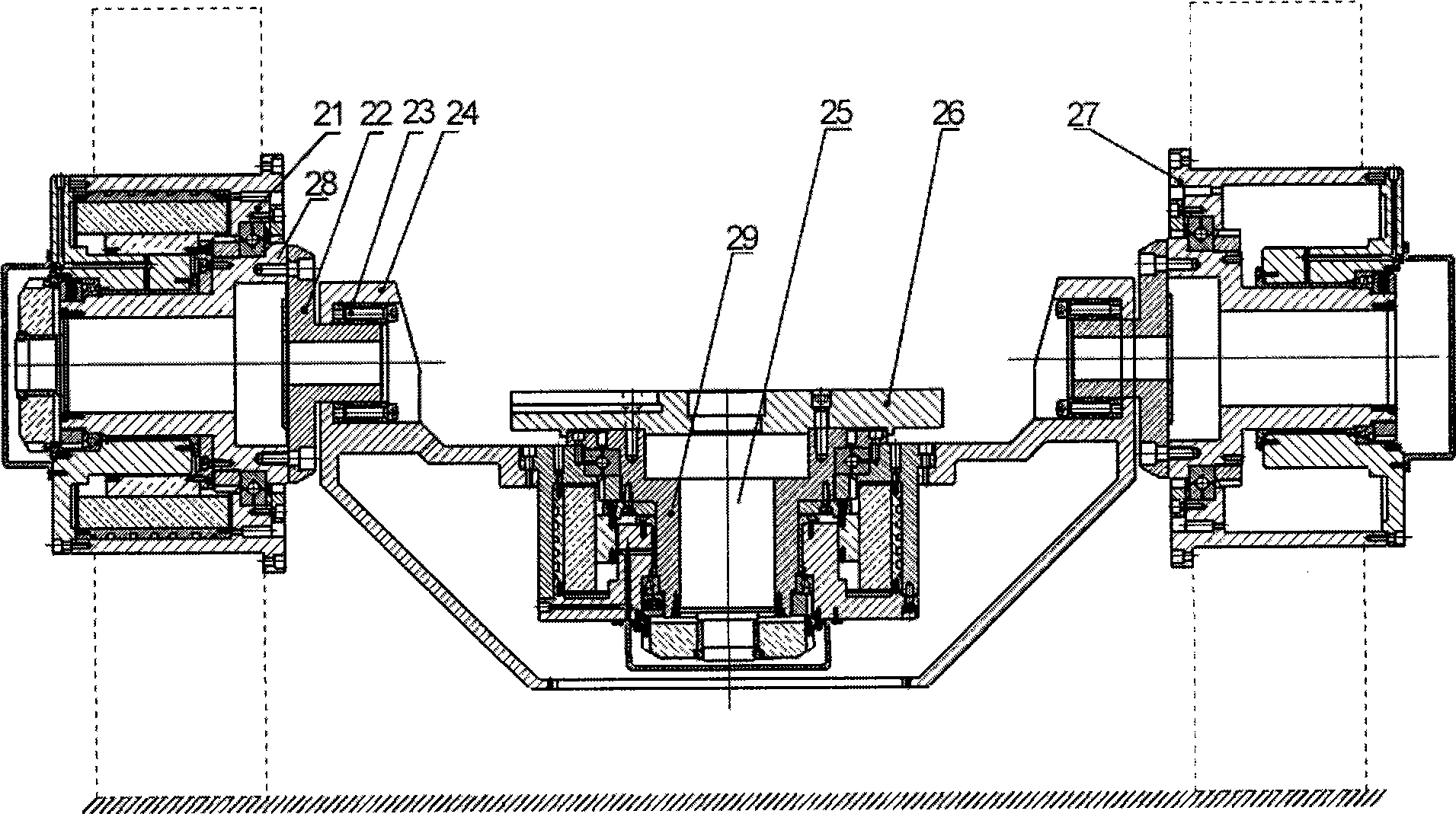

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

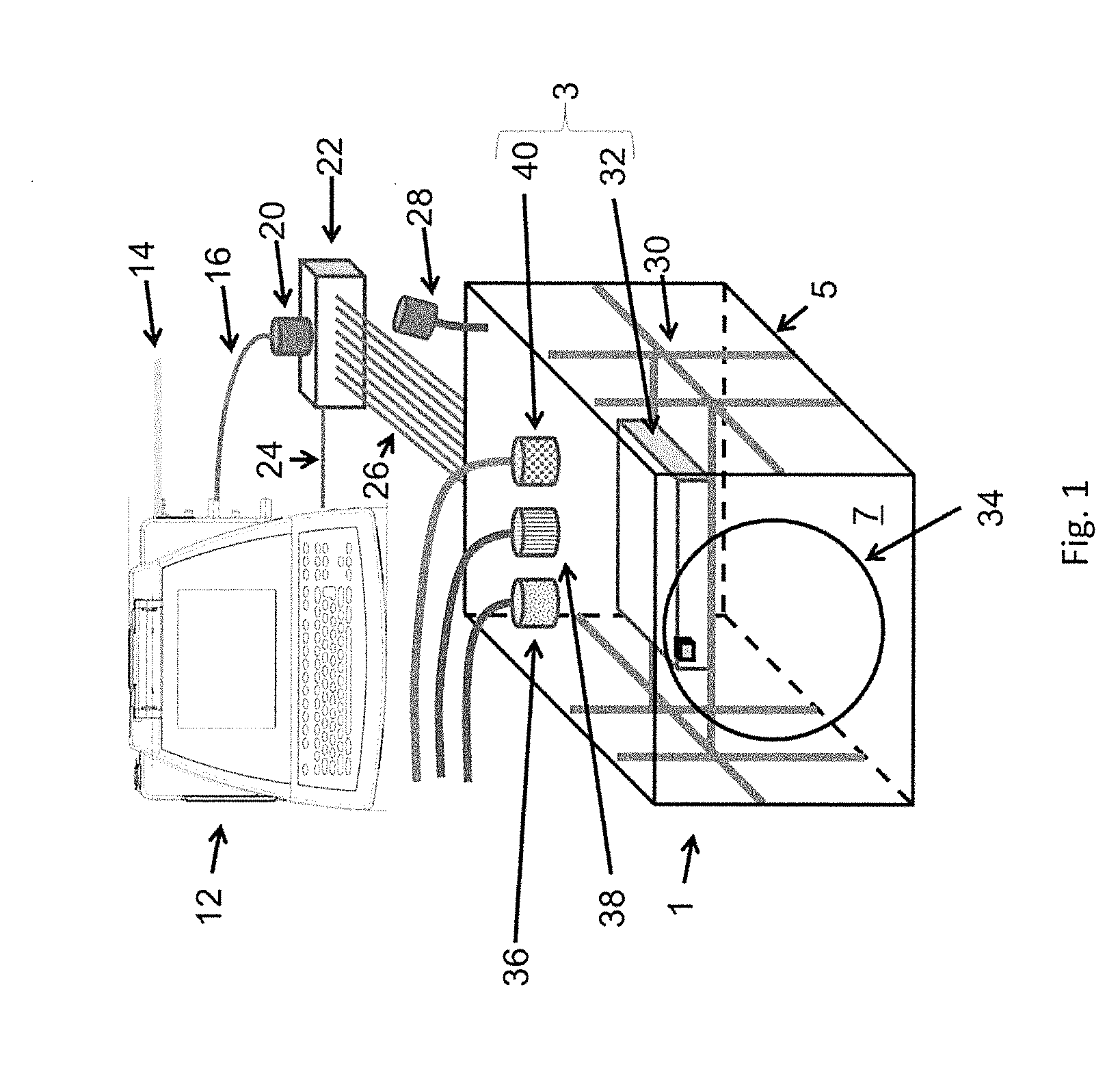

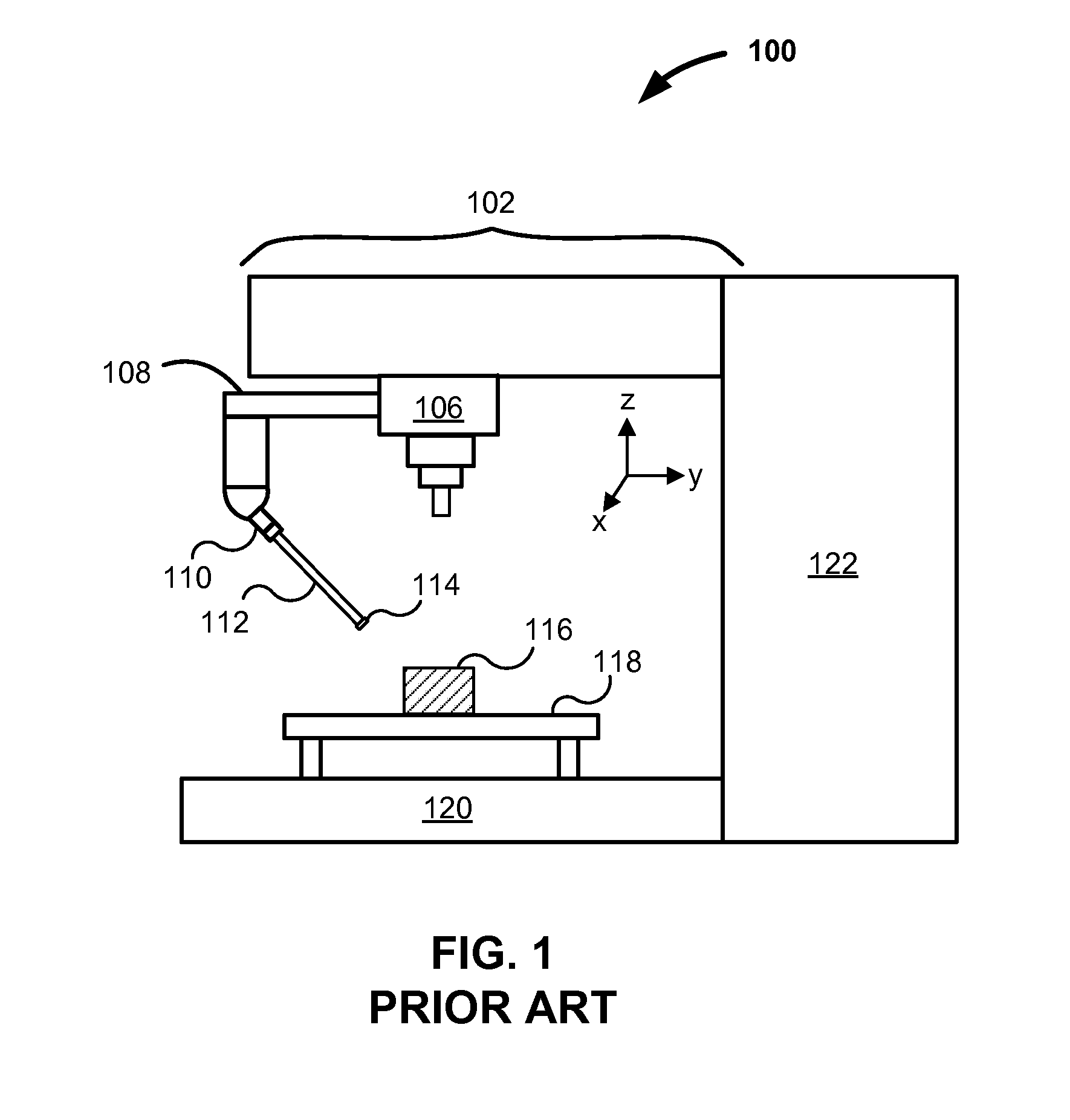

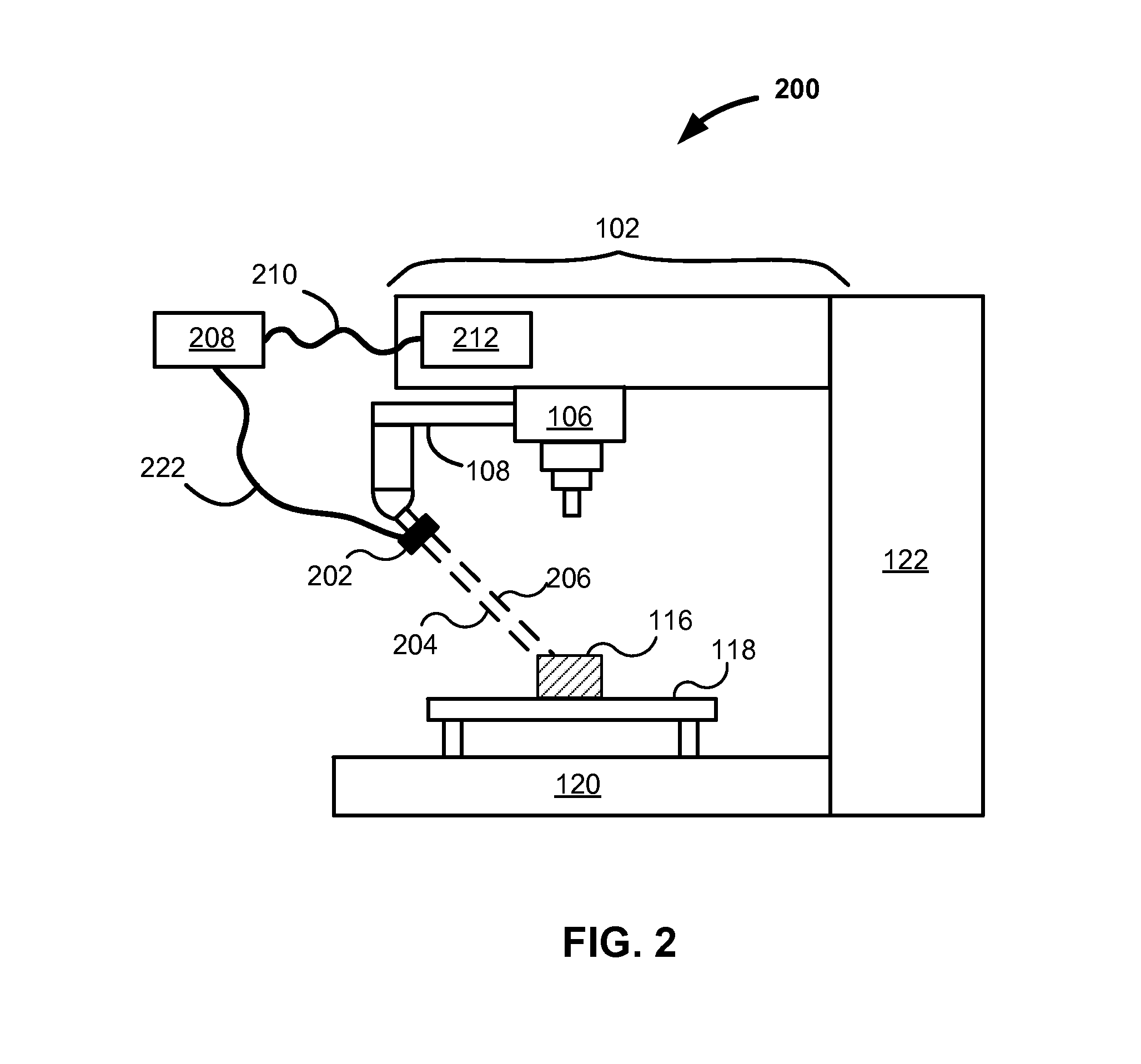

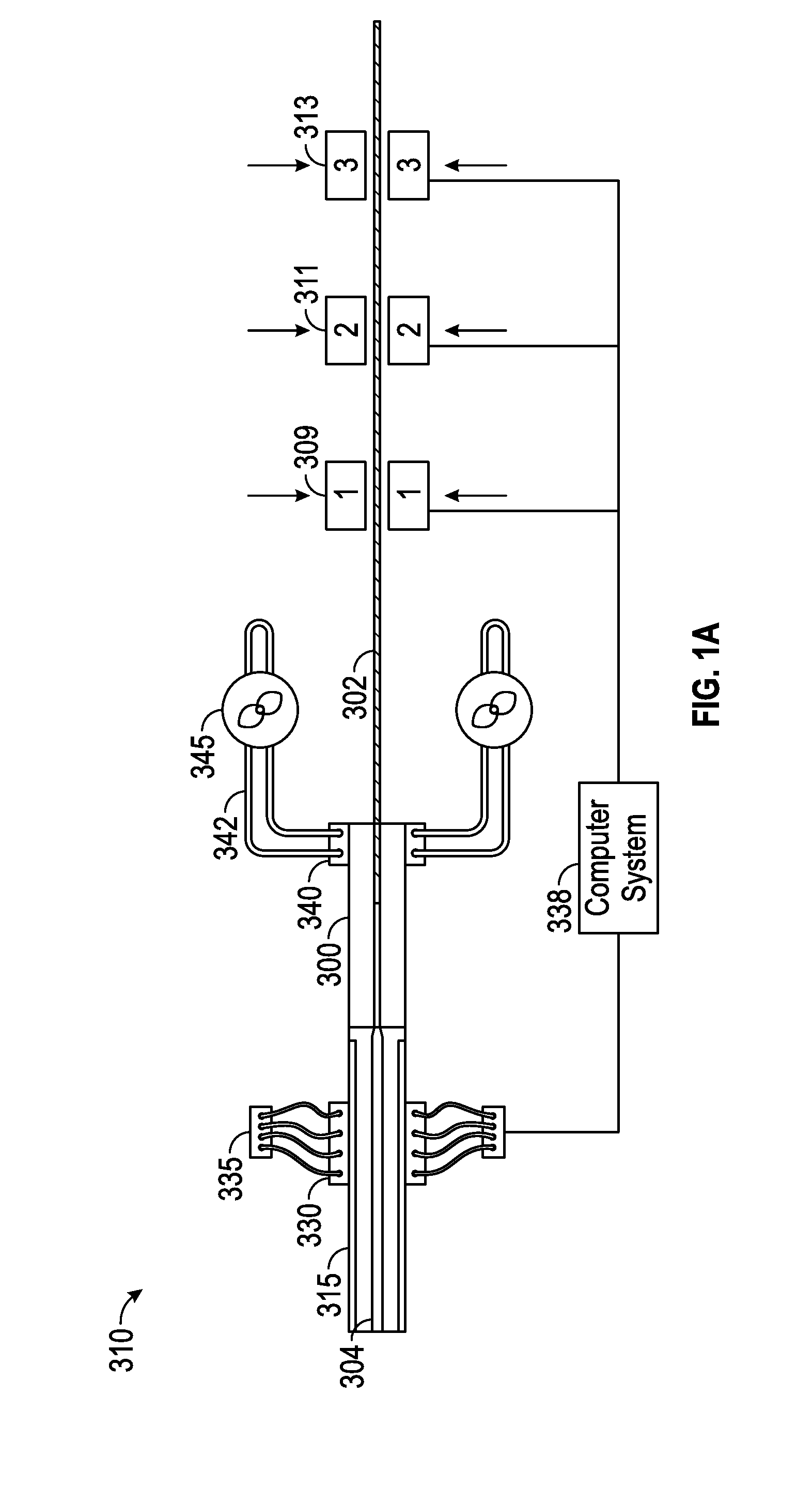

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

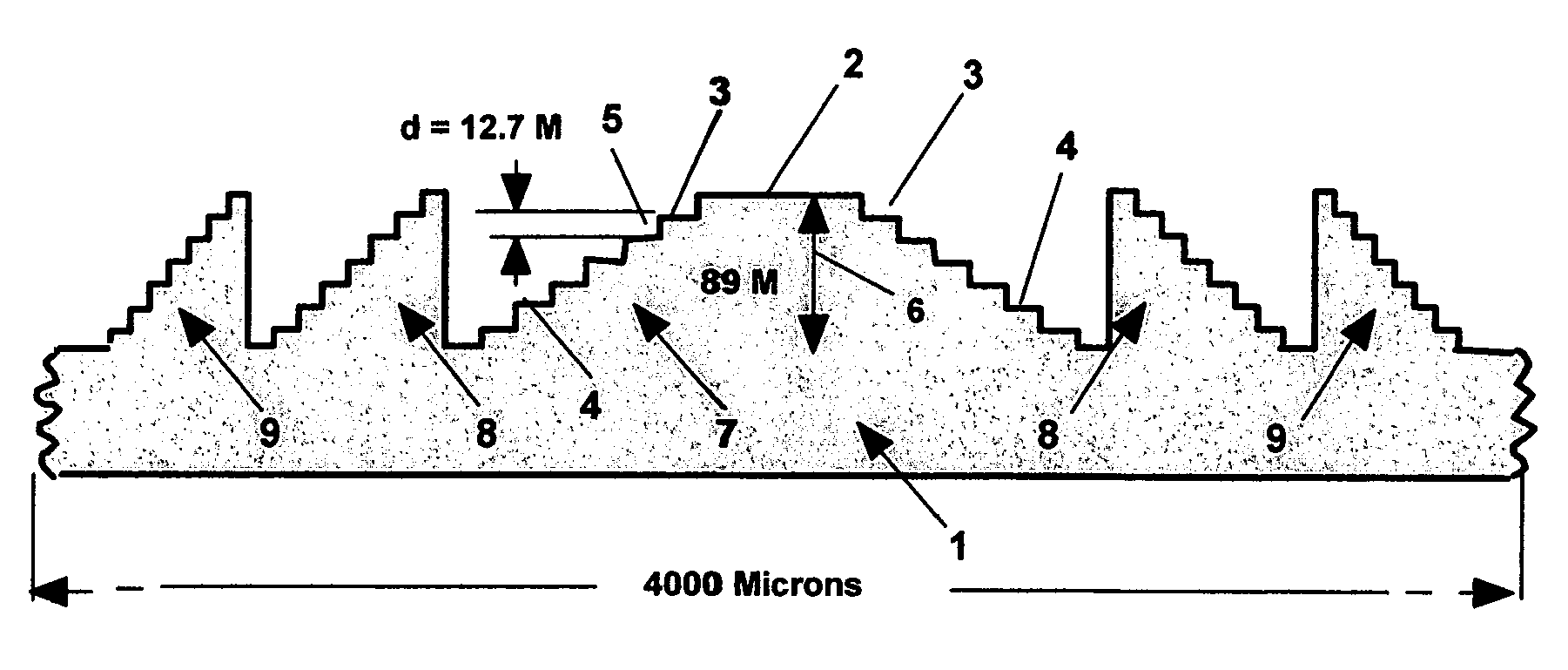

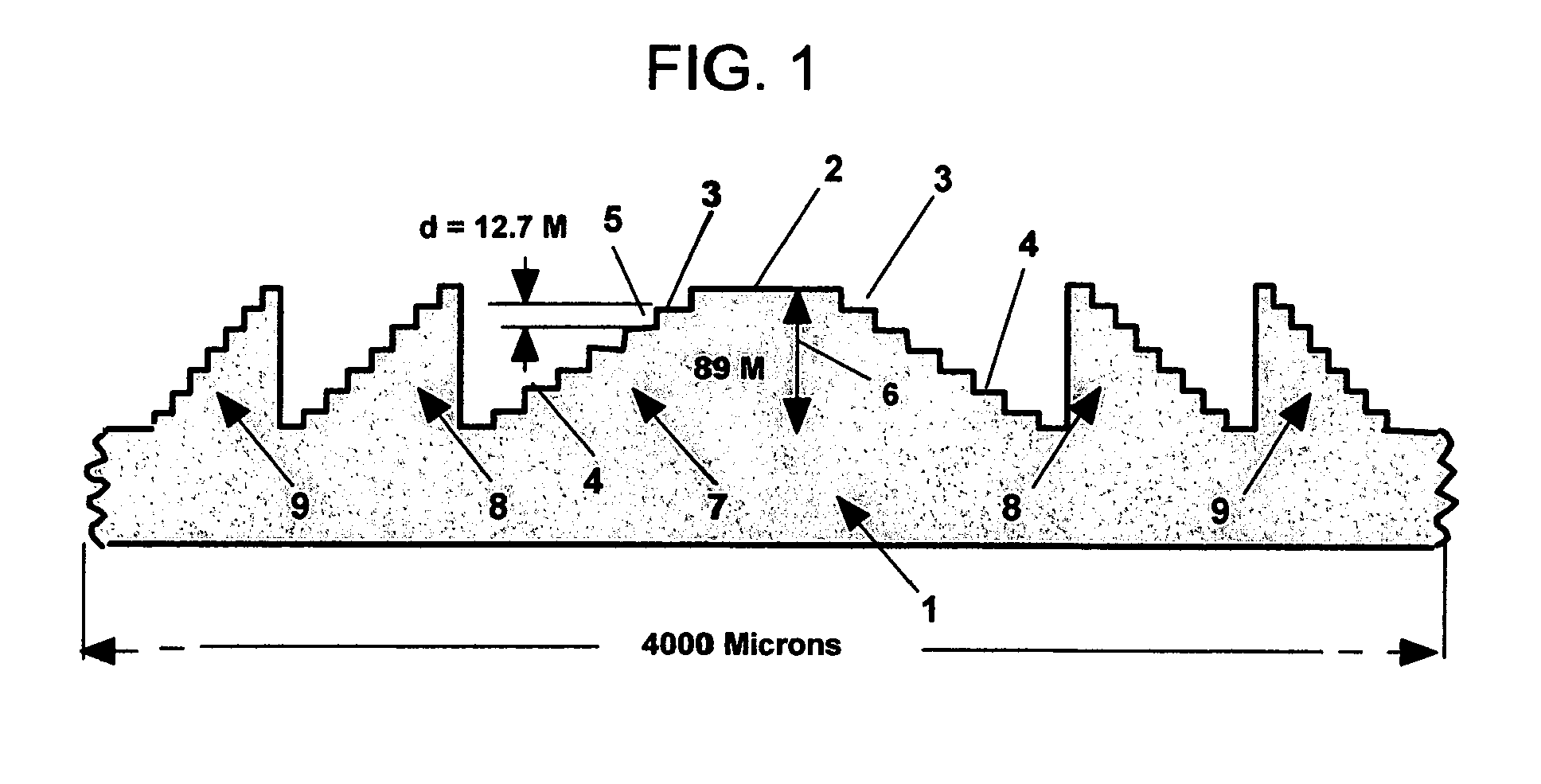

Efficient wave propagation for terahertz imaging and sensing

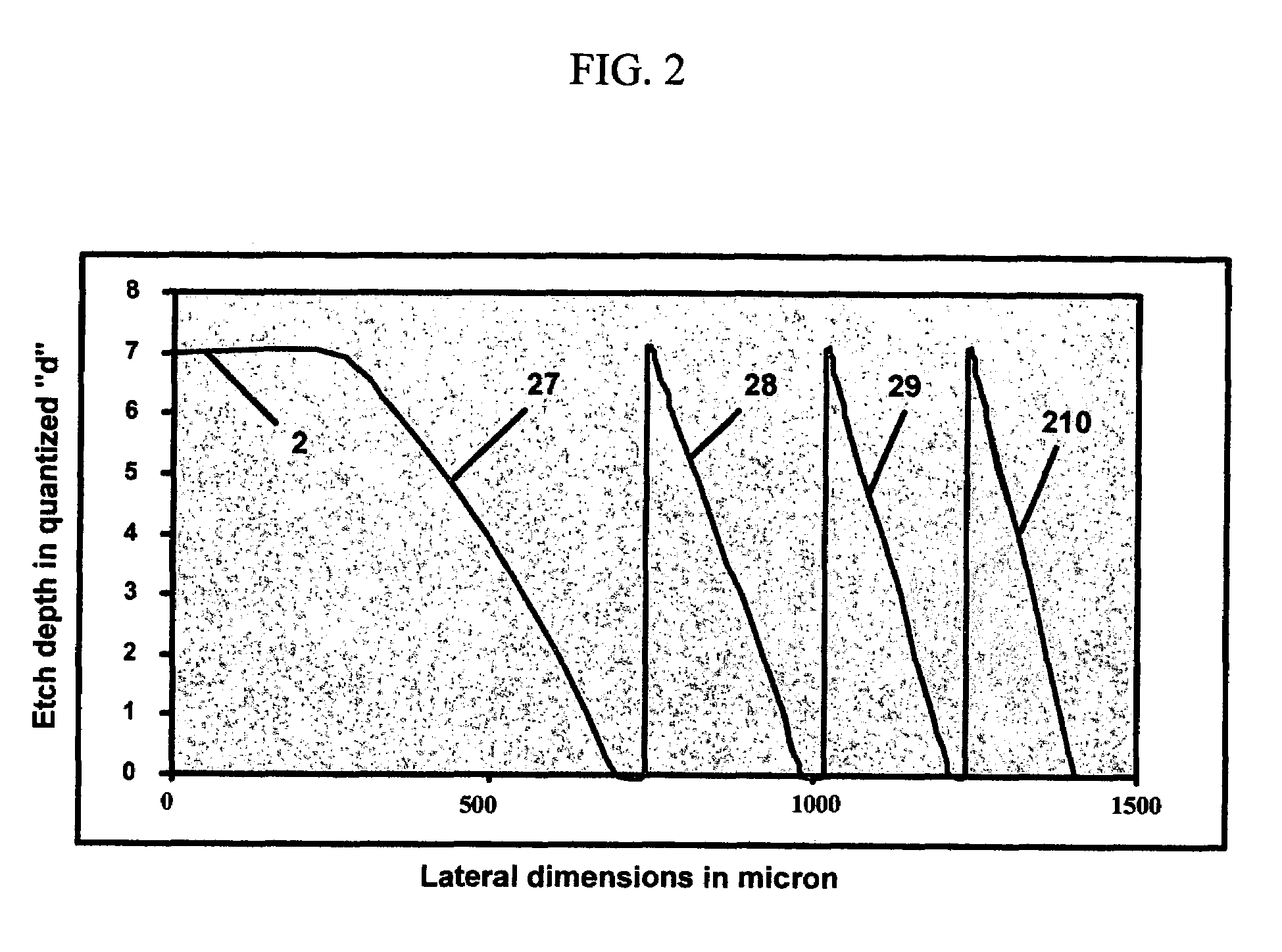

A method of wave propagation from 100–10000 GHz. The currently disclosed method and apparatus adapts micro-opto-electro-mechanical systems (MOEMS) technologies and processes to construct Kinoform optical components from microwave to terahertz range. The method uses induced coupled plasma (ICP) and gray scale processes for upper terahertz band; LIGA-based high aspect ratio (HAR) and gray scale processes are for the mid band; and computer numerical control (CNC) for lower band. In all cases, the thickness of any processed components is about the respective wavelength and system efficiency is about 95%. A Kinoform lens element is designed at 5000 GHz. However, the method is applicable for the entire terahertz band.

Owner:MOTAMEDI MANOUCHEHR E +1

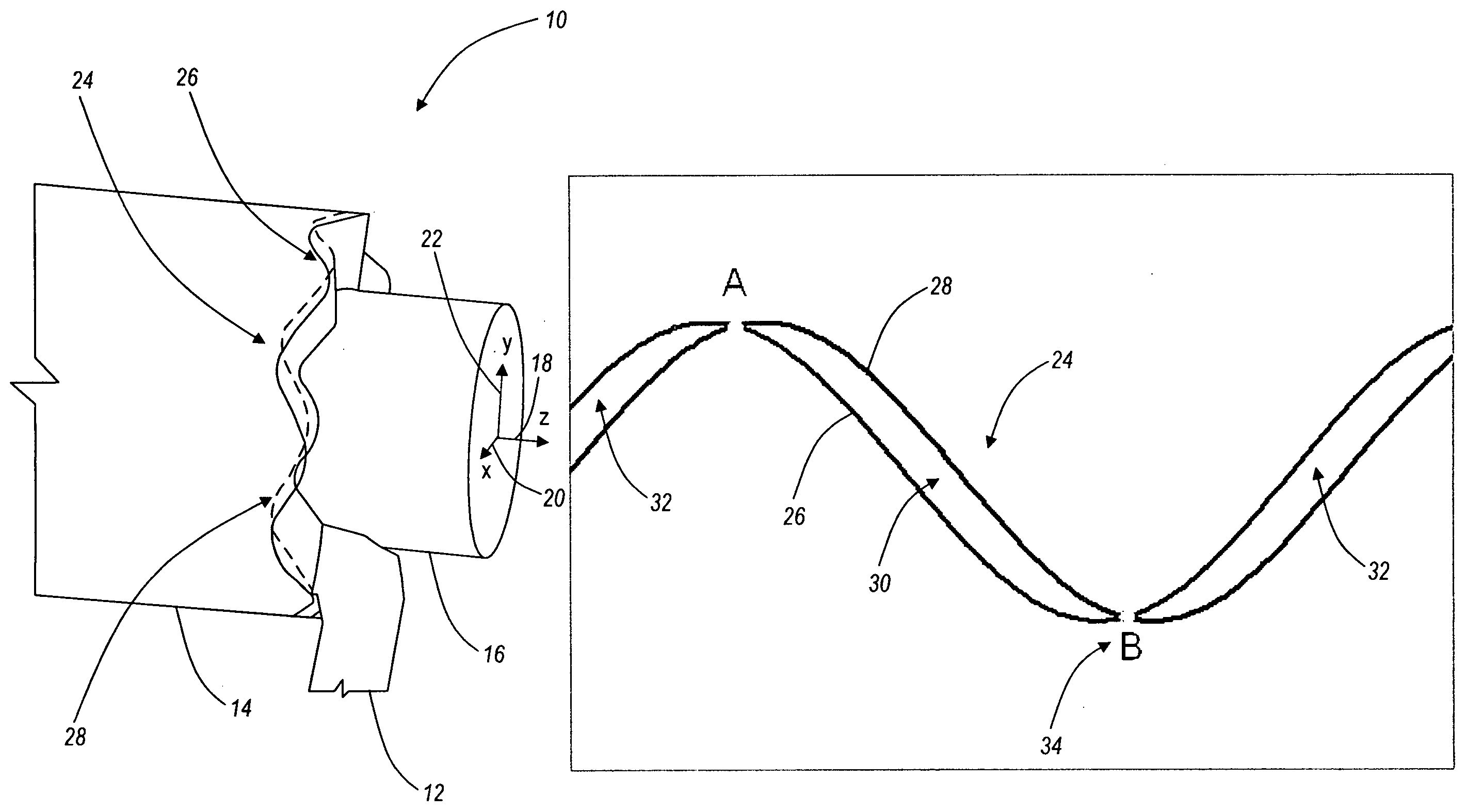

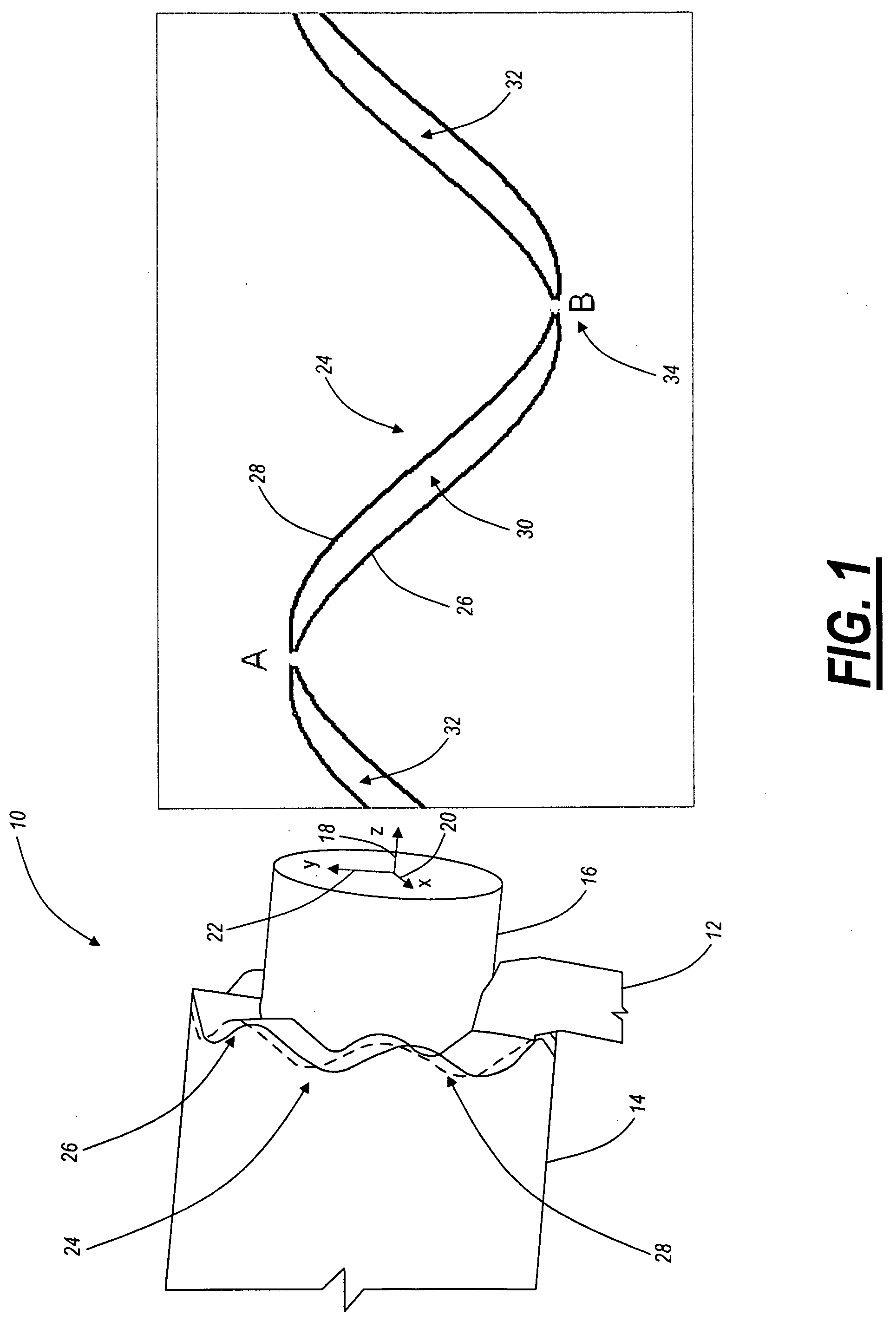

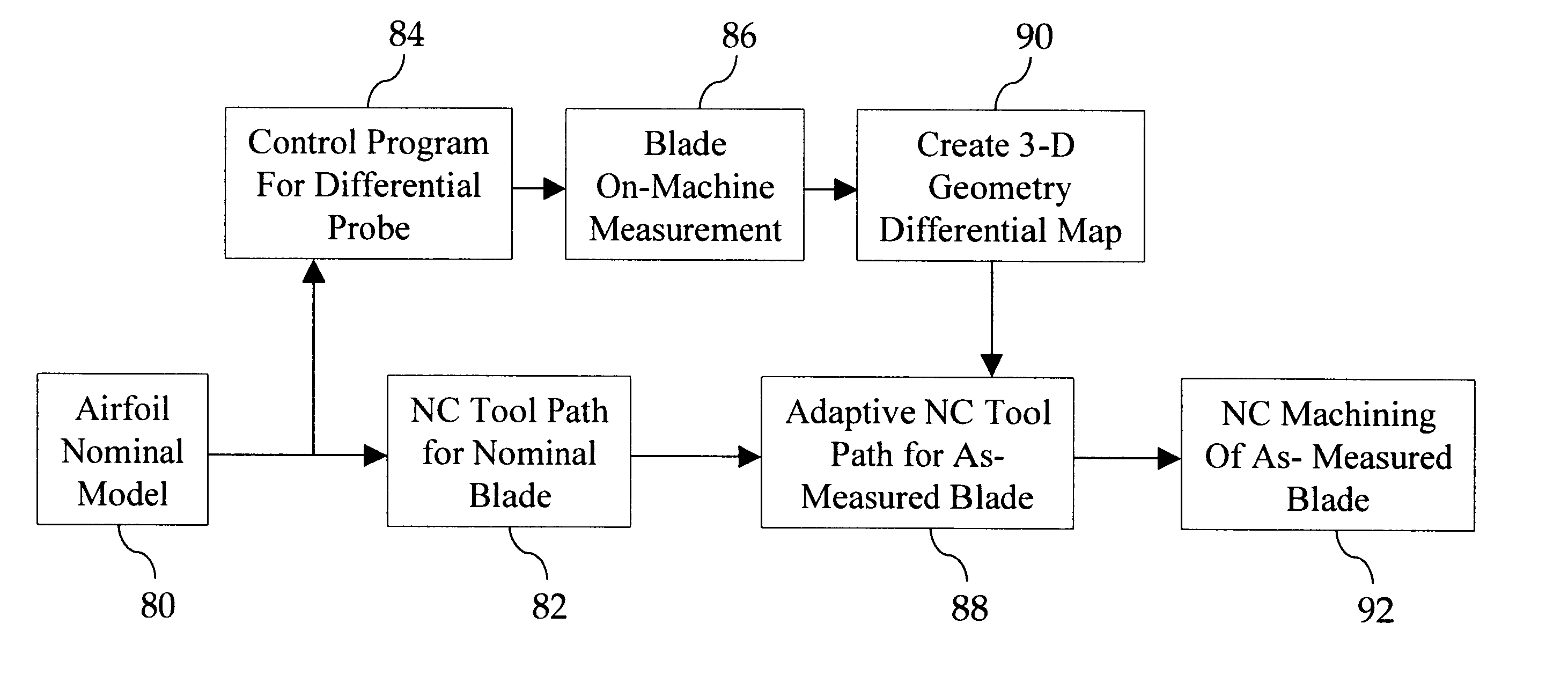

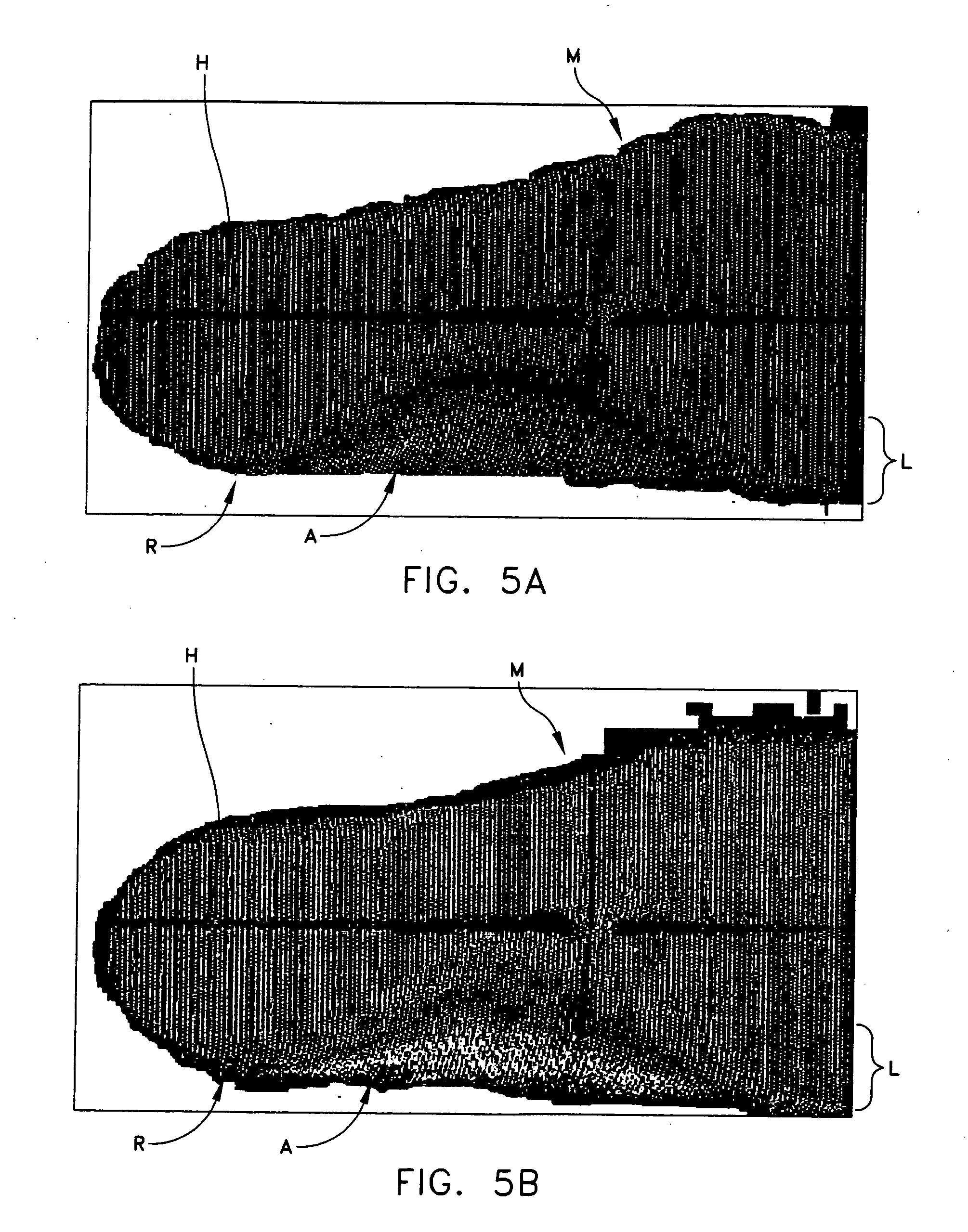

Systems and methods for automated sensing and machining for repairing airfoils of blades

InactiveUS6912446B2AdaptableEasy maintenanceProgramme controlTurbinesNumerical controlData acquisition

A method for repairing an airfoil comprising creating a nominal numerically-controlled tool path based on a nominal shape of the airfoil, measuring the airfoil using a displacement sensor, capturing differences in the airfoil shape as compared to the nominal shape, creating a three-dimensional map by synchronizing x, y and z coordinates and readings from the sensor, modifying the tool path based on the three-dimensional map, and machining the airfoil. A system for measuring and machining an airfoil comprising a computer operable for data acquisition and numerically-controlled tool path generation, a numerically-controlled machine, a cutting tool holder comprising a plurality of cutting tools, and a displacement-sensing probe.

Owner:GENERAL ELECTRIC CO

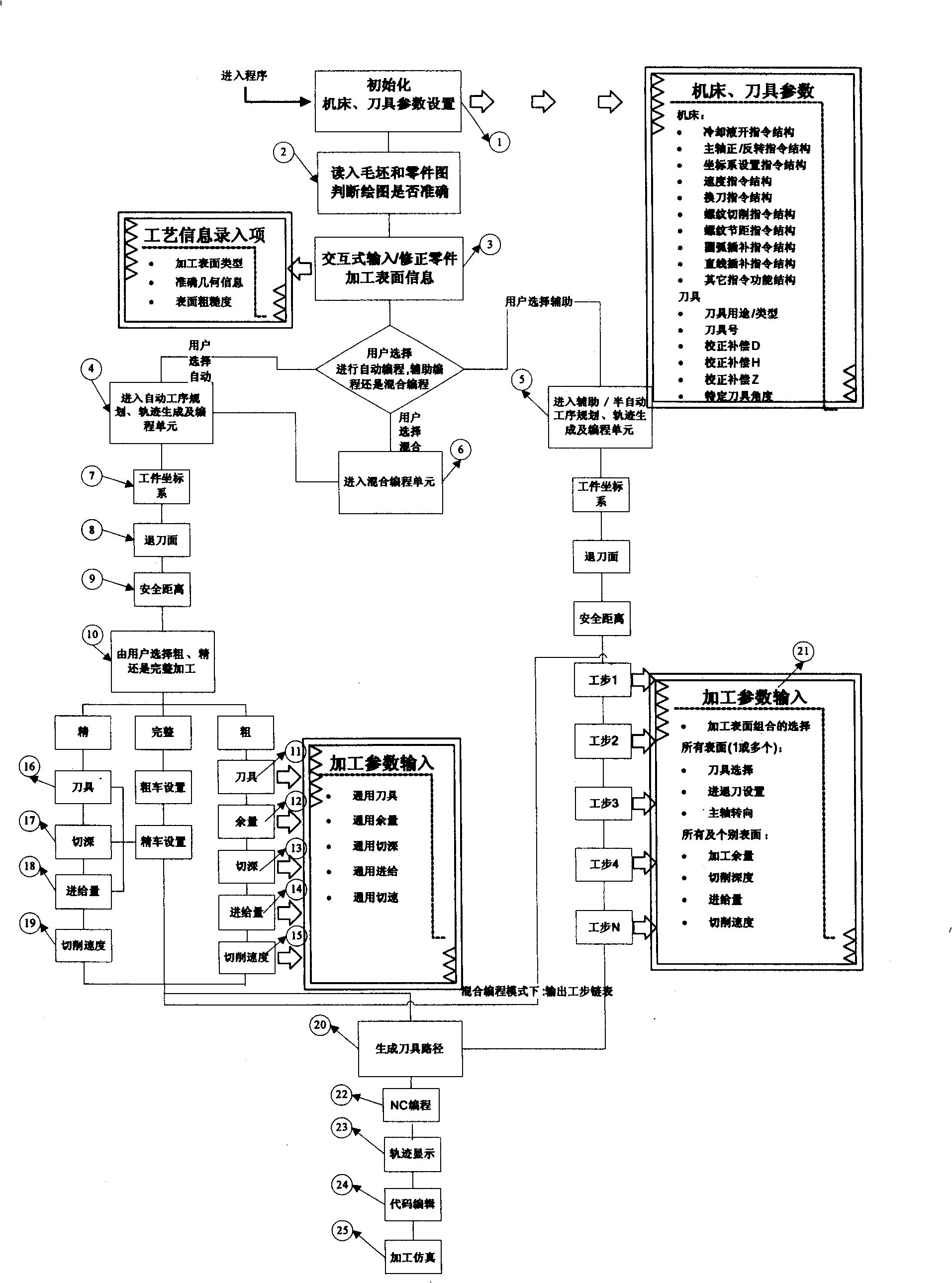

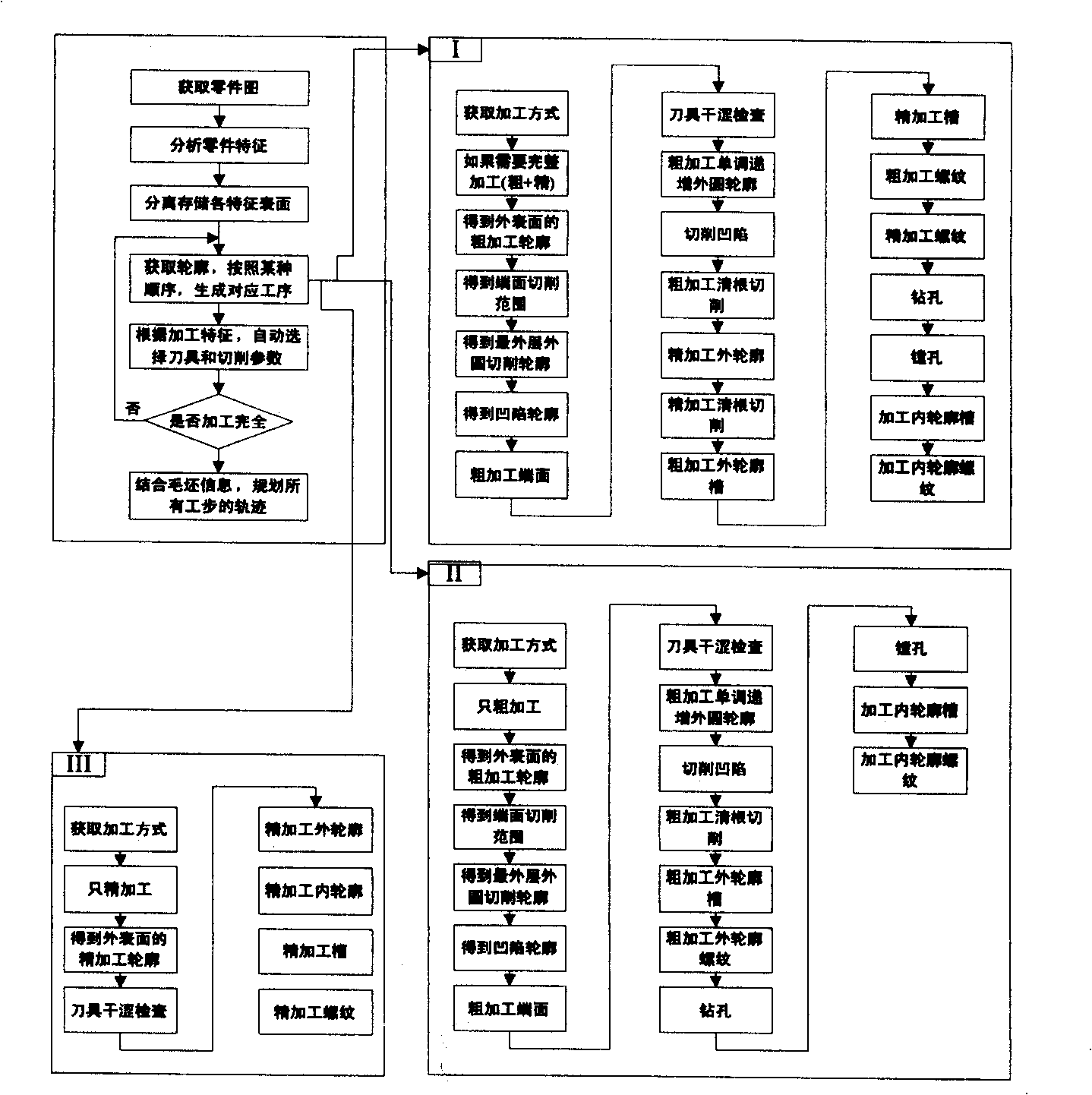

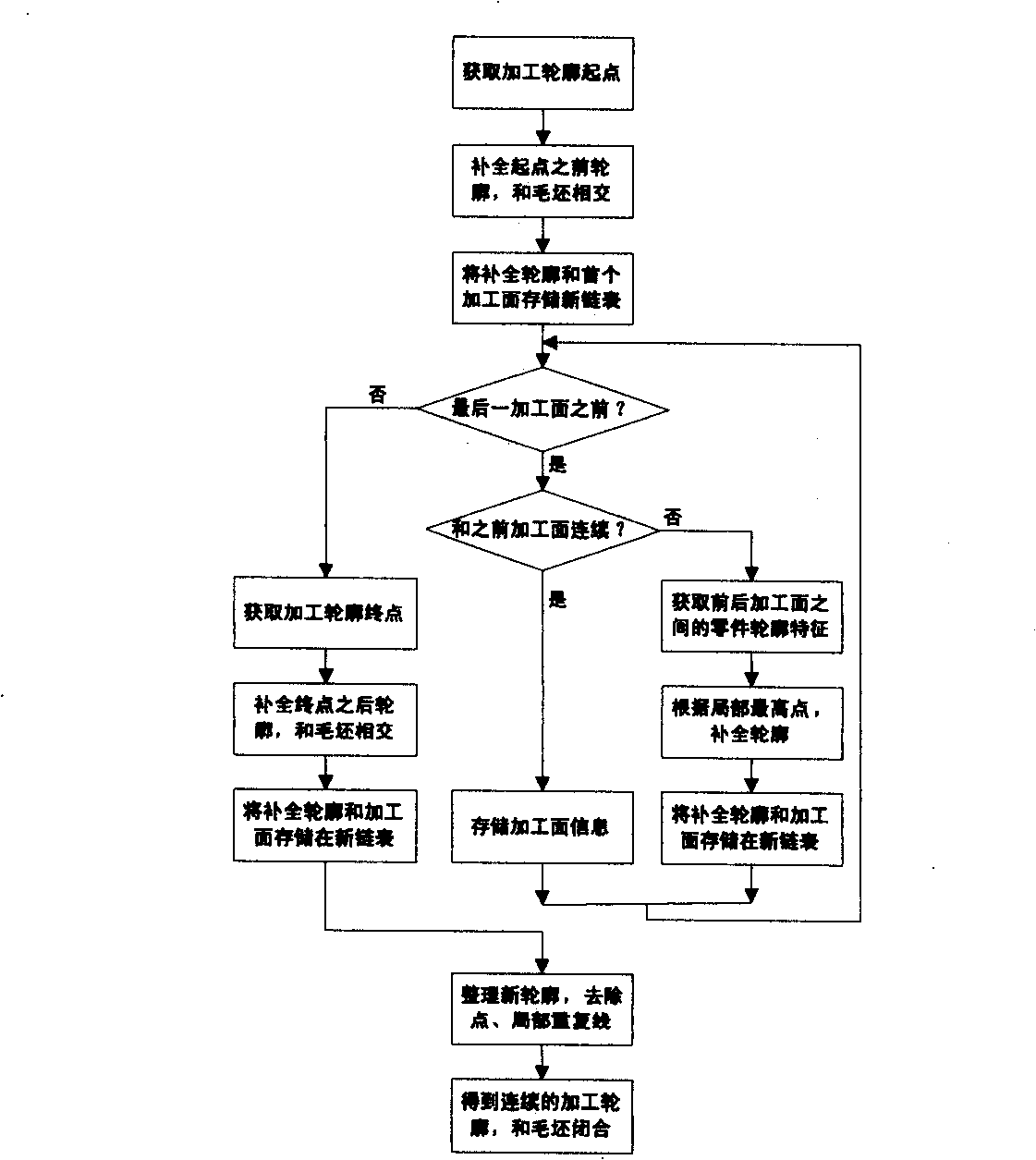

Imaging interactive numerical control turning automatic programming method and system

The invention provides an automatic graphical interaction-typed numerical control (NC) turning programming method and system used for improving programming efficiency and NC code quality, prompting quick product process realization (RPPR) and integrated product process development (IPPD). The technical proposal of the invention is that the automatic graphical interaction-typed numerical control turning programming method is characterized in that the method comprises the steps of: reading in blank and part drawing, removing redundant information, and judging whether the graphics are exact; leading the graphics to have real-time interaction function and be capable of correcting the information of the part processing surface, including processing surface type, exact geometrical information and surface roughness; determining whether to execute the corresponding system function modules by carrying out automatic programming or auxiliary programming or mixed programming according to the selection of the user. The automatic graphical interaction-typed numerical control turning control system is characterized in that the automatic graphical interaction-typed NC turning control system comprises a CAD data reading-in module which is respectively connected with an automatic programming module, an auxiliary programming module and a mixed programming module which are respectively connected with an automatic track layout module which is connected with an NC code generation module.

Owner:TSINGHUA UNIV

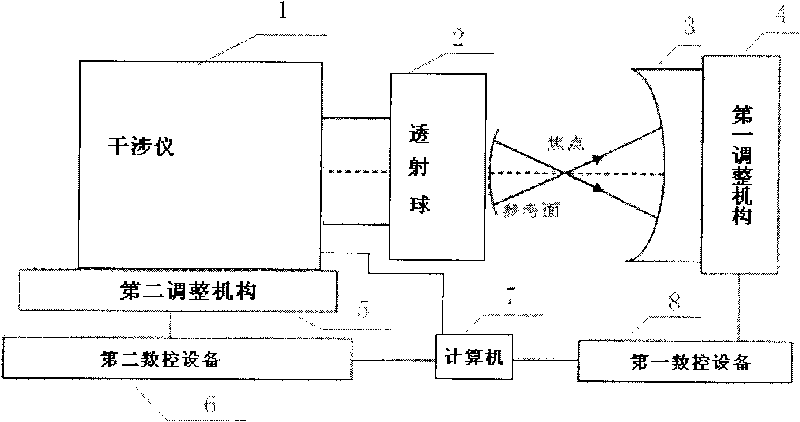

Device for detecting surface shape of optical aspheric surface by sub-aperture stitching interferometer

InactiveCN101709955AWiden horizontallyExpand the scope ofUsing optical meansNumerical controlFace shape

The invention relates to a device for detecting a surface shape of an optical aspheric surface by a sub-aperture stitching interferometer, which comprises an interferometer, a transmission sphere, an adjusting mechanism, a numerical control device and a computer, wherein parallel light emitted by the interferometer is changed into a standard spherical wave through the transmission sphere; the computer controls the action of the adjusting mechanism by the numerical control device to adjust the relative position of the interferometer and an aspheric surface to be detected so that the standard spherical wave is incided to each sub-aperture of the detected optical aspheric surface sequentially and returns to the interferometer; and the computer extracts phase distribution data of each sub-aperture measured by the interferometer for analysis and processing, and the error distribution of the surface shape of a full aperture of the detected optical aspheric surface is obtained by a stitching algorithm. The device broadens horizontal and vertical dynamic range tested by the interferometer, can detect surface shapes of large-aperture concave and convex aspheric surfaces and an off-axis aspheric surface in high resolution and high precision without other auxiliary optical elements, and has low testing cost and short construction period.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

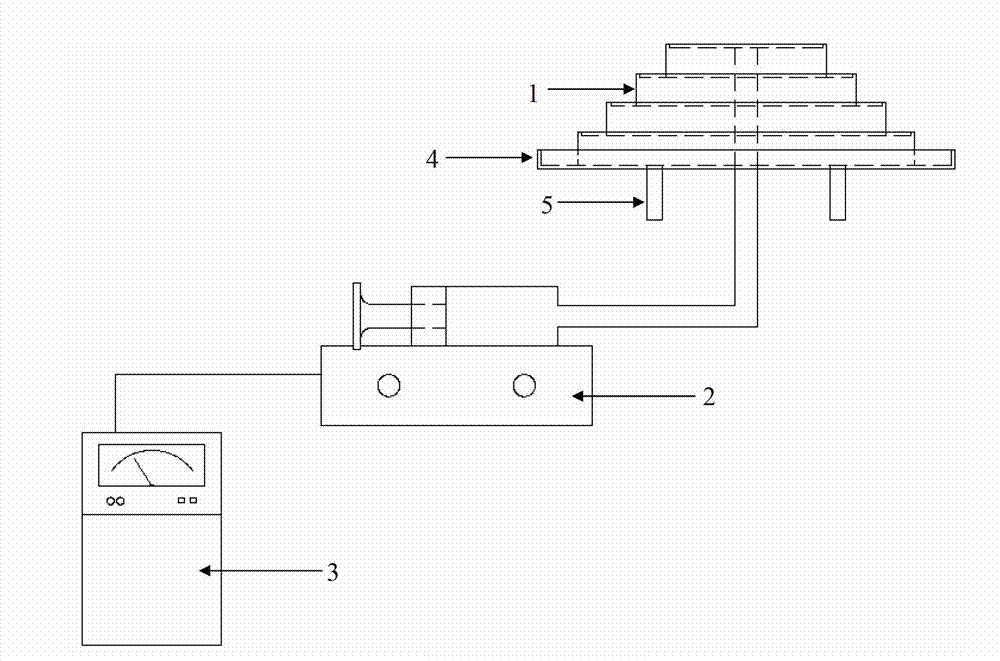

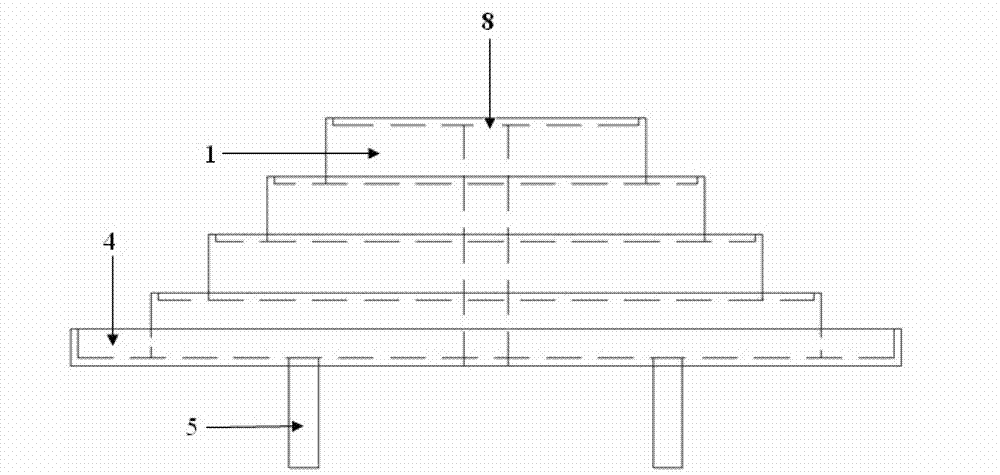

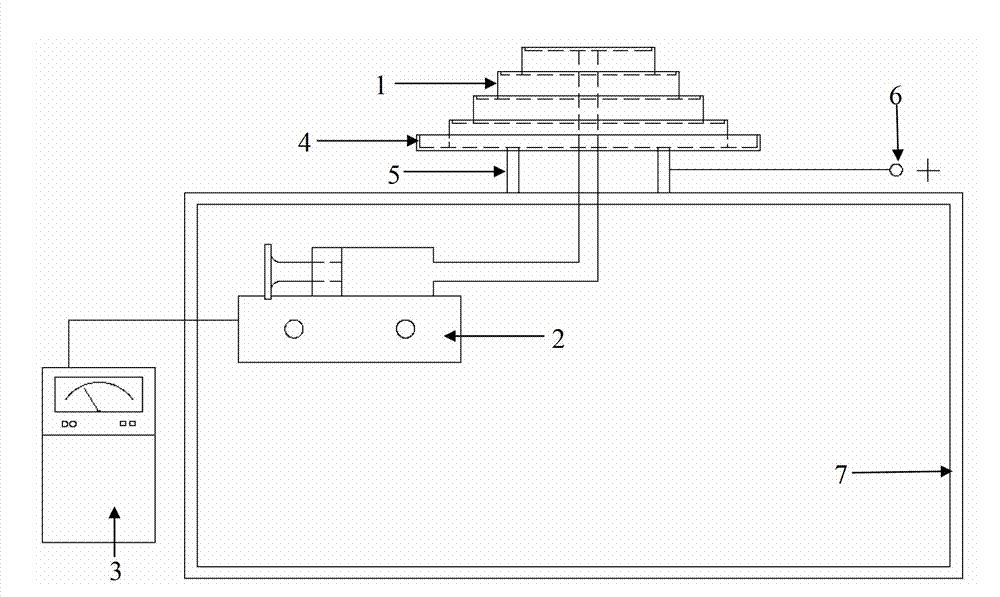

Umbrella-shaped electrostatic spinning sprayer and electrostatic spinning method

ActiveCN103088443AOvercoming easy blockageOvercome efficiencySpinnerette packsFilament/thread formingNumerical controlFiber

The invention relates to an umbrella-shaped electrostatic spinning sprayer and an electrostatic spinning method. The sprayer comprises an umbrella-shaped spinning nozzle, a numerical control type infusion device and a solution collecting groove, wherein the numerical control type infusion device mainly comprises a solution propeller and a controller; the middle of the umbrella-shaped spinning nozzle is provided with a cylindrical hollow portion, and an output end of the solution propeller is placed into the cylindrical hollow portion of the umbrella-shaped spinning nozzle; the controller controls flow velocity and flow of spinning solutions; and the solution collecting groove is placed in the bottom of the umbrella-shaped spinning nozzle. The electrostatic spinning method comprises that a binding post on the umbrella-shaped spinning nozzle is connected with a high-voltage positive electrode, conducting polymer solutions are continuously added to the umbrella-shaped spinning nozzle which is horizontally placed through the numerical control type infusion device, electrostatic spinning is started, collection is achieved through a collecting device, and nano-fibers are formed. The sprayer avoids blocking phenomena, and is easy to clean and good in stability; and the electrostatic spinning method improves production efficiency and the yield of electrostatic spinning.

Owner:DONGHUA UNIV

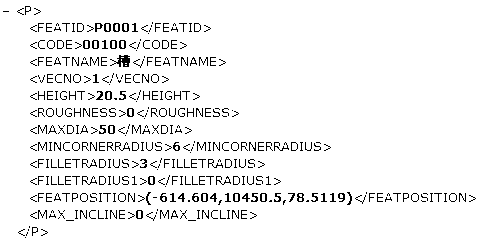

Feature-based numerical-control method for processing and manufacturing complicated parts

ActiveCN103235556AAchieve integrationAchieve deliveryProgramme controlComputer controlNumerical controlClosed loop

Disclosed is a feature-based numerical-control method for processing and manufacturing complicated parts. The feature-based numerical-control method includes expressing features on the basis of a body and an object-oriented process; expressing geometrical and technological information of a part in an integral manufacturing procedure on the basis of the features; utilizing the features as carriers of manufacturing knowledge and experience to implement effective integration and closed-loop control for information of manufacturing stages of designing, processing, detecting and the like; and carrying out automatic technological decision, automatic numerical-control programming, post-processing, control for a processing procedure, online detection, technology optimization and working hour prediction on the basis of automatic feature identification and the features. The feature-based numerical-control method has the advantages that information links are effectively connected with one another in the processing procedure, the manufacturing procedure is automatic and intelligent, dependence on manual experience is reduced in the manufacturing procedure, production management for the manufacturing procedure is facilitated, the manufacturing efficiency is improved, and the production cost is reduced.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

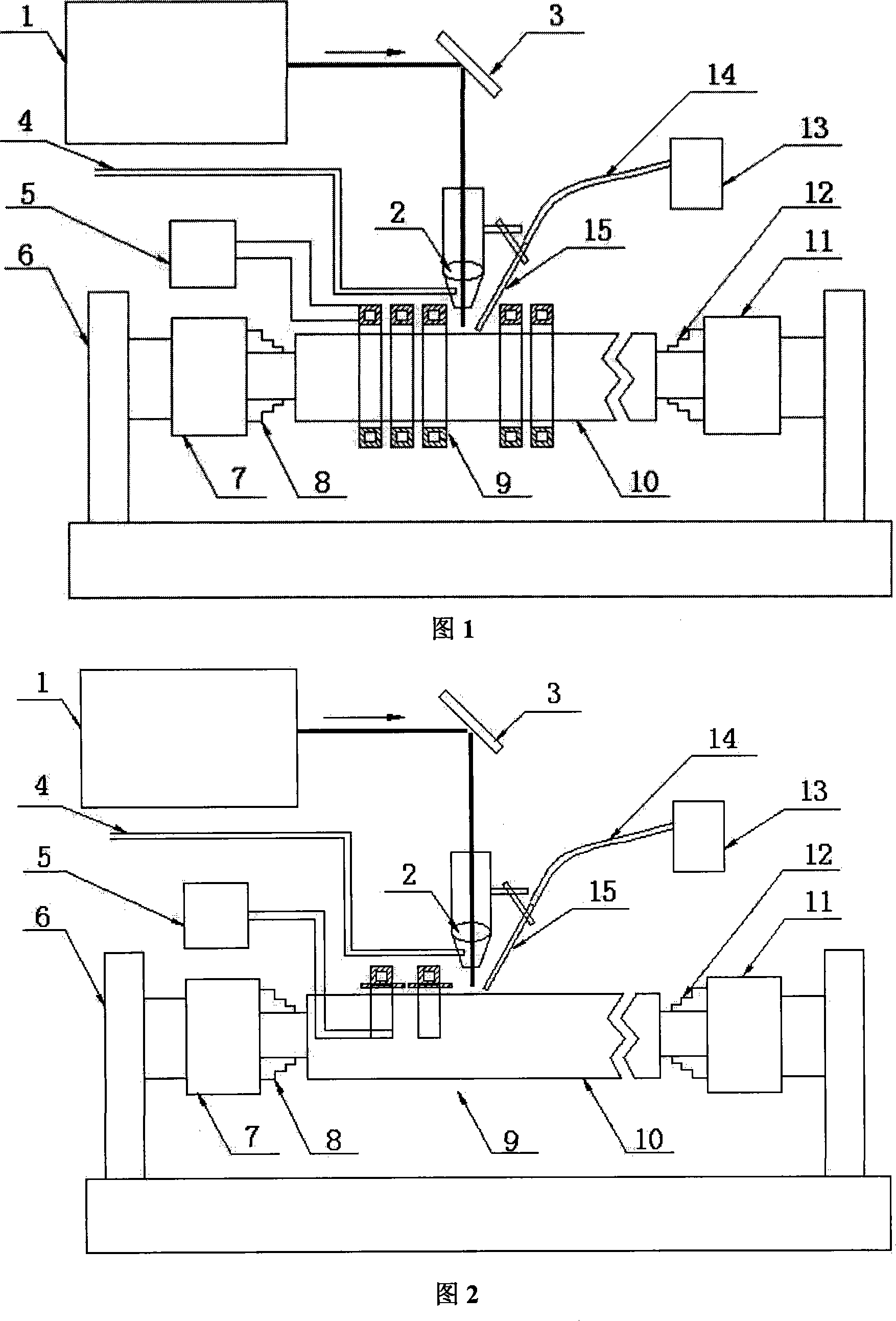

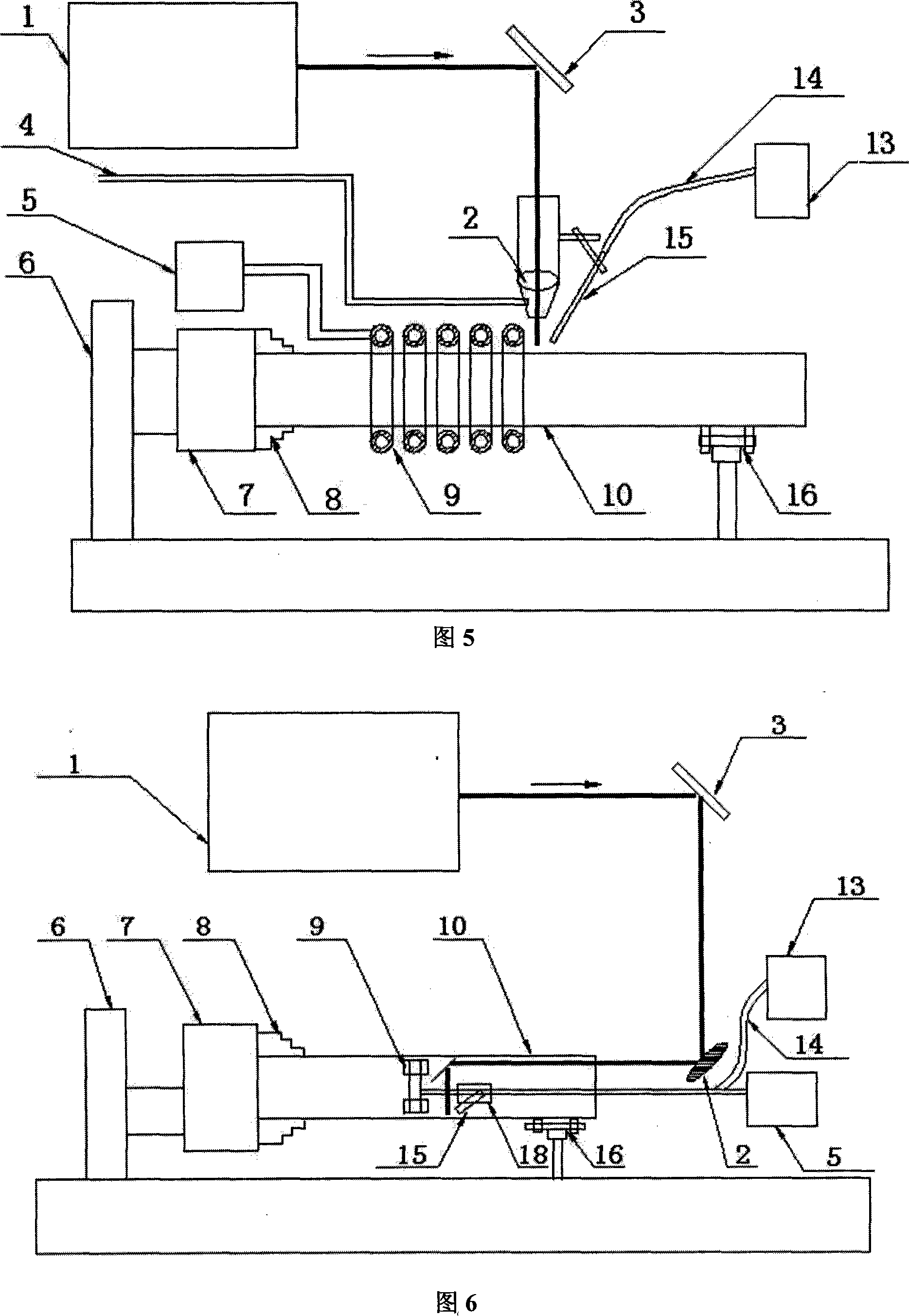

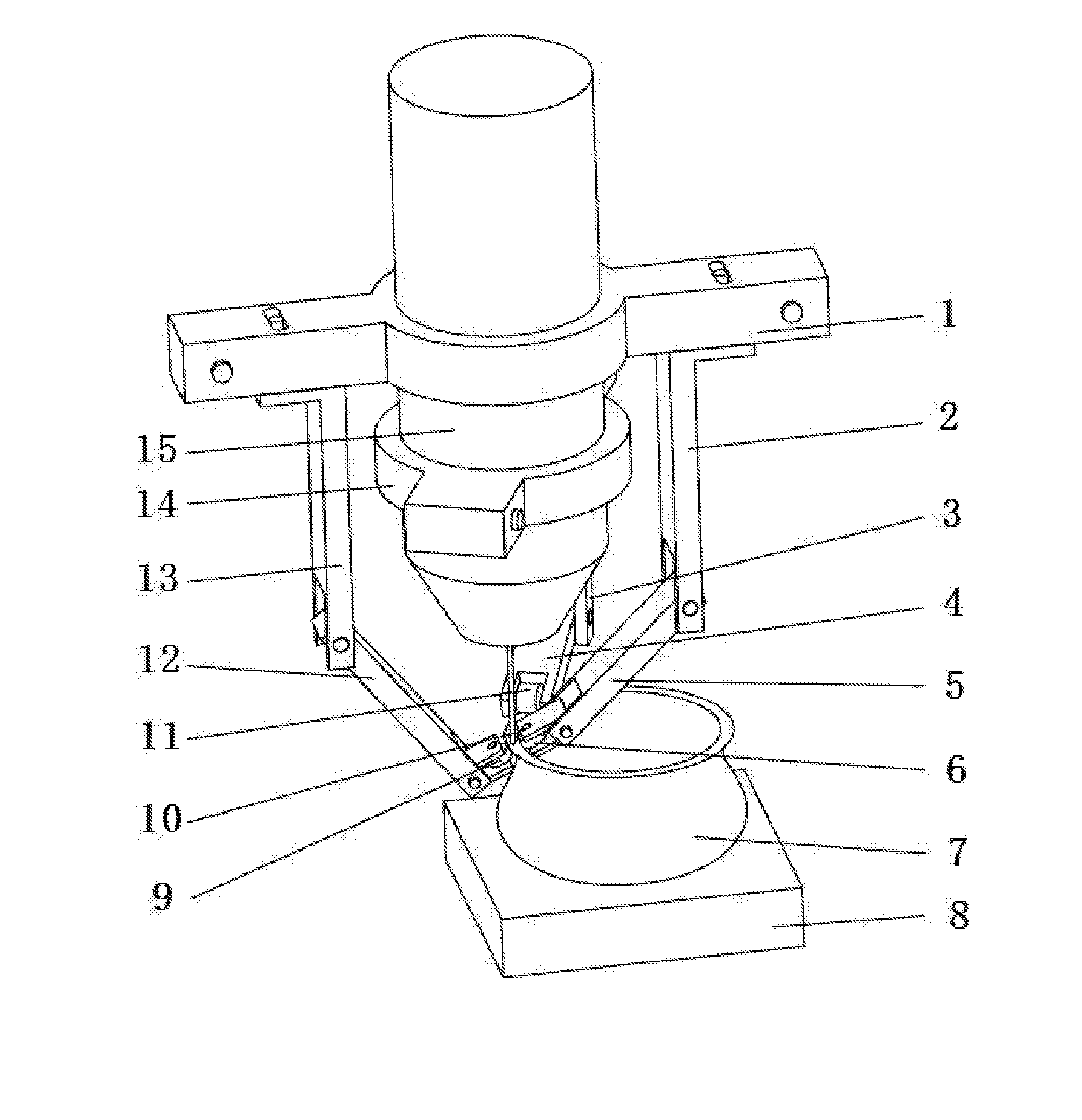

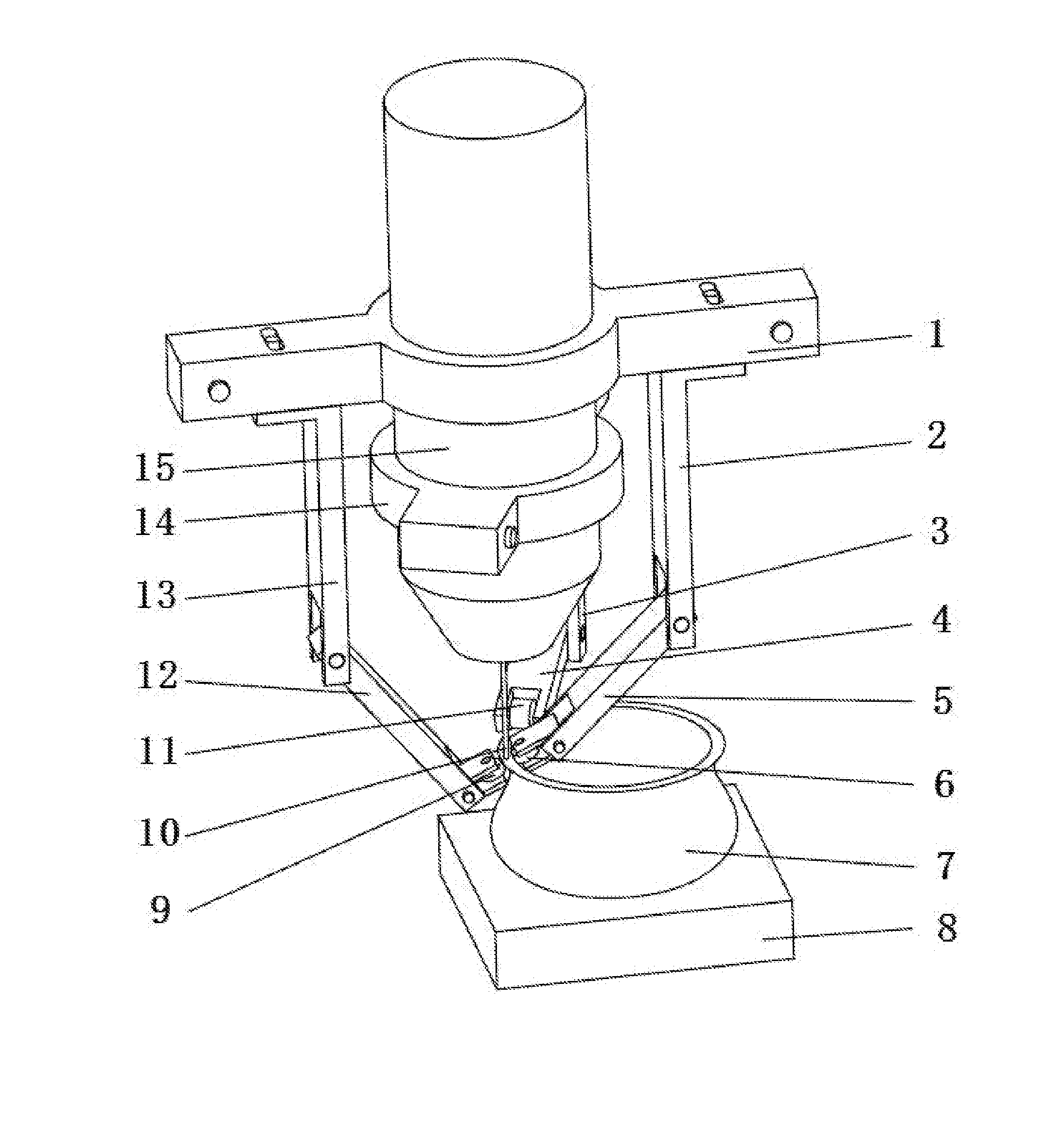

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

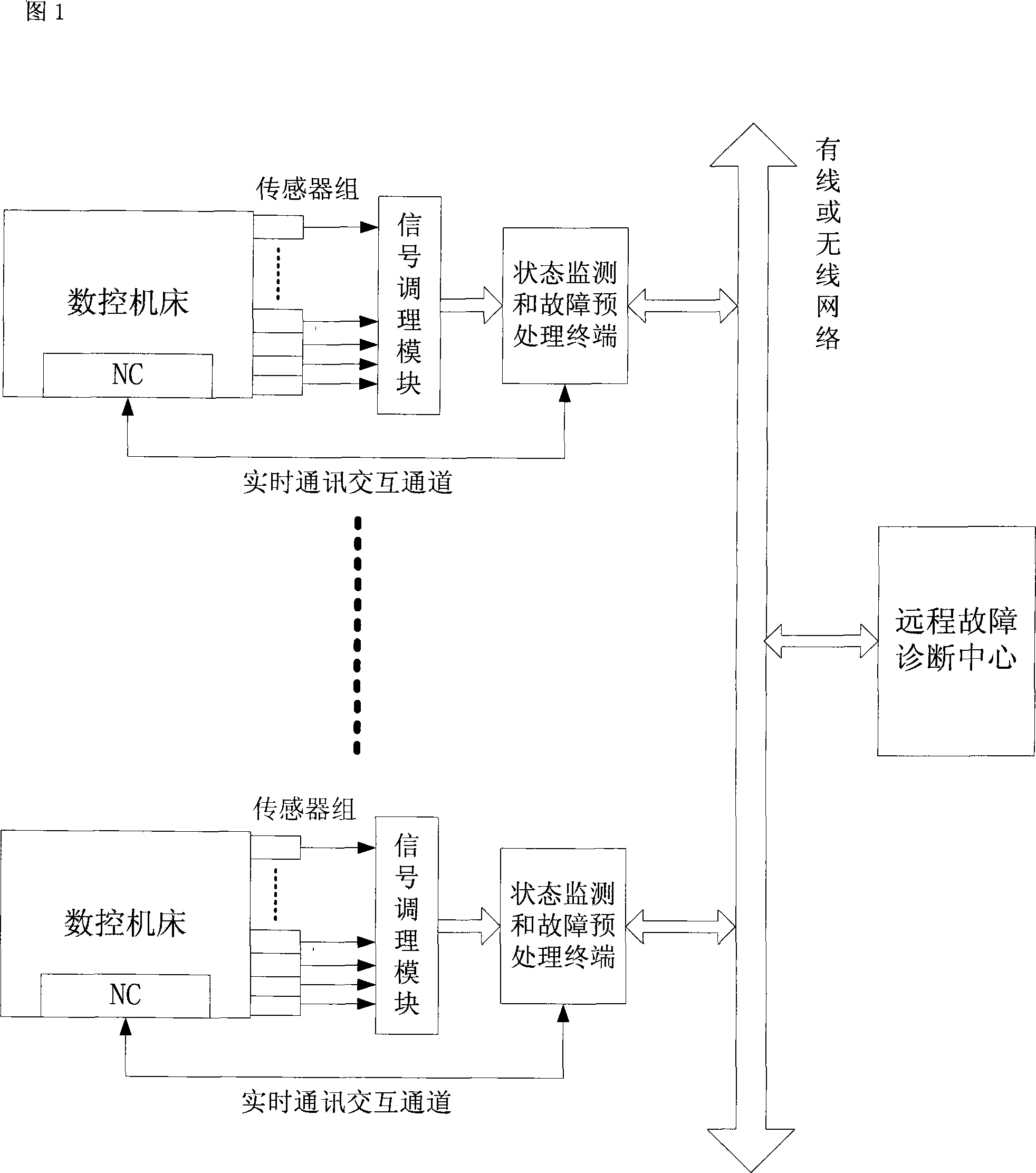

New style numerically controlled machine remote condition monitoring and failure diagnosis system realizing method

The present invention discloses an implementation method of a long-distance state monitor and failure diagnosis system of a novel numerical control machine, and belongs to the numerical control machine, information processing, network technology, industrial control technology fields, and relates to the digital control technology, long-distance telemetry tracking and command, failure diagnosis, network communication, automatic control and signal processing, and mainly makes the use of the modern long-distance telemetry tracking and command technology and the failure diagnosis analysis technology, and combines the characteristics of the state monitor and failure diagnosis of the numerical control machine, and builds the method of the state monitor and failure diagnosis system of the novel numerical control machine based on the wired and the wireless internet.

Owner:石毅

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

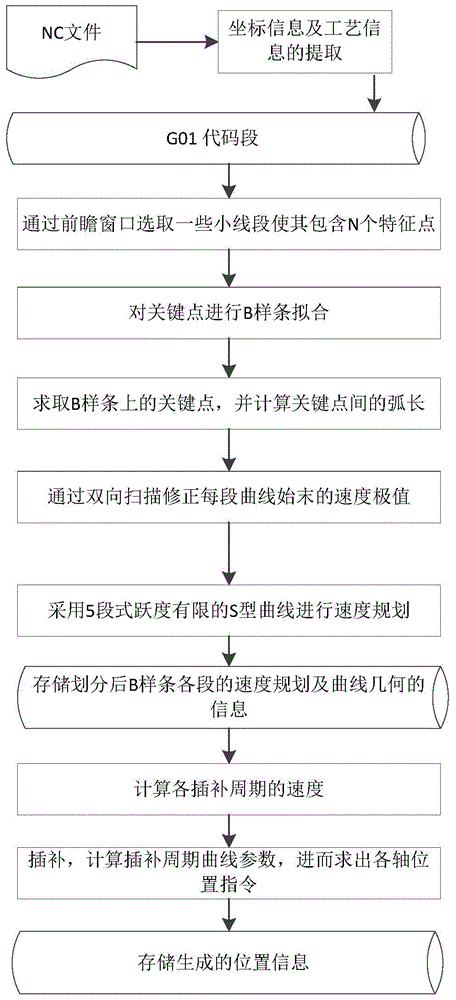

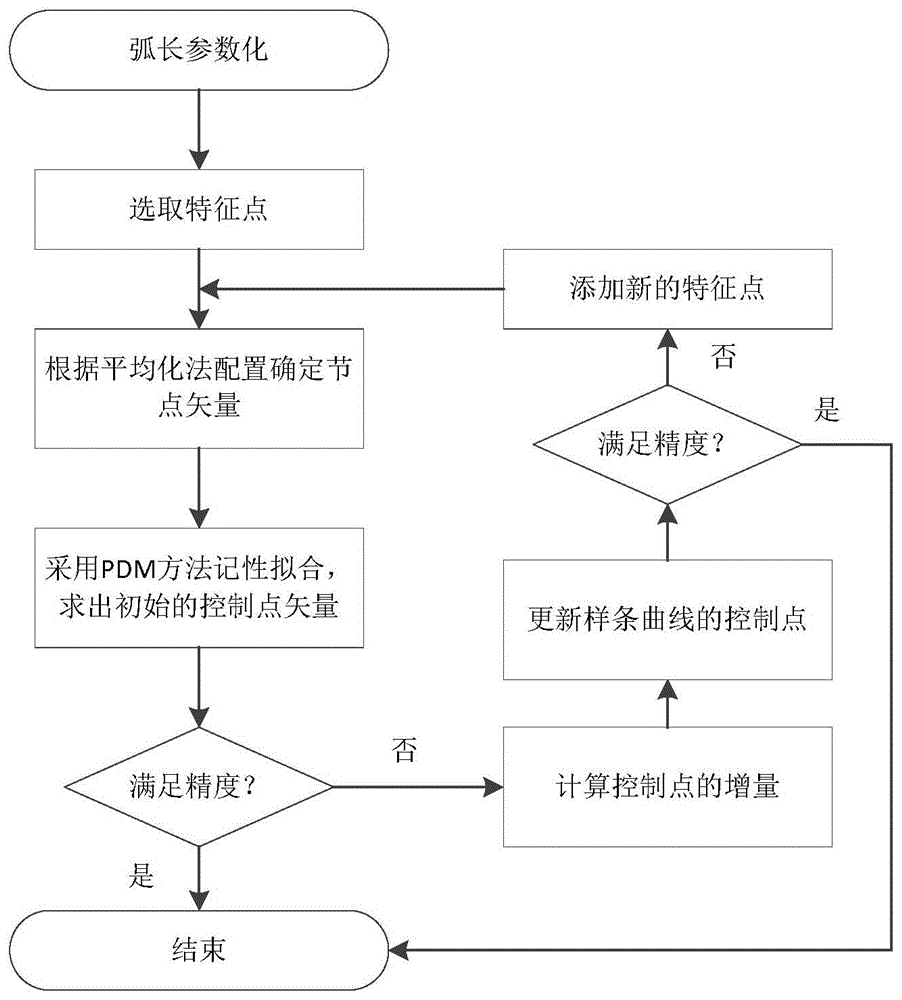

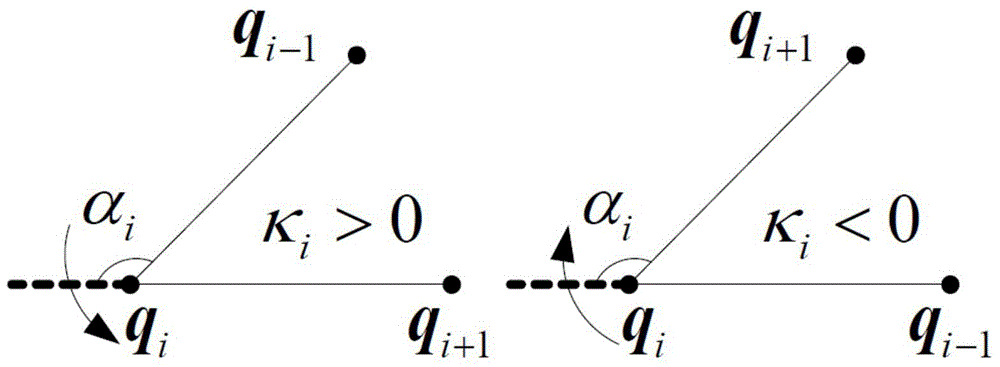

Prospective interpolation system for compressing and smoothening small segment paths

ActiveCN104007705AImprove efficiencyEnsure continuityProgramme controlComputer controlNumerical controlClosed loop

The invention provides a prospective interpolation system for compressing and smoothening small segment paths. The prospective interpolation system comprises a path smoothening module, a curve scanning and segmenting module, a bidirectional acceleration module, a speed planning module and an interpolation module, wherein the path smoothening module is used for extracting small segment coordinate information in codes by reading information of G01 segments of numerical control codes G, conducting calculation according to the coordinate information and conducting path compression and smoothening on small segments; the curve scanning and segmenting module, the bidirectional acceleration module and the speed planning module complete S-shaped speed planning tasks with limited jerk; the interpolation module is used for generating discrete interpolation points according to planning speed obtained through calculation; the interpolation points can be stored and used for position closed-loop control. The prospective interpolation system is high in calculation efficiency in the whole process, small in calculation quantity, simple in programming realization and capable of being further applied to a high-speed and high-precision numerically-controlled machine tool.

Owner:SHANGHAI JIAO TONG UNIV

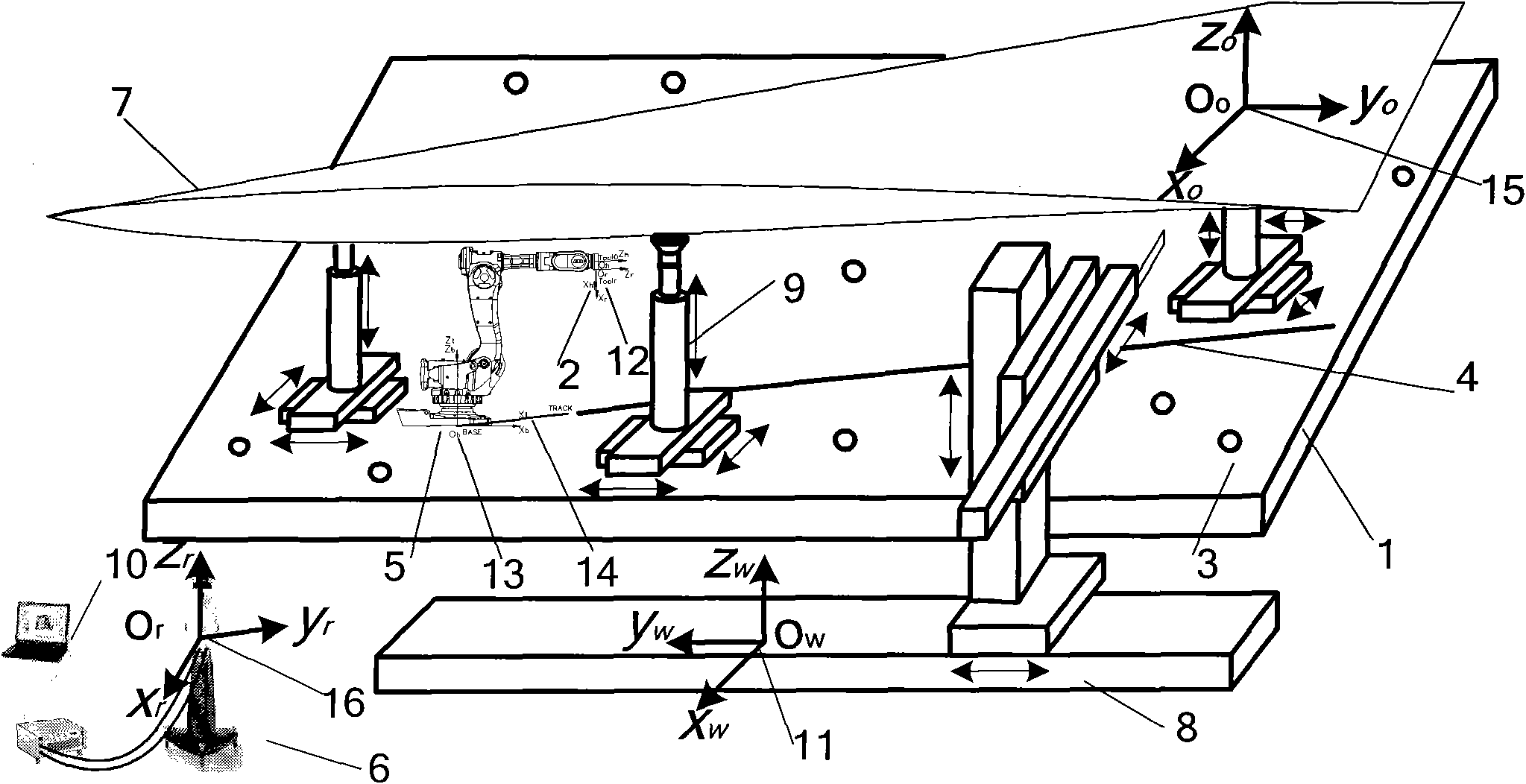

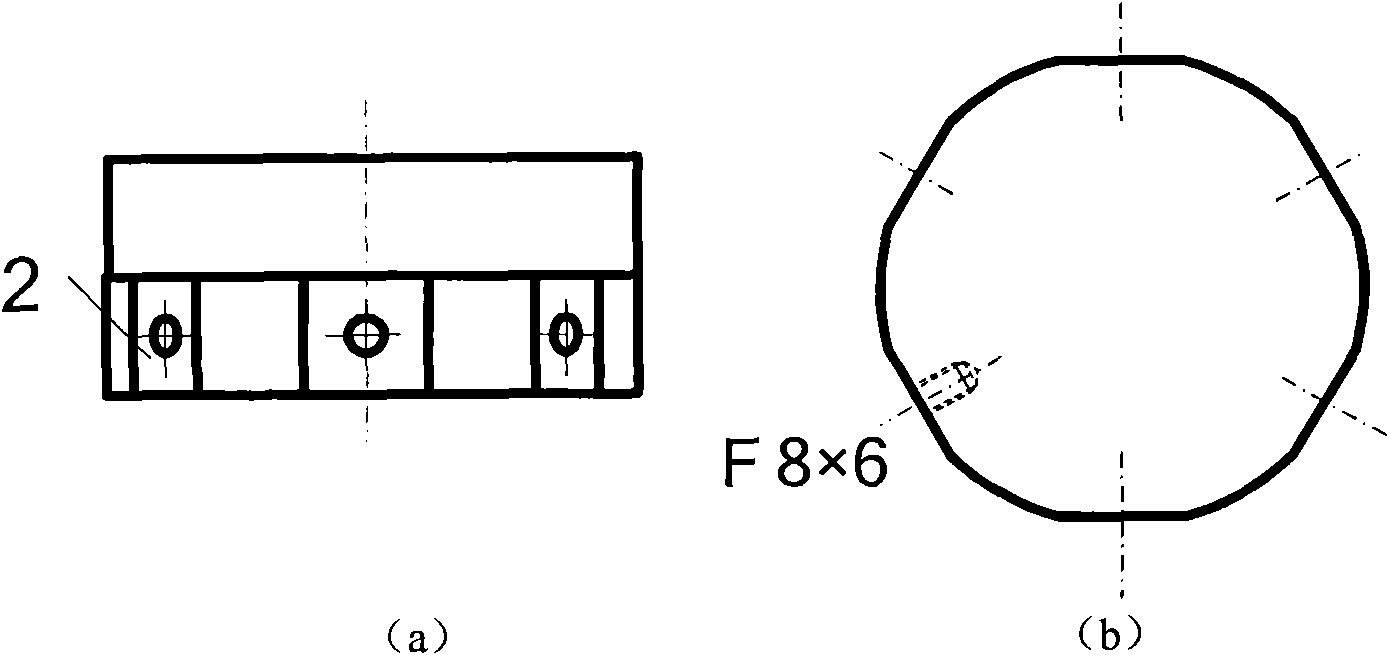

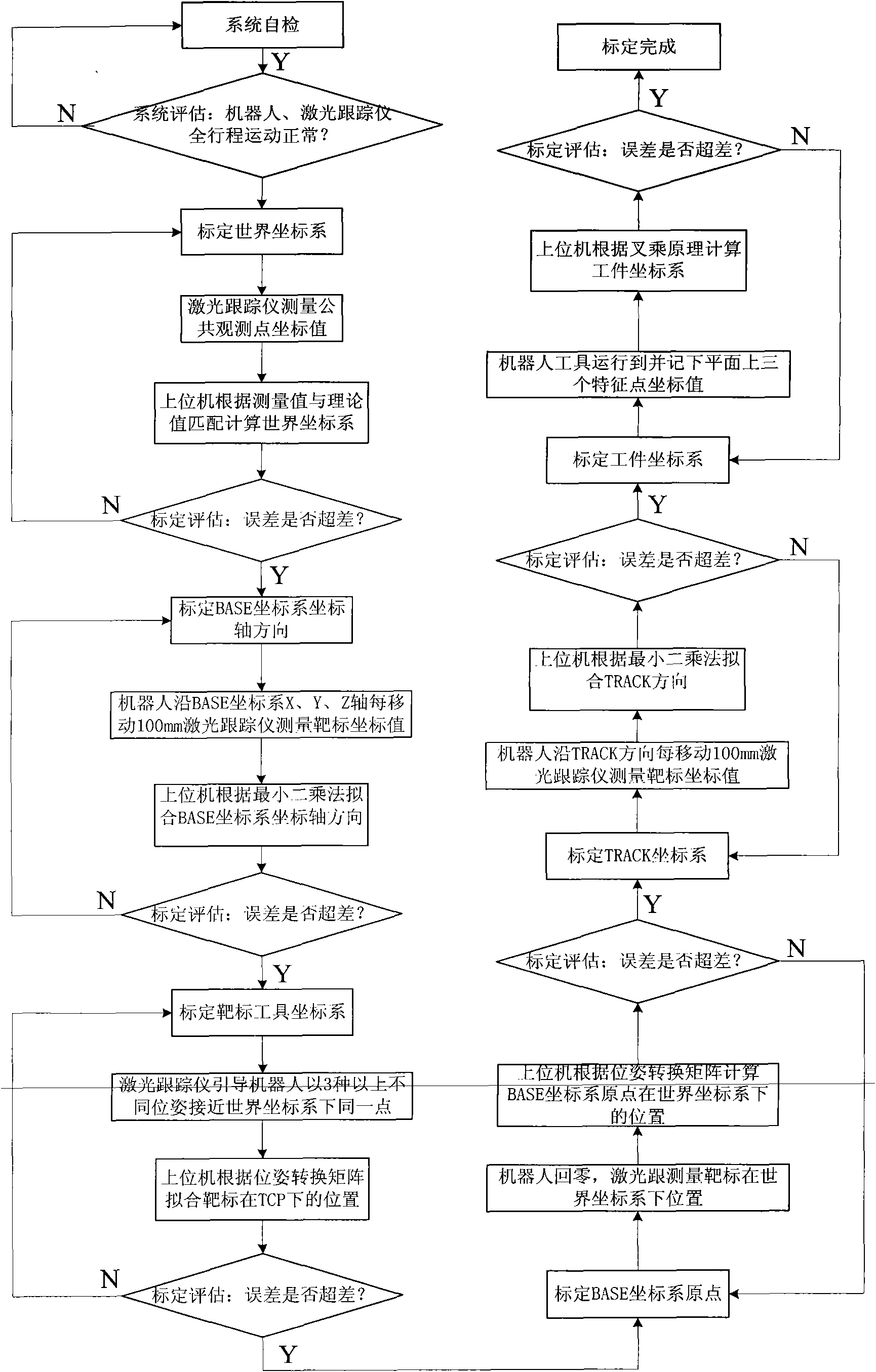

Device for automatically marking additional external axis robot based on laser tracking measurement and method thereof

InactiveCN102062576AThe calibration process is stable and reliableHigh precisionUsing optical meansNumerical controlEngineering

The invention discloses a device for automatically marking an additional external axis robot based on laser tracking measurement and a method thereof. The device comprises a system platform, a target flange, target mounting holes, a robot guide rail, a robot, a laser tracker, a workpiece, a numerical control finish machining machine tool, a three-coordinate numerical control locator, and an upper computer, wherein the system platform is provided with 9 target mounting holes processed by the numerical control finish machining machine tool, the three-coordinate numerical control locator and the robot guide rail; the workpiece is fixed on the three-coordinate numerical control locator; the robot is arranged on the robot guide rail; the target flange is arranged on the robot; 6 target mounting holes are arranged on the target flange; the targets are arranged on the target mounting holes; the numerical control finish machining machine tool, the laser tracker and the upper computer are installed at the outer side of the system platform. The device has the advantages that: (1) the device is capable of automatically marking the robot coordinate system with the additional external axis; (2) the device is high in marking precision and reliable in marking result; and (3) the device is further simple in marking operation and high in efficiency.

Owner:ZHEJIANG UNIV

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

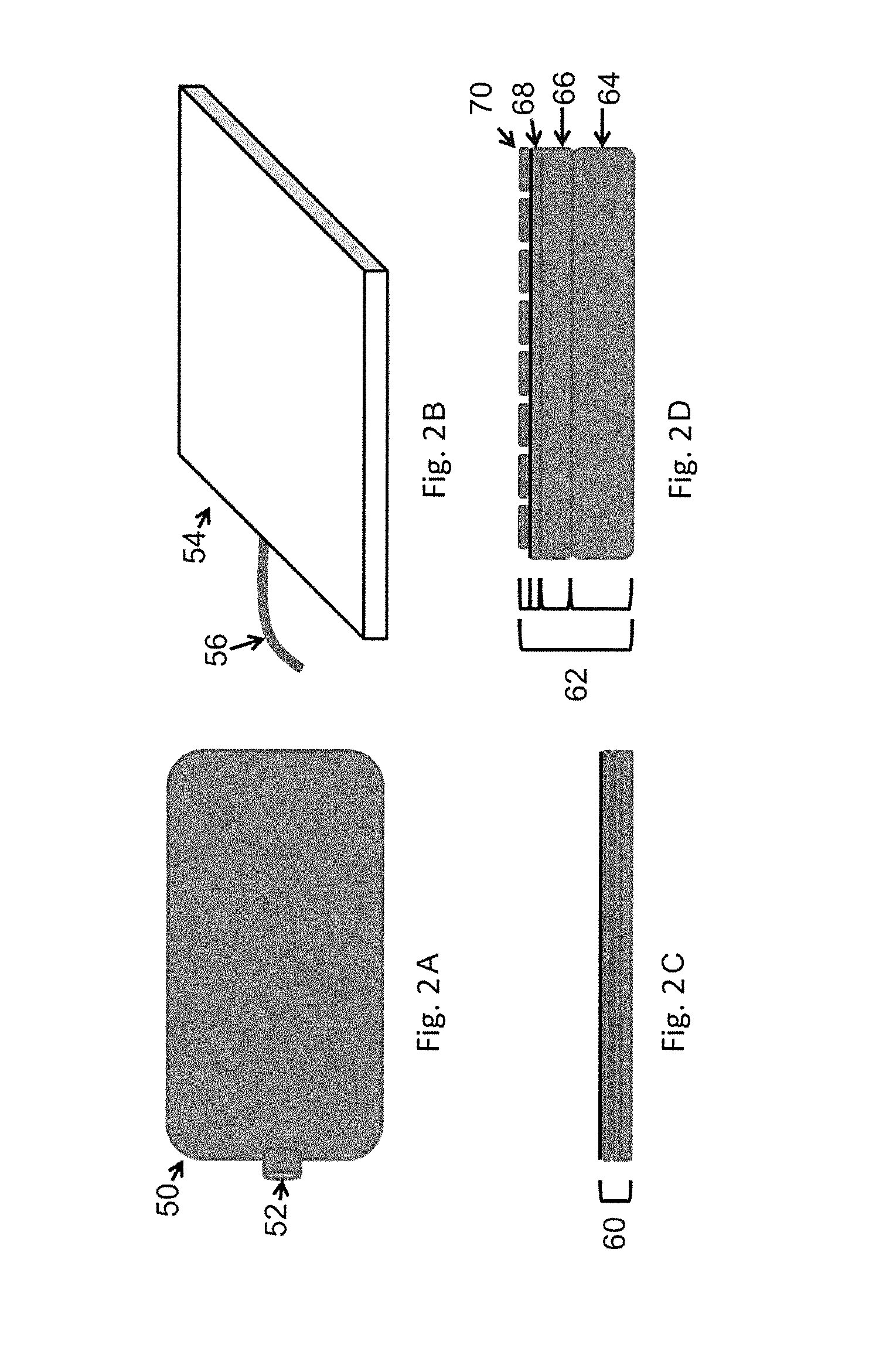

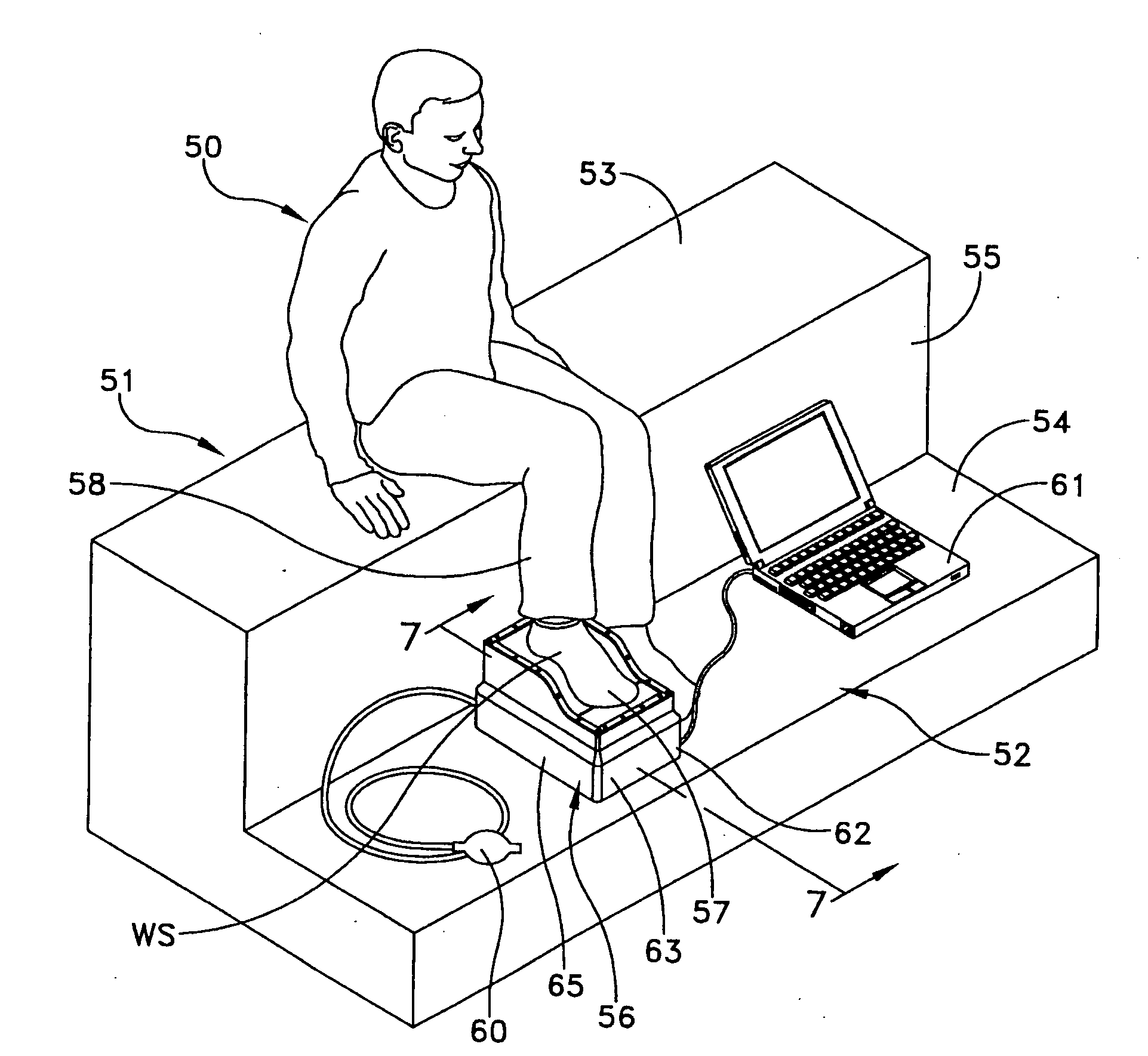

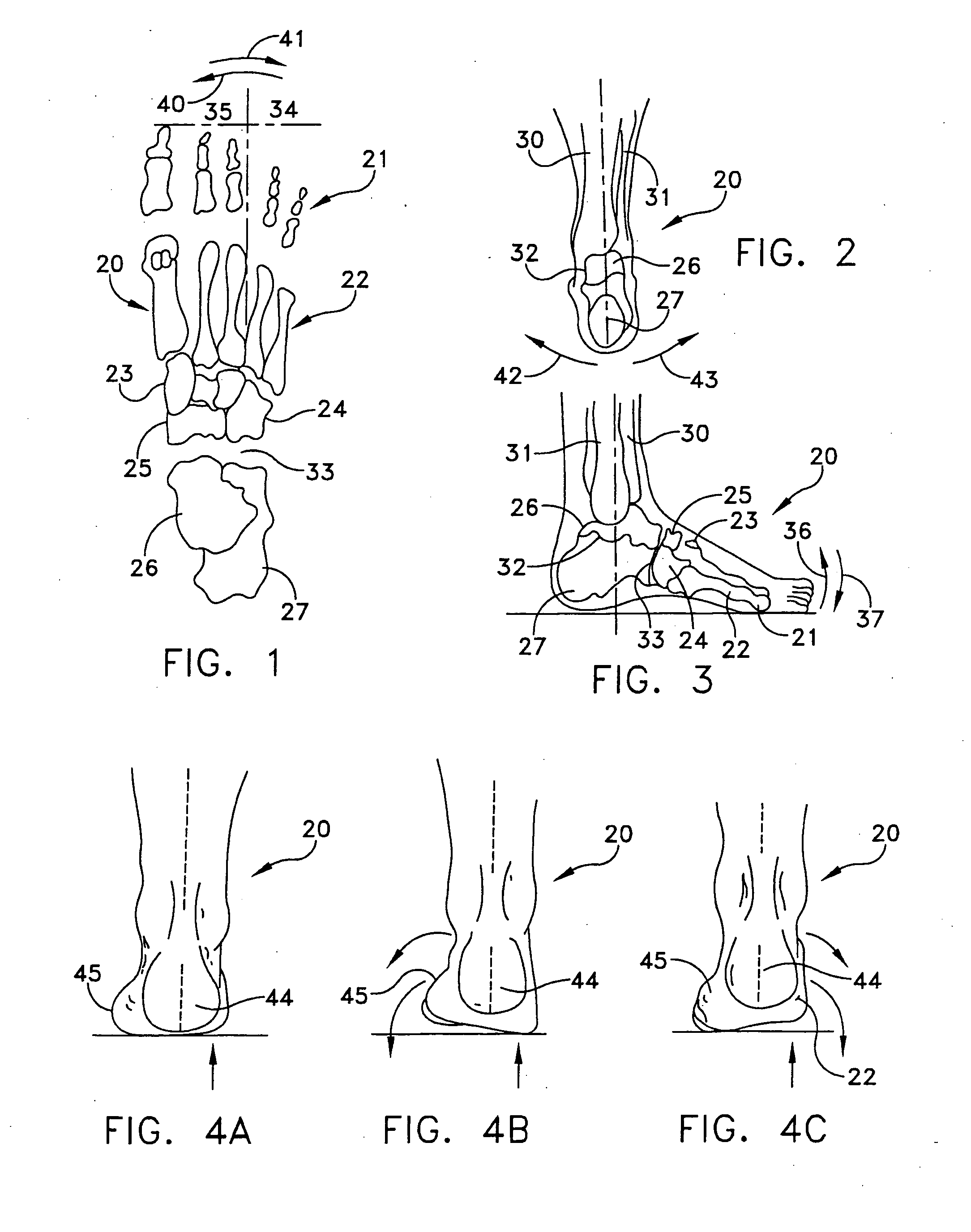

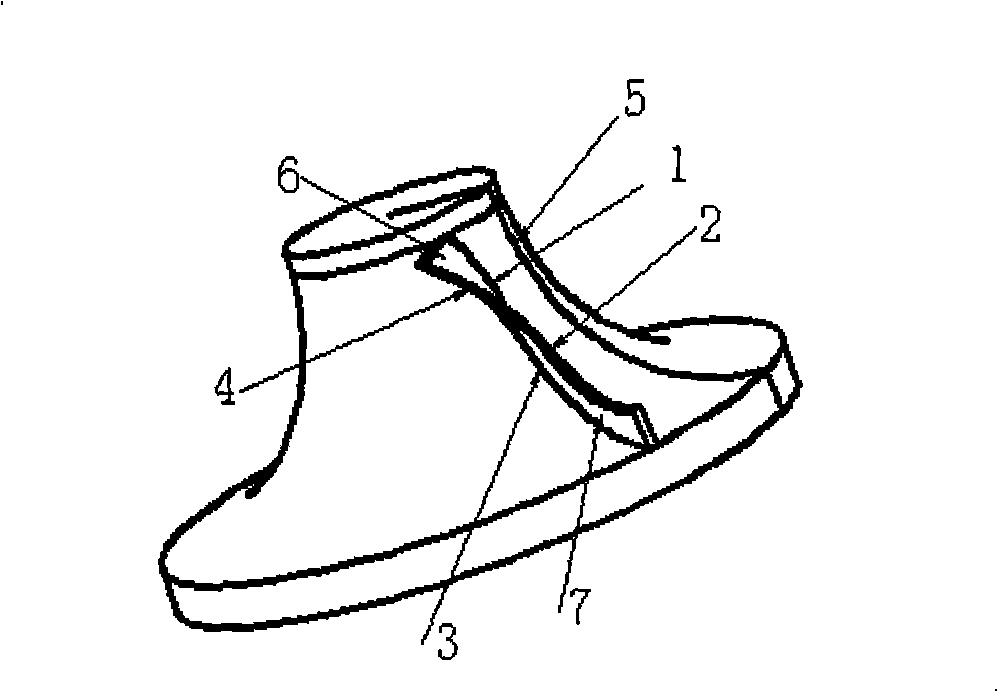

Method and apparatus for manufacturing custom orthotic footbeds

InactiveUS20060283243A1Promote generationUse minimizedFoot measurement devicesStructural/machines measurementNumerical controlOrthopedic inserts

A method and apparatus for providing a topographical map of the bottom of a patient's rear foot with the foot in a semi-weight bearing condition and in the neutral position. A flexible membrane defines the top of an air cushion that captures the patient's foot in the neutral position when the air pillow is inflated. The membrane also conforms to the bottom of the foot. A three-dimensional scanner located below the membrane measures the distances to the bottom of the membrane over an array of positions. A manufacturing facility converts these measurements into information by which computer numerical controlled equipment machines an orthotic insert for the patient's footwear.

Owner:ESOLES LLC

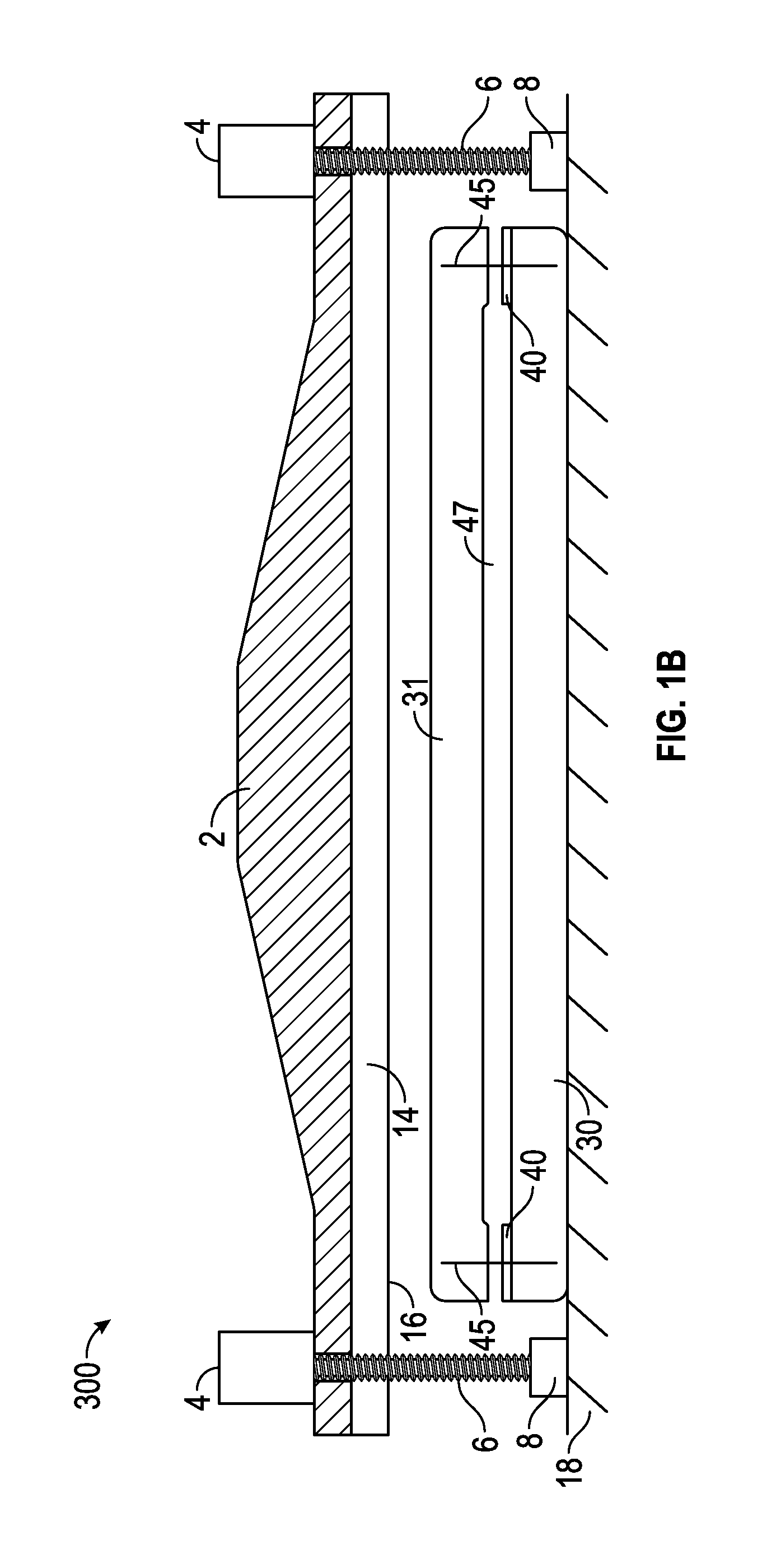

Thermoplastic pultrusion die system and method

ActiveUS8747098B1High compression forceFacilitated releaseAdhesive processesConfectioneryNumerical controlEngineering

A thermoplastic pultrusion die system for pultruding a thermoplastic composite includes a first pultrusion die member with a curved, concave top surface; a second pultrusion die member with a curved, convex bottom surface; a curved die cavity gap formed between the a curved, concave top surface of the first pultrusion die member and the curved, convex bottom surface of the second pultrusion die member; a die cavity gap adjustment mechanism that imparts movement to at least one of the first pultrusion die member and the second pultrusion die member to vary the die cavity gap from closed to a specified location to open at a specified location; a pultrusion gripper mechanism having one or more grippers in series, and a computer numerical control (CNC) computer system controlling the die cavity gap adjustment mechanism.

Owner:EBERT COMPOSITES

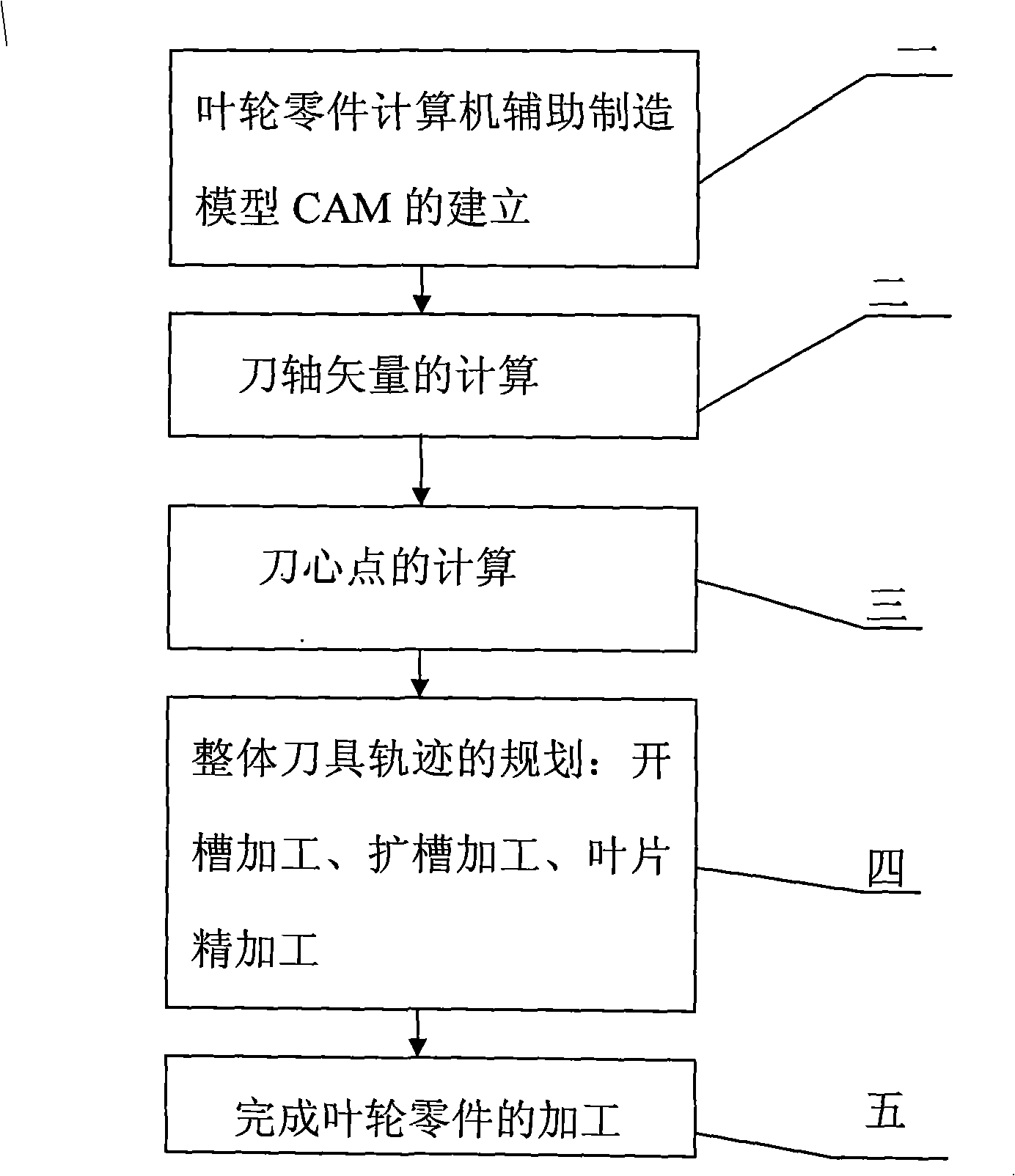

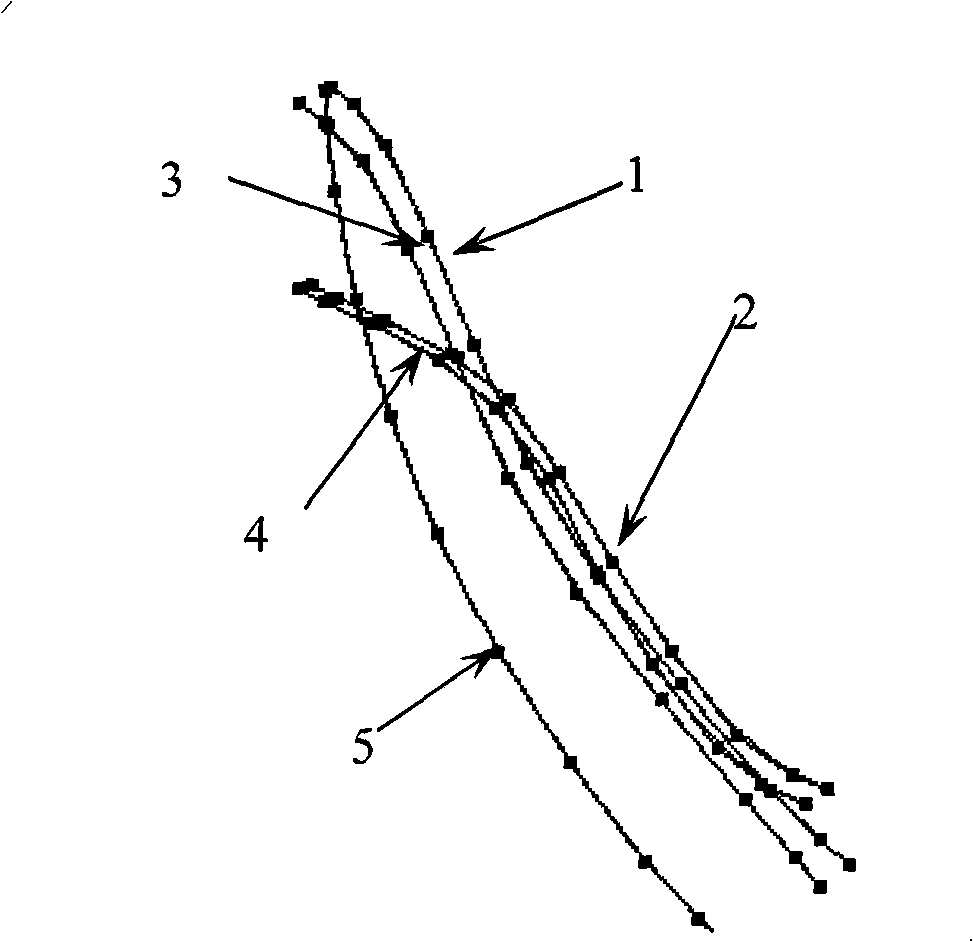

Ruled surface impeller tool path planning and processing method

InactiveCN101271326ASolving the Problems of Five-Axis MachiningHigh degree of automationProgramme controlComputer controlImpellerNumerical control

A path planning processing method of a ruled surface impeller cutter relates to a cutter path planning processing method. The invention solves the problems of the prior numerical control processing method of an impeller part, the problem are that a whole processing technology for processing a integral type ruled surface impeller is not proposed, the calculating method of the point of a knife centre or the point of a knifepoint is not given, the processing cutting efficiency is low, the operation is complex and the degree of automation is low and the five-axis processing of the ruled surface impeller can not be realized etc. The main steps of the method are the establishment of the calculator assistant manufacturing model CAM of an impeller part, the calculation of the vector of a cutter shaft, the calculation of the point of the knife centre, the planning of whole cutter path and the achievement of the processing of the impeller part. The method of the invention solves the problem of the five-axis processing of the ruled surface impeller and has the advantages of high processing cutting efficiency, easy operation and high degree of automation The ruled surface impeller processed by the method has the characteristics of orderly linage of flow passage, symmetrical structure and the uniform distribution of cutter path at the surface of the flow passage, thus reducing the workload of subsequent polishing processing greatly.

Owner:哈尔滨工大宏图橡塑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com