Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve cutting conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

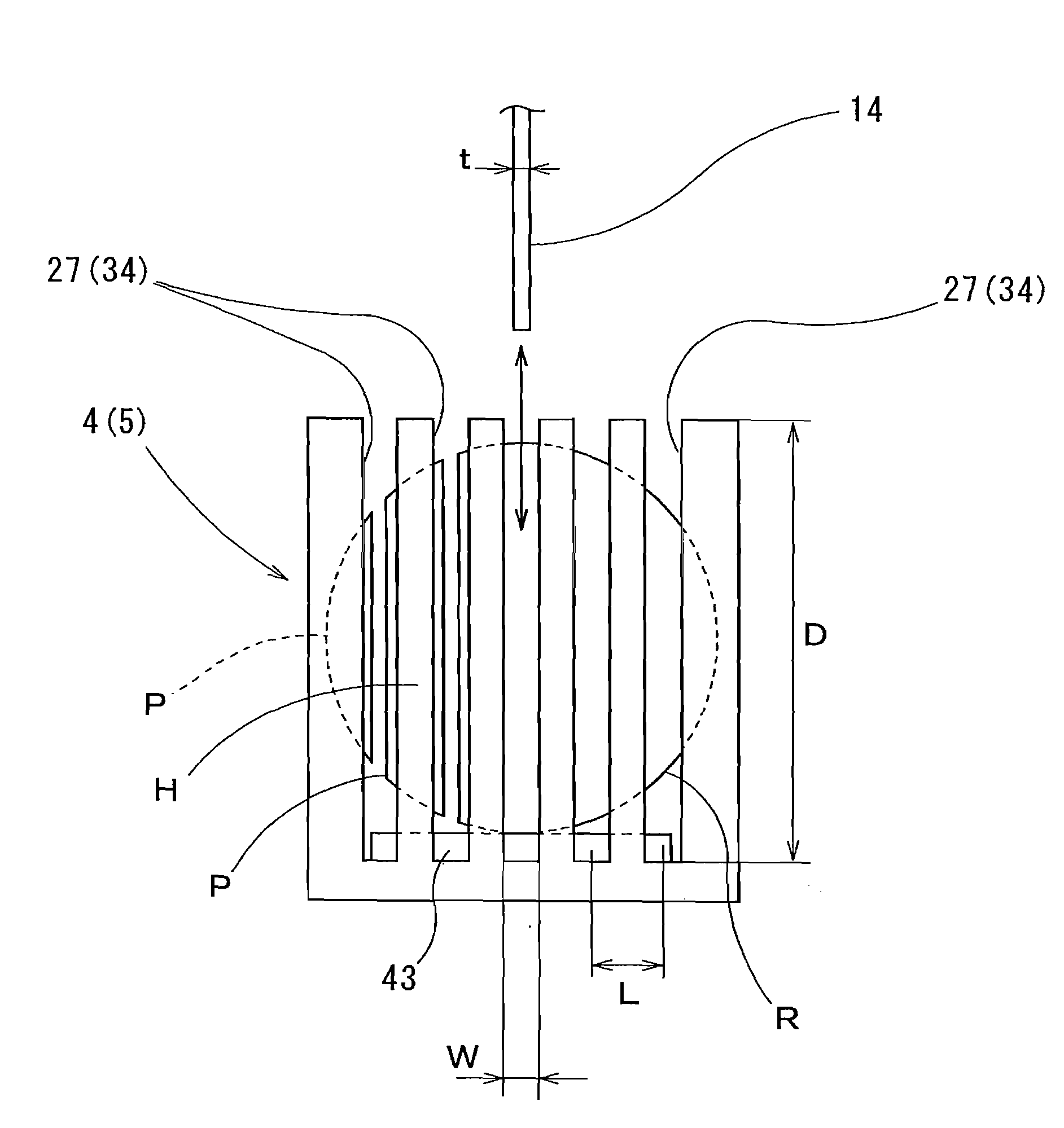

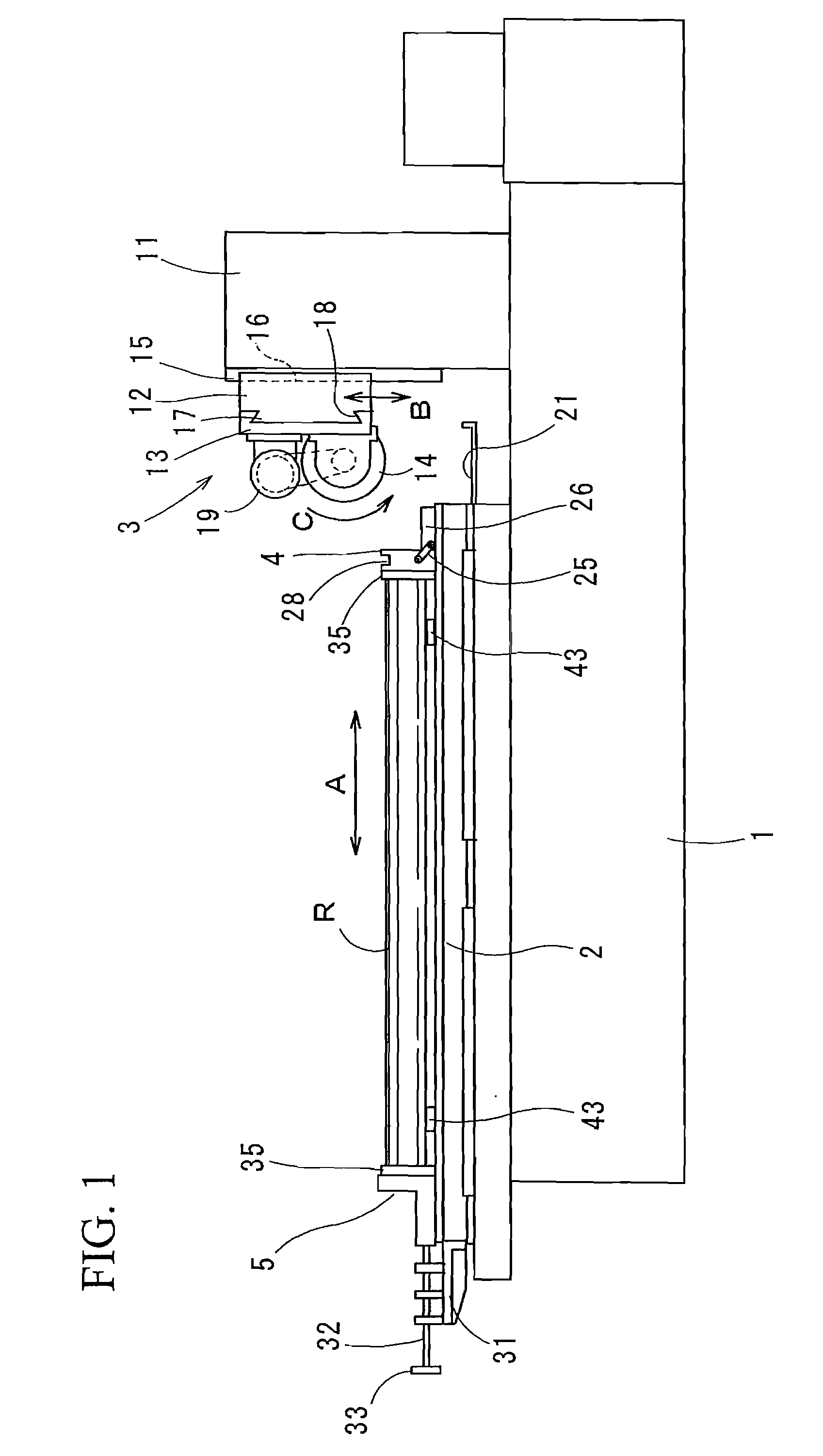

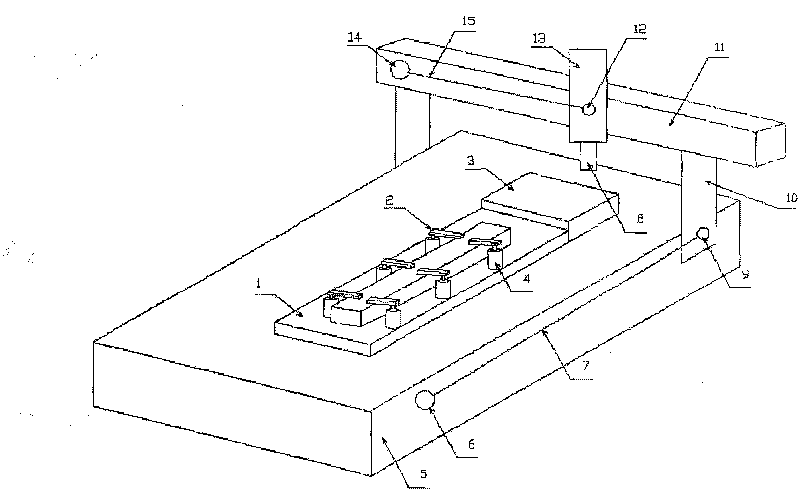

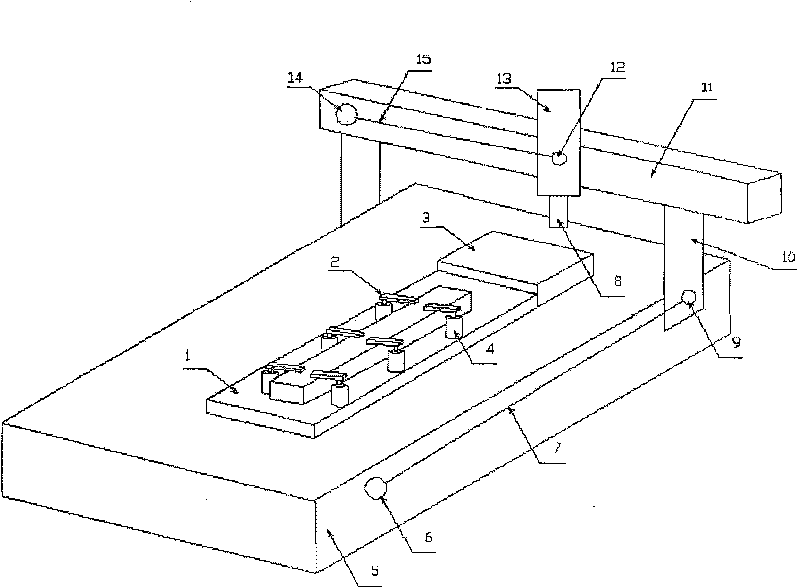

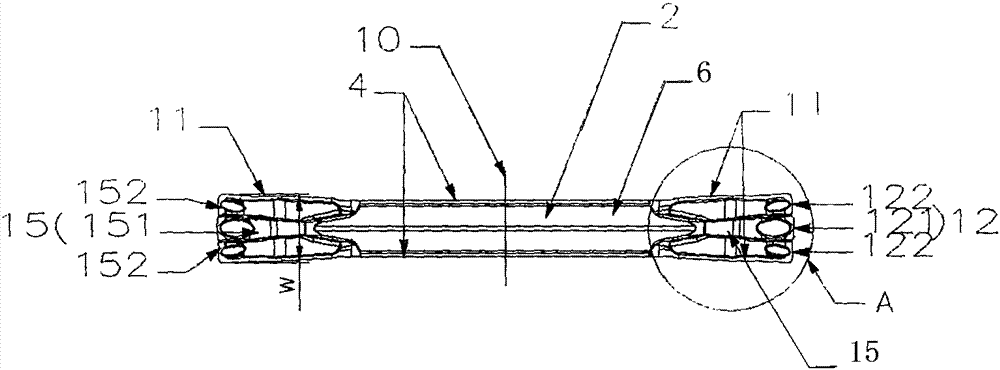

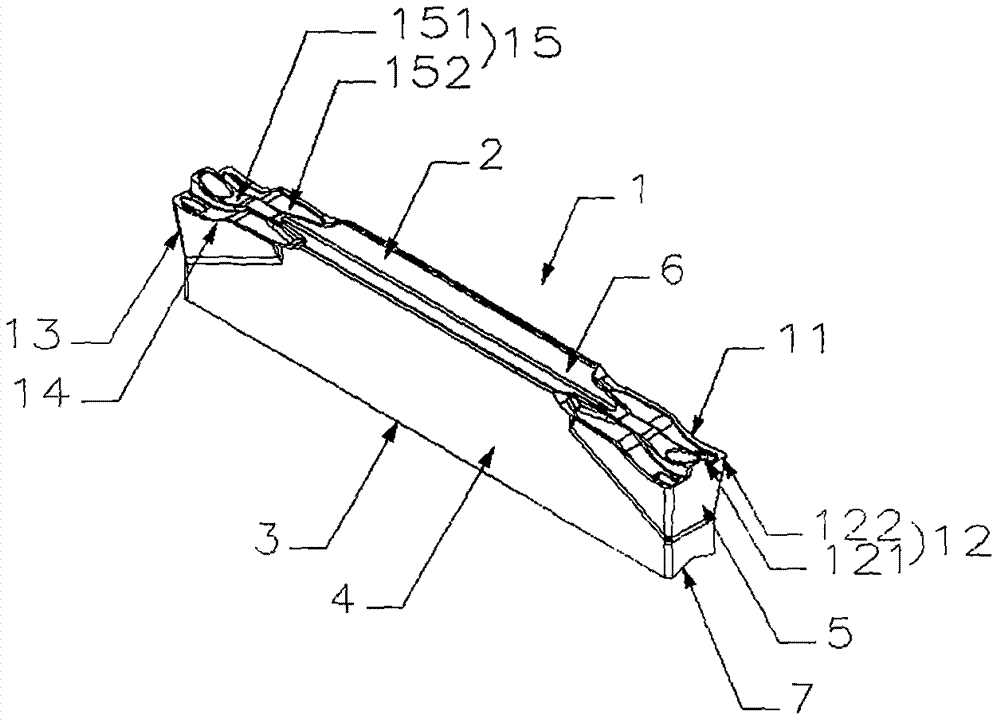

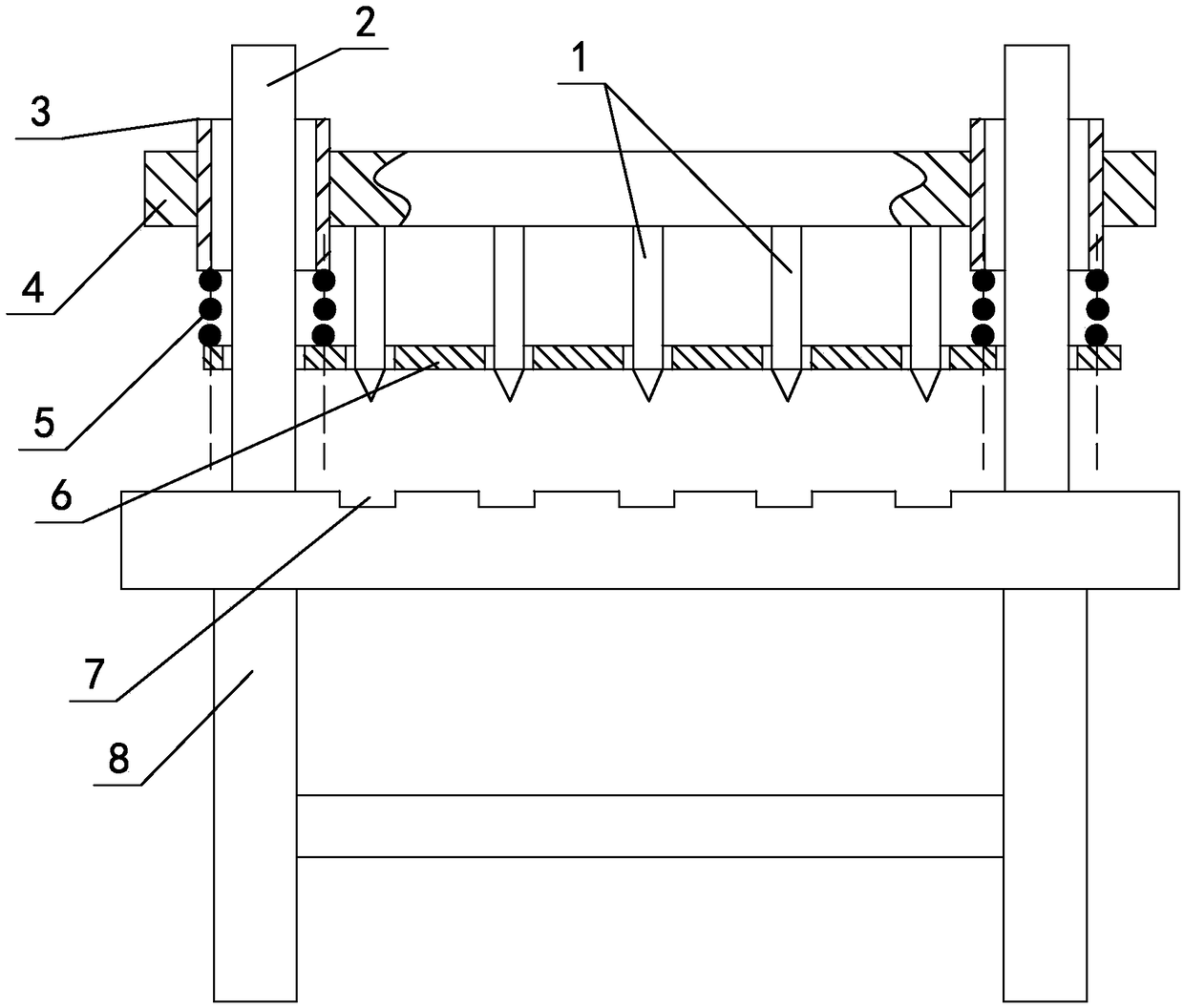

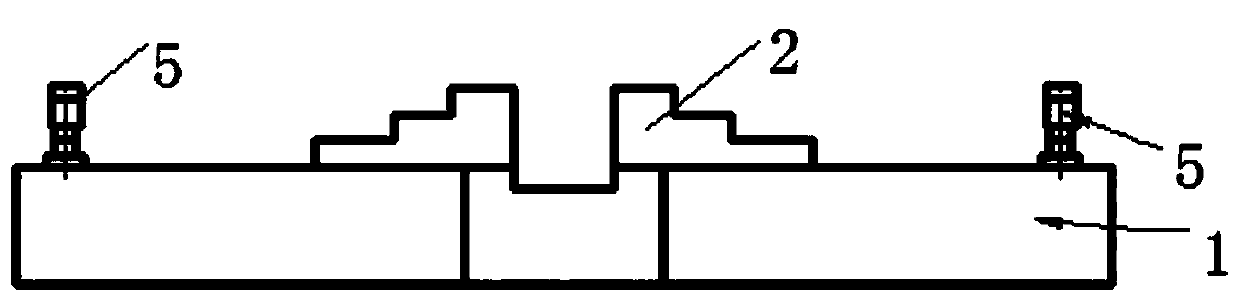

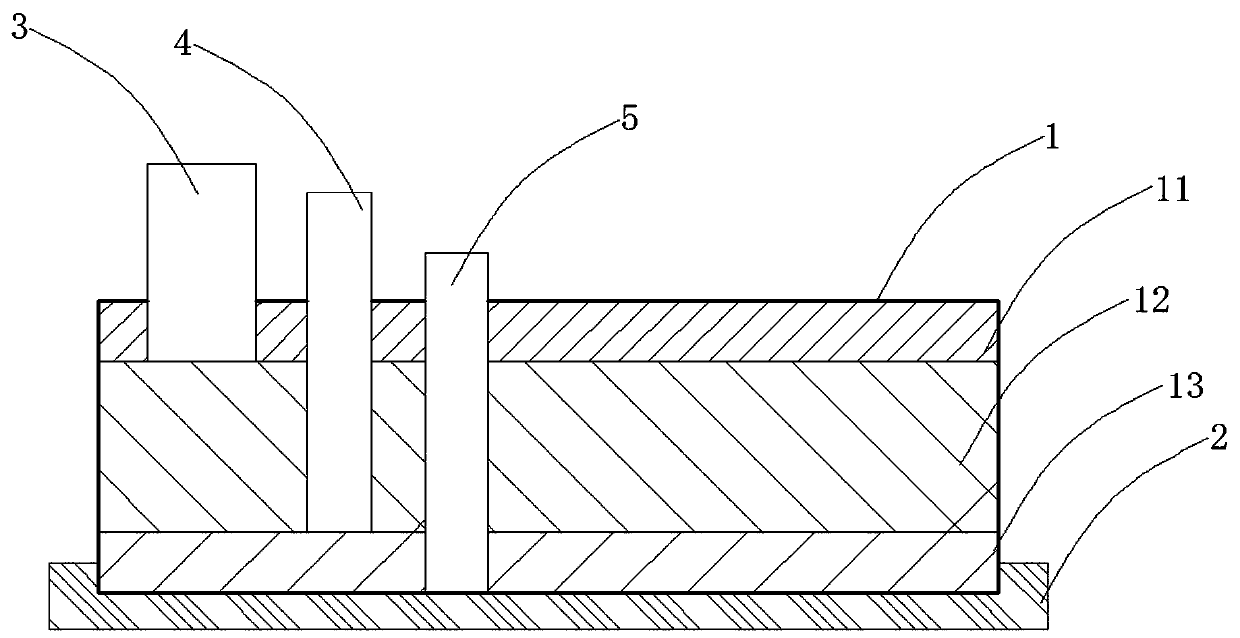

Apparatus for manufacturing seeds for polycrystalline silicon manufacture

ActiveUS20100077897A1Reduce manufacturing costAvoid bendingEdge grinding machinesRevolution surface grinding machinesKnife bladesPolycrystalline silicon

An apparatus for manufacturing seeds for polycrystalline silicon manufacture by cutting a silicon rod in an axial direction into at least one plate-like member, and cutting at least one of the silicon plate-like member lengthwise into seeds that are square in cross section, that includes a table which mounts the silicon rod or at least one of the plate-like member, a pair of end-face supporting members which support the silicon rod or at least one of the plate-like member by pressing both end faces thereof in the axial direction, and a cutting blade which cuts the silicon rod or at least one of the plate-like member in the axial direction, in addition the end-face supporting members includes comb-like grooves that allow the cutting blade to pass through.

Owner:HIGH-PURITY SILICON CORP +1

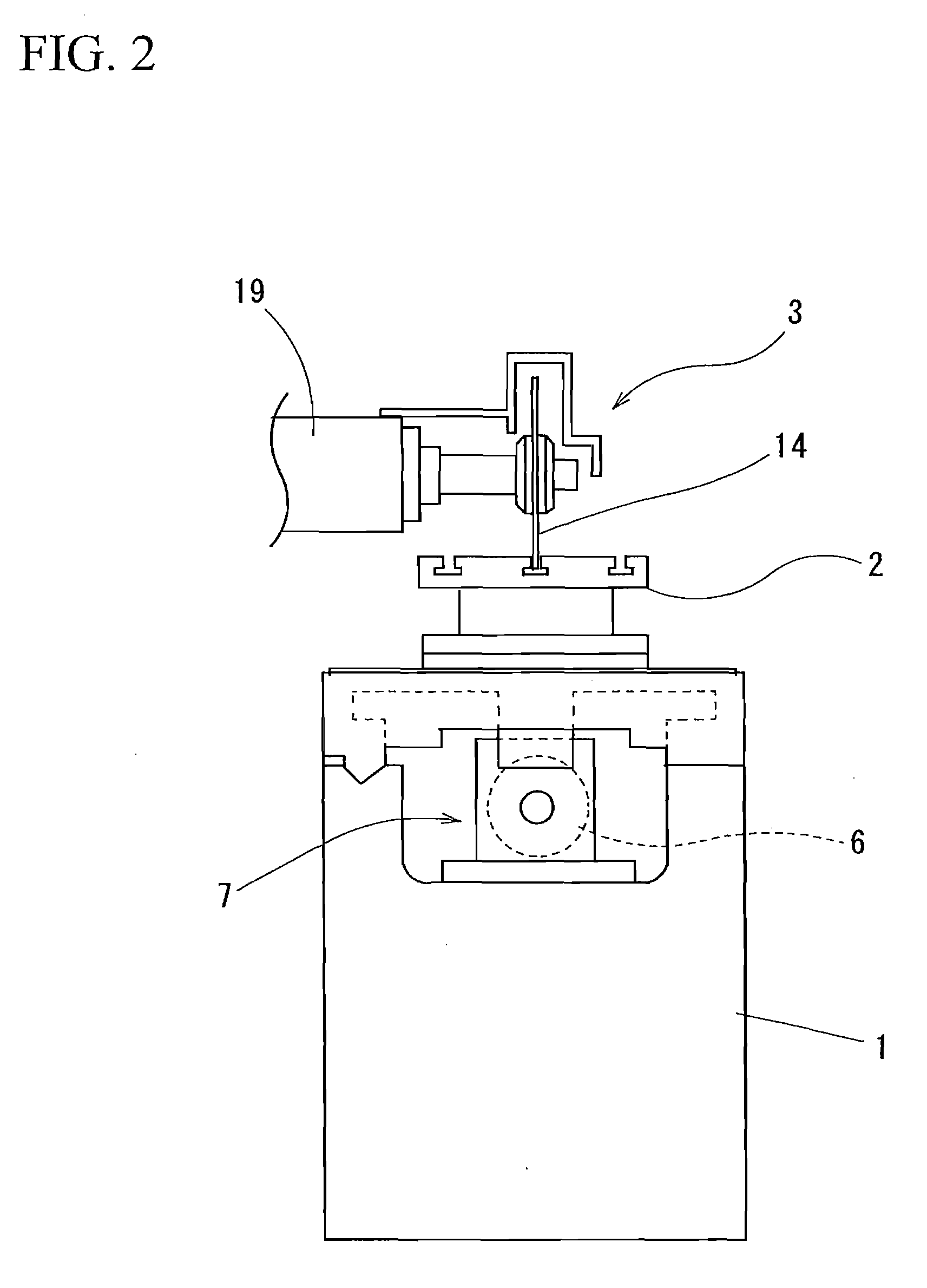

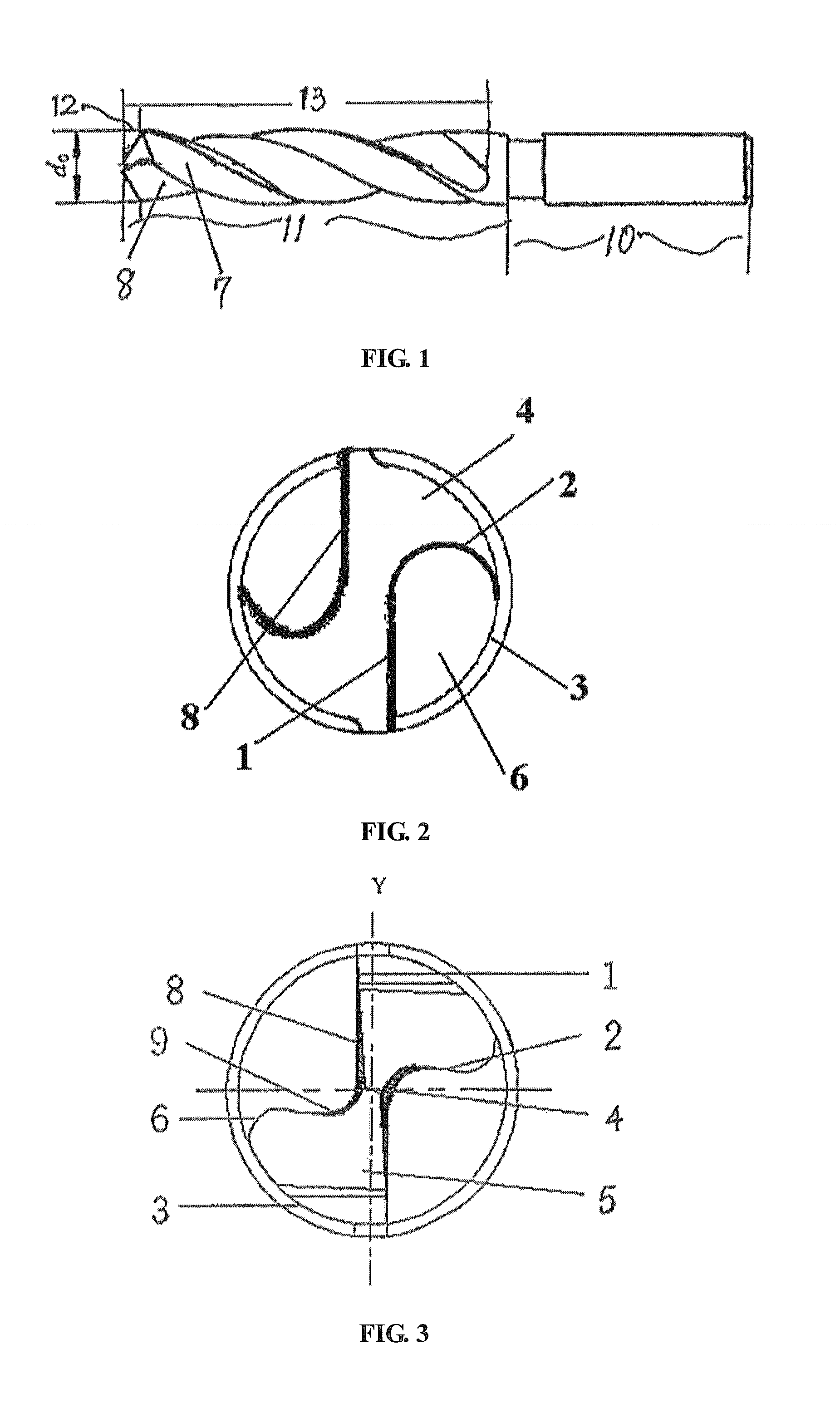

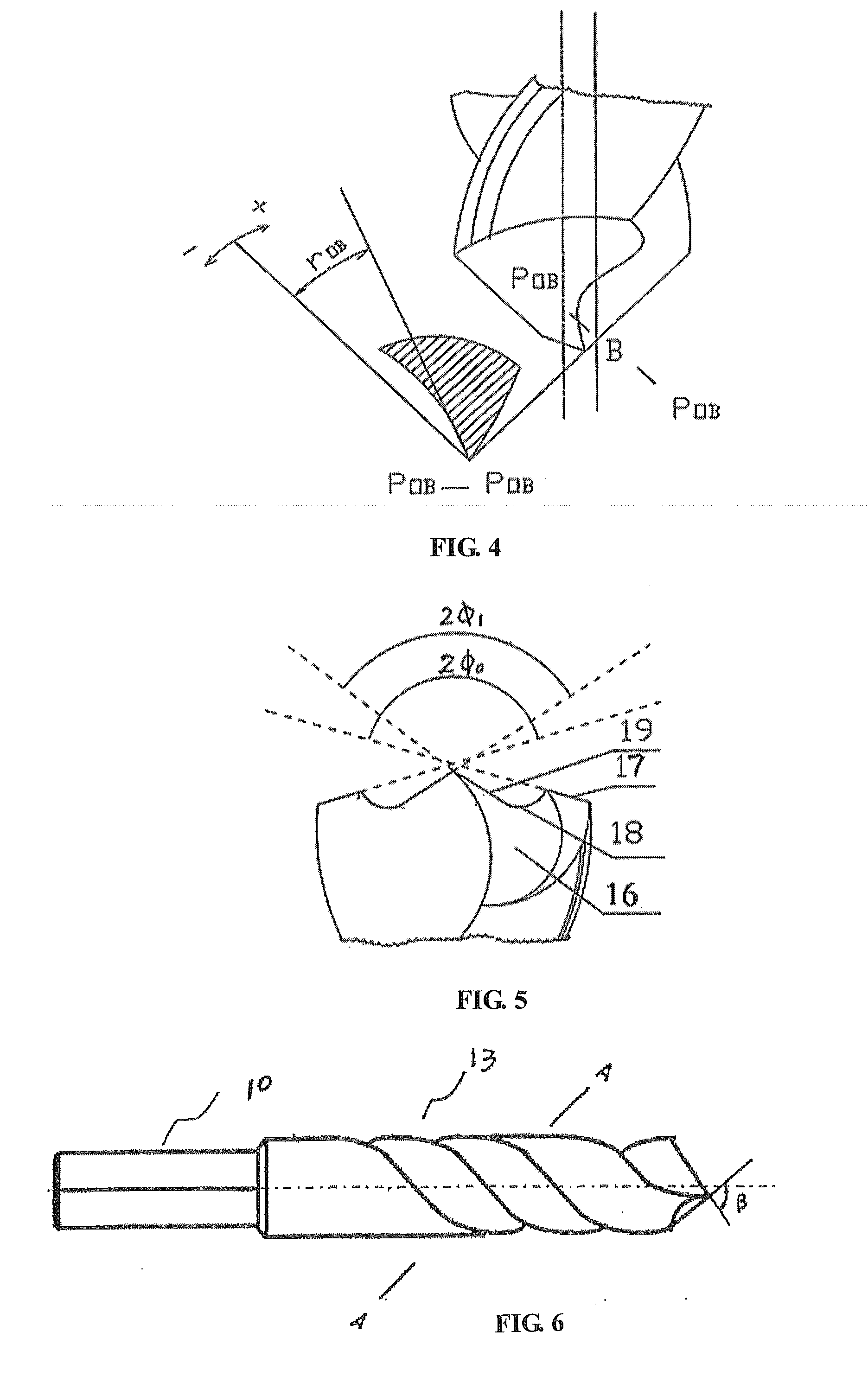

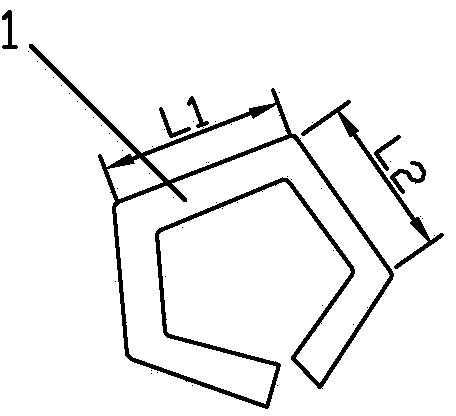

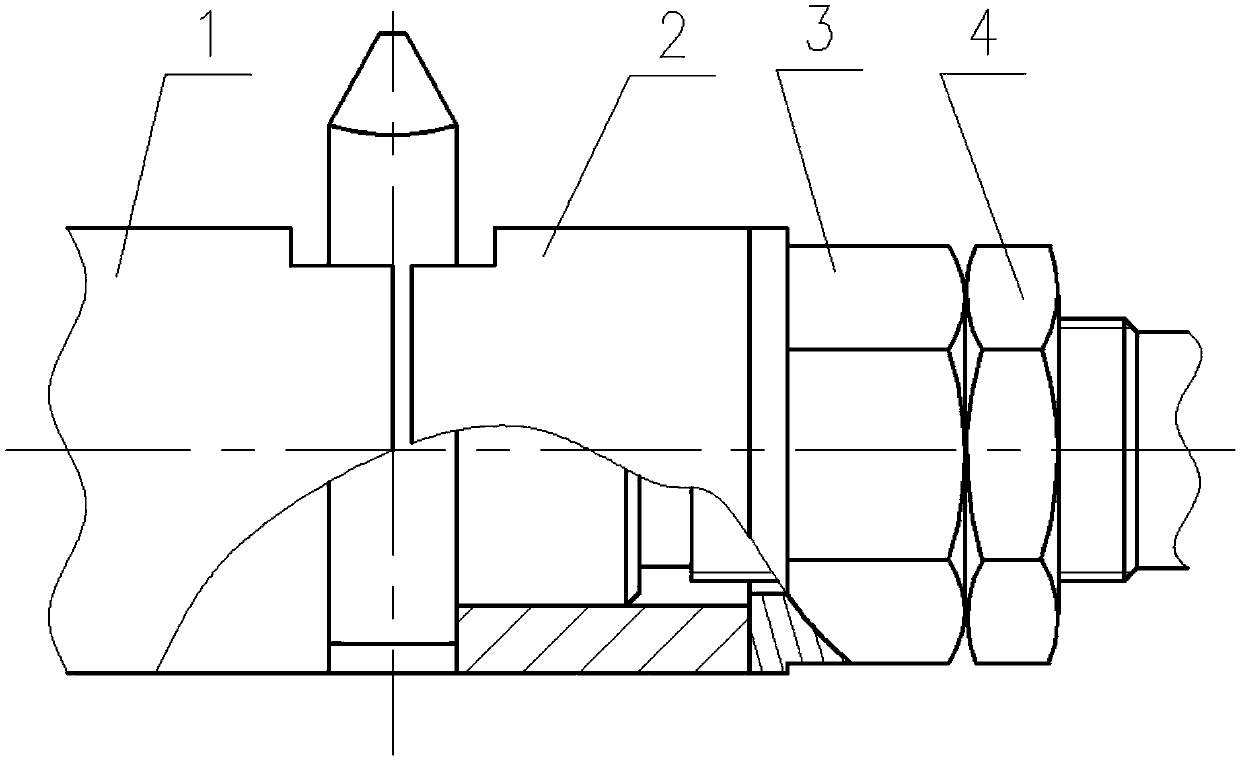

Strong high performance twist drill

InactiveUS20090317202A1Increasing drill strength against twistingIncreasing the thicknessWood turning toolsTransportation and packagingFluteChisel

A strong high performance twist drill which aims at providing a high performance twist drill to solve the existing problems effectively. The twist drill can reduce the change in value of the rake angle, increase the value of the rake angle especially at the position approaching the drill core, and improve the cutting condition. The twist drill comprises a shank and a working part. Said working part comprises a cutting part and a guiding part. Said cutting part includes a rake face, a relief face, a main cutting edge and a chisel edge; said guiding part includes rear groove edges and flutes; wherein, said main cutting edge tilts towards the drill core from outside to inside; the angle between the main cutting edge and the center vertical line at the cross section is in the range of 3-25°; said main cutting edge intersects with back groove face at the narrow chisel edge; the length of the narrow chisel edge is in the range of 0.03-0.5 mm; and the rake angle at the drill core is positive.

Owner:JIANGSU TIANGONG TOOLS CO LTD

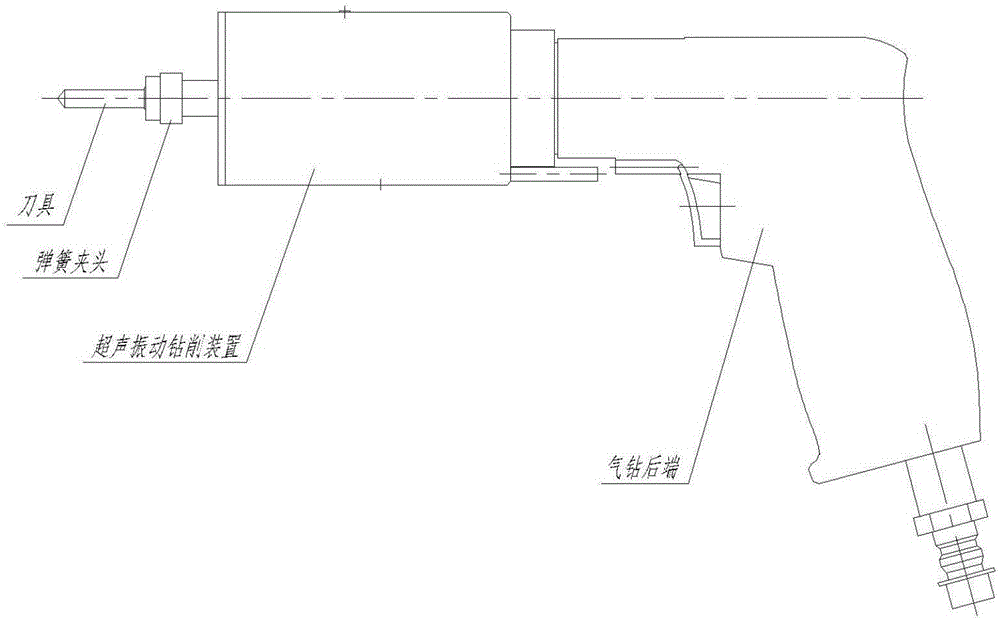

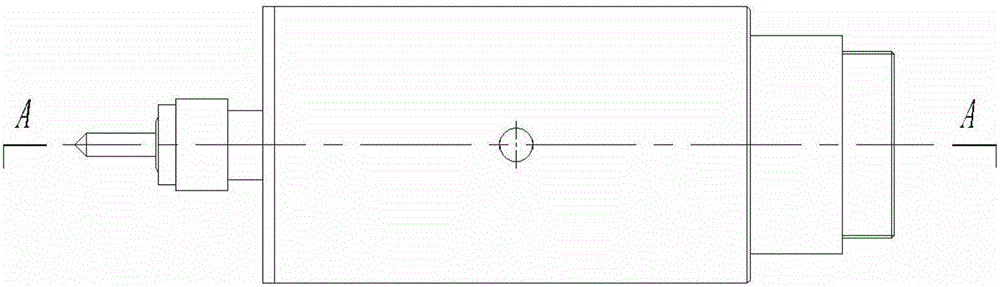

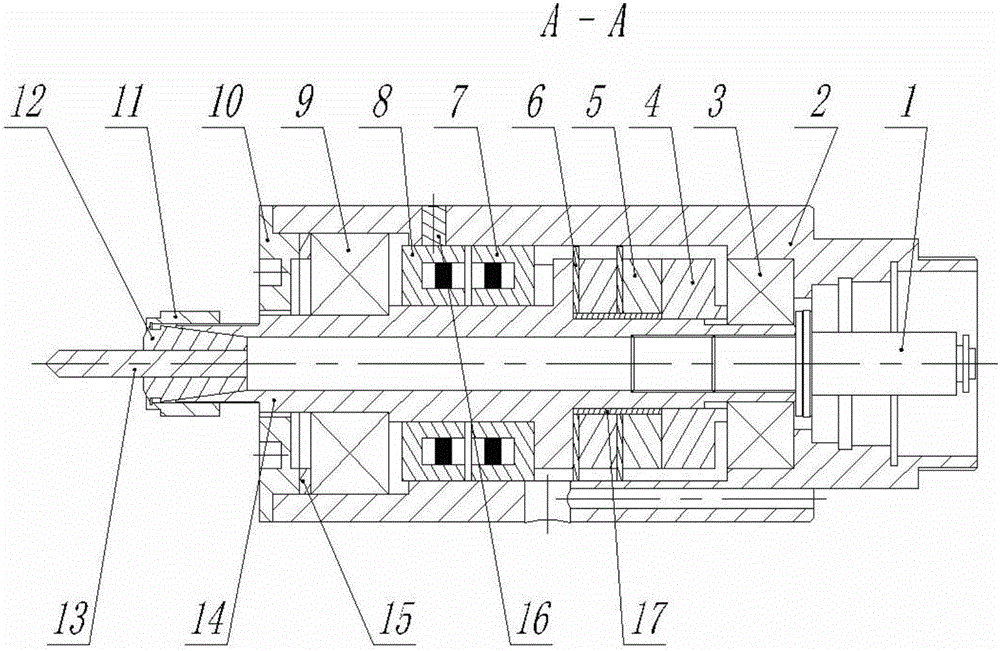

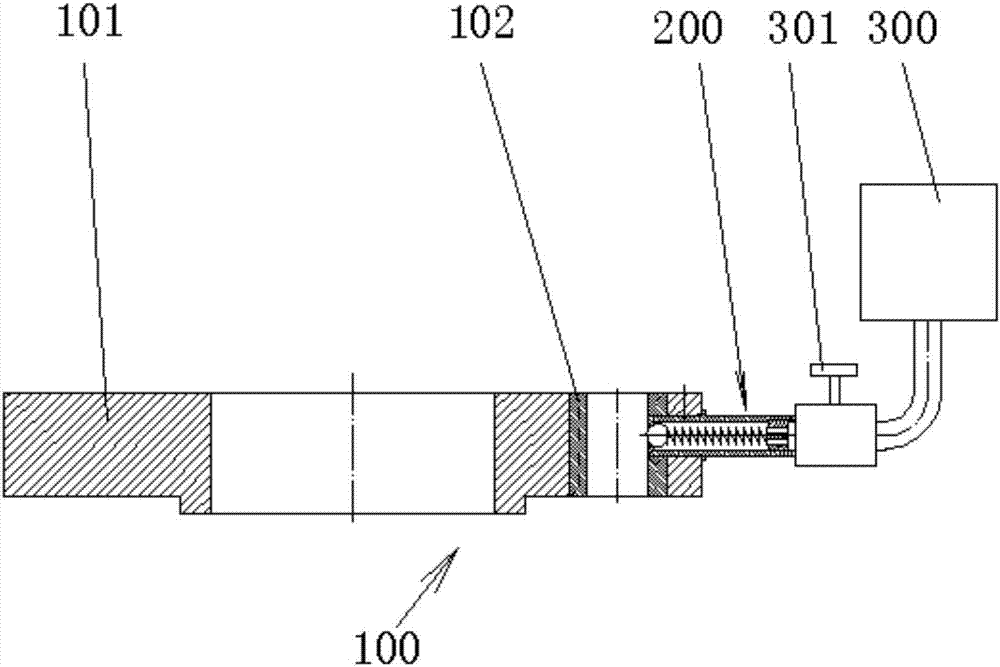

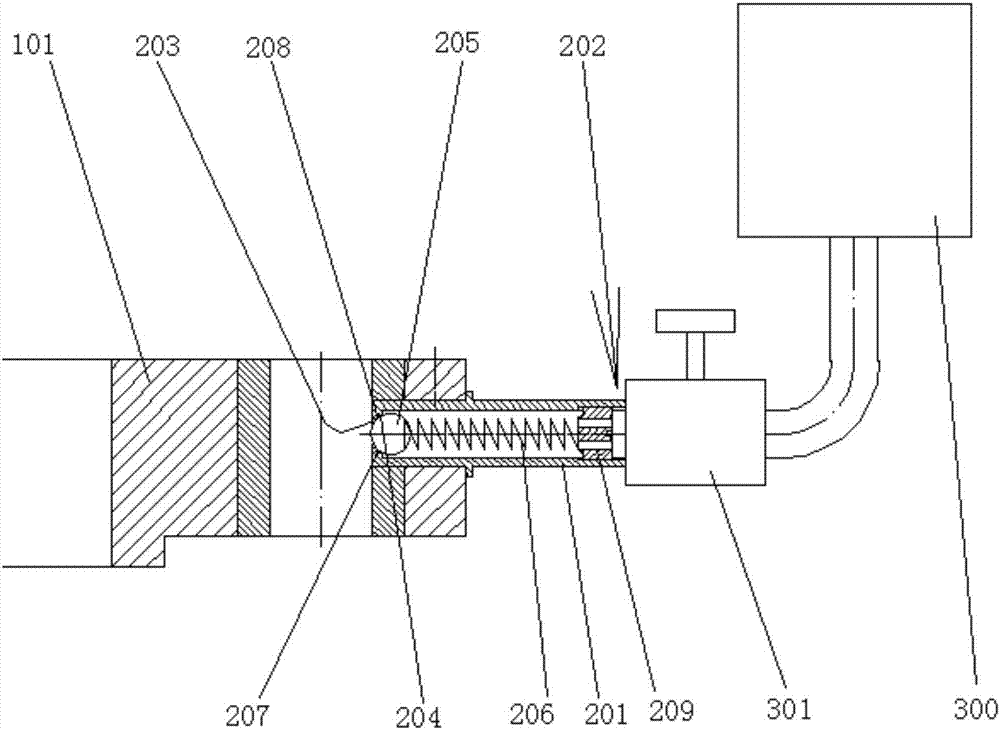

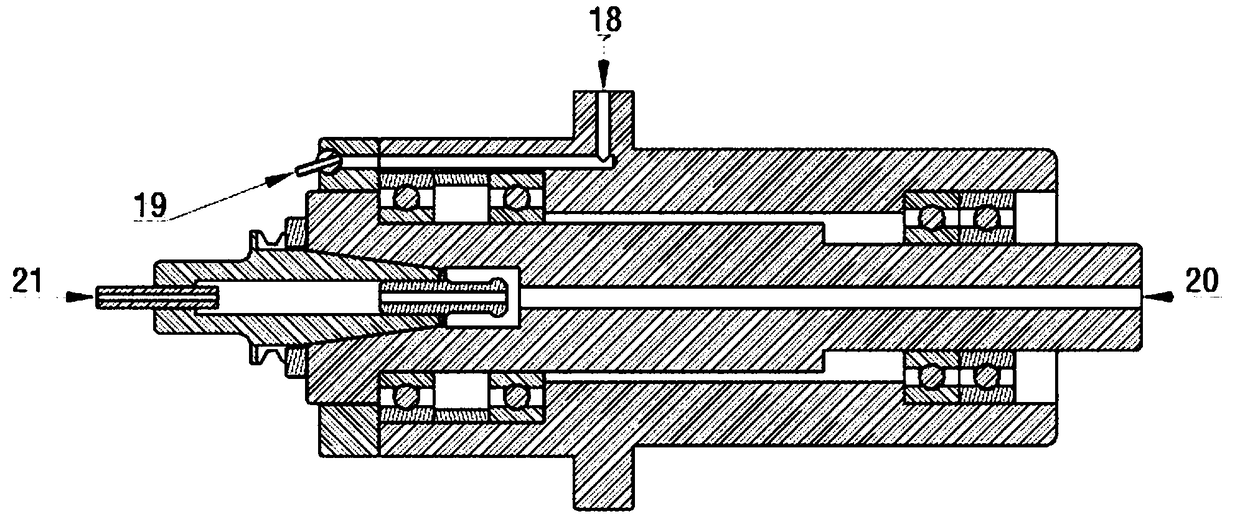

Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

InactiveCN106825679AKeep it workingImprove processing qualityCircuit arrangementsPortable drilling machinesElectric power transmissionSmall amplitude

The invention discloses an ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission. The ultrasonic vibration pneumatic drill comprises a rotary wireless electric power transmission assembly, an ultrasonic transduction assembly, an amplitude-change pole, a spring chuck assembly and a connecting assembly, wherein the rotary wireless electric power transmission assembly is used for realizing electric power transmission between two mechanisms rotating oppositely and comprises a wireless electric power transmission primary unit and a wireless electric power transmission secondary unit; the ultrasonic transduction assembly is used for converting ultrasonic-frequency electric signals into ultrasonic-frequency mechanical vibration; the ultrasonic vibration amplitude-change pole is used for amplifying small-amplitude mechanical vibration into large-amplitude mechanical vibration to meet requirements of ultrasonic vibration drilling machining; the spring chuck assembly is used for clamping tools; the connecting assembly is used for connecting ultrasonic vibration drilling parts with the rear end of the pneumatic drill so as to realize power transfer and electric power transmission. Ultrasonic vibration is applied to the traditional drilling machining process, and a combined machining mode of coupling of ultrasonic vibration and traditional drilling motion is formed, so that machining quality is effectively improved and machining efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Technique for preparing machine holding carbide alloy rack type gear shaper cutter

The invention relates to a manufacturing process of a machine-clamped hard alloy rack type cutter; the blade of the cutter chooses YT798 and is pre-punched out a positioning wire hole by an electro discharge drilling machine; a grinder is used for grinding the thickness and the width of two sides of the blade to satisfy the thickness size and the roughness required by the design, and then a wire electro-discharge machining is used for cutting the shape of the blade and a positioning hole used for assembling; AlTiN is coated on the blade evenly; a special fixture is used for finish milling the shape of a blade groove, at last an assembly positioning hole is bored in a coordinated borer. The knife body chooses 42CrMo, and the special fixture is used for milling the knife body shape of the rack type cutter, including clamping sizes and front angles; the hardening and tempering process and the nitrogen treatment are carried out to reach HB265-305, and the special fixture is used for crude grinding and fine grinding the clamping position surfaces and the planes of the front angles of the knife body; a special clamping fixture is used for cutting the tooth shape of the knife body on the wire electro-discharge machining; the tooth shape and back angles are clamped and cut once time. The machine-clamped hard alloy rack type cutter can be formed by finishing and grinding the blade groove through once assembly by template fitters; the manufacturing process of the machine-clamped hard alloy rack type cutter can be applied to the processing of gears with large module and high hardness.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Hard alloy precision working rack type cutter and processing technique

InactiveCN101134255AHigh cutting hardnessMeet the process requirementsGear teeth manufacturing toolsGear teethAlloyHardness

The present invention is one kind of hard alloy combing cutter for finish machining and its machining process. The hard alloy combing cutter has one cutting blade made of YT798 hard alloy plate and one cutter body of 40Cr steel. It is machined through semi finishing of cutting blade, milling the cutter body in a universal milling machine to form the front edge and tooth form and boring the locating hole for the blade in a high accuracy jig boring machine, assembling the blade locating board onto the cutter body while controlling the tooth pitch and tooth thickness of the cutting edge, high frequency welding the cutting blade to the cutter body and timely tempering, grinding the front edge of the cutting edge in a cutter grinding machine, and wire electrode cutting the tooth form in high precision wire electrode cutting equipment. The hard alloy combing cutter has high cutting hardness and high wear resistance, and may be applied for finish machining great modulus gear with medium hardness tooth surface.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Roller bit parallel inlayed compacts

This invention relates to a roller bit applying for the oil, natural gas, mine and geological drilling, and more particularly relates to a kind of roller bit with the parallel inlayed compacts, it includes head and cone, the compact land and the teeth-groove are arranged on the cone, the difference is that there are 2 to 3 compacts having the cylindrical body being arranged on the top of the base teeth along the teeth direction.The cutting performance of the present invention is similar to that of the oblate compacts, and, by utilizing the conventional cylindrical compacts, it is not only easy to process and with low manufacturing cost, but the bit can effectively drill through the stringered earth formation with both hard and soft formation and thus better economic benefit from drilling the stringered formation can be obtained.

Owner:KINGDREAM PLC CO

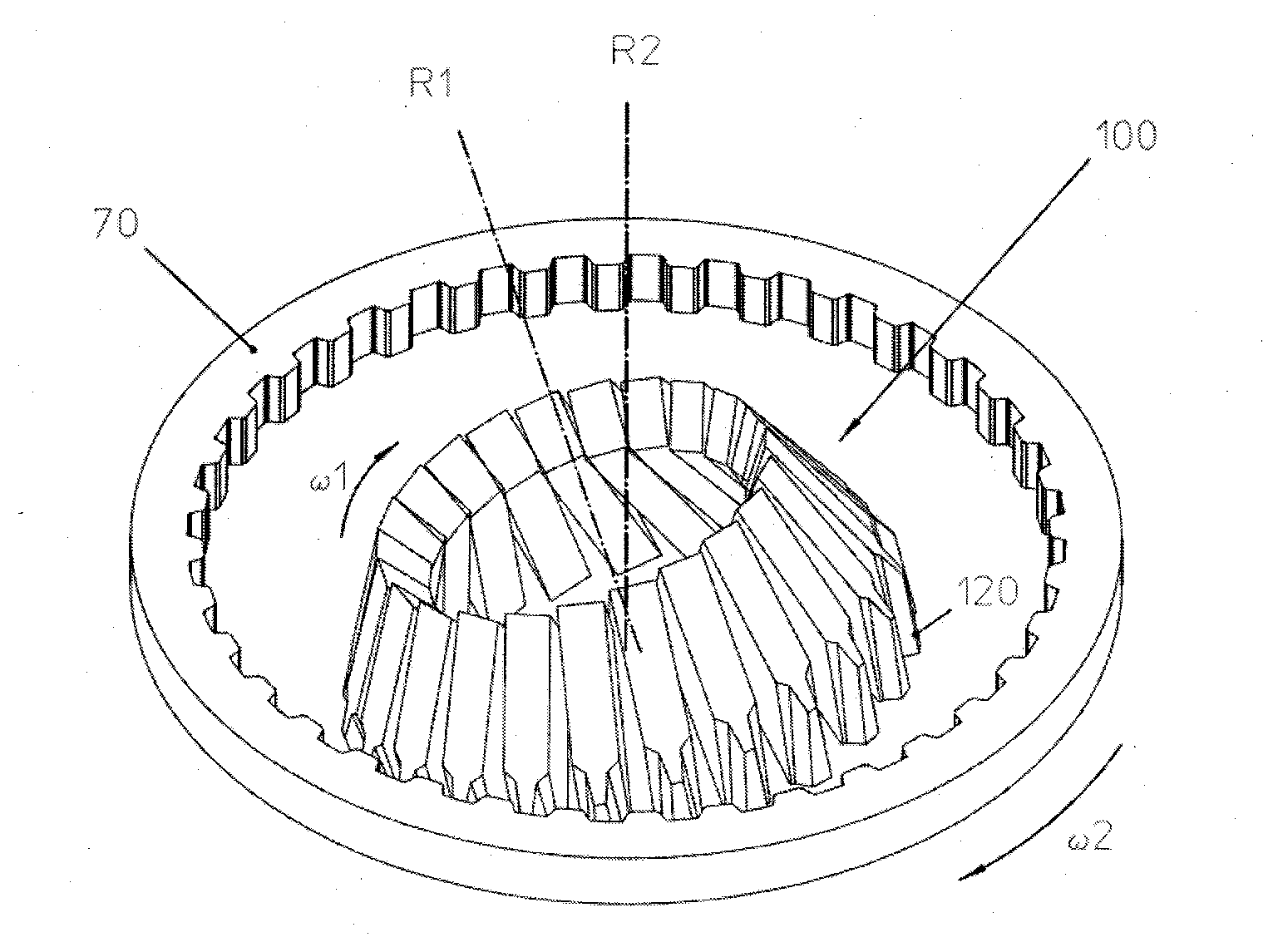

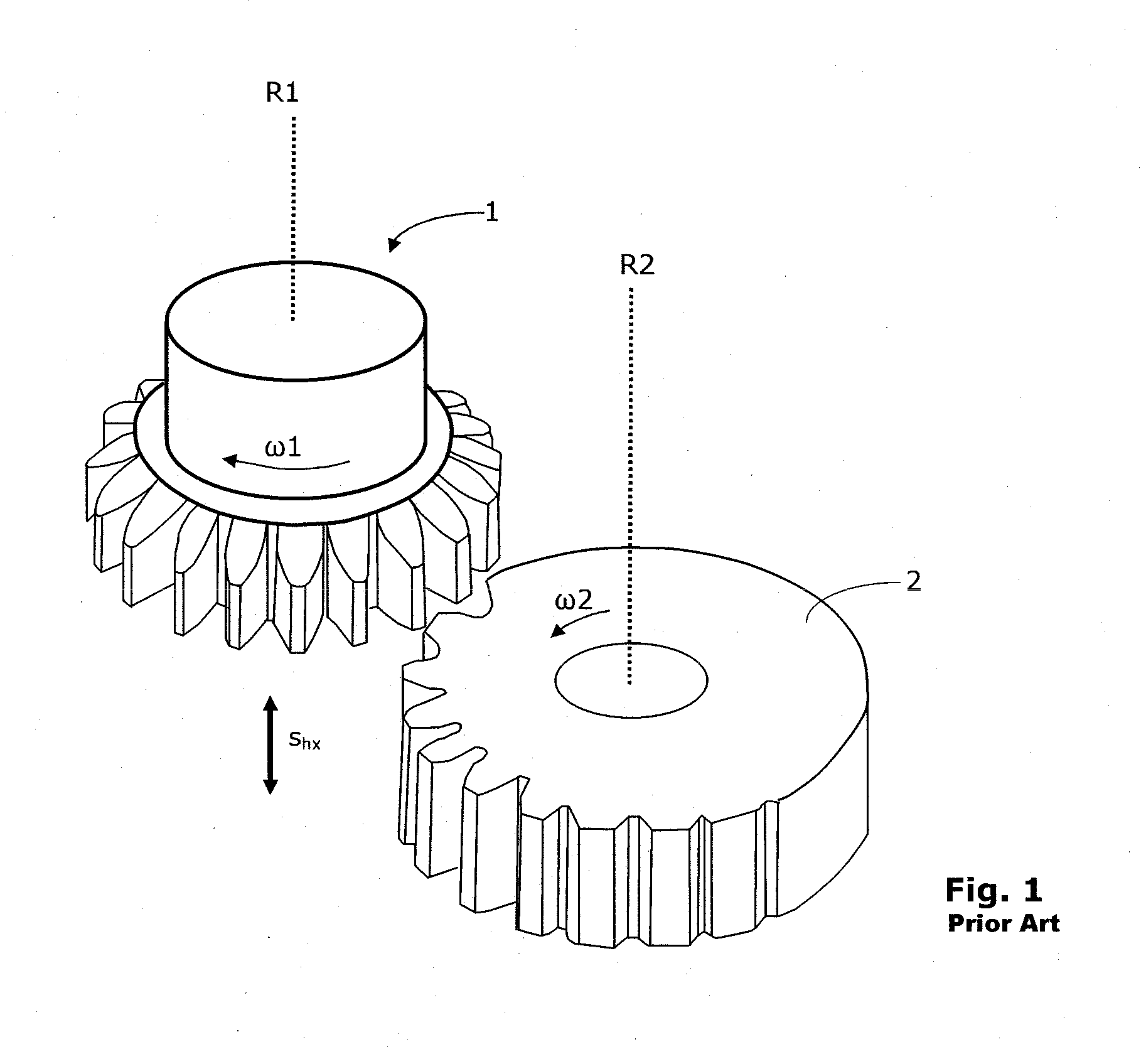

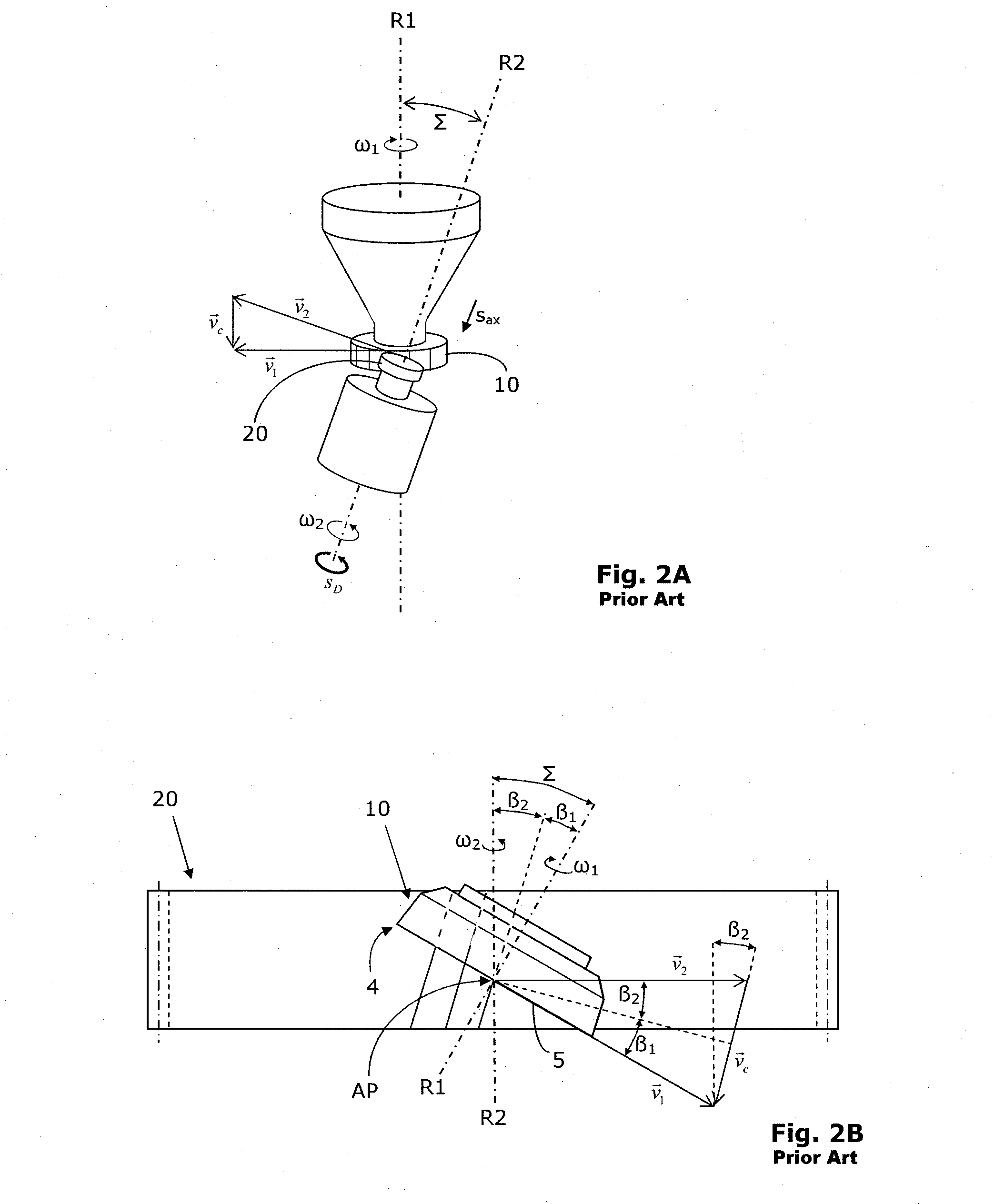

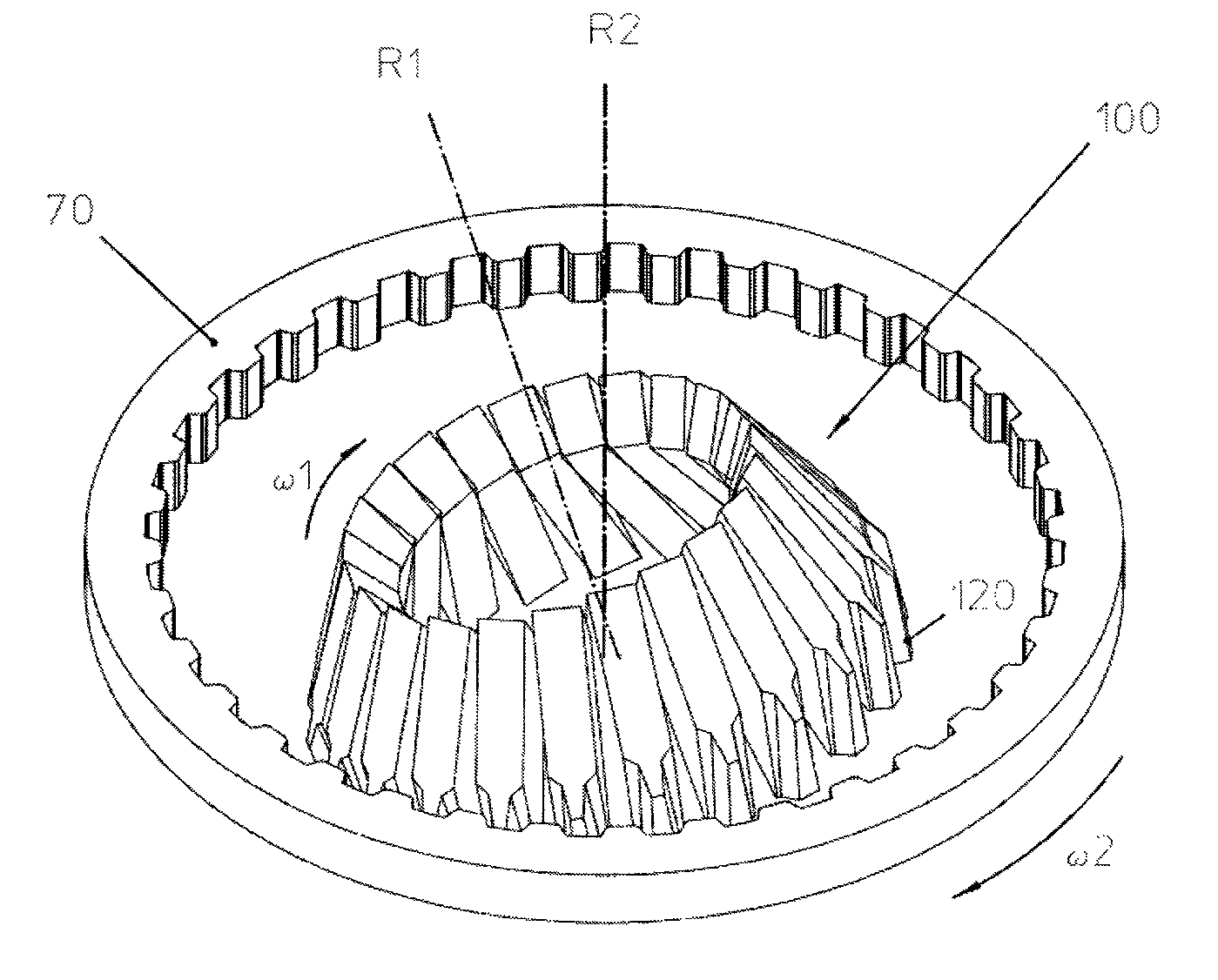

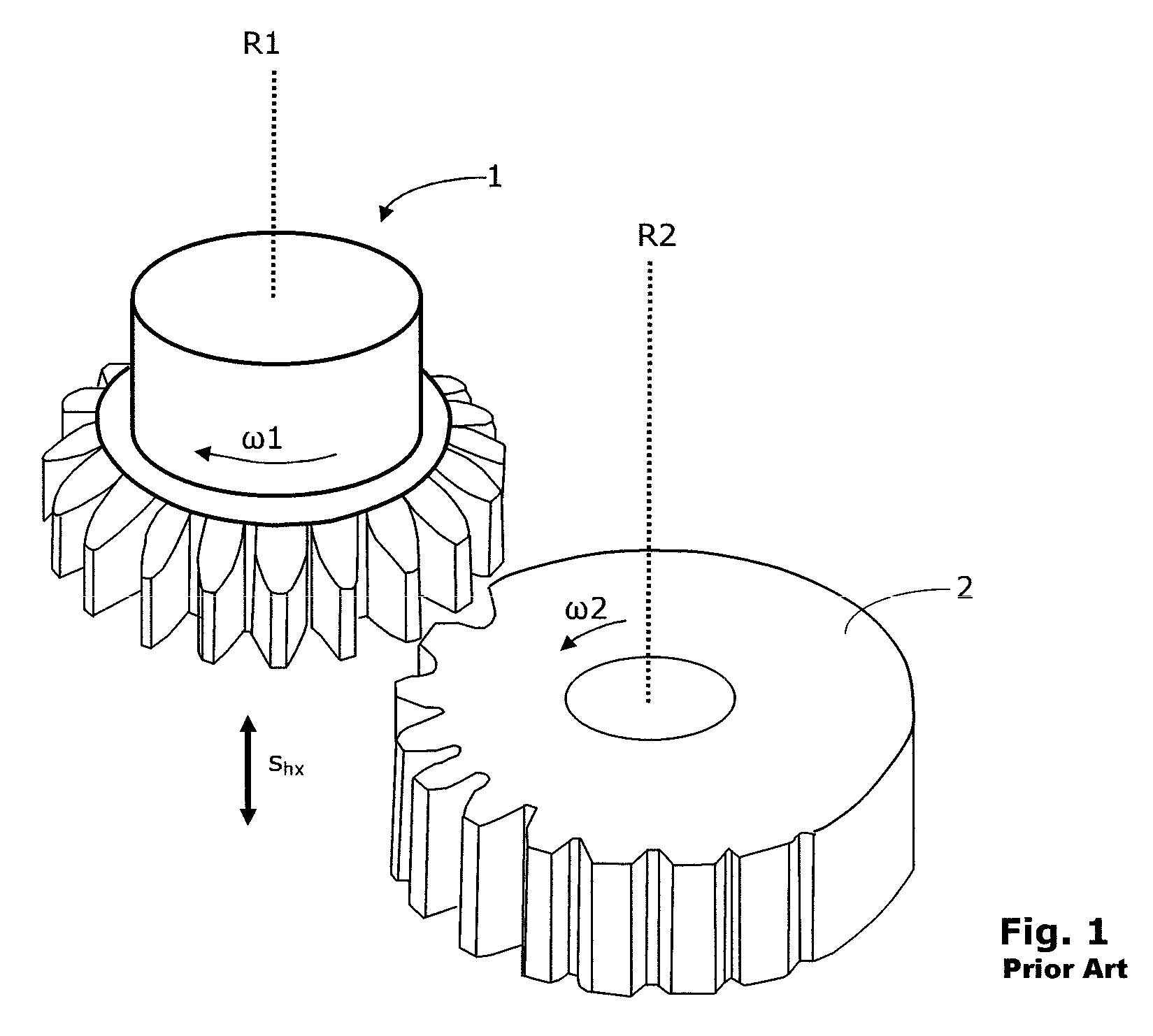

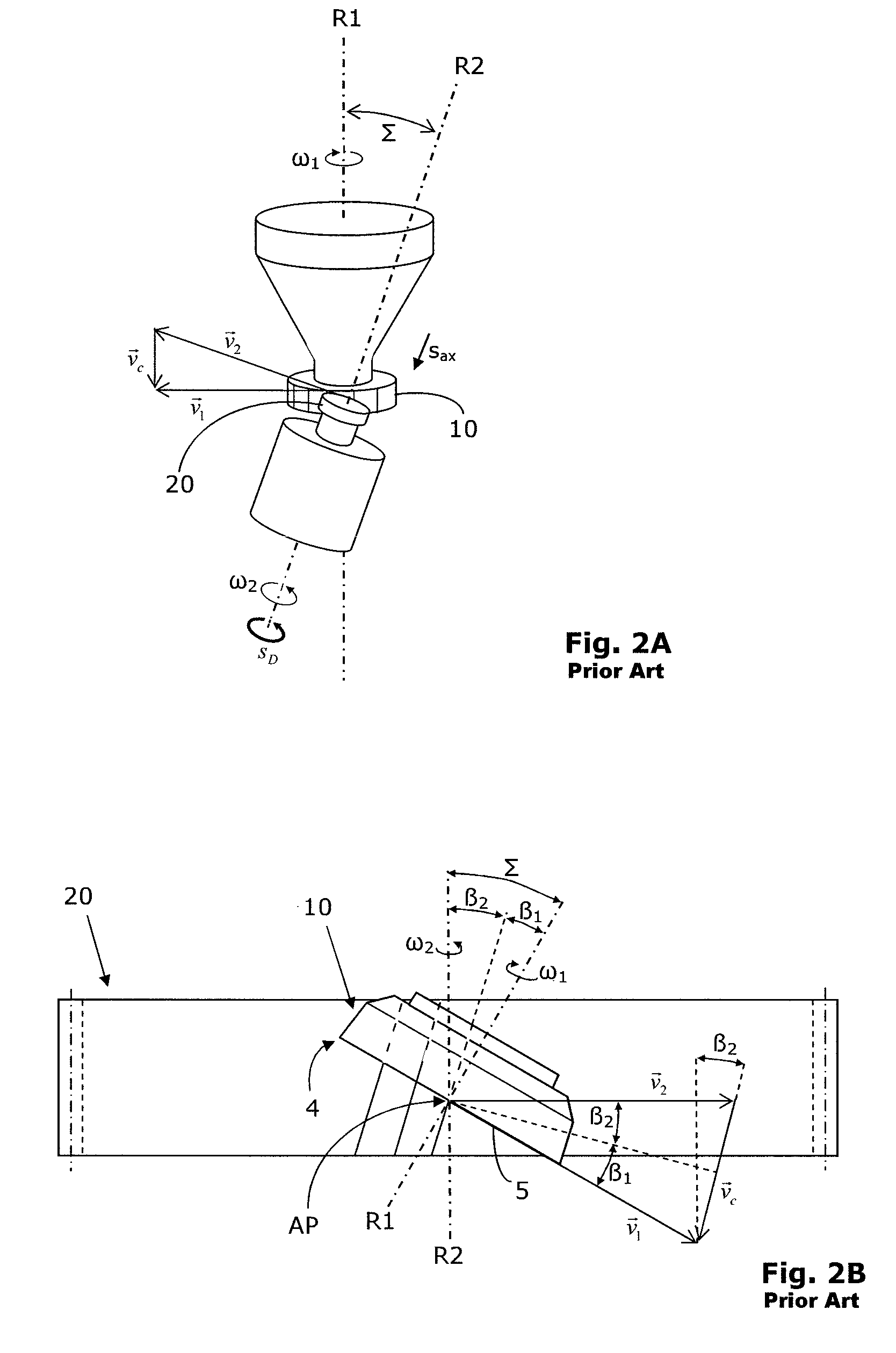

Robust Method for Skiving and Corresponding Apparatus Comprising a Skiving Tool

ActiveUS20120328384A1Increase production capacityReduce processing timeBroaching machinesGear cutting toolEngineeringMechanical engineering

Owner:KLINGELNBERG AG

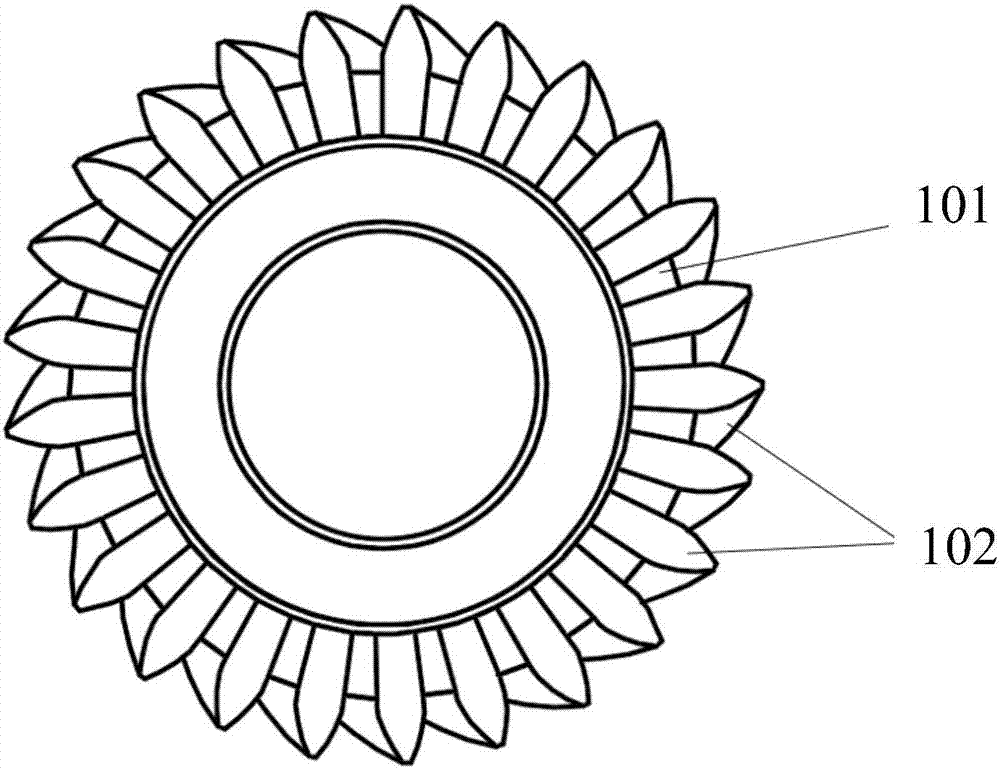

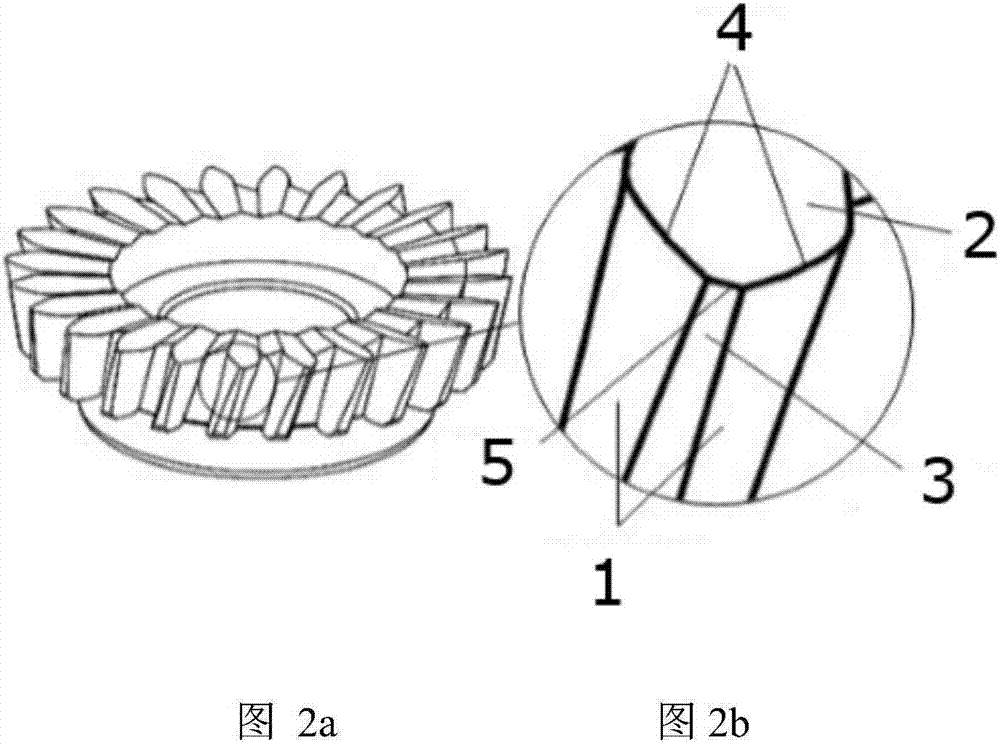

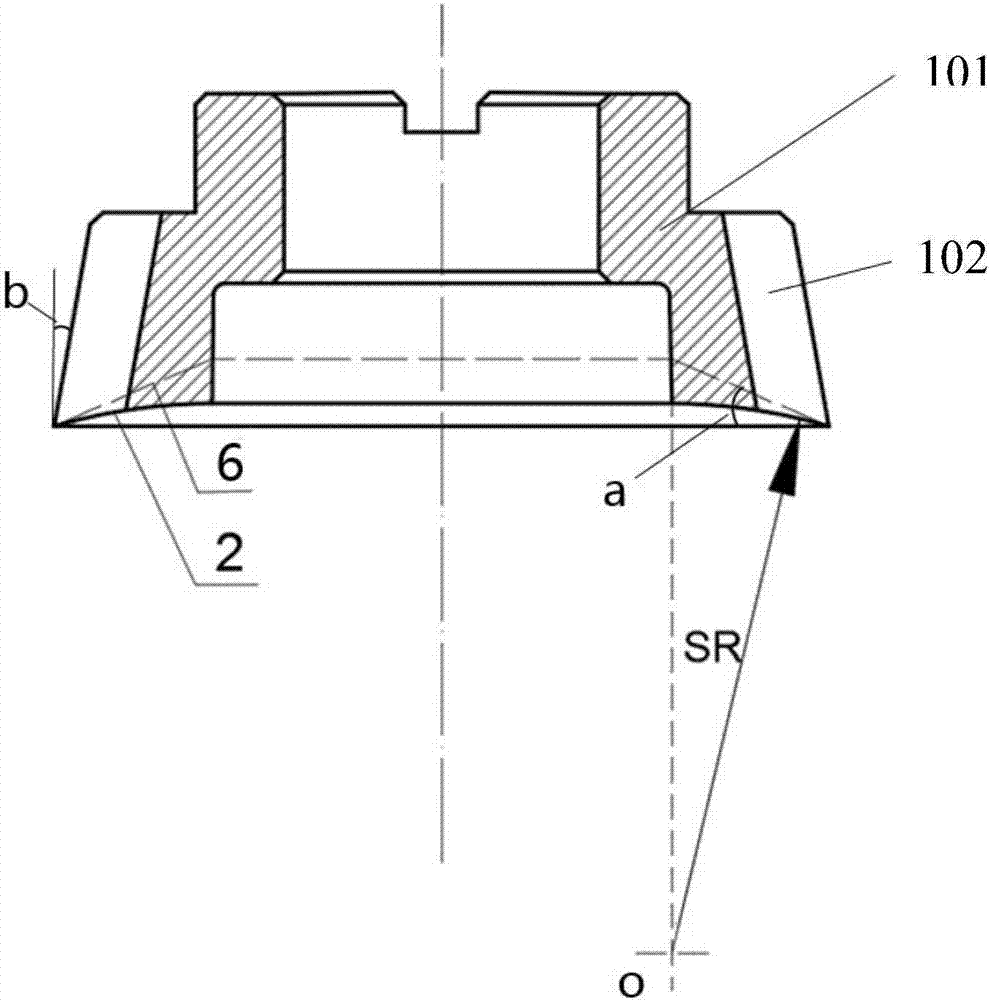

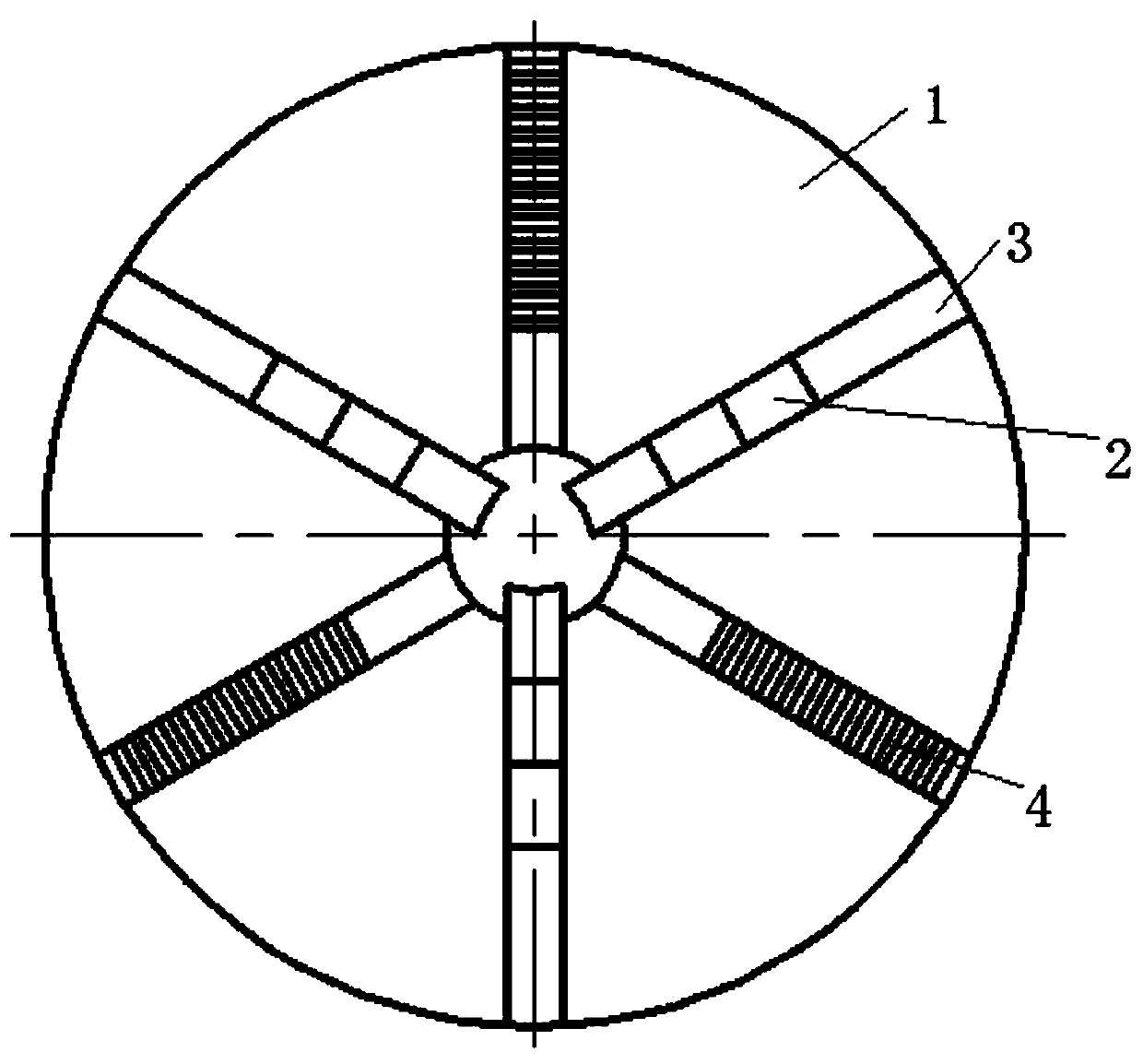

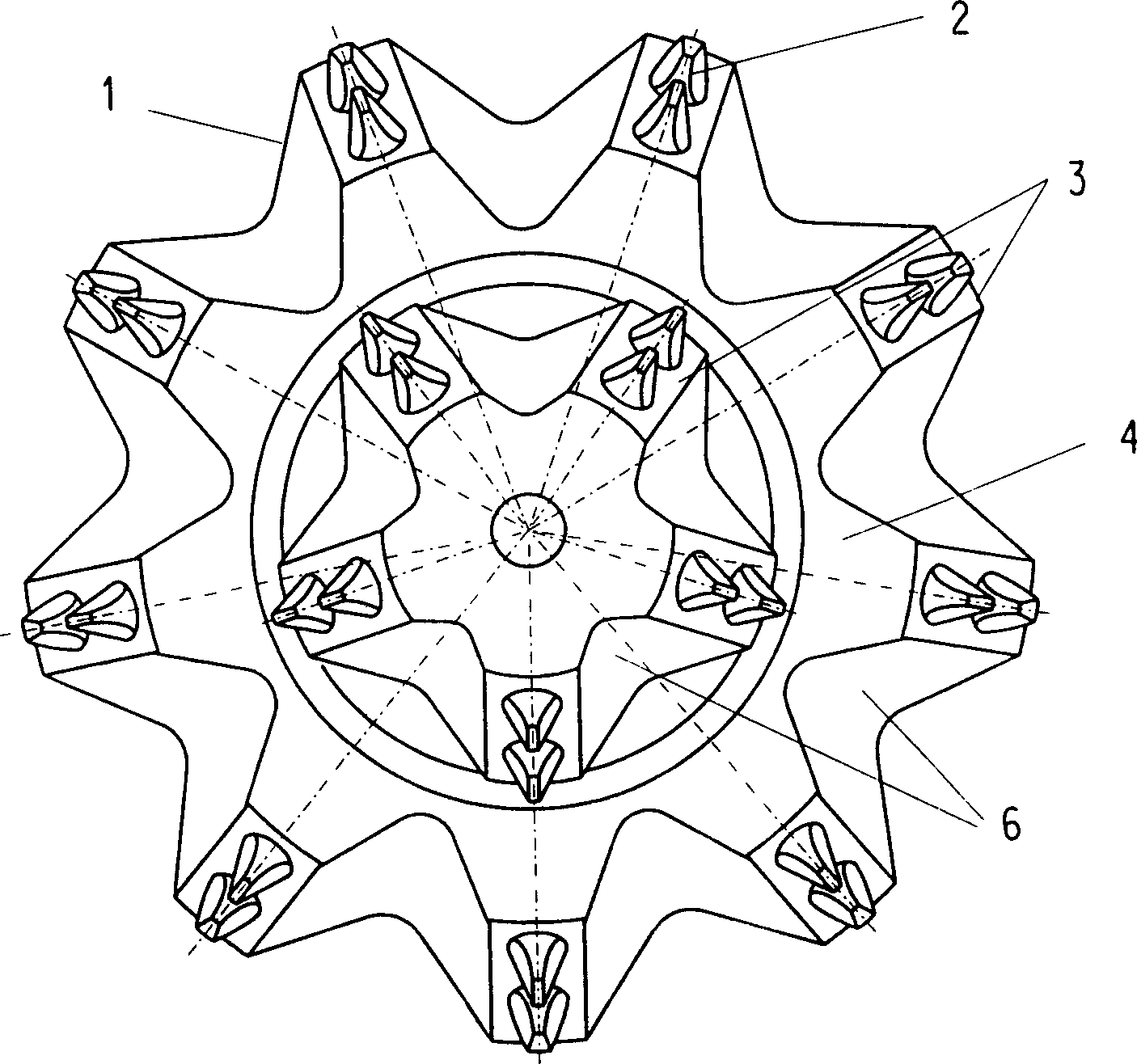

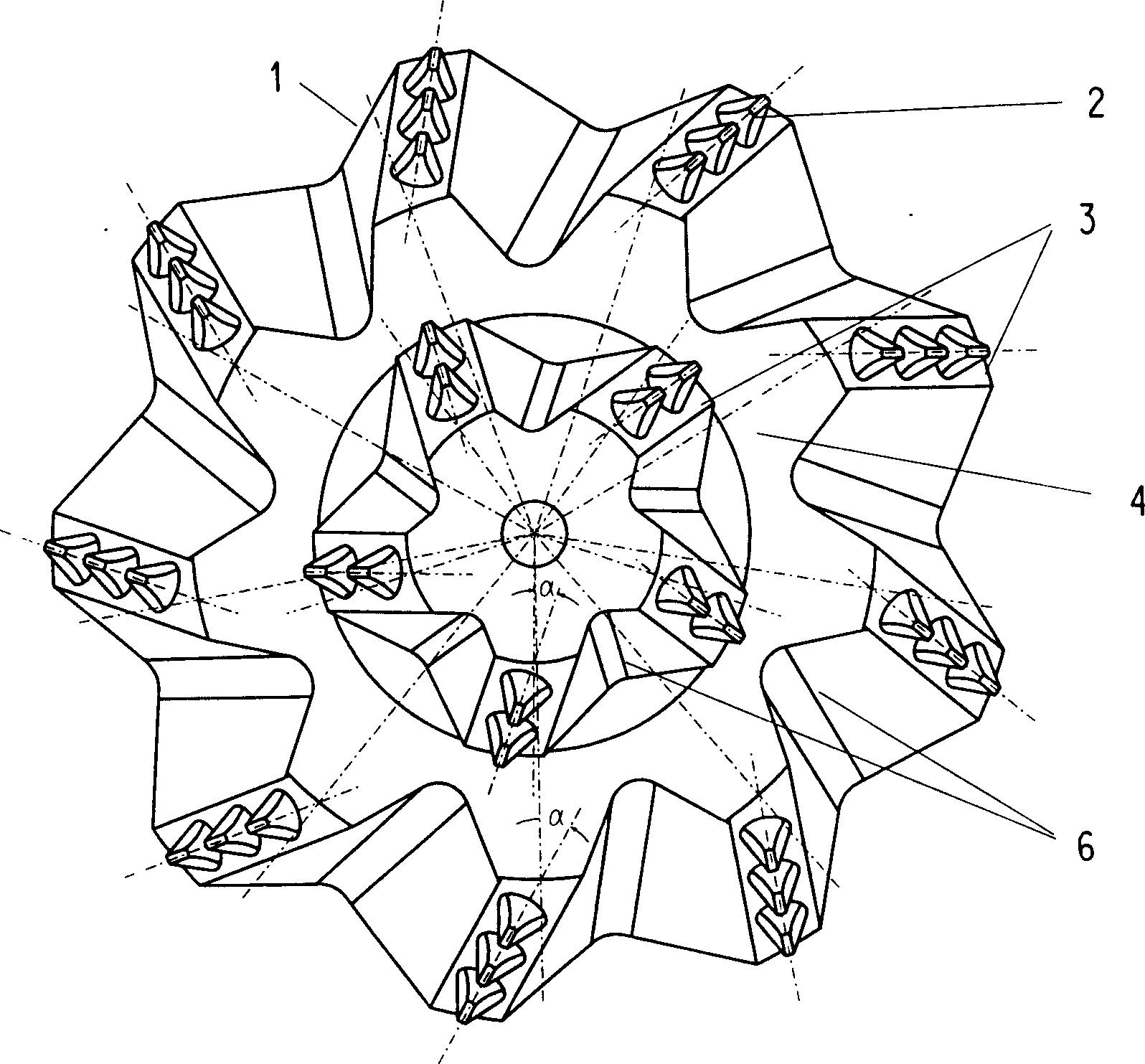

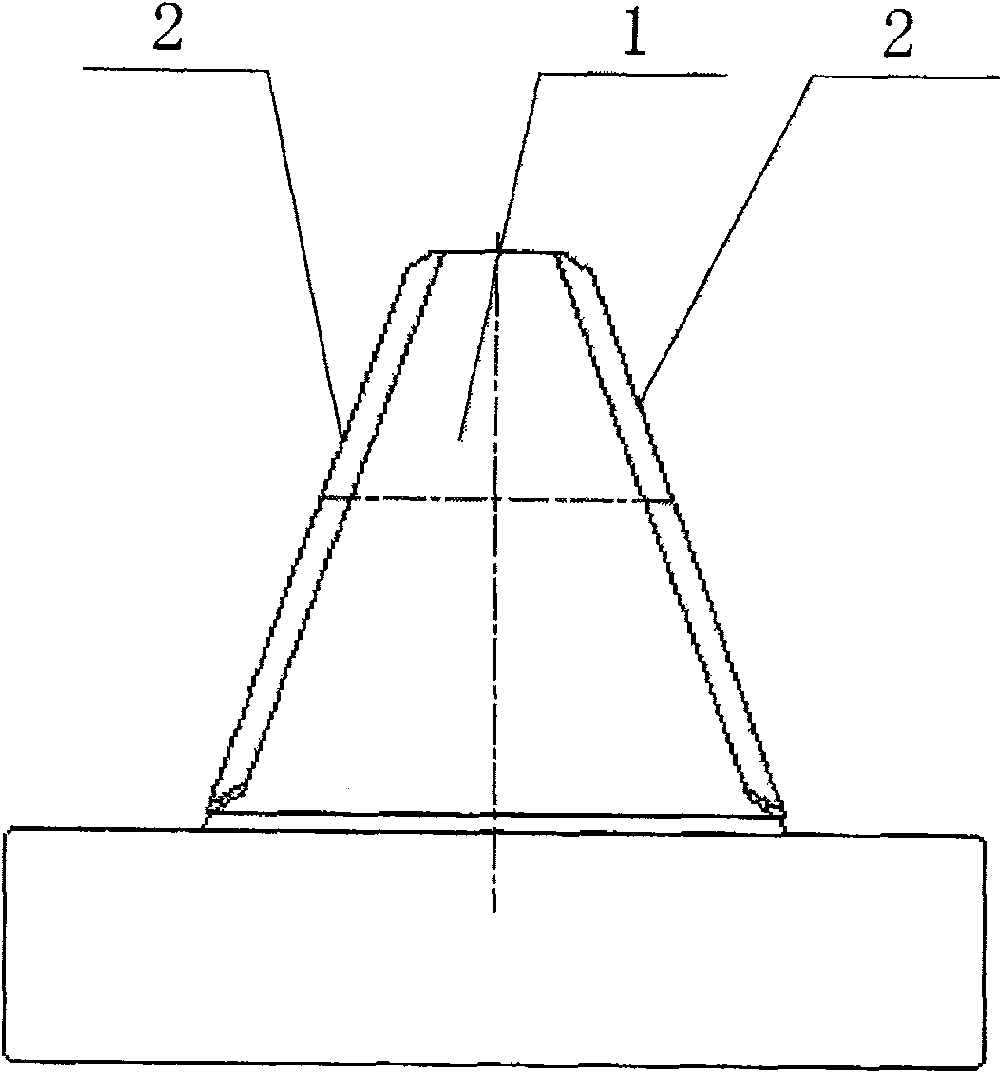

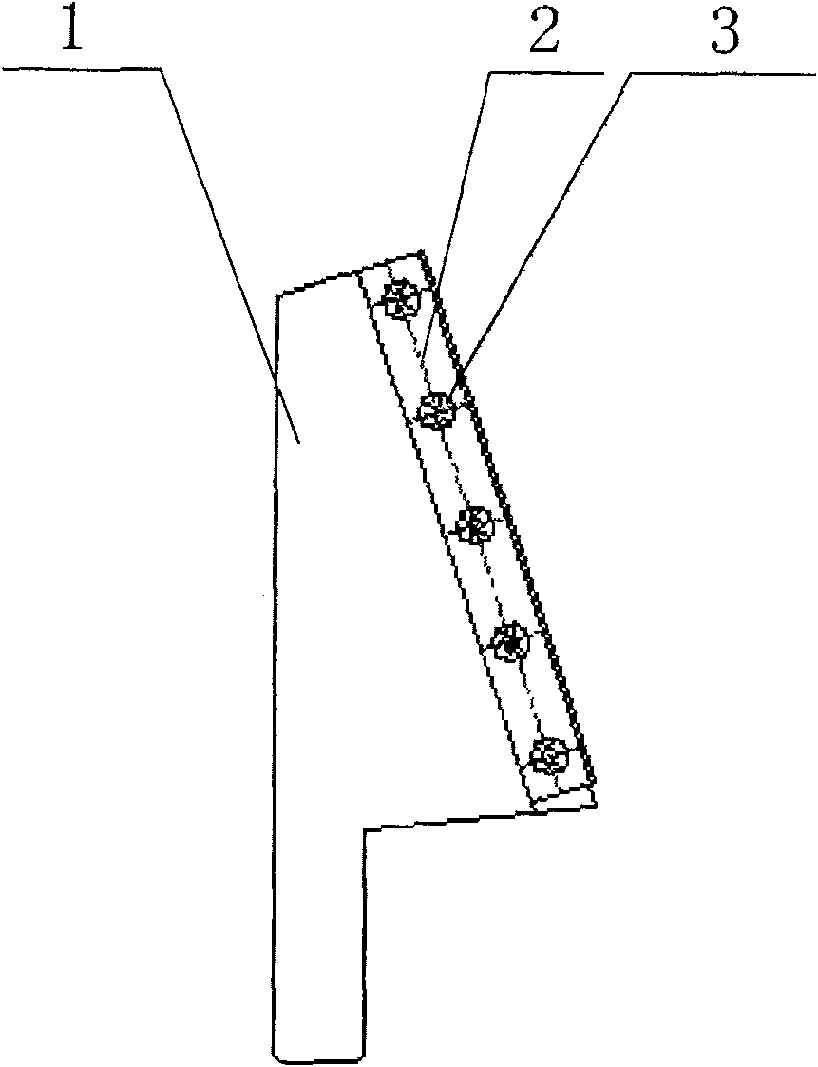

Gear shaper cutter free of theoretical edge shape errors

InactiveCN107378141AImprove machining accuracyImprove cutting conditionsGear teeth manufacturing toolsGear teethCircular coneEngineering

The invention provides a gear shaper cutter free of theoretical edge shape errors. The gear shaper cutter comprises a cutter body and cutter teeth evenly distributed on the circumference of the cutter body. Each cutter tooth comprises lateral rear cutter faces, a front cutter face, a rear-top cutter face, a plurality of side edges and a top edge, wherein the front cutter face is a spherical face; the rear-top cutter face is a conical face, and the tip diameter of the rear-top cutter face is decreased gradually backwards from the front end of the cutter; the top edge is the intersecting line between the front cutter face and the rear-top cutter face; the side edges are the intersecting lines between the lateral rear cutter faces and the front cutter face and are in conjugation with the tooth face of a machined gear all the time in the machining process; and the lateral rear cutter faces are free curved faces composed of the side edges, and side edges of the cutter are still in conjugation with the tooth face of the machined gear after being sharpened again. According to the gear shaper cutter free of theoretical edge shape errors, the spherical faces are used as the front cutter faces of the gear shaper cutter, so that the strength of the cutter is improved; since the side edges are in conjugation with the tooth face of the machined part, edge shape errors are avoided theoretically, and the machining precision of the gear shaper cutter is improved greatly; and the front angle and the back angle of the gear shaper cutter are larger, and the cutting condition of the gear shaper cutter is improved.

Owner:TIANJIN UNIV

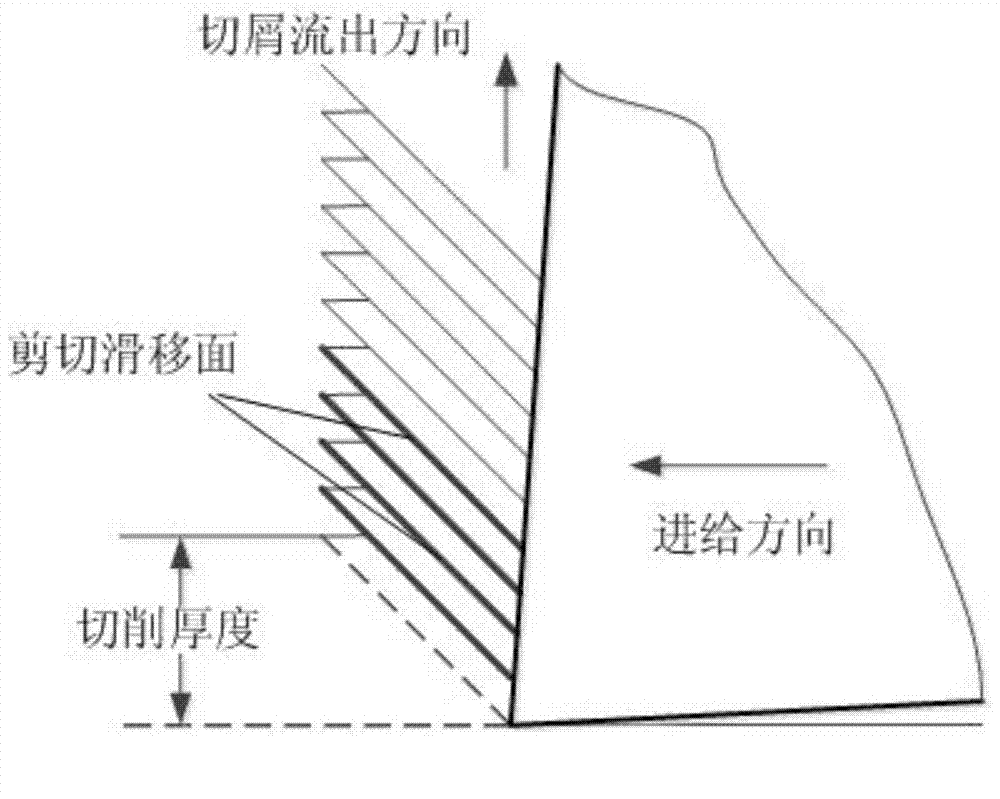

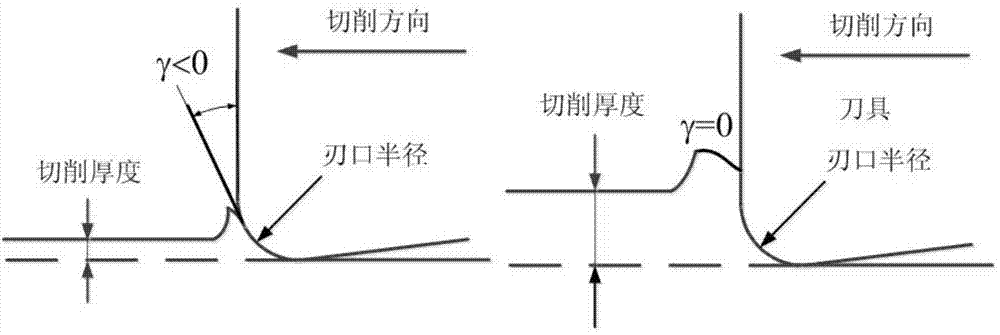

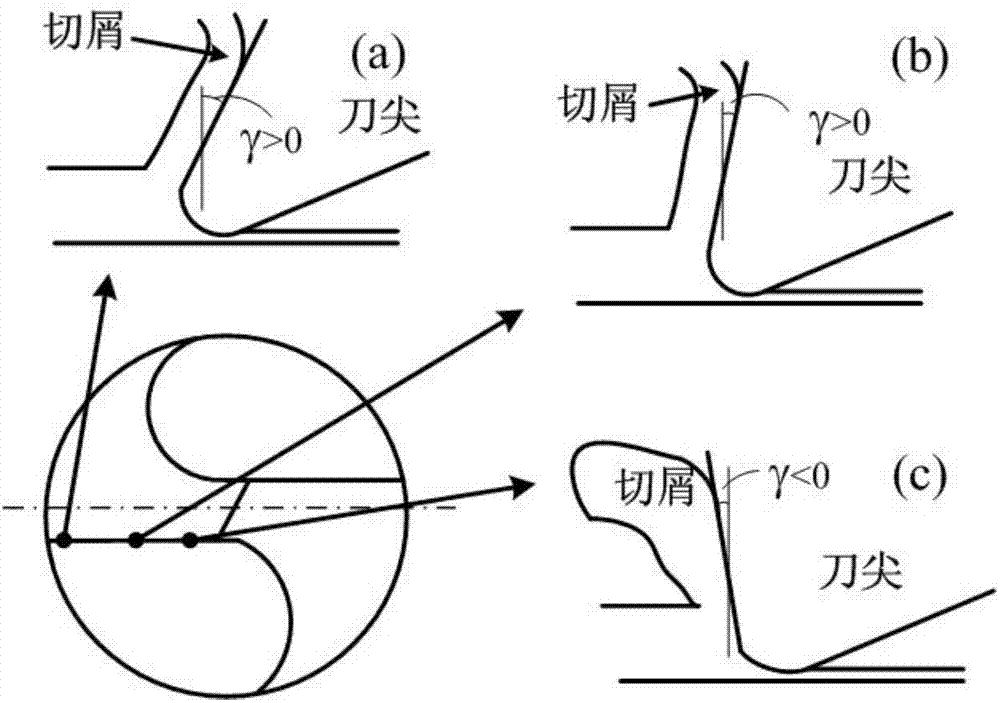

Method for reinforcing cutting edge of micro-cutting tool based on critical cutting thickness

ActiveCN104209559AImprove cutting conditionsImprove machining accuracyTransportation and packagingMicrostructural devicesEngineeringFocused ion beam

The invention relates to a method for reinforcing a cutting edge of a micro-cutting tool based on critical cutting thickness. The method comprises the following steps of dividing a cutting edge area of the micro-cutting tool into a main edge outer edge area, an intermediate transitional area and a near transverse edge area, respectively determining and trimming the respective cutting-edge radii of the main edge outer edge area, the intermediate transitional area and the near transverse edge area according to the critical cutting thicknesses of different processed materials so as to reinforce the strength of the cutting edge and optimize the cutting performance. The method comprises the following steps: (1) determining the critical cutting thickness of a processed material through orthogonal cutting experiment or cutting finite element simulation; (2) dividing the cutting edge area of the micro-cutting tool into the main edge outer edge area, the intermediate transitional area and the near transverse edge area; (3) respectively determining respective cutting edge radii of the three areas according to the critical cutting thickness of the processed material; (4) trimming the cutting edges of the main edge outer edge area, the intermediate transitional area and the near transverse edge area in a micro-scale manner by utilizing a focus ion beam, and gradually trimming the cutting edge to the determined cutting edge radius. The method is feasible, the strength of the cutting edge is improved, the cutting state is improved, the service life of the cutting tool is prolonged, and the method is applicable to all micro-cutting tools.

Owner:SHANGHAI JIAO TONG UNIV +1

Robust method for skiving and corresponding apparatus comprising a skiving tool

InactiveUS9120165B2Improve cutting conditionsEasy to manufactureBroaching machinesGear cutting toolEngineeringMechanical engineering

Owner:KLINGELNBERG AG

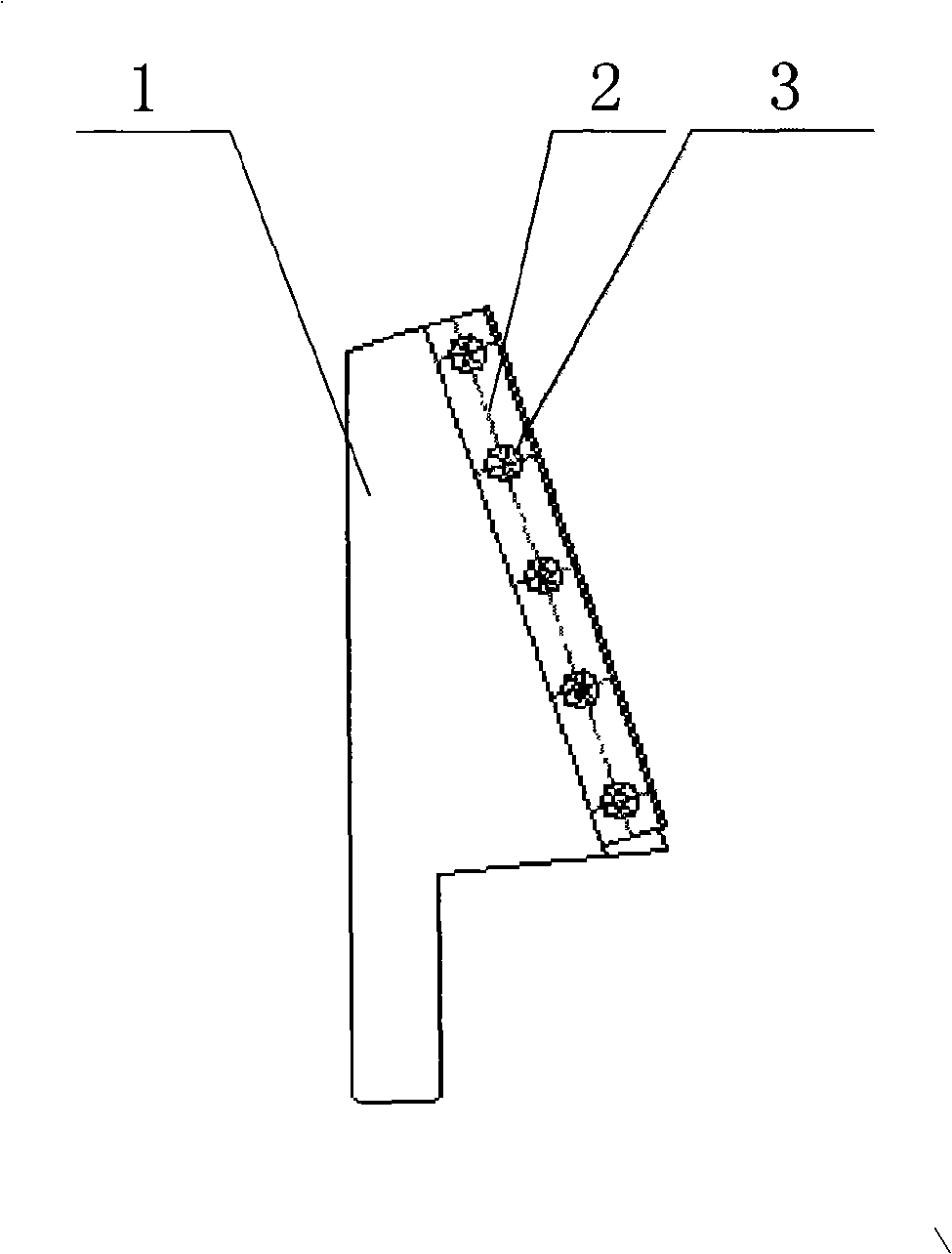

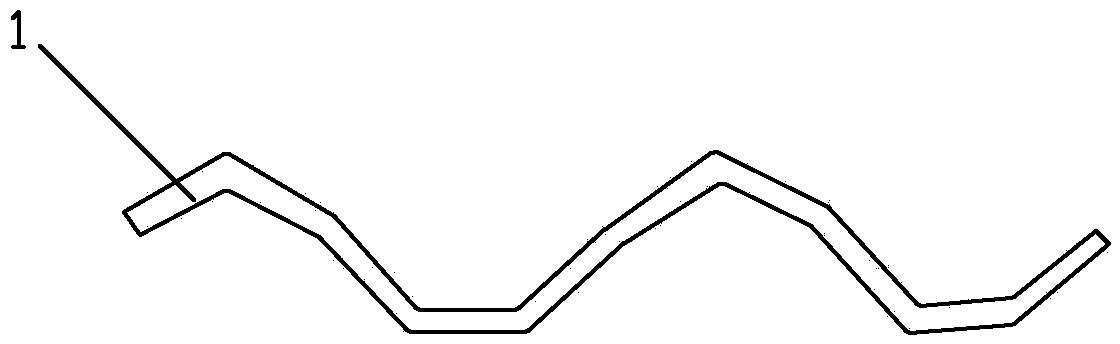

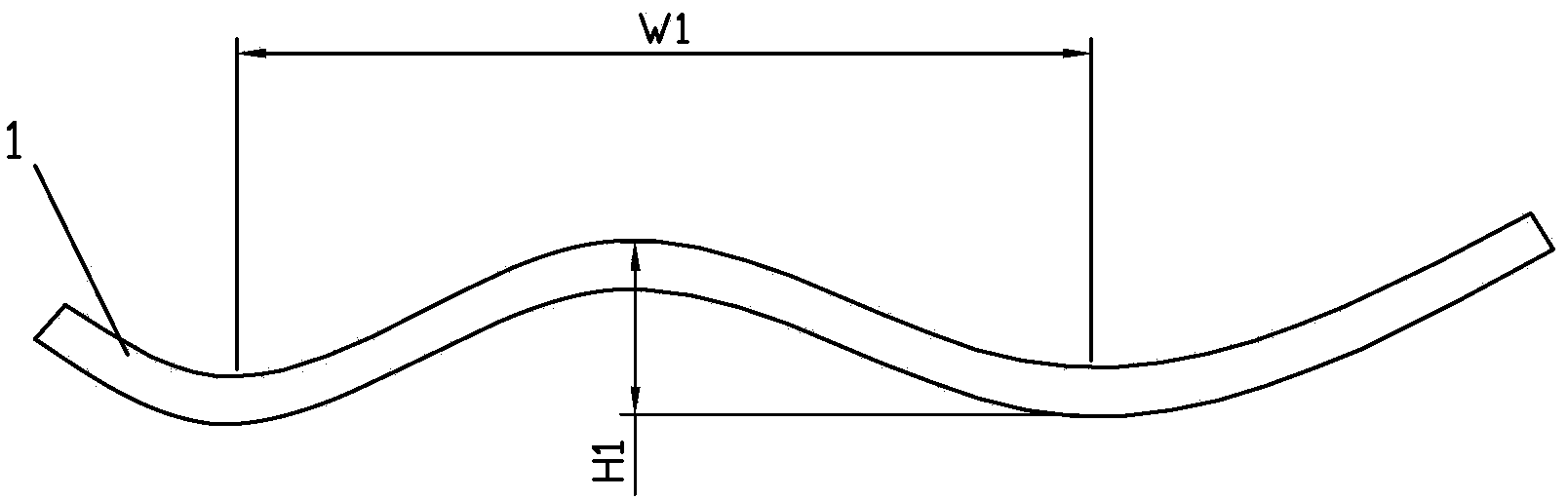

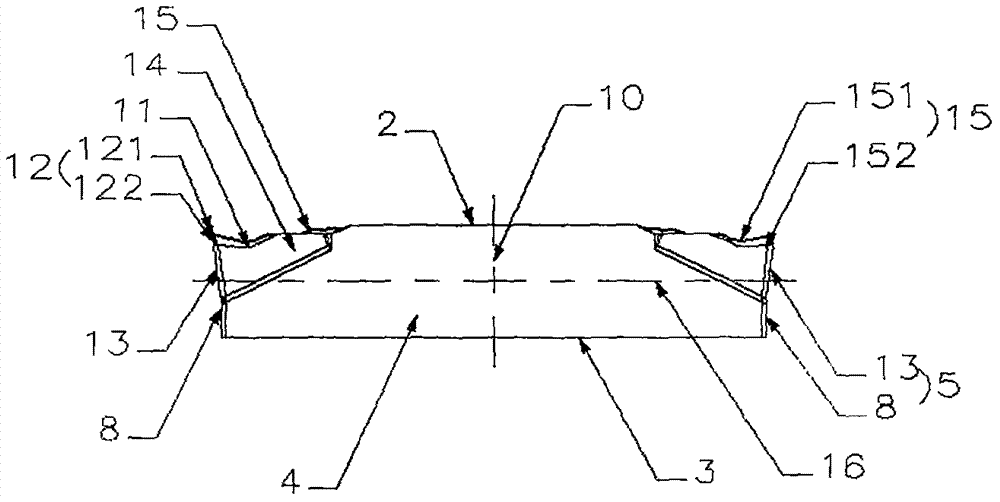

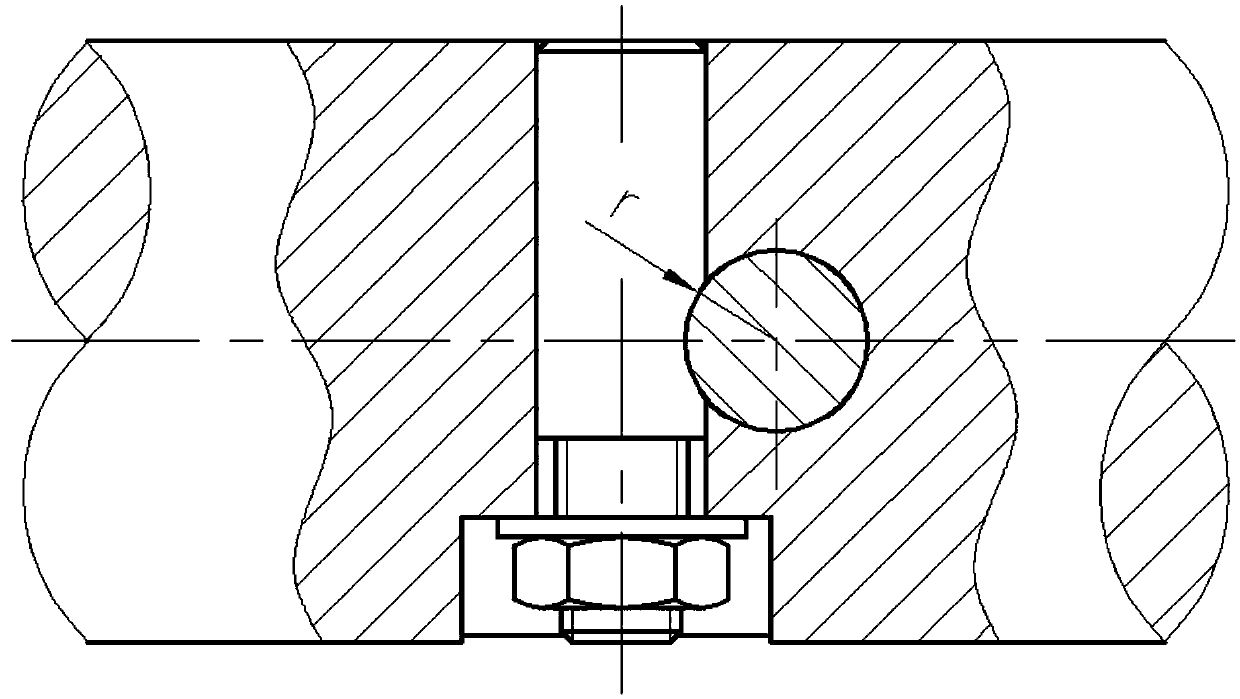

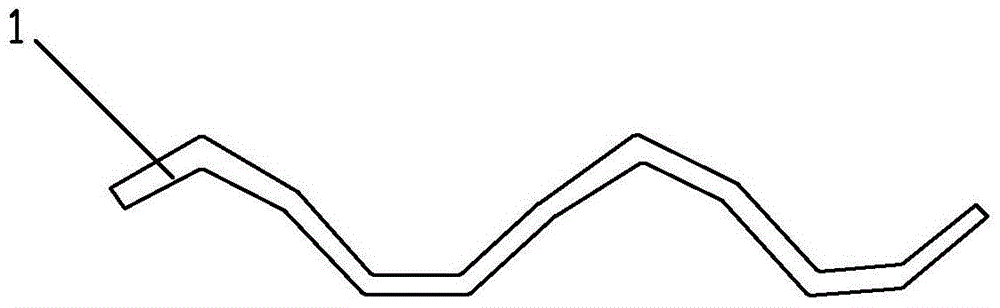

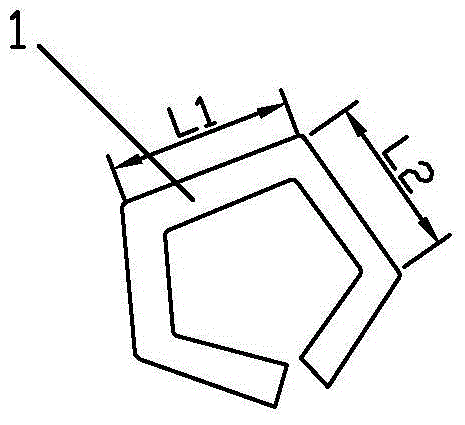

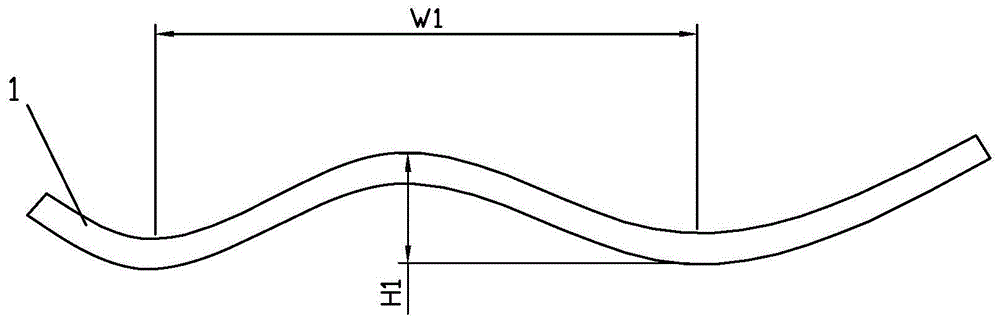

Composite deformation type high-strength sawing wire and manufacturing method thereof

ActiveCN103963181ASimple Waveform FeaturesIncrease cutting kinetic energyWire articlesFine working devicesWire cuttingCeramic

The invention discloses a composite deformation type high-strength sawing wire and a manufacturing method thereof. The sawing wire is of a structure that edge-folding deformation exists in a single plane and bending deformation exists in three-dimensional space. In the single plane, the sawing wire is bent into a wavy structure, and crest heights of a composite deformed wire are identical within the spatial range. The composite deformation type high-strength sawing wire and the manufacturing method thereof solve the problems existing in traditional multi-wire cutting. The sawing wire has a periodical deformation feature, multiple inner spatial structures are formed by the deformed wire in each period, and then more mortar can be brought in when the sawing wire is used; meanwhile, auxiliary blades formed by edge-folding and bending deformation can play a role in chip removal, and the sawing wire is especially good at cutting hard and brittle materials such as solar silicon wafers, quartz, silicon ingots, ceramics, sapphire, gallium arsenide and stone.

Owner:江苏宝钢精密钢丝有限公司

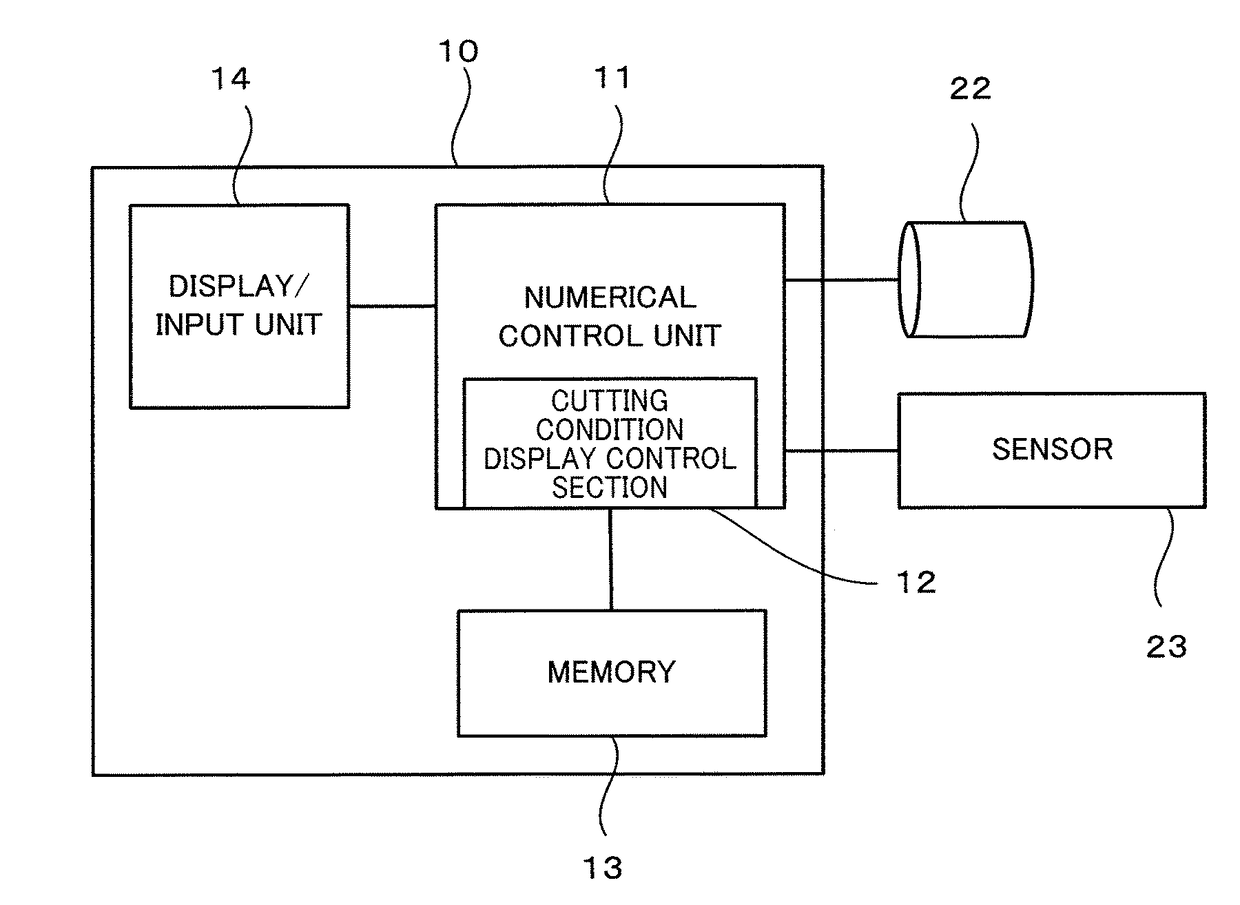

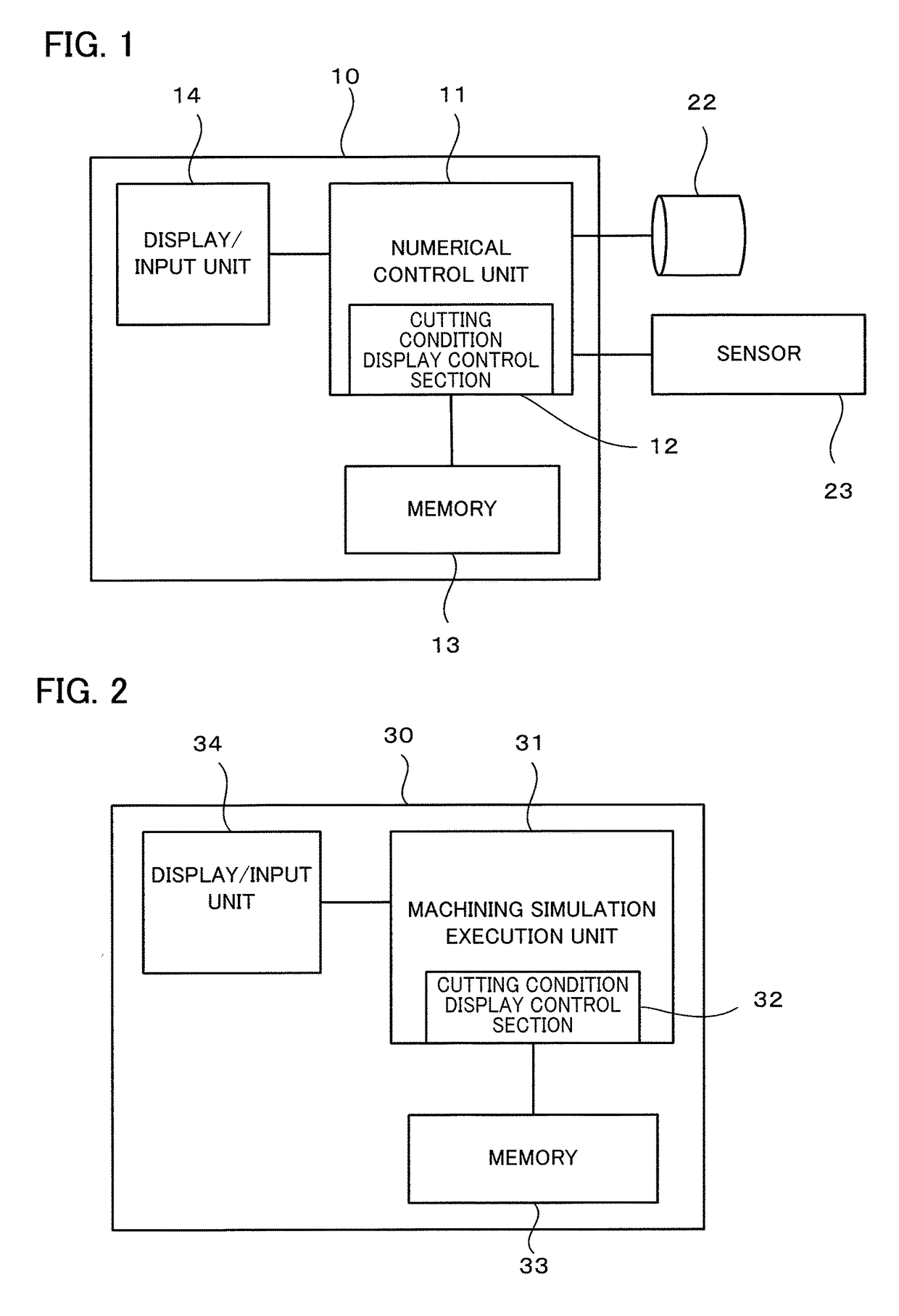

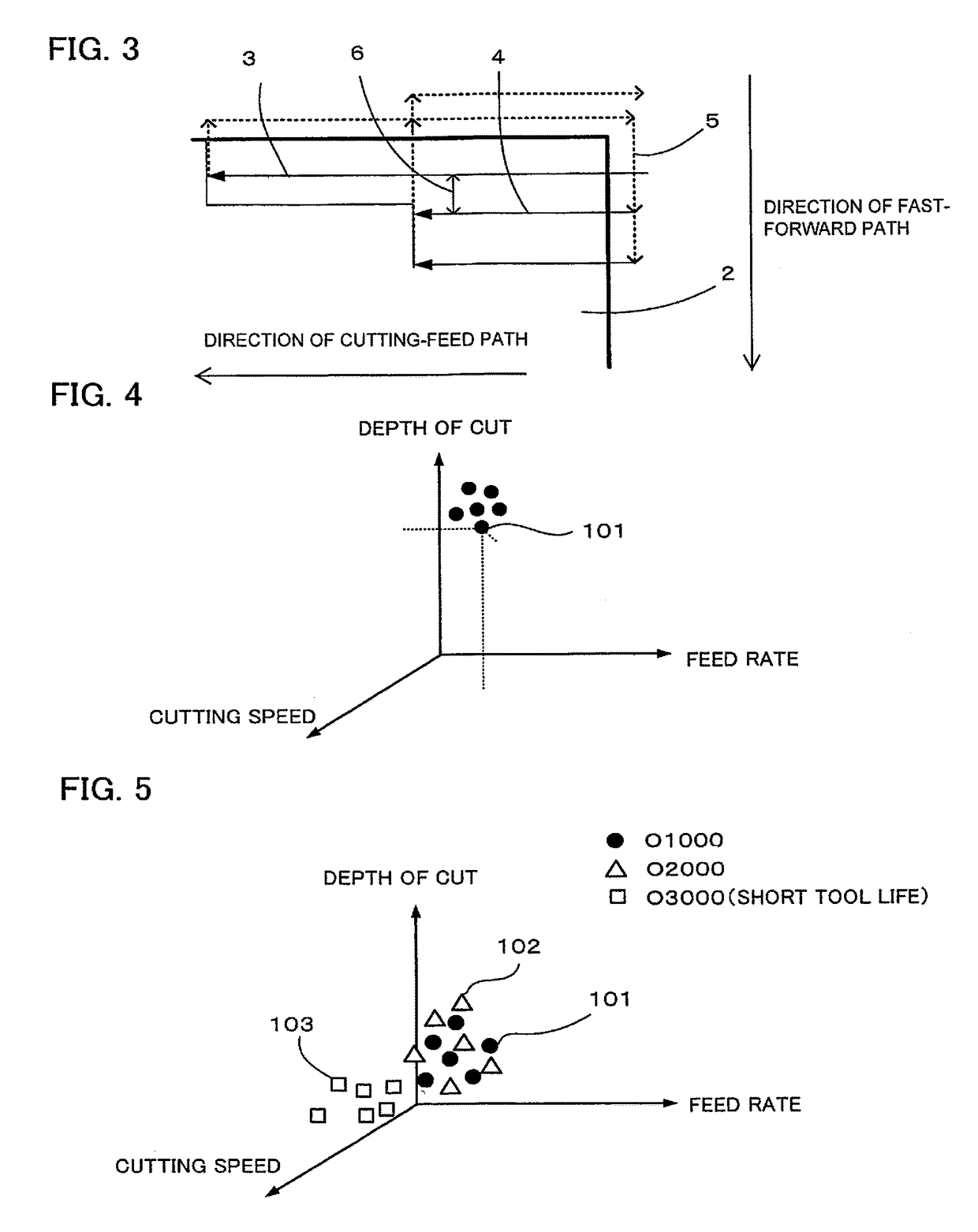

Cutting condition and tool life display device for a numerical controller

ActiveUS9665085B2Solution to short lifeIncreased durabilityProgramme controlComputer controlControl engineeringDisplay device

A numerical controller controls a spindle and / or a movable axis of a finishing machine based on a machining program. A cutting condition display device configured to display a cutting condition for the numerical controller calculates cutting conditions including a cutting speed, a feed per spindle revolution per cutting edge of a tool, and a depth of cut for each fixed time during an operation of the finishing machine, based on any or a combination of data on the spindle, the movable axis, a cutting tool, and an object to be cut, which are held by the numerical controller. The calculated cutting condition is stored for each tool and displayed in a graph.

Owner:FANUC LTD

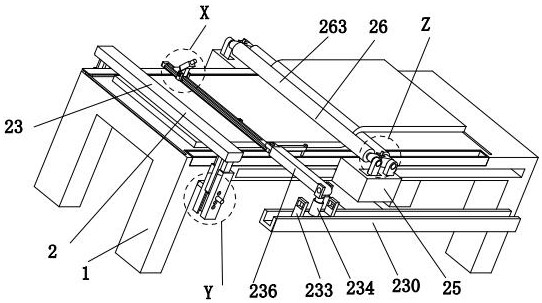

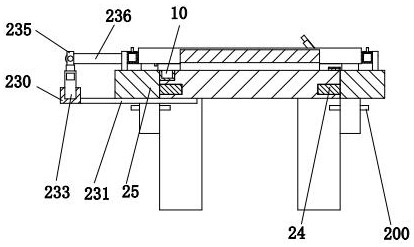

Method for continuously non-interrupt numerical control processing for plate parts

ActiveCN101382793BEasy to operateEasy to disassembleProgramme controlComputer controlNumerical controlControl system

The invention discloses a continuous digital control method for processing a plate part. A displacement signal of a displacement sensor with pulling thread is fed back to a control system of a follow-up clamp; a teaching method is used for remembering the coordinate position of an anti-collision press plate; the control system of the follow-up clamp is used for collecting the displacement signal of the displacement sensor with pulling thread in real time; and the forward movement range of the press plate on the clamp for avoiding the collision with a digital control cutting tool is calculatedand analyzed according to the length of the press plate on the follow-up clamp; the press plate on the clamp is controlled to avoid collision and be compressed automatically; and an anti-collision control command or a clamping command is initiated to a press plate executing mechanism. In the method, the displacement sensor with pulling thread is utilized to collect the coordinate position of the press plate for avoiding the collision with the digital control cutting tool; the teaching method is adopted to cause the cutting tool to be moved within the forward movement range of the press plate for avoiding the collision with the digital cutting tool; the control system is used for controlling the press plate executing mechanism on the clamp to cause the press plate to avoid collision automatically. The method solves the problem that safety accidents easily occur and processing efficiency and processing quality are affected since running stop and manual disassembling the press plate on the clamp are required when the digital control cutting tool collides with the press plate.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

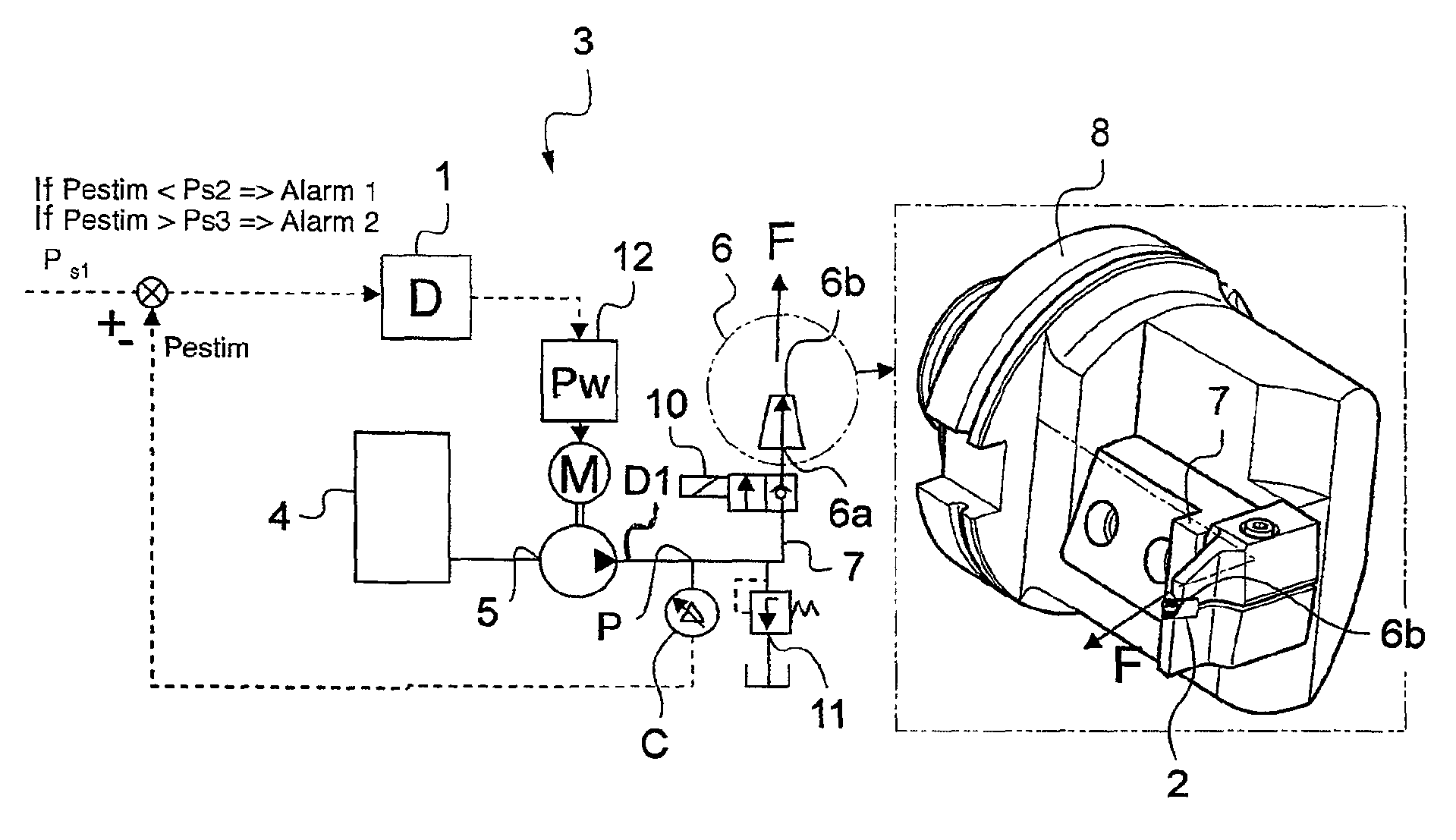

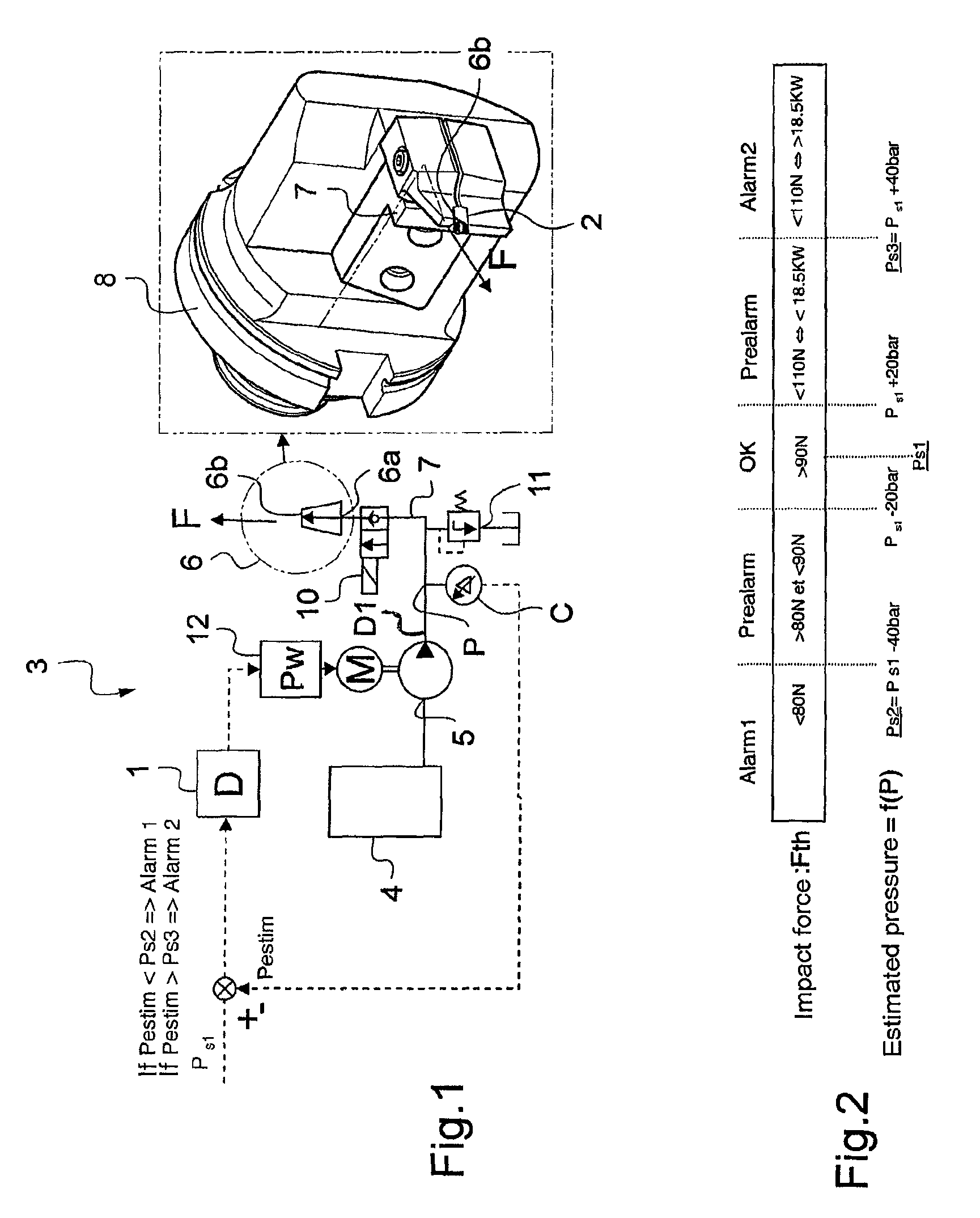

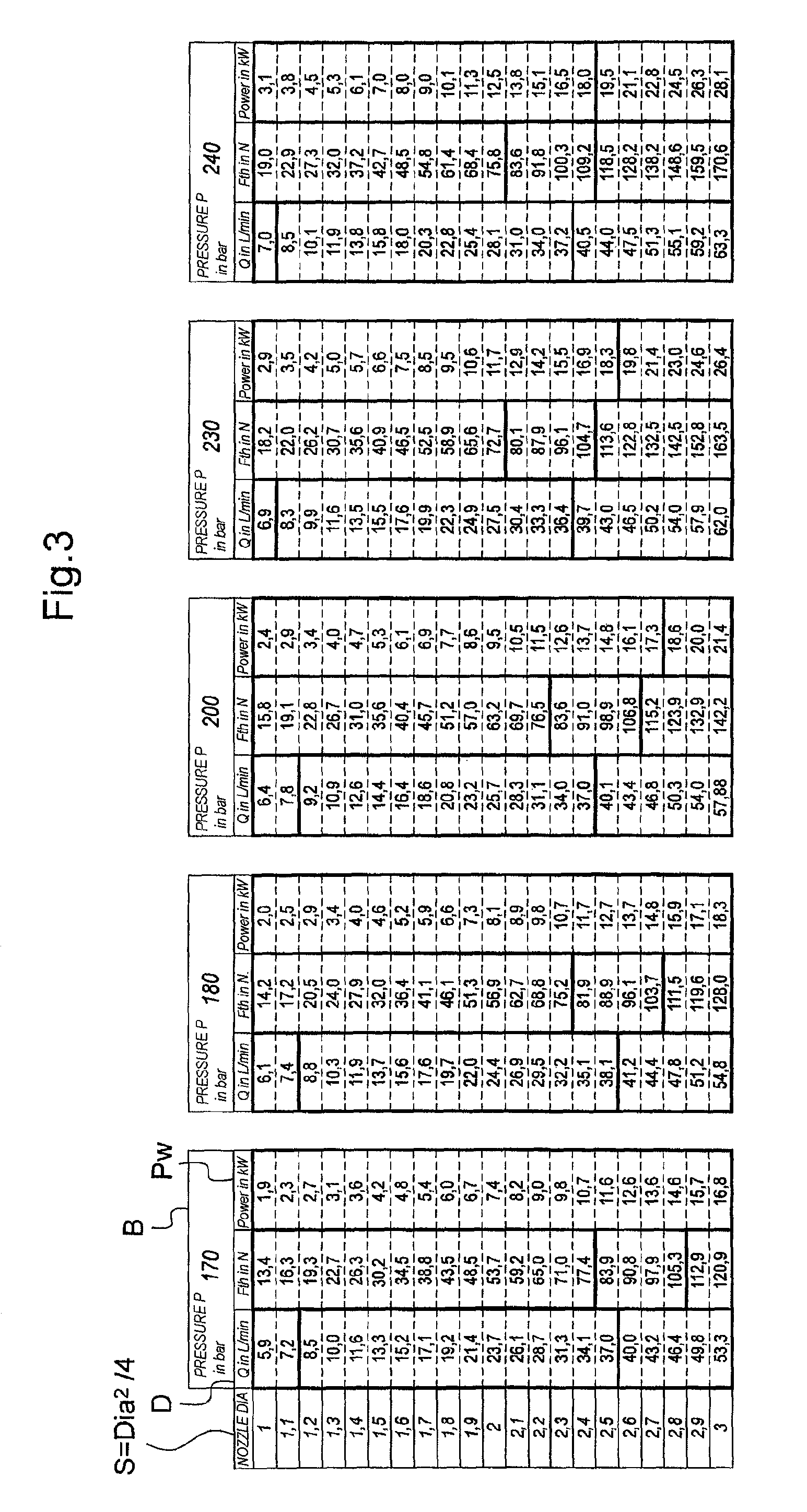

Method of controlling a cooling device for a machine tool

ActiveUS9008847B2Reduce downtimeImprove cutting conditionsMeasurement/indication equipmentsRatio controlEngineeringPressure threshold

A method of controlling a cooling device for cooling a cutting tool in a machine tool. The method comprising the steps of:controlling the motor to drive the pump in such a manner that the pump feeds the nozzle with machining fluid at a constant flow rate D1 that is equal to a first flow rate setpoint;measuring a parameter P representative of a fluid outlet pressure from the nozzle; andcomparing an estimated outlet pressure Pestim as estimated from the parameter P with a first predetermined pressure threshold Ps1, and controlling the motor so as to increase the fluid flow rate D1 as delivered by the pump if the estimated output pressure drops below the first pressure threshold Ps1.

Owner:SAFRAN LANDING SYSTEMS

Groove machining blade

InactiveCN107414110AReduce cutting impactPrevent crashCutting insertsTurning toolsEngineeringMechanical engineering

The invention discloses a groove machining blade. The groove machining blade is defined by an upper positioning surface, a lower positioning surface, two side surfaces and two end surfaces, wherein the two side surfaces and the two end surfaces connect the upper positioning surface with the lower positioning surface. A front cutter surface connecting the upper surface with at least one of the end surfaces is arranged between the end surface and the upper positioning surface. Two side rear cutter surfaces are arranged between the single front cutter surface and the adjacent end surface as well as between the single front cutter surface and the adjacent side surface correspondingly. The side rear cutter surfaces, the end surfaces and the front cutter surface intersect to form a side edge and an end edge correspondingly. The end edge of a double-edged structure is composed of an upper end edge body and a lower end edge body. The groove machining blade has the characteristics of being high in chip breaking ability, high in machining surface quality, long in life and high in cutting efficiency.

Owner:刘辞海

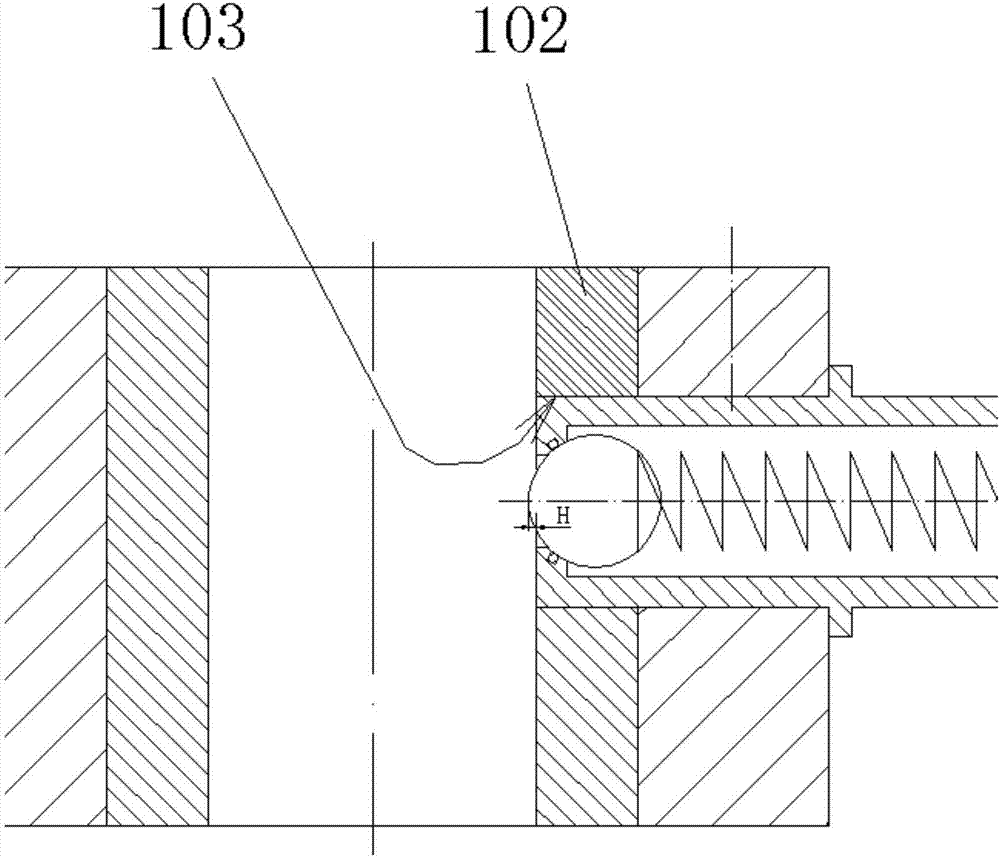

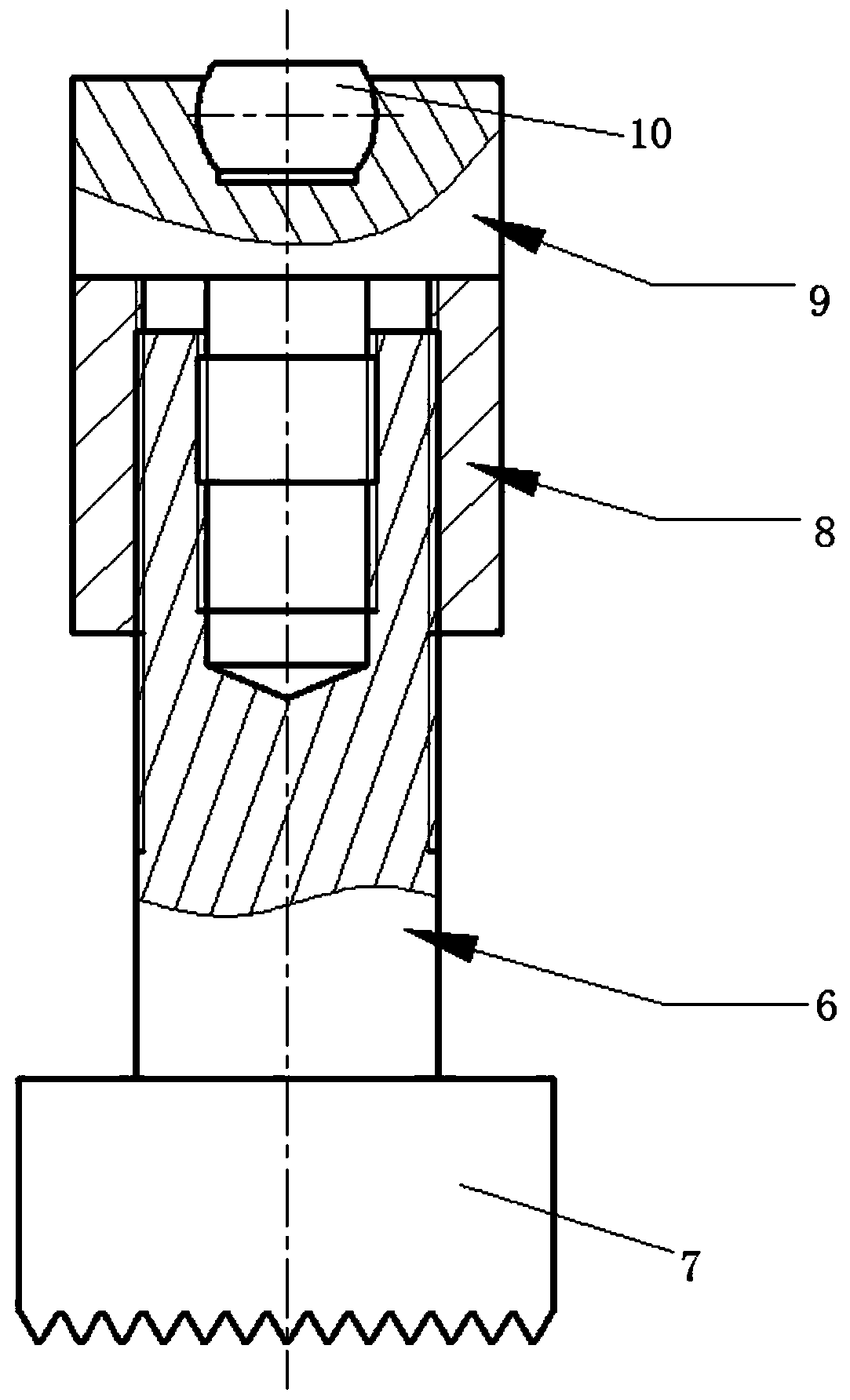

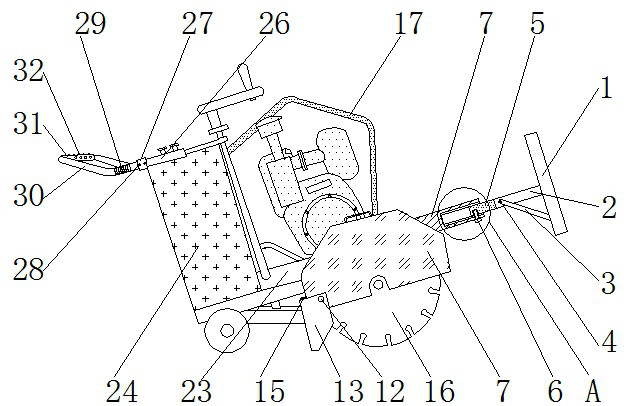

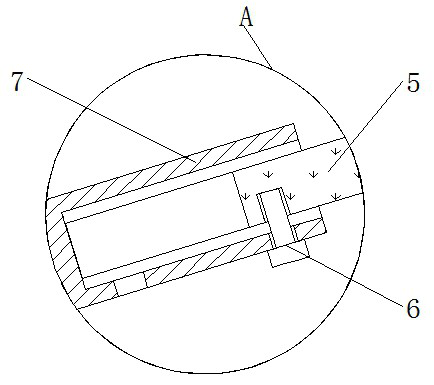

Drilling jig with automatic drill hole lubricating function

PendingCN107127375AImprove cutting conditionsFilling speed controlMaintainance and safety accessoriesDrill jigsThermodynamicsCooling fluid

The invention relates to the technical field of hole drilling, in particular to a drilling jig with an automatic drill hole lubricating function. The drilling jig comprises a drilling jig assembly, a cooling and lubricating assembly and a liquid supplying device. The drilling jig assembly comprises a drilling jig body and a drill bushing. The drill bushing is arranged in the drilling jig body, a transverse through hole is formed in the hole wall of the drill bushing, the cooling and lubricating assembly is arranged on the drilling jig body and communicates with the transverse through hole of the drill bushing, and the liquid supplying device communicates with the cooling and lubricating assembly. The drilling jig achieves automation of filling and stopping of cooling liquid or lubricating liquid during hole drilling and overcomes the defects that in traditional manual cooling liquid or lubricating liquid filling, the hole drilling efficiency is reduced, safety is poor and pollution is caused easily.

Owner:JIANGYIN PUYANG FLANGE

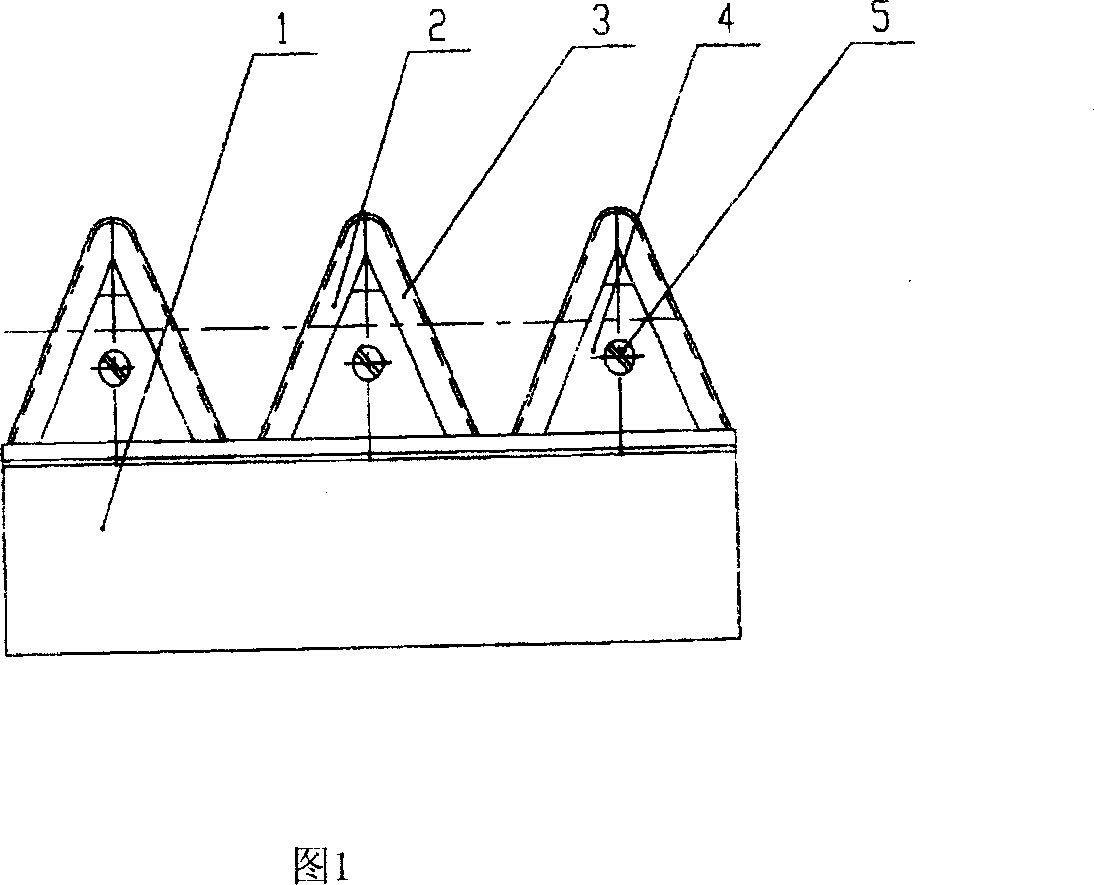

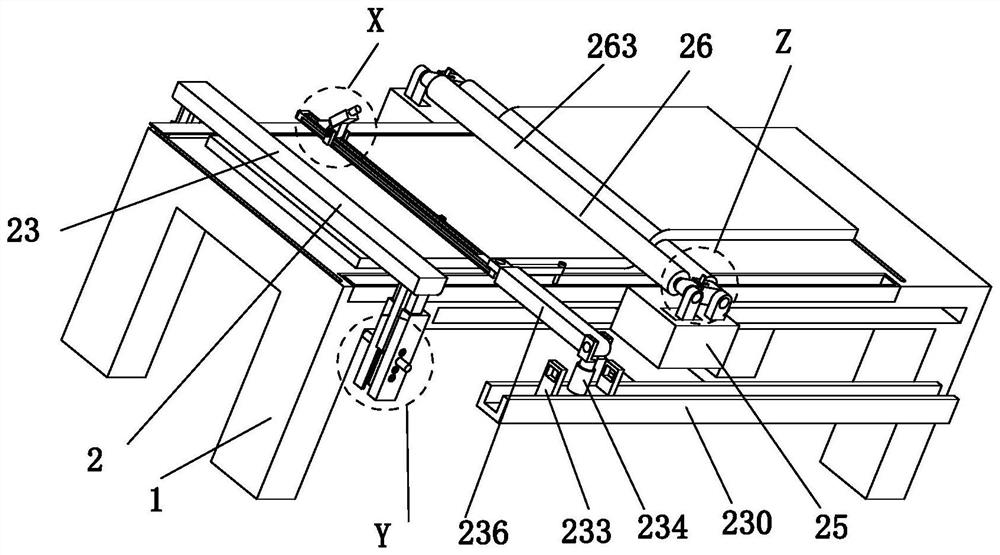

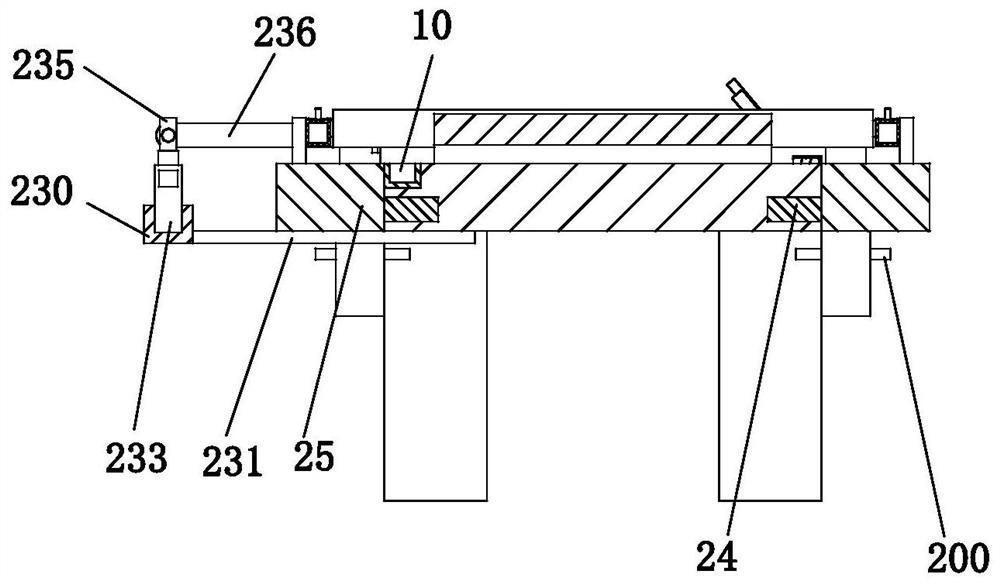

Multifunctional three-dimensional gathering profiling header

The invention relates to the technical field of agriculture and forestry machinery, in particular to a device for profiling cutting of bushes on complex ground. The invention aims to provide a multifunctional three-dimensional gathering profiling header, and aims to solve the problem of poor bush cutting profiling capability in the prior art. After a control console is controlled to enable a gathering and cutting part to complete the cutting action, switching of cutting stations of the gathering and cutting part and a three-dimensional cutting part is achieved through a station switching mechanism. The cutting amplitude of a profiling cutting tool of the three-dimensional cutting part is adjusted through reciprocating swing of a parallel four-bar mechanism, good cutting conditions are provided for the bushes on the complex ground, and therefore the cutting quality of the bushes is improved.

Owner:BEIJING FORESTRY UNIVERSITY

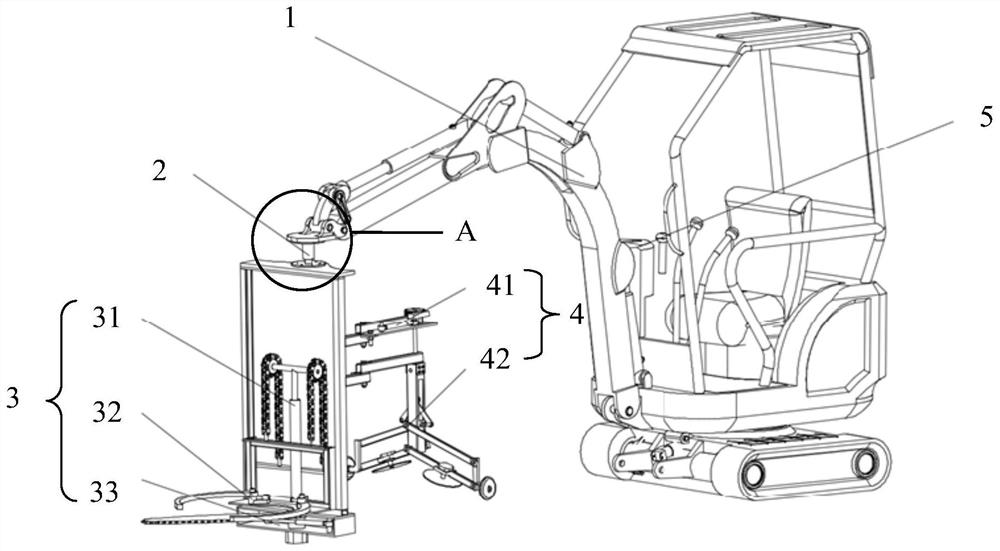

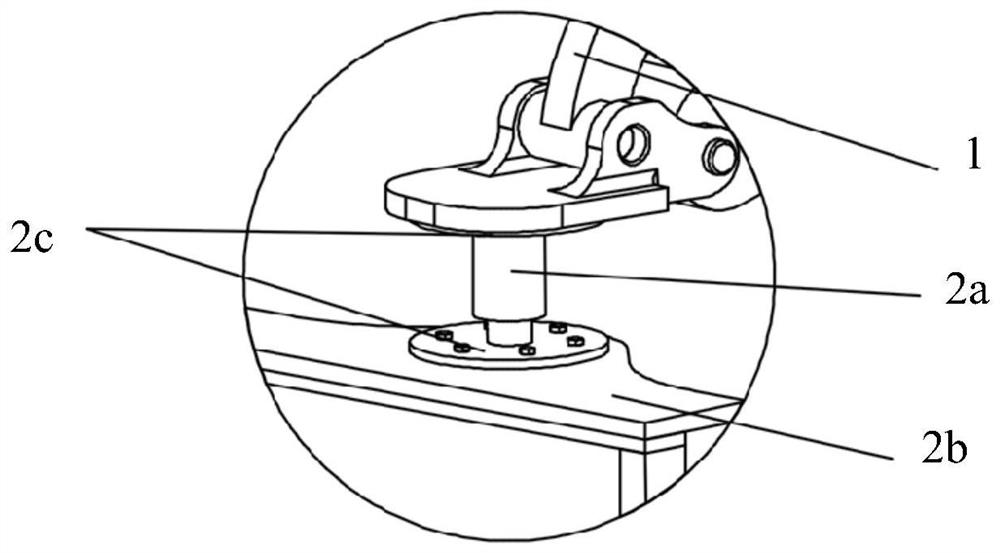

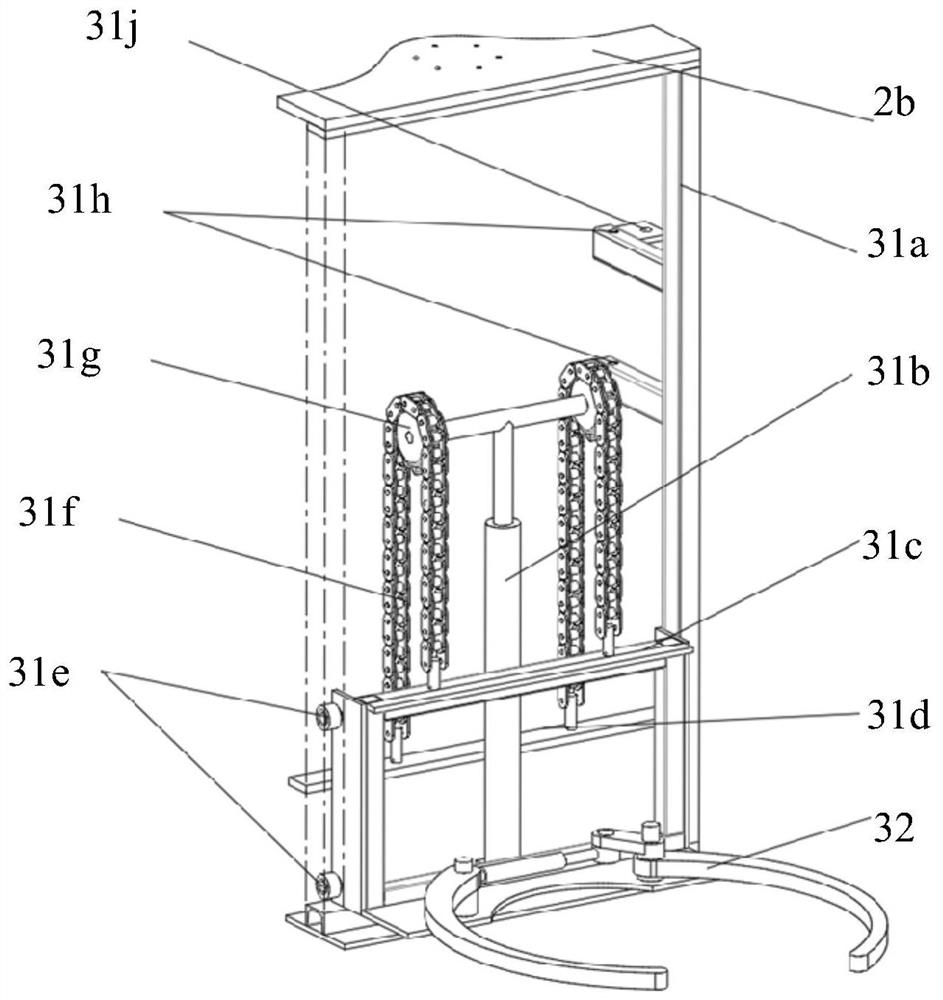

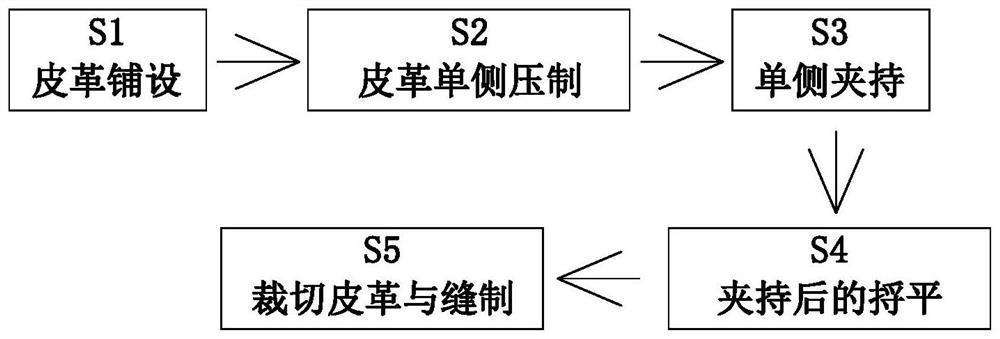

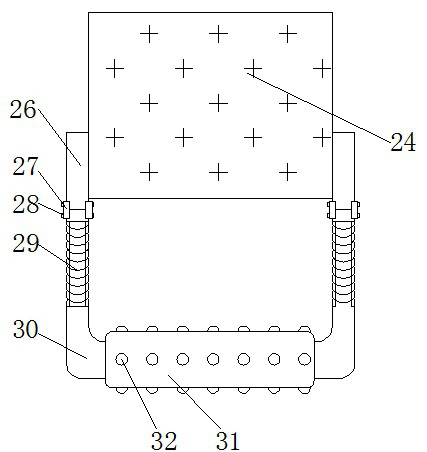

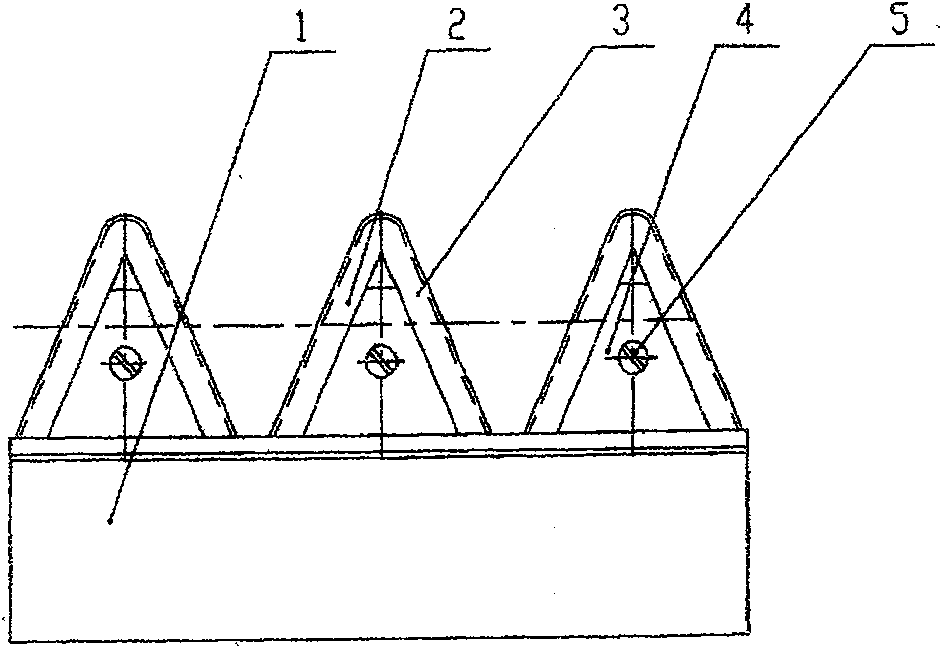

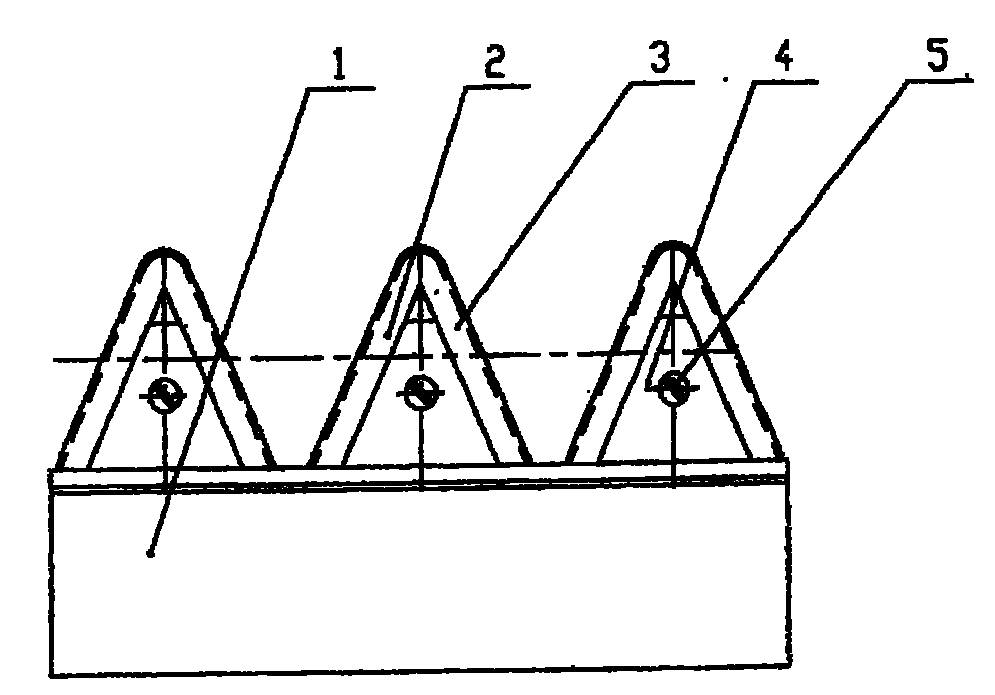

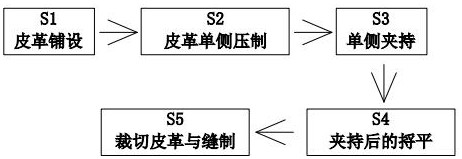

Leather product leather cutting and sewing processing technology

ActiveCN113005241APlay a smoothing roleImprove flatnessLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusProcess engineeringIndustrial engineering

The invention relates to a leather product leather cutting and sewing processing technology which uses a leather product leather cutting and sewing processing device. The leather product leather cutting and sewing processing device comprises a working table and a clamping and fixing mechanism, the working table is installed on the existing ground, and the clamping and fixing mechanism is arranged at the upper end of the working table. According to the leather product leather cutting and sewing processing technology, the multi-adjustment design concept is adopted for leather product leather cutting and sewing processing; the arranged clamping and fixing mechanism can clamp and fix the two side ends of leather and can also play a role in smoothing the leather to keep the optimal flatness of the leather, and then the overall cutting quality of the leather is improved; meanwhile, a rolling smoothing structure is adopted so that the probability of motion clamping stagnation of the structure can be reduced by generating rolling friction; and the whole device can also realize switching between a vertical leather cutting mode and a transverse leather cutting mode, so that the adaptation degree of the device to the leather cutting requirement is greatly improved.

Owner:江苏延立汽车零部件有限公司

Slitting mechanism

Owner:CHONGQING LONGJIAN METAL MFG

Three-jaw chuck with adjustable auxiliary supporting structure and using method for three-jaw chuck

The invention relates to the technical field of machining, in particular to a three-jaw chuck with an adjustable auxiliary supporting structure and a using method for the three-jaw chuck. A machined part is placed in a chuck hole formed in the center of the middle part of a chuck body and is then supported and clamped by the soft jaws in three soft jaw clamping grooves, supporting columns, heightsof which can be adjusted up and down, are put in supporting column gear grooves respectively and are adjusted to leveling the machining surface of the machined part, and finally the machining part ismachined. Through the three-jaw chuck of the structure, the auxiliary supporting position and the supporting height can be adjusted, so that the rigidity of a cutting system is improved, the system can bear more cutting force, the cutting condition is improved, and the cutting process is more stable.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

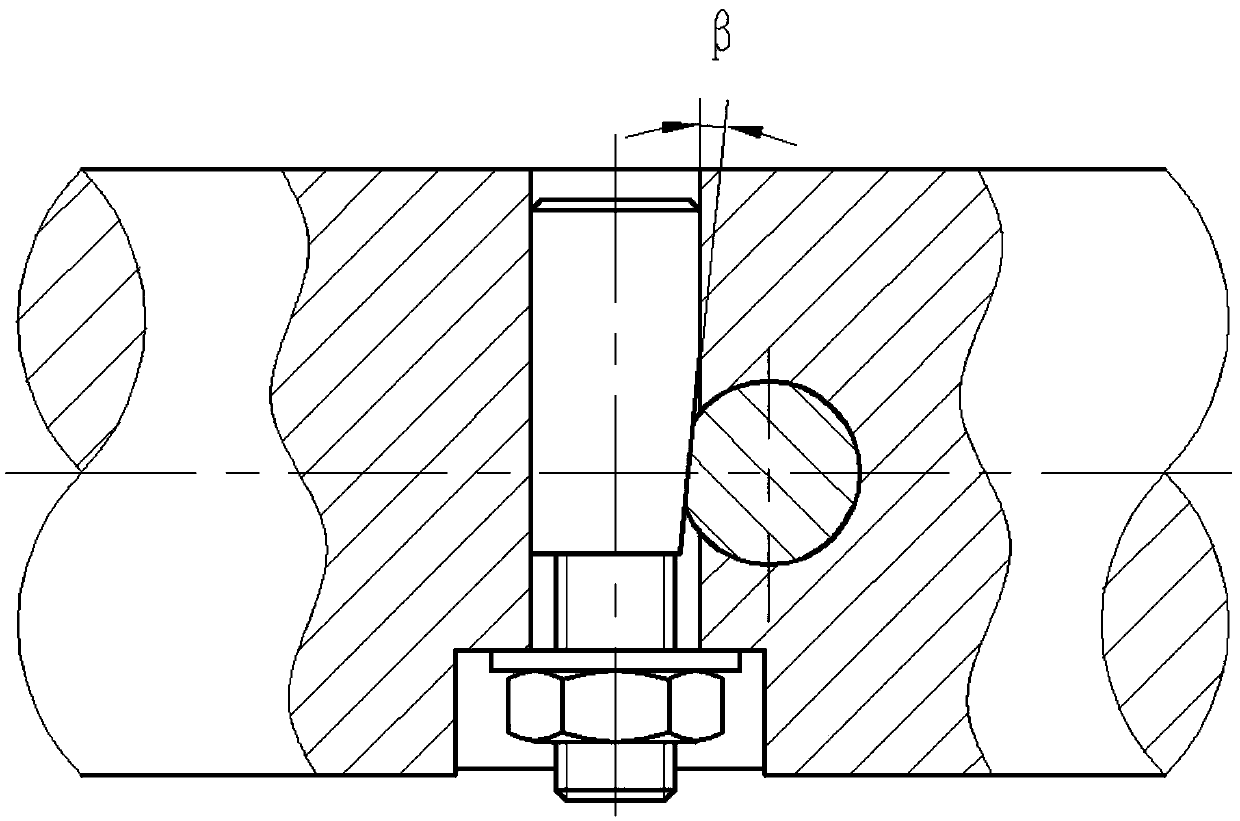

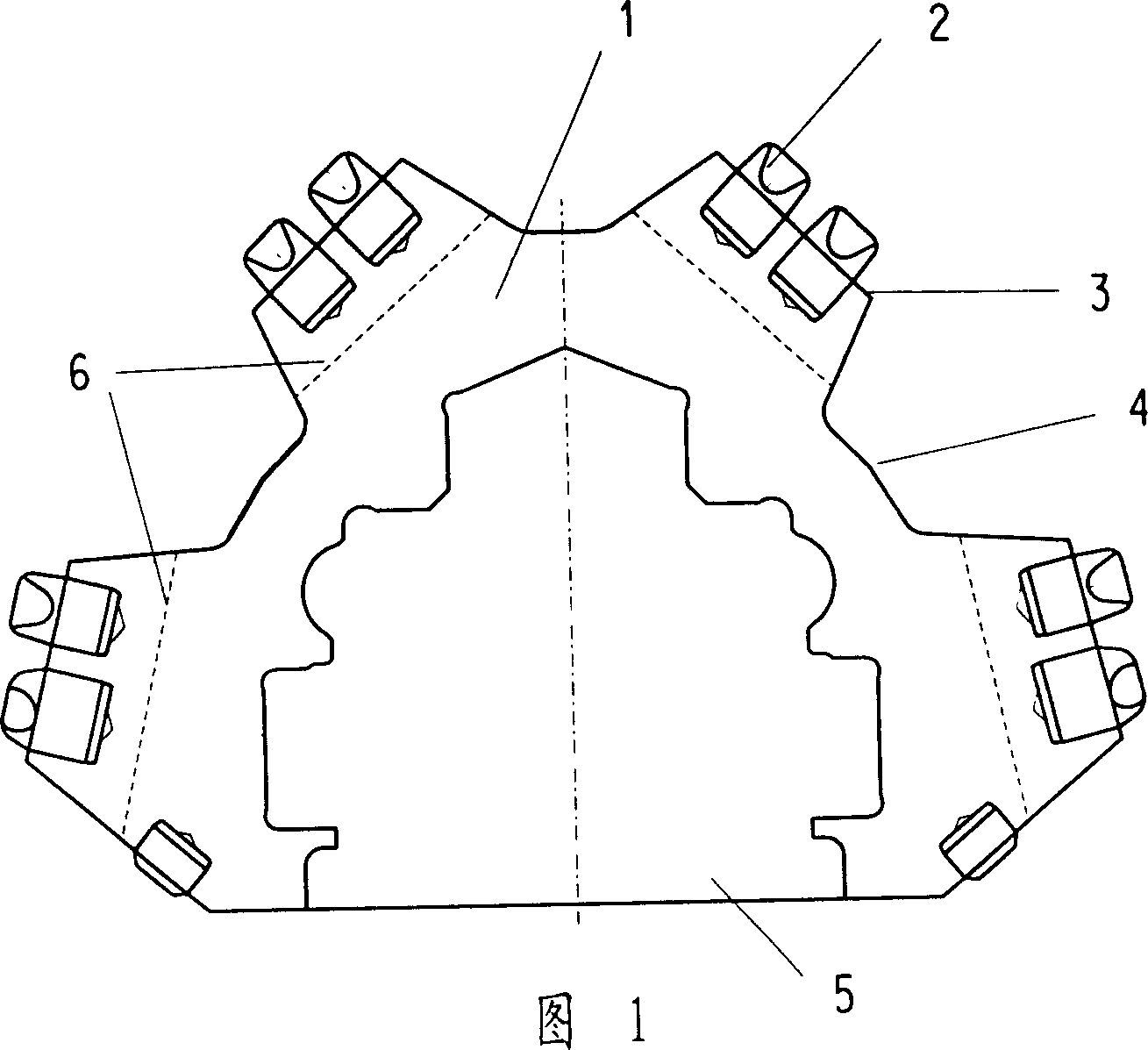

Double vertical clamping structure for finely adjusting double-worm-wheel fly cutter radially

PendingCN111283273AFlexible movementFlexible anti-rustWorm wheelsGear-cutting machinesEngineeringStructural engineering

The invention discloses a double vertical clamping structure for finely adjusting a double-worm-wheel fly cutter radially. A center hole which faces the active end and is concentric with a rotating central line of a cutter bar is formed in the passive end of the cutter bar, two parallel two-section stepped concentric holes for mounting, clamping and finely adjusting the fly cutter are radially formed along the rotating central line of the cutter bar, large holes of the two-section stepped concentric holes are cylindrical holes, small holes of the two-section stepped concentric holes are screwthrough holes, and the center distance between the two-section stepped concentric holes is the axial tooth pitch of a working worm; two sections of threads which are the same in screwing direction anddifferent in screw pitch are arranged on a locking screw and correspondingly connected with the screw through holes and a screw hole formed in a fly cutter round straight handle, so that the fly cutter is never loosened after being finely adjusted and clamped in the radial direction of the cutter bar; and a positioning clamping mechanism is arranged in the center hole, the oblique end faces of the opposite ends of a positioning jacking rod slide onto the obliquely-beveled plane of the fly cutter round straight handle to form close face contact under the combined action of the locking screw and a force applying component, and the fly cutter is fastened in the corresponding cylindrical hole and located at the correct position. The radial fine-adjusting and positioning double vertical clamping technical scheme is suitable for high-precision and large-cutting-force rolling cutting of multi-head worm wheels.

Owner:中钢集团衡阳机械有限公司

A compound deformed high-strength cutting steel wire and its manufacturing method

ActiveCN103963181BIncrease cutting kinetic energyGood chip removal effectWire articlesFine working devicesGallium arsenateWire cutting

The invention discloses a composite deformation type high-strength sawing wire and a manufacturing method thereof. The sawing wire is of a structure that edge-folding deformation exists in a single plane and bending deformation exists in three-dimensional space. In the single plane, the sawing wire is bent into a wavy structure, and crest heights of a composite deformed wire are identical within the spatial range. The composite deformation type high-strength sawing wire and the manufacturing method thereof solve the problems existing in traditional multi-wire cutting. The sawing wire has a periodical deformation feature, multiple inner spatial structures are formed by the deformed wire in each period, and then more mortar can be brought in when the sawing wire is used; meanwhile, auxiliary blades formed by edge-folding and bending deformation can play a role in chip removal, and the sawing wire is especially good at cutting hard and brittle materials such as solar silicon wafers, quartz, silicon ingots, ceramics, sapphire, gallium arsenide and stone.

Owner:江苏宝钢精密钢丝有限公司

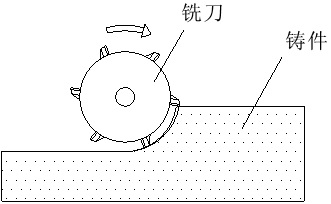

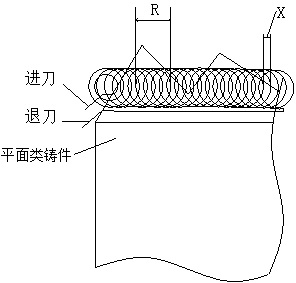

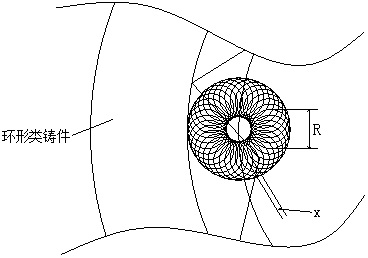

Cycloid machining method for large-allowance casting blank

InactiveCN113523377AAvoid lossAvoid vibrationMilling equipment detailsMechanical componentsMilling cutter

The invention relates to the technical field of machining of mechanical parts, in particular to a cycloid machining method for a large-allowance casting blank. A datum plane of a casting is determined, the blank allowance thickness of the surface of the casting is determined, a cutter is fed in a spiral cycloid manner according to the blank allowance, and the blank is milled by the cutter in a down-milling manner. When the milling cutter cuts into the workpiece blank, the cutter point cuts into the casting blank, the shearing force generated when the cutter point cuts into the casting blank is obviously smaller than the force generated in the mode that the middle section of a cutting edge cuts into the casting blank, and the impact load in the cutting process is also relatively small. According to the method, the cutter path can be determined, the cutter moves circularly and swings in the direction of a straight line or a circle or the edge of a part, materials of the to-be-cut part in a blank workpiece are divided into cutting layers with the uniform thicknesses in the direction of being perpendicular to the swing direction of the cutter, the cutting layers are cut off layer by layer in the swing process of the cutter, and the phenomena that due to the fact that the blank is uneven, large fluctuation of the cutting force is generated, and vibration in the machining process and the loss of the cutter are generated are avoided.

Owner:CRRC YANGTZE TONGLING CO LTD

Roller bit with parallelly inlaid teeth

A roller bit with parallelly inlaid teeth is composed of tooth base and toothed roller with tooth ring and splines, and features that 2-3 cylindrical teeth are parallelly inlaid on the top of each roller tooth on tooth ring along the direction of roller tooth. Its advantags are high cutting performance, easy machining. It is suitable for the sandwith stratum containing soft and hard strata.

Owner:SINOPEC OILFIELD EQUIP CORP

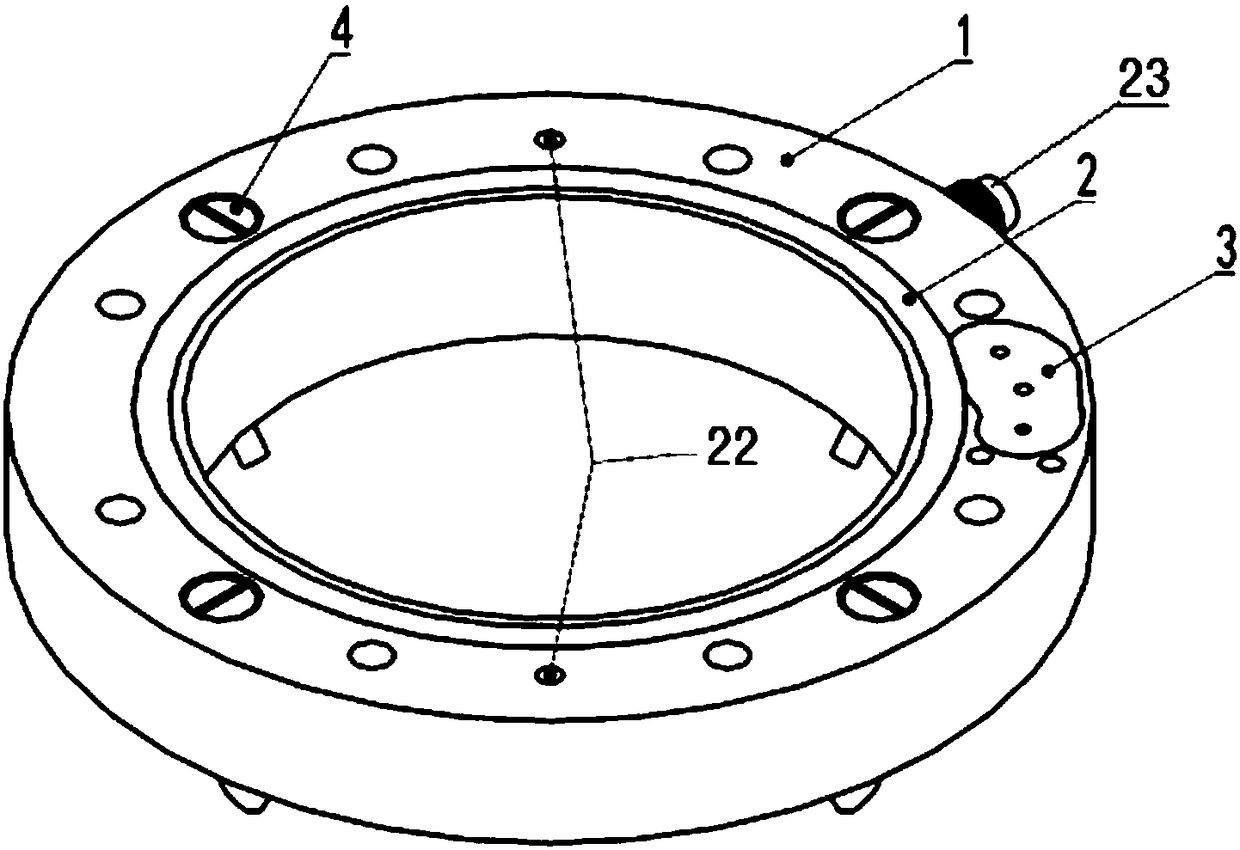

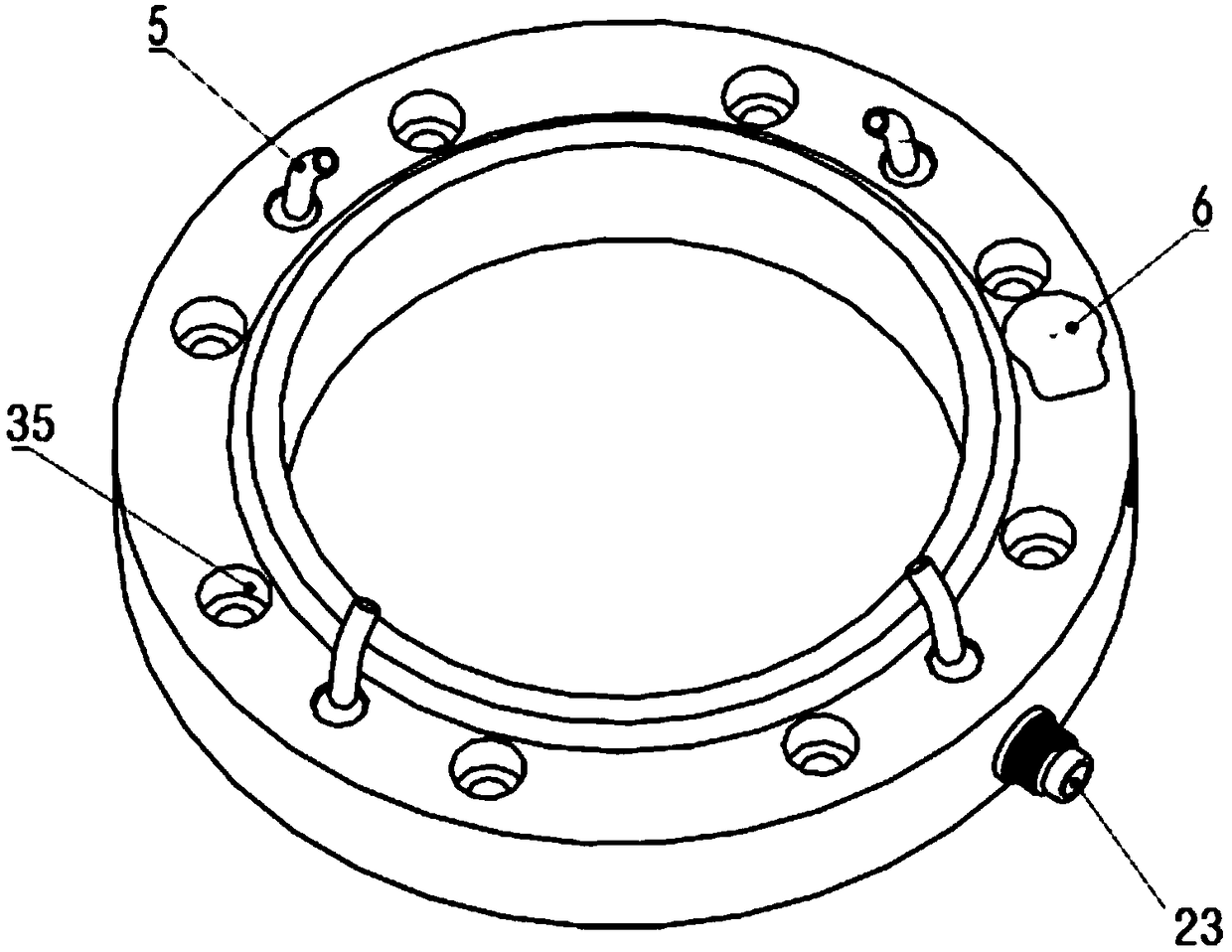

Main shaft annular water spraying device

PendingCN108097485AImprove cutting conditionsHigh degree of automationMovable spraying apparatusSpray nozzleEngineering

The invention discloses a main shaft annular water spraying device, and belongs to the field of machining machine tool main shafts. The main shaft annular water spraying device comprises an annular end cover main body, a gear ring and water spraying devices; the gear ring cooperates with the annular end cover main body, and can be coaxially rotated relative to the annular end cover main body; an internal water tank is formed in the annular end cover main body; the annular end cover main body is provided with a water inlet communicating with the internal water tank; the annular end cover main body is provided with multiple water spraying devices along the internal water tank; the water spraying devices are provided with nozzles; the nozzles communicate with the internal water tank through the water spraying devices; and when each water spraying device is coaxially rotated along with the gear ring relative to the annular end cover main body, each water spraying device synchronously and consistently swings back and forth in the axial direction relative to the gear ring. The main shaft annular water spraying device is compact in structure and free of occupying external space near mainshafts, can totally save external water spraying pipes, can automatically adjust the positions of the nozzles to achieve higher convenience and accuracy, improves the cutter cutting conditions, reduces the defect of gradual manual adjustment, and improves the automation degree and the machining efficiency of machine tools.

Owner:鲁光波

Machining method of stainless steel part with aluminum honeycomb core

ActiveCN111054954AGuarantee processing qualityImprove cooling effectMilling equipment detailsPositioning apparatusNumerical controlMilling cutter

The invention discloses a machining method of a stainless steel part an aluminum honeycomb core. The method comprises the following steps that 1) a part body is mounted on a machine tool workbench through a positioning clamp, the lower surface of the part body is fitted to the upper surface of the positioning clamp, and the fitted plane is taken as a clamping positioning surface; (2) in the process of numerical control machining of the part body, different milling cutters are used for milling different materials in the part body layer by layer, and the milling cutters all carry out cycloid milling; and 3) after milling is completed, burrs are removed, and machining is completed. According to the method, by means of layered machining, it can be guaranteed that the different cutters are usedfor the different materials in a sandwich structure during part machining, and the machining quality is guaranteed; under the condition that fluid cooling liquid cannot be used, cuttings can be automatically taken away in a cycloid milling mode, cooling is sufficient, heat dissipation is guaranteed, conditions are improved, deflection and flutter of the cutters can be reduced, the cutting force is stable, and the service life of the tools is prolonged; and due to effective diffusion of cutting heat, the machining quality and efficiency of parts are improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Road cutting machine with cutting track synchronous observation function and cutting method

InactiveCN112554021ASynchronously observe cutting track functionImprove cutting conditionsRoads maintainenceButt jointEngineering

The invention discloses a road cutting machine with a cutting track synchronous observation function. The road cutting machine with the cutting track synchronous observation function comprises a mirror, a protective plate and a connecting block, a storage groove is formed in one side of the mirror, a supporting rod is embedded in the surface of the storage groove, a rotating shaft is connected into the supporting rod, and a connecting rod is connected to the surface of the middle of the rotating shaft; a bolt is connected to the interior of the connecting rod, and a sleeve rod is connected tothe surface of the bolt. The road cutting machine with the cutting track synchronous observation function is provided with the mirror, the mirror is in butt joint with the corresponding mounting holein the sleeve rod through the bolt, so that the sleeve rod and the connecting rod are fixed, the mirror is rotated through the rotating shaft on one side of the mirror, and meanwhile, the supporting rod connected to one side of the mirror rotates through the rotating shaft to support the mirror; therefore, the mirror can better reflect the cutting condition of the saw blade, and a worker can observe the cutting track of the saw blade in real time in the cutting process.

Owner:宁波曼汶智能装备有限公司

Hard alloy precision working rack type cutter and processing technique

InactiveCN101134255BHigh cutting hardnessMeet the process requirementsGear teeth manufacturing toolsGear teethAlloyHardness

The present invention is one kind of hard alloy combing cutter for finish machining and its machining process. The hard alloy combing cutter has one cutting blade made of YT798 hard alloy plate and one cutter body of 40Cr steel. It is machined through semi finishing of cutting blade, milling the cutter body in a universal milling machine to form the front edge and tooth form and boring the locating hole for the blade in a high accuracy jig boring machine, assembling the blade locating board onto the cutter body while controlling the tooth pitch and tooth thickness of the cutting edge, high frequency welding the cutting blade to the cutter body and timely tempering, grinding the front edge of the cutting edge in a cutter grinding machine, and wire electrode cutting the tooth form in high precision wire electrode cutting equipment. The hard alloy combing cutter has high cutting hardness and high wear resistance, and may be applied for finish machining great modulus gear with medium hardness tooth surface.

Owner:CITIC HEAVY INDUSTRIES CO LTD

A kind of processing technology of leather material cutting and sewing thread

ActiveCN113005241BPlay a smoothing roleImprove flatnessLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusProcess engineeringIndustrial engineering

The invention relates to a process for processing leather trimming stitches for leather products, which uses a leather trimming stitching processing device for leather products. The leather trimming stitching processing device includes a workbench and a clamping mechanism. The workbench is installed on the existing ground, and the upper end of the workbench is provided with a clamping mechanism. The present invention adopts a multi-adjustment design concept for leather cutting and suture processing. The implementation of the clamping treatment can also smooth the leather to maintain the best flatness of the leather, thereby improving the overall cutting quality of the leather. At the same time, the rolling and smoothing structure is adopted to reduce the appearance of the structure by generating rolling friction The probability of motion jamming is reduced, and the device as a whole can also realize the conversion between the dual modes of vertically cutting leather and horizontally cutting leather, thereby greatly improving the adaptability of the device to leather cutting requirements.

Owner:江苏延立汽车零部件有限公司

Technique for preparing machine holding carbide alloy rack type gear shaper cutter

InactiveCN100571969CHigh cutting hardnessMeet the requirements of comb processingMilling cutterGear wheel

A manufacturing process of machine-clamped hard alloy comb-tooth cutter. The blade is YT798, and the positioning threading hole is pre-punched by the electric spark piercer, and then the thickness and width of the blade are ground by a grinder to meet the design requirements. The required thickness size and roughness, then use slow wire cutting to cut the shape of the blade and the positioning hole for assembly, and evenly coat the blade with titanium aluminum nitride, use a special fixture to fine-mill the groove shape of the blade, and finally in the coordinate boring Bore assembly pilot holes. The cutter body is made of 42CrMo, and the shape of the cutter body, including the clamping size and rake angle, is adjusted and tempered and nitrided to HB265-305 with a special fixture, and the clamping position of the cutter body is roughly and finely ground with a special fixture. Finally, use a special mold to cut the tooth shape of the cutter body on the wire cutting machine, and cut the tooth shape and back angle in one clamping. It is assembled at one time through the fine repair and grinding of the blade groove by the model fitter. It is used for processing large modulus and high hardness gears.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com