Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Guaranteed anti-rust performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

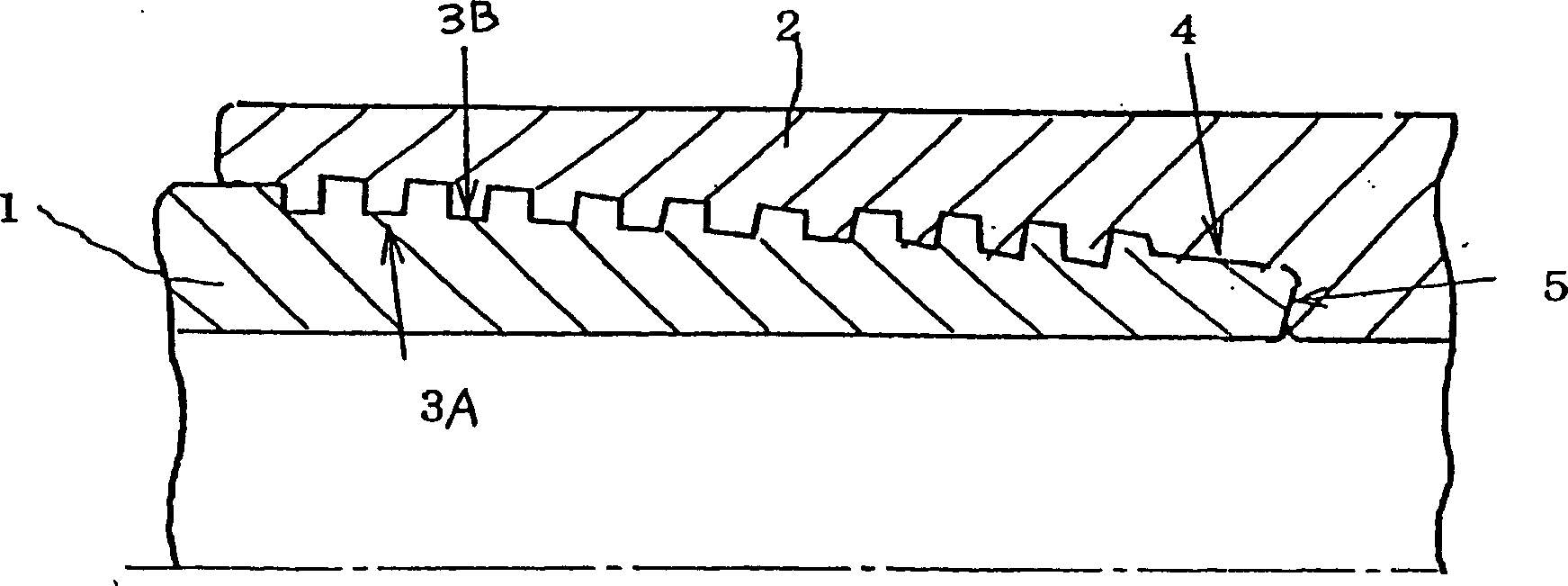

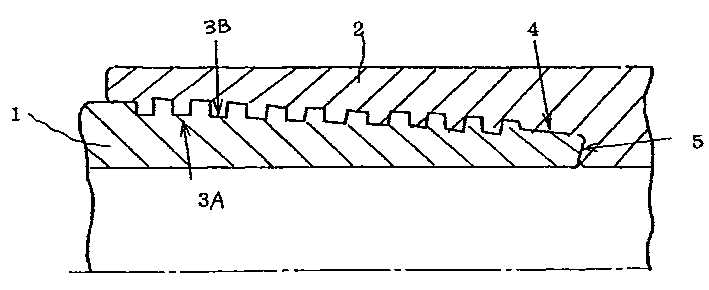

Threaded joint for steel pipe with excellent seizure and corrosion resistances

InactiveCN1488051AImprove wear resistanceGuaranteed air tightnessDrilling rodsCorrosion preventionZinc alloysAir tightness

A threaded joint for steel pipe, comprising a pin and a box allowed to be fitted to each other, wherein a porous zinc or zinc alloy layer as a lower layer by a projection plating method and a solid lubrication film (film containing lubricating powder in organic or inorganic binder) or a liquid lubricating film not containing heavy metal powder (example: liquid film formed mainly of high base organic metallic salt such as high base sulphonate) as an upper layer are provided on the thread part and the metal contact part without thread of at least either of the pin and box, whereby the threaded joint can provide excellent seizure resistance, corrosion resistance, and airtightness even after exposed to high temperature, and is allowed to be tightened and loosened repeatedly in a hot oil well without using compound grease containing heavy metal powder.

Owner:NIPPON STEEL CORP

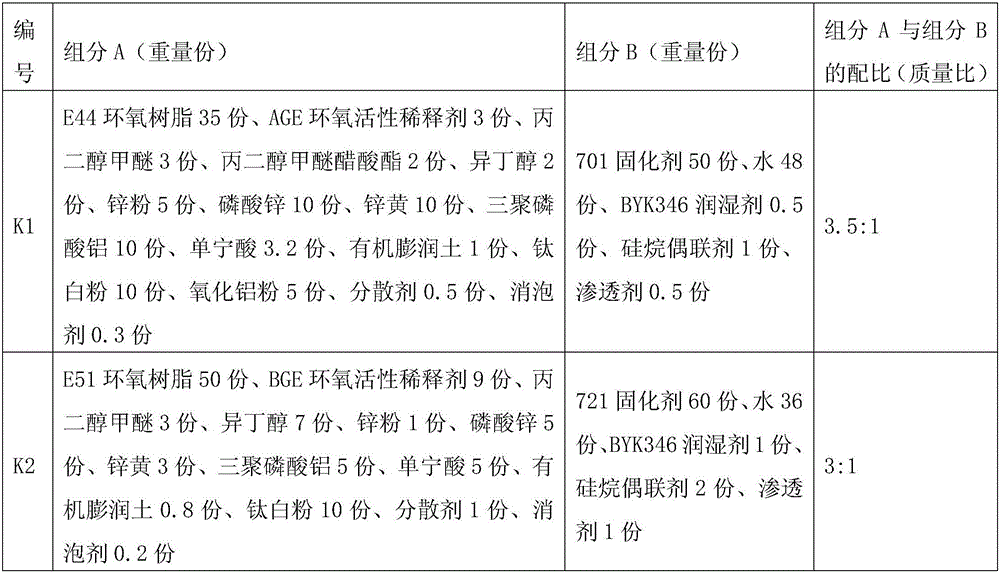

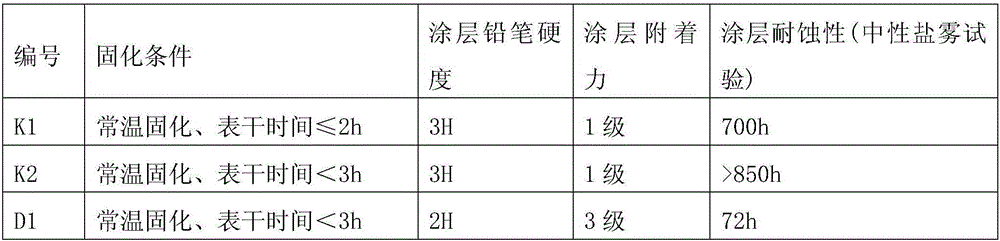

Antirust coating and preparation method thereof

ActiveCN105885644AGuaranteed anti-rust performanceReduce manufacturing costAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention belongs to the technical field of coating and in particular designs antirust coating and a preparation method thereof. The antirust coating is prepared from a component A and a component B according to the mass ratio of (3 to 4): 1, wherein the component A is prepared from the following components in parts by weight: 20 to 50 parts of epoxy resin, 1 to 10 parts of an epoxy diluting agent, 6 to 20 parts of a co-solvent, 0 to 15 parts of zinc powder, 0 to 20 parts of zinc phosphate, 0 to 15 parts of zinc yellow, 0 to 20 parts of aluminum tripolyphosphate, 0 to 5 parts of tannic acid, 0.8 to 1 part of organic bentonite, 0 to 30 parts of pigment, 0.1 to 2 parts of a dispersant and 0.1 to 2 parts of a de-foaming agent; the component B is prepared from the following components in parts by weight: 20 to 70 parts of a curing agent, 30 to 50 parts of water, 0.5 to 2 parts of a wetting agent, 0 to 2 parts of a silane coupling agent and 0 to 2 parts of a penetrating agent. The coating provided by the invention can be used for corrosion prevention on a steel-structure material with rusts and a paint film, can realize coating on the rusts and curing at a room temperature, and is more convenient for construction; the construction cost is reduced.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

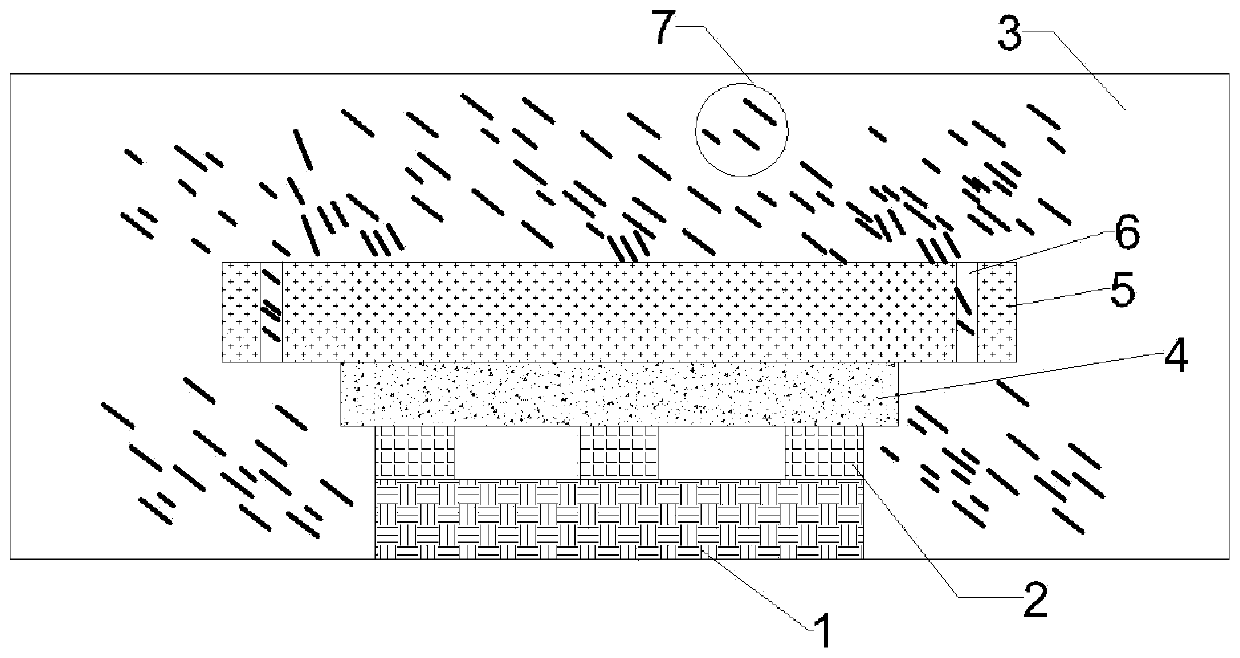

Polishing treatment method of surface of back plate of target material

ActiveCN110877235ASolve problems with a certain orientationNot easy to rustGrinding/polishing apparatusSputteringPolishing

The invention provides a polishing treatment method of the surface of a back plate of a target material. The polishing treatment method of the surface of the back plate of the target material comprises the steps that a target material assembly is inversely arranged in a magnetic polishing device, the back plate of the target material faces upward, and magnetic polishing treatment is carried out. The polishing efficiency is high, polishing lines on the surface of the back plate of the target material are uniform and disordered after polishing, the back plate of the target material is not proneto rusting, rust and burrs in holes of the back plate of the target material can be removed cleanly, the requirements of sputtering of the back plate of the target material are well met, and relatively high industrial application value is achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

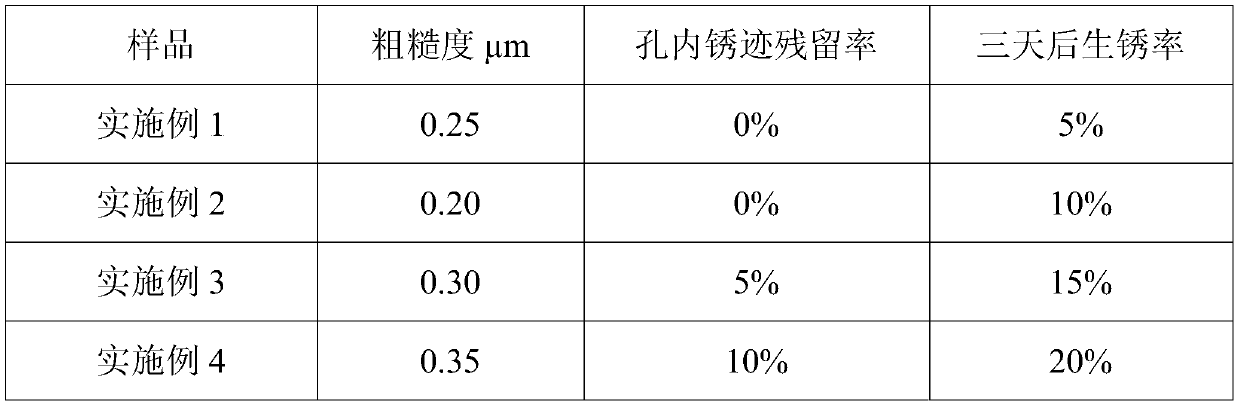

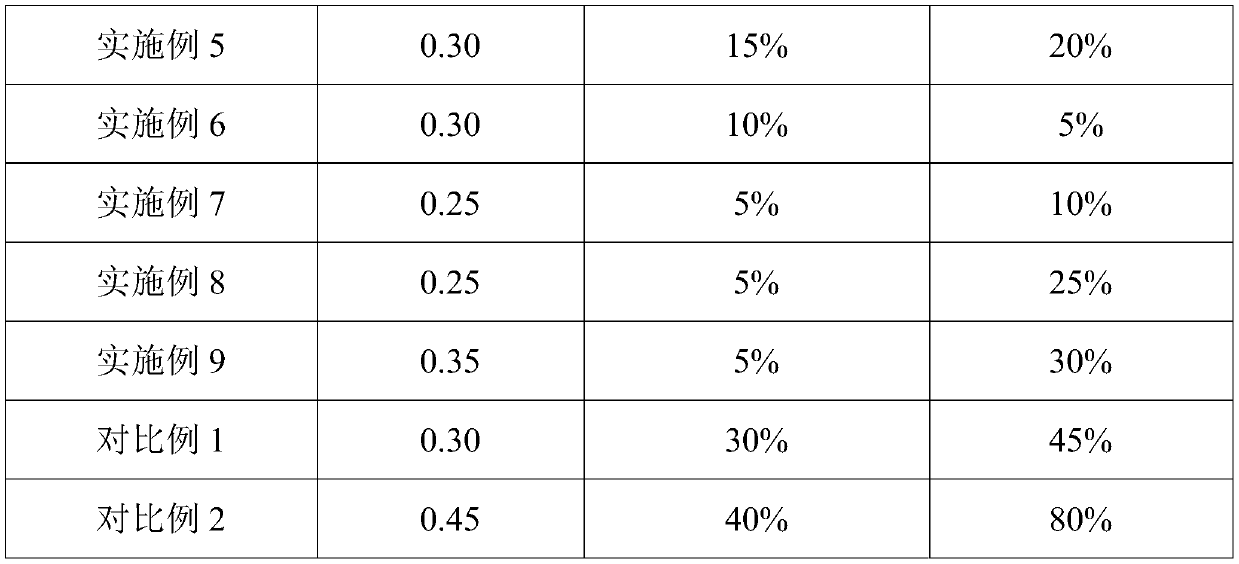

Environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and preparation method of protective paint

InactiveCN106928791AValid setLow VOC contentAnti-corrosive paintsPolyester coatingsWater basedMechanical equipment

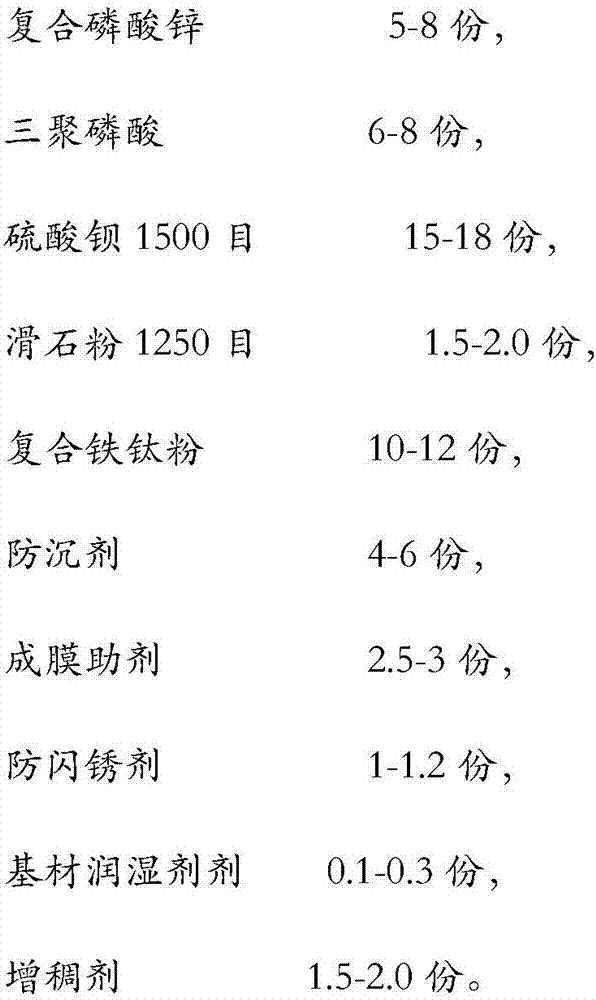

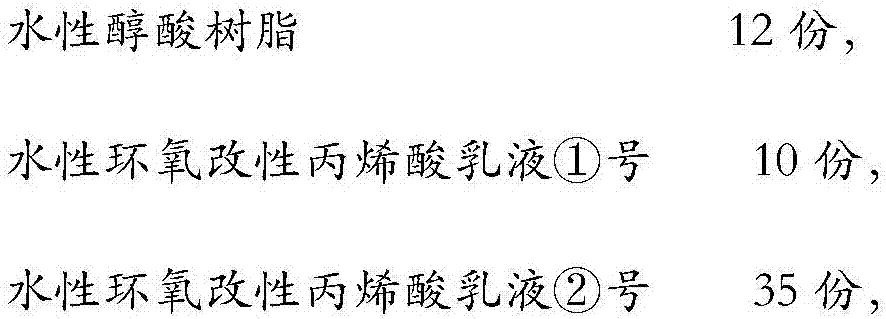

The invention discloses environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and a preparation method of the protective paint. The environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying the mechanical equipment comprises the following components in parts by weight: 10-12 parts of water-based alkyd resin, 40-47 parts of acrylic emulsion,20-25 parts of water, 1.8-2.4 parts of a pH (potential of hydrogen) regulator, 0.3-0.6 parts of a dispersant, 0.1-0.15 parts of a defoaming agent, 4.0-5.0 parts of rutile titanium dioxide, 0.4-0.5 parts of carbon black, 5-8 parts of compound zinc phosphate, triphosphoric acid, barium sulfate, talcum powder, iron-titanium compound powder, an anti-settling agent, a film forming assistant, a flash-rust preventive, a base material wetting agent and a thickening agent. The protective paint has excellent chemical properties such as corrosion resistance and water resistance, and is high in drying rate, excellent in low-temperature film forming effect, high in plumpness and good in weather resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

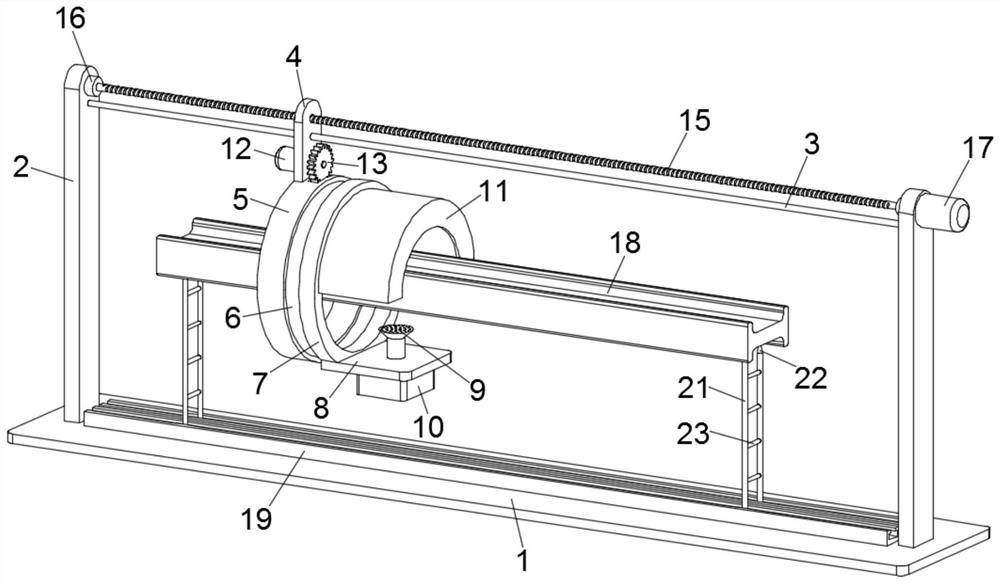

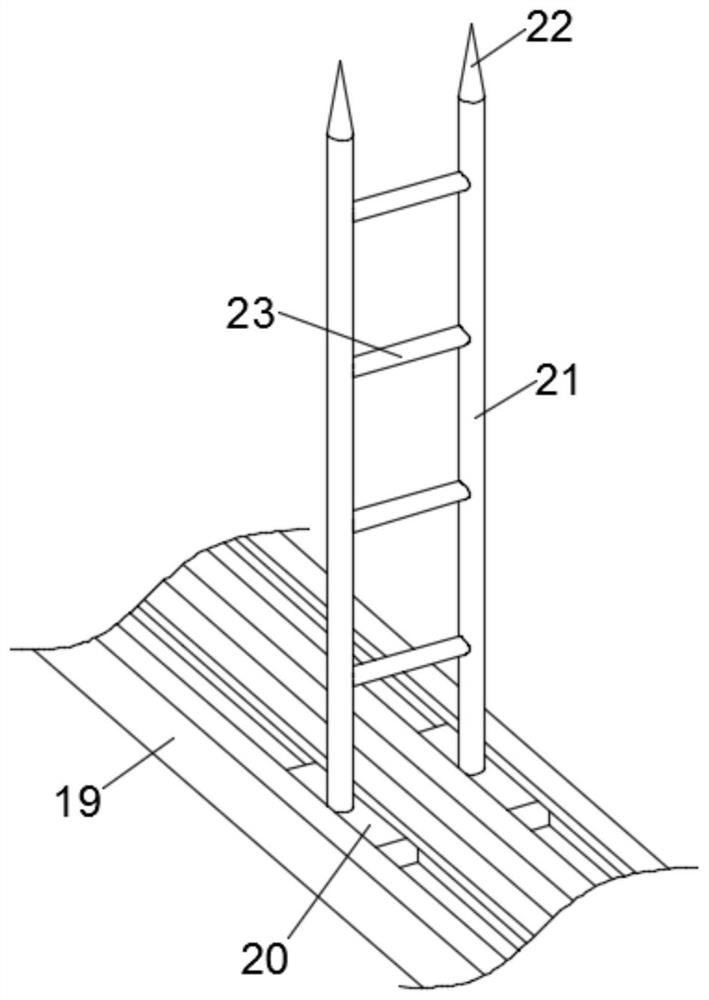

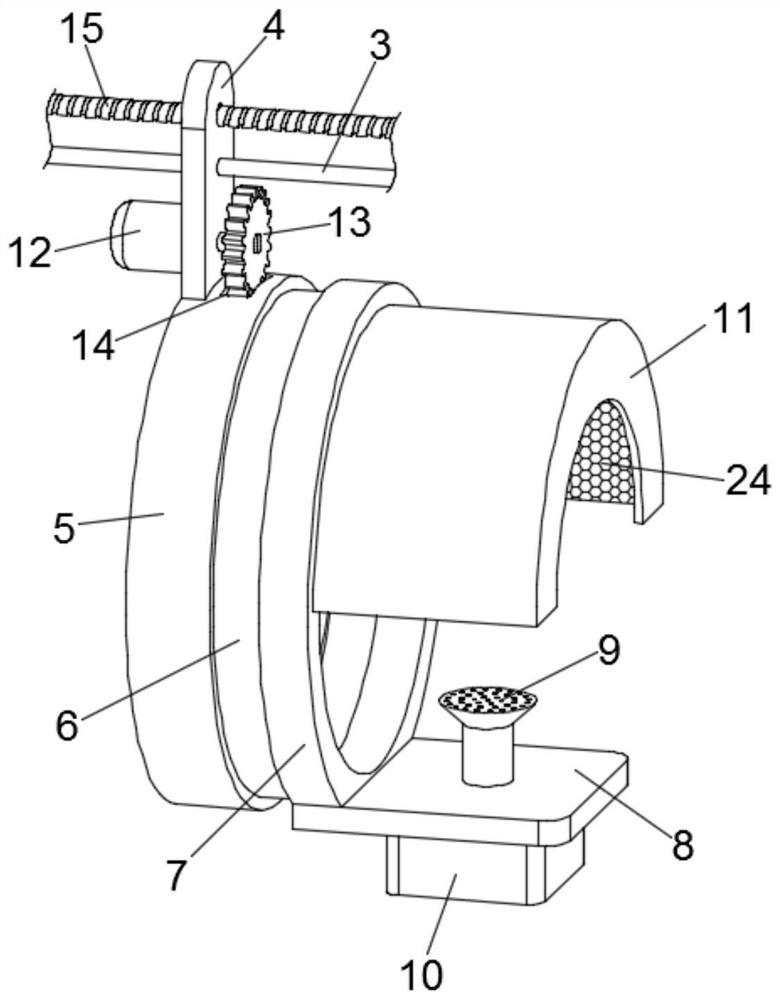

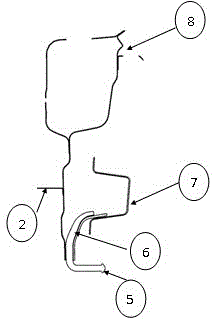

Steel structure paint spraying device

InactiveCN112138907AUniform spraying effectImprove spraying efficiencySpraying apparatusManufacturing engineeringSlide plate

The invention discloses a steel structure paint spraying device. The steel structure paint spraying device comprises a base, supporting frames are vertically fixed to the two ends of the base, a guidecolumn is horizontally fixed between the supporting frames, the guide column is slidably provided with a sliding plate in a sleeved mode, and horizontal-moving mechanisms are further installed on thesupporting frames; a fixed ring sleeve is connected to the lower end of the sliding plate, a rotating ring is rotationally arranged in the fixed ring sleeve in an embedded mode, a rotating motor is installed on the sliding plate, a gear is rotationally installed at the output end of the rotating motor, and a gear ring is arranged on the rotating ring; a mounting plate is fixed to the rotating ring, a spray head and a paint sprayer are arranged on the mounting plate, and a shielding cover is arranged on the opposite side of the spray head; and a plurality of sliding rails are fixed to the base, and supporting columns are slidably installed in the sliding rails. The spray head in the steel structure paint spraying device can rotate around a steel structure in the circumferential direction for spraying and horizontally move along the steel structure, so that omni-directional paint spraying of the steel structure is achieved, no dead angle exists in the paint spraying process, and the spraying effect is uniform and consistent; and the shielding cover is arranged on the opposite side of the spray head to block paint sprayed from the spray head, so that the paint is prevented from splashing everywhere.

Owner:冯剑茹

Multifunctional barium-free anti-rusting oil and preparation process thereof

InactiveCN103602492AConcentration is easy to monitor and adjustGuaranteed anti-rust performanceLubricant compositionSulfonateCresol

The invention discloses multifunctional barium-free anti-rusting oil. The multifunctional barium-free anti-rusting oil comprises the following components in percentage by weight: 8%-10% of petroleum calcium sulfonate, 4%-6% of petroleum sodium sulfonate, 2%-5% of S-80, 0.1%-0.5% of T501 / 2, 6 di-tert-butyl p-cresol, 0.3%-0.5% of T706 benzotriazole, 10%-20% of 32# base oil, and 60%-70% of a refined petroleum solvent. The preparation process of the multifunctional barium-free anti-rusting oil comprises the following steps of: adding the refined base oil, the petroleum calcium sulfonate, the S-80 and the petroleum sodium sulfonate into a reaction kettle; heating to 90 DEG C-95 DEG C, cooling to 70 DEG C-80 DEG C after dissolving uniformly, adding the T706 benzotriazole and the T501 / 2, 6 di-tert-butyl p-cresol for uniformly dissolving, preserving the heat for stirring for over half an hour; and finally, filtering and filling into a barrel after diluting by using the refined petroleum solvent. Compared with the prior art, the multifunctional barium-free anti-rusting oil disclosed by the invention has the advantages that anti-rusting requirements of various metals can be satisfied at the same time, an oil film is thin, easy to clean, and the multifunctional barium-free anti-rusting oil is compatible with automobile lubricating oil, can be used for oil assembling, and is barium-free and environment-friendly.

Owner:SHANGHAI THRIVING SPECIAL OIL SCI & TECH

Two-component silicate coating

ActiveCN107446392ASolve instabilityImprove performanceAlkali metal silicate coatingsAnti-corrosive paintsPigmentMaterials science

The invention belongs to the field of coatings. Corresponding products can be applicable to industrial corrosion prevention and architectural ornament. The invention discloses a multifunctional environmental-friendly inorganic silicate coating which comprises a component A and a component B, wherein the component A comprises pigments; the component B comprises a silicate solution and a modifier. The coating is excellent in stability and excellent in film-forming effect.

Owner:珠海市威旗防腐科技股份有限公司

Settleability water base grinding fluid and preparation method thereof

ActiveCN103131331AReduce surface tensionReduce pollutionAqueous dispersionsEthylenediamineWater based

The invention provides settleability water base grinding fluid and a preparation method thereof. The settleability water base grinding fluid comprises, by weight, the following ingredients: 5-20% of settling agents, 25-60% of antirust agents, 15-40% of lubricating agents, 1-3% of sterilizing agents and the balance water. The settling agents are selected from one or more mixtures of polyethylene dichloro ethyl ether tetramethyl ethylenediamine, polyglycerol and ethylene glycol butyl ether (EGBE). The settleability composite grinding fluid has the advantages of being good in settleability, rapid in defoaming, good in antirust effect, long in service life and high in comprehensive performance cost ratio.

Owner:广东恒昌科技润滑油有限公司

Aerosol can type metal mold rust inhibitor and manufacturing method thereof

InactiveCN101967315AReplacement effect is goodStrong rust resistanceAnti-corrosive paintsKeroseneLanolin

The invention discloses an aerosol can type metal mold rust inhibitor with stable thermal property and long rust-proof life, which uses the following raw materials in parts by weight: 40-70 parts of barium petroleum sulfonate, 30-50 parts of zinc naphthenate, 5-10 parts of lanolin magnesium soap, 10-25 parts of rosin, 30-50 parts of N32 machine oil, 80-120 parts of turpentine oil and 550-675 parts of aviation kerosene. The manufacturing method is carried out according to the following steps: a) firstly stirring the measured rosin in the turpentine oil in a stainless steel container, and stirring till being transparent; b) stirring the measured barium petroleum sulfonate and the lanolin magnesium soap in part of the aviation kerosene in another stainless steel container, and stirring till being uniform and translucent; c) adding the remaining aviation kerosene into a reaction kettle, leading the rotational speed to be 60 turns / min, sequentially slowly adding the measured zinc naphthenate, the N32 machine oil and preparations prepared by the steps a) and b) into the reaction kettle, and stirring till being dark brown, uniform and translucent liquid.

Owner:DALIAN SANDAAOKE CHEM

Aluminized steel fastener type scaffold steel pipe and preparation method thereof

InactiveCN103343613AImprove toughnessEliminate surface brittle zonesHot-dipping/immersion processesScaffold accessoriesMicrometerAlloy

An aluminized steel fastener type scaffold steel pipe comprises a scaffold steel pipe body. The scaffold steel pipe body is sequentially divided into a base body layer, an iron-and-aluminum alloy layer and an aluminum layer from inside to outside, the thickness of the iron-and-aluminum alloy layer is 14-29 micrometers, and the thickness of the pure aluminum layer is 15-100 micrometers. A preparation method of the aluminized steel fastener type scaffold steel pipe includes the following steps of using a common seamless or seamed steep pipe as a workpiece, drying and unoiling the workpiece, acid cleaning and removing rust, washing, activating the surface, promoting permeation, drying, and rapidly aluminizing in an induction mode. The scaffold steel pipe with the aluminized surface is acquired through the steps. The mechanical performance of the aluminized steel fastener type scaffold steel pipe can be guaranteed, the excellent corrosion resistant performance is possessed, the service life is long, and using cost of the scaffold steep pipe is reduced.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

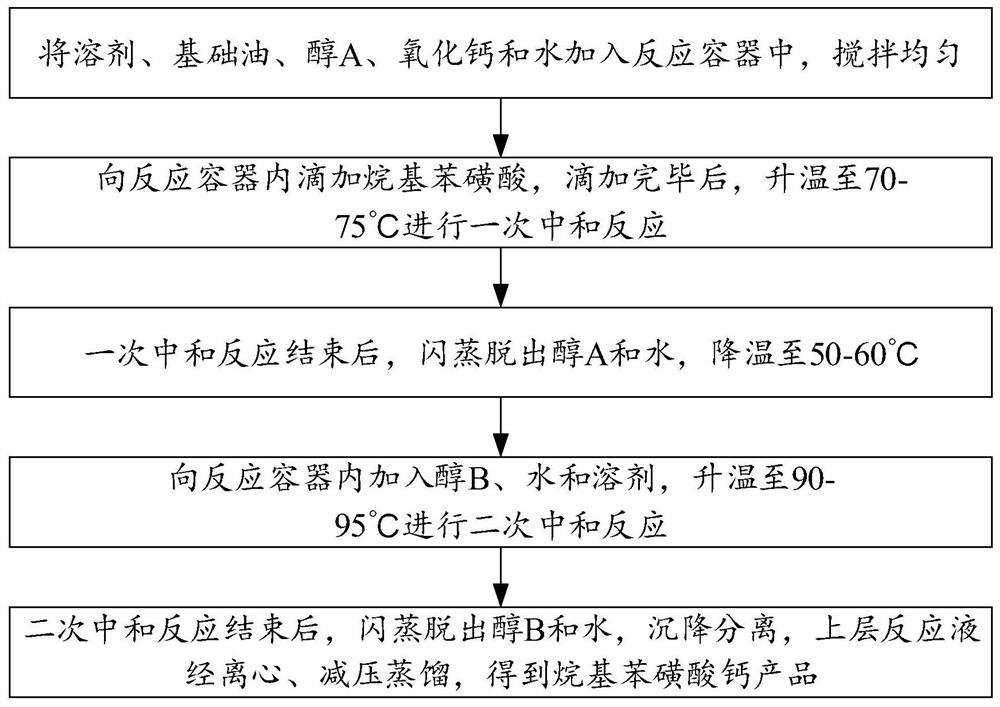

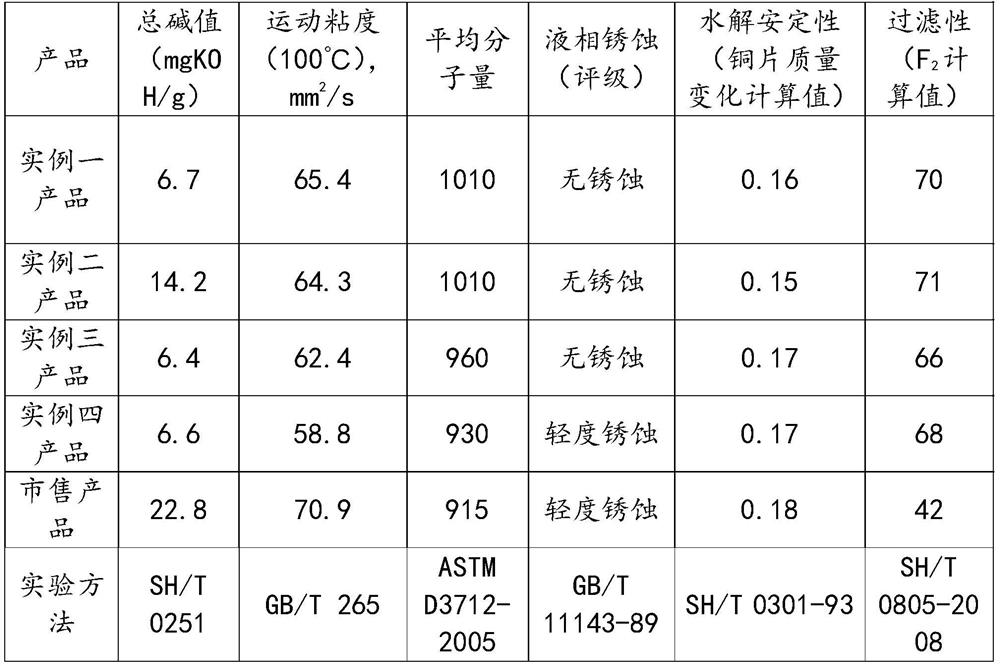

Preparation method of low-base-number and high-molecular-weight calcium alkyl benzene sulfonate antirust agent

InactiveCN111606830AHigh molecular weightGuaranteed anti-rust performanceOrganic compound preparationSulfonic acids salts preparationAlcoholDistillation

The invention discloses a preparation method of a low-base-number and high-molecular-weight calcium alkyl benzene sulfonate antirust agent, which comprises the following steps: adding a solvent, baseoil, alcohol A, calcium oxide and water into a reaction vessel, and uniformly stirring; dropwise adding alkyl benzene sulfonic acid into the reaction vessel, and after dropwise adding is completed, heating to 70-75 DEG C for a primary neutralization reaction; after the primary neutralization reaction is finished, performing flash evaporation to remove alcohol A and water, and reducing the temperature to 50-60 DEG C; adding alcohol B, water and a solvent into the reaction vessel, heating to 90-95 DEG C, and carrying out a secondary neutralization reaction; and after the secondary neutralizationreaction is finished, carrying out flash evaporation to remove alcohol B and water, carrying out settling separation, centrifuging the upper reaction solution, and carrying out reduced pressure distillation to obtain the calcium alkyl benzene sulfonate product. The molecular weight of the calcium alkyl benzene sulfonate antirust agent is relatively large, so that the antirust property of the calcium alkyl benzene sulfonate antirust agent in lubricating oil is ensured; and due to the ultralow base number of the product, the product is not easy to interact with acidic substances in the system,so that the universality of the product is better.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

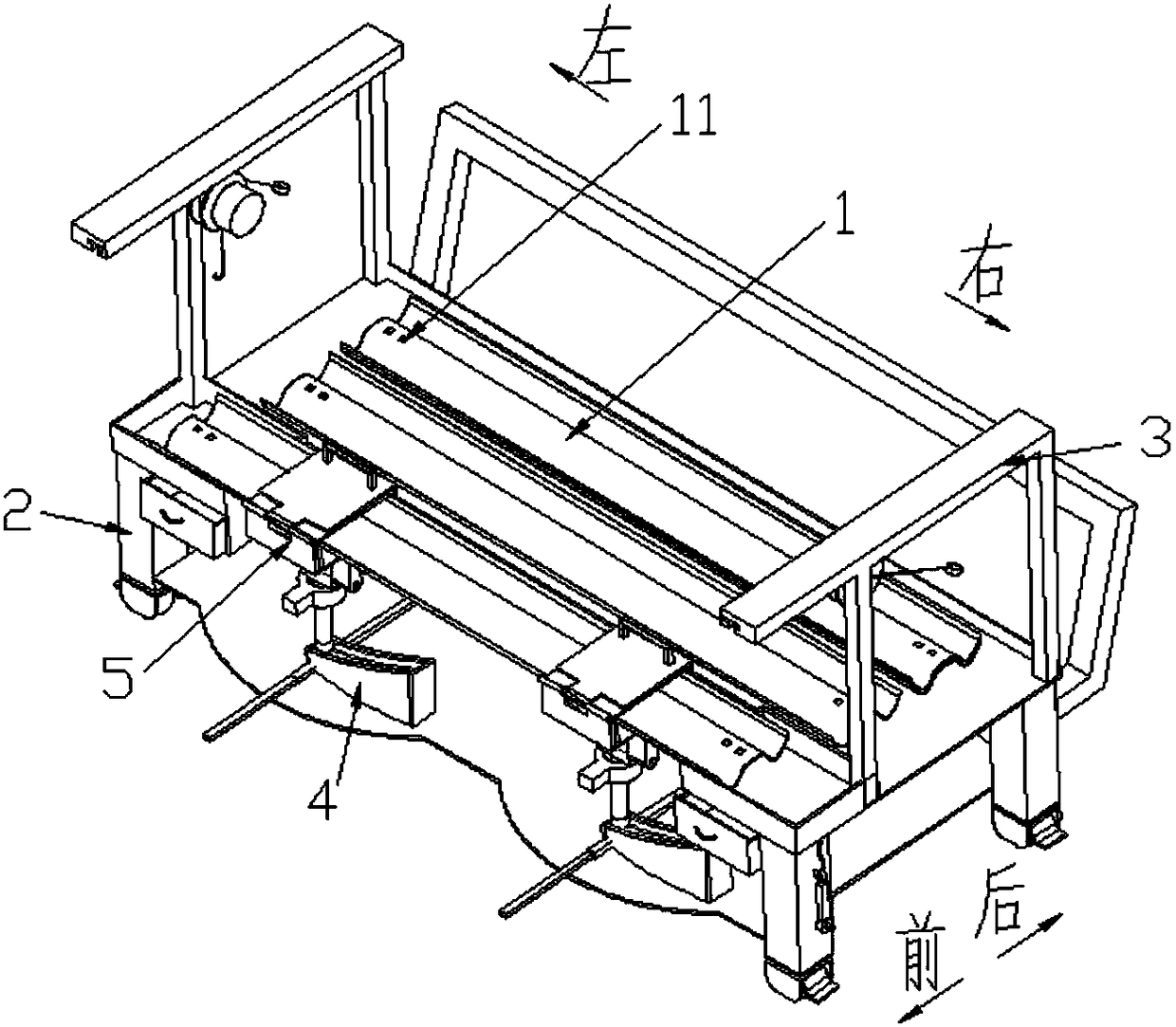

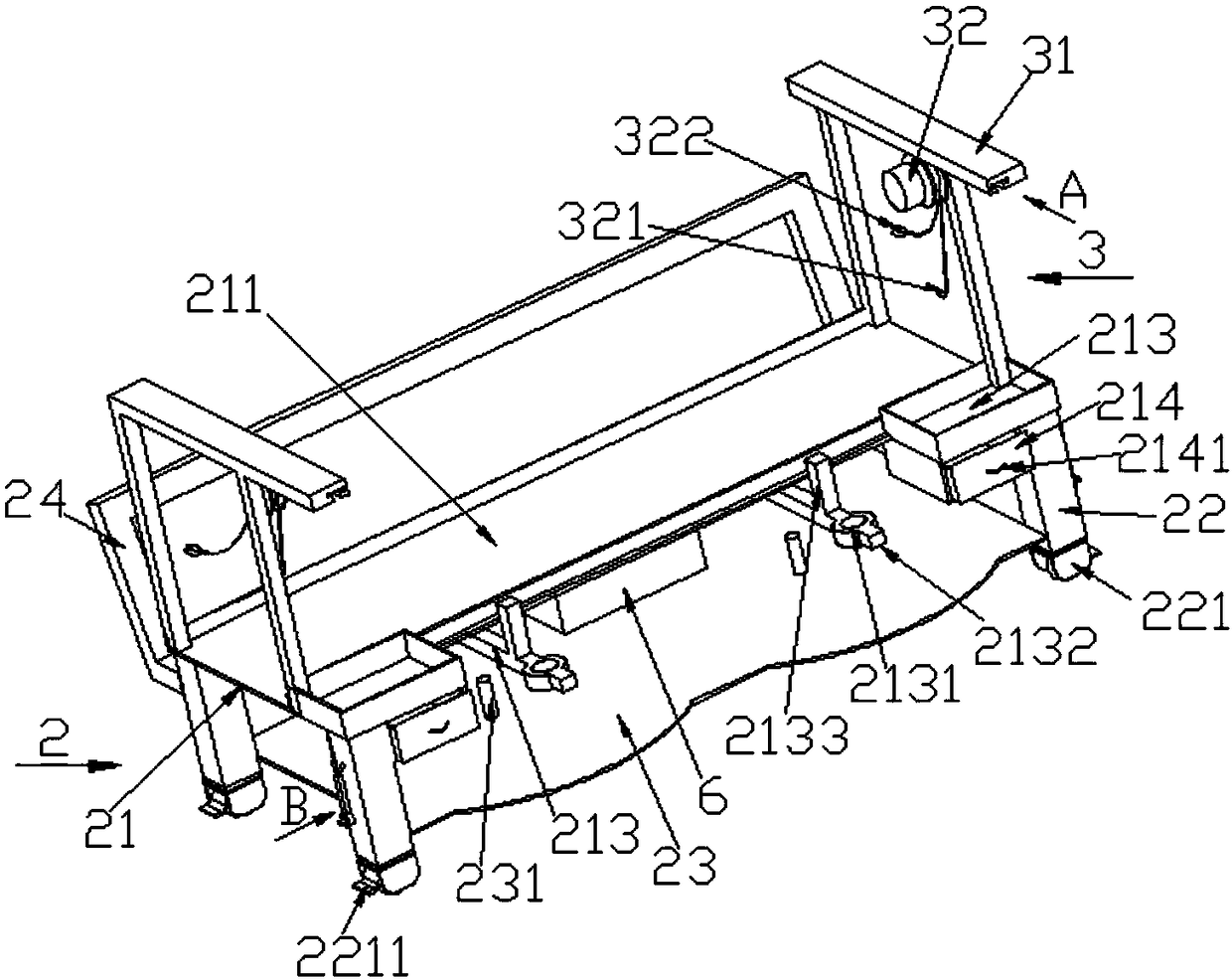

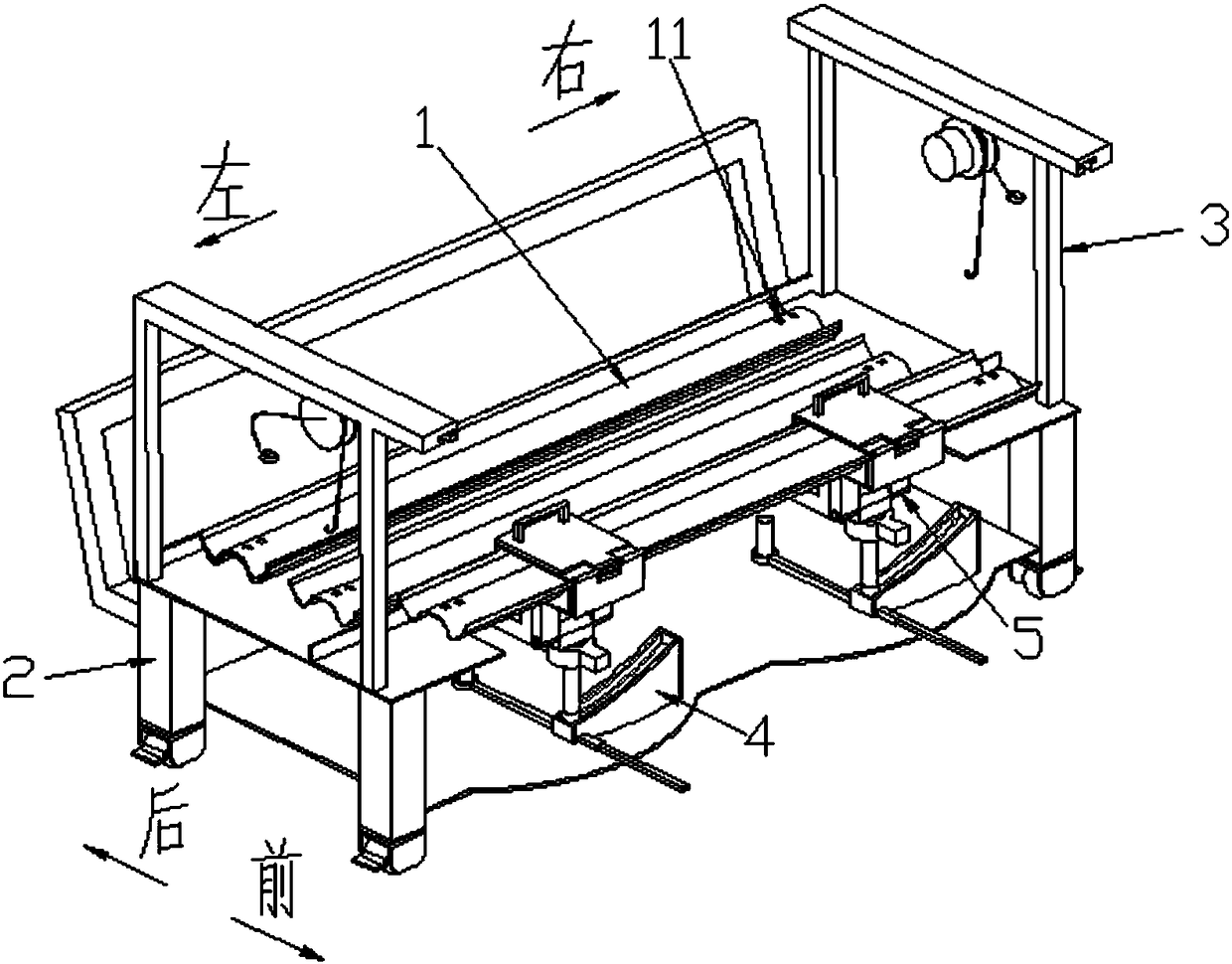

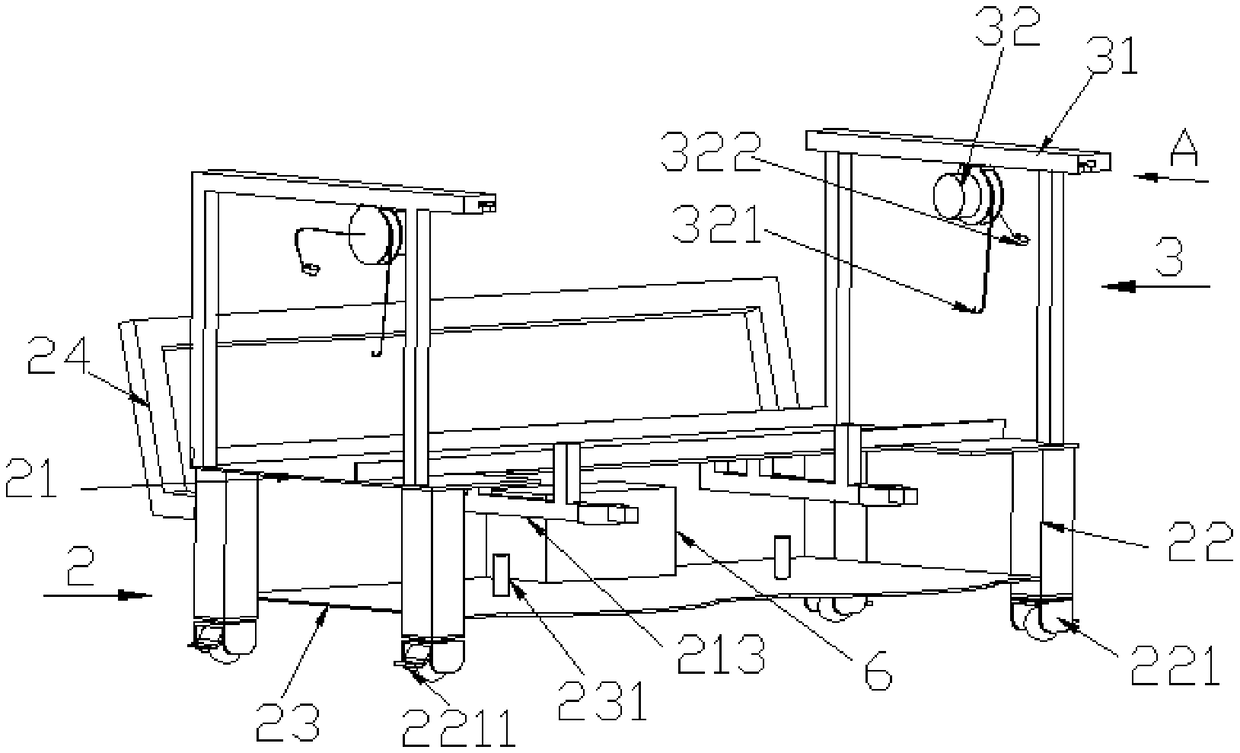

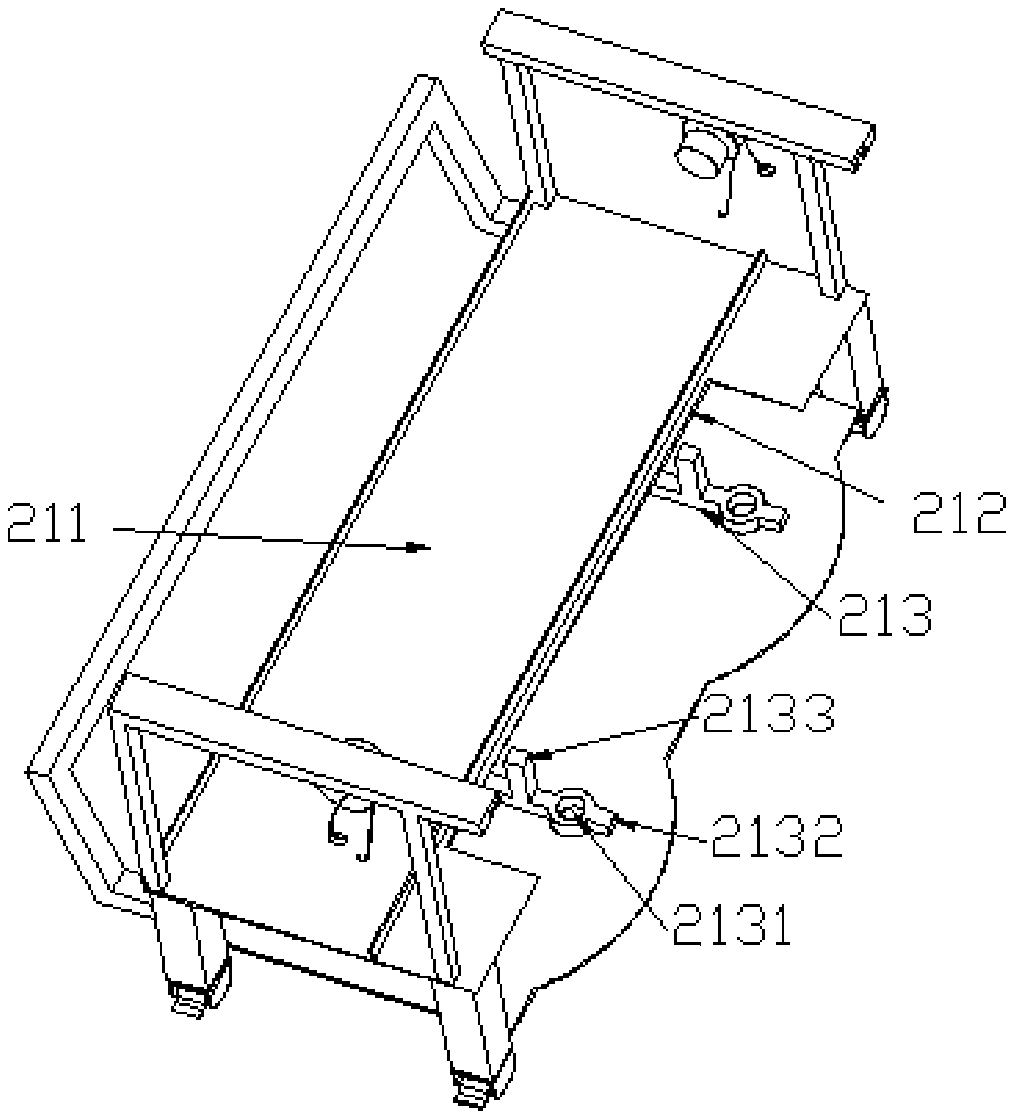

Corrugated plate carrying and mounting cart with electric wrenches

InactiveCN108316197AEasy to installEasy to useRoadway safety arrangementsEngineeringUltimate tensile strength

The invention relates to the field of road construction machinery, in particular to a corrugated plate carrying and mounting cart with electric wrenches, comprising corrugated plates, a cart frame, alifting frame, adjusting components, turning components, a battery, and the electric wrenches. It is convenient to carry and mount corrugated plates; labor intensity is greatly reduced; working efficiency is improved.

Owner:HUZHOU JIACHUANG AUTOMATION TECH CO LTD

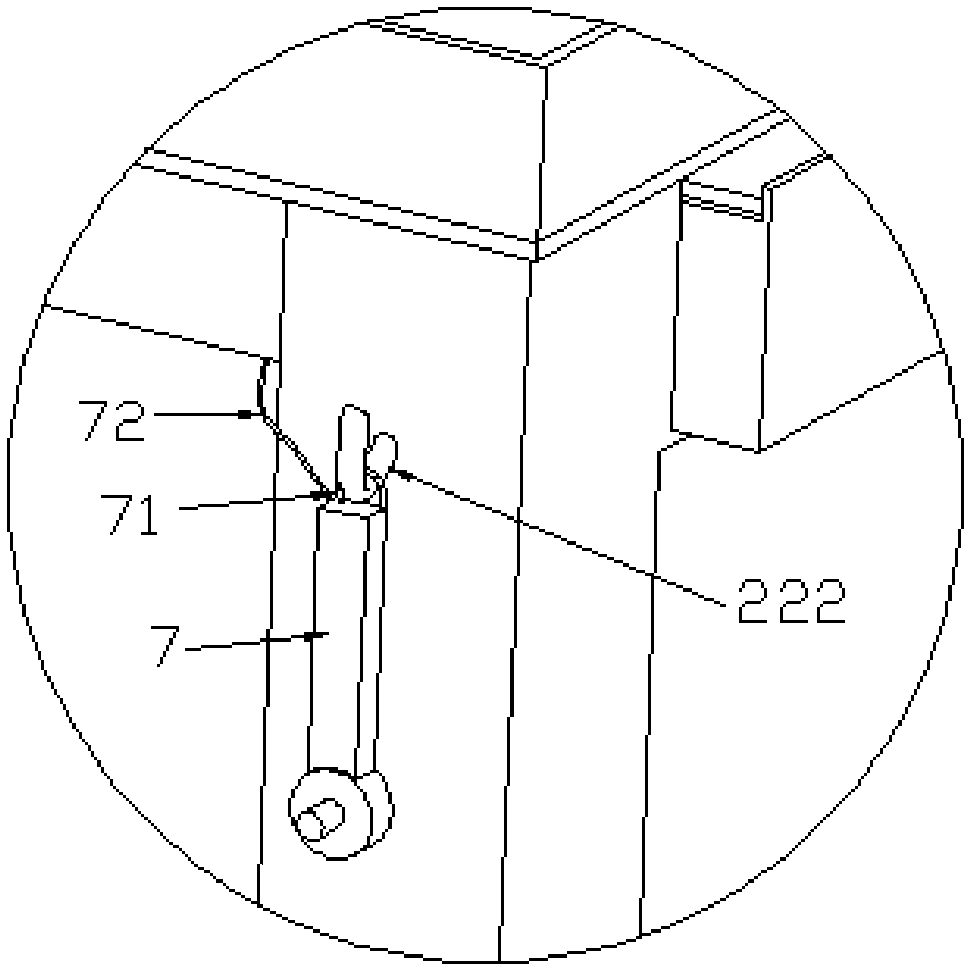

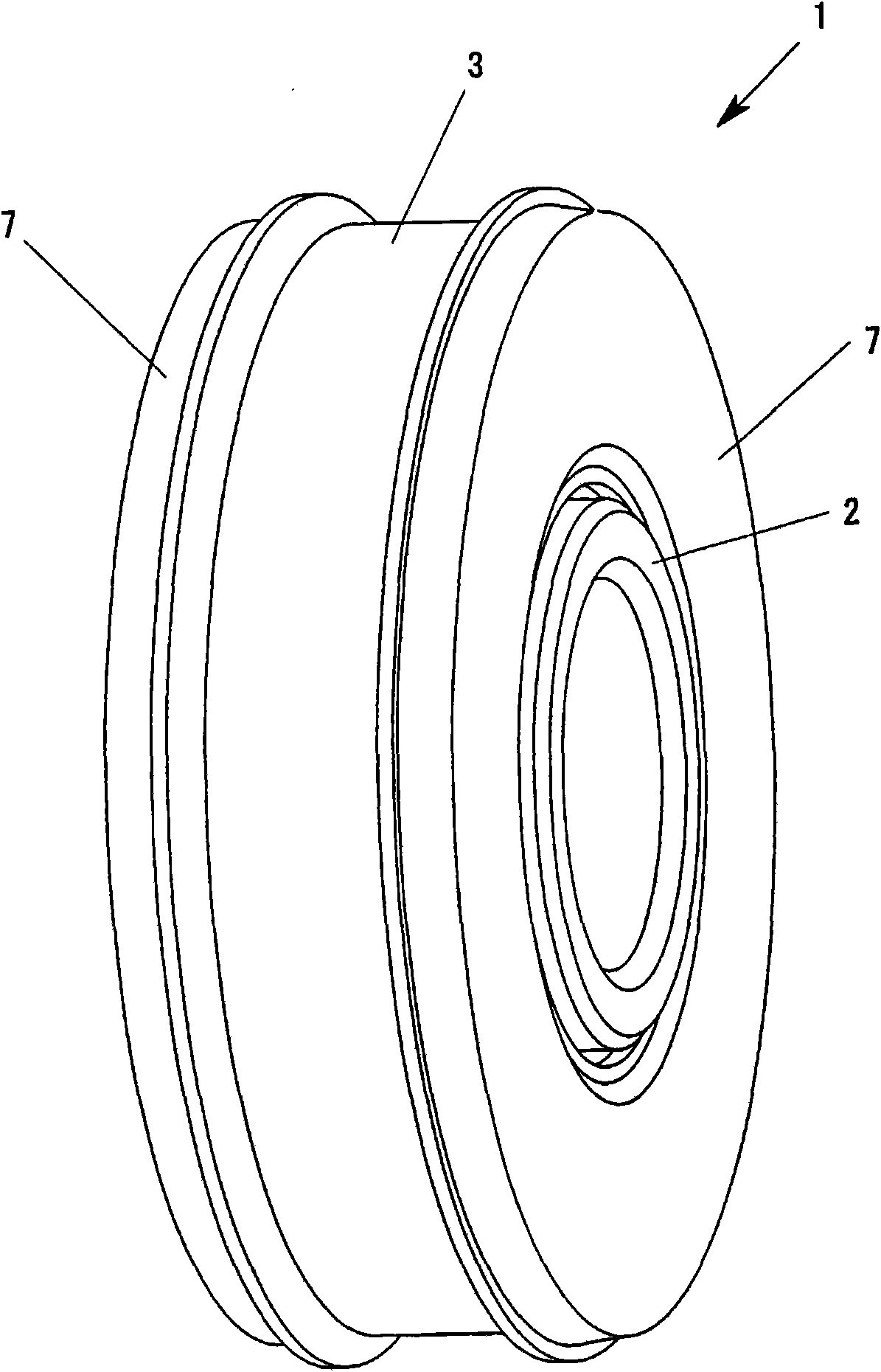

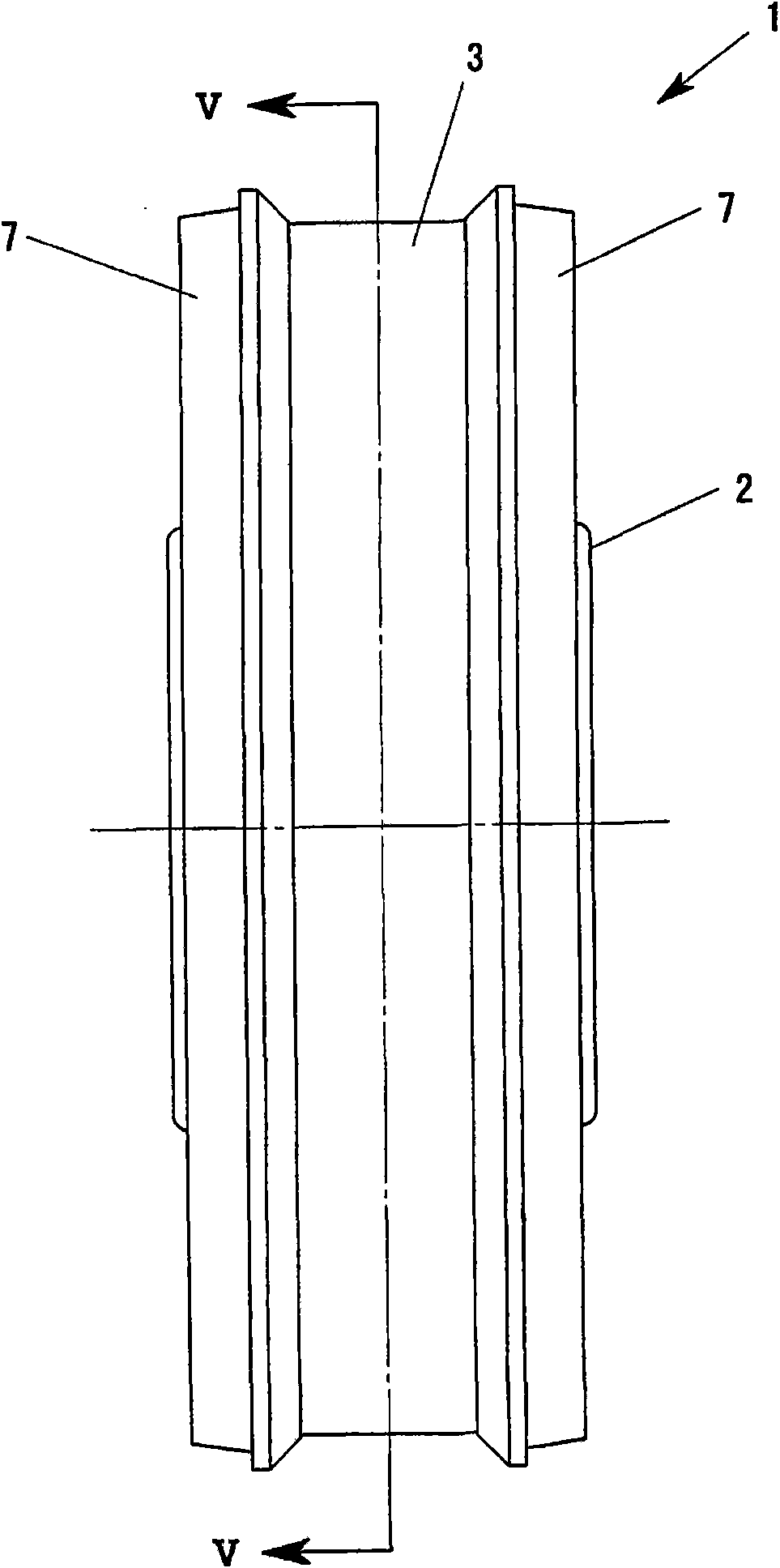

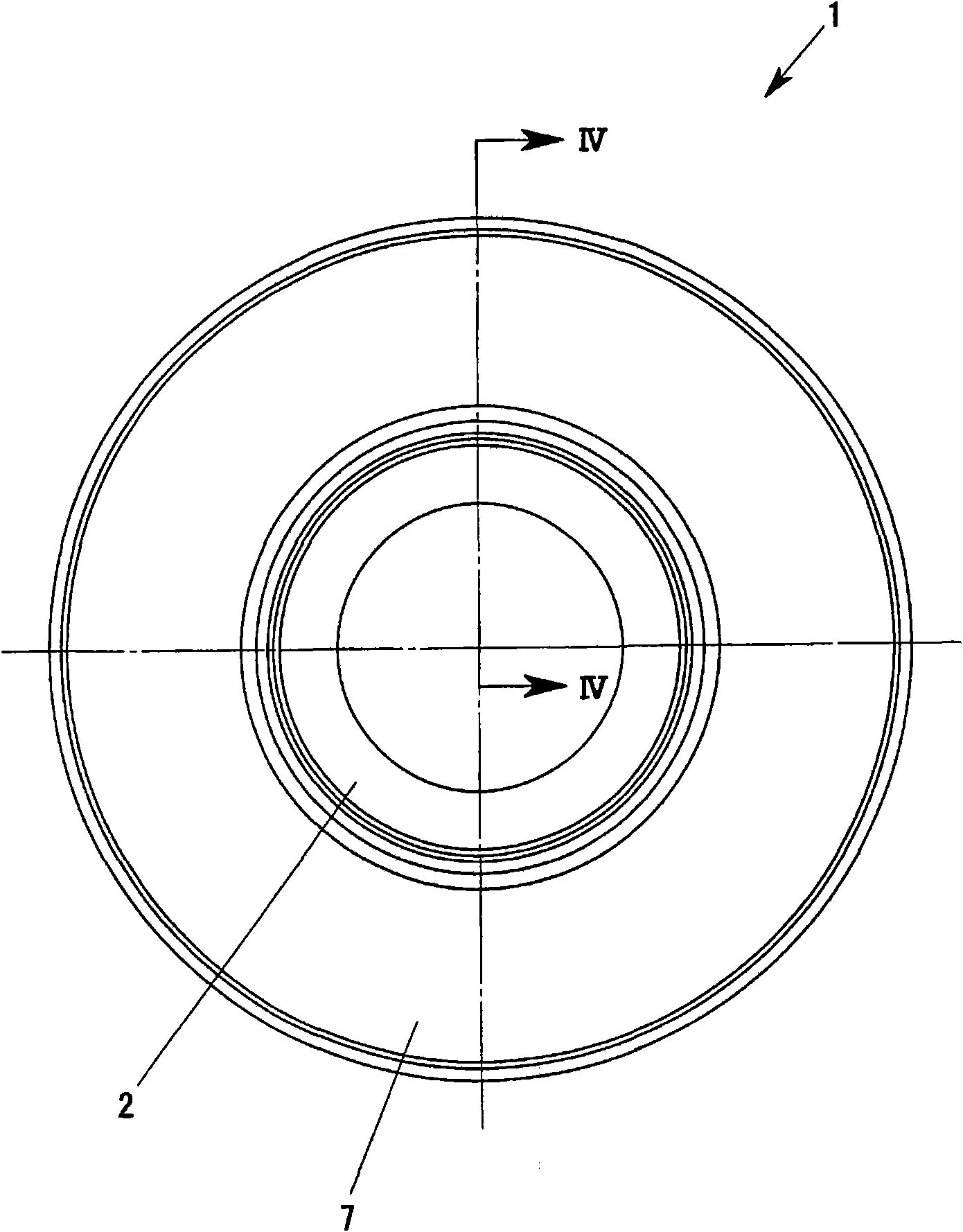

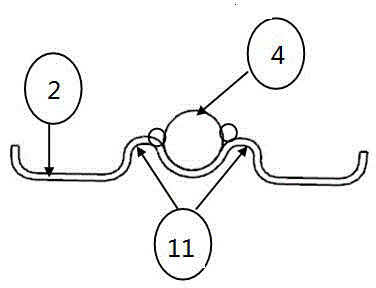

Rolling bearing and sealing component for rolling bearing

ActiveCN101566192AImprove rust resistanceReduce or thicken the widthBall bearingsBearing unit rigid supportRolling-element bearingSteel ball

The invention provides a cheap bearing with excellent rustproof capability and excellent appearance, which is capable of being made compactly without damaging waterproof and dustproof function. The sealing component (7) comprises an approximately cylindric embedded part extending to external circumstance side of a perforated circular plate shaped base (71). An embedded part (73) is embedded into the external circumstance side of a grain wheel (3), for fixing the sealing component (7). A most easily rusty chamfered part (38) completely covers the grain wheel (3) of the rolling bearing (1) from the side face (31) to the external circumstance. As a result, excellent rust prevention effect can be achieved even if expensive stainless steel is not used. The embedded part (73) is not inserted into an annular space (4). Therefore, embedded depth of the embedded part (73) need not to be decreased and the width of the grain wheel (3) need not to be enlarged for avoiding interference between the steel balls in the annular space (4) and a retainer (6). The compact rolling bearing with the sealing component can be implemented without reducing waterproof and dustproof function.

Owner:SHANGHAI RUCHONG WIND ENERGY EQUIP CO LTD

Paint-spraying treatment process of electric vehicle metal plate

InactiveCN104275293AReduce the number of timesGuaranteed smoothLiquid surface applicatorsCoatingsEmulsionElectric vehicle

The invention discloses a paint-spraying treatment process of an electric vehicle metal plate. The paint-spraying treatment process of the electric vehicle metal plate is characterized by comprising the following process steps: (1) brushing emulsion, namely coating one layer of the emulsion on the electric vehicle metal plate; (2) scraping putty powder, namely after the emulsion on the metal plate is dried, scraping the putty powder on a part, needing to be subjected to paint spraying, of the metal plate; drying and polishing; (3) coating priming paint, namely coating the priming paint on the metal plate on which the putty powder is scratched; (4) spraying finishing paint, namely shielding one part which does not need to be subjected to paint spraying and spraying paint on the metal plate by a paint spraying manner, and drying; and (5) polishing, namely polishing the metal plate sprayed with the finishing paint and sticking a label. According to the paint-spraying treatment process of the electric vehicle metal plate, the disadvantages in the prior art are overcome; the emulsion is brushed to further isolate air and prevent the metal plate from being rusted; the appearance of the metal plate is flat by scraping the putty powder and polishing; finally, the priming paint is brushed and the finishing paint is sprayed so that the times of brushing the priming paint can be reduced under the precondition that the dustproof capability is guaranteed; and the cost is effectively lowered, the dustproof capability is high, the appearance is beautiful and the application range is wide.

Owner:HEFEI HUAXIN ELECTRIC VEHICLE TECH DEV

Metal antirust agent meeting spraying adhesion and preparation method of metal antirust agent

ActiveCN108659708AImprove rust resistanceGuaranteed anti-rust effectAnti-corrosive paintsMetallic material coating processesIonHydroxypropylmethyl cellulose

The invention relates to a metal antirust agent meeting the spraying adhesion and a preparation method of the metal antirust agent. The metal antirust agent comprises the following components and is prepared from the following raw materials in parts by weight: 18-30 parts of a polyquaternium-hyperbranched benzimidazole block polymer, 10-16 parts of polyacrylate, 5-8 parts of a surfactant, 0.5-2 parts of an organic phosphonic acid compound, 4-8 parts of ferrocene, 5-9 parts of a defoamer, 3-8 parts of hydroxypropyl methyl cellulose, 0.2-1.2 parts of a pH regulator, and 70-90 parts of deionizedwater; and the preparation method comprises the following steps in the preparation: adding the polyquaternium-hyperbranched benzimidazole block polymer, the polyacrylate and the deionized water into areaction kettle, raising the temperature to 105-20 DEG C, stirring, adding the organic phosphonic acid compound and the surfactant; then raising the temperature to 150-160 DEG C, then adding the hydroxypropyl methyl cellulose, the ferrocene and the defoamer, adding the pH regulator, and regulating the pH to 6-8. Compared with the prior art, the metal antirust agent is high in stability, a film layer is electrically conductive, the postprocessing of a metal part is convenient, the anti-rust property and the anti-corrosion property are excellent, and the spraying adhesion is excellent.

Owner:深圳市鸿美特科技有限公司

Cutting fluid for after-cutting processing of neodymium iron boron

InactiveCN102766519AExcellent anti-rust and anti-oxidation effectLow costLubricant compositionChemistryKetone

The invention discloses a cutting fluid for after-cutting processing of neodymium iron boron. The cutting fluid comprises the following components, by weight: 5-7% of ethylenediamine, 14-16% of isopropanol amine, 8-10% of oleic acid, 1-3% of sebacic acid, 3-5% of water-soluble phosphate, 4-6% of polyether, 12-14% of methyl benzotriazole, 0.5-0.7% of TX-10, 6-8% of polyvinyl alcohol, 0.1-0.3% of 5-chlorine-2-methyl-4-isothiazolin-3-one, 0.5-0.7% of emulsified oil, 3-5% of isopropyl alcohol and the balance of water.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Rust-proof anti-fog PE shrink film and processing method thereof

ActiveCN111469520AGood heat sealing performanceImprove aging resistanceFlexible coversWrappersFluorine containingAnti-fog

The invention relates to a rust-proof anti-fog PE shrink film and a processing method thereof. The rust-proof anti-fog PE shrink film sequentially comprises an outer layer, a middle layer and an innerlayer from outside to inside, the outer layer is prepared from the following raw materials in parts by weight: 350 to 550 parts of LDPE, 150 to 300 parts of HDPE, 150 to 300 parts of mLLDPE, 10 to 30parts of a delustering agent, 5 to 15 parts of white carbon black and 10 to 30 parts of a compatilizer; the middle layer is prepared from the following raw materials in parts by weight: 400 to 600 parts of LDPE, 150 to 300 parts of HDPE, 150 to 300 parts of mLLDPE, 100 to 200 parts of an antirust agent, 15 to 35 parts of a delustering agent and 10 to 30 parts of a compatilizer; the delustering agent is a fluorine-containing elastomer; the PE shrink film provided by the invention has excellent antirust and antifogging properties.

Owner:安徽冠宝新材料科技有限公司

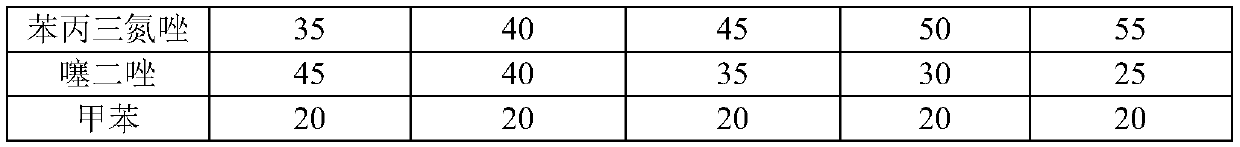

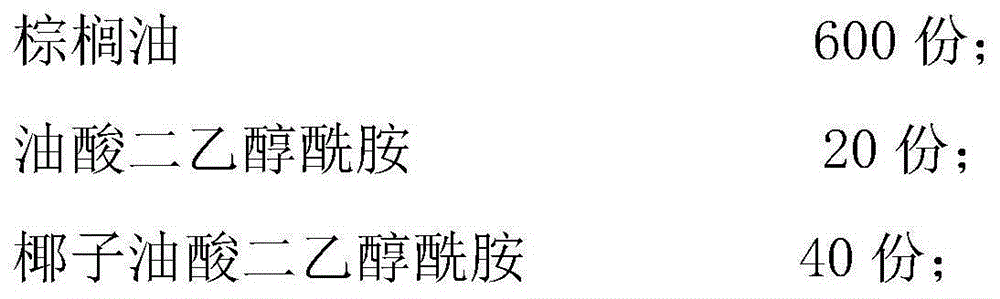

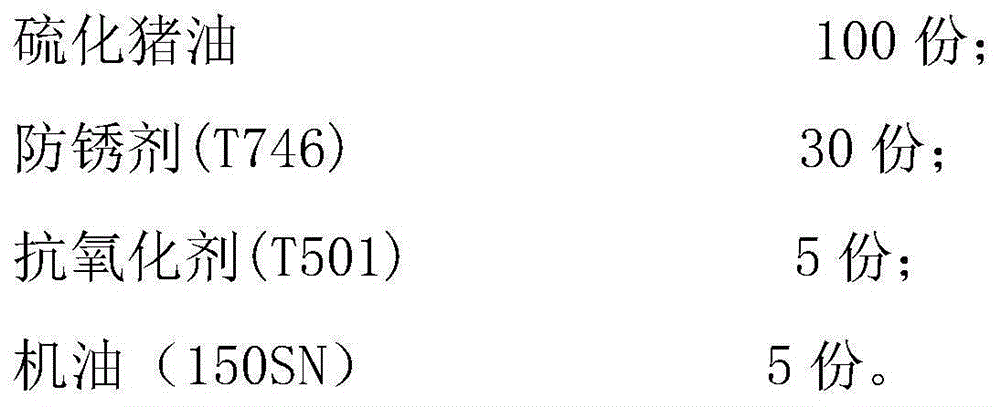

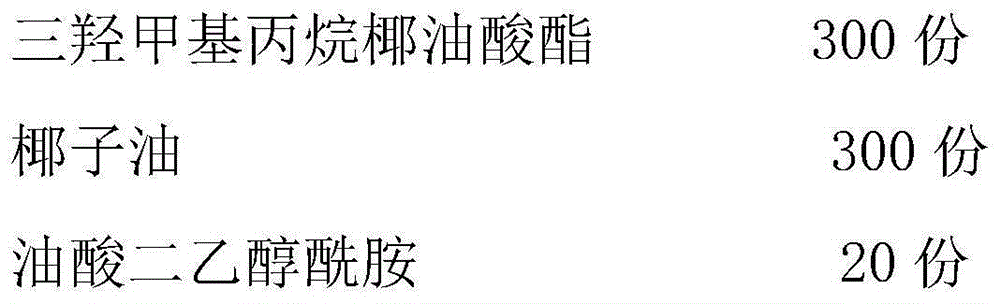

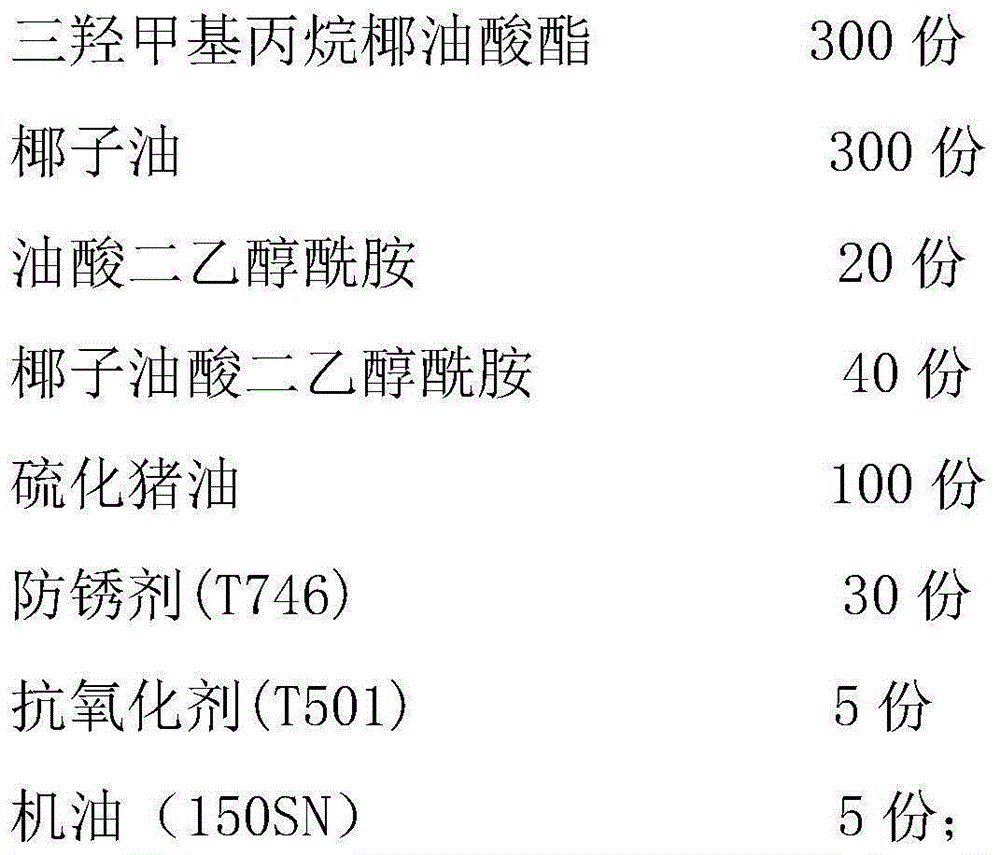

Rolling oil composition for cold rolling of ordinary carbon steel plate and preparation method

InactiveCN105154186AMeet lubrication requirementsGuaranteed anti-rust performanceLubricant compositionAntioxidantCoconut oil

The invention relates to a rolling oil composition and a preparation method, belongs to the field of oil for metallurgy and rolling mills, and particularly relates to a rolling oil composition for cold rolling of an ordinary carbon steel plate and a preparation method, wherein the rolling oil composition for an ordinary carbon steel plate rolling mill comprises the following components in parts by weight: 600 parts of palm oil; 20 parts of oleic diethanolamide; 40 parts of coconut oil diethanoamine condensate; 100 parts of sulfurized lard oil; 30 parts of antirust agent (T746); 5 parts of antioxidant (T501); 5 parts of engine oil (150SN). The rolling oil composition is applied to the rolling mill, can meet the requirement on rolled steel lubrication at high temperature and guarantee the stability of a steel rolling process, and also can guarantee annealing detergence, rolling mill detergence and anti-rust property under the no-clean condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

Fixing structure for exhaust pipes

ActiveCN104670002AImprove dynamic stiffnessReduce in quantityPropulsion unit gas exhaustDynamic stiffnessResonance

The invention provides a fixing structure for exhaust pipes, comprising a rear longitudinal beam, a rear floor, a first exhaust pipe mounting support, a first exhaust pipe mounting hook, a second exhaust pipe mounting hook, a second exhaust pipe mounting support and a rear anti-collision beam. The rear anti-collision beam is connected with the rear longitudinal beam and the rear floor. The first exhaust pipe mounting support and the second exhaust pipe mounting support are both connected with the rear anti-collision beam. The first exhaust pipe mounting hook is disposed on the first exhaust pipe mounting support. The second exhaust pipe mounting hook is disposed on the second exhaust pipe mounting support. The fixing structure has the advantages that dynamic stiffness of the fixing structure is greatly improved, the problem that shaking of the exhaust pipe easily causes resonance and shaking of the floor during running of a vehicle is avoided, electro-coating is sufficient, and the sufficient electrophoretic paint film ensures rust resistance of the fixing structure.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

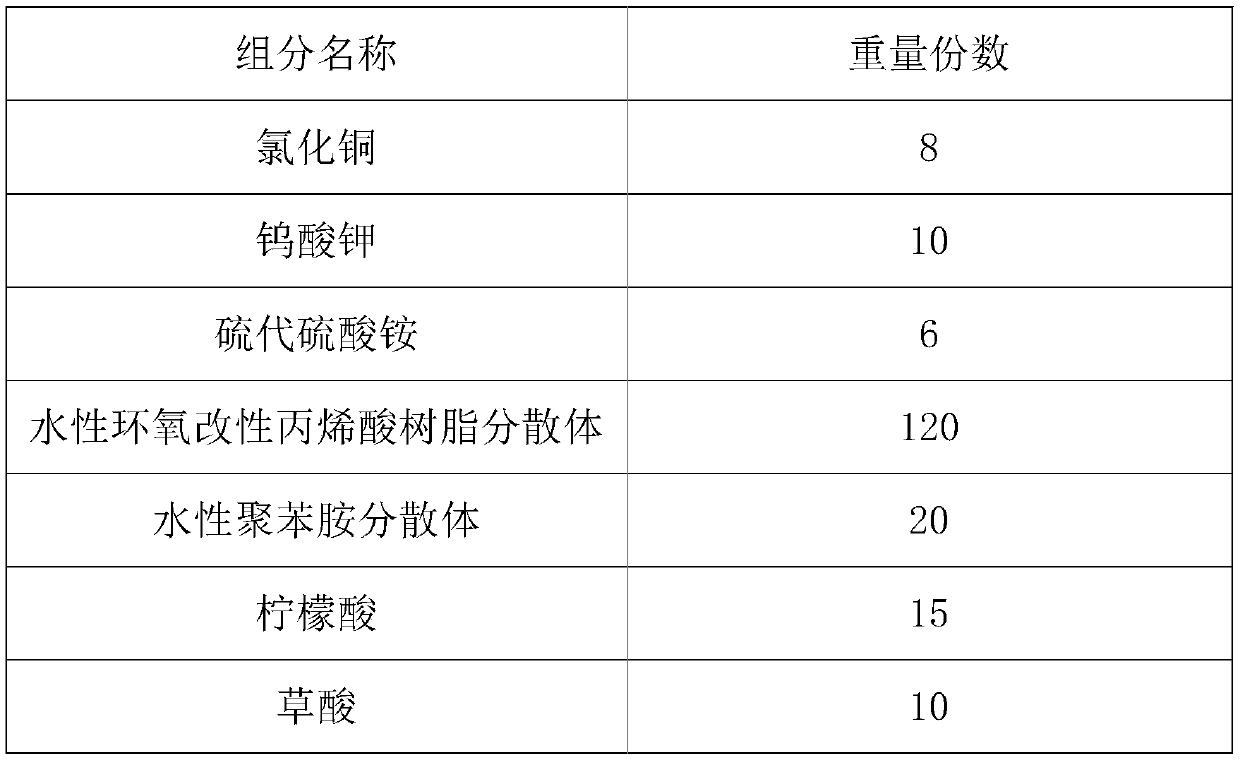

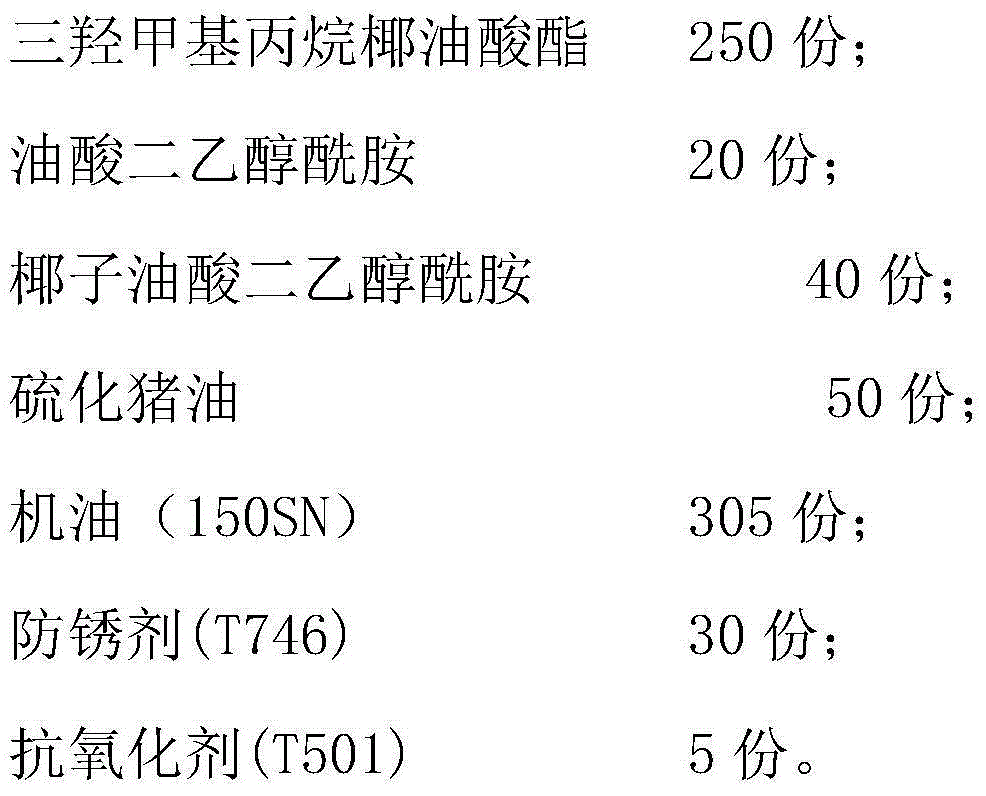

Rolling oil composition for cold rolling of low alloy steel plate and preparation method

InactiveCN105154184AImprove the lubrication effectMeet lubrication requirementsLubricant compositionSheet steelAntioxidant

The invention relates to a rolling oil composition and a preparation method, belongs to the field of oil for metallurgy and rolling mills, and particularly relates to a rolling oil composition for cold rolling of a low alloy steel plate and a preparation method, wherein the rolling oil composition for a low alloy steel plate rolling mill comprises the following components in parts by weight: 300 parts of trimethylolpropane coconut acid ester; 300 parts of coconut oil; 20 parts of oleic diethanolamide; 40 parts of coconut oil diethanoamine condensate; 100 parts of sulfurized lard oil; 30 parts of antirust agent (T746); 5 parts of antioxidant (T501); 5 parts of engine oil (150SN). The rolling oil composition is applied to the rolling mill, can meet the requirement on rolled steel lubrication at high temperature and guarantee the stability of a steel rolling process, and also can guarantee annealing detergence, rolling mill detergence and anti-rust property under the no-clean condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

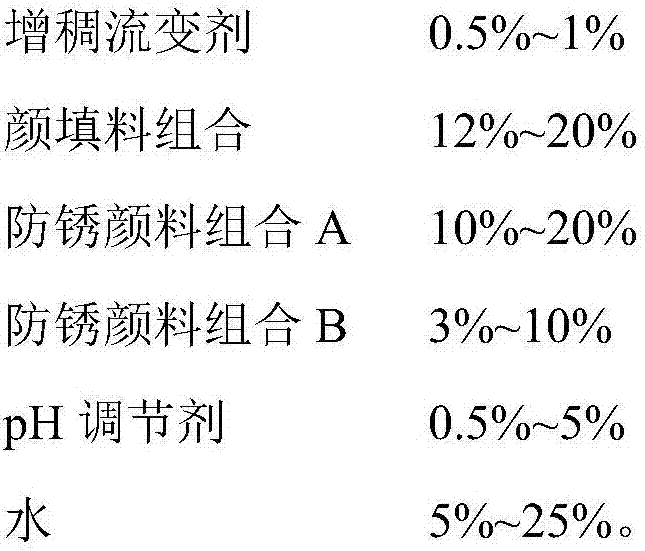

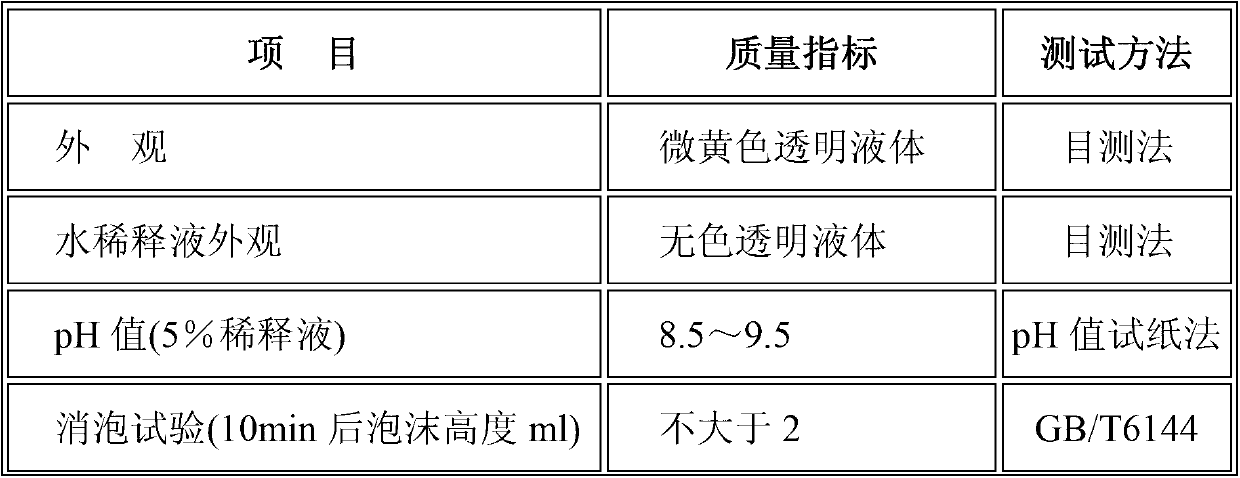

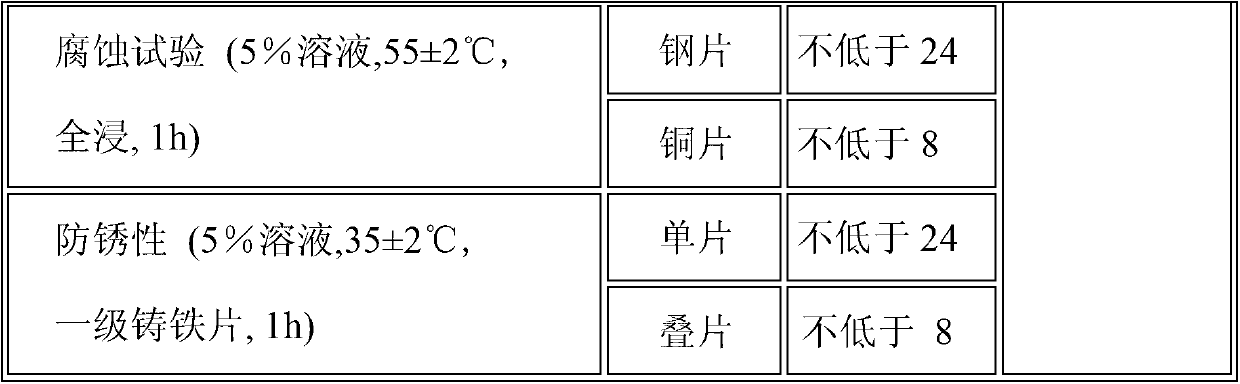

Hydrophilic anti-rusting metal intermediate coating

The invention discloses a hydrophilic anti-rusting metal intermediate coating. The hydrophilic anti-rusting metal intermediate coating is prepared from, by weight, 21-56 parts of hexakis methoxyl melamine formaldehyde resin, 8-13 parts of 1,2-propylene glycol-1-monobutyl ether, 30-44 parts of vinyl tri(2-methoxyl ethyoxyl) silane, 7-15 parts of cetyltrimethylammonium bromide, 13-27 parts of isoprene, 1-9 parts of ammonium stearic acid, 2-22 parts of acetyl triethyl citrate, 5-10 parts of tetraethylenepentamine, 6-14 parts of maleic anhydride, 7-31 parts of sorbital, 16-26 parts of alkylphenol polyoxyethylene ether, 3-19 parts of moonstone powder and 11-28 parts of titanium dioxide. The prepared coating prepared through the method is environmentally friendly, free of toxicity, harmless to the human body, long in anti-rusting time and capable of being well combined with metal priming paint and face paint, the anti-rusting effect is ensured, meanwhile, the stripping strength of the coating is improved, and the thickness of the coating is reduced and ranges from 140 micrometers to 160 micrometers.

Owner:TONGLING MINGCHENG FOUNDRY

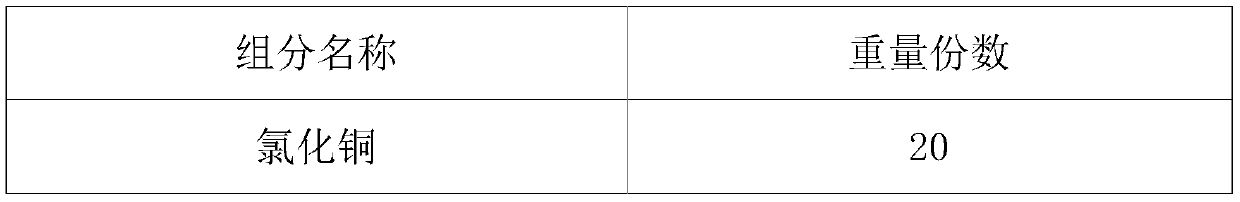

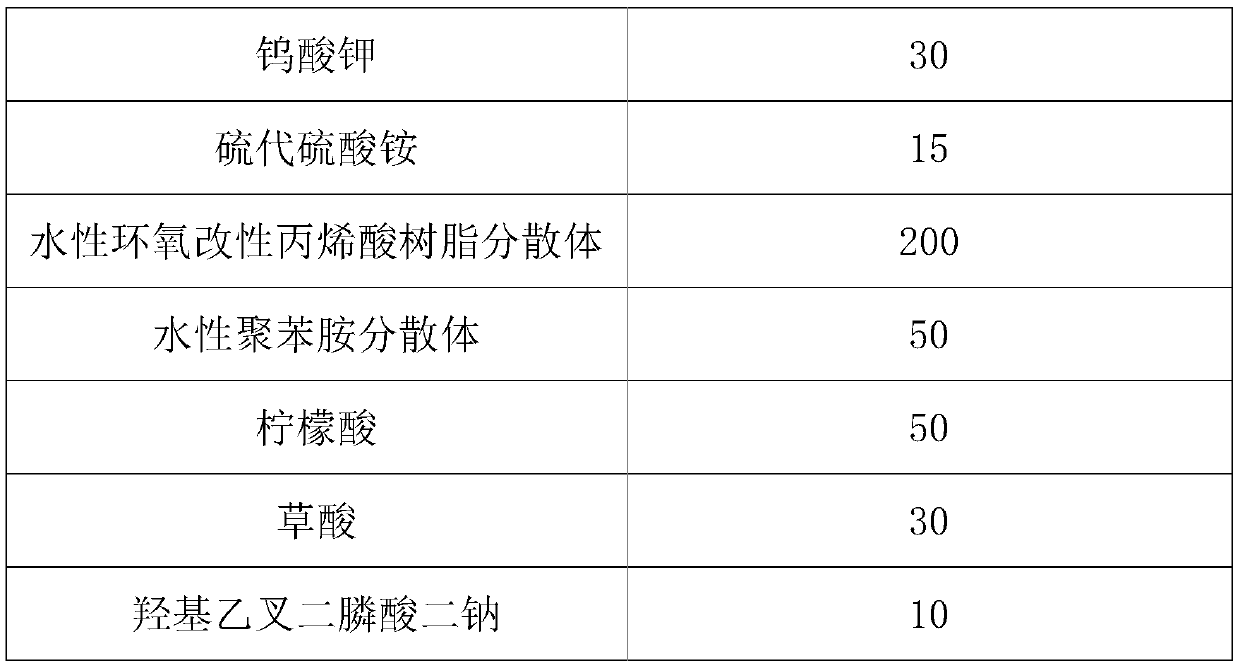

Oil-immersion-free antirust blackening agent and preparation method and application thereof

ActiveCN111087877AReduce porosityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsOXALIC ACID DIHYDRATEEpoxy

The invention discloses an oil-immersion-free antirust blackening agent and a preparation method and application thereof, and relates to the technical field of metal surface treatment. The oil-immersion-free antirust blackening agent comprises the following components: 1-20 parts by weight of copper chloride, 2-30 parts of potassium tungstate, 1-15 parts of ammonium thiosulfate, 50-300 parts of waterborne epoxy modified acrylic resin dispersion, 5-50 parts of waterborne polyaniline dispersion, 5-50 parts of citric acid, 2-50 parts of oxalic acid, 0.5-10 parts of disodium 1-hydroxyethylidene-1,1-diphosphonate and a proper amount of deionized water. After the oil-immersion-free antirust blackening agent is used for blackening treatment, antirust performance requirements under most conditions can be met even if oil immersion treatment is not carried out.

Owner:HUNAN JINHUA SCI & TECH GRP

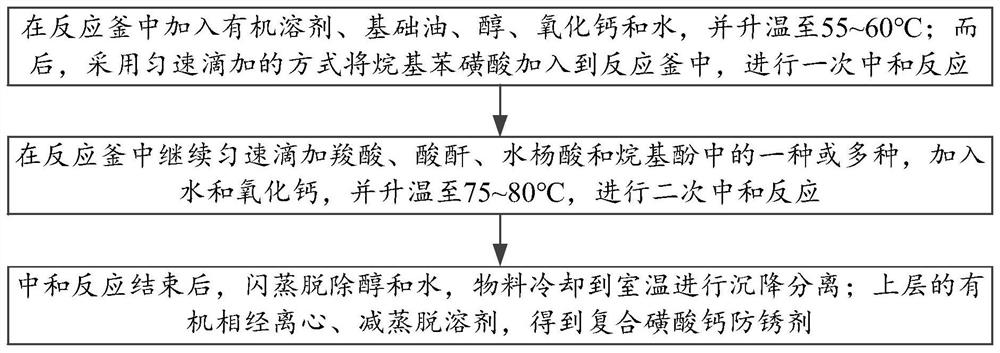

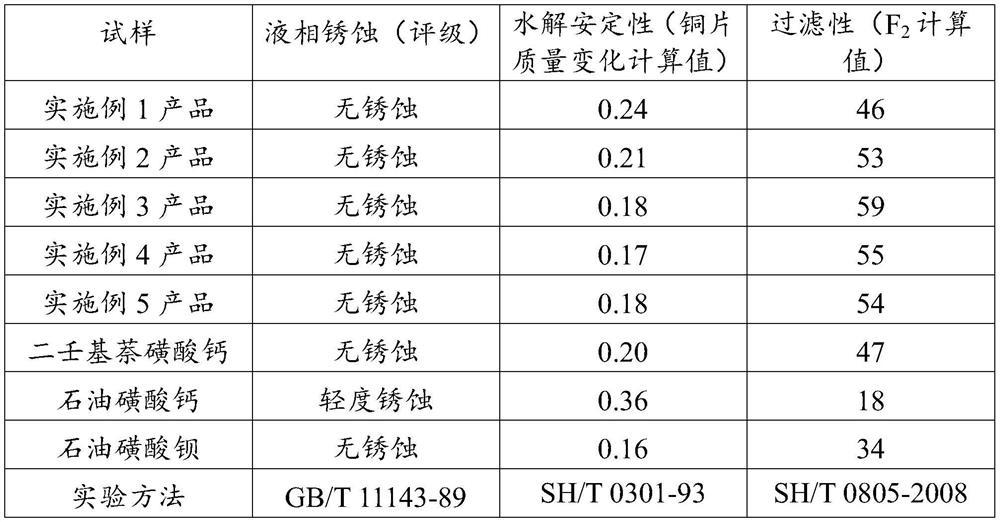

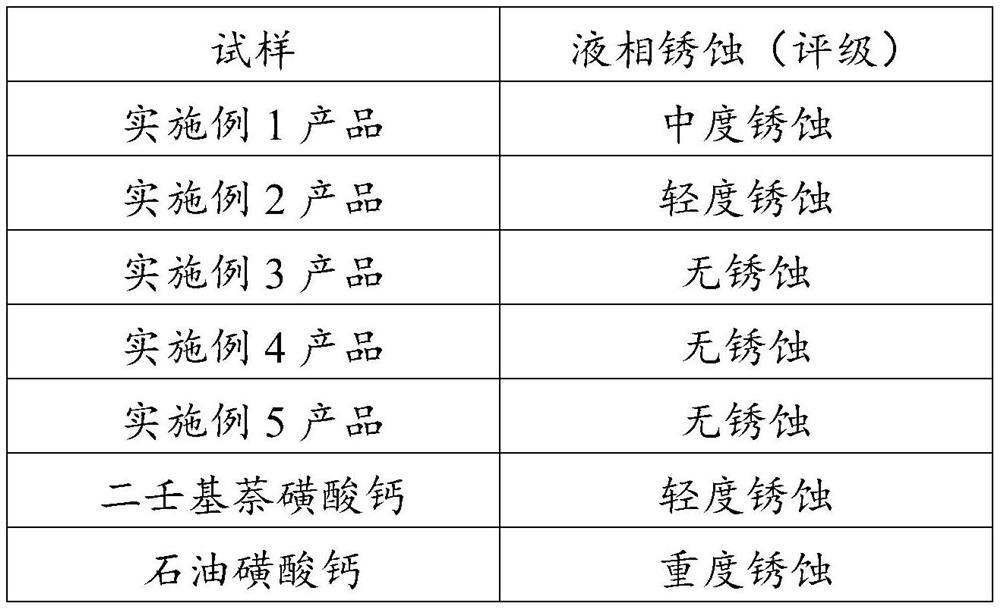

Preparation method of composite calcium sulfonate antirust agent

PendingCN113249162AProportion of high sulfonic acidGuaranteed anti-rust performanceLubricant compositionSulfonateOrganic solvent

The invention discloses a preparation method of a composite calcium sulfonate antirust agent, which comprises the following steps: adding an organic solvent, base oil, alcohol, calcium oxide and water into a reaction kettle, and heating to 55-60 DEG C; then, adding alkyl benzene sulfonic acid into the reaction kettle in a constant-speed dropwise adding manner, and carrying out primary neutralization reaction; continuously dropwise adding one or more of carboxylic acid, anhydride, salicylic acid and alkylphenol into the reaction kettle at a constant speed, adding water and calcium oxide, heating to 75-80 DEG C, and carrying out secondary neutralization reaction; after the neutralization reaction is finished, removing alcohol and water through flash evaporation, and cooling materials to the room temperature for settling separation; and centrifuging the organic phase on the upper layer, and desolventizing by reduced pressure evaporation to obtain the composite calcium sulfonate antirust agent. The prepared composite calcium sulfonate antirust agent has high sulfonic acid proportion, and the antirust property of the composite calcium sulfonate antirust agent in lubricating oil is guaranteed; the product is compounded, so that the compatibility of the product in the lubricating oil is better, the product is not easy to interact with other components in the system, and the universality of the product is better.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Silencing antirust paint for electric machine room and preparation method thereof

InactiveCN107151502AEasy to prepareEnvironmental pollution is smallFireproof paintsAntifouling/underwater paintsEmulsionOxide

The invention discloses silencing antirust paint for an electric machine room, and belongs to the technical field of antirust paint. The silencing antirust paint is prepared from the following raw materials in parts by weight: 45 to 50 parts of silicone acrylic emulsion, 15 to 20 parts of fluorocarbon emulsion, 8 to 12 parts of aluminum silicate fiber, 5 to 8 parts of inositol hexaphosphate, 4 to 6 parts of aluminum triphosphate, 10 to 12 parts of talcum powder, 7 to 9 parts of calcium carbonate, 4 to 6 parts of clay, 8 to 10 parts of sericite powder, 3 to 6 parts of aluminum powder, 3 to 6 parts of alundum powder, 3 to 6 parts of zinc oxide, 1 to 2 parts of carboxymethylcellulose, 2 to 4 parts of texanol, 1 to 2 parts of moistening agent, 1 to 3 parts of dispersing agent, 0.5 to 1 part of antifoaming agent, 0.5 to 1 part of thickener, 0.1 to 0.8 part of mildew preventive, and 20 to 30 parts of water. The invention further discloses a preparation method of the silencing antirust paint for the electric machine room. The silencing antirust paint has the advantages of easiness in preparing, low environment pollution, high noise reduction capability and excellent high temperature resistance.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

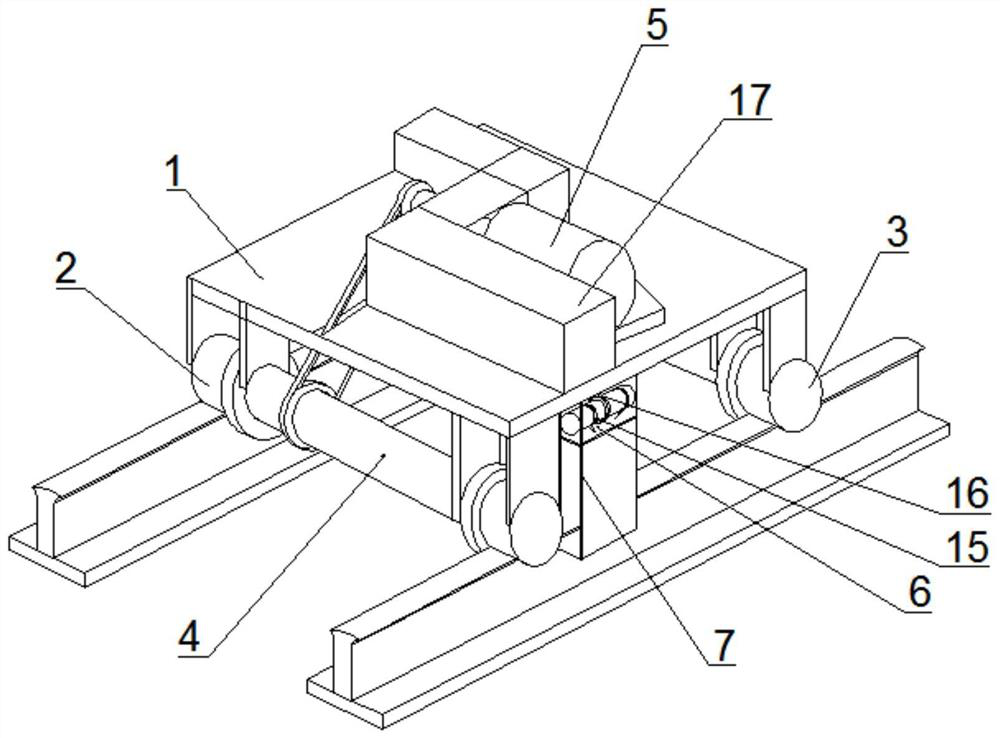

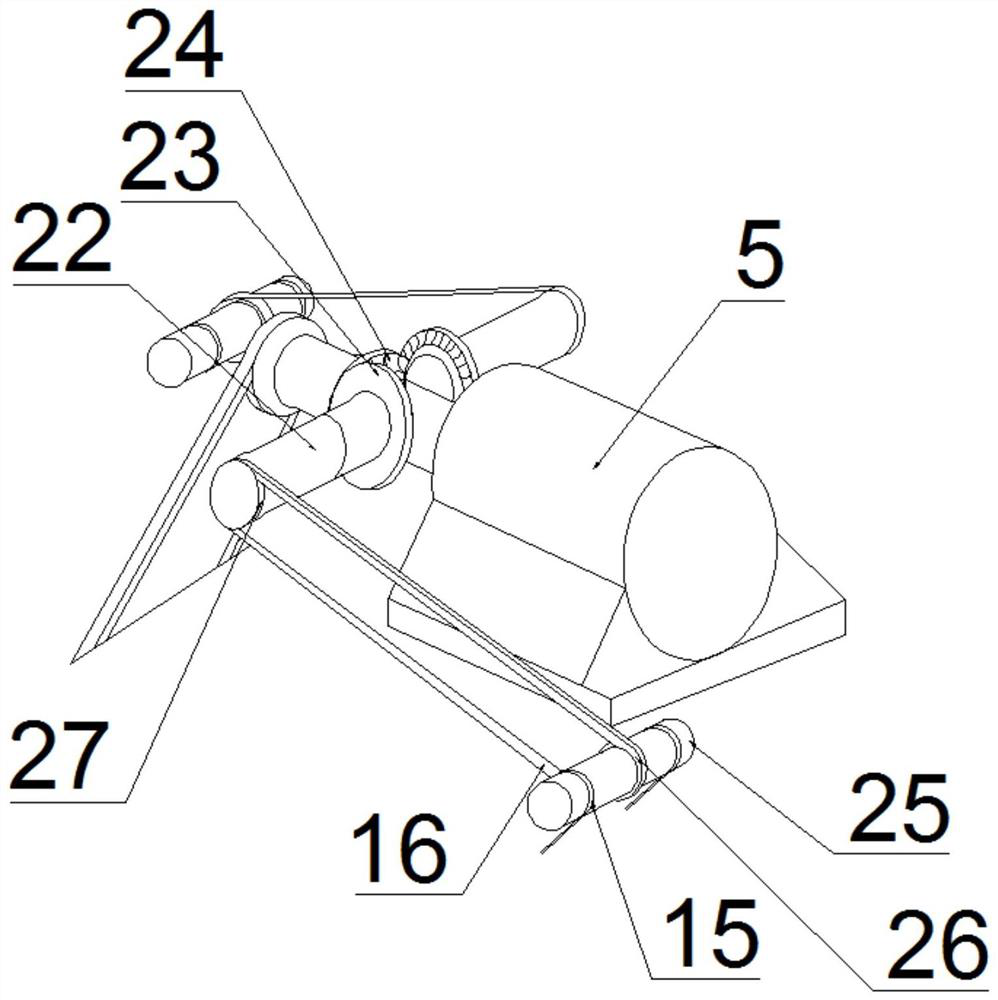

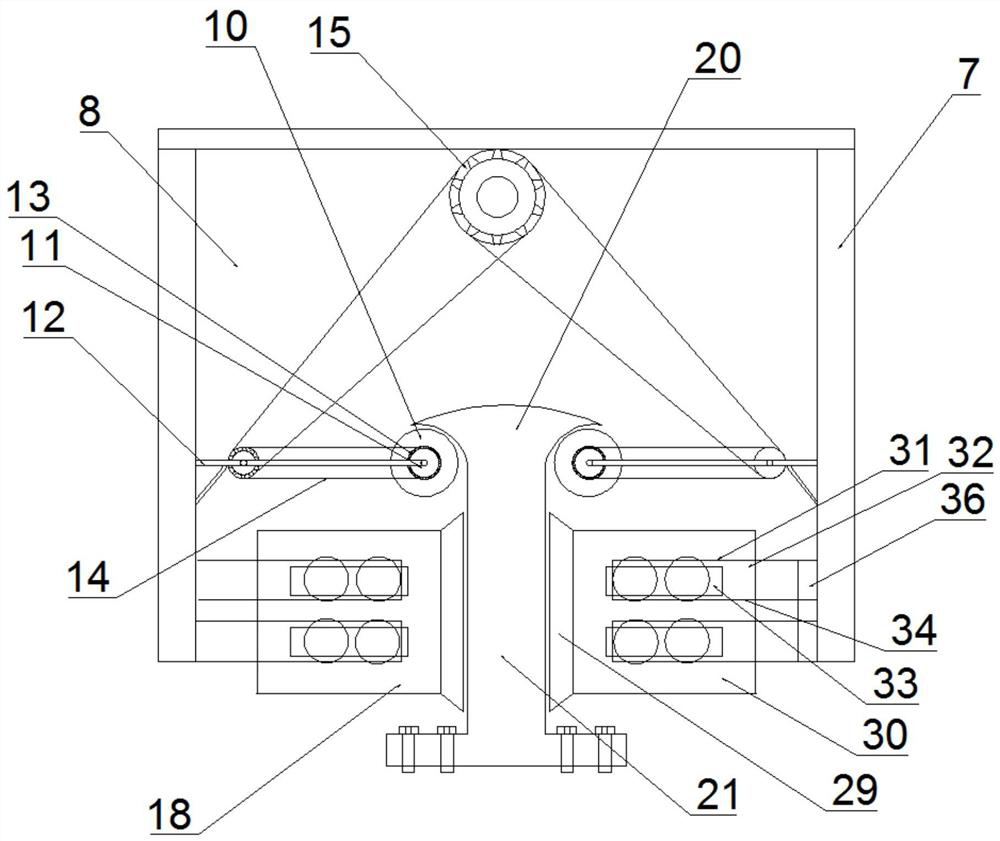

Double-rail rust removing and grinding device and using method thereof

ActiveCN111893818ALong post-maintenance periodReduce maintenance costsRailway track constructionDrive shaftElectric machinery

The invention discloses a double-rail rust removing and grinding device, which comprises a device base, wherein a front rail wheel and a rear rail wheel are symmetrically installed at the lower ends of the two sides of the device base, the rail wheels are mounted on a transmission shaft, a driving motor is mounted at the upper end of the device base, a shaft of the driving motor is rotationally connected to the front rail wheel, a grinding device is mounted between the front rail wheel and the rear rail wheel; a grinding frame is installed on the two sides of the lower end of the device base,a first grinding mechanism and a second grinding mechanism are mounted on the grinding frame, and the second grinding mechanism is arranged at the rear end of the first grinding mechanism. According to the double-rail rust removing and grinding device provided by the invention, by means of the double-rail rust removing and grinding device, rust on the rails is removed at a time, repeated rust removing is avoided, it is guaranteed that the later maintenance time period of the rails is prolonged after rust removing, the maintenance cost is reduced, and meanwhile, the influence on rail transportation caused by repeated maintenance is avoided.

Owner:株洲伟雄工程机械有限公司

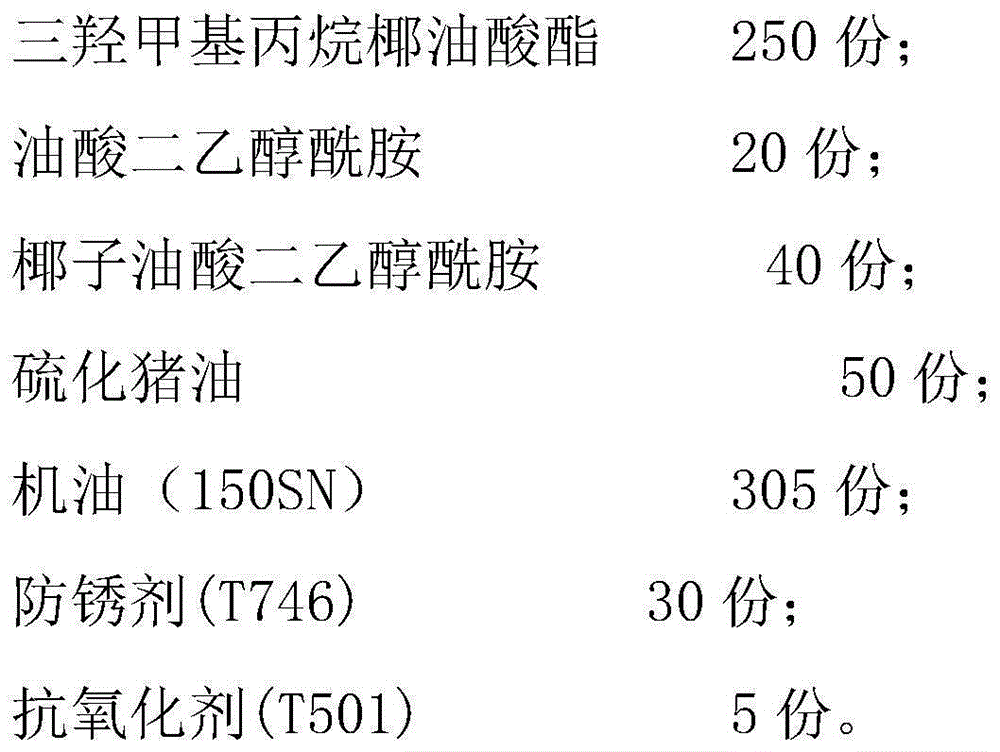

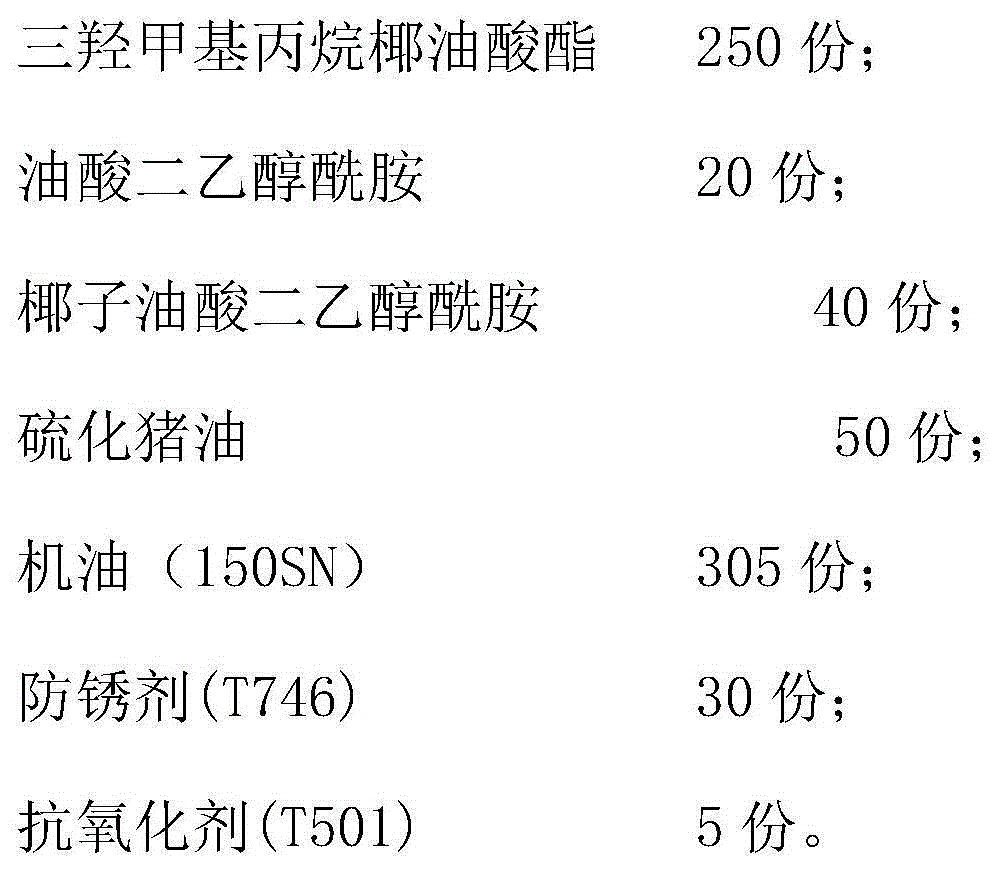

Rolling oil composition used for cold rolling of common carbon steel plate with size less than 650mm and preparation method of rolling oil composition

InactiveCN105132106AImprove the lubrication effectMeet lubrication requirementsLubricant compositionCoconut oilTrimethylolpropane

The invention relates to a rolling oil composition and a preparation method thereof, belongs to the field of oil products used for metallurgical rolling mills, and particularly relates to a rolling oil composition used for cold rolling of a common carbon steel plate with the size less than 650mm and a preparation method of the rolling oil composition. The rolling oil composition comprises the following components in parts by weight: 250 parts of trimethylolpropane cocoate, 20 parts of oleic diethanolamide, 40 parts of coconut oil diethanolamine condensate, 50 parts of vulcanized lard oil, 305 parts of engine oil (150SN), 30 parts of an antirust agent (T746) and 5 parts of an antioxidant (T501). The rolling oil composition provided by the invention can meet the requirements of lubricating rolled steel under a high temperature so as to guarantee the stability of a steel rolling process; annealing cleanliness, and cleanliness and antirust property of the rolling mills can be guaranteed in a washing-free condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

Corrugated plate carrying and mounting trolley

InactiveCN108313914AEasy to carryEasy transferPortable liftingLifting framesEngineeringMechanical engineering

The invention relates to the field of road construction machines, in particular to a corrugated plate carrying and mounting trolley. The corrugated plate carrying and mounting trolley comprises corrugated plates, a trolley frame, a lifting frame, an adjusting assembly and an overturning assembly. Carrying and mounting of the corrugated plates are convenient, and the labor intensity is greatly reduced.

Owner:HUZHOU JIACHUANG AUTOMATION TECH CO LTD

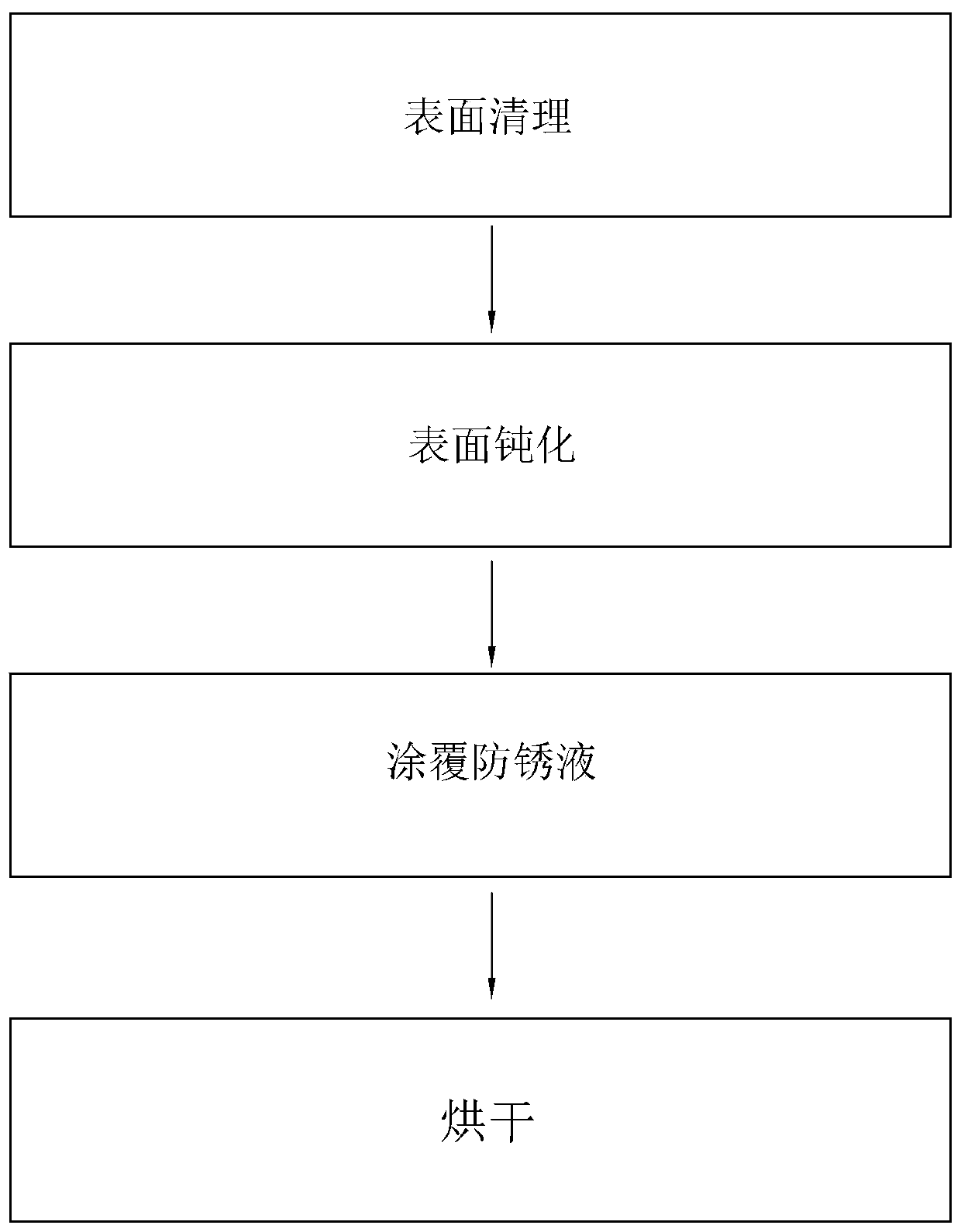

Treatment process of rust-proof bolt

InactiveCN110438481AEffective protectionImprove corrosion resistanceMetallic material coating processesHexamethylenetetramineSurface cleaning

The invention discloses a treatment process of a rust-proof bolt. The treatment process of the rust-proof bolt comprises the following steps of S1, surface cleaning; S2, surface passivation; S3, smearing of a rust-proof solution; S4, drying, wherein the rust-proof solution comprises, by weight, 20-25 parts of trisodium phosphate, 2-5 parts of sodium silicate, 3-5 parts of urotropin, 3-5 parts of 2-mercapto benzimidazole, and 80-90 parts of water. The treatment process of the rust-proof bolt has the following advantages that trisodium phosphate can form a phosphating film on the surface of thebolt, and sodium silicate can form an oxidation film on the surface of the bolt, so that an anti-oxidation function and a rust-proof function are achieved, and the rust-proof cycle is long. Urotropincan improve the corrosion resistance of the bolt and has a complexing function to improve the adhesive force of the oxidation film and the phosphating film on the surface of the bolt. 2-mercapto benzimidazole has a good anti-oxidation effect, can improve the anti-oxidation and rust-proof effects of the bolt and improve the storage performance of the rust-proof solution, and has good corrosion inhibition.

Owner:ZHEJIANG LIANGTAI STANDARD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com