Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268 results about "Machine simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

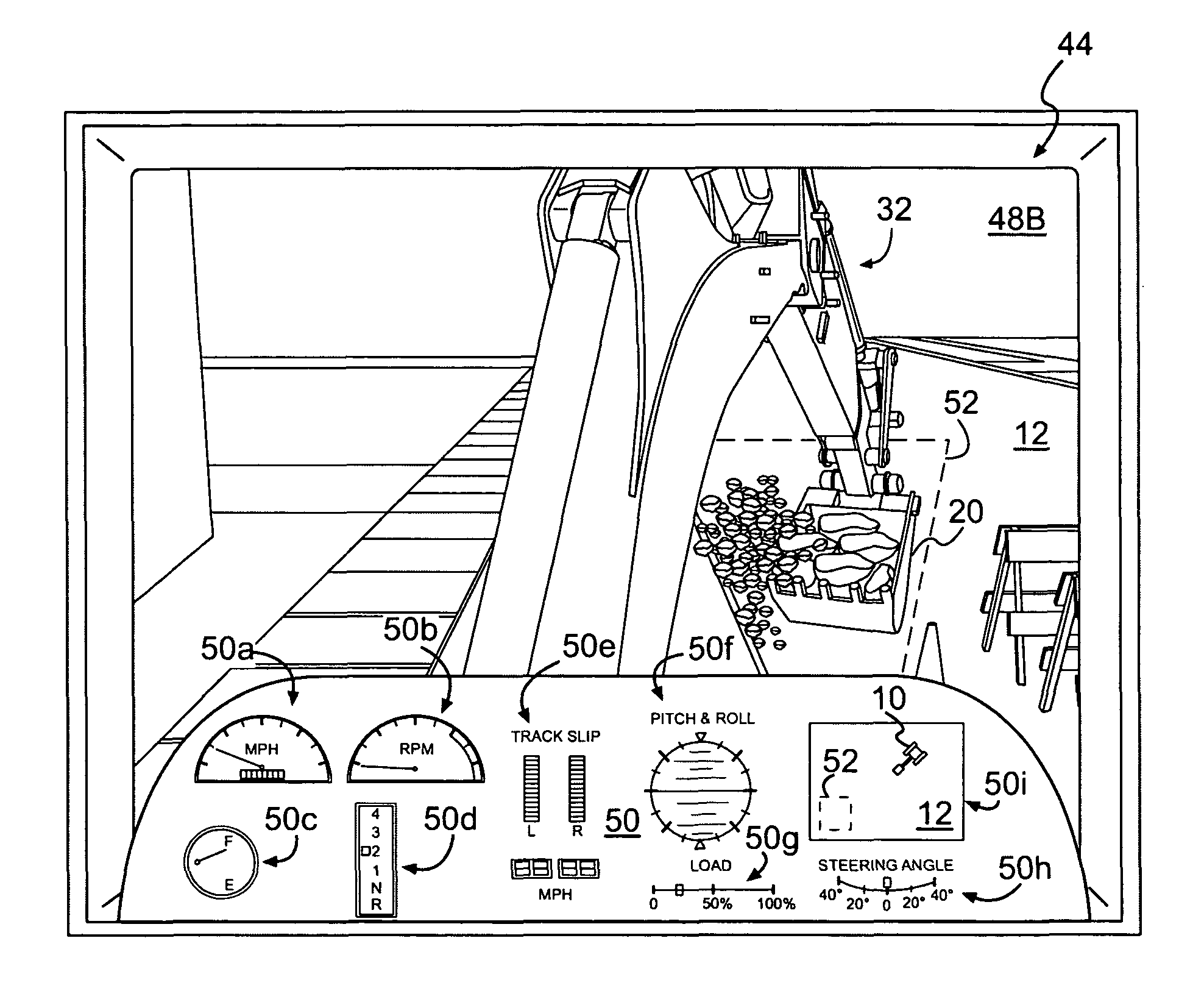

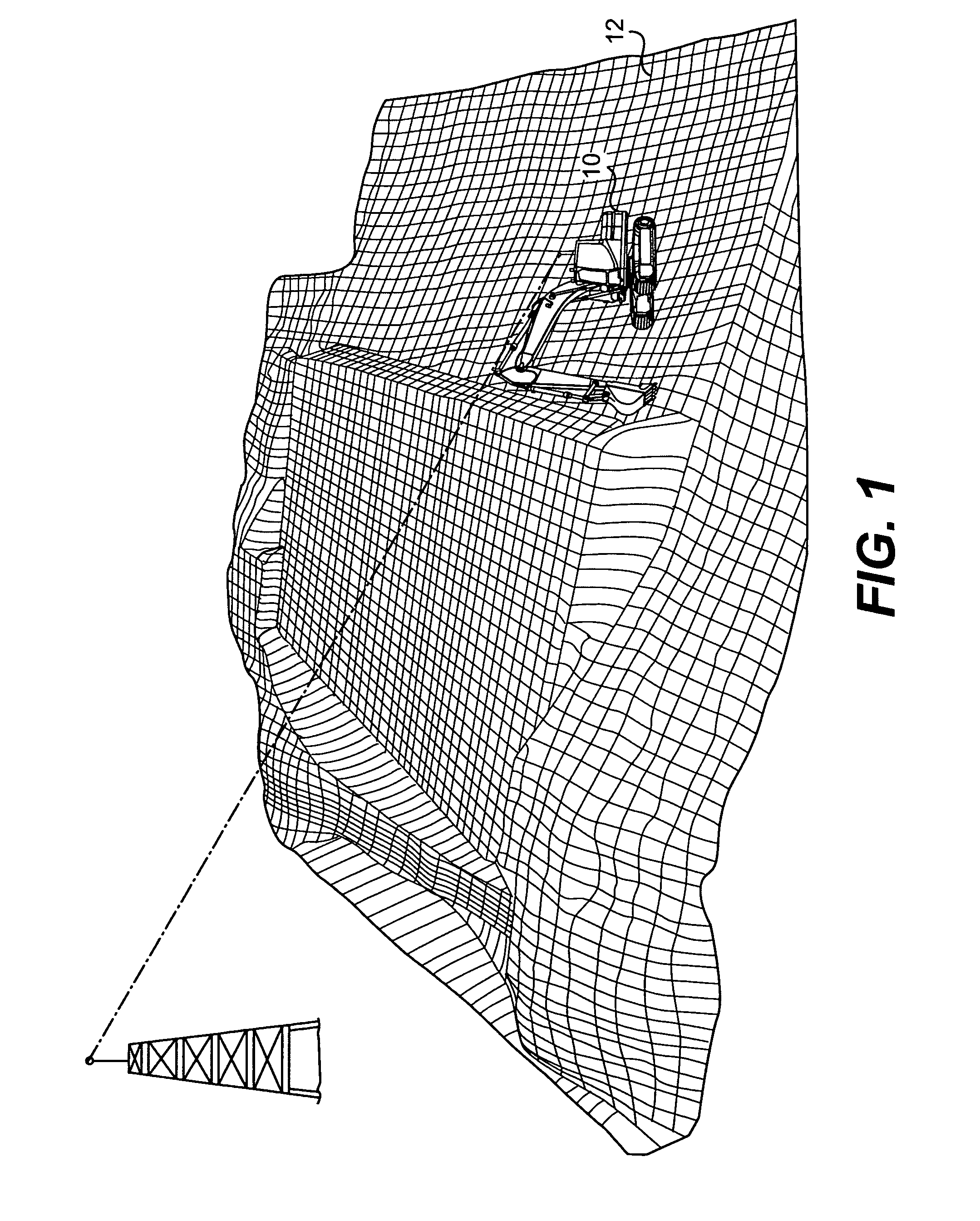

Simulation system implementing real-time machine data

ActiveUS20080180523A1Affect operationCosmonautic condition simulationsColor television detailsTime informationControl system

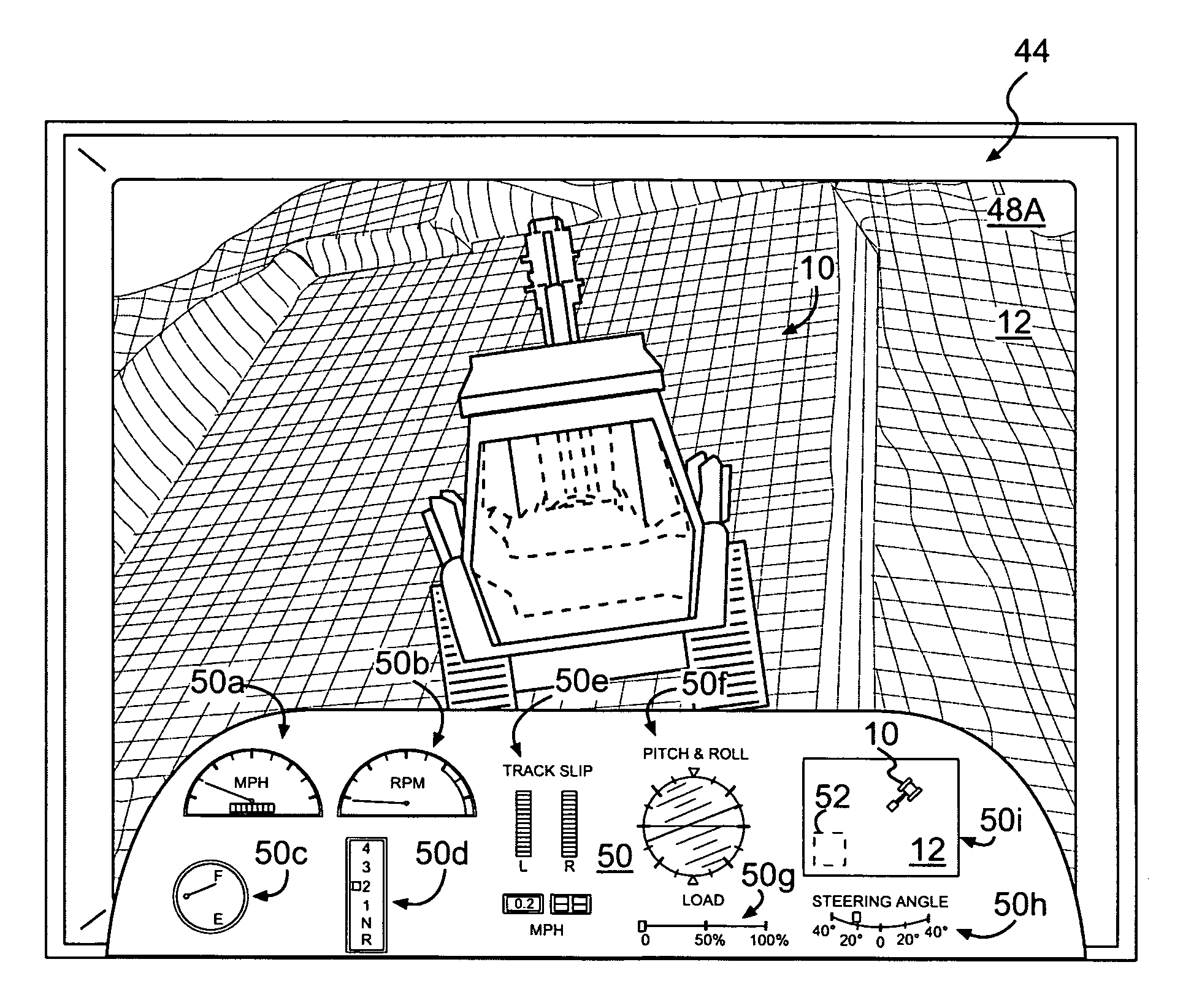

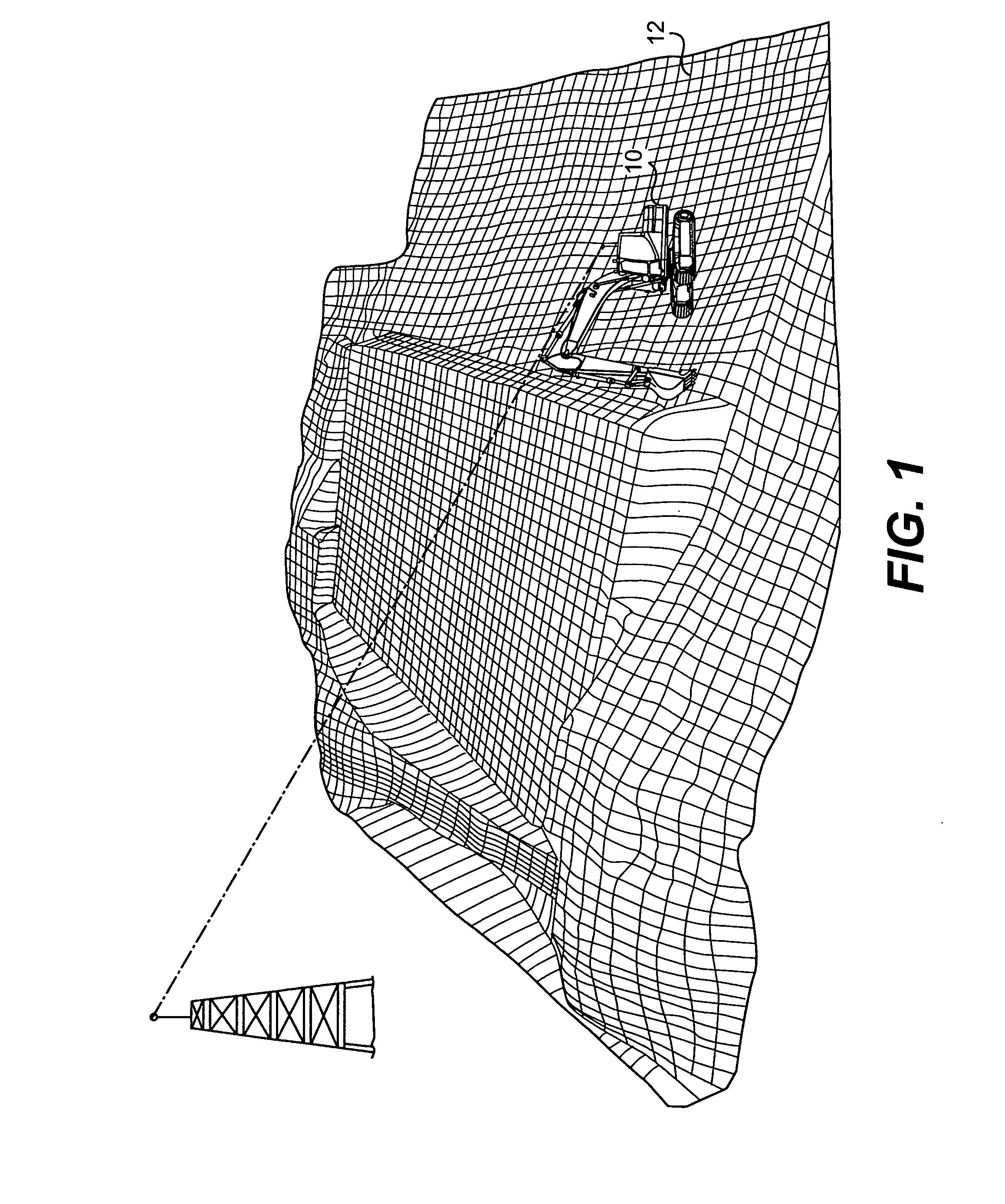

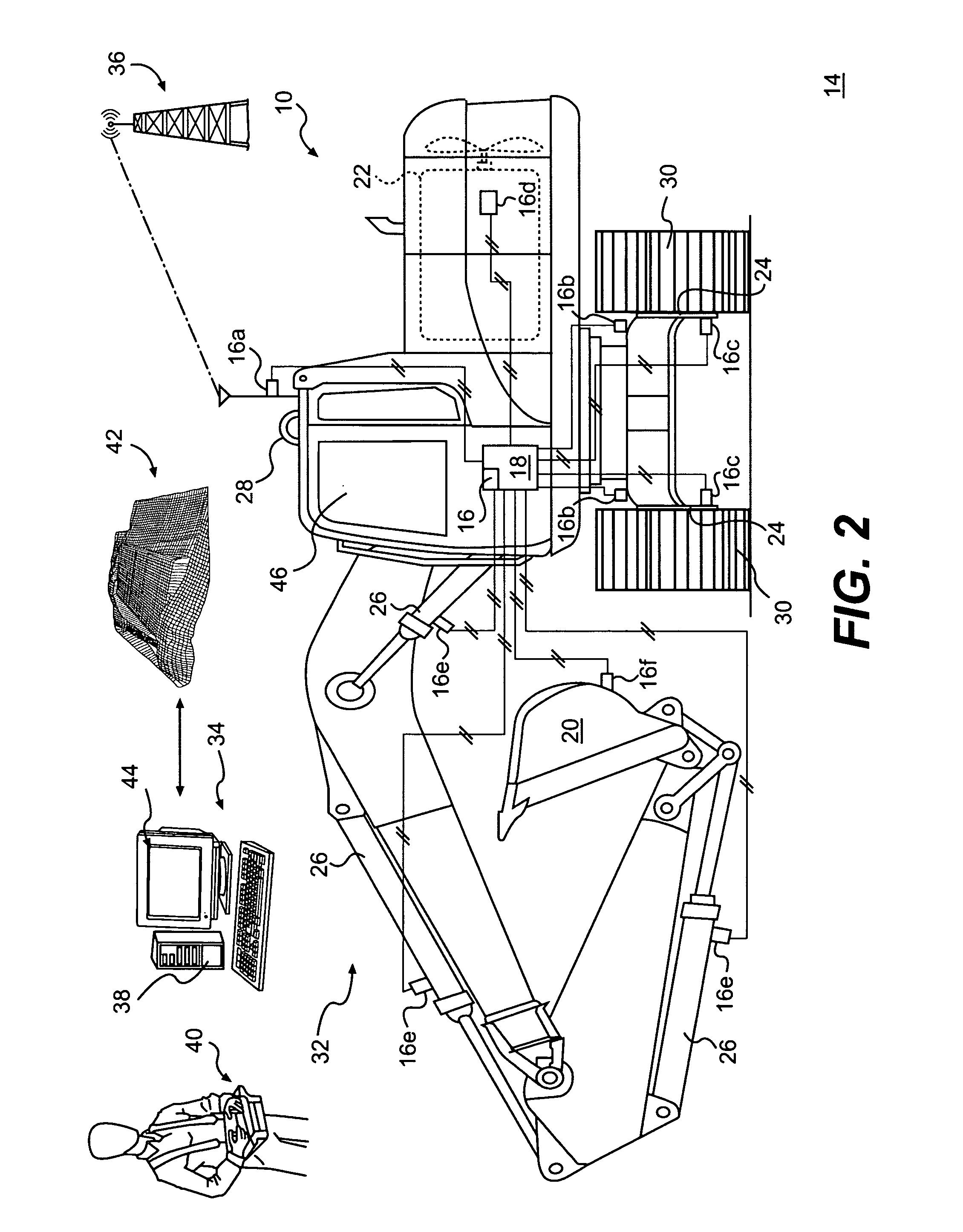

A simulation and control system for a machine is disclosed. The simulation and control system may have a user interface configured to display a simulated environment. The machine simulation and control system may also have a controller in communication with the user interface and a remotely located machine. The controller may be configured to receive from the machine real-time information related to operation of the machine at a worksite. The controller may also be configured to simulate the worksite, operation of the machine, and movement of a machine tool based on the received information. The controller may further be configured to provide to the user interface the simulated worksite, operation, and movement in the simulated environment.

Owner:CATERPILLAR INC

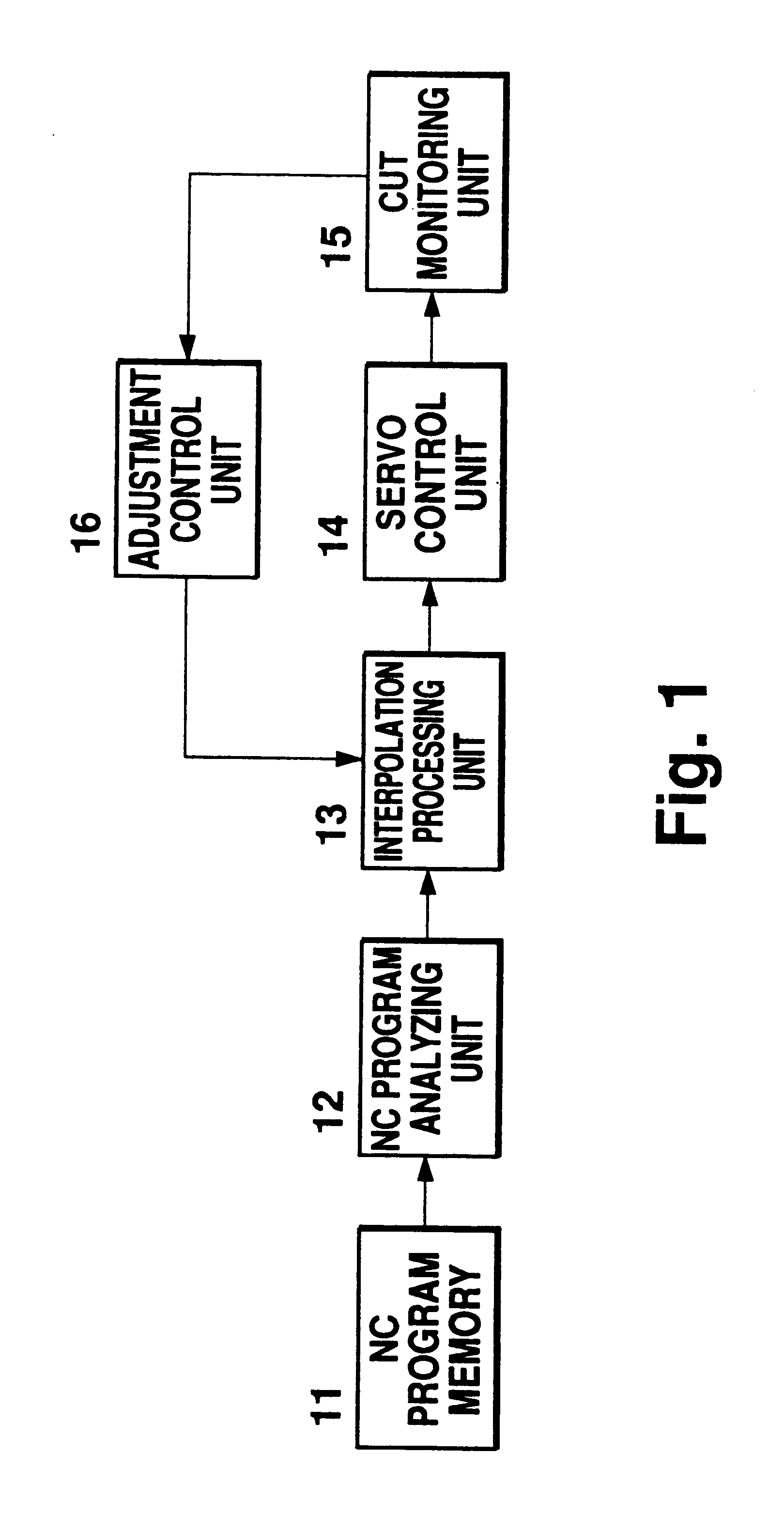

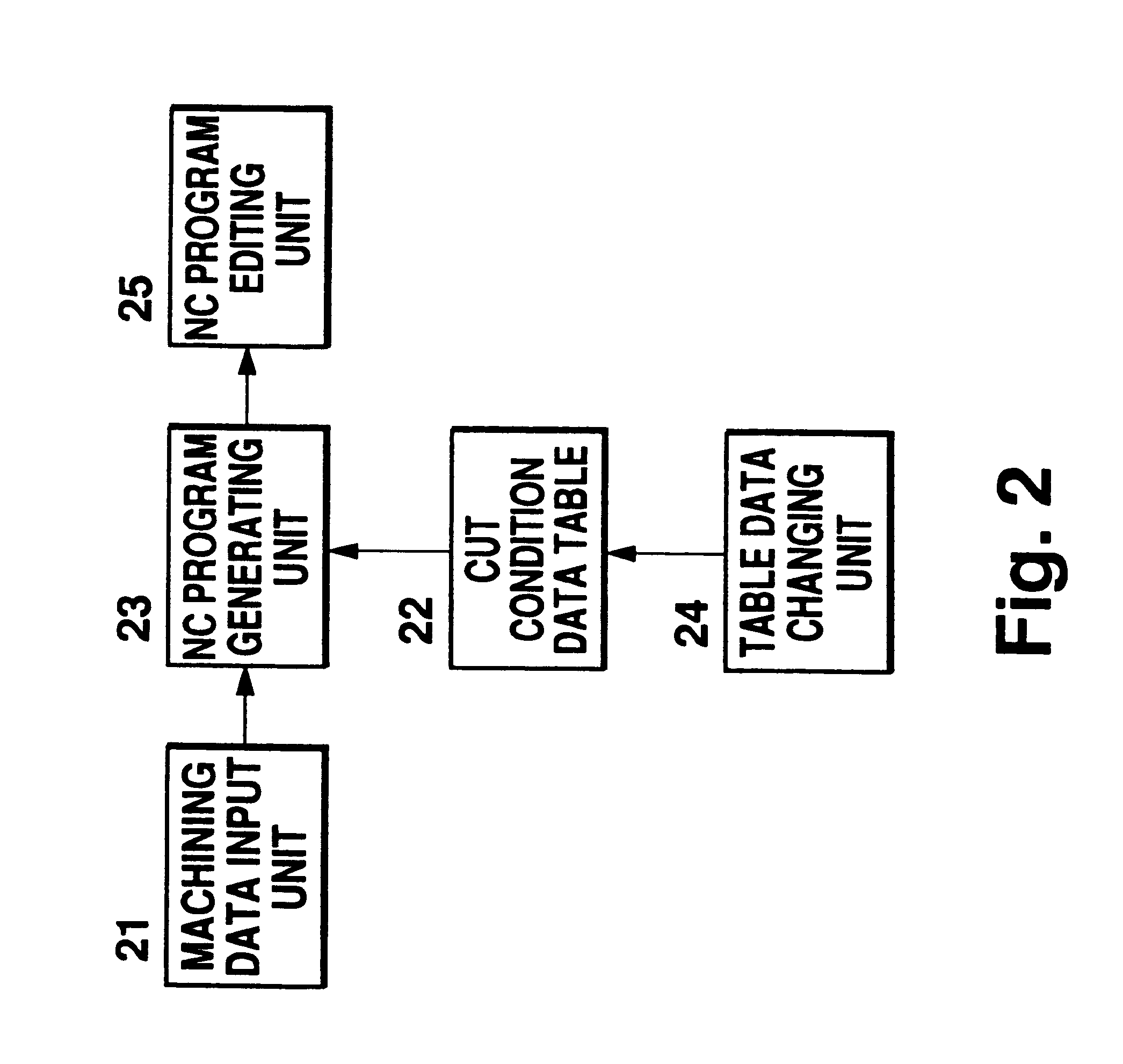

Apparatus for generating a numerical control command according to cut resistance value and cut torque value of machining simulation

InactiveUS6266572B1Solution to short lifeImprove wear resistanceProgramme controlAutomatic control devicesNumerical controlMachine simulation

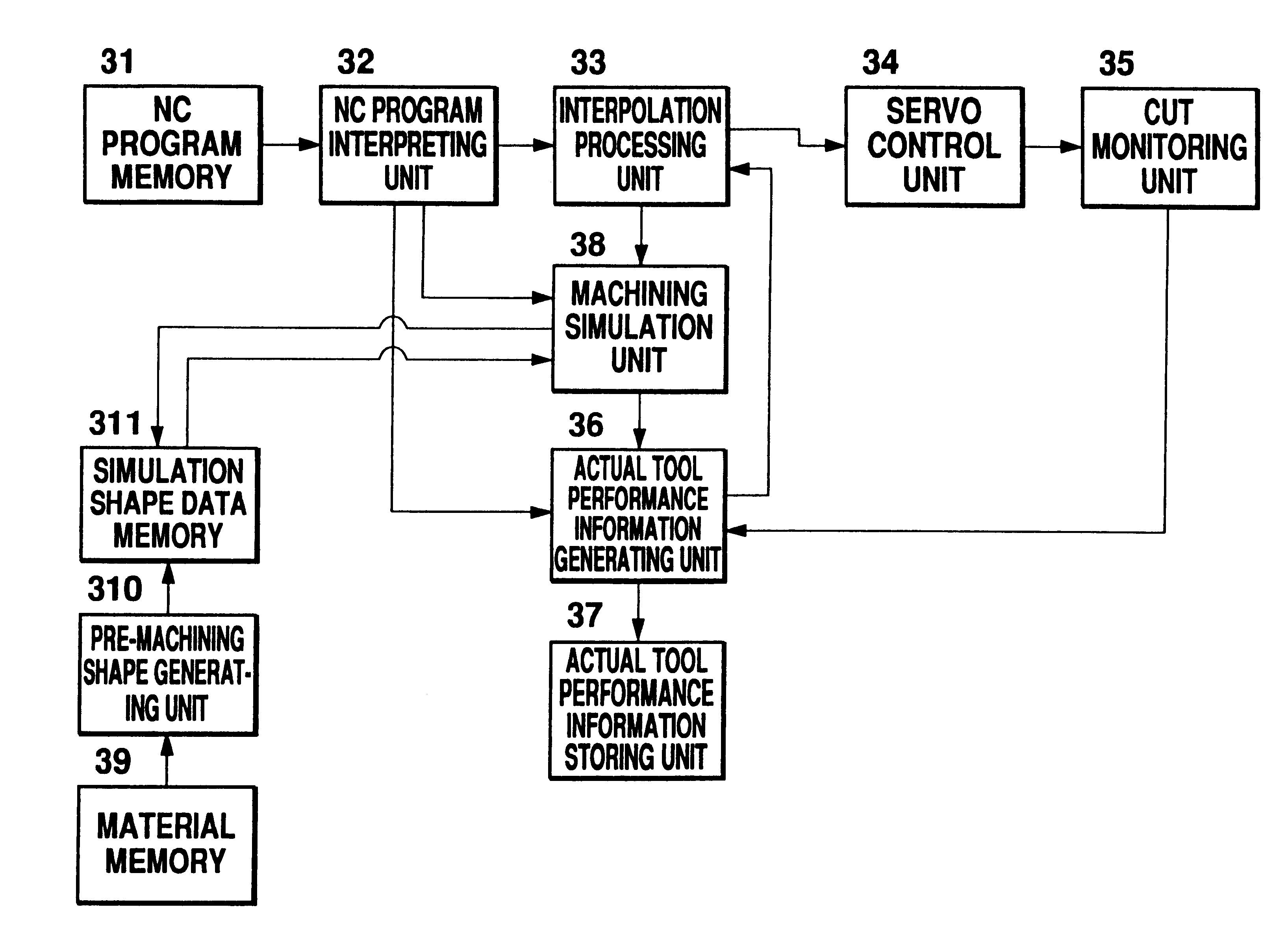

A method of simulation of NC machining, wherein machining simulation is carried out according to blank shape data, tool shape data and an NC program to modify the NC program or interpolation data by feedforward control so that optimum cutting conditions can be obtained. The simulation result can be used for correcting the NC program and the interpolation data at the next stage. Further, a record of tools used can be generated on the basis of this simulation result.

Owner:OKUMA CORP +3

Simulation system implementing real-time machine data

ActiveUS8139108B2Cosmonautic condition simulationsDigital data processing detailsTime informationControl system

A simulation and control system for a machine is disclosed. The simulation and control system may have a user interface configured to display a simulated environment. The machine simulation and control system may also have a controller in communication with the user interface and a remotely located machine. The controller may be configured to receive from the machine real-time information related to operation of the machine at a worksite. The controller may also be configured to simulate the worksite, operation of the machine, and movement of a machine tool based on the received information. The controller may further be configured to provide to the user interface the simulated worksite, operation, and movement in the simulated environment.

Owner:CATERPILLAR INC

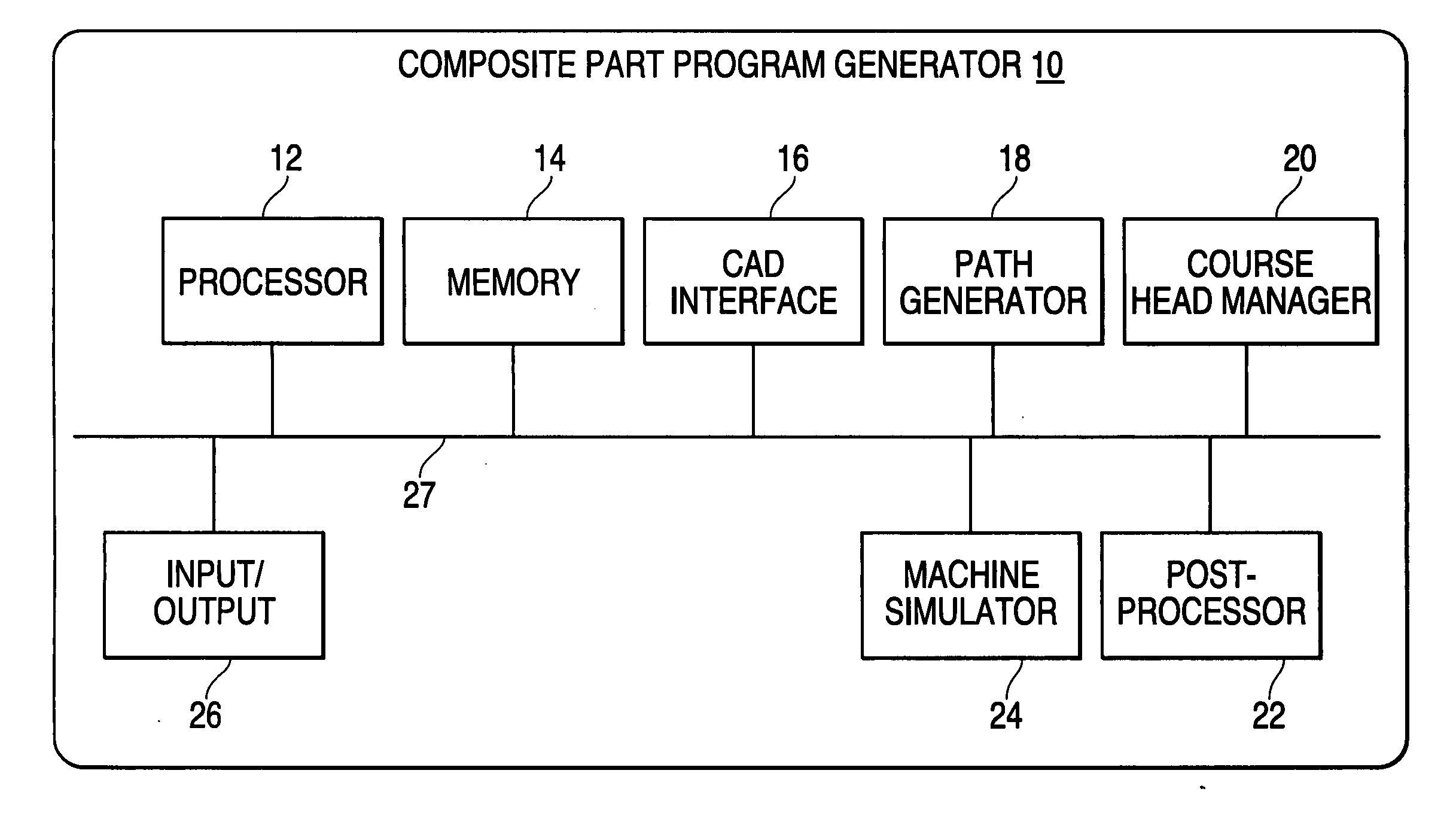

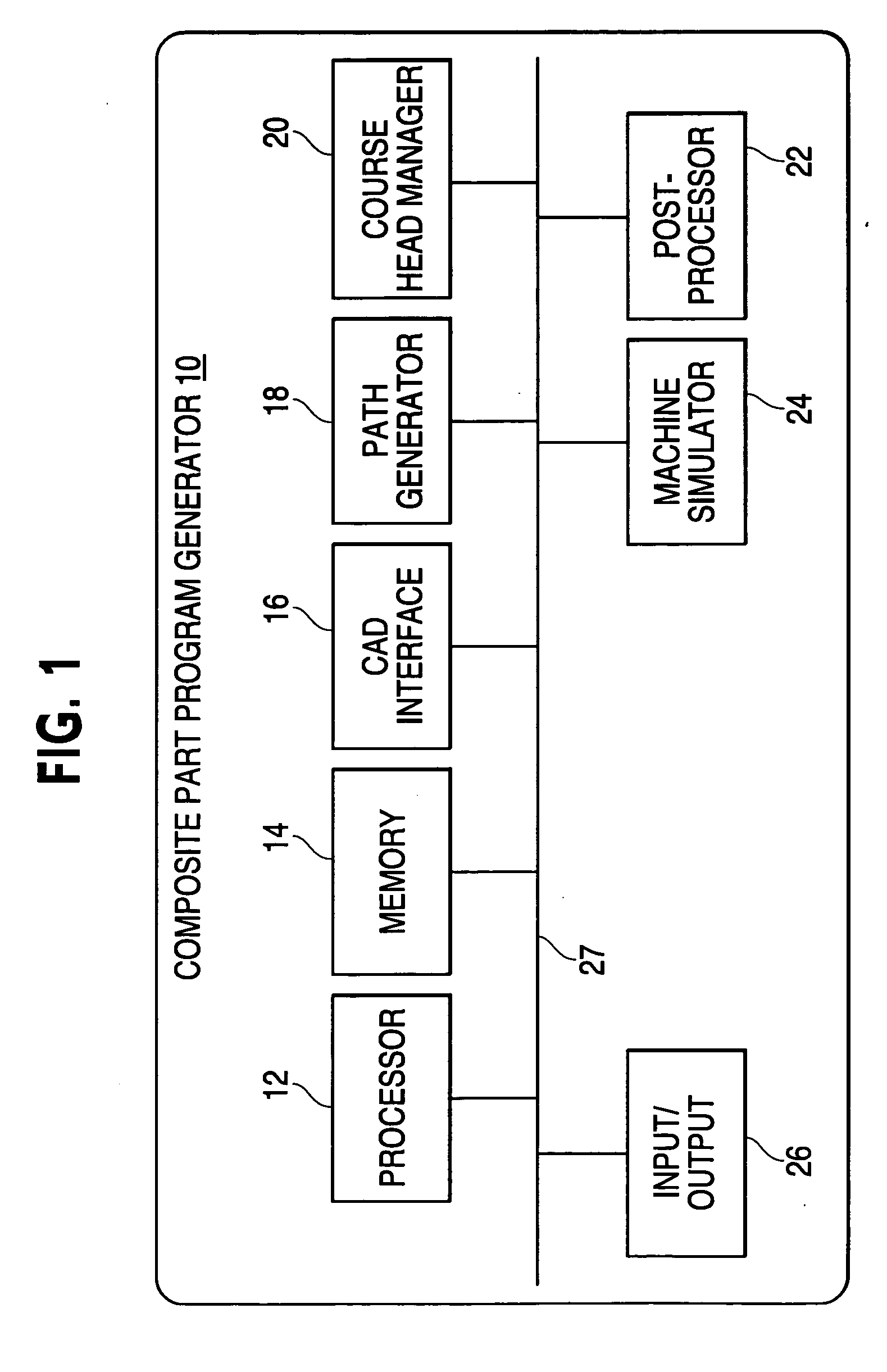

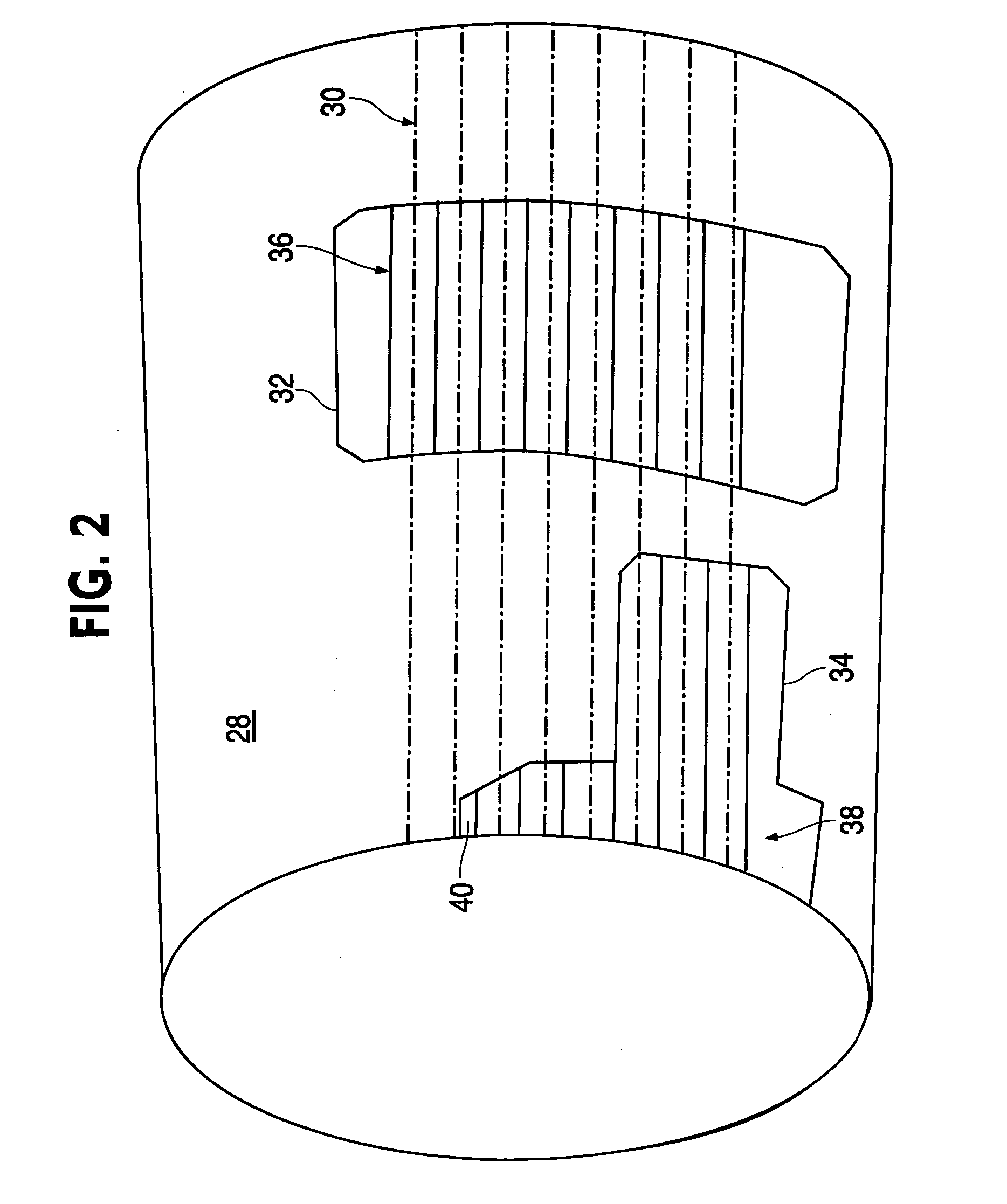

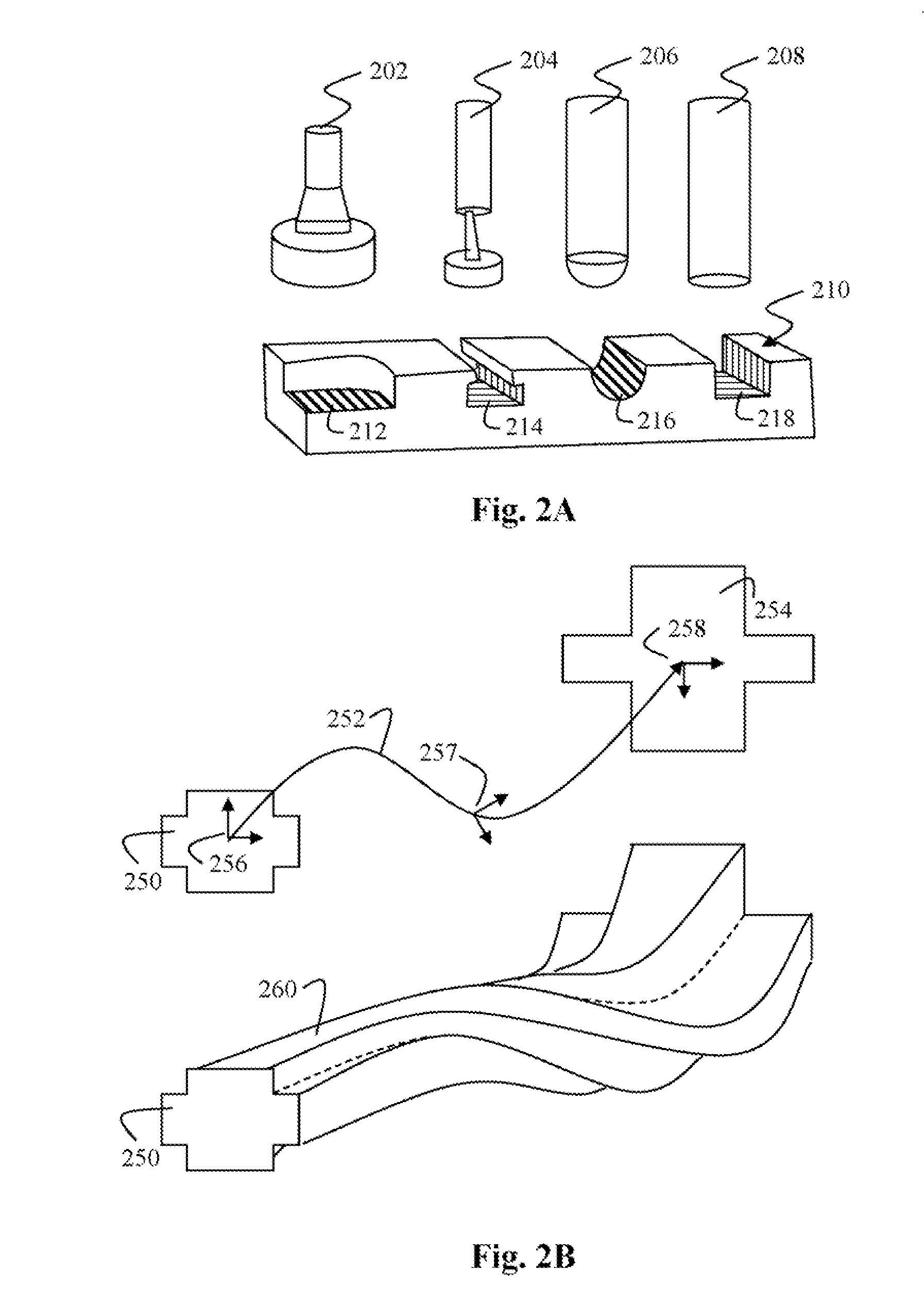

Multihead composite material application machine programming method and apparatus for manufacturing composite structures

ActiveUS20070106418A1Efficient productionProgramme controlTotal factory controlFiberComputer Aided Design

A composite part program generator includes a computer-aided design (CAD) system interface, a path generator, a course head manager, a post-processor and a machine simulator. The composite part program generator produces composite part programs for use on a multihead composite material application machine, such as a composite tape lamination machine or an automated fiber placement (AFP) machine, to manufacture a complex composite parts, including relatively flat, contoured, or generally cylindrical composite parts. This programming method can reduce the labor and time required to produce a composite part program for a multihead composite material application machine by an order of magnitude with respect to manual or existing automated programming methods.

Owner:THE BOEING CO

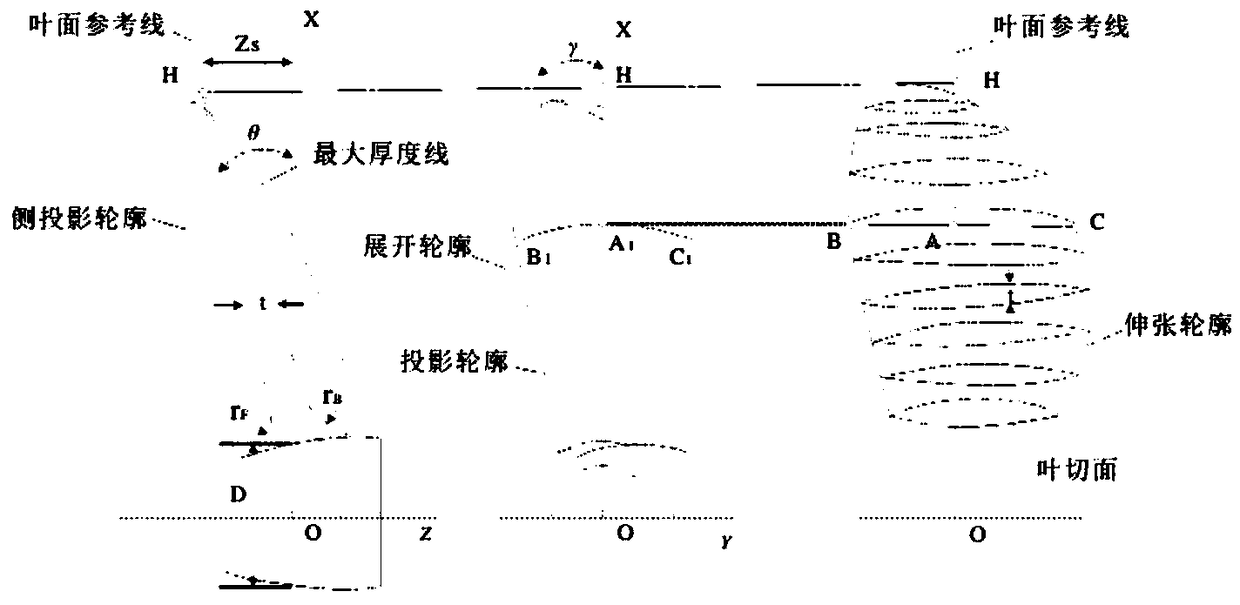

Aeroelastic stability fluid-structure interaction prediction method of turbo-machine changed interblade phase angles

InactiveCN101882177AReduce computing costCoupling calculation simplificationSpecial data processing applicationsElement modelPredictive methods

The invention relates to an aeroelastic stability fluid-structure interaction prediction method of turbo-machine changed interblade phase angles, which predicts the aeroelastic stability of a turbo-machine through the modal pneumatic damping ratio of different interblade phase angles by adopting an energy method. The method adopts the modal analysis containing prestress on established single-sector finite element models, realizes the vibration displacement transfer on the fluid-structure interaction interface through a data transfer method, adopts the dynamic mesh technology for obtaining mesh files taking the interblade phase angles into consideration, is used for unsteady computation fluid mechanic analysis of Junction Box modules in CFX, further obtains the modal pneumatic damping ratio of each interblade phase angle, and is used for predicting the aeroelastic stability. The method based on the fluid-structure interaction fully utilizes the cutting edge technology of the computational structural mechanics and the computation fluid mechanics, ensures the computation precision in each sub system, and improves the computation efficiency through the division of a fixed region and a movable region. The invention has good practical value and wide application prospects in the technical field of turbo-machine simulation.

Owner:BEIHANG UNIV

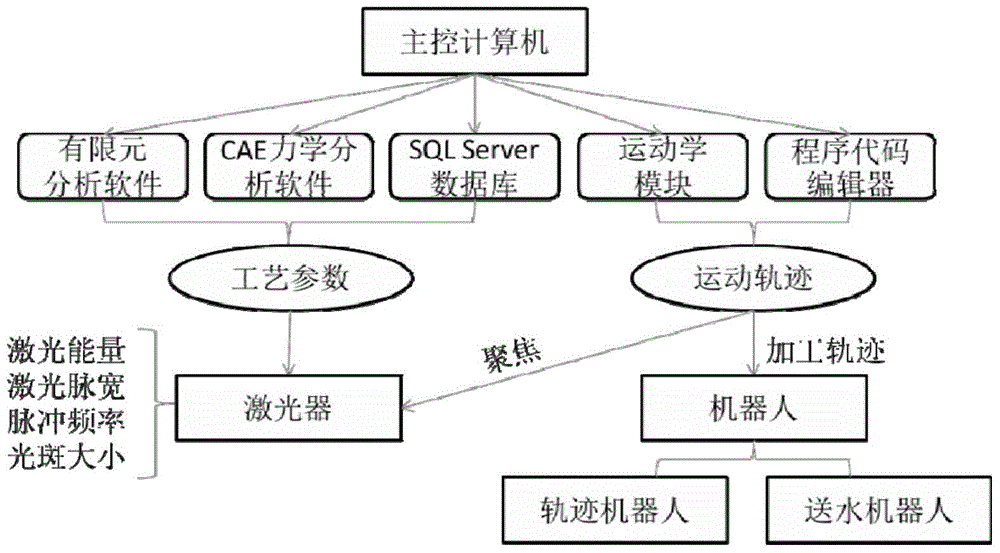

System and method for automatic control over laser shock peening

InactiveCN105385839AAchievement of laser shock strengtheningRealization of automatic open distributed control of laser shock strengthening equipmentForeign matterShock wave

The invention relates to a method for automatic control over laser shock peening. The method comprises the following steps that a part analysis model is built in mechanical analysis software according to the machining requirement, and residual stress distribution is obtained; residual stress distribution is guided into CAE analysis software, and a machining motion track acting on the surface of a part is automatically generated; meanwhile, technological parameters corresponding to a laser shock wave pressure set value are selected by an industrial personal computer according to the relation between laser shock wave pressure and laser peening technological parameters; the machining motion track and the technological parameters are guided into the mechanical analysis software for simulation so as to obtain a strain value after machining simulation; and if the strain value is within the set range, the technological parameters are sent to a laser device through the industrial personal computer, the machining motion track is sent to a robot, and automatic laser machining is achieved. By means of the method, laser shock peening of an integral blade disc can be achieved, quantitative precise control over residual stress is achieved, the service life of the integral blade disc is effectively prolonged, and the foreign matter damage resisting capacity of the integral blade disc is effectively improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Machining simulation method and apparatus

InactiveUS6862560B1Simulating machiningQuick and accurate operationProgramme controlComputer controlComputer graphics (images)Image resolution

A machining simulation method using a plurality of equally sized regular volumes such as cubes to represent the surface of a raw stock object at a relatively low resolution. Each regular volume contains a reference to that portion of the original stock surface falling within that regular volume. The regular volumes affected by the swept volume of each tool movement are readily determined, and a pointer to that tool movement is added to each affected regular volume. The finished data may be expanded in detail at any portion of interest to create fully realised surface geometry with full boundary information by combining the original stock surface and the relevant surfaces of each tool movement. The original stock object may be displayed using the low-resolution regular volumes from any convenient view point, and may be animated in real time to show the effects of each tool movement.

Owner:MACHINEWORKS

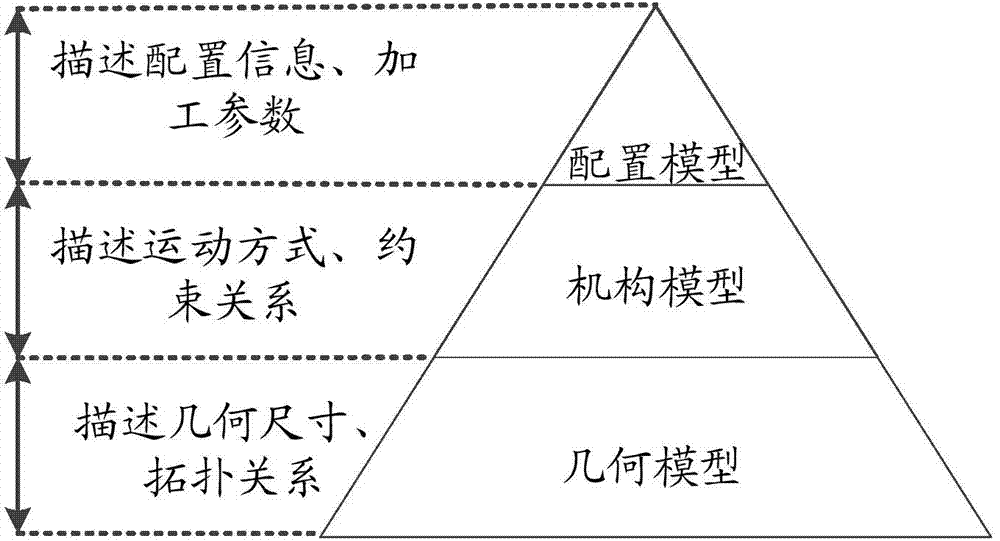

Double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method

InactiveCN102866638AImprove Simulation EfficiencyImprove manufacturing precisionSimulator controlNumerical controlDimensional modeling

The invention discloses a double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method and provides a simulation method capable of improving simulation efficiency under the premise of guaranteeing simulation correctness. The method includes: modeling; conducting three-dimensional modeling of blanks and clamps required in all moving components, a machine tool body and numerical control machining; connecting all moving components and the machine tool body to conduct virtual assembling according to a moving relation by using a Pro / E three-dimensional platform; operating a virtual simulating machine tool; outputting models of all components in a standard template library (STL) form on the basis of the same coordinate system; establishing a double-turntable five-axis numerical control machine tool virtual model; establishing a model tree in VERICUT, and the sequence of model components includes two branches: machine tool body Base - Y axis - X axis - A axis - C axis - clamp - blank and machine tool body Base - Z axis - main axis - tool; the STL assembly model output by Pro / E is led into corresponding components in VERICUT directly, namely the double-turntable five-axis numerical control machine tool virtual model is established; and numerical control machining simulation is operated.

Owner:TIANJIN UNIV OF COMMERCE

Large-sized water turbine blade multi-shaft linkage numerical control machining method based on casting roughcast

ActiveCN103317171AFlexible preprocessingImprove cutting conditionsMilling equipment detailsSpecial data processing applicationsNumerical controlPoint cloud

The invention discloses a large-sized water turbine blade multi-shaft linkage numerical control machining method based on a casting roughcast. The method comprises the steps: 1) carrying out a three-dimensional coordinate measurement on a water turbine blade roughcast by a large-sized coordinate measuring machine, carrying out a point cloud acquisition of the blade roughcast by a scanner; 2) according to three-dimensional coordinate data and point cloud data of the blade roughcast obtained in the step 1), processing the three-dimensional coordinate data and the point cloud data of the blade roughcast by a computer, and then generating a computer model of the blade roughcast entity; and 3) based on the computer model of the blade roughcast entity obtained in the step 2), machining the roughcast entity of the giant water turbine blade by a numerical control programming, planning tool paths, and performing a machine simulation cutting emulation. Through the method, the accurate computer model of the blade roughcast entity can be obtained, and the roughcast entity can be flexibly preprocessed; the tool path empty knives are fewer, and thus the machining efficiency is high; the cutter spacing is reliable, and thus the quality accident is reduced; and the cutting condition is good, and thus the effective utilization rate is high.

Owner:DONGFANG ELECTRIC MACHINERY

Simulation system implementing real-time machine data

InactiveUS20120154572A1Color television detailsClosed circuit television systemsTime informationKinematic controller

Owner:STRATTON KENNETH L +5

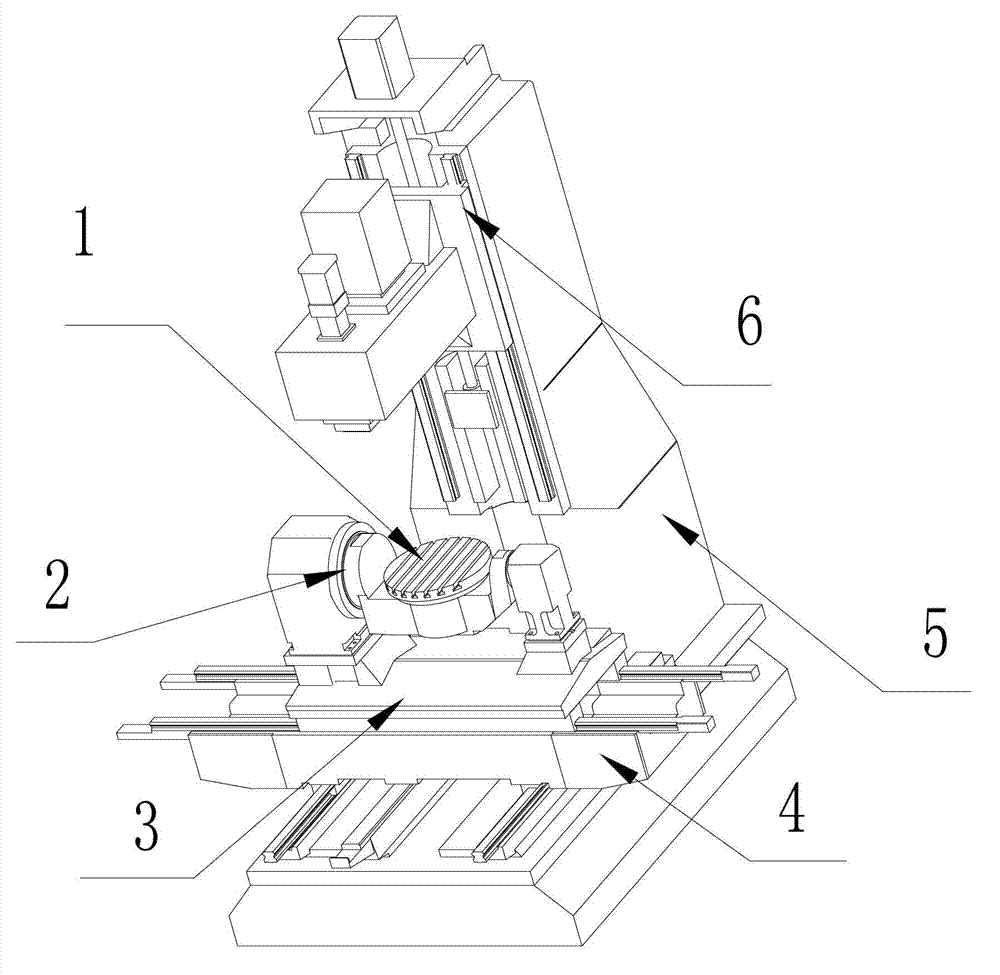

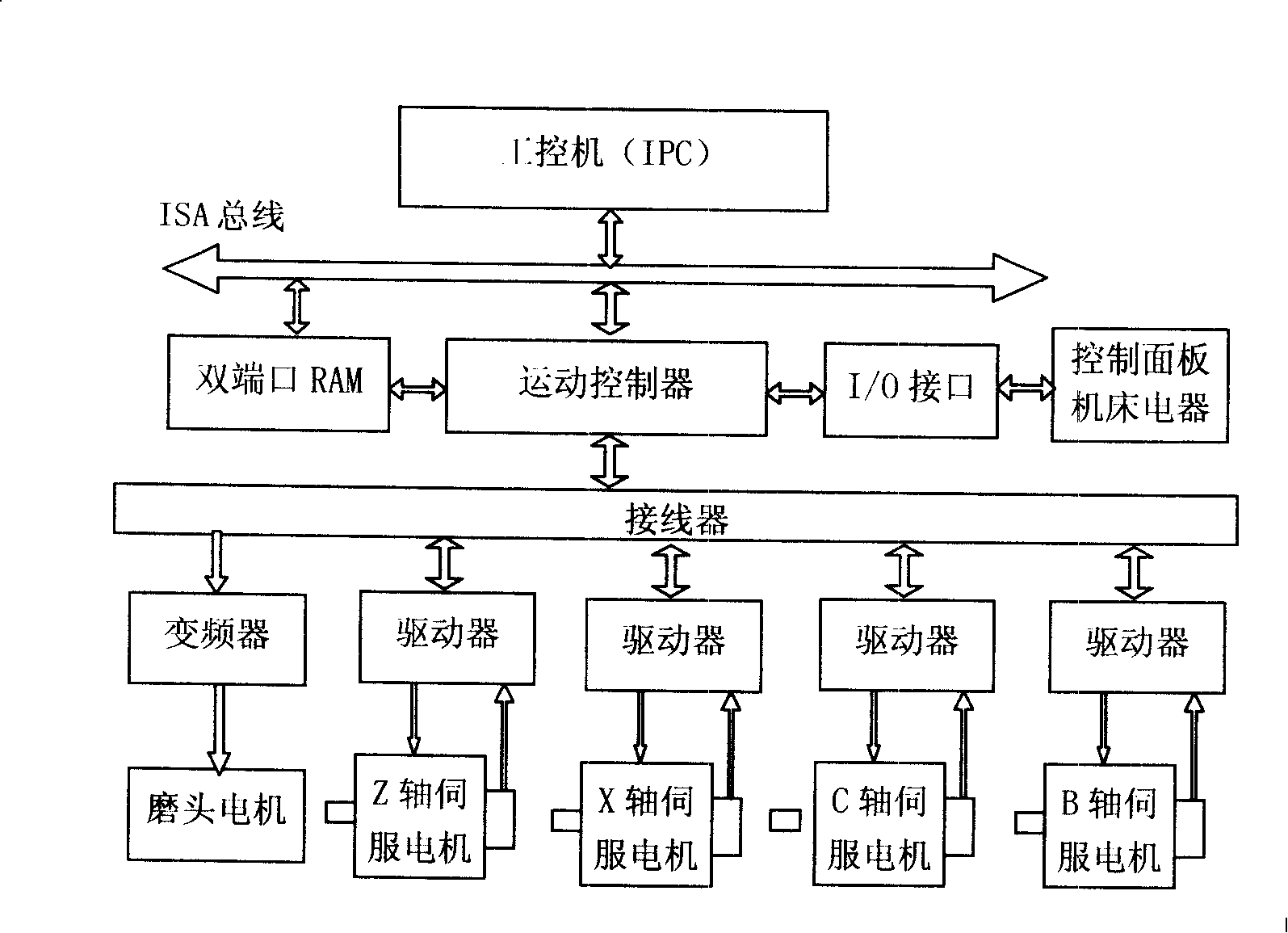

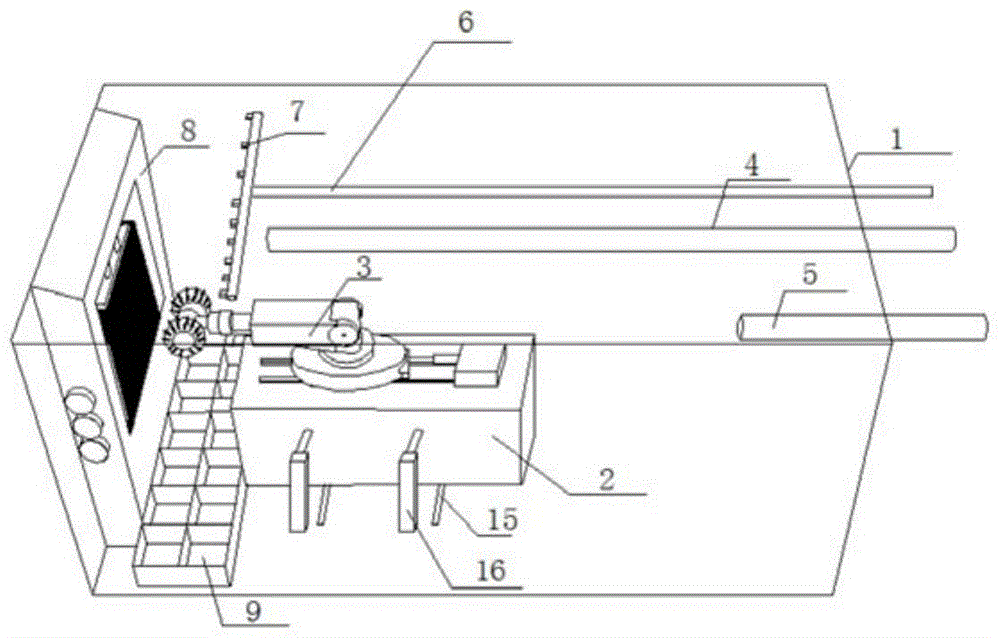

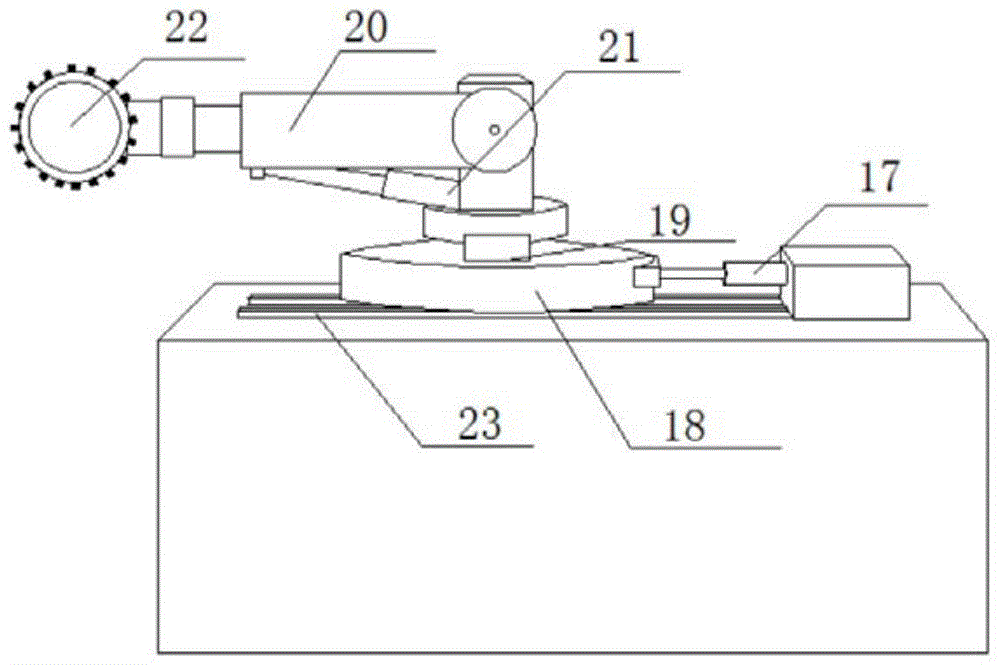

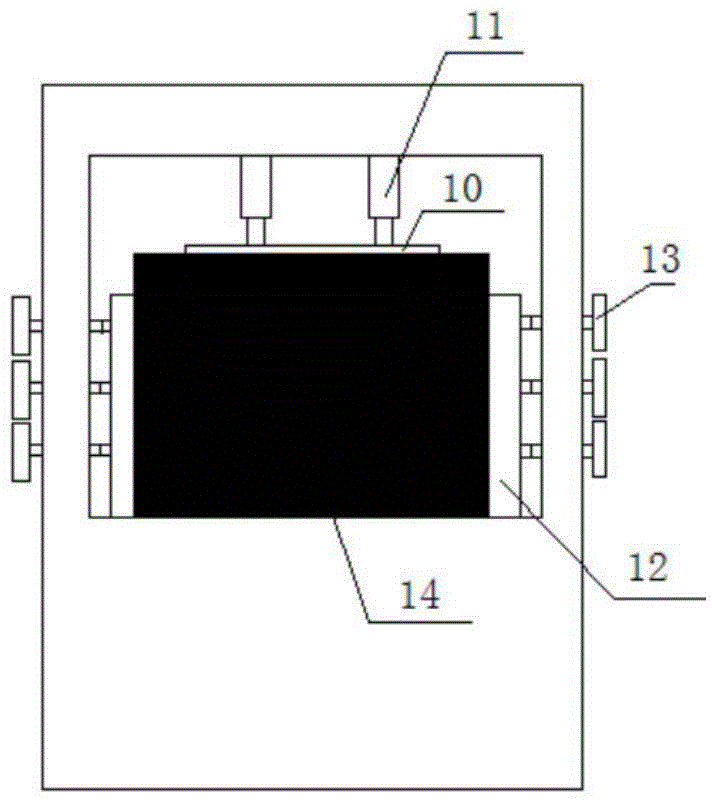

Turbine blade digital control abrasive belt grinding machine and operating method thereof

InactiveCN101234480AImprove grinding efficiencyGood grinding precisionBelt grinding machinesGrinding feed controlDigital controlSoftware modules

The invention discloses a turbine blade numerical control belt grinder and a control method thereof, which relates to a grinding and processing device of a turbine blade and the control method thereof, and is characterized in that: a belt wheelhead and an open numerical control system is provided on the basis of the basic parts of the original machine tool; the belt wheelhead is provided with a grinding belt tightening device and a transmission belt tightening device; a Z-axis serving motor drives a big carriage; an X-axis serving motor drives a small carriage; a C-axis drives a head frame; a B-axis drives a turret; a D-axis is a belt wheelhead motor; and each motor is connected with the control system; the control system is provided with a memory, a control circuit and a blade grinding and a controlling software module. During the operation, the original parameter is firstly input; then a blade grinding and controlling software module is automatically setting up by the system to generate a processing program, make error analysis and machining simulation; and finally a blade actual grinding processing is carried out. The turbine blade numerical control belt grinder is a five-axis and four-linkage numerical control belt grinder, and has the advantages of high efficiency, good accuracy, simple structure, low cost, and convenient control.

Owner:YANGZHOU UNIV

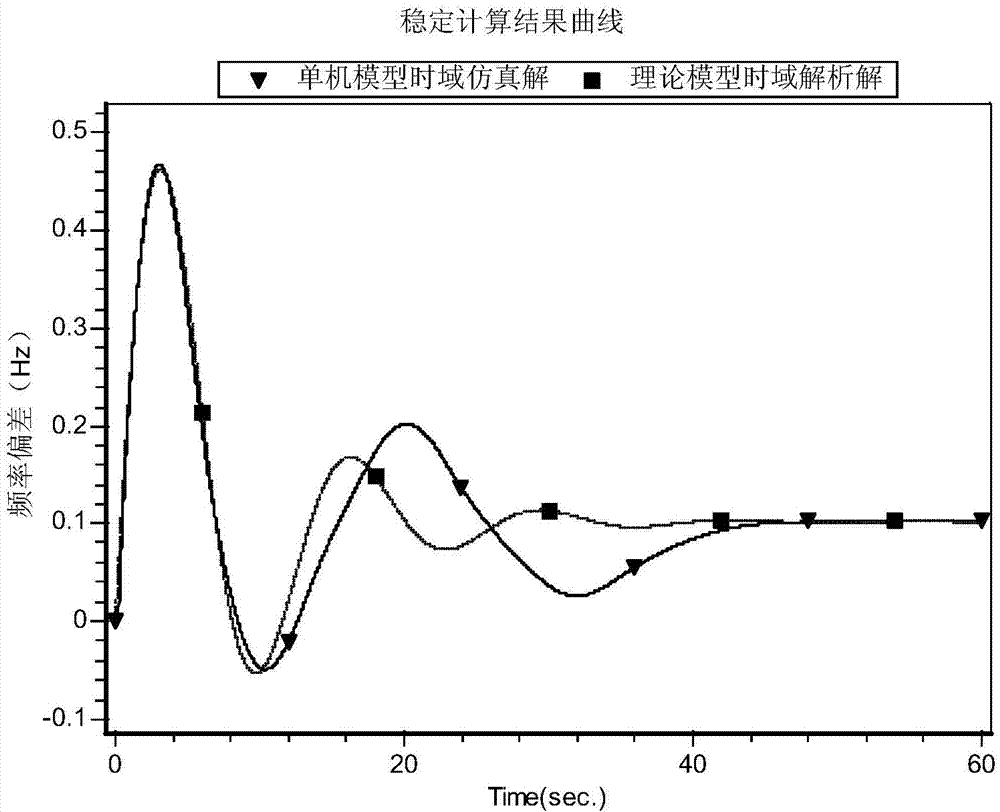

High-frequency cutting machine simulation configuration method based on frequency characteristics of regional interconnected power grid

ActiveCN104268332AImprove configuration efficiencyQuickly determine frequency characteristicsSpecial data processing applicationsLoad modelPower Balance

The invention provides a high-frequency cutting machine simulation configuration method based on frequency characteristics of a regional interconnected power grid. The high-frequency cutting machine simulation configuration method is based on the characteristics of frequency feature, a topological structure, power balance and the like of an interconnected system, determines the basic configuration principle of a high-frequency cutting machine, and then establishes a single-machine load model to perform detailed configuration on an optimal cutting machine frequency section, minimum cutting machine capacity, cutting machine rounds, cutting machine delay, cutting machine proportions of cutting machine rounds and other parameters. The high-frequency cutting machine simulation configuration method has the advantages of being good in adaptability, comprehensive in considered factors, reasonable in scheme and the like.

Owner:STATE GRID CORP OF CHINA +2

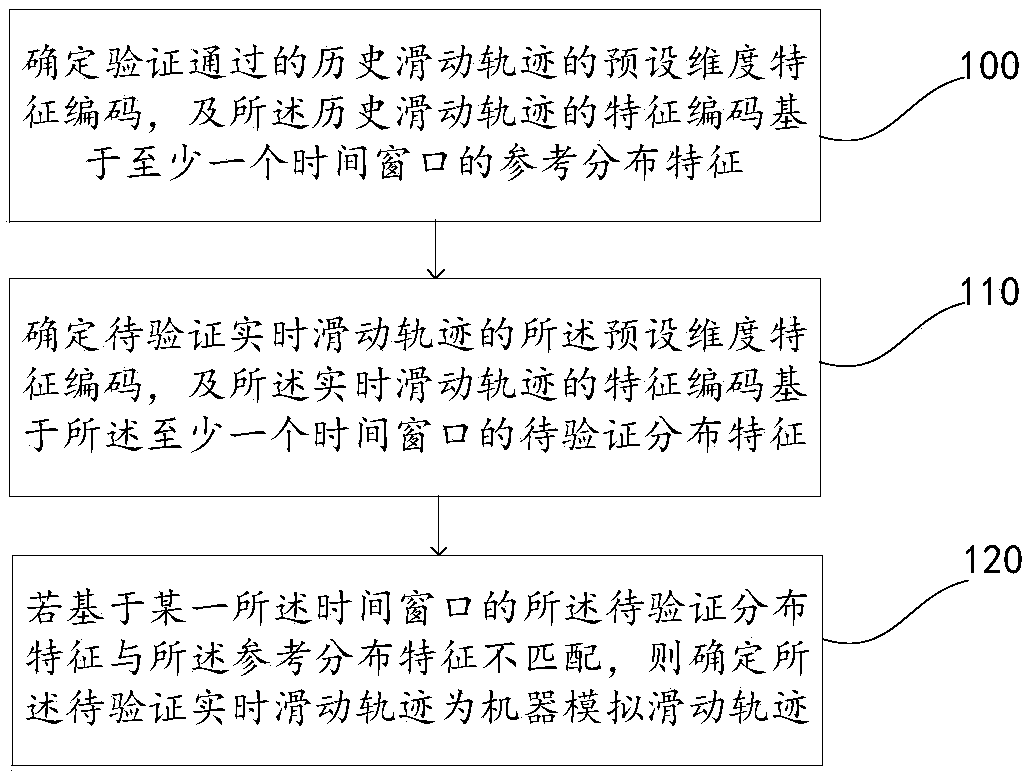

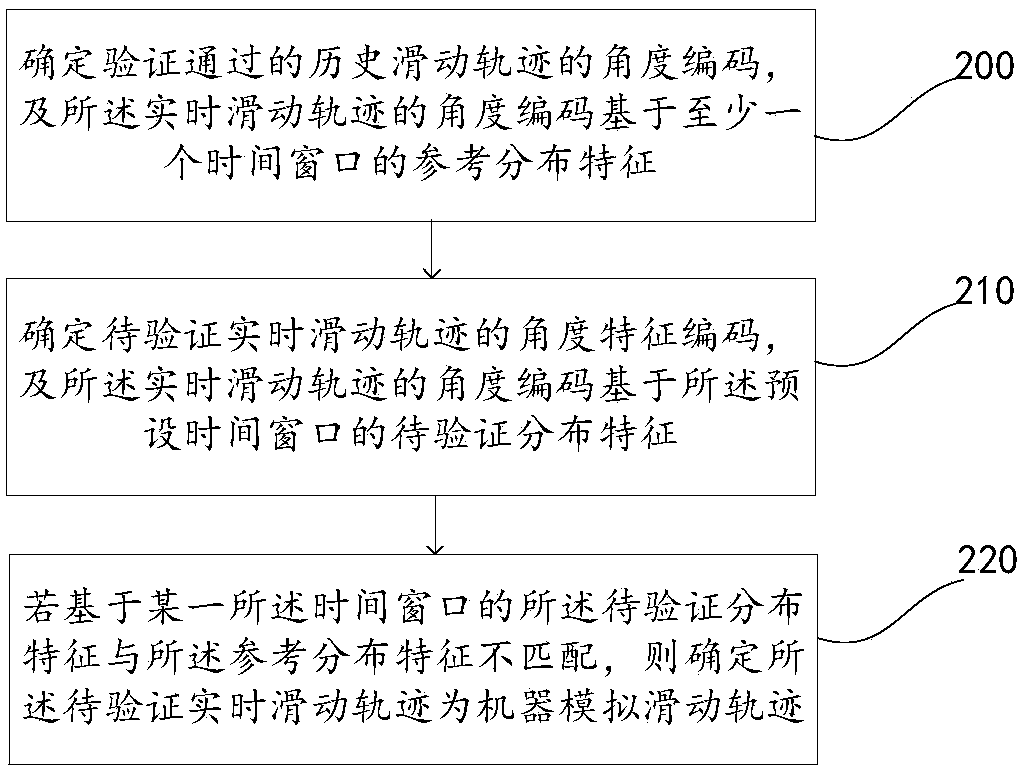

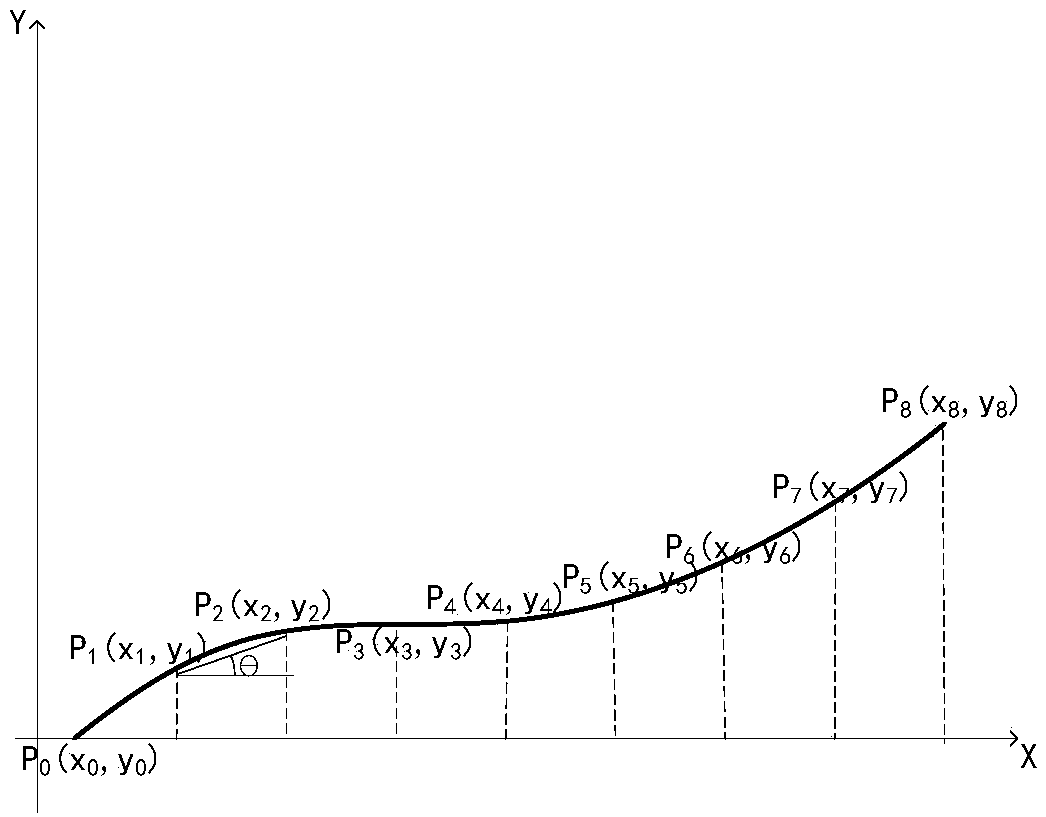

Human-computer identification method and device based on sliding trajectory, and electronic equipment

ActiveCN107679374ALow resolution accuracyImprove accuracyCharacter and pattern recognitionDigital data authenticationState of artFeature coding

The invention provides a human-computer identification method based on a sliding trajectory, belongs to the technical field of computers and is used for solving the problem of low accuracy when a human-computer identification method simulates a sliding trajectory input by a user in the prior art. The method comprises the following steps that: determining the preset dimension feature coding of a historical sliding trajectory which is qualified, and the reference distribution feature of the feature coding of a historical sliding trajectory on the basis of at least one time window; determining the preset dimension feature coding of a real-time sliding trajectory to be verified, and the distribution feature to be verification of the feature coding of a historical sliding trajectory on the basis of at least one time window; and if the distribution feature to be verification on the basis of a certain time window is not matched with the reference distribution feature, determining that the real-time sliding trajectory to be verified is a machine simulation sliding trajectory. By use of the method disclosed by the embodiment of the invention, accuracy for identifying the machine simulationsliding trajectory can be effectively improved.

Owner:北京钱袋宝支付技术有限公司

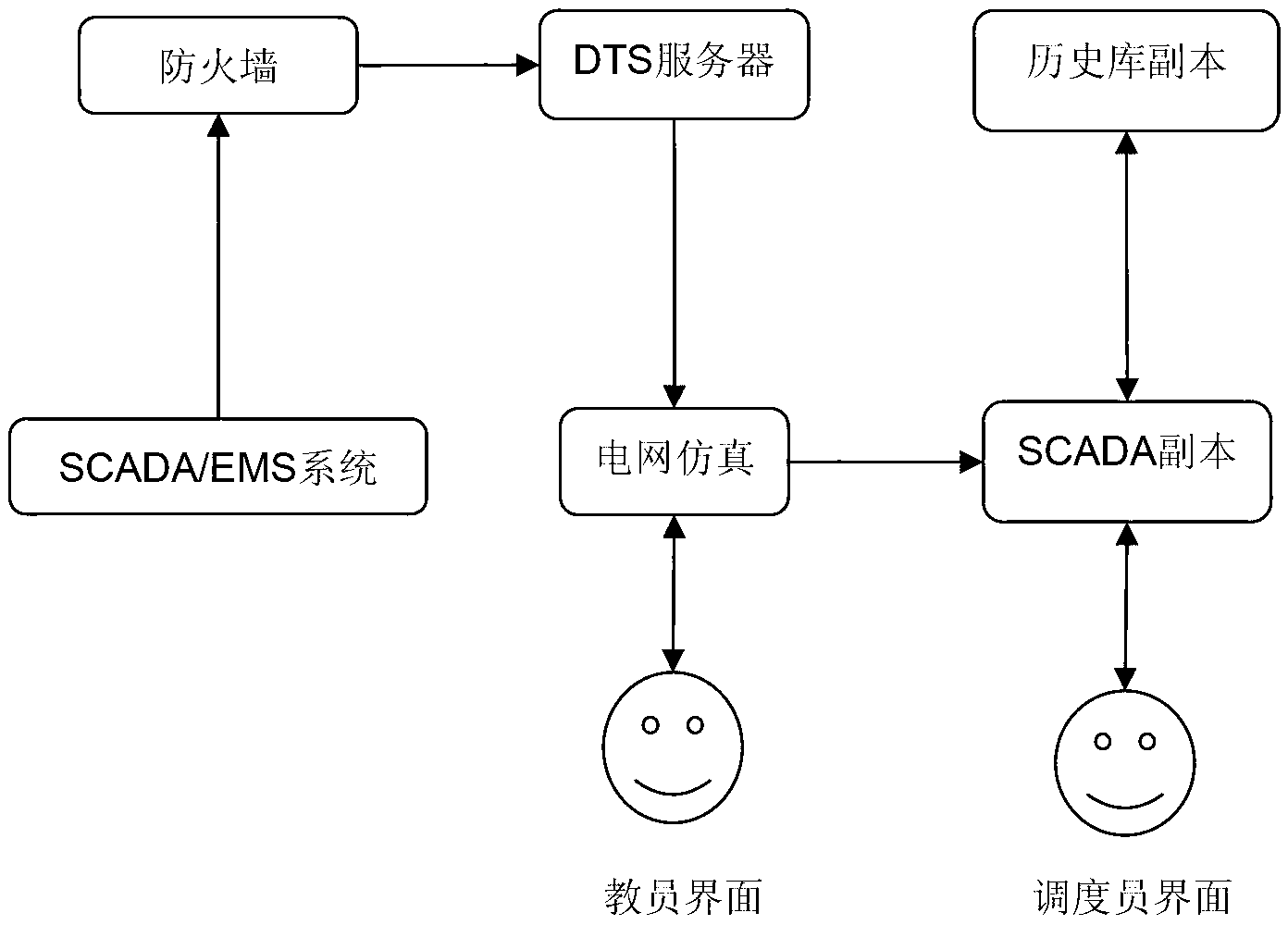

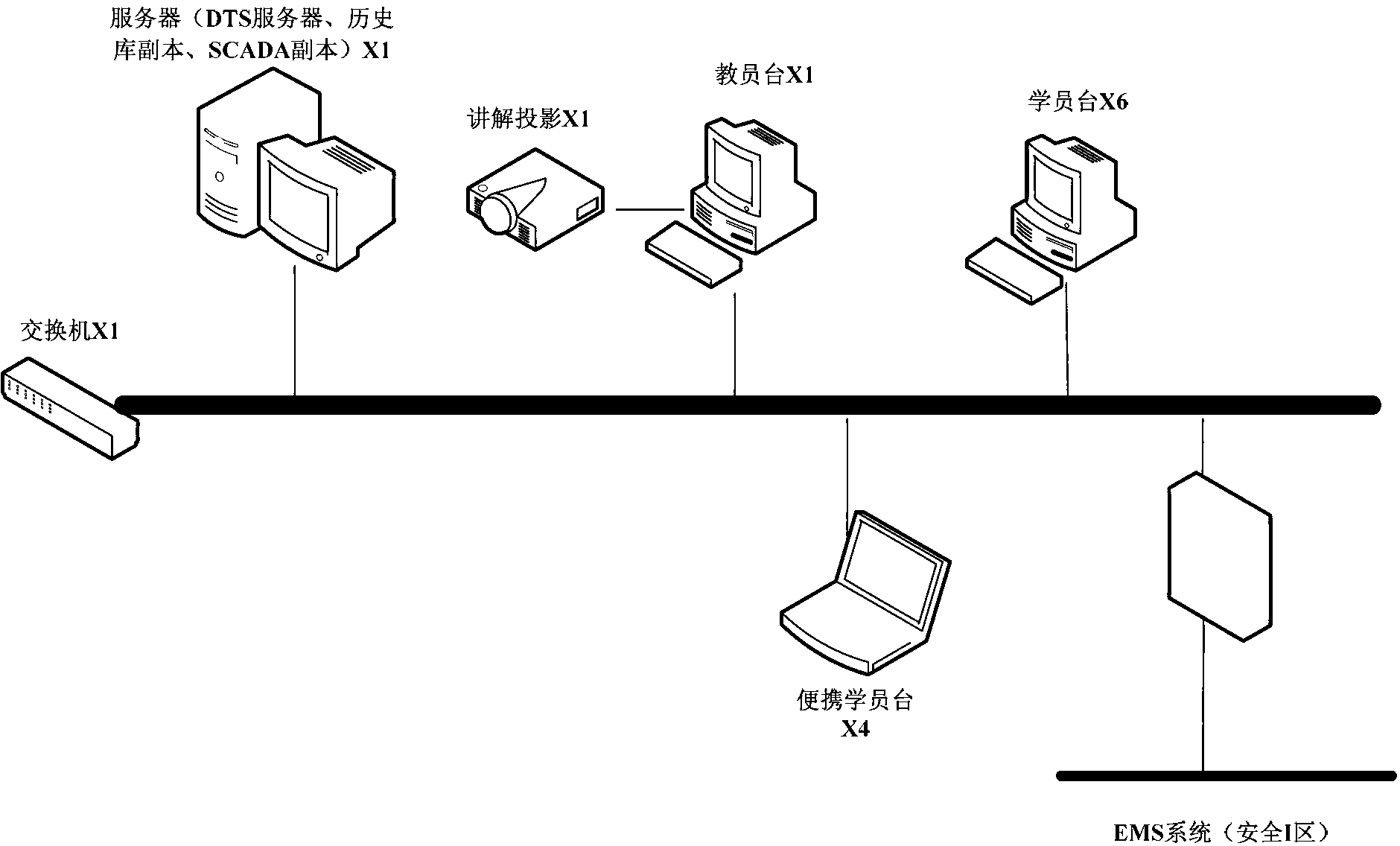

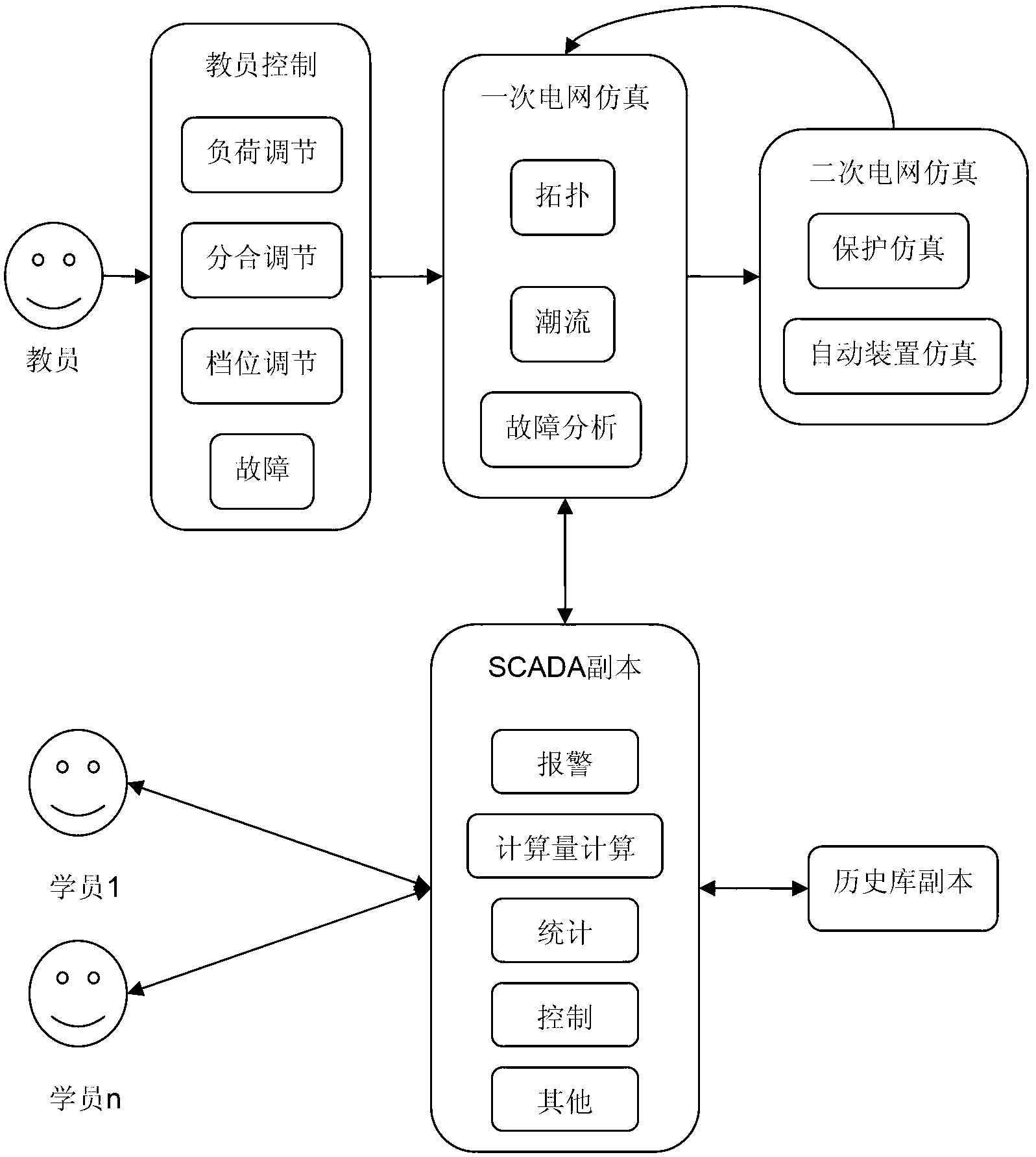

Method for improving reality of power grid dispatcher training simulation system

ActiveCN103177642AEasy to popularize and applyReduced popularityEducational modelsTraining planSCADA

The invention discloses a method for improving the reliability of a power grid dispatcher training simulation system. The method comprises the following steps that: (1) at a plant station end of a teacher machine simulation actual system, an EMS system sends the data of a DTS server as the acquired data through a firewall; (2) at a master station end of a student machine simulation actual system, the function and the interface of an SCADA system at the master station end are copied to form an SCADA copy; (3) a teacher generates a training state on the DTS server, can adjust the power, modify the section, set the fault and the like to form a corresponding training plan, and sends the training plan to the SCADA copy; and (4) a student operates a simulation power grid in the environment of the SCADA copy to finish the training. According to the invention, a database of a DTS system is refreshed in the case of any change or upgrade of the SCADA system, and complete consistence with the new function of the SCADA system can be realized, thereby reducing the re-development process of the system, greatly reducing the cost and time and realizing good upgradability.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

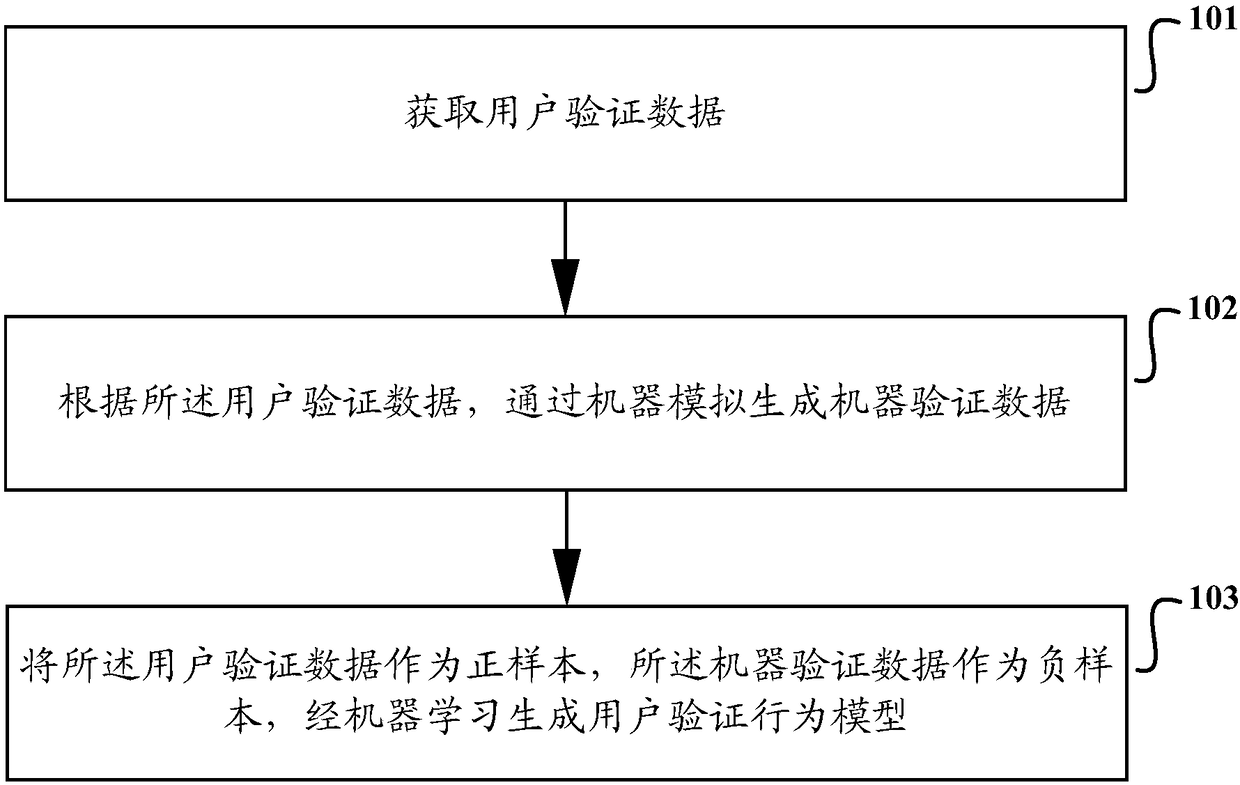

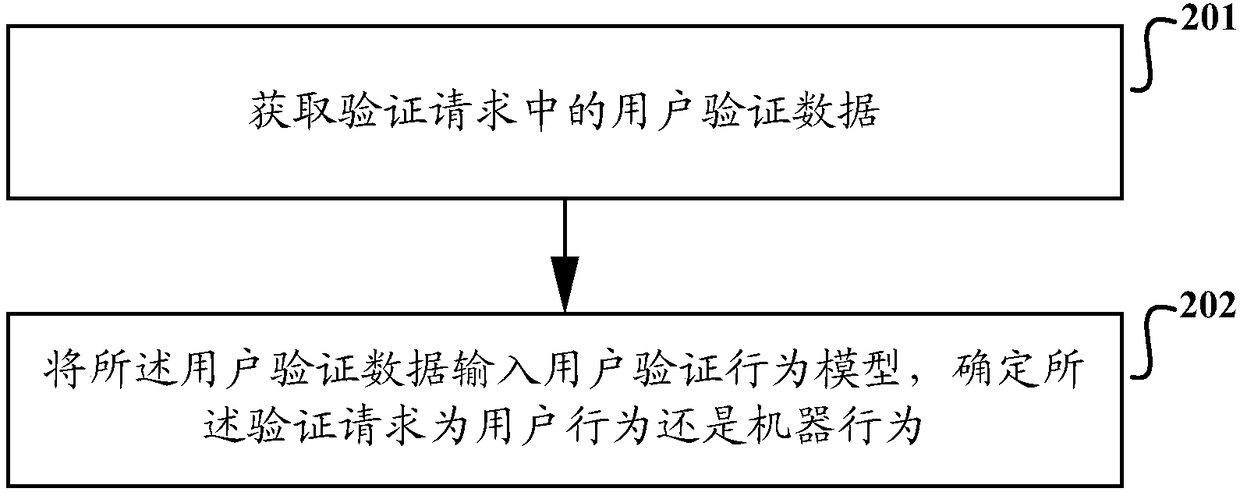

Verification method and device

ActiveCN108229130AImprove experienceIncrease the difficultyUser identity/authority verificationDigital data authenticationPositive sampleUser verification

An embodiment of the invention provides a verification method and device. The method includes: acquiring user verification data which are generated by user behaviors; generating machine verification data through machine simulation according to the user verification data, wherein the machine verification data are used for representation of verification data generated by machine behaviors; taking the user verification data as a positive sample and the machine verification data as a negative sample to generate a user verification behavior model through machine learning, wherein the user verification behavior model is used for judging whether verification requests are user behaviors or machine behaviors.

Owner:CHINA UNIONPAY

Atrial fibrillation catheter ablation simulator based on three-dimensional electroanatomic mapping system (CARTO)

InactiveCN102831289AReduce surgical riskSurgical instruments for heatingEducational modelsMachine controlMedicine

The invention discloses an atrial fibrillation catheter ablation simulator based on a three-dimensional electroanatomic mapping system (CARTO), which comprises a work station, a sheathing canal measuring device, a catheter measuring device and a force feedback device, an ablation catheter, an ablation catheter movement guide rail, a first display, a second display, a third display, a fourth display, an X-ray machine control panel, a point accessing pedal plate, a point deleting pedal plate, a discharge pedal plate, a perspective pedal plate, a movie storage pedal plate and the like, wherein the work station is internally provided with three-dimensional mapping simulation software, polygraph simulation software, catheter ablation operation simulation software and X-ray machine simulation software, and the sheathing canal measuring device, the catheter measuring device and the force feedback device are respectively connected with the work station through serial ports. The simulator completely simulates the three-dimensional electroanatomic mapping system, so that a doctor achieves the purpose of mastering the atrial fibrillation catheter ablation based on the CARTO system by operating the simulator.

Owner:董建增 +1

System and Method for Analyzing Engagement Surfaces Between Tools and Workpieces During Machining Simulation

A method determines an engagement surface between a tool and a workpiece during a simulation of a machining of the workpiece by a relative motion between the object and the tool. A set of points is arranged on at least a part of a surface of the tool. A distance between each point in the set of points and a surface of the workpiece modified by the motion is determined and the engagement surface is formed based on a subset of points having the distance below a threshold.

Owner:MITSUBISHI ELECTRIC RES LAB INC

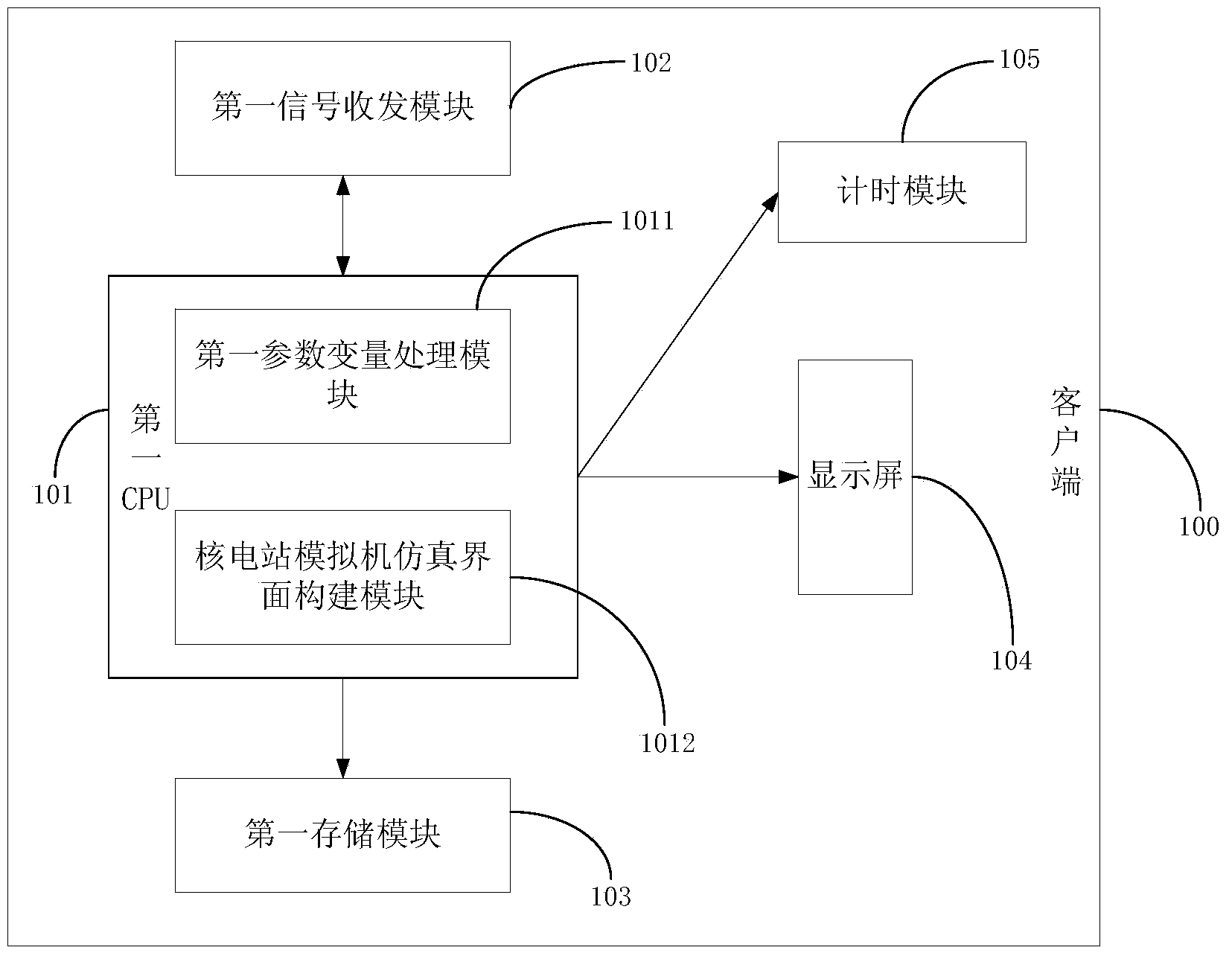

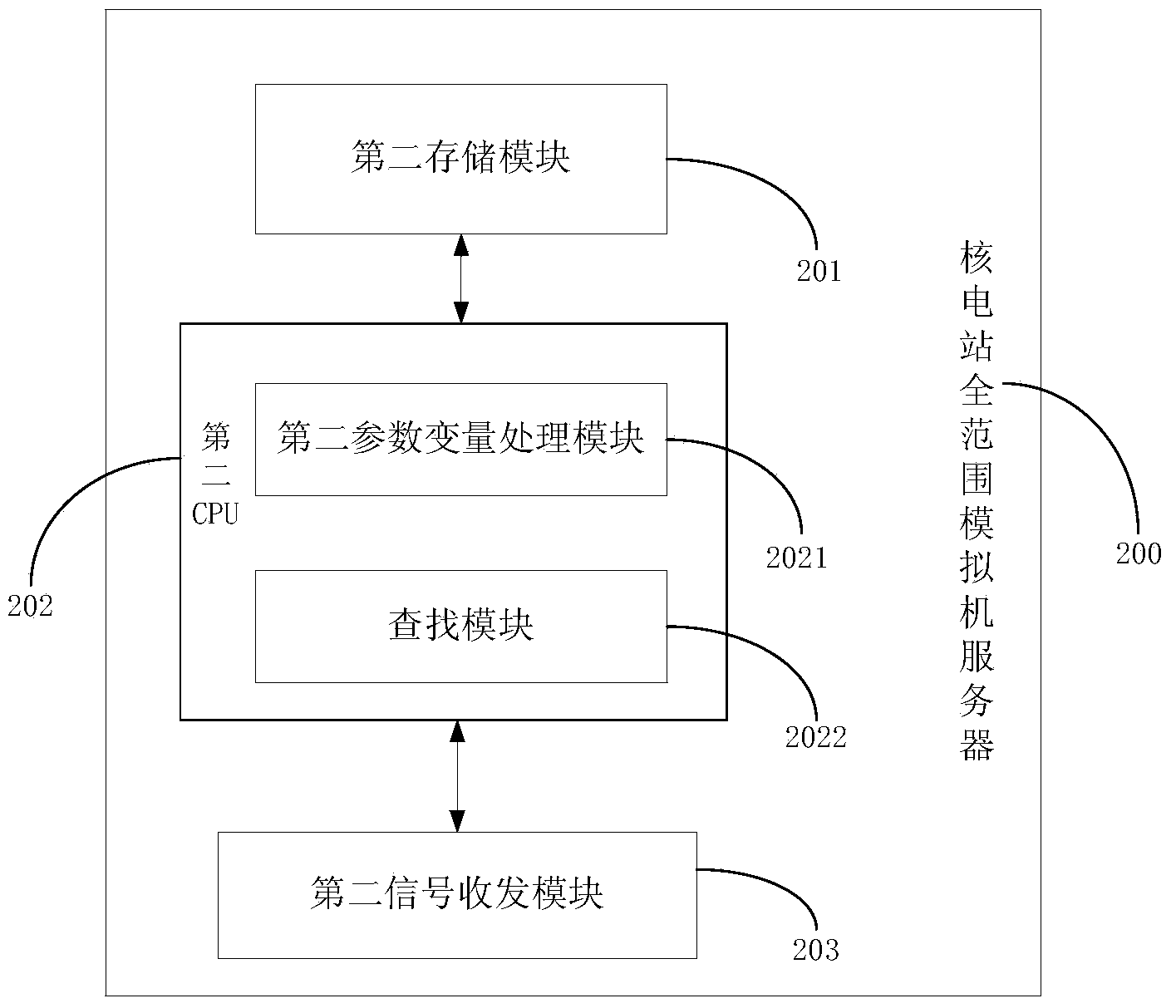

Remote monitoring method and system for full-range analog machines of nuclear power station

ActiveCN103973513AOvercome data debugging difficultiesOvercome the defects that it is difficult to realize the remote monitoring of system parameters of nuclear power plant simulatorsPower plant safety arrangementNuclear energy generationNuclear powerClient-side

The invention discloses a remote monitoring method and system for full-range analog machines of a nuclear power station. The system comprises a client side (100) and a nuclear power station full-range analog machine server (200). The client side (100) is used for establishing a nuclear power station analog machine simulation interface view which is identical to the project file organizational structure of a nuclear power station full-range analog machine to be monitored on the basis of SimDV software, and extracting the parameter variables of the system frames of all analog systems under the simulation interface view. The client side (100) is further used for sending selected monitoring parameters to the nuclear power station full-range analog machine server (200) after the selected monitoring parameters are written in a datagram format. The nuclear power station full-range analog machine server (200) is used for extracting the monitoring parameters in a datagram, searching for the real-time values of the monitoring parameters, and sending the real-time values back to the client side (100) after the real-time values are written in the datagram format. The client side (100) is further used for extracting the real-time values of the monitoring parameters in the datagram, and displaying the real-time values of the monitoring parameters.

Owner:中广核(北京)仿真技术有限公司 +1

System and Method for Optimizing Machining Simulation

ActiveUS20110245954A1Programme controlAnalogue computers for control systemsTheoretical computer scienceMachine simulation

Embodiments of the invention disclose a method for optimizing a simulation of a machining of a workpiece performed by removing a set of swept volumes from a volume of the workpiece, wherein the volume is partitioned into a set of cells, comprising the steps of: associating with each cell a subset of distance fields representing a subset of swept volumes intersecting with the cell, wherein at least part of the subset of swept volumes forms a composite surface of the cell; subjecting the cell with a set of rays incident to the cell from at least one direction; and selecting a distance field of the subset of distance fields into an optimal subset associated with the cell, wherein a boundary of the swept volume represented by the distance field intersects with at least one ray at a point of intersection lying on the composite surface.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Track-based man-machine recognition method for sliding verification codes

ActiveCN108287989AGood protection againstImprove accuracyCharacter and pattern recognitionDigital data authenticationPattern recognitionMan machine

The invention discloses a track-based man-machine recognition method for sliding verification codes. The method comprises the following steps of: acquiring track data of a user; constructing a multi-dimensional feature system according to the track data; and carrying out track differentiation on the multi-dimensional feature system according to a designed man-machine recognition model. According to the method, the multi-dimensional feature system is designed by combining two phenomena of human tracks, and features are used for describing sliding verification code habits of users, so that useroperations and machine simulations are differentiated, advantages are provided in confront with black product tools of attackers, and a relatively good confront protection effect is provided.

Owner:CHECC DATA CO LTD +1

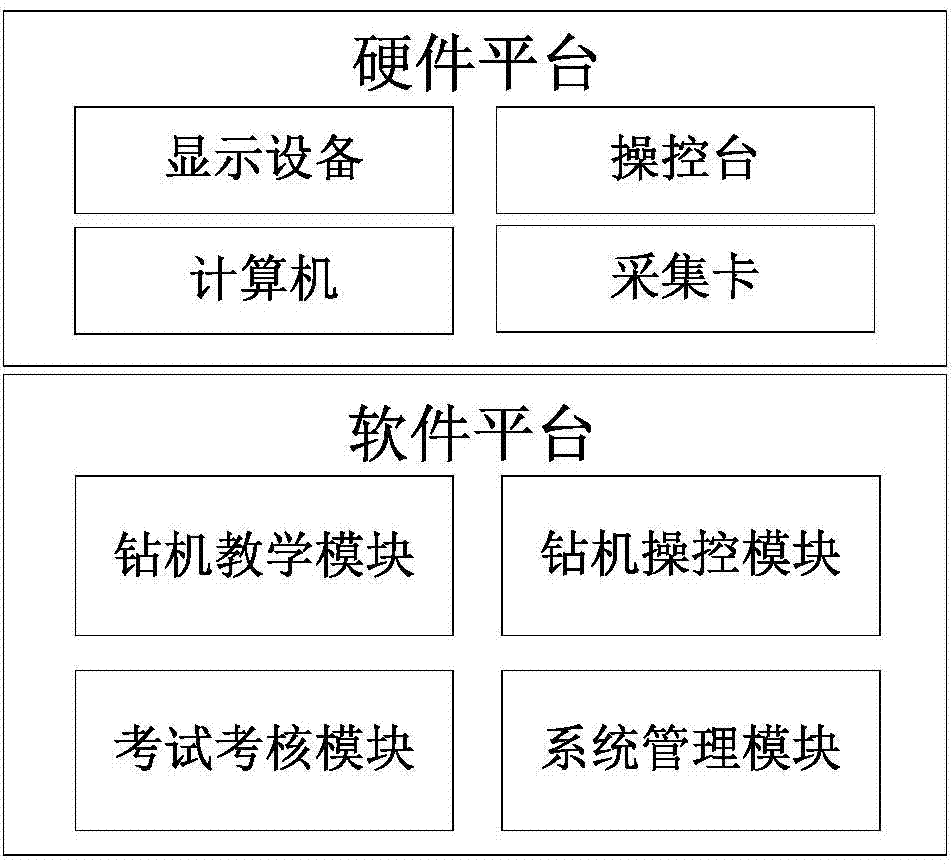

Coal mine full-hydraulic directional drilling machine simulation training system

InactiveCN104766506AAvoid damageImprove operational proficiencyCosmonautic condition simulationsData processing applicationsMultiway switchingData acquisition

The invention discloses a coal mine full-hydraulic directional drilling machine simulation training system. The coal mine full-hydraulic directional drilling machine simulation training system comprises a central processing part, a data collecting part, a display part and a control part, wherein the central processing part is used for processing data collected by the data collecting part to finish data interface work and providing virtual platform display data to the display part; the data collecting part is used for collecting a multi-way switch amount and a multi-way simulation amount from the control part and an operation instruction sent by the control part; the display part is used for displaying a virtual interface; the control part comprises a control handle, a function conversion handle, a control switch and an adjustment knob.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

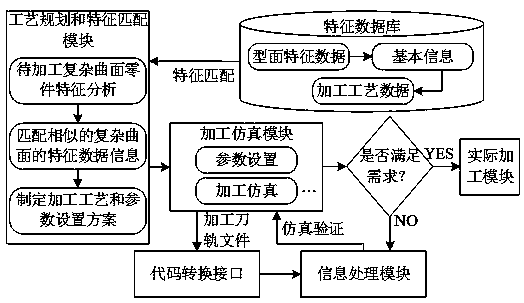

Feature library-based complex curved surface part mechanical arm machining system and method

InactiveCN107807610AImprove milling efficiencyResolve incompatibilitiesProgramme controlComputer controlInformation processingEngineering

The invention discloses a feature library-based complex curved surface part mechanical arm machining system and method and belongs to the new technical field of complex curved surface part mechanicalarm milling machining. The system includes a feature database, a technique planning and feature matching module, a code conversion interface, an information processing module, a machining simulation module, and an actual machining module. The method includes the following steps that: the features of a complex curved surface part are analyzed and extracted, information similar to the features is obtained from the feature database by means of matching, a machining technique flow is formulated, and corresponding machining technique parameters are set; digital simulation analysis is performed on the machining process of the complex curved surface part to be machined; and mechanical arm milling machining is performed on the complex curved surface part to be machined through the actual machiningmodule. According to the system and method of the invention, a mechanical arm is utilized to directly perform milling machining on the complex curved surface part; a complete and universal complex curved surface milling matching technique flow and data link are established, and the efficient machining of the complex curved surface part can be realized.

Owner:KUNMING UNIV OF SCI & TECH

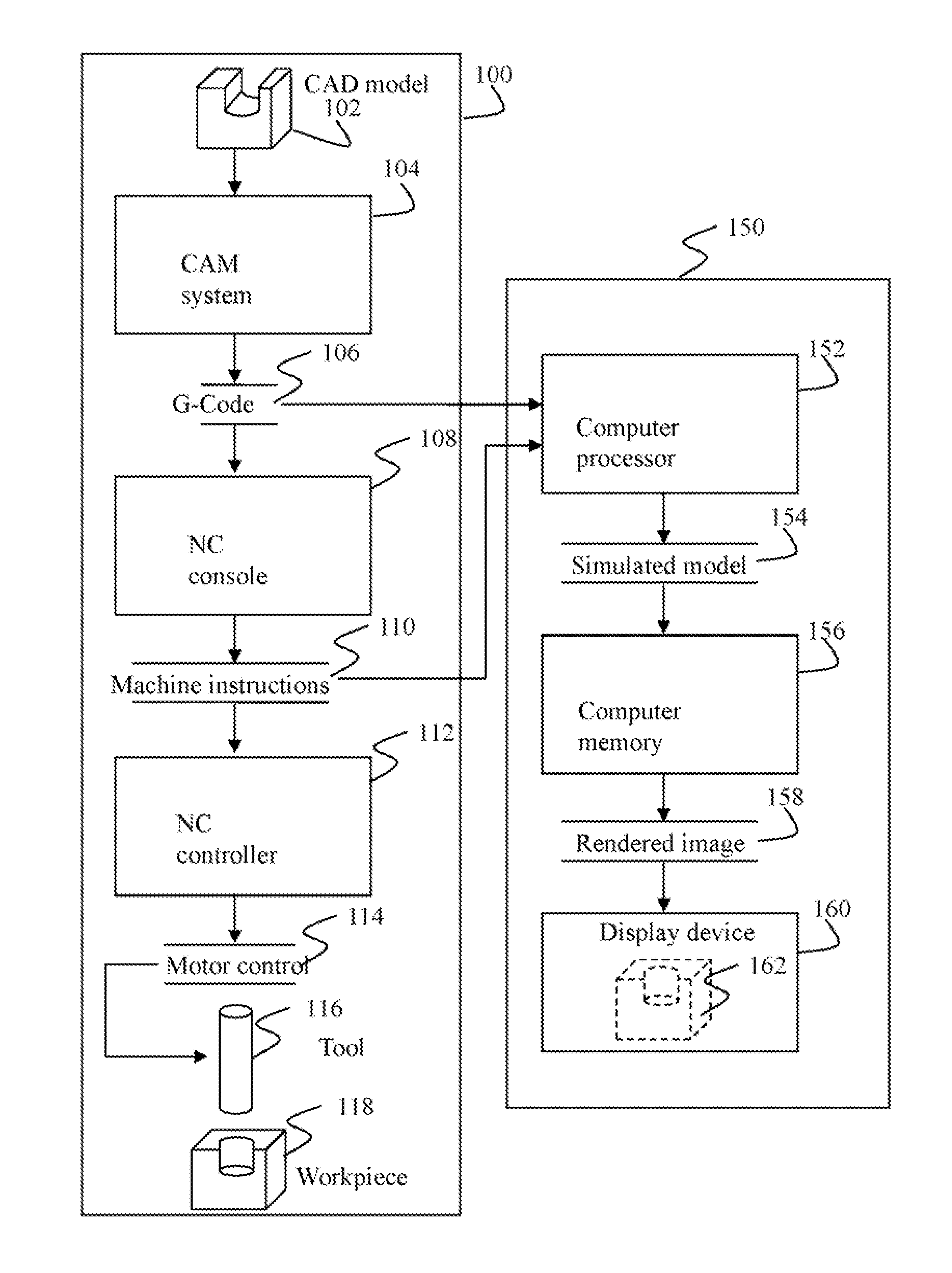

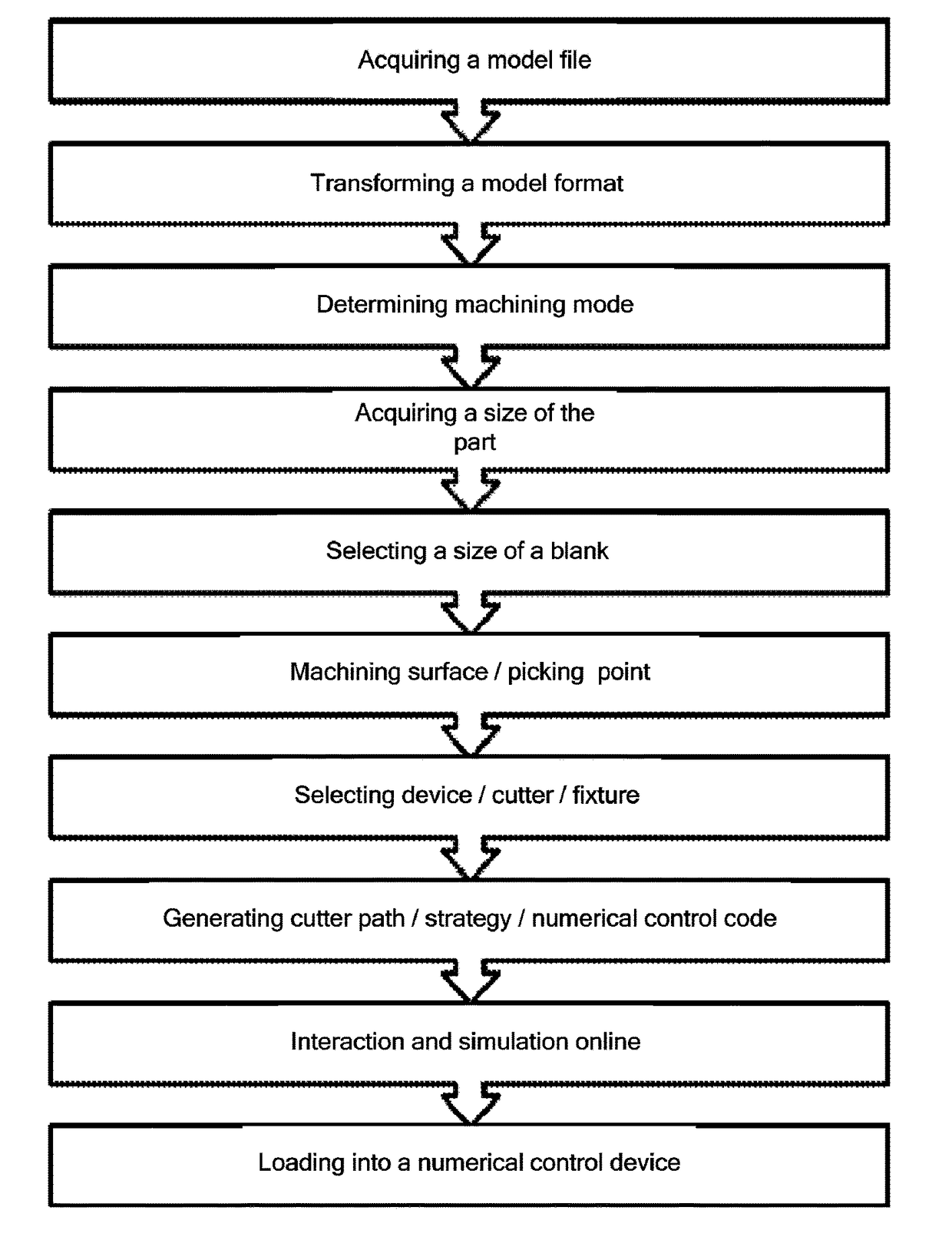

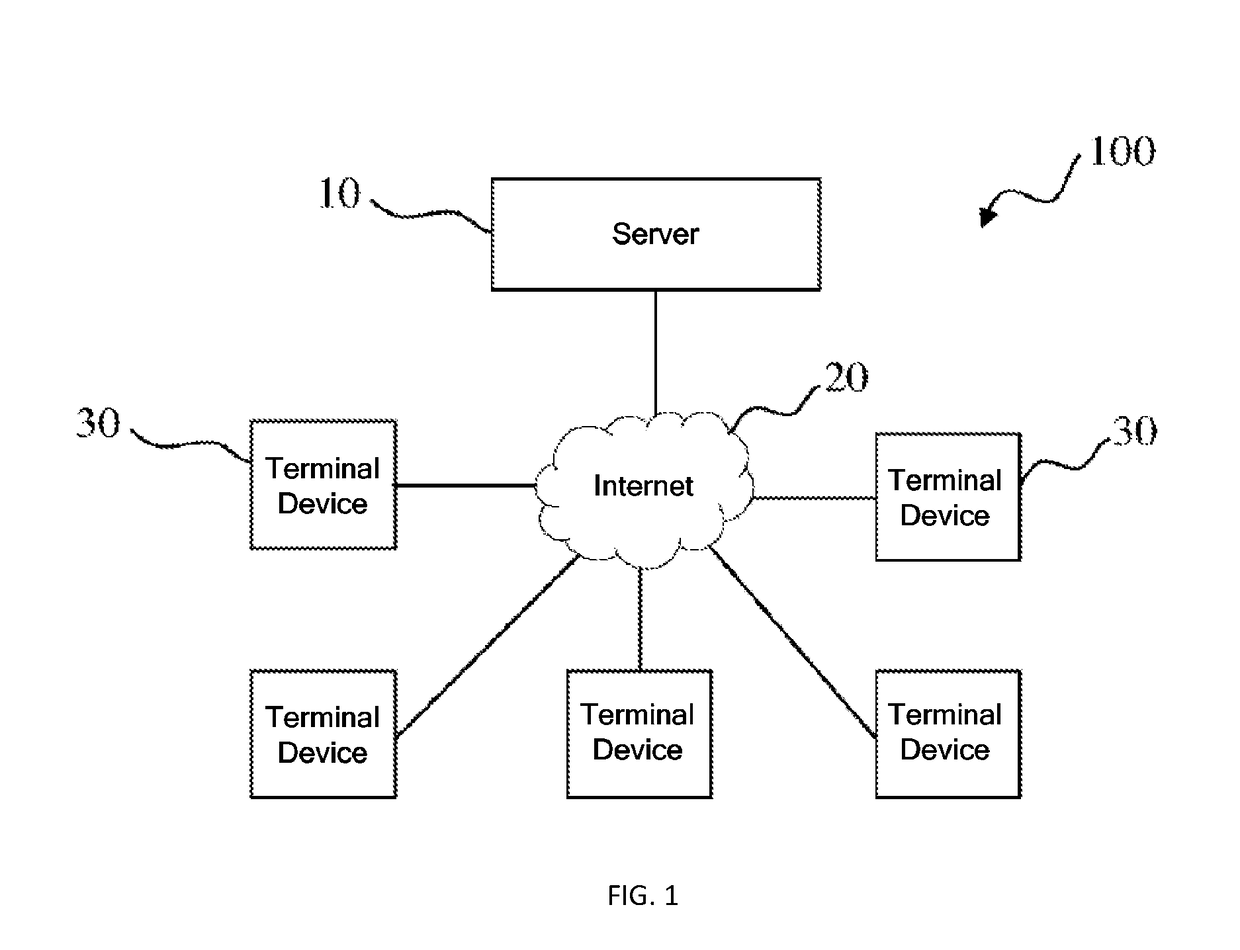

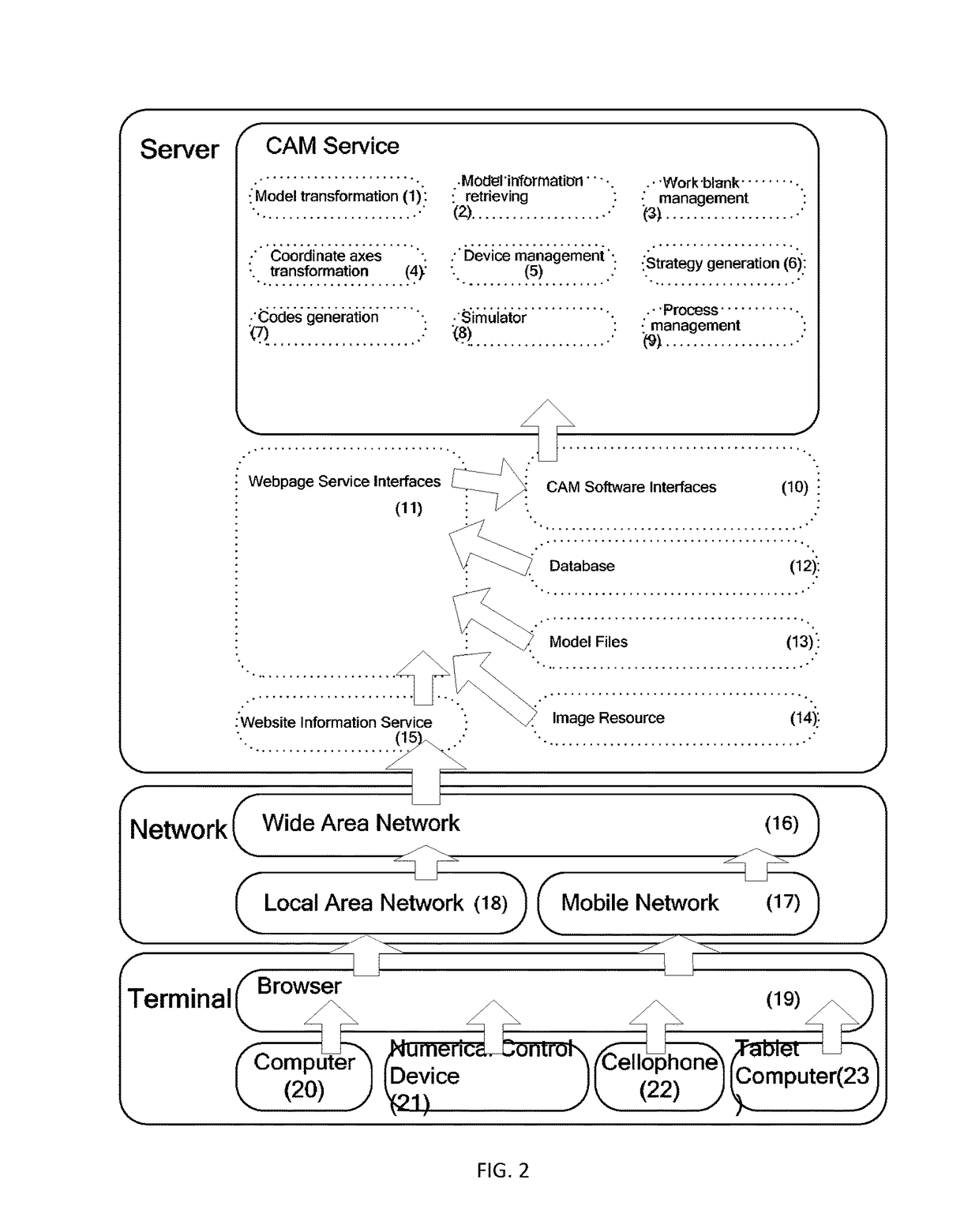

System and method for generating machining control data of numerical control machine tool

ActiveUS20170343983A1Reduce use 's software/hardware costLow costProgramme controlComputer controlNumerical controlMachine control

A system (100) and method for generating machining control data of a numerical control machine tool. The system (100) comprises a server (10) and at least one terminal device (30). The server (10) is installed with computer-aided manufacturing software, a numerical control machine tool model library and a cutter and fixture library. The terminal device (30) is connected to the server (10) through the Internet (20) to generate machining program data of a part model and / or to carry out machining simulation of a part model. The method for generating machining control data of a numerical control machine tool comprises: sending a part model file to the server (10) through the Internet (20); and generating program code that can be executed by the numerical control machine tool. The system (100) and the method have the beneficial technical effects of being convenient to operate, low in cost and flexible and easy to use and so on.

Owner:SHENYANG MACHINE TOOLGRP RES & DESIGN INST CO LTD SHANGHAI BRANCH

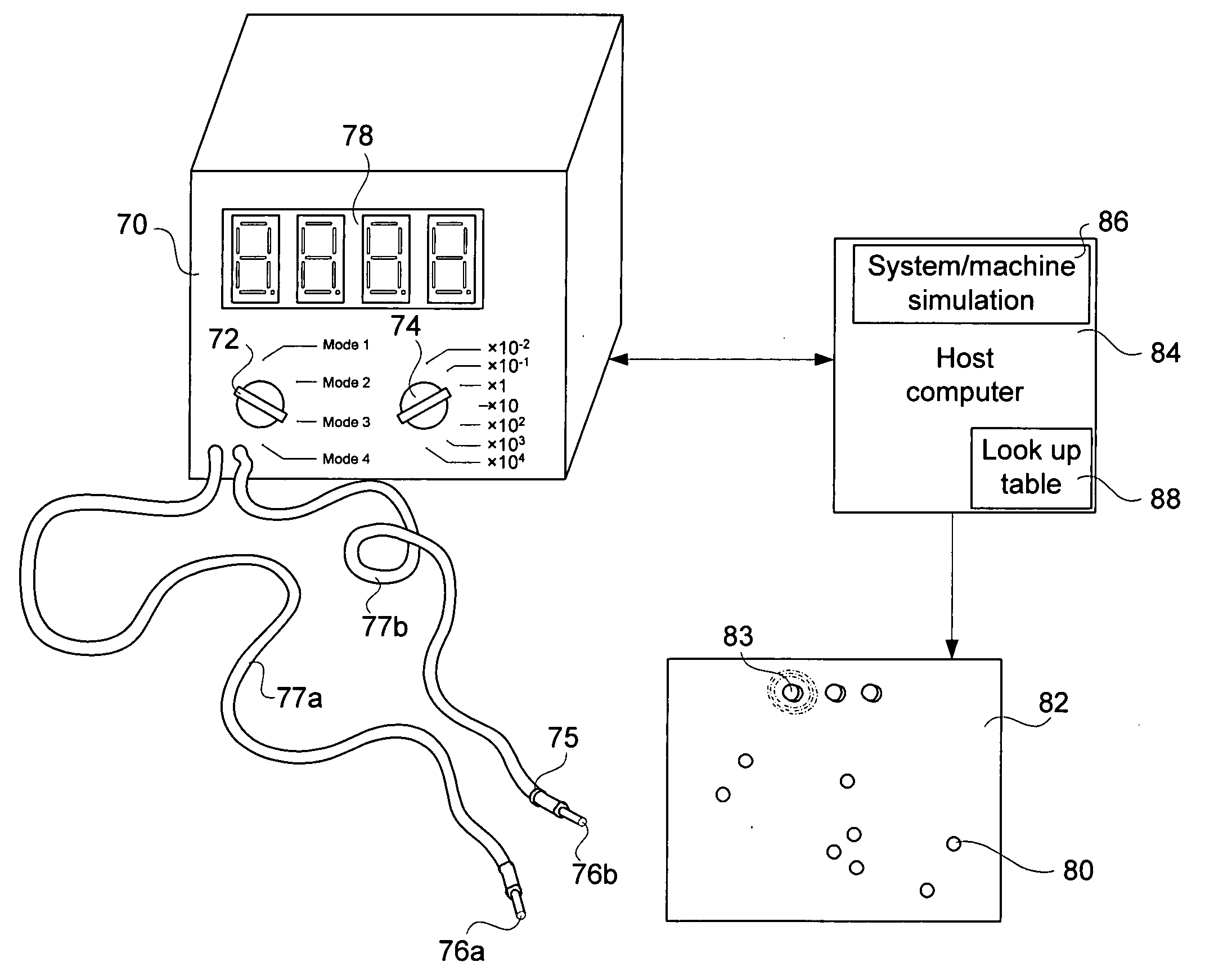

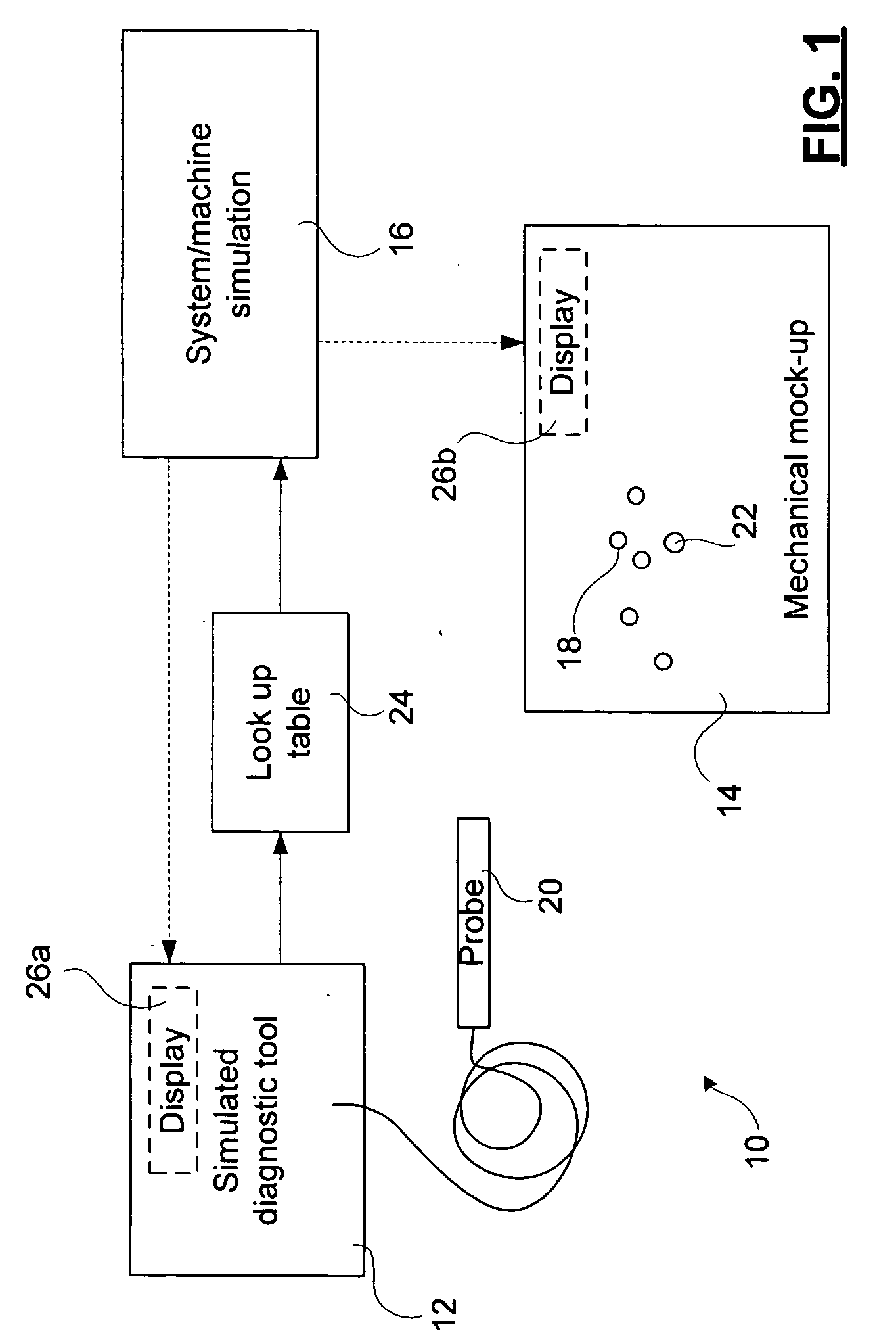

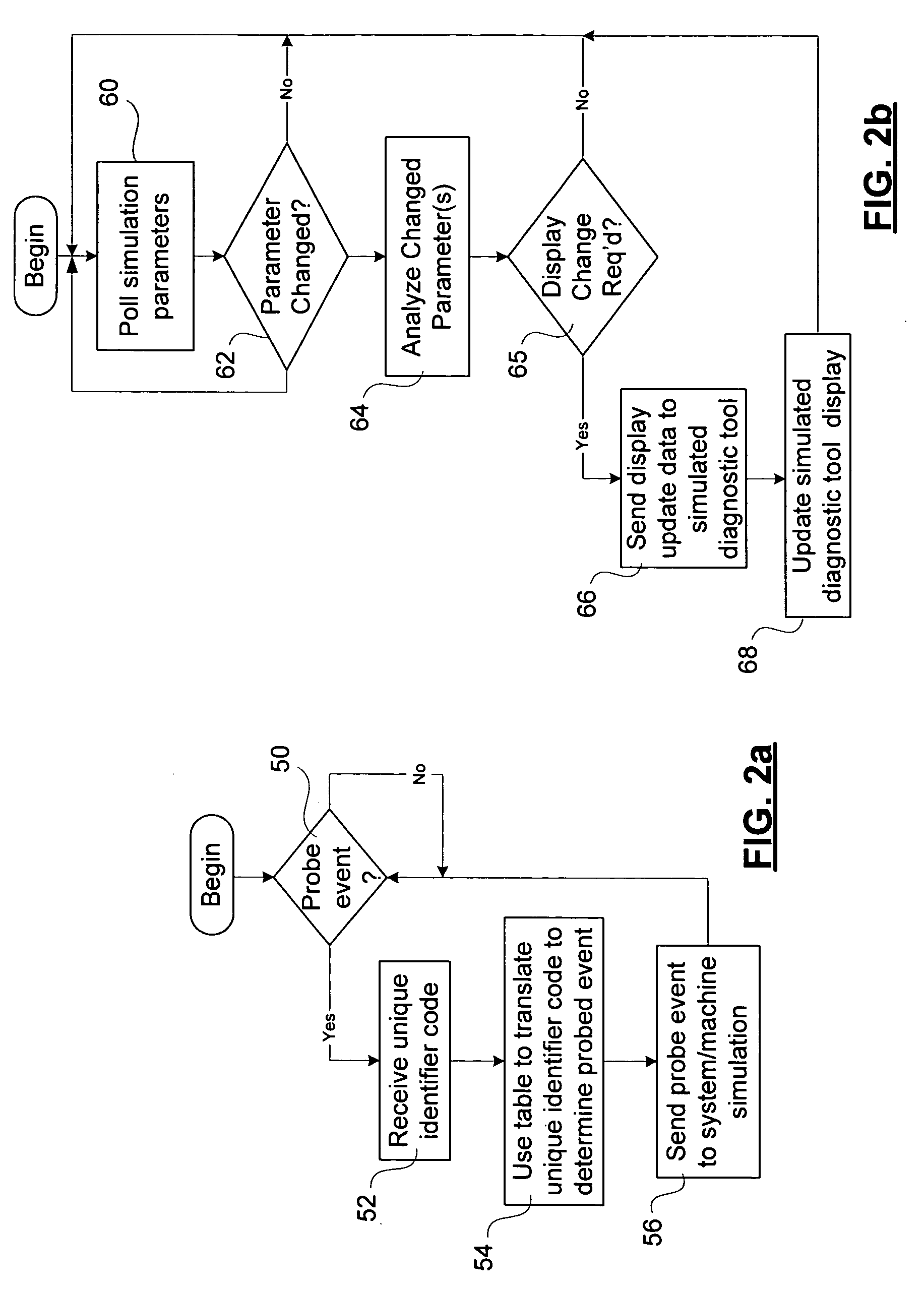

Training simulator and method of constructing same

InactiveUS20050084831A1Simple and inexpensive to constructEasy to reconfigureCosmonautic condition simulationsEducational modelsMock upsMechanical models

A training system uses a mechanical mock-up with electrically conductive probe points connected to electronically readable memories, and a simulated diagnostic tool to interface with a system or machine simulation for the purpose of operation, maintenance or procedure training. When a probe of a simulated diagnostic tool comes into contact with a probe point of the mechanical mock-up, the electronically readable memory supplies a unique identifier code that is communicated by the simulated diagnostic tool to the simulation to indicate the contact of the probe with the corresponding probe point. Complex wiring connections between the mechanical mock-up and a computer that runs the simulation are eliminated and construction of the training system is significantly simplified.

Owner:CAE INC

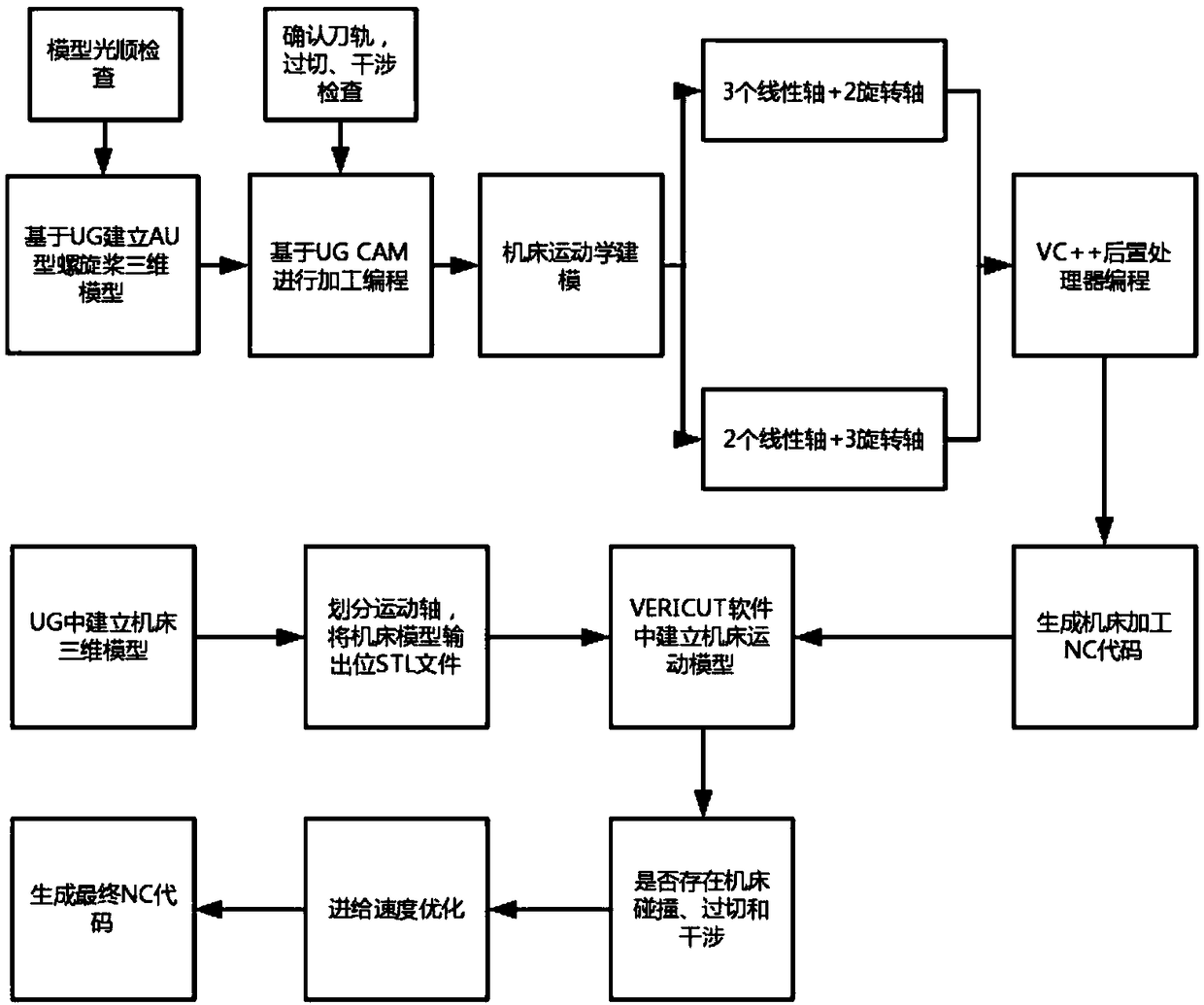

UG-based propeller overall numerical control machining method

InactiveCN108829037AImprove processing efficiencyReduce processing timeProgramme controlComputer controlNumerical controlPropeller

The invention discloses a UG-based propeller overall numerical control machining method. The method comprises the following steps: for various kinds of propellers, carrying out modeling in UG NX; carrying out editing through a UG CAM processing module to generate a machining tool path trajectory; translating the tool path trajectory generated by the UG CAM processing module into NC codes, which can be identified and used directly by a CNC machine tool, through a VC++ programming postprocessor; carrying out machine tool modeling through VERICUT software, and then, inputting the generated NC codes into the software for machining simulation verification to check whether the phenomenon of undercutting, overcutting and interference and the like exist; and finally, carrying out cutting speed optimization through an OptiPath module of the VERICUT software, so that the machining speed is optimized by adding speed codes to the original codes on the premise of not changing the NC machining codes.

Owner:BEIJING UNIV OF TECH

System and method for optimizing machining simulation

ActiveUS8483858B2Programme controlComputation using non-denominational number representationTheoretical computer scienceMachine simulation

Embodiments of the invention disclose a method for optimizing a simulation of a machining of a workpiece performed by removing a set of swept volumes from a volume of the workpiece, wherein the volume is partitioned into a set of cells, comprising the steps of: associating with each cell a subset of distance fields representing a subset of swept volumes intersecting with the cell, wherein at least part of the subset of swept volumes forms a composite surface of the cell; subjecting the cell with a set of rays incident to the cell from at least one direction; and selecting a distance field of the subset of distance fields into an optimal subset associated with the cell, wherein a boundary of the swept volume represented by the distance field intersects with at least one ray at a point of intersection lying on the composite surface.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Dust production simulation experiment device for heading machine cutting head and experiment method thereof

ActiveCN105699061AAdjustable and controllable speedRealize detectionMachine part testingCoal briquetteOrganic glass

The invention discloses a dust production simulation experiment device for a heading machine cutting head and an experiment method thereof. The device comprises: an organic glass cover, a heading machine simulation device mounting platform, a heading machine simulation device, a compressed air airduct, a ventilation air duct, a pushing rod, and a measuring meter; According to the method, combination of outer computer control and manual regulation is adopted; through adjusting parameters such as stress of coal briquettes or rocks to be cut, cutting angles, cutting positions, and rotation speed during cutting operation, and air-flowing field of the organic glass cover, the real condition of dust production by the heading machine cutting head in the process of coal mining is simulated. The device is simple in structure, reasonable in layout, and is easy to adjust; the dust production condition of the heading machine cutting head with different cutting angles, at different rotation speed, and under different coal bed conditions can be simulated; the method also has functions of timing record and synchronous data processing.

Owner:SHANDONG UNIV OF SCI & TECH

Machining simulation system

ActiveUS20080103741A1Reduce the numberReduce frequencyProgramme controlComputation using non-denominational number representationNumerical controlCommunication unit

A numerical control apparatus can perform a machining simulation or an interference check that reflects worksite information. However, a machining simulation apparatus cannot use worksite information in a machining simulation or an interference check. Thus, simulation conditions of the machining simulation apparatus are different from those of the numerical control apparatus. To solve this problem, a machining simulation apparatus and a numerical control apparatus according to the present invention can communicate with each other via a communication unit or a storage medium so as to mutually transmit and receive data. The machining simulation apparatus includes a network transmission / reception control unit or an external memory reading / writing unit. Similarly, the numerical control apparatus includes a network transmission / reception control unit or an external memory reading / writing unit.

Owner:OKUMA CORP

Track traffic safety shielding door simulation test system

ActiveCN104634554ATroubleshootImprove Simulation EfficiencyMachine part testingRailway componentsMonitoring systemMachine simulation

The invention discloses a track traffic safety shielding door simulation test system, which comprises a simulation shielding door structure platform and a simulation control system, wherein the simulation control system comprises a signal simulation system, a central control unit simulation system, a door control simulation system and a monitoring system, a door machine simulation system is arranged in the simulation shielding door structure platform, the signal simulation system, the door control simulation system and the monitoring system are respectively in signal connection with the central control unit simulation system, and in addition, the door control simulation system is provided with a plurality of door control unit simulation systems. The track traffic safety shielding door simulation test system has the advantages that under a design scheme of the whole conception, the simulated recurrence on the control, communication, mechanical design, engineering management and the like of a platform safety shielding door is respectively realized, in addition, for all simulation tests, except the safety shielding door structure part is simplified, the rest parts adopt components identical to those of the safety shielding door, the simulation efficiency and the simulation accuracy are improved, in addition, the problems generated in the installing process of the safety shielding door can be really simulated, and some difficult problems of engineering can be effectively solved.

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI +1

Numerical control elbow machining simulation method and device

ActiveCN103792885AReduce processingSimplify the modeling processProgramme controlComputer controlMachine simulationTube bending

The invention provides a numerical control elbow machining simulation method which comprises the steps of establishing a geometric model of a numerical control tube bending machine; establishing a mechanical model of the numerical control tube bending machine according to the geometric model, wherein the mechanical model is a mathematical equation including the motion feature information of the numerical control tube bending machine; establishing an allocation model including the performance parameter information of the numerical control tube bending machine; establishing a mechanism kinematics model including the positions and postures of the numerical control tube bending machine according to the mechanical model and the allocation model; solving the mechanism kinematics model to determine the positions and the postures of the numerical control tube bending machine in a machining process; simulating a numerical control tube bending machining process according to the positions and the postures of the numerical control tube bending machine in the machining process and the data control information of elbows to be machined. According to the technical scheme, the modeling process is simple, the generality of motion laws and characteristics of the performance parameters of the numerical control tube bending machine can be described, and thus high generality is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com