Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7200results about "Fine working devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing semiconductor article

InactiveUS6534382B1Guaranteed high speed operationReduce power consumptionSemiconductor/solid-state device testing/measurementFinal product manufacturePorous semiconductorsSemiconductor

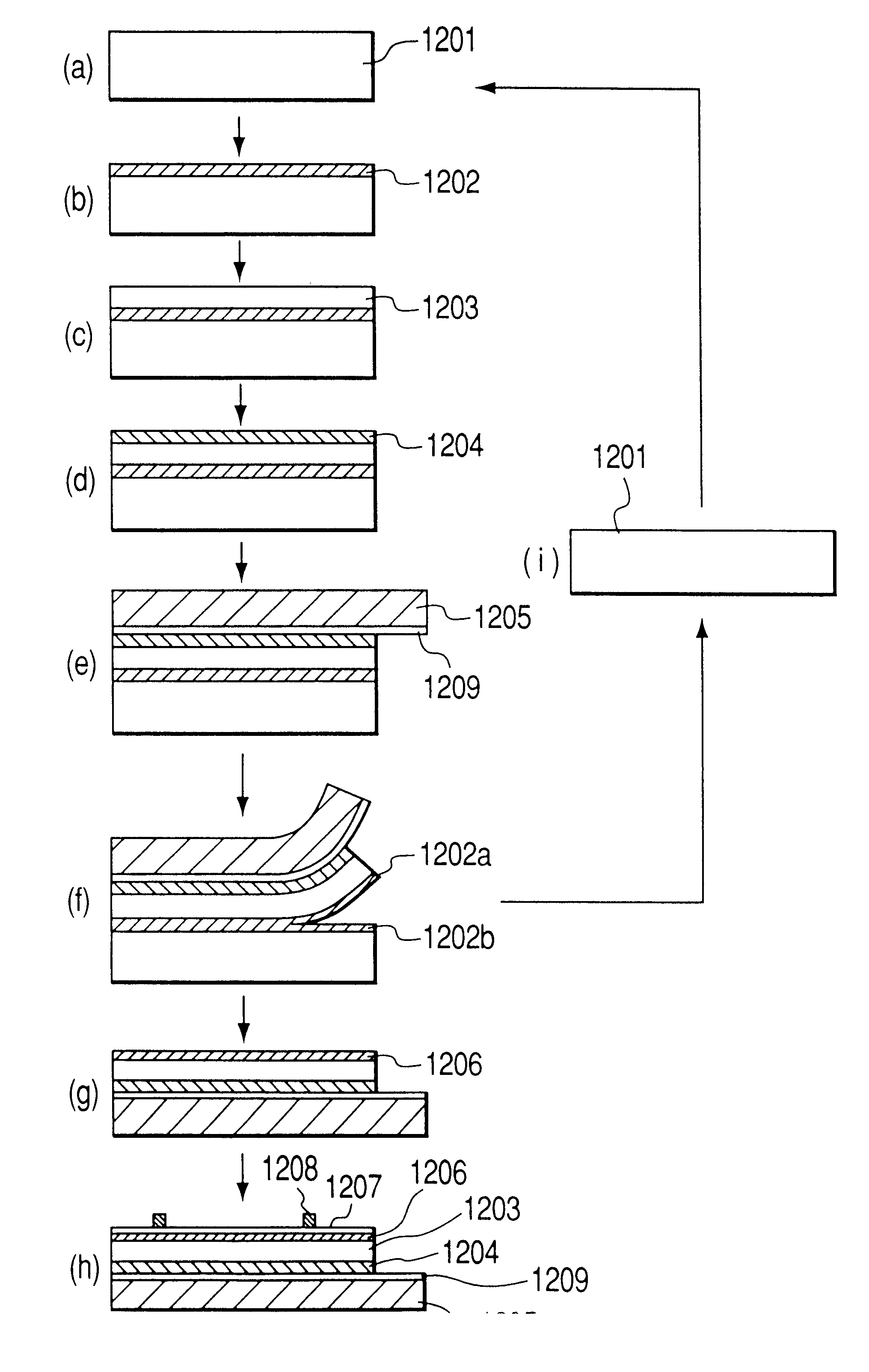

A process for producing a semiconductor article is provided which comprises the steps of bonding a film onto a substrate having a porous semiconductor layer, and separating the film from the substrate at the porous semiconductor layer by applying a force to the film in a peeling direction.

Owner:CANON KK

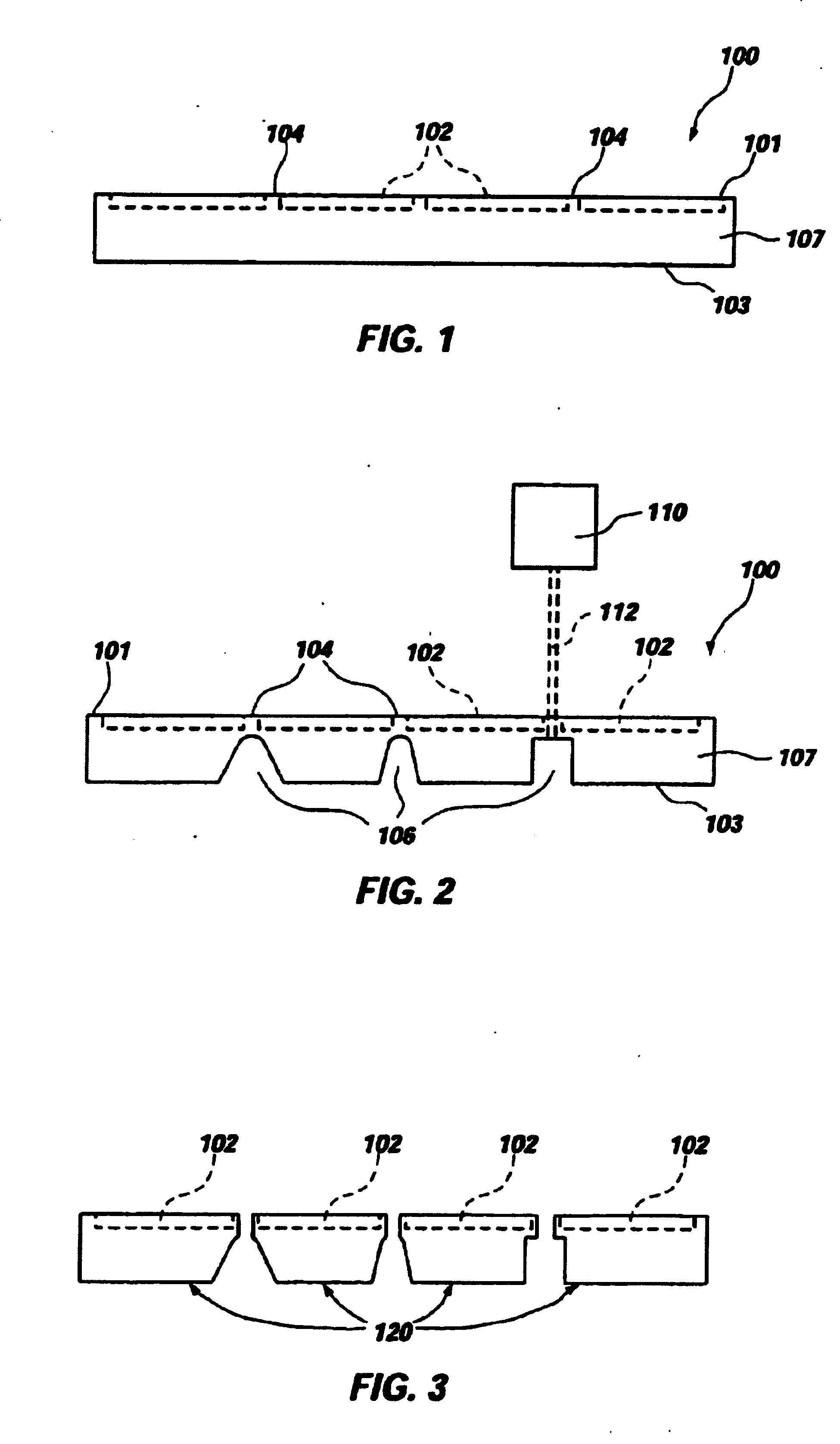

Process for the production of thin semiconductor material films

InactiveUSRE39484E1Uniform and controlled thicknessHigh implantationFluid pressure measurement by electric/magnetic elementsSolid-state devicesIon bombardmentMicrobubbles

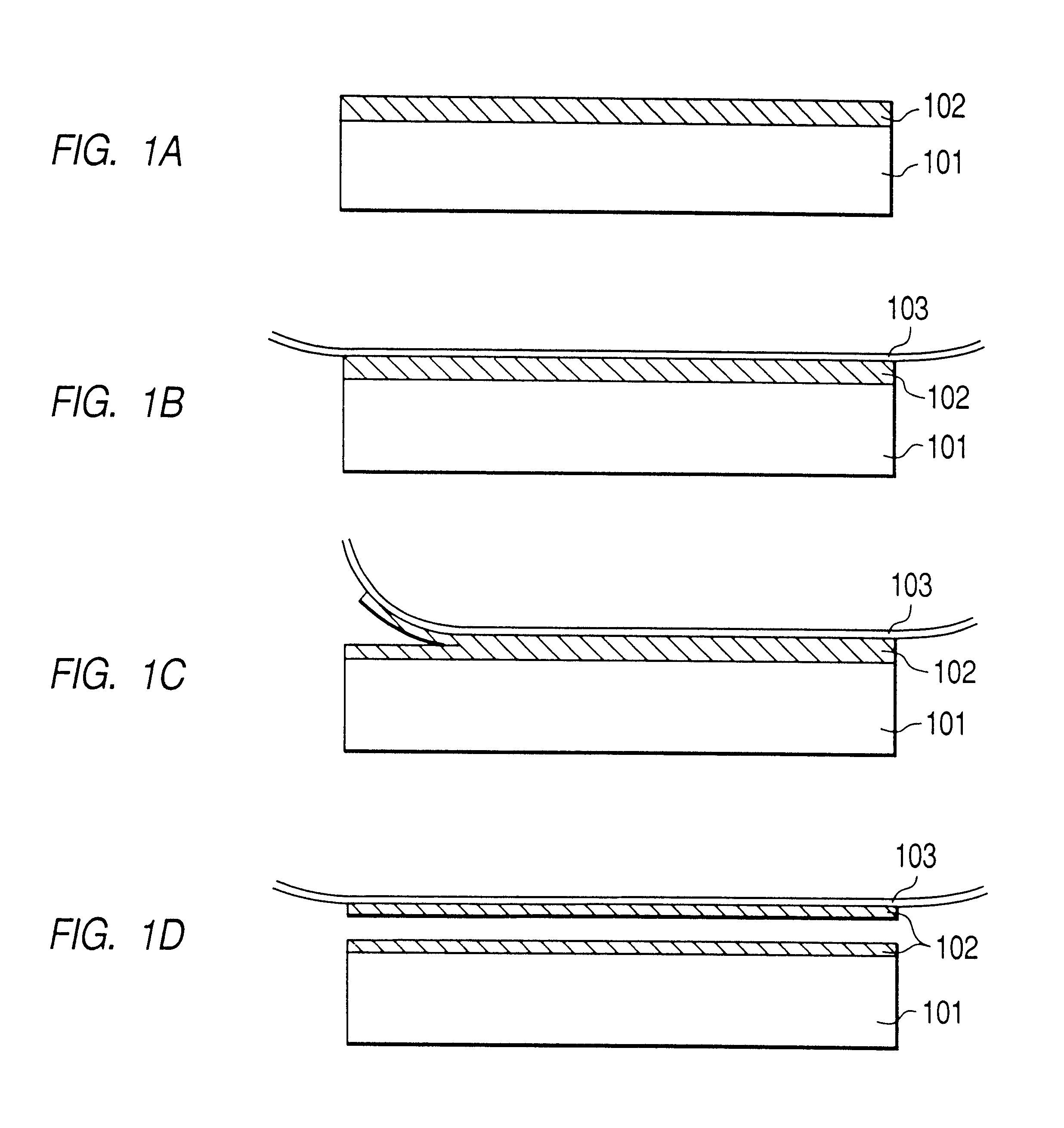

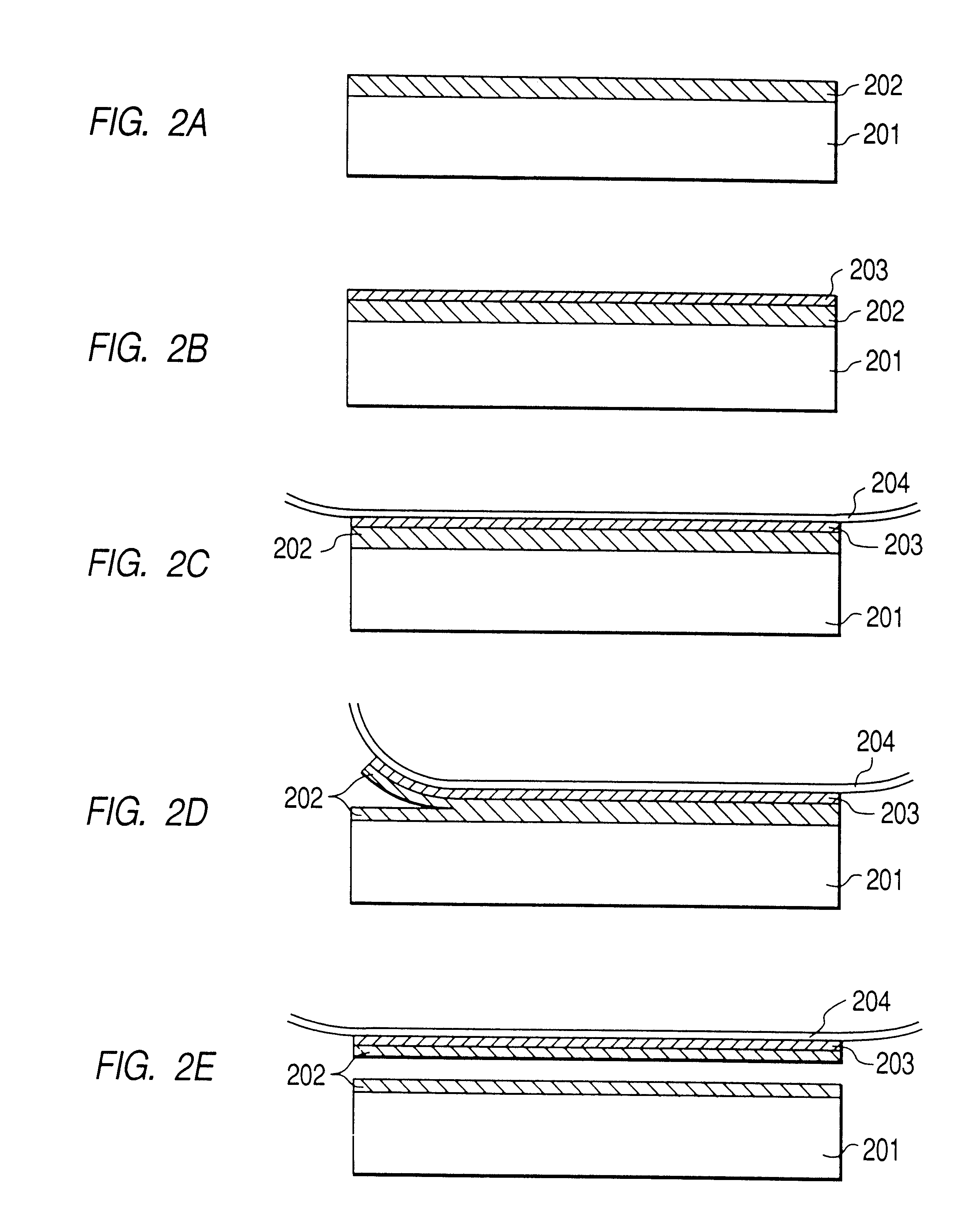

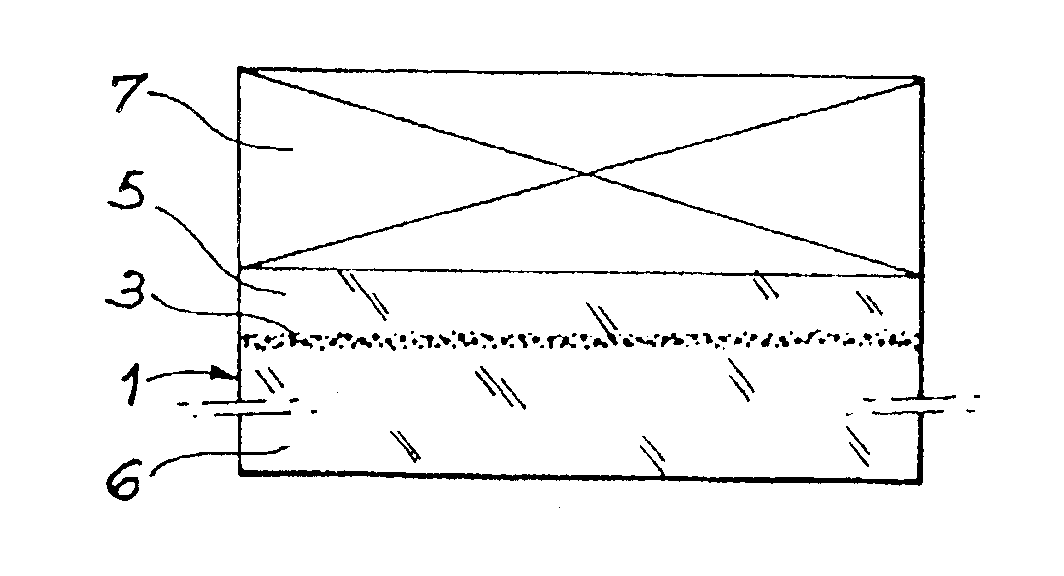

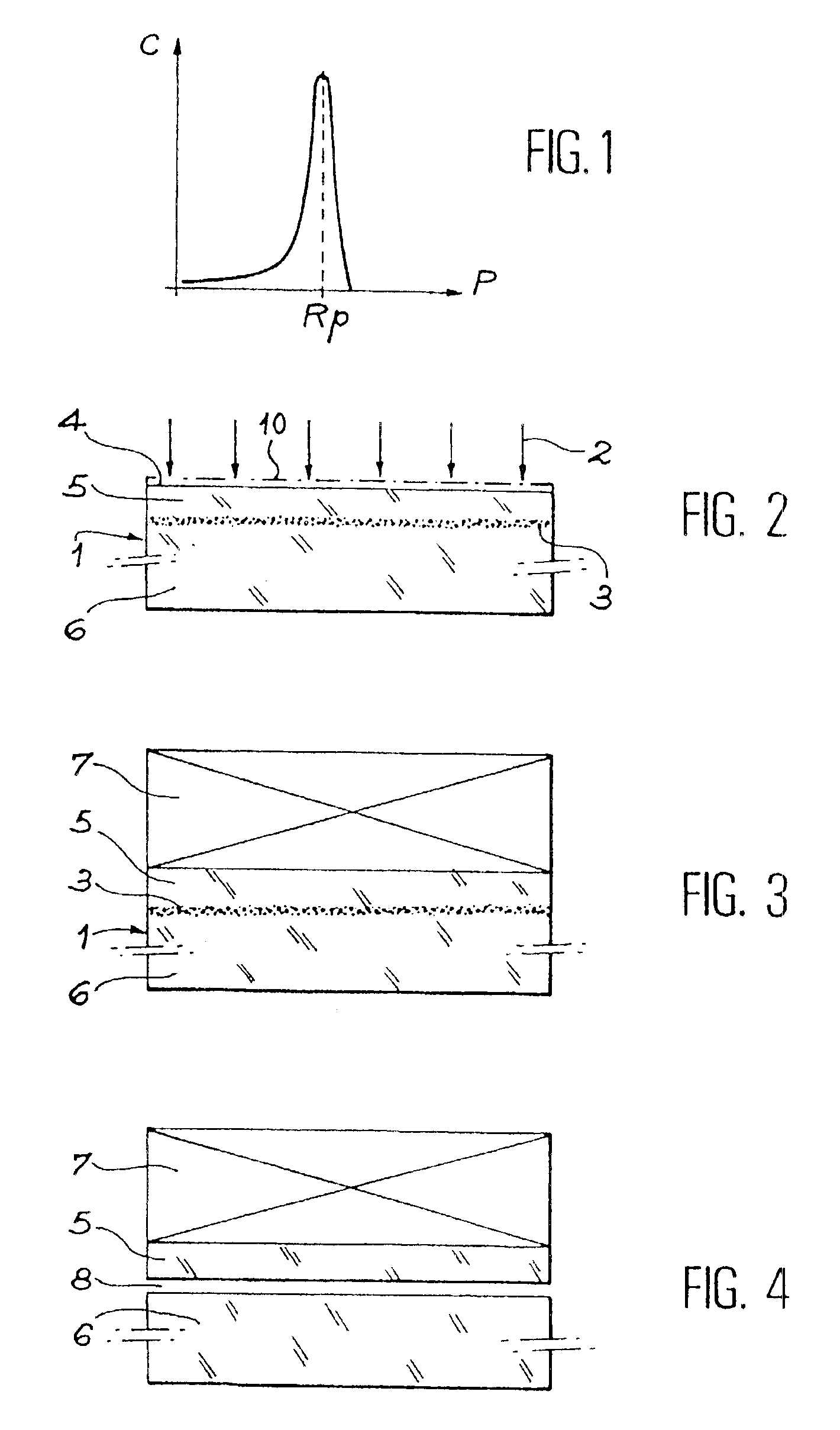

Process for the preparation of thin monocrystalline or polycrystalline semiconductor material films, characterized in that it comprises subjecting a semiconductor material wafer having a planar face to the three following stages: a first stage of implantation by bombardment (2) of the face (4) of the said wafer (1) by means of ions creating in the volume of said wafer a layer (3) of gaseous microbubbles defining in the volume of said wafer a lower region (6) constituting the mass of the substrate and an upper region (5) constituting the thin film, a second stage of intimately contacting the planar face (4) of said wafer with a stiffener (7) constituted by at least one rigid material layer, a third stage of heat treating the assembly of said wafer (1) and said stiffener (7) at a temperature above that at which the ion bombardment (2) was carried out and sufficient to create by a crystalline rearrangement effect in said wafer (1) and a pressure effect in the said microbubbles, a separation between the thin film (5) and the mass of the substrate (6).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

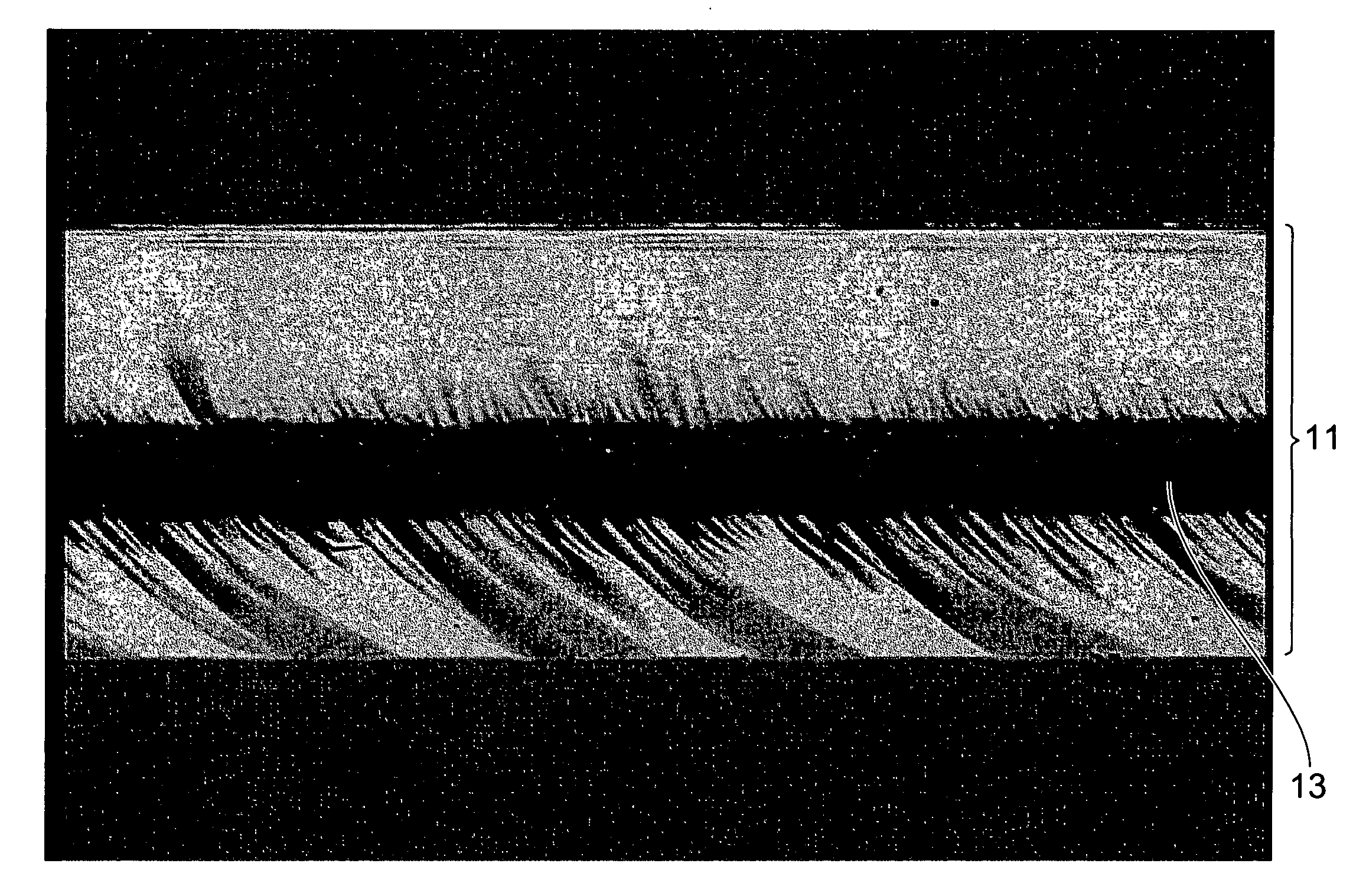

Transparent material processing with an ultrashort pulse laser

InactiveUS20100025387A1Reduce quality problemsPoor precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

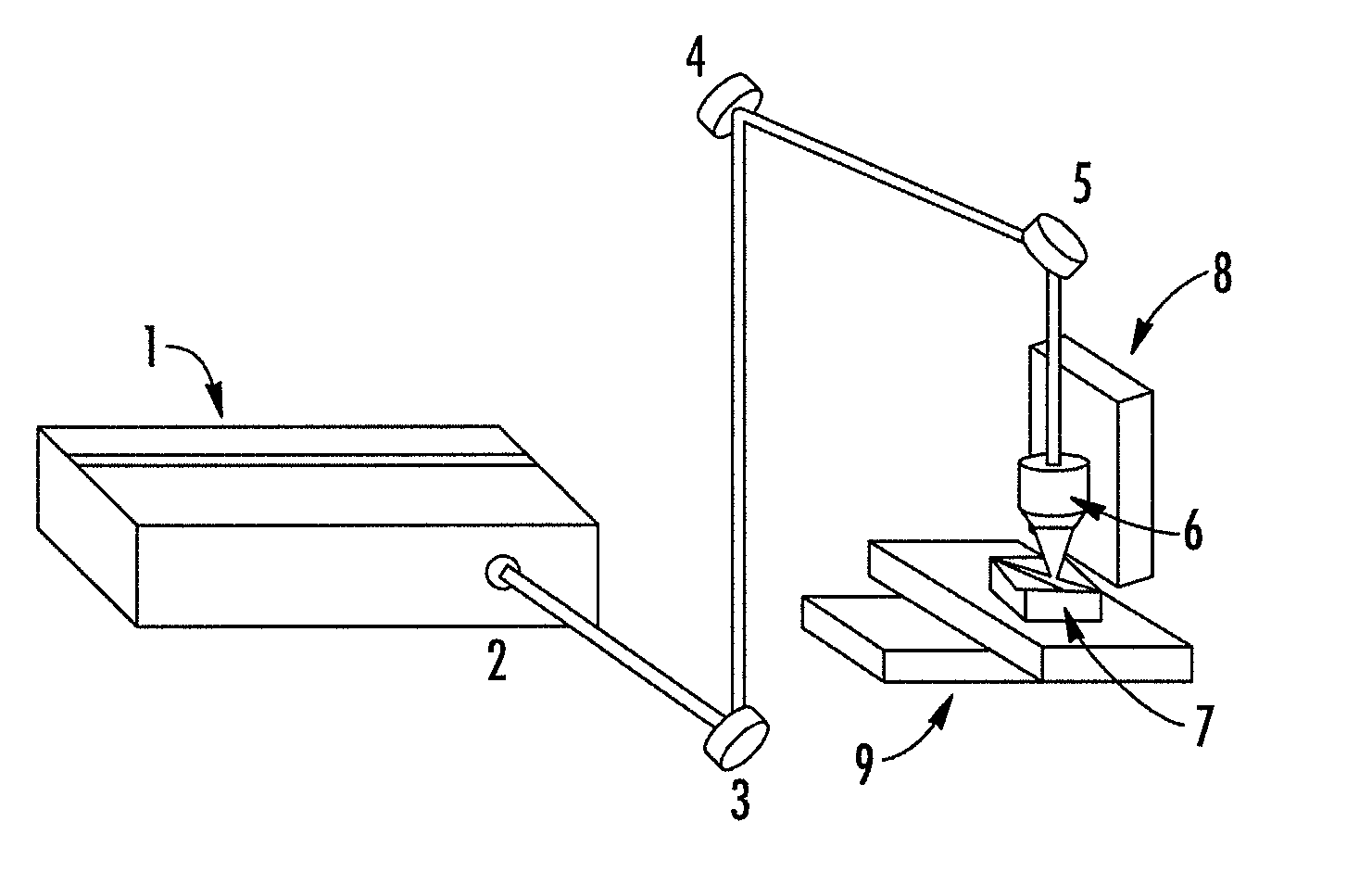

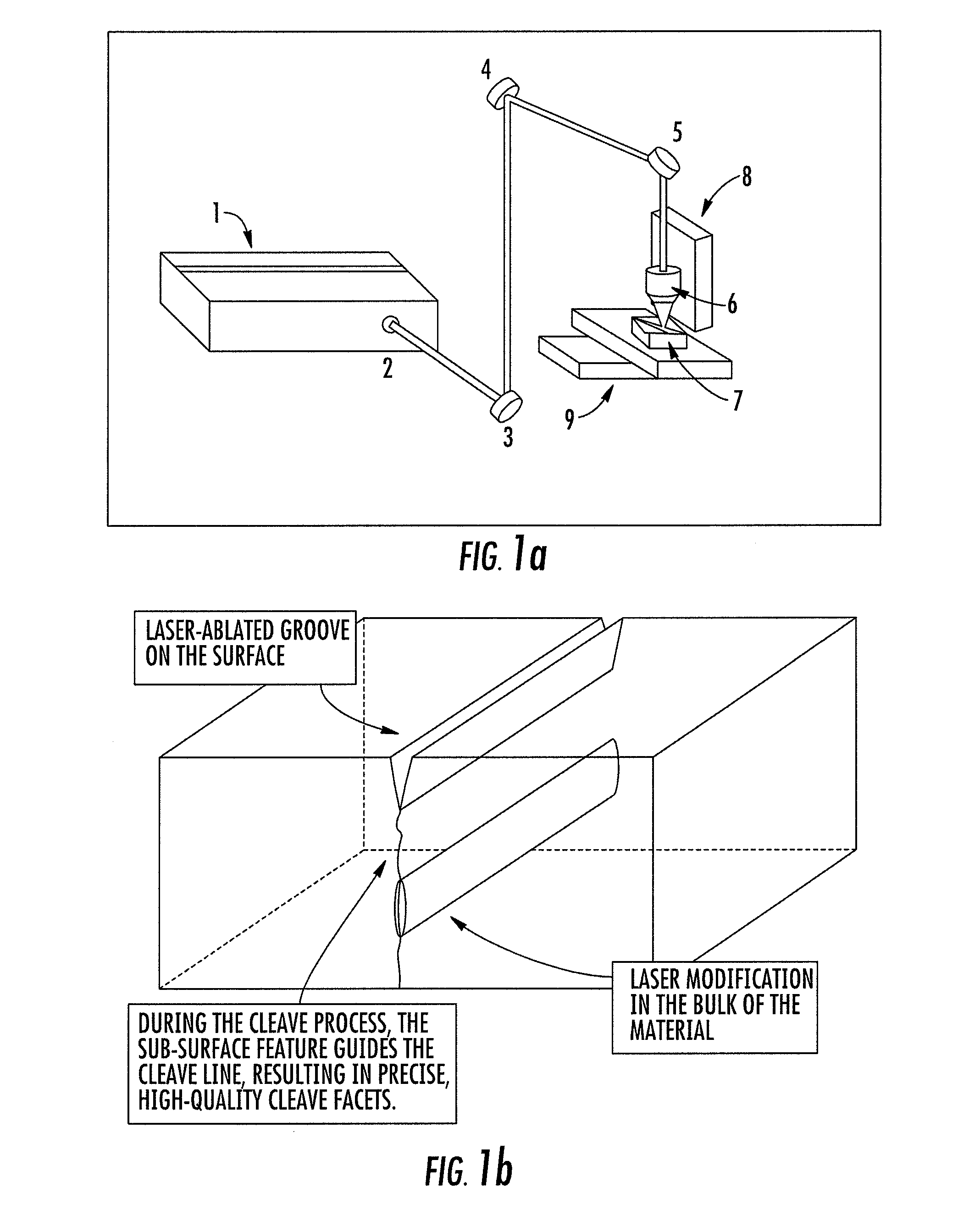

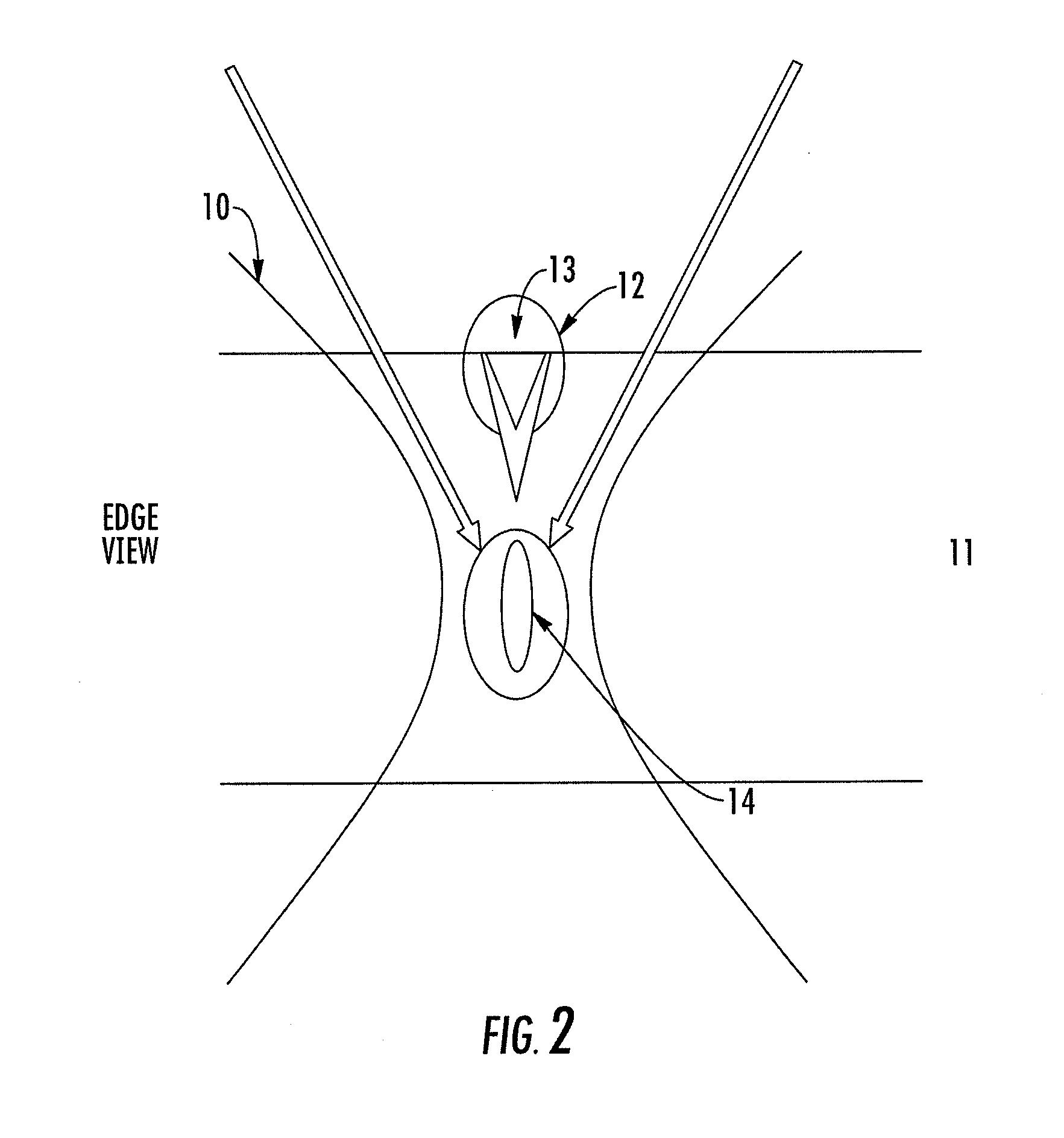

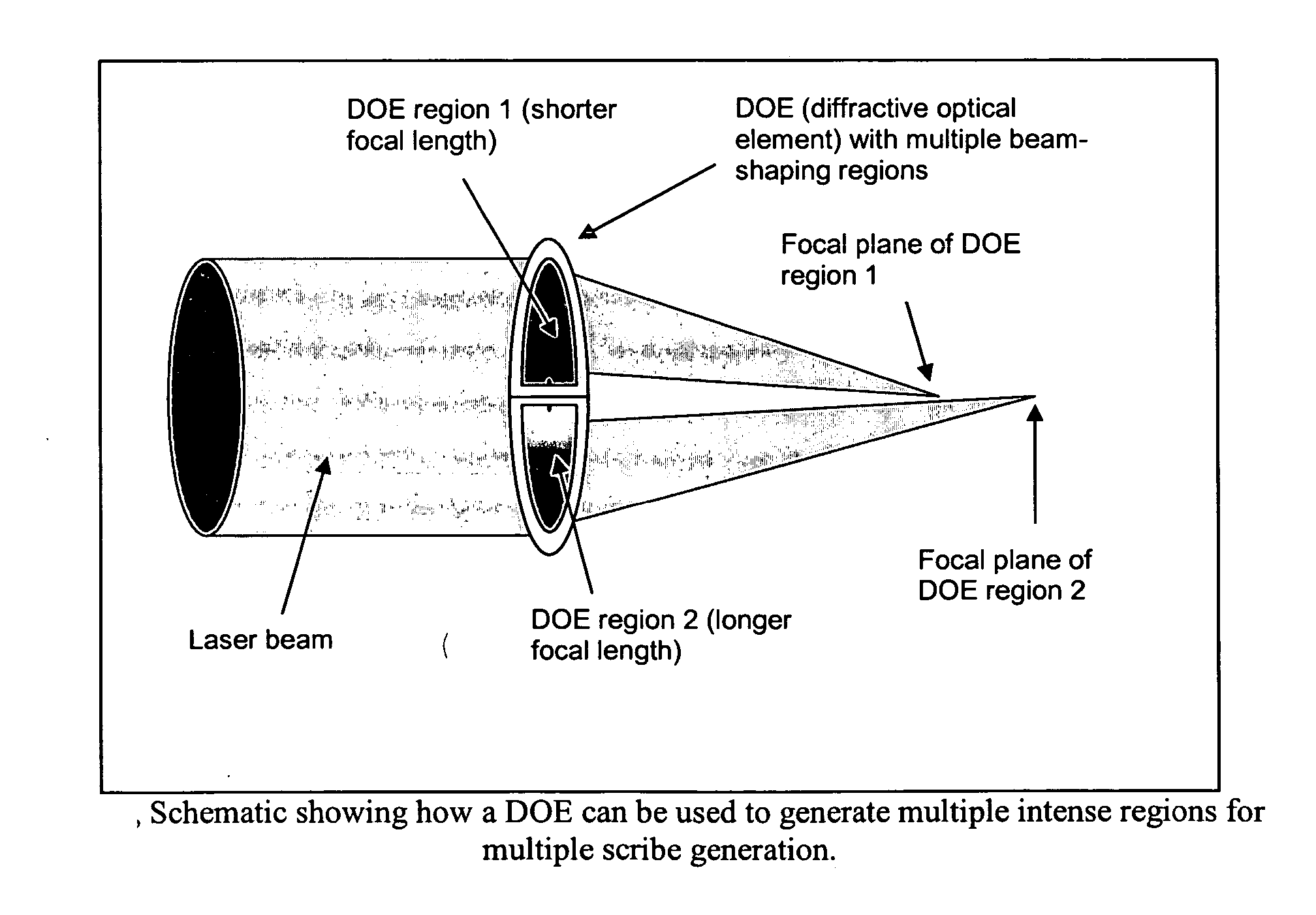

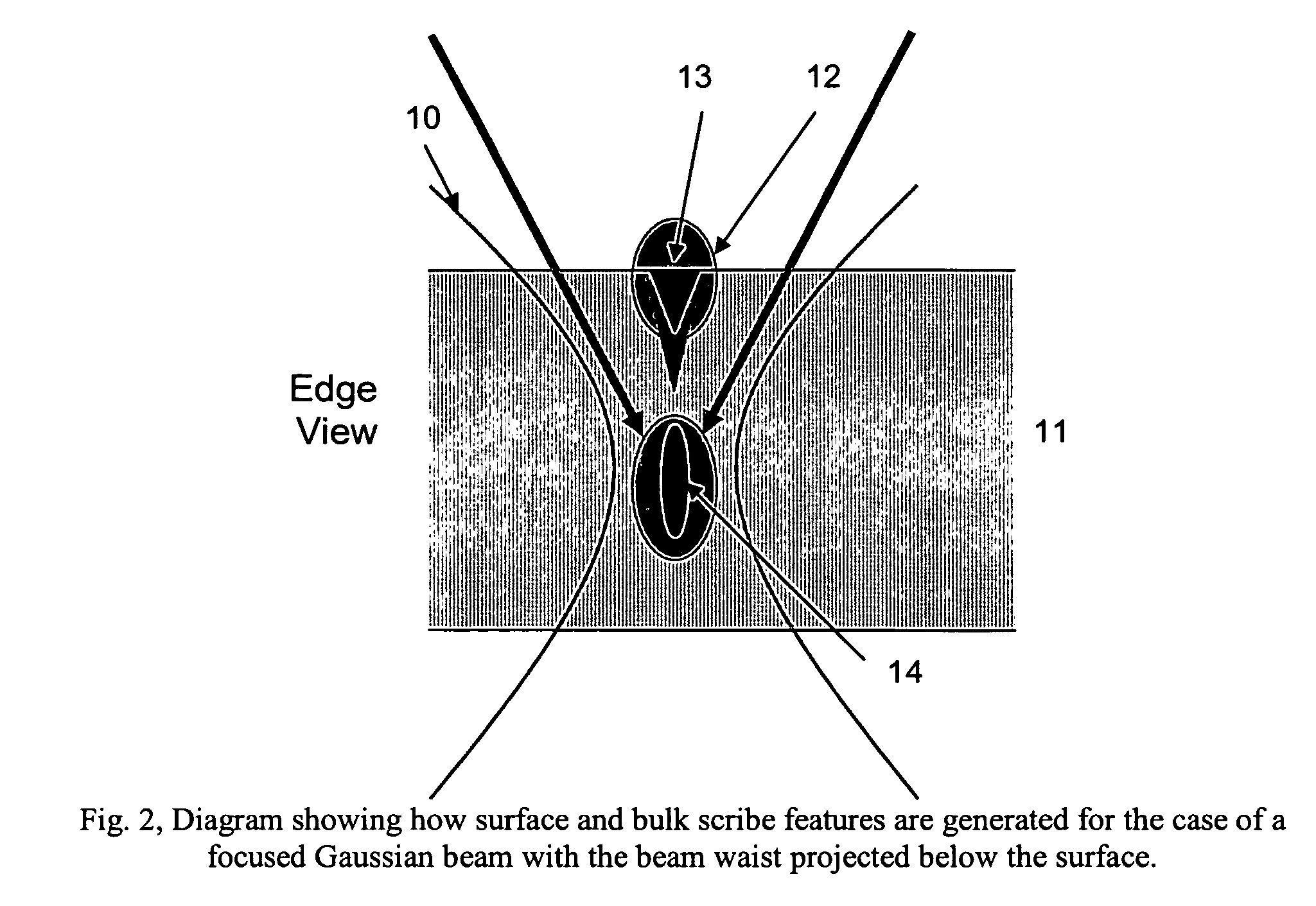

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are disclosed, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination. Reflective marks may also be formed with control of laser parameters. A transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

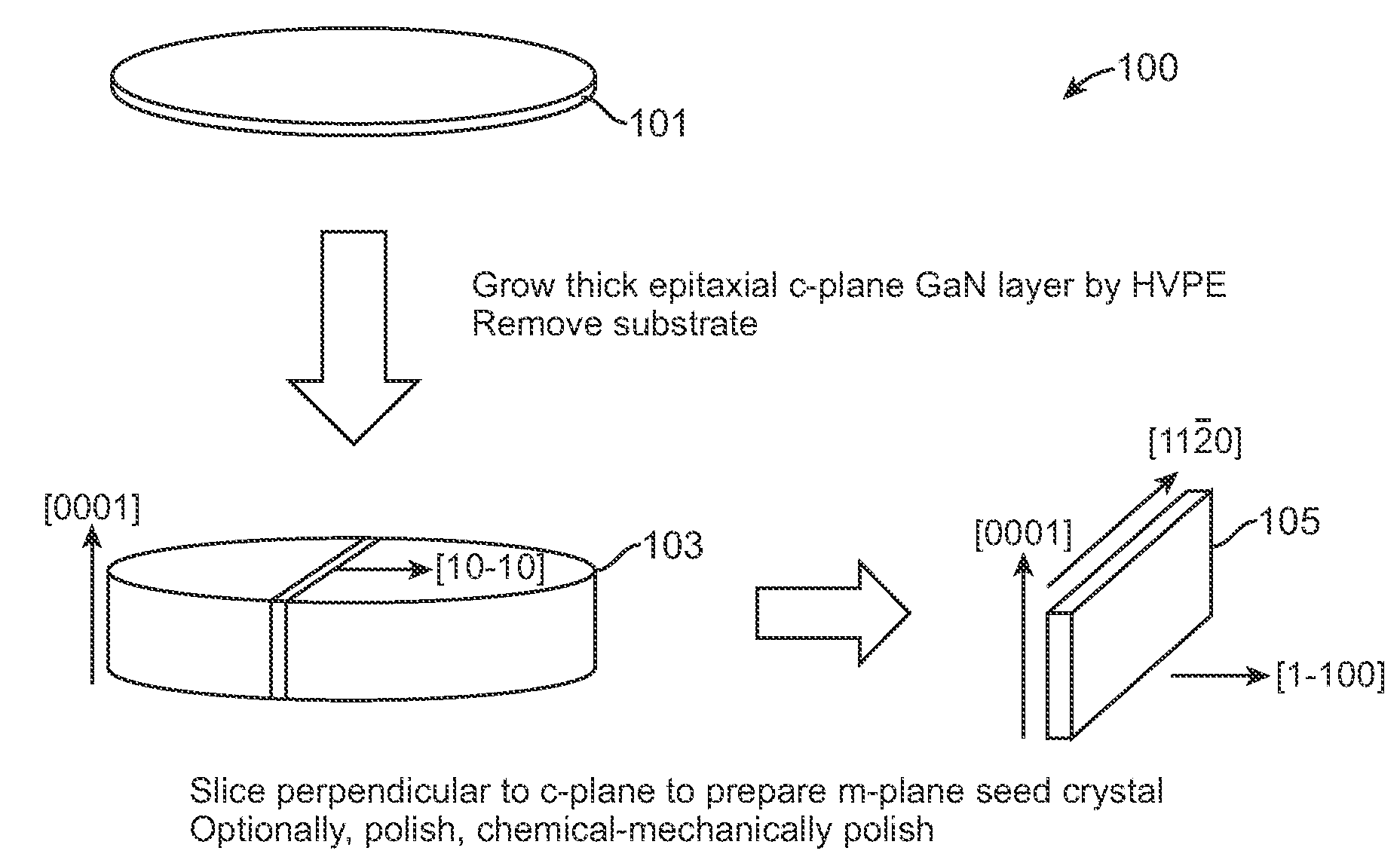

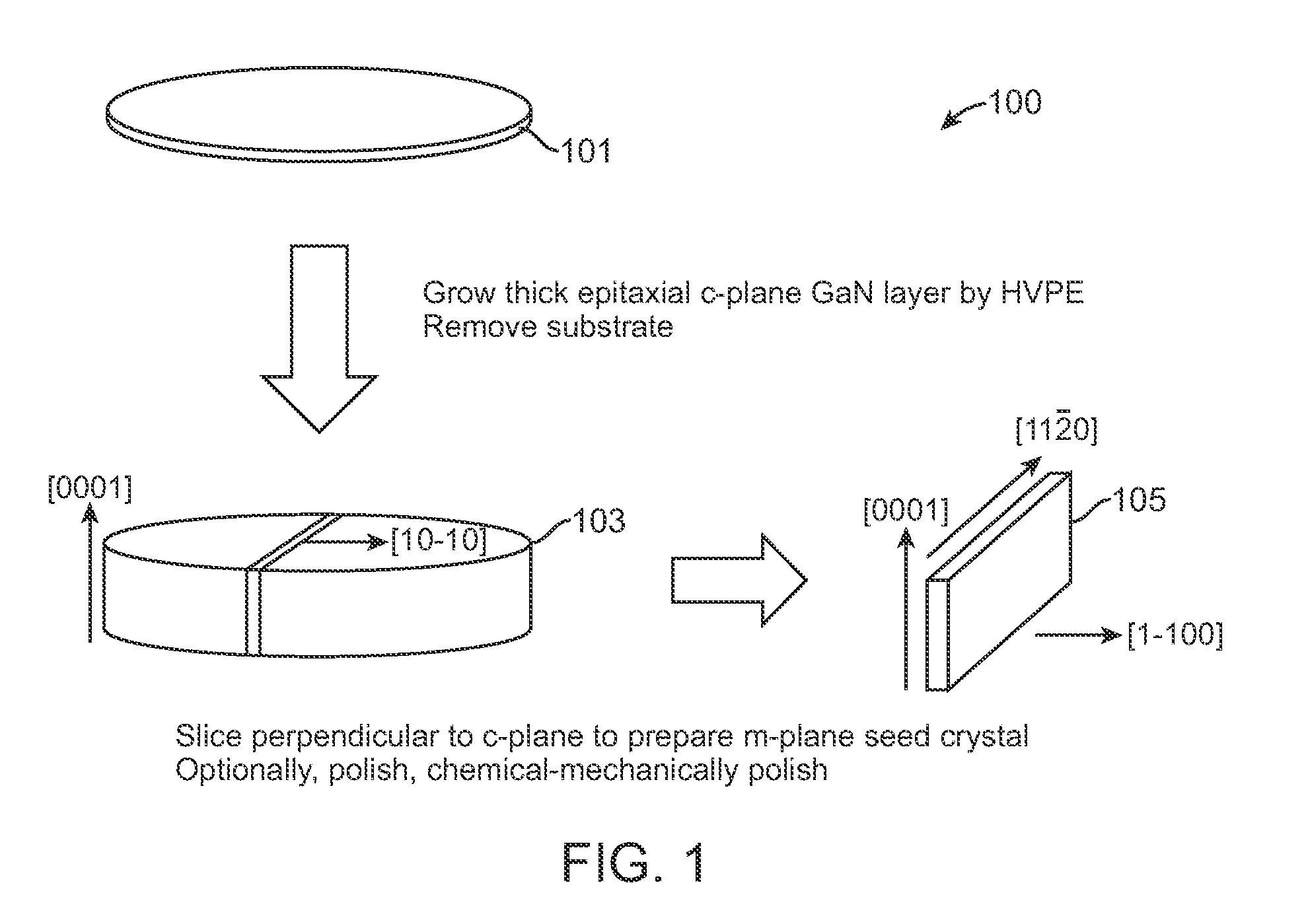

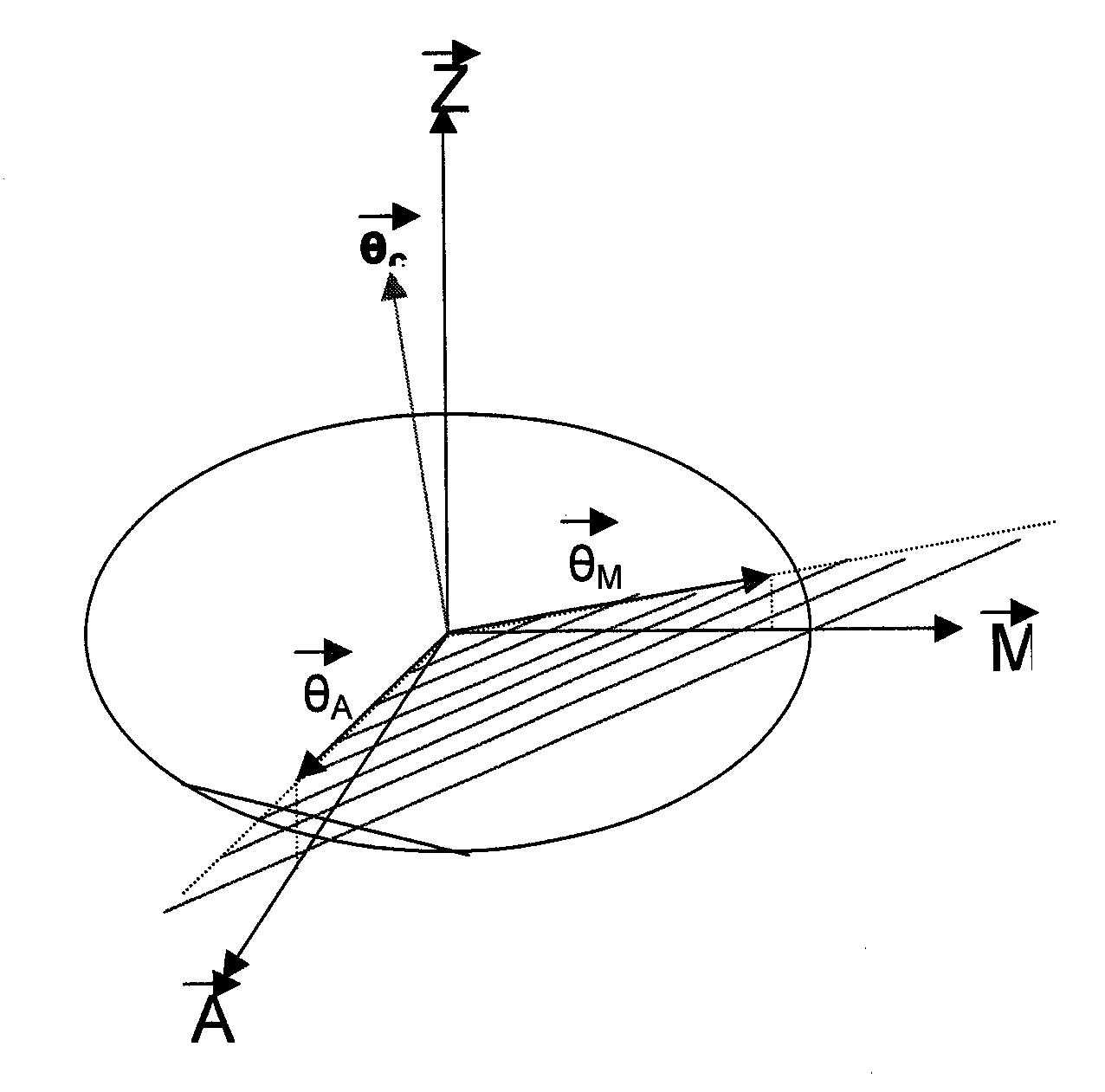

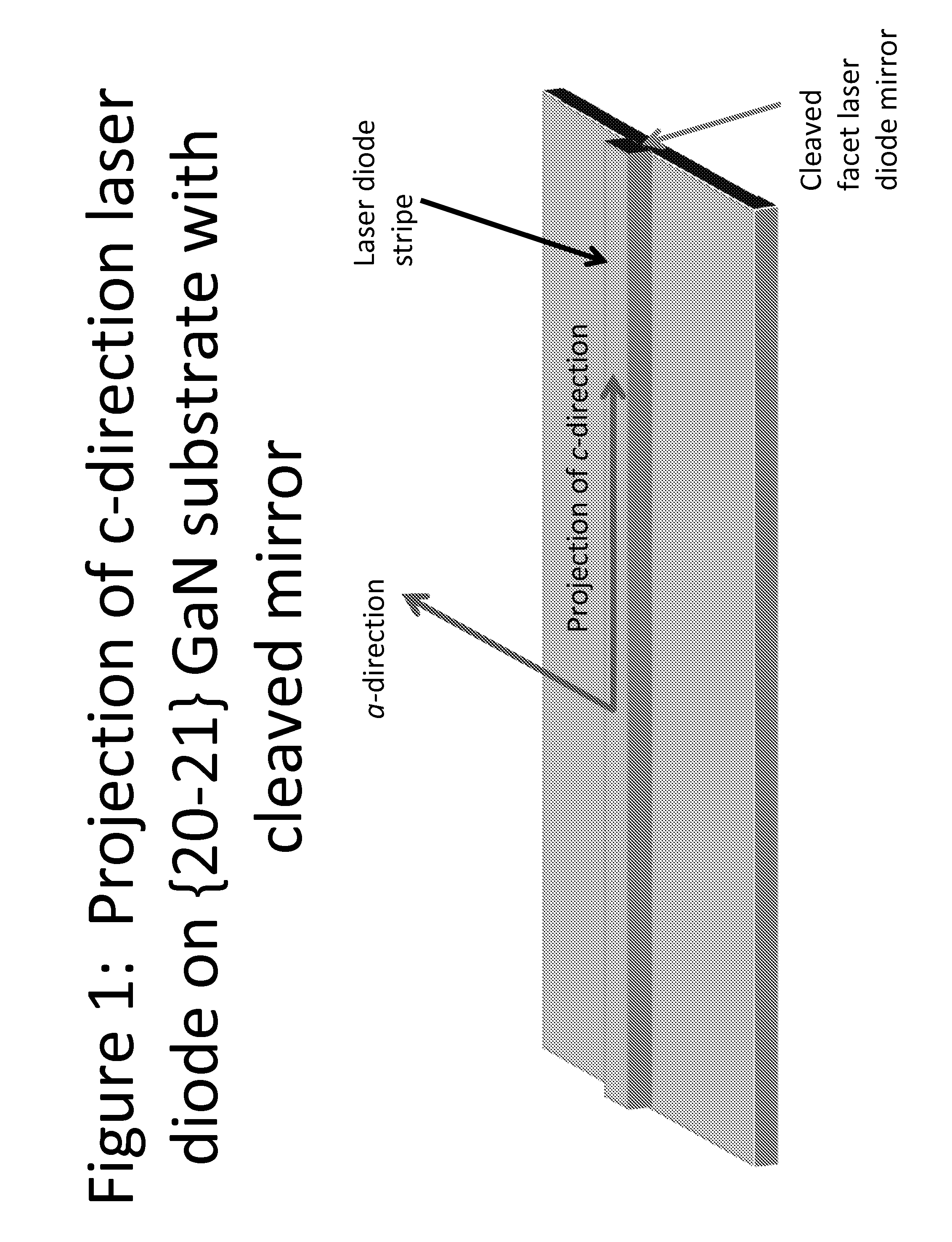

High quality large area bulk non-polar or semipolar gallium based substrates and methods

InactiveUS20100003492A1Great area of substrateCost-effective manufacturingPolycrystalline material growthConductive materialPhotodetectorSolar cell

A large area nitride crystal, comprising gallium and nitrogen, with a non-polar or semi-polar large-area face, is disclosed, along with a method for making. The crystal is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SORAA

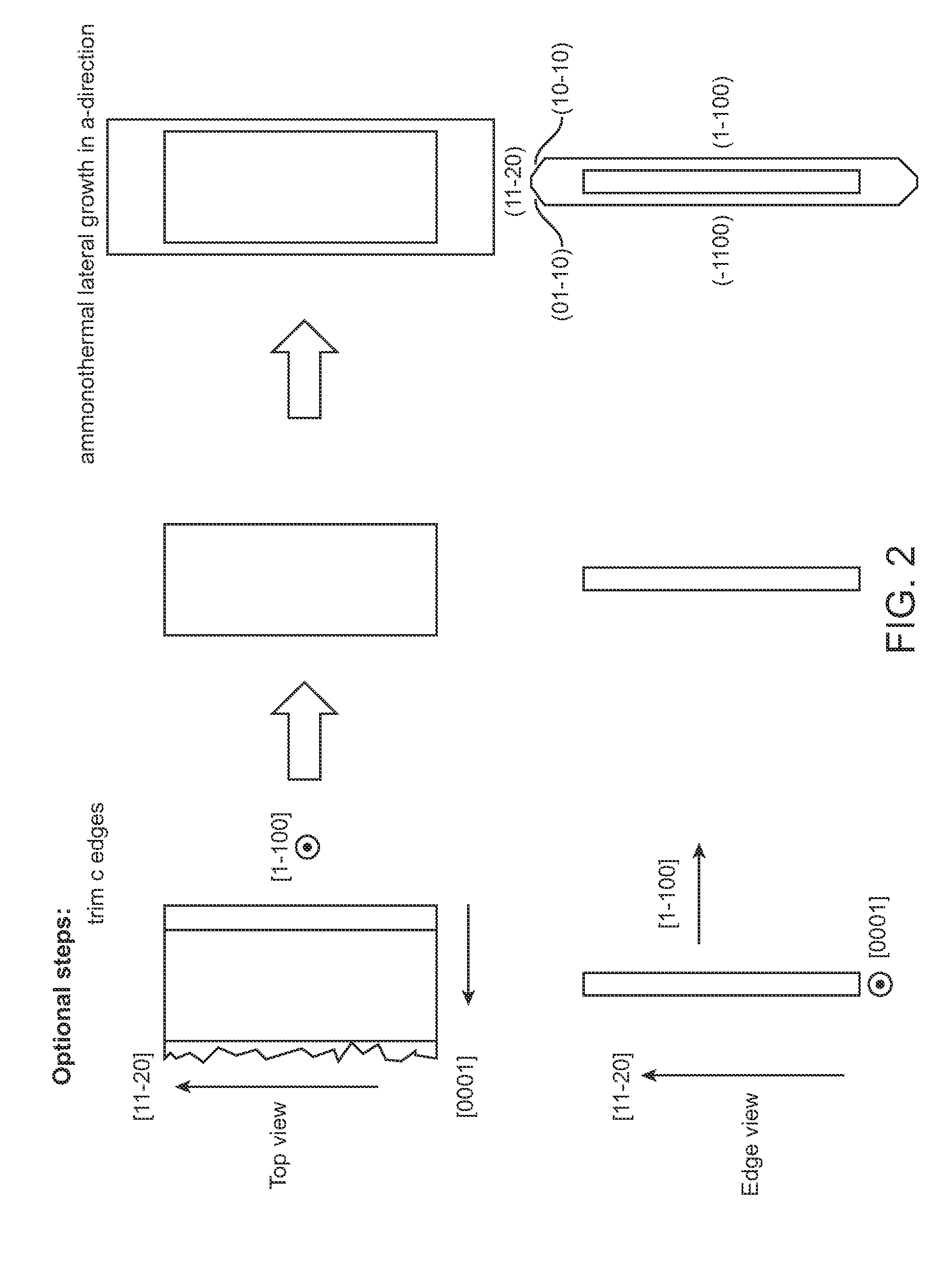

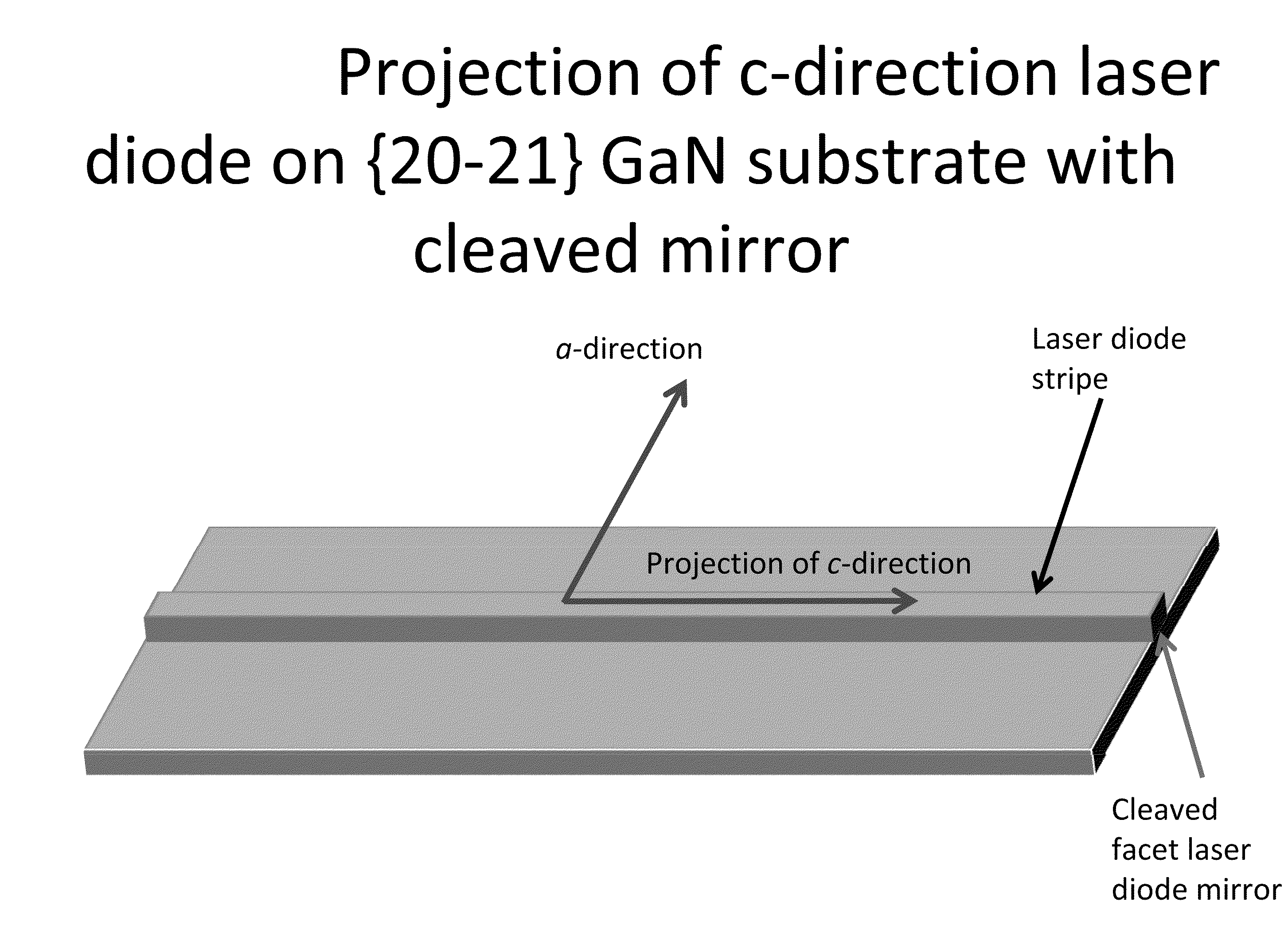

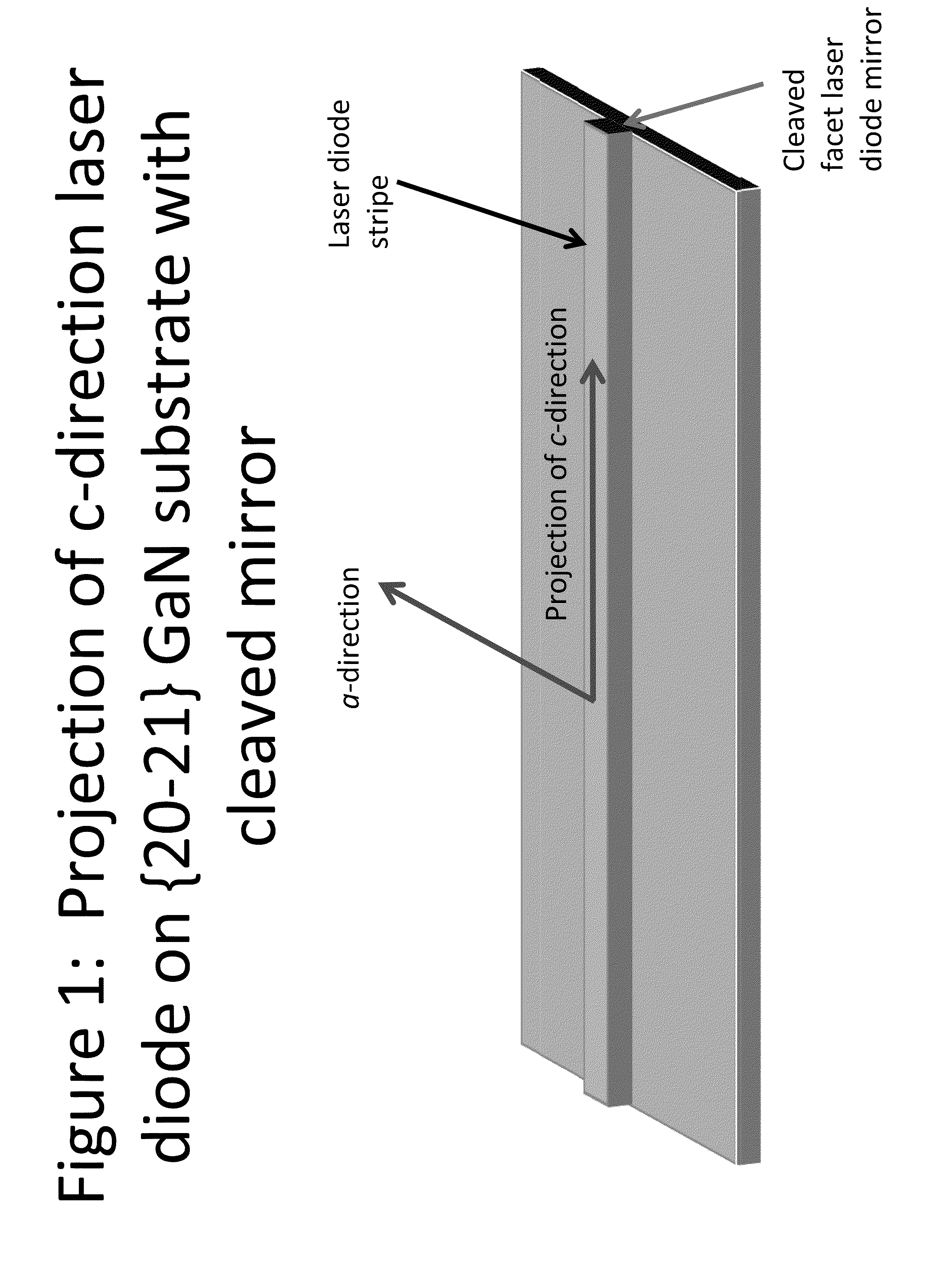

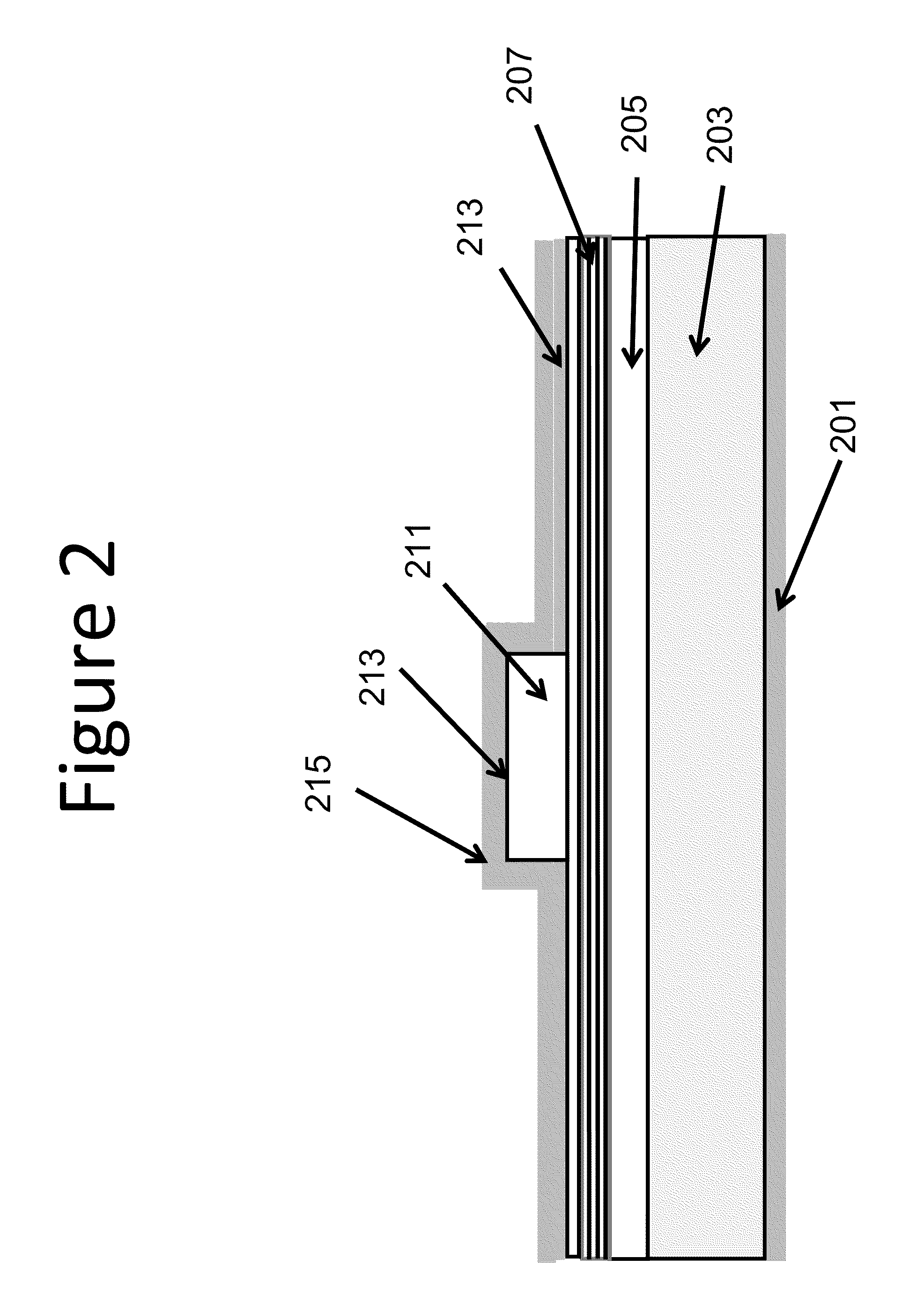

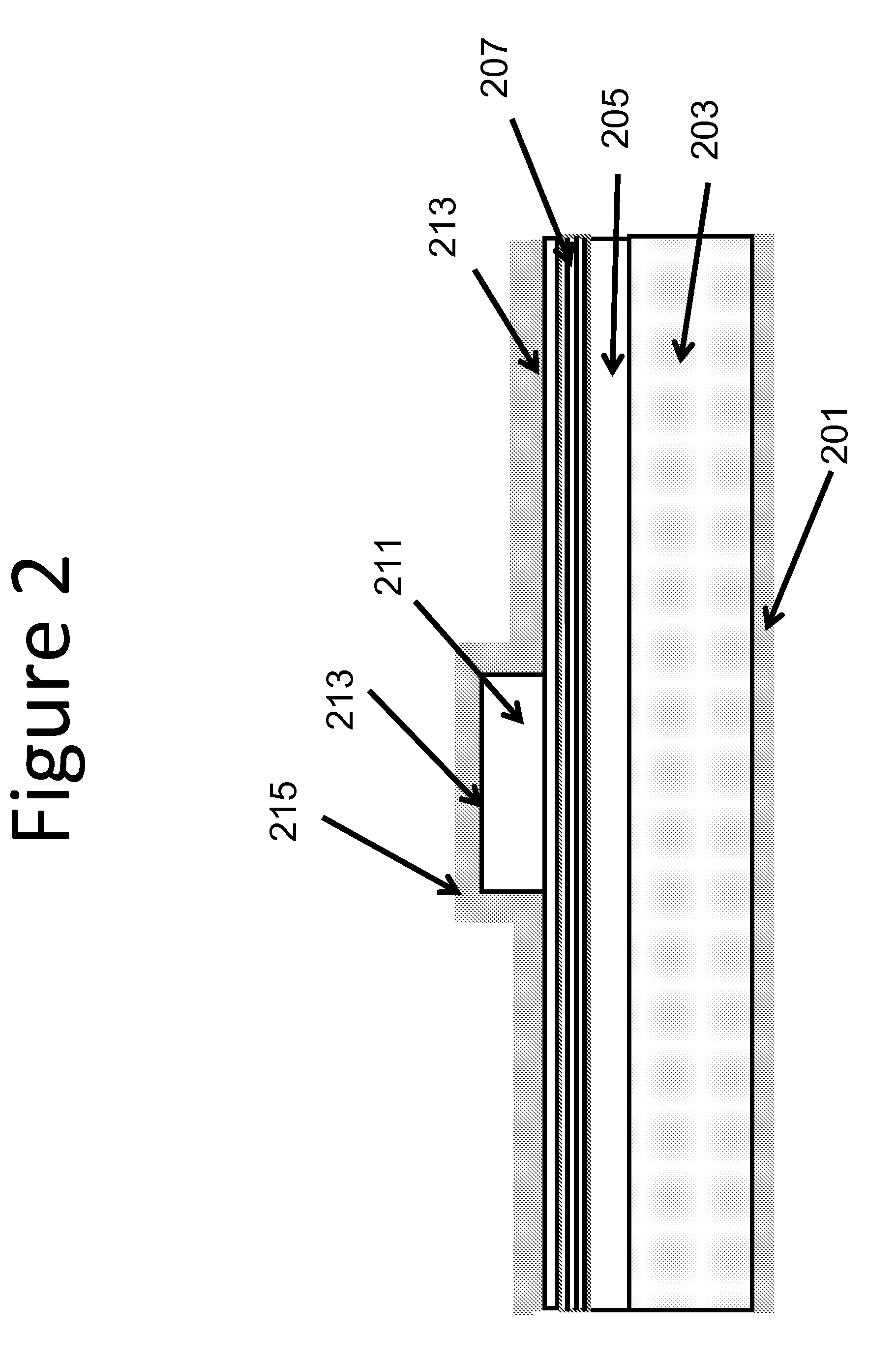

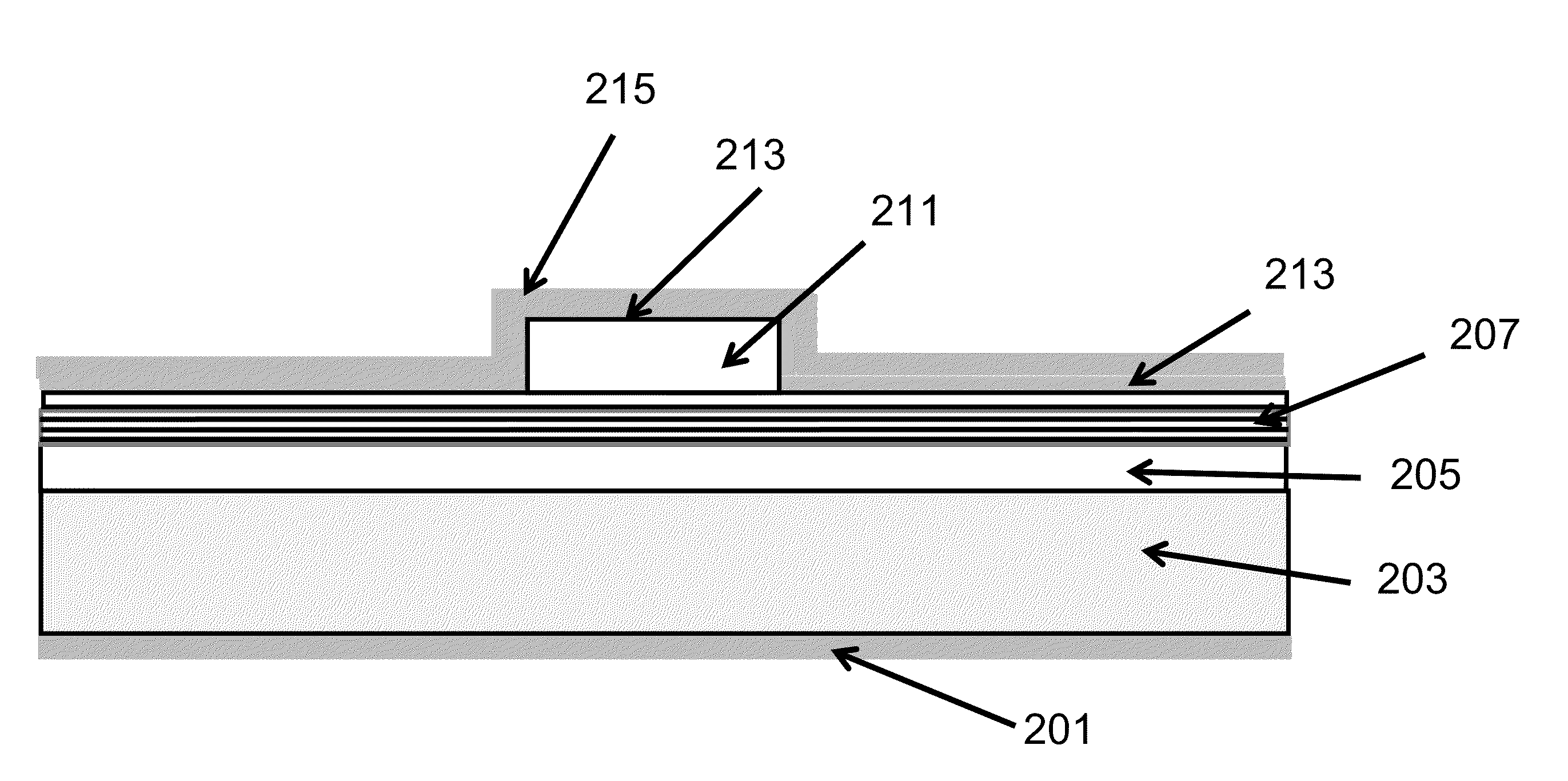

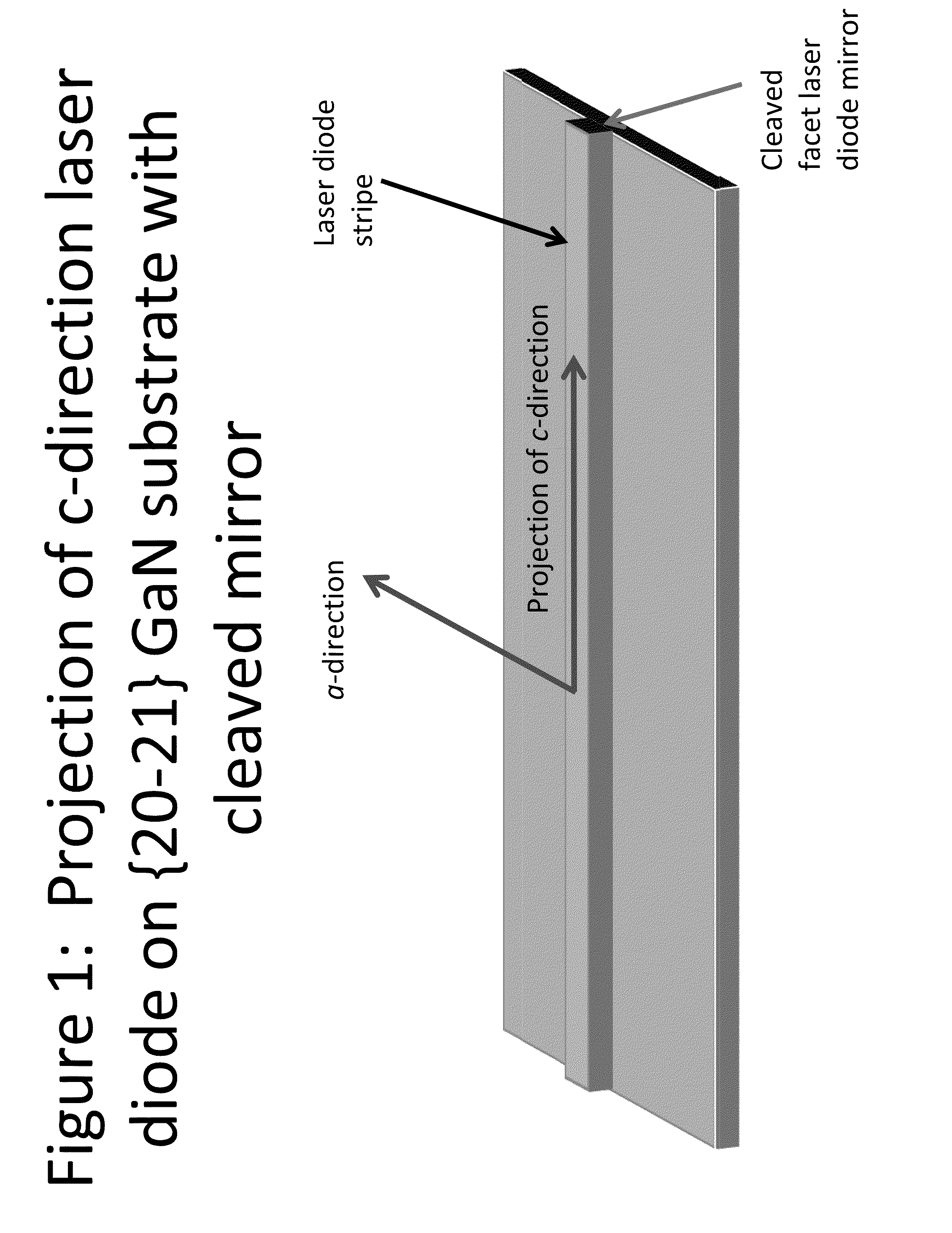

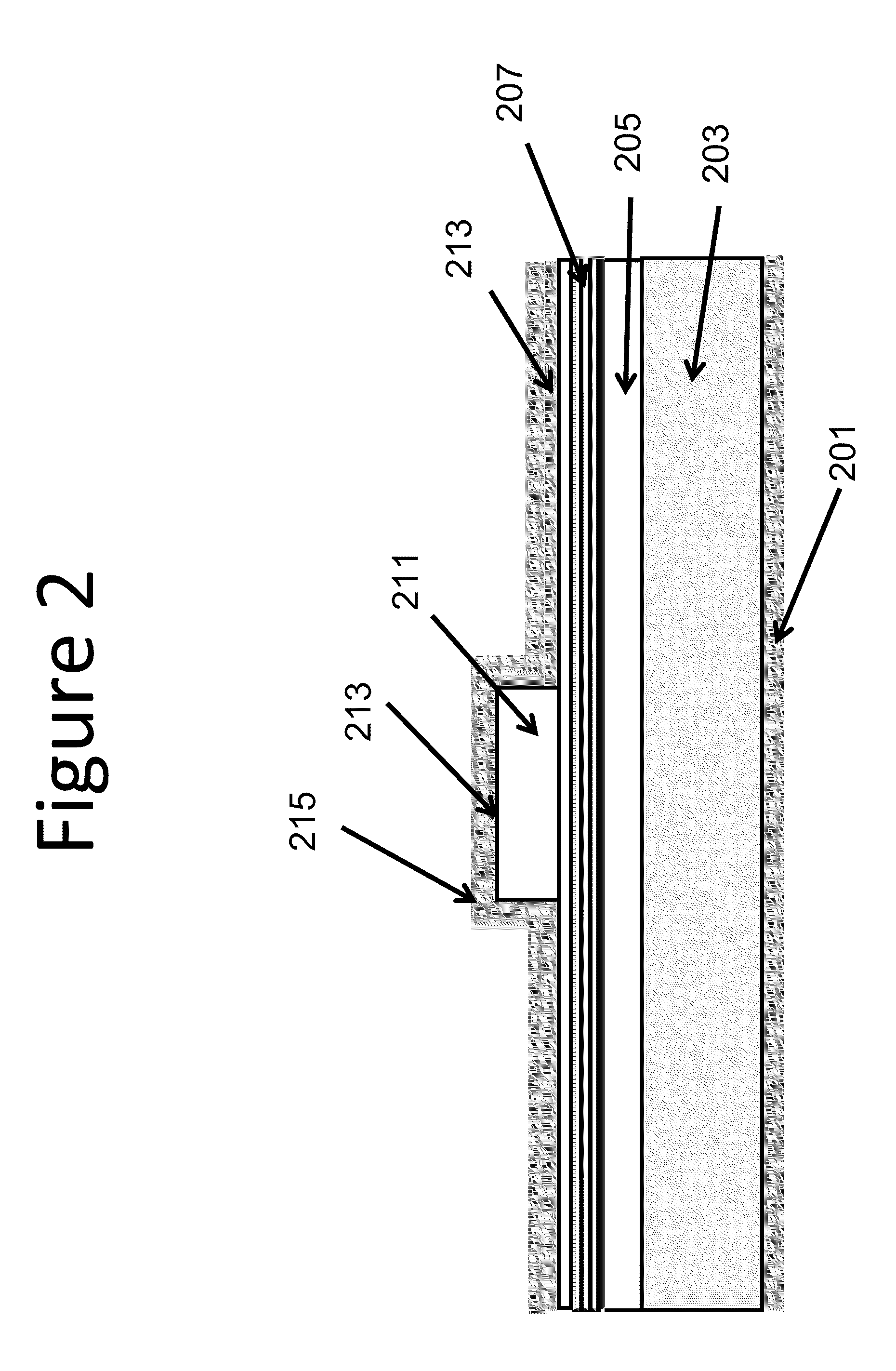

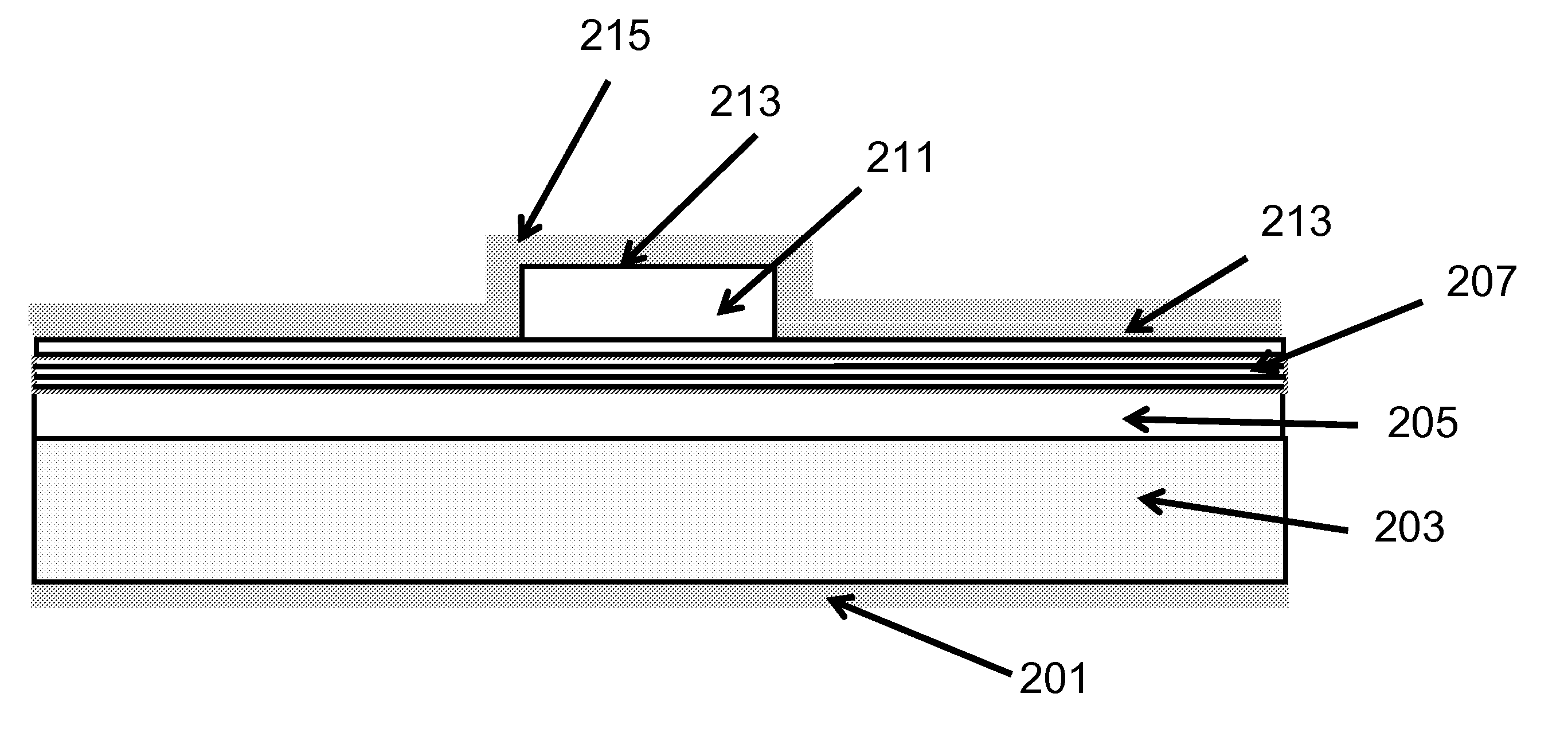

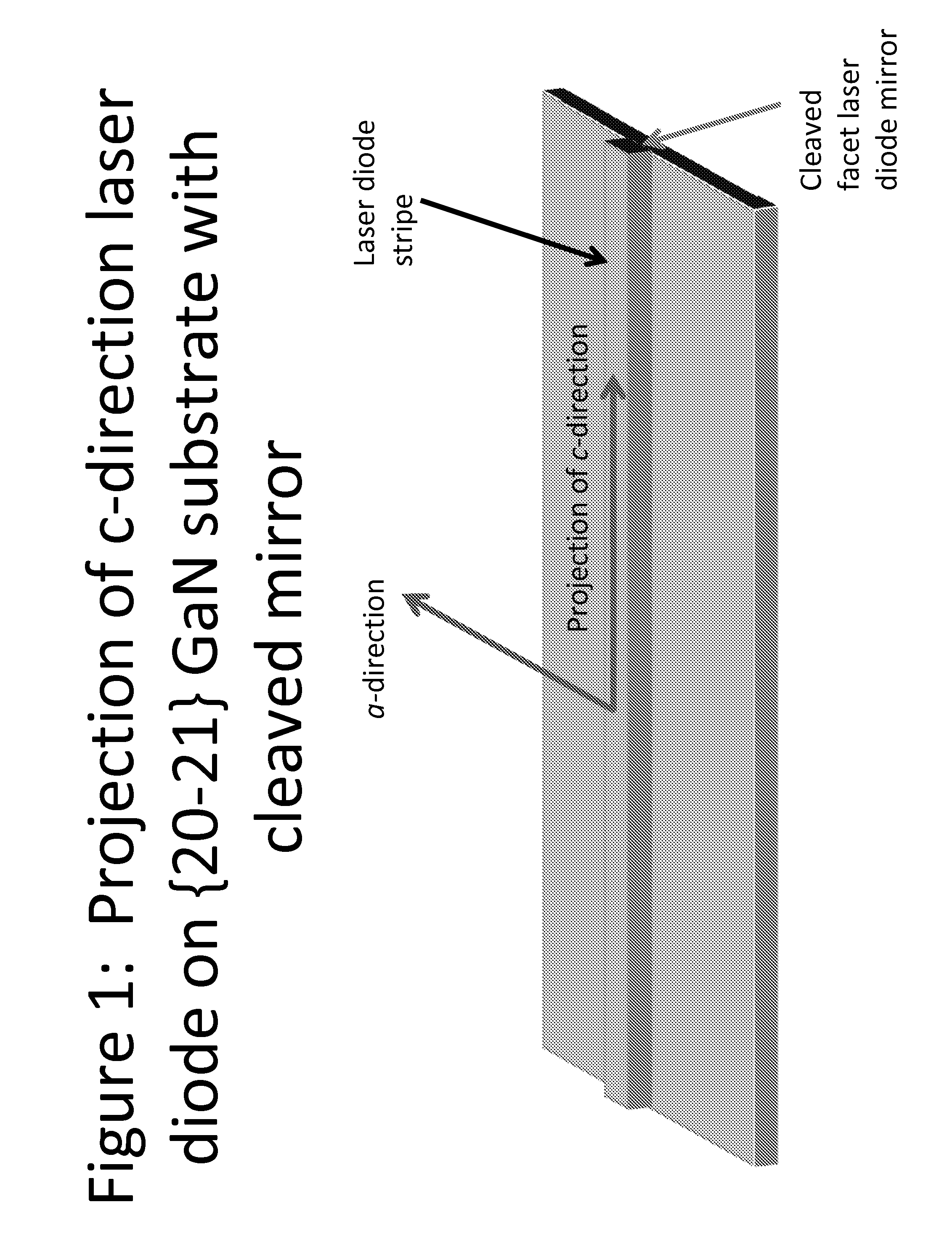

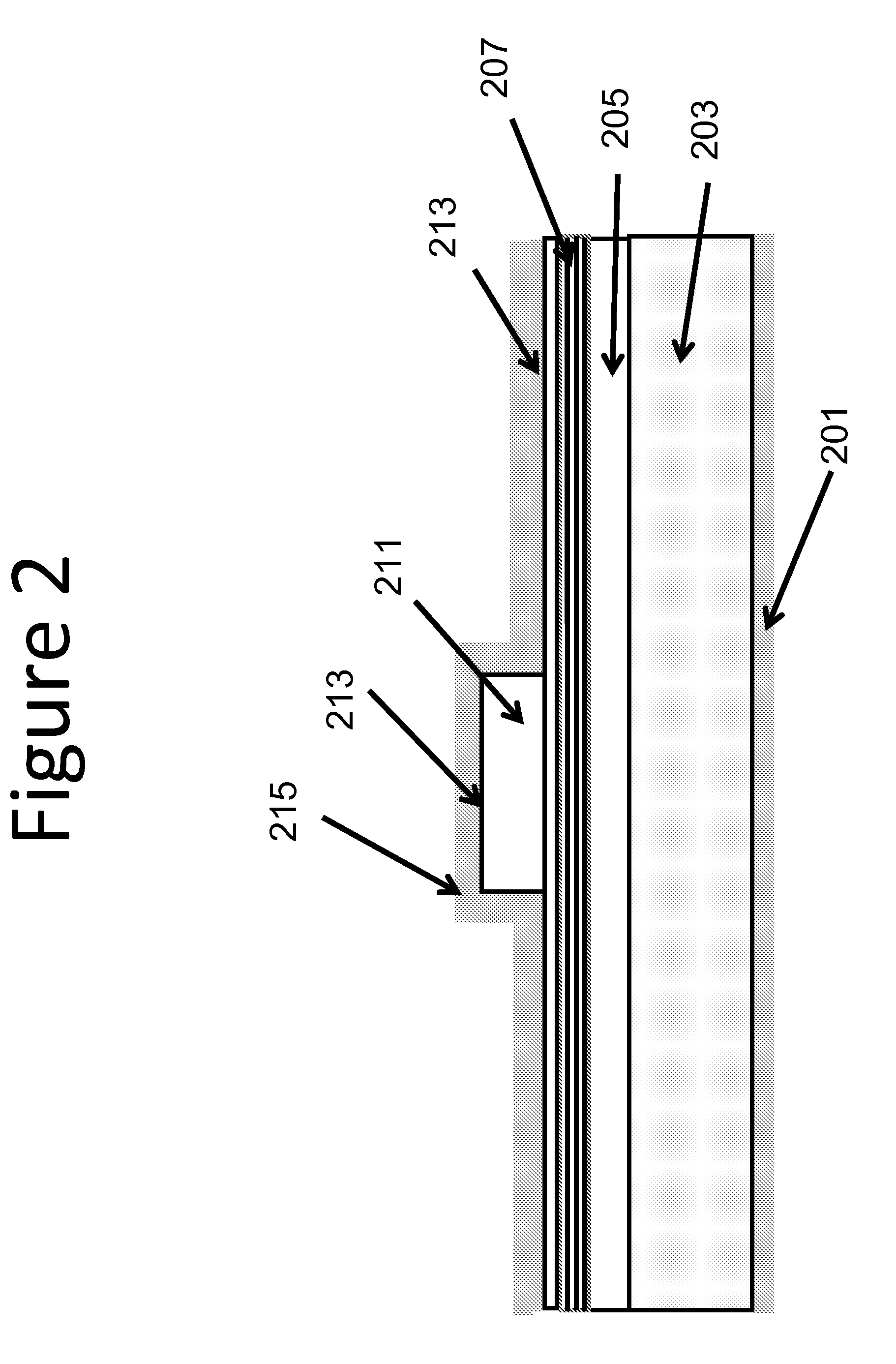

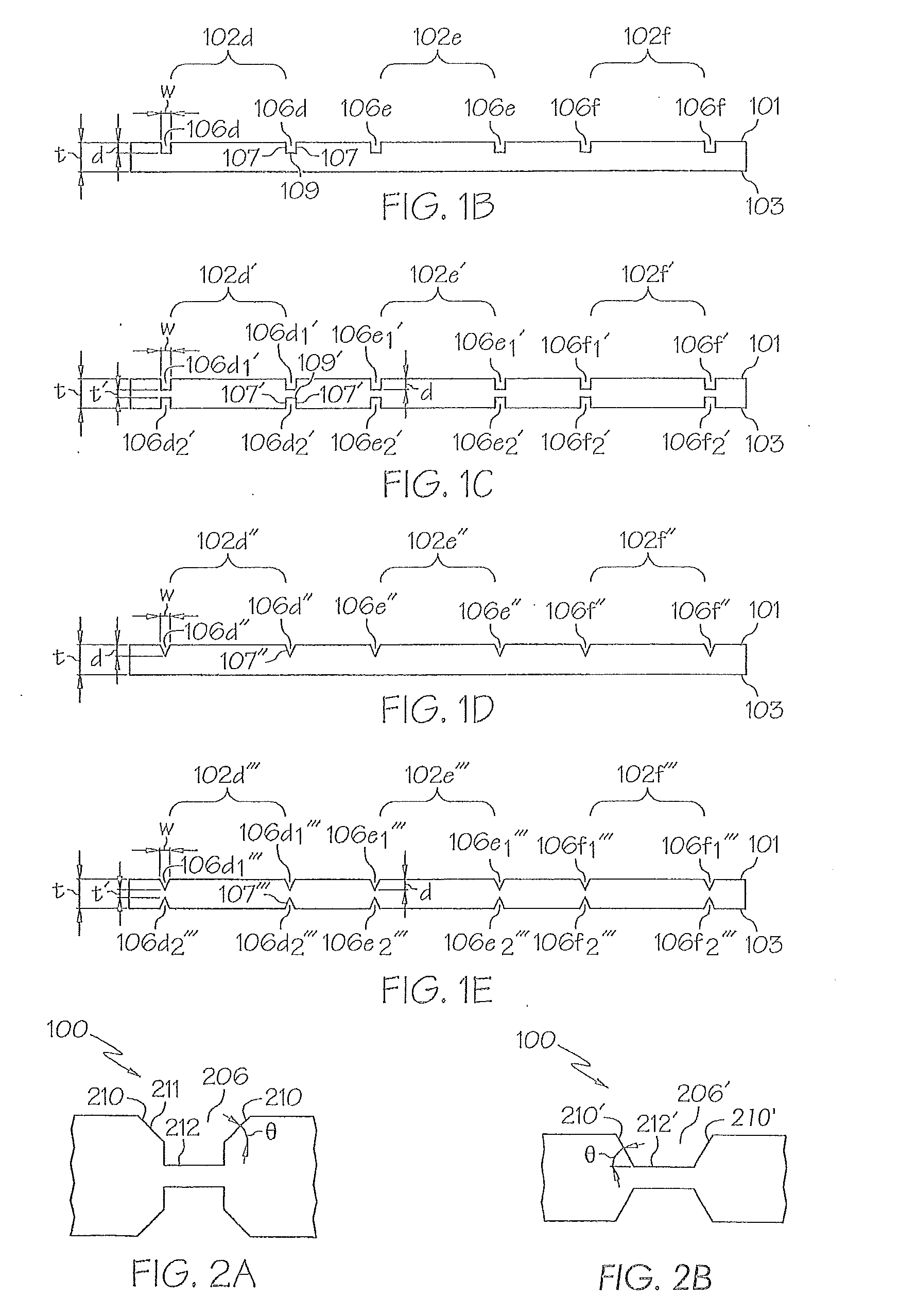

Growth Structures and Method for Forming Laser Diodes on or Off Cut Gallium and Nitrogen Containing Substrates

ActiveUS20110064100A1Improved cleavesCost-effectiveLaser detailsLaser optical resonator constructionNitrogenLength wave

Owner:KYOCERA SLD LASER INC

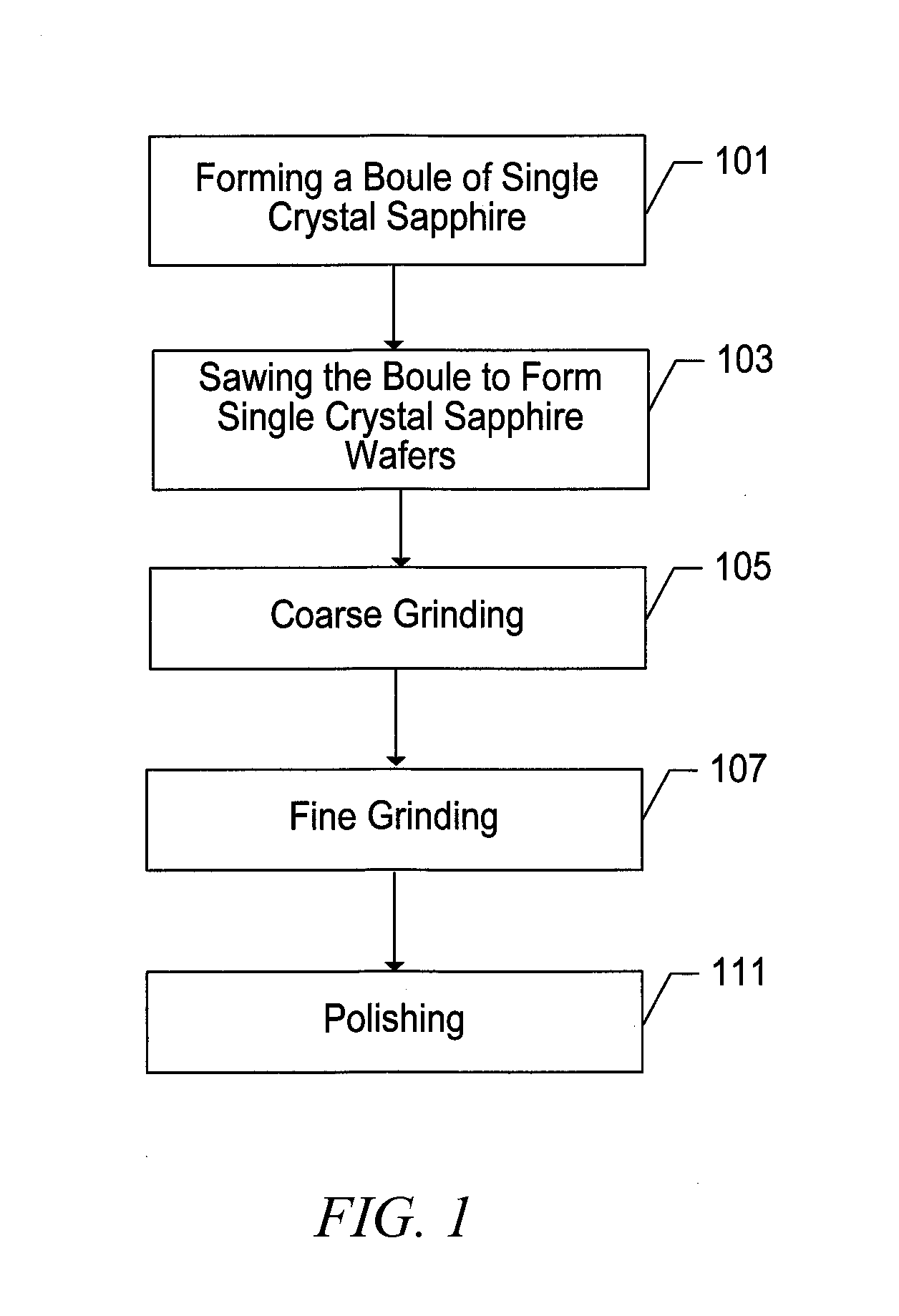

Sapphire substrates and methods of making same

InactiveUS20080164578A1Polycrystalline material growthFine working devicesPlane orientationTotal thickness

A sapphire substrate includes a generally planar surface having a crystallographic orientation selected from the group consisting of a-plane, r-plane, m-plane, and c-plane orientations, and having a nTTV of not greater than about 0.037 μm / cm2, wherein nTTV is total thickness variation normalized for surface area of the generally planar surface, the substrate having a diameter not less than about 9.0 cm.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Growth Structures and Method for Forming Laser Diodes on or Off Cut Gallium and Nitrogen Containing Substrates

ActiveUS20110064102A1Improved cleavesCost-effectiveOptical wave guidanceLaser detailsNitrogenLength wave

Owner:KYOCERA SLD LASER INC

Low Voltage Laser Diodes on Gallium and Nitrogen Containing Substrates

ActiveUS20110064101A1Improved cleavesSimple and cost-effectiveOptical wave guidanceLaser detailsLow voltageNitrogen

A low voltage laser device having an active region configured for one or more selected wavelengths of light emissions.

Owner:KYOCERA SLD LASER INC

Growth structures and method for forming laser diodes on {30-31} or off cut gallium and nitrogen containing substrates

ActiveUS8351478B2Improved cleavesCost-effectiveLaser detailsSemiconductor/solid-state device manufacturingNitrogenGallium

Owner:KYOCERA SLD LASER INC

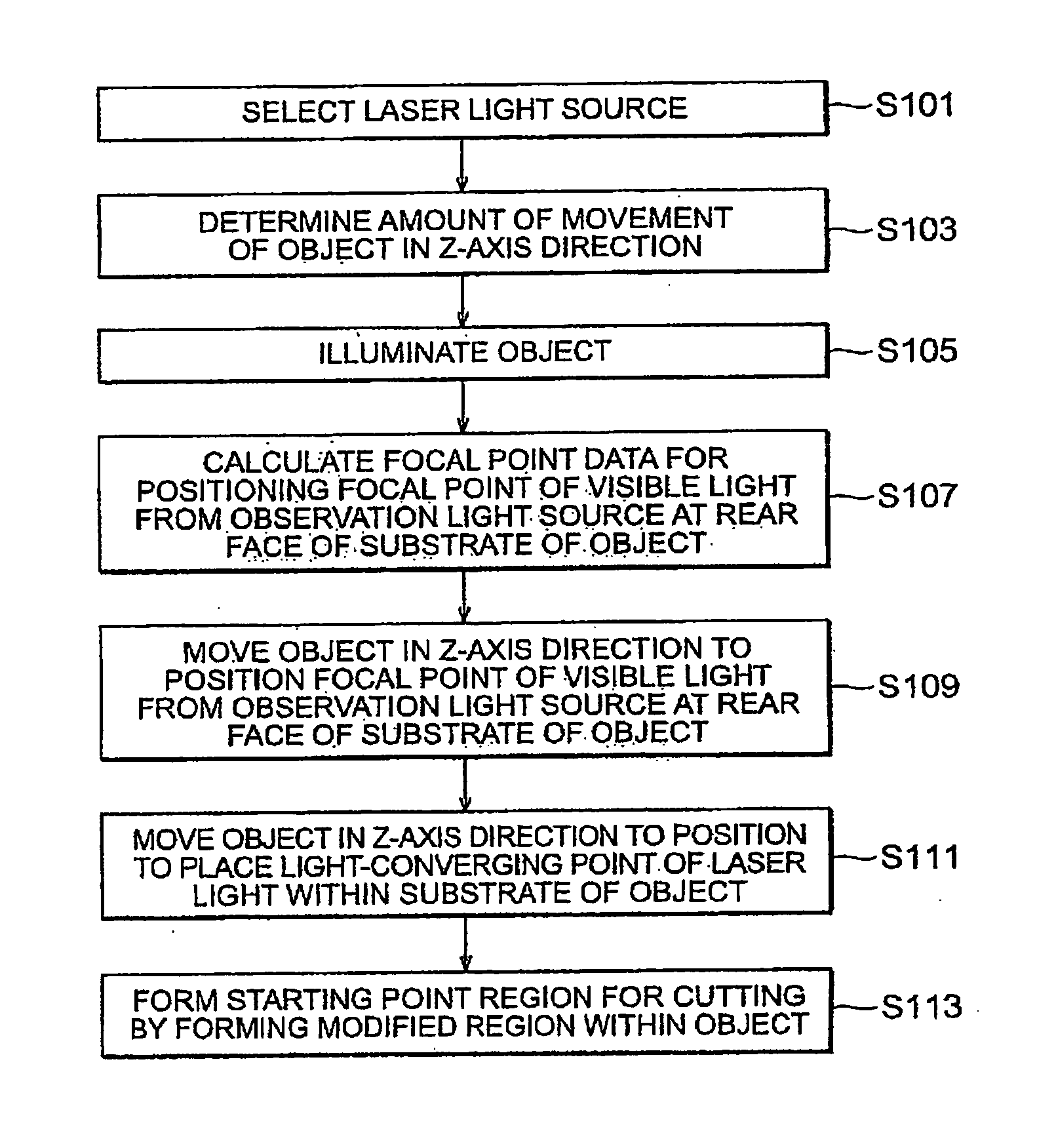

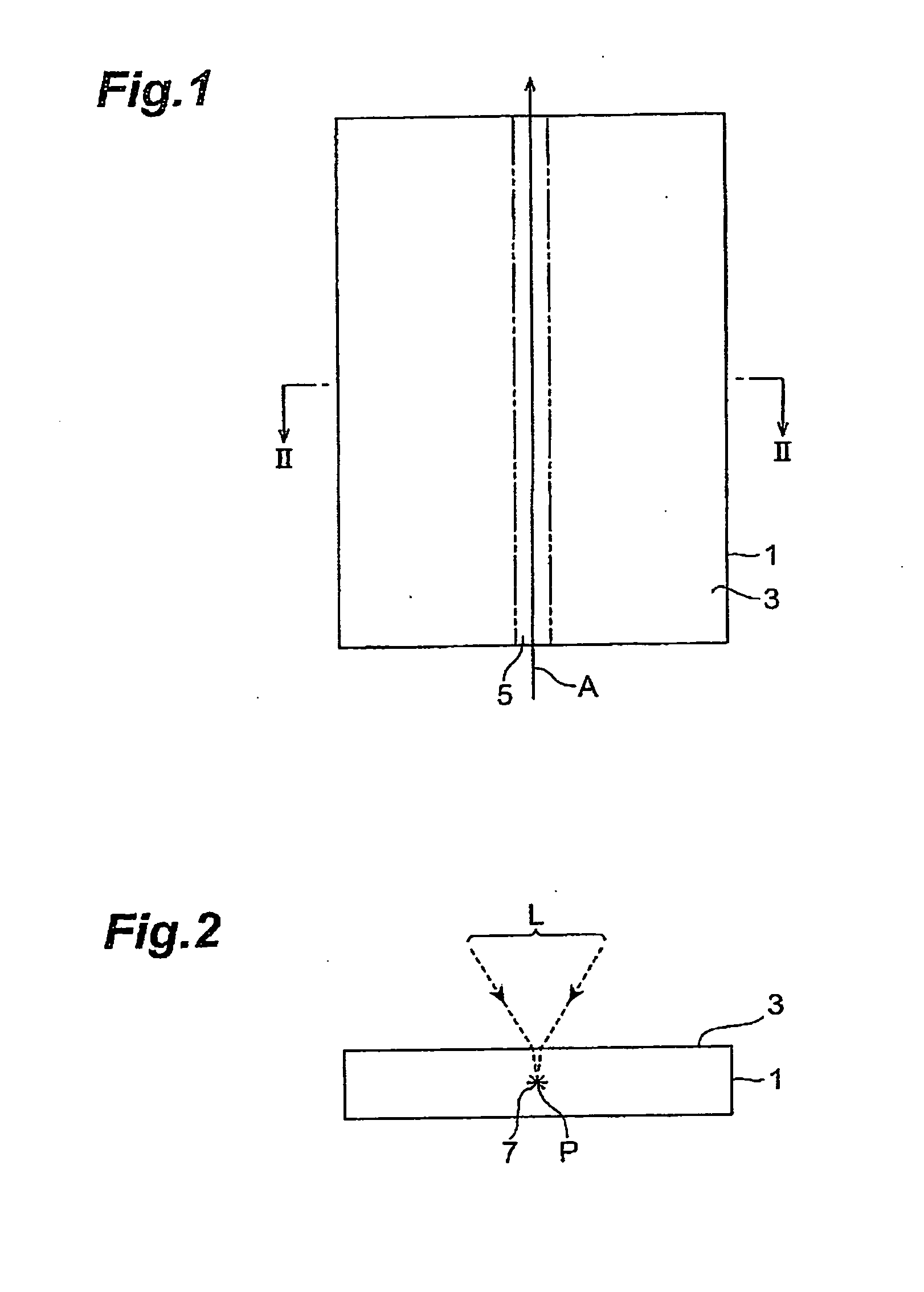

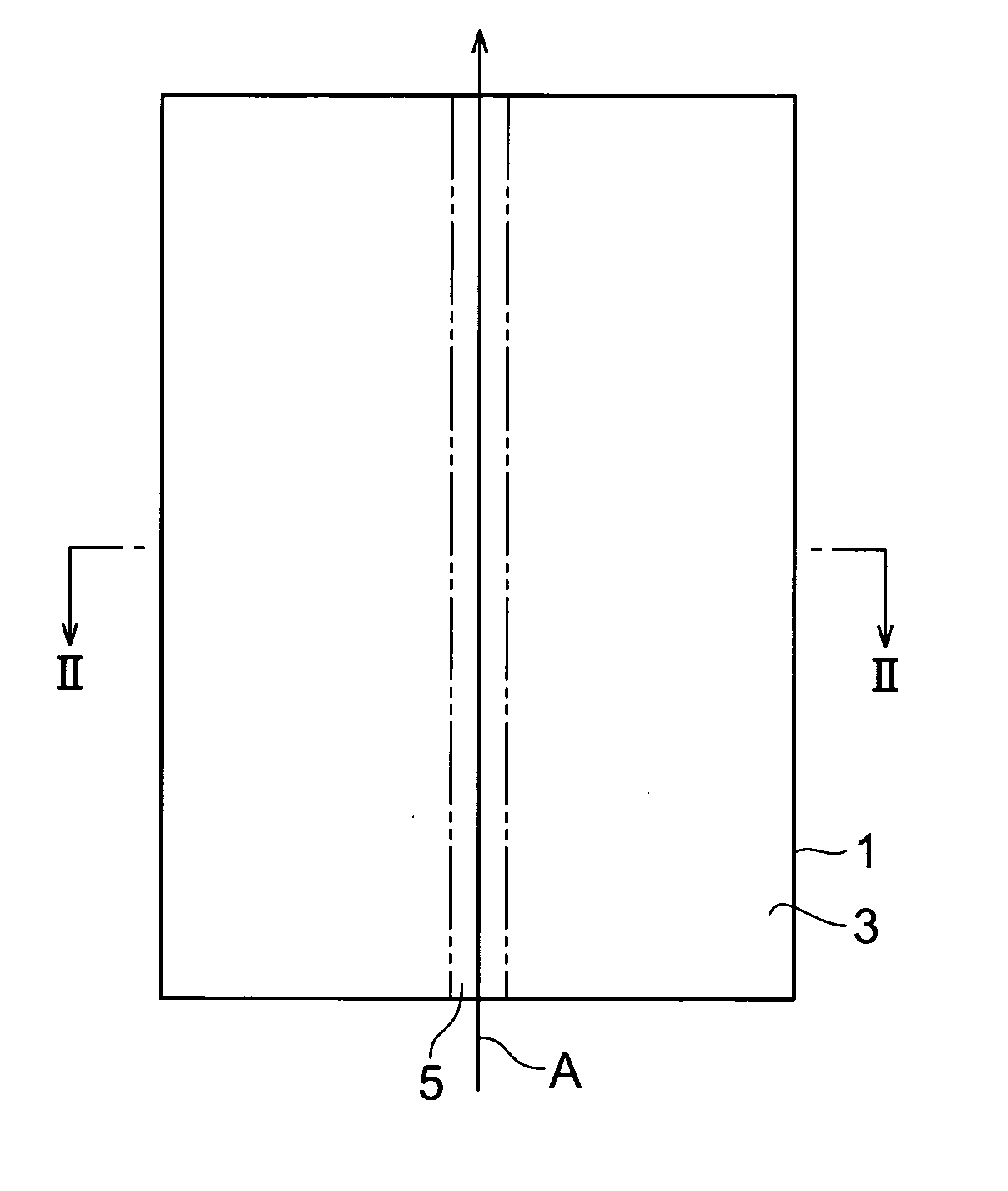

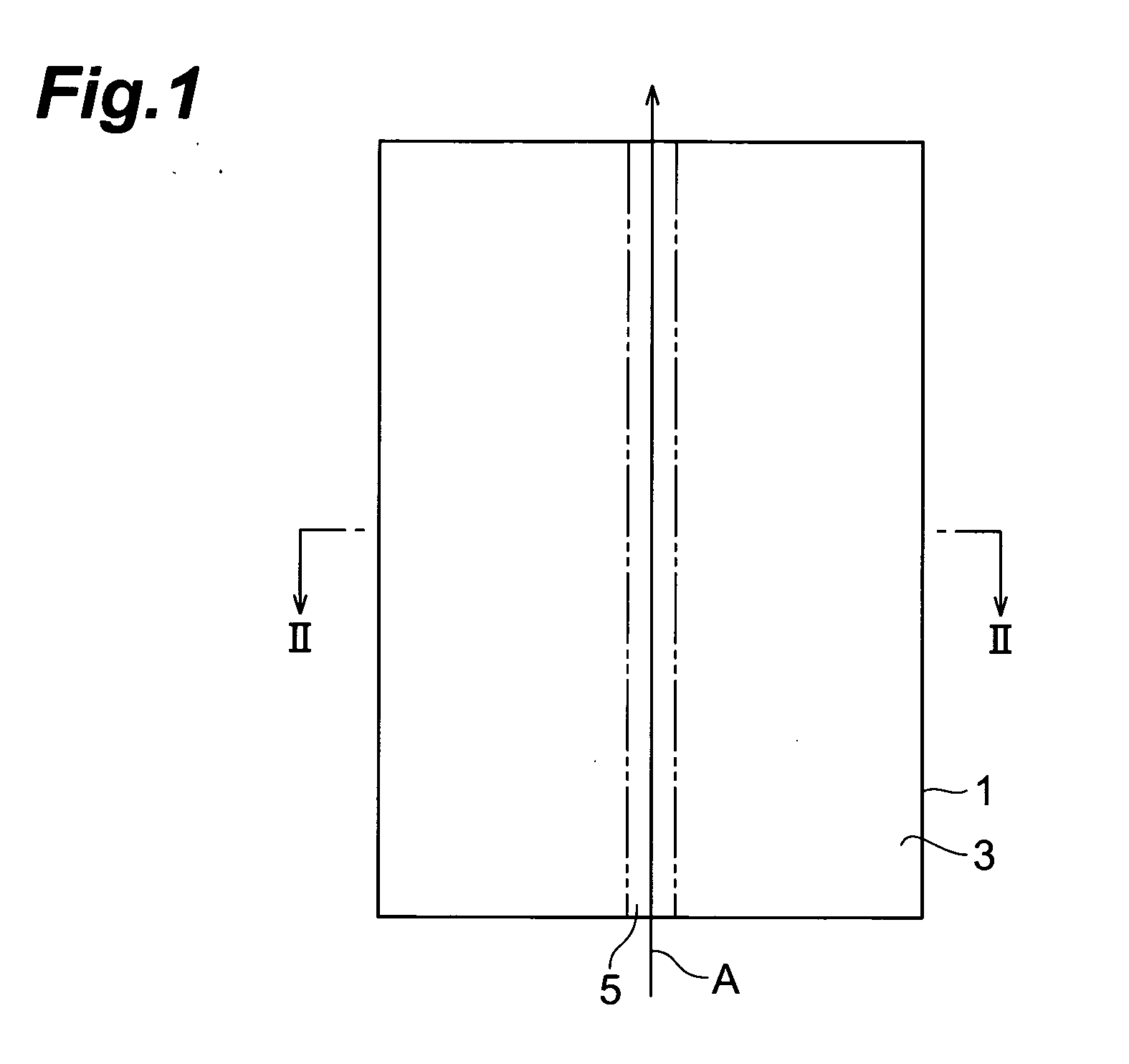

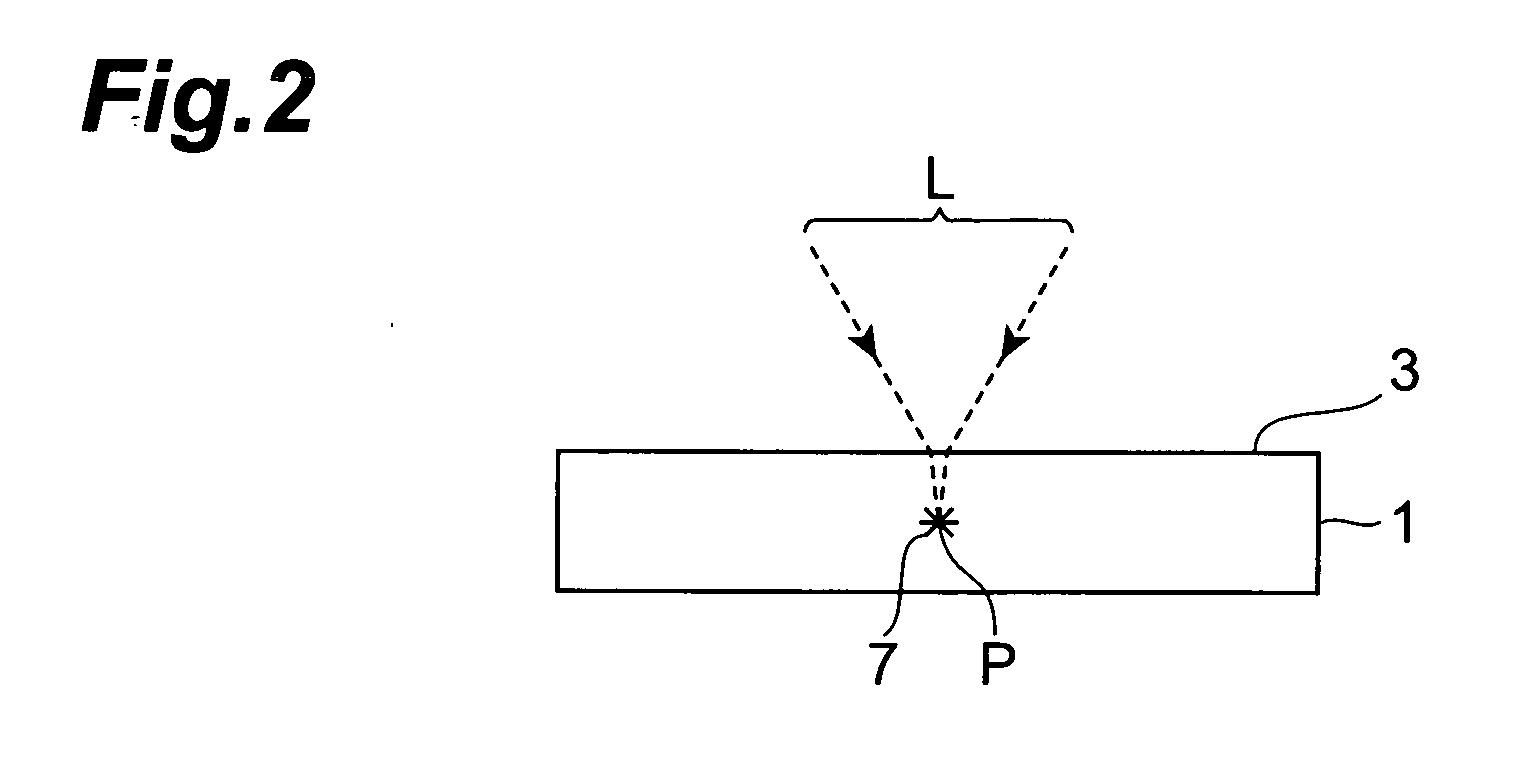

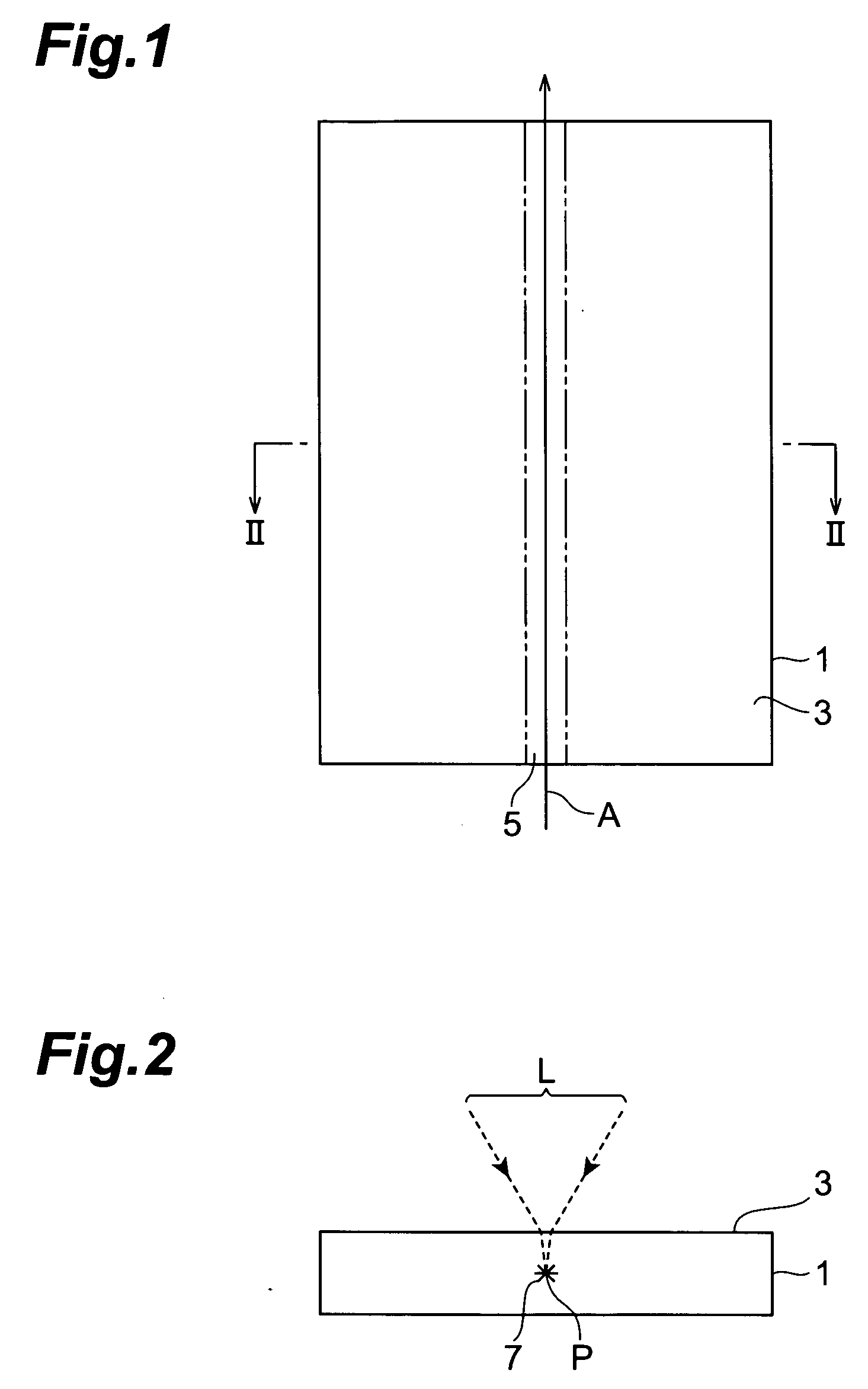

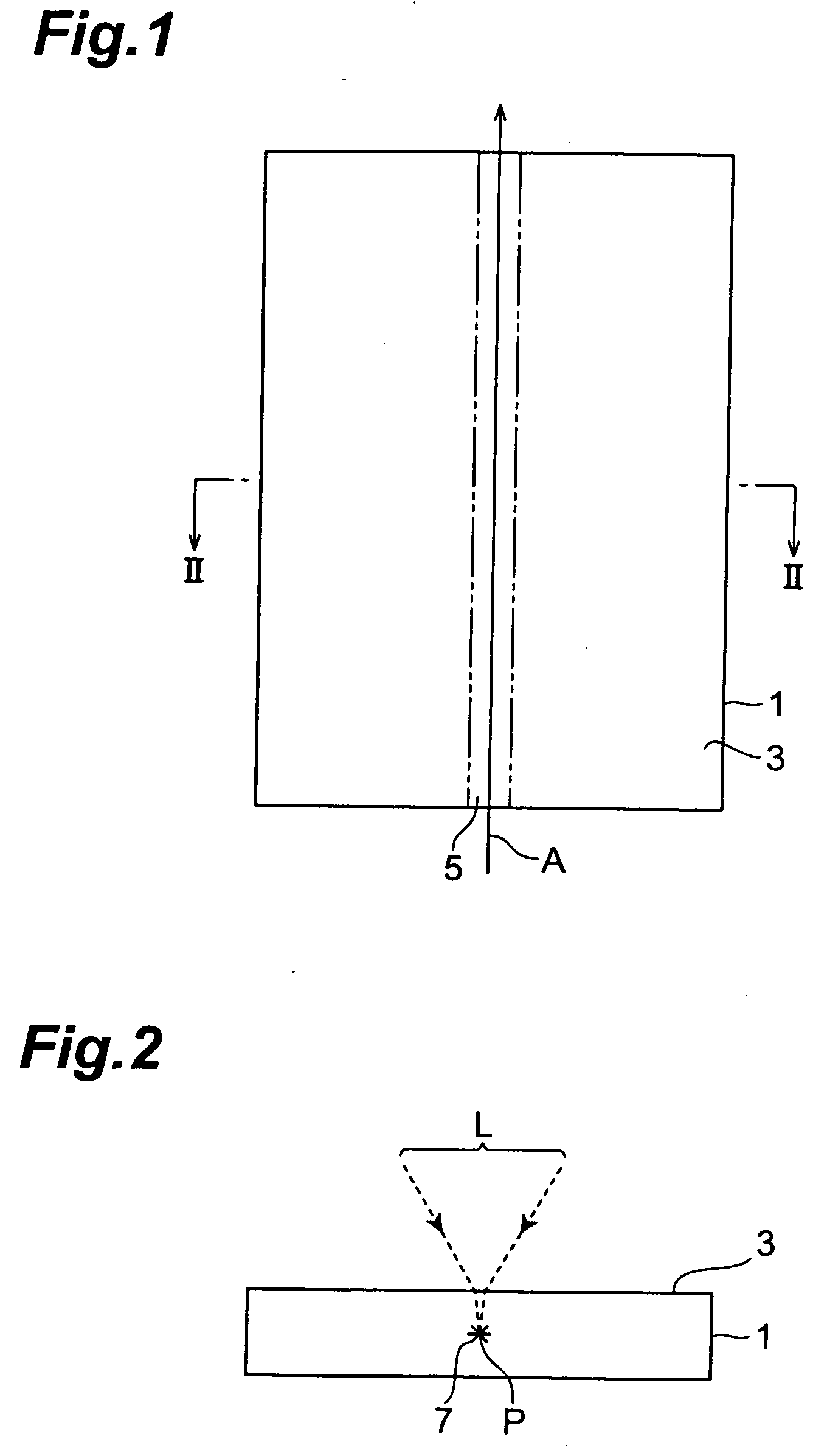

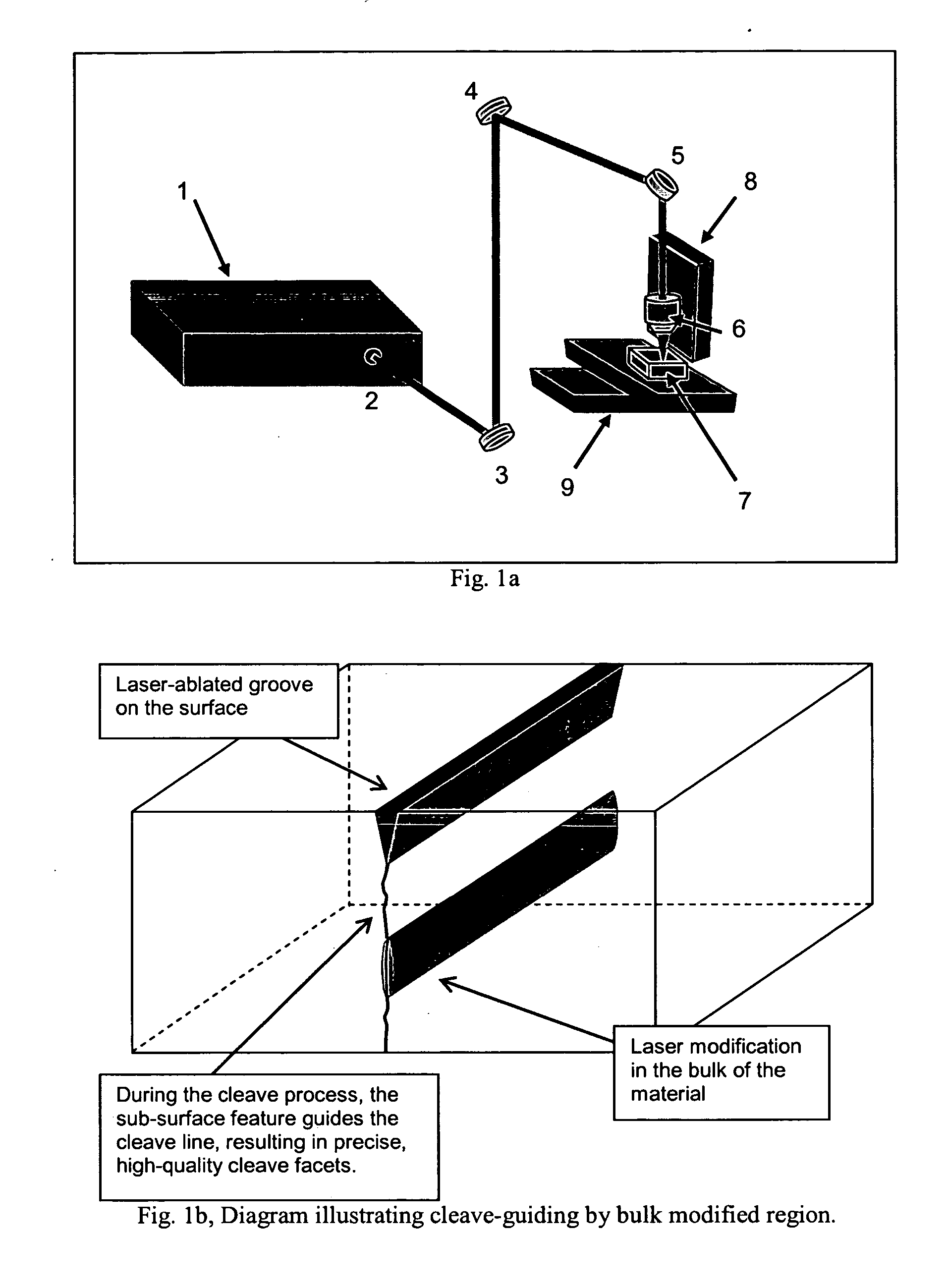

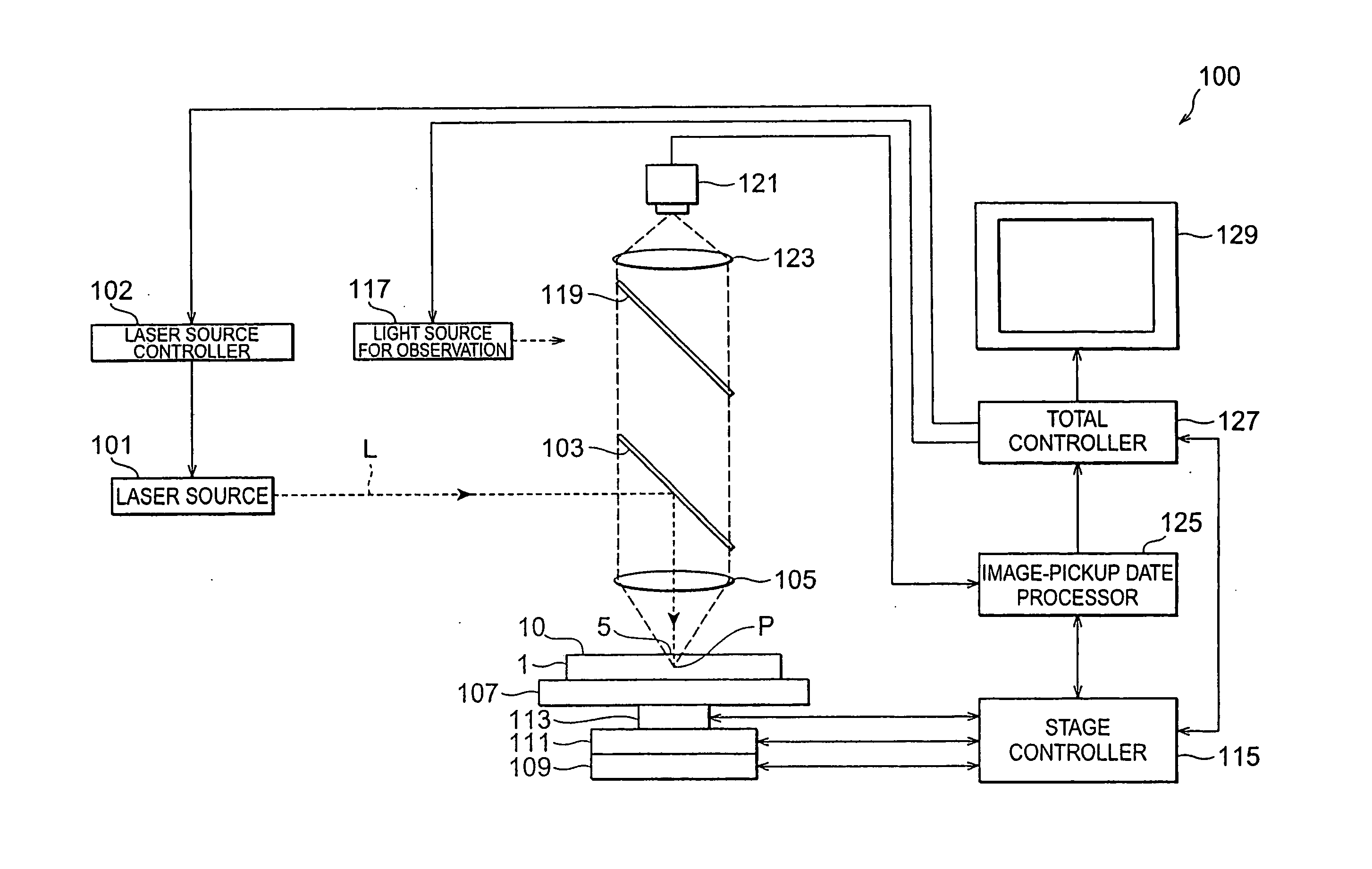

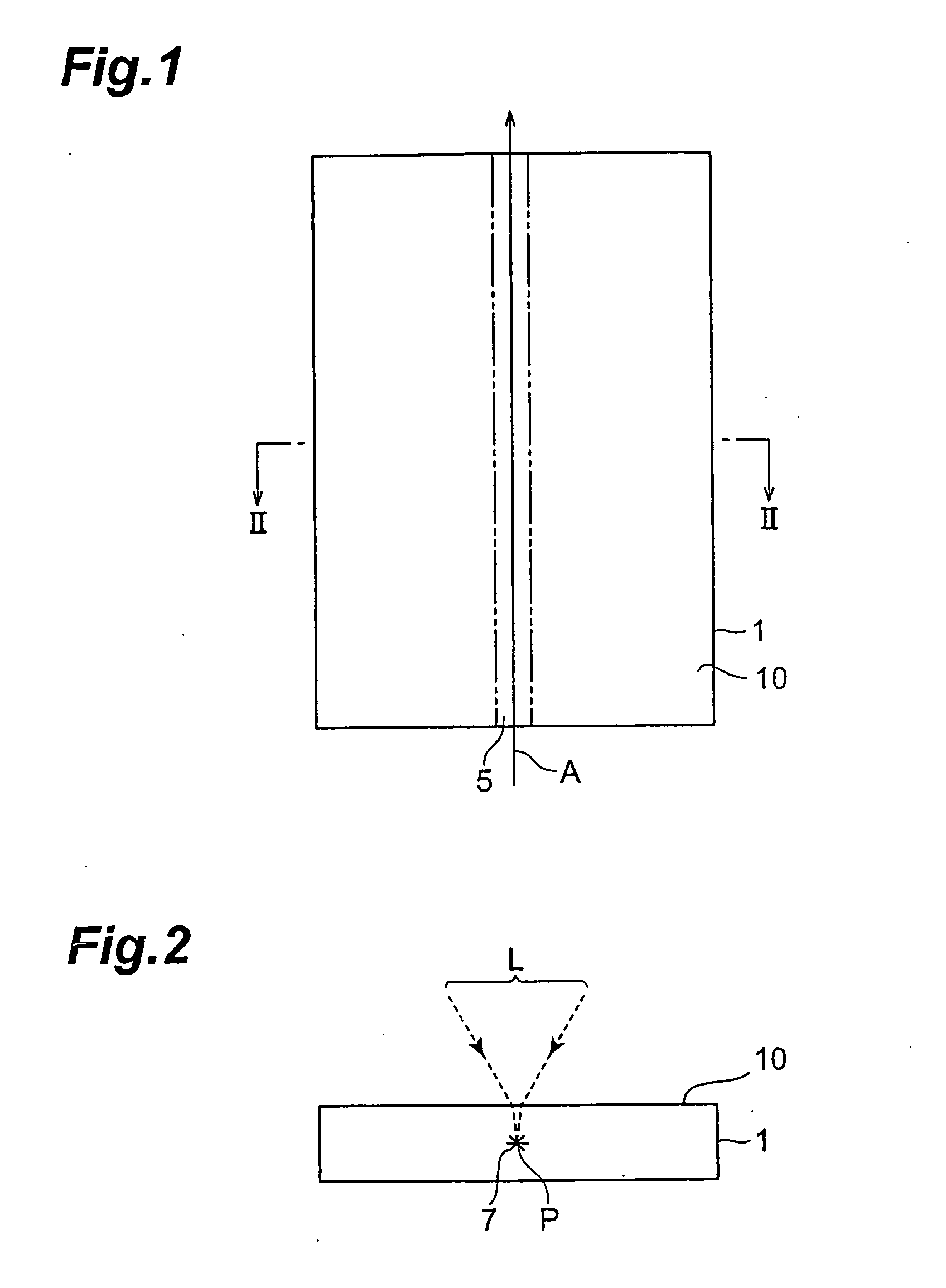

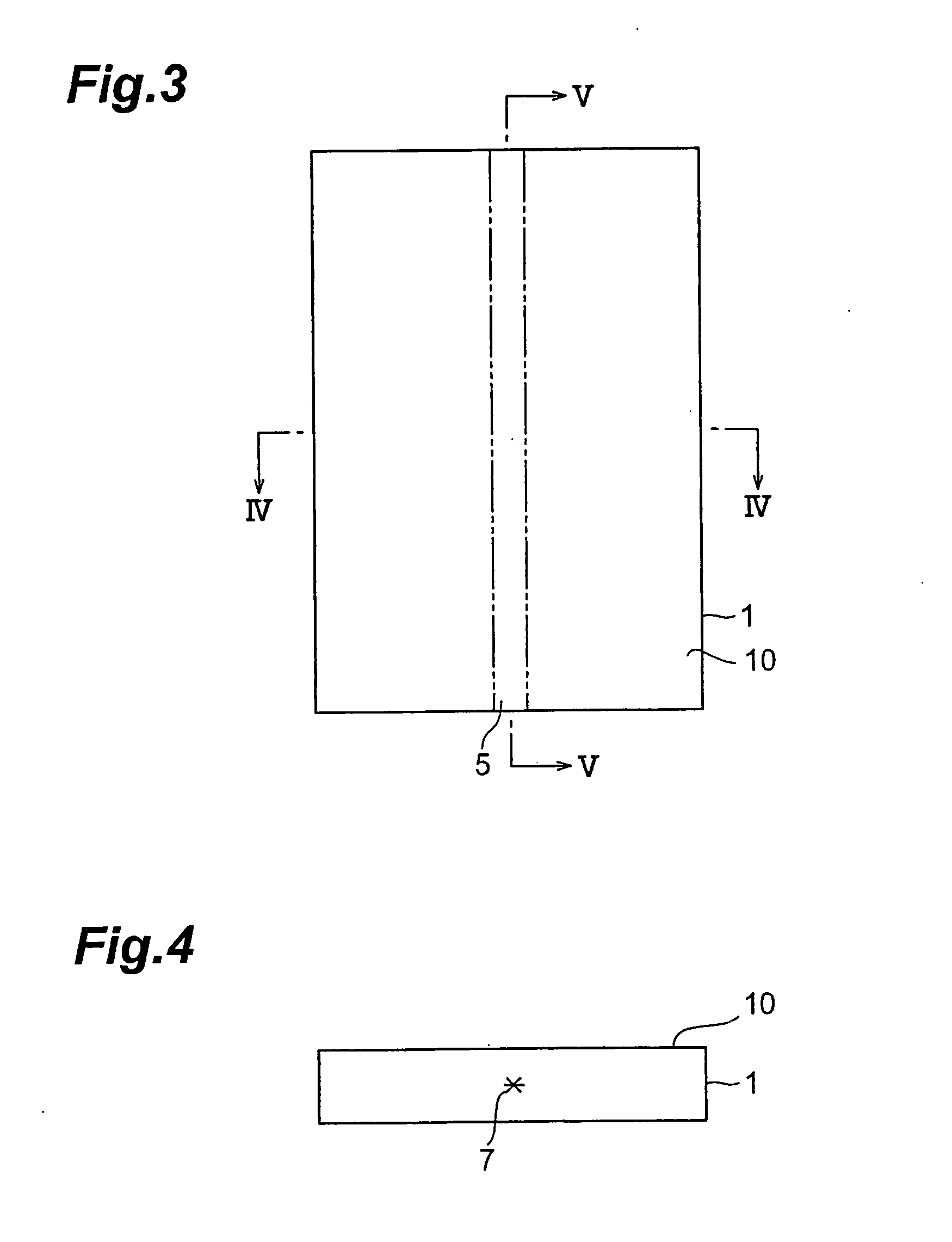

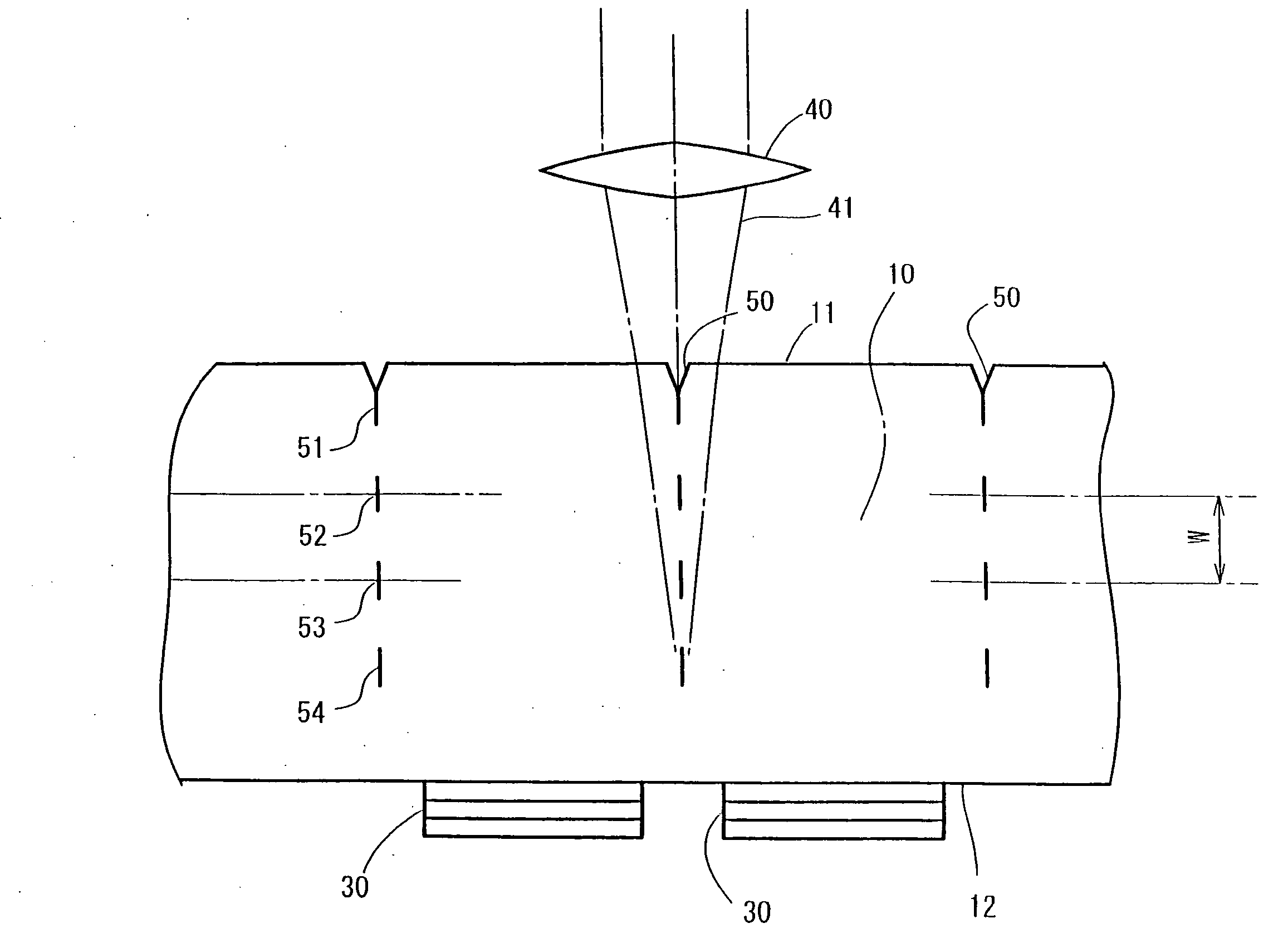

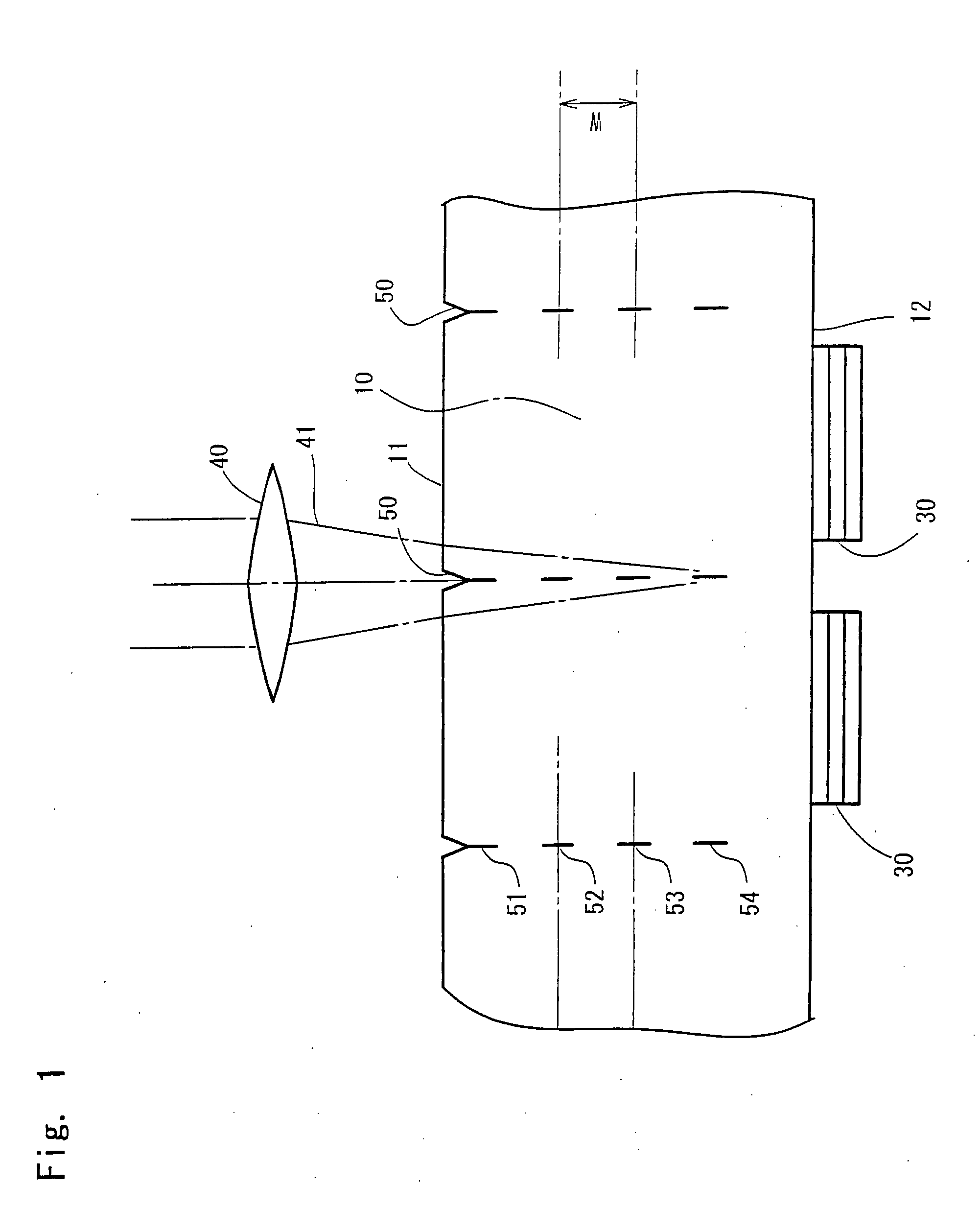

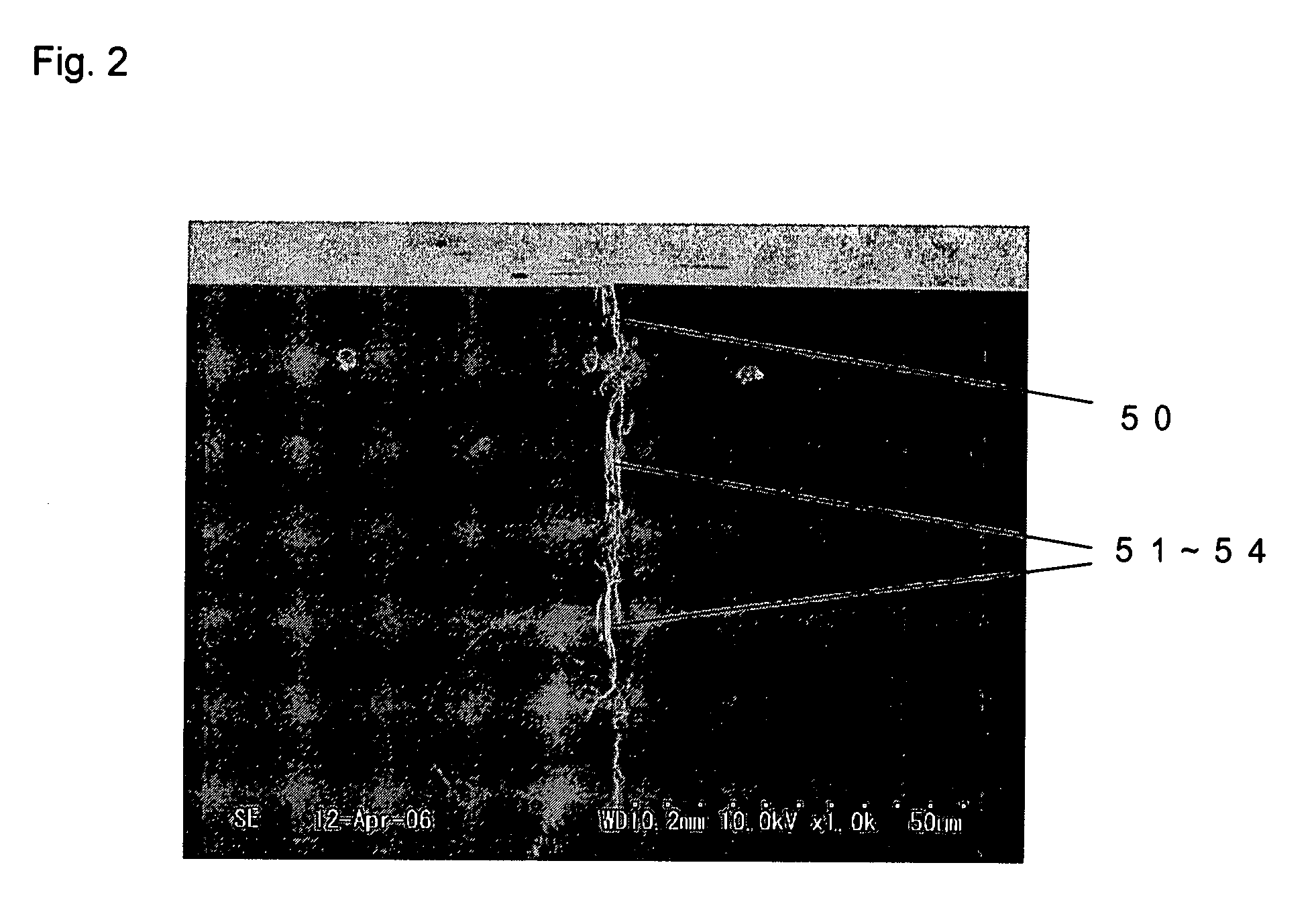

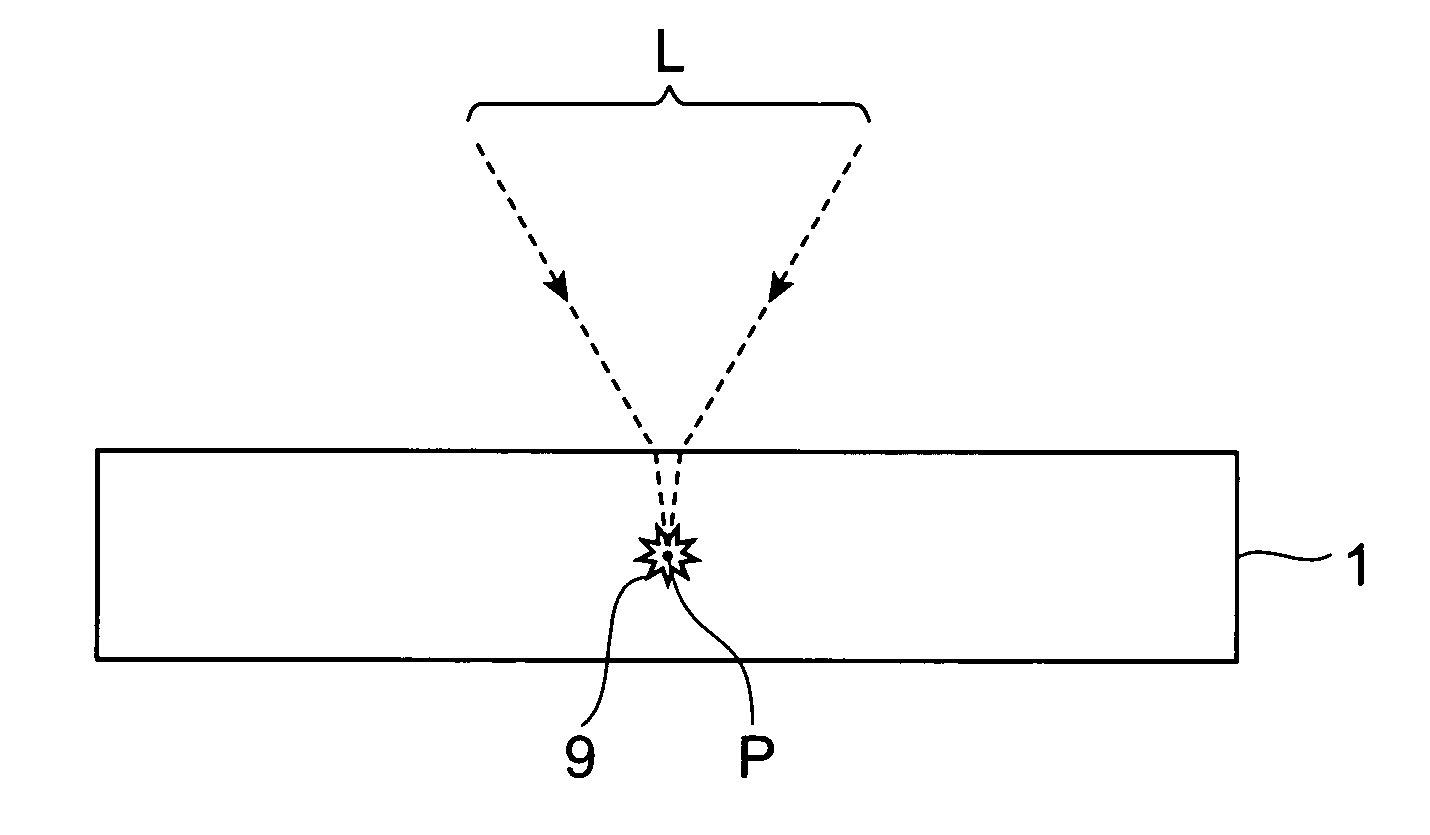

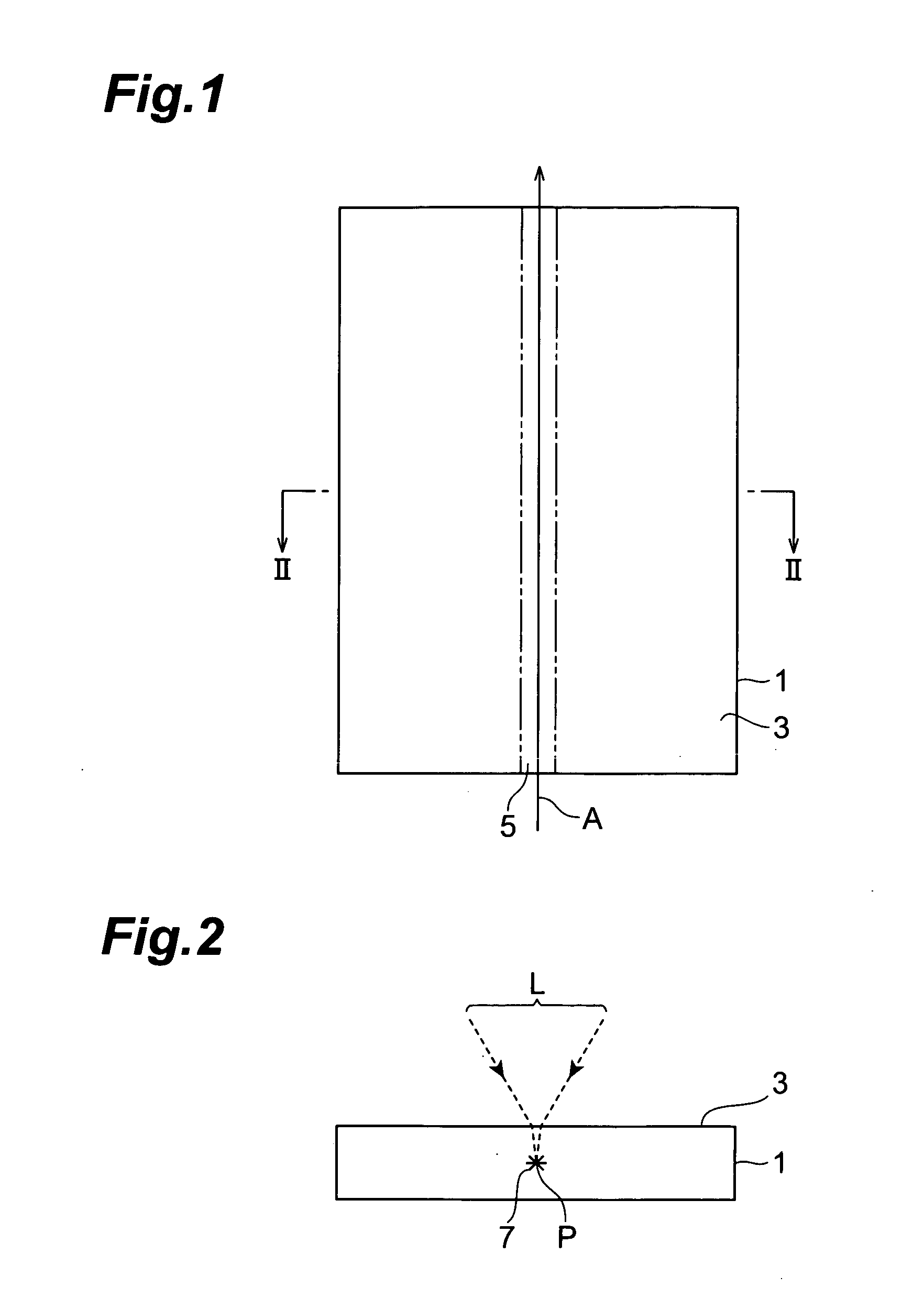

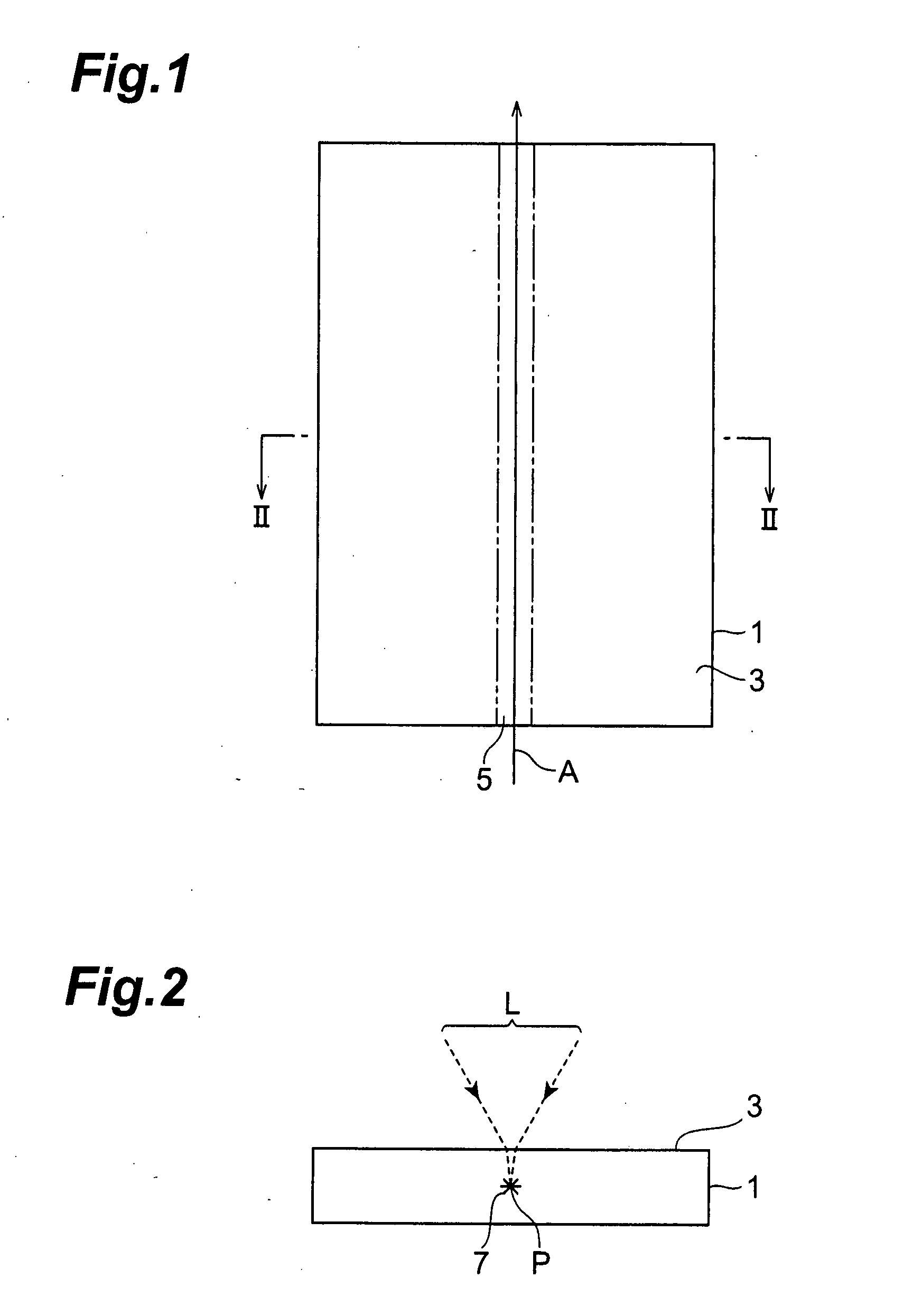

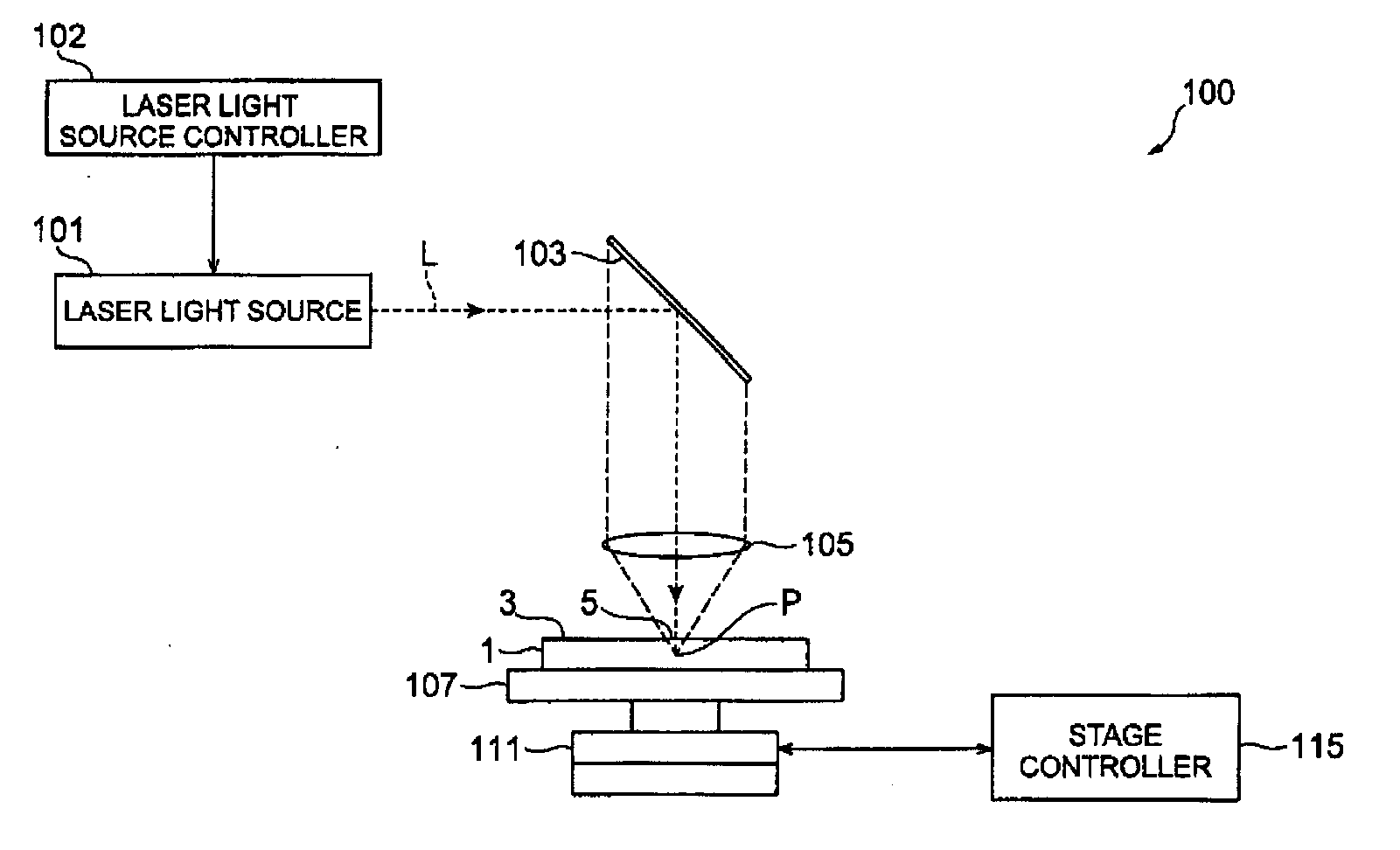

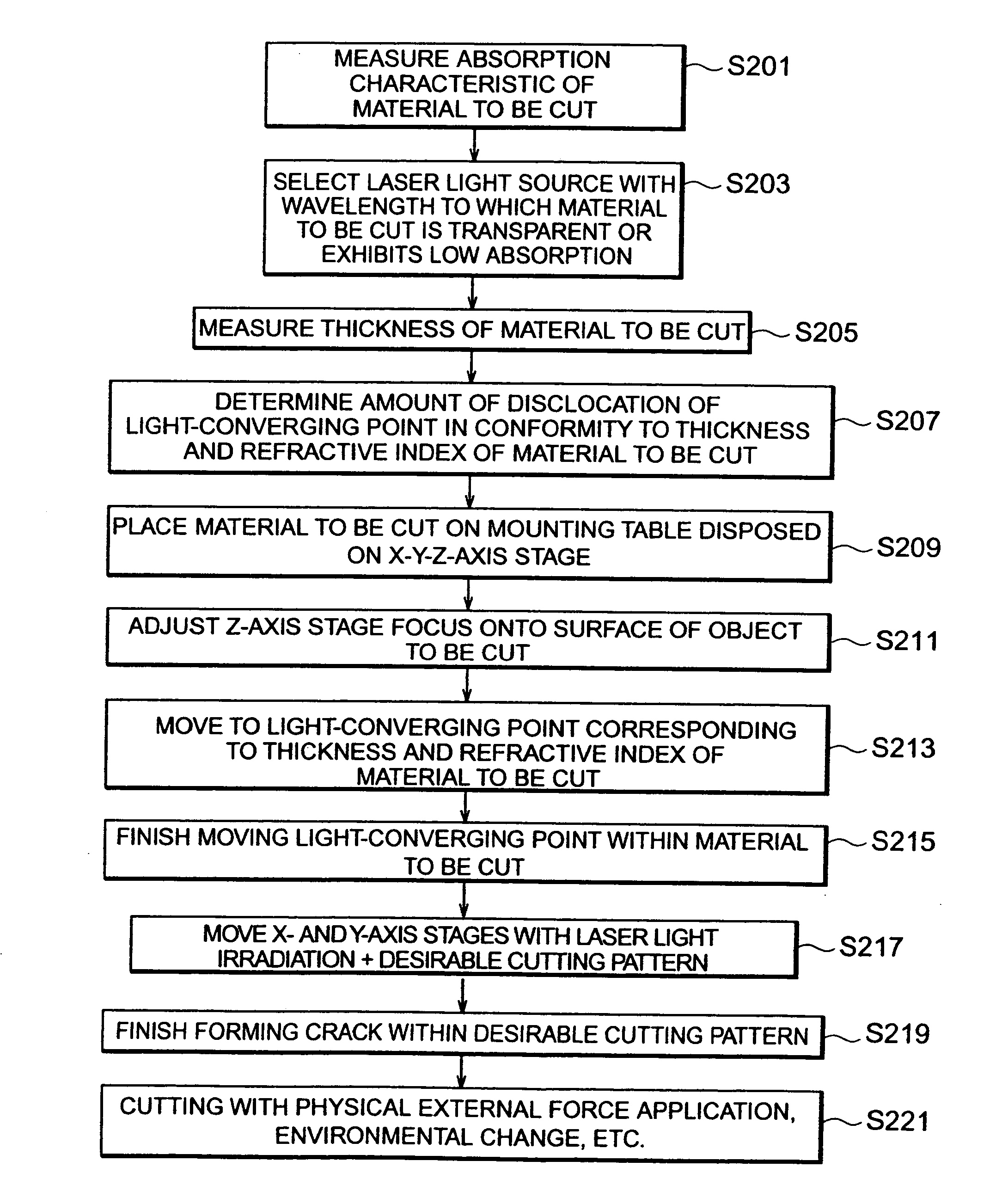

Laser processing method

ActiveUS20050202596A1Force is smallImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser light

A laser processing method which can highly accurately cut objects to be processed having various laminate structures is provided. An object to be processed comprising a substrate and a laminate part disposed on the front face of the substrate is irradiated with laser light L while a light-converging point P is positioned at least within the substrate, so as to form a modified region due to multiphoton absorption at least within the substrate, and cause the modified region to form a starting point region for cutting. When the object is cut along the starting point region for cutting, the object 1 can be cut with a high accuracy.

Owner:HAMAMATSU PHOTONICS KK

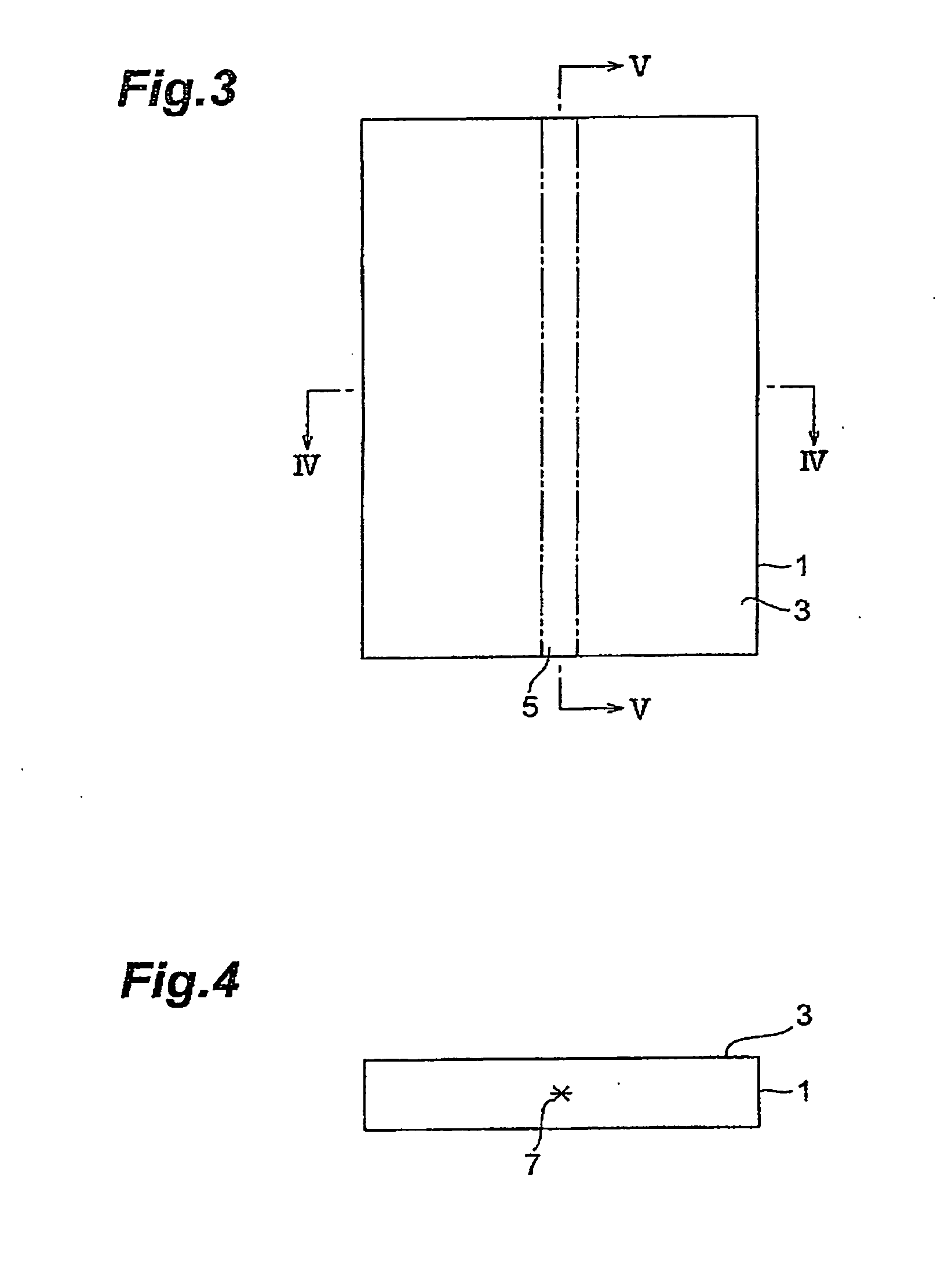

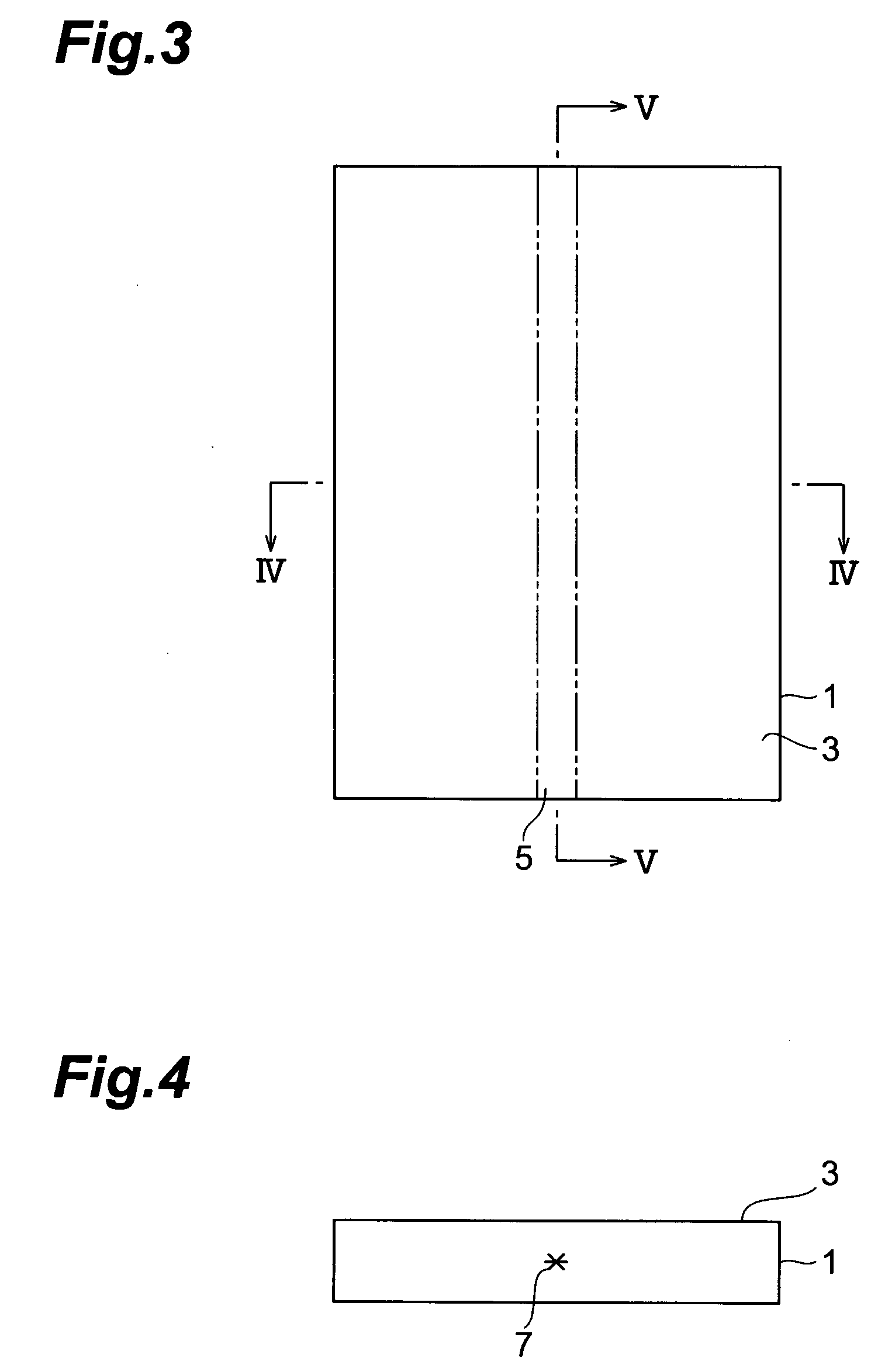

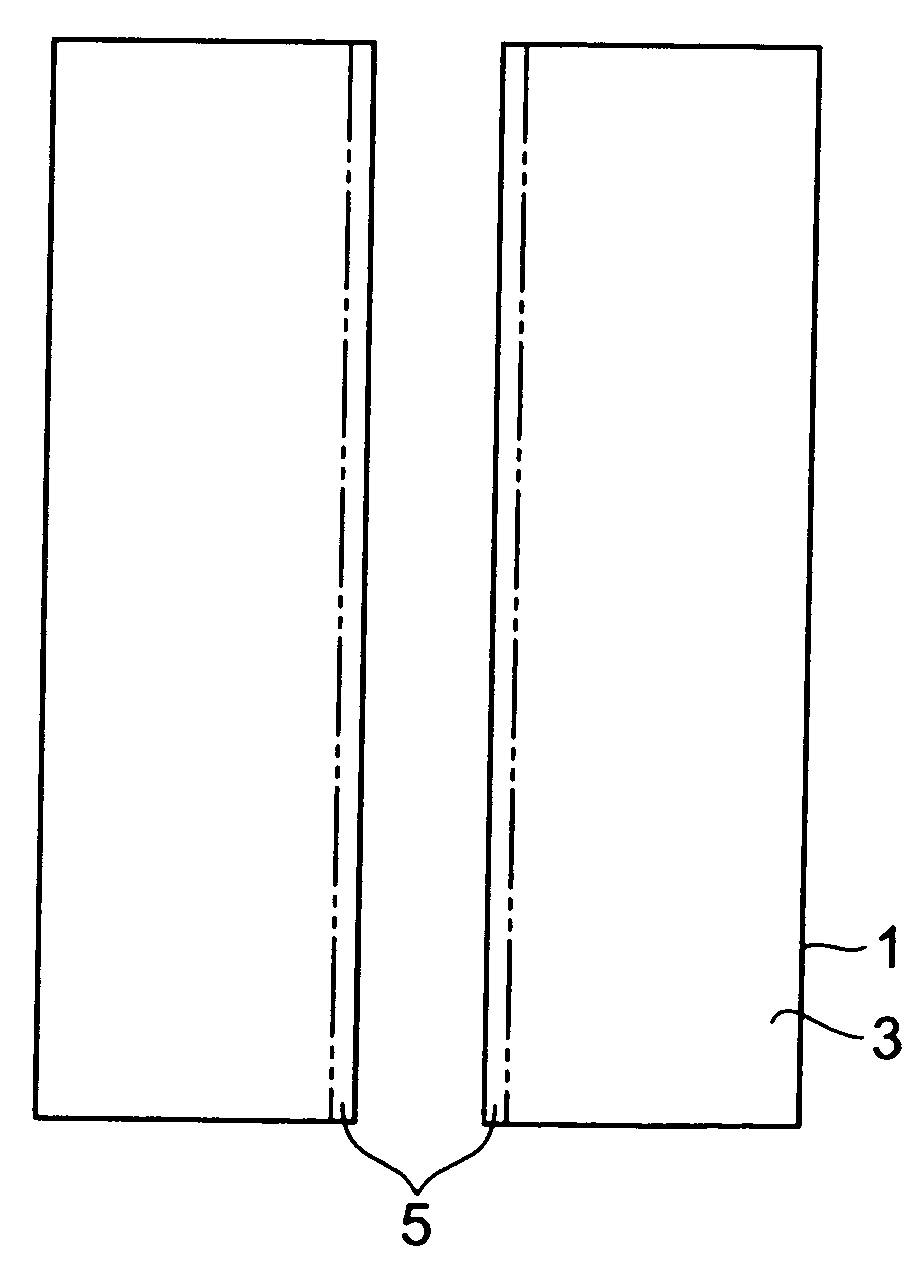

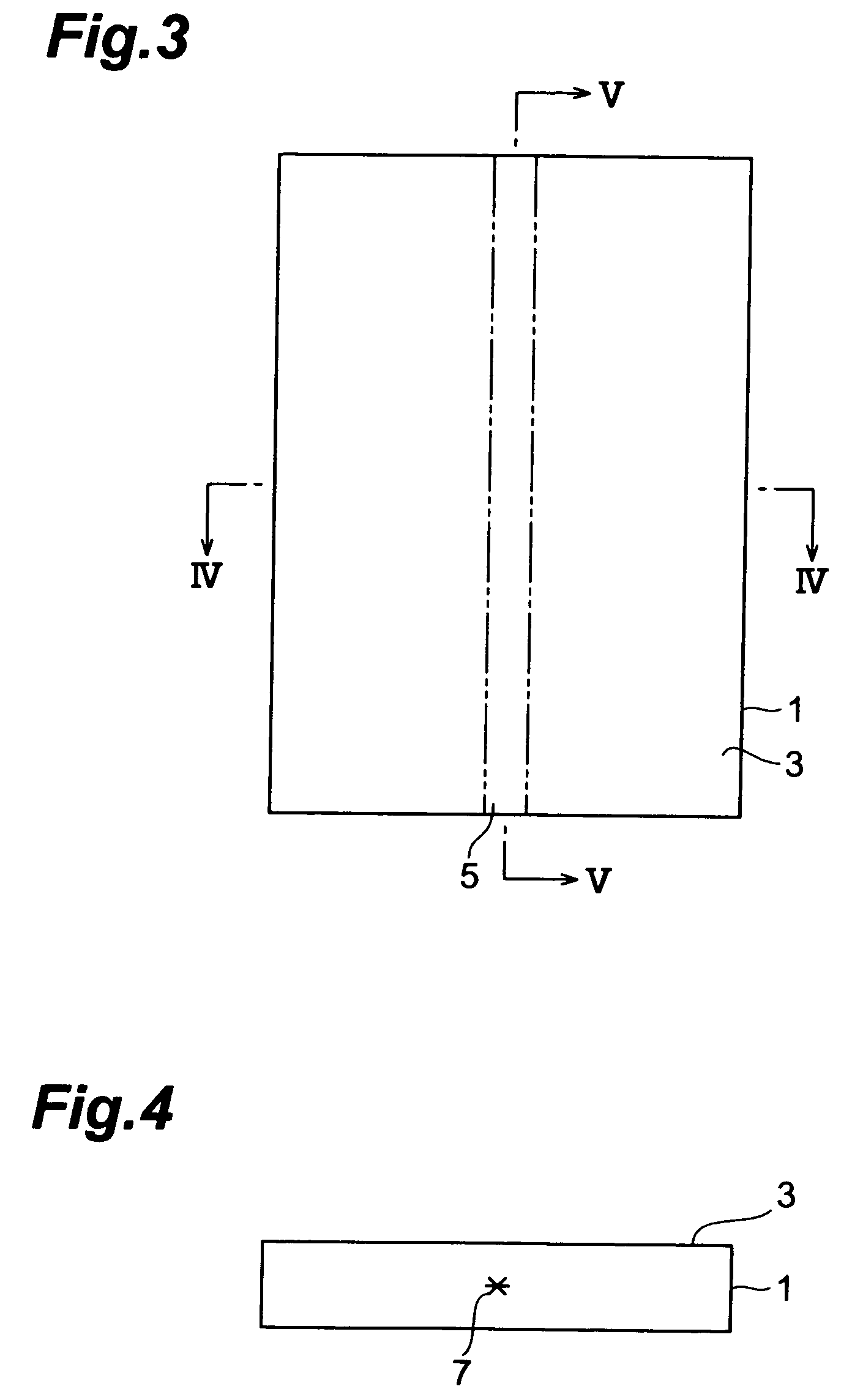

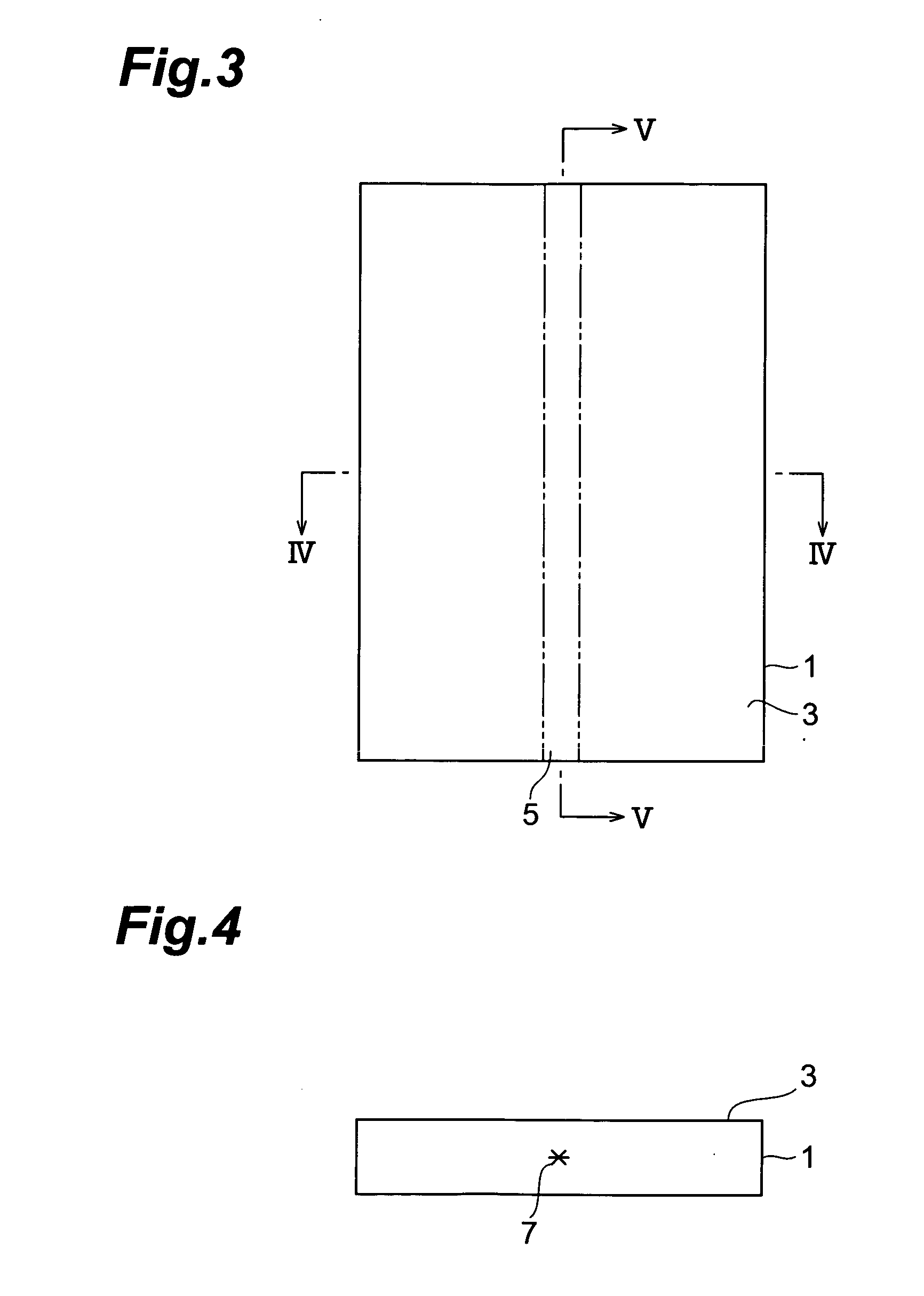

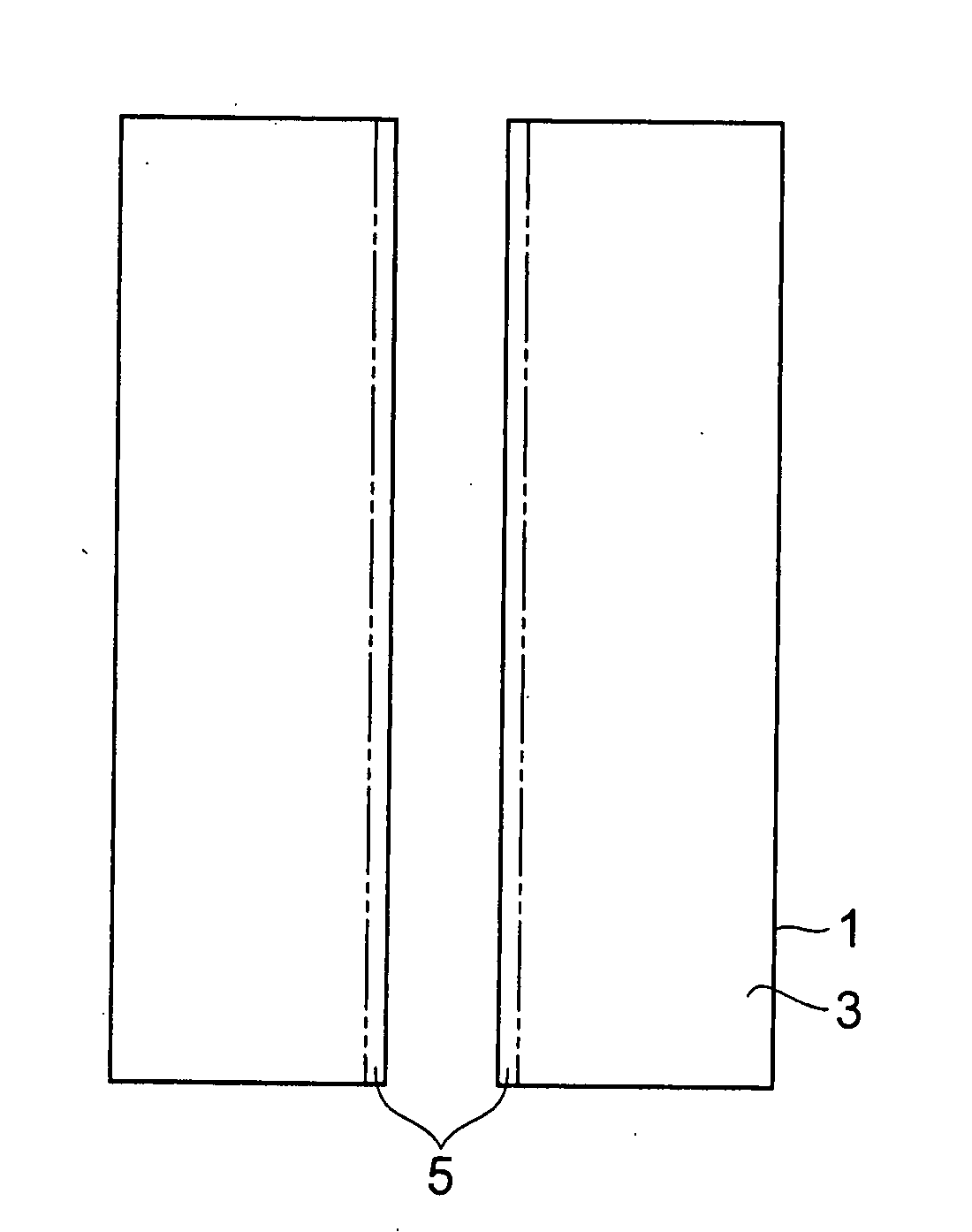

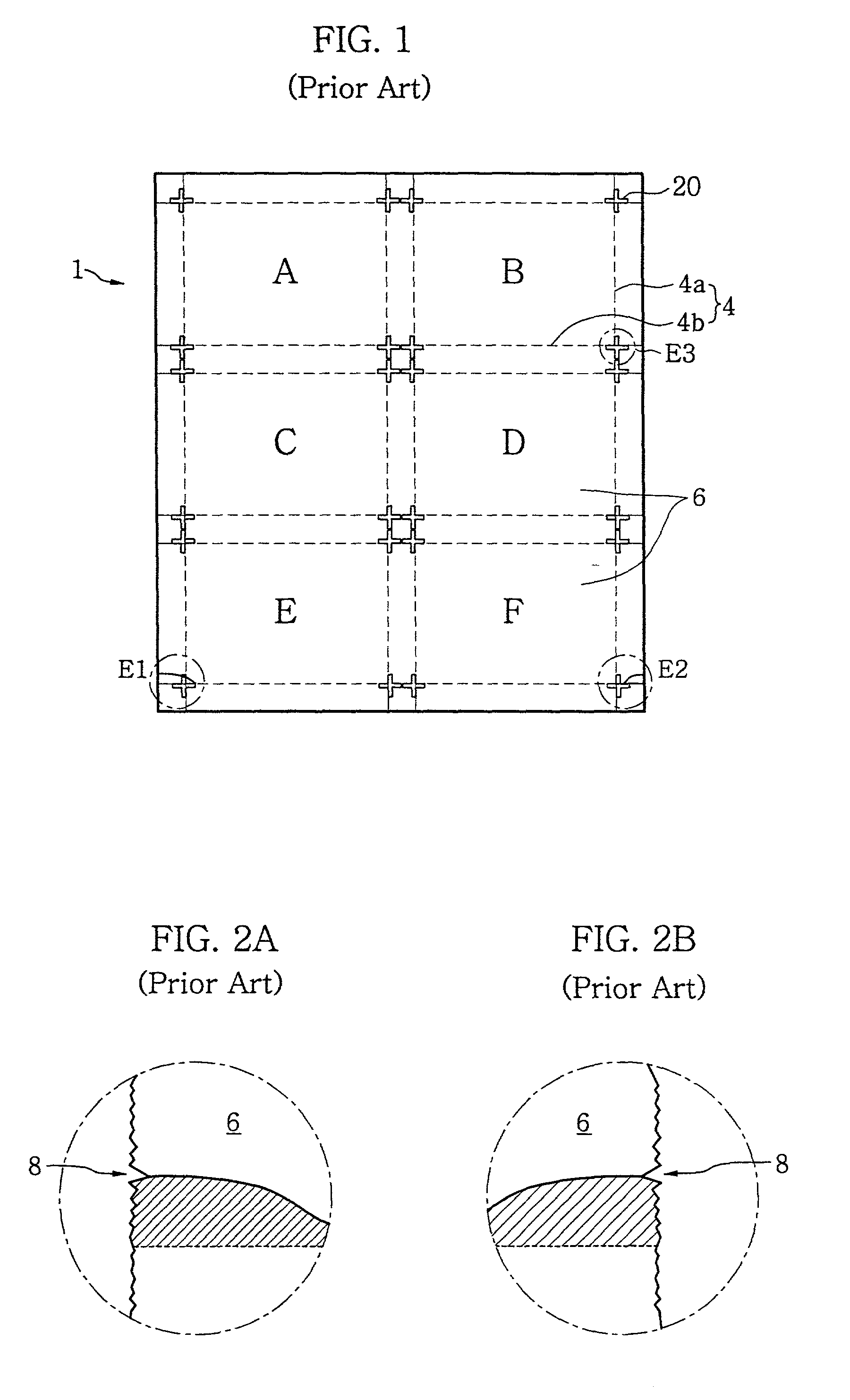

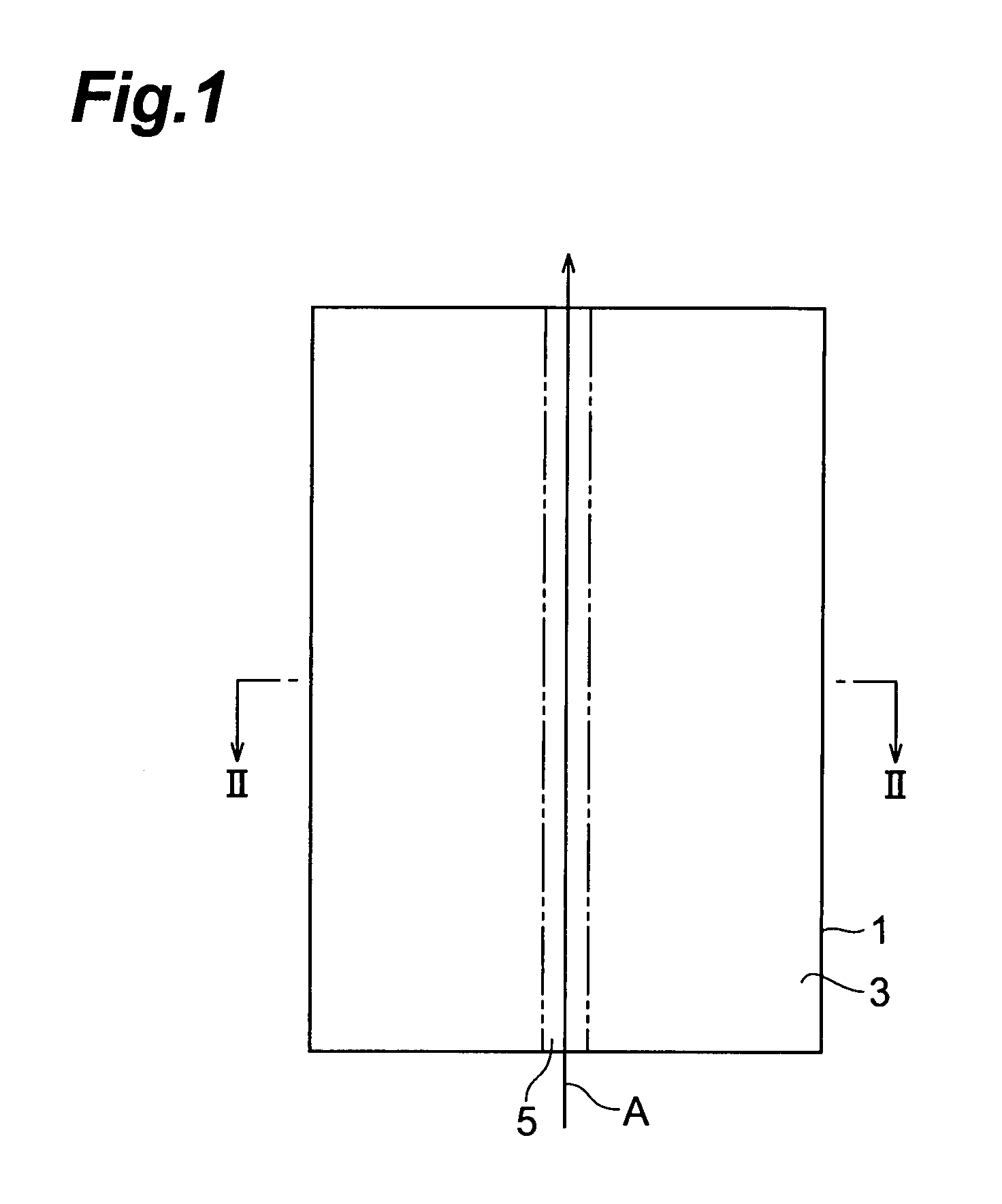

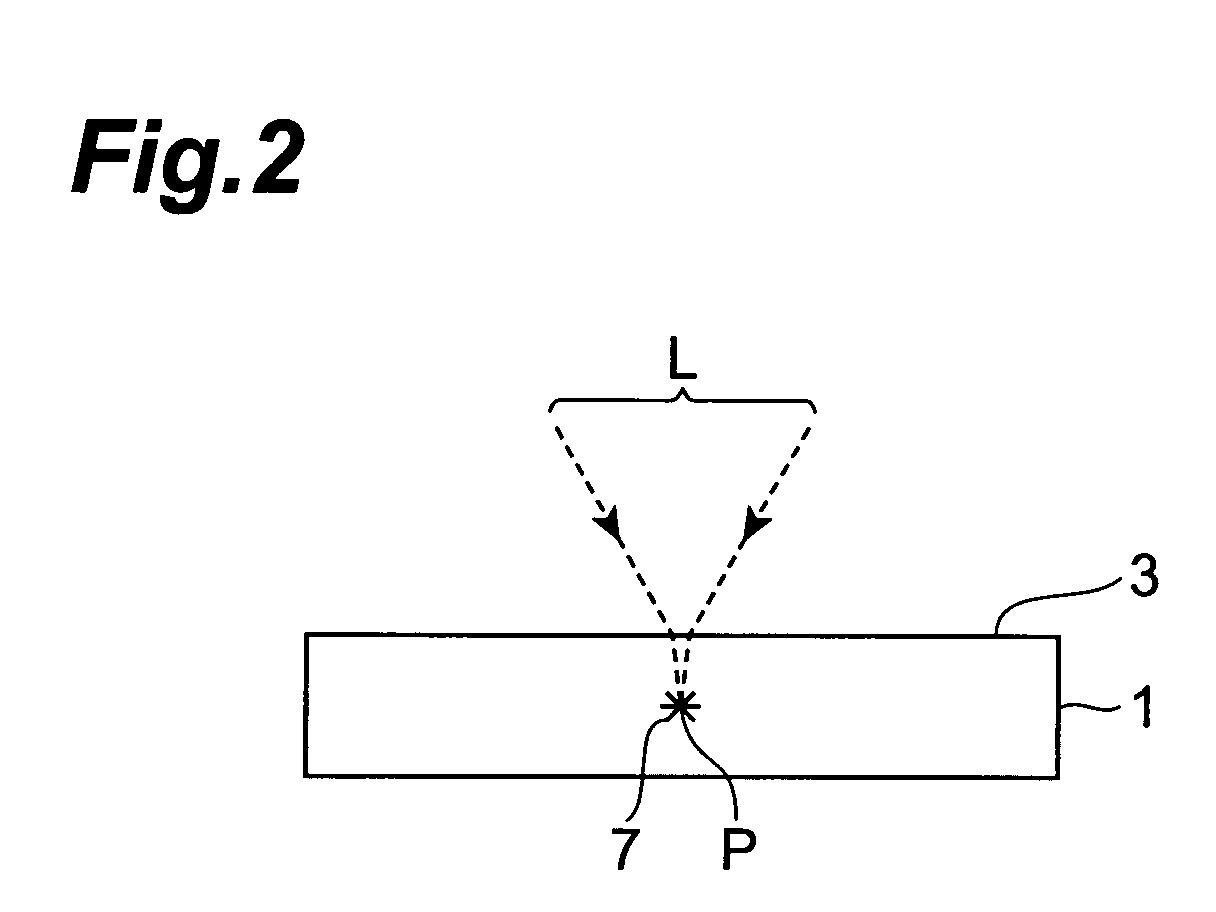

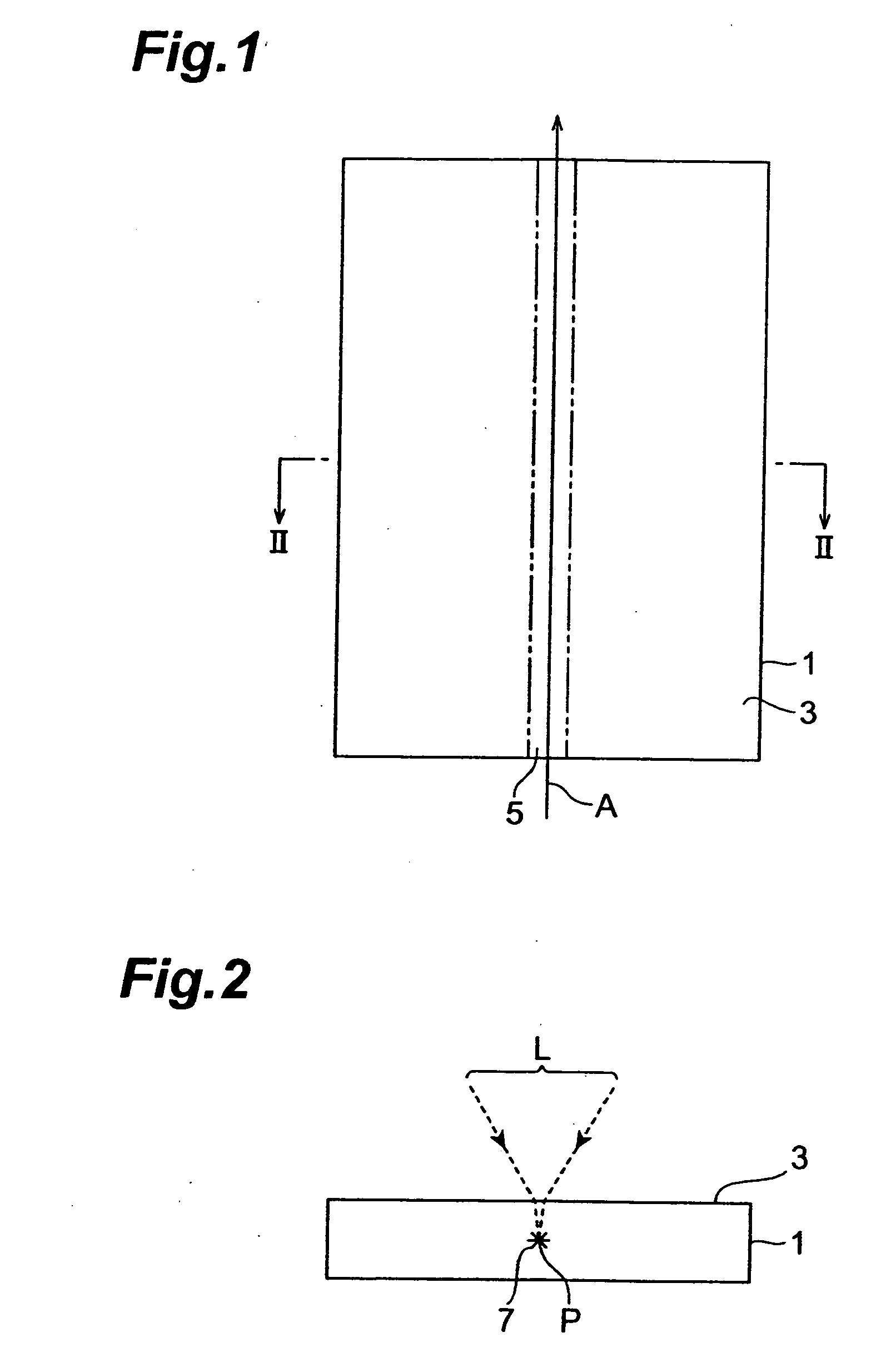

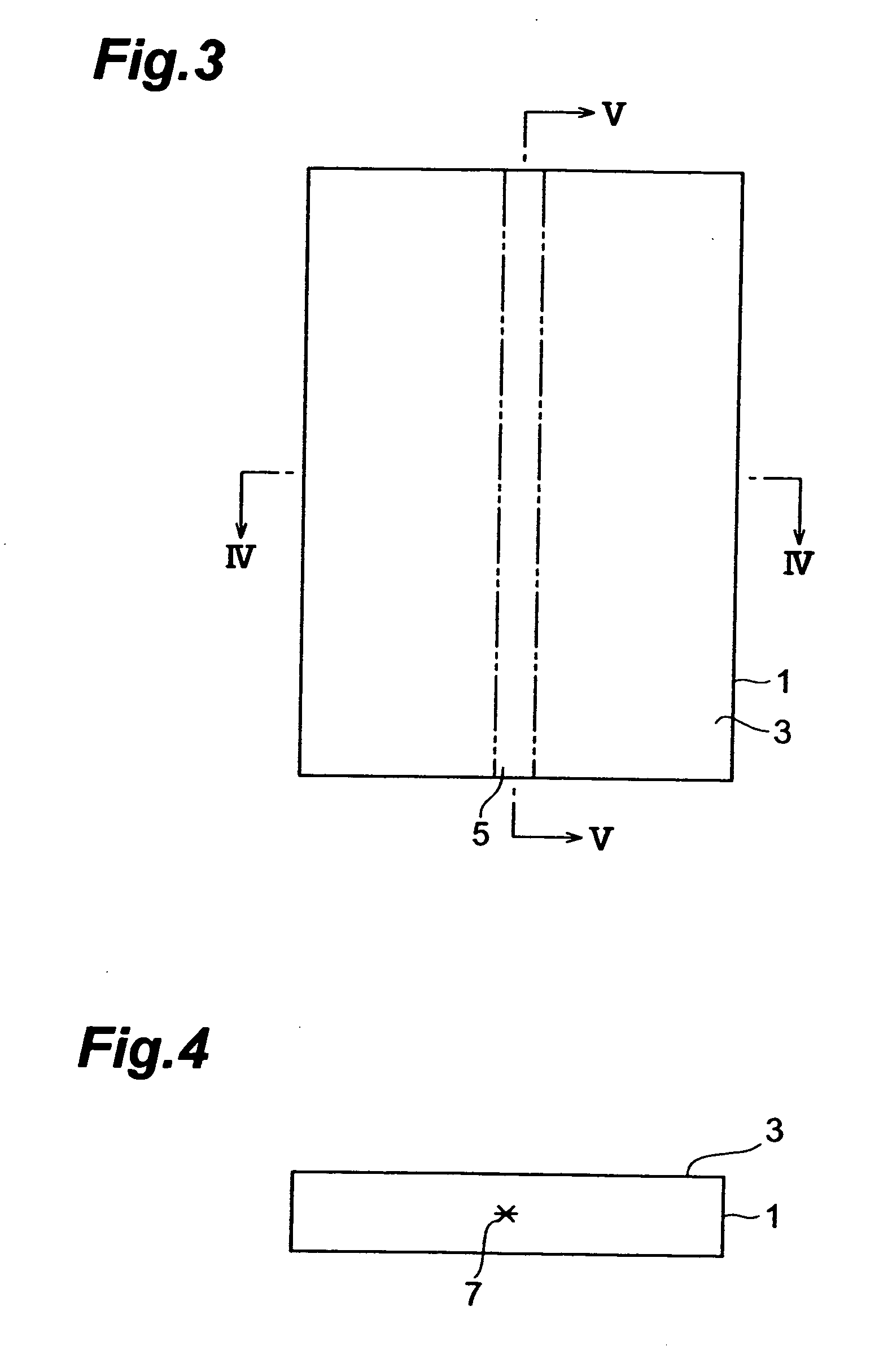

Method of cutting processed object

InactiveUS20060011593A1Precise cuttingPrevent unnecessary fracturesSolid-state devicesSemiconductor/solid-state device manufacturingClassical mechanicsLaser light

A method of cutting an object which can accurately cut the object is provided. An object to be processed 1 such as a silicon wafer is irradiated with laser light L while a light-converging point P is positioned therewithin, so as to form a modified region 7 due to multiphoton absorption within the object 1, and cause the modified region 7 to form a starting point region for cutting 8 shifted from the center line CL of the thickness of the object 1 toward the front face 3 of the object 1 along a line along which the object should be cut. Subsequently, the object 1 is pressed from the rear face 21 side thereof. This can generate a fracture from the starting point region for cutting 8 acting as a start point, thereby accurately cutting the object 1 along the line along which the object should be cut.

Owner:HAMAMATSU PHOTONICS KK

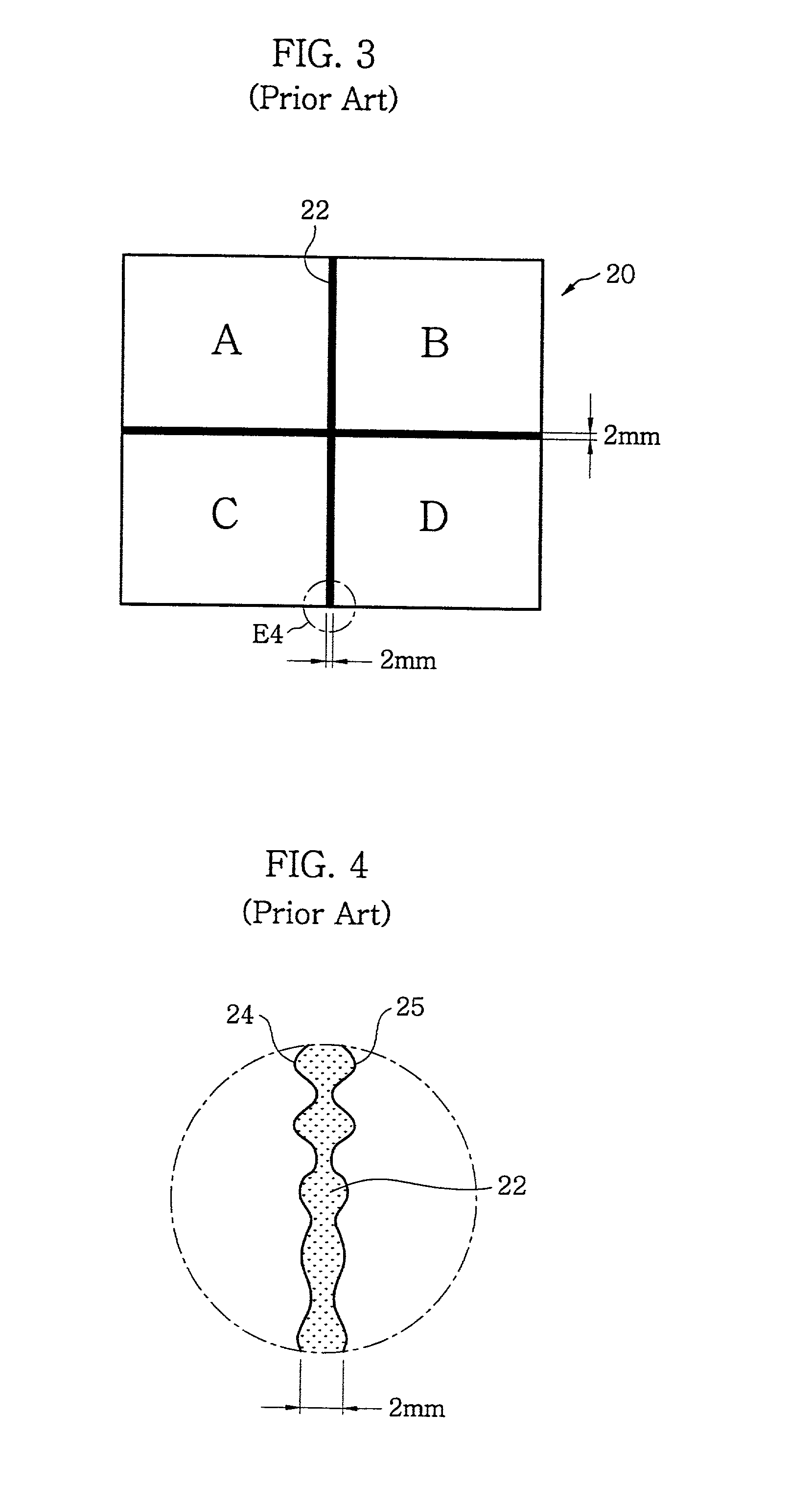

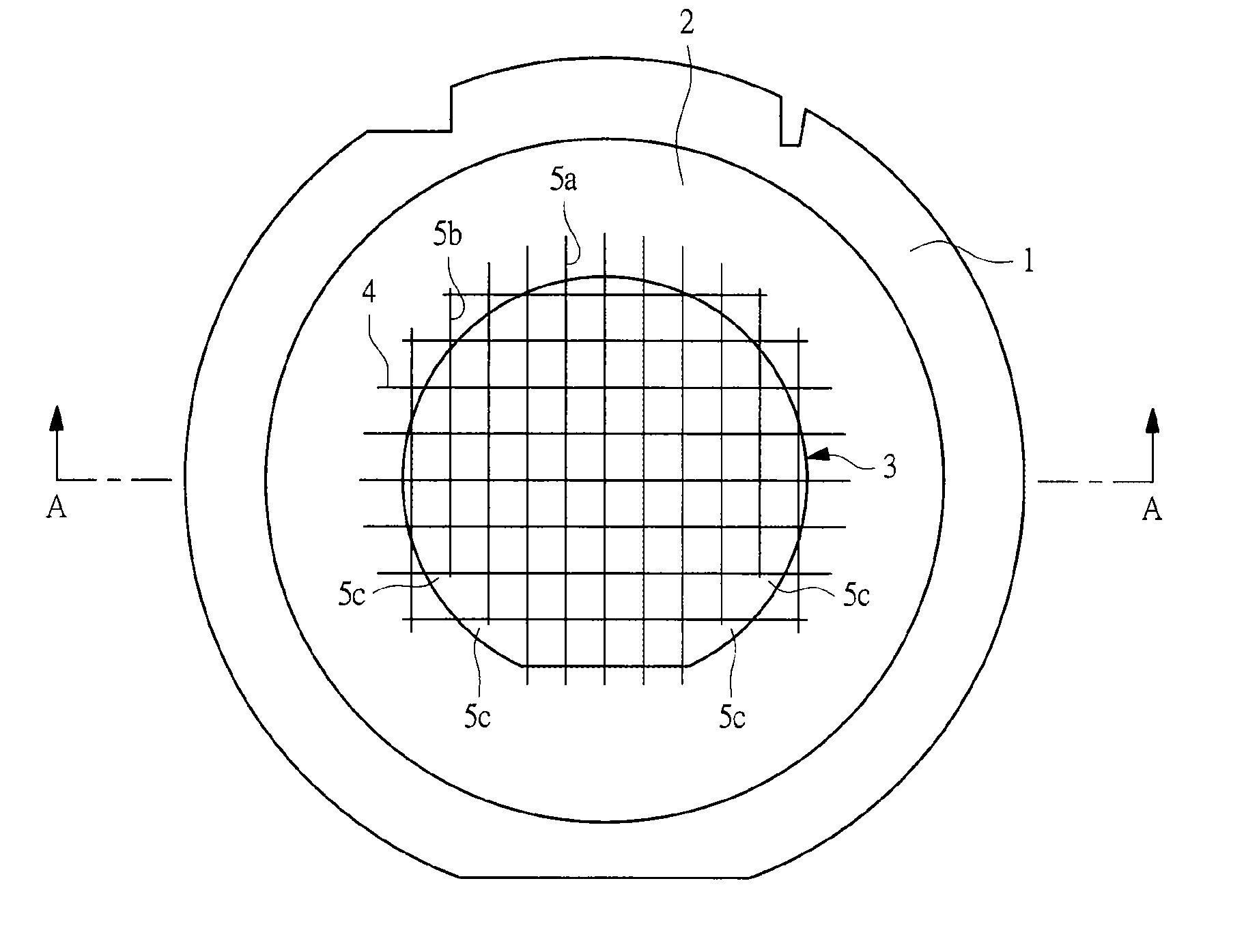

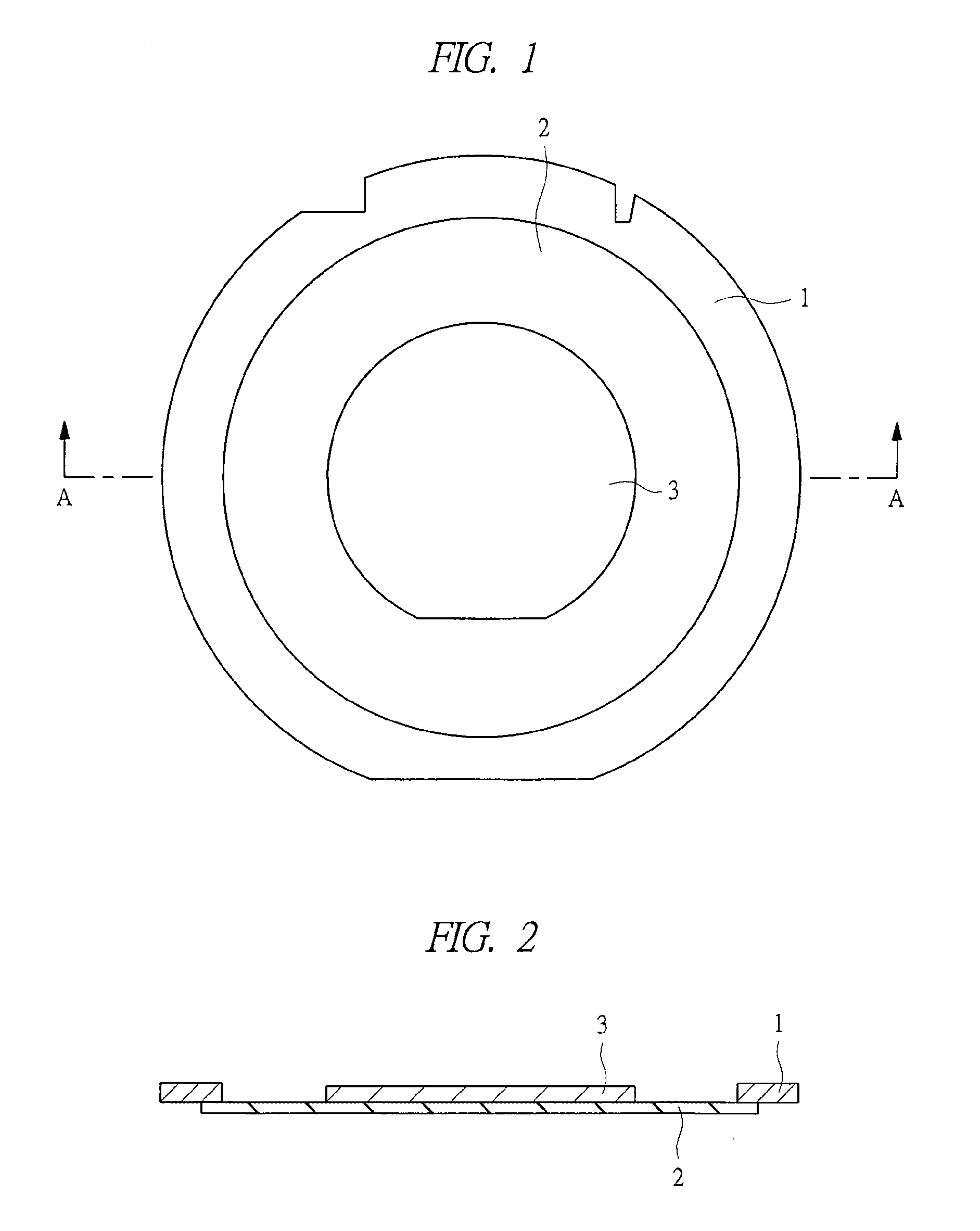

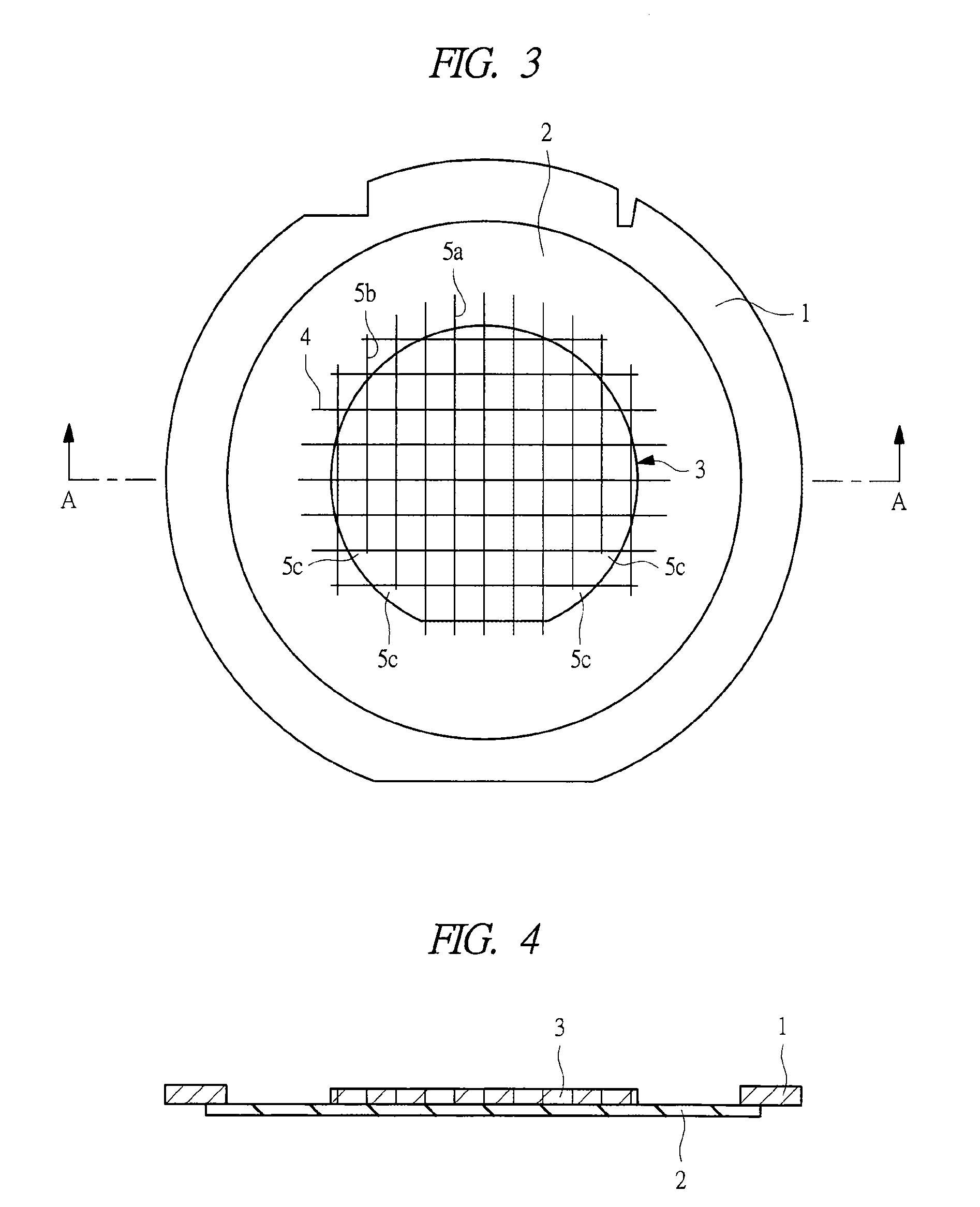

Method for dicing substrate

ActiveUS20050272223A1Improve transverse breaking strengthAvoid chippingSemiconductor/solid-state device detailsSolid-state devicesProcess regionLaser light

A substrate dividing method which can thin and divide a substrate while preventing chipping and cracking from occurring. This substrate dividing method comprises the steps of irradiating a semiconductor substrate 1 having a front face 3 formed with functional devices 19 with laser light while positioning a light-converging point within the substrate, so as to form a modified region including a molten processed region due to multiphoton absorption within the semiconductor substrate 1, and causing the modified region including the molten processed region to form a starting point region for cutting; and grinding a rear face 21 of the semiconductor substrate 1 after the step of forming the starting point region for cutting such that the semiconductor substrate 1 attains a predetermined thickness.

Owner:HAMAMATSU PHOTONICS KK

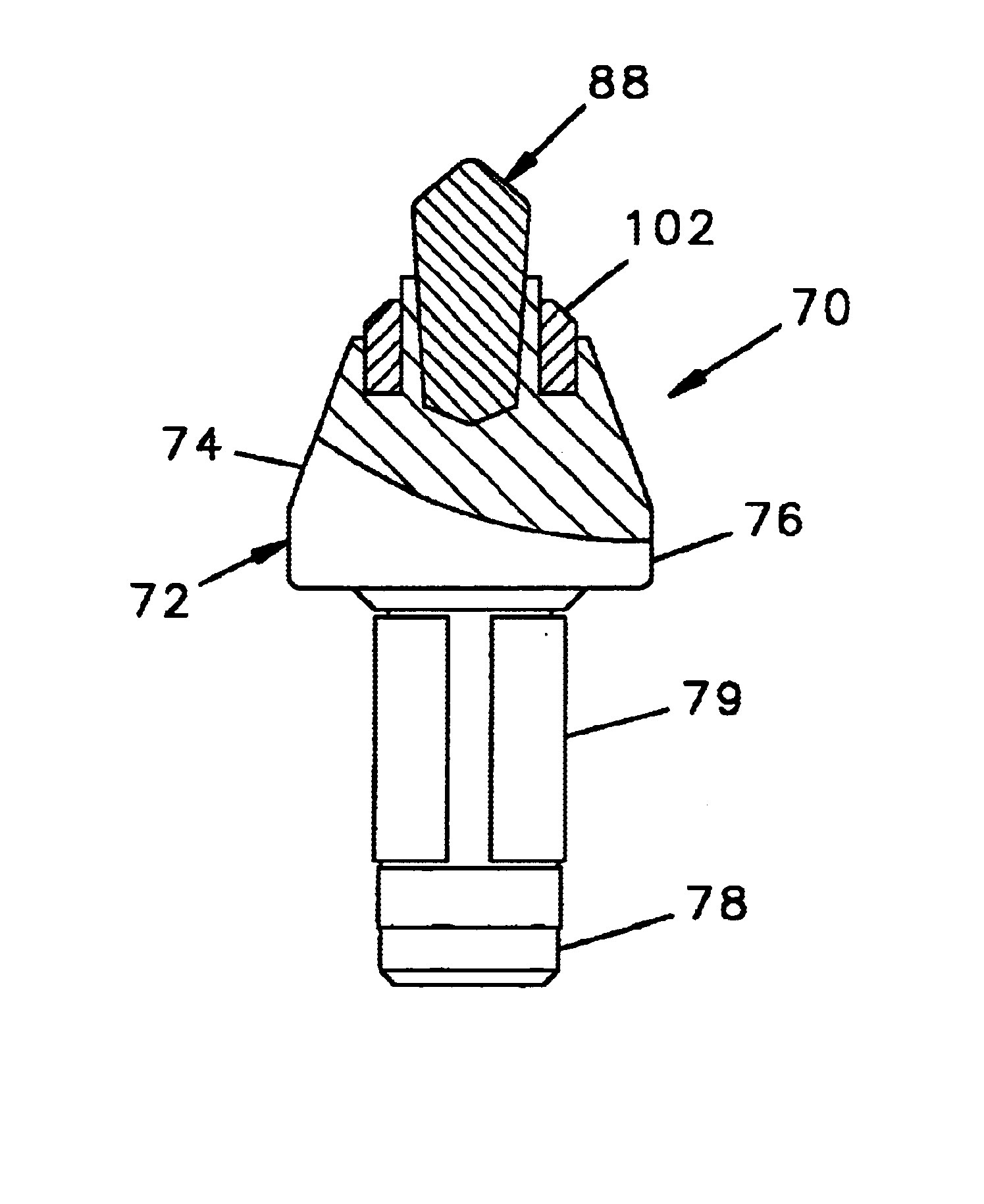

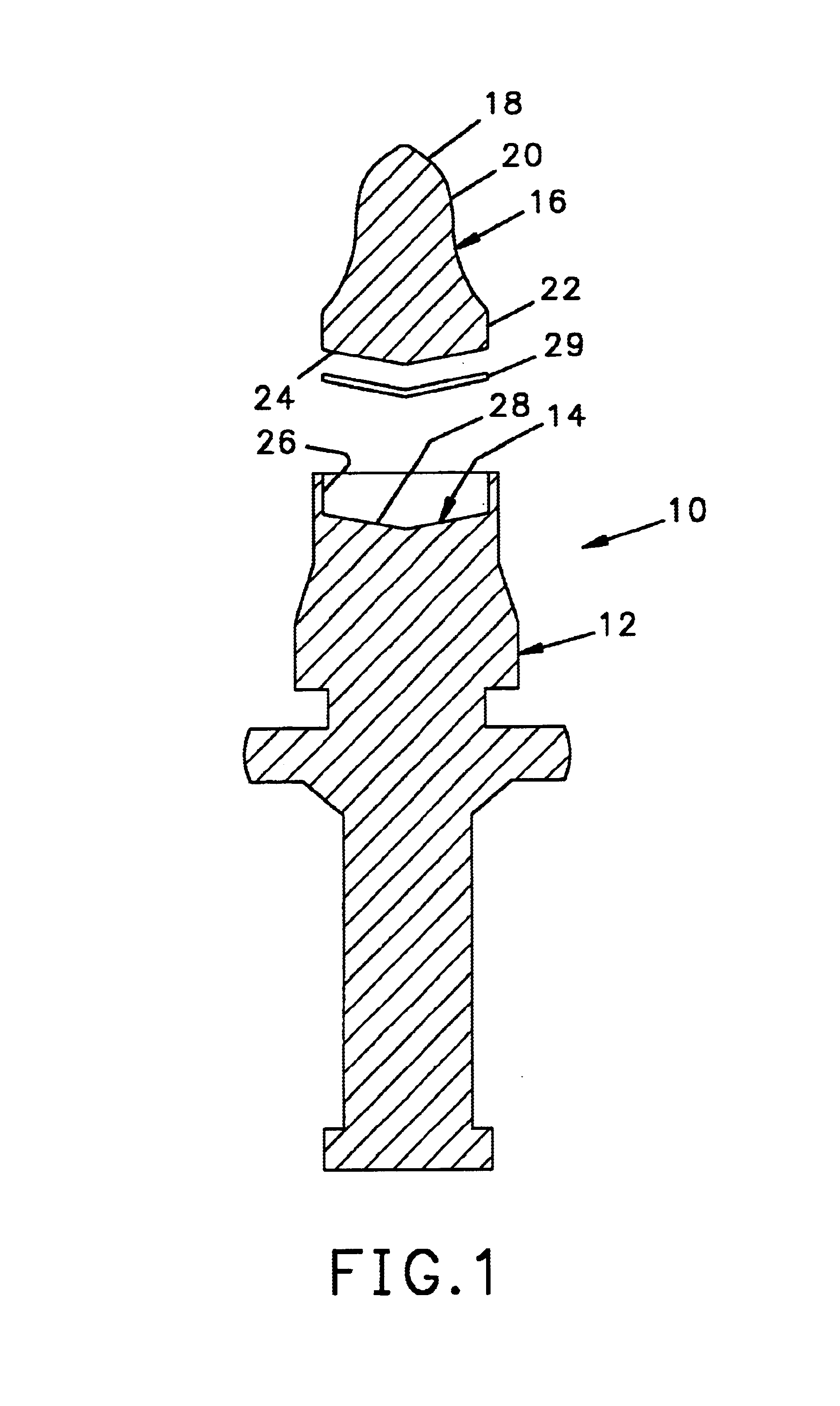

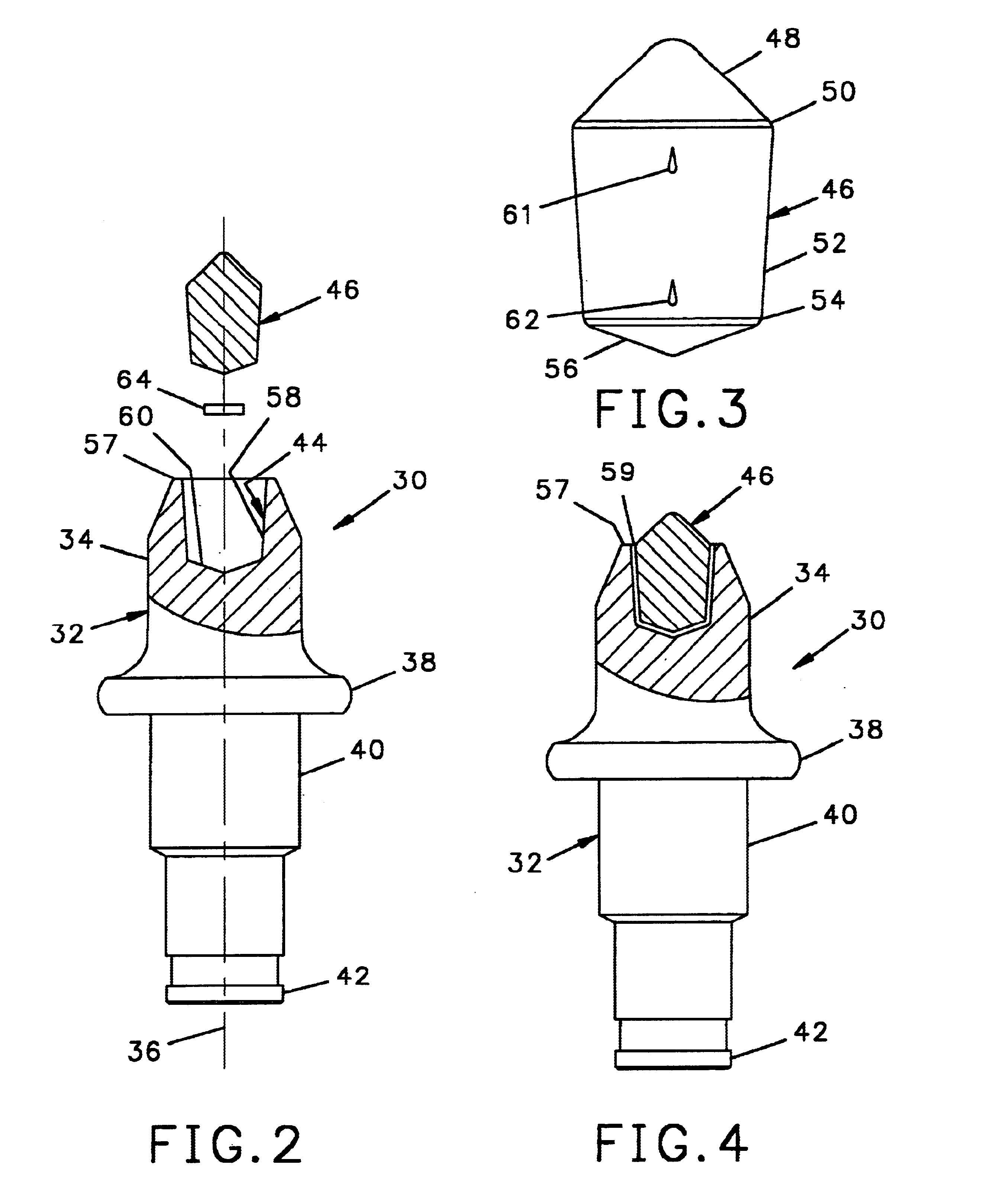

Cutting tool with hardened tip having a tapered base

InactiveUS6739327B2Improved cutting tipReduce harmSlitting machinesFine working devicesEngineeringMechanical engineering

A cutting tool has a centrally located tungsten carbide insert brazed into a seat at the forward end of the tool. The seat has a circular mouth and rearward of the mouth is a frustoconical inner wall. At the bottom of the seat is a transverse surface. A tungsten carbide insert is brazed into the seat and the base of the insert is complementary in shape to the seat. A second annular insert may also be brazed into a complementary shaped annular seat that surrounds the centrally located seat.

Owner:THE SOLLAMI COMPANY

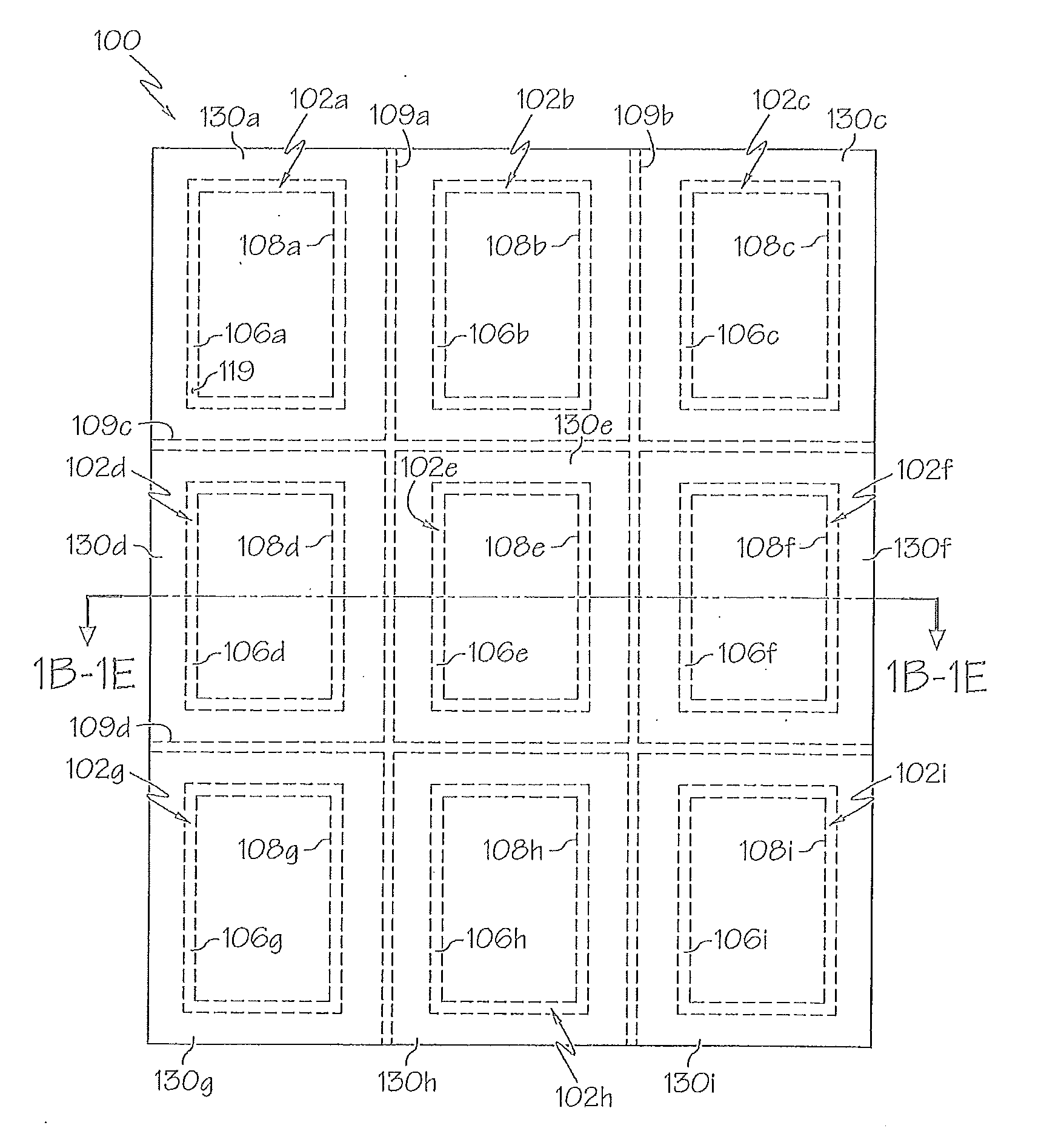

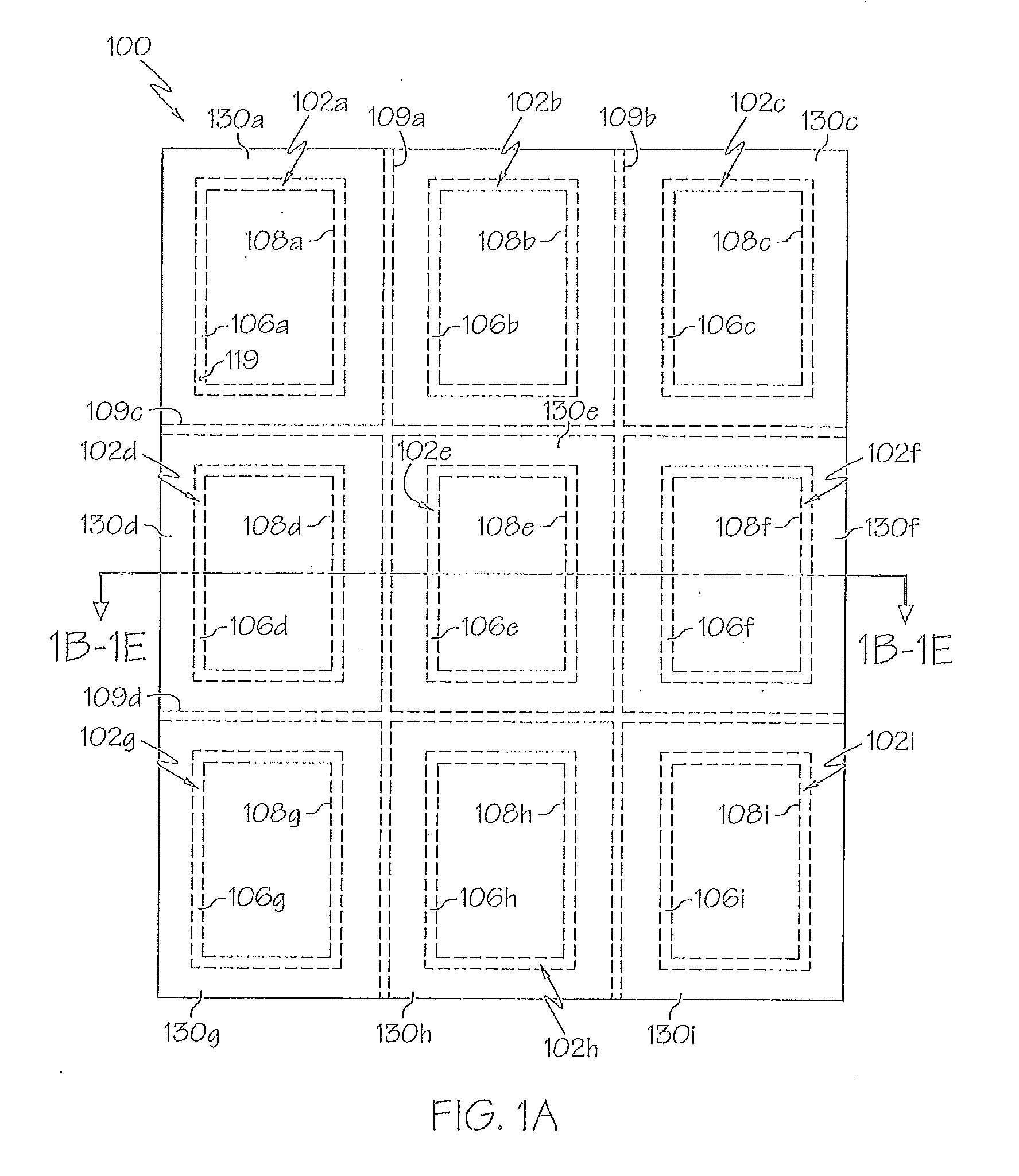

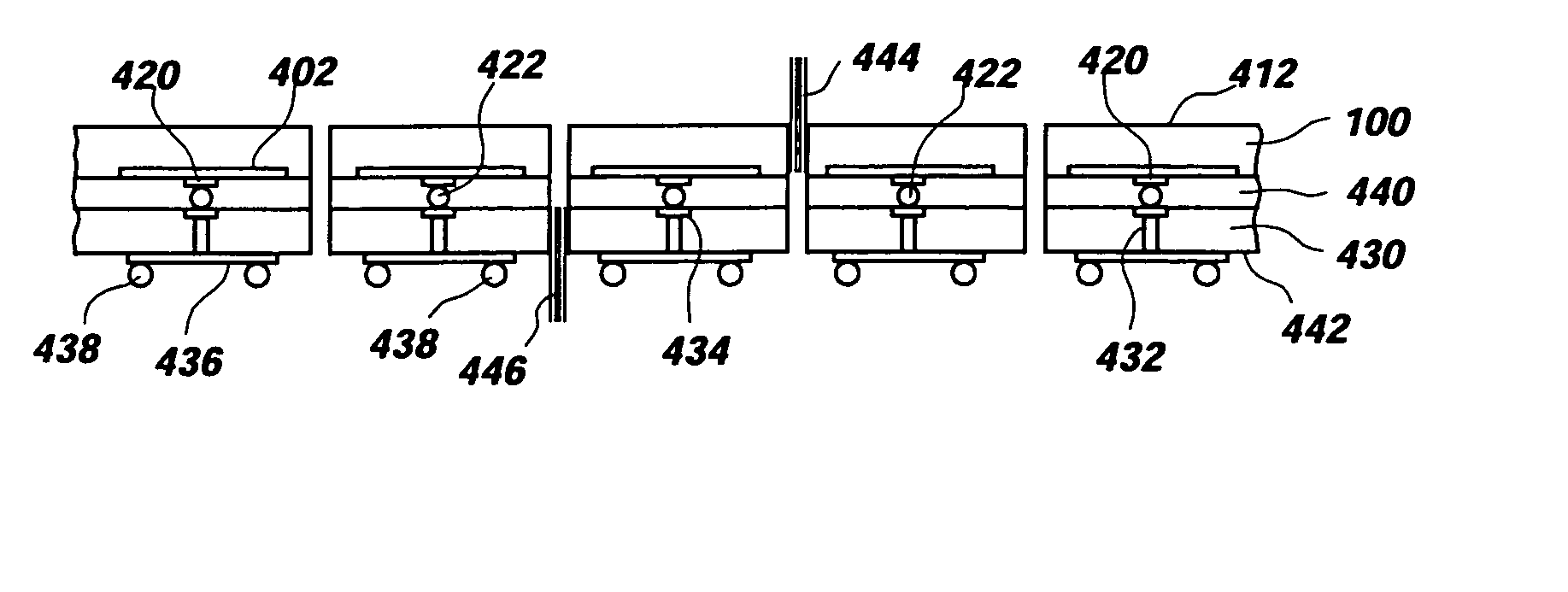

Methods for separating glass articles from strengthened glass substrate sheets

Methods for separating glass articles from strengthened glass substrate sheets and strengthened glass substrate sheets are provided. In one embodiment, a method includes forming at least one groove on at least one surface of the glass substrate sheet and strengthening the glass substrate sheet by a strengthening process. The groove defines the glass article and partially extends through a thickness of the glass substrate sheet. The method further includes generating an initiation defect on the groove at an initiation location to cause a through crack to self-propagate through the glass substrate sheet along the groove, thereby separating the glass article from the glass substrate sheet. In another embodiment, a strengthened glass substrate sheet includes a strengthened glass having a glass article groove and an initiation groove on a surface, the glass article groove defining a glass article.

Owner:CORNING INC

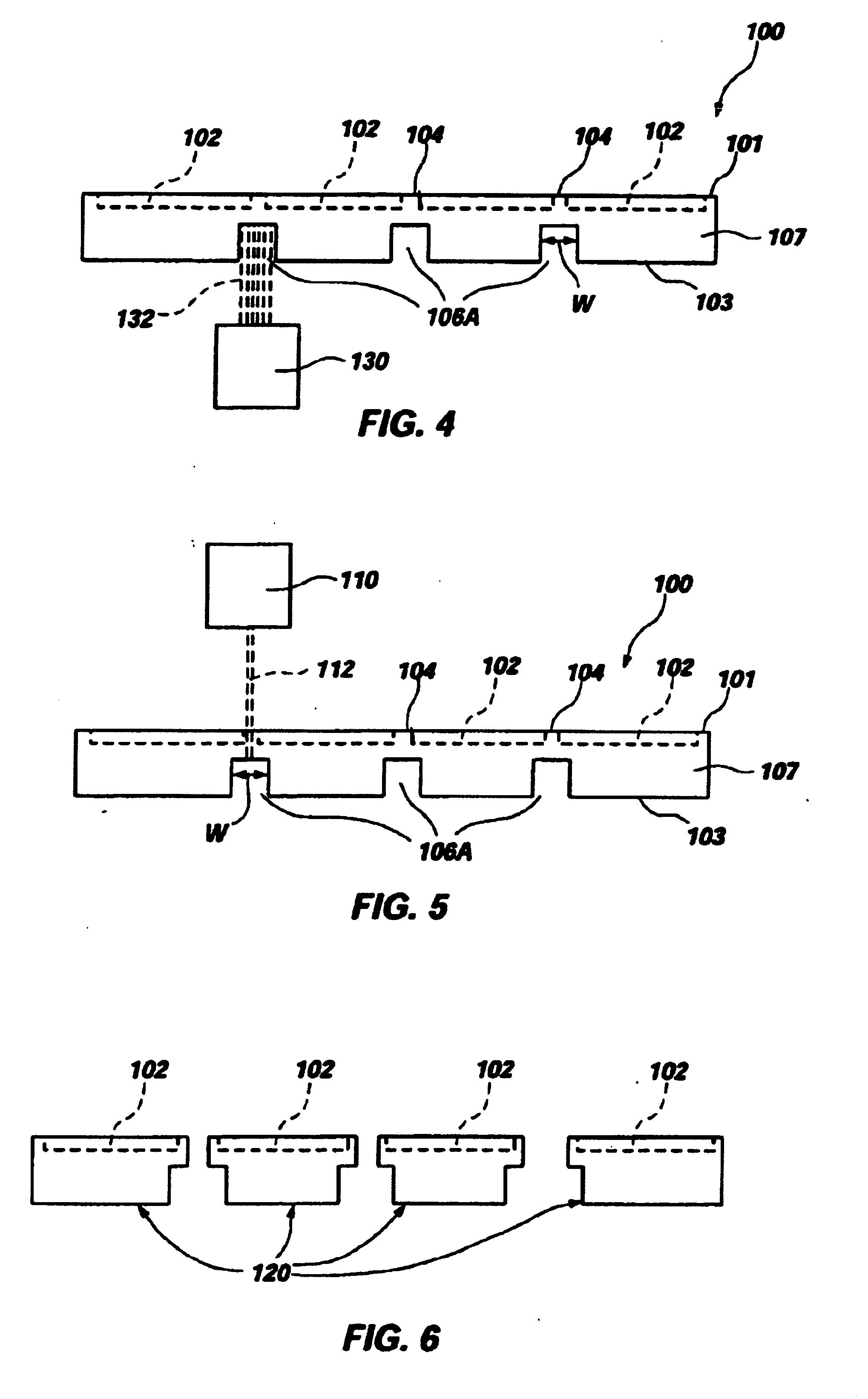

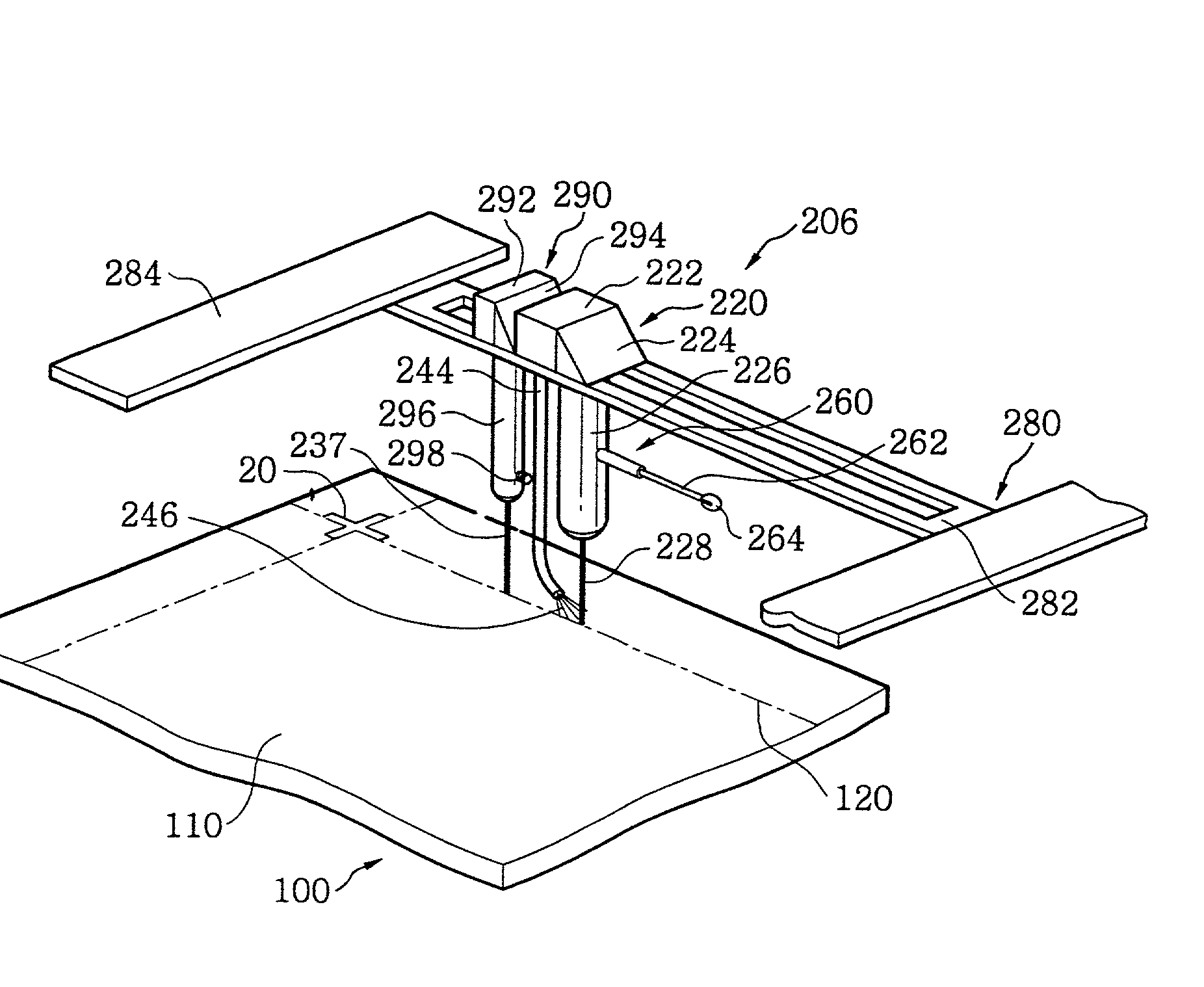

Laser processing method and laser processing apparatus

InactiveUS20050173387A1No unnecessary fracture in surfaceNo unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

Transparent material processing with an ultrashort pulse laser

InactiveUS20070051706A1Reduce quality problemsPoor precisionFixed microstructural devicesThin material handlingHigh energyNonlinear absorption

Methods for ultrashort pulse laser processing of optically transparent materials. A method for scribing transparent materials uses ultrashort laser pulses to create multiple scribe features with a single pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. This enables clean breaking of transparent materials at a higher speed than conventional techniques. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with side-illumination and not clearly visible without side-illumination. In addition, a method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. The ultrashort pulse duration causes nonlinear absorption of the laser radiation, and the high repetition rate of the laser causes pulse-to-pulse accumulation of heat within the materials. The laser is focused near the interface of the materials, generating a high energy fluence at the region to be welded. This minimizes damage to the rest of the material and enables fine weld lines.

Owner:IMRA AMERICA

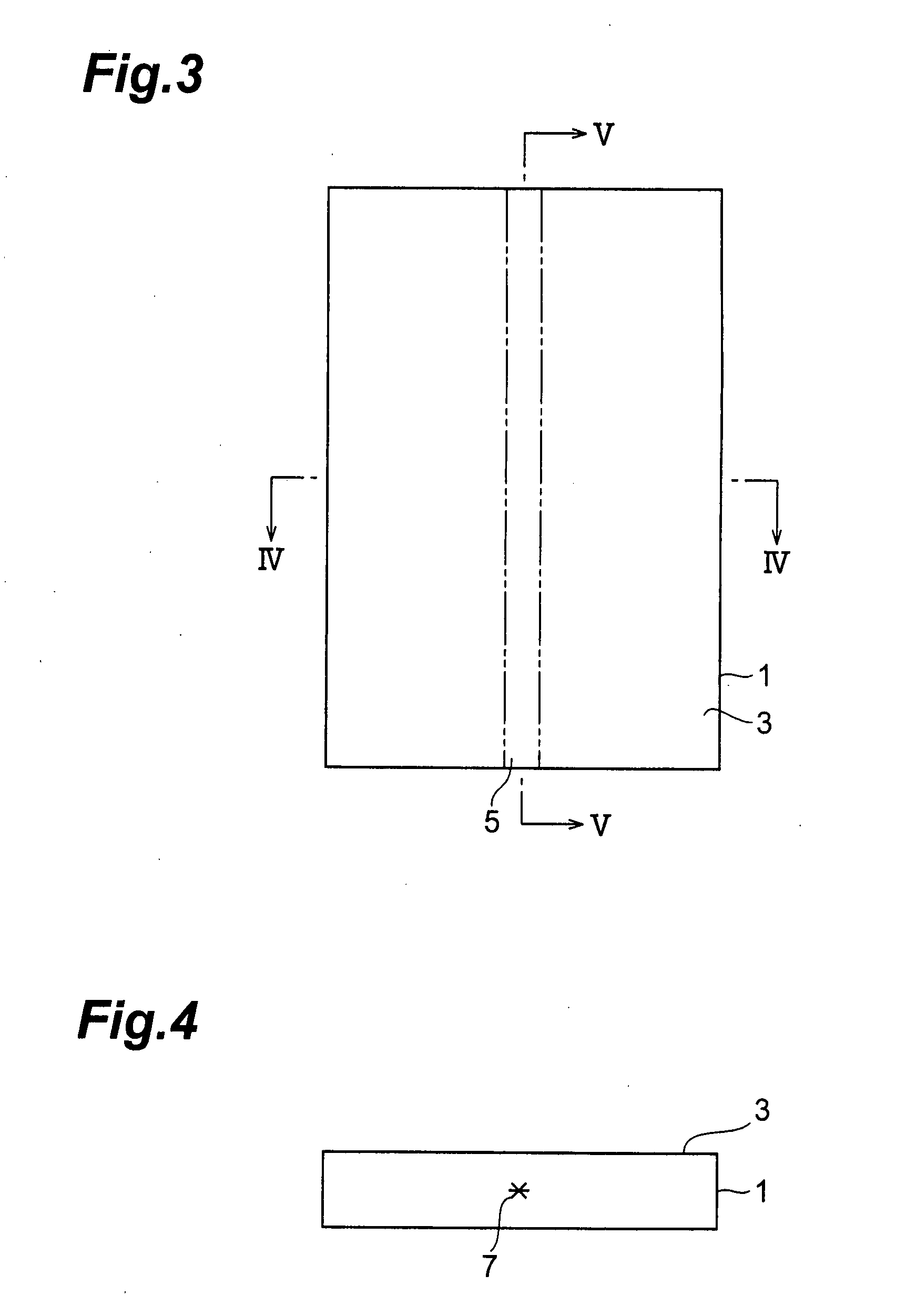

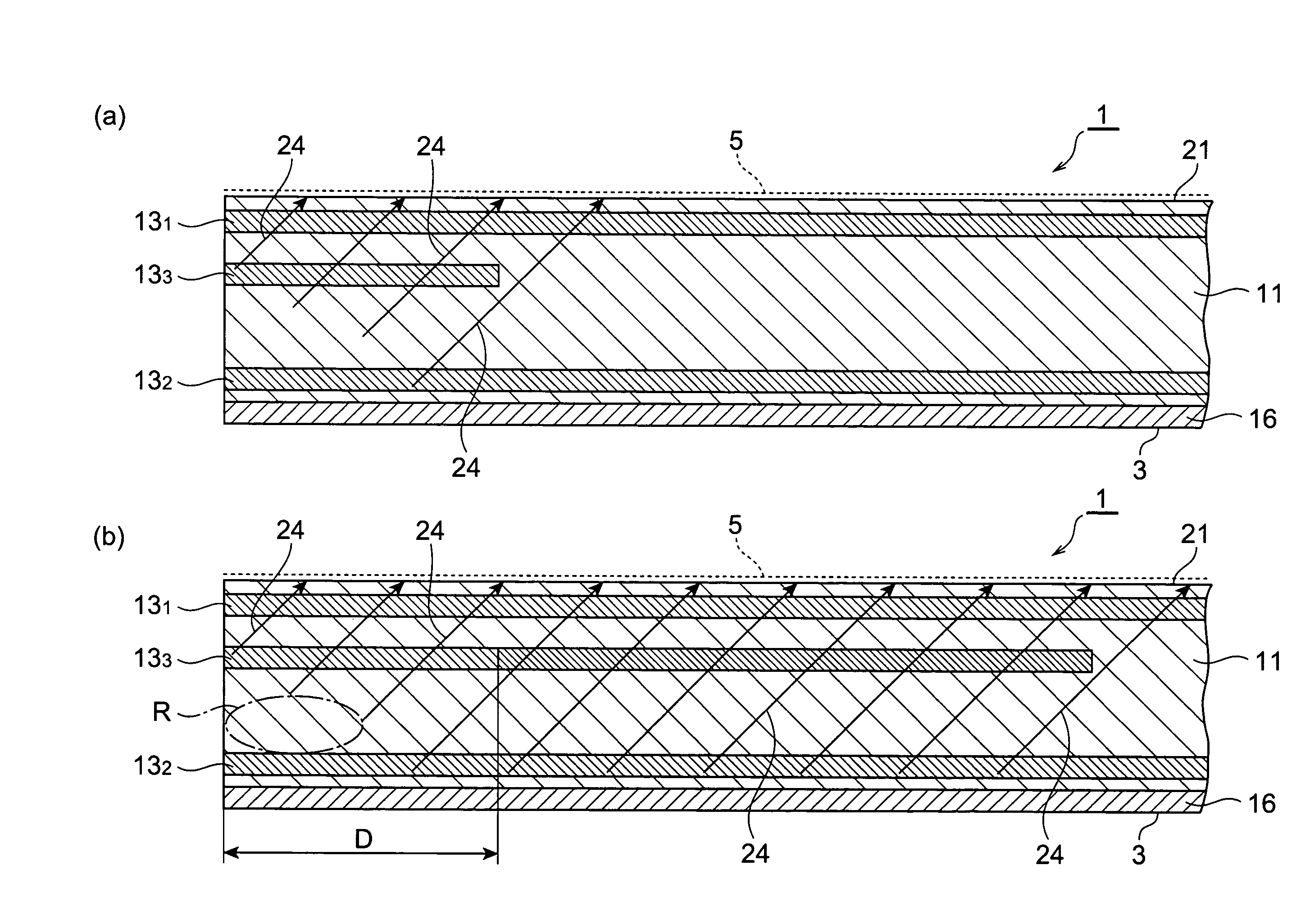

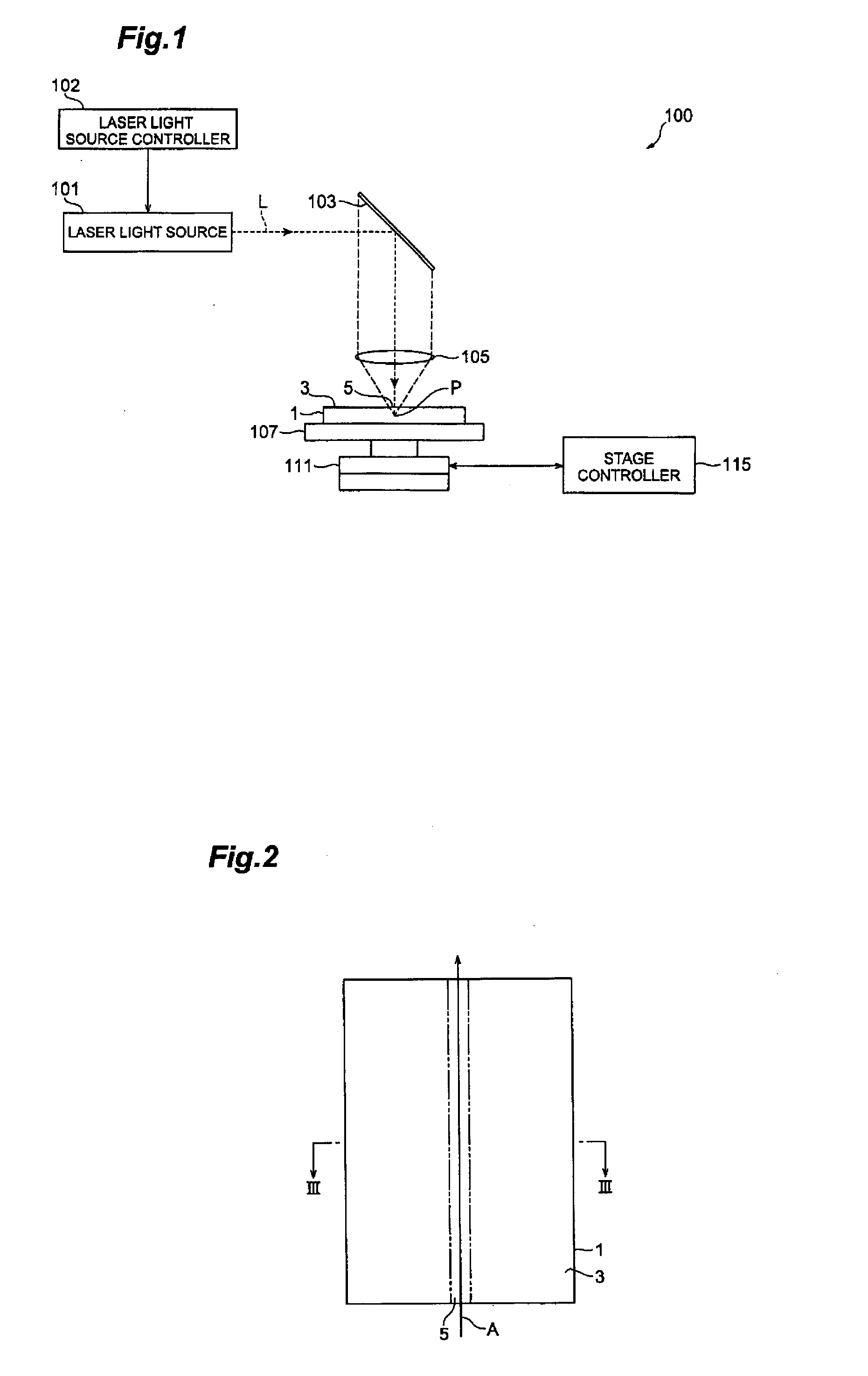

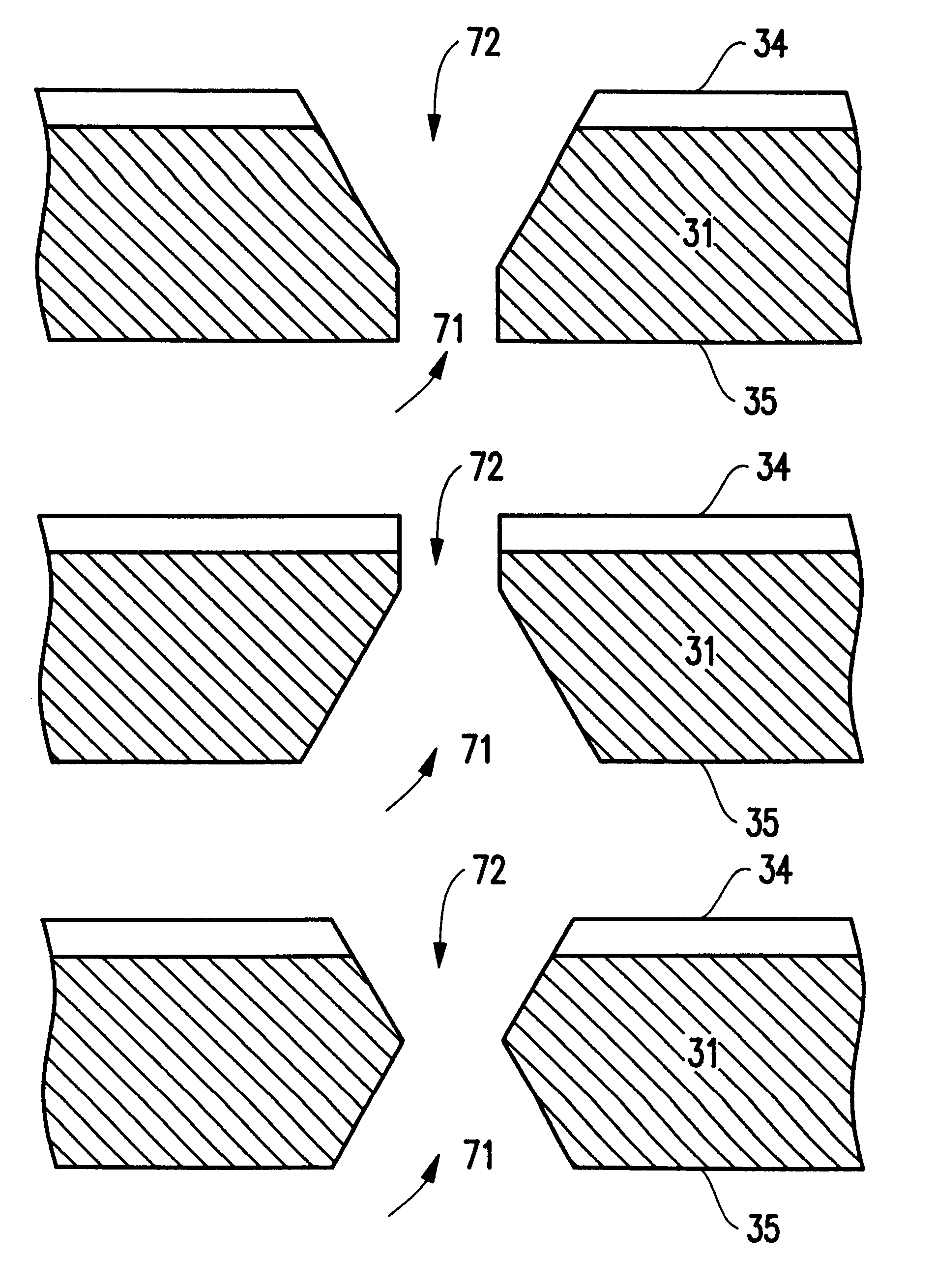

Laser processing method

ActiveUS20070158314A1Reduce manufacturing stepsImprove accuracyFine working devicesWelding/soldering/cutting articlesLaser processingProcess region

The present invention provides a laser processing method comprising the steps of attaching a protective tape 25 to a front face 3 of a wafer 1a, irradiating a substrate 15 with laser light L while employing a rear face of the wafer 1a as a laser light entrance surface and locating a light-converging point P within the substrate 15 so as to form a molten processed region 13 due to multiphoton absorption, causing the molten processed region 13 to form a cutting start region 8 inside by a predetermined distance from the laser light entrance surface along a line 5 along which the object is intended to be cut in the wafer 1a, attaching an expandable tape 23 to the rear face 21 of the wafer 1a, and expanding the expandable tape 23 so as to separate a plurality of chip parts 24 produced upon cutting the wafer 1a from the cutting start region 8 acting as a start point from each other.

Owner:HAMAMATSU PHOTONICS KK

Semiconductor light-emitting device and method for separating semiconductor light-emitting devices

InactiveUS20070298529A1Reliably splitLight absorptionSolid-state devicesSemiconductor/solid-state device manufacturingSplit linesPulsed laser beam

The invention provides a method for separating semiconductor light-emitting devices formed on a substrate. In the method, a pulse laser beam having a pulse width less than 10 ps in a substrate is focused on the substrate, to thereby cause multi-photon absorption in the substrate. Through multi-photon absorption, a groove is formed through the pulse laser beam along a split line predetermined on a surface of the substrate, the groove being substantially continuous in the direction of the predetermined split line. In addition, internal structurally changed portions are formed through the pulse laser beam at a predetermined depth of the substrate on a predetermined split face, the structurally changed portions being discontinuous in the direction of the predetermined split line. Subsequently, an external force is applied to thereby form a split face along the continuous groove and the discontinuous internal structurally changed portions, whereby the semiconductor light-emitting devices are separated from one another

Owner:TOYODA GOSEI CO LTD

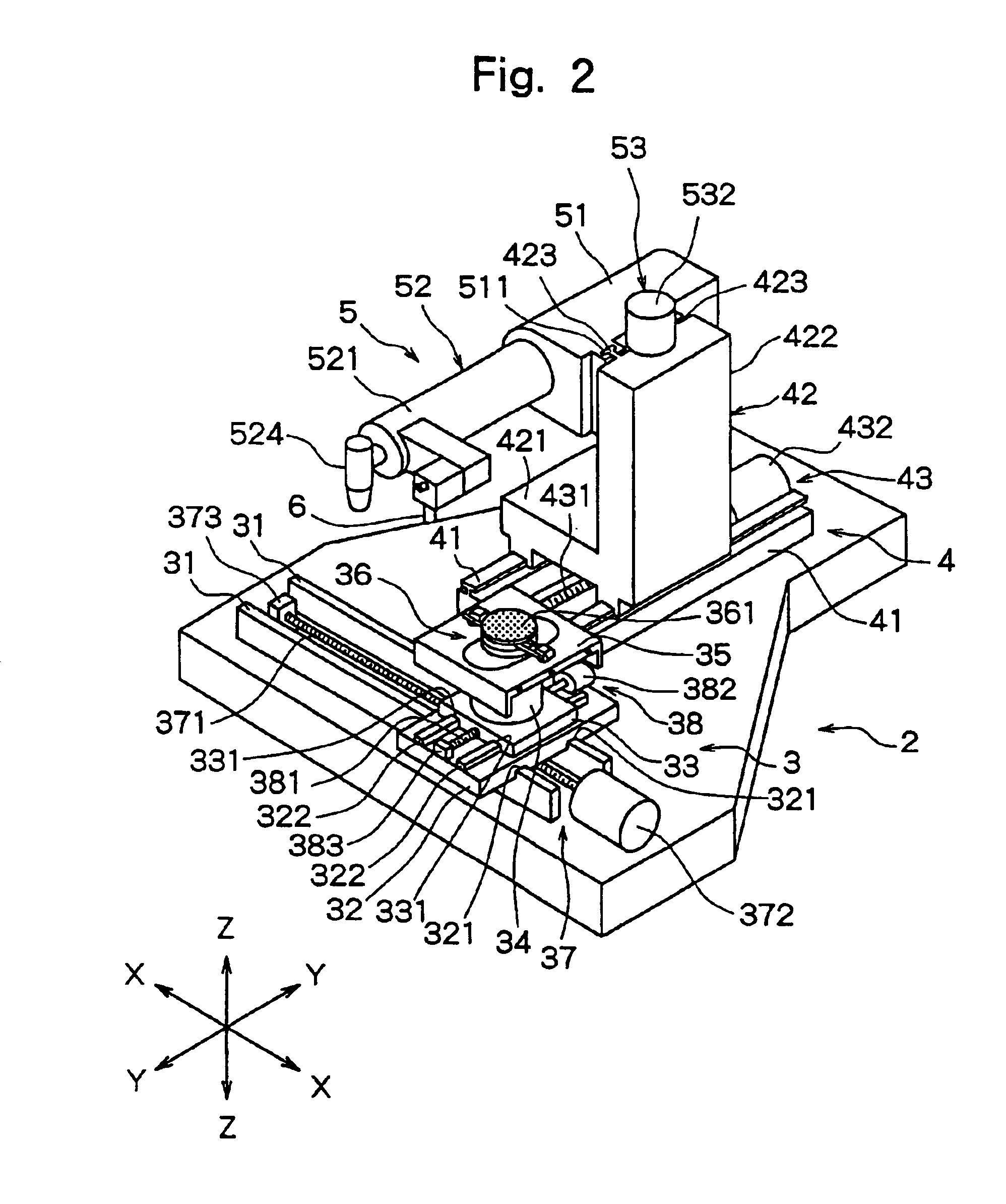

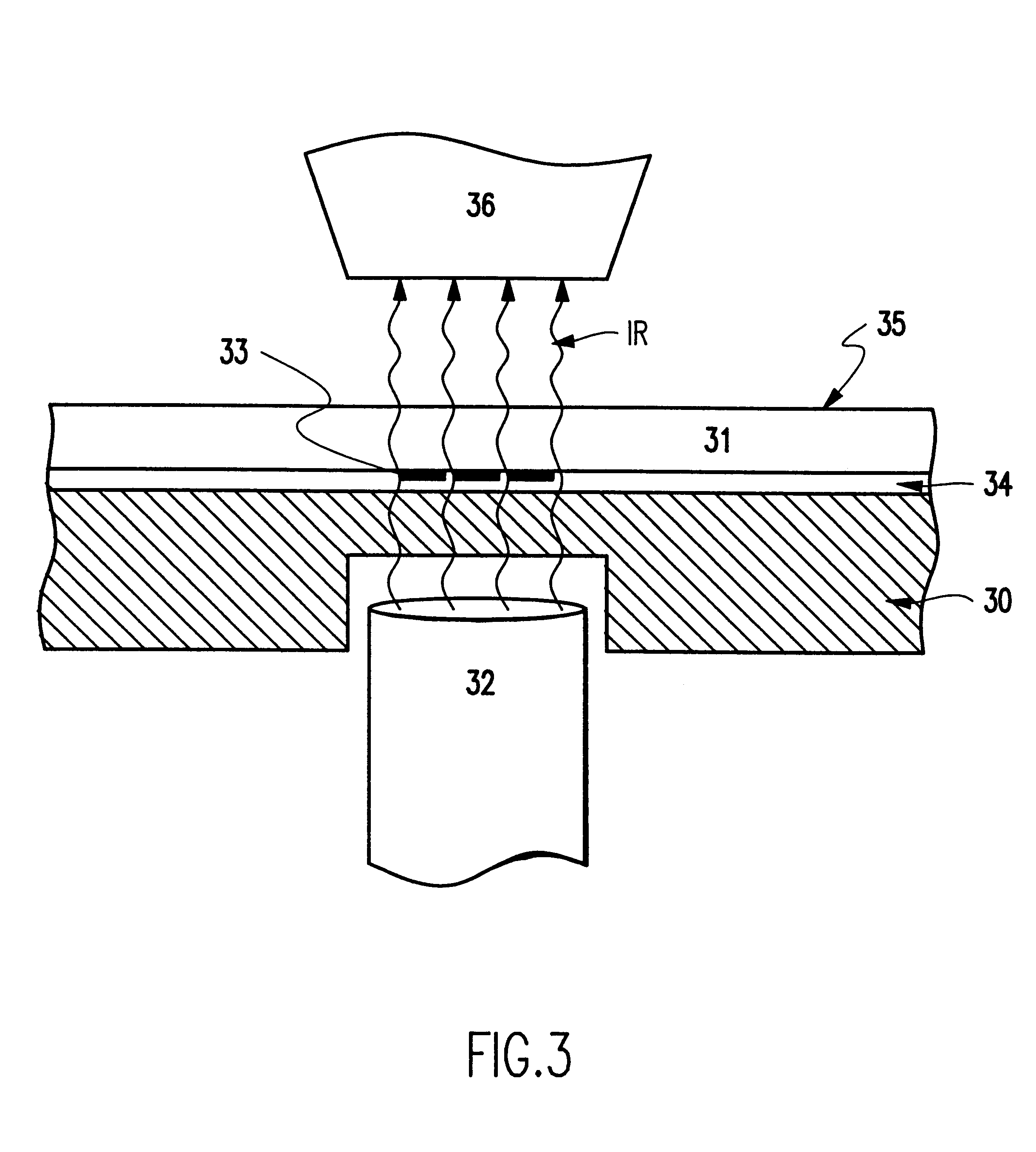

Device and method for laser processing

InactiveUS20060144828A1Prevent movementImprove accuracyLaser detailsSemiconductor/solid-state device manufacturingLaser processingLaser light

A laser processing apparatus and a laser processing method which can accurately converge processing laser light at a predetermined position are provided. In the laser processing apparatus, a condenser lens 31 converges processing laser light L1 and rangefinding laser light L2 onto an object to be processed 1 on the same axis. Here, light-converging point position control means40 detects reflected light L3 of the rangefinding laser light reflected by the front face 3 of the object 1, and places a light-converging point P1 of the processing laser light L1 at a predetermined position. Since the processing by the processing laser light L1 and the measurement of displacement of the front face 3 by the rangefinding laser light L2 are carried out on the same axis as such, the light-converging point P1 of processing laser light L1 can be prevented from shifting from the predetermined position because of vibrations of the stage 21 and the like. Therefore, the processing laser light L1 can accurately be converged at the predetermined position.

Owner:HAMAMATSU PHOTONICS KK

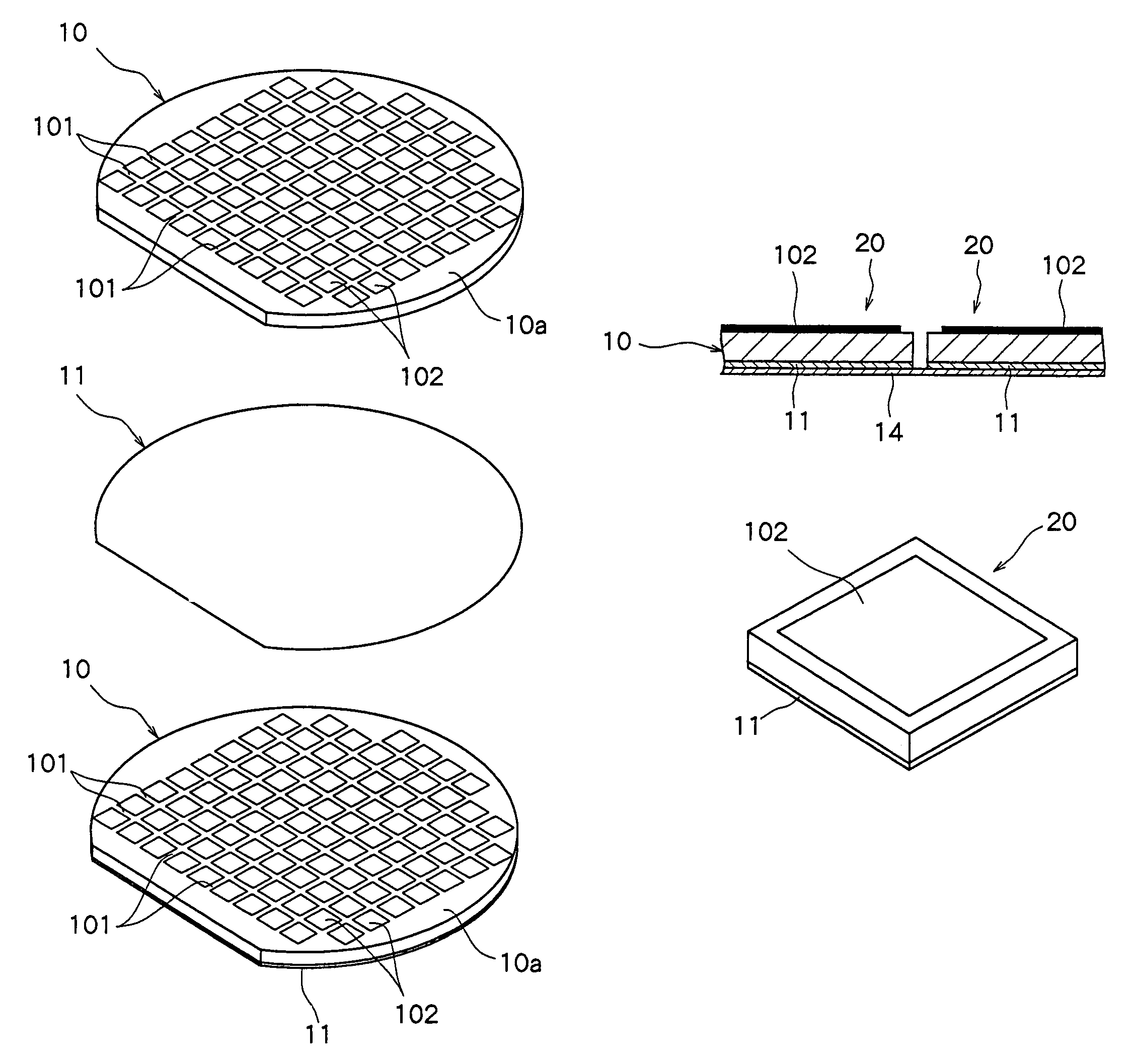

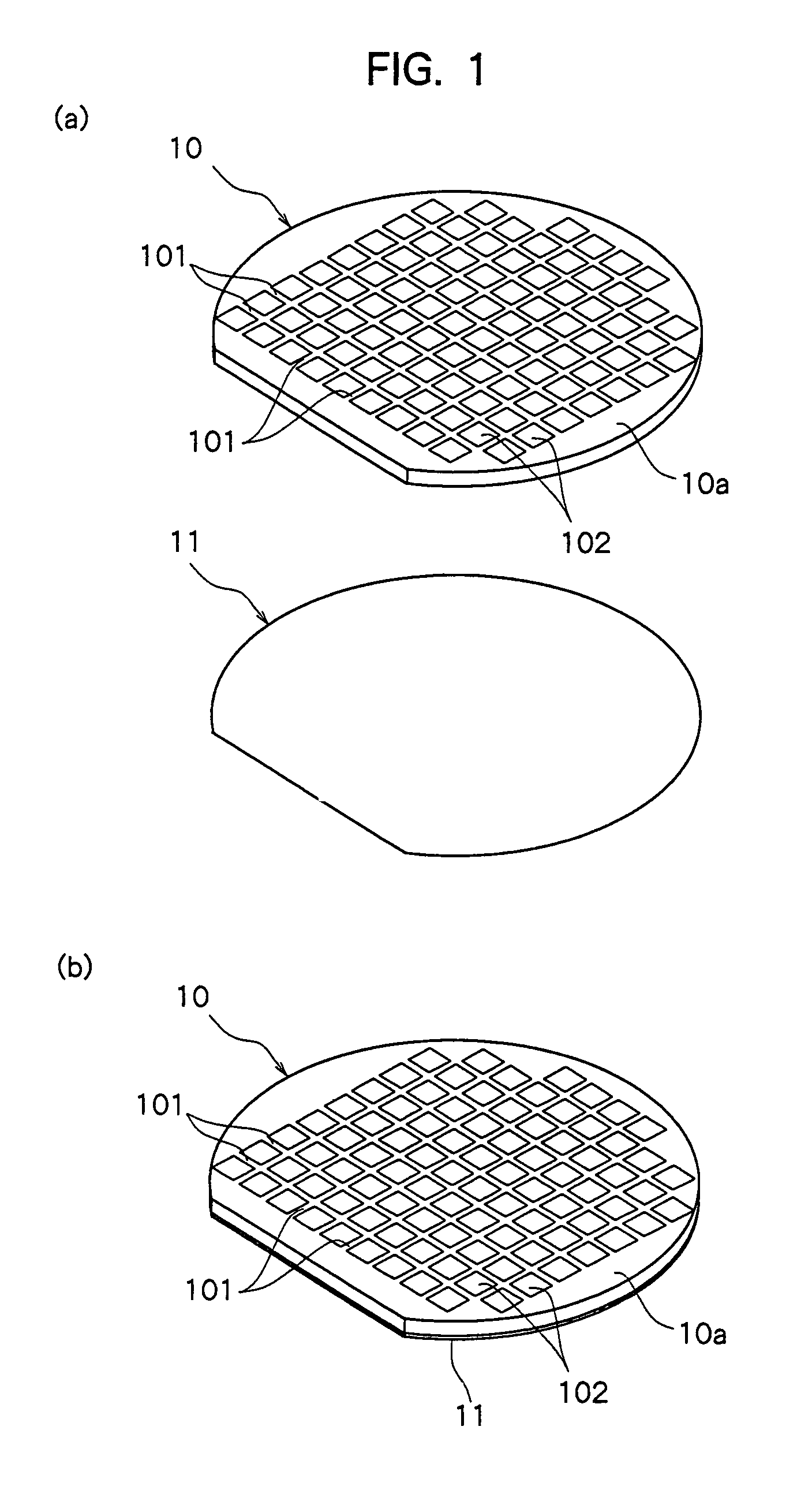

Method of dividing a semiconductor wafer

ActiveUS7129150B2Solid-state devicesSemiconductor/solid-state device manufacturingAdhesive beltSemiconductor chip

A method of dividing a semiconductor wafer comprising:a bonding film adhering step of adhering a bonding film for die bonding to the back surface of the semiconductor wafer;a protective adhesive tape affixing step of affixing an extensible protective adhesive tape to the bonding film side of the semiconductor wafer having the bonding film on the back surface;a dividing step of dividing the semiconductor wafer affixed to the protective adhesive tape into individual semiconductor chips by applying a laser beam along the streets;a bonding film breaking step of breaking the bonding film for every semiconductor chip by extending the protective adhesive tape so as to give tensile force to the bonding film; anda semiconductor chip removing step of removing the semiconductor chips having the broken bonding film from the protective adhesive tape.

Owner:DISCO CORP

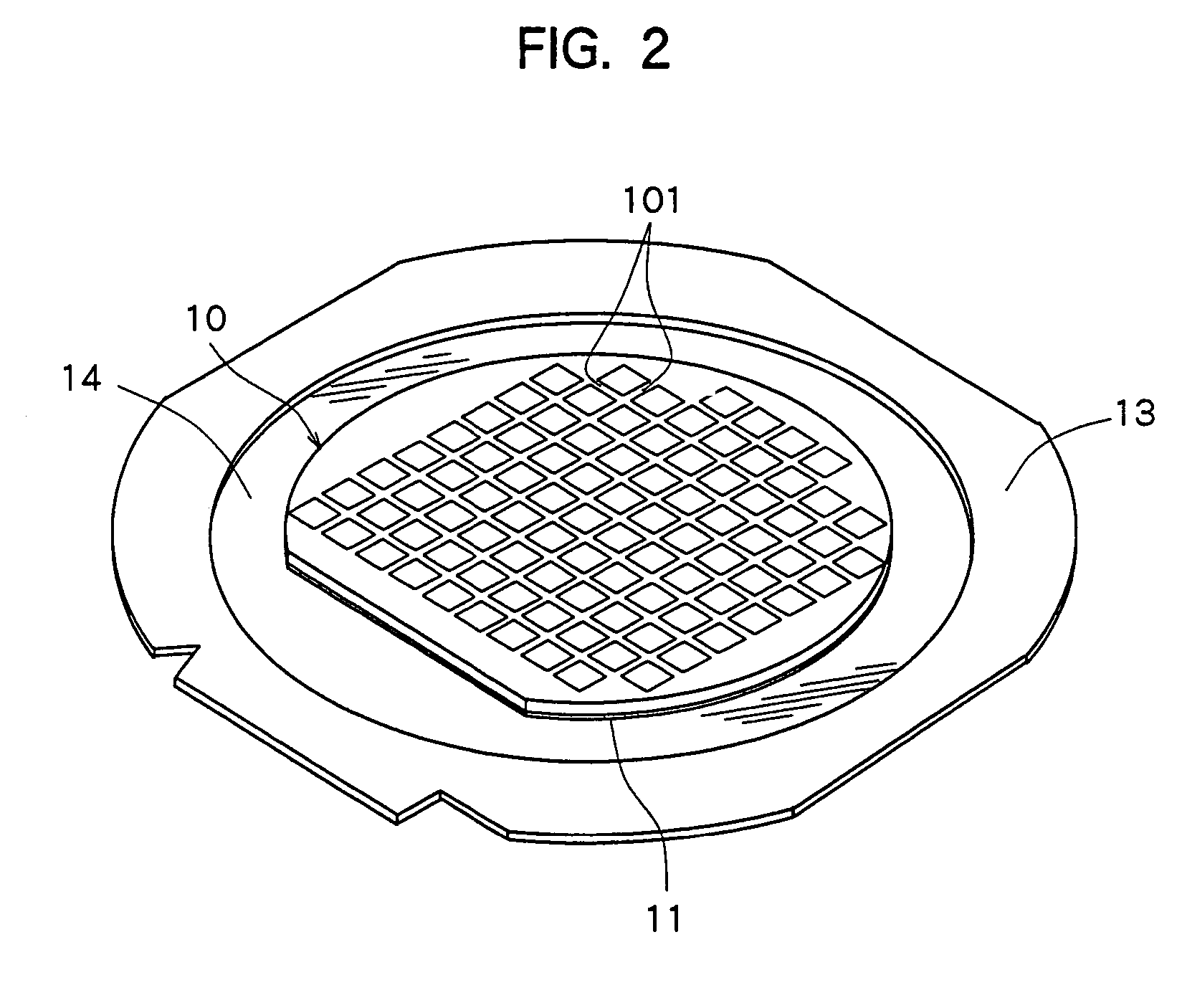

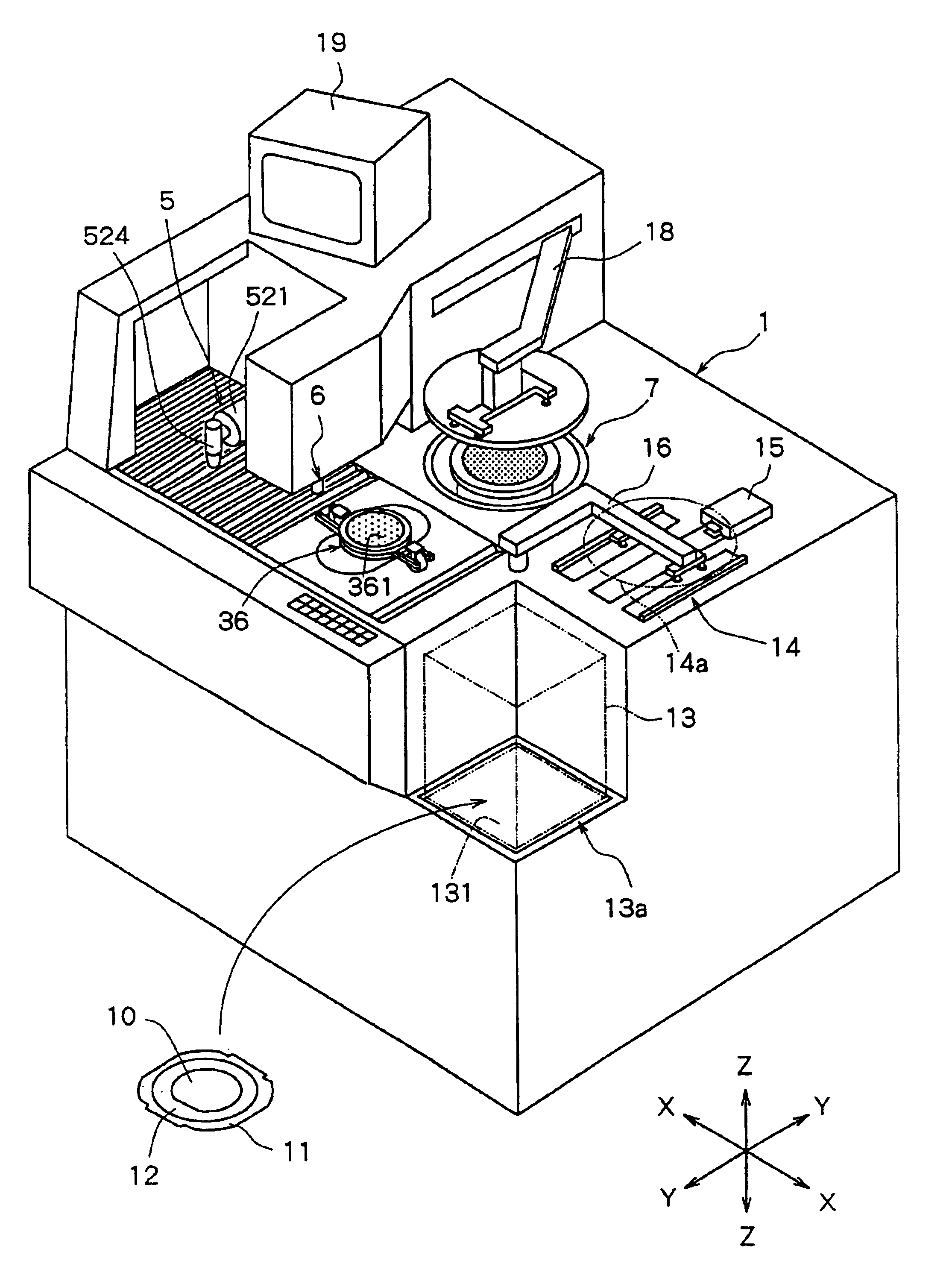

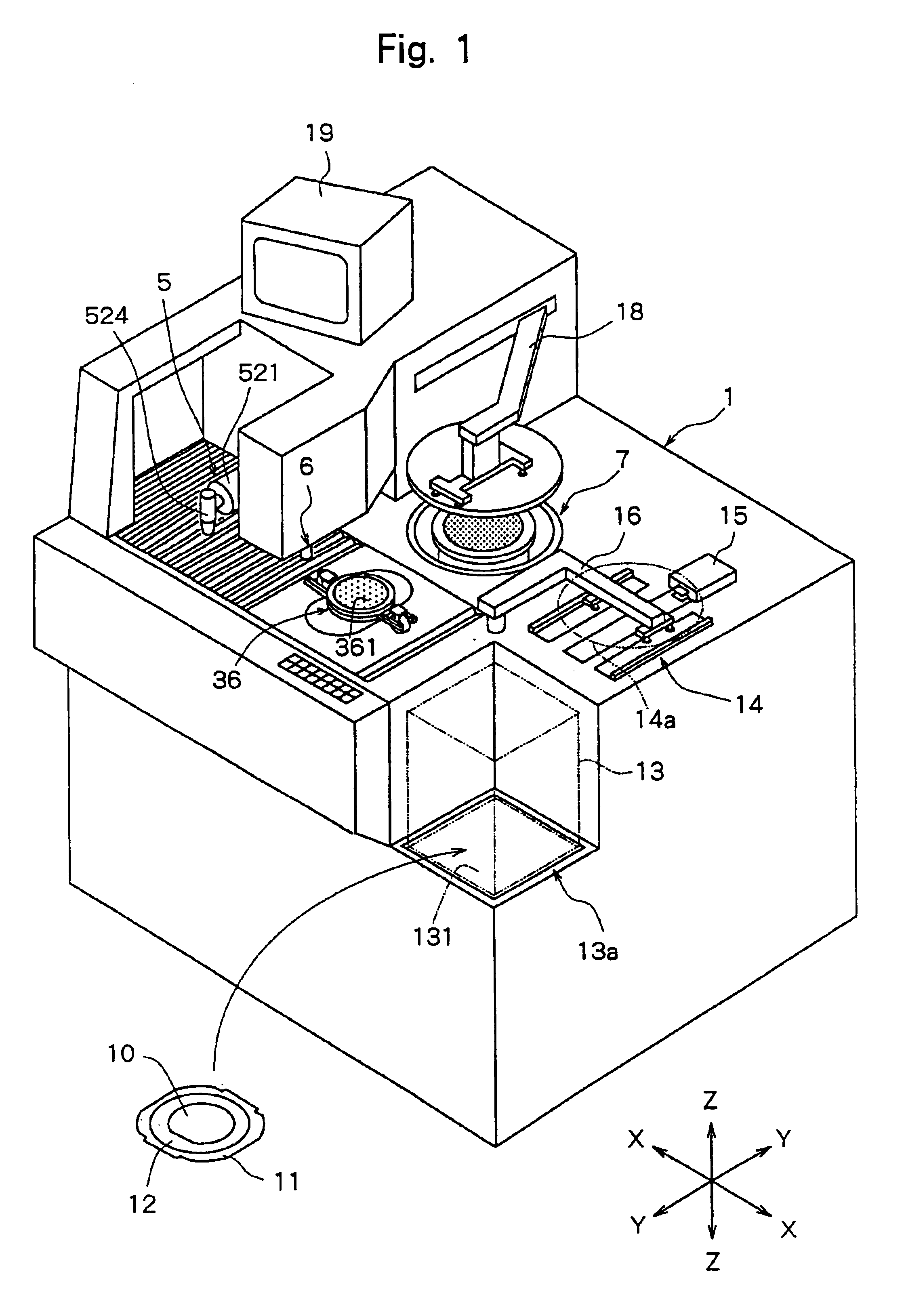

Laser beam processing machine

ActiveUS6998571B2Welding/cutting auxillary devicesSemiconductor/solid-state device manufacturingTectorial membraneLaser beam machining

A laser beam processing machine comprising a chuck table for holding a workpiece and a laser beam application means for applying a laser beam to the workpiece held on the chuck table, wherein the machine further comprises a protective film forming means for forming a protective film on the to-be-processed surface of the workpiece before laser beam processing.

Owner:DISCO CORP

Methods and apparatus relating to singulating semiconductor wafers and wafer scale assemblies

ActiveUS20050202651A1Increase distanceAvoid excessive widthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Methods relating to the singulation of dice from semiconductor wafers. Trenches or channels are formed in the bottom surface of a semiconductor wafer, corresponding in location to the wafer streets. The trenches may be formed by etching or through an initial laser cut. The wafer is then singulated along the streets with a laser preferably having a beam narrower than the trenches. Multiple, laterally spaced lasers may be used in combination during a single pass to perform simultaneous singulating cuts. Additional edge protection for integrated circuitry on the active surface of the semiconductor dice may be provided by forming trenches or channels along the streets in the active surface instead of the bottom surface, disposing protective material along the streets and within the trenches prior to singulation and cutting through the wafer, leaving protective material on the sidewalls of the channels.

Owner:MICRON TECH INC

Substrate dividing method

InactiveUS20080090382A1Avoid crackingPrevent chipping and crackingSemiconductor/solid-state device detailsSolid-state devicesProcess regionOptoelectronics

A substrate dividing method which can thin and divide a substrate while preventing chipping and cracking from occurring. This substrate dividing method comprises the steps of irradiating a semiconductor substrate 1 having a front face 3 formed with functional devices 19 with laser light while positioning a light-converging point within the substrate, so as to form a modified region including a molten processed region due to multiphoton absorption within the semiconductor substrate 1, and causing the modified region including the molten processed region to form a starting point region for cutting; and grinding a rear face 21 of the semiconductor substrate 1 after the step of forming the starting point region for cutting such that the semiconductor substrate 1 attains a predetermined thickness.

Owner:HAMAMATSU PHOTONICS KK

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

Laser processing method and chip

ActiveUS7897487B2High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

Object cutting method

ActiveUS20090098713A1Reliable preventionReliably preventedSemiconductor/solid-state device manufacturingWorking accessoriesProcess regionSemiconductor chip

An object cutting method which can reliably remove particles remaining on cut sections of chips is provided. An expandable tape 23 is electrically charged in a state where a plurality of semiconductor chips 25 obtained by cutting a planar object to be processed along a line to cut are separated from each other on the expandable tape 23. This electric action causes particles remaining on cut sections of the semiconductor chips 25 to eject therefrom even when a molten processed region is formed in the cut sections Therefore, particles remaining on the cut sections of the chips 25 can reliably be removed.

Owner:HAMAMATSU PHOTONICS KK

Method and system for dicing wafers, and semiconductor structures incorporating the products thereof

A method and system for dicing a semiconductor wafer providing a structure with greatly reduced backside chipping and cracking, as well as increased die strength. Semiconductor chip structures obtained from wafers diced according to this invention are also encompassed.

Owner:IBM CORP

Laser processing method and laser processing apparatus

InactiveUS20050181581A1No unnecessary fractureSolid-state devicesSemiconductor/solid-state device manufacturingLaser processingLaser beam machining

A laser beam machining method and a laser beam machining device capable of cutting a work without producing a fusing and a cracking out of a predetermined cutting line on the surface of the work, wherein a pulse laser beam is radiated on the predetermined cut line on the surface of the work under the conditions causing a multiple photon absorption and with a condensed point aligned to the inside of the work, and a modified area is formed inside the work along the predetermined determined cut line by moving the condensed point along the predetermined cut line, whereby the work can be cut with a rather small force by cracking the work along the predetermined cut line starting from the modified area and, because the pulse laser beam radiated is not almost absorbed onto the surface of the work, the surface is not fused even if the modified area is formed.

Owner:HAMAMATSU PHOTONICS KK

Method for fabricating semiconductor device

ActiveUS20090162993A1Small sizeLower manufacturing yieldSemiconductor/solid-state device manufacturingFine working devicesSemiconductorSemiconductor device

An object is to provide a technology capable of improving a manufacturing yield of semiconductor devices by preventing scattering of irregular-shaped scraps formed at the time of dicing. To achieve the above object, for dicing lines, by which an irregular-shaped outer periphery may possibly be cut off, among a plurality of dicing lines, formation of the dicing lines starts from an outside of a semiconductor wafer, and after the semiconductor wafer is cut off partway, formation of the dicing lines is ended before reaching the irregular-shaped outer periphery formed on a outer periphery of the semiconductor wafer. For other dicing lines, formation of the dicing lines starts from the outside of the semiconductor wafer, and after the semiconductor wafer is cut off, is ended outside the semiconductor wafer.

Owner:RENESAS ELECTRONICS CORP

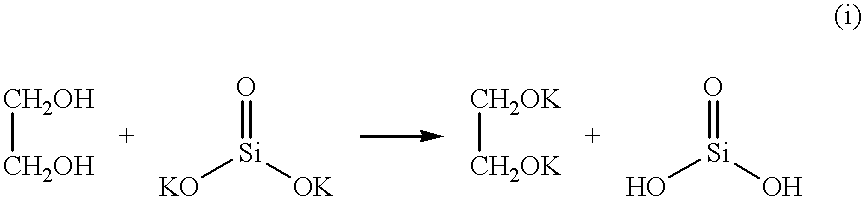

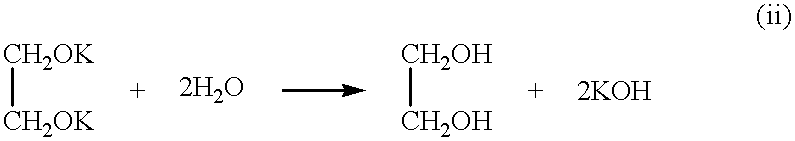

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com