Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4335 results about "Cutting fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, such as machining and stamping. There are various kinds of cutting fluids, which include oils, oil-water emulsions, pastes, gels, aerosols (mists), and air or other gases. They may be made from petroleum distillates, animal fats, plant oils, water and air, or other raw ingredients. Depending on context and on which type of cutting fluid is being considered, it may be referred to as cutting fluid, cutting oil, cutting compound, coolant, or lubricant.

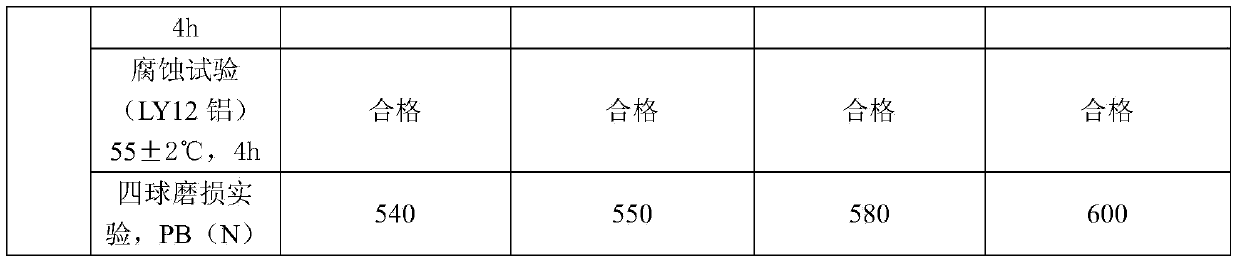

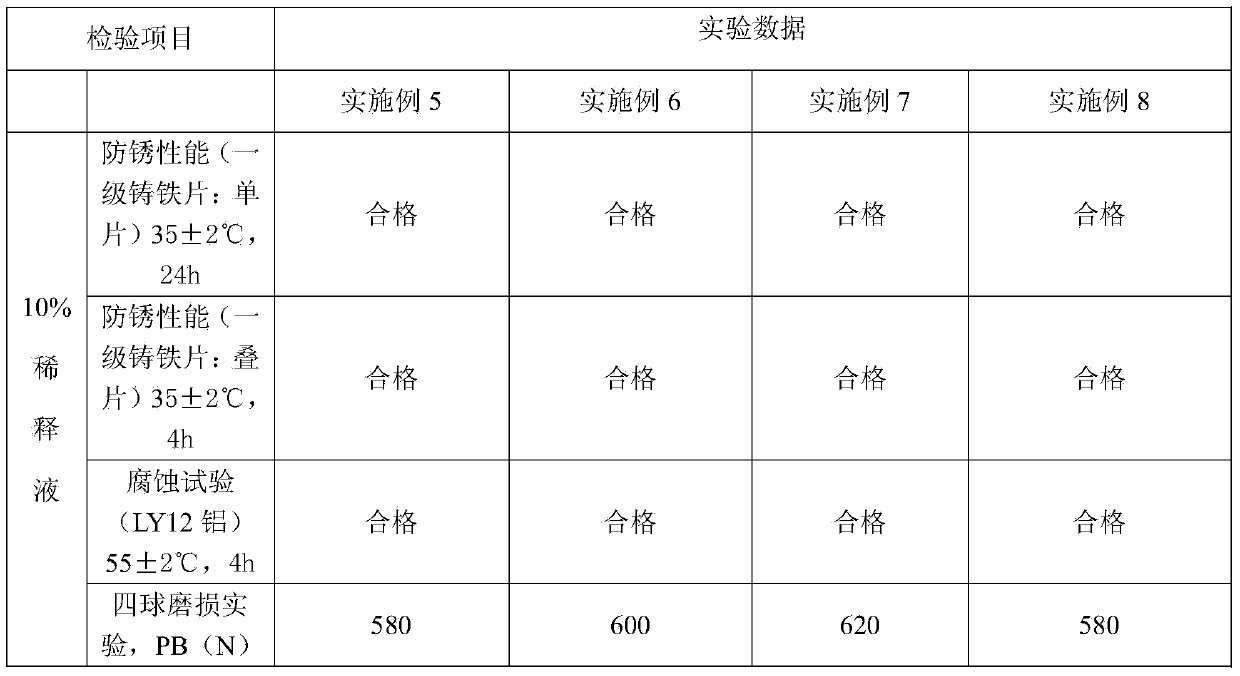

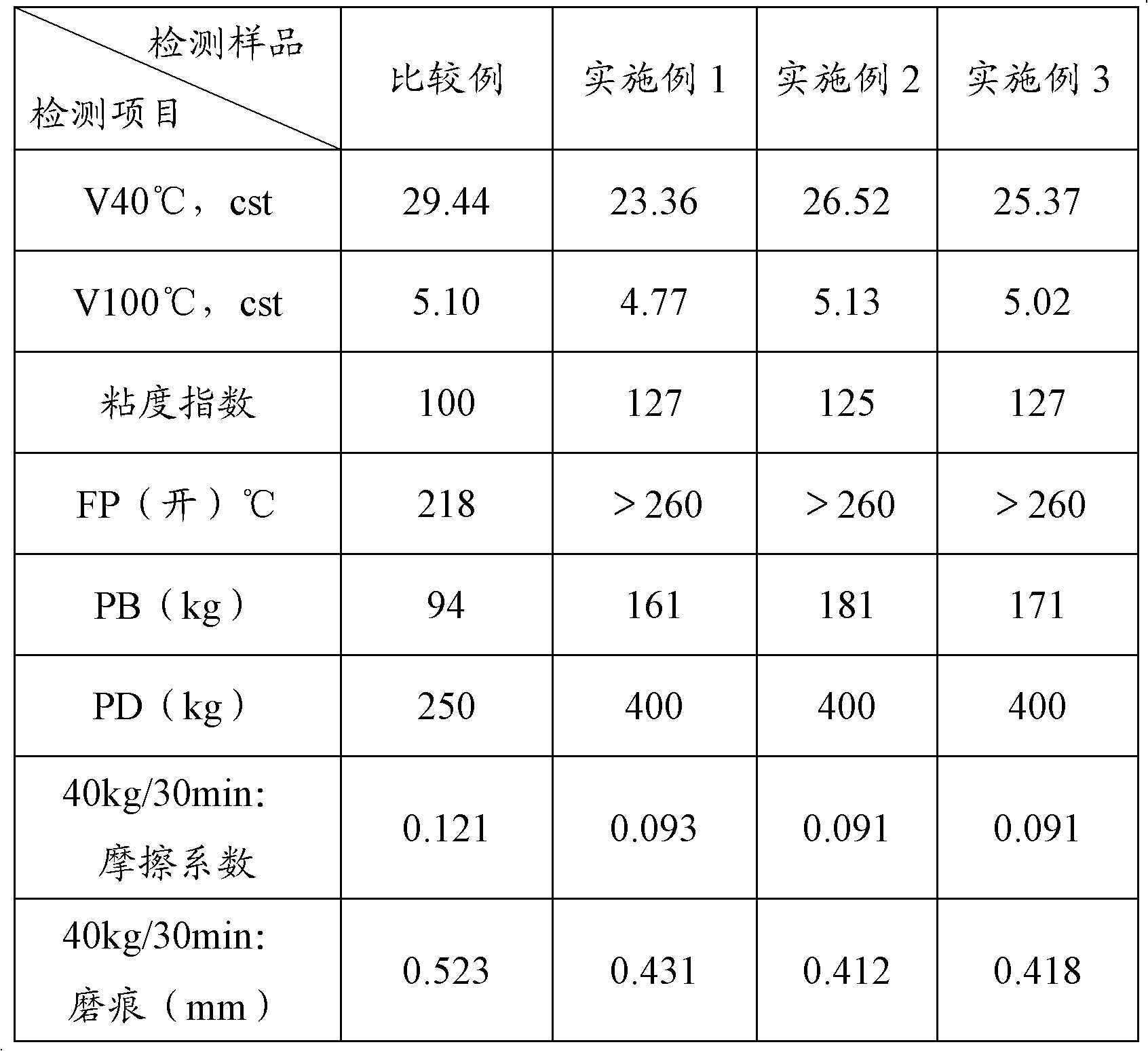

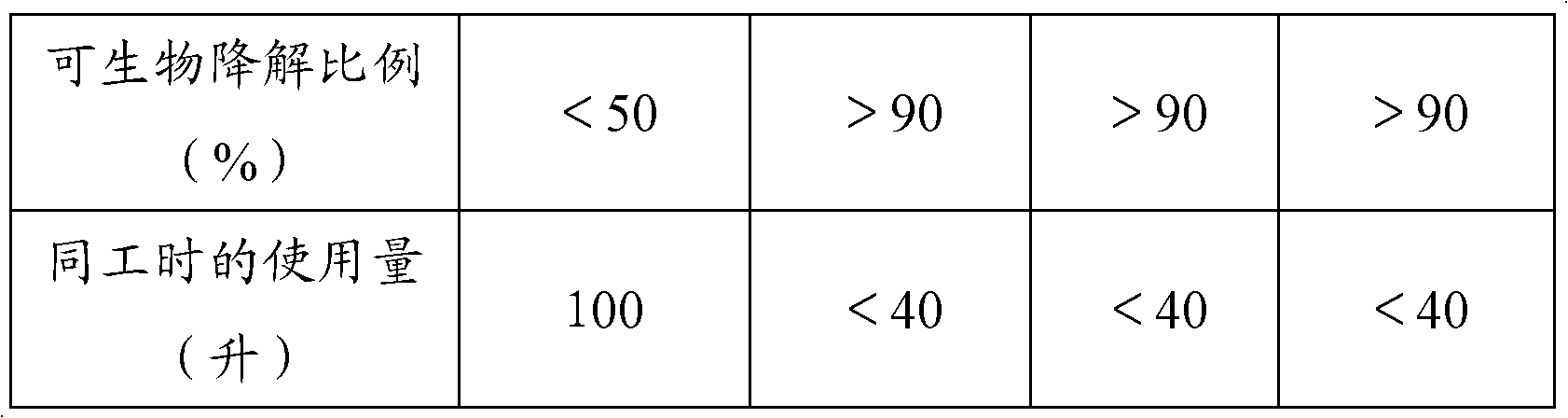

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

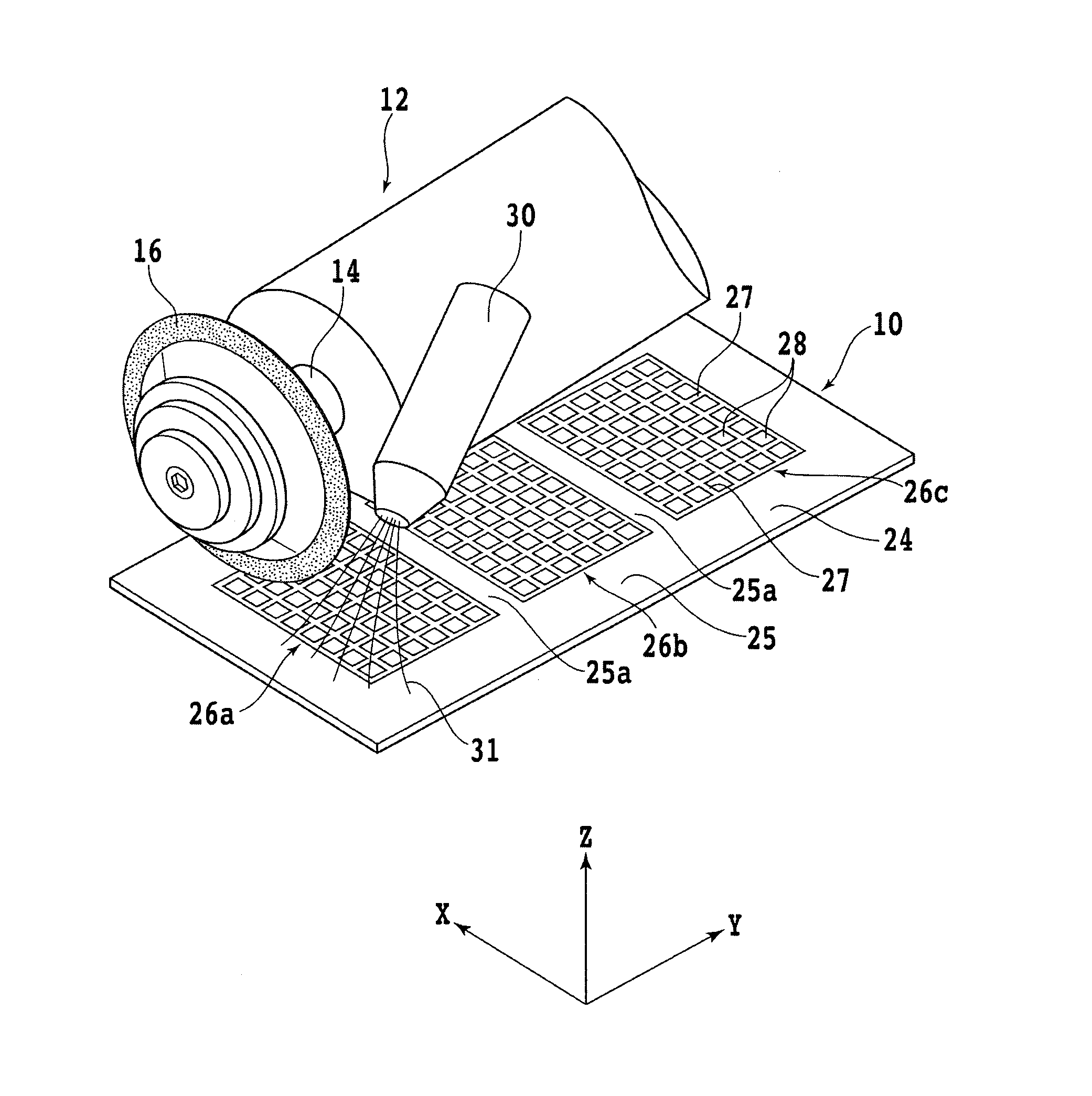

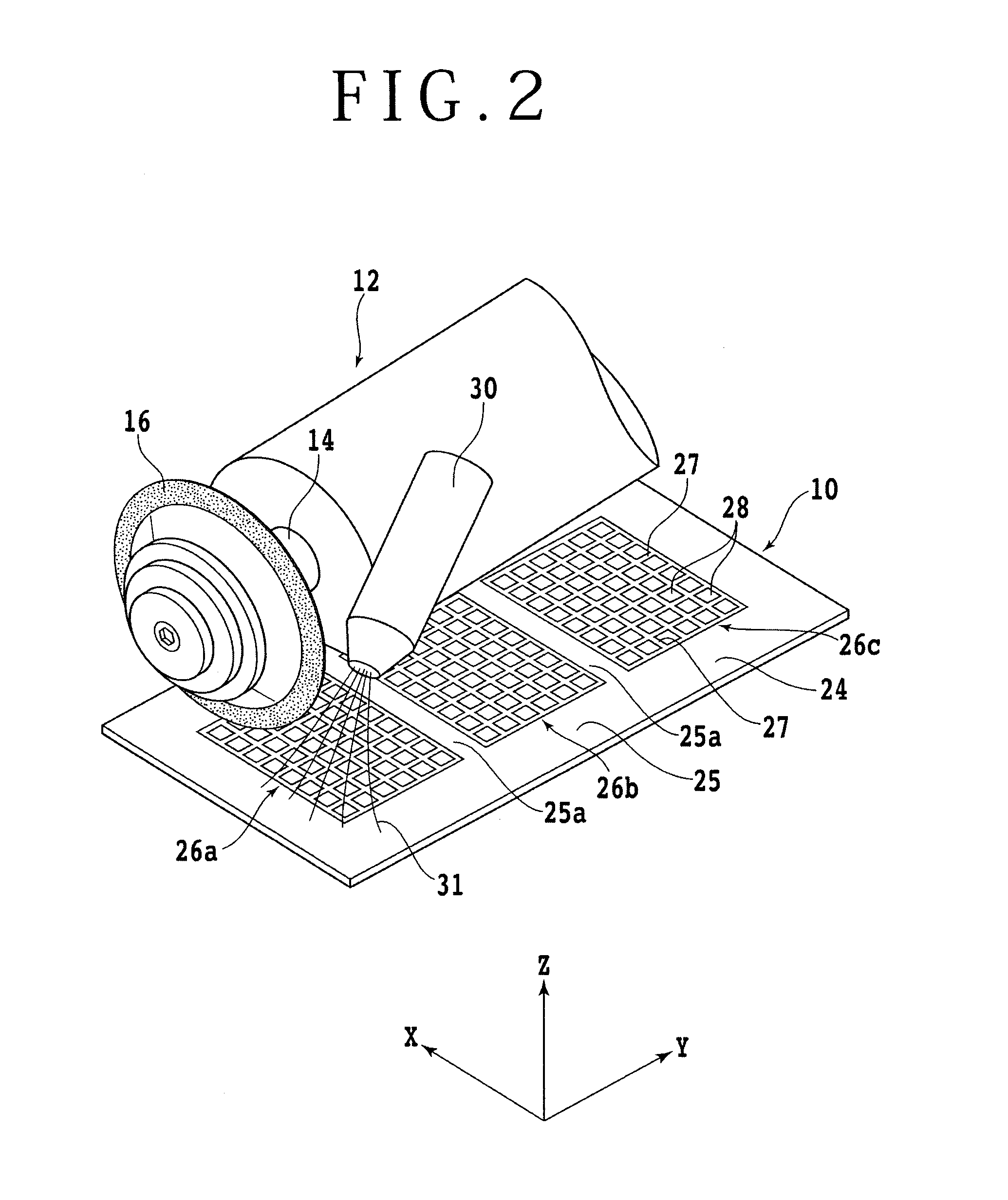

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

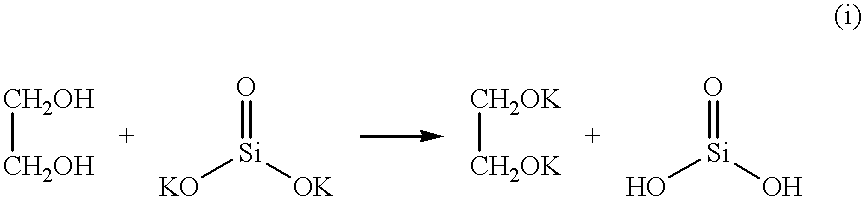

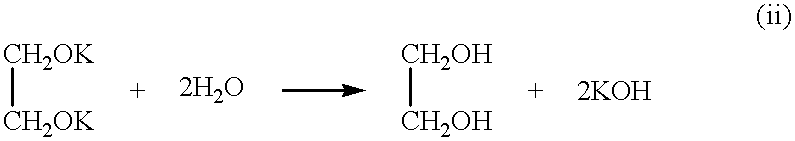

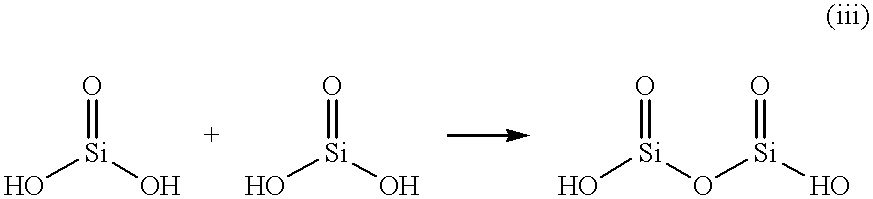

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

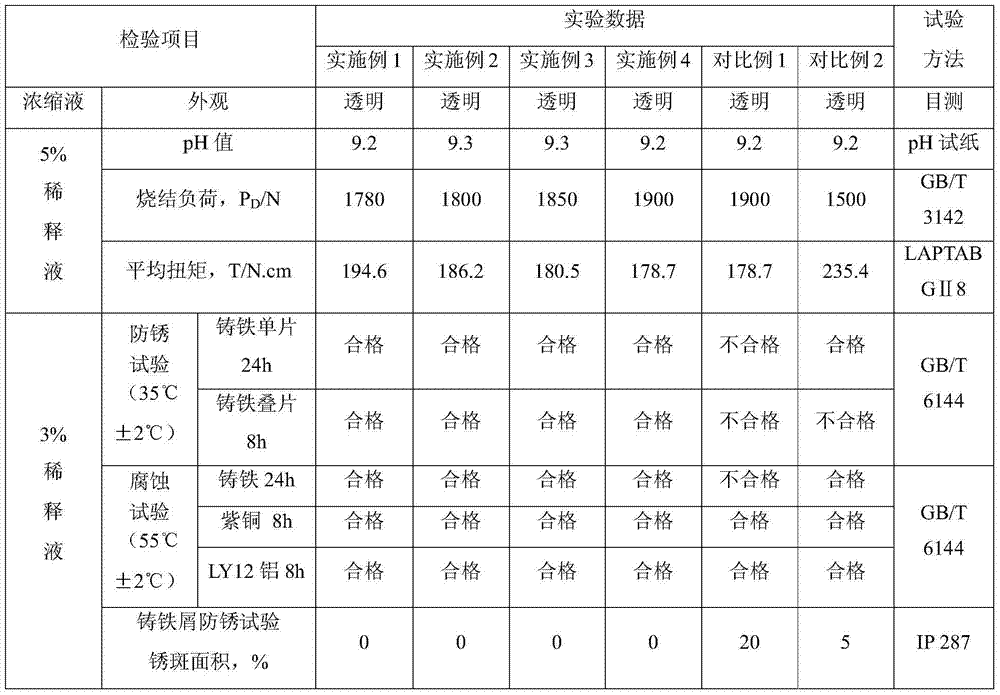

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

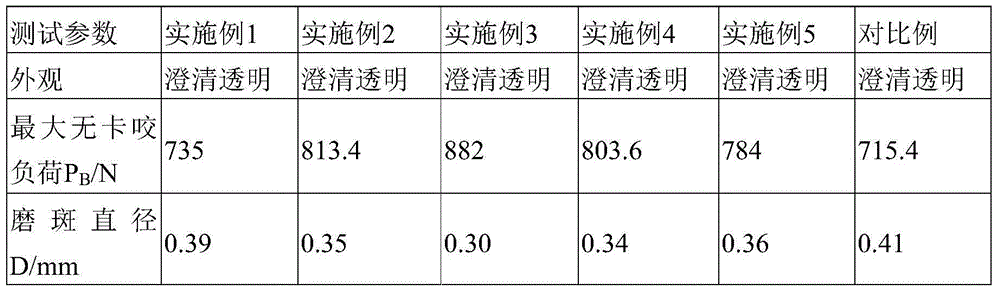

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

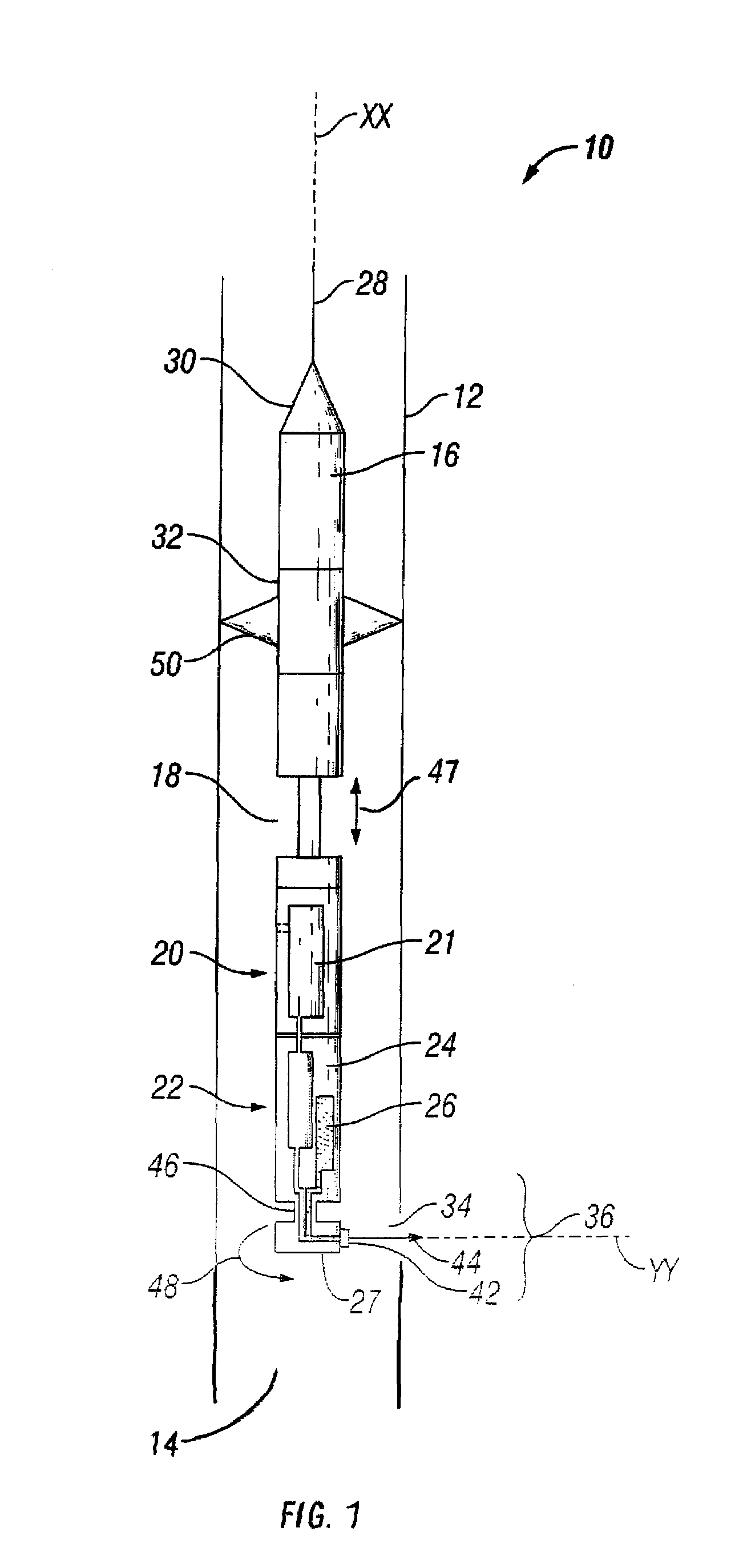

Severing of downhole tubing with associated cable

Methods for severing tubing having a cable extending along its length include lowering a first cutting torch into the tubing to a desired location, igniting the first cutting torch, and directing cutting fluids in a circumferential arc to form a first cut in the tubing and sever the cable. A second cutting torch can be lowered and positioned relative to the first cut, and ignited to direct cutting fluids radially to cut the tubing all around the circumference, enabling retrieval of the tubing. The need for precise positioning and alignment of the torches to sever both the cable and tubing is thereby eliminated.

Owner:ROBERTSON INTPROP

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

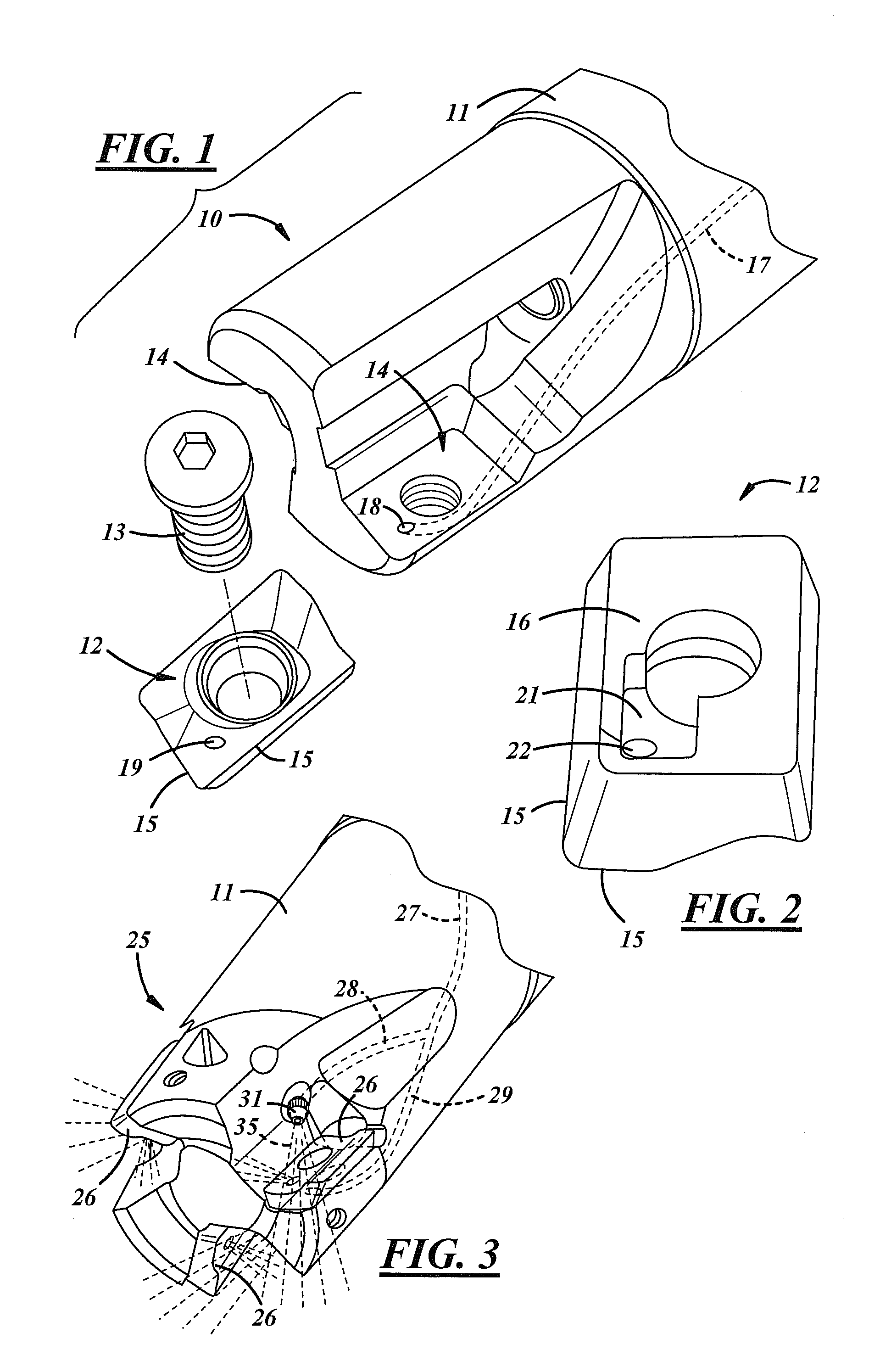

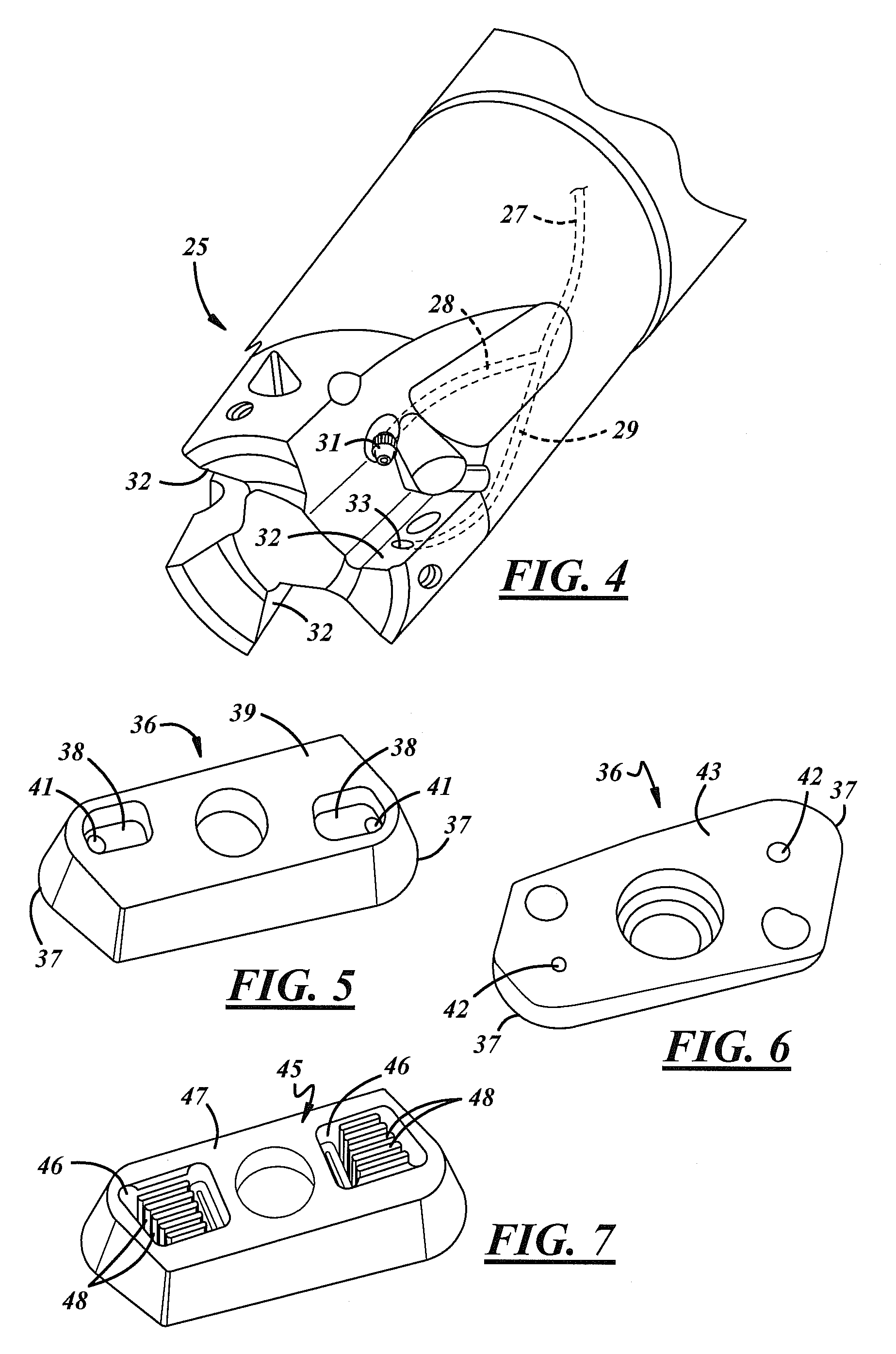

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

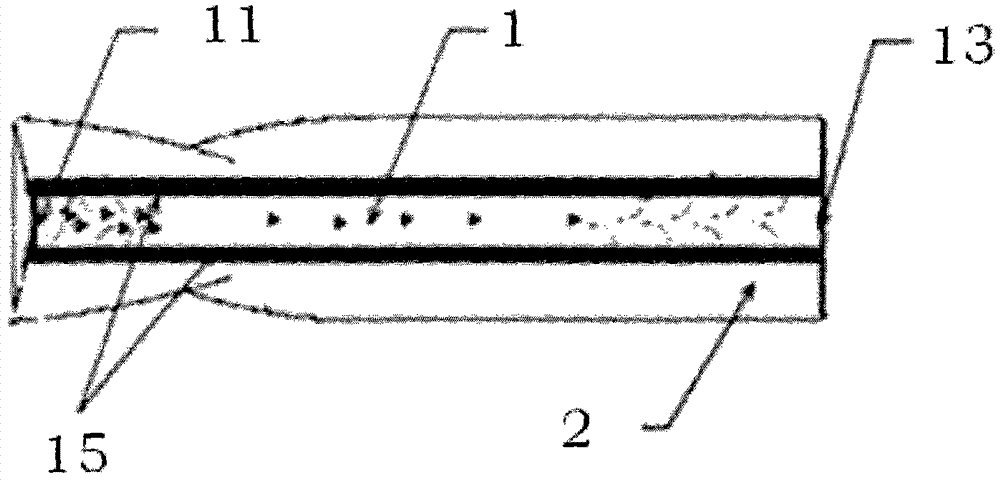

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

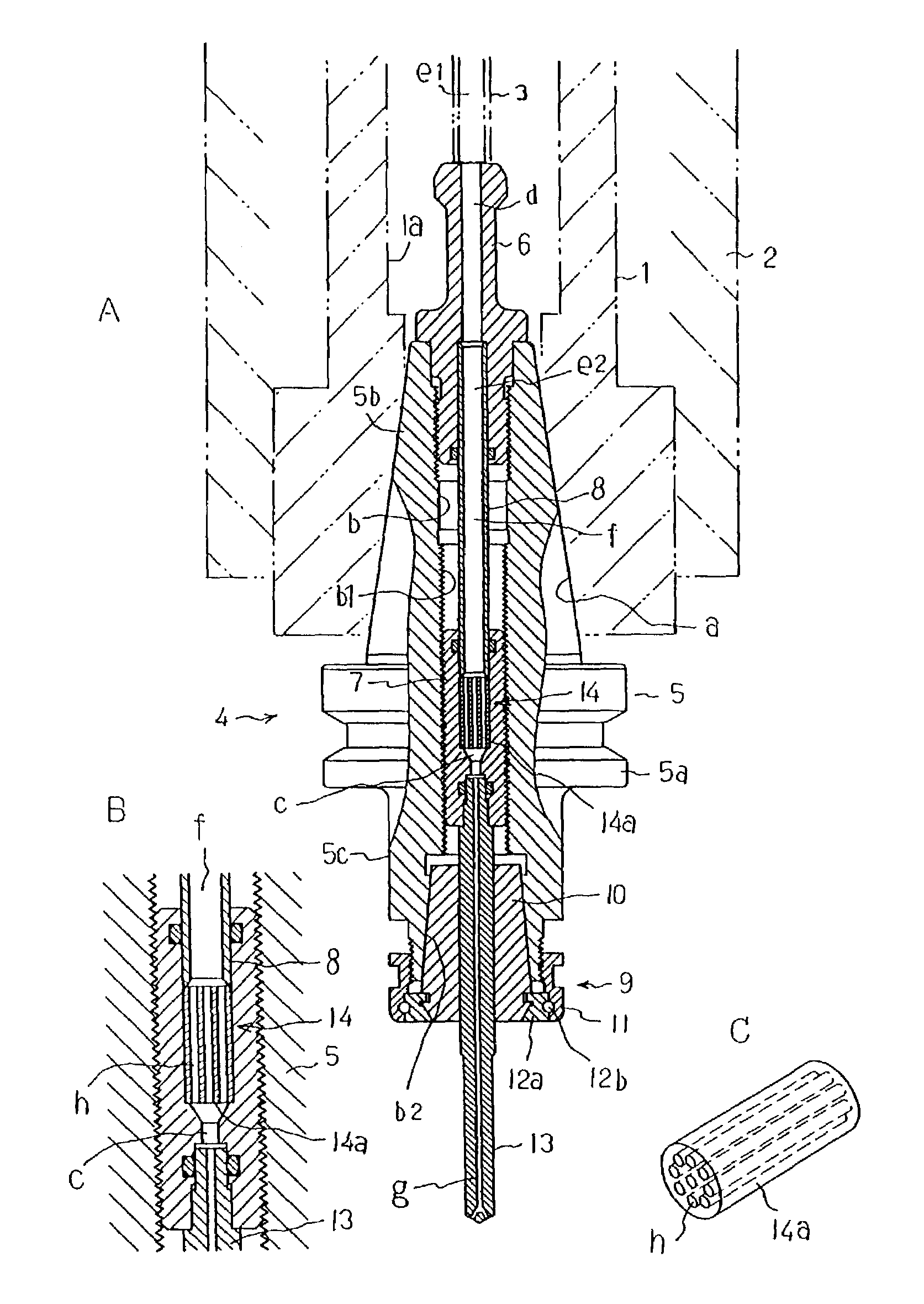

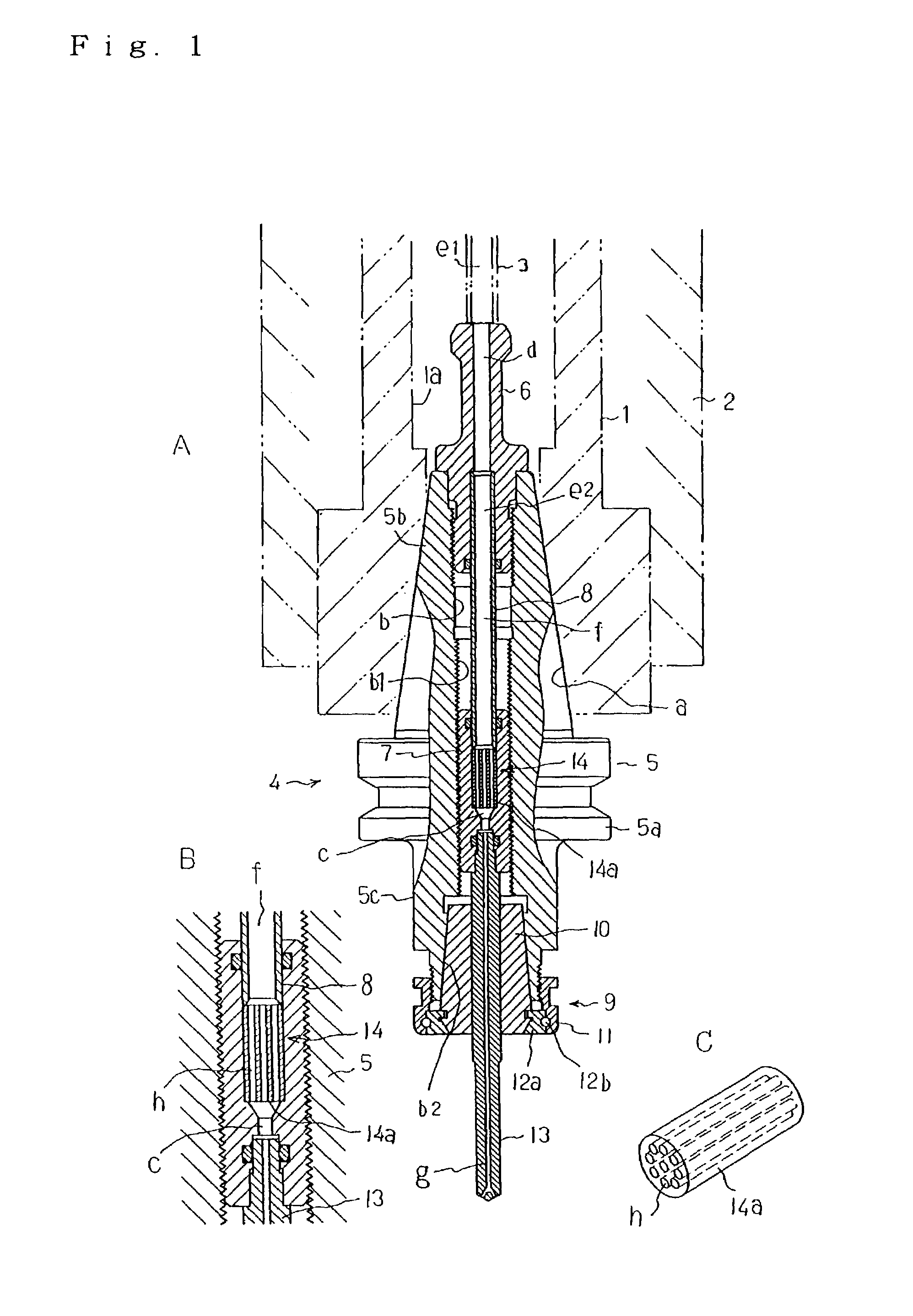

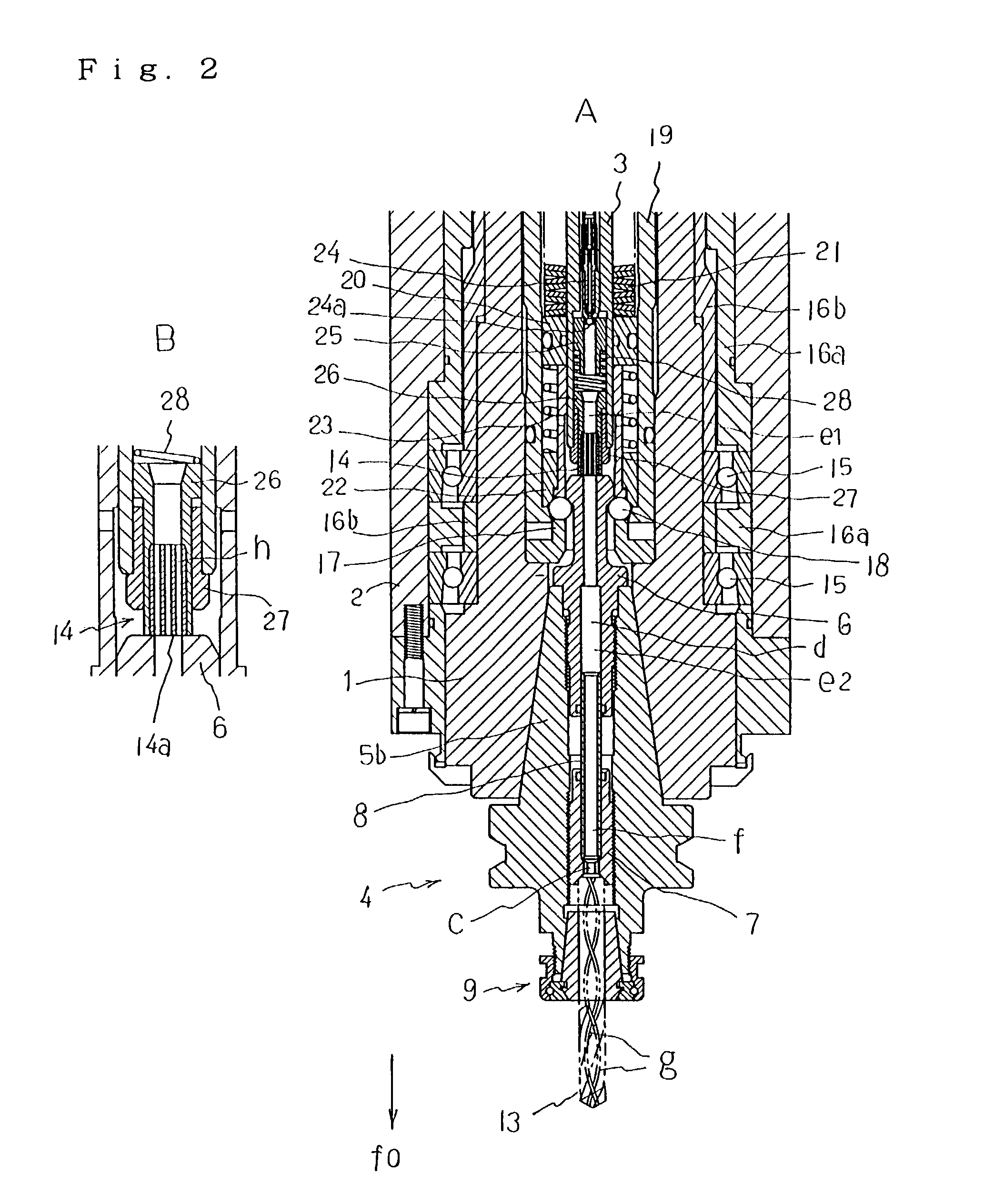

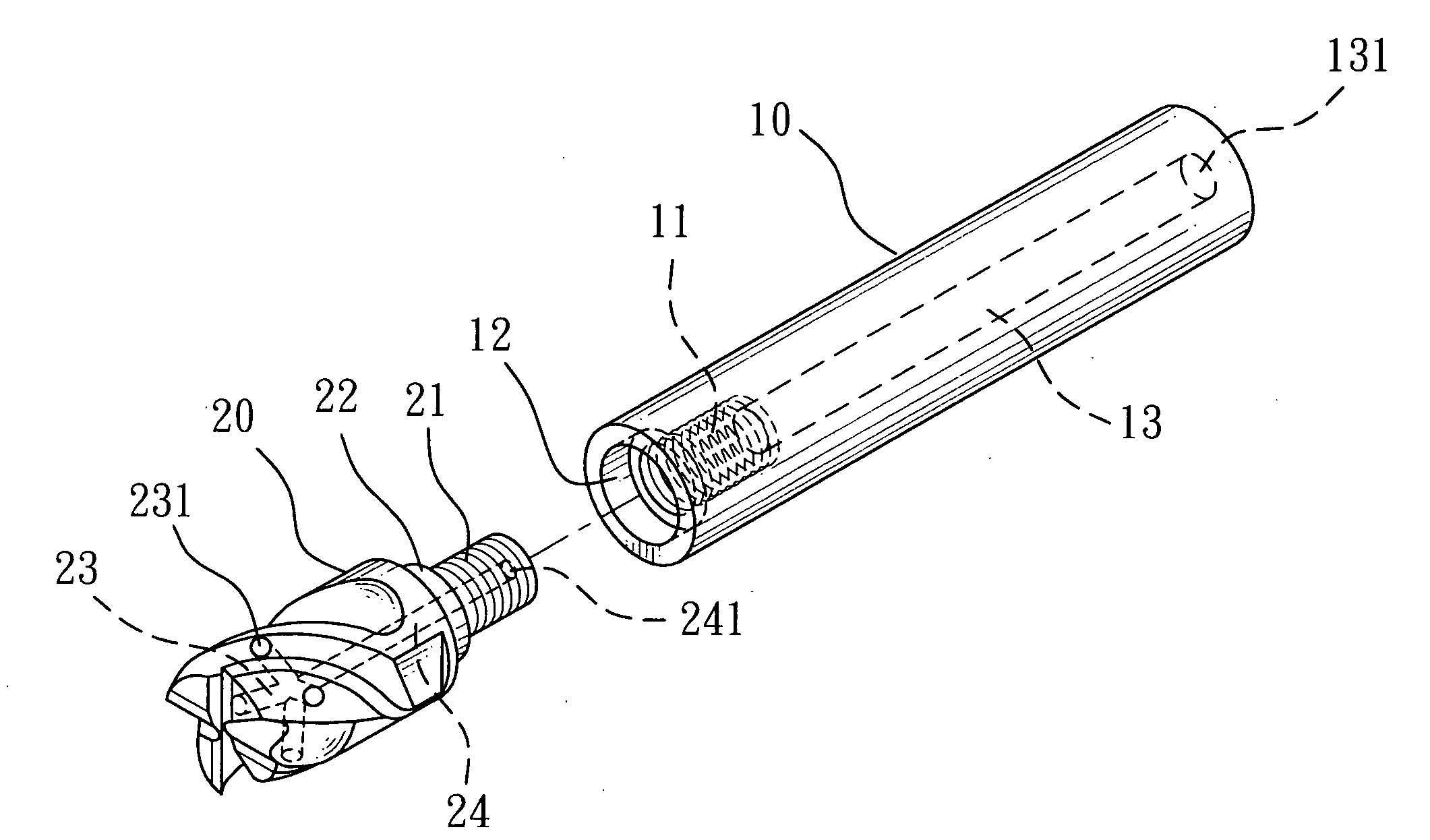

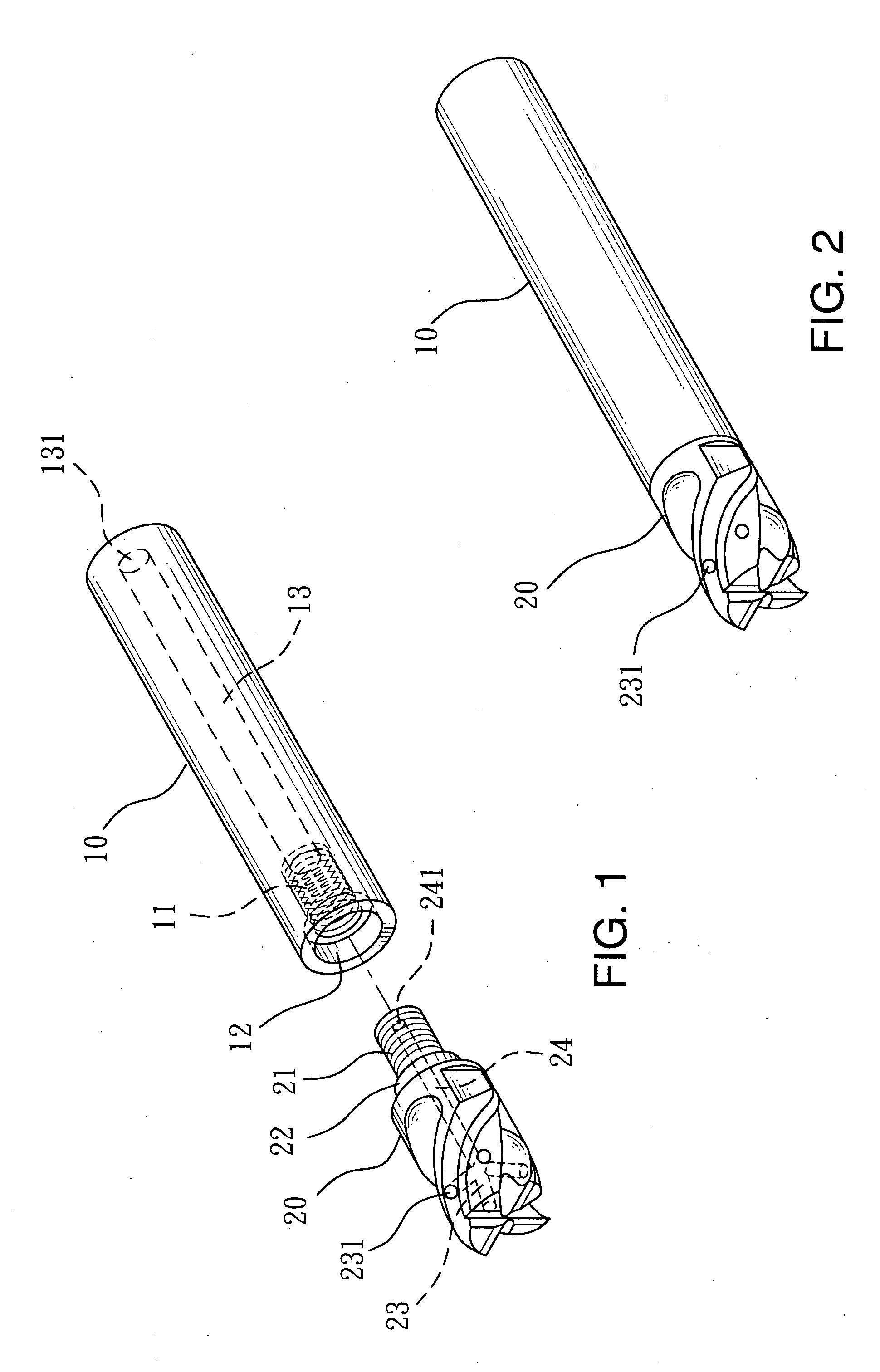

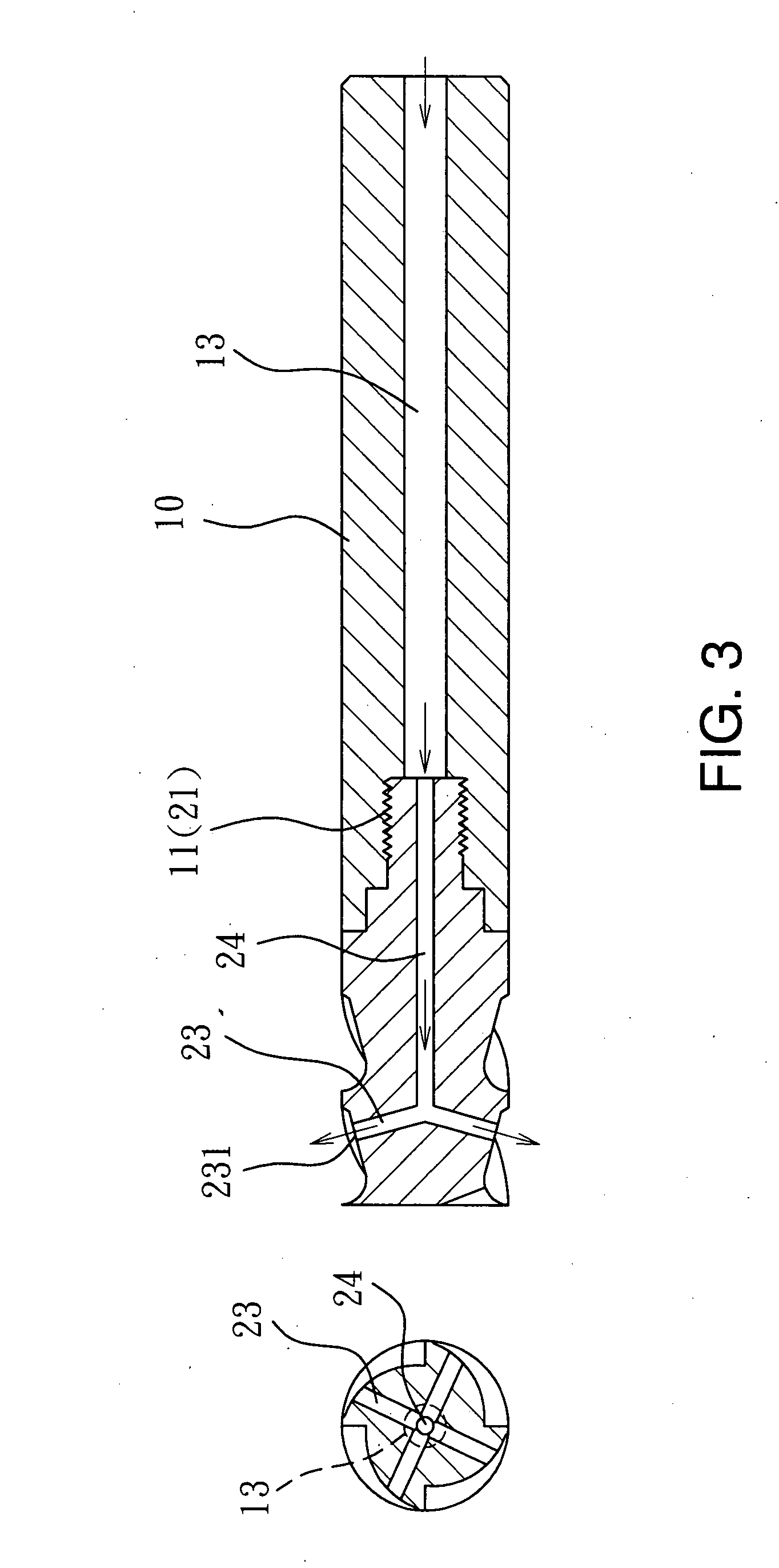

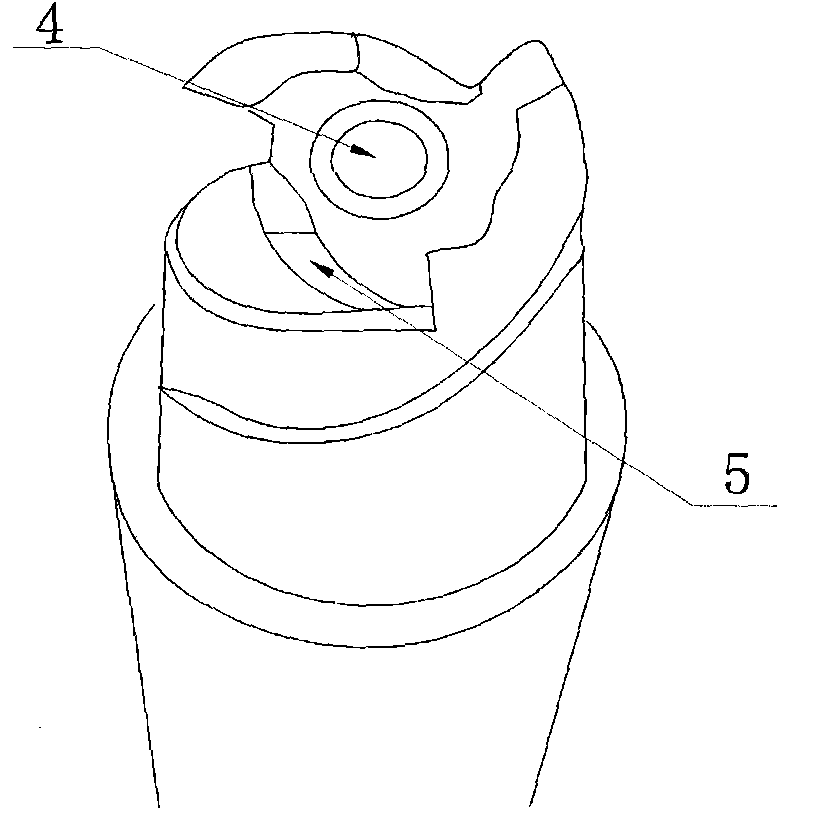

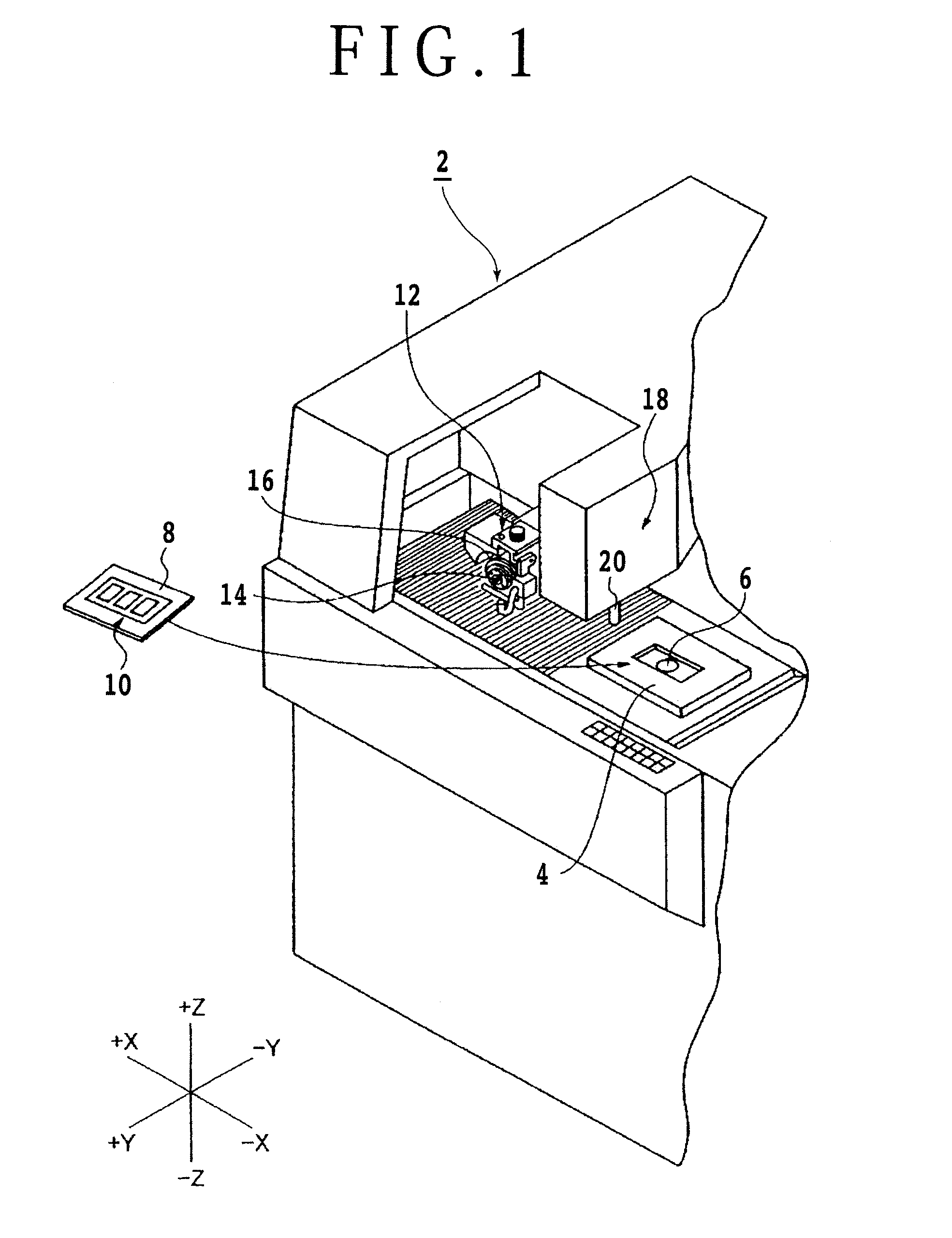

Cutting fluid device for a spindle of a machine tool

InactiveUS7048481B2Easy to producePrevent liquefactionTransportation and packagingMulti-purpose machinesMachine toolCutting fluid

A spindle device of a machine tool, which can prevent the liquefaction of atomized cutting fluid in atomized cutting fluid passage downstream of a straightening unit 14, enhance a responsiveness to an ejecting start or stop instruction, and prevent a waste of cutting fluid. The spindle device for a machine tool has atomized cutting liquid passage (e1, e2) each having a single-shape passage section and formed inside the device ranging from the spindle 1 to the tip end of a cutting tool 13 mounted thereto in one piece, and is operated so as to eject atomized cutting tool 13 via the atomized cutting fluid passages (e1, e2), wherein a straightening unit 14 formed with a plurality of small-diameter passages h are provided in the middle of the cutting liquid passages (e1, e2).

Owner:HORKOS

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

High-antiwear cutting fluid

InactiveCN104277900AImprove anti-wear performanceLow costLubricant compositionLanthanum fluoridePolyethylene glycol

The invention discloses a high-antiwear cutting fluid, which comprises the following raw materials in parts by weight: 10-25 parts of soybean oil, 5-15 parts of rapeseed oil, 8-25 parts of 2-ethylhexyl oleate, 15-30 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of disodium sulphonatoacetate, 1-5 parts of copper / silica composite nano materials, 5-12 parts of citric acid-modified lanthanum fluoride nanoparticles, 20-40 parts of an imidazoline-ammonium salt corrosion inhibitor, 3-15 parts of glycerin, 2-15 parts of triethanolamine, 2-6 parts of borax, 0.5-1.5 parts of benzotriazole, 8-20 parts of polyethylene glycol and 30-50 parts of water. The high-antiwear cutting fluid is excellent in antiwear, cooling, lubrication, cleaning and antirust functions, and is low in cost and strong in stability.

Owner:CHAOHU GUANGFENG METAL PROD

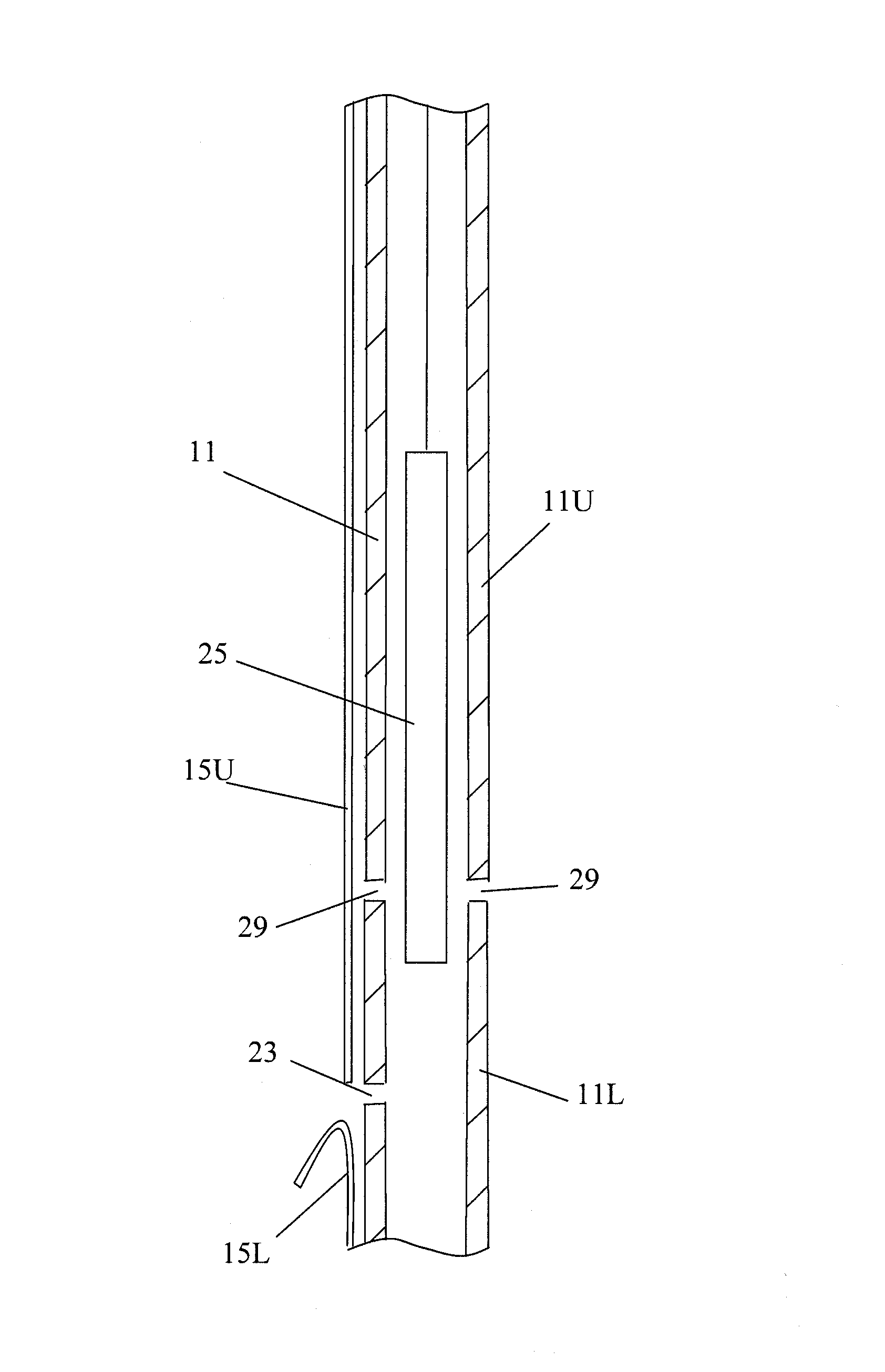

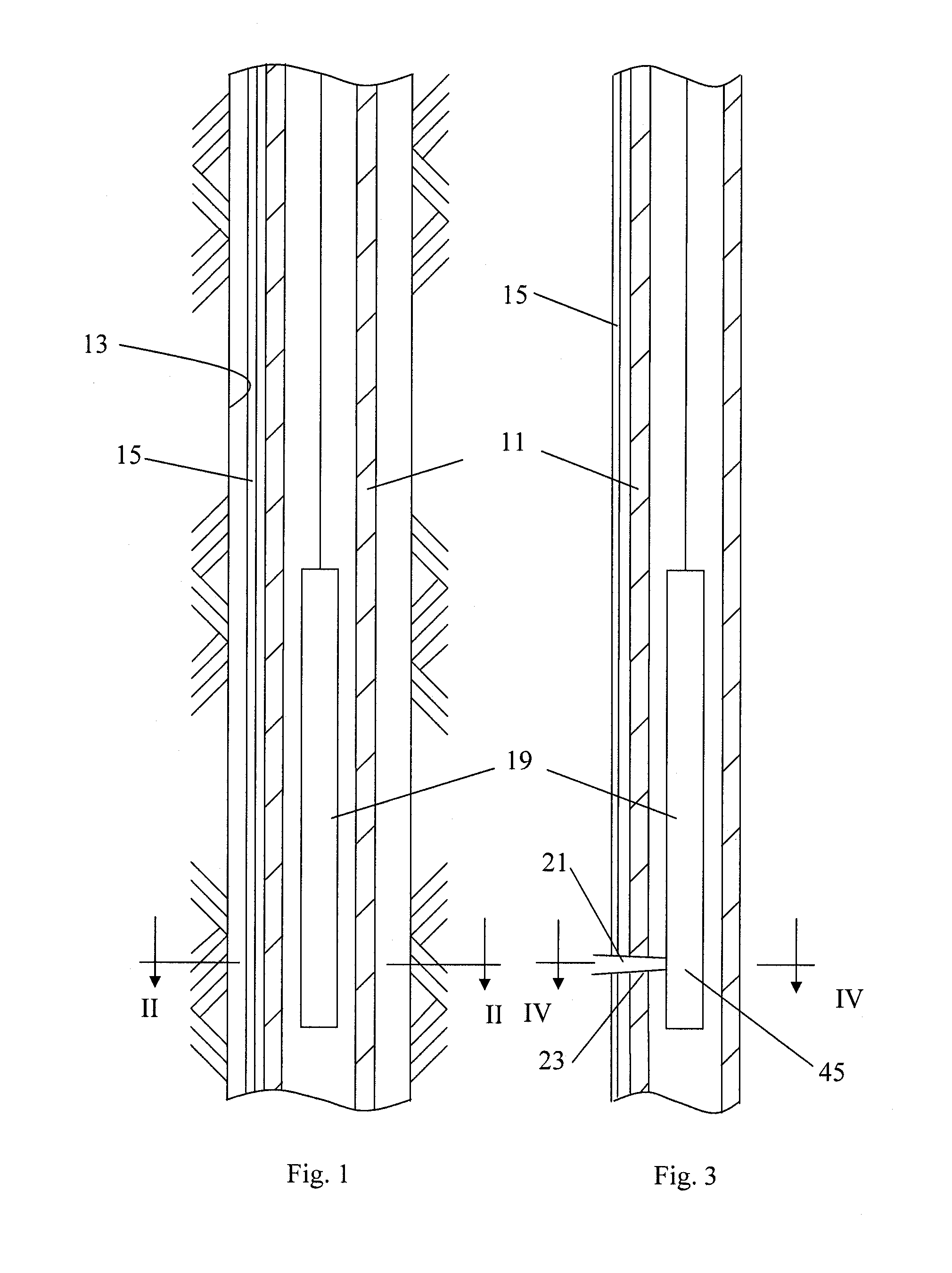

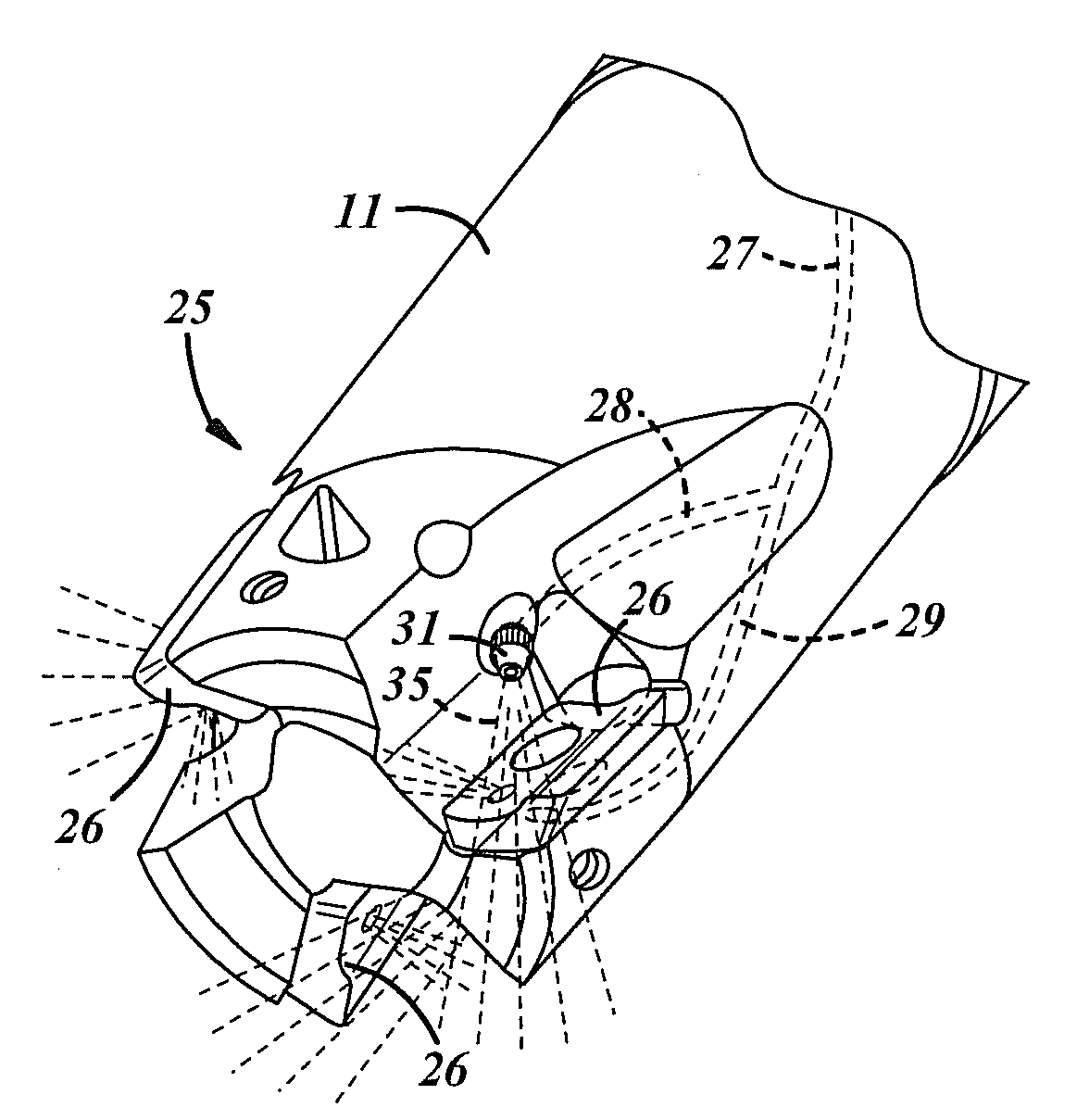

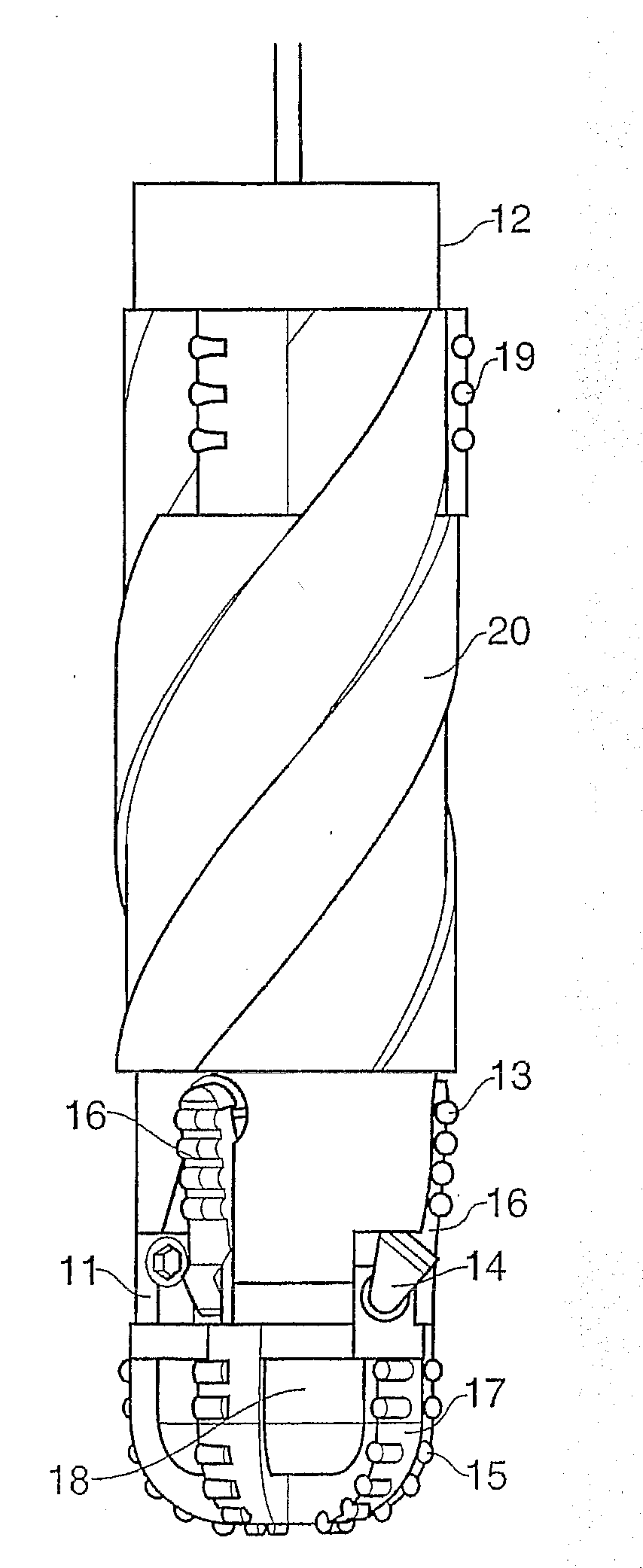

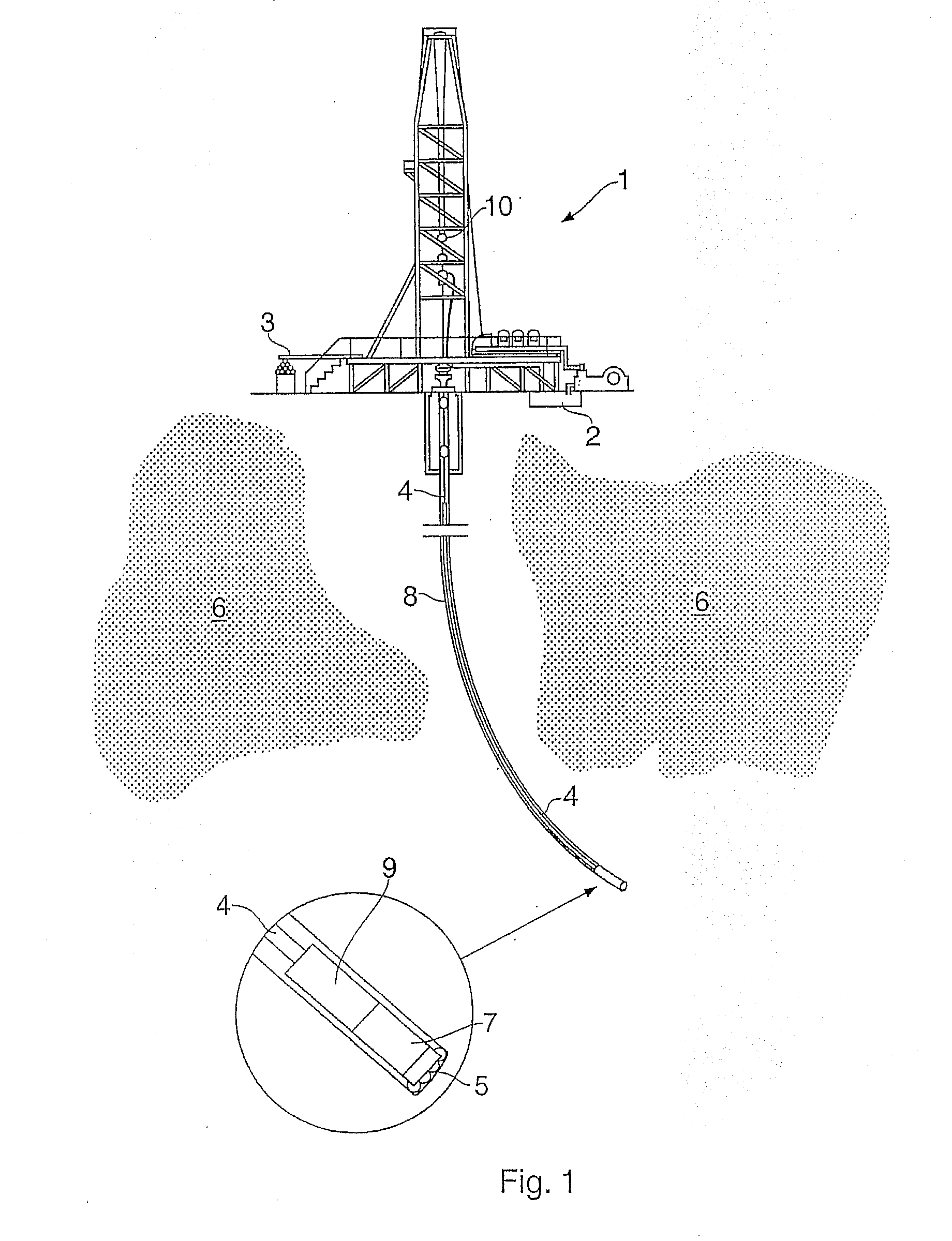

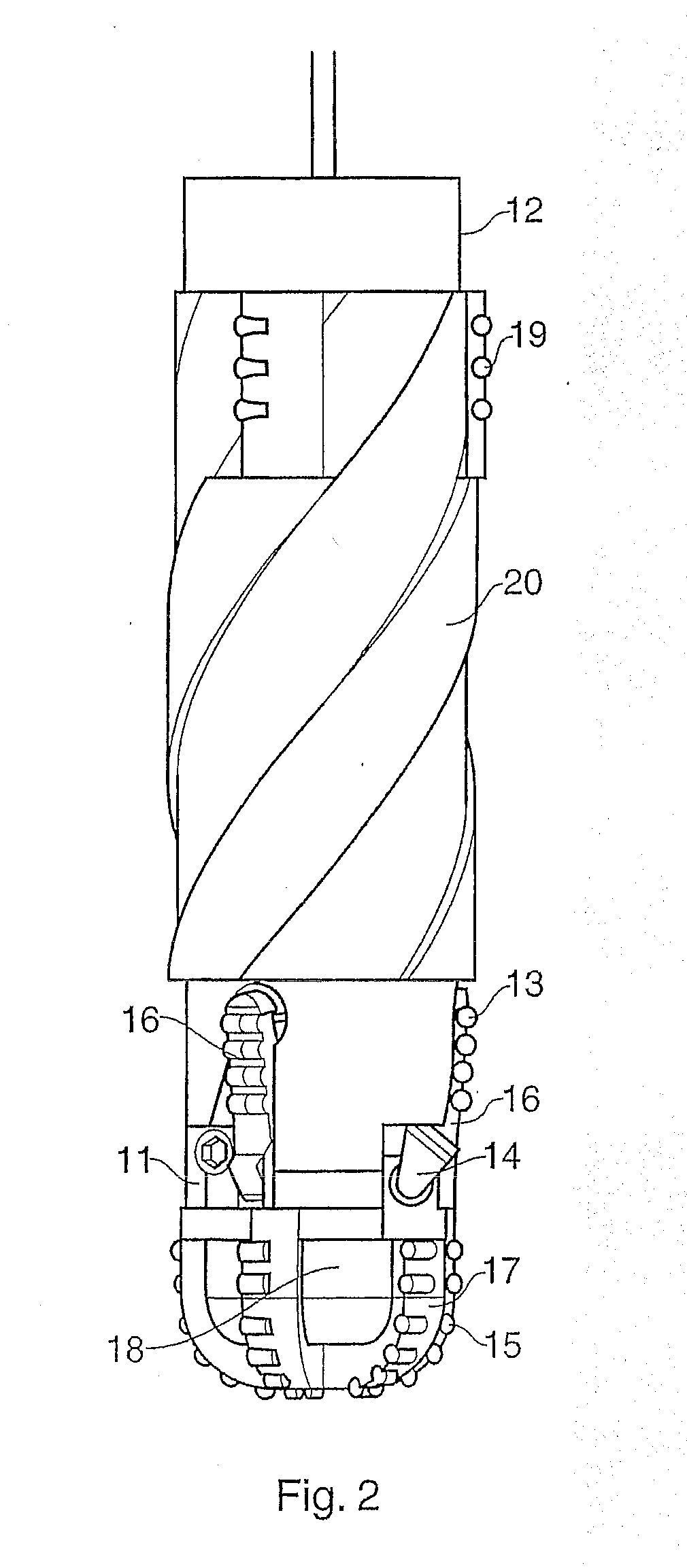

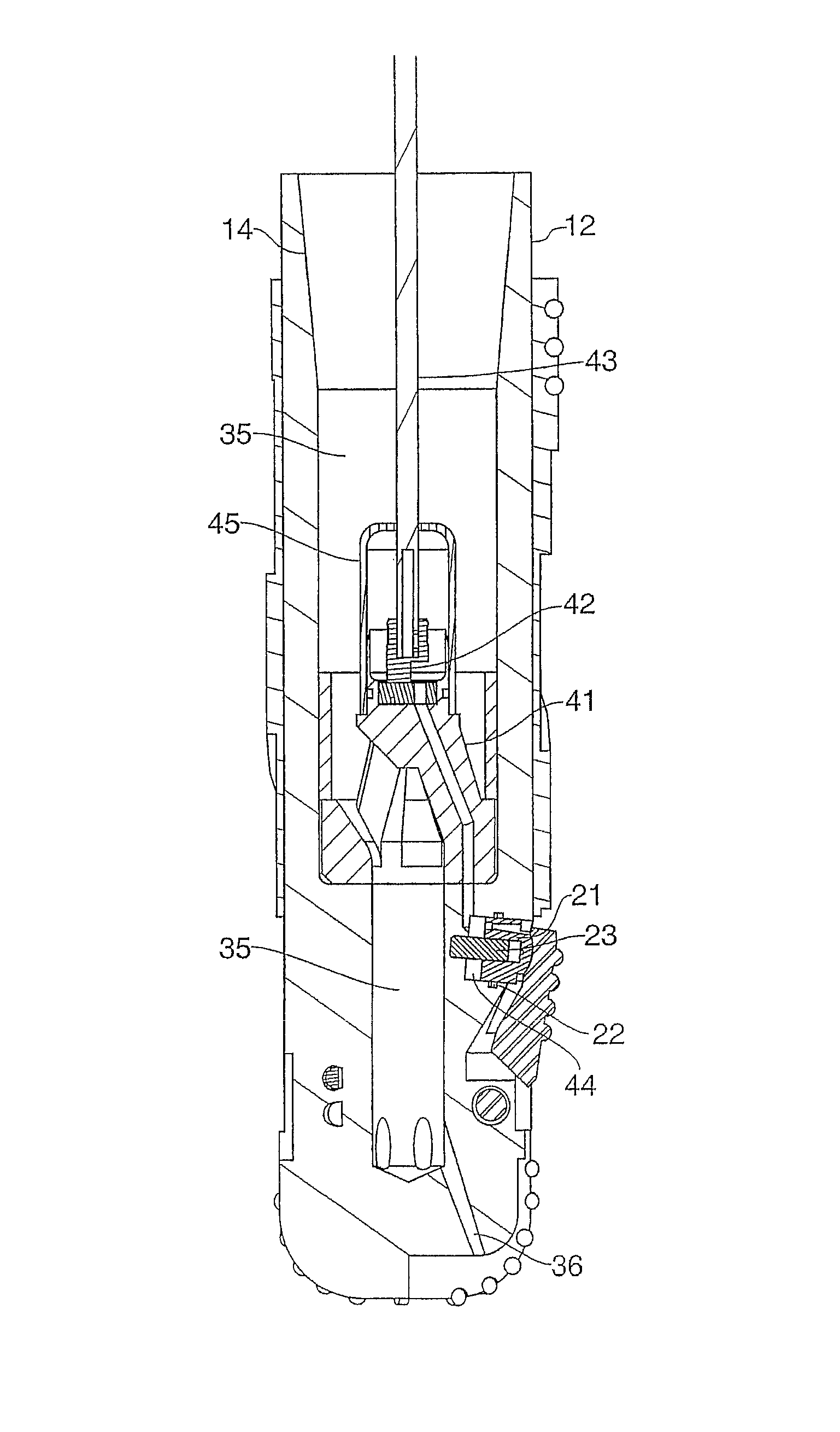

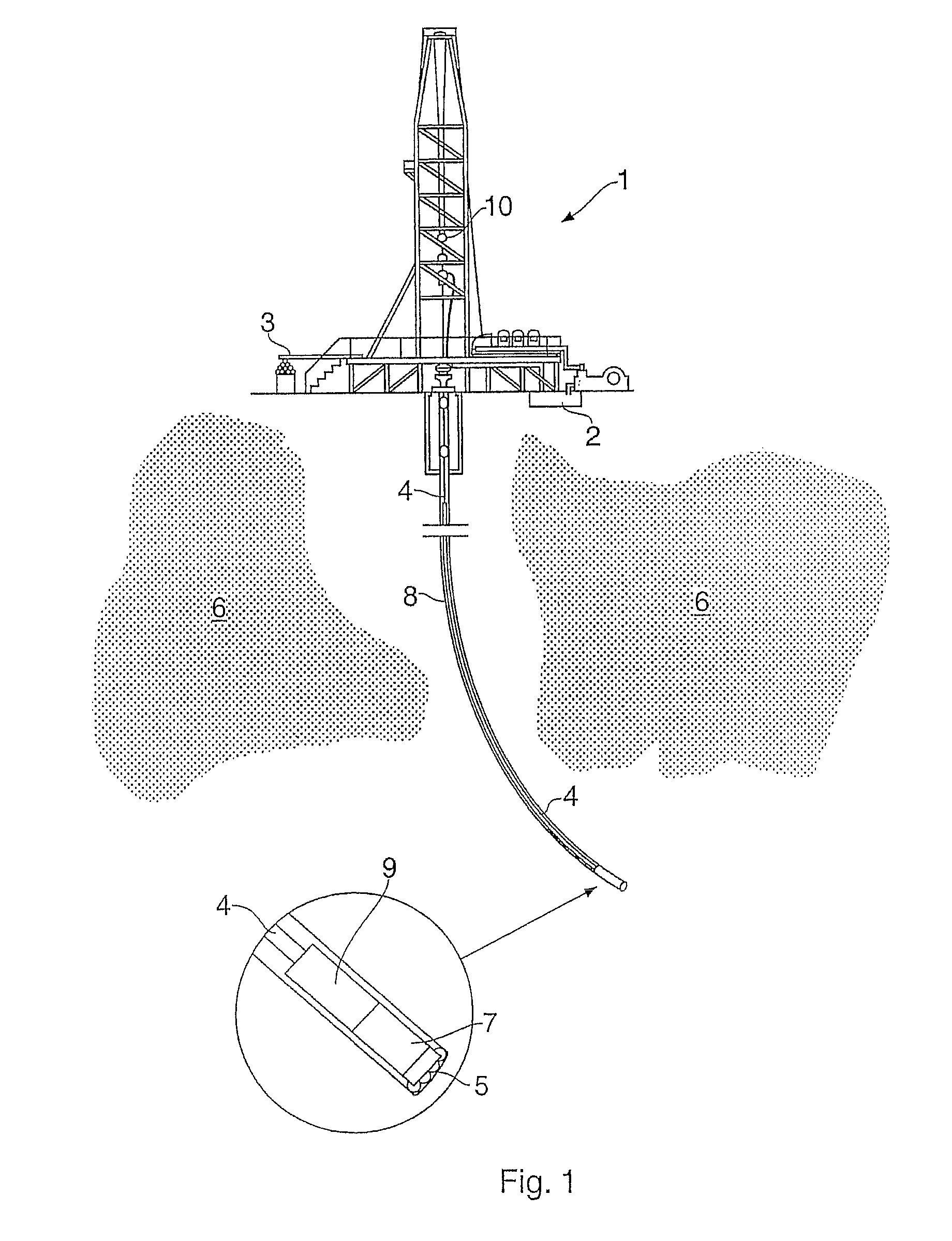

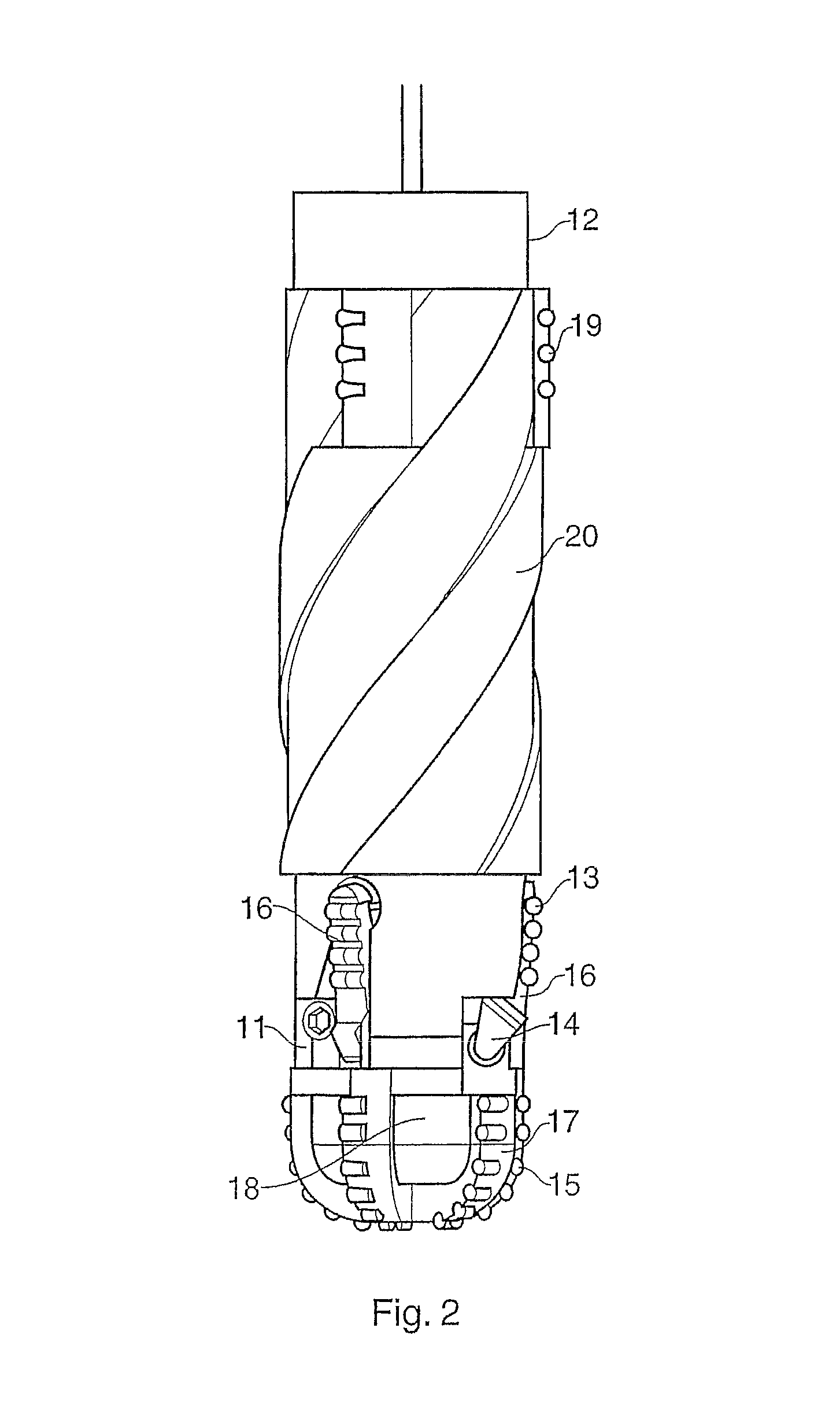

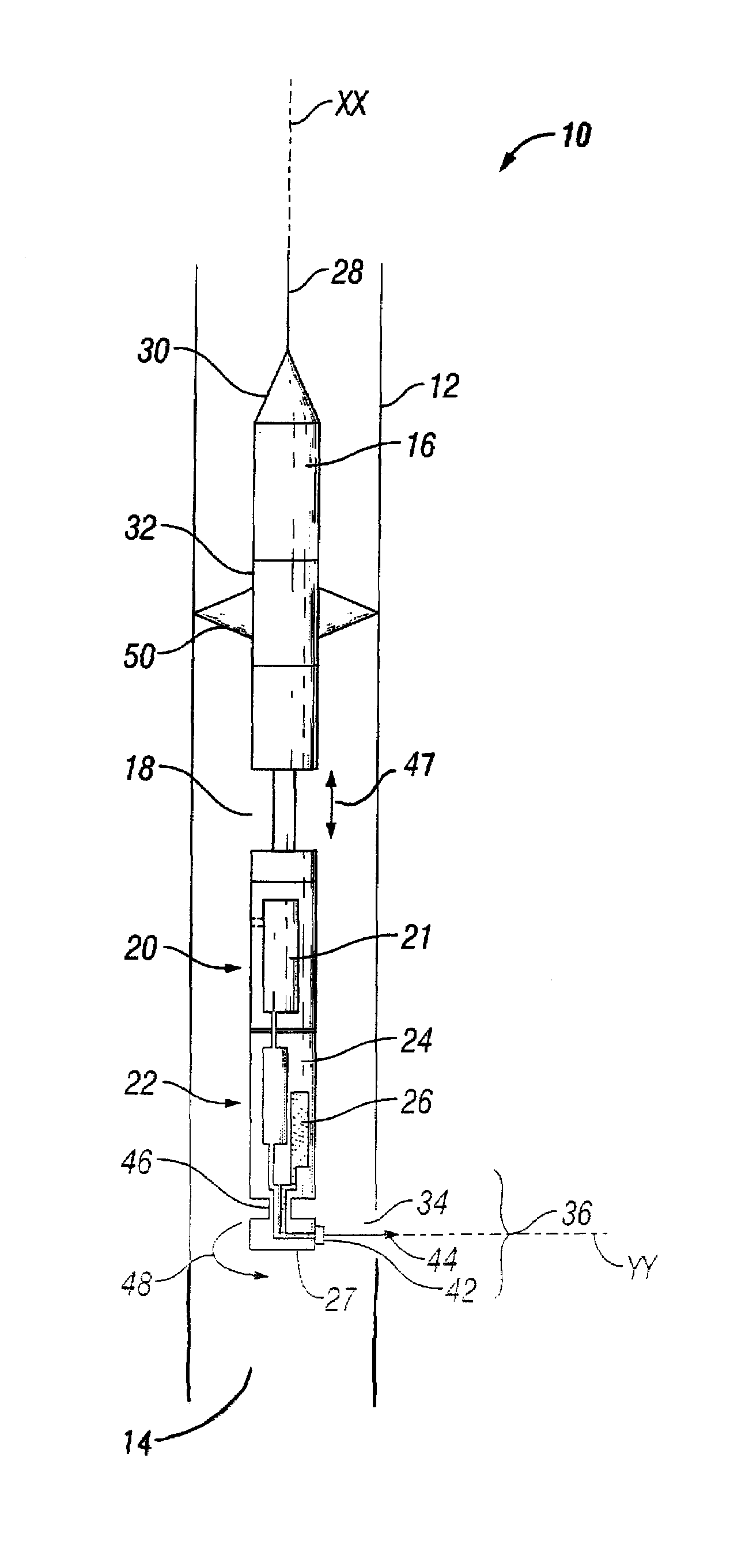

Steerable rotary directional drilling tool for drilling boreholes

The present invention provides a directional drilling apparatus and method for use in drilling bore holes. The apparatus comprises a plurality of movably mounted cutting elements, wherein the cutting elements are movable between radially retracted and extended cutting positions. A rotary valve is provided for synchronizing the movement of the cutting elements between their respective extended and retracted positions. Control of the directional drilling system is affected by synchronized movement of the cutting elements from an inner to an outer radial position in accordance with the angular position of the drill bit. Means are provided for directing high pressure cutting fluid to the region between the cutting elements and the rotatable body to prevent the accumulation of debris that could prevent movement of the cutting elements. The cutting elements enlarge the bore hole formed by the drill bit, so that the cutting elements continuously engage the wall of the bore hole.

Owner:MECIRIA LTD

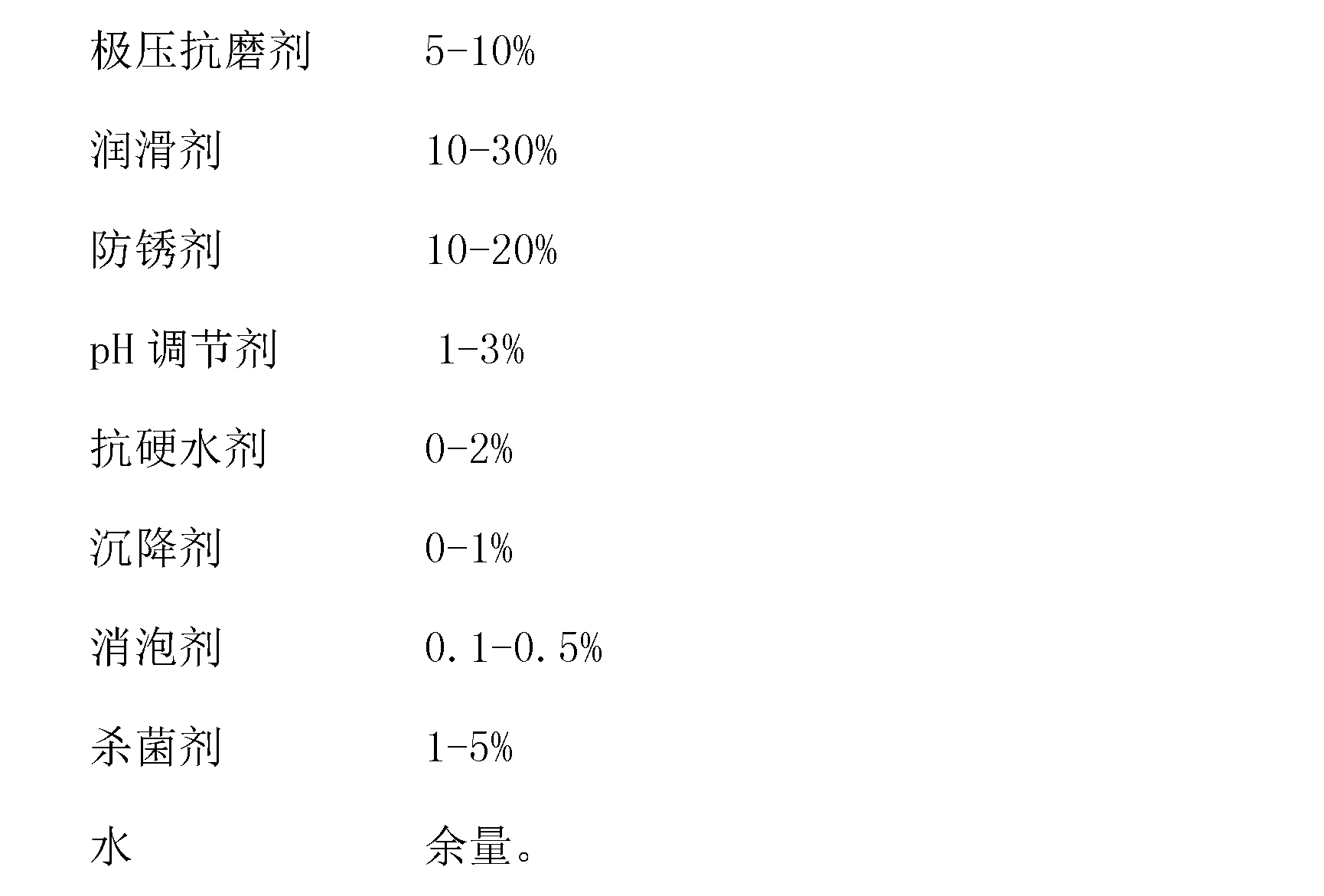

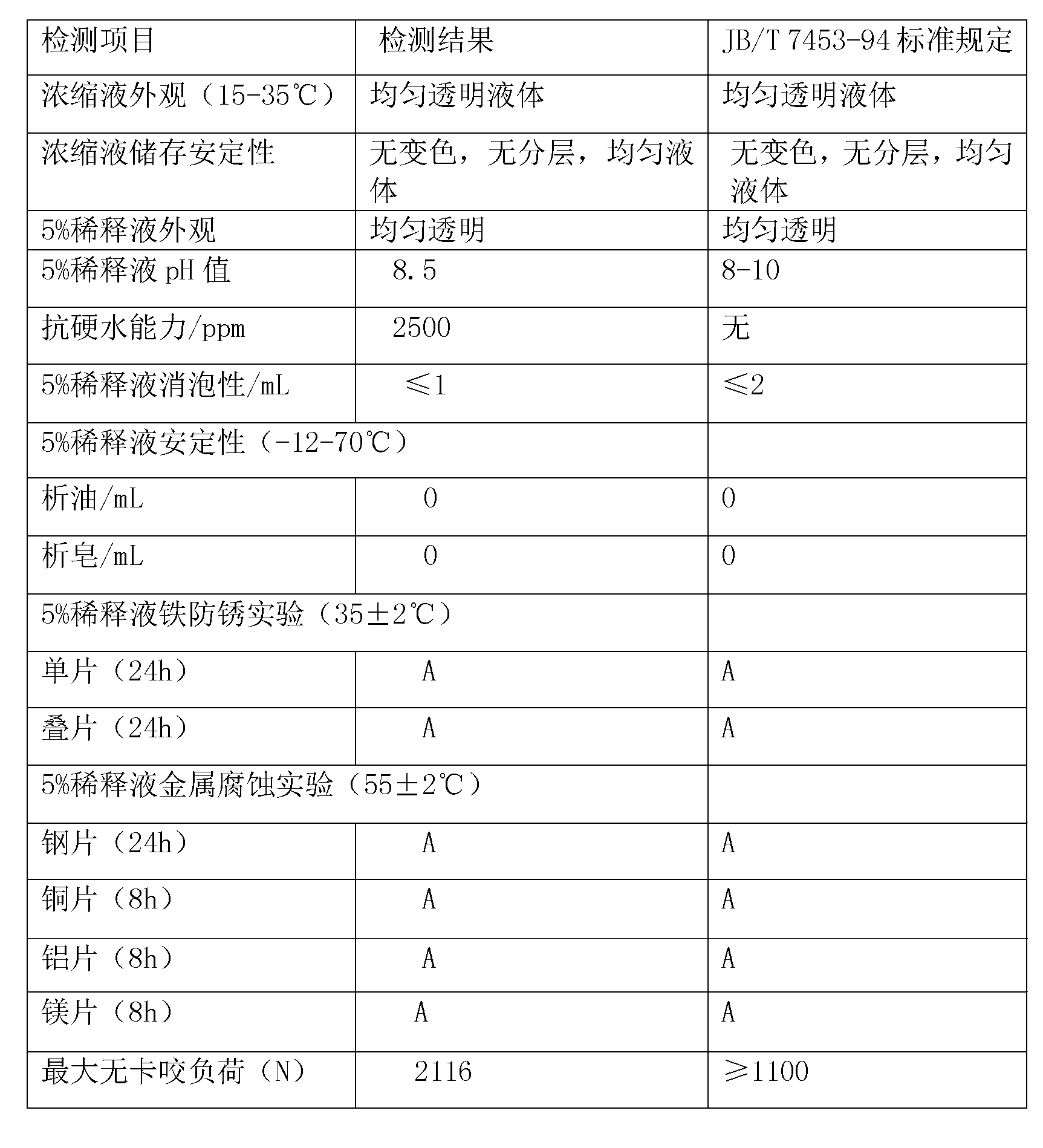

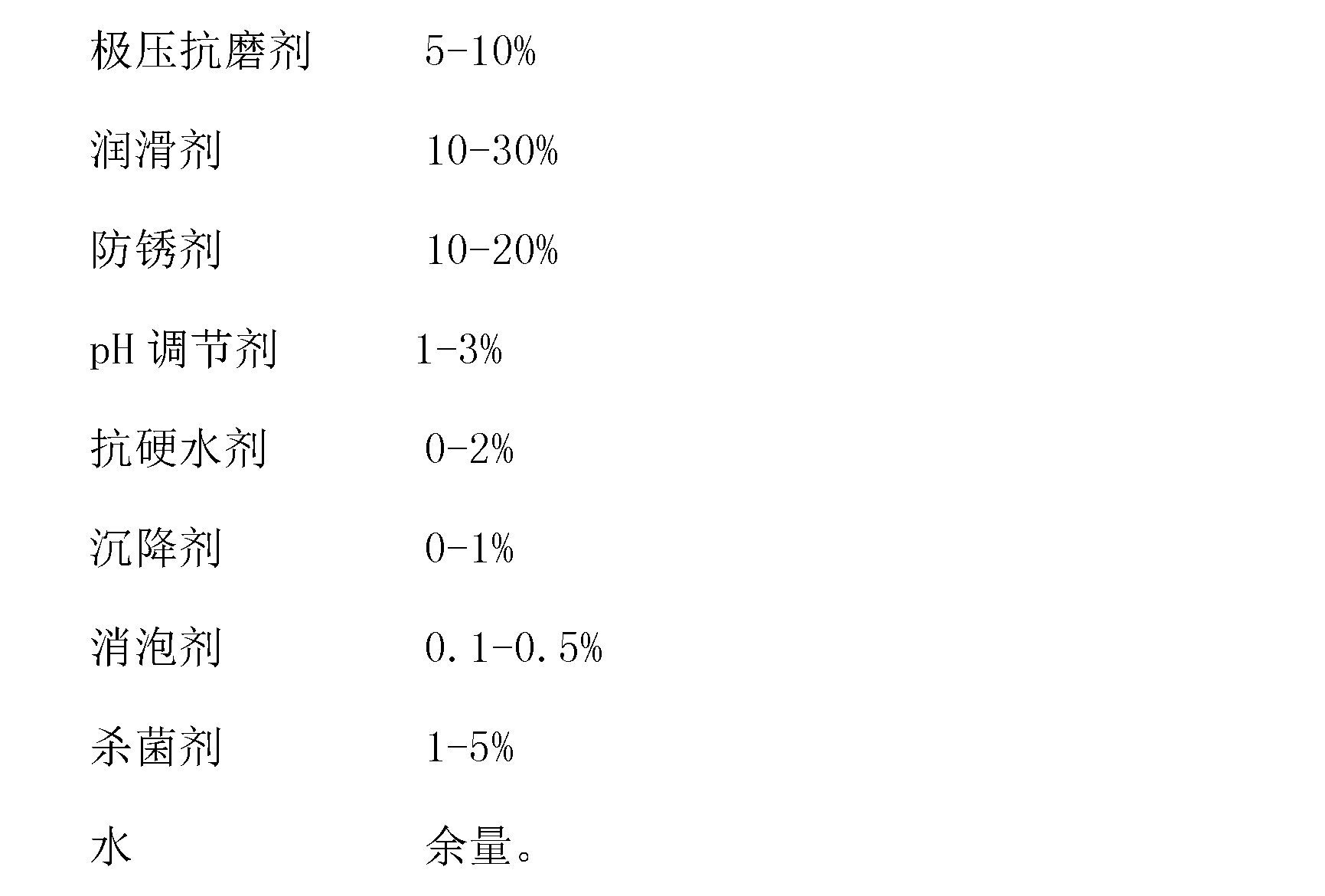

Aluminum-magnesium alloy cutting fluid

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

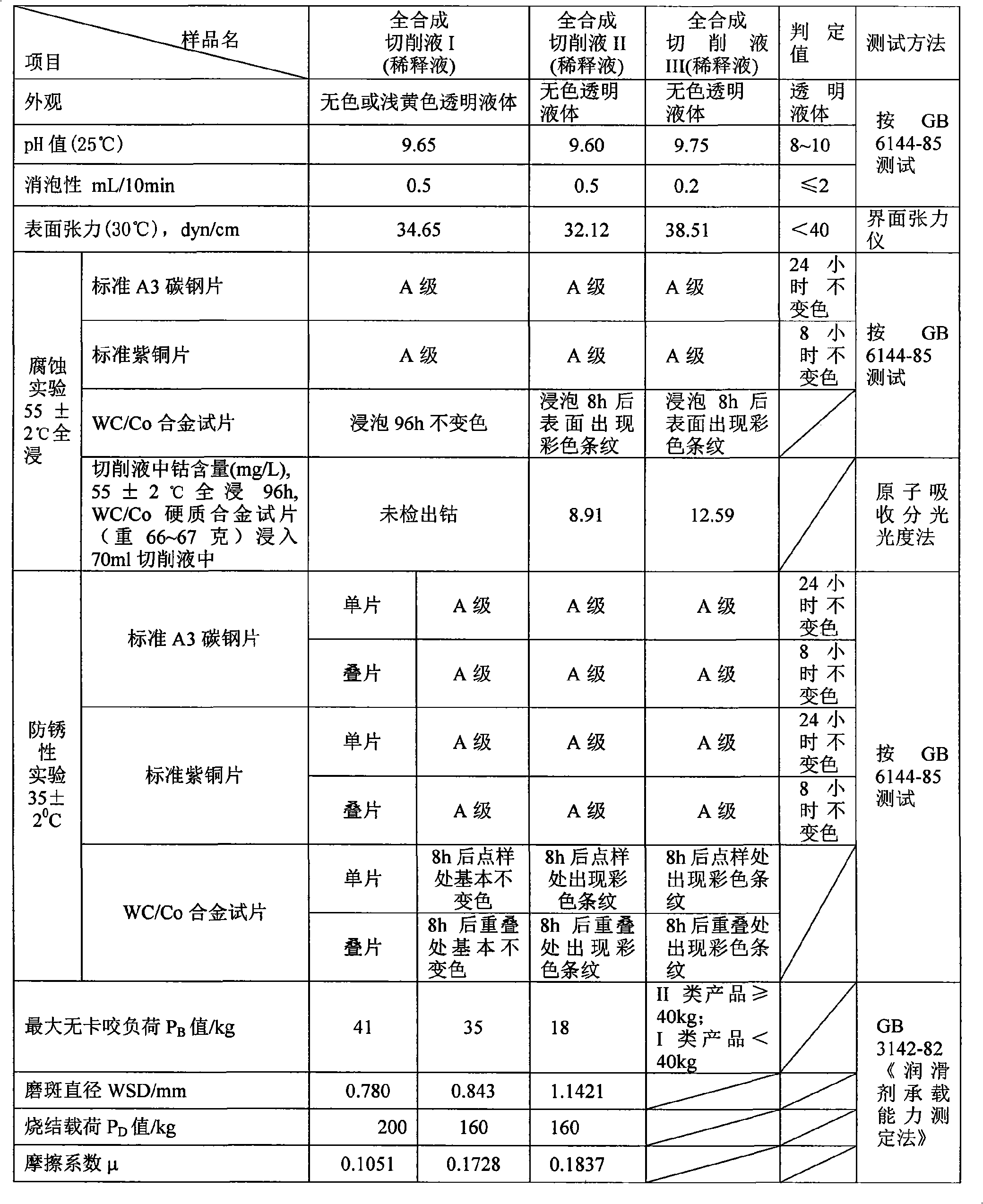

Fully synthetic cutting fluid

InactiveCN101560430ASolve the problem of protocobaltAvoid leachingLubricant compositionActive agentPolyethylene glycol

The invention discloses a fully synthetic cutting fluid which comprises anion active agent, non-ionic surface active agent, polyethylene glycol, borax, bactericide, foam suppressor, pH regulator, water and additive; wherein, the additive is prepared by the following method: the surface active agents are dissolved by acetone, the mixed solution is added with toluene and heated up to 50-60 DEG C, and the reaction system is dripped with acrylate monomer as well as azodiisobutyronitrile (AIBN) or ammonium persulfate (APS) evocating agent; after that, the temperature is preserved for 3-5h, the reaction stops, and organic solvent is removed, so that the additive is obtained. Compared with the existing fully synthetic cutting fluid, the fully synthetic cutting fluid of the invention can completely inhibit leaching of cobalt element in hard alloy containing cobalt when metal is processed, well solves the problem of separating the cobalt in the existing fully synthetic cutting fluid, and is environment-friendly and efficient.

Owner:CENT SOUTH UNIV

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

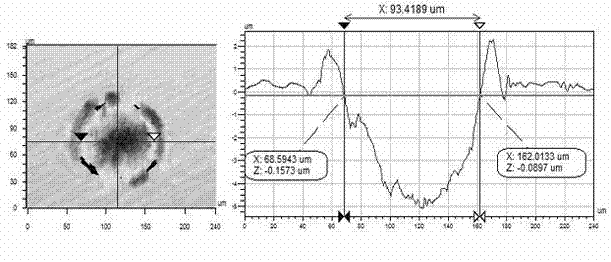

Preparation method of cutter surface antisticking antifriction micro mosaic composite texture

InactiveCN103111819AIncreased durabilityImprove cutting efficiencyManufacturing technologyBuilt up edge

The invention discloses a preparation method of a cutter surface antisticking antifriction micro mosaic composite texture and belongs to the technical field of mechanical cutting tool manufacture. The preparation method comprises the steps of carrying out texturing overlaid and microcavity / groove composite texture processing on the working surface of a cutter by using laser, and filling solid lubricant into the microcavity / groove texture of the cutter surface in a pressed and embedded mode. The preparation method of the cutter surface antisticking antifriction micro mosaic composite texture overcomes monotony of the existing cutter texture method, improves aintisticking performance of the front cutter surface of the cutter, preventing generation of a built-up edge, performs the function of storing and conveying of the texturing overlaid and microcavity / groove composite texture on cutting fluid, performs cooling and lubrication action on the cutter and achieves the purposes of improving durability and cutting efficiency of the cutter and ensuring machining quality of a workpiece surface.

Owner:JIANGSU UNIV

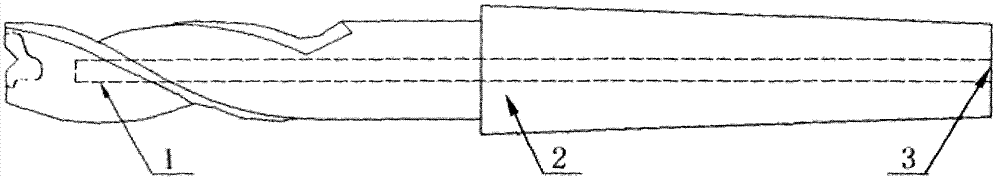

Tungsten steel cutter

InactiveUS20090142150A1Overcomes shortcomingAvoid accumulationWood turning toolsTransportation and packagingWater dischargeCoupling

A tungsten steel cutter which is lower cost to use and can increase fabrication efficiency and improve quality mainly includes a shank and a bit screwing at a front end of the shank. Both are made of tungsten steel and formed in an integrated fashion. The shank has a screw hole at the front end and a coupling trough formed at the front end of the screw hole. The bit has a screw bar extended from the bottom end thereof and a coupling neck at the front section of the screw bar. The coupling trough is formed at a depth same as the height of the coupling neck and the coupling trough and the coupling neck are formed at the same size. The bit and the shank have respectively a water discharge passage and a water drawing passage, and a water intake passage that communicate with each other. The water intake passage is formed at a greater diameter than the water discharge passage and water drawing passage. Thus when the bit and the shank are screwed together, in addition to screw coupling of the screw hole and the screw bar, the coupling trough and the coupling neck also form a tight coupling to minimize gaps that might otherwise happen between them like the conventional ones do. The water discharge passage and water intake passage provide cooling effect for cutting fluid and prevent debris from accumulating on the bit and affecting cutting quality. The invention provides a two-section coupling that can save the cost and improve steadiness and fabrication efficiency of precision tools.

Owner:DHF PRECISION TOOL TRADING

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

Steerable rotary directional drilling tool for drilling boreholes

The present invention provides a directional drilling apparatus and method for use in drilling bore holes. The apparatus comprises a plurality of movably mounted cutting elements, wherein the cutting elements are movable between radially retracted and extended cutting positions. A rotary valve is provided for synchronizing the movement of the cutting elements between their respective extended and retracted positions. Control of the directional drilling system is affected by synchronized movement of the cutting elements from an inner to an outer radial position in accordance with the angular position of the drill bit. Means are provided for directing high pressure cutting fluid to the region between the cutting elements and the rotatable body to prevent the accumulation of debris that could prevent movement of the cutting elements. The cutting elements enlarge the bore hole formed by the drill bit, so that the cutting elements continuously engage the wall of the bore hole.

Owner:MECIRIA LTD

Method for prolonging service life of face milling cutter based on heat pipe phase changes

InactiveCN103537950AImprove heat transfer efficiencyNo personal injuryMilling cuttersMaintainance and safety accessoriesMilling cutterHeat transfer efficiency

The invention provides an environment-friendly method for prolonging the service life of a face milling cutter based on heat pipe phase changes, so durability of the face milling cutter can be remarkably improved under a milling especial for high-speed milling machining condition. The method comprises a novel face milling cutter. The novel face milling cutter comprises a heat pipe, a face milling cutter shank, a face milling cutter body and a face milling head. The face milling head is arranged at one end of the face milling cutter body, the face milling cutter shank is arranged at the other end of the face milling cutter body, the heat pipe is implanted into the face milling cutter body from the face milling cutter shank in the direction parallel with the axis of the face milling cutter body and is close to the main cutting edge part on the face milling head, and the heat pipe is filled with a liquid absorption core. Heat pipe phase change heat transferring is adopted in the method, so the heat pipe is higher than cutting fluid in heat transfer efficiency. A heat pipe technology is adopted, the cutting temperature of the face milling cutter is lowered, the heat pipe is more environment-friendly than the cutting fluid, and personal injuries to operation staff do not exist. In addition, the heat pipe adopted in the method is cheaper than the cutting fluid in market price, and therefore manufacturing cost of products of enterprises can be reduced.

Owner:ANHUI AGRICULTURAL UNIVERSITY

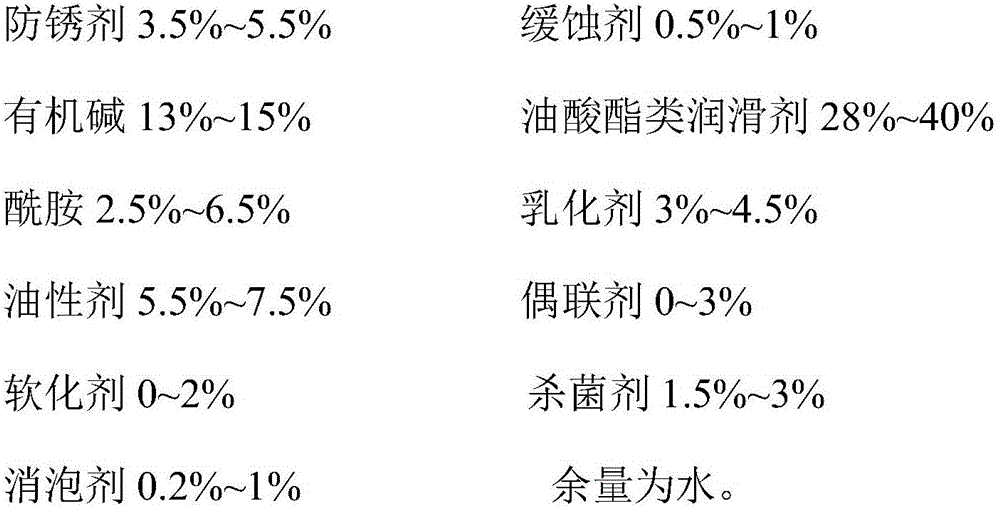

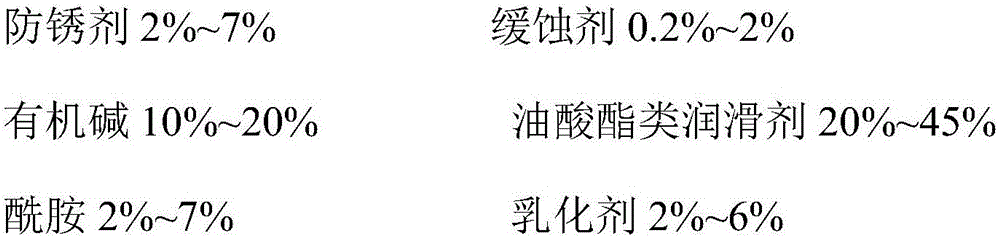

Water-based metal cutting liquid

InactiveCN106479654AGood compatibilityStrong synergistic functionLubricant compositionWater basedSulfur

The invention discloses a water-based metal cutting liquid. The water-based metal cutting liquid is prepared from raw materials in percentage by mass as follows: 2%-7% of an antirust agent, 0.2%-2% of a corrosion inhibitor, 10%-20% of organic alkali, 20%-45% of an oleate lubricant, 2%-7% of amide, 2%-6% of an emulsifier, 4%-9% of an oiliness agent, 0%-5% of a coupling agent, 0%-3% of a softener, 1%-5% of a sterilizing agent, 0.1%-2% of a defoaming agent and the balance of water. The water-based metal cutting liquid provided by the invention contains no sulfur, phosphorus, chlorine or boric acid and is efficient, environment-friendly and recyclable.

Owner:深圳市宏达威表面处理技术有限公司

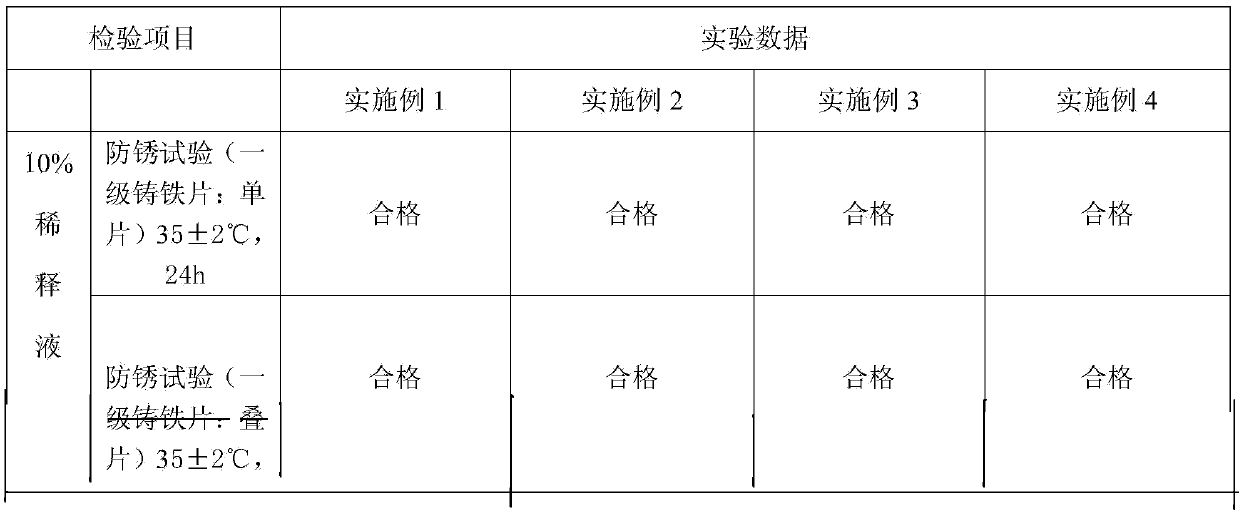

Water-based cutting fluid for vermicular cast iron processing, and dilution solution thereof

ActiveCN104877749AImprove the lubrication effectImprove cooling effectLubricant compositionWater basedNitro compound

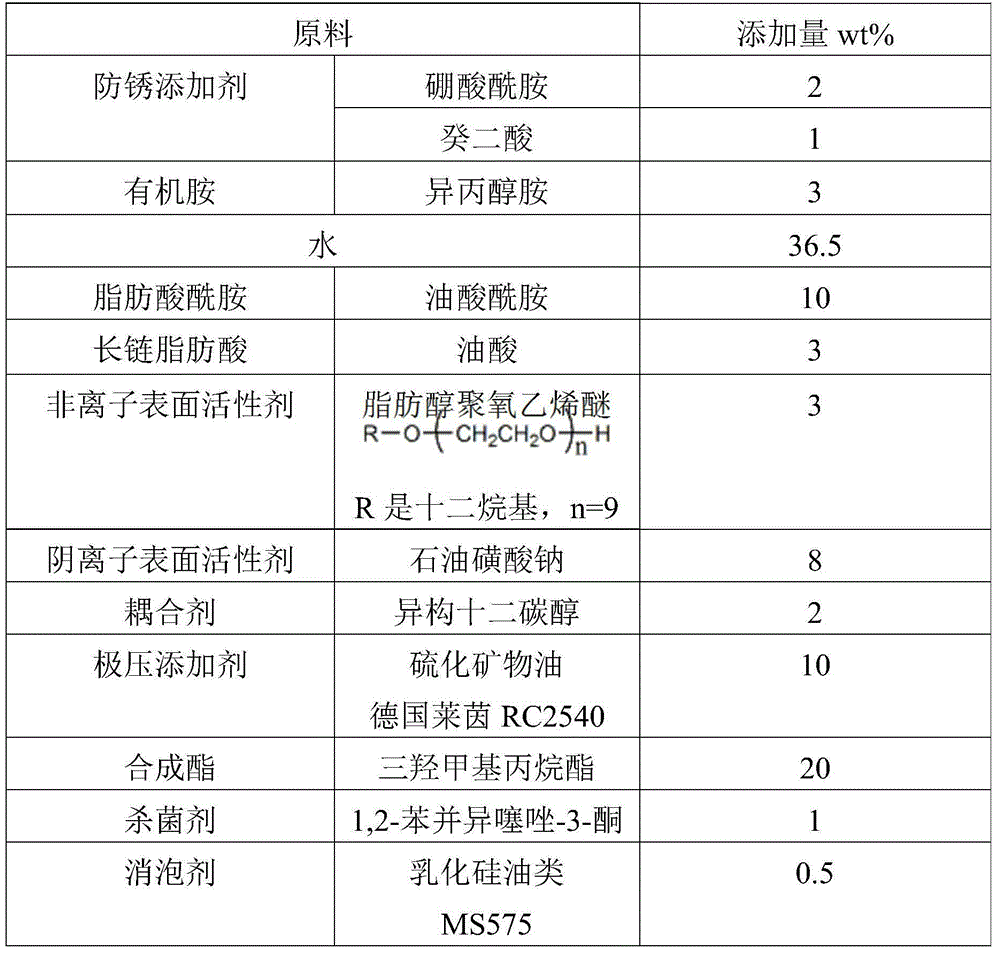

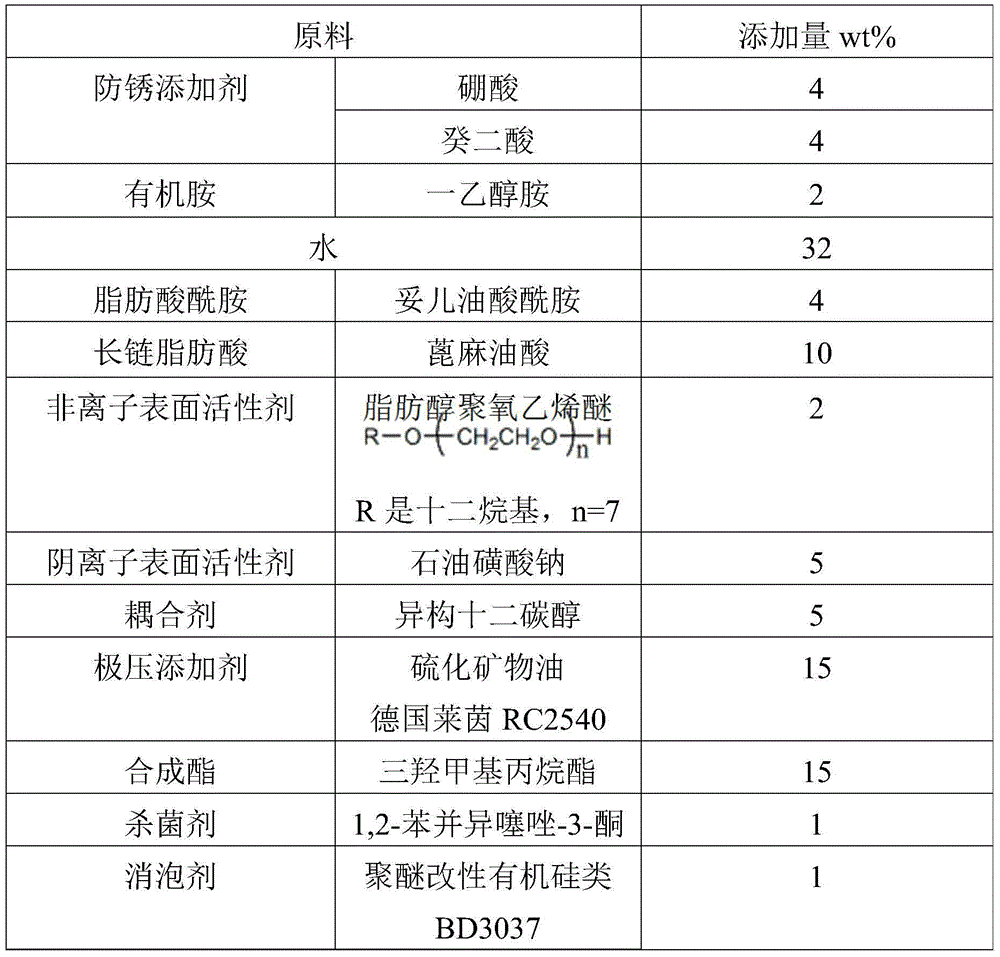

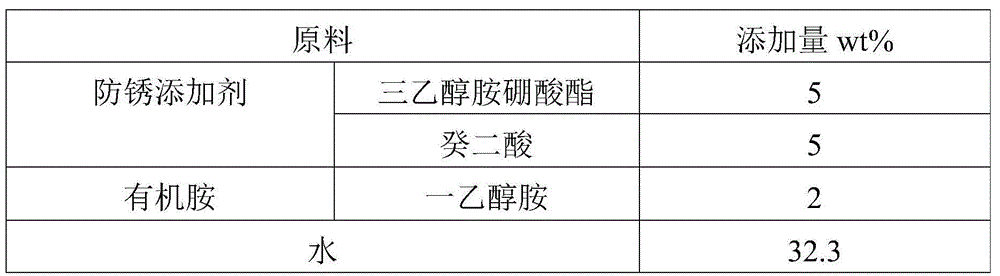

The present invention discloses a water-based cutting fluid for vermicular cast iron processing, and a dilution solution thereof. The water based cutting fluid comprises 3-10% of an anti-rust additive, 4-10% of fatty acid amide, 2-3% of organic amine, 3-10% of long-chain fatty acid, 2-5% of fatty alcohol polyoxyethylene ether, 5-8% of petroleum sodium sulfonate, 1-5% of a coupling agent, 10-15% of an extreme pressure additive, 15-20% of a synthetic ester, 1-2% of a sterilization agent, 0.5-1.0% of an anti-forming agent, and 32-45% of water, wherein the anti-rust additive is a boric acid anti-rust additive and dicarboxylic acid, and the coupling agent is a fatty alcohol and / or aliphatic ether. The water-based cutting fluid of the present invention has characteristics of good lubrication performance, good cooling performance, good anti-rust property, no chlorine, diamine, nitrite and other nitro compounds, no environmental pollution, no irritating odor, easy cutting, easy powder settlement, and effective cutter service life prolonging.

Owner:上海德润宝特种润滑剂有限公司

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

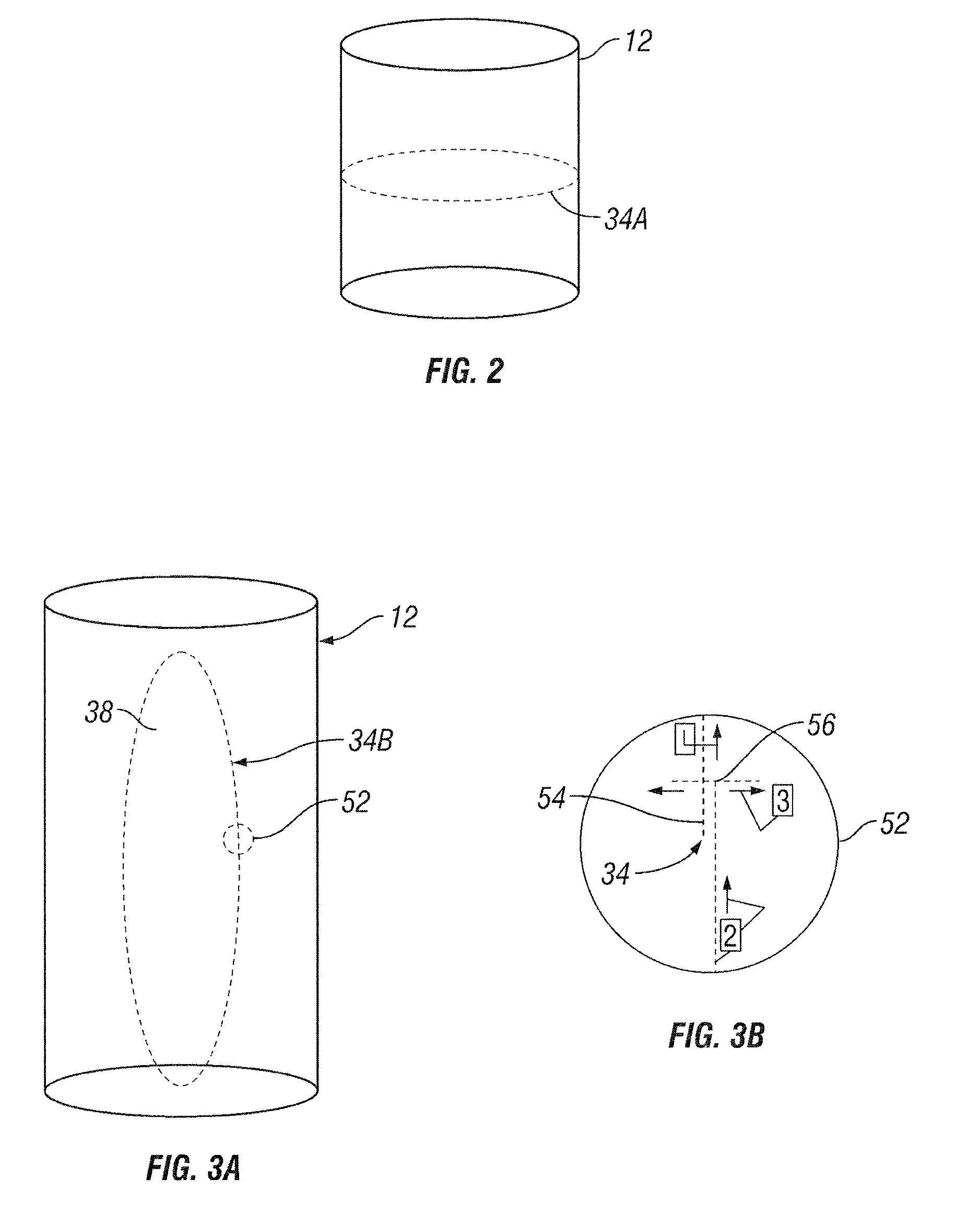

Abrasive jet cutting system and method for cutting wellbore tubulars

An embodiment of a cutting tool positionable in a tubular for creating a cut in a tubular includes a body securable within the tubular and a cutting head having a nozzle for discharging a pressurized cutting fluid, wherein the cutting head is rotationally and axially moveable relative to the body. The cutting tool may further include one or more of a positioning mechanism, a linear actuator in connection with the cutting head, a rotary actuator in connection with the cutting head, a cutting fluid pump, a mechanism for mixing a fluid and an abrasive to form the abrasive cutting fluid, and reservoirs for storing the abrasive cutting fluid or for storing a fluid and the abrasive separately.

Owner:SCHLUMBERGER TECH CORP

Cutting oil and preparation method thereof

InactiveCN102031190AImprove low temperature performanceImprove filtering effectBase-materialsEcological environmentEnvironmental index

The invention provides environmentally-friendly efficient atomization cutting oil, which comprises the following components in percentage by weight: 20 to 40 percent of synthetic ester, 60 to 80 percent of vegetable oil, 0 to 3 percent of antioxidant, 0 to 2 percent of anti-rusting agent, 0 to 5 percent of extreme pressure abrasion-resistant agent and 0 to 1 percent of metal passivator. The synthetic ester and the vegetable oil are matched and used base oil, so the cutting oil has the advantages of good lubricating property and biodegradability, resource recycle, no toxicity and the like, has low toxin and low harm to the human body and the ecological environment, meets the requirements of related environmental indexes, has good low-temperature performance and oxidation stability and strong universality, is suitable for metal cutting and processing of most materials, is particularly special cutting oil for modern advanced semi-dry and trace lubrication processing and development, and is mainly used for oil mist lubrication; and the gas and liquid two-phase oil mist can play a role in lubricating, take away a large amount of heat, reduce the consumption of cutting fluid, lower the cost and reduce the discharge of waste solution, and is favorable for environmental protection.

Owner:东莞太平洋博高润滑油有限公司

Water-based response type multifunctional metal machining liquid and preparation method thereof

InactiveCN101519622AImprove cooling effectImprove the lubrication effectLubricant compositionChemistryTriethanolamine

The invention relates to a water-based response type multifunctional metal machining liquid, the composition formula of which comprises a surfactant, a solvent, plant oleic acid, triethanolamine, sodium salts with a corrosion inhibitive function, an inhibiter, dimeric dibasic acid, a defoamer, a preservative, deionized water, defoamer 903, preservative 1227, deionized water, and the like. The metal machining liquid is nontoxic, harmless and pollution-free, has no harm to human bodies or corrosion to metal surfaces, has no abnormal taste or deterioration after long time usage, and has superior auxiliary machining functions of cooling, lubricating, cleaning, extreme pressure, rust prevention, and the like. The metal machining liquid can be used for the metal working of devices for machining, milling, planning, drilling, boring, punching, wire-electrode cutting, and the like, and is especially suitable for high-grade numerical control machines. The machining liquid has high physical stability and small surface mightiness, and can effectively reduce the machining temperature, reduce the thermal deformation of workpieces and cutting tools, increase the abrasion resistance of the cutting tools, increase the machining precision and the surface finish quality of the workpieces to a great extent, effectively remove dirt on the surfaces of the workpieces, and prolong the natural antirust time of the processed workpieces to be longer than 45 days.

Owner:天津市澳路浦润滑科技股份有限公司

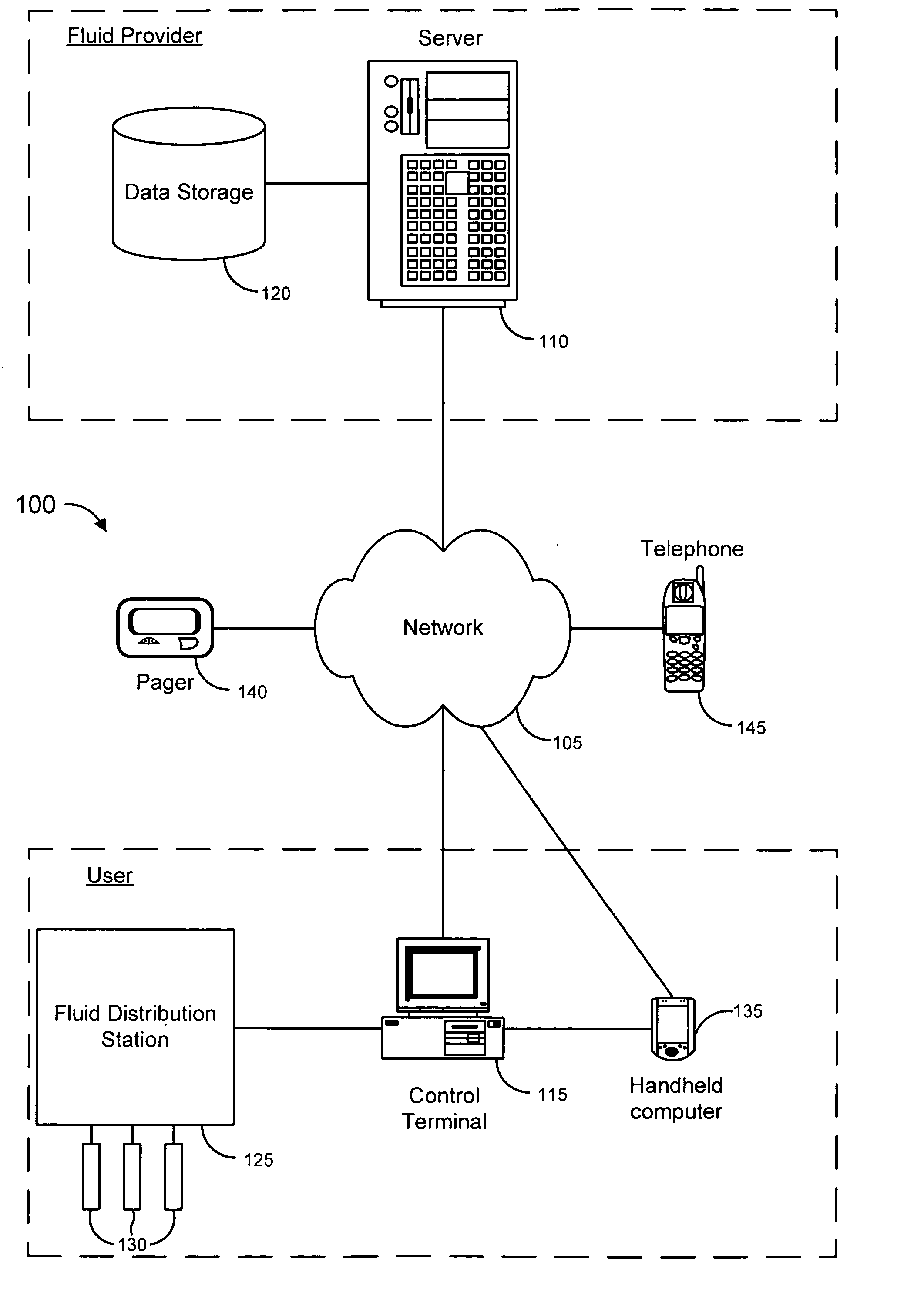

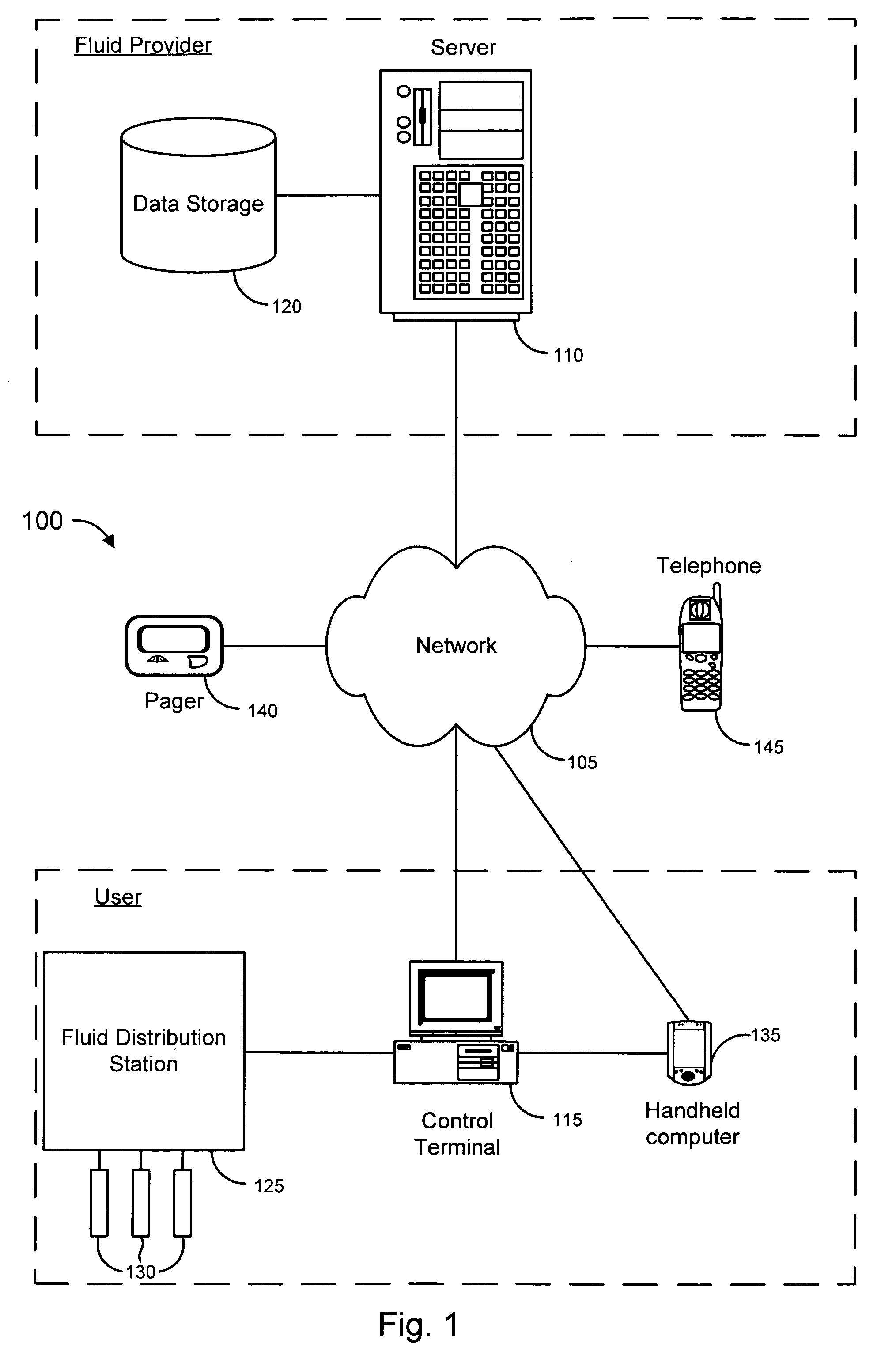

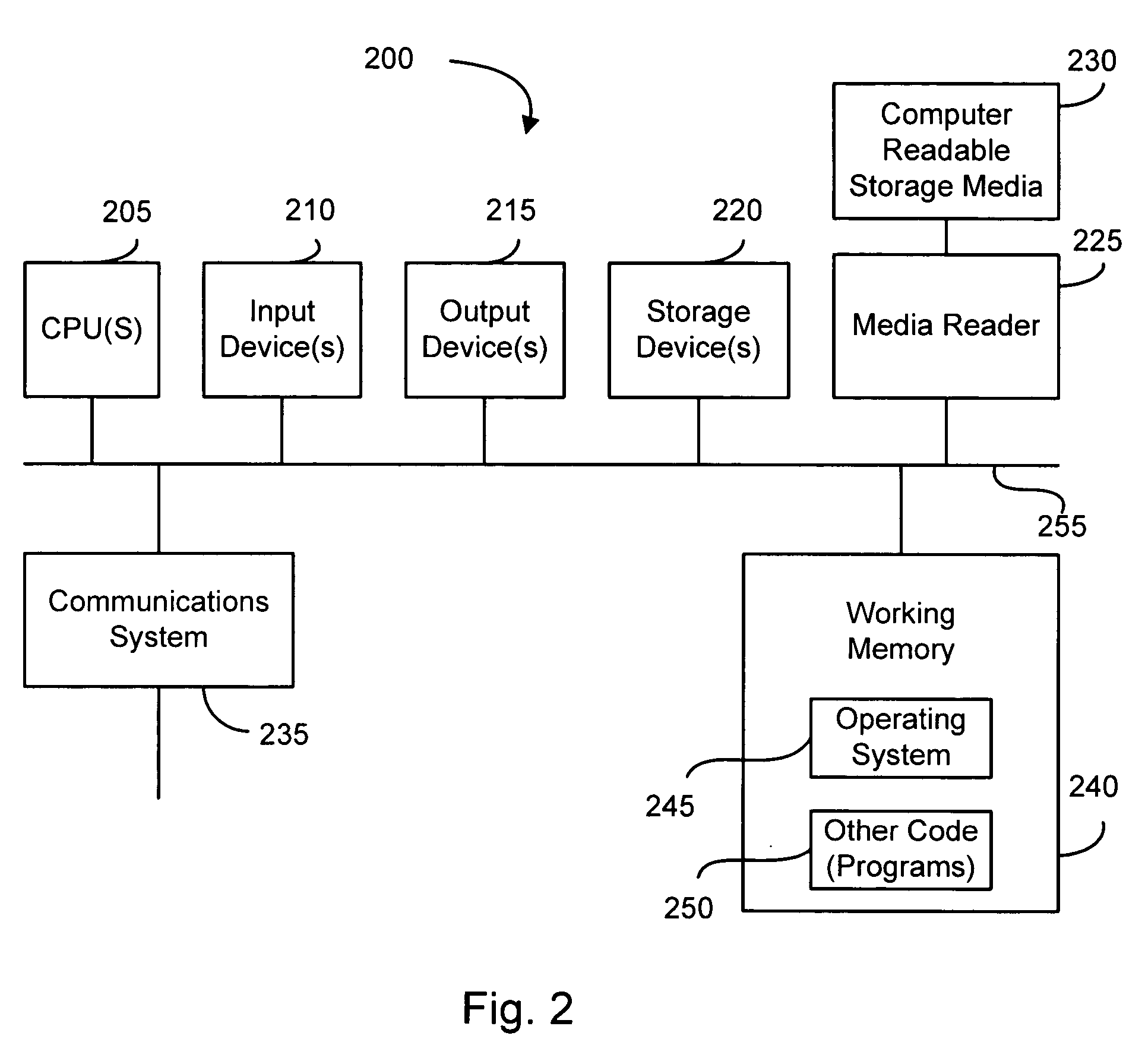

Systems and methods of fluid distribution

InactiveUS20050184084A1Facilitate efficient packagingReduce deliveryOpening closed containersBottle/container closureGeneral purposeOperational costs

Embodiments of the invention provide novel containers, systems, methods and software products to facilitate efficient delivery, packaging and / or dispensing of fluids, and in particular, industrial fluids. Such industrial fluids can include, without limitation, petroleum-based fluids, automotive fluids, industrial lubricants, cutting fluids, cooling fluids, and the like. In accordance with certain embodiments of the invention, fluids may be delivered in transportable and / or ready-to-dispense containers, eliminating the need for expensive, custom delivery solutions. Advantageously, therefore, such containers may be delivered using general purpose delivery vehicles, allowing delivery to be outsourced to a third party (if desired), and reducing the capital expenditures and operating costs fluid suppliers experience in securing delivery of their supplied fluids. Moreover, receipt of fluids packaged in such containers allows the users of fluids to forego expensive equipment installation and provides a more flexible environment for the use of fluids.

Owner:THERMATECH SYST

Cutting method

ActiveUS20150262881A1Easy to disassembleLow ductilitySemiconductor/solid-state device manufacturingFine working devicesEngineeringMechanical engineering

A cutting method for cutting by a cutting blade a workpiece which includes metal at least in a predetermined cutting position. The cutting method includes a cutting step of cutting by the cutting blade the predetermined cutting position of the workpiece while supplying a cutting fluid, containing an organic acid and an oxidizing agent, to a processing point at which the cutting blade cuts into the workpiece.

Owner:DISCO CORP

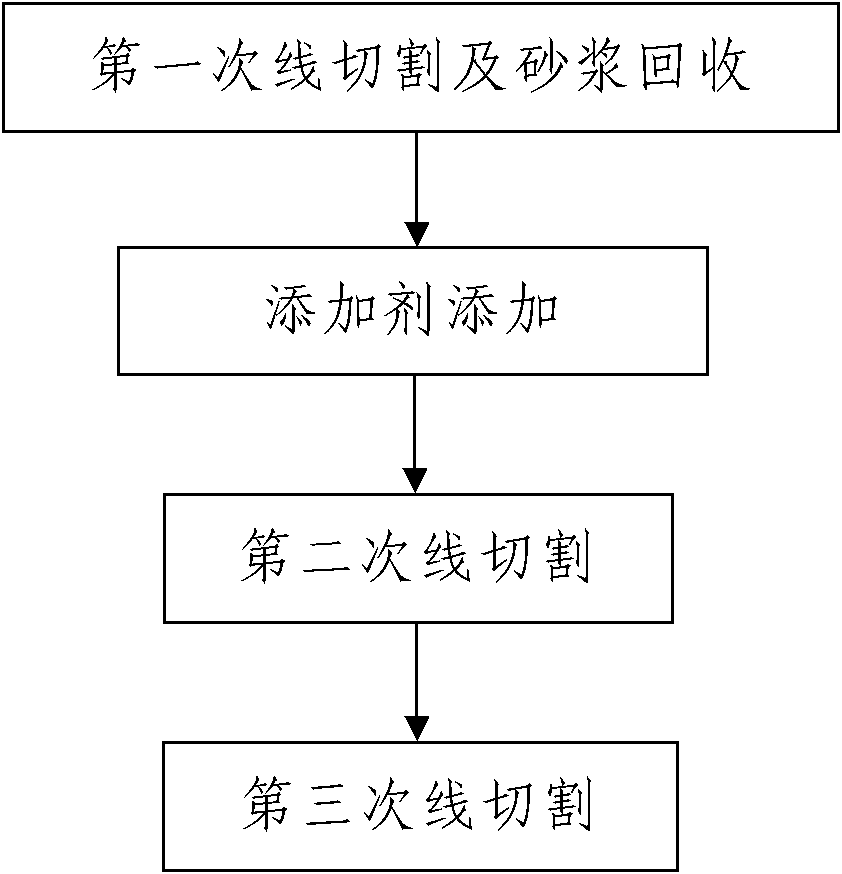

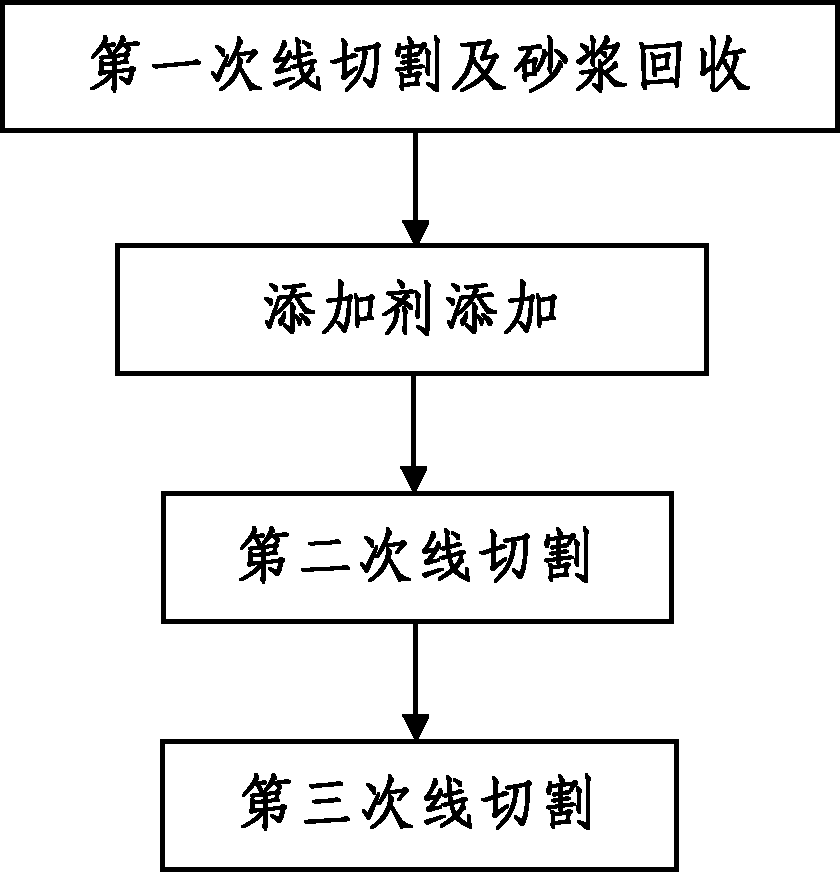

Additive for improving utilization ratio of silicon crystal line cutting mortar as well as preparation method and application method of addictive

InactiveCN102041138AIncrease profitReduce manufacturing costLubricant compositionAlcoholPolyethylene glycol

The invention discloses an additive for improving utilization ratio of silicon crystal line cutting mortar as well as a preparation method and application method of the addictive. The additive is composed of the following raw materials in percentage by weight: 50-96.5% of polyethylene glycol, 1-10% of penetrating agent, 1-20% of ether alcohol surfactant, 0.5-10% of extreme pressure resistant chelator and 1-10% of assistant detergent. The preparation method comprises the steps of weighing and mixing the raw materials. The application process comprises the following steps: 1. carrying out the first line cutting the mortar and recovering the mortar; 2. adding the additive: adding the additive to the recovered mortar after the first linear cutting based on the weight ratio of 1:100 plus / minus 10, and then evenly stirring; 3. carrying out the second line cutting; and 4. carrying out the third line cutting and recovering the mortar. The addictive is reasonable in design and has good use effect and practicable value, addictive preparation and use processes are simple, operation is convenient, and the defects of the existing silicon wafer cutting fluid such as more severe pollution, higher rejection rate, high production cost, low utilization ratio and the like can be overcome.

Owner:XIAN HUAJING ELECTRONICS TECH

Metal cutting fluid containing graphene dispersion solution and preparation method thereof

The invention relates to a metal cutting fluid containing a graphene dispersion solution and a preparation method thereof. The metal cutting fluid is composed of the following raw materials: 0.2-2.0% of lubricating additive, 5-7% of rust inhibitor, 0.2-0.5% of corrosion inhibitor, 0.05-0.15% of hard water resisting agent, 15-20% of lubricant and the balance of water. The lubricating additive is the graphene dispersion solution. The metal cutting fluid has favorable lubricating property and antirust property; by using the water base as the carrier, the metal cutting fluid is free of base oil; and the production process has the advantages of low energy consumption and low production cost, and is simple to operate.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com