Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7304 results about "Suspending Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of suspending agent. : a substance (such as carrageenan, xanthan gum, or cellulose ether) that is added to fluids to promote particle suspension or dispersion and reduce sedimentation.

Alloplastic injectable dermal filler and methods of use thereof

InactiveUS20090110736A1Reduce wrinklesReduce scarsPowder deliveryCosmetic preparationsFiller ExcipientReticular Dermis

A composition comprising an alloplastic injectable suspension for use as a dermal filler comprising a biocompatible and pliable material and a physiologically acceptable suspending agent is provided. A method of making a composition comprising an alloplastic injectable suspension for use as a dermal filler comprising a biocompatible and pliable material and a physiologically acceptable suspending agent, said method comprising admixing a biocompatible and pliable material with a physiologically acceptable suspending agent, is also provided. A method of augmenting soft tissue to provide long-term reduction of a skin defect, said method comprising stimulating collagen beneath the skin defect is further provided. In an embodiment of the method of augmenting soft tissue, the stimulation of collagen production is effected by injecting into the deep reticular dermis an a dermal filler, said dermal filler being an alloplastic injectable suspension and comprising a biocompatible and pliable material and a physiologically acceptable suspending agent.

Owner:BOUTROS AYMAN

Storable water-microsphere suspensions for use in well cements and methods

Storable water-microsphere suspensions for use in well cements and methods of cementing well bores are provided. The storable water-microsphere suspensions are basically comprised of water, microspheres and an effective amount of a suspending agent selected from the group consisting of microfine or colloidal materials and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

Topical otic compositions and methods of topical treatment of prevention of otic infections

InactiveUS20060046970A1Avoid concentrationDosing is simpleAntibacterial agentsBiocideAzalideSuspending Agents

A topical otic composition containing an azalide antibiotic. A topical otic composition containing an azalide antibiotic and an medicament. A topical otic composition containing an azalide antibiotic and a polymer suspending agent. And methods for treating or preventing infections in the ear using azalide antibiotic compositions.

Owner:INSITE VISION

Method for recycling silica powder and carborundum powder from cut waste mortar

The invention discloses an extracting method of high-purity silicon powder and carborundum powder from waste slurry of monocrystalline silicon cutting or grinding course, which comprises the following steps: separating solid from liquid for the waste slurry; using organic solvent to remove suspending agent and adhesive; doing gas float for solid sand; obtaining certain purity silicon powder; doing liquid float and gravity sorting for the silicon powder further; acidifying the silicon powder through acid; obtaining high-purity silicon powder; doing magnetic float for the composite powder of carborundum-metal through gravity; obtaining the pure carborundum powder. The invention can recycle high-purity silicon from waste slurry in the silicon bar cutting manufacturing course effectively, which changes waste into value with high receiving rate to solve the problem of resource shortage of high-purity silicon.

Owner:XI AN JIAOTONG UNIV

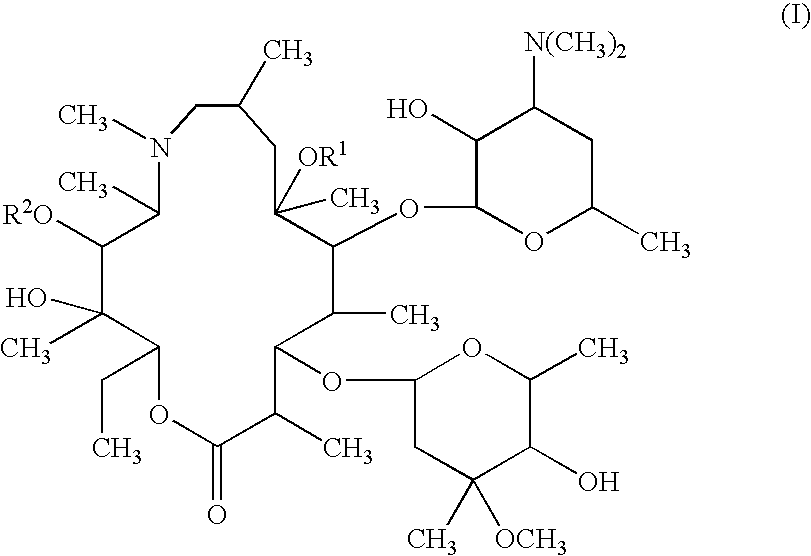

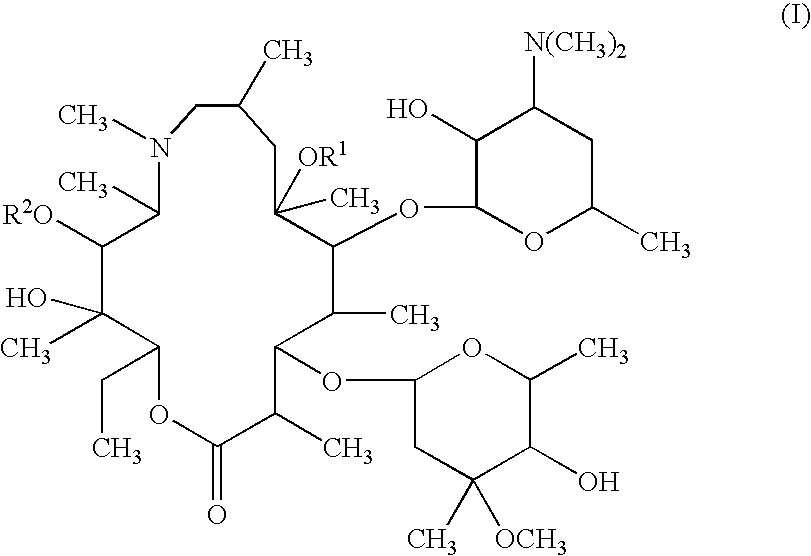

Oral fast dissolving films for erectile dysfunction bioactive agents

InactiveUS20090047330A1Improved ease of handlingIncrease usageBiocideAnimal repellantsVardenafilActive agent

A novel edible polymer based film dosage form manufactured using natural, synthetic, semisynthetic, pharmaceutically acceptable polymers addressing the issues of swallowing difficulties (Dysphagia and Dynaphagia), of tablet or capsule dosage forms and handling and storage difficulties associated with liquid dosage forms, that also includes materials such as emulsifying agents, suspending agents, buffering agents, effervescence agents, colorants, flavorants, sweeteners and specified amounts of bioactive agents, for erectile dysfunction. A flexible film dosage form containing sildenafil citrate, tadalafil or Vardenafil is presented. The film system is enabled to be used in various applications such as oral, mucosal and external environments.

Owner:BANGALORE RAMESH

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binderis 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtainedpulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

Physically stable aqueous suspensions of active pharmaceuticals

The present invention concerns methods of making physically stable aqueous suspensions of sparingly soluble to insoluble in water, active pharmaceuticals. More particularly, the invention provides an aqueous pharmaceutical suspension composition comprising an active pharmaceutical component which is sparingly soluble to insoluble in water; a water soluble, low viscosity grade cellulose polymer with a viscosity range of 3 mPa·s to 50 mPa·s as a surfactant; a suspending agent; and water.

Owner:TRIAD GRP

Moisture barrier film coating composition, method and coated form

A dry moisture barrier film coating composition for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, and optionally a flow aid, a colorant, and / or a suspending agent. A liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent. A method of coating pharmaceutical tablets and the like with a moisture barrier film coating comprises forming a liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprising polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent, applying the coating solution or dispersion onto the tablets to form a film coating on the tablets, and drying the film coating on the tablets.

Owner:BPSI HLDG LLC

Liquid soap with vitamin beads and method for making same

InactiveUS6846785B2Reduce breakageAppropriate amount of clarityCosmetic preparationsOrganic detergent compounding agentsCross-linkSuspending Agents

A liquid soap having vitamin-containing microcapsules including a base having an anionic surfactant and a chelating agent, a cross-linked acrylic polymer suspending agent, and multiple vitamin-containing microcapsules uniformly suspended in the liquid soap. The liquid soap is formulated at an elevated temperature which is maintained throughout the formulation process.

Owner:DIAL CORPORATION

Recipe composition of dry turbid agent and its preparation process

ActiveCN101011360ALow costUniform particle sizePowder deliveryPharmaceutical non-active ingredientsActive componentSuspending Agents

The invention relates to a method for preparing dry mixture suspending agent, comprising 0.1-35.0% active components, 29.0-99.3% shaping agents, and 0.05-36.4% suspending agents. The preparation comprises that selecting the shaping agents, arranging the shaping agents, holing agents, and disintegration agent into the water to obtain suspending medium; adding active component into suspending medium to obtain the mixture suspending solution; arranging the shaping agent into fluid bed, atomizing drug mixed suspending solution, and drying. Compared with present technique, the invention contains suspending agent, without block and tacky contacted with water. The fluid bed can quickly dry material, with high efficiency and low cost.

Owner:SINOPHARM ZHIJUN (SHENZHEN) PHARMA CO LTD

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Detergent compositions comprising coloured particles

ActiveUS20060019860A1Organic detergent compounding agentsDetergent dyesSuspending AgentsAqueous solution

The present invention relates to a coloured particles and to detergent compositions containing them that can be used to impart a hueing effect to fabrics contacted with these coloured particles in aqueous solution. The invention enables the effective hueing whilst alleviating problems of staining or spotting by combining in the coloured particle, hueing agent, preferably pigment, binding agent and suspending agent.

Owner:THE PROCTER & GAMBLE COMPANY

Storable water-microsphere suspensions for use in well cements and methods

Owner:HALLIBURTON ENERGY SERVICES INC

Shield type coating composition and preparation process of coating thereof

InactiveCN101817058APrevent sulfidation defectsGuaranteed qualityFoundry mouldsFoundry coresPowder mixtureCarrier fluid

The invention discloses a shield type coating composition, comprising a fire-proof powder mixture, a suspending agent, a binder and a carrier fluid, wherein the fire-proof powder composition consists of high temperature resistant components and functional components, and has a particle size of 200-325 meshes. The invention selects a reasonable fire-proof powder composition to prepare the shield type sand coating, thus achieving good sand burning resistance, and preventing the defects of recarburization on extra-low-carbon stainless steel piece surface and desulphurization on nodular cast iron piece surface, thereby realizing the aim of ensuring casting quality.

Owner:深圳市景鼎现代科技有限公司

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

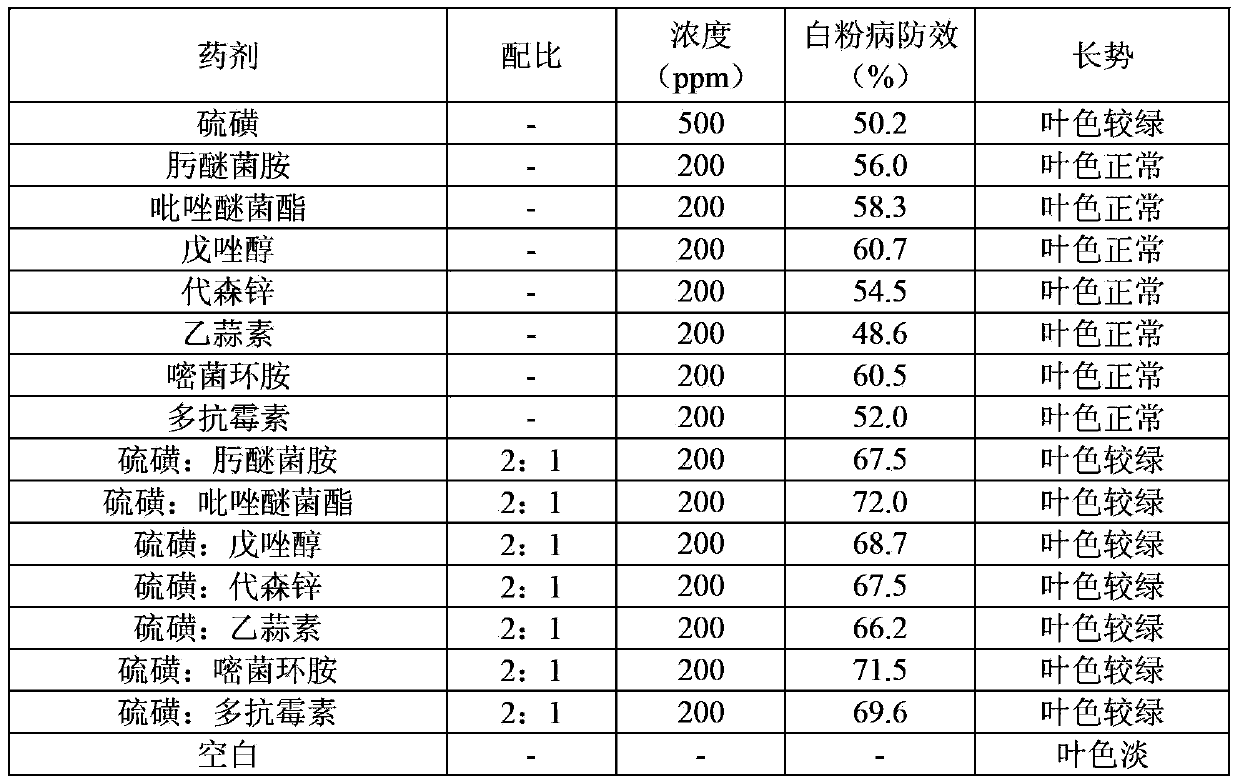

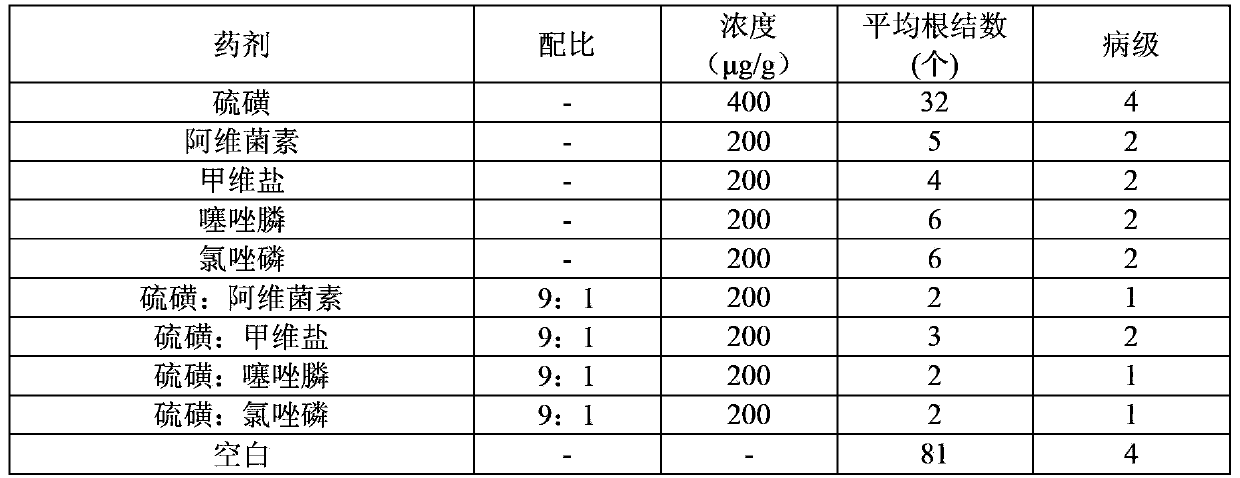

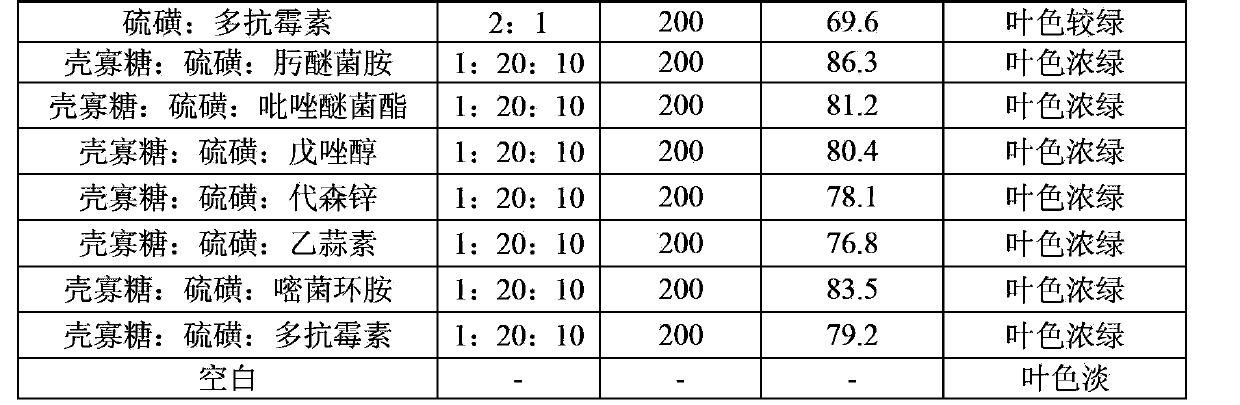

Agricultural composition containing sulphur

InactiveCN103355343AReduce dosageReduce the number of medicationsBiocideFungicidesPhyllocoptruta oleivoraNematode

The invention belongs to the field of plant protection, and especially relates to the agricultural composition containing sulphur and applications thereof. The agricultural composition containing sulphur also comprises another one or two pesticide components, and the weight part ratio of sulphur to pesticide is 0.1-200:1. The agricultural composition containing sulphur can compound with other bactericidal ingredient or insecticidal and mite-killing ingredient, improves the effects on killing bacterium, inspects, and mites, can be processed into granules and suspending agents, prevents multiple crop diseases and pests, and is especially used for preventing crop powdery mildew, nematode, spider mites, and phyllocoptruta oleivora ashmead.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Compositions and methods for calcium fortification of dairy products and oleaginous foods

InactiveUS6299914B1Easy to meetLessen the shelf-life of the dairy productEdible oils/fats ingredientsMilk preparationSuspending AgentsCalcium EDTA

Calcium amino acid chelate complexes for fortification of dairy products and oleaginous foods, dairy products and oleaginous foods fortified with calcium amino acid chelate complexes, and methods of preparing calcium amino acid chelate complexes are disclosed and described. The calcium amino acid chelate complexes of the present invention are stable, palatable, and bioavailable. Preparation steps include reacting a calcium compound, an amino acid ligand, a pH adjuster, and, optionally, a stabilizing / suspending agent in an aqueous environment.

Owner:ALBION INT

Storable cementitious slurries containing boric acid and method of using the same

A storable, hydraulically-active, cementitious slurry is made and used to cement within subterranean foundations for oil and gas wells. The slurry is made from a hydraulically-active cementitious material, a suspending agent, and, as a retarder, boric acid. The boric acid is present in the cementitious slurry in an amount sufficient to lower the pH of the storable cementitious slurry to at least 12.0, preferably to at least 11.0 or preferably, for reasons of longevity, to a pH of at least 9.0. Generally the amount of boric acid in the cementitious slurry is between from about 1 to about 6 percent by weight. Preferred as suspending agent are iota carrageenan as well as poly (methyl vinyl ether / maleic anhydride) decadiene copolymer. The slurry remains liquid during storage. The slurry is activated when needed for cementing and is pumped into the subterranean formation where it is allowed to set.

Owner:BJ SERVICES CO

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

Compositions, methods, and kits comprising a dry shampoo composition

The present invention relates to compositions, methods, and kits comprising a dry shampoo composition. In some cases, a dry shampoo composition is provided as an aerosol. A dry shampoo composition may comprise at least one clay material, at least one starch material, and at least one carrier material. The composition may additional comprise one or more additive components, such as an oil-absorbing compound, a suspending agent compound, and / or a perfume.

Owner:THE PHARMASOL CORP

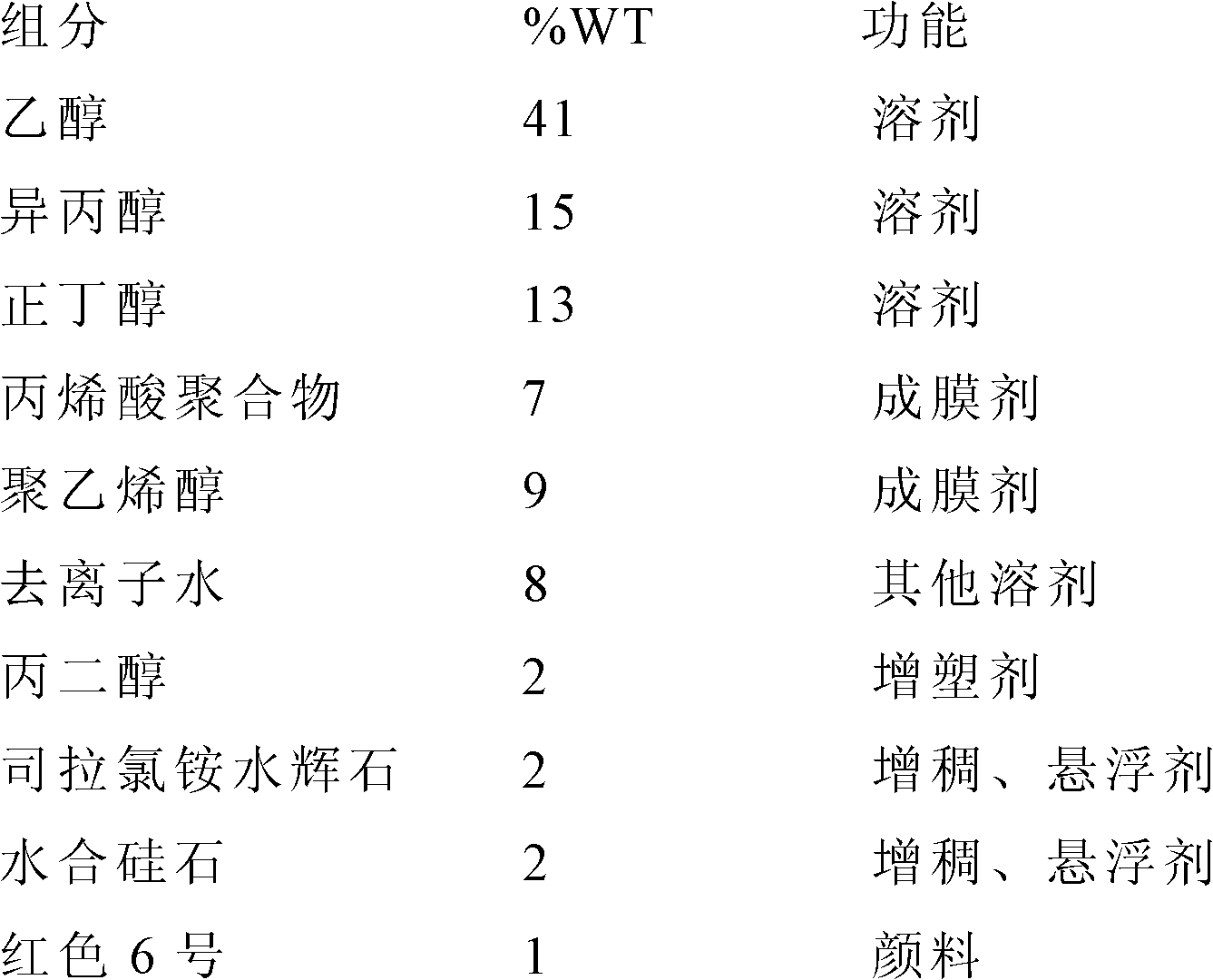

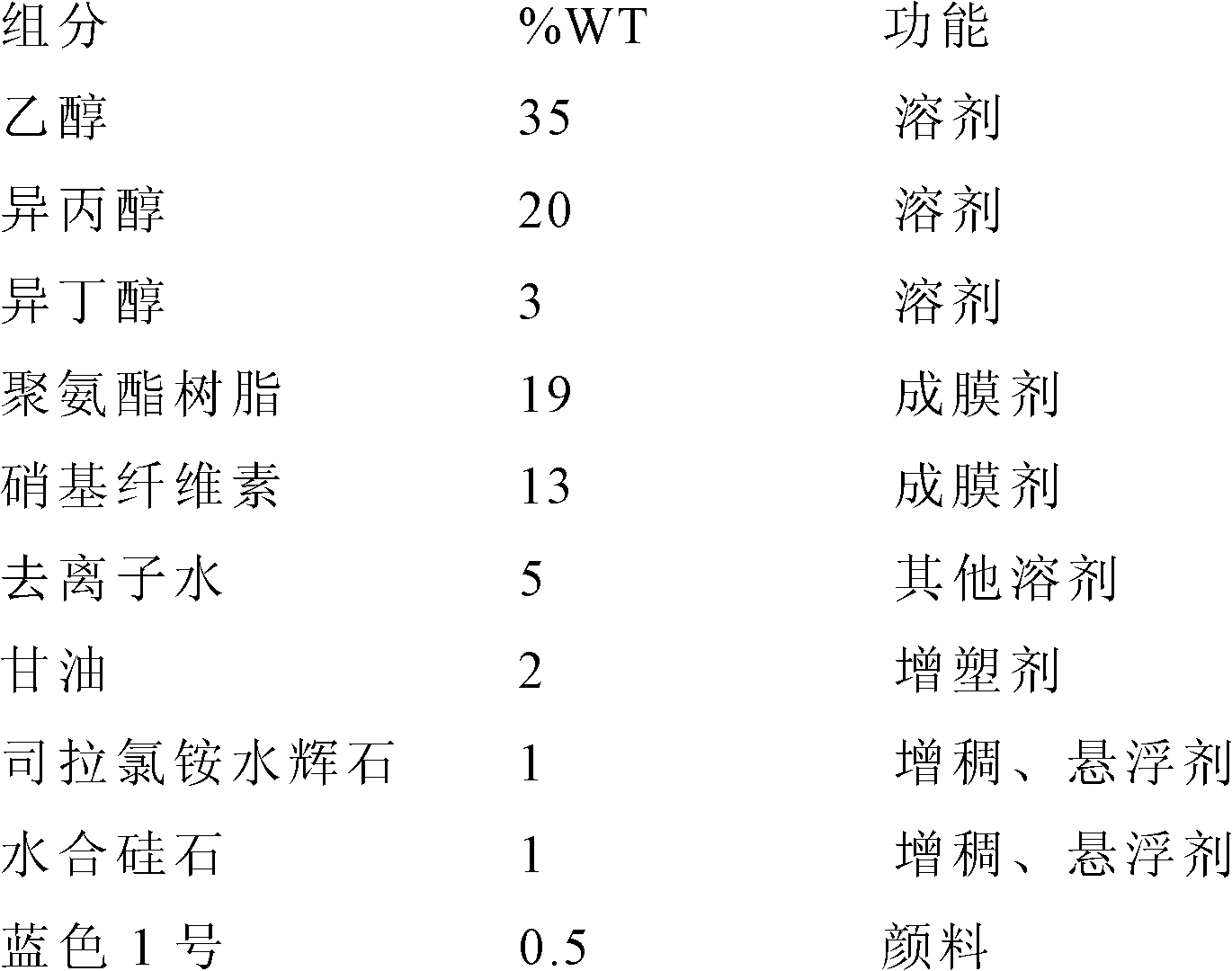

Nail polish with low stimulation

ActiveCN102552059ALess irritatingDoes not cause soluble corrosionCosmetic preparationsToilet preparationsFiberIrritation

The invention provides a nail polish with low stimulation, which belongs to the cosmetic technical field. The nail polish solves the problems of strong stimulation and easy shedding meeting water of the current nail polishes. The nail polish comprises the following components by weight part: 30-85 parts of alcohols solvent, 10-40 parts of alcohol soluble film forming agent, 1-10 parts of plasticizer, 1-10 parts of thickening agent, 1-10 parts of suspending agent, 0-5 parts of pigment, 0-5 parts of essence and 0-30 parts of solvents besides alcohol. The invention has the advantages that 1, the smell is light, only slight alcohol smell is provided, various essences are added to obtain the fragrance which is analogous with the perfume; 2, the stimulation on nail and skin of the human body is small; 3, dissolvability corrosion can not be caused when the nail polish is contacted with chemical fiber clothes and plastics; 4, the water resistance is excellent, the adhesion of the nail polish of the invention is equivalent with the ester solvent type nail polishes; 6, returning-viscosity is not generated after the nail polish is dried; and 7, the surface brightness of the nail polish of the invention is equivalent with the ester solvent type nail polishes.

Owner:JINHUA MINGSHI TECH

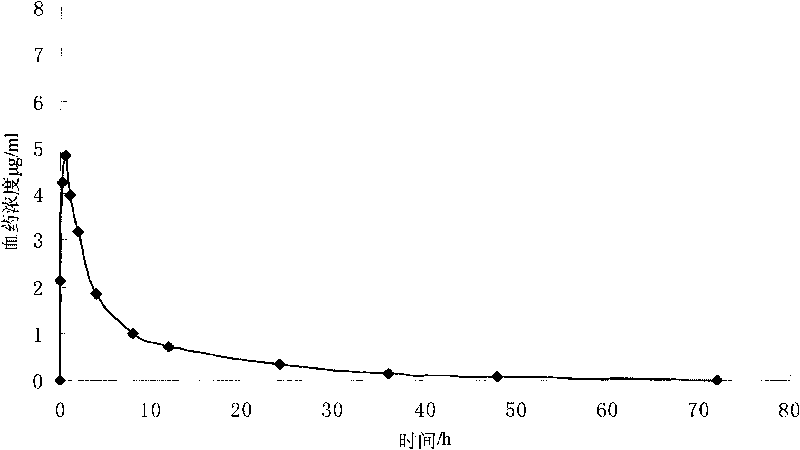

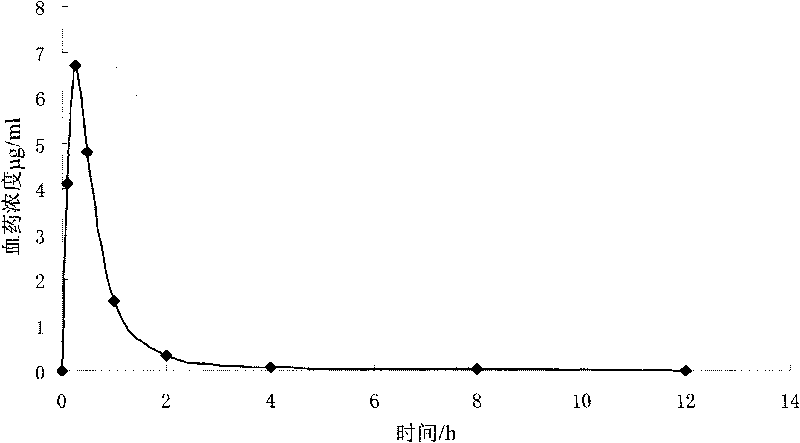

Components and preparation method of beta-lactam injection

ActiveCN101721366AReduce the number of dosesReduce stressAntibacterial agentsSolution deliverySterile environmentVegetable oil

The invention discloses the components and preparation method of beta-lactam injection. The beta-lactam injection comprises 5 to 20 percent of beta-lactam antibiotics, 0.05 to 5 percent of suspending agent, 0.005 to 0.3 percent of antioxygen, 0.1 to 0.2 percent of nonionic surfactant and the balance of vegetable oil or grease for injection. The injection can be used for preventing and curing animal bacterial infectious diseases and can be injected hypodermically or in muscle and be applied through breast for a few times. The preparation method provided by the invention comprises: firstly, making the antibiotics and the antioxygen into micro powder and making the suspending agent into fine powder; secondly, adding the vegetable oil or grease for injection, which is sterilized at high temperature, into the fine powder of the suspending agent, heating the mixture, uniformly mixing the mixture and keeping the mixture in a sterile environment to cool the mixture to room temperature for later use; and finally, transferring the prepared oil or grease added with the suspending agent to a colloid mill, adding medicament micro powder, the antioxygen and the non-ionic surfactant with stirring, and performing uniform mixing and sterilization to obtain the beta-lactam injection.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

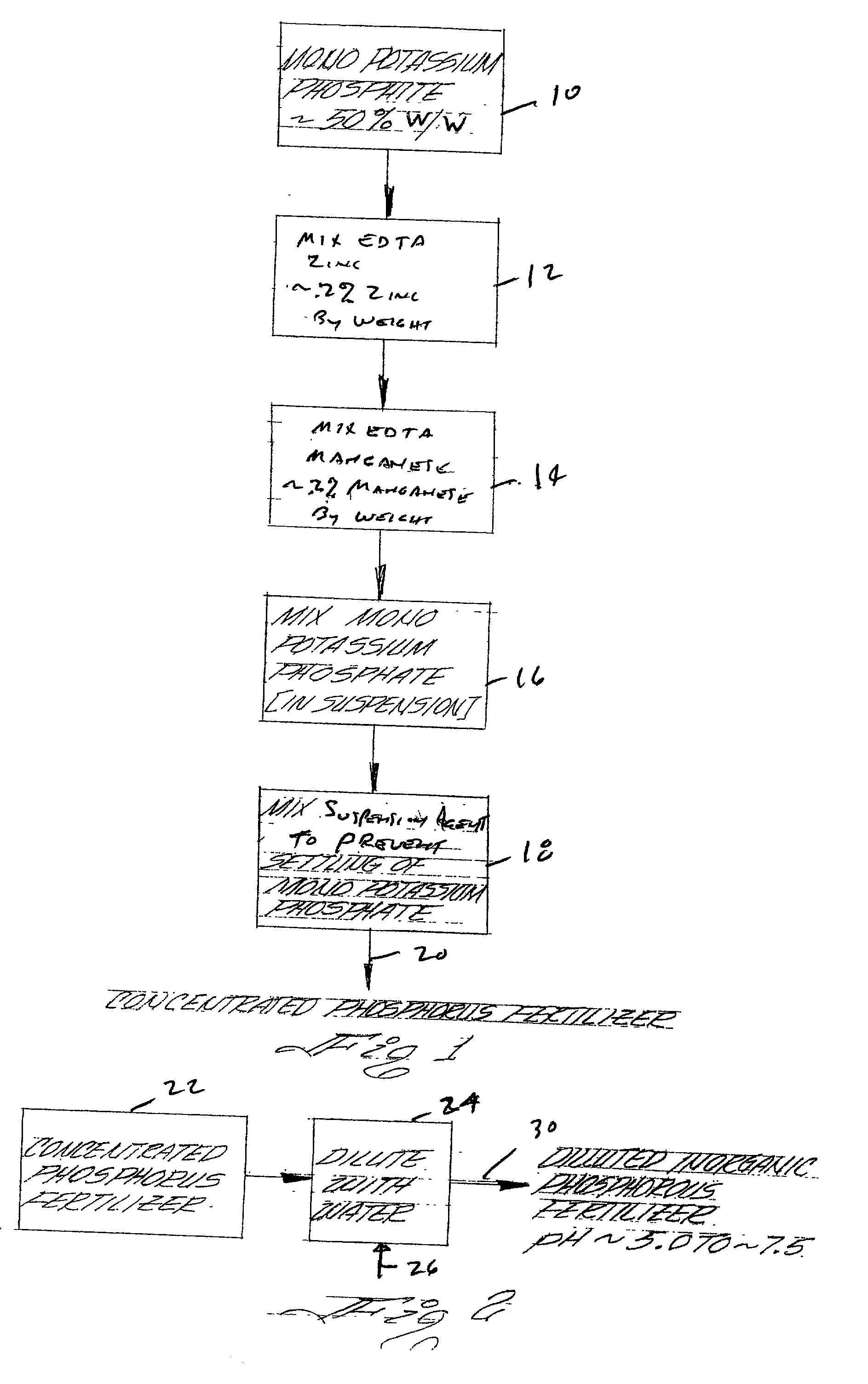

Concentrated phosphorus fertilizer

InactiveUS20020129632A1Easy to diluteImproving phosphorus uptakeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorous acidSalt content

A concentrated fluid phosphorus fertilizer is shown. In the preferred embodiment, the concentrated fluid phosphorus fertilizer is an aqueous suspension fertilizer composition. The composition comprises one or more phosphorus-containing acids or salts thereof selected from the group consisting of phosphoric acid, polyphosphoric acid, phosphorous acid, polyphosphorous acid, hypophosphorous acid and polyhypophosphorous acid, and salts thereof. A suspension agent maintains undissolved solids in substantially homogeneous suspension wherein the suspension has a total acid and salt content of about 50% w / w to about 80% w / w. The concentrated fluid phosphorus fertilizer is a stable suspension and when diluted with water a substantially fully soluble fertilizer having acceptable pH for phosphorus uptake is formed. Methods for improving the phosphorus uptake and improving the growth rate of plants is also shown.

Owner:INTERFARM

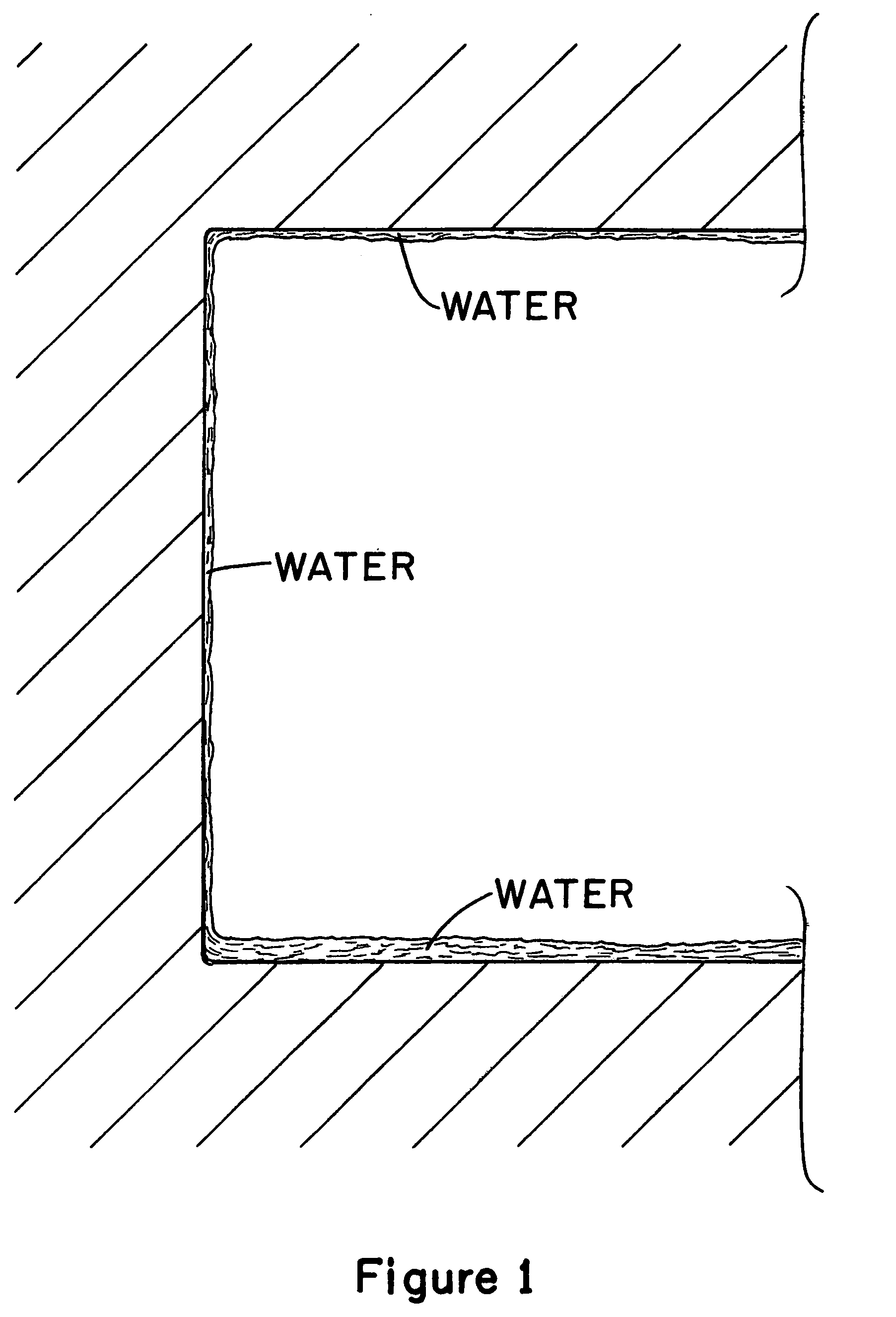

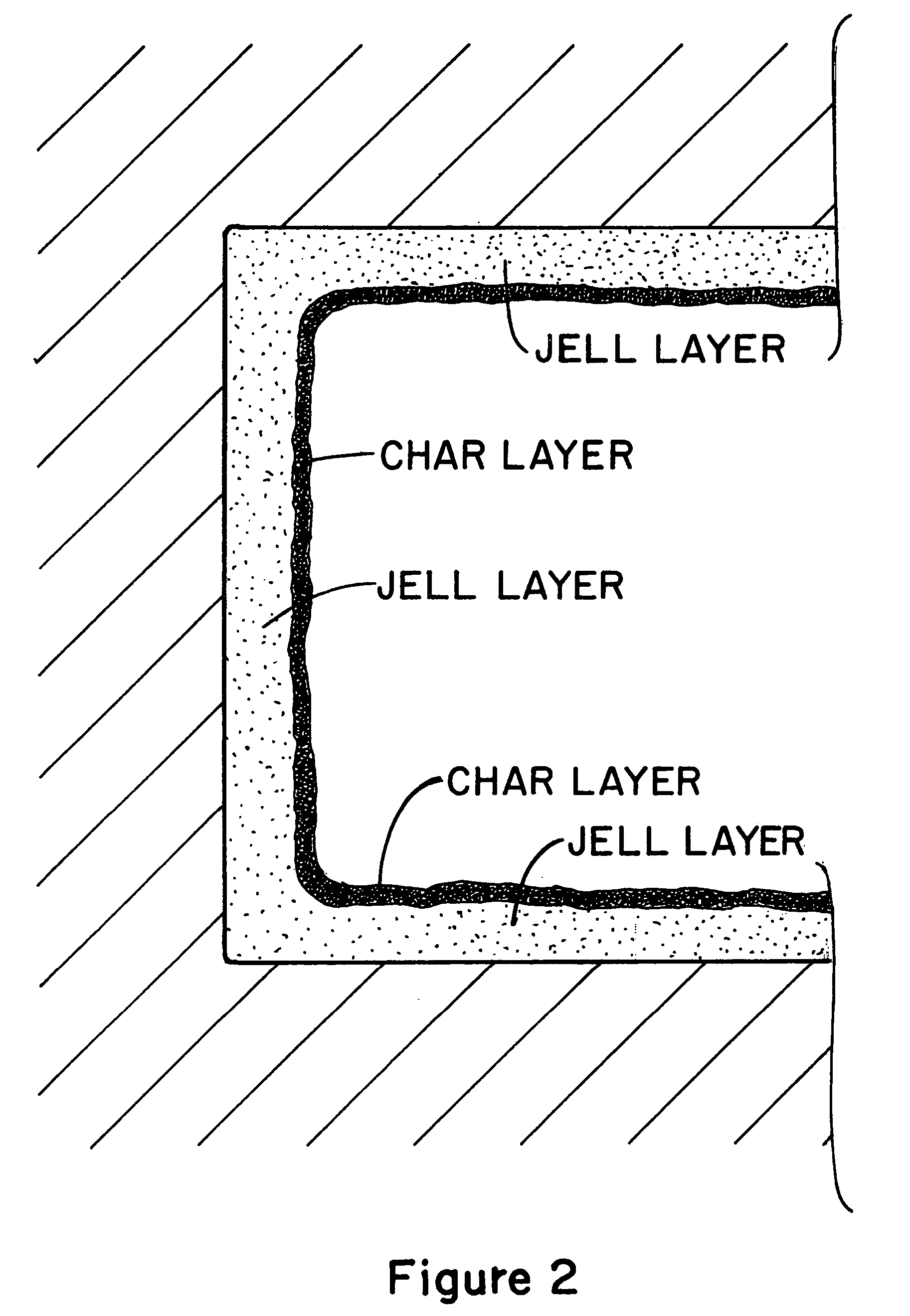

Composition inhibiting the expansion of fire, suppressing existing fire, and methods of manufacture and use thereof

InactiveUS20060076531A1Extended shelf lifeEasy to addFire rescueBoring toolsFoaming agentSuspending Agents

The invention relates to compositions that prevent expansion of a fire, suppress existing fire, as well as methods of preparing and using such compositions. The composition is comprised of water, pseudo-plastic high yield suspending agent and starch. Compositions may contain additional functional agents, such as rheological, wetting, foaming, coloring, chelating, antimicrobial and stabilizing agents. In the description of the present invention, all composition modifications are referred to as compositions. The composition, an augmentation of water, exhibits the characteristics of a sag resistant aqueous gel in the tank, but has shear thinning capacity, allowing the composition to be pumped or sprayed as easily as water. At the point of impact, when the sprayed composition is again at rest, it instantly reverts to a sag resistant aqueous gel. The composition also forms an intumescent, surface char layer upon contacting a fire. Foaming of the augmented composition on impact can be incorporated, which is advantageous for fighting petroleum fires.

Owner:EARTHCLEAN CORPRATION

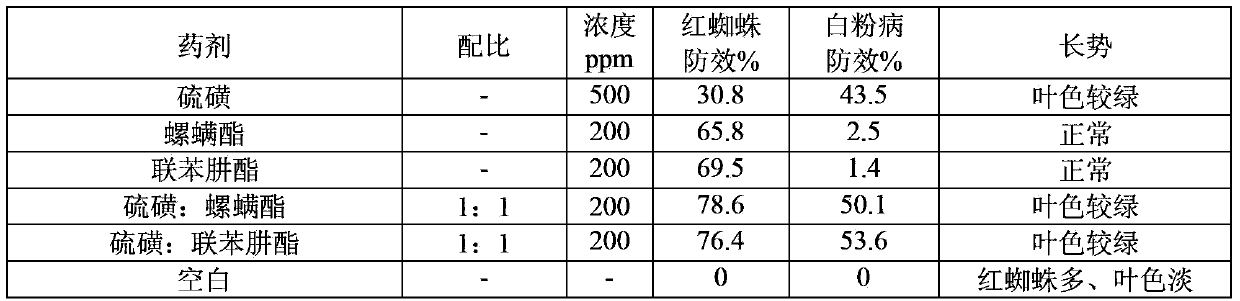

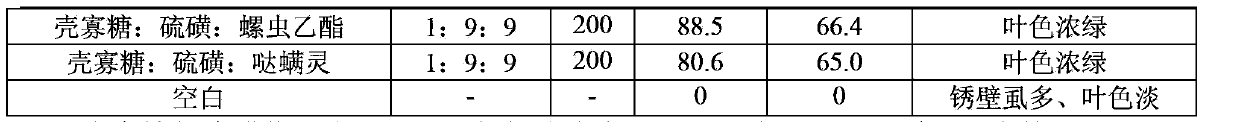

Agricultural composition taking oligosaccharide and sulphur as synergistic components

ActiveCN103392737AImprove insecticidal and acaricidal ingredientsImprove the bactericidal effectBiocideFungicidesPhyllocoptruta oleivoraNematode

The invention belongs to the field of plant protection, and in particular relates to an agricultural composition taking oligosaccharide and sulphur as synergistic components and an application of the agricultural composition in prevention and treatment of agricultural pests. The mass part ratio of oligosaccharide to sulphur is 1:(0.1-200) and the mass part ratio of oligosaccharide to sulphur to other pesticide components is 1:(0.1-200):(0.1-100). In the composition, oligosaccharide is pectin oligosaccharide, sodium alginate oligosaccharide or chitosan oligosaccharide. The synergistic composition containing oligosaccharide and sulphur can be processed to particles, suspending agents and the like with other insecticidal and mite-killing components or sterilizing components to realize the synergistic effect of the agricultural composition, and the agricultural composition is used for preventing and treating nematode, red spiders, Phyllocoptruta oleivora Ashmead or powdery mildew of crops.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Preparation method of wear-resistant high-chromium cast iron

The invention discloses a preparation method of wear-resistant high-chromium cast iron and belongs to the technical field of metal materials. According to the preparation method, common scrap steel, carburant, ferrochromium, ferromolybdenum, copper plates, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum are smelted in an electric furnace so as to form the wear-resistant high-chromium cast iron. The molten wear-resistant high-chromium cast iron comprises the following chemical components in percentage by mass: 3.0-3.5% of C, 18-25% of Cr, 0.3-0.5% of Mn, 0.3-0.5% of Si, 0.18-0.25% of N, 0.5-0.8% of Mo, 0.2-0.4% of B, 0.08-0.12% of Al, 0.5-1.0% of Cu, less than 0.05% of S, less than 0.05% P and the balance of Fe. Molten iron is treated with an inoculator when taken out from the electric furnace, and is treated with a suspending agent when poured, so as to obtain fine solidification structures. Therefore, the wear-resistant high-chromium cast iron has excellent properties.

Owner:BEIJING UNIV OF TECH

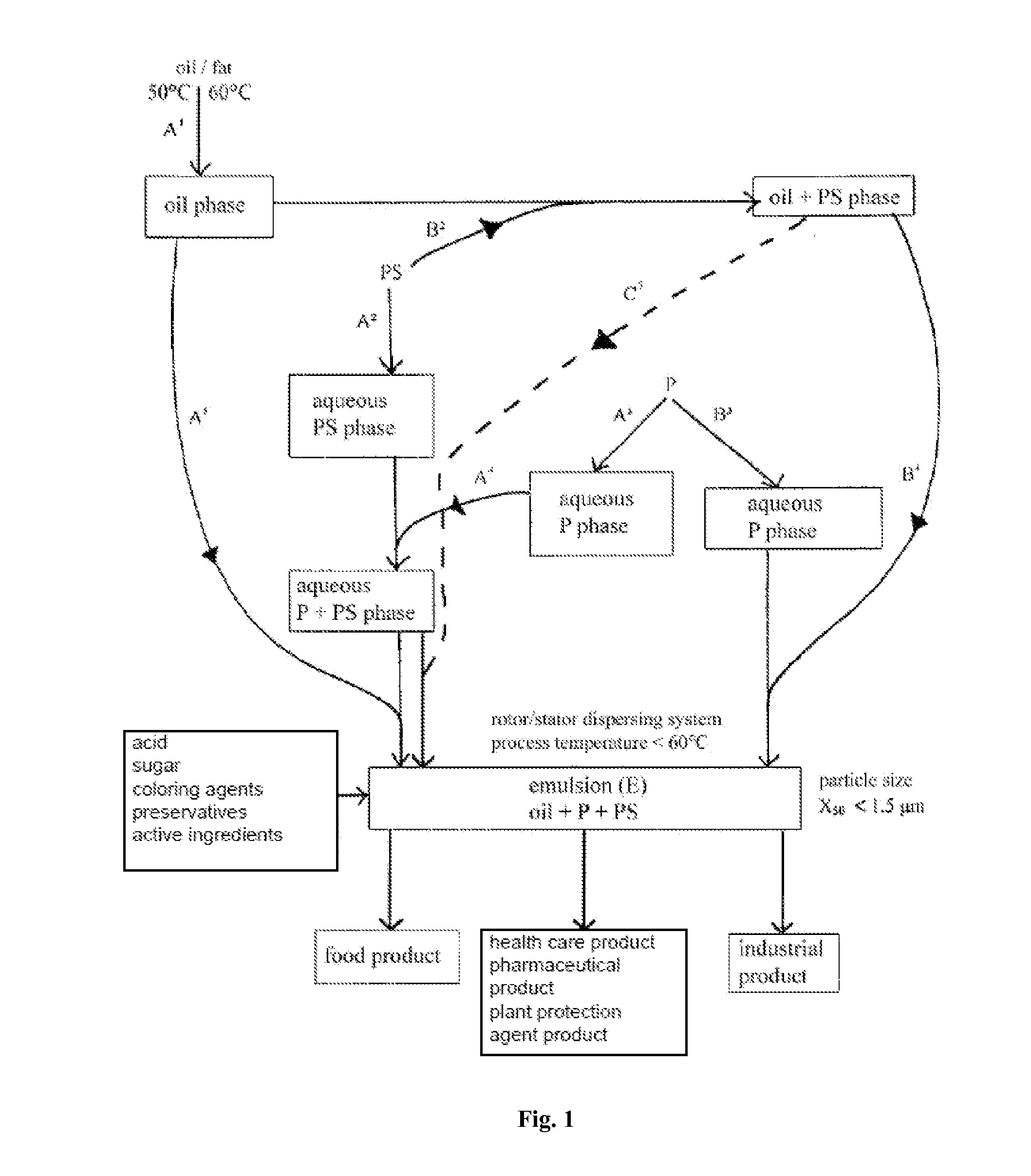

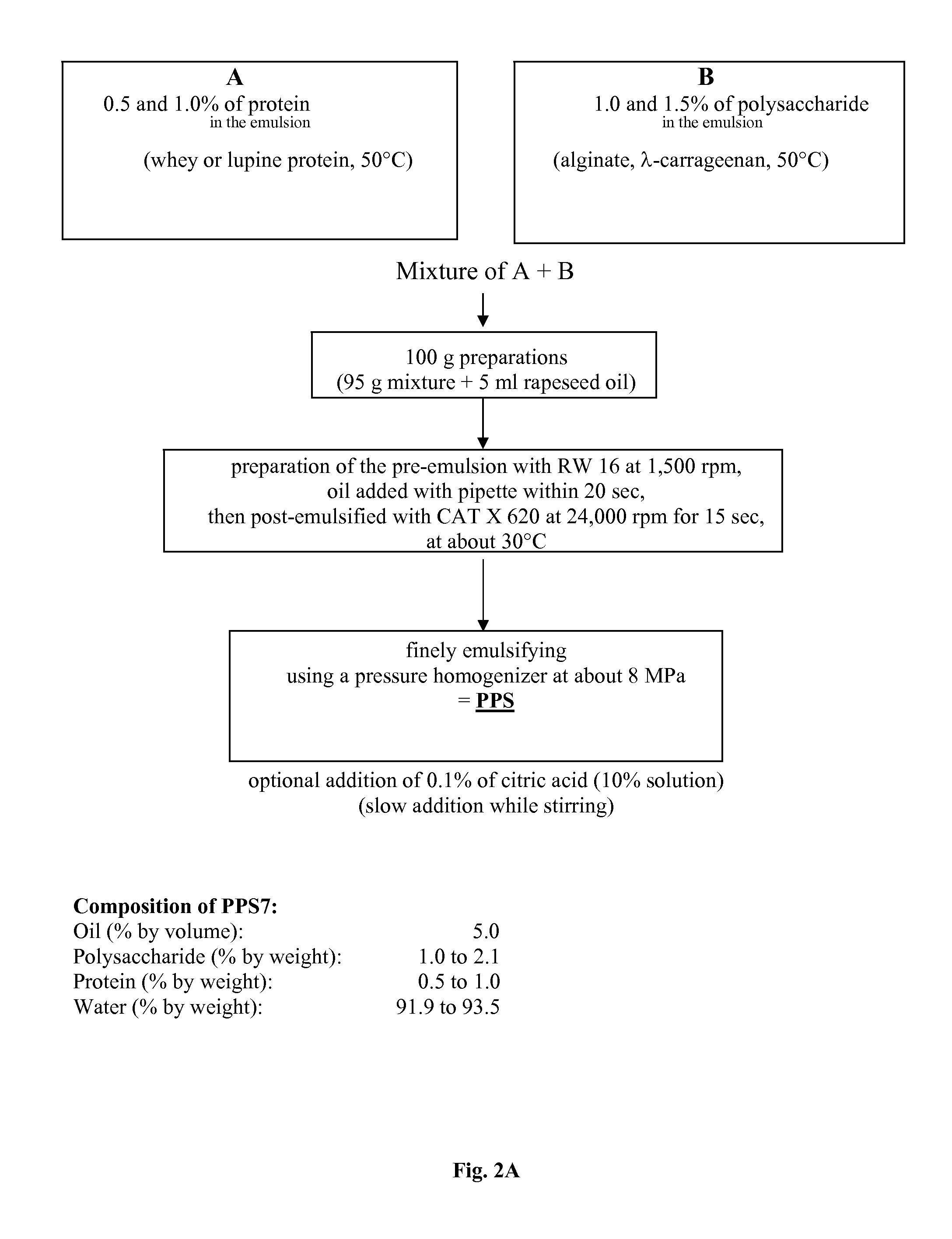

Concentrated, creamy to solid and dry compositions of an oil-in-water emulsion, method for the production thereof and use thereof for producing improved foods in terms of sensory aspects and nutrition physiology

InactiveUS20120135125A1Improve featuresEdible oils/fats ingredientsCosmetic preparationsFood additiveNutrition physiology

The invention relates to an oil-in-water emulsion, substantially comprising protein, polysaccharide and oil or fat having unique stabilizing properties, which is suited for use as a thickener, suspending agent, coating material and as an additive to food in the production of a plurality of products. Furthermore, foods are provided which have improved properties in terms of sensory aspects and nutrition physiology compared to conventionally produced products, and a method for the production thereof is provided. In addition, the emulsion and products produced according to the invention can be dried and subsequently rehydrated in order to obtain compositions that have substantially the same properties as the non-dried compositions.

Owner:OPTISENS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com