Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3716 results about "Alkylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkylphenols are a family of organic compounds obtained by the alkylation of phenols. The term is usually reserved for commercially important propylphenol, butylphenol, amylphenol, heptylphenol, octylphenol, nonylphenol, dodecylphenol and related "long chain alkylphenols" (LCAPs). Methylphenols and ethylphenols are also alkylphenols, but they are more commonly referred to by their specific names, cresols and xylenols.

Process and composition for cleaning soft tissue grafts optionally attached to bone and soft tissue and bone grafts produced thereby

InactiveUS6024735AEfficient removalEfficient formationSurgical needlesVaccination/ovulation diagnosticsPresent methodAdditive ingredient

The invention relates to compositions effective for the cleansing of mammalian soft tissue optionally attached to bones, and particularly the removal of blood deposits and bone marrow therefrom. The compsotions are composed of an aqueous solution containing as its essential ingredients a detergent having a functionality of the nature of a polyoxyethylene-23-lauryl either, a detergent having a functionality of the nature of exyethylated alkylphenol, and water, where the compositions are free from any membrane stabilizers. The present invention is also directed to a method and composition for cleaning cadaveric soft tissue optionally attached to bone to produce soft tissue grafts optionally attached to bone suitable for transplantation into a human. The present method involves removing bone marrow elements, blood deposits and any bacteria, virus or fungi contamination, from the donor bone and / or associated soft tissues.

Owner:LIFENET HEALTH

Anionic surfactants based on alkene sulfonic acid

InactiveUS6043391AIncrease productionImprove yieldGroup 3/13 element organic compoundsFlushingAlkylphenolAlpha-olefin

New anionic surfactants and methods of preparation which are derived from aromatic or substituted aromatic molecules and alkenesulfonic acid. Wherein the aryl compound is alkylated and sulfonated in one-step with an alkene sulfonic acid prior to sulfonic acid neutralization. The methods allow the functional sulfonate group to be attached to the end of the alkyl chain rather than to the aromatic ring thus allowing for selective substituted groups, either branched, linear or alkoxylated or combinations thereof to be placed on the aryl compound prior to sulfonation and alkylation. The invention uses the alkene sulfonic acid produced from thin-film sulfonation of an alpha-olefin to alkylate benzene, mono-substituted aromatic, poly-substituted aromatic, alkylbenzene, alkoxylated benzene, polycyclic aromatic, mono-substituted polycyclic aromatic, poly-substituted polycyclic aromatic, naphthalene, alkylnaphthalene, phenol, alkylphenol, alkoxylated phenol, and alkoxylated alkylphenolalkyl substituted or polysubstituted cyclic or polycyclic compounds to produce the corresponding sulfonic acid having an additional alkyl group derived from the alpha-olefin used during the thin-film sulfonation which is either linear or branched.

Owner:OIL CHEM TECH

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives , phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

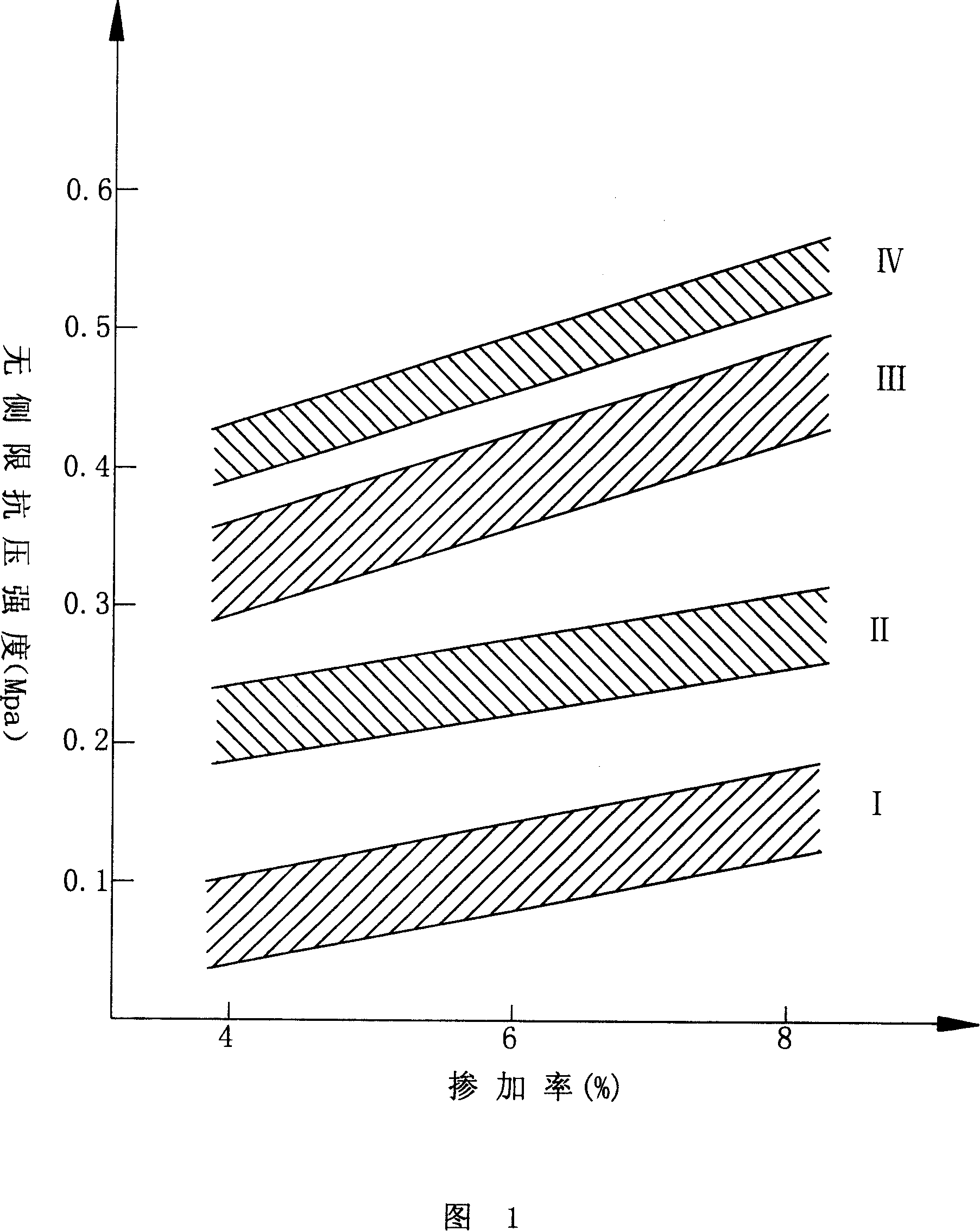

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

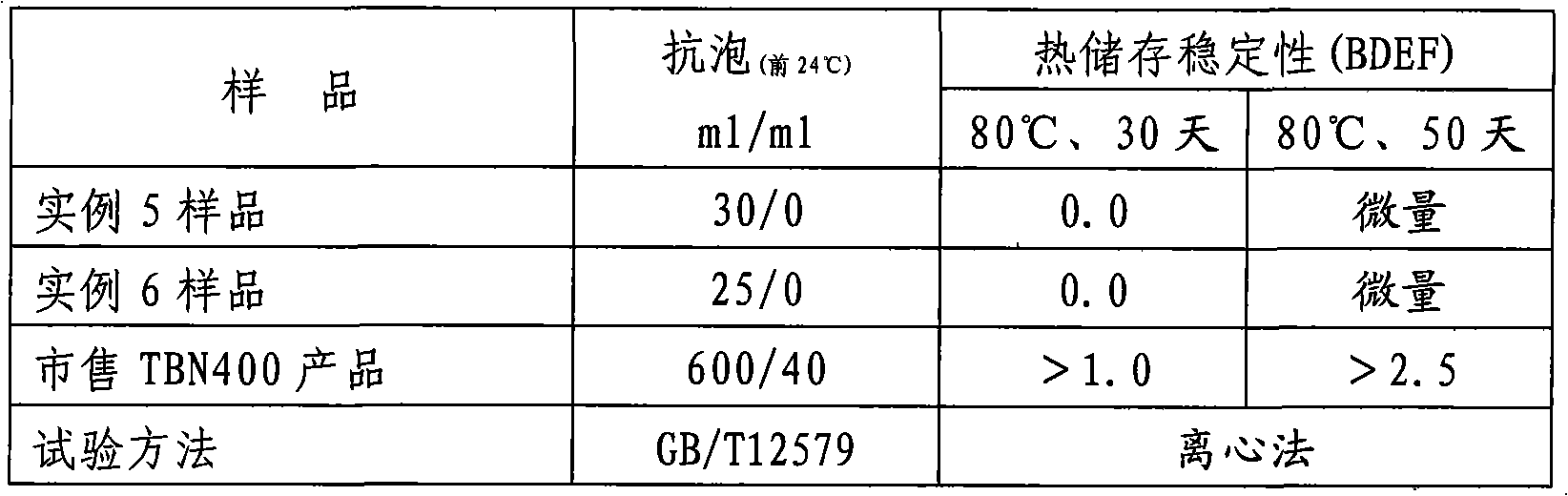

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

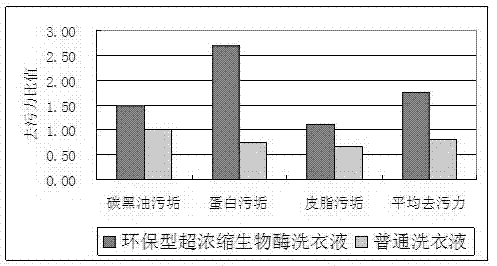

Environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and preparation method thereof

ActiveCN102242022ANo pollution in the processReduce consumptionNon-ionic surface-active compoundsDetergent mixture composition preparationHydrotropePhosphate

The invention relates to a detergent for daily use, and specifically relates to an environment-friendly type hyperconcentration biological enzyme liquid laundry detergent and a preparation method thereof. The prepared product in the invention is mobile liquid with low viscosity, contains no phosphates, fluorescent brightening agents or alkylphenol polyoxyethylene, and has no pollution to environment. The production process for the product is simple; preparation and mass production of the product are easy; the product can be widely used for washing of various fabrics and clothing and is both applicable to hand wash and machine wash. The environment-friendly type hyperconcentration biological enzyme liquid laundry detergent comprises, by weight, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether sodium sulfate-70, 0.5 to 50 parts of fatty alcohol polyoxyethylene ether-9, 0.5 to 30 parts of sodium alkylbenzene sulfonate-60, 0.2 to 15 parts of triethanolamine, 0.1 to 10 parts of sodium citrate, 0 to 5 parts of citric acid, 0 to 5 parts of aliphatic acid, 0.02 to 8 parts of biological enzyme, 0.1 to 20 parts of an enzyme stabilizer, 0.5 to 30 parts of a solvent, 0 to 15 parts of a hydrotropic agent, 0 to 5 parts of a bactericide, 0.001 to 5 parts of an antiseptic, 0 to 3 parts of essence and 1.0 to 40 parts of softened water.

Owner:上海开米科技有限公司

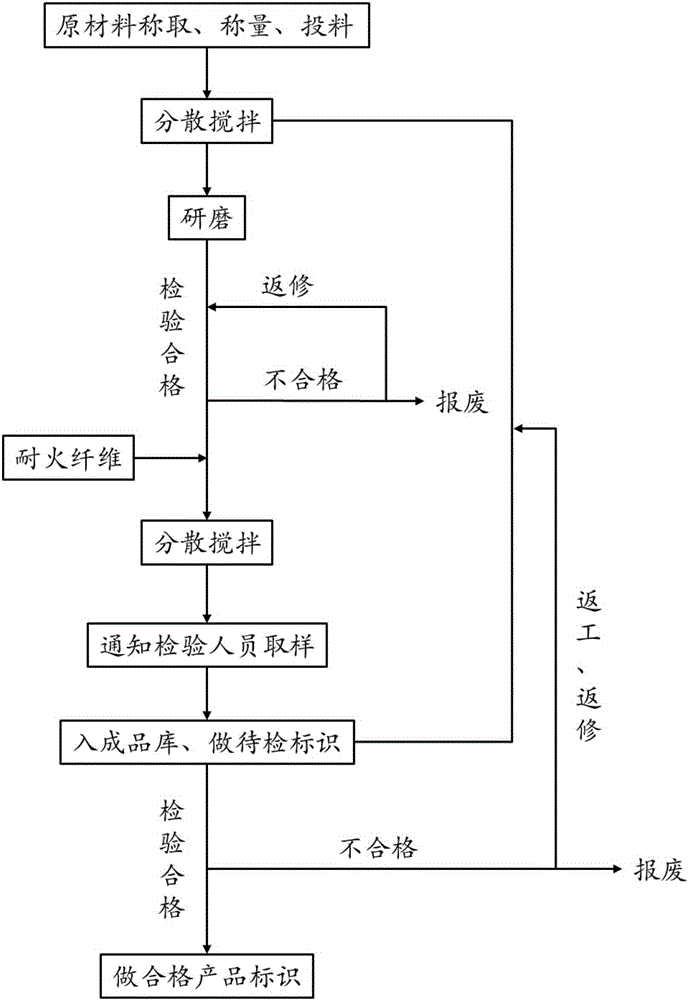

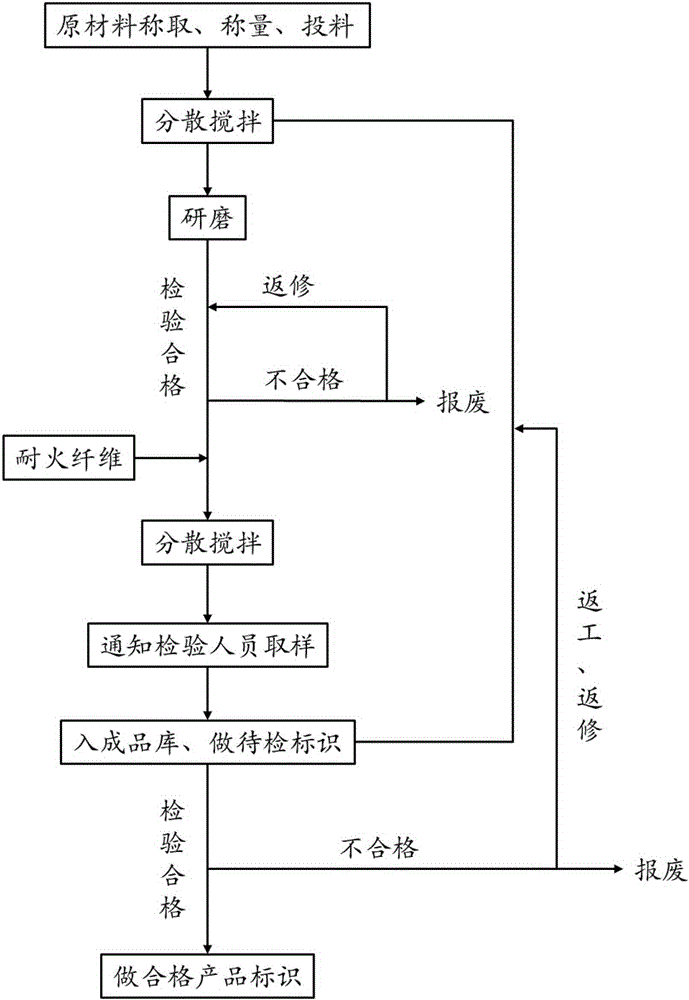

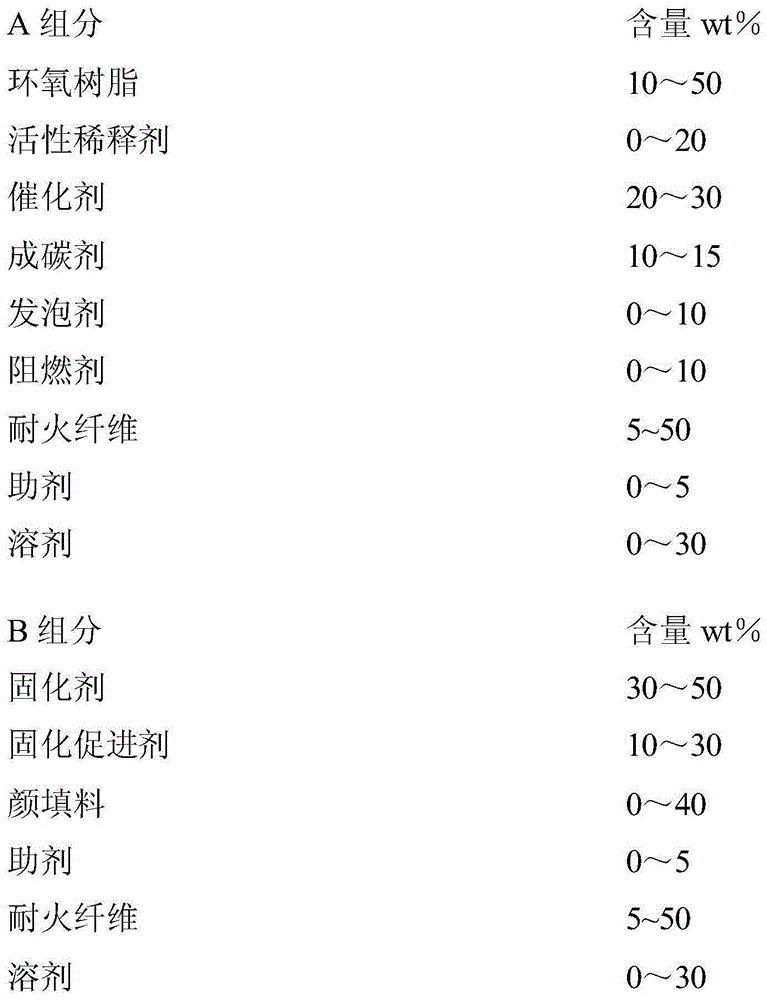

Environment-friendly epoxy intumescent fire-retardant coating and preparing method thereof

ActiveCN105238222AImprove acid resistanceGood alkali resistanceFireproof paintsEpoxy resin coatingsFiberAlkylphenol

The invention relates to an environment-friendly epoxy intumescent fire-retardant coating and a preparing method thereof, and belongs to the field of functional coatings. The environment-friendly epoxy intumescent fire-retardant coating is prepared from a component A and a component B, wherein the component A uses epoxy resin as a main film forming matter and is added with a reactive diluent, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent, and the component B is composed of a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. In the component A, the ratio of the epoxy resin to the reactive diluent is 1:1-5:1. In the component B, the ratio of the curing agent to the curing accelerator is 1:1-5:1, and the usage quantity of the refractory fibers accounts for 5-50% of the total mass. The environment-friendly epoxy intumescent fire-retardant coating is free of alkylphenol, or halogen compounds, or boron compounds or sulfocompounds. The prepared environment-friendly epoxy intumescent fire-retardant coating is good in acid resistance, alkali resistance, water resistance, ageing resistance and salt mist resistance and is particularly suitable for fire-retardant protection for maritime and severe outdoor environments, the petrochemical industry and places with hydrocarbon fire potential hazards.

Owner:MARINE CHEM RES INST

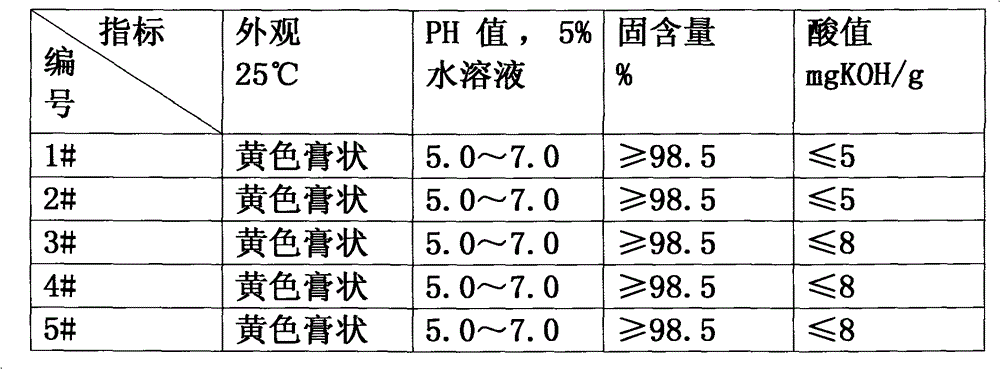

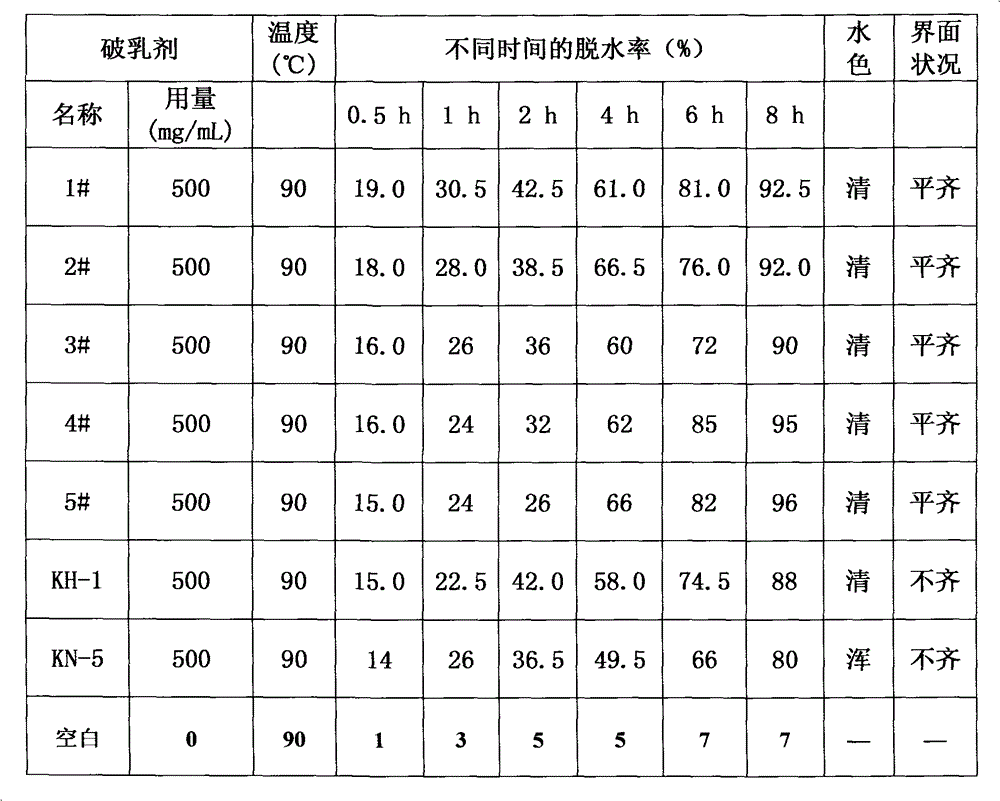

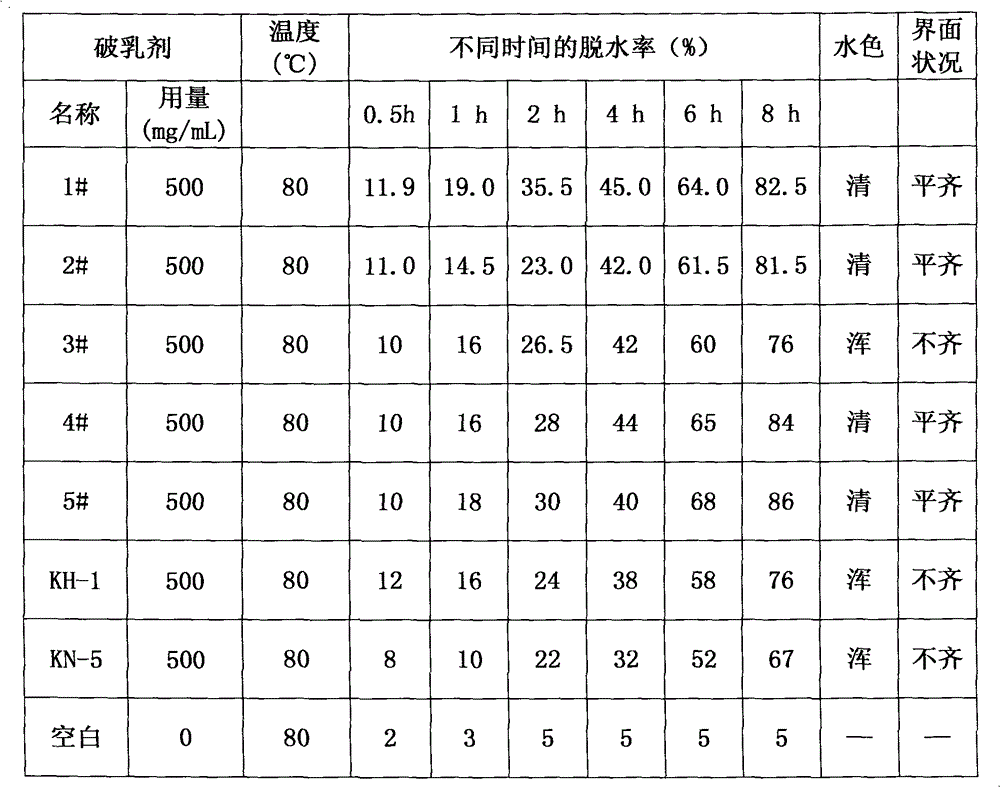

Preparation method of efficient deemulsifier for naphthenic extra heavy oil and product thereof

ActiveCN102746470AWeak elasticityReduce viscosityDewatering/demulsification with chemical meansAlkylphenolPhenol

The invention relates to a preparation method of an efficient deemulsifier for naphthenic extra heavy oil and a product thereof, belonging to the technical field of petroleum processing. The efficient deemulsifier is prepared by polymerizing alkylphenol, polyethylene polyamine and formaldehyde to obtain thermoplastic phenol-amine resin as an initiator, polymerizing the initiator with oxirane and epoxypropane to generate polyether blocked copolymer, and then esterifying the polyether blocked copolymer with acrylic acid and other unsaturated acids to generate a modified polyether product by grafting olefine acid. The product prepared by the method has the characteristics of quick dehydration and low dosage. The efficient deemulsifier of the invention is suitable for dehydrating the naphthenic extra heavy oil of Karamay oil fields, meeting the requirements of proper temperature, quick dehydration, high dehydration rate, clear water color, and tidy oil-water interface, and has high efficiency demulsification and dehydration performance.

Owner:克拉玛依市天明化工有限责任公司

Inspissated oil emulsion viscidity reducer

ActiveCN1778862AStrong resistance to mineral saltHigh emulsifying colloidDrilling compositionPhosphateOil emulsion

A thickened oil emulsifying viscosity reducer consists of anion surface activator, non-ionic-anion surface activator, demulsifier and water in proportion by 1:0.1-50:0.01-20 and water content is 0.2-5000 times of the sum of a, b and c. Anion surface activator comprises sodium salt and calcium salt of petroleum sulfoacid salt methyl condensate and sulfonated lignin; non-ionic-anion surface activator is chosen organic phosphate salt, sulfuric ester salt , carboxylate and sulfosalt of alkylphenol or fatty alcohol-polyoxyethylene ether; demulsifier is copolymer of alkyl ammonium halide cation demulsifier, polyethylene glycol polyoxytrimethylene polylol ether non-ionic demulsifier or polyethylene glycol polyoxytrimethylene polyethylene polyamines block. It has strong emulsifying ability and low thickened oil viscosity,

Owner:CHINA PETROLEUM & CHEM CORP +1

Linear alkylphenol derived detergent substantially free of endocrine disruptive chemicals

Disclosed is a lubricating oil composition displaying reduced endocrine disruption response, comprising a major amount of an oil of lubricating viscosity; and a detergent comprising an unsulfurized alkali or alkaline earth metal salt of a reaction product of(1) an olefin having at least 10 carbon atoms, wherein greater than 80 mole % of the olefin is a linear C20-C30 n-alpha olefin, wherein less than 10 mole % of the olefin is a linear olefin of less than 20 carbon atoms, and wherein less than 5 mole % of the olefin is branched chain olefin of 18 carbons or less, and(2) a hydroxyaromatic compound.

Owner:CHEVROU USA INC +2

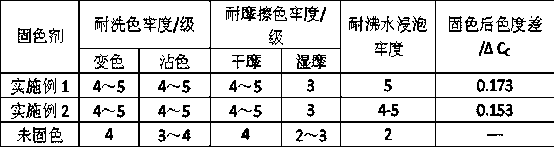

Formaldehyde-free fixing agent and preparation method thereof

The invention discloses a formaldehyde-free fixing agent, which comprises the following components in parts by weight: 80 to 120 parts of cationic monomer, 5 to 20 parts of unsaturated high-grade organic amine monomer, 3 to 10 parts of dicyandiamide, 4 to 18 parts of pH regulator, 0.001 to 0.05 part of metal ion chelating agent, 0.5 to 1 part of initiator, 2 to 10 parts of epichlorohydrin and 20 to 50 parts of deionized water. The formaldehyde-free fixing agent provided by the invention does not contain formaldehyde and alkylphenol ethoxylates (APEO); and meanwhile, the film-forming property of the fixing agent is utilized, a meshed film layer can be formed on the surface of the fiber, so that the dye dissolution is reduced, the color fastness of reactive dye dyed fabrics is improved, a fixing effect is good, the formaldehyde-free fixing agent can be applied to fixing colors of the reactive dye dyed fabrics, and the washable color fastness and boiling water soaking fastness of the fabrics are improved.

Owner:苏州联胜化学有限公司

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives, phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

Wet etching solution

InactiveUS20080041823A1High oxide selectivityDecorative surface effectsDetergent mixture composition preparationAmmonium dodecyl sulfateHydrogen fluoride

A wet etching solution includes hydrogen fluoride in an amount of about 0.1% to about 3% by weight of the etching solution, an inorganic acid in an amount of about 10% to about 40% by weight of the etching solution, the inorganic acid being one or more of nitric acid, sulfuric acid, and / or hydrochloric acid, a nonionic surfactant in an amount of about 0.0001% to about 5% by weight of the etching solution, the nonionic surfactant including one or ore of alkylphenol ethoxylate and / or ammonium lauryl sulfate, and water.

Owner:KPX CHEM

Modified phenolic tackifying resins for rubber compounding applications

This invention is related to modified alkylphenol aldehyde resins and a method for preparing them from the reactions of alkylphenols, aldehydes, amines, rosins and fatty acids. When used in rubber compounds, these modified alkylphenol aldehyde resins provide much improved tack properties.

Owner:SINO LEGEND CHINA CHEM

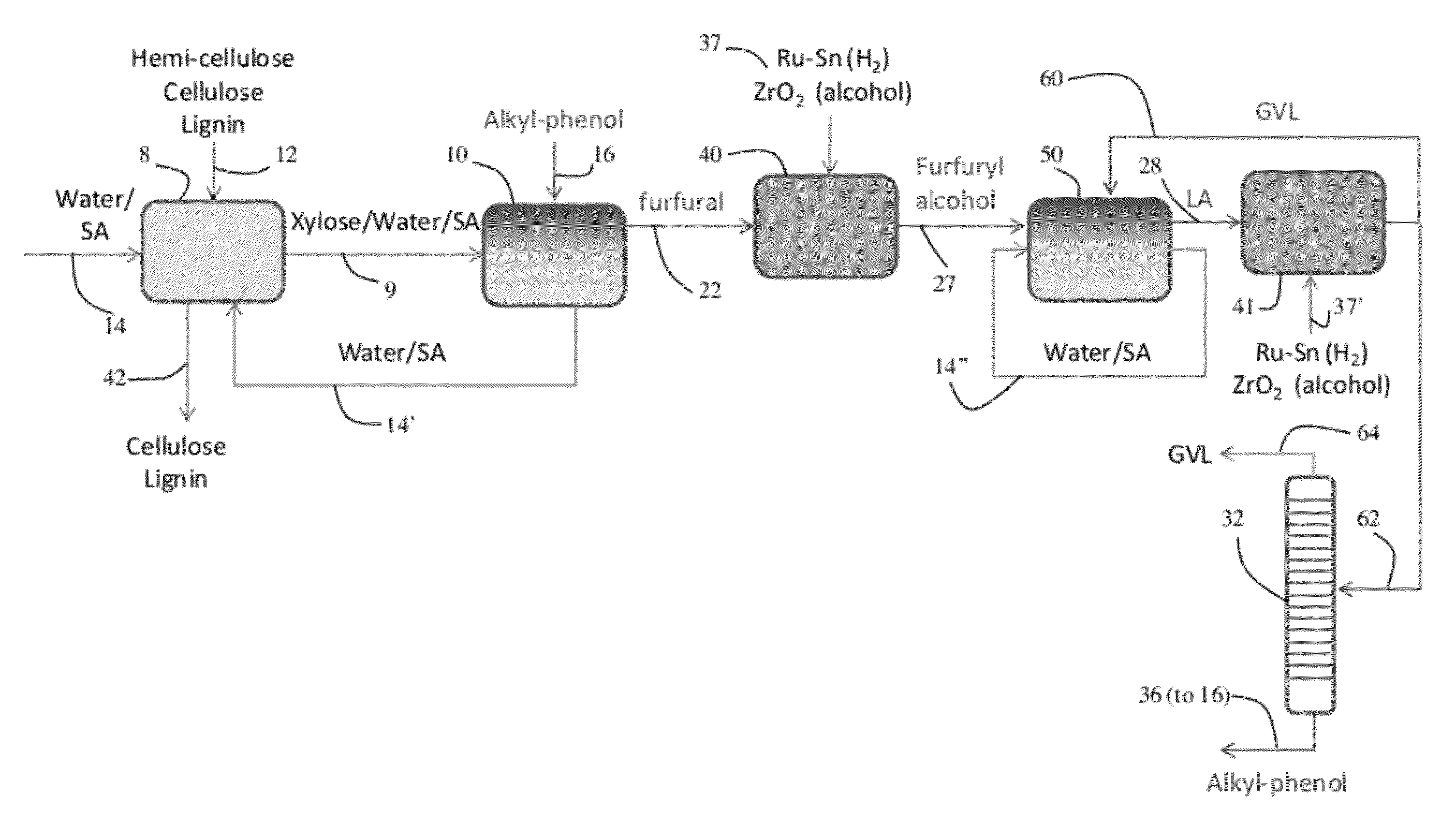

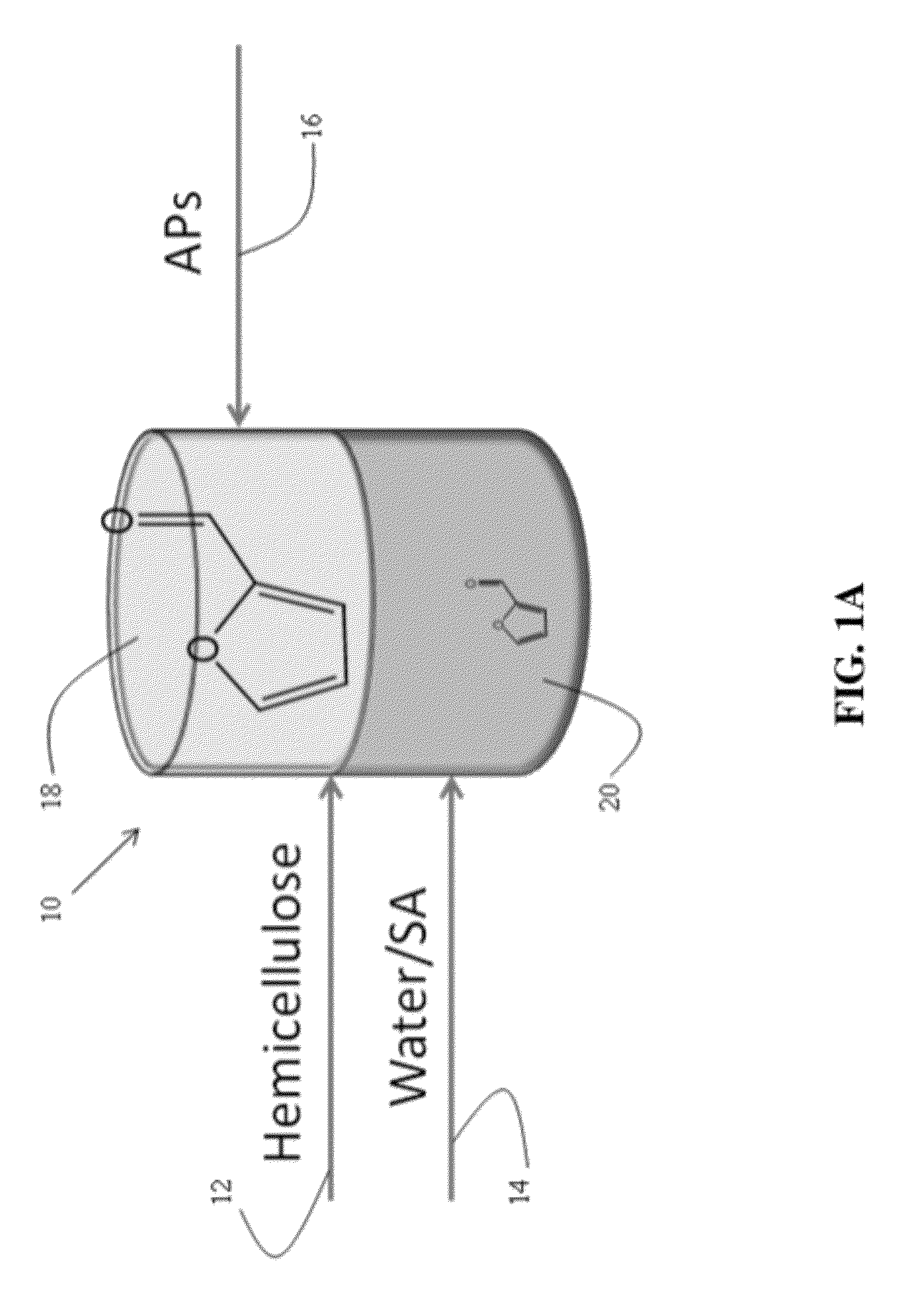

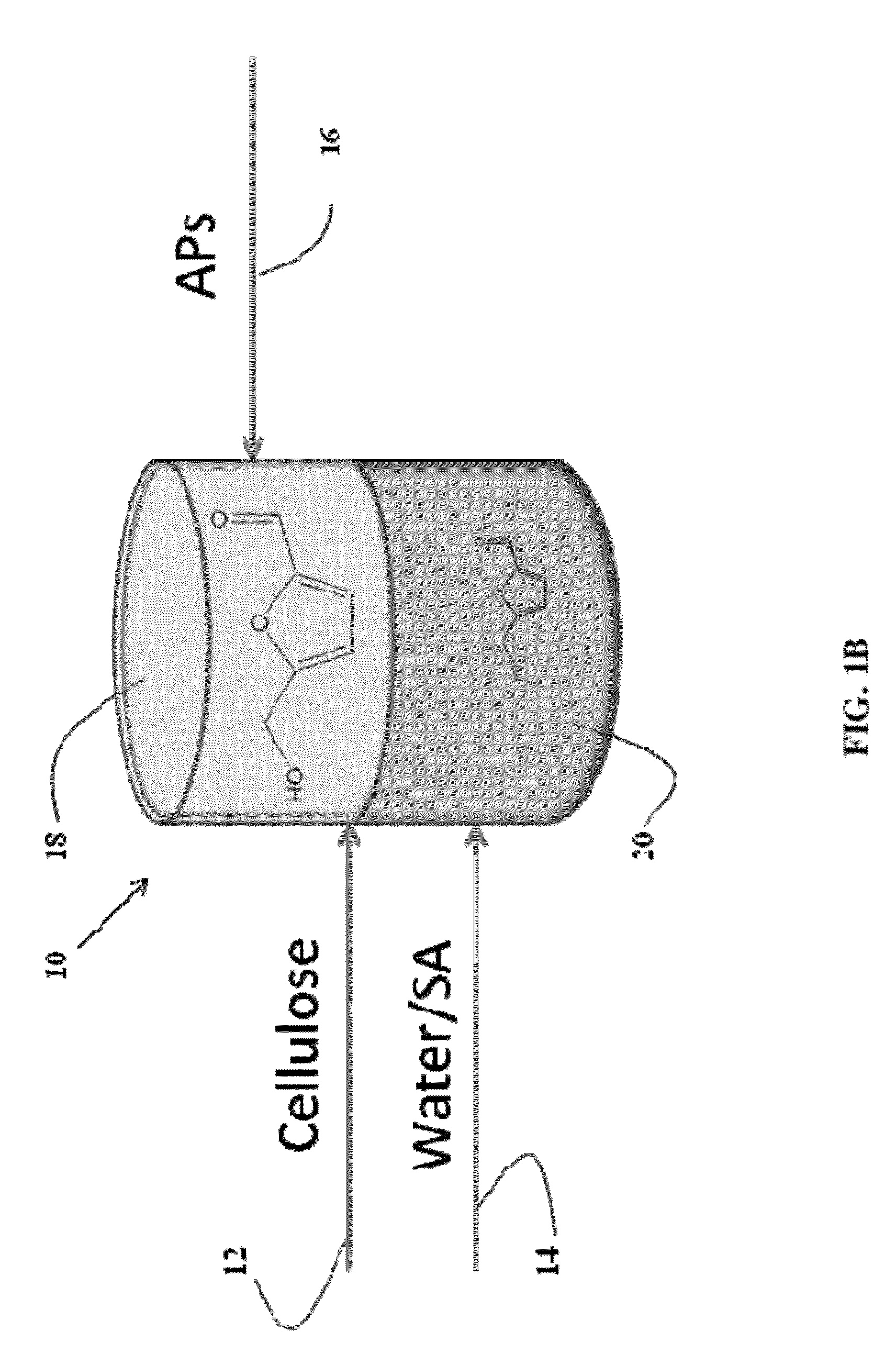

Method to produce, recover and convert furan derivatives from aqueous solutions using alkylphenol extraction

ActiveUS20120302765A1Cost-effectiveLow production costOrganic compound preparationCarboxylic acid esters preparationFuranAlkylphenol

Described is a catalytic process for converting biomass to furan derivatives (e.g., furfural, furfuryl alcohol, etc.) using a biphasic reactor containing a reactive aqueous phase and an organic extracting phase containing an alkylphenol. The process provides a cost-effective route for producing furfural, furfuryl alcohol, levulinic acid hydroxymethylfurfural, γ-valerolactone, and the like. The products formed are useful as value-added intermediates to produce polymers, as precursors to diesel fuel, and as fuel additives.

Owner:WISCONSIN ALUMNI RES FOUND

Linear alkylphenol derived detergent substantially free of endocrine disruptive chemicals

ActiveUS20070049508A1Reduced endocrine disruptive formulationDeterminationOrganic chemistryOrganic compound preparationAlkaline earth metalAlkylphenol

Disclosed is a lubricating oil composition displaying reduced endocrine disruption response, comprising a major amount of an oil of lubricating viscosity; and a detergent comprising an unsulfurized alkali or alkaline earth metal salt of a reaction product of (1) an olefin having at least 10 carbon atoms, wherein greater than 80 mole % of the olefin is a linear C20-C30 n-alpha olefin, wherein less than 10 mole % of the olefin is a linear olefin of less than 20 carbon atoms, and wherein less than 5 mole % of the olefin is branched chain olefin of 18 carbons or less, and (2) a hydroxyaromatic compound.

Owner:CHEVROU USA INC +2

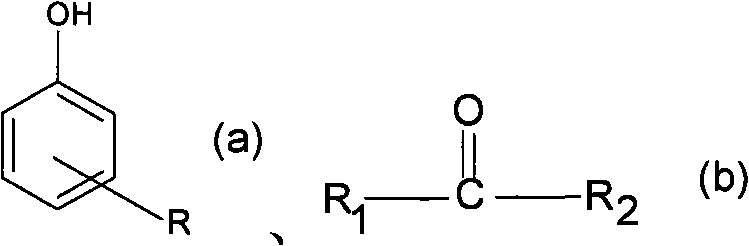

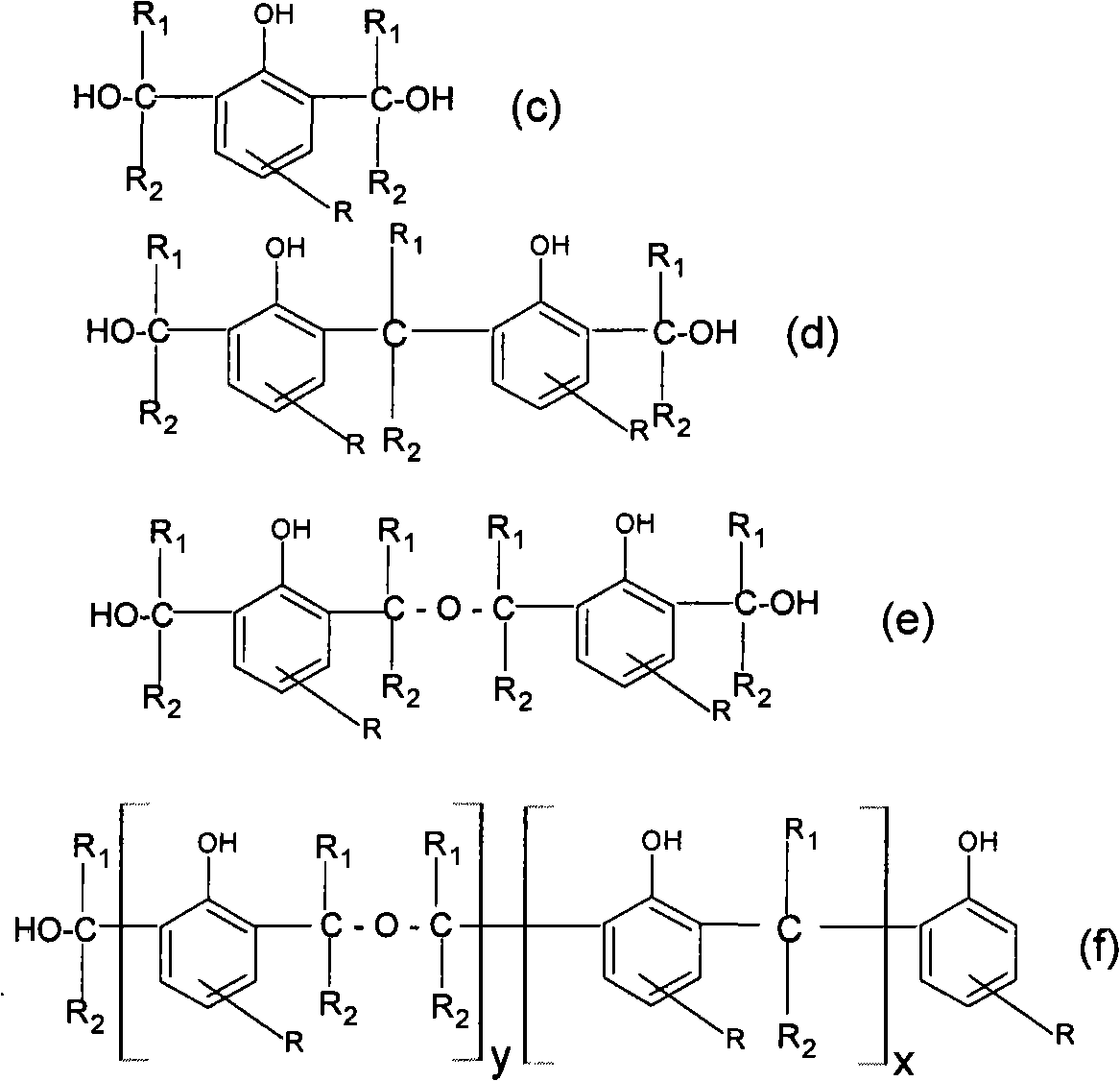

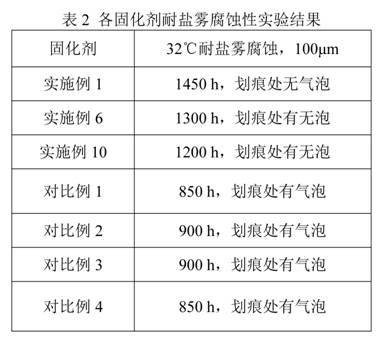

Alkylphenol modified phenolic amide curing agent and preparation method thereof

ActiveCN102633991AStrong resistance to salt spray corrosionHigh impact strengthOrganic compound preparationCarboxylic acid amides preparationAlkylphenolPerylene derivatives

The invention discloses an alkylphenol modified phenolic amide curing agent and a preparation method thereof. The alkylphenol modified phenolic amide curing agent comprises the raw components including phenol or phenol derivatives, methanal or paraformaldehyde, polyamine and fatty acid or fatty acid polymer. The preparation method comprises the following steps of: uniformly mixing the fatty acid or the fatty acid polymer and the polyamine, heating the mixture, cooling the mixture, adding the phenol or the phenol derivatives in the mixture, uniformly mixing the methanal or the paraformaldehyde with the mixture, heating the new mixture, and performing dehydration on the new mixture to obtain the product; or the preparation method comprises the following steps of: uniformly mixing the phenol or the phenol derivatives, the polyamine and the methanal or the paraformaldehyde, heating the mixture, adding the fatty acid or the fatty acid polymer into the mixture, heating the new mixture, and performing the dehydration on the new mixture to obtain the product. The curing agent disclosed by the invention is very strong in salt spray corrosion resistance, is superior to polyamide curing agent and curing agent products of modified phenolic aldehyde amide resin and mixtures of the modified phenolic aldehyde amide resin, and has good impact strength and flexibility as well as excellent water tolerance.

Owner:CARDOLITE CHEM ZHUHAI

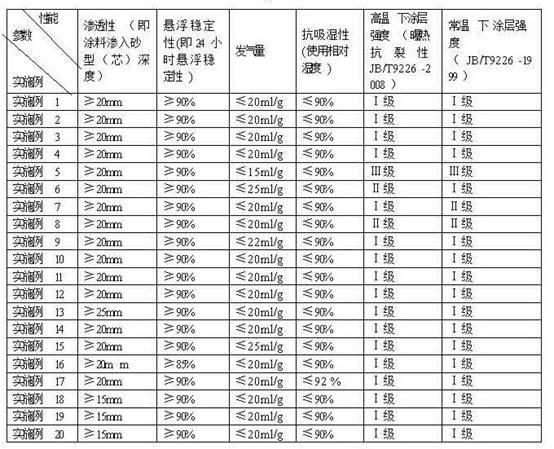

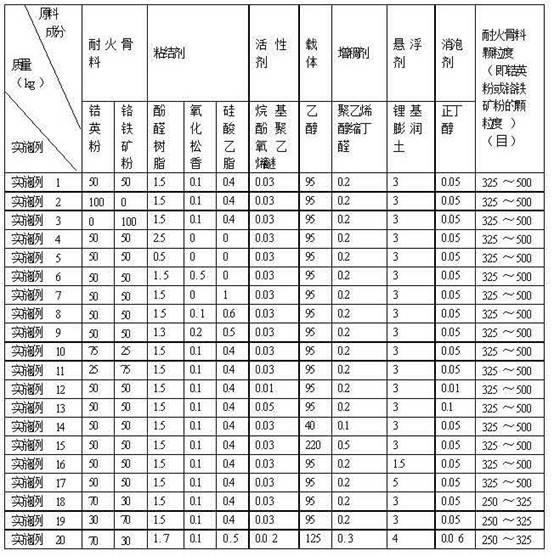

High-permeability sand-burning-preventing paint for casting and preparation method thereof

InactiveCN102139342AImprove permeabilityImprove high temperature strengthFoundry mouldsFoundry coresAlkylphenolSuspending Agents

The invention discloses high-permeability sand-burning-preventing paint for casting and a preparation method thereof. The high-permeability sand-burning-preventing paint is prepared from the following raw materials: refractory aggregate, a binding agent, an activating agent, a thickening agent, a suspending agent, a defoaming agent and a carrier, wherein the masses of the binding agent, the activating agent, the thickening agent, the suspending agent, the defoaming agent and the carrier respectively account for 0.5-2.5 percent, 0.01-0.05 percent, 0.1-0.5 percent, 1.5-5.0 percent, 0.01-0.1 percent and 40-220 percent of the mass of the refractory aggregate; the refractory aggregate is a mixture of one or two of zircon powder and chromite fines in any proportion; the binding agent is phenolic resin or a mixture of the phenolic resin and one or more than two of oxidized rosin and ethyl silicate; the activating agent is alkylphenol ethoxylates; the carrier is ethanol; the thickening agent is polyvinyl butyral; the suspending agent is lithium bentonite; and the defoaming agent is normal butanol.

Owner:衡阳中钢衡重铸锻有限公司

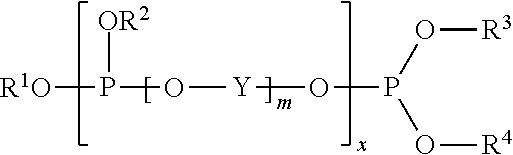

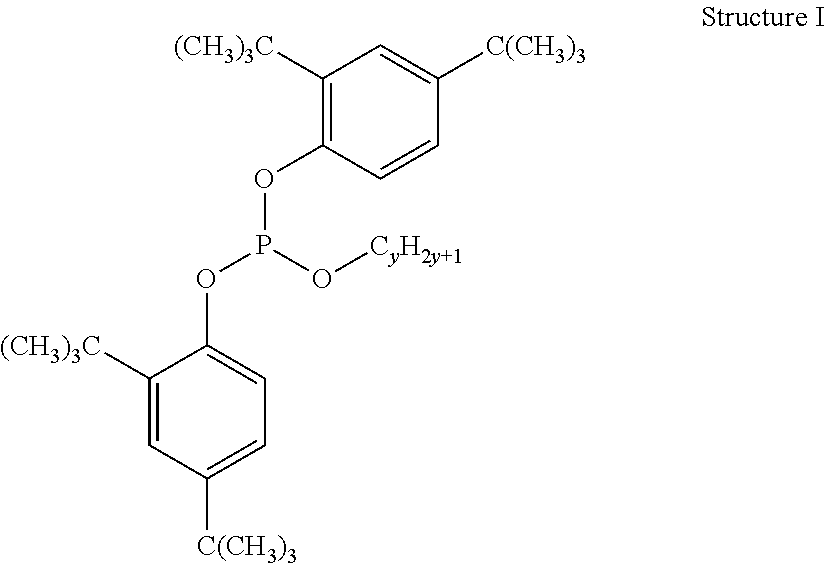

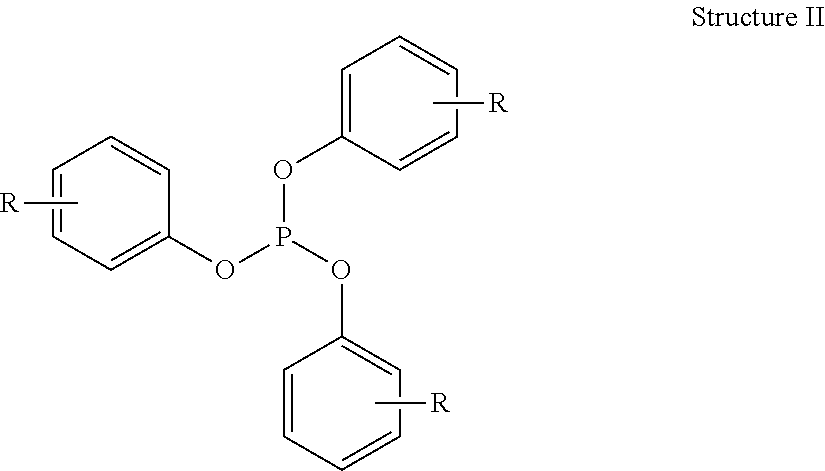

Alkylphenol free-liquid polymeric phosphite polymer stabilizers

ActiveUS8563637B2Difficult to extractImprove hydrolytic stabilityPhosphorus organic compoundsAlkylphenolGlycol ethers

Owner:DOVER CHEM CORP

Stainless steel degreasing agent

InactiveCN101979711AImprove solubilityImproves the properties of uniform corrosionActive agentBrominated hydrocarbon

The invention provides a stainless steel degreasing agent, which comprises the following components in percentage by weight: 5 to 25 percent of organic solvent, 2 to 5 percent of corrosion inhibitor, 10 to 25 percent of surfactant, 5 to 10 percent of inorganic salt, 1 to 3 percent of defoaming agent and the balance of deionized water, wherein the organic solvent is bromohydrocarbon; the corrosion inhibitor is sodium benzoate, ammonium benzoate, triethanolamine, ethanolamine or benzotriazole; the surfactant is one or more of alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether; the inorganic salt is alkaline salt; and the defoaming agent is tributyl phosphate, organic silicon, oleic acid or sodium oleate. The stainless steel degreasing agent can replace the currently used ODS cleaning agents, can achieve the cleaning effect of the ODS cleaning agents, does not damage the surface of the stainless steel, has obvious cleaning effect, can clean a large number of products, and does not harm a human body; and the preparation method is simple, safe, and environment-friendly.

Owner:JIANGSU TIANHENG NANO SCI & TECH

Poured epoxytar concrete material and its prepn process

InactiveCN101020601AImprove low temperature performanceReduce construction temperatureRoadwaysEpoxyEther

The present invention relates to poured road surface laying material, and is especially one kind of poured epoxy asphalt concrete material with low construction temperature, high flowability and construction convenience and its preparation process. The poured epoxy asphalt concrete material consists of component A and component B in the weight ratio of 8-50 as well as stone material in the amount of 3-9 times the component A. The component A consists of asphalt 45-90 weight portions, epoxy resin 4.5-36 weight portions, modified alkylphenol 9-27 weight portions and glycidol ether 0-3 weight portions, and the component B is curing agent. The poured epoxy asphalt concrete material is prepared through mixing the materials of the component A, stirring at 120-160 deg.c, adding stone material, and final adding the heated curing agent and maintaining the temperature for 0-120 min.

Owner:重庆市智翔铺道技术工程有限公司

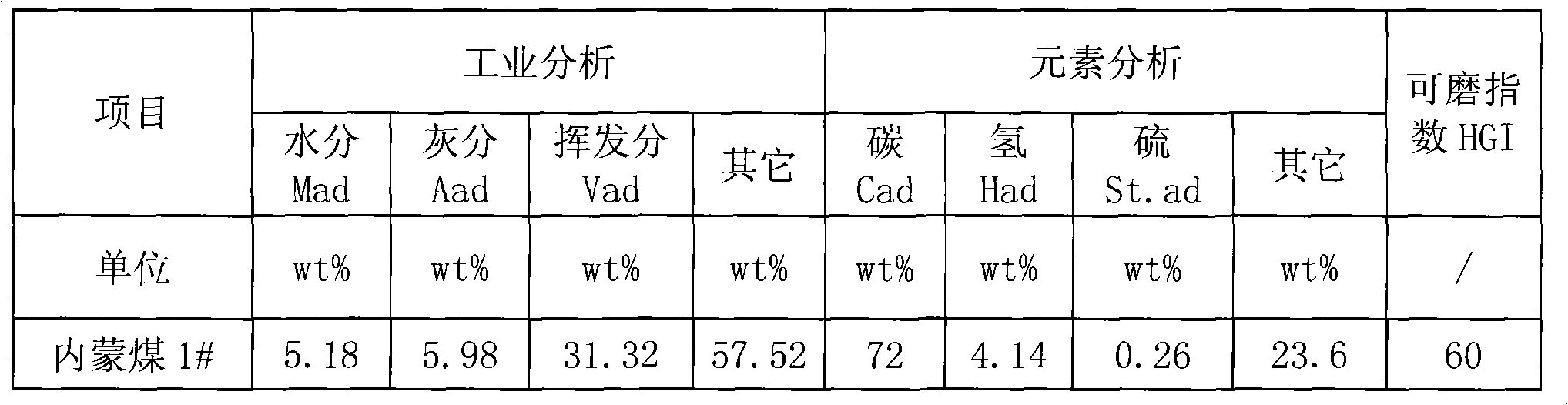

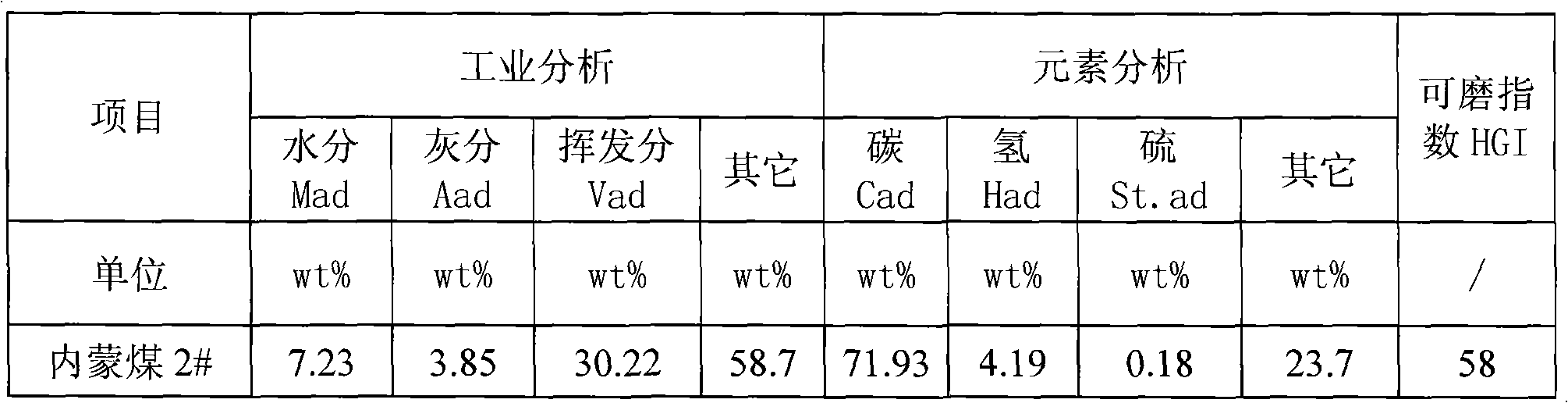

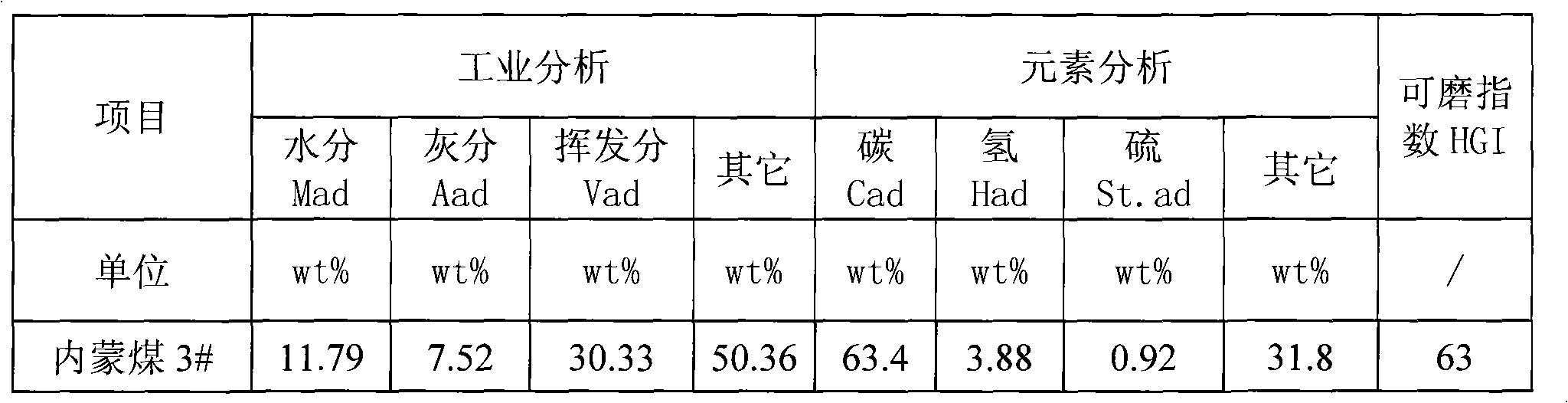

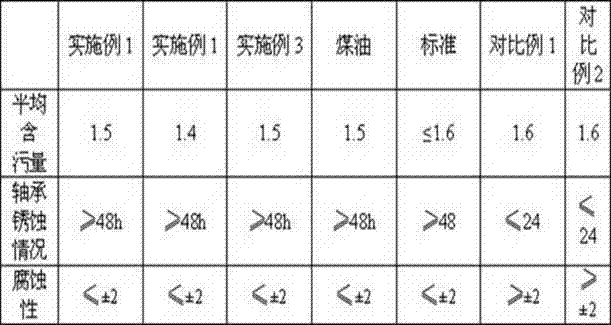

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

Polycarboxylic superplasticizer, synthesis method thereof and application method thereof

The invention discloses a synthesis method of a polycarboxylic superplasticizer. The raw materials for synthesis of the polycarboxylic superplasticizer are APEG of two types of molecular weight (respectively 500-1000 and 1600-2200), MPEGMA of two types of molecular weight (respectively 800-1400 and 2000-2500), maleic anhydride, acrylic acid, alkylphenol ethoxylate, hydrogen peroxide, ascorbic acid, ferrous sulfate, sodium persulfate, sodium hydroxide and deionized water. Since the APEG and MPEGMA of different types of molecular weight are simultaneously adopted as crossing branch chains, the invention not only has a high water-reducing rate, but also maintains good water-reducing rate, has good adaptability to sands and stones with high clay contents, and improves the strength of concrete, Compared with the prior art, the invention has the advantages that the raw materials of the product are easily available, the synthesis process can be easily controlled, the performance of the reaction product is stable, and the cost is reduced by 5-10 percent.

Owner:GUANGDONG REDWALL NEW MATERIALS

Adjuvant Compositions, Agricultural Pesticide Compositions, and Methods for Making and Using Such Compositions

PendingUS20130123104A1Improved spray drift controlGood dispersionBiocideAnimal repellantsLiquid mediumAdjuvant

An agricultural adjuvant composition includes (a) one or more first nonionic surfactants selected from the group consisting of fatty acid glycol ester surfactants, polyalkoxylated triglyceride surfactants, alkoxylated fatty alcohol surfactants, and sorbitan fatty acid ester surfactants, (b) at least one of: (b)(i) one or more second nonionic surfactants selected from the group consisting of polyalkoxylated alkylphenol surfactants, polyalkoxylated alkarylphenol surfactants, amine oxide surfactants, alkanolamide surfactants, glycoside surfactants, and ethylene / propylene block copolymers, and (b)(ii) one or more anionic components selected from the group consisting of anionic surfactants and polyanionic polymers, (c) optionally, a liquid medium comprising one or more fatty acid (C1-C3)alkyl esters, optionally, one or more water soluble deposition aid polymers, and (e) optionally, one or more thickening agents.

Owner:RHODIA OPERATIONS SAS

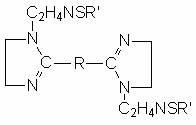

Sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and preparation method thereof

InactiveCN102321463AImprove protectionGood water solubilityOrganic chemistryBorehole/well accessoriesCarbon dioxide corrosionActive agent

The invention discloses a sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and a preparation method thereof. The corrosion inhibitor comprises the following components in percentage by weight: 20-50 percent of sulfur-containing bis-imidazoline quaternary ammonium salt, 1-5 percent of nonionic surfactant, 40-70 percent of low molecular alcohol solvent and 5-10 percent of alkynol, wherein a sulfur-containing bis-imidazoline compound has a general formula of a structure which is shown in the specification; the number of carbon atoms in R of the formula is 5 or 8; the nonionic surfactant is fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylate; the low molecular alcohol solvent is methanol, ethanol, isopropanol or ethylene glycol; and the alkynol is propargyl alcohol or hexynol. In the invention, the sulfur-containing bis-imidazoline compound which is generated through dehydration between dicarboxylic acid and polyamine molecule, dehydration reaction in the molecule and further reaction with the sulfur-containing compound is adopted; the molecule contains a plurality of active adsorption centers such as two diazo five-membered heterocyclic rings, a sulfur-containing group and the like; and a formed organic adsorption membrane has better protection effect on carbon steel.

Owner:UNIV OF SCI & TECH BEIJING

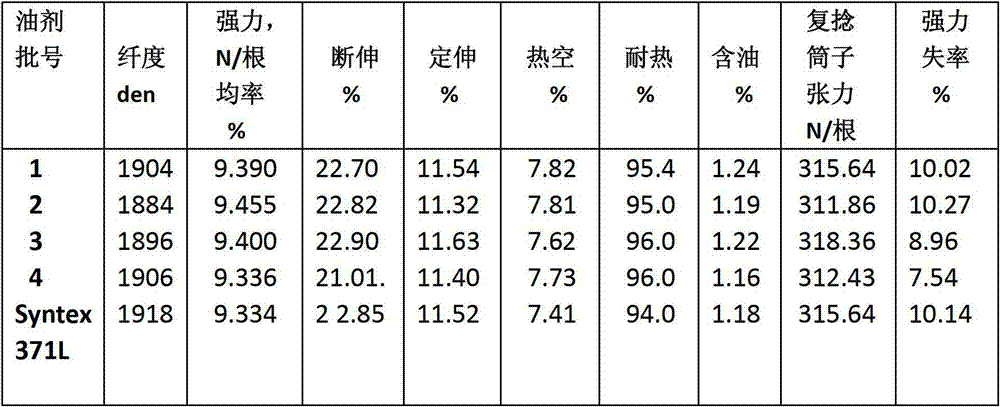

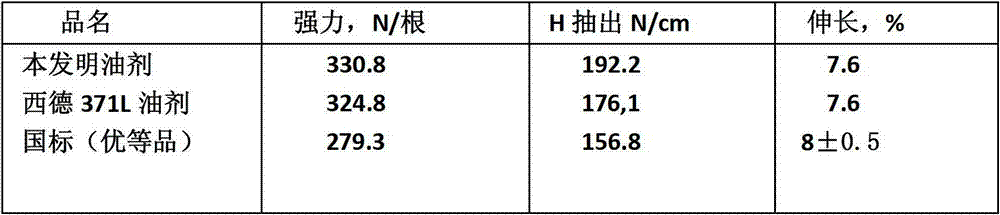

Non-emulsion type pure oiling agent for high speed spinning of polyamide-6 filaments

The invention discloses a non-emulsion type pure oiling agent for the high speed spinning of polyamide-6 filaments, wherein a smoothing agent consists of three polyether type non-ionic surfactants, i.e. fatty alcohol-ethylene oxide-propylene oxide copolyether, fatty alcohol-polyoxyethylene ether and polyxyethylated alkylphenol; a collecting agent is the non-ionic surfactant, i.e. fatty acid polyoxyethylene ether ester; an antistatic agent is fatty alcohol-polyoxyethylene ether phosphate and amine (kali) salt of alkyl phosphate; a binding additive is Ac; and a regulating agent is water. The pure oiling agent for the high speed spinning of the polyamide-6 filaments generates little smoke, does not gel, gather or deposit, and is of good heat stability and chemical properties; and in addition, after a spray nozzle is applied with oil, the process requirements on air bath at the high temperature of 230 DEG C, high speed spinning (3000m / min) and strong drafting can be met. The requirements on the properties of precursors, thrown silk, dipping glue and tyre cords are met, so that the property of a polyamide-6 tyre fabric reaches the high level of national standards.

Owner:SHAANXI HAIAN IND

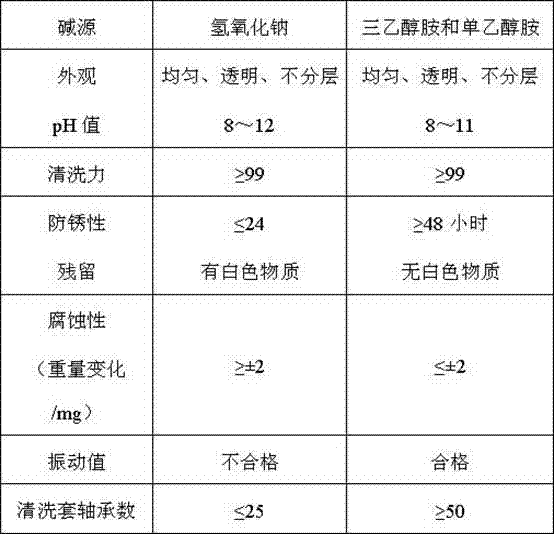

Metal bearing water-based cleaning agent and preparation method and application thereof

The invention discloses a metal bearing water-based cleaning agent and a preparation method and application thereof. The cleaning agent comprises the following components in percentage by mass: 2 to 8 percent of fatty alcohol polyoxyethylene ether, 2 to 8 percent of alkylphenol polyoxyethylene ether, 3 to 10 percent of fatty acid alkanolamide, 5 to 25 percent of triethanolamine oleate, 10 to 22 percent of triethanolamine, 5 to 18 percent of monoethanolamine, 0.5 to 3 percent of alkyl sodium sulfonate, 0.01 to 0.5 percent of benzotriazole, 1 to 2 percent of disodium ethylene diaminetetraacetate and 3.5 to 71.49 percent of water. During use, the cleaning agent is prepared into 2 to 10 percent working solution, and a bearing part is ultrasonically cleaned, rinsed, subjected to spray washing and dried to meet the cleaning degree standard and the finished product vibration value standard. The product is environment-friendly, does not influence a bearing material, is prepared from readily available raw materials, has low cost, can replace the conventional cleaning gasoline and kerosene, reduces the potential safety hazard, avoids environmental pollution, and saves energy.

Owner:白马轴承技术(洛阳)有限公司 +1

Emulsion type carbon fiber sizing agent containing graphene oxide and preparation method thereof

The invention discloses an emulsion type carbon fiber sizing agent containing graphene oxide and a preparation method thereof. The sizing agent is prepared from a nonionic epoxy emulgator, epoxy resin, graphene oxide and a water dispersion medium. The preparation method of the emulsion type carbon fiber sizing agent comprises the following steps: taking epoxy resin, adding polyethylene glycol and an organic solvent, adding a coupling agent at the reflux temperature and reacting for 2-2.5 hours, adding alkylphenol ethoxylates, stirring for 1-2 hours, then pumping vacuum and extracting the organic solvent, lowering the temperature to room temperature to obtain the nonionic epoxy emulgator; and adding epoxy resin on the basis of the obtained nonionic epoxy emulgator, then slowly and quantitatively adding a graphene oxide aqueous solution, and finally adding the water dispersion medium until the phase is converted to obtain the emulsion type carbon fiber sizing agent. By virtue of the emulsion type carbon fiber sizing agent, the defects of economy, safety, environmental pollution and hygiene caused by a large quantity of organic solvents required for the solution type carbon fiber sizing agent can be overcome; the prepared sizing emulsion has the characteristics of being small in granularity and uniform in pavement on the surface of the carbon fiber.

Owner:HARBIN INST OF TECH

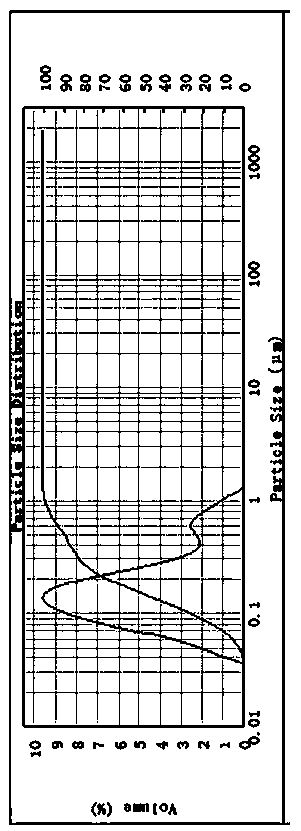

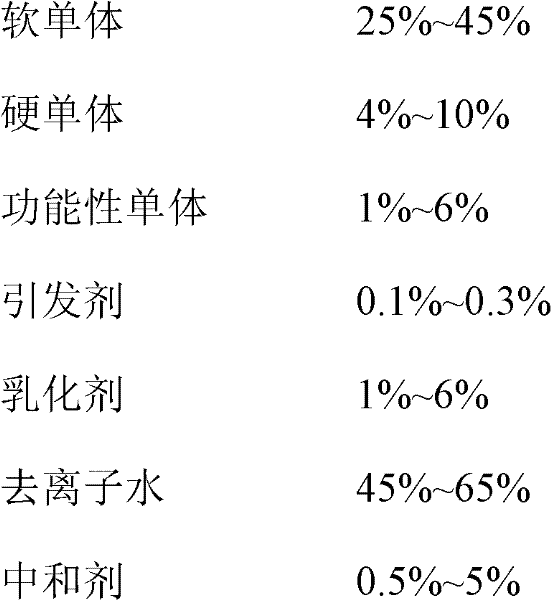

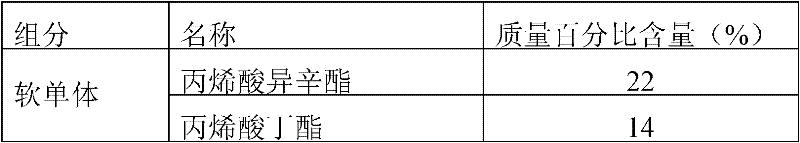

Environment-friendly printing platen adhesive emulsion and preparation method thereof

InactiveCN102344522ANot easy to slideNot easy to break awayEster polymer adhesivesDyeing processTextile printerPolymer science

The invention discloses an environment-friendly printing platen adhesive emulsion and a preparation method thereof, and the emulsion comprises the following components by weight: 25%-45% of soft monomers, 4%-10% of hard monomers, 1%-6% of functional monomers, 0.1%-0.3% of initiators, 1%-6% of emulsifiers, 45%-65% of deionized water, and 0.5%-5% of neutralizers. The adhesive of the invention is anaqueous environment-friendly product, adopts water as a solvent, does not contain any volatile solvent, is environment-friendly, does not discharge toxic substances such as formaldehyde and the like,does not contain alkylphenol additives; the adhesive has good adhesive force to various textile fabrics; fabrics are not easy to slide on the platen or be separated from the platen; printing color register is accurate; the preparation method of the invention adopts a new crosslinking monomer, and increases the water resistance and cohesive adhesion lasting force of the adhesive; the adhesive can be used repeatedly; because of the good cohesive adhesion lasting force of the adhesive, no adhesive is left at the fabric bottom during fabric removal; meanwhile the adhesive of the invention has moderate and adjustable viscosity, is convenient for using, and is easy to adhesive application by a scraper plate.

Owner:连云港百利合新材料发展有限公司

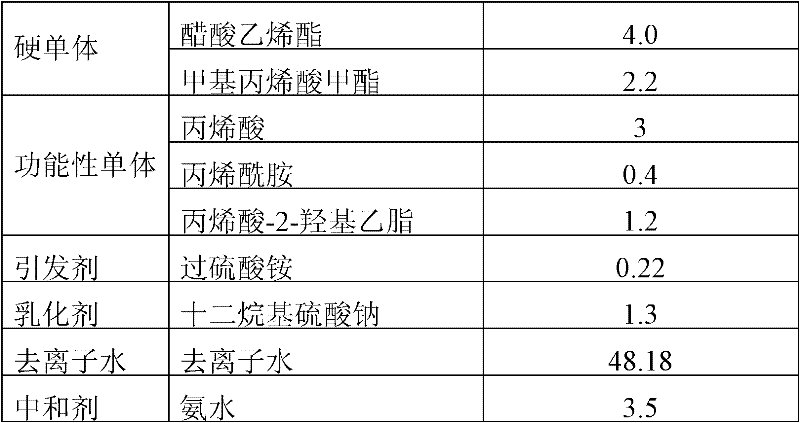

Alkyl phenol sulfonic polyoxyethylene ether sulfonate and preparation thereof

ActiveCN101279937AEnhanced overall recoveryImprove technical effectDrilling compositionSulfonic acid preparationSulfonateAlkylphenol

The invention relates to alkylphenol sulfonic polyoxyethylene ether sulfonate and the preparation method thereof, mainly aiming at solving the problems that current oil displacement agent containing surfactant is poor in oil displacement efficiency under high temperature with the existence of high salt and that the oil displacement agent contains alkali and causes damages to the stratum and the oil field and erodes the equipment and the pipes, which results in high production cost. The invention adopts alkylphenol sulfonic polyoxyethylene ether sulfonate with general molecular formula (I)to solve the problem; wherein M is alkali metal; R is alkyl from C1-C22; n is any integer from 1 to 20. The alkylphenol sulfonic polyoxyethylene ether sulfonate can be applied to the production of tertiary oil recovery in oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com